Patents

Literature

1837results about How to "Avoid light leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

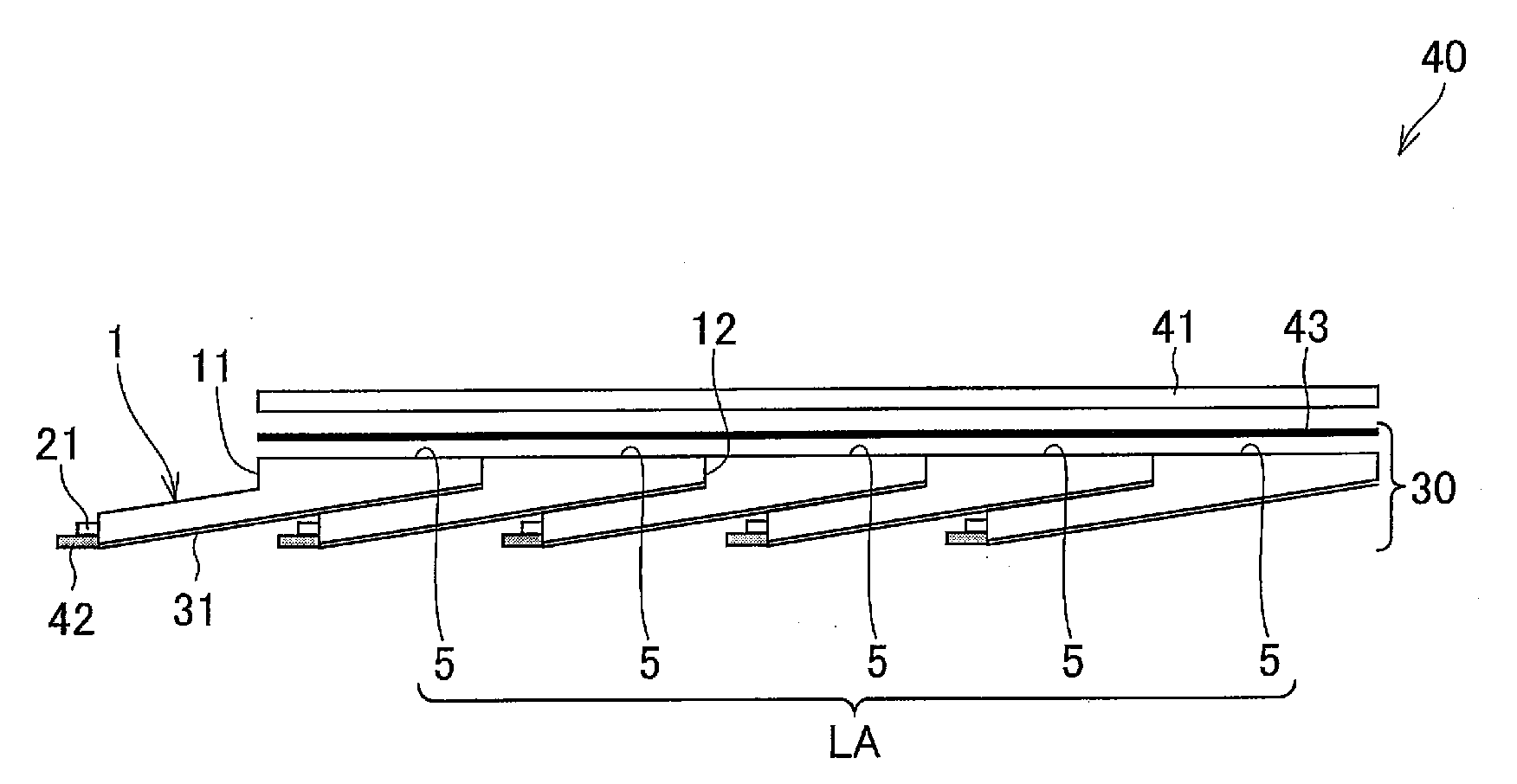

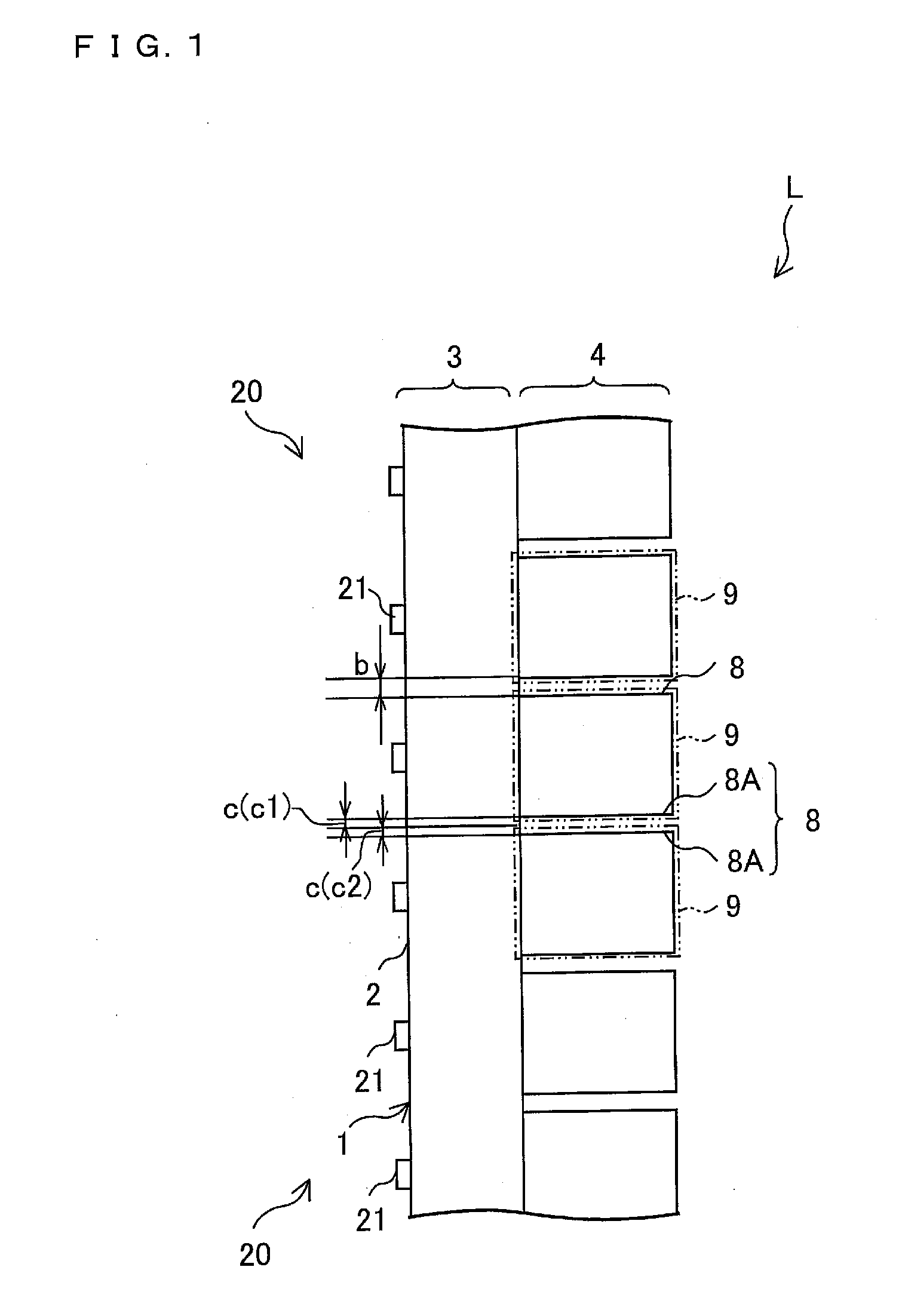

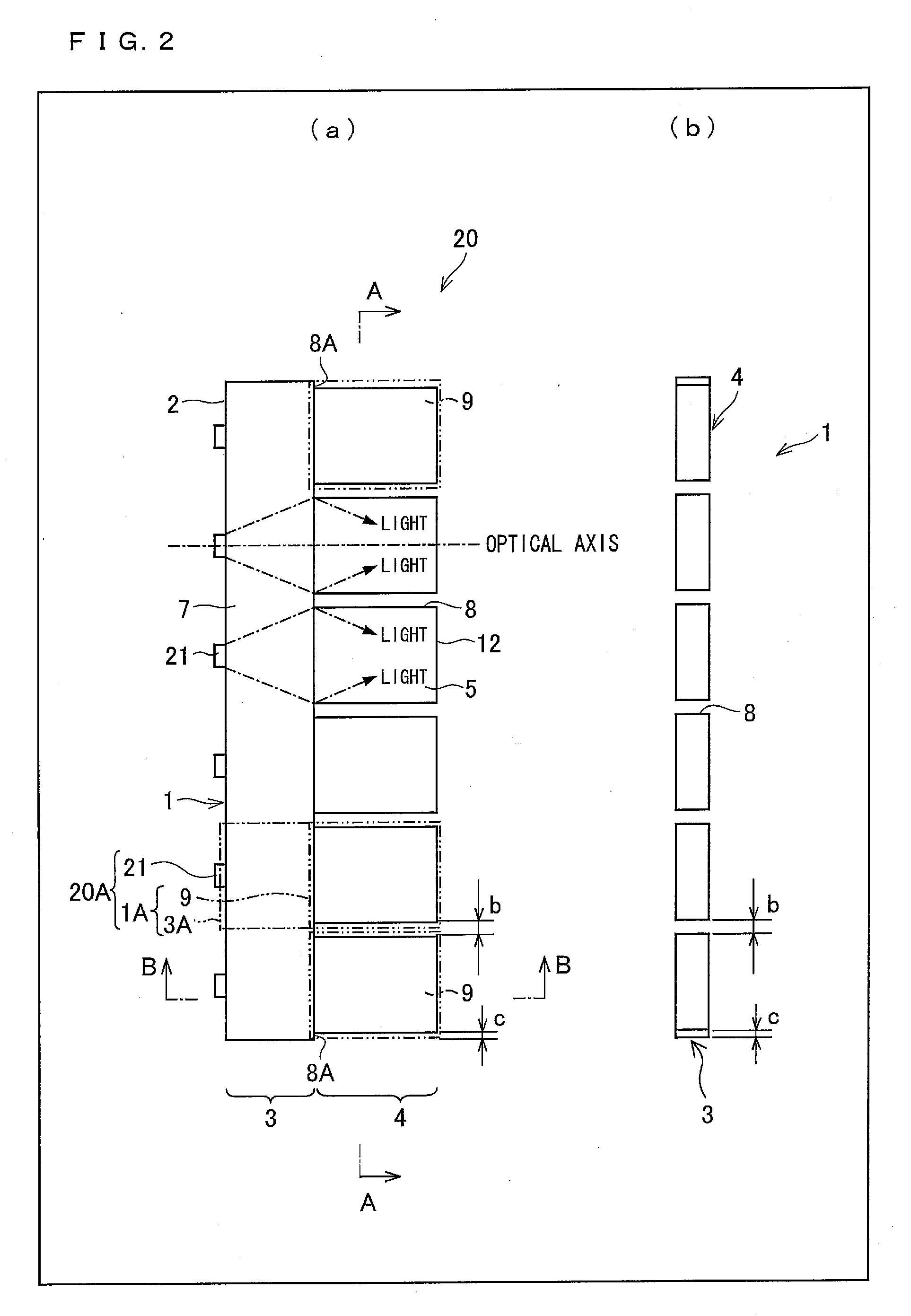

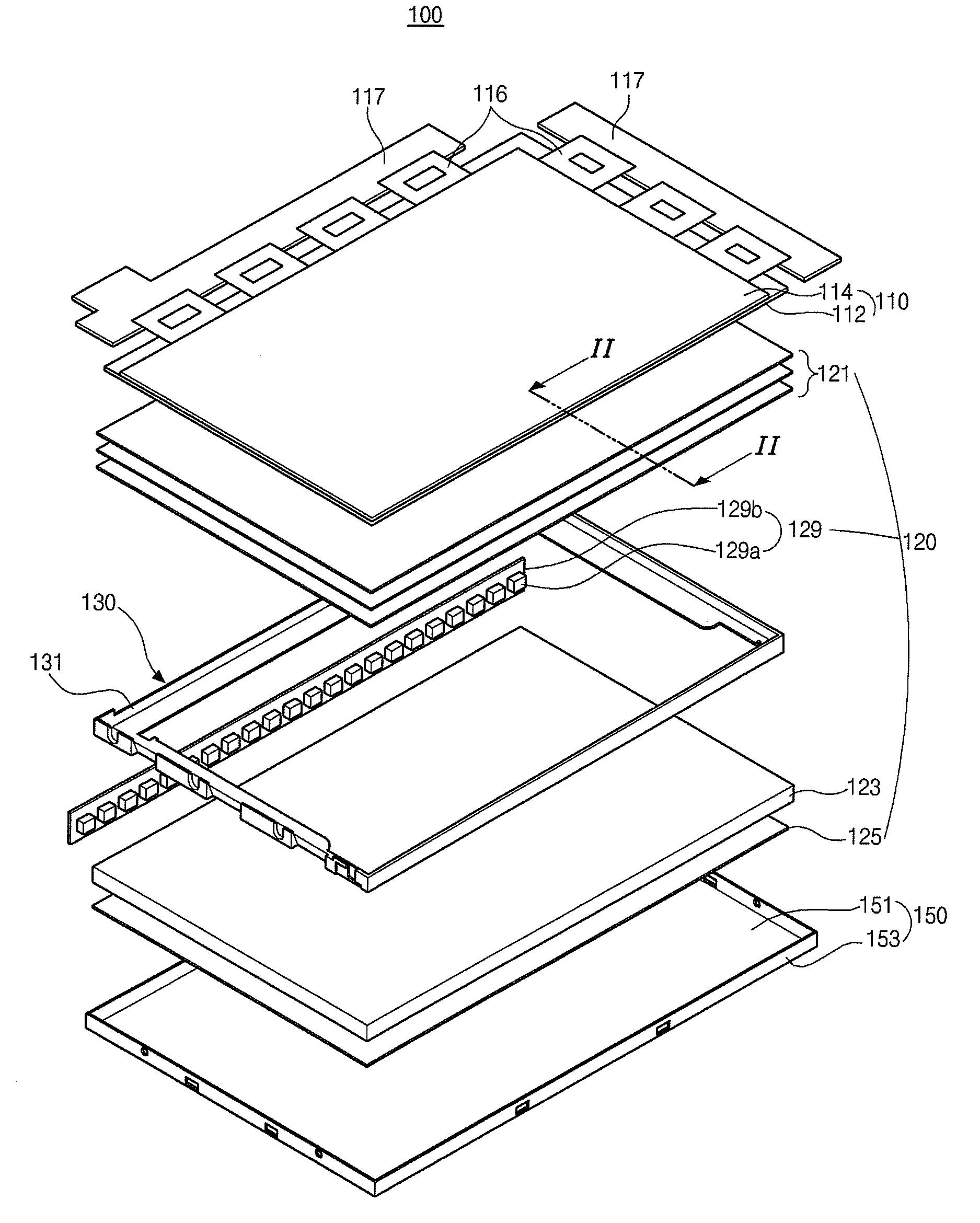

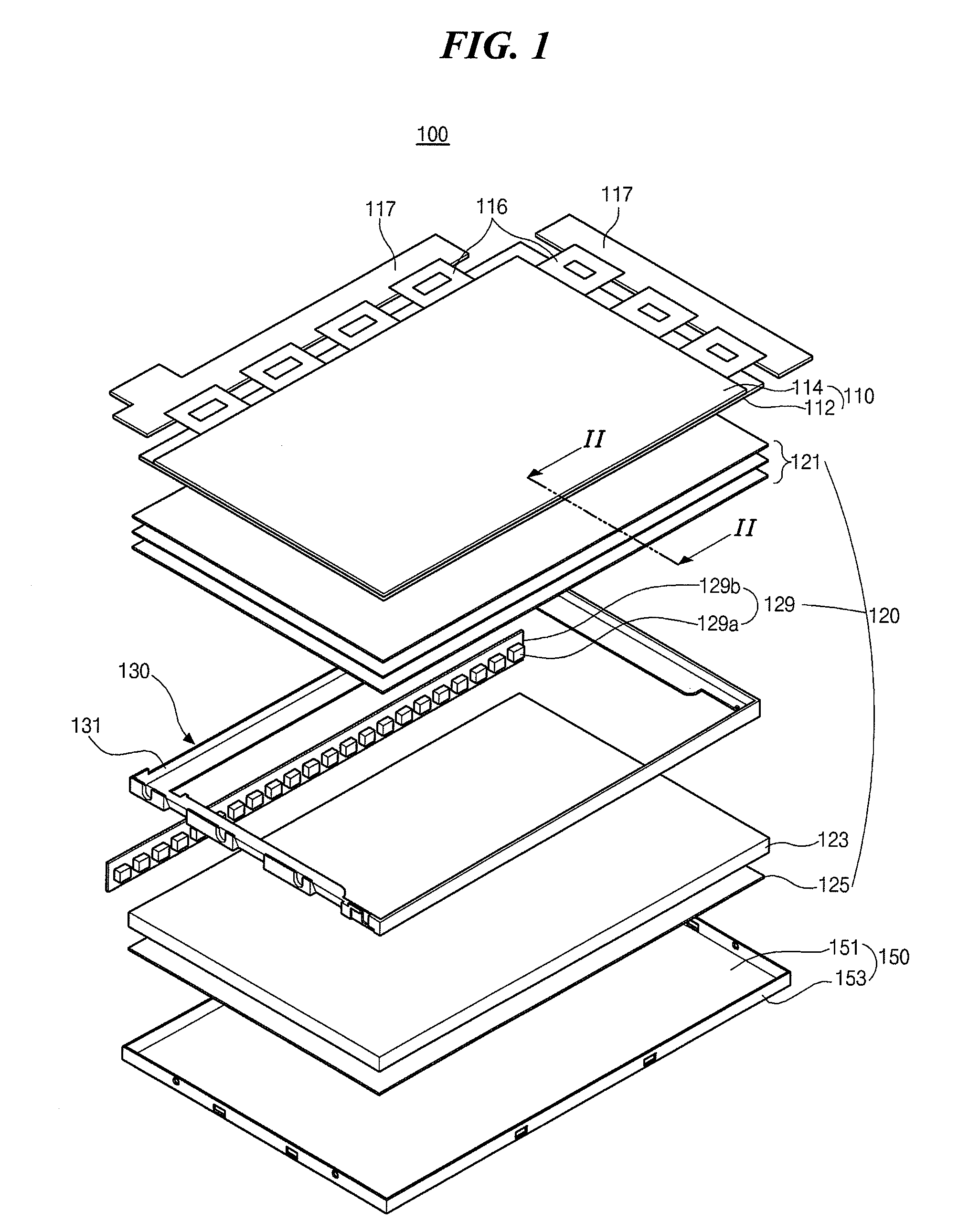

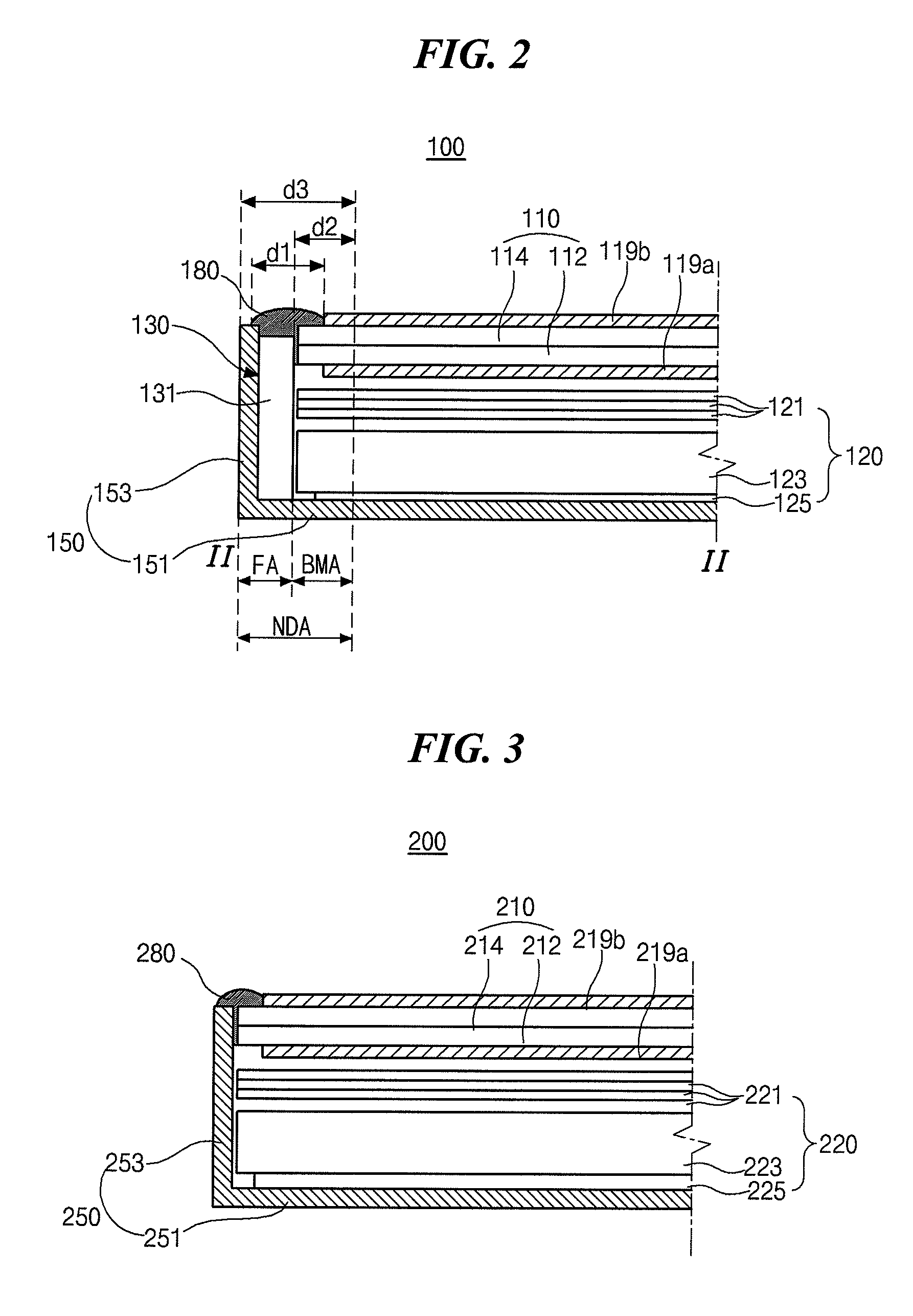

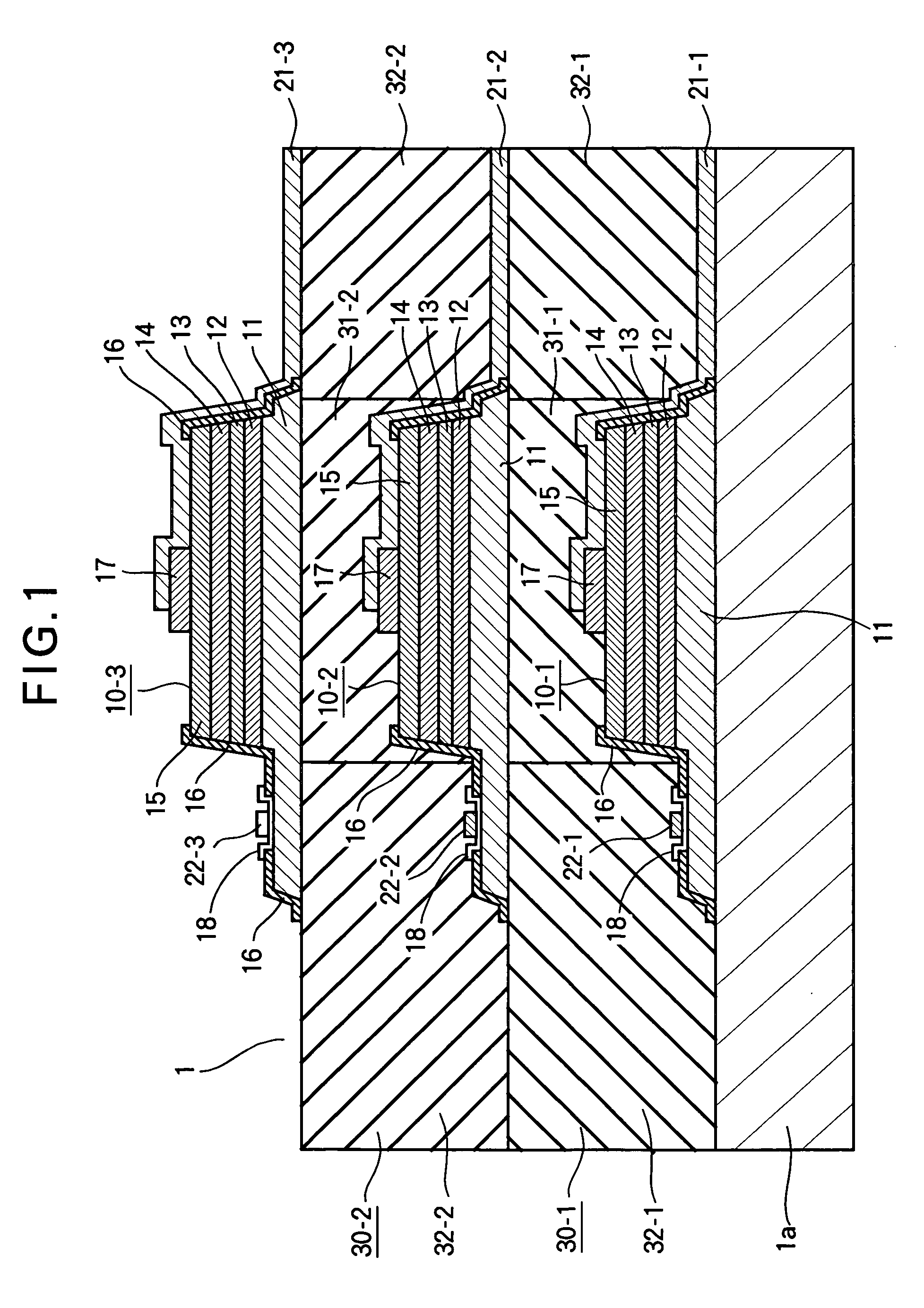

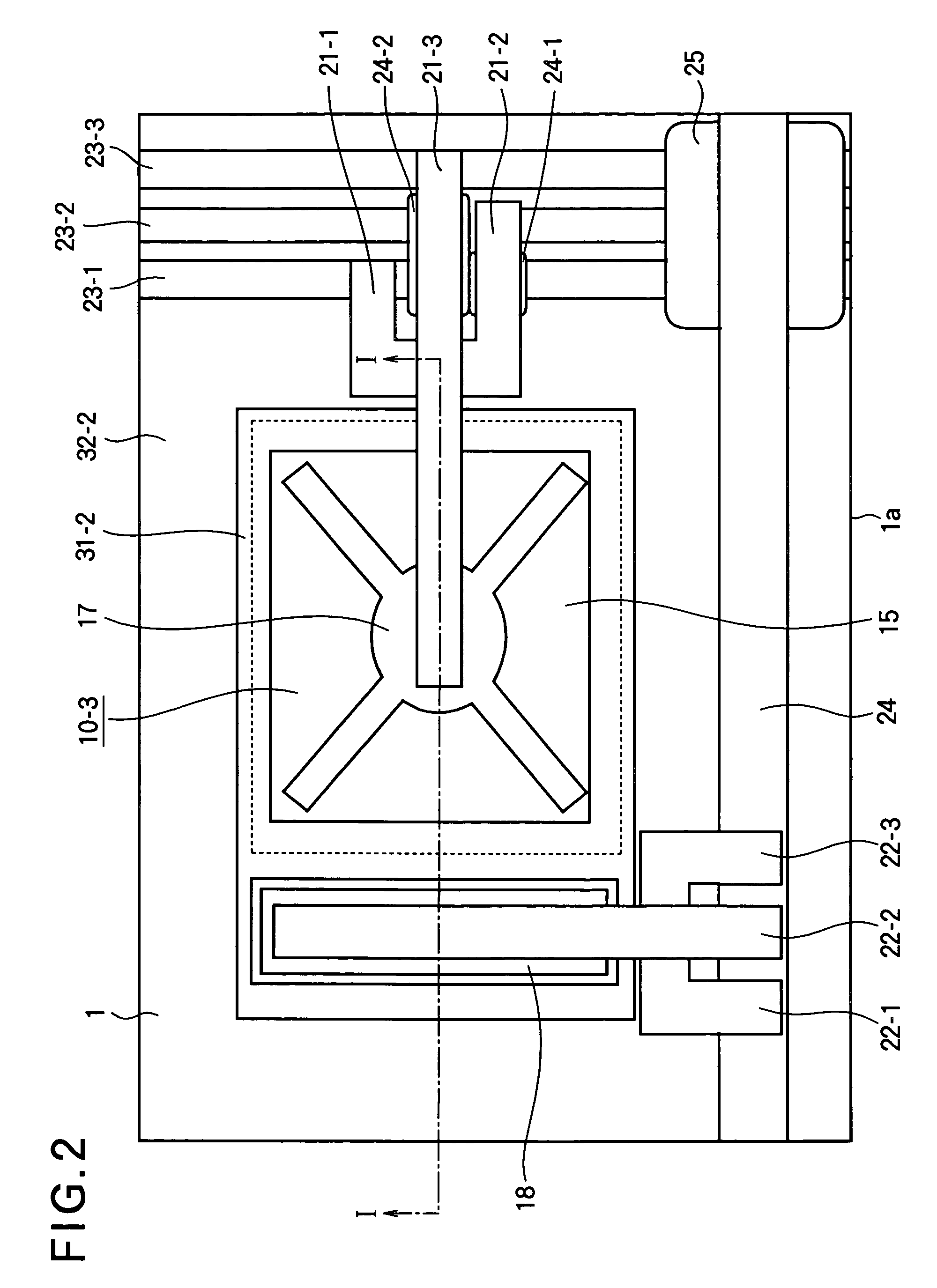

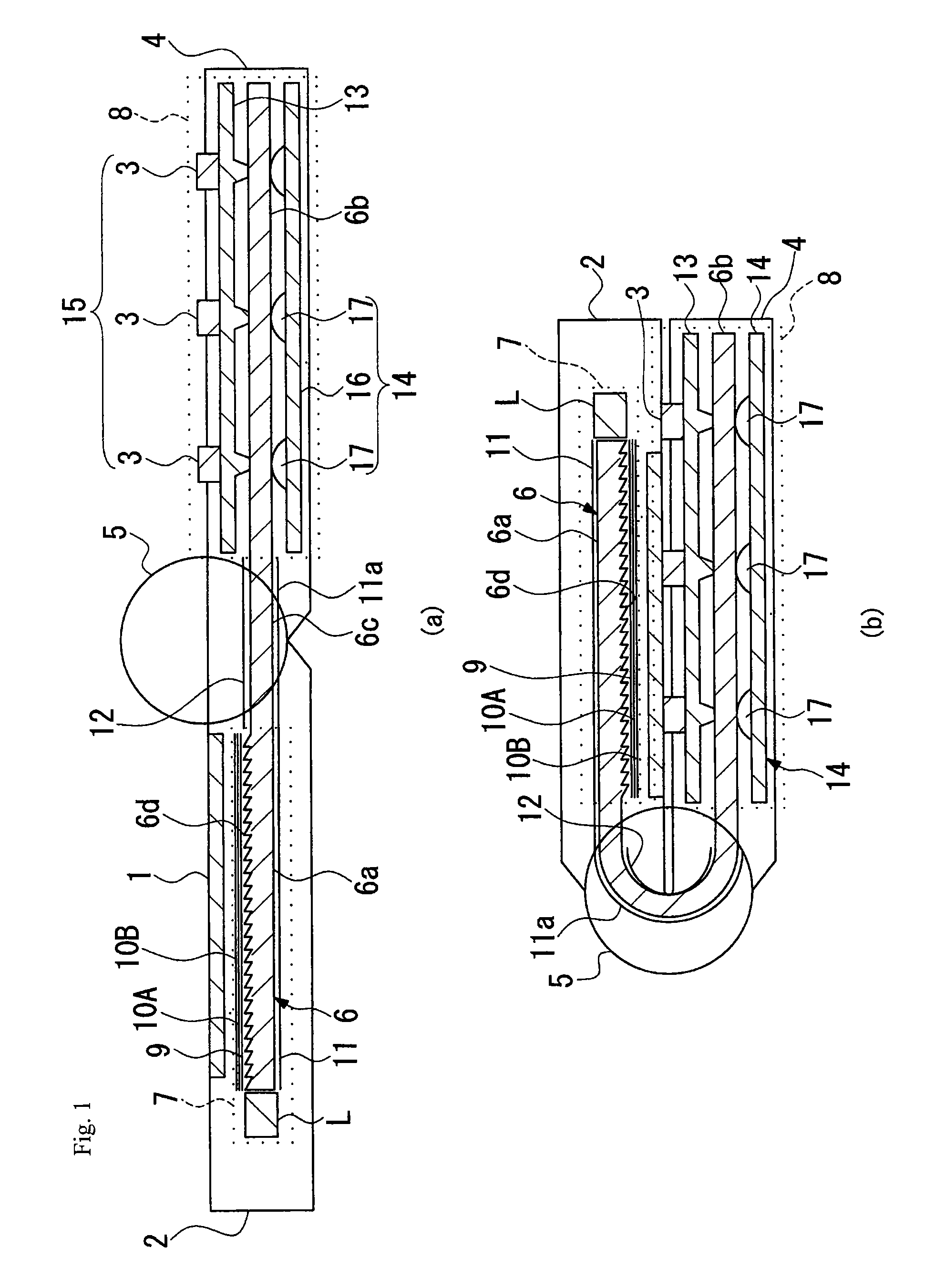

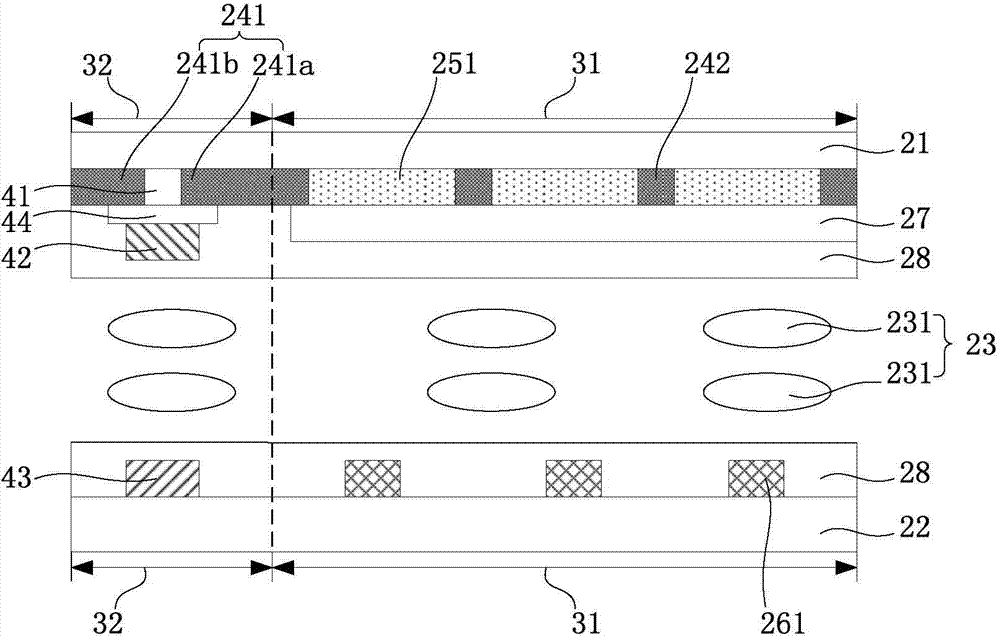

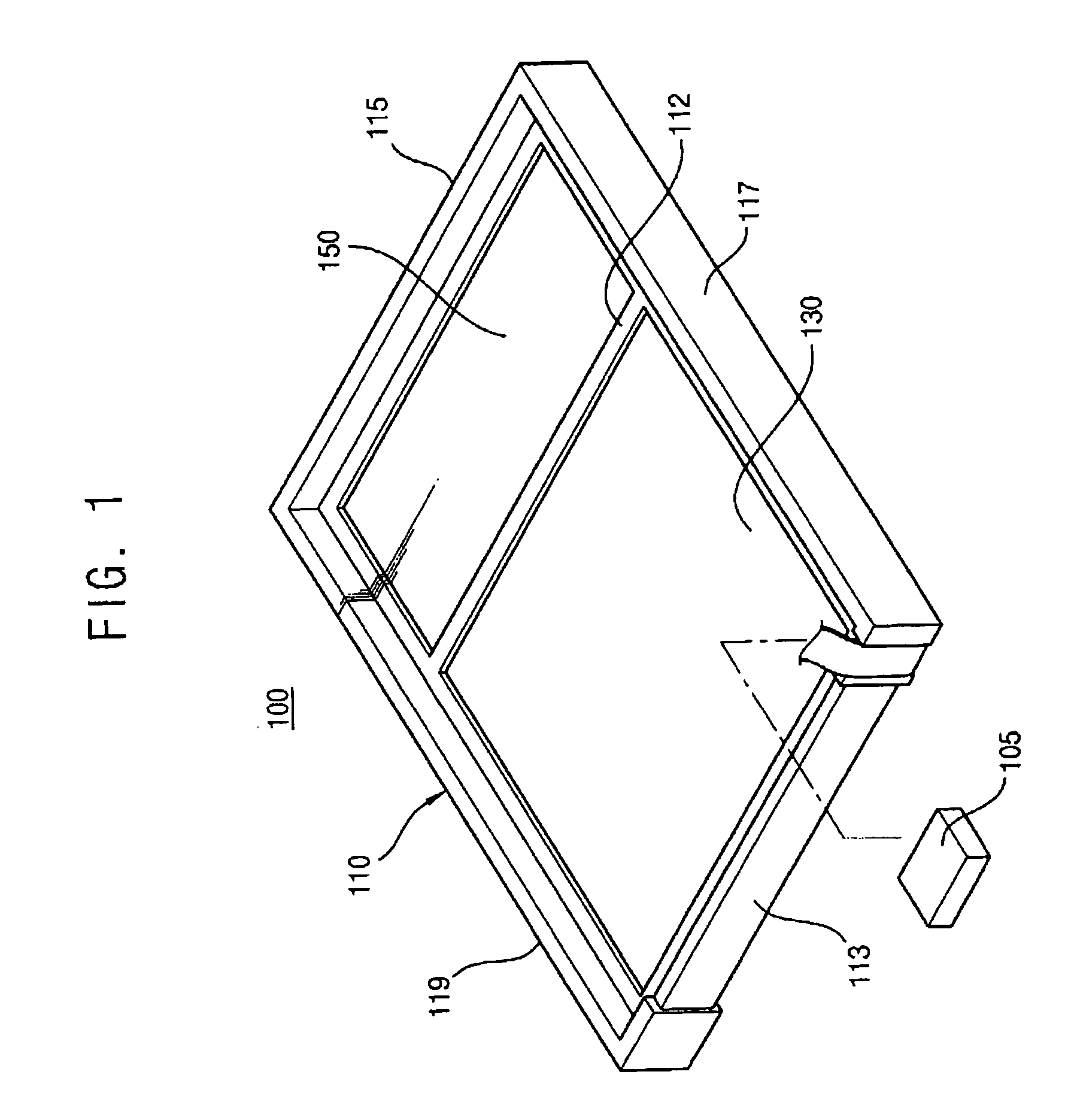

Illumination device, display device, and light guide plate

InactiveUS20110025730A1Reduce light leakageRetention strengthCathode-ray tube indicatorsPlanar/plate-like light guidesLight guideOptical axis

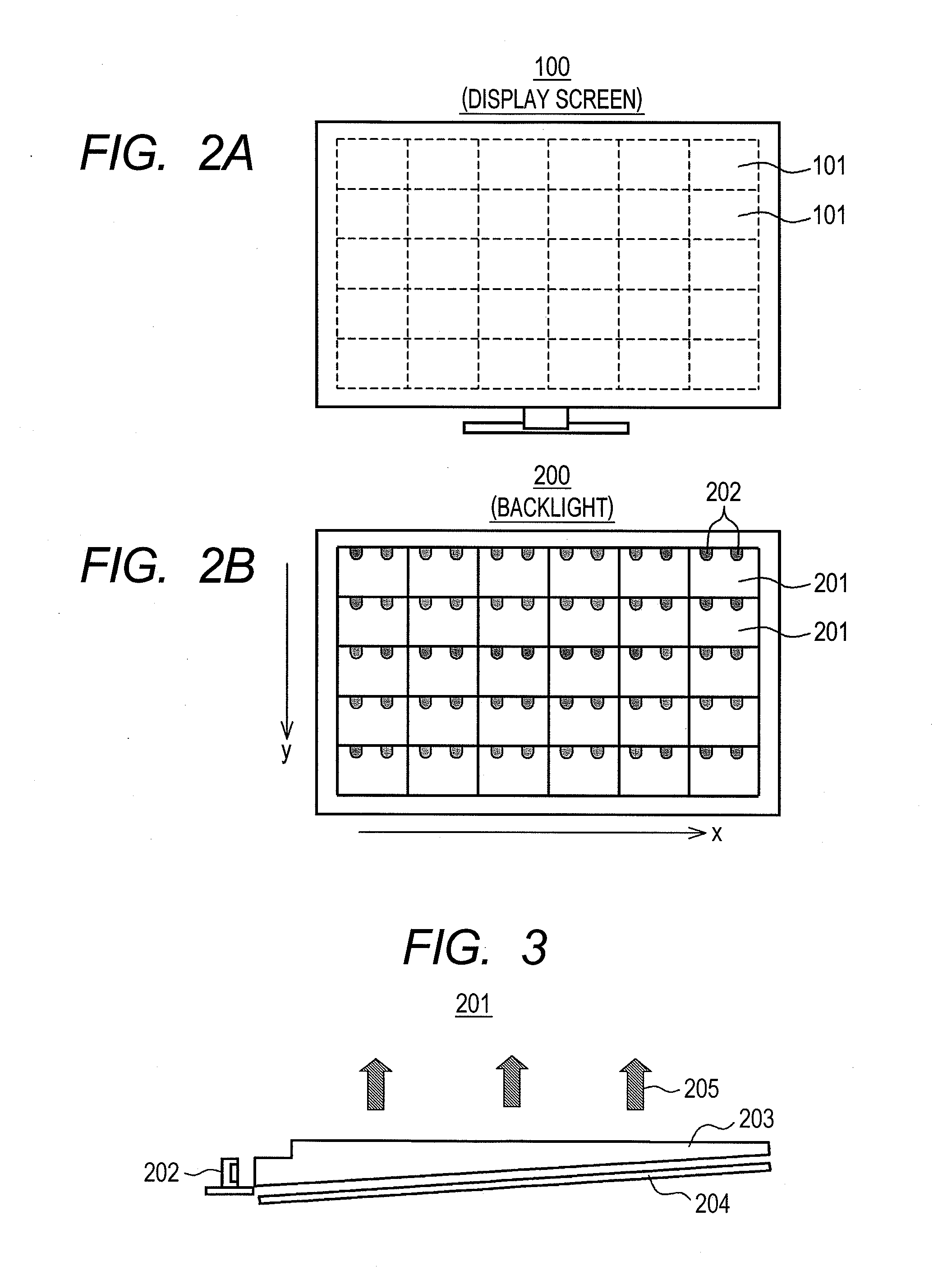

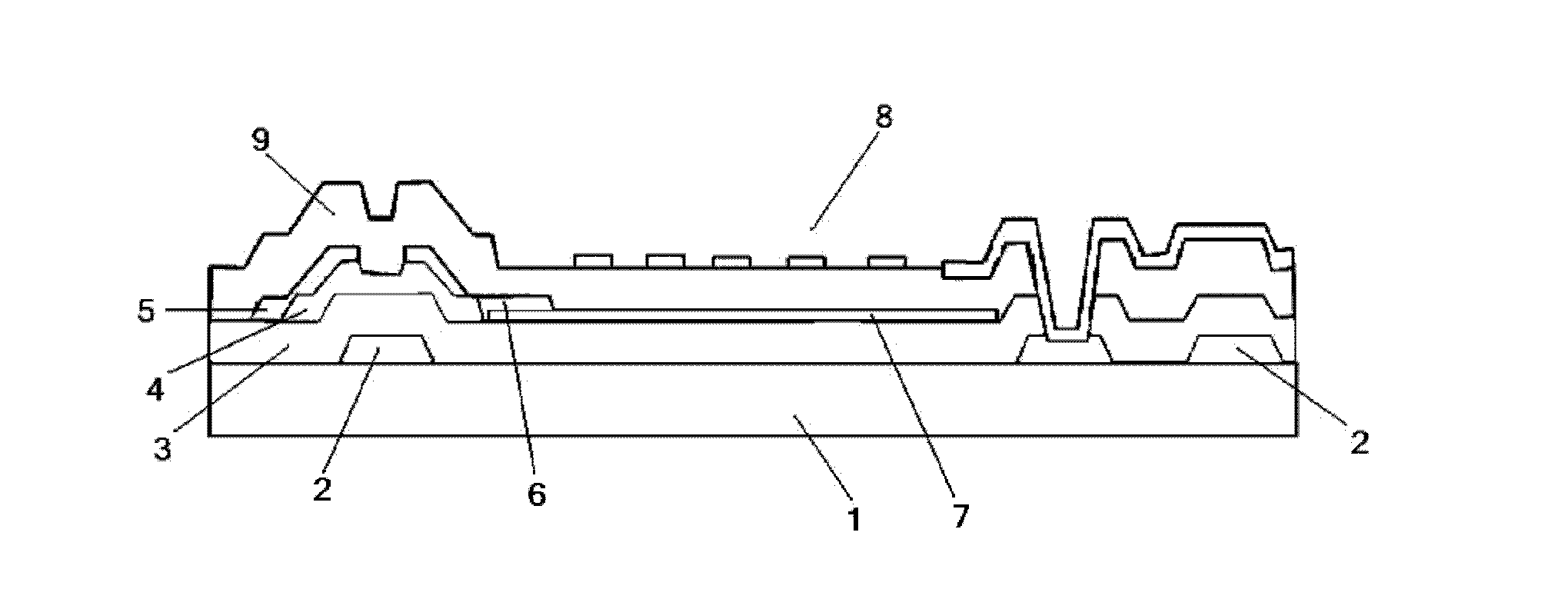

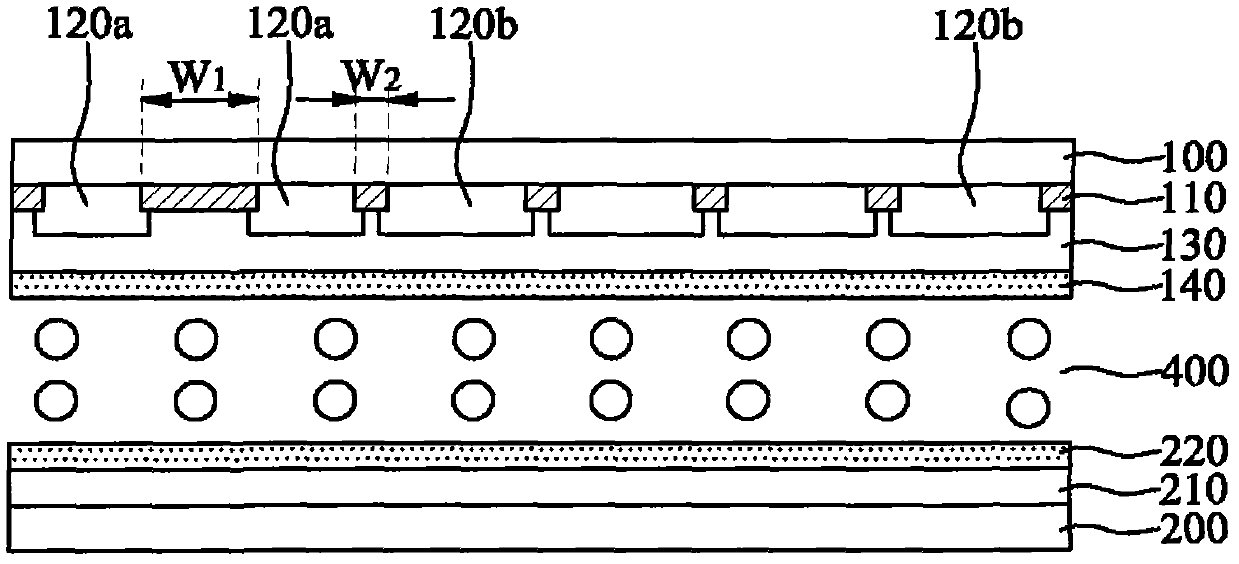

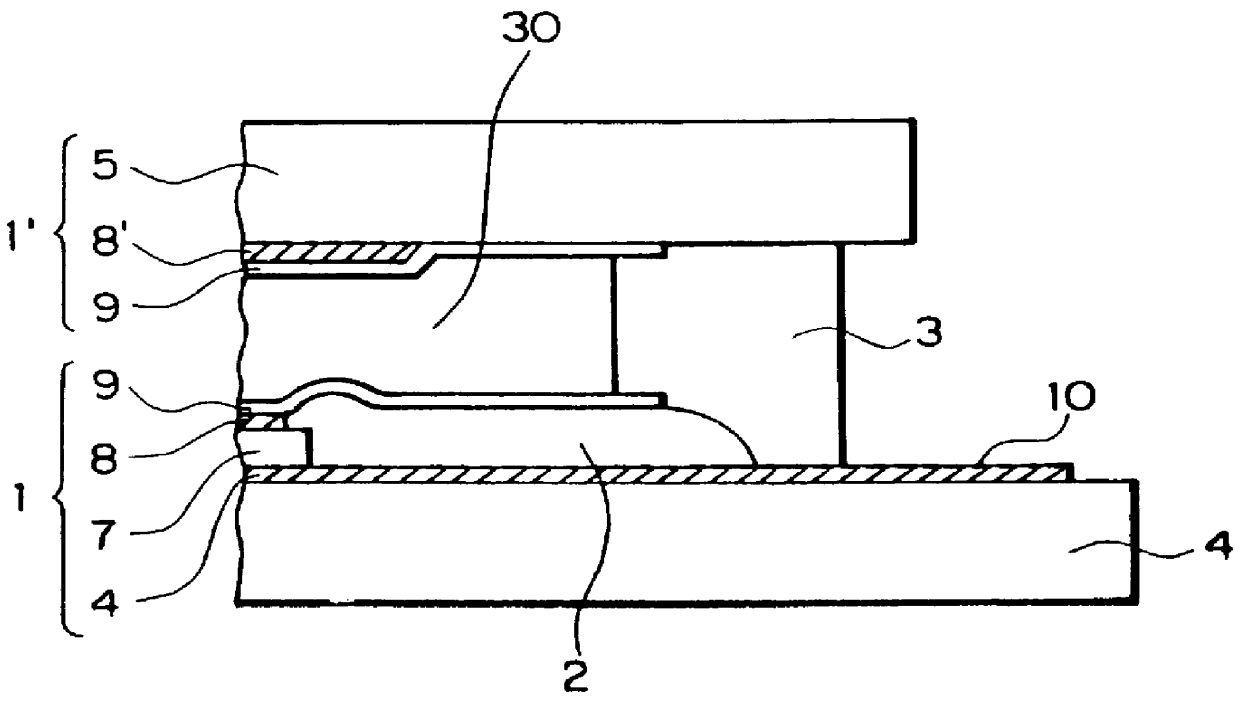

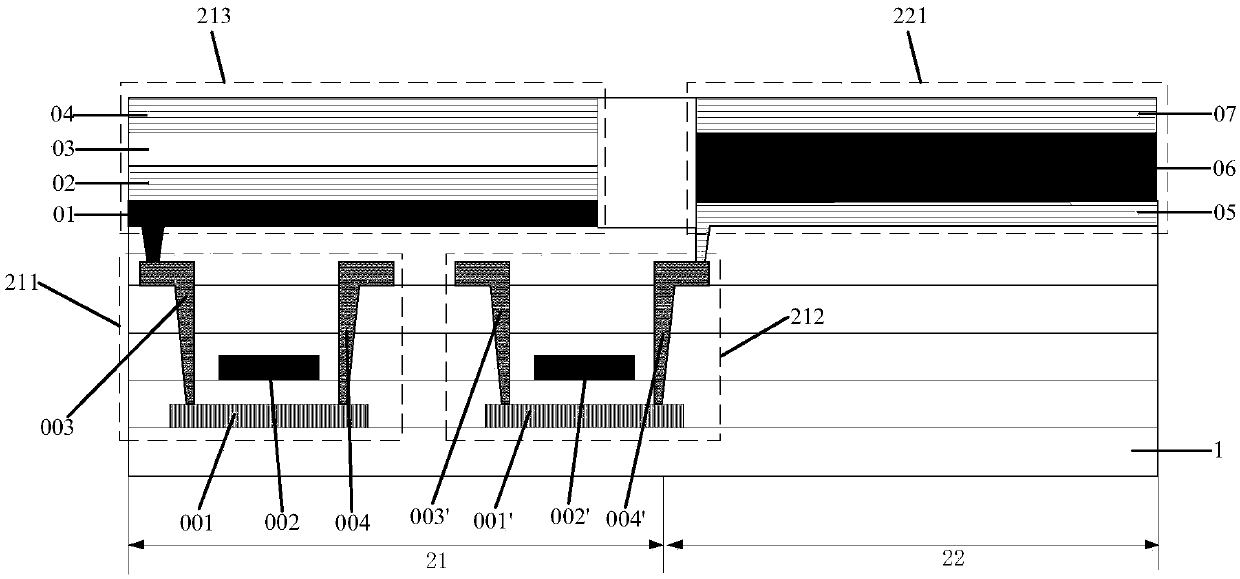

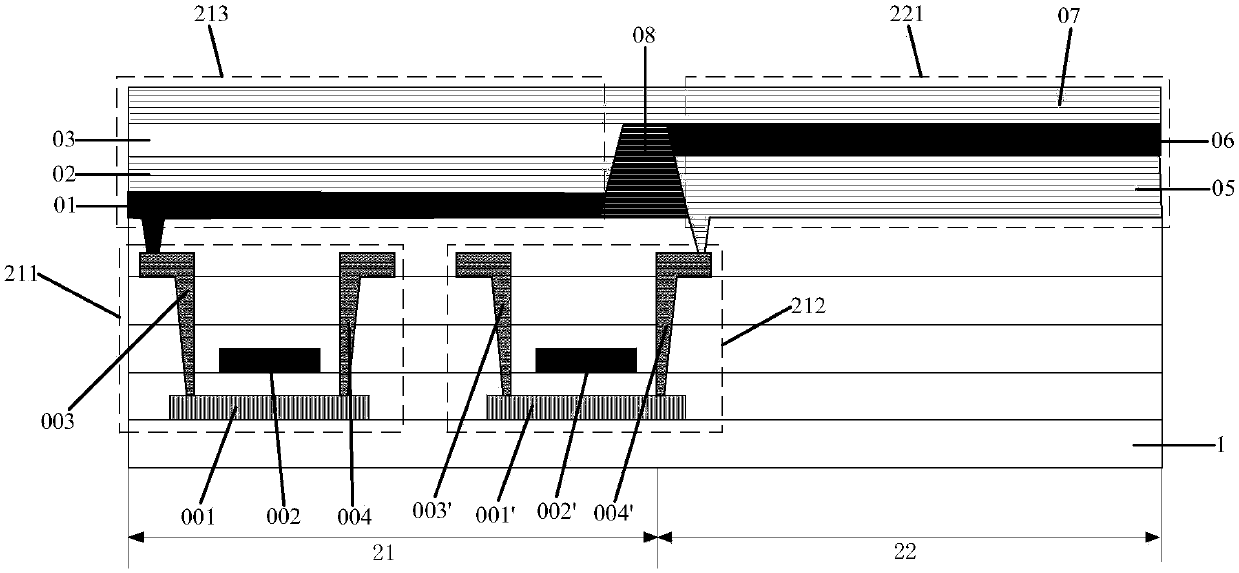

An illumination device (L) includes a plurality of light source units (20) each having a light guide plate (1) and a plurality of light sources (21). The light guide plate (1) has an illumination region (4) through which incident beams of light from the light sources (21) are emitted outward and a light guide region (3) through which the incident beams of light from the light sources (21) are guided toward the illumination region (4), with the light guide region (3) and the illumination region (4) laid side-by-side. The illumination region (4) is divided into a plurality of light-emitting sections (9) by slit sections (8), provided in such a way as to extend along directions of optical axes of the light sources (21), which restrict transmission of light. At least one of the light sources (21) is provided to each of the light-emitting sections (9) in such a way as to be placed side-by-side along the light guide region (3). The light source units (20) are provided in such a way as to be placed side-by-side along at least along a first direction along which the light-emitting sections (9) are arranged in the illumination region (4). There is also provided a slit section (8) in at least part of a space between light-emitting sections (9) between light source units (20) adjacent to each other along the first direction. This makes it possible to provide an illumination device (L) capable of retaining its strength as a combination of light guide blocks while reducing leakage of light into an adjacent area and capable of emitting uniform light.

Owner:SHARP KK

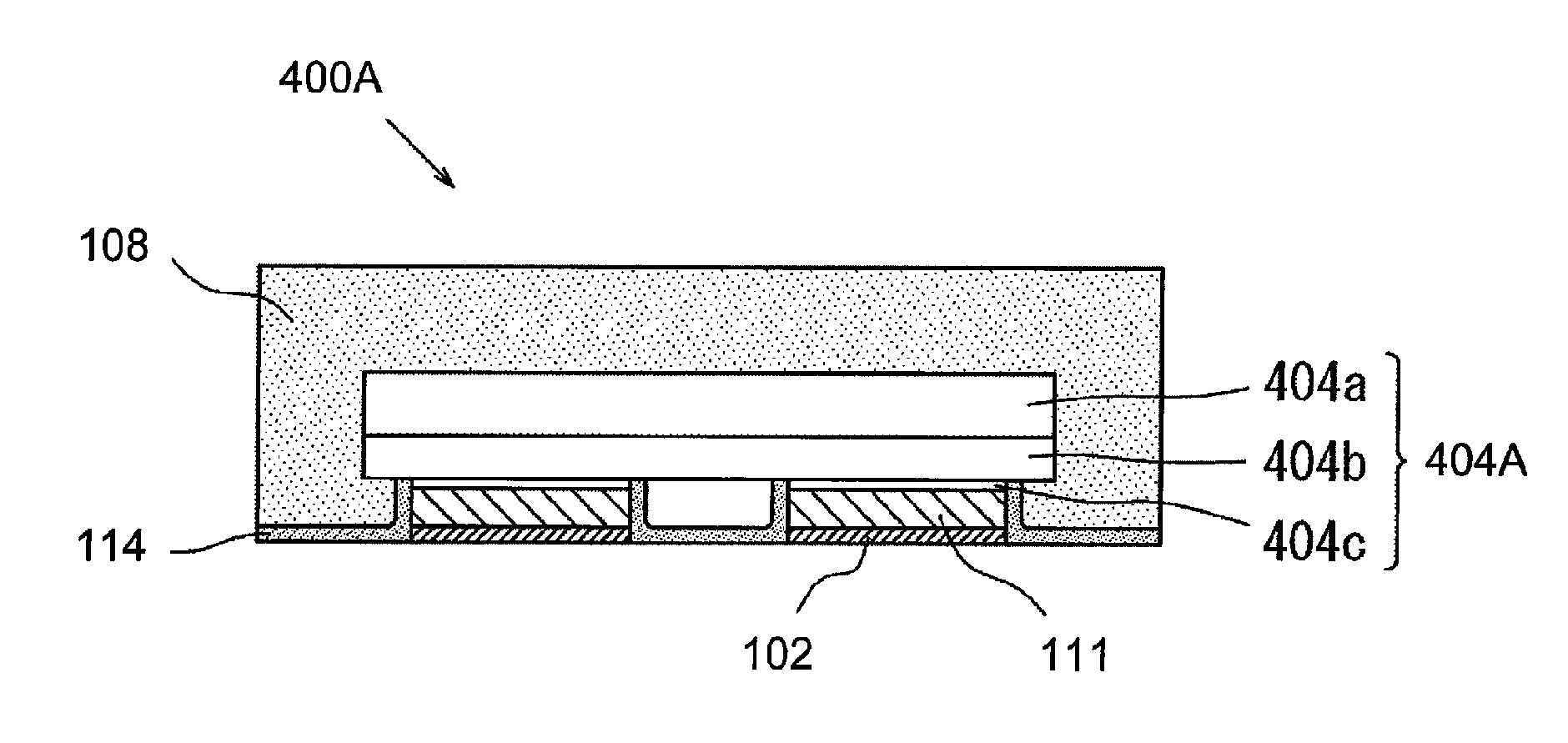

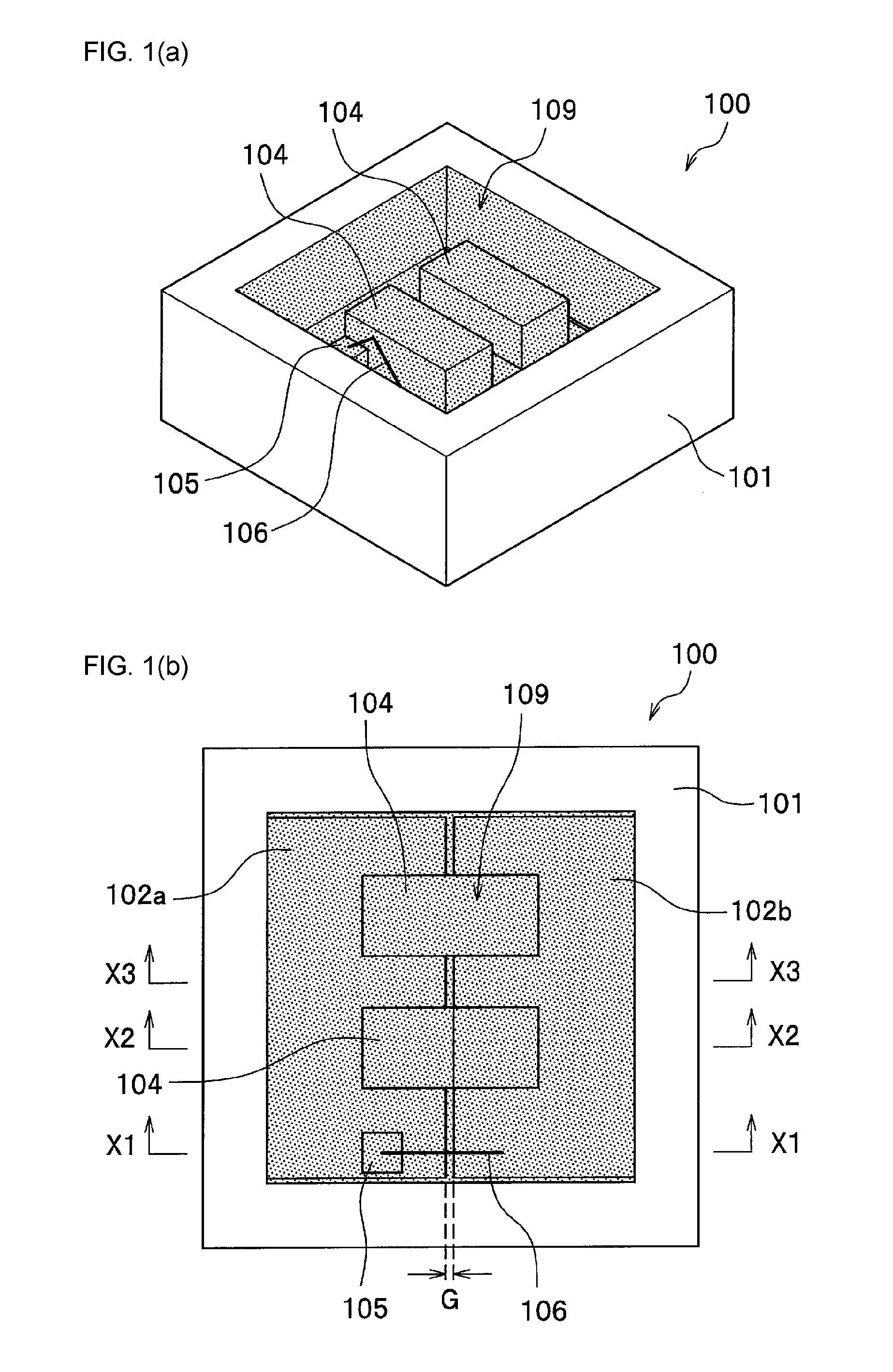

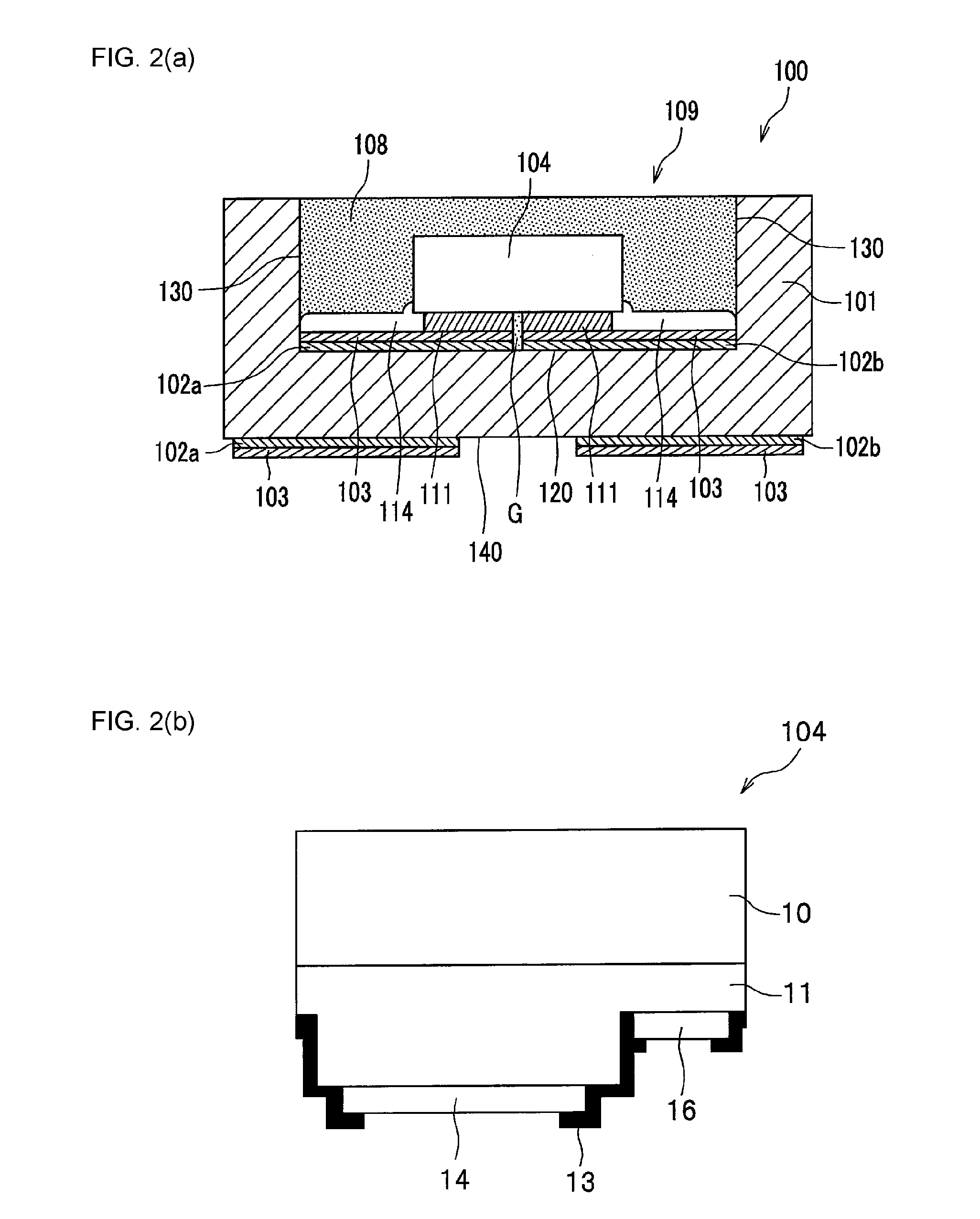

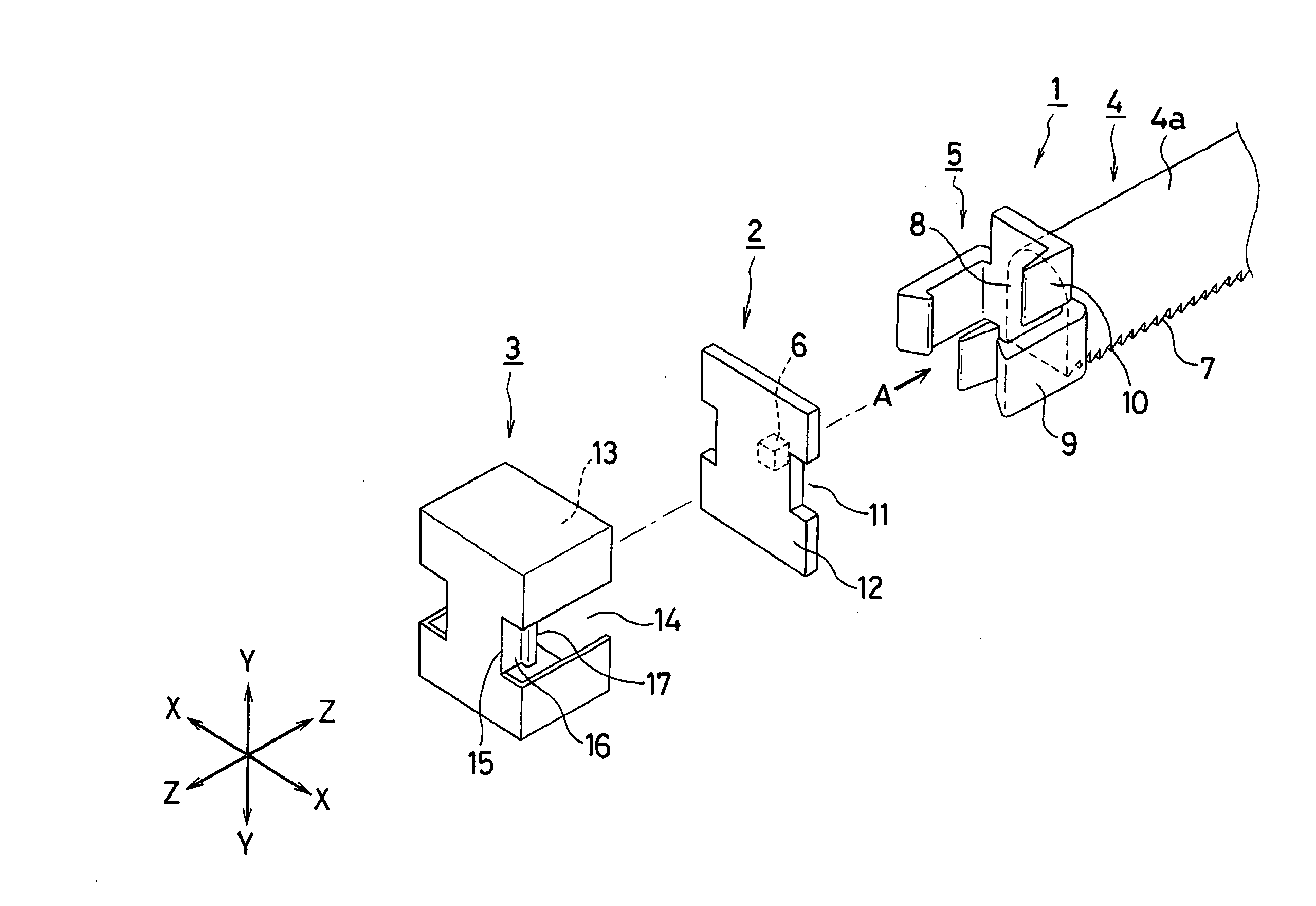

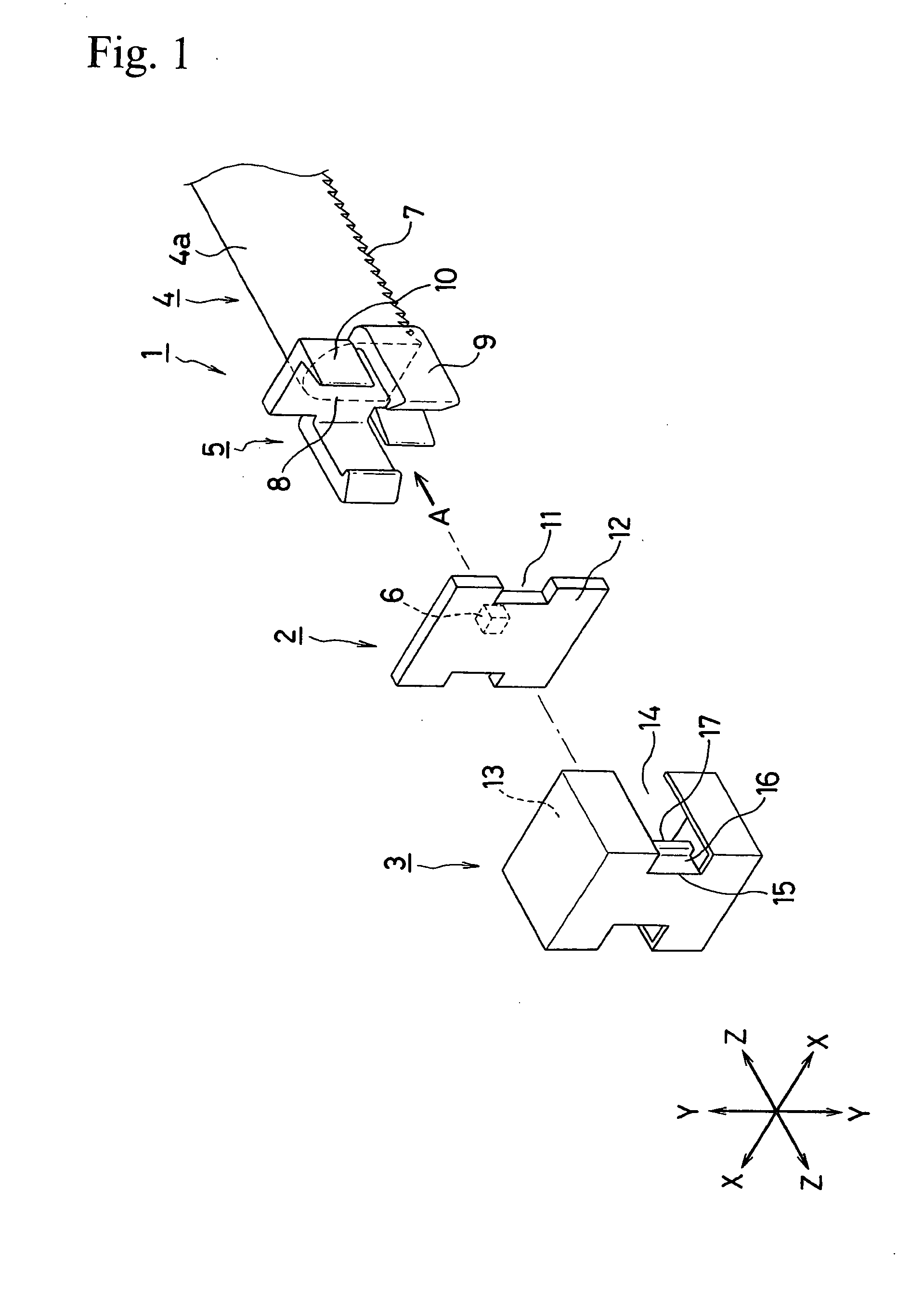

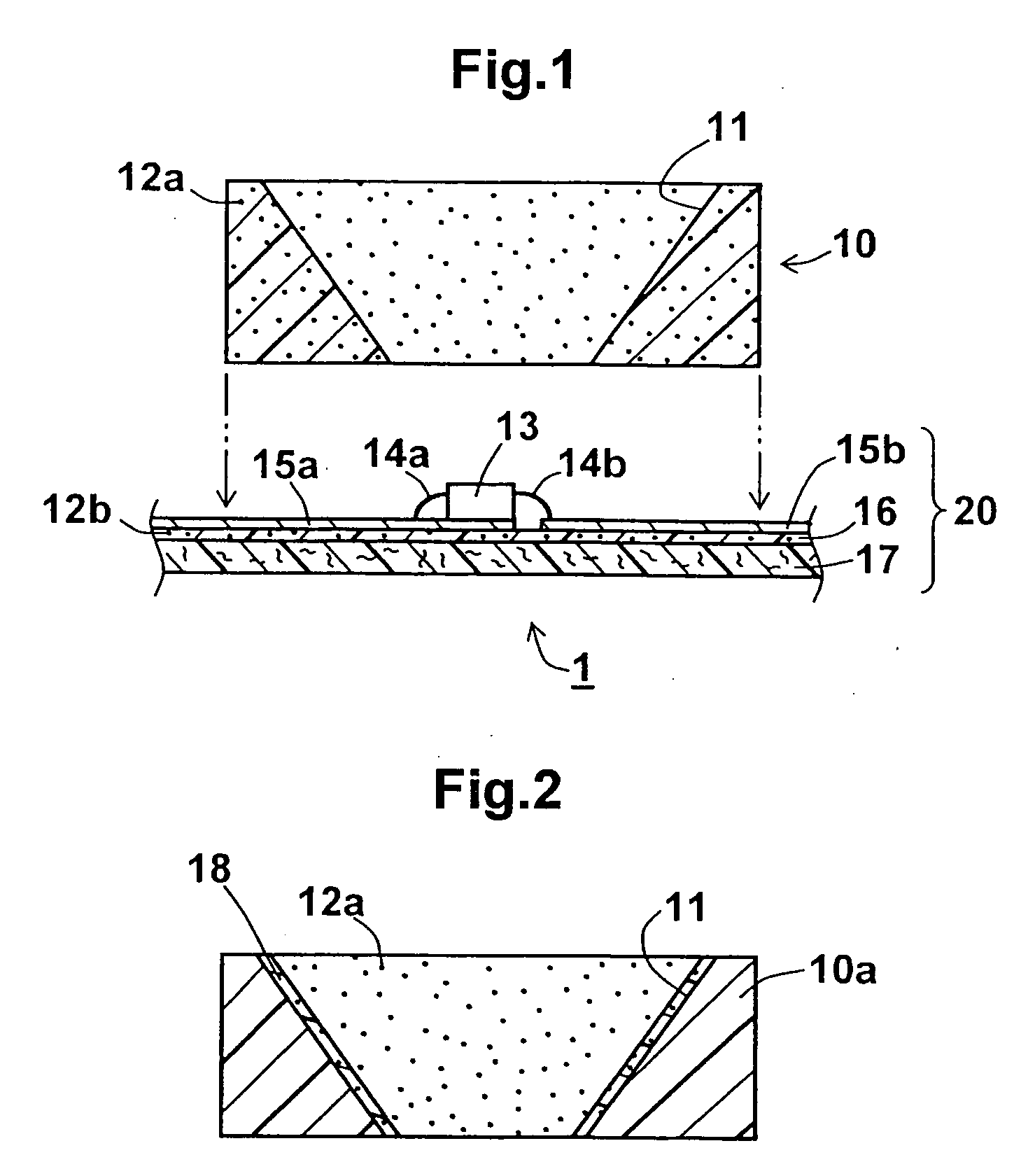

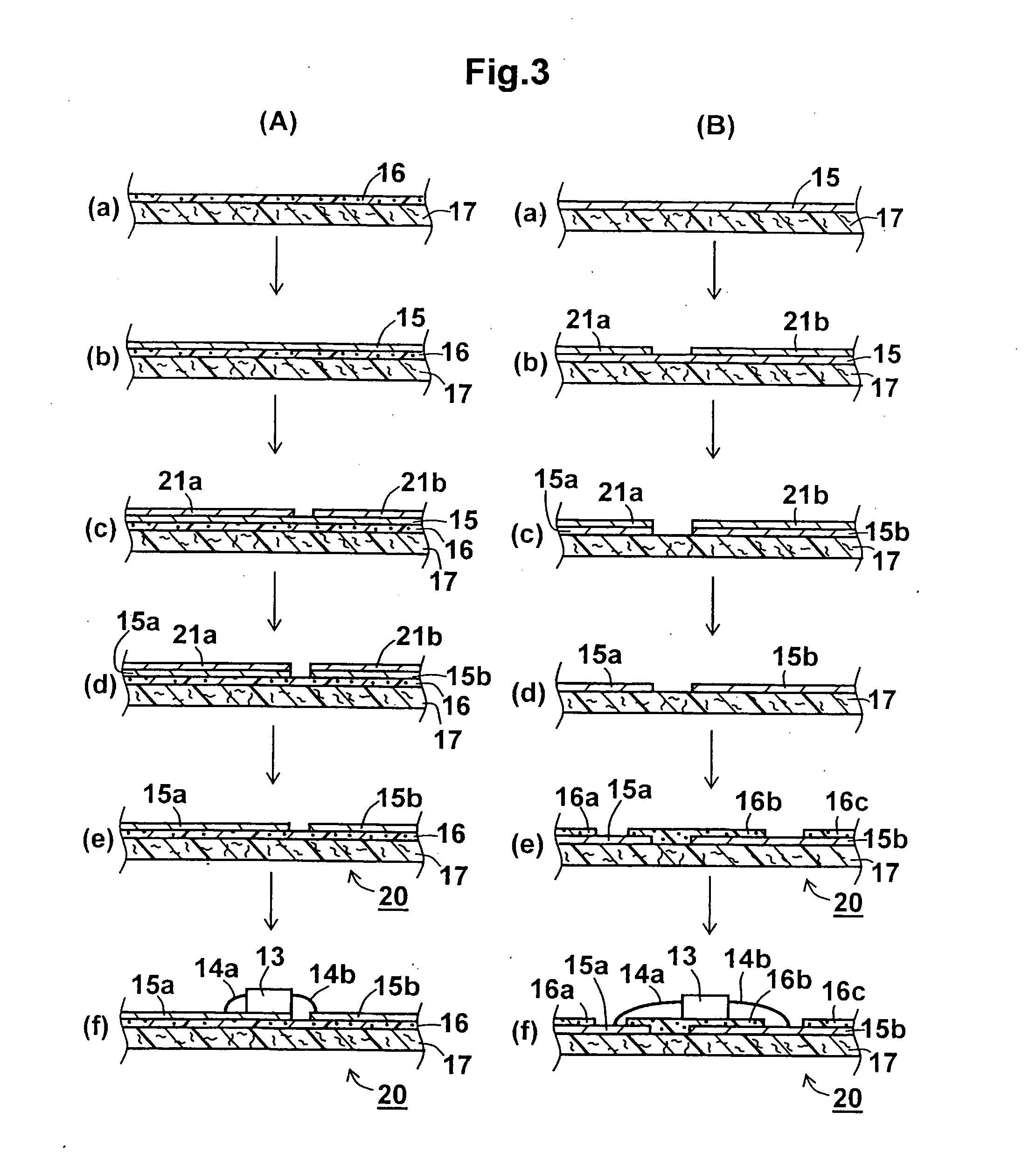

Light emitting device and method for manufacturing light emitting device

ActiveUS20130037842A1Increase productionAvoid light leakageSolid-state devicesSemiconductor devicesLight emitting deviceLight-emitting diode

A light emitting device (100) includes a base member (101), electrically conductive members (102a, 102b) disposed on the base member (101), a light emitting element (104) mounted on the electrically conductive members (102a, 102b), an insulating filler (114) covering at least a portion of surfaces of the electrically conductive members (102a, 102b) where the light emitting element (104) is not mounted, and a light transmissive member (108) covering the light emitting element (104).

Owner:NICHIA CORP

Display device and method of fabricating the same

ActiveUS20130027857A1Avoid light leakageReduce manufacturing costDigital data processing detailsLaminationAdhesiveDisplay device

A display device includes: a display panel displaying an image; a first frame surrounding the display panel; and an adhesive between a side surface of the display panel and a side surface of the first frame, wherein the display device is attached and fixed to the first frame by the adhesive.

Owner:LG DISPLAY CO LTD

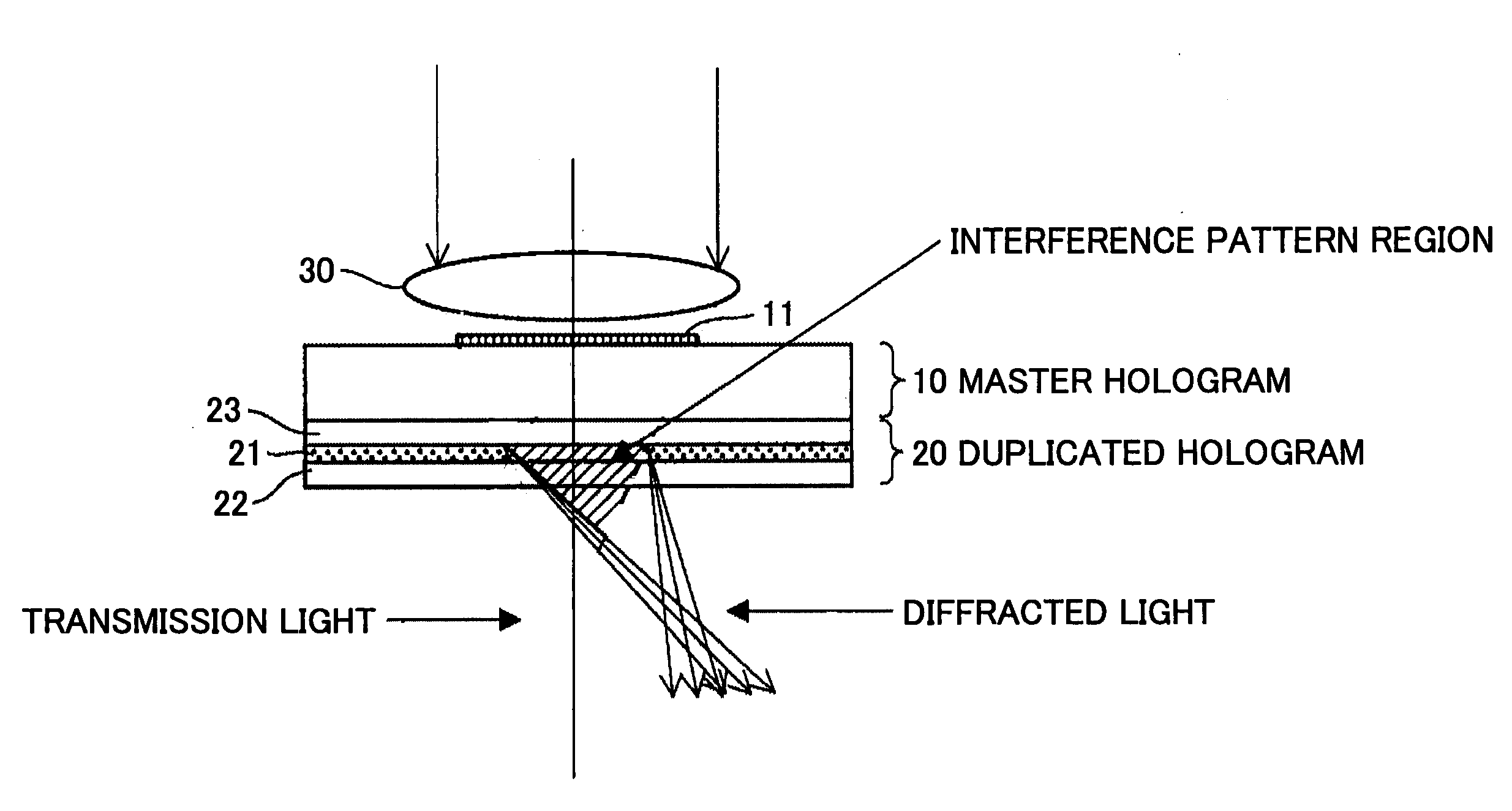

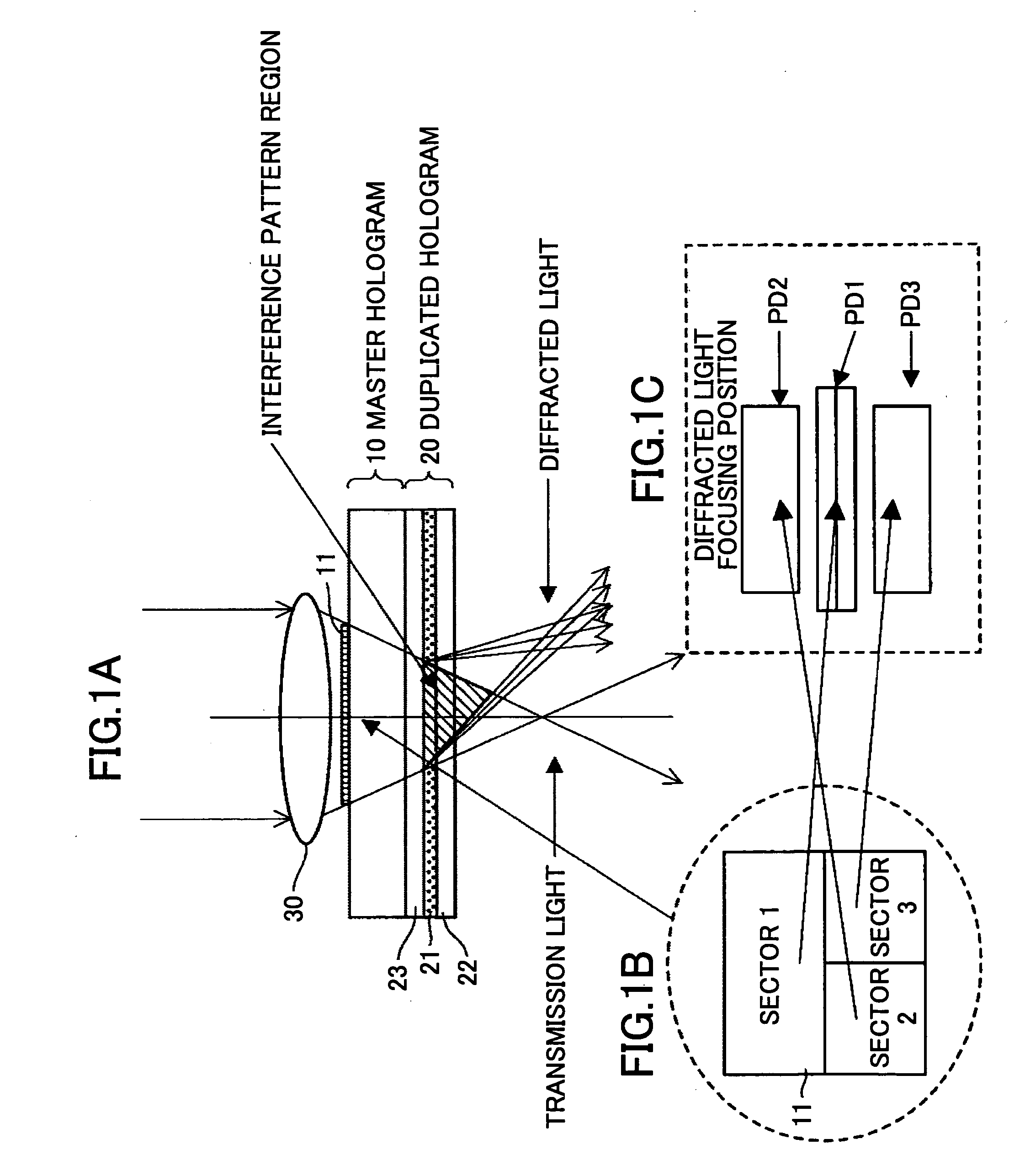

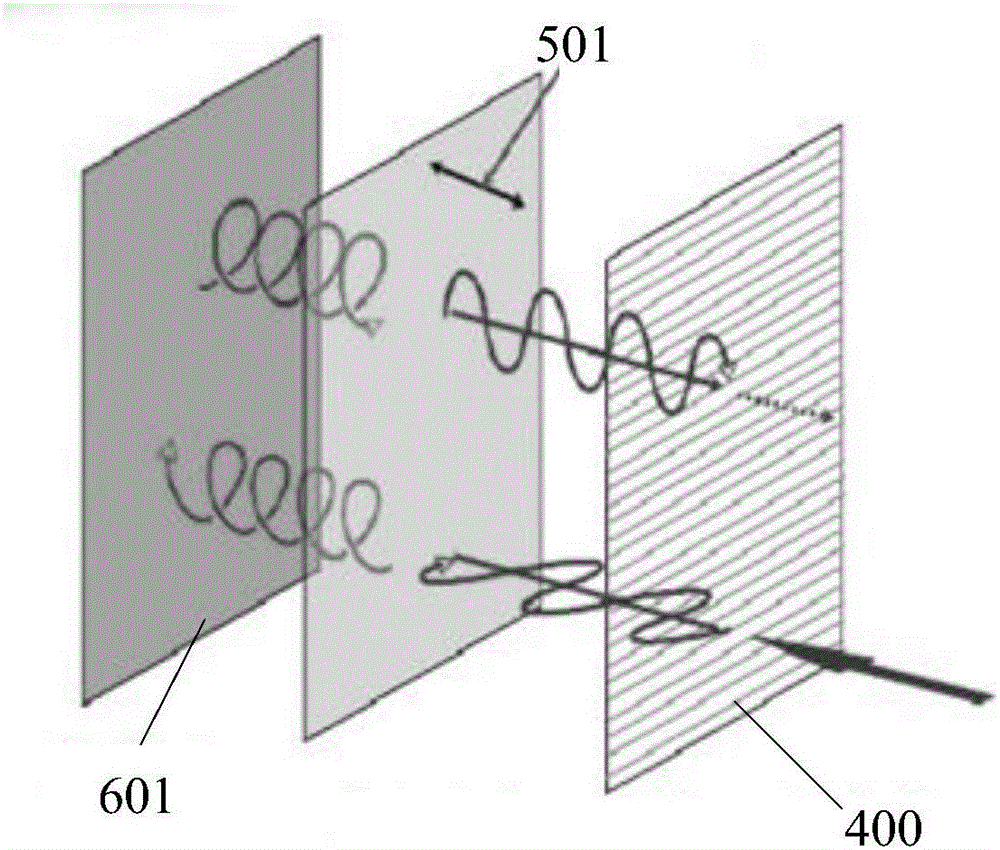

Hologram element, production method thereof, and optical header

InactiveUS20060055993A1High film thicknessImprove productivityHolographic light sources/light beam propertiesRecord information storageProduction rateLight beam

A method of producing a hologram element is disclosed that is able to prevent spread of a polymerization reaction and light leakage during exposure with interference light, and improve productivity in mass production. The hologram element is for transmitting, reflecting, diffracting, or scattering incident light, and includes a pair of substrates, an isolation member between the substrates that forms an isolated region, and a photo-sensitive recording material sealed in the isolated region. The hologram element includes a periodic structure formed by exposing the recording material to interference light. The interference light is generated by two or more light beams, or by using a master hologram. The recording material is formed from a composite material including a polymerized polymer or a polymerized liquid crystal. The periodic structure is formed by exposing the recording material to the interference light to induce the polymerization reaction and phase separation in the composite material.

Owner:RICOH KK

Liquid crystal display device

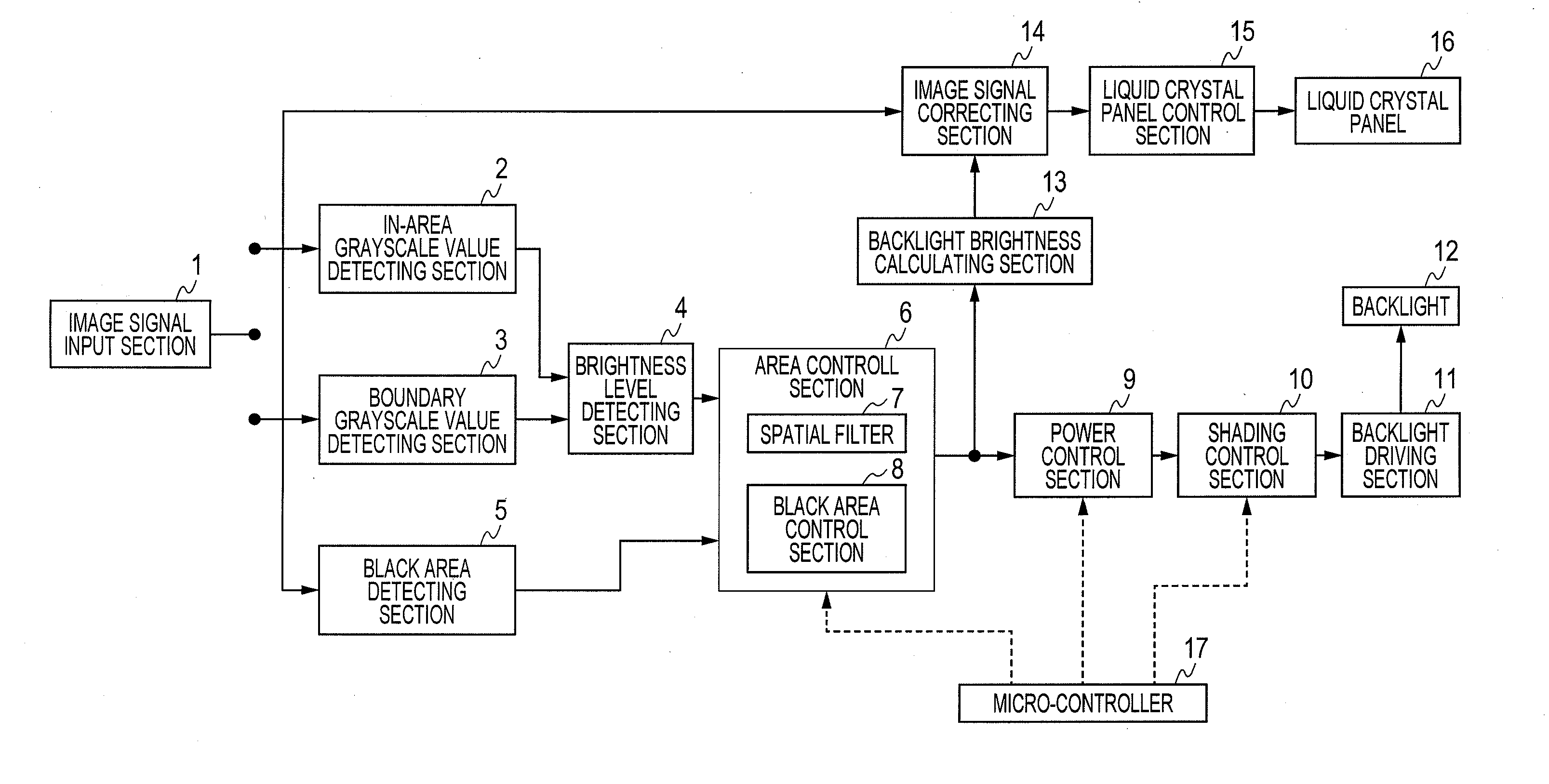

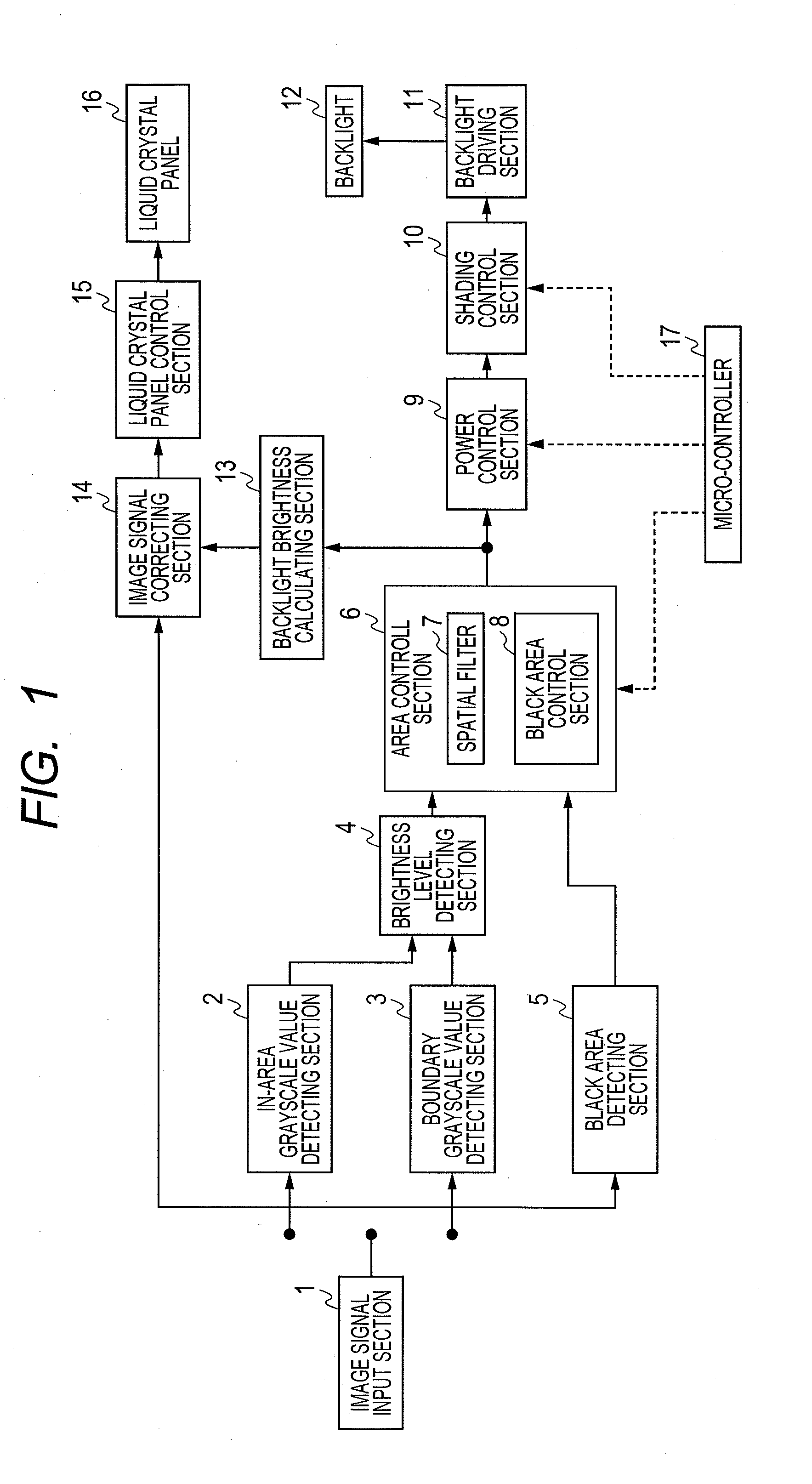

ActiveUS20110292018A1Reduce brightnessEasy to set upCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayLimit value

An area control section individually sets illumination intensity (light control value) of each backlight cell corresponding to each area of the display screen. A spatial filter corrects the light control values so that spatial distribution of the light control values becomes more moderate between adjoining areas. A black area control section sets the minimum value of the light control value based on a “black area” in the screen. A power control section corrects the light control values so that power consumption of the backlight does not exceed a limit value. A shading control section corrects the light control values to relatively lower brightness in the peripheral part of the screen compared to the central part of the screen. A micro-controller switches the operations of the above light control value correcting sections according to an image display mode selected by the user.

Owner:MAXELL HLDG LTD

Layered semiconductor light emitting device and image forming apparatus

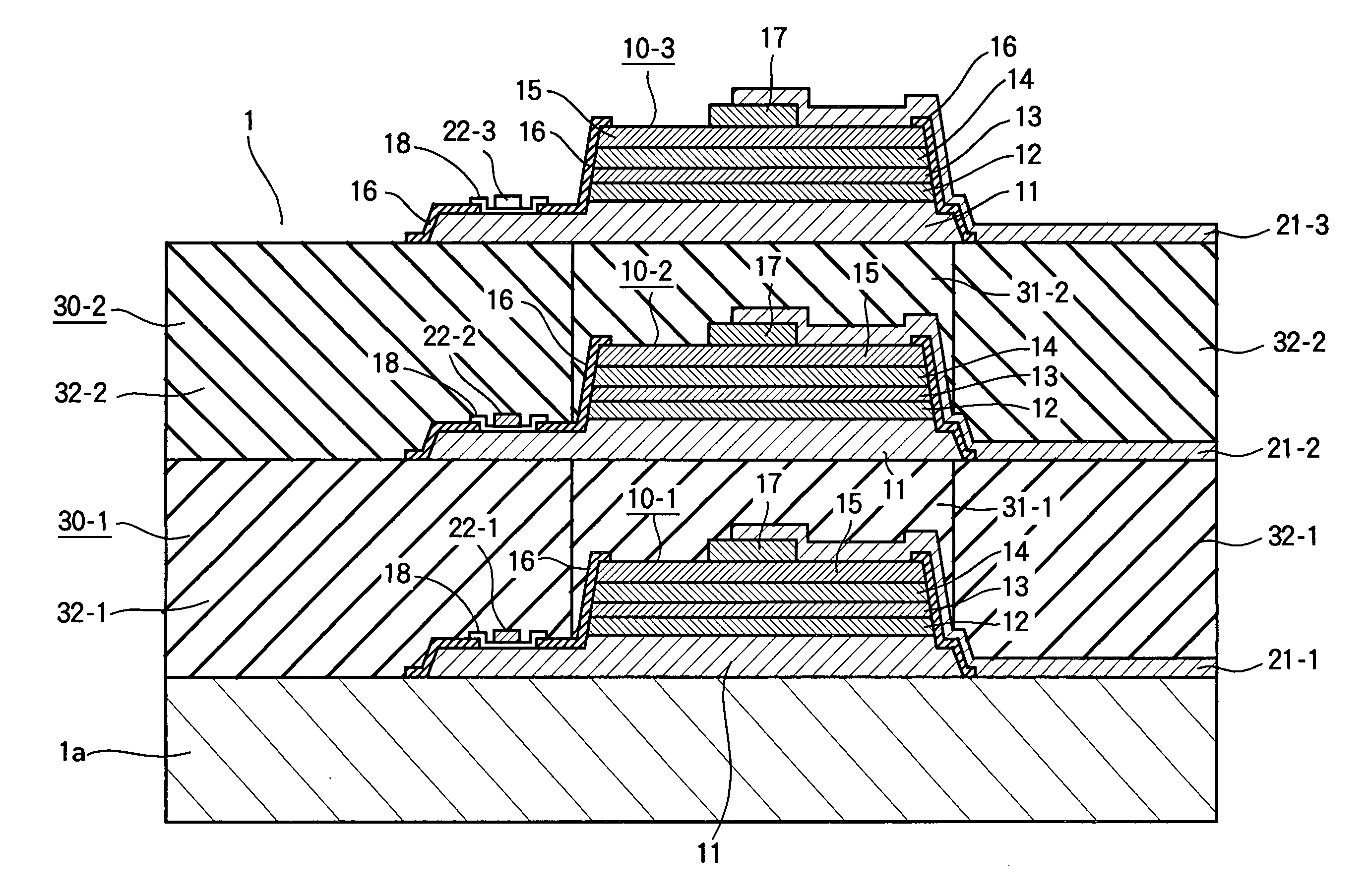

InactiveUS20100051975A1Reduce light leakageImprove light output efficiencySolid-state devicesSemiconductor devicesRefractive indexLight emitting device

A layered semiconductor light emitting device includes a plurality of semiconductor light emitting elements each of which includes a light emitting region that converts electricity into light and emits the light. The semiconductor light emitting elements are layered in a layering direction perpendicular to the light emitting regions, and are bonded to each other via a planarizing layer having electrical insulation property. The planarizing layer includes a first planarizing region disposed above or below the light emitting regions of the semiconductor light emitting elements in the layering direction and formed of a first planarizing film having higher refractive index than air, and a second planarizing region other than the first planarizing region and formed of a second planarizing film having lower refractive index than the first planarizing film. In the layering direction, the upper semiconductor light emitting element transmits light emitted by the lower semiconductor light emitting element.

Owner:OKI DATA CORP

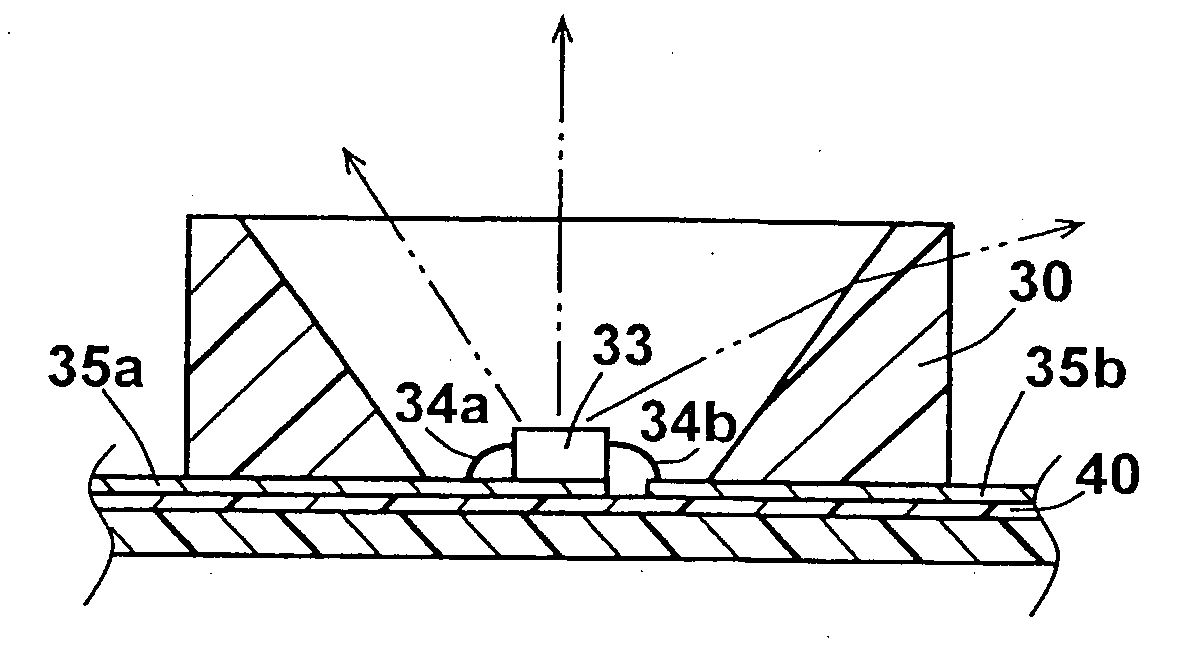

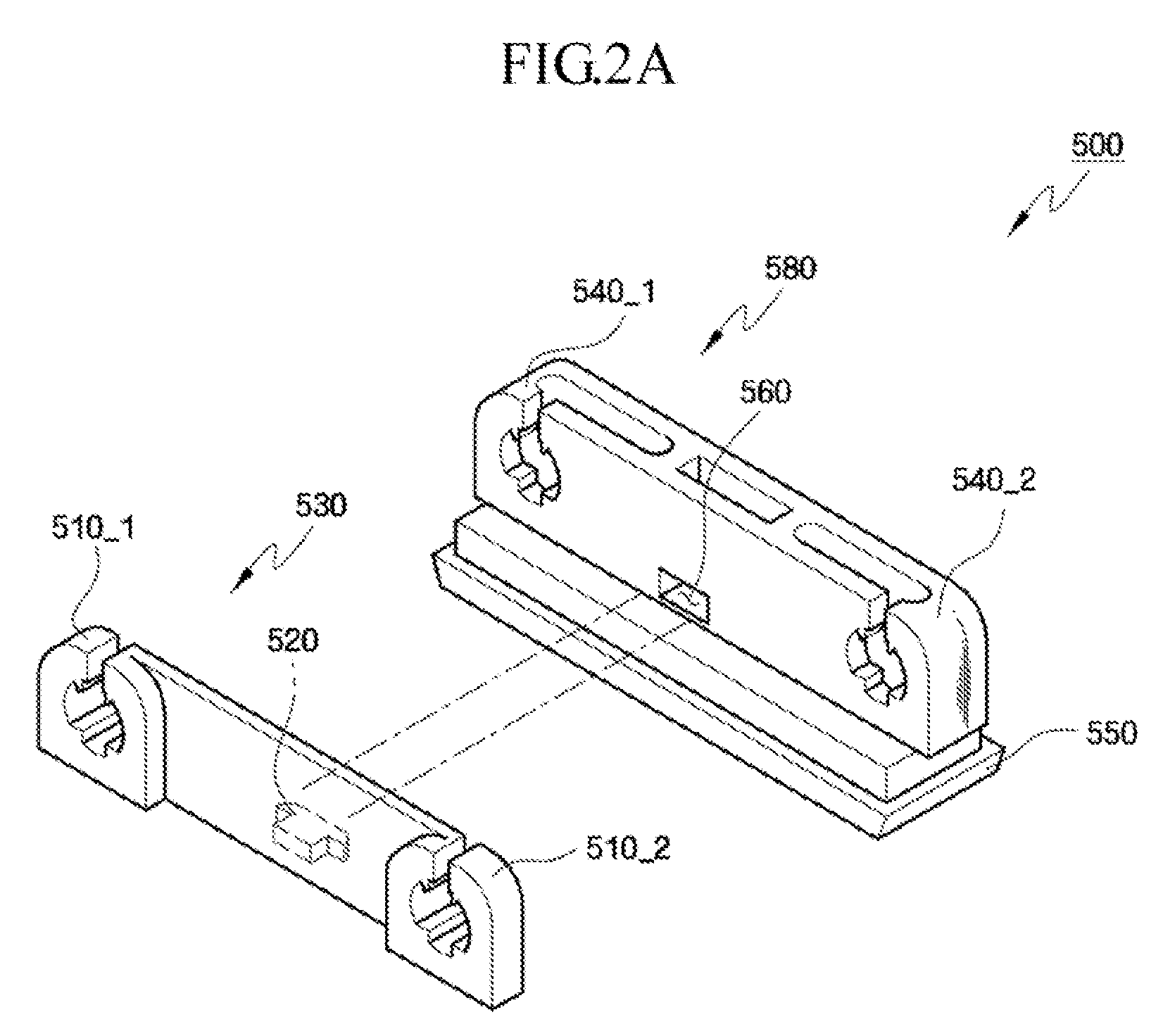

Illumination device

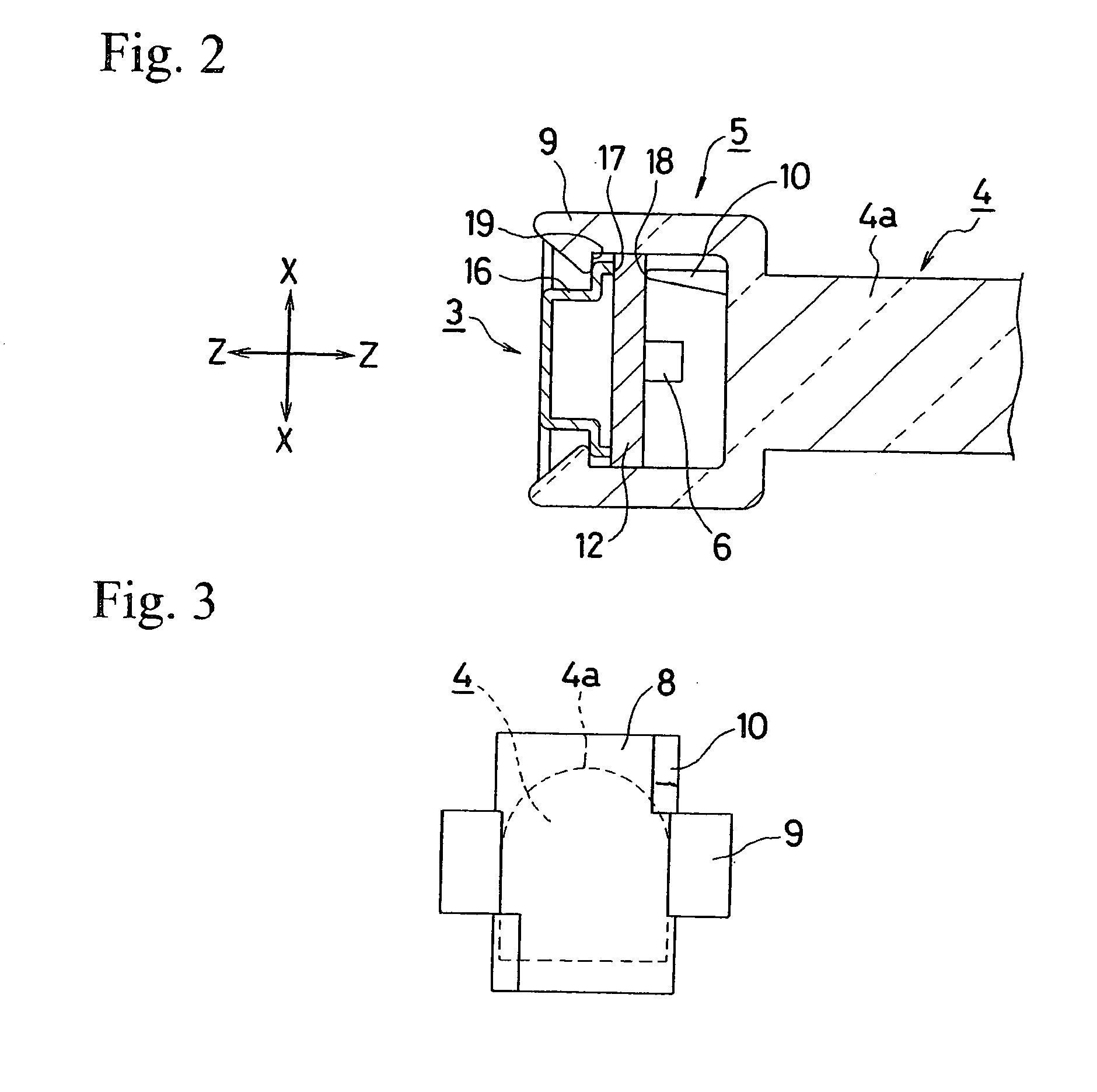

InactiveUS20050270794A1Reduce power consumptionProlong lifeMechanical apparatusPoint-like light sourceLight guideEngineering

A light access can be integrally formed with a light guide on at least one end of the light guide. A printed circuit board with an LED lamp mounted thereon can be press-fitted in the light access for transient arrangement, and can be fixed by a cover. The position of the printed circuit board can be determined in relation to the light guide. For example, engagement hooks of the light access can be fitted with recesses in the printed circuit board for positioning the circuit board in a plane normal to the longitudinal direction of the light guide. Similarly, positioning ribs of the light guide can be employed for positioning in the longitudinal direction of the light guide. The light guide can be formed in an almost rod shape having four sides in section normal to the longitudinal direction of the light guide. A light guide lens can be formed in one surface and a diffuser cut can be formed in the opposite surface of the light guide.

Owner:STANLEY ELECTRIC CO LTD

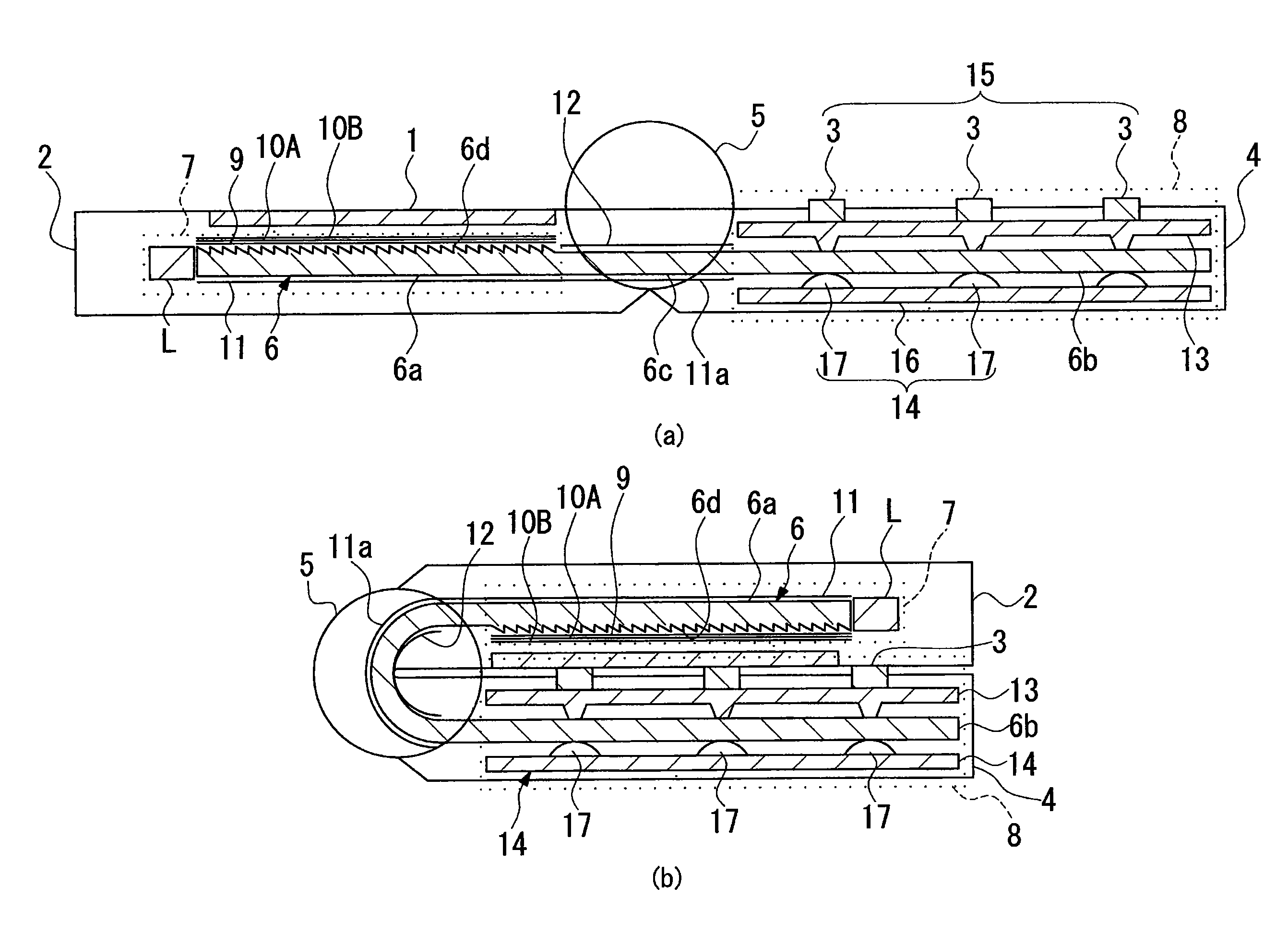

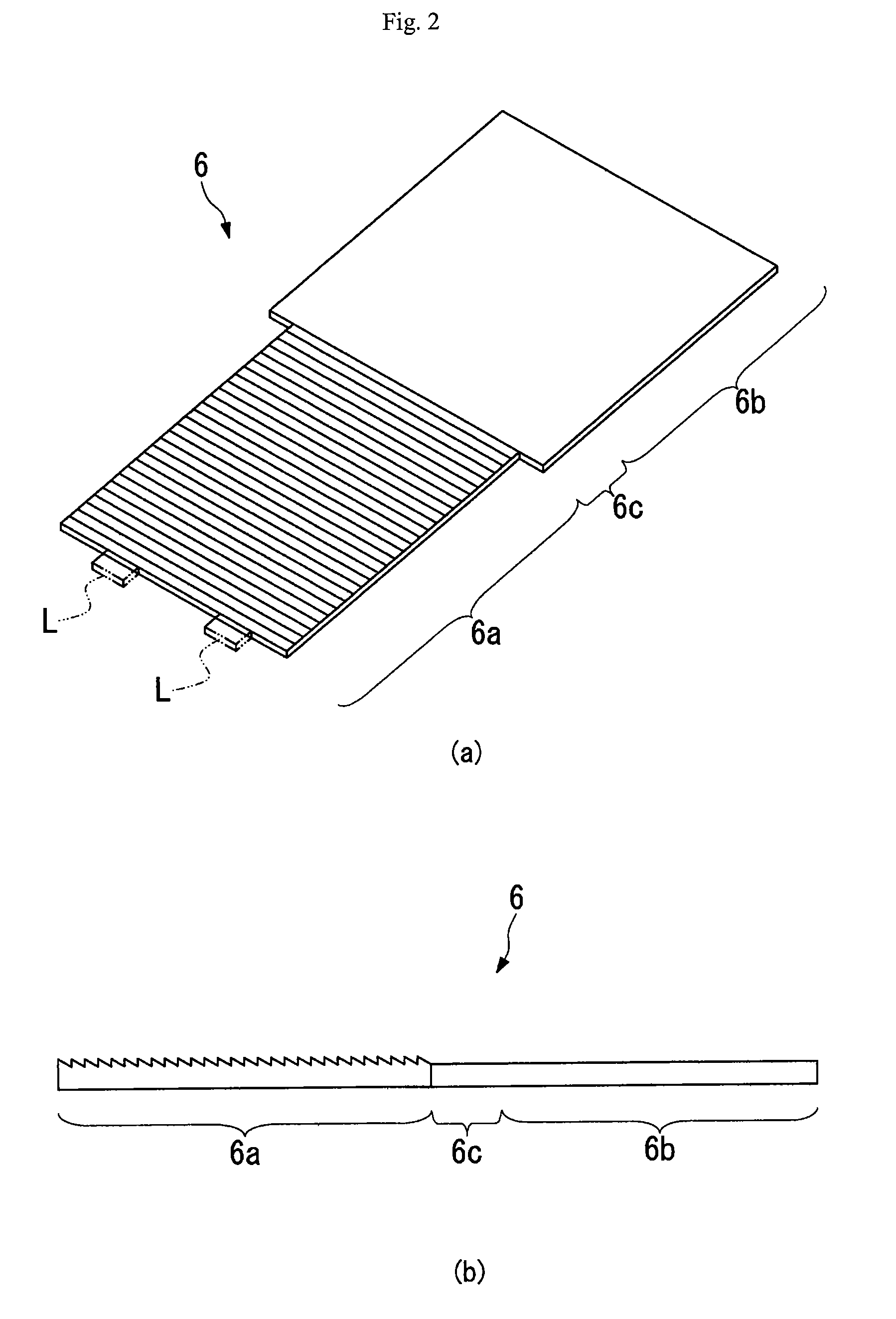

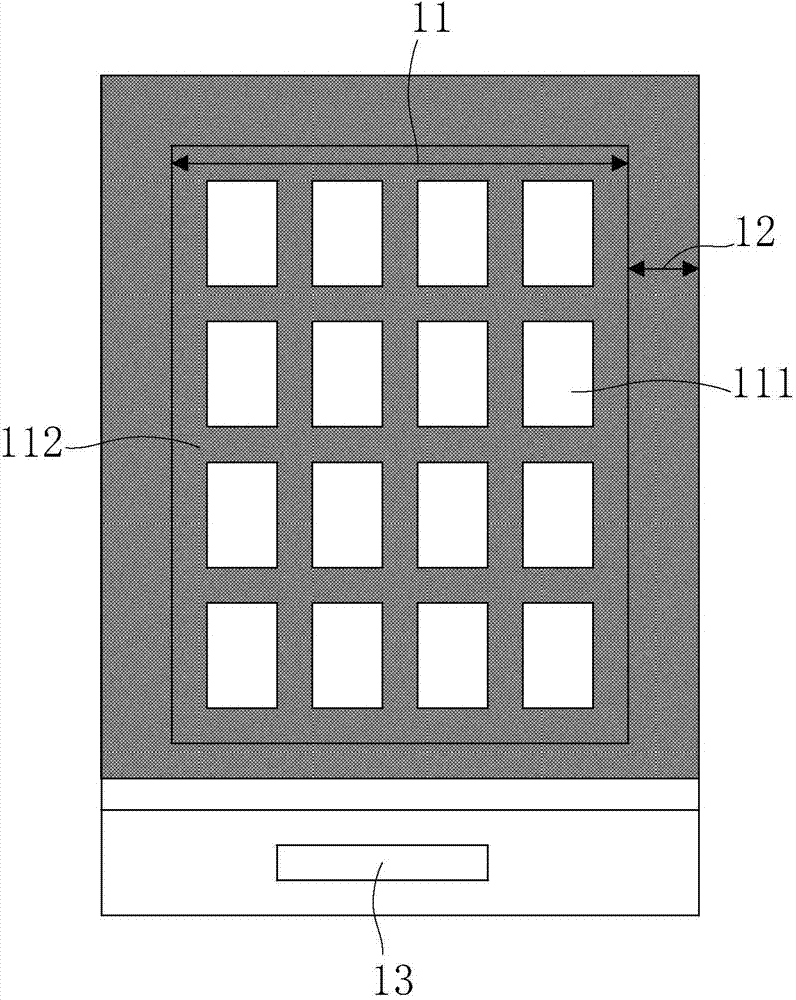

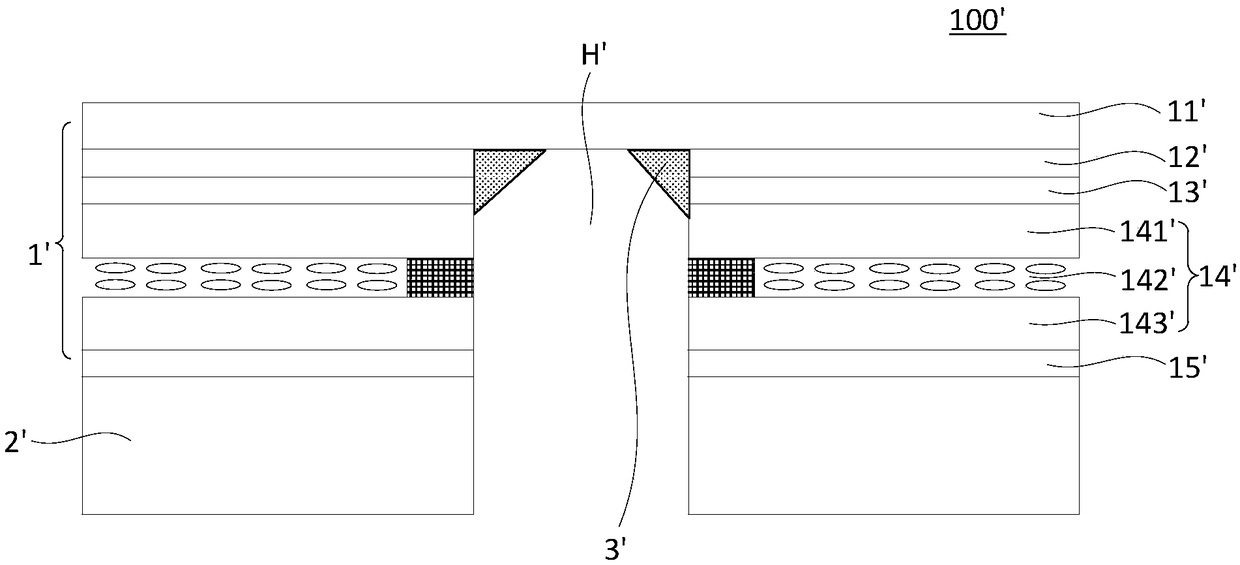

Lightguide plate and electronic device

InactiveUS7932890B2Avoid light leakageStatic indicating devicesDigital data processing detailsDisplay deviceEngineering

An electronic device includes a casing having a display part (2) provided with an image display panel (1), a operation part (4) provided with operation keys (3), and a joint part (5) that connects together the display part and the operation part, and a lightguide plate (6) disposed in the casing. The lightguide plate is an edge-light type lightguide plate having a display illuminating part (6a) illuminating the image display panel, a key illuminating part (6b) illuminating the operation keys, and a connecting part (6c) that connects together the display illuminating part and the key illuminating part and that guides light therebetween. The lightguide plate is deformable in accordance with the deformation of the casing.

Owner:CITIZEN ELECTRONICS CO LTD

Colored film substrate and liquid-crystal display panel

ActiveCN103926742AImprove the display effectAvoid light leakageNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a colored film substrate and a liquid-crystal display panel. The liquid-crystal display panel comprises the colored film substrate, an array substrate and a liquid crystal layer, wherein the array substrate is arranged oppositely to the colored film substrate, the liquid-crystal layer is arranged between the colored film substrate and the array substrate, the liquid-crystal display panel is divided into a display area and a periphery area surrounding the display area. A black matrix is arranged in the periphery area of the inner side of the colored film substrate and is provided with at least one opening arranged on at least one side of the periphery area, and the black matrix on the side of the periphery area is divided into a portion close to the display area and a portion distant from the display area by the openings; a first electrode and a second electrode are arranged on the inner side of the liquid-crystal display panel and correspond to the openings. By the aid of the openings, affection on display effect of the liquid-crystal display panel from external static electricity can be avoided; by arranging the first electrode and the second electrode corresponding to the openings, light leak of the openings can be prevented, and display effect of the liquid-crystal display panel is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

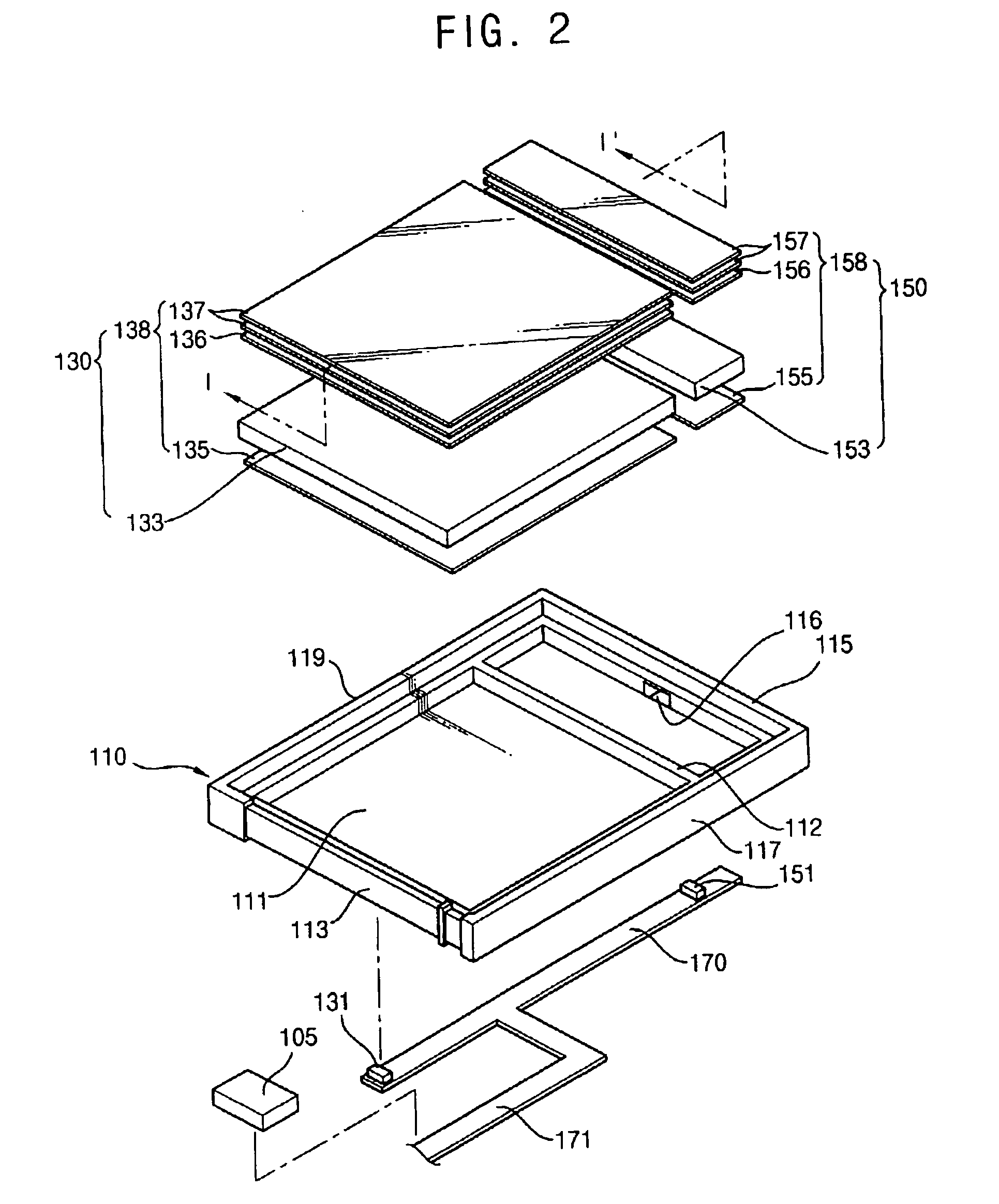

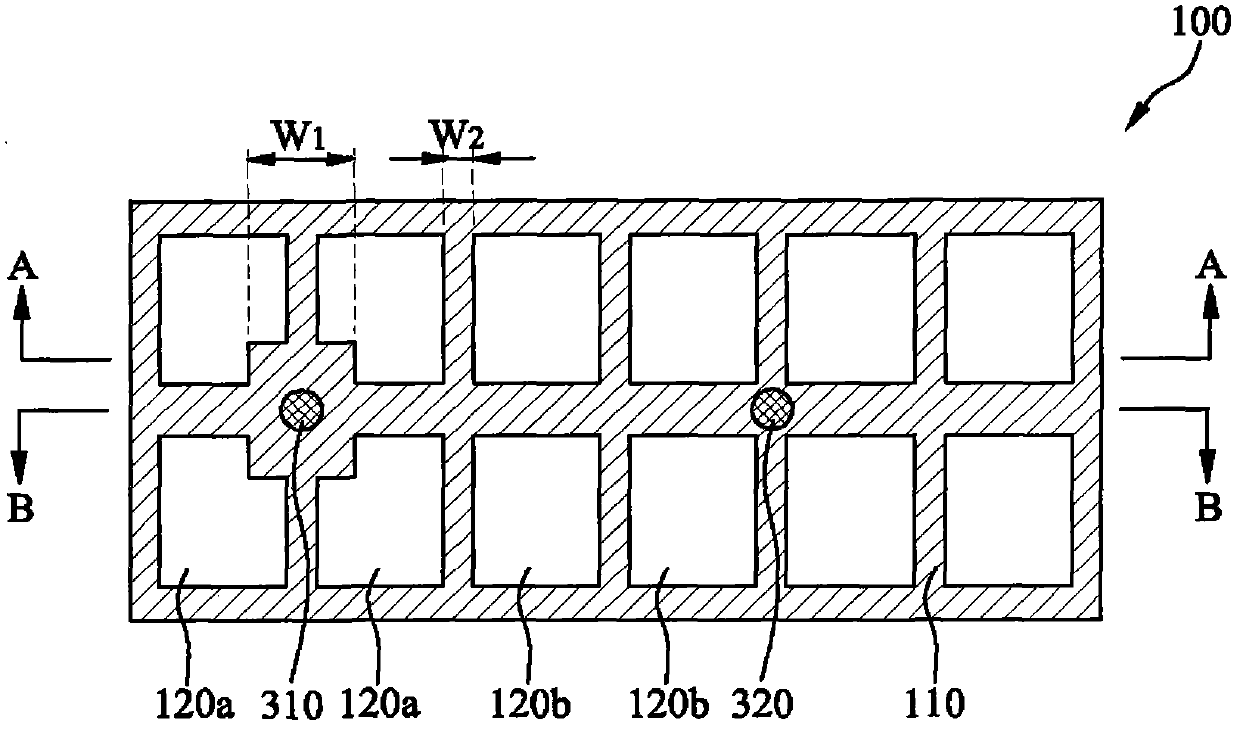

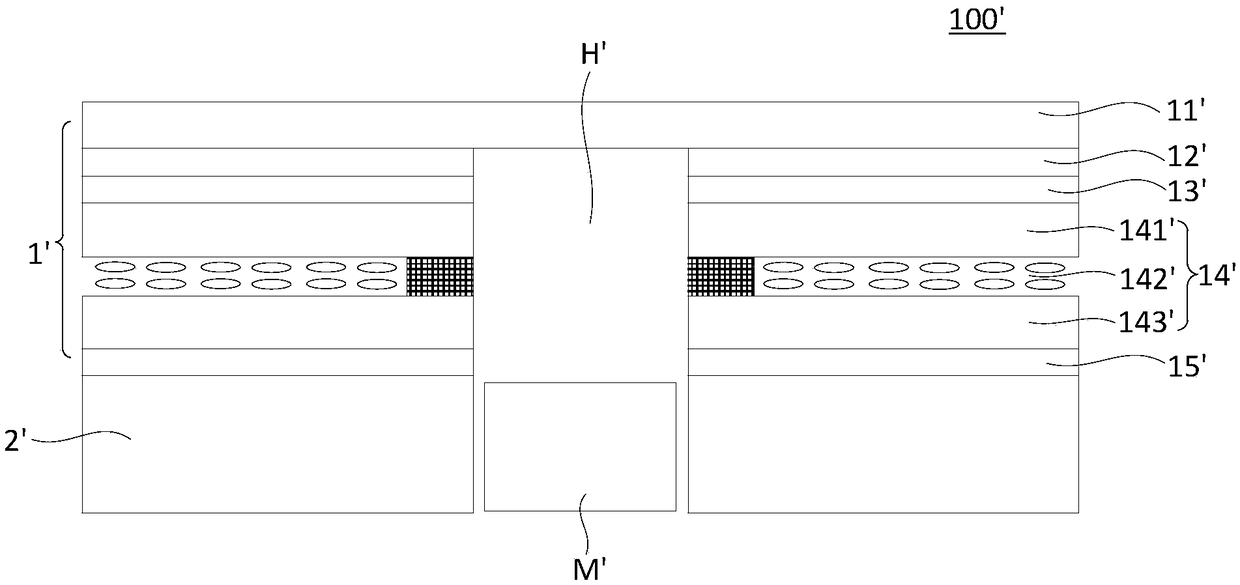

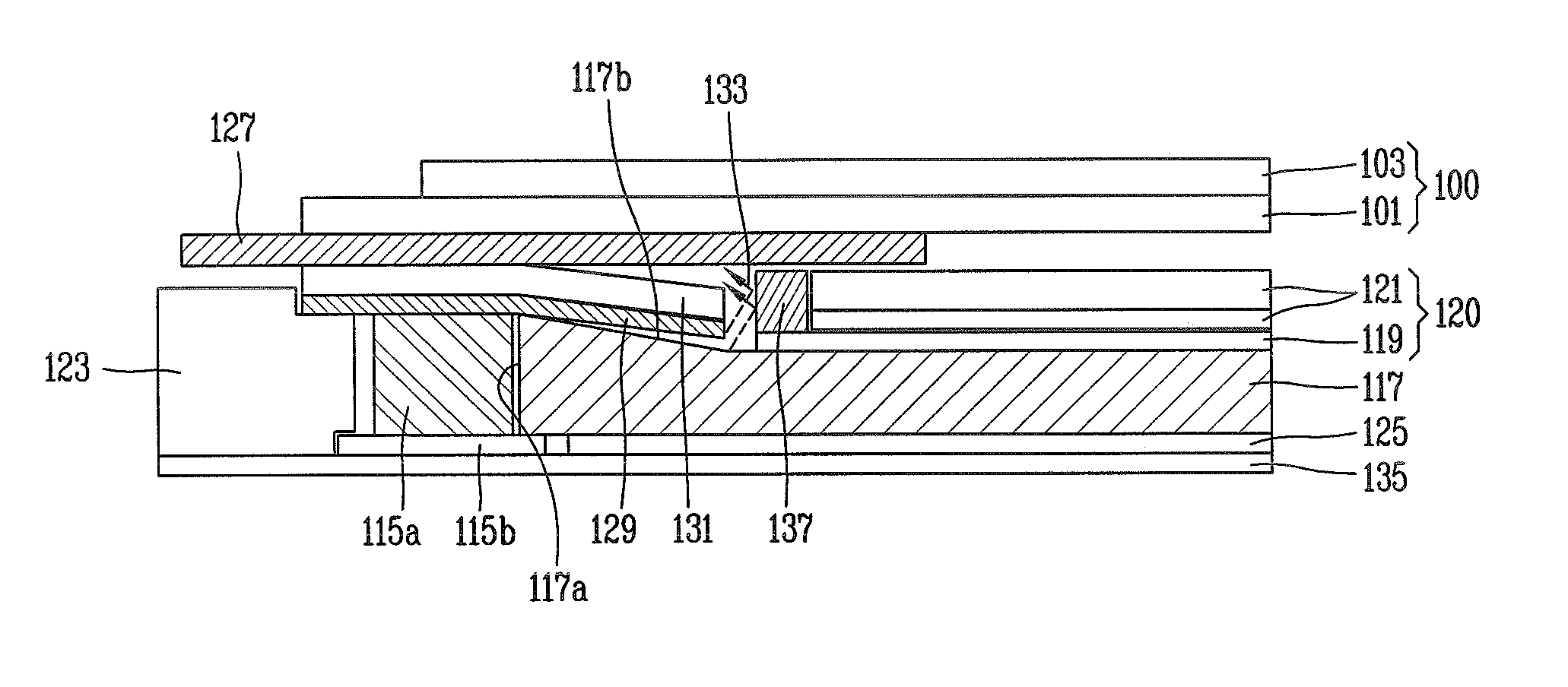

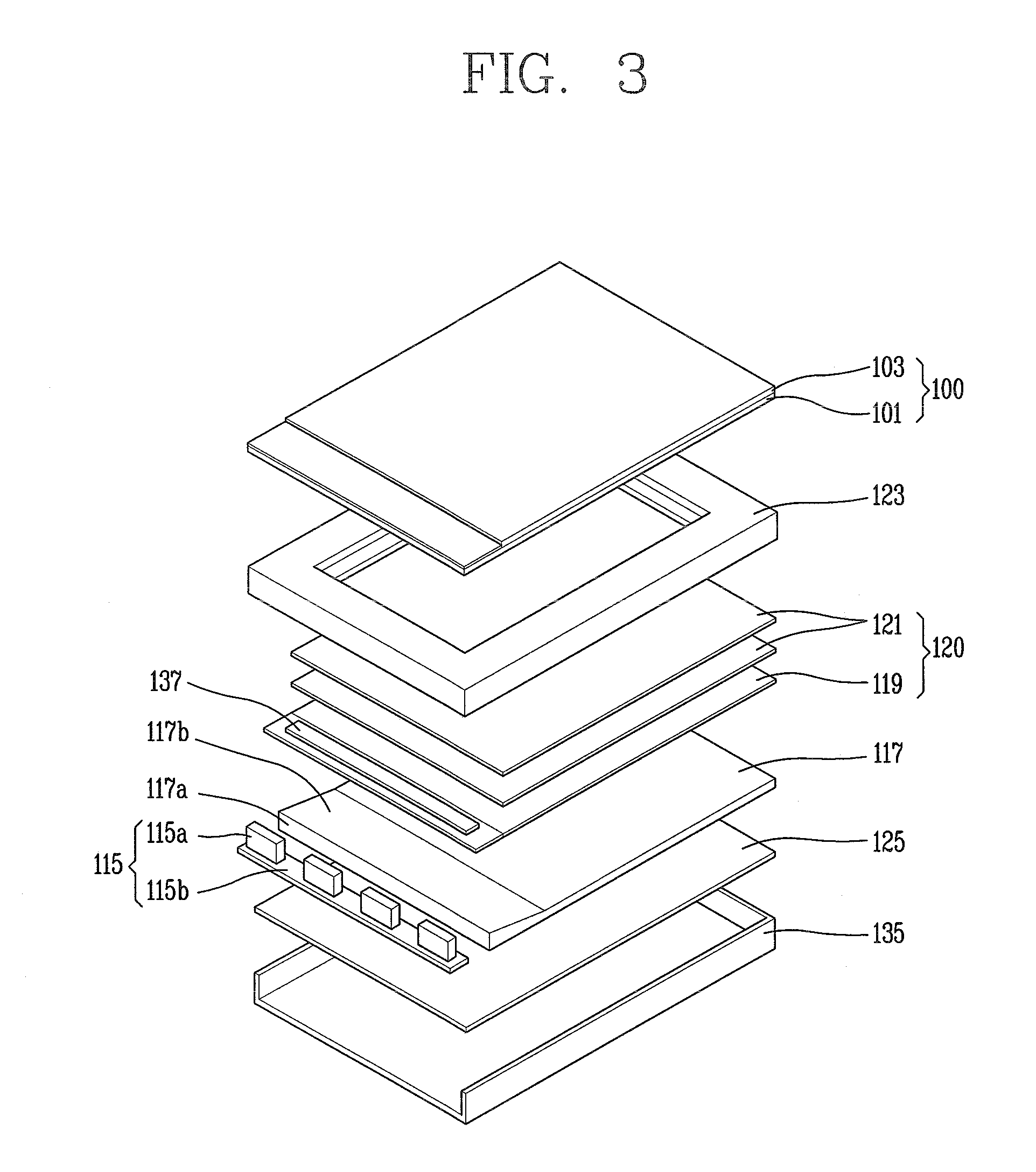

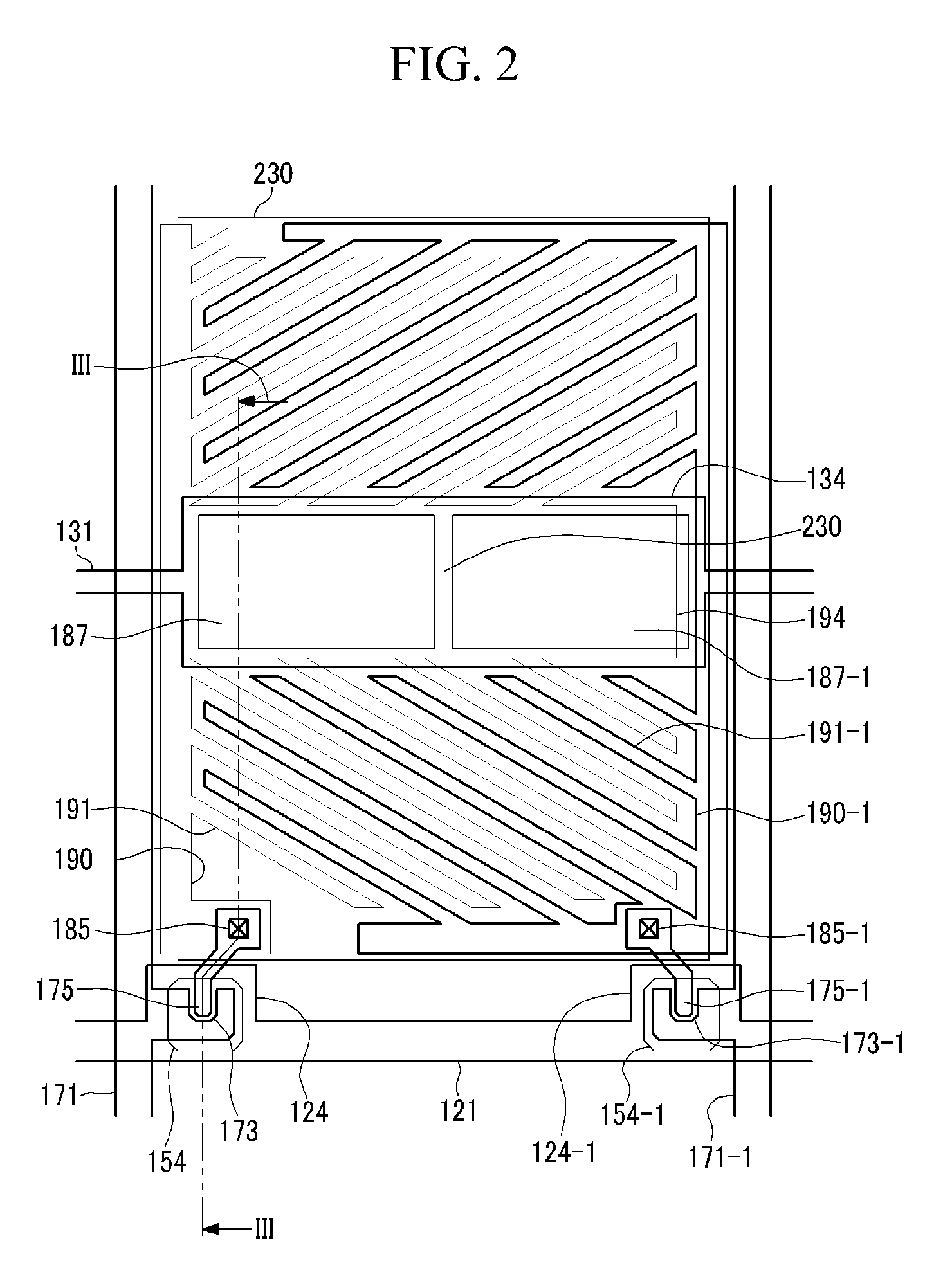

Backlight assembly, display device having the same, display substrate for the same and method of manufacturing the same

ActiveUS20070013828A1Increase brightnessReduce power consumptionNon-linear opticsSemiconductor devicesDisplay deviceEngineering

A backlight assembly includes first and second backlight units independently operating based on driving modes, and a light blocking member interposed between the first and second backlight units. The first backlight assembly includes a first light source generating and supplying a first light to a main display part of a display panel in a main mode and turned-off in a sub mode. The second backlight assembly includes a second light source generating and supplying a second light having different color from the first light to a sub display part of the display panel in a main mode and a sub mode.

Owner:SAMSUNG DISPLAY CO LTD

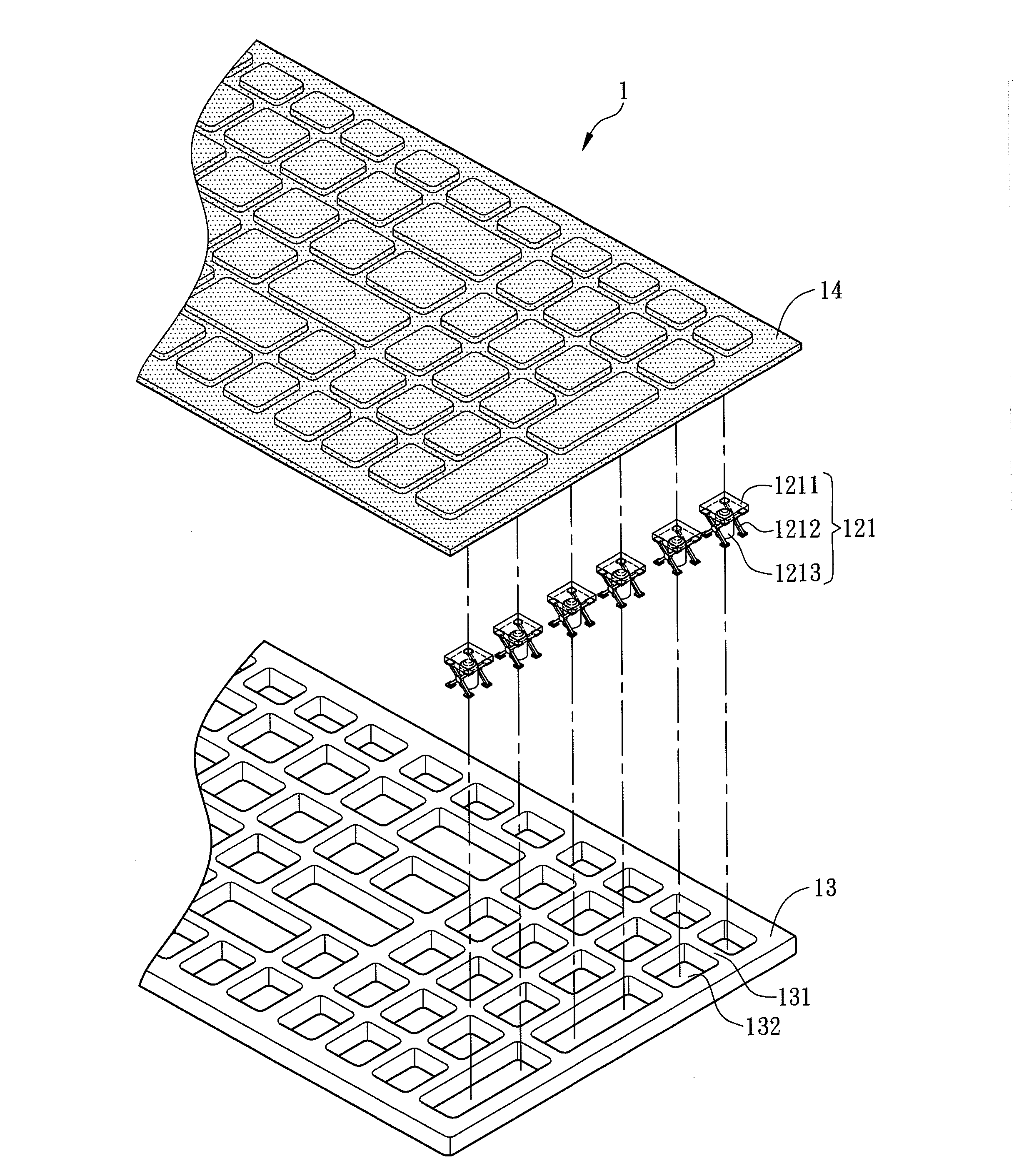

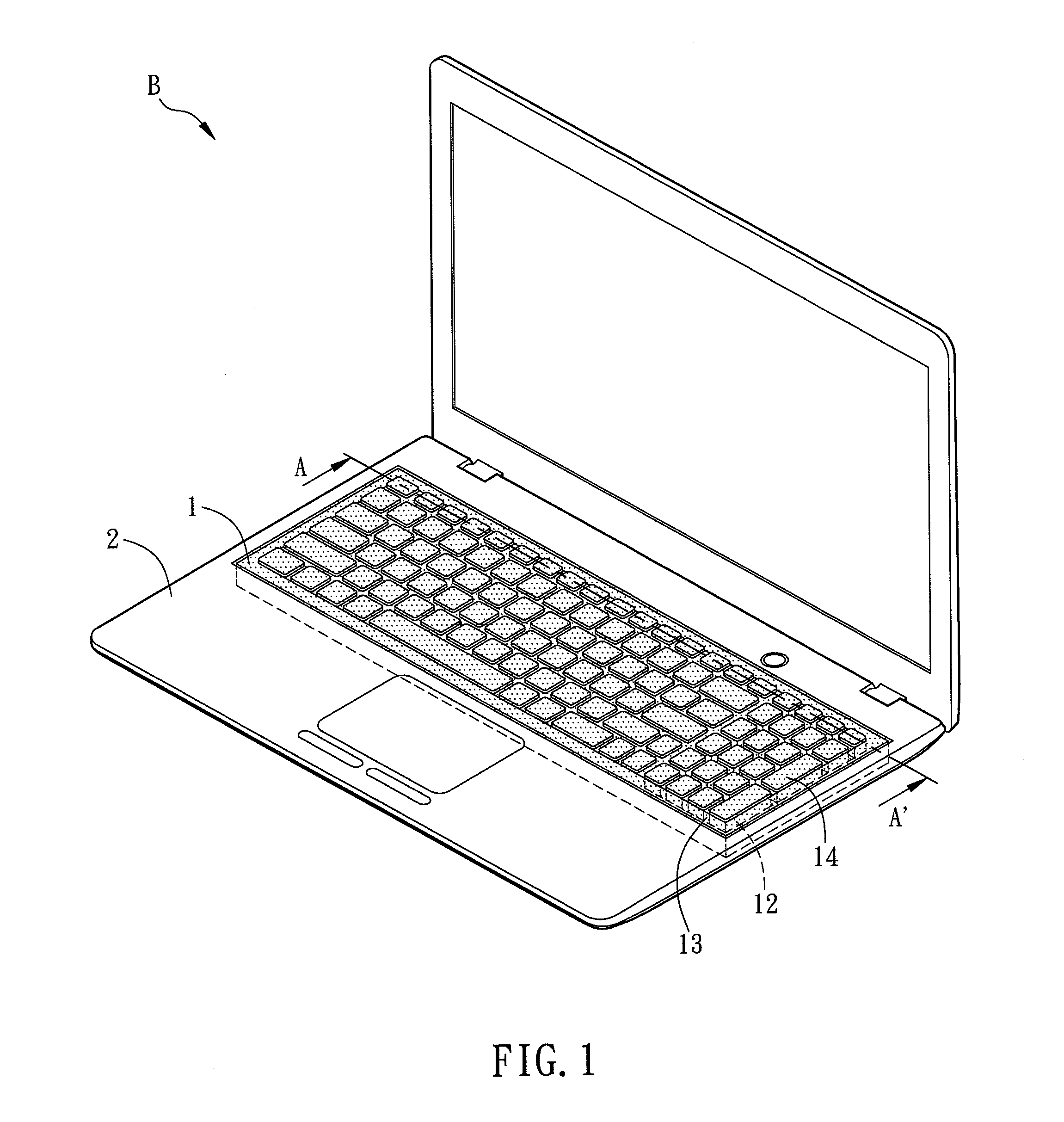

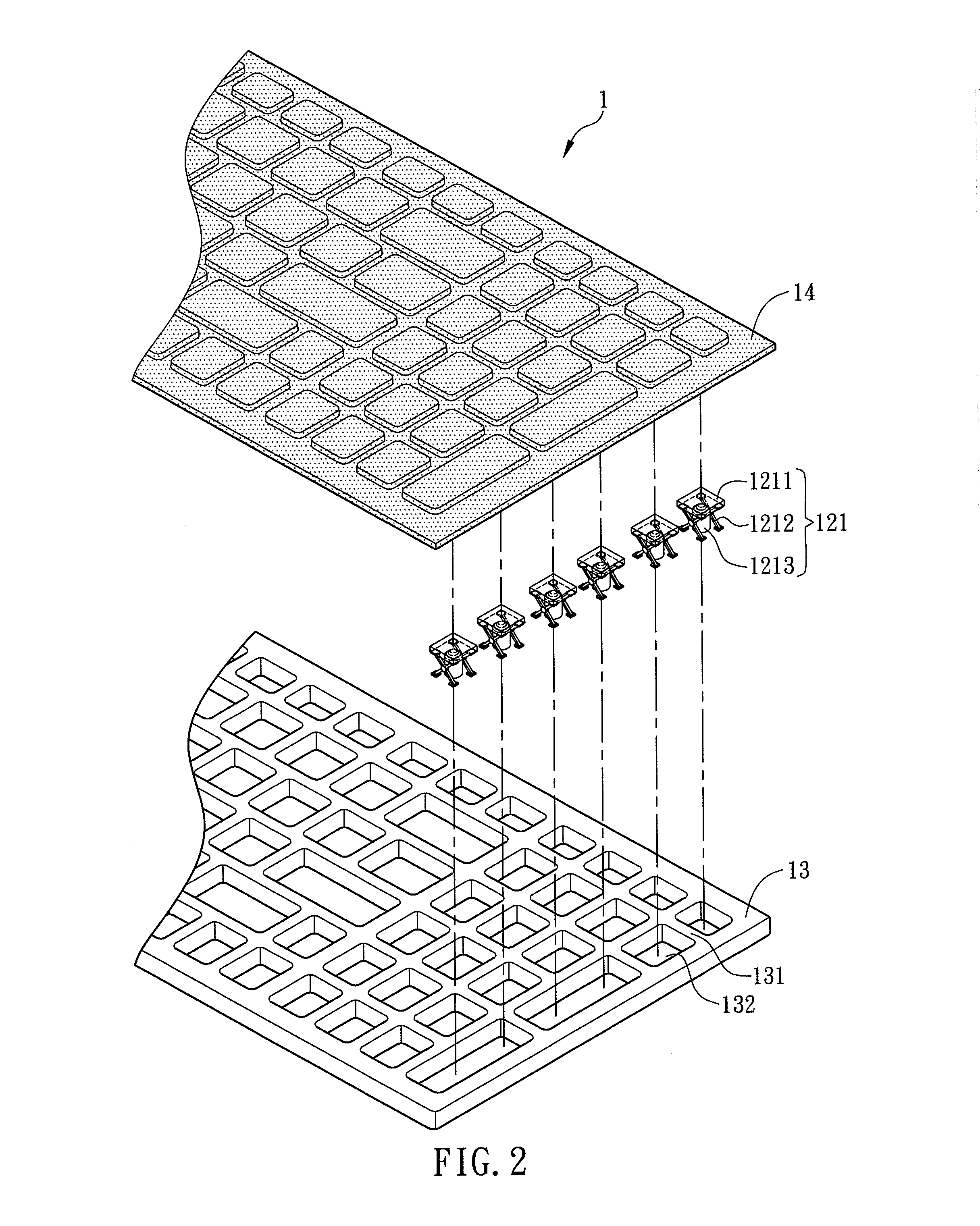

Keyboard module

InactiveUS20130043115A1Avoid light leakageReduce gapDigital data processing detailsElectric switchesEngineering

Owner:ASUSTEK COMPUTER INC

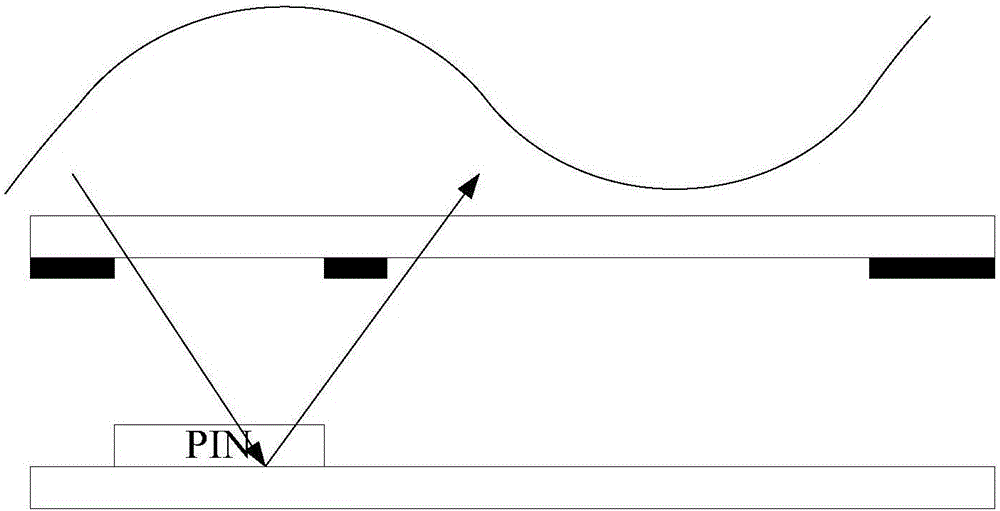

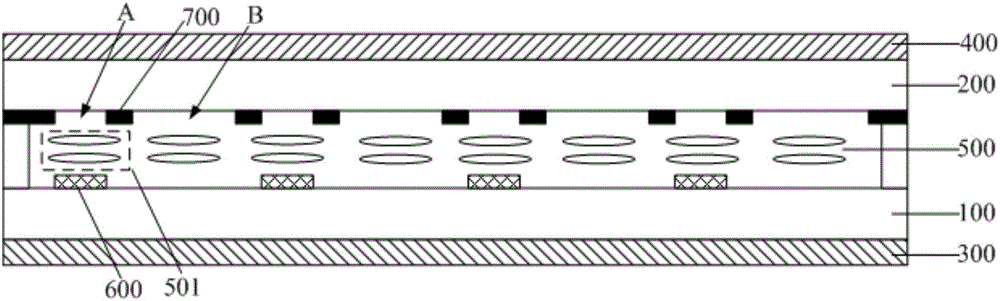

Fingerprint identification display panel and display device

ActiveCN106067018AAvoid light leakagePrint image acquisitionNon-linear opticsLong axisDisplay device

The invention discloses a fingerprint identification display panel and a display device. In a liquid crystal layer arranged at a position corresponding to a first open area, positioned at a place corresponding to a photosensitive induction unit, in a light shielding layer, an initial direction of long axes of liquid crystal molecules is set in such a way that the initial direction and a direction of a light transmission axis of an upper polaroid form an included angle of 45 degrees, and the liquid crystal layer arranged at the position corresponding to the first open area is controlled to form an equivalent quarter wave plate. Linearly polarized light which comes in via the upper polaroid is enabled to be synthesized into circularly polarized light after going through the equivalent quarter wave plate; a rotation state of the circularly polarized light is changed after being reflected via a reflection film layer positioned below the photosensitive induction unit, linearly polarized light which is formed when the circularly polarized light again runs through the equivalent quarter wave plate is perpendicular to the direction of the light transmission axis of the upper polaroid, and therefore the linearly polarized light cannot be emitted out from the upper polaroid and anti-light leakage effects are realized.

Owner:BOE TECH GRP CO LTD

Array substrate, method for manufacturing same and display device comprising same

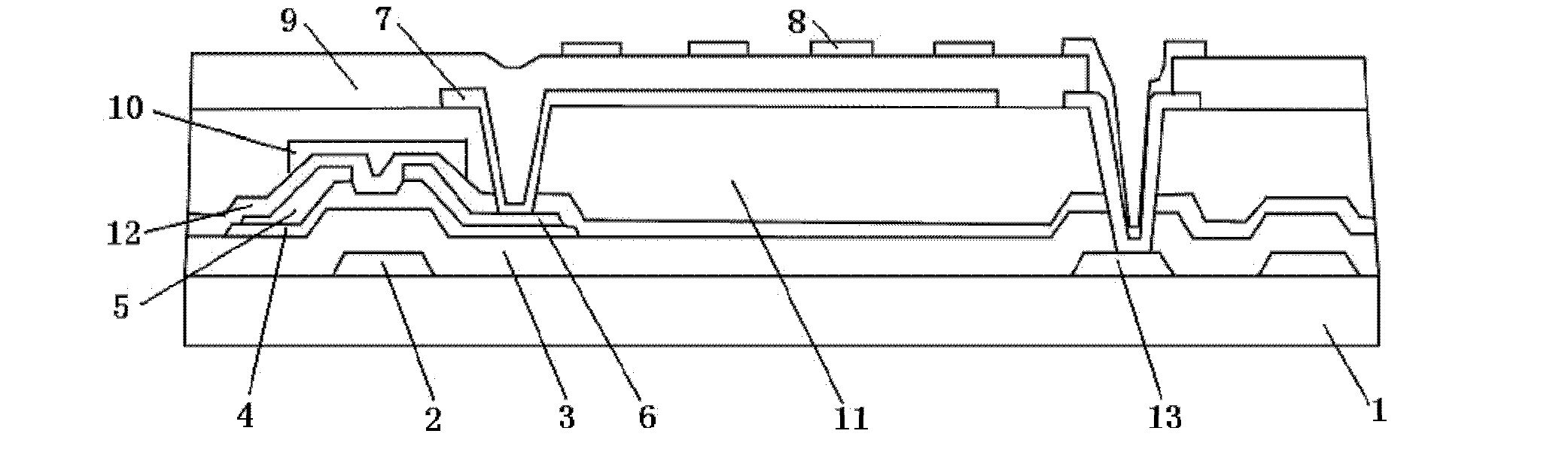

ActiveCN102681276AStructure planarizationPrevent irregular arrangementSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceActive layer

The invention relates to an array substrate, a method for manufacturing the array substrate and a display device comprising the array substrate, belonging to the technical field of displaying and aiming to solve the problem that the contrast of the existing liquid crystal panel is too low. The array substrate comprises a grid line and a data line for defining a pixel region; the pixel region comprises a thin film transistor region and a pixel electrode pattern region; a grid electrode, a grid insulating layer, an active layer, a source electrode, a drain electrode and a passivation layer are formed in the thin film transistor region; a grid insulating layer, a pixel electrode, a passivation layer and a common electrode are formed in the pixel electrode pattern region; a multidimensional electric field is formed by the common electrode and the pixel electrode; and a colored resin layer is formed between each grid insulating layer and each pixel electrode. According to the technical scheme provided by the invention, because a colored resin layer is formed above the grid insulating layer of a thin film transistor, the structure in the pixel region can be flattened, the irregular arrangement of the liquid crystal in the reflection region can be avoided, the light leakage can be prevented, and the contrast can be improved.

Owner:BOE TECH GRP CO LTD

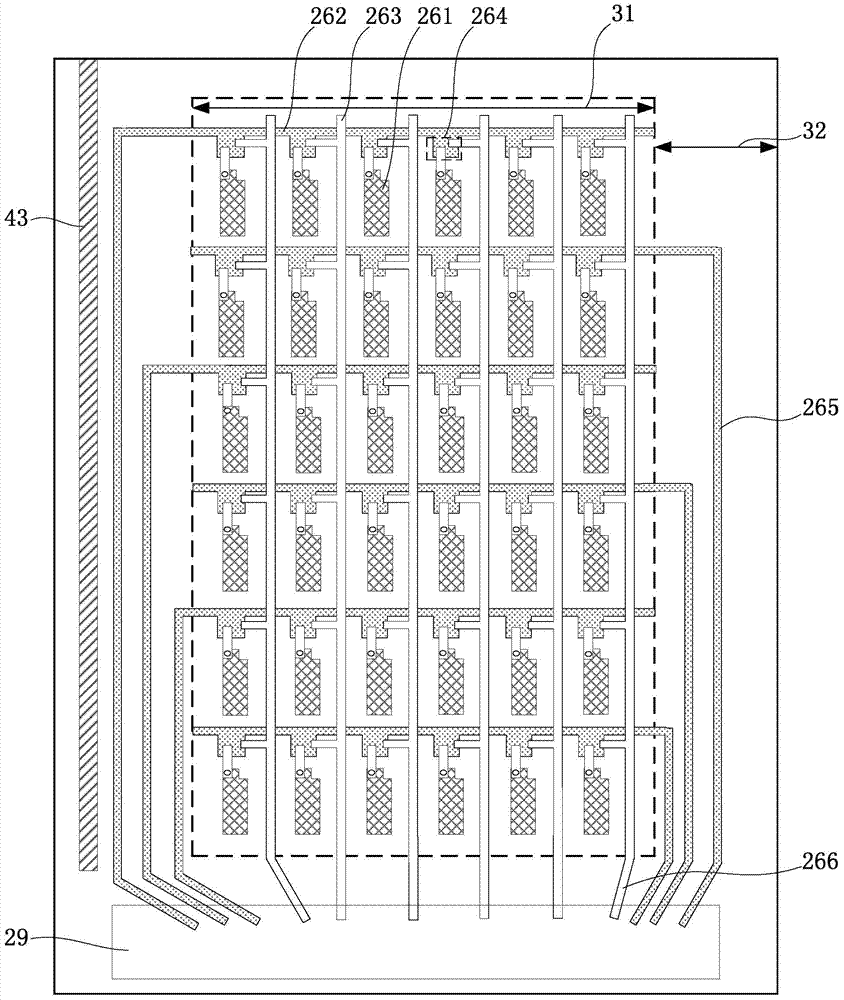

Array substrate, fabrication method thereof and liquid crystal display panel

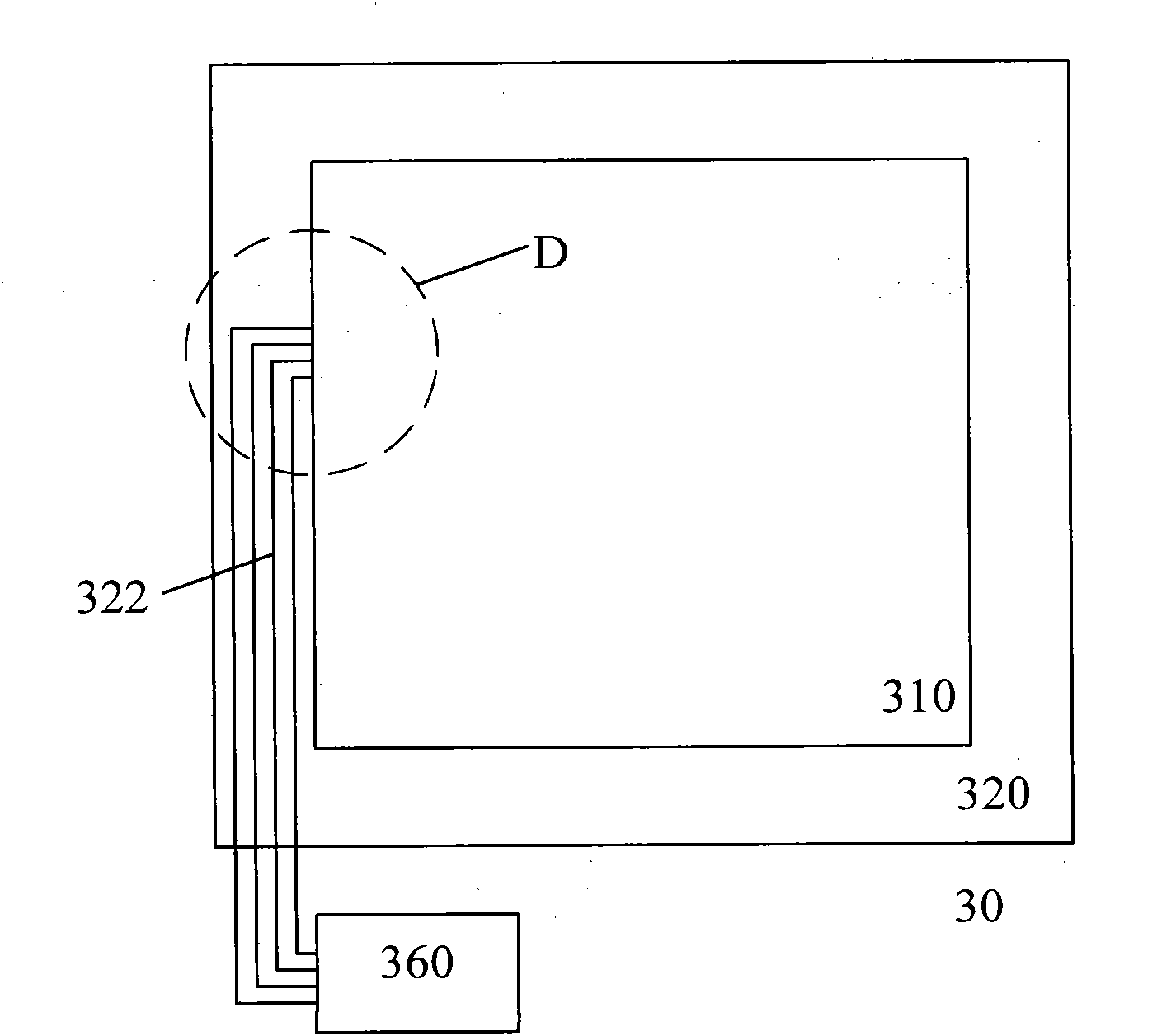

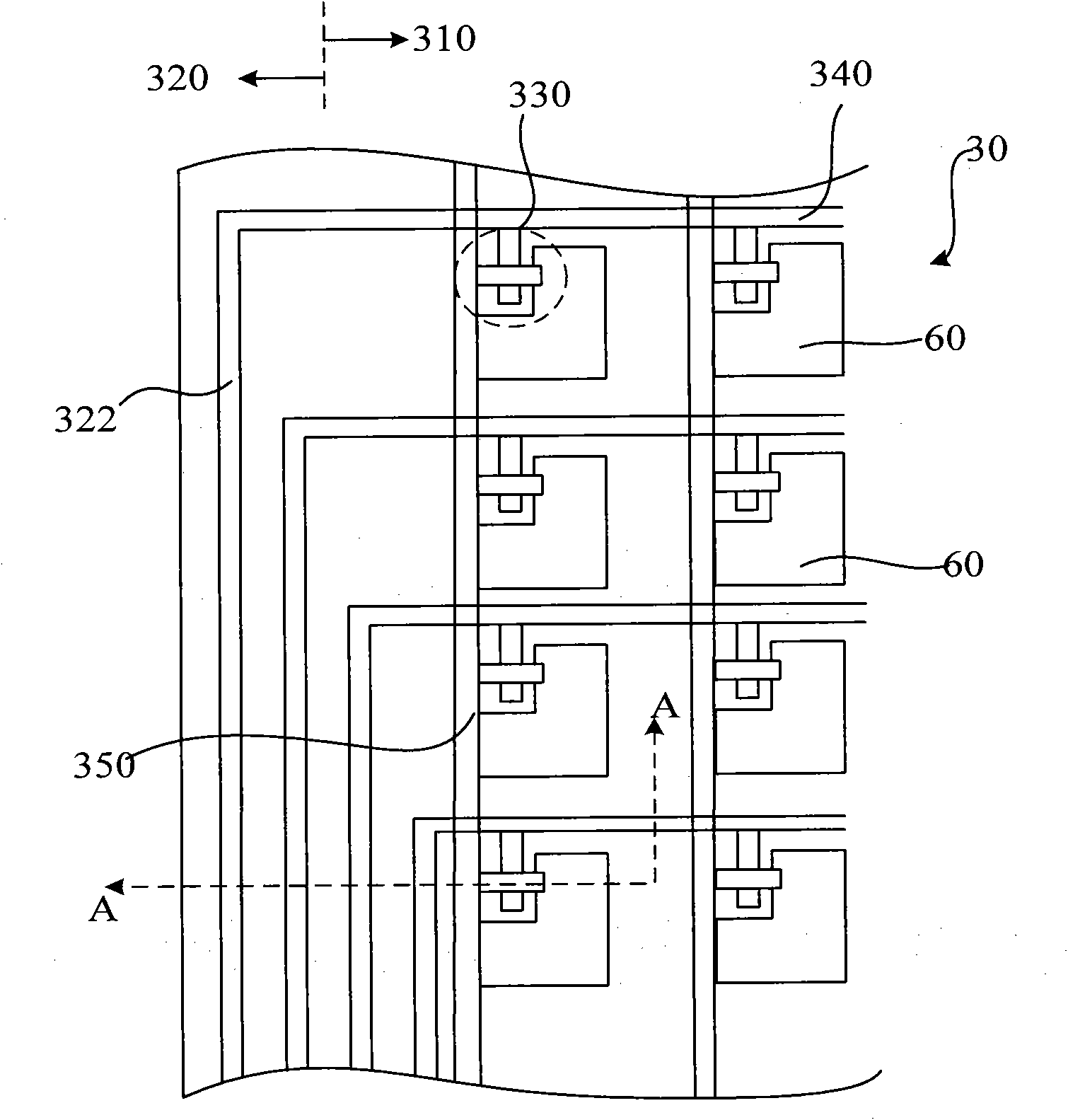

ActiveCN102385200AReduce areaRealize narrow frameStatic indicating devicesSolid-state devicesLiquid-crystal displayEngineering

The invention provides an array substrate, a fabrication method thereof and a liquid crystal display panel comprising the array substrate. The array substrate comprises a substrate, a plurality of pixel electrodes, a plurality of scanning lines, a plurality of data lines and scanning line connection lines; the substrate is divided into a display area and a frame area, and the display area is surrounded by the frame area; the pixel electrodes are arranged in the form of an array in the display area; the scanning lines are positioned among the pixel electrodes; the data lines are positioned among the pixel electrodes, and are insulatively intersected with the scanning lines; and the scanning line connection lines are positioned in the display area, are in parallel with the data lines, and are correspondingly and electrically connected with the scanning lines to transmit the signals of a scanning drive circuit to the corresponding scanning lines. The area of the frame area of the array substrate and the liquid crystal display panel is reduced, consequently, the frame of a liquid crystal display is narrowed, and the utilization rate of the substrate is increased.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

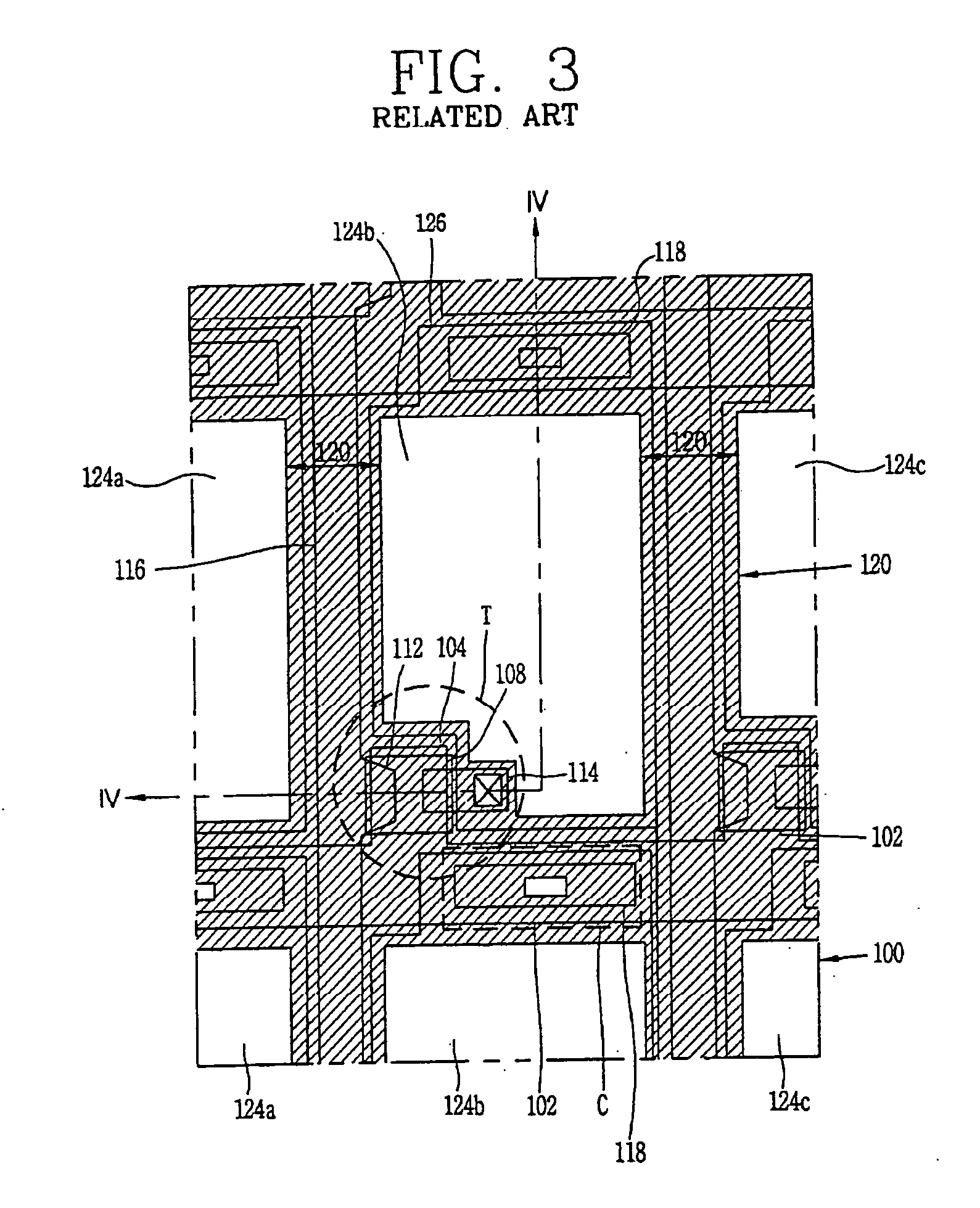

Liquid crystal display device

A liquid crystal display device is discussed, which includes a first substrate and a second substrate, which face each other; a liquid crystal layer formed between the first substrate and the second substrate; and a column spacer formed between the first substrate and the second substrate, wherein the column spacer is formed within a light-shielding region on the first substrate or the second substrate, and a width of the light-shielding region in the periphery of the column spacer is greater than that of the light-shielding region where the column spacer is not formed. Since the width of the light-shielding region in the periphery of the column spacer is greater than that of the light-shielding region where the column spacer is not formed, even though an alignment film is damaged by the column spacer, light leakage can be prevented from occurring at the damaged portion.

Owner:LG DISPLAY CO LTD

Display device

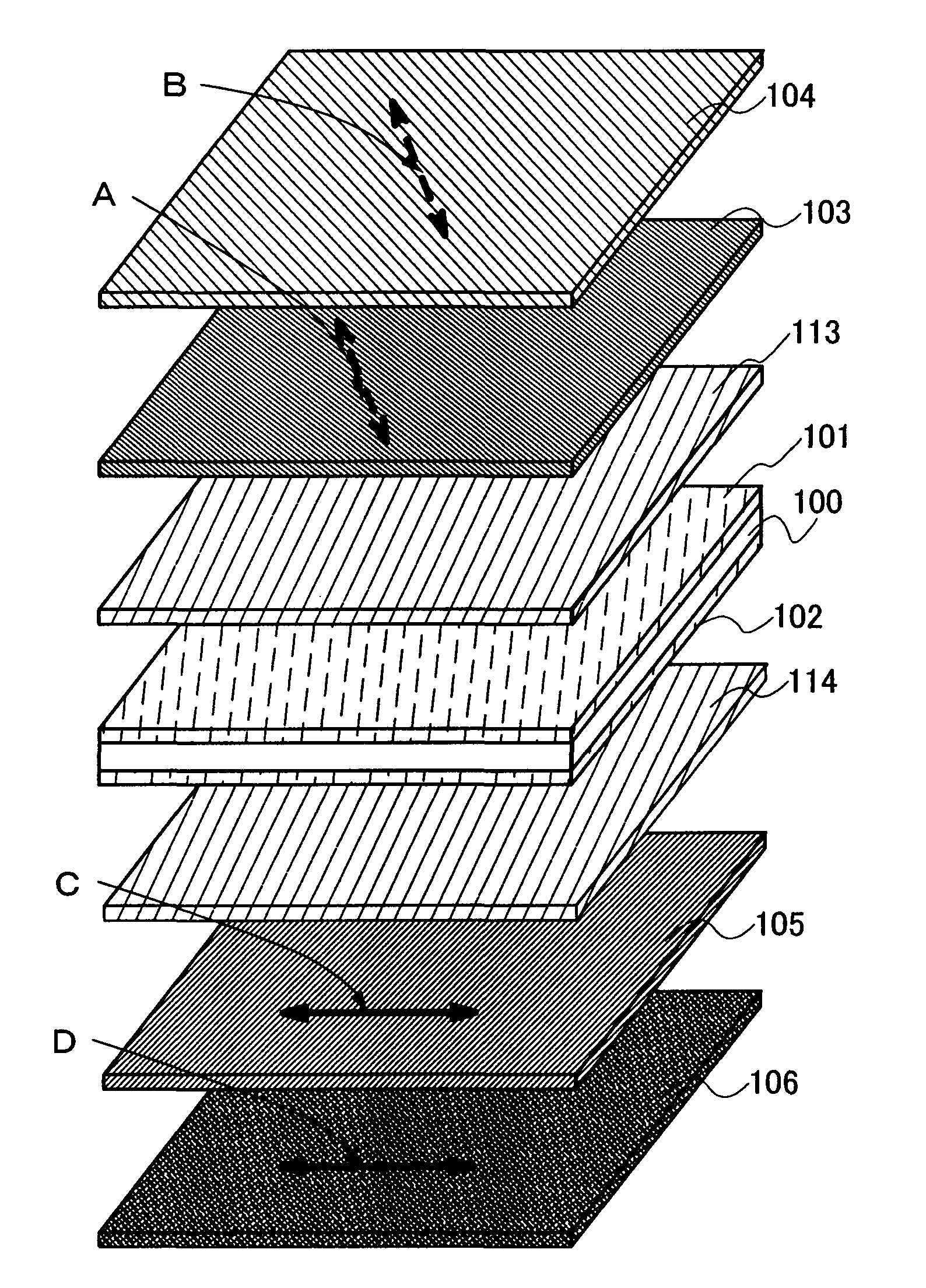

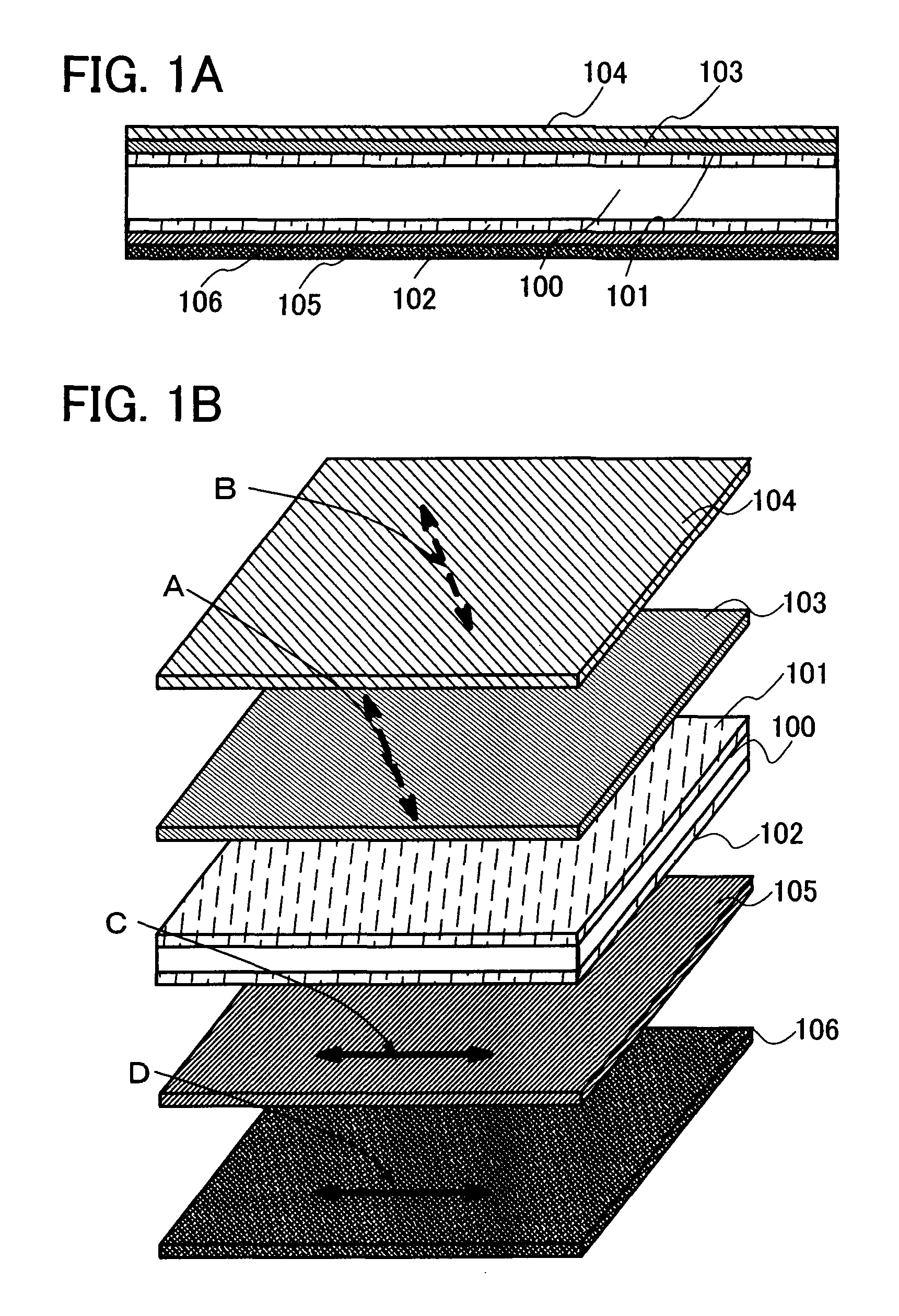

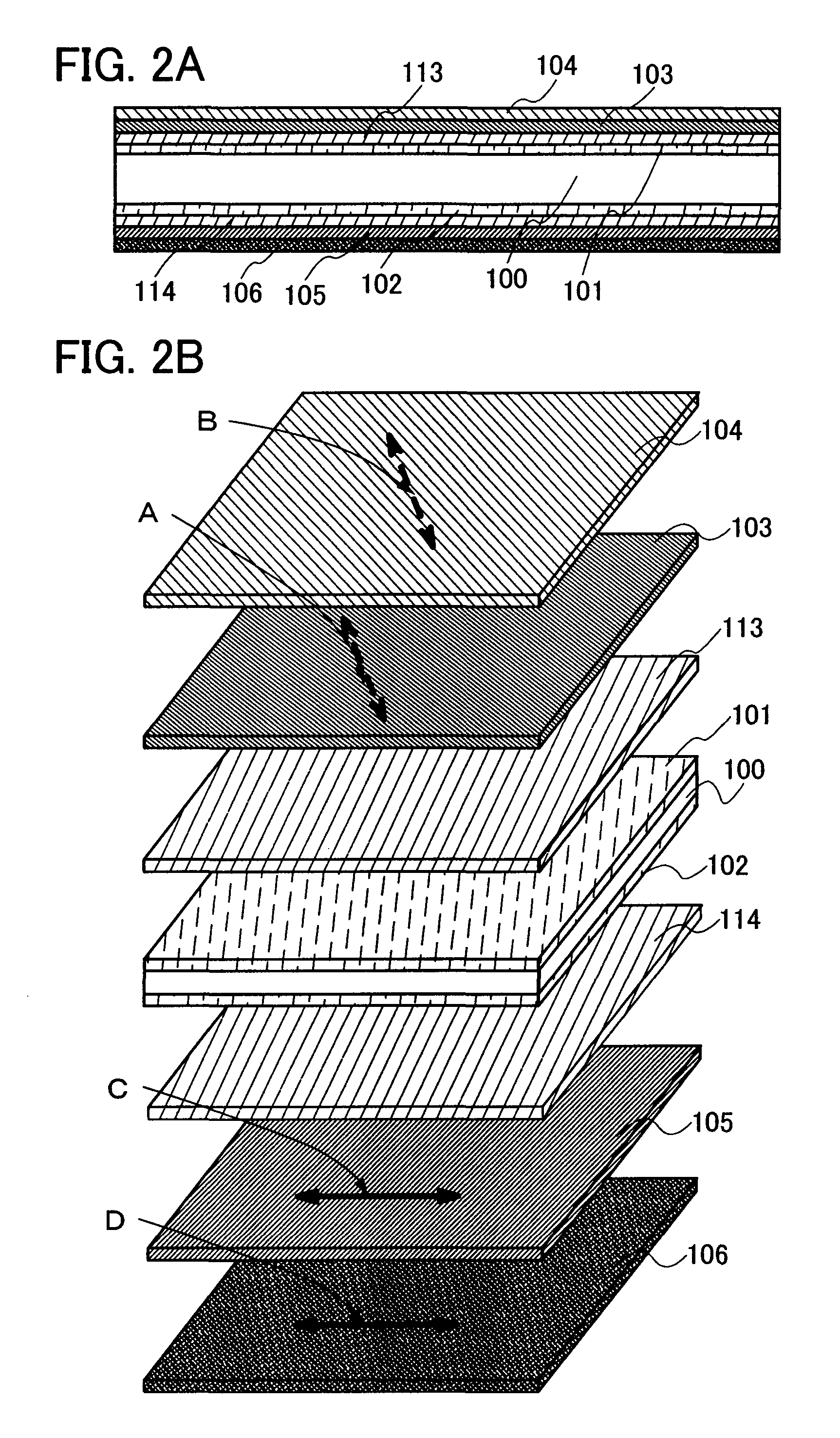

An object of the invention is to provide a display device having a high contrast ratio. Another object of the invention is to manufacture such a high-performance display device at low cost. In a display device having a display element between a pair of light-transmissive substrates, polarizer-including layers, which have different wavelength distributions of extinction coefficients, are stacked so that absorption axes are in a parallel nicol state, over each light-transmissive substrate. Absorption axes of one of a pair of stacks of polarizers and the other together which interpose the display element are deviated from a cross nicol state. A retardation plate may be provided between the stack of polarizing plates and the substrate.

Owner:SEMICON ENERGY LAB CO LTD

White color reflecting material and process for production thereof

ActiveUS20120138997A1Improve heat resistanceImprove light resistanceDiffusing elementsSolid-state devicesUltravioletRutile

A general-use white color reflecting material, and a process for production thereof are provided. The white color reflecting material, without troublesome surface treatment such as formation of a reflective layer by plating, is capable of reflecting a near-ultraviolet ray of a wavelength region of 380 nm or longer or a near-infrared ray sufficiently without light leakage; does not become yellow even when exposed to near-ultraviolet rays; has excellent lightfastness, heat resistance, and weatherability; has high mechanical strength and chemical stability; is capable of maintaining a high degree of whiteness; and is easily moldable at a low cost. Further a white color reflecting material used as an ink composition for producing the white color reflecting material in a film shape is also provided. The white color reflecting material comprises; a silicone resin or silicone rubber formed from titanium oxide-containing silicone composition, in which anatase-type or rutile-type titanium oxide particles are dispersed.

Owner:ASAHI RUBBER

Display module, display device and display device manufacturing method

ActiveCN109445171AAvoid light leakageAvoid affecting the display effectPrintersProjectorsGlass coverAdhesive

The invention provides a display module, a display device and a display device manufacturing method. The display module comprises a first substrate, a second substrate, an optical adhesive and shadingglue. The first substrate and the second substrate are in opposite arrangement; the optical adhesive is used for adhering a glass cover plate and the first substrate and comprises an optical adhesiveopening, the first substrate comprises a first substrate opening which includes the optical adhesive opening in a direction perpendicular to the display panel, and an area, exceeding the first substrate, of the optical adhesive is a first step area; the shading glue and the first step area are coincided in a direction perpendicular to the display panel and cover one side, close to the first substrate opening, of the first substrate. The first substrate opening is larger than the optical adhesive opening, so that a first step is formed; the first step is capable of blocking up the shading glueand beneficial for the shading glue to cover the lateral side, close to a porous area, of the first substrate, and accordingly light leakage of the first substrate is avoided.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

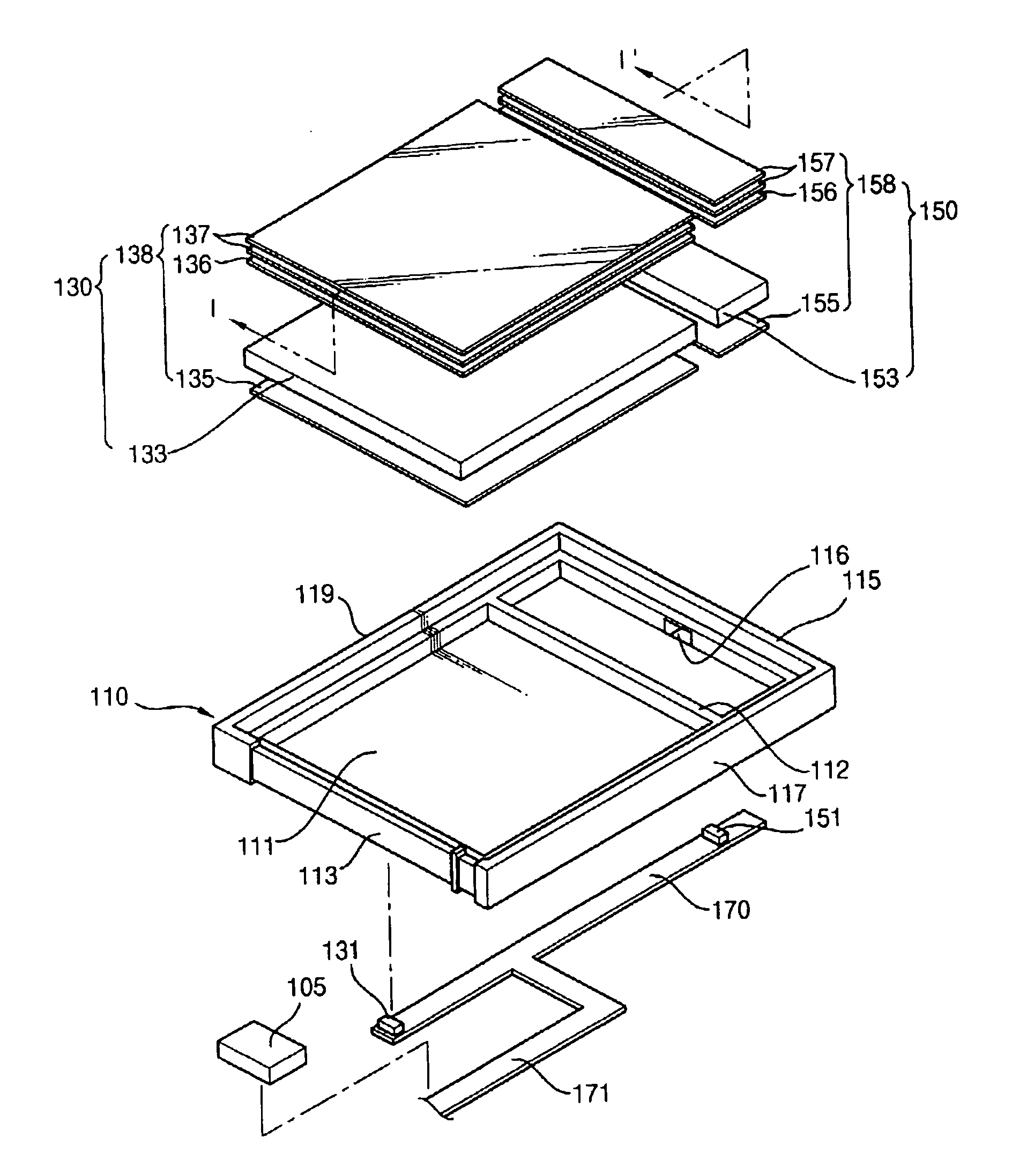

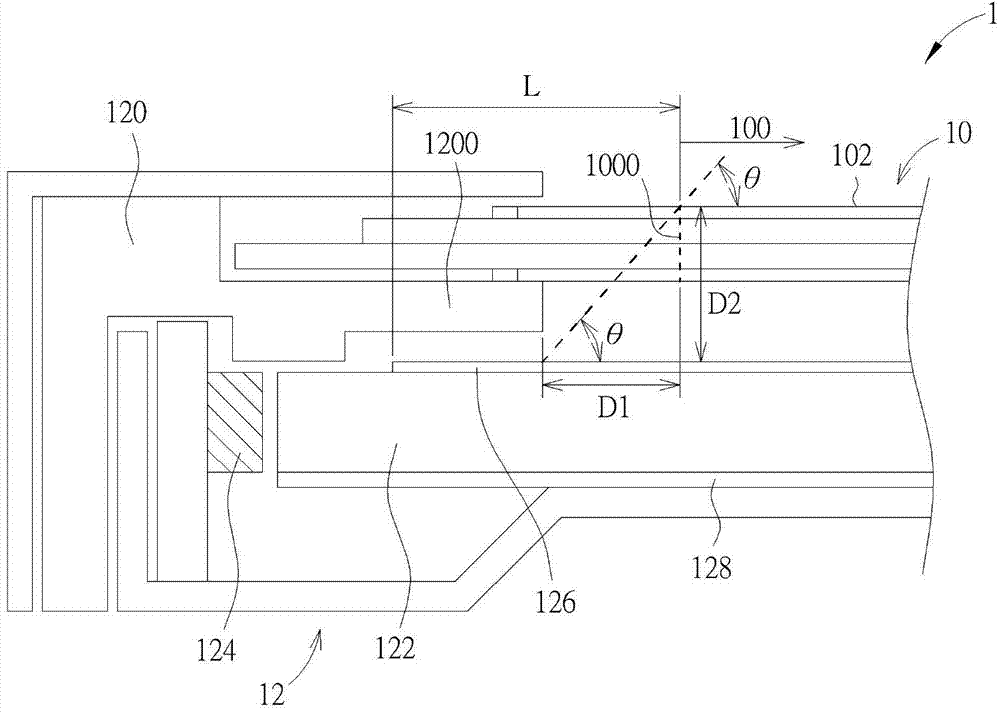

Liquid crystal display device

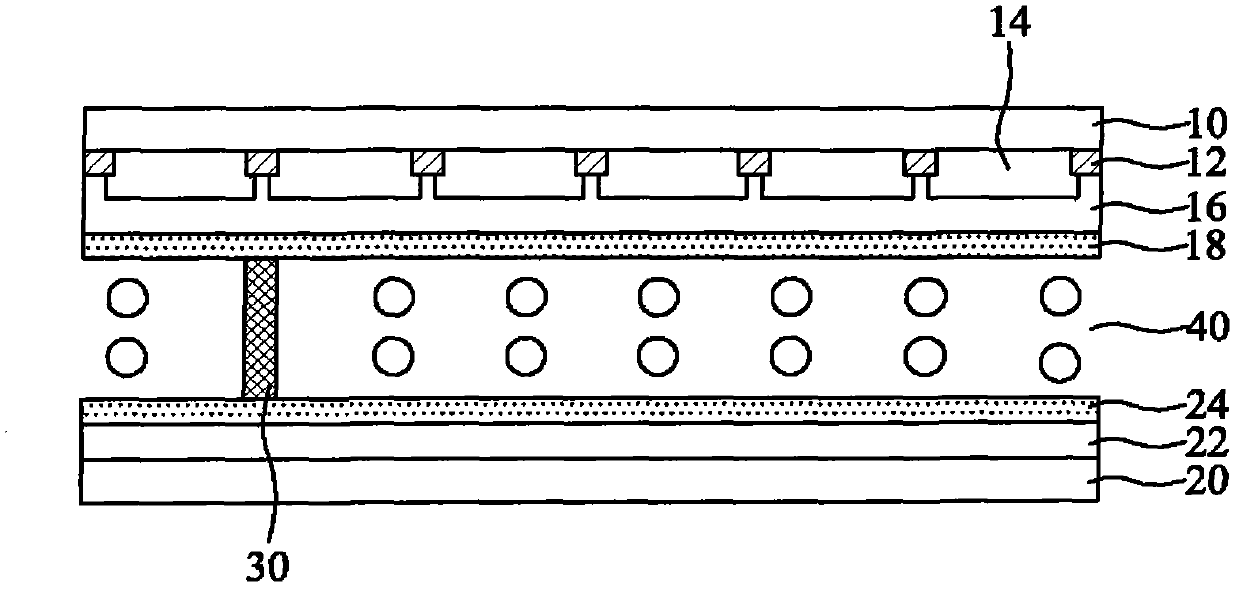

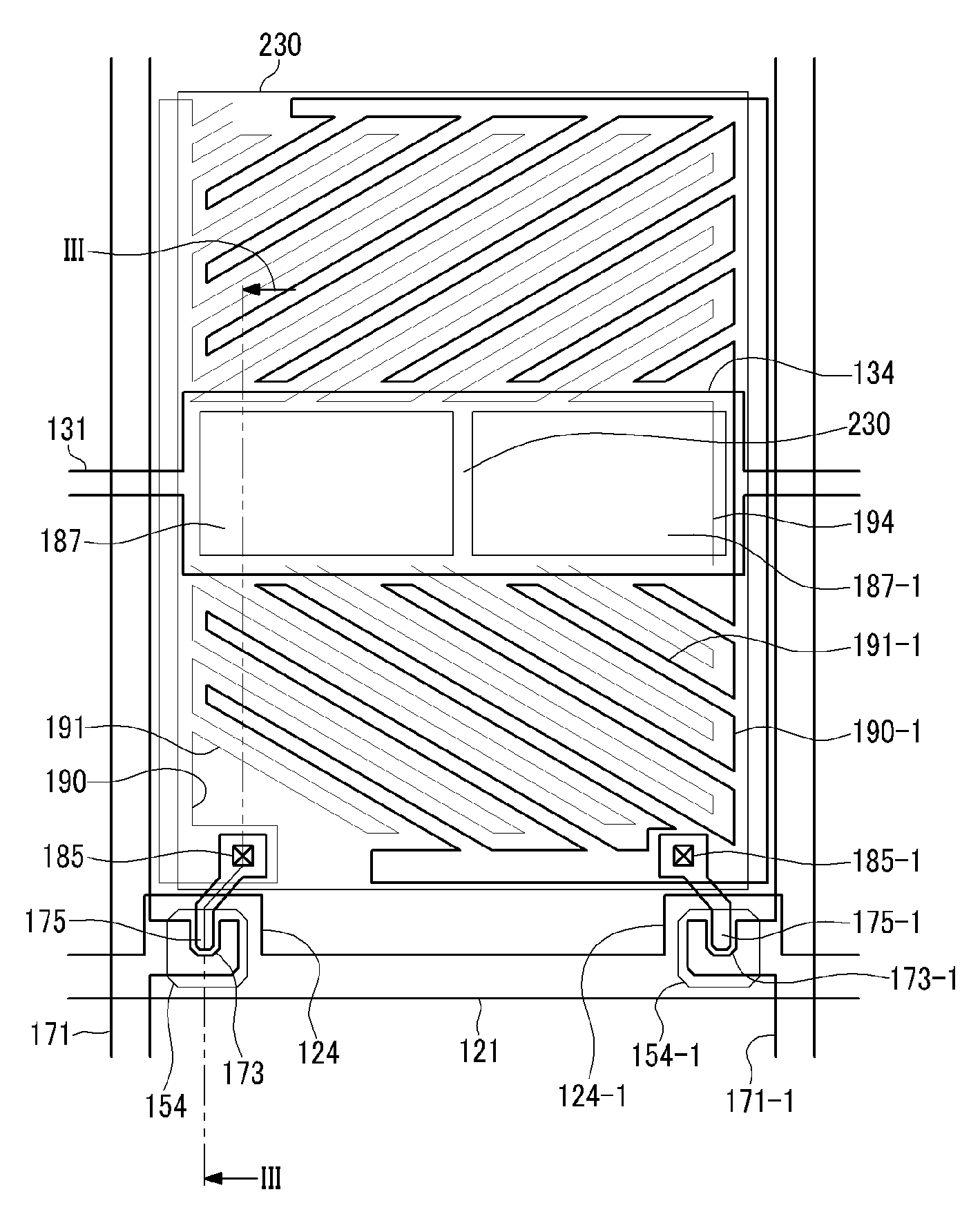

ActiveUS20100328580A1Improve brightness uniformityAvoid light leakageOptical light guidesNon-linear opticsLiquid-crystal displayPrism

Disclosed is a liquid crystal display (LCD) device capable of enhancing brightness uniformity by preventing light leakage. The LCD device comprises an LC panel; an optical source for providing light to the LC panel; a light guide plate coupled to a light emission surface of the optical source; a light emitting diode (LED) printed circuit board (PCB) disposed on the light guide plate and the optical source; an optical sheet disposed on the light guide plate, and having a diffusion plate and a prism sheet on an upper surface of one side corresponding to the LED PCB, the diffusion plate having a light shielding member attached thereto; and a mold frame for accommodating therein the optical source, the light guide plate, and the optical sheet.

Owner:LG DISPLAY CO LTD

Display device and backlight module thereof

The invention discloses a display device which comprises a display panel and a backlight module, wherein the display panel is provided with a valid display boundary; the backlight module comprises a frame, a light-guiding plate, a blue-ray light source and a quantum dot enhancing film; the frame is provided with a supporting part; the display panel is arranged on the supporting part; the valid display boundary is arranged a first preset distance away from the supporting part; the light-guiding plate is arranged in the frame; the light-guiding plate is located under the supporting part; the blue-ray light source is arranged in the frame and is located on one side of the light-guiding plate; the quantum dot enhancing film is arranged on the light-guiding plate; the distance of the quantum dot enhancing film exceeding the valid display boundary is a preset length; the preset length is greater than the first preset distance, so that the supporting part is partially overlapped with the quantum dot enhancing film.

Owner:QISDA SUZHOU +1

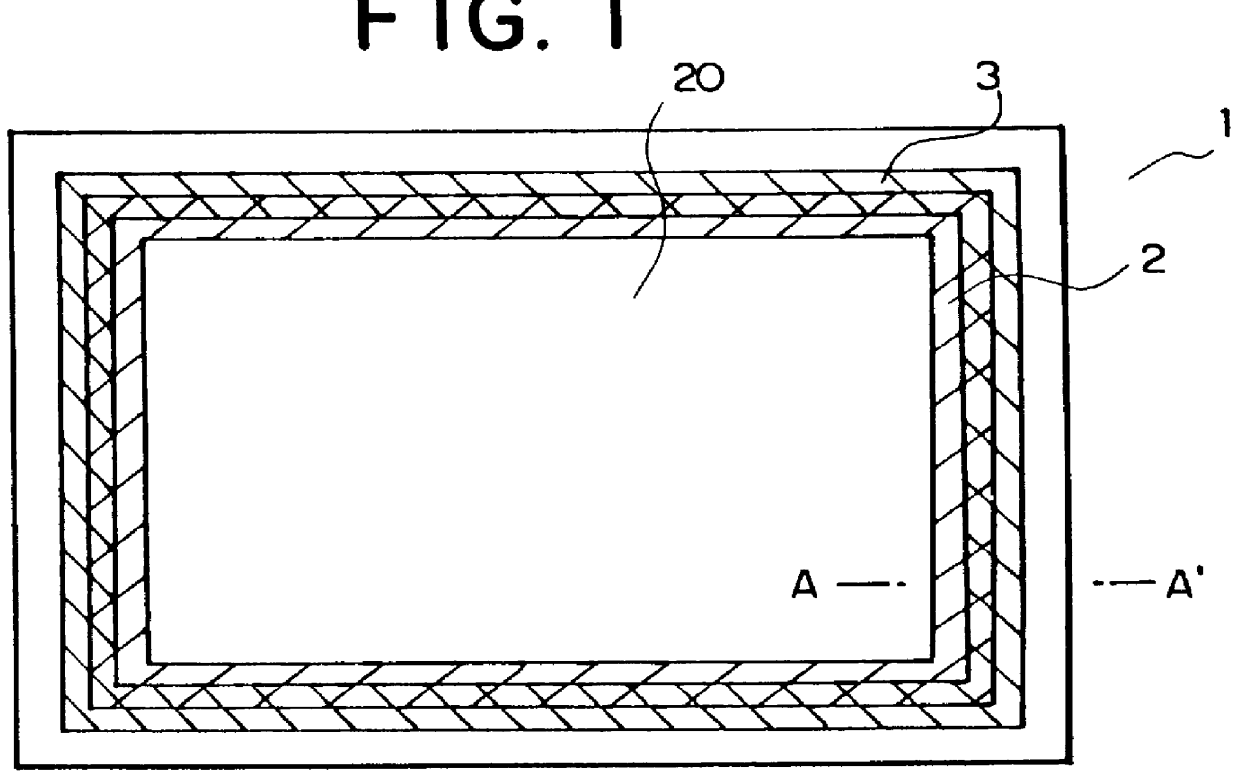

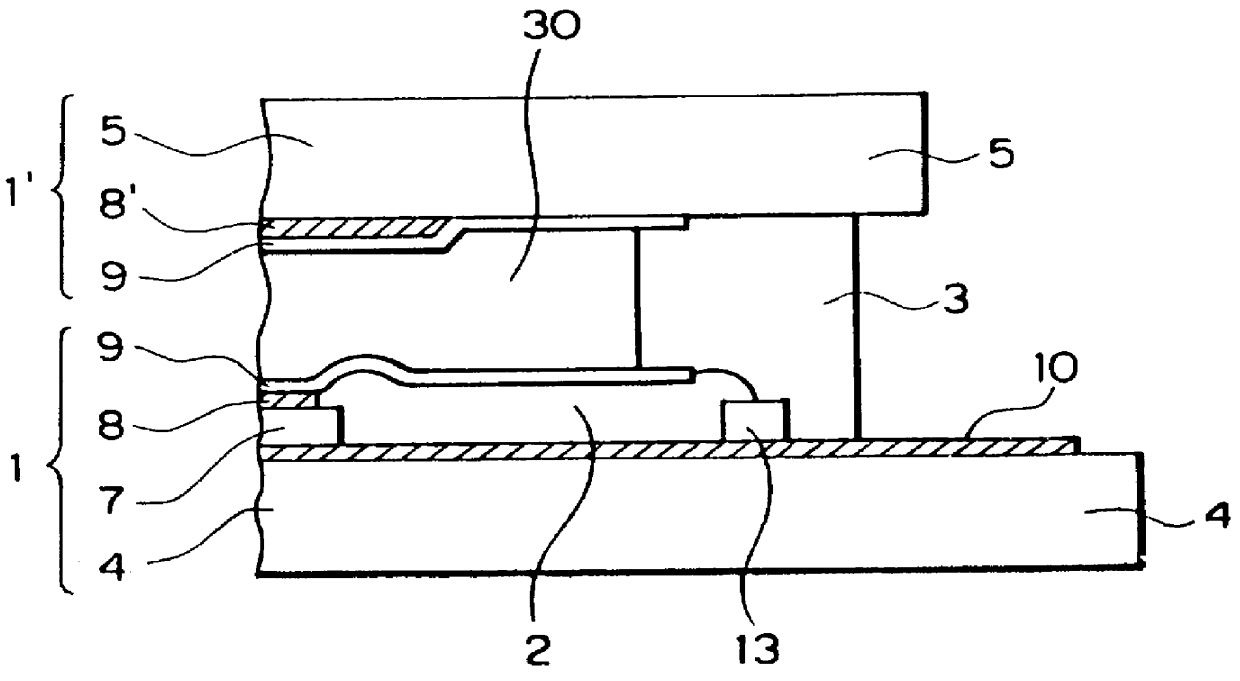

LCD and fabrication method thereof having a pedestal and overlying organic film at a periphery of the display

InactiveUS6104462AProduct defect can be almost preventedPrevent short-circuitingNon-linear opticsOrganic filmLiquid-crystal display

A liquid crystal displaying apparatus is disclosed, that comprises a pair of substrates, a liquid crystal material filled in the space between the pair of substrates, a plurality of lines formed on one of the pair of substrates, an organic film formed on the plurality of lines, a conductive film formed on the organic film, and a pedestal, wherein the plurality of lines extend from a first area to a second area, the organic film being disposed on the plurality of lines in the first area, the second area exceeding an edge portion of the organic film, wherein the pedestal is disposed between the first area and the second area through the edge portion, wherein the organic film is formed between the pedestal to a non-pedestal area, wherein the thickness in the vicinity of at least the edge portion of the organic film formed on the pedestal is smaller than the thickness of the organic film formed in the non-pedestal area, and wherein the thickness of the pedestal is smaller than the thickness of the organic film formed in the non-pedestal area.

Owner:KK TOSHIBA

Display panel and display device including the same

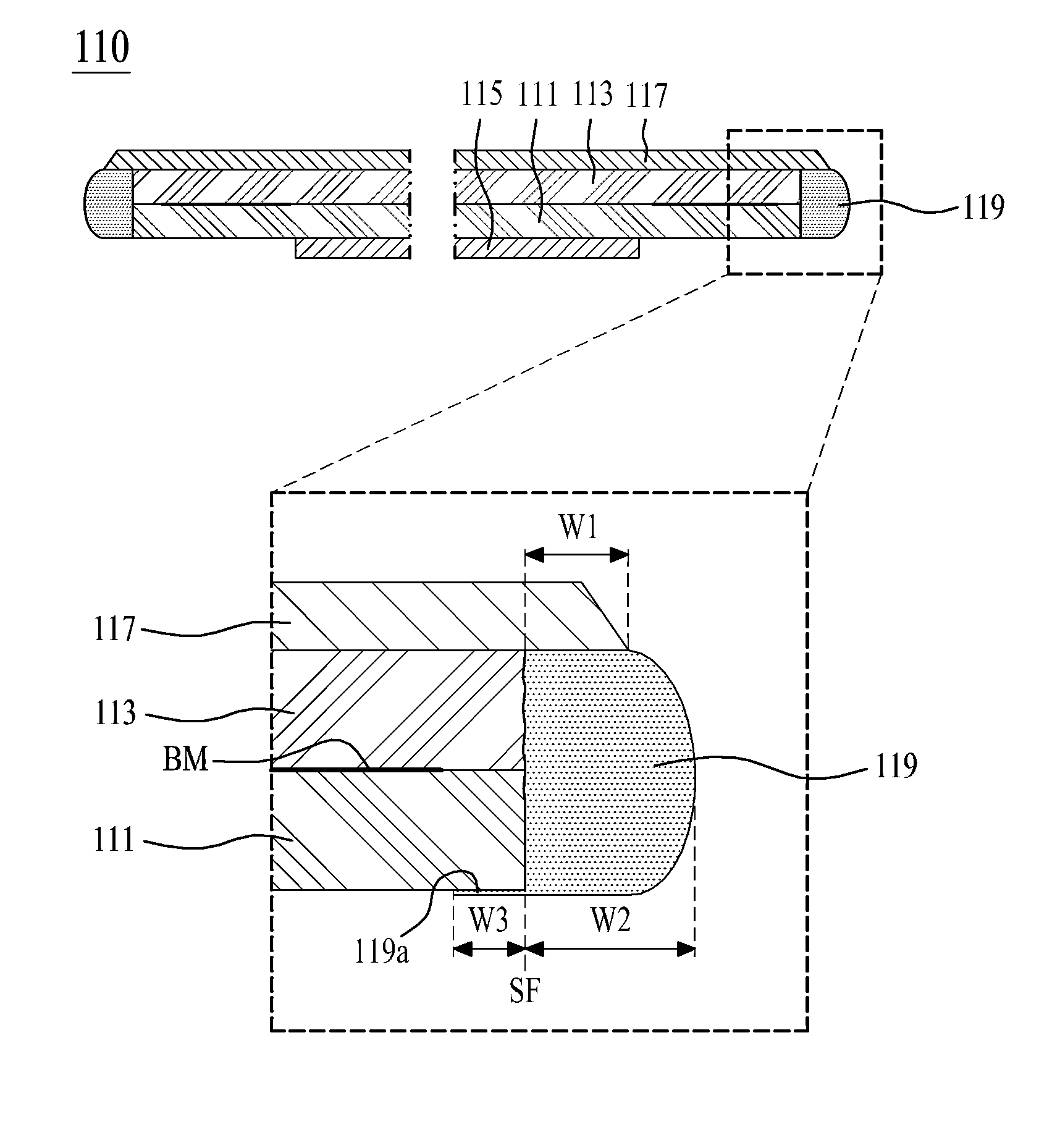

ActiveUS20140204293A1Avoid light leakagePrevent leakageNon-linear opticsIdentification meansDisplay deviceEngineering

Discussed is a display panel capable of preventing a substrate from being directly exposed to the external and preventing a light leakage. The display panel according to an embodiment includes a lower substrate and an upper substrate coupled to each other and configured to display images; an optical film attached to an upper surface of the upper substrate; and a panel protection member for covering side faces of the lower and upper substrates, wherein at least one side of the optical film extends beyond a side face of at least one side of the upper substrate.

Owner:LG DISPLAY CO LTD

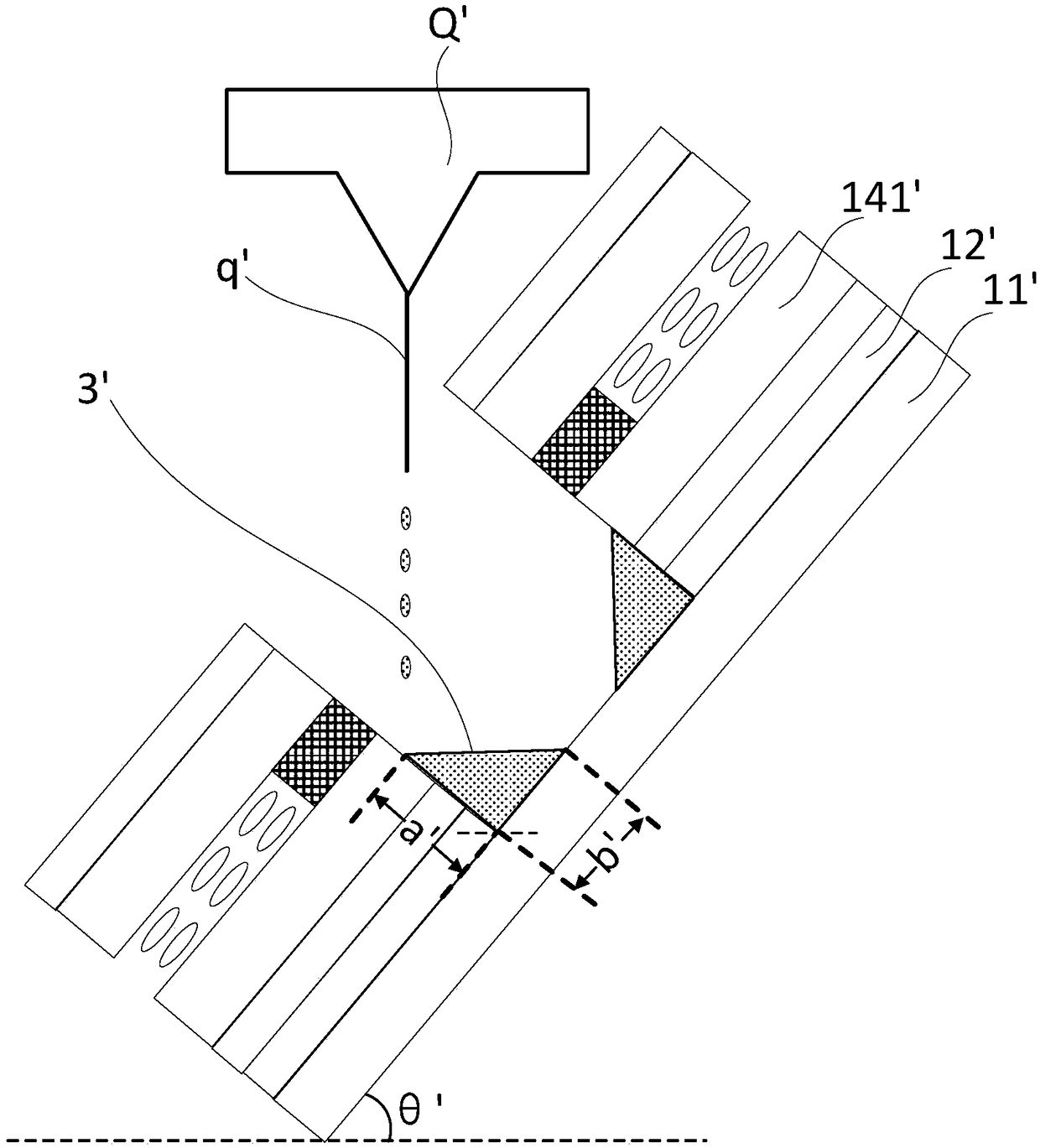

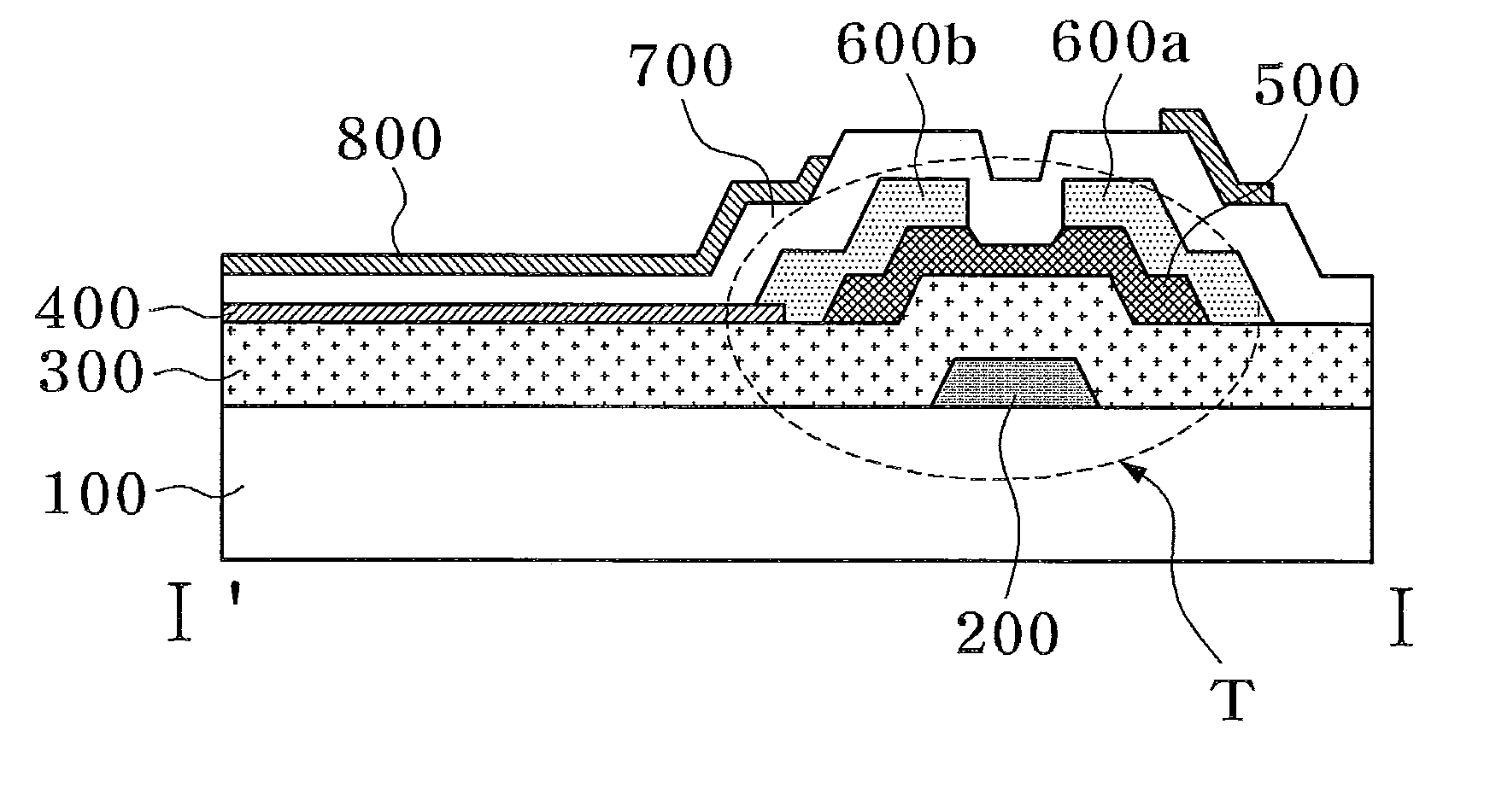

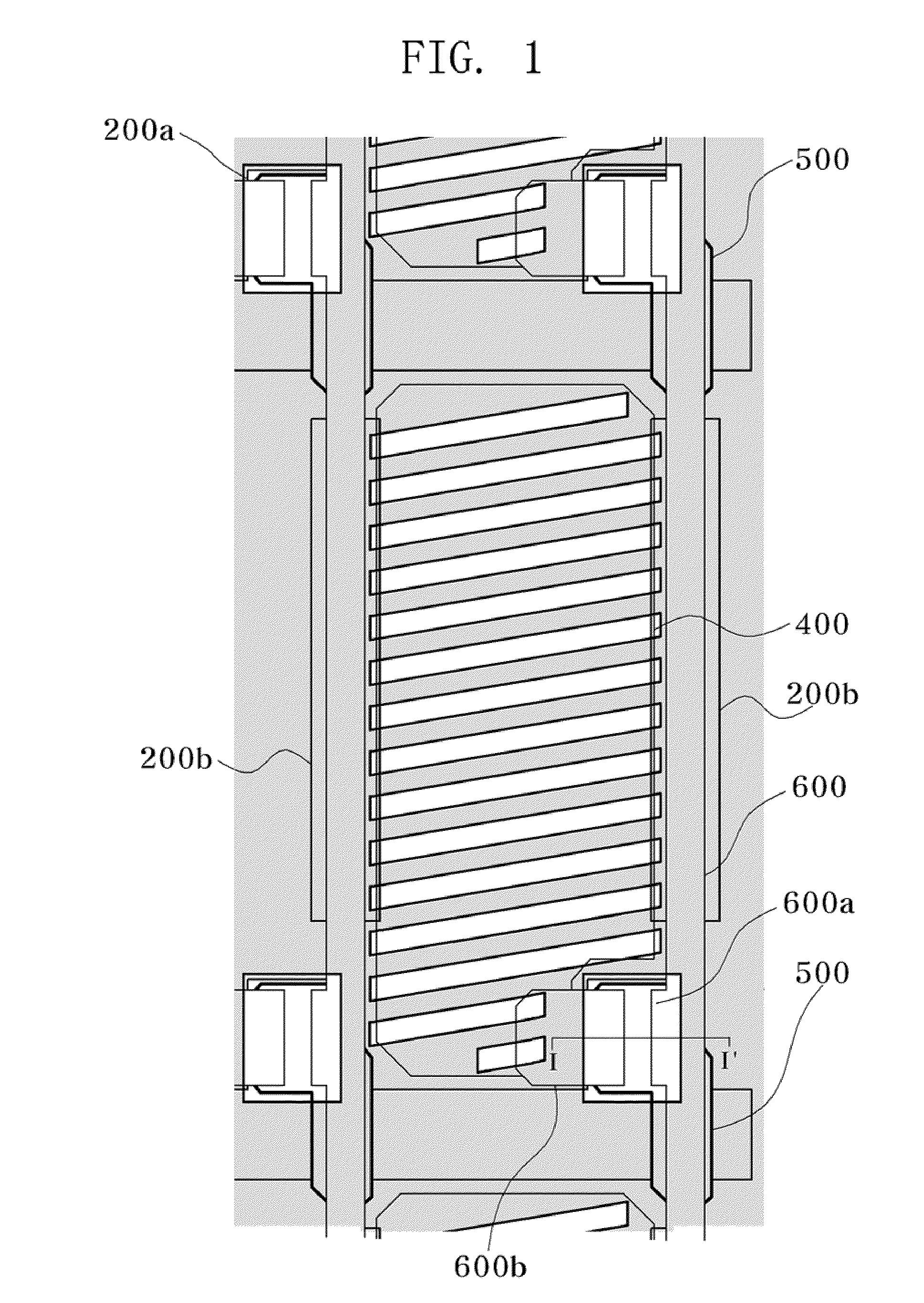

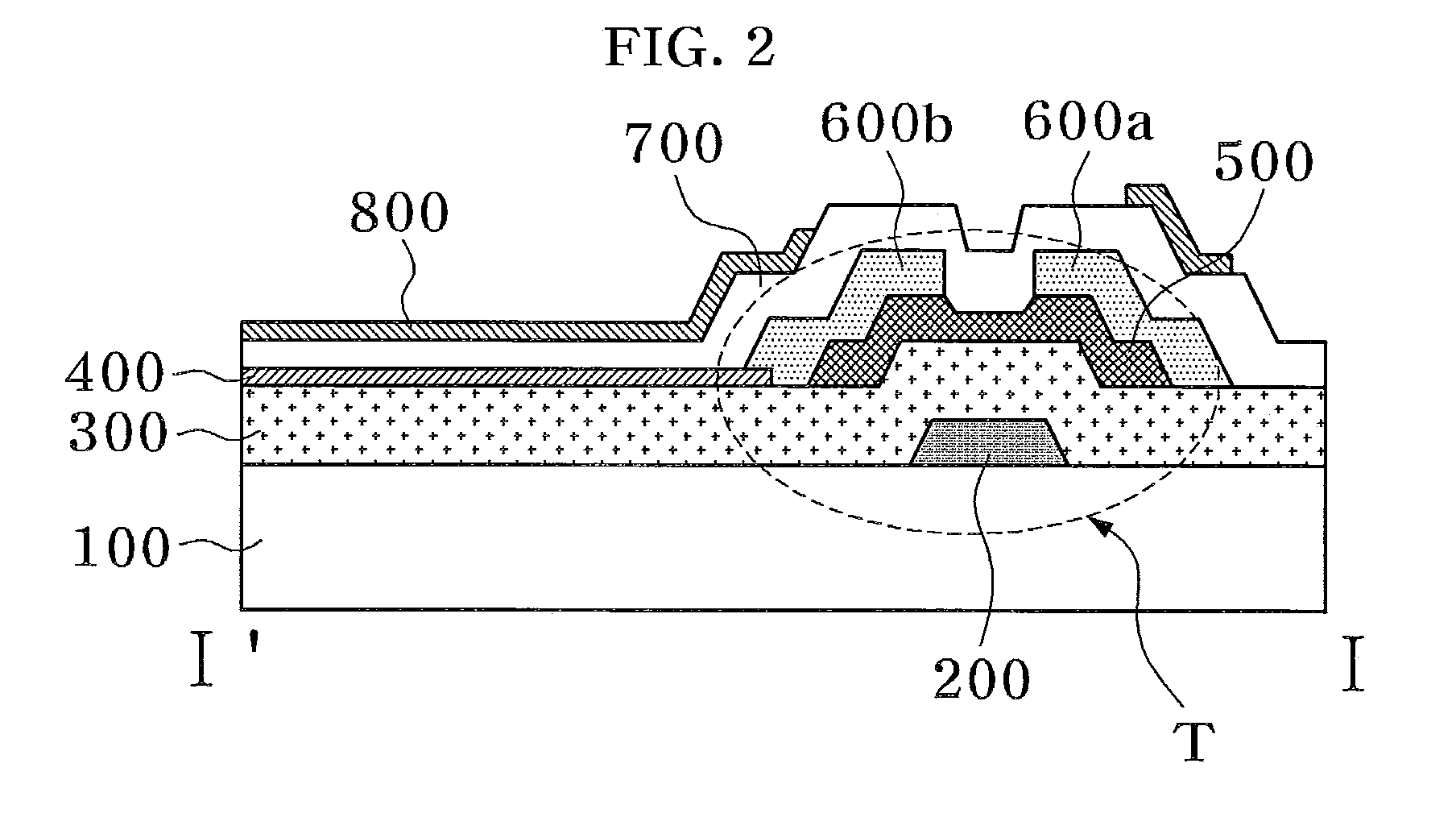

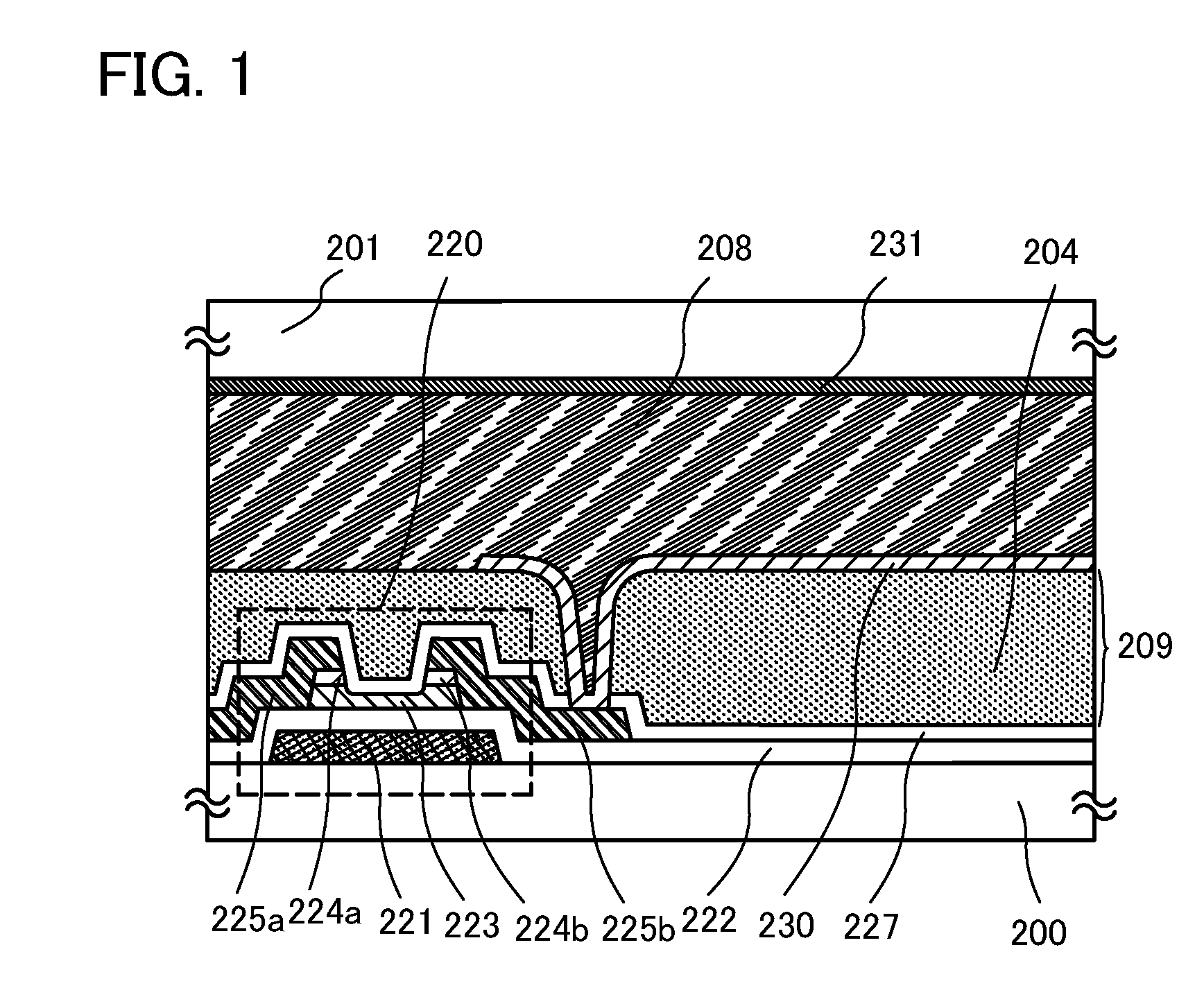

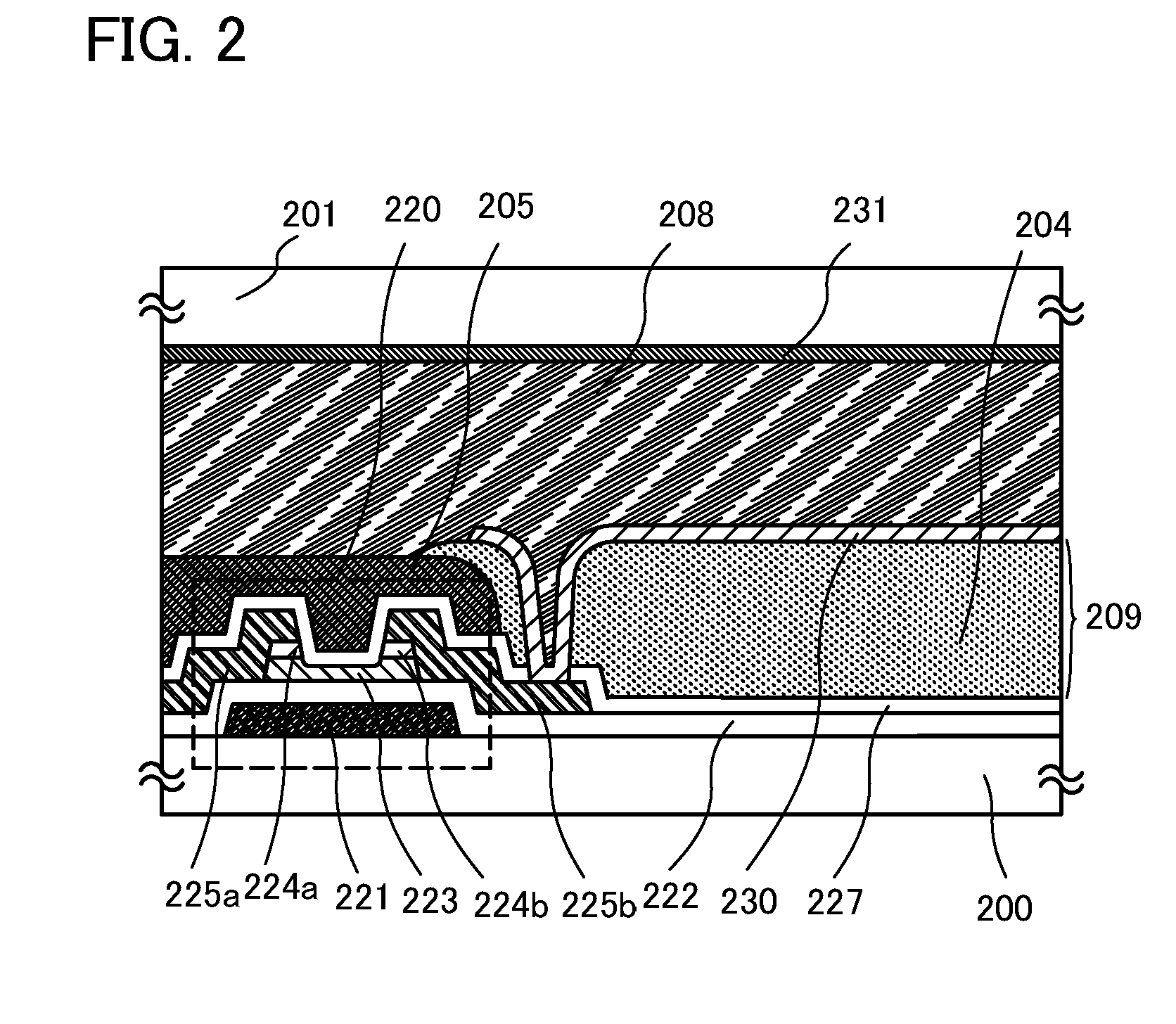

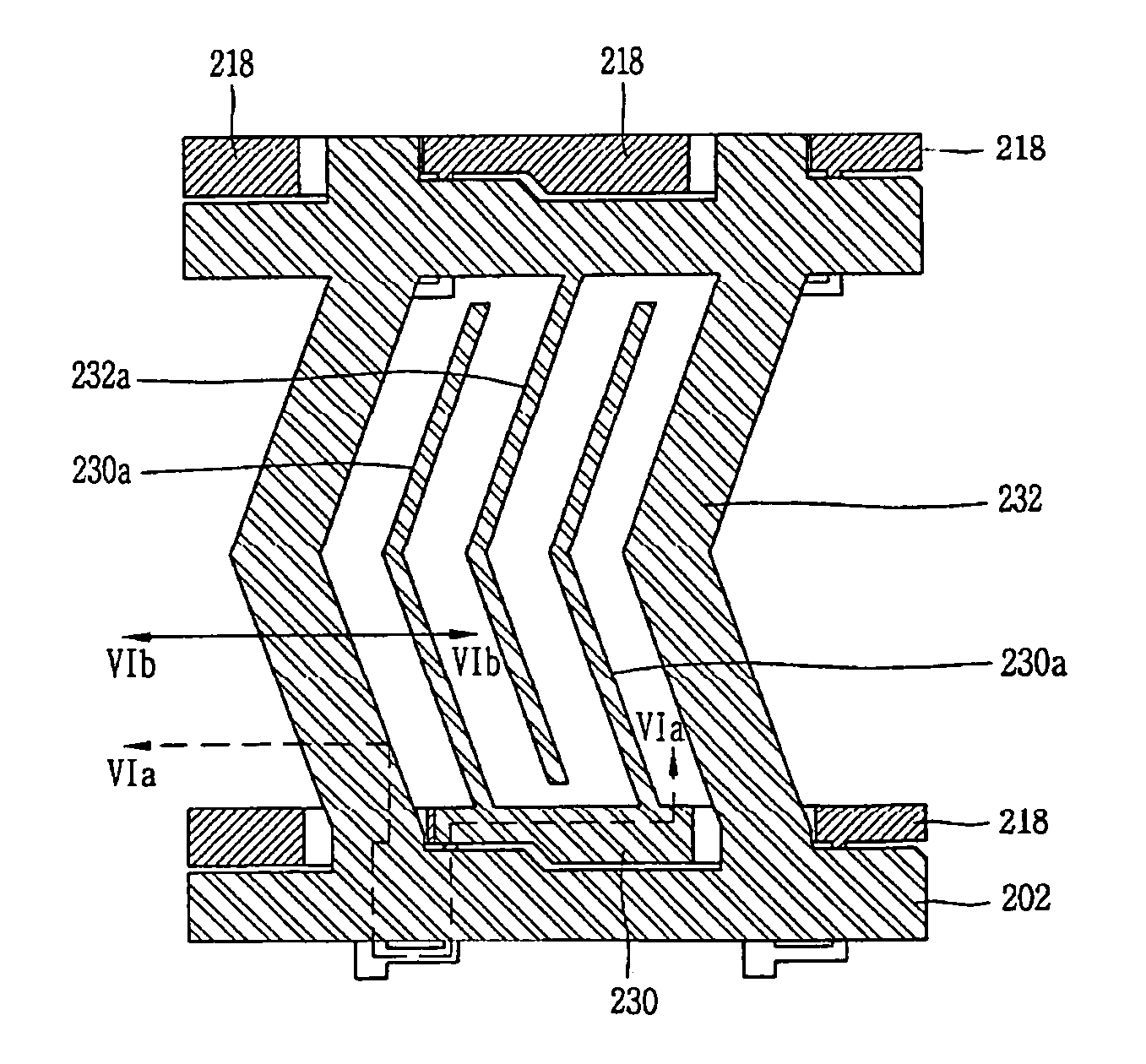

Fringe Field Switching Mode Liquid Crystal Display Device and Method of Fabricating the Same

ActiveUS20110109861A1Simple processIncrease the aperture ratioSemiconductor/solid-state device manufacturingNon-linear opticsLiquid-crystal displayOptoelectronics

Provided is a liquid crystal display including a transparent pixel electrode and a transparent common electrode in a pixel region to drive liquid crystals. The transparent common electrode includes a plurality of slits and is configured to open at least a portion of a switching device to connect unit pixels, the slits have an angle of 5 to 10° with respect to a gate line, and a rubbing direction of a liquid crystal layer is substantially parallel to a gate direction. Therefore, it is possible to provide the liquid crystal display capable of removing factors decreasing an aperture ratio, preventing light from leaking, and further improving internal reflection.

Owner:HYDIS TECH

Organic light emitting display panel and preparation method and driving method thereof and display device

ActiveCN107644895AImprove the display effectRealize the masking functionStatic indicating devicesSolid-state devicesOrganic light emitting deviceTransmittance

The device discloses an organic light emitting display panel and a preparation method and a driving method thereof and a display device. An organic light emitting display device and an electro-chromicdevice are arranged into a horizontal structure, and the organic light emitting display device and the electro-chromic device are controlled to work through different driving control circuits, i.e. different voltage is inputted to the electro-chromic device to adjust different transmittance of the electro-chromic device by a second driving control circuit, the display effect of the display panelcan be enhanced when the electro-chromic device is in the shading state, and transparent display of different transmittance of the display panel can be realized when the electro-chromic device is in the light transmission state; and the voltage is inputted to the electro-chromic device through the second driving control circuit and the electro-chromic device is enabled to be in the shading state when the display panel is in the non-display state so that the shielding function of the display panel can be realized and the phenomenon of light leakage of the display panel in the non-display statecan be prevented.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

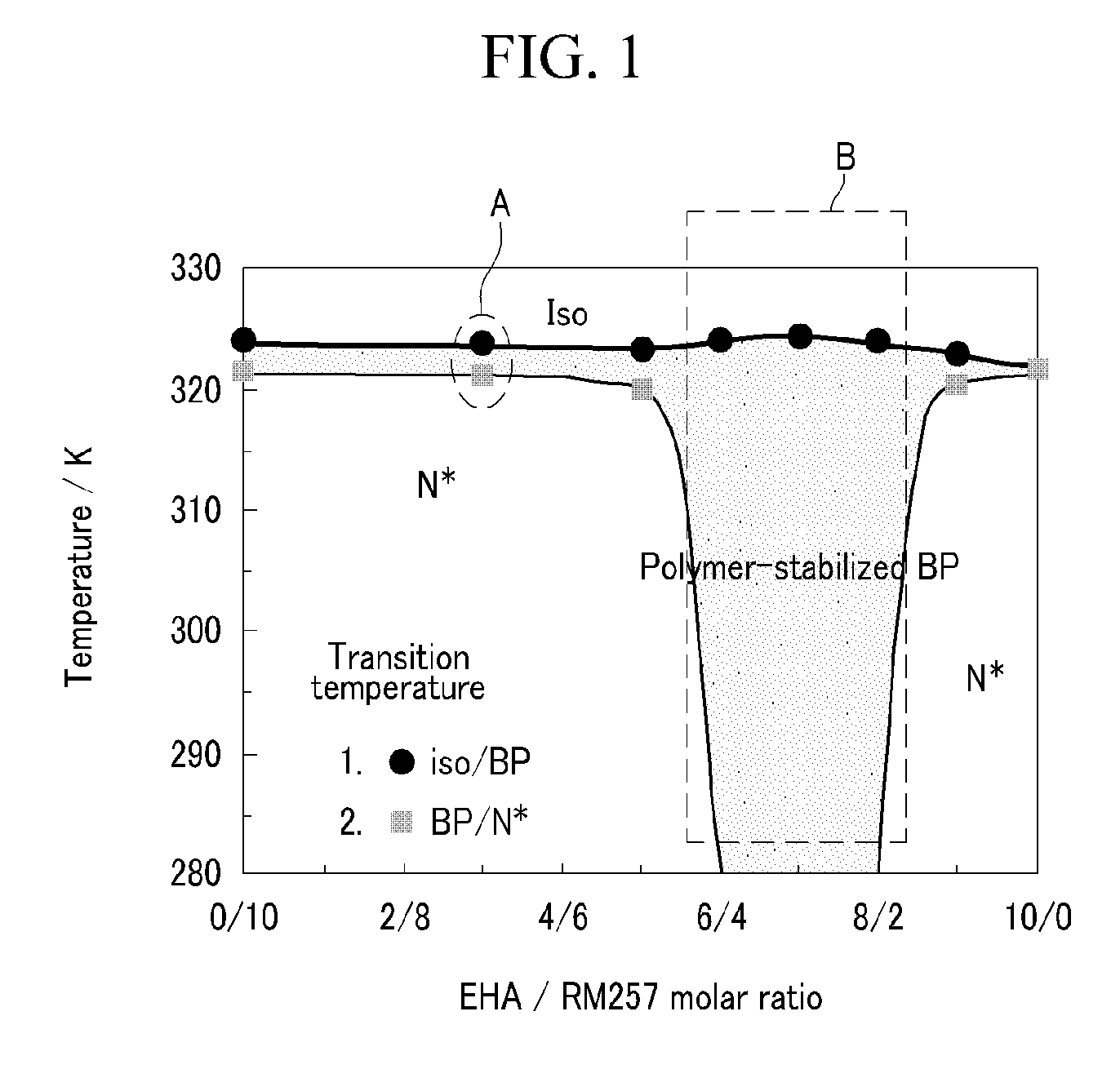

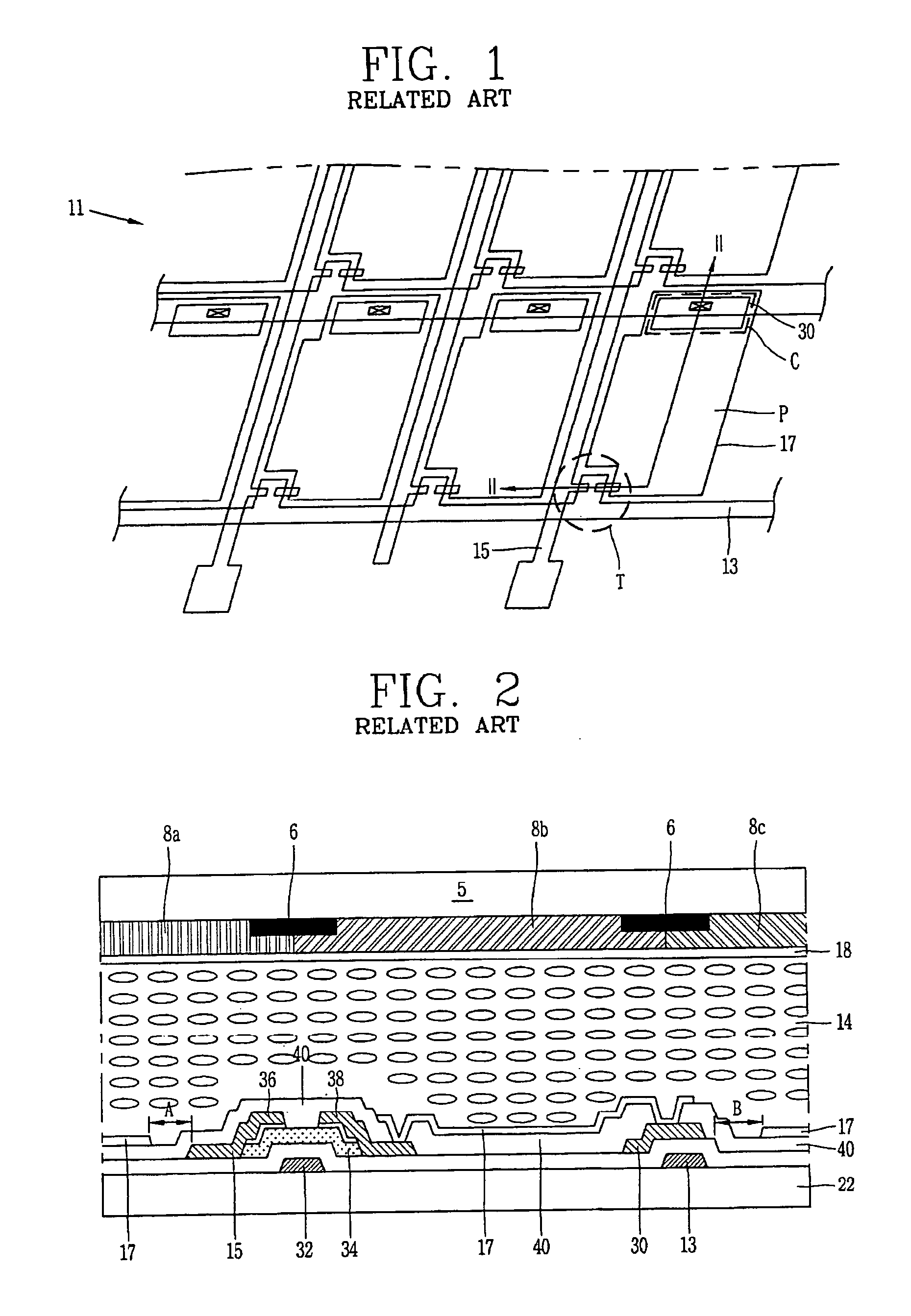

Liquid crystal display and method of manufacturing the same

InactiveUS20100053490A1Reduce the driving voltageImprove picture qualityNon-linear opticsEngineeringTransistor

A liquid crystal display includes a first substrate, a gate line and first and second data lines disposed on the first substrate, a first thin film transistor connected to the gate line and the first data line, a second thin film transistor connected to the gate line and the second data line, a color filter disposed on the first substrate, a protrusion disposed on the color filter, a first pixel electrode including a first linear electrode disposed on the protrusion and connected to the first thin film transistor, a second pixel electrode including a second linear electrode disposed on the protrusion and connected to the second thin film transistor, a second substrate disposed facing the first substrate, and blue phase liquid crystal disposed between the first substrate and the second substrate.

Owner:SAMSUNG DISPLAY CO LTD

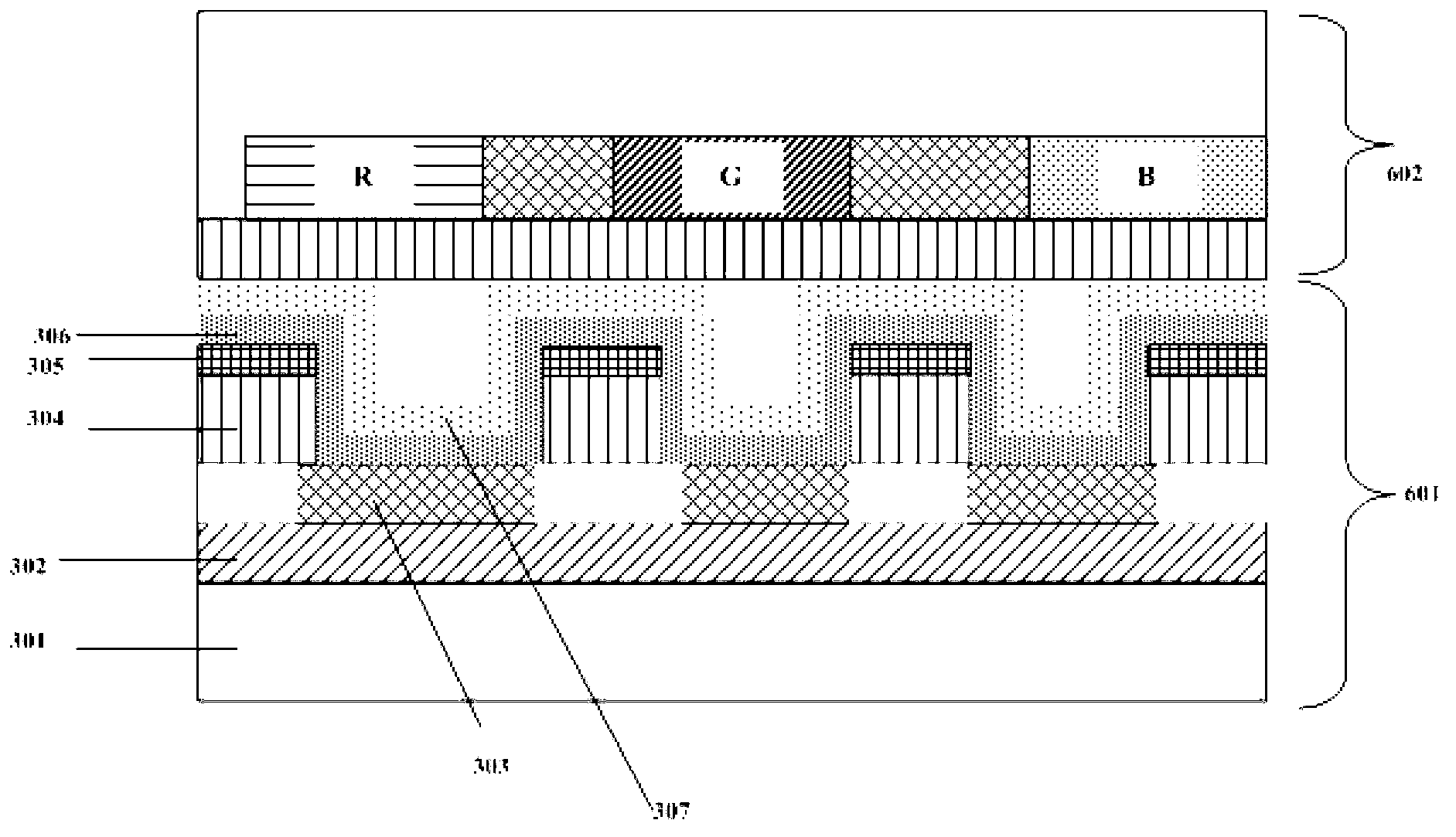

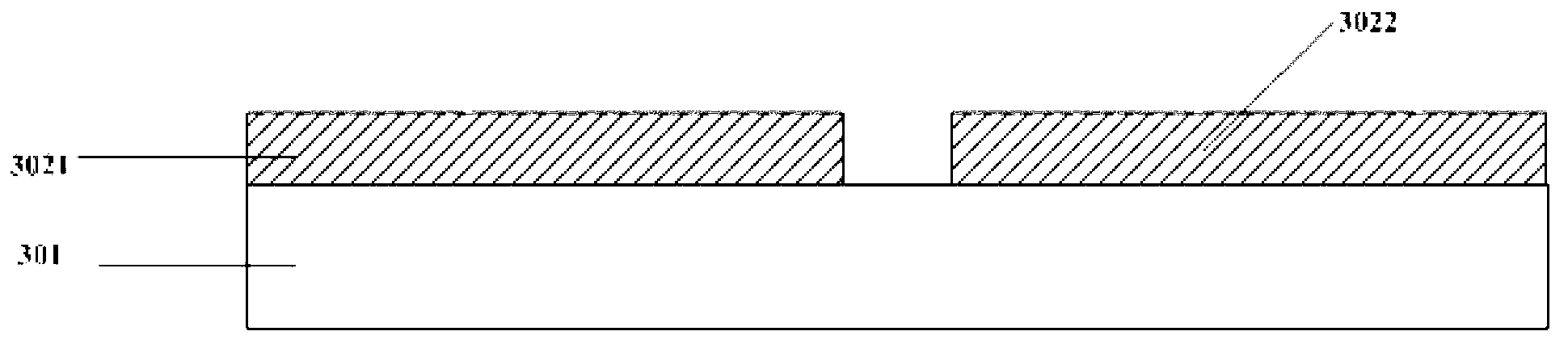

Method for manufacturing WOLED (White Organic Light Emitting Diode), WOLED and display equipment

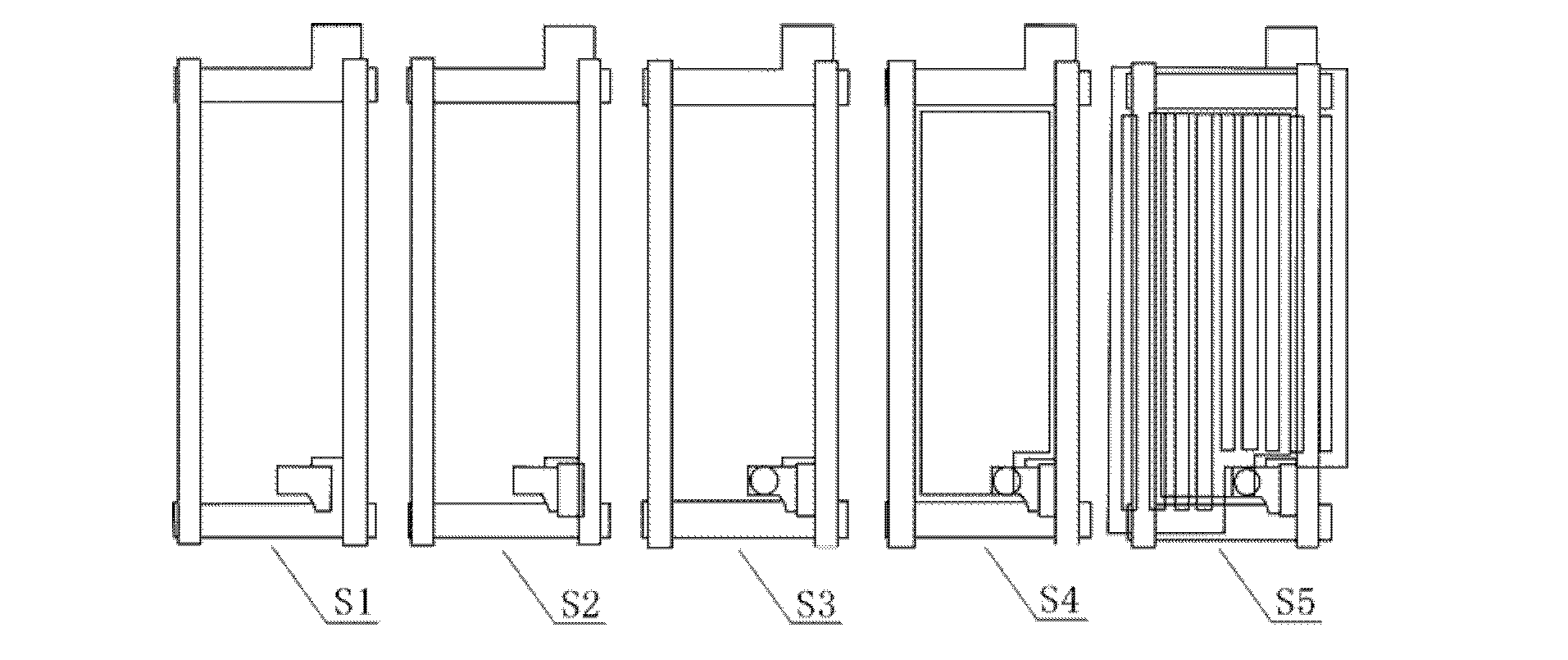

ActiveCN103268921AAvoid light leakageImprove image display qualitySolid-state devicesSemiconductor/solid-state device manufacturingComposition processLight-emitting diode

The invention discloses a method for manufacturing a WOLED (White Organic Light Emitting Diode), the WOLED and display equipment. The method comprises the following steps: forming an array substrate comprising an anode array on a substrate based on a composition process and forming a color filter substrate based on the composition process, including depositing a transparent organic thin film and a reflective metal thin film on the array substrate in sequence; patterning the reflective metal thin film to remove a metal thin film above an anode electrode; etching the transparent organic thin film by taking the patterned metal thin film as a mask to expose the anode electrode so as to form a pixel definition pattern; evaporating an organic light emitting unit and a cathode on the array substrate on which the pixel definition pattern is formed in sequence; and attaching the array substrate comprising the organic light emitting unit and the cathode with the color filter substrate to form the WOLED. According to the method, the light leakage phenomenon of the WOLED existing in the prior art can be avoided better, and the image display quality of the display equipment is improved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

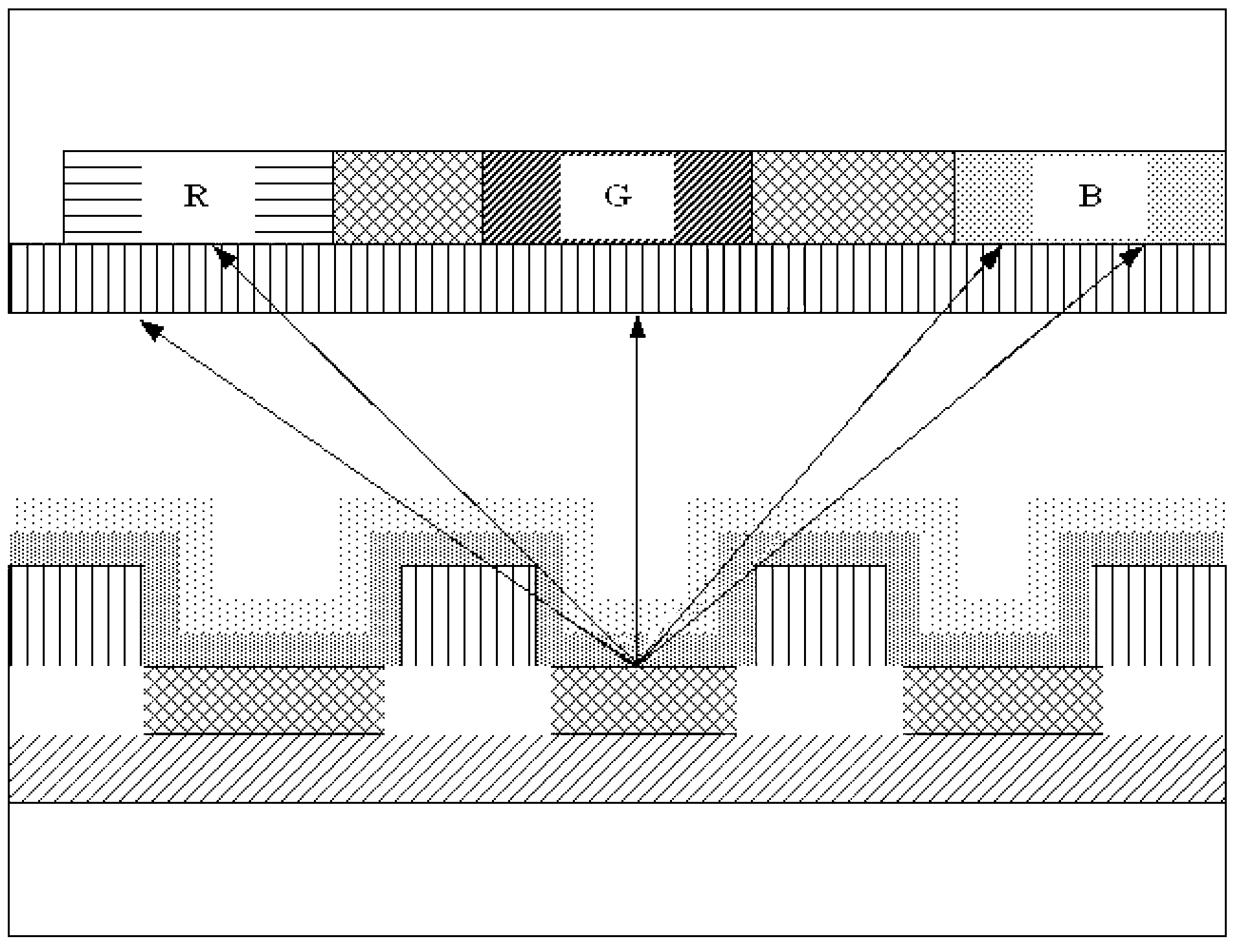

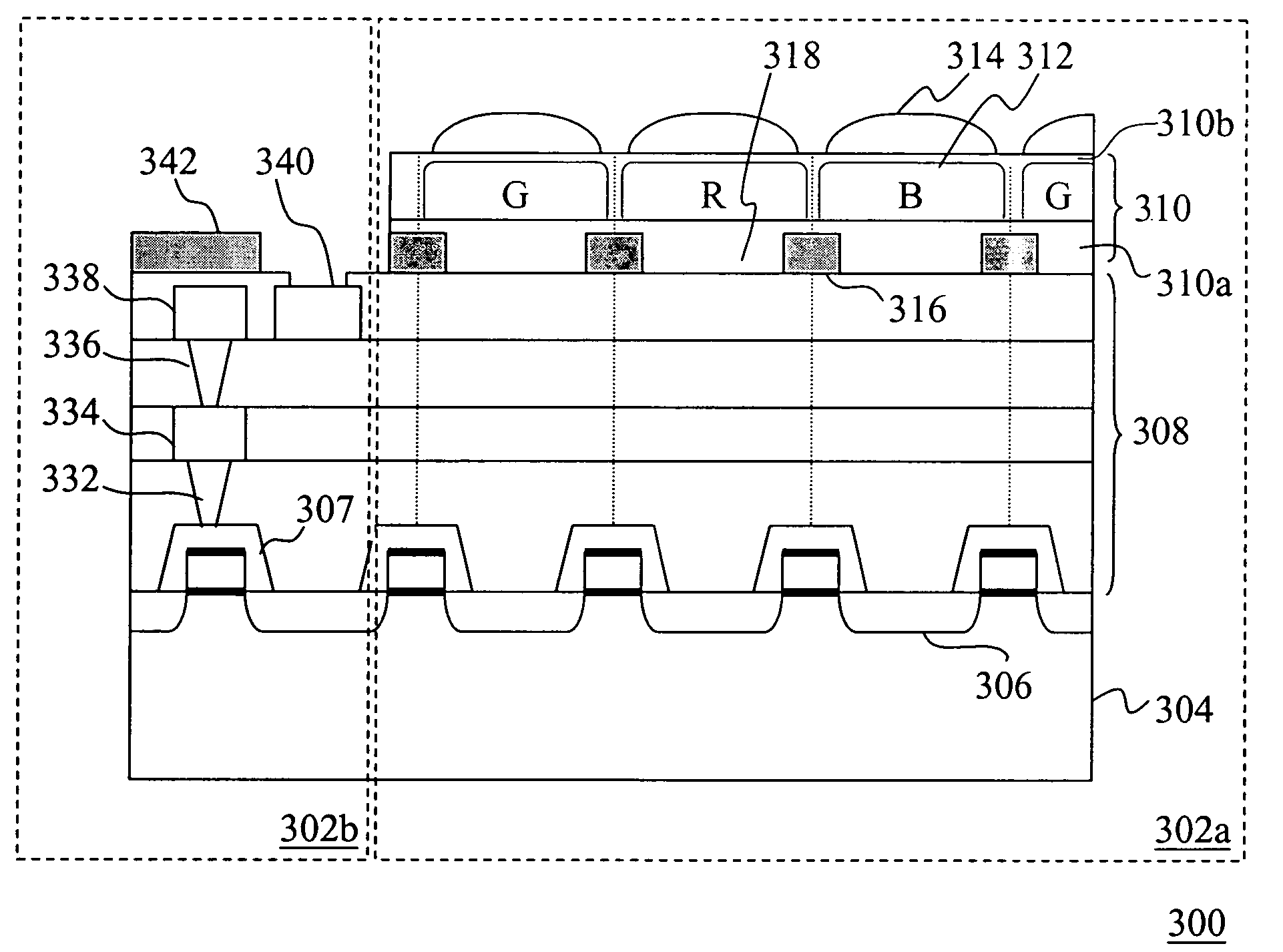

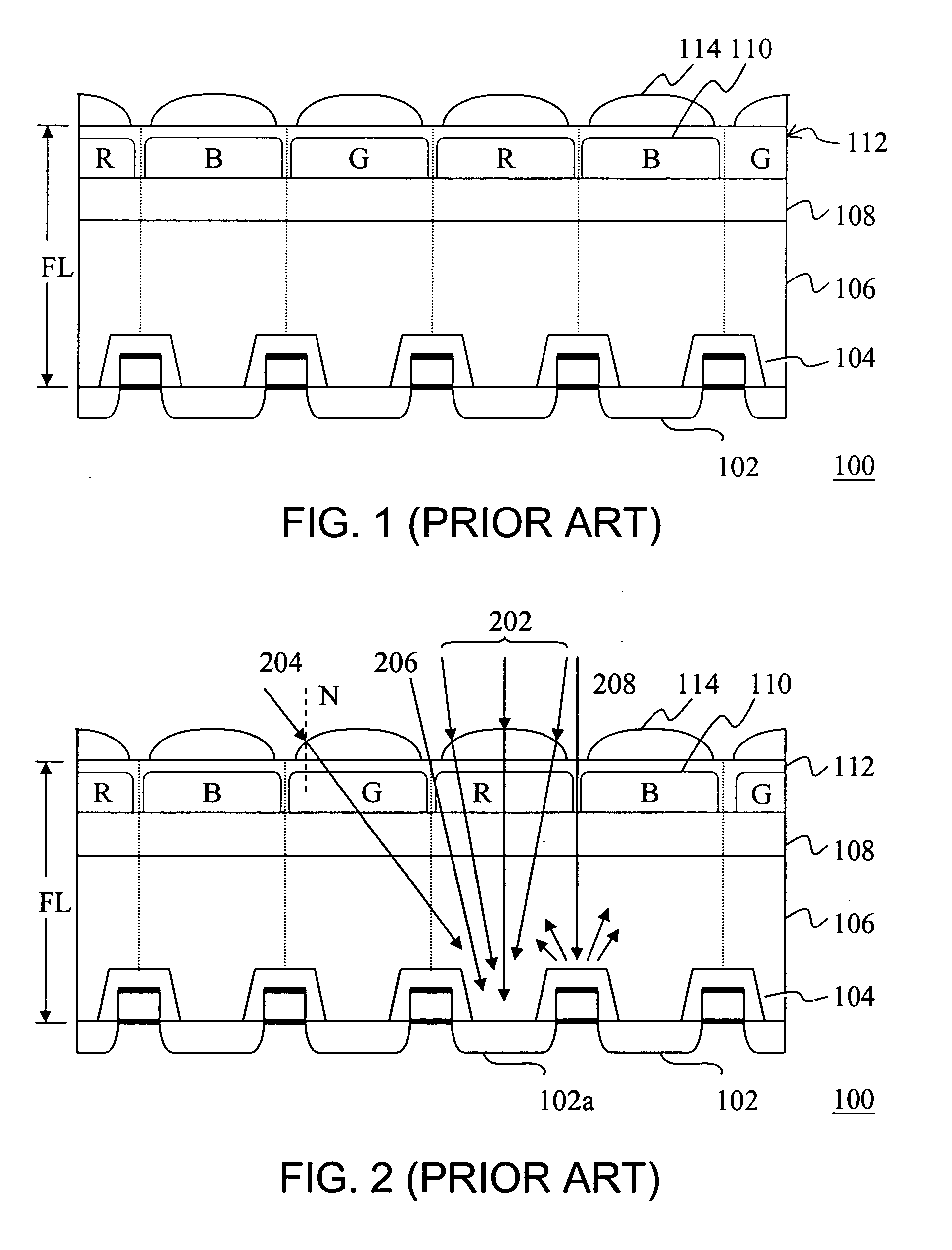

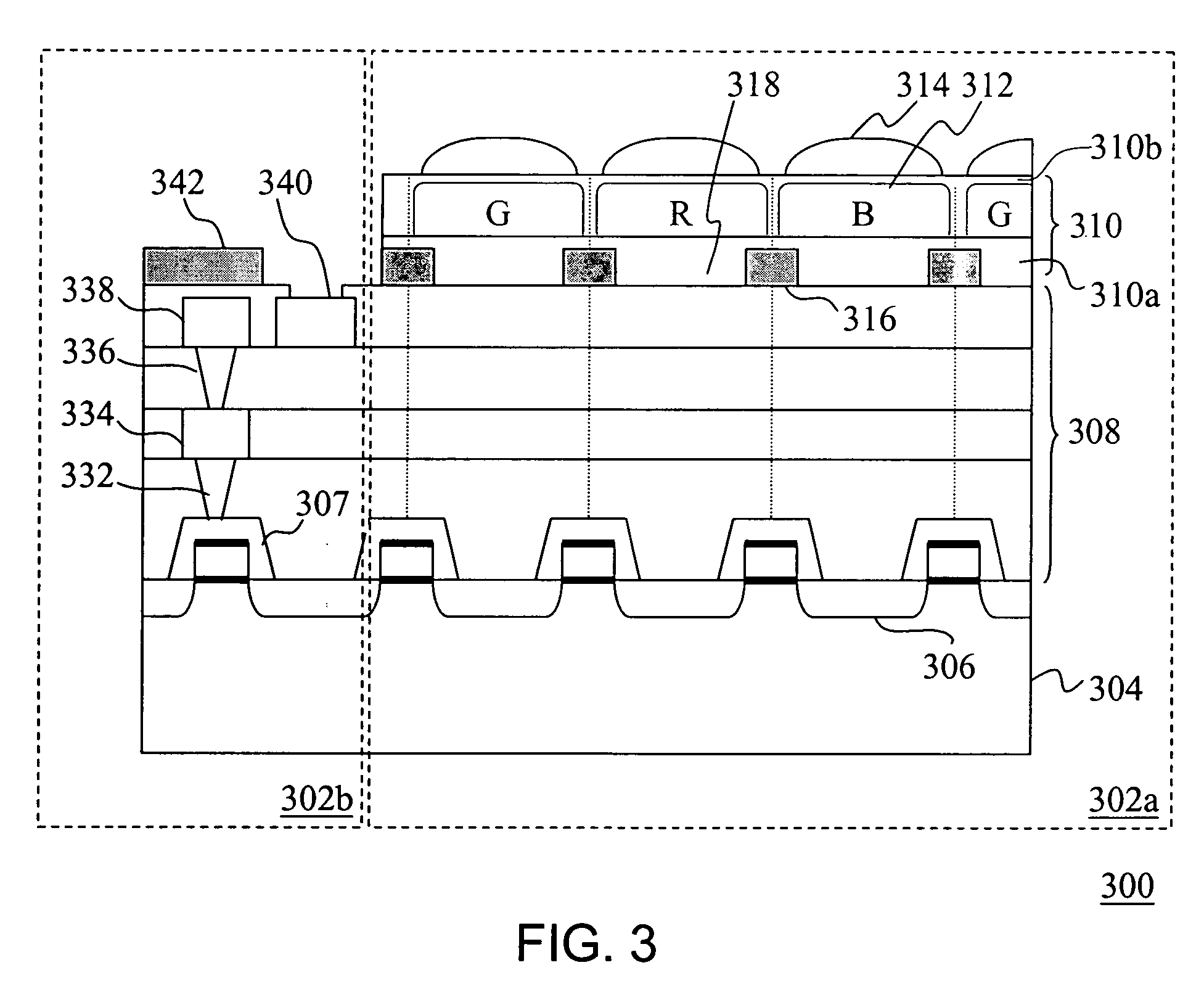

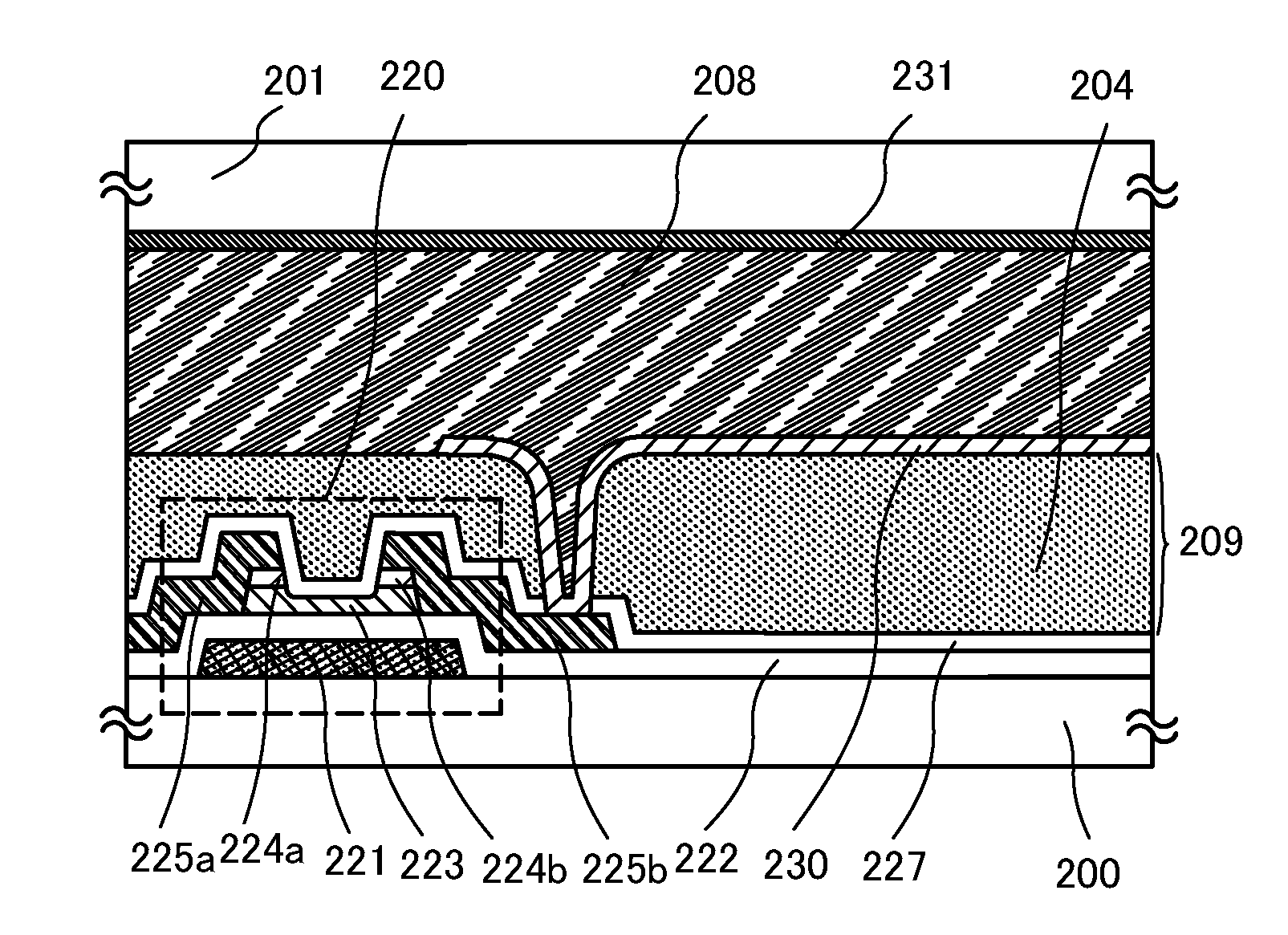

Image sensor device with color filters and manufacturing method thereof

ActiveUS7180044B2Contrasting colorsHigh sensitivitySolid-state devicesMaterial analysis by optical meansDielectric layerMicrolens

An image sensor device including a substrate, a plurality of photo sensors, a dielectric layer, a planar layer, a plurality of color filters, a plurality of microlenses, and a shield layer is provided. The photo sensors are disposed in the substrate, and the dielectric layer is disposed over the photo sensors and the substrate. The planar layer is disposed over the dielectric layer. The color filters are disposed in the planar layer, wherein each of the color filters is disposed over each of the photo sensors. The microlenses are disposed over the planar layer, wherein each of the microlenses is disposed over each of the color filter. The shield layer including a plurality of openings is disposed in the planar layer and is disposed under or over the color filters, wherein each of the openings is disposed over each of the color filters.

Owner:MARLIN SEMICON LTD

Liquid crystal display device

ActiveUS20100134397A1Reduce intensityRaise the ratioStatic indicating devicesSolid-state devicesLiquid-crystal displayBlocking layer

To provide a liquid crystal display device suitable for a thin film transistor which uses an oxide semiconductor. In a liquid crystal display device which includes a thin film transistor including an oxide semiconductor layer, a film having a function of attenuating the intensity of transmitting visible light is used as an interlayer film which covers at least the oxide semiconductor layer. As the film having a function of attenuating the intensity of transmitting visible light, a coloring layer can be used and a light-transmitting chromatic color resin layer is preferably used. An interlayer film which includes a light-transmitting chromatic color resin layer and a light-blocking layer may be formed in order that the light-blocking layer is used as a film having a function of attenuating the intensity of transmitting visible light.

Owner:SEMICON ENERGY LAB CO LTD

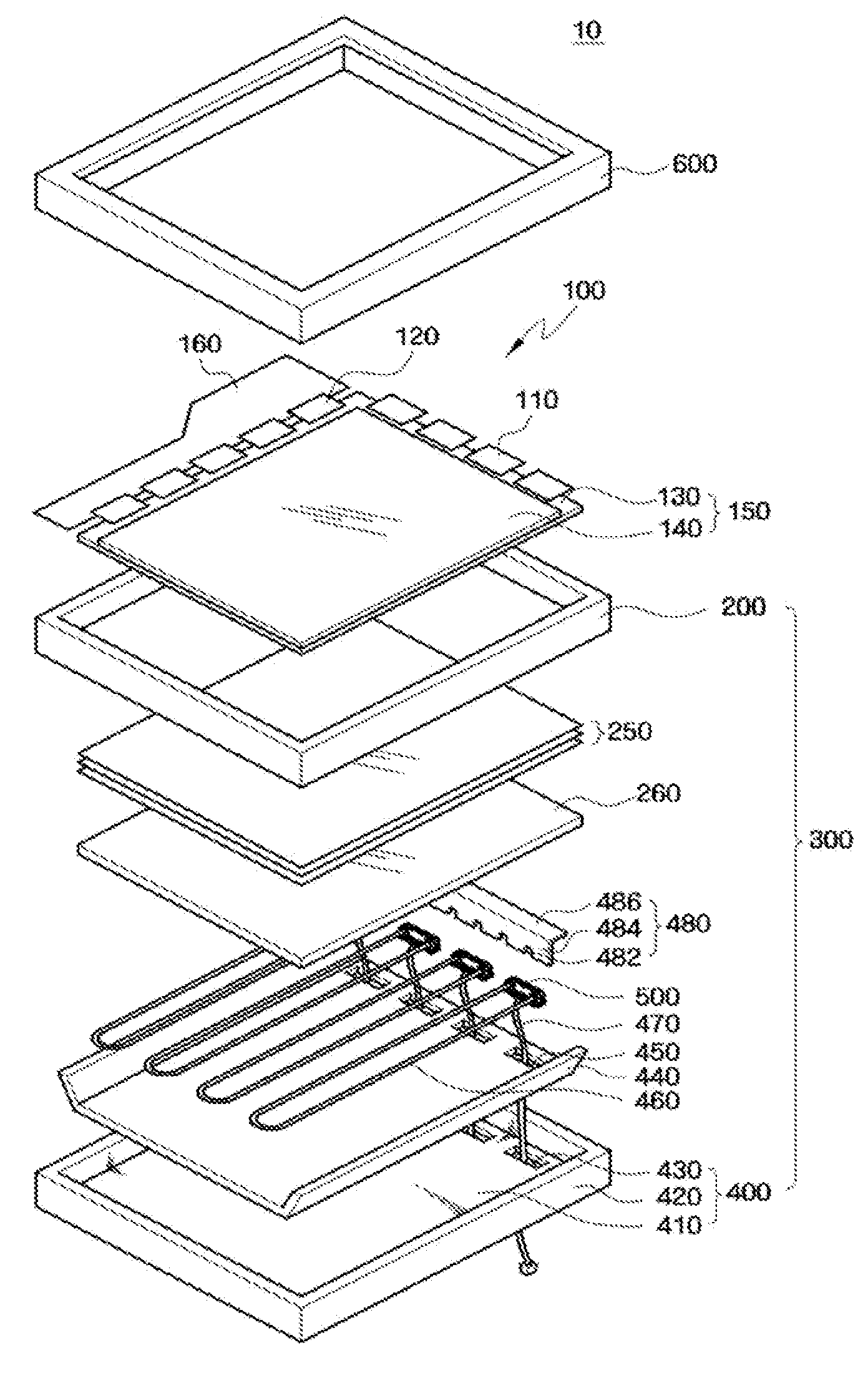

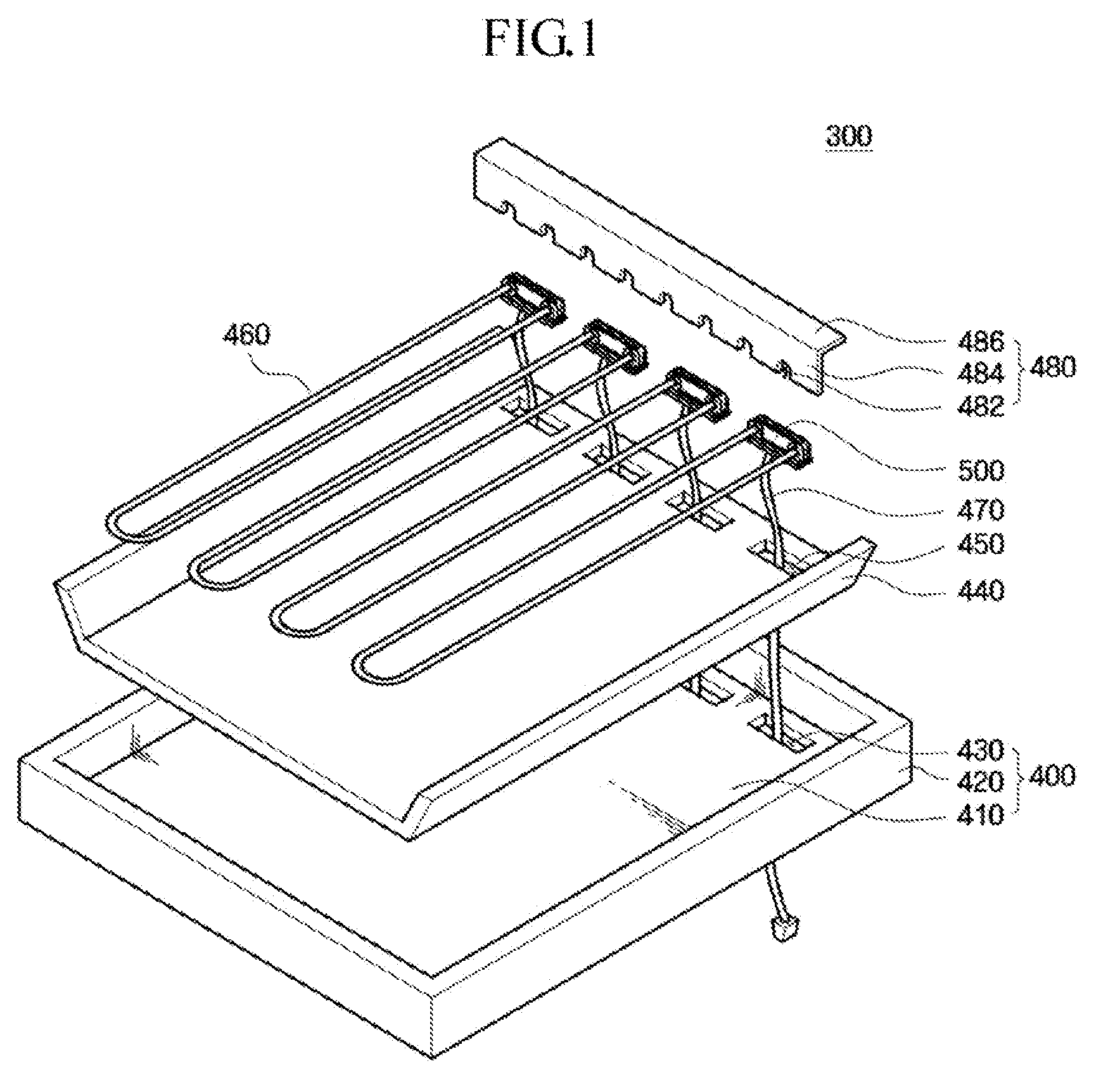

Back-light assembly and liquid crystal display including the same

InactiveUS20080079865A1Avoid light leakageIncrease brightnessElectric lightingIlluminated signsLiquid-crystal displayEngineering

A back-light assembly capable of preventing light leakage and a liquid crystal display including the same. The back-light assembly includes a lamp emitting light, a lamp holder comprising a reflecting part into which the lamp is inserted and an absorbing part, wherein the absorbing part absorbs the light, and the reflecting part reflects the light, a side member comprising a through hole, the lamp being inserted into the through hole, and a bottom chassis comprising a bottom surface and side surfaces, the side surfaces extending from the bottom surface.

Owner:SAMSUNG DISPLAY CO LTD

Liquid crystal display device and method for fabricating the same

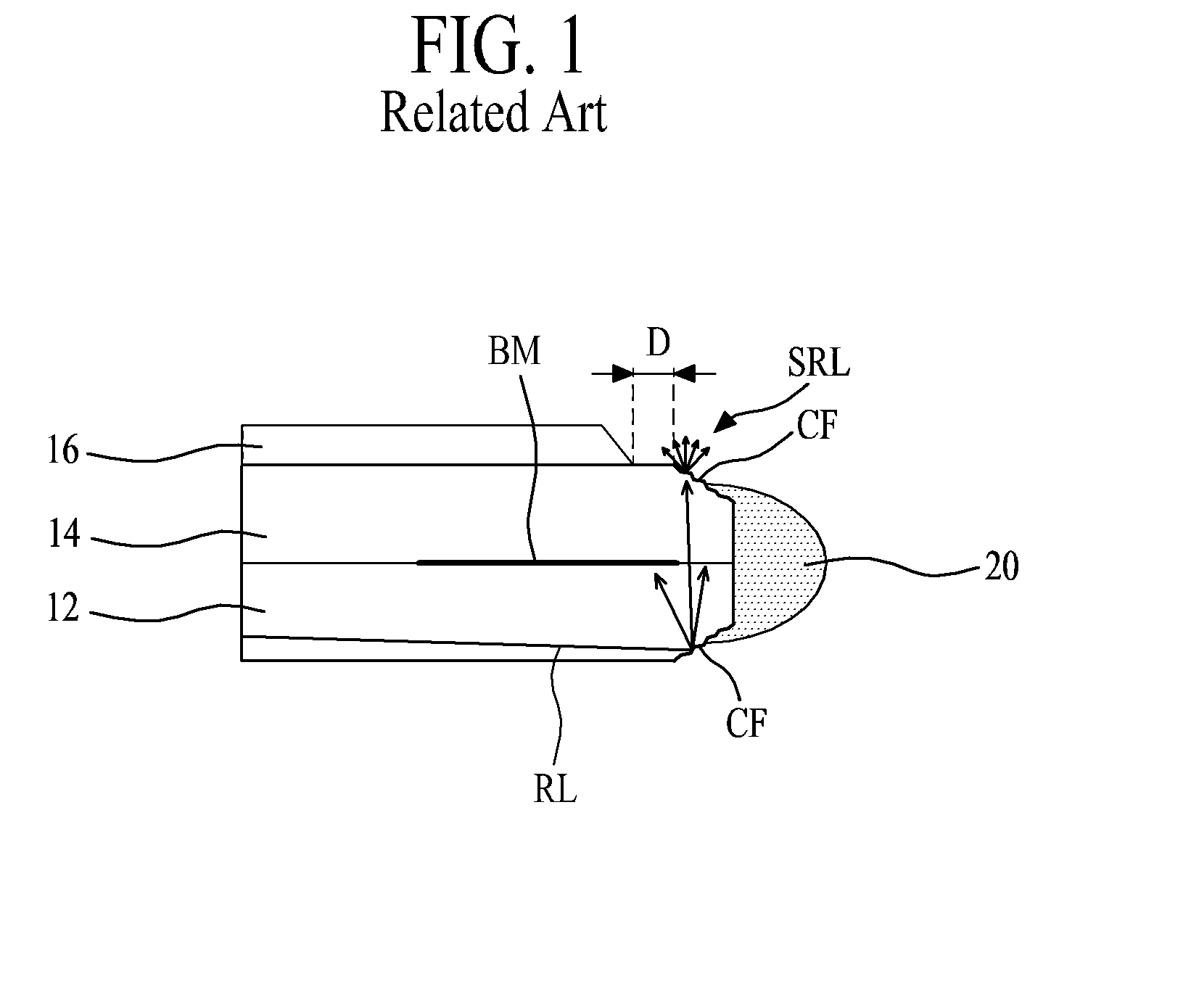

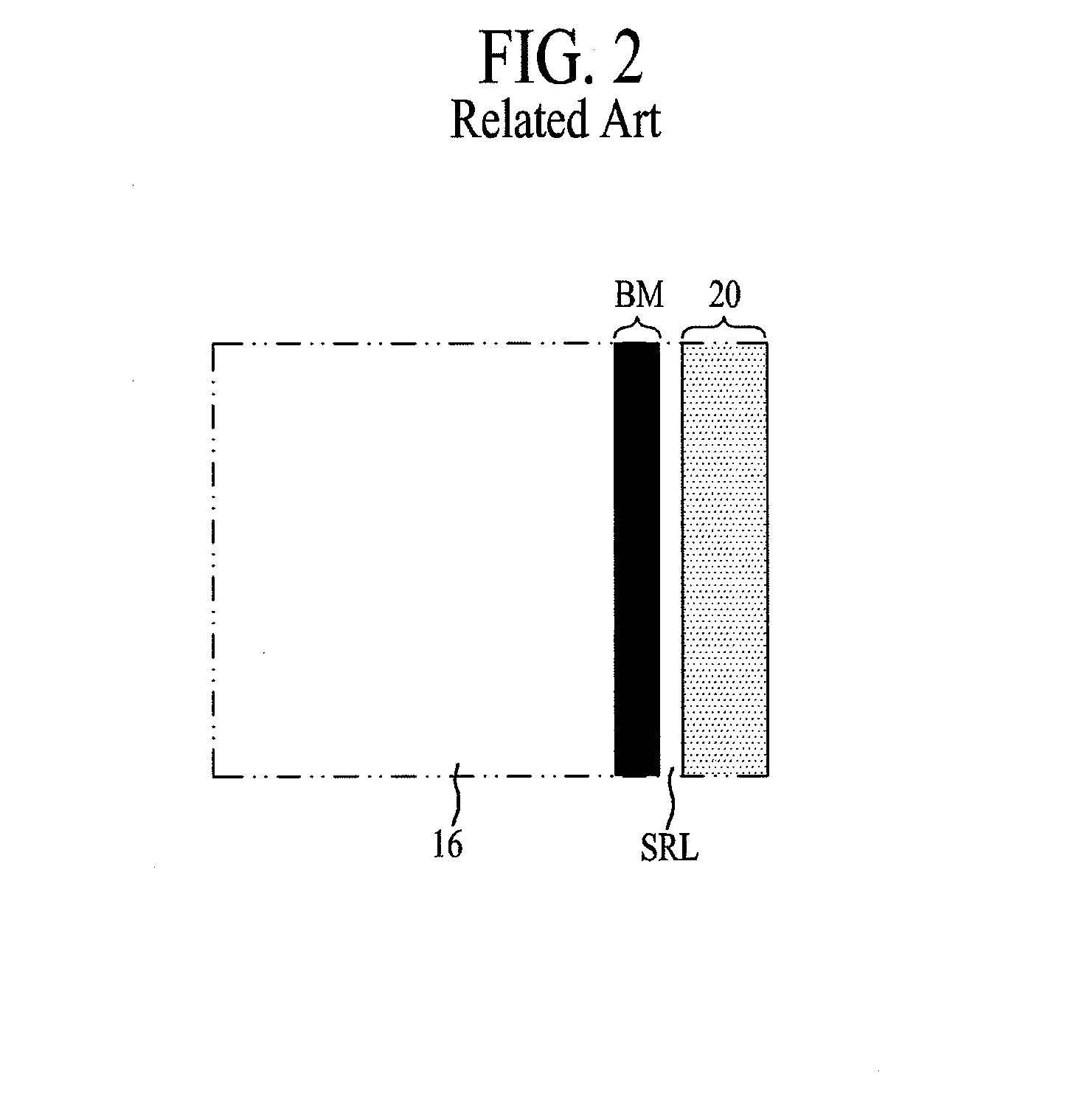

InactiveUS20060146254A1Avoid light leakageReduce manufacturing costNon-linear opticsLight filterBlack matrix

A liquid crystal display device includes a gate line and a data line crossing each other to define a pixel region on a substrate; common electrode parts arranged at both sides of the data line to shield the data line; a black matrix over a region including the data line and a portion of the common electrode parts; and a color filter arranged at the pixel region.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com