Patents

Literature

189results about How to "Less dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation curable nail coatings and artificial nail tips and methods of using same

InactiveUS6803394B2Sufficient viscosityReduce sensitivityCosmetic preparationsImpression capsPhotoinitiatorViscosity

A composition for actinic radiation curable nail coatings and artificial nail tips comprising a BISGMA based urethane resin, an additional polymer, a photoinitiator, and having a viscosity of greater than approximately 80,000 cps. Composition may additionally comprise other additives known in the art and also methods of application of the composition alone and with related compositions.

Owner:CREATIVE NAIL DESIGN SYST INC

Tobacco sheet producing process using improved paper making method

ActiveCN101011182AProminent smoke and smoke smellWoody smell is not obviousTobacco preparationPaper forming aids additionSlagUltra fine

The invention relates to a method for producing the tobacco sheet via improved paper making method, which comprises that preparing the tobacco slag, tobacco powder and ash via grinding machine to the tobacco powder at 60-80 deals and the ultra-fine tobacco powder at 120-800 deals; immerging the tobacco stem in water for 1-2 hours, separating the solid and liquid, concentrating the extractive solution into 15-25 degree / Be', adding the ultra-fine tobacco powder at 5-30% of the weight of concentrated solution, to obtain the coat liquid of sheet; the solid extracted from the tobacco stem is decomposed to prepare pulp, to be mixed with external pulped fiber, adjusting the density to 0.05-0.8%, to be mixed with the tobacco powder at 60-80 deals; preparing via paper machine, compressing, dewatering, drying to obtain the base sheet; immerging and coating the base sheet in the coat liquid, drying, breaking to obtain the final product. The invention can improve the smell of sheet tobacco.

Owner:CHINA TOBACCO HUNAN INDAL CORP

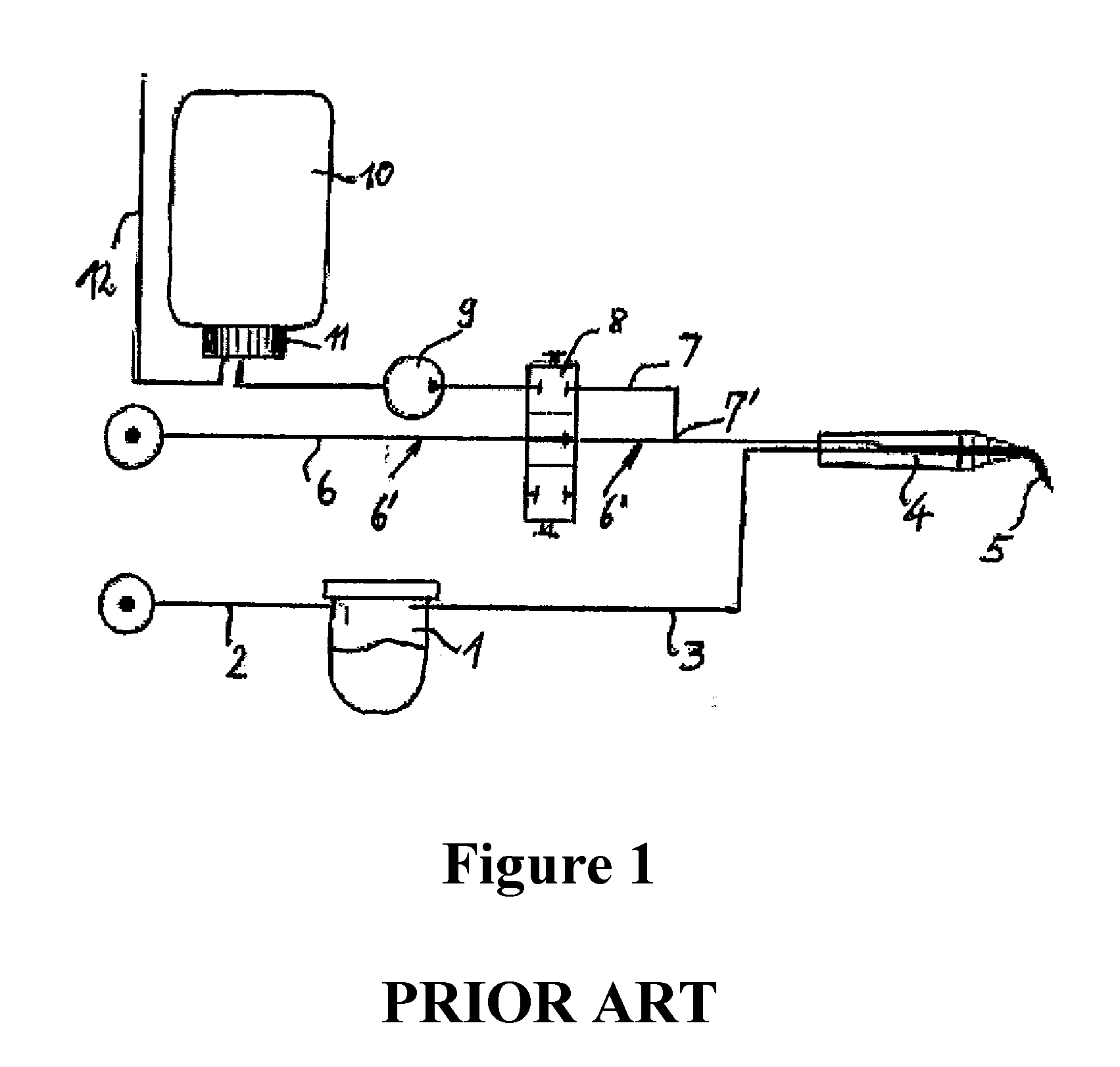

Dust Prevention And Removal Device

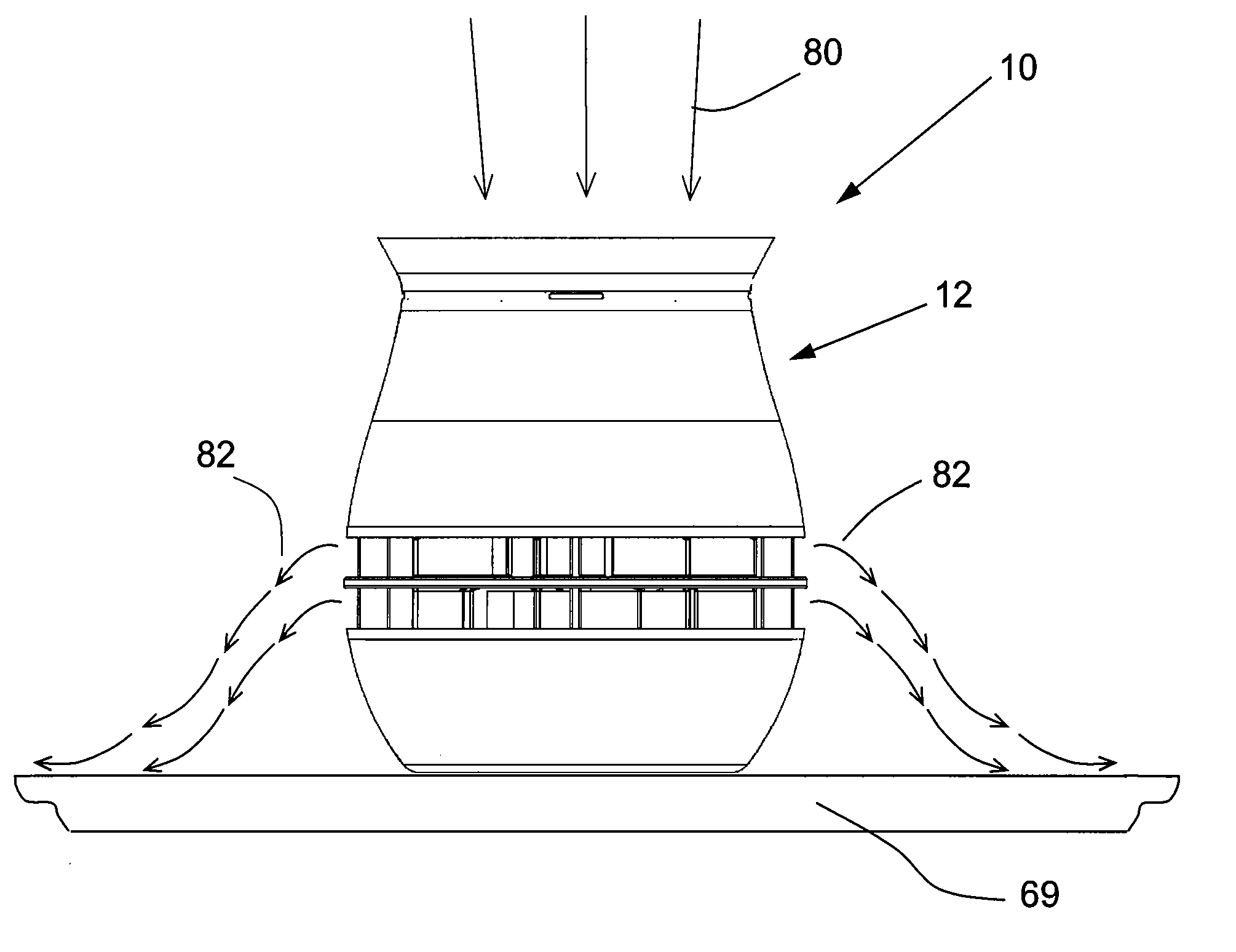

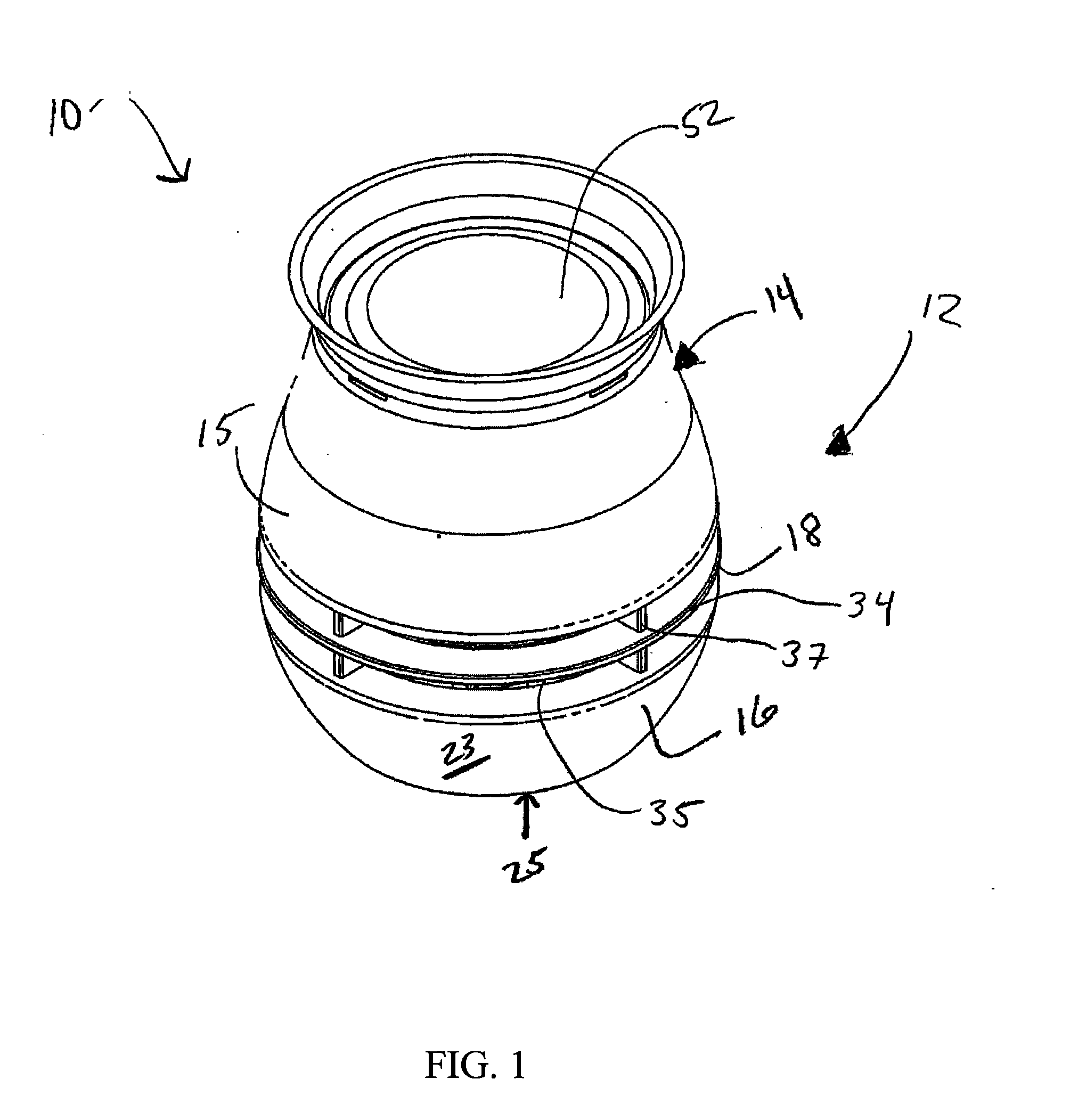

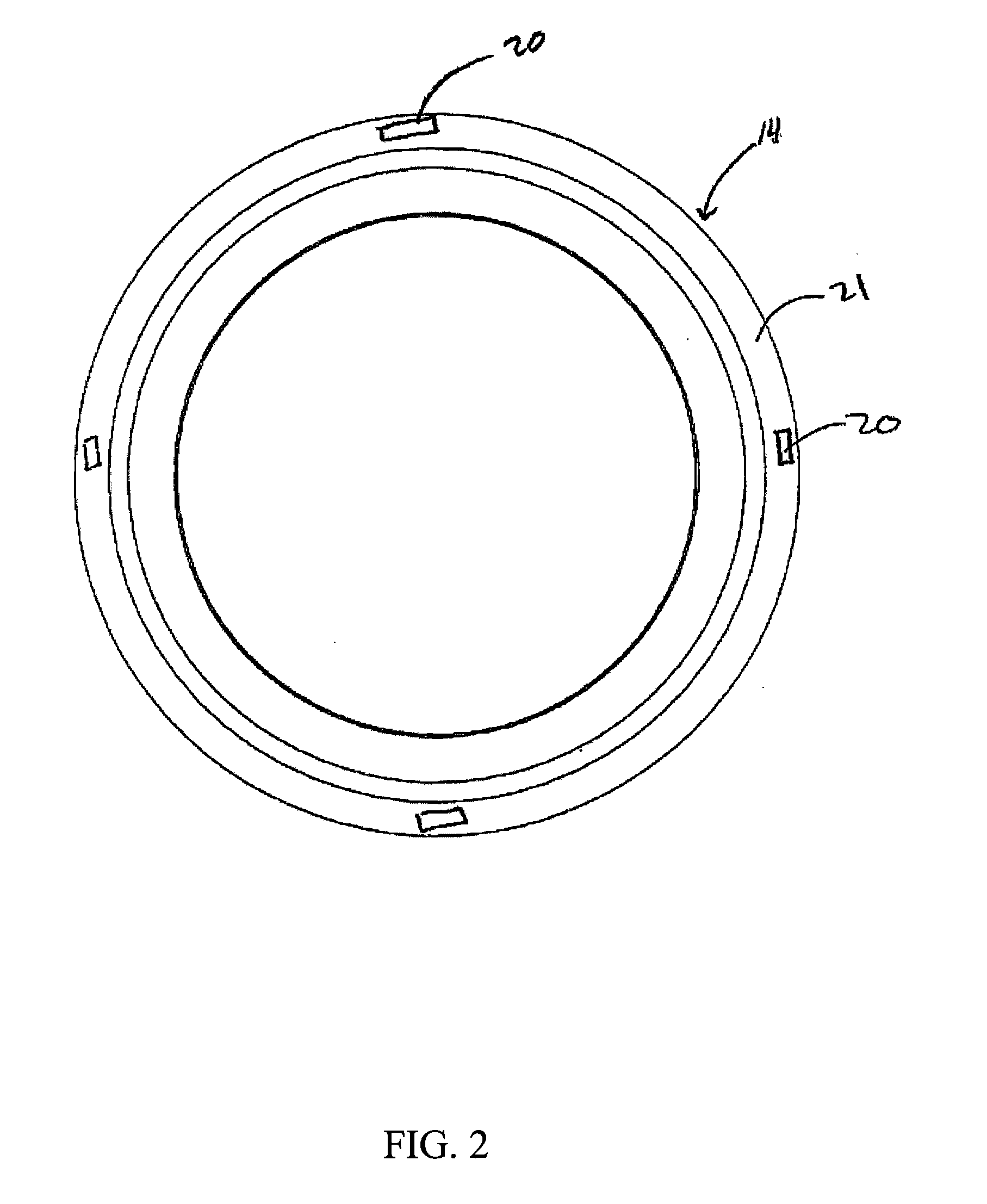

ActiveUS20100064895A1Dust lessReduce amountCombination devicesMechanical apparatusInterior spaceEngineering

A device is provided that is capable of circulating air throughout a personal space as well as collecting and preventing the build up of dust and other particulate matter by drawing in air from the surrounding environment and removing some dust, allergens and other such particulate matter therefrom. The filtered air is then expelled out of the device and back into the surrounding environment. The device includes a housing defining an interior space having a motor and fan assembly disposed therein. The housing includes an inlet with a filter provided therein such that air drawn in through the inlet is filtered. The air is then expelled through a circumferentially disposed outlet. The filter element preferably includes a lock and key system configured to prevent operation of the device in the absence of a properly keyed filter.

Owner:SC JOHNSON & SON INC

Paper making method tobacco sheet producing process using double-grid method

ActiveCN101011183AObvious style traitsShorten the timeTobacco preparationPaper forming aids additionFiberSlag

The invention relates to a method for producing the tobacco sheet via dual-mesh paper making method, which comprises that preparing the tobacco slag, tobacco powder and ash via grinding machine to the tobacco powder at 80-100 deals and the ultra-fine tobacco powder at 120-800 deals; immerging the tobacco stem in water for 1-2 hours, separating the solid and liquid, concentrating the extractive solution into 15-25 degree / Be', adding the ultra-fine tobacco powder at 5-30% of the weight of concentrated solution, to obtain the coat liquid of sheet; the solid extracted from the tobacco stem is decomposed to prepare pulp, to be mixed with external pulped fiber, to be divided into two parts to be shaped via the meshes; spraying the tobacco powder at 80-100 deals on the base sheet of one paper machine, and covering this base sheet via another wet base sheet produced by another paper machine, to obtain the composite wet base sheet; compressing, dewatering, drying to obtain the base sheet; immerging and coating the base sheet in the coat liquid, drying, breaking to obtain the final product. The invention can improve the smell of sheet tobacco.

Owner:CHINA TOBACCO HUNAN INDAL CORP

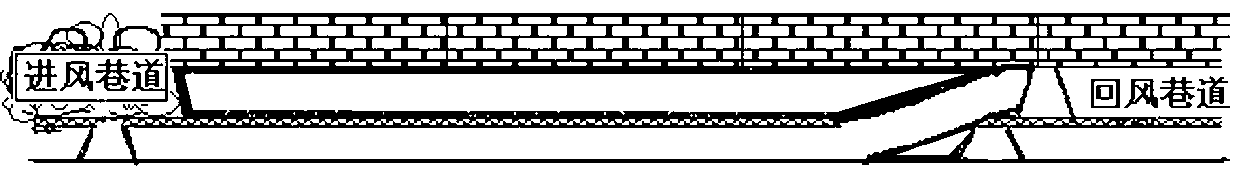

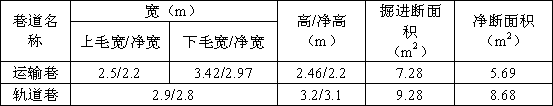

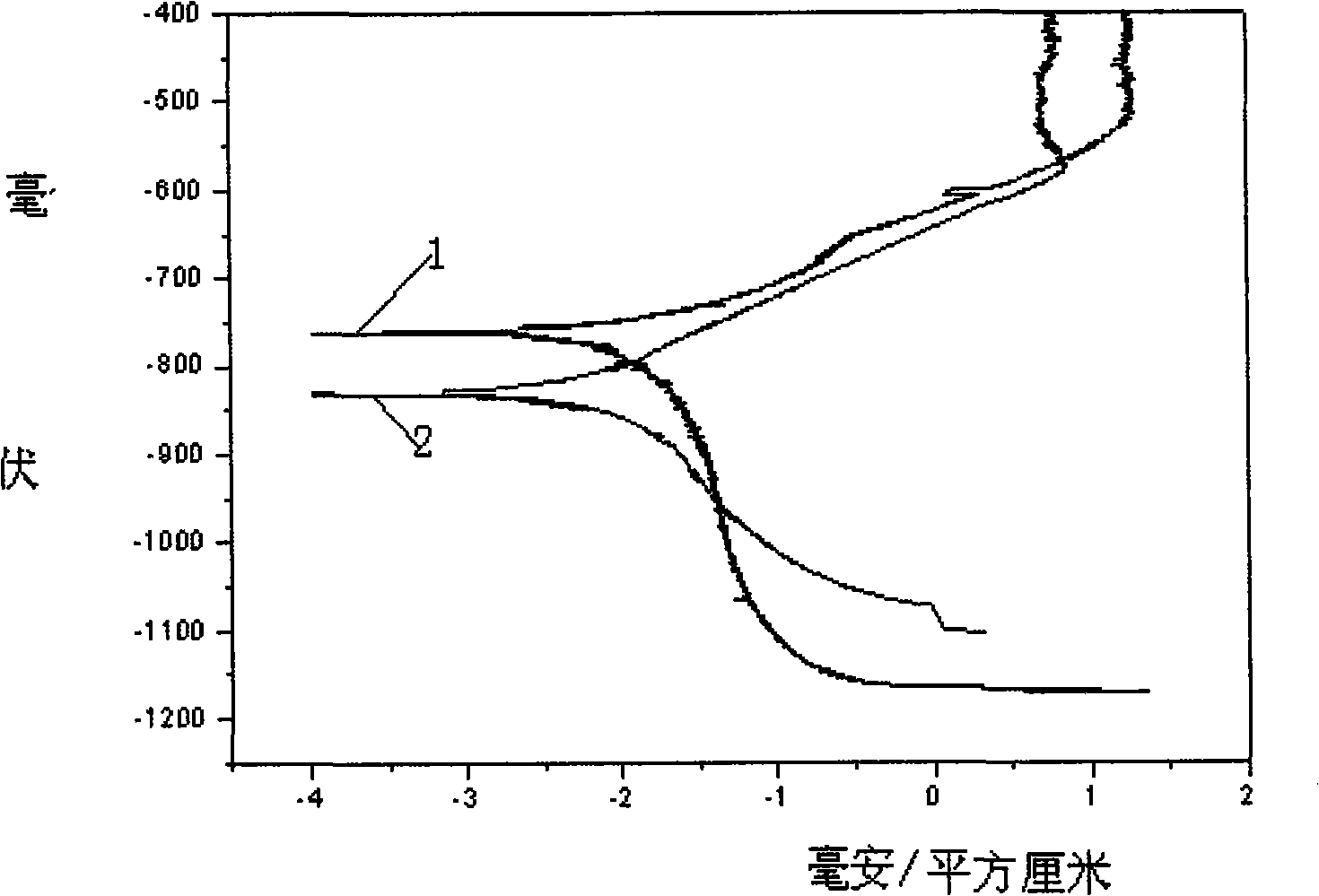

Residual coal full-mechanized repeated mining method of near-distance inflammable seam gob

ActiveCN102900438ALess dustEasy to prevent dustUnderground miningSurface miningMining engineeringResource recovery

The invention provides a residual coal full-mechanized repeated mining method of a near-distance inflammable seam gob, which aims to solve the problem of resource loss, natural inflammation and gas discharge difficulty in mining a near-distance underlying seam above which a tool post gob covers. The method comprises the following steps that: upper coal covering pillars are put when a lower seam is mined; a staggered roadway arrangement method is adopted, i.e. an air inlet transportation roadway is arranged in an underlying seam, and tunneling along with the bottom is performed; an air return transportation roadway is arranged in an upper covering seam, and tunneling along with the top is performed; and a process procedure combining a mode that one upper coal covering pillar is put while mining for twice and a mode that one upper coal covering pillar is put while mining for one time is adopted in a working plane, i.e. when the whole seam is not mined, one upper coal covering pillar is put while mining for twice, and when the whole seam is mined in different layers, one upper coal covering pillar is put while mining for one time. With the adoption of the method, the recycling of residual coal is realized while new seams are mined, so that not only is the non-renewable coal resource saved, but also the service life of a mining well is prolonged, and the resource recycling efficiency is significantly improved.

Owner:SHANXI COKING COAL GROUP +1

Environment protection heat-proof acrylic resin insulation paint

The invention discloses an environment-friendly heat-proof acrylic resin insulating coating, comprising nm inorganic modified acrylic acid latex, nm acrylic acid resin, inorganic filler, curing agent, wherein the weight ratio of nm inorganic modified acrylic acid latex, nm acrylic acid resin, inorganic filler and curing agent is 10-40:20-40:20-40:5-15. The coating has no chromate and the adhesive force thereof can be 1 lever, and the interface resistance is above 800 omega.mm2, with excellent waterproof and antirust property. The coating does not come off after annealing at 750 degree with good interface resistance and corrosion resistance.

Owner:MAANSHAN IRON & STEEL CO LTD

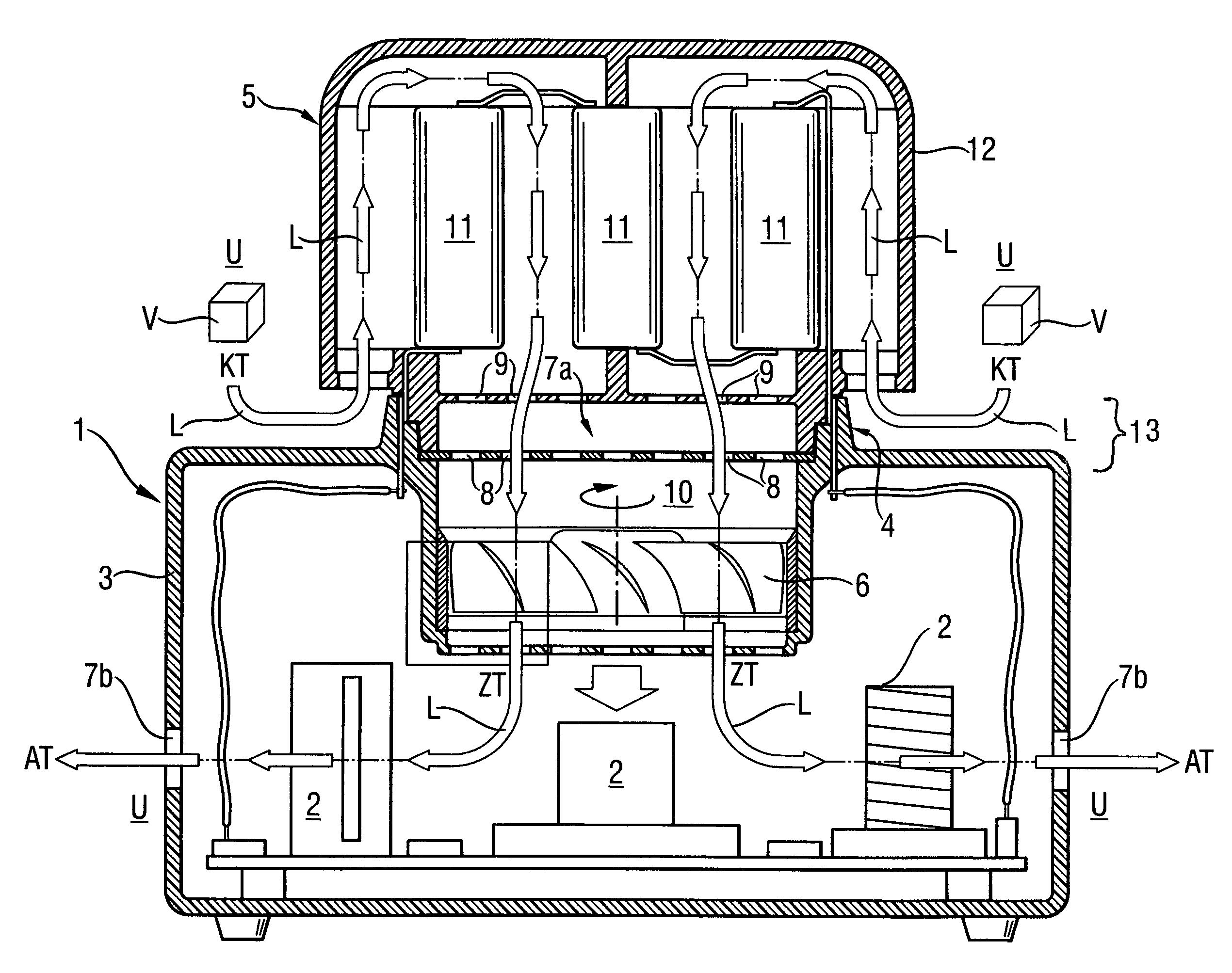

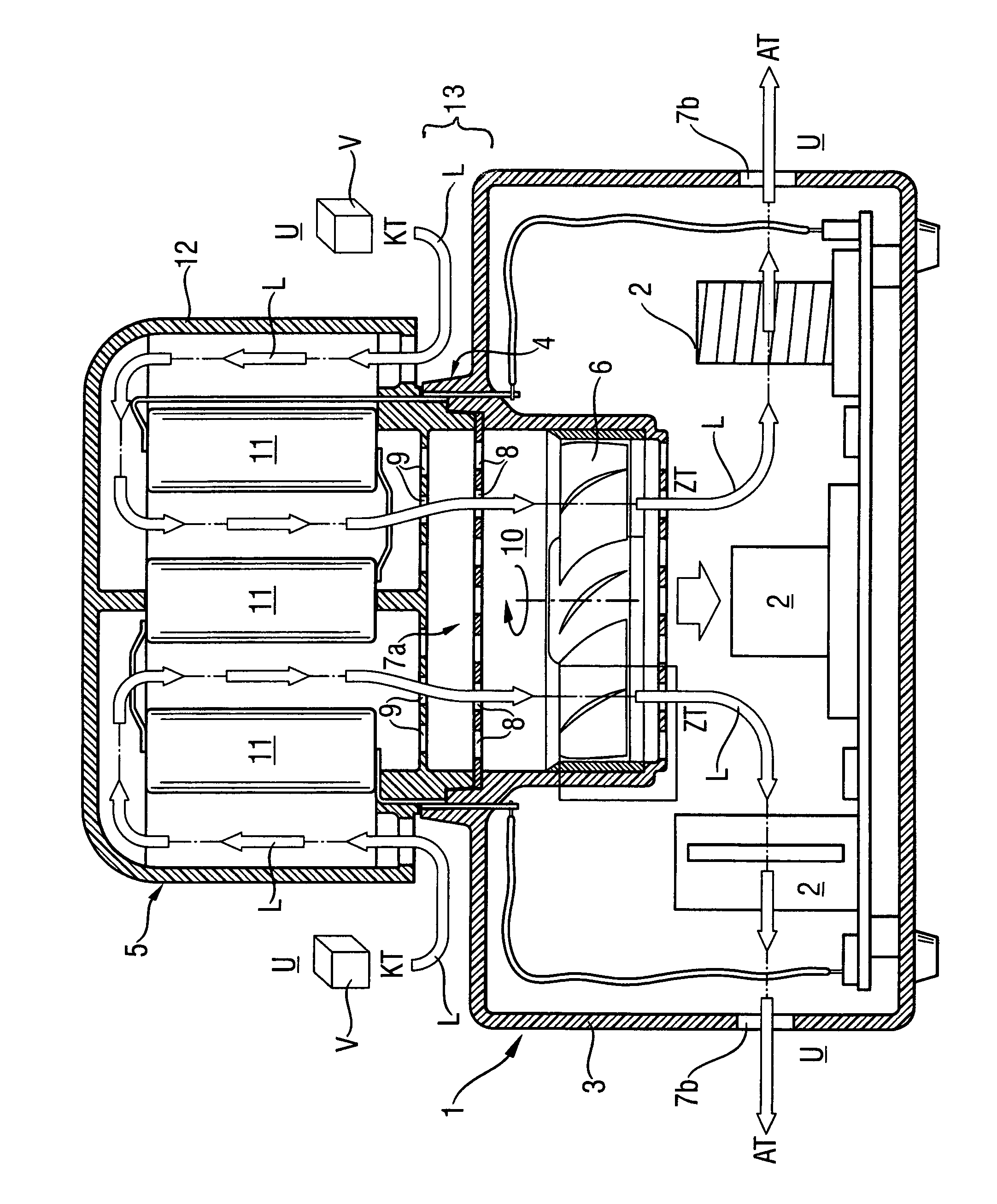

Storage battery charging station

InactiveUS6967464B2Improve cooling effectLower overall flow resistanceBatteries circuit arrangementsSecondary cells charging/dischargingElectricityAir volume

A charging station (1) for a rechargeable battery (5) that can be electrically and physically connected to the rechargeable battery (5). The charging station (1) has charger electronics (2) in a charger housing (3) and an electrical and physical contact interface (4) for the battery (5). An air blower (6) producing an air current (L) through two air vents (7a, 7b) is arranged in the charger housing (3). The air vent (7a) of the physical contact interface (4) is spatially associated with the battery (5) and the charger electronics (2) is arranged in the air current (L) to transfer heat. In the cooling process, in a first stage, an air volume (V) at cooling temperature CT is moved past the battery to transfer heat into and onto the battery and, in a second stage, the air volume (V) at an intermediate temperature IT>CT permeates the charger housing (2) containing the charging electronics (2.).

Owner:HILTI AG

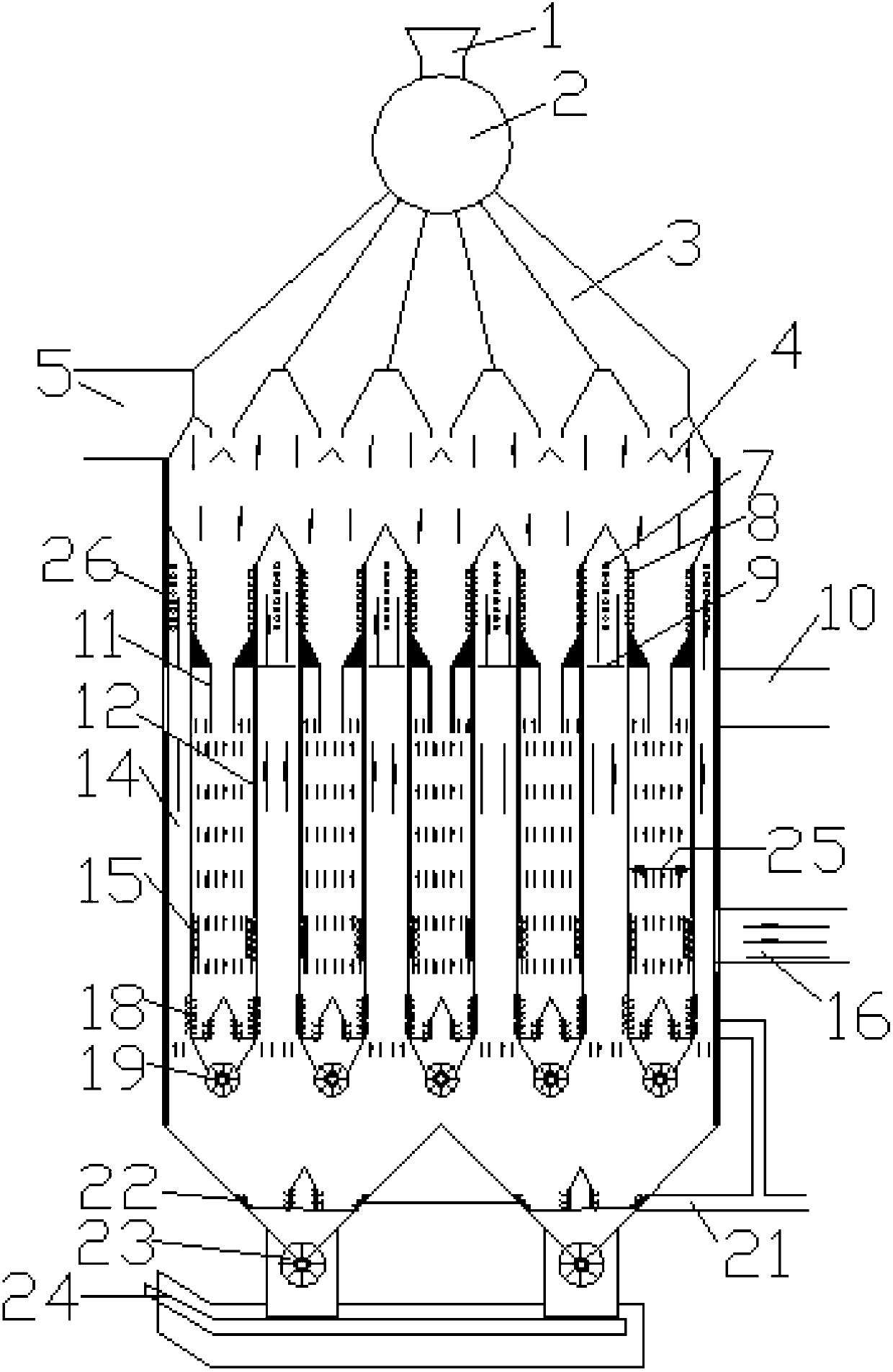

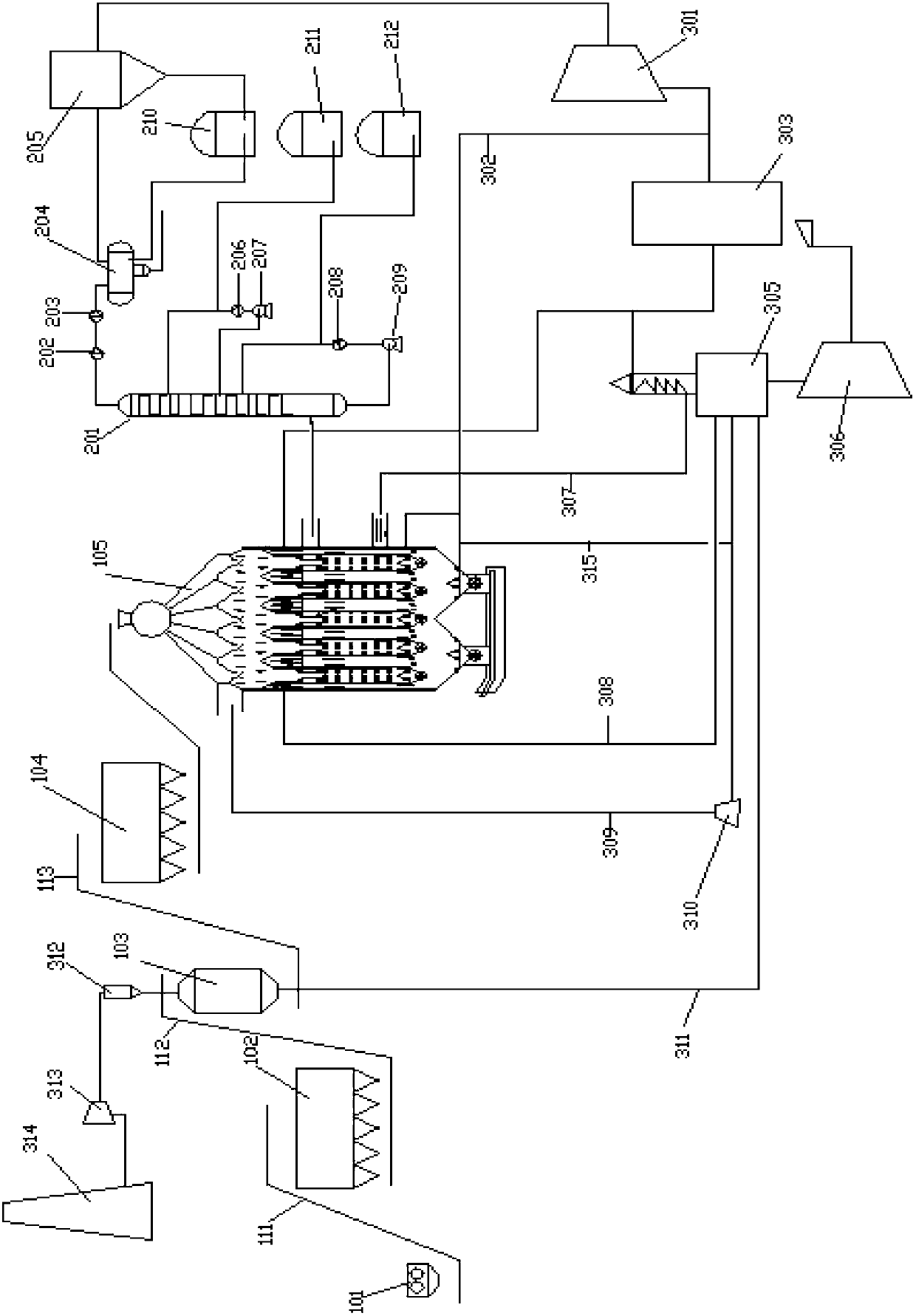

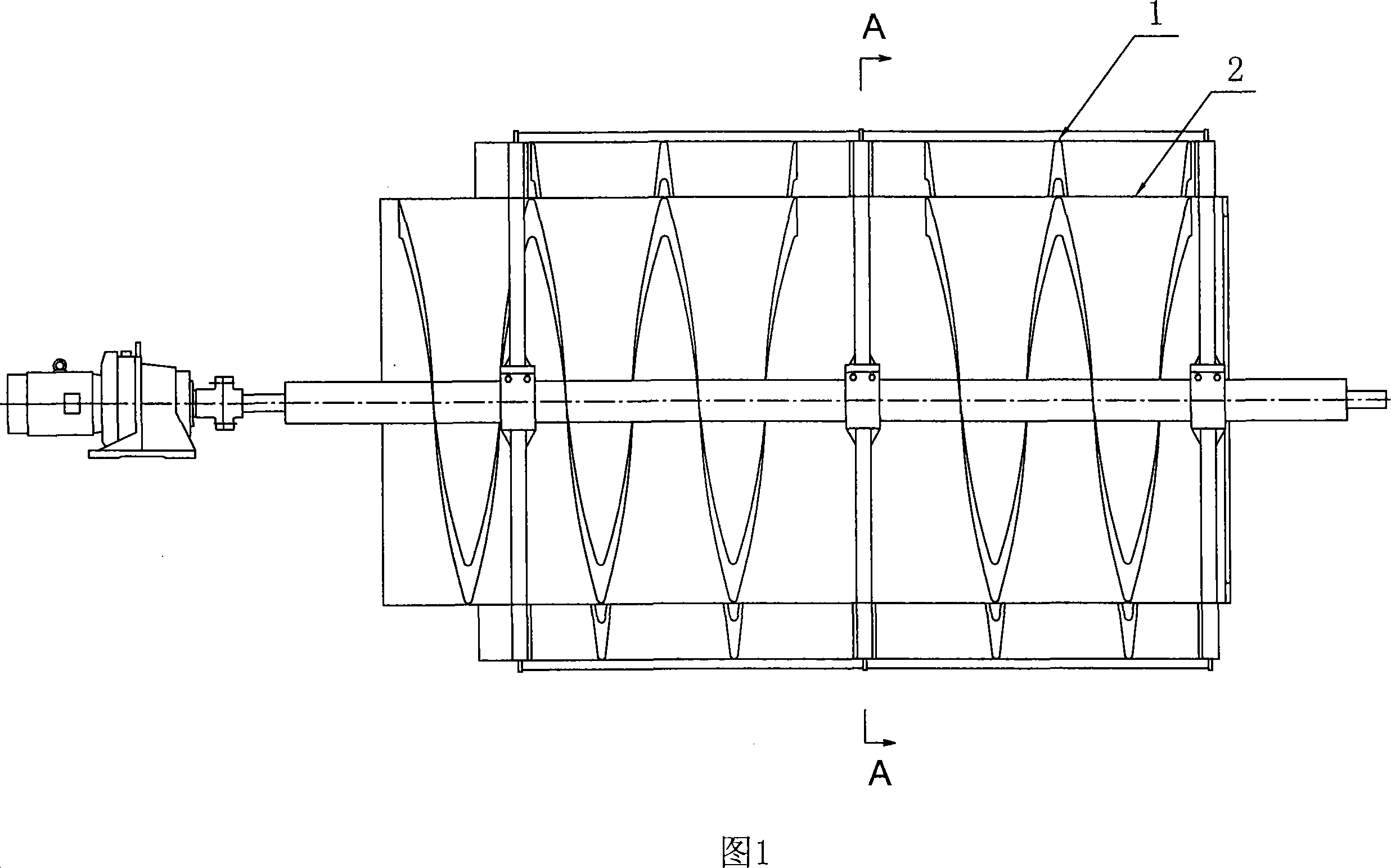

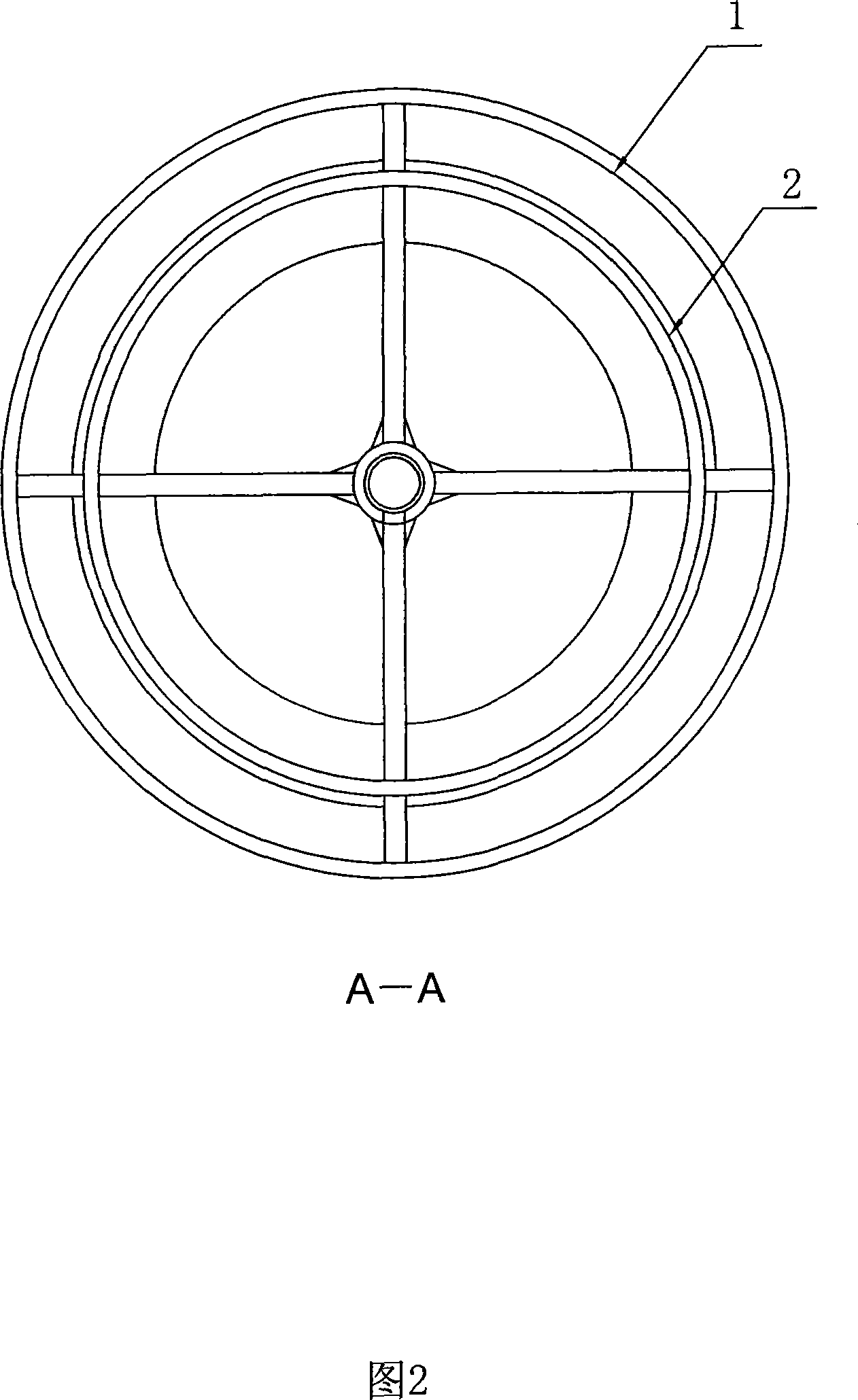

Tunnel pipe thin-layer retort for coal and oil shale and retort process thereof

InactiveCN103013544AImprove heat transfer performanceIncrease profitChemical industrySpecial form destructive distillationThin layerOil shale gas

The invention discloses a tunnel pipe thin-layer retort for coal and oil shale and a retort process thereof, relates to a retort and a process for producing coal tar and shale oil, and solves the problems that the conventional retorts and processes have large heat loss at semicoke cooling sections, the retort time is difficultly controlled accurately, the oil yield is low and the treatment capacity of the single furnace is small. The retort comprises a drying section, a retort section, a high temperature cooling section and a low temperature cooling section, wherein the semicoke cooling section is divided into two sections by a roller feeding machine, heat exchange of cooling wind is carried out at the high temperature semicoke section, the low temperature cooling section is communicated with a tunnel pipe, and drying gas enters the drying section via the tunnel pipe. According to the process, retort oil gas led out from a retort oil gas outlet of a retort furnace is purified and then used as circulation retort gas, and gas led out from a drying gas outlet of the retort furnace is used as the circulation drying gas to carry out retort. With the retort and the retort process, an addition of 20 percent of semicoke residual heat is recovered from per ton raw material, the retort time is accurately controlled, the oil yield is high, and the treatment amount of the single furnace is large; and the retort and the retort process are mainly applied to the field of coal chemical industry.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

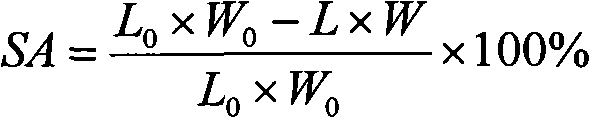

Full dry purification and residual heat utilization equipment and method for converter gas

InactiveCN101492756ALess dustLess waterIncreasing energy efficiencyManufacturing convertersSuperheated steamMoisture

The invention provides devices for purifying converter gas by dry process and using afterheat of the converter gas and a method thereof. In a converting period, waste gas exhausted from the converter is cooled by a movable gas hood and a vaporizing cooling duct, then is sent into a gravity dust collector to reduce dust content thereof, is conducted into a flue and then to an afterburning afterheat boiler; the afterburning afterheat boiler generates overheated vapor by using large quantity of sensible heat of the converter gas and sends the converter gas after being cooled into a bag dust collector through the flue to purify; the purified converter gas is sent to a draft fan to be pressurized through the flue, then passes through a three-way valve, and is sent to a converter gas cabinet; in a non-blowing period of the converter, converter gas is not generated; afterburning afterheat boiler burns a certain amount of blast furnace gas to stabilize load thereof and vapor yield. The three-way valve is switched to cause the afterheat boiler waster gas exhausted from the draft fan to flow to a waste gas discharging chimney. The converter gas processed by the method and devices has very low dust and moisture contents and is an ideal purified gas. During the operation process, large quantity of industrial water is saved, and large quantity of secondary energy is recycled.

Owner:袁长胜

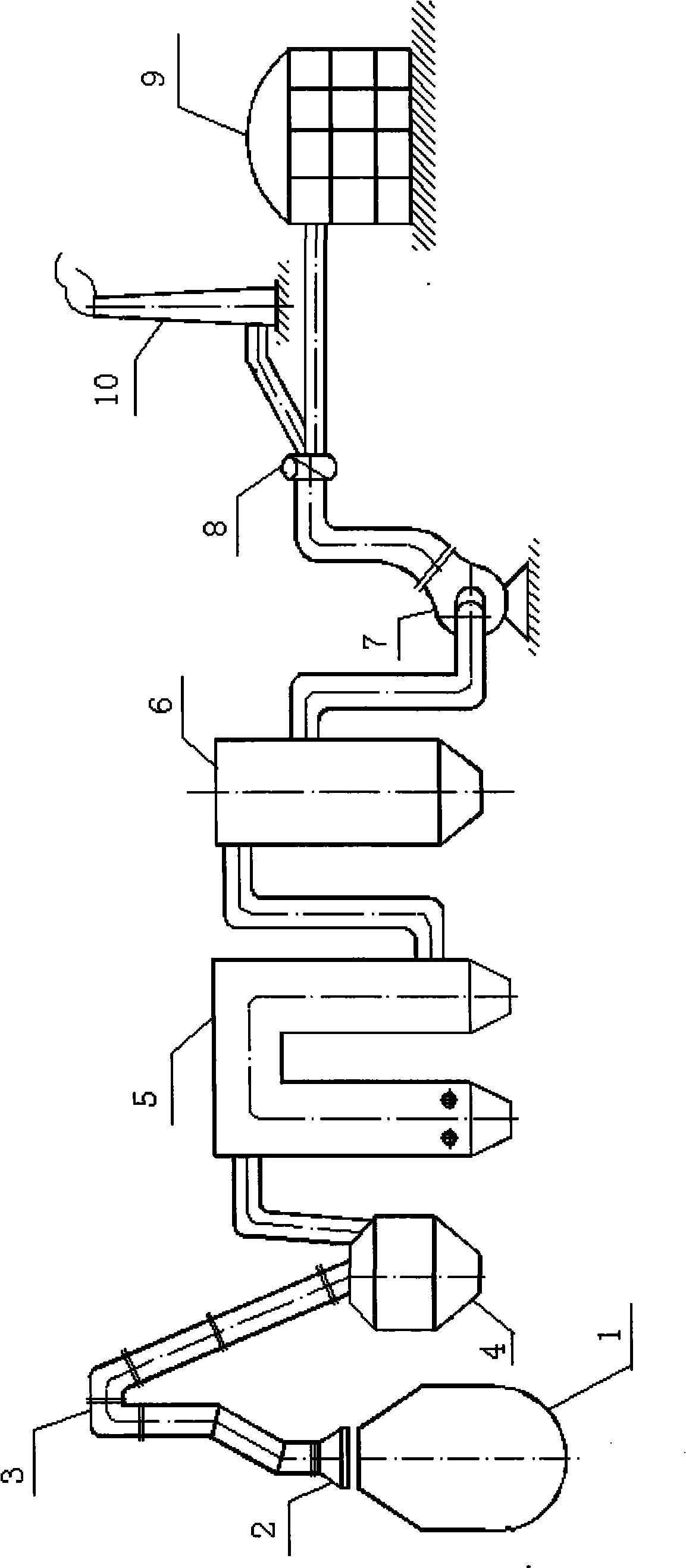

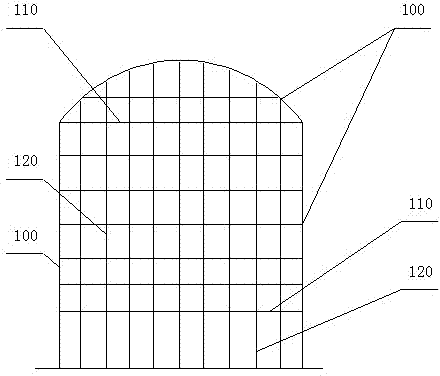

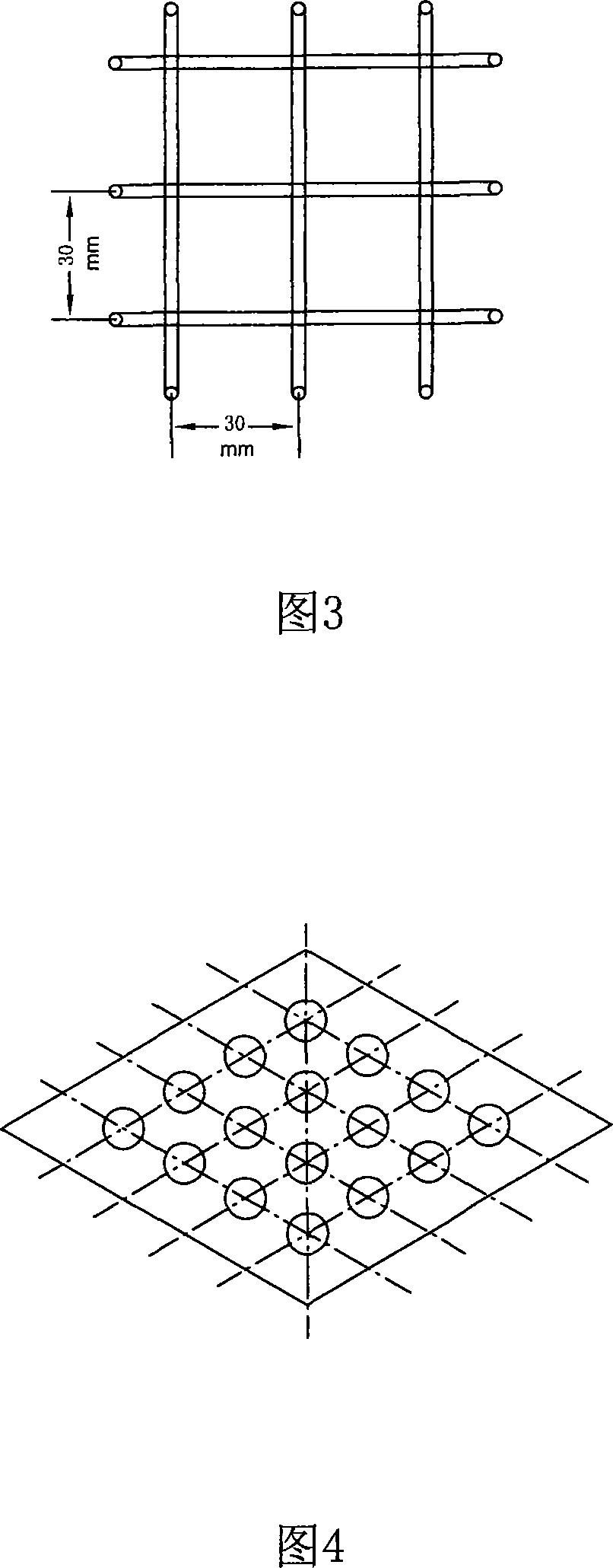

Excavation construction method for mine hard rock roadway

The invention discloses an excavation construction method for a mine hard rock roadway. A cutting device is used for cutting out the outline of the roadway, cutting in the horizontal direction and in vertical direction is carried out in the outline of the roadway to obtain parallel horizontal cut grooves and parallel vertical cut grooves, and the horizontal cut grooves and the vertical cut grooves intersect and cut the section of the roadway inside the cut grooves of the outline to a longitudinally and transversely intersected grid-shaped structure. A crushing device is used for crushing or breaking a first rock inside the grid-shaped structure of the section of the roadway in a prizing mode and then crushing or breaking other rocks in the prizing mode, the crushed or broke rocks are taken out until all the rocks within the cutting depth are taken out, and a manual or mechanical conveying device is used for conveying cut rocks. The excavation construction method for the mine hard rock roadway resolves the problem of excavation of hard rocks or superhard rocks through a mechanical method, eliminates an explosion work procedure, is safe and efficient, and is not restrained by use and management regulations of explosive products. The roadway is good in forming performance, damage to surrounding rocks is small, supporting can be simplified or eliminated, operation time and engineering cost are saved, the construction speed is improved, and excavation cost is lowered.

Owner:重庆能投渝新能源有限公司

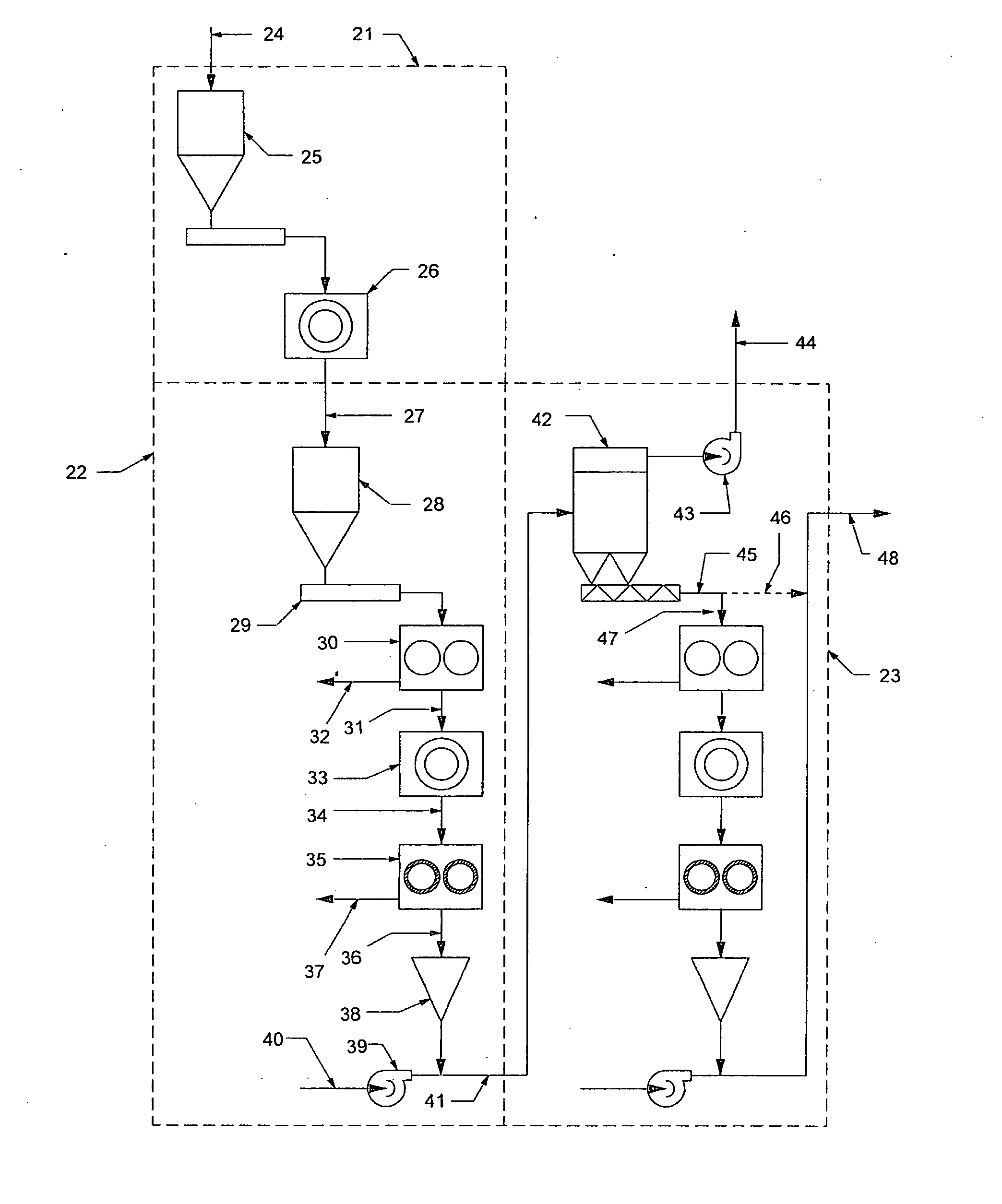

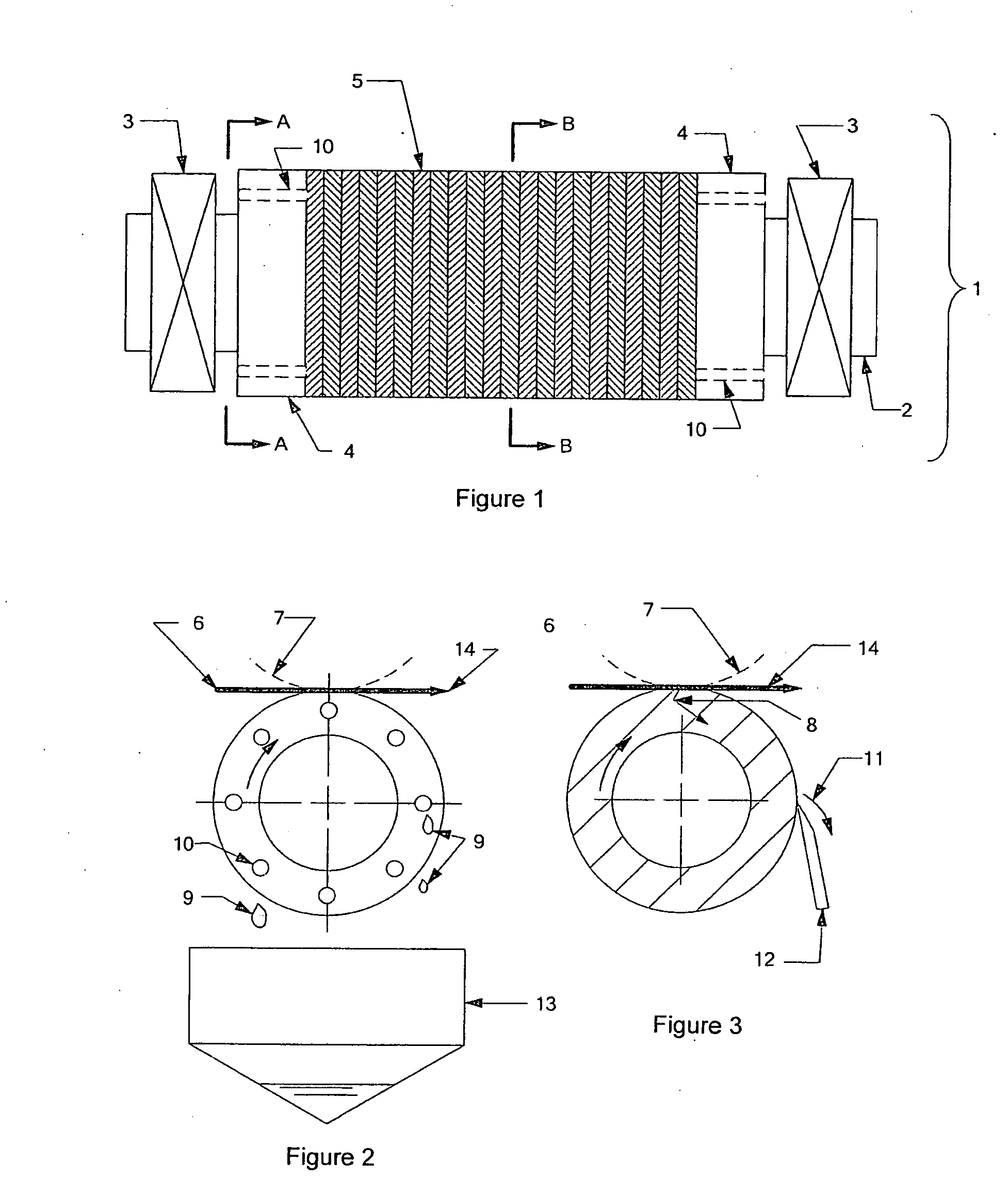

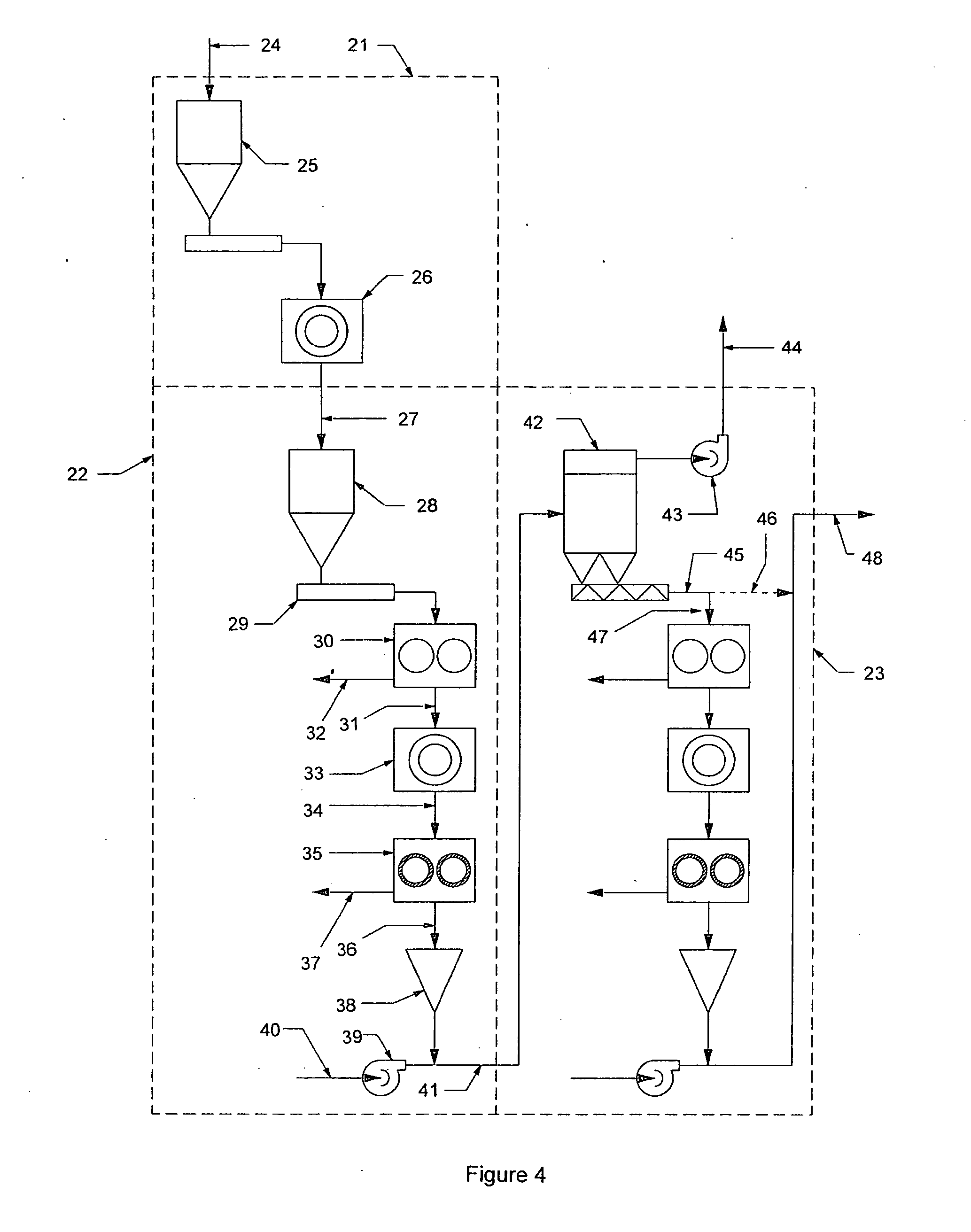

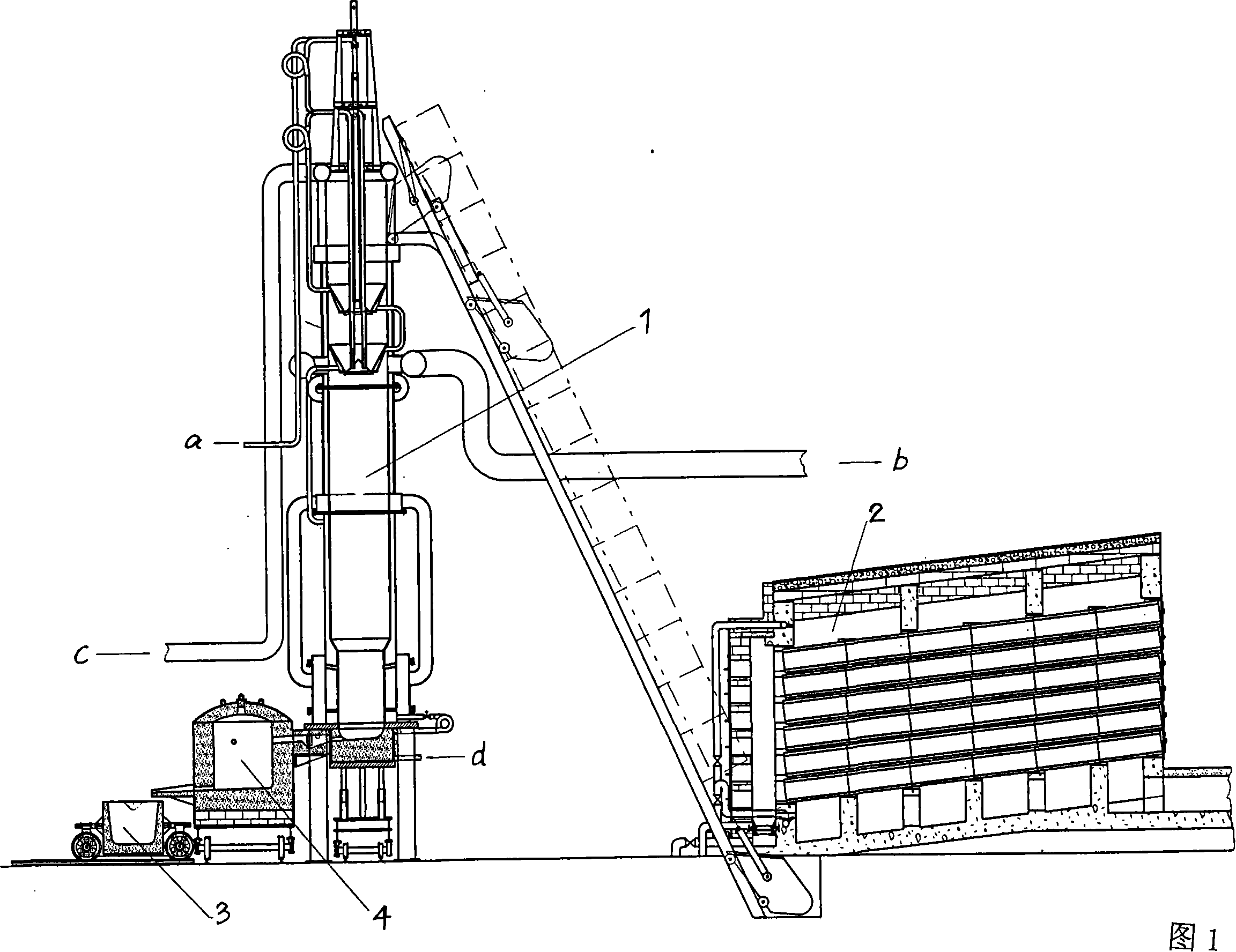

Method to transform bulk material

InactiveUS20070023549A1High energyFew deleterious componentSolid waste disposalSolid fuelsBrown coalCombustion

The invention provides low-cost, non-thermal methods to transform and beneficiate bulk materials, including low rank coals such as peat, lignite, brown coal, subbituminous coal, other carbonaceous solids or derived feedstock. High pressure compaction and comminution processes are linked to transform the solid materials by eliminating interstitial, capillary, pores, or other voids that are present in the materials and that may contain liquid, air or gases that are detrimental to the quality and performance of the bulk materials, thereby beneficiating the bulk products to provide premium feedstock for industrial or commercial uses, such as electric power generation, gasification, liquefaction, and carbon activation. The handling characteristics, dust mitigation aspects and combustion emissions of the products may also be improved.

Owner:GTL ENERGY LTD

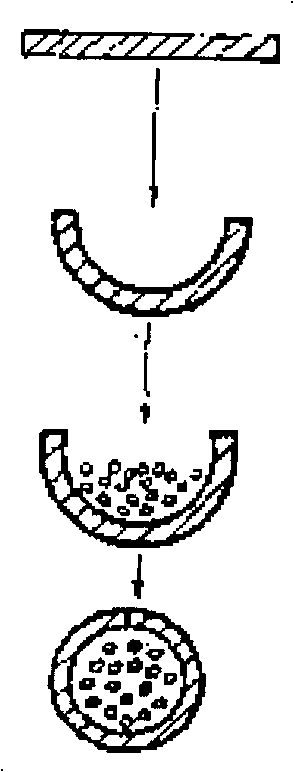

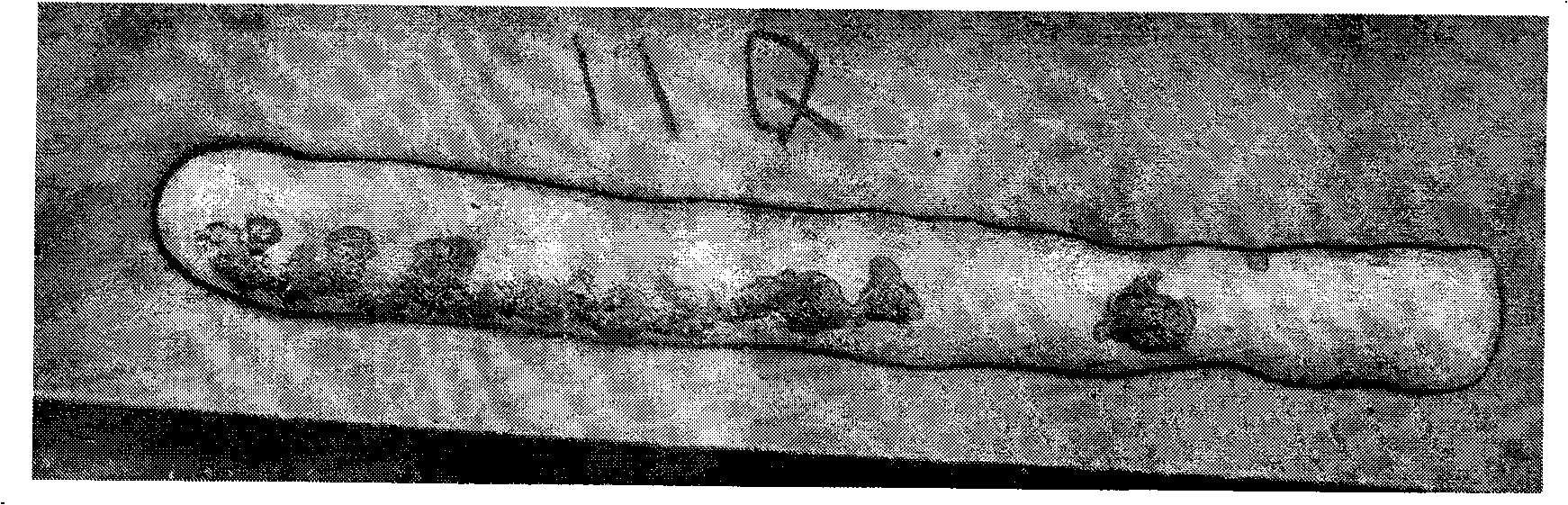

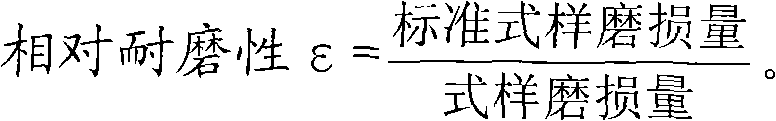

Sleeve-friendly wear-resistant strip flux-cored wire

InactiveCN101524789AImprove the safety of useHigh hardnessWelding/cutting media/materialsSoldering mediaElectrolysisIron powder

A sleeve-friendly wear-resistant strip flux-cored wire belongs to the welding field of material processing project. The aim of the invention is to settle the problem of wearing on the sleeve by the wear-resistant strip. The sleeve-friendly wear-resistant strip flux-cored wire provided by the invention adopts steel strip for packaging the flux core powder which accounts for 22-37% of total weight of flux-cored wire. The flux core powder comprises the following substances by mass percent: 10-30% of high carbon ferro-chrome, 8-17% of ferroboron, 0.5-4% of ferromolybdenum, 5-10% of nickel powder, 1-3% of low carbon ferrosilicium, 2-8% of medium-carbon ferromanganese and the balance of electrolytic iron powder. The preparing method of the invention adopts the prior art. The sleeve-friendly wear-resistant strip flux-cored wire provided by the invention can effectively increase the using safety of wear-resistant strip, reduce the wearing on the sleeve and prolong the lifetime of drill pipe.

Owner:BEIJING GABBARD ENG & TECH

Stainless steel electrode

InactiveCN102554510AStable physical and chemical propertiesImprove pass rateWelding/cutting media/materialsSoldering mediaElectrolysisManganese

A stainless steel electrode belongs to the field of welding materials, and is characterized in that chemical components of the electrode (in weight percent) include 40% of rutile, 8% of potassium feldspar, 3% of iron ores, 1.8% of potassium titanate, 1.8% of titanium white powder, 1.8% of metal chromium, 2.4% of fluorite (dried), 2.4% of cryolite, 8% of electrolytic manganese, 0.18% of bismuth oxide, 12% of micro-carbon ferrochromium, 7% of mica (dried), 1.5% of alginate calcium, 0.4% of ferroaluminium and 9.72% of marble. Compared with the prior art, the stainless steel electrode can generate arc, can also be melted to form filler metal for a welding line, and is high in corrosion resistance, and physical and chemical performances of deposited metal are stable.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

Powder for powder blasting, powder mixture and method of use for the treatment of tooth surfaces

InactiveUS20100297576A1High digestive toleranceReliably be swirledCosmetic preparationsGum massagePowder mixtureErythritol

A powder and a powder mixture, respectively, preferably for powder blasting with a powder-jet device, said device mixing the powder or the powder mixture with air to a powder / air mixture, wherein said powder and powder mixture is an alditol or contains such alditol. Preferably, mannitol and / or erythritol are used; because of the anti-cariogenic effect, xylitol is also well suitable for the cleaning of tooth surfaces, especially of less strongly mineralized tooth surfaces like dentine.

Owner:FERTON HLDG

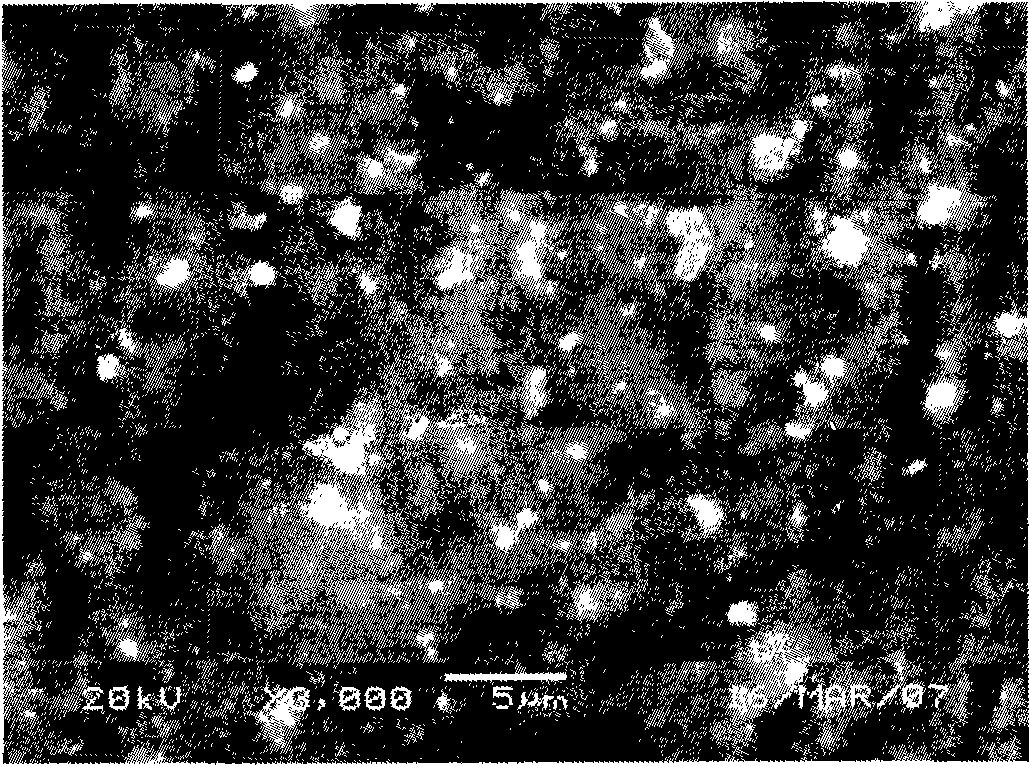

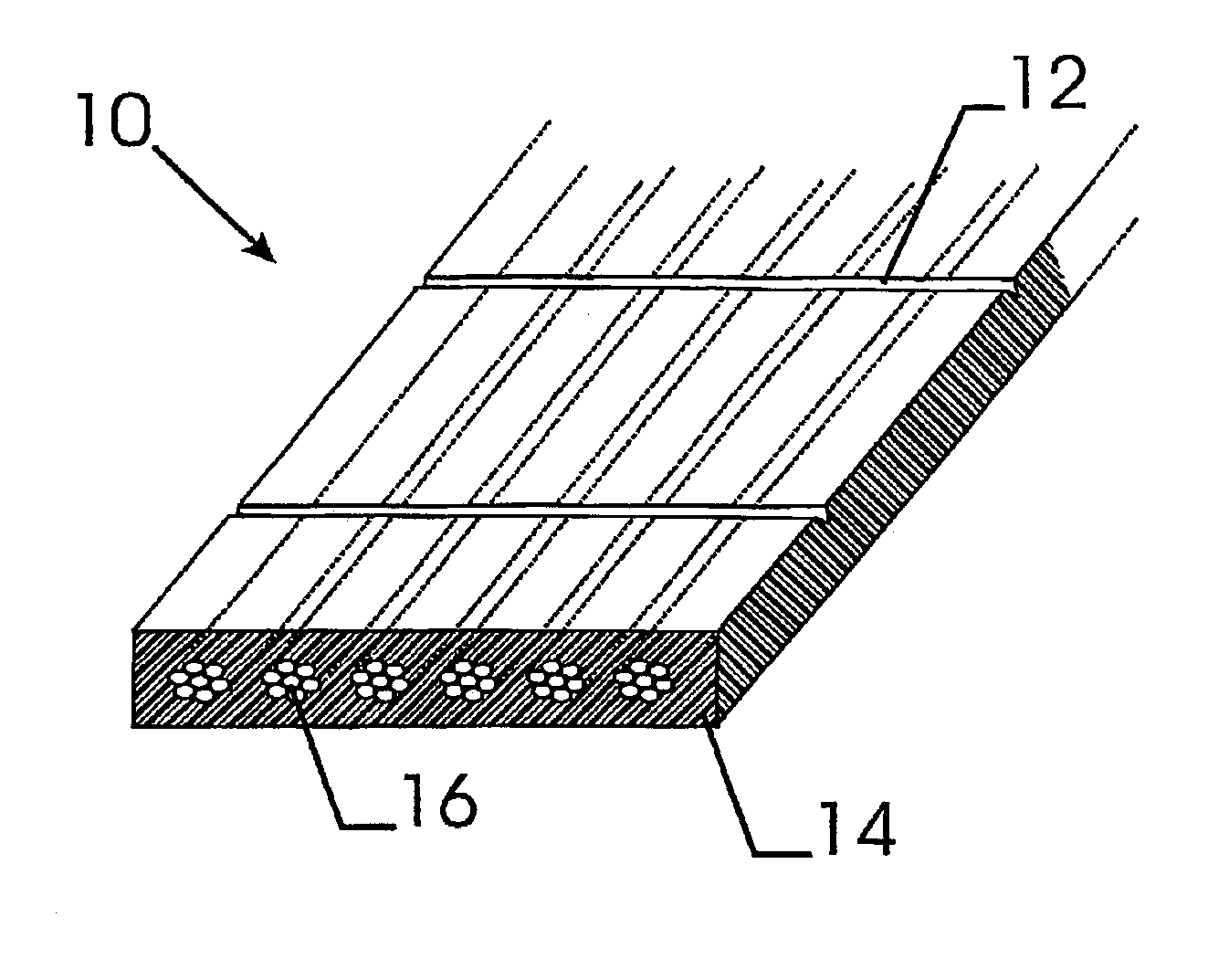

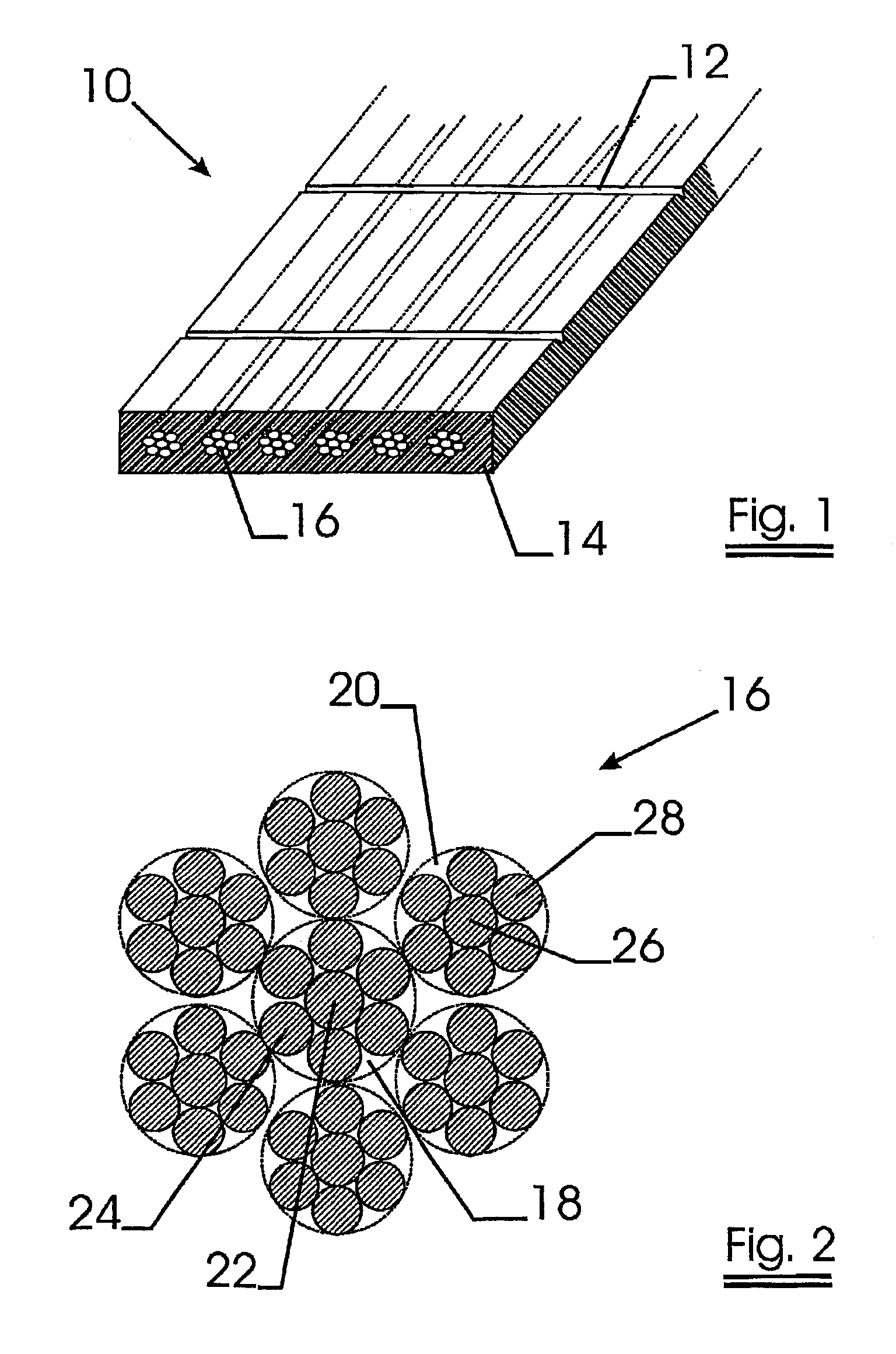

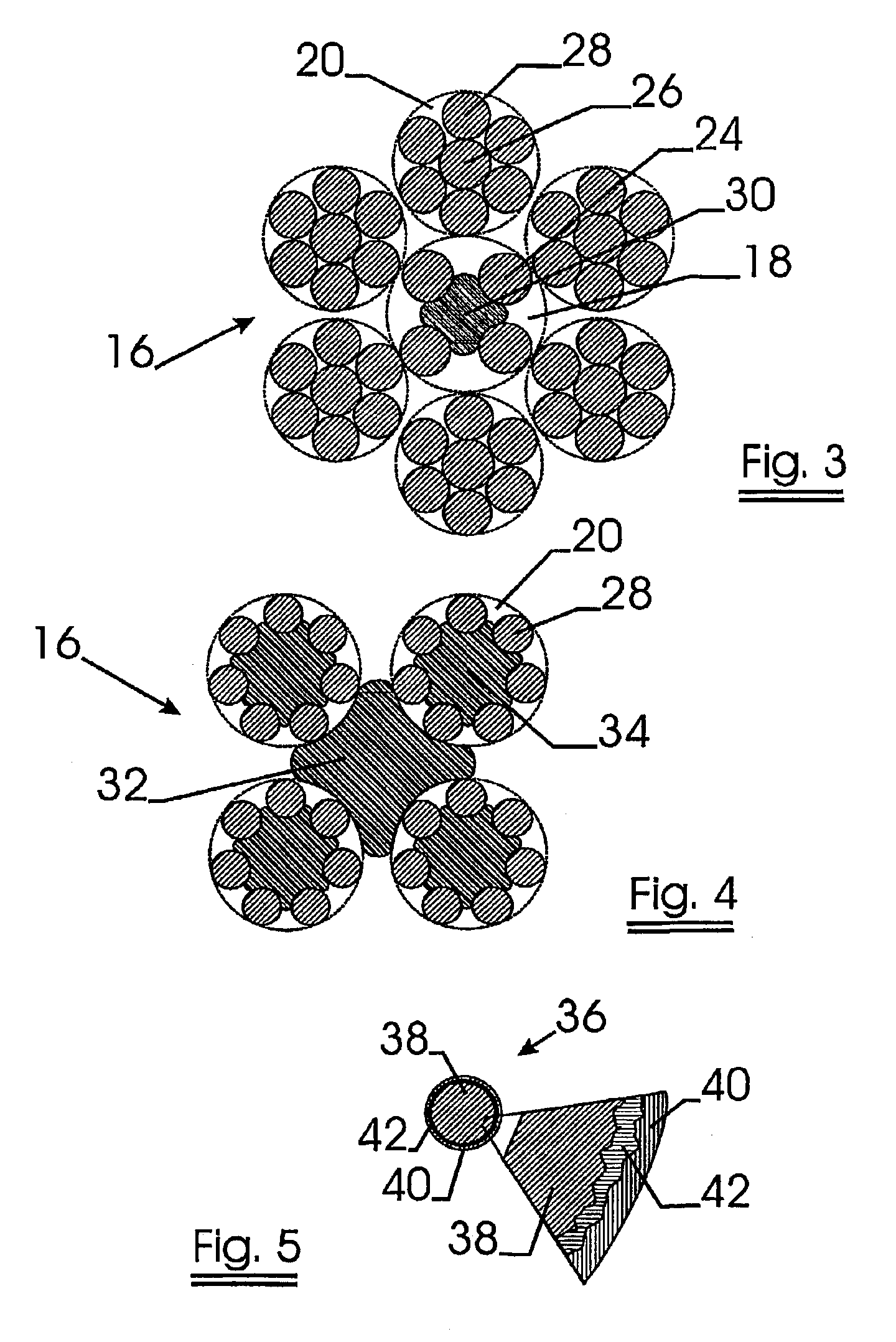

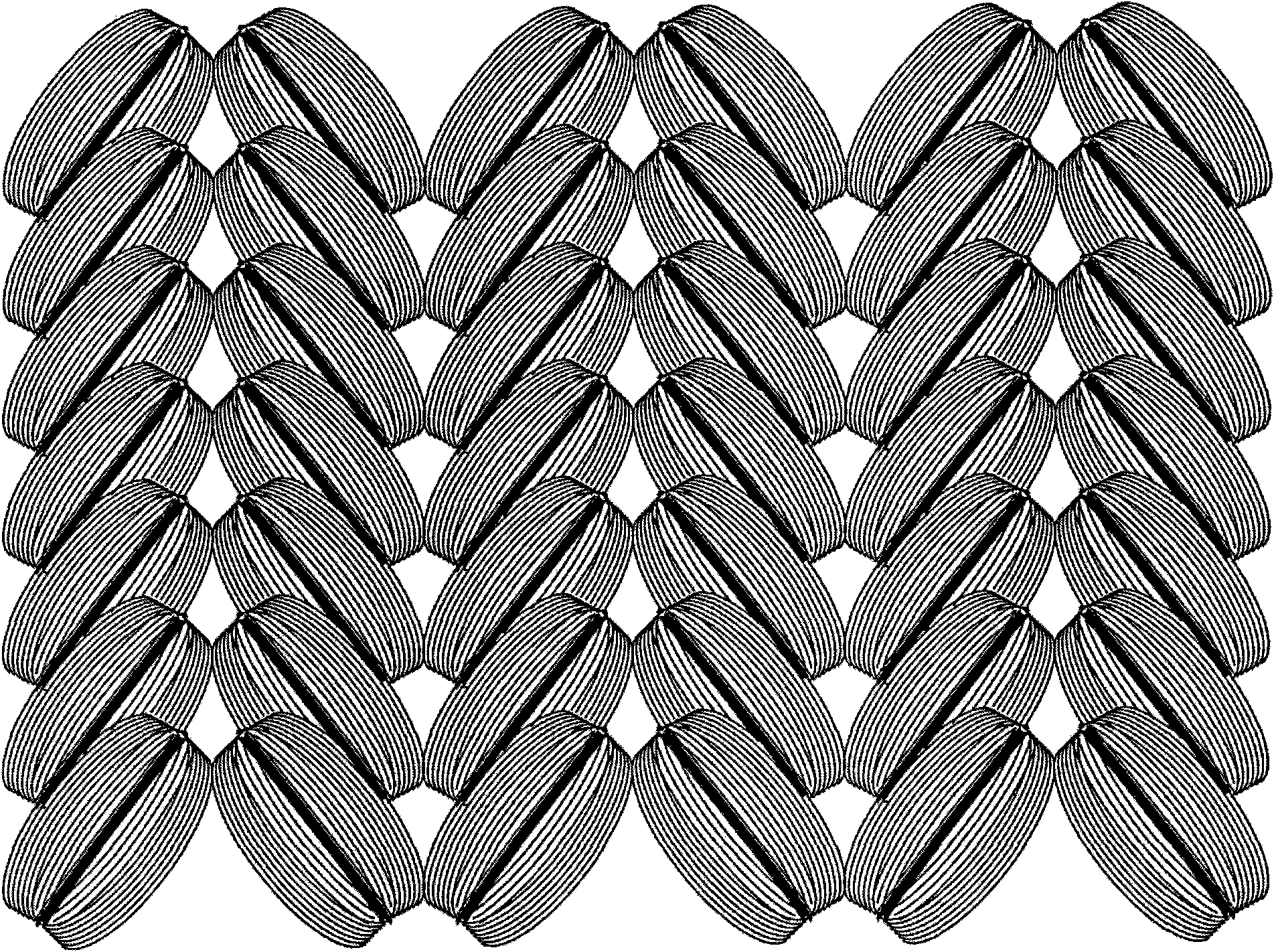

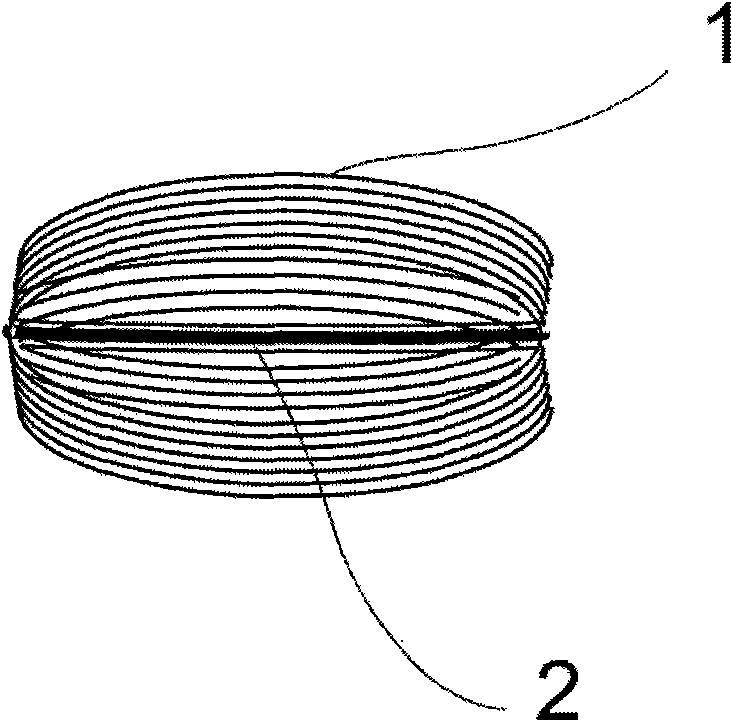

Zinc-coated steel cord with improved fatigue resistance

InactiveUS6920745B2Less dustMechanical anchoringHot-dipping/immersion processesV-beltsThermoplastic elastomerMicrometer

A steel cord for the reinforcement of thermoplastic elastomers, the steel cord including more than one strand, each strand including two or more steel filaments, at least some of said the steel filaments being provided with a zinc coating. The zinc coating has a thickness lower than two micrometer and an alloy layer zinc-steel is present between the zinc coating and the steel.

Owner:BEKAERT ADVANCED CORDS AALTER NV

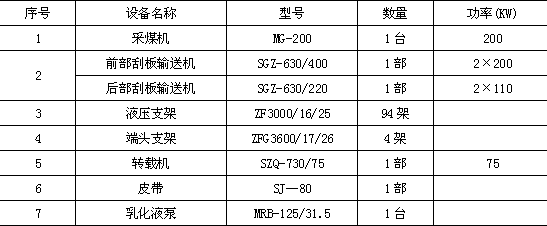

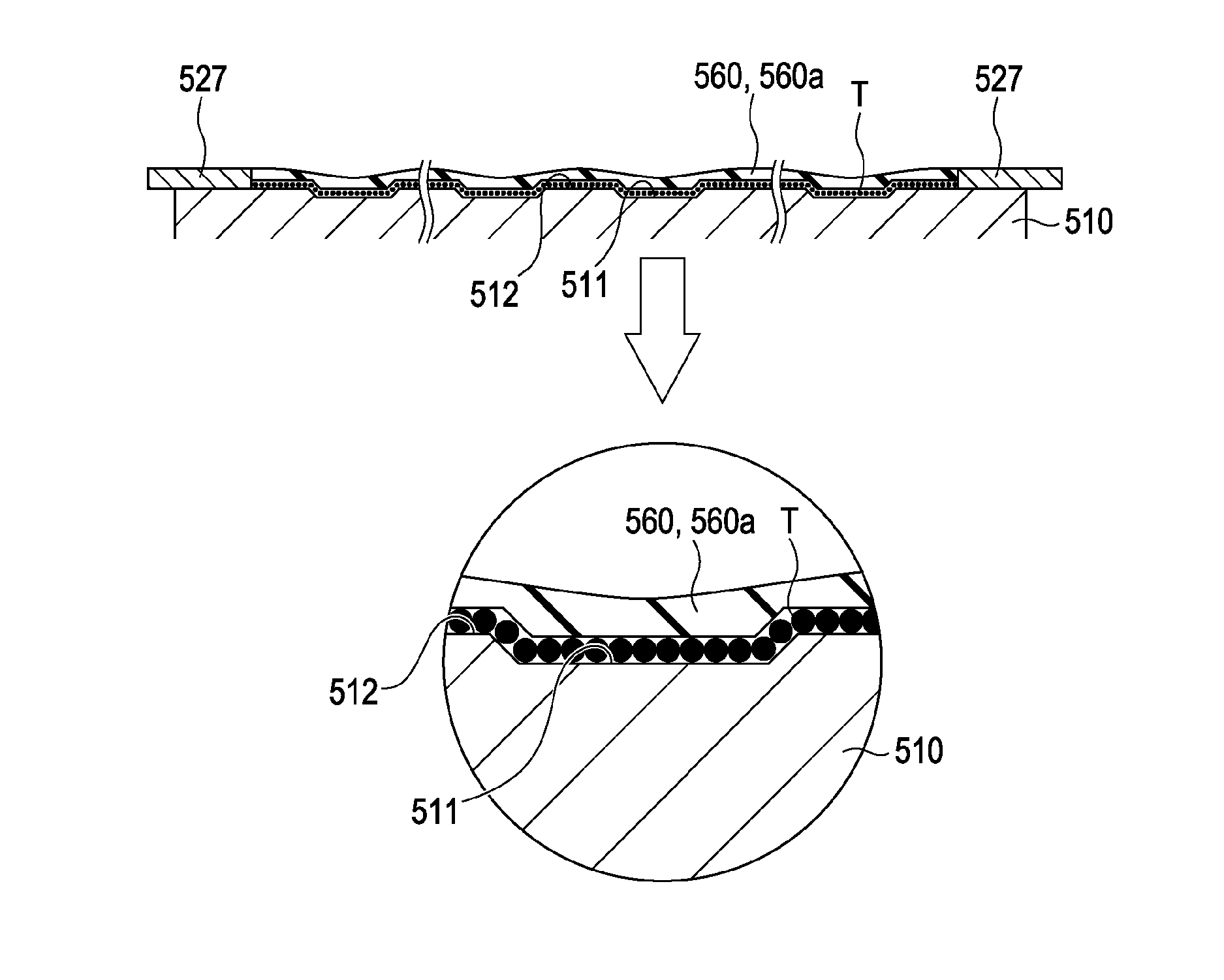

Method for manufacturing negative electrode of lithium titanate battery

InactiveCN102420315AImprove electrochemical performanceHigh-rate fast charge and discharge performance improvementCell electrodesEngineeringElectrochemistry

The invention provides a method for manufacturing a negative electrode of a lithium titanate battery, which comprises the following steps of: firstly coating a conductive layer sizing agent on a current collector, then coating an active layer sizing agent mainly made of lithium titanate, and improving and optimizing components and proportioning of the conductive layer sizing agent and the active layer sizing agent. The method is used for manufacturing the negative electrode of the lithium titanate battery and has the advantages that the bonding effect of the material of the negative electrode of the battery and the current collector is obviously improved, the powder falling phenomenon is effectively reduced, the conductivity performance of the electrode is improved, the combination property of the electrode is promoted to exert, and the electrochemistry performance of the manufactured lithium titanate battery is increased.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

High-density low-dust-generation wiping cloth used for dust-free room and manufacture method thereof

The invention discloses high-density low-dust generation wiping cloth used for a dust-free room and a manufacture method thereof. The wiping cloth is manufactured by textile fabrics which is obtained by boiling water refining, steaming, tentering, shaping, dyeing and finishing after covering yarn is weaved, wherein the covering yarn is obtained by covering, twisting and spinning high-shrinkage fiber filament which is used as core yarn by low-shrinkage fiber filament. The manufacture method comprises the following step: (1) spinning: covering the high-shrinkage fiber filament which is used as the core yarn by the low-shrinkage fiber filament to manufacture the covering yarn; (2) weaving: weaving the covering yarn into gray cloth according to weft knitting knitted structure; and (3) postprocessing: refining the gray cloth, steaming, drying, tentering, shaping, cutting, and super-cleaning to obtain the high-density low-dust-generation wiping cloth. The high-density low-dust-generation wiping cloth disclosed by the invention has the characteristics of low dust generation amount, high dust containing amount and excellent wiping performance. The manufacture method has simple process; and by using the manufacture method, the dust generation amount of the textile fabric can be effectively lowered, and the wiping performance of the textile fabric is improved.

Owner:SHENZHEN SELEN SCI & TECH CO LTD +1

Tube furnace-shaft furnace twin coal-base fusing reduction iron-smelting method

The invention relates to a coal-based smelting reduction iron making process, specifically to a duplex coal-based smelting reduction iron making method of tubular furnace and shaft furnace, which solves the problems existing in the coal-based smelting reduction iron making methods of the prior art. Technological procedures include: preparation: iron ore powder, coal powder and lime powder; adding water to mix; shaping by high-pressure briquette; enhancing preheating and drying; pre-reducing the tubular furnace; carrying out final reduction of shaft furnace smelting reduction and practicing forehearth separation of iron and slag. The invention has advantages of small overall investment, low overall energy consumption, little pollution, low failure rate of equipments and stable production operation; flexible production scale, easiness in unified production for casting; low cost and high investment return; short process, easiness in operation, few equipments needed and easiness in maintenance.

Owner:郭瑛

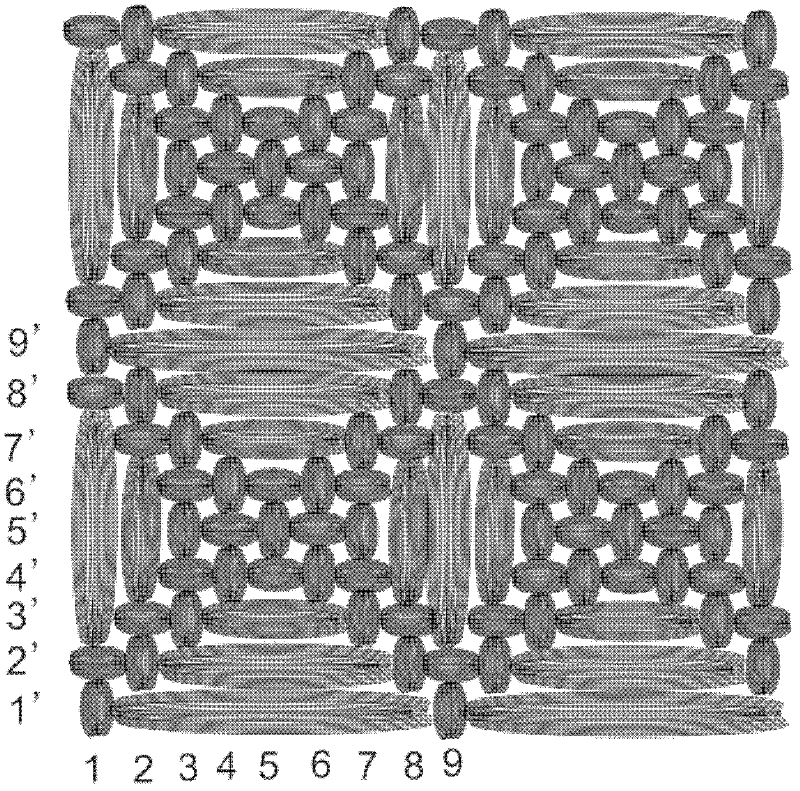

Super absorbent dust-free wiping cloth and manufacturing method thereof

InactiveCN102505253ALoose arrangementLarge specific surface areaCarpet cleanersFloor cleanersSuper absorbentLaser cutting

The invention discloses a super absorbent dust-free wiping cloth and a manufacturing method thereof. The wiping cloth is formed by interweaving warps and wefts and is characterized in that the dust-free wiping cloth is formed by circularly arranging square concave weave repeat units formed by interweaving the warps and the wefts along the warp direction and the weft direction respectively; at least one of the warp and the weft is formed by superfine fiber filaments; and in one weave repeat unit, the warps and the wefts are respectively arranged stepwise and upward in sequence from the central lowest point, and the floating length of the adjacent warps and the adjacent wefts on the steps increases in sequence to form concavo-convex patterns which are piled up alternately from low to high and have four high sides and low middle. The manufacturing method comprises the steps of beaming, drafting and reeding, weaving, weight reducing, tenter setting, laser cutting and packaging, thereby obtaining the super absorbent dust-free wiping cloth. The super absorbent dust-free wiping cloth has soft handfeel, good wiping effect and super absorbency and can be used in a dust-free room with a higher cleanliness requirement. The manufacturing method is simple and can be used for manufacturing the high-quality dust-free wiping cloth.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

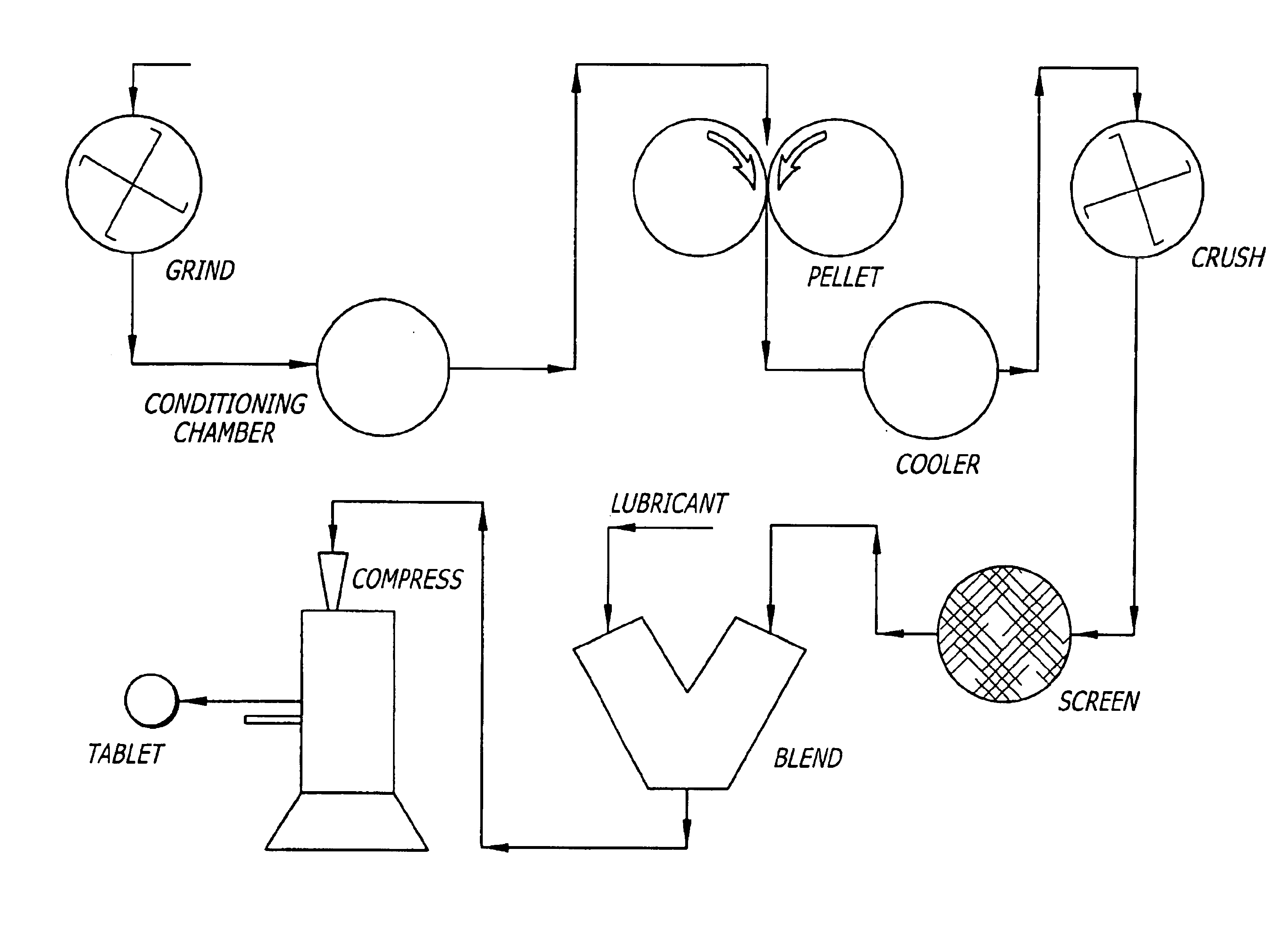

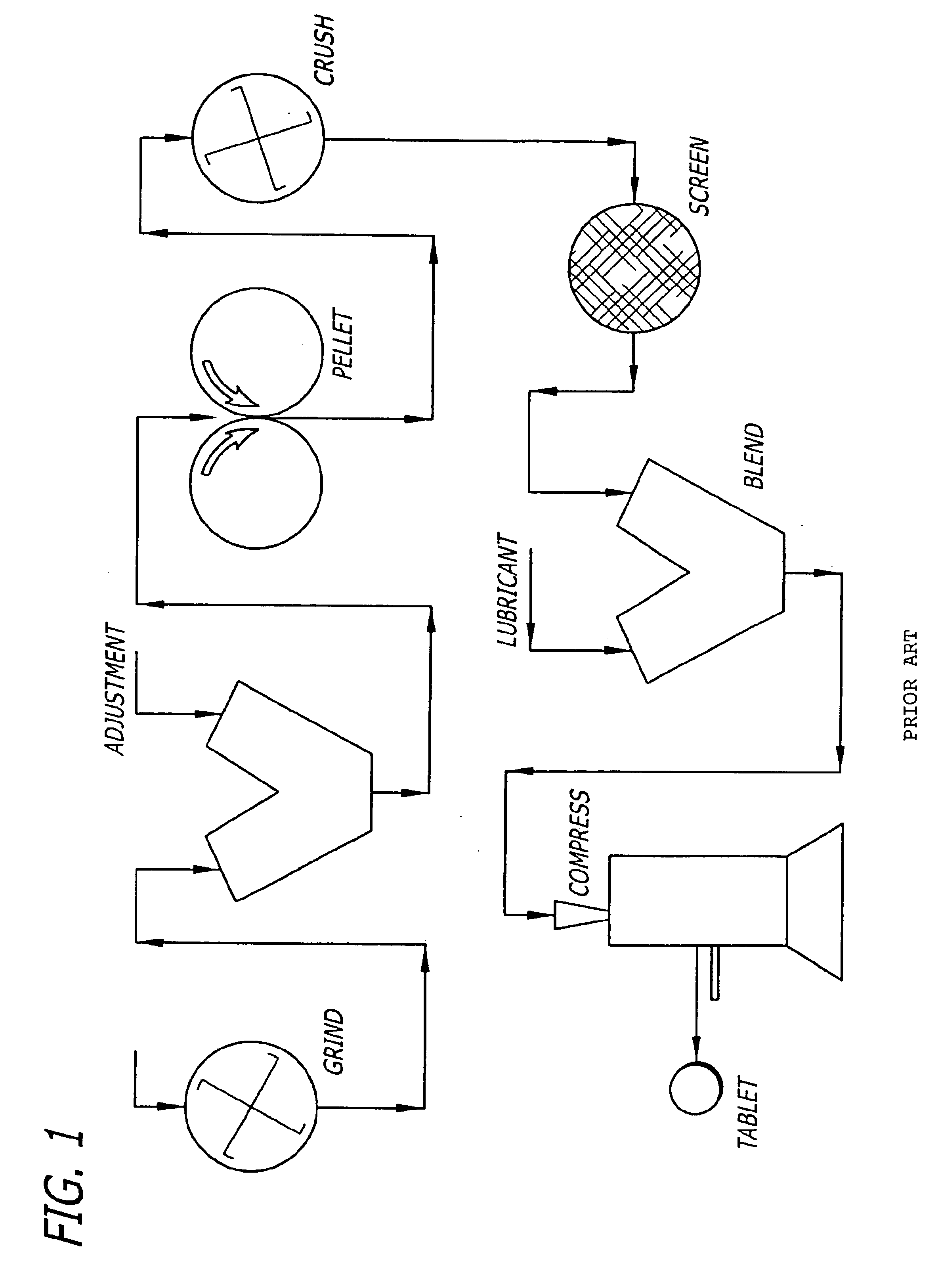

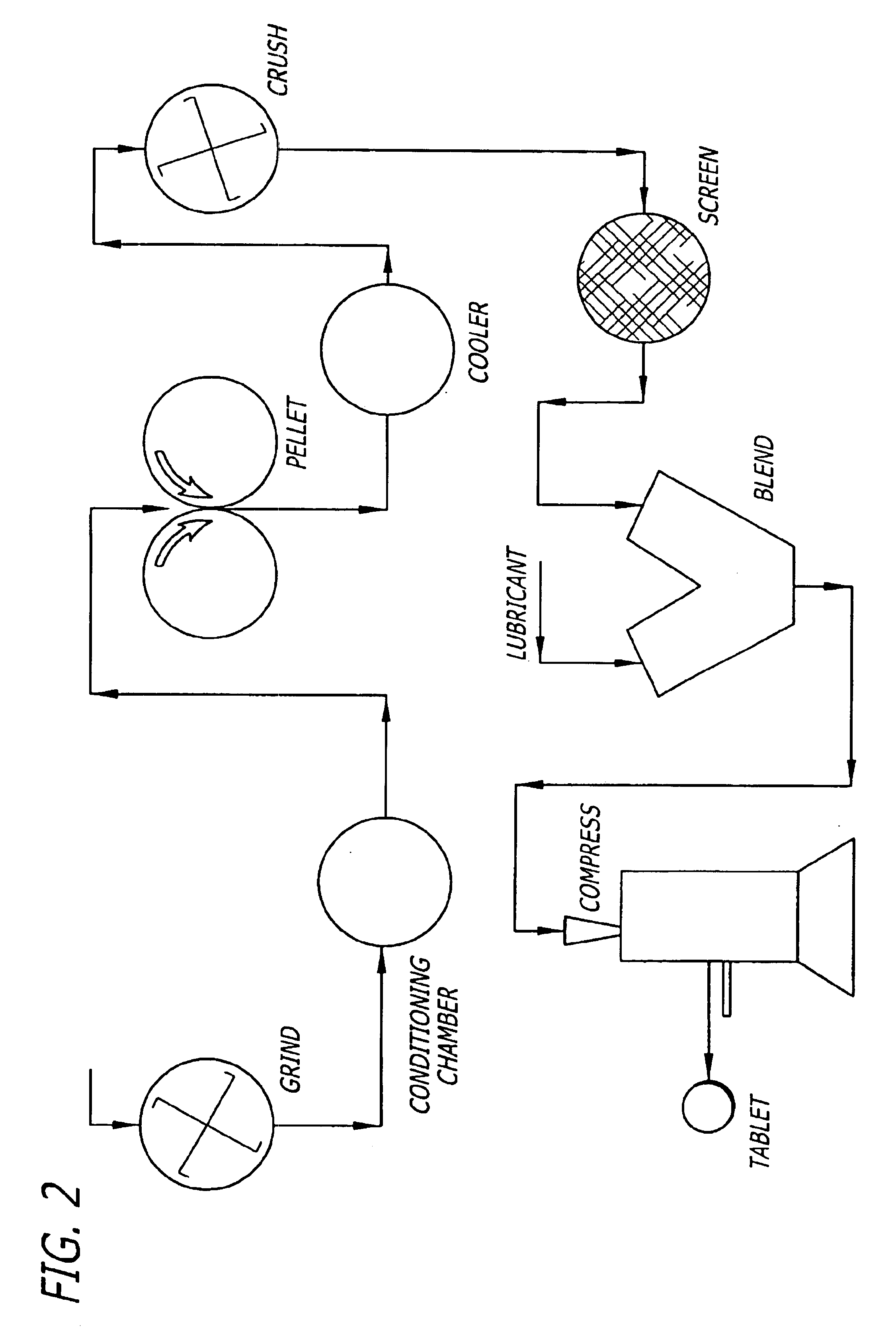

Powder processing

InactiveUS6889923B2Reduce disadvantagesHigh densityPowder deliveryPigmenting treatmentParticulatesPrill

A system is provided for pelletizing particulate raw matter having a first density, and thereafter subjecting the pellets to a milling process to obtain a powdered form of the particulate. During pelletizing steam can be added. The resulting powder is denser, or more granular or has better flow with less dust than the pre-pelletized particulate matter having the first density. The powderized particulate has applications for pharmaceutical, nutritional and herbal end products.

Owner:BI NUTRACEUTICALS INC

Method for preparing LiFePO4/SiC lithium battery positive plate by microwave heating

The invention discloses a method for preparing a LiFePO4 / SiC lithium battery positive plate by microwave heating. The method is characterized in that: the method comprises the following steps of 1, immersing LiFePO4 in a lithium silicate aqueous solution having mass concentration of 20 to 30% for 2 to 5 hours, fully stirring and evaporating water of the lithium silicate aqueous solution, 2, carrying out calcination of the immersed LiFePO4 at a temperature of 500 DEG C for 2 to 5 hours, 3, adding SiC having particle sizes of 100 to 150 microns into LiFePO4 powder obtained by calcination, wherein a use mount of SiC is 5 to 10wt% of that of LiFePO4, and carrying out uniform ball-milling mixing, 4, heating the mixture obtained by the step 3 in a microwave oven under the conditions of microwave power of 300 to 500W and heating time of 10 to 25 minutes, and 5, mixing the mixture obtained by the step 4, a binder, a conductive agent, an additive and a solvent into slurry, and carrying out coating, drying, rolling and cutting of the slurry to obtain the LiFePO4 / SiC lithium battery positive plate. The method can effectively solve the problem of falling-off of LiFePO4 powder in coating and assembling and can obviously improve electrochemical performances of the LiFePO4 / SiC lithium battery positive plate, and is simple in application and low in cost.

Owner:SHANGHAI JINZHONG INFORMATION TECH

Automotive disc ceramic brake without heavy metal, heavy metal sulfide or heavy metal fluoride

The invention relates to an automotive disc ceramic brake without heavy metal, heavy metal sulfide or heavy metal fluoride. The automotive disc ceramic brake is prepared from the following components in parts by weight: 9-16 parts of barium sulfate, 1-5 parts of high-lead alumina powder, 5-15 parts of garnet powder, 3-8 parts of palygorskite powder, 1-5 parts of magnesium oxide powder, 1-6 parts of diatomite powder, 3-9 parts of mica powder, 3-6 parts of talcum powder, 1-6 parts of white carbon black, 3-6 parts of aluminum hydroxide, 6-10 parts of calcium hydroxide, 1-3 parts of zinc borate, 3-7 parts of friction particles, 6-10 parts of vermiculite powder, 1-4 parts of tire powder, 5-12 parts of nitrile modified resin, 2-8 parts of nitrile gelatine powder, 2-4 parts of rigid cellulose fiber, 5-8 parts of natural organic fiber, 4-8 parts of mineral fiber, 10-15 parts of ceramic fiber and 8-15 parts of friction powder. The raw materials are mixed, baked and formed to obtain the brake. The automotive disc ceramic brake without heavy metal, heavy metal sulfide or heavy metal fluoride has good friction performance and is environment-friendly and harmless to human health.

Owner:重庆绿陶摩擦材料有限公司

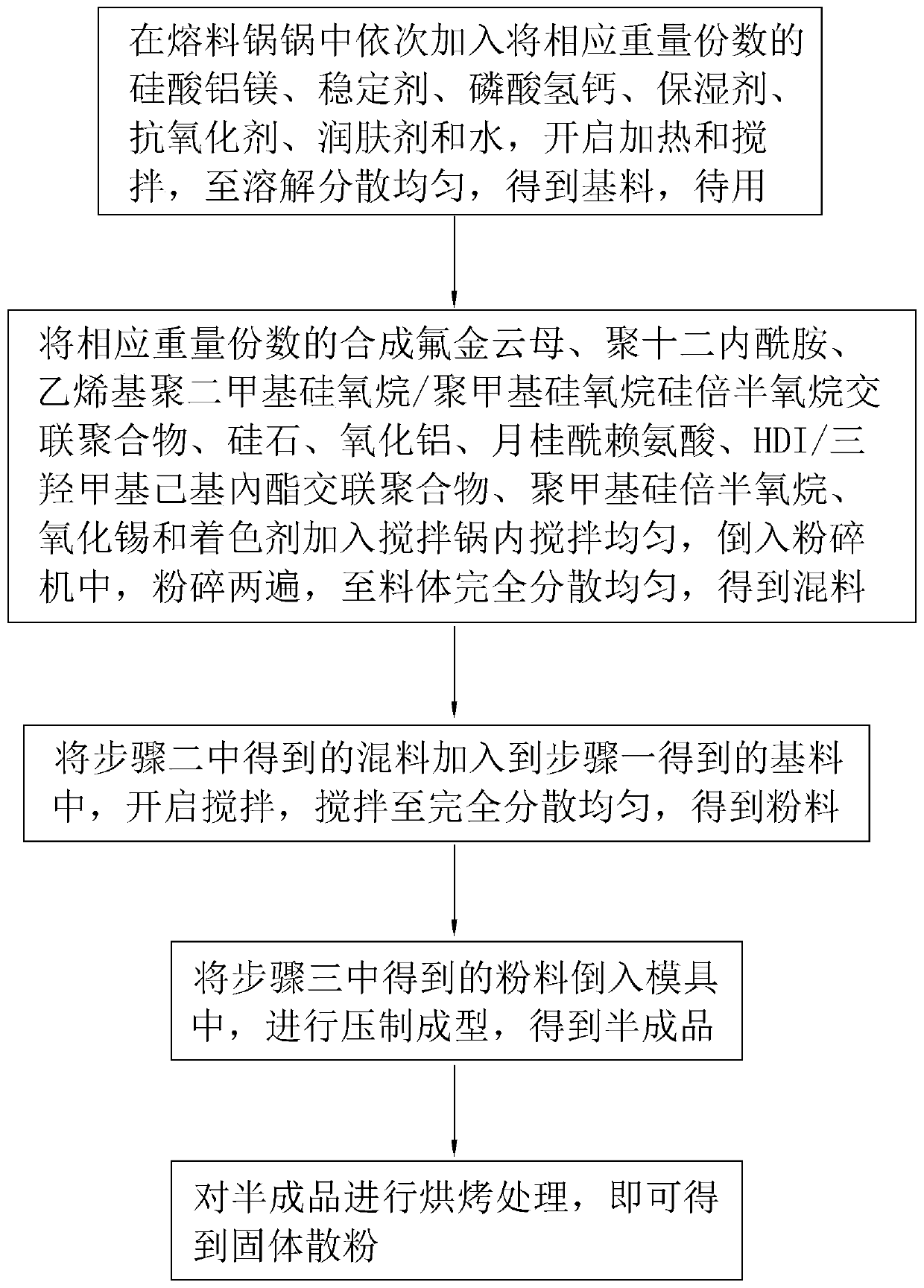

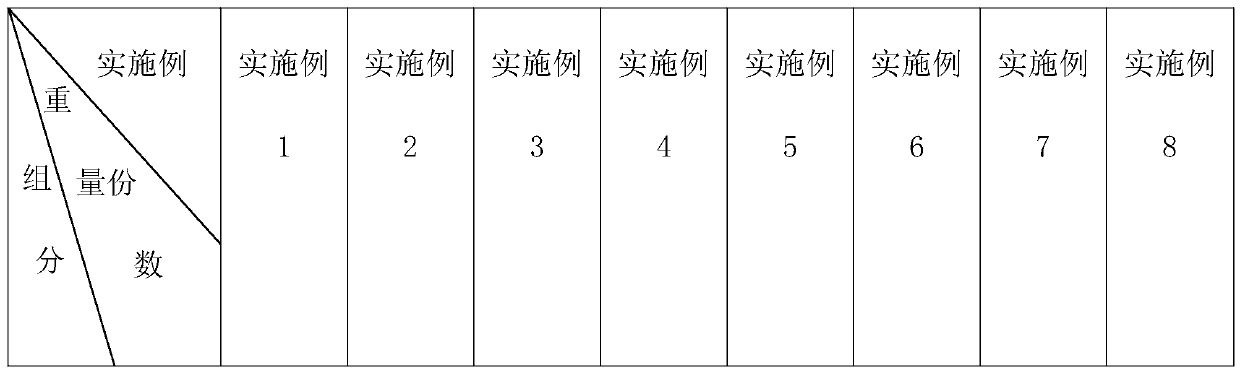

Solid loose powder and preparation method thereof

The invention discloses solid loose powder and a preparation method thereof, relates to the technical field of cosmetics and aims to solve the problem that loose powder is poor in overall applicationeffect as a massive powder dropping phenomenon can be easily caused in a use process. The solid loose powder comprises the following components in parts by weight: 15-25 parts of synthetic fluorophlogopite, 5-10 parts of polylaurylamide, 5-10 parts of a vinyl dimethyl siloxane / methylsiloxane silsesquioxane cross-linking polymer, 5-10 parts of silica, 8-10 parts of aluminum oxide, 3-8 parts of lauroyl lysine, 2-5 parts of HDI-trihydroxymethyl hexyl lactone cross-linking polymer, 3-5 parts of polymethyl silsesquioxane, 1-5 parts of tin oxide, 1-5 parts of magnesium aluminum silicate, 0.1-3 partsof water, 0.1-3 parts of a coloring agent, 0.5-3 parts of calcium hydrophosphate, 8-20 parts of an emollient, 2-10 parts of a humectant, 1-5 parts of a stabilizer and 0.5-3 parts of an antioxidant. The solid loose powder disclosed by the invention is free of the massive powder dropping phenomenon in the use process, and is good in overall application effect.

Owner:上海欧润化妆品有限公司

Non-woven fabric for manufacturing dust-free wiping paper and manufacturing method thereof

The invention provides a non-woven fabric for manufacturing dust-free wiping paper. The non-woven fabric for manufacturing the dust-free wiping paper comprises a non-woven fabric containing cellulosic fibers, wherein the non-woven fabric is prepared by treating a treatment solution containing polyvinyl alcohol, water-borne polyacrylate and a water-borne isocyanate cross-linking agent. The provided non-woven fabric is firm, high in cleanliness and soft. The invention also provides a method for manufacturing the non-woven fabric. The manufacturing method comprises the following steps: preparing the treatment solution containing polyvinyl alcohol, water-borne polyacrylate and a water-borne isocyanate cross-linking agent; padding the non-woven fabric containing cellulosic fibers by adopting the treatment solution, and baking. The method is simple and low in cost.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Selecting technology during preparing grass material

The present invention provides grass material sieving process, which includes the following steps: 1. cutting grass material excluding reed into 20-80 mm long chopped pieces and dedusting; 2. sieving; and 3. storing the sieved grass material in material storing storehouse. The grass material sieving process can eliminate most of grass knots likely to form yellow spot in the made paper, and this can reduce the alkali consumption in the papermaking process.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

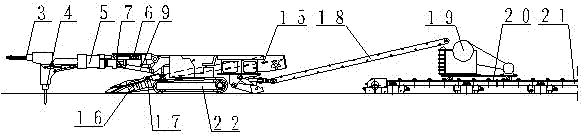

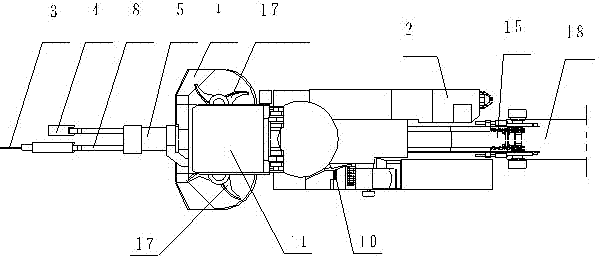

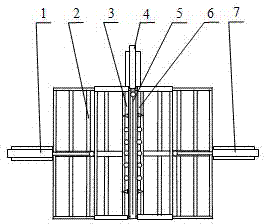

Automatic bag breaking discharge device

InactiveCN104760735ASimple structureReduce labor intensityLoading/unloadingConveyor partsEngineeringCylinder block

The invention relates to an automatic bag breaking discharge device. According to the technical scheme, a bag cutting tool (5) is installed on the middle position of the upper plane of a bag breaking tool rack (2) in the front-back direction, a left bag breaking tool (3) and a right bag breaking tool (6) are correspondingly installed on the left side and the right side of the bag cutting tool (5), and the left bag breaking tool (3) and the right bag breaking tool (6) are symmetrically arranged on the upper plane of the bag breaking tool rack (2); the working end of a piston rod of a bag cutting tool air cylinder (4) is hinged to the bag cutting tool (5), the working end of a piston rod of a left bag breaking air cylinder (1) is hinged to the left bag breaking tool (3), and the working end of a piston rod of a right bag breaking air cylinder (7) is hinged to the right bag breaking tool (6); a cylinder body of the bag cutting tool air cylinder (4), a cylinder body of the left bag breaking air cylinder (1) and a cylinder body of the right bag breaking air cylinder (7) are fixed onto a middle support, a left support and a right support correspondingly. The automatic bag breaking discharge device has the advantages that the volume is small, the dust production volume is small, the efficiency is high, the labor intensity is small, the degree of automation is high, and the requirement of conducting continuous bag breaking and material discharging of powdery materials can be met.

Owner:WUHAN UNIV OF SCI & TECH

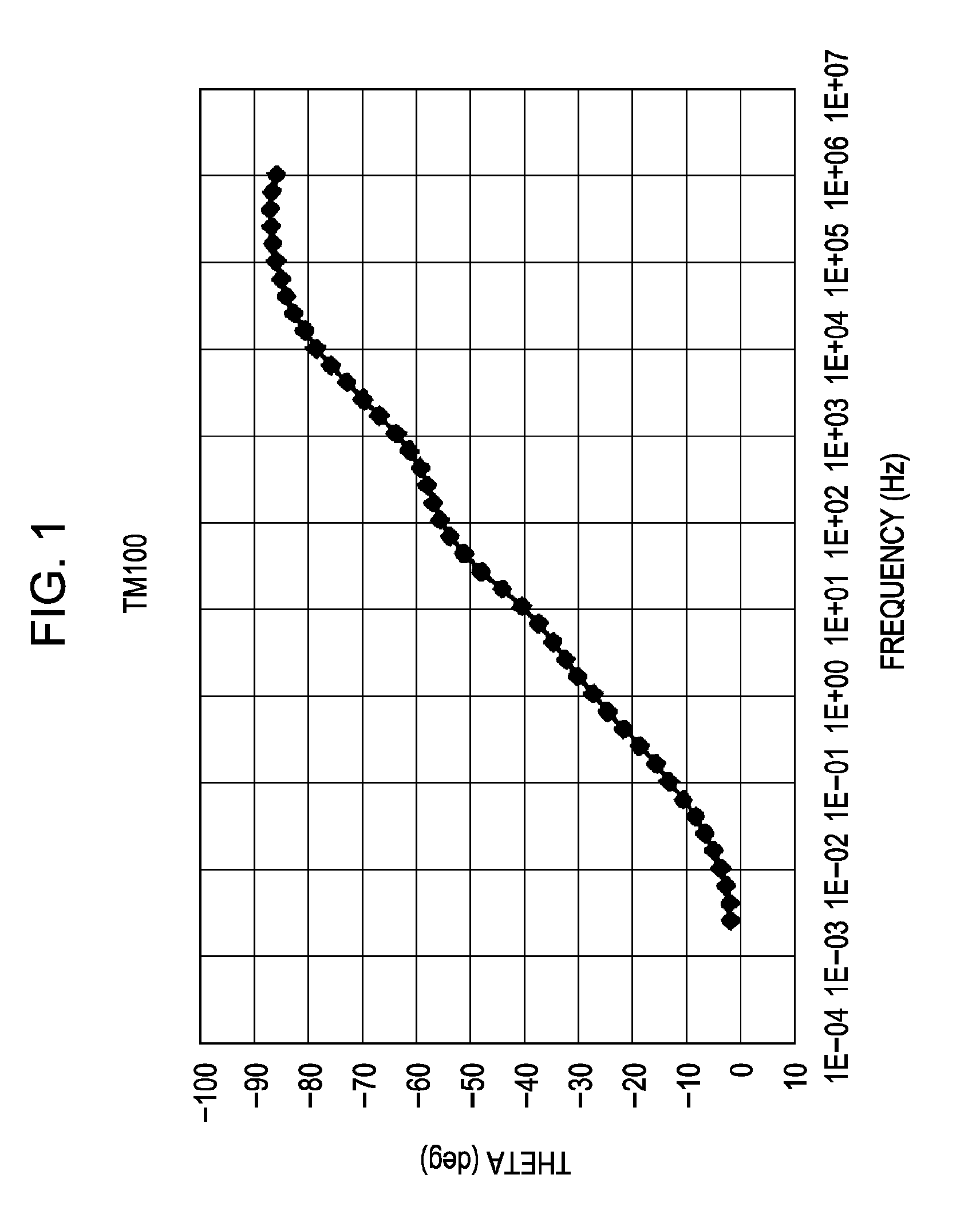

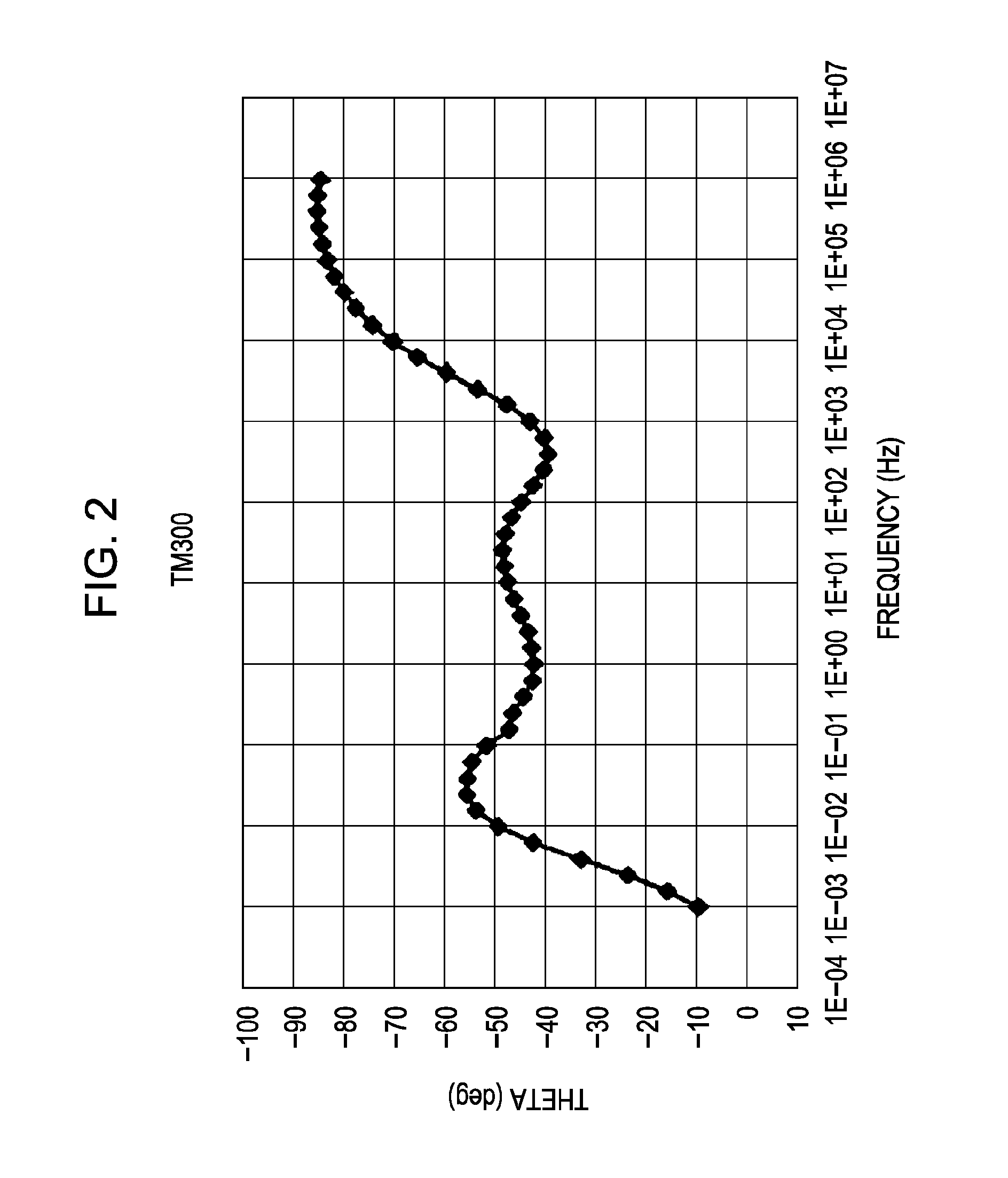

Toner, method for forming image, and image forming apparatus

InactiveUS20100261109A1Suppression gapLess dustElectrographic process apparatusDevelopersImage formationEngineering

A toner includes toner base particles containing at least a binder resin, a coloring agent, and a release agent; and alumina fine particles whose phase angle (θ) is |80°| or less at an alternating current frequency of 1 to 10 kHz in an alternating current impedance method.

Owner:SEIKO EPSON CORP

Forming method of positive pole piece of lithium ion power battery

The invention discloses a forming method of a positive pole piece of a lithium ion power battery. A big positive pole piece roll is symmetrically and continuously coated with blank middle; coating regions are located on positive and negative faces of a pole piece body, are symmetrical in position, and share pole tabs led out of blank middle regions; and eudipleural blank regions are arranged on the two sides of the coating regions. Forming of the positive pole piece adopts integral fillet cutting die punching design, the pole piece adopts rotary compact distribution, and safe boundaries are arranged at the heads and the tails of the coating regions, so that a foil material is utilized to the greatest extent, and the material cost of the battery is lowered. Fillet design avoids upturning and deformation of corners of the pole piece, and the assembling efficiency and the safety performance of the lithium ion battery are further improved. The method can effectively reduce the probability of an internal short circuit due to the fact that a pole piece edge burr generated by die cutting pierces a membrane of the battery; a powder falling phenomenon of dressing in a next manufacturing process is greatly reduced; self-discharge of a battery cell is reduced; and the electrical performance and the safety performance of the battery are improved.

Owner:重庆鲁岳实业有限公司

LNG structure as well as nickel-based welding rod for marine 9Ni steel welding, and preparation method thereof

ActiveCN107214434AIncrease alkalinityStrong desulfurization abilityWelding/cutting media/materialsSoldering mediaChemical compositionUltimate tensile strength

The invention discloses an LNG structure as well as a nickel-based welding rod for marine 9Ni steel welding, and a preparation method thereof. The welding rod comprises a nickel-based welding core and a coating coated on the surface of the welding core, wherein the nickel-based welding core comprises the following chemical components with percentage contents: not greater than 0.10% of C, not greater than 0.10% of Si, not greater than 0.10% of Mn, not greater than 0.10% of Cu, not greater than 0.10% of Mg, not greater than 0.005% of S, not greater than 0.40% of Fe and not less than 99.5% of Ni+Co, and the total content of the components is 100%. The welding rod disclosed by the invention is high in manufacturability, and capable of being smoothly coated in a pressing manner during a production process, the coating of the welding rod is high in strength and good in surface quality, and the welding rod is controllable in core shift; and the chemical components of deposited metal meet standards, and weld metal is free from pores and cracks, high in normal-temperature tension and low-temperature toughness, good in mechanical property, and capable of being widely applied.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

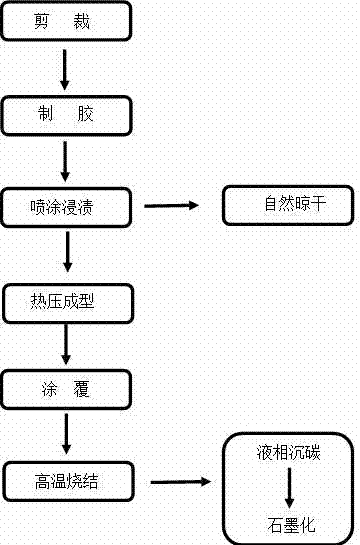

Preparation method of carbon/carbon composite thermal insulation material containing anti-oxidization coating

The invention relates to a preparation method of a carbon / carbon composite thermal insulation material containing an anti-oxidization coating. The method mainly comprises the following steps: mixing soluble thermosetting phenolic resin with ethanol evenly to form an impregnant; spraying the impregnant on the surface of a carbonization felt, and then carrying out hot press molding; mixing SiC powder, thermosetting resin and ethanol evenly at a certain ratio, coating the surface of a hot press plate, putting the hot press plate into a graphitization furnace and graphitizing; and cooling to form the carbon / carbon composite thermal insulation material with a ceramic-coated surface. According to the preparation method, the problem that the carbon / carbon composite thermal insulation material is easily oxidized in the use procedure or the production process is solved, and the service life of the carbon / carbon composite thermal insulation material is greatly prolonged. In addition, the preparation method is synchronous with the preparation process of the carbon / carbon composite thermal insulation material, and is simple and feasible.

Owner:SHANGHAI DINGXIN IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com