Patents

Literature

39results about How to "Reduce the effective cross-sectional area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

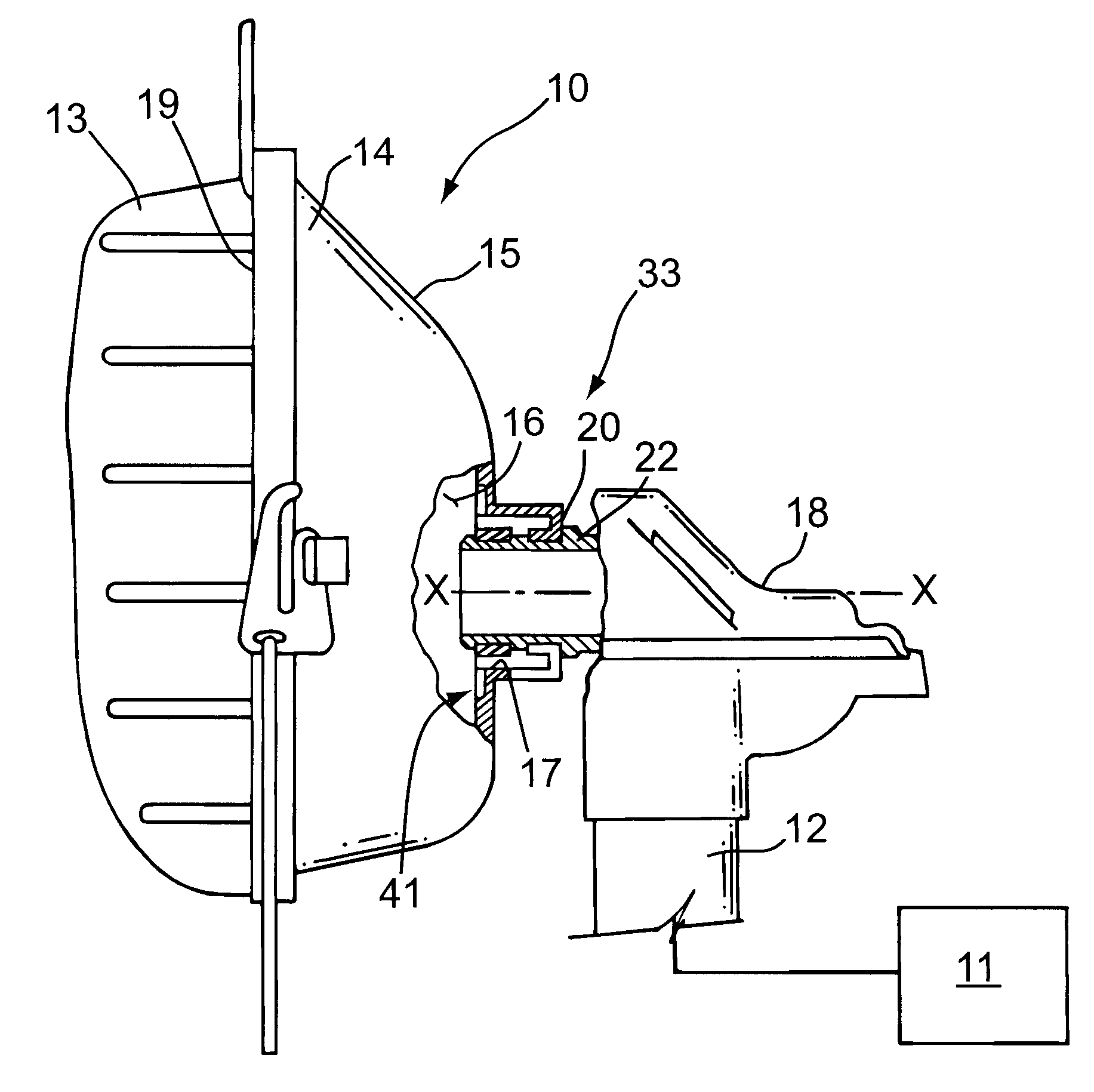

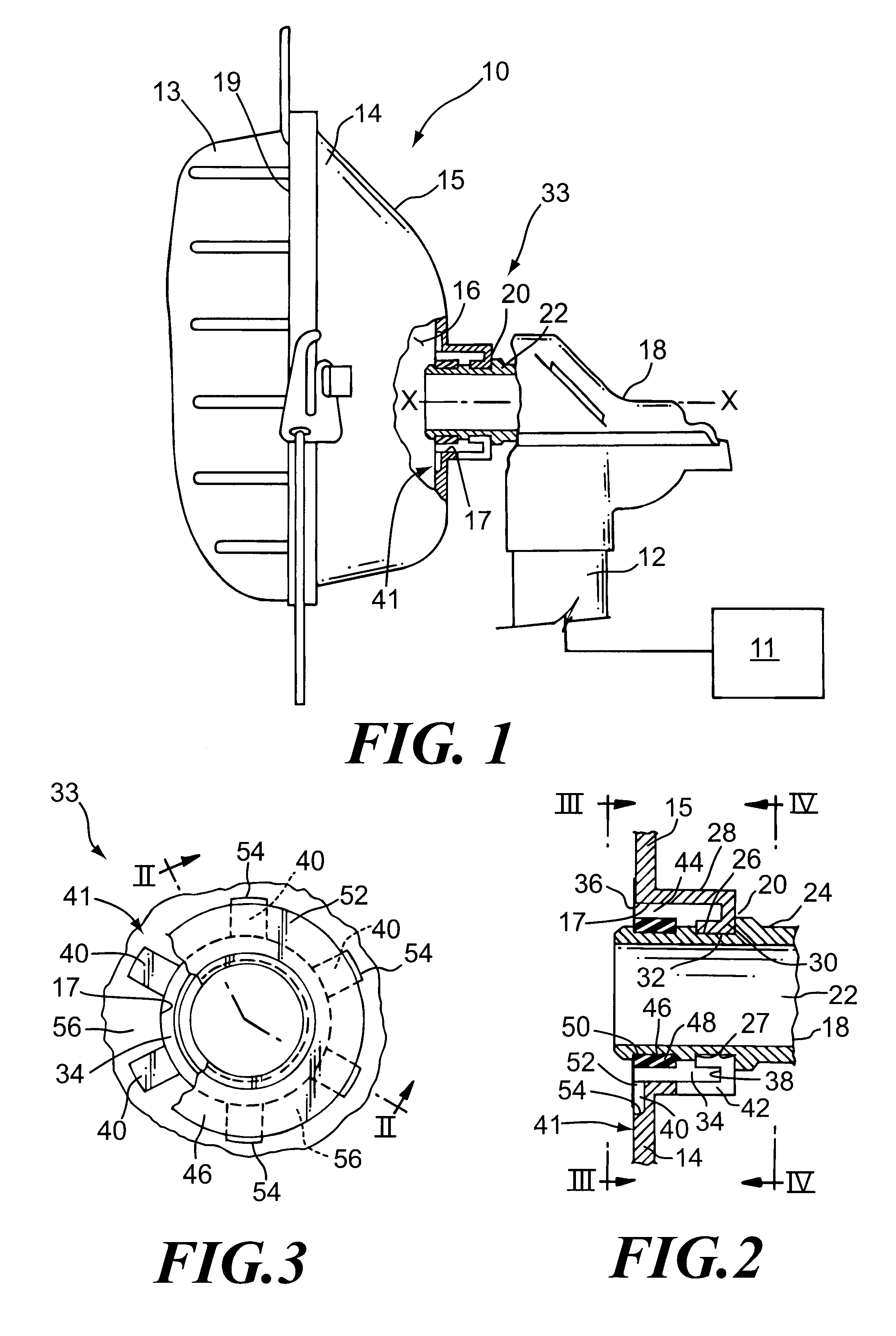

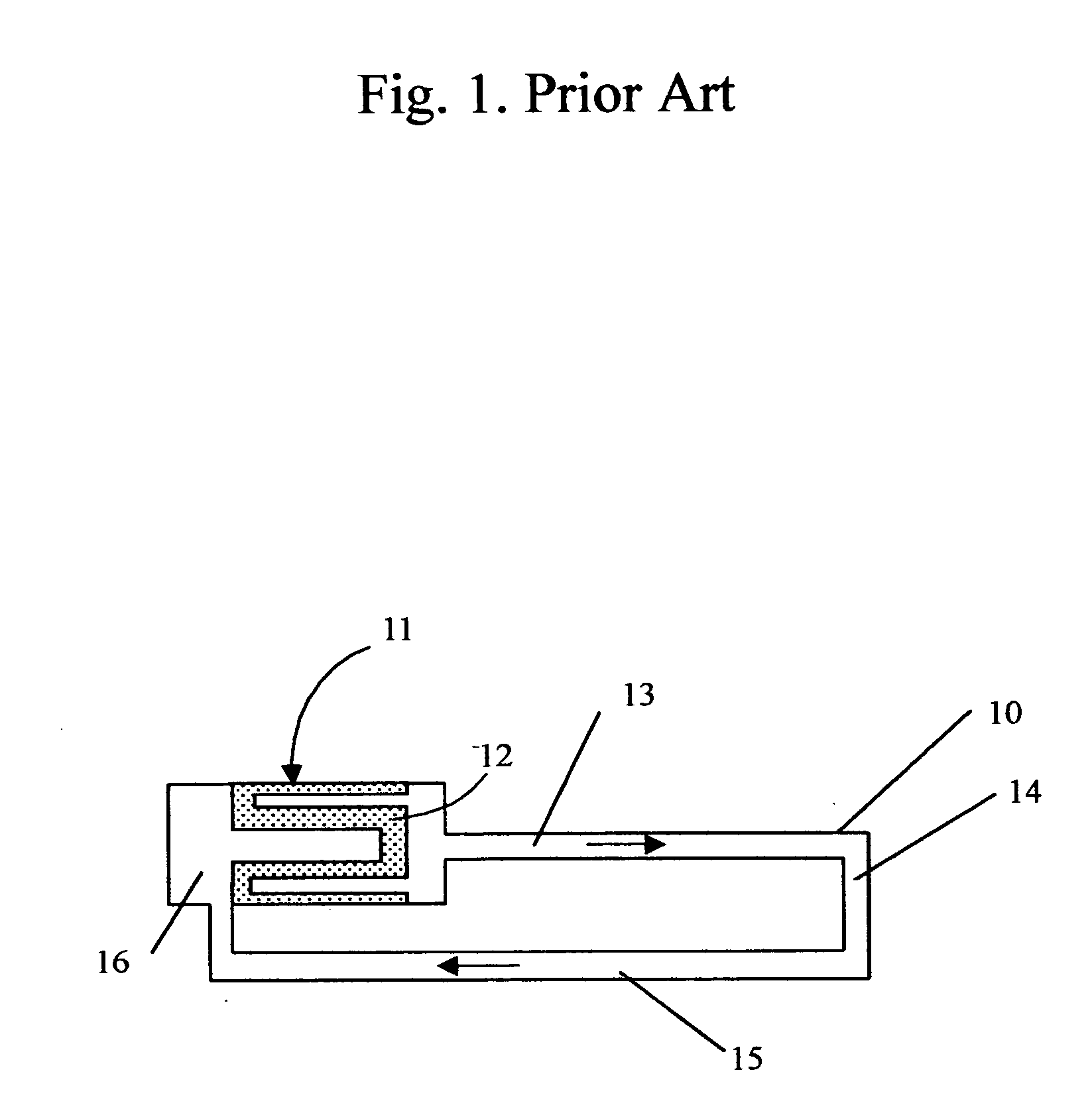

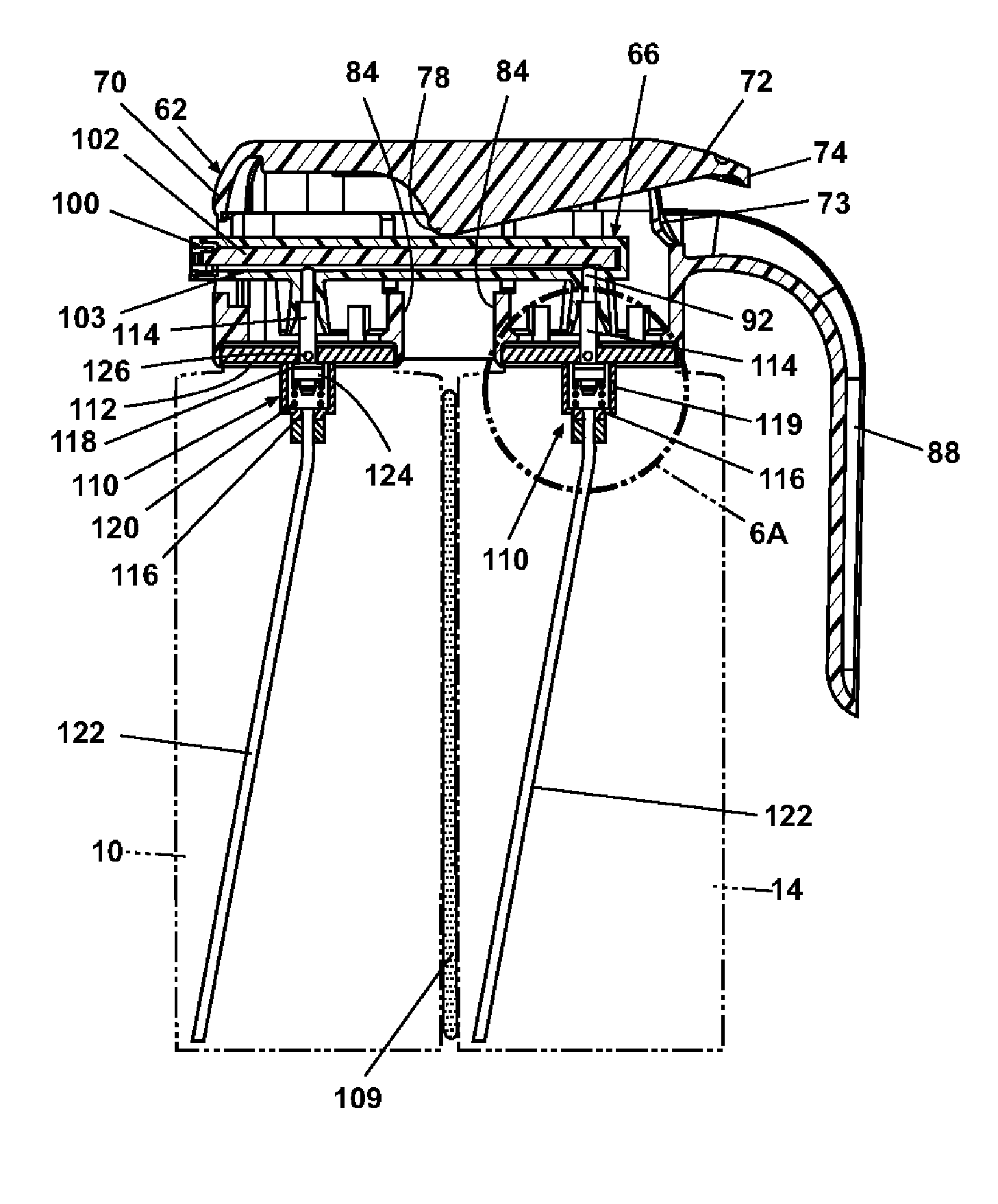

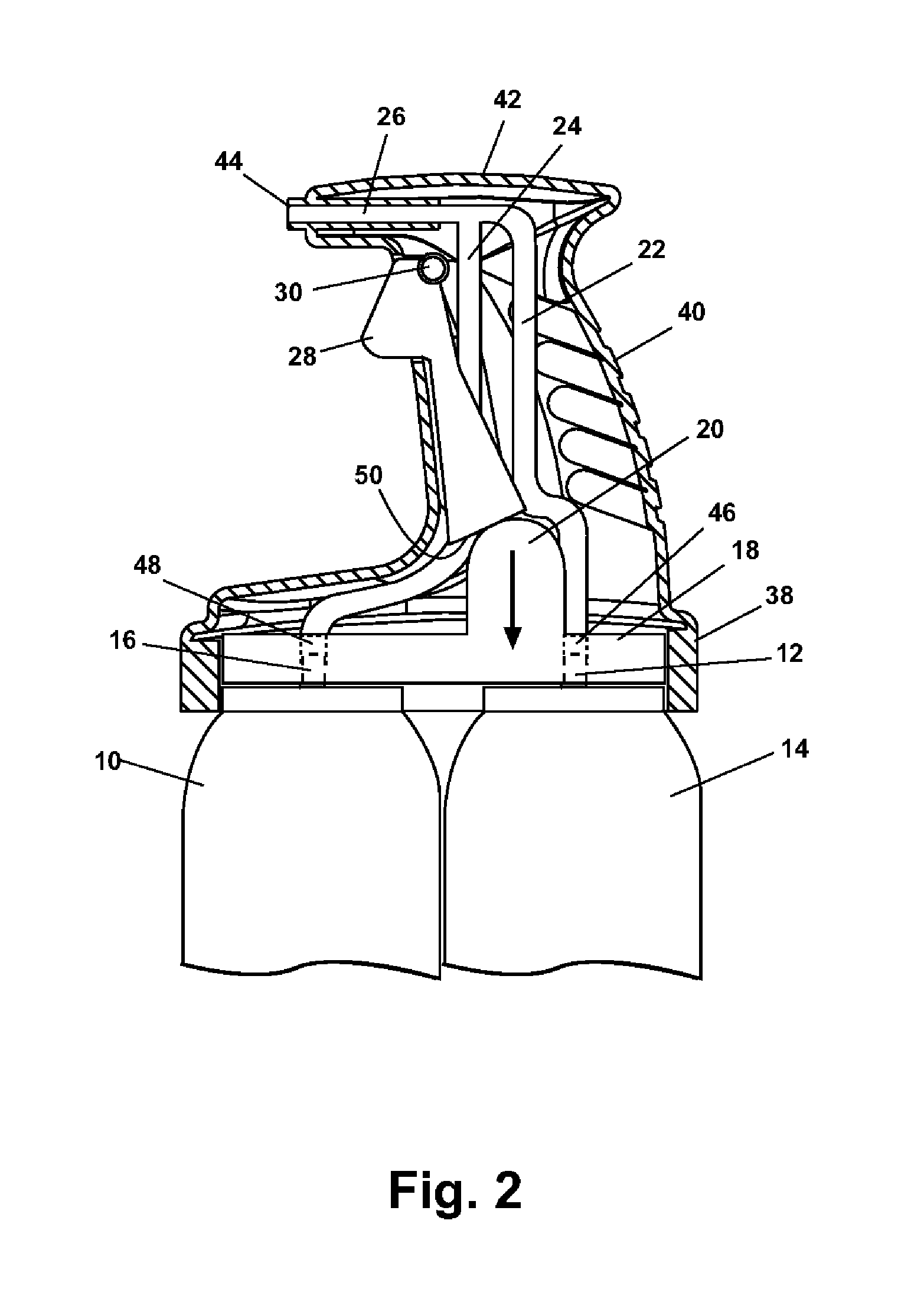

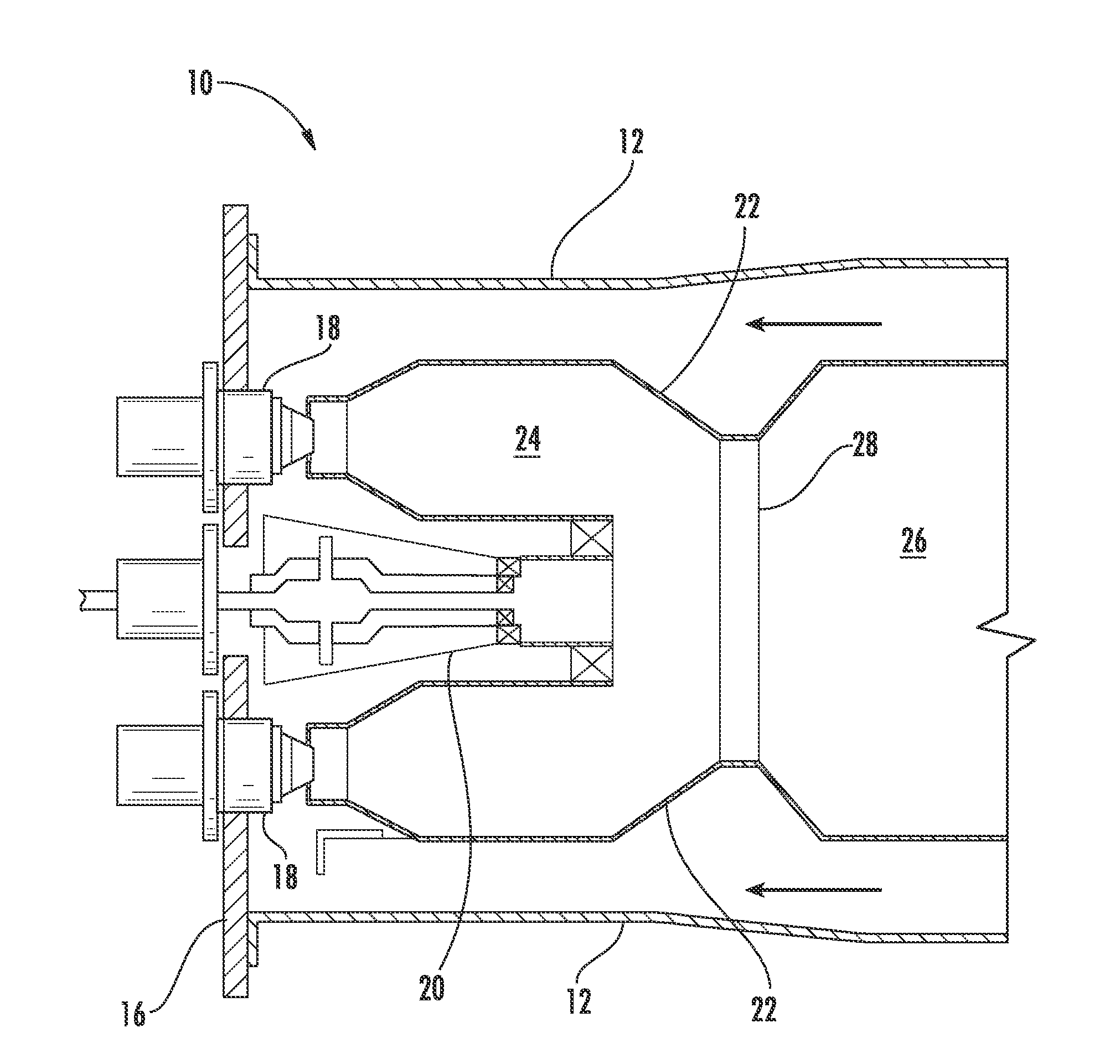

Combined patient interface and exhaust assembly

InactiveUS6584977B1Narrowing the exhaust pathReduce the effective cross-sectional areaBreathing masksRespiratory masksMedicineMechanical engineering

A combined patient interface and integrated exhaust assembly that passes a controlled flow of gas from an interior of a patient interface to ambient atmosphere at a predetermined flow rate irrespective of variations of pressure in the interior of the patient interface device relative to ambient atmosphere. Control of the flow of exhaust gas is achieved by varying the effective cross sectional area of the exhaust path communicating the interior of the patient interface with ambient atmosphere based on the pressure in the interior of the patient interface relative to ambient atmospheric pressure.

Owner:RIC INVESTMENTS LLC

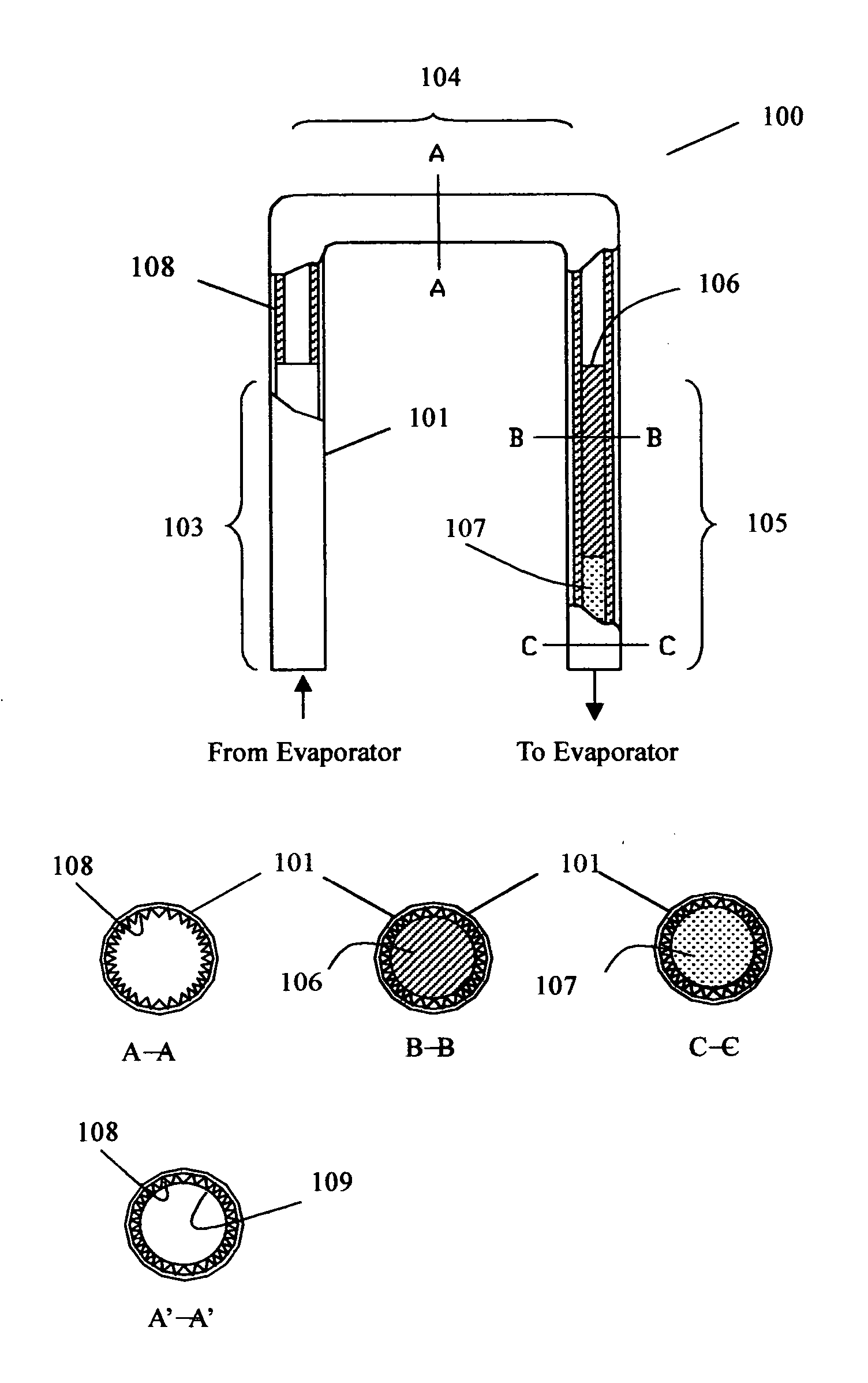

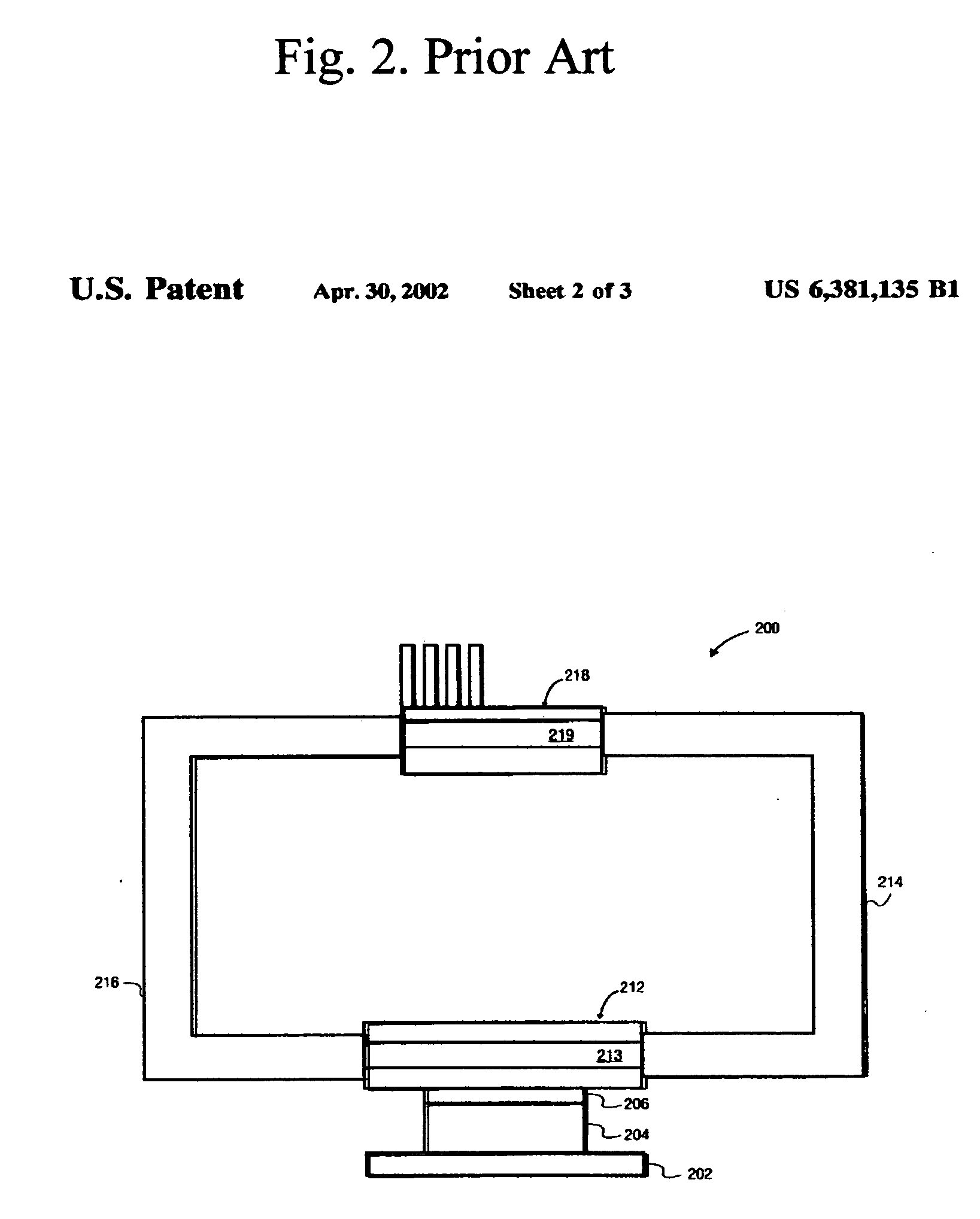

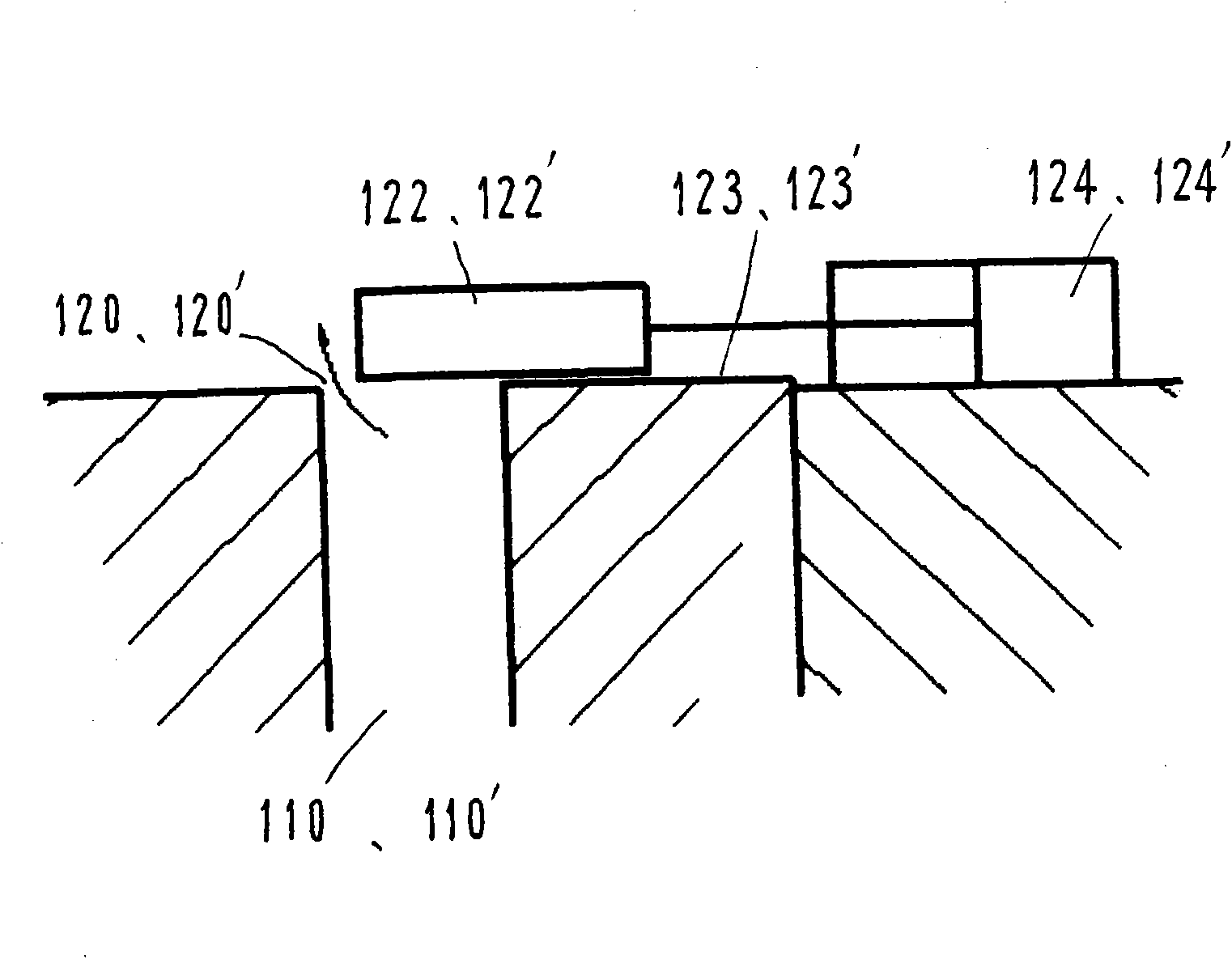

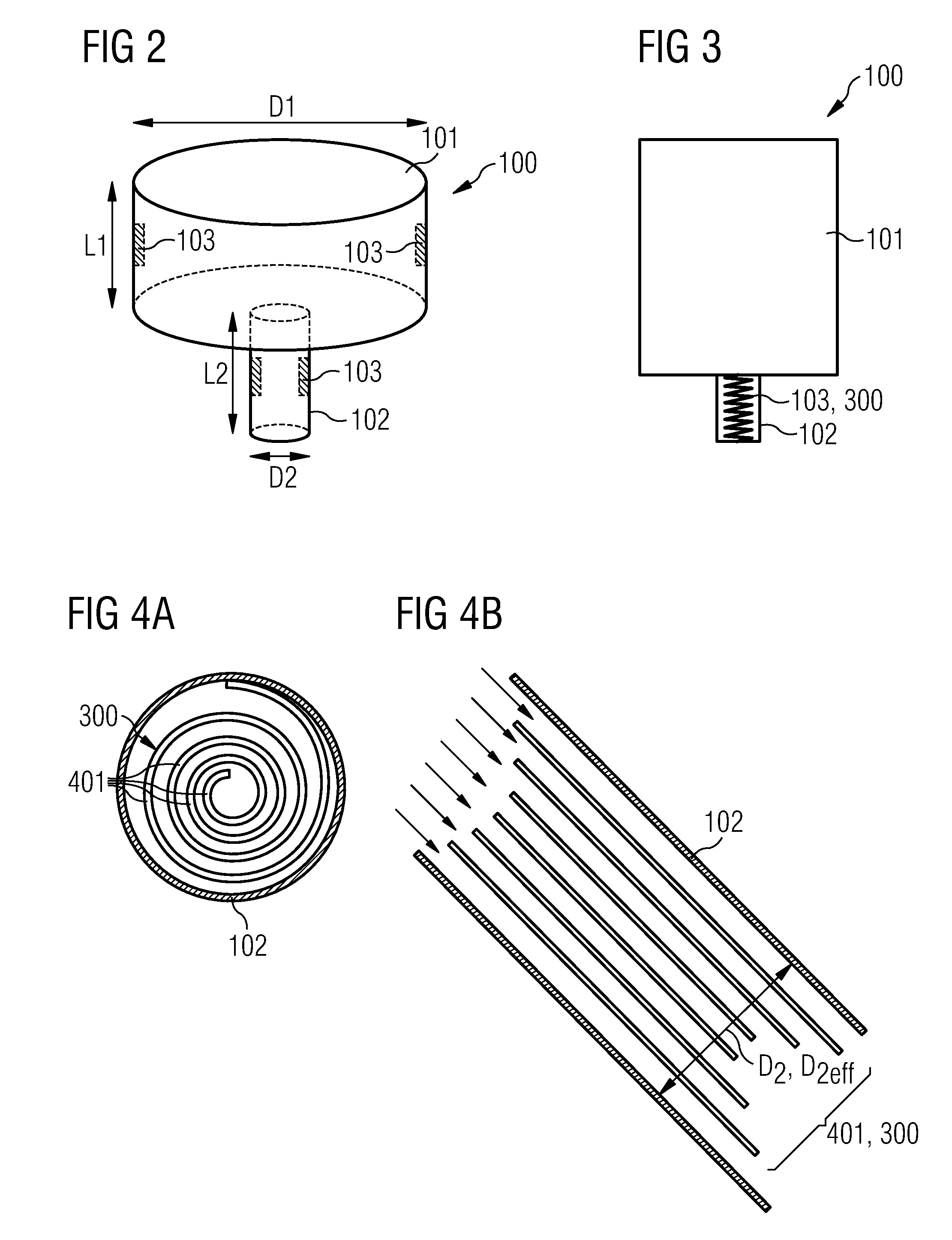

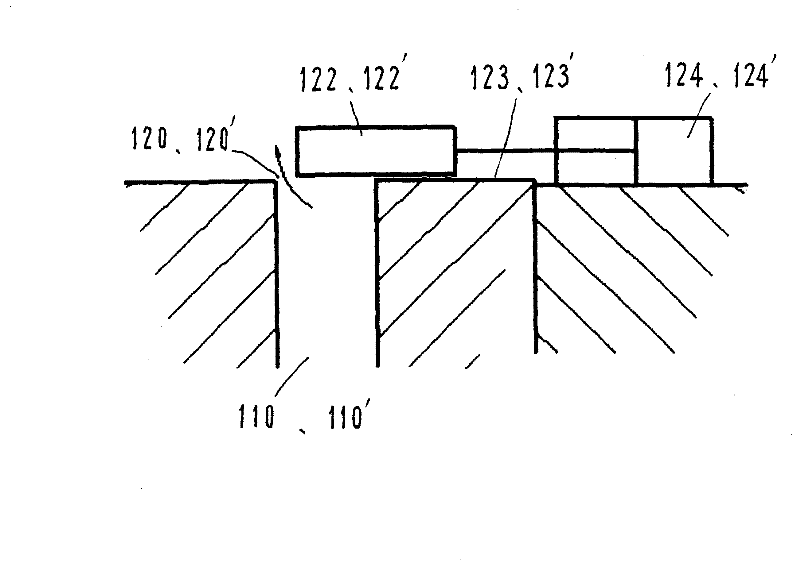

Transport line with grooved microchannels for two-phase heat dissipation on devices

InactiveUS20050077030A1Ensure efficient flowReduce forceSemiconductor/solid-state device detailsSolid-state devicesLiquid lineLoop heat pipe

Grooved microchannels are used to enhance the capillary action in the transport line of two-phase heat dissipation devices, such as loop heat pipes, capillary pump loops, or spray cooling devices, or others. Efficient heat dissipations achieved by enhancing the capillary pumping force for the liquid flow without significantly increasing the friction force. The effective cross-sectional area of the liquid line is made smaller than that of the condensation section, either by inserting a plug or shrinking the liquid line, to provide additional pumping force for the coolant recycling.

Owner:WONG SHWIN CHUNG

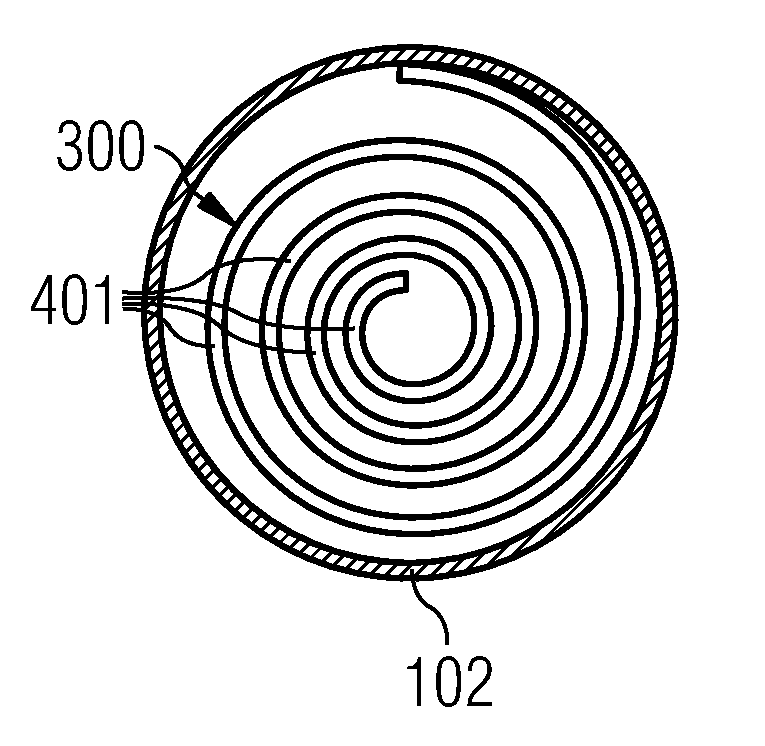

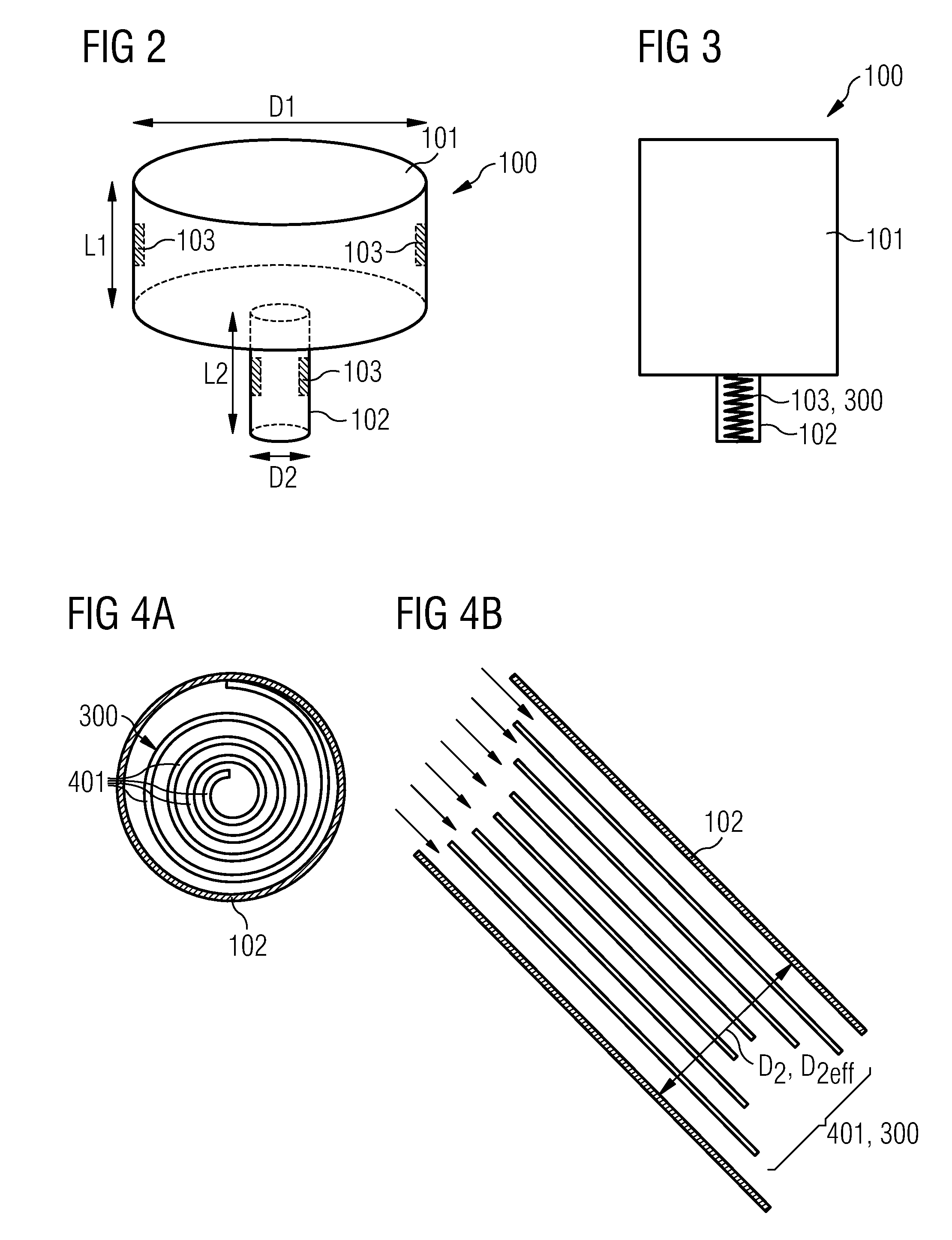

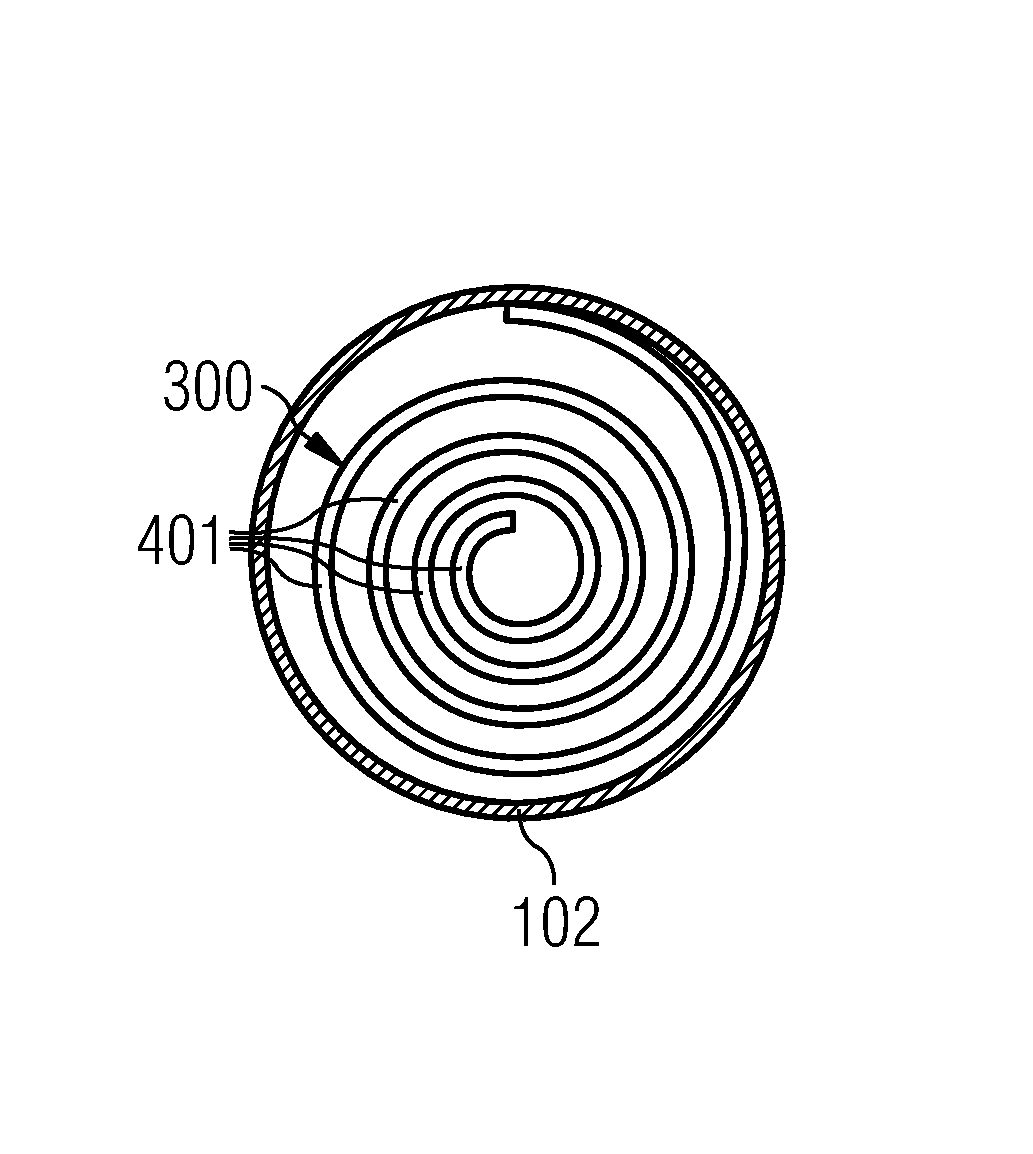

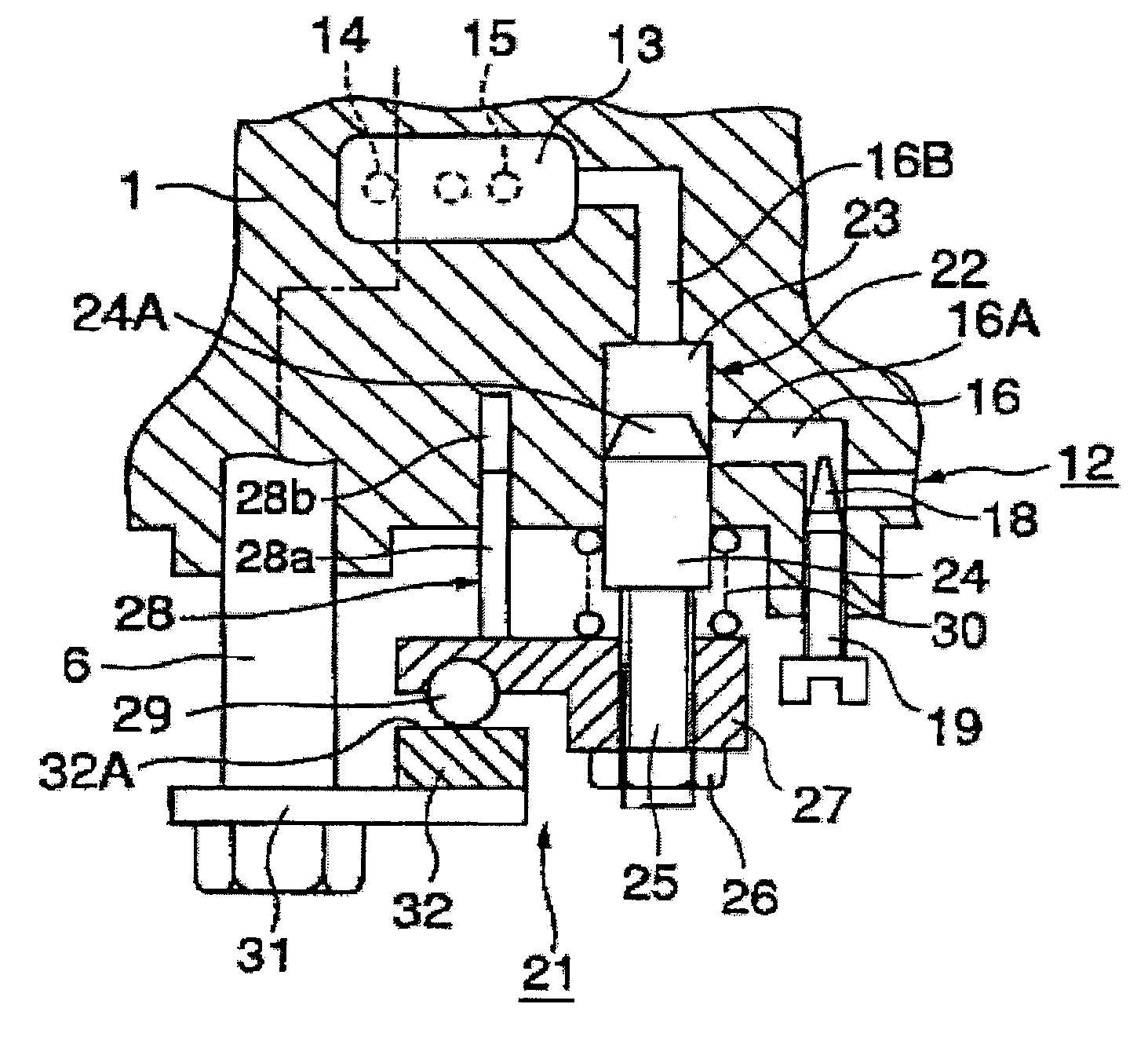

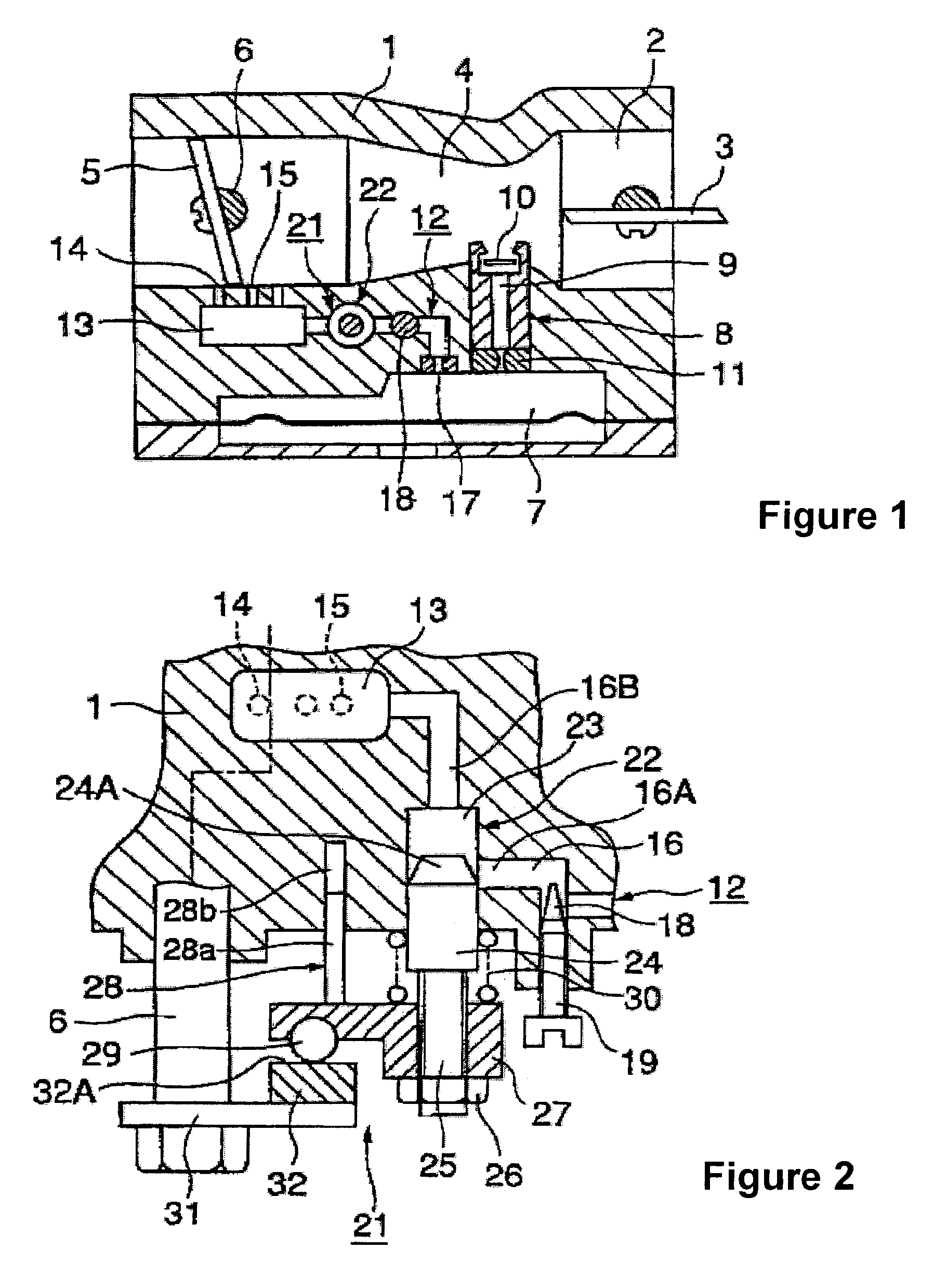

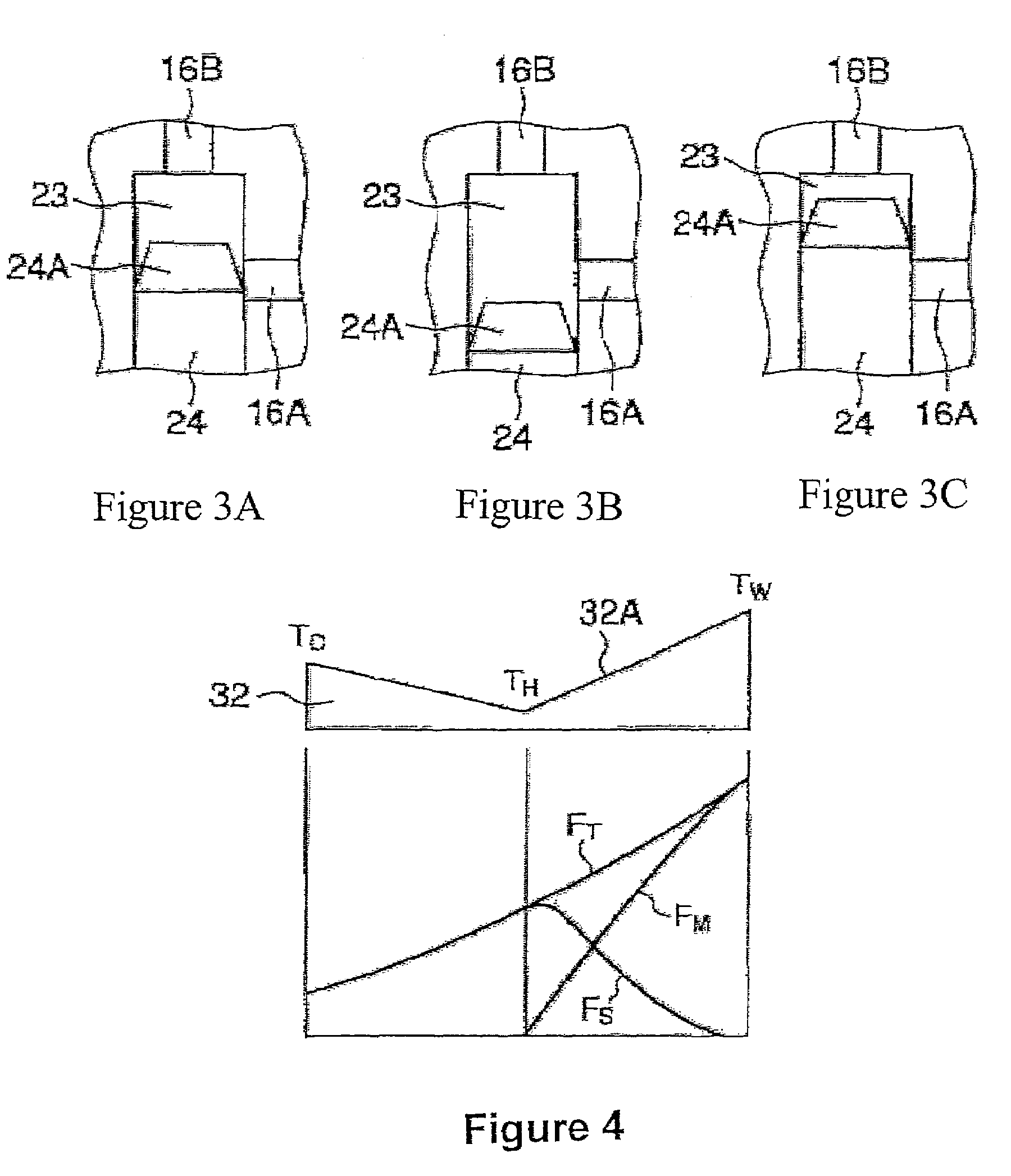

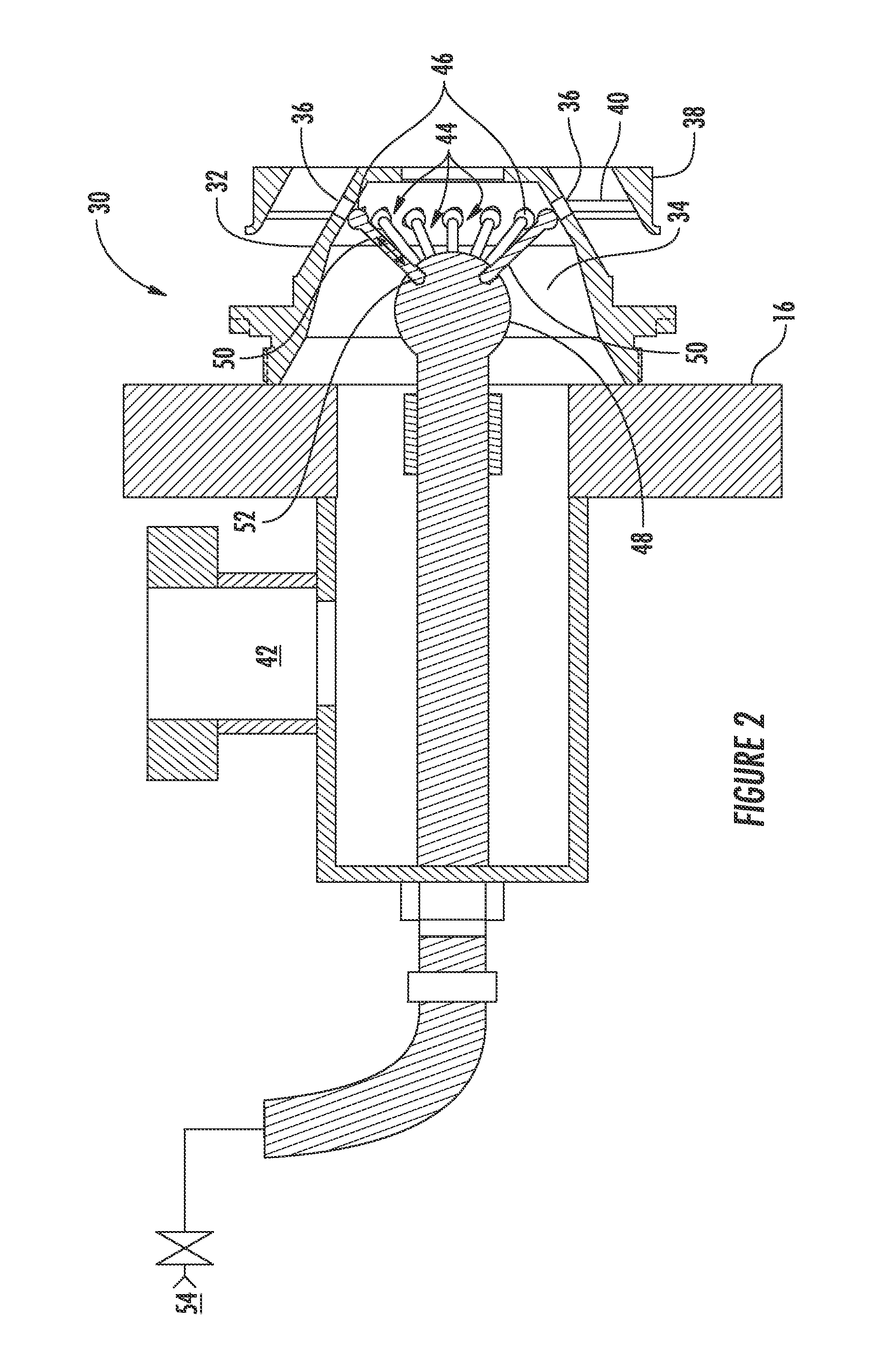

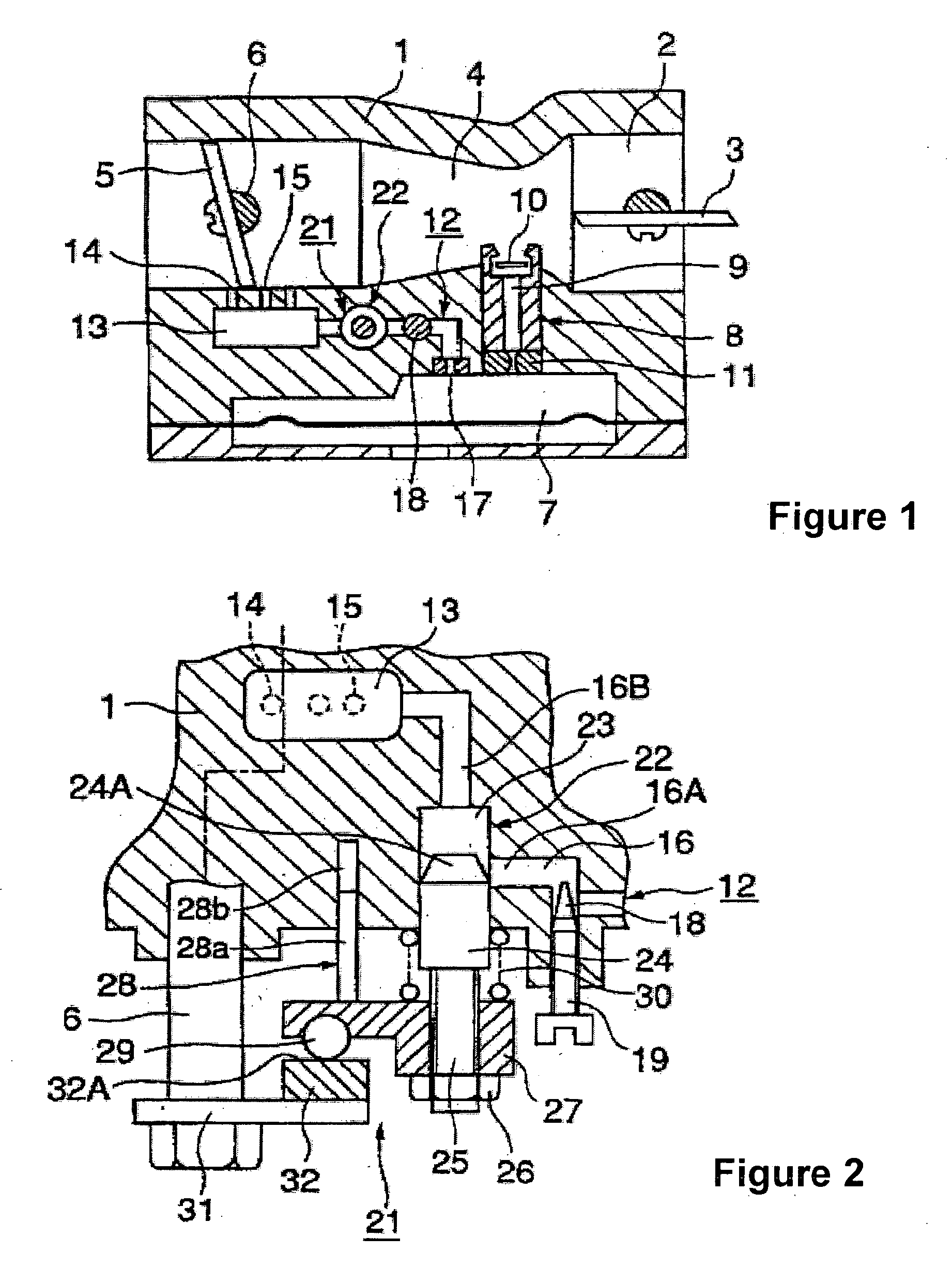

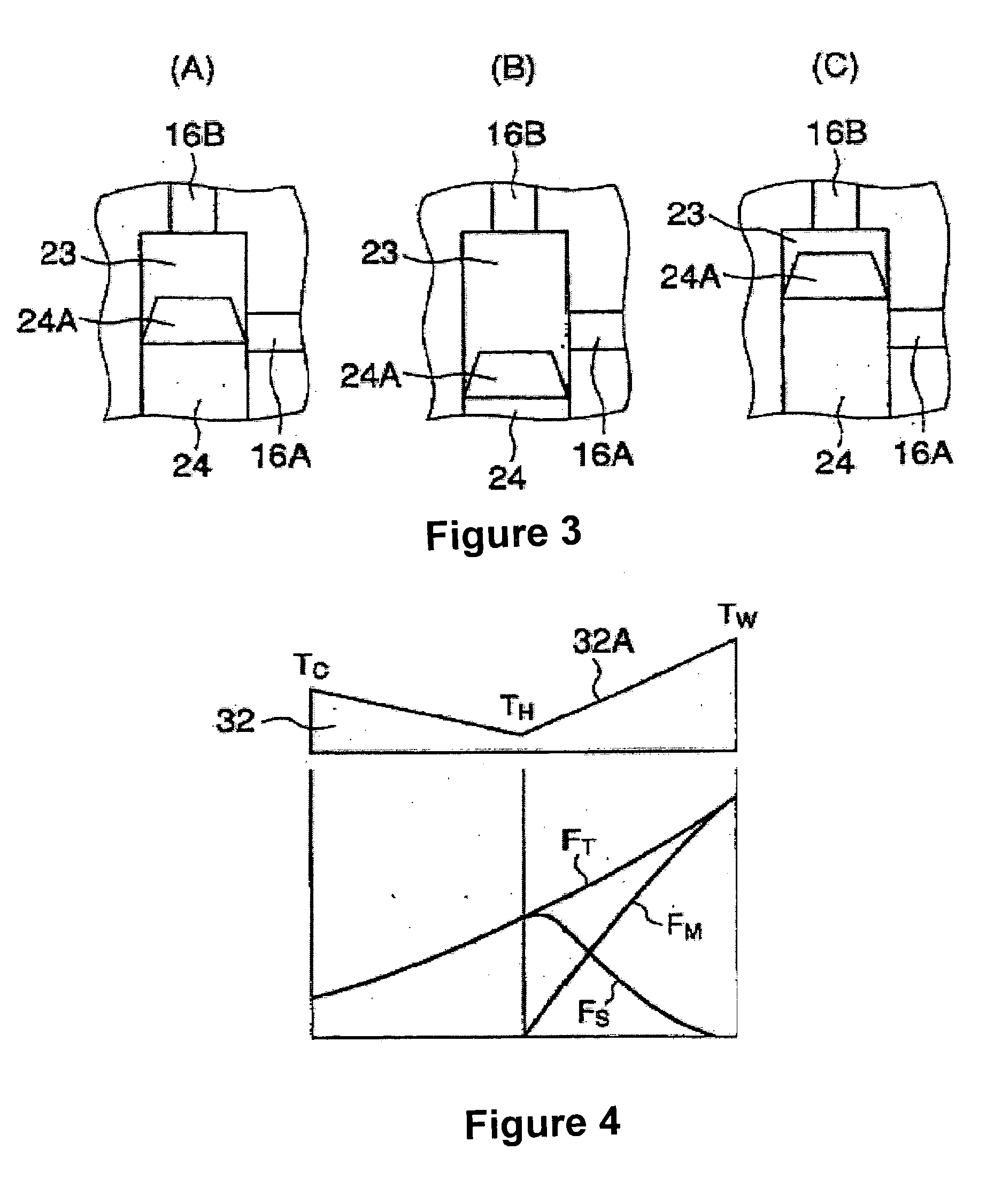

Helmholtz resonator for a gas turbine combustion chamber

InactiveUS20120228050A1Efficient changeAdjustable frequencyContinuous combustion chamberSilencing apparatusCombustion chamberHelmholtz resonator

A resonator is provided, having an adaptable resonator frequency for absorbing sound generated by a gas stream of a gas turbine. The resonator includes a neck section, a chamber and a deformable element being deformable under influence of a change of a gas turbine temperature of the gas stream. The shape of the deformable element is predetermined with respect to a respective gas turbine temperature. The neck section and the chamber form a volume of the resonator. The neck section forms a passage coupling the volume with the gas turbine. The deformable element is thermally coupled to the gas turbine in such a way that the shape of the deformable element depends on the respective gas turbine temperature. The deformable element forms a spiral and is installed to the neck section in such a way that an effective diameter of the neck section depends on the gas turbine temperature.

Owner:SIEMENS AG

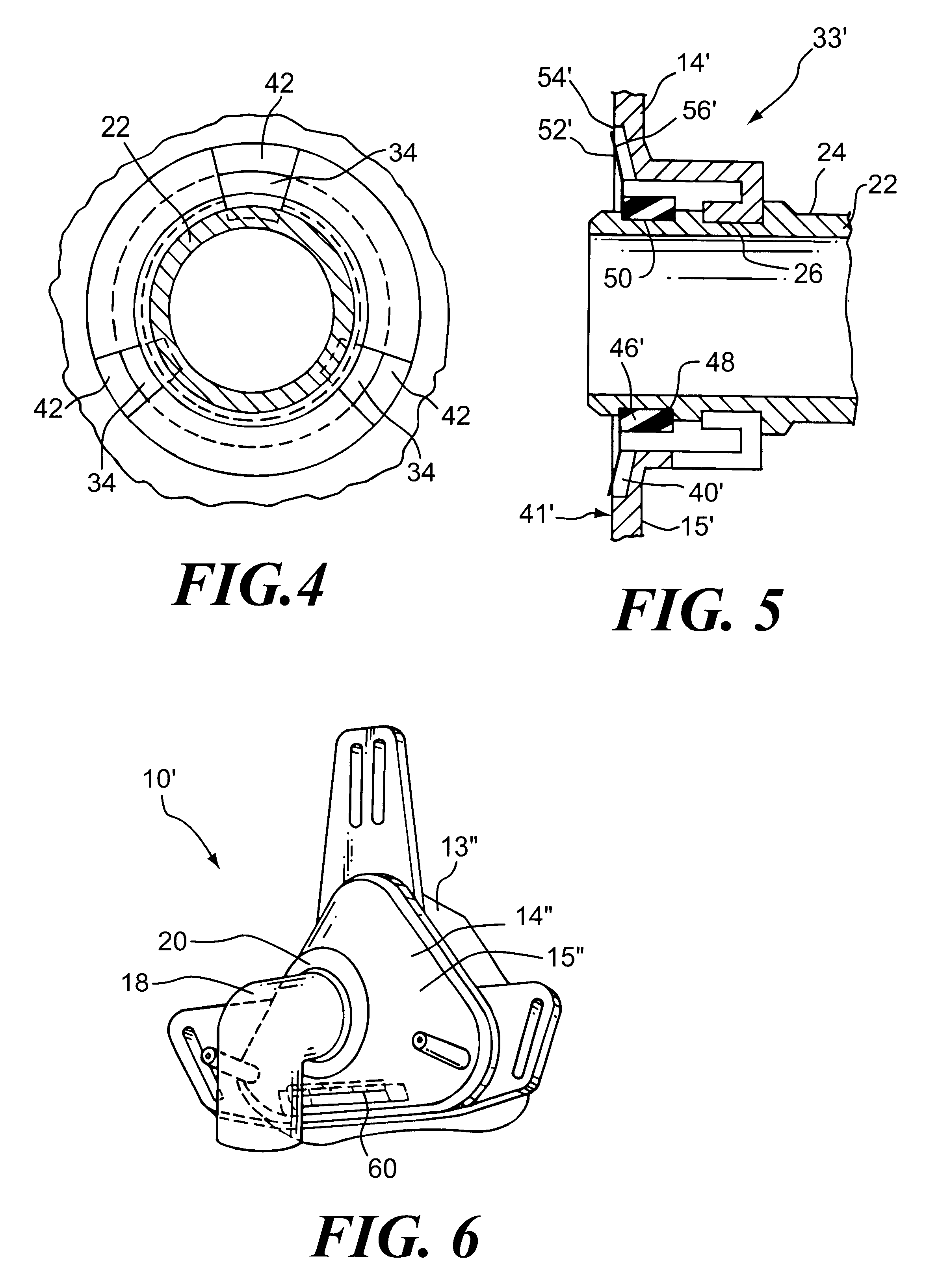

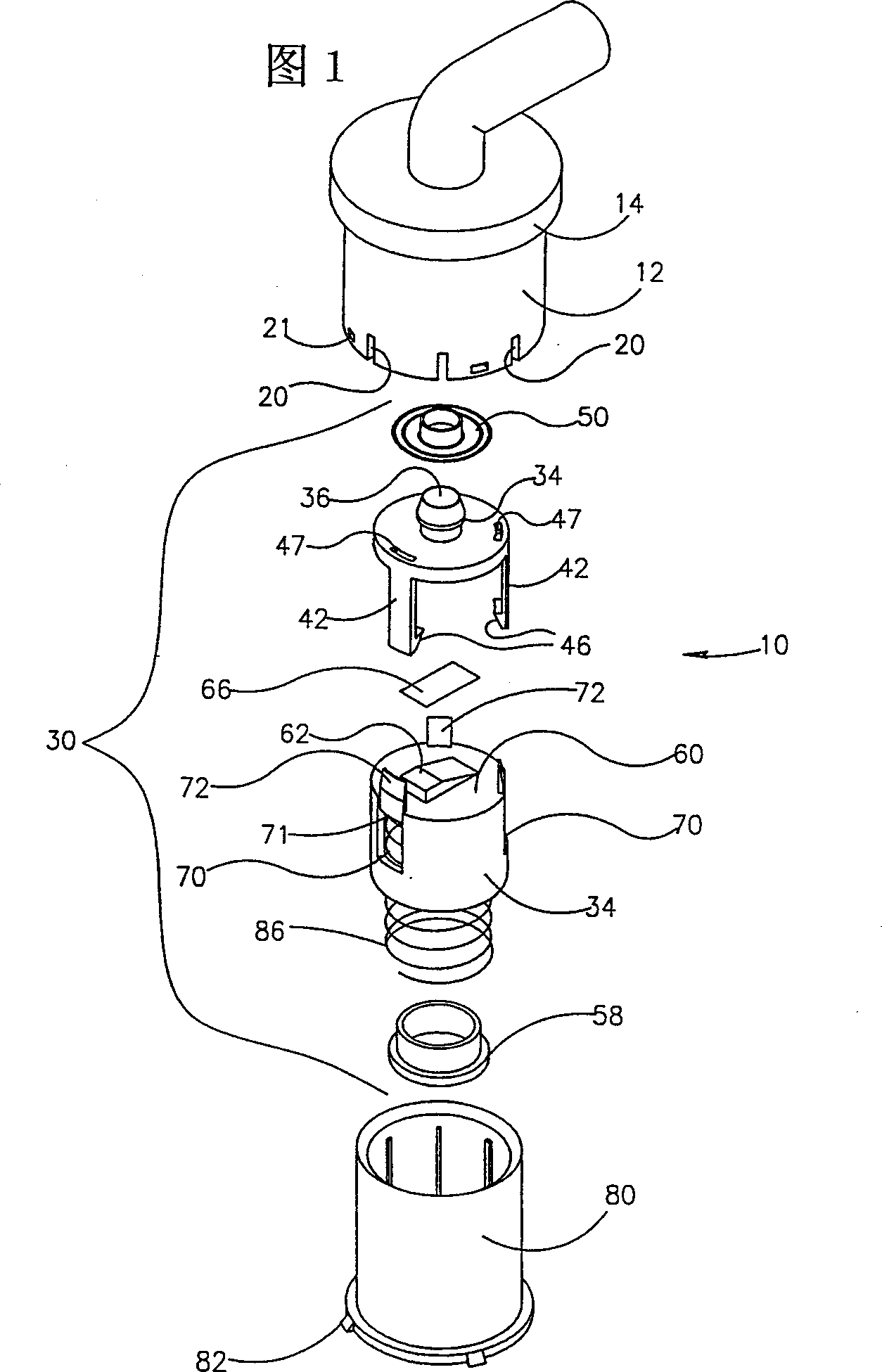

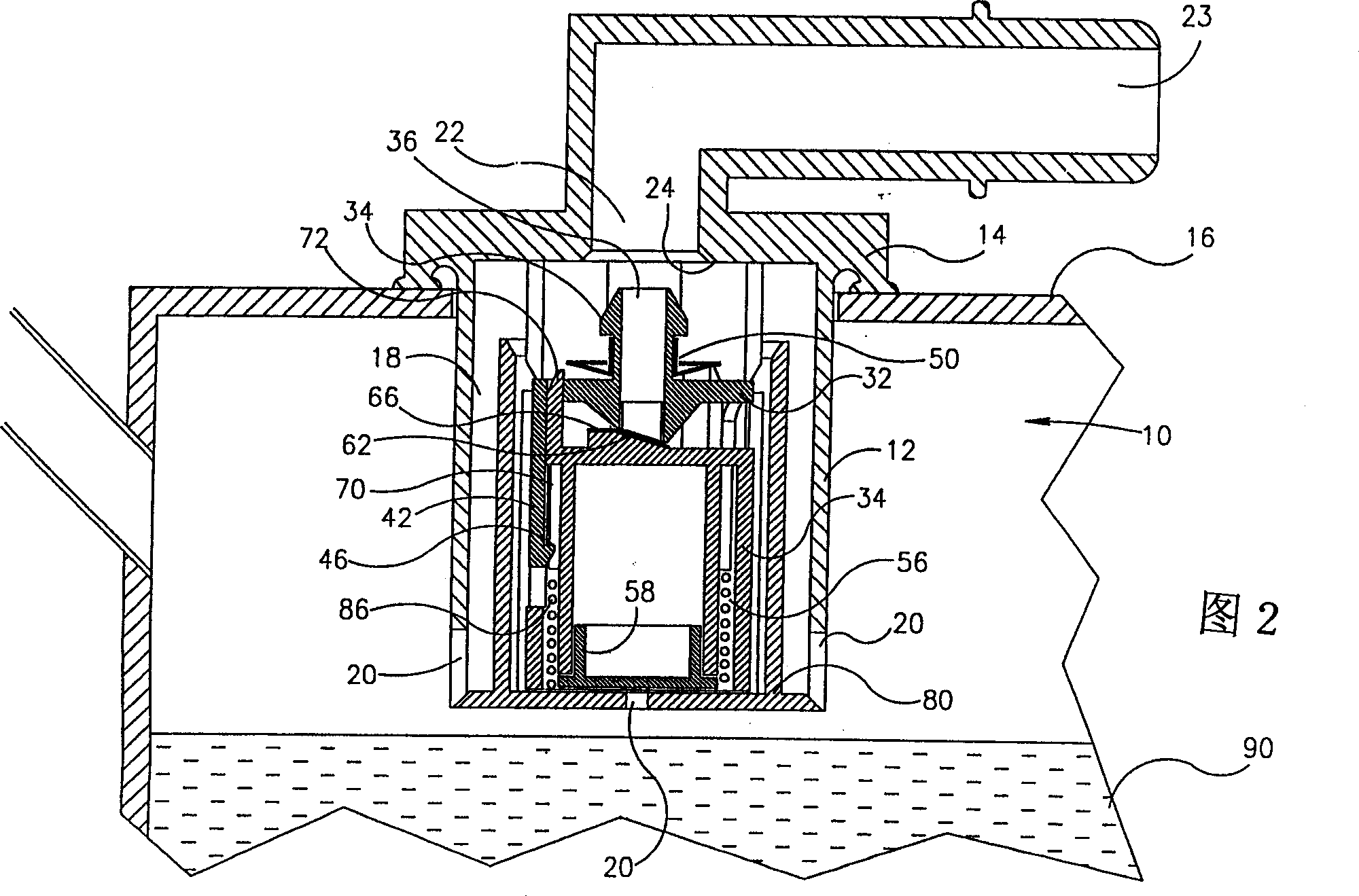

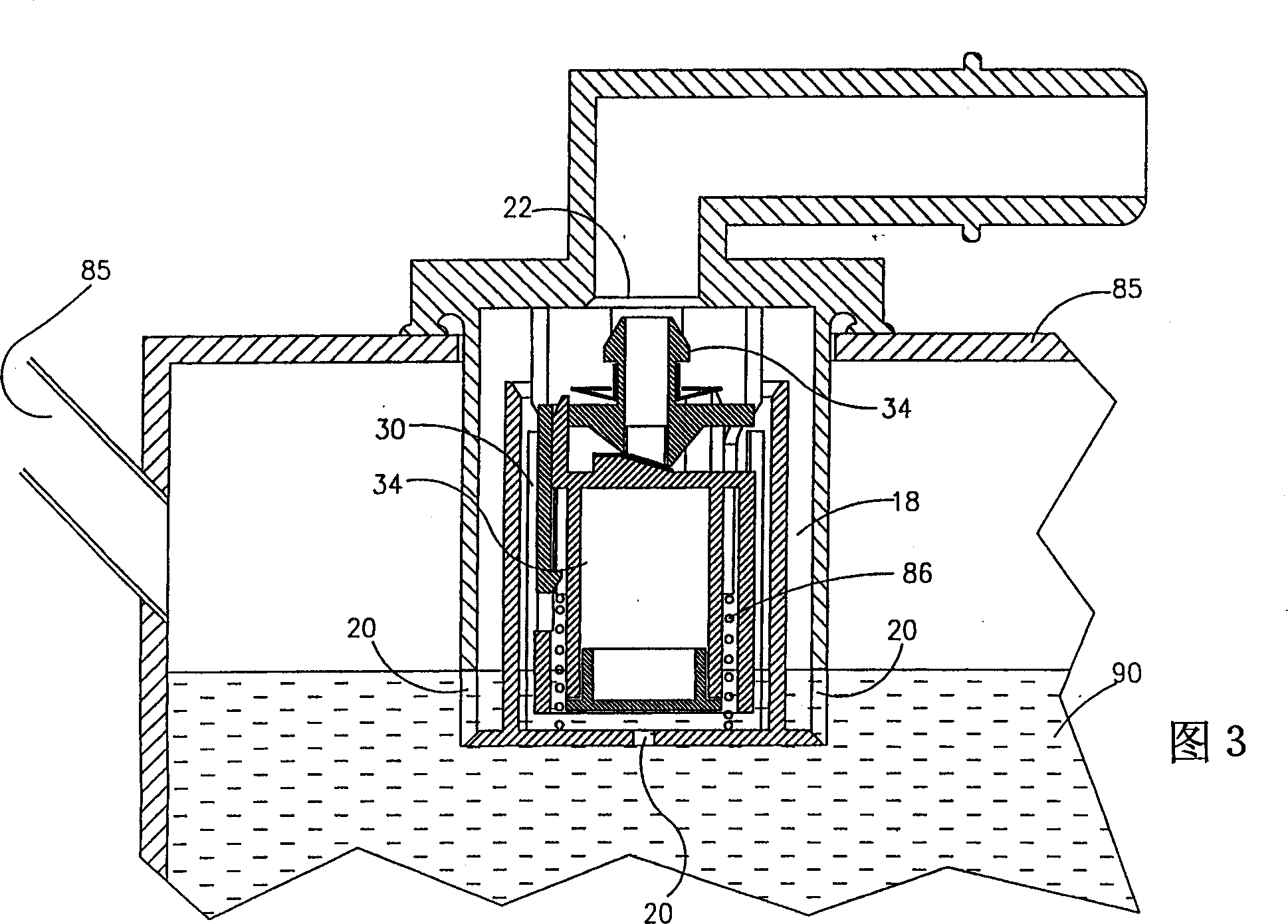

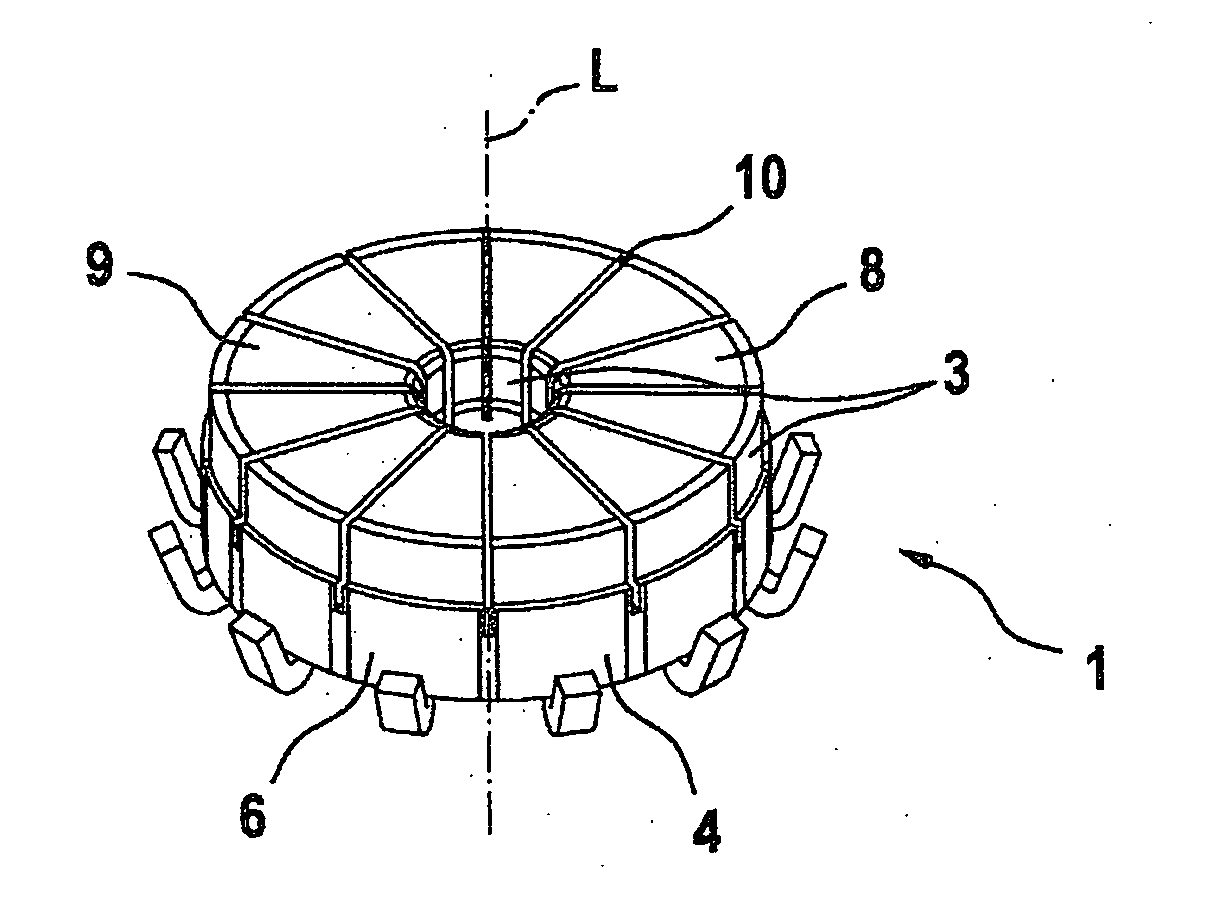

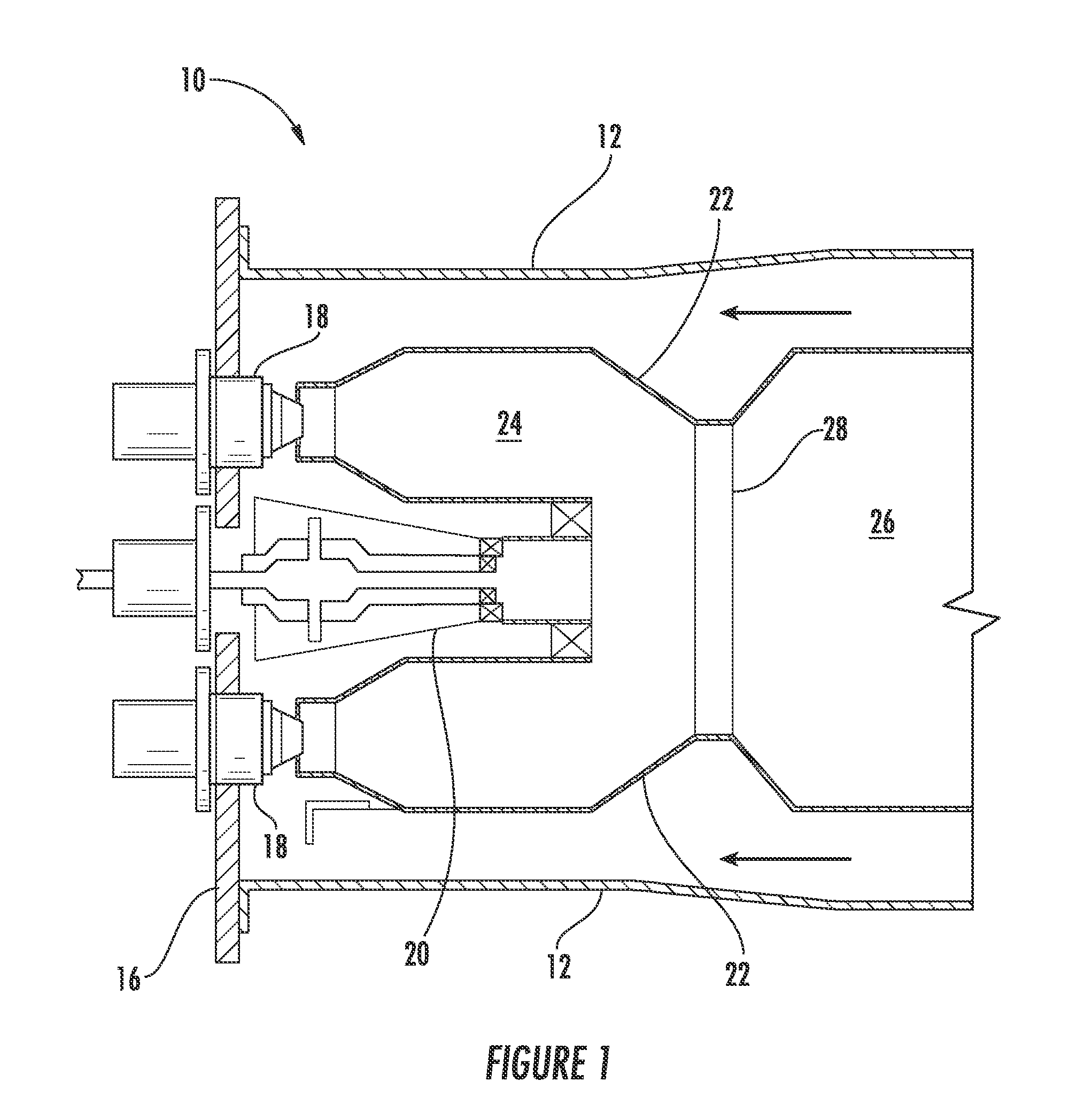

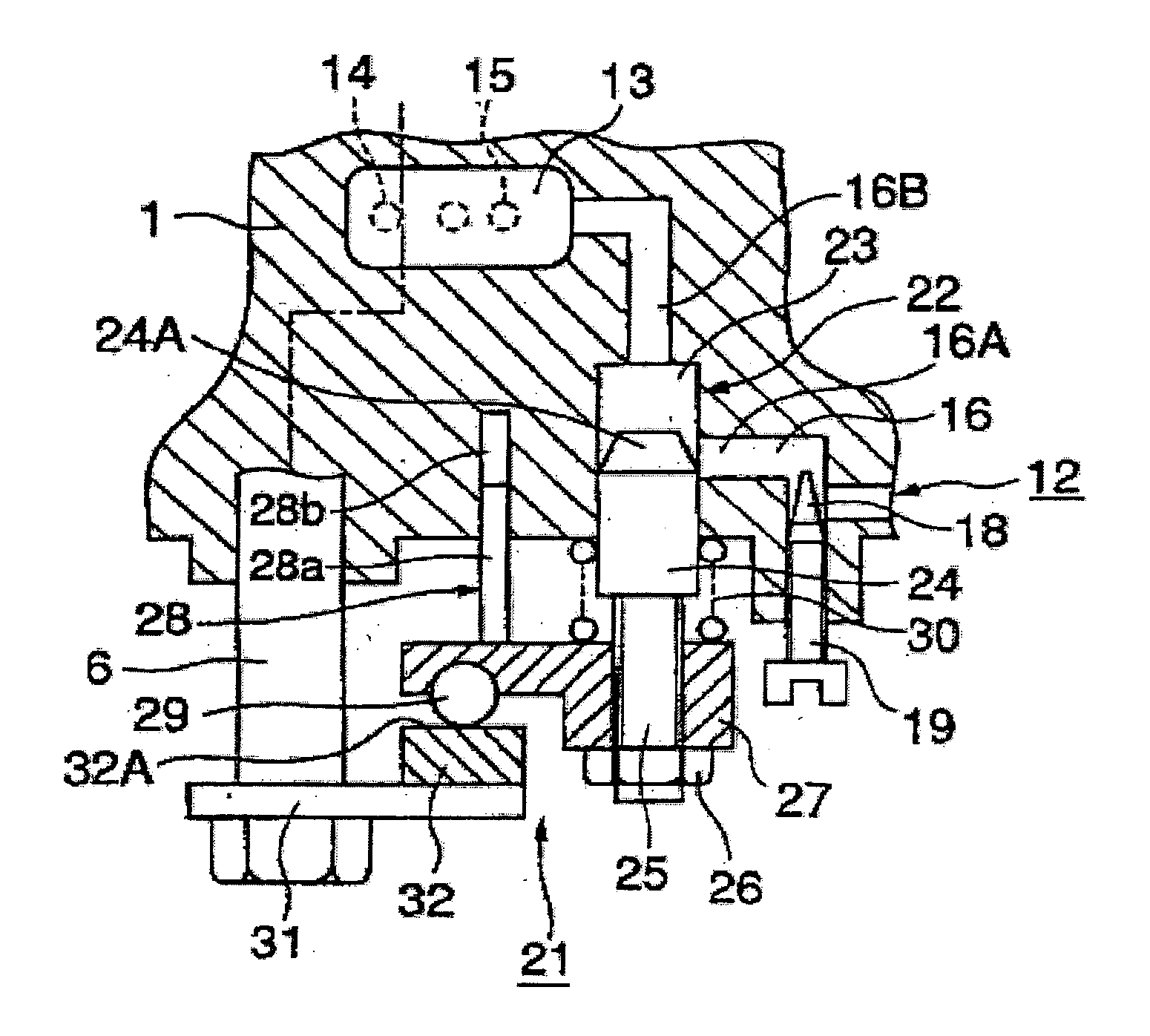

Over filling interdiction, vent and roll over valve

InactiveCN1349598AReduce the effective cross-sectional areaSoft closeElectric propulsion mountingEqualizing valvesInterdictionConfined space

An over filling interdiction and roll over valve (10) comprising a housing (12) defining a confined space (18) formed with fluid inlets (20), a fluid outlet port (22) at a top end of the confined space (18), and a valve seating (24) bounding the outlet port (22). A valve assembly is located within the confined space and comprises a first stage member (32) and a second stage member (34), both being substantially coaxially displaceable within the housing. The first stage member has at a bottom end thereof a substantially elongated slit-like inlet aperture (36), and at a top end thereof an outlet aperture being in flow communication with the inlet aperture. The first stage member is axially displaceable between a first position in which the outlet aperture progressively sealingly engages the outlet port of the housing, and a second position in which it is disengaged therefrom. The second stage member is a float fitted with a flexible closure membrane strip (66) anchored at one end thereof to a top wall (62) of the float member. The closure membrane faces the inlet aperture of the first stage member, and the second stage member is displaceable between a first position in which the closure membrane sealingly engages the inlet aperture, and a second position in which it is progressively disengaged therefrom. At least one anchoring member (42) extending between the first stage member (32) and the second stage member (34).

Owner:拉瓦尔农业合作社有限公司

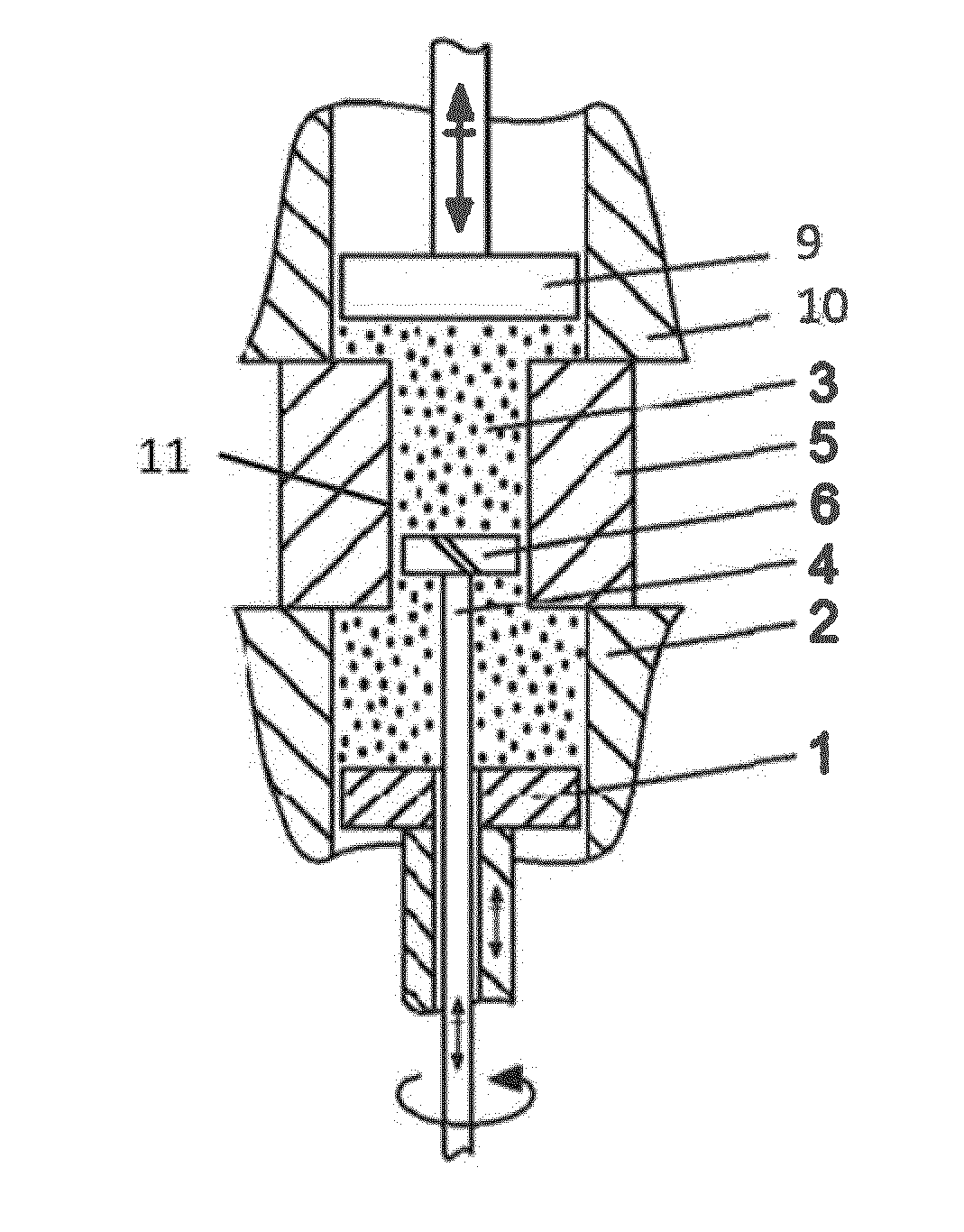

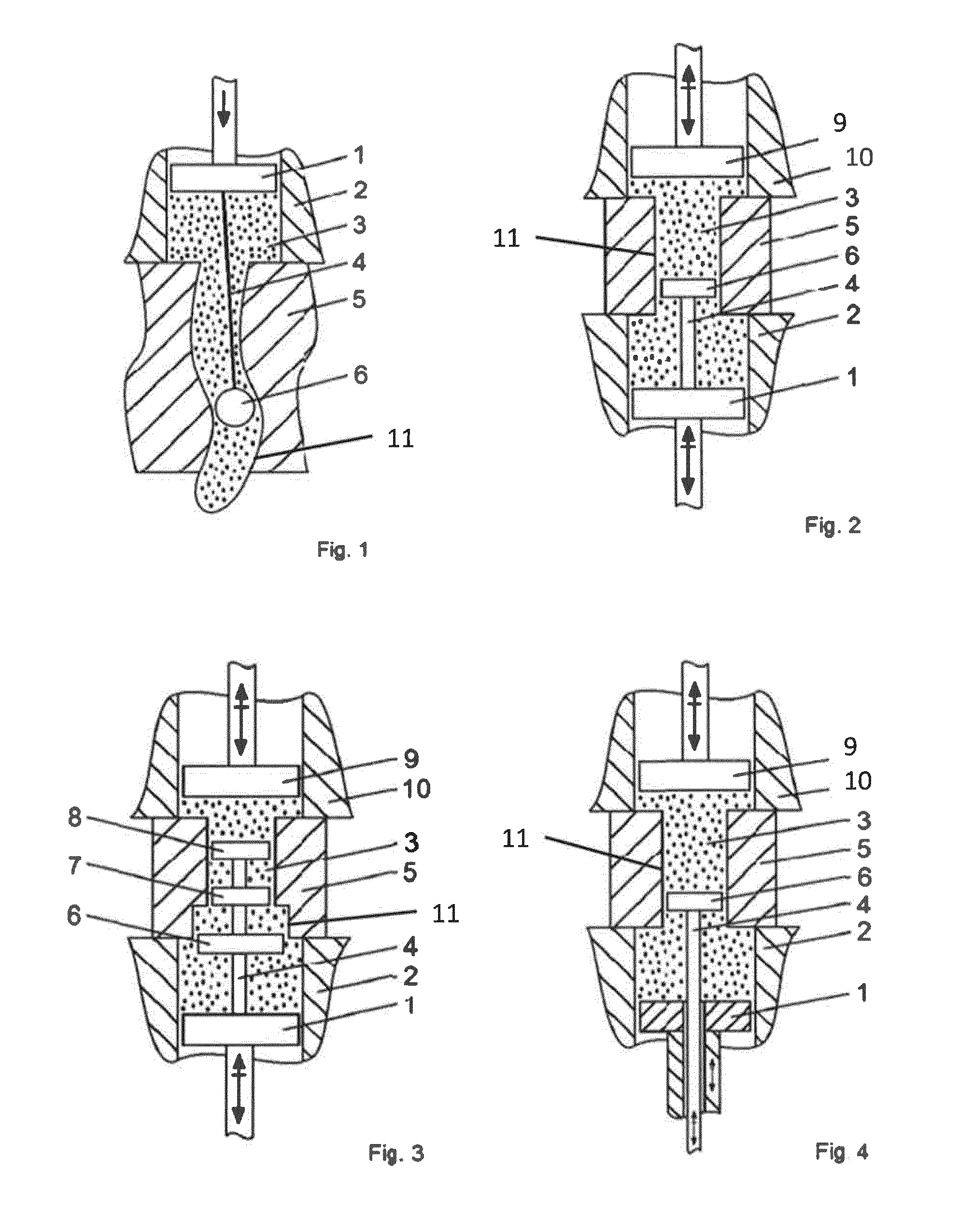

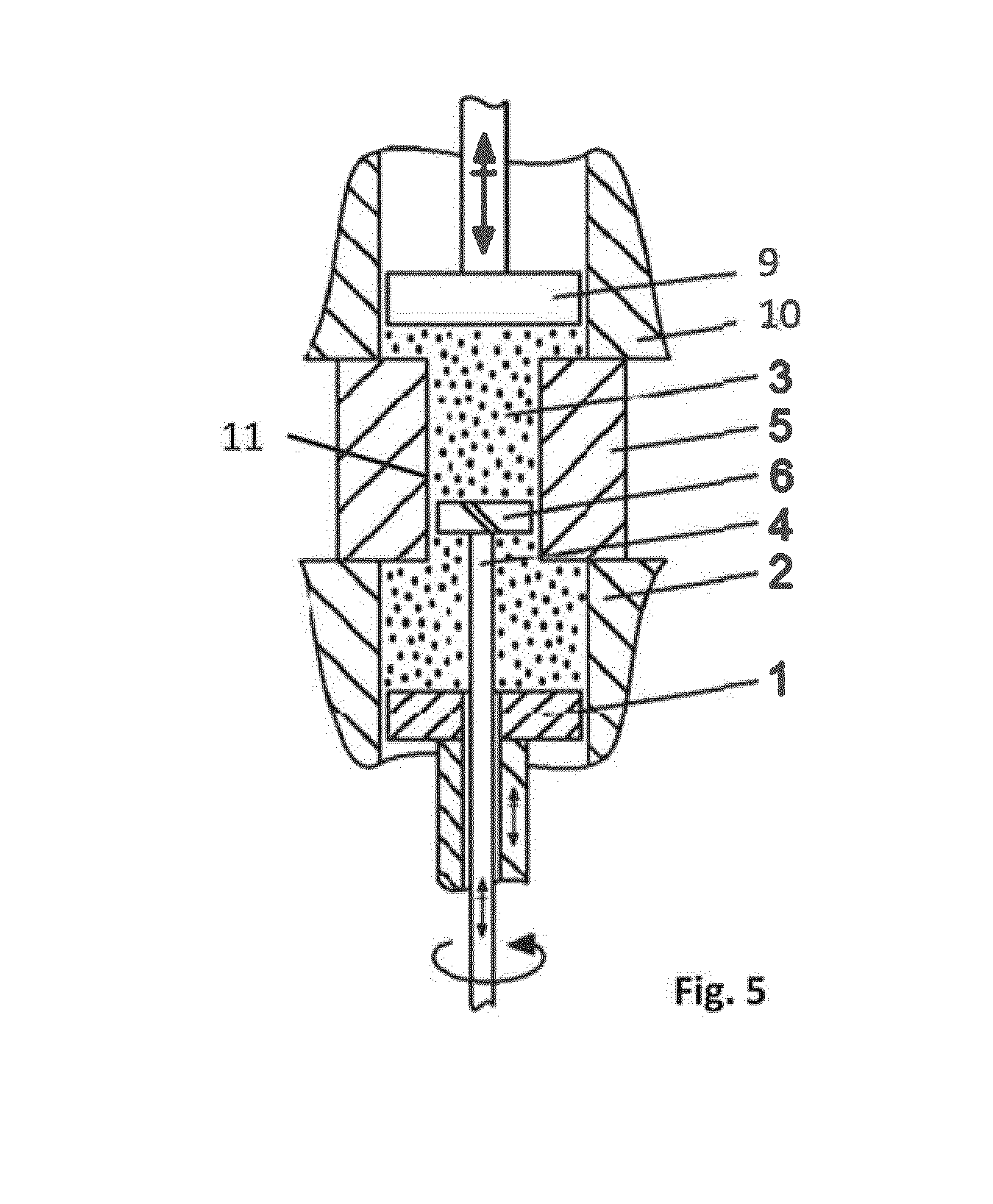

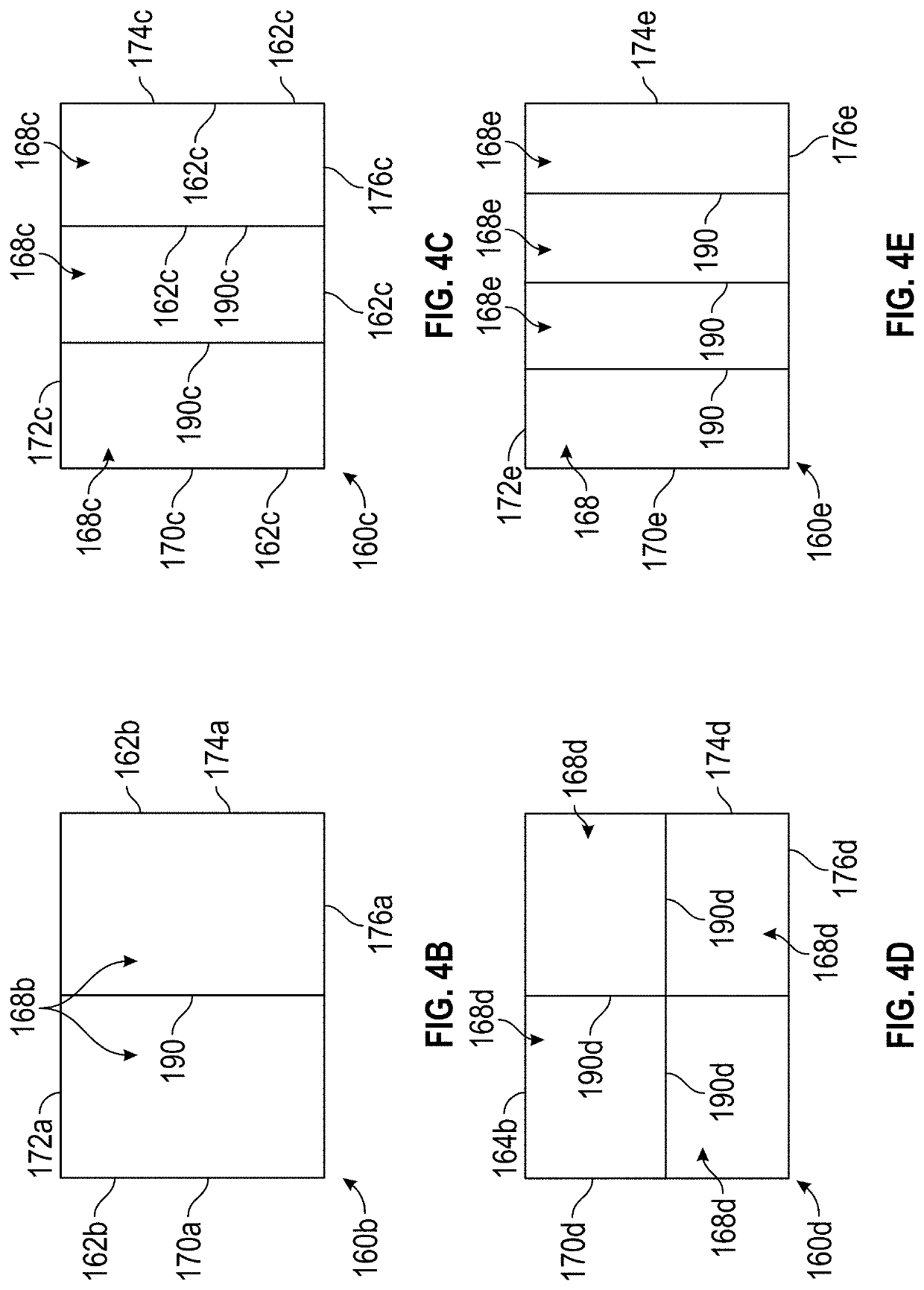

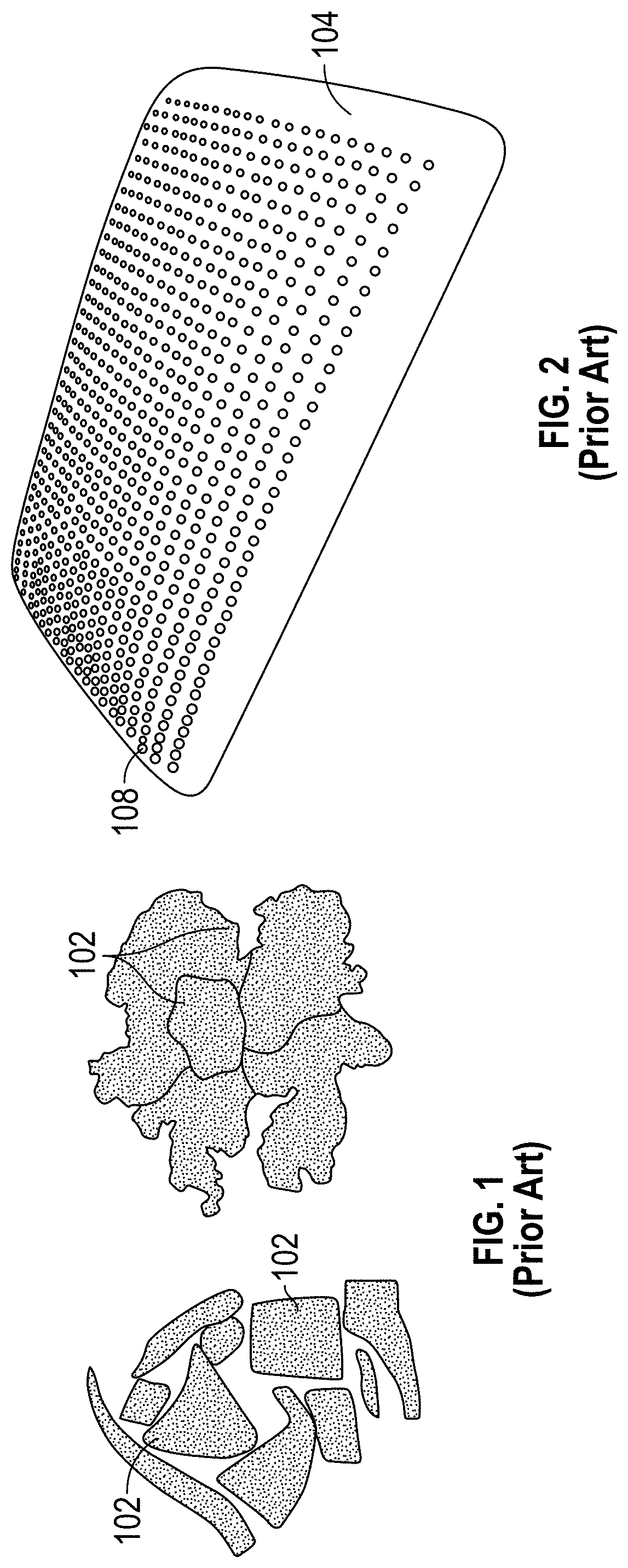

Arrangements and methods for abrasive flow machining

InactiveUS20160082565A1Increase the cross-sectional areaReduce the effective cross-sectional areaEdge grinding machinesPolishing machinesEngineeringAbrasive flow machining

A method of treating an interior surface of a workpiece (5); said method comprising providing a workpiece (5) having an interior passage (11) defined at least partly by said interior surface to be treated, said passage (11) having an inlet section and an outlet section; providing in said interior passage (11) at least one deflecting object (6), said deflecting object (6) having an outer surface, whereby a space is formed between said outer surface of said at least one deflecting object (6) and said interior surface of said workpiece (5); providing an abrasive fluid (3) in said space, such that said space is substantially filled with said abrasive fluid (3); and effecting flow of said abrasive medium (3) through said interior passage (11) from said inlet portion to said outlet portion.

Owner:UNIVERSITY OF LJUBLJANA

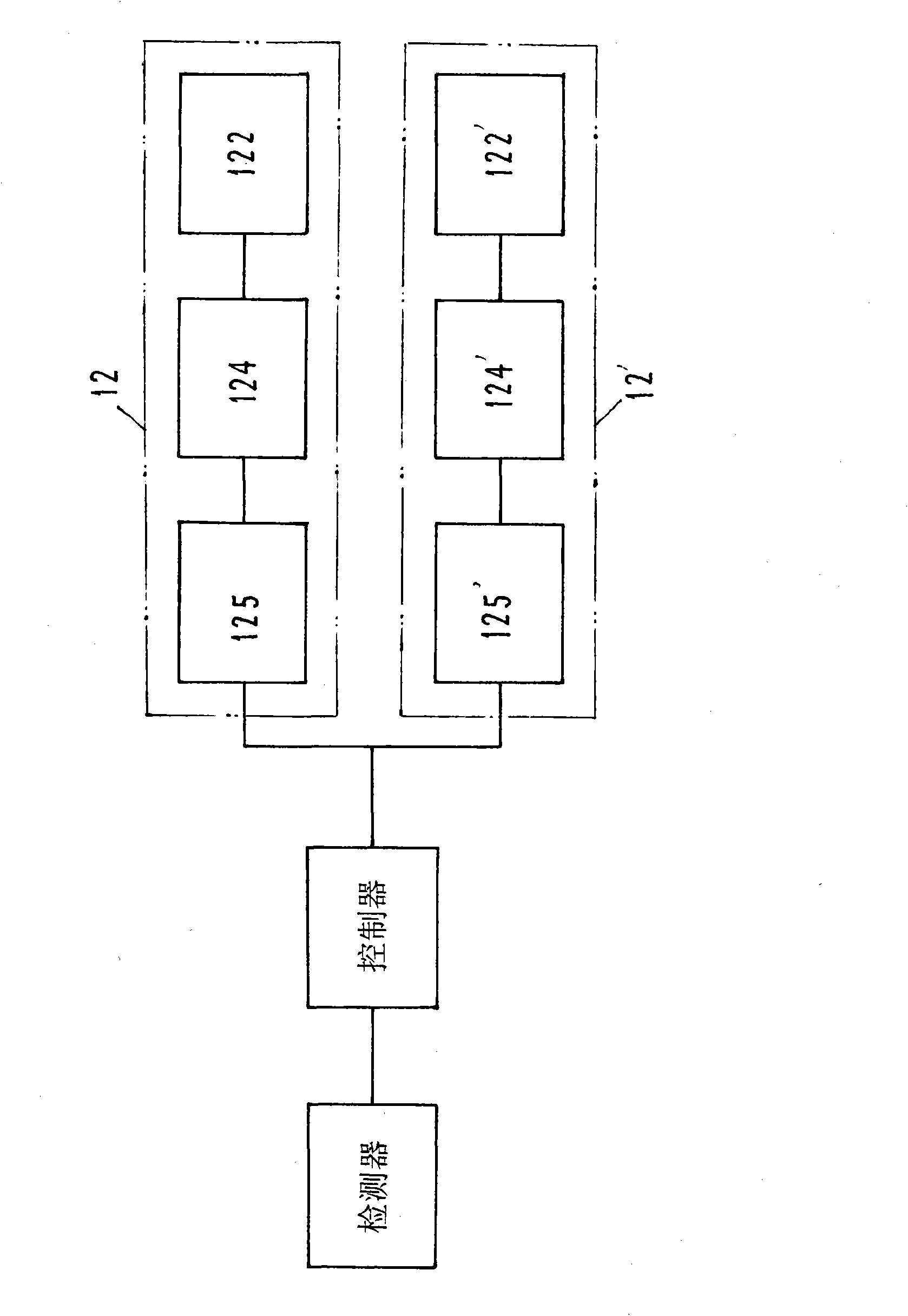

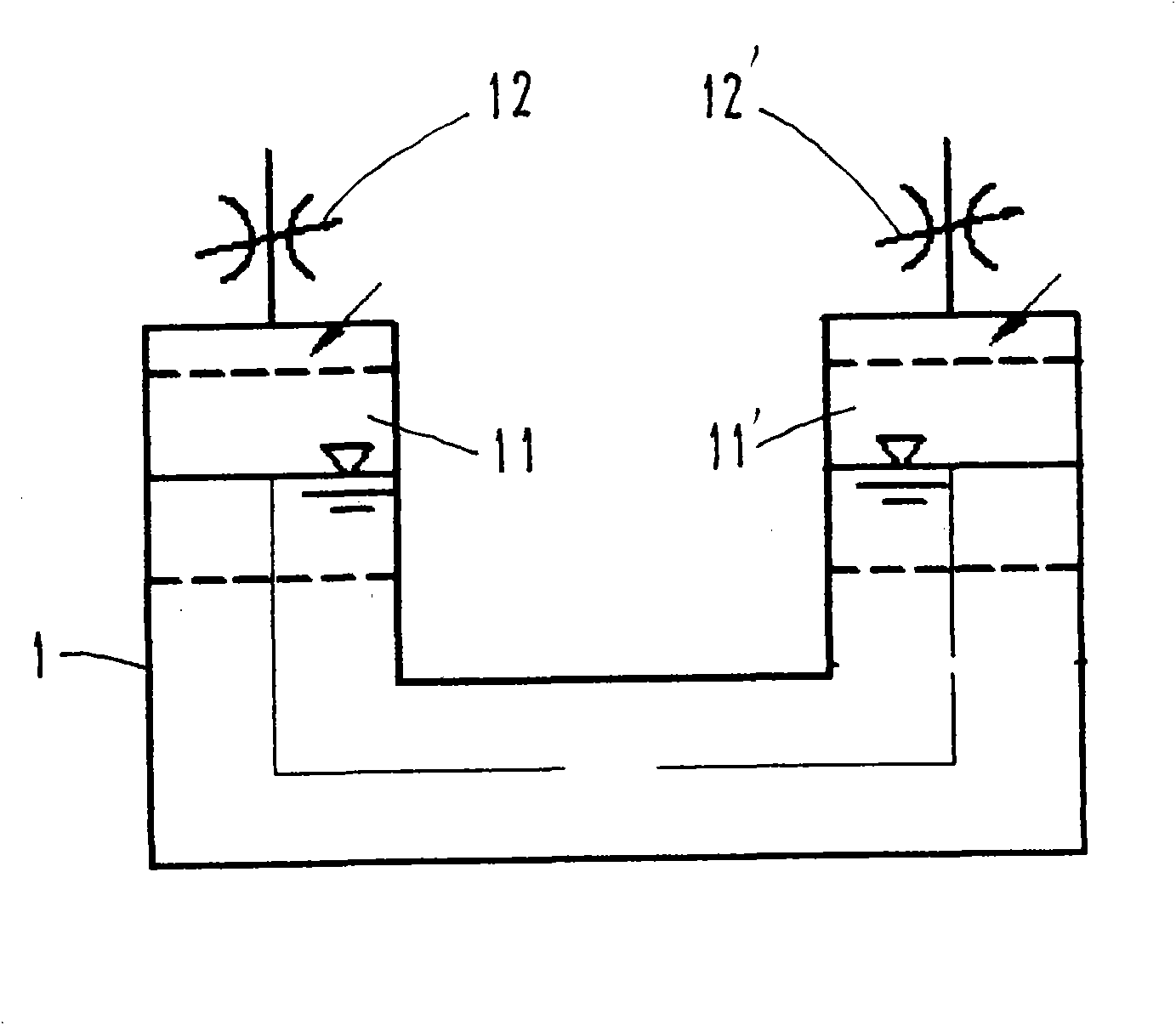

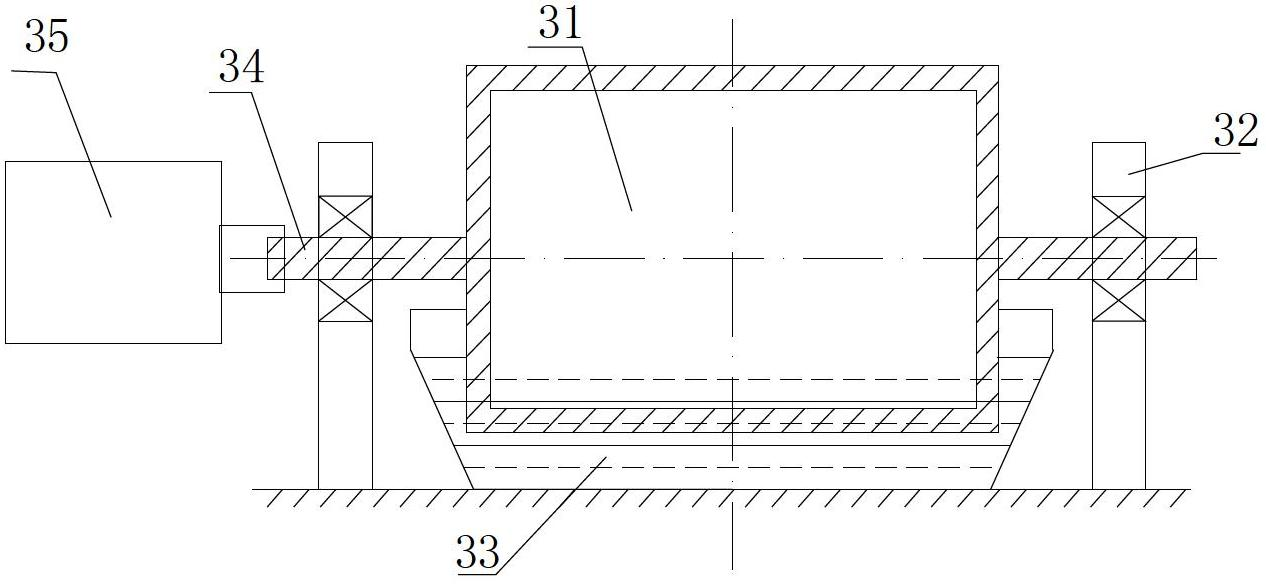

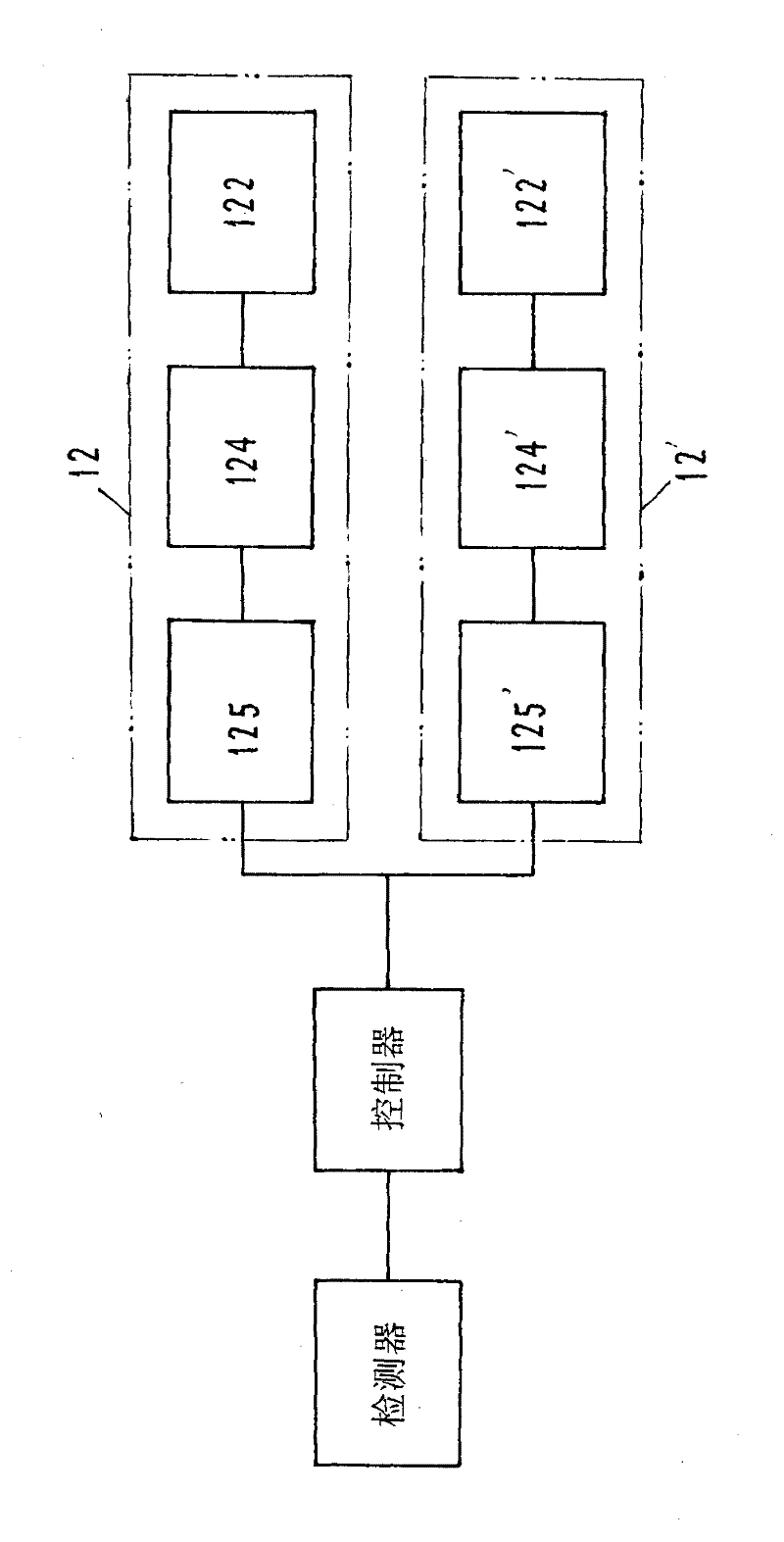

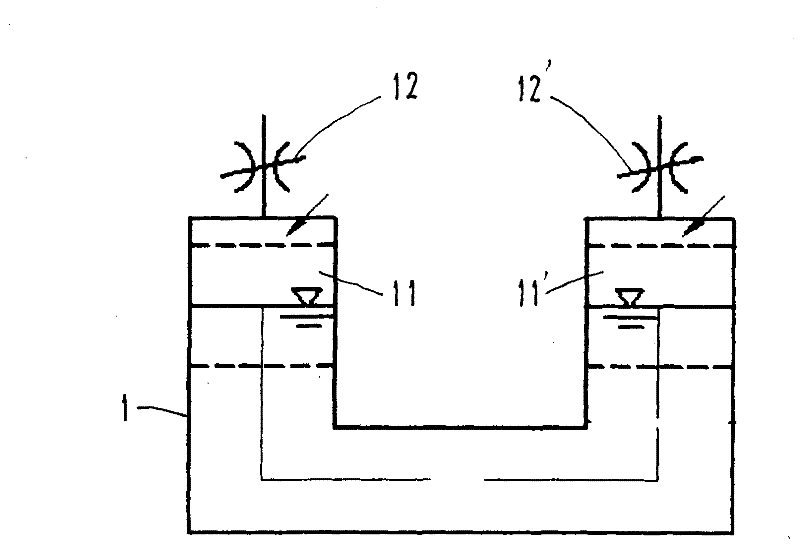

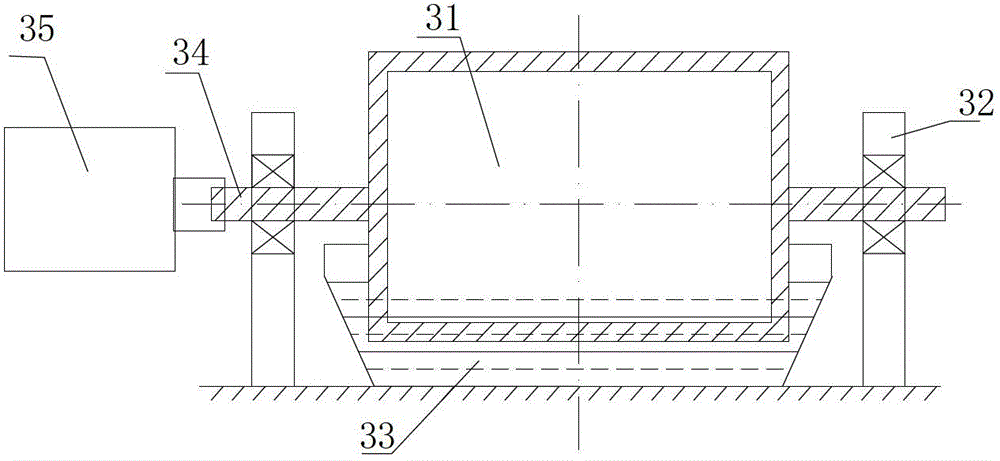

Tank stabilizer control device

ActiveCN101624087AImprove sailing performanceIncrease the effective cross-sectional areaVessel movement reduction by mass displacementEngineeringWater level

The invention discloses a tank stabilizer control device, which mainly solves the technical problems of improving the pitch damping effects of ships and the like, and adopts the technical scheme that: a left throttling passage and a right throttling passage are arranged at the top parts of a larboard air chamber and a starboard air chamber of a U-shaped tank stabilizer, throttling components are arranged on the two passages, the two components are connected with a controller which is connected with a detector, detected ship swinging period signals are input to the controller, control signals are output to the two throttling components according to set rules, and the throttling components adjust effective sectional areas of the two throttling passages so as to realize the water level alternation period of the U-shaped tank stabilizer the same as the ship swinging period. The tank stabilizer control device is applied to various U-shaped tank stabilizers.

Owner:SHANGHAI HUNTER MARINE EQUIP CO LTD

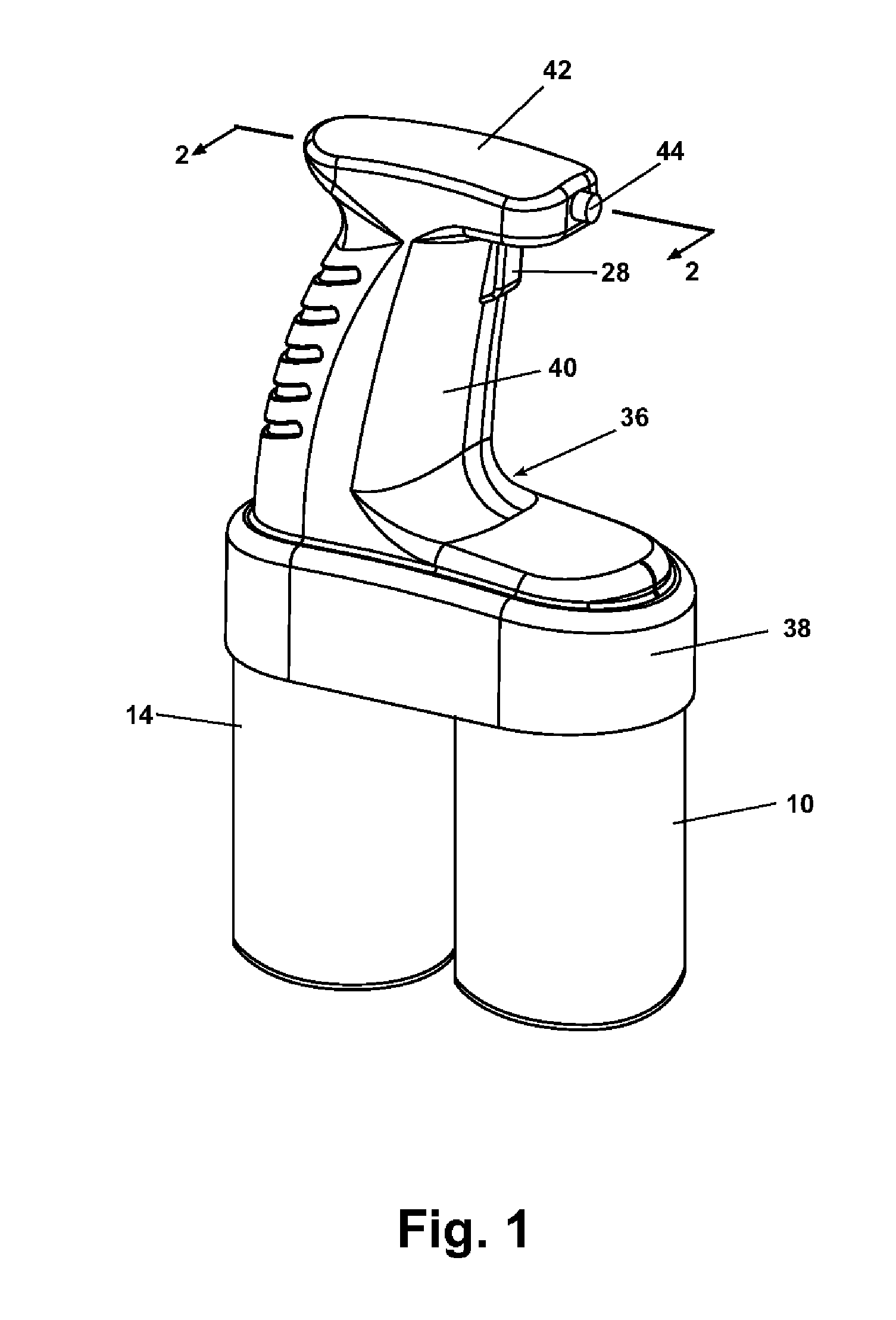

Aerosol package

InactiveUS20050029296A1Reduce the effective cross-sectional areaCleaning machinesDry-cleaning apparatus for textilesAerosol sprayEngineering

An aerosol spray cleaner comprises two containers and a dispenser with a single dispensing spray outlet. One container has a cleaning composition and the other has an oxidizing composition. An integrally molded actuator includes a resiliently cantilevered lever connected to container valves to simultaneously open the valves to dispense the two fluids through the dispensing spray outlet. A handle extends laterally of the containers so grasp the handle and depress the actuator with a thumb.

Owner:BISSELL INC

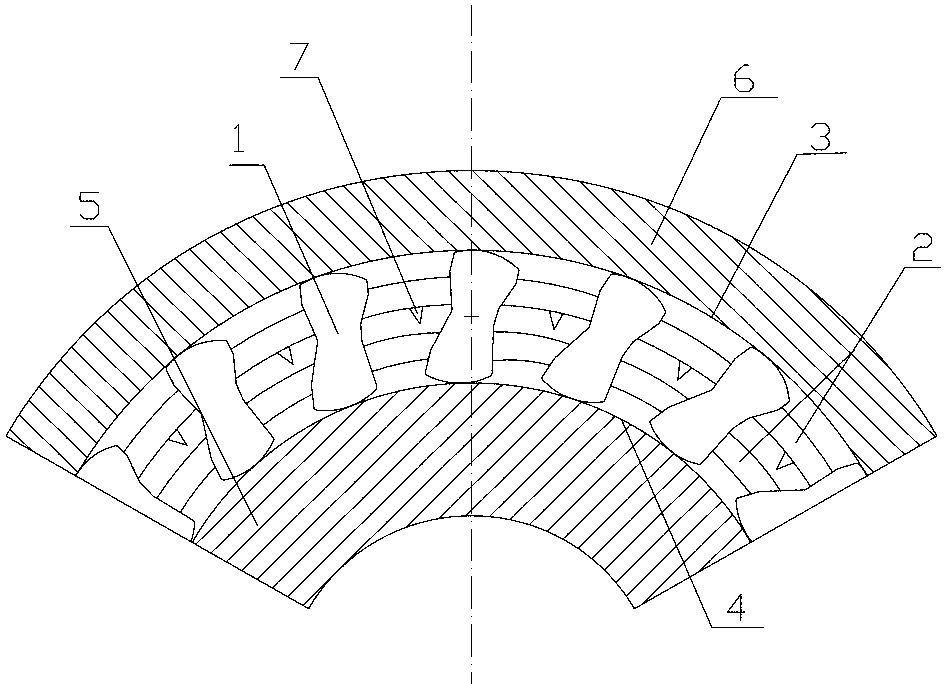

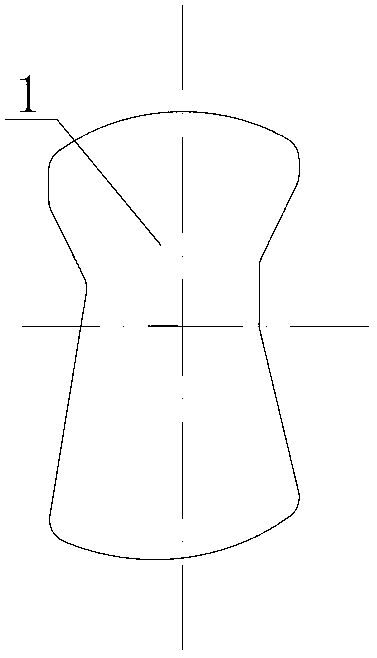

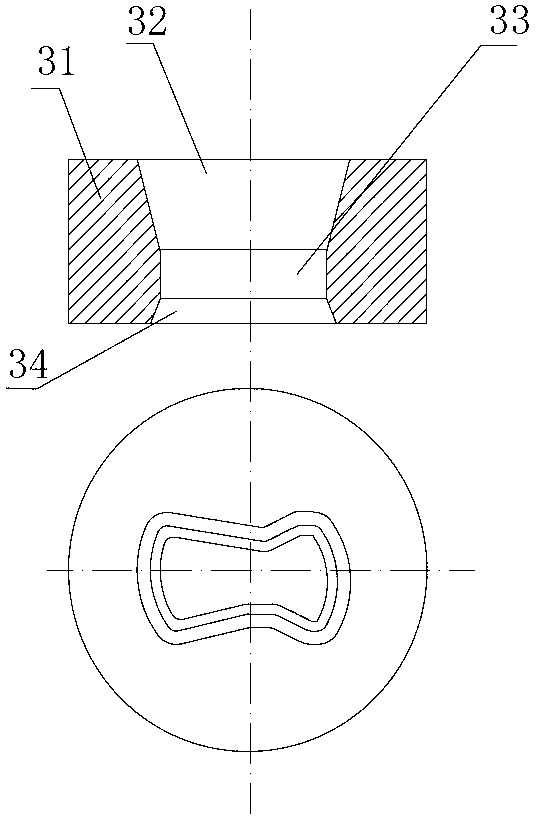

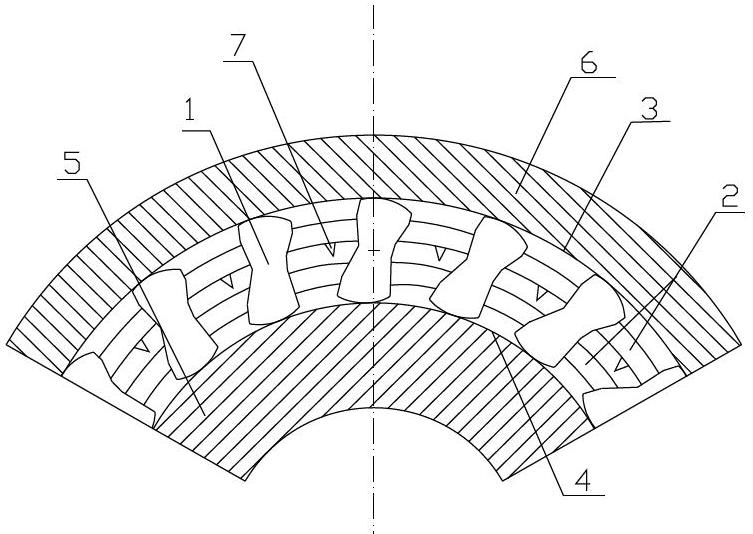

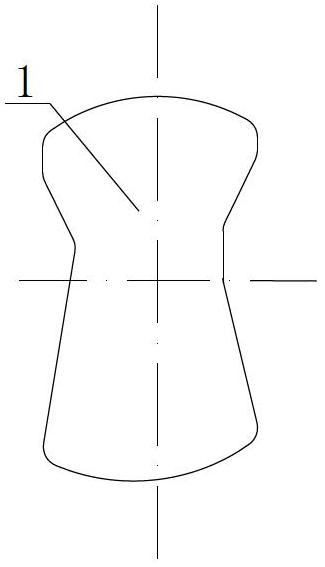

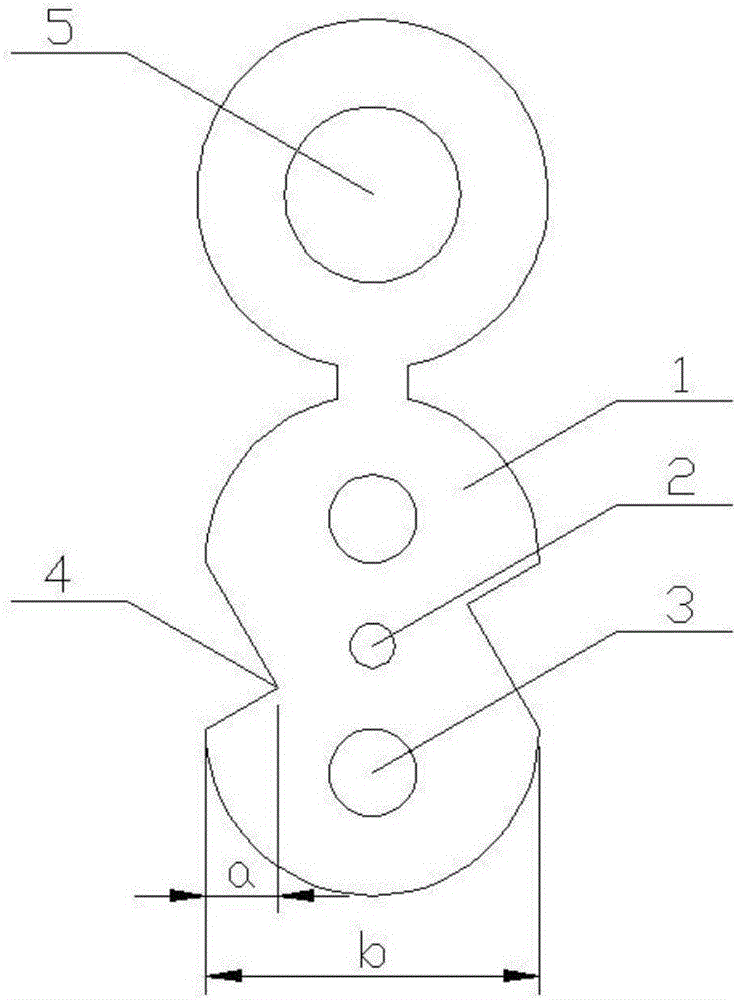

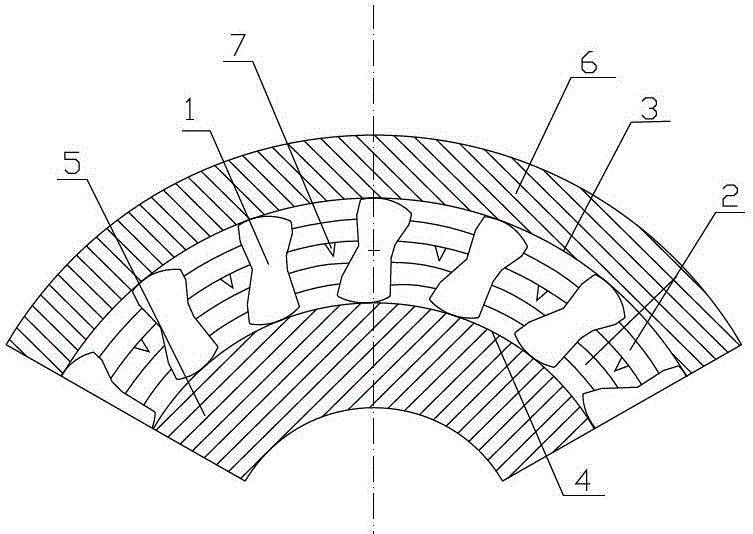

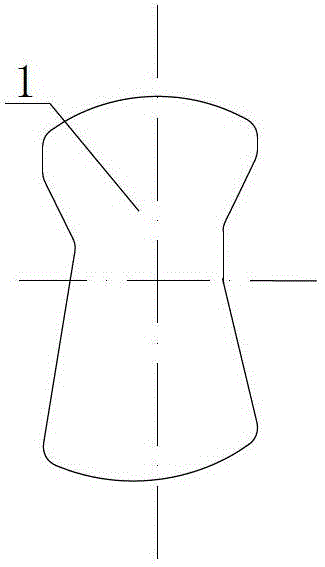

Processing method for wedge block of wedge block-type overrunning clutch

ActiveCN102699631AReduce the effective cross-sectional areaMeet the precision requirementsSand blastingAgricultural engineering

A processing method for the wedge block of a wedge block-type overrunning clutch relates to a processing method for the overrunning clutch. The processing method provided by the invention has higher manufacturing accuracy, can prolong the service life of the clutch, and comprises the following steps: a wedge block, of which a single side has a margin ranging from 0.02 to 0.04 mm, is manufactured by conducting cold drawing and cutting off on bearing steel (GCr15); after vacuum quenching and tempering, the wedge block is polished with a polishing machine to remove surface oil stain and edges; sand blasting is conducted on the wedge block; the formed wedge block is cleaned; and the cleaned wedge block passes through a forming mold under the action of an extruder, so as to obtain the wedge block of the wedge block-type overrunning clutch after processing.

Owner:XIAMEN UNIV

Chemical treatment and processing method of overrunning clutch wedge

ActiveCN102689144AReduce the effective cross-sectional areaMeet the precision requirementsExtrusion diesChemical treatmentBall bearing

The invention relates to an overrunning clutch, and in particular relates to a chemical treatment and processing method of an overrunning clutch wedge... The wedge provided by the invention has high production precision so as to prolong the service life of the clutch. The method comprises the following steps of: carrying out cold drawing and cutting to produce a wedge with the margin being 0.02-0.04mm on the single side by using ball bearing steel; polishing after vacuum hardening and tempering, and removing the oil stain and edge on the surface; carrying out acid corrosion on the wedge; disacidifying the wedge after acid corrosion; carrying out rustproof treatment; and molding the wedge after rustproof treatment by using an extruder, thus finishing the chemical treatment and processing of the overrunning clutch wedge.

Owner:XIAMEN UNIV

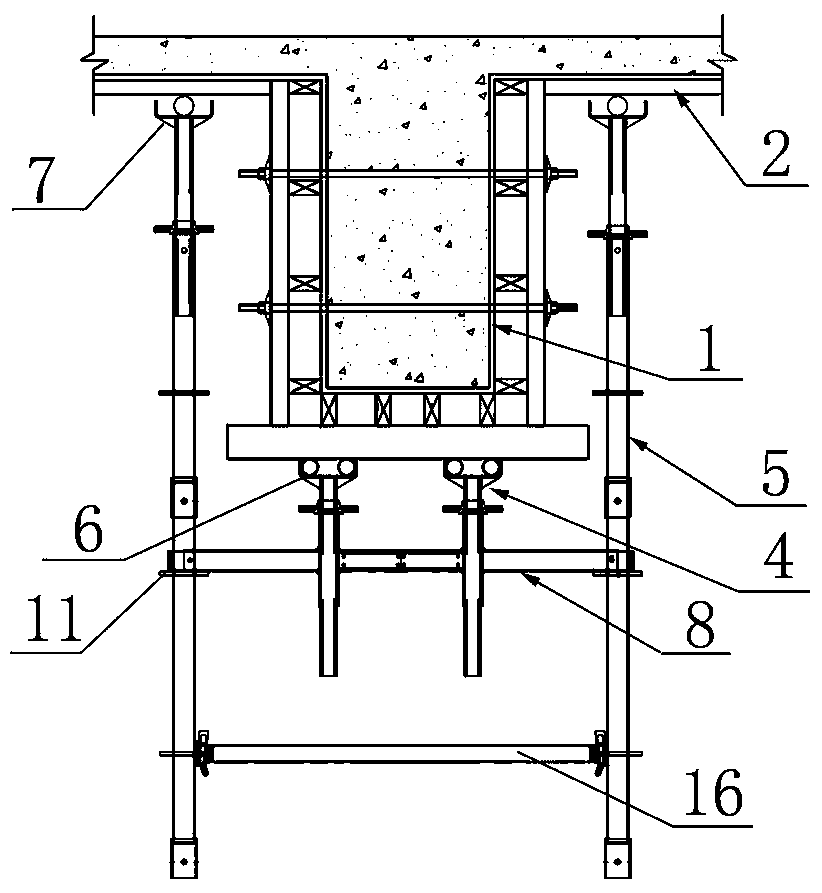

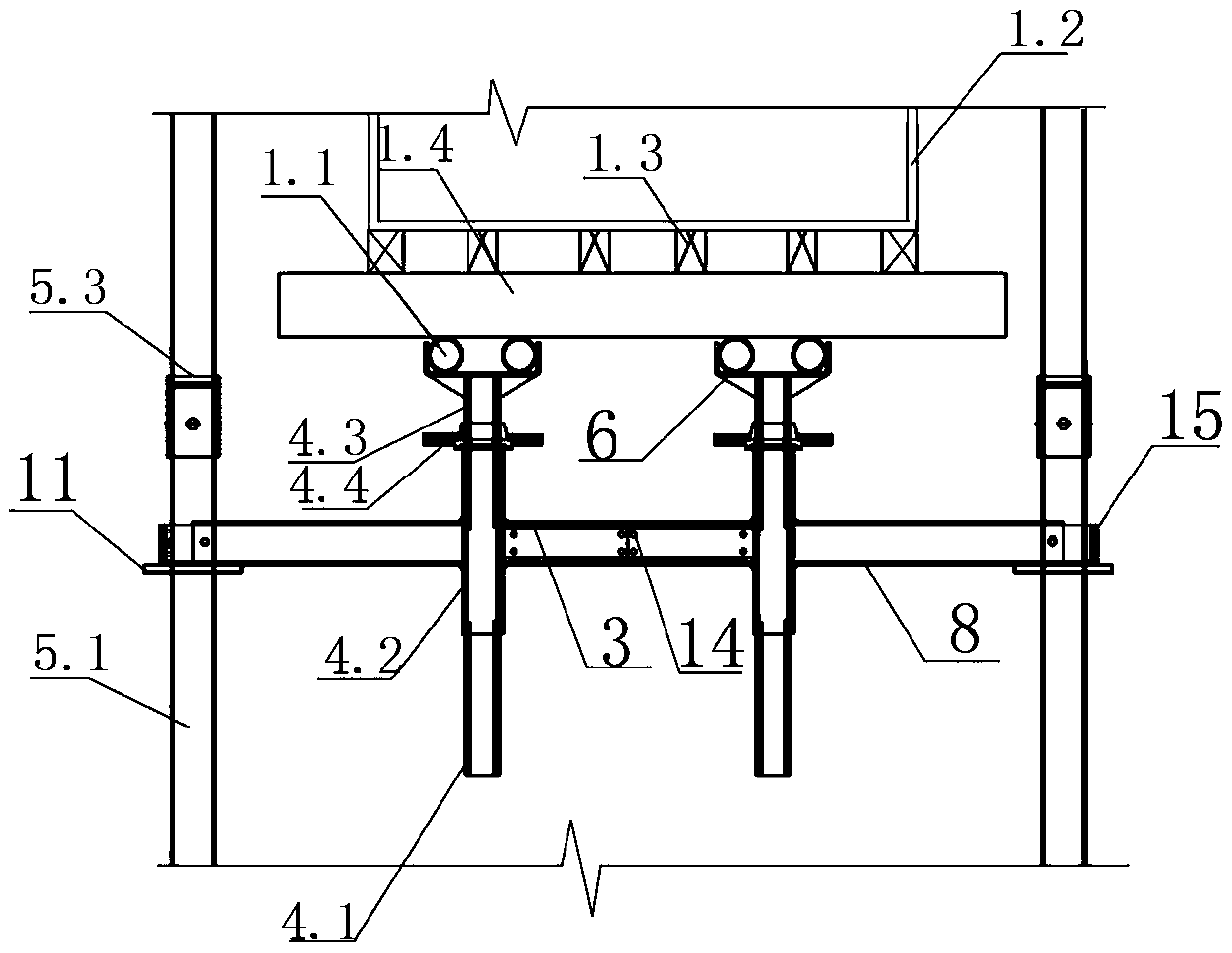

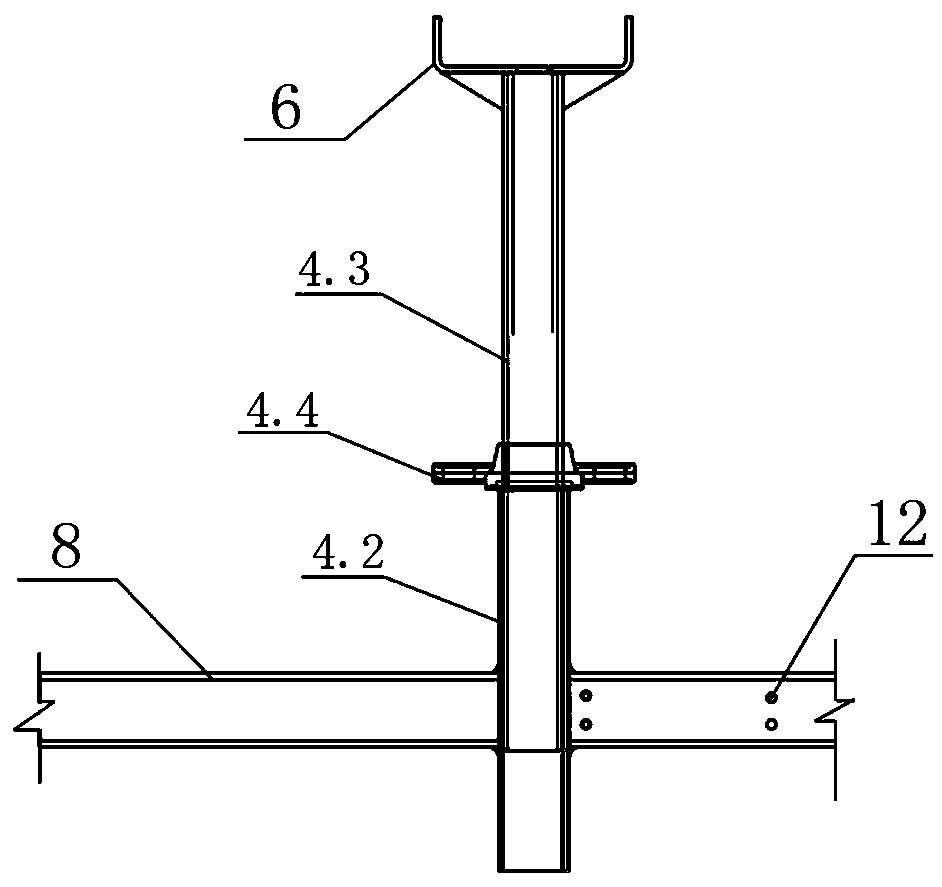

Self-locking adjustable square tube joist supporting frame and construction method thereof

PendingCN109695344AReduce steel consumptionLight weightForms/shuttering/falseworksEngineeringSelf locking

The invention discloses a self-locking adjustable square tube joist supporting frame and a construction method thereof. The self-locking adjustable square tube joist supporting frame comprises two supporting frame units which are symmetrically arranged relative to the longitudinal axis of a beam form; in addition, the two supporting frame units are transversely and adjustably connected by a connecting cross beam; each supporting frame unit comprises a beam bottom bracket, a buttonhole loop vertical rod and a cross beam unit; a first U-shaped tray is arranged at the top of each beam bottom bracket; each first tray is in supported joint with a beam bottom longitudinal backridge at the bottom of the beam form; each buttonhole loop vertical rod is vertically adjustable; a second U-shaped trayis arranged at the top of each buttonhole loop vertical rod; each second tray is in supported joint with a plate bottom longitudinal backridge at the bottom of a plate form; a clamping groove is formed in the end part of one end of each cross beam unit and is clamped in the corresponding buttonhole loop vertical rod. According to the self-locking adjustable square tube joist supporting frame and the construction method thereof disclosed by the invention, the technical problems that a jacking cross beam cannot be stretched for adjusting and is poor in stability are solved, and the technical effects of saving steel, reducing dead weight of a frame body and improving the working efficiency are realized.

Owner:CHINA CONSTR FIRST BUREAU GRP INTERIOR FITOUT ENG +1

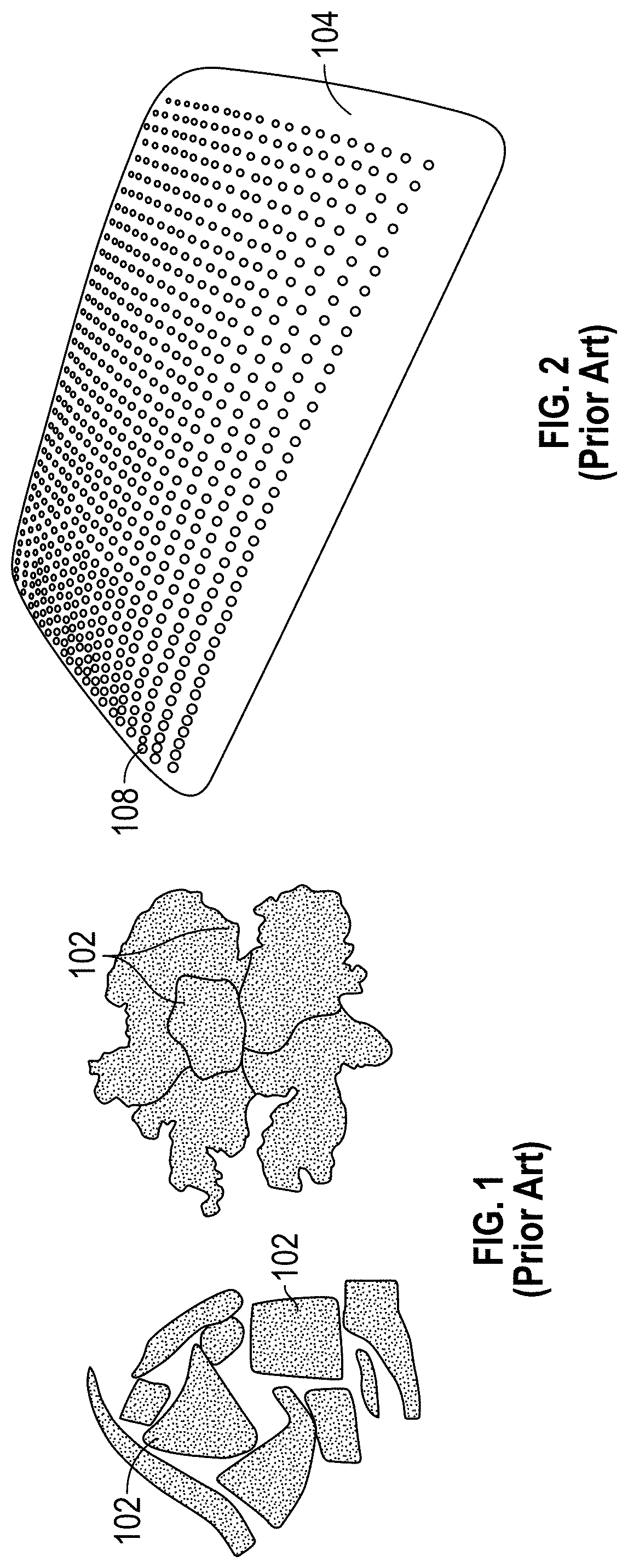

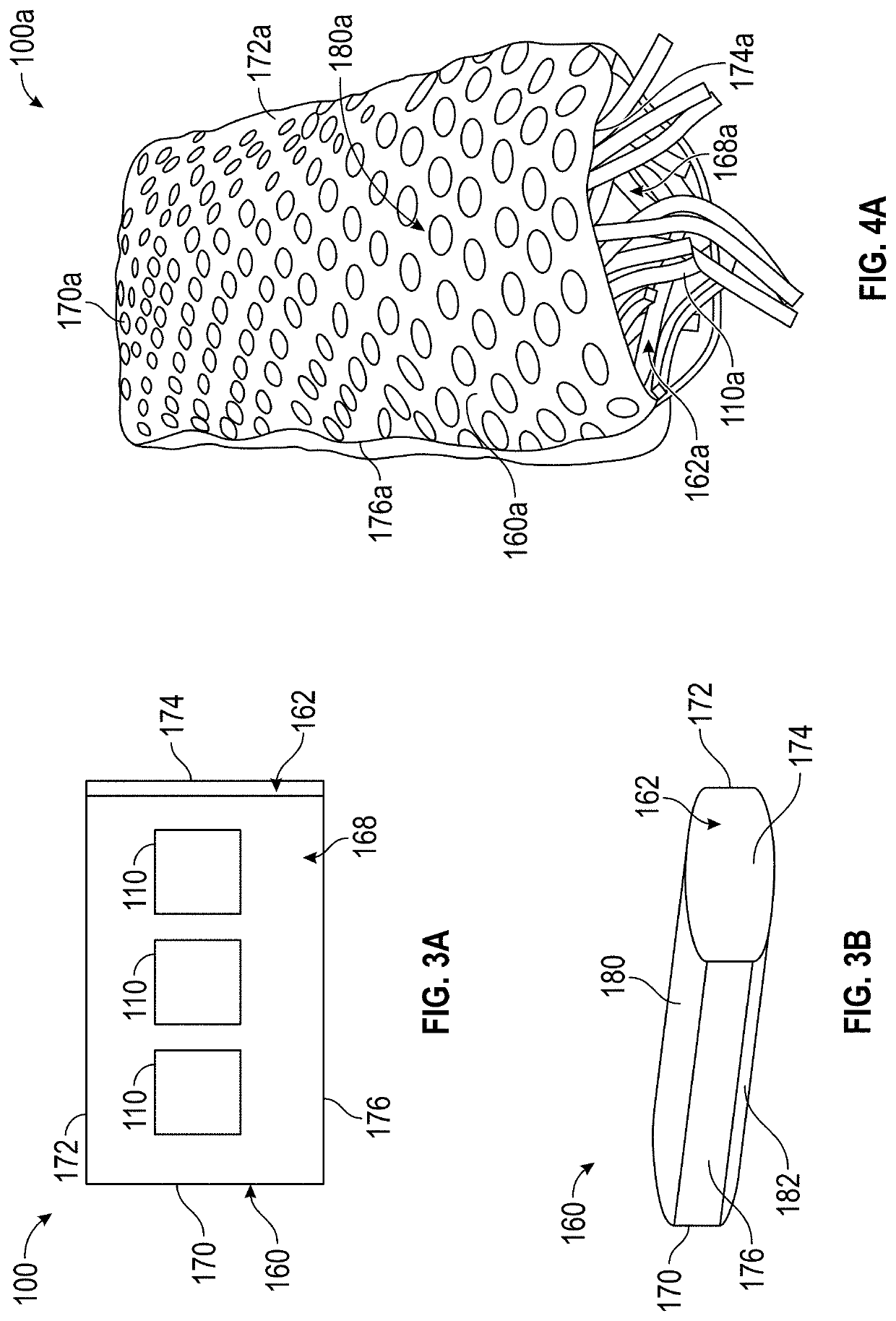

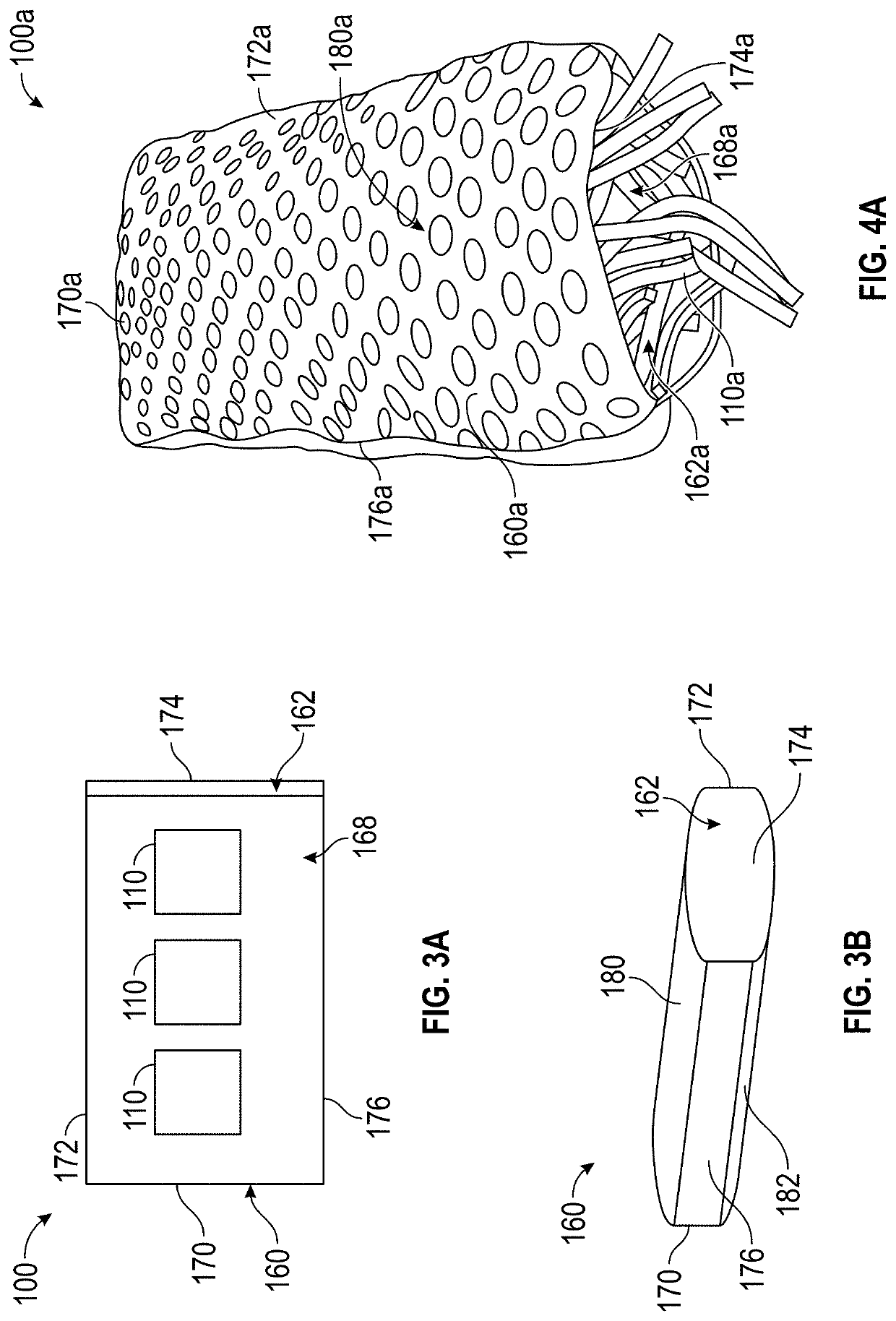

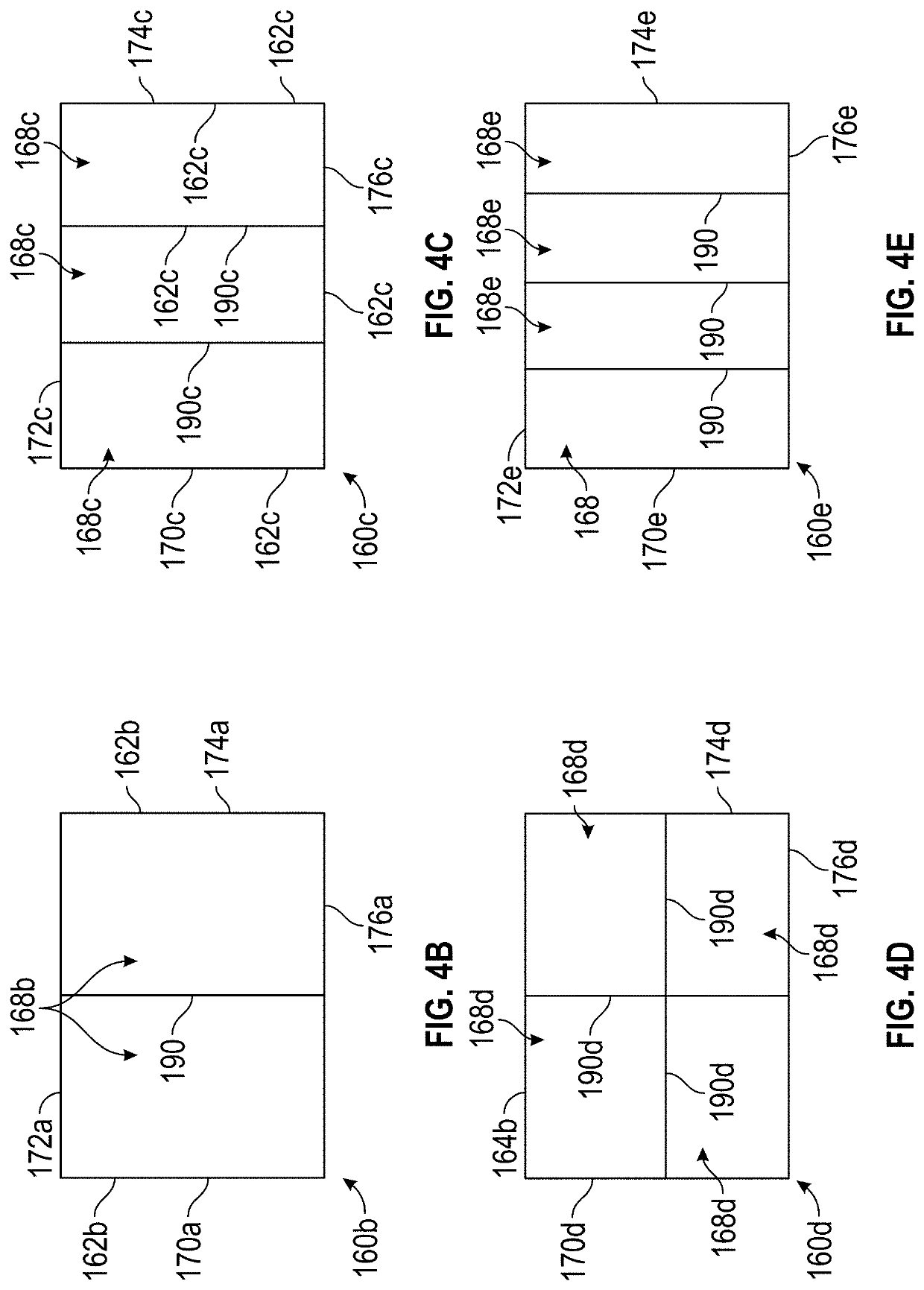

Personal support device with elongate inserts

ActiveUS10660461B1Extend your lifeLess dustPillowsDwelling equipmentClassical mechanicsStructural engineering

Owner:INNOVATIVE BEDDING SOLUTIONS INC

Helmholtz resonator for a gas turbine combustion chamber

InactiveUS8689933B2Reduce the effective cross-sectional areaIncrease distanceContinuous combustion chamberSilencing apparatusCombustion chamberHelmholtz resonator

A resonator is provided, having an adaptable resonator frequency for absorbing sound generated by a gas stream of a gas turbine. The resonator includes a neck section, a chamber and a deformable element being deformable under influence of a change of a gas turbine temperature of the gas stream. The shape of the deformable element is predetermined with respect to a respective gas turbine temperature. The neck section and the chamber form a volume of the resonator. The neck section forms a passage coupling the volume with the gas turbine. The deformable element is thermally coupled to the gas turbine in such a way that the shape of the deformable element depends on the respective gas turbine temperature. The deformable element forms a spiral and is installed to the neck section in such a way that an effective diameter of the neck section depends on the gas turbine temperature.

Owner:SIEMENS AG

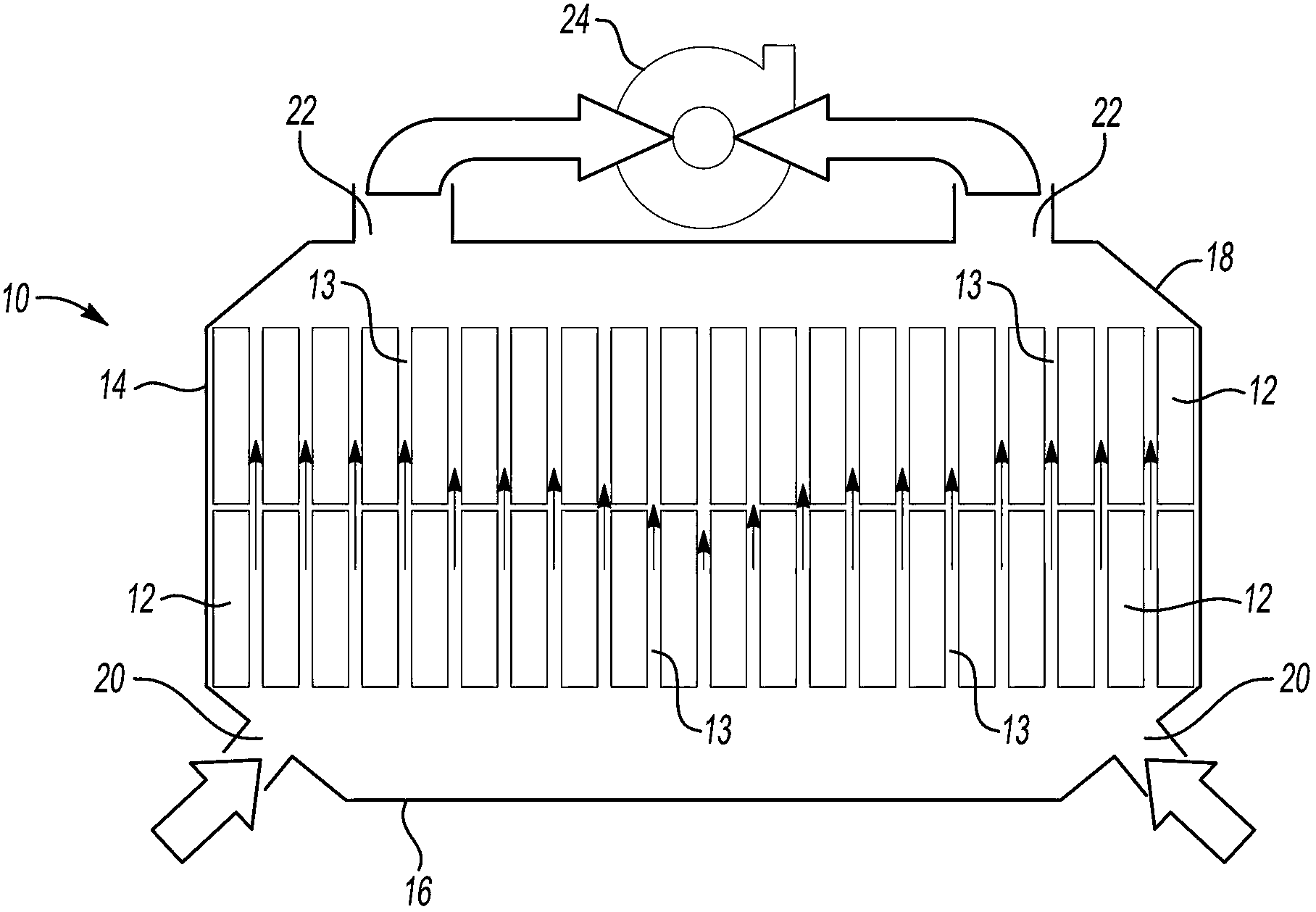

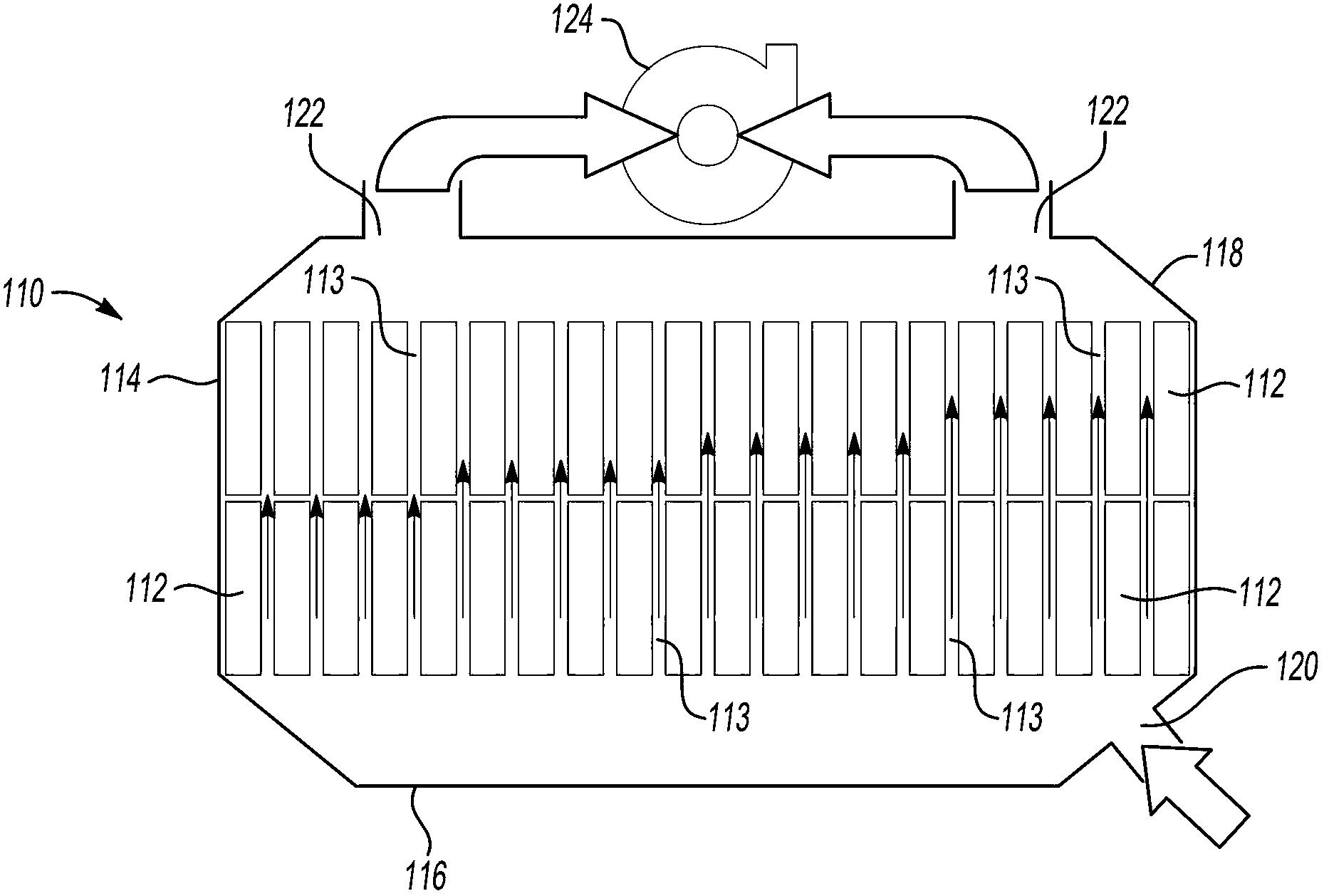

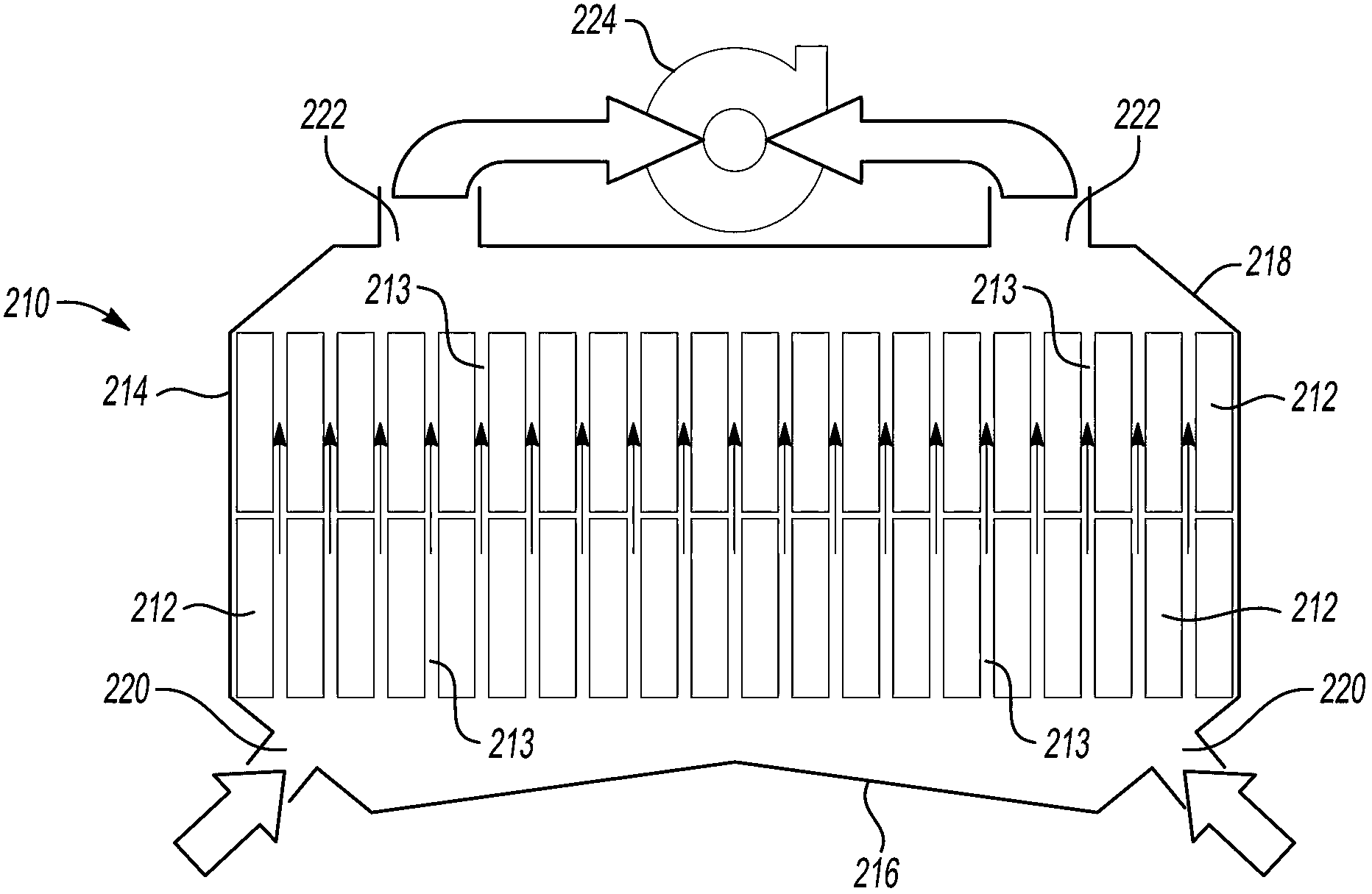

Battery assembly

InactiveCN103227353AReduce the effective cross-sectional areaUniform pressureSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringBattery cell

A vehicle battery assembly includes a housing defining a plenum having an inlet, and a plurality of battery cells disposed within the housing. The plenum has an effective cross-sectional area that decreases as a distance from the inlet increases and is arranged to promote development of generally uniform pressure within the plenum.

Owner:FORD GLOBAL TECH LLC

Manufacturing process of wrinkly liner-free down-proof fabric

ActiveCN110761025ASolve the disappearance of wrinkleSolve for uniformityLiquid/gas/vapor treatment of propelled fabricsHeating/cooling textile fabricsMechanical engineeringIndustrial engineering

The invention provides a manufacturing process of wrinkly liner-free down-proof fabric and relates to the field of fabric production. The manufacturing process includes: desizing, setting a blank, press-polishing, dyeing and wrinkling, shaping and drying, sprinkling water for shaping, and performing finish inspection. Dyeing and wrinkling are performed after press-polishing, down-proof requirements can be met without down-proof press-polishing after wrinkling, so that the problem that wrinkle degree of the fabric is nonuniform due to the fact that cloth surface is press-flattened by high temperature caused by the fact that down-proof press-polishing is performed for multiple times after dyeing and wrinkling or the problem that wrinkle degree of the surface of the fabric is damaged due to the fact that press-polishing is performed to realize down-proof effect of the fabric in the prior art is solved; further, a metal elbow identical with a cloth incoming elbow in bending direction curvature is mounted on the inner wall of the cloth incoming elbow below a nozzle of an overflow dyeing machine, and the metal elbow is about 3-4cm away from the elbow wall, so that effective cross sectionarea of the cloth incoming elbow can be reduced, guiding and constraining control effect on the fabric is improved, and the fabric is prevented from being twisted to be vertical-strip-shaped during dyeing.

Owner:FUJIAN SUNTION TEXTILE SCI & TECH +1

Side-slot-reinforced leading-in optical cable and production process

InactiveCN105866908AIncrease wall thicknessHigh strengthFibre mechanical structuresStress concentrationUltimate tensile strength

The invention provides a side-slot-reinforced leading-in optical cable and a production process. The side-slot-reinforced leading-in optical cable comprises an optical fiber, a sheath and reinforcement pieces and is characterized in that the playground type sheath covers the outer side of the optical fiber; diagonal side slots are formed in straight side surfaces of the playground type sheath and are triangular slots; the optical fiber is arranged at the center of the playground type sheath; the reinforcement pieces are placed on the circular ends of the playground type sheath and are symmetrically arranged on the two sides of the optical fiber. According to the side-slot-reinforced leading-in optical cable and the production process, the utilized side slots are diagonally staggered, and a stress centralizing point avoids the optical fiber, so that walls on the two sides of the optical fiber are thickened; the optical fiber is protected, the integral wall thickness of the optical cable is increased, and the improvement on the integral strength of the optical cable is ensured; by means of the designed staggered side slots, tearing of slotted parts due to the weight outdoors for a long term can be avoided; according to application environments, the tearing force of the optical cable can be freely controlled; the effective section area is further shortened, and the utilization rate of materials is further increased; a prefabricated end forming process and the traditional butterfly-shape leading-in optical cable are not different and can match with the existing devices.

Owner:SHENYANG HENGTONG OPTICAL COMM CO LTD

Personal support device with elongate inserts

PendingUS20210059441A1Increase likelihoodReduce the effective cross-sectional areaPillowsDwelling equipmentClassical mechanicsEngineering

Owner:INNOVATIVE BEDDING SOLUTIONS INC

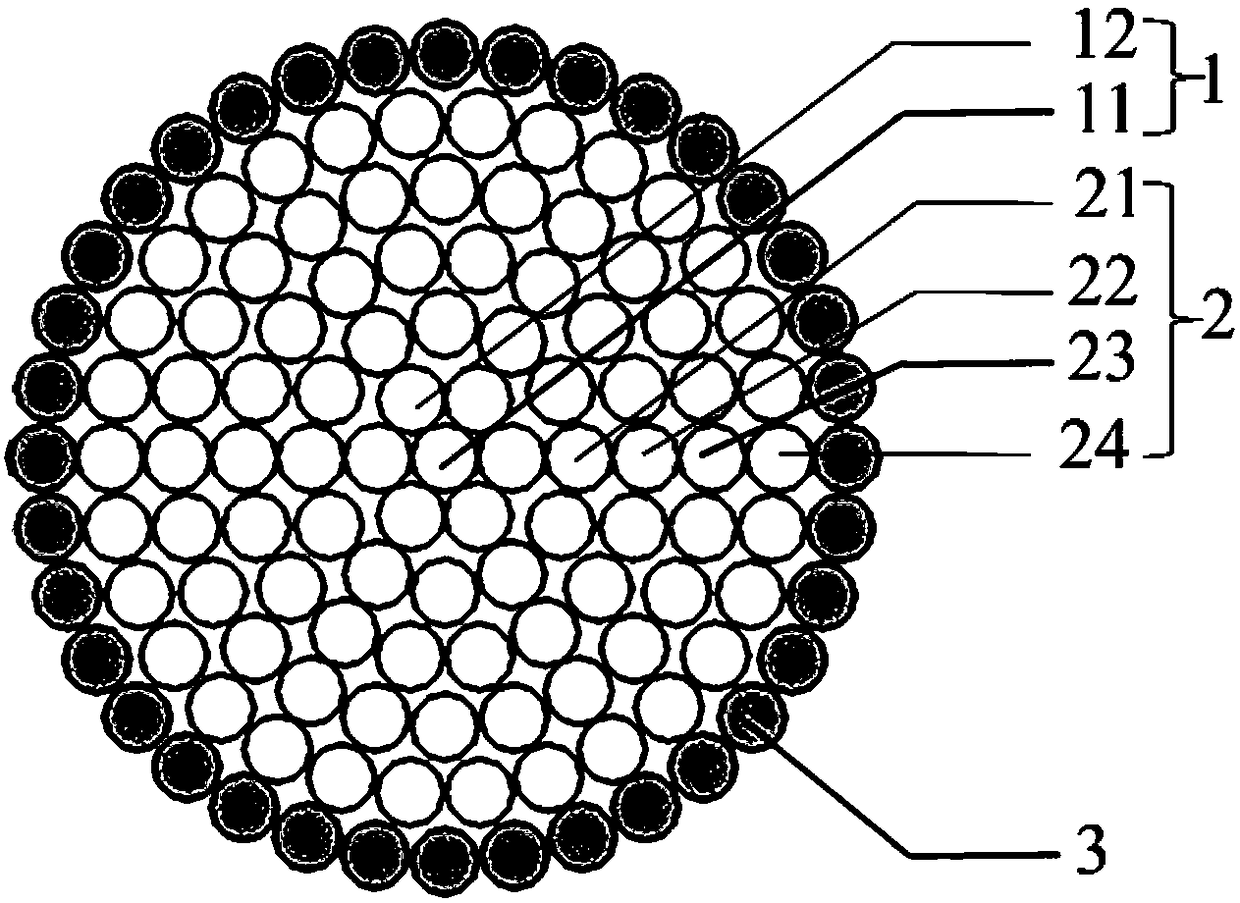

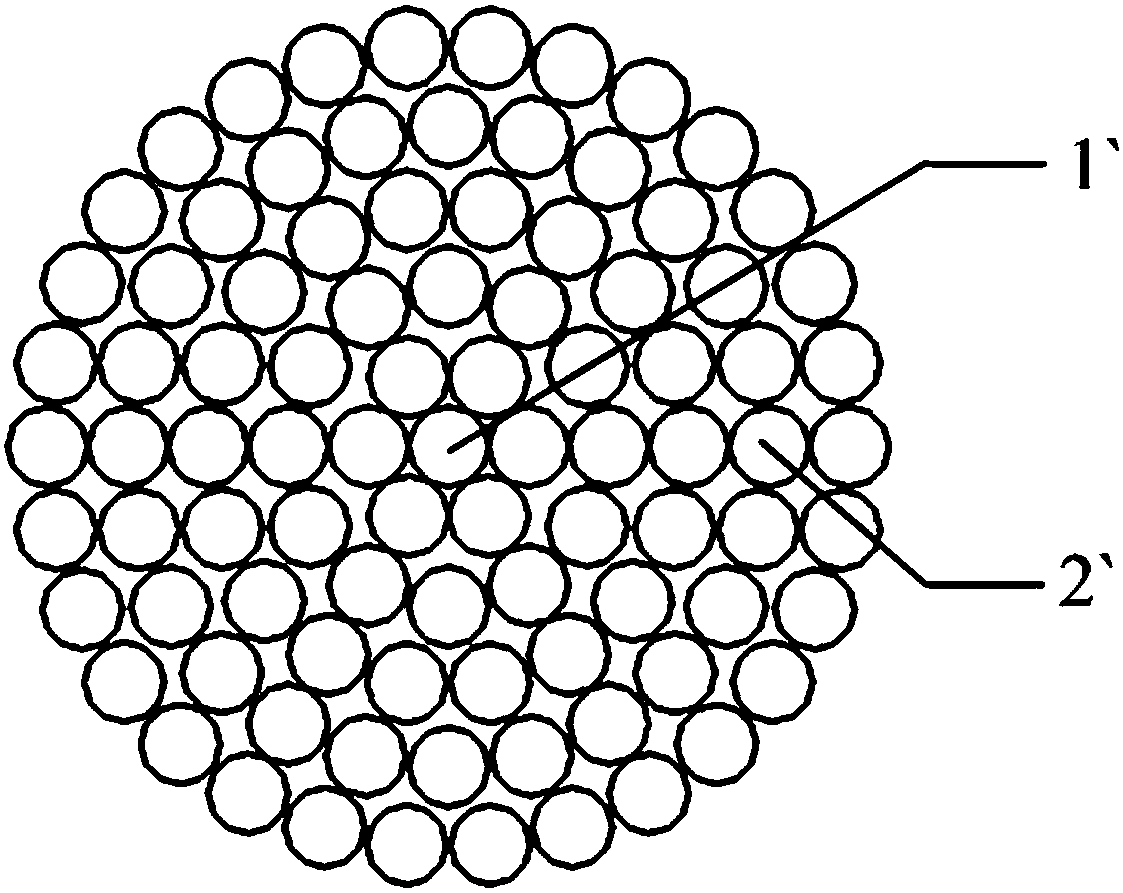

Special high-efficiency and energy-saving enameled and stranded wire cable and manufacturing method thereof

InactiveCN103531274AIncrease girthTotal girth increaseCommunication cablesInsulated cablesSocial benefitsElectrical resistance and conductance

The invention discloses a special high-efficiency and energy-saving enameled and stranded wire cable and a manufacturing method thereof. The cable is a novel product capable of increasing the perimeter of the cross sections of conductors, and the manufacturing method is a novel method. The technical means such as hole shrinkage, root increase, ellipse perimeter increase and insulation and isolation perimeter increase are adopted on the basis of the prior art, so that the perimeter of the conductors is increased greatly. Particularly, in a stranded wire range, the perimeter of the total cross sections of the conductors is increased greatly, so that the surface areas of the conductors are increased greatly, the heat dissipation efficiency of the conductors is improved, the resistance of the conductors is reduced, the conduction efficiency of the conductors is improved greatly, the line loss is reduced, the voltage quality is improved, a raw material is saved, and the electric energy is saved. Figure 10 is effect representation after three technical measures are taken. A rule is found that the maximum alternating current allowed to pass through the conductors is directly proportional to the perimeter of the cross sections of the conductors. The rule is a great discovery in physics; a theoretical foundation is laid for researching and developing the wire cable and more efficiently utilizing the electric energy; and the wire cable and the method have significant economic and social benefits.

Owner:陈胜民

Carburetor

InactiveUS7278629B2Easy complianceIncrease productionLighting and heating apparatusUsing liquid separation agentLow speedEngineering

A flow rate control mechanism is provided to a low-speed fuel system that is independent from the main fuel system of a carburetor. The mechanism causes the valve element to move in a linear fashion by means of a cam coupled to the throttle stem. The mechanism increases the effective cross-sectional area of the low-speed fuel channel as the throttle valve opens from the idle position to the maximum degree of opening until the point in time at which the main fuel begins to flow, and thereafter causes the low-speed fuel flow rate to decrease and become zero in the high-output region. The transition from low-speed fuel to main fuel is made smooth, ensuring higher output and a stable fuel flow rate in the high-output region.

Owner:ZAMA JAPAN

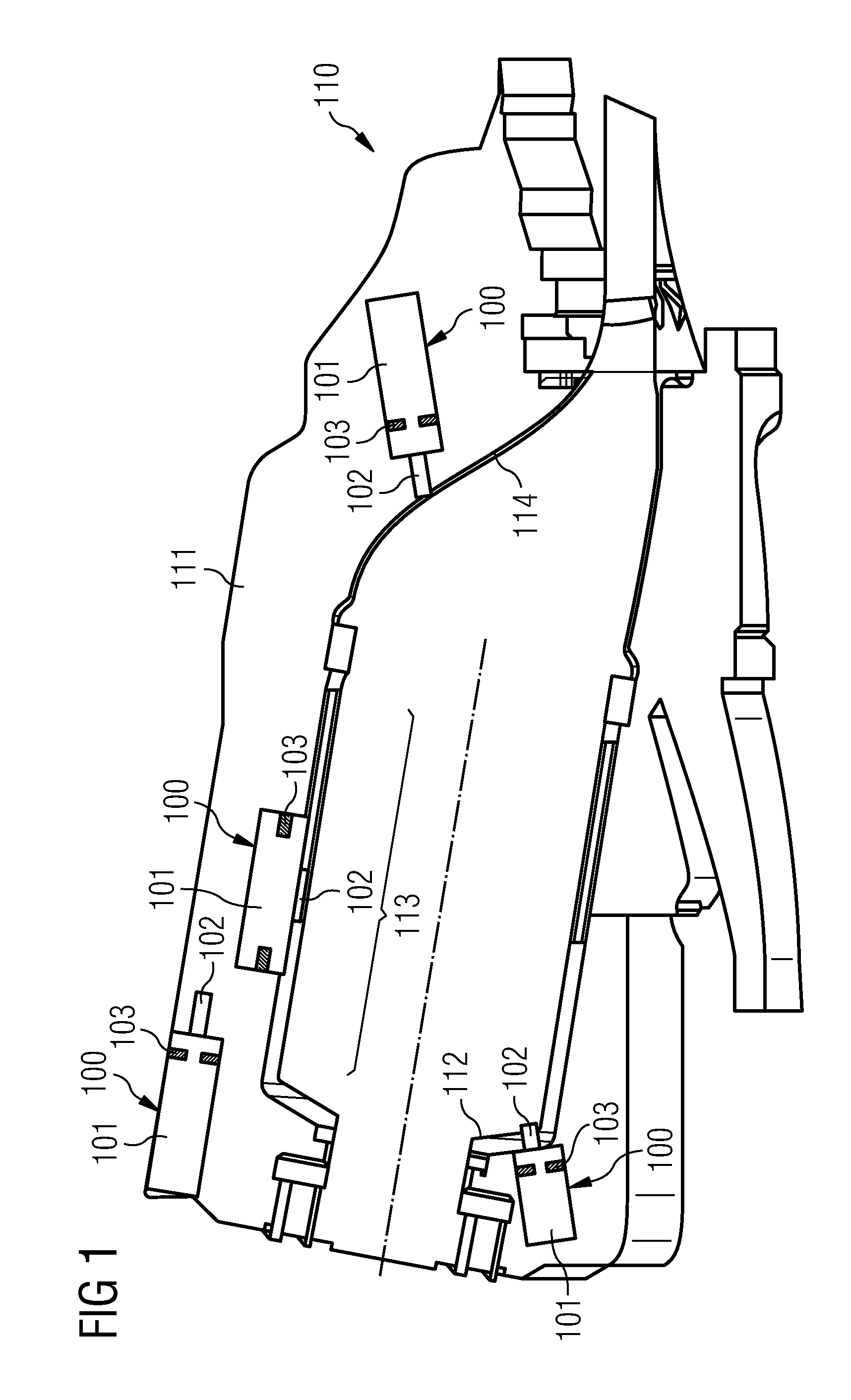

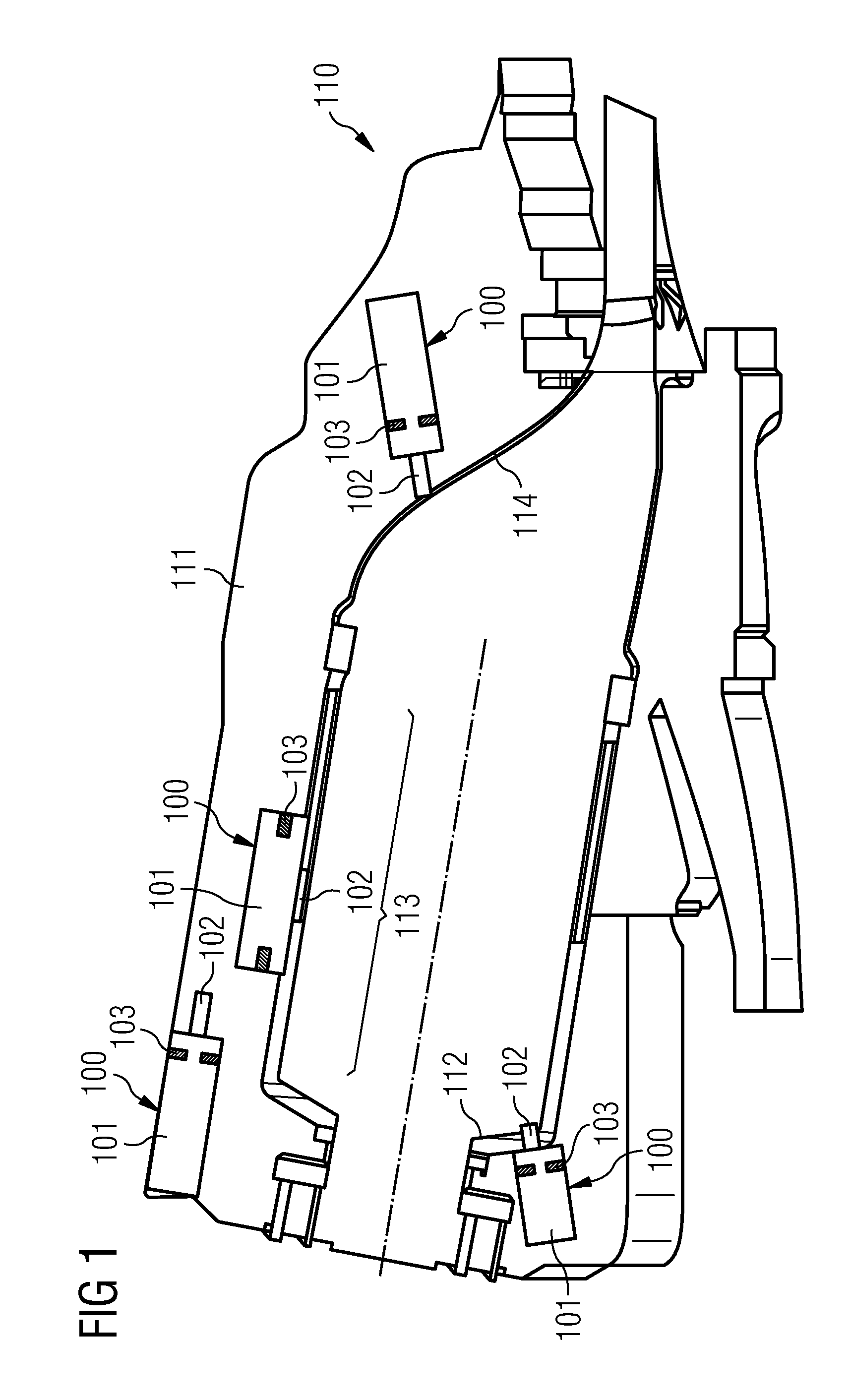

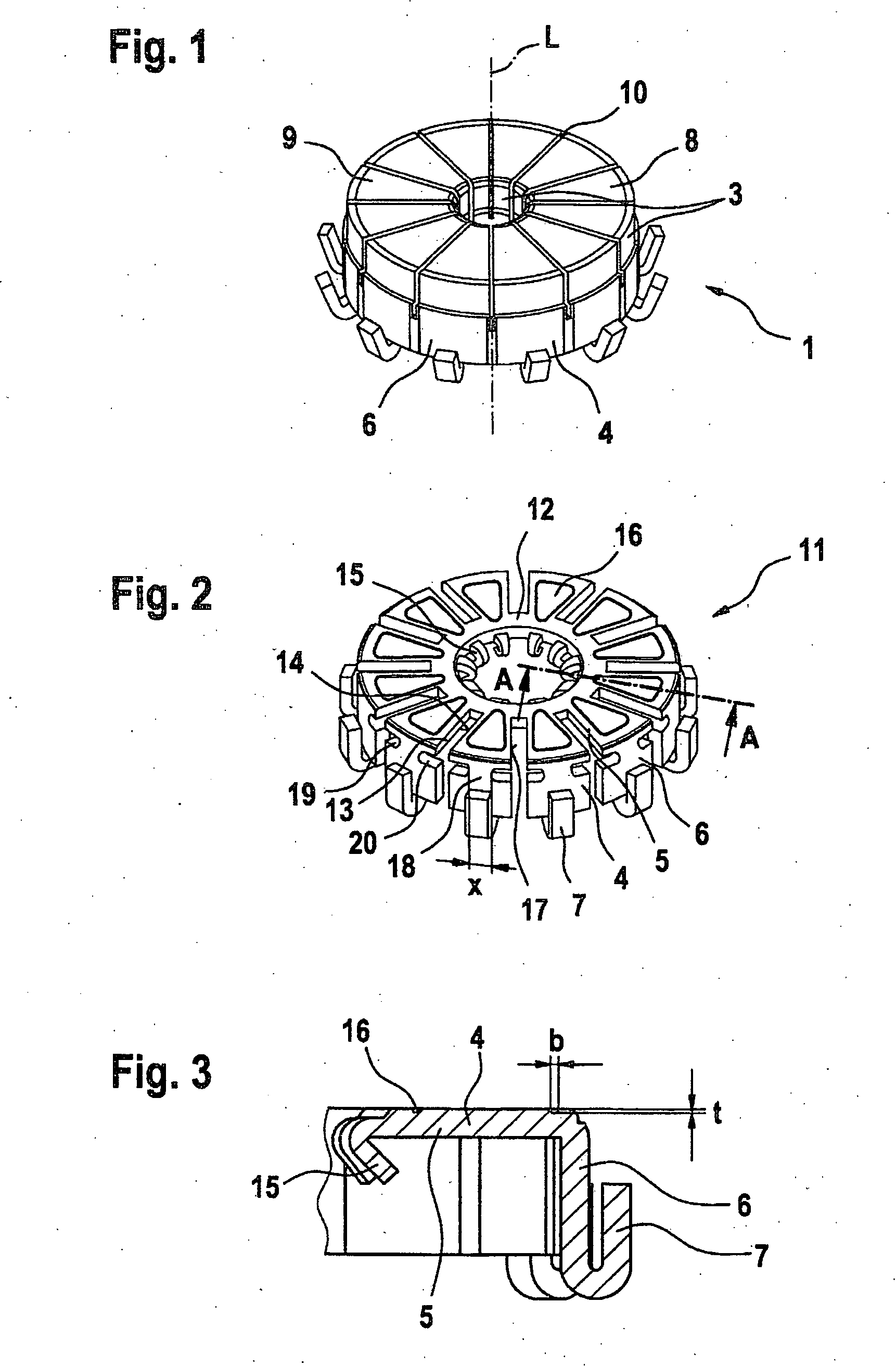

Commutator for an electrical machine

ActiveUS20100019615A1Avoid flowSufficient holdElectrically conductive connectionsRotary current collectorConductor CoilMechanical engineering

The invention relates to a commutator with contact segments, arranged at a distance from each other and forming a brush running surface. Each contact segment is soldered to a securing portion of a metal segment support piece. The commutator has a hub body made from an electrically insulating material which supports the segment support pieces which are each provided with a winding connector hook. According to the invention, at least one solder barrier recess is provided in the upper side of the securing portion facing the contact segment and / or in the under side of the contact segment facing the securing portion.

Owner:ROBERT BOSCH GMBH

Single special-shaped efficient energy-saving electric wire

InactiveCN103545037AIncrease the effective resistanceLow conductivityInsulated cablesPower cablesSocial benefitsElectrical resistance and conductance

The invention discloses a single special-shaped efficient energy-saving electric wire with changed section perimeter. Effective resistance of a circular wire is increased by the skin effect of the alternating current, according to the newly discovered theory that the allowed largest current in a conductor is in direct proportion to the section perimeter of the conductor, the section perimeter of the wire needs to be increased while the sectional area of the wire is unchanged, the section perimeter of the elliptical wire is larger than the circular wire with the same section, so that the circular wire is changed into the elliptical wire. Due to the fact that the section perimeter and the surface area of the elliptical wire are increased, effective resistance is reduced, conductivity of the wire is increased, conducting efficiency of the wire is increased, and the wire has significant economical and social benefits.

Owner:陈胜民

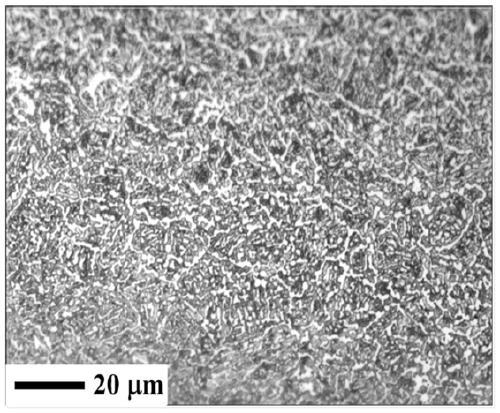

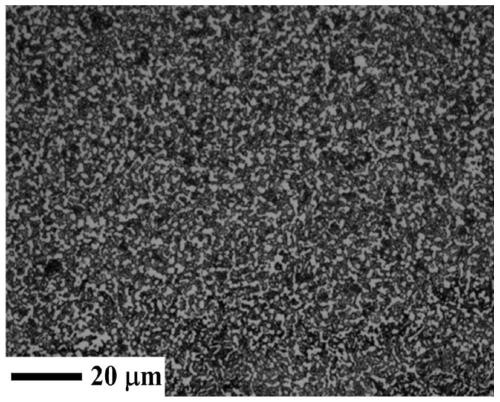

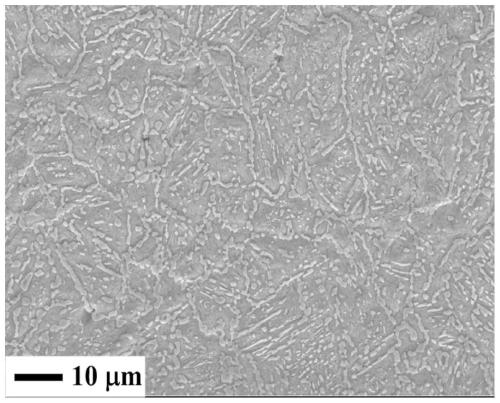

Carburizing method capable of inhibiting high-chromium high-cobalt carburizing steel network carbide structure and increasing carburizing speed

ActiveCN109735796AIncrease carburizing speedAvoid Carbide NetworksVacuum evaporation coatingSputtering coatingCarbideCobalt

The invention discloses a carburizing method capable of inhibiting a high-chromium high-cobalt carburizing steel network carbide structure and increasing the carburizing speed, and relates to the field of material surface heat treatment. The technical problems that a network carbide structure is prone to occurring to existing high-chromium high-cobalt carburizing steel, and thus, a material is high in brittleness and poor in fatigue resistance need to be solved. The method comprises the steps that 1, a metal film is plated on the surface of high-chromium high-cobalt carburizing steel; and 2, the film plated workpiece is subjected to carburizing. Through the carburizing method, a carburizing layer structure of which the carburizing layer is free of the network carbide structure is obtained,and carbide is uniformly distributed in the carburizing layer. The technical problem that the network carbide structure is prone to occurring during high-alloy steel carburizing is solved. The carburizing method is applied to the field of aircraft bearing gears.

Owner:HARBIN INST OF TECH

Apparatus and method for modifying a combustor nozzle

InactiveUS20120088201A1Reduce effective cross-sectional areaReduce the effective cross-sectional areaContinuous combustion chamberGaseous fuel burnerEngineeringNozzle

A combustor nozzle includes a nozzle body that defines a cavity. An orifice in the nozzle body provides fluid communication from the cavity through the nozzle body. A movable barrier proximate to the orifice has a first position in which the movable barrier at least partially obstructs the orifice. A method for supplying fuel to a combustor includes flowing fuel through an orifice in a nozzle, determining a reactivity of the fuel, and adjusting an effective cross sectional area of the orifice based on the reactivity of the fuel.

Owner:GENERAL ELECTRIC CO

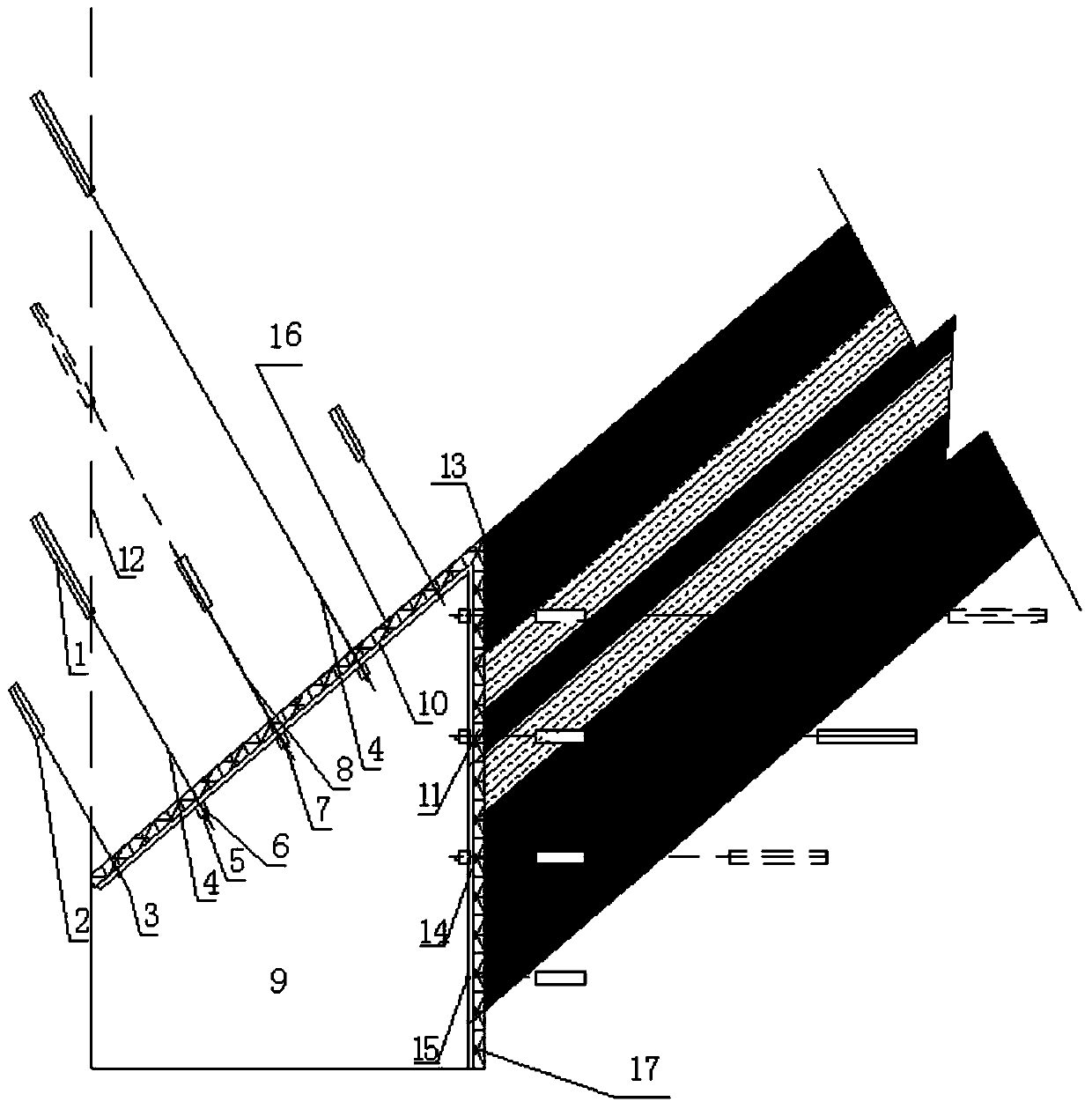

Advance support structure of large dip angle coal mining face

ActiveCN105484760BReduce labor intensityReduce the effective cross-sectional areaUnderground chambersTunnel liningEngineeringCoal mining

The invention relates to the field of coal mining methods, in particular to a forepoling structure of a large-dip-angle coal face. The forepoling structure of the large-dip-angle coal face is safe and efficient. According to the technical scheme, the forepoling structure of the large-dip-angle coal face comprises a special-shaped section, a top plate and an upper edge plate; the top plate is arranged at the top of the special-shaped section, and the upper edge plate is arranged on one side of the upper edge of the side wall of the special-shaped section; the top plate is fixedly connected with an anchor cable anchoring segment through a reinforcing anchor cable and a middle anchor cable and also fixedly connected with an anchor rod anchoring segment through a top plate anchor rod; the upper edge plate is fixedly connected with an upper edge anchor cable through an upper edge anchor rod; the top plate and the upper edge plate intersest at the surface intersection line between the top plate and the upper edge of a roadway. The method creates more favorable conditions for high yield and high efficiency and is particularly suitable for the forepoling structure of the large-dip-angle coal face.

Owner:四川川煤华荣能源有限责任公司花山煤矿

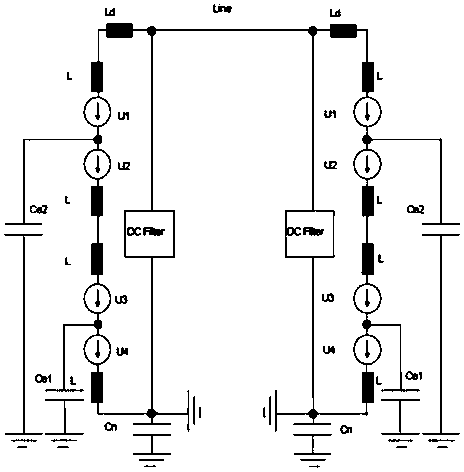

High-voltage direct current transmission conductor

PendingCN108565062AThe effective cross-sectional area is reducedIncrease the equivalent resistanceNon-insulated conductorsPower cables for overhead applicationEngineeringHigh pressure

The present invention discloses a high-voltage direct current transmission conductor. The conductor comprises a strengthening core, an inner current carrying layer twisted at the outer surface of thestrengthening core and an outer current carrying layer twisted at the outer surface of the inner current carrying layer; the strengthening core is made by twisting one or more than one mongline, the inner current carrying layer is made by twisting a plurality of conductor monglines, the outer current carrying layer is made by twisting a plurality of metal monglines, and the skin depth of the metalmonglines is smaller than the skin depth of the conductor monglines. The high-voltage direct current transmission conductor can effectively inhibit the harmonic current, can improve the current carrying amount of the transmission conductor and can facilitate remote transmission.

Owner:CHINA SOUTH POWER GRID ELECTRIC POWER RES INST +1

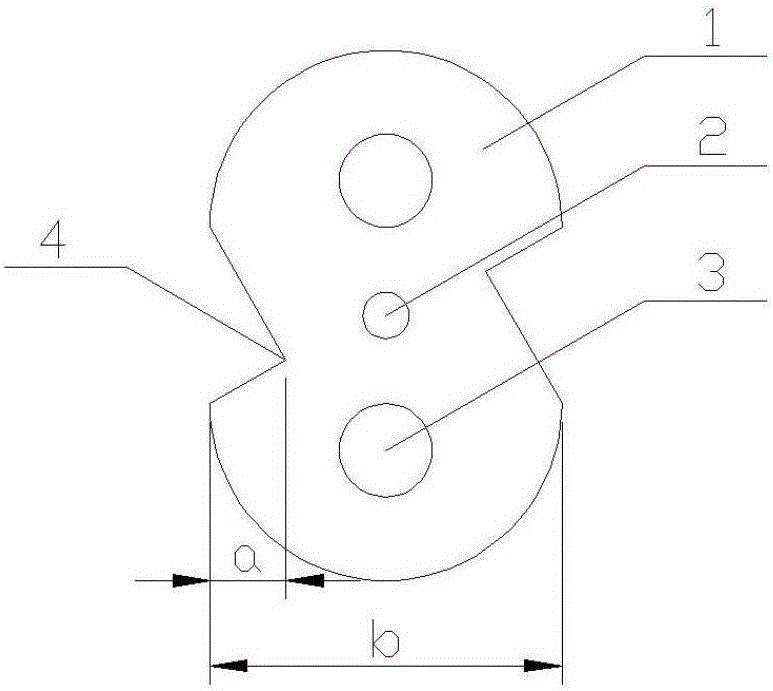

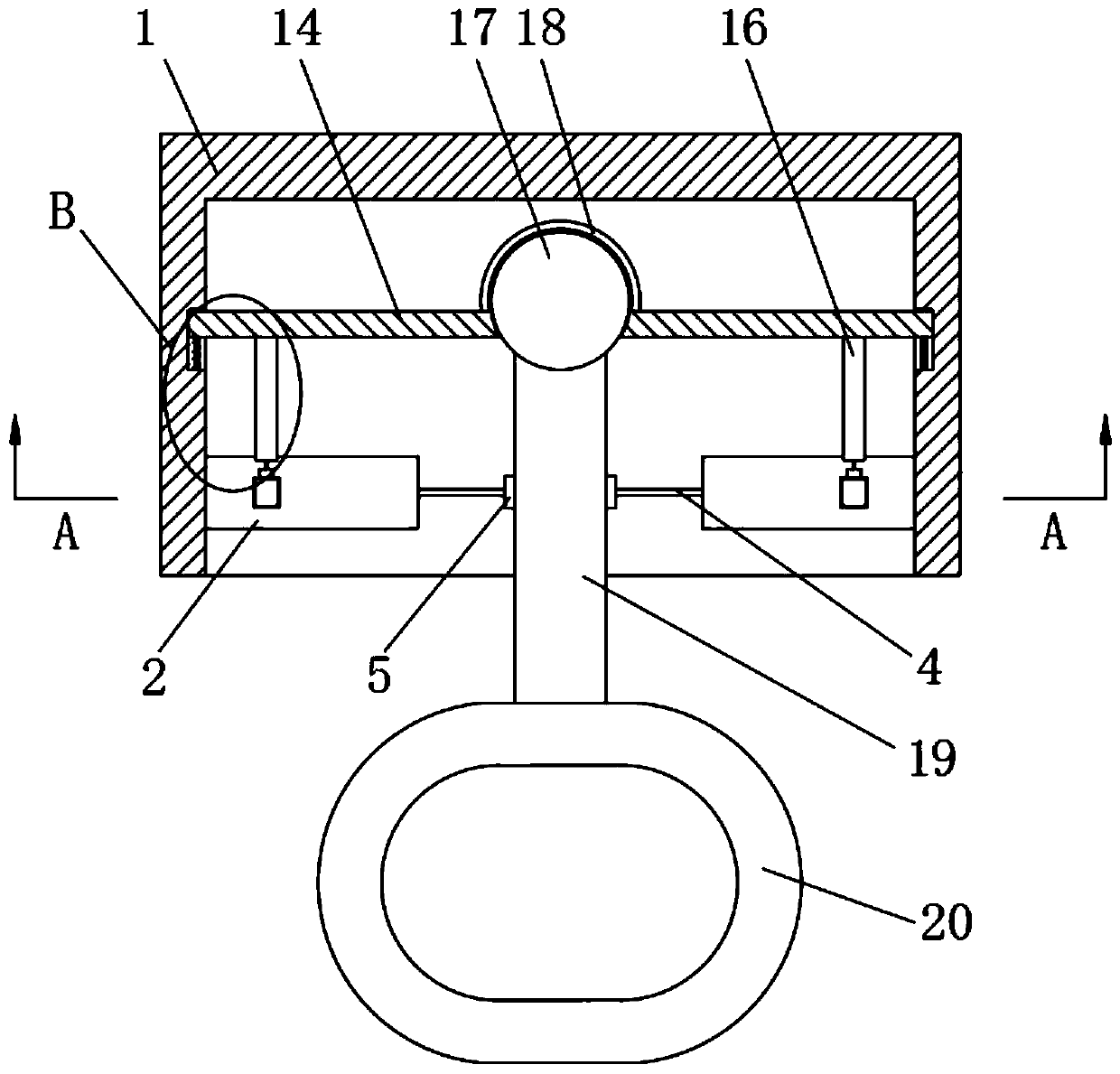

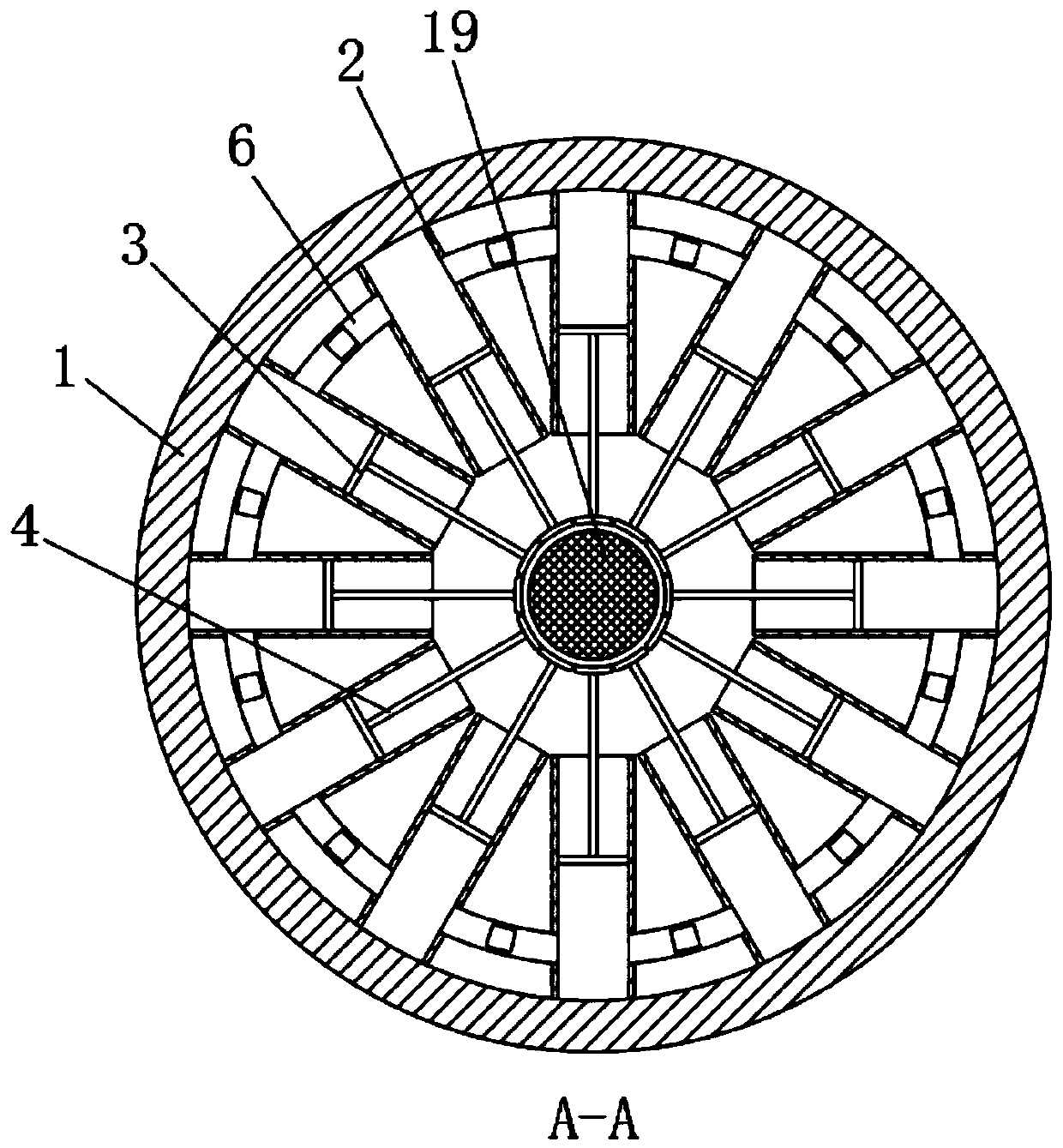

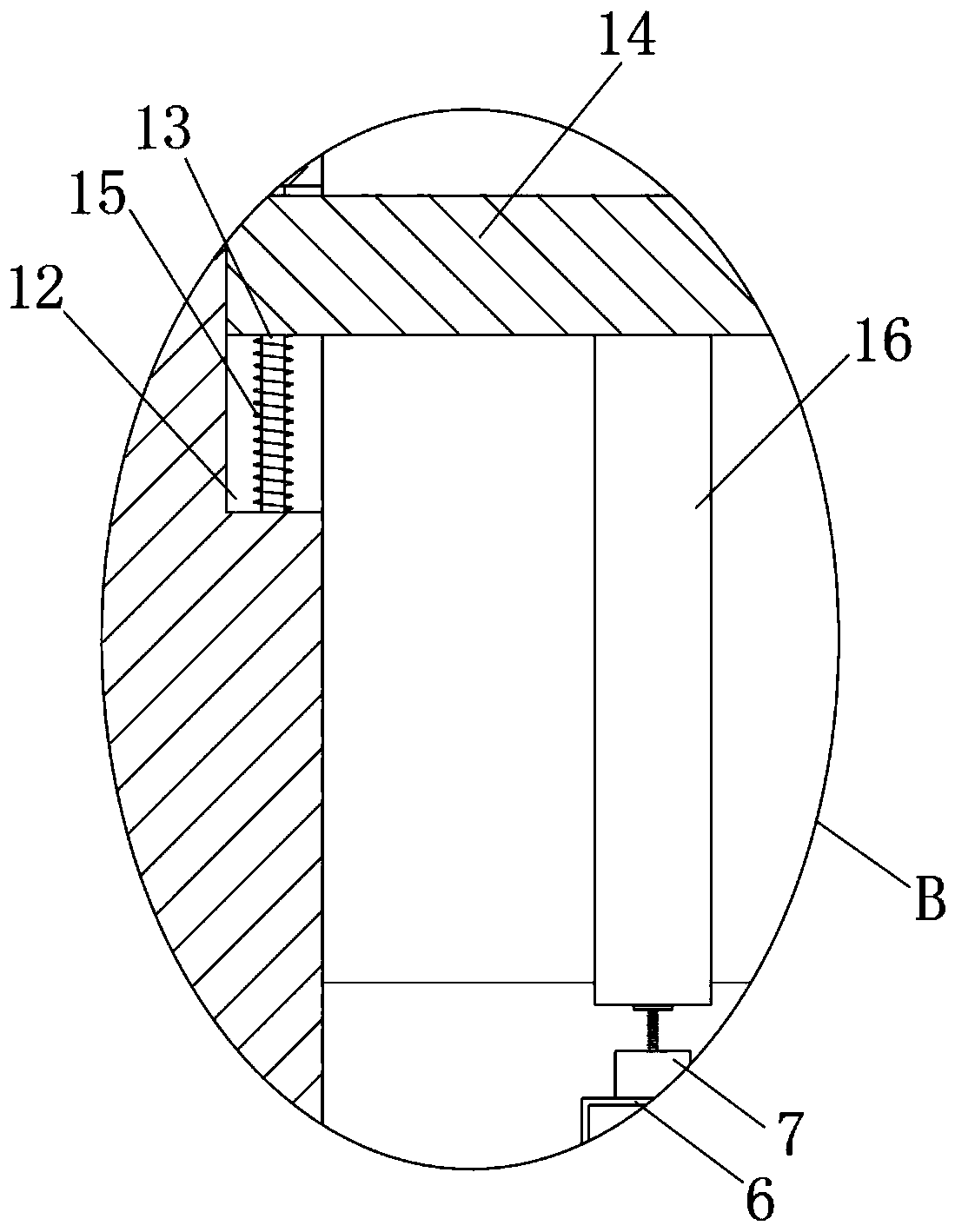

An anti-sudden braking bus hoisting ring

ActiveCN109532610BAvoid falling situationsReduce the effective cross-sectional areaVehicle arrangementsStructural engineeringMechanical engineering

The invention discloses an anti-emergency-brake bus lifting ring. The lifting ring comprises a shell, wherein the shell is of a circular barrel-shaped structure; a plurality of cylinders are symmetrically arranged on the inner wall of the shell, a piston is hermetically and slidably connected to the inner wall of each cylinder, and each piston is fixedly connected with a push rod; the side, away from the corresponding piston, of each push rod is fixedly connected with an arc-shaped plate. The lifting ring has the advantages that when a bus takes a sudden turn and brakes, a standing passenger can tightly hold and pull a holding ring with force subconsciously, a round plate is driven to move downwards to make a straight rod extrude a baffle, and a U-shaped plate extends into a hard tube, sothat the effective cross-sectional area of liquid flowing in the straight rod and the hard tube is reduced, and the amount of a fluid which can flow through in unit time in the hard tube is greatly reduced, that is, the fluid in each cylinder cannot be rapidly circulated. Therefore, the holding ring generates large supporting force on the hands of the passenger, and the situation that the passenger falls down is avoided.

Owner:临沂临港经济开发区市政工程有限公司

Carburetor

InactiveUS20050035471A1Easy complianceIncrease productionLighting and heating apparatusUsing liquid separation agentLow speedEngineering

A flow rate control mechanism is provided to a low-speed fuel system that is independent from the main fuel system of a carburetor. The mechanism causes the valve element to move in a linear fashion by means of a cam coupled to the throttle stem. The mechanism increases the effective cross-sectional area of the low-speed fuel channel as the throttle valve opens from the idle position to the maximum degree of opening until the point in time at which the main fuel begins to flow, and thereafter causes the low-speed fuel flow rate to decrease and become zero in the high-output region. The transition from low-speed fuel to main fuel is made smooth, ensuring higher output and a stable fuel flow rate in the high-output region.

Owner:ZAMA JAPAN

A kind of manufacturing process of wrinkle-feeling gutless anti-velvet fabric

ActiveCN110761025BEnhance downproof performanceReduce the effective cross-sectional areaLiquid/gas/vapor treatment of propelled fabricsLiquid/gas/vapor removalMechanical engineeringCalendering

The invention provides a manufacturing process of a wrinkle-free fleece-proof fabric, which relates to the field of fabric production; the process flow of the invention is: desizing-blank setting-calendering-dyeing and wrinkling-setting drying-water-splashing setting-forming Inspection, that is, dyeing and wrinkling after calendering, after wrinkling, no need to perform anti-down calendering to meet the down-proof requirements, solve the problem of dyeing and wrinkling in the prior art, and then repeatedly anti-down calendering, so that the cloth surface is covered High-temperature flattening makes the wrinkle of the fabric uneven or due to calendering in order to achieve the anti-down effect of the fabric, thereby destroying the wrinkle of the surface of the fabric; The metal elbow with the same curvature as the cloth inlet elbow is installed on the inner wall of the cloth inlet elbow, and the metal elbow is designed to be 3 to 4 cm away from the pipe wall, which can reduce the effective cross-sectional area of the cloth inlet elbow and increase the The guiding and tightening control function of the fabric prevents the fabric from being twisted into vertical strips during dyeing.

Owner:FUJIAN SUNTION TEXTILE SCI & TECH +1

Anti-rolling tank control device

ActiveCN101624087BIncrease the effective cross-sectional areaReduce the effective cross-sectional areaVessel movement reduction by mass displacementMarine engineeringControl signal

An anti-rolling water tank control device mainly solves technical problems such as improving ship anti-rolling effect. There is a throttling component on the second channel, the second component is connected to a controller, the controller is connected to a detector, the detected ship swing period signal is input to the controller, and the control signal is output to the second throttling component according to the set rules. The flow assembly adjusts the effective cross-sectional area of the second throttling channel to realize the water level alternation period of the U-shaped anti-rolling tank which is the same as the ship's swaying period, and is suitable for various U-shaped anti-rolling tanks.

Owner:SHANGHAI HUNTER MARINE EQUIP CO LTD

Chemical treatment and processing method of overrunning clutch wedge

ActiveCN102689144BReduce the effective cross-sectional areaMeet the precision requirementsExtrusion diesChemical treatmentBall bearing

The invention relates to an overrunning clutch, and in particular relates to a chemical treatment and processing method of an overrunning clutch wedge... The wedge provided by the invention has high production precision so as to prolong the service life of the clutch. The method comprises the following steps of: carrying out cold drawing and cutting to produce a wedge with the margin being 0.02-0.04mm on the single side by using ball bearing steel; polishing after vacuum hardening and tempering, and removing the oil stain and edge on the surface; carrying out acid corrosion on the wedge; disacidifying the wedge after acid corrosion; carrying out rustproof treatment; and molding the wedge after rustproof treatment by using an extruder, thus finishing the chemical treatment and processing of the overrunning clutch wedge.

Owner:XIAMEN UNIV

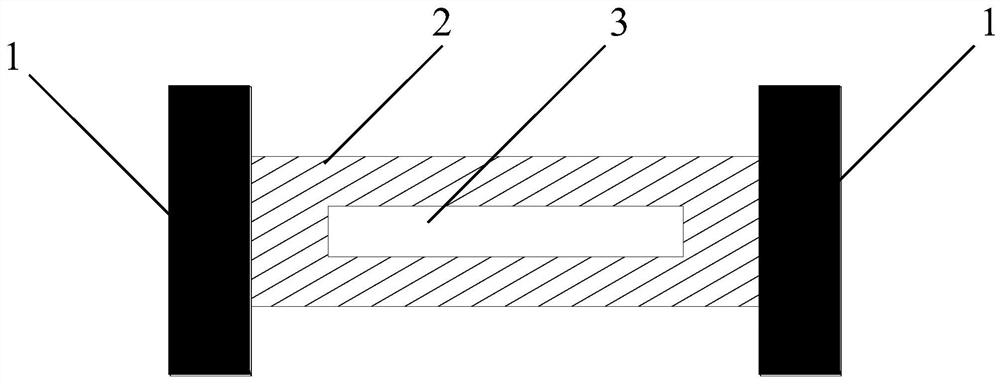

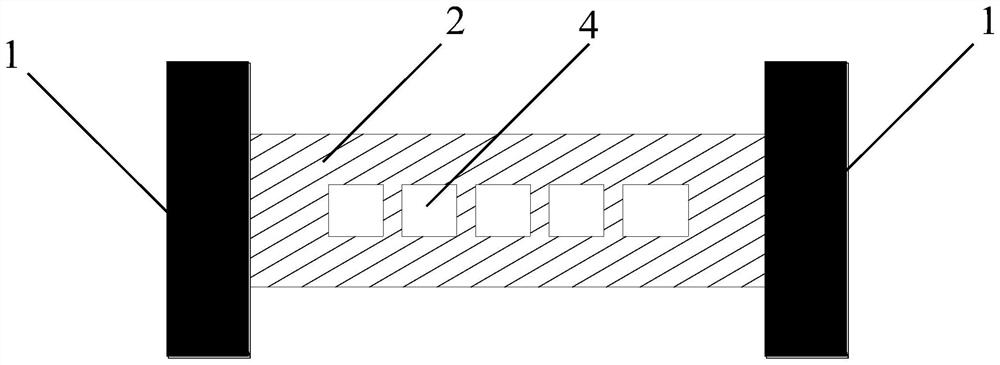

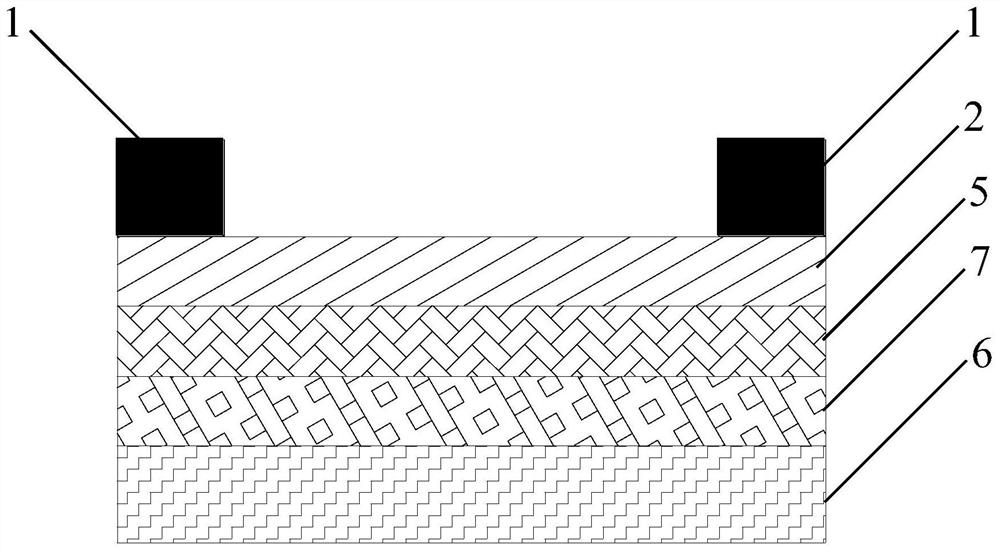

A photodetection structure based on perovskite nanowires

ActiveCN110224068BEnhanced couplingEasy to separateSolid-state devicesSemiconductor/solid-state device manufacturingNanowirePerovskite (structure)

The invention relates to the technical field of photodetection structures, in particular to a photodetection structure based on perovskite nanowires, including electrodes, perovskite nanowires with gaps, a silicon dioxide layer, and a silicon substrate layer. A silicon dioxide layer is placed on a silicon substrate layer, a perovskite nanowire with a gap is placed on the silicon dioxide layer, and electrodes are loaded on both ends of the perovskite nanowire with a gap. The perovskite nanowires with gaps can enhance the light absorption and reduce the cross-sectional area of the current, thereby improving the detection sensitivity.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com