Household paper and preparation method thereof

A technology for household paper and paper, which is applied in the field of papermaking, can solve the problems of insufficient, high strength, and few applications, and achieve the effects of improving comfort, high crystallinity, and low orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

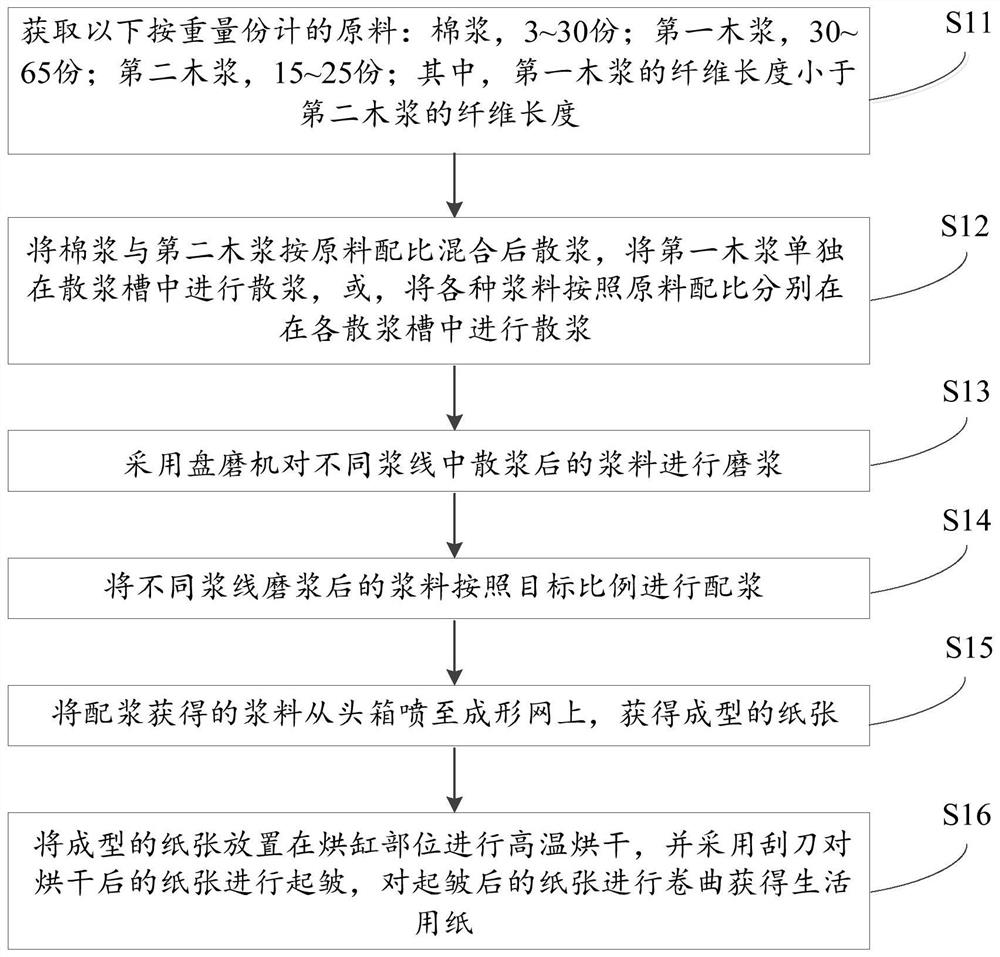

[0042] Specifically, see figure 1 , figure 1 It is a schematic flow diagram of an embodiment of the preparation method of tissue paper of the present invention, in this embodiment, the method includes:

[0043] S11: Obtain the following raw materials in parts by weight: cotton pulp, 3-30 parts; the first wood pulp, 30-65 parts; the second wood pulp, 15-25 parts; wherein, the fiber length of the first wood pulp is less than that of the first wood pulp Second, the fiber length of wood pulp.

[0044] Wherein, the first wood pulp is short-fiber wood pulp, and the fiber length range of short-fiber wood pulp is 0.5-1.0 mm; the second wood pulp is long-fiber wood pulp, and the fiber length range of long-fiber wood pulp is 1.5-2.8 mm; The cotton pulp is cotton linters, and the fiber length of the cotton linters ranges from 1.2 to 1.8 mm.

[0045] In other embodiments of the present invention, the raw material may further include 0-30 parts by weight of other pulp, and the other pul...

Embodiment 1

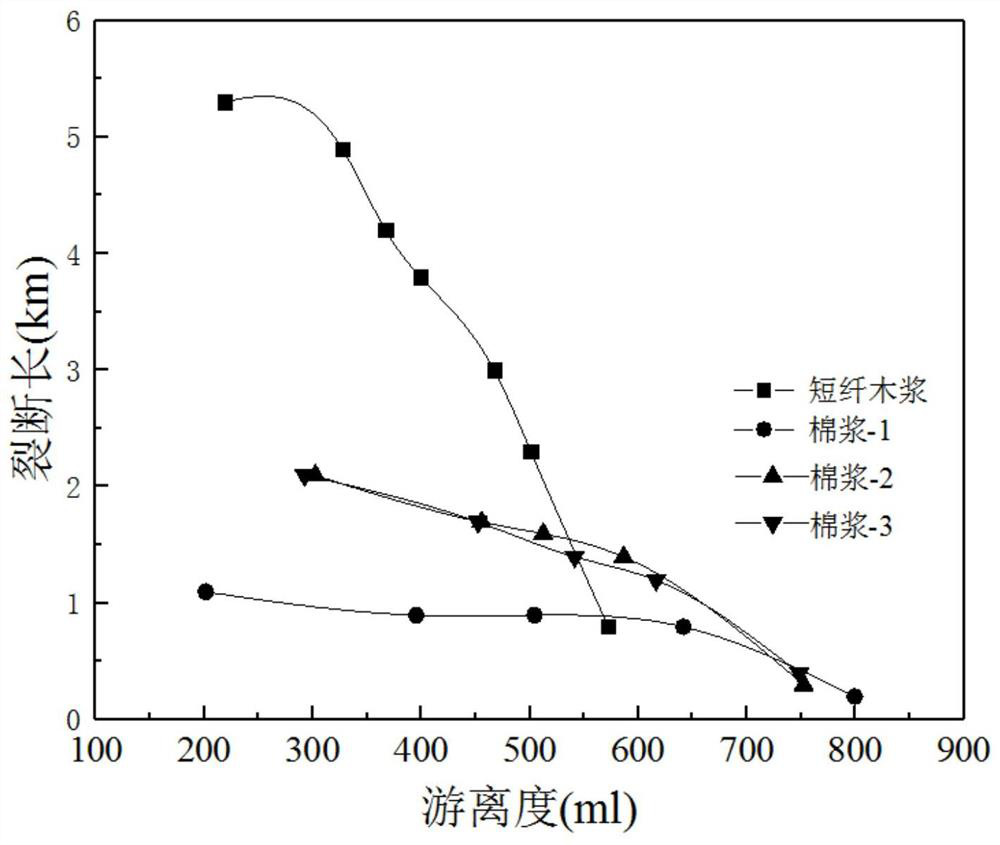

[0061] The purpose of this example is to explore the impact of cotton pulp and short fiber wood pulp on the paper breaking length under the condition of reduced freeness.

[0062] The laboratory refining test was carried out on the cotton pulp fibers provided by the three suppliers, and the freeness-fracture long refining curve was made, and compared with the short fiber wood pulp.

[0063] Refining curve production method: use PFI refiner, adopt different refining speeds, refine the pulp to obtain pulp with different freeness; then use pulp with different freeness to make a quantitative rate of 30g / m 2 Test the fracture length of the handwritten sheet, and make a refining curve based on the obtained freeness and fracture length data.

[0064] Note: This is a laboratory simulation. After refining, the freeness of the slurry will decrease, and the smaller the fracture length of the handmade sheet, the smaller the strength of the handmade sheet and the softer the handwritten she...

Embodiment 2

[0070] The purpose of this example is to investigate the effect of the proportion of cotton pulp in the slurry on the strength of the paper.

[0071] After mixing the cotton pulp fibers and wood pulp fibers provided by the two suppliers in different proportions, the hand-sheets were made under laboratory conditions, and the weight of the hand-sheets was 30g / m 2 . Table 1 shows the test results of the hand-sheet strength.

[0072] Table 1 The influence of slurry ratio on the strength of handmade tablets

[0073] Slurry ratio BL(km) Strength reduction ratio (%) 100% wood pulp 4.46 —— Wood pulp: Cotton pulp-1=95:5 4.14 7.1 Wood pulp: Cotton pulp-1=90:10 3.91 12.4 Wood pulp: Cotton pulp-2=95:5 4.04 9.5 Wood pulp: Cotton pulp-2=90:10 3.89 12.8

[0074] Note: This is a laboratory simulation.

[0075] It can be seen from the above table that adding cotton pulp to the wood pulp fiber can effectively reduce the fracture length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com