Array substrate, fabrication method thereof and liquid crystal display panel

A technology of an array substrate and a manufacturing method, which is applied in the field of liquid crystal display panels, can solve the problems such as the limitation of the size of the display area 320 and cannot be further enlarged, and achieve the effects of saving the area of scanning line connecting lines, improving display quality, and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

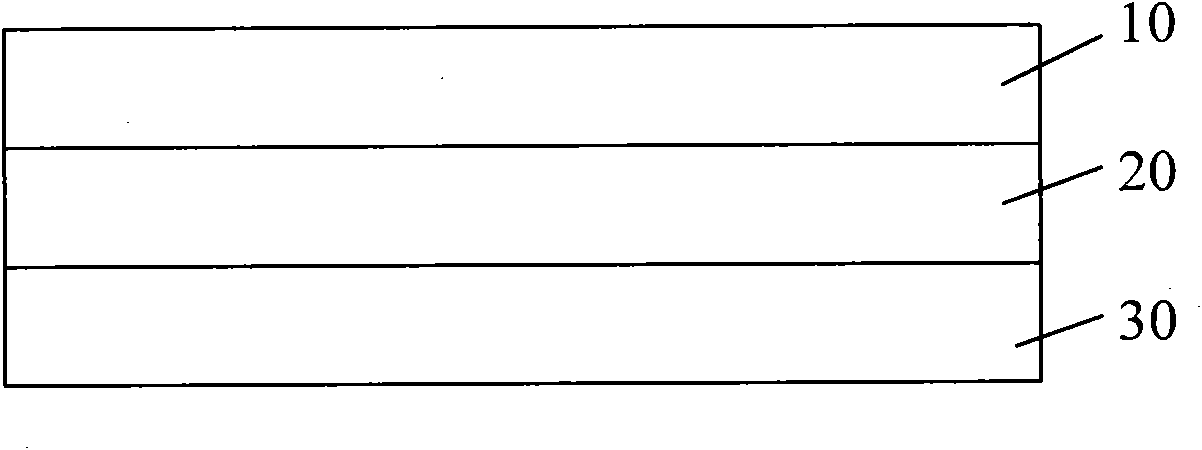

[0046] In order to solve the above problems, the inventors of the present invention propose a liquid crystal display panel, which includes an array substrate, a color filter substrate, and a liquid crystal layer located between the array substrate and the color filter substrate. The structures of the color filter substrate and the liquid crystal layer are the same as those of the prior art, and the array substrate includes:

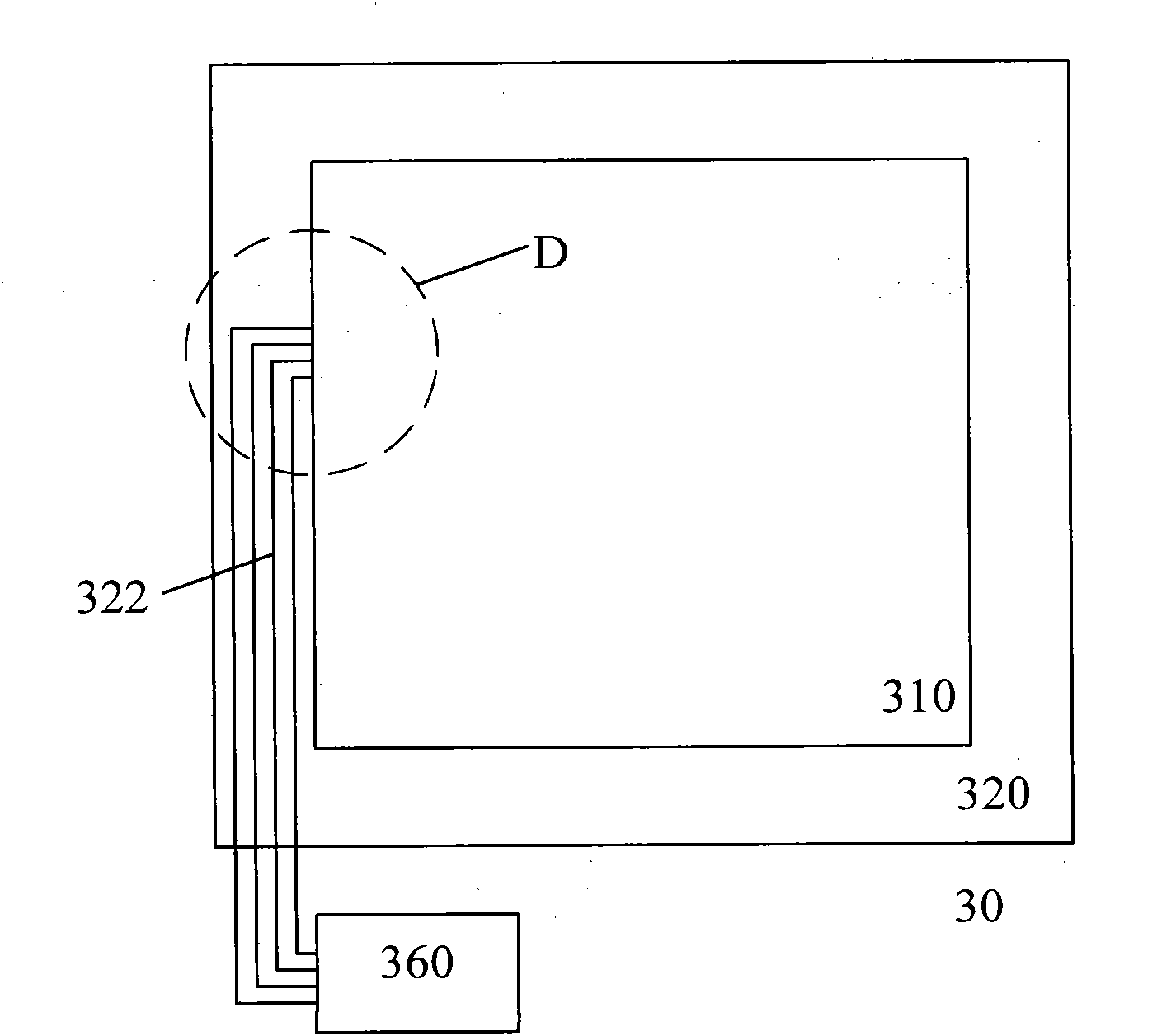

[0047] a substrate, the substrate is divided into a display area and a frame area, and the frame area surrounds the display area;

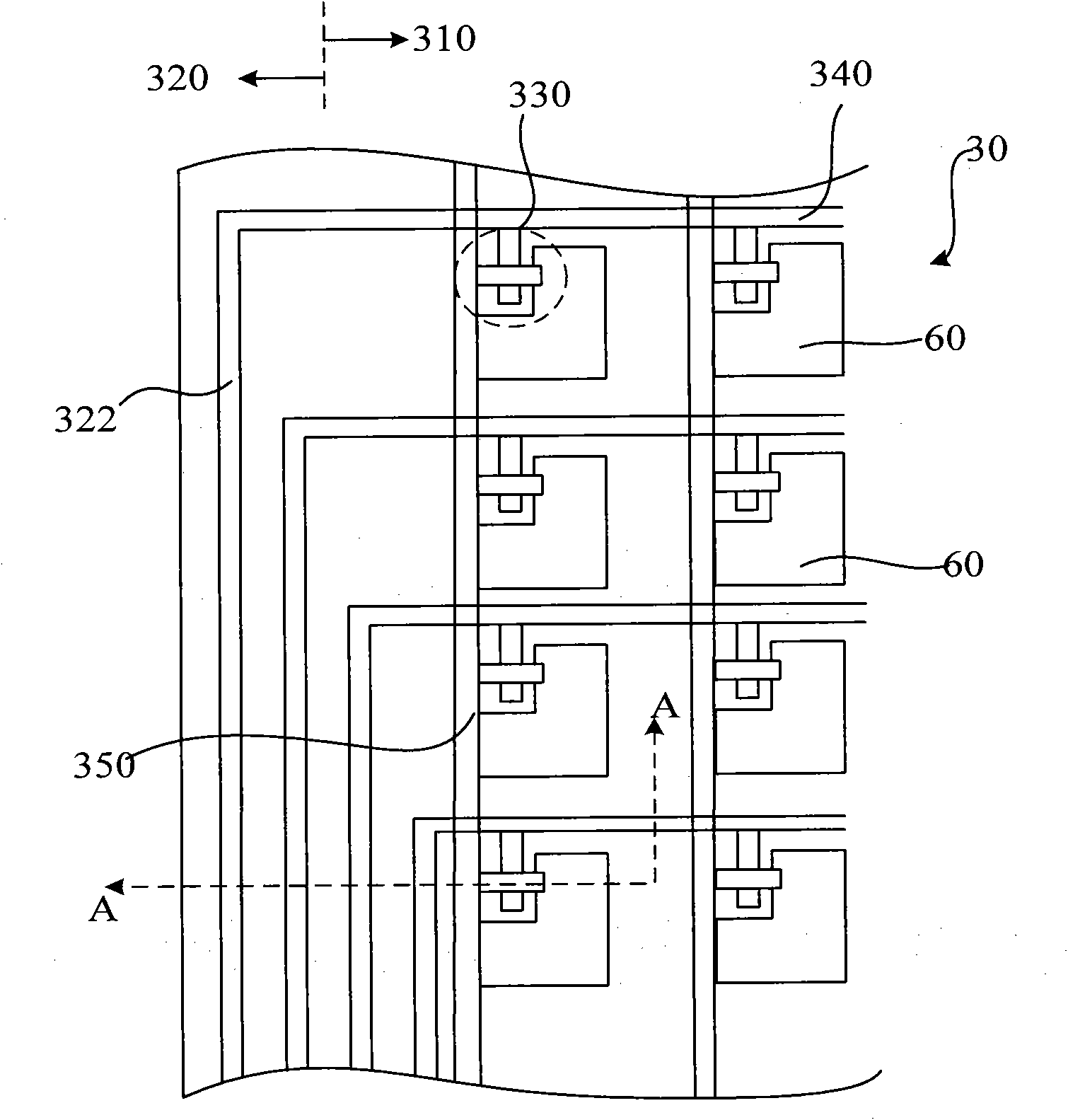

[0048] a plurality of pixel electrodes arranged in a matrix in the display area;

[0049] A plurality of scanning lines, located between a plurality of pixel electrodes;

[0050] A plurality of data lines are located between the plurality of pixel electrodes, and the data lines intersect with the scanning lines insulated;

[0051]The scanning line connection line is located in the display area, the scanning line connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com