Patents

Literature

180results about How to "Low melt index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

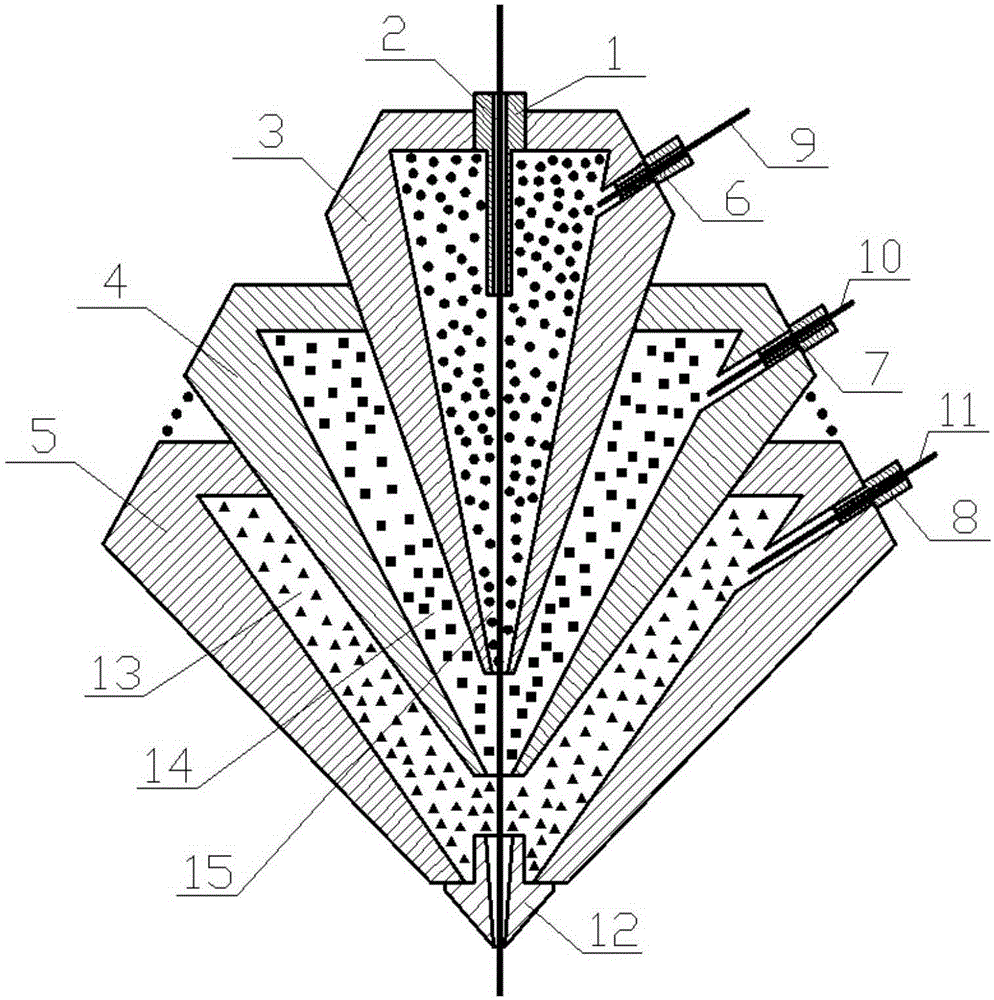

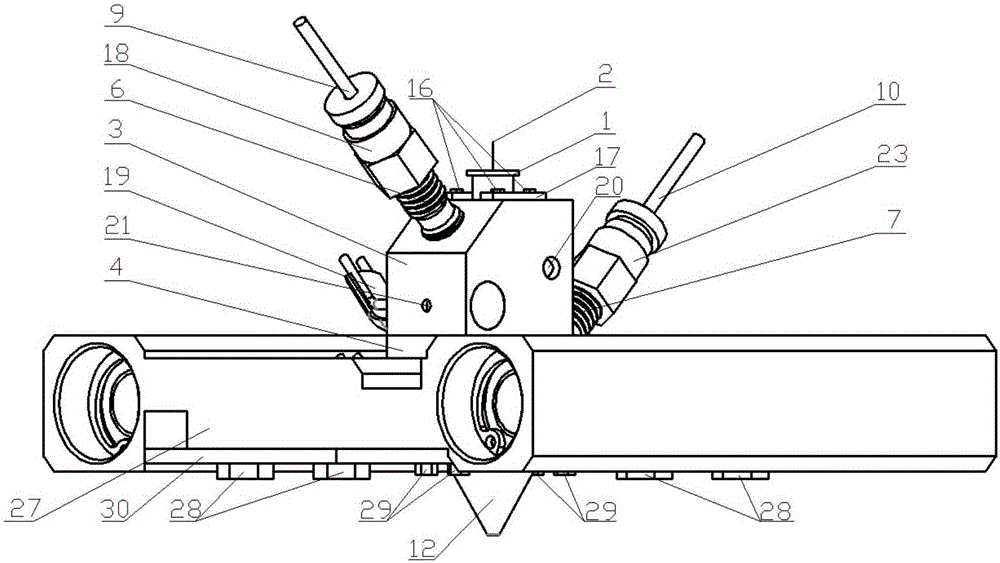

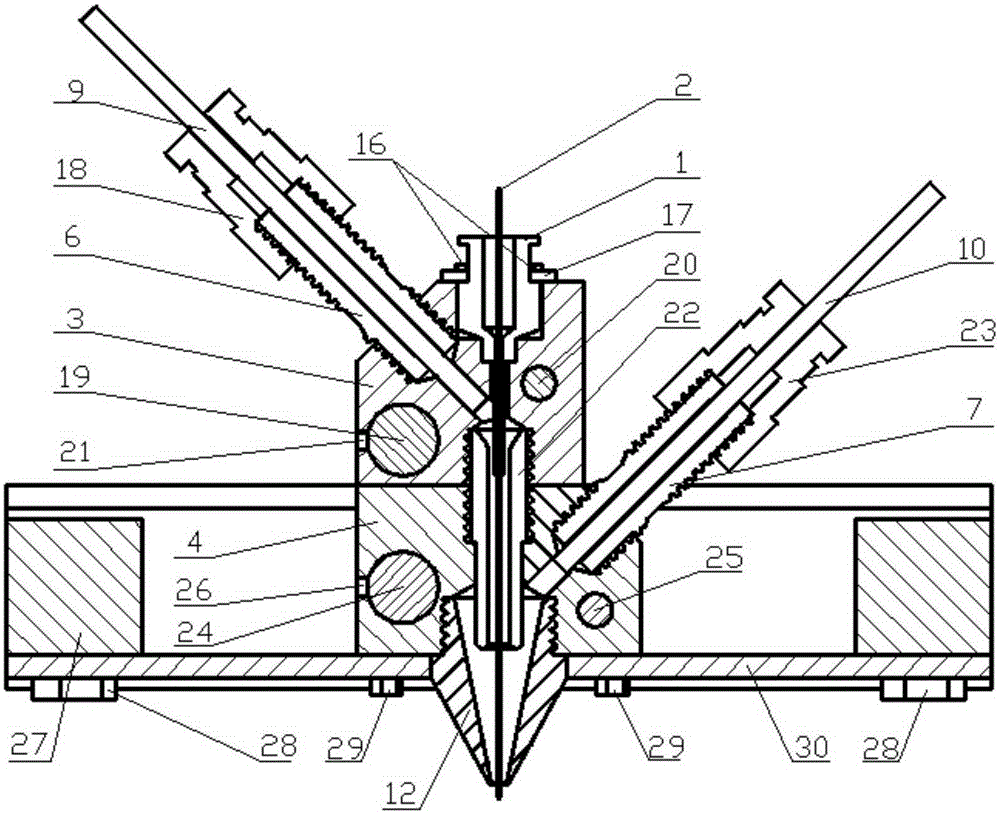

Multi-stage wire feeding printing head for 3D printing of continuous fiber reinforced composite materials

ActiveCN105172144AEnhanced interface bindingImprove performanceAdditive manufacturing apparatusSpray nozzleFiber-reinforced composite

A multi-stage wire feeding printing head for 3D printing of continuous fiber reinforced composite materials comprises a fiber guiding pipe fixed to the upper surface of a first-stage heating block. An inner hole channel of the fiber guiding pipe forms a fiber channel. A first-stage throat pipe is fixed to one side of the first-stage heating block. An inner hole channel of the first-stage throat pipe forms a first-stage inner hole channel. High polymer materials penetrate the first-stage inner hole channel and enter a melting cavity of the first-stage heating block. The first-stage heating block is fixed above a second-stage heating block. A second-stage throat pipe is fixed to one side of the second-stage heating block. A second-stage throat pipe inner hole channel forms a second-stage inner hole channel. High-performance thermoplastic materials penetrate the second-stage inner hole channel and enter a melting cavity of the second-stage heating block. As analogized according to the same structure, finally, all the heating blocks are fixed to the upper face of the last-stage heating block, and a spray nozzle is fixed to the lower surface of the last-stage heating block. The multi-stage wire feeding printing head is adopted, multi-stage wrapping can be well performed on base materials for continuous fibers, and continuous fiber reinforced composite material parts with good comprehensive performance are obtained.

Owner:XI AN JIAOTONG UNIV

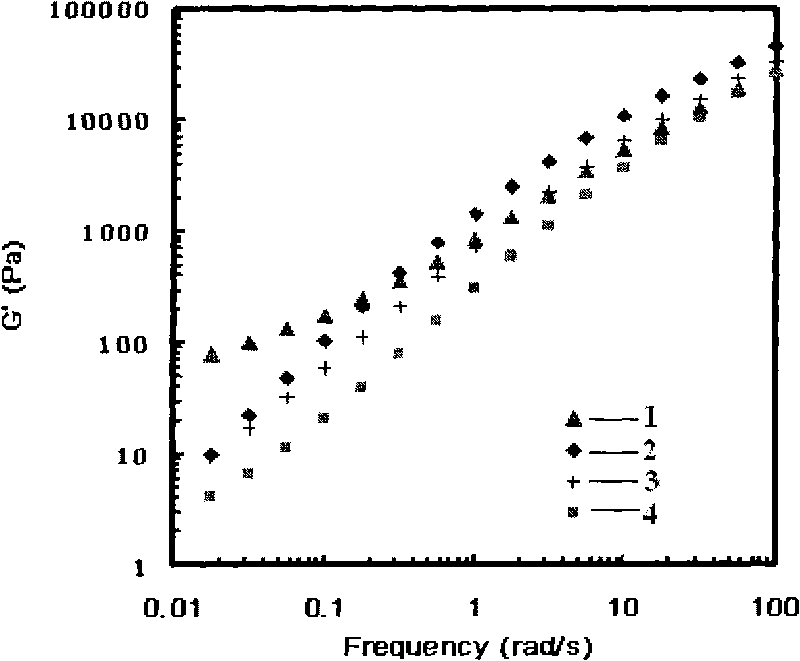

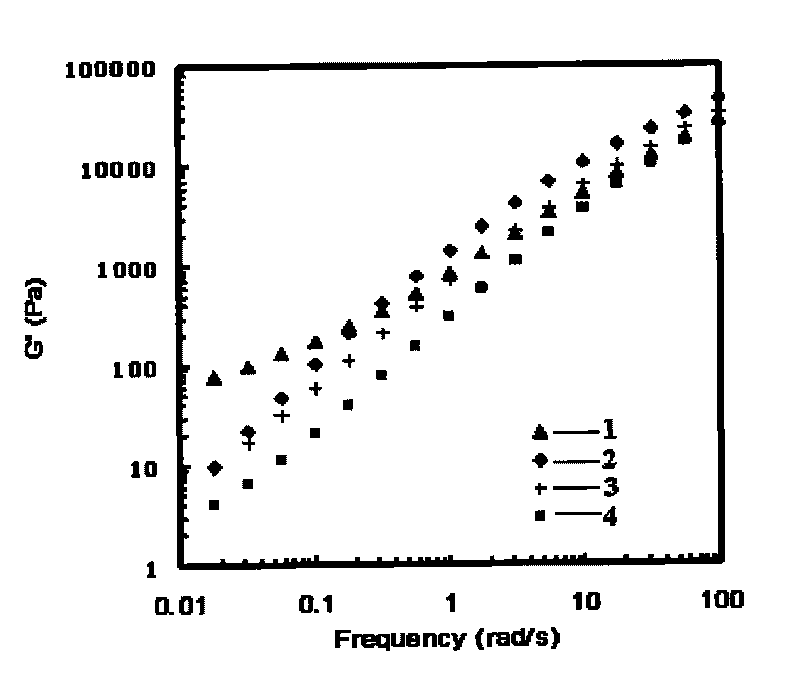

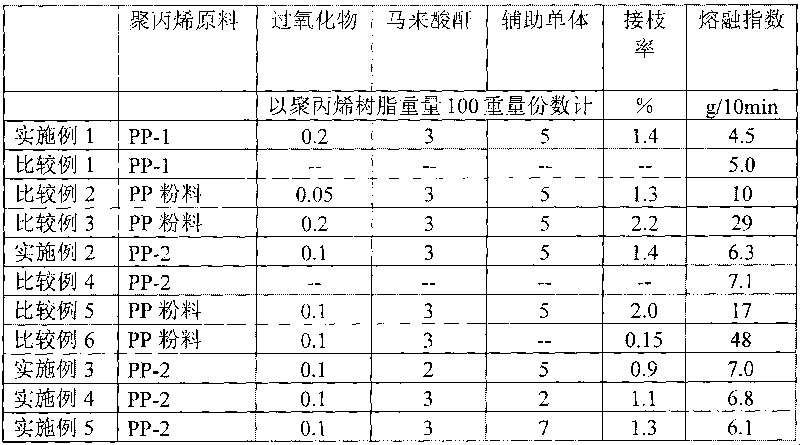

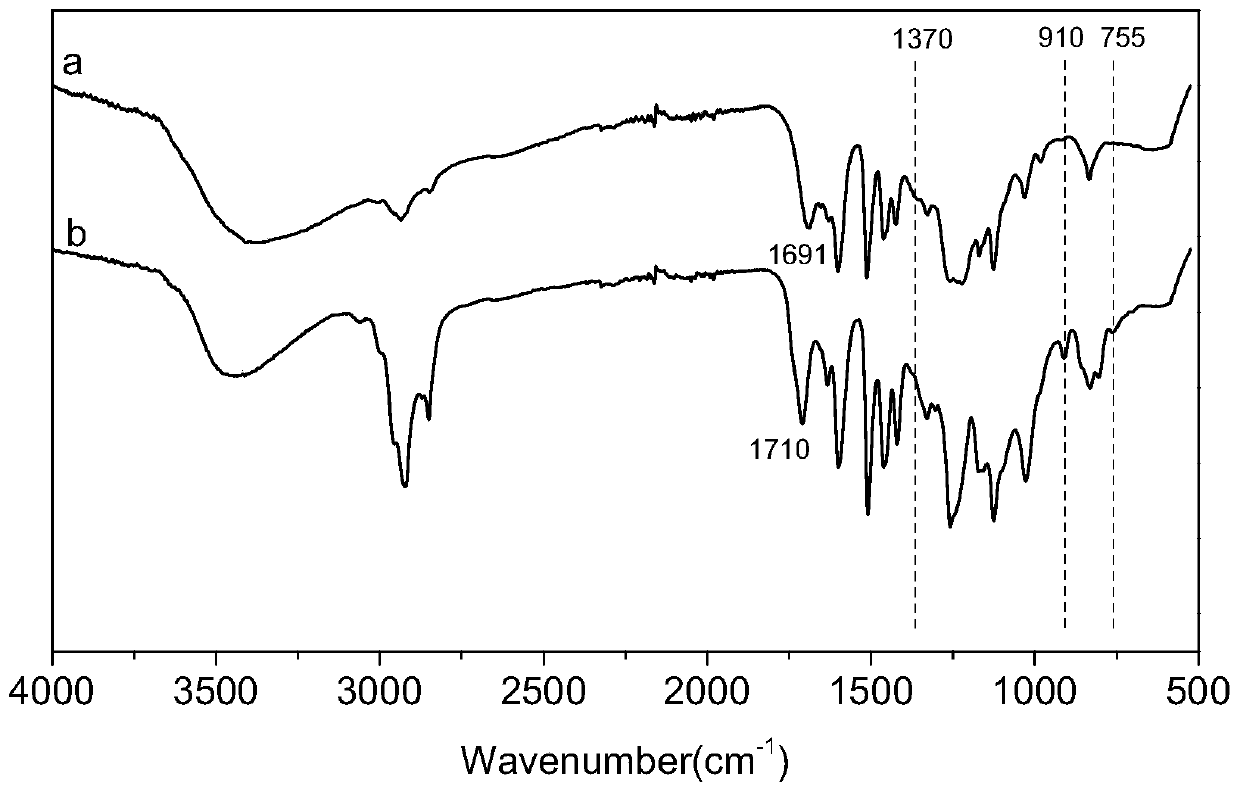

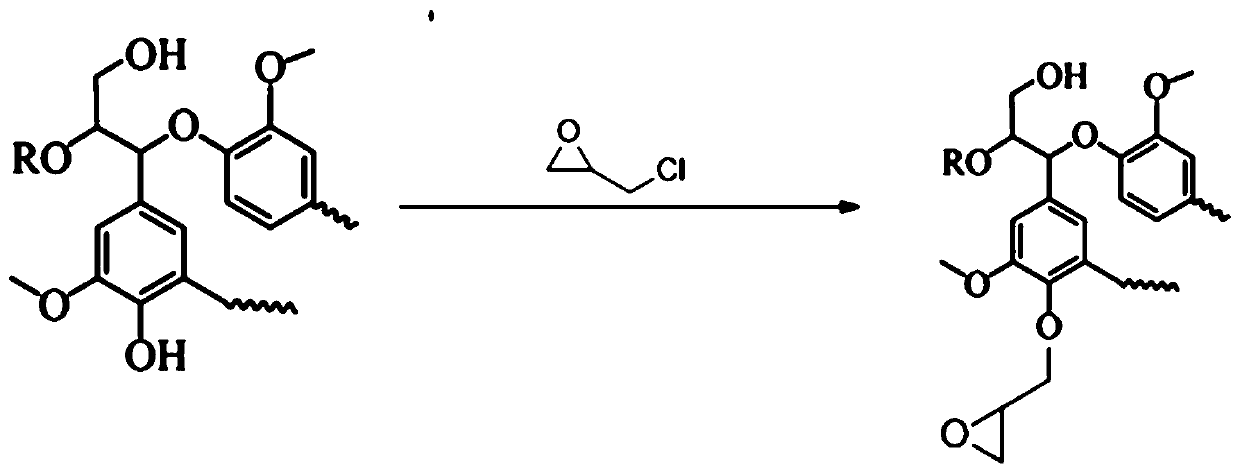

Preparation method of maleic anhydride drafted polypropylene resin graft polymer

ActiveCN101724128AMitigation of thermo-oxidative degradationImproved melt elasticityMaleic anhydrideDouble bond

The invention provides a preparation method of a maleic anhydride drafted polypropylene resin graft polymer, relating to a maleic anhydride melt-drafted polypropylene resin technology. The polypropylene resin is an antioxidant-free polypropylene powder. The preparation method comprises the following steps of: melting and blending 0.1 to 1 part of antioxidant and the polypropylene powder in 100 parts by weight of the polypropylene, and then carrying out the melting free radical grafting reaction on the polypropylene resin melted and blended with the antioxidant; initiating the melting free radical grating reaction by a peroxide initiator, and introducing an auxiliary monomer except for adding grafting monomer maleic anhydride, wherein the auxiliary monomer is an organic monomer containing two or more carbon-carbon double bonds, the using amount of the auxiliary monomer is 2 to 8 parts in 100 parts by weight of the polypropylene resin, and the using amount of the maleic anhydride is 1 to 8 parts in 100 parts by weight of the polypropylene resin. The preparation method of the maleic anhydride drafted polypropylene resin can obtain the polypropylene resin graft polymer with higher molecular weight and melt strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

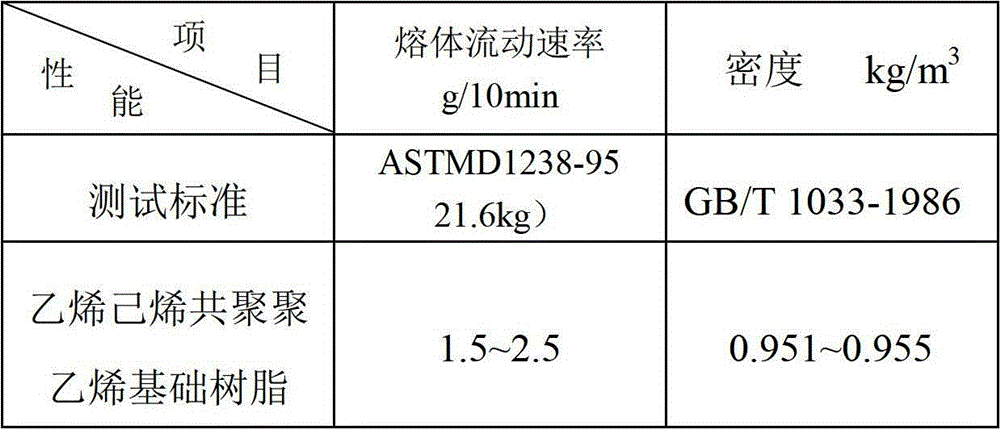

Large hollow container blow molding material and preparation method thereof

The present invention discloses a large hollow container blow molding material, which comprises the following raw materials, by weight, 99.9-100.0 parts of an ethylene hexene copolymerization polyethylene base resin, 0.05-0.10 part of an antioxidant, 0.07-0.12 part of a co-antioxidant, and 0.03-0.05 part of a slip agent. The present invention further discloses a preparation method for the large hollow container blow molding material. The large hollow container blow molding material has characteristics of low fusion index, large molecule weight, high strength, and the like, and is suitable for blowing of large size containers, wherein the product has prominent rigidity and toughness balancing capacity, creep resistance, excellent ESCR and good chemical resistance.

Owner:CHINA PETROLEUM & CHEM CORP

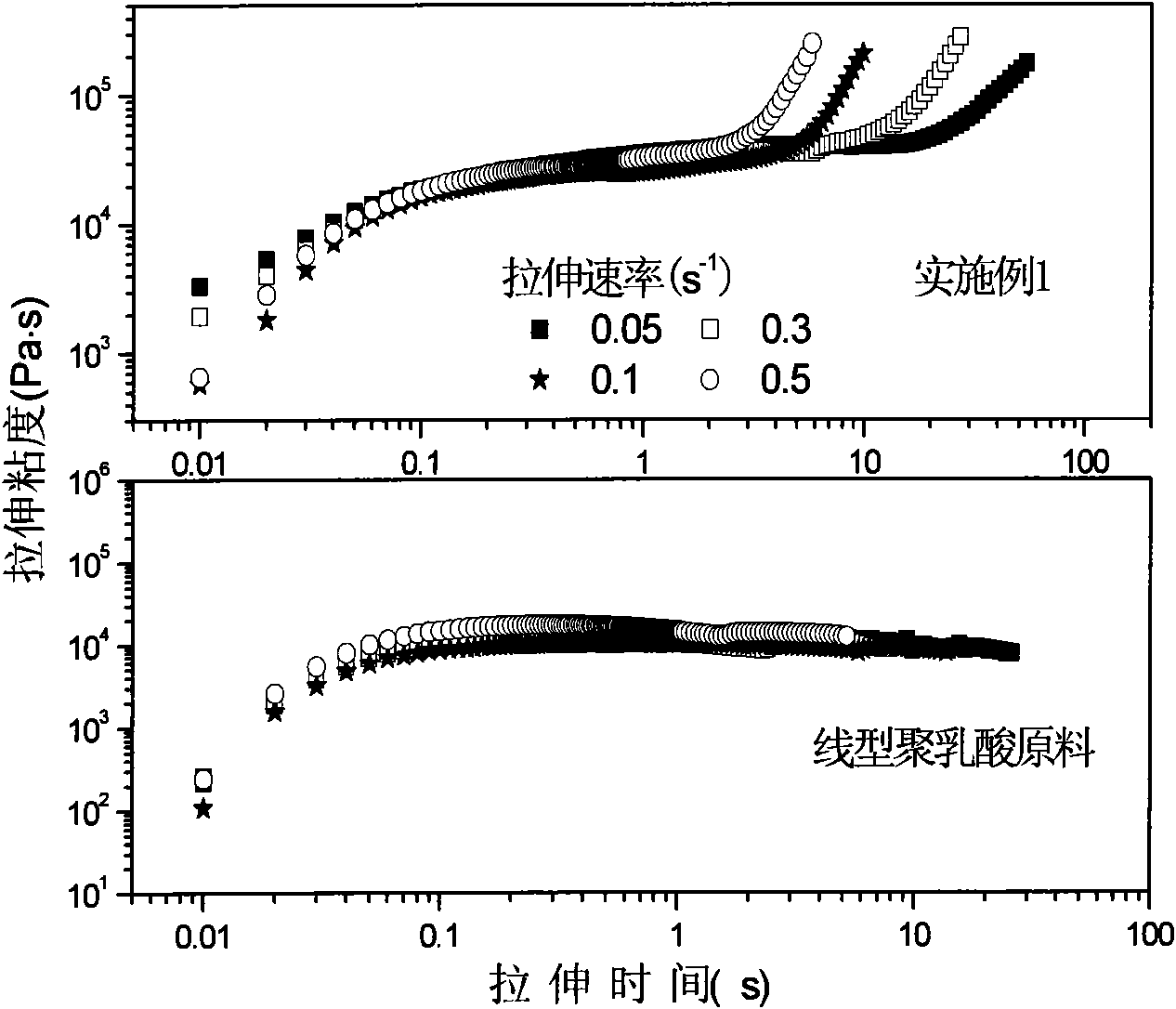

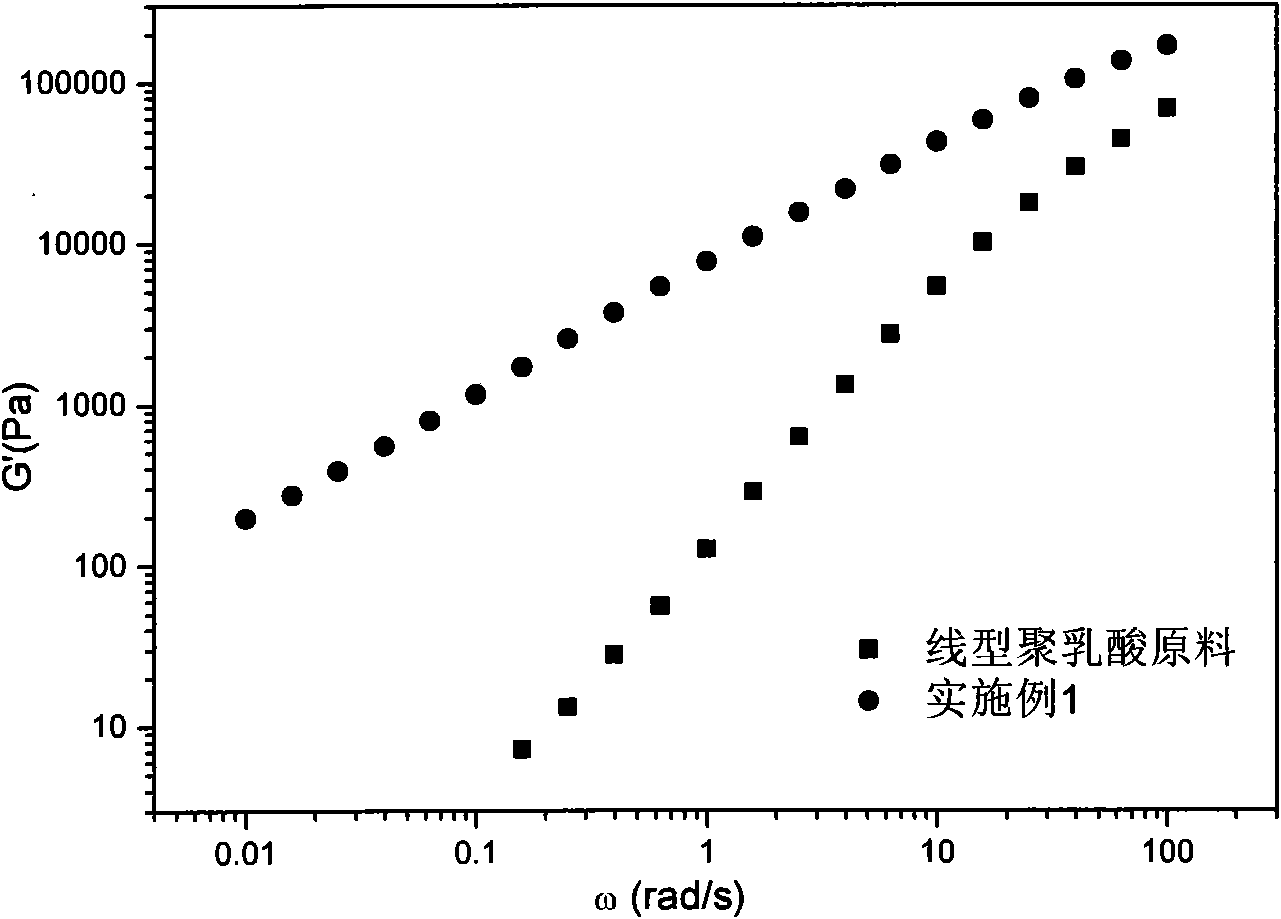

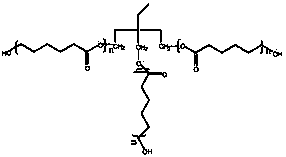

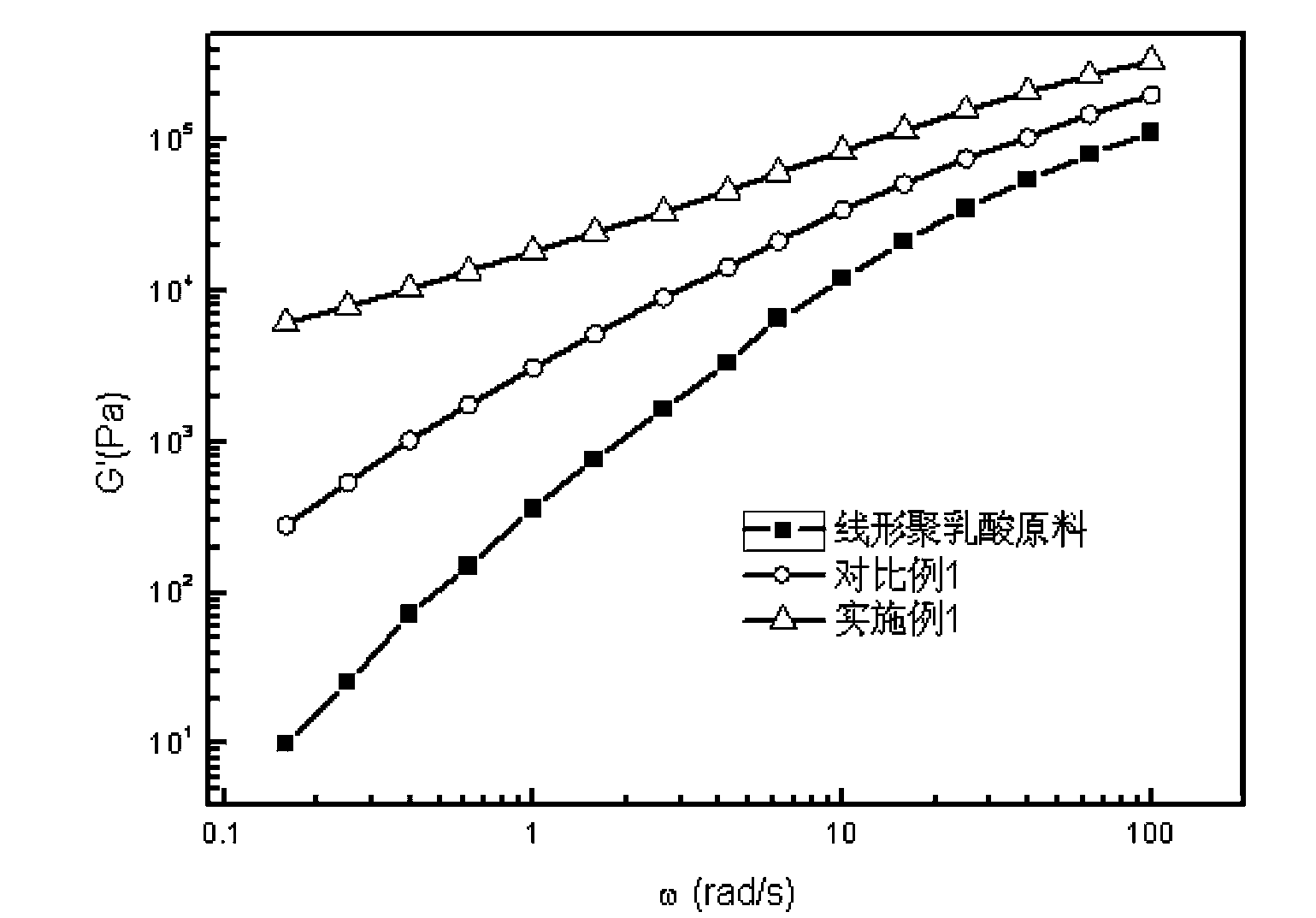

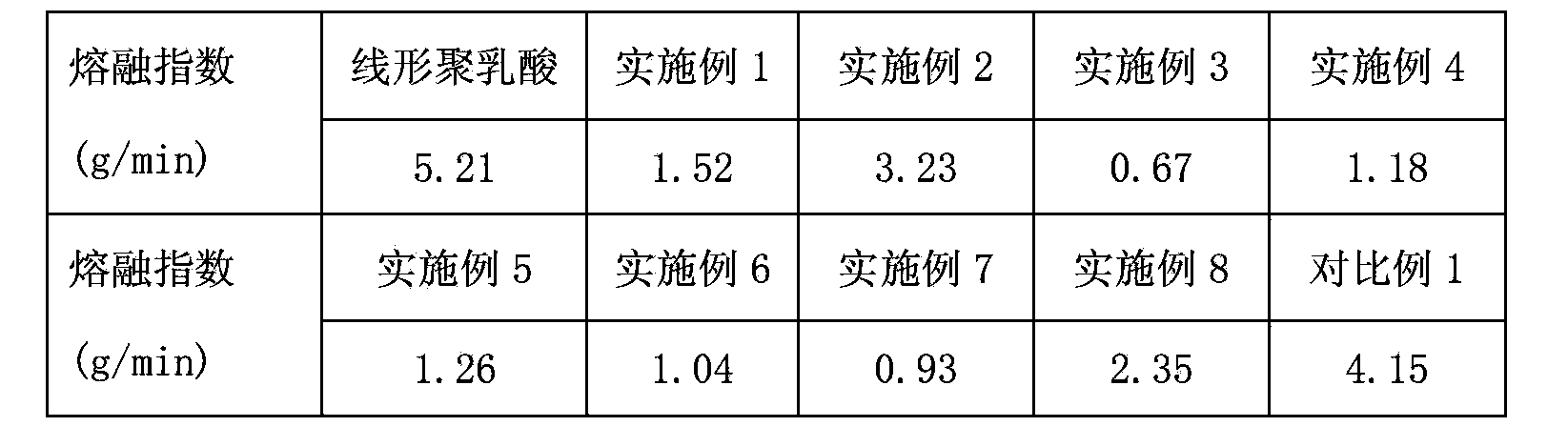

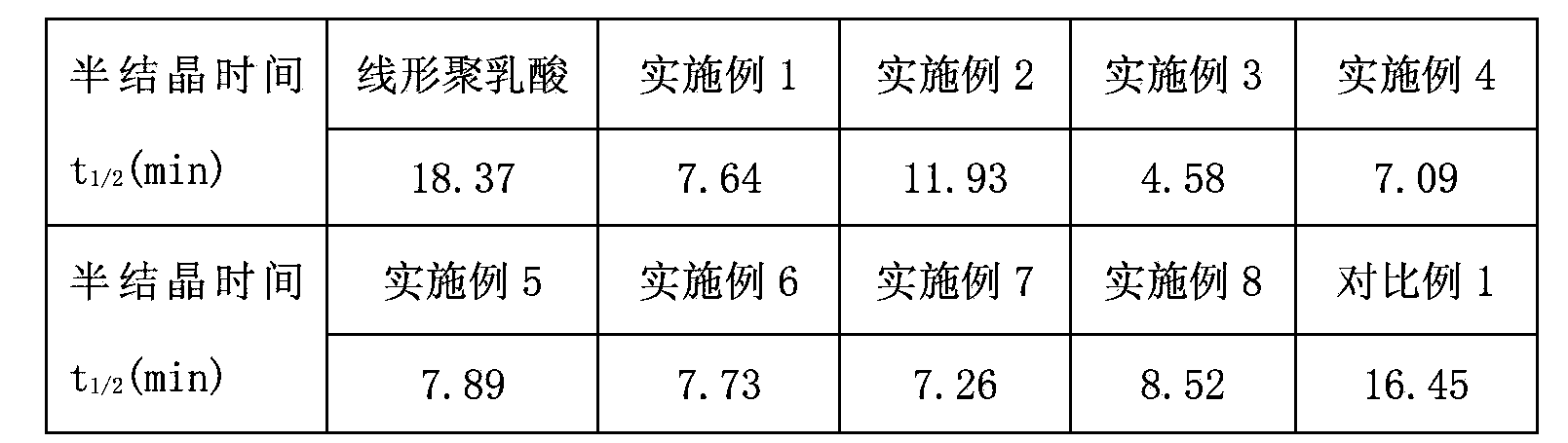

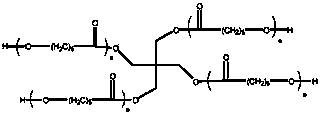

Long chain branch polylactic acid preparation method

A long chain branch polylactic acid preparation method comprises the following steps: firstly, melting 100 parts of linear polylactic acid by weight at 190-210 DEG C, adding 0.5-1 part of antioxygen by weight, then adding 0.03-0.06 part of polyfunctional monomer by weight, and mixing the mixture for 10-30min to obtain the long chain branch polylactic acid; wherein, the polyfunctional monomer is one or more epoxy monomers with 3 or more of functionality. The molecular weight, the modulus and the melt strength of the product prepared by the invention are improved and the product can be used in forming processes such as foaming, film blowing and the like.

Owner:SHANGHAI JIAO TONG UNIV

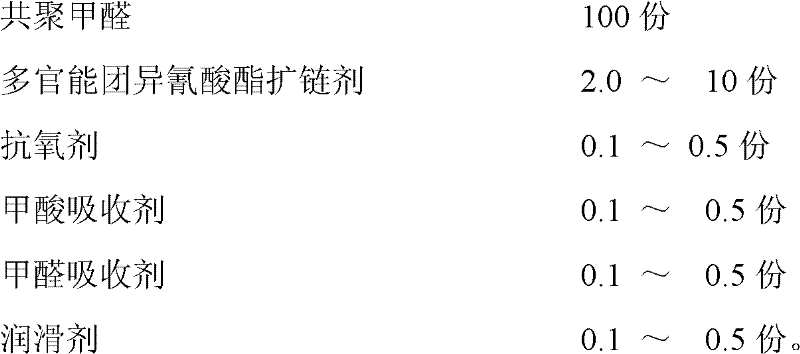

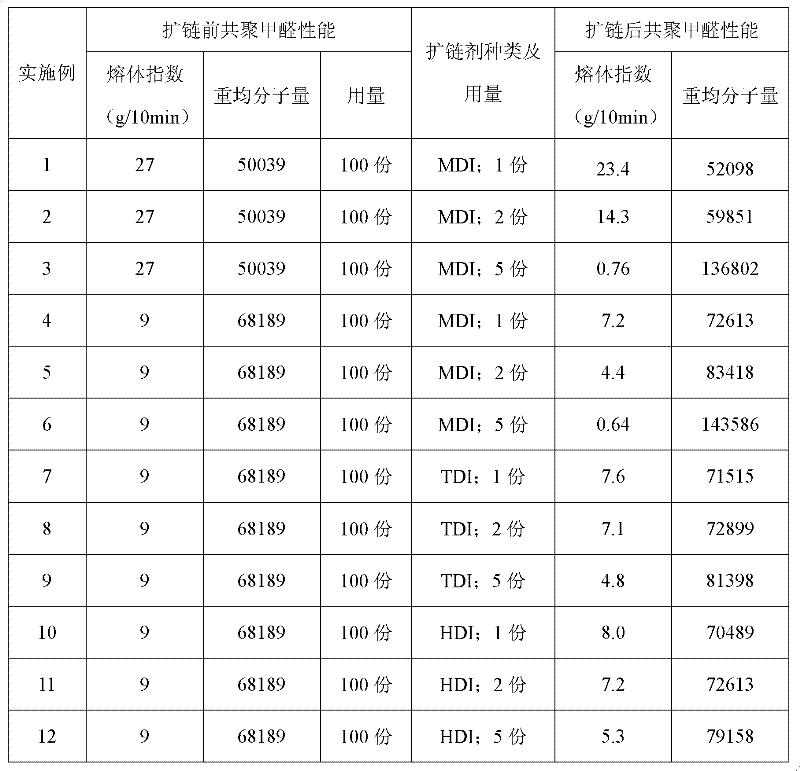

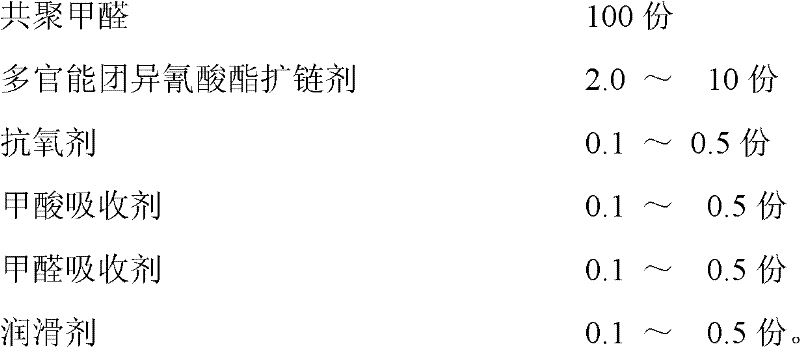

Chain-extended modified and copolymerized formaldehyde resin and preparation method thereof

The invention discloses chain-extended modified and copolymerized formaldehyde resin and a preparation method thereof. The resin mainly comprises polyoxymethylene, polyfunctional isocyanate chain extender, antioxidant, formic acid absorbent, formaldehyde absorbent, lubricant, and the like. The chain-extended modified and copolymerized formaldehyde resin is characterized in that a polyfunctional isocyanate compound is adopted as the chain extender, isocyanate is utilized to react with a compound containing active hydrogen and a melt extrusion manner is adopted, so that the polyfunctional isocyanate and terminal hydroxyl of different molecular chains of the copolymerized formaldehyde are enabled to directly conduct a chain-extending reaction in the extrusion process, thereby increasing the molecular weight of the formaldehyde and achieving the aims of reducing a melt index and increasing the resin viscosity. After the copolymerized formaldehyde resin is melt-extruded to realize chain extension, a resin variety with a melt index within a range of 0.5 to 27g / 10min, particularly a copolymerized formaldehyde resin variety with a low melt index below 2.5g / 10min and high viscosity can be obtained.

Owner:SICHUAN UNIV

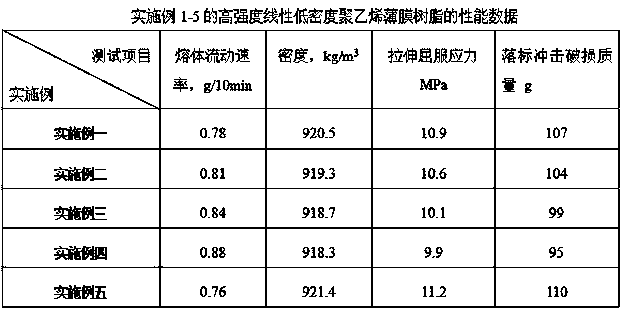

High-strength linear low density polyethylene film resin and preparation method thereof

ActiveCN103554632AHigh molecular weightHigh strengthLinear low-density polyethyleneLow-density polyethylene

The invention discloses a high-strength linear low density polyethylene film resin which is mainly prepared from the following raw materials in parts by weight: 99.7-99.85 parts of base resin, 0.02-0.06 part of antioxidant, 0.04-0.09 part of auxiliary antioxidant, 0.03-0.08 part of heat stabilizer and 0.03-0.08 part of antistatic agent. The invention also discloses a preparation method of the high-strength linear low density polyethylene film resin. The high-strength linear low density polyethylene film resin has the advantages of low melt index, high molecular weight and high strength, and is suitable for blowing repackaging films and agricultural films; and the product has the advantages of outstanding puncture resistance, excellent impact strength, excellent tearing strength and excellent aging resistance.

Owner:CHINA PETROLEUM & CHEM CORP

Polyurethane hot melt adhesive for adhesive interlinings and preparation method thereof

ActiveCN101760164ASimple production processRaw materials are easy to obtainPolyureas/polyurethane adhesivesFibre treatmentInterliningAlcohol

The invention discloses a polyurethane hot melt adhesive for adhesive interlinings. The formula of polyurethane hot melt adhesive includes diisocyanate, dihydric alcohol, chain extender, crosslinking agent, antioxidant, anti-yellowing agent, catalyst, coupling agent and the like, a reaction type double-screw extruder is used for continuous production, the production technique is simple, the efficiency is high, the produced adhesive can be ground into powder under a low temperature, and is coated on a base fabric in the form of points by special-purpose equipment, the base fabric is then dried, so that an adhesive interlining is produced, and the produced adhesive interlining has the advantages of high bonding strength, good water resistance and good handle.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

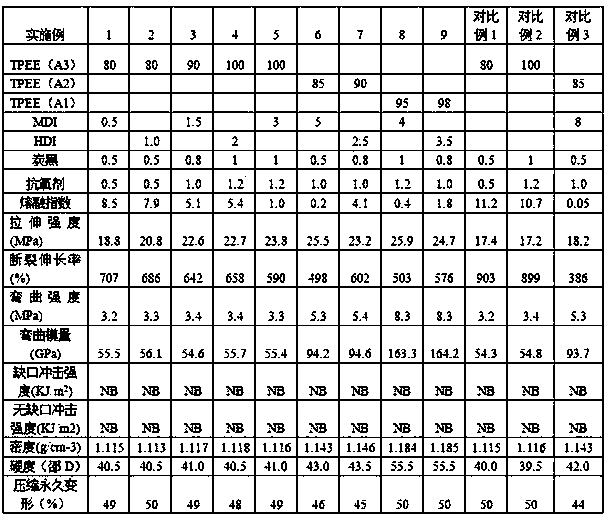

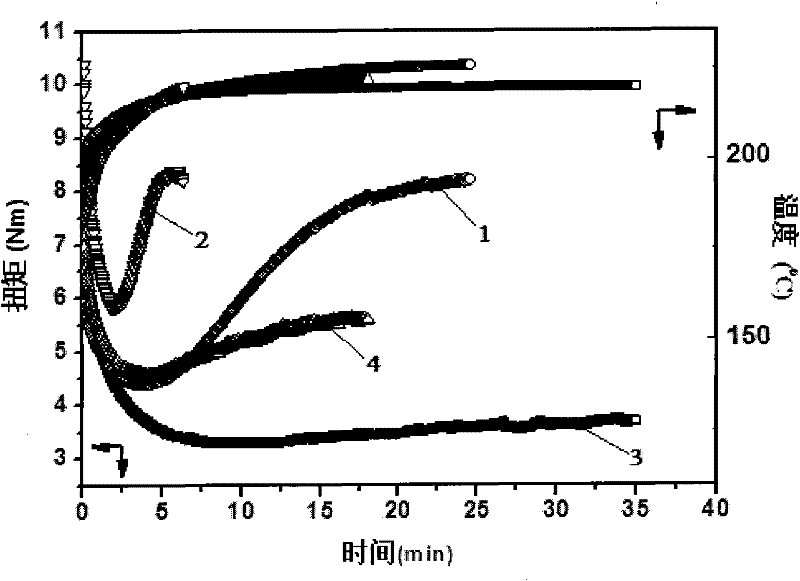

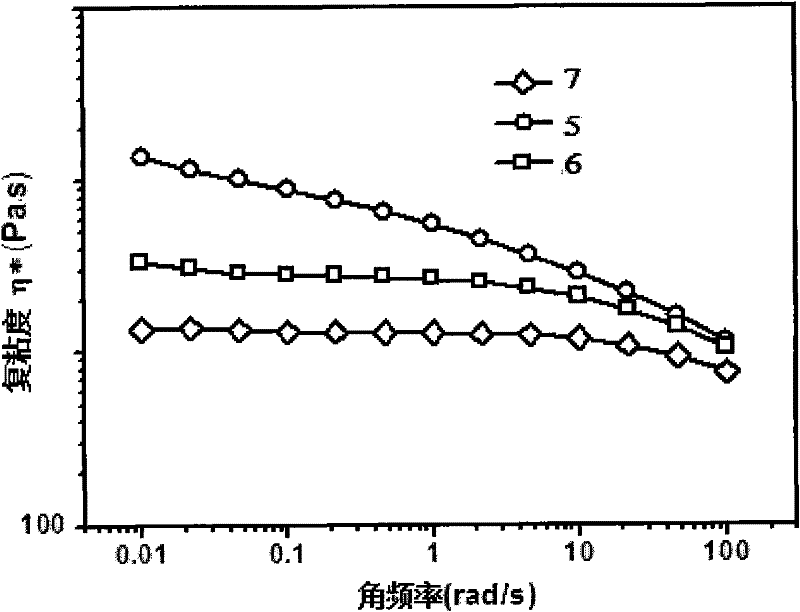

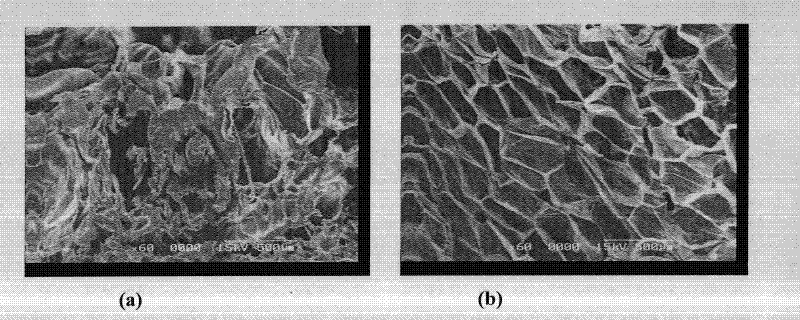

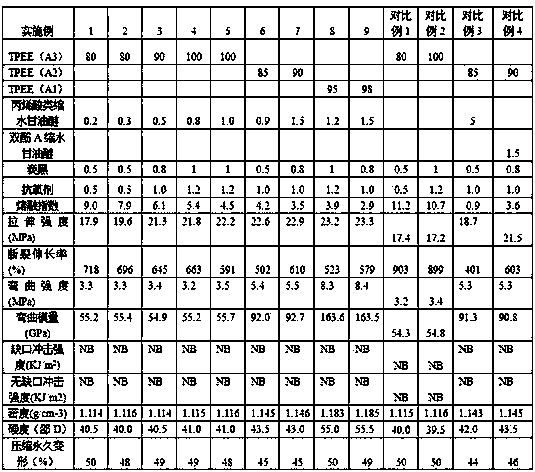

Thermoplastic polyether ester elastomer composition as well as preparation method and application thereof

The invention discloses a thermoplastic polyether ester elastomer composition as well as a preparation method and application thereof. The thermoplastic polyether ester elastomer composition comprises 80-100 parts of polyether ester elastomer and 0.2-5 parts of isocyanate compound. The preparation method comprises the steps of adding the components to a high-speed mixer so as to be mixed at a high speed, and then adding the mixture to a double-screw extruder so as to be subjected to extruding granulation at 210-250 DEG C, thus obtaining the thermoplastic polyether ester elastomer composition. The thermoplastic polyether ester elastomer composition and the preparation method have the beneficial effects that by adding the isocyanate compound to modify the polyether ester elastomer, the melt index of the material can be obviously reduced, the tensile strength of the material can be improved, the elongation at break of the material is relatively high, and the material has good resilience effect and good dynamic / static stiffness; the process is simple, and the production cost is relatively low; the thermoplastic polyether ester elastomer composition can be used in the fields such as track traffic gaskets and the like.

Owner:KINGFA SCI & TECH CO LTD

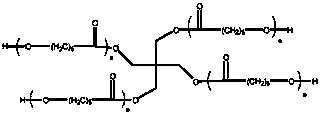

Method for preparing long chain branched polylactic resin by combining two-step functional group reaction

ActiveCN102453250ASignificant branching effectControl the degree of branchingAntioxidantReaction rate

The invention provides a method for preparing long chain branched polylactic resin by combining two-step functional group reaction, and relates to the technical field of polymer processing. The method for preparing the long chain branched polylactic resin by combining two-step functional group reaction comprises the following steps of: (1) melting polylactic resin; (2) adding an antioxidant, anhydride polyfunctional monomers and epoxy polyfunctional monomers, and mixing uniformly; and (3) melting and blending until the reaction is finished to obtain the long chain branched polylactic, whereinbased on 100 weight parts of linear polylactic resin, the antioxidant is 0.1 to 0.5 part, the anhydride polyfunctional monomers are 0.1 to 1 part; and the epoxy polyfunctional monomers are 0.1 to 1 part; and the epoxy polyfunctional monomers have the functionality of more than or equal to 3. By the method, the reaction rate is improved by 5 to 10 times; the obtained long chain branched polylacticproduct has an obvious branching effect, the melt strength and viscosity are greatly improved, and the product material meets the requirement of forming and can be easily subjected to film making, foaming and other processes according to product requirements; and the branching degree and the melt strength of the product can be controlled to a certain extent by regulating a monomer proportion and reaction temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

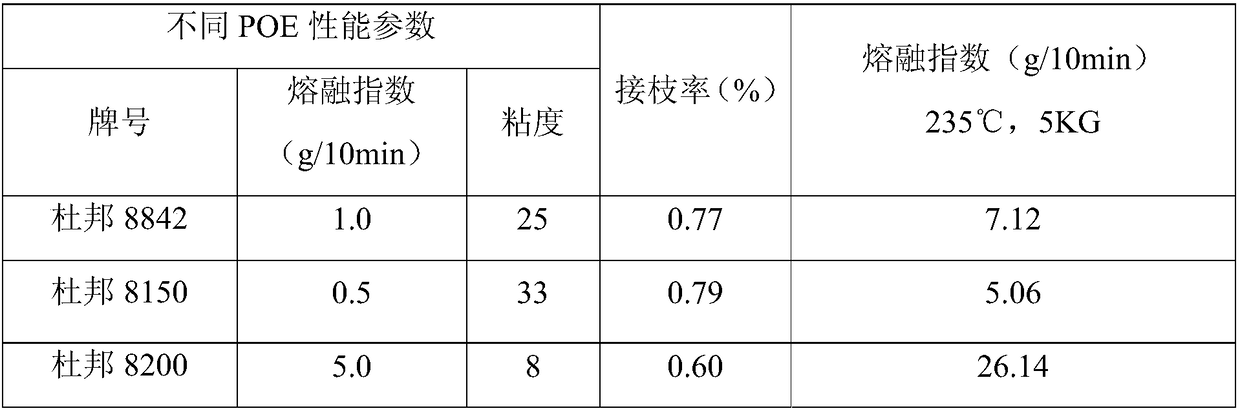

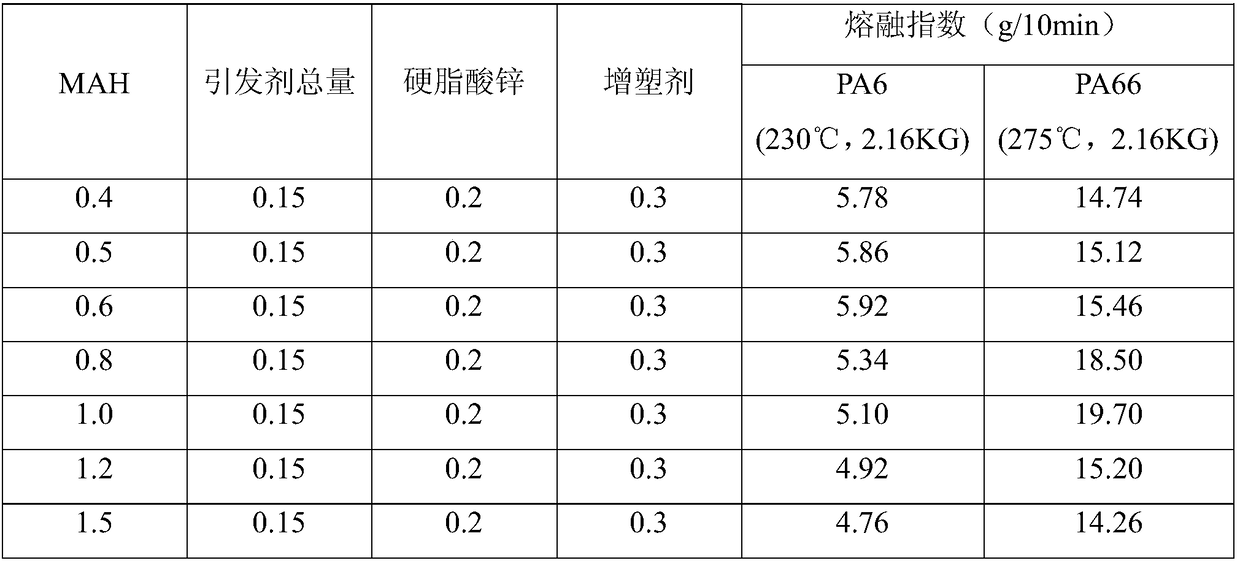

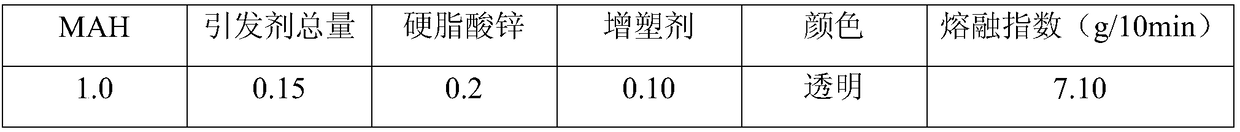

Low-temperature-resistant polyolefin grafted maleic anhydride flexibilizer used for nylon and preparation method of flexibilizer

ActiveCN108129833AImprove low temperature impact performanceGood compatibilityElastomerNylon material

The invention belongs to the field of polymer materials, and in particular relates to a low-temperature-resistant polyolefin grafted maleic anhydride flexibilizer used for nylon and a preparation method of the flexibilizer. The flexibilizer comprises the following raw materials in parts by weight: 100 parts of a polyolefin elastomer, 0.3-1.5 parts of maleic anhydride, 2-6 parts of an ionic polymer, 1.0-2.0 parts of polypropylene powder, 0.05-0.15 part of graft polypropylene, 0.05-0.25 part of a lubricant, 0.1-0.3 part of a plasticizer, 0.05-0.2 part of an initiator, and 0.1-0.3 part of an antioxidant. According to the flexibilizer provided by the invention, the maleic anhydride is grafted through the polyolefin elastomer, the polarity of the polyolefin elastomer is enhanced, and the grafted polyolefin elastomer can be used as a flexibilizer, an interfacial modifier and a compatibilizer of the nylon; and the flexibilizer can obviously improve the compatibility of the polyolefin elastomer and a strong-polarity nylon material, and can effectively improve the low-temperature impact performance.

Owner:SHENYANG KETONG PLASTIC

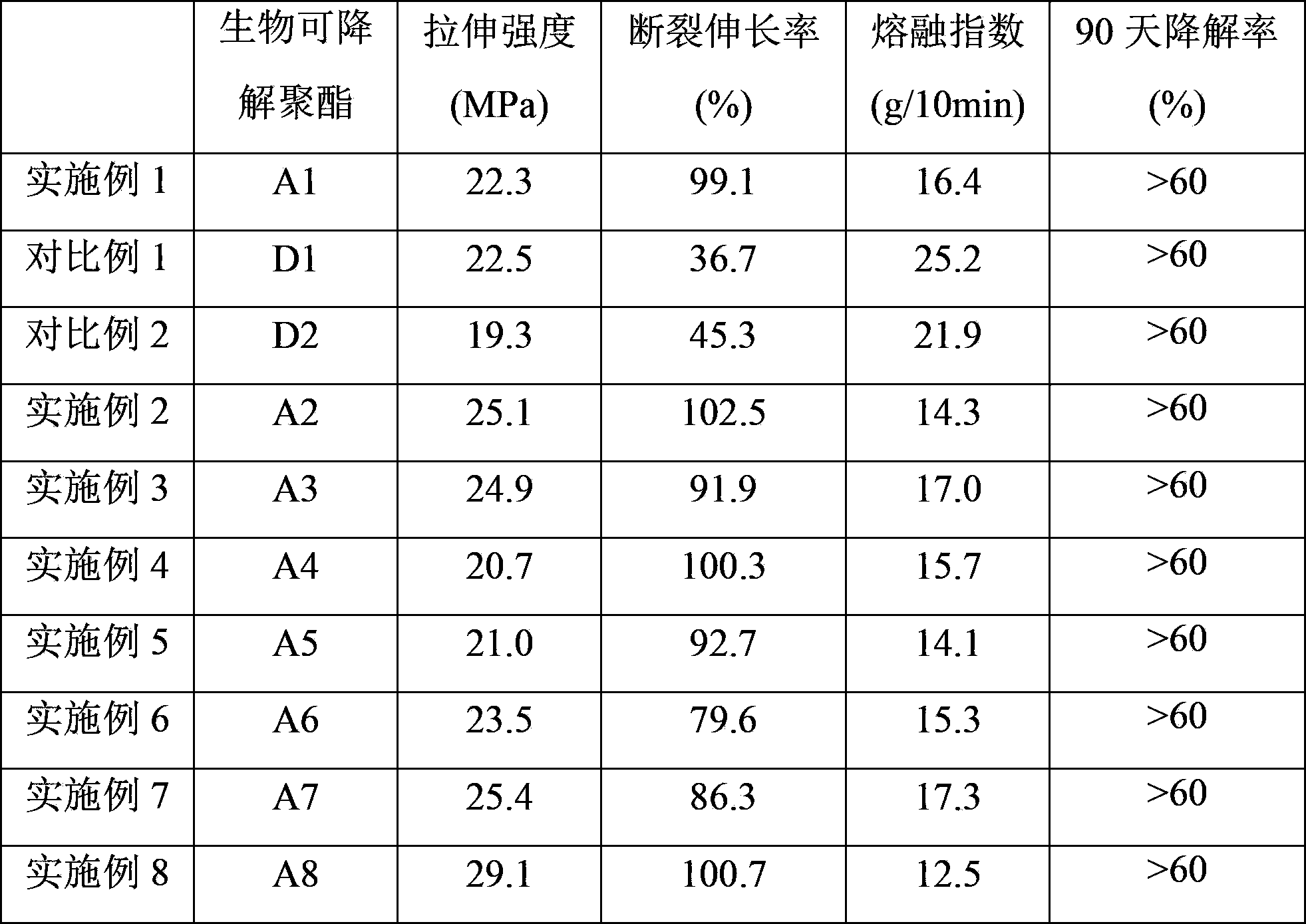

Biodegradable polyester and preparation method thereof

The invention relates to a biodegradable polyester preparation method and a biodegradable polyester prepared through the method. The method comprises the following steps: allowing aliphatic aromatic copolyester with a branched chain to be mixed and contact with and an organic tin catalyst, and carrying out a contact reaction on a mixture obtained after the mixing contact and lactide. The biodegradable polyester prepared through the method has good mechanical performances and a good biodegradation performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of easily-processed easily-crystallized polylactic acid

The invention relates to a preparation method of easily-processed easily-crystallized polylactic acid by melting processing. The preparation method comprises: melting 100 parts by weight of linear polylactic acid at 190-220 DEG C, then successively adding 0.1-0.5 part by weight of an anti-oxidant, 2-10 parts by weight of functionalized nanometer silica and 0.1-0.5 part by weight of a catalyst, mixing for 5-15 min, then adding 0.1-0.5 part by weight of an epoxy polyfunctional monomer and mixing until the reaction is finished, to prepare the high-melt-strength easily-processed easily-crystallized polylactic acid. The functional nanometer silica is nanometer silica modified by an isocyanate polyfunctional monomer, and the epoxy polyfunctional monomer is one or a mixture of multiple epoxy monomers each with functionality being 3 or more. The prepared long-chain branch polylactic acid not only substantially improved in molecular weight, modulus and melt-strength, but also has a substantial accelerated crystallization speed, and is applicable to moulding processes such as foaming, film blowing and the like.

Owner:PETROCHINA CO LTD

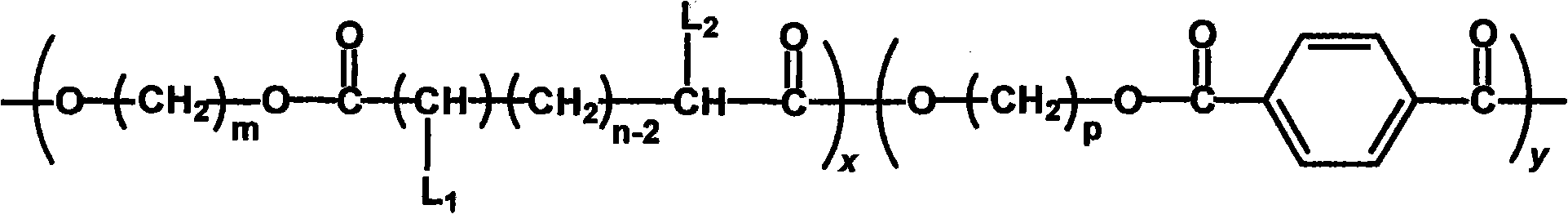

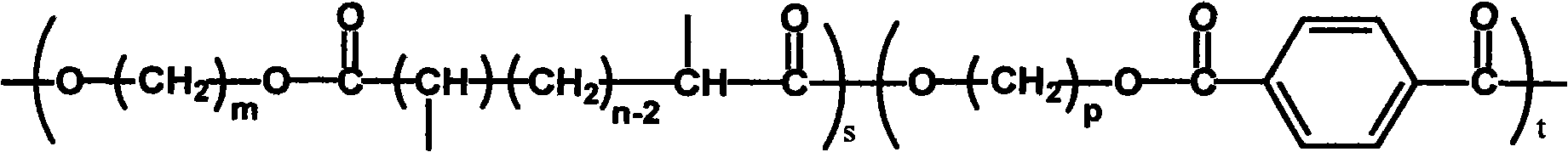

Application of chain extender in improving viscosity of polyester compound, modified polyester compound and preparation method of modified polyester compound

The invention provides an application of a chain extender in improving the viscosity of a polyester compound, a modified polyester compound and a preparation method of the modified polyester compound, and belongs to the field of polyester processing. The invention provides an application of a chain extender in improving the viscosity of polyester compounds. The chain extender is a hydroxyl addition type chain extender and / or a carboxyl addition type chain extender. The chain extender is a hydroxyl addition type chain extender and / or a carboxyl addition type chain extender, and can be subjected to chain extension reaction with terminal hydroxyl or carboxyl of PBT or TPEE, so that the molecular chain of the polyester compound can be prolonged, and the molecular weight can be obviously improved, thereby enhancing the intrinsic viscosity of the polyester compound, lowering the melt index and enhancing the processability of the polyester compound. The defects of high equipment requirement, high energy consumption and low economic benefit of a traditional method such as a solid-phase tackifying technology are avoided, and the method has the advantages of short time consumption, high efficiency and good economic benefit.

Owner:新疆蓝山屯河高端新材料工程技术研究中心(有限公司) +1

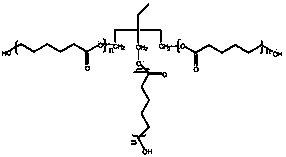

Thermoplastic polyether ester elastomer composition as well as preparation method and application thereof

The invention discloses a thermoplastic polyether ester elastomer composition as well as a preparation method and application thereof. The thermoplastic polyether ester elastomer composition comprises 80-100 parts of polyether ester elastomer and 0.1-2 parts of epoxy resin. The preparation method comprises the steps of adding the components to a high-speed mixer so as to be mixed at a high speed, and then adding the mixture to a double-screw extruder so as to be subjected to extruding granulation at 210-250 DEG C, thus obtaining the thermoplastic polyether ester elastomer composition. The thermoplastic polyether ester elastomer composition and the preparation method have the beneficial effects that by adding the epoxy resin to modify the polyether ester elastomer, the melt index of the material can be obviously reduced, the tensile strength of the material can be improved, the elongation at break of the material is relatively high, and the material has good resilience effect and good dynamic / static stiffness; the process is simple, and the production cost is relatively low; the thermoplastic polyether ester elastomer composition can be used in the fields such as track traffic gaskets and the like.

Owner:KINGFA SCI & TECH CO LTD

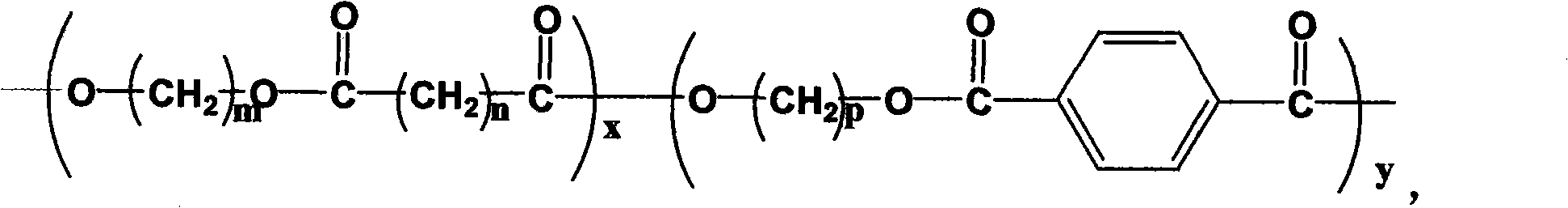

Viscous modified aliphatic-aromatic copolyester and preparation method thereof

ActiveCN102040736APeroxide bond energy is smallImprove melt strengthAlcoholCrystallization temperature

The invention relates to viscous modified aliphatic-aromatic copolyester and a preparation method thereof, in particular to biodegradable aliphatic-aromatic copolyester. A monomer of the fat-aromatic copolyester is extracted from aliphatic diacid of C2-C10, aliphatic dihydric alcohol of C2-C10 and terephthalic acid or an esterified product thereof, and then an organic peroxide is introduced underthe condition of obtaining linear random copolyester by condensation polymerization, thereby a polymerized product with increased melt viscosity is obtained. After the aliphatic-aromatic copolyester is modified by the organic peroxide, the melt index of the aliphatic-aromatic copolyester is obviously reduced, and the value (2.19kg, 190 DEG C) of the melt index MI is changed to 0.1-10g / 10min from 10-50g / 10min. The crystallization temperature is greatly improved, and the viscous modified aliphatic-aromatic copolyester solves the problems of bubble pipe adhesion, unstability of the bubble pipe, bubble destroy, bubble collapse and the like, thereby meeting the technique requirements of film blowing and film coating.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyester for 3D printing, and preparation method thereof

The invention discloses a polyester for 3D printing, and a preparation method thereof. According to the present invention, an aromatic dibasic acid or a dimethyl ester thereof, an aliphatic dibasic acid or a dimethyl ester thereof, and diol are used as monomers and are subjected to a normal pressure esterification reaction in the presence of a nucleation agent, a branching agent, a filler and a catalyst, heating pressure reducing is performed after the esterification reaction is completed, and a condensation polymerization reaction is performed to obtain the copolyester material, wherein the aromatic dibasic acid is an aromatic C6-C10 dibasic acid, the aliphatic dibasic acid is an aliphatic C2-C10 dibasic acid, the diol is a C2-C10 diol, and the branching agent is a polybasic acid or a polyol. According to the present invention, the obtained material has advantages of high elongation at break, large number average molecular weight, low melt index and degradability, and can be used as a3D printing material.

Owner:SINOPEC YIZHENG CHEM FIBER +1

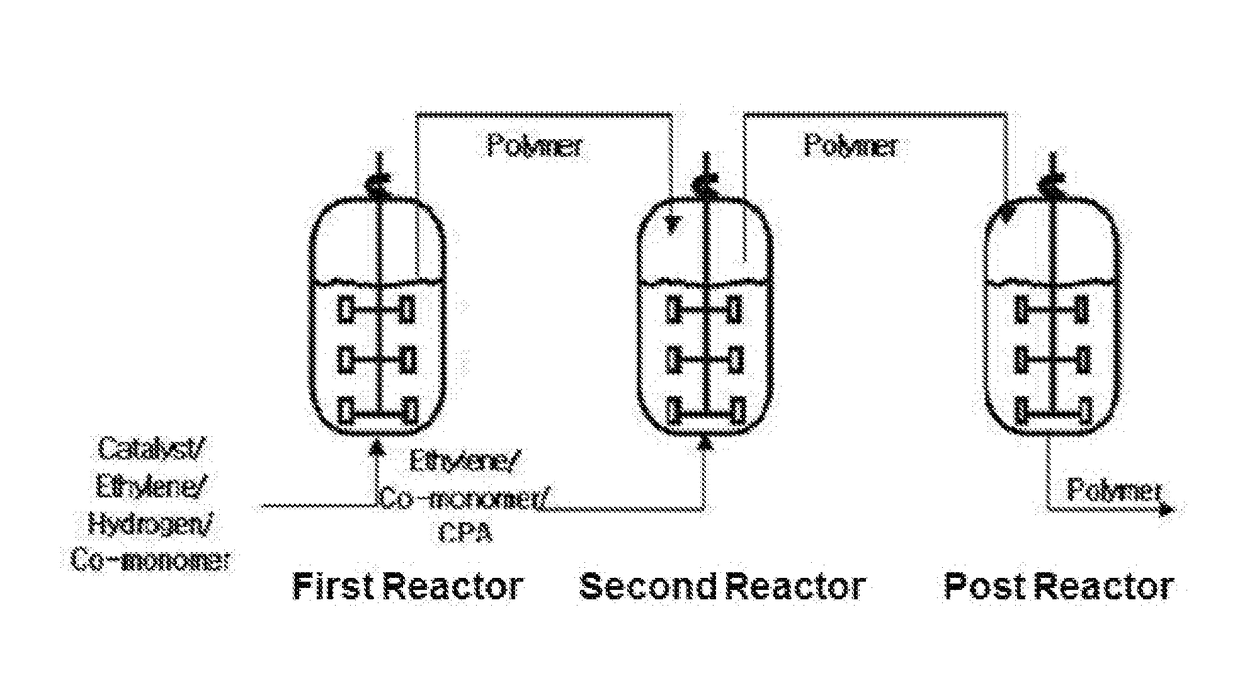

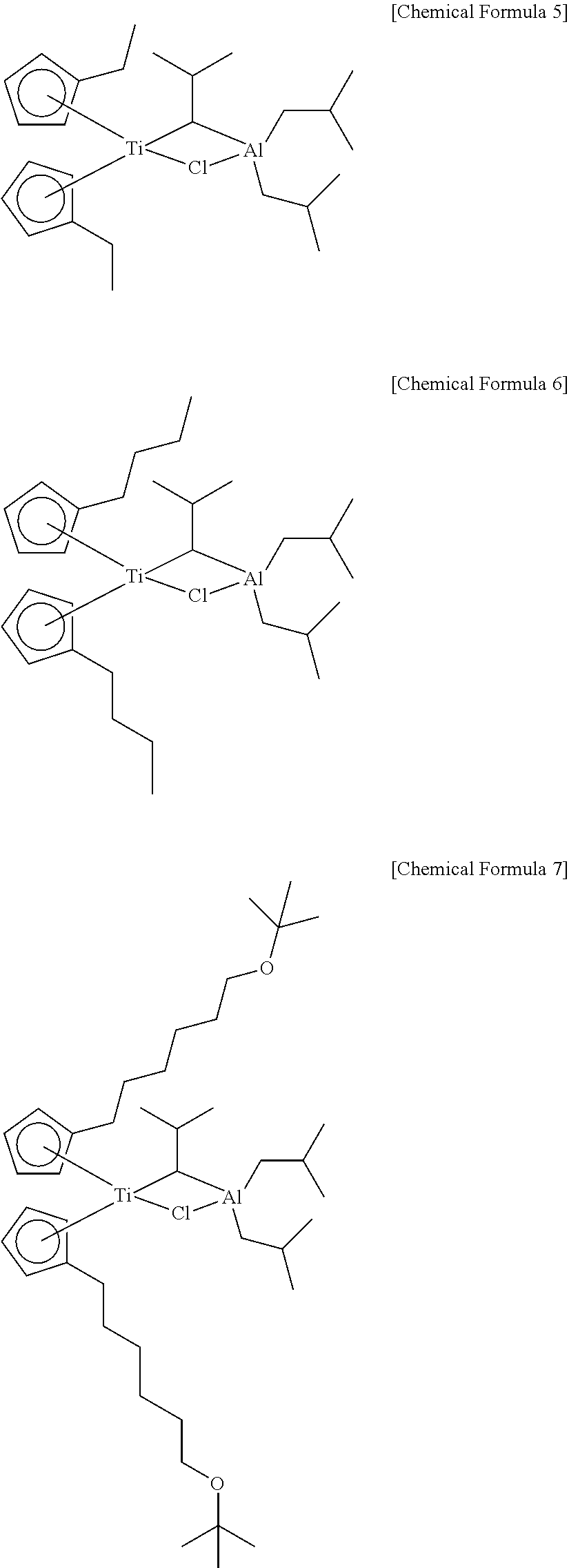

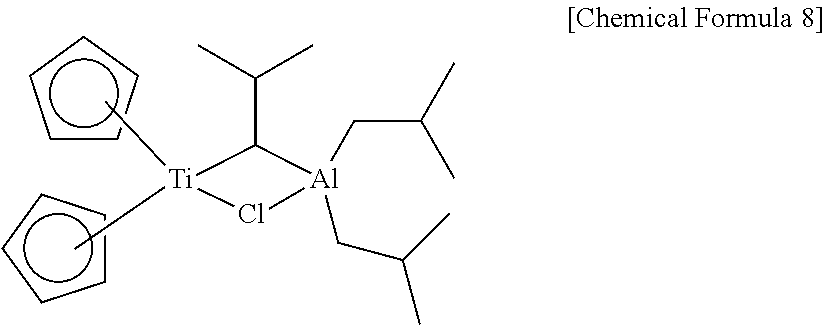

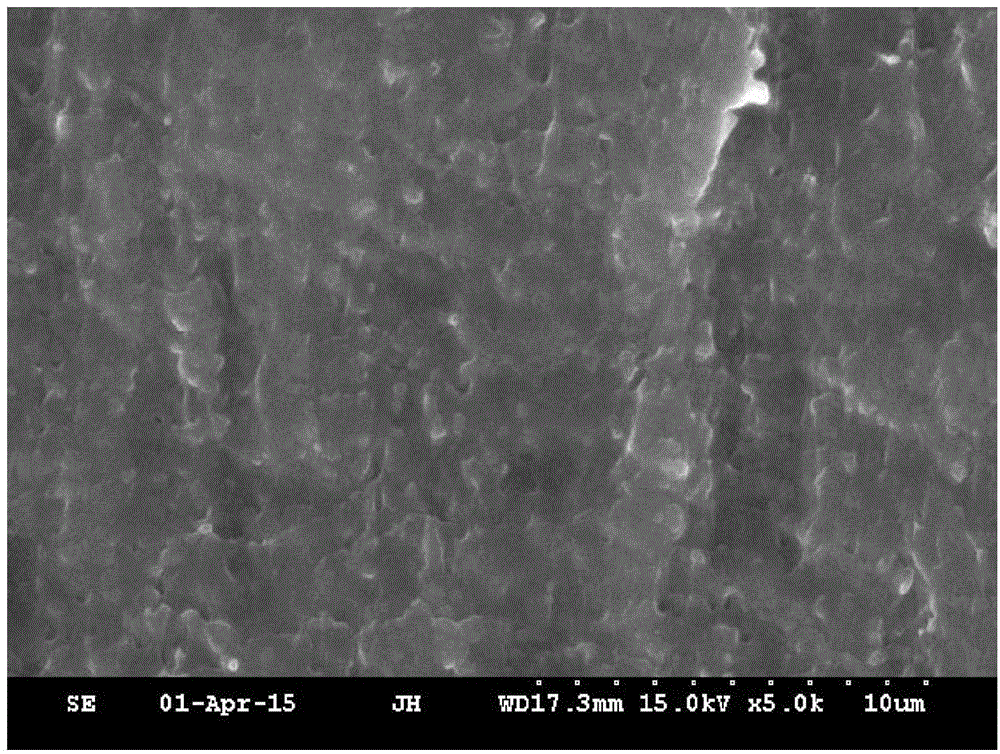

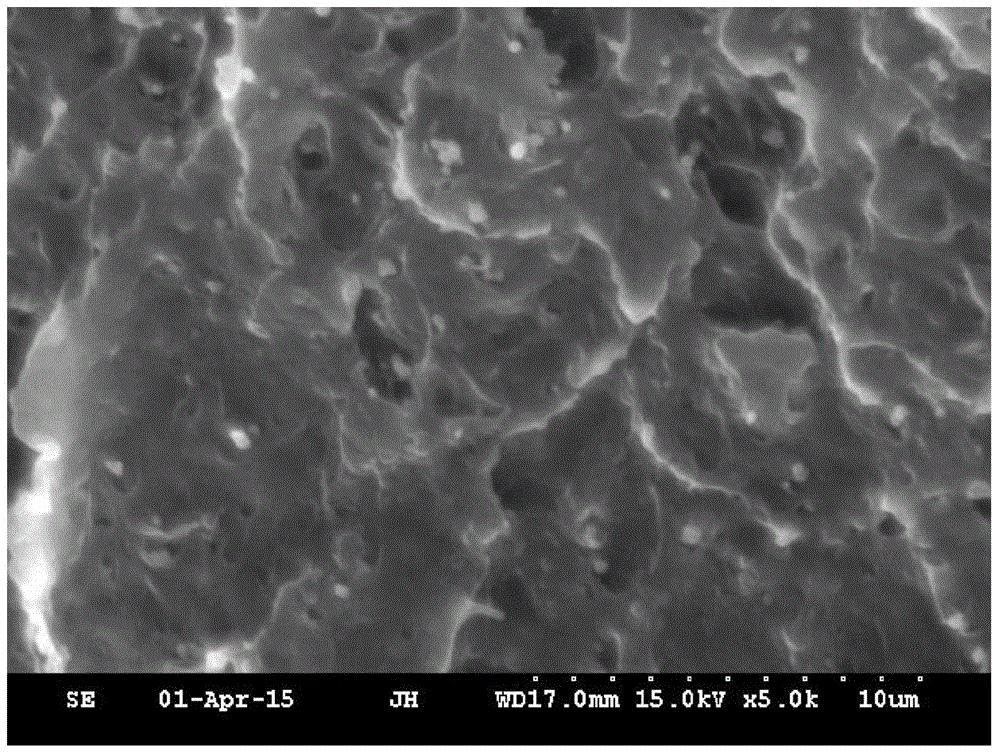

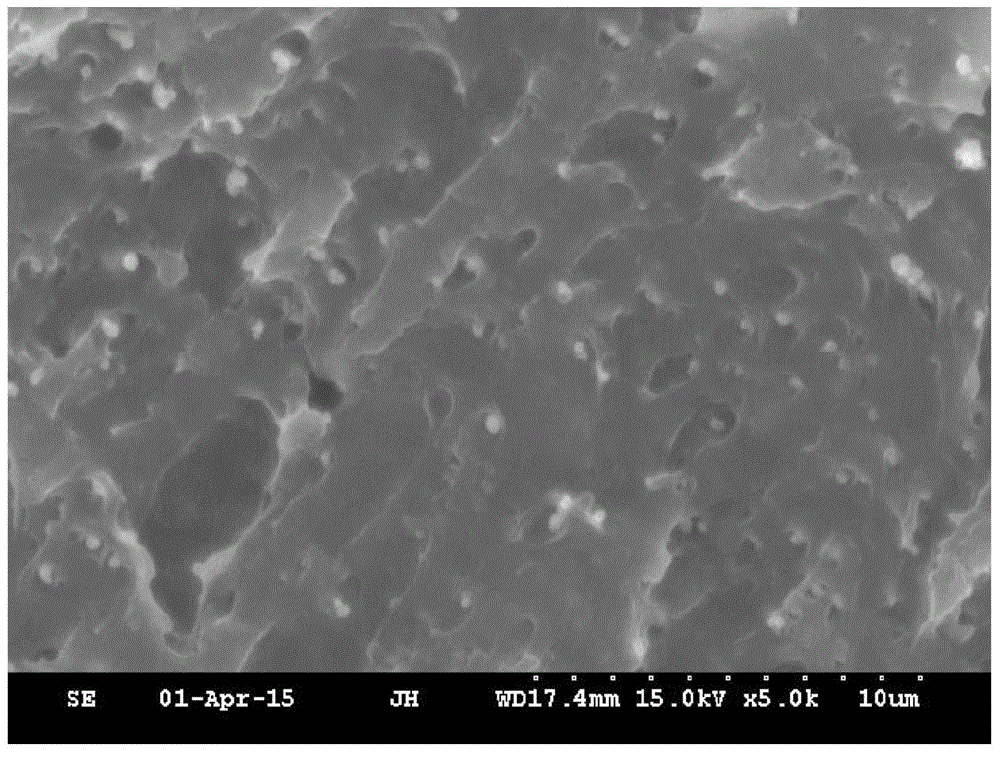

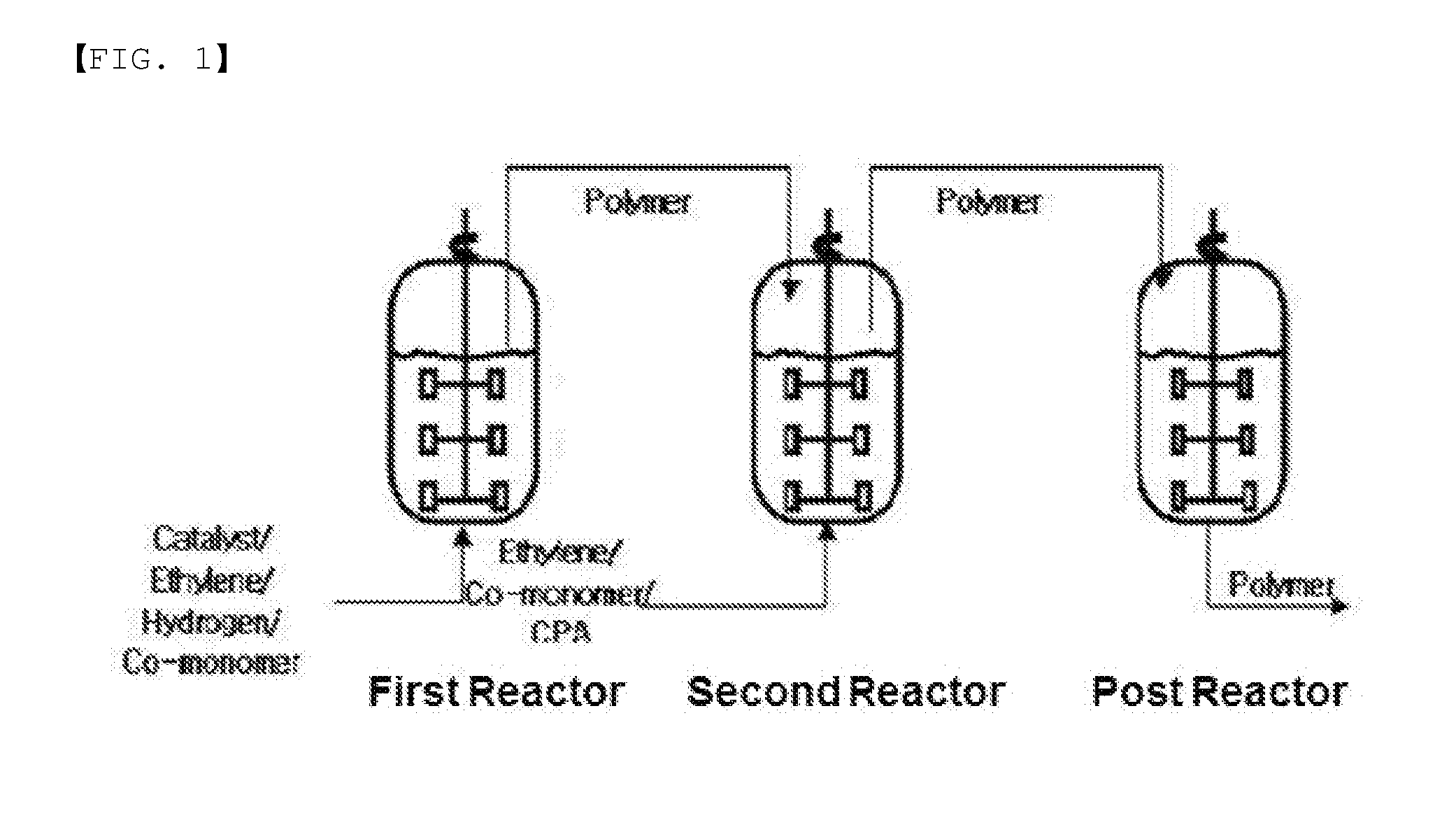

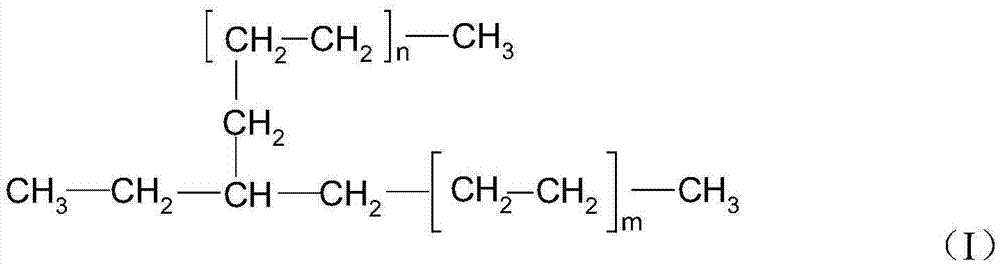

Method of preparing polyolefin, and polyolefin prepared thereby

ActiveUS9975969B2High molecular weightWider multimodal molecular weight distributionBlow moldingPolyolefin

A method of preparing a polyolefin, wherein the method is used to more effectively prepare a polyolefin which has a high molecular weight and multimodal molecular weight distribution, thereby being preferably used for blow-molding or the like, and a polyolefin prepared thereby, are provided.

Owner:LG CHEM LTD

Composite titanium dioxide and preparation method thereof

InactiveCN104945958AGood dispersionStir wellPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsBarium sulfateBrightness perception

The invention discloses a composite titanium dioxide and a preparation method thereof. The preparation method of the composite titanium dioxide comprises the steps that nano-calcium carbonate is prepared through a bubbling method, a small amount of methyl methacrylate is added to the nano-calcium carbonate for surface decoration, the decorated calcium carbonate, barium sulfate, titanium dioxide are mixed proportionally and added to a reaction device, a titanate coupling agent, simethicone, silane coupling agent and isopropanol are added to the reaction device dropwise, and after filtering and drying, high-dispersion high-brightness composite titanium dioxide is obtained. The composite titanium dioxide can be effectively dispersed into polymer matrix, improves the whiteness of titanium dioxide and reduces the use cost of titanium dioxide.

Owner:JILIN UNIV

METHOD OF PREPARING POLYOLEFIN, AND POLYOLEFIN PREPARED THEREBY (As Amended)

ActiveUS20160222139A1High molecular weightWider multimodal molecular weight distributionBlow moldingPolyolefin

A method of preparing a polyolefin, wherein the method is used to more effectively prepare a polyolefin which has a high molecular weight and multimodal molecular weight distribution, thereby being preferably used for blow-molding or the like, and a polyolefin prepared thereby, are provided.

Owner:LG CHEM LTD

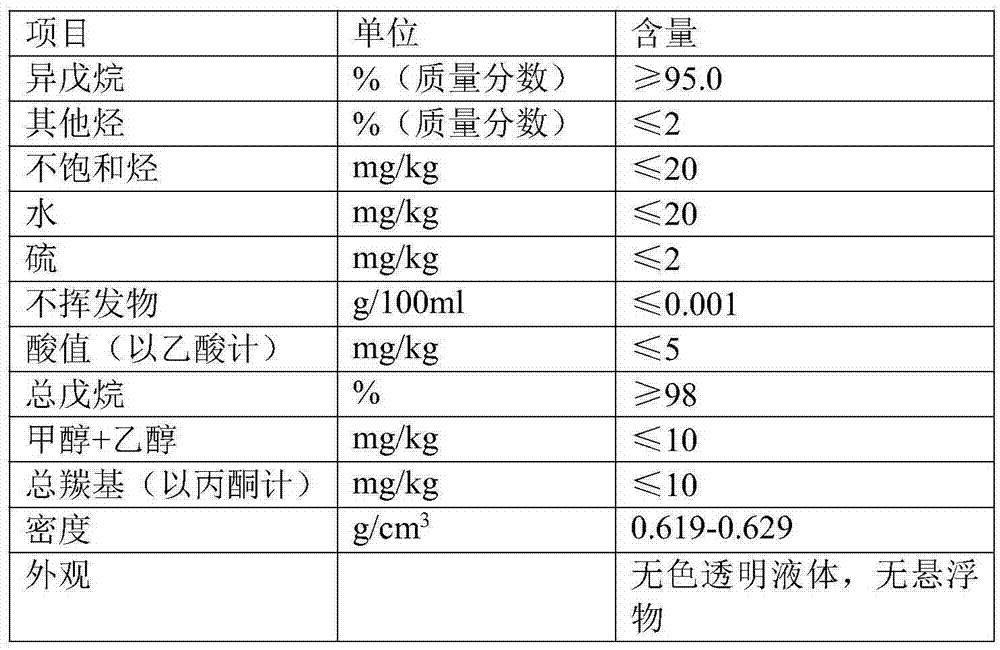

Polyethylene base resin powder and preparation method thereof

The invention relates to a polyethylene base resin powder for preparing an IBC barrel special material and a preparation method thereof. Polyethylene base resin is produced by a gas phase polyethylene process, the polymerization temperature is 96 DEG C-120 DEG C, and the polymerization pressure is 0.85-2.5 MPa. The prepared base resin powder is generated by copolymerization of ethylene and long-chain alpha-olefin, the weight-average molecular weight is 200-350 thousand, the molecular weight distribution index is 7-15, the alpha-olefin content is 0.5-1.5%, the melt flow rate is 5-8 g / 10 min, the density is 0.942-0.952 g / cm<3>, the low temperature impact strength (-30 DEG C) is more than 30 kJ / m<2>, and the melt strength is more than 15 cN. The special material is guaranteed to have high mechanical strength, good processing performance and high melt strength, can be guaranteed to have good antisagging property, and can meet various properties of the IBC barrel special material.

Owner:PETROCHINA CO LTD

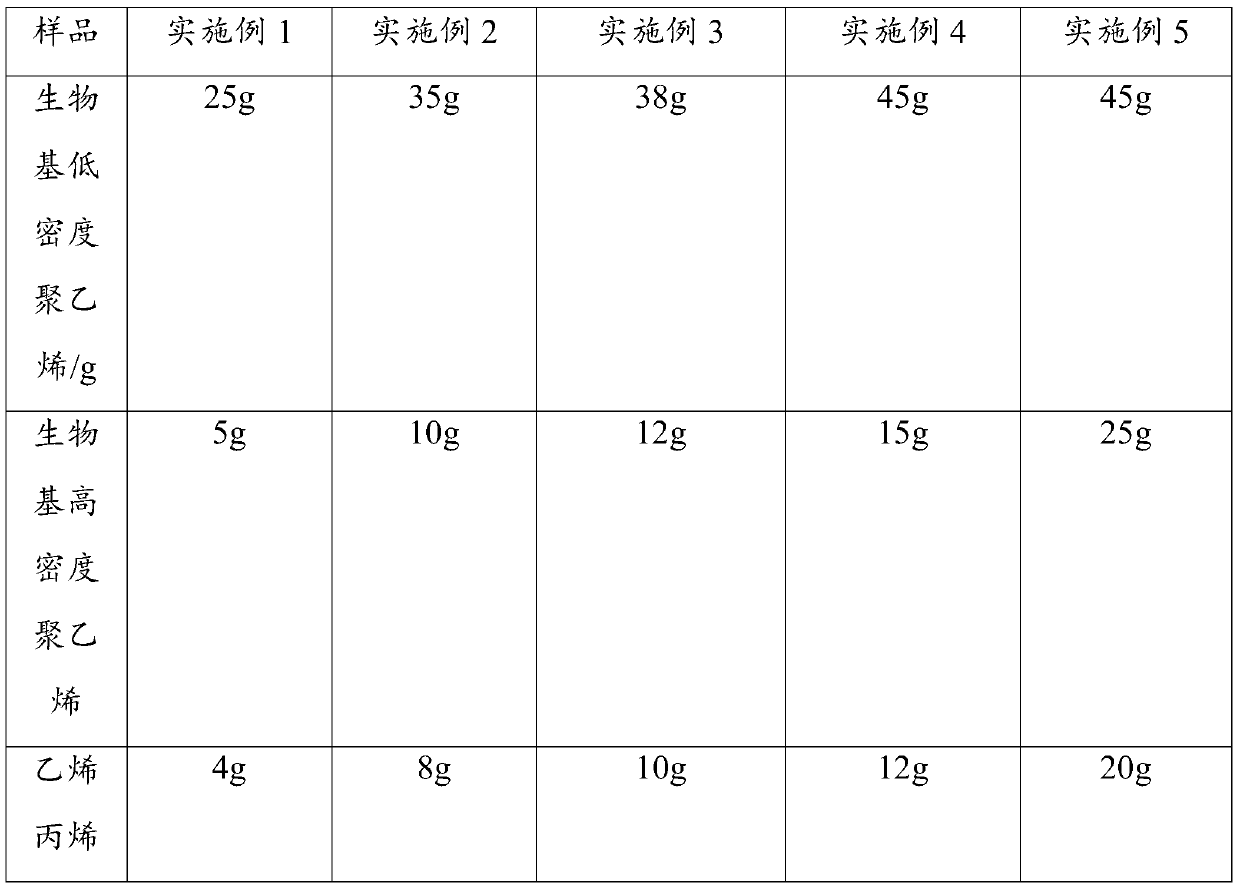

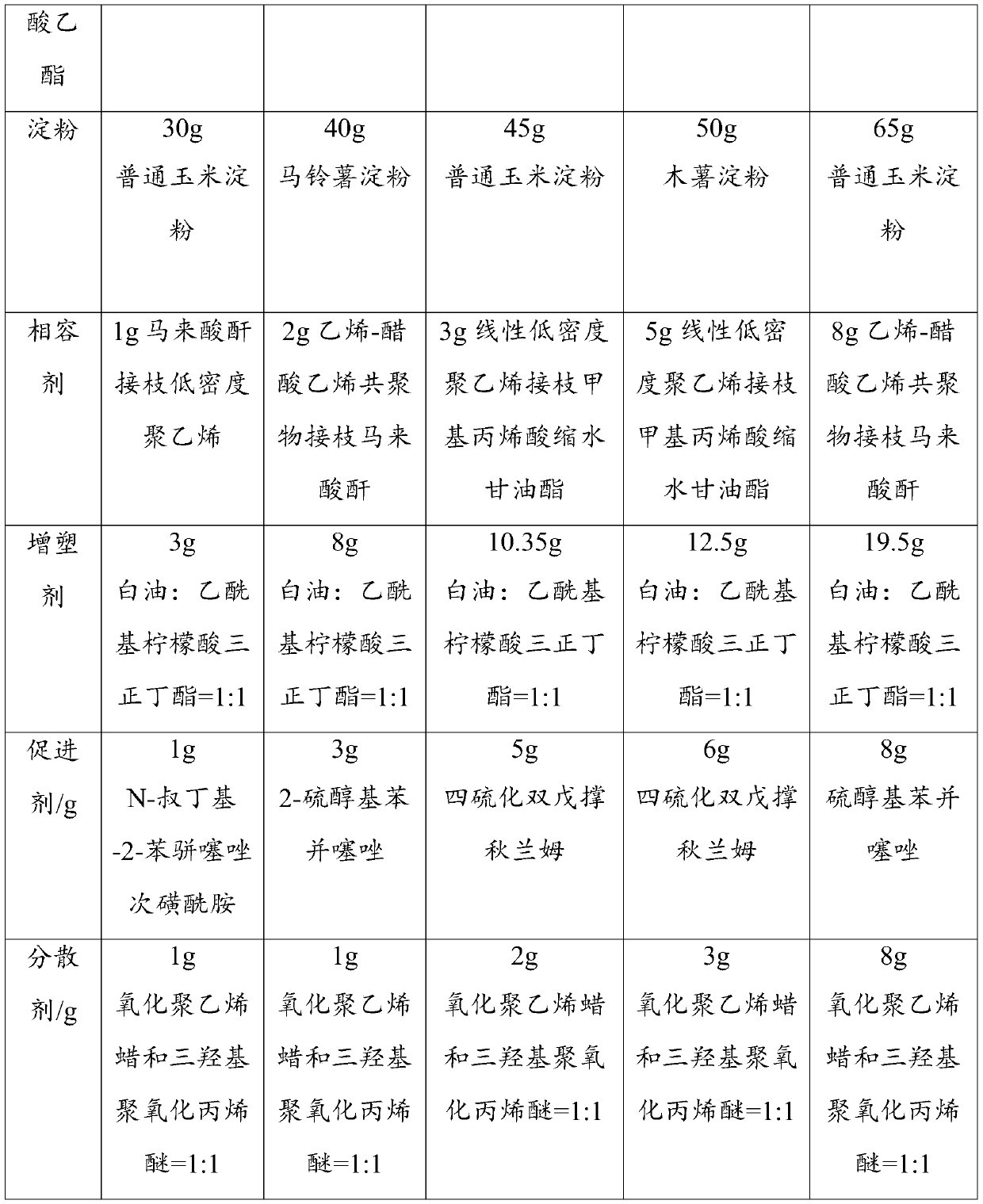

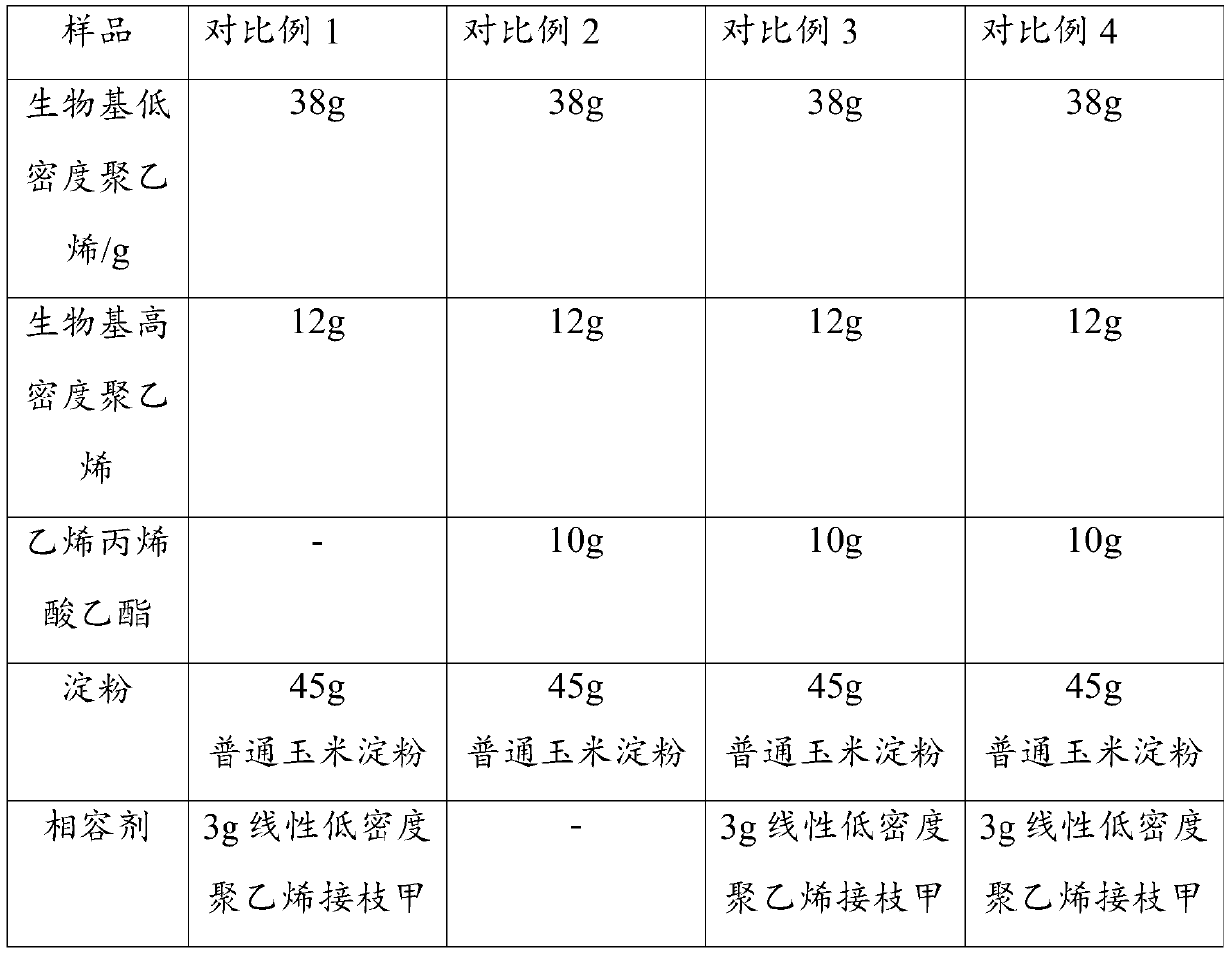

Bio-based polyethylene/starch blending modified film blowing material and preparation method thereof

The invention belongs to the field of plastic preparation, and particularly relates to a bio-based polyethylene / starch blending modified film blowing material and a preparation method thereof. The bio-based polyethylene / starch blending modified film blowing material comprises the following components in parts by weight: 25-45 parts of bio-based low-density polyethylene, 5-25 parts of bio-based high-density polyethylene, 4-20 parts of ethylene-ethyl acrylate, 1-8 parts of a compatilizer, 30-65 parts of starch, 3-19.5 parts of a plasticizer, 1-8 parts of a dispersing agent and 1-8 parts of an accelerant. The film blowing material provided by the invention has the advantages of high bio-based content, a low melt index, good processability and strong mechanical properties, and is beneficial for industrial popularization and utilization.

Owner:SHENZHEN HONGCAI NEW MATERIAL TECH

Preparation method of conductive polyether ether ketone composite material

The invention belongs to the technical field of high molecular materials and specifically discloses a preparation method of a conductive polyether ether ketone composite material. After a large numberof comparative tests on a polyether ether ketone substrate, a conductive filler and an additive, an optimal formula is finally obtained; the prepared conductive composite material can be used for a long term under the condition of 250-300 DEG C and has a very good mechanical property; compared with an existing alkane-based and rubber-based material, the conductive polyether ether ketone compositematerial has higher mechanical property and is greatly improved in tensile, compression and impact resistance; the conductive polyether ether ketone composite material can be widely used in chemical,metallurgy, medicine and other industries, so that the application field of the high molecular composite material under high-temperature and severe conditions is expanded.

Owner:YIBIN TIANYUAN GRP CO LTD

Bamboo powder/PP (propene polymer) wood-plastic reinforced wall board and processing method thereof

A bamboo powder / PP(propene polymer) wood-plastic reinforced wall board is characterized by comprising, by weight, 30-45 parts of bamboo fibers, 40-50 parts of PP plastic, 2-4 parts of coupling agent, 2-5 parts of lubricating agent and 0.2-0.8 part of reinforcing agent. A processing method includes the steps of pretreatment, material stirring, mat formation, hot-press curing, drying, maintaining and the like. The wood-plastic reinforced wall board prepared according to the processing method has low water absorption and high mechanical property, is better than wall boards with the same specification in the market, and is simple in process, low in production cost and widely applied to construction industry, thereby having good market prospect.

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE

Ethylene polymerization method and polyethylene

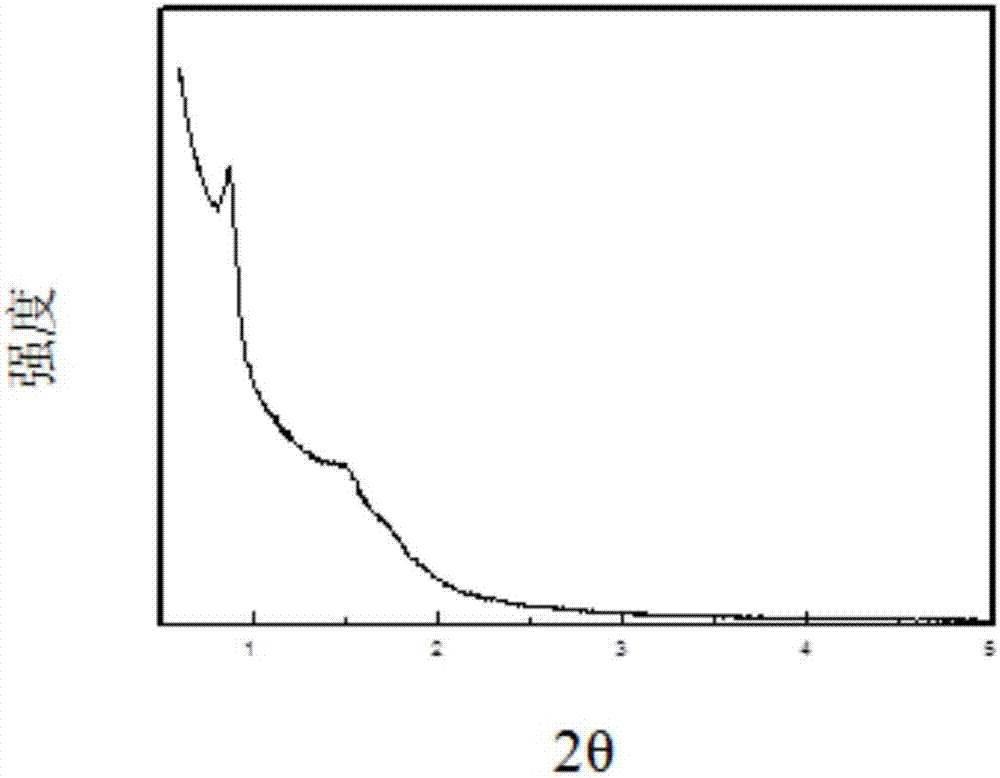

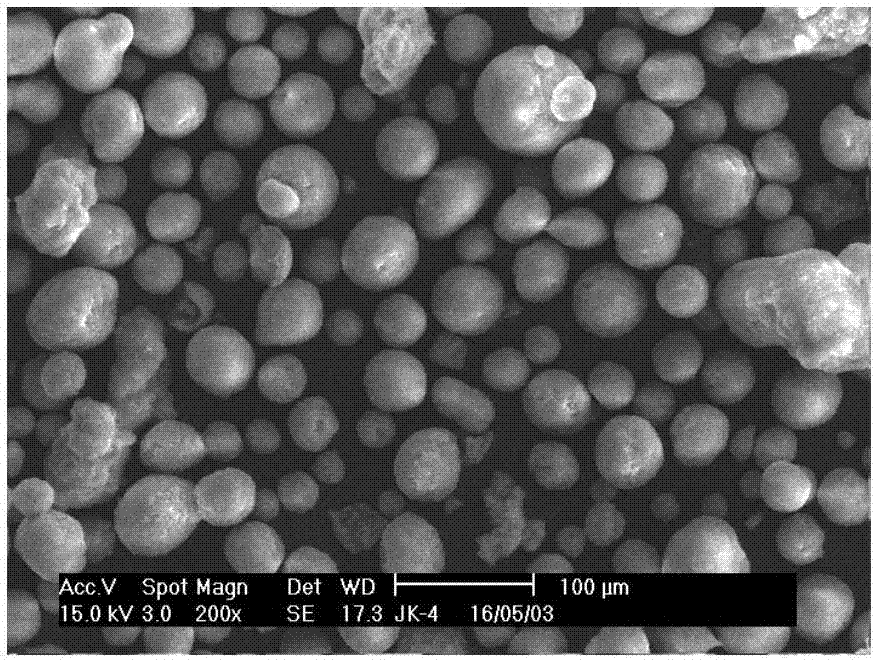

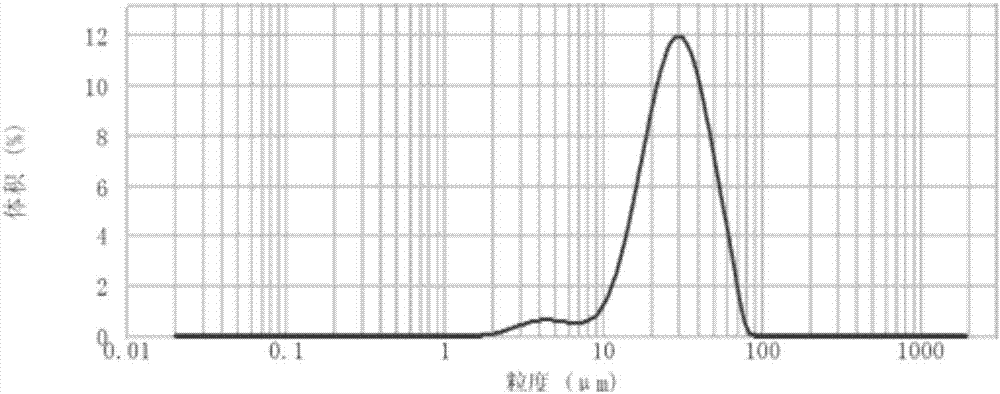

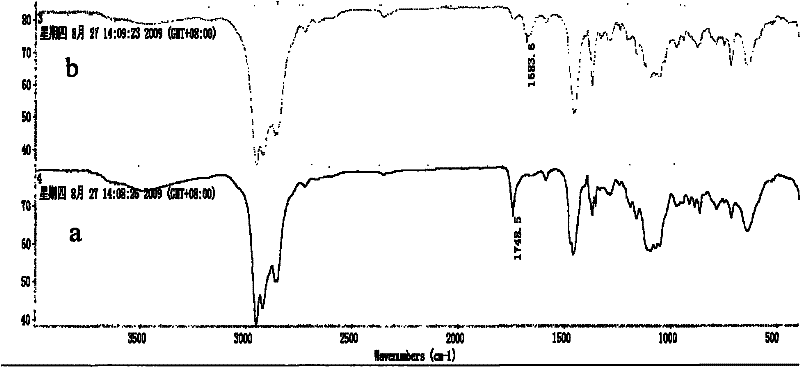

The present invention relates to the field of polymerization reactions, and discloses an ethylene polymerization method and polyethylene obtained through the ethylene polymerization method. The ethylene polymerization method comprises: carrying out a polymerization reaction on ethylene in the presence of a catalyst under a polymerization reaction condition, wherein the catalyst contains a spherical porous mesoporous composite material and a magnesium salt and / or a titanium salt supported on the spherical porous mesoporous composite material, and the spherical porous mesoporous composite material contains a mesoporous molecular sieve material with a one-dimensional through-hole structure, and a mesoporous molecular sieve material with a hexagonal pore channel structure. According to the present invention, the supported catalyst with the stable mesoporous structure is used, such that the polyethylene product with characteristics of low bulk density, low melt index and breaking resistancecan be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

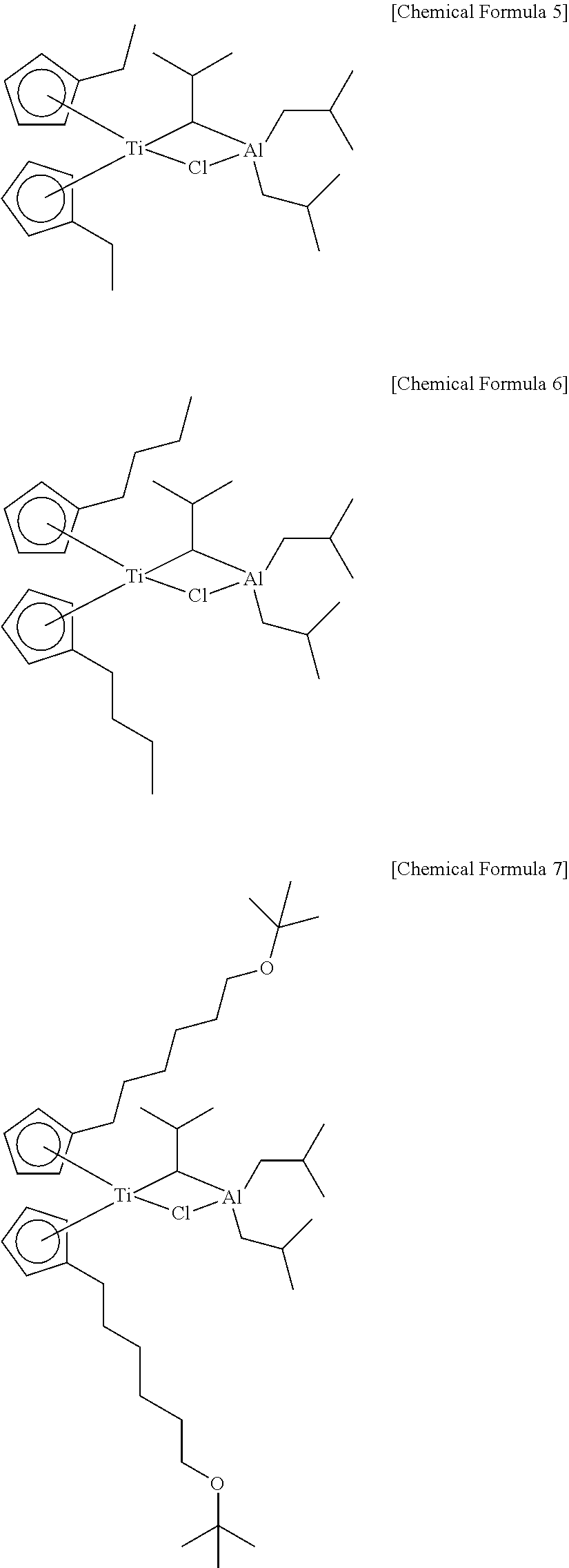

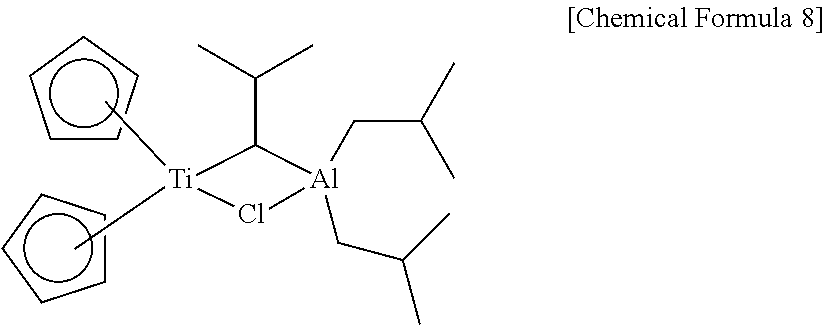

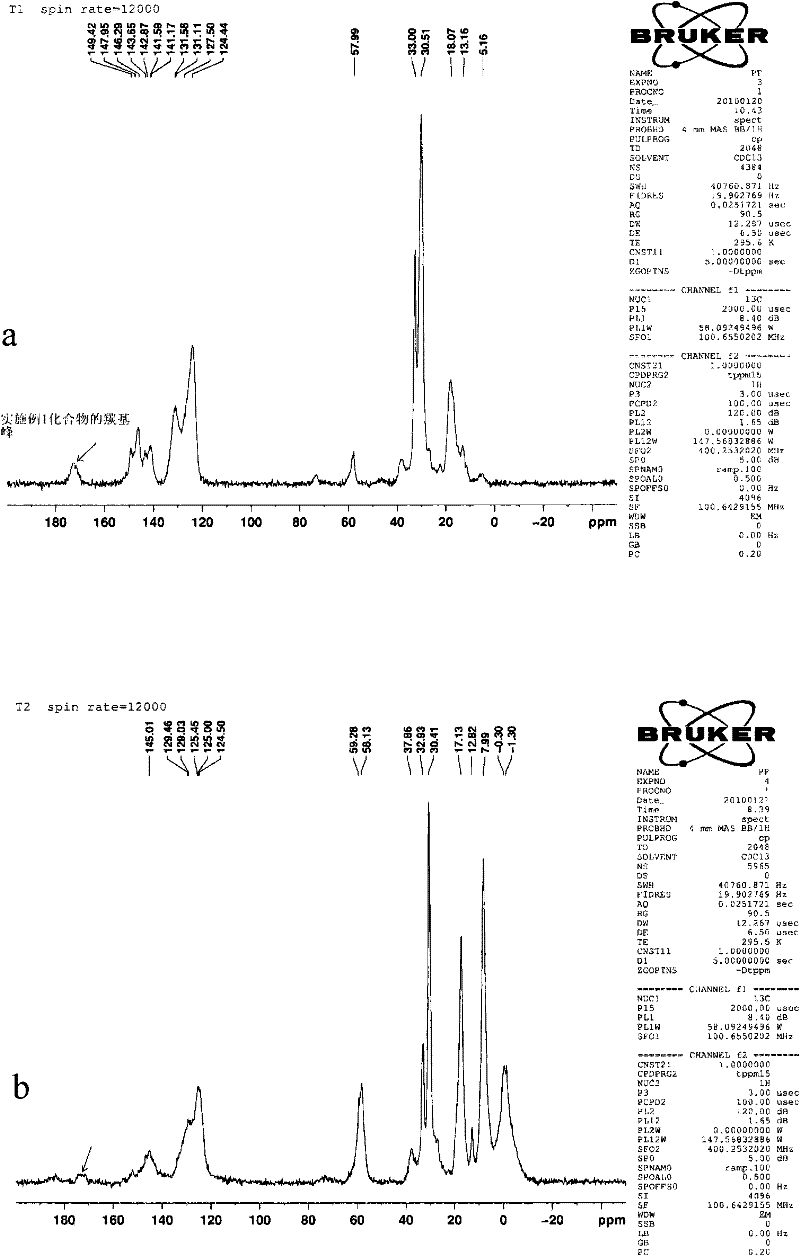

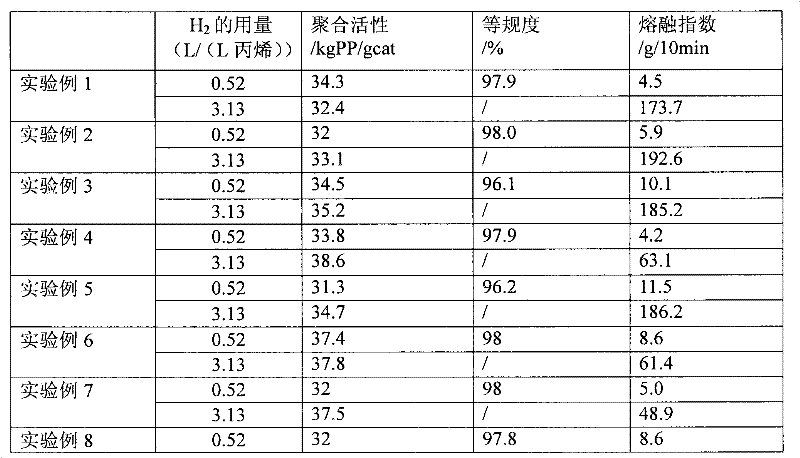

External donor compound

ActiveCN102453057AHigh activityLow melt indexSilicon organic compoundsGroup 3/13 element organic compoundsHydrogenAluminium alkyl

The invention provides an external donor compound. Aluminium alkyl is introduced into a compound with calixarene group and organosilicon amino group; when used as an external donor compound of olefin polymerization catalyst with a main catalyst of Ziegler-Natta type catalyst, the compound can endow the olefin polymerization catalyst with high stereoselectivity and hydrogen response, so as to actively prepare a polymer with high fusion index and high isotacticity and a polymer with low fusion index and high isotacticity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing flow rate of polyethylene melt

The invention relates to a method for reducing a flow rate of polyethylene melt, which comprises the following process steps: A, preparation of auxiliary agents: taking 100 parts of polyethylene and 5-10 parts of polyethylene cross-linking agent; B, mixing: mixing the auxiliary agents at the room temperature; C, dilution: diluting the polyethylene according to a ratio of 100:1, putting 1 part of prepared auxiliary agents into 100 parts of polyethylene, and mixing; D, feeding: putting the well diluted mixture into an extruder for granulation and extrusion, thereby achieving the effect of reducing the flow rate of the polyethylene melt. The method has the advantages of simple process, easy operation and no pollution, and can realize the industrial mass production; and the method can reduce the flow rate of the polyethylene melt with the high melt index, so that the polyethylene melt can be used as a raw material suitable for pipeline production. The invention can be widely applied in product production with the extrusion, emptying, film blowing, drawing and the like of the polyethylene melt.

Owner:邓忠权

Biodegradable film modified by epoxidized lignin and preparation method thereof

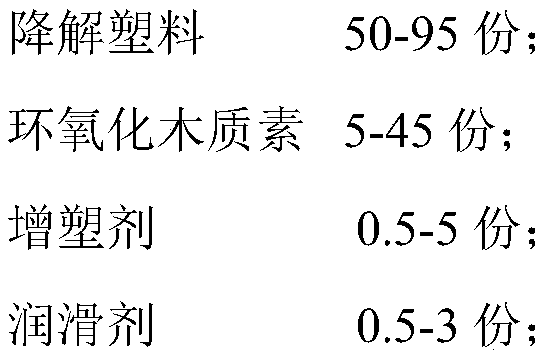

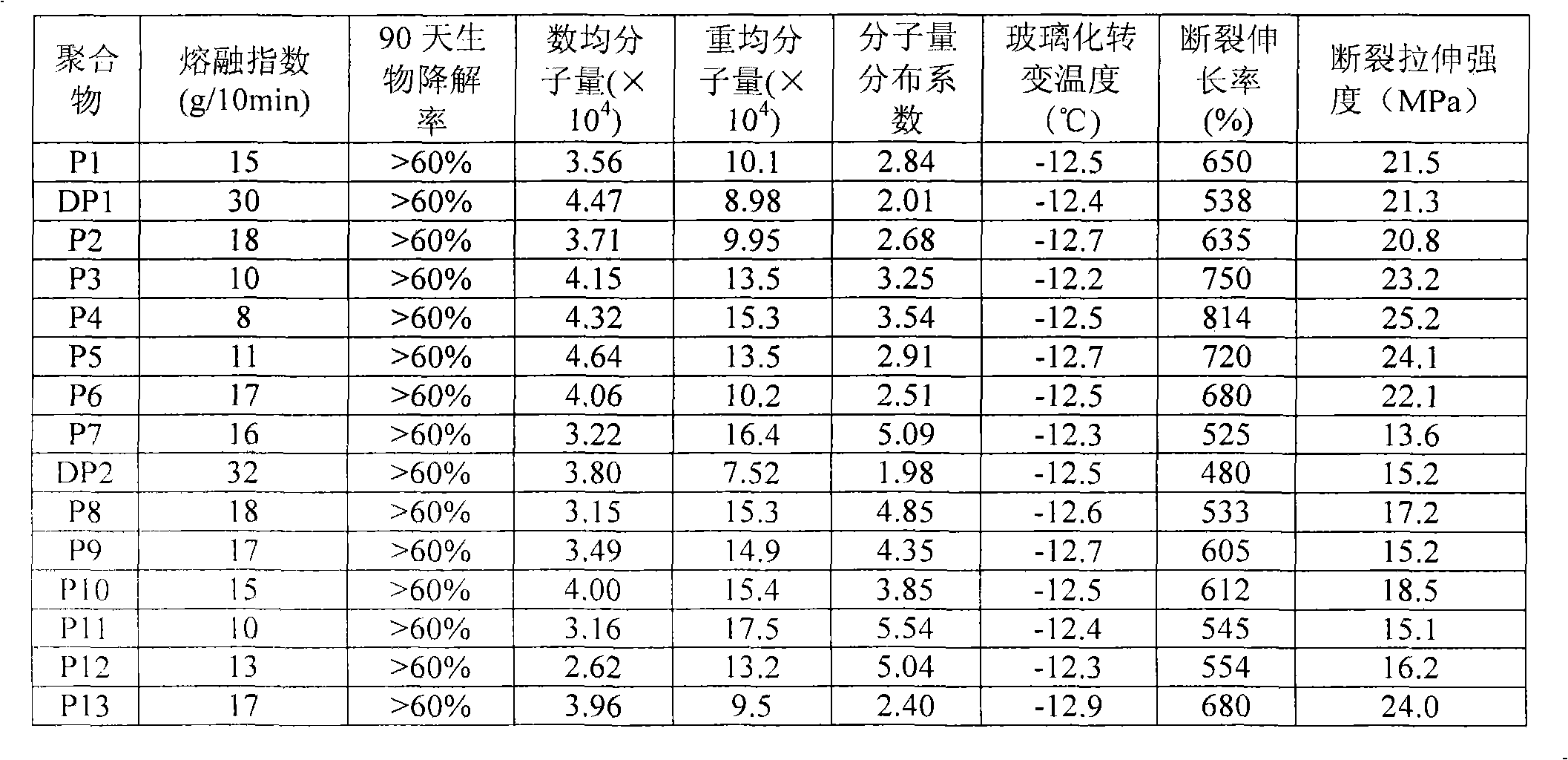

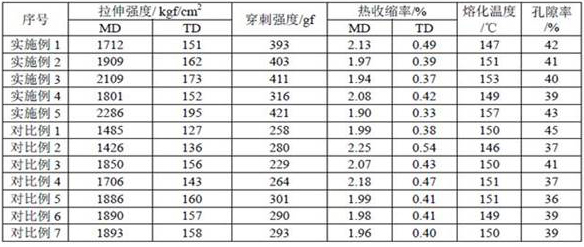

The invention discloses a biodegradable film modified by epoxidized lignin and a preparation method thereof. The biodegradable film comprises the following components in parts by weight: 50-95 parts of degradable plastic; 5 to 45 parts of epoxidized lignin; 0.5 to 5 parts of a plasticizer; and 0.5-3 parts of a lubricant, wherein the weight-average molecular weight of the epoxidized lignin is not less than 5000. The epoxidized lignin with a certain molecular weight is used for modifying and degrading plastic, the compatibility and dispersity of lignin in a plastic matrix are improved, meanwhile, an epoxy group of the epoxidized lignin and plastic macromolecules are subjected to a grafting chain extension reaction, and the processing performance and mechanical performance of the material areimproved.

Owner:NANJING UNIV OF TECH

Aliphatic-aromatic copolyester and preparation method thereof

The invention relates to aliphatic-aromatic copolyester and a preparation method of the aliphatic-aromatic copolyester. The method comprises the steps of allowing an ingredient a to react with an ingredient b with the existence of catalysts comprising a first catalyst and selectively comprising a second catalyst, allowing an obtained reaction mixture, an ingredient c, an ingredient d and the selectively added ingredient b to react with the existence of the first catalyst and the second catalyst, and allowing an obtained reaction mixture to be subjected to polycondensation. The first catalyst is a titanic oxide, an antimony oxide, a zinc oxide, M(OR1)n or M(-OOCR2)m; the second catalyst is a chemical compound with the chemical formula of RE(R3)3; the ingredient a contains aromatic dibasic acid and / or dibasic anhydride; the ingredient b is aliphatic dibasic alcohol; the ingredient c is aliphatic dibasic acid and / or dibasic anhydride; and the ingredient d is polyhydric alcohol, polybasic carboxylic acid or polybasic carboxylic anhydride with the degree of functionality greater than 2. The aliphatic-aromatic copolyester prepared according to the method is lower in melt index, and better in biodegradability and tensile mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-fluidity polyamide magnetic composite material and preparation method thereof

The invention discloses a high-fluidity polyamide magnetic composite material, prepared from the following ingredients in percentage by weight: 4.3-12.2wt% of polyamide resin, 85-93wt% of strontium ferrite, 0.5-1wt% of an internal lubricant, 1-3wt% of a flow modifier, 0-0.2wt% of an external lubricant, 0-0.1wt% of a primary antioxygen, 0-0.1wt% of an auxiliary antioxygen and 0.3-0.8wt% of a coupling agent. A a sa a preparation method comprises the following steps: (1) mixing the strontium ferrite with the coupling agent, then adding the polyamide resin, the internal lubricant, the flow modifier, the external lubricant, the primary antioxygen and the auxiliary antioxygen, and mixing to obtain a mixture; (2) adding the mixture through a main feeding hole of a double-screw extruder, mixing uniformly, then extruding, and granulating by virtue of a granulator, thereby obtaining the high-fluidity polyamide magnetic composite material.

Owner:SICHUAN UNFIRE POLYMER MATERIALS TECH

High-strength three-layer co-extrusion lithium ion battery diaphragm and preparation method thereof

ActiveCN114497896AHigh crystallinityImprove puncture strengthSecondary cellsCell component detailsPhysical chemistryStearic acid

The invention relates to the technical field of lithium ion battery diaphragms, and discloses a high-strength three-layer co-extrusion lithium ion battery diaphragm and a preparation method thereof.The diaphragm comprises a layer B and layers A arranged on the two sides of the layer B; the component of the layer A comprises co-polypropylene, and the melt index of the co-polypropylene at 230 DEG C is greater than or equal to 30 g / 10 min; the layer B is prepared from the following components in parts by weight: 90 to 99 parts of homo-polypropylene and 1 to 10 parts of lubricating nucleating particles, and the melt index of the homo-polypropylene at 230 DEG C is 1 to 5g / 10min; the lubricating nucleation particles are prepared from polytetrafluoroethylene micro powder, pimelic acid and calcium stearate through step-by-step ball milling. According to the invention, the diaphragm with an A / B / A structure is prepared from two different types of polypropylene with relatively large melt index difference in a three-layer co-extrusion manner, and the lubricating nucleation particles are added into the middle layer, so that the mechanical property of the diaphragm is effectively improved while the processing property of the diaphragm is ensured.

Owner:NINGBO CHANGYANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com