Patents

Literature

456 results about "Uniform - quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

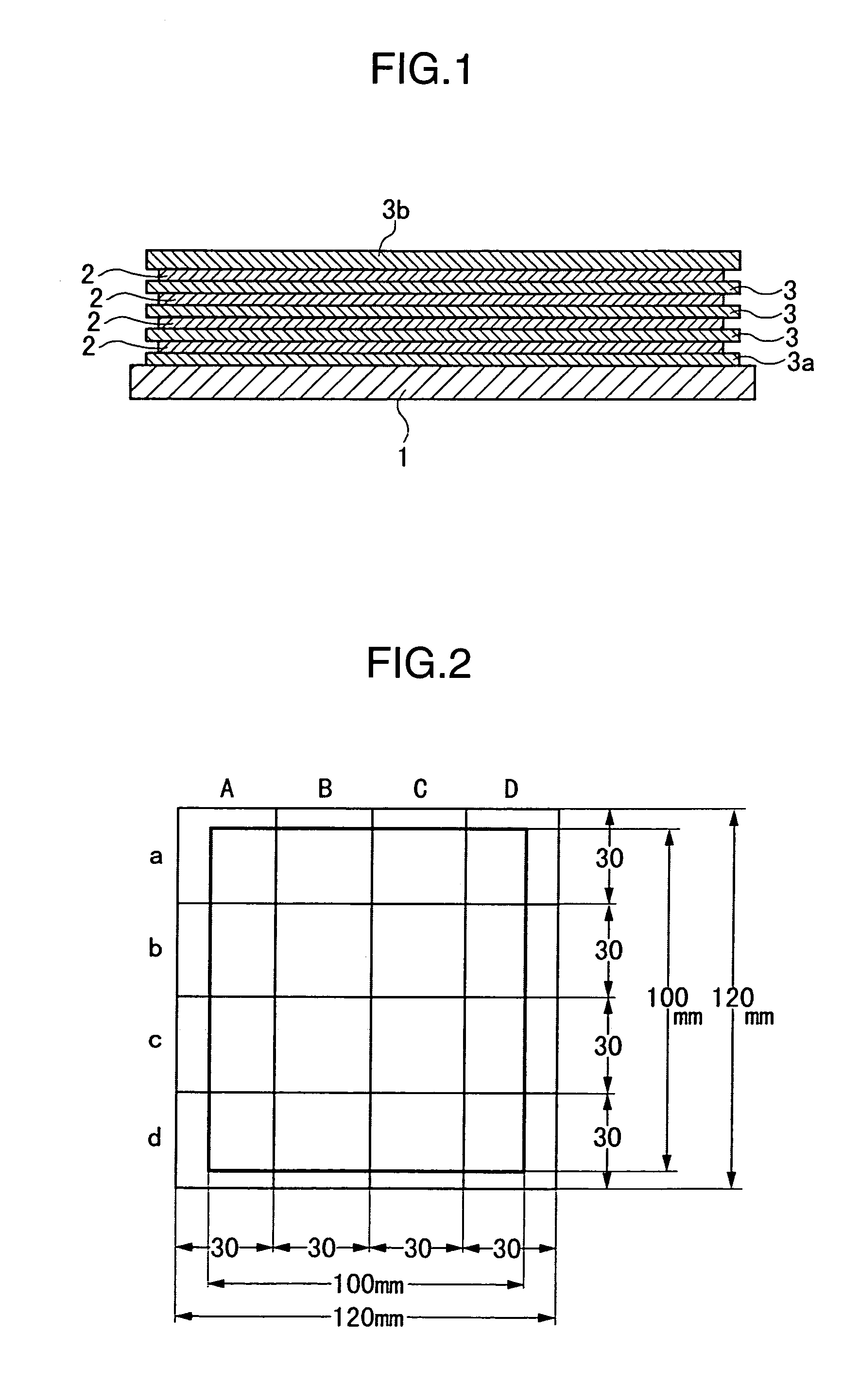

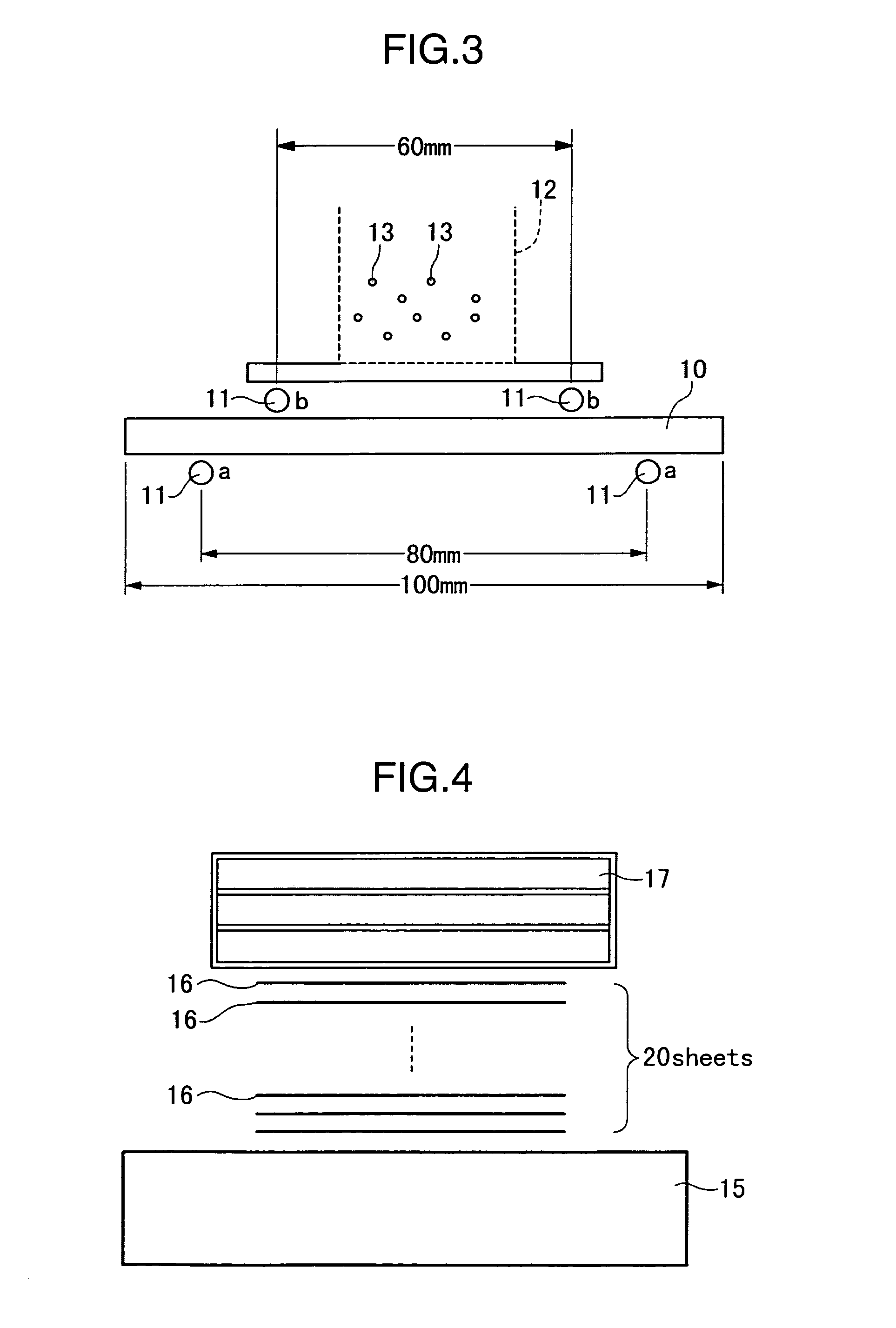

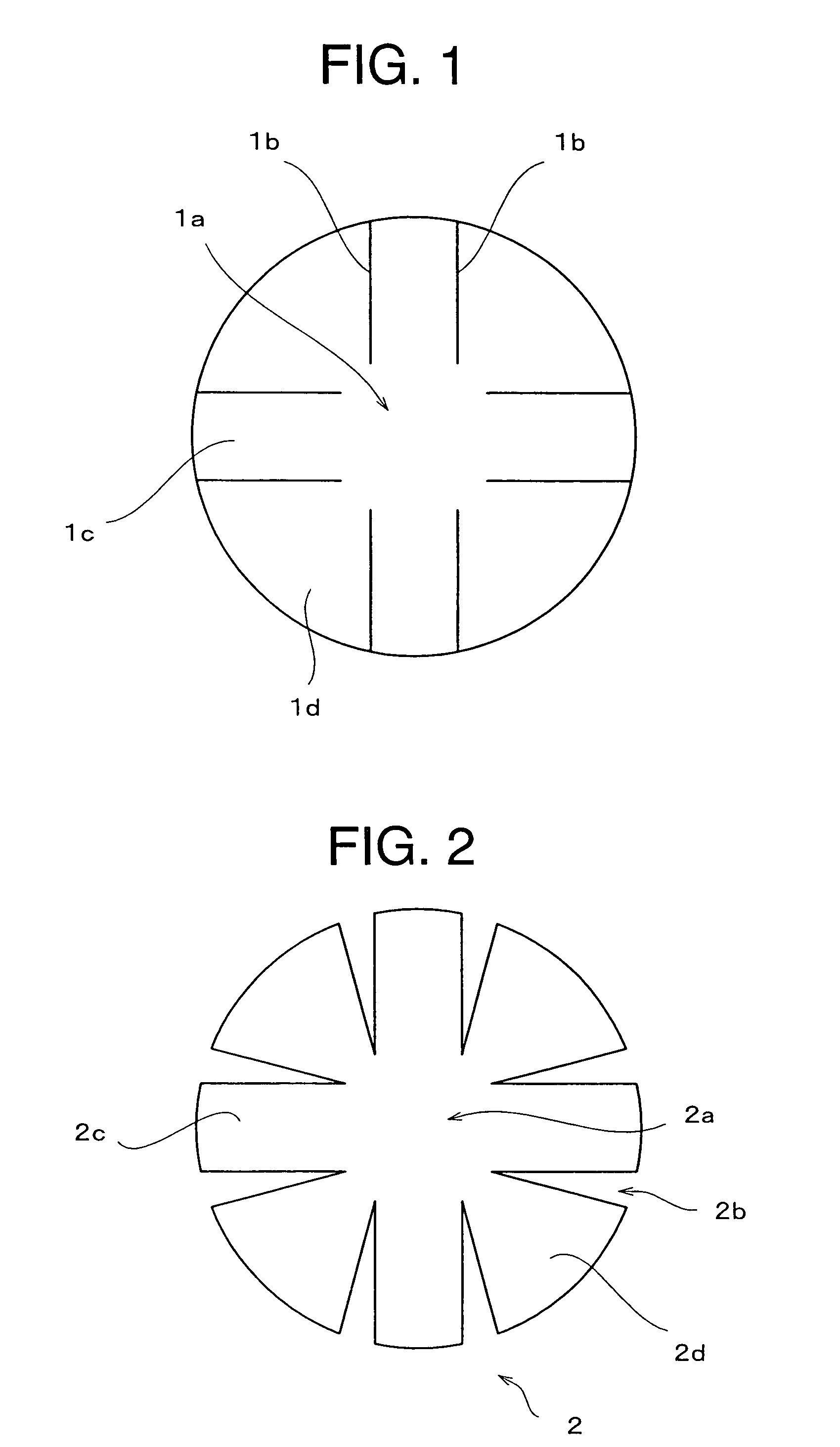

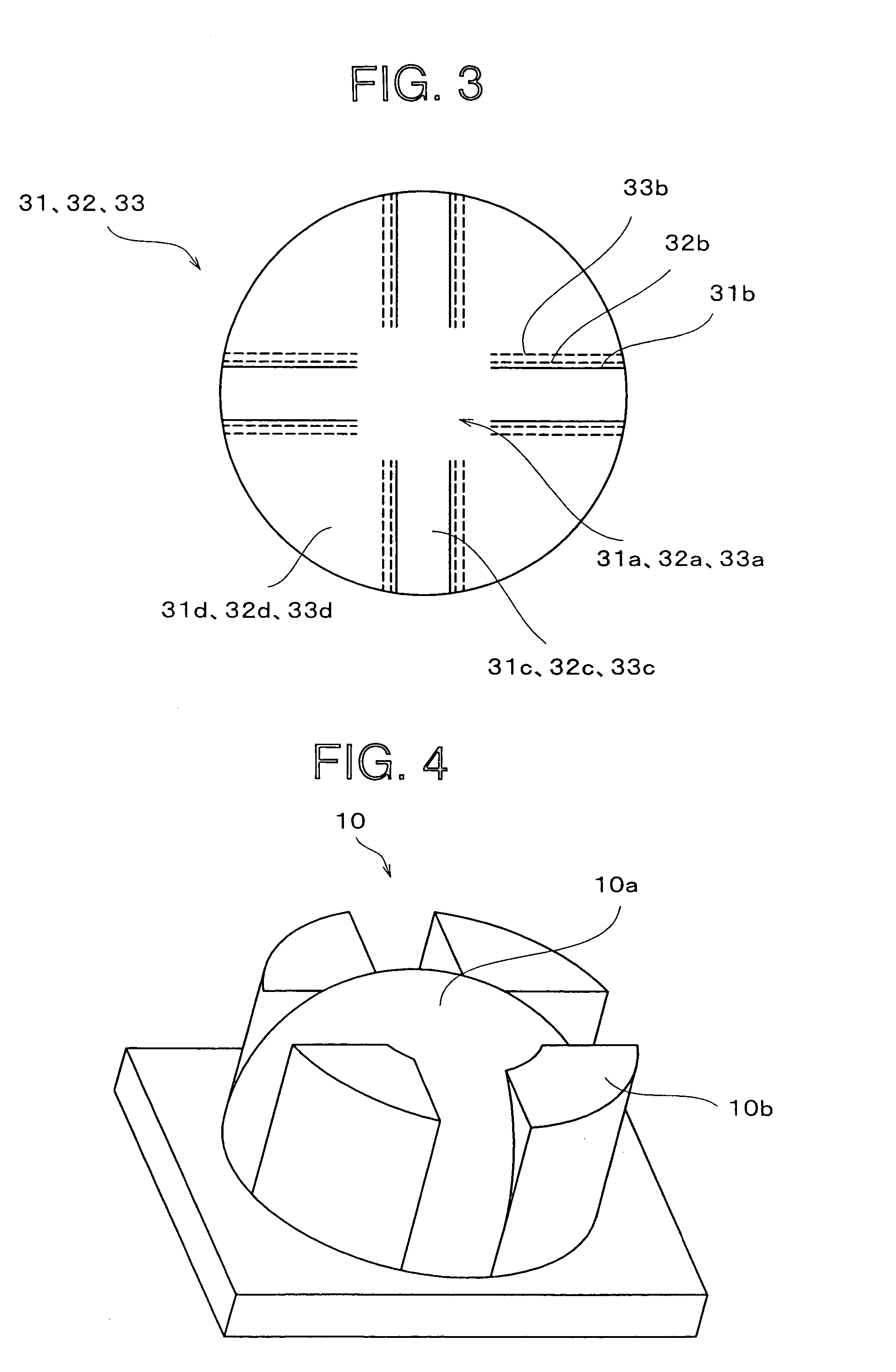

Ceramic sheet and method of producing ceramic sheet

InactiveUS7108827B1Suppress blemishesReduce frictional resistanceSynthetic resin layered productsRecord information storageForeign matterMetallurgy

The present invention relates to a ceramic sheet having uniform quality over its entire surface with a decreased number of defects such as foreign matters and flaws. When the ceramic sheet was divided into sections of 30 mm square or smaller, each divided section has 5 or less defects detected based on an image obtained with a charge coupled device (CCD) camera. The present invention also relates to a method of producing the ceramic sheet. In this method, a green sheet or a calcined sheet mainly including spherical ceramic particles having an average particle diameter of 0.1 to less than 5 μm was used as a spacer. By using this spacer, the green sheet for ceramic sheet slides smoothly on the spacer surface when it shrinks in baking, and the friction resistance between the green sheet for ceramic sheet and the spacer is lowered. In this manner, the method of the present invention can mass-produce the above-described high quality ceramic sheets.

Owner:NIPPON SHOKUBAI CO LTD

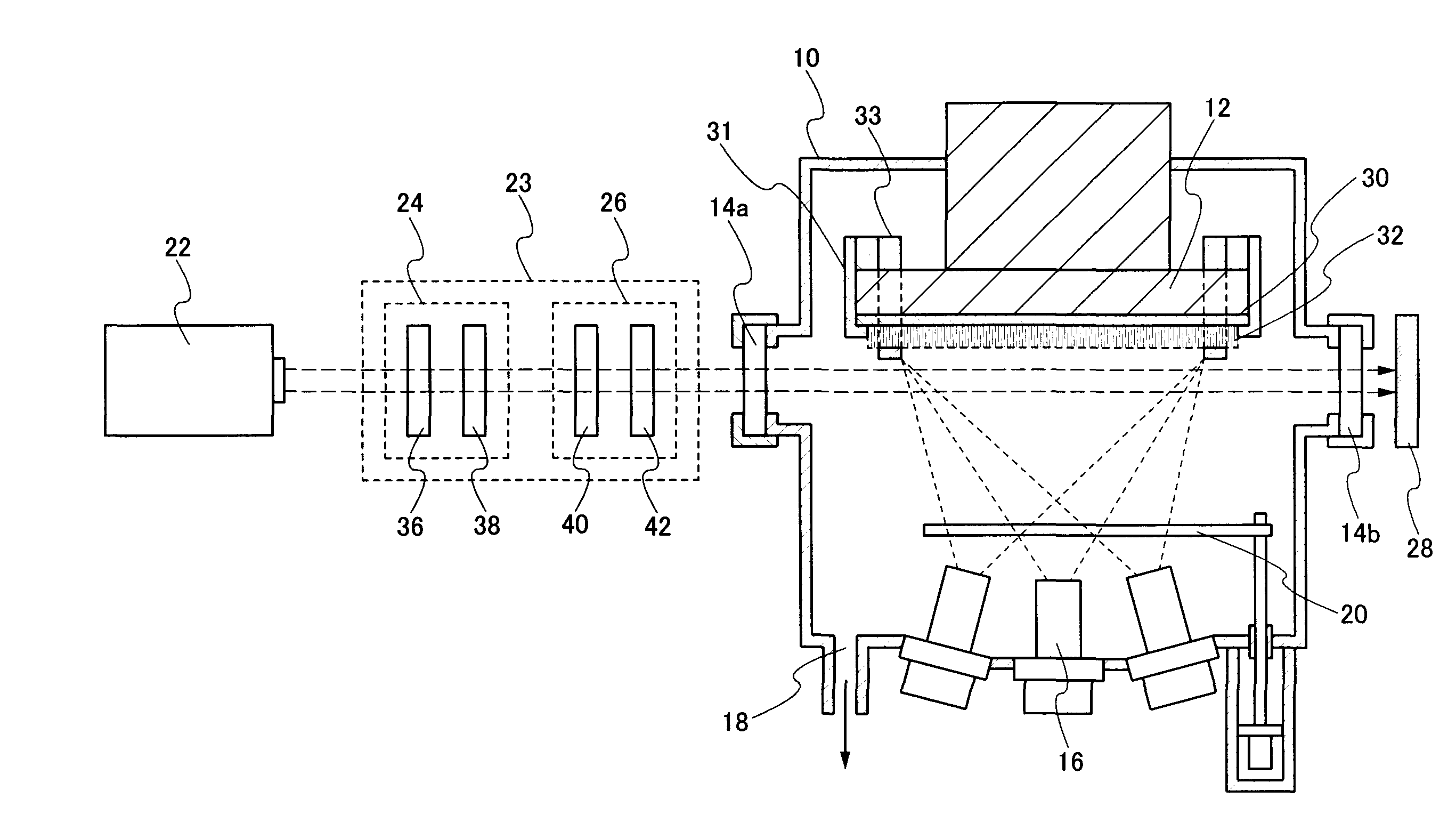

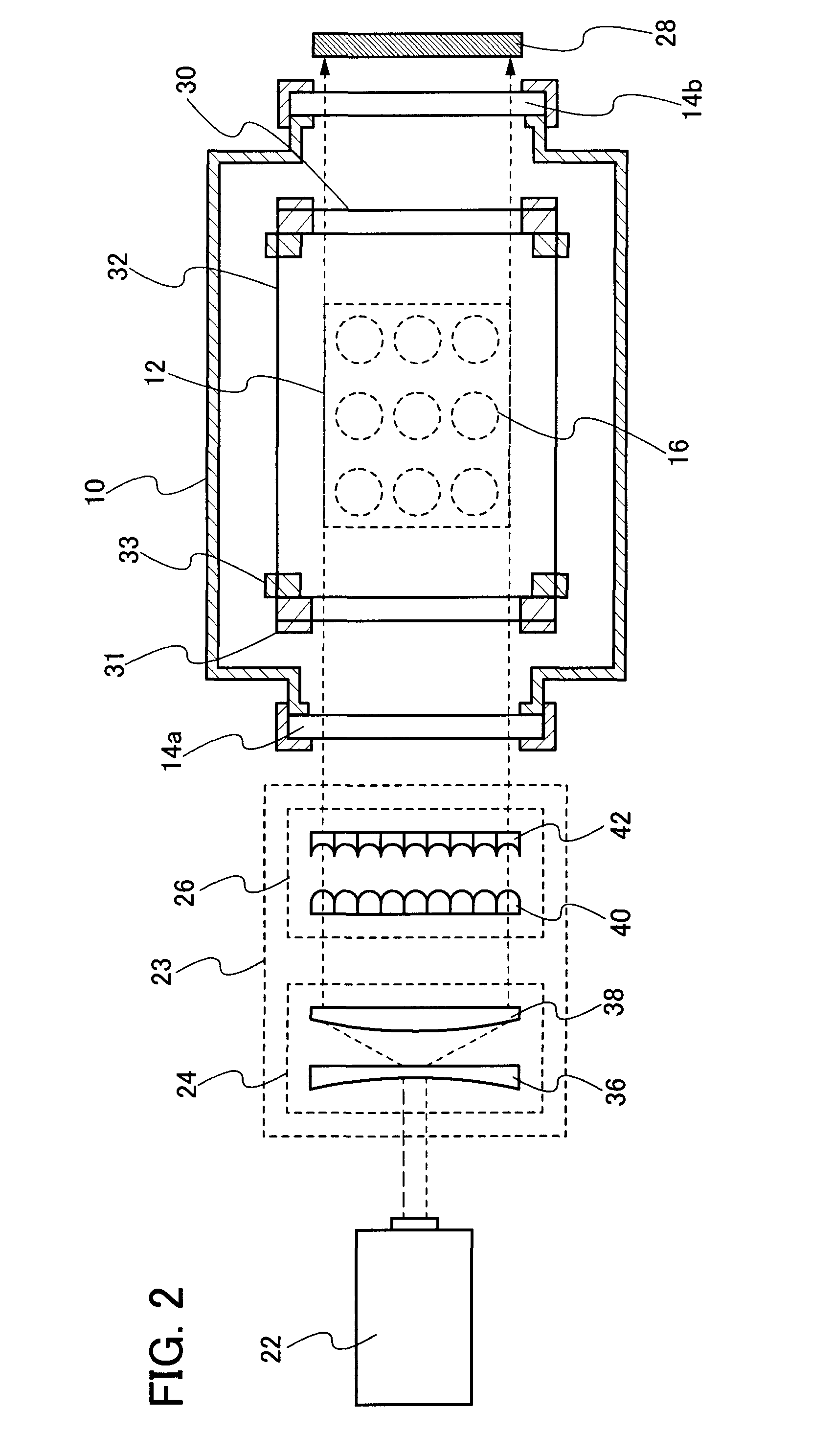

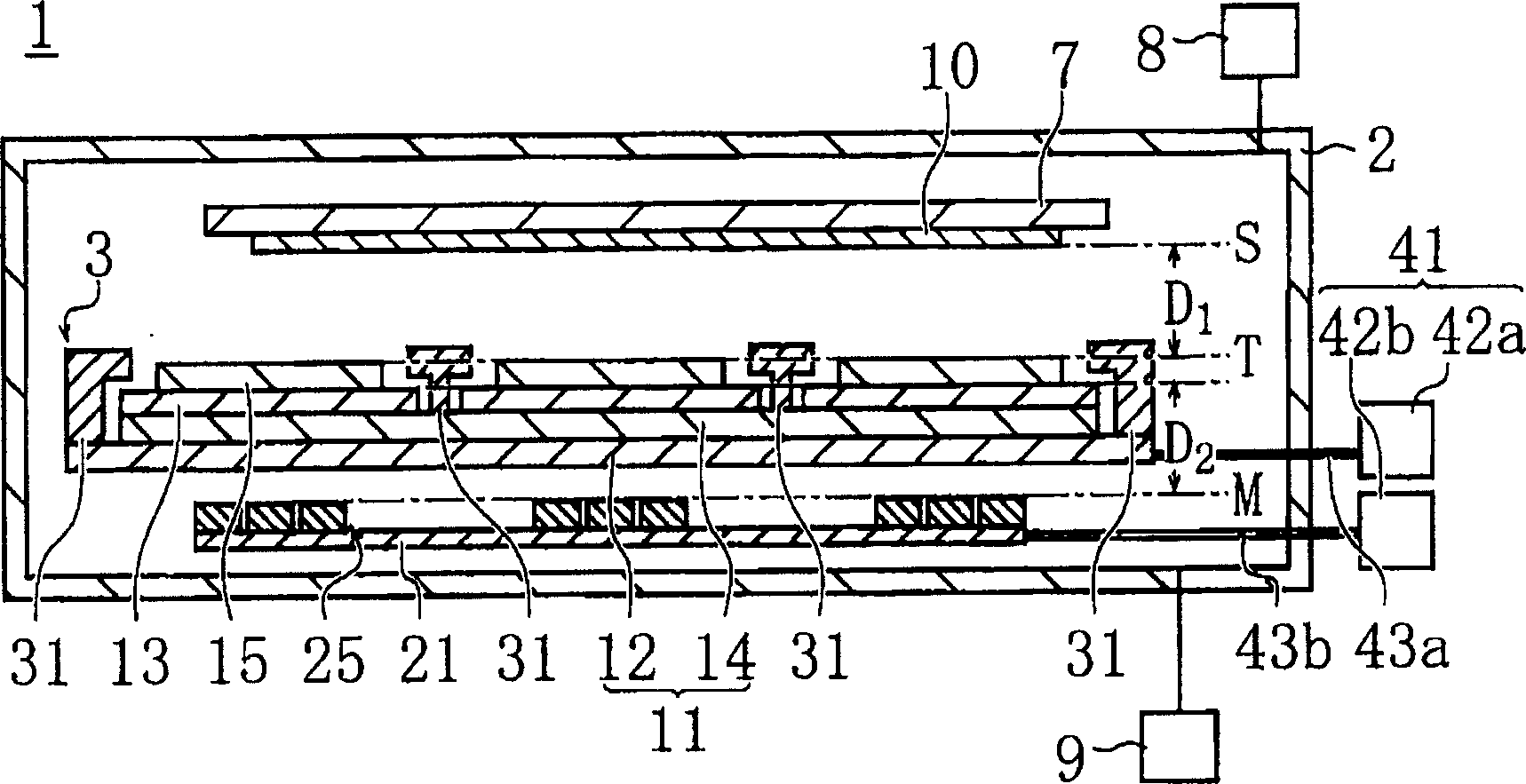

Film forming apparatus, film forming method, and manufacturing method of light emitting element

InactiveUS20070190235A1Reduce strainReduce defectsElectroluminescent light sourcesVacuum evaporation coatingLow voltageEvaporation

An object of the present invention is to provide a film forming method for forming a film with reduced defect and to provide a film forming method for forming a film with a uniform quality. In addition, another object is to provide a manufacturing method of a light emitting element which can be driven with low voltage. Further, another object is to provide a manufacturing method of a light emitting element with high light emission efficiency. A film with reduced defect and a uniform quality can be formed by fixing a substrate to a substrate holding unit so that at least a part of a surface of the substrate is exposed, evaporating a vapor deposition material from an evaporation source filled with the vapor deposition material, irradiating the vapor deposition material which is evaporated with a laser beam, and depositing the vapor deposition material on the surface of the substrate.

Owner:SEMICON ENERGY LAB CO LTD

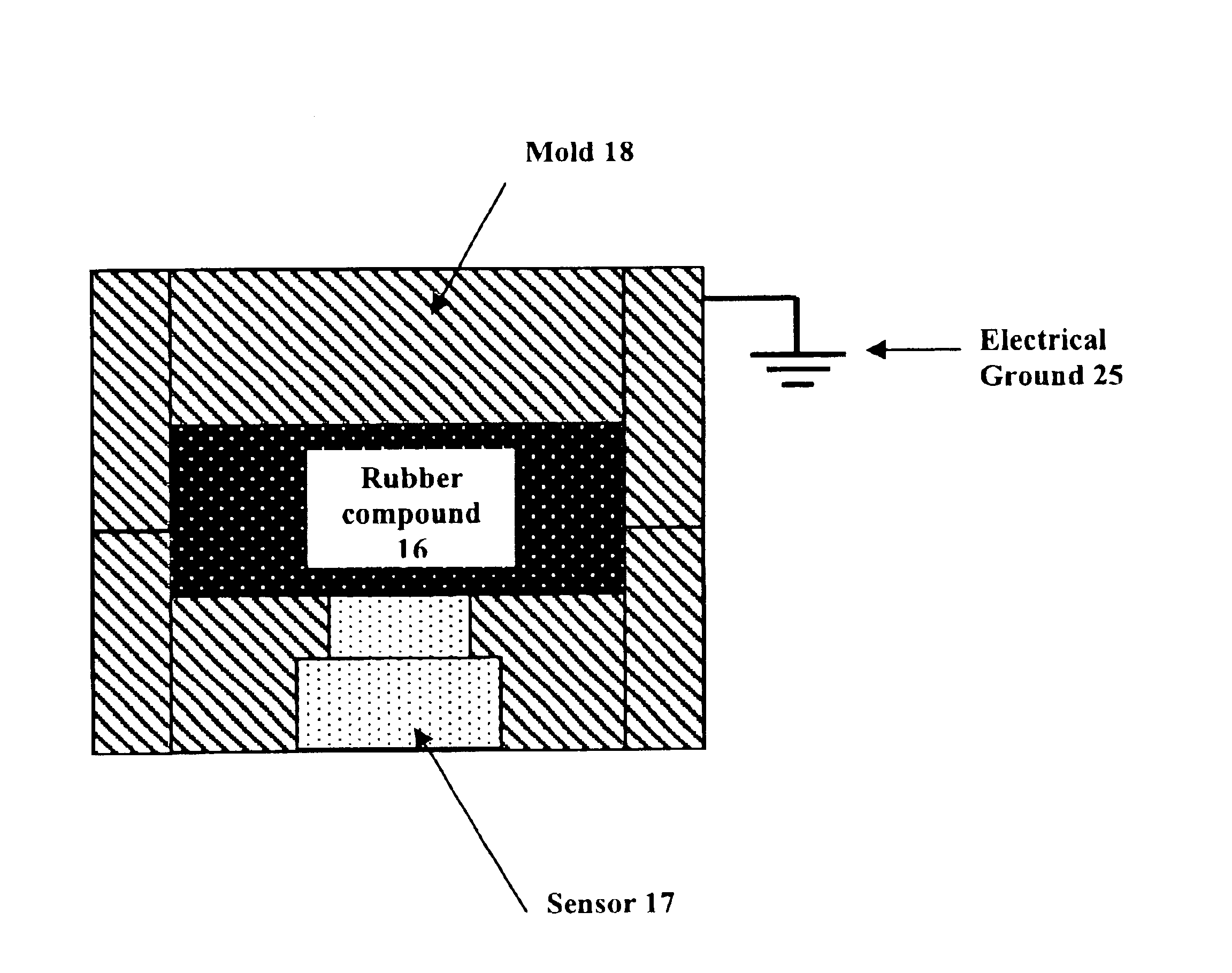

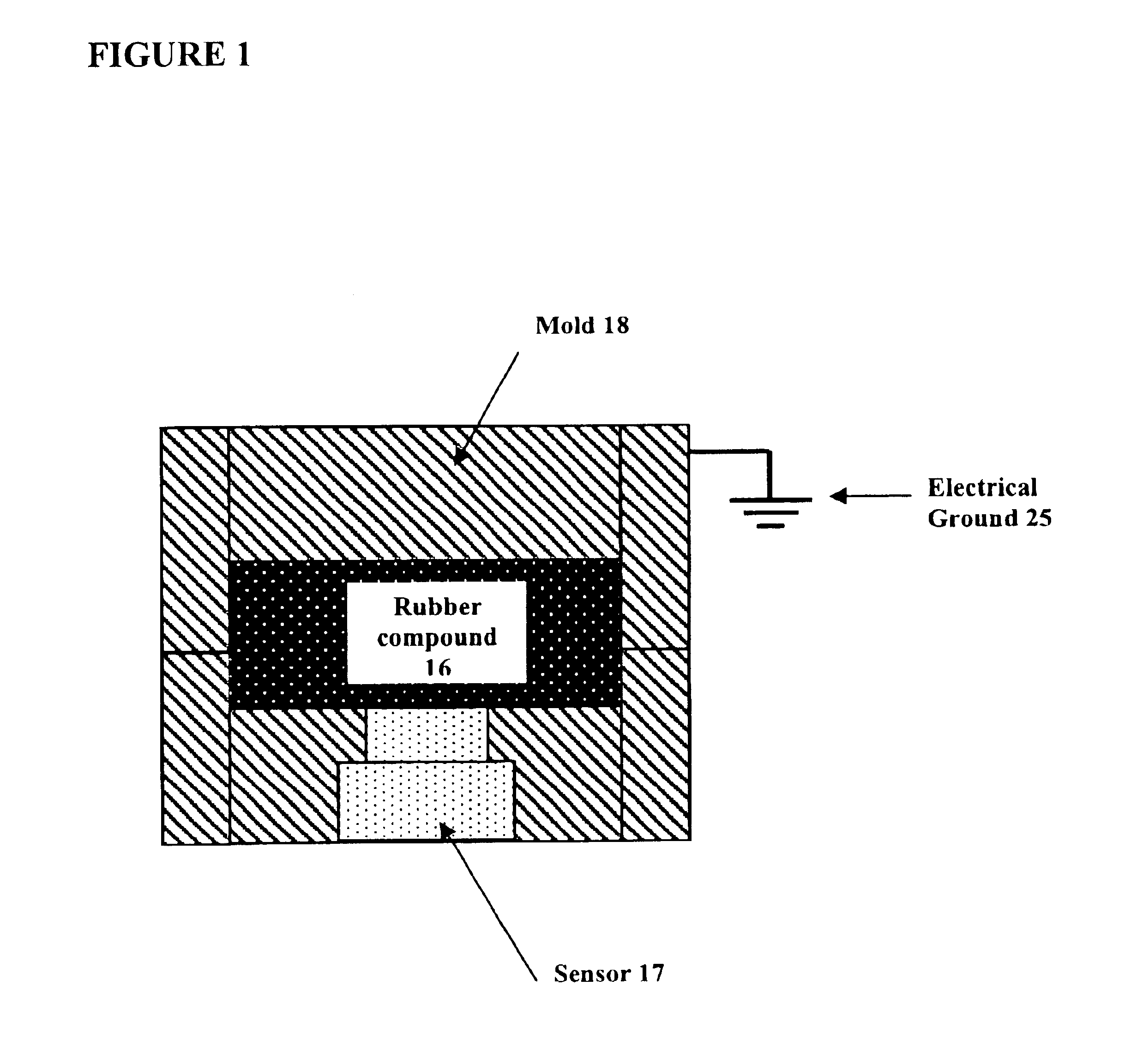

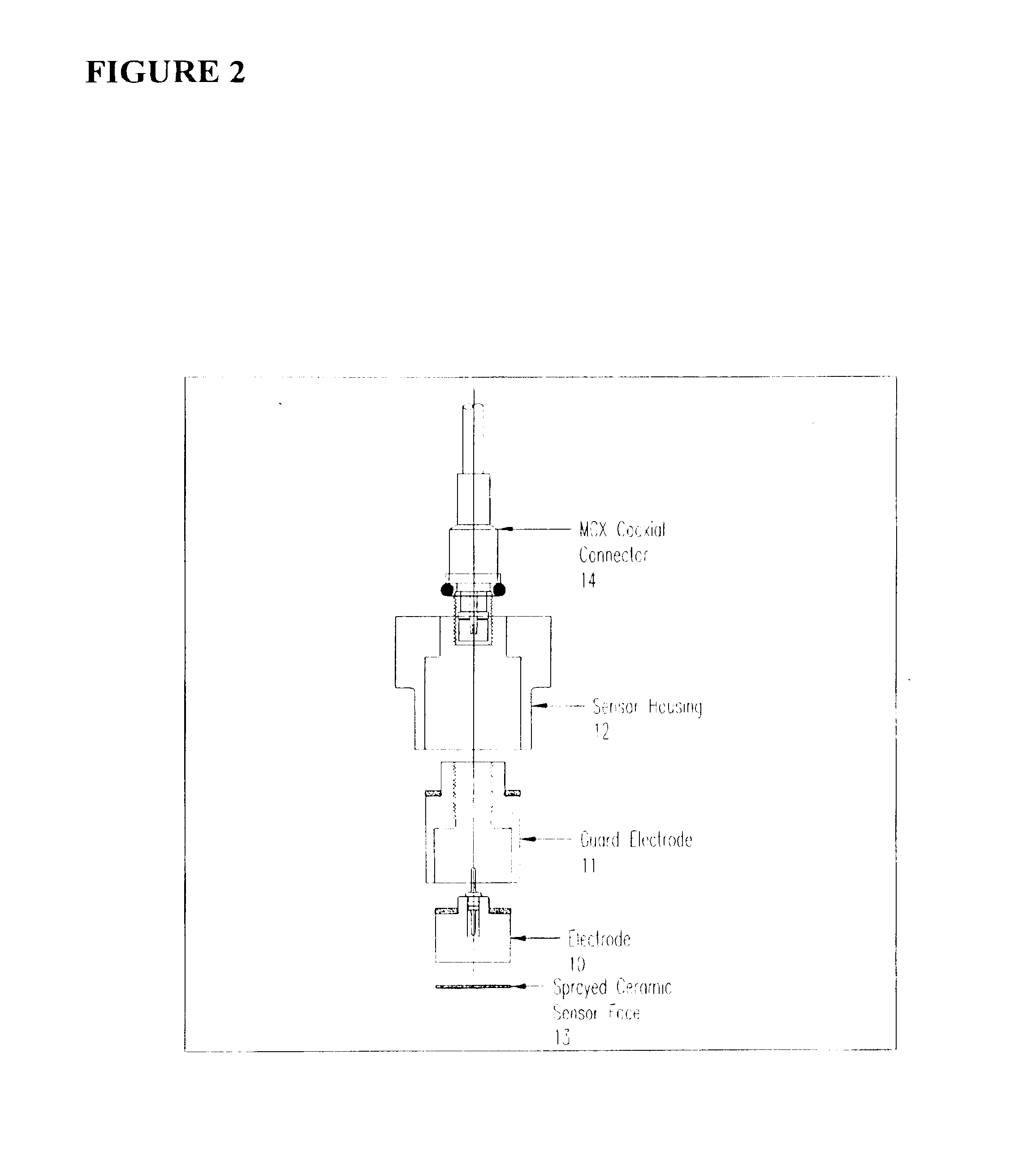

Process and apparatus for improving and controlling the vulcanization of natural and synthetic rubber compounds

InactiveUS6855791B2Unique shapeQuality improvementFlow propertiesThermometer testing/calibrationCompound aElectricity

A process for curing a natural or synthetic rubber includes the measuring of curing conditions by dielectric or impedance means to produce a process curve (impedance property data versus time) followed by analyzing the process curve with a software algorithm which defines and statistically quantifies the correlation between the process curve and the desired part properties. The correlation relationship is applied in real time to end the curing process at the optimum time and to produce rubber parts of uniform quality and with reduced process cycle time.

Owner:SIGNATURE CONTROL SYST

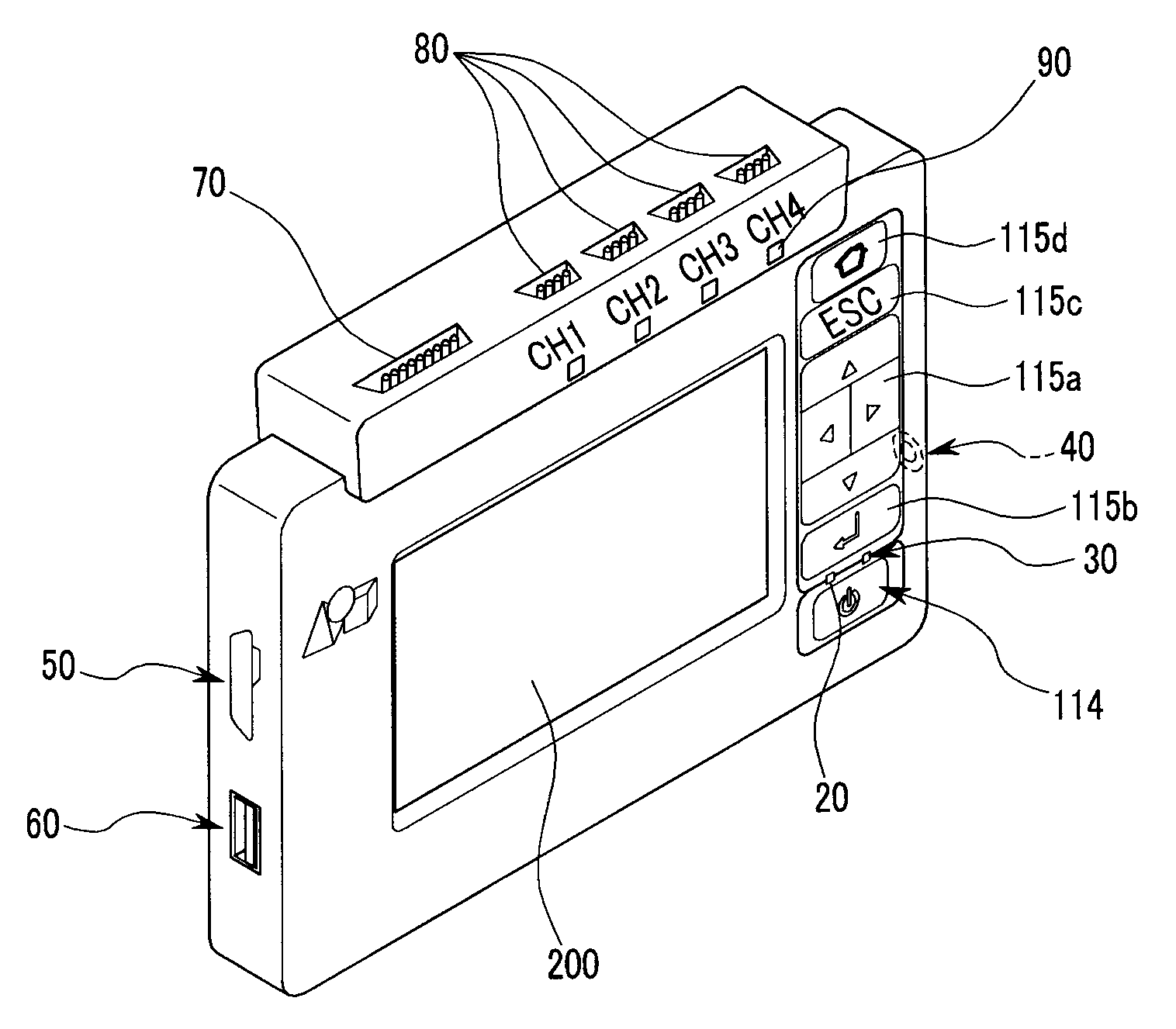

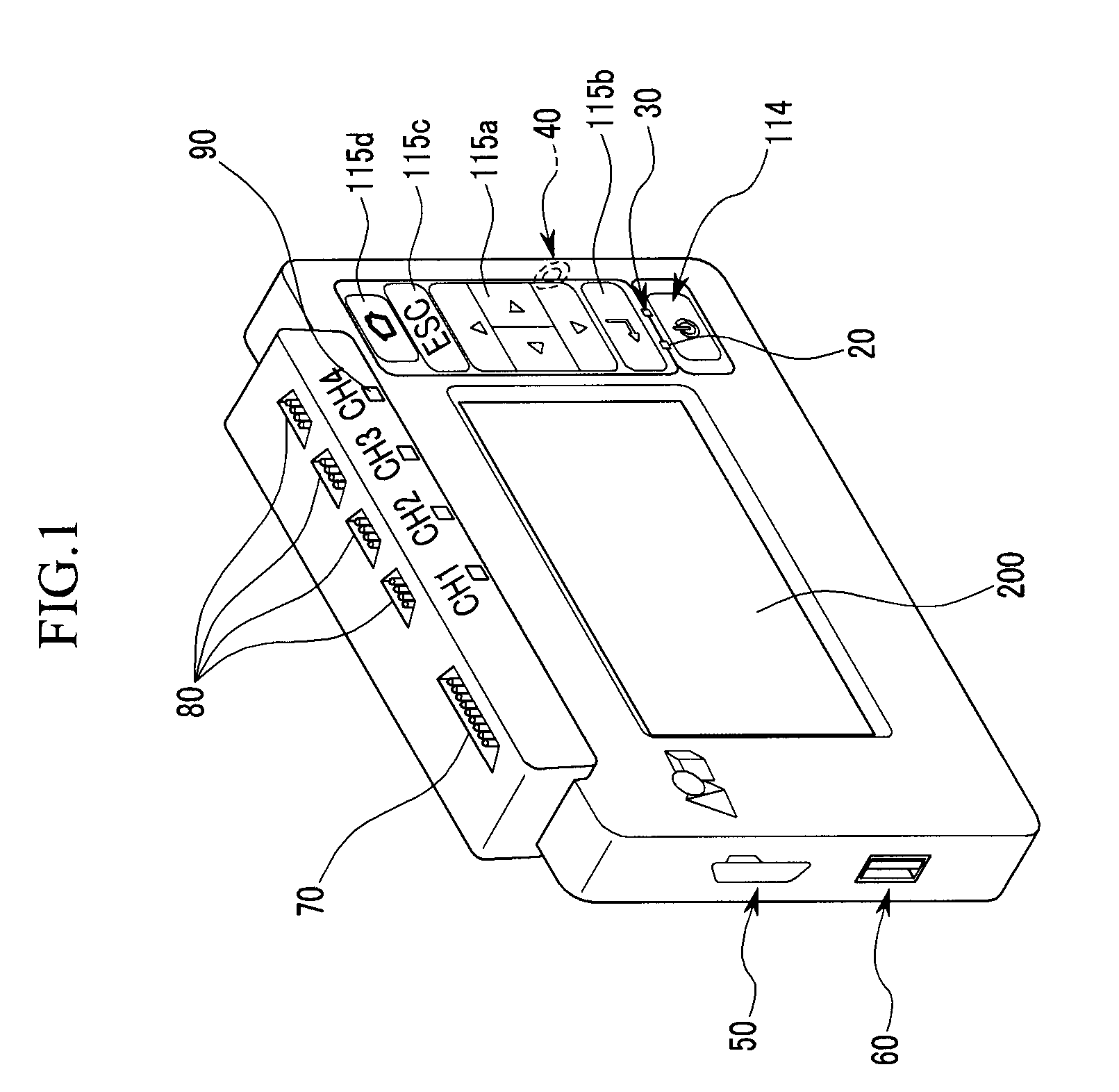

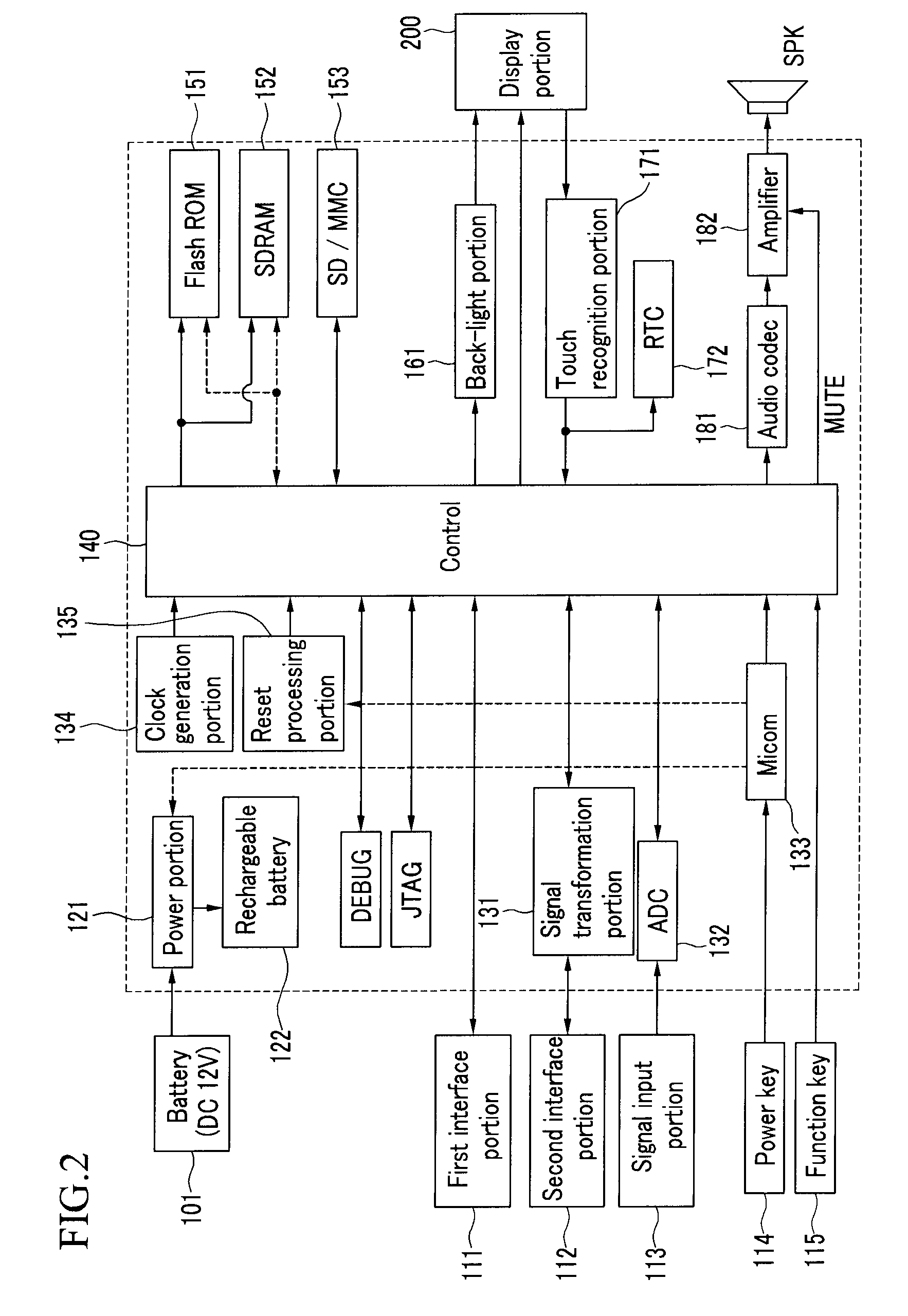

Noise and Vibration Diagnosis Device for Vehicle and Control Method Thereof

ActiveUS20100082274A1Reliable serviceUniform qualityVibration measurement in solidsVehicle testingMeasurement deviceEngineering

A noise and vibration diagnosis device and control method thereof are provided for measuring noise and vibration generated in a vehicle. The device may include a measuring sensor configured to be attached at a predetermined position of a vehicle to measure noise and vibration thereof, a signal input portion to which the noise and vibration signal that is generated from the measuring sensor is inputted, and a control portion configured to receive the signal that is transferred from the signal input portion and compare it with a predetermined reference value to output a replacement signal by which it is determined whether the component on which the measuring device is attached is to be replaced or not in accordance with the comparison result. The noise and vibration causing a dissatisfaction that is expressed by a customer can be diagnosed in a short time, and an objective maintenance service is provided such that the mechanic can provide reliable service to the customer. Also, the diagnosis is performed through a standard process to reduce the maintenance time and the cost thereof, and a data base for the maintenance data can be established such that the maintenance data can be commonly used to provide uniform quality among maintenance centers through a network.

Owner:HYUNDAI MOTOR CO LTD +1

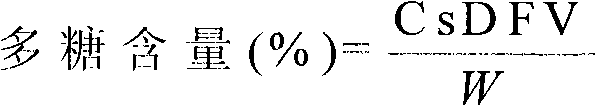

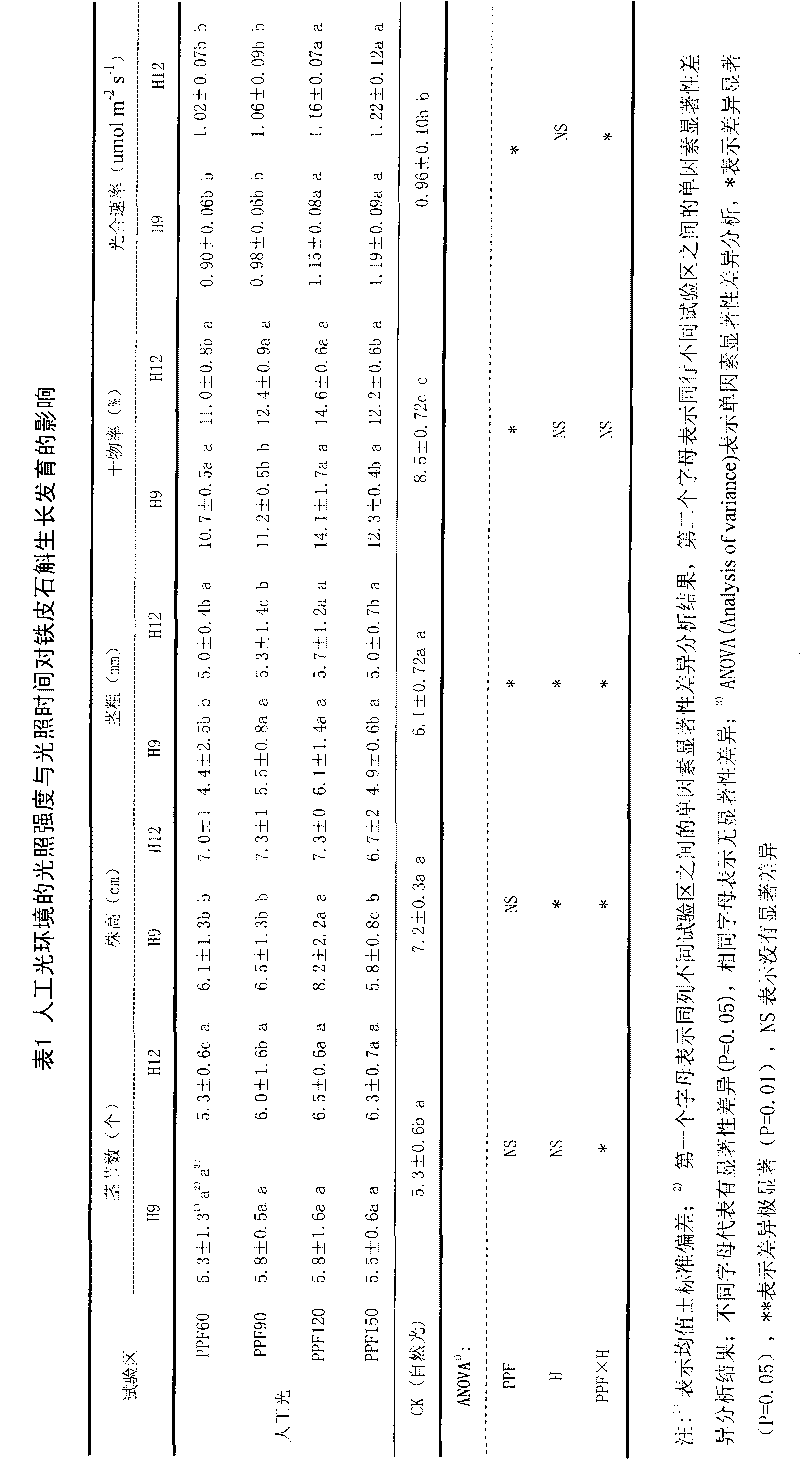

Artificial light cultivating method of dendrobium candidum

ActiveCN101699984AShorten the production cycleUniform qualityColor/spectral properties measurementsAgriculture gas emission reductionAir velocityNutrition

The invention discloses an artificial light cultivating method of dendrobium candidum, belonging to the technical field of medical plant cultivation. The method comprises the following steps: naturalized young plants are transplanted to a nutrition pot or a potted tray containing base material and placed in a three-dimensional cultivating shelf of an artificial light closed plant factory; wherein cultivating conditions are as follows: the illumination intensity is 60-150 mu mol.m-2.s-1; the illumination time is 9-12h.d-1, the temperature is 24-27 DEG C; the relative humidity is 65-80%; the CO2 concentration is 400-800 mu mol.m-1; and the air velocity is 0.3-0.6 m.s-1; after the young plants are transplanted, atomizing keeps the humidifying state of leaf surfaces of the young plants before 2 weeks; after two weeks, the young plants are watered; according to the principle of keeping the humidification of the base material, macroelement nutrient solution is applied every 7 to 15 days; microelement nutrient solution is applied every 25 to 35 days; bottom surface is watered every 3 to 5 days; the young plants are harvested after being cultivated for 1.5 to 2 years and every half year is a picking time. The method shortens the production period, guarantees the uniform quality of the products, increases the yield, and is easy to realize standardization, industrialization and scale production.

Owner:CHINA AGRI UNIV

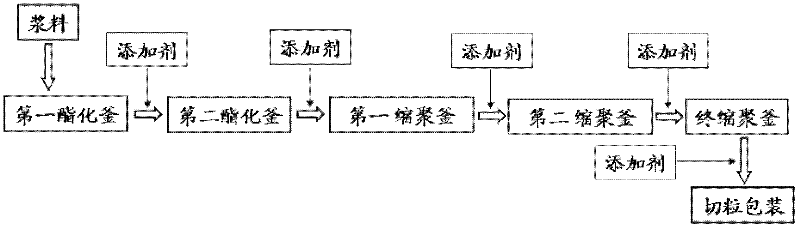

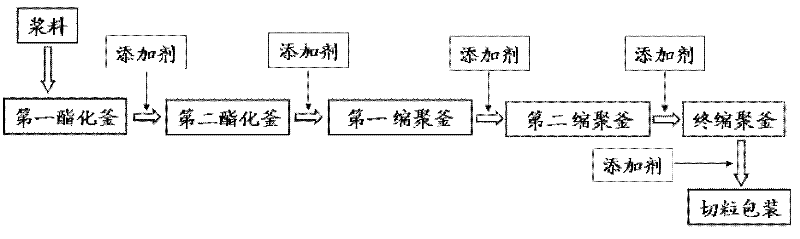

Method for continuously preparing biodegradable plastic

The invention discloses a method for continuously preparing biodegradable plastic, which consists mainly of the steps of continuously adding slurry prepared from one or more dibasic acid and one or more diol into a first esterification kettle, allowing esterification to obtain homopolyester or copolyester oligomer, allowing further esterification in a second esterification kettle to obtain an esterified substance, continuously introducing the esterified substance to a first condensation kettle, allowing condensation to remove small molecule under the condition of low vacuum and obtain prepolymer, continuously introducing the prepolymer to a high-vacuum second condensation kettle, allowing condensation to remove small molecule and obtain polymer, and subjecting the polymer to continuous thickening and polymerization in a final condensation kettle having a thickening function to obtain biodegradable plastic sections with high molecular weight and melting index smaller than 5. The inventive process has simple operation and high automation degree, and the obtained biodegradable plastic sections have uniform quality and no batch difference.

Owner:SHANGHAI JUYOU CHEM ENG

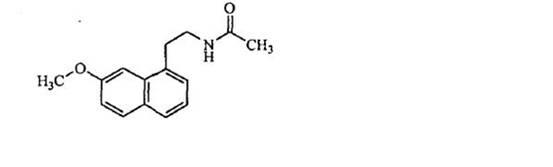

Pharmaceutical composition for treating depression

The invention belongs to the technical field of medicines, and discloses a pharmaceutical composition for treating depression. The pharmaceutical composition is composed of a raw material agomelatine and auxiliary materials, wherein the raw material agomelatine is micronized agomelatine. Based on a deep research of the physical and chemical properties of agomelatine, the scientific researchers of the company accidentally find that agomelatine can be micronized for obtaining agomelatine with a certain particle size to produce a preparation, the invention has the advantages of uniform quality and good dissolution rate.

Owner:北京美迪康信医药科技有限公司

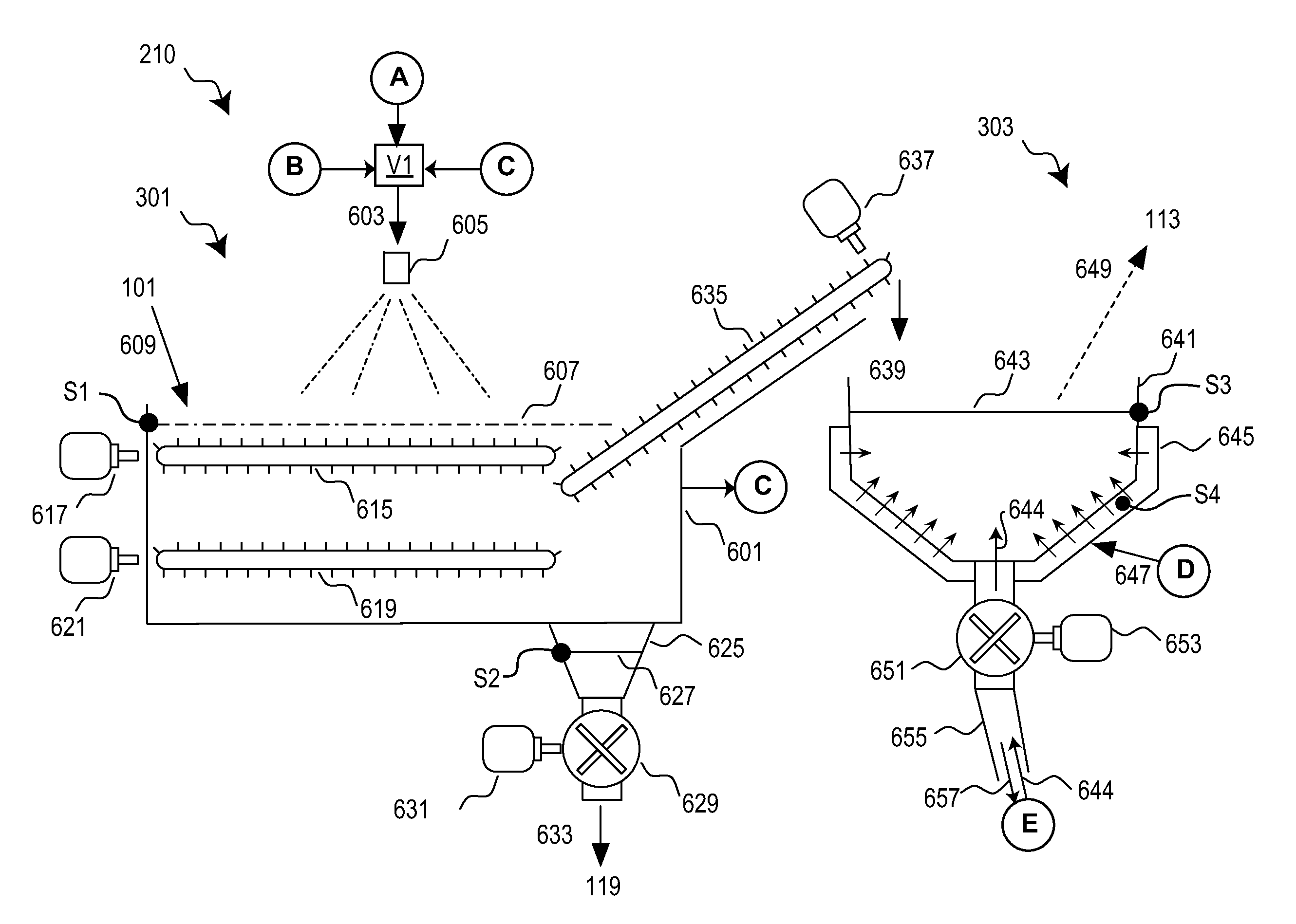

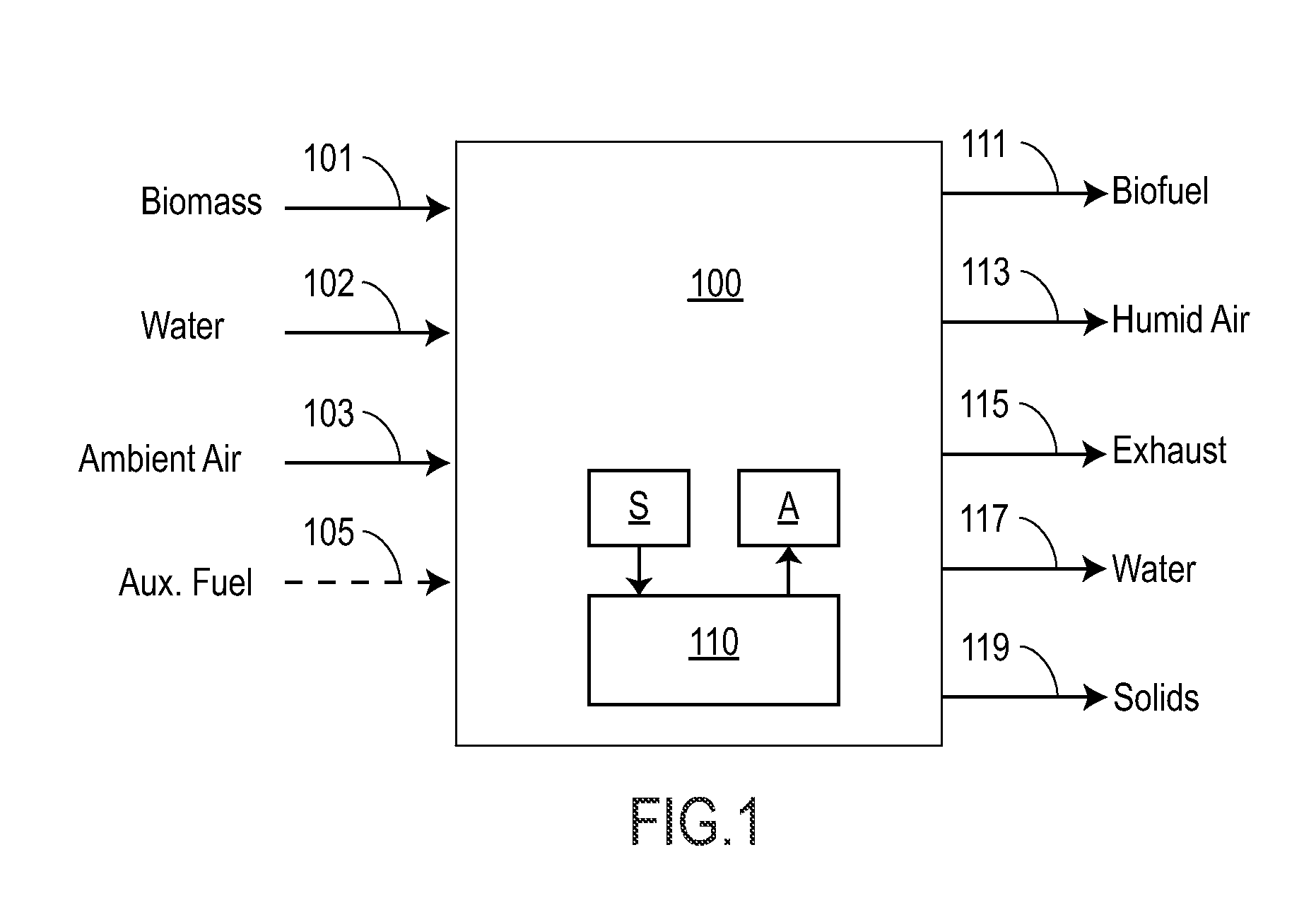

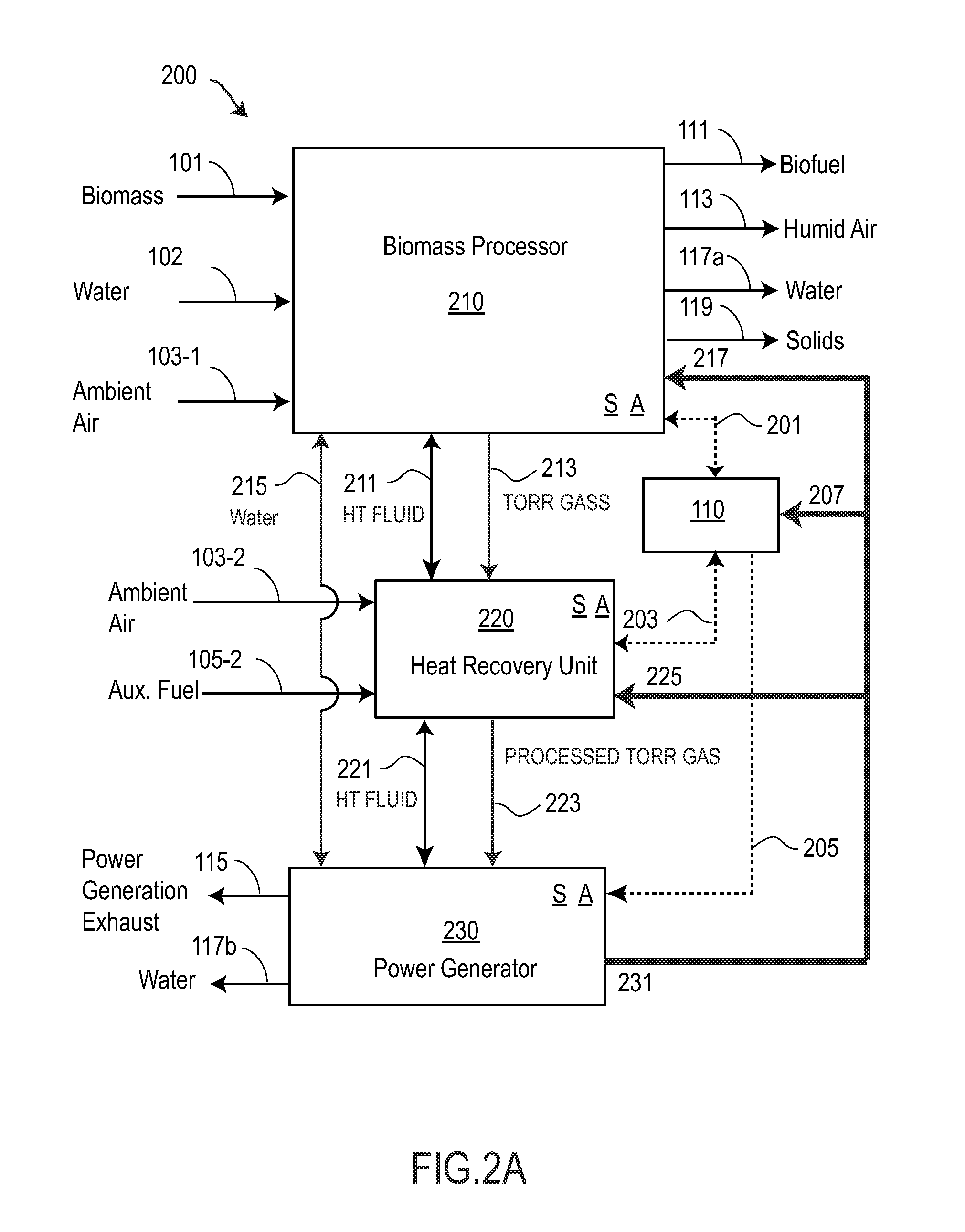

Device and method for controlling the conversion of biomass to biofuel

InactiveUS20120117815A1Drying solid materials with heatDrying solid materials without heatControl systemSolid fuel

Embodiments presented herein describe an apparatus and method to control the conversion of carbonaceous materials, particularly biomass and those biomass resources, into a high performance solid fuel. This method, and the apparatus described as the means to accomplish this method, provides a process having a control system that enables the system to produce a fuel of uniform quality, even with a change in biomass supply.

Owner:RENEWABLE FUEL TECH

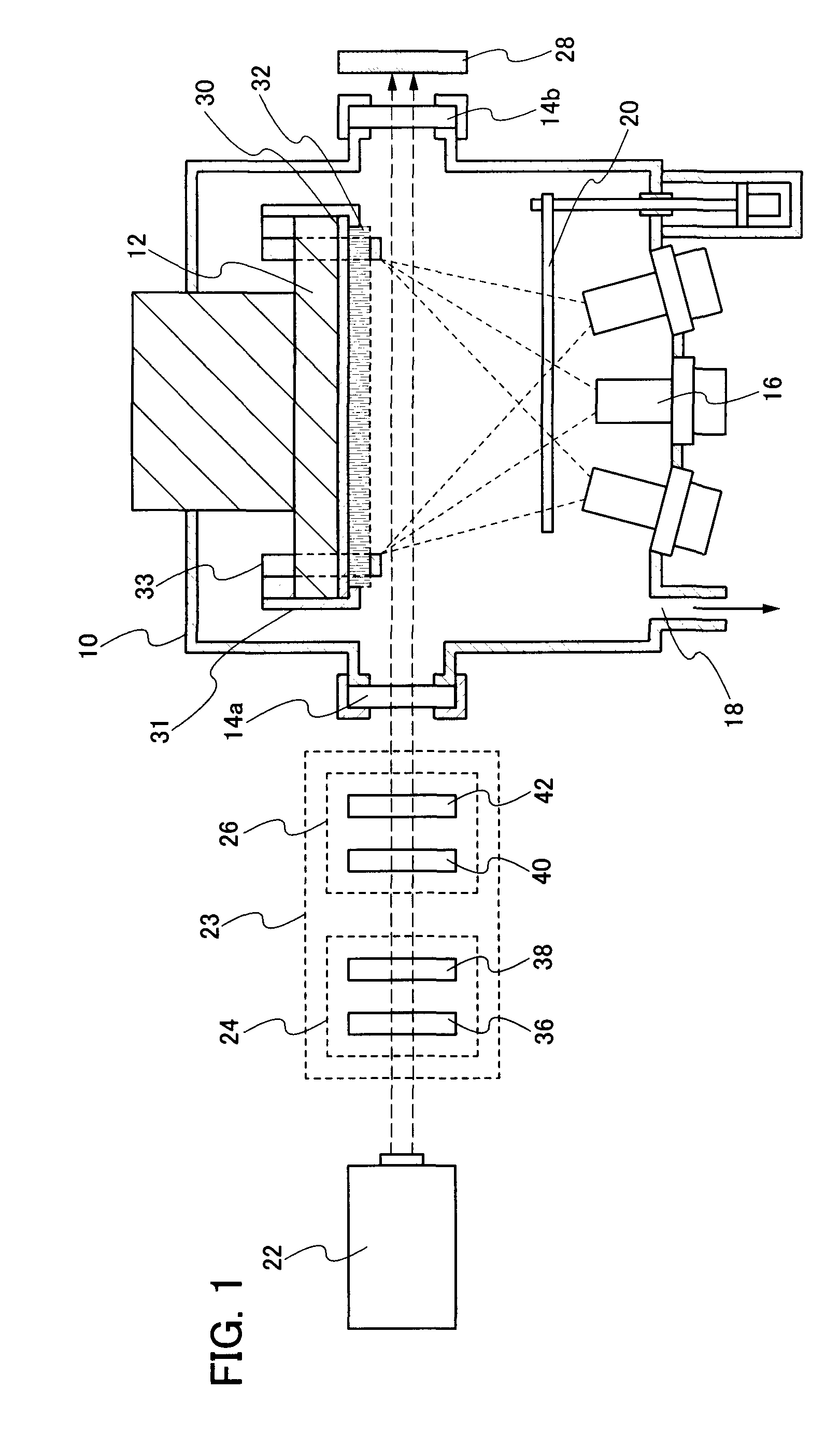

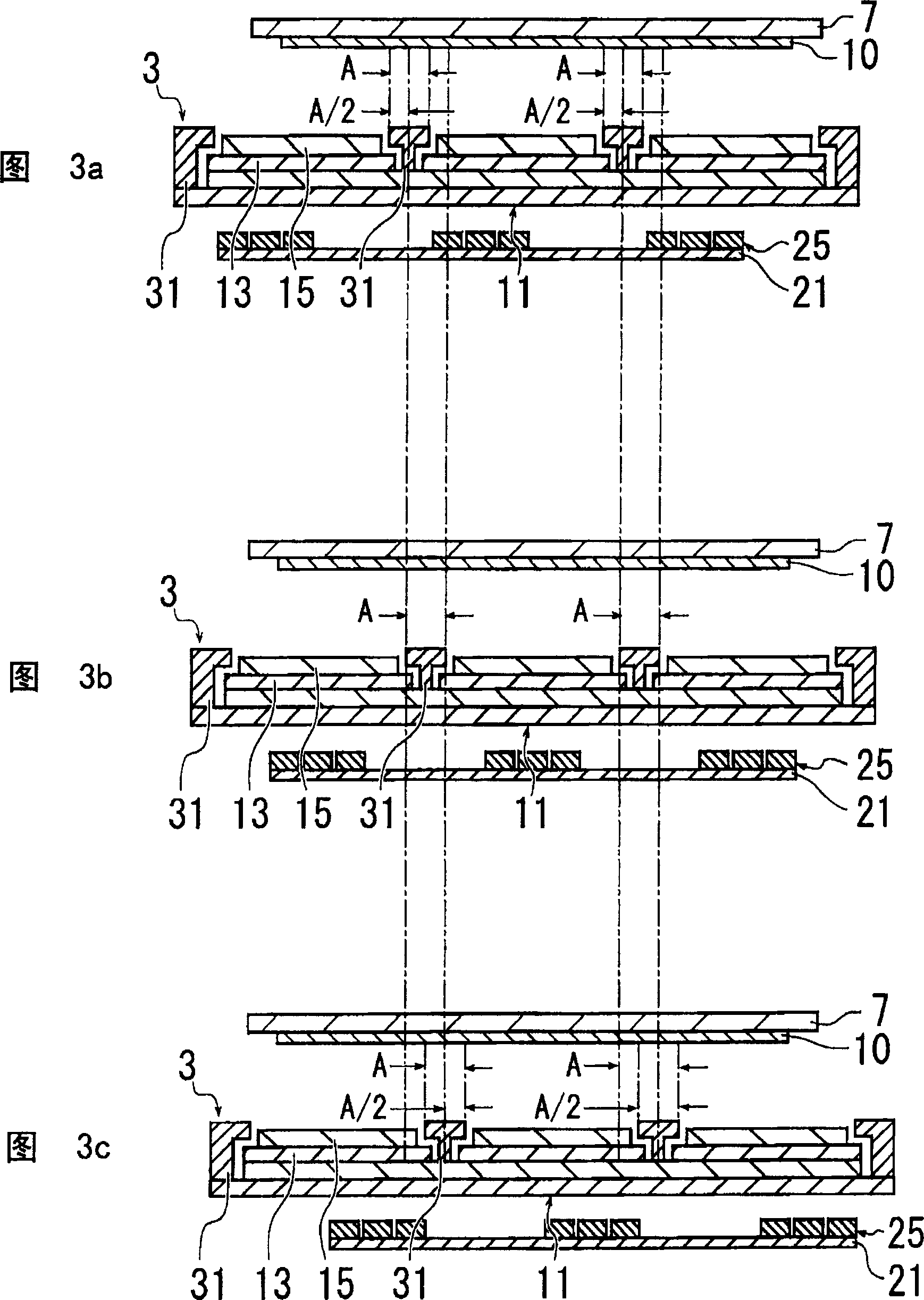

Sputter source, sputtering device, and sputtering method

When sputtering a target 15, each target 15 is moved with respect to the substrate 10. Therefore, the entire area of the substrate 10 faces the target 15 at sputtering, which enables the formation of the film with a uniform quality on the surface of the substrate 10. At sputtering, not only the target 15 but also a magnetic field-forming unit 25 are moved with respect to the target 15, so a large area of the target 15 can be sputtered. If the magnetic field-forming unit 25 is moved with respect to the substrate 10, an extensively sputtered area of the target 15 is moved with respect to the substrate 10, which yields a more uniform quality distribution in the film formed on the substrate 10.

Owner:ULVAC INC

Walnut cake making method

The invention discloses a walnut cake making method. A formula and a making process are included in the walnut cake making method. By adopting the technical scheme that the formula with wheat flour, edible blend oil, white granulated sugar, malt sugar as major constituents is used in cooperation with the making process, the defects of high working intensity, low working efficiency, high cost, poor mouthfeel and non-uniform quality of the prior art are overcome. By means of the walnut cake making method, walnut cake making is suitable for semi-mechanized mass production in small-and-medium-sized food enterprises, and the purposes of reducing working intensity, improving working efficiency, reducing cost, improving mouthfeel and keeping quality uniform are achieved.

Owner:NINGBO CAOHU FOOD

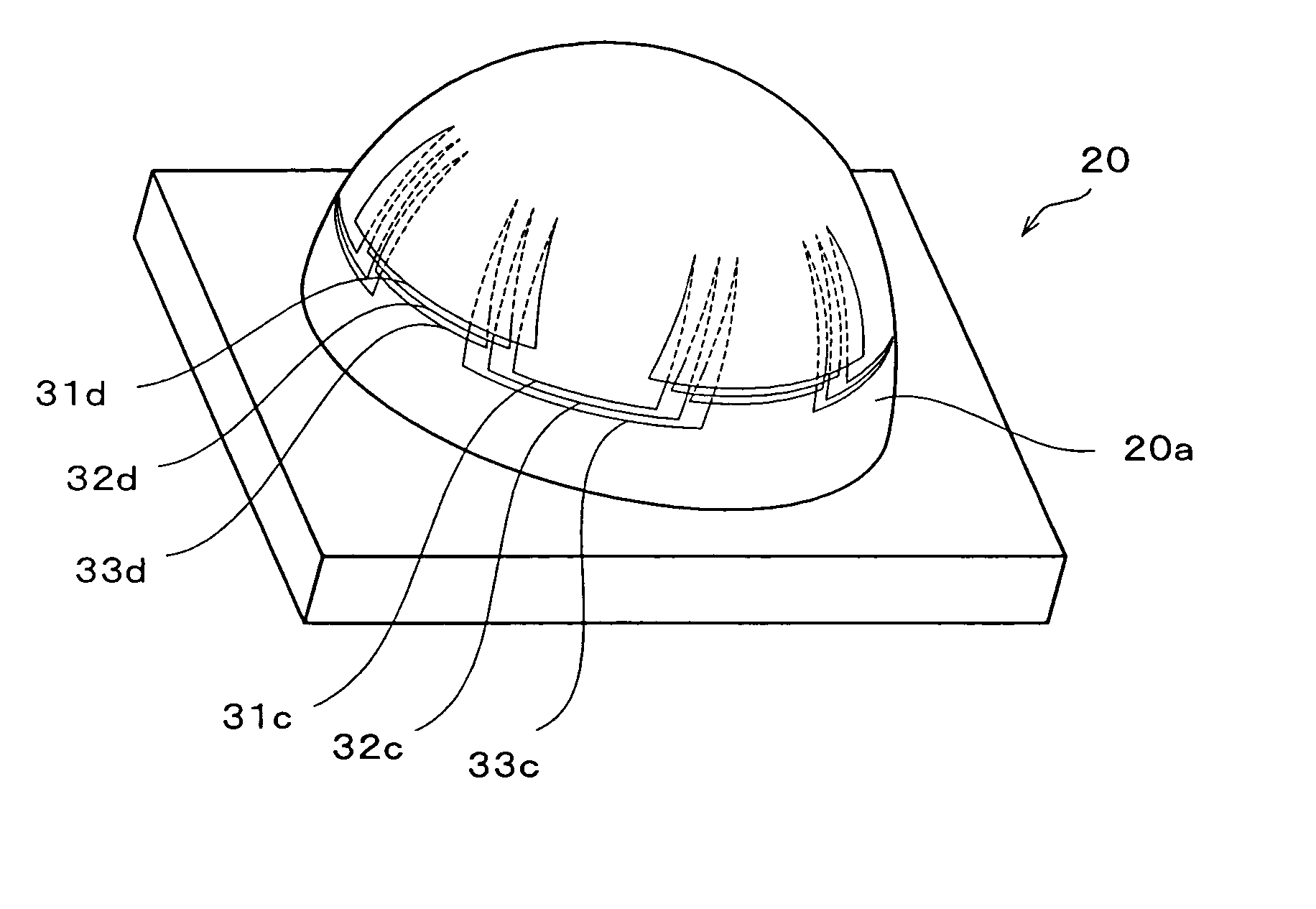

Method of producing formed product of fiber-reinforced composite material and the formed product

ActiveUS20050253294A1Reduce dispersionShort timeFrameless domesDomestic articlesFiber-reinforced compositeThree dimensional shape

A method is presented for stably, highly, and efficiently producing a three-dimensional molded article of a fiber-reinforced composite material having a three-dimensional shape, uniform quality, and free from wrinkles by press molding a plurality of prepregs cut out in a predetermined shape and also to a molded article.

Owner:MITSUBISHI CHEM CORP

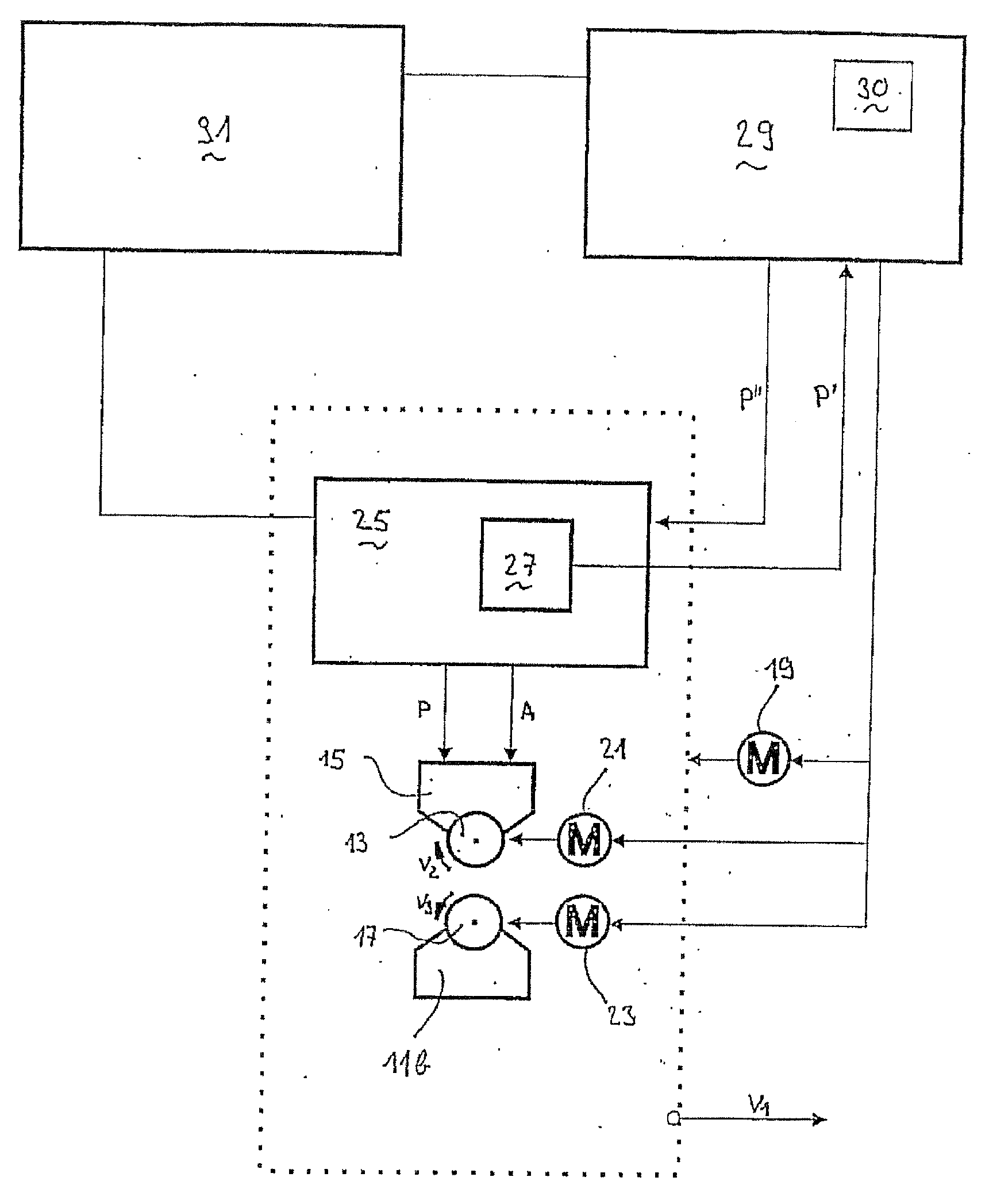

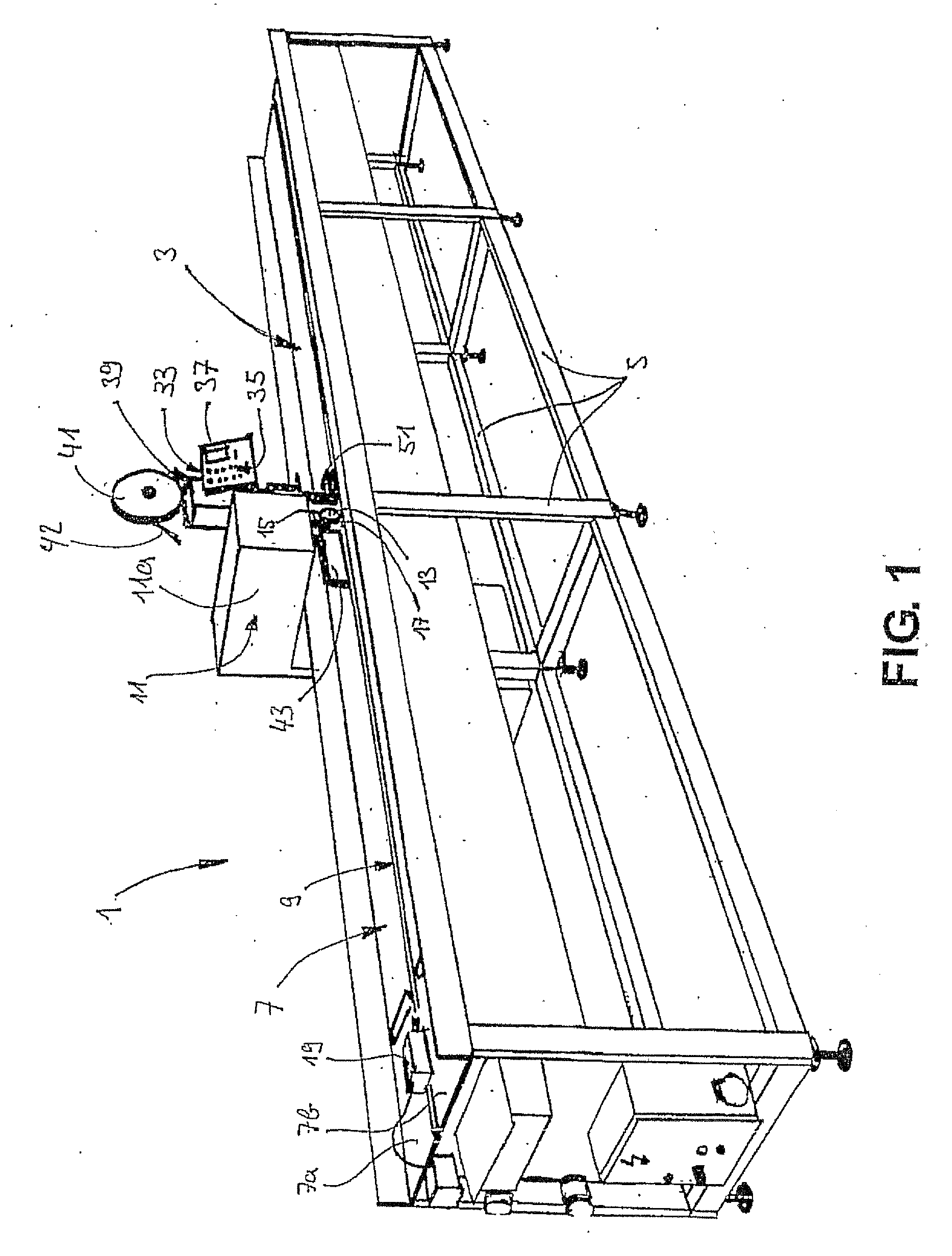

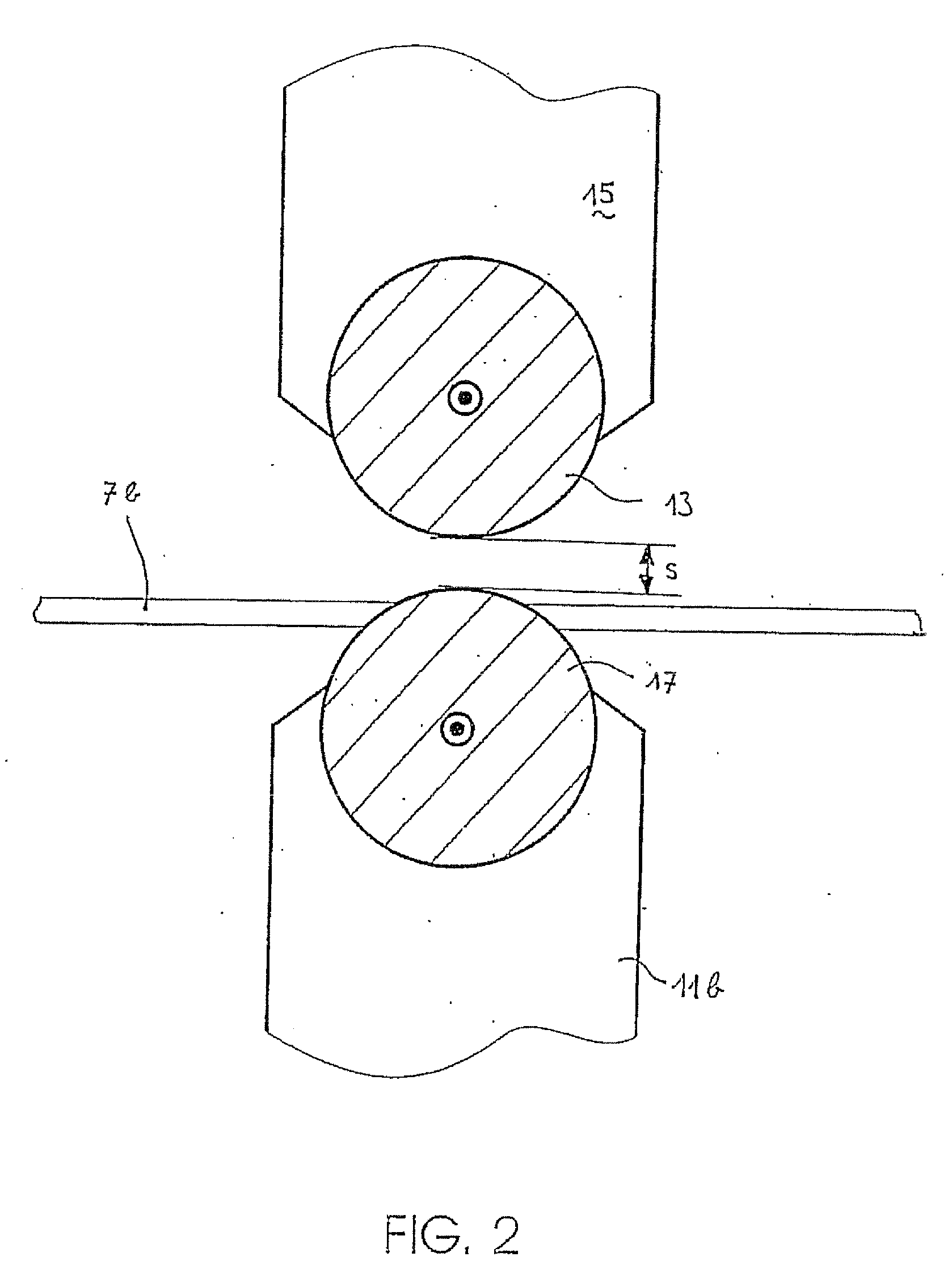

Ultrasound welding device

InactiveUS20070158012A1Reduce energy consumptionPower peakMechanical working/deformationLaminationLoop controlUltrasonic welding

The ultrasonic welding device (1) comprises a continuously operable roller sonotrode (13). The power of the roller sonotrode (13) may be closed-loop controlled depending on other welding parameter in a manner such that long welding seams or adhesive seam with a uniform quality may be manufactured. The method may be used for manufacturing canopies, tarpaulins, or pieces of clothing

Owner:JENTSCHMANN ZURICH

Preparation method for rose tea

InactiveCN104304594ABeautiful appearance and not brittleBright colorTea substituesUniform - qualityWater content

The invention relates to a preparation method for rose tea. The preparation method specifically comprises the following steps: (1) withering collected fresh roses and controlling the water content to be 90 to 95 percent; (2) performing deactivation on the withered roses at 180 to 200 DEG C; (3) spreading and air-drying the roses subjected to deactivation for 15 to 20 minutes to fully dissipate heat, drying the roses for four times, controlling the temperature of the dried rose tea to be 100 to 120 DEG C for fragrance extraction to obtain peculiar fragrance of the rose tea which is slightly sweet in taste and rosy, refining the rose tea by the grade, performing checking according to the particle sizes, colors and uniform quality standards of the rose tea, and packaging, weighing and warehousing qualified products. The rose tea obtained by the preparation method is attractive in appearance, non-fragile and bright in color, is lovely as fresh flowers when being impregnated in water, and is deeply loved by females.

Owner:贵州遵义铭东商贸有限公司

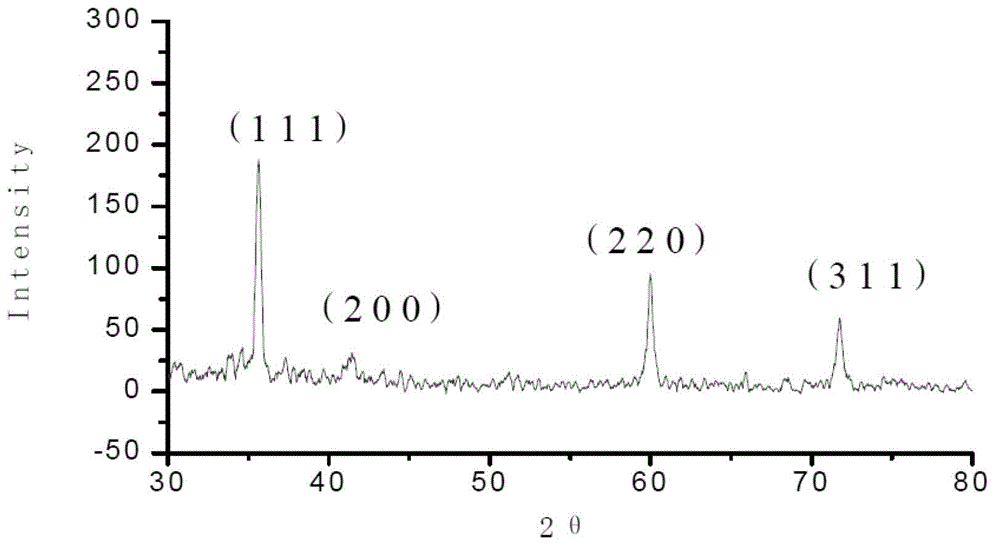

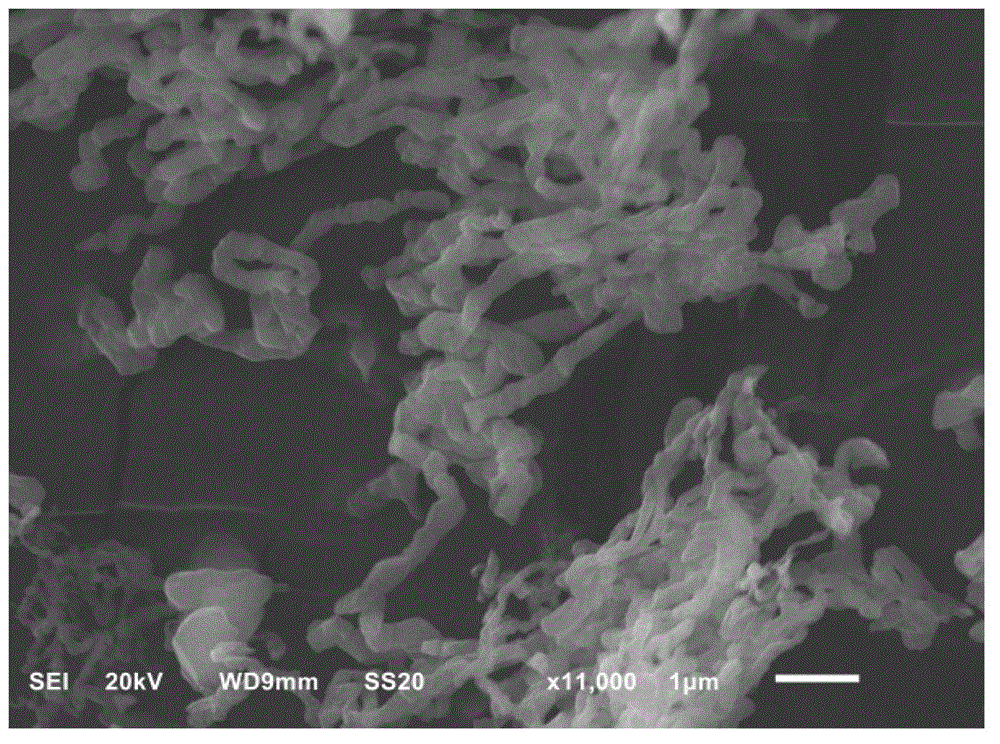

High purity linear silicon carbide powder and preparation method

The invention relates to a high purity linear silicon carbide powder and a preparation method, the linear silicon carbide powder product presents light green color and has a cubic crystal system, a microstructure presents a linear state, and the content of the silicon carbide is no less than 99%. The preparation method provided by the present invention comprises the following steps: silica sol and oxidized graphene are uniformly mixed, then subjected to ultrasonic treatment, and completely stirred to obtain a composite precursor. The composite precursor is subjected to solidification, drying and grinding to obtain a powdery precursor with fine and uniform quality. Argon is introduced in the powdery precursor, a carbon thermal reduction is carried out under high temperature in a high temperature tubular furnace to obtain the carbonized silicon powder crude product; the carbonized silicon powder crude product is immersed in inorganic acid and then the pumping filtration is carried out, the unreacted carbon is removed, and cooled to obtain the silicon carbide powder with content of less than 99%. According to the invention, a silicon source is silica sol, a carbon source is oxidized grapheme, the invention has the advantages of no requirement of subsequent processing, no requirement of pressurization, addition of metal catalyst, simple process and short production period; the precursor with homogeneousness is prepared in advance, then the carbon thermal reduction is carried out, the product purity is high, and the method provided by the invention enables large-scale industrial production.

Owner:HUBEI UNIV +1

Anthocyanin rice wine and making method thereof

InactiveCN101906371AHigh in nutrientsFull of nutritionMicroorganism based processesAlcoholic beverage preparationVitamin CFood flavor

The invention discloses rice wine and a making method thereof, in particular anthocyanin rice wine and a making method thereof. The anthocyanin rice wine is prepared from the following raw materials in part by weight: 650 to 850 parts of cooked sticky rice, 65 to 85 parts of cooked purple sweet potato paste, 2 to 4 parts of Tianjiucao and 12 to 20 parts of yeasts. The rice wine of the invention contains anthocyanin of which the free radical removing capacity is 20 times that of vitamin C and 50 times that of vitamin E. The purple sweet potatoes contain proteins which can be absorbed and digested by human bodies easily, 18 kinds of amino acids, vitamins A, B, C and the like and various mineral elements including phosphorus, iron, zinc, copper, manganese, calcium, selenium and the like. The rice wine of the invention has the characteristics of rich nutrients, unique flavor, high health-care function, high stability and uniform quality.

Owner:SUIZHONG SIWEITEEN BIO TECH

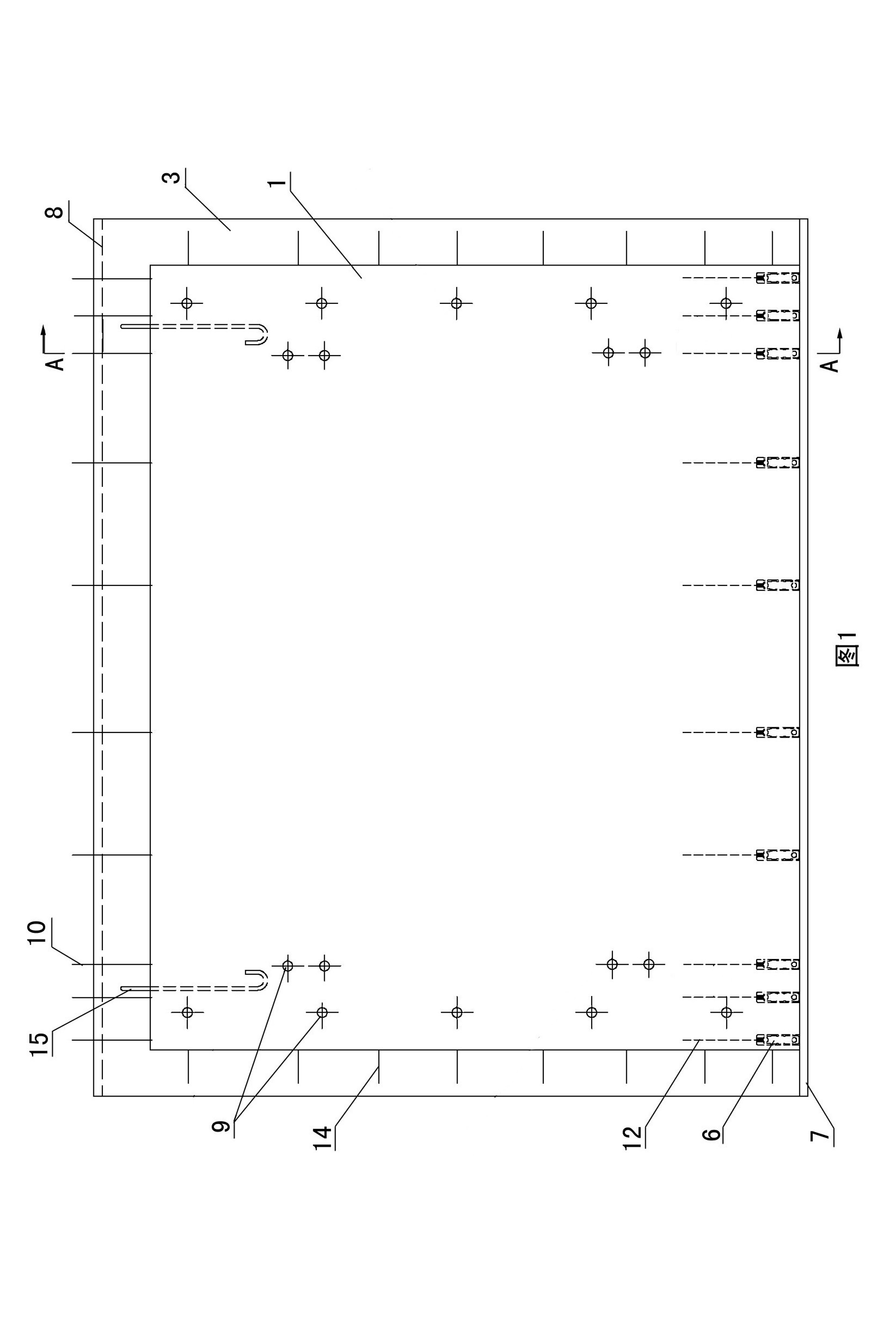

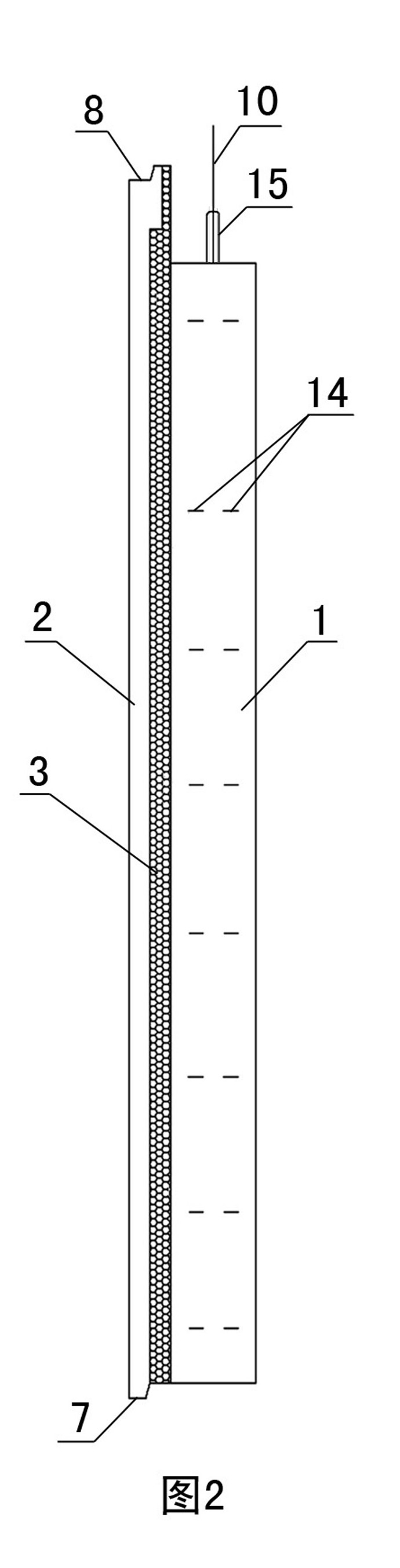

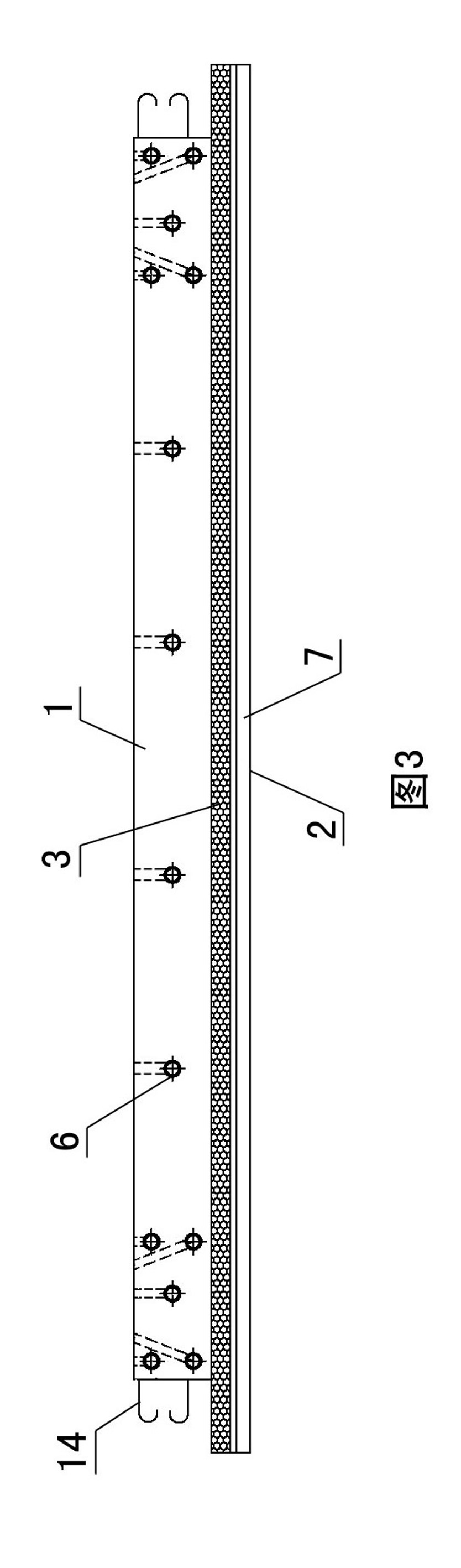

Precast composite outer insulated wall plate and manufacturing method thereof

ActiveCN101831986AGuarantee the construction qualityLow costConstruction materialBuilding material handlingReinforced concreteArchitectural engineering

The invention relates to a precast composite outer insulated wall plate and a manufacturing method thereof. The plate body of the precast composite outer insulated wall plate is sequentially provided with a structural layer, an insulated layer and a protective layer from inside to outside, wherein a reinforcing cage is arranged in the structural layer; a reinforcing mesh is arranged in the concrete of the protective layer; the structural layer, the insulated layer and the protective layer are alternately anchored together through connecting pieces which are in point distribution; the left edges and the right edges of the protective layer and the insulated layer protrude out of the structural layer; a convex opening downwards extends from the lower edge of the protective layer; the tops of the protective layer and the insulated layer upwards protrude out of the structural layer; and the upper edge of the protective layer is provided with a concave opening corresponding to the convex opening of the adjacent precast composite outer insulated wall plate at the upper layer. The wall plate simplifies the construction processes, accelerates the construction speed and reduces the engineering cost. Moreover, products precast in factories have consistent specification and uniform quality, the construction quality of the building structure can be fully ensured, industrialization, standardization and generalization of building walls are realized, and the invention can be widely applied to construction of reinforced concrete buildings in building industry.

Owner:华筑(辽宁)建筑工程设计有限公司

Method for processing non-autoclaved foam concrete building blocks in producing phosphogypsum through microwave high temperature

InactiveCN102218766AProcessing speedUniform qualitySolid waste managementCeramic shaping apparatusFoam concreteBrick

The invention discloses a method for processing non-autoclaved foam concrete building blocks in producing phosphogypsum through microwave high temperature, which comprises the steps as follows: solid waste phosphogypsum in the phosphate fertilizer industry is arranged in a microwave tunnel furnace and is heated to 200-770 DEG C for 3-5min to lead a plurality of impurities in the phosphogypsum like phosphoric acid, calcium fluoride, iron aluminum oxide, acid-insoluble matters, organic matters and the like to volatilize or convert into inert materials during the heating process, thereby obtaining beta-type semihydrated gypsum or beta II-type anhydrous gypsum; then the beta-type semihydrated gypsum or beta II-type anhydrous gypsum, fly ashes, cements, quicklime and modified additive are mixed and levigated, then are stirred with water and gypsum waterproofing agent, and finally are uniformly mixed with foams of foaming agent and poured into a building brick die. The method disclosed by the invention has the following advantages: the method has simple technique, low equipment investment and lower manufacture cost and avoids secondary pollution; the microwave high temperature method has quick processing speed and uniform quality; the utilization amount of phosphogypsum waste residues is large and the utilization rate is as high as 60-70 percent; moreover, the building blocks belong to obturator structures and has good insulating effect, high strength and good waterproof performance.

Owner:许祯玮 +3

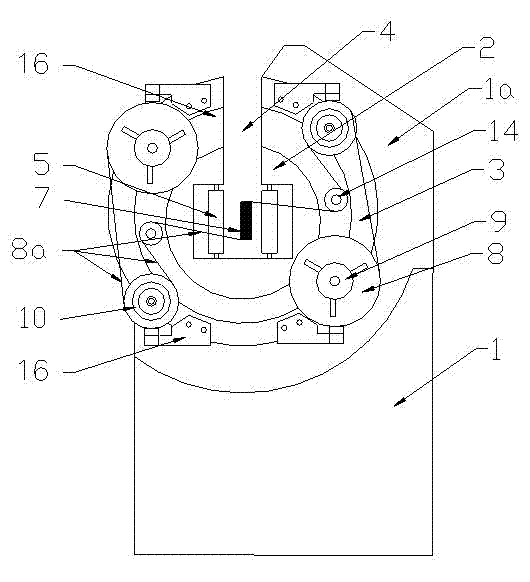

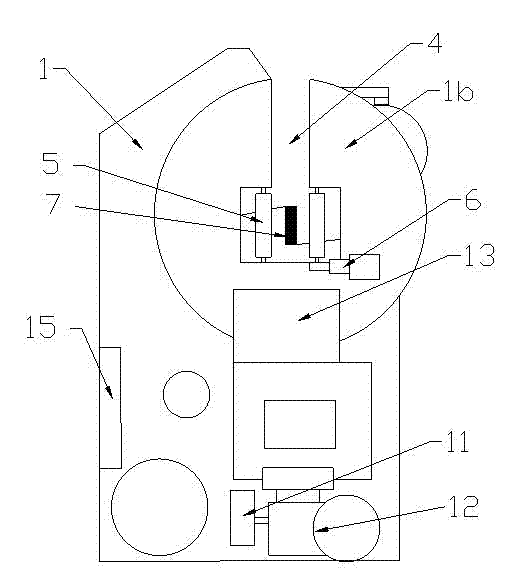

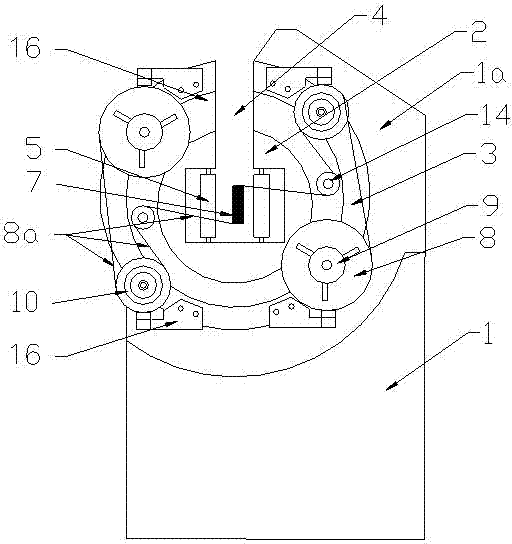

Wrapping head

ActiveCN102185435AUniform qualityGuaranteed constant tensionApplying solid insulationUniform - qualityEngineering

The invention discloses a wrapping head of a wrapping machine, particularly relating to a wrapping head of a generator bar wrapping machine. The wrapping head is characterized by comprising a fixing disc with an opening, and an internal ring arranged on the side surface at one end of the fixing disc, wherein the internal ring is internally provided with a roller that can clamp a bar in a rolling way; the internal ring is externally provided with a wrapping ring that can rotate around the internal ring; the rotating speed and the rotating direction of the wrapping ring can be adjusted; openings are arranged at the positions at the internal ring and the wrapping ring, corresponding to the fixing disc; one side surface of the wrapping ring is provided with a chuck and a tensioning wheel, wherein the wrapping disc can be assembled on the chuck; and the tensioning wheel can adjust the tensioning force of a wrapping belt. The wrapping head can ensure that the wrapping belt has constant tension and is not stretched or broken during the wrapping process; the tensioning force can be freely adjusted within 1kg to 15kg, thus meeting the requirements of different strip belt materials; the superposing degree can be controlled by the superposing positions of 1 / 2, 1 / 3 and the ends, thus ensuring the wrapping belt to have uniform quality.

Owner:GOODE EIS SUZHOU CORP LTD

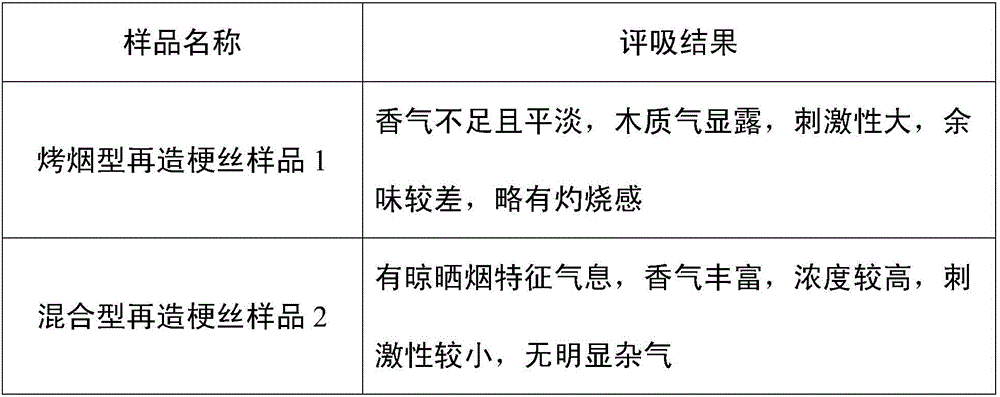

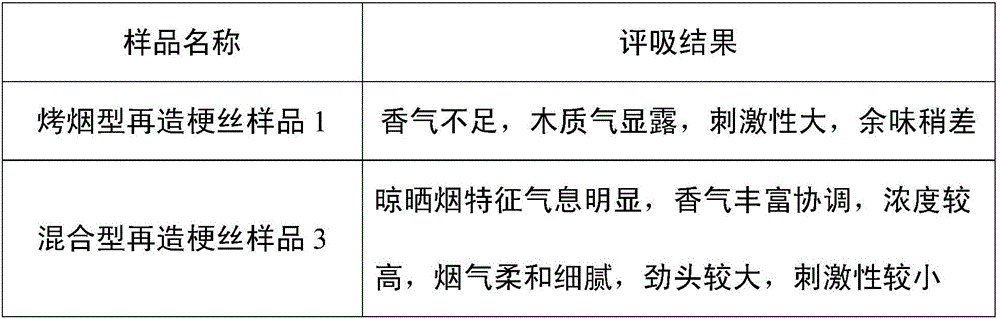

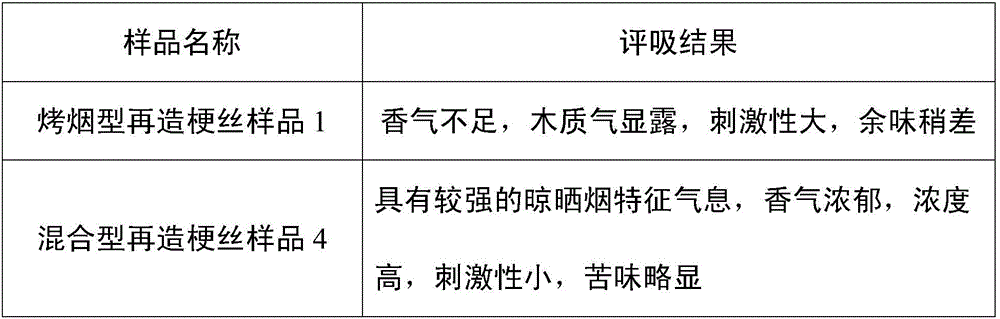

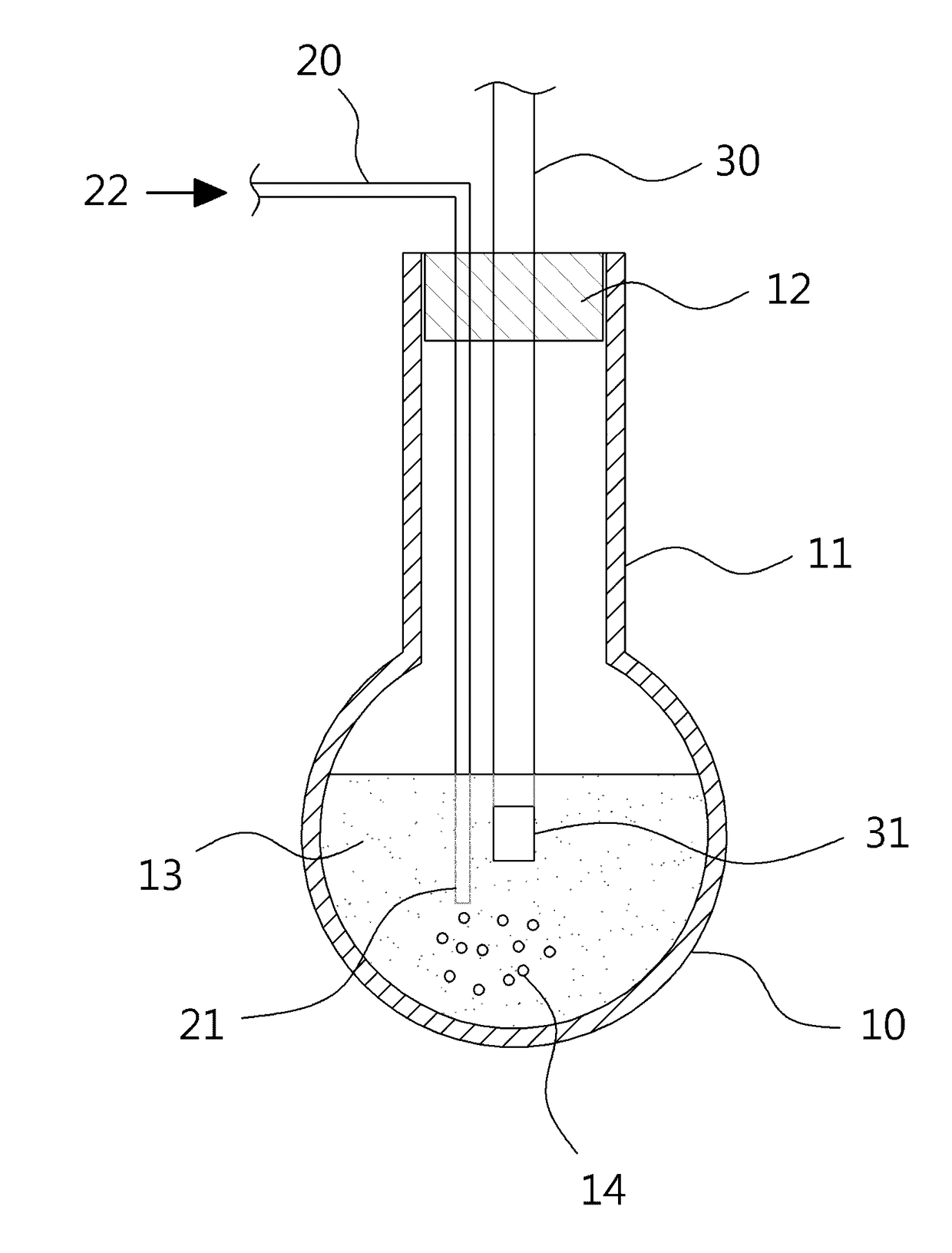

Preparation method of mixed type regenerated cut stems

InactiveCN105707970AIncrease the amount of aromaIncrease smoke concentrationTobacco preparationTobacco treatmentUniform - qualityPre treatment

The invention discloses a method for preparing mixed reconstituted shredded stems, which is characterized in that it comprises the following steps: S01, preparation of blank shredded stems: the pretreated tobacco stems are sequentially cut into shreds, extracted, separated from solid and liquid, and dried Drying process to produce blank shredded stems with uniform quality; S02, sequentially extracting mixed tobacco raw materials, separating solid and liquid, and concentrating the extract to obtain a backfill stock solution; S03, adding a functional flavoring liquid to the backfill stock solution , preparing a backfill solution; S04, spraying the backfill solution evenly on the blank cut stems, fully stirring and mixing, and then drying to obtain a mixed-type reconstituted cut stem finished product. The invention provides a method for preparing mixed reconstituted cut stems. The mixed reconstituted cut stems prepared by this method can significantly increase the aroma and smoke concentration of reconstituted cut stems, enhance the sense of satisfaction and comfort when smoking, and improve the quality of reconstituted cut stems. Stem product quality.

Owner:CHINA TOBACCO JIANGSU INDAL

Tissue cultivation rapid breeding method of spring dendrobium stem

ActiveCN101180950AImprove seedling qualityImprove qualityCultivating equipmentsHorticulture methodsShoot apexBud

A fast propagation method of tissue culture of Dendrobium primulinum Lindl belongs to the technical field of plant fast propagation. The method is characterized by comprising the steps: 1) a young stem of the Dendrobium primulinum Lindl with a length of 3 to 5cm is chosen as an explant; 2) the treating of the explant; 3) inoculation and culture for 10 to15 days in an aseptic inoculation chamber; 4) a survived stem tip is transferred to a inducing medium for inducing an adventitious bud or a protocorm which, after 30 to 40 days, is transferred to a reproducing medium for reproducing of 2 to 3 months; 5) successive transfer and rooting culture; 6) a single plant is transplanted in a 128 plug-tray. The fast propagation method of tissue culture of the Dendrobium primulinum Lindl is not affected by seasons. Due to the easy controlled propagation environment, the Dendrobium primulinum Lindl adapts to various places of China. Therefore, the problems of hard-breeding, easy degeneration, quick variation and irregular seedling quality of the Dendrobium primulinum Lindl are resolved. Seedlings of the Dendrobium primulinum Lindl with good and uniform quality are produced and have wide market prospect.

Owner:ZHEJIANG SENHE SEED

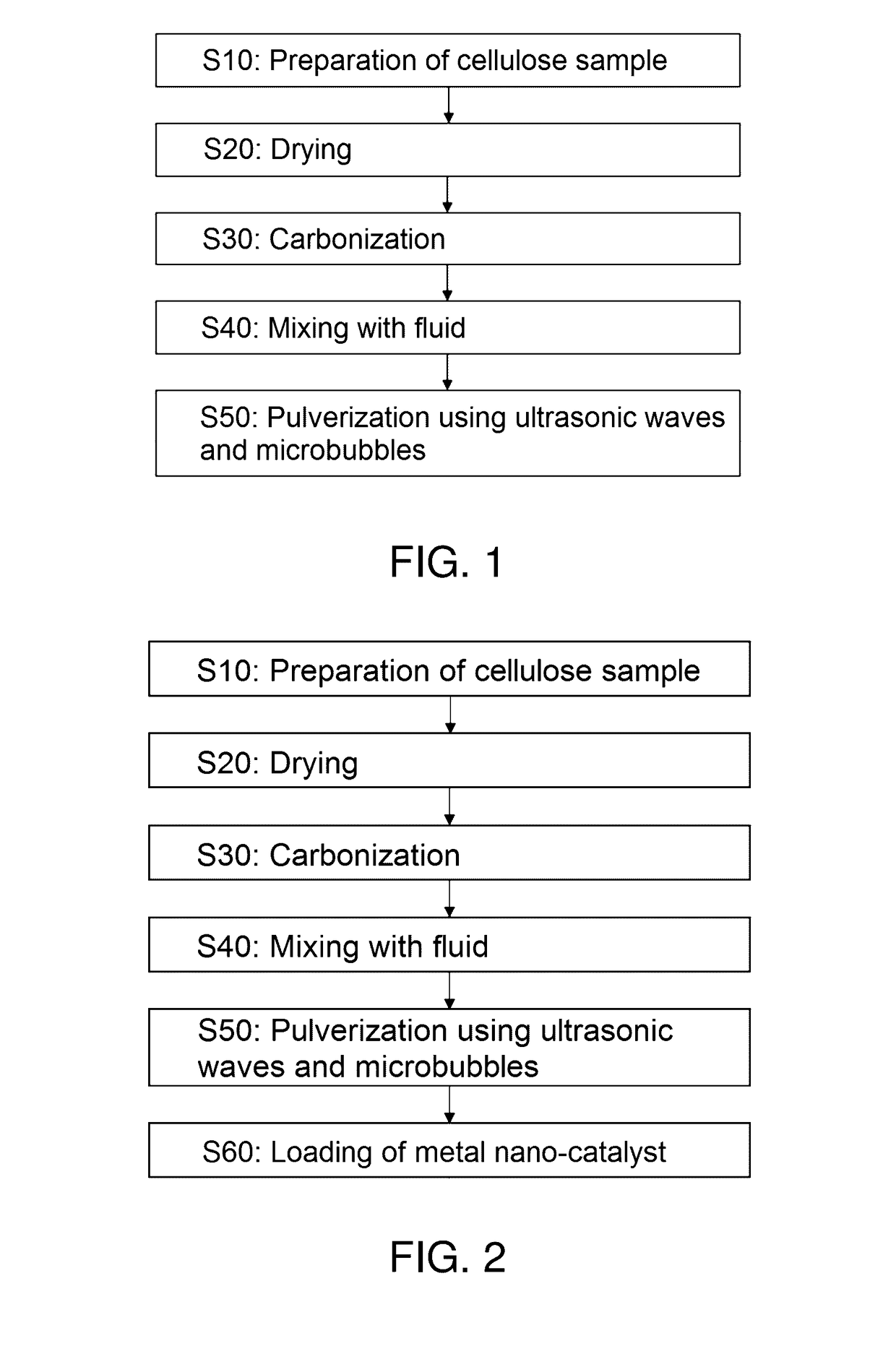

Method of preparing minute carbonized cellulose and method of preparing catalyst support using the same

ActiveUS20170098827A1Increase surface areaReduce manufacturing costCell electrodesBiofuelsManufacturing cost reductionMicro nano

Disclosed is a method of manufacturing carbonized fine cellulose, which enables the formation of carbonized nano-sized cellulose by subjecting cellulose to drying, carbonization, and pulverization by means of shock waves using ultrasonic waves and microbubbles, thus realizing mass producibility, making it possible to fabricate a carbonized nano-sized material having uniform quality, and reducing the manufacturing costs. The carbonized fine cellulose is in the form of a nano-sized uniform carbon powder, and can thus be utilized as a catalyst support in various forms, such as fuel cell electrodes, electrodes of energy storage devices such as supercapacitors or secondary batteries, catalyst supports for micro-nano hybrid reactors, etc.

Owner:KOREA INST OF ENERGY RES

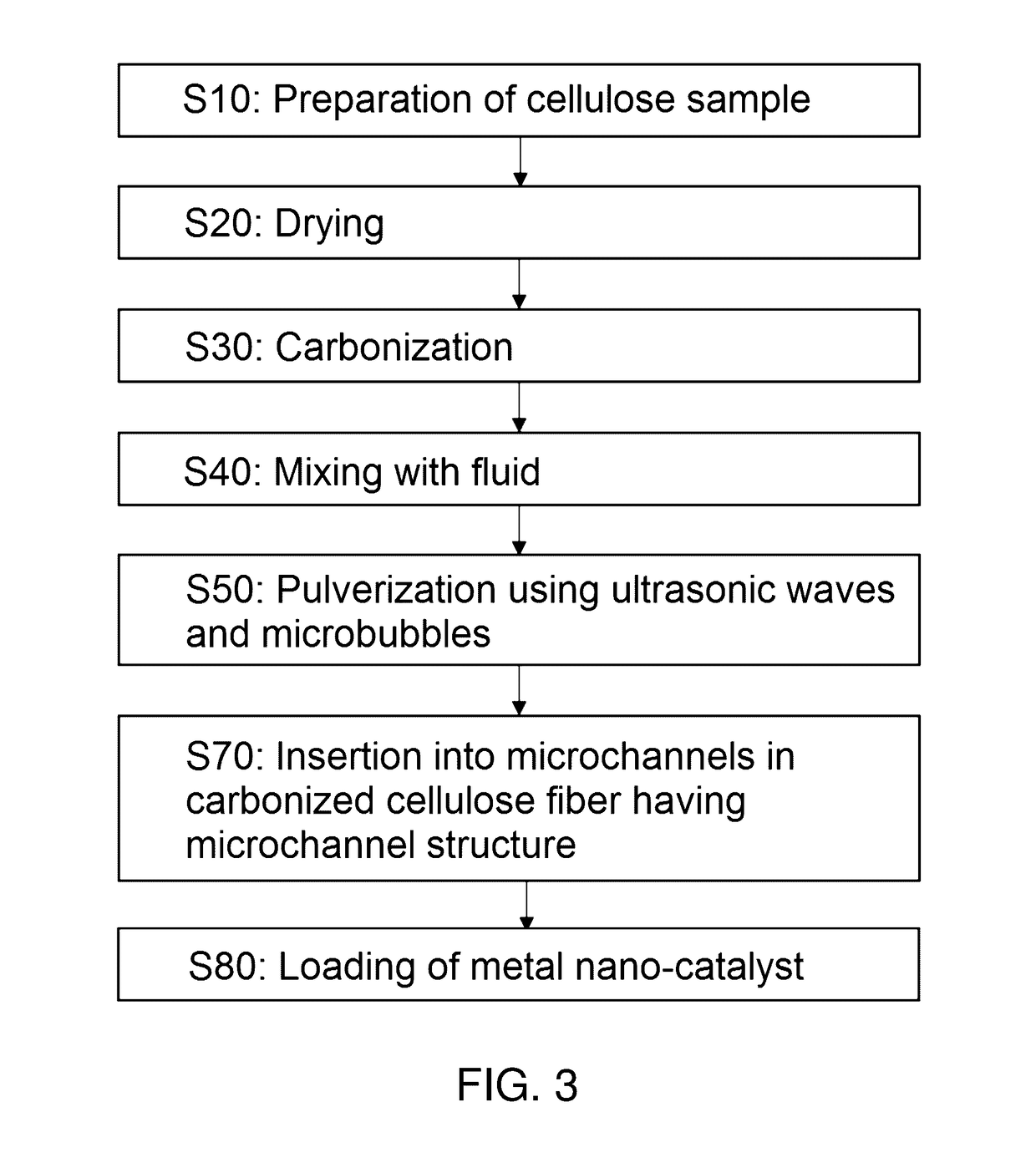

Method for treating dyeing wastewater and dedicated device

InactiveCN101538100ASimple processLow costTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisAutomatic controlSlag

The invention provides a method for treating dyeing wastewater and a dedicated device. The method comprises the following steps of treatment under the automatic control of a central control unit: A, discharging the dyeing wastewater which is uniform quality and uniform quantity into a flocculation precipitating tank, and adding coagulating agent and flocculating agent to the flocculation precipitating tank so as to precipitate the suspended substance and part of organic substances; B, discharging the clear liquid of the wastewater in step A into a hydrolytic acidification tank, and decomposing the macromolecular organic substances in the wastewater into micro molecular substances under the action of facultative anaerobe; C, discharging the wastewater in step B into a contact oxidation tank, feeding air into the contact oxidation tank and decomposing the organic substances in the wastewater under the action of aerobe; D, discharging the wastewater in step C into a membrane bioreactor, and entrapping and decomposing the stale biological membrane slag and the residual organic substances by the membrane bioreactor; and E, sucking the clear water in step D into a clean water tank and discharging the sludge in the membrane bioreactor into the hydrolytic acidification tank or the contact oxidation tank respectively through a return sludge pump by the concentration of the sludge. The invention has the advantages that the treatment cost is low and the treated water is recyclable, thereby helping enterprises to achieve the purposes of energy conservation and emission reduction.

Owner:惠州市雄越保环科技有限公司

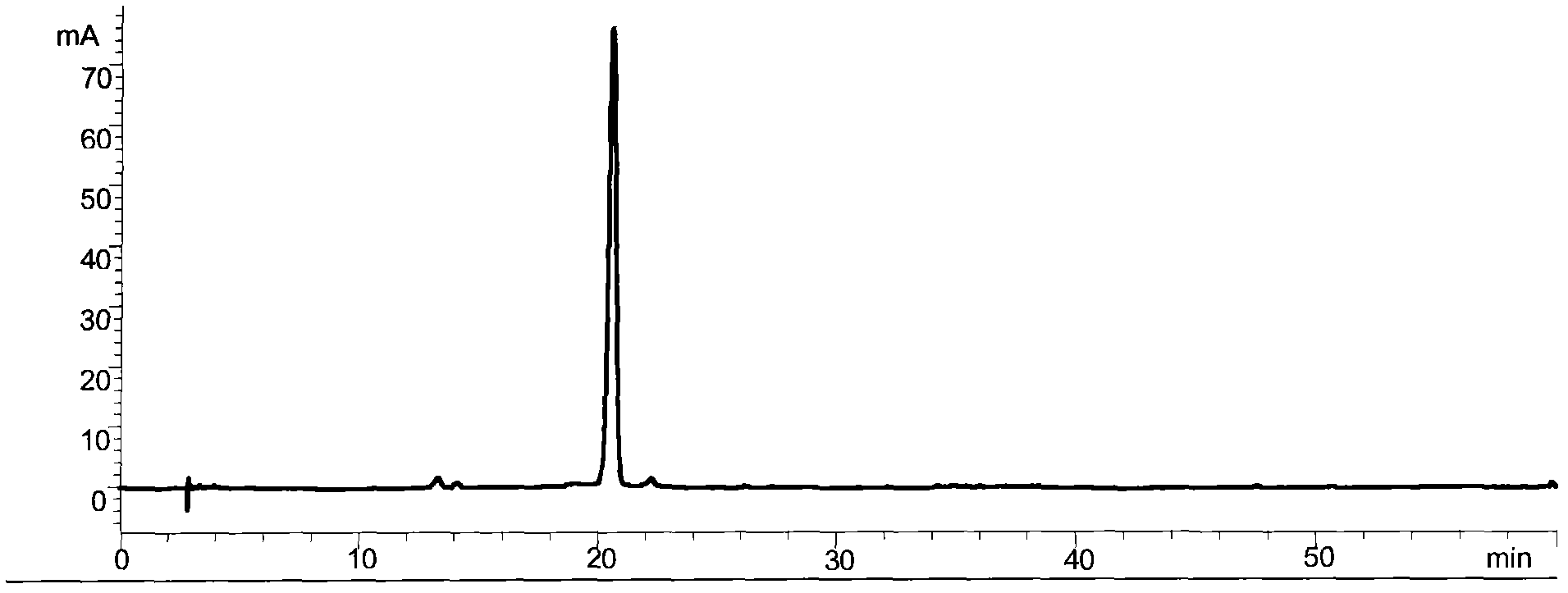

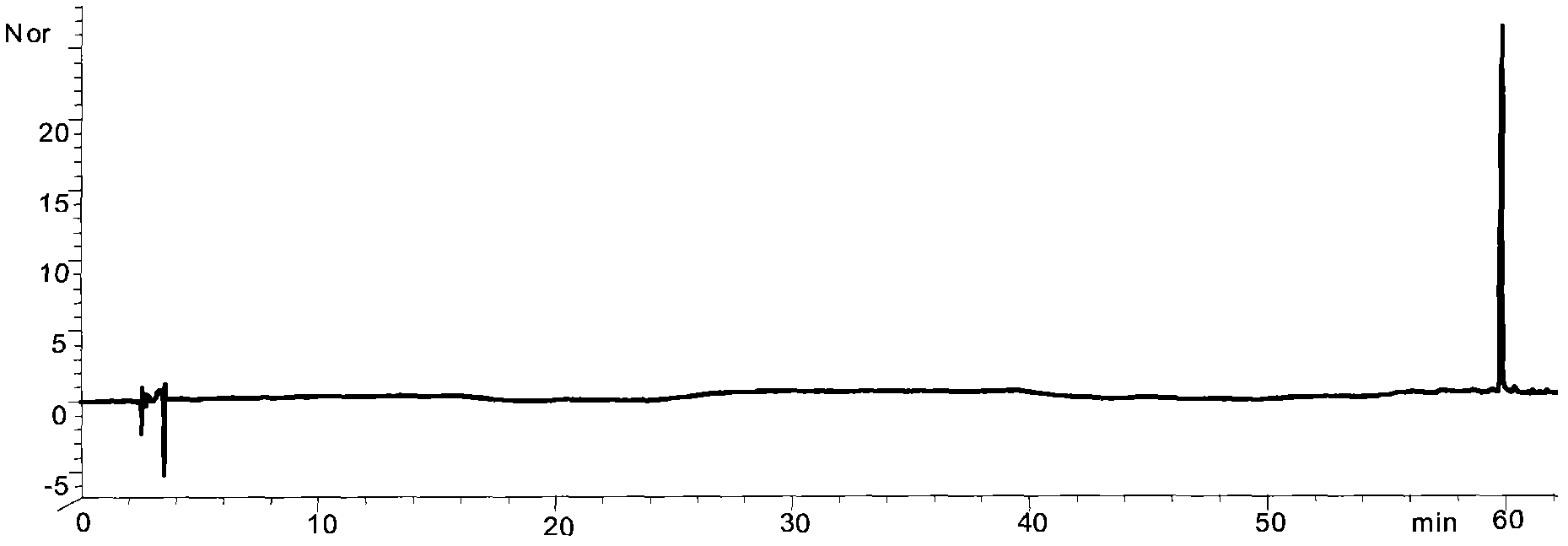

Fingerprint of Polygonum multiflorum and establishment method and application thereof

InactiveCN102114083AGood reproducibilityQuality improvementComponent separationDigestive systemHplc fingerprintPolygonum limbatum

The invention discloses a quality control method of Polygonum multiflorum through the fingerprint thereof. The fingerprint is HPLC (high-performance liquid chromatography) fingerprint obtained through HPLC analysis of Polygonum multiflorum. The fingerprint can be used for completely monitoring the quality of Polygonum multiflorum to ensure the stable and uniform quality of Polygonum multiflorum and related pharmaceutical preparations containing Polygonum multiflorum. The invention further discloses the establishment method and the application of the fingerprint of Polygonum multiflorum.

Owner:KANGMEI PHARMA

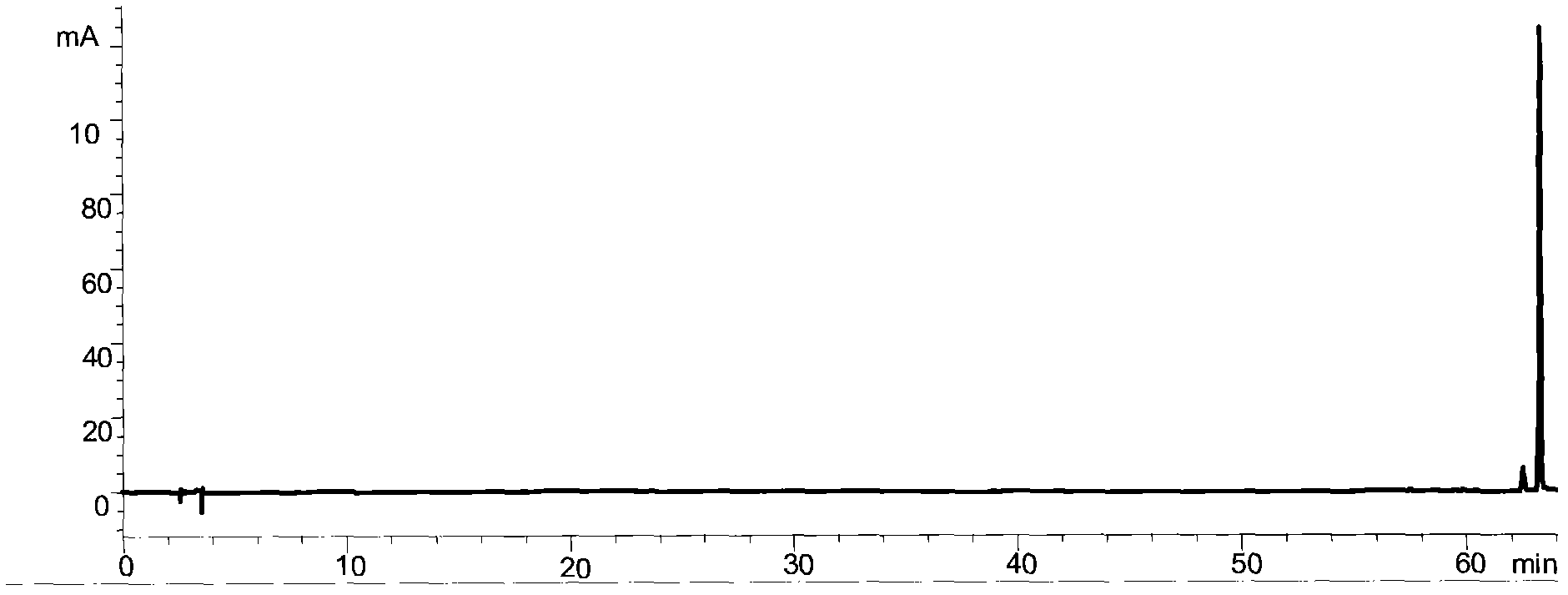

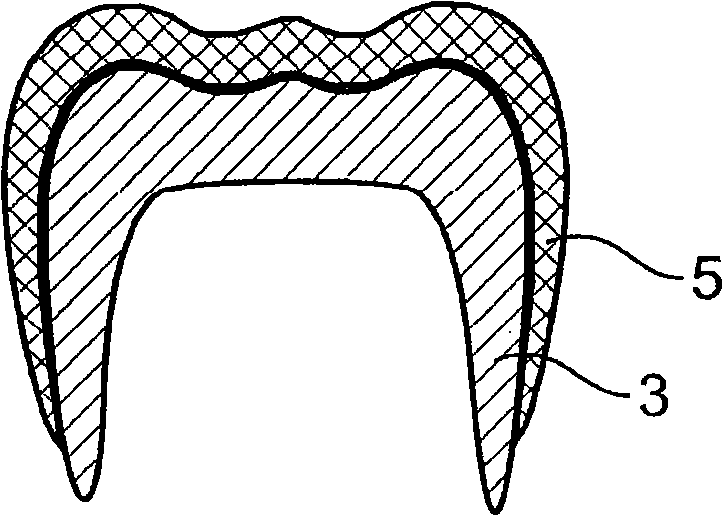

Method and system for producing a dental prosthesis

ActiveCN101360463AEasy to useImprove aestheticsTooth crownsArtificial teethDenturesUniform - quality

The invention relates to a method (100, 200, 300) for producing a dental prosthesis (17) with a framework (3) and a veneer (15), in particular for producing a crown, a bridge, an inlay or an onlay. The invention further relates to a system (40, 50) for producing a dental prosthesis (17) with a framework (3) and a veneer (15) and to a corresponding computer program. To allow the dental prosthesis (17) to be produced in a short time and in uniform quality, irrespective of the skill of the operator, the following steps are provided: definition (110, 210, 310) of three-dimensional geometrical data of the veneer (15), provision (101) or preparation (218, 318) of the framework (3), production (120, 220, 320) of a model (5, 5a, 5b, 5c, 5d) of the veneer (15) on the basis of the three-dimensional geometrical data of the veneer (15), on the framework (3) or separately, formation (124, 224, 324) of a female impression (11) of the veneer (15) by inclusion (126, 226, 326) of the model (5, 5a, 5b, 5c, 5d) between the framework (3) and a shaping material (9), and then removal (128, 228, 328) of the model (5, 5a, 5b, 5c, 5d), and filling (130, 230, 330) of the female impression (11) with veneer material for producing the veneered dental prosthesis (17).

Owner:BEGO BREMER GOLDSCHLAGEREI WILH HERBST

Commercially viable process for in vitro mass culture of jatropha curcas

InactiveUS20080196121A1Reduced phytohormone levelCost-effective processOther foreign material introduction processesTissue cultureJatrophaDisease free

The present invention relates to a commercially viable process for in vitro mass culture of Jatropha curcas. The process for in vitro mass culture of Jatropha curcas is simple, faster, and suitable for production of disease-free root tubers of uniform quality and employs media with a reduced concentration of phytohormones.

Owner:RELIANCE LIFE SCI PVT

Cartialgenous all-component uniform freeze-dried preparation and production method thereof

InactiveCN101757030AUniform and controllable qualityFulfil requirementsAmphibian material medical ingredientsPill deliveryDiseaseFreeze-drying

The invention aims to provide a uniform preparation which contains all components of cartialgenous. Compared with the conventional cartialgenous decoction tablets which are graded into various specifications such as leucogen tablets, wax tablets, sand tablets, sclerites and the like, the uniform preparation contains the all components, of the cartialgenous, existing in a uniform state, provides a medicinal material or a medicament with uniform quality for a doctor or a sufferer to cure diseases with the cartialgenous, and provides a material base for ensuring a curative effect and preventing the fluctuation of a drug effect. Compared with the modern novel processing technology of crashing the cartialgenous into dry powder after the cartialgenous is freeze-dried, the whole process has no high-temperature process, which effectively protects the activity of components of biological factors, and provides a preparation form which can rapidly absorb micromolecular active substances and peptide components through oral mucosa at the same time. Through technical means of flavor-correction and taste-masking, the mouthfeel of the decoction tablets and the preparation is good and the use compliance is improved.

Owner:董玲

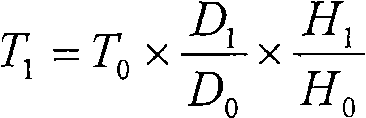

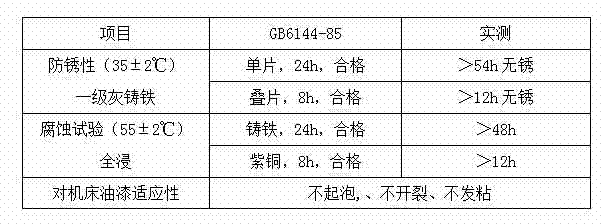

Excellent-antiwear-effect water-based cutting fluid and preparation method thereof

The invention discloses an excellent-antiwear-effect water-based cutting fluid. The invention is characterized in that the cutting fluid is prepared from the following raw materials in parts by weight: 1-2 parts of amide stearate, 2-3 parts of benzotriazole, 4.5-6.5 parts of titanium carbide, 2-3 parts of high-base-number sulfurized calcium alkyl phenate, 4-6 parts of polysorbate-80, 2-3 parts of triethanolamine borate, 1-2 parts of sulfurized isobutylene, 4-6 parts of silicon carbide, 2-3 parts of potassium metaborate, 5-7 parts of assistant and 200 parts of deionized water. By using the grinding technique, the titanium carbide, silicon carbide and surfactant are combined, so that the grinding material is dispersed uniformly and has uniform quality; and the assistant is combined to enhance the wear resistance, dispersity, lubricating property and film formation property, and a protective film is formed on the workpiece surface to protect the workpiece from corrosion. Due to the adoption of the water-based formula, the cutting fluid has the advantages of excellent lubricating property, excellent rust resistance, excellent cooling property and excellent cleaning property, and enhances the surface smoothness of the workpiece after being used for processing.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

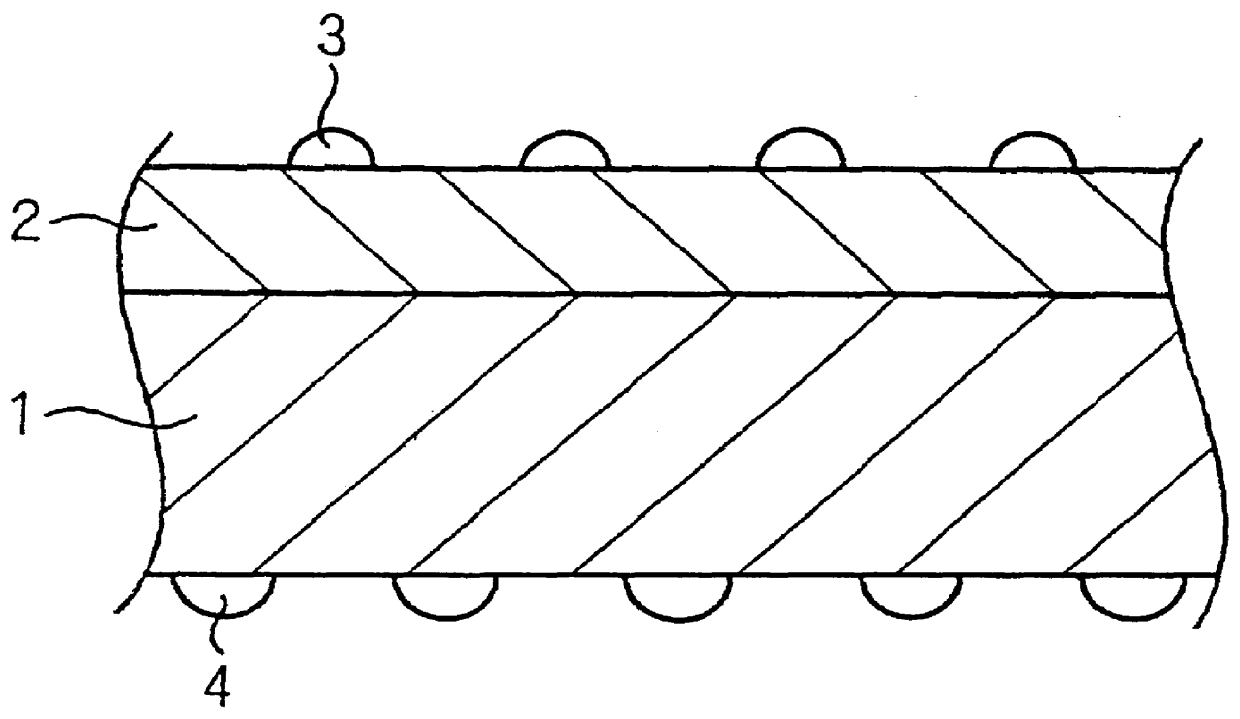

Photosensitive lithographic plate and process for producing same

InactiveUS6110642AInhibit deteriorationLow costRadiation applicationsDiazo compound compositionsEngineeringUniform - quality

In a photosensitive lithographic plate including a photosensitive layer coated on the surface of a substrate and a mat layer formed on the photosensitive layer, plural resinous protrusions are provided on the back surface of the substrate in the form of a layer. Deterioration of vacuum adhesion due to the mat collapsed in a production process of a photosensitive lithographic plate including a step of winding is prevented, consequently, a photosensitive lithographic plate with uniform quality is obtained regardless of its wound position.

Owner:FUJIFILM CORP

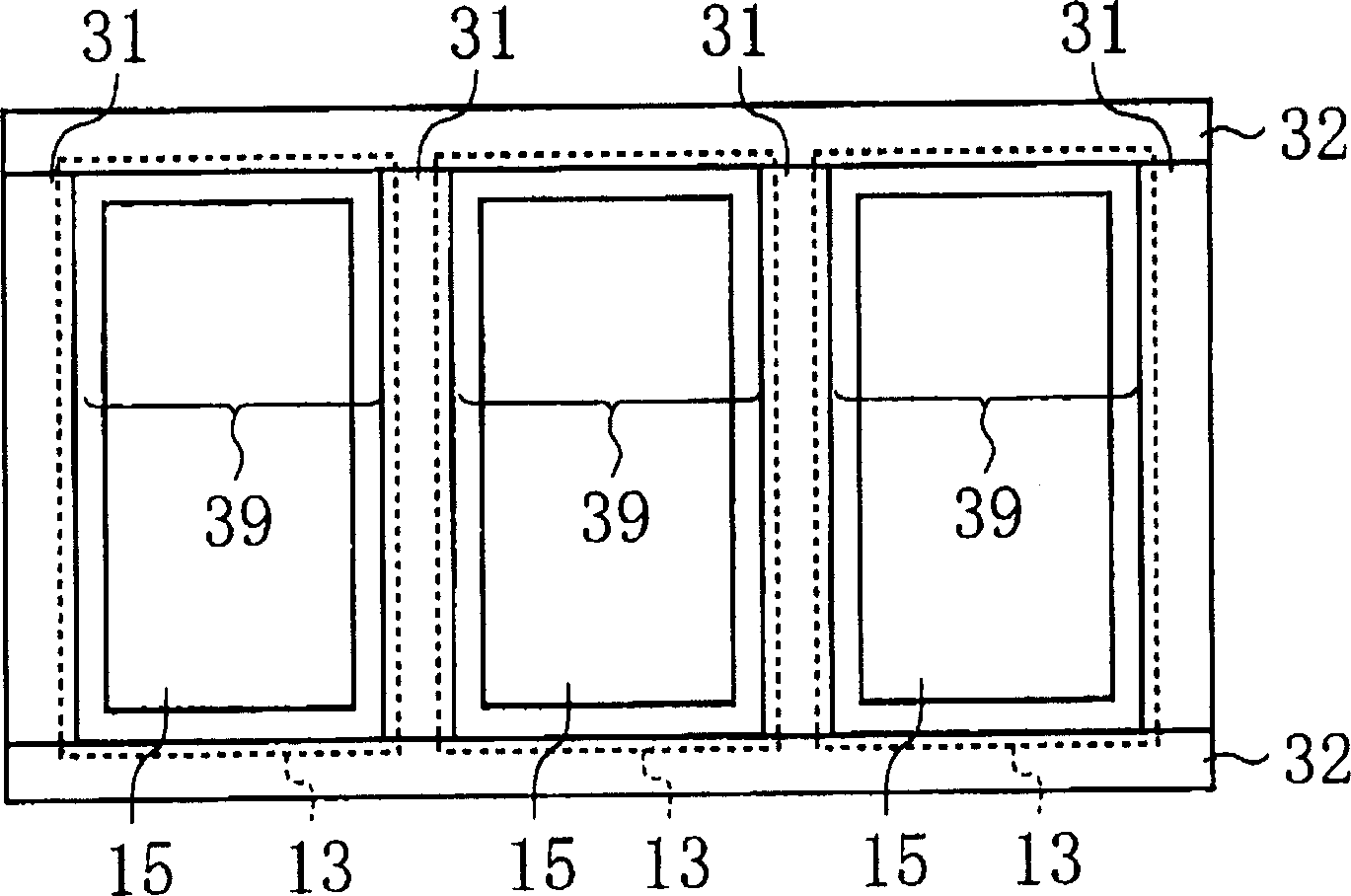

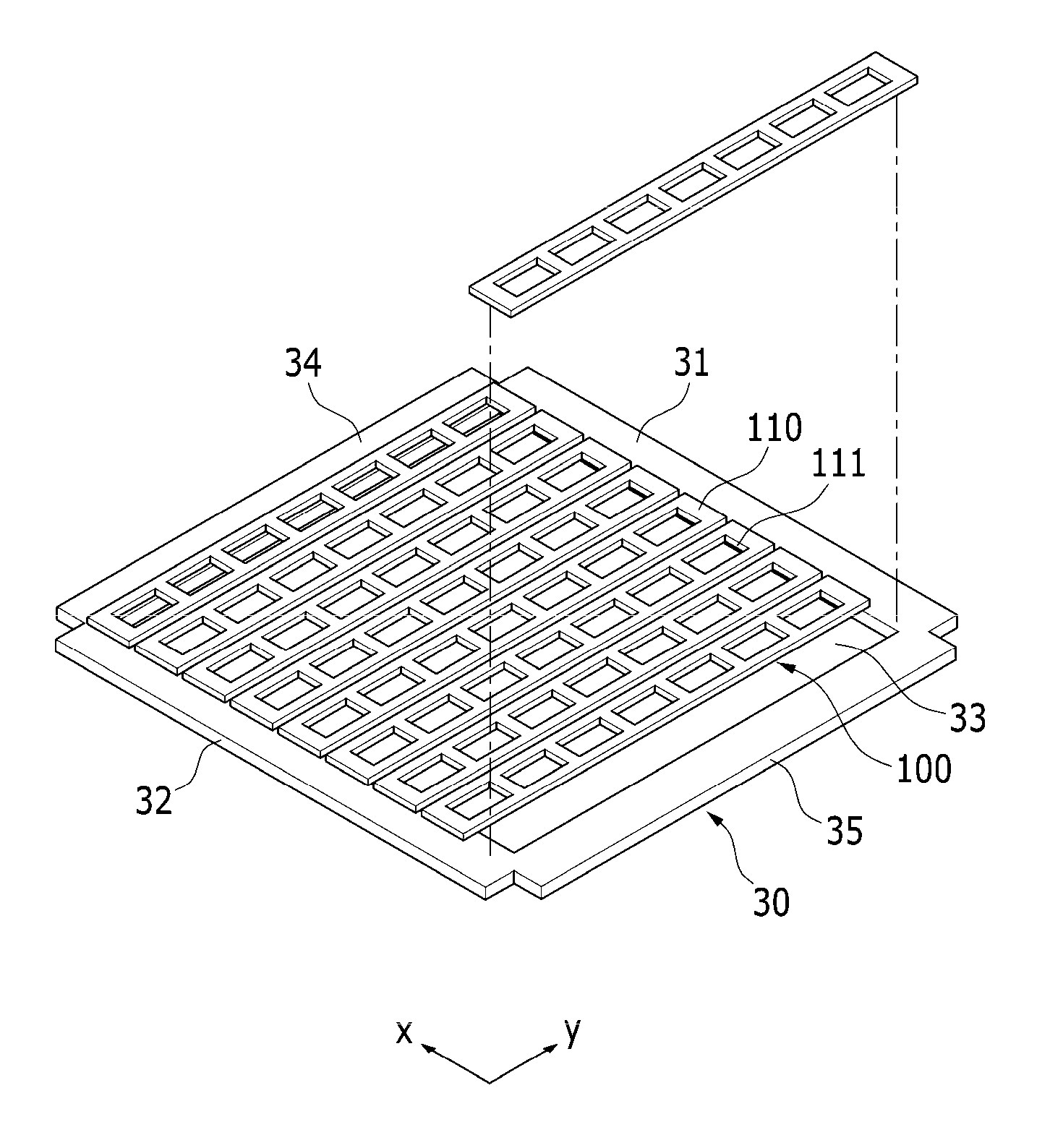

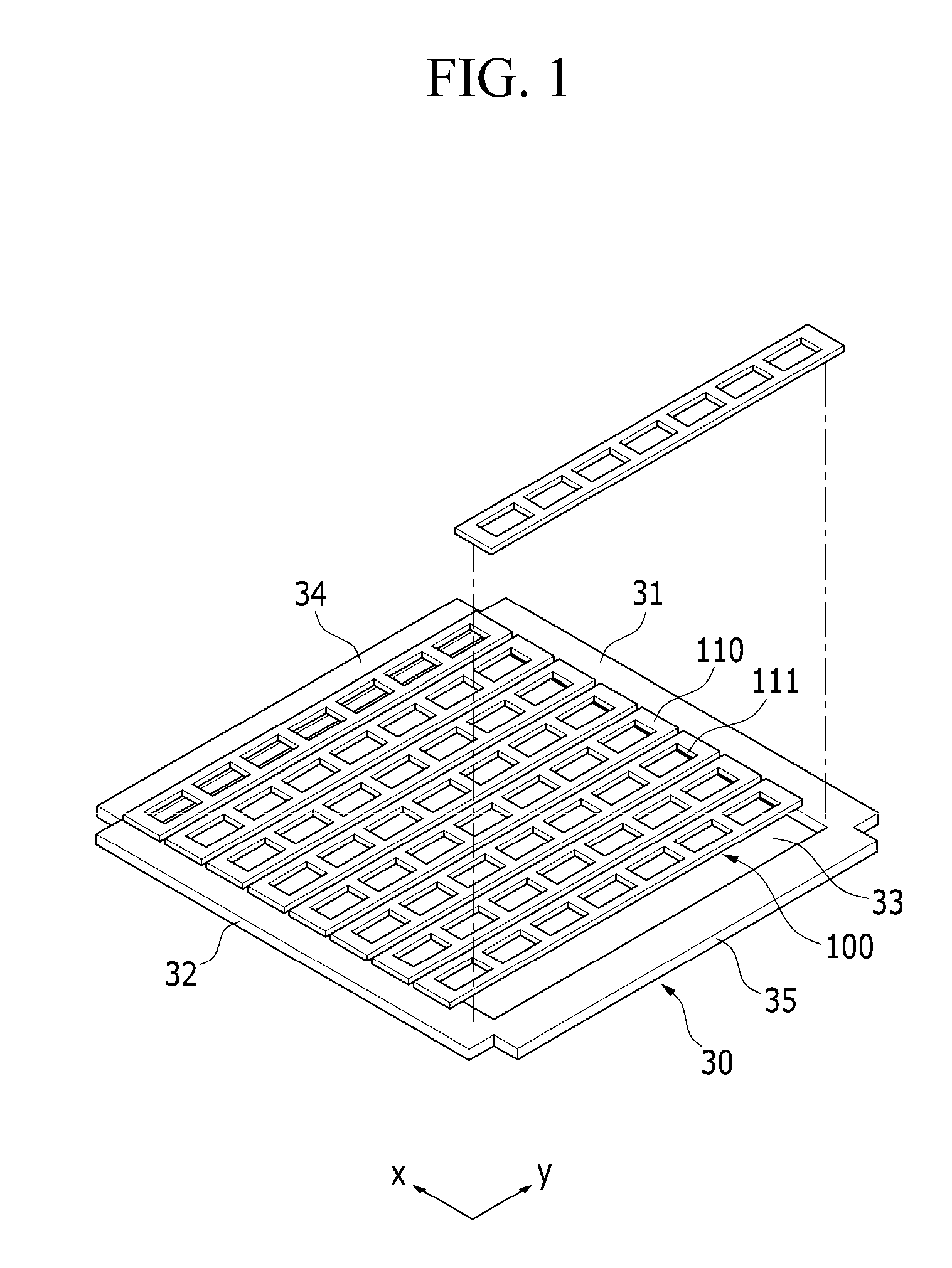

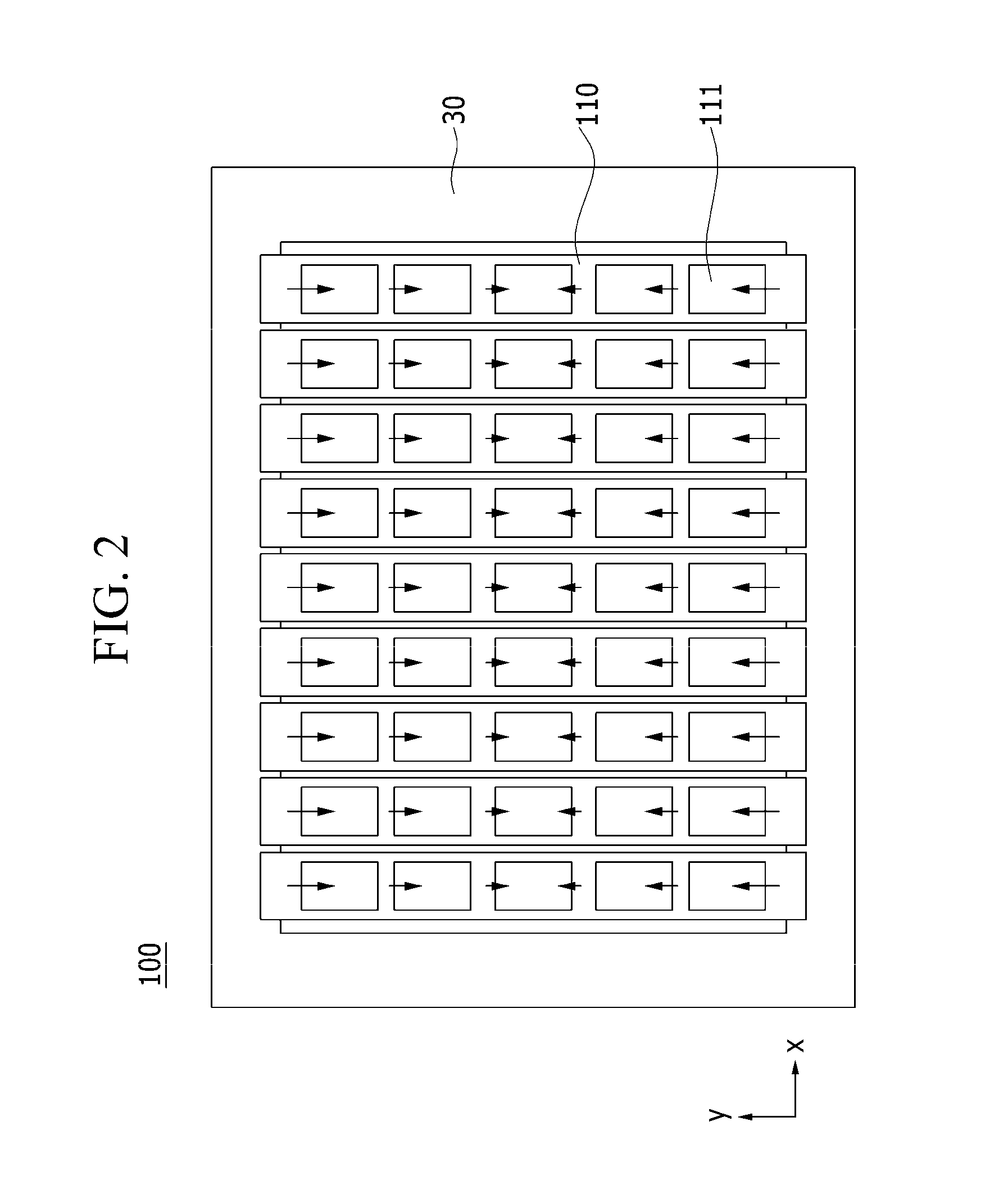

Mask for depositing thin film, method of manufacturing organic light emitting diode display using the same, and organic light emitting diode display using the same

InactiveUS20150102329A1Reduce Pattern DistortionHigh resolutionLiquid surface applicatorsElectroluminescent light sourcesDisplay deviceEngineering

A mask for depositing a thin film according to an exemplary embodiment of the present invention includes: mask strips each including a plurality of pattern portions disposed end to end along one direction; and a frame on which the mask strips are positioned. Intervals between adjacent ends of adjacent pattern portions differ from each other according to distance from a predetermined location, thereby providing an organic light emitting diode display having a more uniform quality.

Owner:SAMSUNG DISPLAY CO LTD

Method for preparing safe environment-friendly phenolic foam

InactiveCN102229706ALow thermal conductivityImprove thermal conductivityAlkaneSimple Organic Compounds

The invention discloses a method for preparing safe environment-friendly phenolic foam. The foam is prepared by a reaction after mixing the following ingredients: 100 weight portions of expandable phenolic resin, 8-15 weight portions of curing agent, 4-8 weight portions of surfactant and 20-50 weight portions of packing. The preparation method comprises the following steps: putting the ingredients in a reaction container in proportion, stirring with high speed, after mixing uniformly, transferring the ingredients to a preheated mould, foaming at the temperature of 60-80 DEG C and under the pressure of 15-40kg / cm<2>, cooling and demoulding. According to the method, because inflammable CFCs, low-carbon alkane and other lower-boiling organic compounds are not used as foaming agent, the production cost is reduced. The prepared phenolic foam has uniform quality, small aperture, low coefficient of thermal conductivity, and good thermal insulation performance, can be widely used in exterior wall, roofing, air-conditioning bellow and other thermal insulation materials, and improves thermal insulation performance and fireproof performance greatly.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com