Patents

Literature

1182results about How to "Reduce light transmittance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

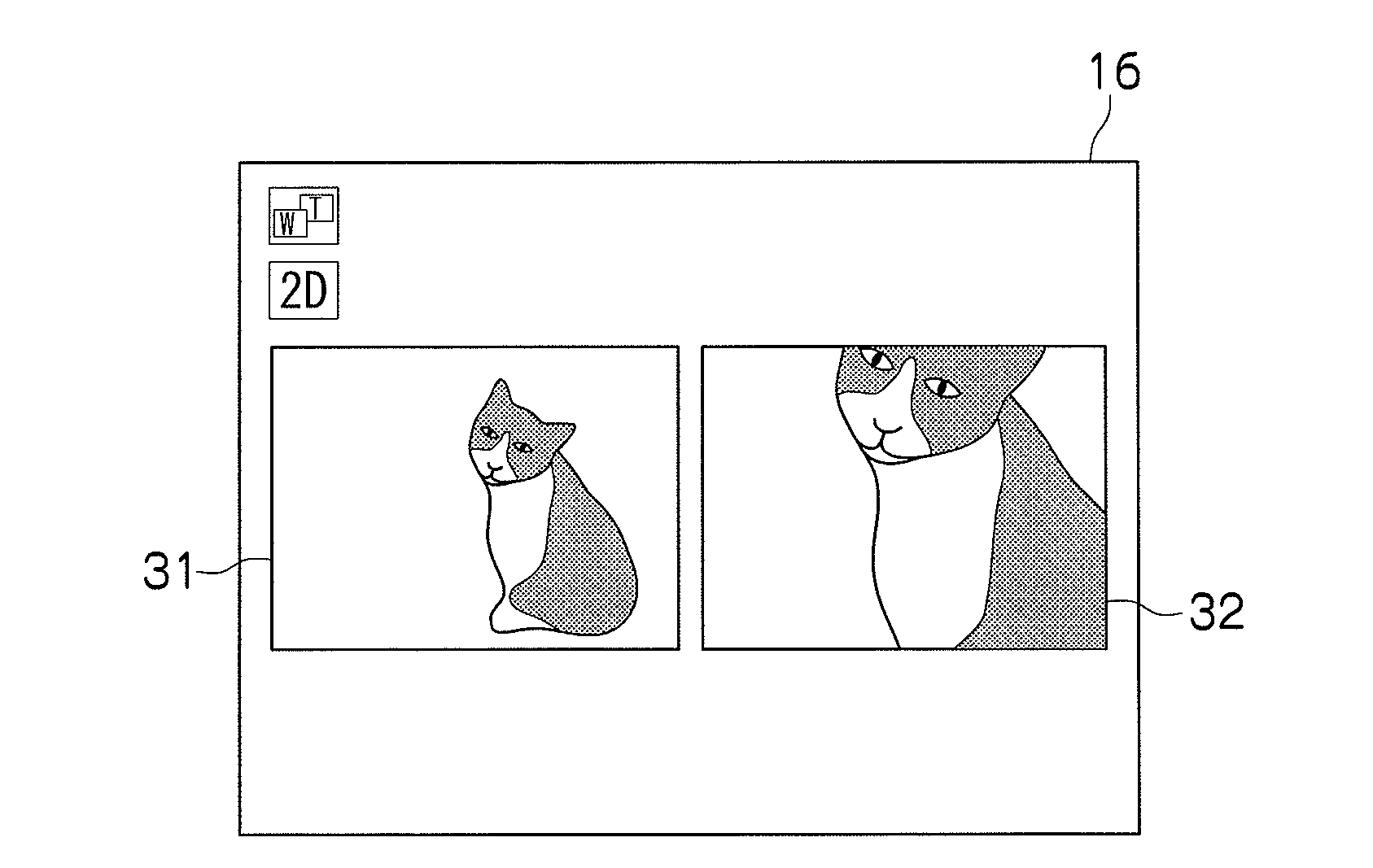

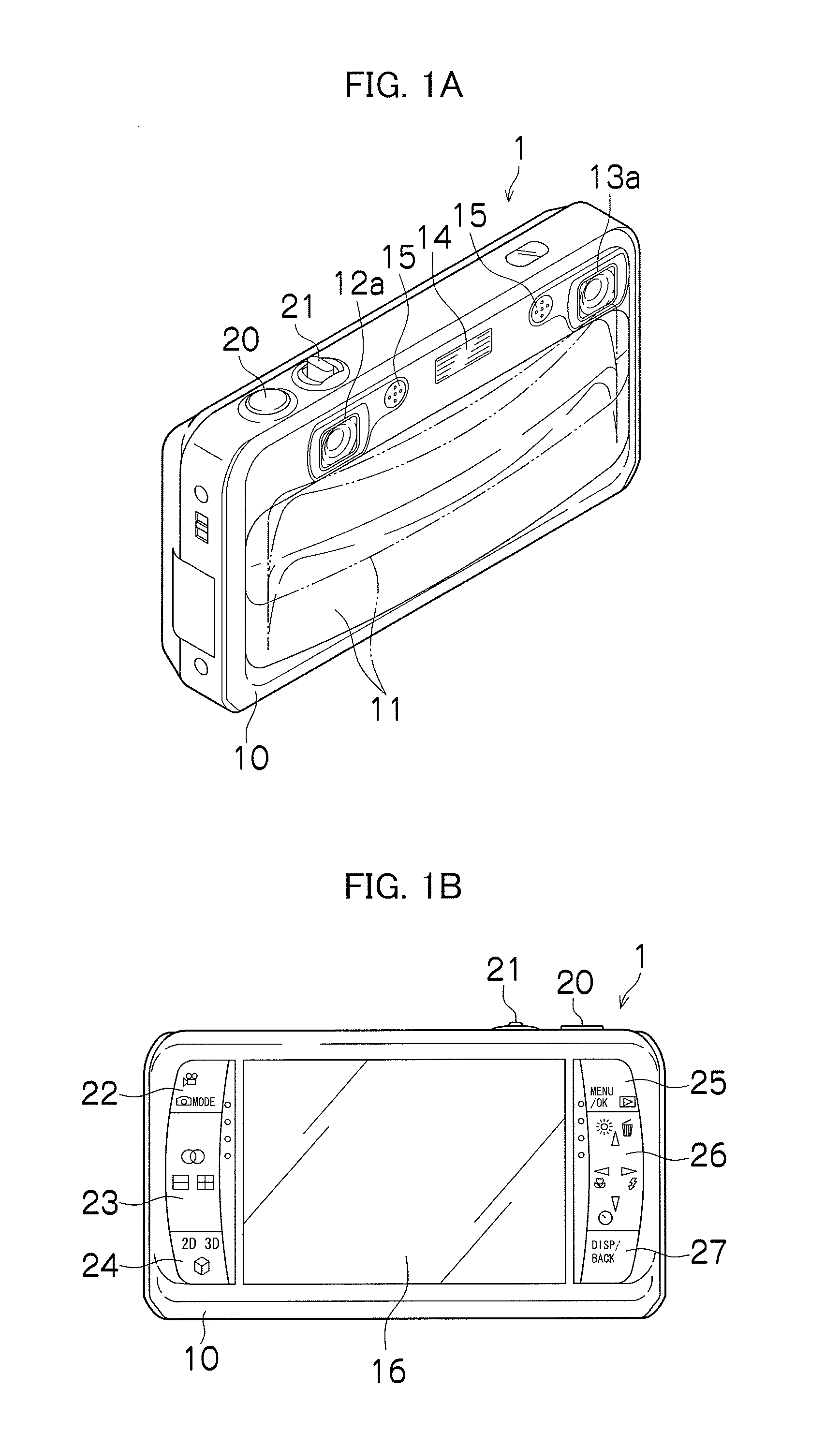

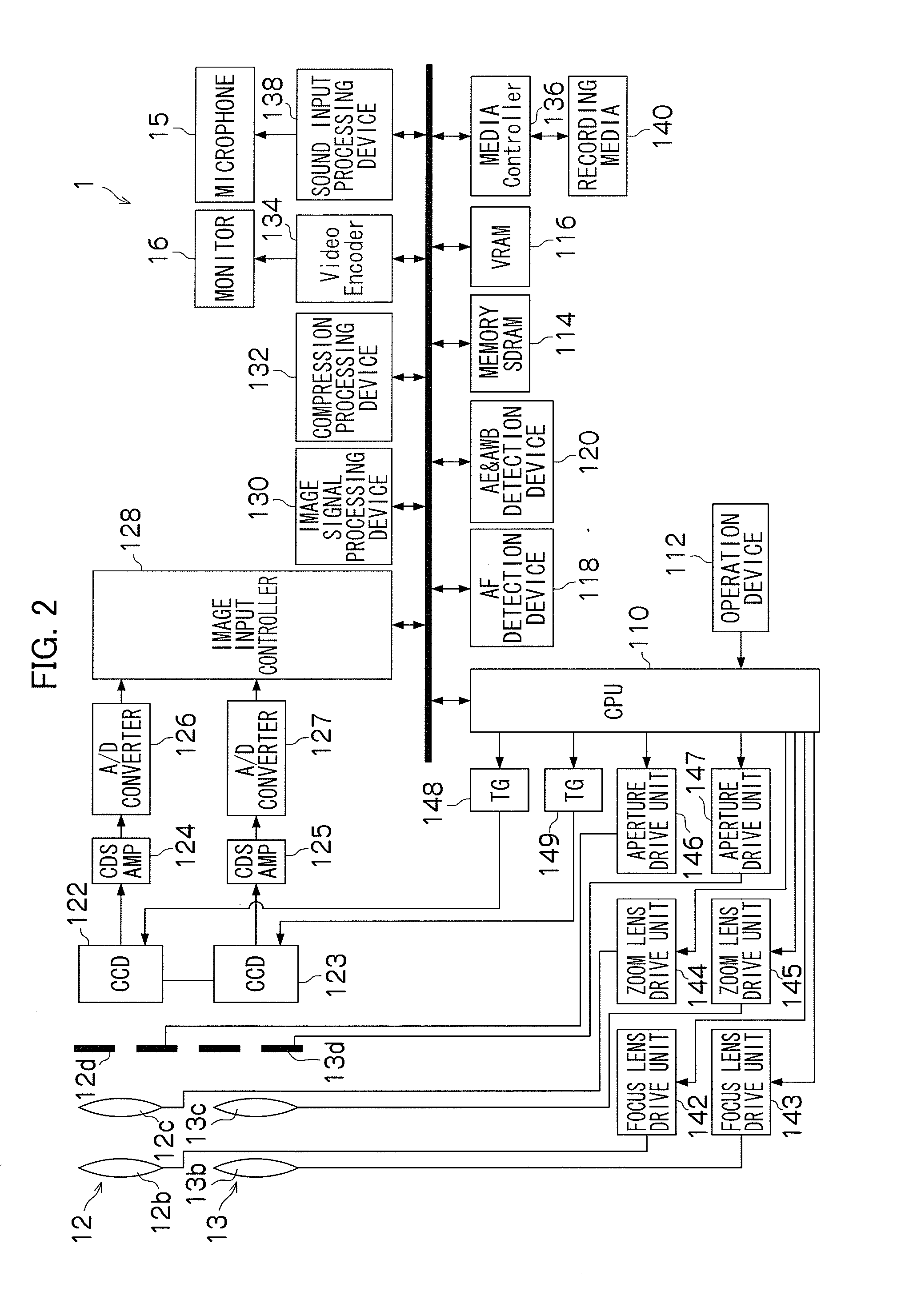

Display apparatus

InactiveUS20110234881A1Easy to understandImprove visibilityTelevision system detailsColor television detailsComputer visionVisibility

Provided is a display apparatus that allows viewing a plurality of plane images in different photographing ranges with high visibility. Two images in different photographing ranges (an image of the telephoto side and an image of the wide side) are taken in a tele / wide simultaneous shooting mode, and the two images are stored in one image file (for example, MP file). The display apparatus acquires the image file and displays the two images on a monitor by a display method stored in ancillary information of the image file. A change in the display method can be inputted from an designation device. If the display method is inputted, a CPU causes the monitor to display the images by the changed display method. If the display method is inputted, the ancillary information of the image file is overwritten by the inputted display method and stored in a main memory.

Owner:FUJIFILM CORP

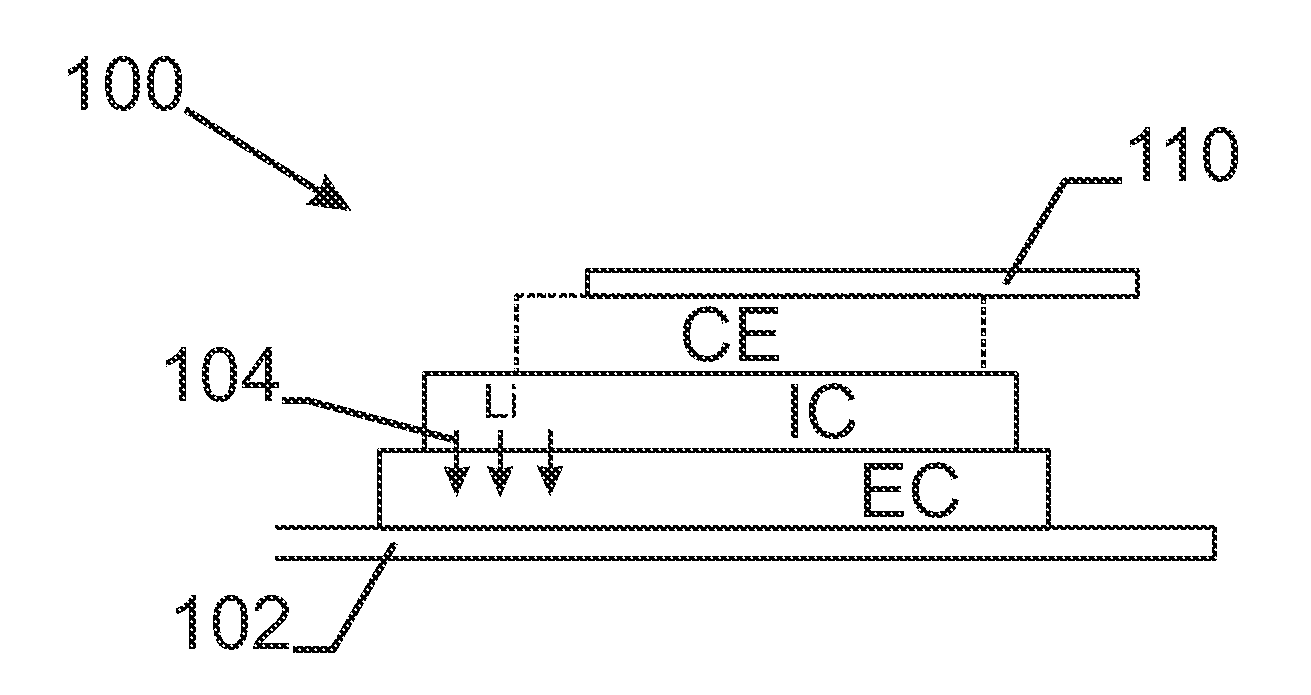

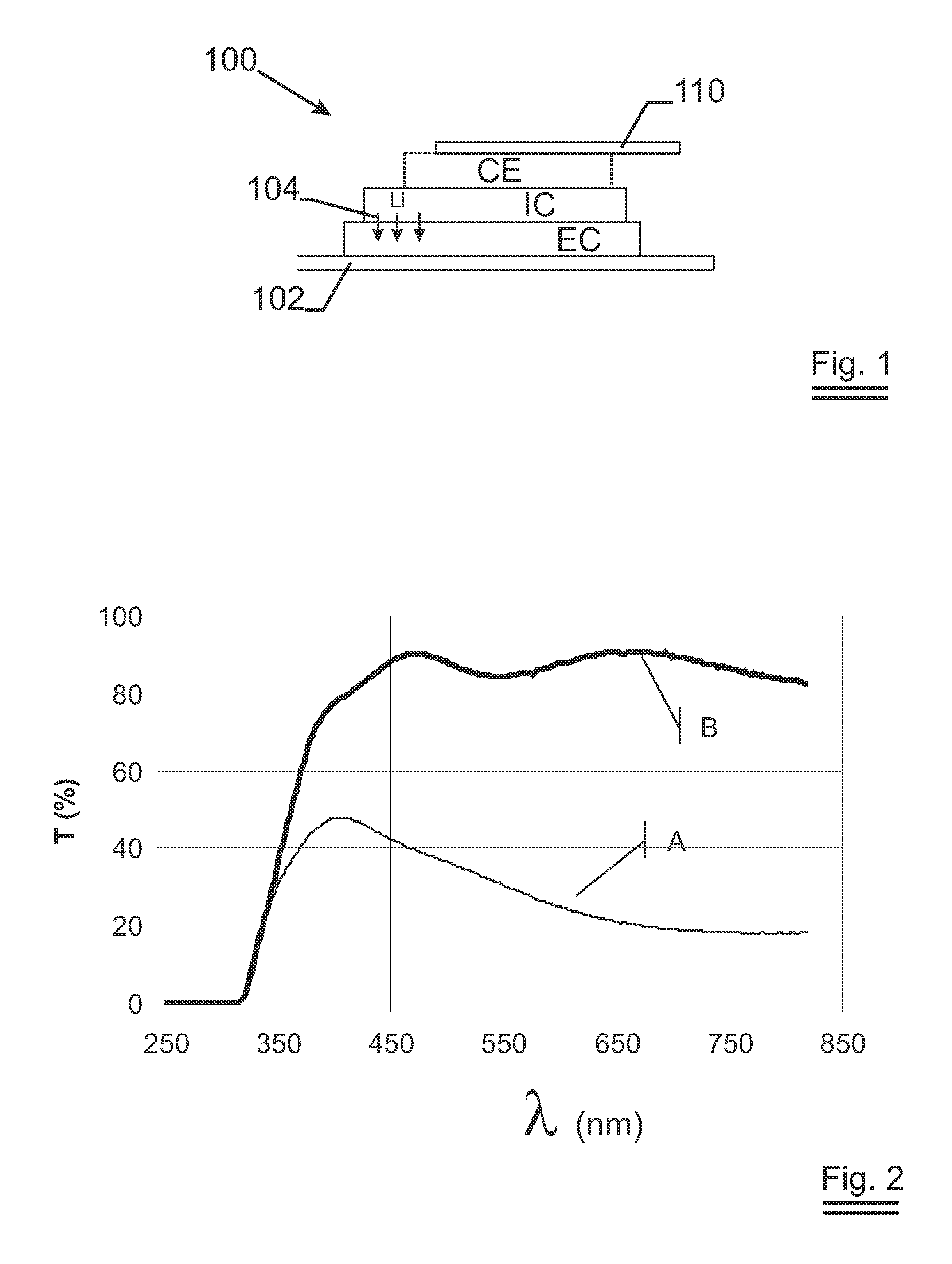

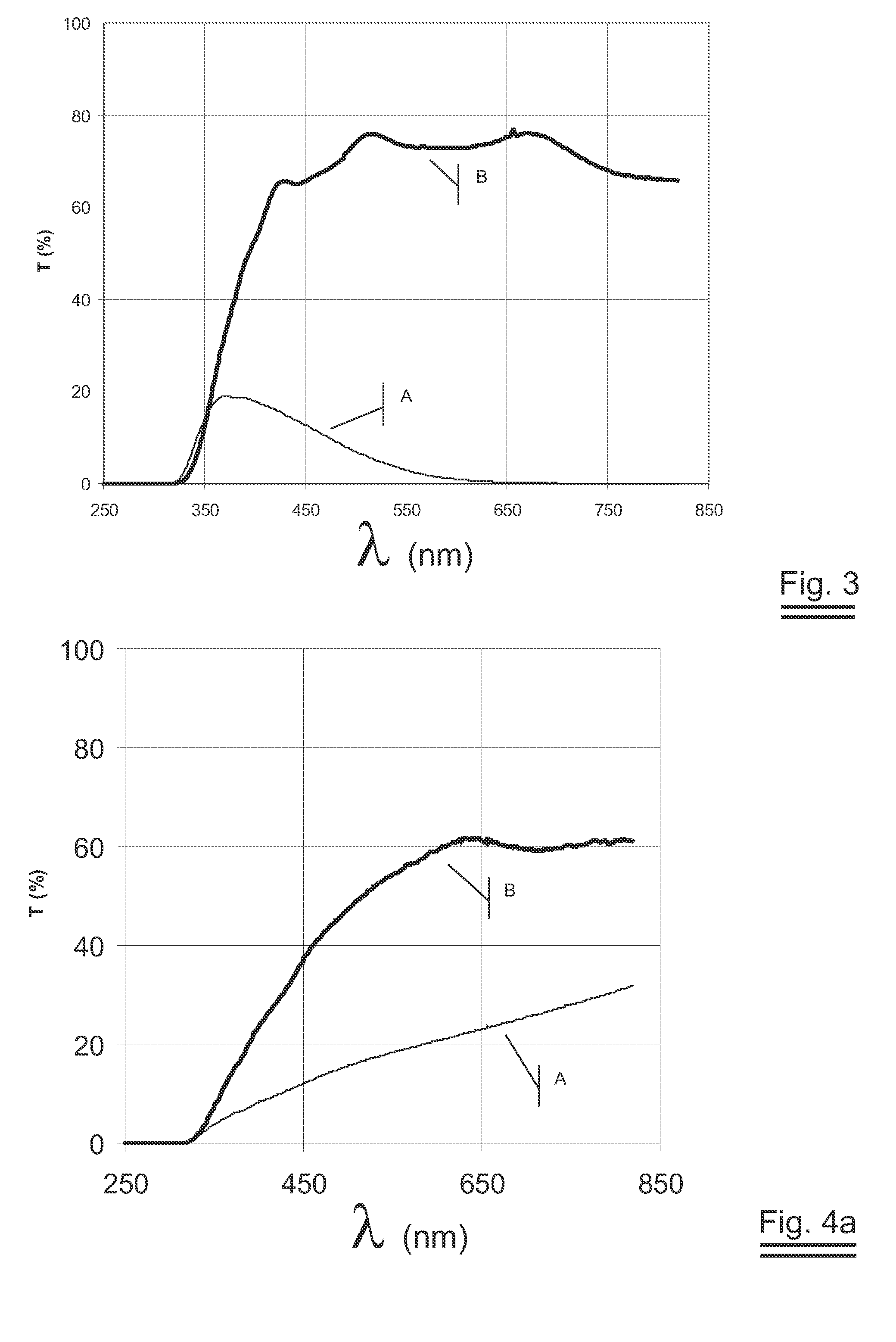

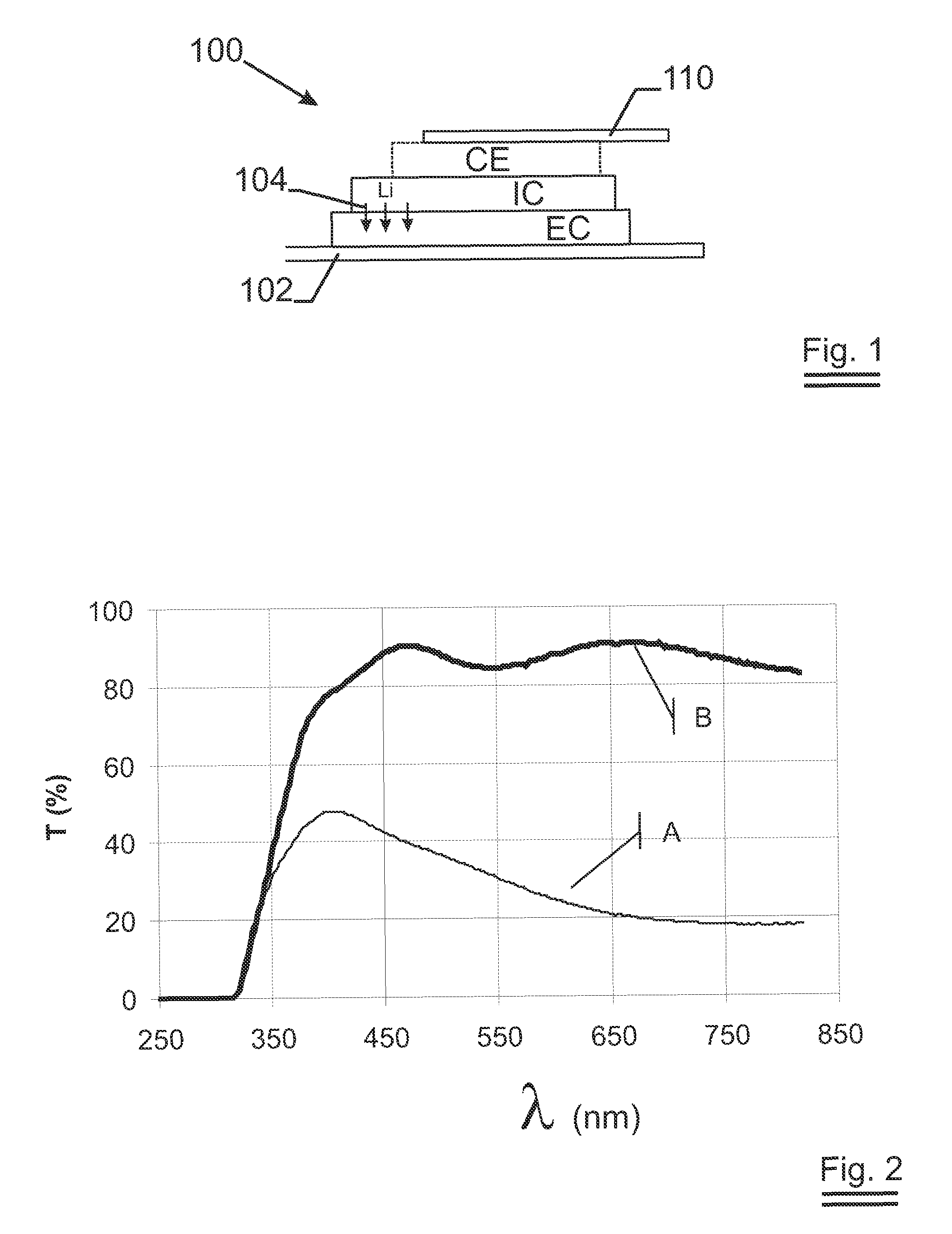

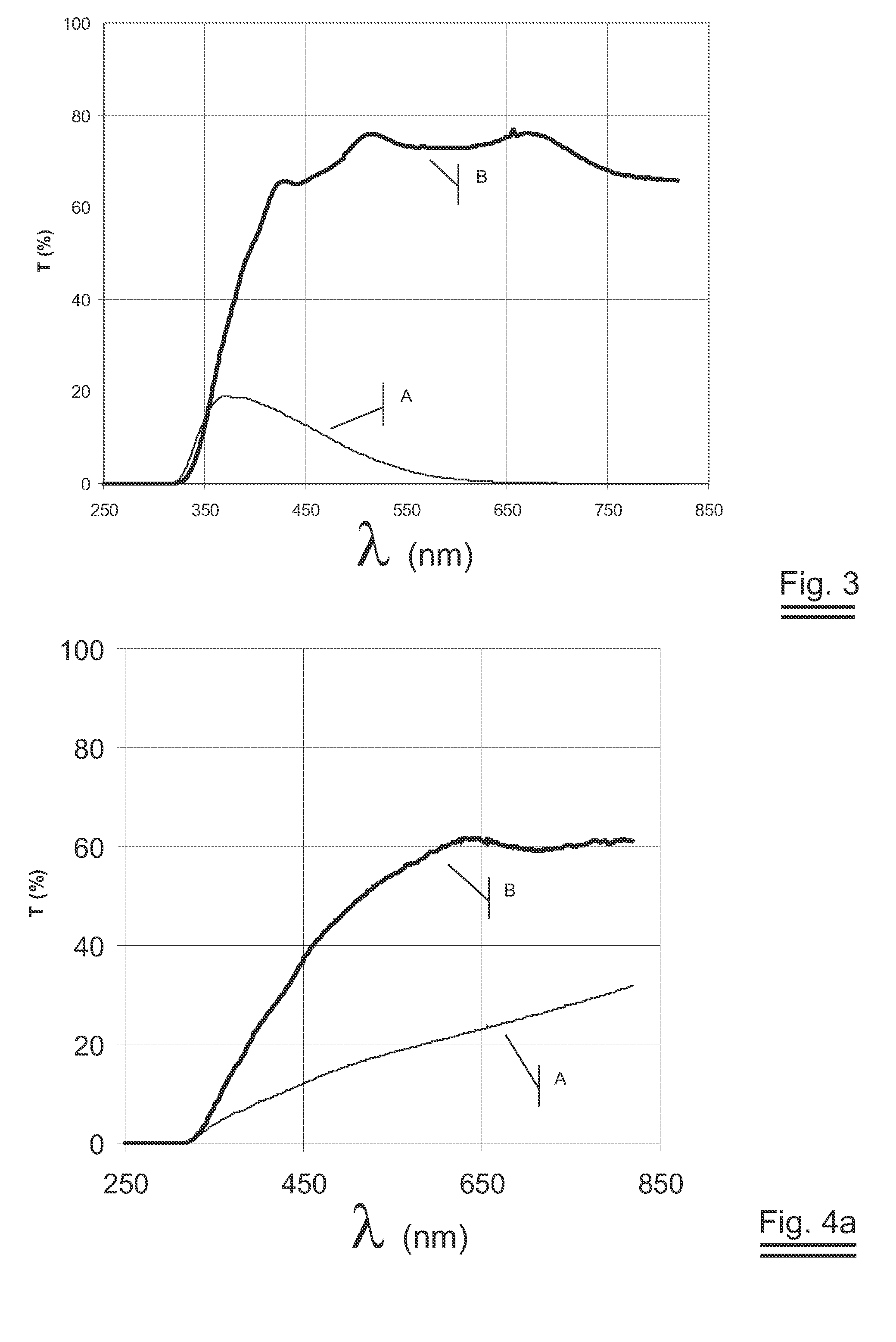

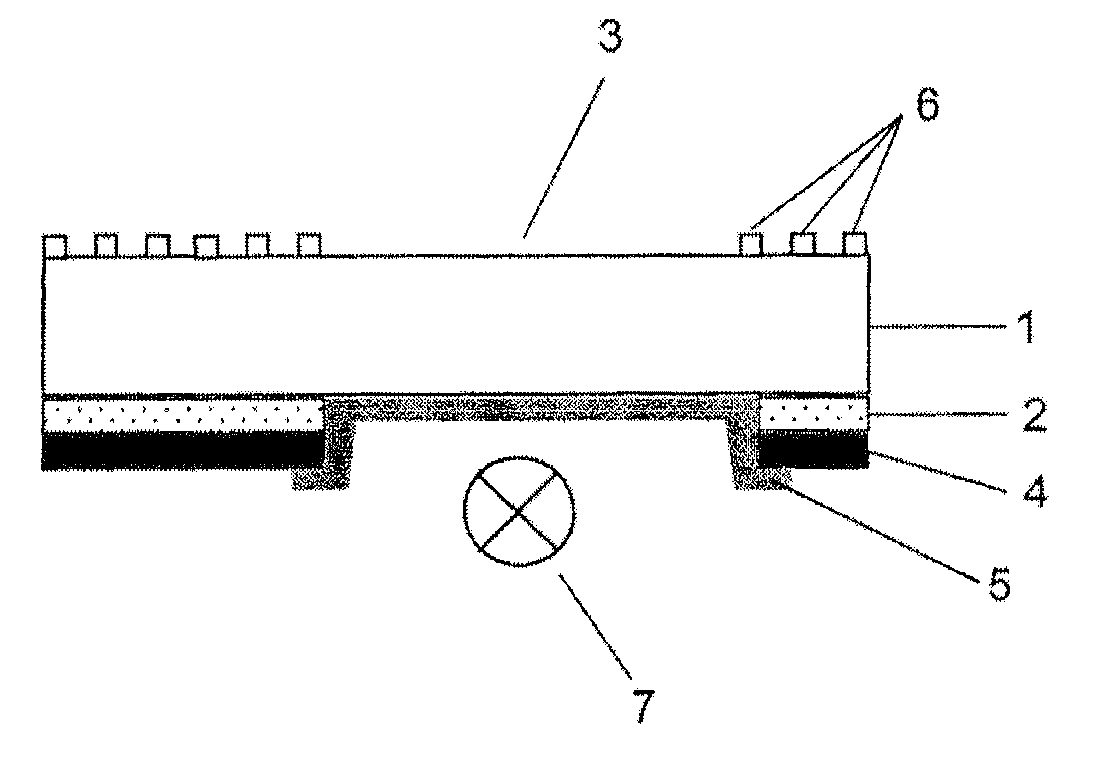

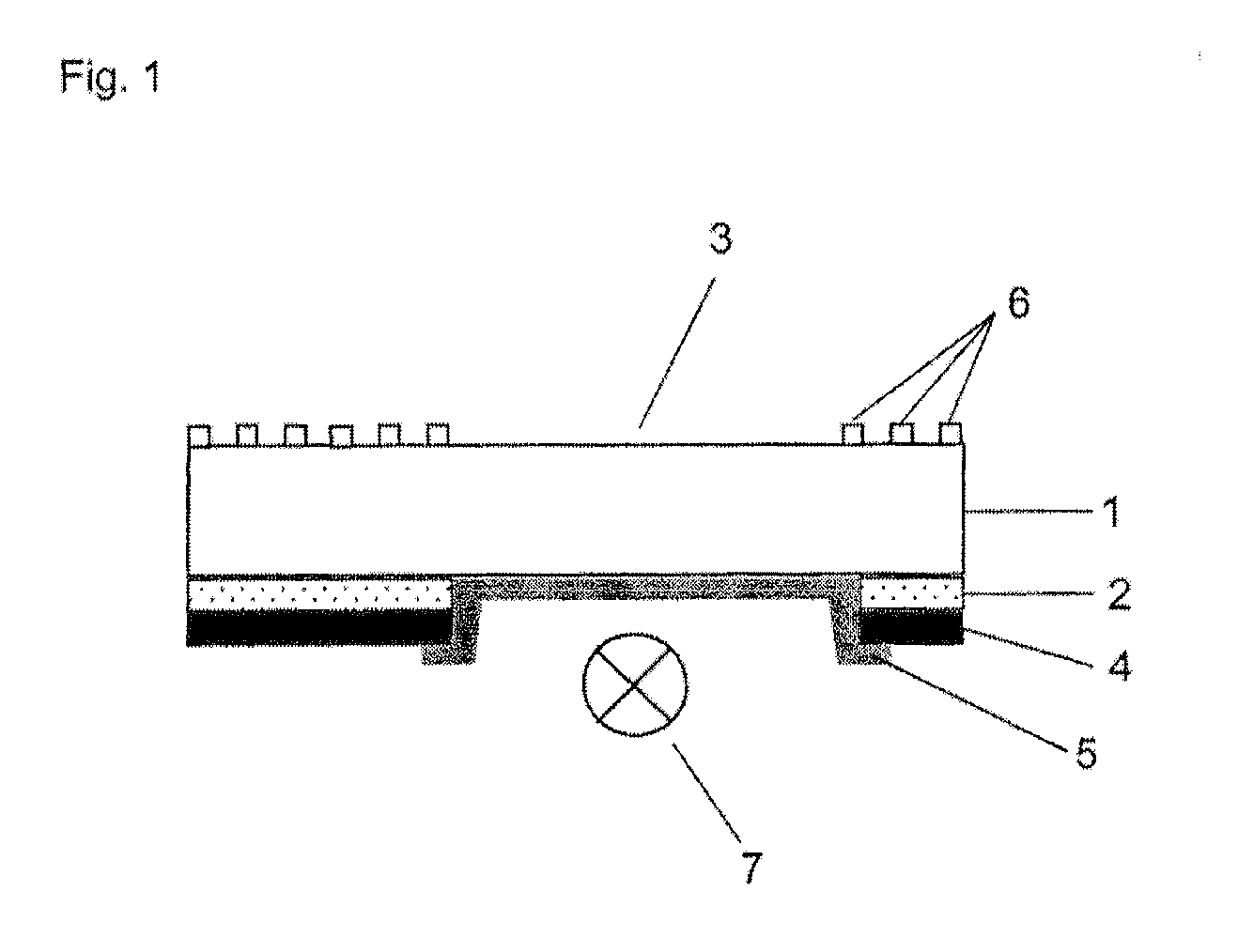

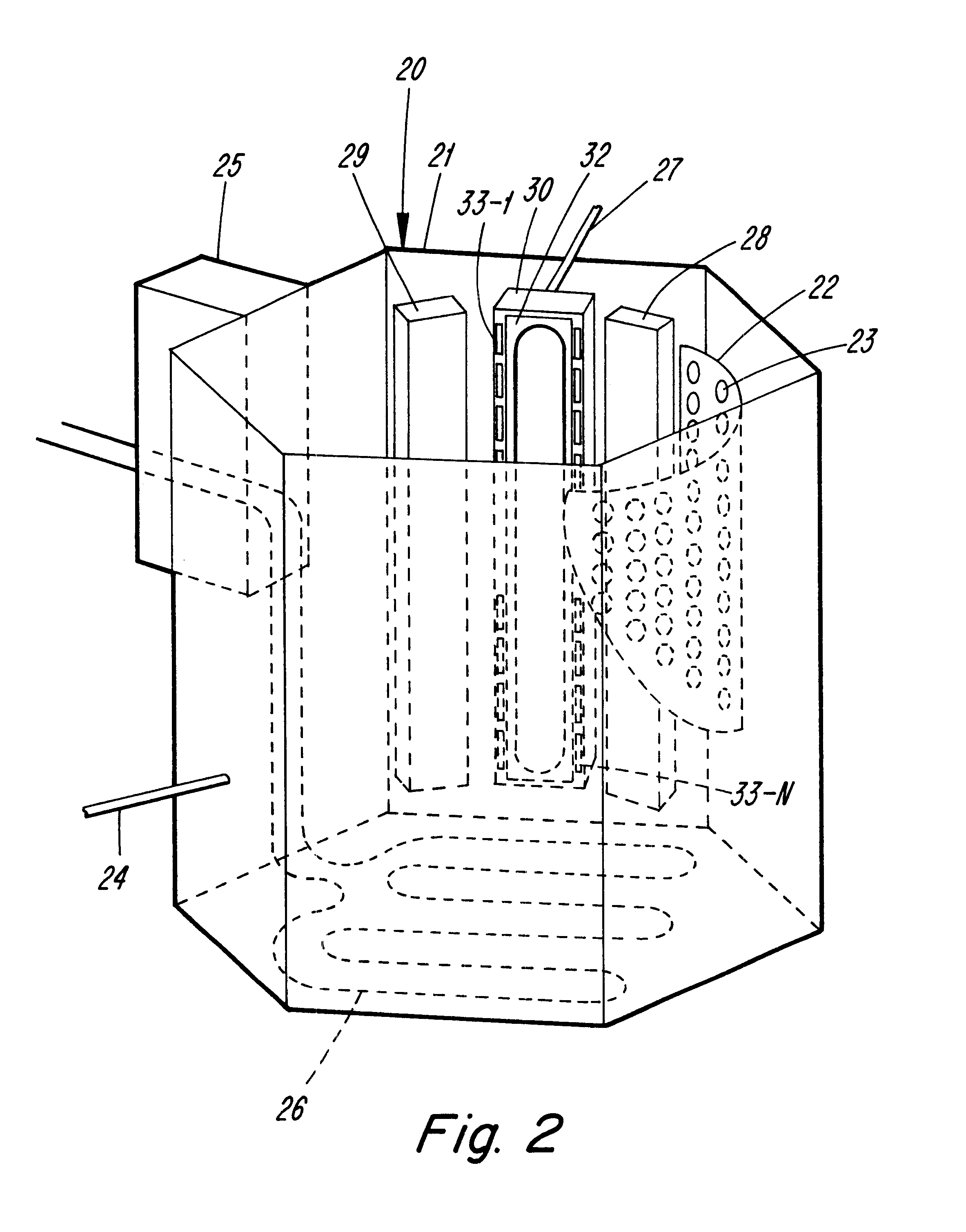

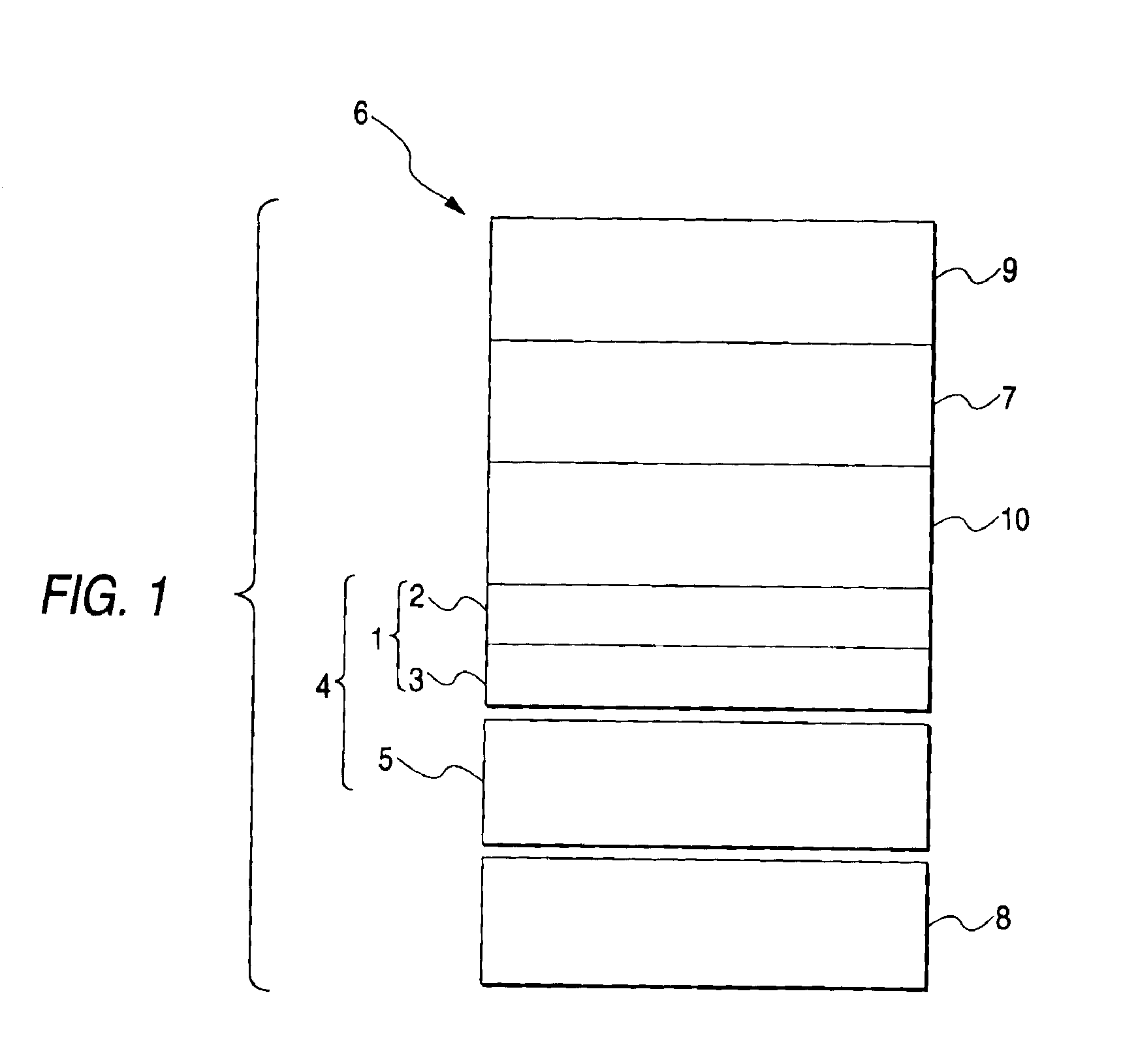

Method of making an ion-switching device without a separate lithiation step

InactiveUS20100007937A1Inhibition formationEfficient processingFinal product manufactureVacuum evaporation coatingChemical physicsElectrical conductor

In any manufacturing sequence for making a lithium ion-switching device, lithium has to be introduced at some stage into the device. An electrode inside the device is filled and depleted with lithium through an ion conductor at every use cycle of the device. Prior-art methods to introduce the lithium are: direct sputtering of lithium on the electrode, or electrochemically loading the electrode in an electrochemical cell, or indirectly loading the electrode after an ion conductor has been deposited on top of the electrode and still other methods. The inventive method disclosed makes such a separate lithiation step obsolete. The lithium is introduced at the same time as the ion-conductor is put on the electrode. This can be achieved by using an oxygen super-stoichiometric compound for the electrode.

Owner:SAGE ELECTROCHROMICS

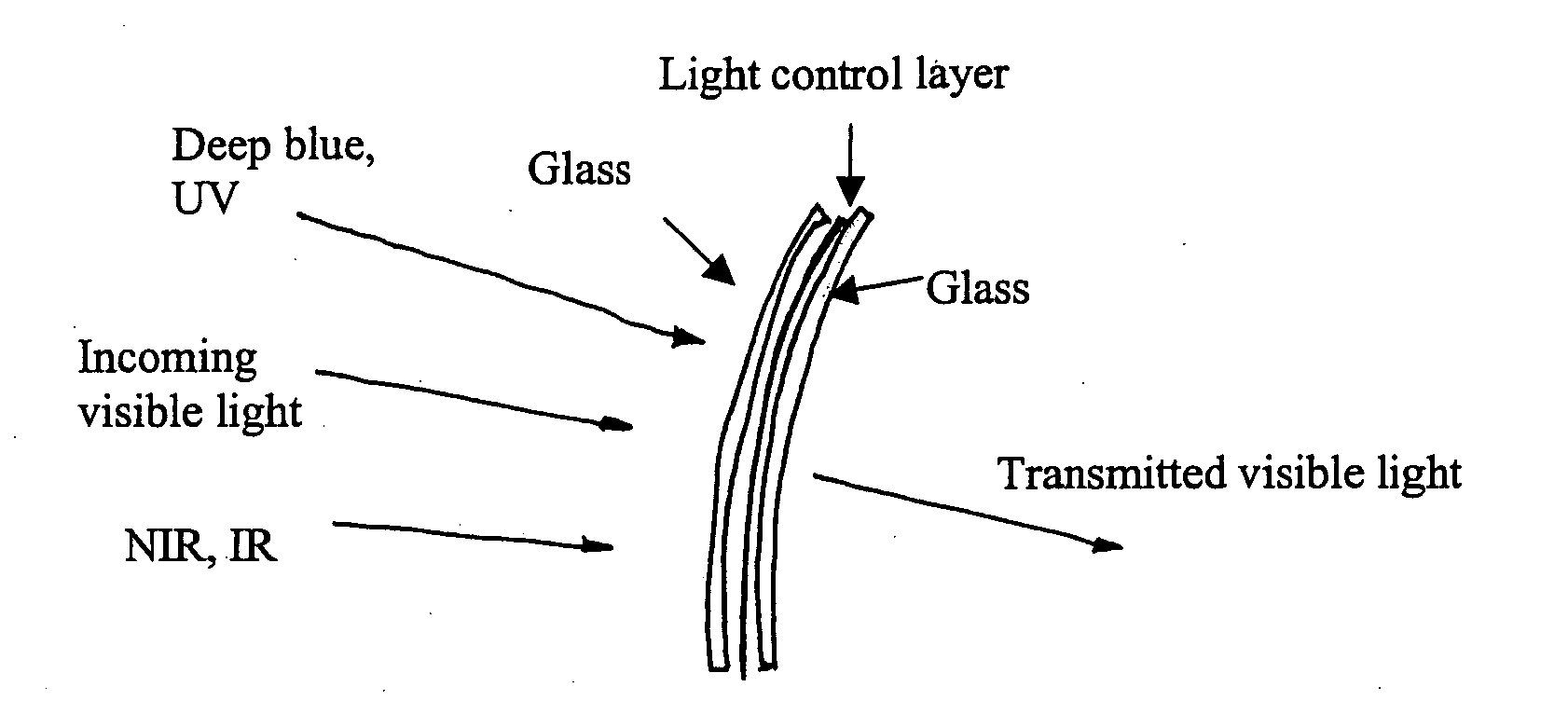

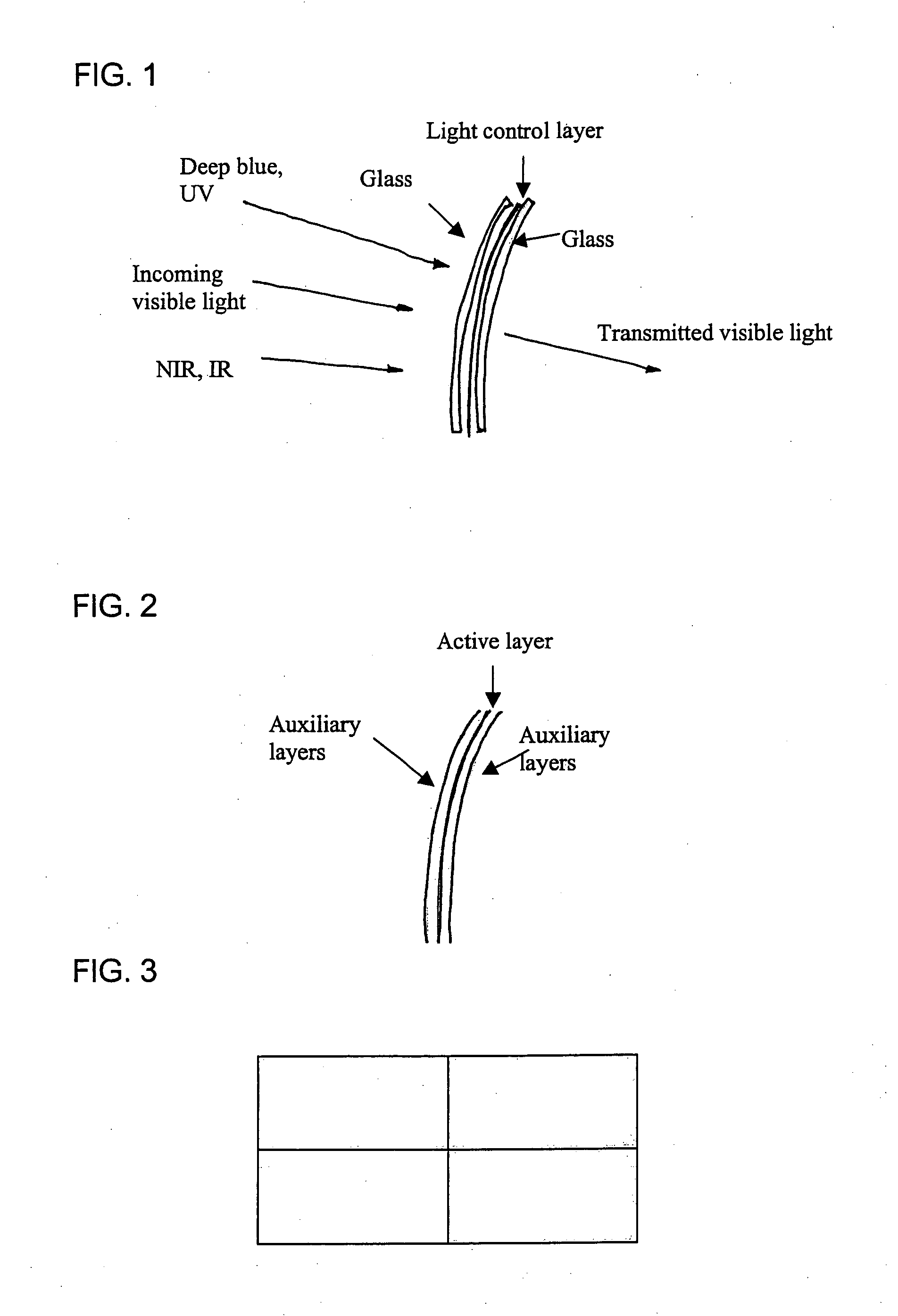

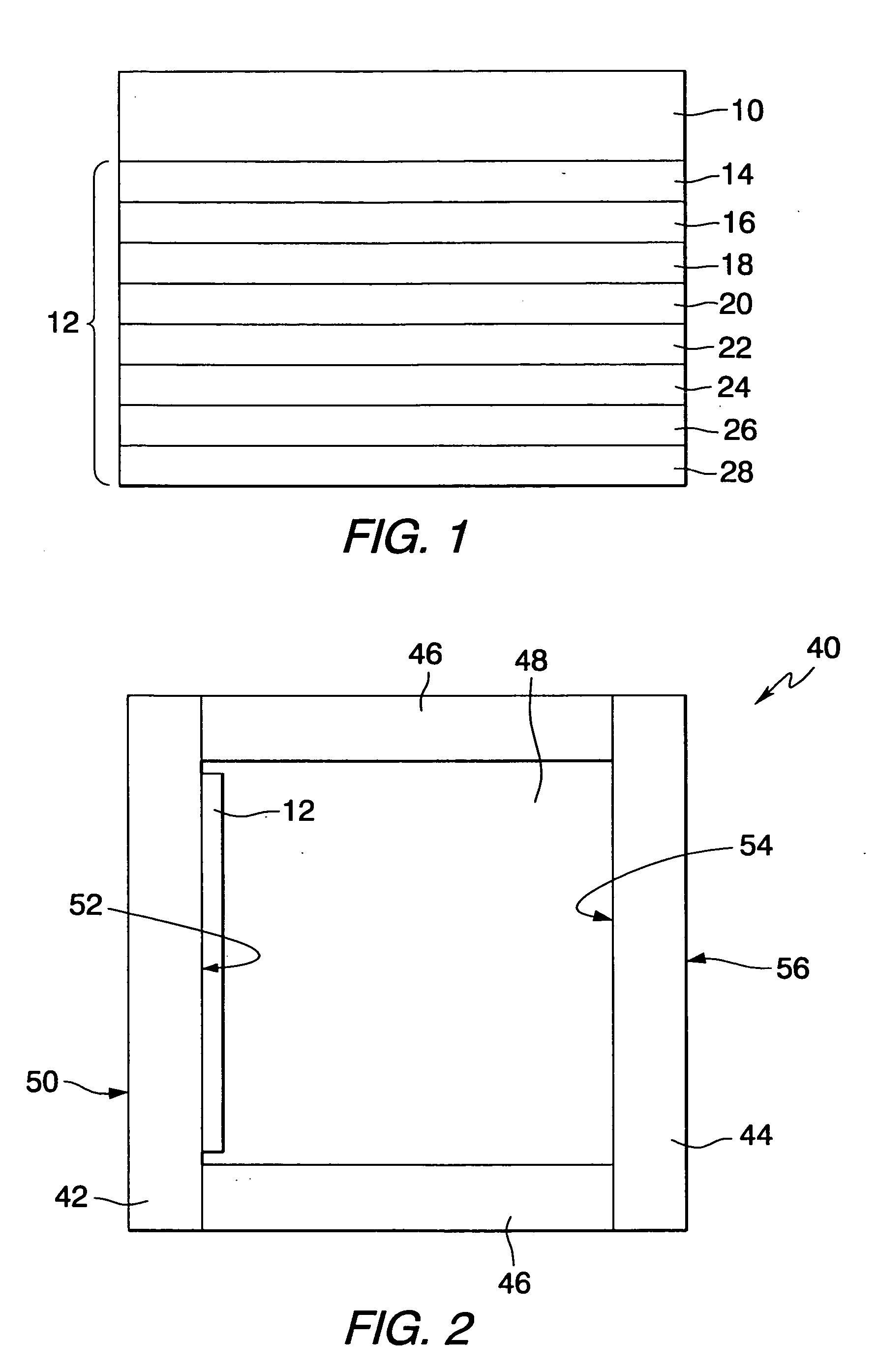

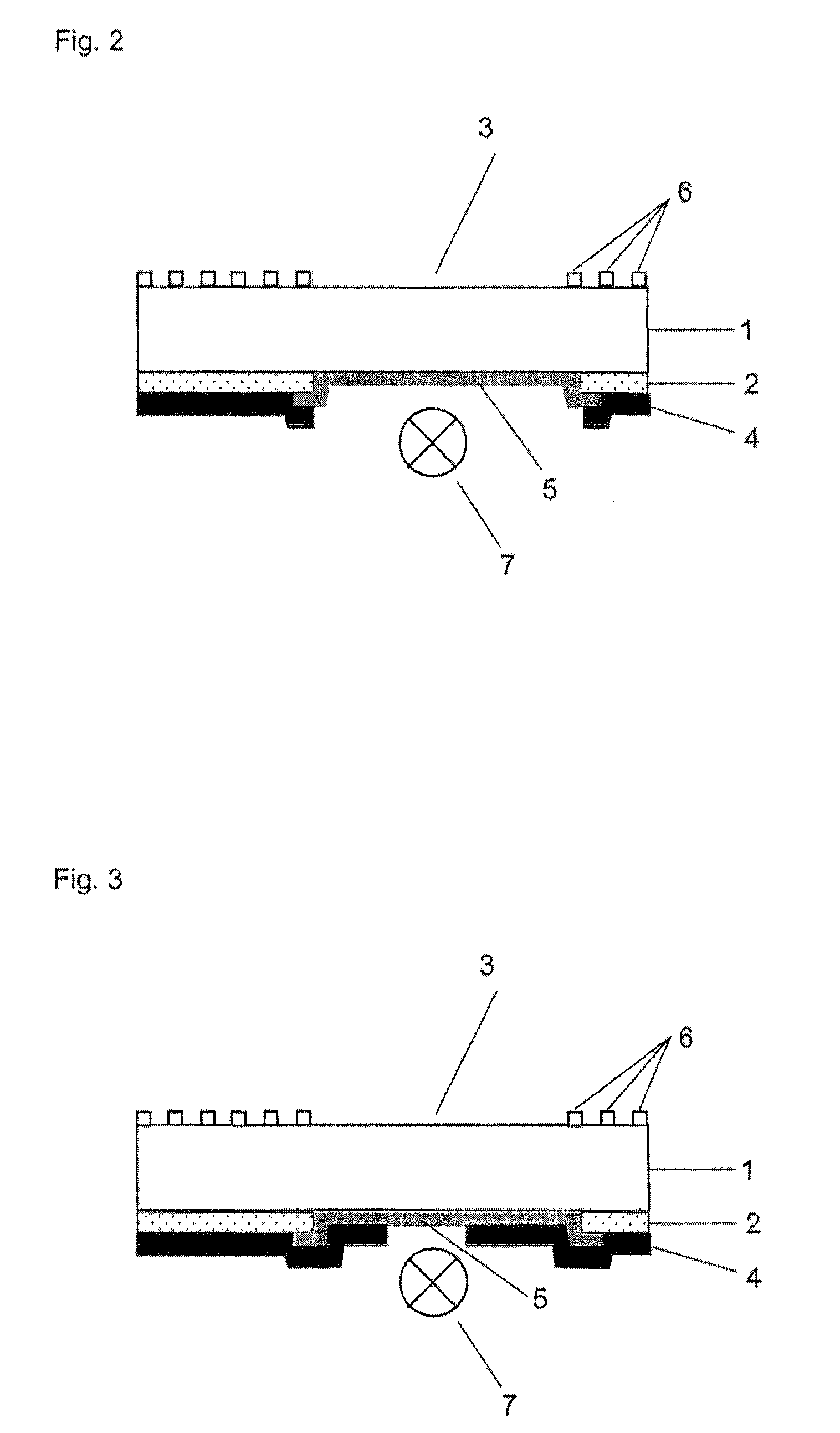

Adjustably opaque window

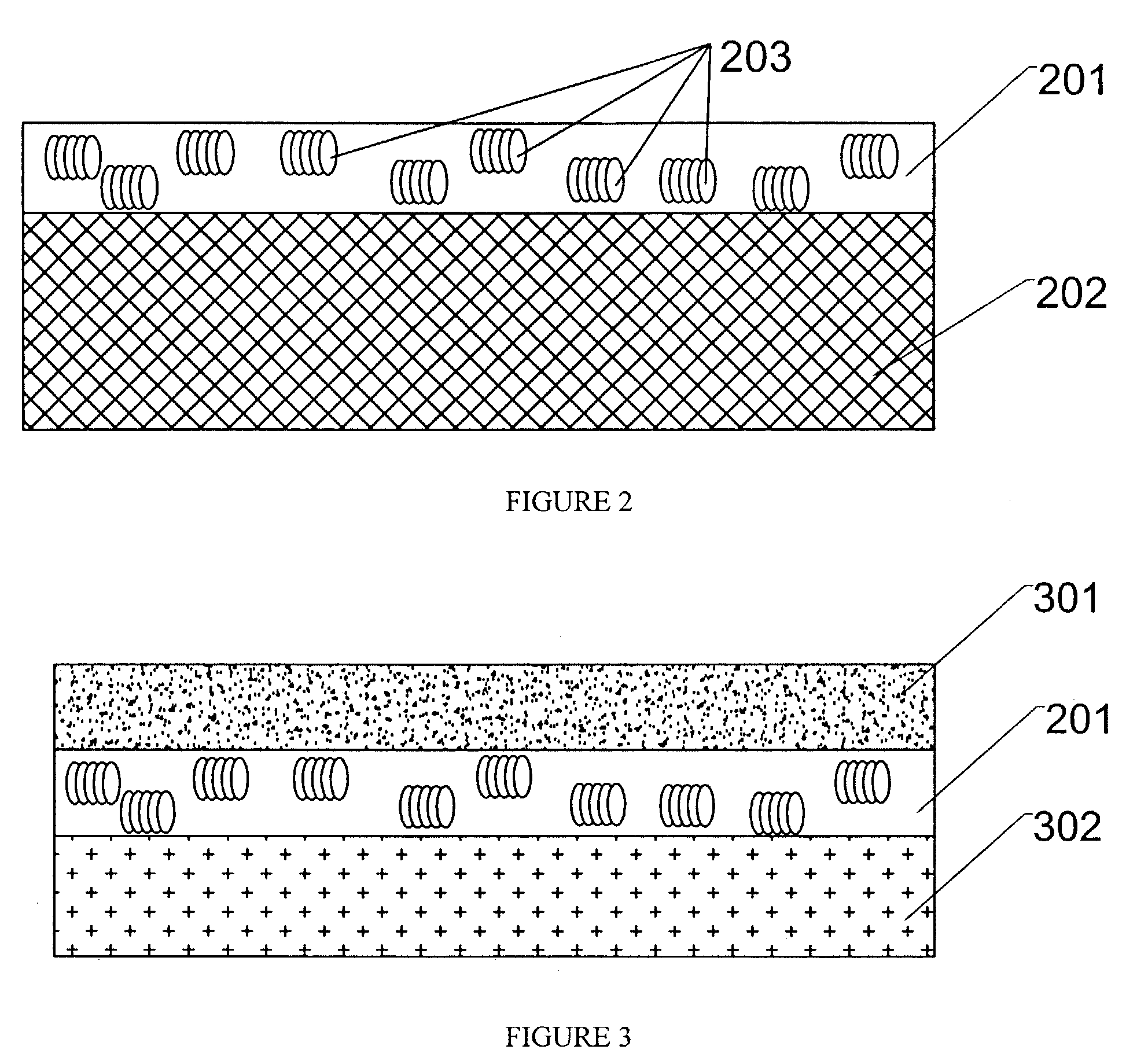

InactiveUS20050068629A1Reduce decreaseMinimized and eliminatedLight dependant control systemsAntiglare equipmentControl layerLight transmission

An adjustably opaque window including an external pane, an internal pane, a light transmission control layer and a shock-absorbing layer is provided. The external pane and the internal pane provide a cavity between them, and the light transmission control layer and the shock-absorbing layer are positioned in the cavity. The shock-absorbing layer is a flexible sheet that supports and protects the light transmission control layer. The light transmission layer consists of liquid crystal cells. The transmission ratio of the cells can be controlled variably.

Owner:LCT ENTERPRISES

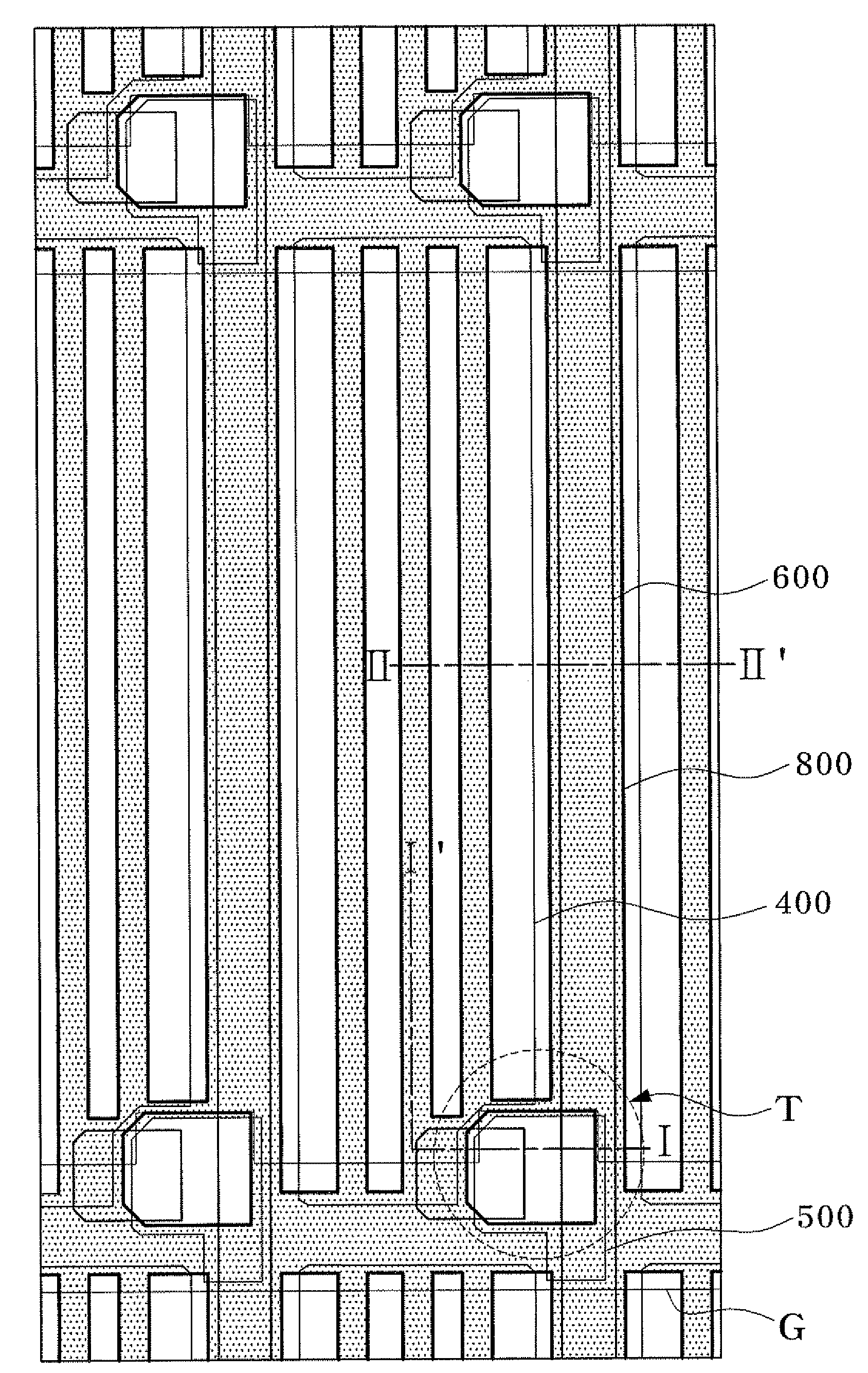

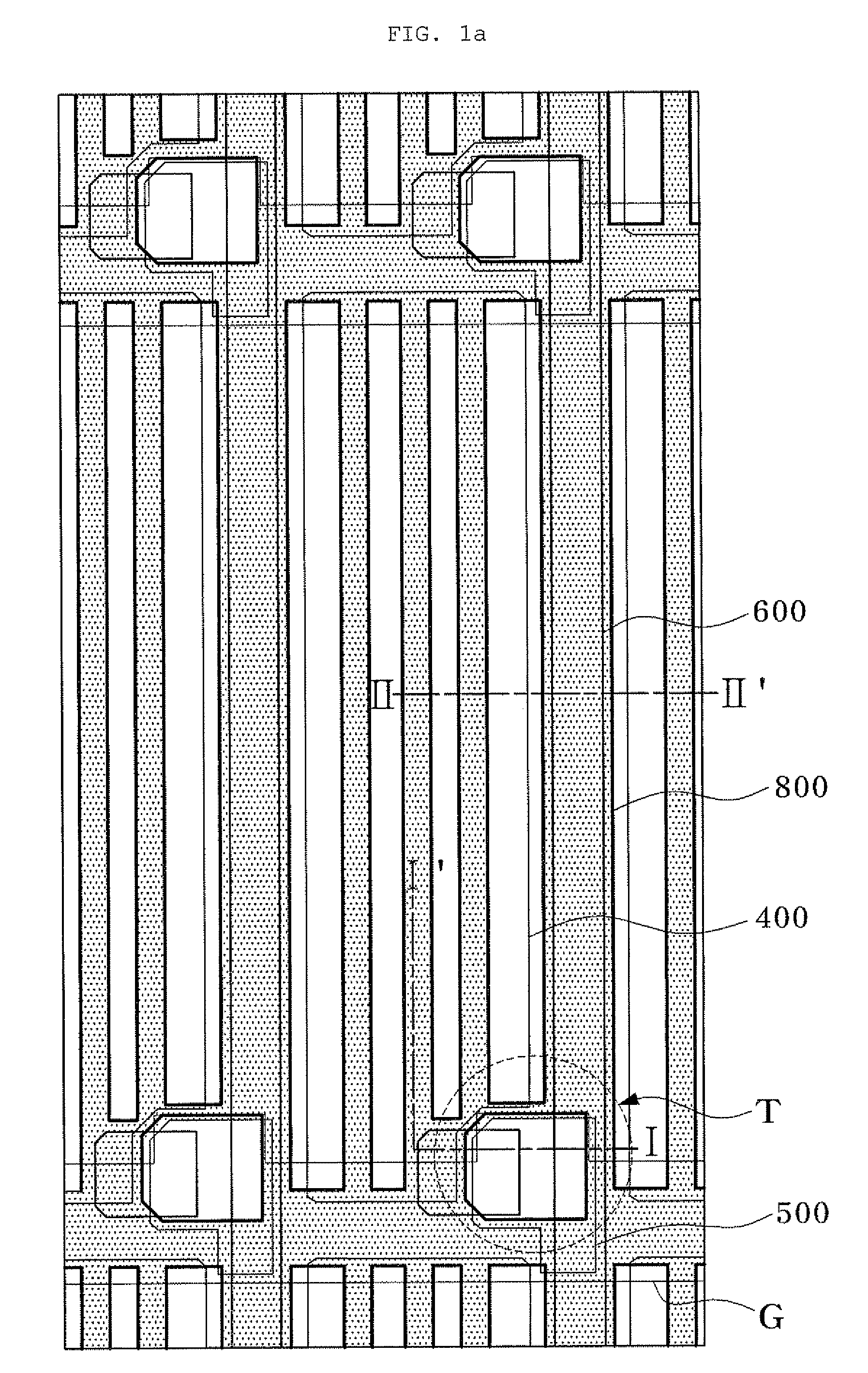

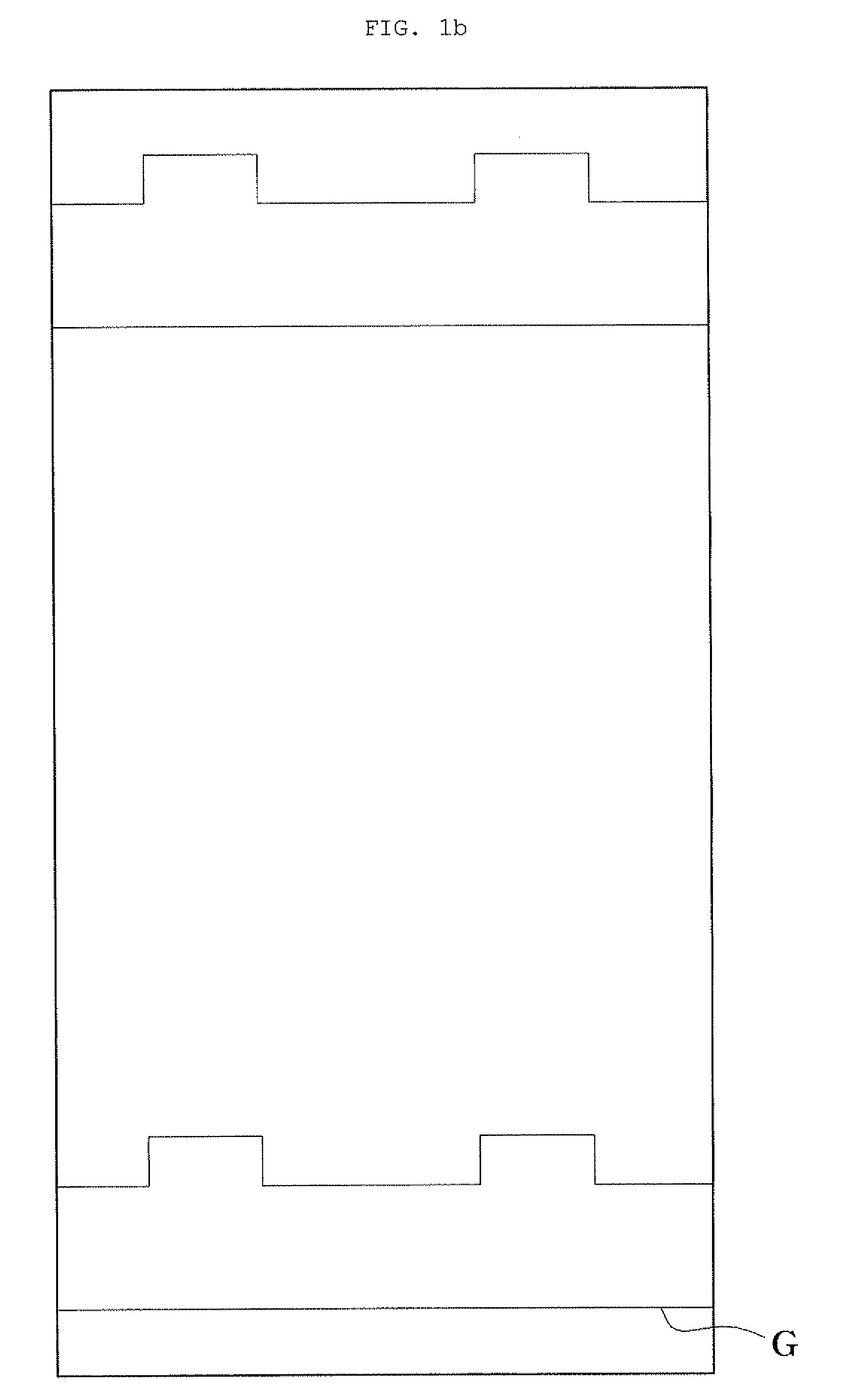

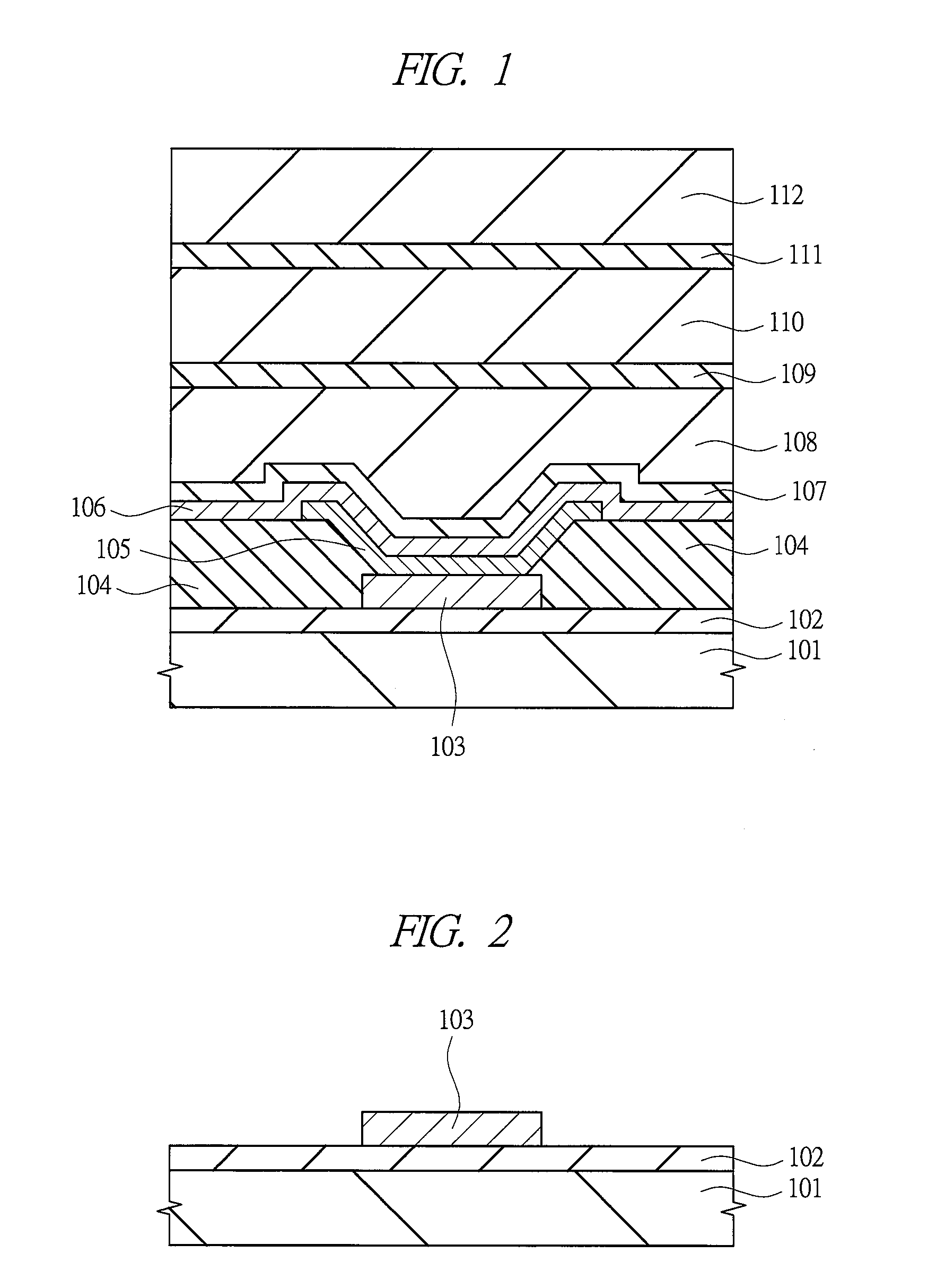

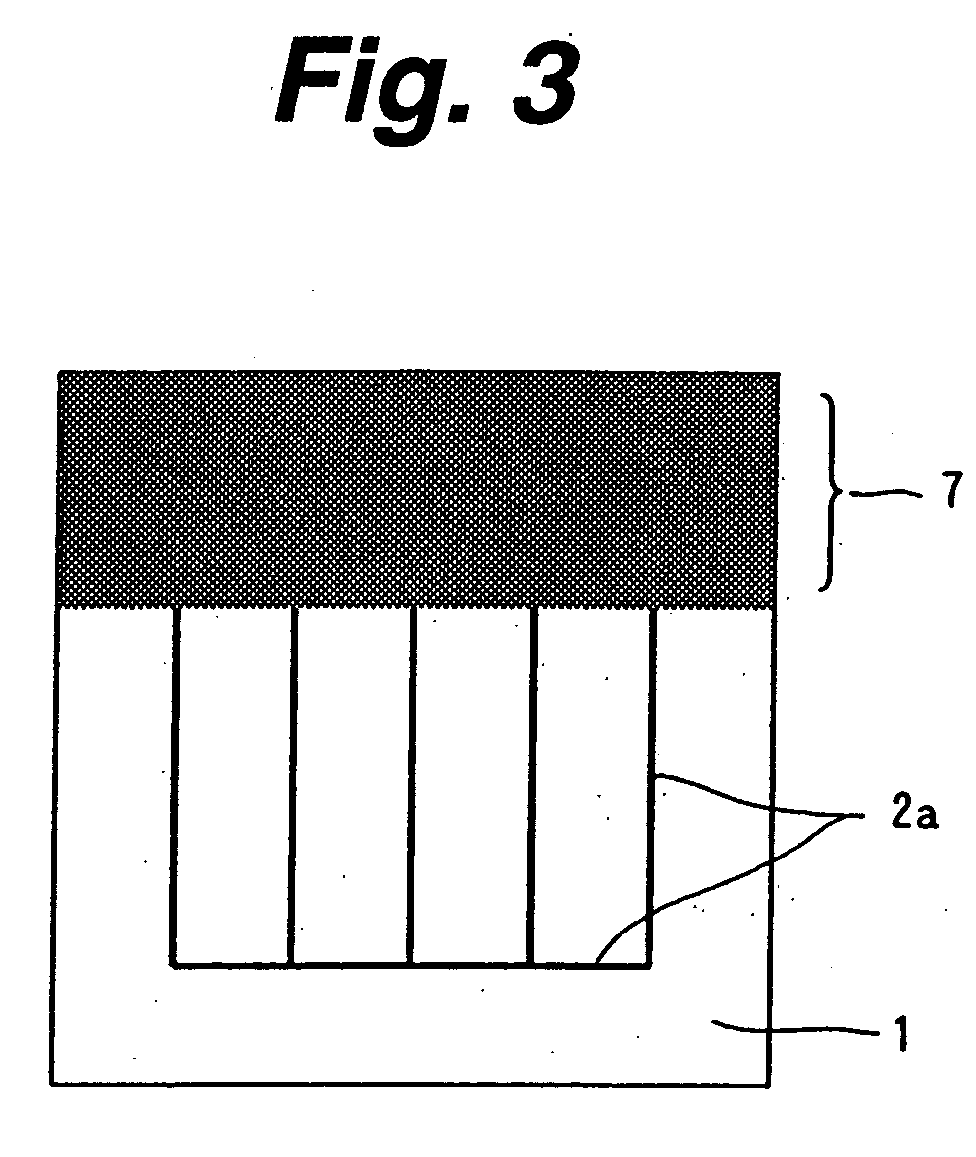

Fringe Field Switching Mode Liquid Crystal Display Device

ActiveUS20080186440A1Increase the aperture ratioAvoid light leakageNon-linear opticsLiquid-crystal displayTransmittance

Provided is a Fringe Field Switching (FFS) mode Liquid Crystal Display (LCD) In the FFS mode LCD, a lower substrate, an upper substrate and a liquid crystal layer interposed between the substrates are included, each pixel region is defined by gate lines and data lines formed to cross each other on the lower substrate, and switching devices are disposed at intersections of the gate lines and the data lines. The FFS mode LCD includes a transparent pixel electrode, and a transparent common electrode disposed apart from the transparent pixel electrode by an insulating layer interposed between the transparent pixel electrode and the transparent common electrode, in the pixel region to adjust transmittance by applying an electric field to the liquid crystal layer, the transparent common electrode has a plurality of bars having a predetermined width in a direction substantially parallel to the data lines, the transparent common electrode has a first bar formed to cover the data lines and a second bar formed adjacent to the first bar in a central area of the pixel region, a distance between the first bar and the second bar is larger than a distance between bars formed in the pixel region, and one end of the transparent pixel electrode is disposed between the first bar and the adjacent secondbar.

Owner:HYDIS TECH

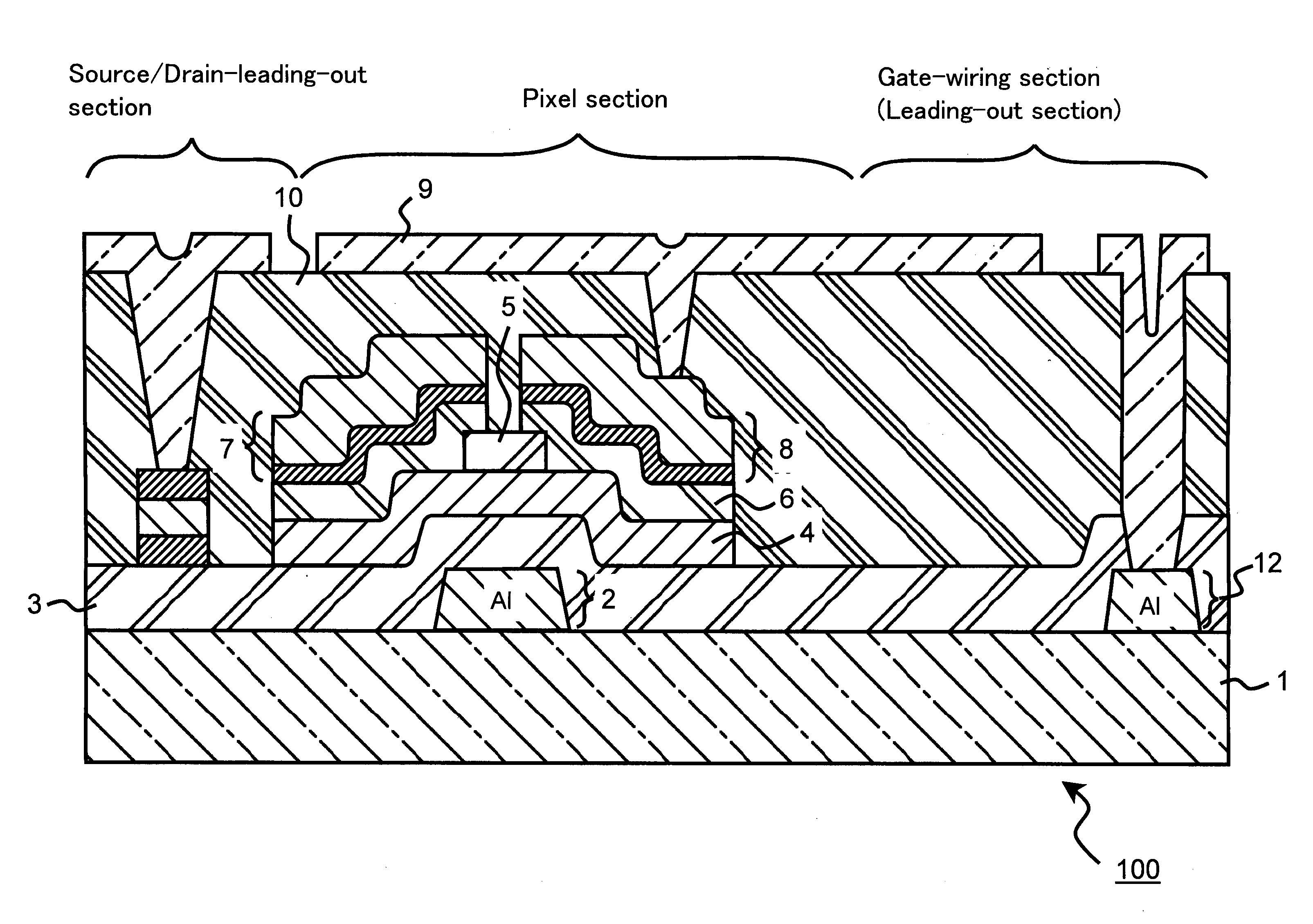

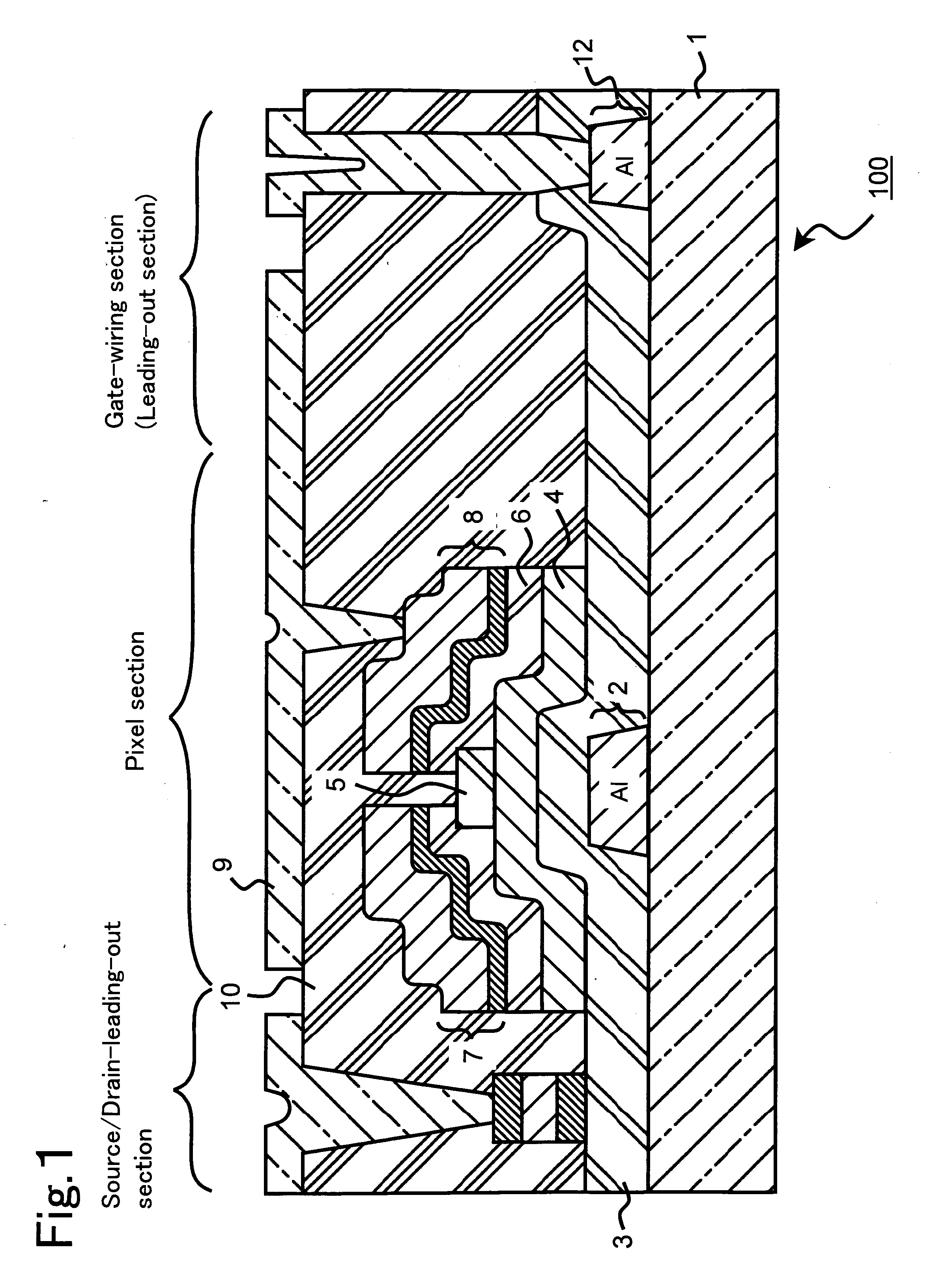

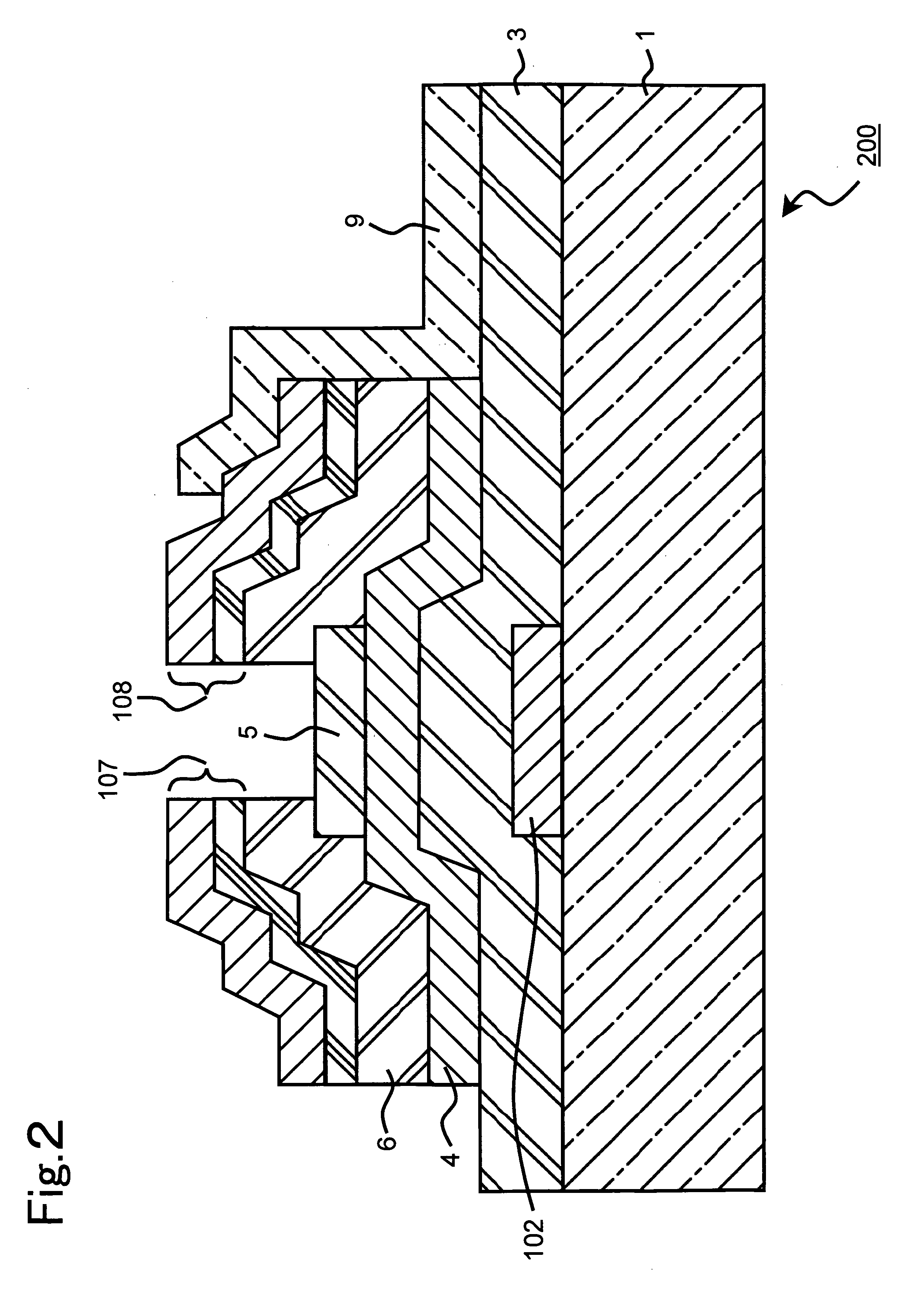

Thin film transistor, thin film transistor substrate, processes for producing the same, liquid crystal display using the same, and related devices and processes; and sputtering target, transparent electroconductive film formed by use of this,transparent electrode, and related devices and processes

InactiveUS20070170434A1Reduce light transmittanceConductive layers on insulating-supportsSemiconductor/solid-state device detailsIndiumLiquid-crystal display

Provided are a thin film transistor substrate having a transparent electroconductive film in which residues and so on resulting etching are hardly generated; a process for producing the same; and a liquid crystal display using this thin film transistor substrate. A thin film transistor substrate, comprising a transparent substrate, a source electrode formed over the transparent substrate, a drain electrode formed over the transparent substrate, and a transparent pixel electrode formed over the transparent substrate, wherein the transparent pixel electrode is a transparent electroconductive film which is made mainly of indium oxide, and further comprises one or two or more oxides selected from tungsten oxide, molybdenum oxide, nickel oxide and niobium oxide, and the transparent pixel electrode is electrically connected to the source electrode or the drain electrode; a process for producing the same; and a liquid crystal display using this thin film transistor substrate.

Owner:IDEMITSU KOSAN CO LTD

Photocatalytic composition and method for preventing algae growth on building materials

InactiveUS6881701B2Reduce light transmittanceLow UV transmittanceRoof covering using sealantsAlkali metal silicate coatingsBuilding materialMaterials science

The present invention provides a coating composition for substrates. The coating composition of the present invention generally includes a silicate binder and a plurality of photocatalytic particles. The silicate binder functions as a bonding agent to establish the coating on the substrate. A plurality of photocatalyst particles are dispersed throughout the silicate binder. The particles are included in an amount that provides sufficient distribution of the particles in the resulting coating. The incorporation of the present invention onto substrates prevents algal growth on building materials utilizing the coated substrates.

Owner:3M INNOVATIVE PROPERTIES CO

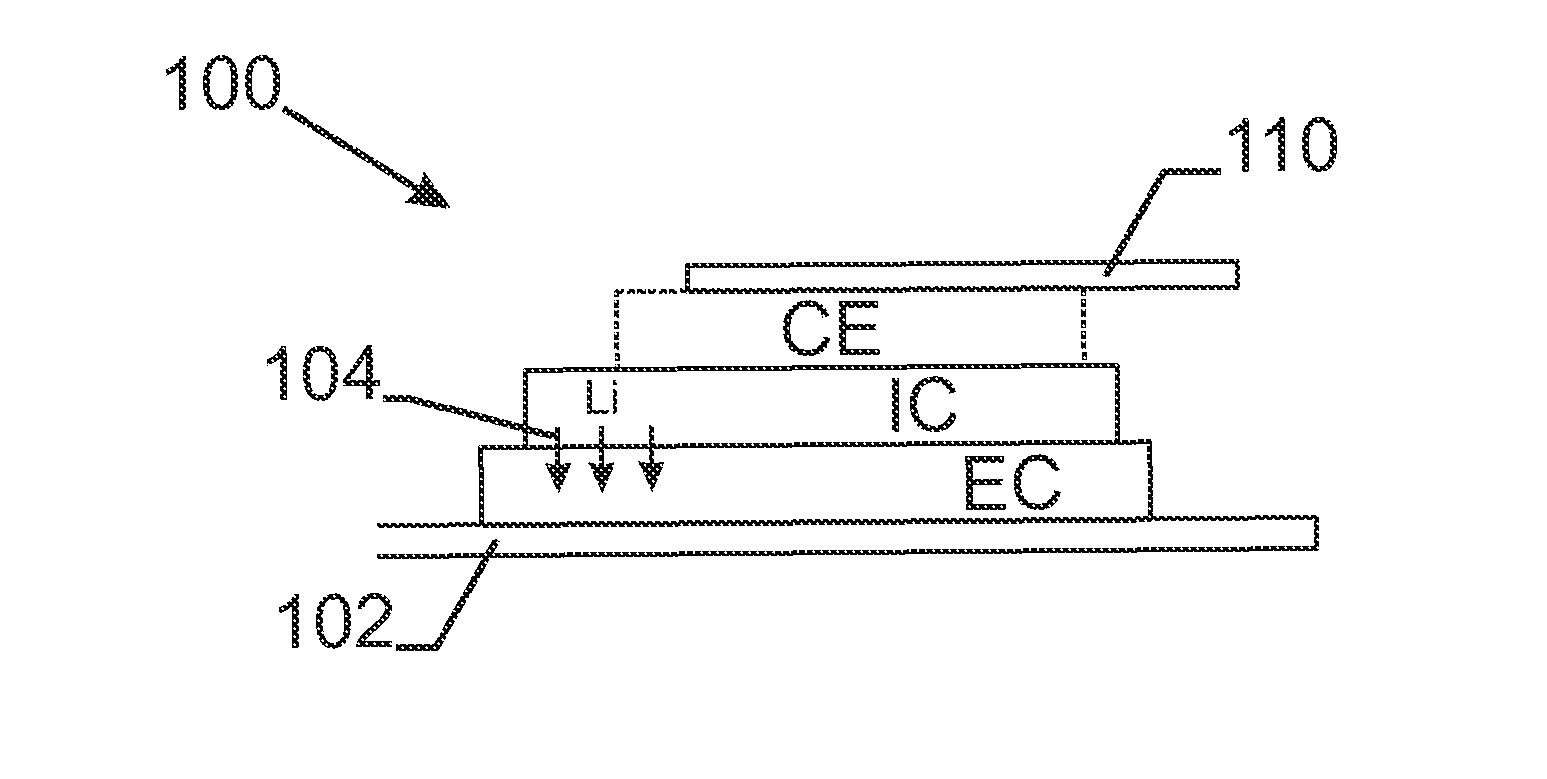

Method of making an ion-switching device without a separate lithiation step

InactiveUS7830585B2Efficient processingFaster ‘ doping ’ of the electrodeFinal product manufactureSecondary cellsLithiumSputtering

In any manufacturing sequence for making a lithium ion-switching device, lithium has to be introduced at some stage into the device. An electrode inside the device is filled and depleted with lithium through an ion conductor at every use cycle of the device. Prior-art methods to introduce the lithium are: direct sputtering of lithium on the electrode, or electrochemically loading the electrode in an electrochemical cell, or indirectly loading the electrode after an ion conductor has been deposited on top of the electrode and still other methods. The inventive method disclosed makes such a separate lithiation step obsolete. The lithium is introduced at the same time as the ion-conductor is put on the electrode. This can be achieved by using an oxygen super-stoichiometric compound for the electrode.

Owner:SAGE ELECTROCHROMICS

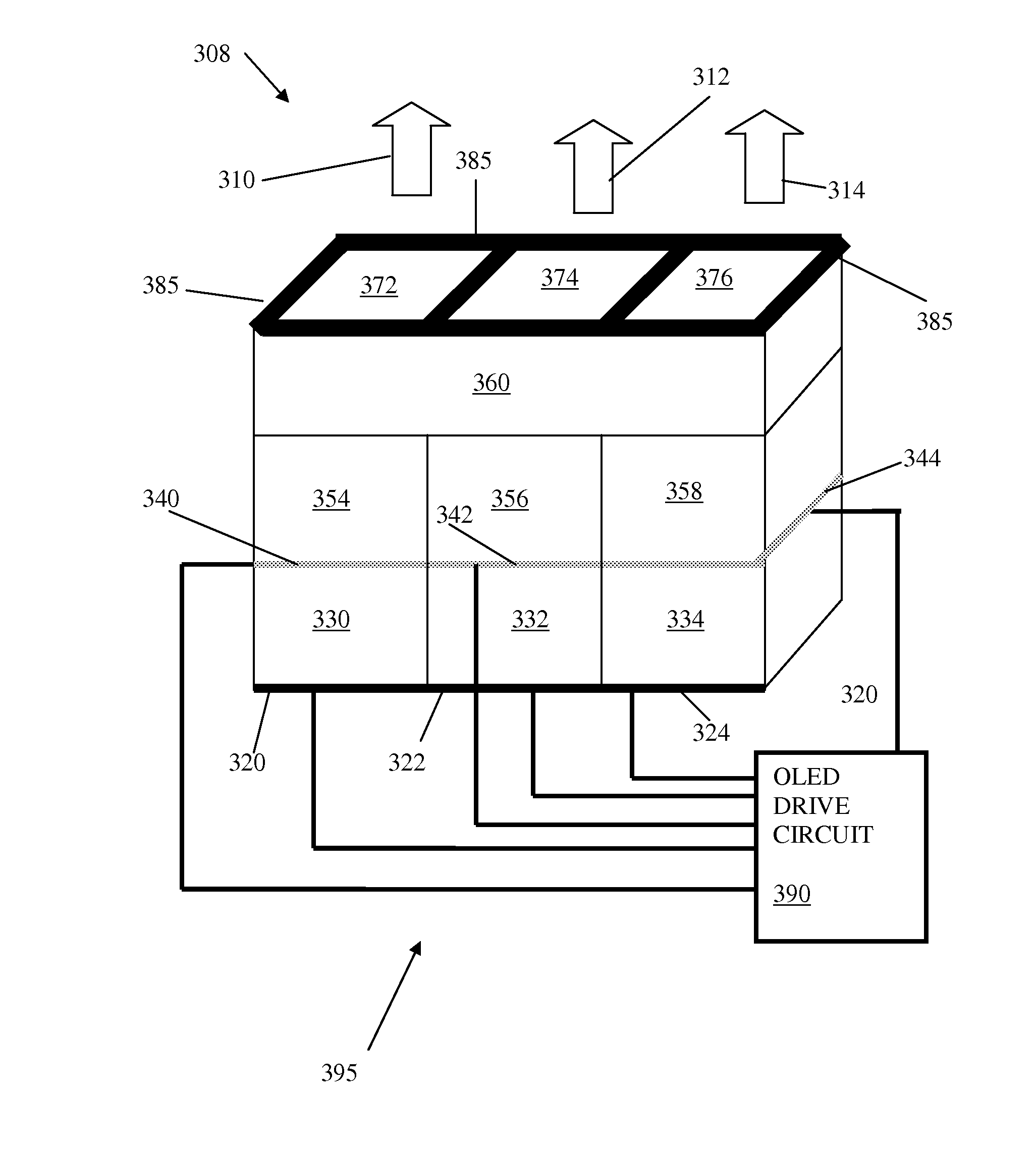

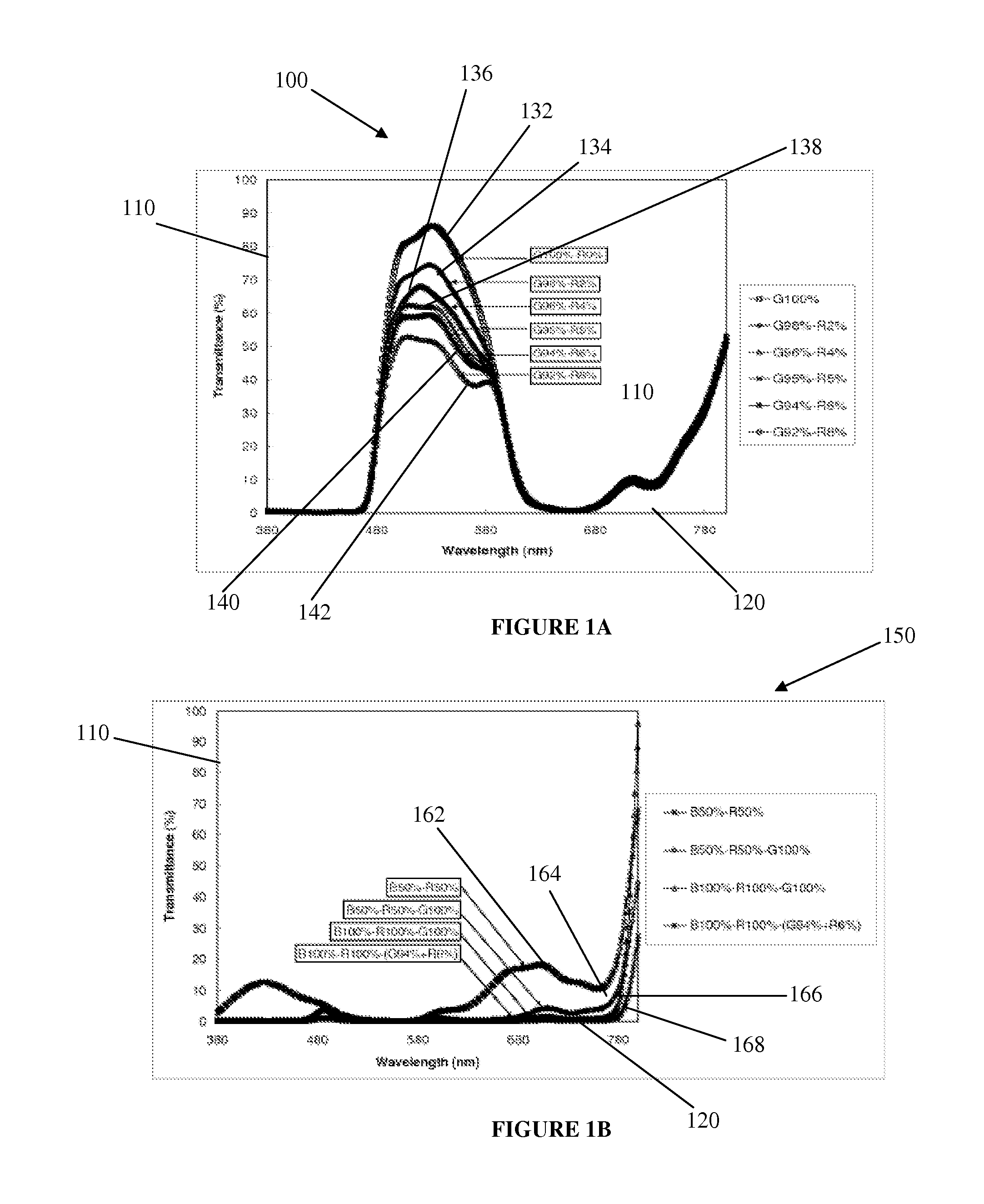

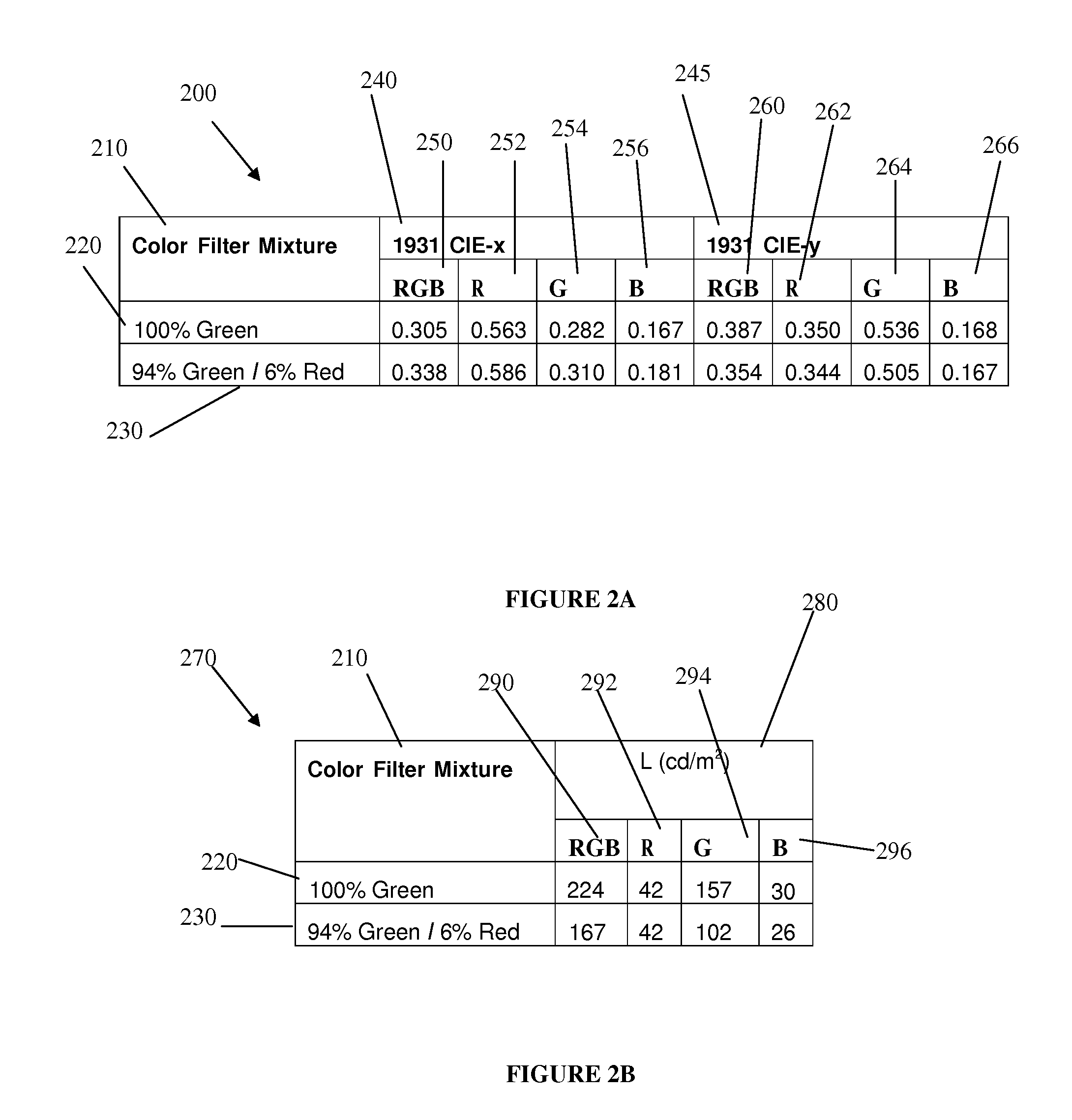

Method of tuning display chromaticity by mixing color filter materials and device having mixed color filter materials

ActiveUS20110316413A1Good white balanceReduce outputDischarge tube luminescnet screensLamp detailsDisplay deviceLight emitting device

A color display is provided that includes a light emitting sub-pixel and a filter layer including first and second color filter materials. The first color filter material is adapted to reduce transmittance of visible light outside a first transmittance spectrum corresponding to a first color, and the second color filter material is adapted to reduce transmittance of visible light outside a second transmittance spectrum corresponding to a second color. The second color is different than the first color. A color display having a white-balanced pixel is provided. A method of white-balancing a light emitting device is provided. A method of reducing unwanted light output due to electrical leakage is provided to fall below a pre-determined threshold. An opaque layer may be interposed between the sub-pixels and / or may frame illuminated areas of sub-pixels, and may be a combination of red, green, and / or a blue filter material.

Owner:EMAGIN CORP

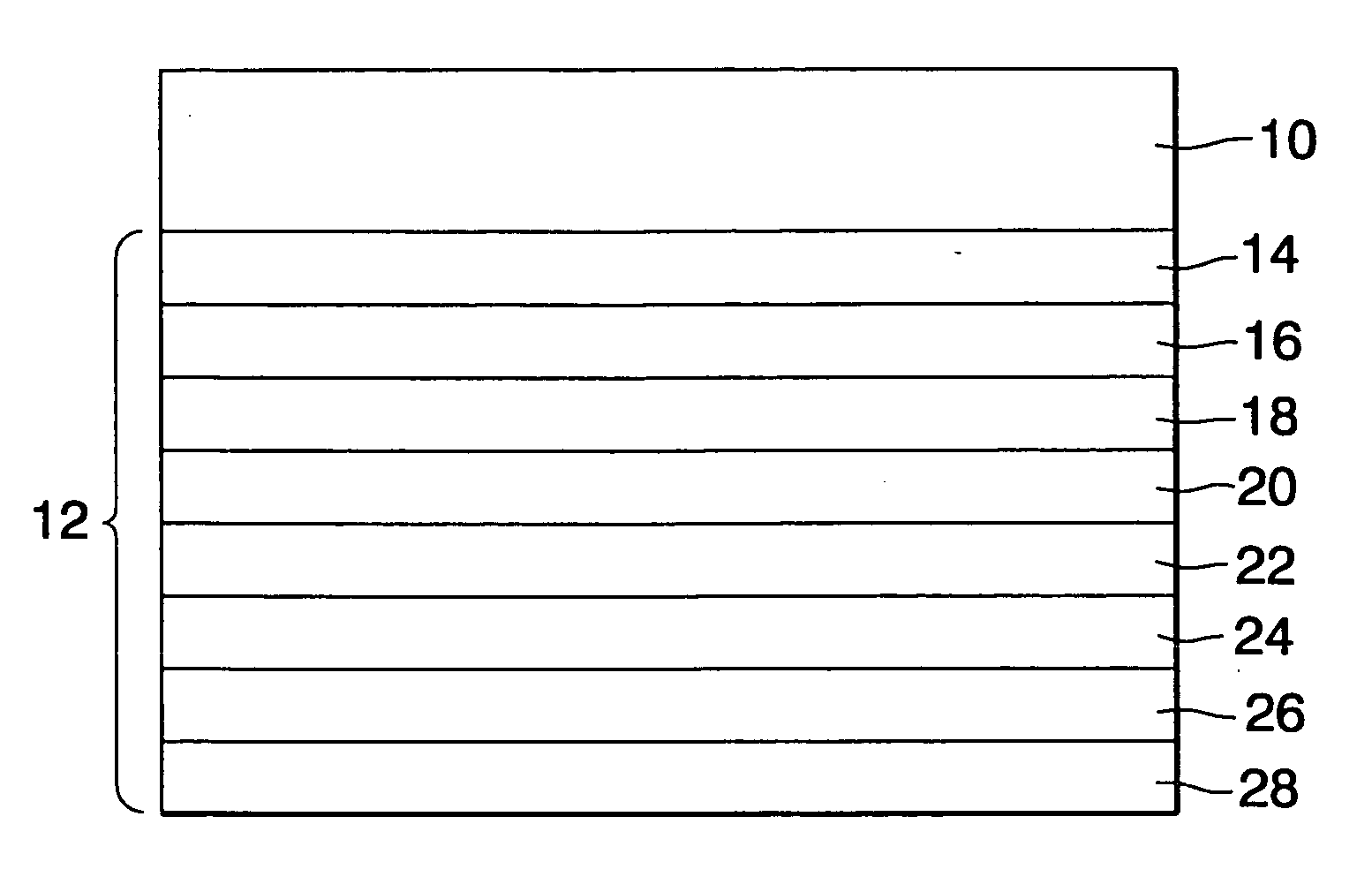

Low shading coefficient and low emissivity coatings and coated articles

InactiveUS20070009747A1Acceptable aestheticImprove reflectivityGlass/slag layered productsCoatingsOrganic filmLow emissivity

The present invention is directed to a low emissivity, low shading coefficient, multi-layer coating and coated article having a luminous transmission of less than about 70 percent, a shading coefficient less than about 0.44 and a solar heat gain coefficient of less than about 0.38 and a ratio of luminous transmittance to solar heat gain coefficient of greater than about 1.85. The coated article, e.g. an IG unit, has a substrate with at least one antireflective layer deposited over the substrate. At least one infrared reflective layer is deposited over the antireflective layer and at least one primer layer is deposited over the infrared reflective layer. Optionally a second antireflective layer is deposited over the first primer layer and optionally a second infrared reflective layer is deposited over the second antireflective layer. Optionally a second primer layer is deposited over the second infrared reflective layer and optionally a third antireflective layer is deposited over the second primer layer, such that the coated article can have the aforementioned optical properties. Also an optional protective overcoat, e.g. an oxide or oxynitride of titanium or silicon, and / or solvent soluble organic film former may be deposited over the uppermost antireflective layer.

Owner:PPG IND OHIO INC

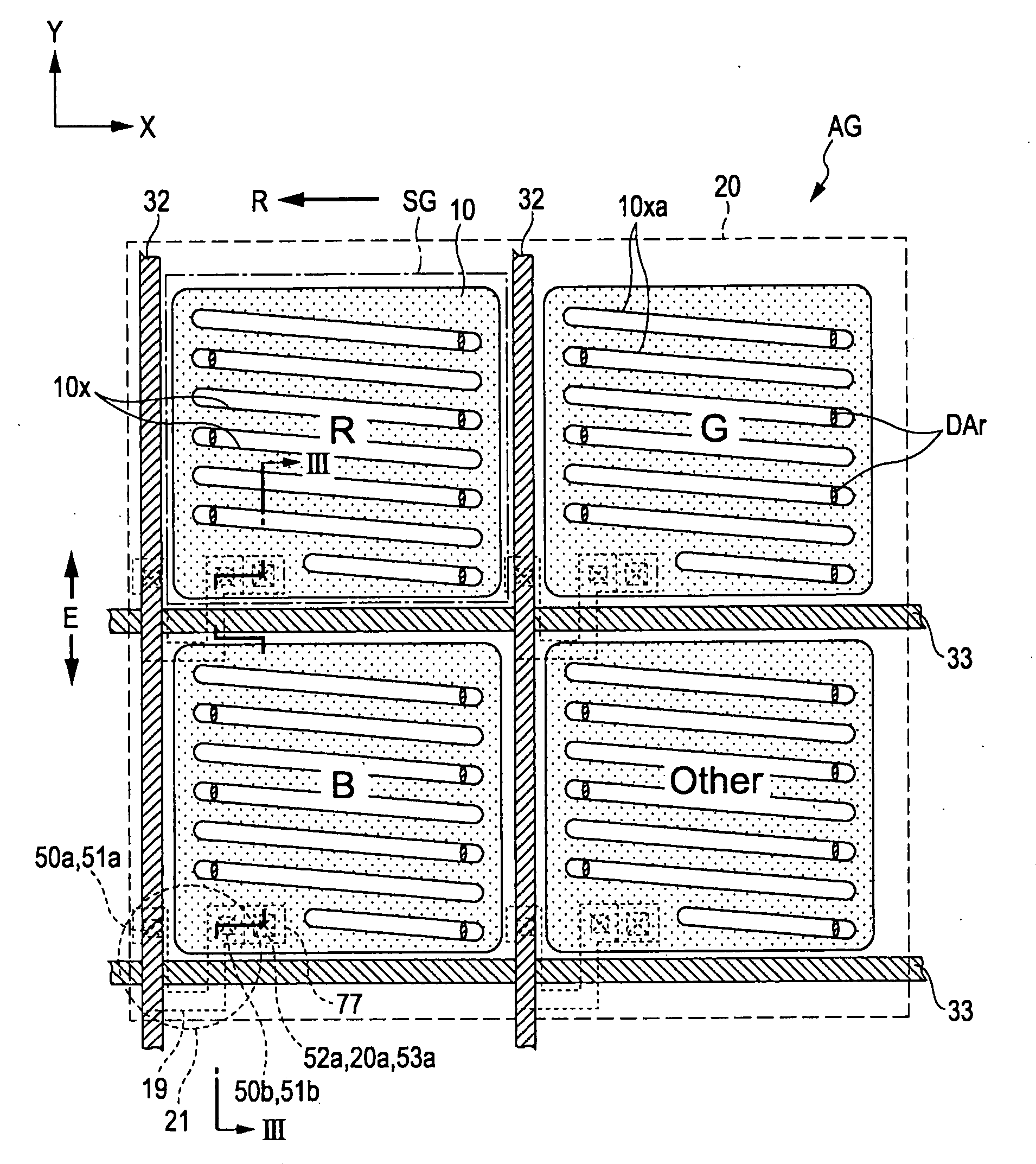

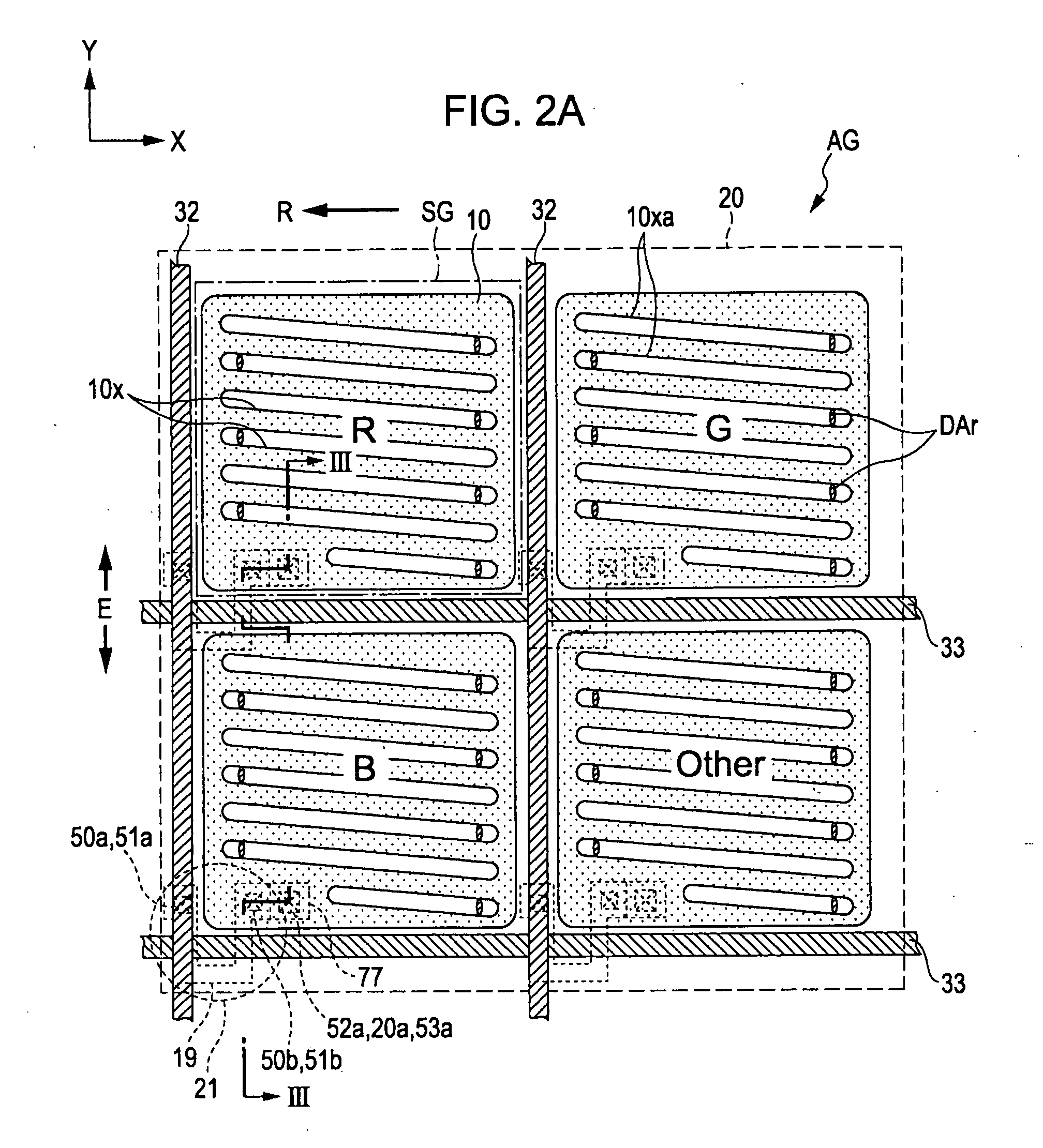

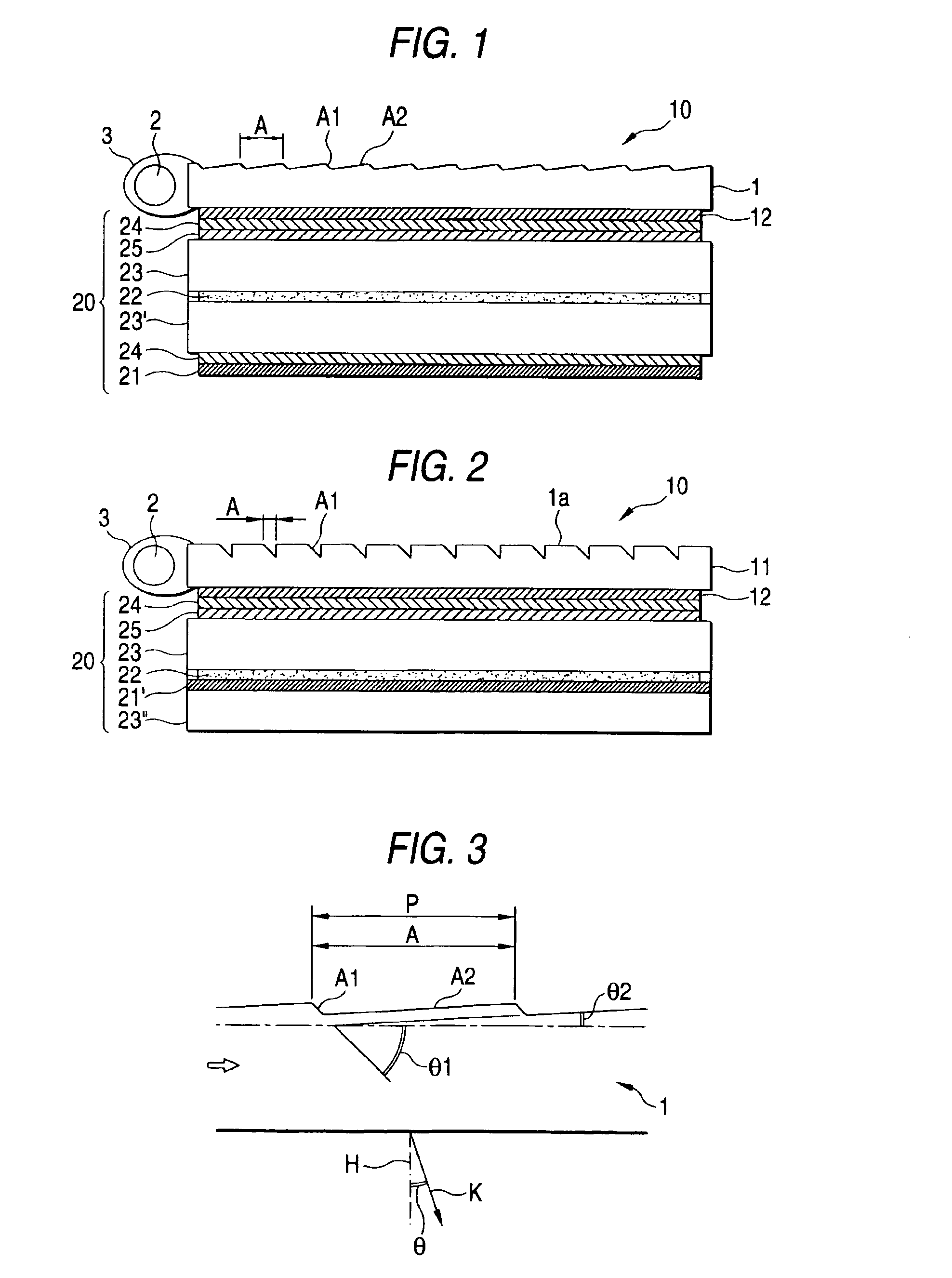

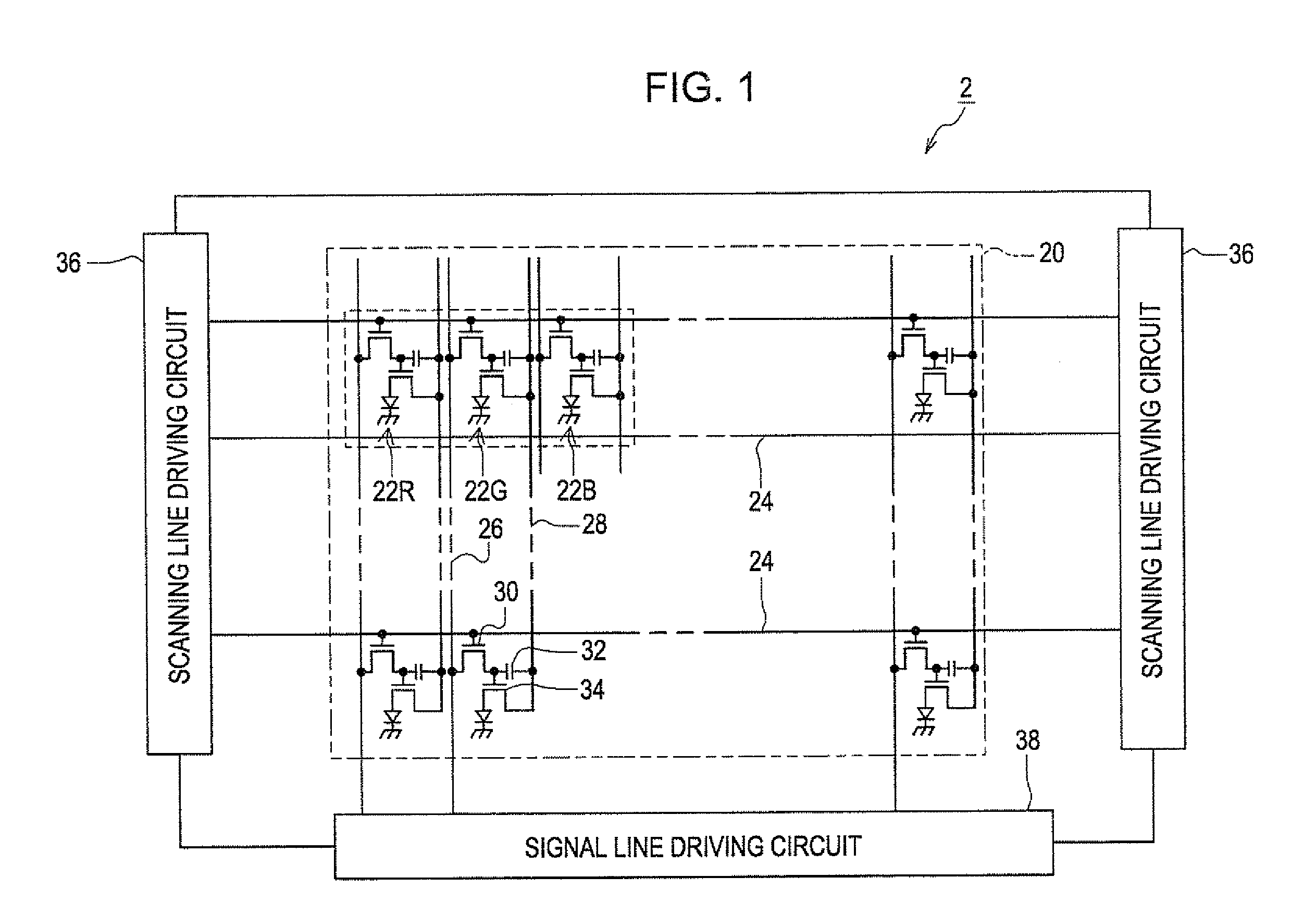

Liquid crystal device and electronics apparatus

ActiveUS20070229748A1Reduce numberReduction in transmittanceNon-linear opticsElectric fieldElectronics

A liquid crystal device includes a substrate having unit pixels, each of which includes a plurality of subpixels arranged in a plurality of rows and a plurality of columns. The substrate includes switching elements, a first insulating film disposed at least on the switching elements, a first transparent electrode disposed on the first insulating film, a second transparent electrode disposed on the second insulating film, having a plurality of slits corresponding to each one of the subpixels, and generating an electric field through the slits between the first and second transparent electrodes. The direction in which a long side of each of the slits extends is defined to be different from the direction in which the columns extend.

Owner:JAPAN DISPLAY WEST

Coating for one or more display areas on a glass or glass-ceramic plate, process for producing said coating, and uses thereof

ActiveUS20100219176A1High surface resistancePrevent electrical conductivityDoors for stoves/rangesDomestic stoves or rangesSol-gelMedicine

The transparent coating for one or more display areas of a glass or glass-ceramic plate is made by a process using a sol-gel paint containing alkyl silicates as binding agents. The transparent coating is provided on areas of the glass or glass-ceramic plate that have been left uncoated by a color-imparting opaque coating and is formed by applying the sol-gel paint to the areas left open and then thermally treating the sol-gel paint so as to cross-link reactive groups of the alkyl silicates. The coating has organic, non-hydrolyzable groups bound directly to silicon. A process for making the coating and the uses of the coated glass or glass-ceramic plate are part of the invention.

Owner:SCHOTT AG

Optical semiconductor device and manufacturing method thereof

InactiveUS20120248422A1Reduce reflectivityLight extraction efficiency can be improvedElectroluminescent light sourcesSolid-state devicesRemote plasmaDevice material

In a device having an anode electrode, an organic EL layer, and a cathode electrode formed on a substrate in this order from a main surface side of the substrate, and an encapsulating film provided on the substrate so as to cover the emission layer, the encapsulating film includes a laminated film obtained by alternately laminating buffer films serving as flattening films and barrier films having high moisture barrier property, and the flattening film and the barrier film include a silicon oxynitride film. In the manufacturing process of the device, the buffer film including silicon oxynitride is formed by an optical CVD method using vacuum ultraviolet light, and in this process, radical irradiation by remote plasma is performed during the irradiation of the vacuum ultraviolet light.

Owner:HITACHI HIGH-TECH CORP +1

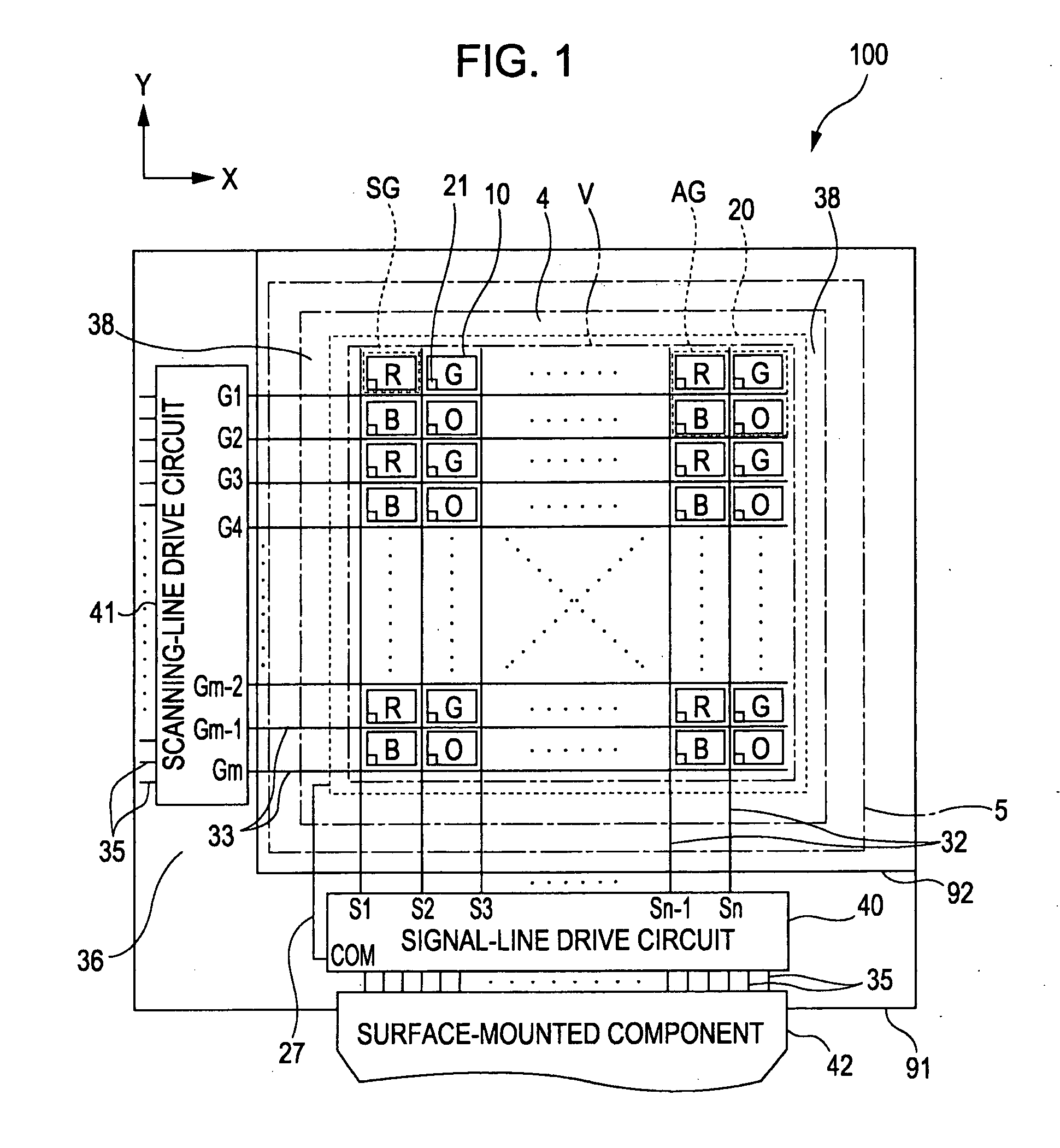

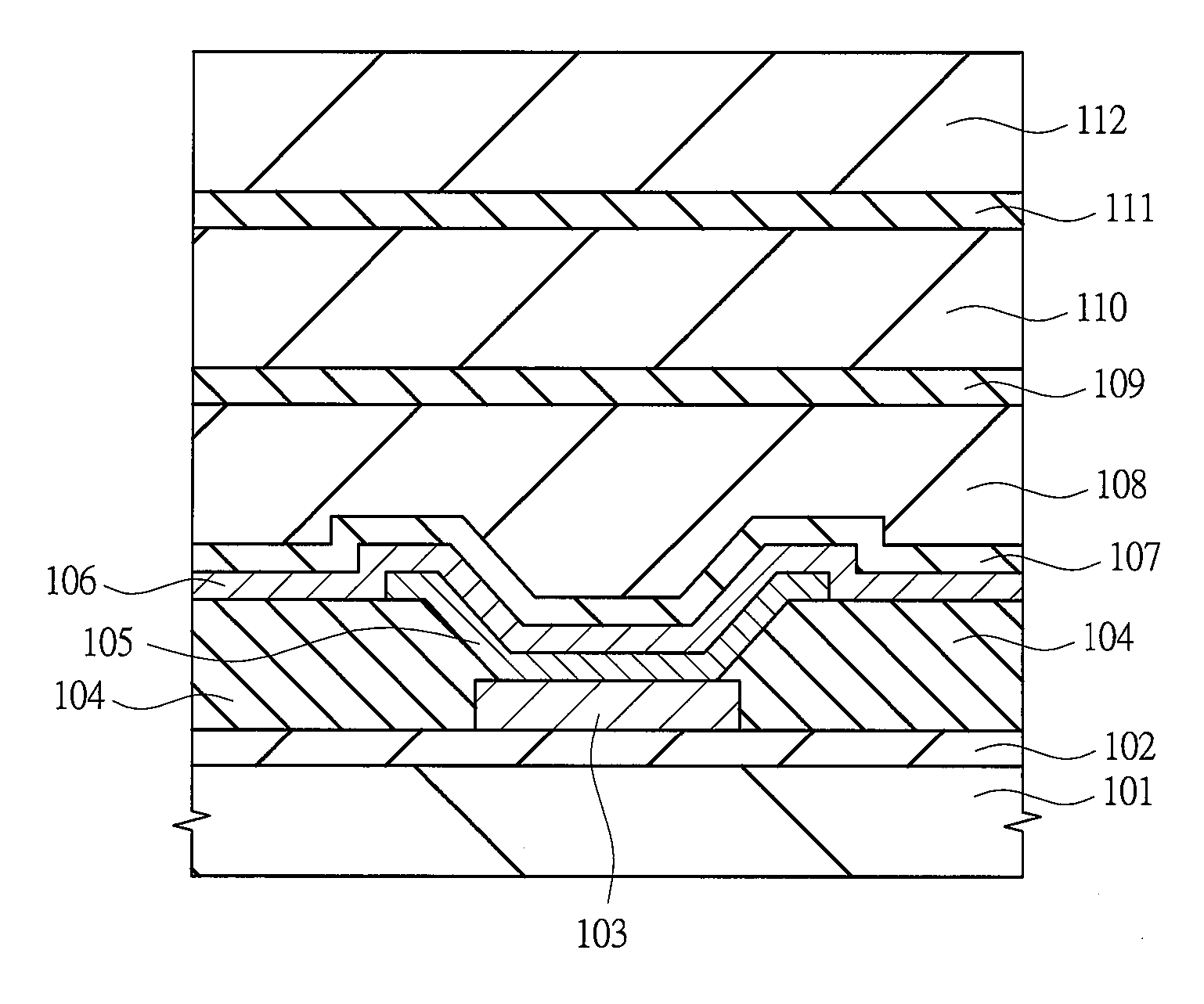

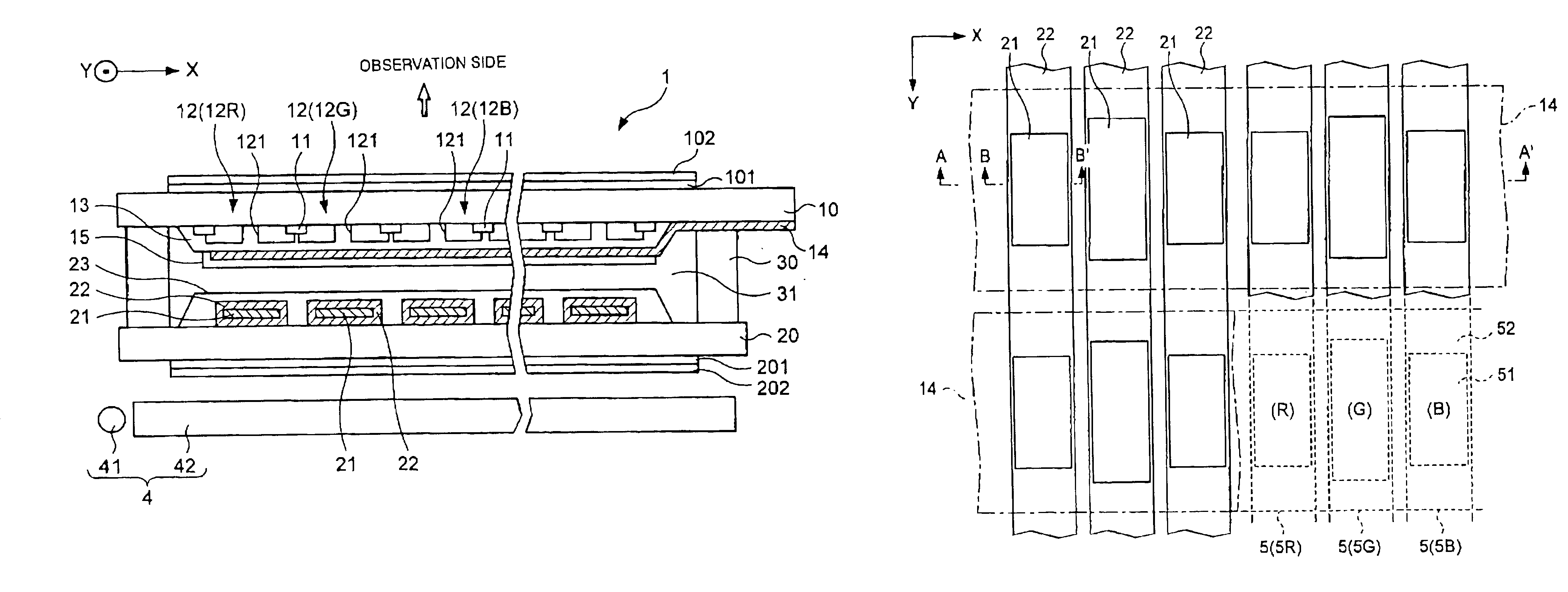

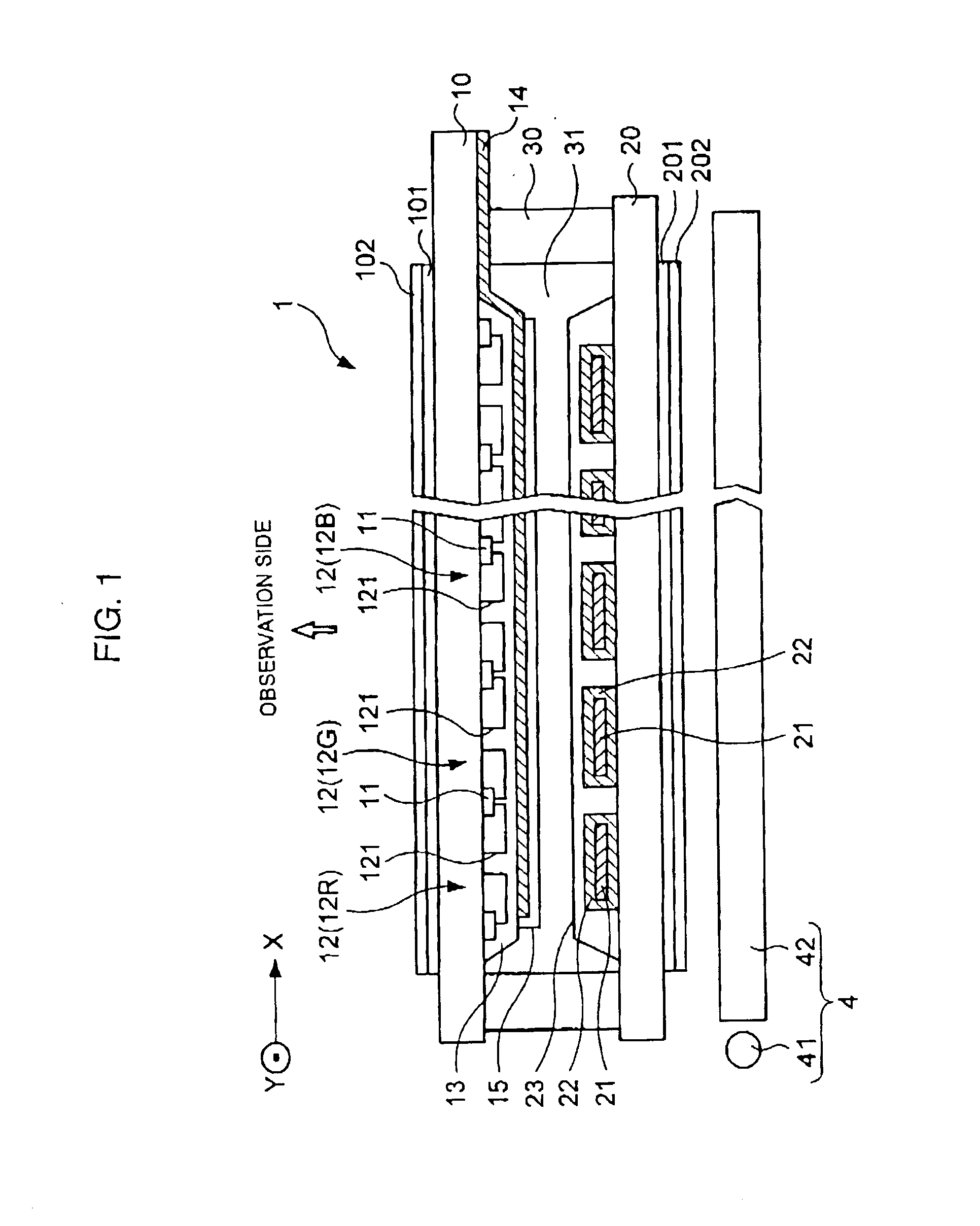

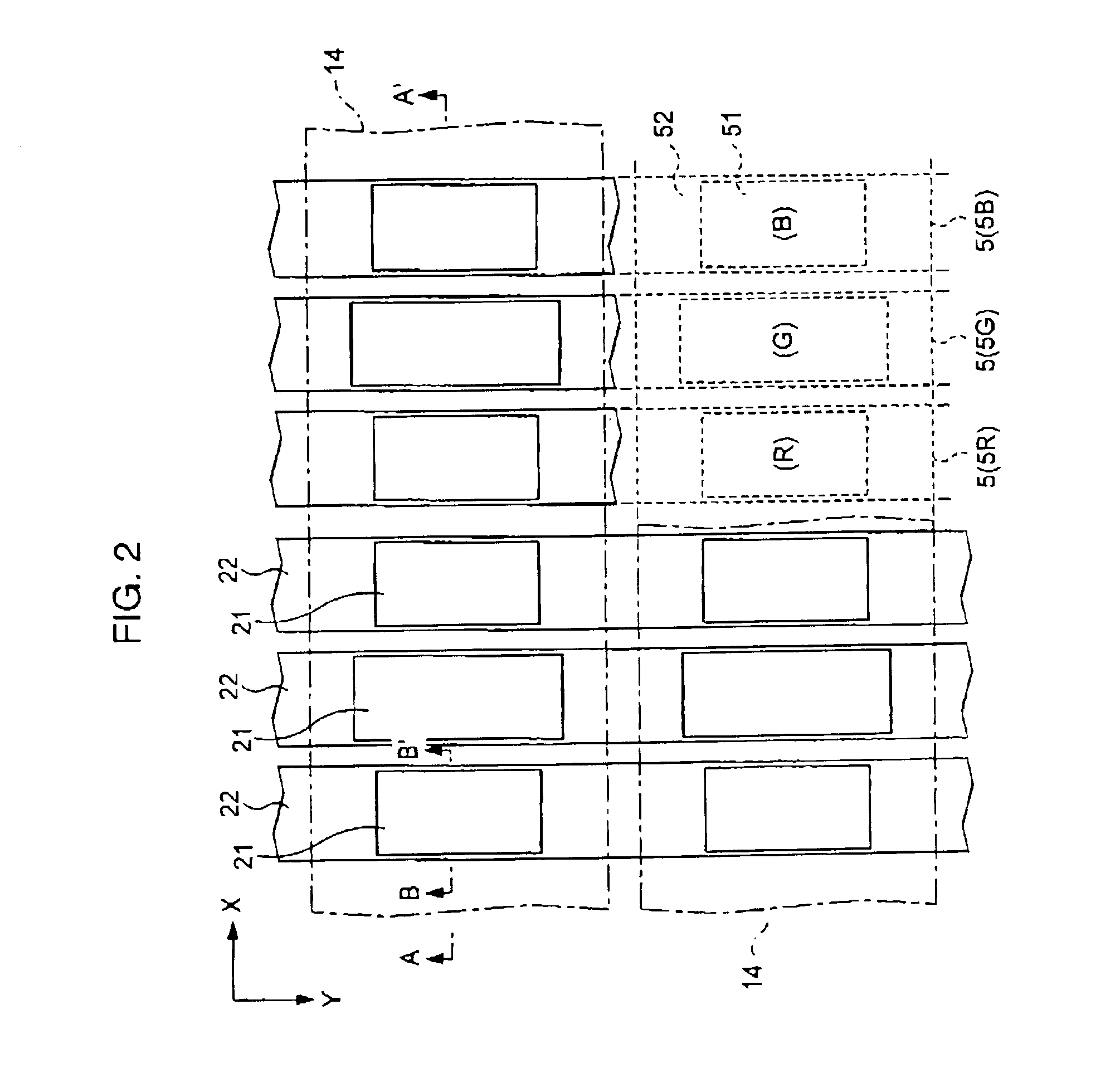

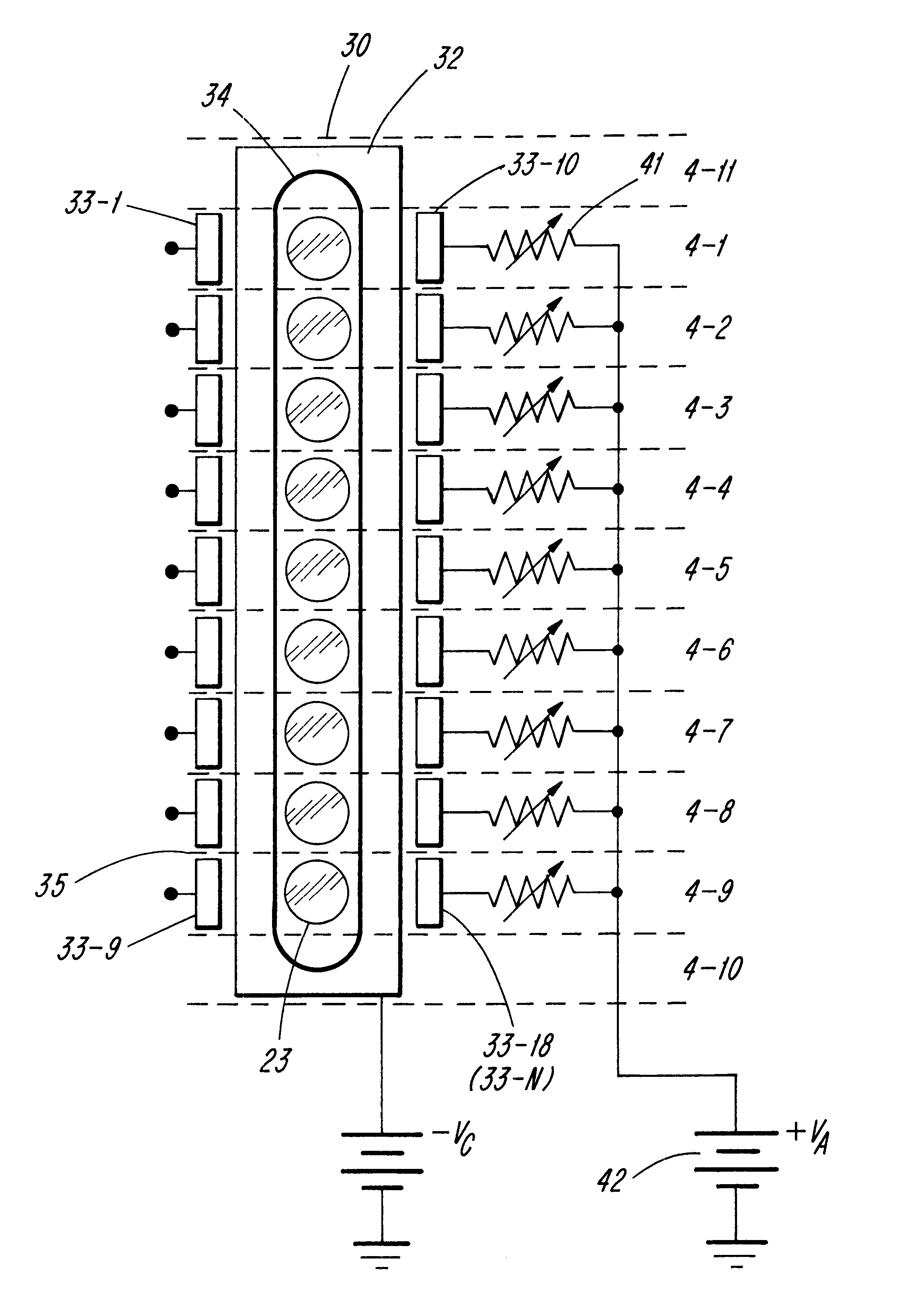

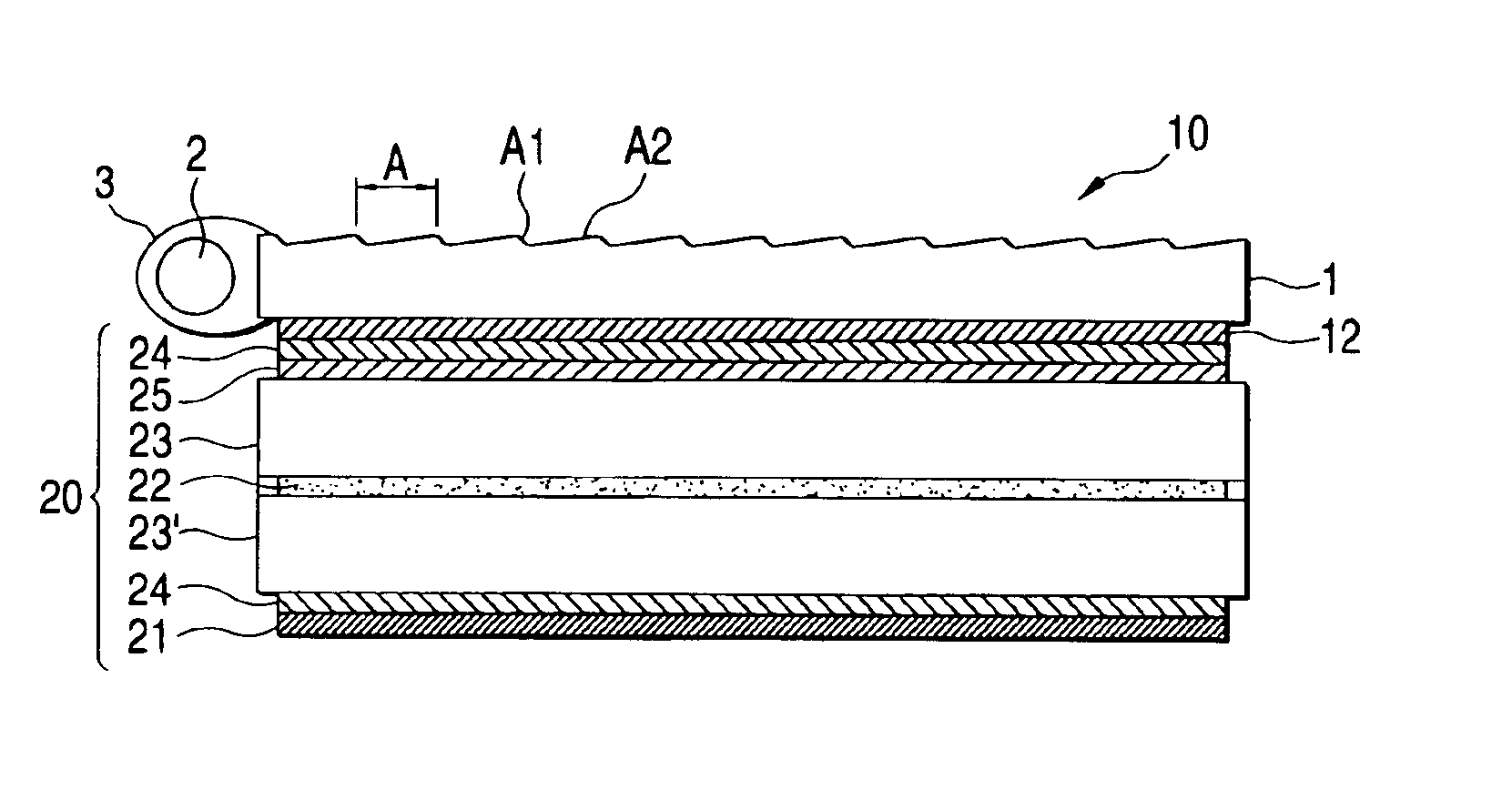

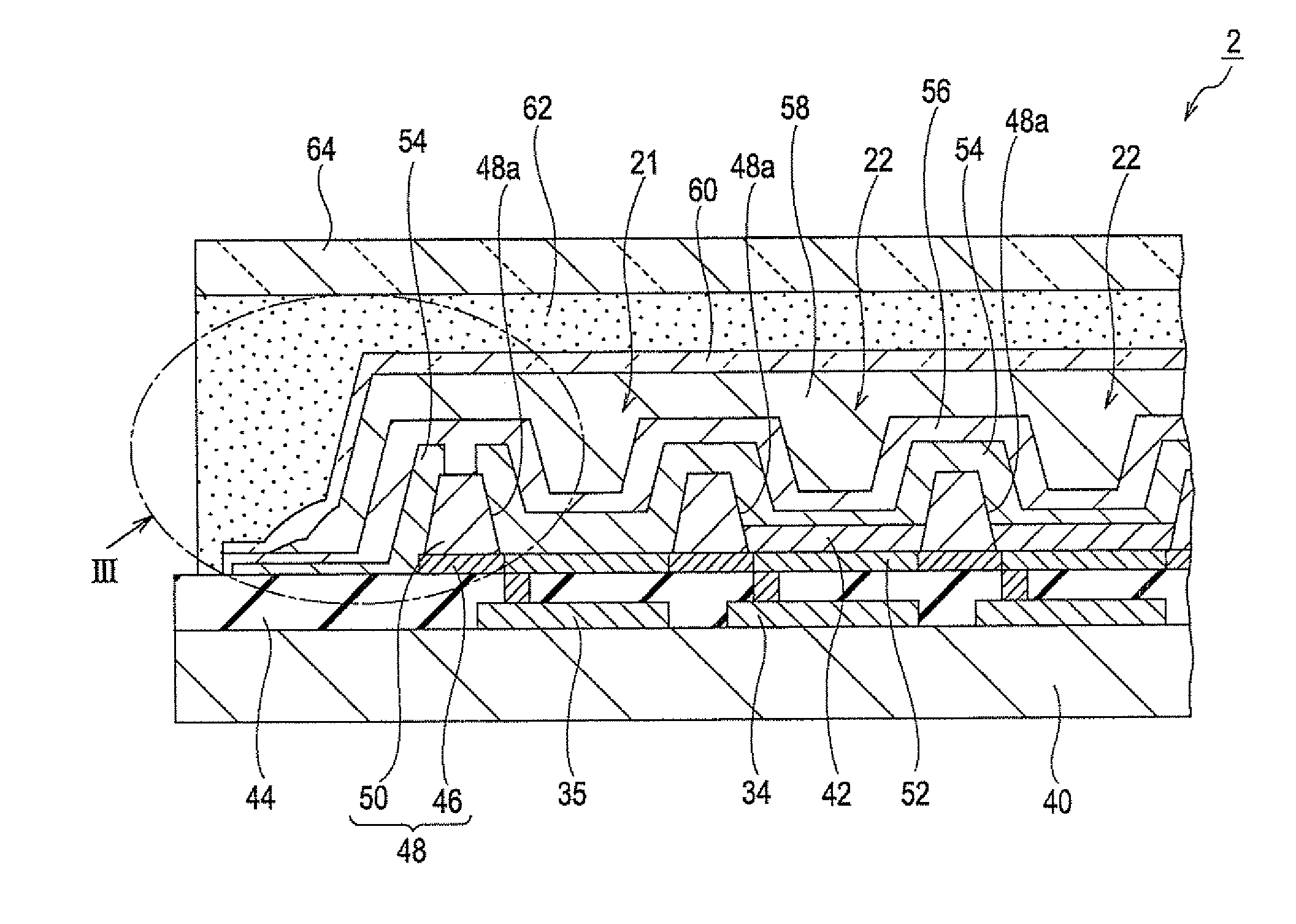

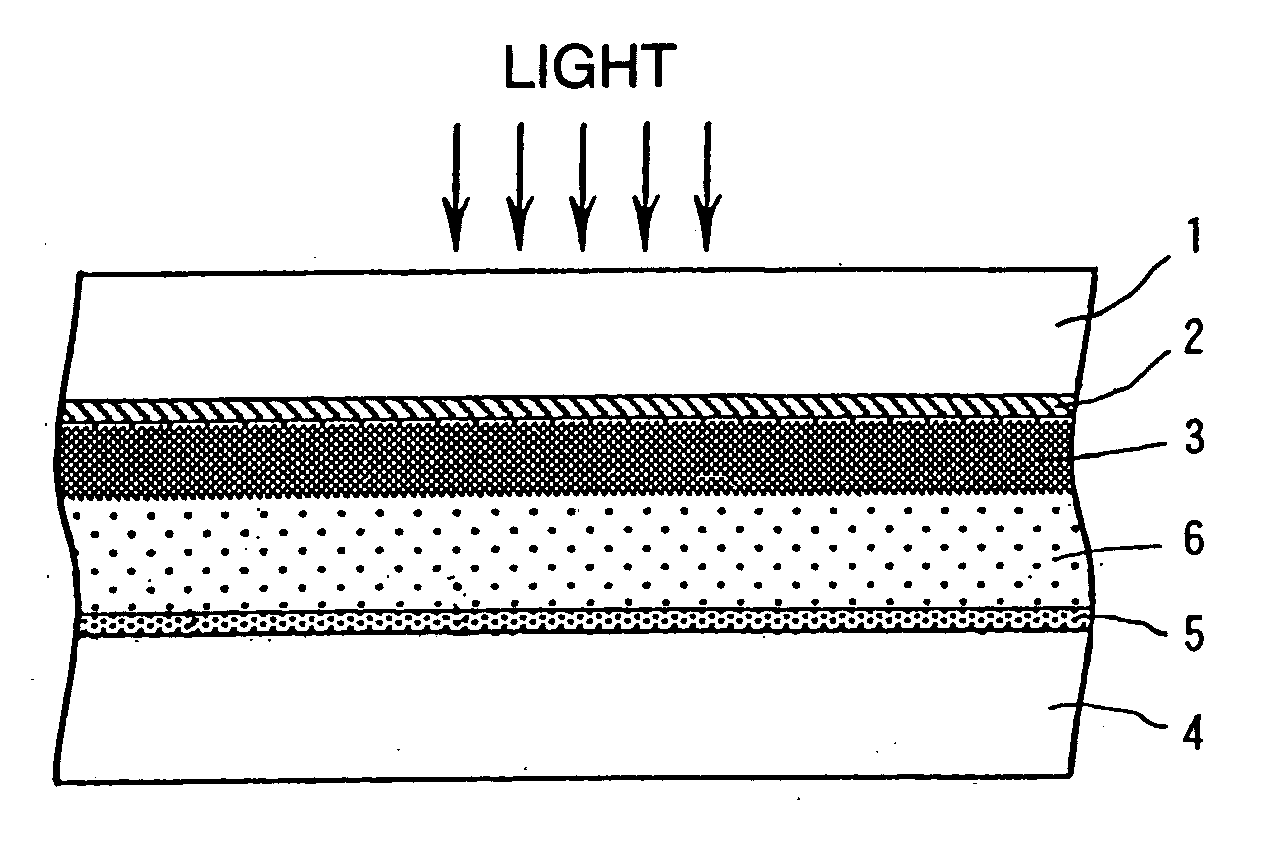

Liquid crystal display device, substrate assembly for liquid crystal display device, and electronic apparatus

InactiveUS20030122998A1Reduce light transmittanceAdd display modeSolid-state devicesOriginals for photomechanical treatmentLiquid-crystal displayLiquid crystal

A transflective color liquid crystal display device in which fine colors can be displayed in both a reflective display mode and a transmissive display mode. The transflective liquid crystal display device comprises a pair of substrates; a liquid crystal layer between the pair of substrates; reflective films are provided on an internal surface of a lower substrate which reflects light incident from an upper substrate; color filters provided above the reflective films, each containing a plurality of color layers which have different colors and are disposed to correspond to dots forming a display region; and lighting means provided at the outer surface side of the lower substrate. The dots have a reflective region in which the reflective film is present and a transmissive region in which the reflective film is not present. In addition, the color filters have opening portions in regions that overlap the reflective film in each dot.

Owner:138 EAST LCD ADVANCEMENTS LTD

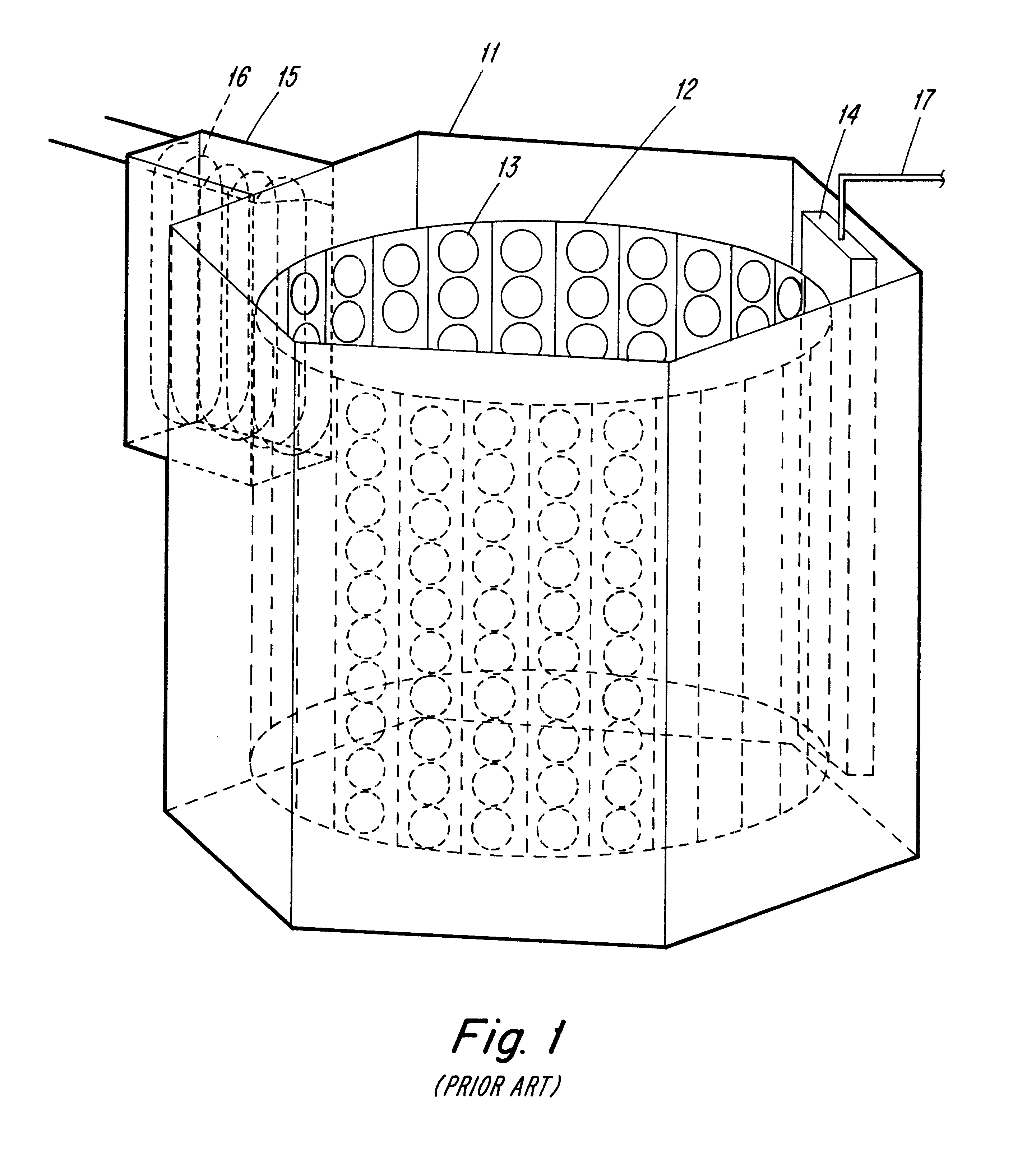

Multi-anode device and methods for sputter deposition

InactiveUS6440280B1Good lookingImprove transmittanceCellsElectric discharge tubesEngineeringSputter deposition

A method and apparatus for vacuum coating plural articles employs a drum work holder configuration and a sputter source with a plurality of individually controlled anodes for effectively providing uniform coatings on articles disposed at different locations on the drum work holder. A small number of measured process parameters are used to control a small number of process variable to improve coating uniformity from batch to batch.

Owner:SOLA INTERNATIONAL INC

Reflective liquid crystal display

InactiveUS6866393B2Avoid changeExcellent in the visual recognition (or visibility)Show cabinetsMechanical apparatusLiquid-crystal displayLight pipe

A reflective liquid crystal display (LCD) is constituted by a light pipe which emits incident light from an incident side from the other surface of its upper and lower surfaces through light emitting means formed on the one of them, a plane light source device with a light source arranged on one or more sides of the light pipe, and a liquid crystal display (LCD) panel having a reflective layer. The light emitting side of the plane light source device and the visual recognition side of the LCD panel are bonded to each other through an adhesive layer having a refractive index lower than that of the light pipe.

Owner:NITTO DENKO CORP

Water-proof sound-transmitting membrane, method for producing the water-proof sound-transmitting membrane, and electrical appliance including the water-proof sound-transmitting membrane

ActiveUS20110143114A1Lose waterproofnessWater leakage and rupture of the membrane startBaby linensUndergarmentsVolumetric Mass DensityMaterials science

The present invention provides a water-proof sound-transmitting membrane including a polytetrafluoroethylene (PTFE) porous membrane, in which the waterproofness is enhanced further with little lowering of the sound transmittance. The water-proof sound-transmitting membrane includes the PTFE porous membrane. The PTFE porous membrane includes a first porous layer, and a second porous layer stacked on and integrated with the first porous layer by a binding force acting between PTFE matrices. The first porous layer and the second porous layer each are composed of PTFE with a number-average molecular weight of 5.0×107 or more determined by a standard specific gravity method. At least one layer selected from the first porous layer and the second porous layer has an average pore diameter of 1 μm or less. The water-proof sound-transmitting membrane has a surface density of 1 g / m2 to 10 g / m2.

Owner:NITTO DENKO CORP

Plastic body having low thermal conductivity, high light transmission and a capacity for absorption in the near-infrared region

InactiveUS20040191485A1Reduce total energy transmittanceHigh selectivity coefficientSynthetic resin layered productsLaminationTransmittanceEngineering

A plastic body including a base molded body produced from a transparent, thermoplastic base material, and that includes at least two opposing flat layers interconnected by vertical or diagonal connecting elements. One of the flat layers is provided with an additional layer of a plastic matrix in a transparent, plastic base material. The additional layer is an IR-absorbent layer containing at least one IR-absorber that does not impair transparency of the plastic body and has an average transmission of less than 80% in the region of the near-infrared radiation (780 nm to 1100 nm). The plastic body has a light transmission of between 15% and 86%, a maximum heat transition coefficient of 4 W / m2K and a minimum Sk value of 1.15. The plastic body can be used, e.g., as a glazing element, a roofing element, a heat insulating element.

Owner:ROEHM GMBH & CO KG

Organic electroluminescence device

InactiveUS20100253215A1Overcome disadvantagesAvoid structureDischarge tube luminescnet screensLamp detailsOrganic electroluminescenceEngineering

An organic electroluminescence device includes on a substrate a plurality of first electrodes, a partition structure having a plurality of openings corresponding to the positions of the first electrodes, an organic luminescent layer, a second electrode covering the partition structure and the organic luminescent layer, and a sealing layer or a sealing member covering the second electrode. The second electrode includes a first portion and a second portion that are separate from each other. The first portion covers the entire partition structure except the outer portion from the edge of the partition structure, and the organic luminescent layer. The second portion covers the outer portion from the edge of the partition structure and at least part of the external region around the partition structure.

Owner:SEIKO EPSON CORP

Gaming machine

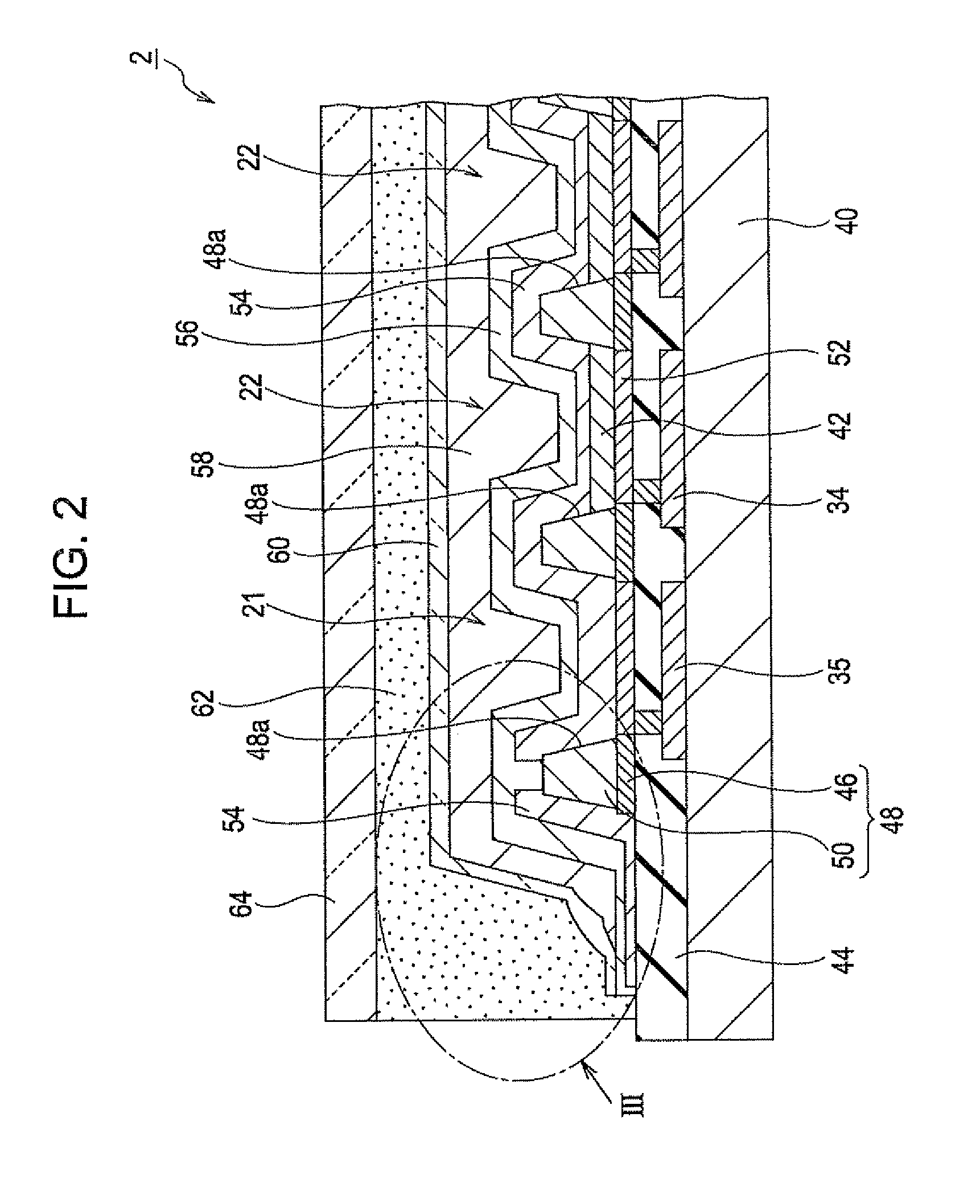

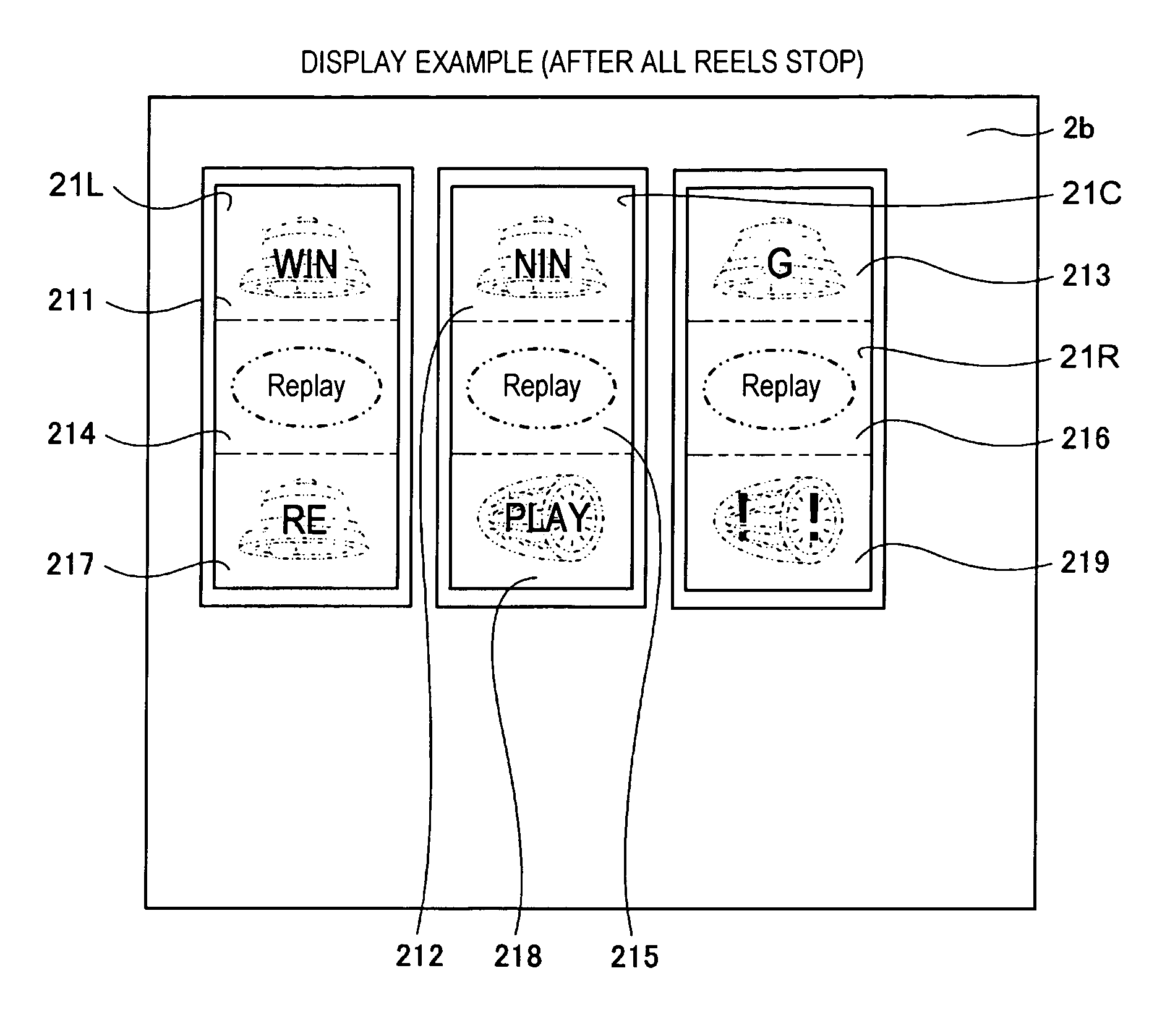

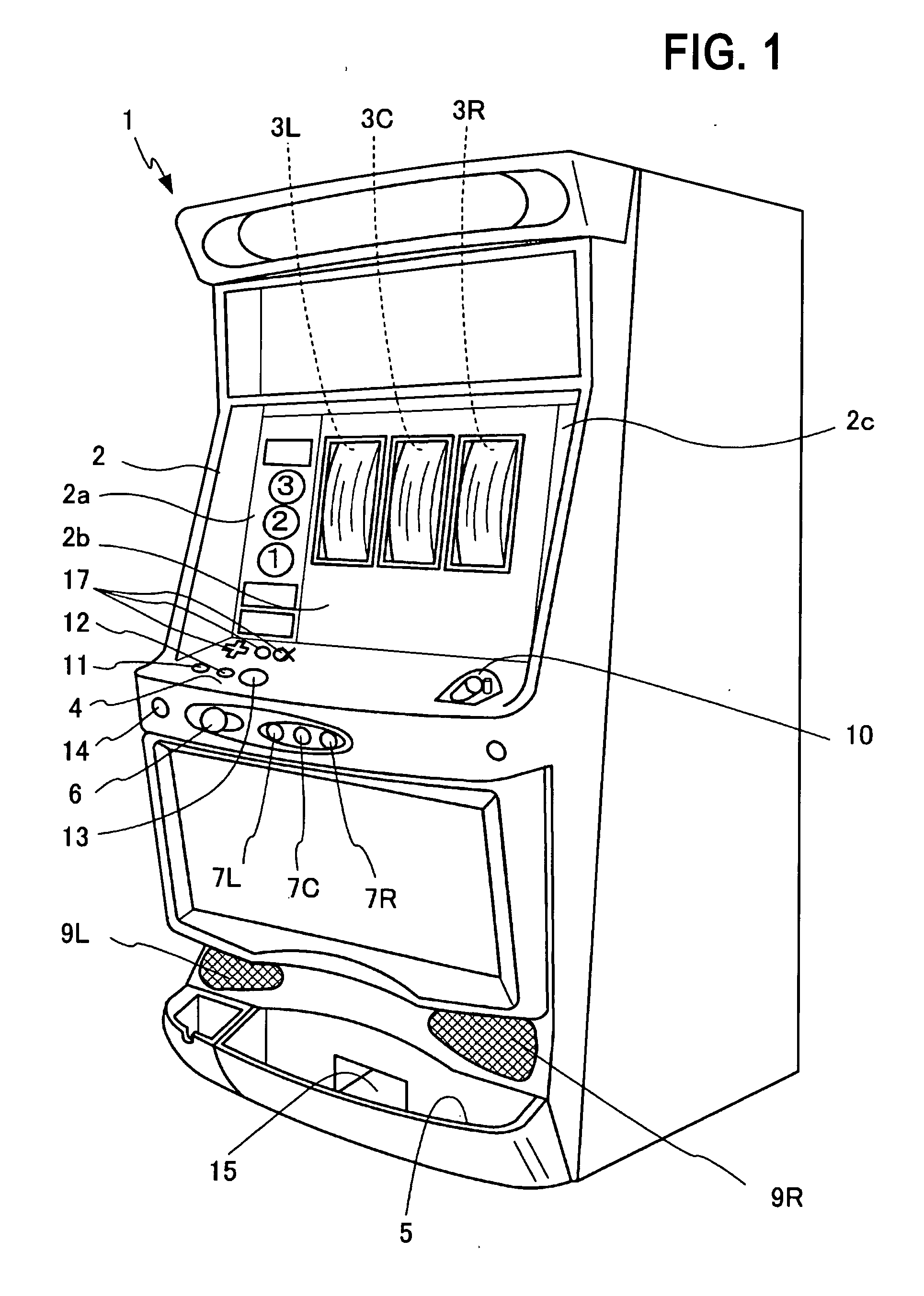

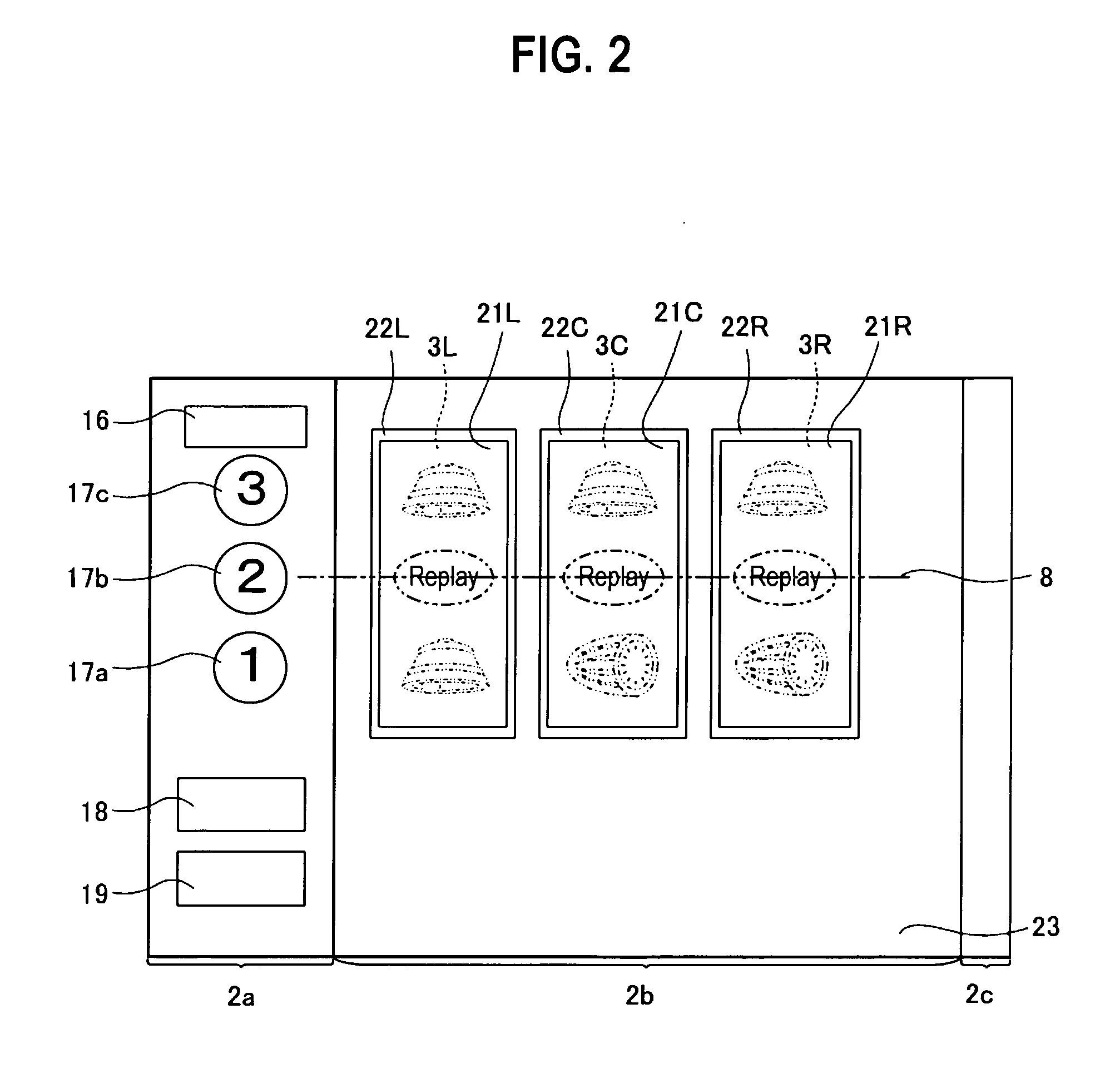

InactiveUS20070123348A1Easy to understandSatisfy regulationApparatus for meter-controlled dispensingVideo gamesTransmittanceEngineering

It is provided a gaming machine having one active line so that a player can be sufficiently entertained from playing games, while complying with regulatory requirements rules on gaming. The gaming machine includes a sub-control circuit for adjusting a light transmittance rate of non-effect areas 214 to 216 placed for each of symbol stop positions connected by an active line, always in a high state. If all the reels stop, the sub-control circuit lowers a light transmittance rate of effect areas placed for each of symbol stop positions that are not connected by an active line.

Owner:UNIVERSAL ENTERTAINMENT CORP

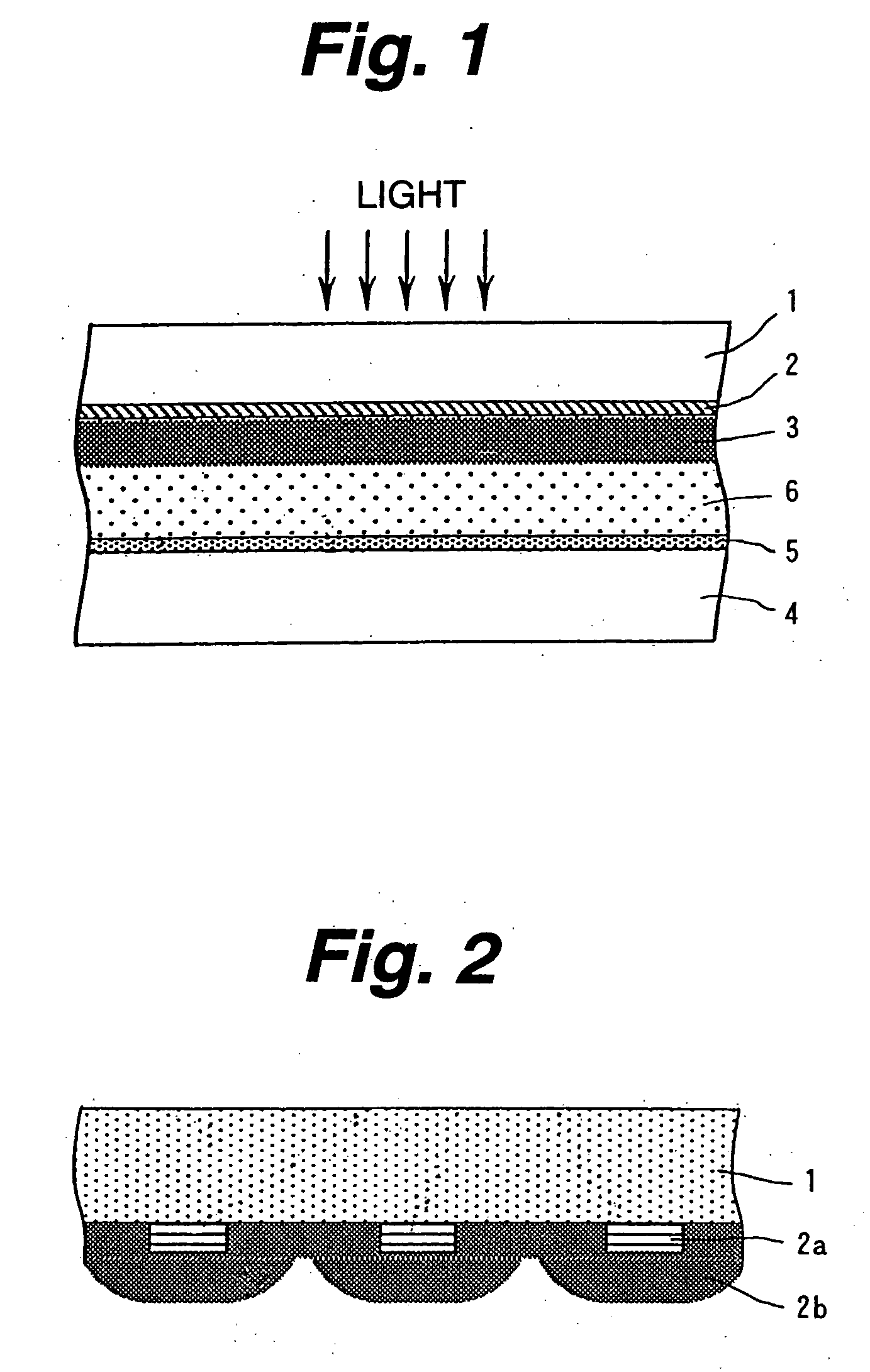

Photoelectric conversion element

InactiveUS20060112988A1Increased durabilityImprove transfer efficiencyLight-sensitive devicesPV power plantsSemiconductor electrodePhotoelectric conversion

In a photoelectric transfer device having a semiconductor electrode composed of semiconductor nanoparticles and an electrolyte layer between a pair of transparent conductive substrates, a transparent conductive substrate at the light-receiving side is made by stacking a transparent substrate, conductive wiring layer and a metal oxide layer in order from the light-receiving side and having sheet resistance equal to or lower than 10 Ω / □. The metal oxide layer is made of an In—Sn composite oxide, SnO2, TiO2, ZnO, or the like.

Owner:SONY CORP

Semi-transmissible reflector, semi-transmission type polarizer and liquid-crystal display device using the sames

InactiveUS6876414B2Lighter in colorReduce light transmittanceMirrorsLayered productsPolarizerLiquid-crystal display

A semi-transmissible reflection layer is formed on a light-transmissible polymer substrate uniaxially drawn to have uniaxial orientation characteristic to thereby form a semi-transmissible reflector.

Owner:NITTO DENKO CORP

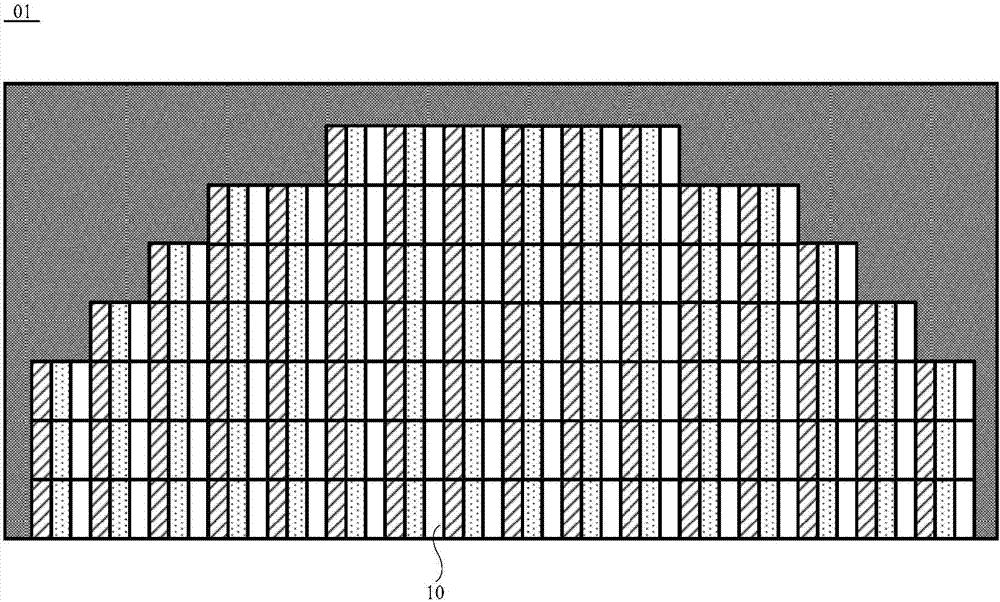

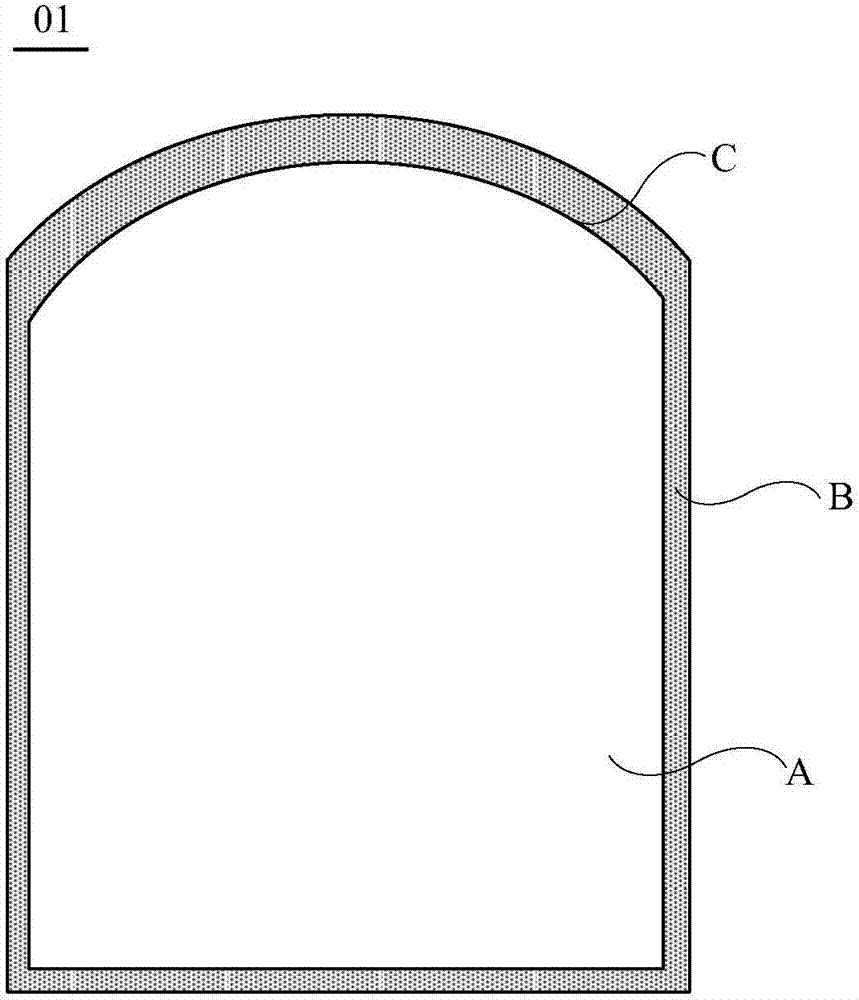

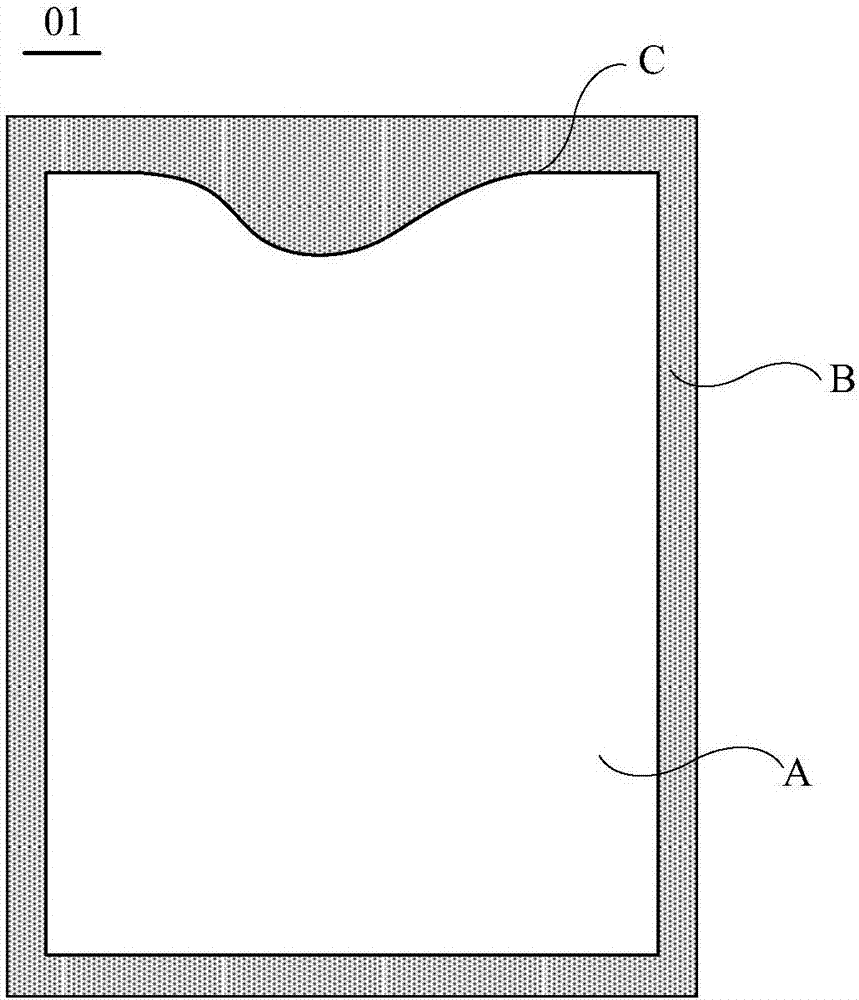

Display substrate and display device

InactiveCN107255883AReduce brightnessReduce light transmittanceSolid-state devicesNon-linear opticsComputer graphics (images)Display device

The embodiment of the invention provides a display substrate and a display device and relates to the technical field of display. The display substrate and the display device are used for solving the problem that the saw tooth effect appears in the edge of an AA area during display when the edge of the AA area is in a non-linear state. The display substrate comprises a black matrix. The display substrate is provided with a display area, and at least part of the edge of the display area is a special-shaped edge in a concave-convex shape. In the display area, the black matrix consists of a plurality of shading bars arranged in a criss-cross mode, so that a plurality of sub pixels arranged in a matrix mode are defined. A visual weakening region near the special-shaped edge is arranged in the display area. In the visual weakening area, the black matrix also comprises shading blocks located in the sub pixels, and the shading blocks occupy part of the sub pixels area. The display substrate is used for display.

Owner:BOE TECH GRP CO LTD +1

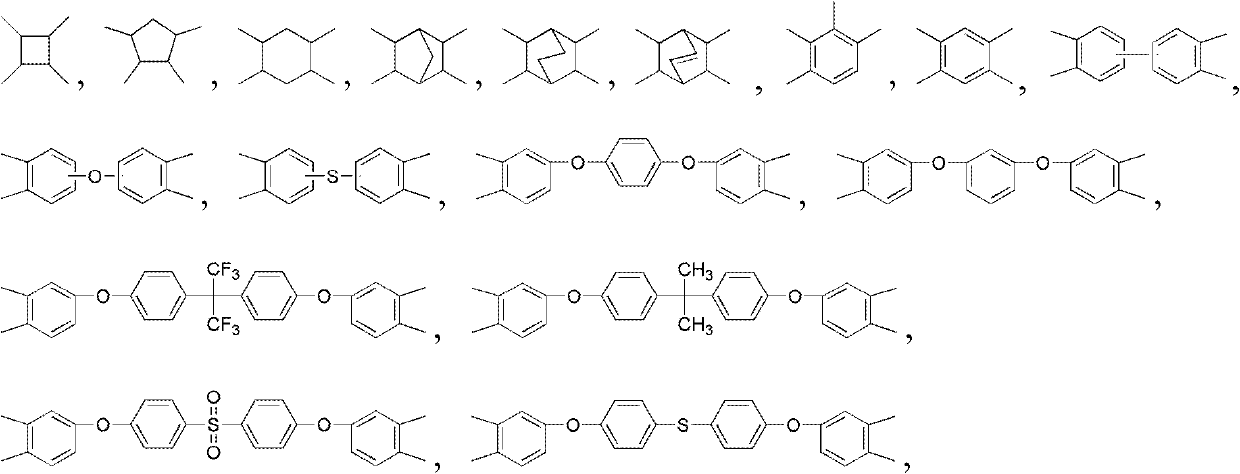

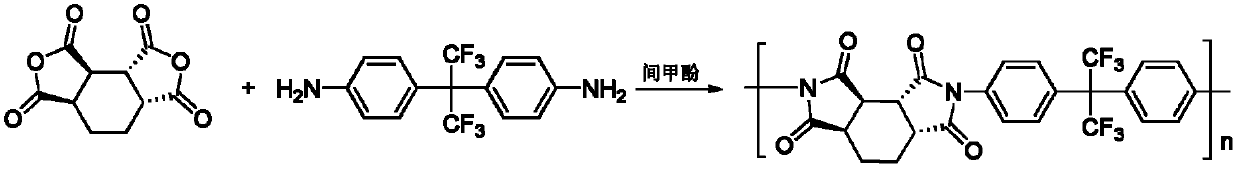

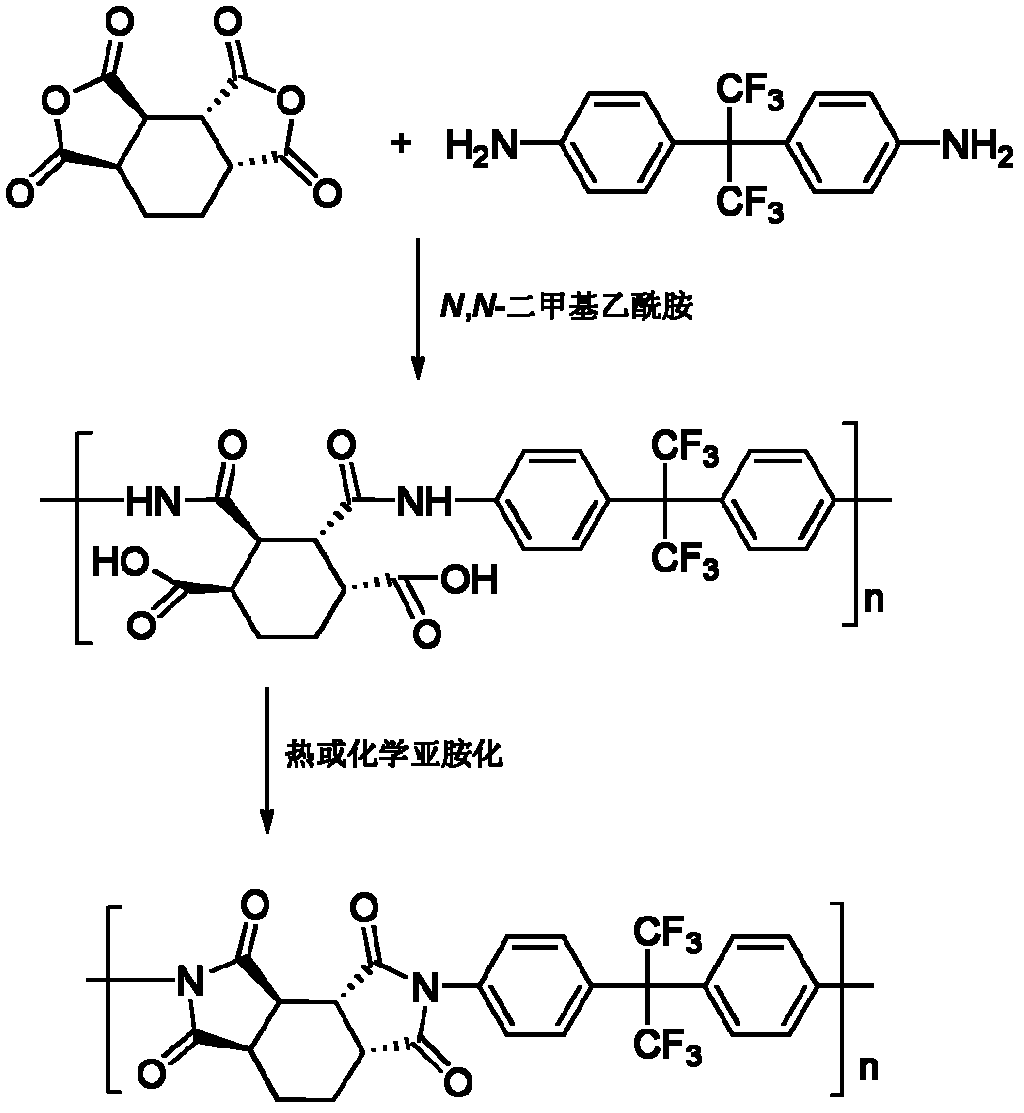

Colorless and transparent polyimide resin material and preparation method thereof

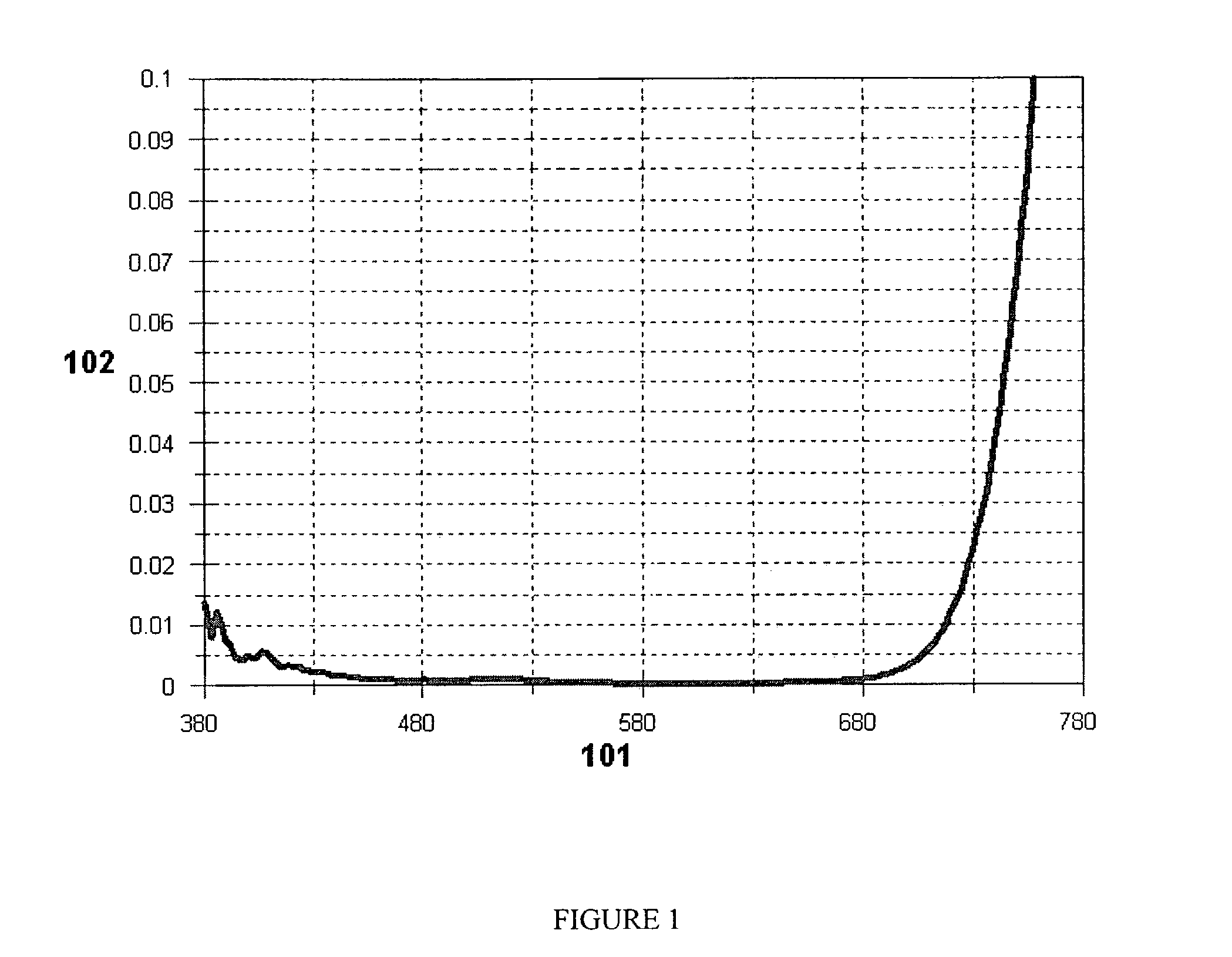

ActiveCN102382303AHigh transparencyHigh glass transition temperatureCharge-transfer complexUltraviolet lights

The invention discloses a colorless and transparent polyimide resin material. 1,2,3,4-cyclohexanetetracarboxylic dianhydride is chosen as dianhydride monomer or comonomer to carry out polycondensation reaction with primary diamine, so that the polyimide resin material is prepared. Because the 1,2,3,4-cyclohexanetetracarboxylic dianhydride comonomer has a distorted molecular structure, a large free volume exists between polymer molecular chains, and thereby the formation of charge transfer complex (CTC) in and between polyimide molecules is inhibited; and meanwhile, because of the introductionof a lipid structure, the electron-stimulated transition mode in the polyimide molecular chains is changed, the absorption of the aromatic polyimide in the visible light region is remarkably weakened, and thereby the transparency of the polymer is greatly increased. The ultraviolet light transmission cutoff wavelength of a produced polyimide film is 280nm to 380nm, the light transmissivity at 450nm is 86 to 94 percent, moreover, the glass-transition temperature is 250 DEG C to 400 DEG C, and the polyimide resin material has a good application prospect in the fields of flexible substrate materials for solar cells, flexible transparent conducting film substrate materials, liquid crystal display materials and the like.

Owner:WUHAN YIMAIDE NEW MATERIALS TECH CO LTD

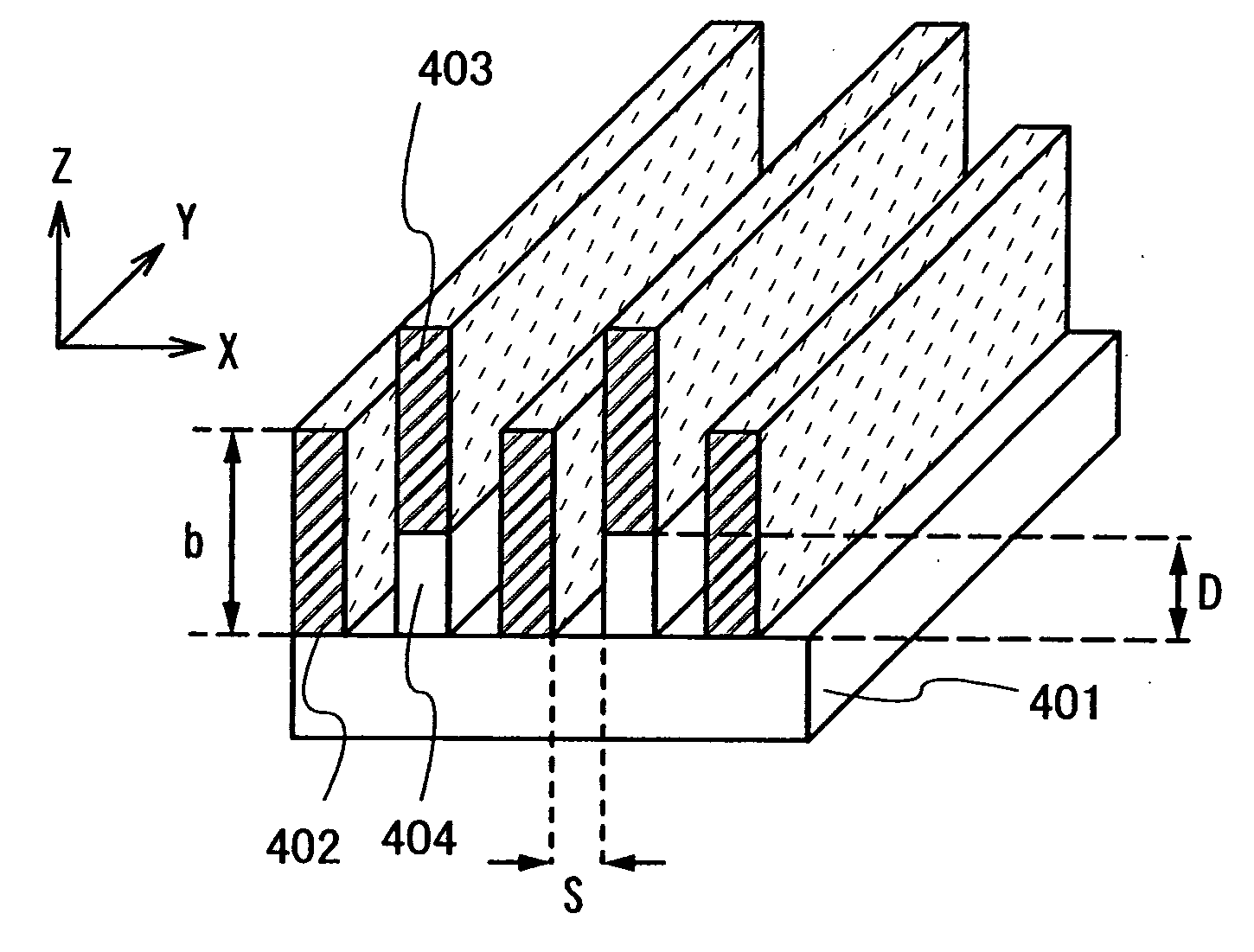

Polarizer and display device including polarizer

ActiveUS20090009865A1Good optical performanceHigh mechanical strengthPolarising elementsSpecial surfacesTransmittanceDisplay device

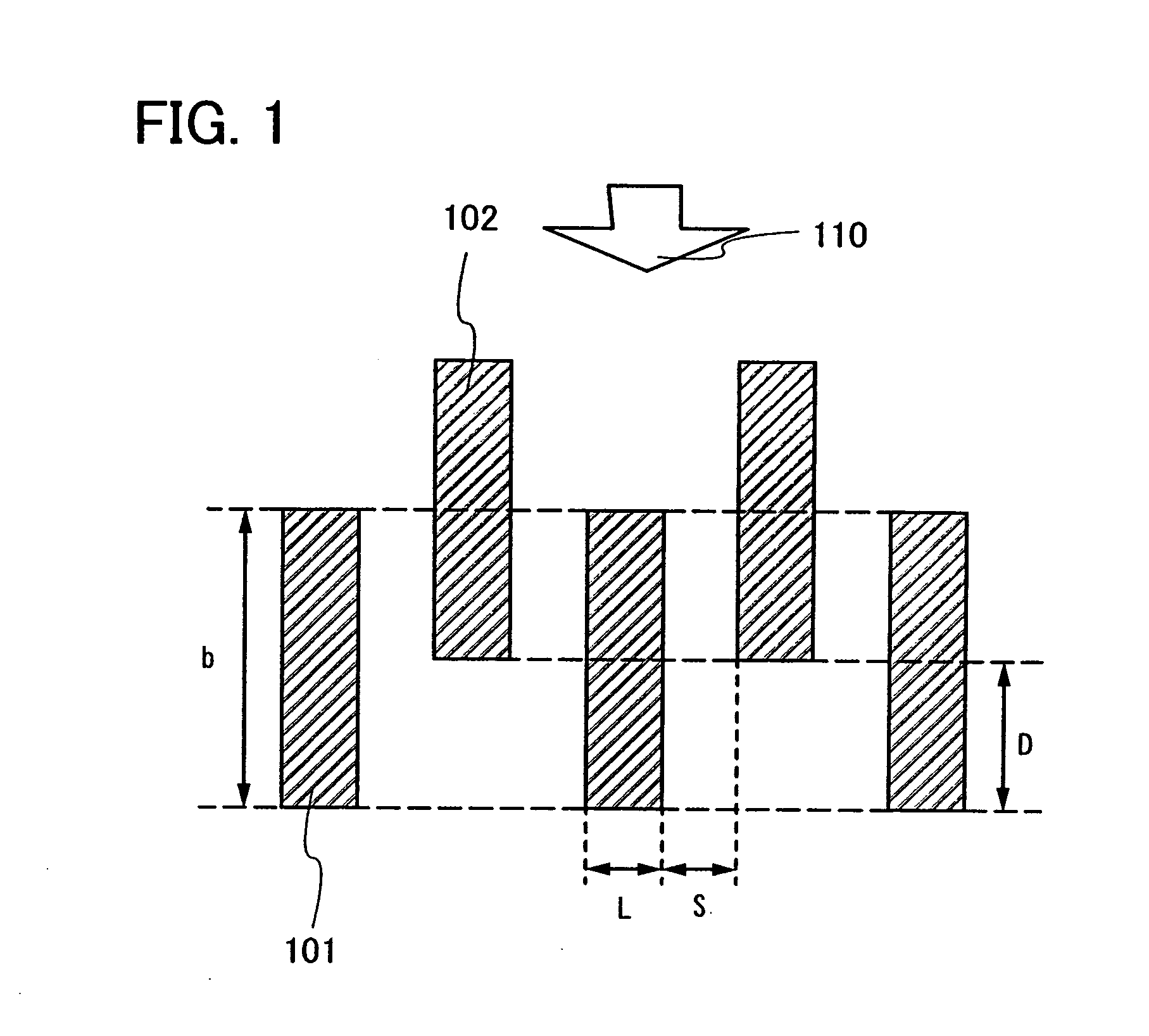

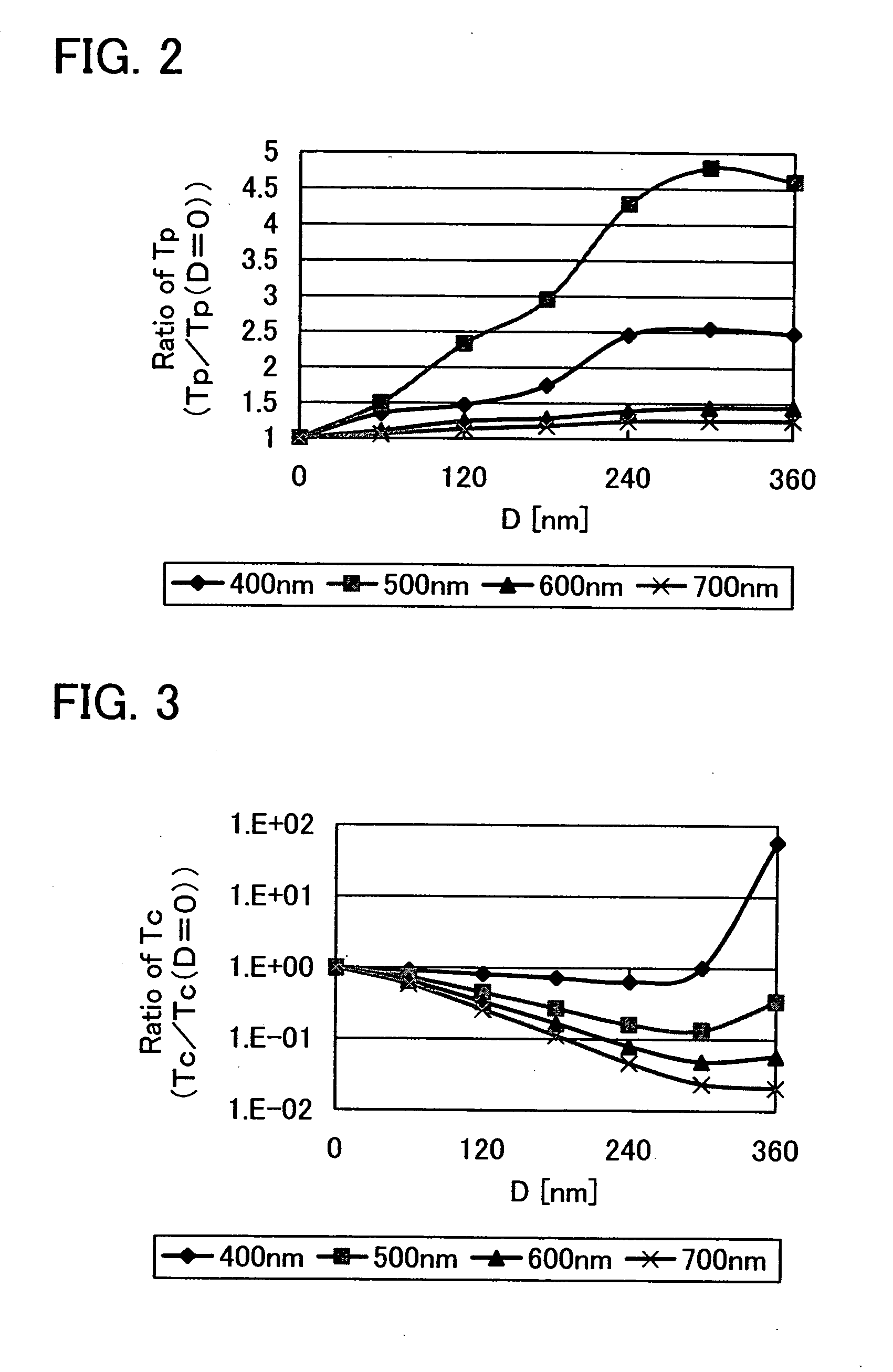

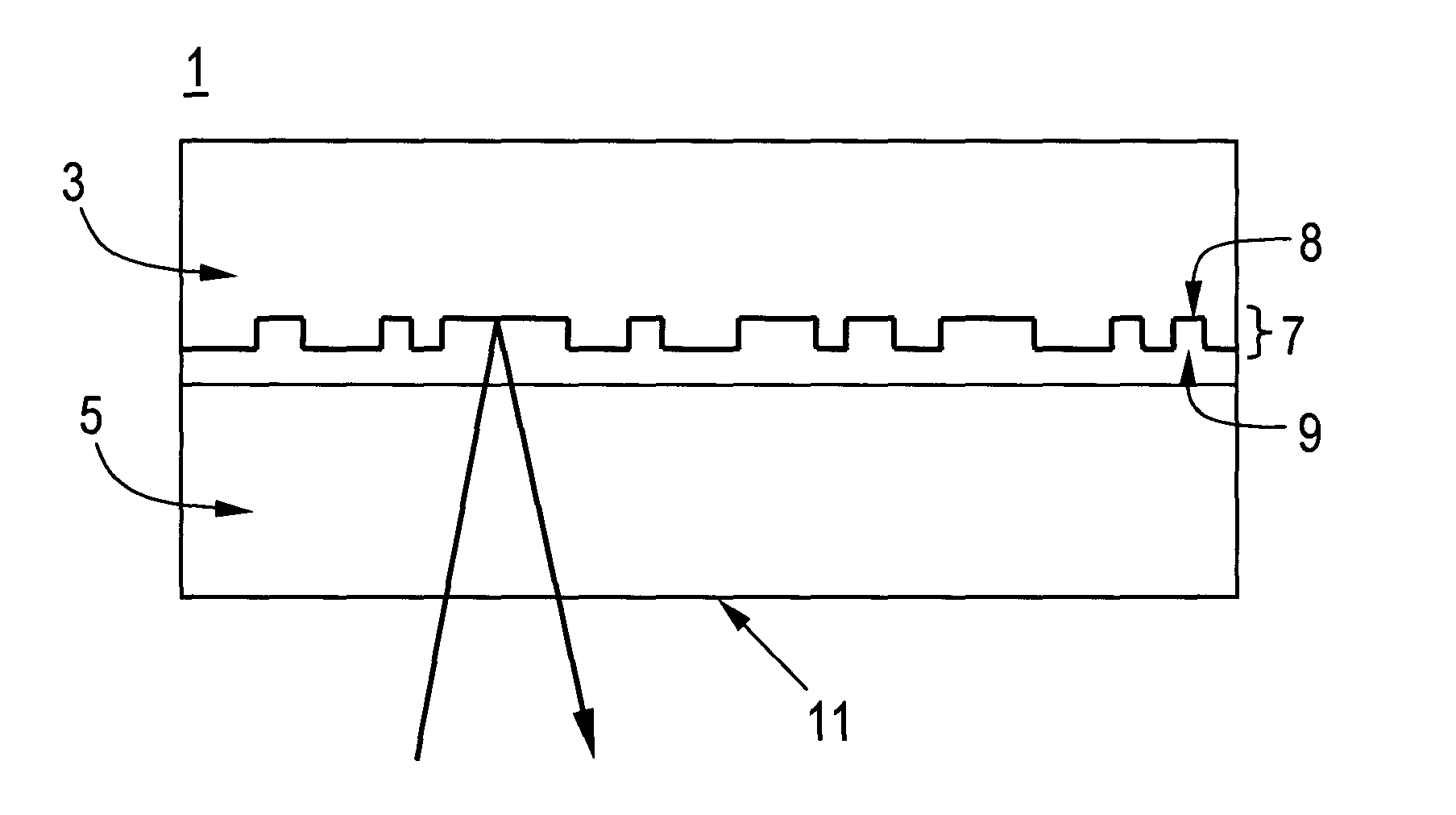

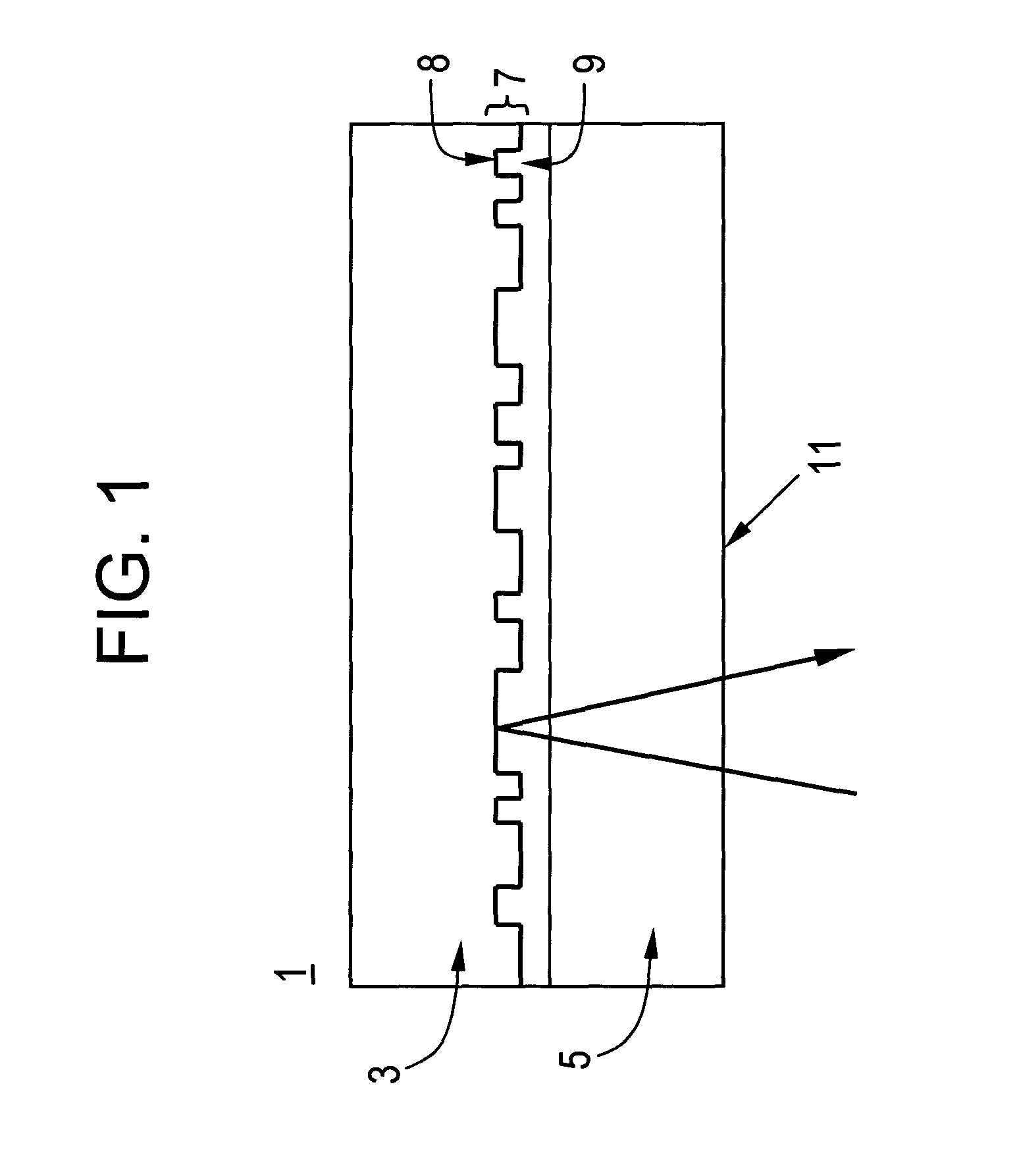

A polarizer in which parallel transmittance TP is increased and crossed transmittance TC is provided. Instead of arranging a plurality of all metal wires on one plane, a plurality of metal wires is separately formed on at least two different parallel planes, and adjacent meal wires among the plurality of metal wires are staggered in the polarizer. The heights of a first group of metal wires formed on a first plane and a second group of metal wires formed on a second plane, from a surface of the light-transmitting substrate are different. Further, a metal wire of the second group is provided to be more distant from the light-transmitting substrate than the first group of metal wires by distance D, and the distance D is smaller than the thickness of the first group of metal wires.

Owner:SEMICON ENERGY LAB CO LTD

Limited play optical storage medium, method for making the same

InactiveUS20050013232A1Timely controlEnhance limited playabilityLayered productsPhotomechanical apparatusExtinctionFiltration

In one embodiment, a limited play optical storage medium for data comprises: a reflective layer, a control portion comprising an optically transparent polymeric resin and a light absorbing material, wherein the control portion has a light transmission of greater than or equal to about 70% at 650 nm, a curing index of greater than or equal to about 0.1 and a filtration index of greater than or equal to about 2.5, and wherein the light absorbing material has a minimum extinction coefficient (measured in CH2Cl2 solution) at 600 nm of greater than or equal to 1,500 mol−1·cm−1·L, a maximum extinction coefficient (measured in CH2Cl2 solution) at 650 nm of less than about 1,000 mol1·cm−1·L, a ratio of extinction coefficient at 650 nm to 600 nm less than about 0.1, and a reactive layer disposed between the reflective layer and the control portion, wherein the reactive layer is designed to limit the time during which data on the medium (disposed on a side of the reactive layer opposite the control portion), can be accessed after exposure to oxygen.

Owner:GENERAL ELECTRIC CO

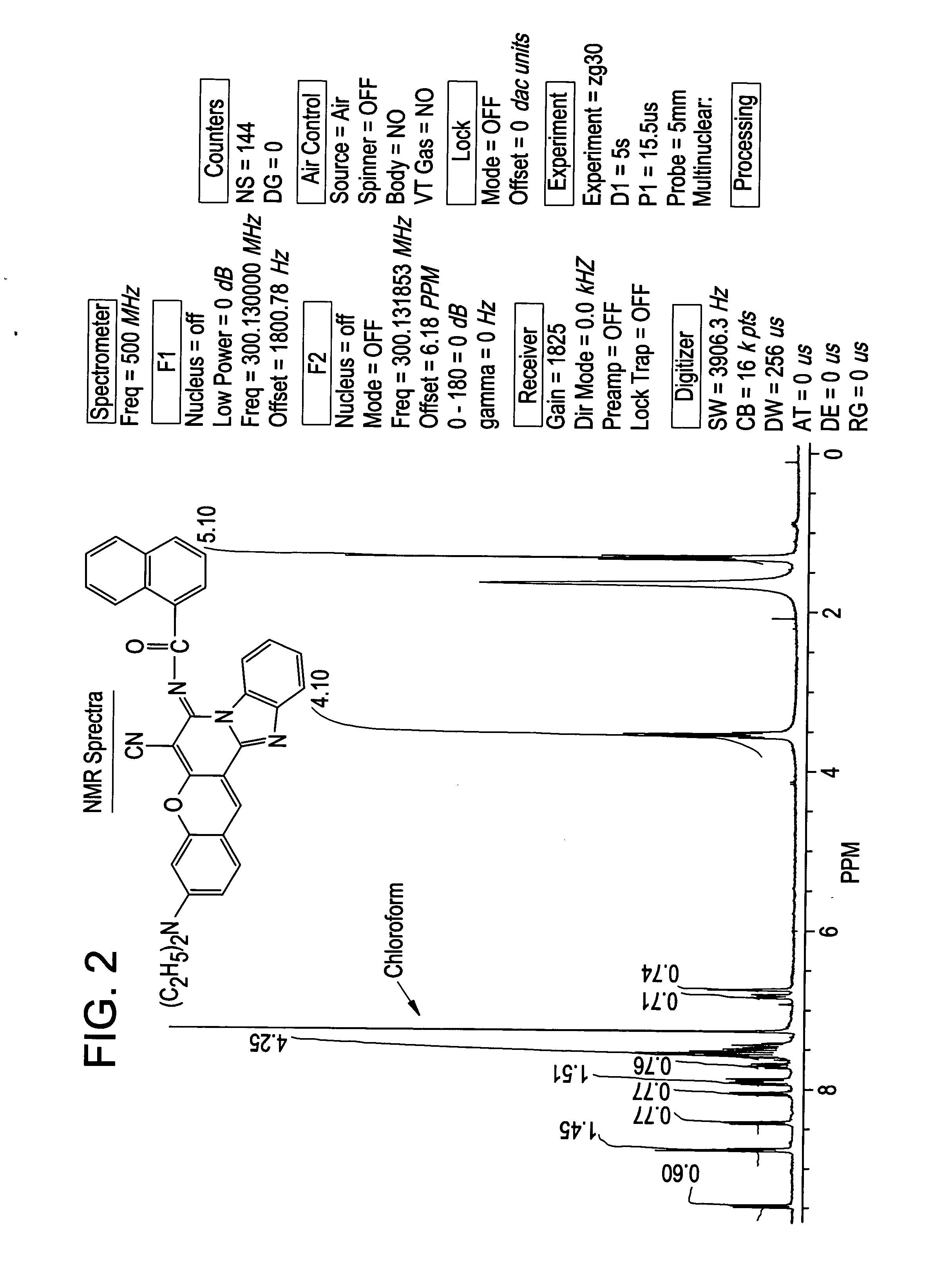

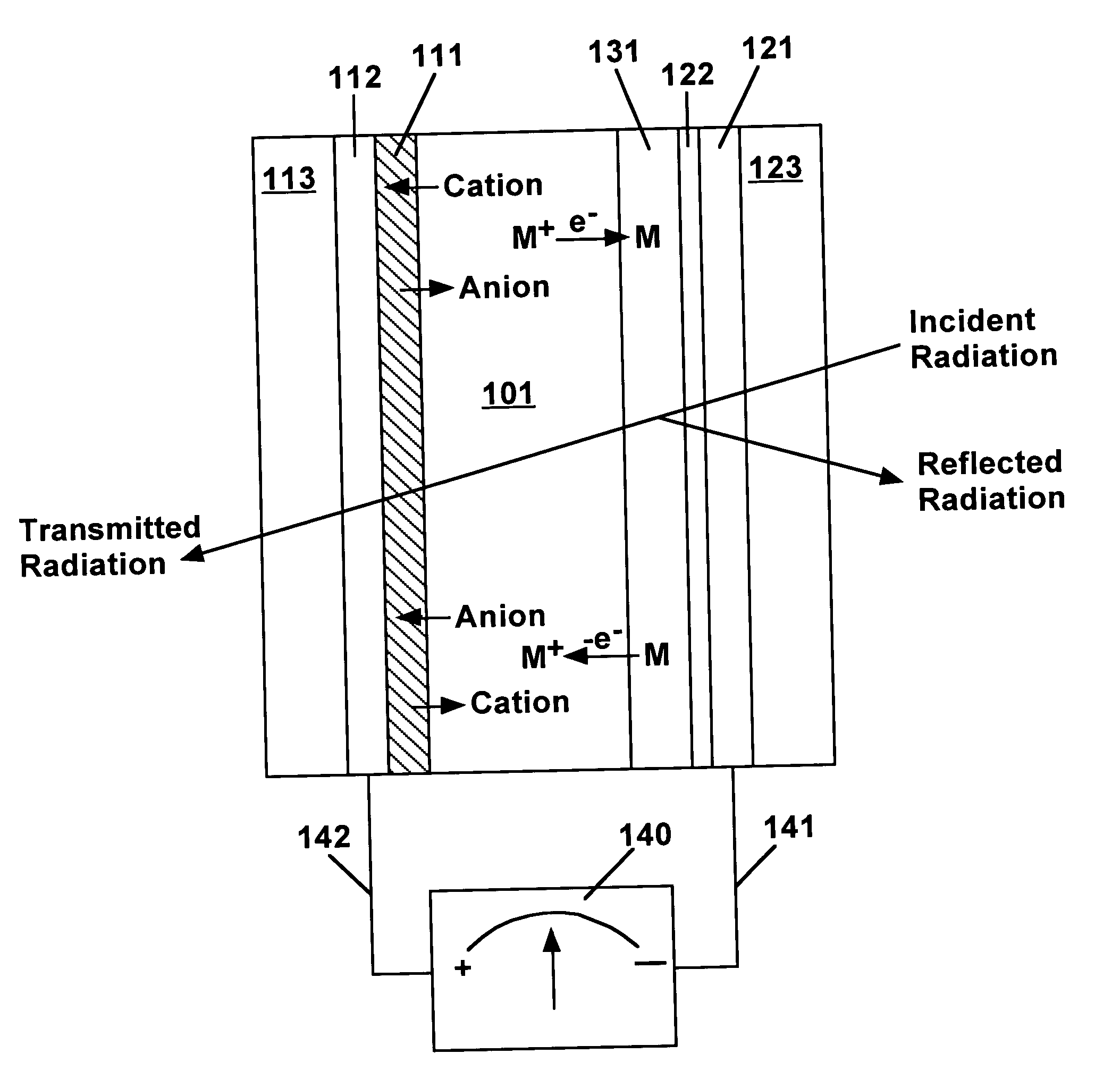

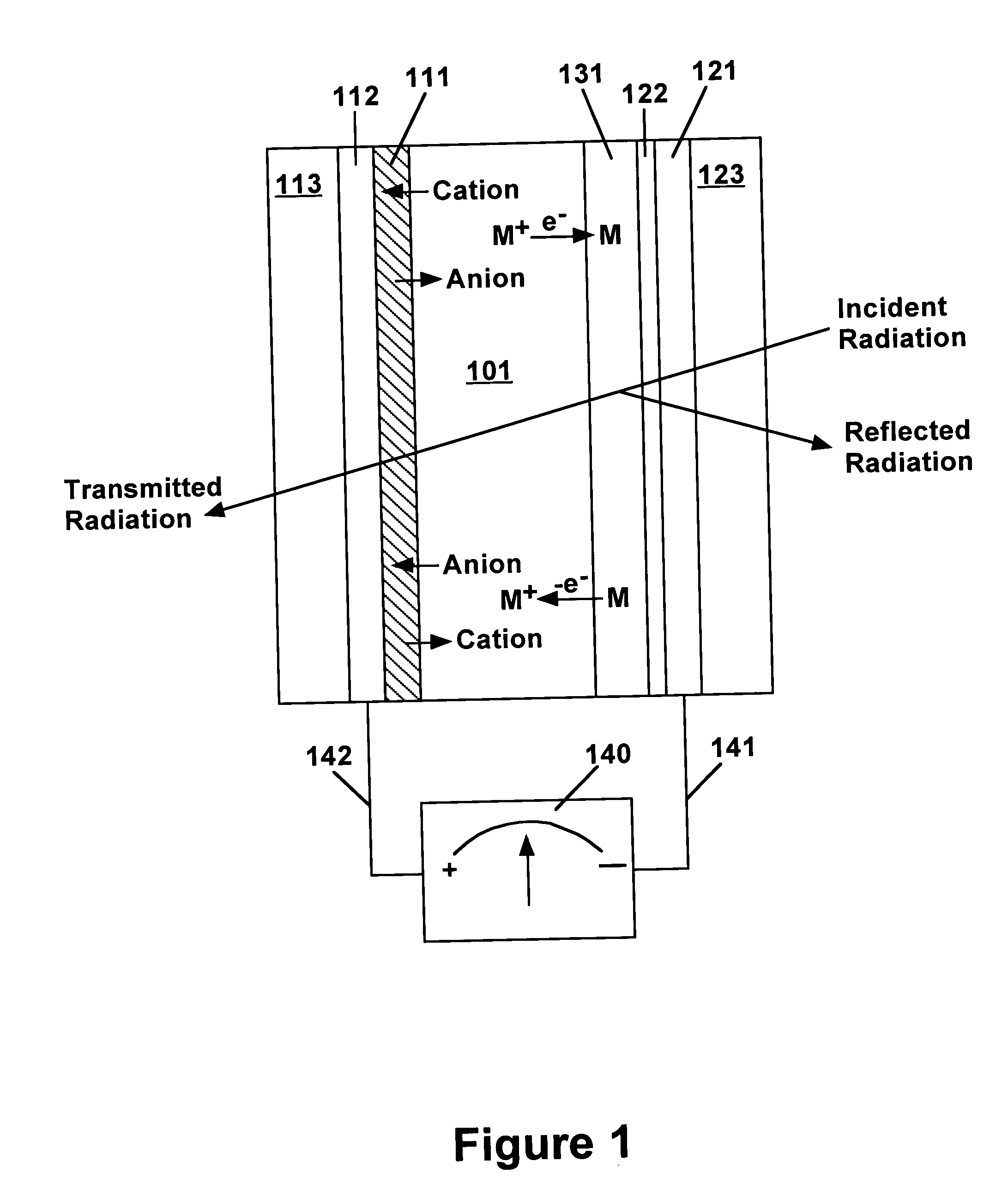

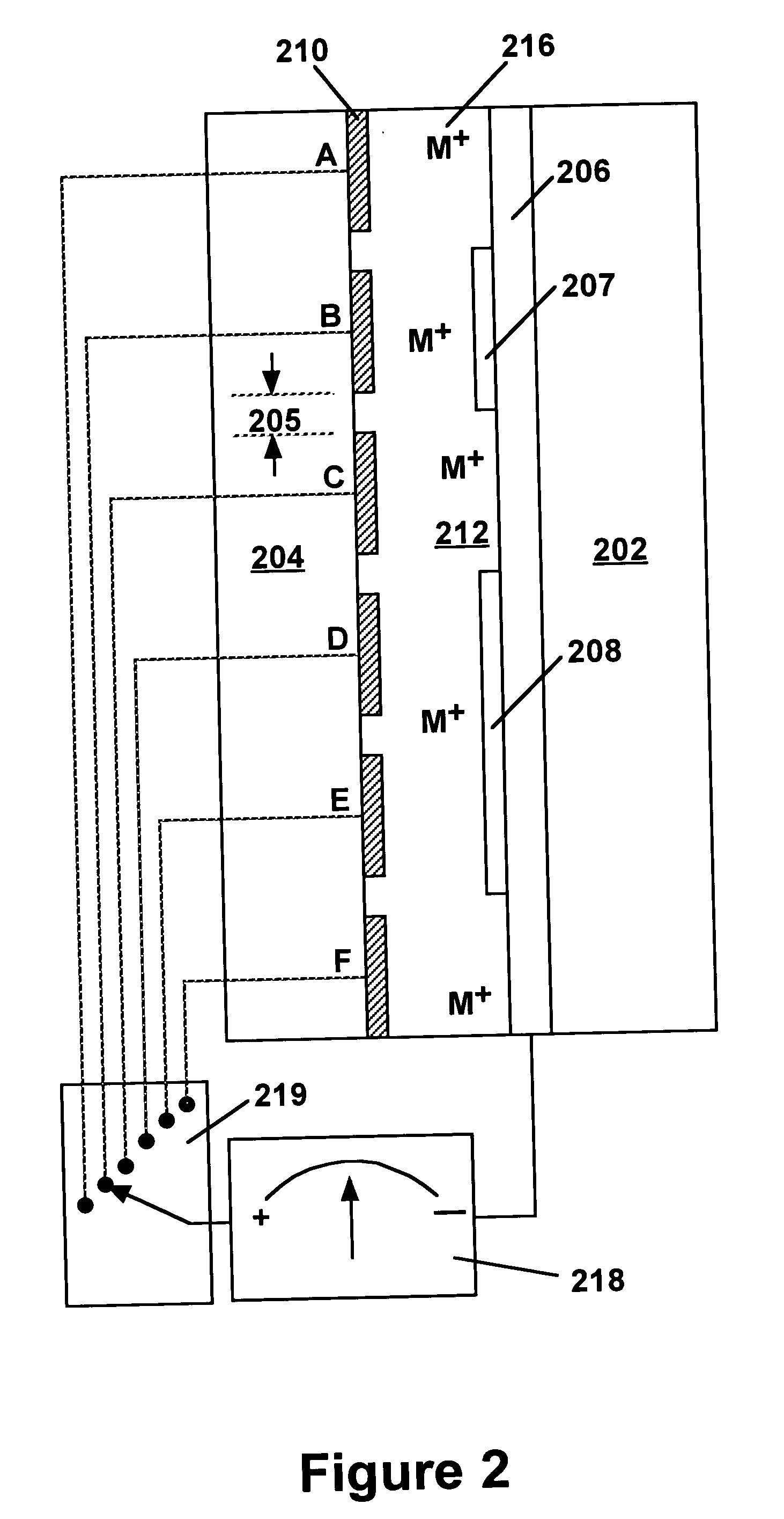

Reversible electrodeposition optical modulation device with conducting polymer counter electrode

InactiveUS20050248825A1Minimal effectReduce transmissionNon-linear opticsDot matrixConductive polymer

An optical modulation device includes an electrolyte containing electrodepositable metal ions sandwiched between a conducting polymer counter electrode and an optical modulation electrode involving reversible metal electrodeposition. The conducting polymer counter electrode does not generate mobile reactive species, and avoids the light blocking associated with grid or dot matrix electrodes involving reversible metal electrodeposition. A polyaniline counter electrode in a smart window device employing a reversible electrochemical mirror modulation electrode provides high light transmission, fast switching, and coloration to mask the backside of the mirror electrode.

Owner:TELEDYNE LICENSING

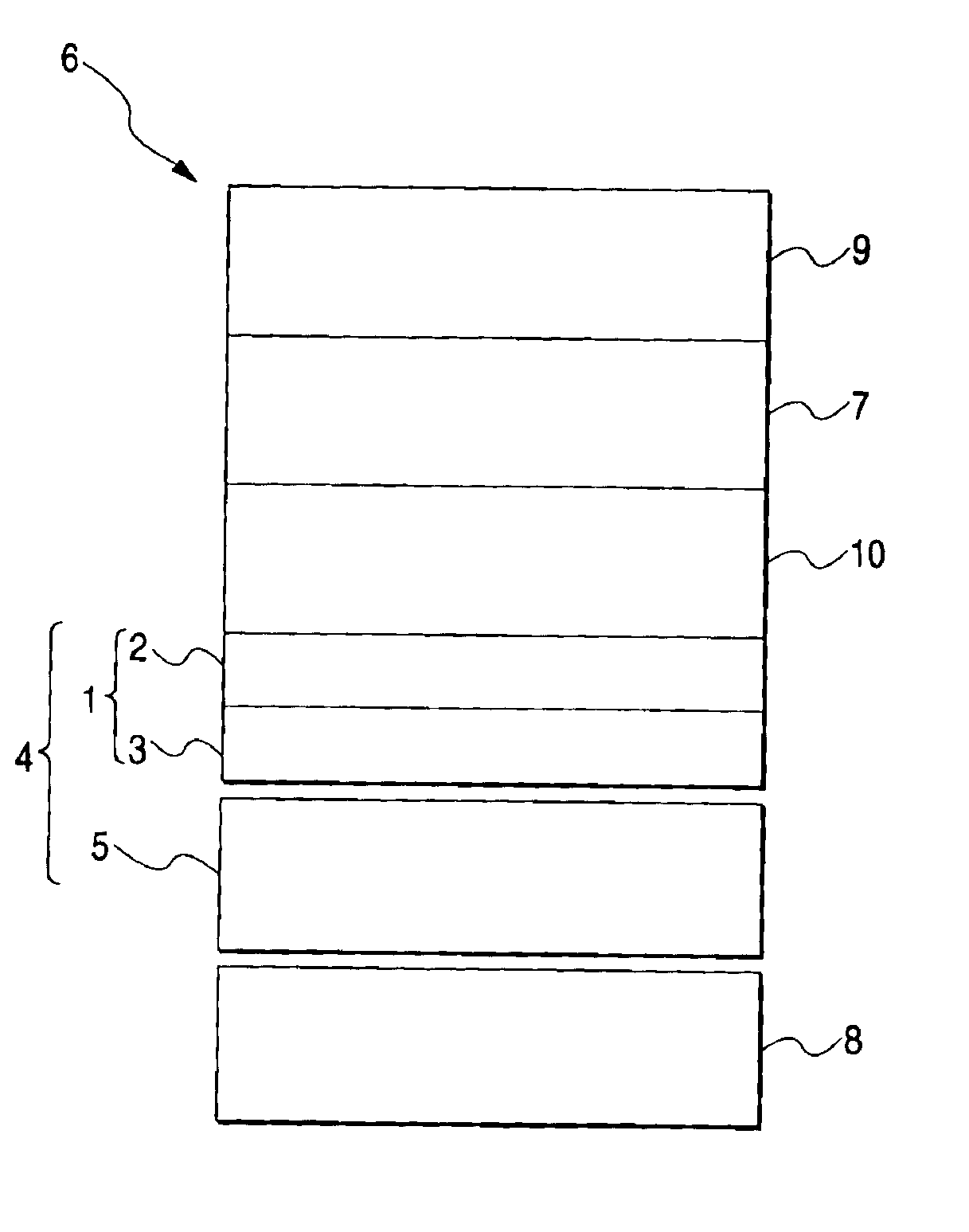

Magnetic recording medium

InactiveUS20030017365A1High running durabilityGuaranteed uptimeMagnetic materials for record carriersRecord information storageParticulatesHigh density

Provided is a particulate magnetic recording medium having good processing properties and being inexpensive to produce, similar to prior recording media, wherein by controlling the magnetic clusters that appear due to recording at short wavelengths and thinning of the magnetic layer, good high-density characteristics are achieved in combination with MR heads. The magnetic recording medium comprising an essentially nonmagnetic lower layer and a magnetic layer comprising a ferromagnetic powder and a binder in this order, wherein the magnetic layer has a thickness ranging from 0.01 to 0.15 mum and a coercivity equal to or higher than 159 kA / m, ferromagnetic particles contained in the ferromagnetic powder have a size less than ½ of the minimum recording wavelength, and an average size of magnetic cluster at DC erase is equal to or higher than 0.5x104 nm2 and less than 5.5x104 nm2.

Owner:FUJIFILM CORP

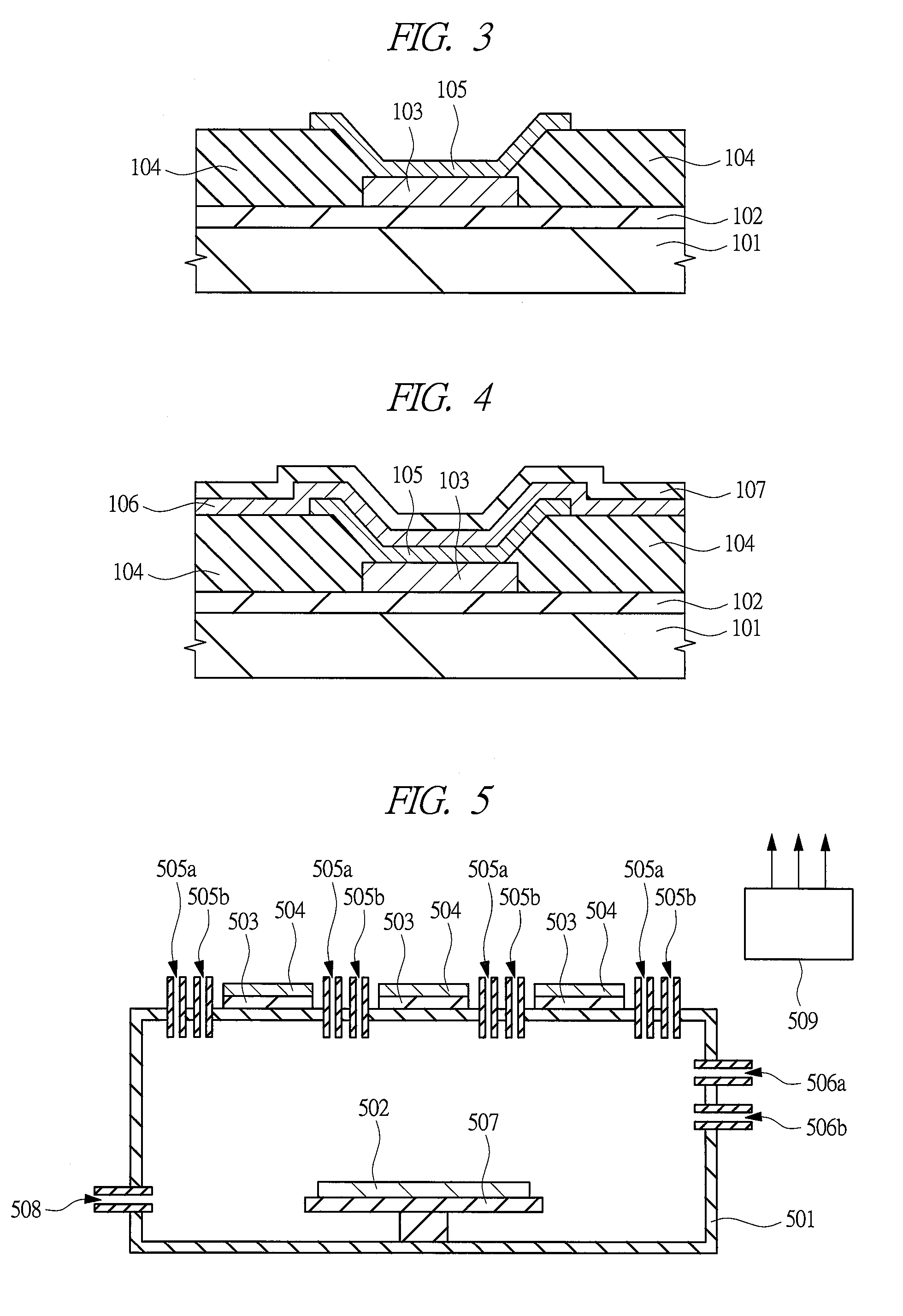

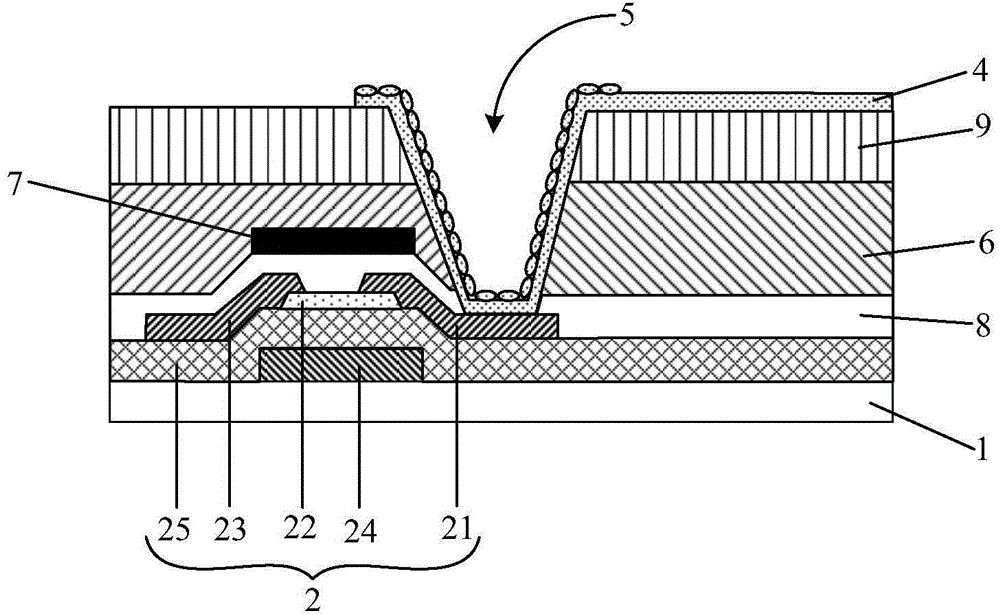

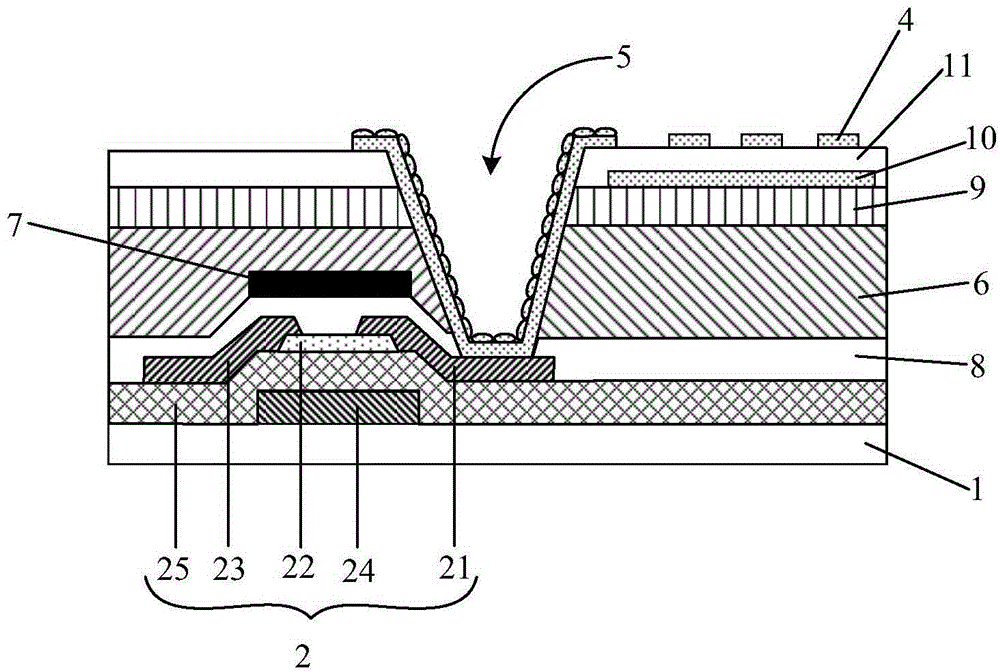

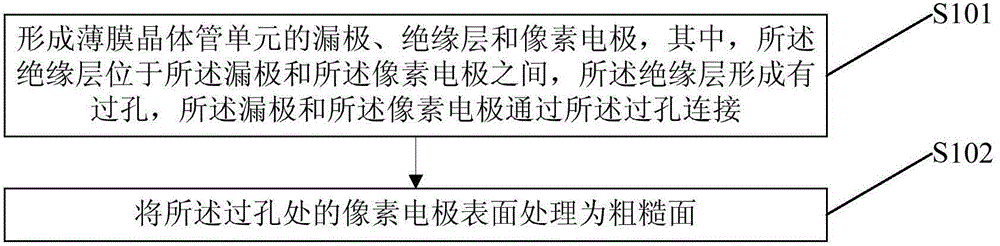

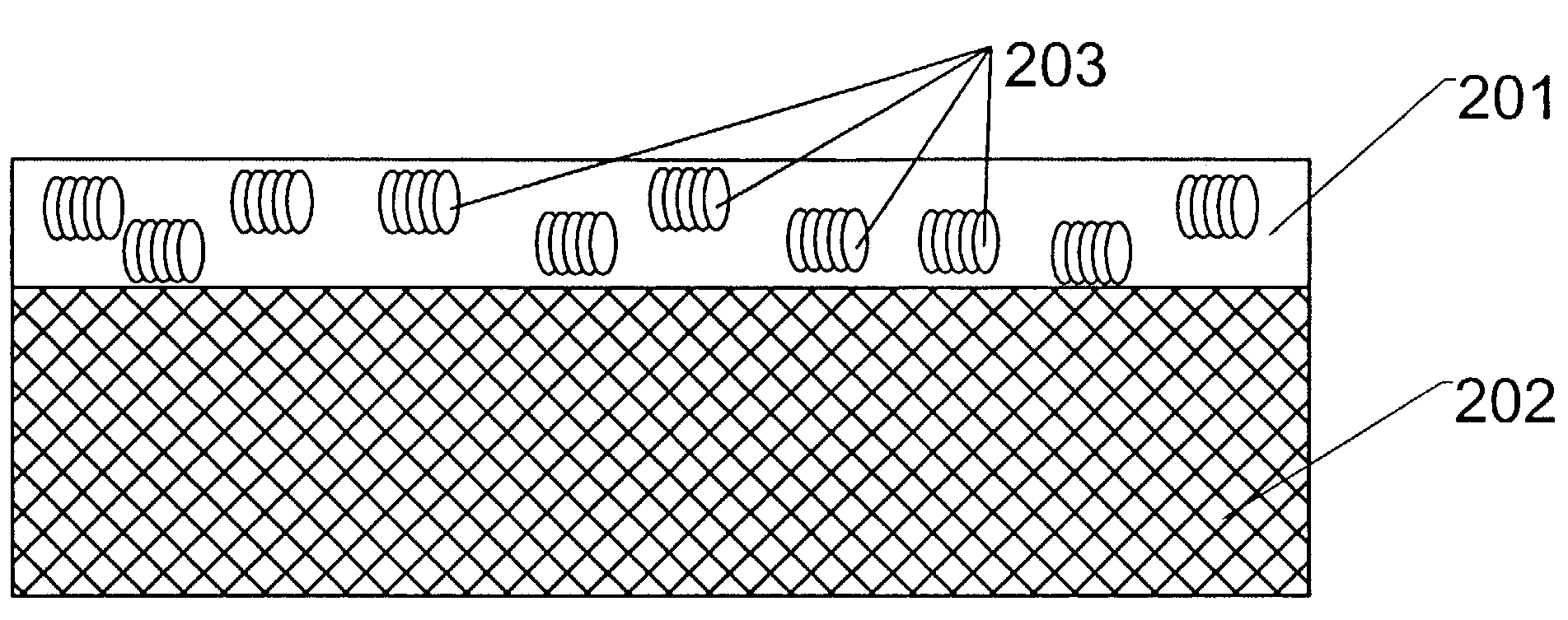

Array substrate, manufacturing method of array substrate, and display device

InactiveCN103985717AReduce light transmittanceReduce reflexesSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceOptoelectronics

The embodiment of the invention discloses an array substrate, a manufacturing method of the array substrate, and a display device, and relates to the technical field of displaying. A drain electrode can be prevented from reflecting light, and the display effect of the display device is guaranteed. The array substrate comprises the drain electrode, an insulating layer and a pixel electrode of a thin film transistor unit, wherein the insulating layer is located between the drain electrode and the pixel electrode and provided with a via hole, the drain electrode and the pixel electrode are connected through the via hole, and the surface, at the via hole, of the pixel electrode is rough.

Owner:BOE TECH GRP CO LTD

Color correcting polarizer

InactiveUS7144608B2Preservation of luminance throughputHigh light transmittanceLiquid crystal compositionsOrganic chemistryPolarizerLength wave

A color-correcting polarizer is provided comprising a polarizer layer and at least one discotic film layer. The discotic film layer is optically transparent within the range of visible wavelength. The discotic film layer works as a polarizer in the wavelength ranges at least from 380 to 500 nm and / or from 600 to 780 nm. A liquid crystal cell comprising the color correcting polarizer is also disclosed.

Owner:NITTO DENKO CORP

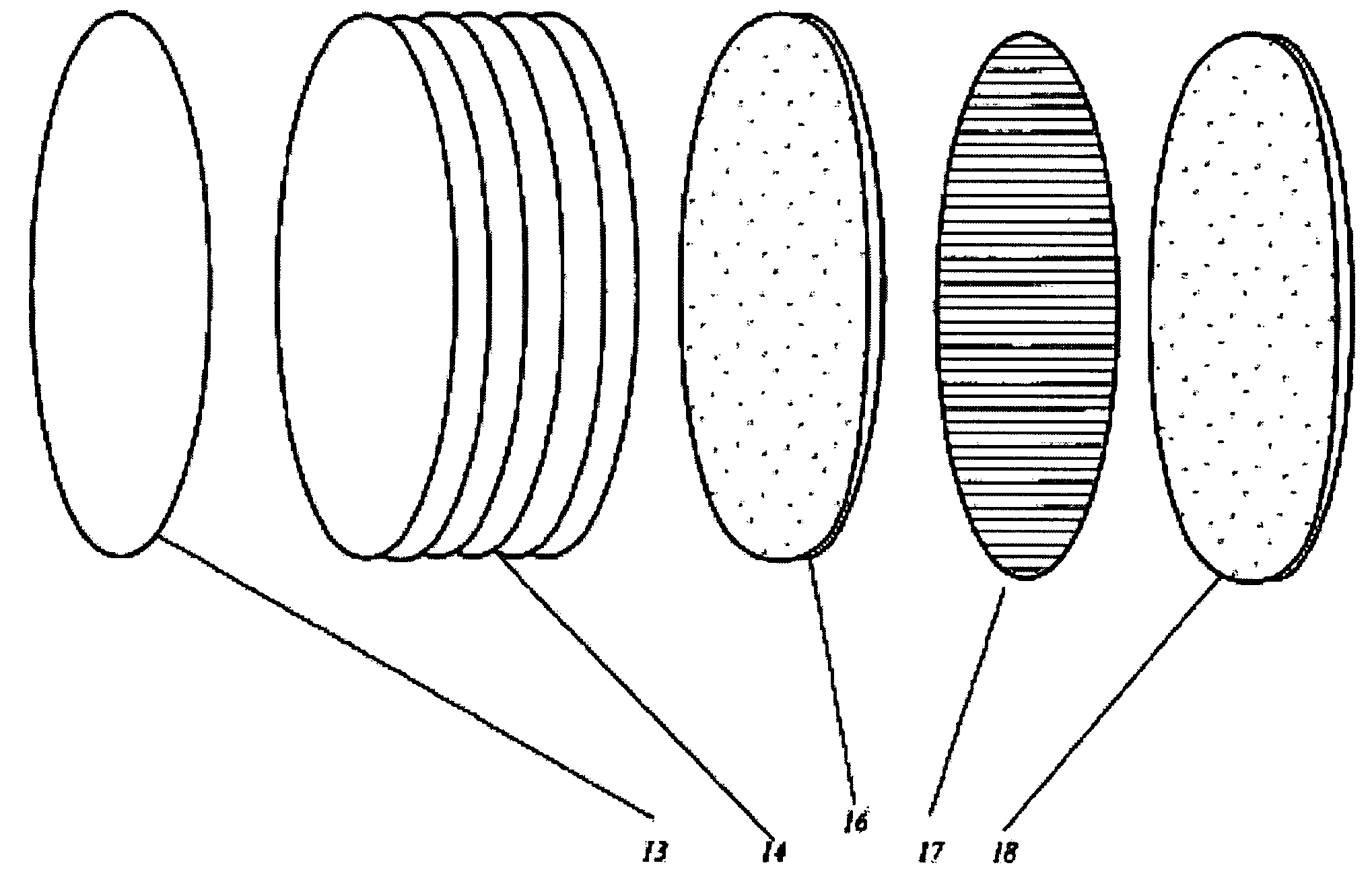

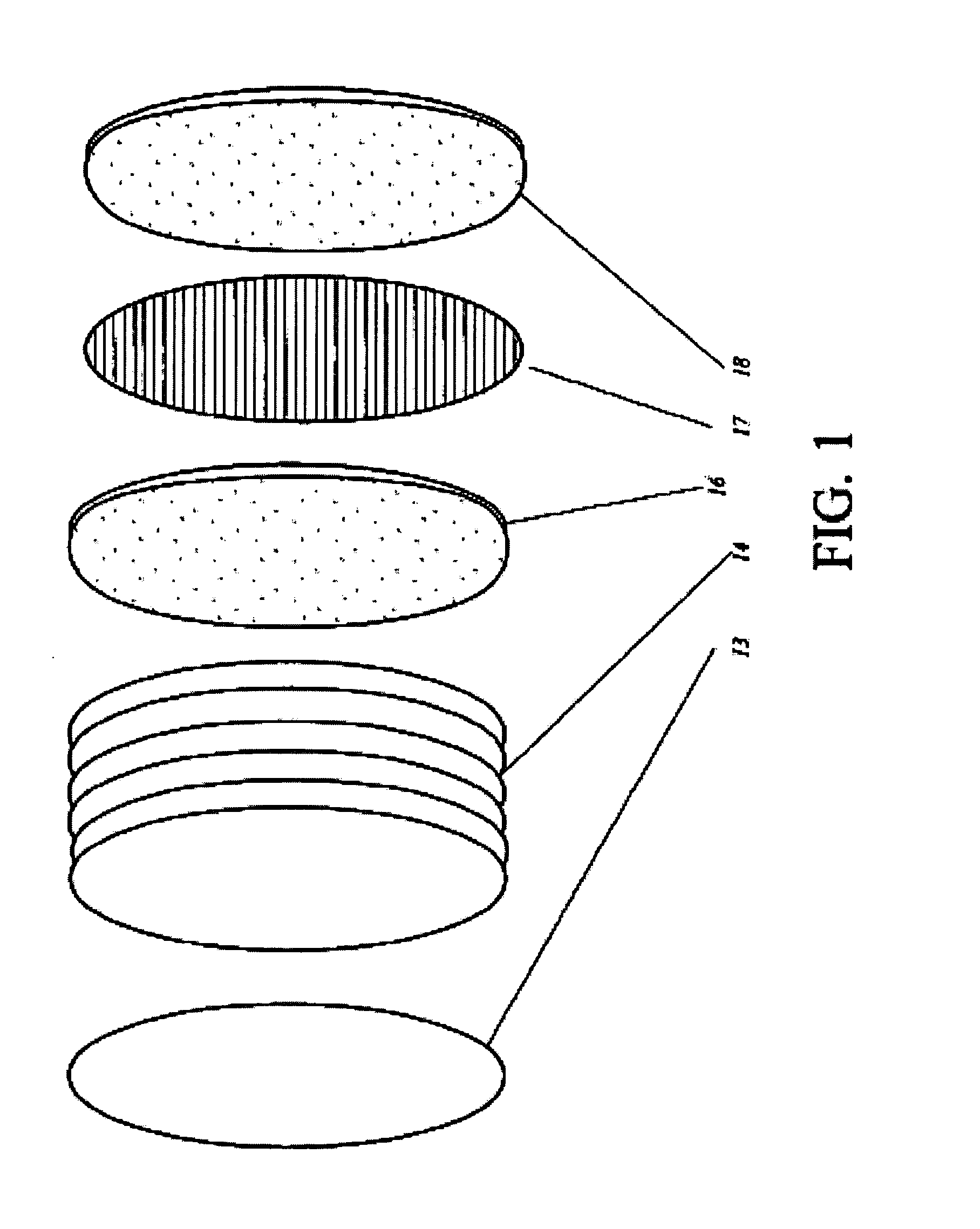

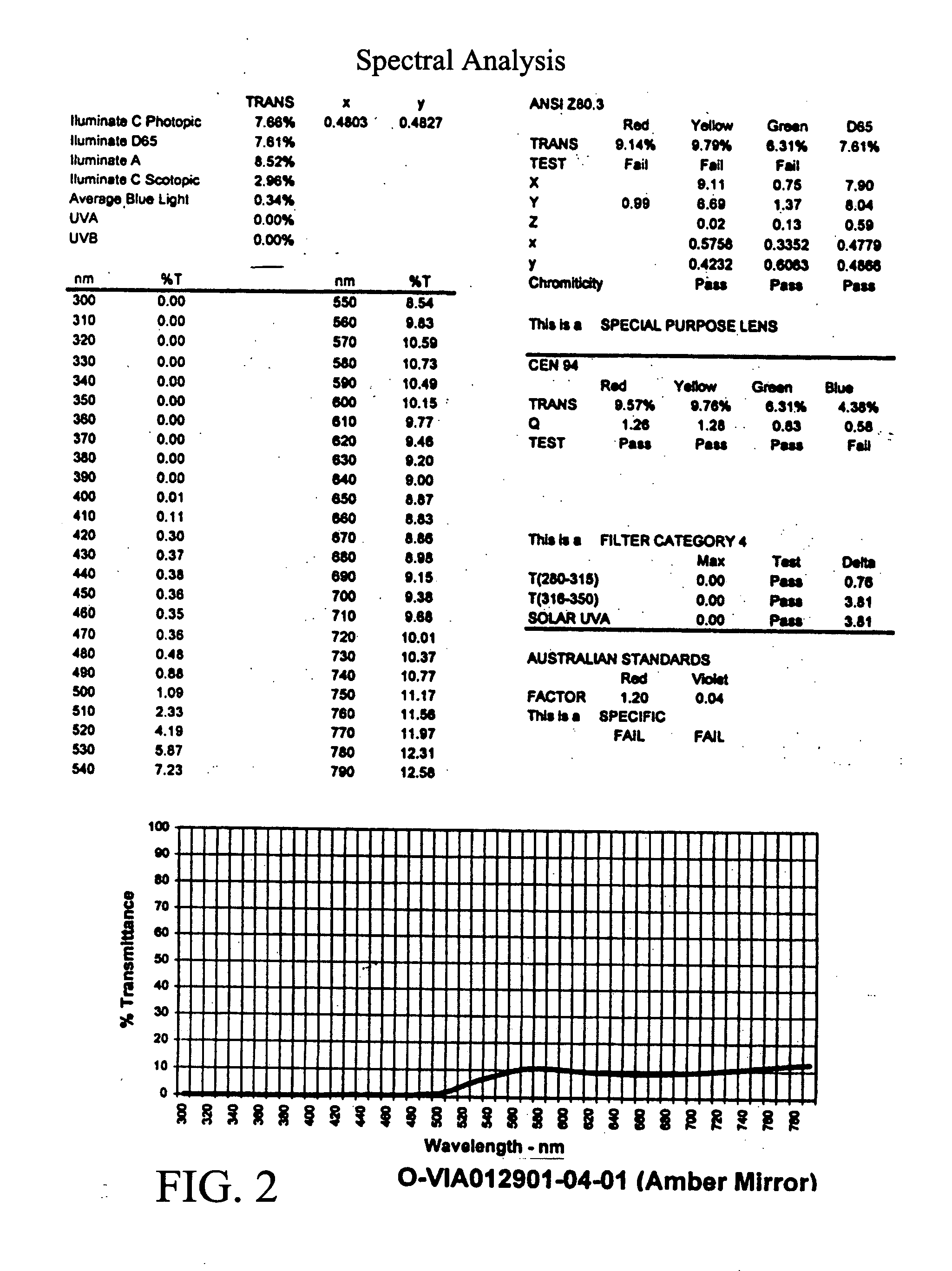

Waterman's sunglass lens

InactiveUS20050099589A1Reduce light transmittanceDecrease transmission valueSpectales/gogglesOptical partsPolycarbonateDielectric mirror

An improved ten-layer performance polarized lens for sunglasses. The lens design maximizes visual acuity while minimizing blue-light transmission using a multi-layer dielectric mirror to reduces glare and overall light transmission, two layers of high-contrast blue-blocking amber CR-39 plastic or polycarbonate, sandwiching a polarizing layer. An outer hydrophobic overcoat is also provided to protect against haze, delamination, and smudging, The foregoing layers are arranged to provide a balanced light transmission profile optimum for use on the water in which 100% of UV-A & B light is absorbed to at least 400 nm. The resulting dielectric-mirrored sunglass lens reduces both overall light transmission and ocular photochemical damage.

Owner:HIGH PERFORMANCE OPTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com