Self compact concrete

A self-compacting concrete and coarse aggregate technology, which is applied in the field of construction engineering materials, can solve the problems of excessive heat of hydration, high cost, and large amount of cement, and achieve the effect of simple preparation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

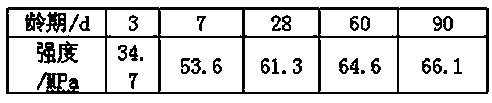

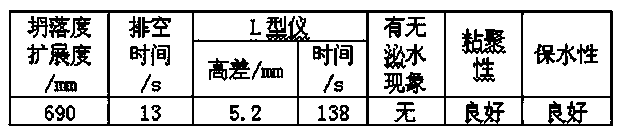

[0017] Embodiment 1: The self-compacting concrete of this embodiment is prepared according to the following composition weight ratio: cement 290 kg / m 3 , fly ash 160 kg / m 3 , coarse aggregate 891 kg / m 3 , fine aggregate 754 kg / m 3 , superplasticizer 5.29 kg / m 3 , water consumption 155 kg / m 3 . The fineness modulus of fine aggregate is 2.8. The cement is C42.5 ordinary Portland cement, with a specific surface area of 370-420 kg / m 3 . Coarse aggregate is continuously graded, with a nominal particle size of 5-25mm and a void ratio of less than 40%. Among them, those with a nominal particle size of 20-25mm account for 8% of the total mass of the coarse aggregate, and those with a nominal particle size of 15-20mm account for 8% of the total mass of the coarse aggregate. 17% of the total mass of coarse aggregate, 32% of the total mass of coarse aggregate with a nominal particle size of 10-15mm, and 43% of the total mass of coarse aggregate with a nominal particle size of 5-...

Embodiment approach 2

[0024] Embodiment 2: The self-compacting concrete of the present embodiment is prepared according to the following composition weight ratio: cement 250kg / m 3 , fly ash 200 kg / m 3 , coarse aggregate 820 kg / m 3 , fine aggregate 700kg / m 3 , superplasticizer 12 kg / m 3 , water consumption 145 kg / m 3 ; Among them, the particle size of coarse aggregate is 5-25mm, and the fineness modulus of fine aggregate is 2.5. Cement is C40. Coarse aggregates are continuously graded, with a nominal particle size of 5-25mm and a void ratio of 38%; among them, those with a nominal particle size of 20-25mm account for 12% of the total mass of the coarse aggregate, and those with a nominal particle size of 15-20mm account for 13% of the total mass, 28% of the total mass of coarse aggregate with a nominal particle size of 10-15mm, and 47% of the total mass of coarse aggregate with a nominal particle size of 5-10mm. The fly ash is Class I fly ash. The water reducing agent is a polycarboxylate hig...

Embodiment approach 3

[0025] Embodiment 3: The self-compacting concrete of this embodiment is prepared according to the following composition weight ratio: cement 300kg / m 3 , fly ash 120 kg / m 3 , coarse aggregate 950 kg / m 3 , fine aggregate 850 kg / m 3 , superplasticizer 5 kg / m 3 , water consumption 160 kg / m 3 ; Among them, the particle size of coarse aggregate is 5-25mm, and the fineness modulus of fine aggregate is 2.6. Cement is C45. Coarse aggregates are continuously graded, with a nominal particle size of 5-25mm and a void ratio below 40%; among them, those with a nominal particle size of 20-25mm account for 10% of the total mass of the coarse aggregate, and those with a nominal particle size of 15-20mm account for 10% of the total mass of the coarse aggregate. 15% of the total mass of coarse aggregate, 30% of the total mass of coarse aggregate with a nominal particle size of 10-15mm, and 45% of the total mass of coarse aggregate with a nominal particle size of 5-10mm. The fly ash is Clas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal particle size | aaaaa | aaaaa |

| Nominal particle size | aaaaa | aaaaa |

| Nominal particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com