Determination method of wheel pressure of crane

A measurement method and crane technology, applied to measuring devices, force/torque/power measuring instruments, instruments, etc., can solve problems such as inaccurate detection results, space constraints, and offset of the center of gravity of the crane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

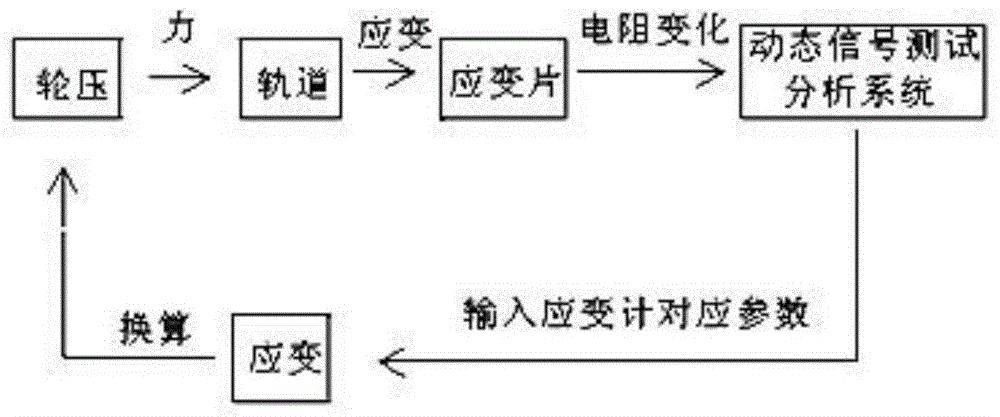

[0057] Embodiment one: a kind of assay method of crane big wheel pressure, comprises the steps:

[0058] (1) Cloth piece: Select the side of the cart track that can ensure that all the wheels of the crane can pass through to paste the strain gauge, and determine the position of the cloth piece, which is generally located in the middle of the adjacent pressure plate;

[0059] Among them, after the resistance strain gauges are pasted on the side of the cart track in such a way that the length direction of the resistance wire is perpendicular to the top surface of the track, the strain gauges are connected by a half-bridge method;

[0060] In this step, the temperature compensation method is used to compensate the strain of the strain gauge caused by the temperature change, and one of the dynamic simulation method and the self-temperature compensation method can be selected.

[0061] In this embodiment, the dynamic simulation method is selected, and the temperature compensation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com