Patents

Literature

199results about How to "Good reflective properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

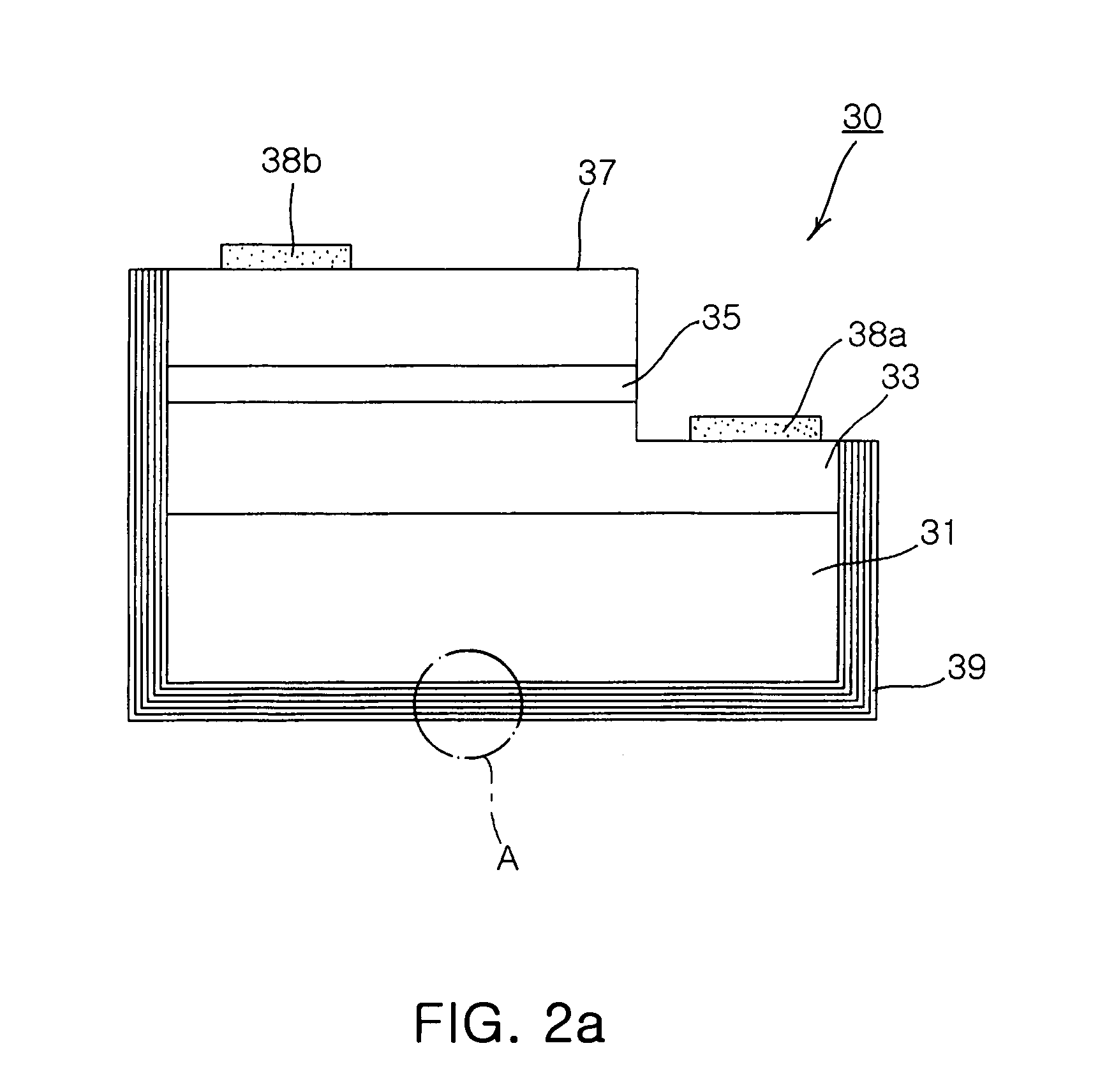

Infrared light reflecting plate, laminated interlayer film sheet for laminated glass and its production method, and laminated glass

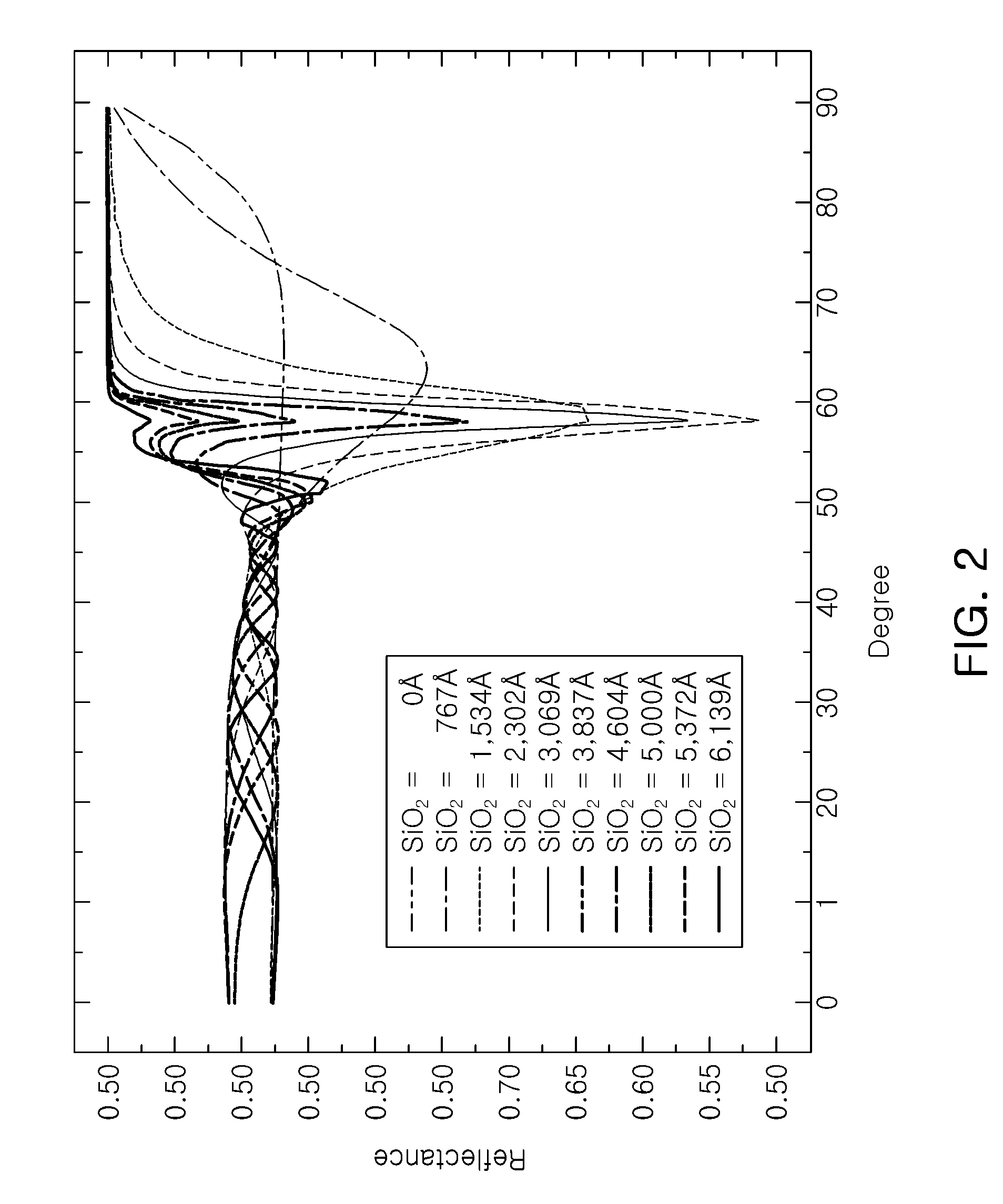

InactiveUS20110181820A1Good reflective propertiesImprove insulation performanceLamination ancillary operationsFilm/foil adhesivesReflective layerLength wave

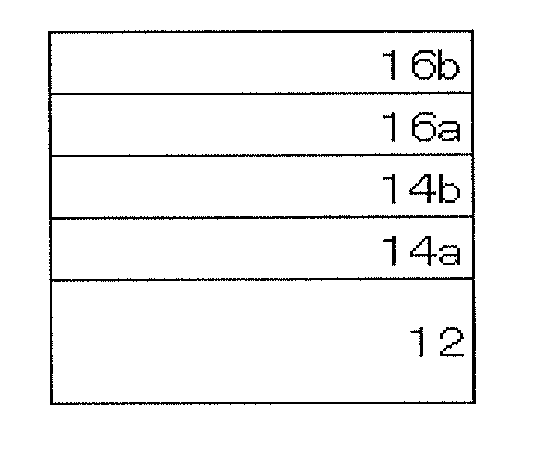

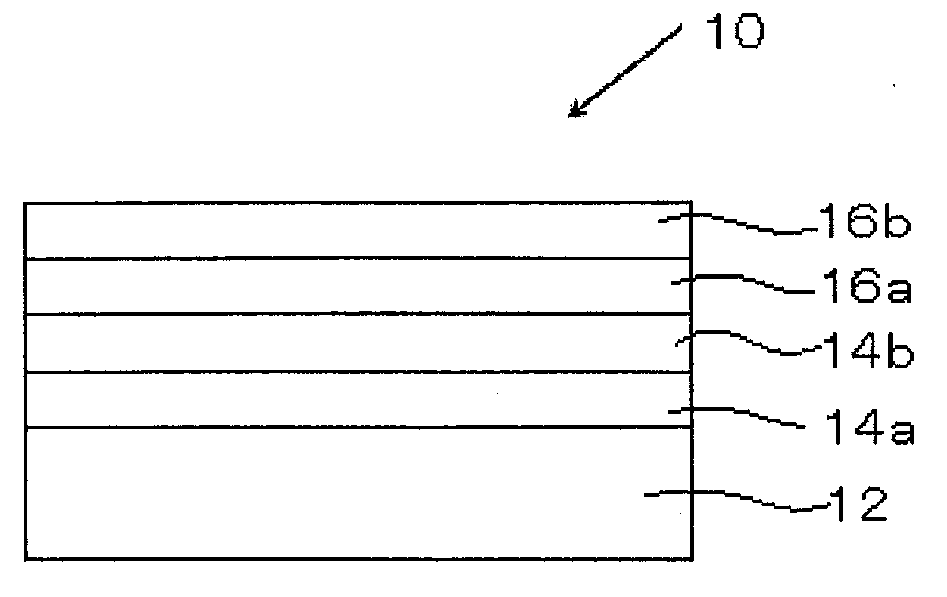

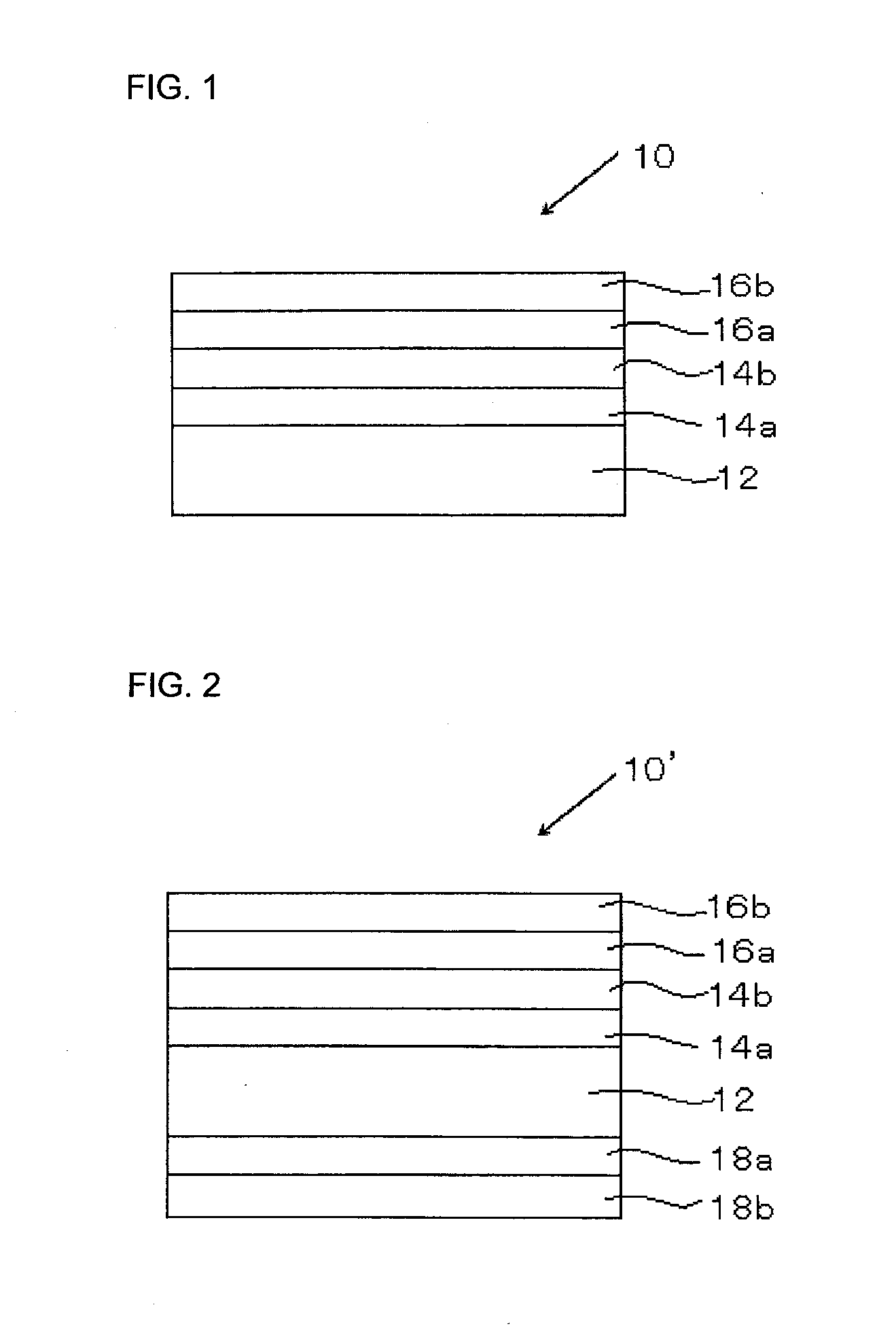

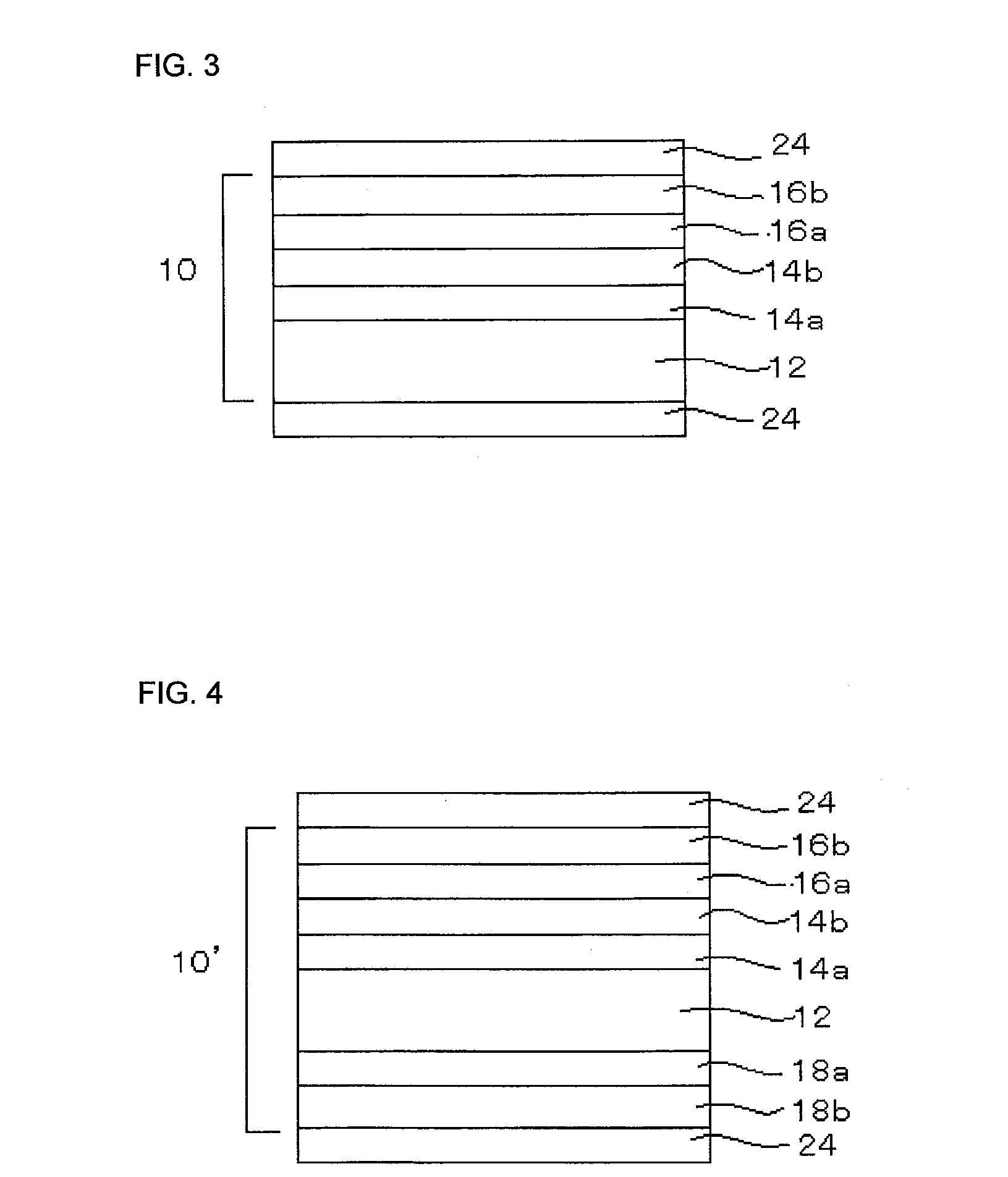

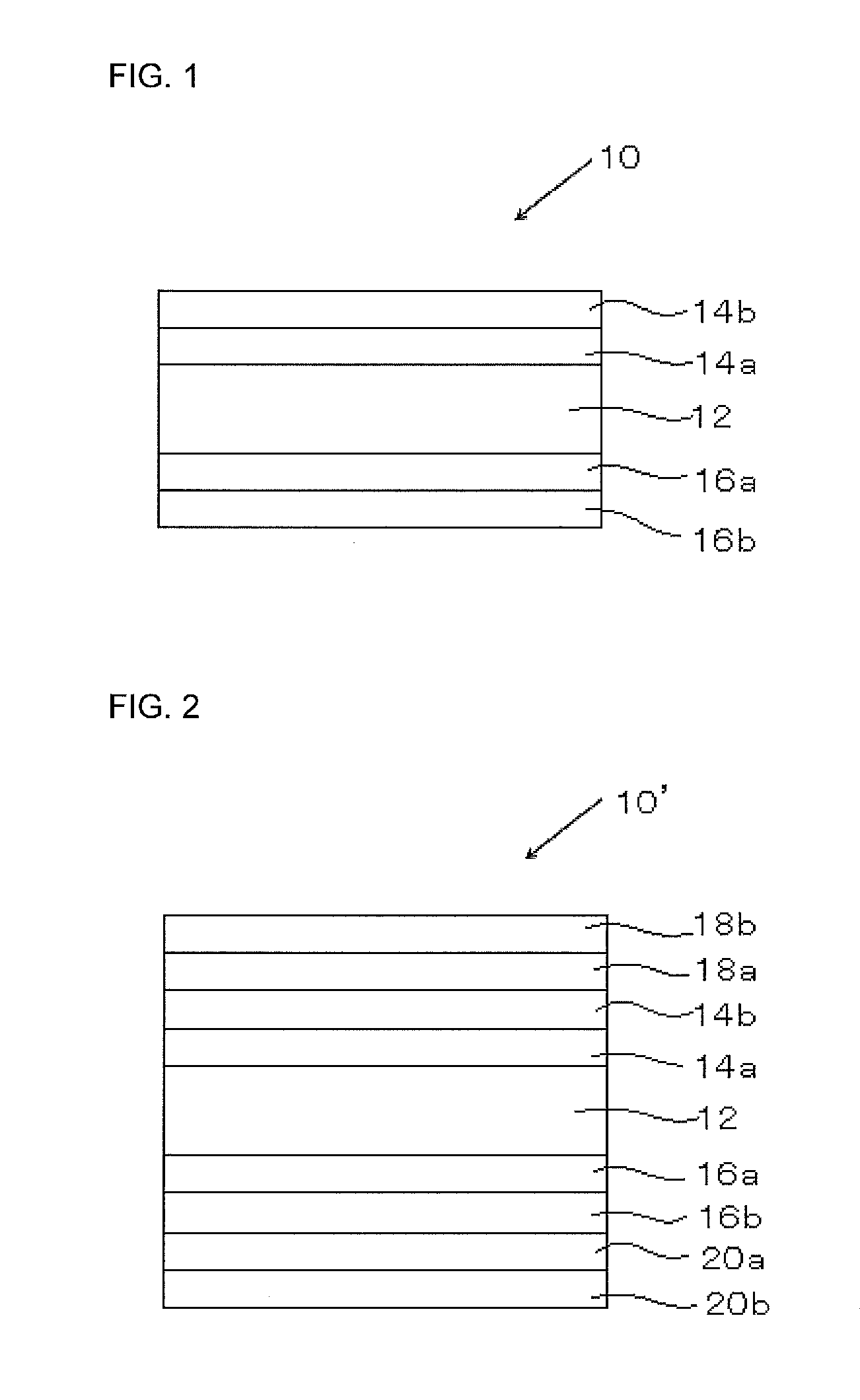

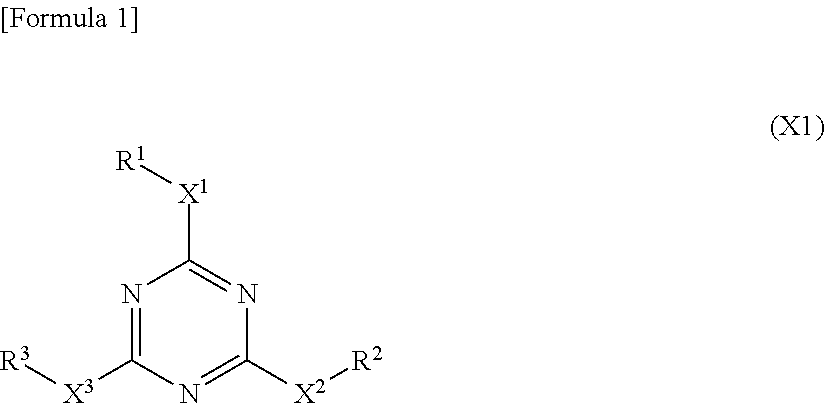

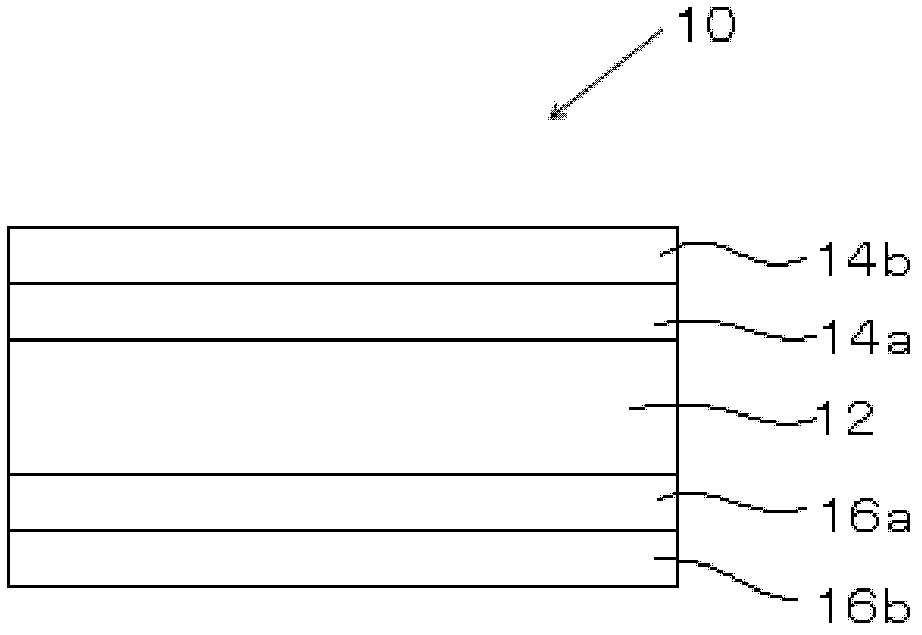

Disclosed is an infrared light reflecting plate for reflecting infrared light, which comprises a substrate and at least four light-reflective layers X1, X2, X3 and X4 each of which is formed of a fixed cholesteric liquid-crystal phase. The reflection center wavelength of the light-reflective layers X1 and X2 is the same and is λ1 (nm), the two layers reflect circularly-polarized light in opposite directions, and the reflection center wavelength λ1 (nm) falls within a range of from 1010 to 1070 nm, and the reflection center wavelength of the light-reflective layers X3 and X4 is the same and is λ2 (nm), the two layers reflect circularly-polarized light in opposite directions, and the reflection center wavelength λ2 (nm) falls within a range of from 1190 to 1290 nm.

Owner:FUJIFILM CORP

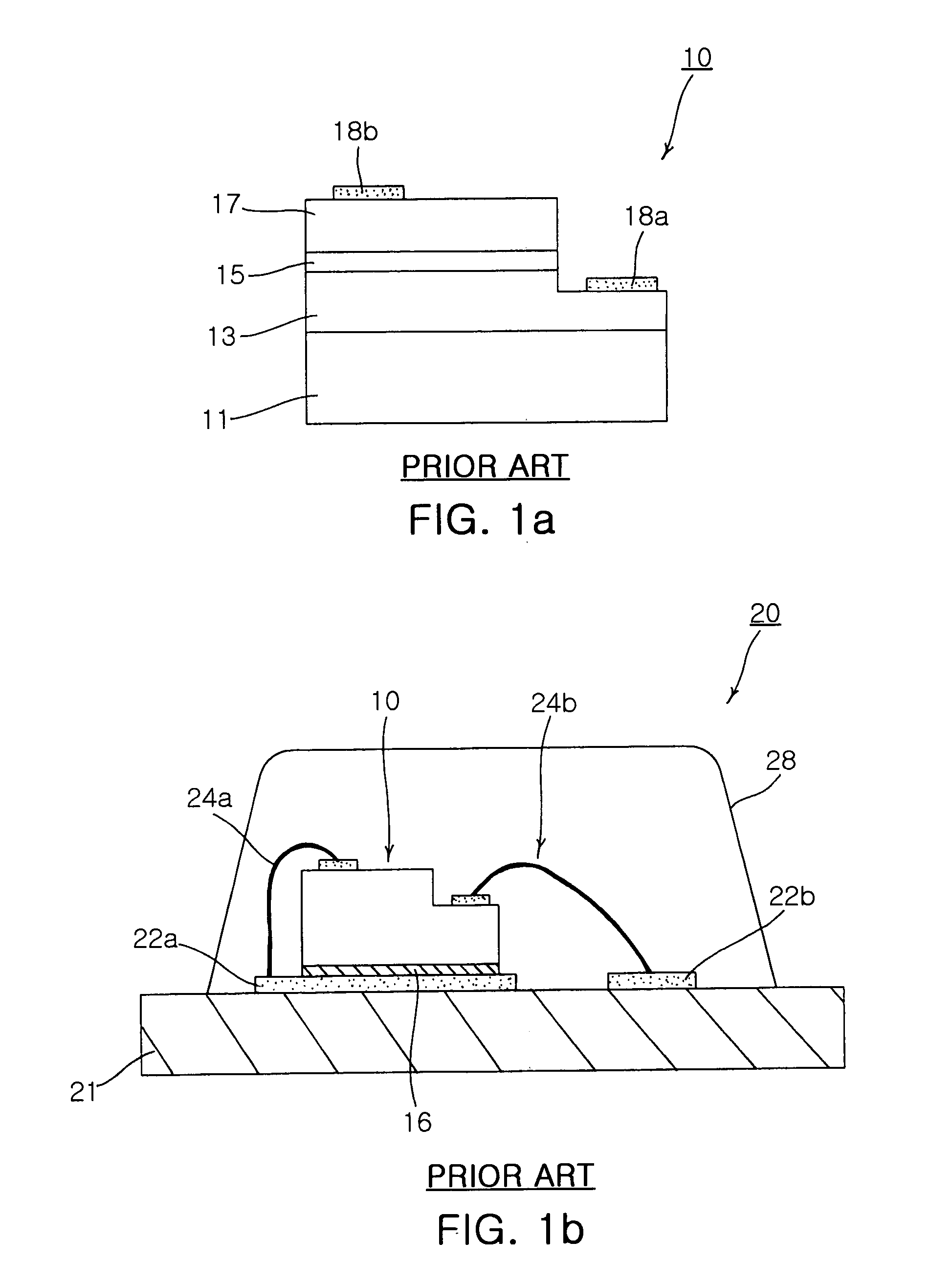

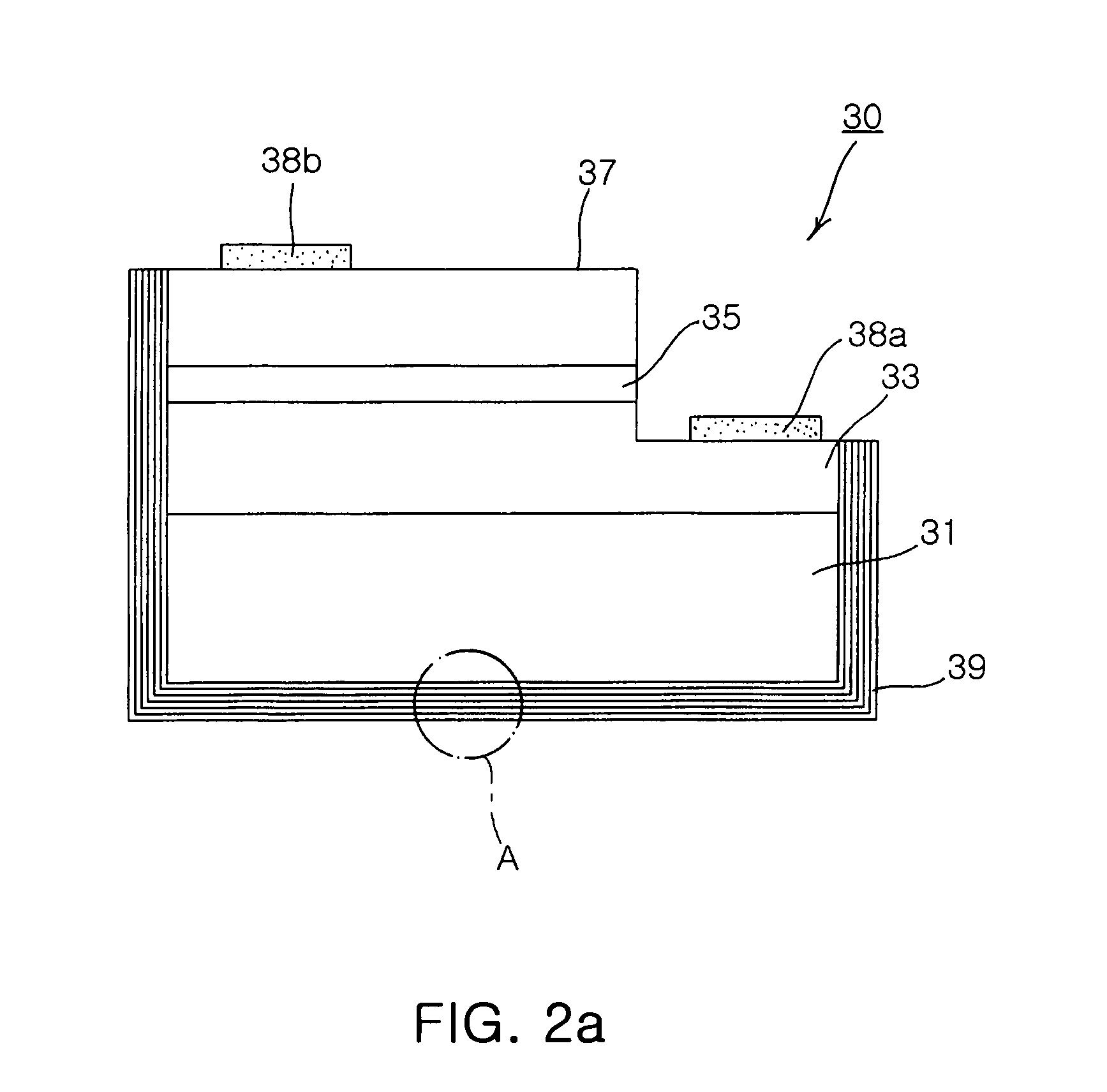

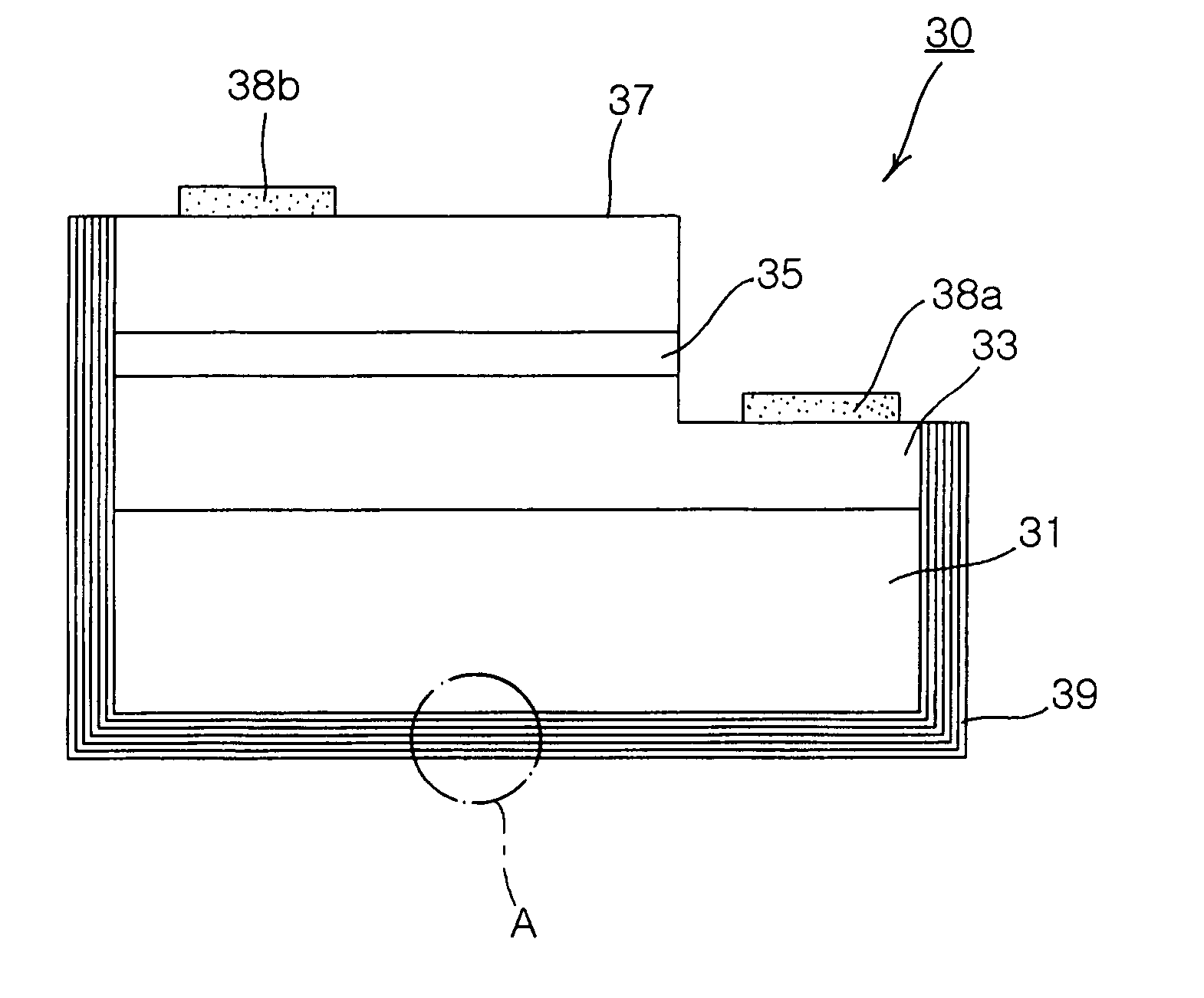

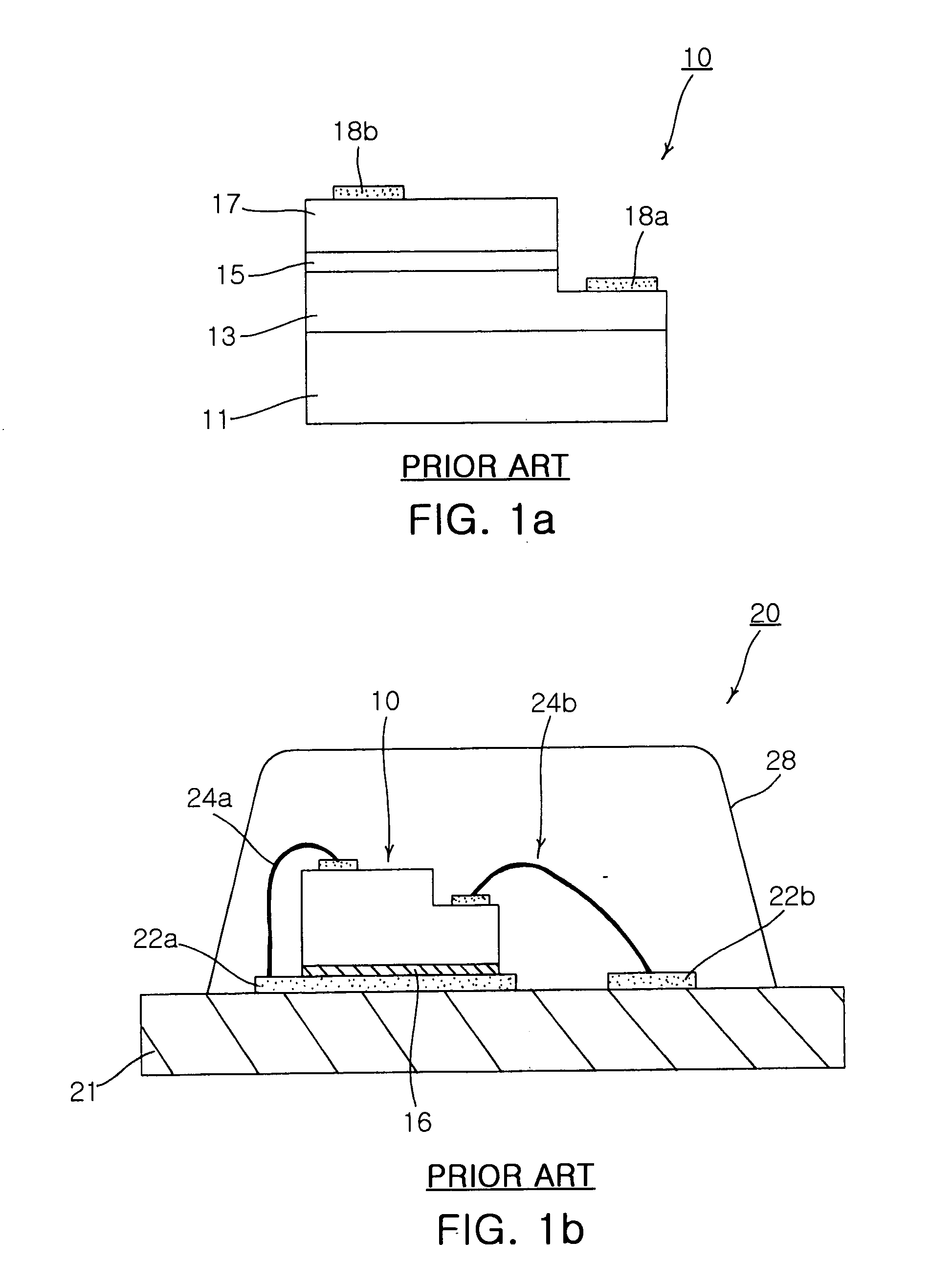

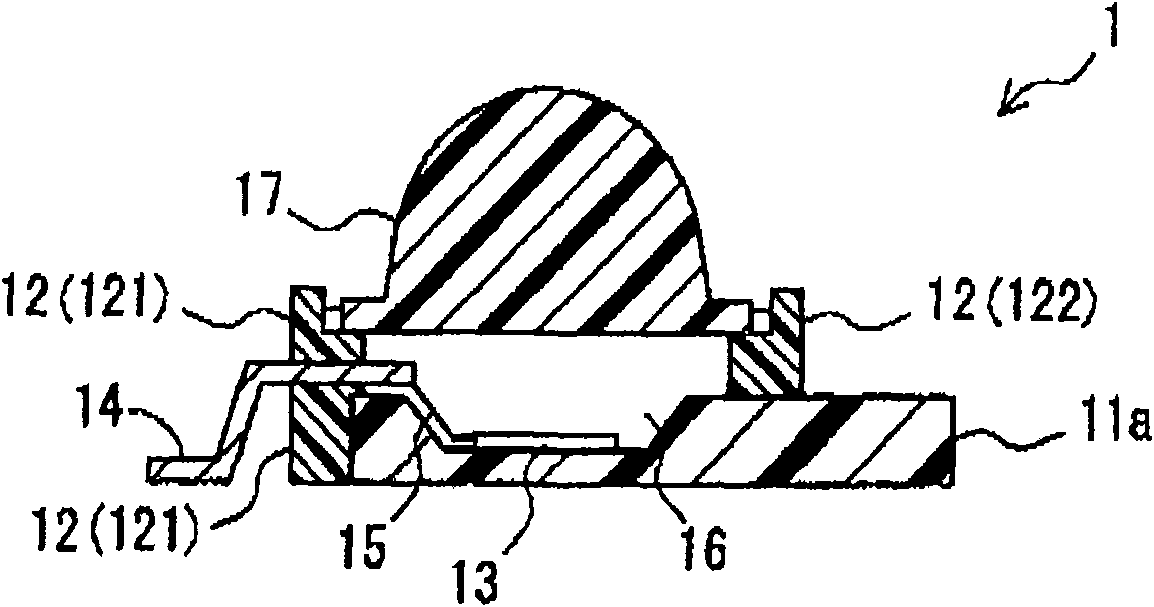

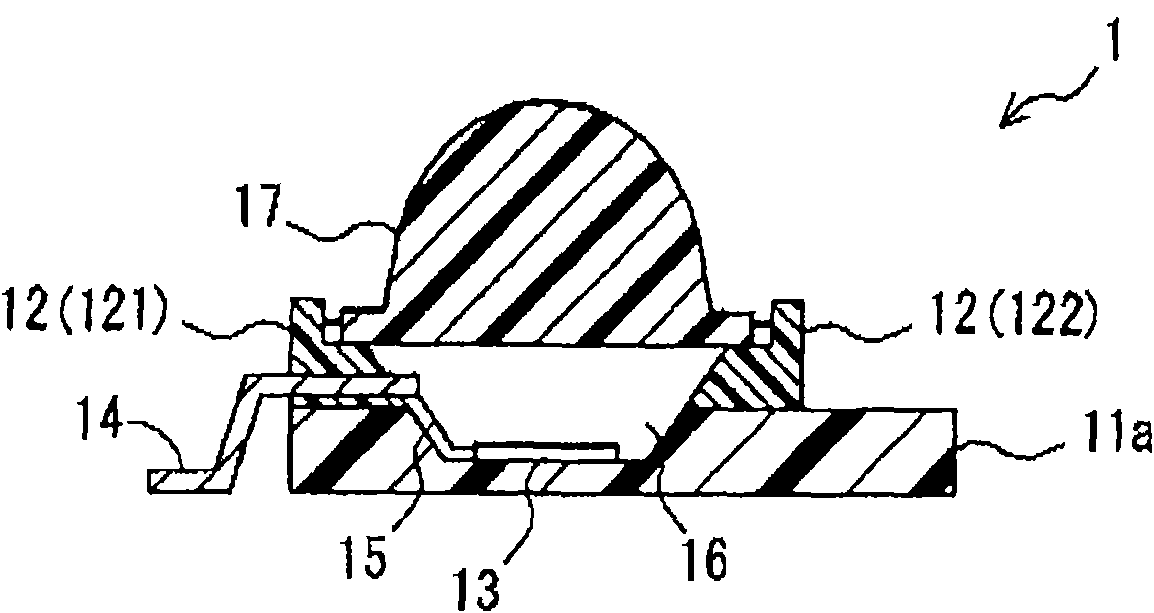

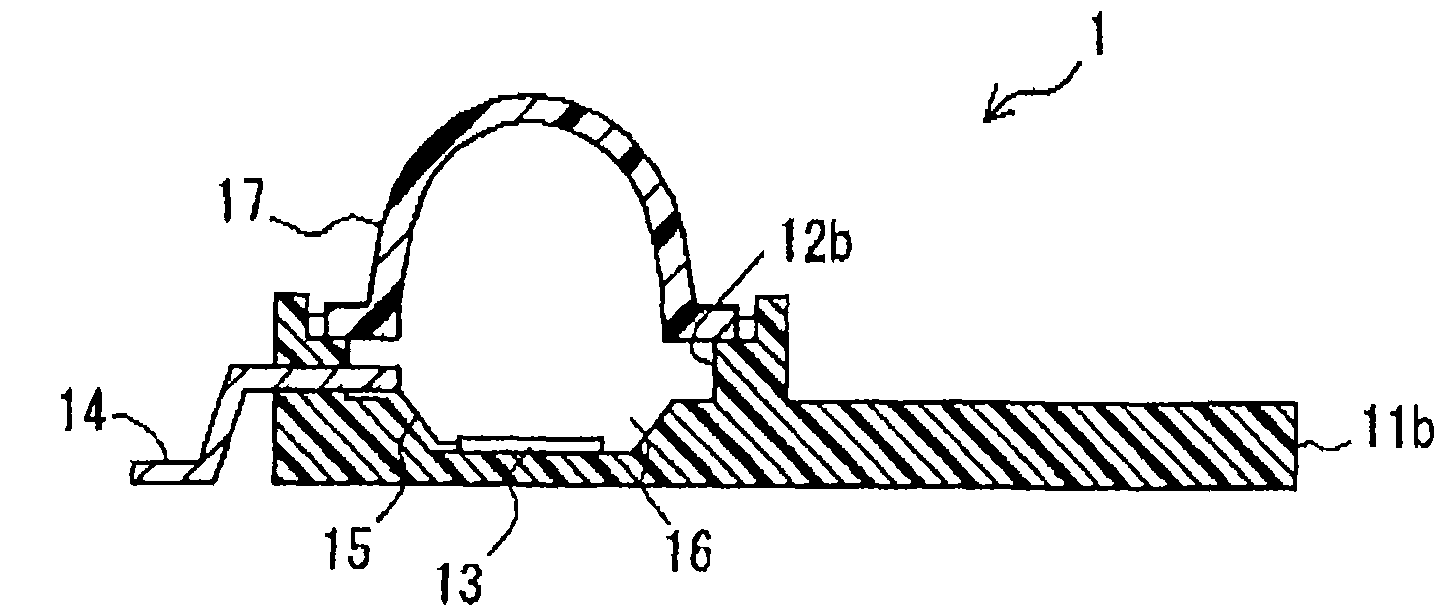

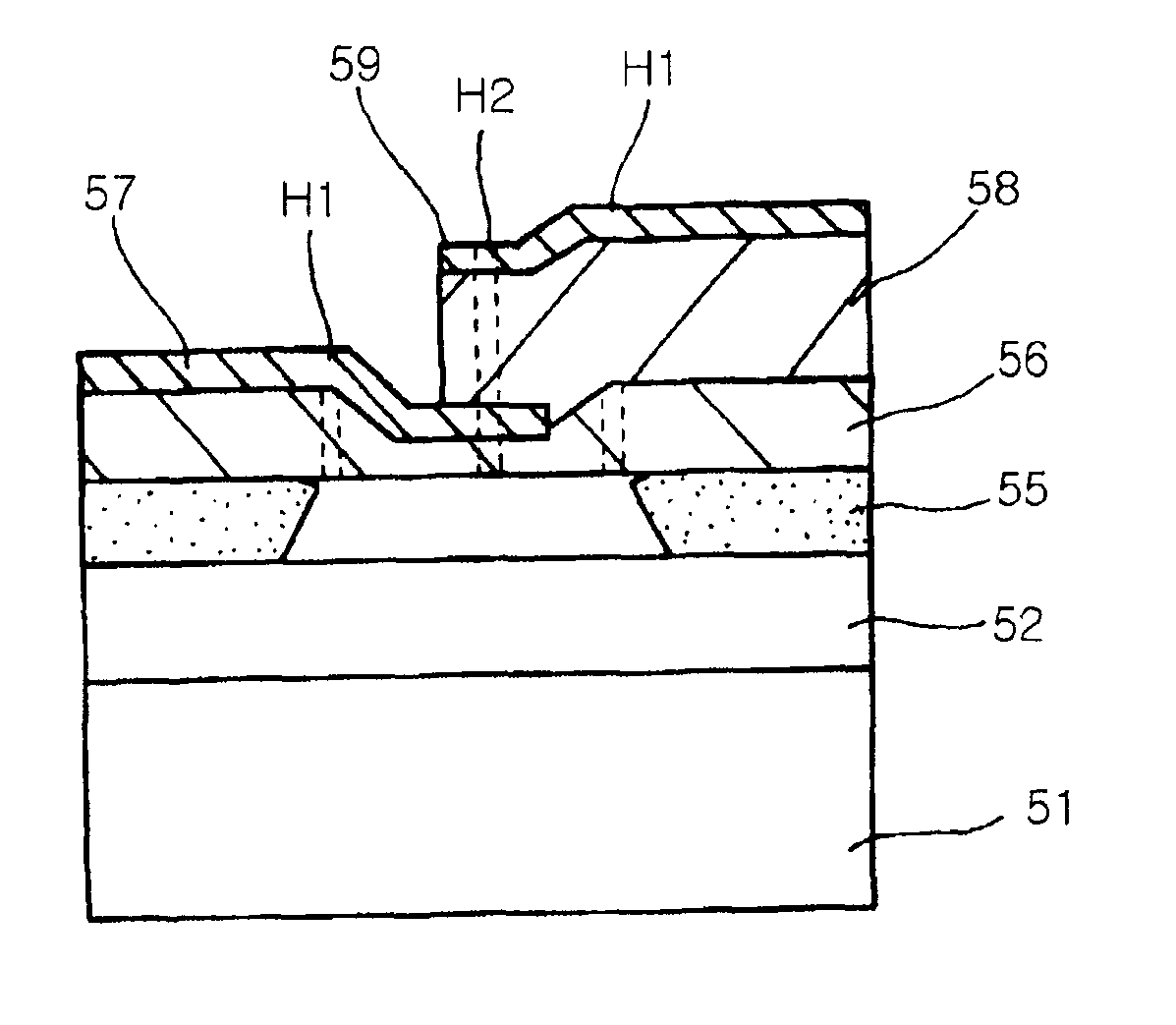

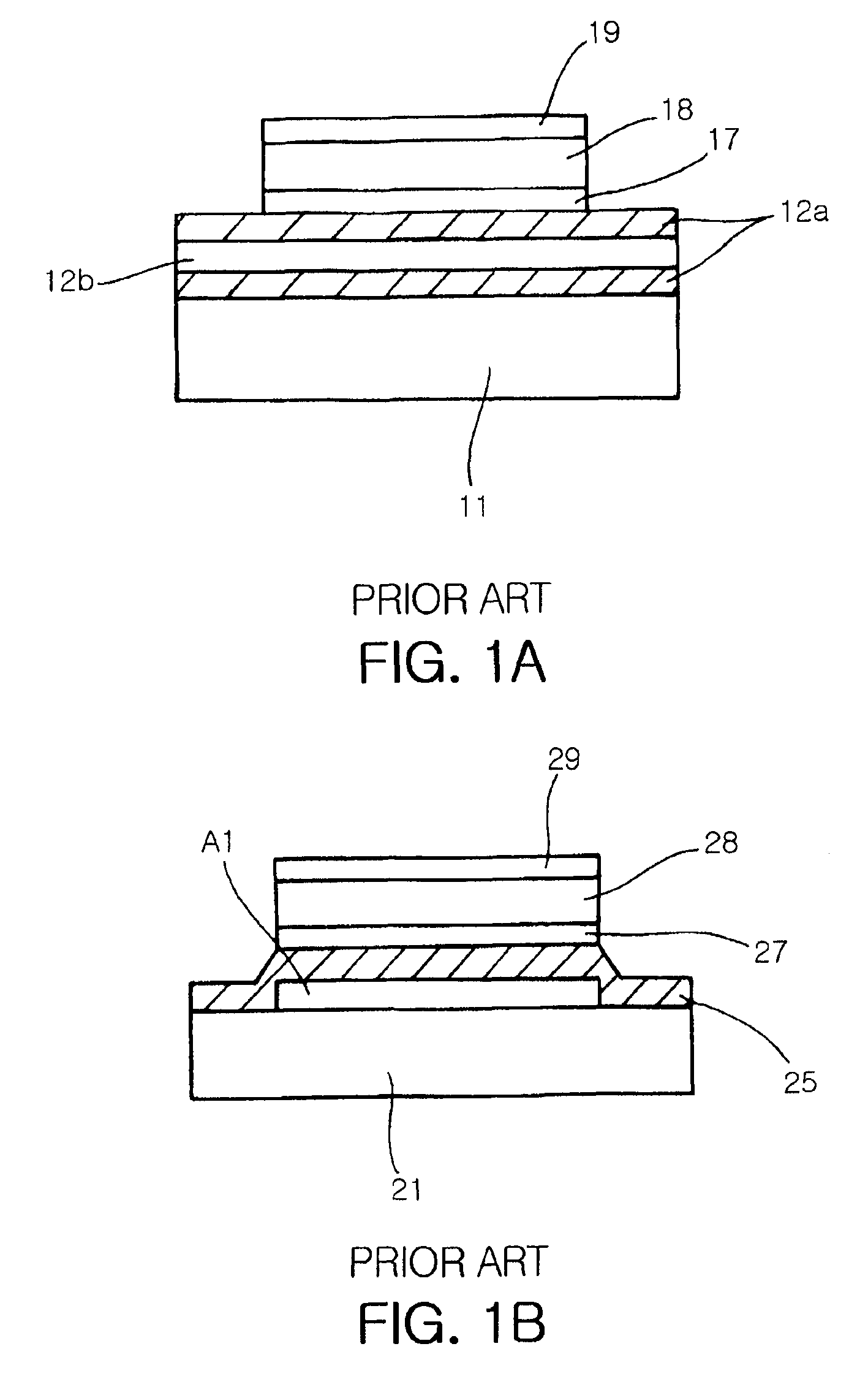

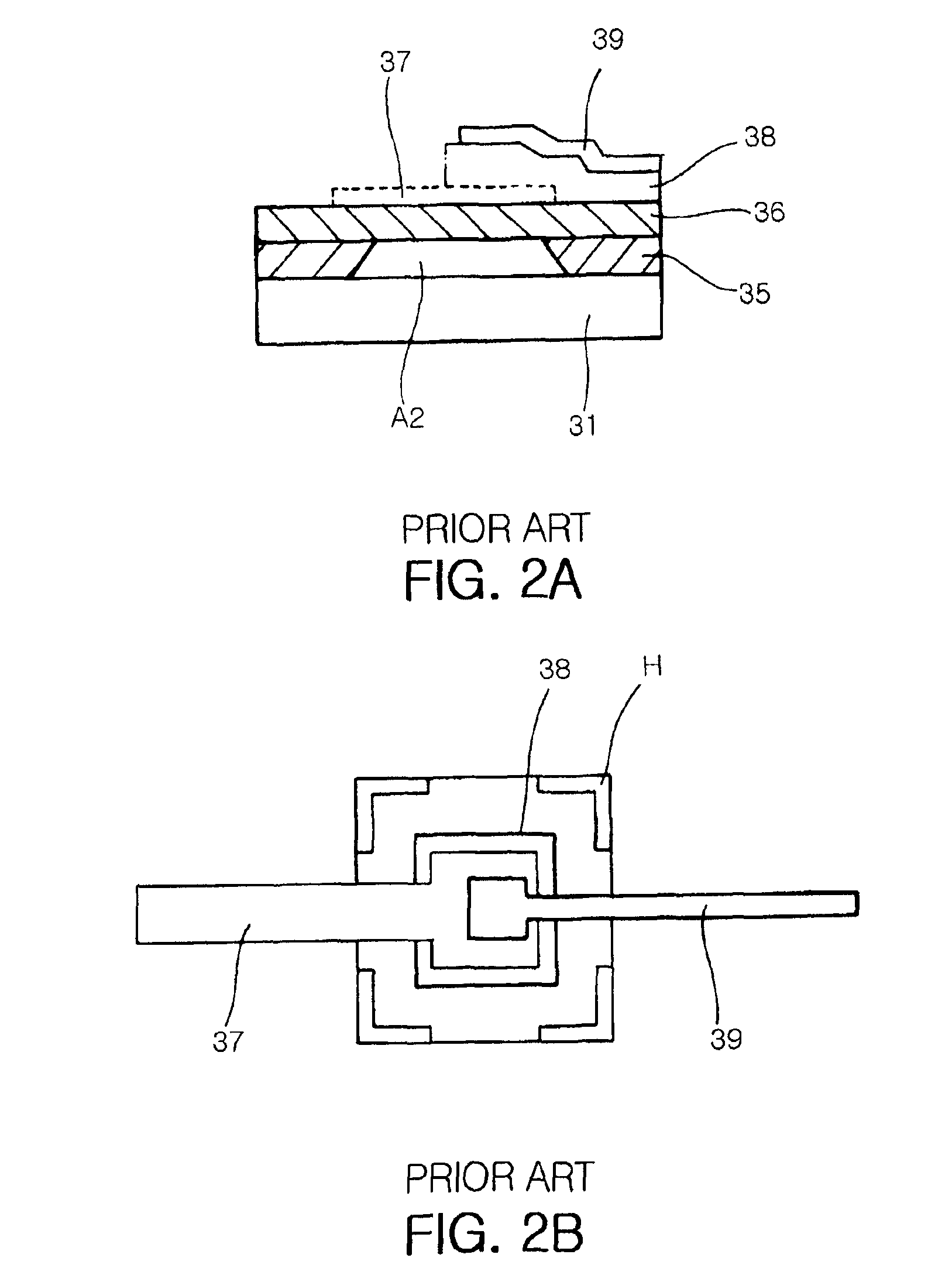

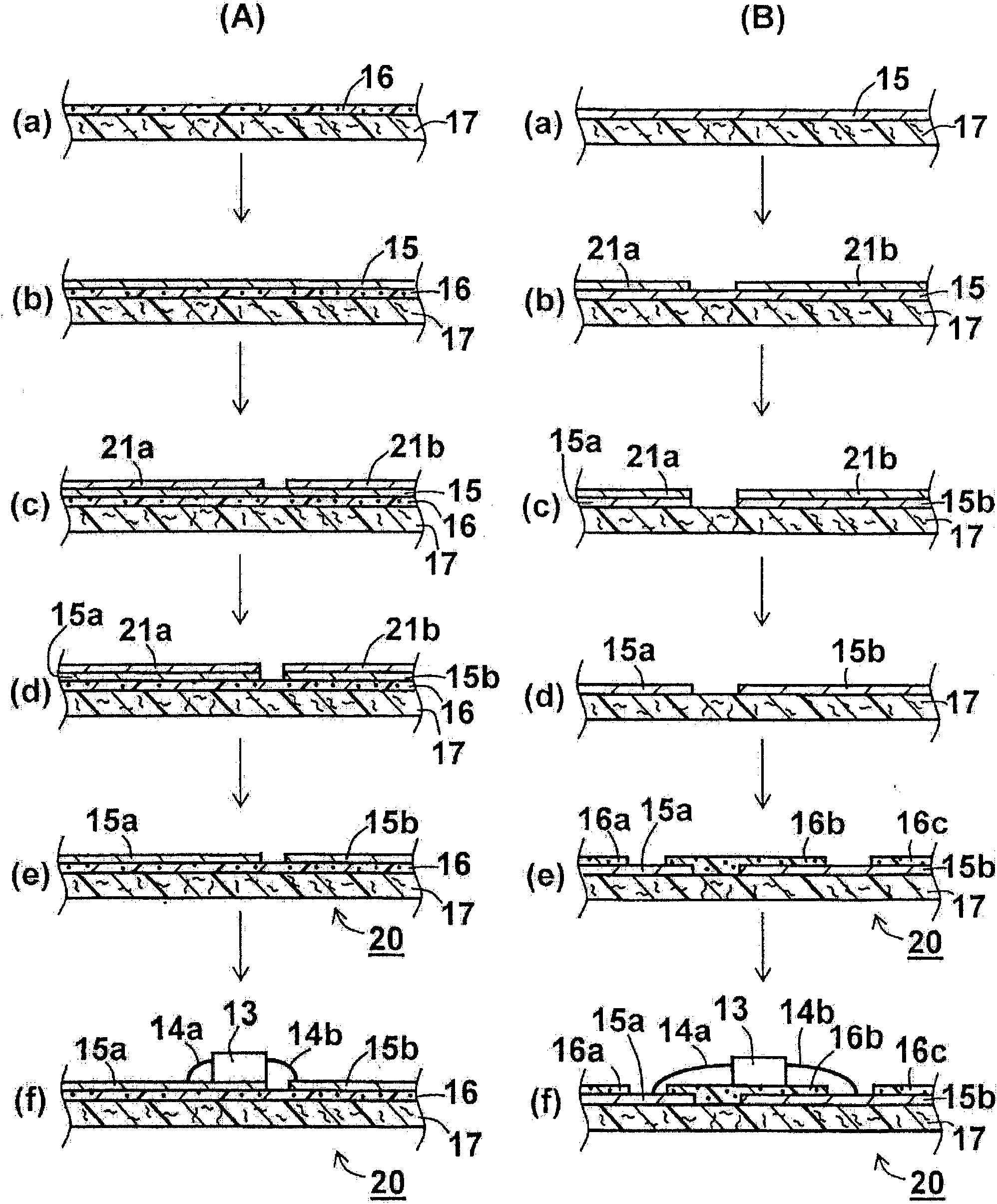

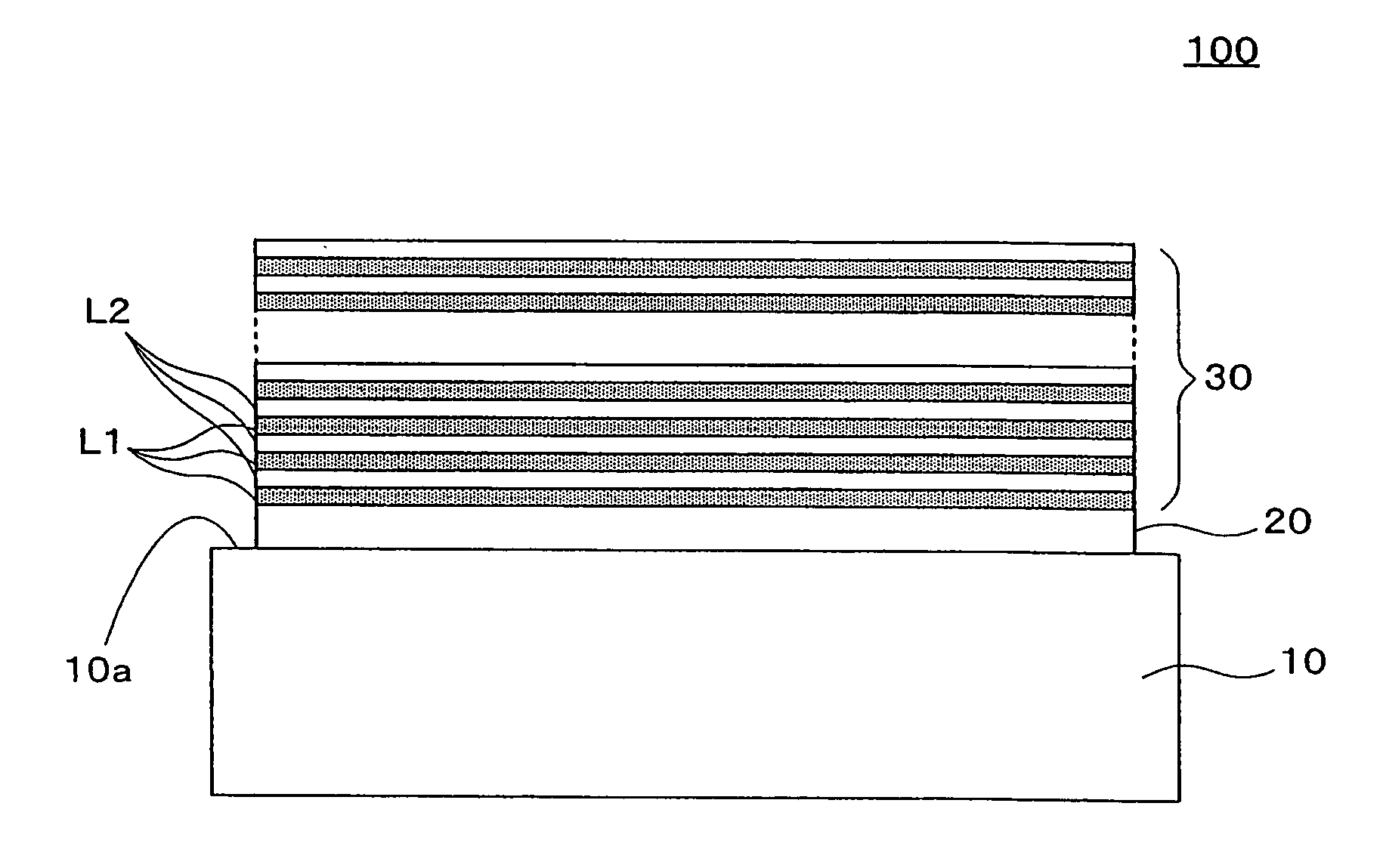

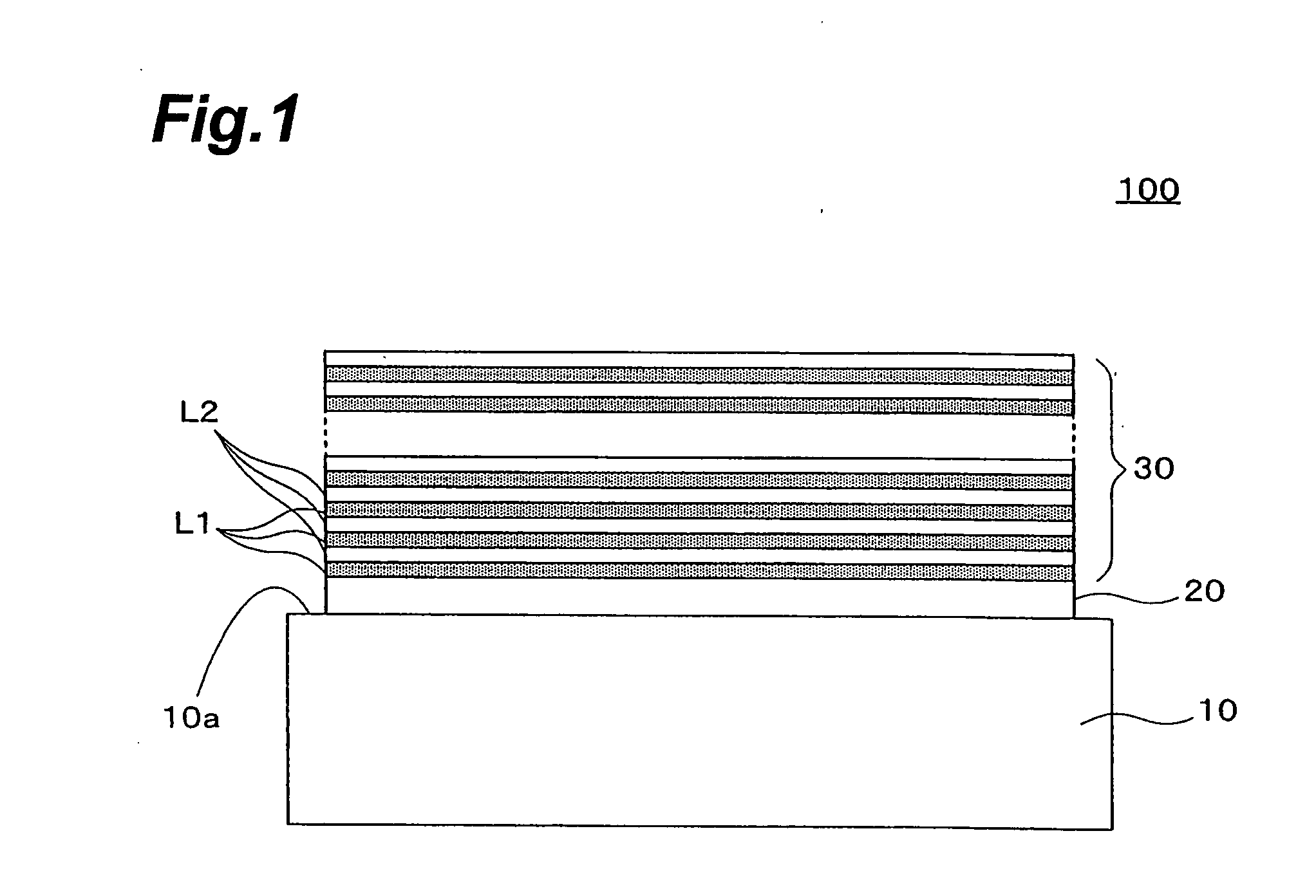

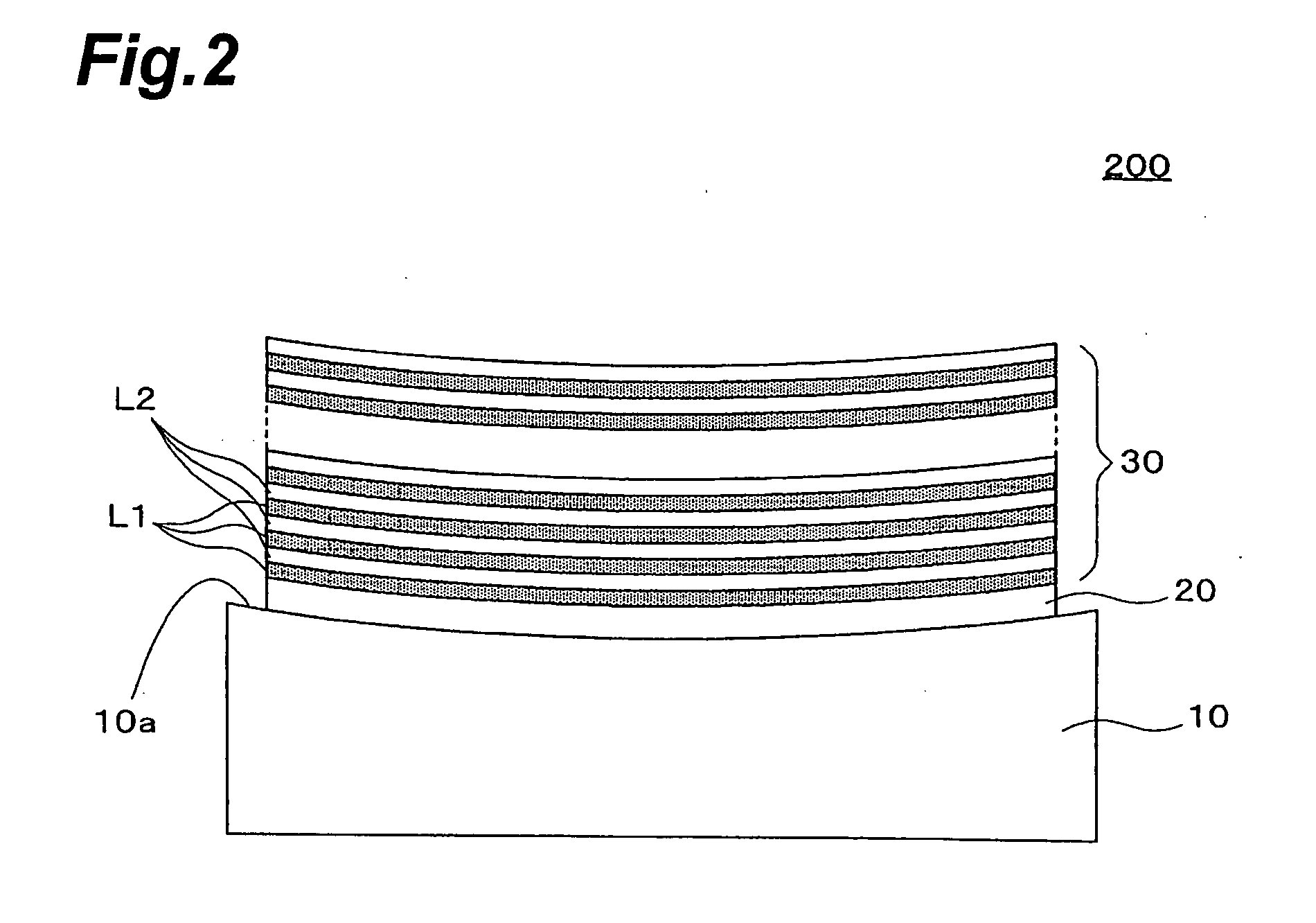

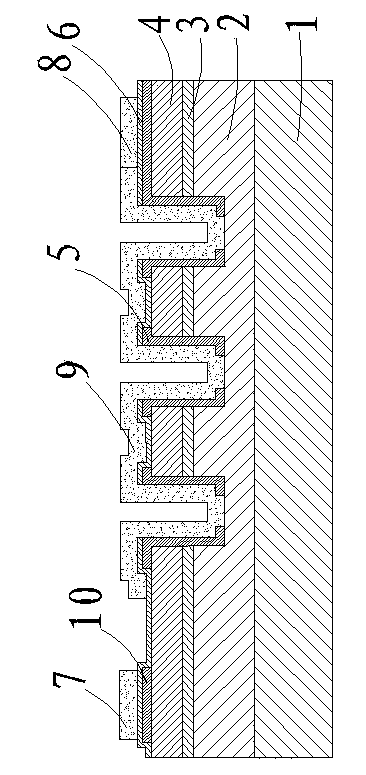

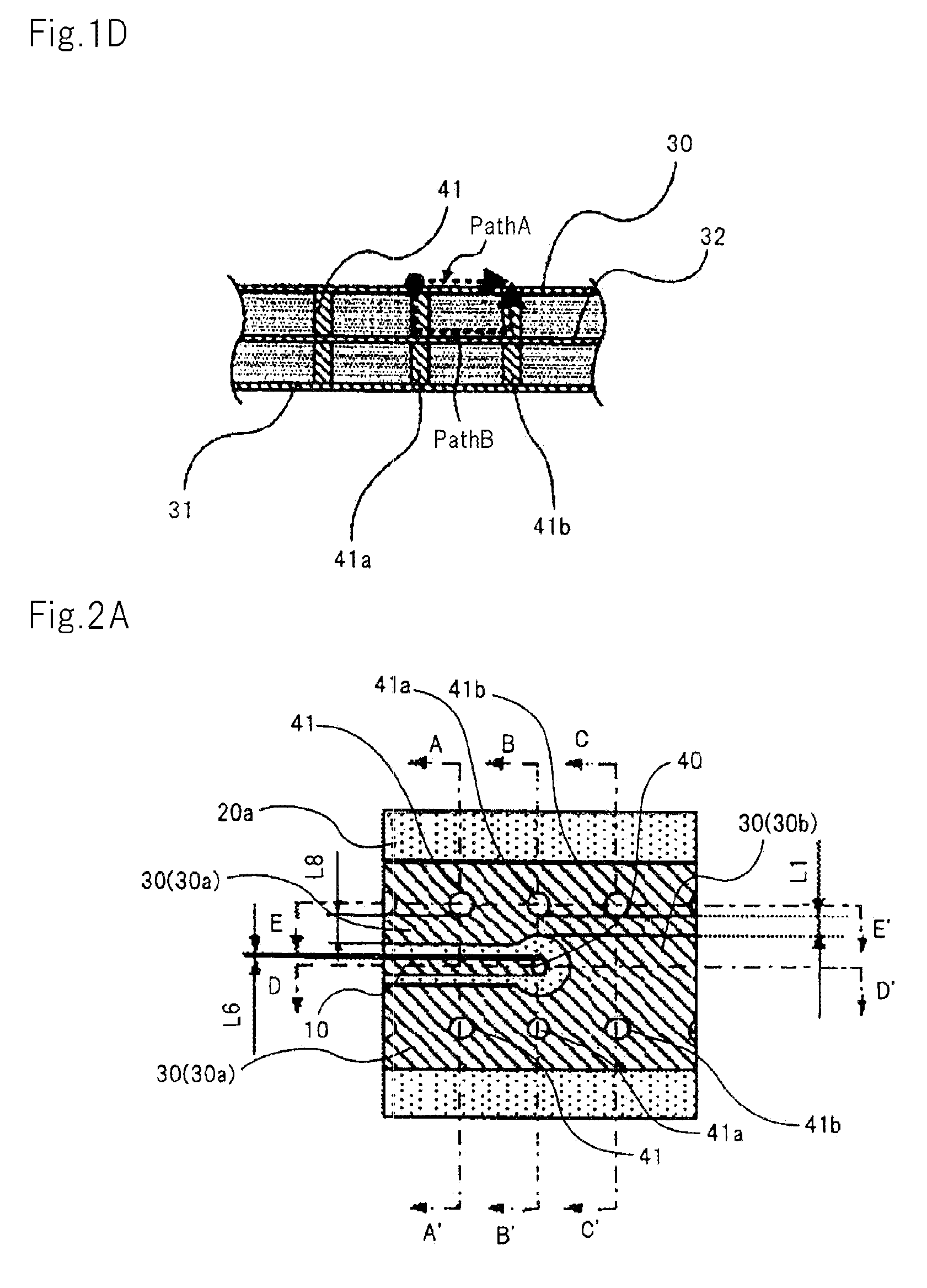

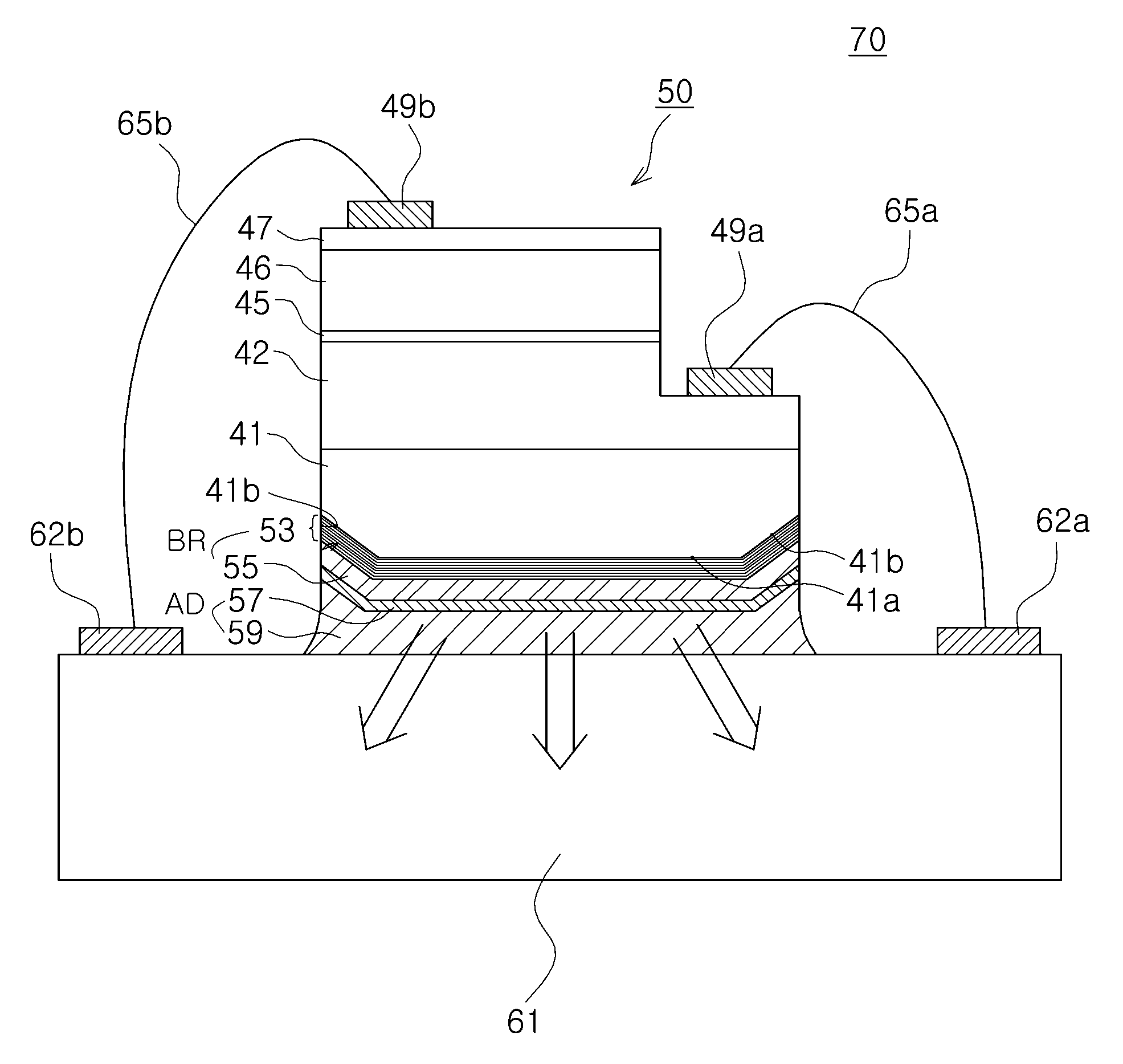

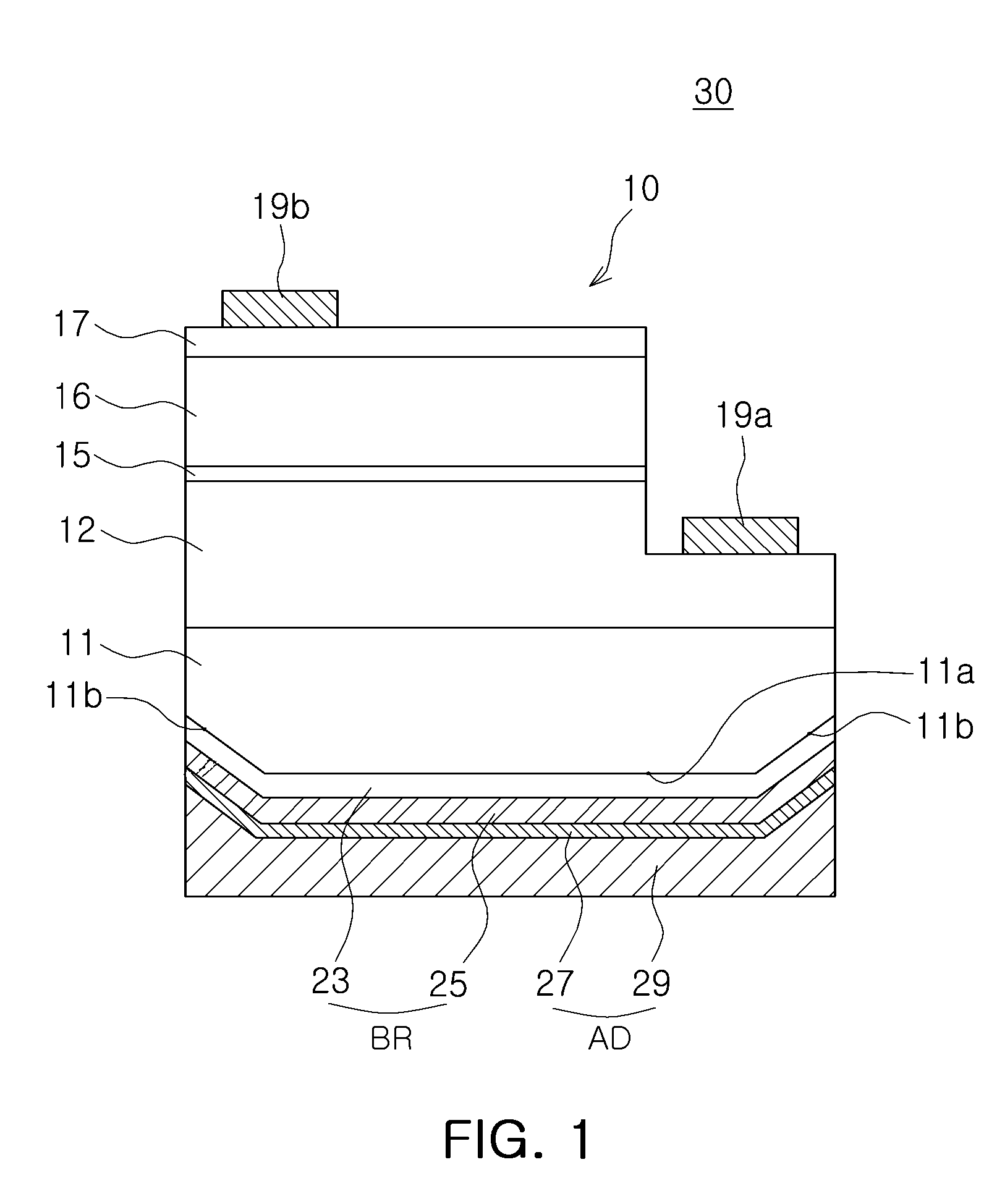

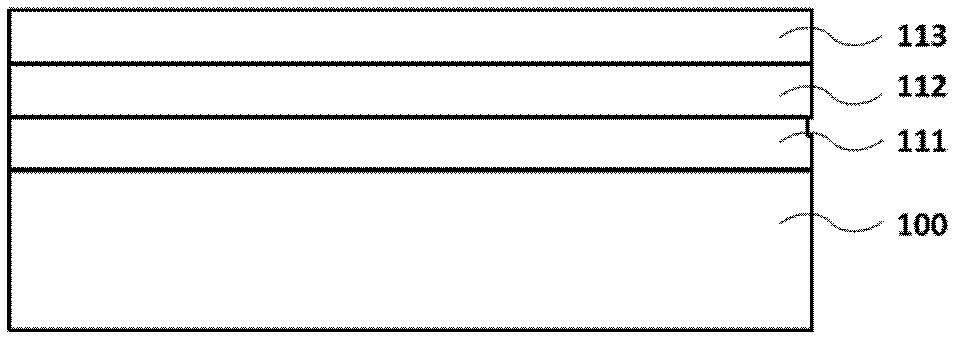

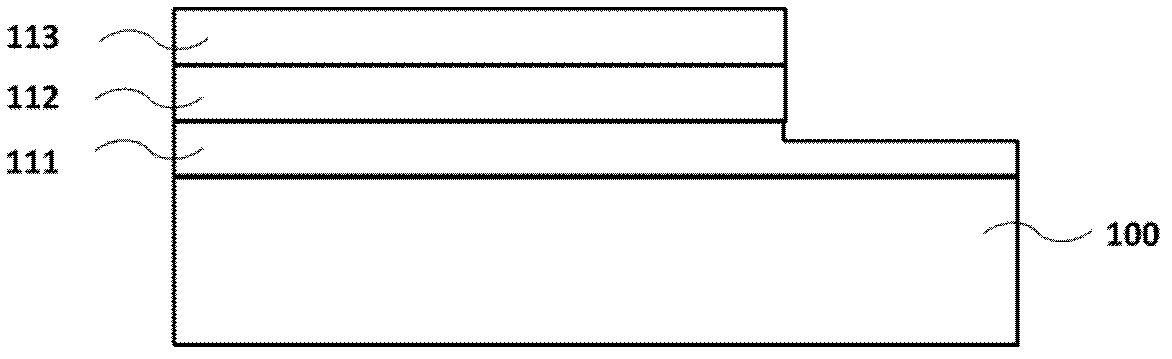

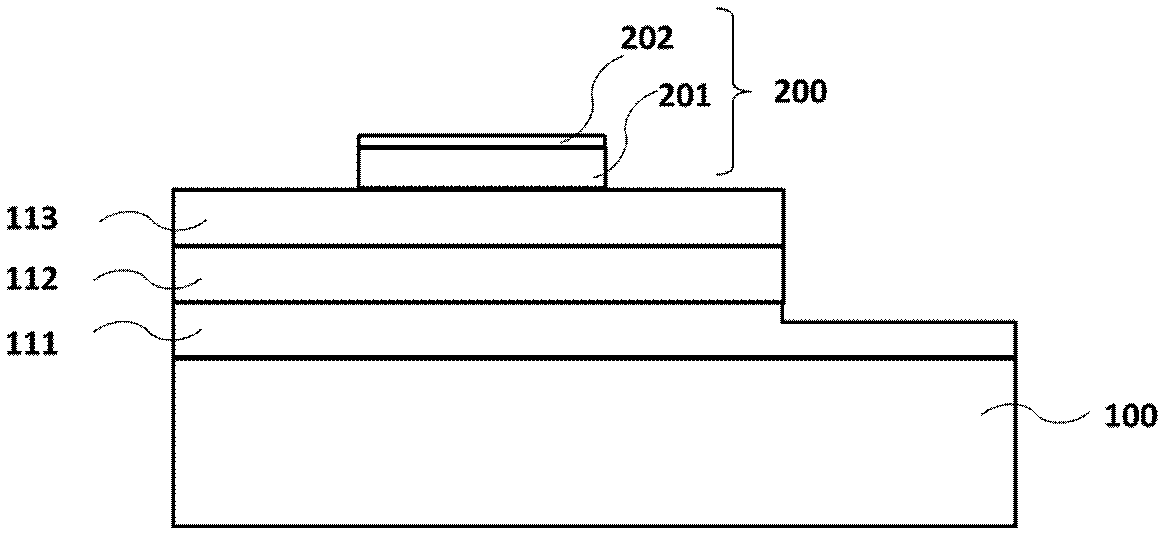

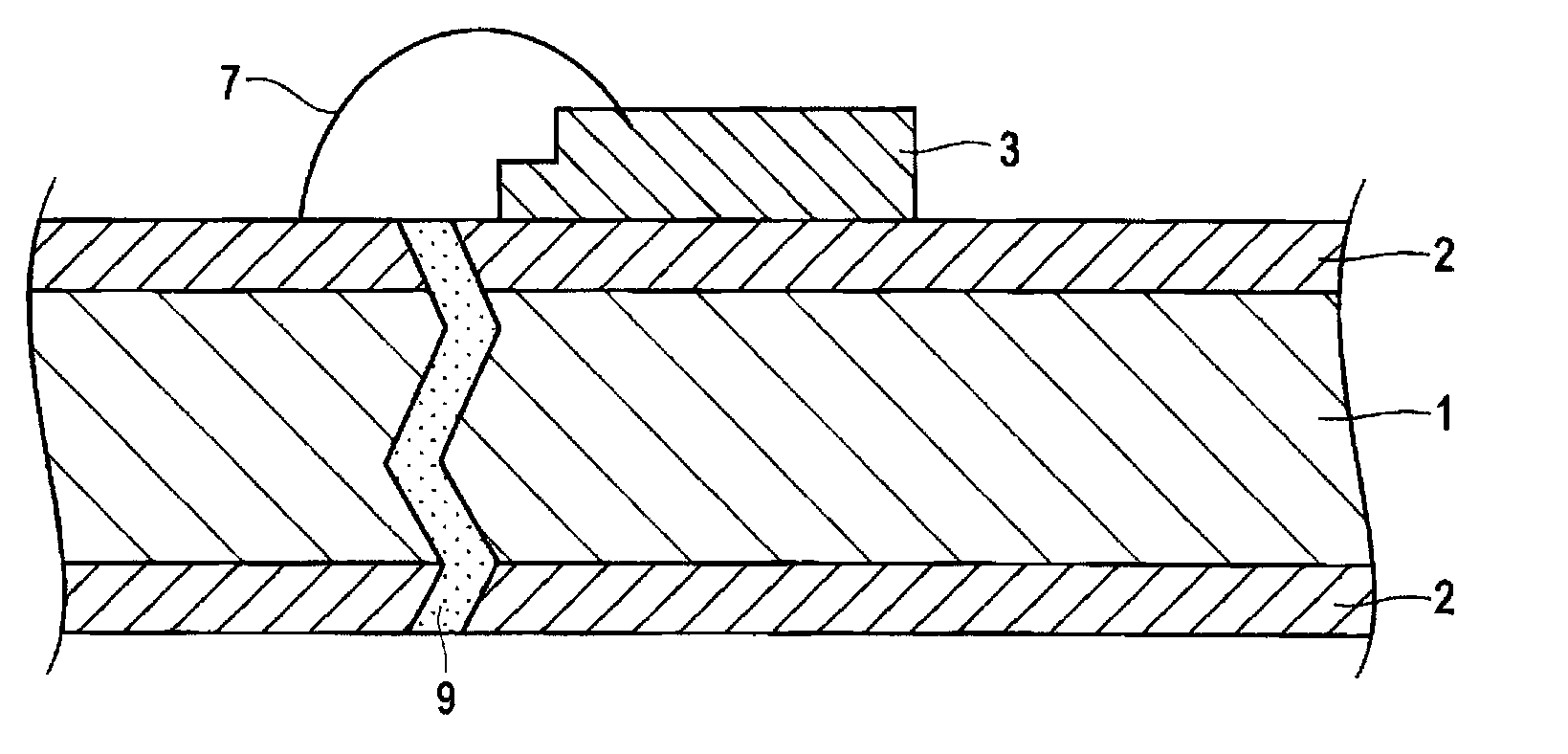

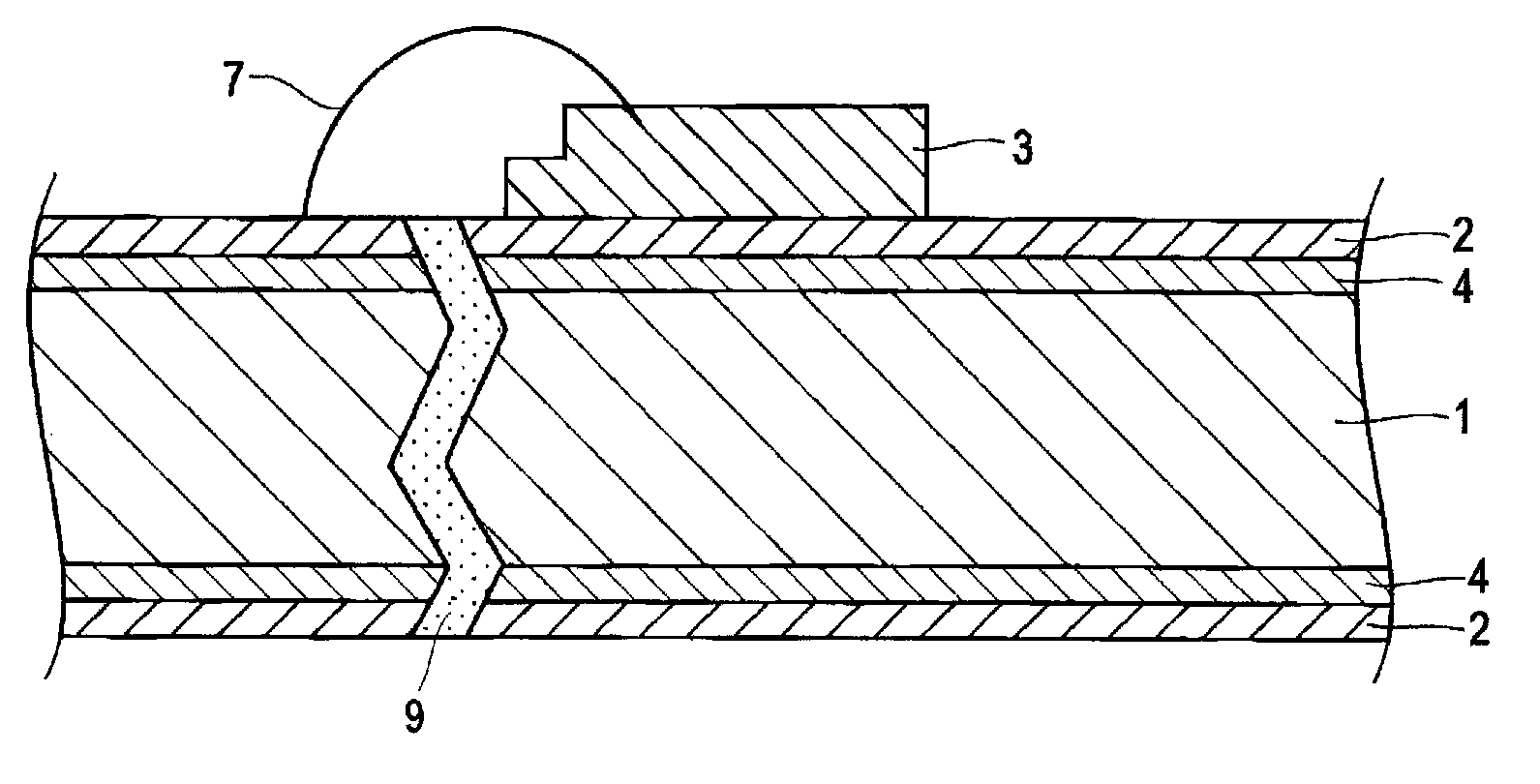

Nitride semiconductor light emitting diode and fabrication method thereof

ActiveUS7148514B2Good reflective propertiesReduce light lossSolid-state devicesSemiconductor devicesInsulation layerRefractive index

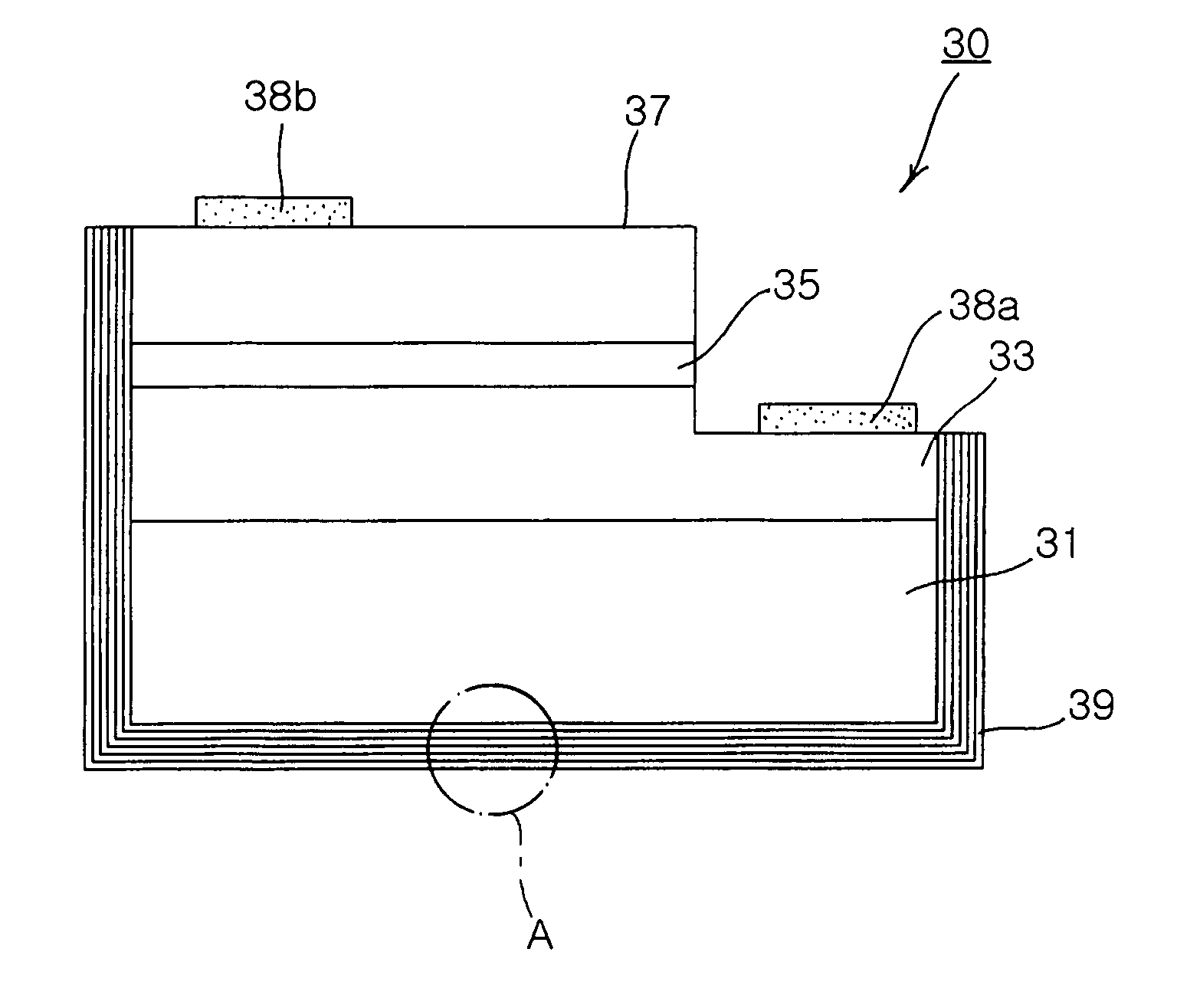

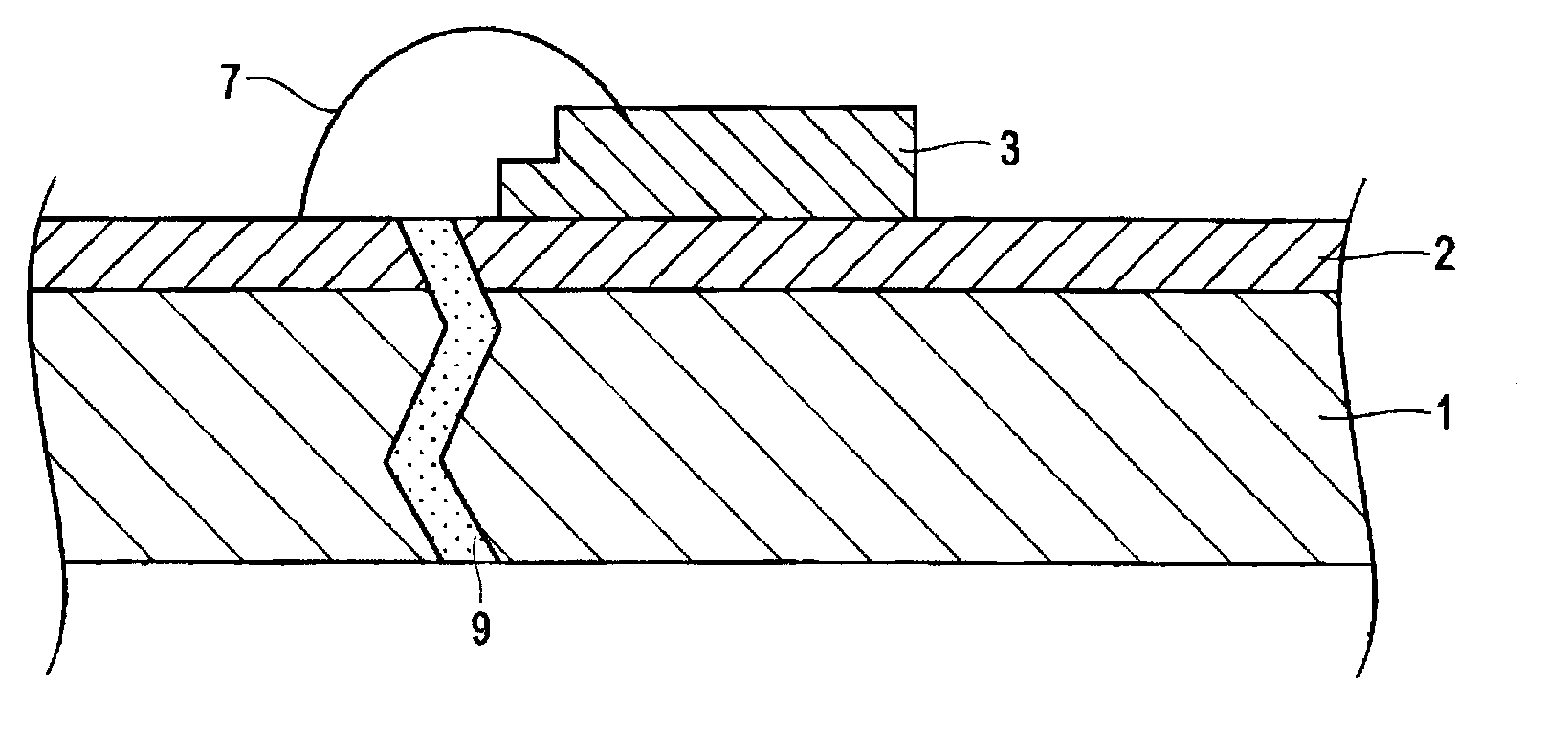

The invention relates to a nitride semiconductor LED and a fabrication method thereof. In the LED, a first nitride semiconductor layer, an active region a second nitride semiconductor layer of a light emitting structure are formed in their order on a transparent substrate. A dielectric mirror layer is formed on the underside of the substrate, and has at least a pair of alternating first dielectric film of a first refractivity and a second dielectric film of a second refractivity larger than the first refractivity. A lateral insulation layer is formed on the side of the substrate and the light emitting structure. The LED of the invention effectively collimate undesirably-directed light rays, which may be otherwise extinguished, to maximize luminous efficiency, and are protected by the dielectric mirror layer formed on the side thereof to remarkably improve ESD characteristics.

Owner:SAMSUNG ELECTRONICS CO LTD

Nitride semiconductor light emitting diode and fabrication method thereof

ActiveUS20050133796A1Good reflective propertiesReduce light lossSolid-state devicesSemiconductor devicesInsulation layerRefractive index

The invention relates to a nitride semiconductor LED and a fabrication method thereof. In the LED, a first nitride semiconductor layer, an active region a second nitride semiconductor layer of a light emitting structure are formed in their order on a transparent substrate. A dielectric mirror layer is formed on the underside of the substrate, and has at least a pair of alternating first dielectric film of a first refractivity and a second dielectric film of a second refractivity larger than the first refractivity. A lateral insulation layer is formed on the side of the substrate and the light emitting structure. The LED of the invention effectively collimate undesirably-directed light rays, which may be otherwise extinguished, to maximize luminous efficiency, and are protected by the dielectric mirror layer formed on the side thereof to remarkably improve ESD characteristics.

Owner:SAMSUNG ELECTRONICS CO LTD

Heat-dissipating resin composition, substrate for LED mounting, reflector, and substrate for LED mounting having reflector portion

InactiveCN101583670AEasy to processImprove impact resistanceSolid-state devicesHeat exchange apparatusHeat deflection temperatureEmissivity

Disclosed is a heat-dissipating resin composition which is used for forming a substrate for LED mounting or a reflector provided on the substrate for LED mounting, and excellent in heat dissipation, electrical insulation, heat resistance and light resistance during the time when an LED element emits light. Also disclosed are a substrate for LED mounting and a reflector respectively containing such a heat-dissipating resin composition. Specifically disclosed is a composition containing a thermoplastic resin such as a modified PBT and a thermally conductive filler such as a flake boron nitride. The composition has a heat distortion temperature of not less than 120 DEG C, a thermal conductivity of not less than 2.0 W / (m K) and a thermal emissivity of not less than 0.7.

Owner:TECHNO POLYMER CO LTD

Film bulk acoustic resonator and method of forming the same

InactiveUS6992420B2Good reflective propertiesReduced insertion lossPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksStructural ProblemInsulation layer

A film bulk acoustic resonator (FBAR) includes an insulation layer on a substrate to prevent a signal from being transmitted to a substrate. The FBAR includes a portion of a membrane layer corresponding to an activation area to adjust a resonance frequency band and improve a transmission gain of the resonance frequency band, the portion of the membrane layer being partially etched to have a thickness less than the other portion of the membrane layer. A method of forming the FBAR includes forming an sacrificing layer made of polysilicon, forming an air gap using a dry etching process, and forming a via hole. The method prevents structural problems occurred in a conventional air gap forming process and provides locations and the number of the via holes to be controlled.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

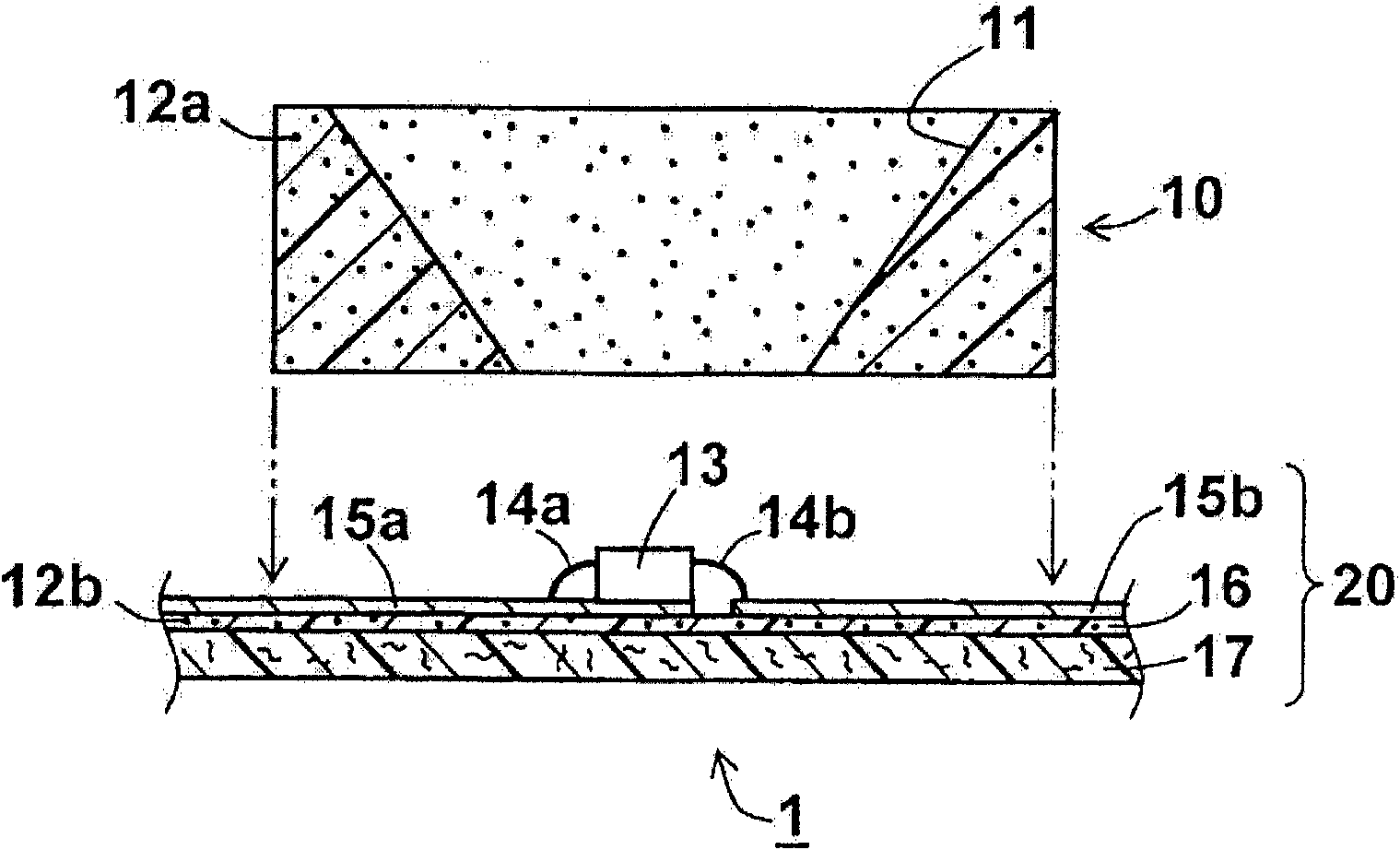

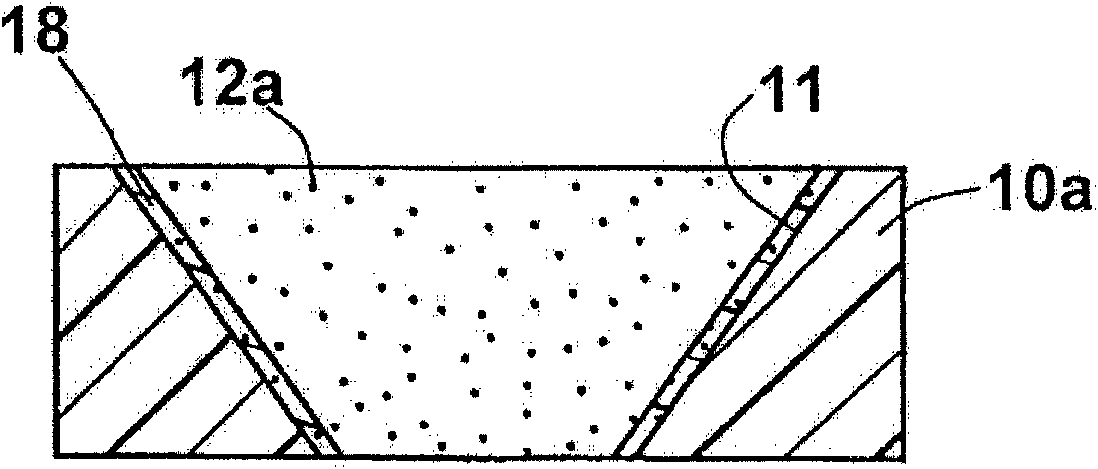

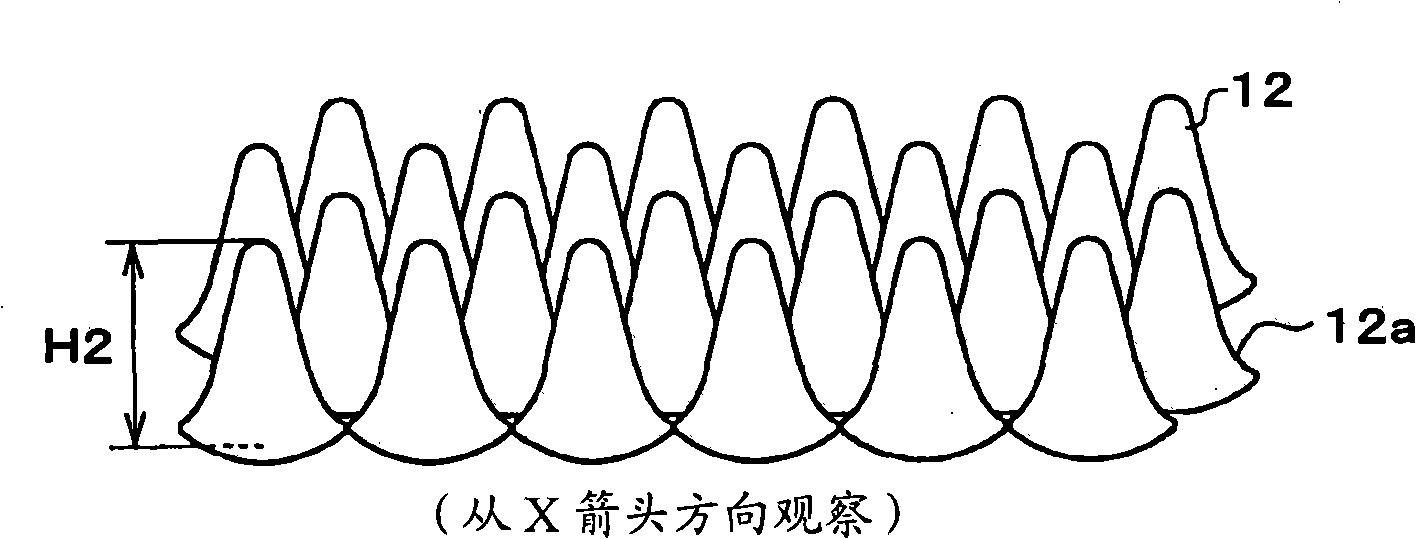

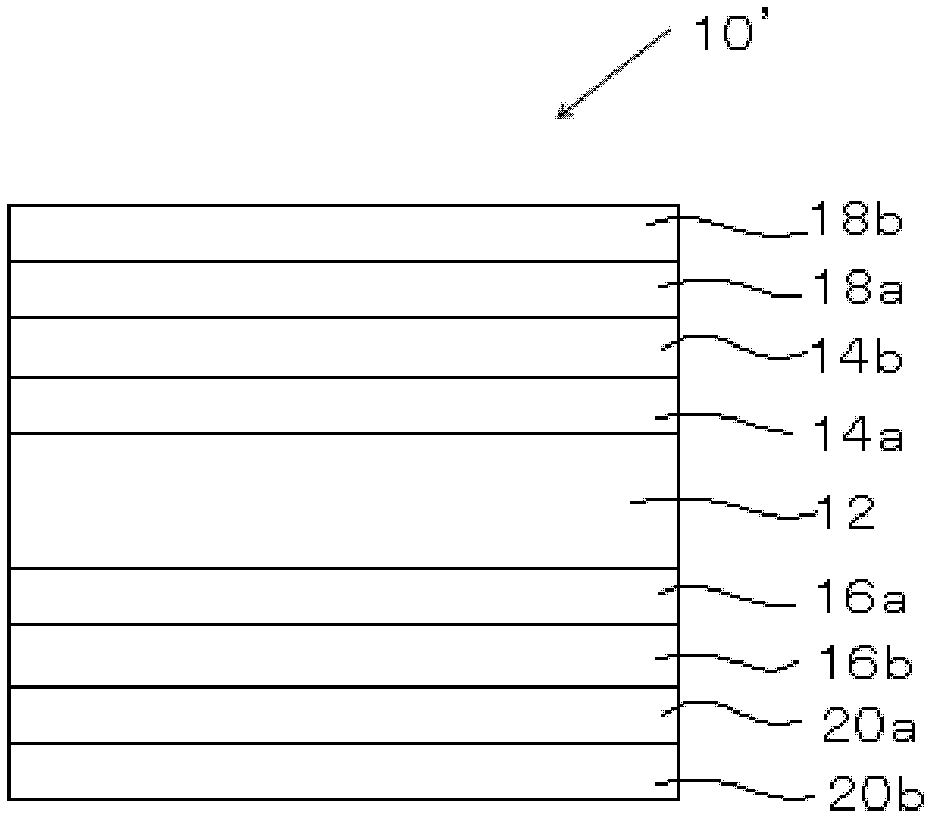

White color reflecting material and process for production thereof

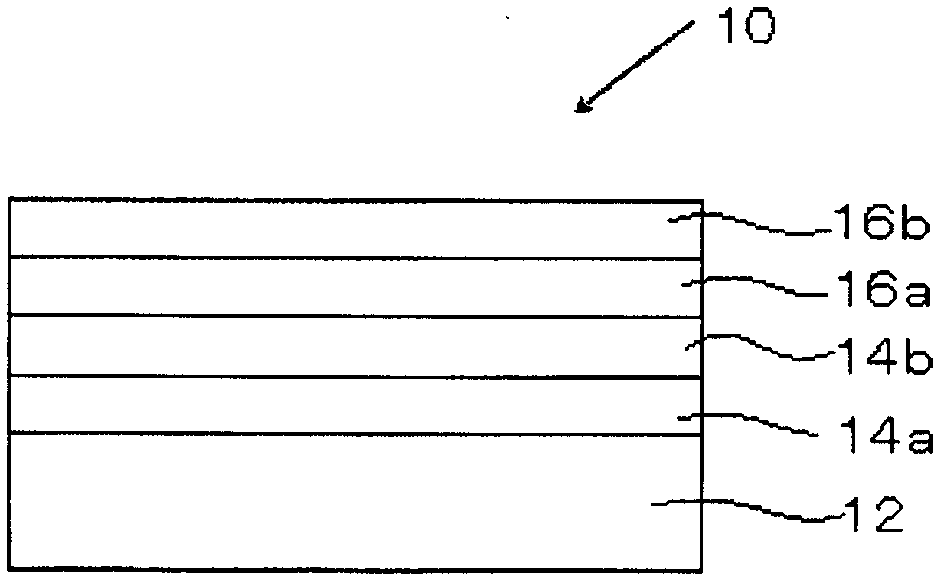

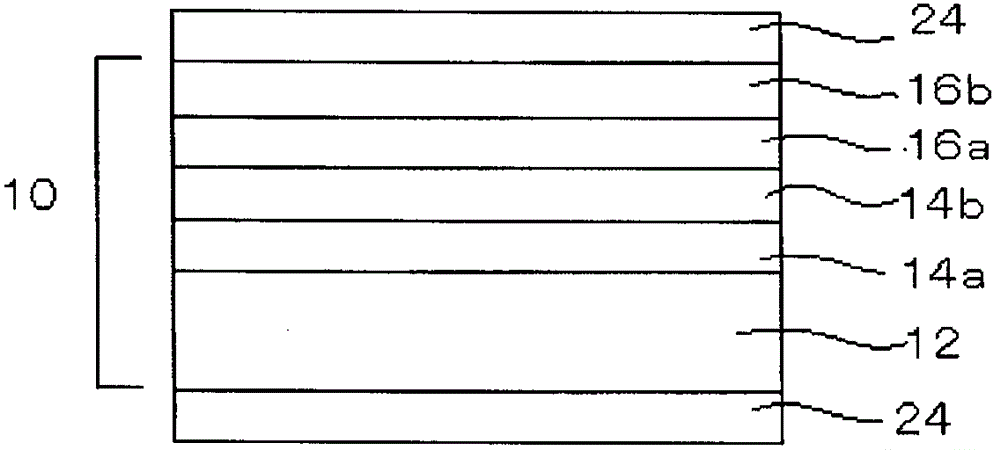

A general-use white color reflecting material, and a process for production thereof are provided. The white color reflecting material, without troublesome surface treatment such as formation of a reflective layer by metallization, is capable of reflecting a near-ultraviolet ray of a wavelength region of 380 nm or longer or a near-infrared ray sufficiently without light leakage; does not become yellow even when exposed to near-ultraviolet rays; has excellent lightfastness, heat resistance, and weatherability; has high mechanical strength and chemical stability; is capable of maintaining a high degree of whiteness; and is easily moldable at a low cost. Further a white color reflecting material used as an ink composition for producing the white color reflection material in a film-shape is also provided. The white-color reflecting material (10. 16) is molded as a dispersion of particles (12a. 12b) of anatase-type or rutile-type of titanium oxide in a silicone resin or silicone rubber, and comprises a titanium oxide-containing silicone composition.

Owner:ASAHI RUBBER

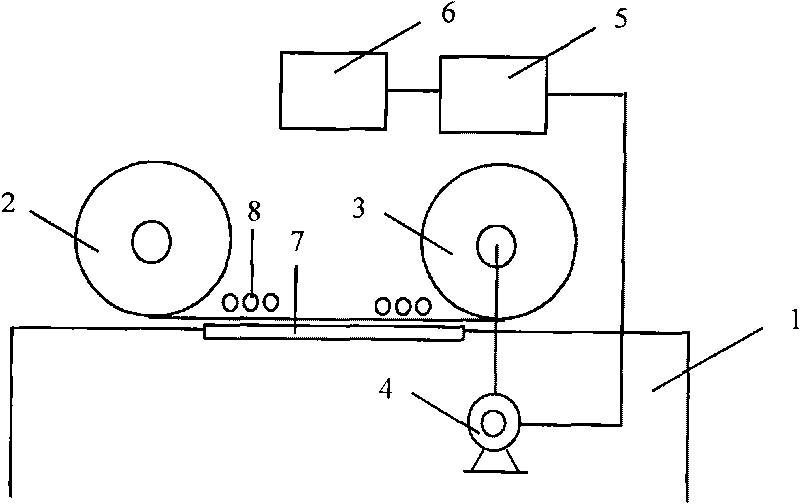

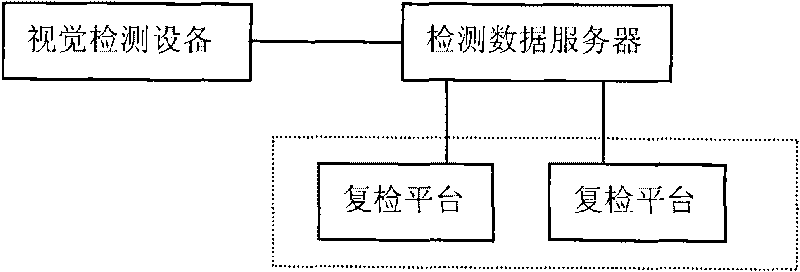

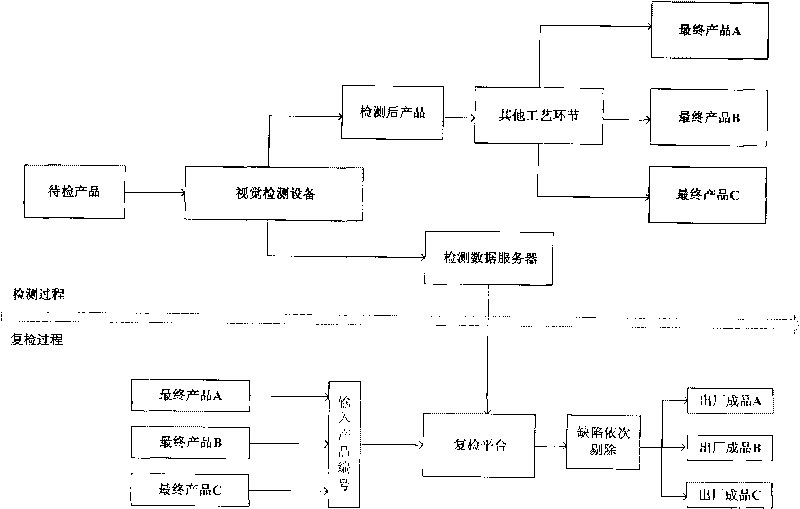

Recheck platform and quality inspection system of prints

InactiveCN101738396AReduce the burden onEasy to operateOptically investigating flaws/contaminationMicrocontrollerLocation detection

The invention discloses a recheck platform which is used for rechecking defects in quality inspection of prints and comprises a rack, a working table, an unwinding wheel, a winding wheel, a position detection device, a power device and a microcontroller, wherein, the unwinding wheel and the winding wheel are arranged on the rack; the unwinding wheel transmits the prints to the winding wheel to rewind the prints; the winding wheel is connected with a power device; the position detection device detects the position to which the prints are transmitted and is connected with the microcontroller; the microcontroller stores the position information of defects of the prints and compares with the information of the position when the prints are transmitted to control the power device. The recheck platform can lighten the burden of visual sense detection device, thus the visual sense detection device is only responsible for detection, reconstructs the detection process, separates the process links such as time consuming stopping rejection and label supplementing and the like from the detection process, lowers cost and improves the efficiency of quality detection. The invention also relates to a system adopting the platform to detect the quality of prints.

Owner:BEIJING LUSTER LIGHTTECH

Optical element, exposure apparatus using the same, and device manufacturing method

InactiveUS20080123073A1Reduce internal stressGood reflective propertiesMirrorsOptical filtersExtreme ultravioletAlloy

There is disclosed an optical element, comprising, a supporting substrate, a multilayer film being supported on the substrate and reflecting extreme ultraviolet light, and an alloy layer provided between the multilayer film and the substrate.

Owner:NIKON CORP

Infrared light reflector, infrared light reflecting laminated glass, and laminated glass and laminate have cholesteric liquid crystal layers

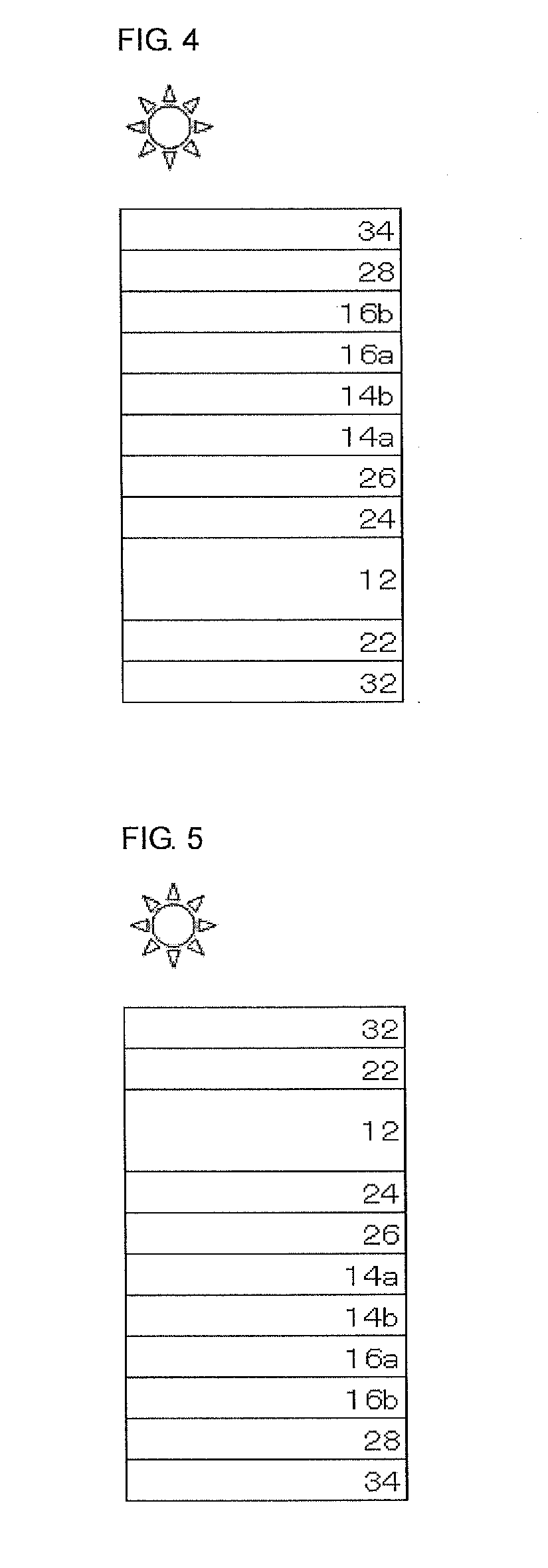

InactiveUS20120094118A1Good reflective propertiesImprove insulation performanceMirrorsFilm/foil adhesivesCholesteric liquid crystalLaminated glass

To provide an infrared-light reflective plate having improved selective reflectivity characteristics, there is provided an infrared-light reflective plate reflects an infrared-light of equal to or longer than 700 nm including a substrate, and, on at least one of surfaces of the substrate, at least four light-reflective layers, X1, X2, X3 and X4, formed of a fixed cholesteric liquid crystal phase, and disposed in this order from the substrate, wherein the reflection center wavelengths of the light-reflective layers X1 and X2 are same with each other and are λ1 (nm), and the two layers reflect circularly-polarized light in opposite directions; the reflection center wavelengths of the light-reflective layers X3 and X4 are same with each other and are λ2 (nm), and the two layers reflect circularly-polarized light in opposite directions; and λ1<λ2 is satisfied.

Owner:FUJIFILM CORP

Infrared-light reflective plate and infrared-light reflective laminated glass

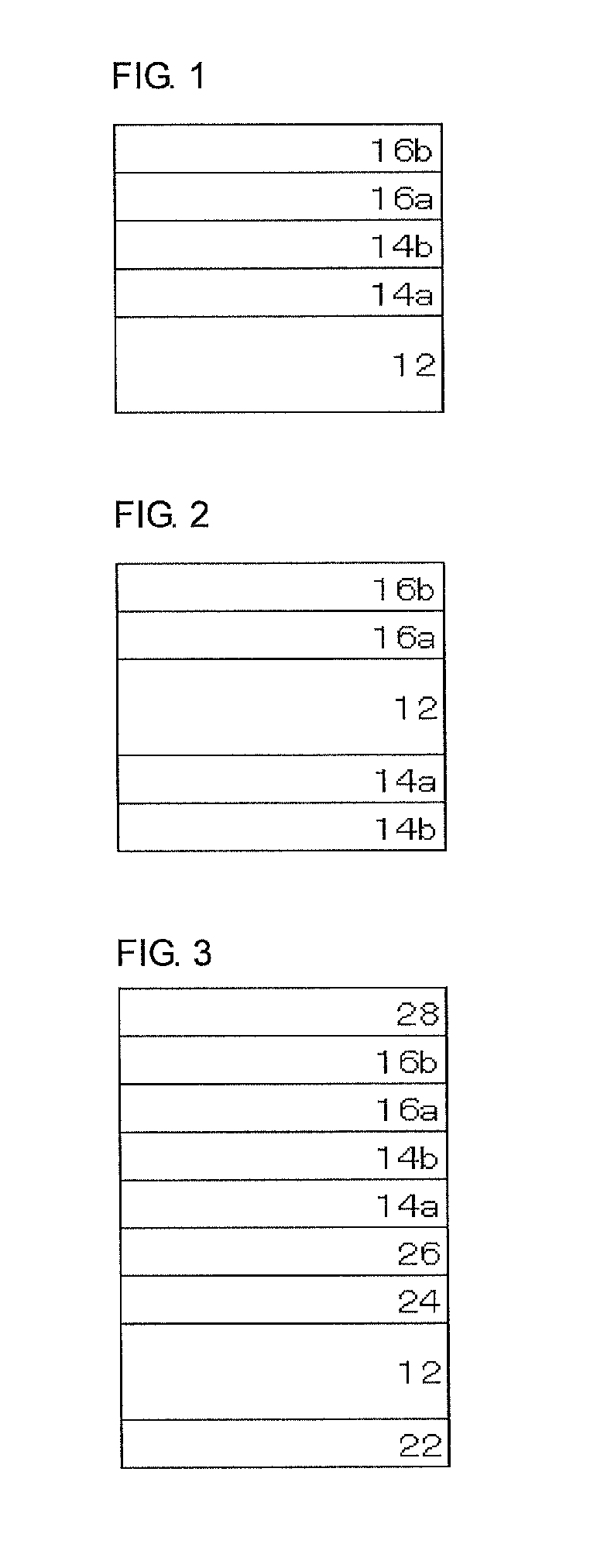

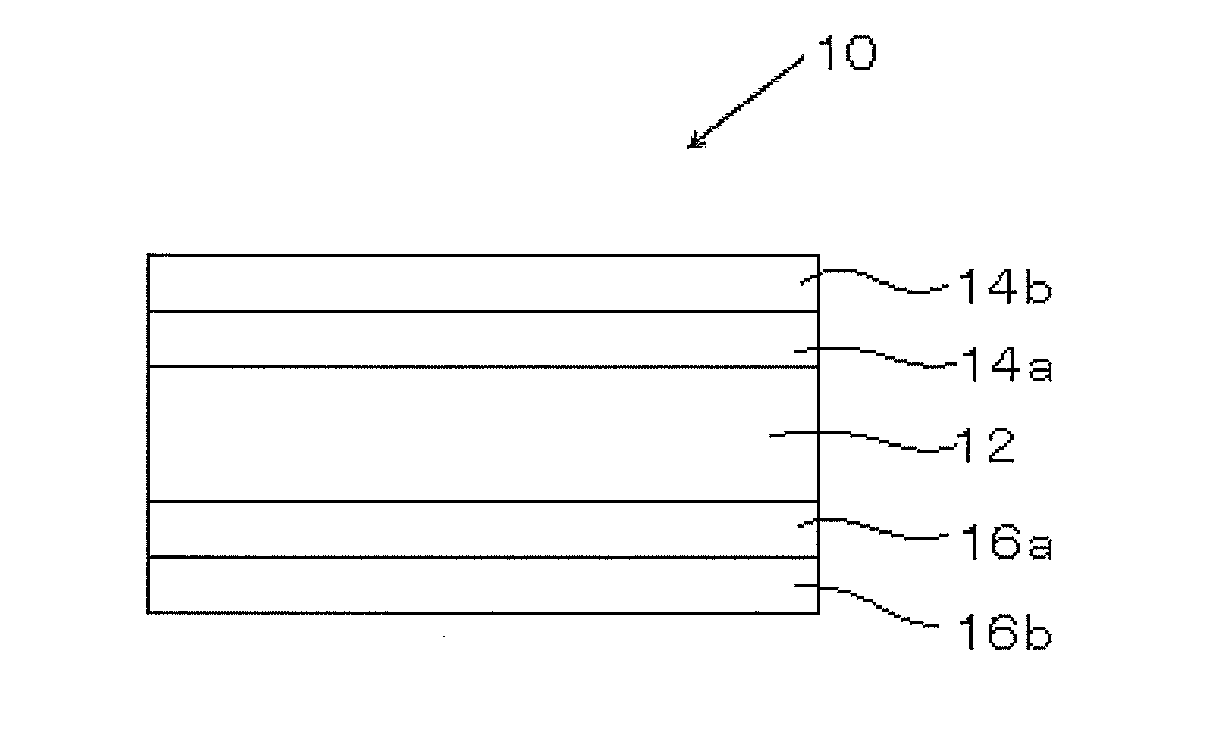

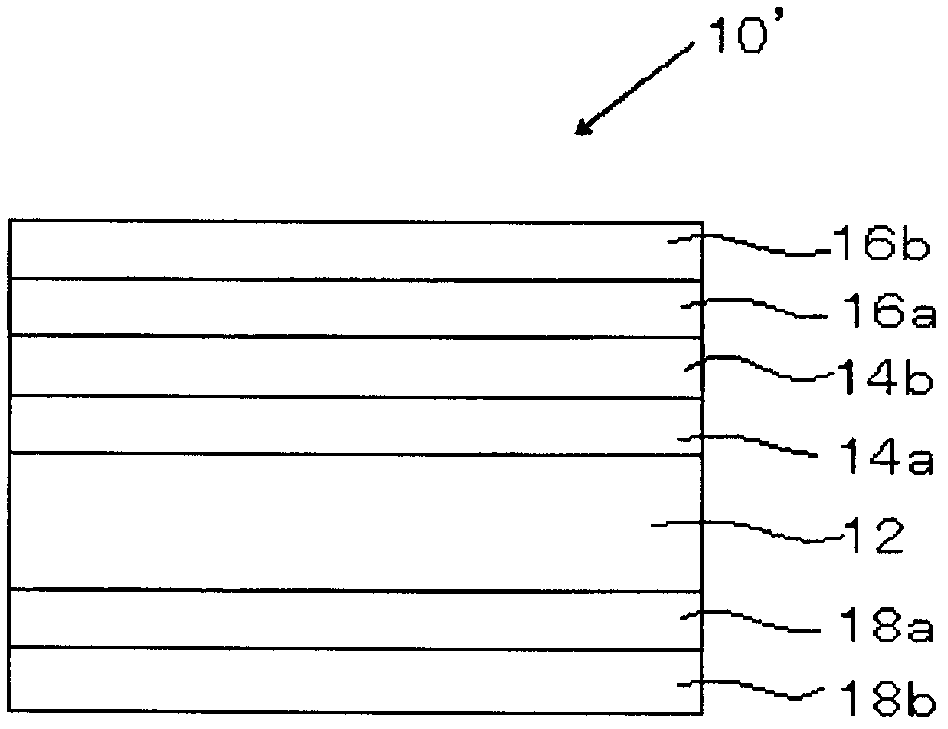

InactiveUS20120086904A1Good reflective propertiesGood choiceGlass/slag layered productsNon-linear opticsPhysicsIn plane

An infrared-light reflective plate reflects an infrared-light ≧700 nm including a substrate of which fluctuation of retardation in plane at a wavelength of 1000 nm, Re(1000), ≧20 nm, on a surface of the substrate, at least two light-reflective layers, X1 and X2, formed of a fixed cholesteric liquid crystal phase, and, on another surface of the substrate, at least two light-reflective layers, Y1 and Y2, formed of a fixed cholesteric liquid crystal phase. The reflection center wavelengths of X1 and X2 are both λX1 (nm), and the two layers reflect circularly-polarized light in opposite directions; the reflection center wavelengths of Y1 and Y2 both λY1 (nm). The two layers reflect circularly-polarized light in opposite directions; λX1≠λY1; and refractive anisotropy of X1 and X2, ΔnX1 and ΔnX2 satisfy ΔnX2<ΔnX1. Refractive anisotropy of the light reflective layers Y1 and Y2, ΔnY1 and ΔnY2 satisfy ΔnY2<ΔnY1.

Owner:FUJIFILM CORP

LED chip and processing technology thereof

InactiveCN103515504AIncrease the effective luminous areaIncrease brightnessSemiconductor devicesPower flowQuantum well

The invention relates to an LED chip and a processing technology thereof, and belongs to the technical field of manufacturing of photoelectron devices. The technology comprises the following steps: a P-type nitride layer on an epitaxial wafer substrate is etched to expose an N-type nitride layer; a current blocking layer is manufactured under a P-type electrode bonding pad area, an insulating substance under the P-type electrode bonding pad area, an insulating substance in direct contact with an N-type electrode bonding pad, and an expanding electrode and the P-type nitride layer, and an insulating substance on the side walls of a quantum well and P-type nitride are reserved through etching; an ITO film deposits on the surface of the substrate, a current expanding layer and alloy are manufactured through photoetching, a metal layer is formed on the surface of the substrate through vapor deposition, and after a part of the metal layer is stripped, a P-type electrode bonding pad, an N-type electrode bonding pad and an N metal expanding electrode are formed. Both the P-type electrode bonding pad and the N-type electrode bonding pad of the product are positioned on a P-type light-emitting surface and are the same in height; a part or all of the N metal expanding electrode is in direct contact with the N-type nitride layer. The invention has the advantages that the routing is convenient, the light-emitting efficiency and the brightness of the LED chip on the nitride substrate can be improved.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

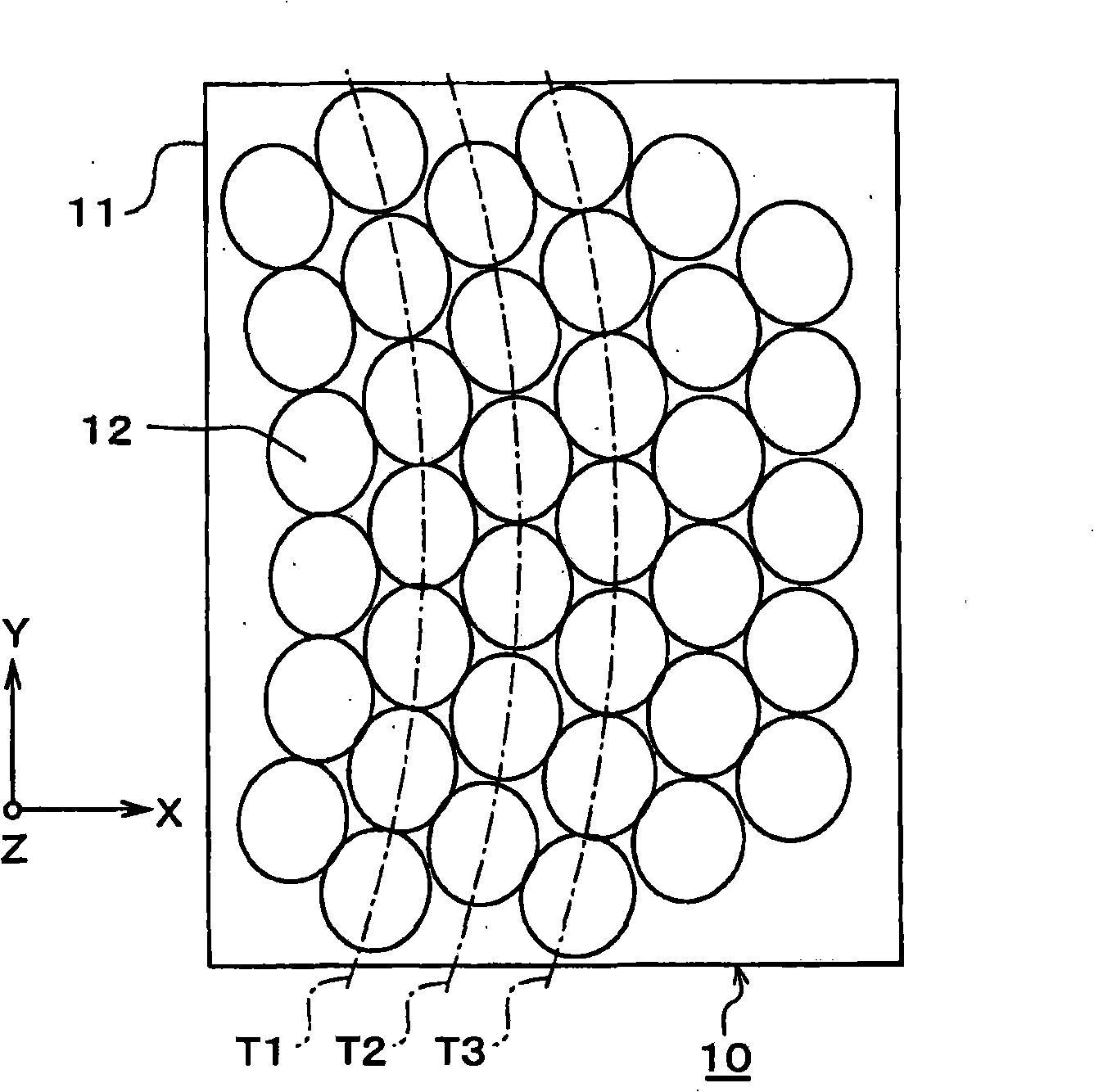

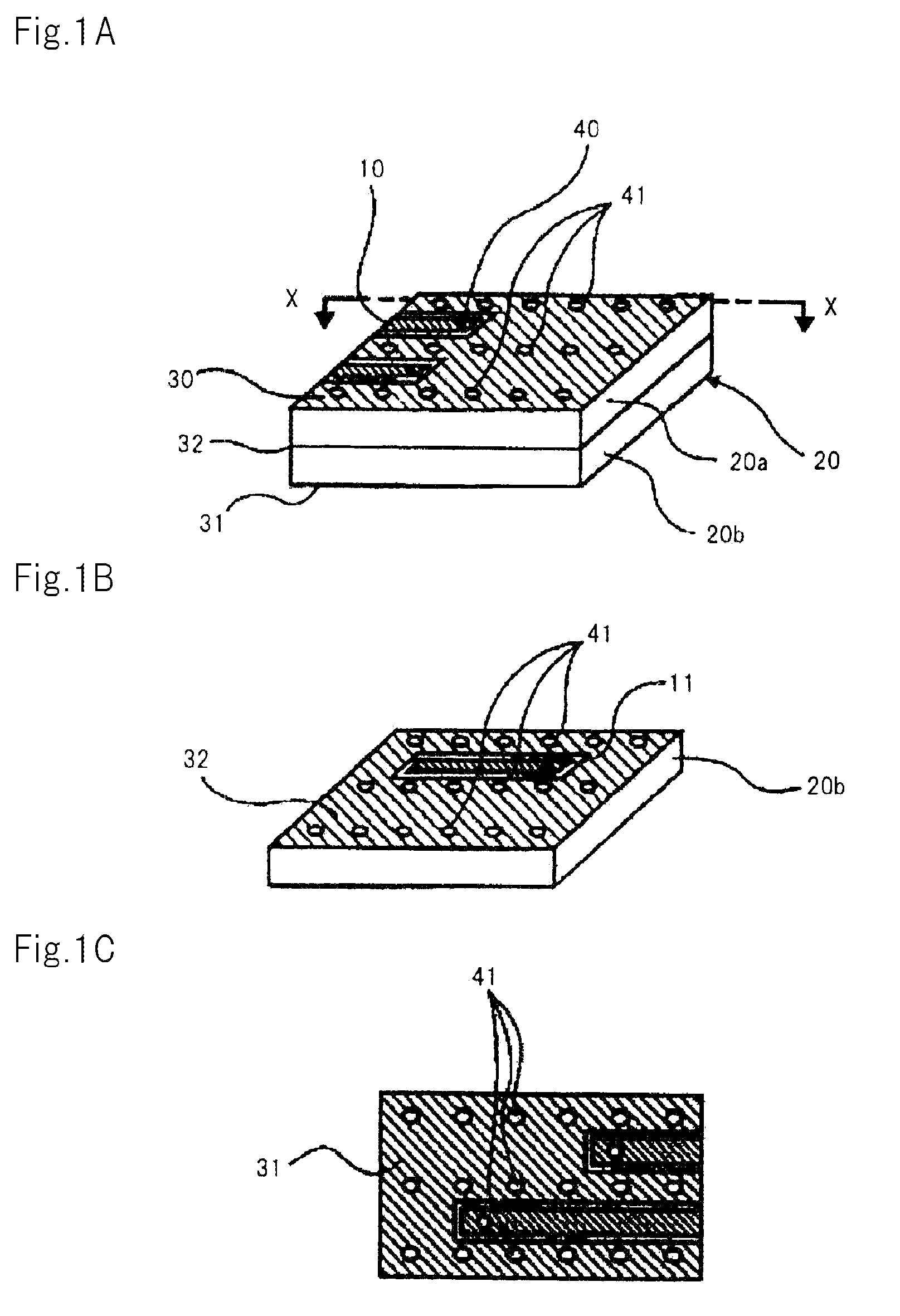

Optical device, method for producing master for use in producing optical device, and photoelectric conversion apparatus

InactiveCN101356454AExcellent light transmission characteristicsImprove light utilization efficiencyFinal product manufactureOptical articlesGrid patternEllipse

The present invention provides an optical device, method for producing master for use in producing optical device, and photoelectric conversion apparatus. In an optical element, a large number of structures, each of which is composed of a protruding section or a recessed section, are arranged on a surface of a base body at a fine pitch smaller than the wavelength of visible light. The structures are arranged to form a plurality of rows of circular tracks on the surface of the base body and to form a quasi-hexagonal grid pattern. The structure is an elliptical cone or an elliptical cone trapezoid having a long axis direction in the circumference direction of the circular track.

Owner:SONY CORP +1

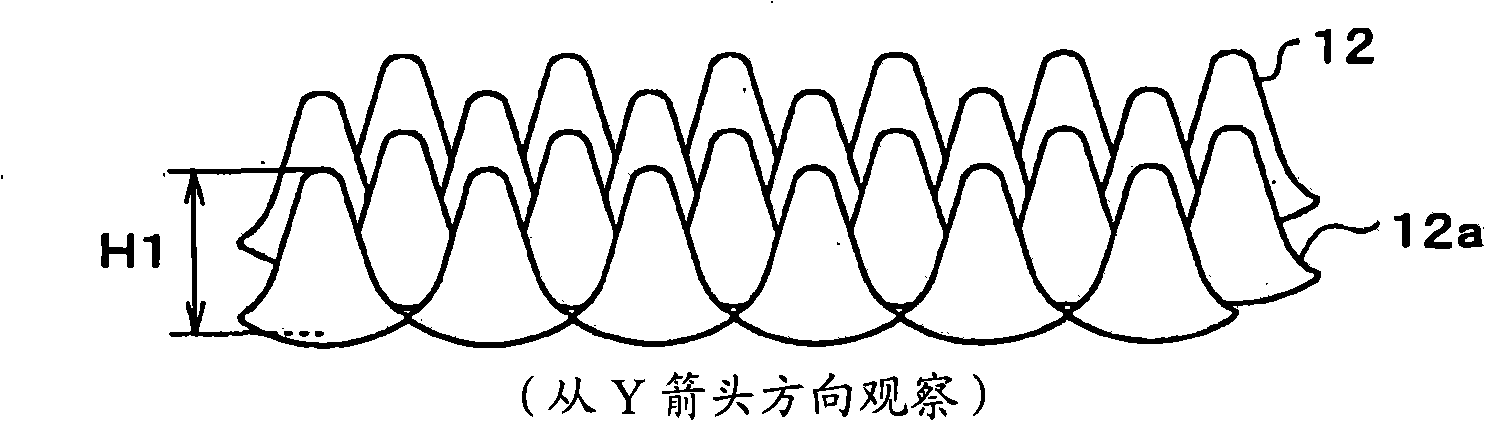

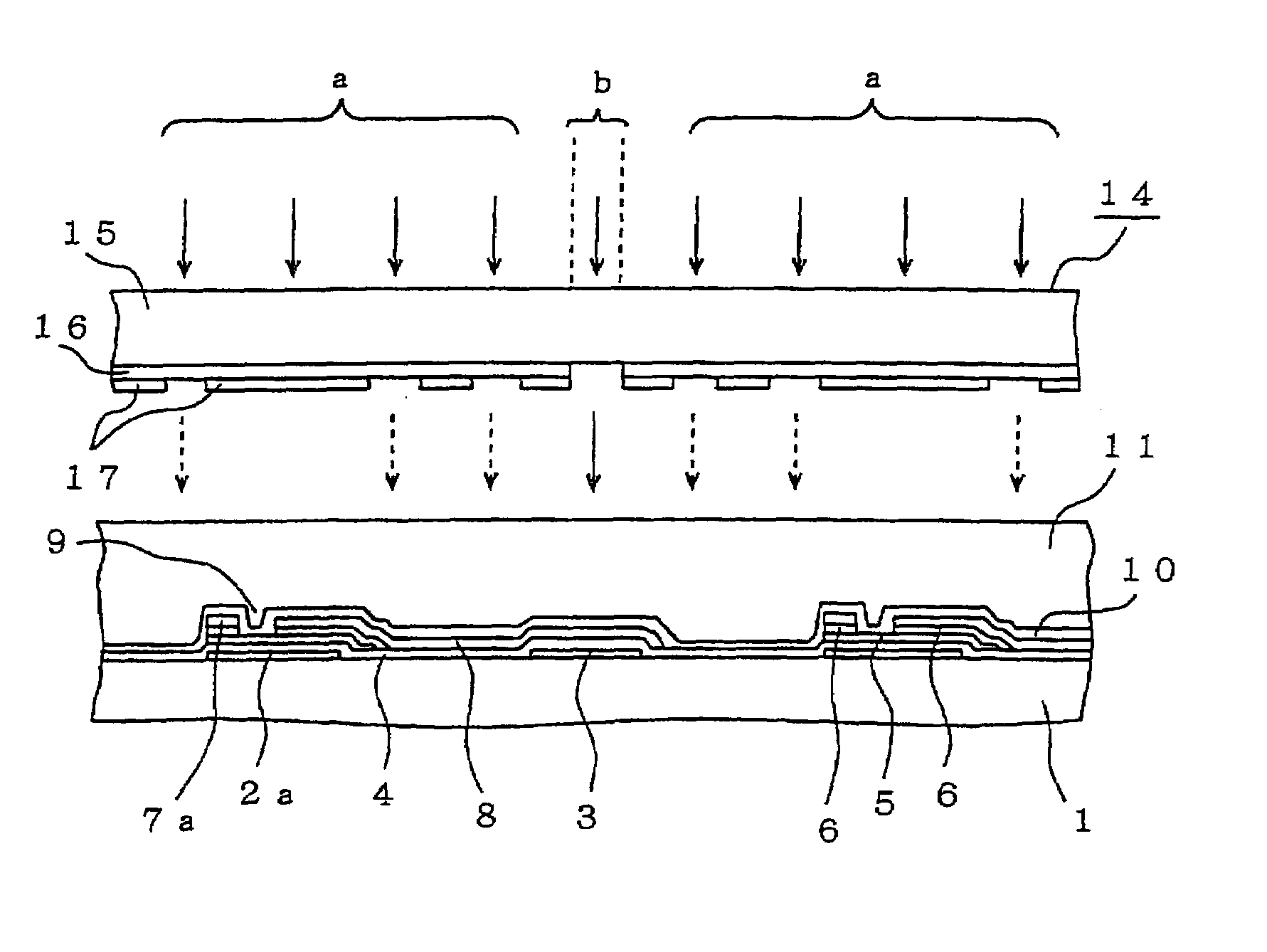

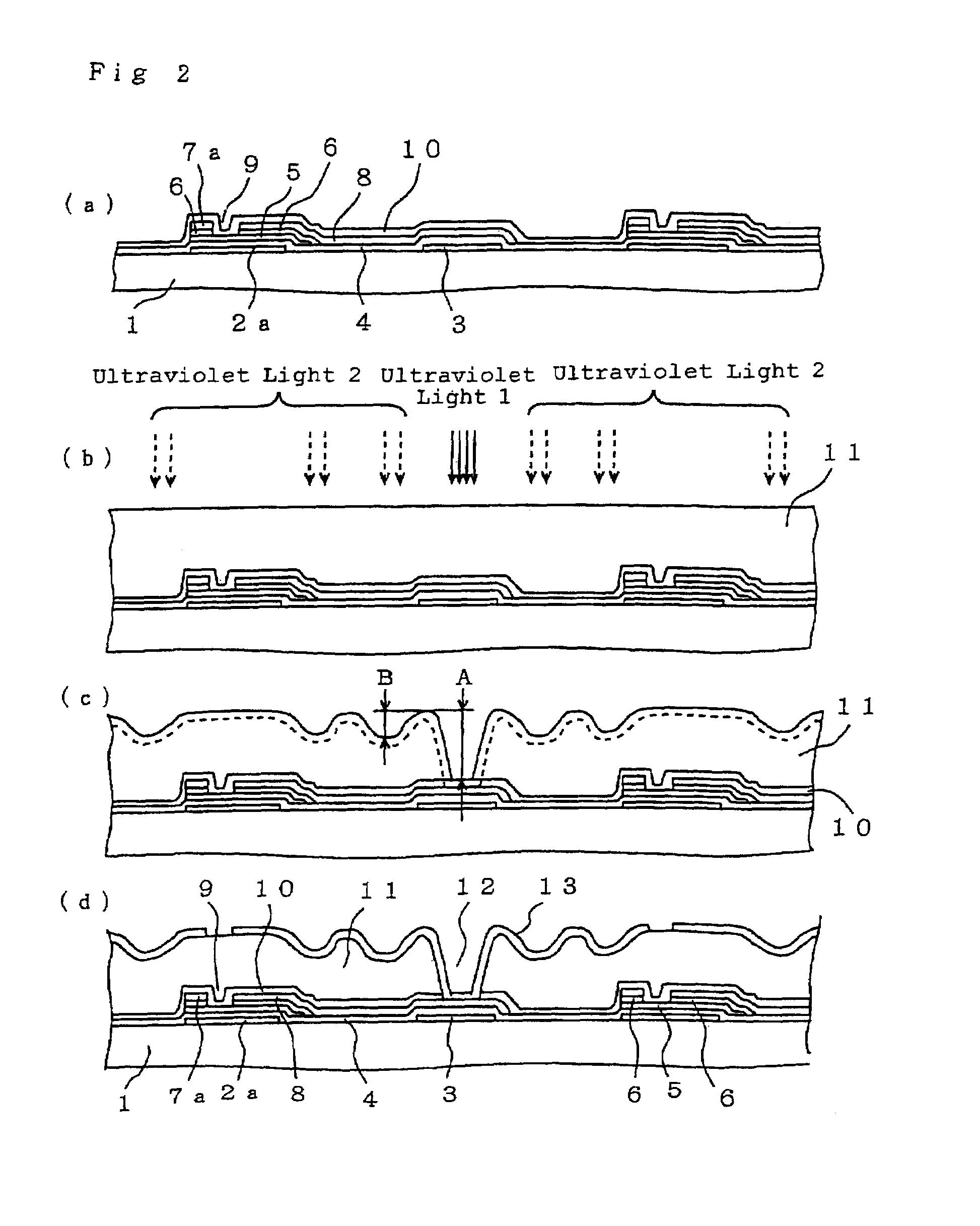

Reflection type liquid crystal display and method for manufacturing the same and mask for manufacturing reflection type liquid crystal display

InactiveUS6985195B1High yieldGood reflective propertiesPhotomechanical apparatusSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A reflection type liquid crystal display is formed by an interlayer insulating film having appropriate unevenness of an inseparable pattern in a picture element region and having a contact hole of a separable pattern on a drain electrode of a TFT is formed by plainly applying a photosensitive insulating resin so that it may dissolve difference in level caused by a gate electrode wiring, source electrode wiring, and the TFT, and conducting exposure and development while changing exposure amount. The exposure of the insulating resin is conducted through divisional exposure in which the inseparable pattern and the separable pattern are arranged on different masks, and the inseparable pattern is exposed by a predetermined exposure amount of 20 to 80% of an exposure amount for the separable pattern.

Owner:TRIVALE TECH

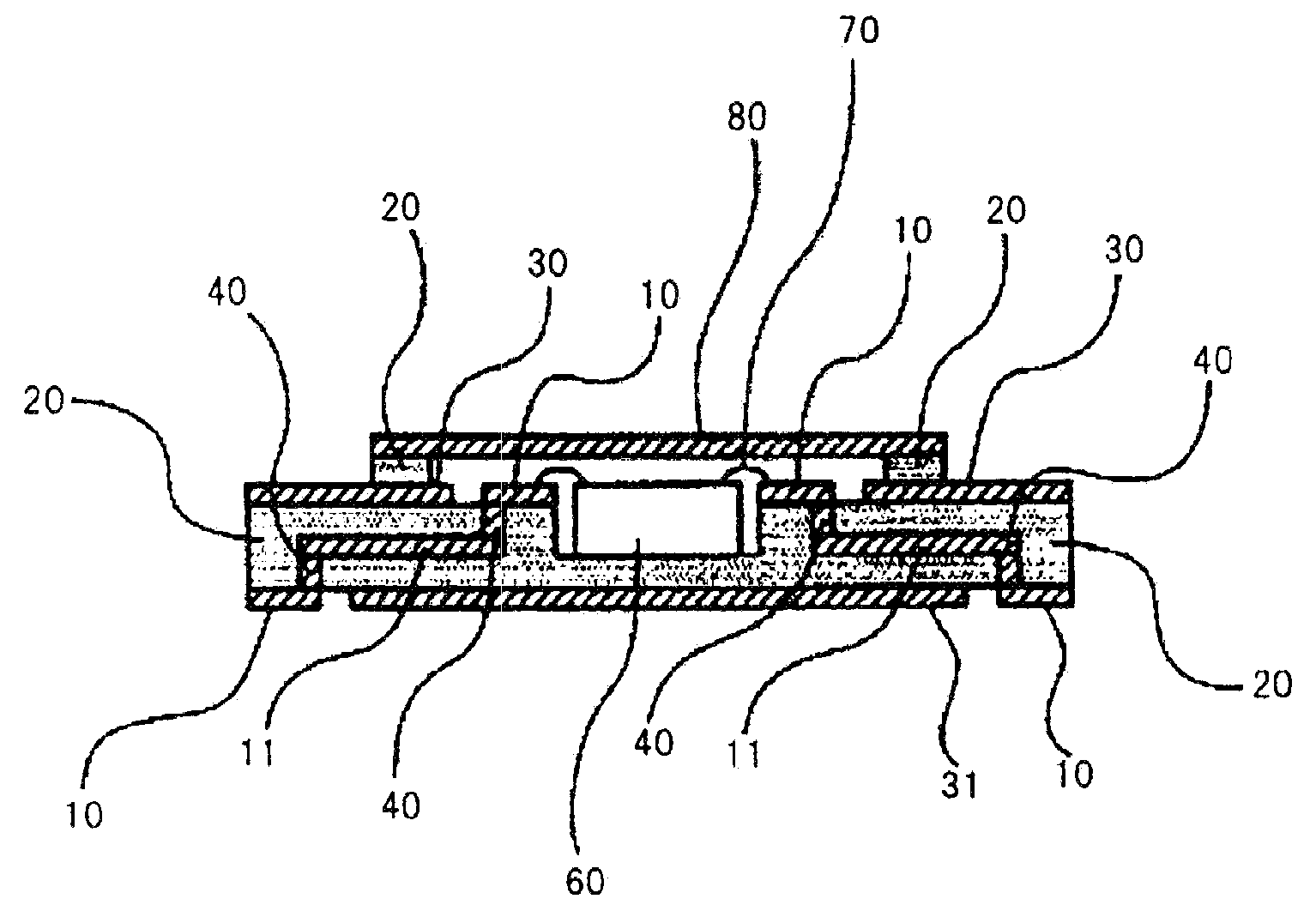

High-Frequency Wiring Board and High-Frequency Module That Uses the High-Frequency Wiring Board

InactiveUS20100254094A1Good reflective propertiesSolid-state devicesElectrical apparatus contructional detailsEngineeringGround pattern

The high-frequency wiring board of the present invention is a wiring board that includes first coplanar lines and second coplanar lines formed on a different layer than the first coplanar lines; the first coplanar lines and second coplanar lines being connected at the line ends of each. The first coplanar lines are provided with a first signal line (10) and a first planar ground pattern (30a) formed on the same wiring layer as the first signal line (10). The second coplanar lines are provided with second signal line (11) formed on a wiring layer that differs from that of the first signal line (10), a second planar ground pattern 32 formed on the same wiring layer as the second signal line, and a first ground pattern (30b) formed on the same wiring layer as the first coplanar lines. The end of the first planar ground pattern (30a) and the end of the first ground pattern (30b) are connected and thus unified. In this high-frequency wiring board, the second planar ground pattern (32) is separated from the connection portion at the end of the first planar ground pattern (30a) in the direction in which the second coplanar lines extend from the vicinity of the connection portion of the first signal line and the second signal line.

Owner:NEC CORP

Light-reflecting polycarbonate resin sheet and light-reflecting laminate using same

InactiveUS20070054110A1Maintain good propertiesImprove light resistanceMirrorsDiffusing elementsUltraviolet lightsPolycarbonate

A light-reflecting polycarbonate resin sheet is characterized in that a light-resistant layer for cutting or absorbing ultraviolet light is provided on at least one side of a polycarbonate resin foam layer. A light-reflecting laminate is obtained by superposing such a light-reflecting polycarbonate resin sheet on a metal plate. The light-reflecting polycarbonate resin sheet has high light resistance while maintaining excellent reflective characteristics.

Owner:IDEMITSU KOSAN CO LTD

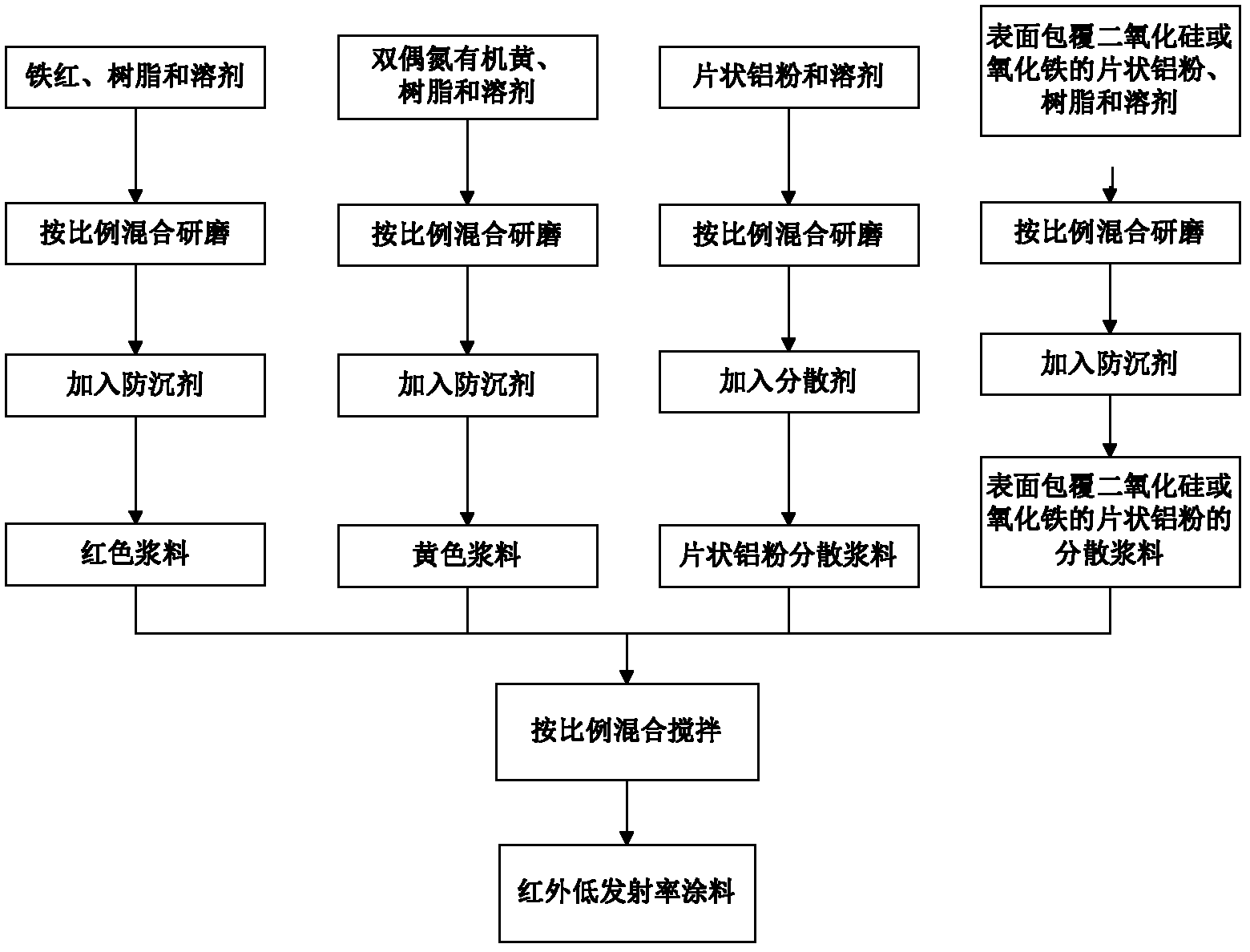

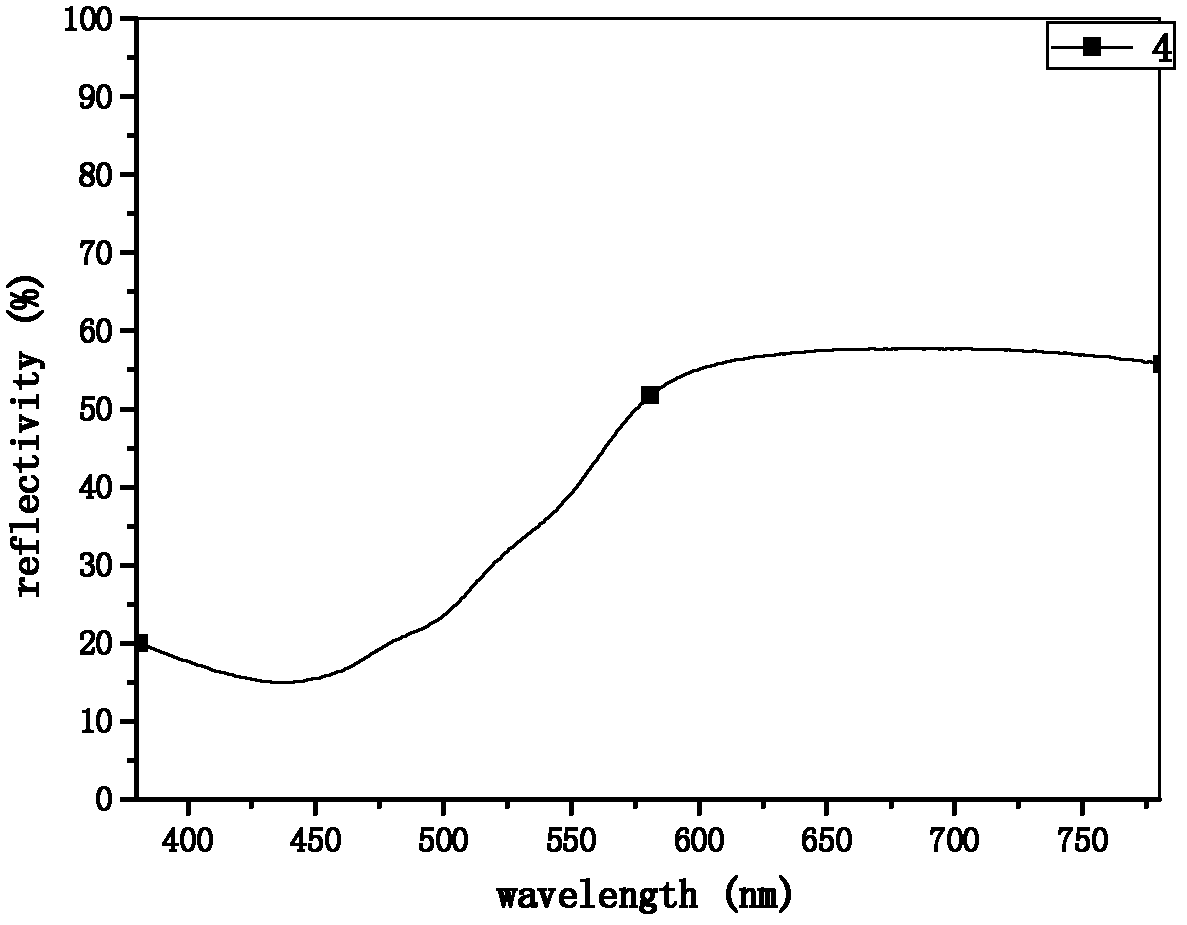

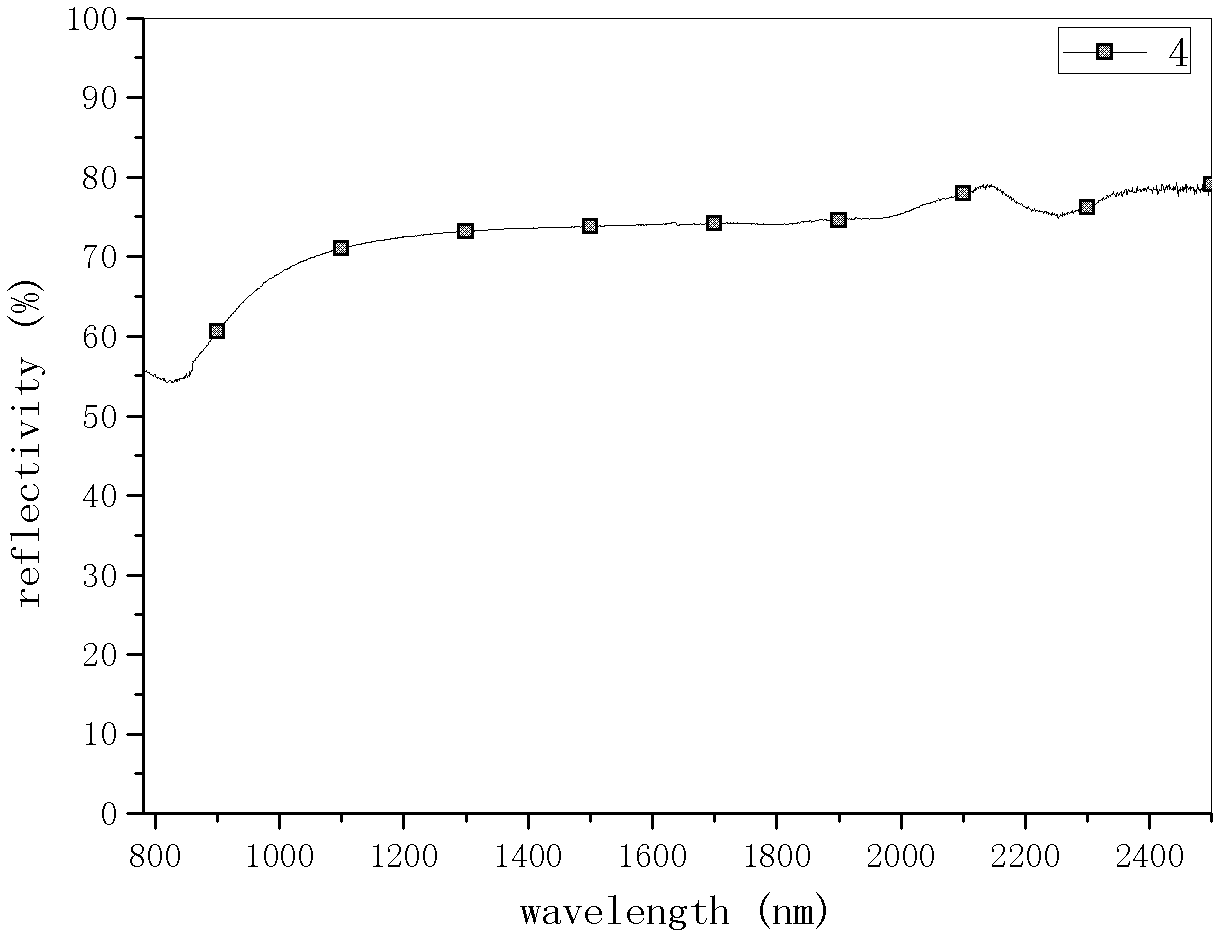

Infrared low-emissivity coating material and preparation method thereof

InactiveCN102618157ALow emissivityLow reflective propertiesPolyurea/polyurethane coatingsCamouflage paintsLow emissivityAluminium powder

An infrared low-emissivity coating material and a preparation method thereof belong to the technical field of functional materials. The infrared low-emissivity coating material comprises the following components by weight: 0.8 to 1 part of red slurry, 2 to 4 parts of yellow slurry, 1 to 3 parts of dispersing slurry of sheet aluminium powder, 35 to 37 parts of dispersing slurry of sheet aluminium powder coated with silicon dioxide or ferric oxide, 50 to 58 parts of solvent, 3 to 5 parts of curing agent and 0.1 to 0.3 part of flatting agent. The infrared low-emissivity coating material provided by the invention can simulate the spectral reflection curve of the northern ocher background, wherein a near infrared band has higher solar reflectivity, the average emissivity of a thermal infrared band of 3 to 5 Mum is lower than 0.35, and the average emissivity of a thermal infrared band of 8 to 14 Mum is lower than 0.45; and industrial production can be achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

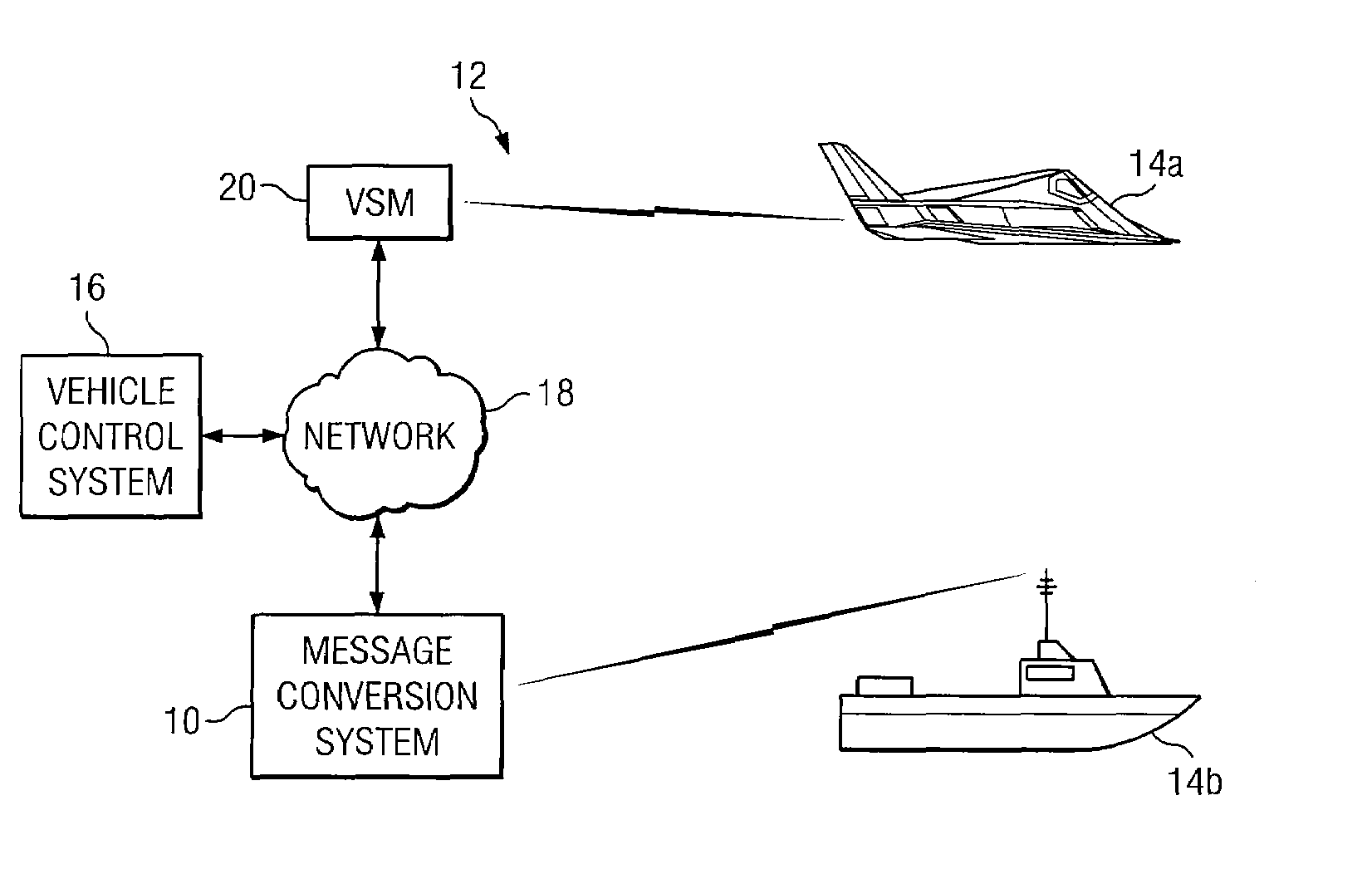

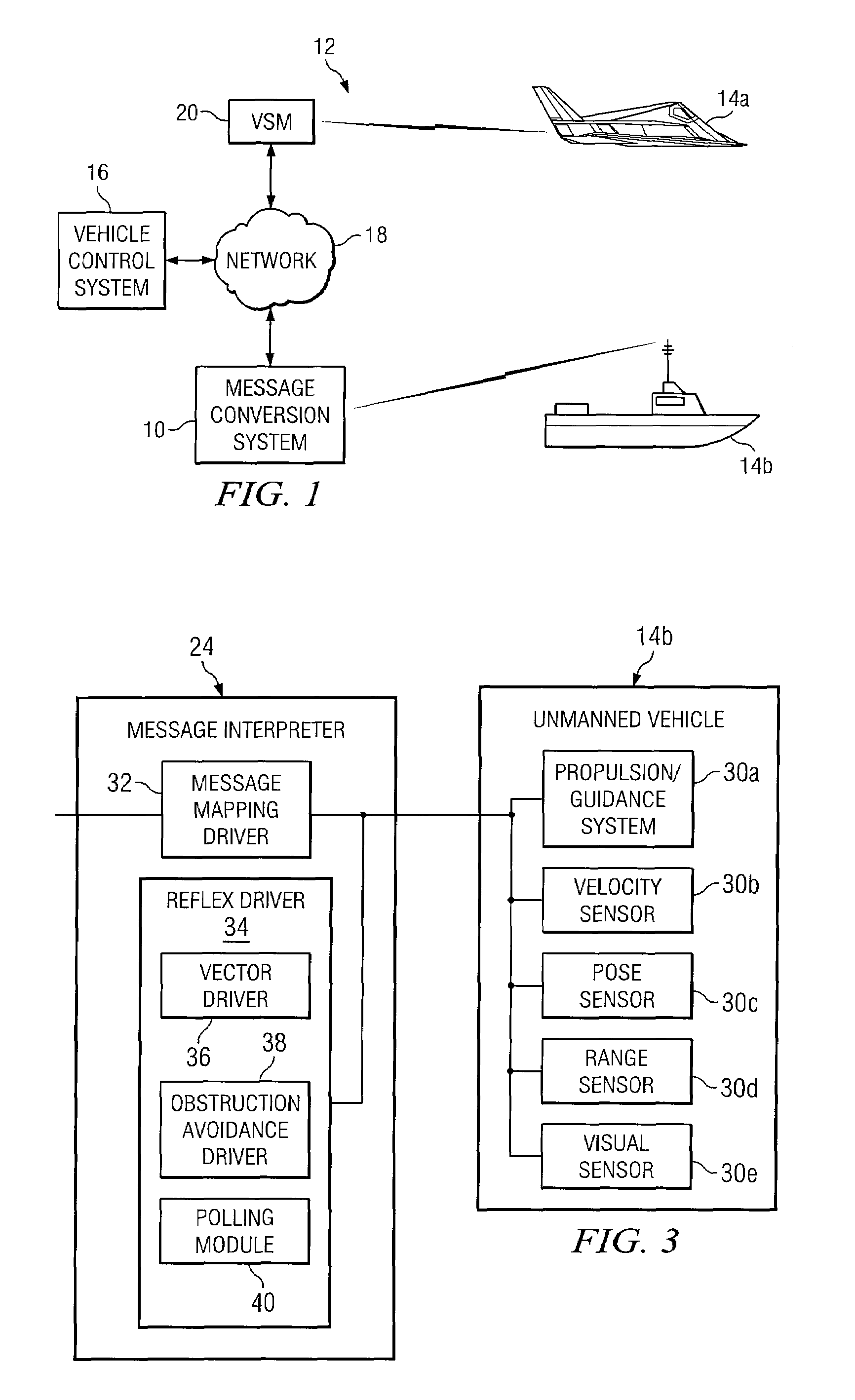

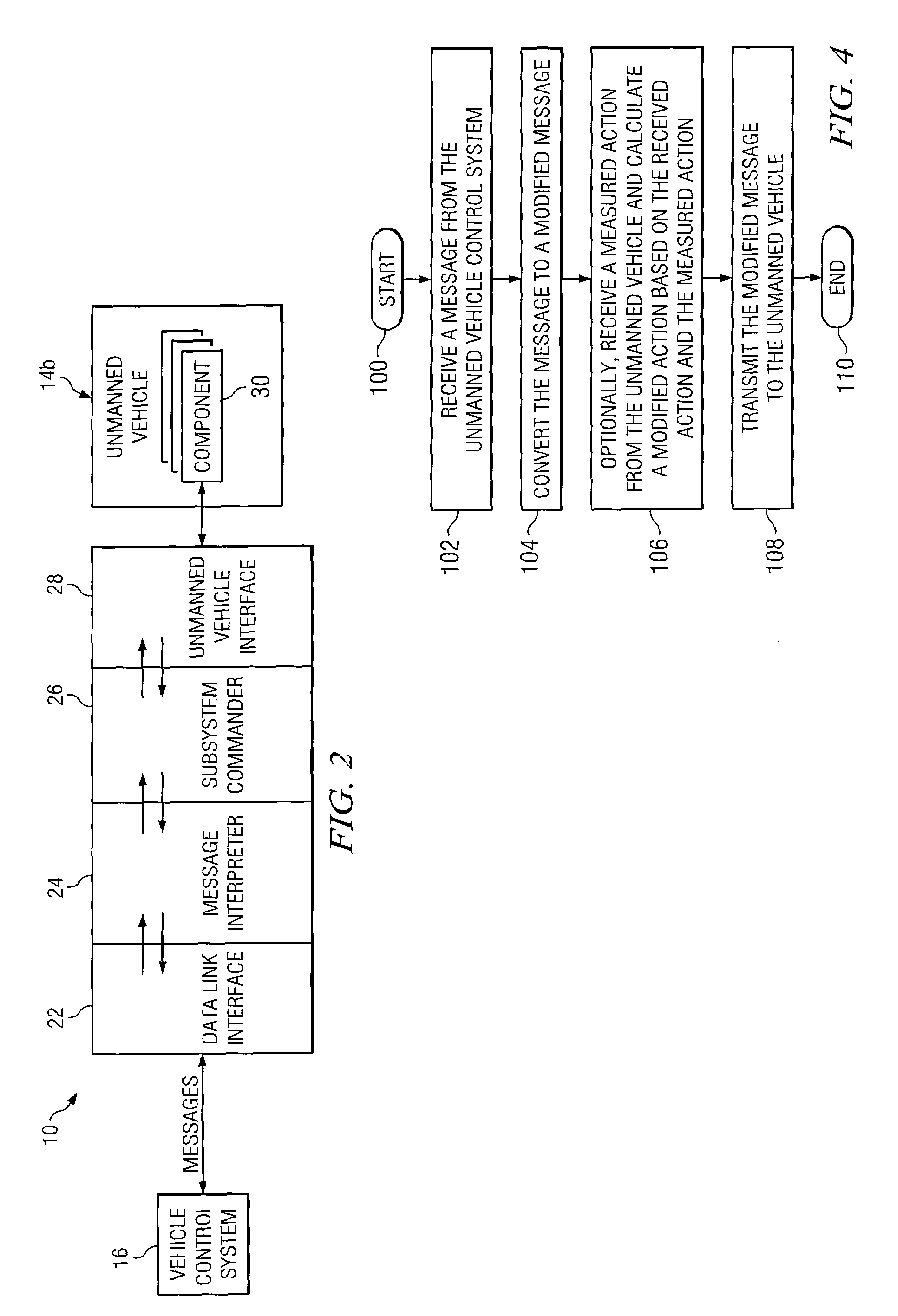

Unmanned vehicle message conversion system

ActiveUS8265800B2Good reflective propertiesGood suppression characteristicsDigital data processing detailsActuated automaticallyControl systemMessage passing

According to one embodiment of the disclosure, an unmanned vehicle message conversion system generally includes a message interpreter that is coupled between a first unmanned vehicle control interface and a second unmanned vehicle control interface. The second unmanned vehicle control interface is configured to transmit and receive messages with a messaging protocol that is different than the first unmanned vehicle control interface. The message interpreter is operable to receive a first message from the unmanned vehicle control system, convert the first message to a second message having the second protocol, and transmit the second message to the unmanned vehicle.

Owner:RAYTHEON CO

Semiconductor light emitting diode chip and light emitting device using the same

InactiveUS20120286309A1Improvement effect of reflective characteristicImprove reflectivitySolid-state devicesSemiconductor devicesMetallic materialsDiffusion barrier

A semiconductor light emitting device includes: a light emitting diode unit including a light-transmissive substrate having a face sloped upwardly at a lower edge thereof. A rear reflective lamination body is formed on the lower face and the surrounding sloped face of the light-transmissive substrate. The rear reflective lamination body includes an optical auxiliary layer and a metal reflective film formed on a lower face of the optical auxiliary layer. A junction lamination body is provided to a lower face of the rear reflective lamination body. The junction lamination body including a junction metal layer made of a eutectic metal material and a diffusion barrier film.

Owner:SAMSUNG ELECTRONICS CO LTD

GaN-based luminous diode chip with current blocking structure and manufacturing method thereof

ActiveCN103325905AGood reflective propertiesReduce areaSemiconductor devicesPower flowMaterials science

The invention relates to a GaN-based luminous diode chip with a current blocking structure and a manufacturing method of the GaN-based luminous diode chip. The GaN-based luminous diode chip comprises an epitaxial layer structure, a p electrode and an n electrode. The p electrode is composed of an ITO transparent electrode and a metal electrode. The metal electrode is located between the ITO transparent electrode and a p-type GaN and is surrounded by the ITO transparent electrode, the lower layer of the metal electrode is contacted with the p-type GaN in a Schottky mode, the metal electrode is contacted with the ITO transparent electrode in an Ohmic mode, the ITO transparent electrode is contacted with the p-type GaN in a Ohmic mode, and a window is formed in part of the ITO transparent electrode on the metal electrode. When the GaN-based luminous diode chip works, a great amount of light obliquely emitted to the lower surface of the metal electrode from the two sides is reflected back to the epitaxial layer layer, therefore, light absorbing amount of the metal electrode is reduced and external quantum efficiency of an LED is improved.

Owner:吴江市民福电缆附件厂

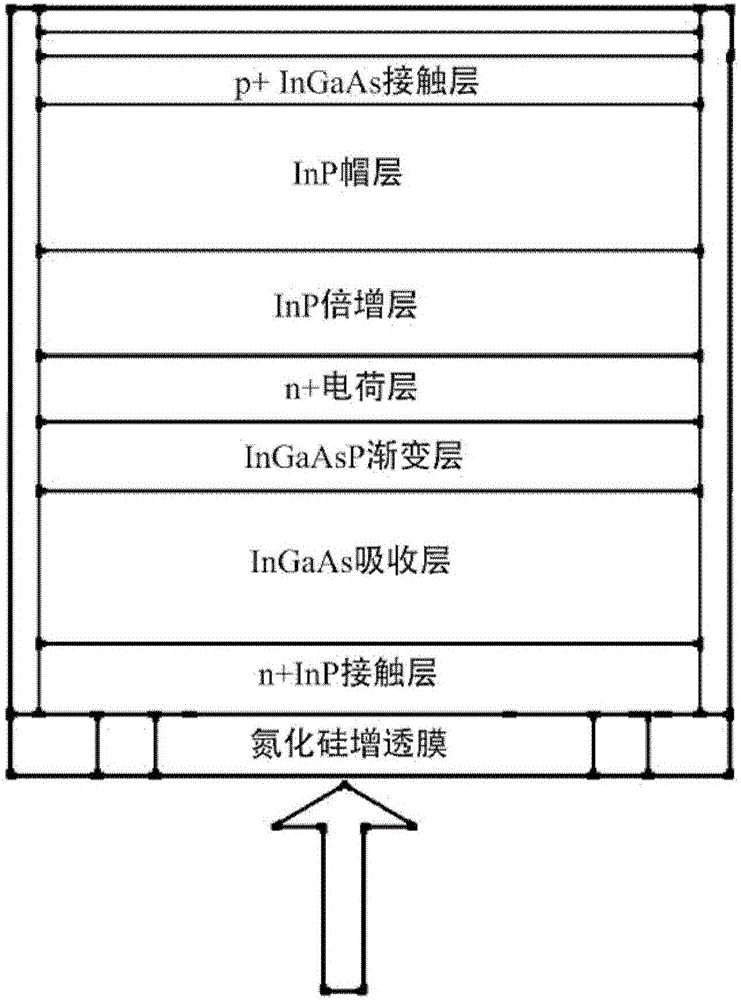

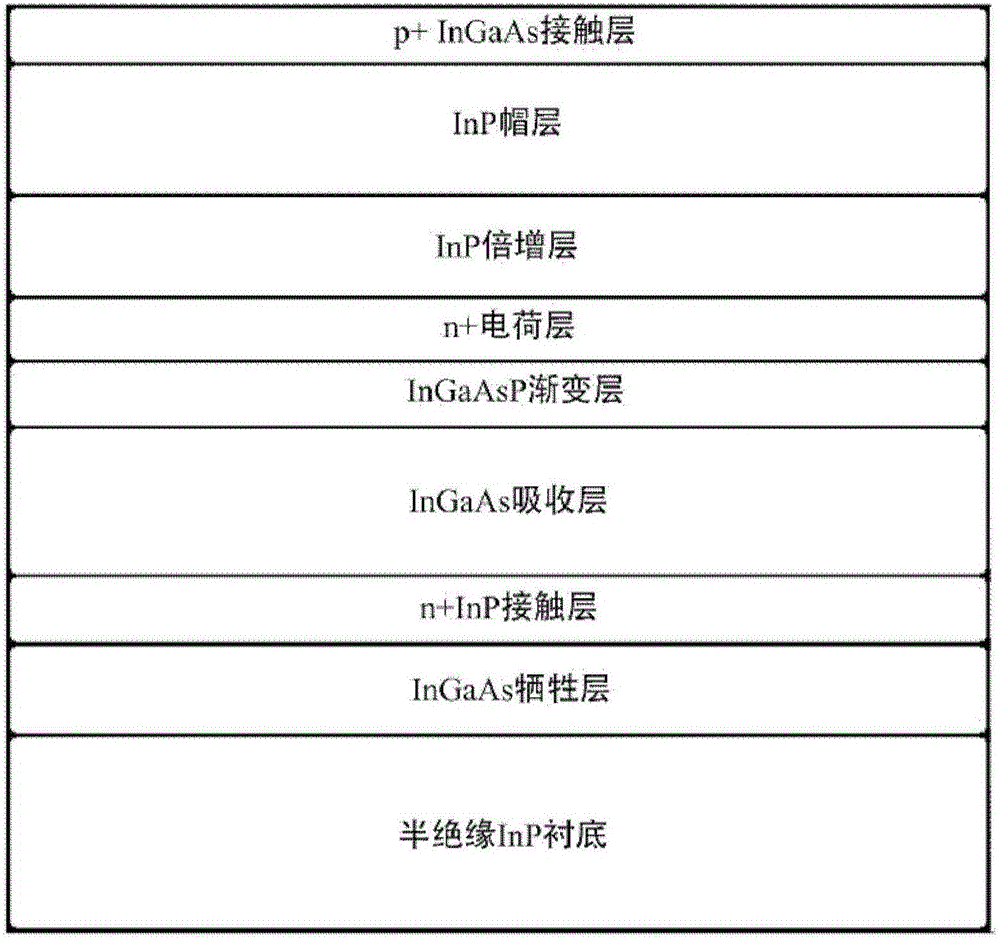

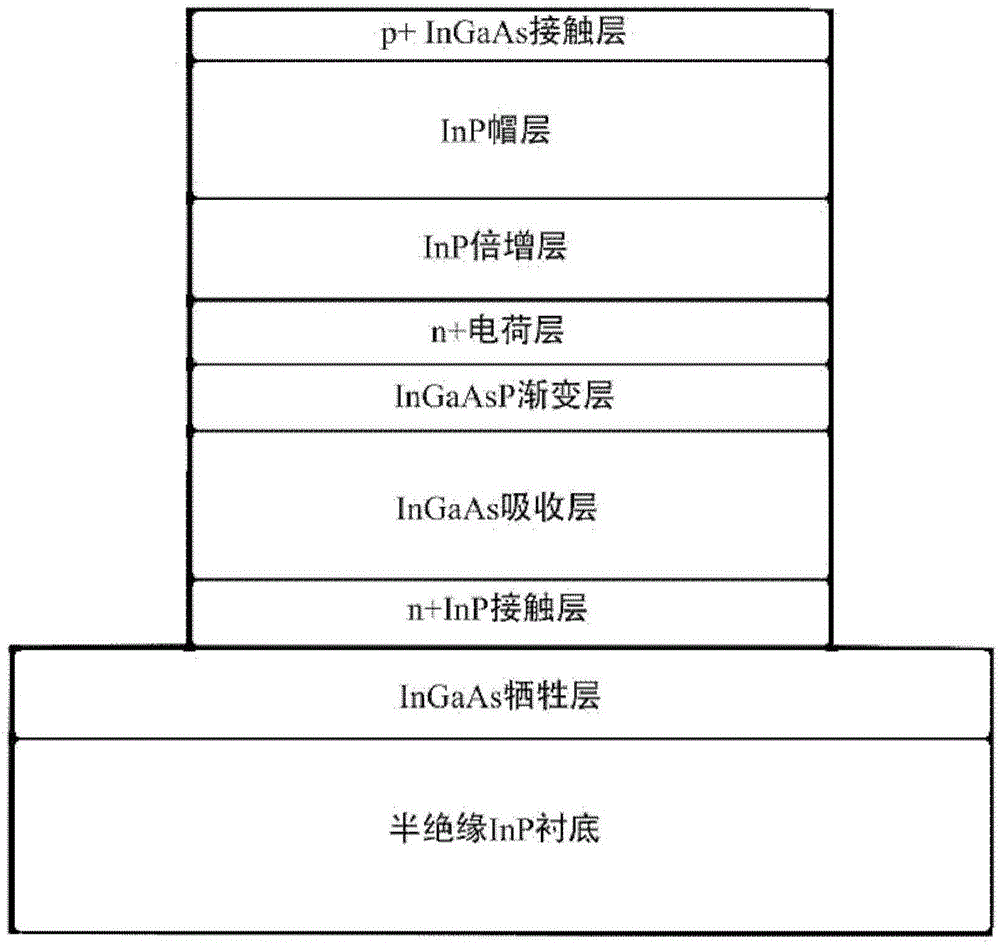

High-response avalanche photodiode fabrication method

InactiveCN105118886AIncrease light absorption lengthImprove responsivenessSemiconductor devicesOhmic contactMetal

The invention discloses a vertical-type avalanche photodiode and a fabrication method thereof. The avalanche photodiode fabrication method comprises steps: a vertical mesa is etched until an In0.53Ga0.47As sacrificial layer; the side wall and the upper surface of the mesa are passivated; the In0.53Ga0.47As sacrificial layer is corroded and removed to realize substrate stripping; an optical antireflection film is prepared on the surface of an N-type InP ohmic contact layer; a P contact metal layer and an N contact metal layer are prepared on the upper surface and the lower surface, and a flat high-reflective mirror metal layer is then formed on the P contact metal layer. Through effective combination between the optical antireflection film and the flat high-reflective mirror metal layer, the response of the avalanche photodiode can be effectively improved. The high-response vertical-type InP / In0.53Ga0.47As avalanche photodiode has the advantages of low cost, simple fabrication process and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

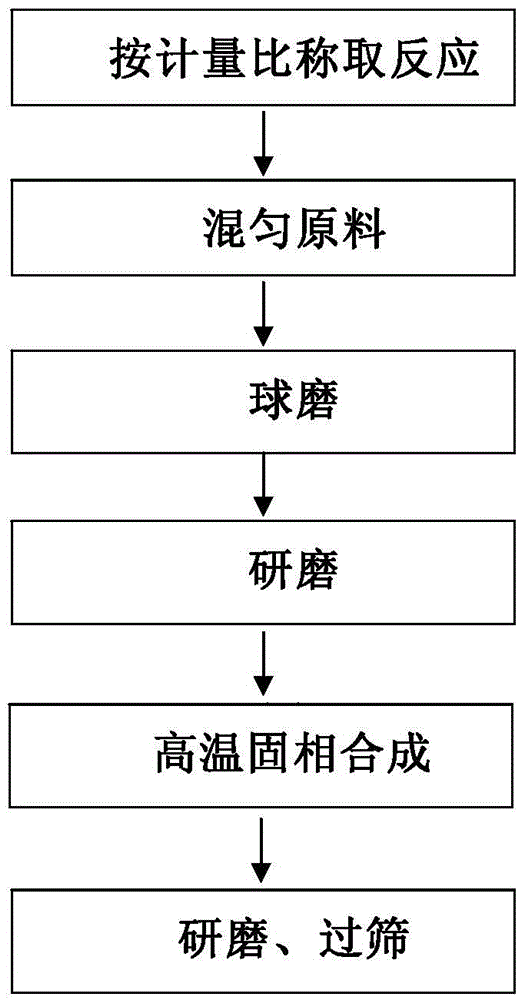

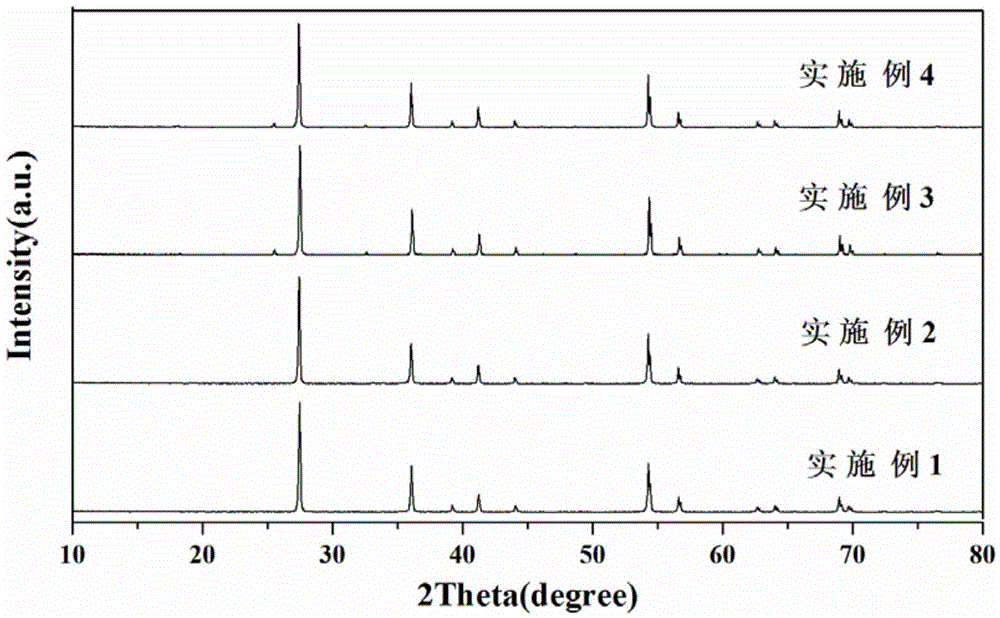

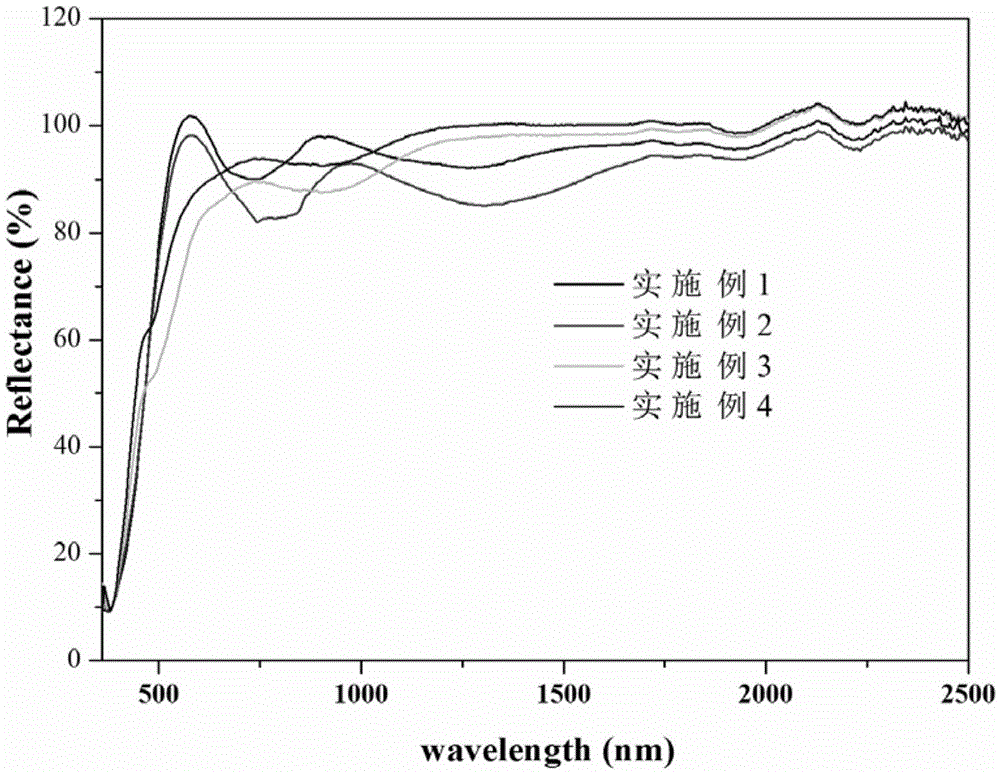

Yellow pigment able to reflect near infrared rays and preparation method thereof

InactiveCN105542516AStrong coloring powerStrong covering powerPigment physical treatmentSolid-phase synthesisHigh heat

The invention discloses a yellow pigment able to reflect near infrared rays and a preparation method thereof. The pigment is prepared from a main phase, a doping phase and a mineralizing agent in a mass ratio. The main phase is titanium dioxide with a molar percentage content of 80-98%, the doping phase is 1-10% of basic nickel carbonate and 1-10% of antimony oxide, or 1-10% of iron oxide and 1-10% of magnesium oxide. The mineralizing agent is boric acid or boric acid and ammonium chloride, and accounts for 0.5-3wt% of the total mass of the main phase and the doping phase. The preparation method comprises: batching, ball milling, grinding, high temperature solid phase synthesis, grinding, sieving and other processes. The pigment product is an anatase phase structure, and the obtained product has very good thermal stability. The method provided by the invention is a high temperature solid phase synthesis process, and the equipment and operation are simple and practicable, thus being convenient for large-scale and industrialized production.

Owner:SHAANXI UNIV OF TECH

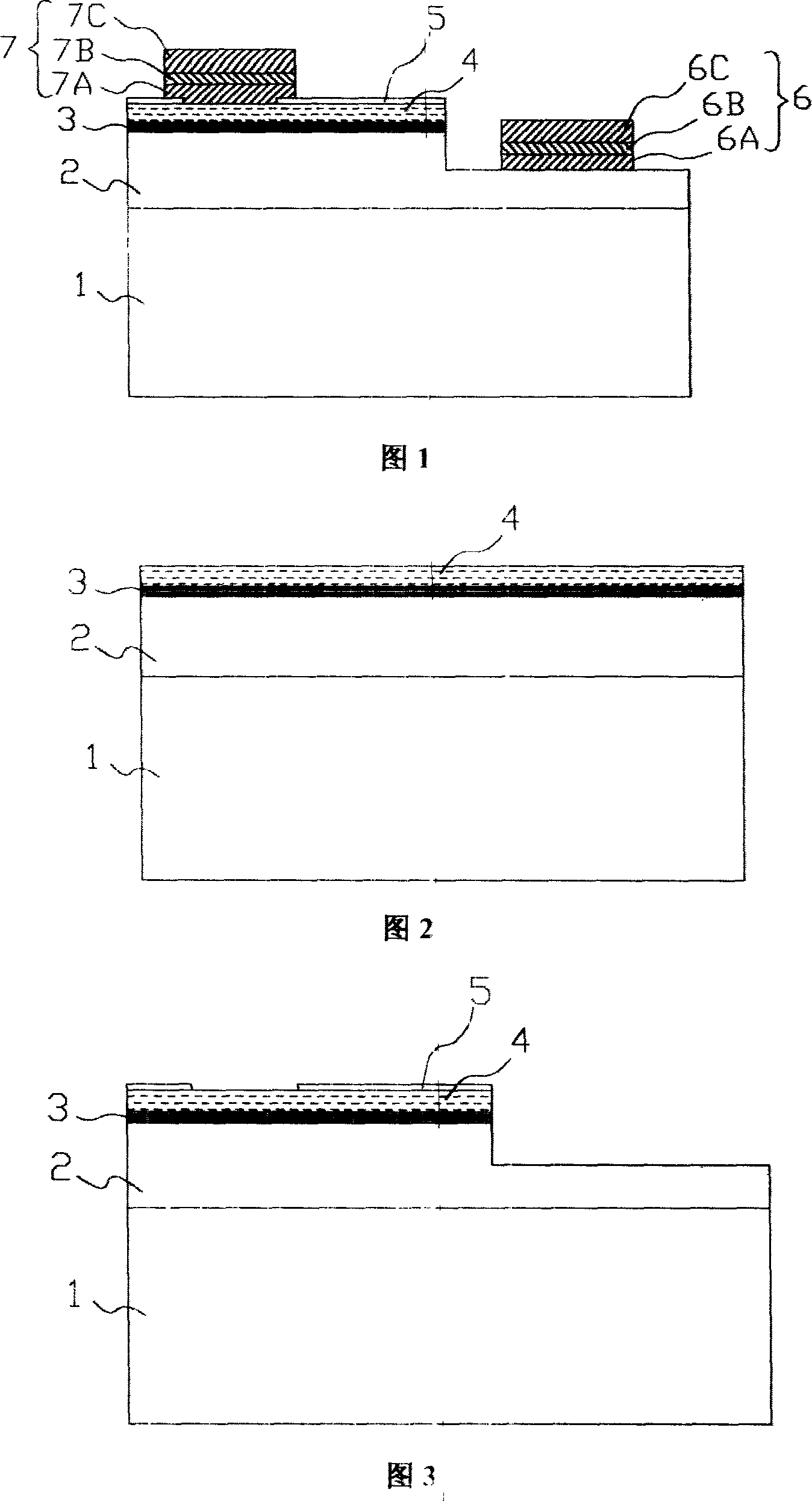

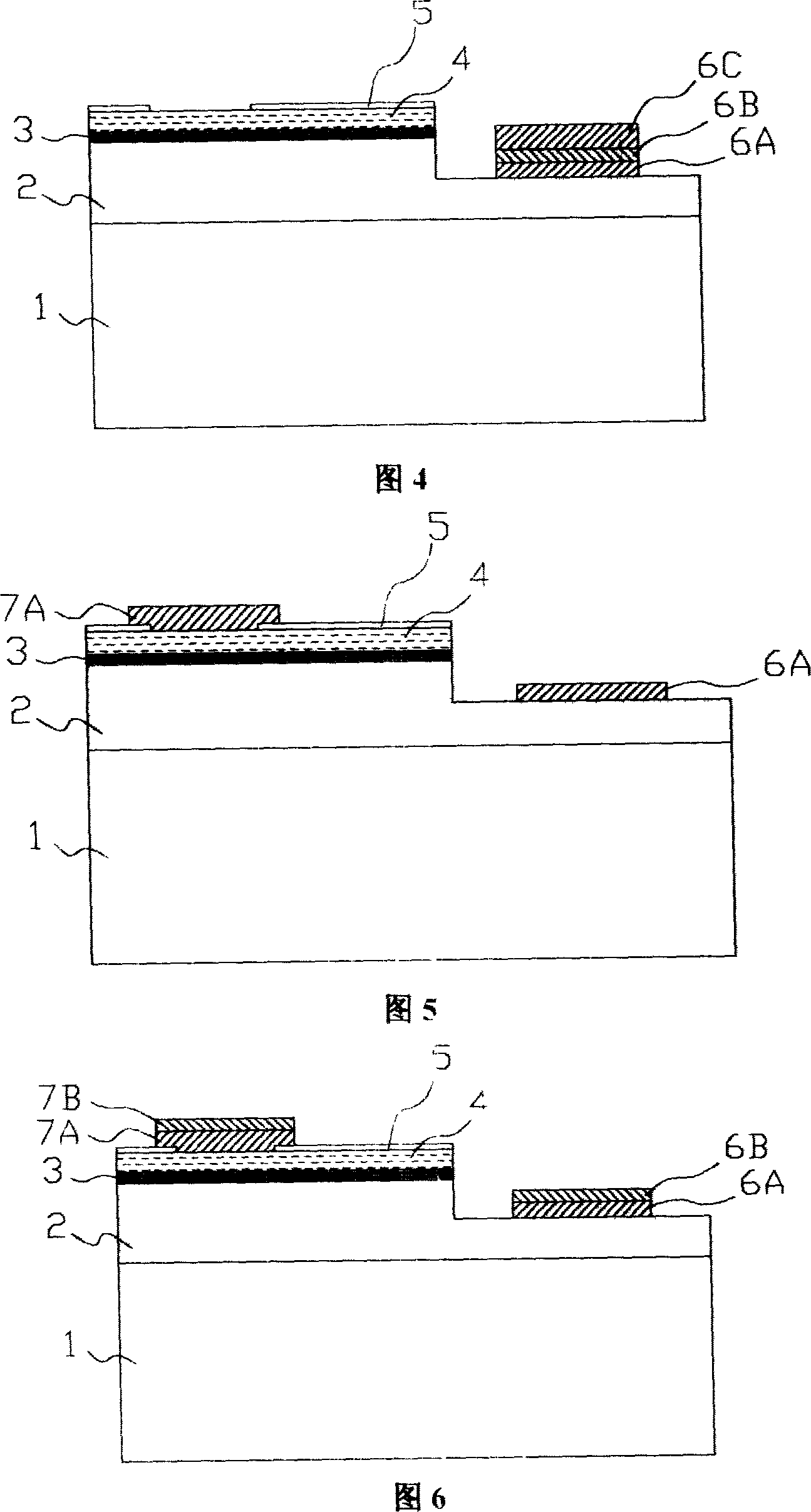

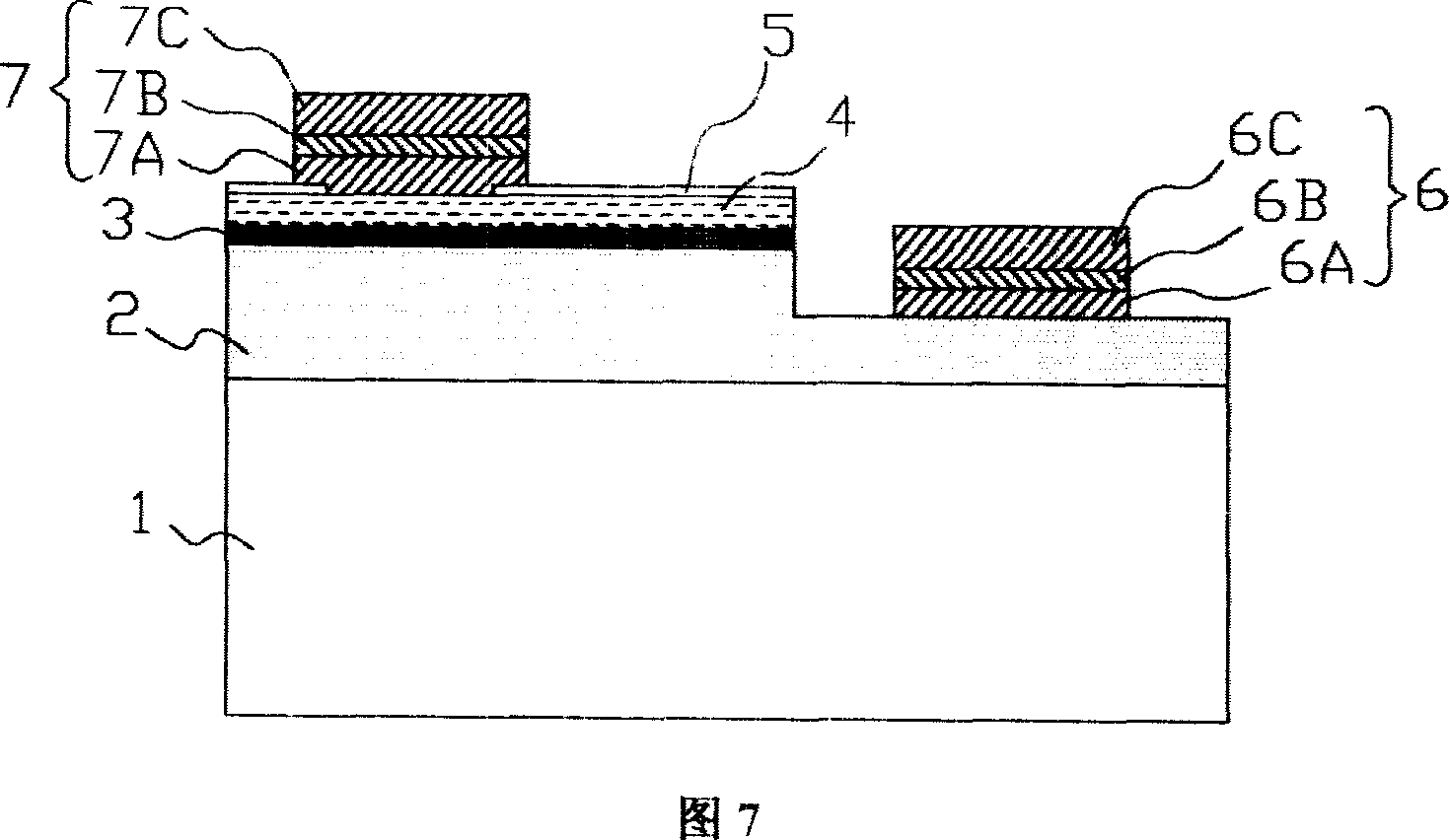

Electrode of gallium nitride base III-V. class compound semiconductor

ActiveCN101000942AGood reflective propertiesImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesGallium nitrideOhmic contact

The invention relates to the electrodes of semiconductor device of GaN-based III-V compound, which includes: n electrode 6 and p electrode 7, and the n electrode 6 locates on the n-typed GaN (n - GaN) layer of the Epi-Wafers of the semiconductor device of GaN-based III-V compound, and the p electrode 7 locates on the p-typed GaN (p-Ga N) 4 and the transparent electrode 5 of the Epi-Wafers of the semiconductor device of GaN-based III-V compound. The n electrode 6 is composed of a ohmic contacting layer 6A, a barrier layer 6B and a metal pressed welding layer 6C, and p electrode 7 is composed of a adhesion conductive layer 7A, a barrier layer 7B and a metal pressed welding layer 7C. Its feature is: the ohmic contacting layer 6A and adhesion conductive layer 7A are Cr, and metal pressed welding layer 6C and 7C is Al.

Owner:HC SEMITEK SUZHOU

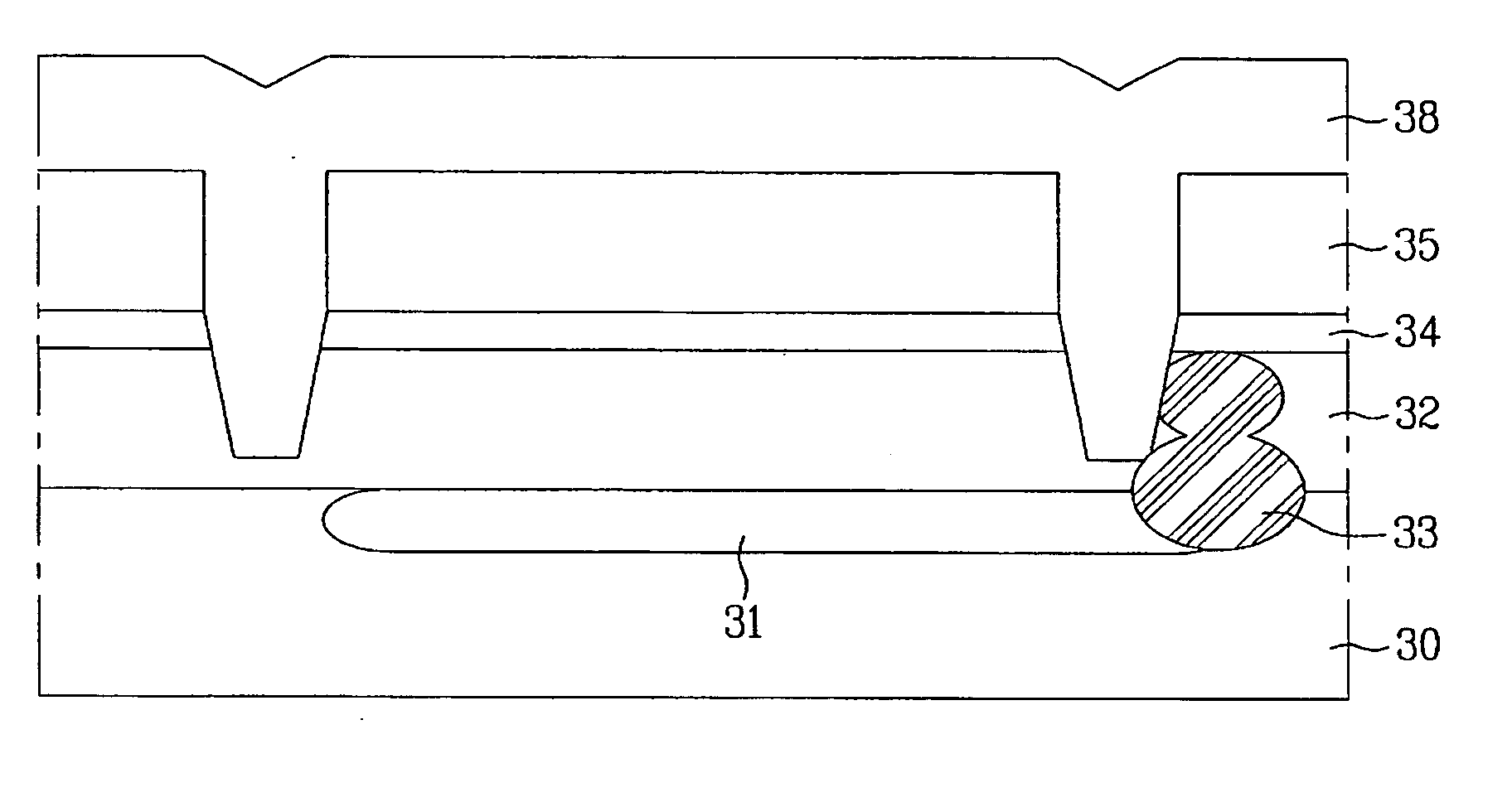

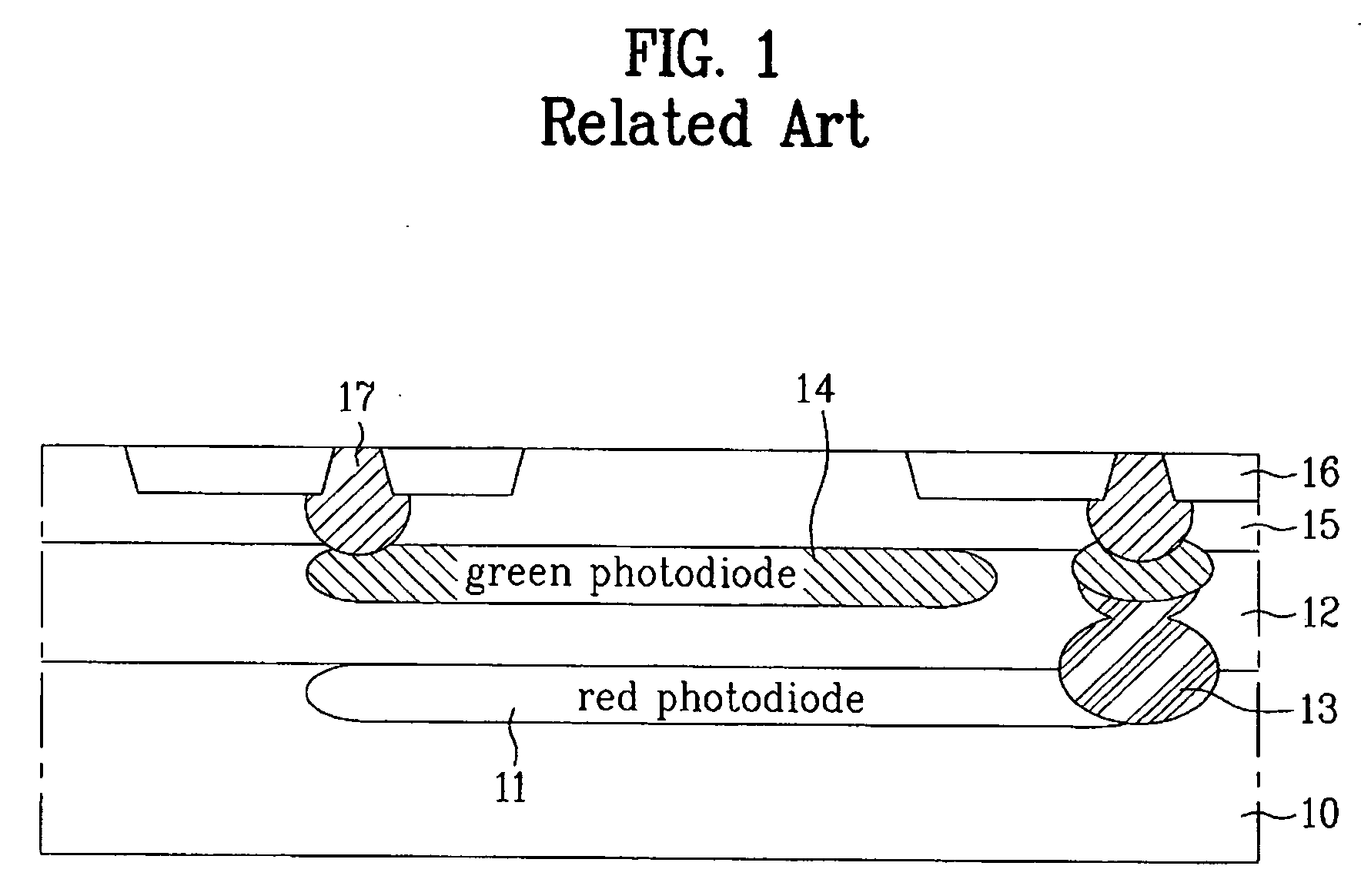

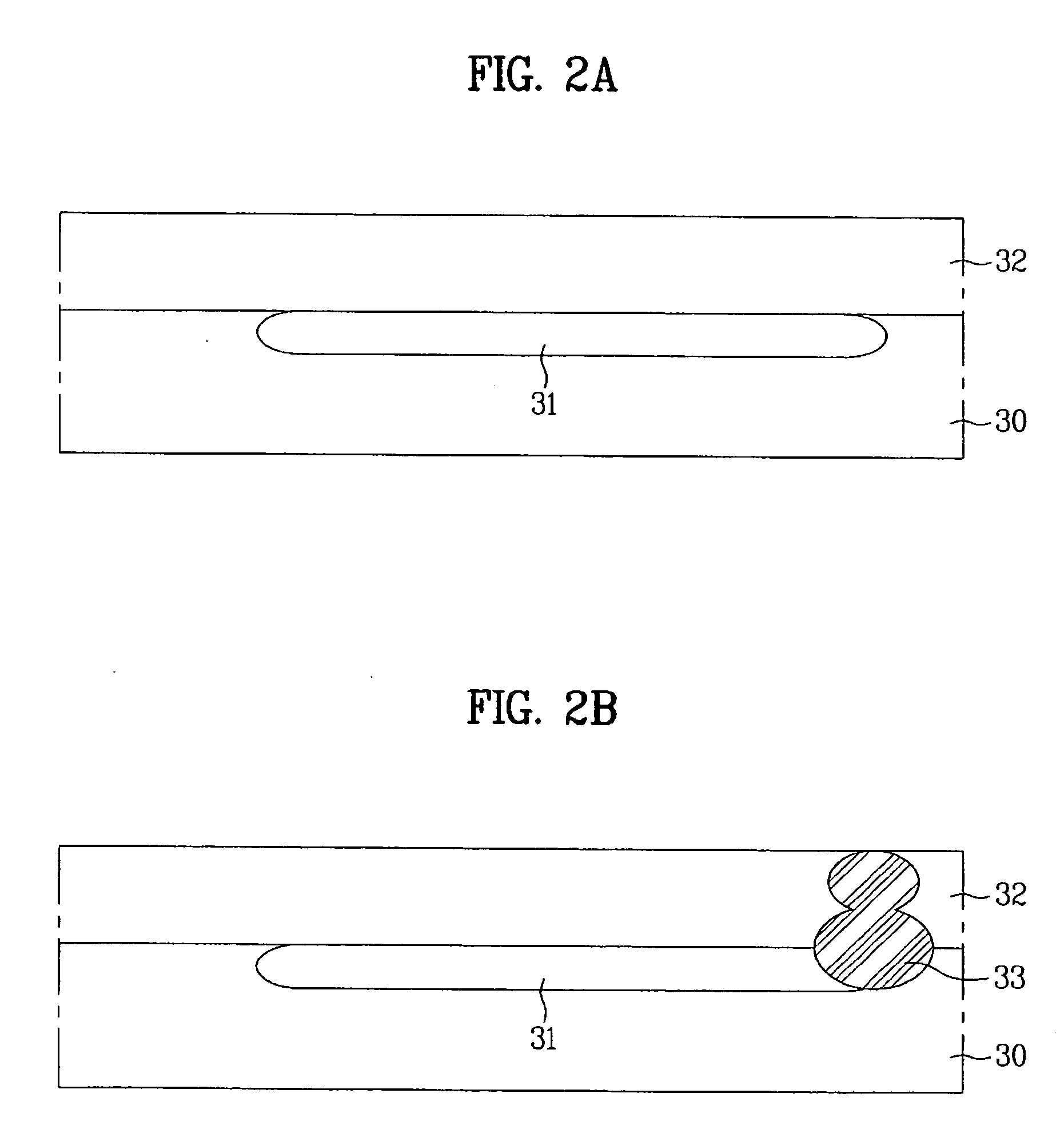

CMOS image sensor and method for fabricating the same

ActiveUS20060145221A1Good reflective propertiesImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingCMOSIsolation layer

A CMOS image sensor and a method for fabricating the same can ensure isolation characteristics using a shallow trench isolation (STI) process and a selective epitaxy method. The CMOS image sensor and method for fabricating the same can also reduce pixel size. The CMOS image sensor includes a semiconductor substrate, a first photodiode, a first epitaxial layer, a second epitaxial layer, a plurality of device isolation layers formed in isolation regions formed at the second epitaxial layer, a second photodiode formed between the device isolation layers, and a third epitaxial layer.

Owner:DONGBU HITEK CO LTD

Infrared reflecting plate and infrared reflective bonded glass sheet

Disclosed is an infrared reflecting plate exhibiting an improved selective reflection characteristic. The infrared reflecting plate comprises a substrate having Re (1000) the variation of which is 20 nm or more, at least two light reflecting layers (X1, X2) provided on one surface of the substrate and containing a fixed cholesteric liquid crystal phase, and at least two light reflecting layers (Y1, Y2) provided on the other surface of the substrate and containing a fixed cholesteric liquid crystal phase. The reflective center wavelength of the light reflecting layers (X1, X2) is Lambda X1 (nm), the light reflecting layers reflect circularly polarized light beams the directions of the polarization of which are opposite to each other and which are equal to each other, the reflection center wavelength of the light reflecting layers (Y1, Y2) is Lambda Y1 (nm), the light reflecting layers (Y1, Y2) reflect circularly polarized light beams the directions of the polarization of which are opposite to each other and which are equal to each other, Lambda X1 and Lambda Y1 are not equal to each other, the respective refractive index anisotropies Delta nX1, and Delta nX2 of the light reflecting layer (X1) (lower layer) and the light reflecting layer (X2) (upper layer) satisfy Delta nX2<Delta nX1, and the respective refractive index anisotropies Delta nY1, Delta nY2 of the light reflecting layer (Y1) (lower layer) and the light reflecting layer (Y2); (upper layer) satisfy Delta nY2 < Delta nY1.

Owner:FUJIFILM CORP

Coating material, preparation of optical film, optical film, polarizing plate and image display device

InactiveCN1918252AHigh hardnessFull hardnessLiquid surface applicatorsSynthetic resin layered productsCyclohexanonePolymer science

The present invention provides a coating material for forming a coating layer that can achieve excellent adhesion to a transparent film. The coating material is prepared so that it contains a thermosetting resin, an inorganic filler, and a mixed solvent containing cyclohexanone. The content of the thermosetting resin is in the range from 5 to 20 wt % with respect to the total amount of the thermosetting resin and the inorganic filler, and the content of the cyclohexanone is in the range from 25 to 35 wt % with respect to the entire mixed solvent. By coating a surface of a transparent film with this coating material and then heat-treating the resultant coating, a coating layer with excellent adhesion can be formed on transparent film. The thus-obtained laminate of the transparent film and the coating layer can be used as an antireflection film.

Owner:NITTO DENKO CORP

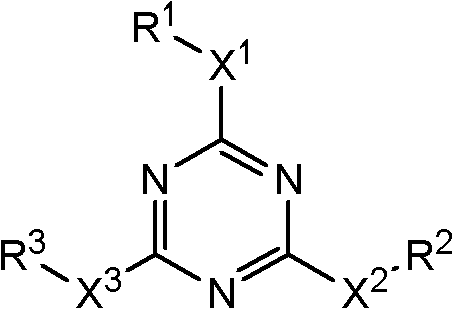

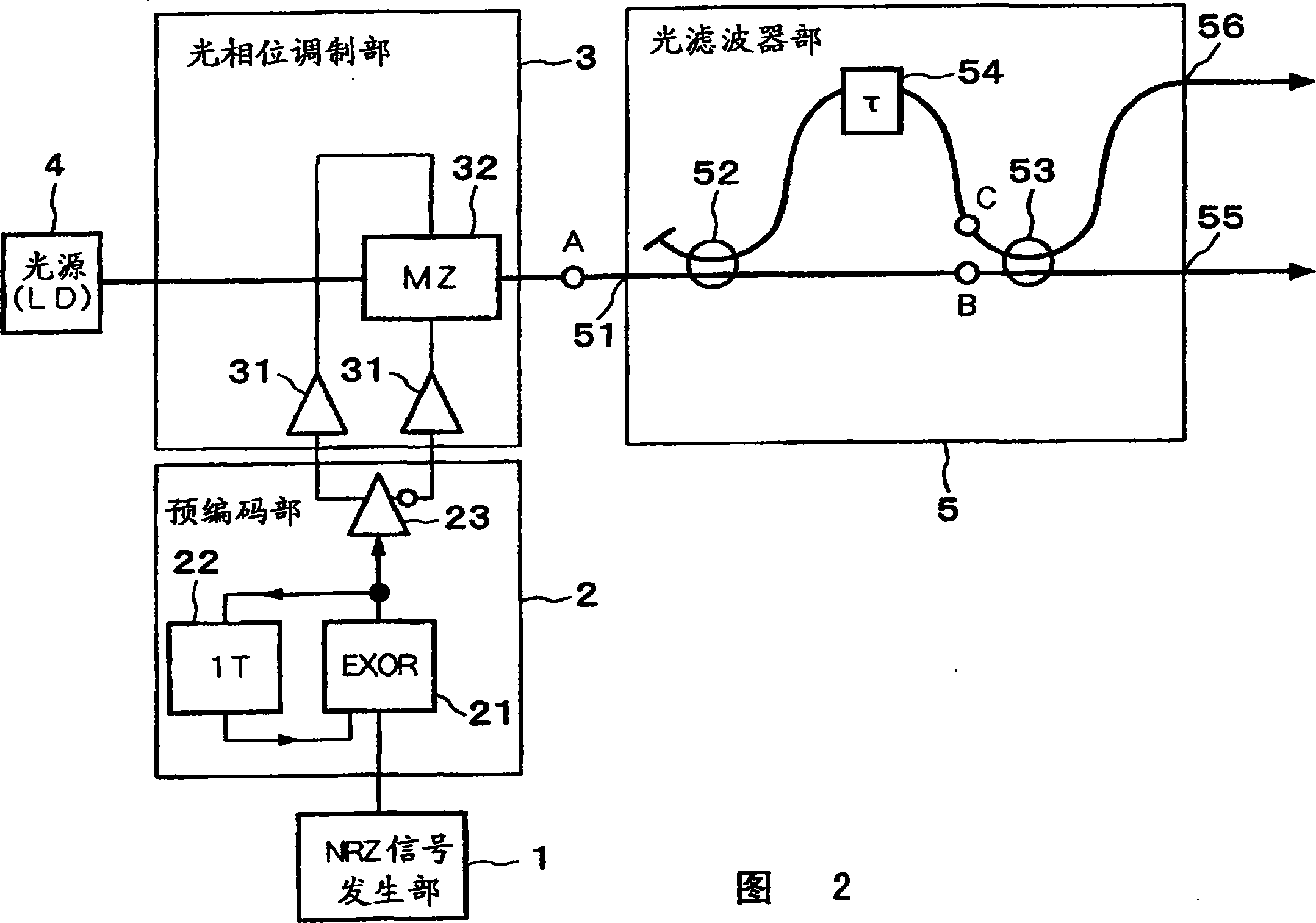

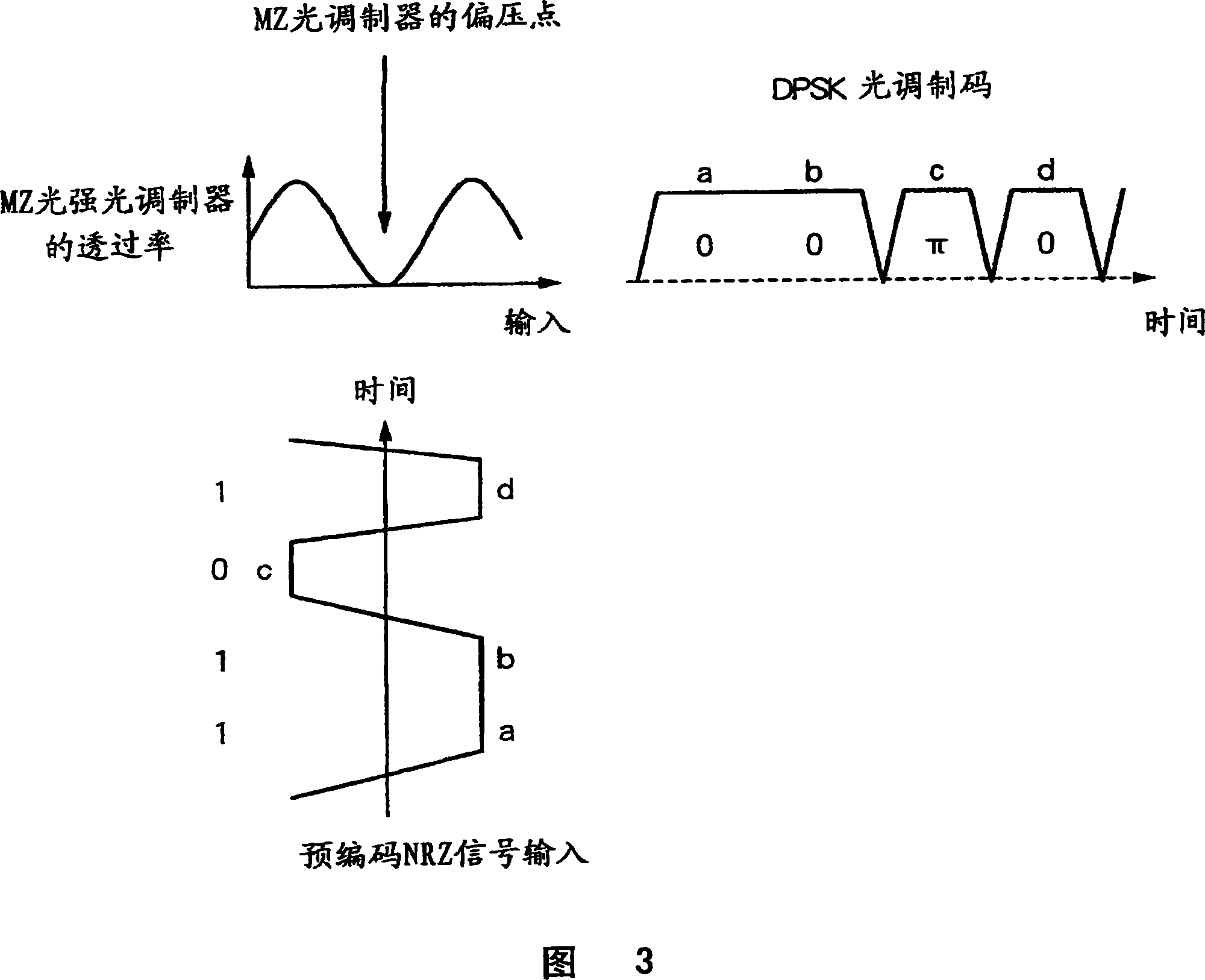

Optical transmitter and optical transmission system

InactiveCN101064567AReduce the numberGood reflective propertiesDistortion/dispersion eliminationOptical multiplexEngineeringWavelength

The present invention suppresses to a minimum the degradation of the transmission quality caused by chromatic dispersion characteristic of an optical transmission medium, and the interplay between the chromatic dispersion and non-linear optical effects in dense WDM transport systems. A baseband input data signal is pre-coded in advance by a pre-coding unit, phase modulation is carried out using a pre-coded signal by the optical phase modulating unit, and the phase modulated optical signal is converted to an RZ intensity modulated signal by the optical filter unit that performs phase-shift-keying to amplitude-shift-keying conversion. For example, an optical phase modulating unit generates an encoded DPSK phase modulated signal using a differential phase shirt keying (DPSK) format, and a phase modulated signal is converted to an RZ intensity modulated signal by the optical filter unit disposed downstream of the optical phase modulating unit.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Coating material, method for manufacturing optical film using the coating material, optical film, polarizing plate and image display apparatus

InactiveUS20070128370A1Improve adhesionHigh strengthSynthetic resin layered productsPolarising elementsCyclohexanoneSolvent

The present invention provides a coating material for forming a coating layer that can achieve excellent adhesion to a transparent film. The coating material is prepared so that it contains a thermosetting resin, an inorganic filler, and a mixed solvent containing cyclohexanone. The content of the thermosetting resin is in the range from 5 to 20 wt % with respect to the total amount of the thermosetting resin and the inorganic filler, and the content of the cyclohexanone is in the range from 25 to 35 wt % with respect to the entire mixed solvent. By coating a surface of a transparent film with this coating material and then heat-treating the resultant coating, a coating layer with excellent adhesion can be formed on transparent film. The thus-obtained laminate of the transparent film and the coating layer can be used as an antireflection film.

Owner:NITTO DENKO CORP

Leadframe for optical semiconductor device, method for manufacturing leadframe for optical semiconductor device, and optical semiconductor device

InactiveCN102844897AGood reflective propertiesImprove reflectivityMirrorsSemiconductor/solid-state device detailsAlloyLead frame

A lead frame for an optical semiconductor device, having a reflection layer at least on one side or each side of the outermost surface of a substrate, partially or entirely, in which the reflection layer has, on the outermost surface at least in a region where light emitted by an optical semiconductor element is reflected, a microstructure with at least the surface thereof having been mechanically deformed, which is converted from a plating microstructure formed of a metal or an alloy thereof; a method of producing the same, and an optical semiconductor device having the same.

Owner:FURUKAWA ELECTRIC CO LTD

Infrared light reflector, infrared light reflecting laminated glass, and laminated glass and laminate having cholesteric liquid crystal layers

ActiveCN102804004AImproved selective reflection propertiesImprove insulation performanceWindowsWindscreensSelective reflectionReflective layer

Provided is an infrared light reflector exhibiting improved selective reflection properties. The infrared light reflector is provided with a substrate and at least four light reflecting layers (X1, X2, X3, X4), which is obtained by immobilizing a cholesteric liquid crystal phase, on at least one surface of the substrate in the order from X1 to X4. The light reflecting layers (X1, X2) both have a reflection center wavelength of [lambda]1 (nm) and reflect circularly-polarized light having inverse propagation directions, and the light reflecting layers (X3, X4) both have a reflection center wavelength of [lambda]2 (nm) and reflect circularly-polarized light having inverse propagation directions; and [lambda]2 is greater than [lambda]1.

Owner:FUJIFILM CORP

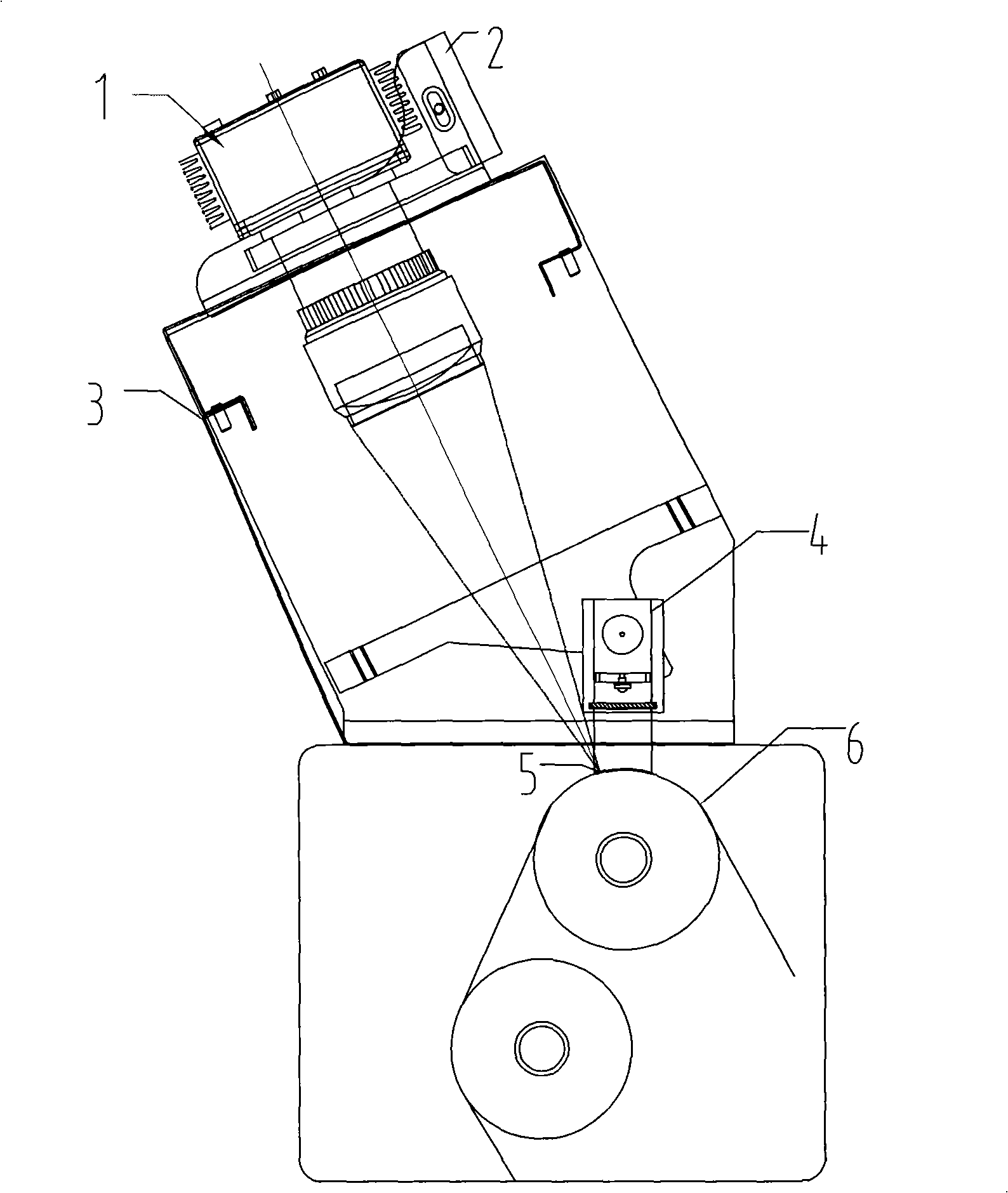

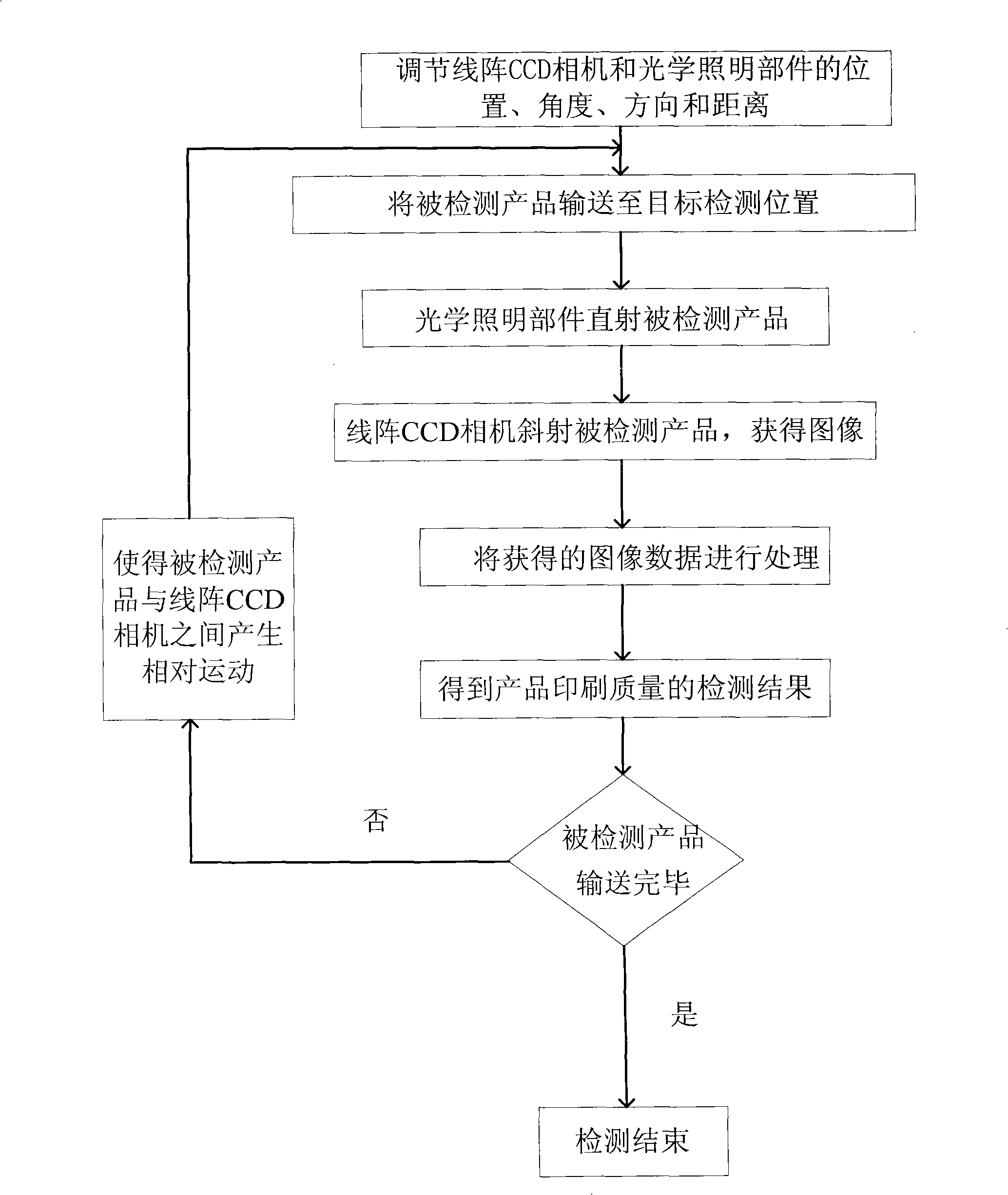

Laser printing quality checking system and method based on CCD image-forming

ActiveCN101339145AReduced lighting uniformity requirementsGood reflective propertiesMaterial analysis by optical meansImaging processingEffect light

The invention provides a detection system of laser printing quality and a method thereof, which are based on CCD imaging and which are used for detecting the printing quality of the detected product in the target detection position. The system comprises an optical imaging system and an image processing system. The optical imaging system comprises a linear array CCD camera, an optical lighting component and an installation regulating component; the optical lighting component is superposed on the normal line of the target detection position; the included angle of the linear array CCD camera and the target detection position is more than 0 degree and less than 90 degrees; the installation regulating component is respectively connected with the linear array CCD camera and the optical lighting component. The detection system adopts the CCD imaging method to collect high-quality images of laser printed matters, which are processed by the image processing system, and realizes the automatic detection of the quality of the printed matter in the special technologies of gold tooling, silver tooling, laser, and so on in the current printing industry.

Owner:BEIJING LUSTER LIGHTTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com