Patents

Literature

131 results about "Opacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Opacity is the measure of impenetrability to electromagnetic or other kinds of radiation, especially visible light. In radiative transfer, it describes the absorption and scattering of radiation in a medium, such as a plasma, dielectric, shielding material, glass, etc. An opaque object is neither transparent (allowing all light to pass through) nor translucent (allowing some light to pass through). When light strikes an interface between two substances, in general some may be reflected, some absorbed, some scattered, and the rest transmitted (also see refraction). Reflection can be diffuse, for example light reflecting off a white wall, or specular, for example light reflecting off a mirror. An opaque substance transmits no light, and therefore reflects, scatters, or absorbs all of it. Both mirrors and carbon black are opaque. Opacity depends on the frequency of the light being considered. For instance, some kinds of glass, while transparent in the visual range, are largely opaque to ultraviolet light. More extreme frequency-dependence is visible in the absorption lines of cold gases. Opacity can be quantified in many ways; for example, see the article mathematical descriptions of opacity.

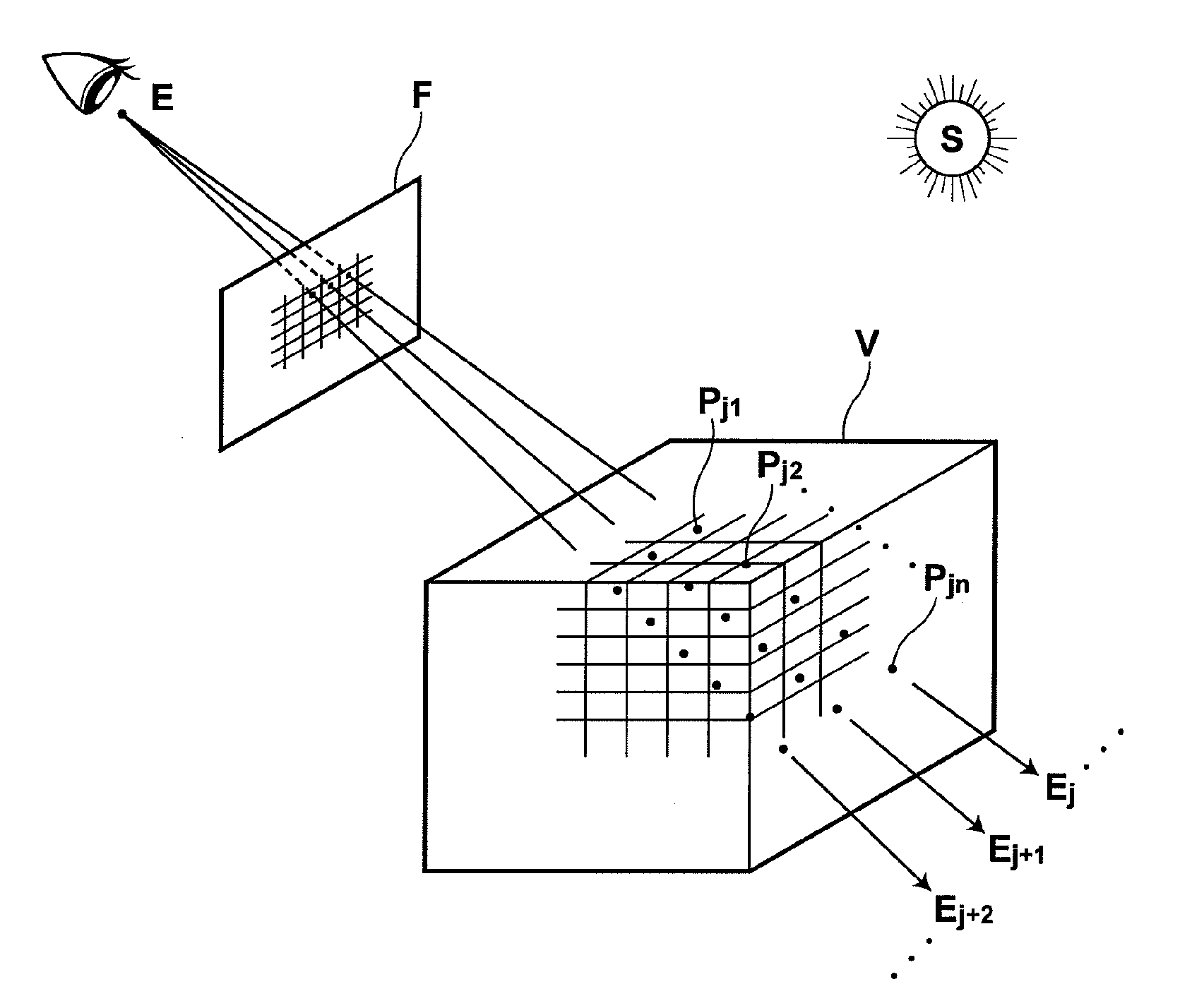

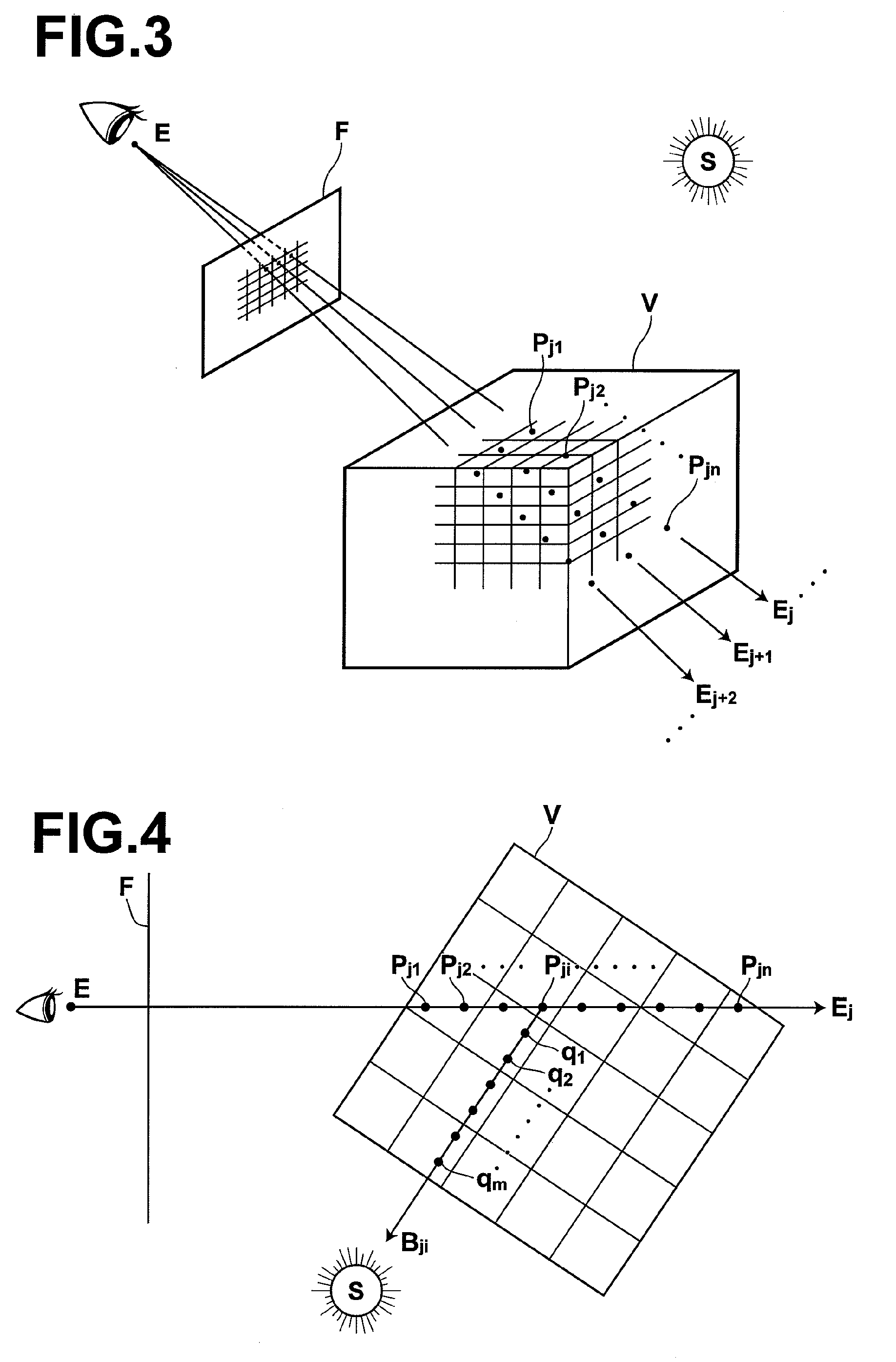

Image-based 3D modeling rendering system

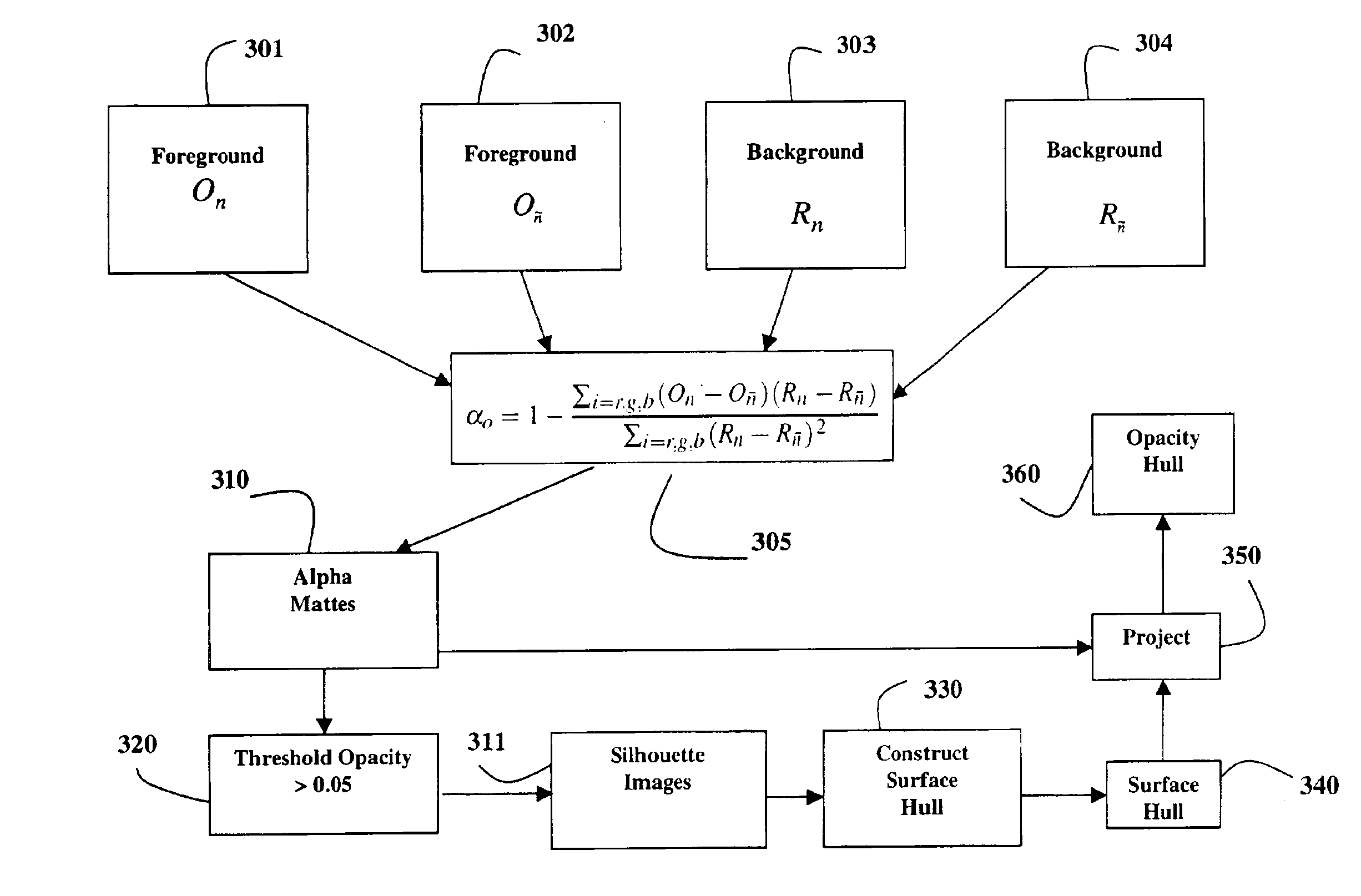

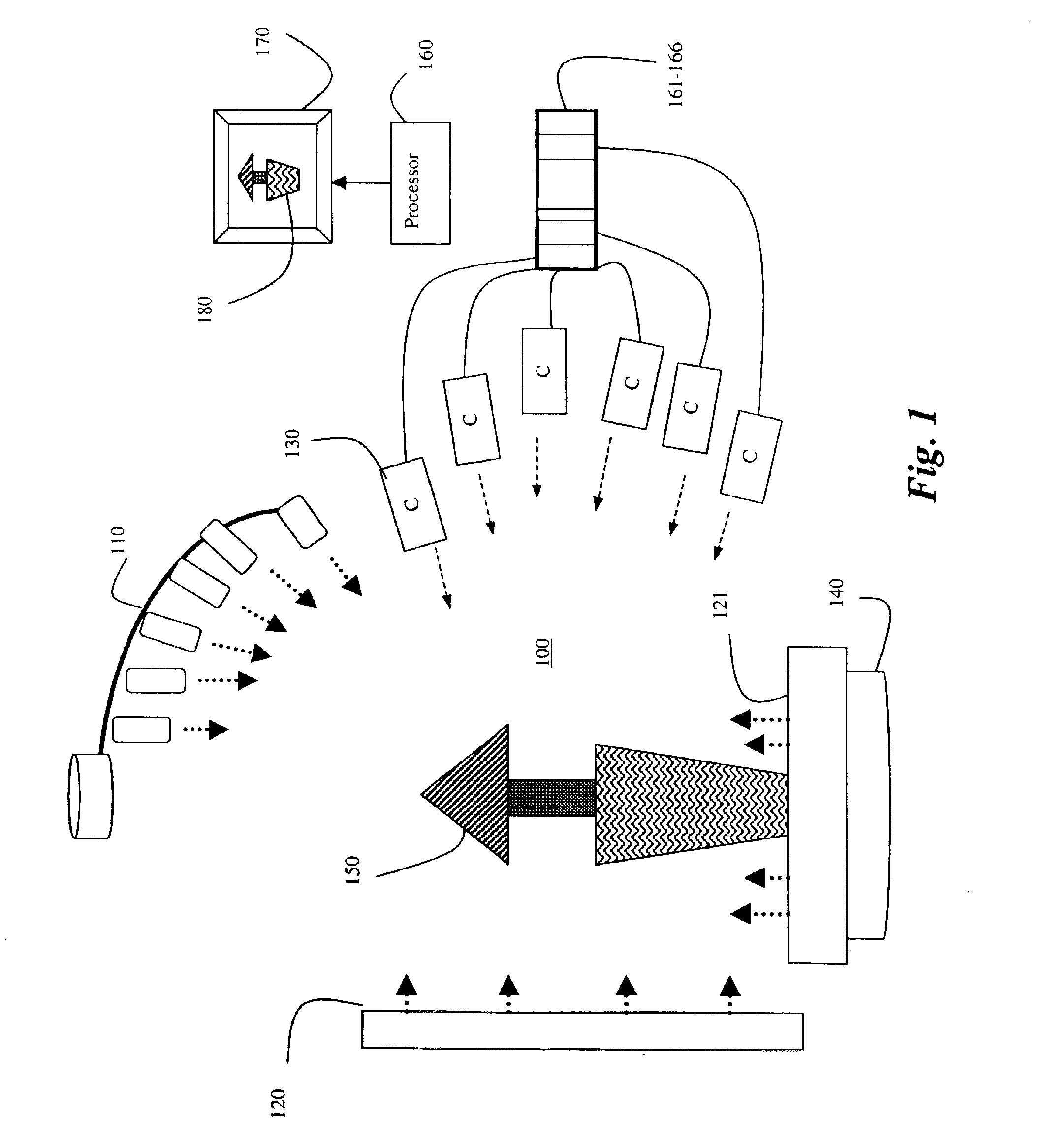

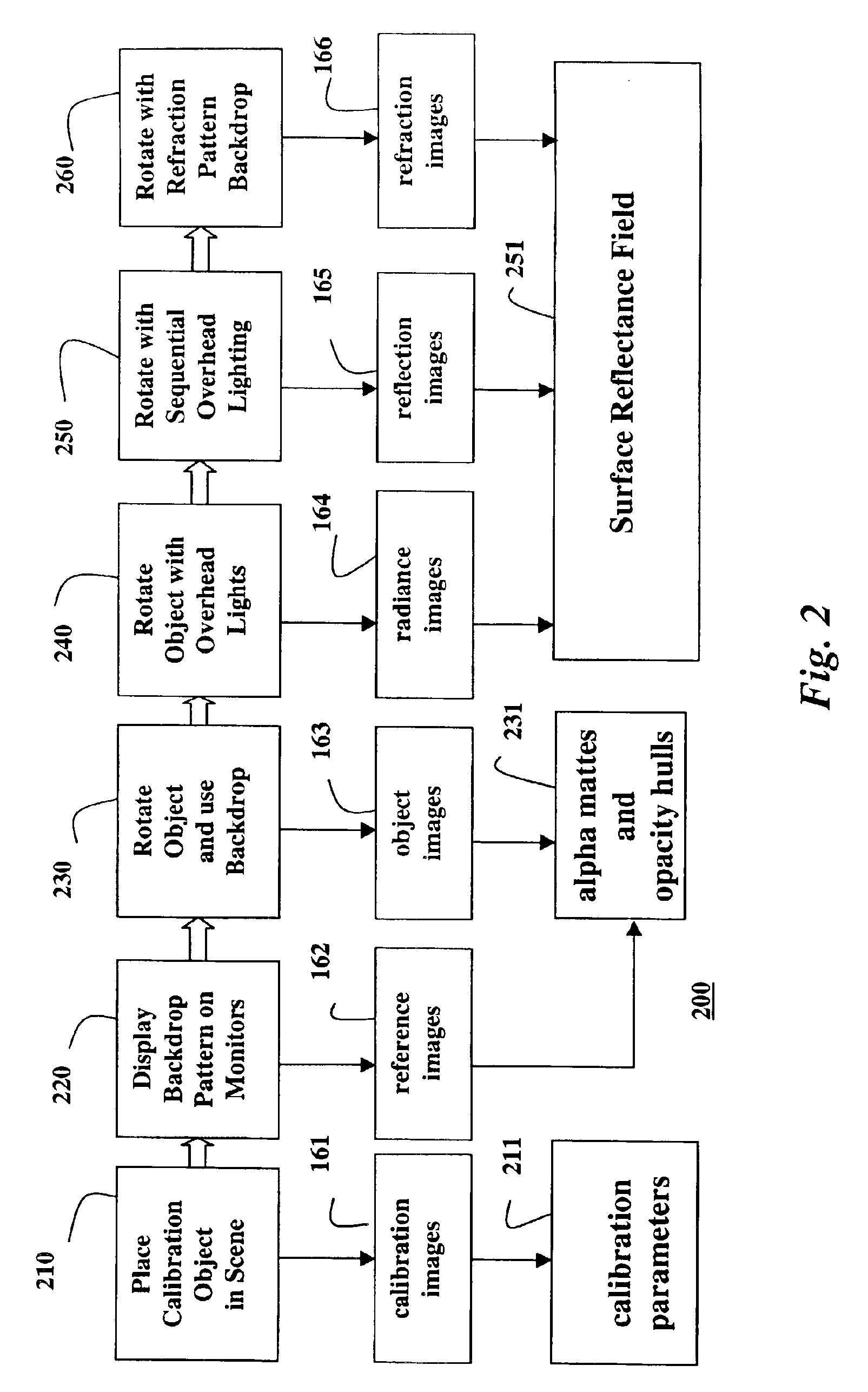

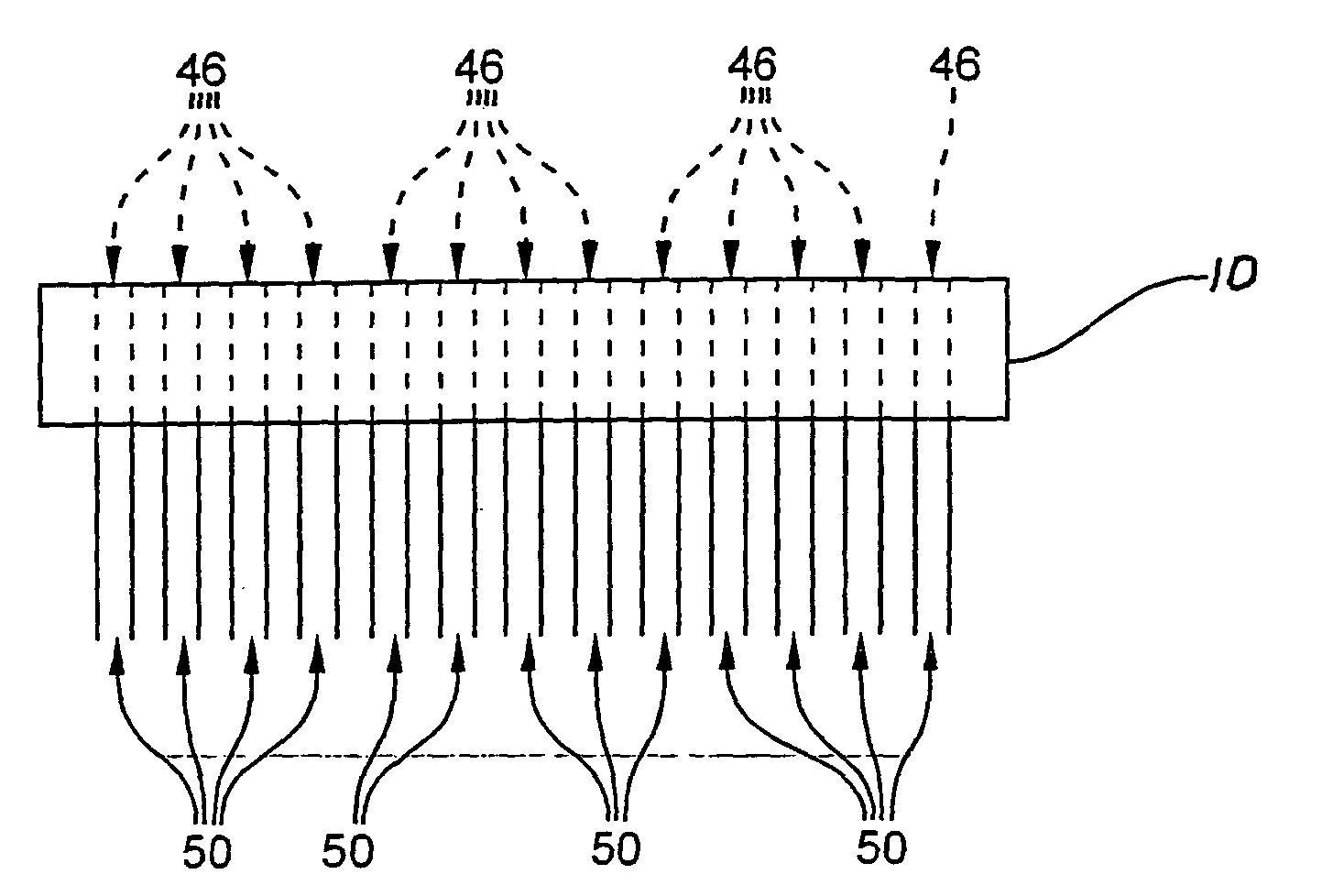

InactiveUS6903738B2Easy to useSimple setup3D-image rendering3D modellingMultiple viewpoint3D modeling

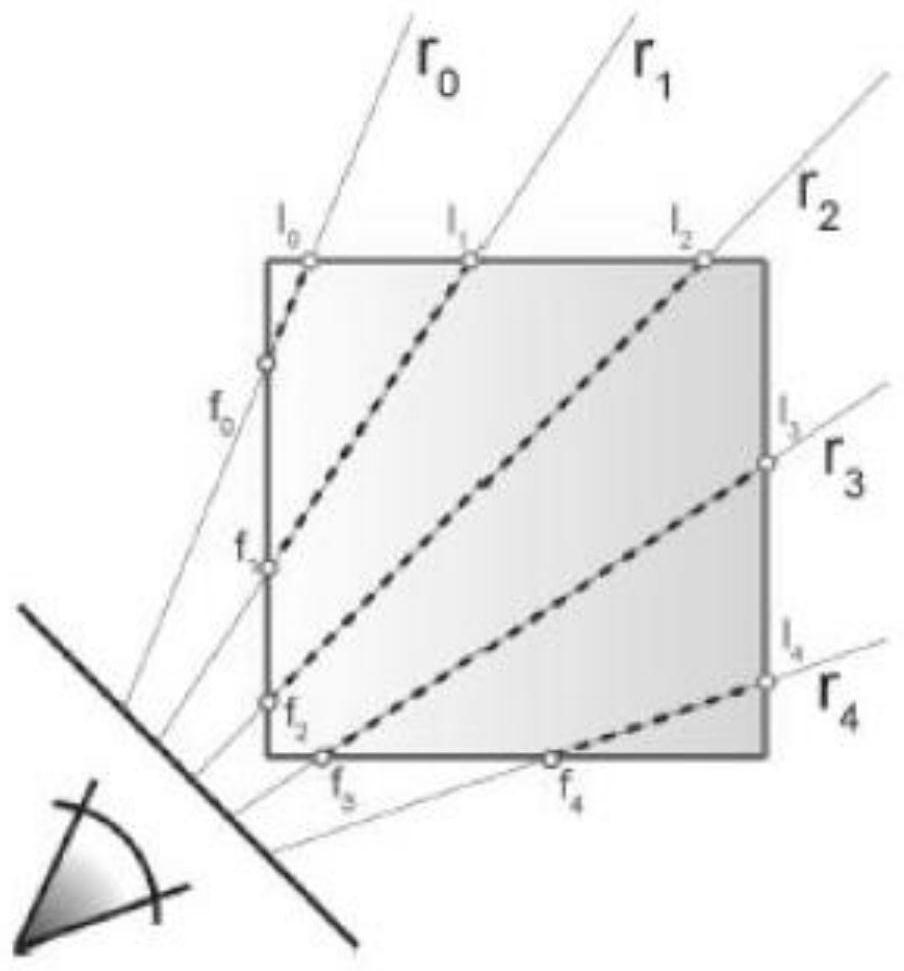

A method models a three-dimensional object by first acquiring alpha mattes of the object for multiple viewpoints. The alpha mattes are then projected onto a surface hull completely enclosing the object to construct an opacity hull storing opacity values of the surface of the object. The object is illuminated for various lighting conditions while images are acquired. The images are projected onto the opacity hull to render the object under arbitrary lighting conditions for arbitrary viewpoints.

Owner:MITSUBISHI ELECTRIC RES LAB INC

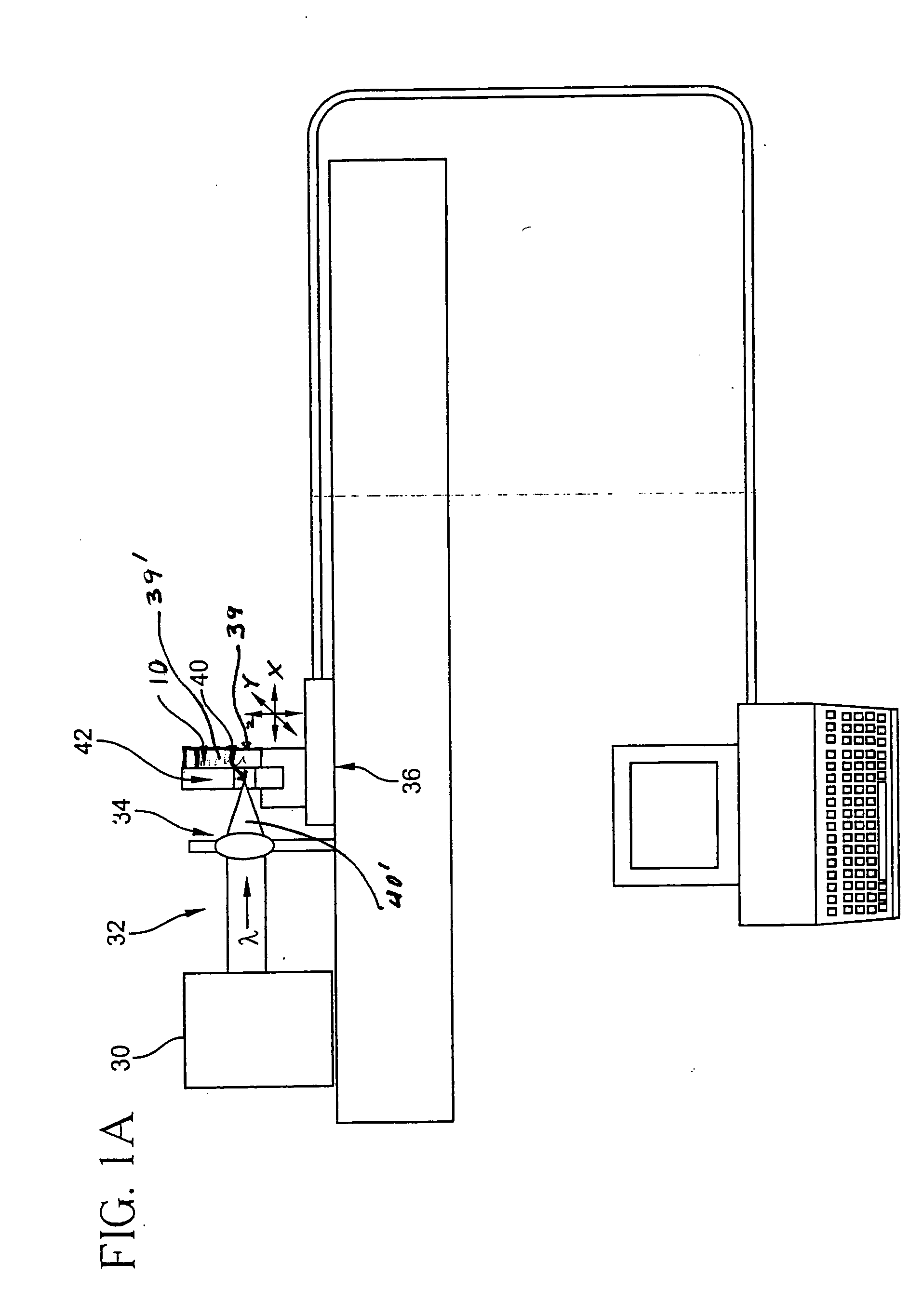

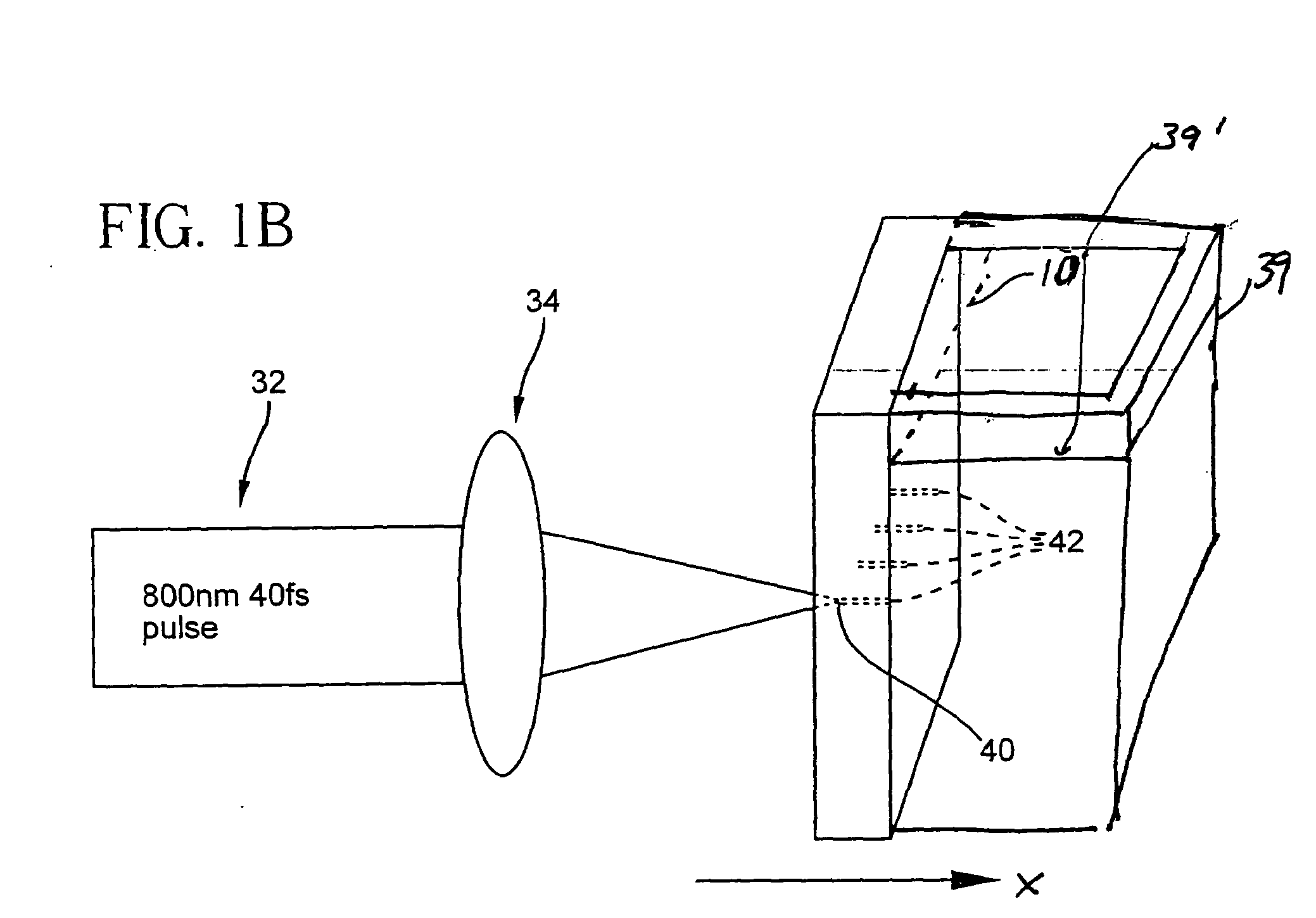

Method of making at least one hole in a transparent body and devices made by this method

InactiveUS20050025445A1Improved micromachining speedCoupling light guidesGlass reforming apparatusPicosecond laser pulseErbium lasers

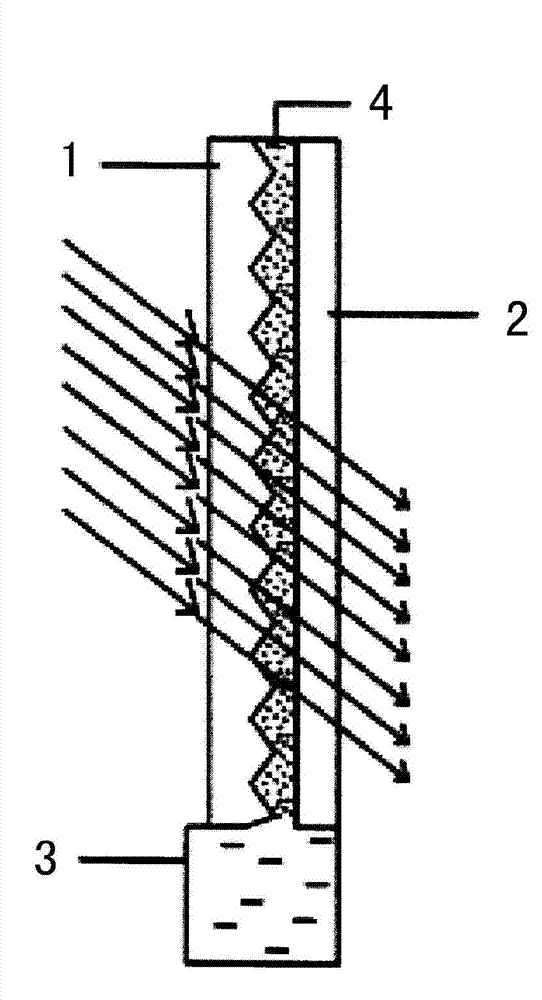

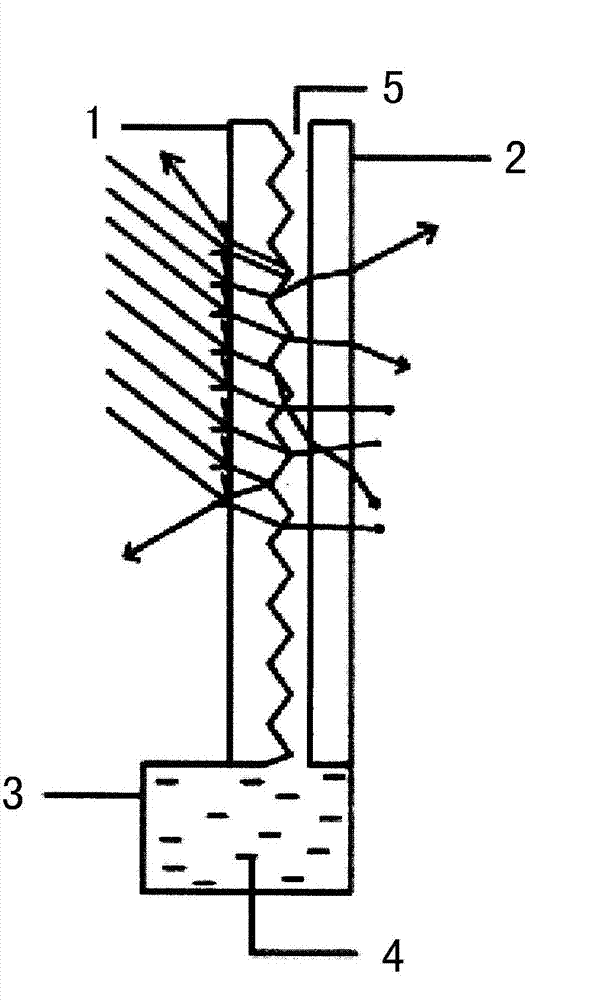

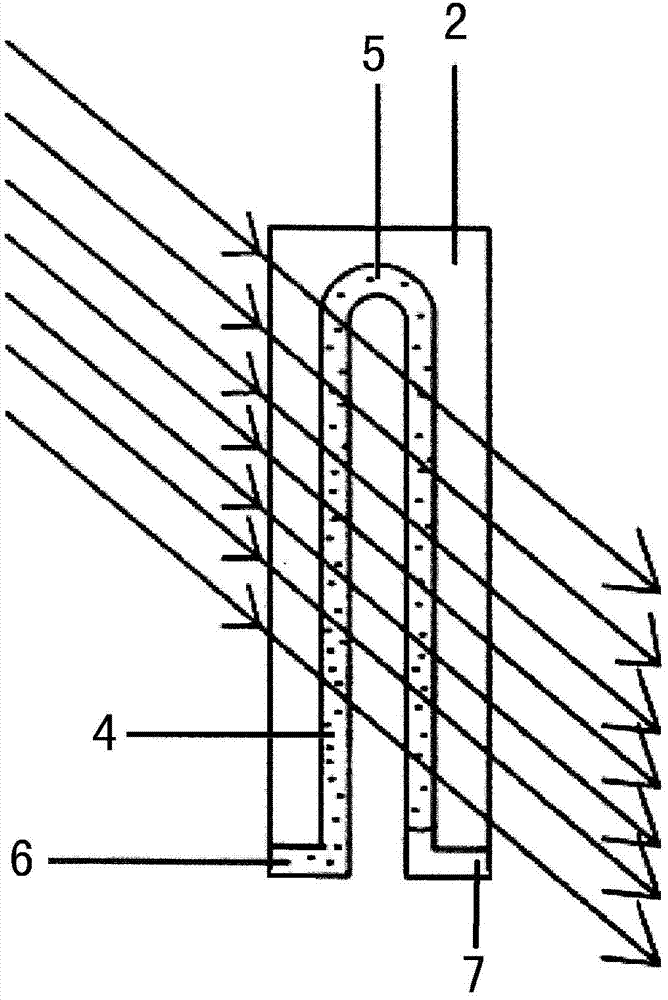

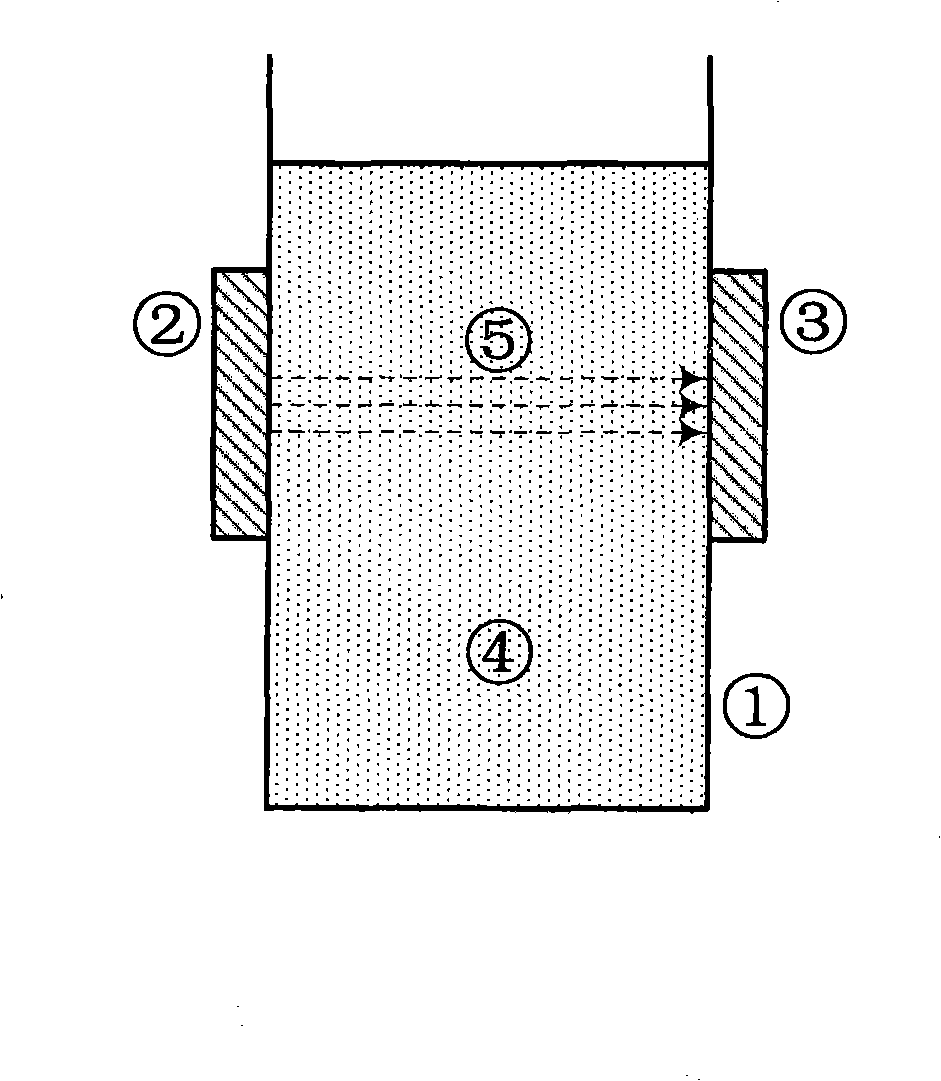

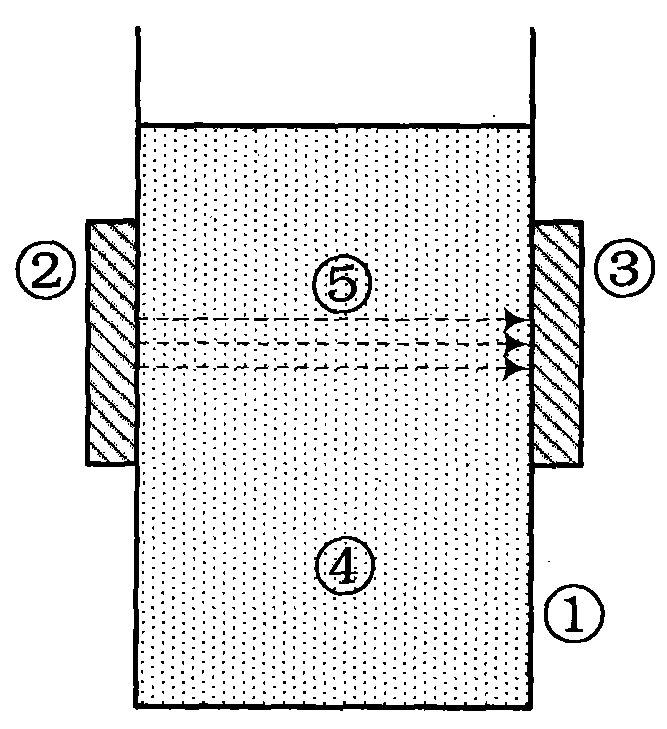

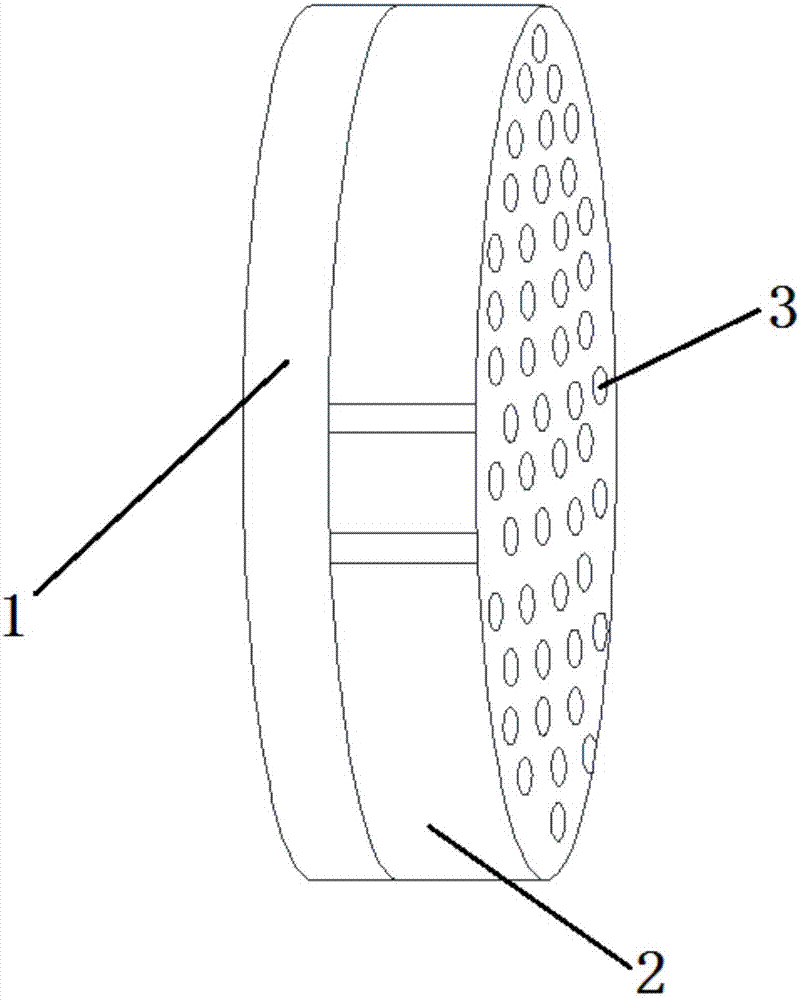

A method of making an at least one hole in an optically transparent body comprises the following steps: (i) providing an ultrashort pulse laser for producing a laser output with a wavelength λ, the laser output having a subpicosecond laser pulse duration; (ii) providing a laser output focusing lens for focusing the laser output, the focusing lens having a numerical aperture NA; (iii) providing an optically transparent body, the optically transparent body having a transparency at λ of at least 90% / cm; (iv) providing a liquid filled container situated proximate to the optically transparent body, such that the optically transparent body is in direct contact with the liquid; and (v) directing the laser output through the focusing lens to produce a focused laser output with a subpicosecond laser pulse duration proximate the optically transparent body, wherein the focused laser output traces at least one hole track pattern through the transparent glass body while the optically transparent body and said focused laser output move relative to one another in X-Y-Z directions. The at least one hole track pattern is in contact with the liquid and the focused laser output, in conjunction with the liquid, creates at least one hole in the optically transparent body.

Owner:CORNING INC

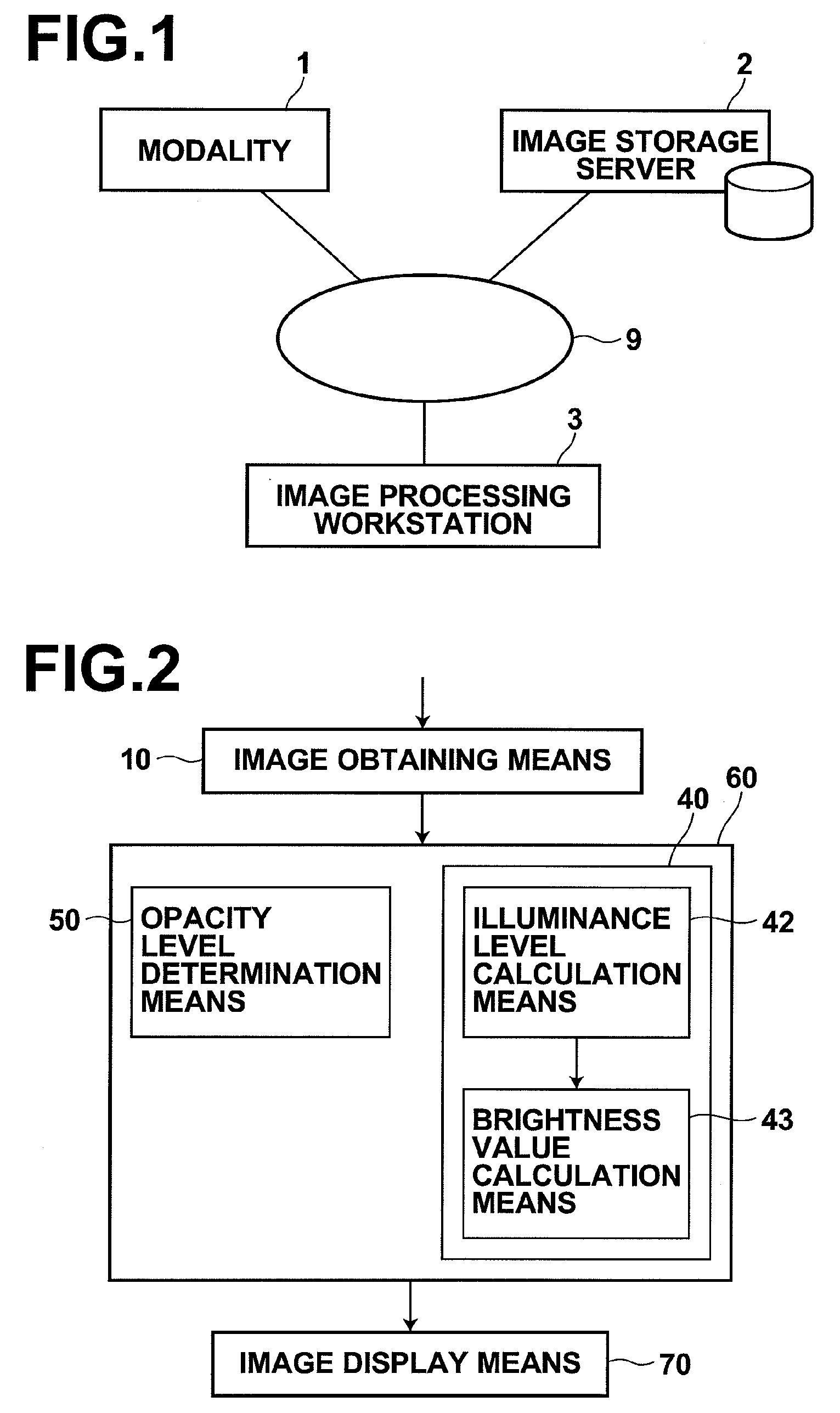

Image processing method, apparatus, and program

ActiveUS20080259080A1Improve fidelityComputerised tomographsDiagnostic recording/measuringImaging processingIlluminance

In an image processing method for generating a pseudo three-dimensional image by a volume rendering method in which a pixel value of each pixel on a projection plane on which a three-dimensional image illuminated by an arbitrary light source is projected is determined using a brightness value at each examination point, which is a point on the three-dimensional image sampled along each of a plurality of visual lines connecting an arbitrary viewpoint and each pixel on the projection plane, an illuminance level at each examination point is calculated based on an opacity level at each calculation point, which is a point on the three-dimensional image sampled along each of a plurality of light rays connecting the light source and each examination point, and the brightness value at each examination point is determined based on the calculated illuminance level.

Owner:FUJIFILM CORP

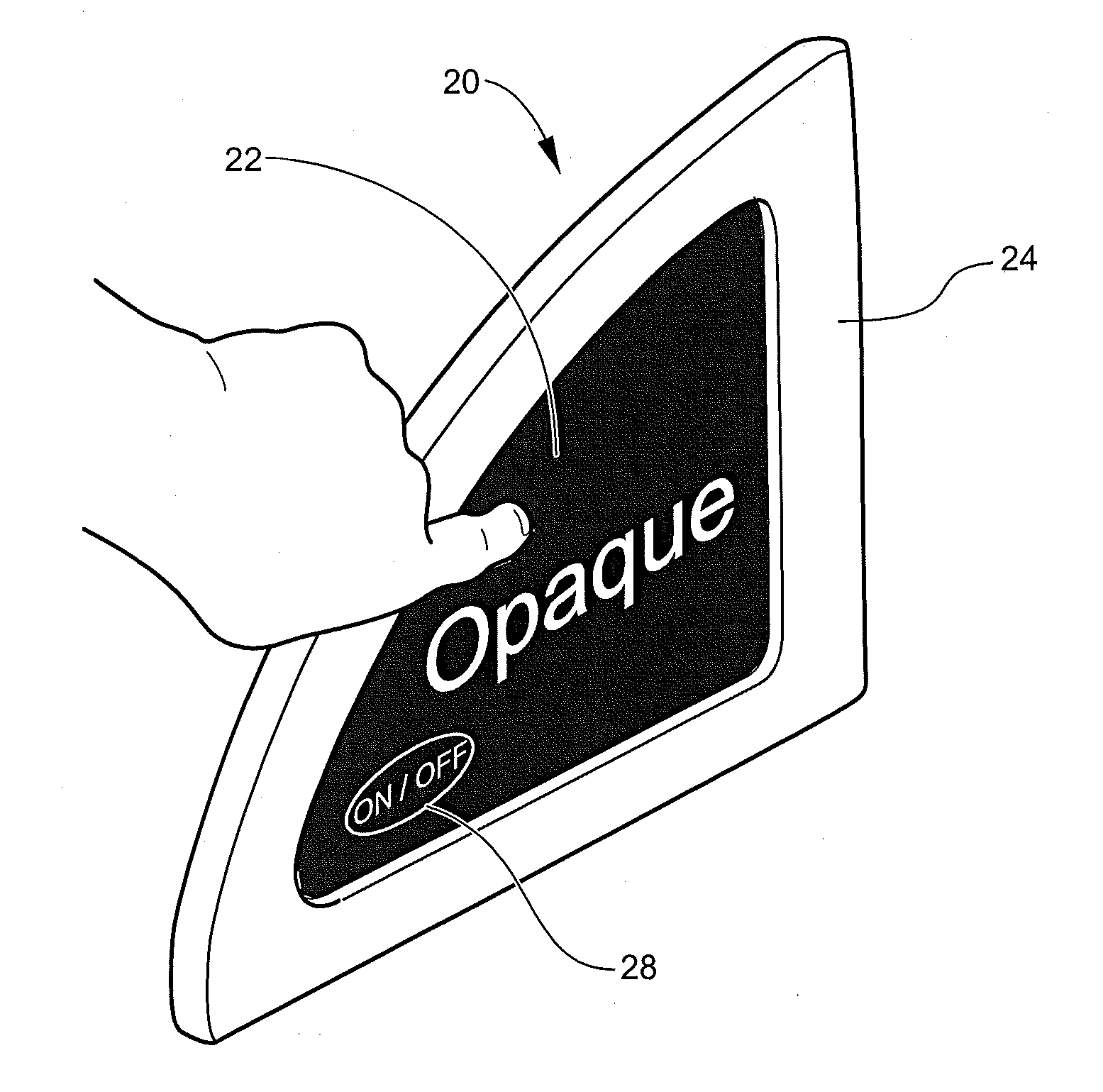

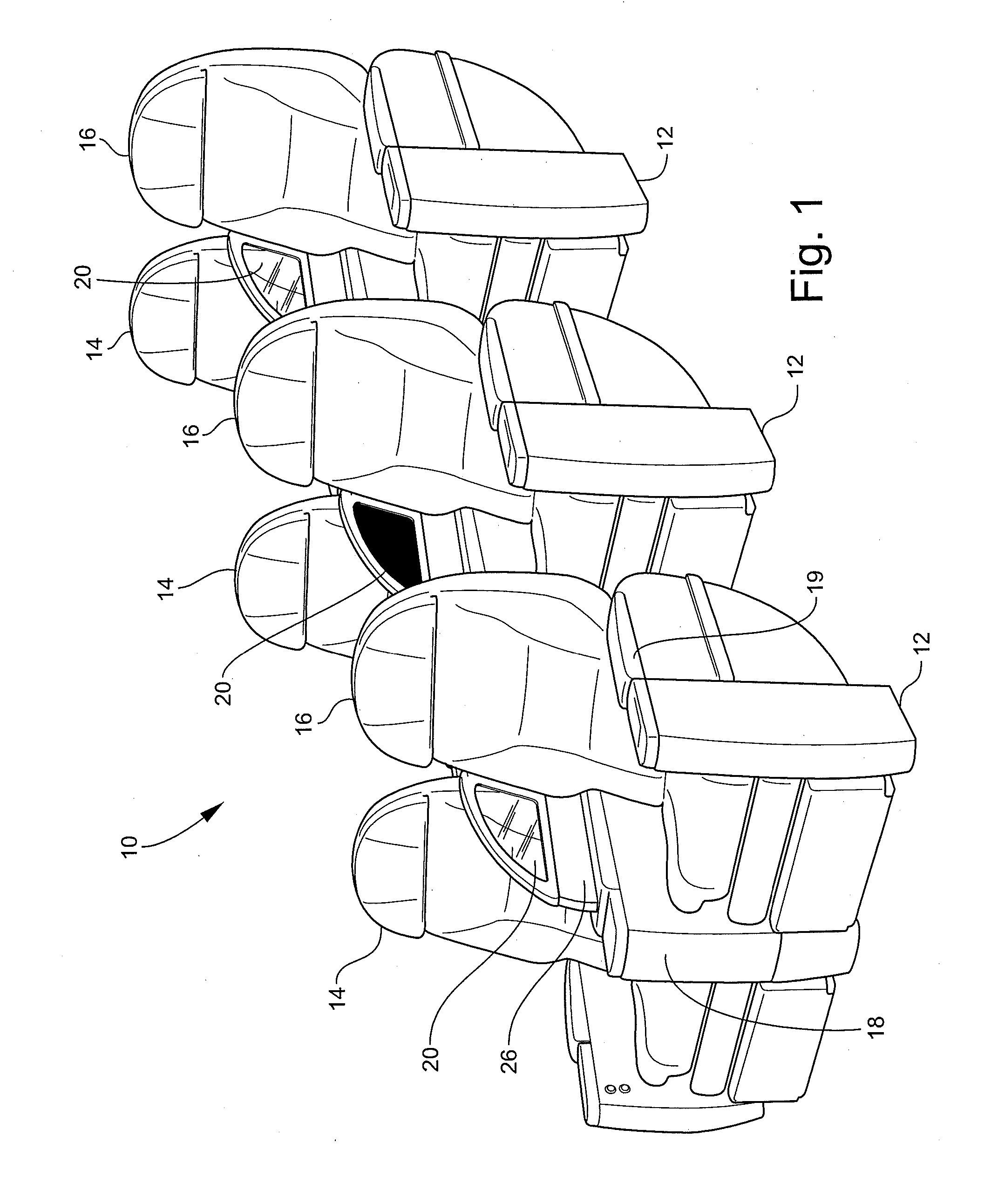

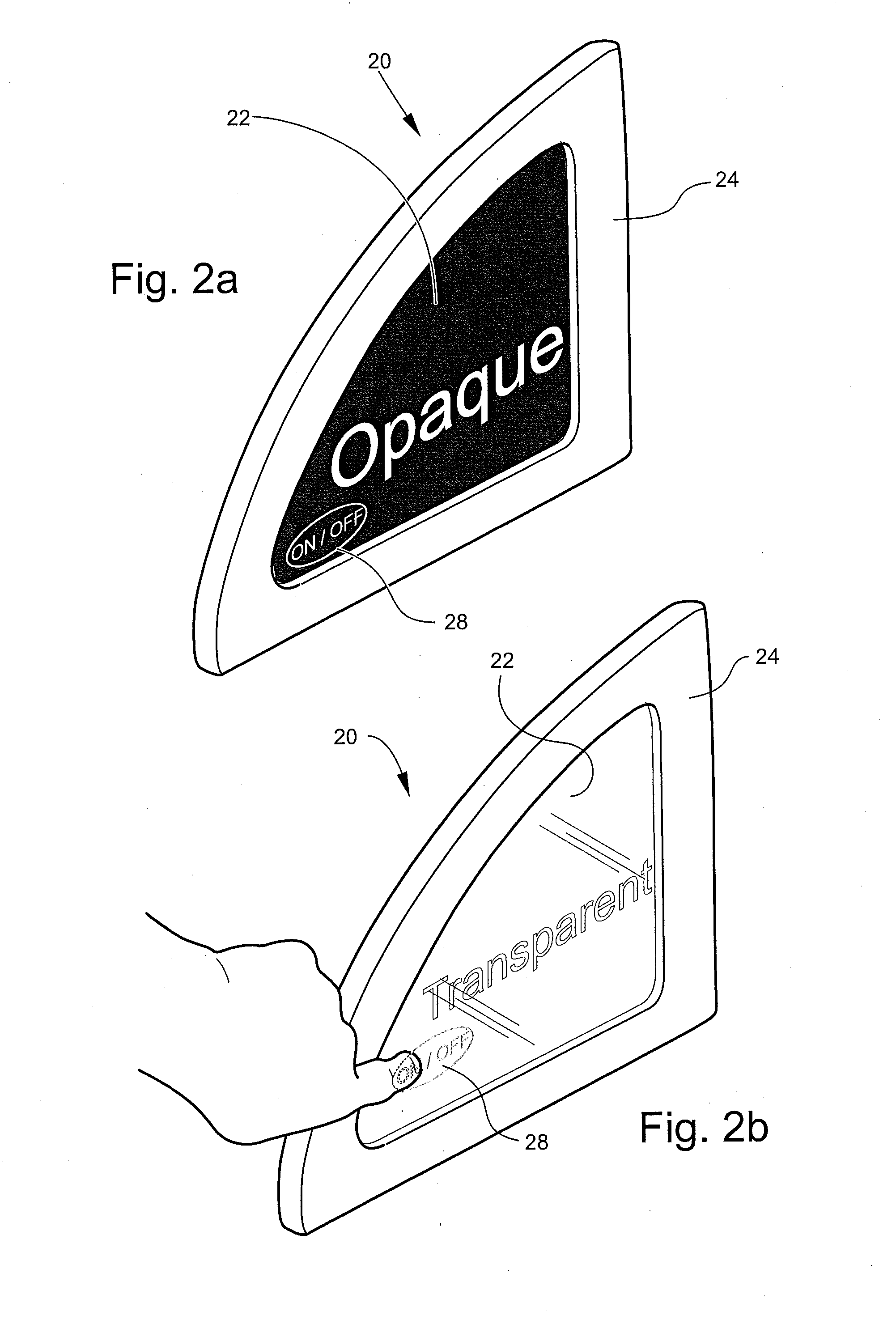

Touch responsive privacy partition

An aircraft passenger seat privacy partition including a screen selectively switchable between an opaque optical state and a substantially transparent optical state in response to a change in voltage applied to the screen, and a touch-responsive switch embedded in the screen for detecting a change in capacitance in the screen and applying the voltage change to the screen to selectively switch between the opaque and substantially transparent optical states.

Owner:BE AEROSPACE INCORPORATED

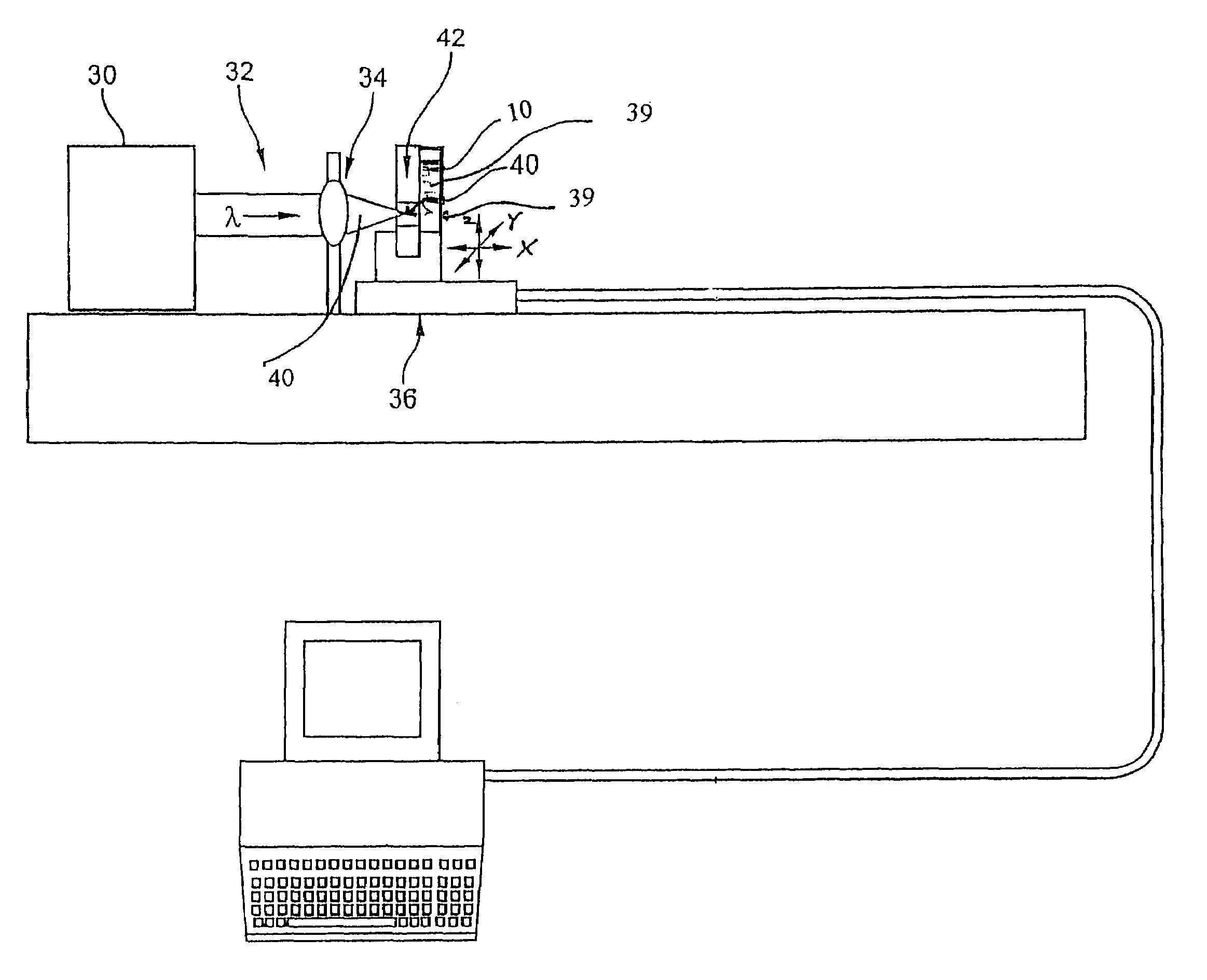

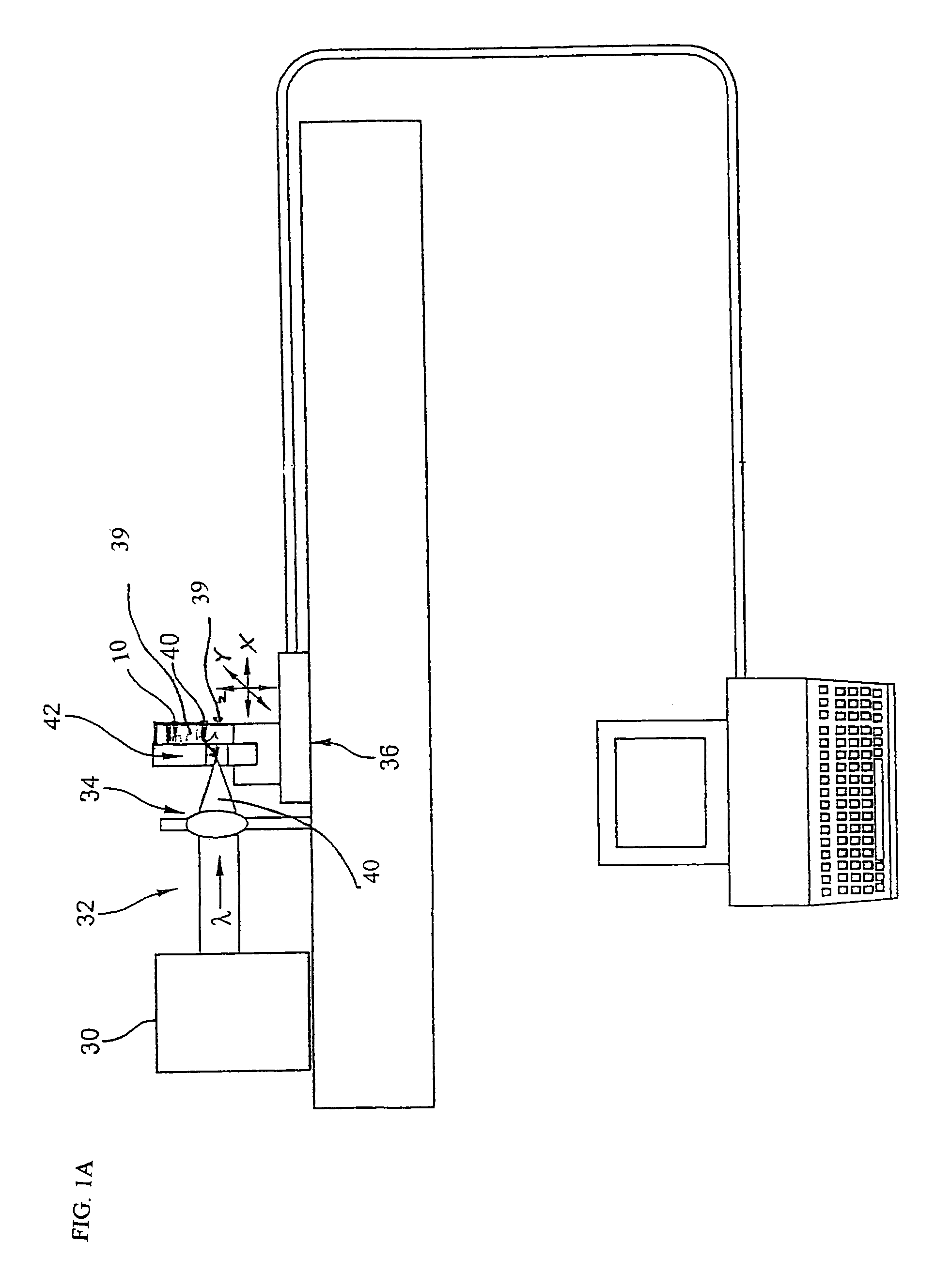

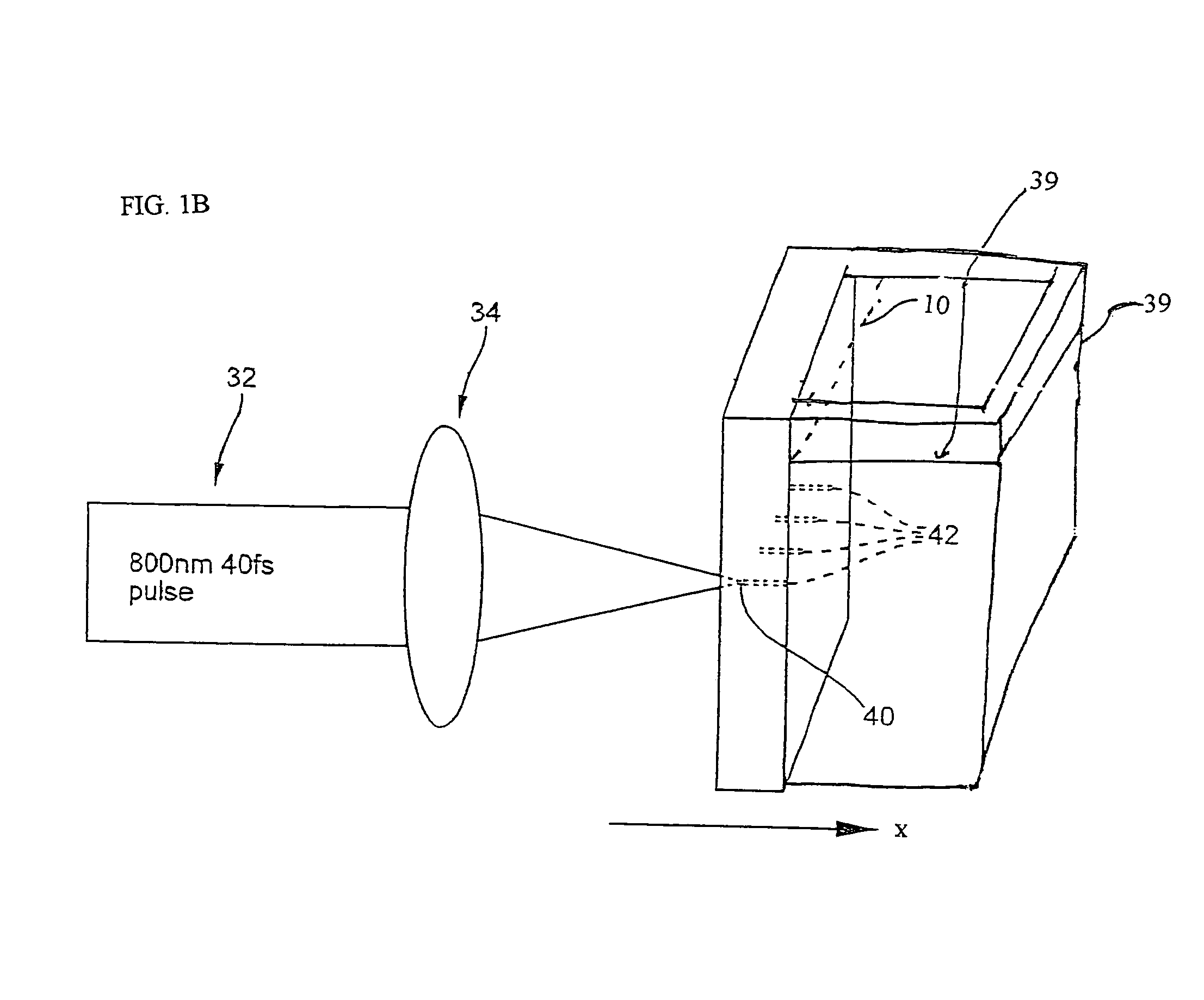

Method of making at least one hole in a transparent body and devices made by this method

InactiveUS6990285B2Improved micromachining speedCoupling light guidesGlass reforming apparatusPicosecond laser pulseErbium lasers

A method of making an at least one hole in an optically transparent body comprises the following steps: (i) providing an ultrashort pulse laser for producing a laser output with a wavelength λ, the laser output having a subpicosecond laser pulse duration; (ii) providing a laser output focusing lens for focusing the laser output, the focusing lens having a numerical aperture NA; (iii) providing an optically transparent body, the optically transparent body having a transparency at λ of at least 90% / cm; (iv) providing a liquid filled container situated proximate to the optically transparent body, such that the optically transparent body is in direct contact with the liquid; and (v) directing the laser output through the focusing lens to produce a focused laser output with a subpicosecond laser pulse duration proximate the optically transparent body, wherein the focused laser output traces at least one hole track pattern through the transparent glass body while the optically transparent body and said focused laser output move relative to one another in X-Y-Z directions. The at least one hole track pattern is in contact with the liquid and the focused laser output, in conjunction with the liquid, creates at least one hole in the optically transparent body.

Owner:CORNING INC

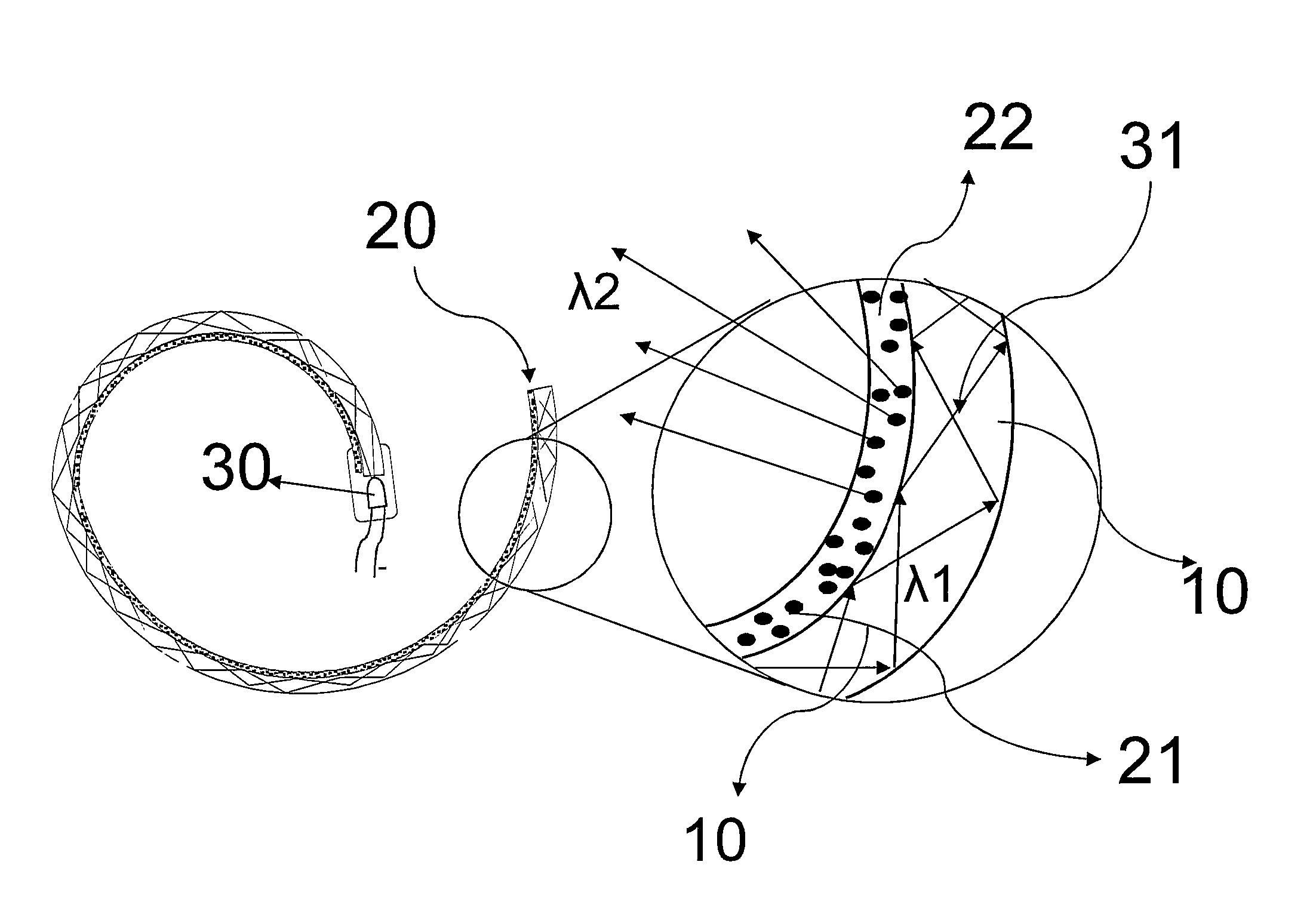

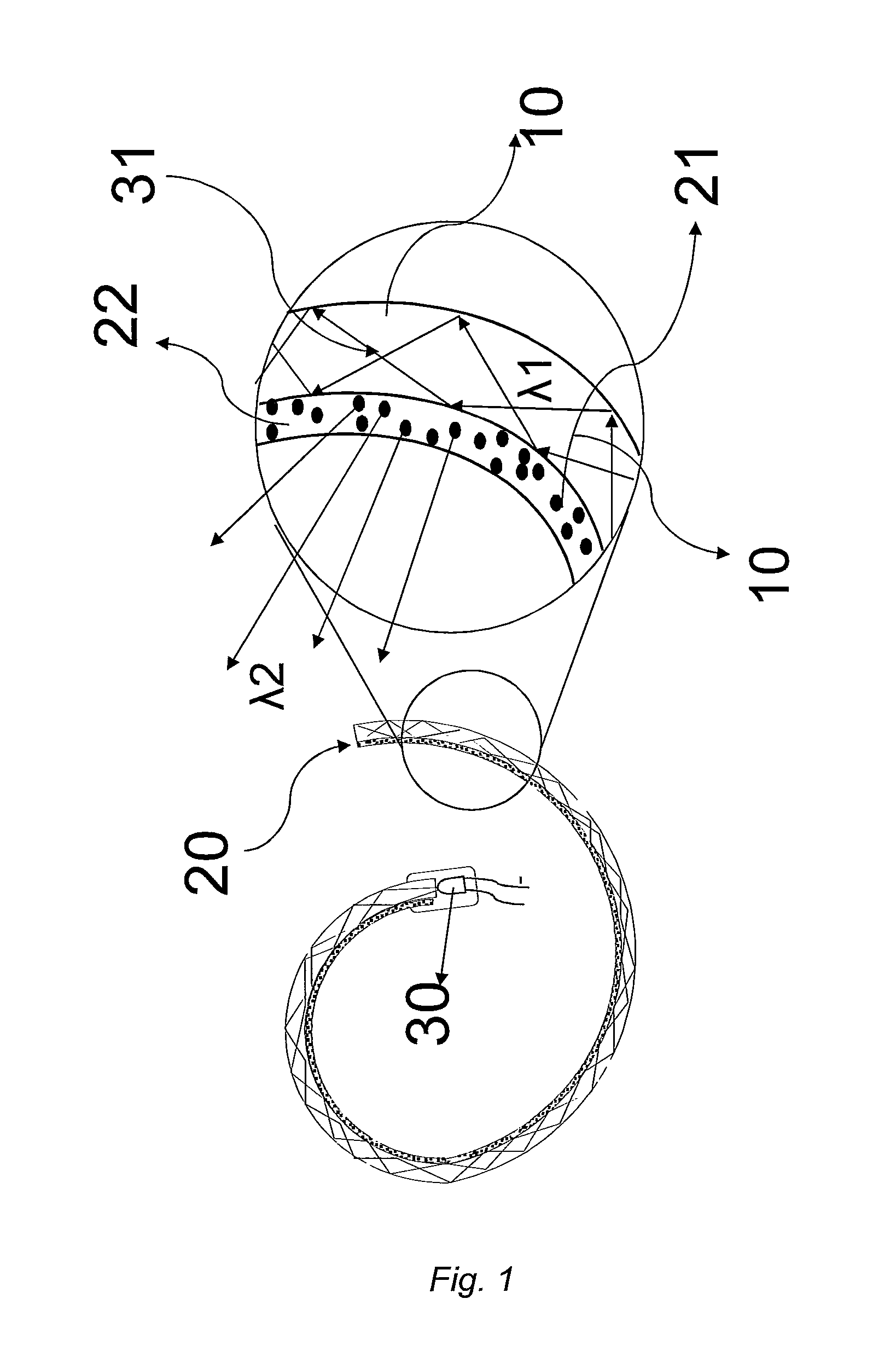

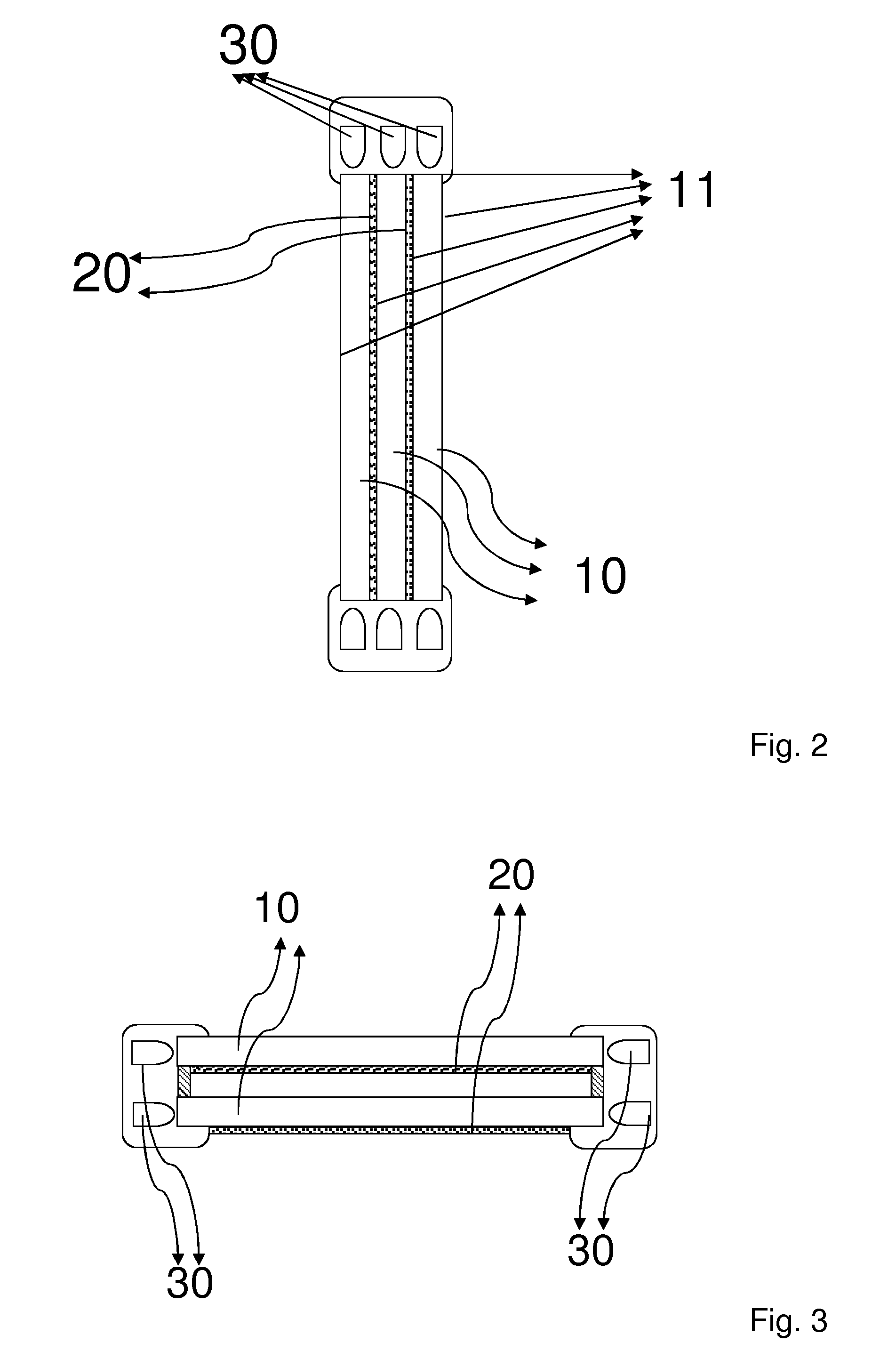

Switchable luminescent see-through system

InactiveUS20140286048A1Transparent highImpart luminescent propertyAircraft componentsMechanical apparatusLuminophoreOptical property

The present invention relates to a switchable see-through luminescent system, e.g. for luminous signage, characterized by its mode to exist in two different states, transparent (‘off-state’) and luminescent (‘on-state’), due to the presence of a luminescent material (20), coated on to the transparent surface (10), capable of being excited on command by means of lighting sources (30) (e.g. LEDs) characterized by suitable emission spectra. In the off-state of the luminescent material (20), the surface appears transparent and it is not evident any significant modifications of the optical properties (transparency, color, etc.) of the surface. The excitable luminescent material, from which a large variety of luminophores can be conveniently applied on to a substantially transparent support, of arbitrary geometry, realized with a plurality of homogenous and heterogeneous materials, including laminated glass or double glazed windows, provides a large variety of possible shapes capable of satisfying varied application requirements.

Owner:HELIV GRP SRL

Polycarbonate composition having high light reflectivity and uses thereof

The invention provides a polycarbonate combination with high light reflectivity, which comprises 63 to 90 shares of polycarbonate (PC), 3 to 6 shares of bromide polycarbonate, 2 to 5 shares of Acrylic Acid Core-Shell Copolymer, 5 to 25 shares of TiO2, 0.1 to 0.3 shares of antioxidant, 0.2 to 0.4 shares of lubricant and 0.3 to 0.5 shares PTFE fine powder. The combination has the advantages of anti-flaming, high light reflectivity, high temperature resistant, easy modeling and good opacity and can be used for producing the spare parts for electronic electric appliances such as the LED display, the LCD display, etc.

Owner:广东瑞能新材料有限公司

Photoresist and preparation method

InactiveCN101200570ASolve the poor light blocking effectEffective light blocking propertiesPhotoresistMetallurgy

The present invention relates to opacity material, characterized in that the material consists of the following components in terms of weight portion: 50 to 95 portions of matrix resin, 2 to 30 ports of opacifier A, 1 to 20 portions of opacifier B and 0.1 to 40 portions of assistant. The light-colored opacity material prepared by the present invention can achieve effective opacity when the thickness is only 3mm, thus solving the poor opacity of the light-colored material. The present invention can be applied to various fields with requirements of opacity and optical crosstalk prevention, such as automobile instrument panel and apparatus control and operation components.

Owner:SHANGHAI KINGFA SCI & TECH +1

Multi-layered thermoplastic films and bags with enhanced light transmittance and methods for making the same

ActiveUS20150030266A1Reduce light transmittanceLight transmittance becomes lessBox making operationsPaper-makingTransmittanceLight transmission

Implementations described herein include films with maintained or decreased light transmittance despite a reduction in gauge. In particular, one or more implementations include a multi-layer film with each layer having differing opacity agents. The combination of the two different opacity agents in two different layers can have a synergistic effect that provide decreased light transmittance. Indeed, in one or more embodiments a multi-layer film with differing opacity agents in each layer has a decreased light transmittance despite a reduction in gauge and opacity agents.

Owner:THE GLAD PROD CO

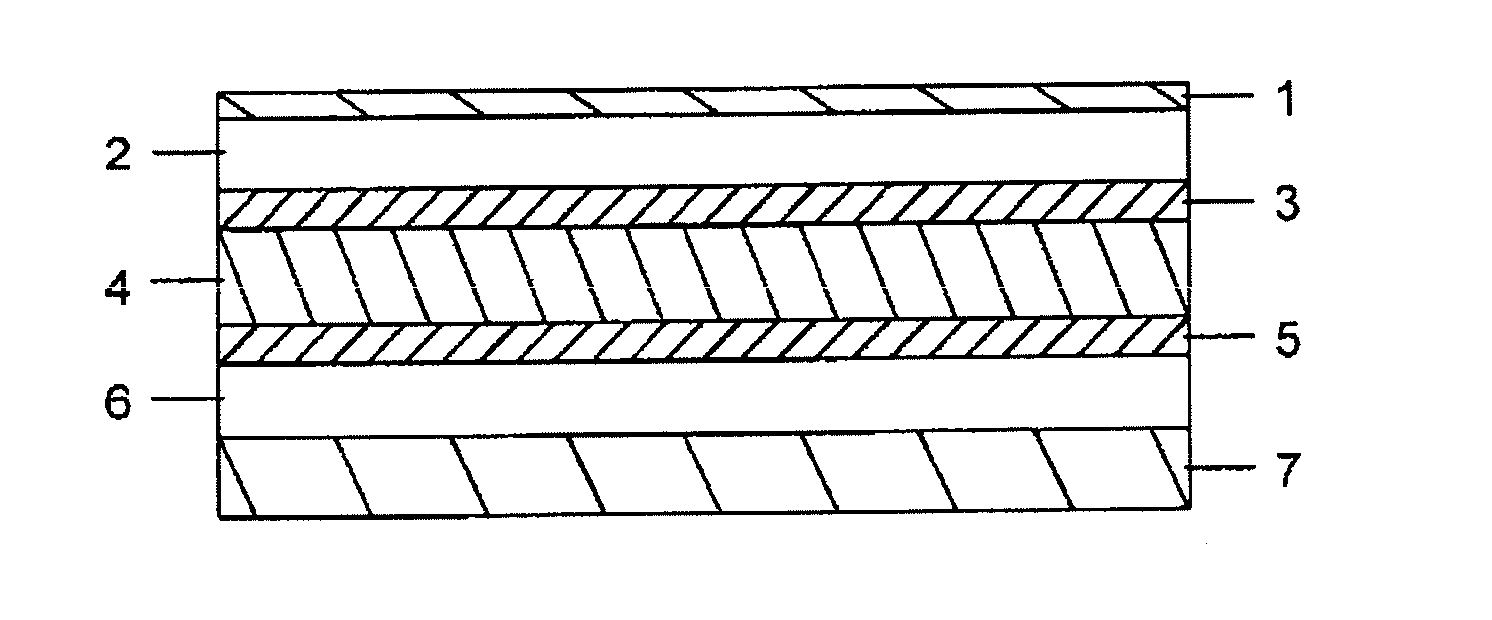

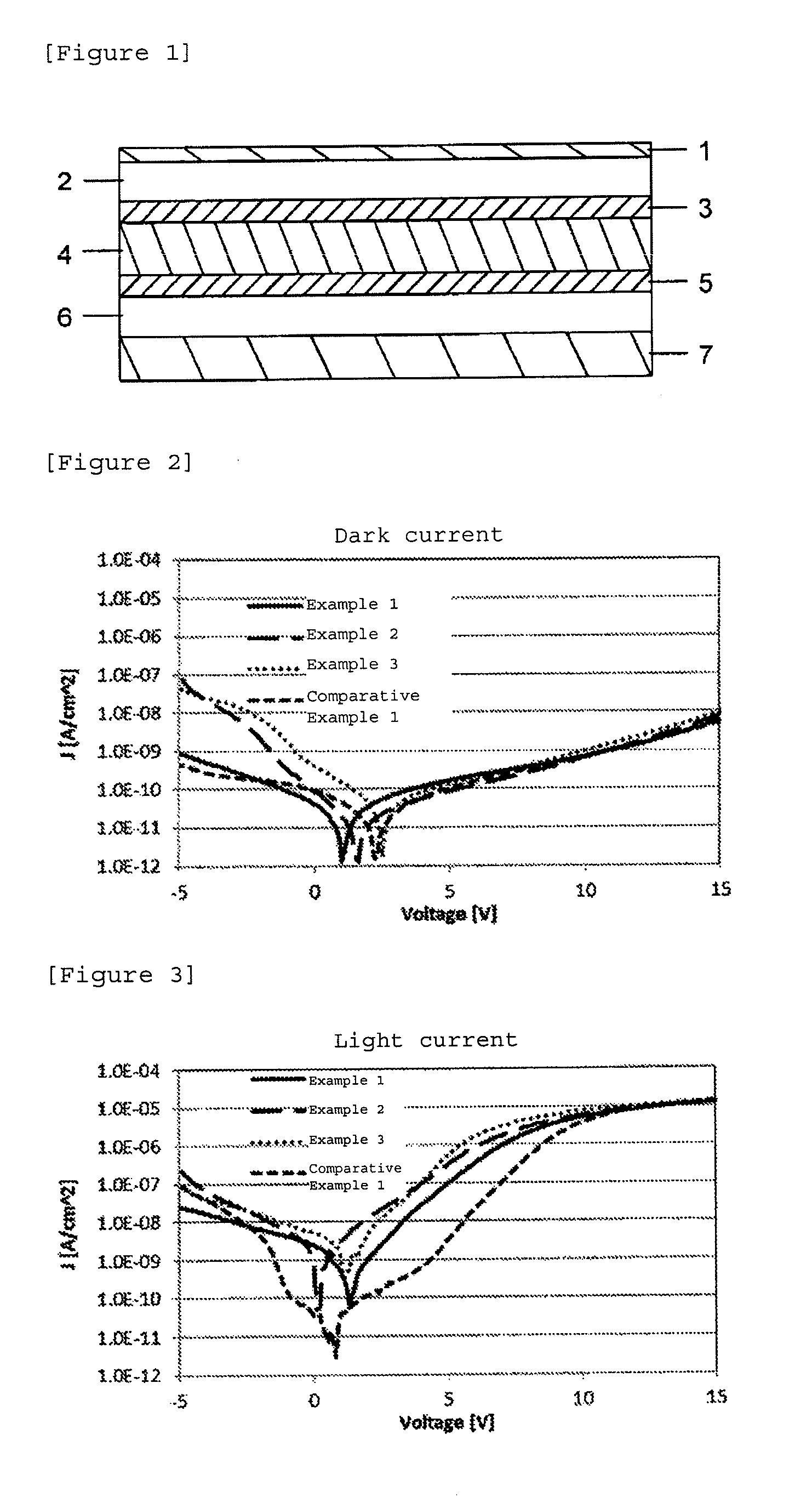

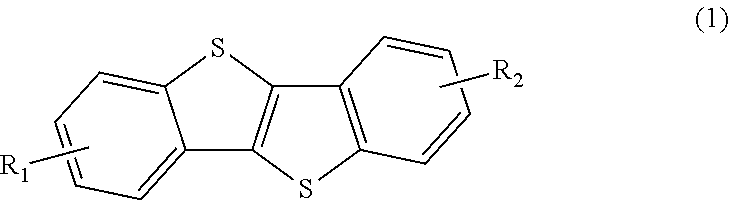

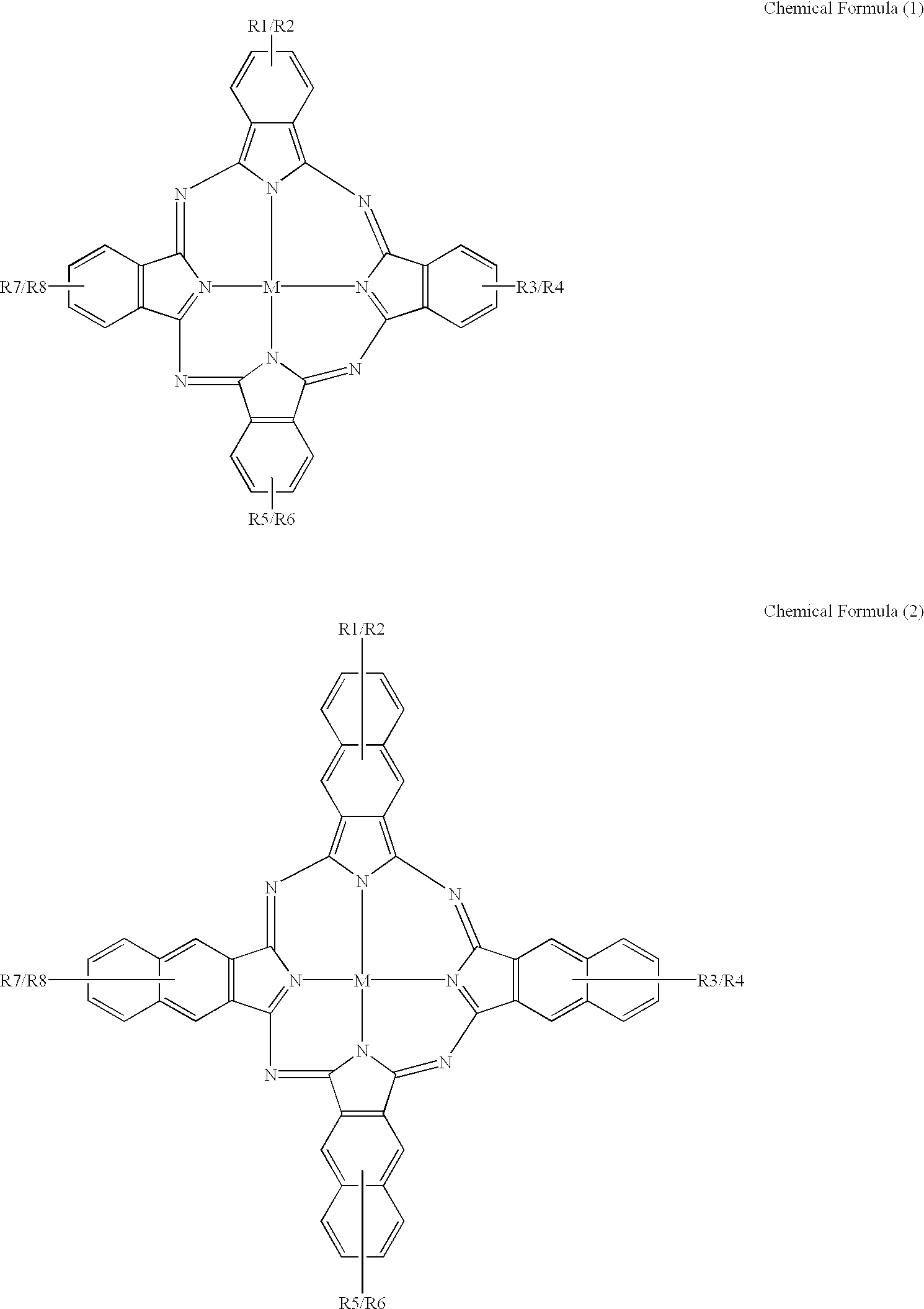

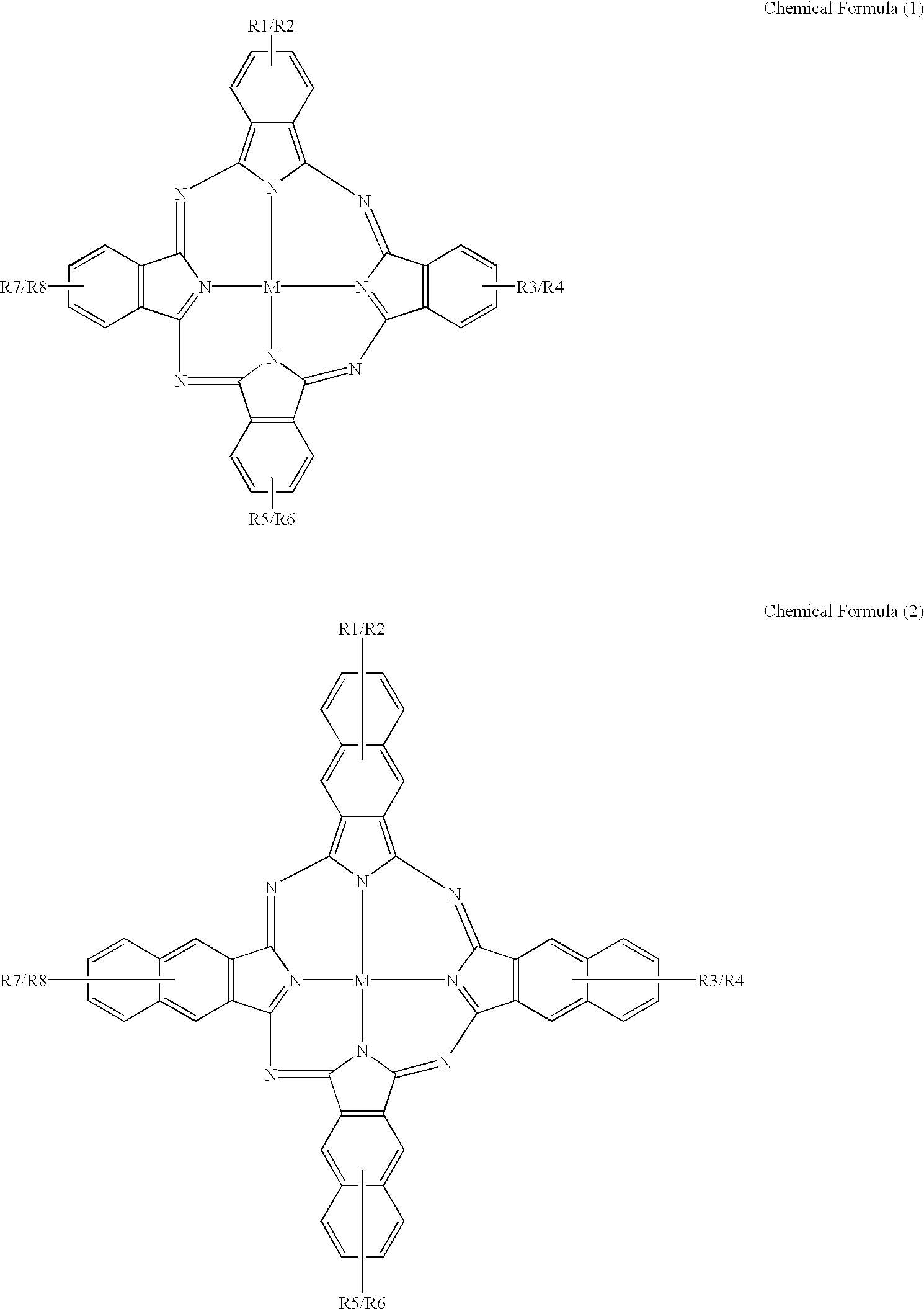

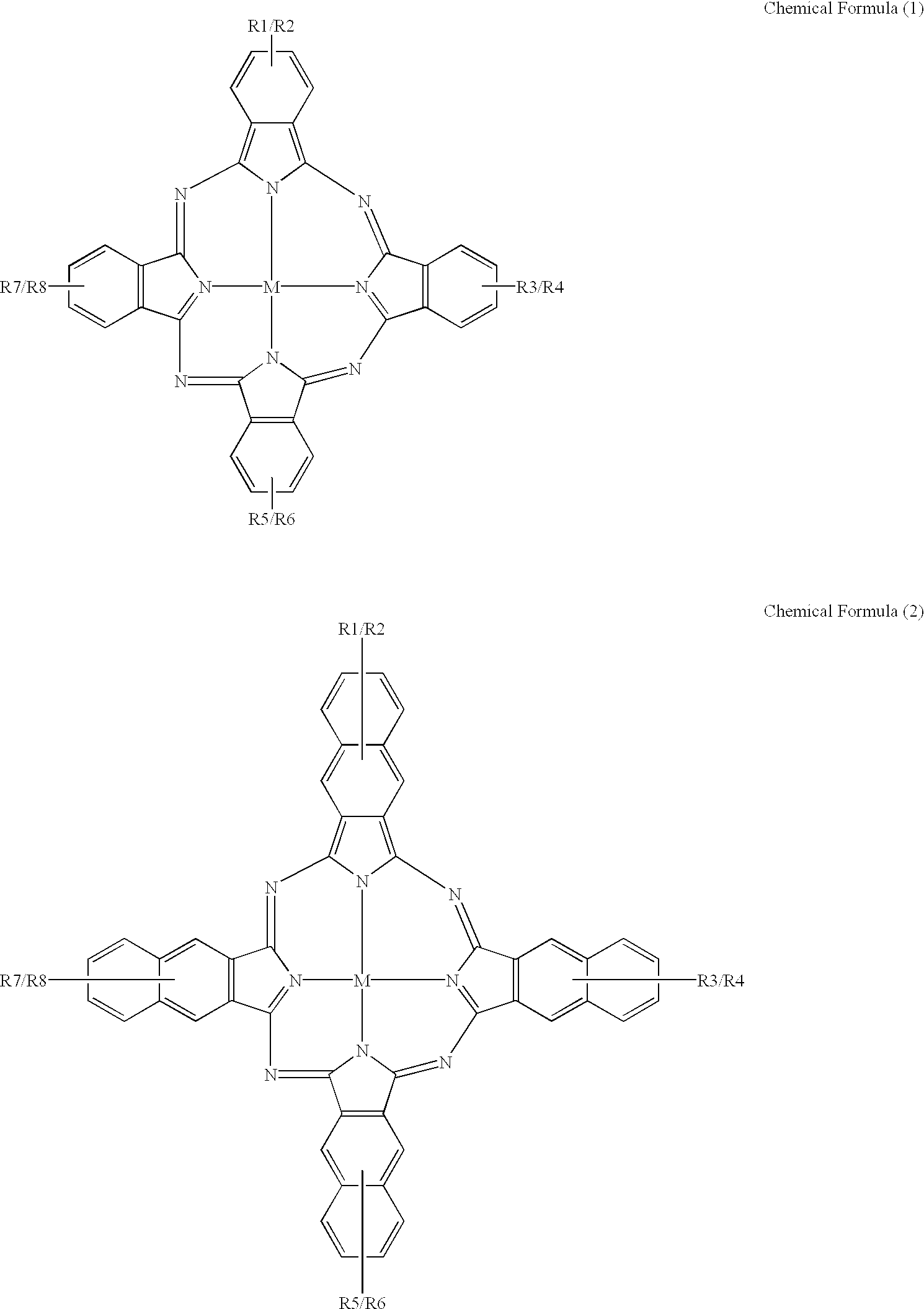

Material for photoelectric conversion element for use in imaging element, and photoelectric conversion element including same

InactiveUS20170040550A1Improve featuresExcellent in required characteristicOrganic chemistrySolid-state devicesHeat resistancePhotoelectric conversion

The present invention provides a material for photoelectric conversion elements for use in imaging elements which comprises a compound represented by the following formula (1). The material for photoelectric conversion elements for use in imaging elements, which comprises a compound represented by the following formula (1), is used to produce a photoelectric conversion element which is excellent in terms of hole- or electron-leakage prevention, thermal resistance to processing temperatures, transparency to visible light, etc. (In formula (1), R1 and R2 each independently represent a substituted or unsubstituted aromatic group.)

Owner:NIPPON KAYAKU CO LTD

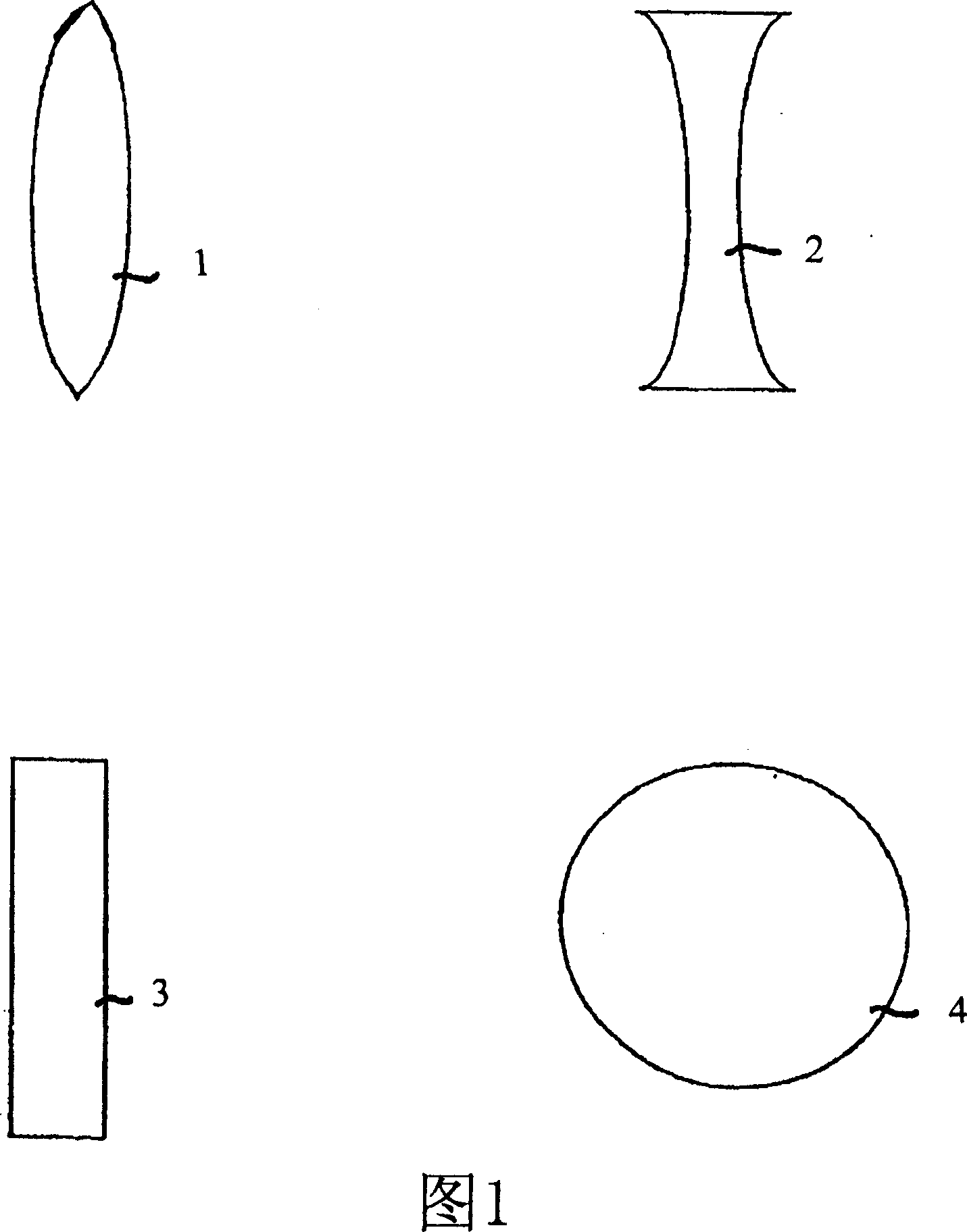

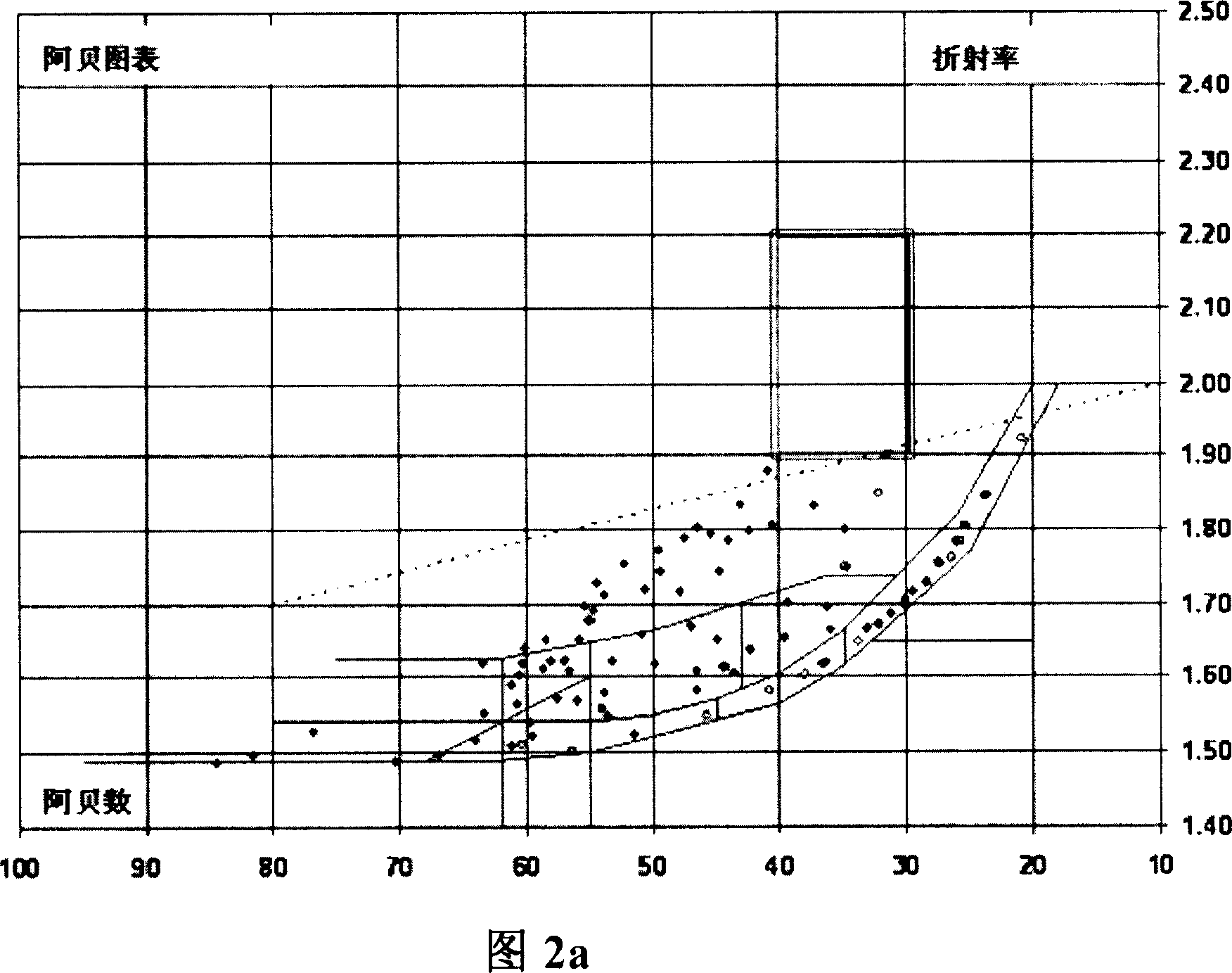

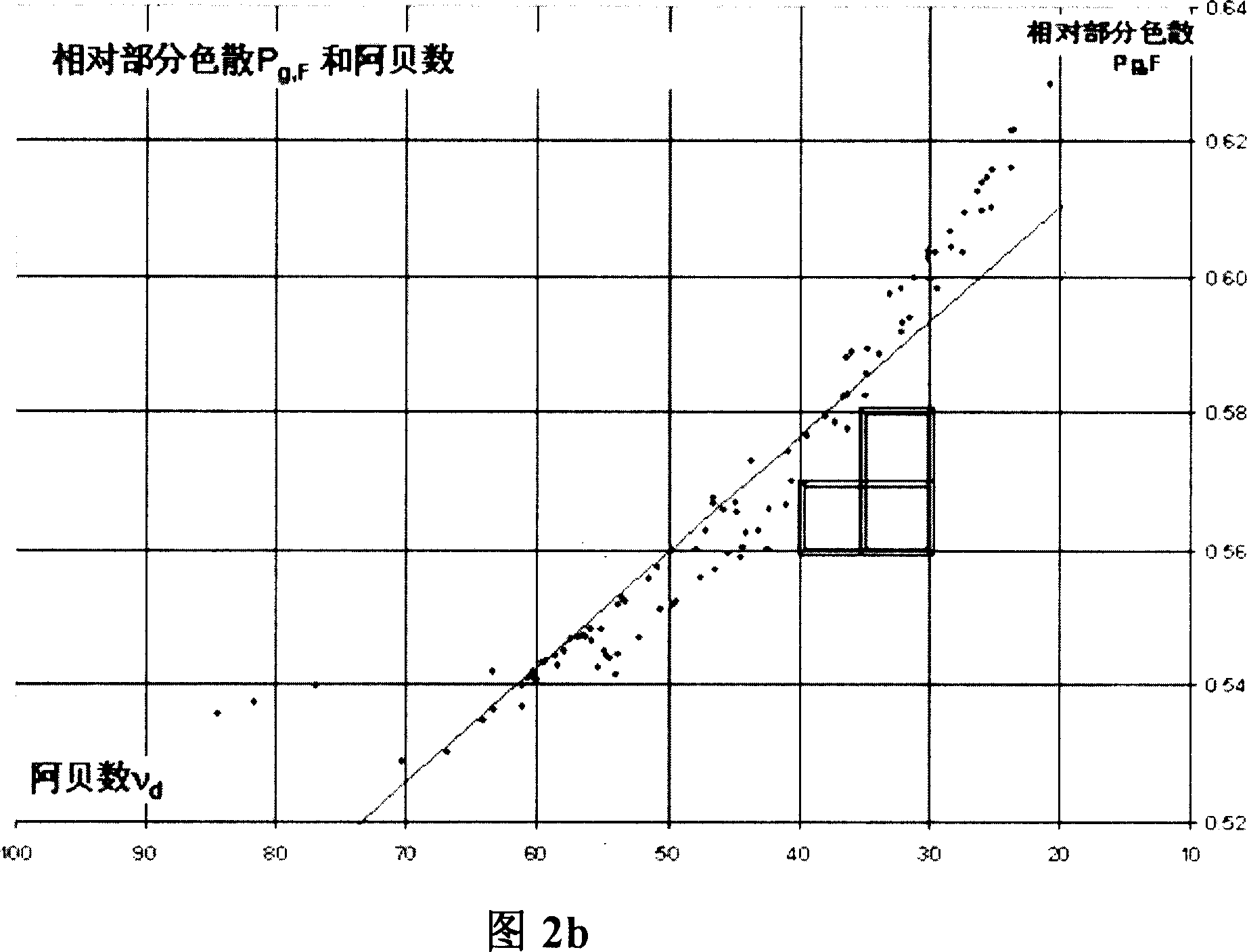

Optical elements and imaging optics comprising them

The present invention relates to the optical element of refraction, diffraction or transmission which is made of optical ceramics that has high transparency degree to the visible light and / or infrared light. Concretely speaking the invention relates to the optical element which is made of the optical ceramic that is suitable for the imaging optical element, such as the object lens which has the imaging characters of reducing the color difference and especially the apochromatism.

Owner:SCHOTT AG

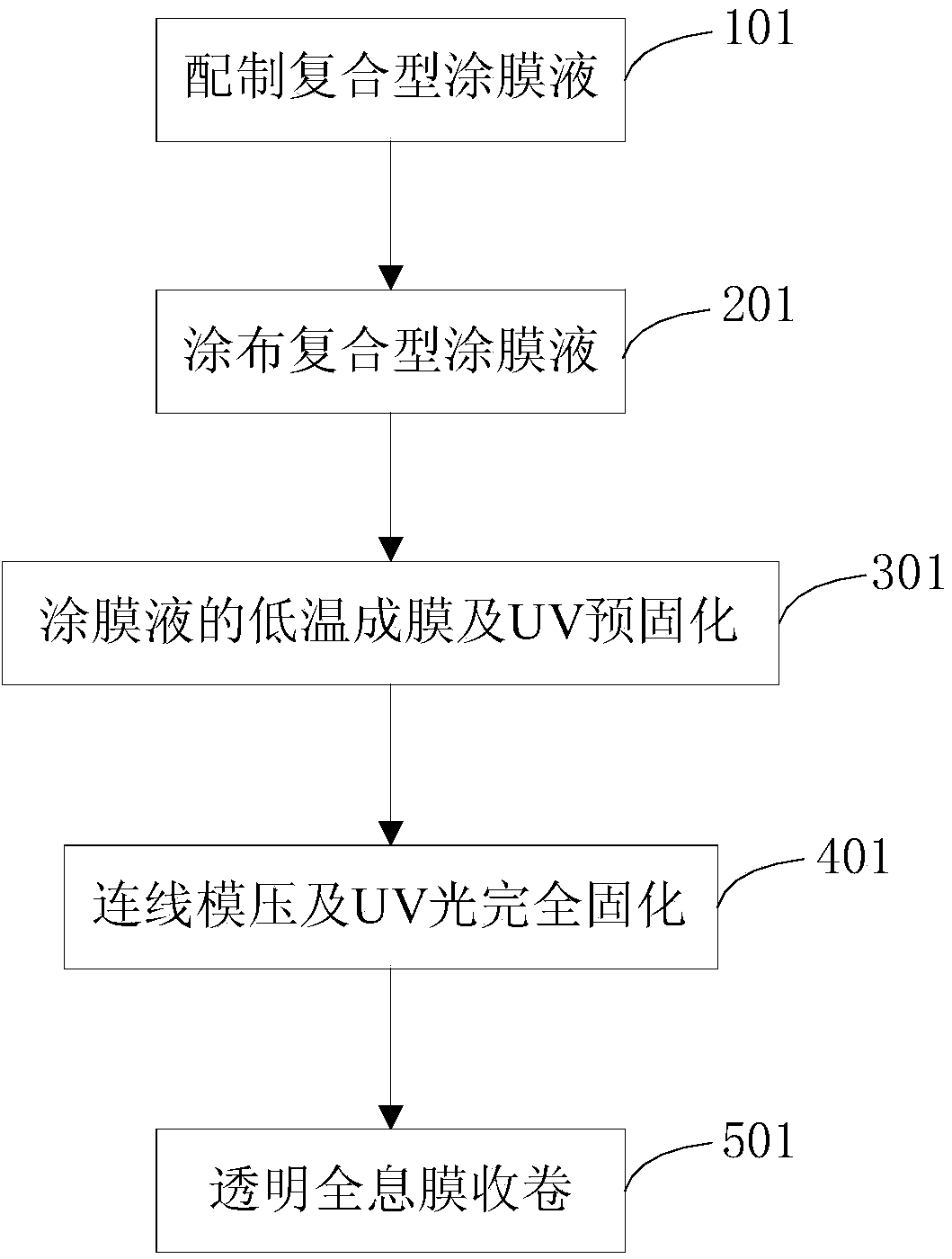

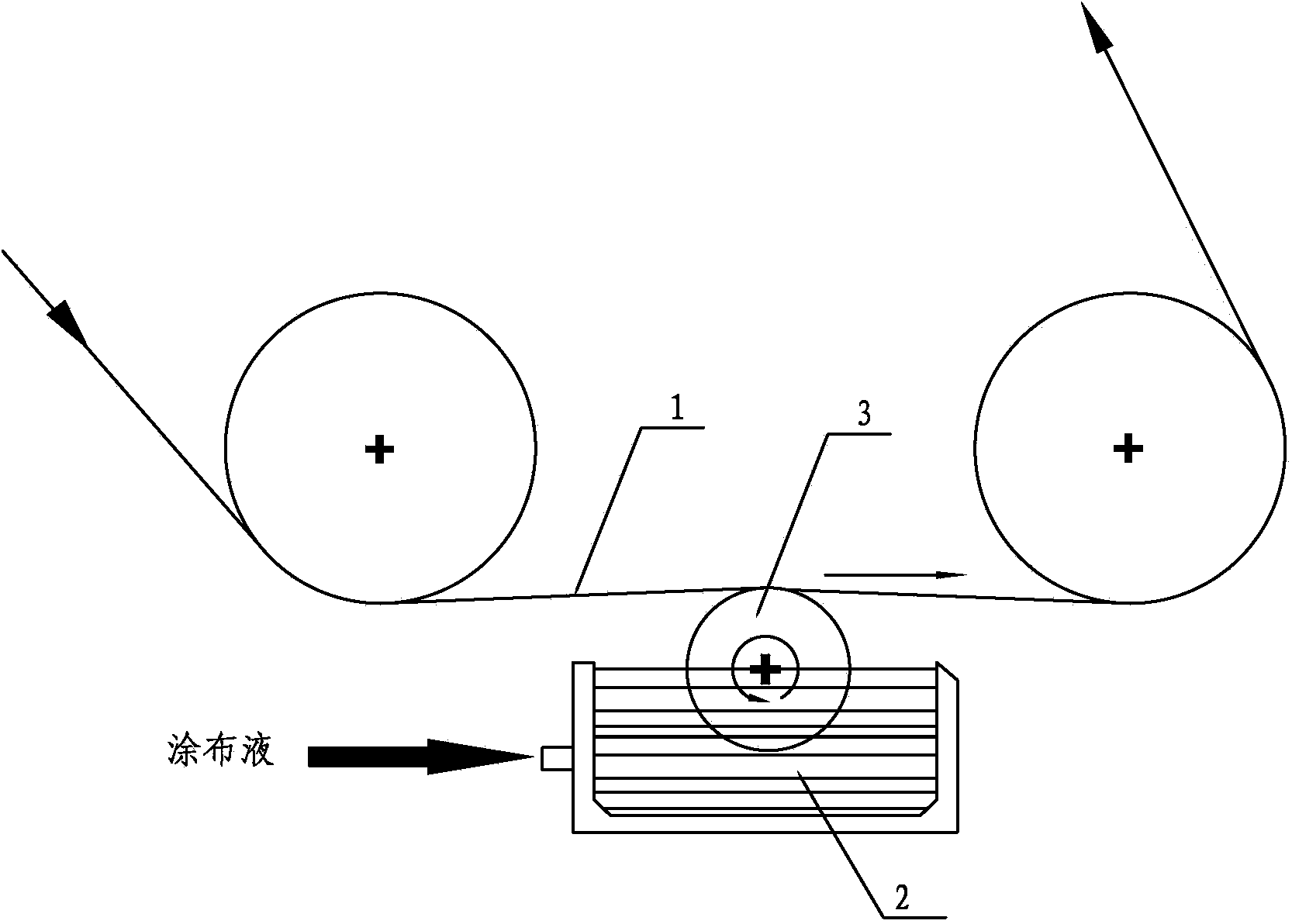

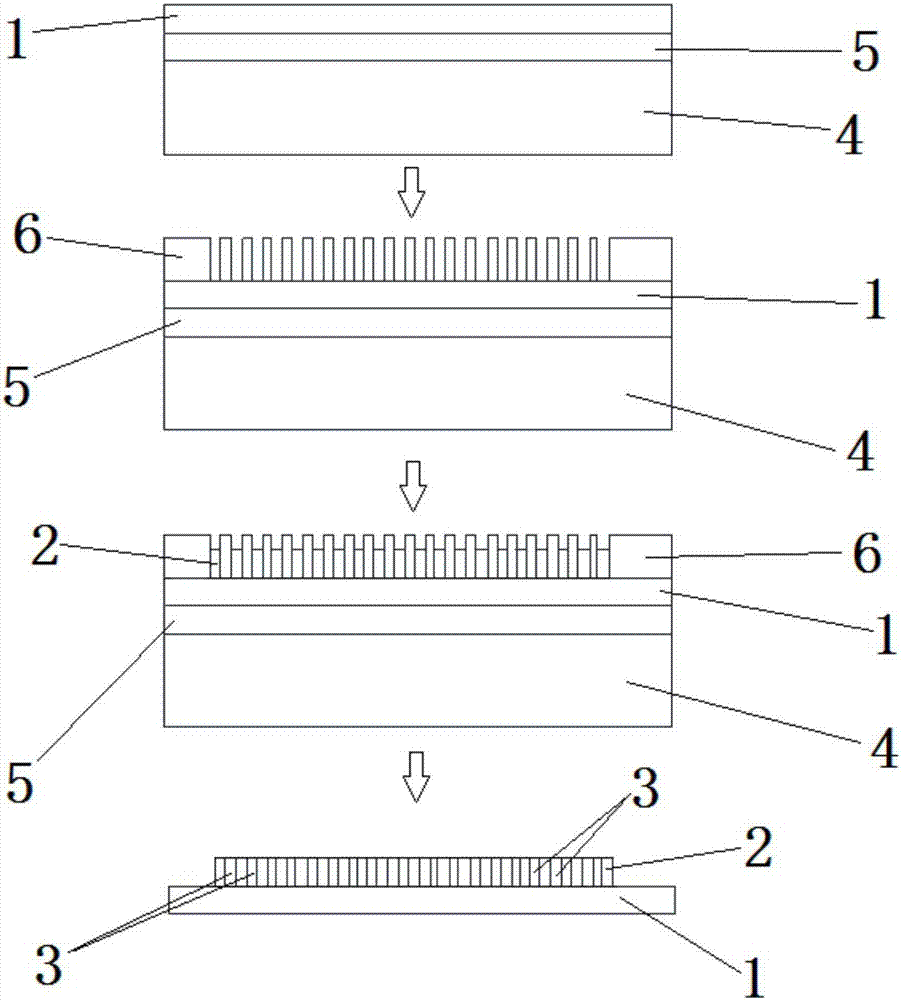

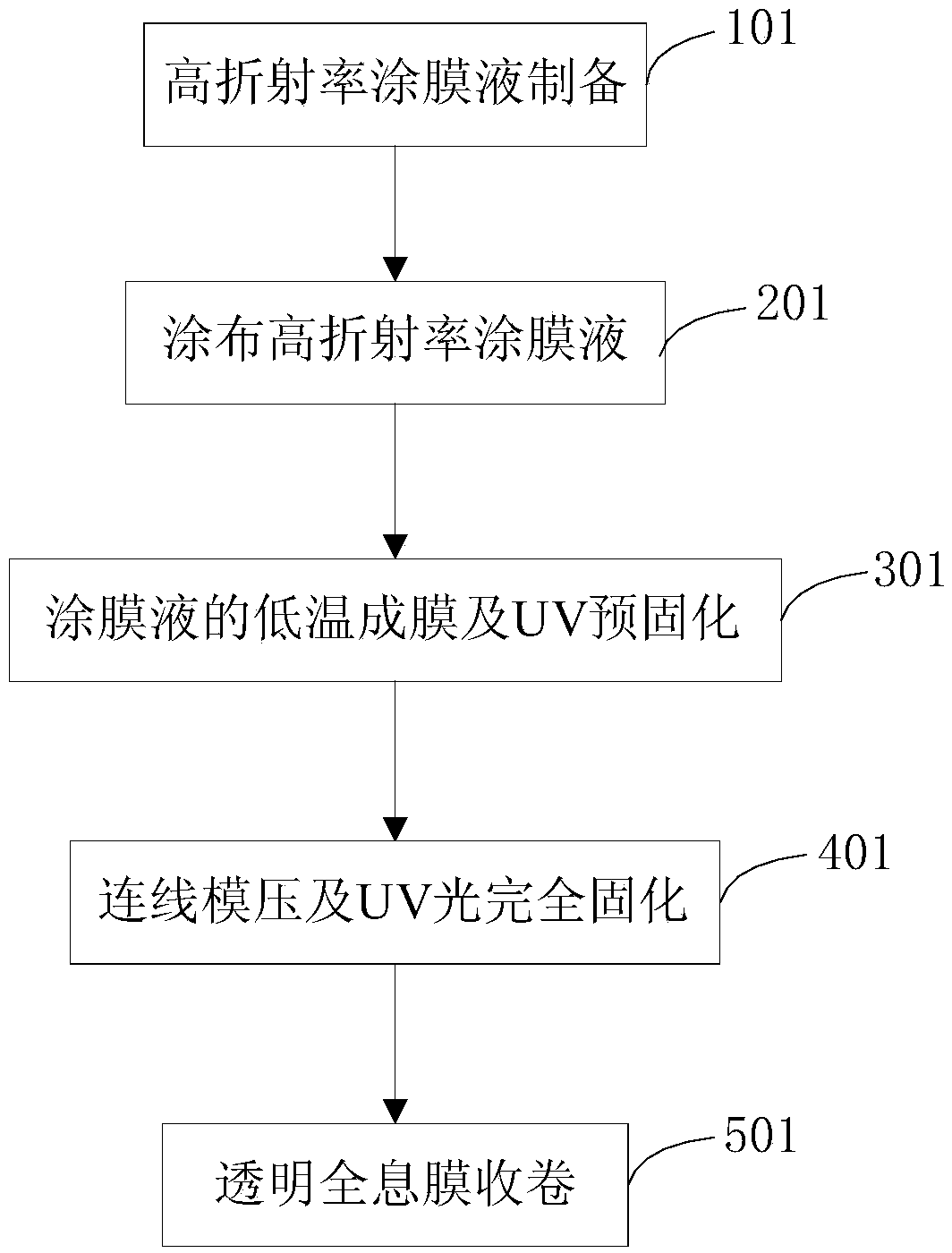

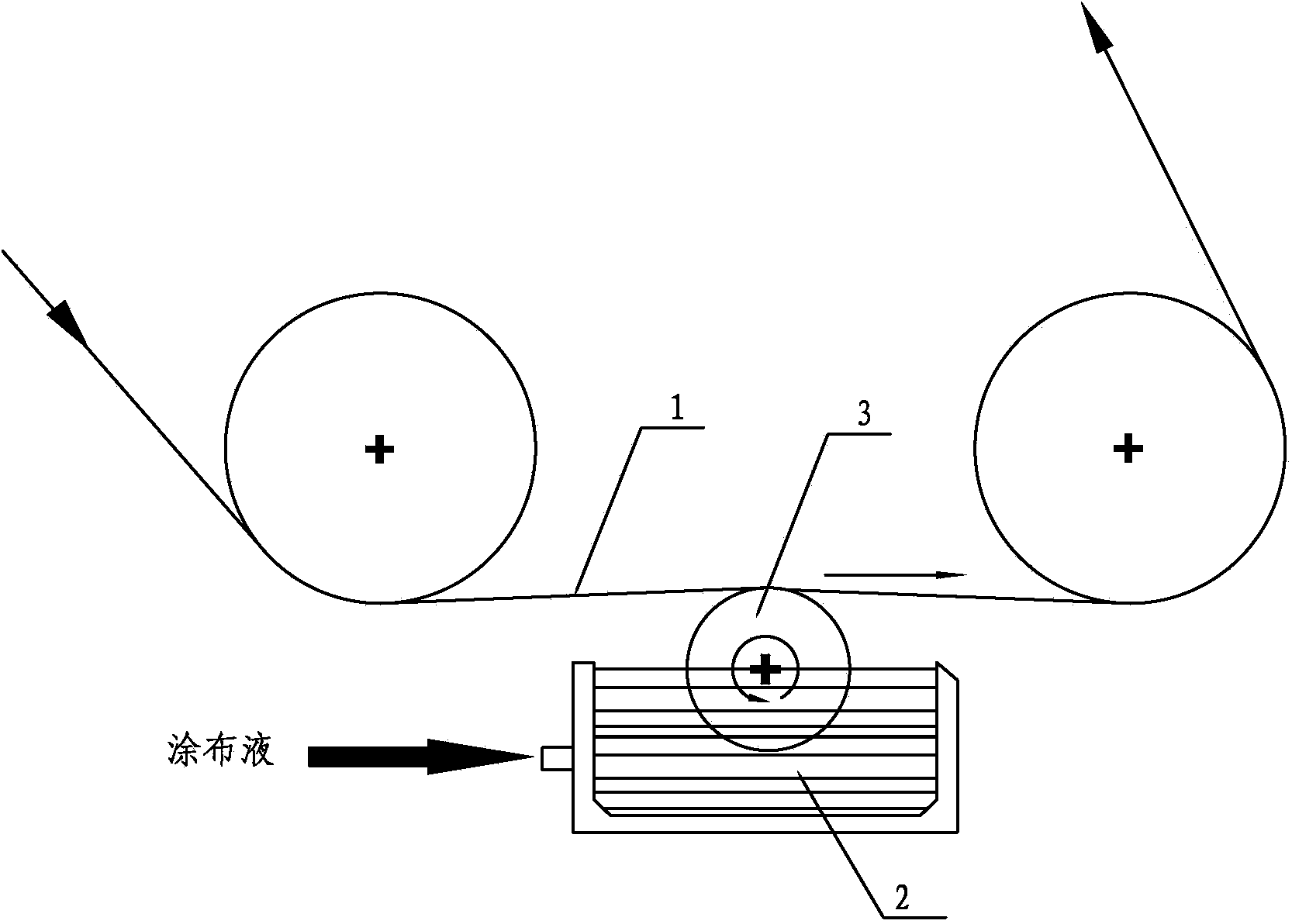

Production process of compound transparent holographic film

ActiveCN104029513AHigh refractive indexHigh transparencyLamination ancillary operationsDuplicating/marking methodsInformation layerImage contrast

The invention discloses a production process of a compound transparent holographic film, and belongs to the technical field of laser anti-counterfeit. The production process comprises the preparation of compound film coating liquid, the coating of the compound film coating liquid, the low-temperature film formation and UV pre-curing of the film coating liquid, the wired mold pressing and UV light full curing, and the rolling of the transparent holographic film; and the production process combines an information layer with a medium layer as a whole through the compound film coating liquid to form a compound coating layer, so that the prepared transparent holographic film has such characteristics as high refraction index, high transparency and signal-to-noise ratio, excellent wear and ageing resistance and obvious holographic image contrast, the technical bottlenecks of difficult tracking and difficult positioning due to small contrast in a traditional transparent holographic image are broken through, the random positioning of a transparent holographic pattern in a certificate is really achieved, and the comprehensive anti-fake effect of transparent hologram is enhanced.

Owner:ZHEJIANG JINGHUA LASER TECH CO LTD

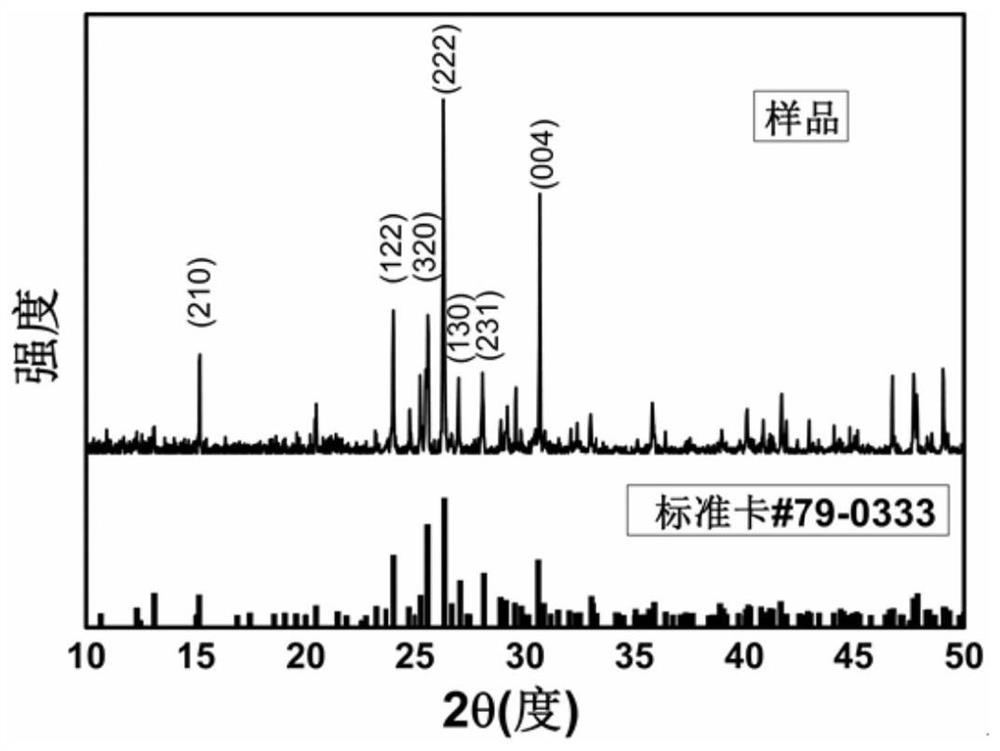

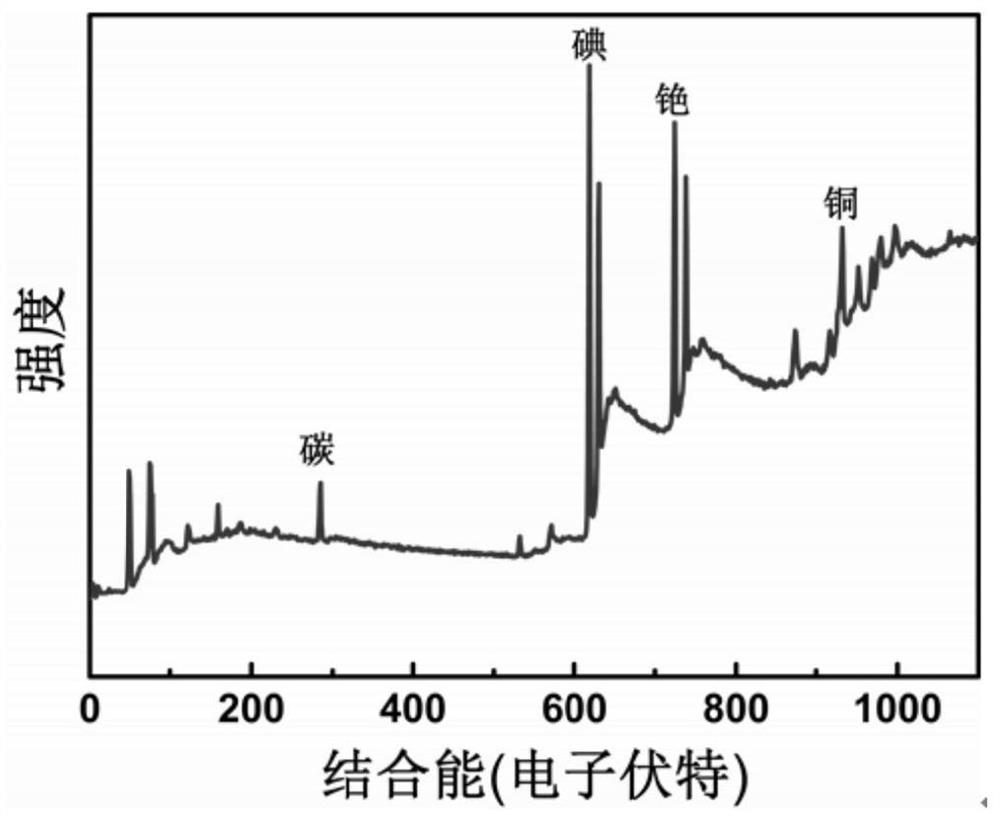

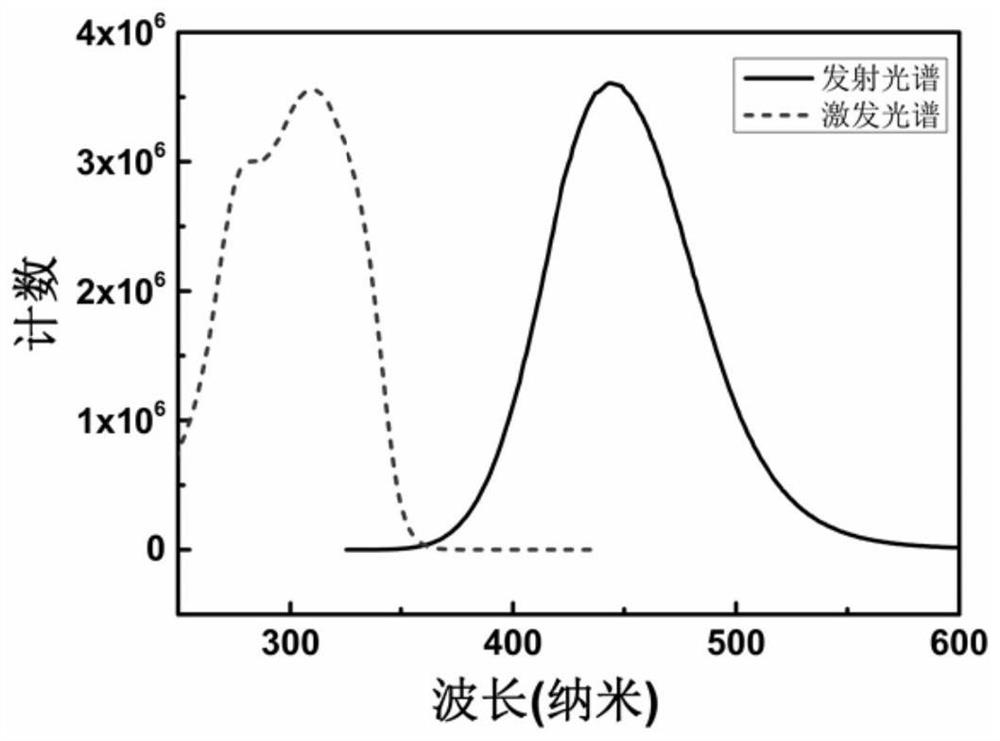

Zero-dimensional Cs3Cu2I5 perovskite scintillation crystal and application thereof

ActiveCN112048764AHigh transparencyImprove stabilityPolycrystalline material growthFrom normal temperature solutionsScintillation crystalsCesium iodide

The invention discloses a zero-dimensional Cs3Cu2I5 perovskite scintillation crystal and application thereof. The zero-dimensional Cs3Cu2I5 perovskite scintillation crystal is prepared through the steps that firstly, N, N-dimethylformamide and dimethyl sulfoxide are mixed evenly to prepare a mixed solution, cesium iodide and cuprous iodide are added into the mixed solution, stirring is conducted to prepare a supersaturated precursor solution, and finally crystal growth is conducted through an inverse temperature crystallization method after the supersaturated precursor solution is filtered. When the Cs4PbI6 perovskite crystal is prepared, the inverse temperature crystallization method is adopted, operation is easy, controllability is high, repeatability is good, and large-scale industrialproduction can be achieved; meanwhile, the crystal prepared by the method is good in transparency, good in stability, high in quantum luminous efficiency and high in responsivity, and can be used fornuclear radiation detection.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

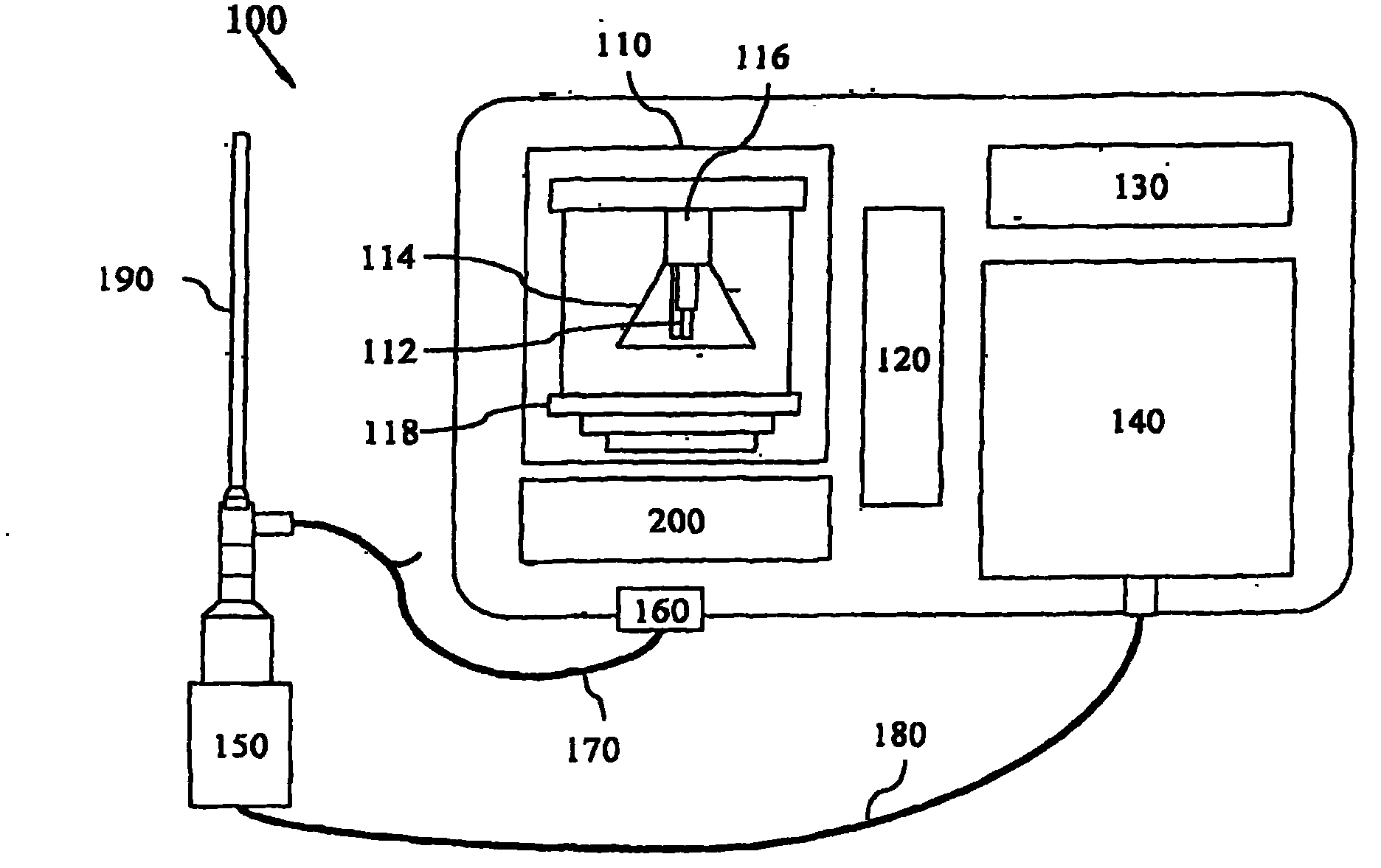

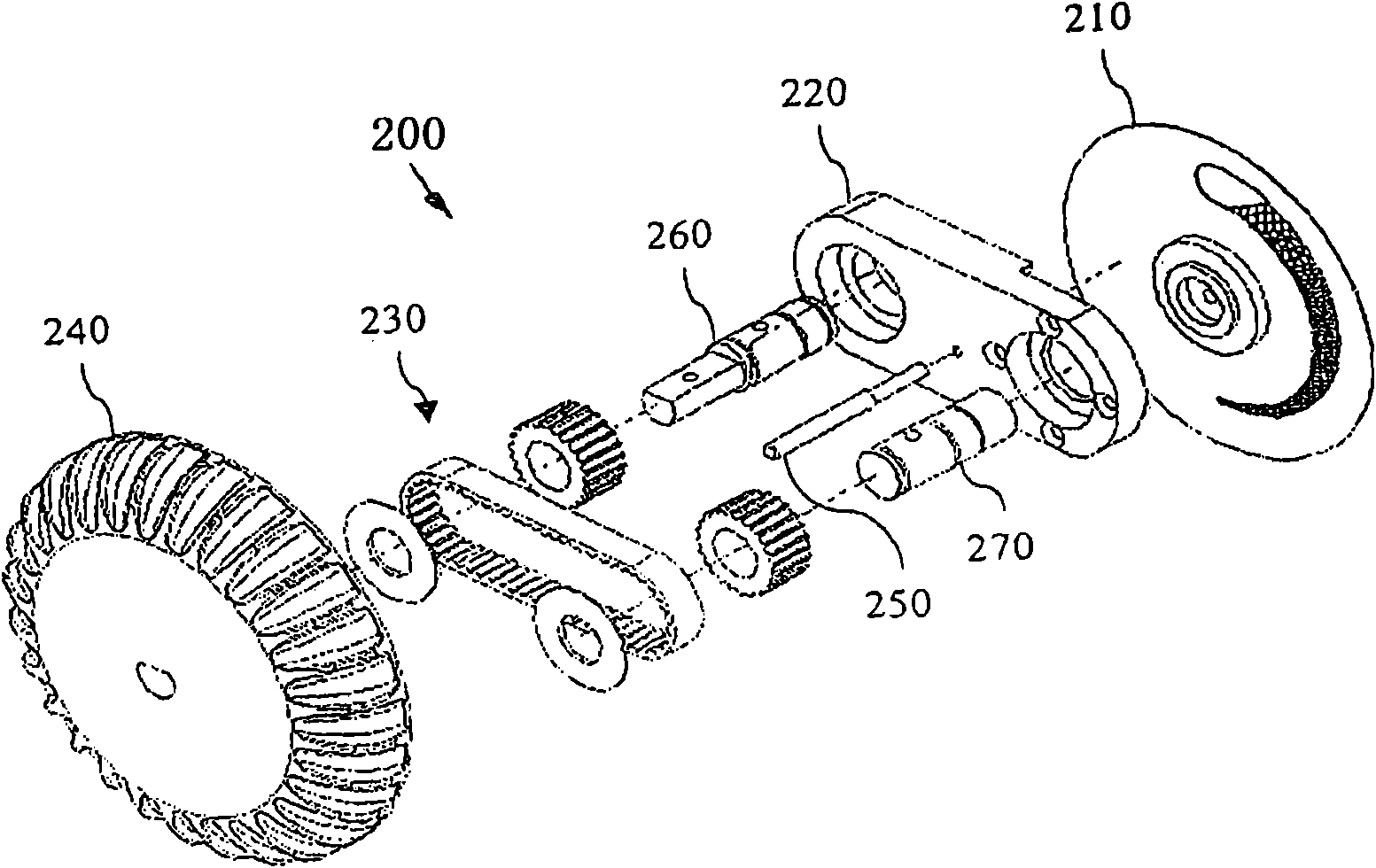

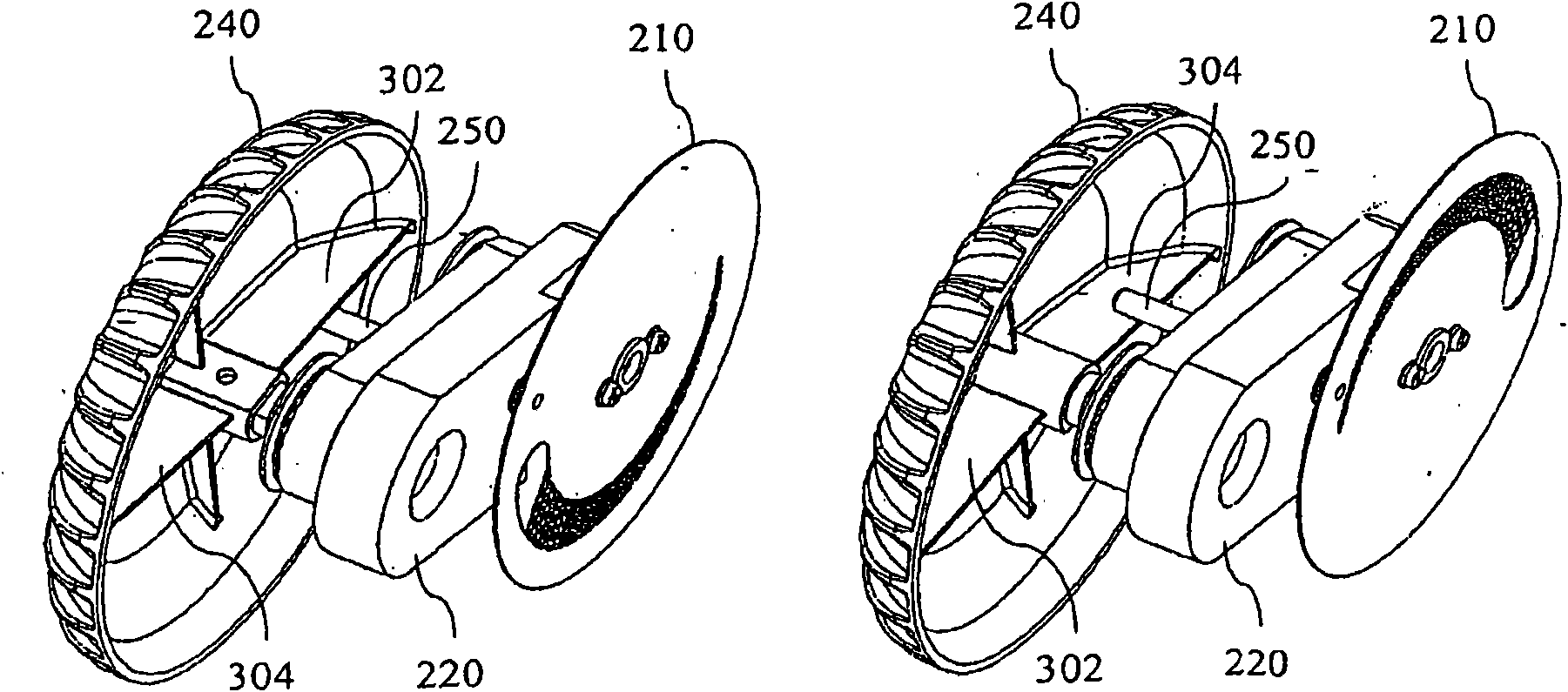

An illumination control device in an endoscopic imaging system

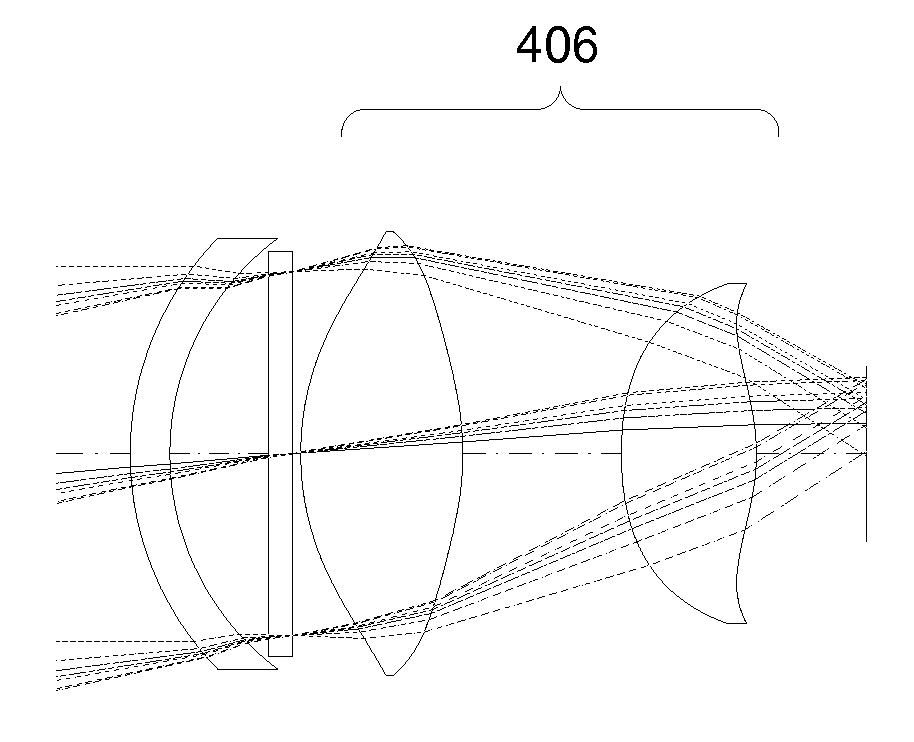

This invention relates to an illumination control device (200) in an endoscopic imaging System comprising; a control member (210) wherein the control member comprises; an aperture (404) in the form of a variable opening in a carrying or bearing member (402), and disposed between the optical port (160) and the light source (112), the movement of the aperture (404) across the optic port (160) corresponding to the movement of the control member (210) controls the area of the optic port (160) transmitting the light to the endoscope (190), and in turn controlling the illumination intensity at the examination site; and a grating (406) having at least two holes (410, 412), the pattern of the holes (410, 412) being variable across a guiding curve (414) so as to gradually vary the opacity of the grating (406), the illumination intensity control being dependent on the width of the aperture (404) and the opacity of the grating (406).

Owner:JOHNSON & JOHNSON GMBH

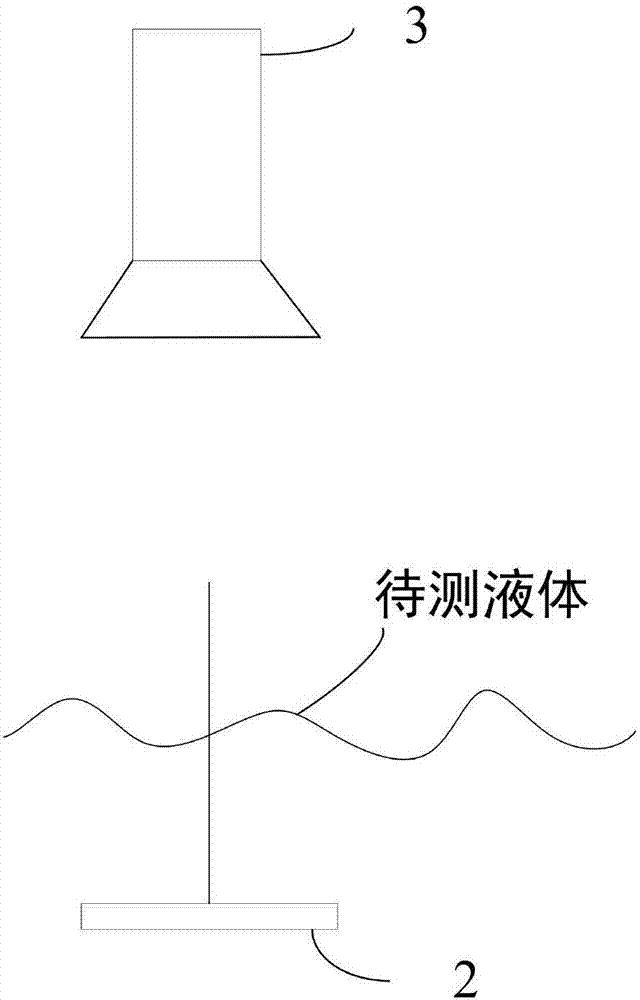

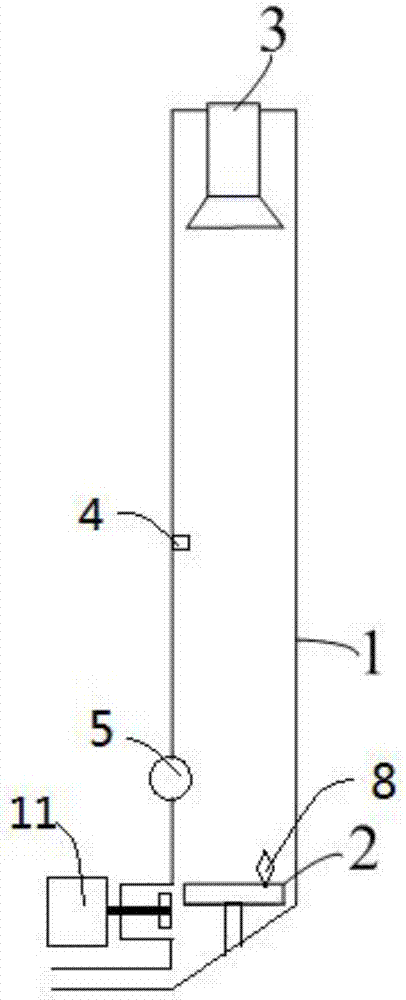

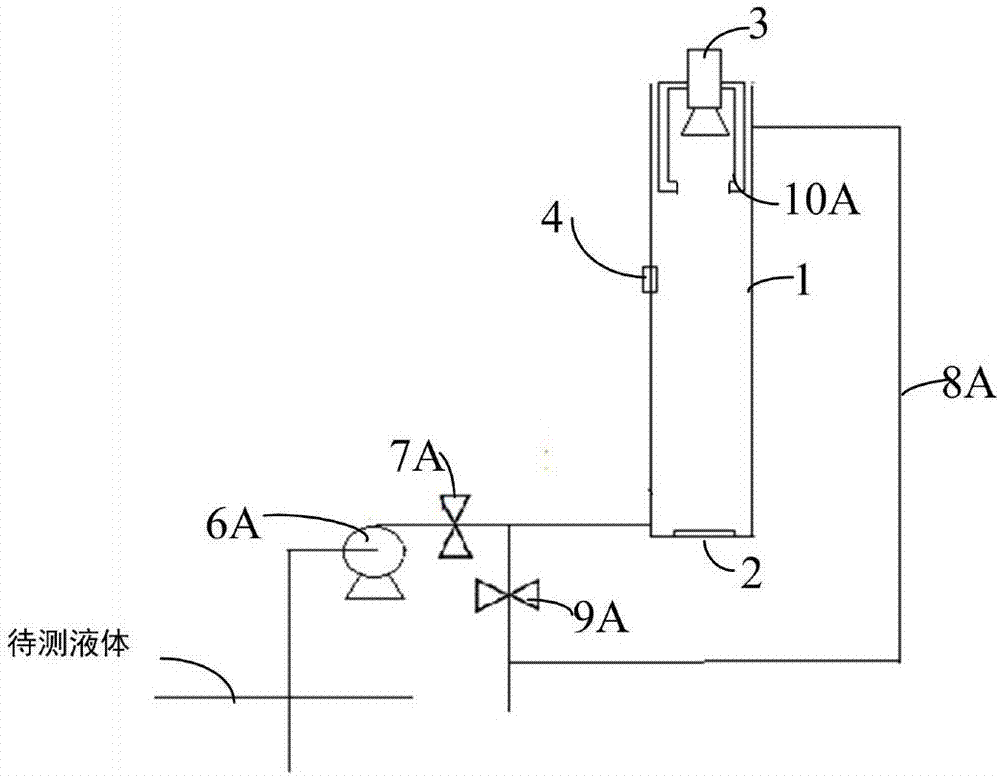

Liquid transparency apparatus, system and network

InactiveCN107084931ASimple product structureStable performanceColor/spectral properties measurementsLight sourceEngineering

The invention discloses a liquid transparency apparatus, a system and a network. The liquid transparency apparatus comprises an identification picture layer used for detection, an acquisition device (3) used for acquiring the signal of the identification picture layer, a measuring barrel (1) used for holding a to-be-measured sample, a liquid sensor (4) used for detecting the position of liquid, a light source (5) used for providing light, an optical detection device (8) used for detecting light intensity and a stirring device (11) used for preventing suspended solids in a sample from settlement. The liquid transparency apparatus provided by the invention can realize continuous automatic detection of liquid transparency, reduce influence of settlement of suspended solids in the sample on determination, is not affected by the eyesight of determination personnel and external light, accurately deliver the measured value of transparency and improves the work efficiency of detection personnel.

Owner:薛永富

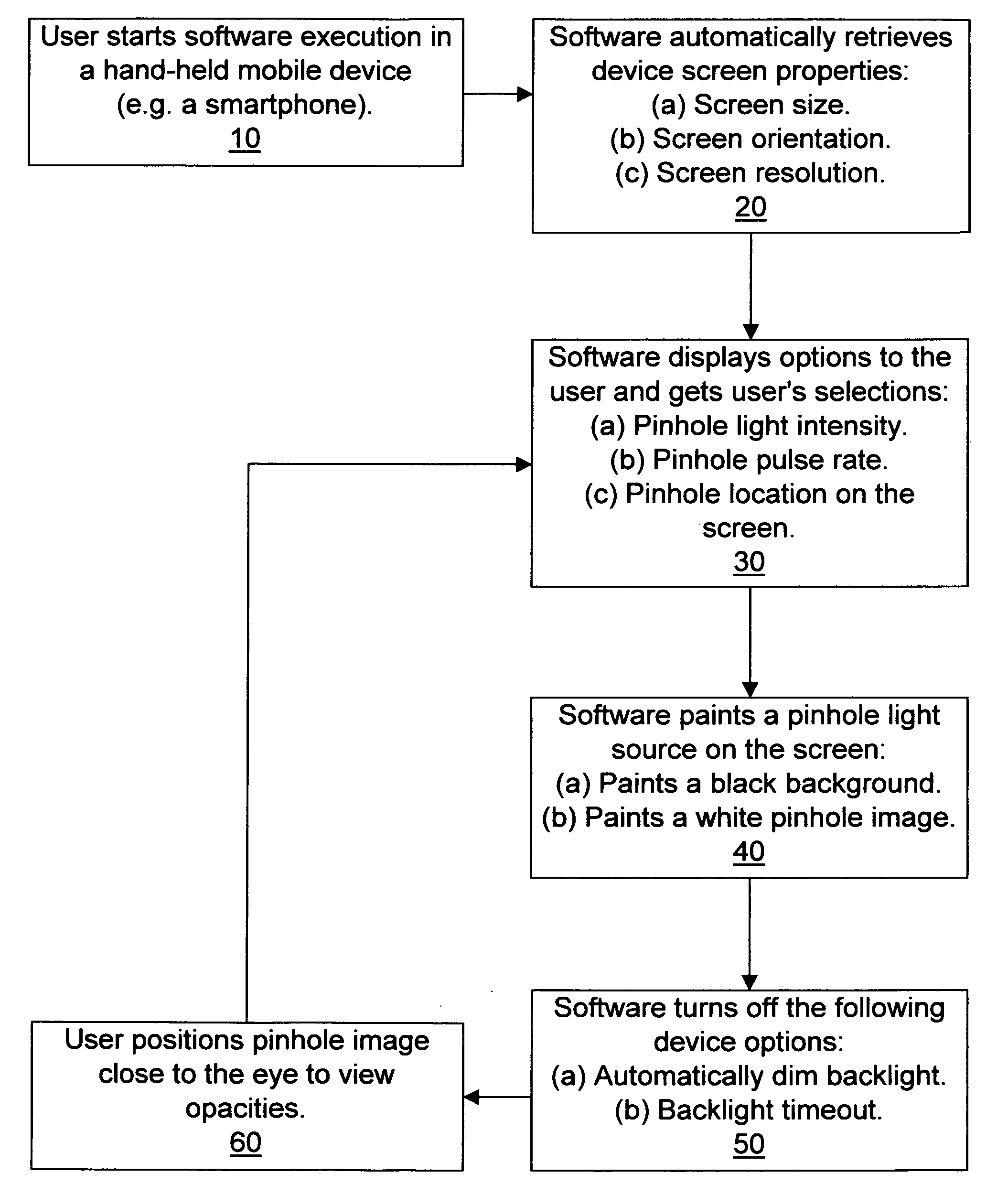

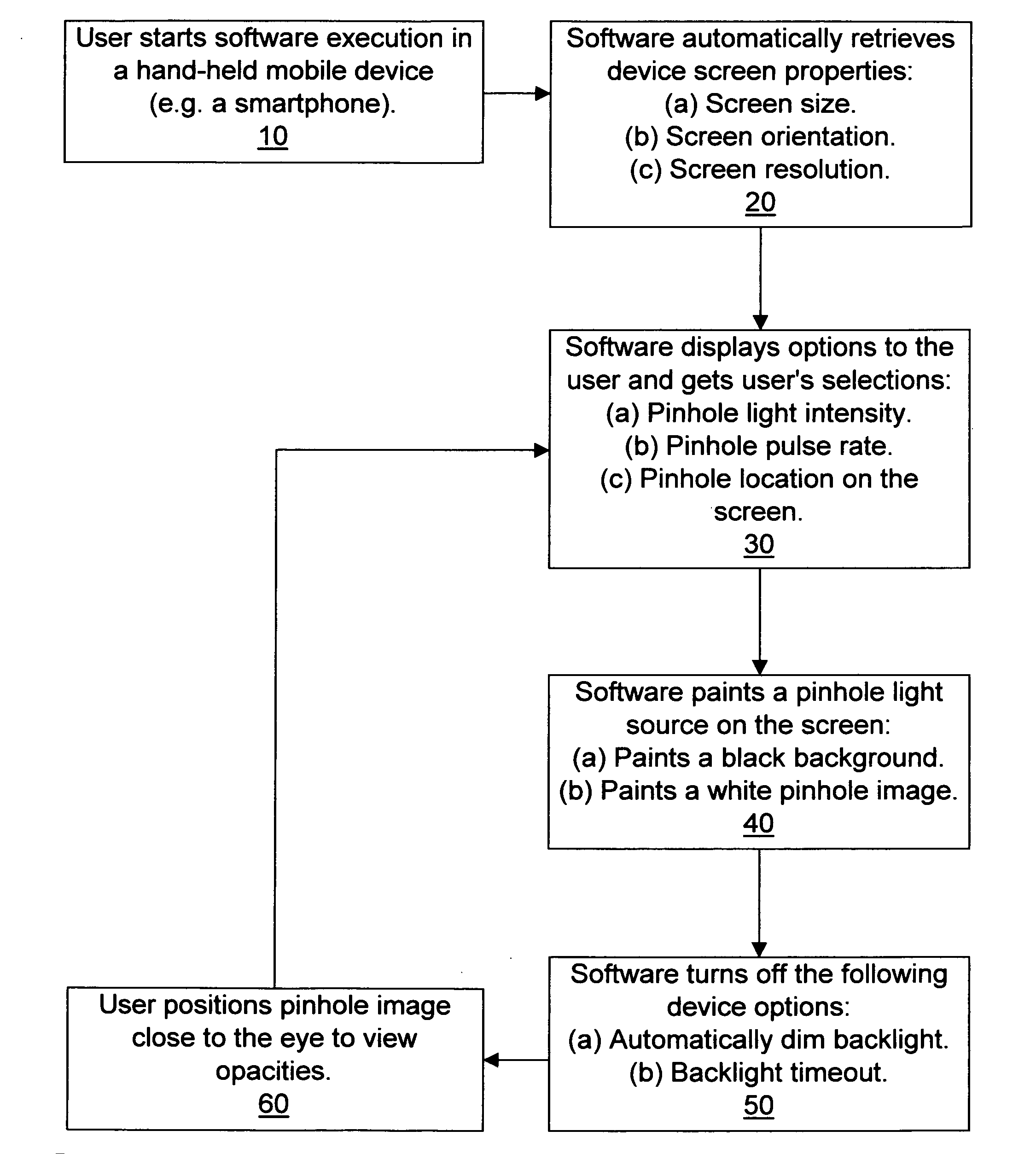

Method and apparatus for self-examination of the eye

A method to enable the use of hand-held mobile devices for self-examination of opacities in the eye. Specifically, an image of a pinhole light source is created on the screen of a mobile device. The user then holds the screen of the mobile device close to the eye such that the pinhole image is along the optical axis of the eye. A detailed image of opacities in the eye is thus formed on the retina. The following features are used for optimizing the image of opacities: The light intensity of the pinhole image is adjustable. The pinhole image can be pulsed. The location of the pinhole image on the screen can be changed.

Owner:OPTICOM DATA RES

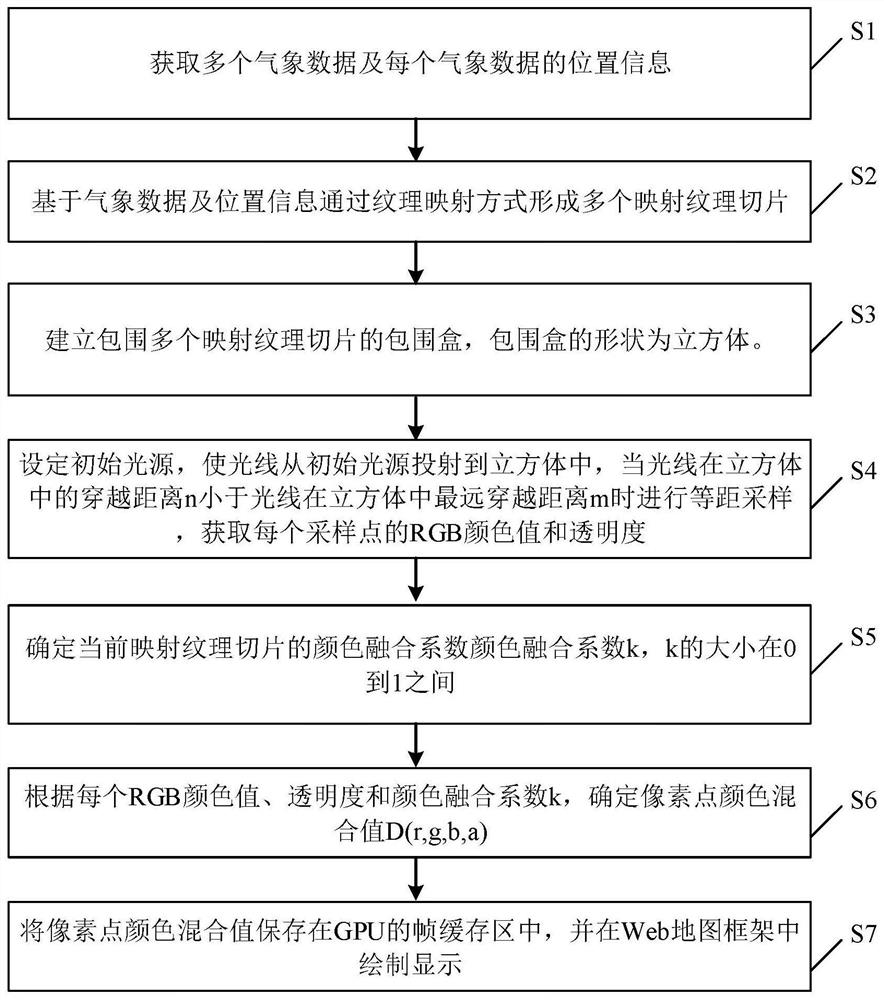

Volume rendering method and device for meteorological data and computer equipment

PendingCN114219902AIntuitive displayImprove visual experienceICT adaptation3D-image renderingSlicingAtmospheric sciences

The invention provides a volume rendering method and device for meteorological data and computer equipment. The method comprises the steps of forming a plurality of mapping texture slices through a texture mapping mode based on the meteorological data and position information; establishing a bounding box surrounding the plurality of mapping texture slices; an initial light source is set, light is projected into the cube from the initial light source, when the crossing distance n of the light in the cube is smaller than the farthest crossing distance m of the light in the cube, equidistant sampling is carried out, and the RGB color value and transparency of each sampling point are obtained; determining a color fusion coefficient k of the current mapping texture slice; according to each RGB color value, the transparency and the color fusion coefficient k, determining a pixel point color mixing value D (r, g, b, a); and storing the pixel point color mixed value in a frame cache region of the GPU, and drawing and displaying the pixel point color mixed value in a Web map frame. Therefore, according to the method, by setting the color fusion coefficient, the meteorological elements can be displayed more visually, the visualization effect is improved, and the visual experience degree of a user is improved.

Owner:江苏及象生态环境研究院有限公司

Transparency-adjustable glass structure

The invention provides a transparency-adjustable glass structure. A piece of light-transmitting obscured glass is taken as a substrate, a liquid level of a light guide medium liquid is formed on an uneven plane of the glass, and the refractive index of the light guide medium liquid and the refractive index of the glass are the same. The glass structure provided by the invention can adjust the transparency at any time according to the actual requirement.

Owner:赵雪冰

Method for detecting transparency transmission of mixed liquid

InactiveCN102401791AImprove accuracyImprove consistencyTransmissivity measurementsLight energyBlack light

The invention discloses a noncontact automatic detection for detecting transparency of mixed liquid such as turbid liquid, emulsified liquid and the like. The noncontact automatic detection method comprises the steps of: generating one group of plane visible light and black light, and the plane visible light and the black light pass through the outer side of a transparent container and horizontally irradiates the mixed liquid to be mixed; the light penetrates through the mixed liquid to lose partial energy, the other part of light arrives at a photoelectric receiving device at the other opposite outer side of the transparent container and a photoelectric converter in the photoelectric receiving device generates a photovoltaic electric signal, the photovoltaic electric signal is processed through a circuit and a computing program, thus a numerical value of absorbing light energy of the mixed liquid to be measured can be obtained, thus the transparency of the mixed liquid is determined.

Owner:WUHAN TEXTILE UNIV

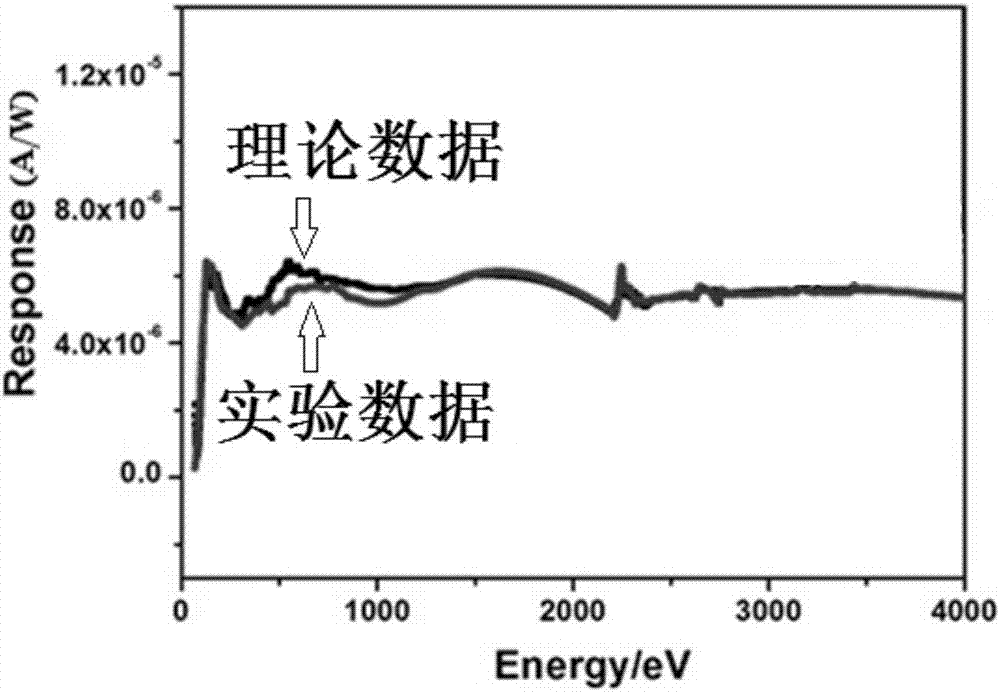

Flat response composite filter and manufacturing method thereof

InactiveCN107219546AUniform surfaceUniform porous structure prepared on the surfaceX/gamma/cosmic radiation measurmentSuperimposed coating processArea ratioMaterials science

The invention provides a flat response composite filter and a manufacturing method thereof. The manufacturing method of the flat response composite filter is simple; by preparing a second gold layer with a specific porous structure on one side surface of a first gold layer, a composite gold layer with certain area ratio can be obtained; and the flat response composite filter is high in yield, excellent in surface flatness, uniform in structure and high in effective area, can effectively reduce the requirements for uniformity, size and position of a calibration light source, can randomly limit a hole in an experiment to prevent signal saturation and effectively improve the accuracy of calibration data and the precision of radiant flux measurement, and can effectively complete soft X-ray radiant flux quantitative measurement of black cavity physics, radiation transport, radiation ablation, radiation opacity and implosion dynamics in the inertial confinement fusion field.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

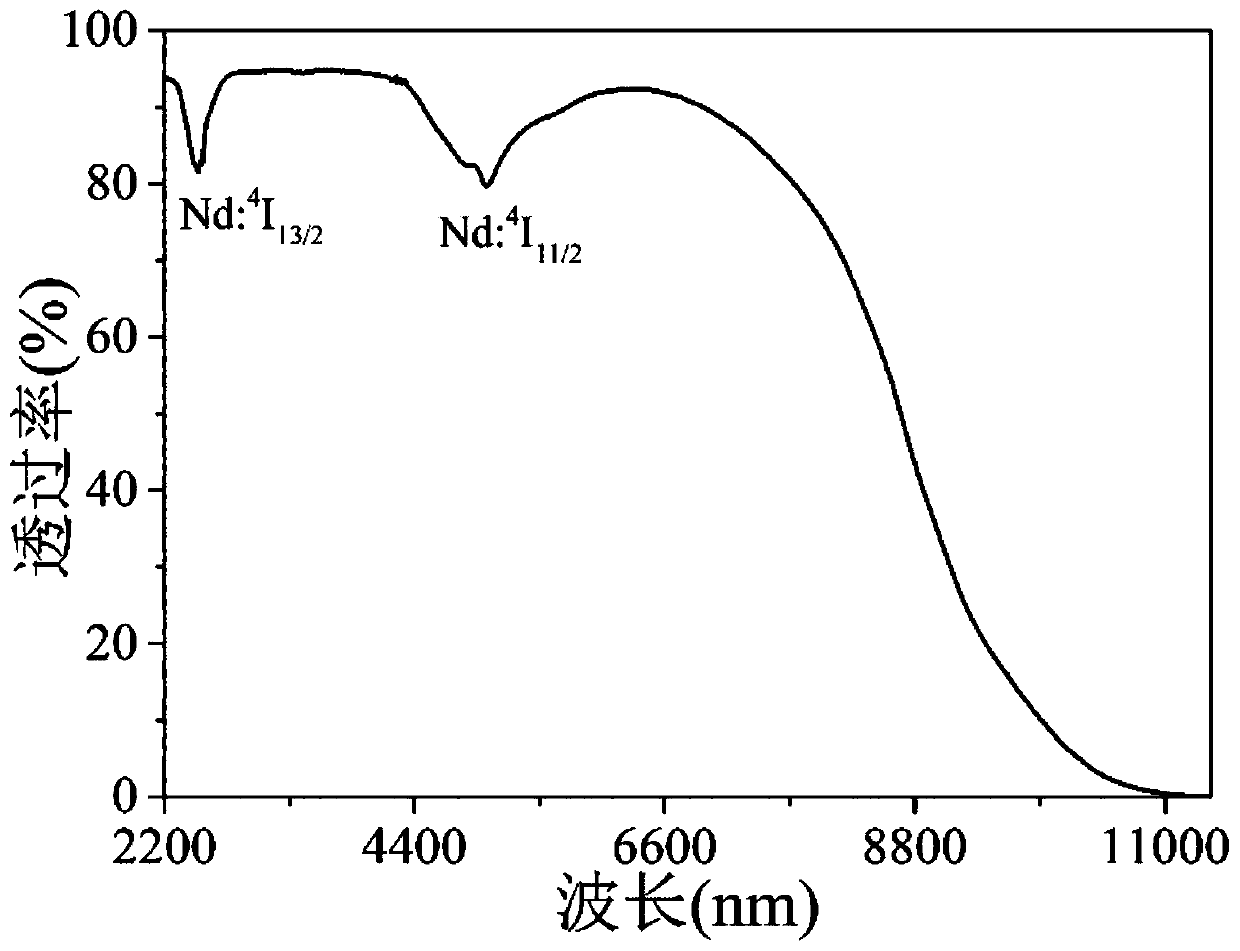

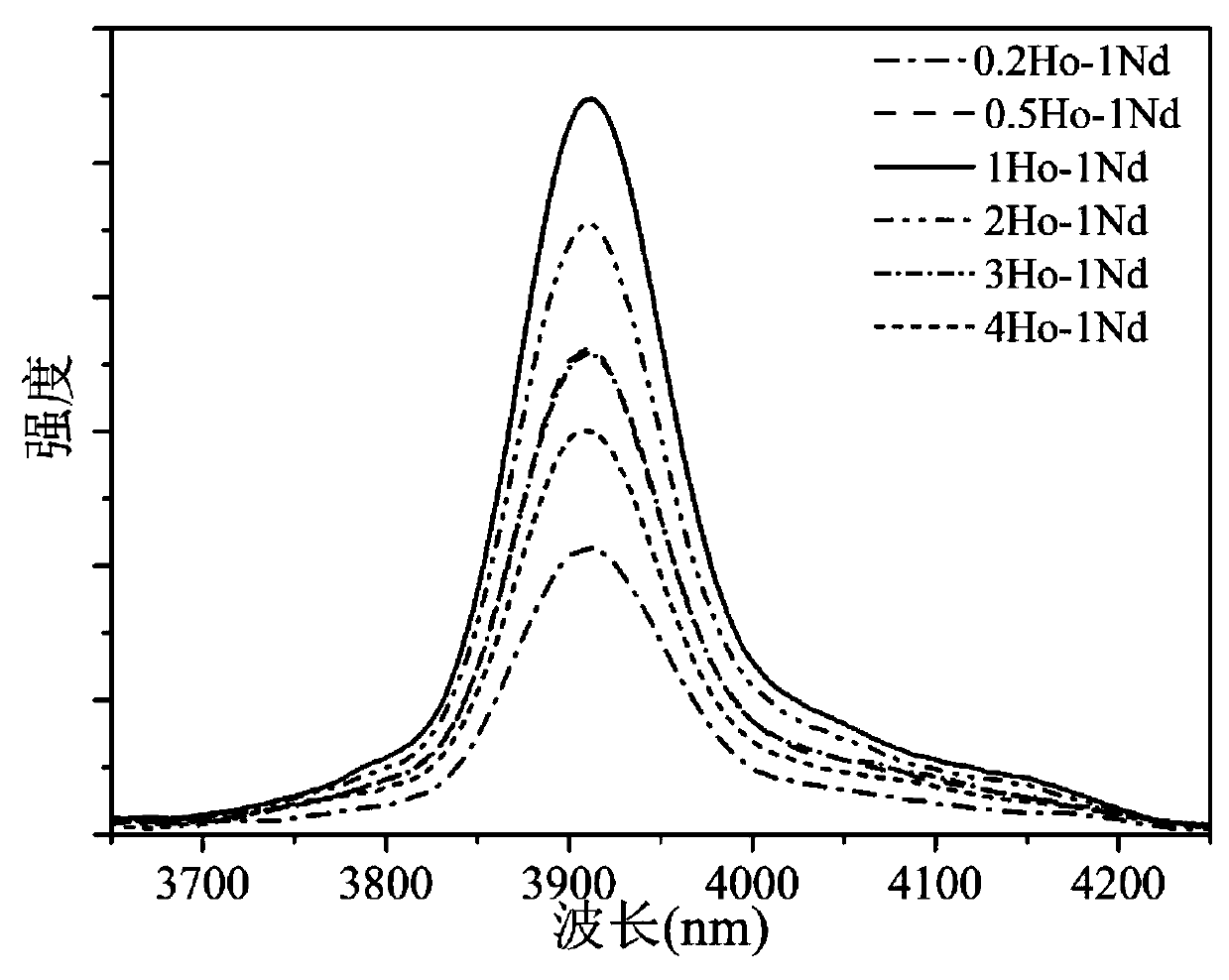

Preparation method of transparent glass with intermediate infrared 3.9 mum luminescence characteristic at room temperature

The invention discloses a preparation method of transparent glass with an intermediate infrared 3.9 mum luminescence characteristic at room temperature. The chemical composition of the glass substrateis (mol%) 26InF3-14ZnF2-19BaF2-11GaF3-8SrF2-12PbF2-5LiF-(4-x)LaF3-xHoF3-1NdF3 (x is equal to 0.2, 0.5, 1, 2, 3, 4, named as xHo-1Nd). The sum of the molar percentages of all the compounds is 100%. The preparation method comprises the following steps of 1) weighing each compound, and stirring and mixing in a mortar, 2) putting the mixture into a platinum crucible, and putting the platinum crucibleinto a 850 DEG C high-temperature furnace for heat preservation for 30 minutes, 3) after the solution glass is cooled, putting the solution glass into a glove box, heating the solution glass for 2 hours at 850 DEG C in an environment full of nitrogen, and pouring the solution glass onto a copper plate preheated at 240 DEG C, and 4) placing the sample in an annealing furnace for annealing treatment to eliminate stress in the glass, and cooling to room temperature after 3 h. The glass prepared by the method has the advantages of high transparency, high luminous efficiency, excellent chemical stability, simple preparation process, and realization of batch production, and can be used as a gain material of an intermediate infrared fiber laser.

Owner:苏州凯文堡尼光电科技有限公司

Toner for optical fixing, manufacturing method therefor and image formation apparatus using it

It is a toner for optical fixing which contains a binder resin, a colorant, and an infrared light absorbent, and the infrared light absorbent has a coloring opacity of 20 or less, and of phthalocyanine compound and / or naphthalocyanine compound.

Owner:FUJIFILM BUSINESS INNOVATION CORP

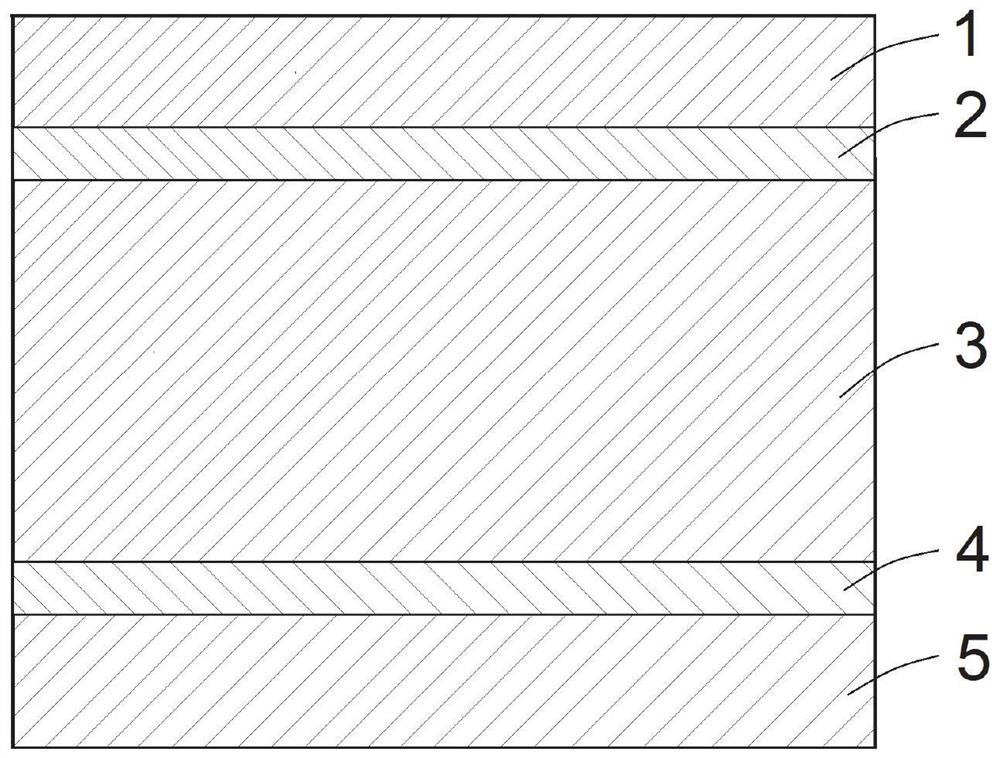

Anti-electromagnetic radiation ultrathin film, device, preparation method and application

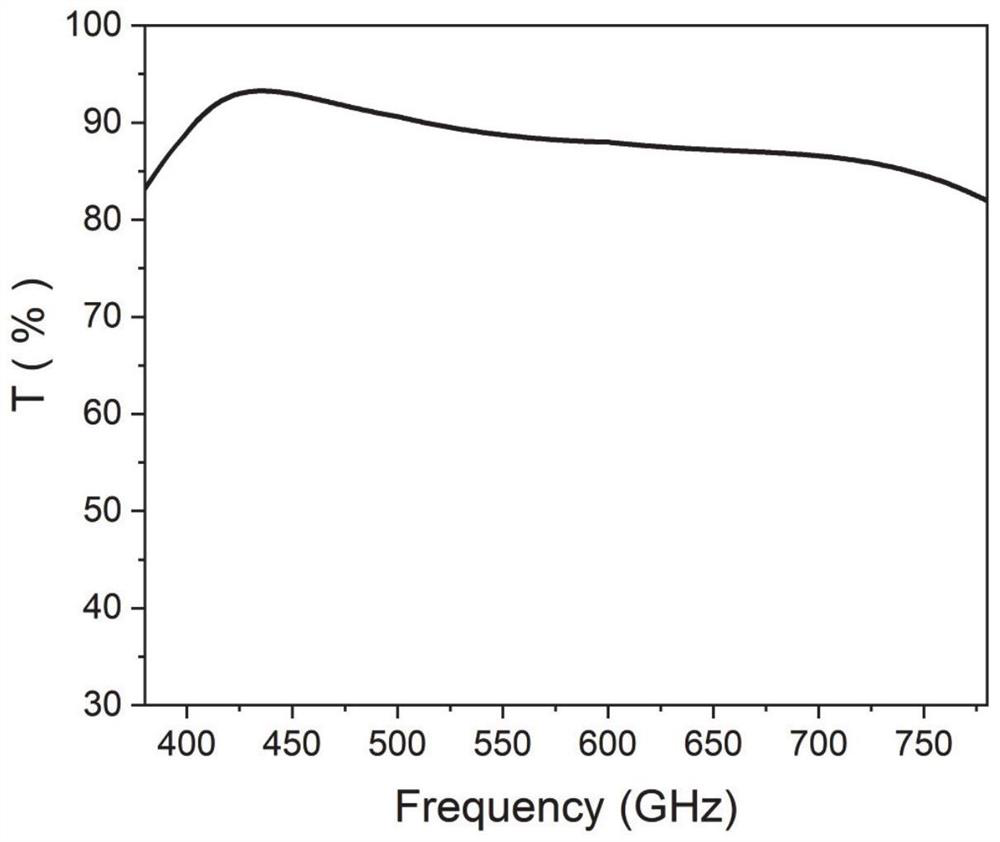

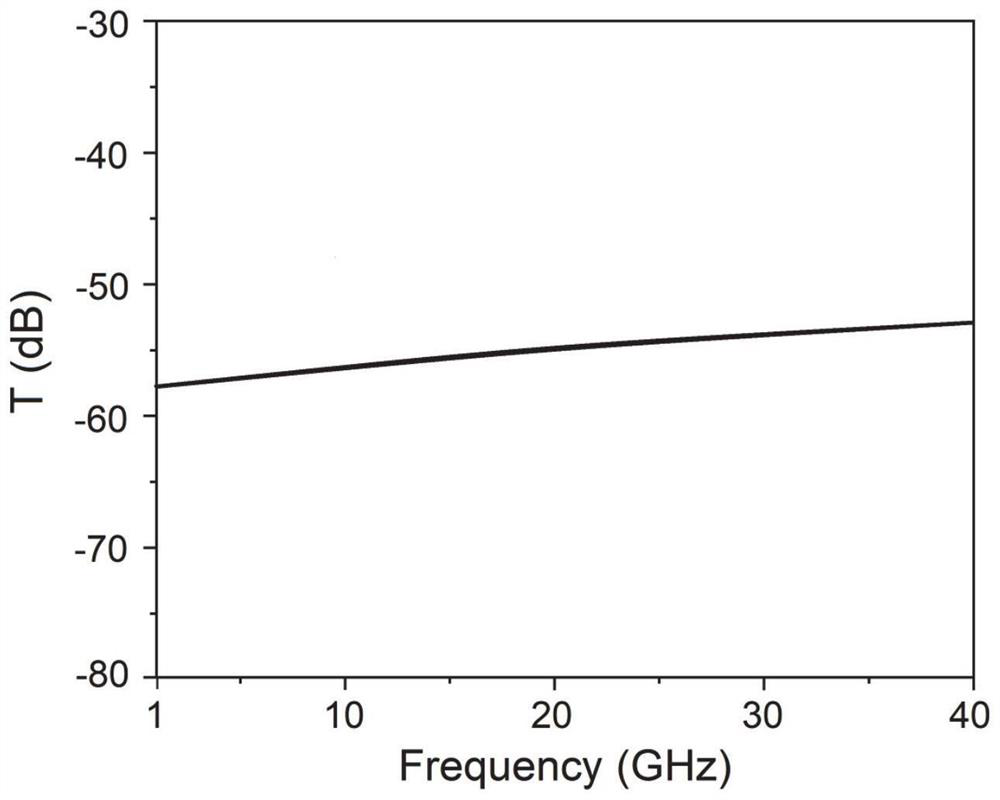

PendingCN111970915AHigh transparencyGood reflective propertiesMagnetic/electric field screeningVacuum evaporation coatingUltra-widebandTransmittance

The invention discloses an anti-electromagnetic radiation ultrathin film, a device, a preparation method and application, and the ultrathin film is of a laminated structure and is sequentially provided with a first dielectric layer, a first metal layer, a second dielectric layer, a second metal layer and a third dielectric layer. The dielectric layer is made of a visible light band transparent dielectric material; the first dielectric layer and the third dielectric layer are the same in thickness and are both smaller than the second dielectric layer in thickness. The anti-electromagnetic radiation ultrathin film is high in transparency in a visible light band, and the transmittance in the visible light band is greater than 80%. An alternate film layer structure composed of metal and a medium is utilized, and multiple reflection of light waves in a multilayer film is utilized, so that enhanced transmission in a visible light wave band is realized. 1G-40GHz ultra-wideband electromagneticshielding can be realized, the shielding effect is good, and the electromagnetic shielding effect is superior to 50dB.

Owner:SHANDONG UNIV

Production process of transparent holographic film with high refractive index

ActiveCN104029512AHigh refractive indexHigh transparencyLamination ancillary operationsDuplicating/marking methodsInformation layerImage contrast

The invention discloses a production process of a transparent holographic film with high refractive index, and belongs to the technical field of laser anti-counterfeit. The process comprises the steps of preparation of film coating liquid with high refractive index, coating of the film coating liquid with high refractive index, low-temperature film formation and UV precuring of the film coating liquid, wired mold pressing, UV light complete curing and rolling of the transparent holographic film. The production process combines an information layer with a medium layer through the film coating liquid with high refractive index to form a composite coating layer, so that the prepared transparent holographic film has such characteristics as high refractive index, high transparency and signal-to-noise ratio, excellent wear resistance and ageing resistance and obvious holographic image contrast, the technical bottlenecks of difficult tracking and difficult positioning caused by small contrast in traditional transparent holographic images are broken through, the random positioning of the transparent holographic images in certificates is truly realized, and the transparent holographic comprehensive anti-counterfeiting effect is promoted.

Owner:ZHEJIANG JINGHUA LASER TECH CO LTD

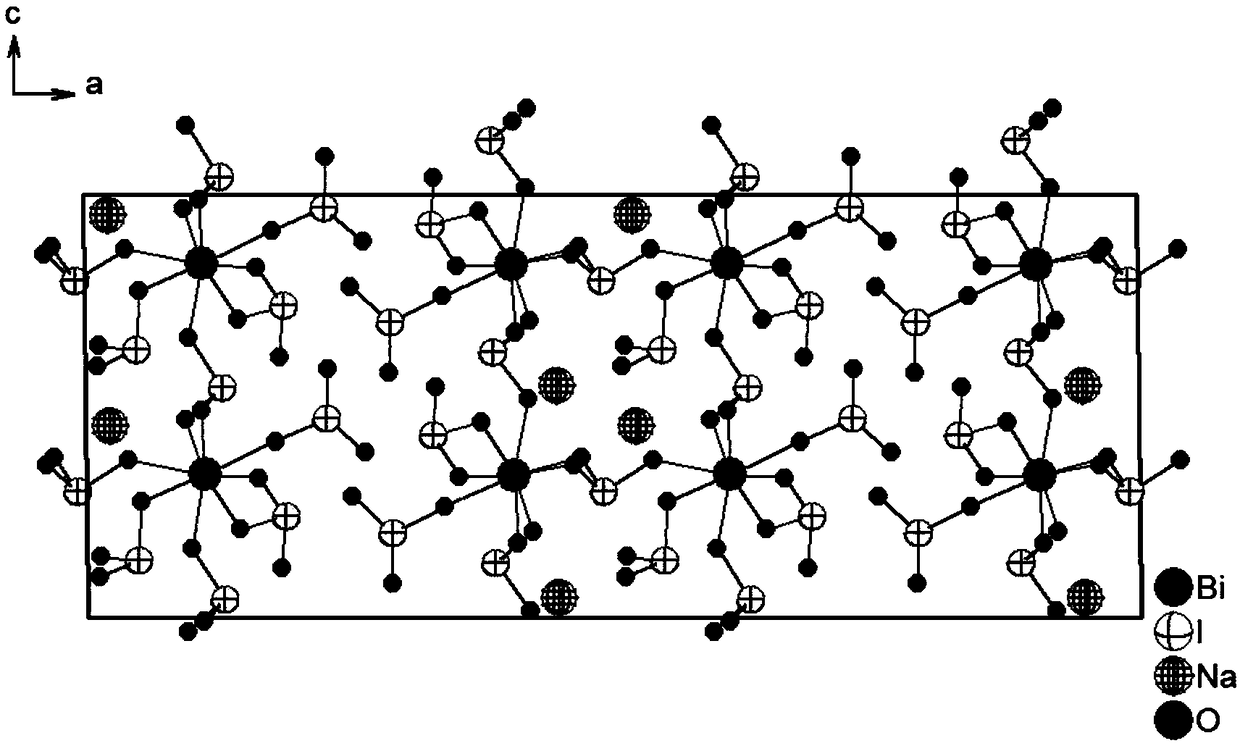

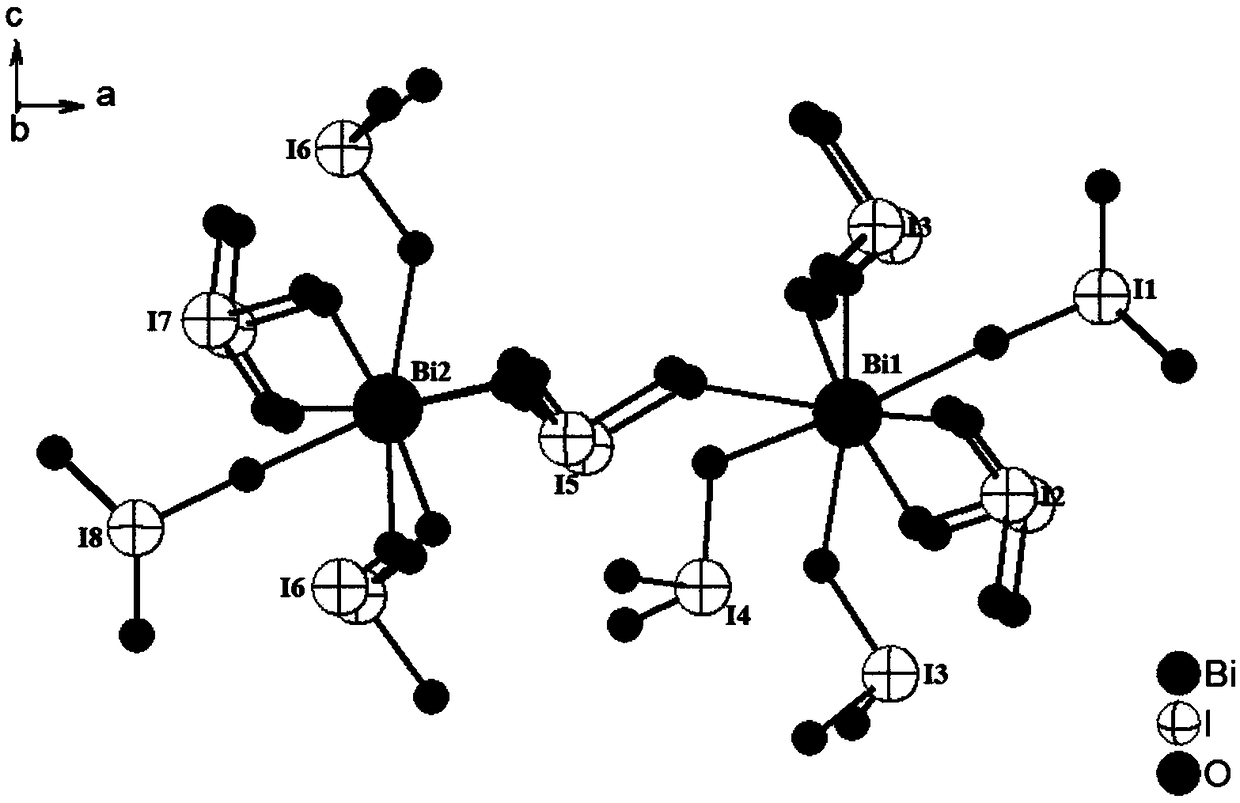

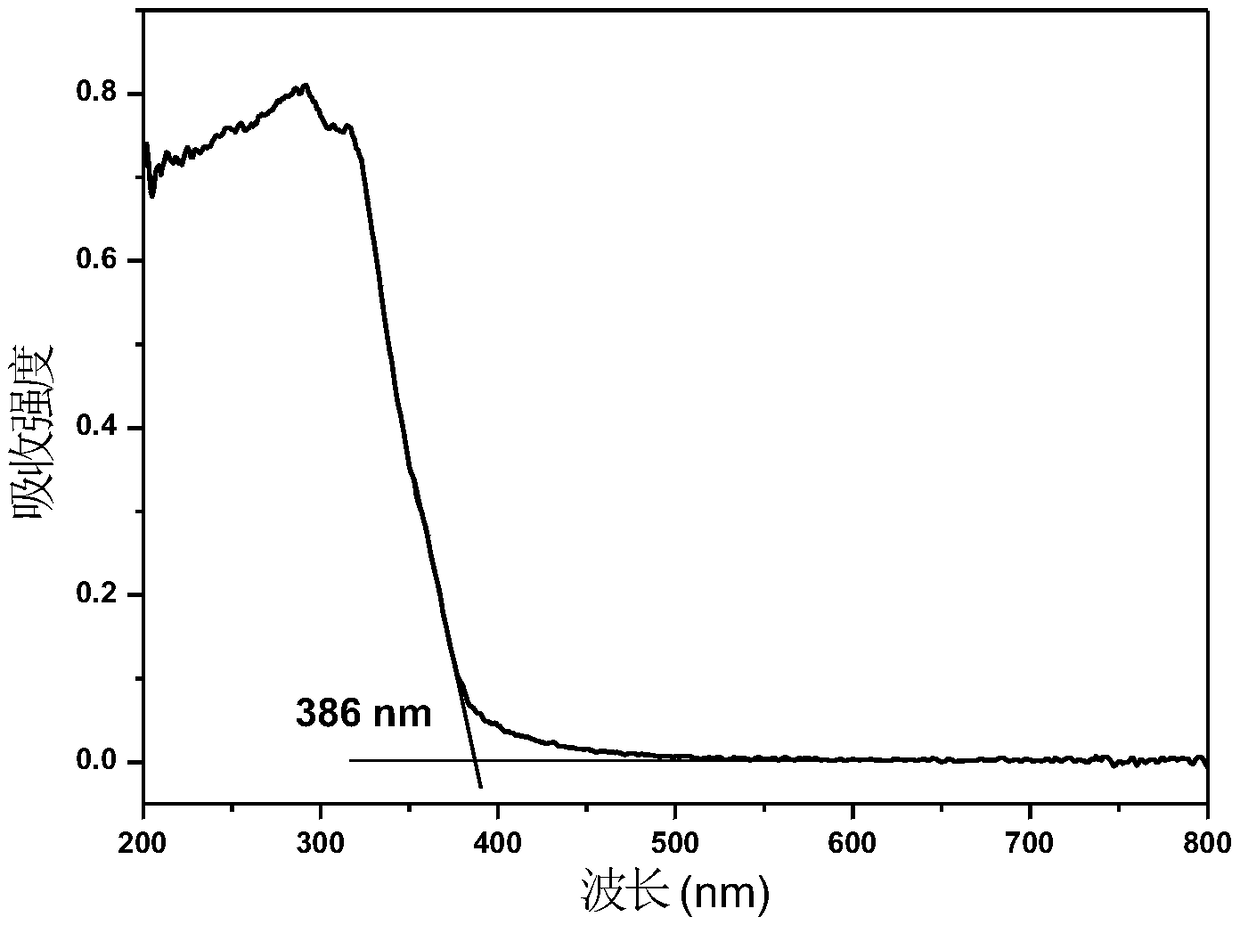

Inorganic non-linear optical crystal sodium iodobismuthate, and preparation and application thereof

ActiveCN109137072ALarge frequency doubling effectAchieve phase matchingPolycrystalline material growthFrom normal temperature solutionsNonlinear optical crystalInorganic compound

The invention discloses inorganic non-linear optical crystal sodium iodobismuthate, and preparation and application thereof. The chemical formula of the inorganic matter is NaBi(IO3)4, the molecular weight is 931.57, the inorganic matter belongs to a monoclinic system, the crystal space group is Cc, and the cell parameters are as shown in the description; the compound can be obtained through a hydrothermal synthesis method at the temperature of 210 to 250 DEG C, the operation is simple, and the experiment condition is mild; the crystal of the inorganic compound has a relatively high second-order nonlinear optical effect, and phase matching can be realized; and the compound has relatively high transparency in visible-near-infrared light zones and medium-infrared light zones, has relativelylarge band gaps and relatively high thermal stability, and can be used as a nonlinear optical crystal material which can be widely applied to the fields such as optics.

Owner:WUHAN UNIV

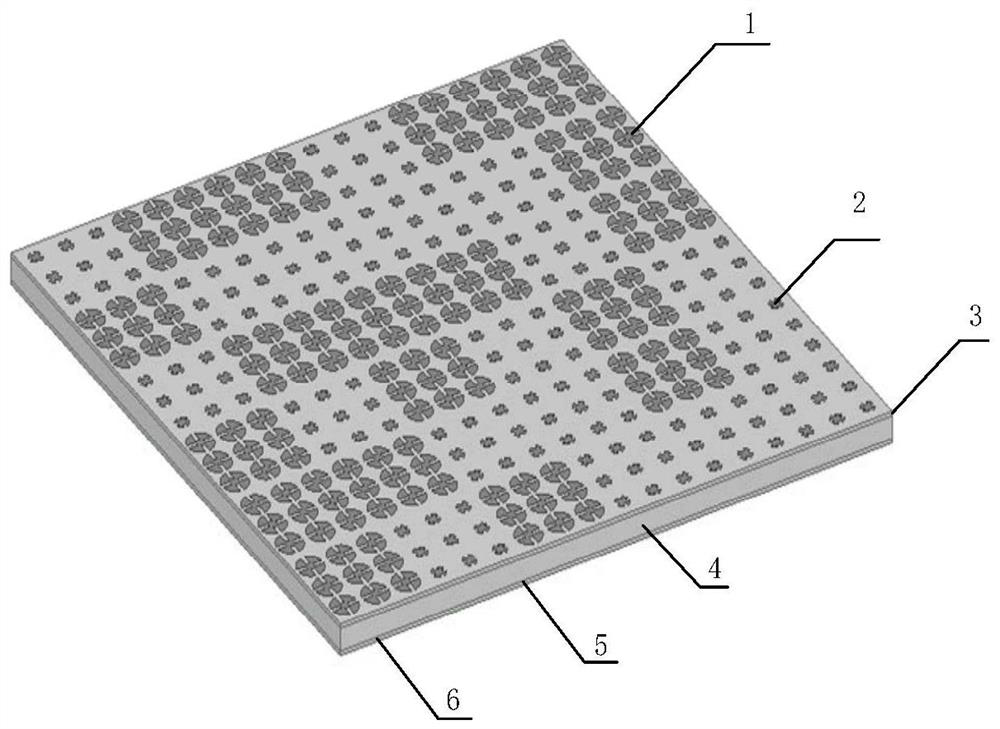

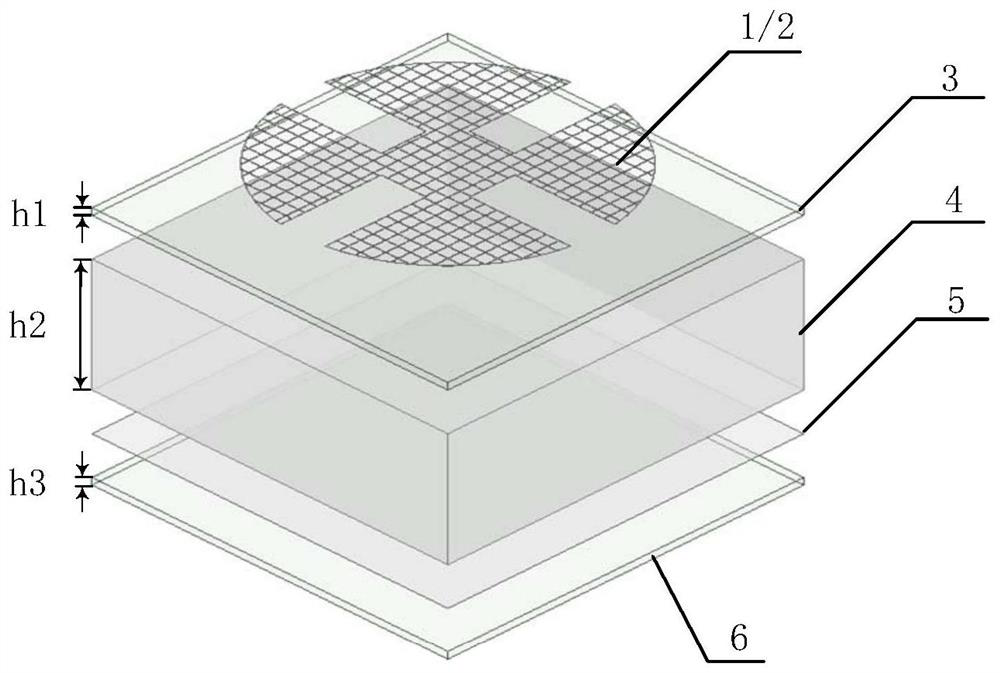

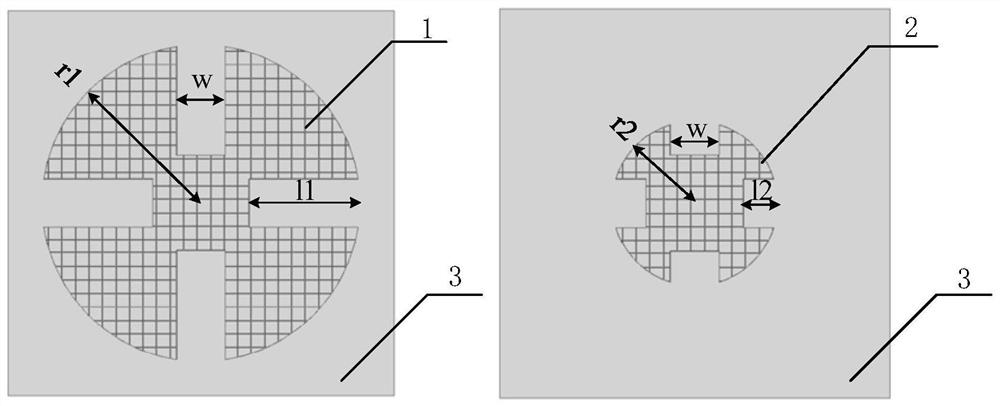

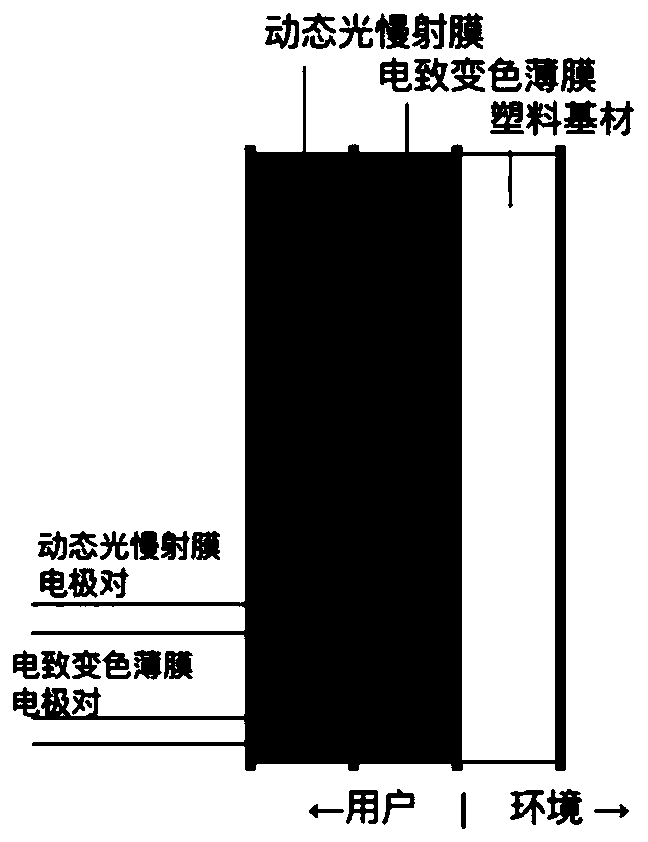

High-transparency diffuse reflection metasurface capable of reducing radar cross section

InactiveCN112821079AApparent backward RCS functionWith ultra-thinAntennasScattering cross-sectionPhase difference

The invention discloses a high-transparency diffuse reflection metasurface capable of reducing a radar cross section. The diffuse reflection metasurface sequentially comprises a top layer, a middle layer and a bottom layer from top to bottom, wherein the bottom layer is ITO; the middle layer is an optical transparent dielectric layer; the top layer is a metal net with two outer contours which are circular Minkowski rings; and two kinds of circular Minkowski ring metal nets are used as basic units, the amplitudes of the two kinds of basic units are approximately equal in the working frequency band range, and the phase difference is 180 degrees + / -30 degrees. The phase of one basic unit can be classified as 0 degree and is called as a 0 element; and the phase of the other one can be classified as 180 degrees and is called as an element 1. The two basic units have the characteristics of self-similarity and polarization insensitivity. The diffuse reflection metasurface is high in light transmittance and easy to implement, and has the function of obviously reducing backward RCS in a wide frequency range.

Owner:WUHAN SECOND SHIP DESIGN & RES INST

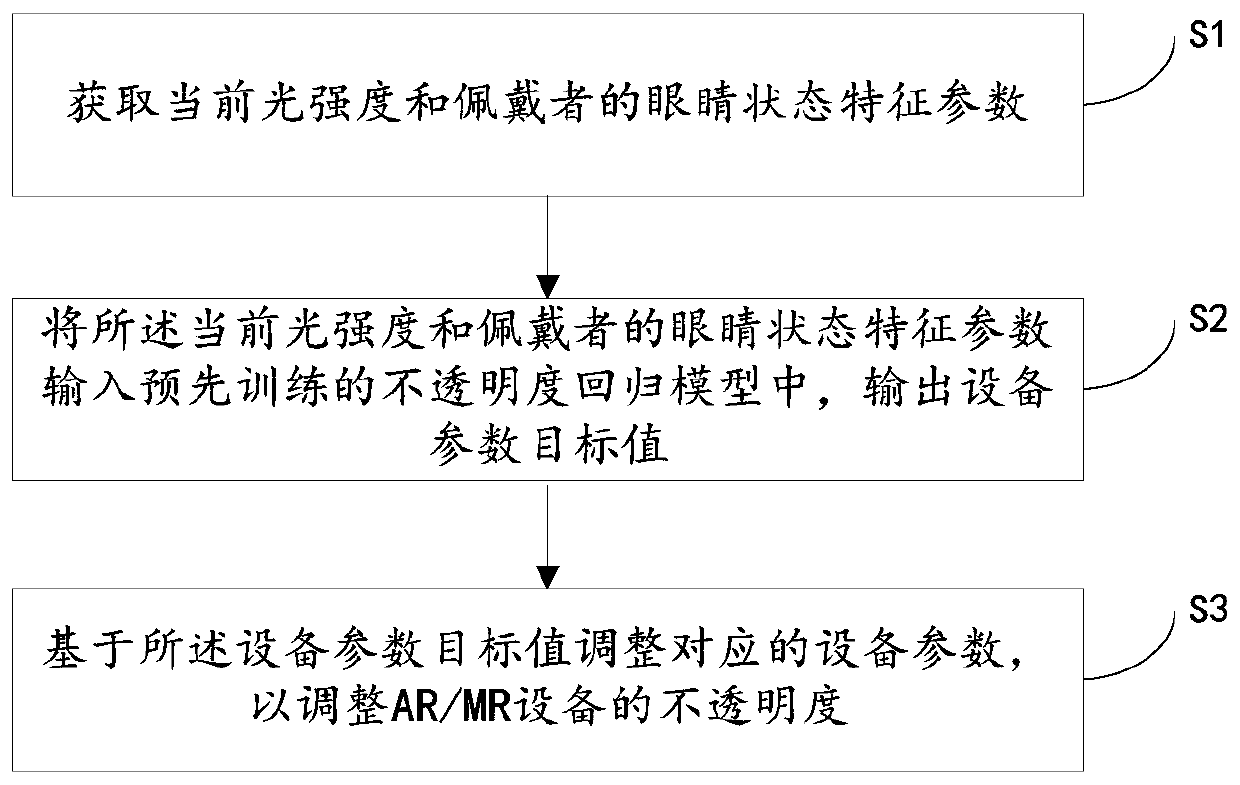

Opaque control method and device, AR/MR equipment, controller and medium

PendingCN111273776AImprove experienceOpacity ControlInput/output for user-computer interactionGraph readingEye stateMedicine

The invention relates to an opacity control method, an opacity control device, AR / MR equipment, a controller and a medium. The opacity control method comprises the following steps: acquiring current light intensity and eye state characteristic parameters of a wearer; inputting the current light intensity and the eye state characteristic parameters of the wearer into a pre-trained opacity regression model, and outputting an equipment parameter target value; and adjusting the corresponding equipment parameter based on the equipment parameter target value so as to adjust the opacity of the AR / MRequipment. According to the most natural state and reaction of the eyes of the user, the opacity of the AR / MR equipment is adaptively adjusted based on the opacity regression model, and the user experience is improved.

Owner:YUTOU TECH HANGZHOU

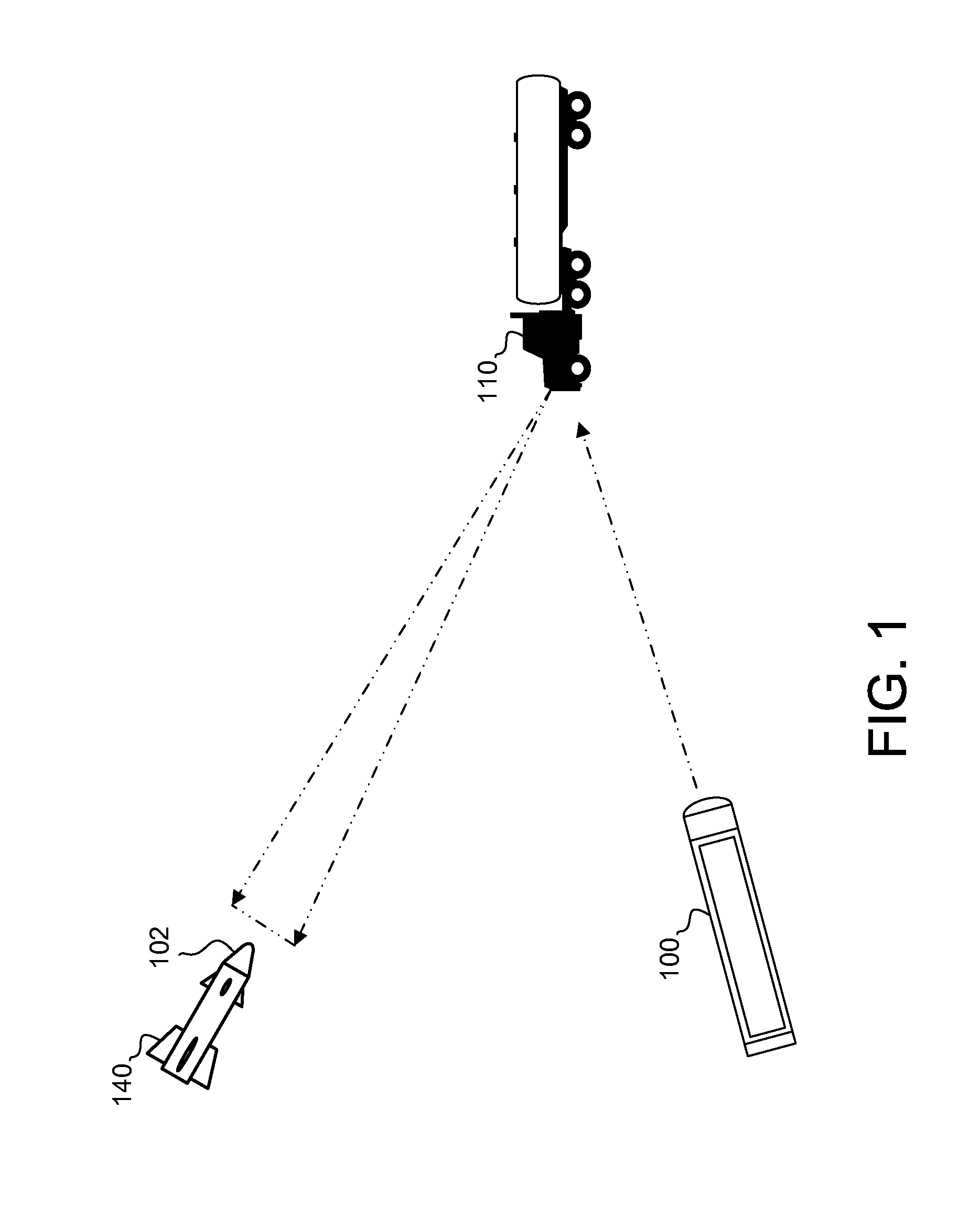

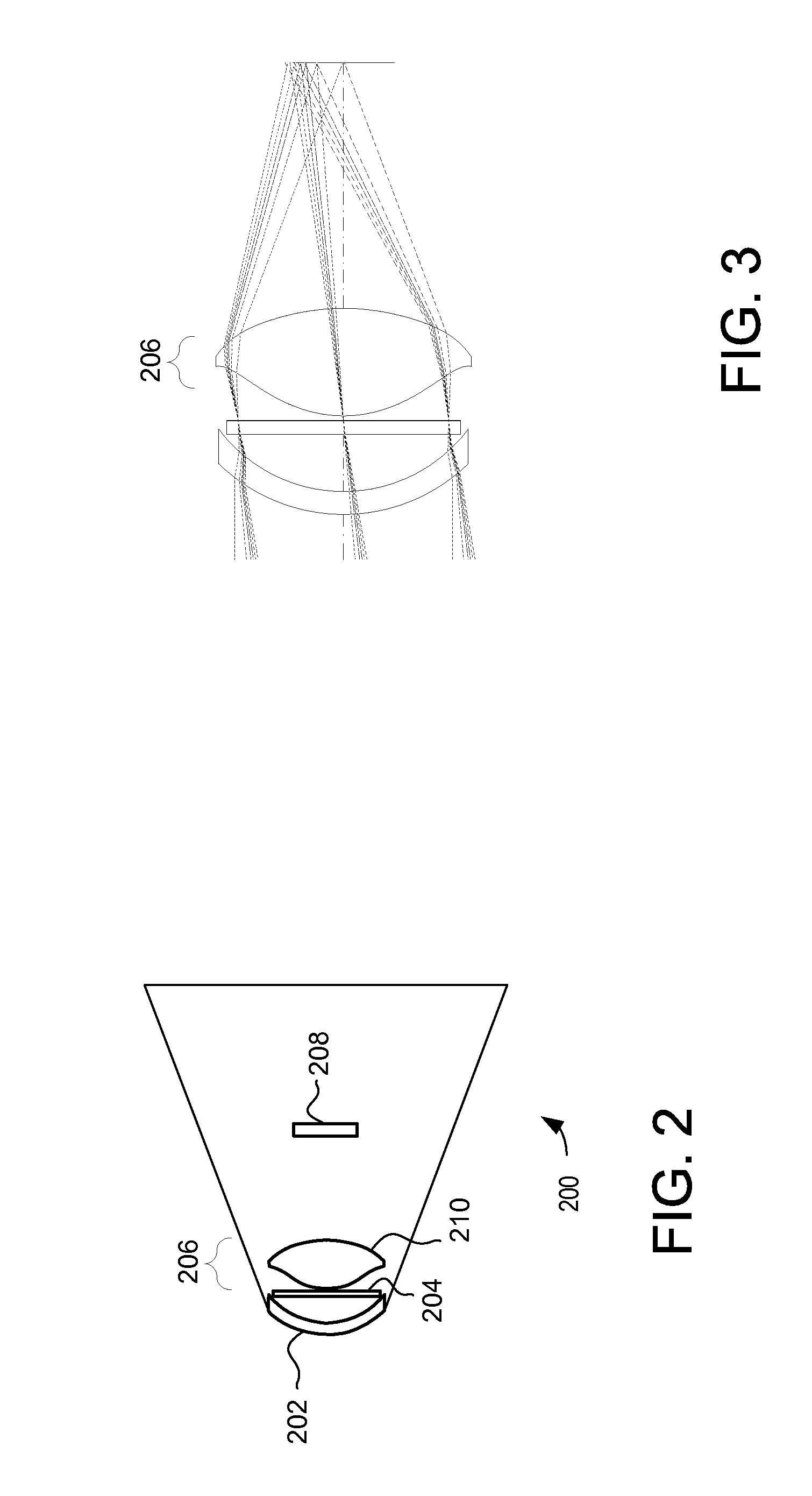

Lens concentrator system for semi-active laser target designation

ActiveUS20120193538A1Improve performanceFacilitate useRadiation pyrometryDirection controllersLaser lightRadiation

A semi-active laser (SAL) sensing system is thus provided that uses a lens concentrator system to pass received reflected laser light from an aperture to a detector. The lens concentrator system facilitates the use of SAL systems with different laser designator wavelengths to improve the performance of the SAL system. In one embodiment, the lens concentrator system is formed from polymer having substantial optical clarity for radiation having wavelengths between approximately 1.5 and approximately 1.65 μm. For example, the lens concentrator system may be formed from amorphous fluoropolymer. The lens concentrator system formed from amorphous fluoropolymer facilitates the use SAL designators using different wavelengths than those in past SAL sensing systems.

Owner:RAYTHEON CO

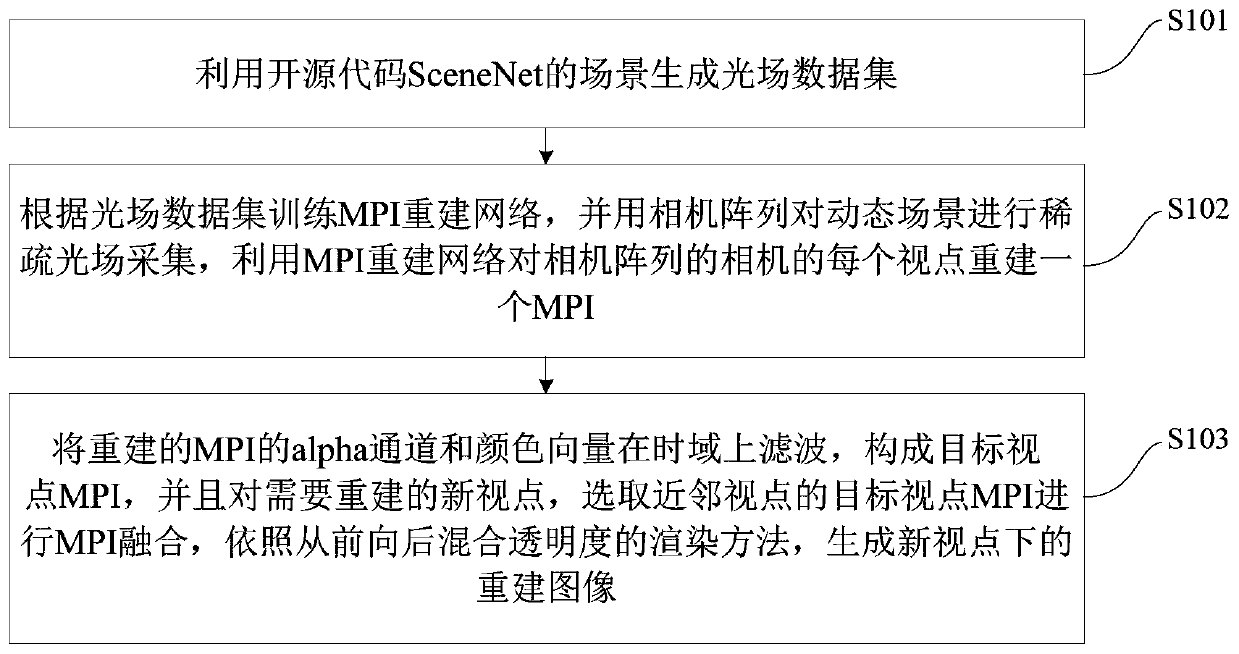

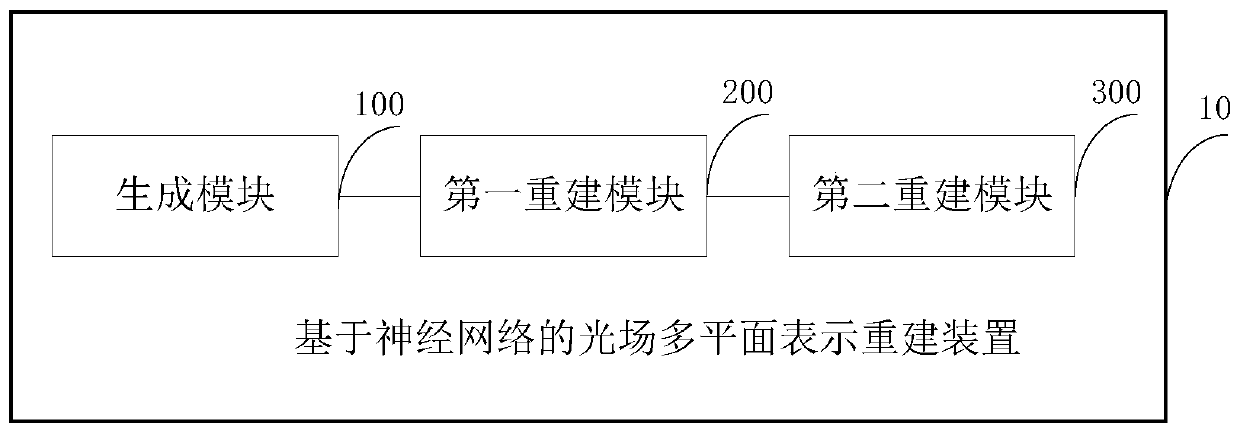

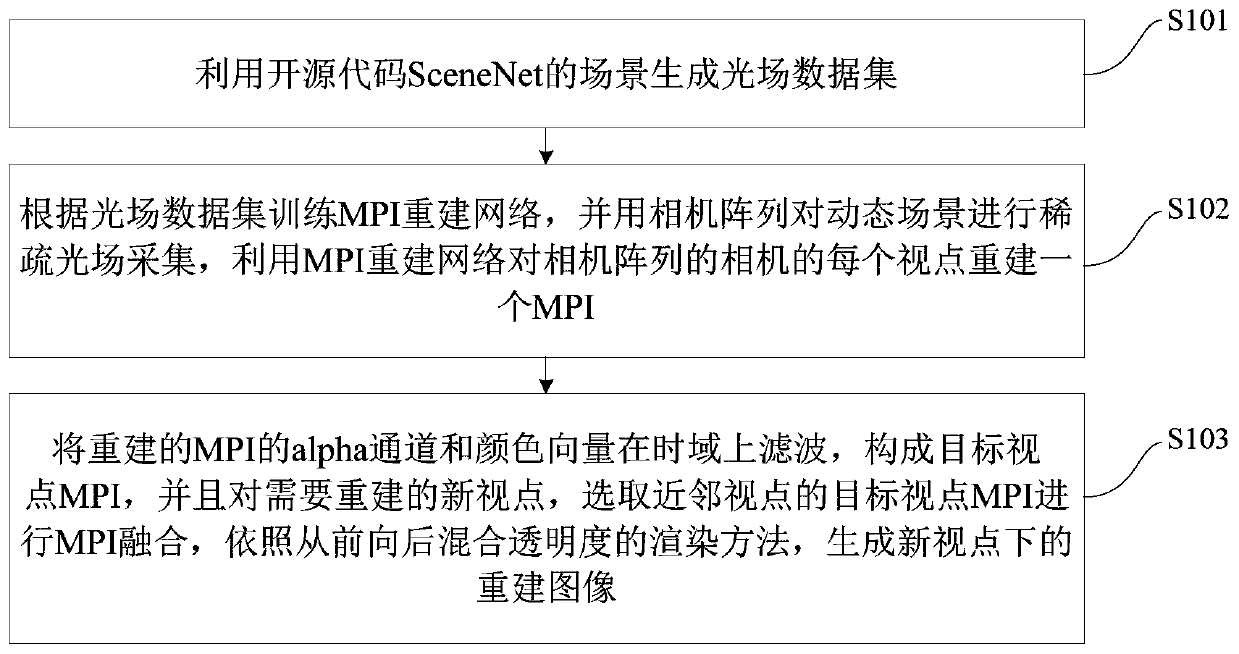

Light field multi-plane representation reconstruction method and device based on neural network

InactiveCN111127536AReduced spatial sampling rate requirementsReduce complexityReconstruction from projectionImage analysisTime domainData set

The invention discloses a light field multi-plane representation reconstruction method and device based on a neural network, and the method comprises the following steps: generating a light field dataset through employing a scene of an open source code SceneNet; training an MPI reconstruction network according to the light field data set, performing sparse light field acquisition on the dynamic scene by using the camera array, and reconstructing an MPI for each viewpoint of a camera of the camera array by using the MPI reconstruction network; and filtering the alpha channel and the color vector of the reconstructed MPI in a time domain to form a target viewpoint MPI, selecting a target viewpoint MPI of a neighbor viewpoint for MPI fusion of a new viewpoint to be reconstructed, and generating a reconstructed image under the new viewpoint according to a rendering method of mixing transparency from front to back. According to the method, the system complexity can be greatly reduced, anda better light field interpolation effect can be realized in a space domain and an angle domain at the same time.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com