Patents

Literature

67results about How to "Loose arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

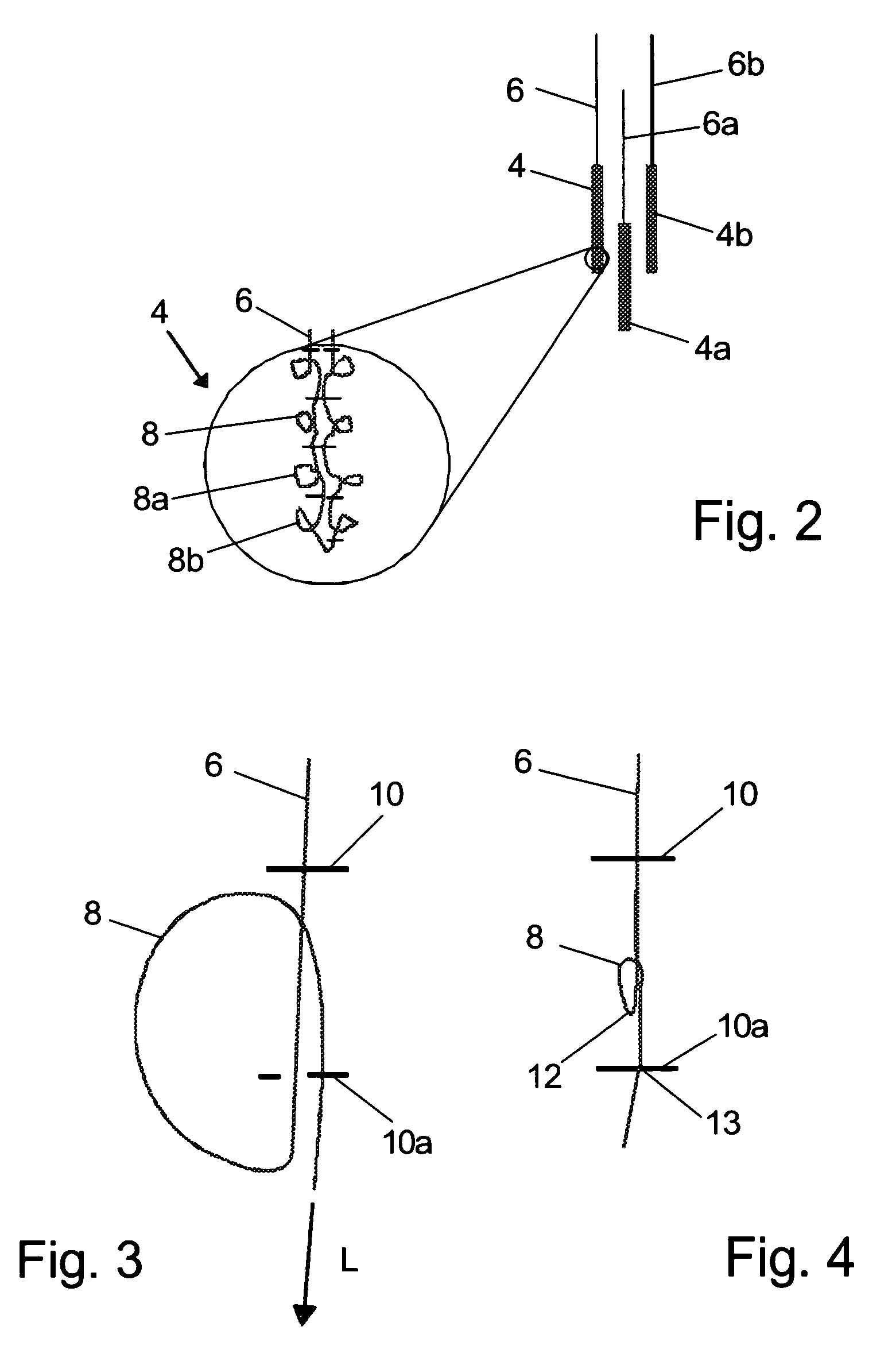

Light-emitting textile structure, in particular for medical purposes, and use thereof

InactiveUS7274844B2Easy to controlIncrease flexibilityDiagnostics using lightLighting support devicesEngineeringMedical treatment

Owner:BIOLITEC UNTERNEHMENSBETEILLIGUNGS II AG

Spontaneous heating moxibustion patch

InactiveCN106038261AEasy to absorbFree from pollutionDevices for heating/cooling reflex pointsAntipyreticPressure sensitiveEmulsion

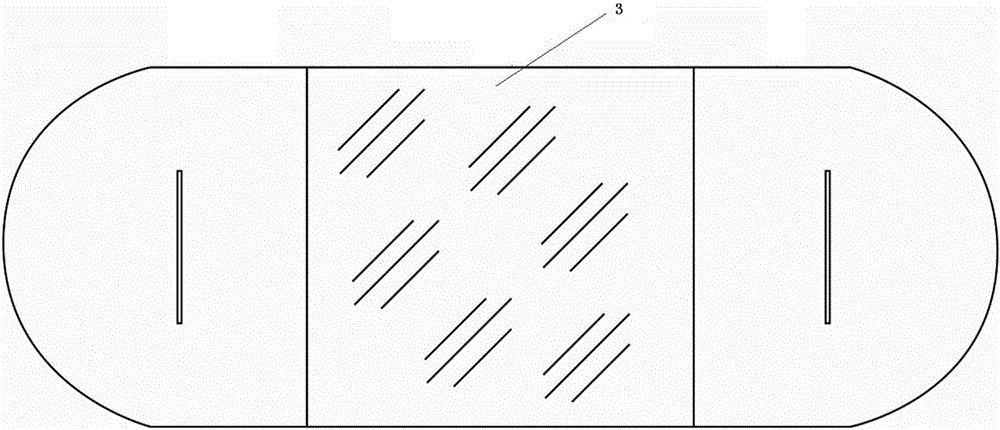

The invention discloses a spontaneous heating moxibustion patch. The spontaneous heating moxibustion patch comprises a back lining layer, a spontaneous heating iron powder bag, a traditional Chinese medicine cataplasm layer and anti-adherent membranes, wherein the two end portions of the back lining layer are each provided with a medical pressure-sensitive adhesive in an adherent mode, and the spontaneous heating iron powder bag is attached to a middle position of the back lining layer; the spontaneous heating iron powder bag generates heat once in contact with air; the Chinese medicine cataplasm layer is attached to the spontaneous heating iron powder bag; the medical pressure-sensitive adhesives and the Chinese medicine cataplasm layer are each provided with an anti-adherent membrane with an adherent mode; the Chinese medicine cataplasm layer is composed of a substrate and a hydrogel layer smeared on the substrate; the substrate is attached to the spontaneous heating iron powder bag; the hydrogel layer is composed of a hydrogel matrix and a medicament; and the two end portions of the back lining layer, after being folded, wrap the middle position of the back lining layer, and thus the spontaneous heating moxibustion patch is obtained. According to the spontaneous heating moxibustion patch, the traditional Chinese medicine cataplasm layer comprises an Artemisia leaf pure dew emulsion with micromolecule terpenoids as its main components, and the micromolecule terpenoids can penetrate human skin quite easily and can penetrate the human skin more successfully under the effect of the spontaneous heating iron powder bag and a penetration enhancer so as to be absorbed by a human body.

Owner:陈颉

Preparation method of polyvinyl chitosan mixed film

InactiveCN101007243AHigh mechanical strengthGood chemical stabilitySemi-permeable membranesAcetic acidMethyl carbonate

The invention involves a preparation method used for separating the polyvinyl alcohol / chitosan mixing film of methanol / dimethyl carbonate, the preparation process is as follows: 1) dissolving the polyvinyl alcohol with the deionized water as solvent in 80 ~ 100 degree C and gaining uniform casting film solution which polyvinyl alcohol concentration is 5wt%; 2) dissolving the chitosan with the glacial acetic acid and deionized water as solvent in 20-40DEG C and gaining uniform casting film solution which chitosan concentration is 1wt%; 3) according certain radio mixing the ratio of PVA and chitosan solution uniformly and debubbling; 4) making film on the glass plate with casting method; 5) thermal treating the film 2~4 hours in 120 ~ 150 degree C. Compared with traditional separation methods, the method has some characteristics such as high one-time separation degree, simple precess, low energy consumption and pollution-free.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

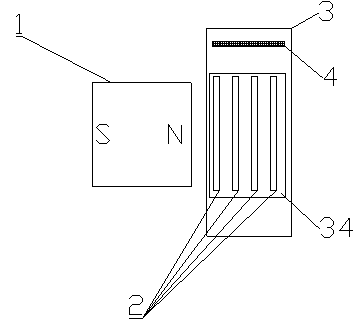

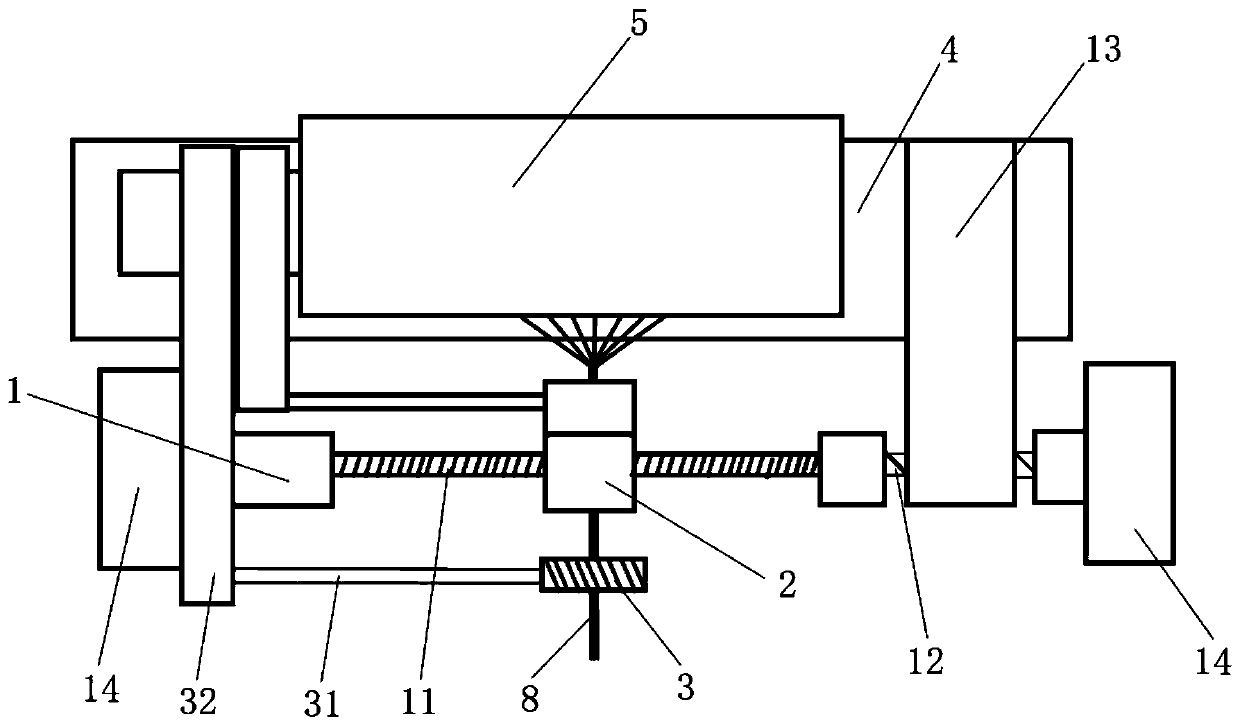

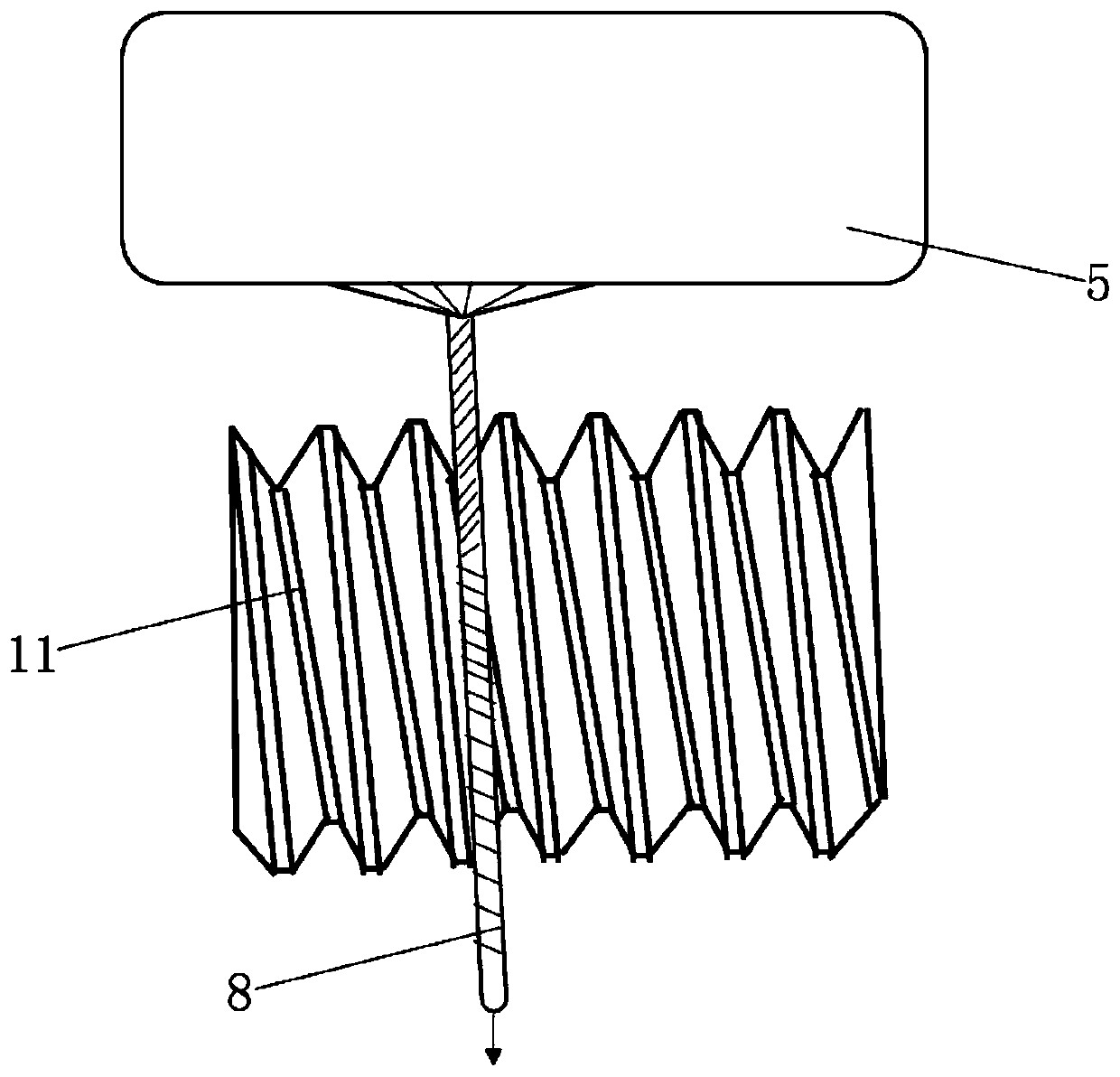

Heating evaporation source for organic materials

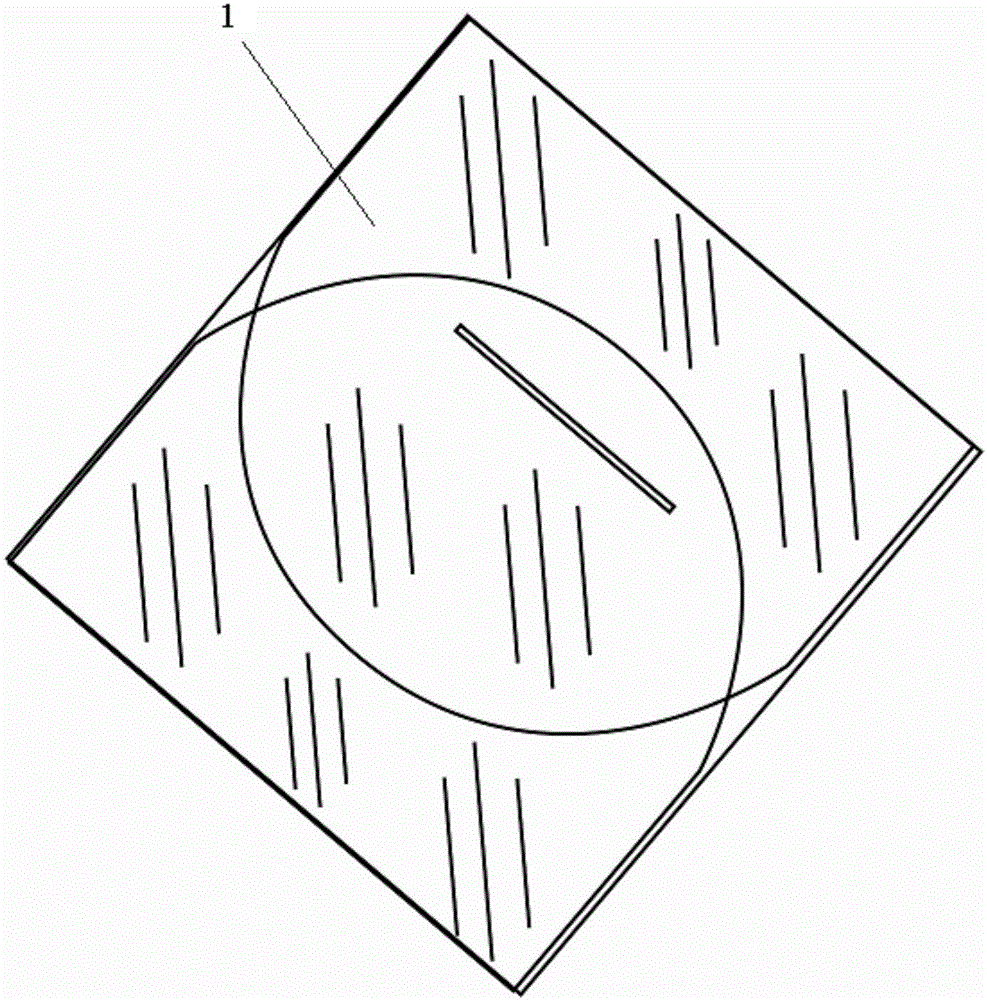

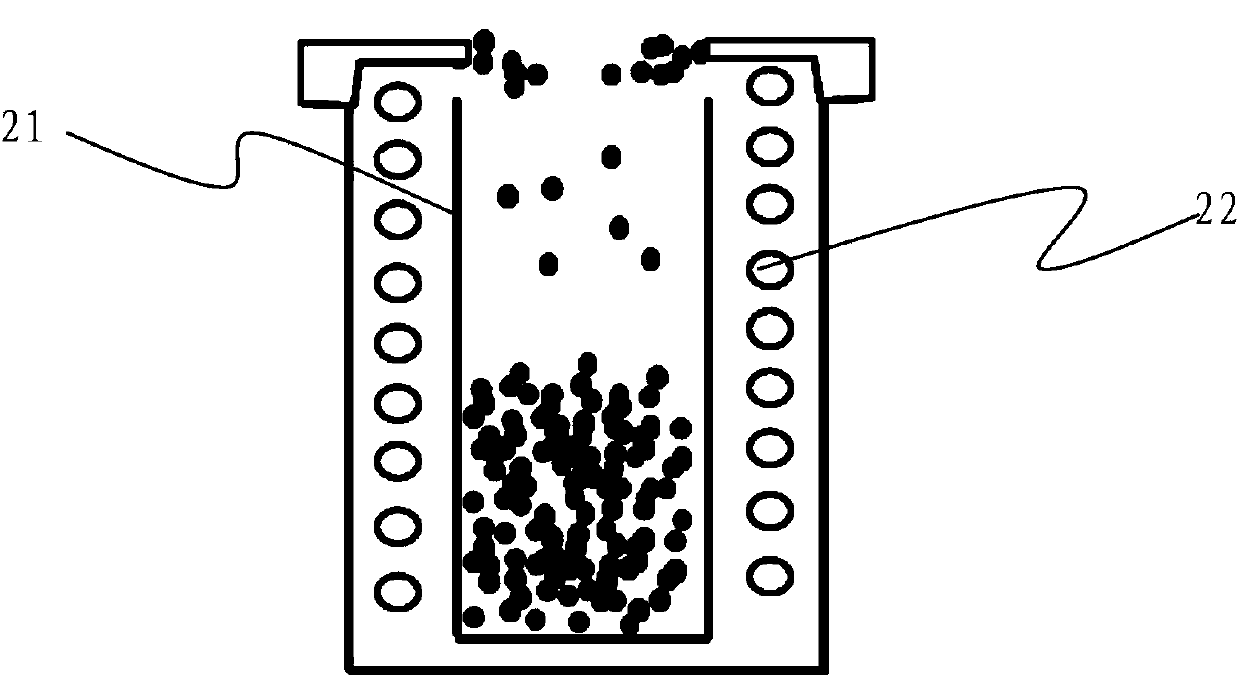

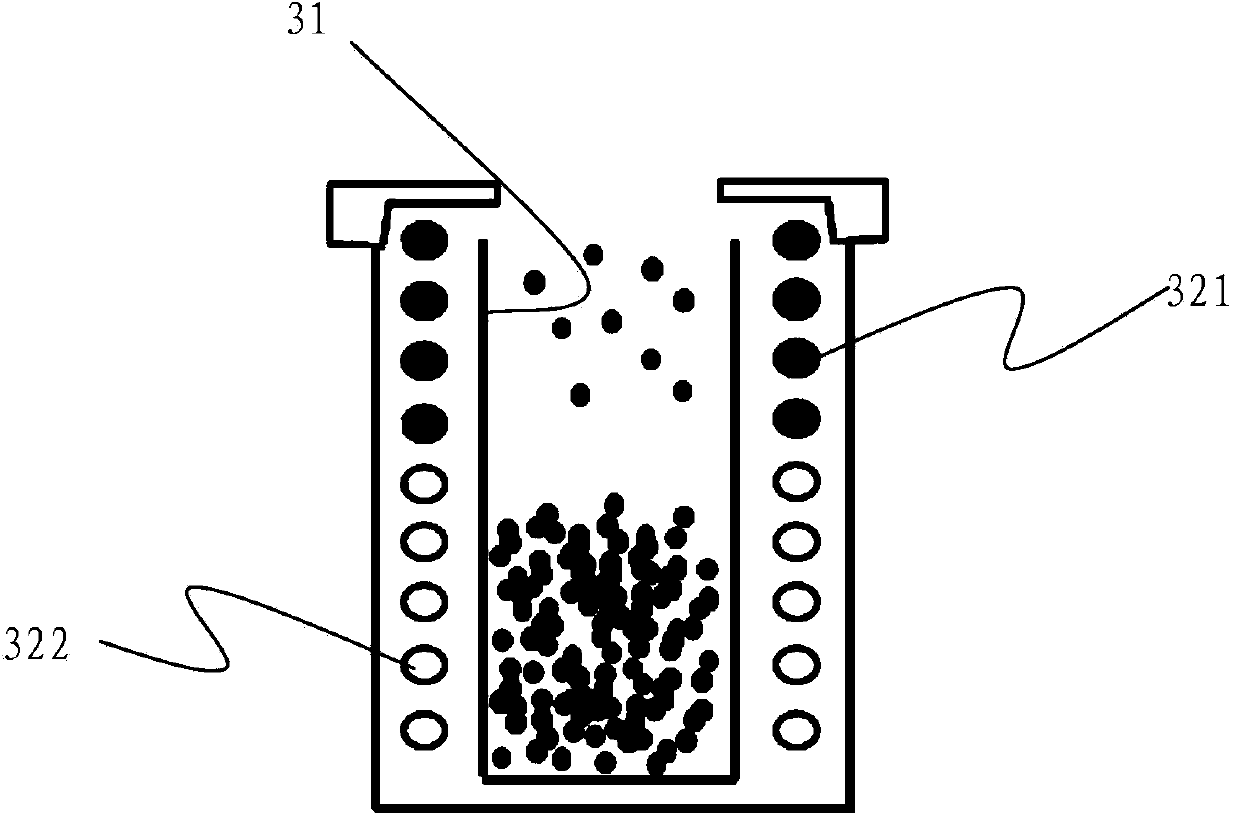

InactiveCN103726022ASolve the problem of condensation blockageLoose arrangementSolid-state devicesVacuum evaporation coatingCrucibleMetallurgy

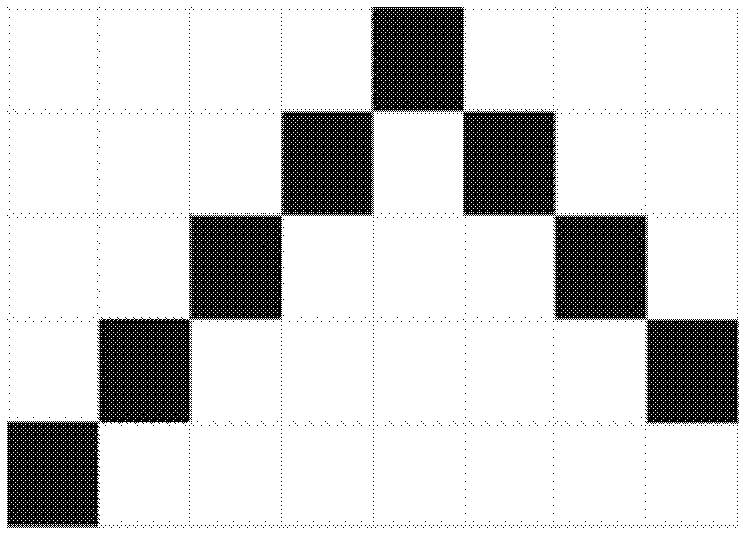

The invention discloses a heating evaporation source for organic materials. The heating evaporation source comprises an evaporation chamber as well as a crucible and heaters which are arranged in the evaporation chamber, wherein the heaters comprise a heating wire distributed on the periphery of the crucible, and in addition, the distribution density of the heating wire at the upper part of the crucible is larger than that of the heating wire in the middle and at the lower part of the crucible. According to the heating evaporation source, one heating wire is used, a group of heaters are matched, two heating sections are divided, the heating wire in the middle and at the lower part of the crucible is loosely arranged while the heating wire at the upper part of the crucible is closely arranged, due to the difference of distribution densities of the heating wire in the middle and at the lower part of the crucible as well as at the upper part of the crucible, the upper part of the crucible is at a higher temperature, and The temperature of the upper part of the crucible is higher than that of the bottom of the crucible, so that evaporation materials cannot coagulate at an upper port of the crucible, and the problem of blockage caused by material coagulation is solved; in addition, only one heating wire is needed, so that only one group of heaters are needed, and the cost is lower.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

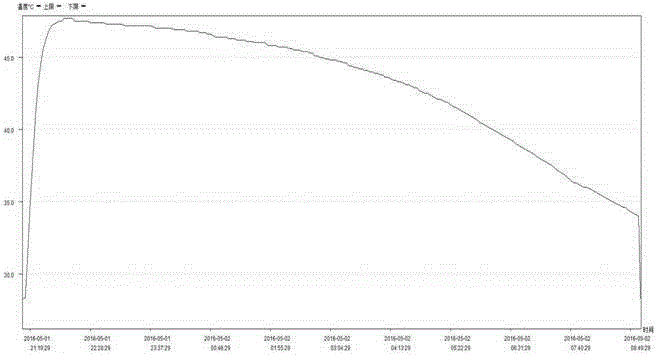

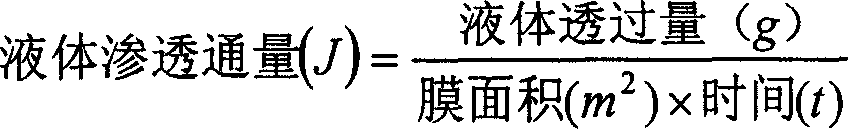

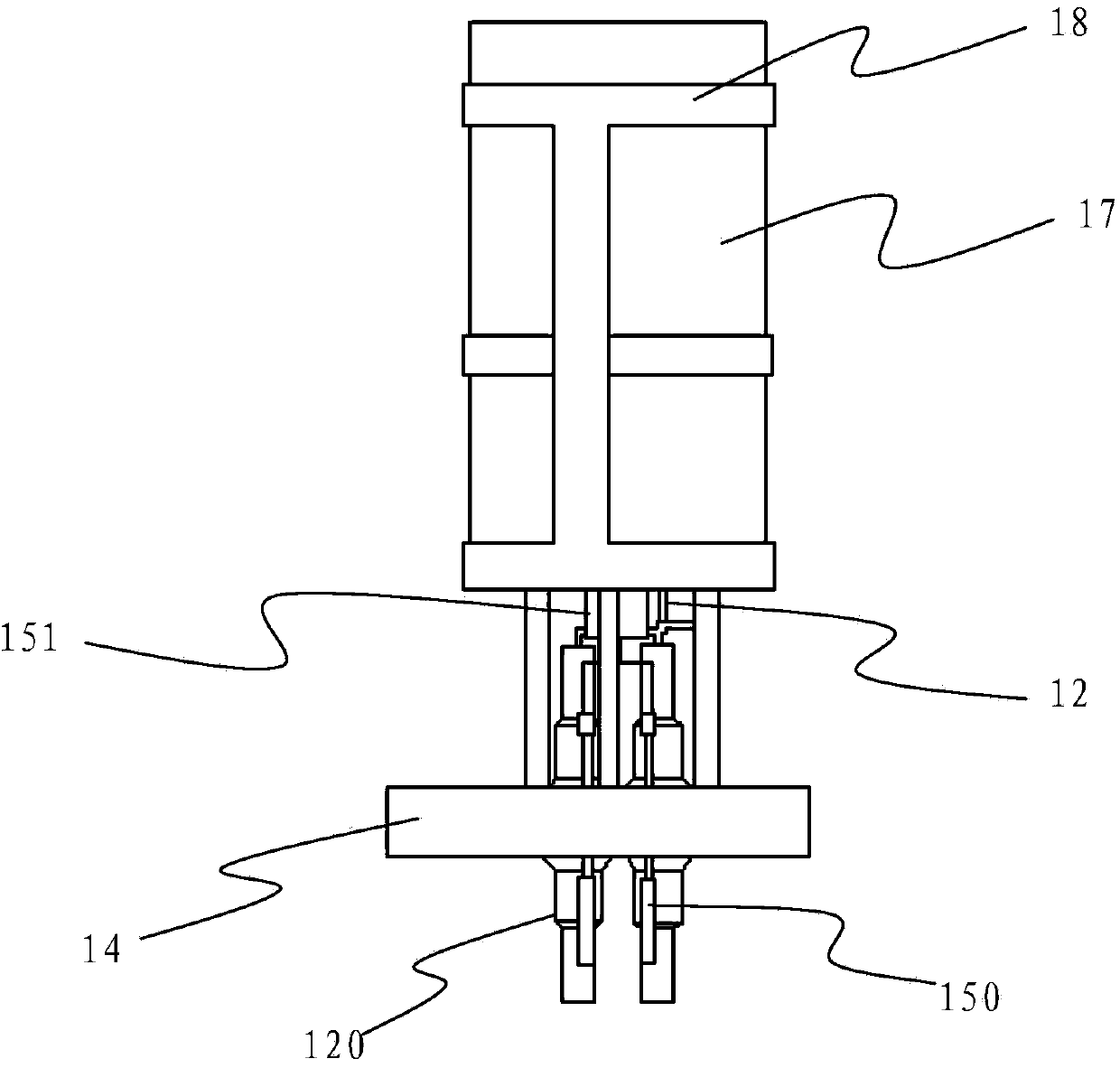

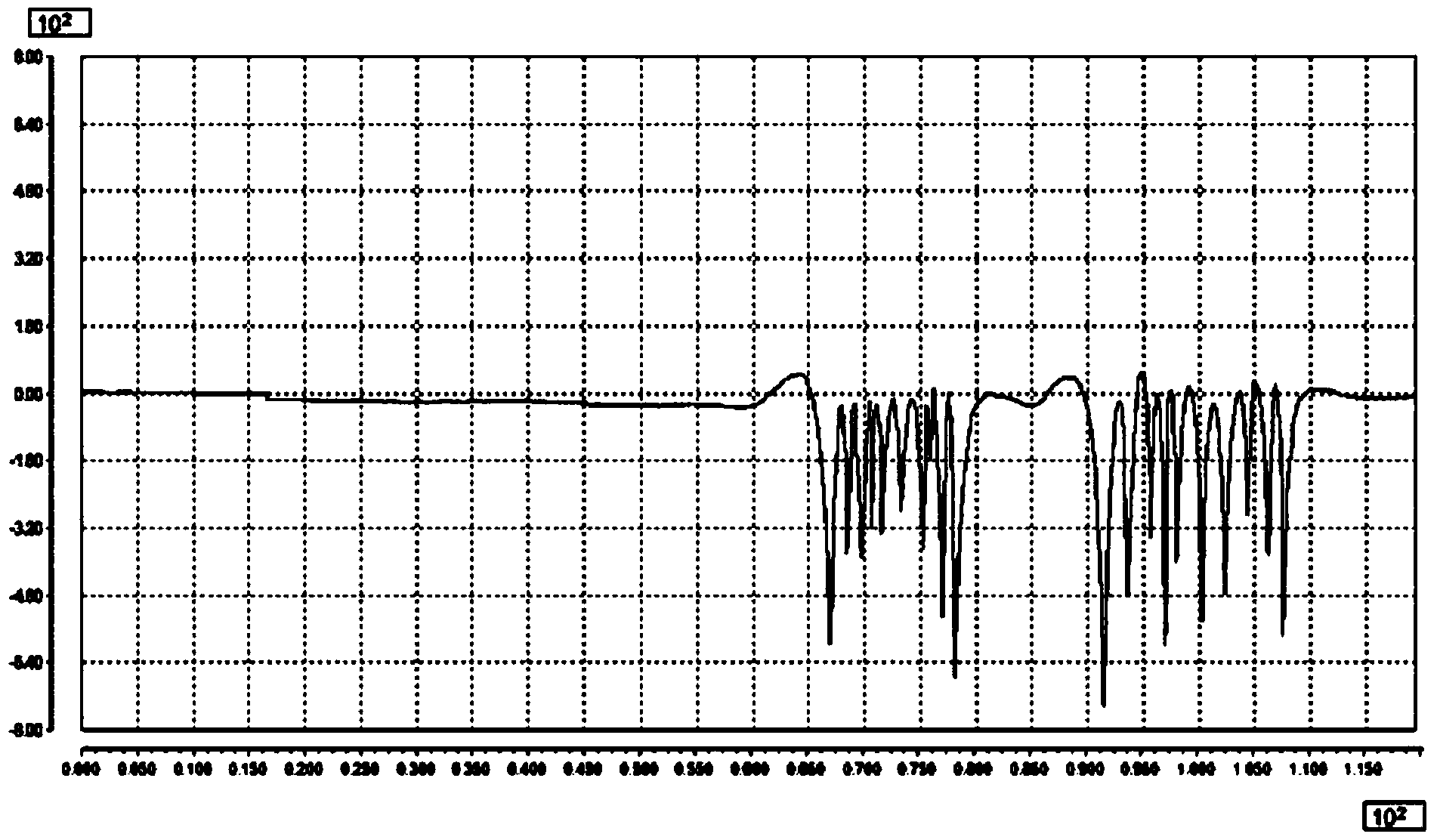

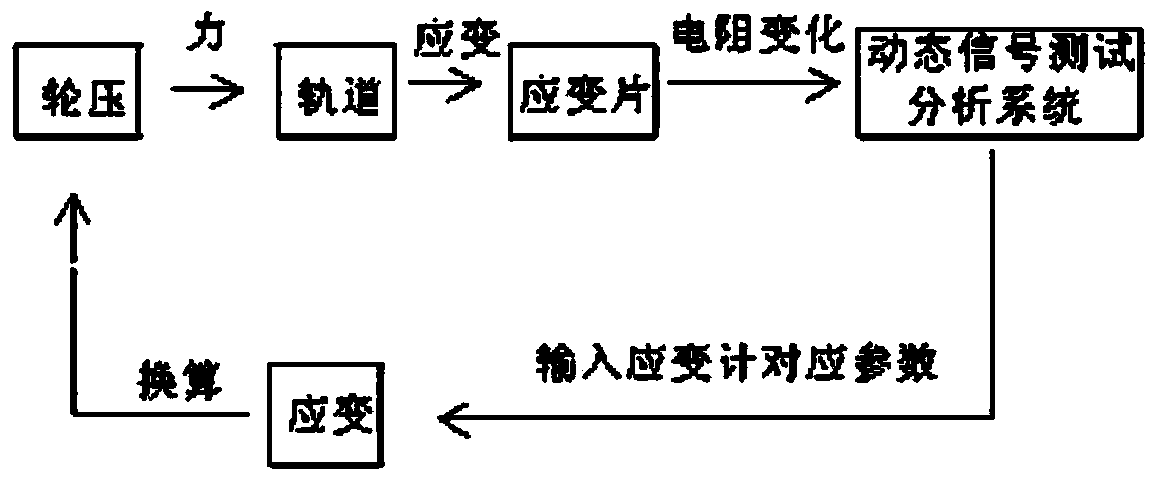

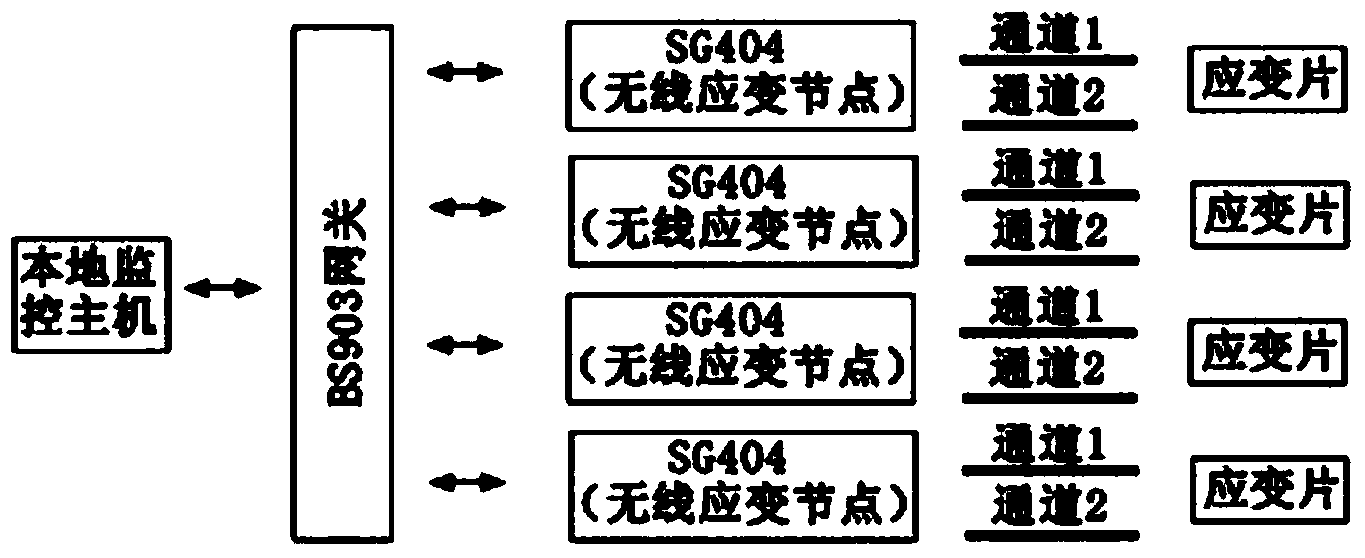

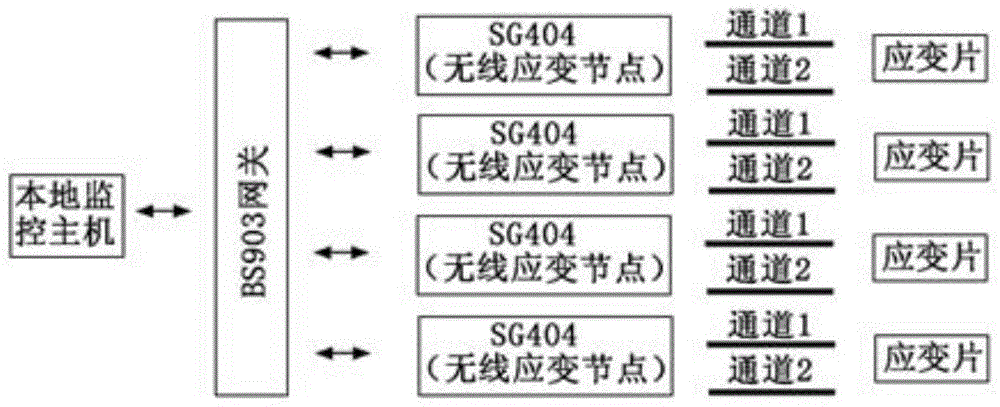

Measuring method for crane cart wheel pressure

ActiveCN104034469ALoose arrangementOptimize layoutApparatus for force/torque/work measurementLifting capacityEngineering

The invention discloses a measuring method for a crane cart wheel pressure. The measuring method for the crane cart wheel pressure includes steps that (1) distributing foils, to be specific, pasting strain foils at the lateral surface of a cart track; (2) building a wheel pressure monitoring system, to be specific, connecting the strain foils and wireless strain nodes with a monitoring host; (3) calibrating, to be specific, enabling a crane to locate in a no-load state, enabling a crane dolly to locate at a proper position, enabling the cart to pass the cart track in a constant speed, and using the wheel pressure monitoring system to record a strain-time curve so as to obtain a wheel pressure and strain calibrating coefficient (shown in the description); (4) measuring the cart wheel pressure on site, to be specific, when the dolly is located at a set position according to a set lifting capacity, gathering the corresponding strain value, and converting the strain value into the corresponding wheel pressure (shown in the description). The measuring method for the crane cart wheel pressure is easy and practical, is capable of precisely measuring the actual value of each wheel pressure, is more direct and reliable than a calculation method, is capable of directly reflecting the wheel pressure non-uniformity of the crane under different working conditions and provides essential data for optimizing, using and maintaining the crane wheels and saving civil engineering cost.

Owner:NANTONG BRANCH OF SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Method for making low basis weight manila board from wood fiber

The invention relates to the technical field of papermaking, in particular to a method for making a low basis weight manila board from wood fiber. The method comprises the steps of: A. dissolution, i.e. dispersing wood fiber and conducting dissolution treatment to obtain a wood fiber slurry; B. beating, i.e. conducting beating treatment on the wood fiber slurry subjected to dissolution treatment; C. coarse screening, i.e. conducting coarse screening treatment on the wood fiber slurry subjected to beating treatment; D. purification, i.e. mixing the wood fiber slurry subjected to coarse screening treatment with an MW slurry, then carrying out fine screening, slag removal, concentration and heat dispersion treatment, thus obtaining a core layer slurry for making coated white board paper; E. papermaking, i.e. processing a surface layer slurry, a lining slurry, a bottom slurry and the core layer slurry prepared by step D to obtain the low basis weight manila board. The method provided by the invention can effectively improve the bulkness of finished paper, reduces the paper basis weight exceeding problem, at the same time avoids the penetration point problem of thick and large wood fiber in finished paper, and greatly reduces the production cost.

Owner:DONGGUAN NINE DRAGONS PAPER IND

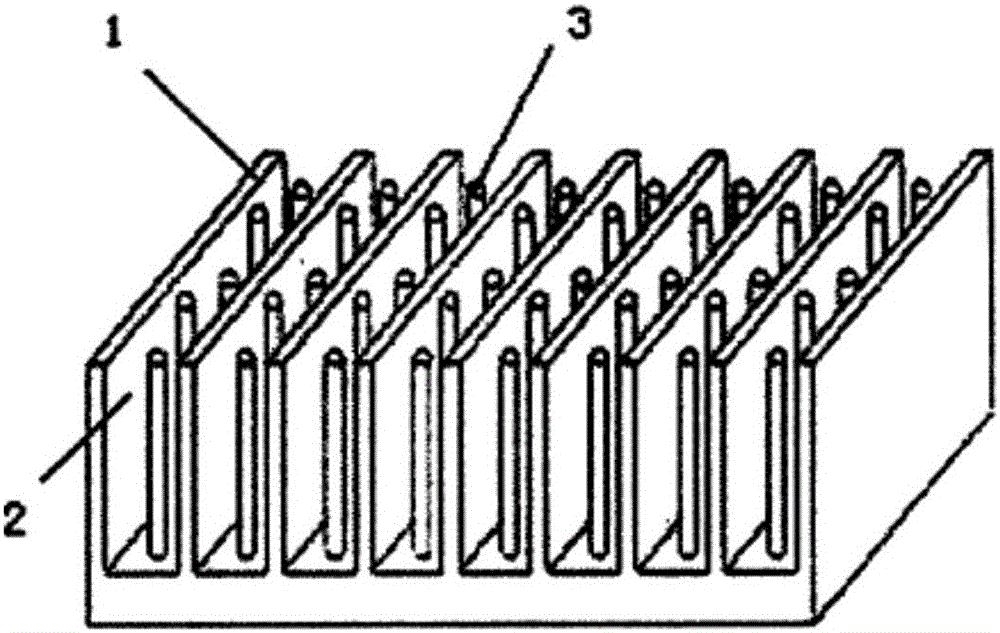

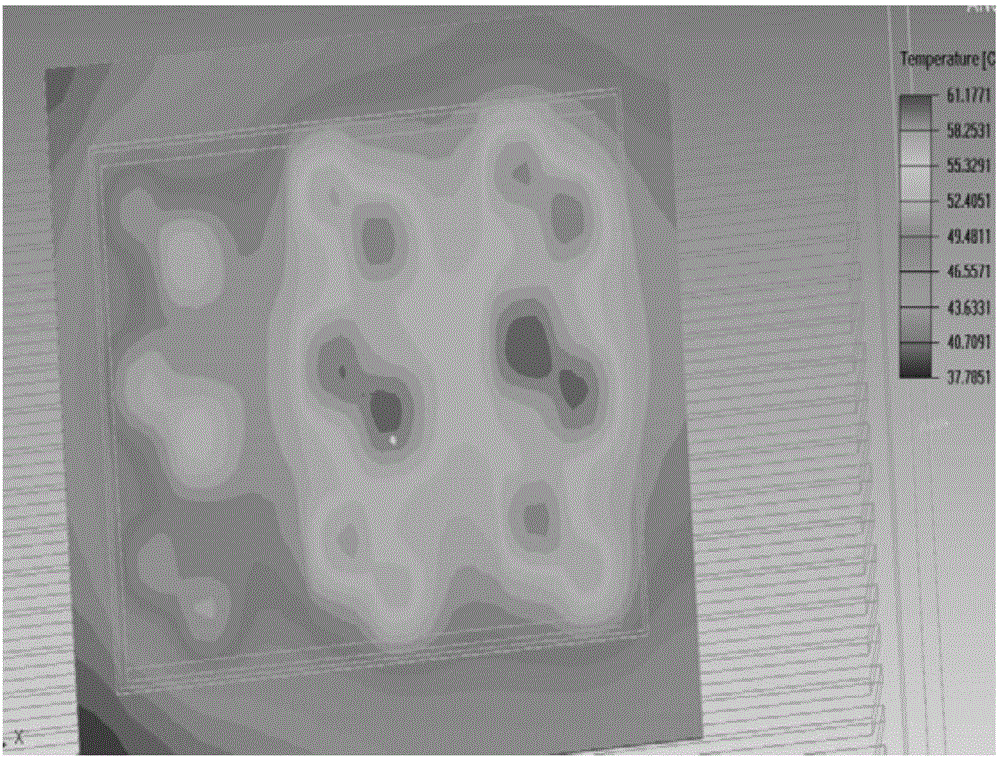

IGBT module heat-radiation apparatus

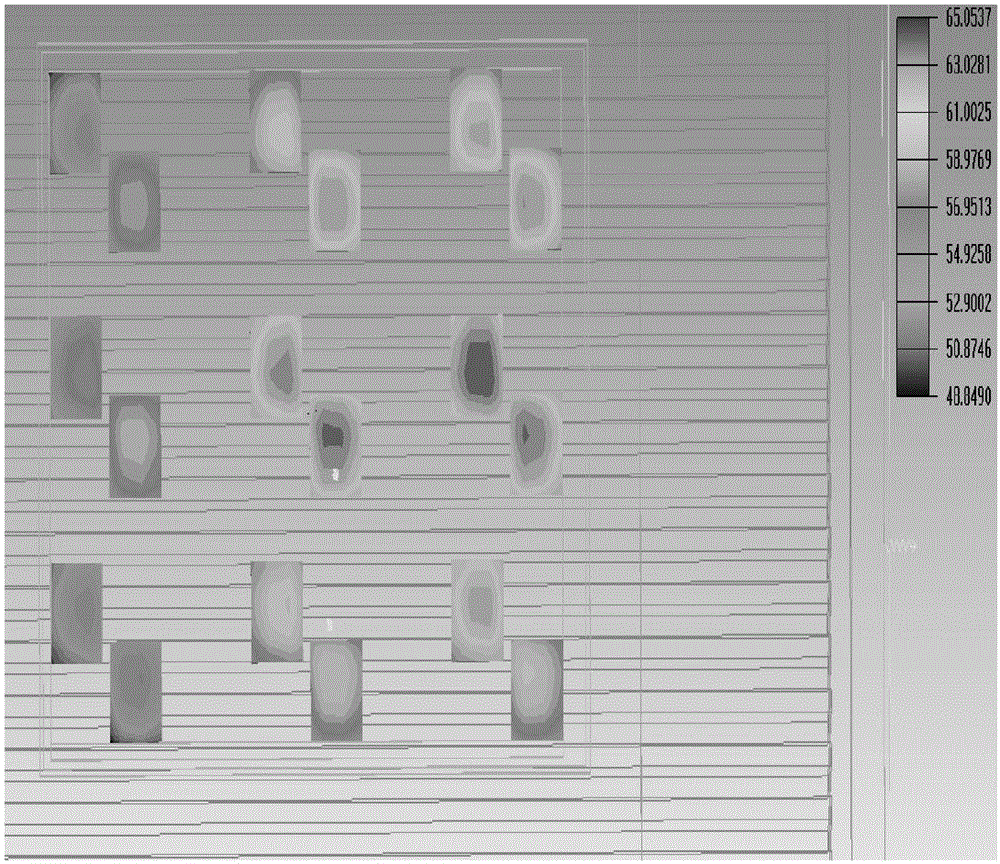

InactiveCN105161470AImprove temperature uniformityIncrease disturbanceSemiconductor/solid-state device detailsSolid-state devicesComputer moduleAir temperature

The invention discloses an IGBT module heat-radiation apparatus. The air temperature in an air inlet position is low while the air temperature in an air outlet position is high. The IGBT module heat-radiation apparatus comprises a plate-fin type radiator. The radiator comprises a plurality of fins. A plurality of projections are arranged inside a fin channel of the plate-fin type radiator. The projections are sequentially increasing from the air inlet position of the plate-fin type radiator to the air outlet position of the plate-fin type radiator. By arranging projections of different densities in the plate-fin type radiator channel to adjust the thermal resistance along the air flow direction, the heat-radiation apparatus has the thermal resistance decreased with the air flow direction. The temperature uniformity of the IGBT module heat-radiation apparatus is thus guaranteed. The IGBT module reliability is further improved.

Owner:XIAN YONGDIAN ELECTRIC

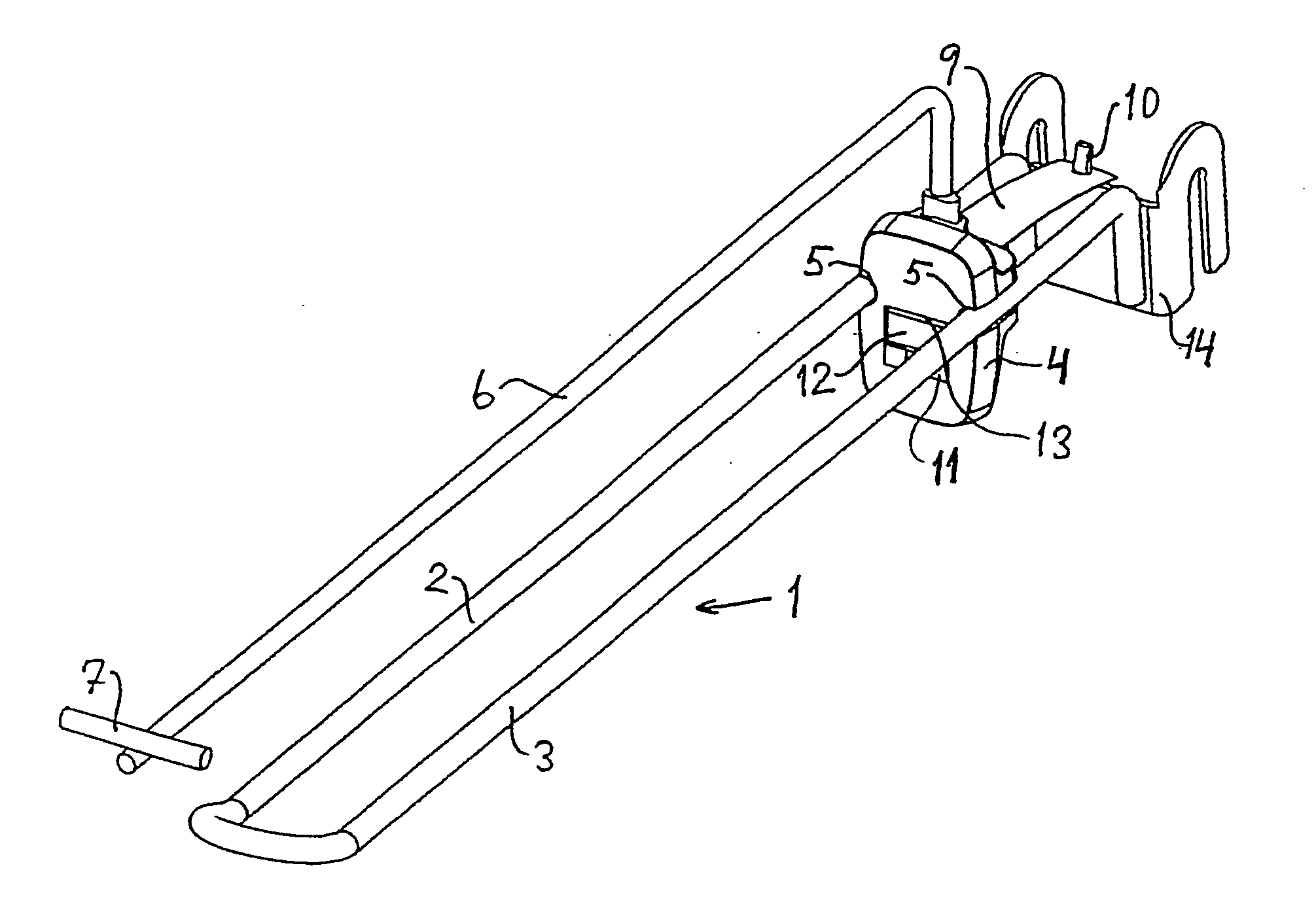

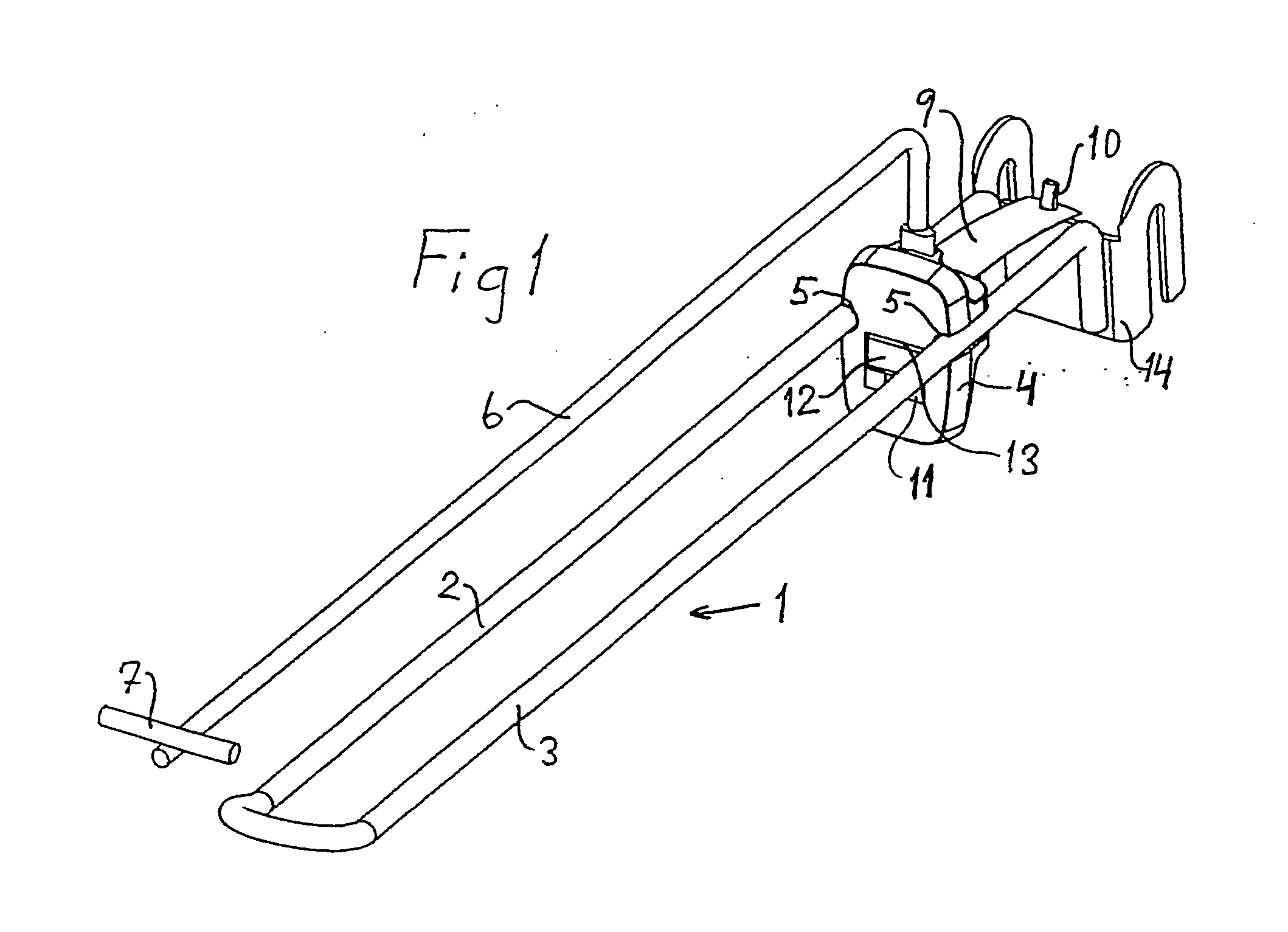

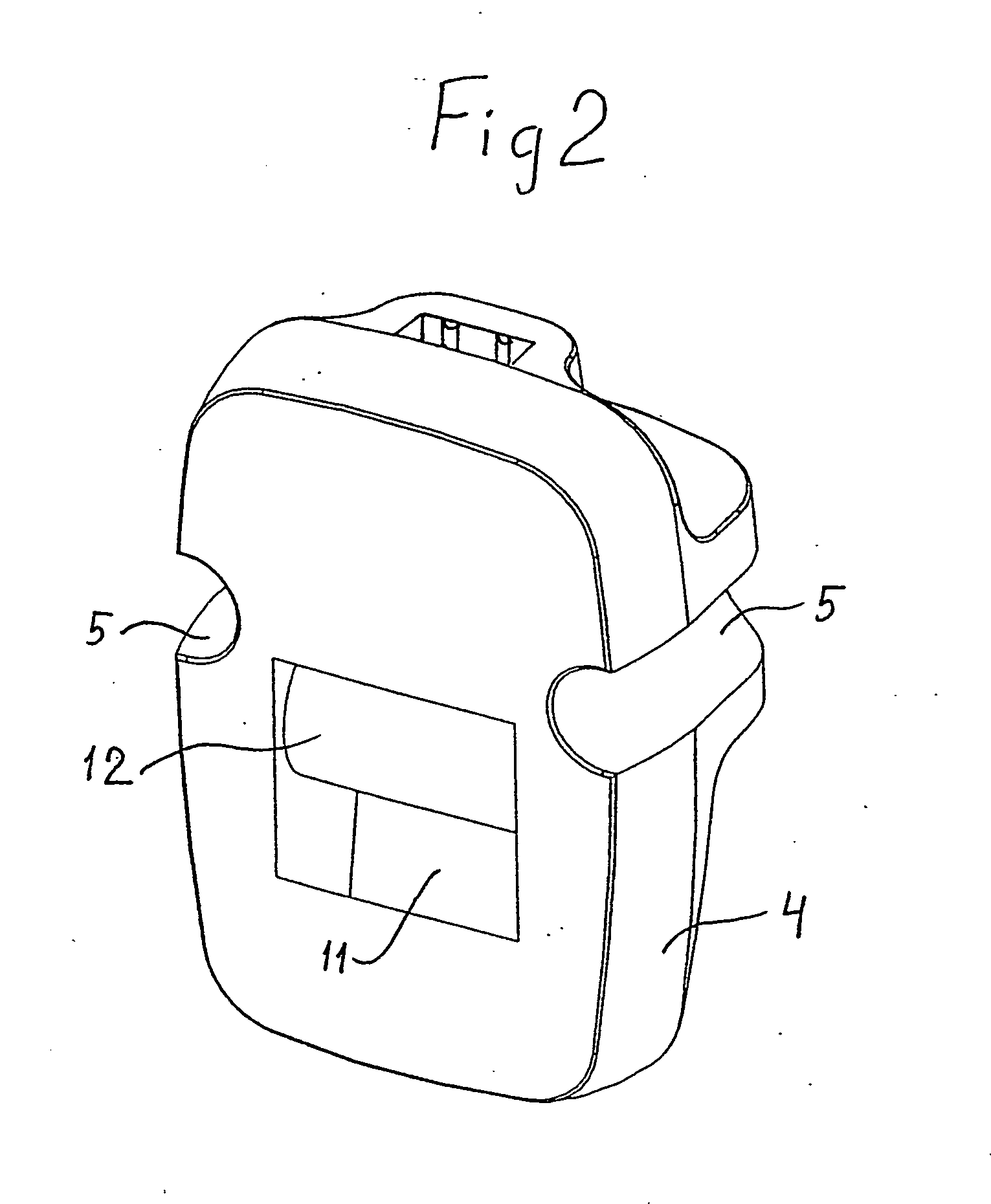

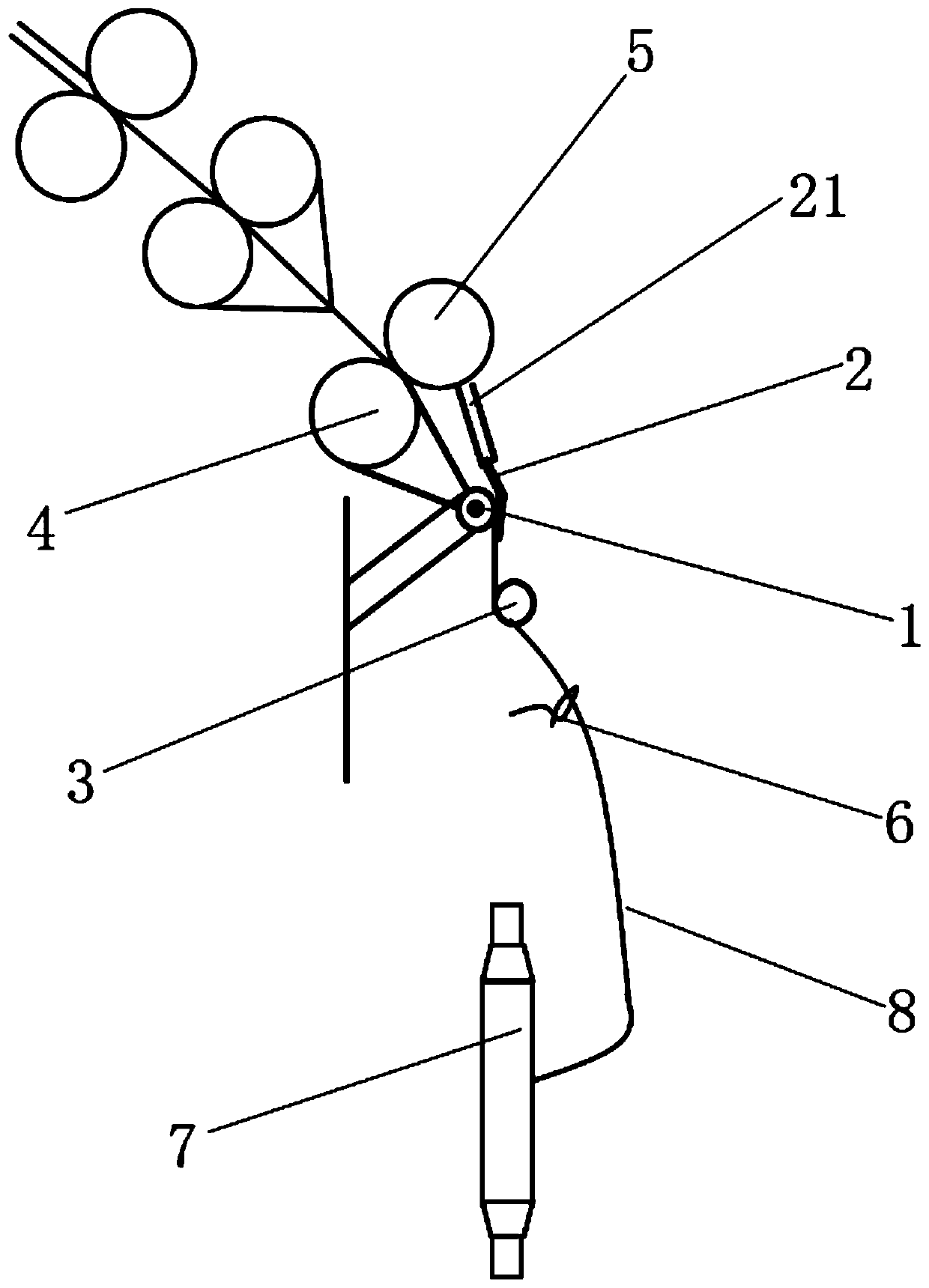

Arrangement for merchandise display prongs

InactiveUS20050077257A1Easy to installSimple and cost-effective preloadingRacksShow shelvesCoil springEngineering

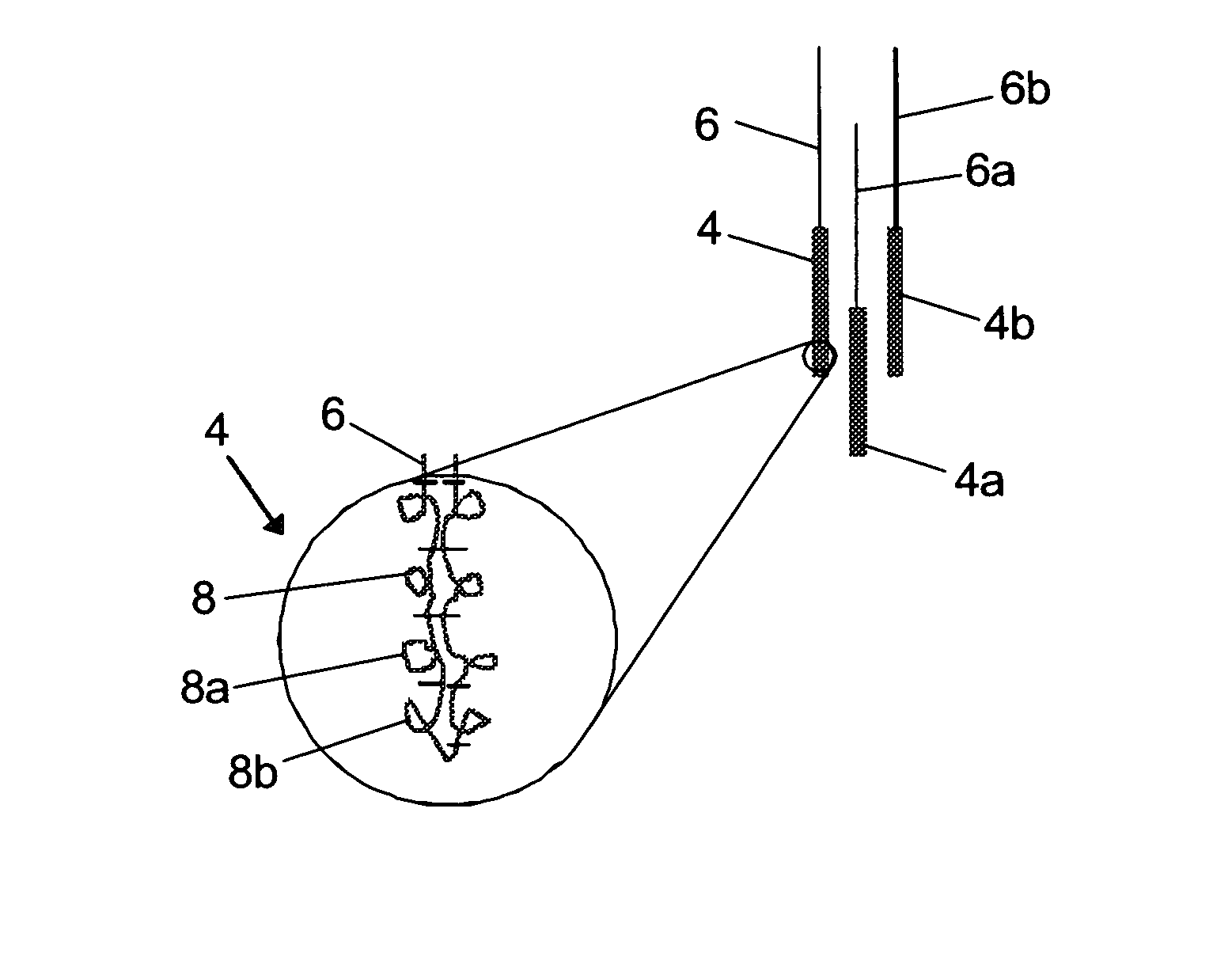

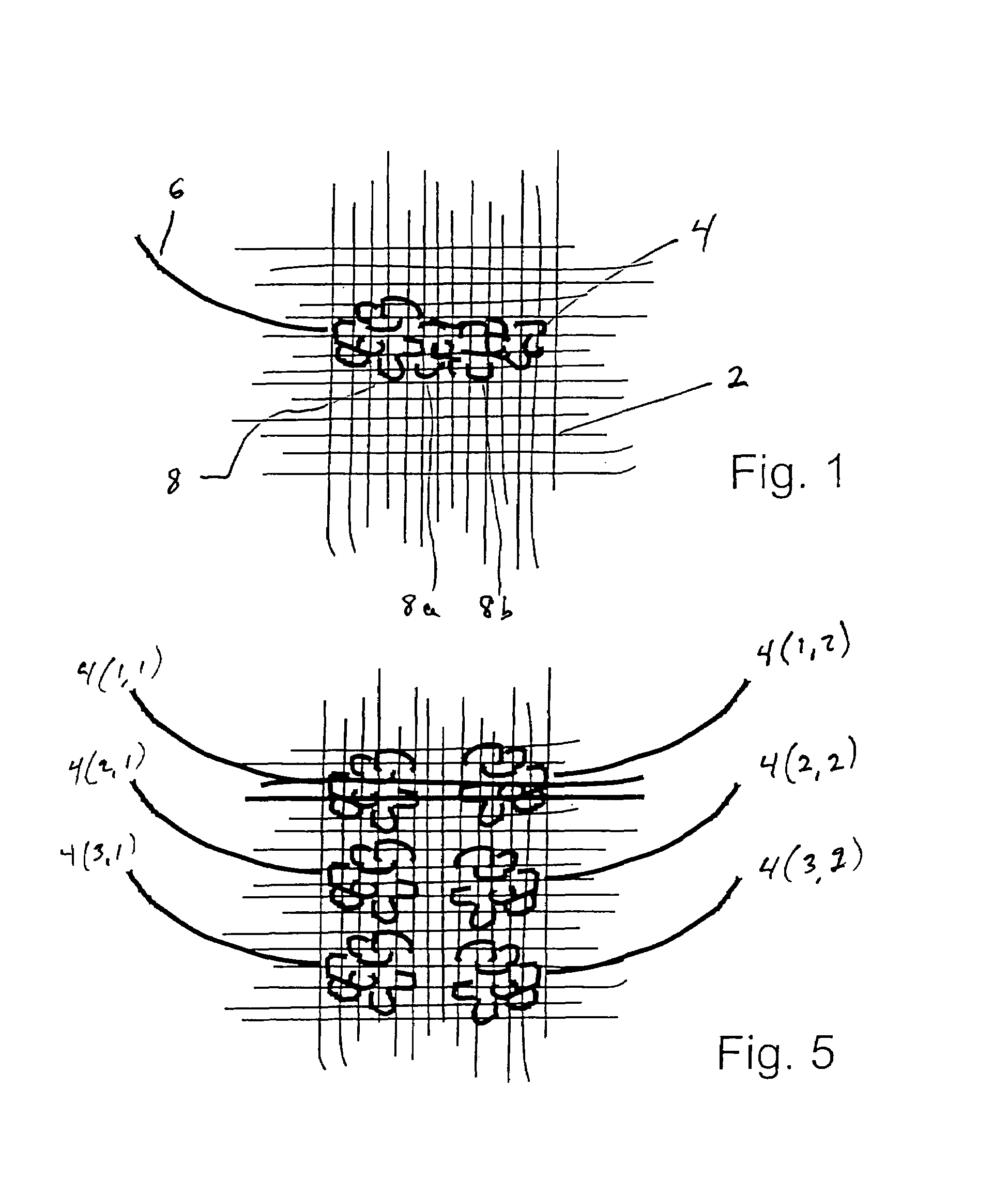

Arrangement for merchandise display prongs intended for displaying merchandise in shops and the like, comprising a cantilever arm (1) for carrying the merchandise and a feed device (4) which is displaceable along the arm and provided with a grip part (6). The feed device is intended to be maneuvered manually in order to displace the merchandise carried by the arm (1) in the forward direction toward its free end for the purpose of bringing about a favorable display of the merchandise. The feed device (4) is spring-preloaded toward the attachment end of the cantilever arm. The arrangement comprises an unrollable spiral spring (9), the spring roll (8) of which is arranged in a seat on that side of the feed device (4) which faces the attachment end of the arm (1). The spring (9) is adapted so as to be unrolled from the spring roll (8) in the direction toward the free end of the arm and to be diverted around a diverting means (12) located in front of the roll in order to allow attachment of the outer end of the spring to the attachment end of the arm (1).

Owner:HL DISPLAY

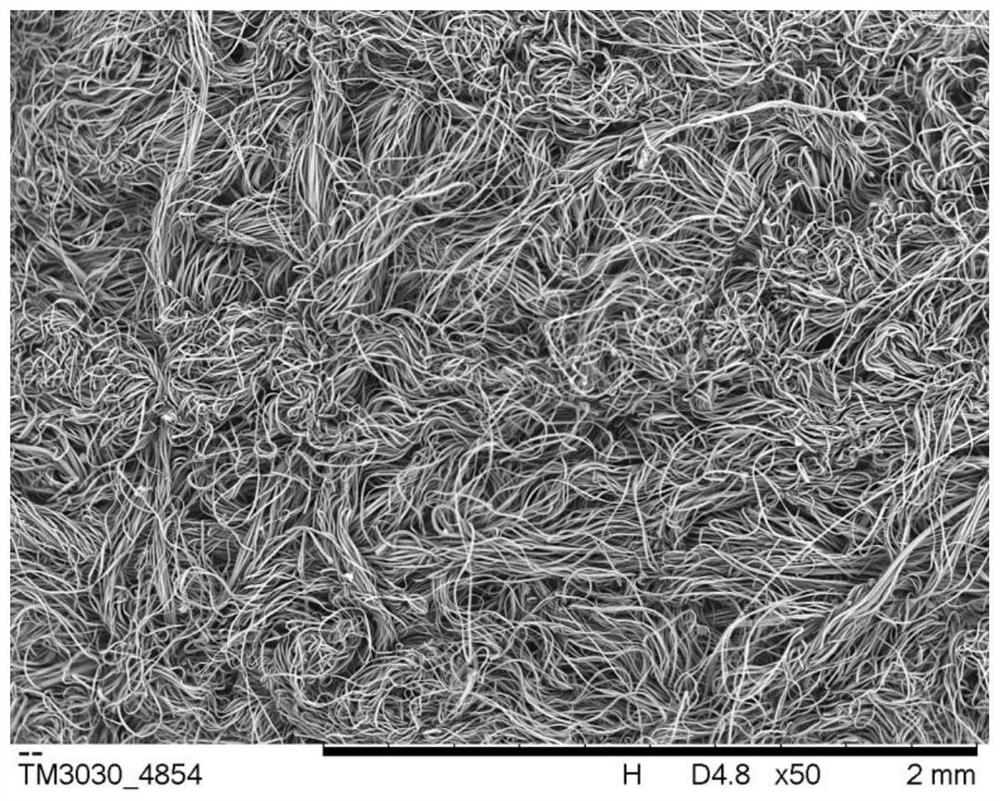

Super absorbent dust-free wiping cloth and manufacturing method thereof

InactiveCN102505253ALoose arrangementLarge specific surface areaCarpet cleanersFloor cleanersSuper absorbentLaser cutting

The invention discloses a super absorbent dust-free wiping cloth and a manufacturing method thereof. The wiping cloth is formed by interweaving warps and wefts and is characterized in that the dust-free wiping cloth is formed by circularly arranging square concave weave repeat units formed by interweaving the warps and the wefts along the warp direction and the weft direction respectively; at least one of the warp and the weft is formed by superfine fiber filaments; and in one weave repeat unit, the warps and the wefts are respectively arranged stepwise and upward in sequence from the central lowest point, and the floating length of the adjacent warps and the adjacent wefts on the steps increases in sequence to form concavo-convex patterns which are piled up alternately from low to high and have four high sides and low middle. The manufacturing method comprises the steps of beaming, drafting and reeding, weaving, weight reducing, tenter setting, laser cutting and packaging, thereby obtaining the super absorbent dust-free wiping cloth. The super absorbent dust-free wiping cloth has soft handfeel, good wiping effect and super absorbency and can be used in a dust-free room with a higher cleanliness requirement. The manufacturing method is simple and can be used for manufacturing the high-quality dust-free wiping cloth.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

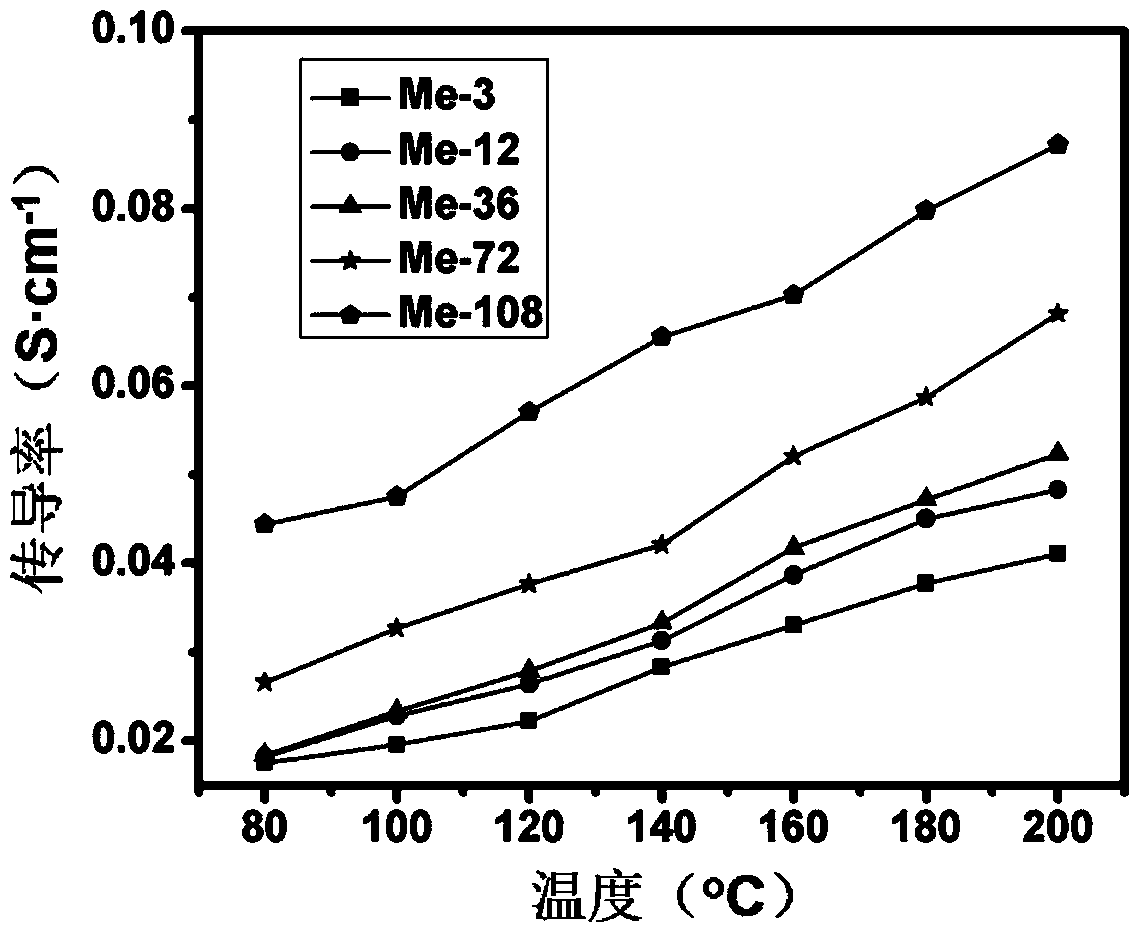

Application of polybenzimidazole polymer containing side group in proton exchange membrane

InactiveCN104341607AHigh doping levelImprove stabilitySolid electrolyte fuel cellsFuel cell detailsPhosphoric acidPoly(benzimidazole)

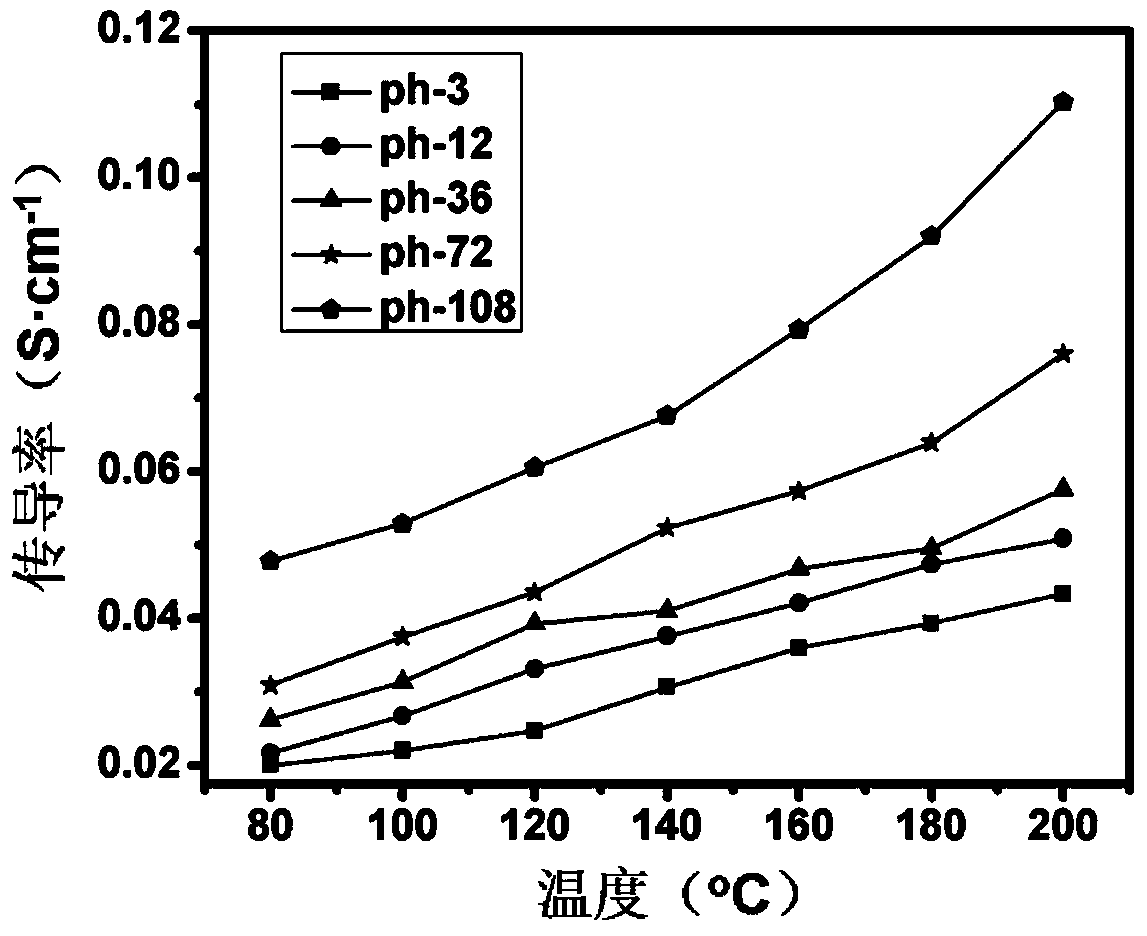

The invention discloses an application of a polybenzimidazole polymer containing a side group in a proton exchange membrane, belonging to the technical field of proton exchange membranes for high-temperature fuel cells. The polybenzimidazole polymer containing the side group is characterized in that the side group is introduced on a PBI molecular chain, and preferably, the polymer is polybenzimidazole containing meta-benzyl or polybenzimidazole containing a benzene side group. A preparation method of the proton exchange membrane comprises the following steps: dissolving the polybenzimidazole polymer containing the side group into DMSO, baking on a glass plate to form a thin film, and then soaking into phosphoric acid for 3-108 hours to prepare a proton exchange membrane of phosphoric acid doped polybenzimidazole containing the side group. The proton exchange membrane of phosphoric acid doped polybenzimidazole containing the side group disclosed by the invention has higher phosphoric acid doping level and conduction rate on the basis of keeping relatively good mechanical performance and chemical stability.

Owner:JILIN UNIV

Degradable non-poisonous seed-coating agent and preparation method thereof

InactiveCN101416650AHigh adhesionSeed coat capacity is goodBiocideAnimal repellantsChemistryApparent viscosity

A degradable nontoxic seed coating agent comprises basic materials of water-soluble chitosan of 1.0-1.5wt%, gelatine of 0.05-0.1wt%, glycerol of 0.05-0.1wt%, PVA of 1.0-1.5wt% and plant extract of remainder, with the tensile strength of 18.7MPa, elongation of 10.1%, vapor transmission rate of 12.69g.mm / mm2.hr.mmHg, air permeability of (CO2)0.358*10-10ml.cm / cm2s.cmHg, air permeability of (O2)0.215*10-10ml.cm / cm2s.cmHg, hygroscopic rate of 47% and apparent viscosity of 290cp; uses water-soluble chitosan, PVA and plant extract to form seed coating film to not only meet performance requirement of conventional seed coating agents, but remarkably improve performance of film.

Owner:DALIAN POLYTECHNIC UNIVERSITY

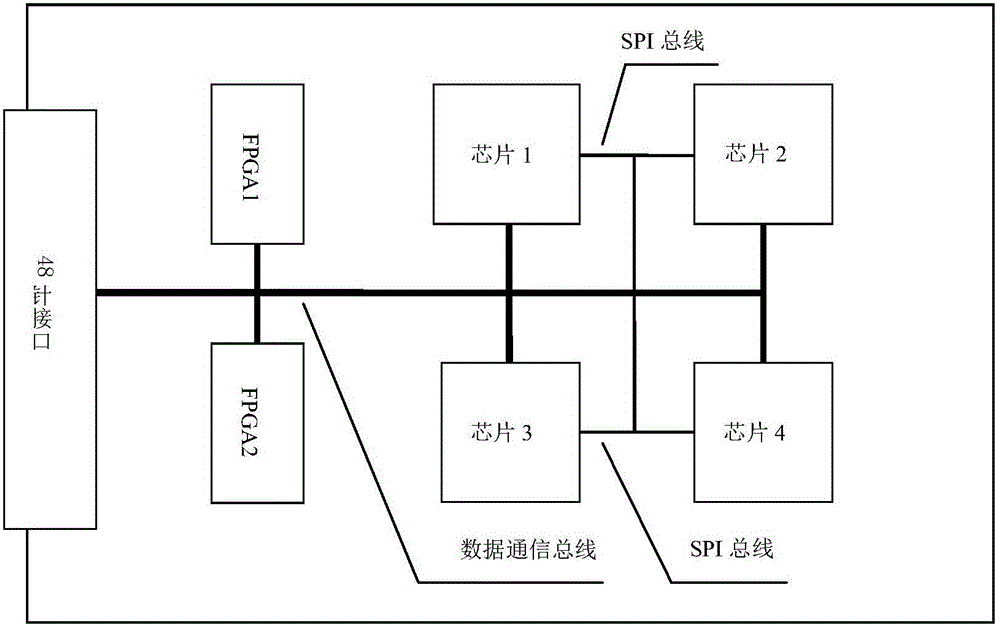

Flax fibre modifying method

InactiveCN1584183AImprove dyeing effectLoose arrangementPhysical treatmentFlax fibreMaterials science

This invention publishes the method of color flax fibre. A kind of character-change flax fibre: (1.) Put the flax fibre into 50-300g per L carbamide liquid. After endosmosis, put it out. (2) Heat the flax fibre in 300-400w micro-wave oven for 1-4 minutes. (3) Heat the flax fibre in the 600-hange the flax fibre. The color deepness can rise by 6%. (4) The flax fibre after character-change, the face will become coarse, it shows the face of some fibre molecule is cloven, and the face of other fibre molecule appears floss. So the fibre is a little loose, and it is dasy to be 800w imcro-wave oven for 0.5-3 minutes. The availability of the invention is: After character-c colored and character-change, the mechanics capability is not changed.

Owner:HEILONGJIANG UNIV

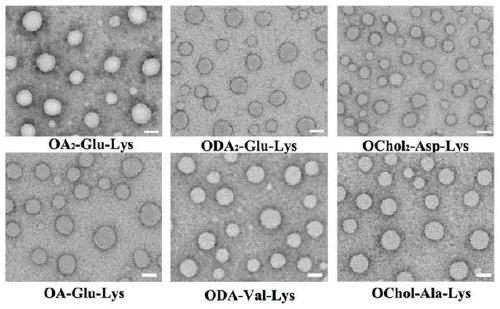

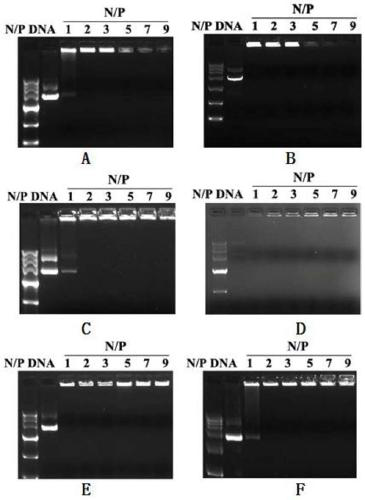

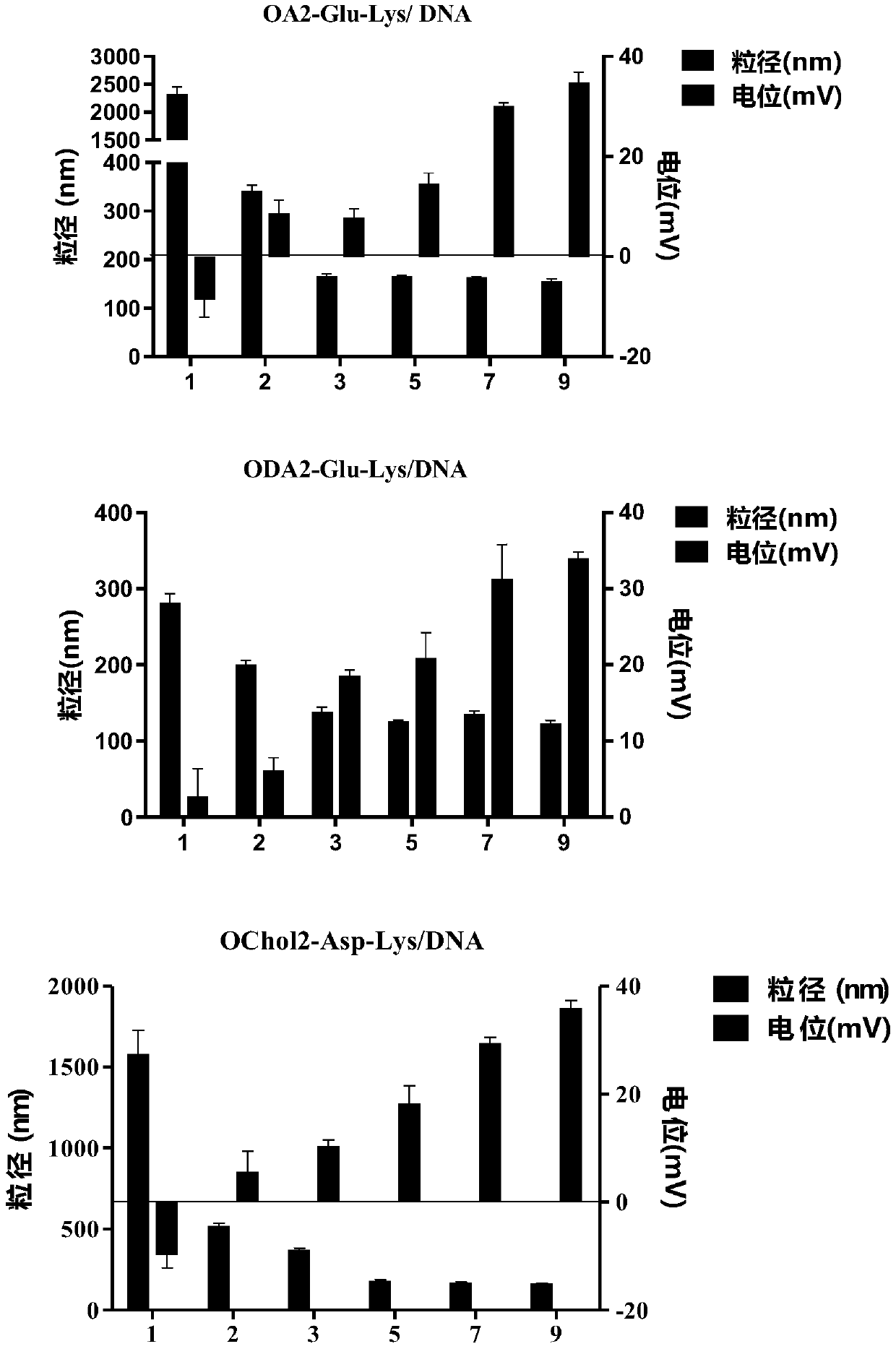

Unsaturated cationic lipid derivative, preparation method, and application in plasmid delivery system

ActiveCN111087317AFacilitated releaseGood biocompatibilityOrganic compound preparationPeptidesAlkaneViral vector

The invention relates to the field of chemistry and preparations, in particular to an unsaturated cationic lipid derivative, a preparation method thereof, and application in a plasmid delivery system.The cationic lipid takes electropositive lysine as a hydrophilic head group, amino acid as a skeleton and an unsaturated alkane chain as a hydrophobic tail chain, so that the cationic lipid has the advantages of good biocompatibility, high safety and the like. The synthesis method is simple and quick, low in synthesis cost and beneficial to large-scale production. The cationic liposome constructed on the basis of the unsaturated cationic lipid designed by the invention can stabilize the load plasmid without leakage, has better gene transfection efficiency on various tumor cells and primary cells than positive control Liponectamine2000, and has no obvious cytotoxic effect on cells. The invention provides a safe and efficient cationic lipid and non-viral vector platform for plasmid delivery.

Owner:CHINA PHARM UNIV

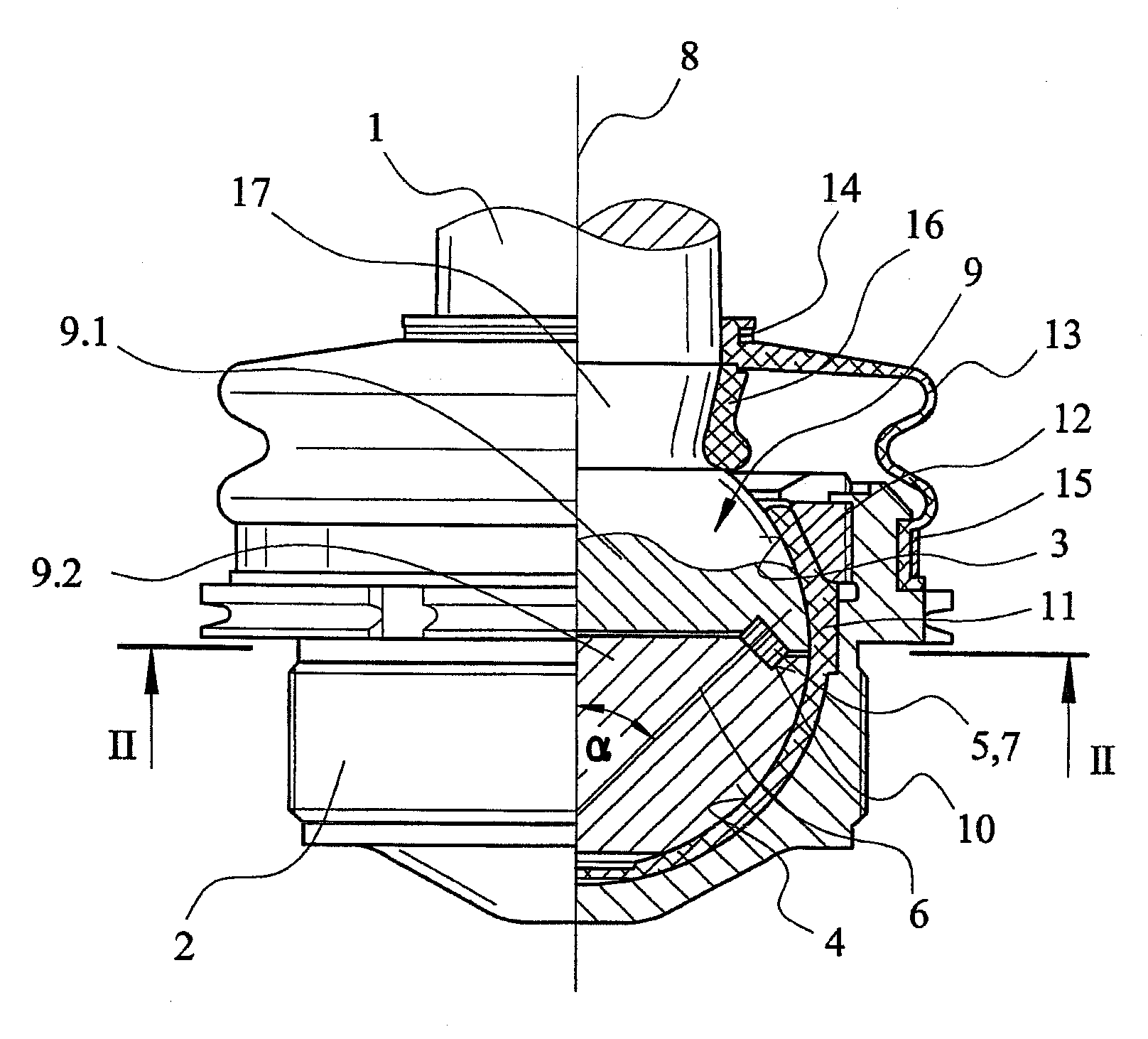

Ball and socket joint

InactiveUS20090245928A1Promote absorptionIncrease loadCouplings for rigid shaftsPivotal connectionsSurface mountingEngineering

A ball and socket joint is provided, especially for the wheel suspension of a motor vehicle, with a ball pivot (1), which is equipped with a first spheroidal bearing surface (3) mounted pivotably and rotatably in a housing (2). A roller bearing (5) is present between the first spheroidal bearing surface (3) and another spheroidal bearing surface (4), which is mounted in the housing (2) and is connected to the ball pivot (1). The roller bearing (5) is a roller bearing transmitting radial and axial forces.

Owner:ZF FRIEDRICHSHAFEN AG

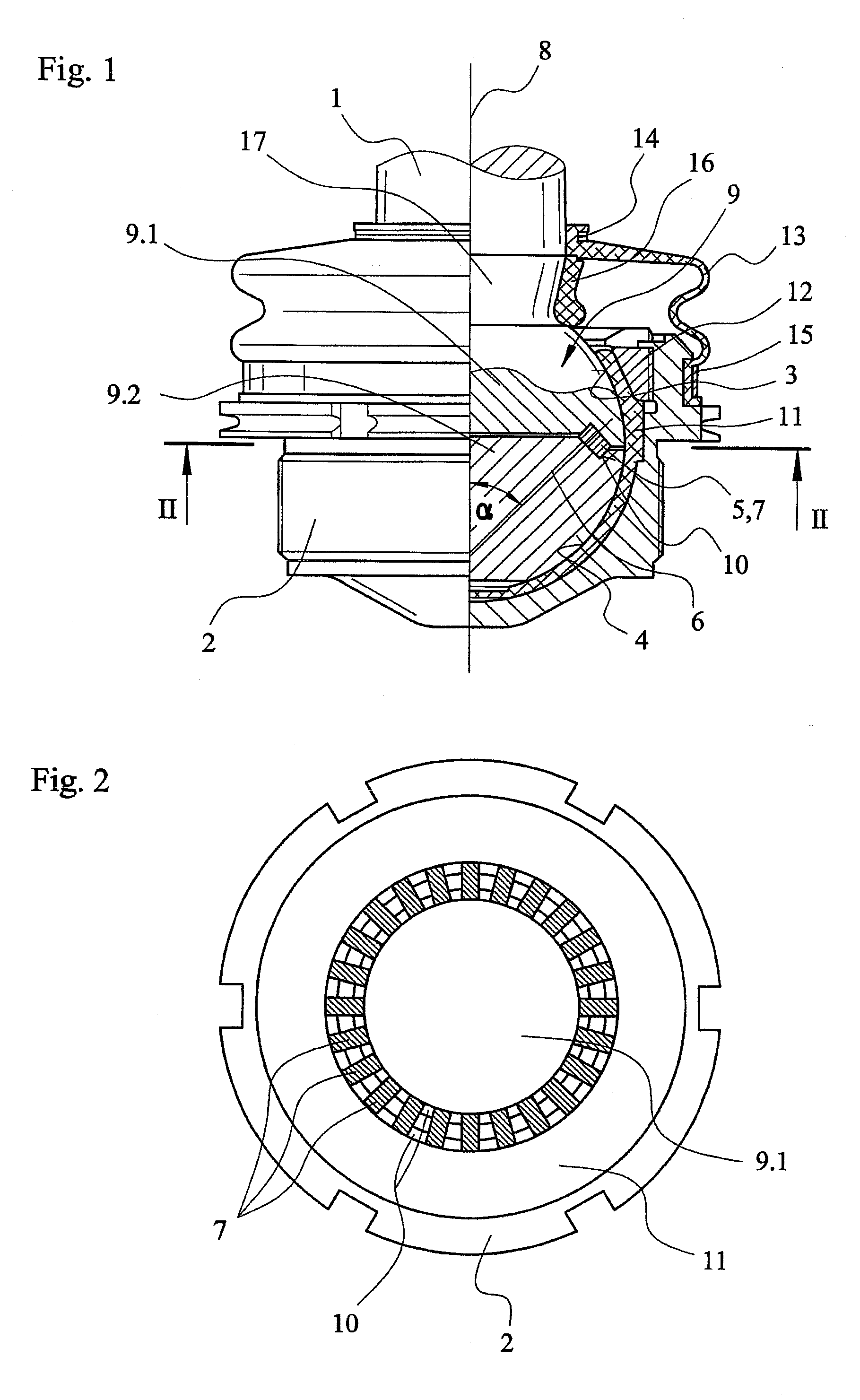

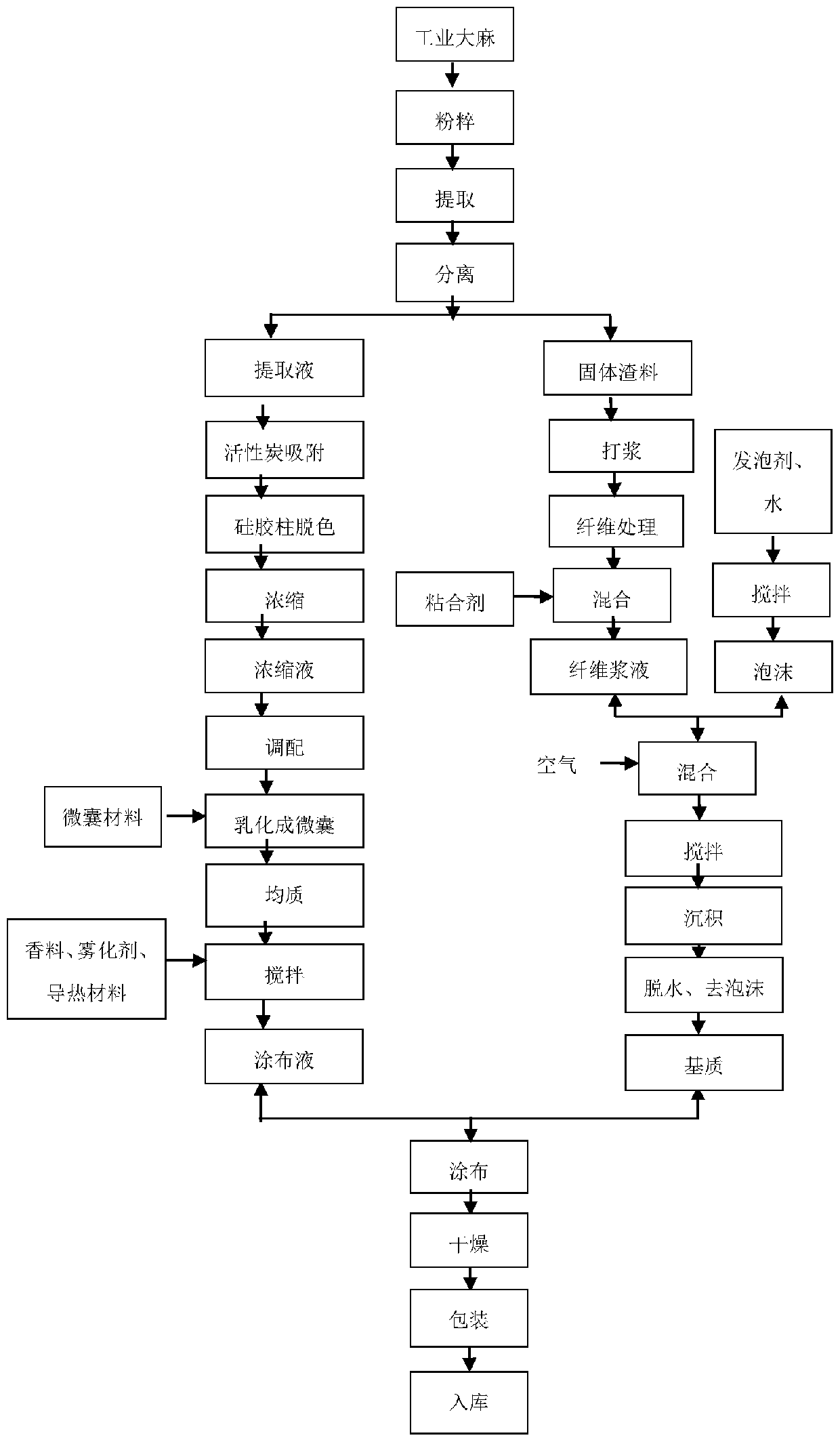

Tobacco product and preparation method thereof

InactiveCN109770411AImprove breathabilityHigh bulkTobacco preparationTobacco treatmentHeat conductingHeat not burn

The invention provides a tobacco product and a preparation method thereof. The preparation method comprises the specific steps that industrial hemp is taken as a raw material, a solid-phase substrateused for the tobacco product is prepared by adopting a foam forming method, a coating liquid containing cannabinoid is sprayed on the solid-phase substrate, and the tobacco product is obtained. The tobacco product has the advantages that the tobacco product replaces a traditional heat-not-burn tobacco product of a cigarette, the volatilization of effective components is fully achieved, the heat-conducting property is good, the smoke amount is large, and the taste is good.

Owner:YUNNAN HANSU BIO TECH CO LTD

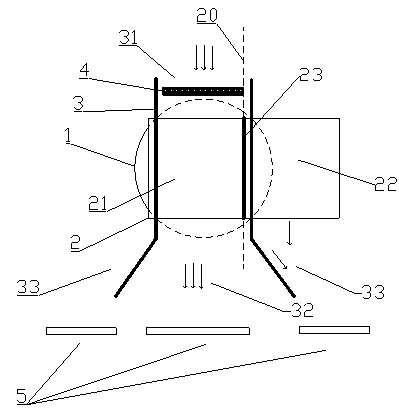

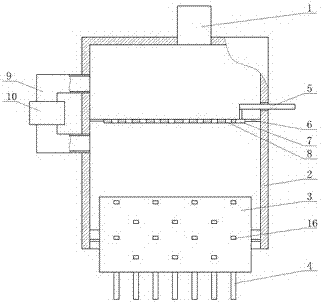

Reciprocating dry-type magnetic separator

ActiveCN103316762ASimple structureEasy to disassembleMagnetic separationSuperconducting CoilsMagnetic separator

The invention provides a reciprocating dry-type magnetic separator. The reciprocating dry-type magnetic separator comprises a superconducting magnet having diverging magnetic force lines and a separation mechanism. The separation mechanism comprises at least one adsorption sheet capable of horizontal reciprocating motion. The magnetic force lines of the superconducting magnet pass through the adsorption sheet. In a horizontal direction, at least one part of the adsorption sheet is separated from a magnetic field zone of the superconducting magnet. The adsorption sheet is prepared from a non-magnetic material and is arranged vertically. The reciprocating dry-type magnetic separator has a simple structure; the magnetic force lines of the superconducting magnet pass through the adsorption sheet and the adsorption sheet and the superconducting magnet are separated so that adsorption sheet dismounting is convenient and maintenance is easy; the magnetic force lines of the superconducting magnet are diverging and magnetic minerals attached to the adsorption sheet are arranged loosely so that the nonmagnetic minerals are separated from magnetic minerals easily; and the adsorption sheet is arranged vertically so that the impact produced by raw ore on the equipment is effectively reduced and a machine failure rate is effectively reduced and continuous large-scale production is realized.

Owner:江苏旌凯中科超导高技术有限公司

Carbon nano tube-containing coating material and preparation method thereof

ActiveCN107740097ALoose arrangementGood flexibilityCarbon compoundsVacuum evaporation coatingThermal dilatationNanotube

The invention relates to a carbon nano tube-containing coating material and a preparation method thereof, and belongs to the technical field of coatings. In the material, a transition layer is a layerof pure carbon nano tube array which is perpendicular to a substrate and a coating, and is positioned between the substrate and the coating; plasma surface modification is adopted for tying the end,close to the coating, of the pure carbon nano tube into a knot; and quantity content of double-wall carbon nano tubes is 60% or more, and length of the double-wall carbon nano tubes is 1nm-1000nm. Anelectron beam deposition method is adopted for preparing a catalysis layer on the surface of the substrate; a catalytic cracking method is adopted for vertically growing a layer of pure carbon nano tube arrays on the surface of the substrate with the catalysis layer, and after plasma surface modification treatment, the coating is prepared on the transition layer, so that the material is obtained.Due to the nano engaging and adhering mechanism of the carbon nano tubes, the bonding strength of the substrate and the coating can be effectively improved, and the carbon nano tube layer is loose inarrangement and good in flexibility, and is an effective stress release layer when the coating and the substrate are heated and cooled, so that the cracking problem caused by thermal expansion coefficient difference between the coating and the substrate is solved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

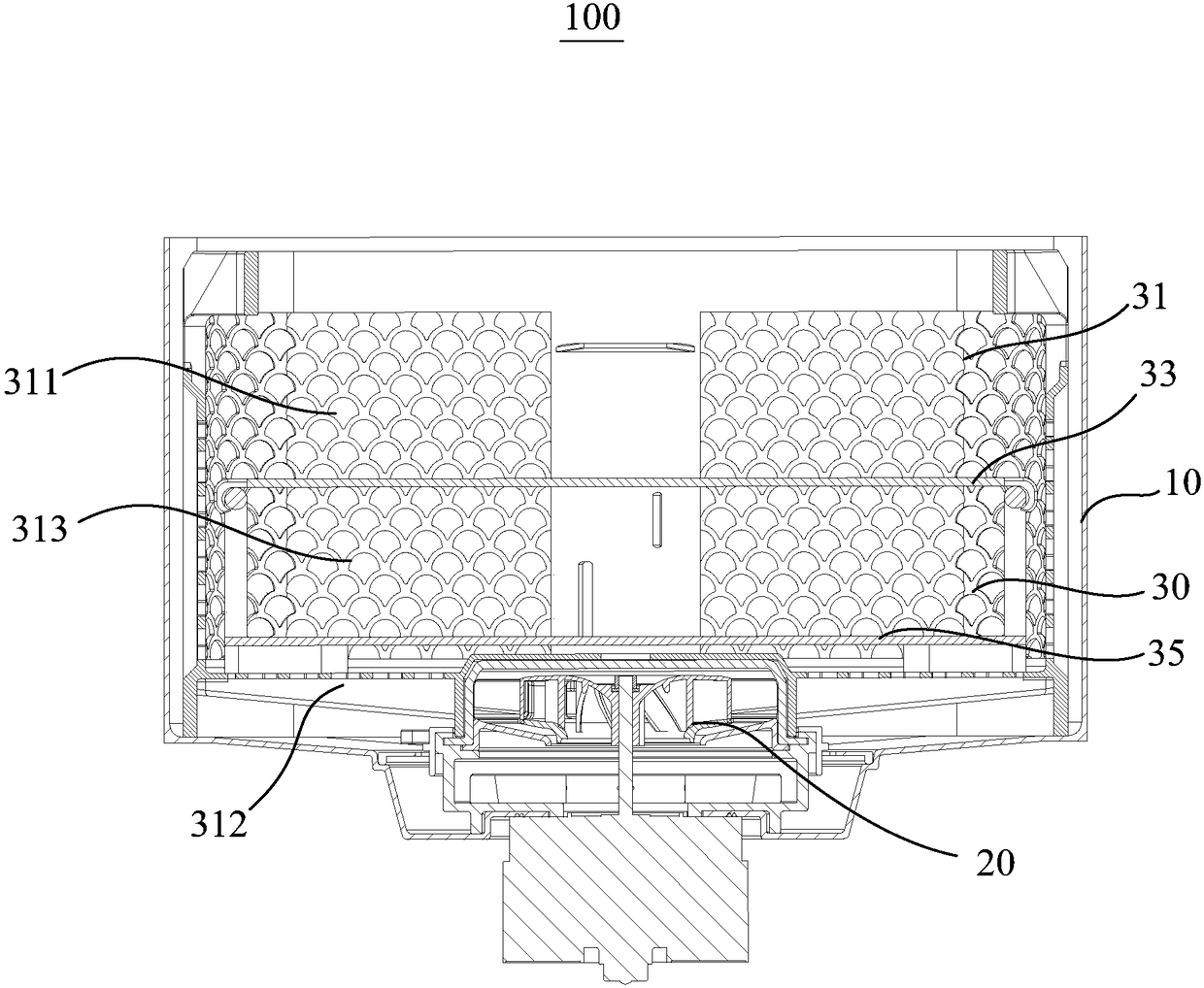

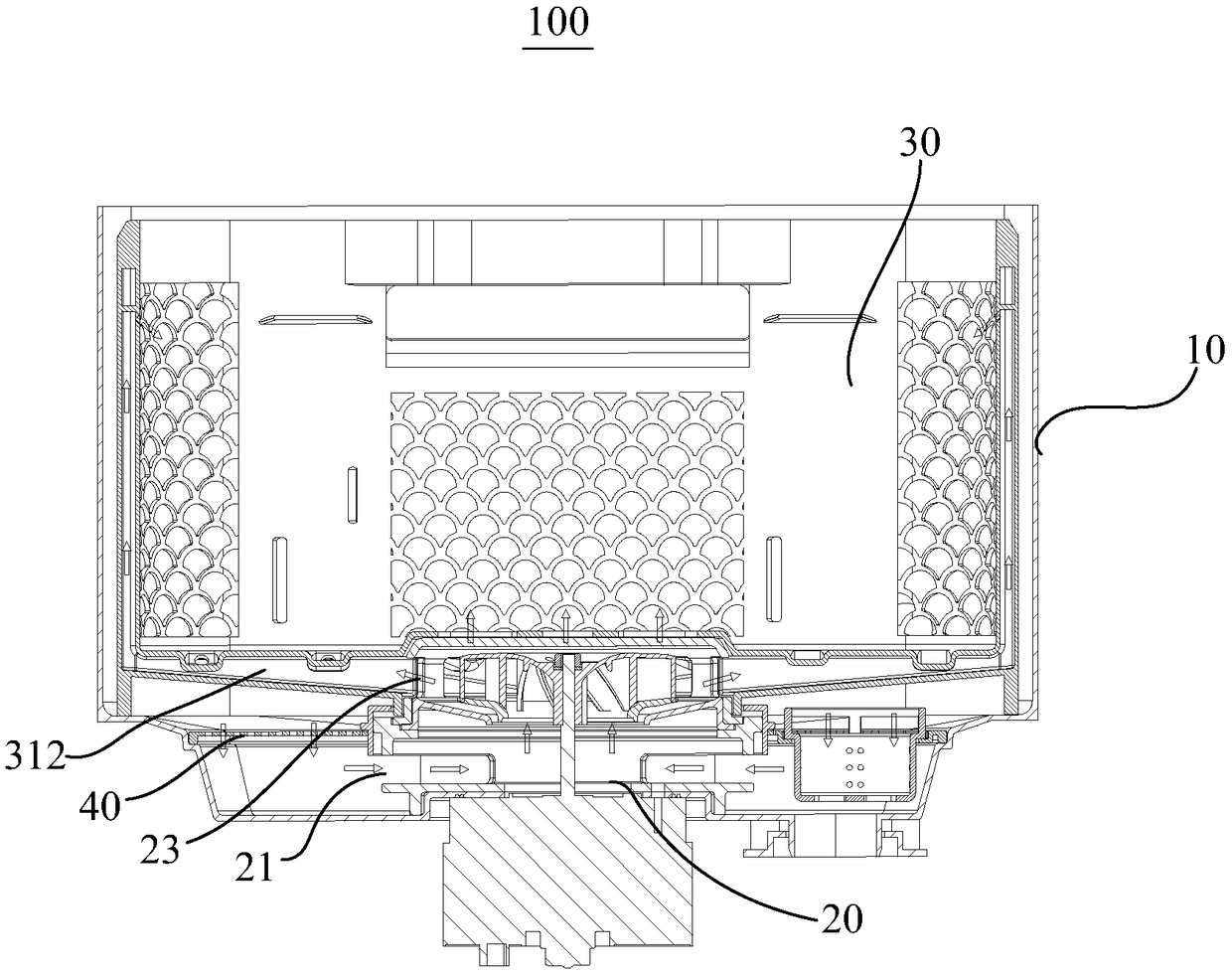

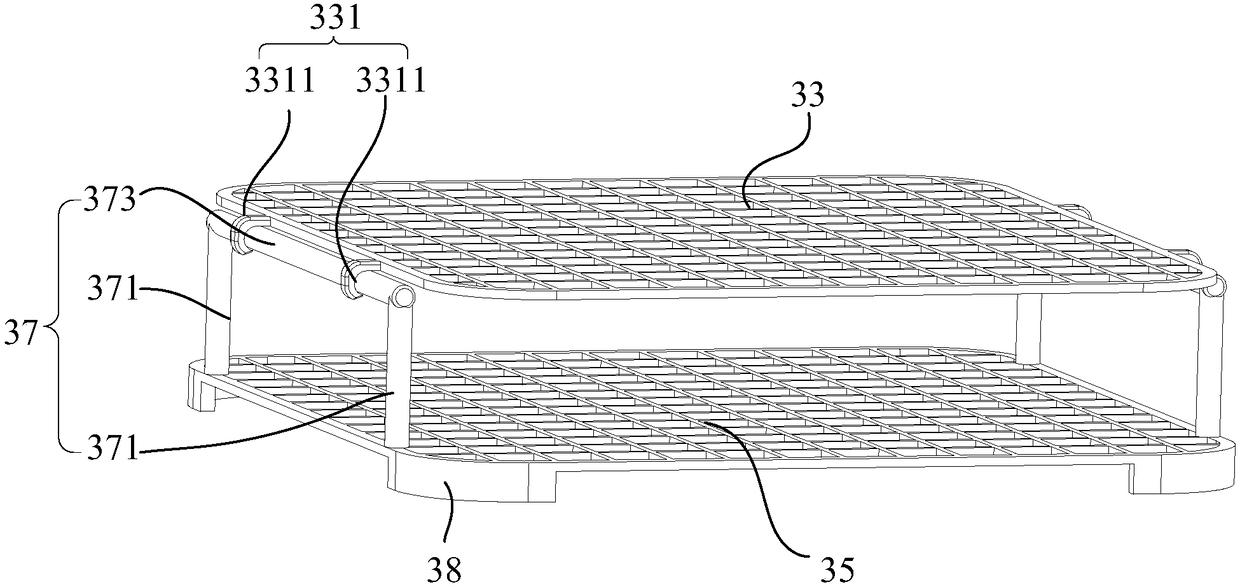

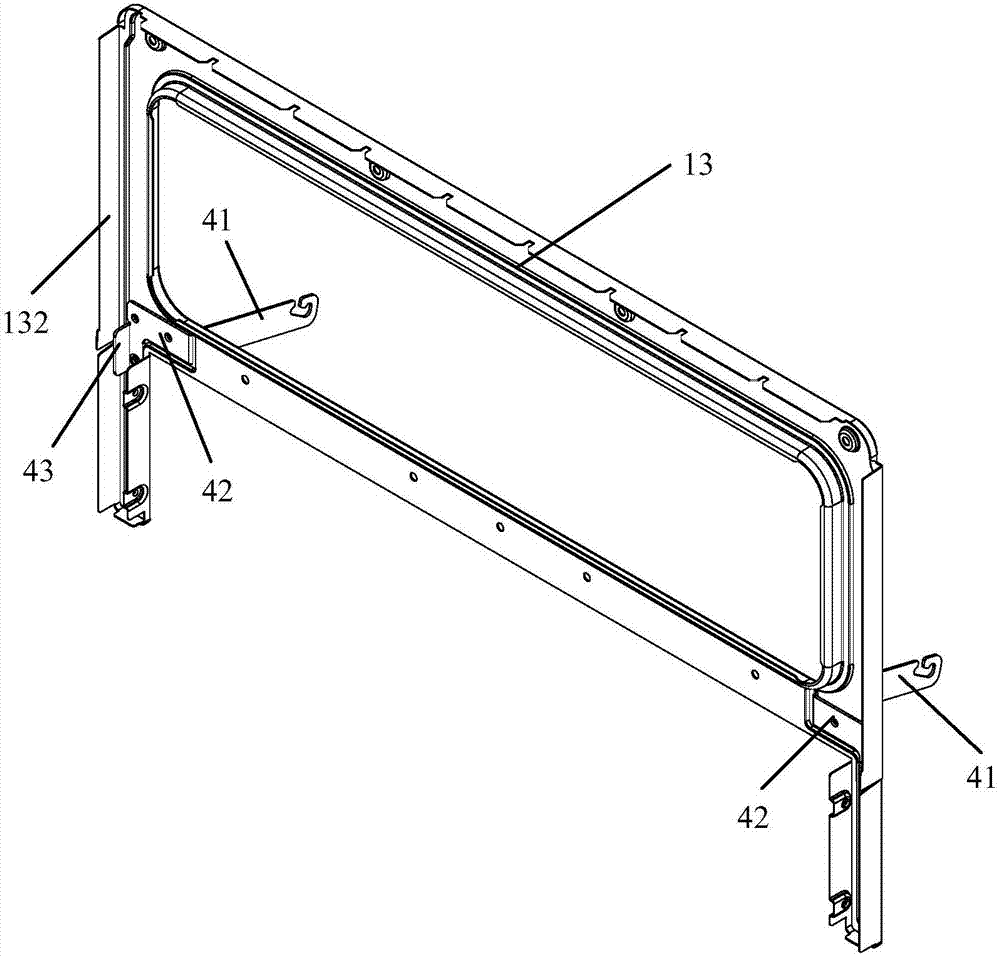

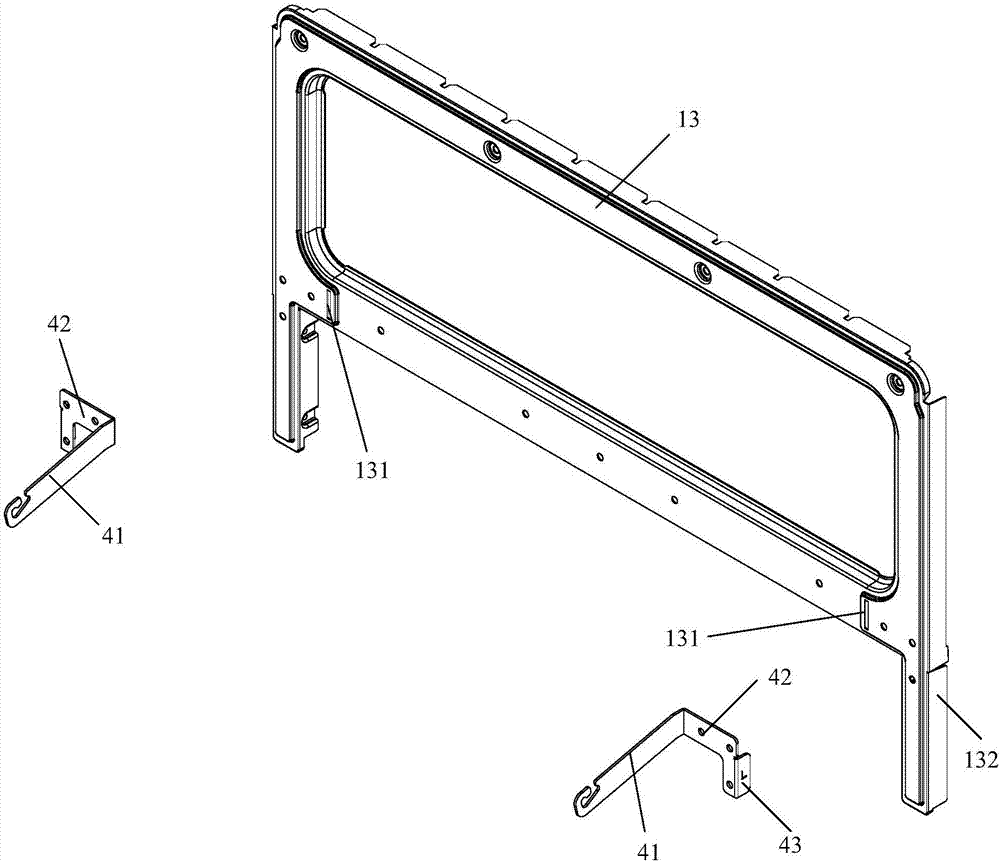

Cleaning basket and cleaning device

InactiveCN108185968ALoose arrangementFully contactedTableware washing/rinsing machine detailsKitchen equipmentEngineeringMechanical engineering

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

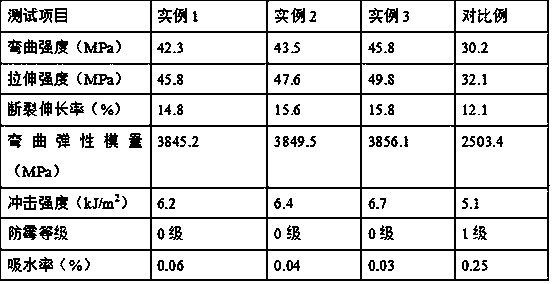

Preparation method of mold-proof water-resistant bamboo-plastic composite material

The invention relates to the technical field of bamboo-plastic composite material preparation, and particularly relates to a preparation method of a mold-proof water-resistant bamboo-plastic compositematerial. According to the preparation method provided by the invention, polypropylene is used as a matrix, modified bamboo fibers and modified nano zinc oxide are used as reinforcing agents, and a self-made antibacterial emulsion, hydrogen-containing silicone oil and the like are supplemented to prepare the mold-proof water-resistant bamboo-plastic composite material. Firstly, the surface modification of the self-made bamboo fibers is carried out by using nano calcium carbonate and ethylenediaminetetraacetic acid disodium salt, so that the mechanical property of the bamboo-plastic compositematerial is improved; the nano zinc oxide is modified by using a silane coupling agent, the zinc ions dissolved out of the nano zinc oxide are combined with the cell membranes and membrane proteins, bacterial propagation is prevented through damaging the cell structure; the effect of sterilization and mildew prevention is achieved through the utilization of special properties of the nano zinc oxide; the hydrogen-containing silicone oil is continuously added, and a dense hydrogen-containing silicone oil hydrophobic protective layer is formed, so that the water resistance of the bamboo-plastic composite material is improved, and a wide application prospect is achieved.

Owner:陈建峰

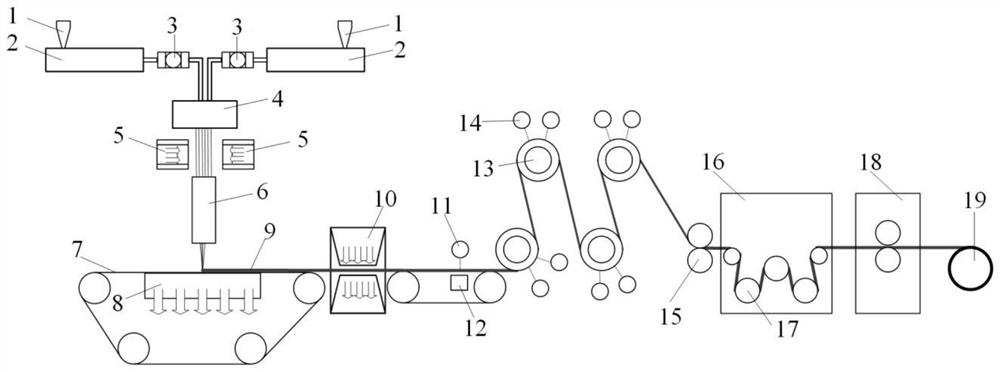

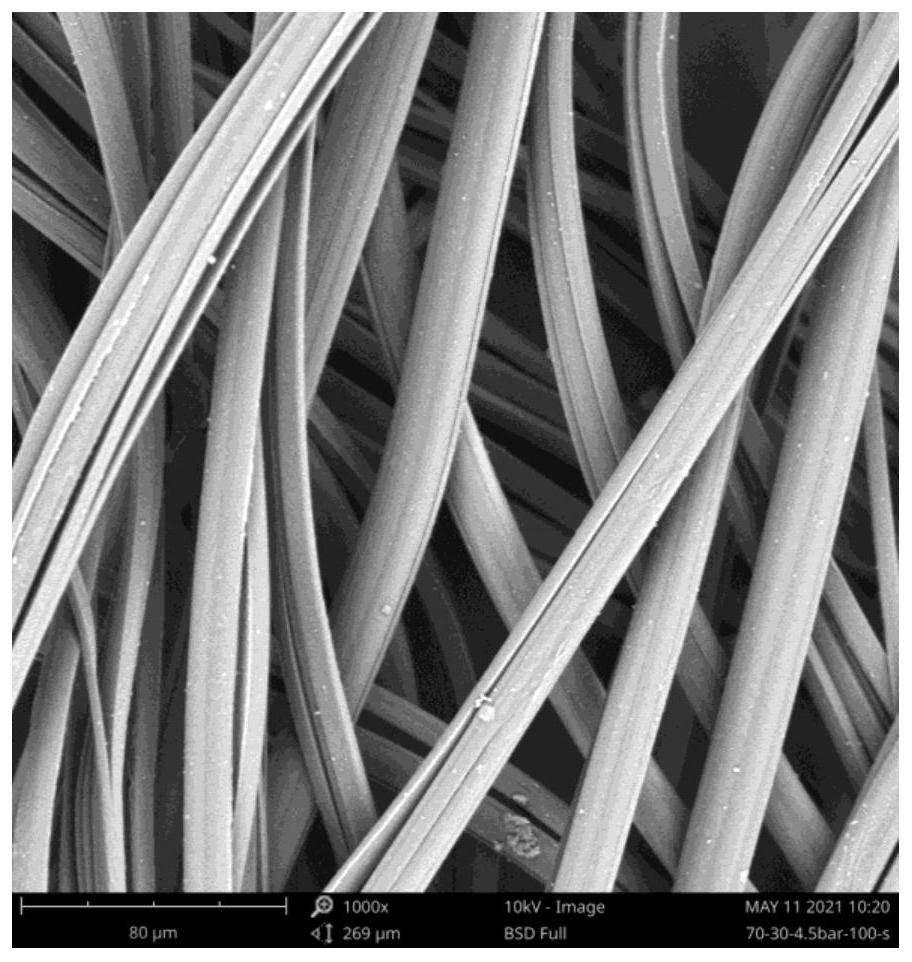

Preparation method of high-shrinkage orange slice type double-component spunbonded spunlace microfiber leather base cloth

ActiveCN113417078AHigh fullnessReduce spunlace energy consumptionFilament/thread formingHeating/cooling textile fabricsMicrofiberThermal shrinkage

The invention discloses a preparation method of high-shrinkage orange slice type double-component spunbonded spunlace microfiber leather base cloth. The method comprises the following steps of firstly, adding a hot air device and a fiber crimping device in a double-component spunbond / spunlace production line, and then spinning double-component composite fibers into a web; conveying the fiber web into the hot air device for thermal shrinkage treatment, and enabling the double-component composite fibers to generate a split trend by utilizing thermal shrinkage of high-shrinkage components in the double-component composite fibers; enabling the double-component composite fibers to be split and mutually entangled through a spunlace technology; conveying the double-component composite fibers into a fiber crimping device, and performing shrinkage and crimping treatment on non-woven cloth by utilizing the fiber crimping device, so that the high-shrinkage components are completely shrunk and crimped, and the double-component spunbonded spunlace microfiber leather base cloth is obtained. The method is simple in technological process and low in production cost and energy consumption, green and clean preparation of the microfiber leather base cloth can be achieved through a one-step method, and the prepared hollow orange slice type double-component spunbonded spunlace leather base cloth has the characteristics of being compact, soft, stiff and smooth and full in hand feeling.

Owner:TIANJIN POLYTECHNIC UNIV +2

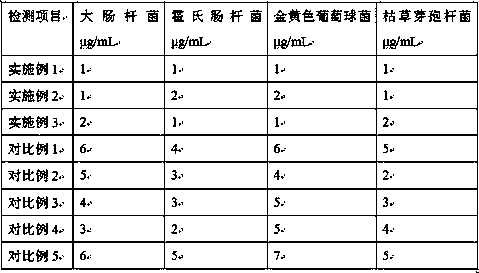

Water dephosphorization agent and preparation method thereof

InactiveCN110002527AReduce inputHigh adsorption activityWater/sewage treatment by irradiationWater treatment compoundsFiltrationCell wall

The invention discloses a water dephosphorization agent and a preparation method thereof, and belongs to the field of water treatment. The prepared surfactant forms a compact saturated adsorption layer for organophosphorus, can accommodate more organophosphorus pollutants to enter, increases adsorption activity for organophosphorus, and reduces the input quantity of phosphorus removal agents; a prepared flocculation additive destabilizes and flocculates particles in the system, sedimentation and filtration dehydration are facilitated, so that treatment efficiency of the organophosphorus pollutants is improved, and flocculation efficiency is improved. A prepared catalyst improves catalytic efficiency, reduces the loss of active substances of the phosphorus removal agent and provides a larger specific surface area, catalytic activity reaction sites are increased, phosphorus removal efficiency is improved, the surface of the montmorillonite is changed from hydrophilic to lipophilic and the substances forming the cell wall of bacteria are mostly lipophilic substances, therefore, the water dephosphorization agent has adsorption effect on active bacteria and is antibacterial. The problems of large dosage of phosphorus removal agent and poor phosphorus removal effect at present are solved.

Owner:陈建峰

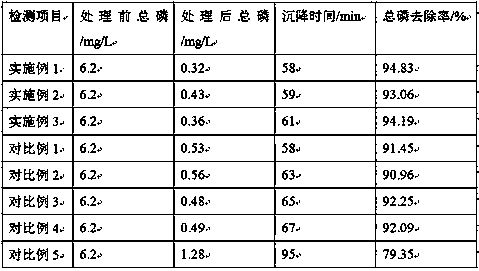

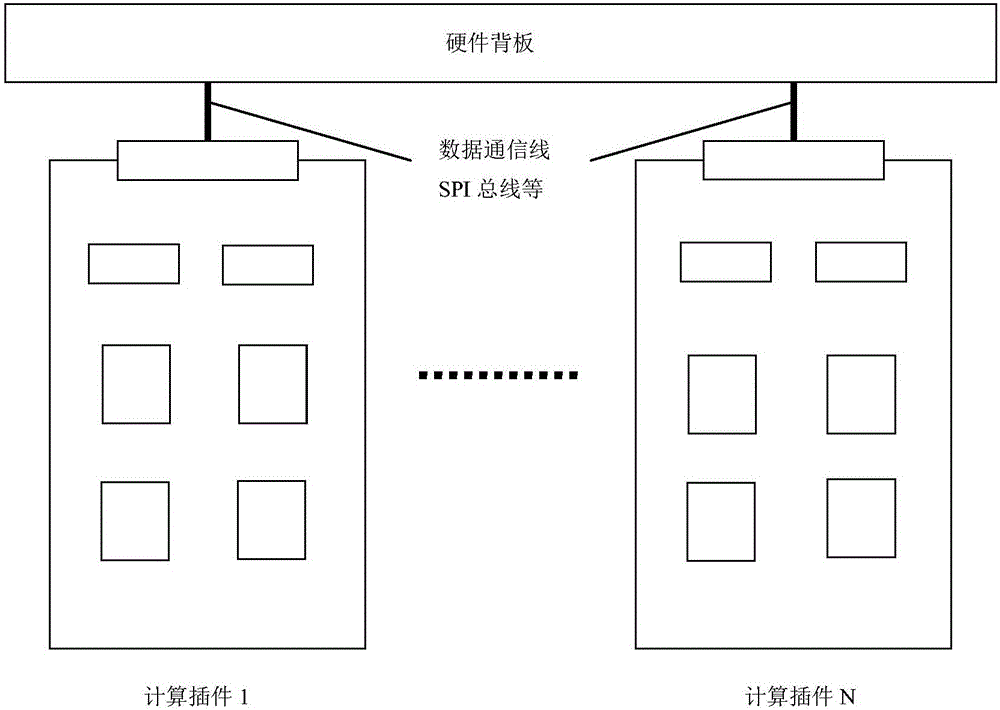

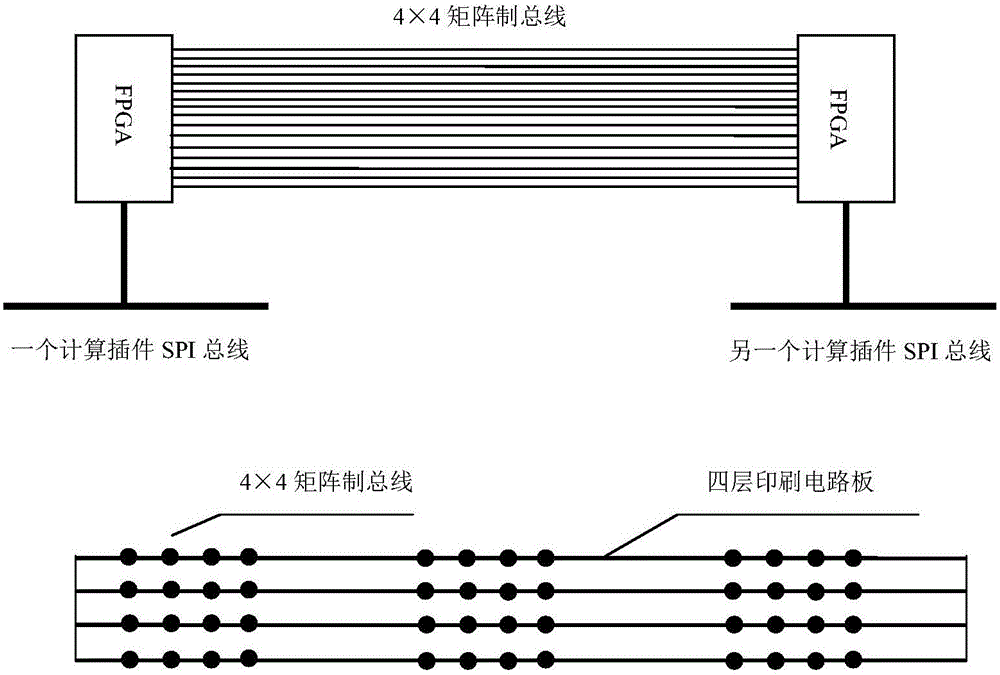

Miniaturized super emulator for study of transient stability of large power system

ActiveCN105760599AImprove communication bandwidthSolve temperature problemsDesign optimisation/simulationSpecial data processing applicationsData transmissionTransient state

The invention discloses a miniaturized super emulator for the study of transient stability of a large power system. The miniaturized super emulator comprises a plurality of cabinets, each cabinet is provided with a plurality of cases, and each case is provided with a plurality of embedded computing plug-ins. The embedded computing plug-ins in the cases are connected with a hardware back plate through a multi-needle interface, and each embedded computing plug-in is provided with a plurality of high-speed computing chips different from conventional computing chips, a plurality of FPGA chips and other necessary supporting components. The high-speed computing chips of the same embedded computing plug-in are directly connected through SPIs and other buses, the high-speed computing chips of all the computing plug-ins of the same case are connected through FPGA-hardware back plate integrated matrix system buses, and communication and data exchange among all the parts are compressed through a secondary codon algorithm. The cases carry out multiple optical fiber data communication through a CAN bus, a USB, the high-speed Ethernet and the like.

Owner:SOUTHEAST UNIV

Three-dimensional, uniform and high-stability seeding device suitable for wheat

InactiveCN107197645AFalling smoothlyAvoid fierce competitionSeed depositing seeder partsNatural resourceEngineering

The invention discloses a three-dimensional, uniform and high-stability seeding device suitable for wheat. The device comprises a case; the upper part of the case is connected with a feeding hole, and a seeding box is installed at the lower part of the case; the seeding box is a hollow box and is provided with a plurality of seed through holes; the lower part of the seeding box is exposed outside the case; a plurality of seeding pipes arranged in rows are installed at the lateral circumference of the seeding box. By reasonably optimizing the internal structure of the seeding device, the seeding device is enabled to realize more uniform seed dropping, so that the phenomenon that seeds compete fiercely for light, water, fertilizer and soil resources due to being not evenly distributed can be avoided, and the utilization efficiency of the seeds for the natural resources is increased. According to the seeding device, a fan is combined with a vent pipe, and air pressures of the upper side and the lower side of a screen plate can be continuously changed by means of forward and reverse reciprocating operation of the fan, so that an up and down reciprocating thrust force is applied onto the seeds accumulated on the screen plate, the seeds are enabled to be arranged more loosely, and the seeds can conveniently pass through holes evenly.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

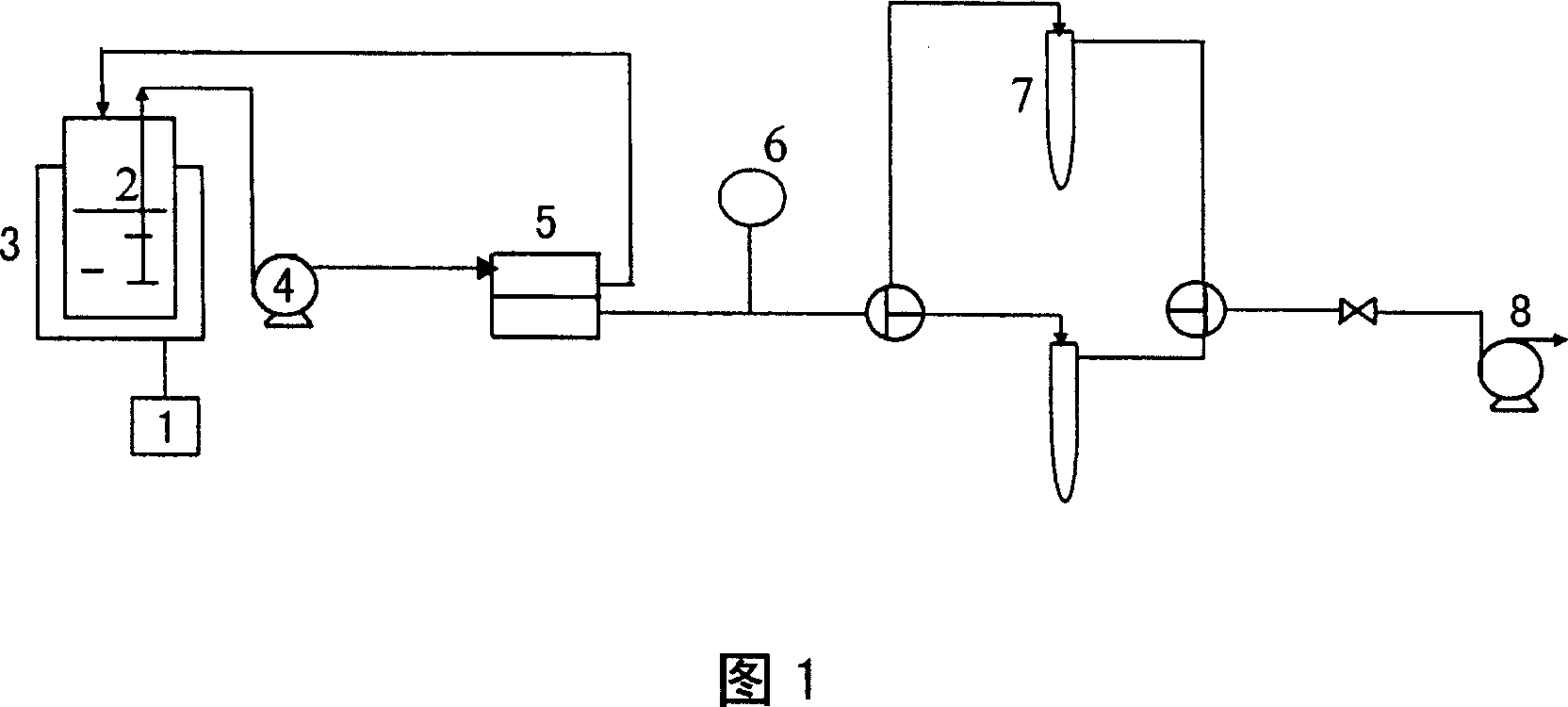

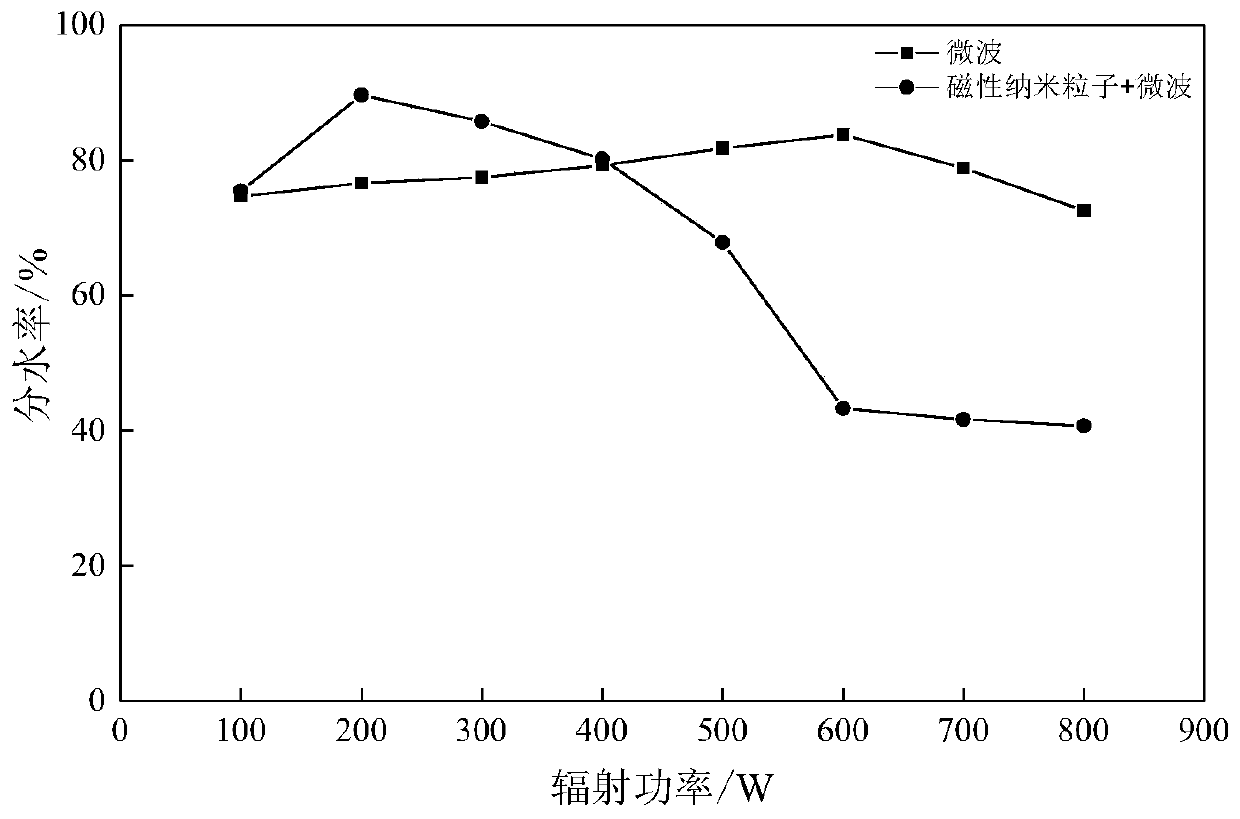

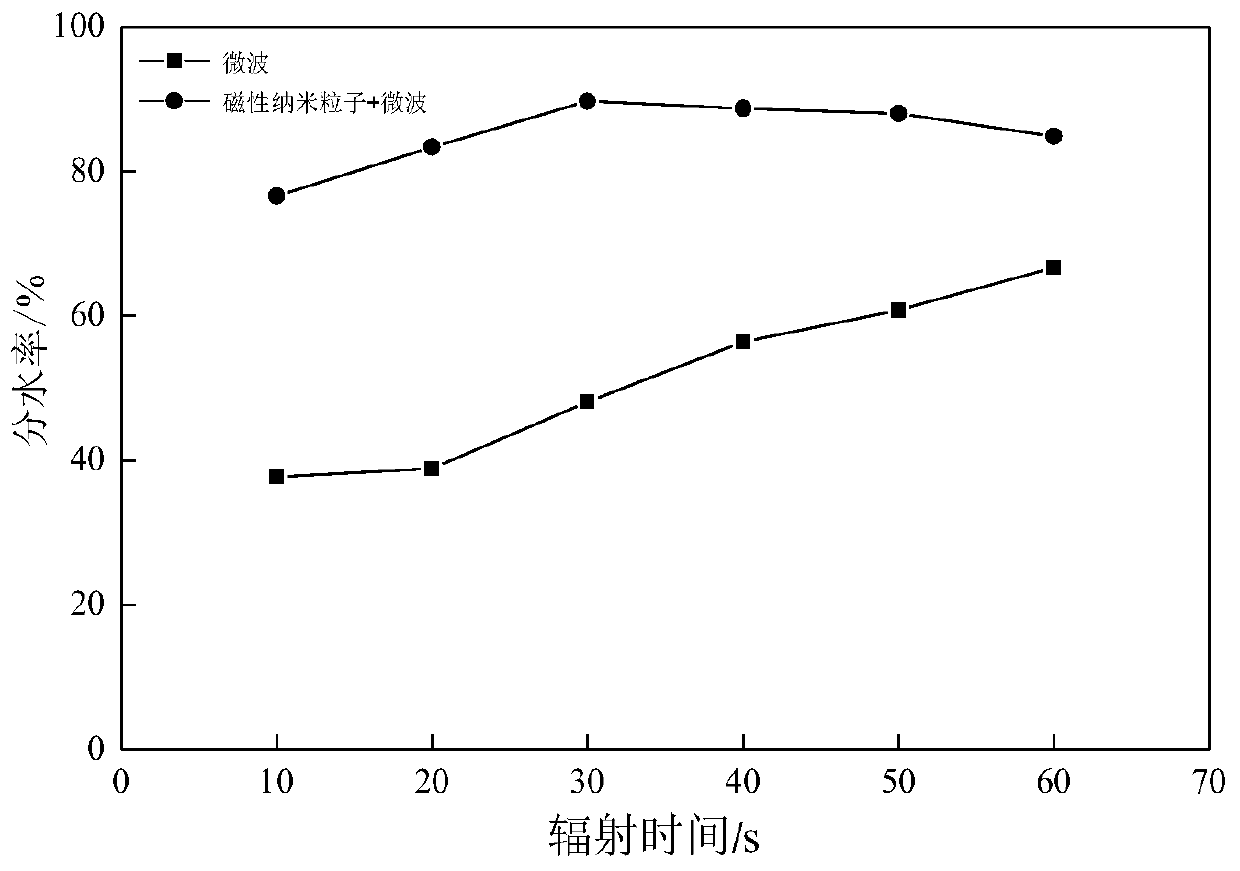

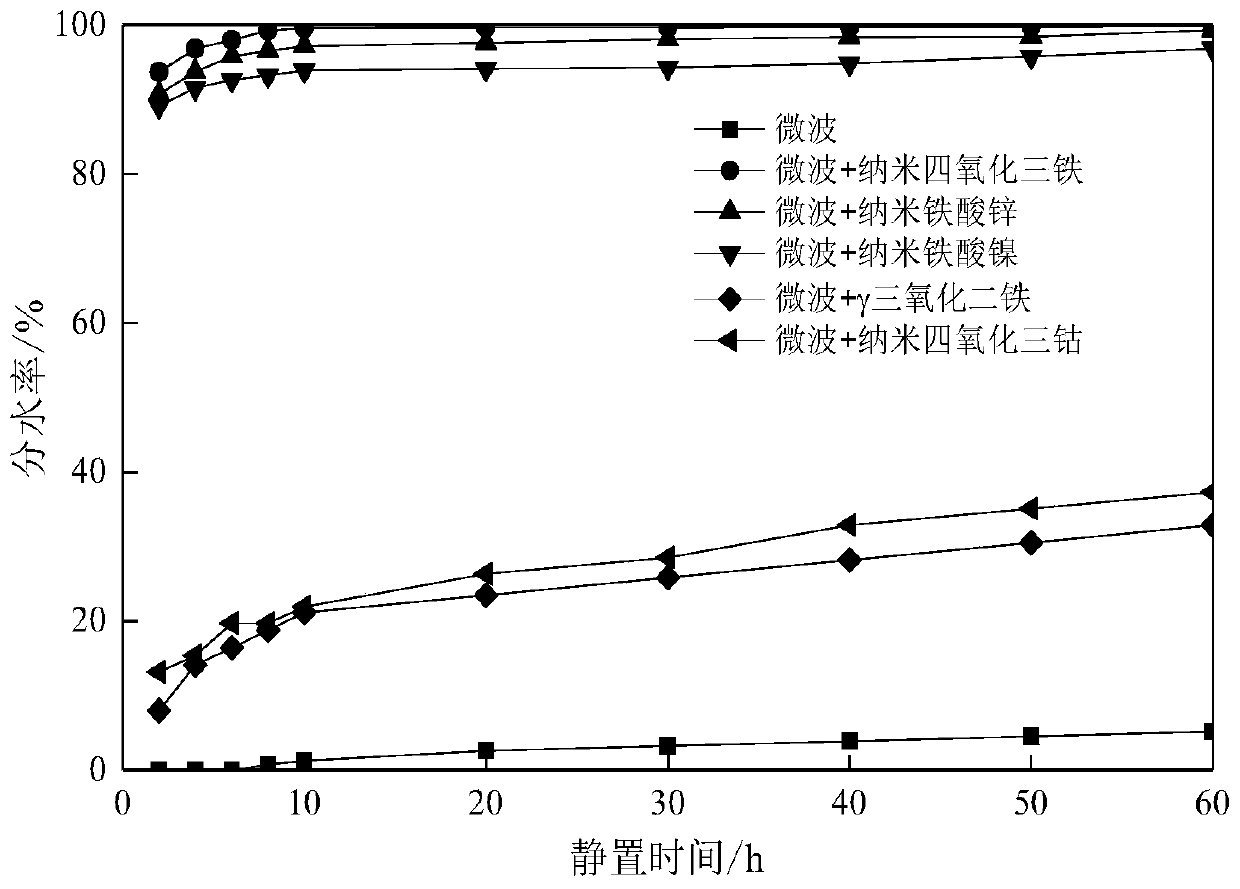

Method for treating thickened oil oil-in-water type emulsion by magnetic nanoparticles and microwave

ActiveCN111253968AHigh demulsification rateImprove demulsification efficiencyDewatering/demulsification with electric/magnetic meansEnvironmental geologyOil phase

The invention discloses a method for treating thickened oil oil-in-water type emulsion through magnetic nano particles and microwaves, which belongs to the technical field of oil-water separation engineering. By means of the coupling synergistic effect of the magnetic nanoparticles and the microwave high-frequency electromagnetic field, the demulsification rate and demulsification efficiency are greatly improved, and the water diversion rate of a high-stability thick oil O / W type emulsion can exceed 99% in a short time. The problems that a traditional chemical demulsifier is large in dosage and limited in application range, so that a catalyst is poisoned, flocculate generated after demulsification stays in a water phase or an oil phase all the time, and secondary pollution is caused to theenvironment are solved. Besides, the magnetic nanoparticles can be repeatedly recycled for multiple times, the demulsification cost is reduced to a great extent, the demulsified magnetic nanoparticles can be adsorbed and recycled again under the action of an external magnetic field, environmental pollution is avoided, and the magnetic nanoparticles have good application prospects.

Owner:XI'AN PETROLEUM UNIVERSITY

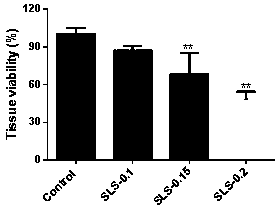

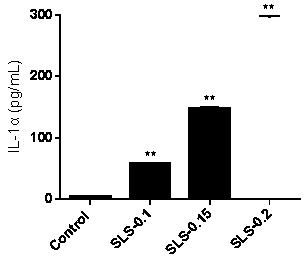

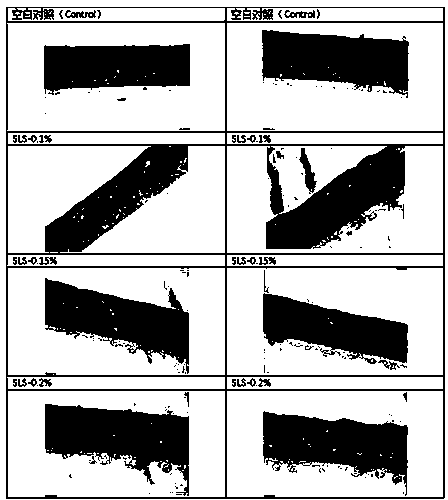

Construction method of diaper dermatitis-like in-vitro recombinant epidermis model

ActiveCN110684713AAvoid species differencesSmall individual differencesMicrobiological testing/measurementDiagnosticsDiaper DermatitisCell

The invention particularly relates to a construction method of a diaper dermatitis-like in-vitro recombinant epidermis model. The construction method comprises the steps as follows: step (1): preparation of epidermis cells; step (2) under-solution culture of epidermis cells; step (3) proliferation and differentiation regulation of epidermis cells; and step (4): construction of the diaper dermatitis-like in-vitro recombinant epidermis model. A specific substance is added to a cell culture solution at each stage to regulate proliferation and differentiation of keratinocytes, a barrier weakened in-vitro recombinant epidermis model is obtained, and then, the diaper dermatitis-like in-vitro recombinant epidermis model is constructed by addition of a stimulant. The diaper dermatitis-like in-vitro recombinant epidermis model constructed by the method has structure and biochemical index change similar to tissue slices in a normal pathological state, species difference and individual differenceare reduced, and the real effectiveness of the model is greatly improved.

Owner:GUANGDONG BOXI BIO TECH CO LTD

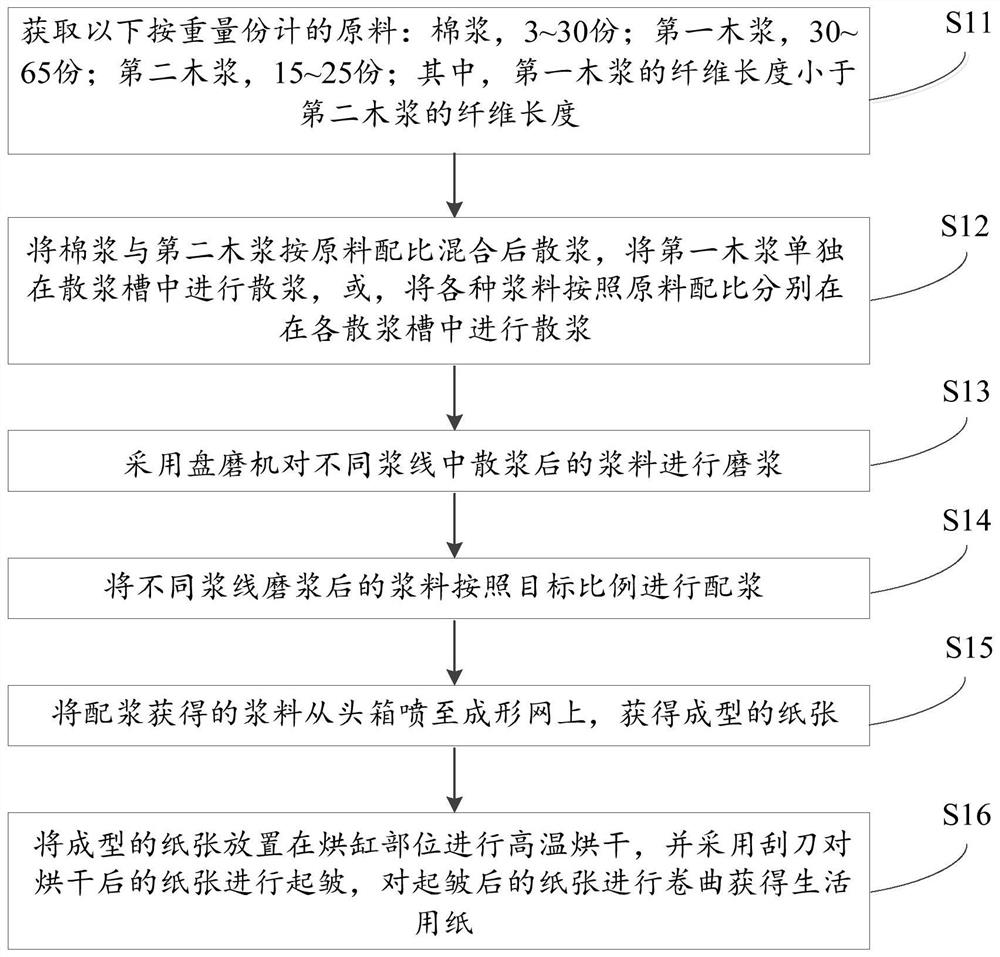

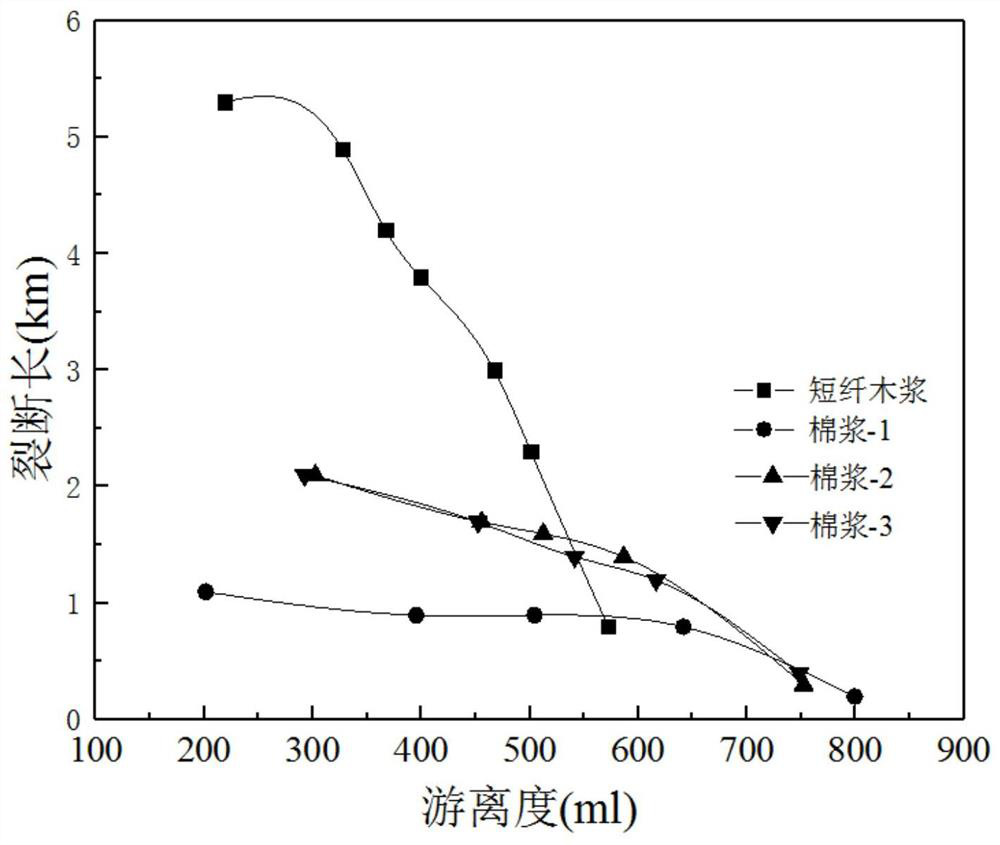

Household paper and preparation method thereof

PendingCN113584939ASoft and skin-friendly to useReduce intensityReinforcing agents additionPaper/cardboardFiberCotton linters

The invention discloses a household paper and a preparation method thereof. The household paper comprises, by weight, 3-30 parts of cotton pulp; 30-65 parts of first wood pulp; and 15-25 parts of second wood pulp. The fiber length of the first wood pulp is smaller than that of the second wood pulp; the first wood pulp is short fiber wood pulp, and the fiber length range of the short fiber wood pulp is 0.5-1.0 mm; the second wood pulp is long-fiber wood pulp, and the fiber length range of the long-fiber wood pulp is 1.5-2.8 mm; and the cotton pulp is cotton linter, and the fiber length of the cotton linter ranges from 1.2-1.8 mm. According to the invention, the cotton pulp with the fiber length between that of the short-fiber wood pulp and that of the long-fiber wood pulp is added into the pulp, the softening agent is added, the ceramic scraper is used, and the angle of the scraper is relatively low, so that the manufactured paper for daily use is softer and fluffy, and the use hand feeling of a user is improved.

Owner:金红叶纸业(湖北)有限公司

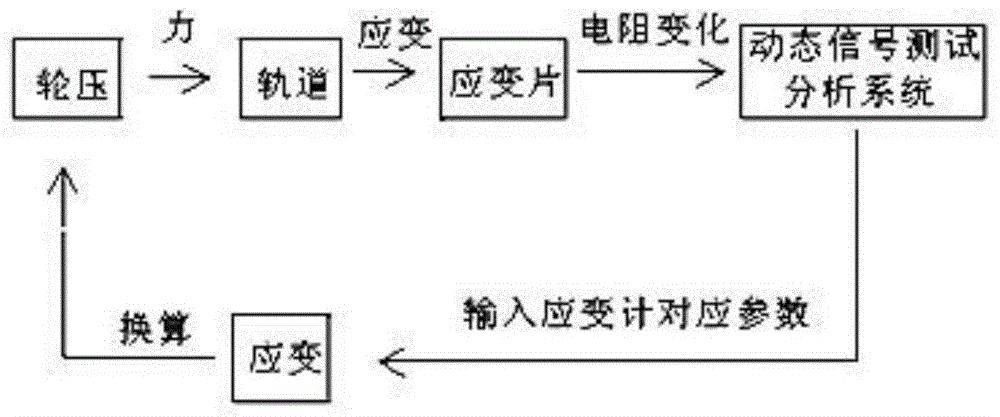

Determination method of wheel pressure of crane

ActiveCN104034469BLoose arrangementOptimize layoutApparatus for force/torque/work measurementLifting capacityEngineering

The invention discloses a measuring method for a crane cart wheel pressure. The measuring method for the crane cart wheel pressure includes steps that (1) distributing foils, to be specific, pasting strain foils at the lateral surface of a cart track; (2) building a wheel pressure monitoring system, to be specific, connecting the strain foils and wireless strain nodes with a monitoring host; (3) calibrating, to be specific, enabling a crane to locate in a no-load state, enabling a crane dolly to locate at a proper position, enabling the cart to pass the cart track in a constant speed, and using the wheel pressure monitoring system to record a strain-time curve so as to obtain a wheel pressure and strain calibrating coefficient (shown in the description); (4) measuring the cart wheel pressure on site, to be specific, when the dolly is located at a set position according to a set lifting capacity, gathering the corresponding strain value, and converting the strain value into the corresponding wheel pressure (shown in the description). The measuring method for the crane cart wheel pressure is easy and practical, is capable of precisely measuring the actual value of each wheel pressure, is more direct and reliable than a calculation method, is capable of directly reflecting the wheel pressure non-uniformity of the crane under different working conditions and provides essential data for optimizing, using and maintaining the crane wheels and saving civil engineering cost.

Owner:NANTONG BRANCH OF SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

Application of chymotrypsin preparation in treating oral ulcer

InactiveCN102755641AOrderly rowsLoose arrangementPeptide/protein ingredientsDigestive systemAcrylic resinOral ulcers

The invention relates to an application of a chymotrypsin preparation in treating oral ulcer. According to the invention, the preparation comprises 0.1-30 parts by weight of chymotrypsin and 70-99.9 parts by weight of a solid excipient which is selected from carboxyvinyl polymer (Carbopol), hyaluronic acid, poly(aspartic acid), gum Arabic, citric acid, sodium alginate, acrylic resin, magnesium stearate, starch, or a combination thereof. The oral ulcer preparation is a solid or semi-solid preparation. In the preparation, the content of the raw material chymotrypsin is higher than 95.0%. The preparation can be powder or tablets. The invention also provides a preparation method of the preparation. The oral ulcer preparation provided by the invention is advantaged in simple application, good curative effect, and long action duration.

Owner:SHANGHAI NATURE STANDARD R&D & BIOTECH +1

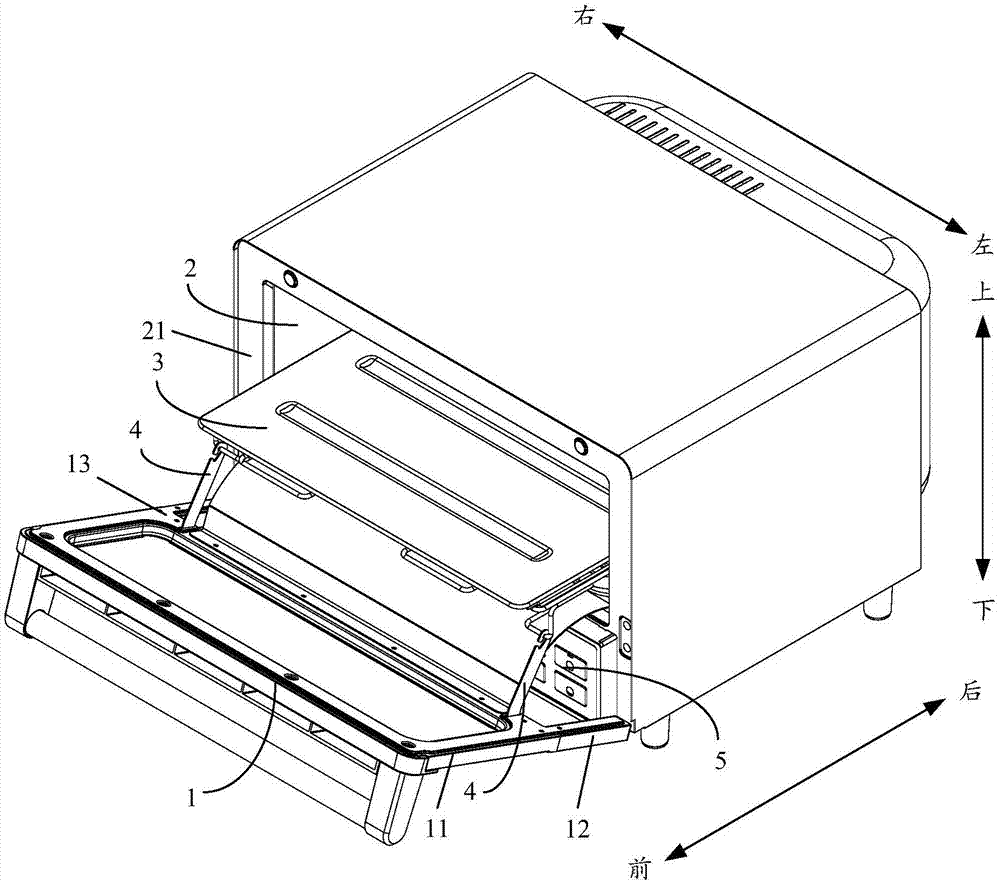

Electric oven

ActiveCN107374390ASimple production processIncrease productivityClimate change adaptationRoasters/grillsEngineeringMechanical engineering

The invention provides an electric oven. The electric oven comprises an oven body and a door, a slidable roasting rack is mounted in a cavity of the oven body, the door of the electric oven comprises a door body and connection legs hinged to the oven body, and door hooks connected to the roasting rack are arranged on a door liner. One end, fixedly connected with the door liner, of each door hook is provided with a fixing plate, and each fixing plate extends from the door body to the corresponding door connection leg and fits the door liner, so that a contact area of each door hook and the door liner is increased greatly, force transferred by the door hooks to the door liner is scattered, intensity of pressure borne by the door liner is reduced, and accordingly deformation of the door liner is prevented. By the scheme, the door hooks are structurally improved to guarantee that strength of the door liner meets utilization requirements, door size increase is avoided, a control box mounting space is not reduced, and accordingly sufficient spaces for keys distributed on a control box can be guaranteed, and convenience in operation is achieved. In addition, increasing of plate thickness of the door liner is avoided, so that product cost is reduced.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Spinning device for controlling fiber arrangement structure through synchronous rotation and spinning process thereof

The invention provides a spinning device for controlling a fiber arrangement structure through synchronous rotation. The spinning device comprises a first rotating shaft, a yarn pressing reed and a second rotating shaft, wherein the two ends of the first rotating shaft are fixed below a front jaw through bearings respectively; a fiber finishing section with a thread and a belt connecting section are arranged on the middle part of the first rotating shaft at intervals; the fiber finishing section is positioned under the front jaw; the belt connecting section is connected with a front roller through a belt; one end of the yarn pressing reed is movably pressed on the fiber finishing section; the second rotating shaft is positioned below the first rotating shaft; a thread is formed on the second rotating shaft; and the direction of the thread on the second rotating shaft is opposite to the direction of the thread in the fiber finishing section. The spinning device has the beneficial effects that the fiber structure of yarns is finished through the cooperation of the first rotating shaft and the second rotating shaft, so that the spun yarns have the advantages of being soft in hand feeling, high in strength, less in hairiness, stable in yarn levelness, small in residual torque and the like.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com