Patents

Literature

291results about How to "Improve puncture strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

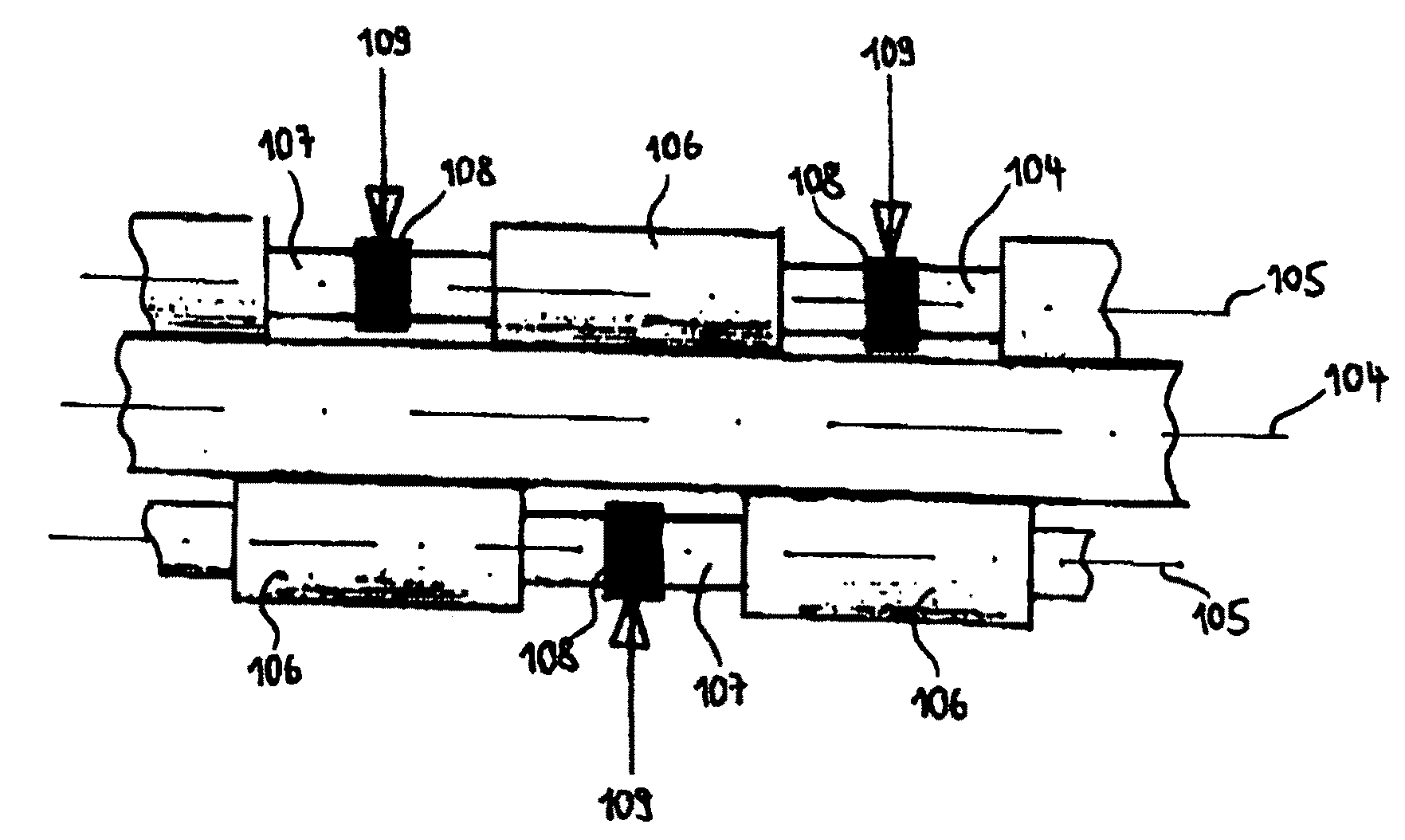

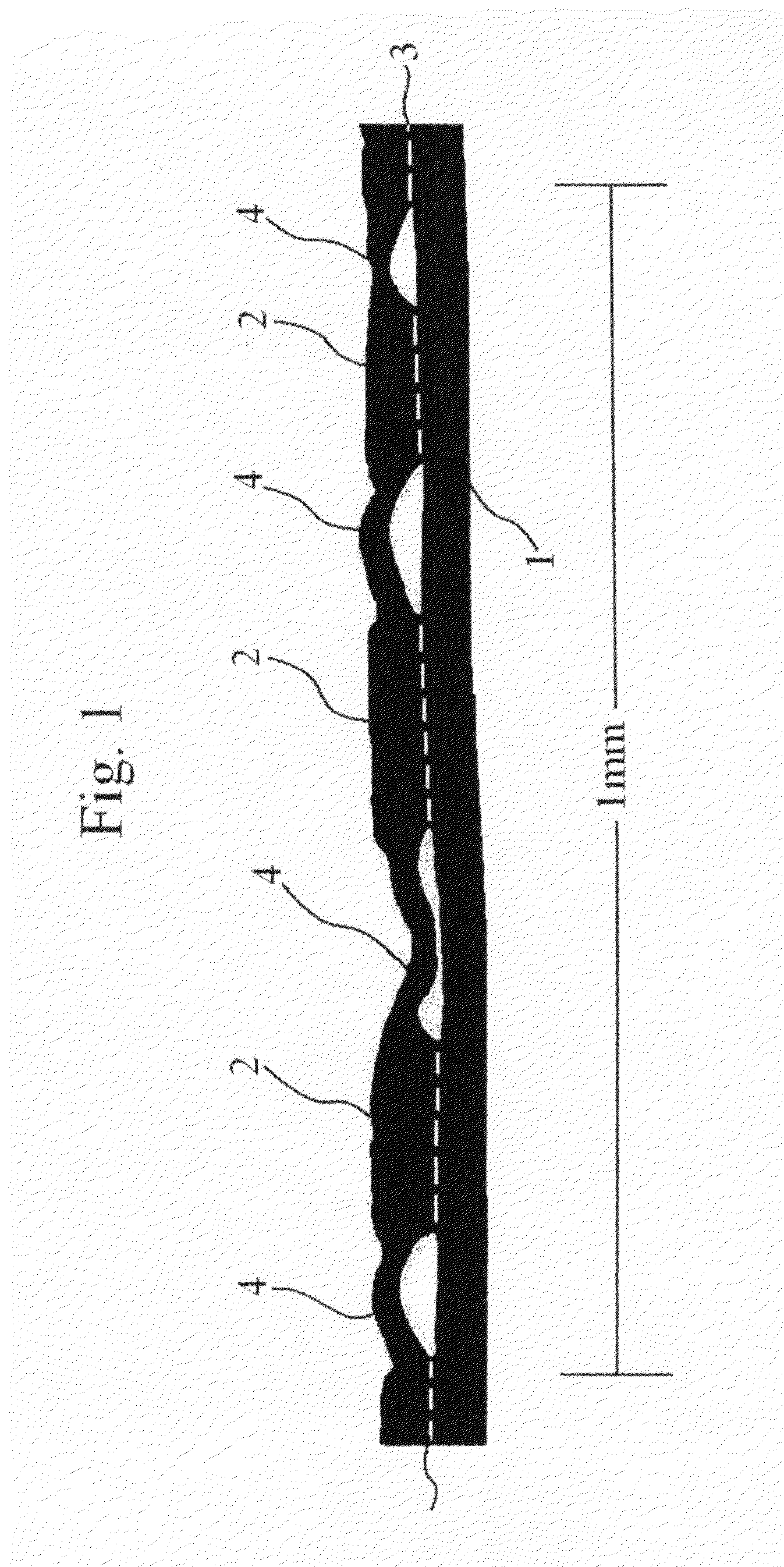

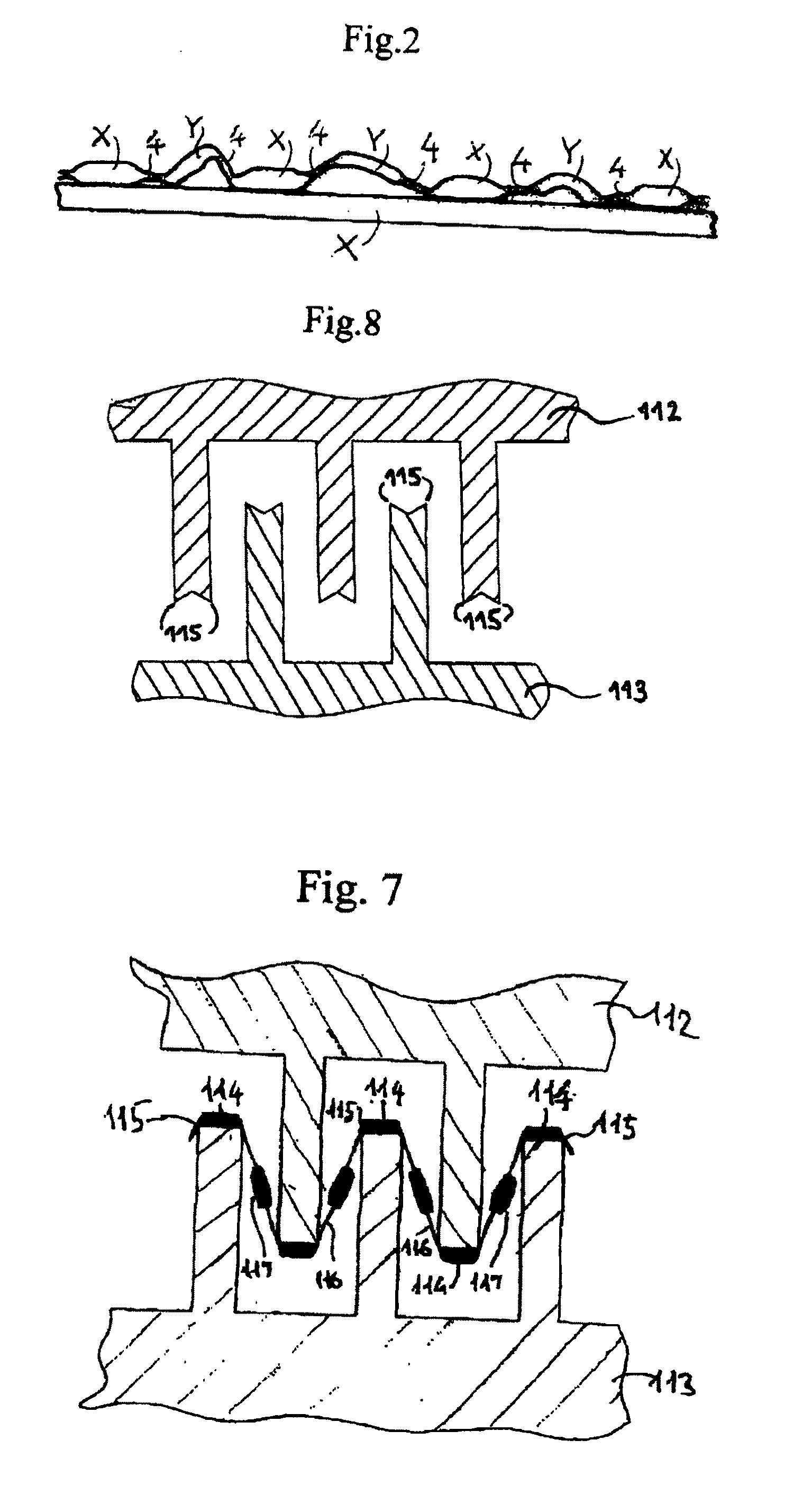

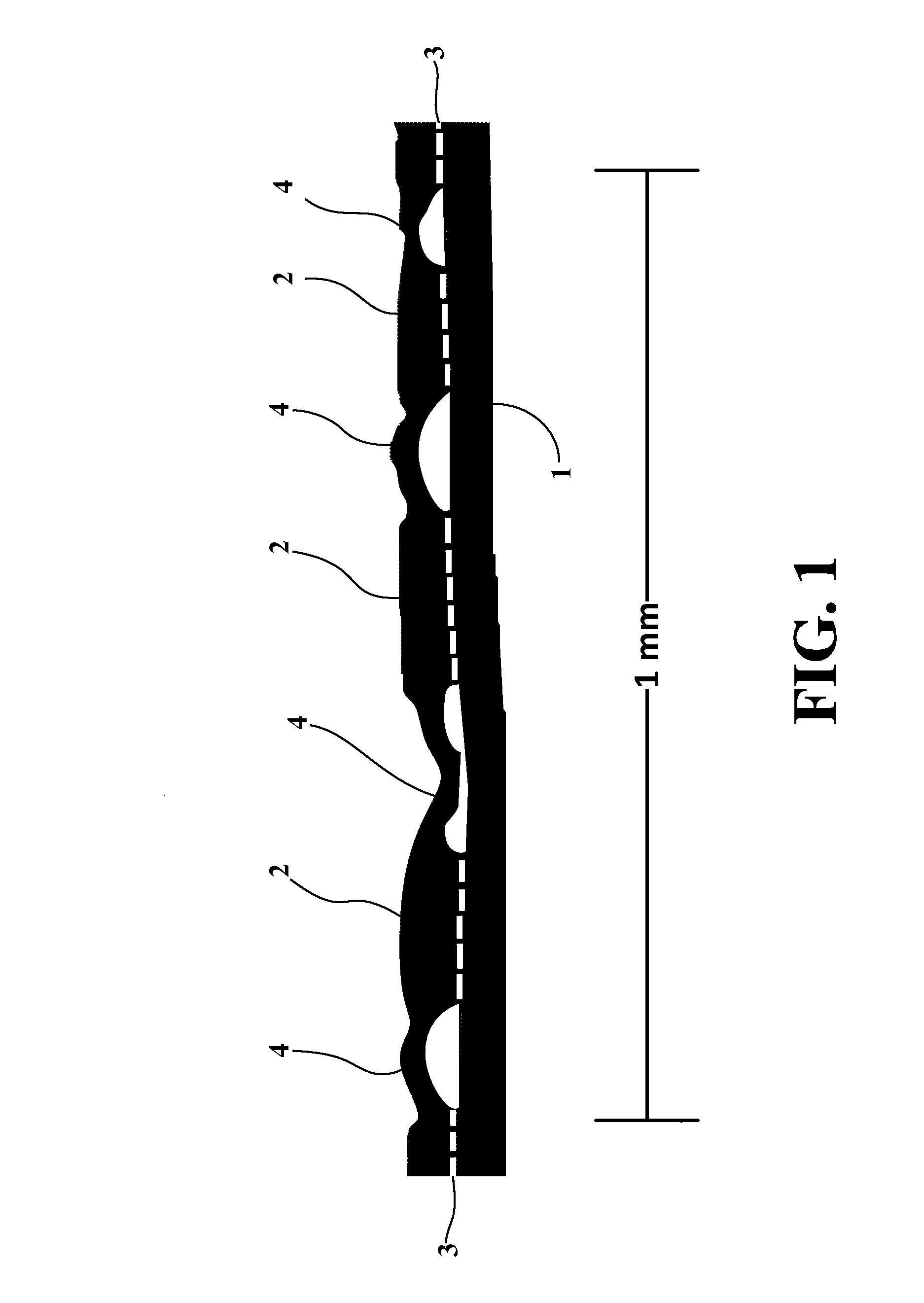

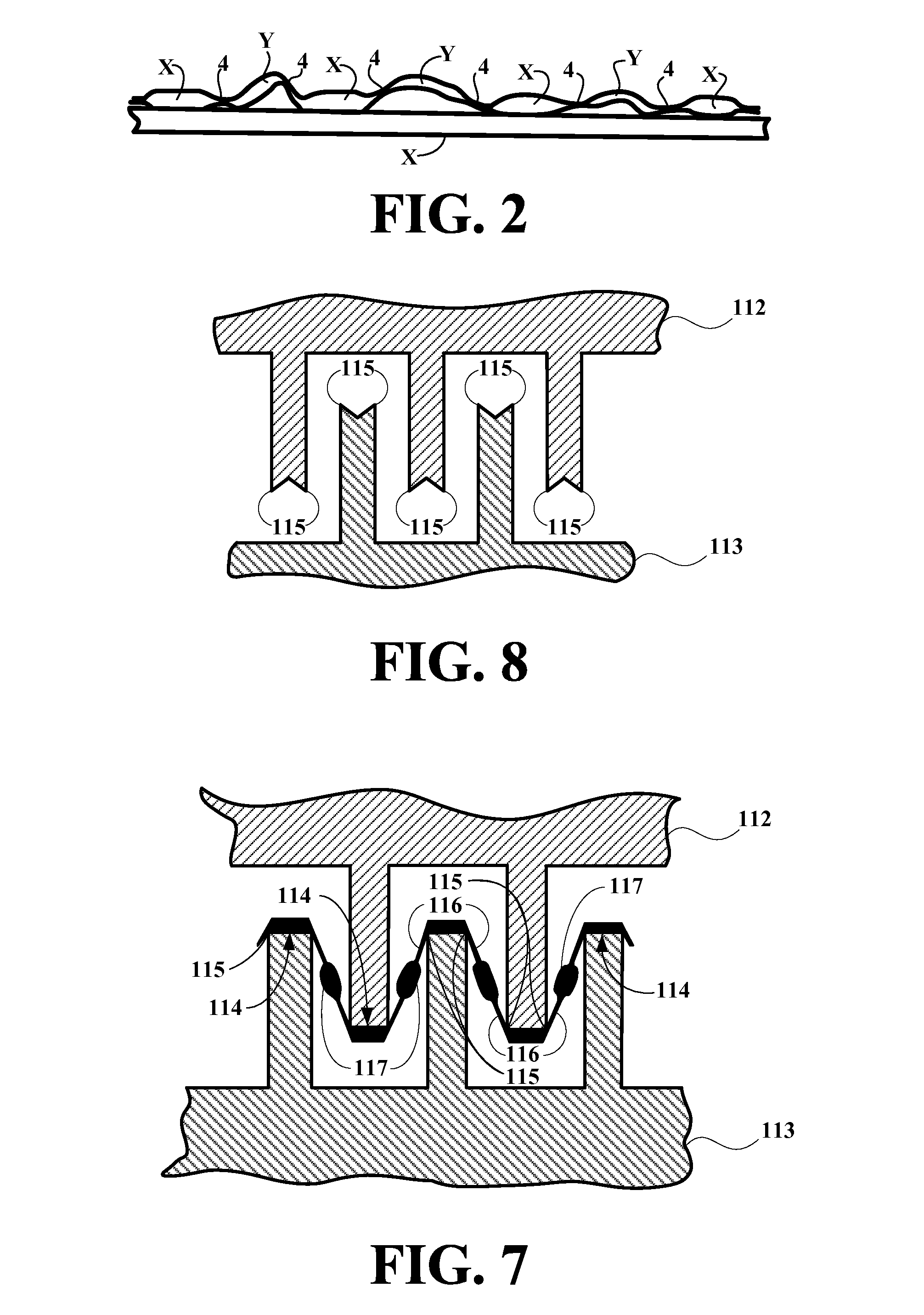

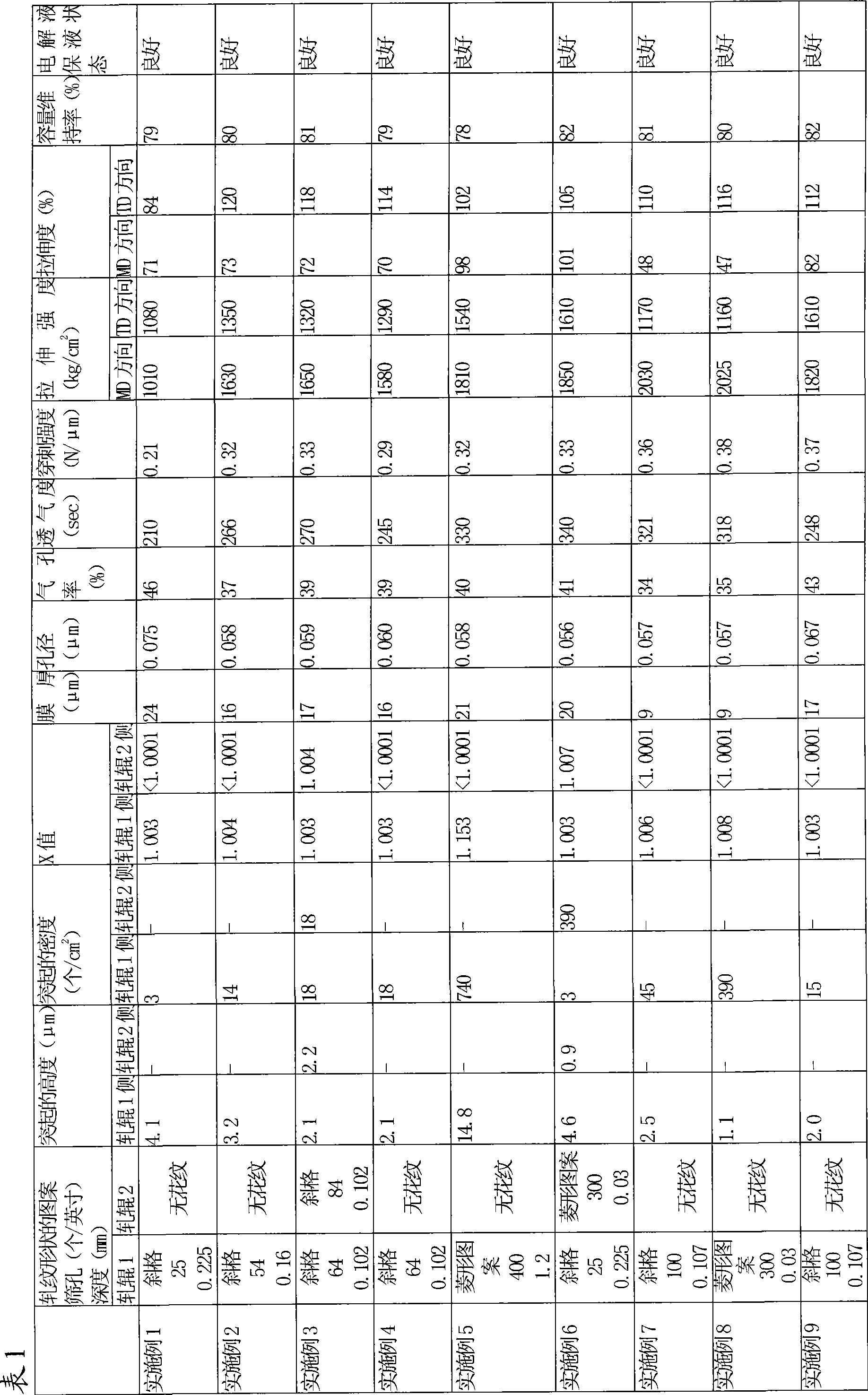

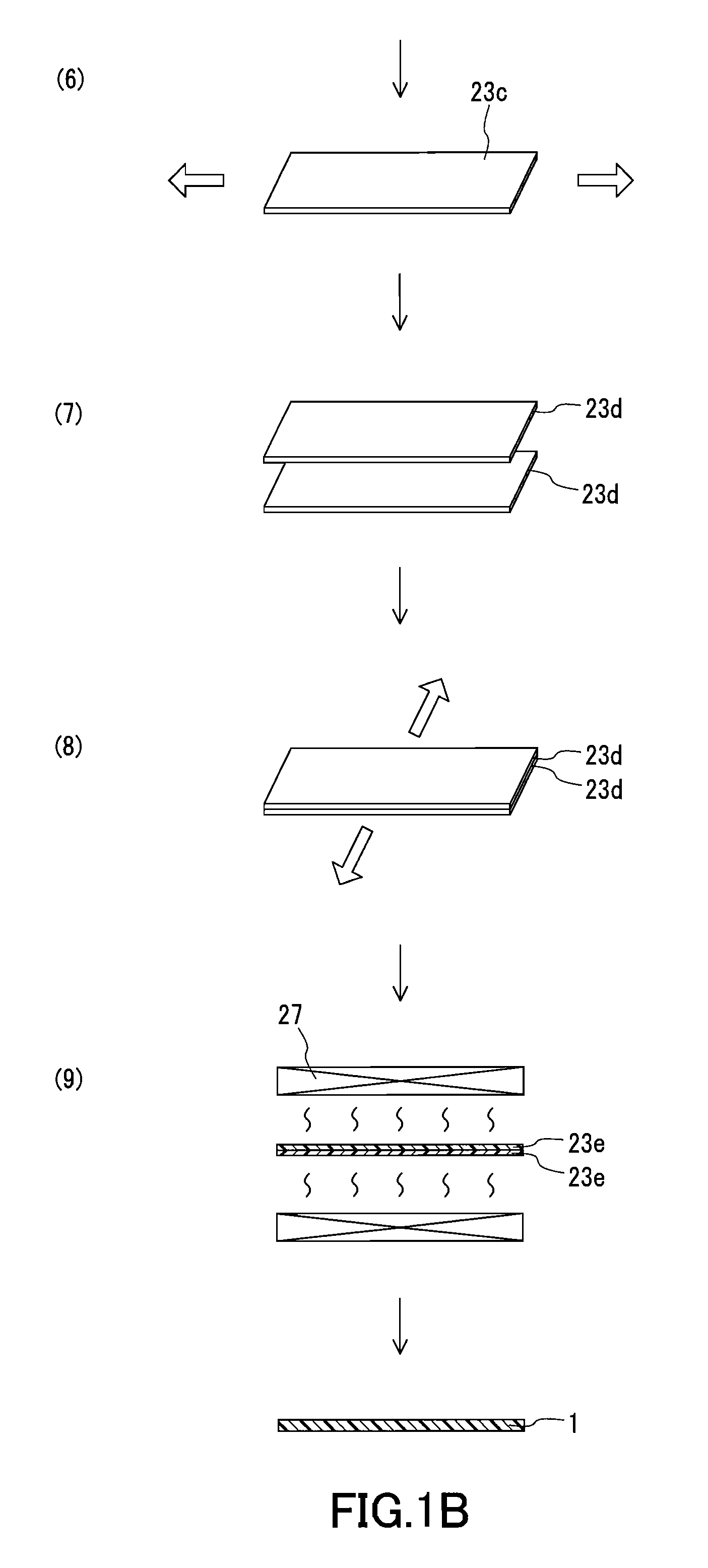

Crosslaminate of oriented films and methods and apparatus for manufacturing same

ActiveUS20090233041A1Improvement of tear propagation resistanceImprove aestheticsConfectioneryPress rollersEngineeringUltimate tensile strength

A crosslaminate is formed from two oriented plies of thermoplastic polymer material, arranged so that their orientation directions cross one another, the plies being heat sealed together. Each ply is semi-fibrillated, that is consist of linear thin regions of biaxially oriented material and thicker linear bosses between the thinner regions. The webs are sealed primarily through bonds formed at the intersection of the bosses (thicker regions). The array of bosses has a division less than 2 mm. The laminate has improved aesthetic and strength properties. A method for forming the crosslaminate involves segmental stretching of the material to form the thinner regions, and apparatus comprising intermeshing grooved stretching rollers having sharp-edged crests is described.

Owner:THE GLAD PROD CO

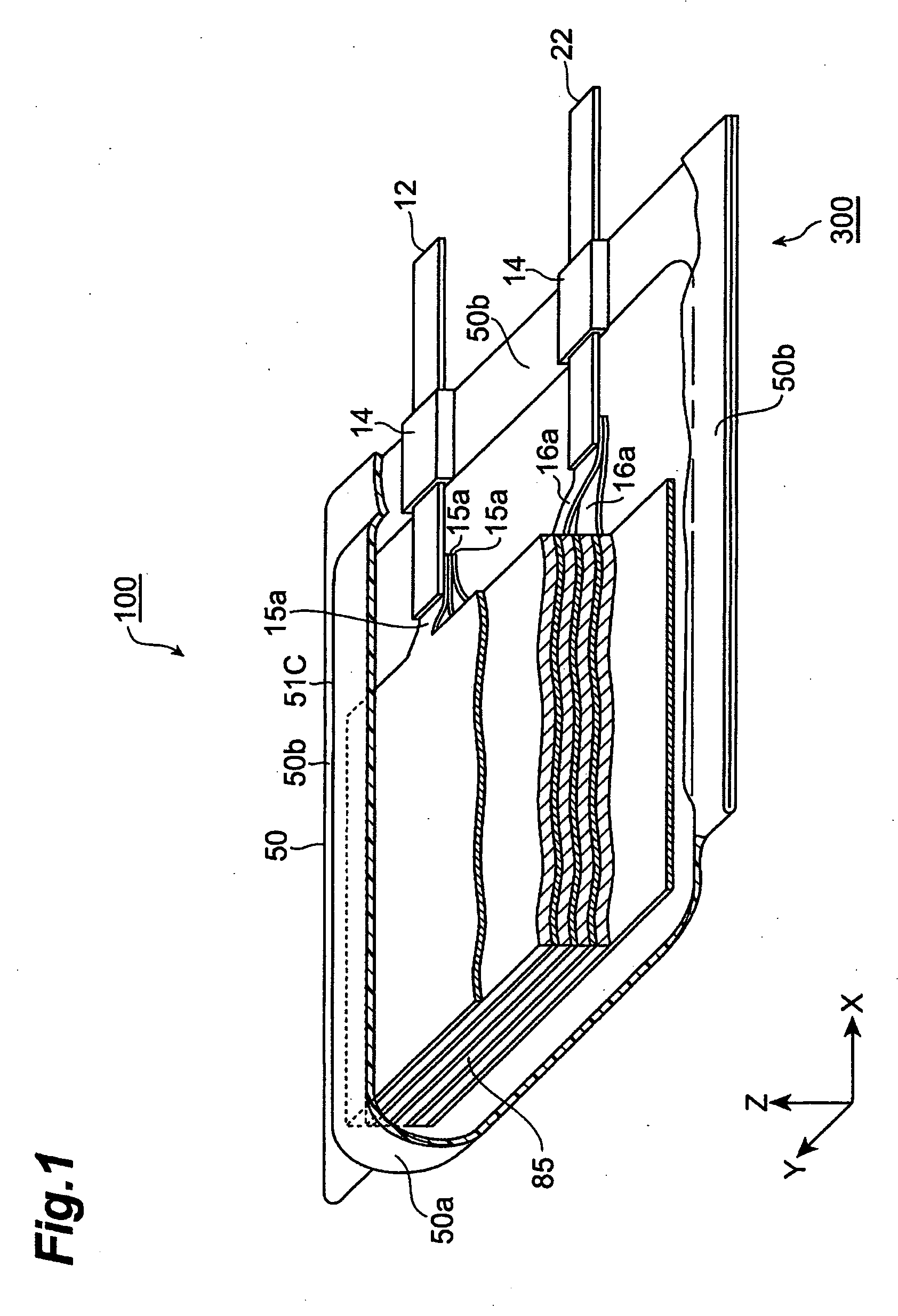

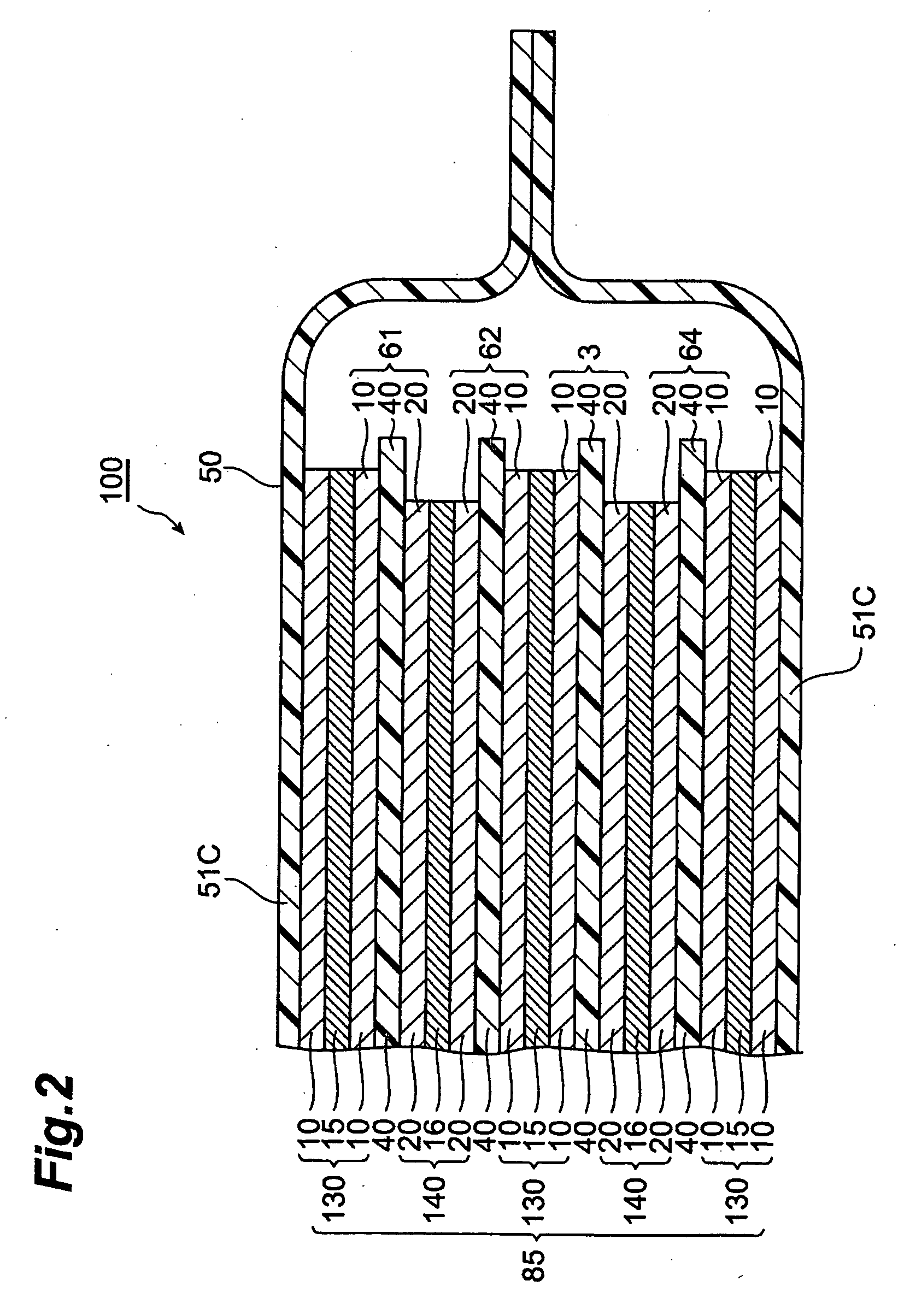

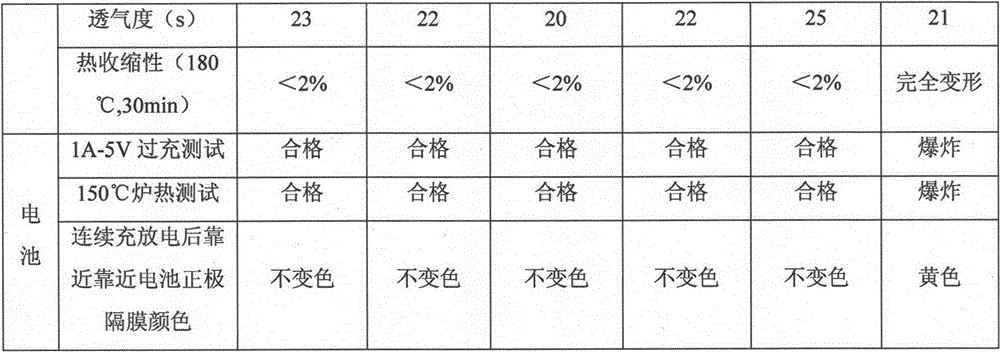

Lithium ion secondary battery

ActiveUS20070134556A1Suppress generationImprove puncture strengthCell seperators/membranes/diaphragms/spacersFinal product manufactureLithiumMaterials science

A lithium ion secondary battery, having a positive electrode, a negative electrode, and a separator provided between the positive electrode and the negative electrode, the positive electrode and the negative electrode each having a collector and an active material layer provided over the collector, and the relationship Ts≧4Tc being satisfied, where Ts is the puncture strength of the separator, and Tc is the puncture strength of the collector of the positive electrode and / or the negative electrode.

Owner:TDK CORPARATION

Porous film and separator for battery using the same

InactiveUS20060055075A1High piercing strengthSuperior ion permeabilityMembranesButtonsPolyolefinChemistry

Provided is a porous film obtained by melt-kneading a high-molecular-weight polyolefin having a weight-average molecular weight of not less than 5×105, a thermoplastic resin having a weight-average molecular weight of not more than 2×104 and fine particles, molding the kneaded matter into a sheet, and then stretching the sheet. The porous film can be easily and simply prepared, and has a high piercing strength, and hence can be advantageously used as a separator for a battery, particularly for a lithium secondary battery.

Owner:SUMITOMO CHEM CO LTD

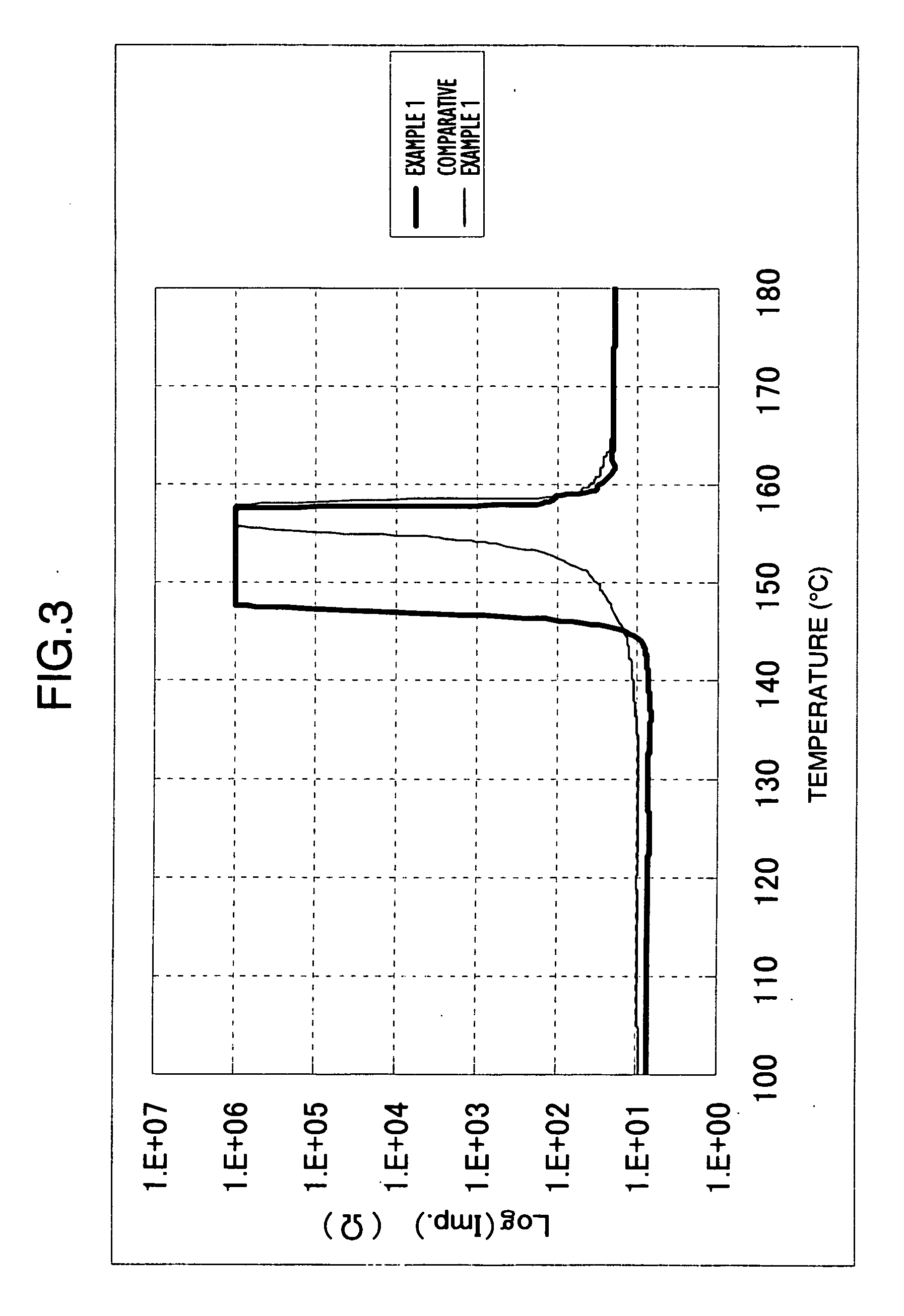

Separator for secondary battery and porous film made of polyolefin blend and process for preparing the same

InactiveUS20060188786A1Improve wettabilityWettabilities in a battery electrolyte are lowSemi-permeable membranesMembranesPolyolefinElectrical battery

It is an object of the present invention to provide a microporous film made of polyolefin blend having outstanding electrolyte wettability, puncture strength, and shut down characteristics, its manufacturing method, and a secondary battery separator. The present invention provides a microporous film and a method for manufacturing the same characterized in that the microporous film is manufactured by molding a film with a mixed blend containing two or more of polyolefins by using a casting or film blowing, and that a microporous film is manufactured by annealing and stretching the molded film, and the microporous film is surface treated by irradiating it with ionizing radiation either before or after the pore formation in order to achieve the above object. Furthermore, the secondary batteries in which this microporous film is applied as a separator, especially lithium ion secondary batteries or alkali secondary batteries, are safer due to their outstanding puncture strength, shut down characteristics, and separator melt resistance under large external electric current flows, can benefit from a great increase in productivity due to the excellent separator electrolyte wettability during battery assembly, and can achieve high charging density due to their thin separator and high mechanical strength.

Owner:LEE SANG YOUNG +3

Water-proof sound-transmitting membrane, method for producing the water-proof sound-transmitting membrane, and electrical appliance including the water-proof sound-transmitting membrane

ActiveUS20110143114A1Lose waterproofnessWater leakage and rupture of the membrane startBaby linensUndergarmentsVolumetric Mass DensityMaterials science

The present invention provides a water-proof sound-transmitting membrane including a polytetrafluoroethylene (PTFE) porous membrane, in which the waterproofness is enhanced further with little lowering of the sound transmittance. The water-proof sound-transmitting membrane includes the PTFE porous membrane. The PTFE porous membrane includes a first porous layer, and a second porous layer stacked on and integrated with the first porous layer by a binding force acting between PTFE matrices. The first porous layer and the second porous layer each are composed of PTFE with a number-average molecular weight of 5.0×107 or more determined by a standard specific gravity method. At least one layer selected from the first porous layer and the second porous layer has an average pore diameter of 1 μm or less. The water-proof sound-transmitting membrane has a surface density of 1 g / m2 to 10 g / m2.

Owner:NITTO DENKO CORP

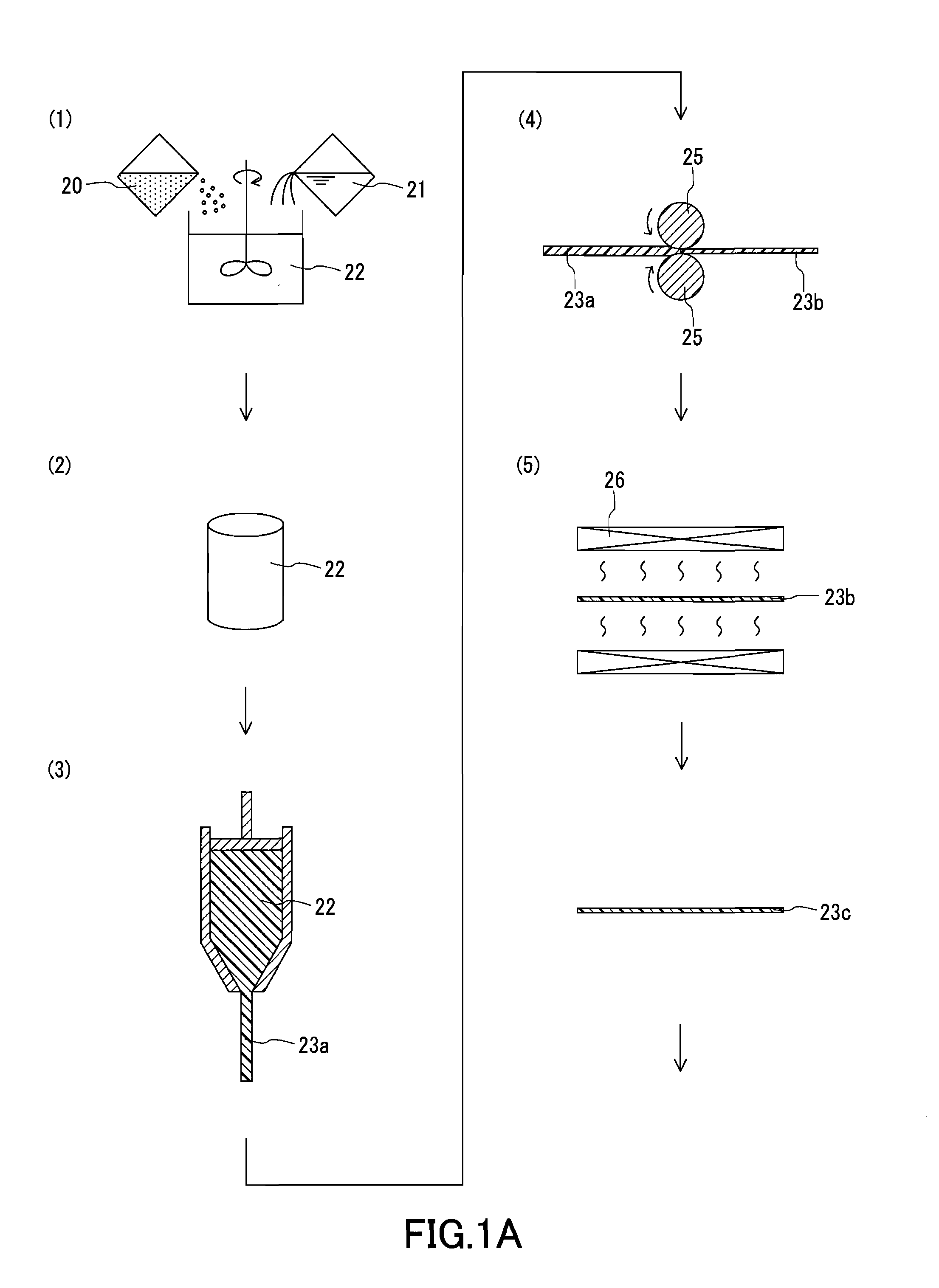

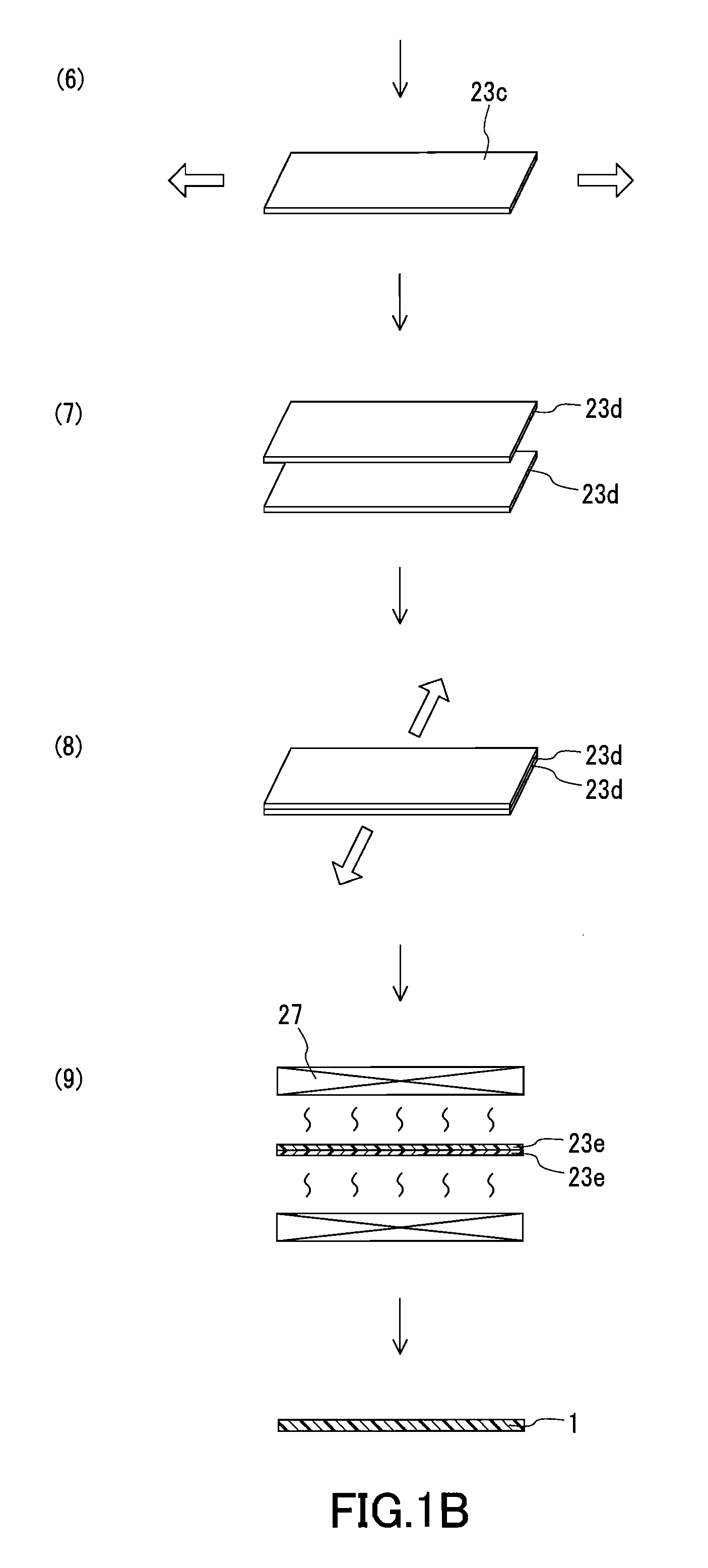

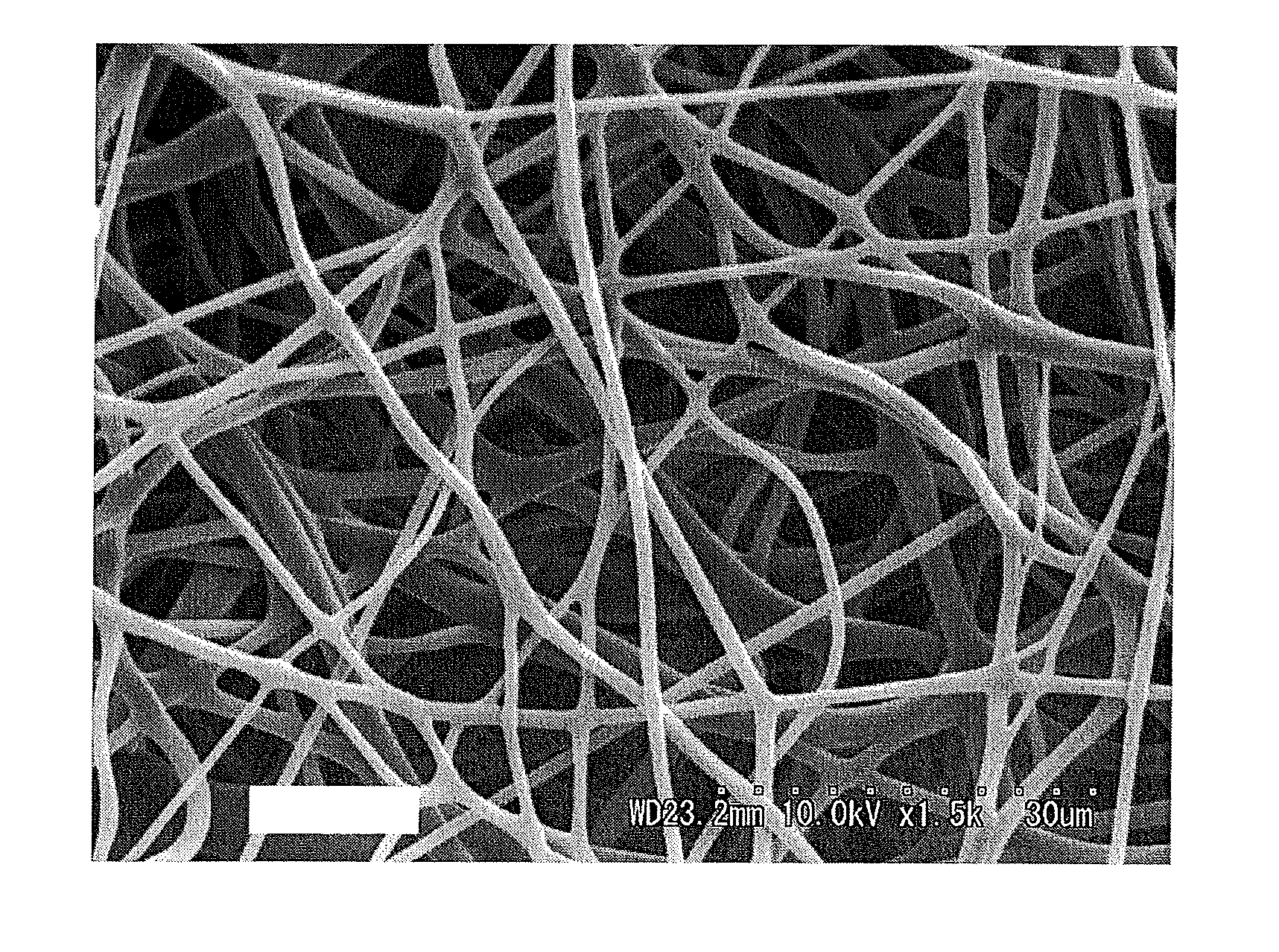

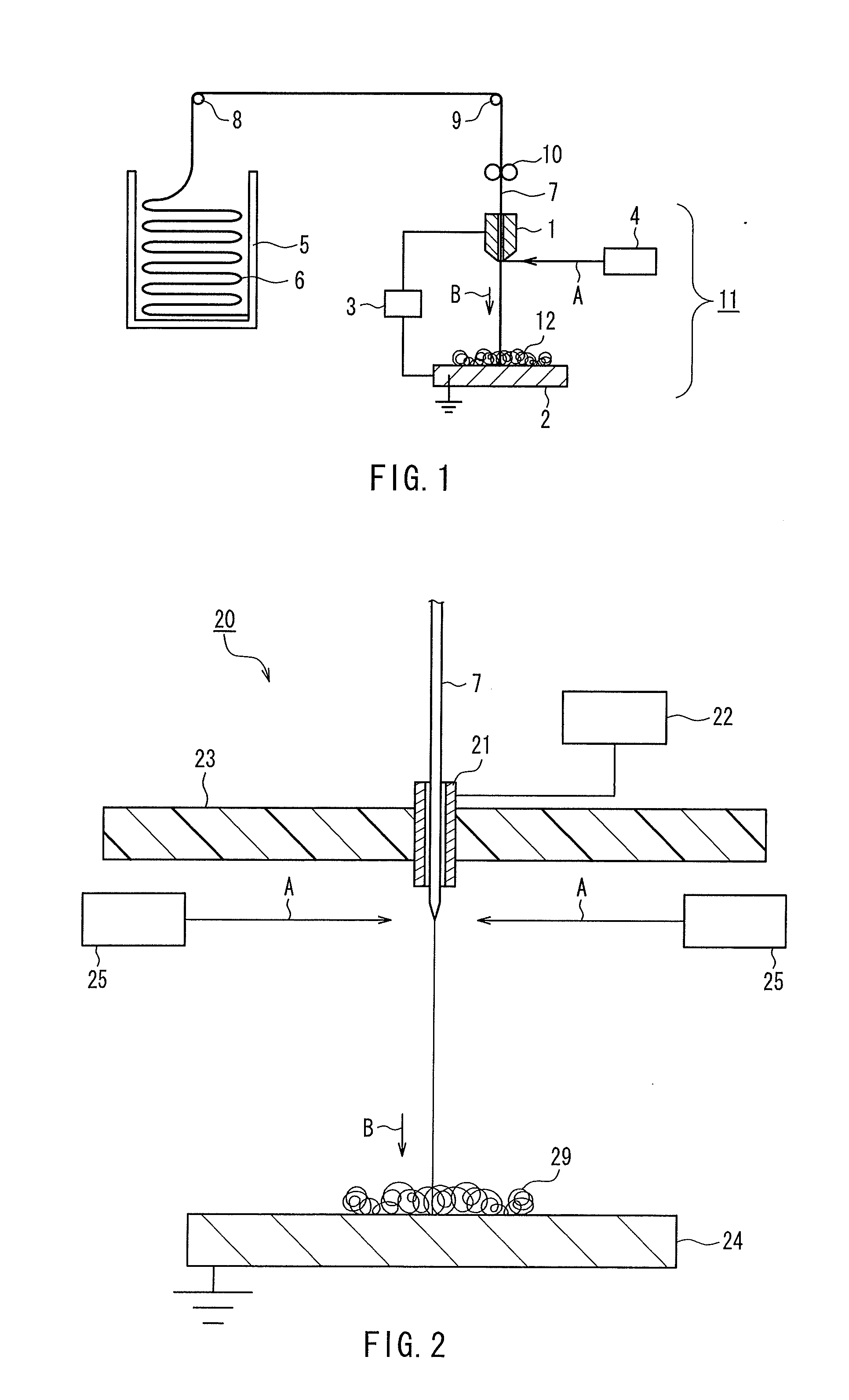

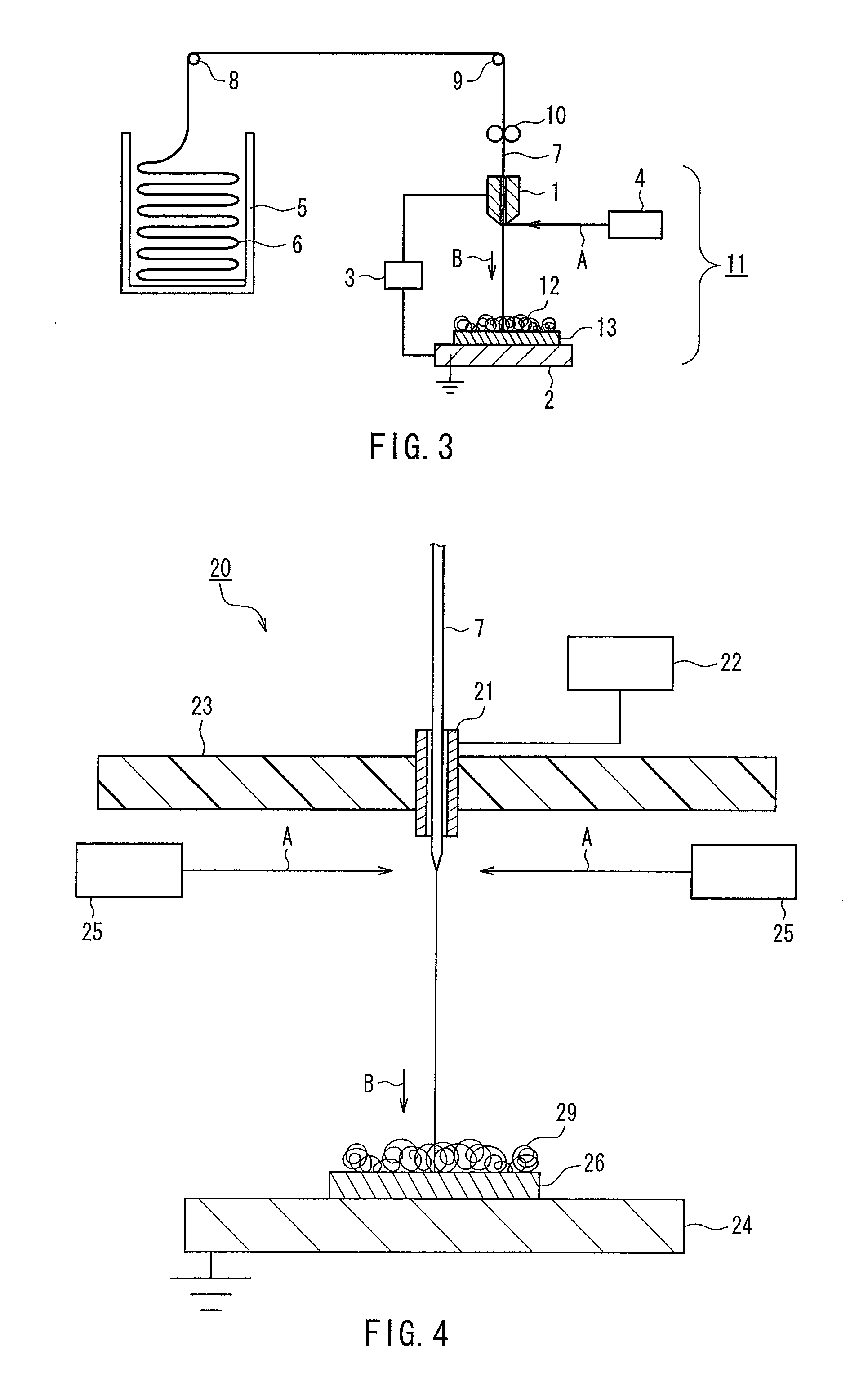

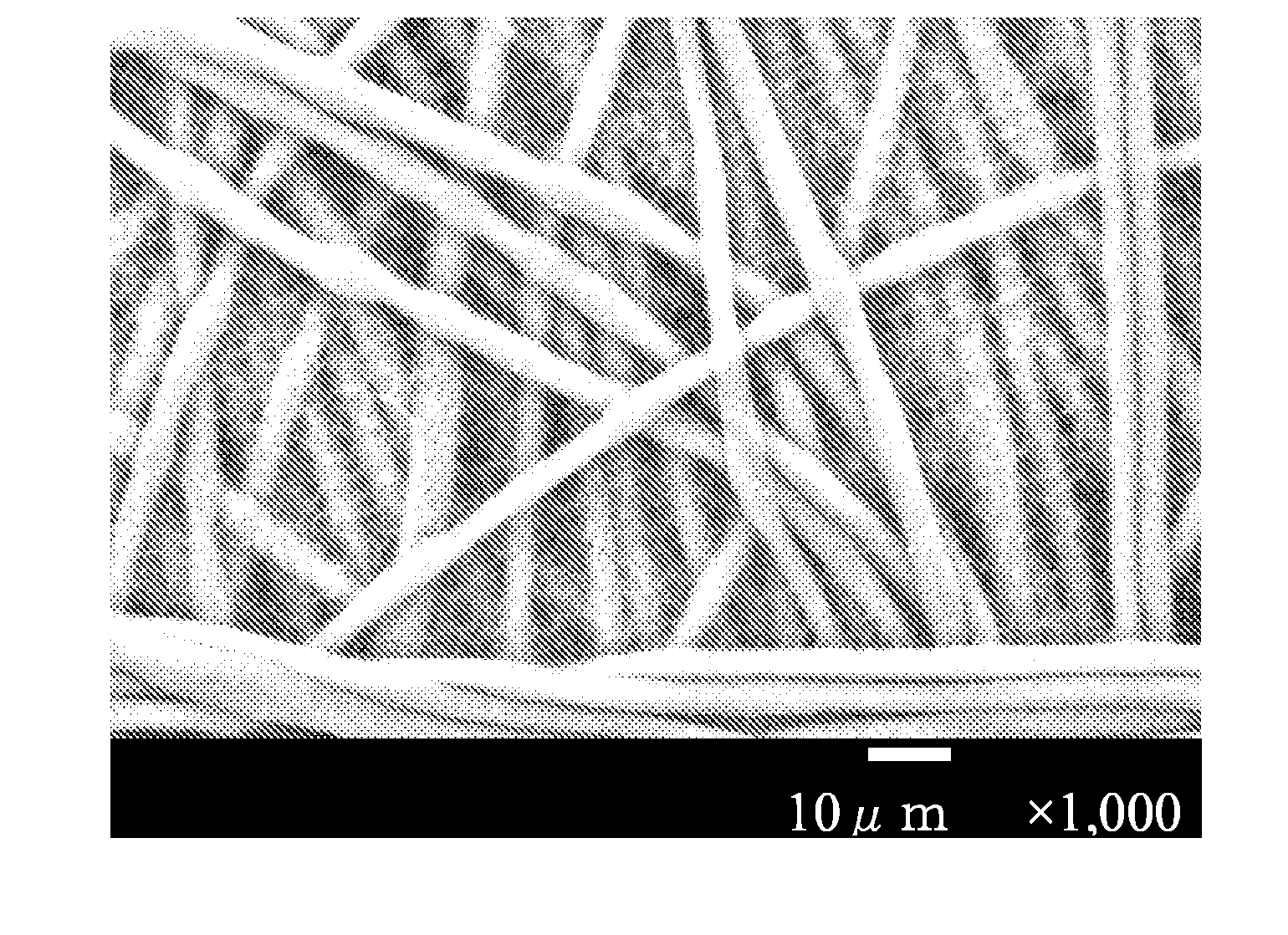

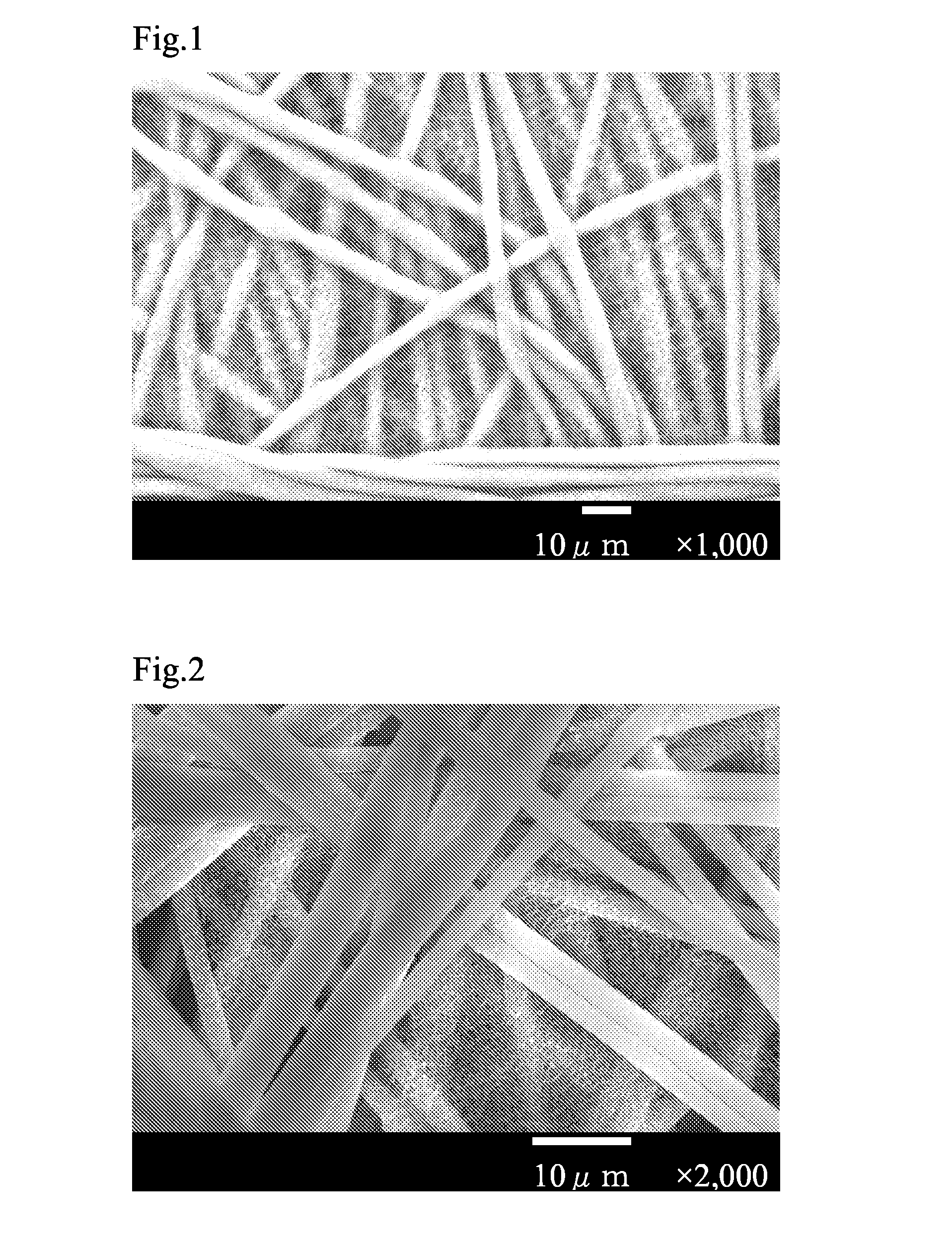

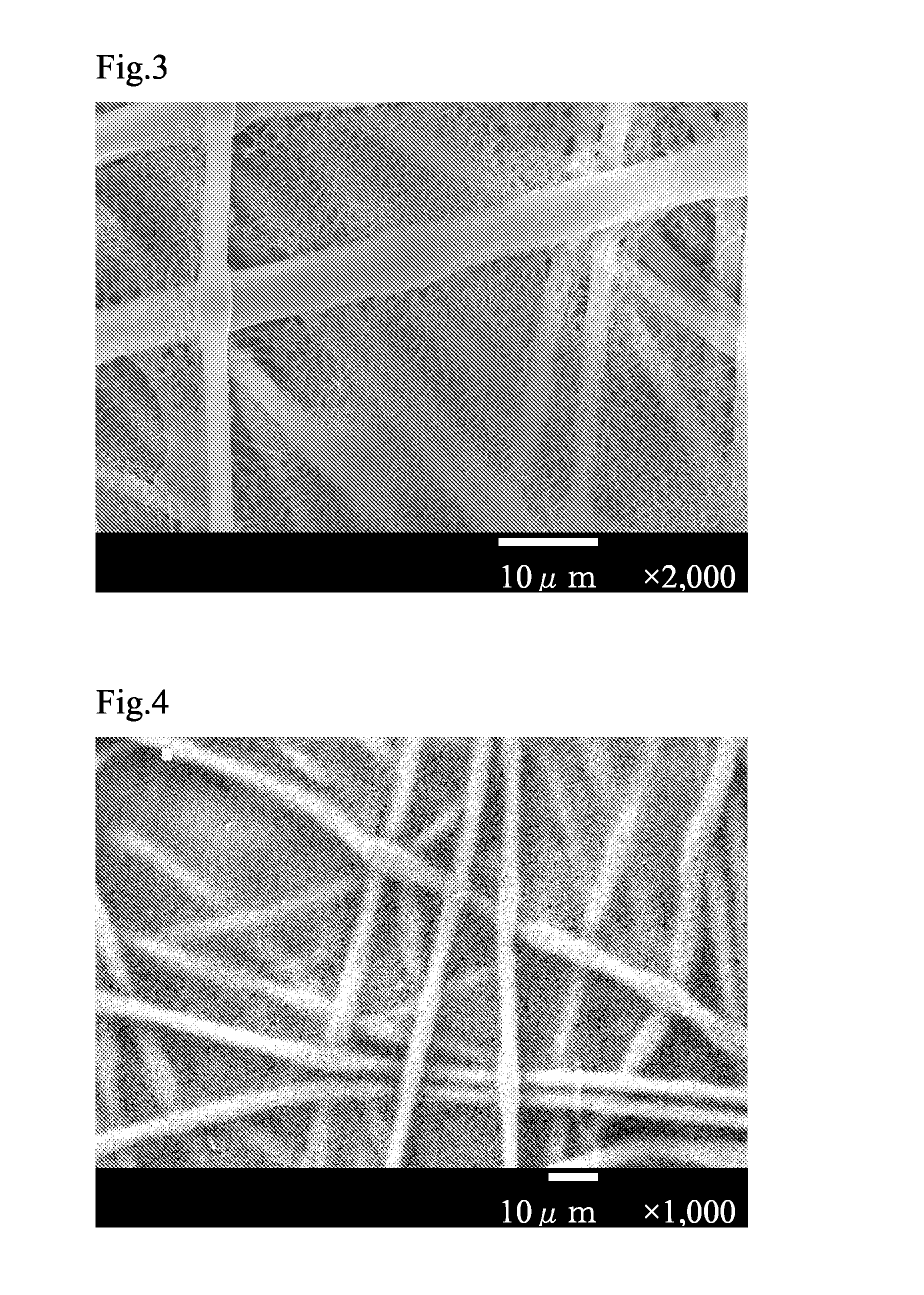

Fiber assembly, composite of electro conductive substrate and fiber assembly, and production methods thereof

InactiveUS20110177395A1Improve puncture strengthHigh tensile strengthElectric discharge heatingLayered productsFiberElectrospinning

The present invention relates to a fiber assembly obtained by electrifying a resin in a melted state by application of voltage between a supply-side electrode and a collection-side electrode so as to extend the resin into an ultrafine composite fiber by electrospinning, and accumulating the ultrafine composite fiber, wherein the ultrafine composite fiber includes at least two polymeric components and the ultrafine composite fiber includes at least one type of composite fiber selected from a sea-island structure composite fiber and a core-sheath structure composite fiber as viewed in fiber cross section, at least one selected from an island component and a core component has a volume specific resistance of 1015Ω·cm or less, and at least one selected from a sea component and a sheath component has a volume specific resistance exceeding 1015Ω·cm. Thereby, the present invention provides a fiber assembly obtained by accumulating an ultrafine composite fiber obtained by electrospinning without the use of any solvent or water as a spinning solution, a composite of an electro conductive substrate and such a fiber assembly, and production methods thereof.

Owner:DAIWABO HLDG +1

Barrier heat sealing type biaxial tensile composite thin film and preparation method thereof

InactiveCN102501511ASimple production processLow costSynthetic resin layered productsLinear low-density polyethyleneLow-density polyethylene

The invention discloses a barrier heat sealing type biaxial tensile composite thin film and a preparation method thereof. The thin film comprises two surface layers, and at least a barrier layer, wherein the surface layer and the barrier layer are connected through bonding layers. The thin film is characterized in that the two surface layers comprise the following components, by weight, 90-99% of metallocene linear low density polyethylene resin with a characteristic of bimodal molecular weight distribution, 0-5% of an antistatic agent, 0-5% of an anti-adhering agent, 0-5% of a smoothing agent, and 0-5% of an antioxidant; the barrier layer is a barrier polymer, and the bonding layer is a high strength and high temperature resistance adhesive. The preparation method adopts a multi-layer co-extruding successive biaxial tensile process or a multi-layer co-extruding simultaneous biaxial tensile process. The composite thin film has excellent gas and moisture barrier property, and the mechanical properties of the thin film are further improved. The thin film has characteristics of high tensile strength, low temperature high heat sealing strength, and high puncture resistance strength.

Owner:FSPG HI TECH

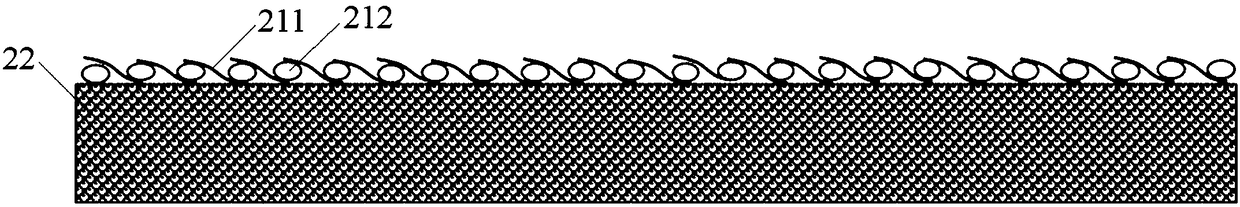

Porous sheet, separator for electrochemical element, and method for manufacturing porous sheet

ActiveUS20100252426A1Improve balanceExcellent in high-rate propertyDouble layer capacitorsPretreated surfacesElectrolytic agentPorous substrate

A porous sheet which has good balance between electrolytic solution permeability and dry-up resistance, is superior in high-rate property, and is suitable for a separator for an electrochemical element, and a manufacturing method thereof are provided.The present invention relates to a porous sheet comprising a porous substrate containing non-fibrillar fibers having an average fiber diameter of 0.01-10 μm and a net-like structural body composed of a polymer, the net-like structural body having penetrating pores with a pore diameter of 0.01-10 μm, wherein the net-like structural body is present at the surface and at the internal of the porous substrate and the non-fibrillar fibers having an average fiber diameter of 0.01-10 μm and the net-like structural body are entangled; to a separator for an electrochemical element comprising the porous sheet; and to a method for manufacturing the porous sheet.

Owner:MITSUBISHI PAPER MILLS LTD

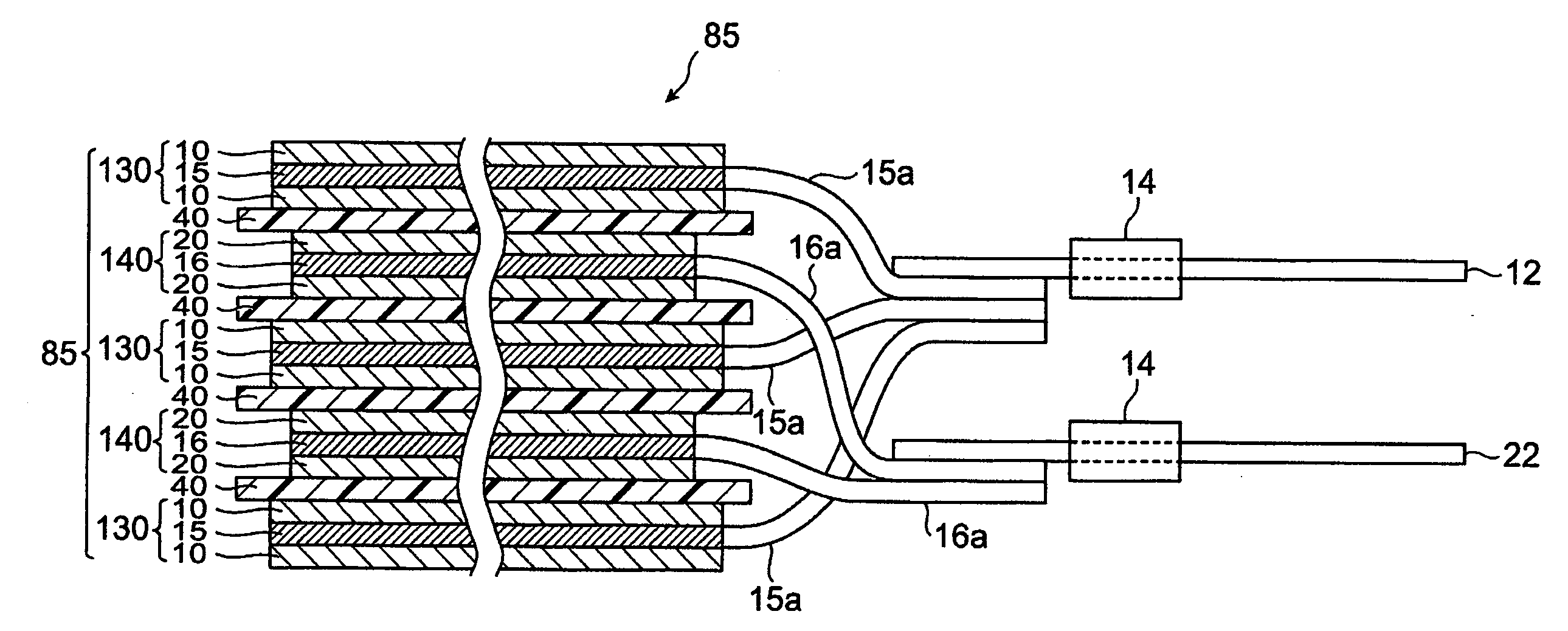

Electrolytic-solution-supporting polymer film and secondary battery

InactiveUS6291106B1Improve puncture strengthAvoid it happening againCell seperators/membranes/diaphragms/spacersFinal product manufactureLithiumPolymer science

A high-strength, heat-resistant and high-safety electrolytic-solution-supporting polymer film which can be applied to secondary batteries typified by lithium and lithium ion secondary batteries and which has an ionic conductivity of at least 5x10-4 S / cm at 25° C., a puncture strength of at least 300 g and a mechanical heat resistance of at least 300° C.

Owner:TEIJIN LTD

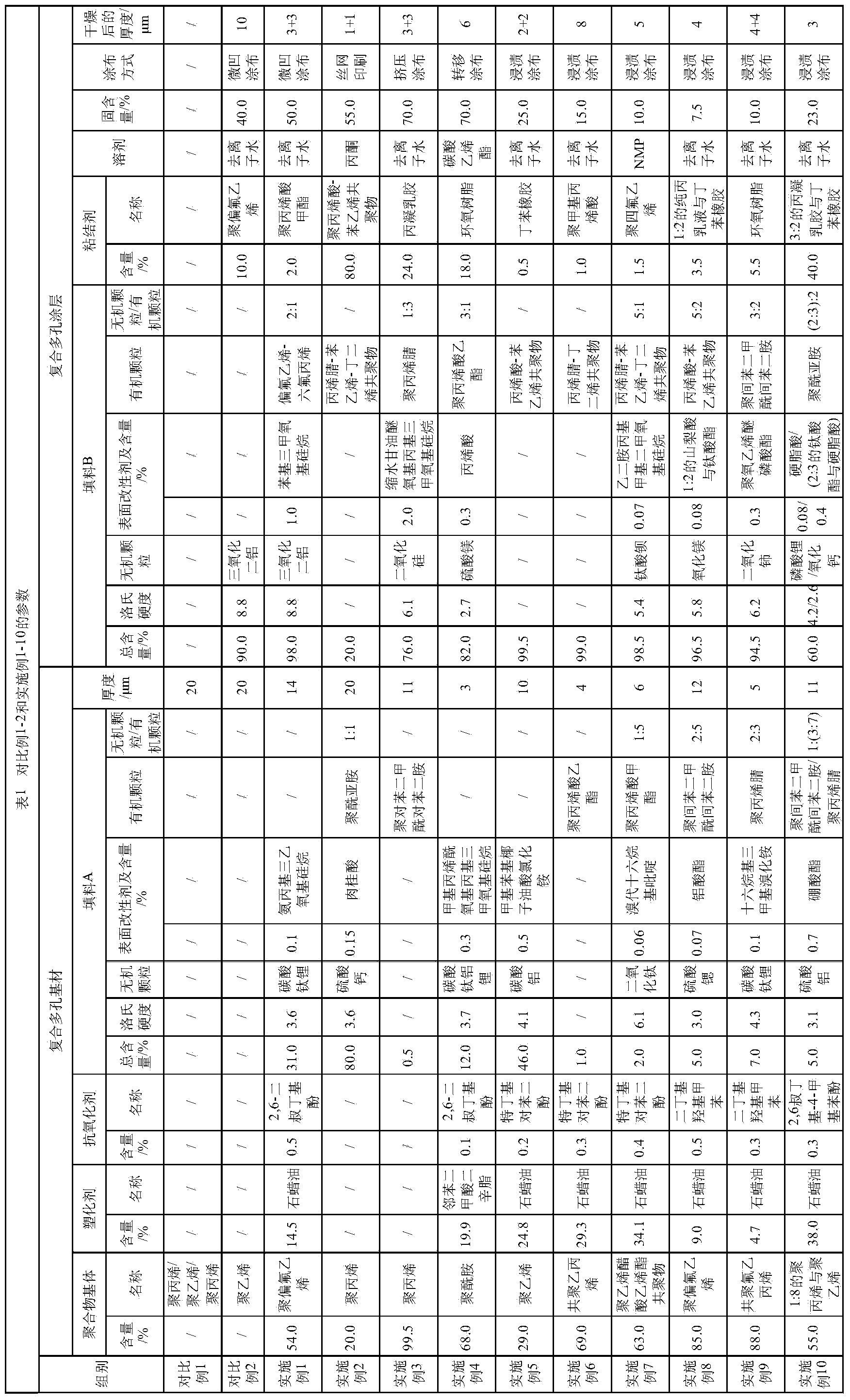

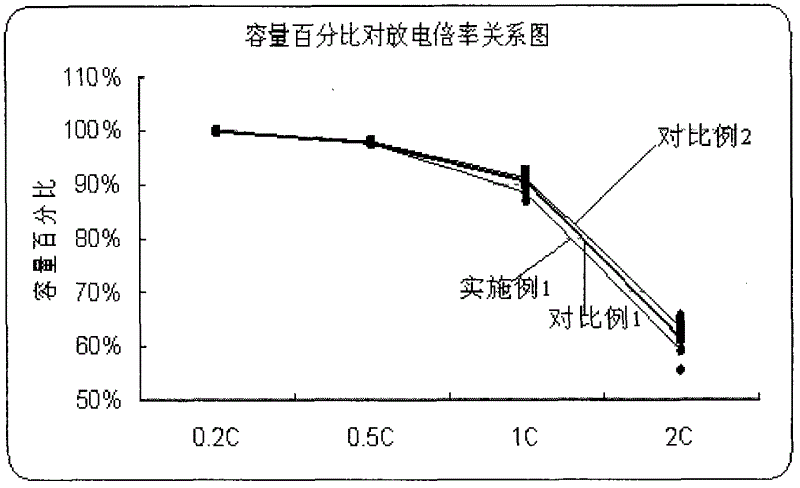

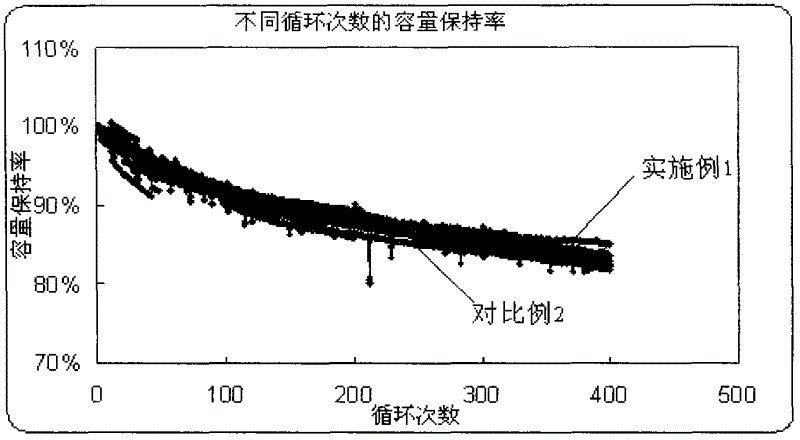

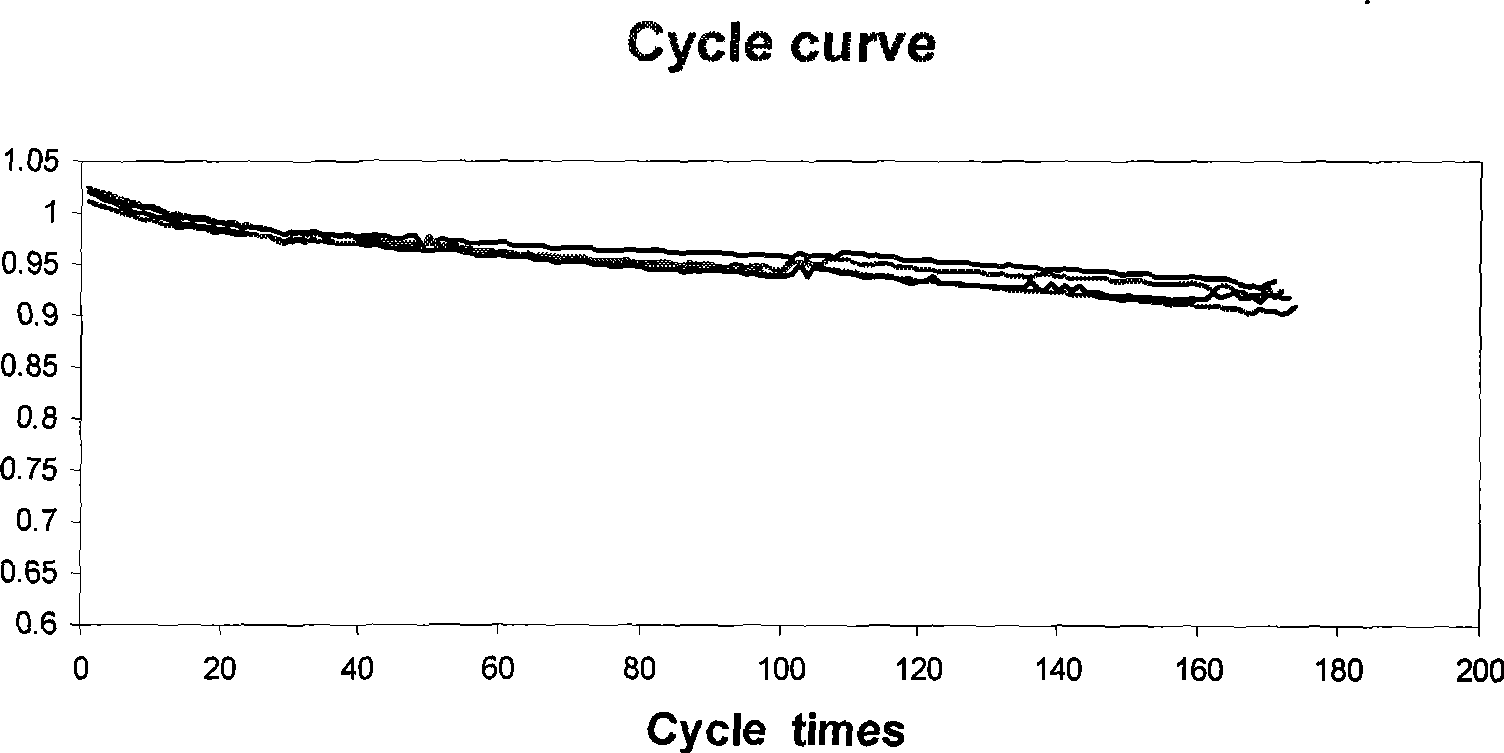

Composite porous isolating film and electrochemical device

ActiveCN103904276AImprove puncture strengthImprove thermal stabilitySecondary cellsCell component detailsPorous substratePorous coating

The invention provides a composite porous isolating film and an electrochemical device. The composite porous isolating film comprises a composite porous base material and a composite porous coating which is coated on at least one surface of the composite porous base material. The composite porous base material comprises filler A and a polymer substrate, and the filler A is selected from at least one of inorganic particles and organic particles; the composite porous coating comprises filler B and an adhesive, and the filler B is selected from at least one of inorganic particles and organic particles. The electrochemical device has a composite porous isolating film. By adopting the composite porous isolating film, the heat stability of the composite porous isolating film is improved, the deformation resistance and the capacity maintaining rate of the electrochemical device can be improved, and the cycling performance and low-temperature kinetic performance of the electrochemical device can be improved.

Owner:DONGGUAN AMPEREX TECH

Anti-corrosion, anti-puncture and anti-short circuit melting through aluminum-plastic packaging film for lithium battery and manufacture method thereof

ActiveCN102602081AExcellent electrolyte resistanceAvoid corrosionLamination ancillary operationsLaminationPlastic packagingElectrical battery

The invention discloses an anti-corrosion, anti-puncture and anti-short circuit melting through aluminum-plastic packaging film for lithium battery and a manufacture method thereof. The aluminum-plastic packaging film has a layer structure, comprises at least seven layers which are respectively to be a protecting layer A, an adhesive layer, a coating material layer, an aluminum foil layer, another coating material layer, another coating material layer and a heat-seal layer, and further comprises a protecting layer B arranged on the protecting layer A by the adhesive layer and / or a protecting layer C arranged between the coating material layer and the adhesive layer at the lower surface of the aluminum foil layer through another adhesive layer. According to the invention, the corrosion of electrolyte can be effectively stopped, the anti-puncture intensity, the tensile strength and the wear-resistant property of the aluminum-plastic film can be improved, the yield and the reliability of the battery can be improved, the heat-seal short circuit caused by the improper operation or the abnormal temperature of a machine during heat sealing can be completely avoided, and the service life of the battery can be greatly prolonged, so that the invention is high in reliability.

Owner:东莞市金恒晟新材料科技有限公司

Polyethylene composition for manufacturing lithium battery diaphragm

InactiveCN102627796AGuaranteed mechanical propertiesReduced precision requirementsCell component detailsPorosityLow-density polyethylene

The invention discloses a polyethylene composition for manufacturing a lithium battery diaphragm. The composition is prepared by blending a polyethylene material and a diluent. Polyethylene resins of different molecular weights are taken as polyethylene materials for manufacturing a lithium battery diaphragm, and are uniformly mixed and blended with a diluent to form a polyethylene composition, so that the lithium battery diaphragm is prepared. The polyethylene material used in the invention is an ordinary super-high-molecular-weight polyethylene resin, a super-high-molecular-weight polyethylene resin or a high-density polyethylene resin. The battery diaphragm prepared from the polyethylene composition has low requirement on the accuracy of manufacturing equipment and high production efficiency, has high tearing strength, high piercing resistance and smaller thickness while keeping the high porosity, high insulating property and high shutoff property of an ordinary polyethylene lithium battery, and is suitable for manufacturing a smaller lithium battery.

Owner:INST OF CHEM CHINESE ACAD OF SCI

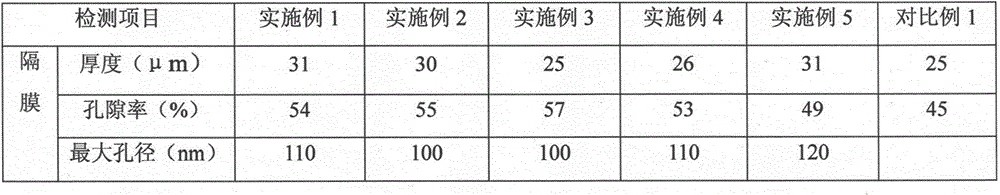

Microporous membrane made from polyolefin

InactiveUS20070148552A1Improve puncture strengthModerate pore sizeMembranesSemi-permeable membranesPolymer sciencePolyolefin

Disclosed is a microporous membrane made from a polyolefin wherein the thickness is 1-30 μm, the porosity is 30-60%, the air permeability is 50-250 sec / 100 cc, the puncture strength is 3.5-20.0 N / 20 μm, the maximum pore diameter determined by a bubble point method is 0.08-0.20 μm, and the ratio between the maximum pore diameter and the average pore diameter (maximum pore diameter / average pore diameter) is 1.00-1.40. Since this microporous membrane made from a polyolefin is highly safe while maintaining a high permeability, it is useful especially as a separator for recent small-sized, high-capacity nonaqueous electrolyte batteries.

Owner:ASAHI KASEI CHEM CORP

Diaphragm and preparation method thereof, and lithium ion battery

ActiveCN102623658AThe absolute value of the surface potential is largeEvenly distributedSecondary cellsCell component detailsHexafluoropropyleneLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an inorganic and organic composite multihole diaphragm. The diaphragm comprises a multihole diaphragm base material and an active coating layer attached to at least one surface of the multihole diaphragm base material, wherein the active coating layer comprises inorganic particles, vinylidene fluoride and hexafluoropropylene copolymer, cellulose based polymer with the molecular weight of 100,000 to 1,000,000 and at least one of polyacrylic acid and polyacrylate. Compared with the prior art, the diaphragm keeps relatively high air permeability and lithium ion transmission capacity; the active coating layer and the multihole diaphragm base material are well bonded; and the overheating contraction performance and the puncture strength of a diaphragm base can be improved remarkably. Furthermore, the invention also discloses a preparation method for the diaphragm and a lithium ion battery with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

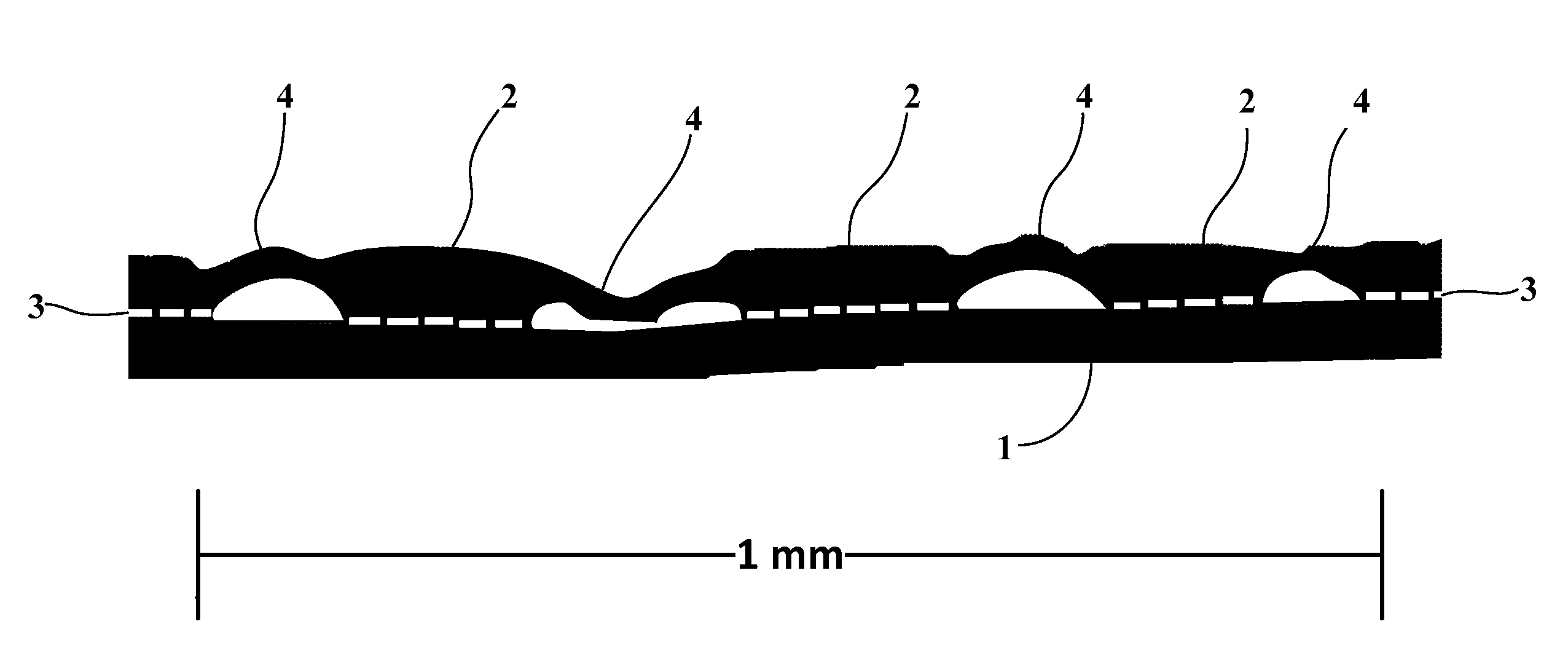

Crosslaminate of oriented films and methods and apparatus for manufacturing same

ActiveUS8263210B2Improvement of tear propagation resistanceReduction of the gaugeLamination ancillary operationsSynthetic resin layered productsEngineeringUltimate tensile strength

A crosslaminate is formed from two oriented plies of thermoplastic polymer material, arranged so that their orientation directions cross one another, the plies being heat sealed together. Each ply is semi-fibrillated, that is consist of linear thin regions of biaxially oriented material and thicker linear bosses between the thinner regions. The webs are sealed primarily through bonds formed at the intersection of the bosses (thicker regions). The array of bosses has a division less than 2 mm. The laminate has improved aesthetic and strength properties. A method for forming the crosslaminate involves segmental stretching of the material to form the thinner regions, and apparatus comprising intermeshing grooved stretching rollers having sharp-edged crests is described.

Owner:THE GLAD PROD CO

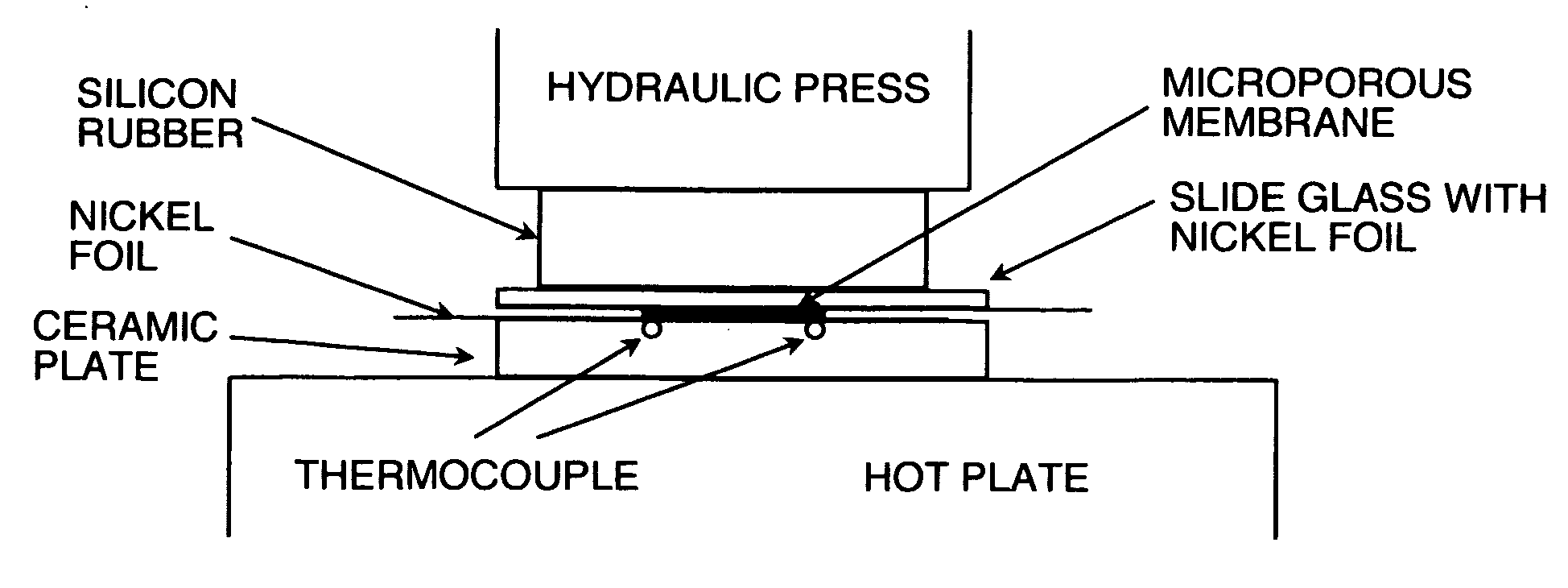

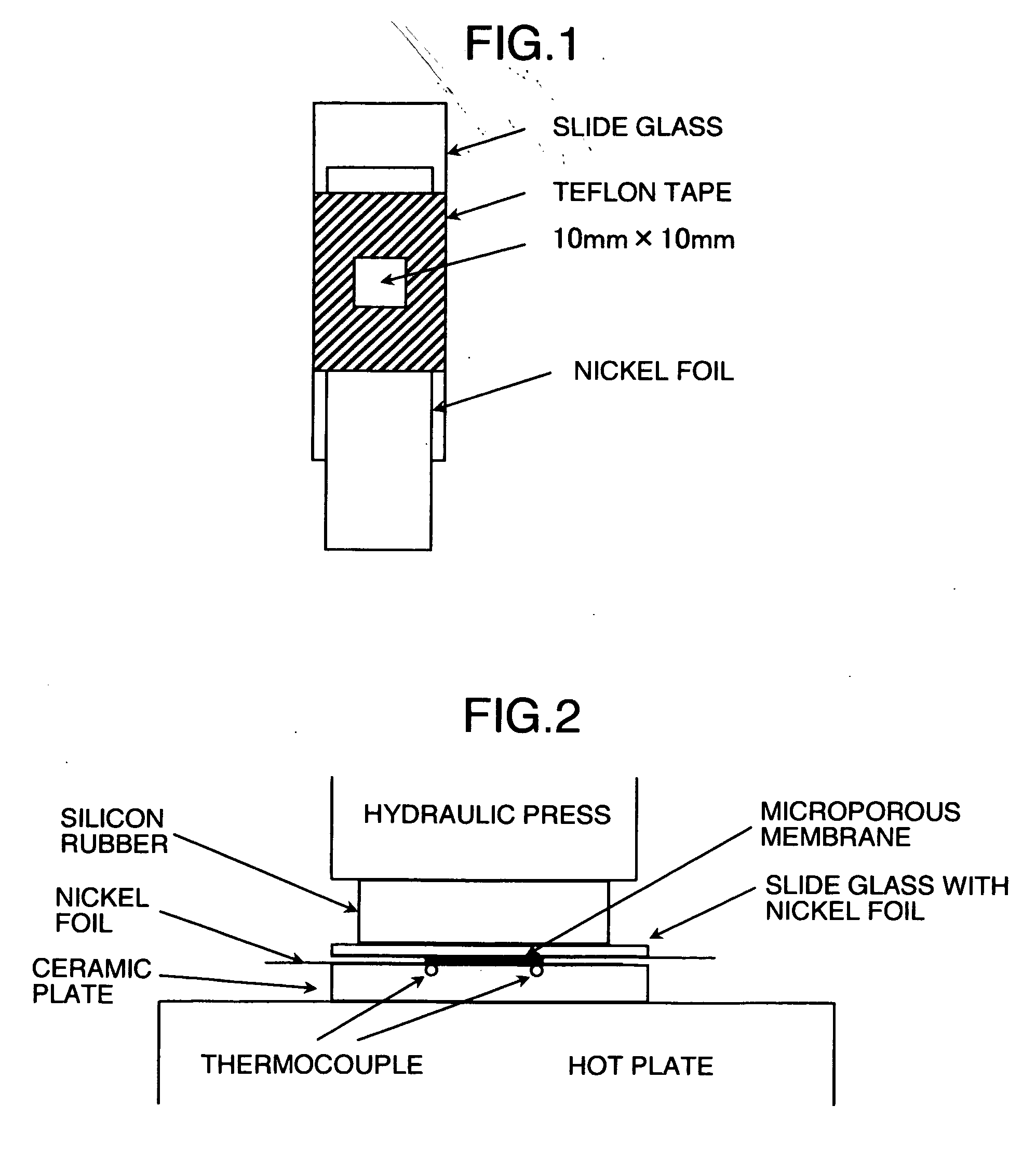

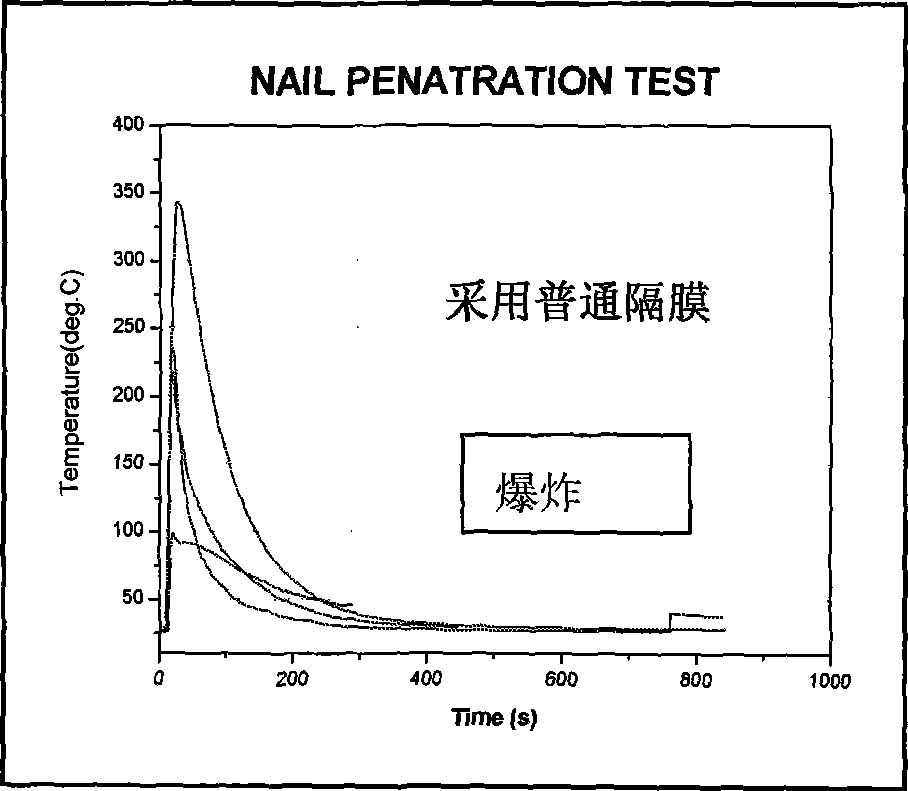

Method of manufacturing diaphragm used for high security lithium ion secondary battery

InactiveCN101369645AAvoid damageImprove heat resistanceCell seperators/membranes/diaphragms/spacersLithiumOrganic solvent

The invention discloses a membrane preparation method of lithium ion secondary battery safety characteristic having better puncture-resistant and heat-resistant characteristics. The method of the invention includes: firstly preprocessing the membrane surface; then preparing inorganic ceramic coarse glue comprising: 30-50 parts of modified inorganic ceramic powder by a lipophilic dispersion stabilizer at the surface, the original grain diameter of the inorganic ceramic powder being 10-300 nm; 5-20 parts of polymonomer; 0.3-1.5% oil-soluble initiator with the addition of the polymonomers, the initiating half period of the oil-soluble initiator being less than 2h at the temperature of 60 degrees centigrade; 20-35 parts of organic solvent; lastly coating at the surface of base material to form a double-face coating structure. The preparation method provided by the invention smartly combines the coat drying process at the membrane surface with the polyreaction such that the liquid membrane made of inorganic ceramic coarse glue at the surface of the base is solidified due to the polyreaction by means of a further drying process.

Owner:TIANJIN LISHEN BATTERY

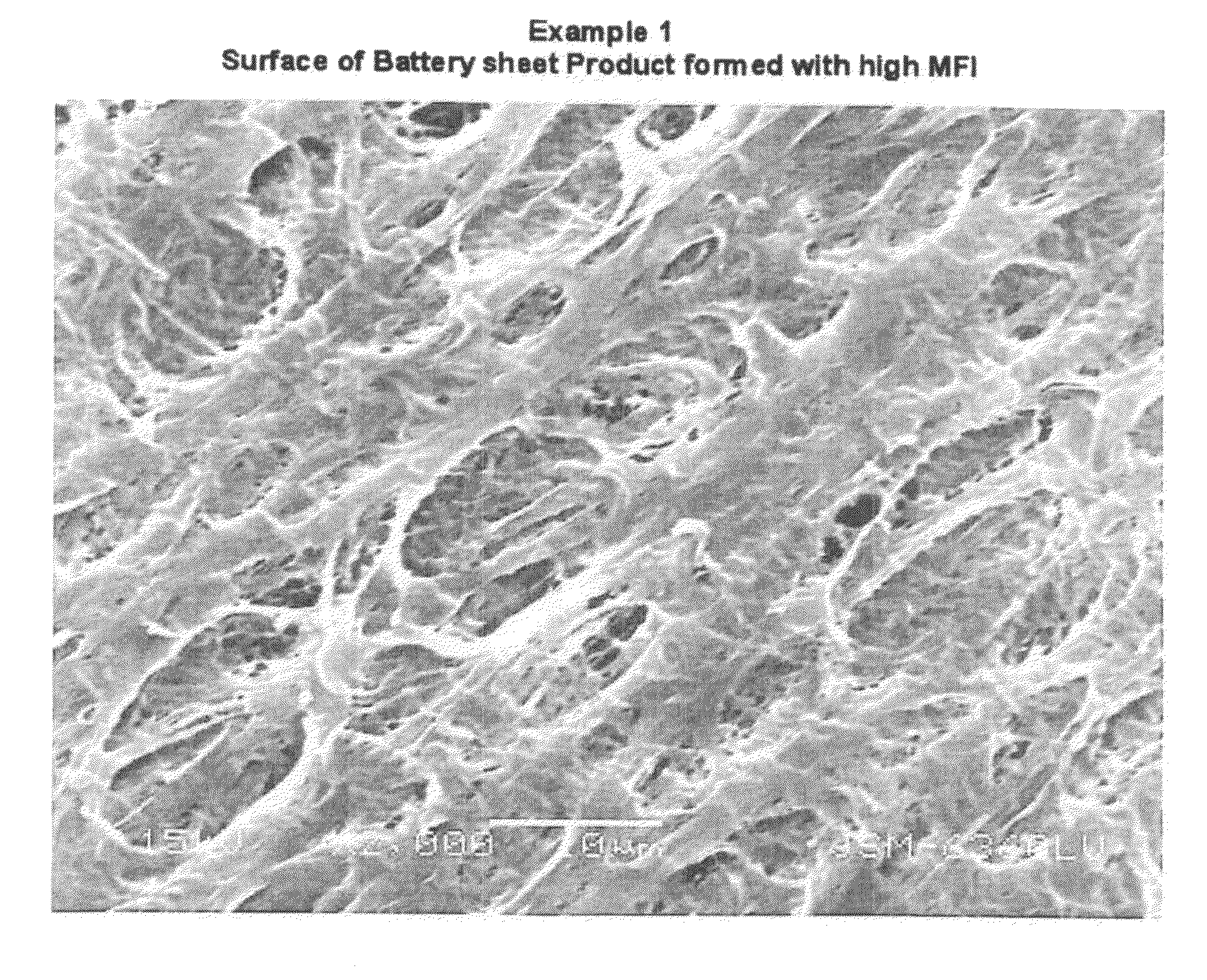

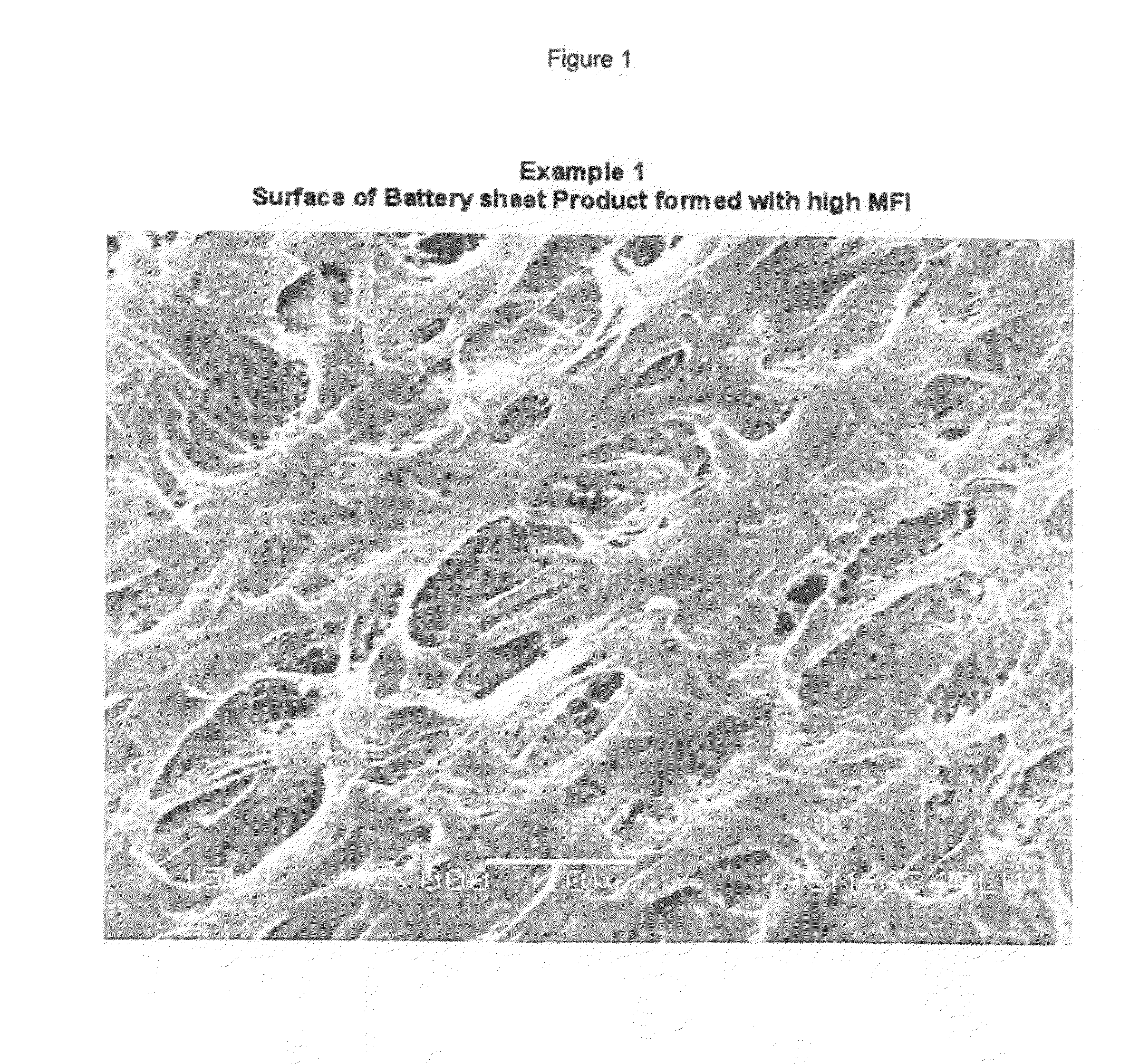

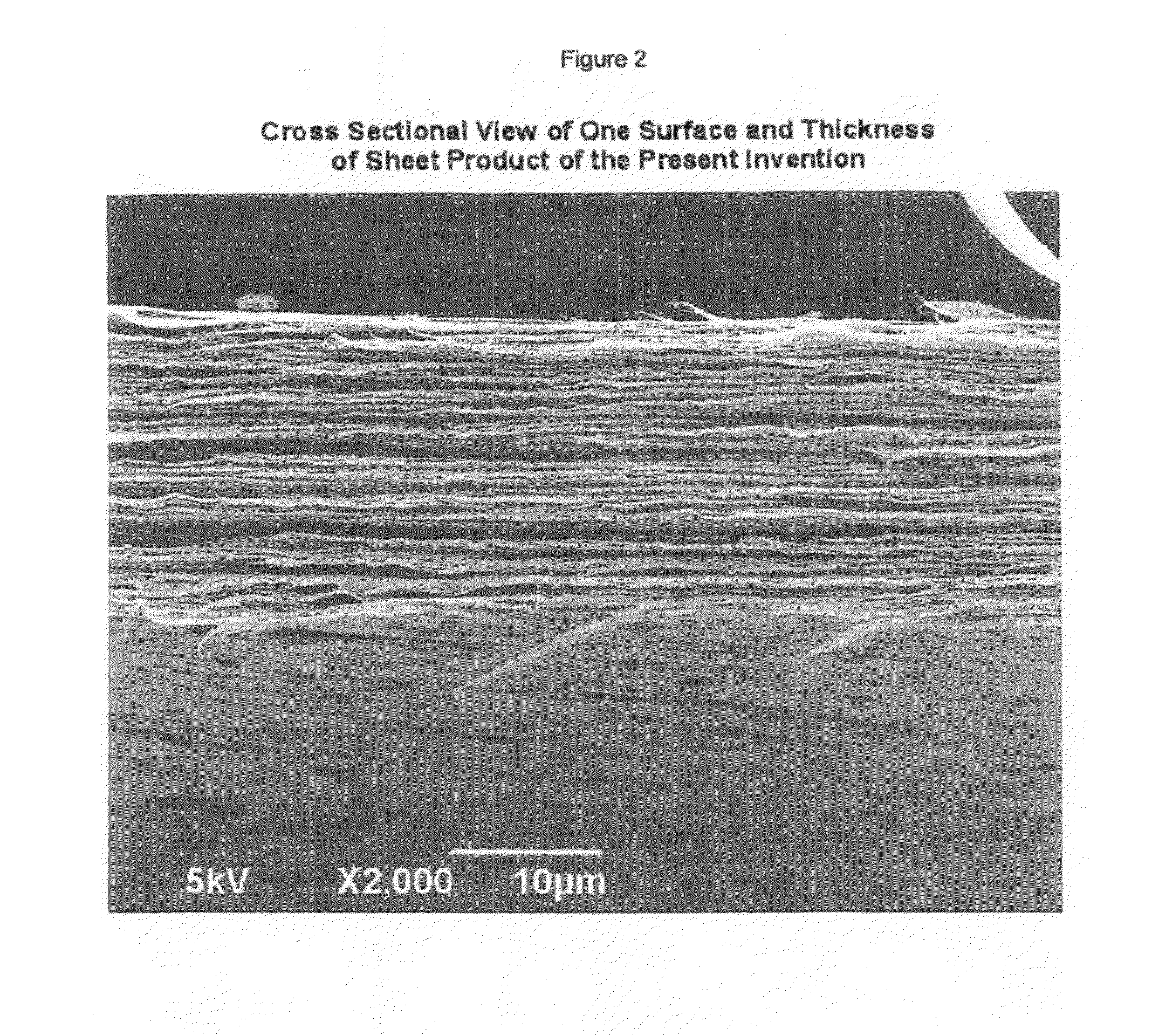

Battery separator and method of forming same

ActiveUS20130029126A1Good dimensional stabilityHigh electrolyte wickingAlkaline accumulatorsFinal product manufactureElectrical batteryVaporization

The present invention is directed to a sheet product and to a method of forming the sheet product suitable for use as a battery separator. The method comprises forming a mixture of a thermoplastic polymer and fluid having a high vapor pressure, shaping the mixture into a sheet material and subjecting the sheet material to stretching / fluid vaporization at high temperature to form an intermediate material having a ratio of percent fluid to percent polymer crystallinity of between 0.15 and 1 followed by a second stretching / fluid vaporization at a lower temperature while removing a portion of the remainder of the fluid from the sheet. The resultant sheet is annealed and remainder of fluid removed to form a sheet product having a thickness comprising a stratified structure of small and larger pore layered configuration across its thickness.

Owner:APOROUS

Battery diaphragm and fabrication method thereof

ActiveCN102820444ALow orientationUniform surface pore size distributionSynthetic resin layered productsSecondary cellsLow-density polyethyleneLinear low-density polyethylene

The invention provides a battery diaphragm. The base material of the diaphragm is a polyvinylidene fluoride non-woven fabric, coating layers are arranged on two sides of the polyvinylidene fluoride non-woven fabric, and the material of the coating layers includes an ultra high molecular weight polyethylene and a linear low density polyethylene. A fabrication method of the battery diaphragm is further provided. According to the battery diaphragm and the fabrication method thereof, the provided battery diaphragm has the advantages that the air permeability is remarkably improved, the closed pore temperature is remarkably lowered, the puncture strength and diaphragm breaking temperature are remarkably improved, a safe protective property is provided for a battery, and the battery diaphragm is applicable to power batteries.

Owner:BYD CO LTD

Power lithium ion battery and composite diaphragm thereof

ActiveCN102751462AHigh porosityReduce the chance of short circuitsSynthetic resin layered productsSecondary cellsComposite filmOxidation resistant

The invention discloses a composite diaphragm of a power lithium ion battery. The composite diaphragm comprises a supporting layer and an inorganic coating layer, and is characterized by further comprising a polytetrafluoroethylene layer, wherein the inorganic coating layer is coated on the supporting layer, the polytetrafluoroethylene layer is coated on the inorganic coating layer, and the surface and interior of the inorganic coating layer have porous interconnection structures. According to the composite diaphragm of the power lithium ion battery, organic / inorganic composite films are compounded with a polytetrafluoroethylene microporous film, and due to the existence of the polytetrafluoroethylene microporous film, in the process of manufacturing the composite diaphragm of the power lithium ion battery and in the process of manufacturing a wound electrode group of the battery, the inorganic coating layer has good adhesive property on the composite diaphragm and is difficult to fall off; and the composite diaphragm has the advantages of high tearing strength, perforation resistant strength, high-temperature and low temperature resistance, high corrosion resistance, electrical insulating property and chemical stability, and particularly the high oxidation-reduction resistance of polytetrafluoroethylene has more superiority for prolonging the service life of the lithium ion battery and improving the use safety of the lithium ion battery.

Owner:CHINA HAISUM ENG

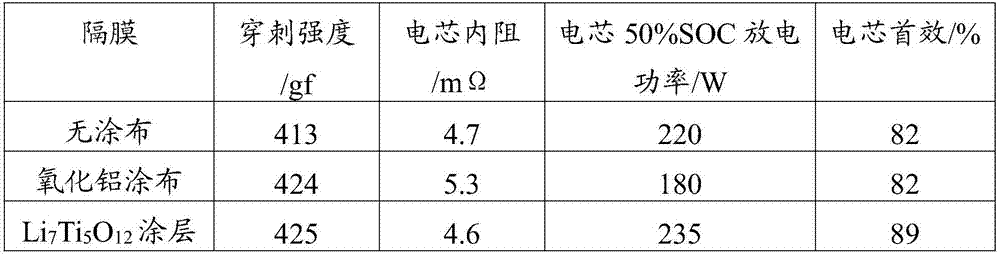

Coating for lithium-battery diaphragm, diaphragm and preparation method for diaphragm

ActiveCN106910860AImprove puncture strengthImprove electrical performanceCell component detailsAdhesivePhysical chemistry

The invention discloses a coating for a lithium-battery diaphragm, the diaphragm and a preparation method for the diaphragm. The coating for the lithium-battery diaphragm comprises powder of a lithium titanate compound and an adhesive, wherein the lithium titanate compound is one or more selected from a group consisting of Li<4+x>Ti<5>O<12> and Li<1+x>Ti<2>(PO<4>)<3>, wherein x is no less than 0 and no more than 3. The coating for the lithium-battery diaphragm can improve the puncture strength of the diaphragm and supplement lithium to an electrical core, and the preparation method is simple in process and easy to operate. Compared with conventional coatings, Li<4+x>Ti<5>O<12> provided by the invention is a substance with certain electron conductivity and high ion conductivity, so the ion conductivity of an electrolyte can be improved and the electrical properties of the electrical core are enhanced; under the condition of over-charging, Li<4+x>Ti<5>O<12> can store a part of Li ions, effectively prevent precipitation of surplus lithium and improve the over-charging performance of the electrical core; and compared with conventional lithium supplementing technology, the coating is easier to operate and enables security to be substantially improved.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

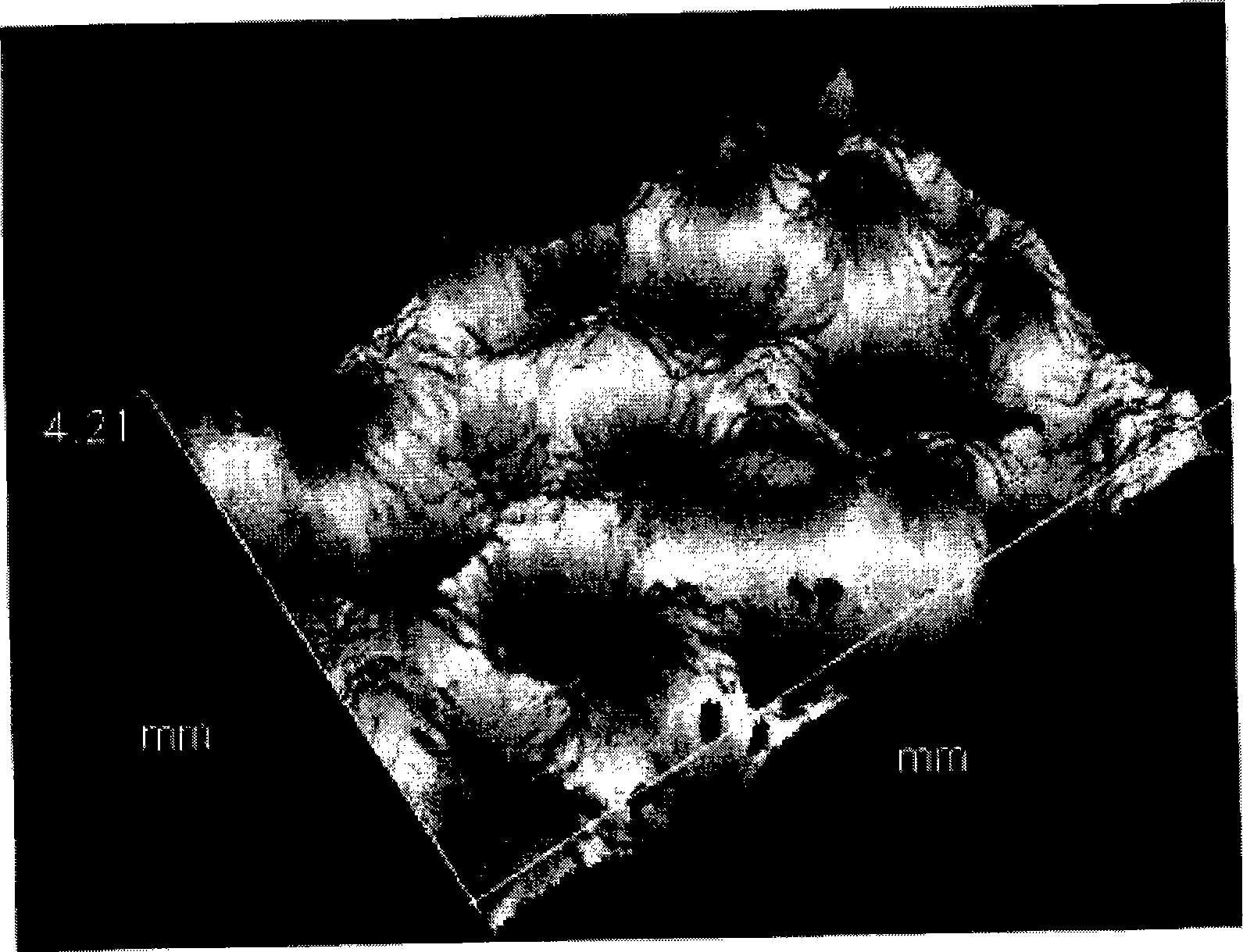

Polyolefin microporous membrane

ActiveCN101535386AAvoid compressionAvoid destructionSolid electrolytesCell seperators/membranes/diaphragms/spacersPolyolefinPolymer science

A polyolefin microporous membrane, which has a thickness of 1-100[mu]m, a pore diameter of 0.01-1[mu]m and a protrusion having a height of 0.5-30[mu]m arranged by embossing at least on one surface, is provided. A method for manufacturing the membrane and a battery separator made of the membrane are also provided.

Owner:ASAHI KASEI KK

Method for preparing polyolefin micro-porous film

InactiveCN102774009ALarge apertureImprove puncture strengthFlat articlesElectrolytic agentPolymer science

The invention discloses a method for preparing polyolefin micro-porous film. The method includes fusing and mixing a polyolefin resin and a film forming solvent in an extruder to prepare a polyolefin homogeneous melt; extruding the polyolefin homogeneous melt from a flat film die to form a molded melt, imposing various temperature fields on the surface of the molded melt for cooling, and imposing a shear force in the thickness direction during the cooling to form sheets; preheating the sheets, and performing longitudinal or bidirectional drawing on the sheets to form micro fibrillated film; extracting the film forming solvent in the micro fibrillated film with an extraction solvent, and drying the film forming solvent to form micro-porous film; preheating the micro-porous film, and subjecting the micro-porous film to secondary drawing and heat shaping. According to the method for preparing polyolefin micro-porous film, the pore diameter of the micro-porous film changes in the film thickness direction, and a compact structure layer and a coarse pore diameter structure layer are provided. The micro-porous film has the advantages of being rapid in electrolyte absorption, high in puncture strength, small in air permeability change and the like, and can meet the use requirements of lithium ion battery diaphragms.

Owner:CHONGQING YUNTIANHUA NEWMI-TECH CO LTD

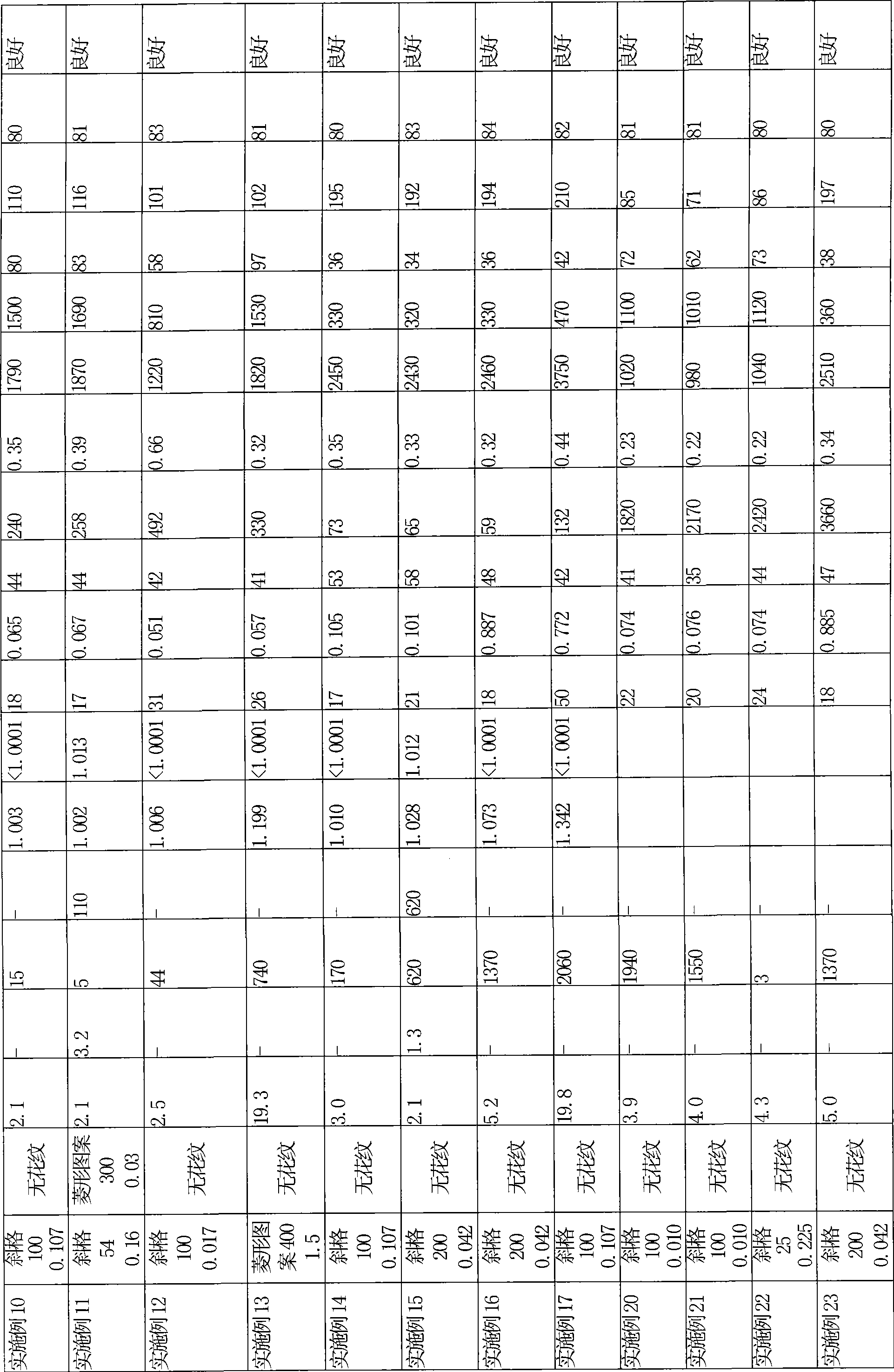

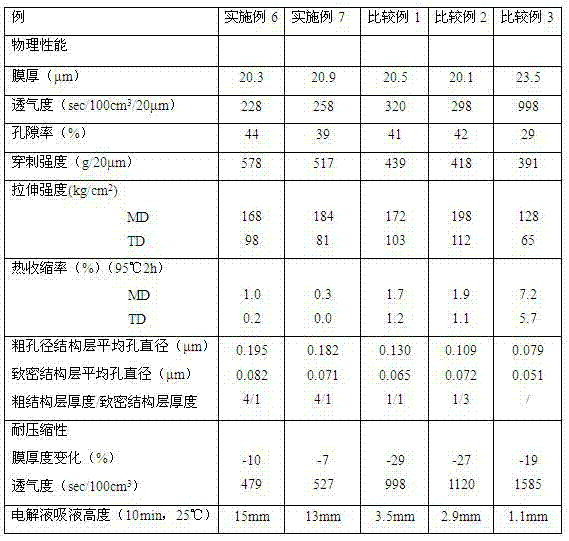

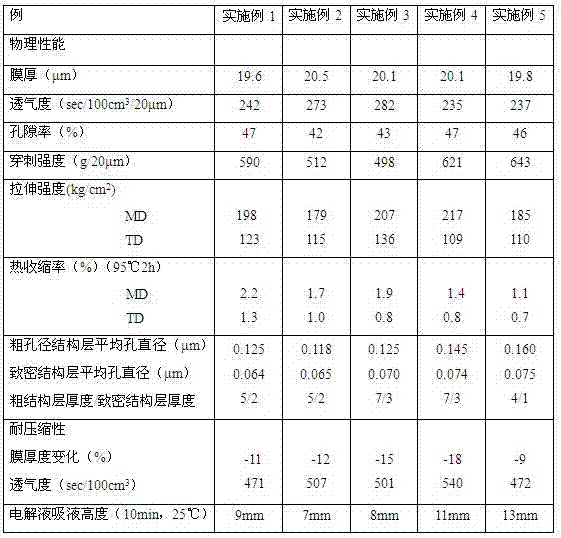

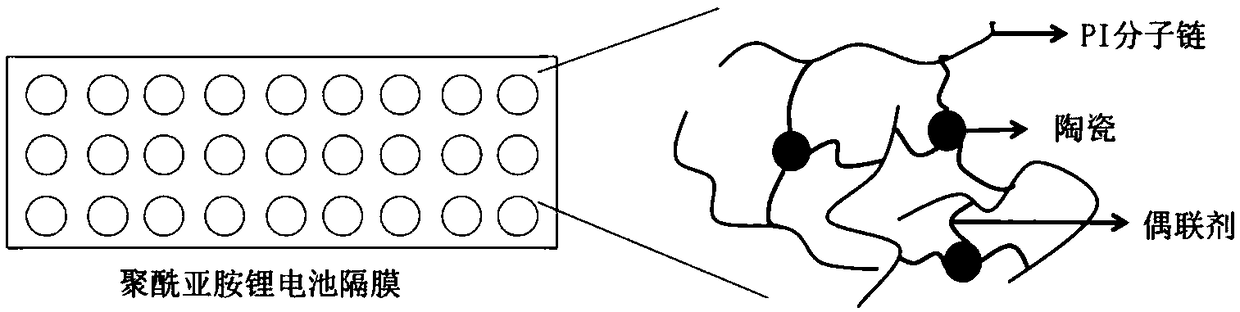

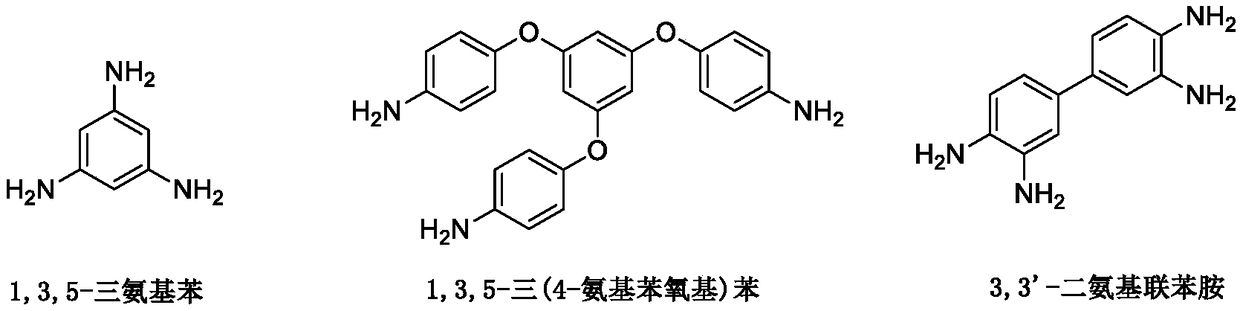

A polyimide lithium battery diaphragm, a preparation method thereof, and a lithium battery comprising the diaphragm

InactiveCN109119572AHigh mechanical strengthImprove puncture strengthCell component detailsCross-linkCoupling

The present application relates to the field of lithium ion battery materials. Disclosed are a polyimide lithium battery diaphragm, a preparation method thereof, and a lithium battery comprising the diaphragm. The polyimide lithium battery diaphragm comprises: 30-50 parts of diorganic amine, 30-50 parts of dibasic organic anhydride, 2-5 parts of a polyamino crosslinking agent and 5-20 parts of polyimide formed by reaction of amino coupling agent surface modified ceramic powder and imidization. The polyimide diaphragm can form cross-linking between polymer molecular chains in the subsequent imidization process by adding polyamino crosslinking, which greatly enhances the mechanical strength; by ceramic powder added with the surface-modified coupling agent, the puncture strength of polyimidediaphragm can be greatly improved, and the pore size of diaphragm can be ensured to be small, the distribution is uniform, and the leakage current problem of a battery can be solved. At the same time,the polyimide lithium battery diaphragm has high production efficiency and is favorable for industrial large-scale production.

Owner:RUYUAN DONGYANG LIGHT FLUORINE RESIN CO LTD

Water-proof sound-transmitting membrane, method for producing the water-proof sound-transmitting membrane, and electrical appliance including the water-proof sound-transmitting membrane

ActiveUS8272517B2Lose waterproofnessWater leakage and rupture of the membrane startBaby linensUndergarmentsPorous layerPorous membrane

The present invention provides a water-proof sound-transmitting membrane including a polytetrafluoroethylene (PTFE) porous membrane, in which the waterproofness is enhanced further with little lowering of the sound transmittance. The water-proof sound-transmitting membrane includes the PTFE porous membrane. The PTFE porous membrane includes a first porous layer, and a second porous layer stacked on and integrated with the first porous layer by a binding force acting between PTFE matrices. The first porous layer and the second porous layer each are composed of PTFE with a number-average molecular weight of 5.0×107 or more determined by a standard specific gravity method. At least one layer selected from the first porous layer and the second porous layer has an average pore diameter of 1 μm or less. The water-proof sound-transmitting membrane has a surface density of 1 g / m2 to 10 g / m2.

Owner:NITTO DENKO CORP

Metallocene geomembrane

InactiveCN101525452AImprove performanceReduce the temperatureLow-density polyethyleneLinear low-density polyethylene

The invention relates to a metallocene geomembrane which is used for railway laying, a refuse landfill, a tunnel, a penstock, a reservoir, a dyke, a sewage tank, an ecological tank, a landscape lake, an aquiculture tank and the seepage resistance and the water resistance of railway and highway engineering and is prepared by ingredients through a coextrusion machine. The metallocene geomembrane is characterized by comprising the following components by the weight percent: 64 to 73 of metallocene linearity low-density polyethylene, 24 to 32 of high-density polyethylene and 0.1 to 3 of assistant, wherein the assistant comprises a modifying assistant and a processing assistant, the modifying assistant is the antioxidant, and the processing assistant is carbon black or PPA. The Metallocene geomembrane has good puncture resistance, good,anti-tear property and high tensile strength.

Owner:SHANDONG TIANHE PLASTIC

Production method of cross-linked polyethylene lithium ion battery diaphragm

ActiveCN104993081AEasy accessSave the long processing timeCell component detailsFlat articlesCross-linkSolvent

The invention relates to the field of polymer materials, and concretely relates to a production method of a cross-linked polyethylene lithium ion battery diaphragm. The method comprises the following steps: extruding to make a membrane, stretching the membrane, extracting a solvent in the membrane, drying, and fixing and cross-linking by using a cross-linking agent in the membrane. The method allows modifier molecules to extremely easily enter the diaphragm, so the long-time processing process of modification of the finished polyethylene diaphragm is omitted, and the method has the advantages of simple process and convenience in operation.

Owner:NINGBO UNIV

High-puncture-strength lithium ion battery diaphragm and preparation method thereof

InactiveCN103633273AImprove lateral strengthImprove puncture strengthCell seperators/membranes/diaphragms/spacersSecondary cellsLithium dendriteLithium electrode

The invention relates to the processing field of lithium ion battery diaphragms and discloses a high-puncture-strength lithium ion battery diaphragm. The high-puncture-strength lithium ion battery diaphragm consists of 75 to 99.9 weight percent of main body olefin resin and 25 to 0.1 weight percent of an auxiliary additive. The invention further discloses a method for preparing the high-puncture-strength lithium ion battery diaphragm, which comprises the following step: carrying out transverse stretching on a micropore diaphragm which is longitudinally stretched, wherein the traveling speed of the micropore diaphragm is 0.5 to 200 mm / min, the stretch temperature is 100 to 150 DEG C and the stretching multiplying power is 0.5 to 3.0. According to the invention, one step of transversely stretching is added on the basis of one-way stretching in an existing dry method; and by transverse stretching according to a certain ratio, under the condition of not influencing basic performance of the micropore diaphragm (air permeability, porosity and the like), the transverse intensity of the micropore diaphragm is improved, i.e. the puncture-resistant intensity of the micropore diaphragm is improved, so that the diaphragm can be better suitable for assembling of a battery, the micro short circuit problem caused by lithium dendrite puncture is reduced or avoided and safety of the battery is improved.

Owner:SHENZHEN SENIOR TECH MATERIAL

High-temperature resistant composite battery separator and preparation method thereof

ActiveCN108281592AGood thickening effectImprove hydrophilicityCell component detailsInorganic particleInorganic particles

The invention discloses a high-temperature resistant composite battery separator and a preparation method thereof. The high-temperature resistant composite battery separator comprises a base film anda high-temperature resistant coating layer, wherein the high-temperature resistant coating layer is coated on at least one surface of the base film and is formed by coating inorganic particles containing nanometer cellulose as a binding agent. In the composite battery separator, the nanometer cellulose is creatively used as the binding agent to prepare the high-temperature resistant coating layer,the interface bonding force of the coating layer and the base film is improved, the stripping strength of the composite battery separator is further improved, and the problems of falling and powder dropping of the coating layer are solved very well; with the addition of the nanometer cellulose, the inorganic particles are better in dispersion effect in water; moreover, the nanometer cellulose isused as the binding agent to form the coating layer, the high-temperature resistant composite battery separator is rapid in liquid conductivity and high in liquid absorption capability, gel is easilyformed after the electrolyte is absorbed, so that the composite battery separator can be attached onto a surface of an electrode very well, and the integral performance of the lithium ion battery is improved.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

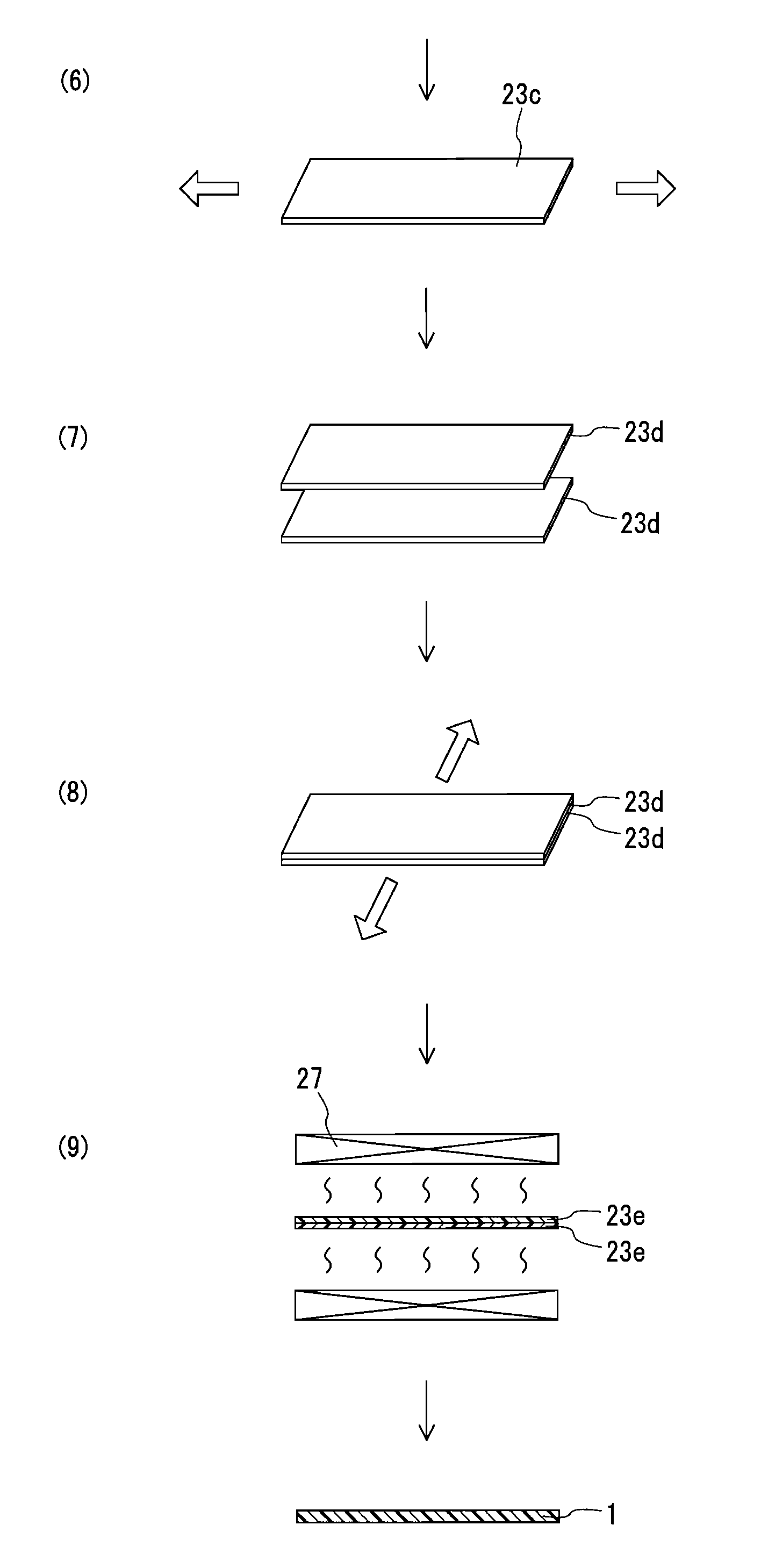

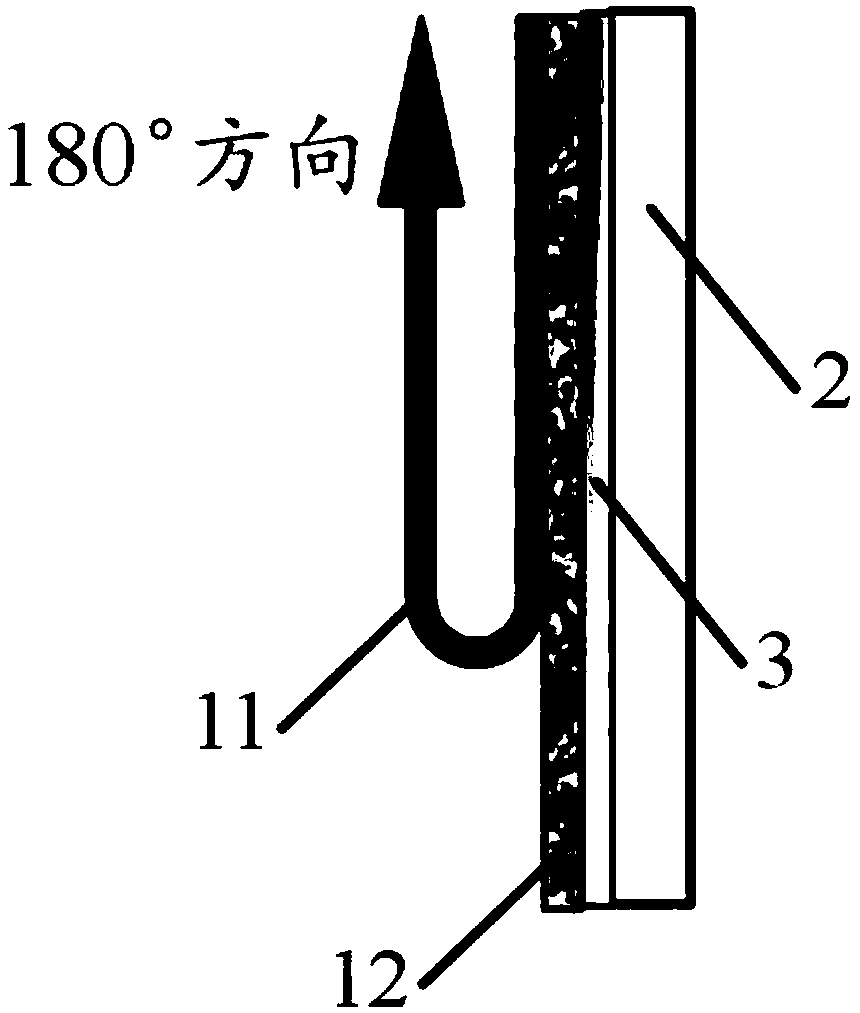

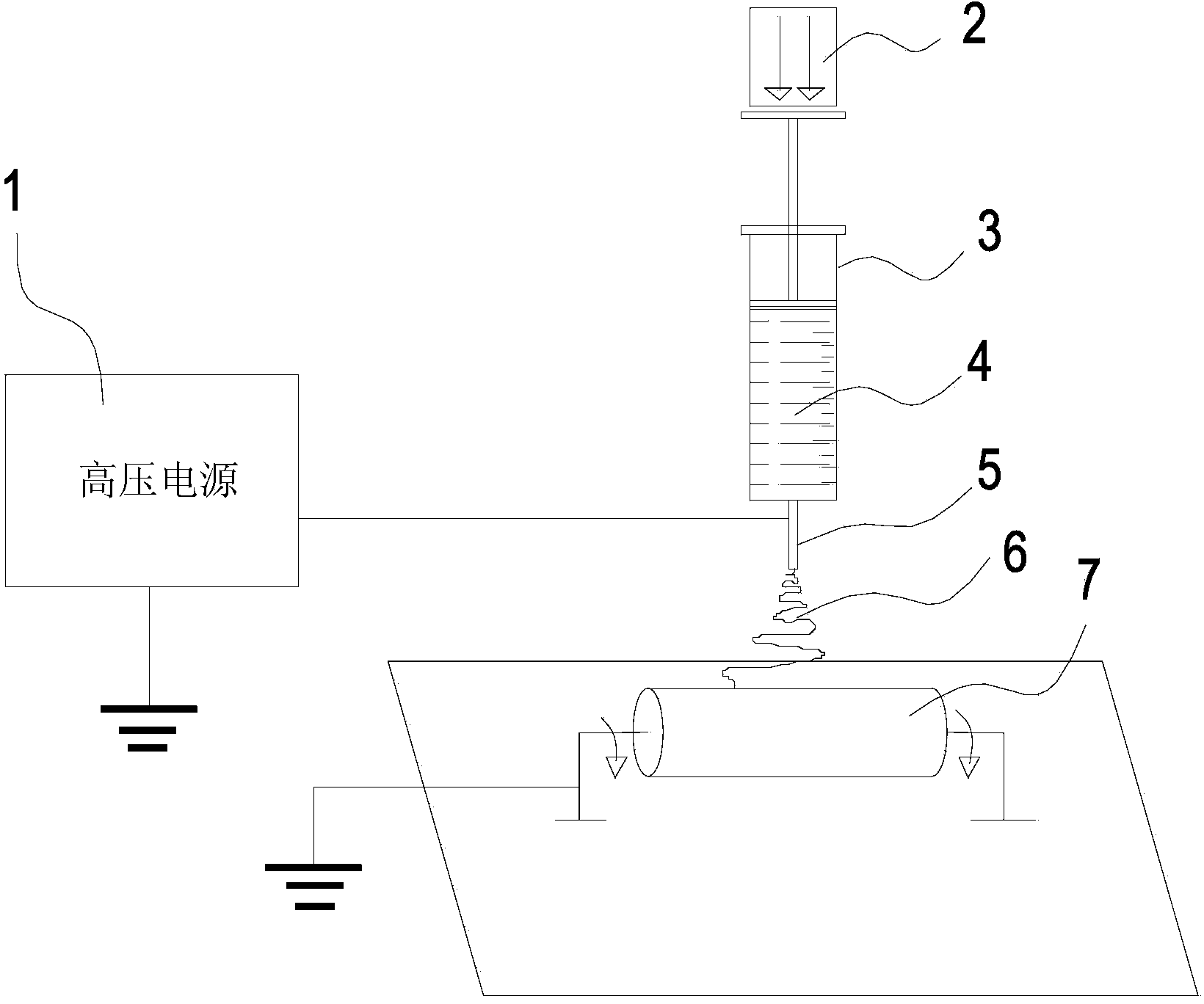

Preparation method of high-performance composite diaphragm and composite diaphragm

ActiveCN103904271AGood heat resistanceAvoid short circuitCell component detailsElectrospinningSolvent

The invention discloses a preparation method of a high-performance composite diaphragm. The preparation method comprises the following steps of 1, smearing a layer of processing liquid on one side of a dry-method unilaterally stretched polyolefin diaphragm; 2, dissolving binary organic anhydride and organic diamine in a polarity aprotic solvent to obtain polyimide, and re-dissolving the polyimide in the polar aprotic solvent to obtain a spinning crude solution; 3, spraying the spinning crude solution on the polyolefin diaphragm processed in the step 1 by utilizing an electrostatic spinning method to form a primary polymer composite diaphragm with an oriented nano polyimide fiber layer; and 4, processing the primary polymer composite diaphragm obtained in the step 3 in the hot air of 50 to 100 DEG C for 1 hour to 12 hours to be dried, and after-treating (such as hot-pressing for shaping) the composite diaphragm to obtain the polymer composite diaphragm. The invention also discloses a composite diaphragm prepared by utilizing the preparation method. The prepared composite diaphragm has the advantages that the strength and safety of the dry-method unilaterally stretched polyolefin diaphragm can be effectively improved.

Owner:SHENZHEN SENIOR TECH MATERIAL

Separator for secondary battery and method for producing the same

InactiveUS6878484B2High tensile strengthExcellent nitrate group trapping performanceIon-exchanger regenerationCell seperators/membranes/diaphragms/spacersLow-density polyethylenePolyolefin

An object of the present invention is to provide a thin battery separator having an excellent nitrate group trapping performance and a high piercing strength. The inventive separator for a secondary battery, which can accomplish such an object, is made of a resin composition mainly containing a polyolefin having a hydrophilic functional group, wherein the resin composition has a content (ratio to a total resin amount) of a low-density polyethylene of 20 mass % or less, a piercing strength of 5 to 100 N, a Metsuke of 20 to 75 g / m2, a thickness of 15 to 150 μm, and an unneutralized hydrophilic functional group amount of 1×10−3 to 5×10−2 mol / m2.

Owner:TOYO TOYOBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com