Infrared light reflector, infrared light reflecting laminated glass, and laminated glass and laminate having cholesteric liquid crystal layers

A light reflective layer, cholesteric technology, applied in glass/slag layered products, windshield, optics, etc., to achieve high heat insulation, improve selective reflection characteristics, and improve light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0122] 3. Preparation method of infrared light reflector

[0123] The infrared light reflecting plate of the present invention is preferably produced by a coating method. An example of the production method is a production method including at least the following steps:

[0124] (1) Coating a curable liquid crystal composition on the surface of a substrate or the like to form a state of a cholesteric liquid crystal phase,

[0125] (2) The curable liquid crystal composition is irradiated with ultraviolet rays to cause a curing reaction to fix the cholesteric liquid crystal phase to form a light reflection layer.

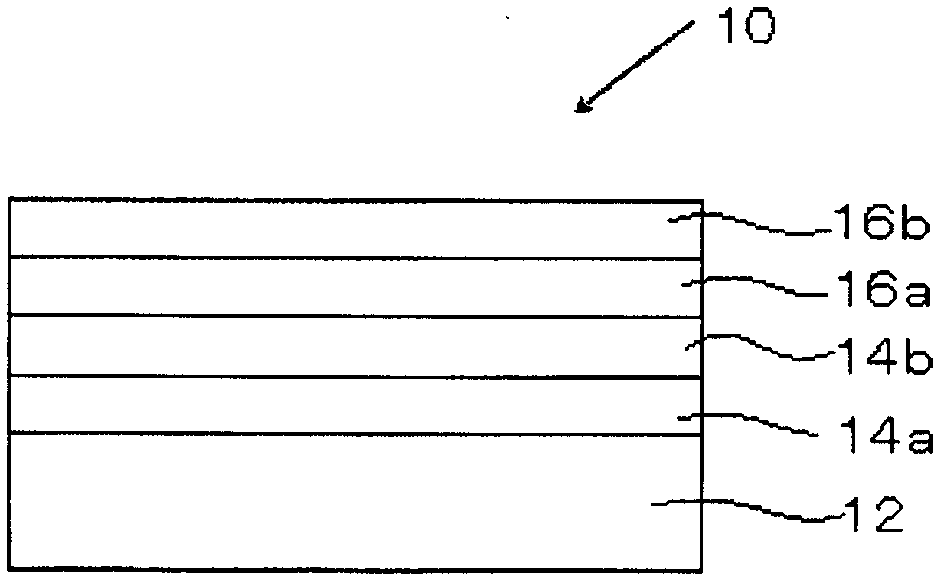

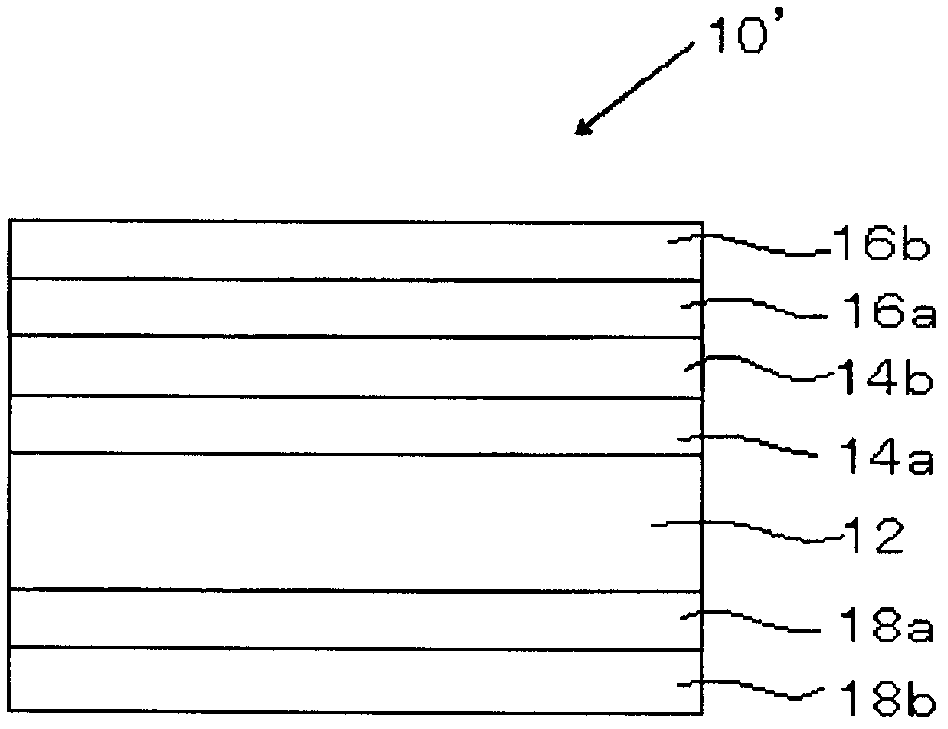

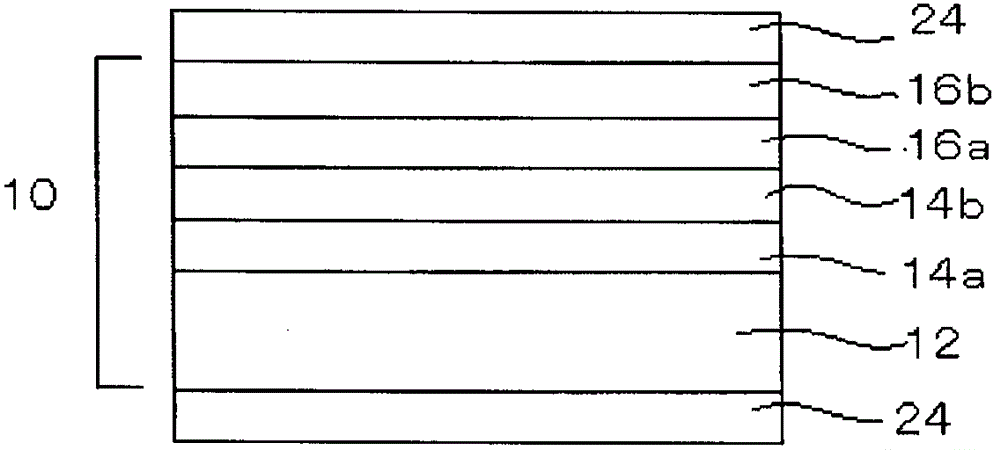

[0126] By repeating the steps (1) and (2) four times on one side of the substrate, it is possible to fabricate figure 1 The infrared light reflecting plate having the same configuration as shown is shown. In addition, by repeating 4 times on one side of the substrate, and repeating (1) and (2) 2 times on the other side of the substrate before, after, or at the same ...

Embodiment 11

[0197] As a substrate, a polyethylene terephthalate film (hereinafter referred to as "PET film") having a thickness of 188 μm was prepared. This PET film is Fujifilm's trade name "FPA14-188", and has the base layer which consists of a polyurethane resin and an acrylic resin on both surfaces.

[0198] The coating liquid (A) used in the above examples was coated on one surface of the substrate, dried and cured to form a cholesteric liquid crystal layer.

[0199] Then, the coating liquid 1 for easily bonding layers of the following composition was prepared. This coating solution was bar-coated on the surface of the cholesteric liquid crystal layer to a dry film thickness of 2 μm, and dried at a temperature of 150° C. for 7 minutes to form an easily bonding layer. Thus, the laminated body 11 which has an easily bonding layer is produced.

[0200] ・Coating liquid for easy bonding layer 1

[0201] 100 parts by mass of methoxypropyl acetate (PGMEA)

[0202] Polyvinyl butyral resi...

Embodiment 12

[0206] Coating solution 2 for an easily bonding layer having the following composition was prepared.

[0207] ・Coating liquid for easy bonding layer 2

[0208] 100 parts by mass of methoxypropyl acetate (PGMEA)

[0209] Ultraviolet absorbent (Tinuvin326, manufactured by Ciba Japan Co., Ltd.) 2.5 parts by mass

[0210] 2.5 parts by mass of HALS (Tinuvin152, manufactured by Ciba Japan Co., Ltd.)

[0211] Polyvinyl butyral resin

[0212] (B1776 Taiwan Changchun Co., Ltd.) 10 parts by mass

[0213] Except having replaced the coating liquid 1 used in Example 11 with the coating liquid 2 prepared above to form an easily bonding layer, it carried out similarly to Example 11, and produced the laminated body 12 which has an easily bonding layer. Furthermore, except replacing the laminated body 11 with the laminated body 12, it carried out similarly, and produced the laminated glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com