Patents

Literature

289results about How to "High temperature stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

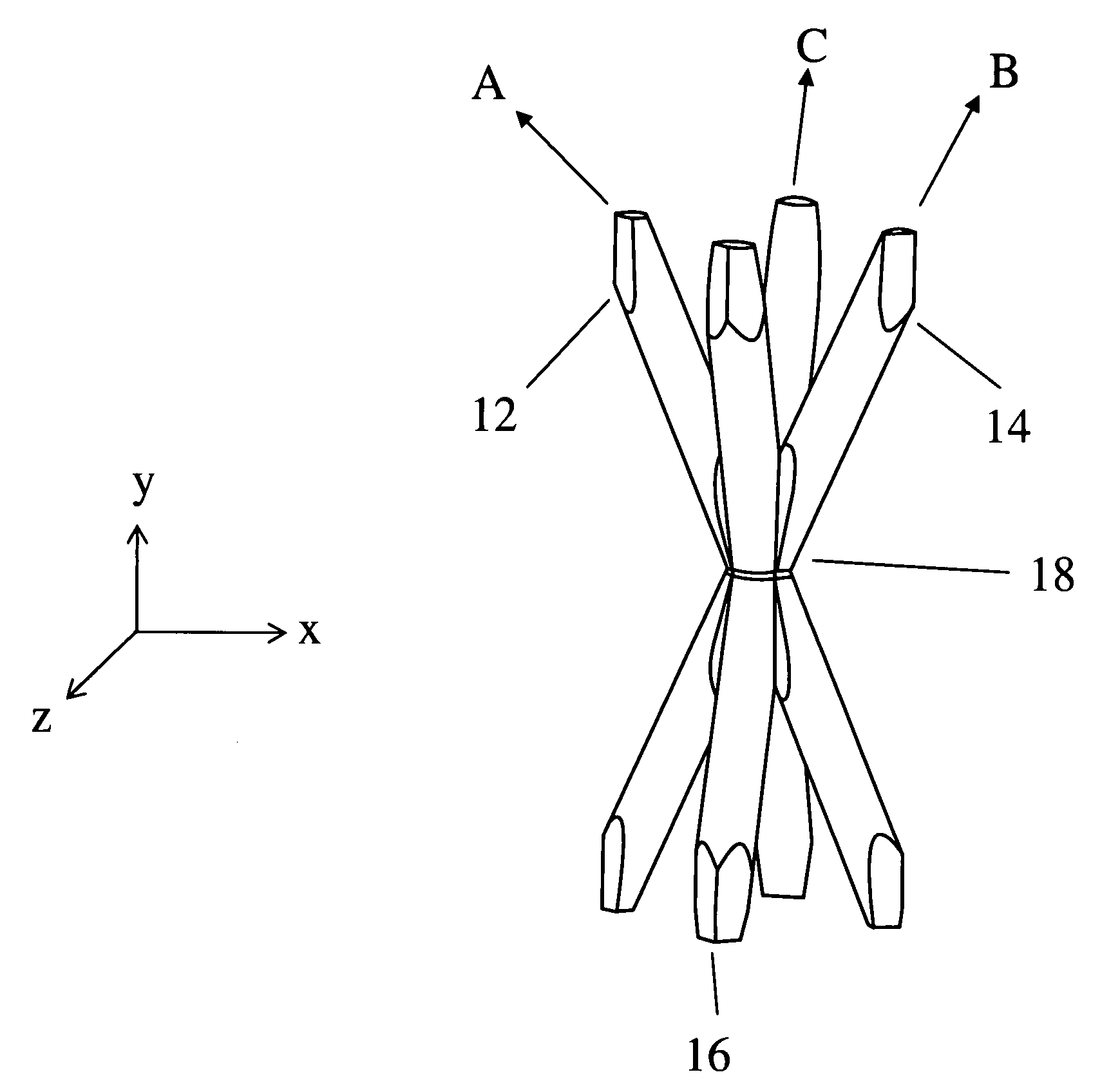

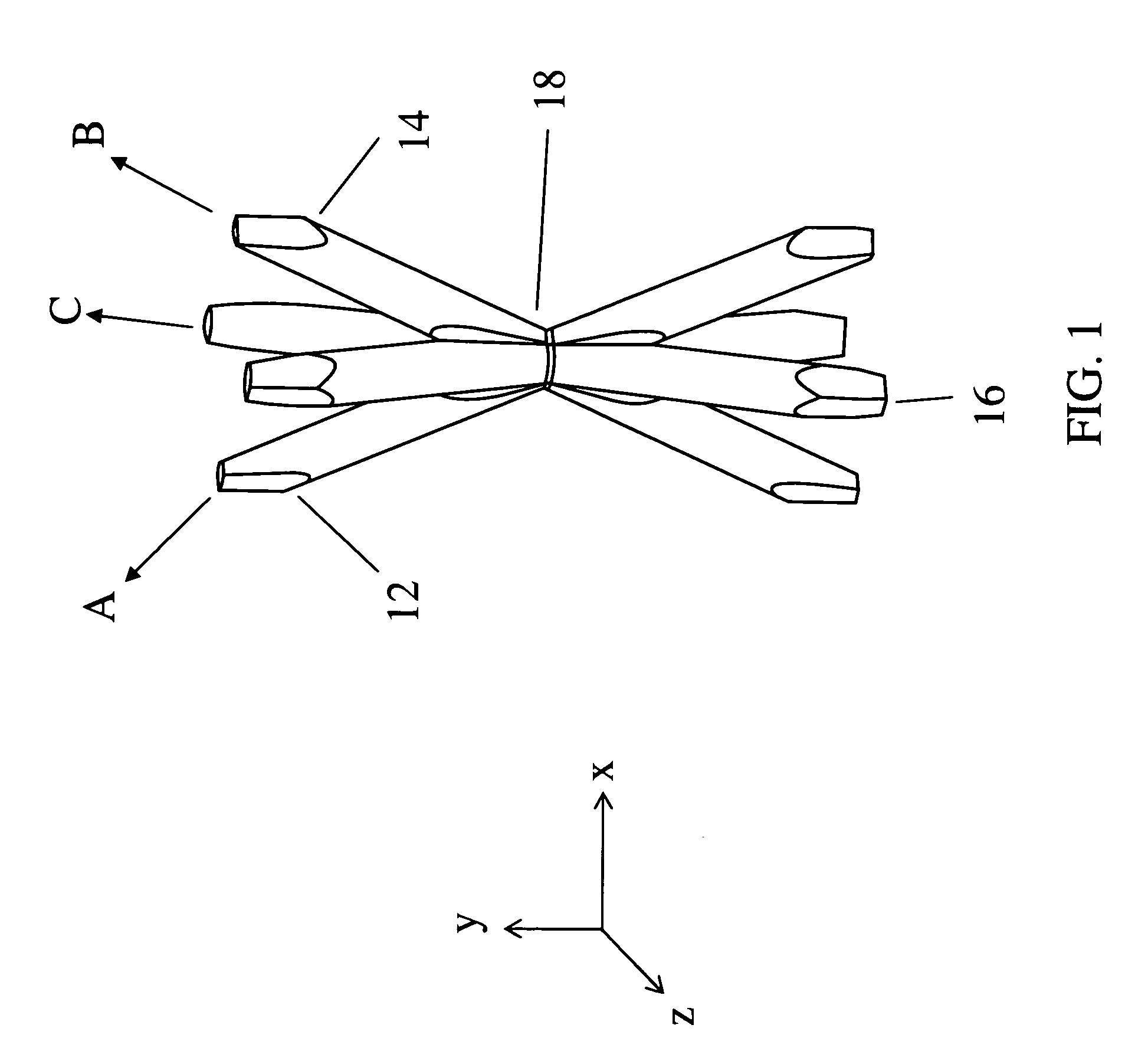

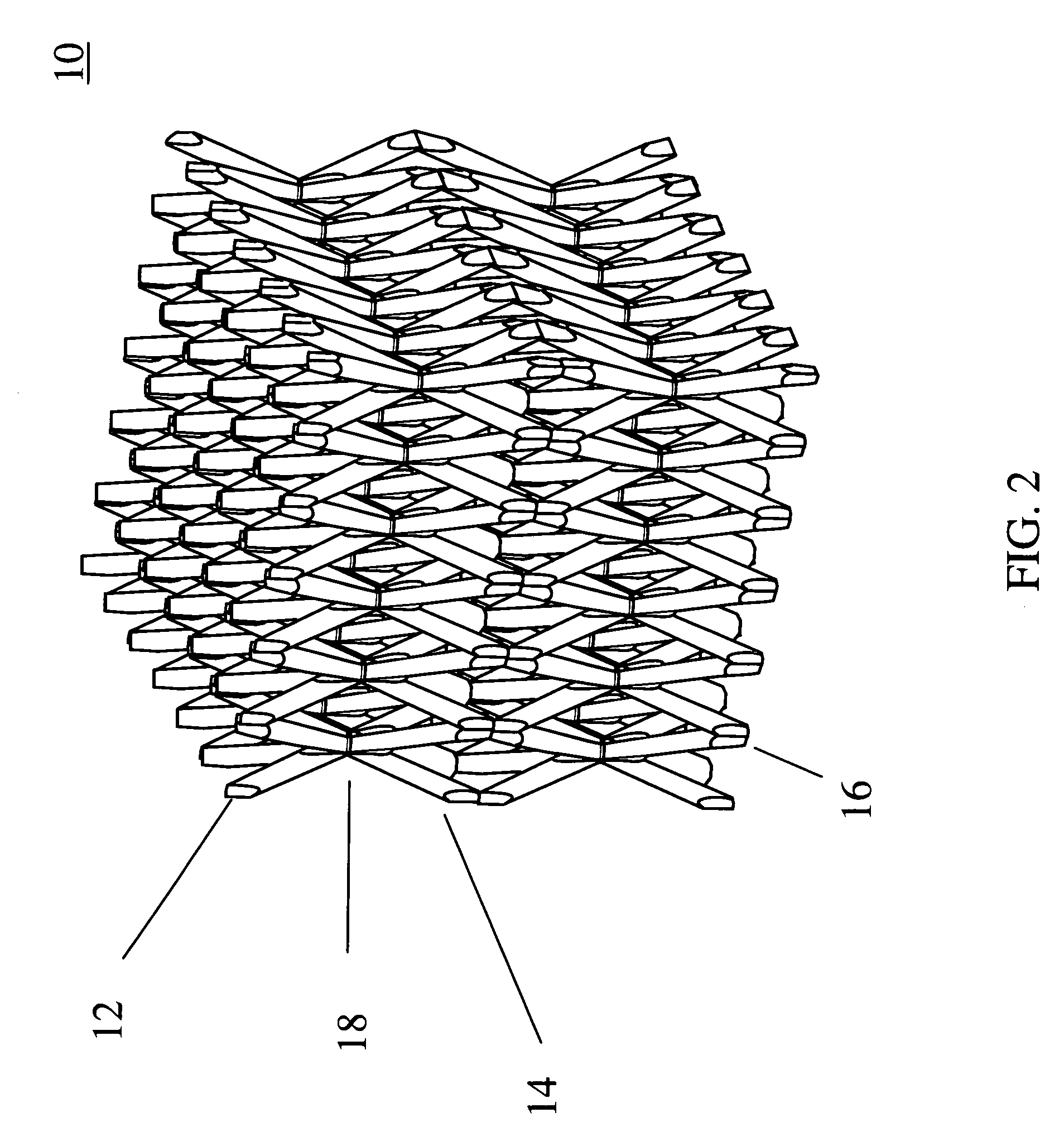

Ceramic microtruss

InactiveUS7687132B1High temperature stabilityHigh strengthMetal-working apparatusGirdersCeramicMicrostructure

An ordered ceramic microstructure and a method of making the same. In one embodiment, the ceramic microstructure includes a base structure and one or more ceramic layers. The base structure includes a plurality of first truss elements defined by a plurality of first self-propagating polymer waveguides and extending along a first direction, a plurality of second truss elements defined by a plurality of second self-propagating polymer waveguides and extending along a second direction, and a plurality of third truss elements defined by a plurality of third self-propagating polymer waveguides and extending along a third direction. Here, the first, second, and third truss elements interpenetrate each other at a plurality of nodes to form a continuous material, and the base structure is self-supporting. In addition, the ceramic layers coat a surface of at least one truss element of the first truss elements, the second truss elements, or the third truss elements.

Owner:HRL LAB

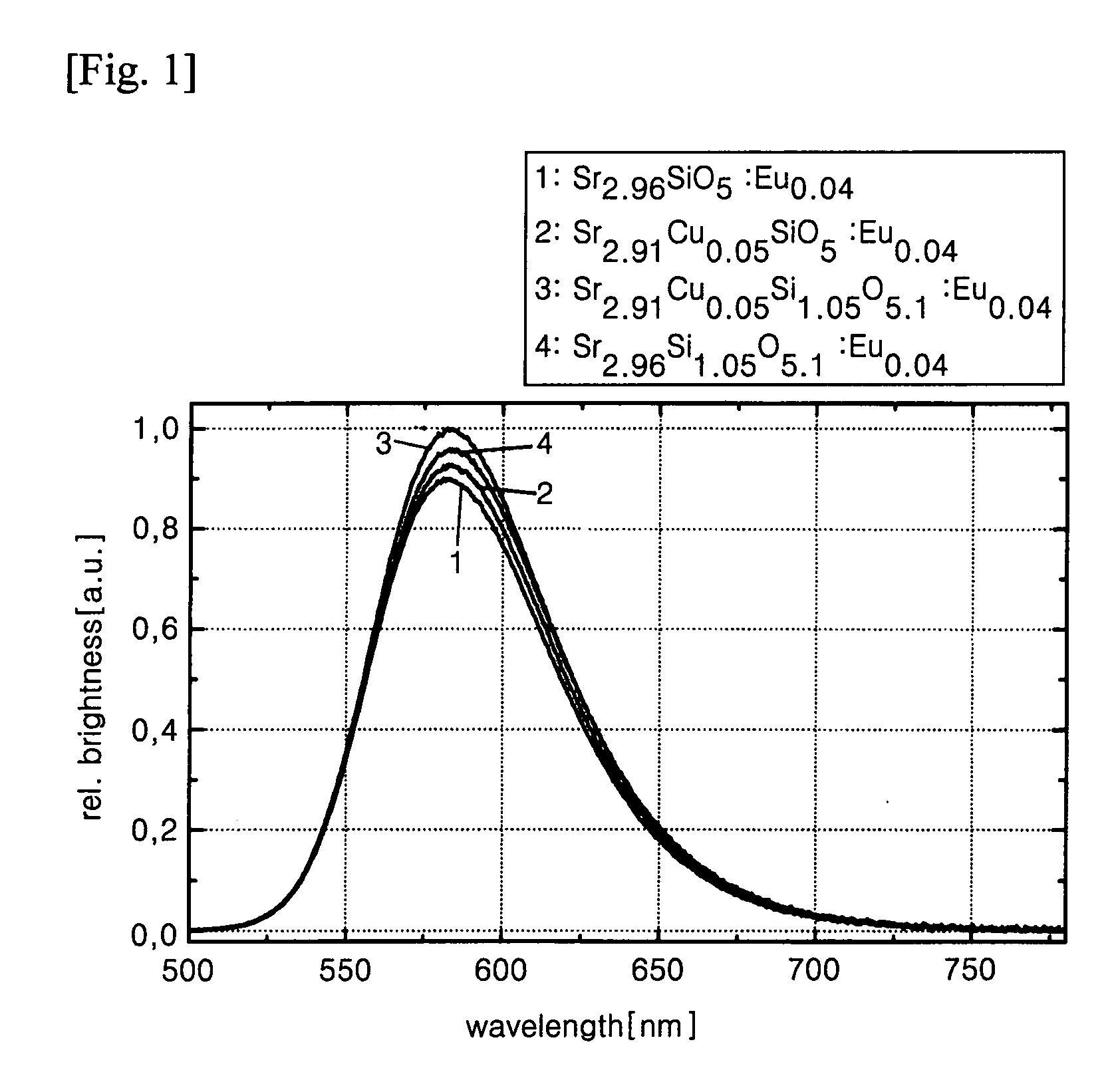

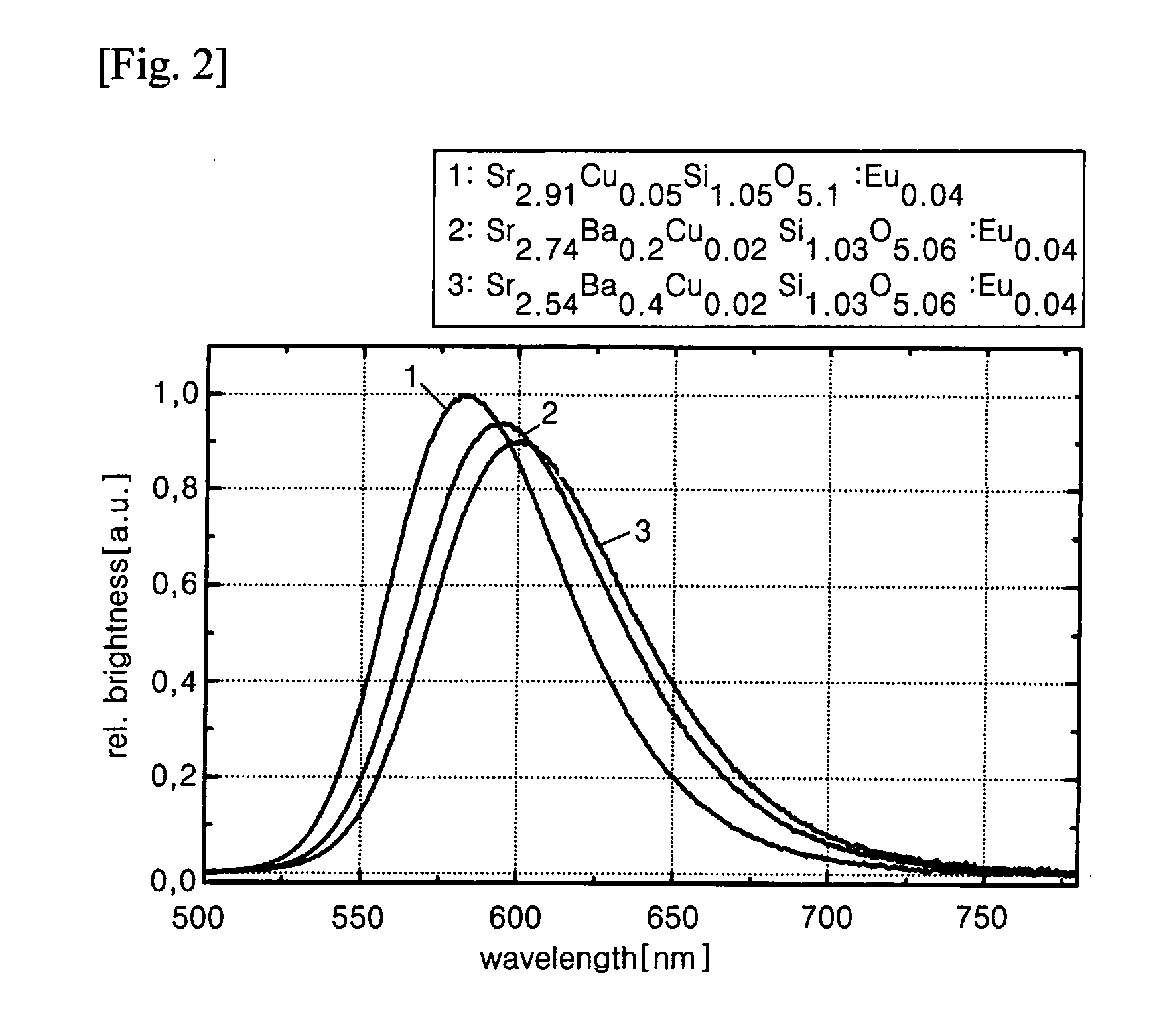

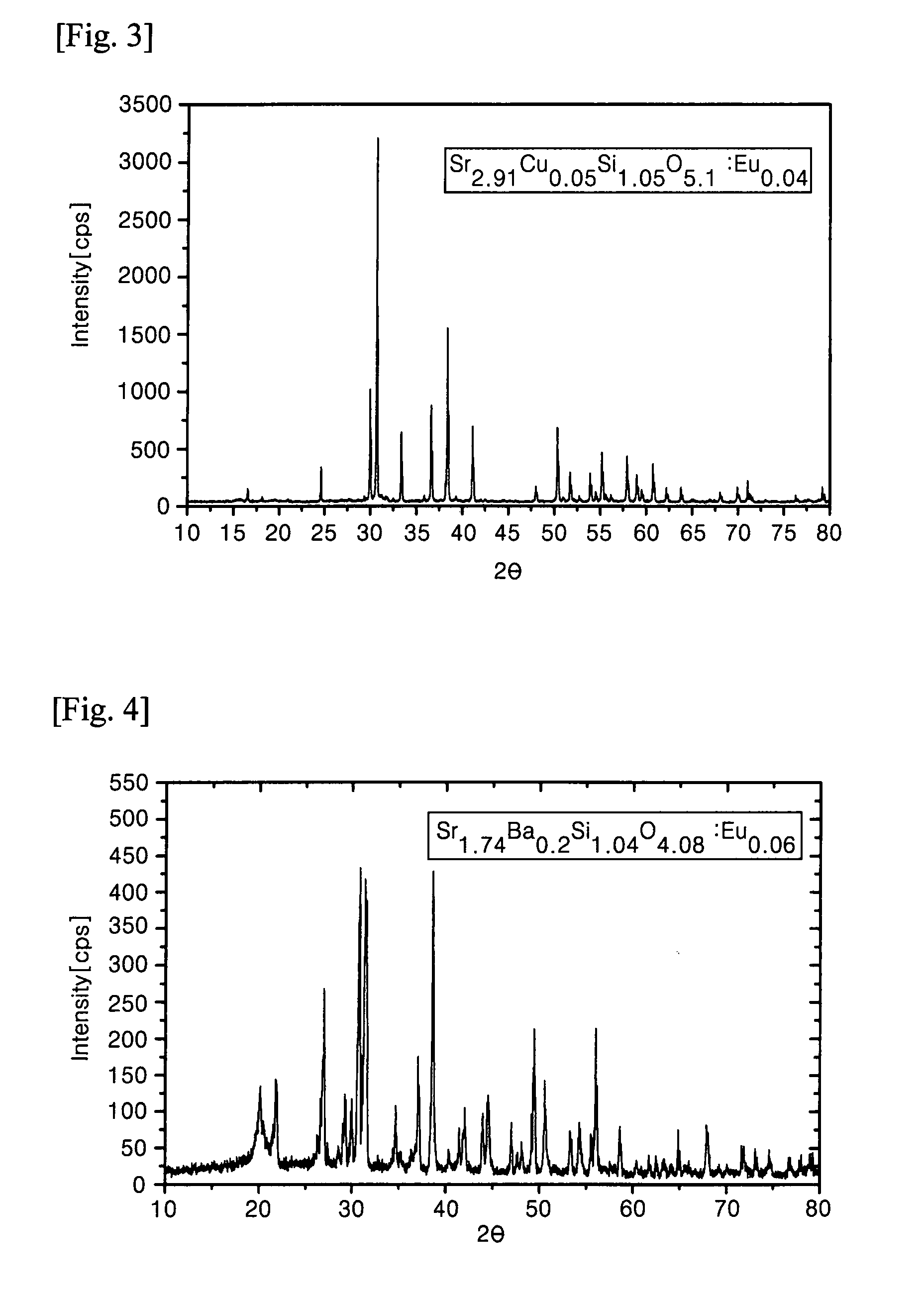

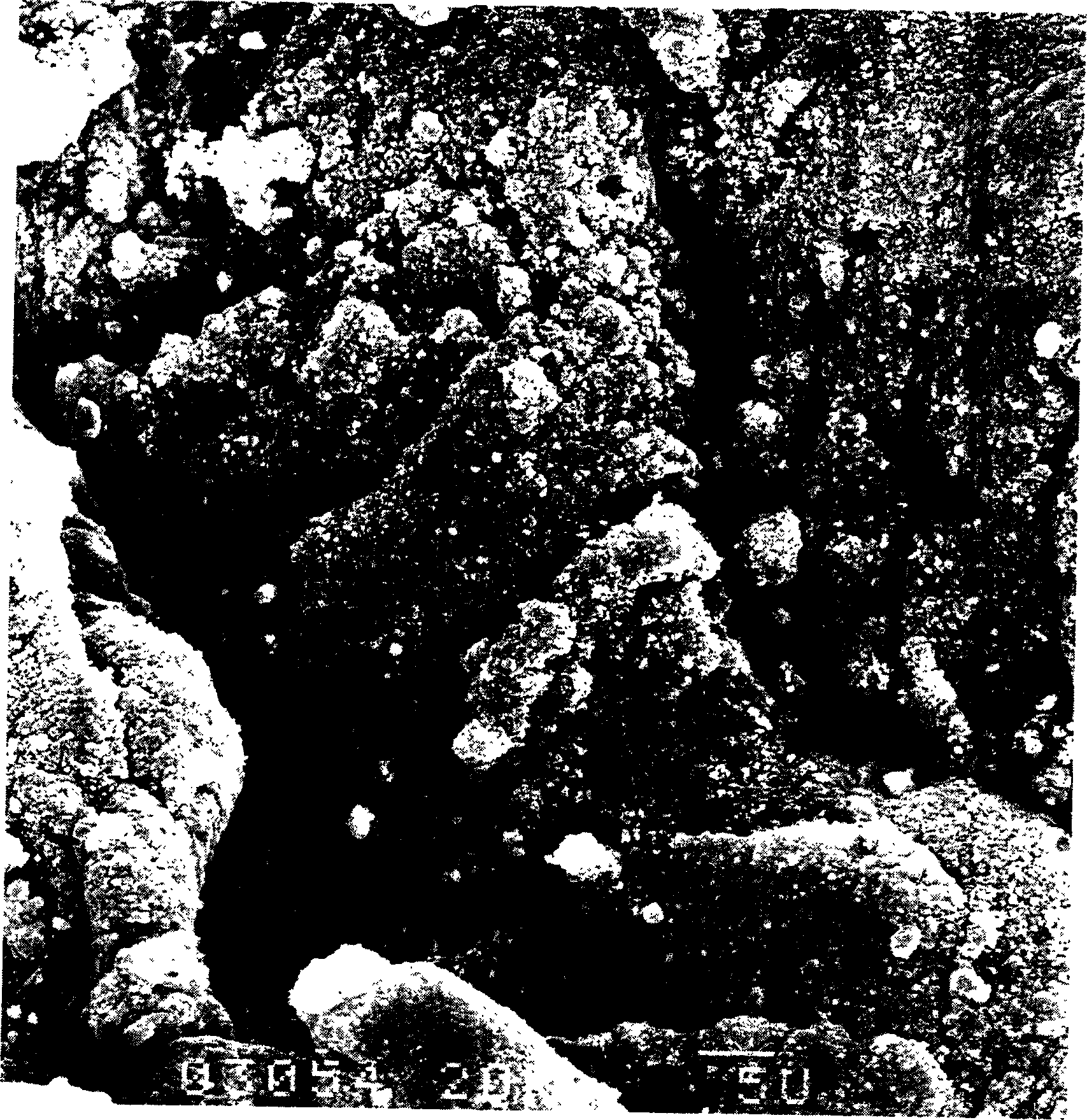

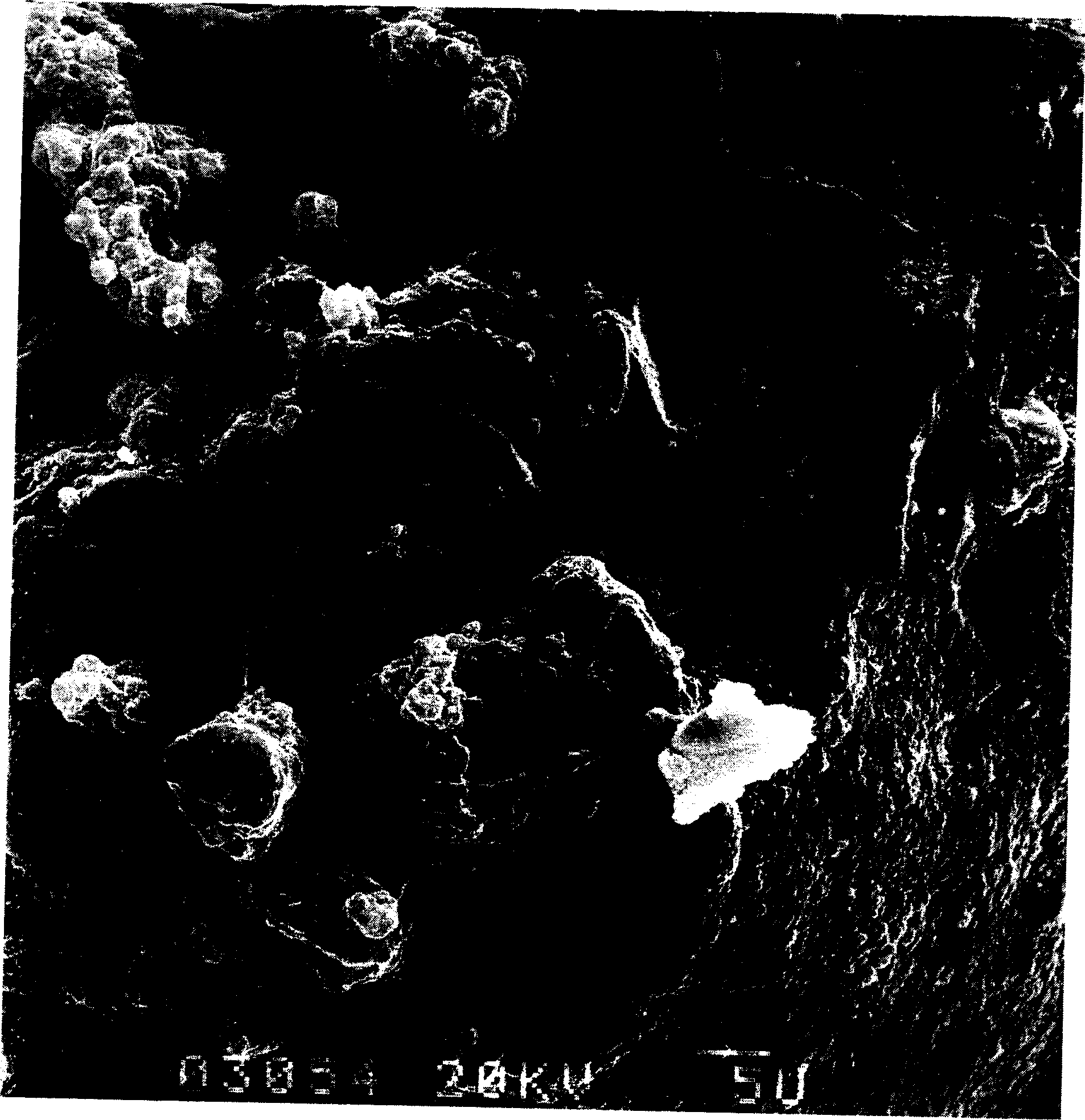

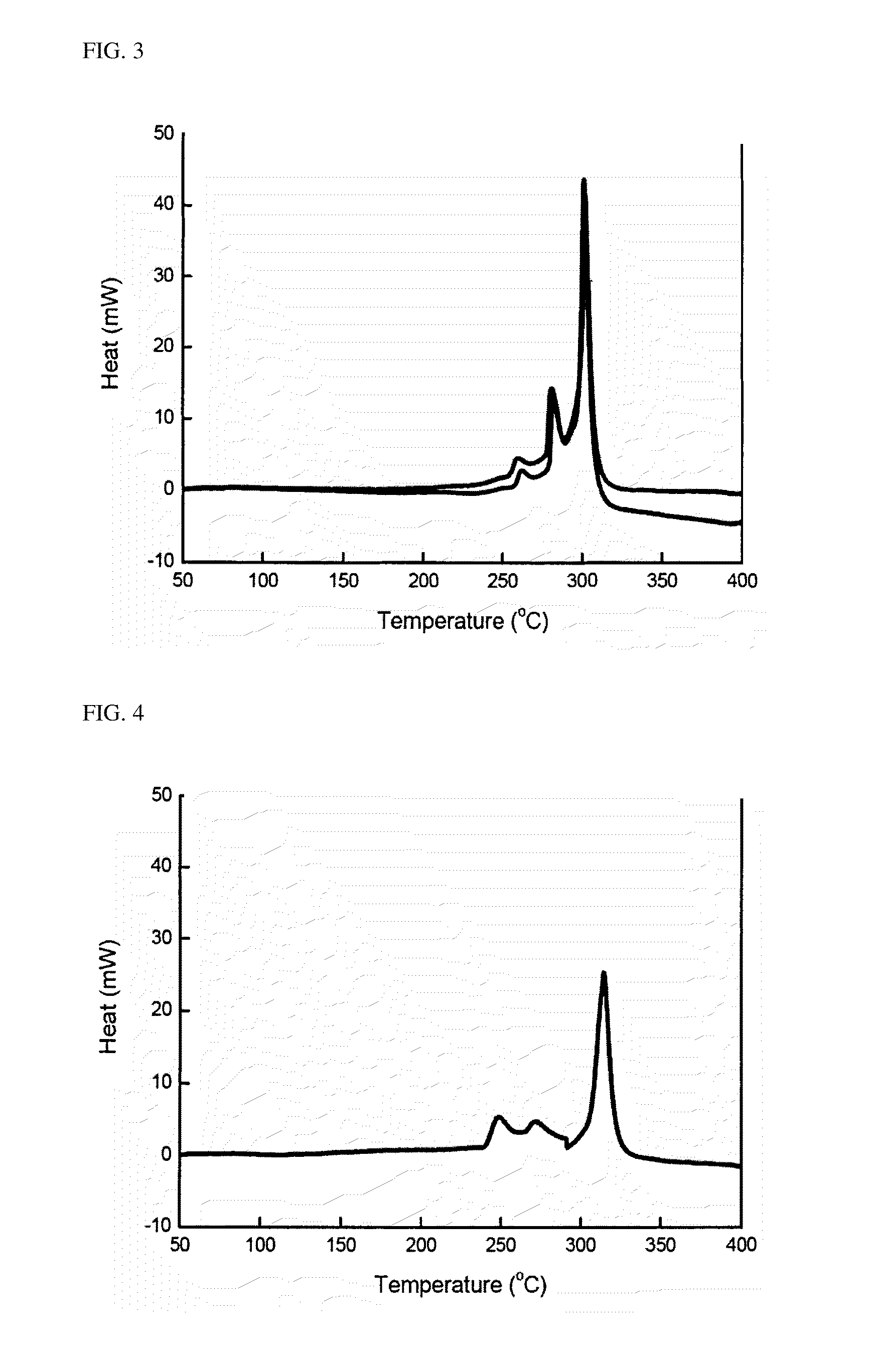

Non stoichiometric tetragonal copper alkaline earth silicate phosphors and method of preparing the same

ActiveUS20090050849A1High temperature stabilitySensitivity against humidityGas discharge lamp usageLuminescent compositionsChemistryColor temperature

Disclosed are non stoichiometric Copper Alkaline Earth Silicate phosphors activated by divalent europium for using them as high temperature stable luminescent materials for ultraviolet or daylight excitation. The phosphors are represented as the formula (BauSrvCawCux)3-y(Zn,Mg,Mn)zSi1+bO5+2b:Eua. The nonstoichiometric tetragonal silicate is prepared in a high temperature solid state reaction with a surplus of silica in the starting mixture. Furthermore, luminescent tetragonal Copper Alkaline Earth Silicates are provided for LED applications, which have a high color temperature range from about 2,000K to 8,000K or 10,000K showing a CRI with Ra=80˜95, when mixed with other luminescent materials.

Owner:SEOUL SEMICONDUCTOR

Composite of modified road asphalt by microwave radiating old rubber powder and its preparation process

InactiveCN1597782AGood dispersionGood physical and mechanical propertiesBuilding insulationsWaxMicrowave

The invention relates to a microwave-irradiated waste-rubber powder modified pitch combination and its preparing method, using higher-wax content pitch as a substrate, adding in powdery butadiene-styrene rubber and microwave-irradiated waste rubber powder, and making high-speed cutting and uniform commixing to make the modified pitch. The modified pitch has the characters of high-temperature stability, obviously increased low-temperature extensibility, good antiaging property, etc, has road performance synthetically improved and can act as high-grade road pitch for use.

Owner:NORTHWEST NORMAL UNIVERSITY

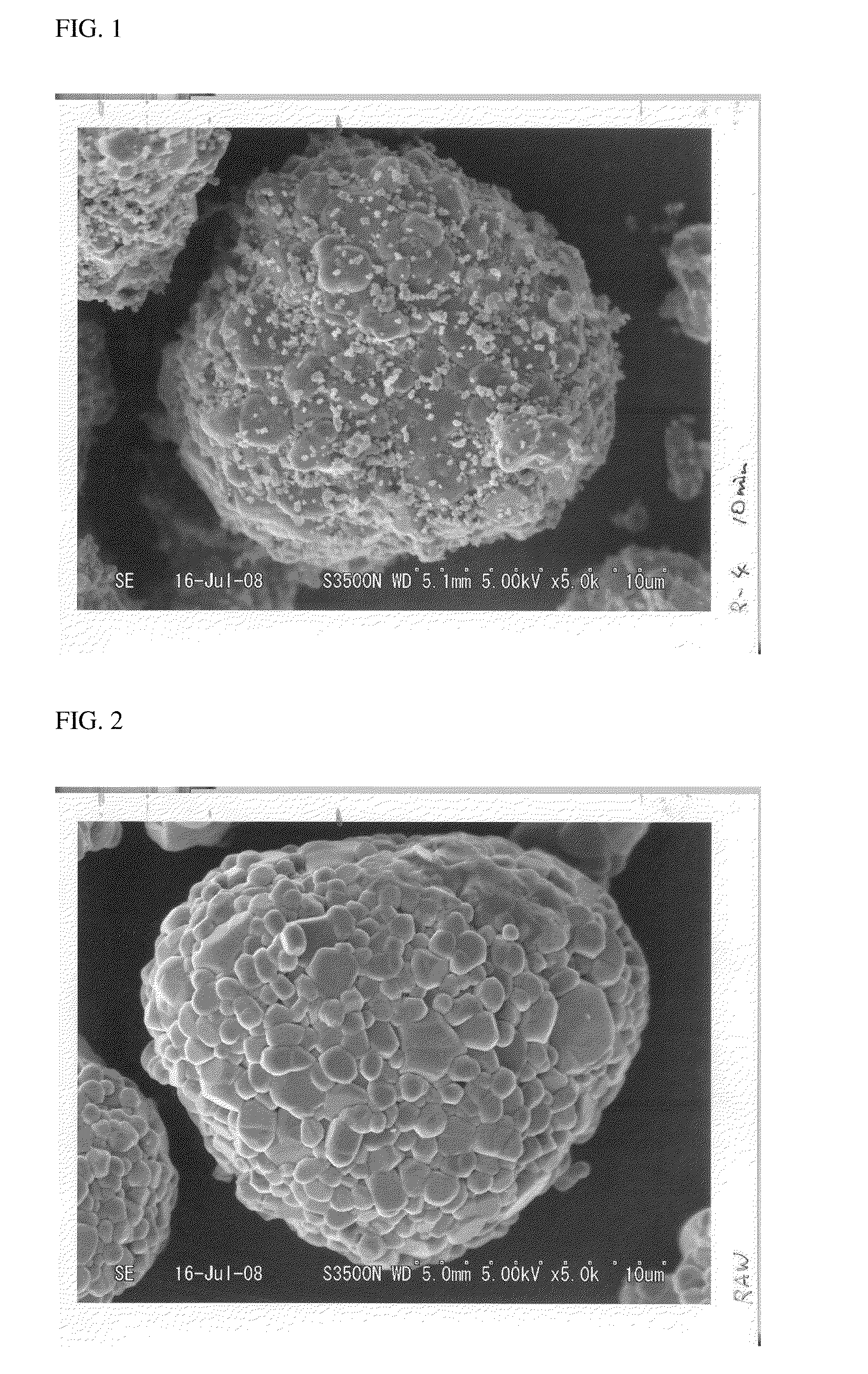

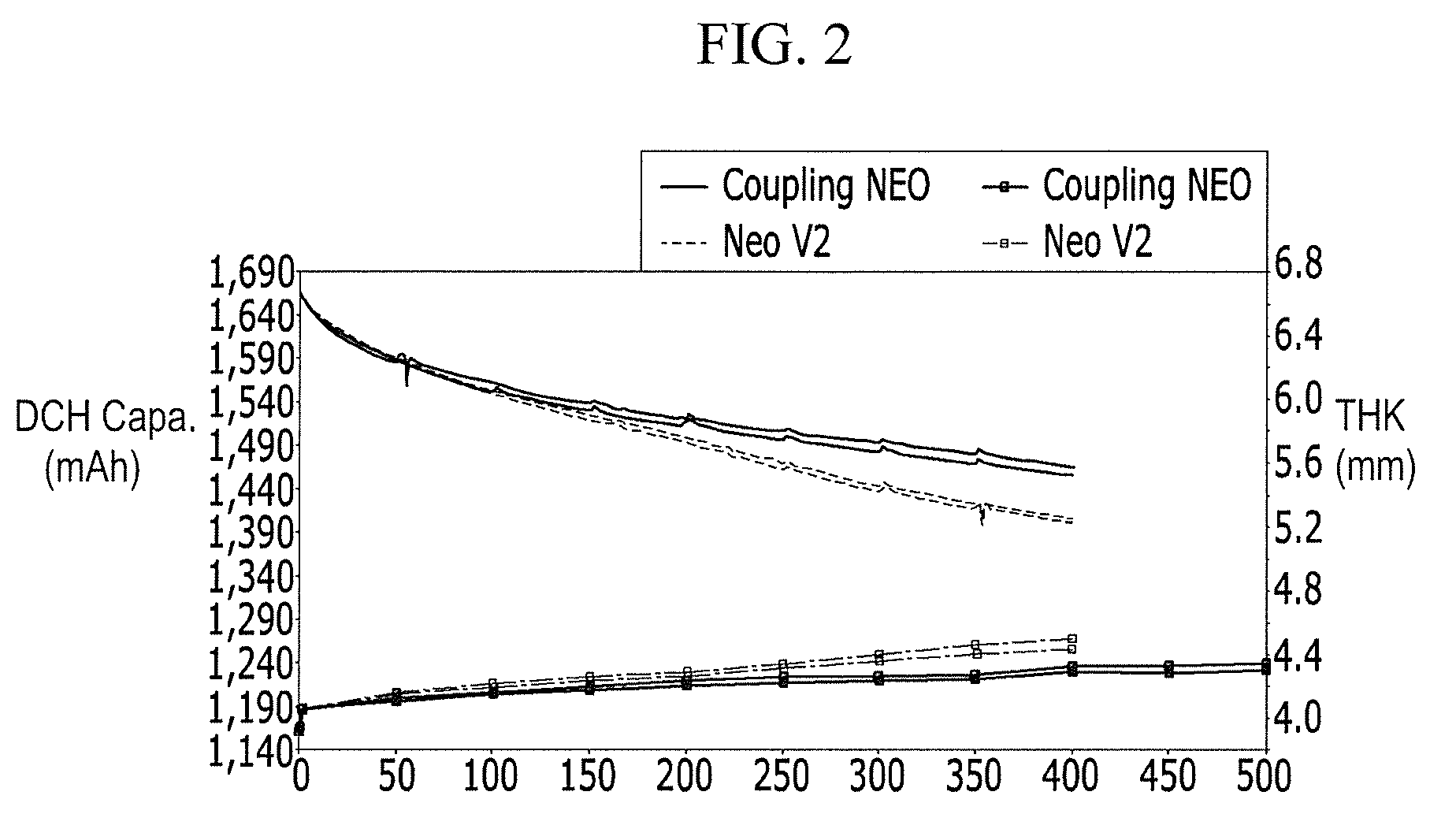

Cathode active material for lithium secondary battery

ActiveUS20110081578A1High battery capacityHigh temperature stabilityPositive electrodesLi-accumulatorsCobalt oxideChemistry

Disclosed herein is a cathode active material based on lithium nickel-manganese-cobalt oxide represented by Formula 1, wherein the lithium nickel-manganese-cobalt oxide has nickel content of at least 40% among overall transition metals and is coated with an ion-conductive solid compound at a surface thereof. A lithium secondary battery having the disclosed cathode active material has advantages of not deteriorating electrical conductivity while maintaining high temperature stability, so as to efficiently provide high charge capacity.

Owner:LG ENERGY SOLUTION LTD

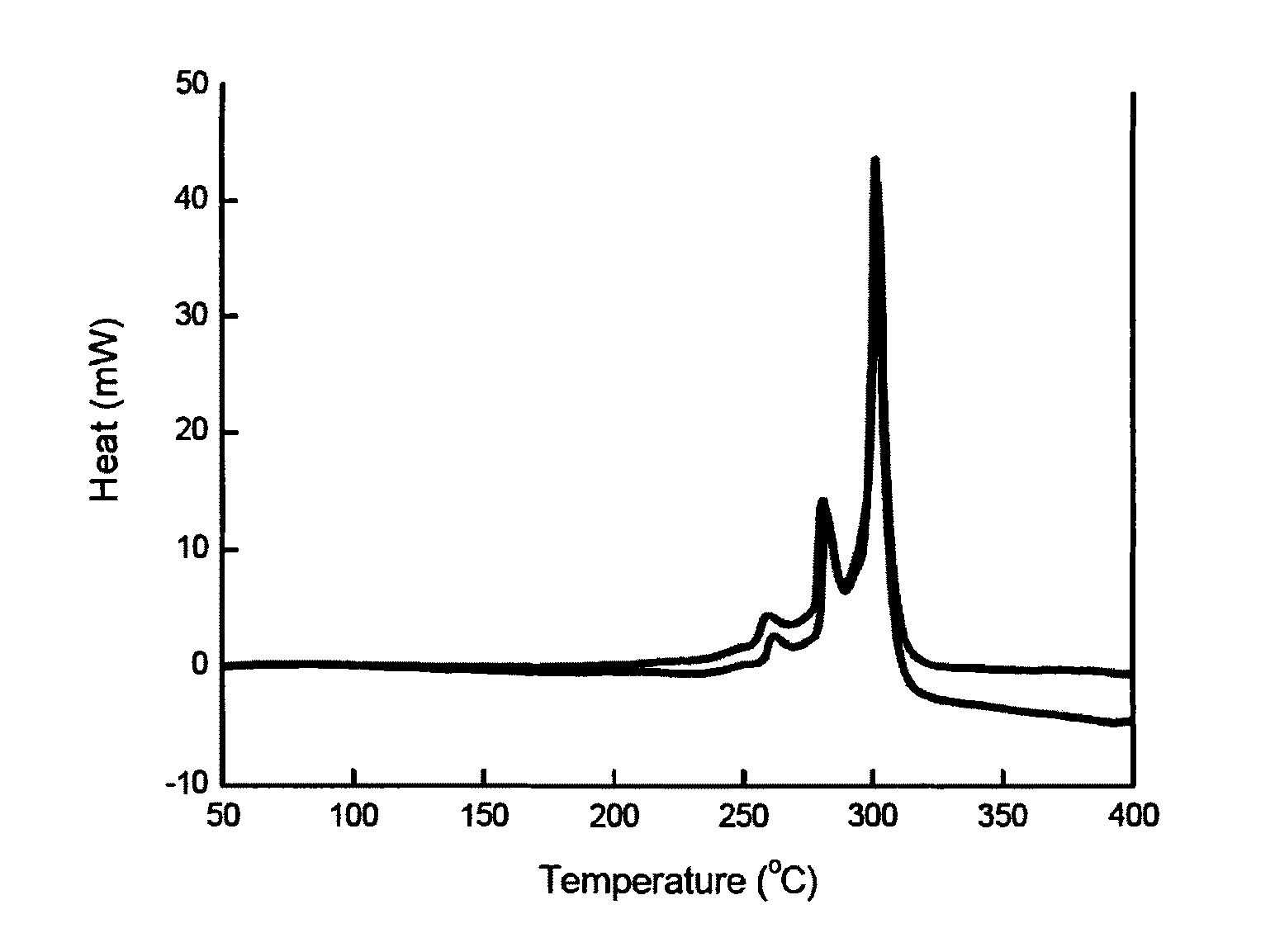

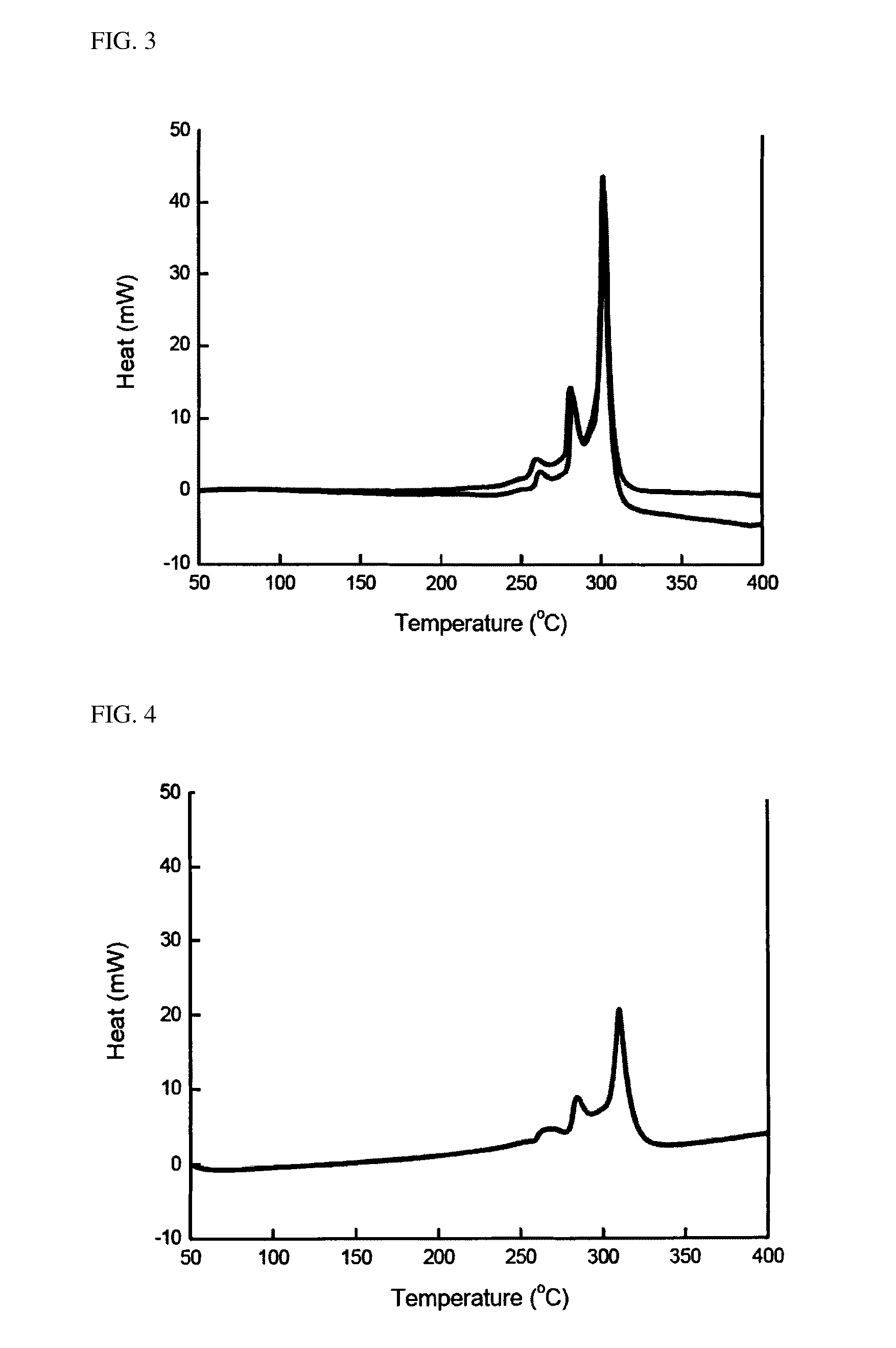

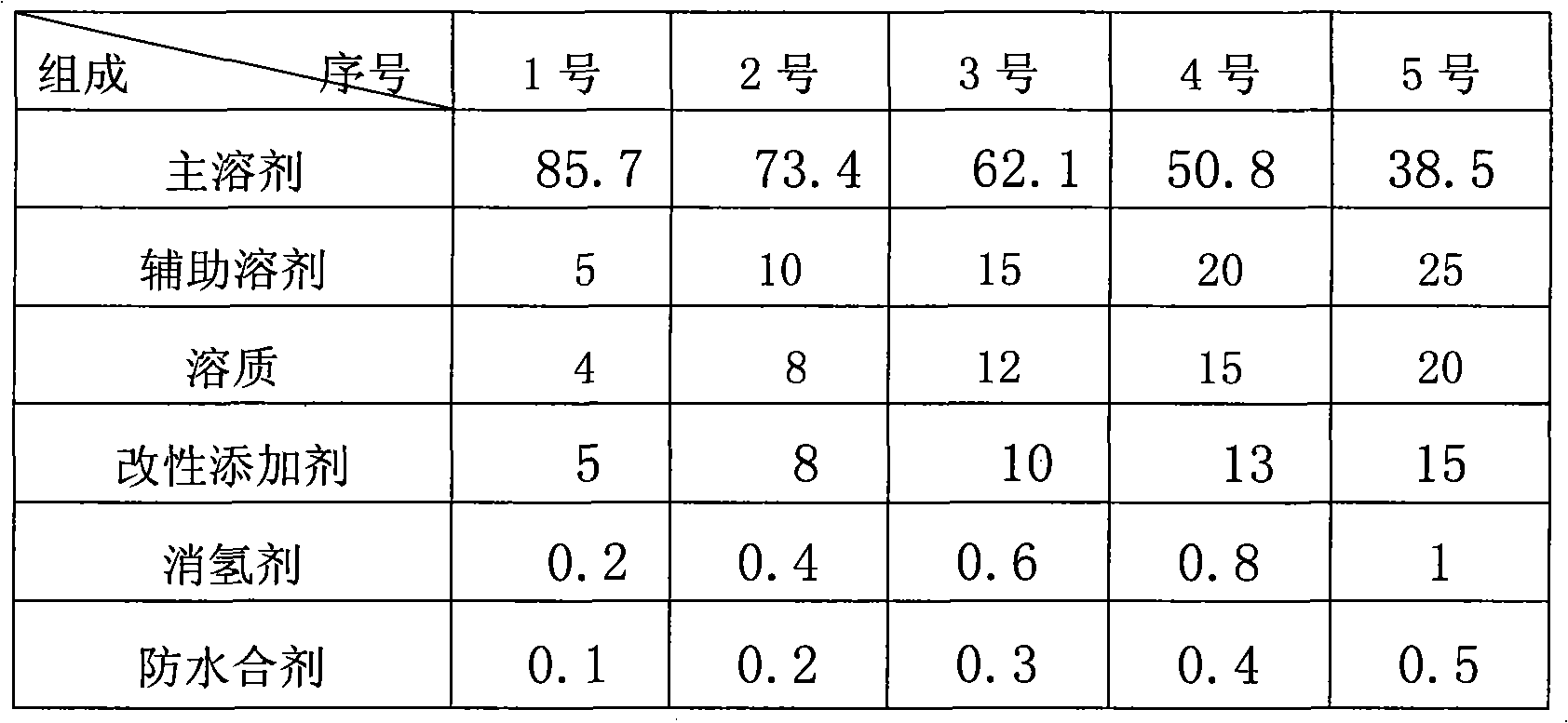

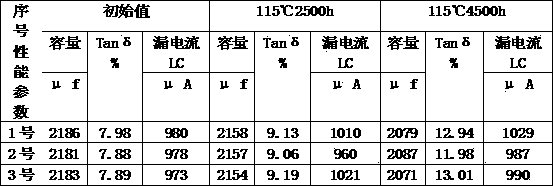

Electrolysis solution and preparation method thereof as well as preparation method for obtained aluminum capacitor

ActiveCN101556867AIncrease the flash voltageStrong corrosion resistanceLiquid electrolytic capacitorsChemistryCorrosion

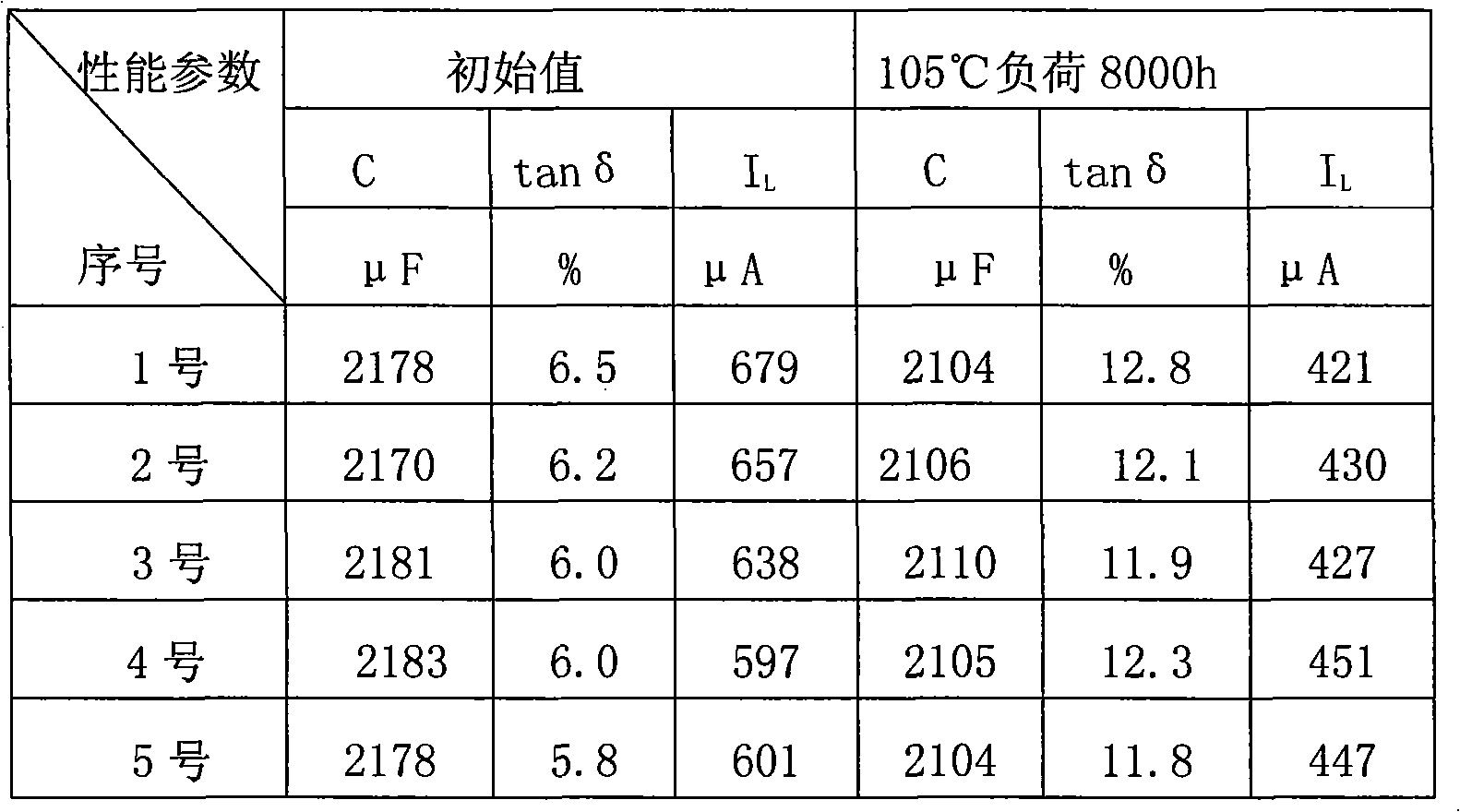

The invention relates to electrolysis solution and a preparation method thereof as well as a preparation method for an obtained aluminum capacitor. The electrolysis solution is composed by the components according to the following weight by parts: 38.5-85.7 wt % of primary solvent, 5-25 wt % of auxiliary solvent, 4-20 wt % of solute, 5-15 wt % of modified additive, 0.2-1 wt % of hydrogen eliminating agent and 0.1-0.5 wt % of waterproof combination agent. The primary solvent is glycol; the auxiliary solvent is one or more of tributyl phosphate, mono butyl ester phosphate, diglycol dibutyl ether; the solute is one or more of ammonium sebacate, 1.6-dodecyl ammonium bisgallic acid, 1.10-dodecyl ammonium bisgallic acid organic carboxylate. In the preparation method for the aluminum capacitor using the electrolysis solution, positive pressure and vacuum-pumping is required to be applied in an impregnation tank in an alternate recycle way with the recycle impregnation interval period being 20-60min.The electrolysis solution has the characteristics of high temperature resistance, high sparking pressure and strong corrosion resistance. The screw large capacitor has a service life of 8,000 hours at 105 DEG C or 2,000 hours at 125 DEG C.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

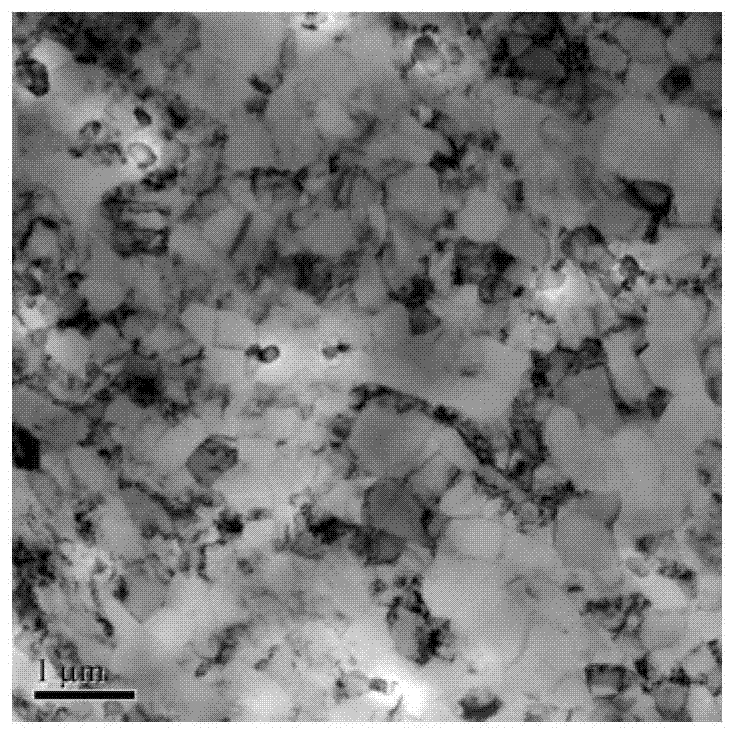

Preparation method of high-performance magnesium alloy plate with double-phase structure

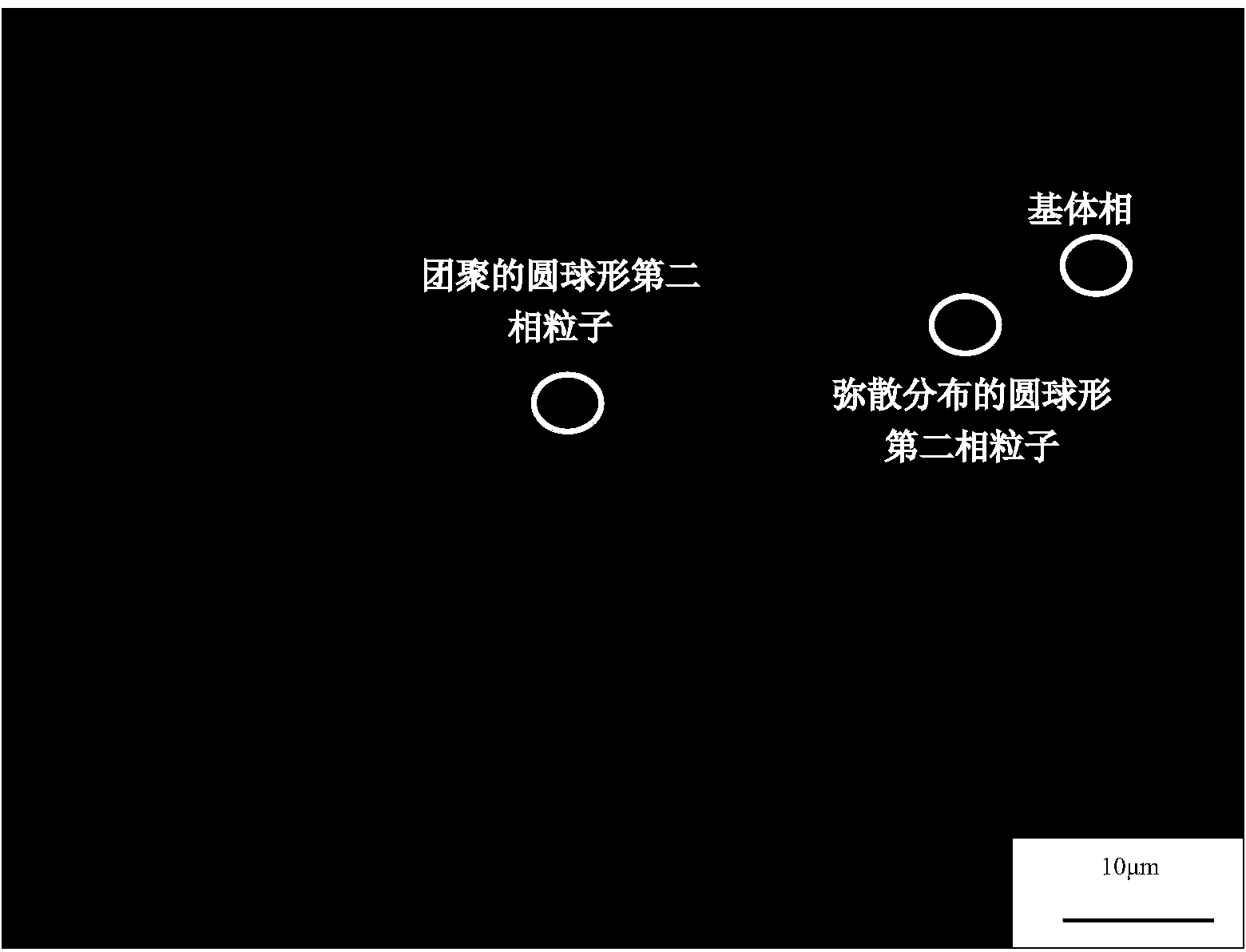

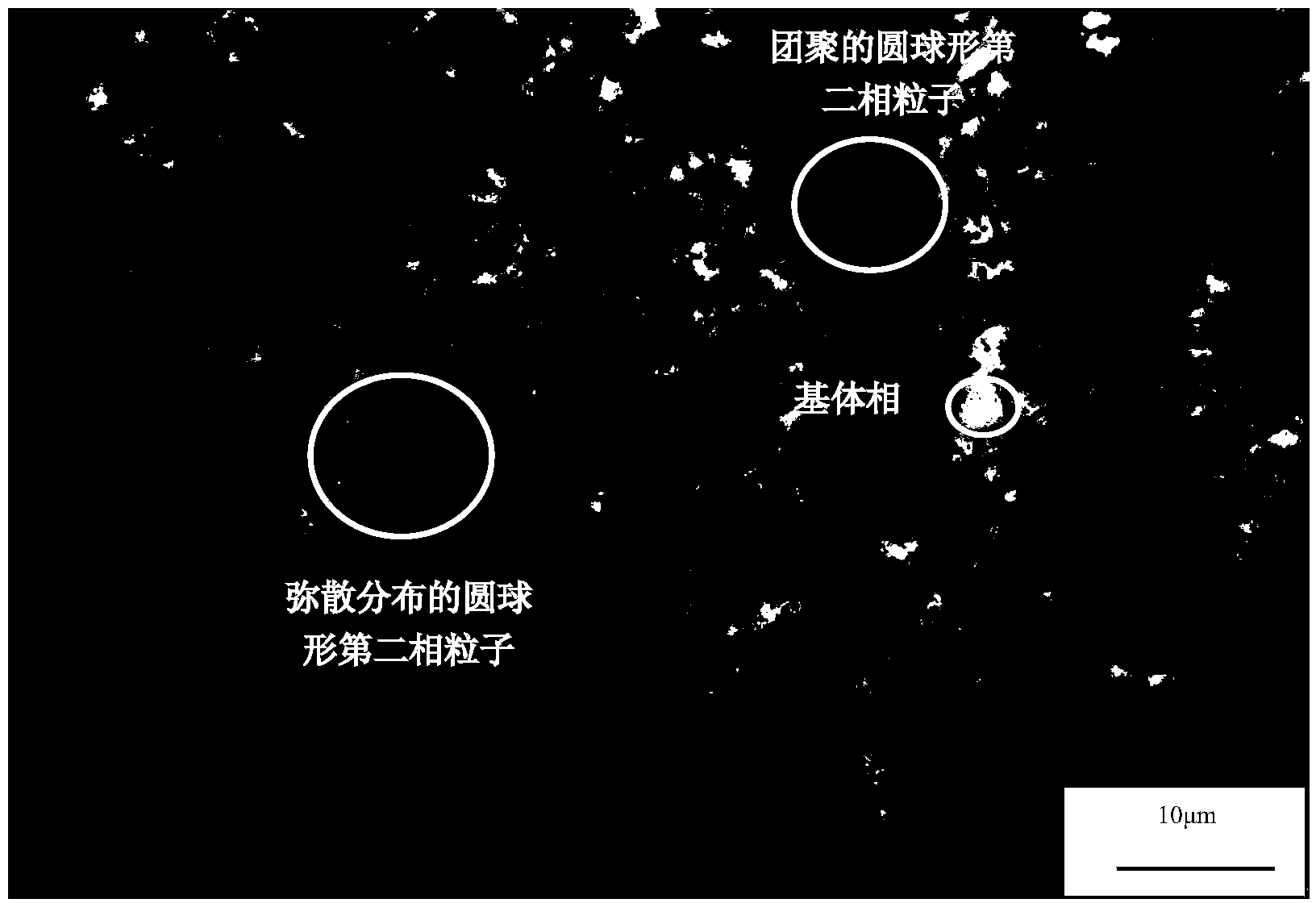

The invention belongs to the technical field of non-ferrous metal magnesium alloy preparation and processing, and particularly relates to a preparation method of a high-performance magnesium alloy plate with a double-phase structure. In the method provided by the invention, a virgin alloy blank of a double-phase microstructure magnesium alloy is prepared by a spray deposition or quick-flow powder preparation or powder metallurgy process; the virgin alloy blank of the double-phase microstructure magnesium alloy is subjected to extrusion, forging, rolling and stamping 'pre-deformation' to form a pre-deformed blank with a 'double-phase texture'; and the pre-deformed blank is subjected to hot rolling or cold rolling to obtain the finished product. The magnesium alloy provided by the invention has the characteristics of 'double-phase structure' (consisting of fine alpha-Mg matrix phase and stable fine second-phase particles) and 'double-phase texture', and a magnesium alloy plate with good comprehensive performance can be obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

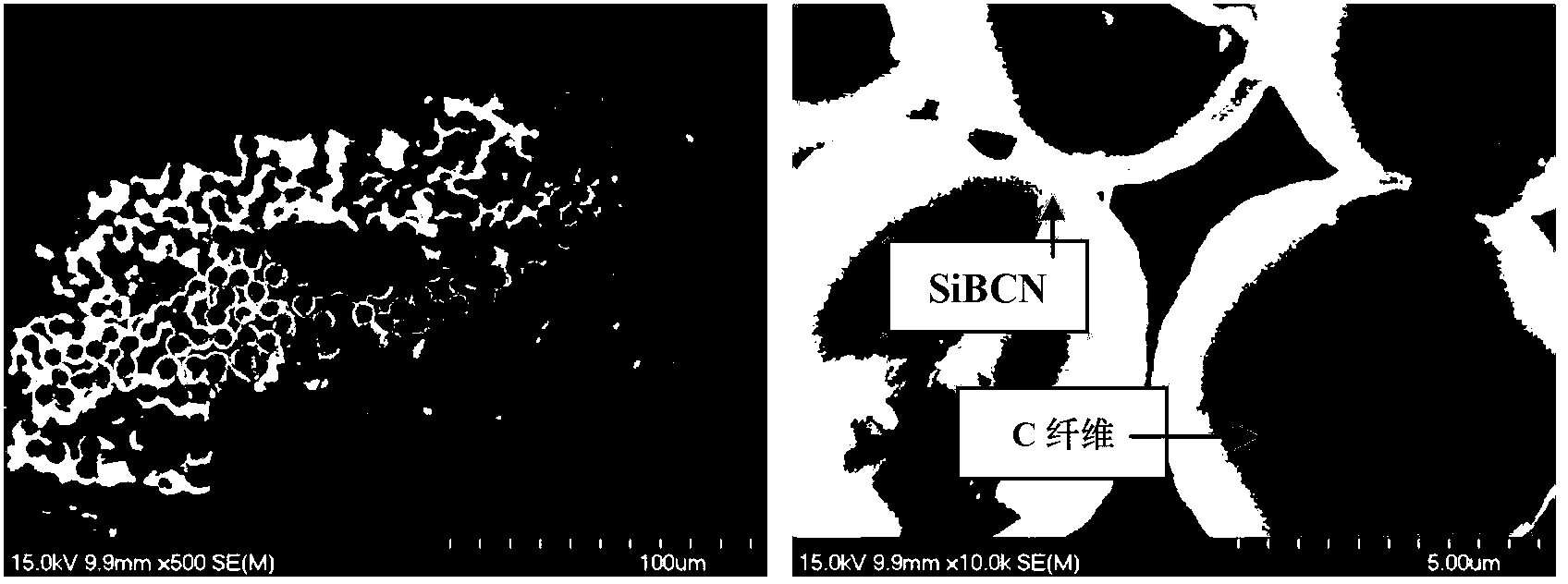

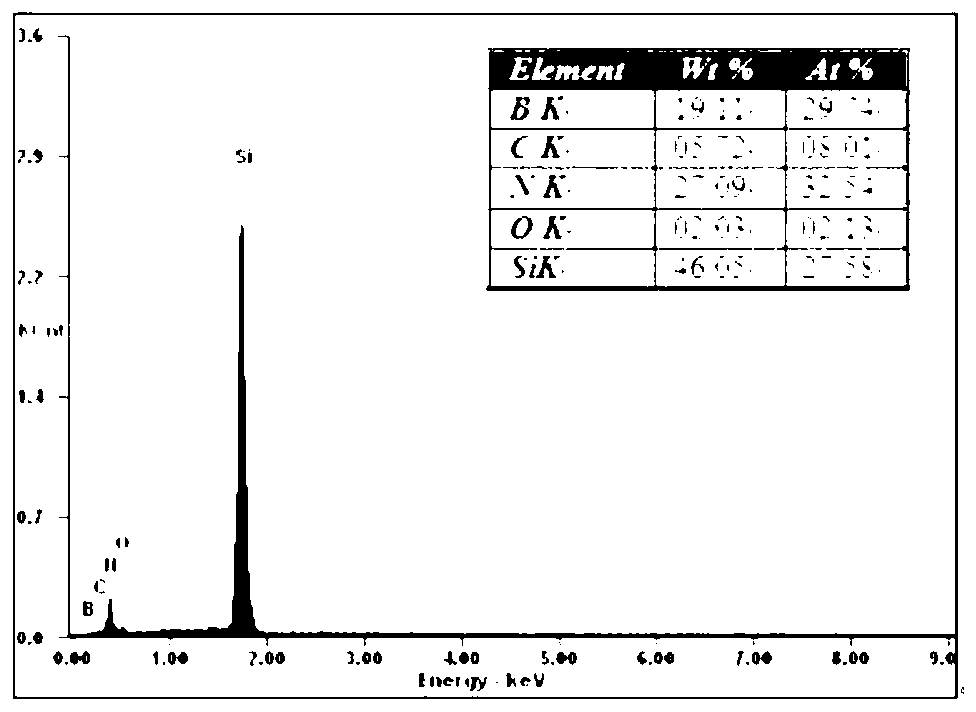

Chemical vapor deposition method of Si-B-C-N amorphous ceramic

The invention relates to a chemical vapor deposition method of a Si-B-C-N amorphous ceramic. The chemical vapor deposition method comprises the following steps of: suspending a substrate material on a matching sample bracket of a vacuum furnace, putting samples in a centre of an isothermal region in the furnace and preparing even Si-B-C-N amorphous ceramic on the surface / interior of the substrate material by using a CVD (Chemical Vapor Deposition) / CVI (Chemical Vapor Infiltration) method. The Si-B-C-N amorphous ceramic prepared by the chemical vapor deposition method can be applied to an interface, a matrix and a coating of a continuous fiber-reinforced ceramic matrix composite, has the advantages of excellent properties such as good high-temperature stability, good anti-oxidation property, strong creep resisting capability, low density, low coefficient of thermal expansion and low heat conductivity coefficient and the like, can replace materials such as SiC and Si3N4, further improves the using temperatures and prolongs the service lives of thermal structure ceramics and ceramic matrix composites and has a great application potentiality in the isothermal and long-life field of aircraft engines and industrial gas turbines; and meanwhile, the Si-B-C-N amorphous ceramic also has electrical properties similar to the semiconductors and interesting optical properties and is widely used in the fields of high-temperature invisibility, semiconductors, photoelectricity, communication and control.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

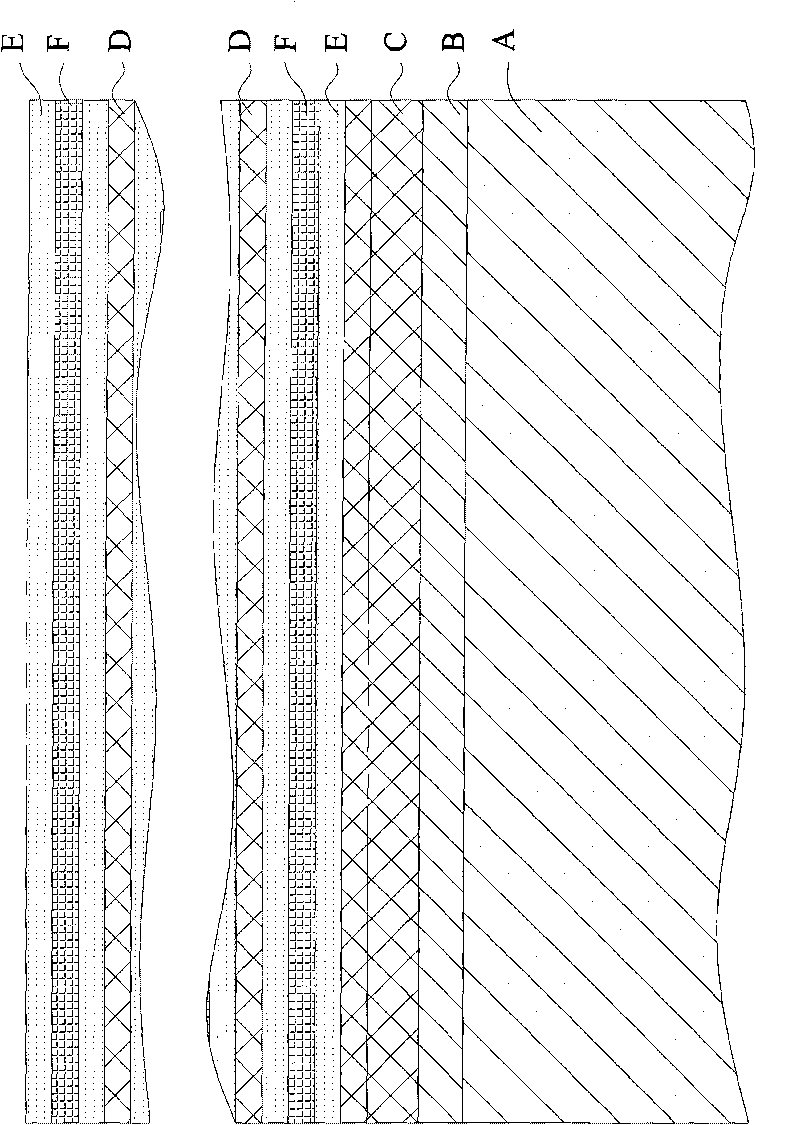

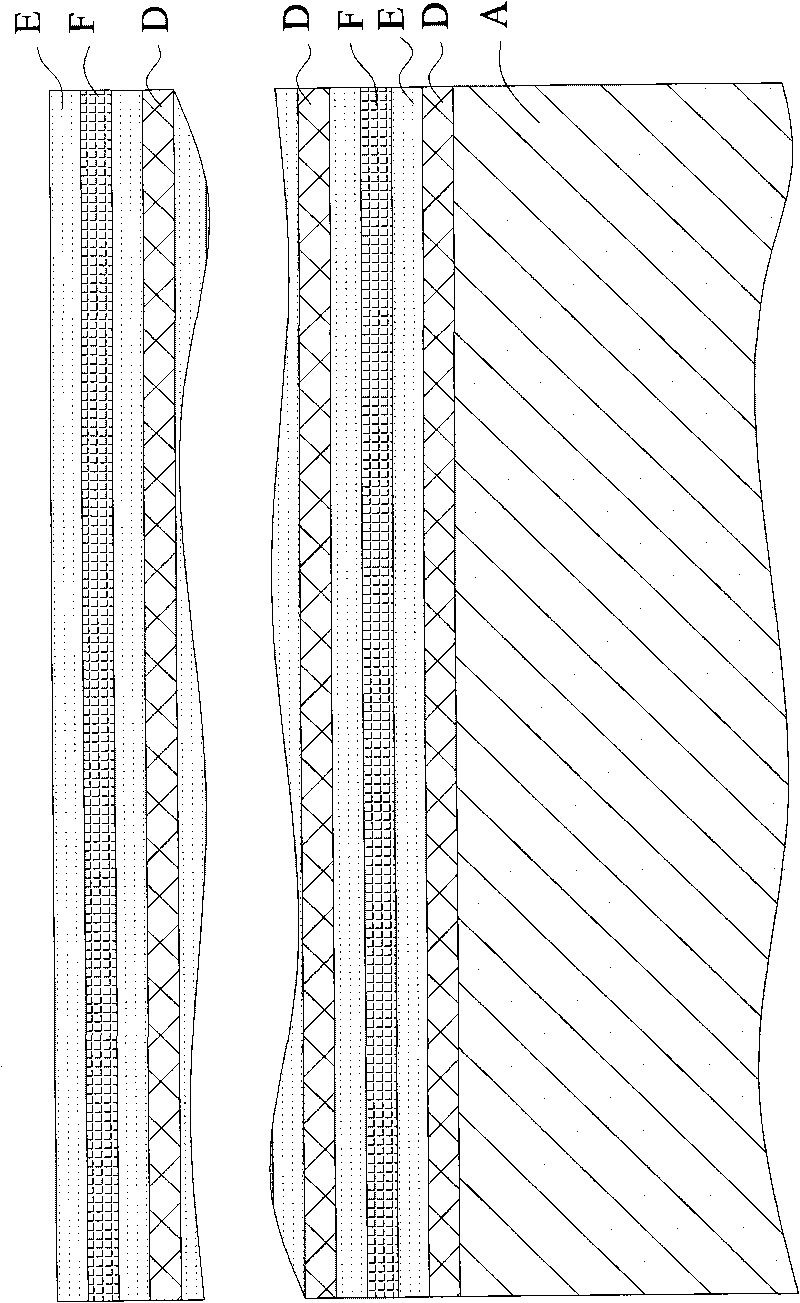

Multi-coating cutting tool deposited in periodicity and preparation method thereof

ActiveCN101690978AAntioxidantHigh temperature stabilityLayered productsTurning toolsOxidation resistantHardness

The invention discloses a multi-coating cutting tool deposited in periodicity and a preparation method thereof. The multi-coating cutting tool comprises a cutting tool matrix and a coating deposited on the cutting tool matrix; the coating comprises a composite coating which is a multiple periodic coating taking TiN layer to TiSiN layer to TiAlSiN layer to TiSiN layer as one period. The multi-coating cutting tool prepared through simple process, conventional equipment and low manufacturing cost has high rigidity, high strength, excellent high-temperature oxidation resistance and high-temperature stability; and the coating and matrix have favorable bonding strength.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Wide-scope modified asphalt and preparation method thereof

InactiveCN101974235AImprove high temperature stabilitySimple production processBuilding insulationsDuctilityButadiene-styrene rubber

The invention relates to modified asphalt for road repairing and building, in particular to wide-scope modified asphalt and a preparation method thereof. The wide-scope modified asphalt is prepared by a method comprising the following steps: (1) taking 91-95 weight parts of hot asphalt at the temperature of 130-140DEG C as the main raw material; (2) taking 2-4 weight parts of powder butadiene styrene rubber as a first modifier; and (3) taking 3-5 weight parts of Tissuemat E as a second modifier, and mixing the components and preparing into the wide-scope modified asphalt. The wide-scope modified asphalt in the invention has high-temperature stability which is indicated by the softening point larger than 70DEG C and low temperature flexibility which is indicated by the ductility at 5DEG C larger than 150cm, as well as high bonding strength of 0.6MPa and simple production process, and is an asphalt product being convenient for application and dissemination.

Owner:河南金欧特实业集团股份有限公司

Cathode active material for lithium secondary battery

ActiveUS20110062378A1High battery capacityHigh temperature stabilityConductive materialNon-aqueous electrolyte accumulator electrodesMetalNickel content

Disclosed herein is a cathode active material based on lithium nickel oxide represented by Formula 1, wherein the lithium nickel oxide has a nickel content of at least 40% among overall transition metals and is coated with a polymer having a melting point of 80 to 300° C. at a surface thereof. A lithium secondary battery having the disclosed cathode active material has advantages of not deteriorating electrical conductivity while maintaining high temperature stability, so as to efficiently provide high charge capacity.

Owner:LG ENERGY SOLUTION LTD

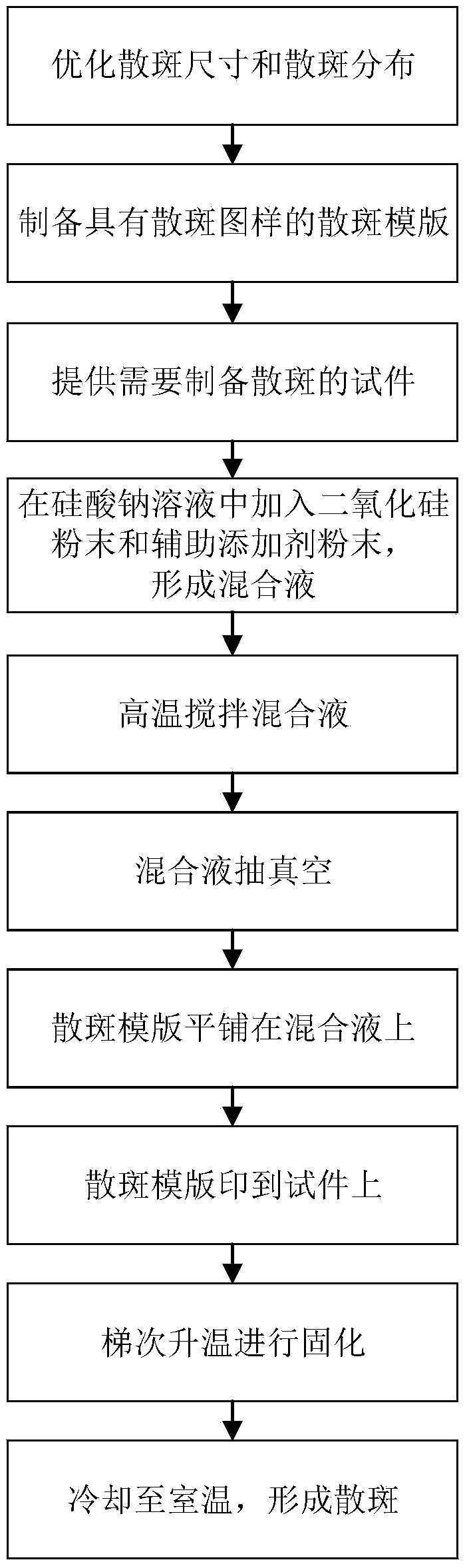

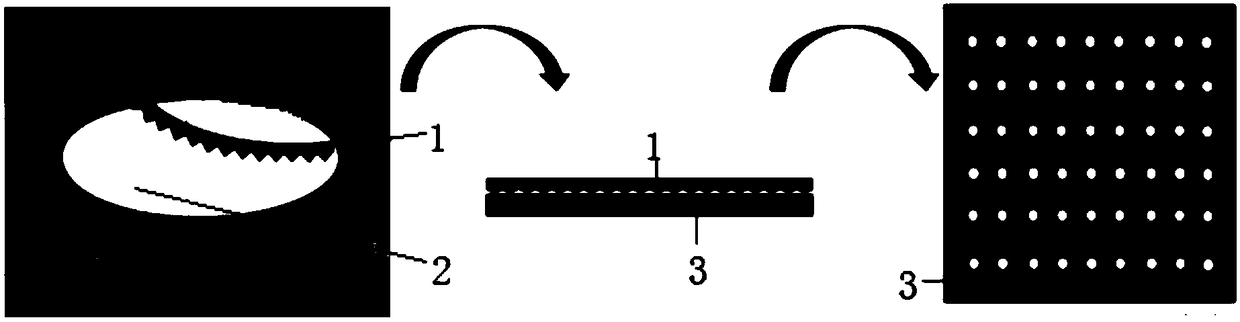

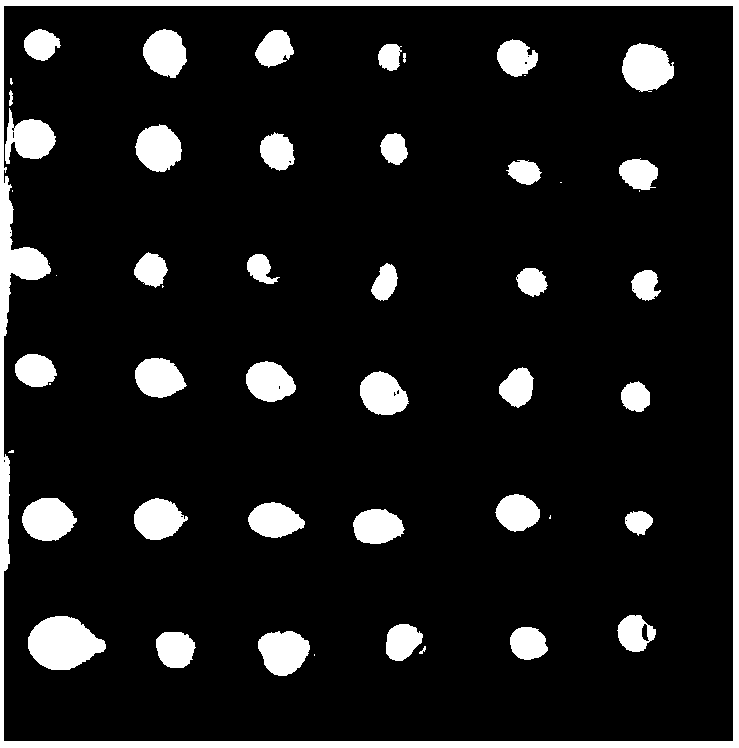

High-temperature speckle and controllable preparation method

ActiveCN108195298AGood high temperature resistance and high temperature adsorption performanceImproves curing strength and stabilityUsing optical meansToxicityEnvironmental resistance

The invention discloses a high-temperature speckle and controllable preparation method thereof. The high-temperature speckle uses a sodium silicate solution as a matrix, silicon dioxide powder and auxiliary additive powder are added to form a mixed liquid, the characteristics of short curing time, low curing temperature, good high-temperature-resistant performance, no toxicity and environmental protection are achieved, and sodium silicate itself has relatively high high-temperautre-resistant performance and high-temperature adsorption performance, and is suitable for being used for high-temperature speckle manufacture; a speckle template having a speckle pattern is prepared, thereby controlling the speckle size and speckle distribution; the speckle template can be repeatedly used, therebyfurther improving preparation efficiency; and after heating stirring, vacuumizing and gradient warming treatment, occurrence of a speckle bubbling phenomenon can be effectively reduced; materials of the high-temperature speckle are all conventional reagents, and are non-toxic under a normal using condition, thereby facilitating engineering practical application and large-scale manufacture; and thespeckle can meet a non-contact measurement requirement in high-temperature complex environments (thermal shock, and tension and compression deformation).

Owner:TSINGHUA UNIV

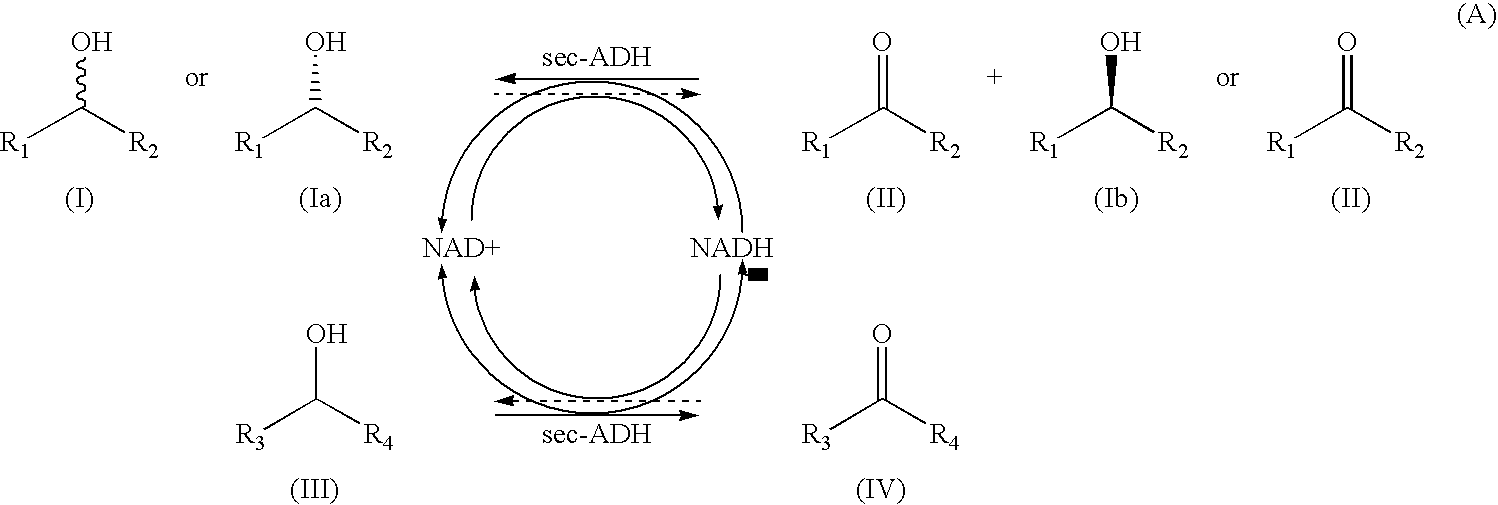

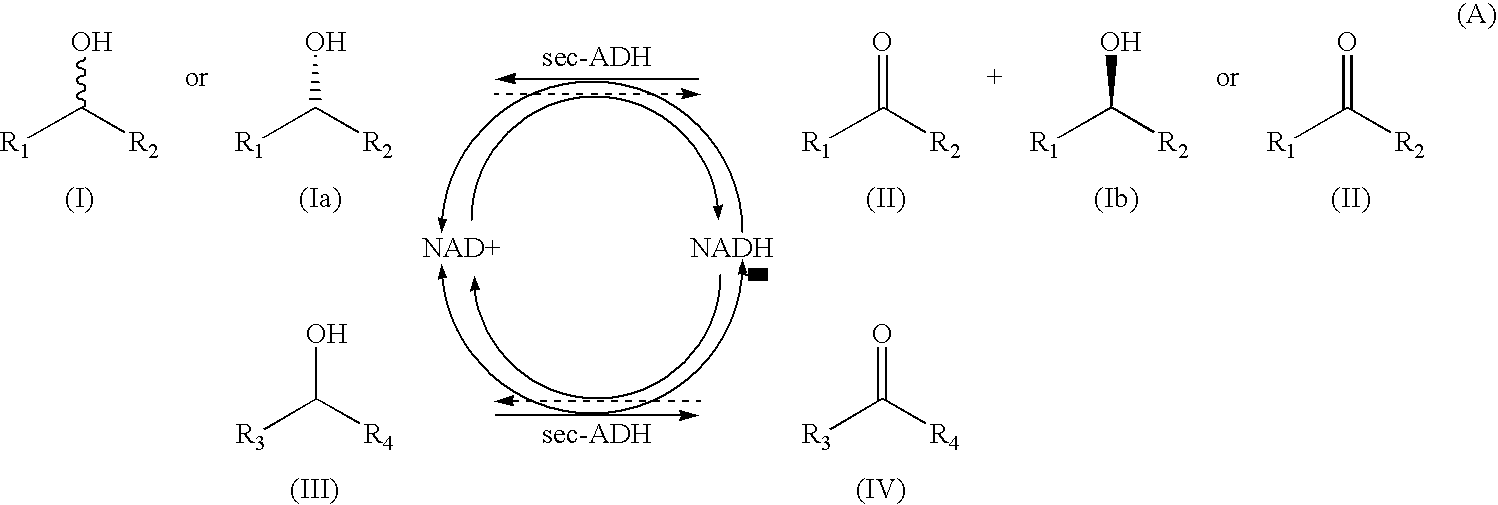

Alcohol dehydrogenases with increased solvent and temperature stability

The invention relates to biocatalysts showing alcohol dehydrogenase activity obtainable from Rhodococcus ruber, their preparation, their use in the oxidation of secondary alcohols and / or the reduction of ketones, as well as nucleic acids coding for these alcohol dehydrogenases and microorganisms transformed with nucleic acids coding for these biocatalysts and their use for producing the biocatalyst or oxidizing secondary alcohols and / or reducing ketones.

Owner:CODEXIS INC

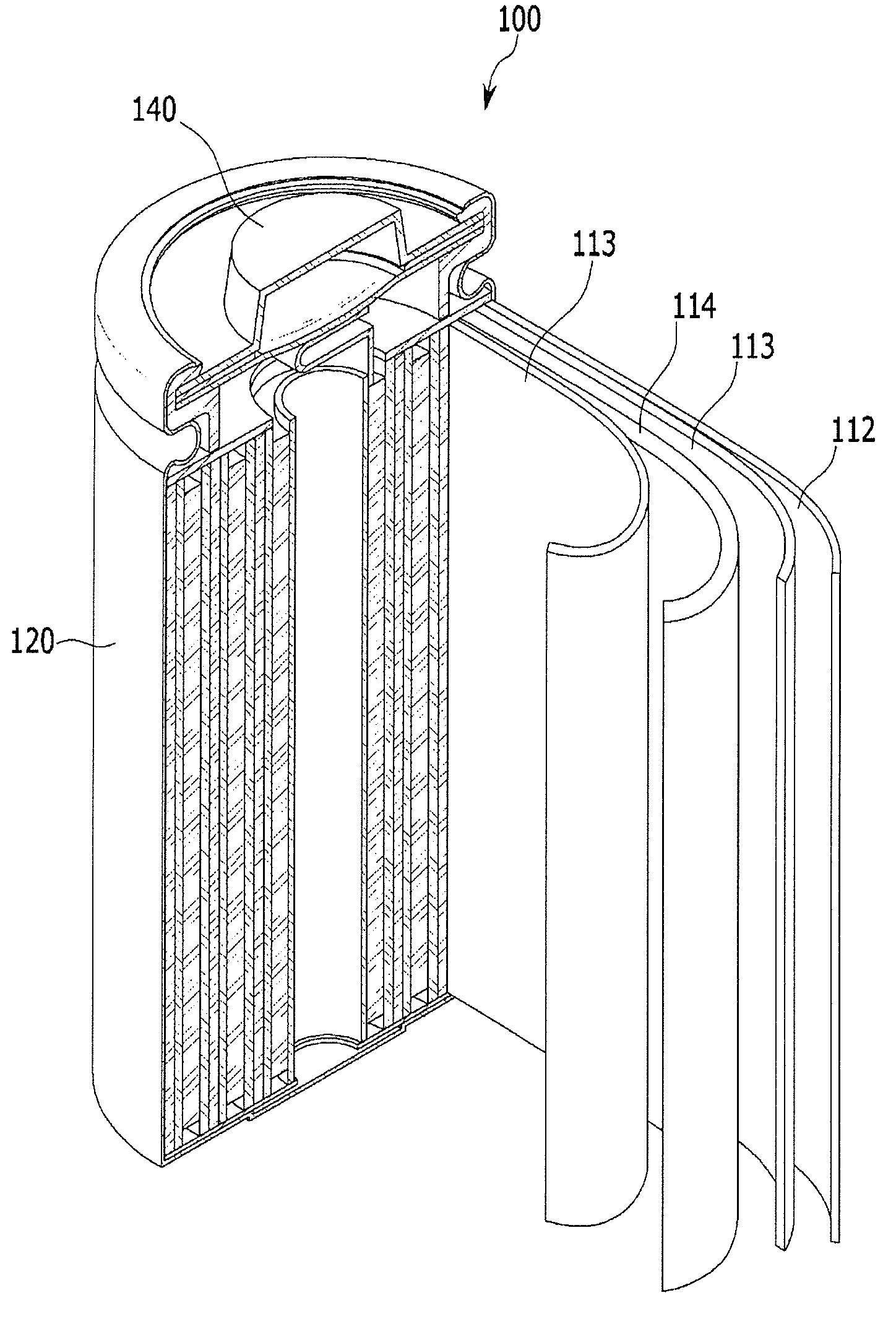

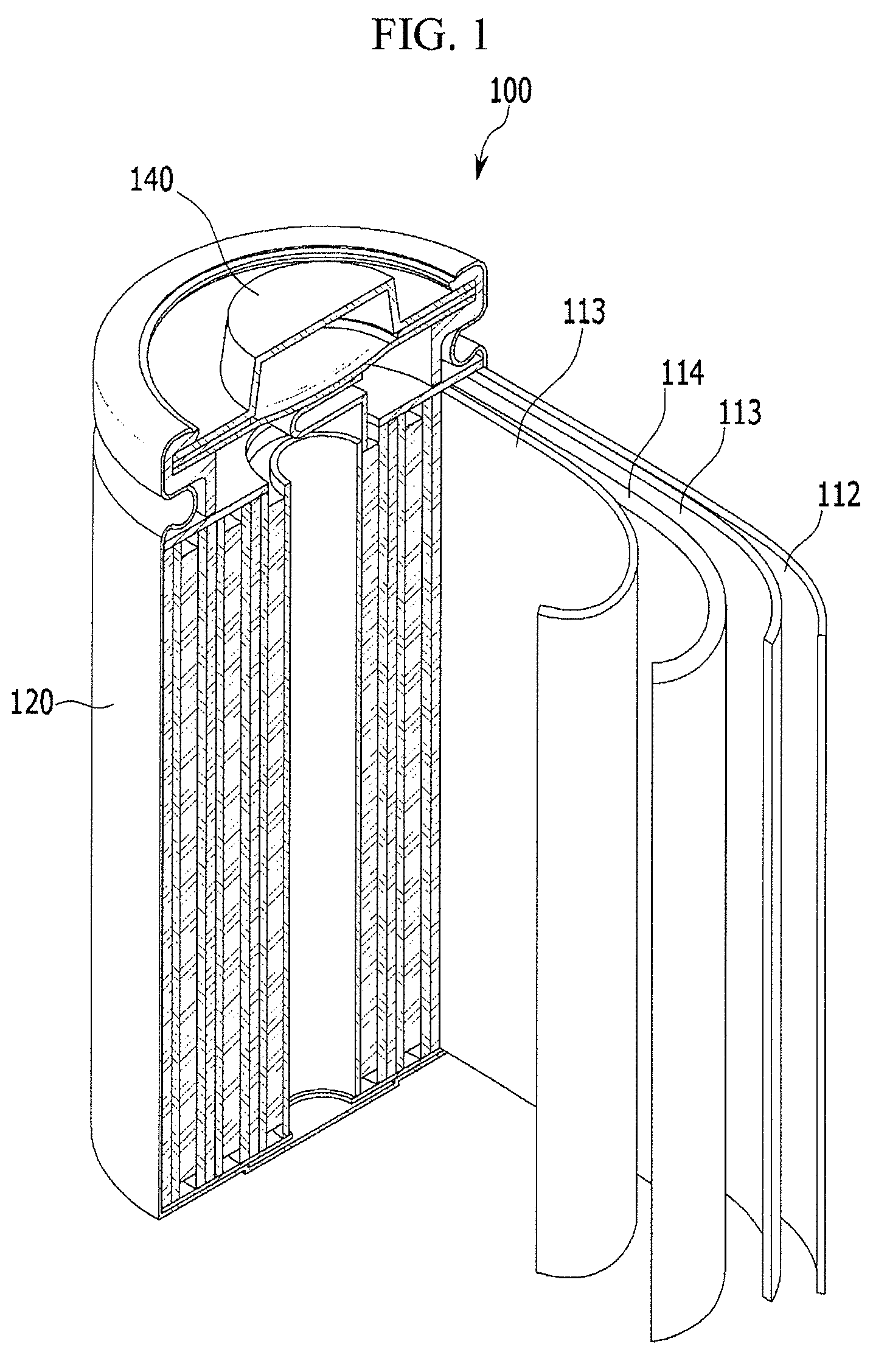

Separator for lithium secondary battery

InactiveUS20130244080A1High temperature stabilityExcellent characteristicsCell seperators/membranes/diaphragms/spacersFinal product manufactureIsocyanateCoating

A separator for a lithium secondary battery includes a coating layer including an organic / inorganic bindable silane compound having a reactive functional group, the reactive functional group being selected from the group consisting of amino groups, isocyanate groups, epoxy groups, mercapto groups, and combinations thereof; and an inorganic compound. The separator has excellent high temperature stability.

Owner:SAMSUNG SDI CO LTD

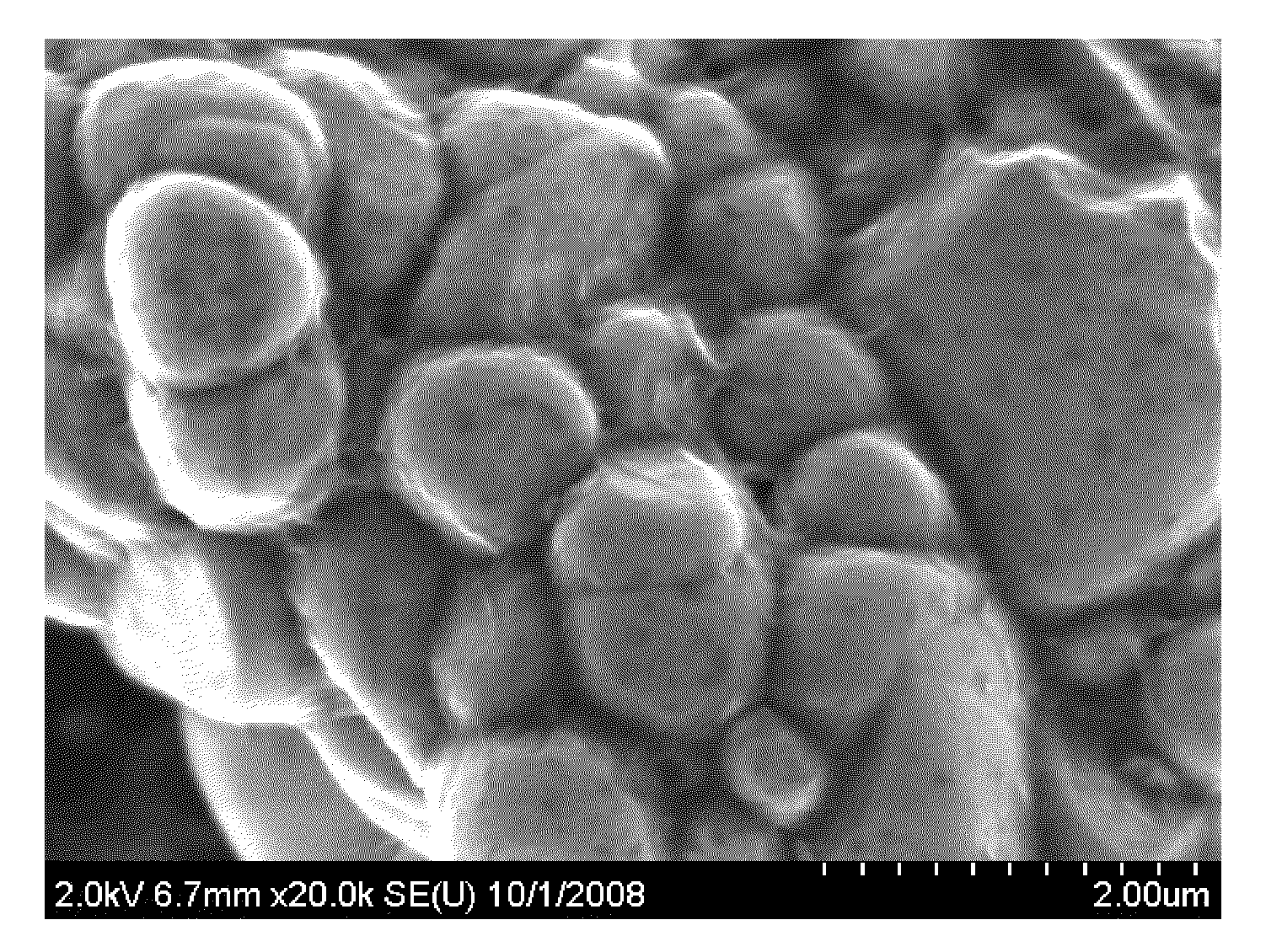

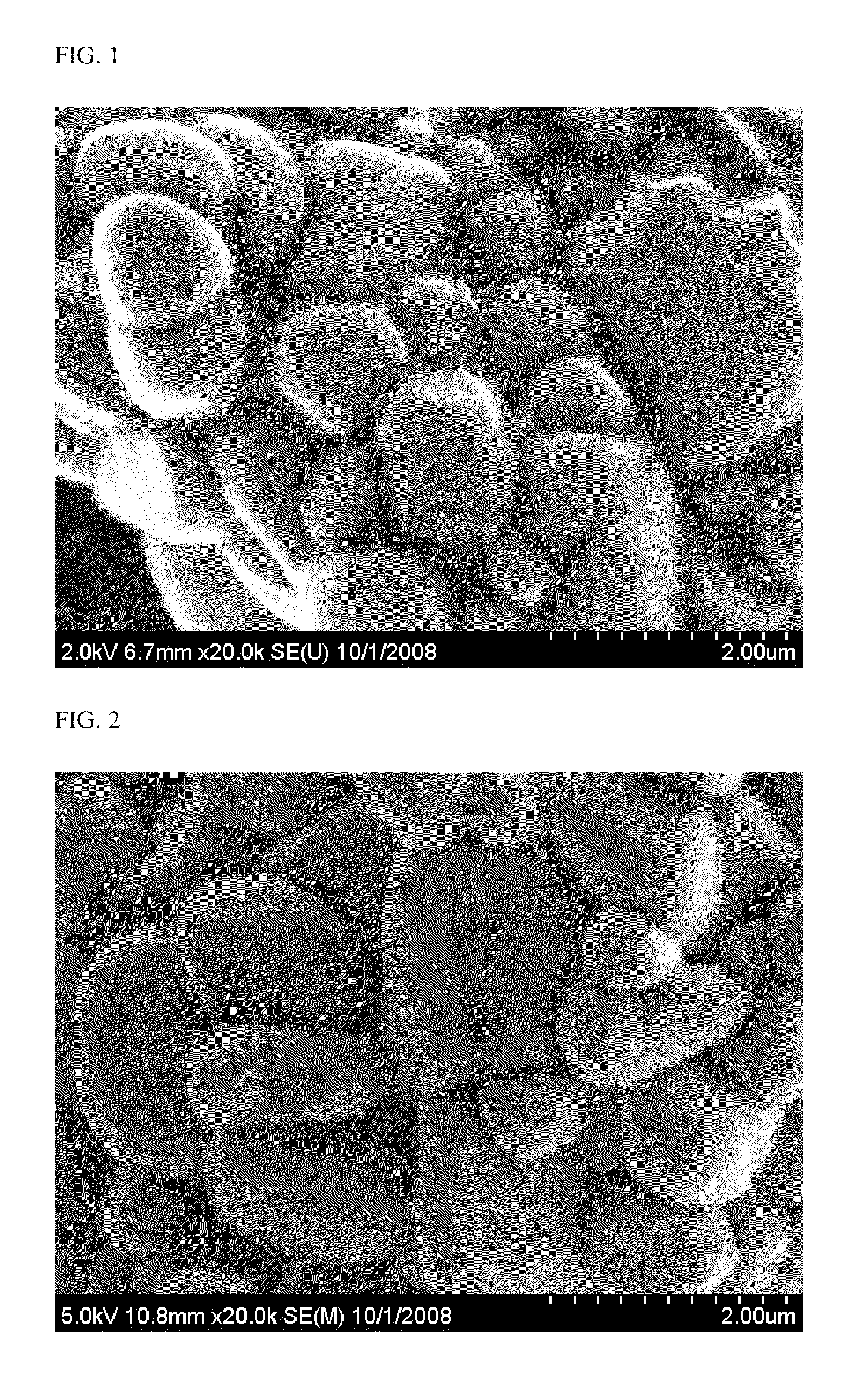

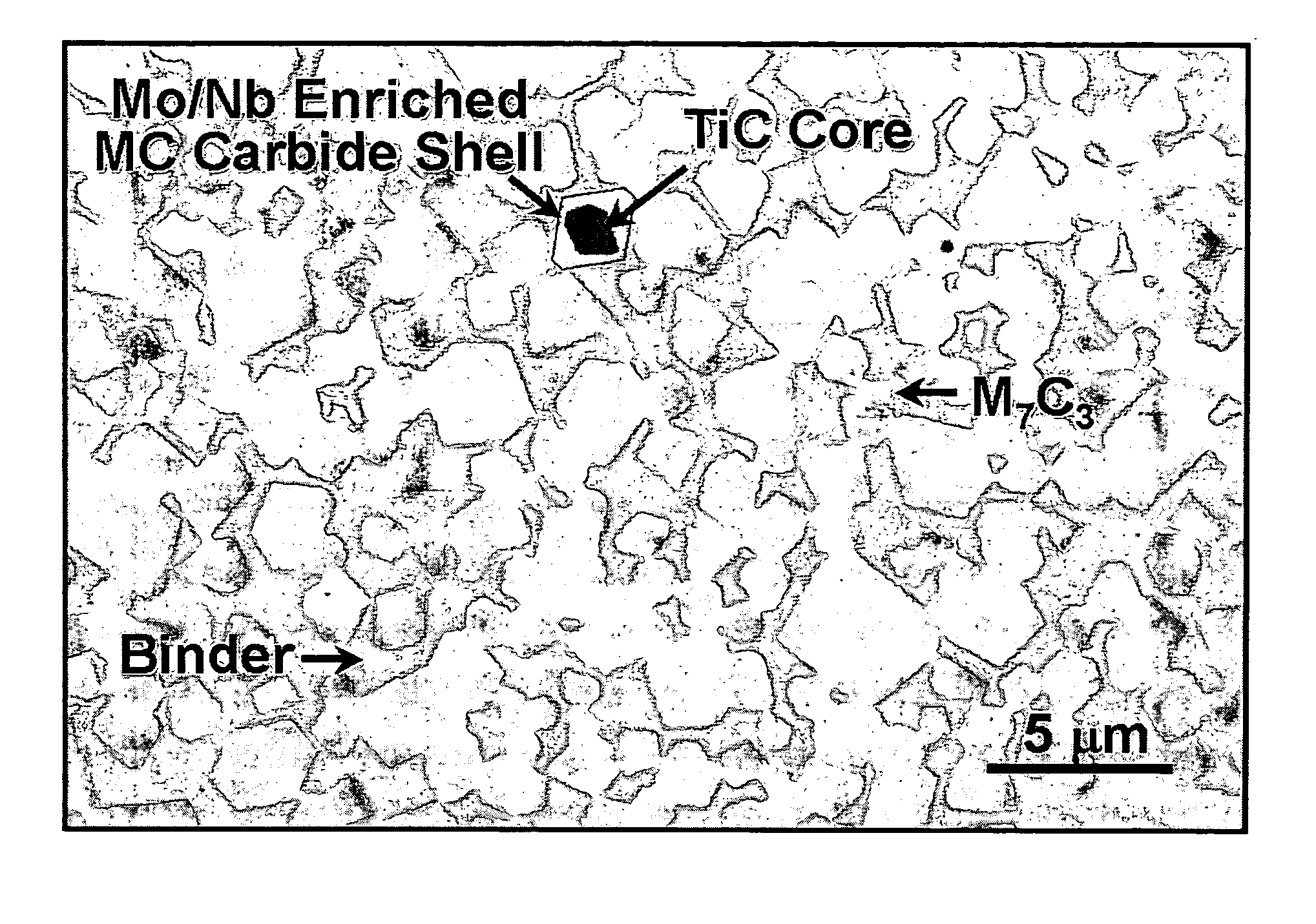

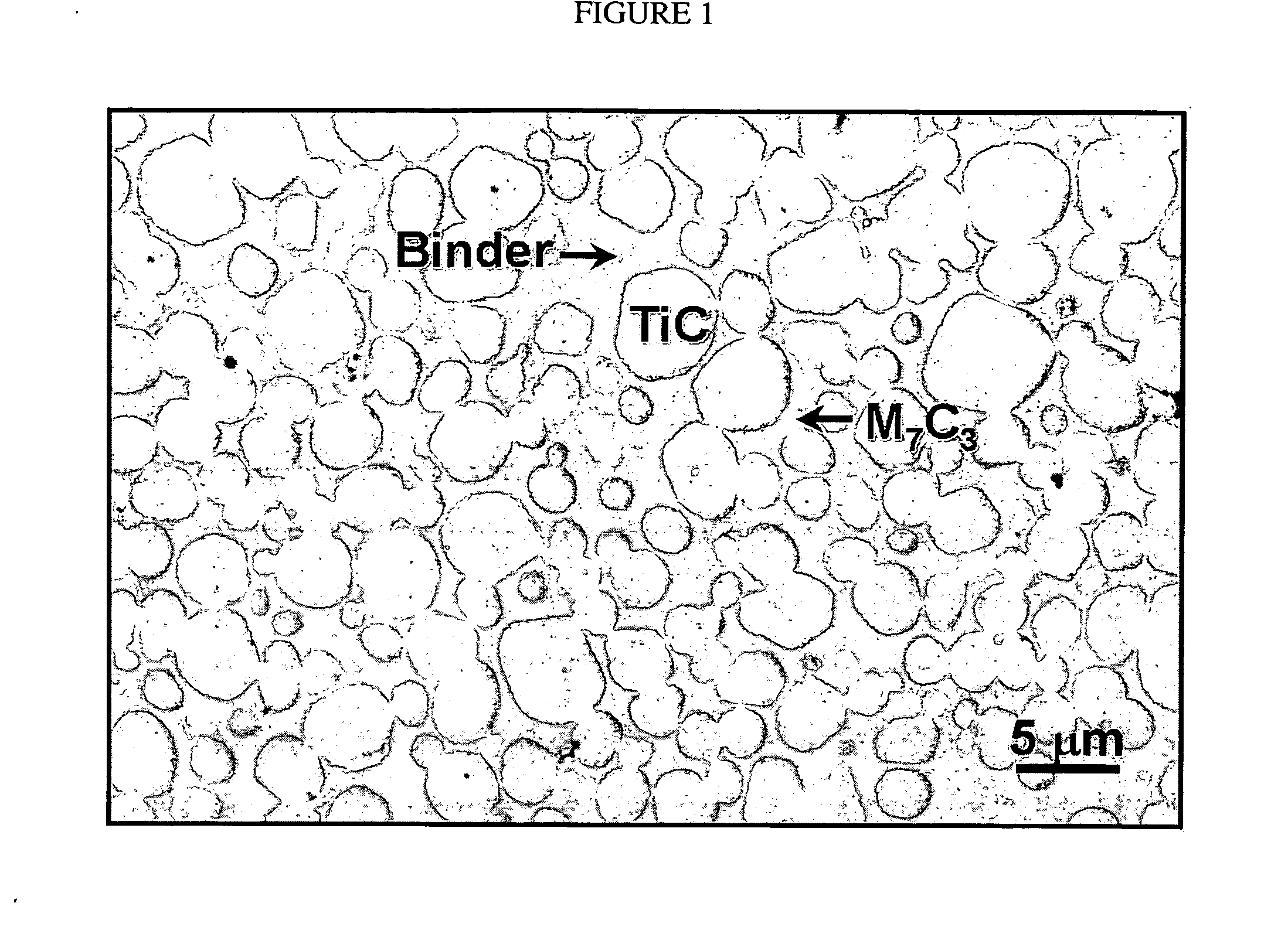

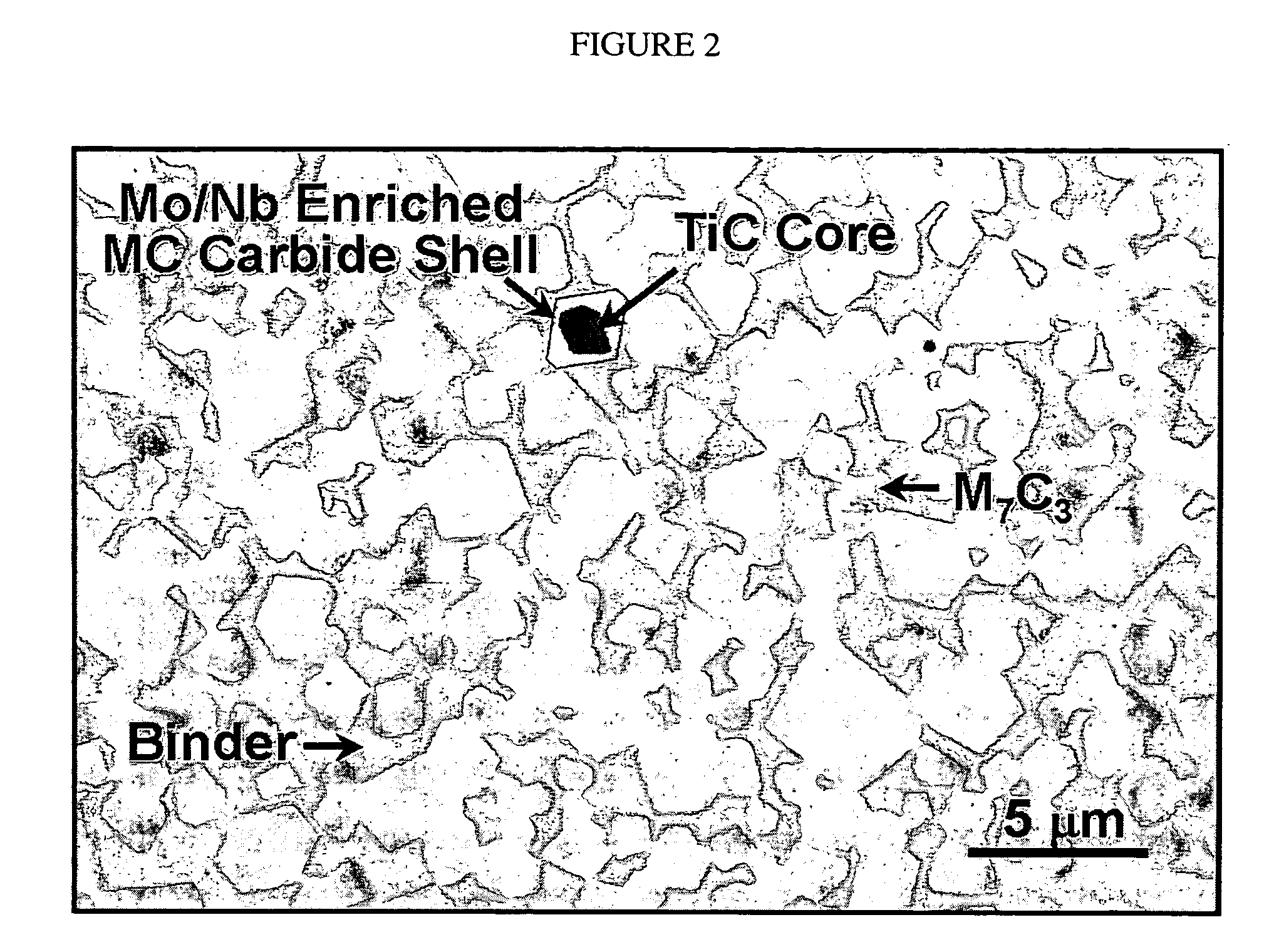

Advanced erosion resistant carbide cermets with superior high temperature corrosion resistance

InactiveUS20040231459A1High temperature stabilityAvoid erosionReversed direction vortexMetal-working apparatusCorrosion resistantCermet

Cermets are provided in which a substantially stoichiometric metal carbide ceramic phase along with a reprecipitated metal carbide phase, represented by the formula MxCy, is dispersed in a metal binder phase. In MxCy M is Cr, Fe, Ni, Co, Si, Ti, Zr, Hf, V, Nb, Ta, Mo or mixtures thereof, x and y are whole or fractional numerical values with x ranging from 1 to 30 and y from 1 to 6. These cermets are particularly useful in protecting surfaces from erosion and corrosion at high temperatures.

Owner:EXXON RES & ENG CO

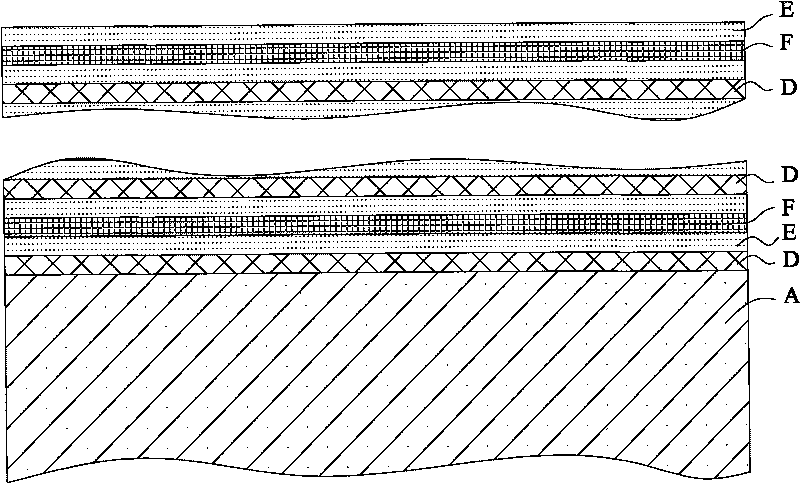

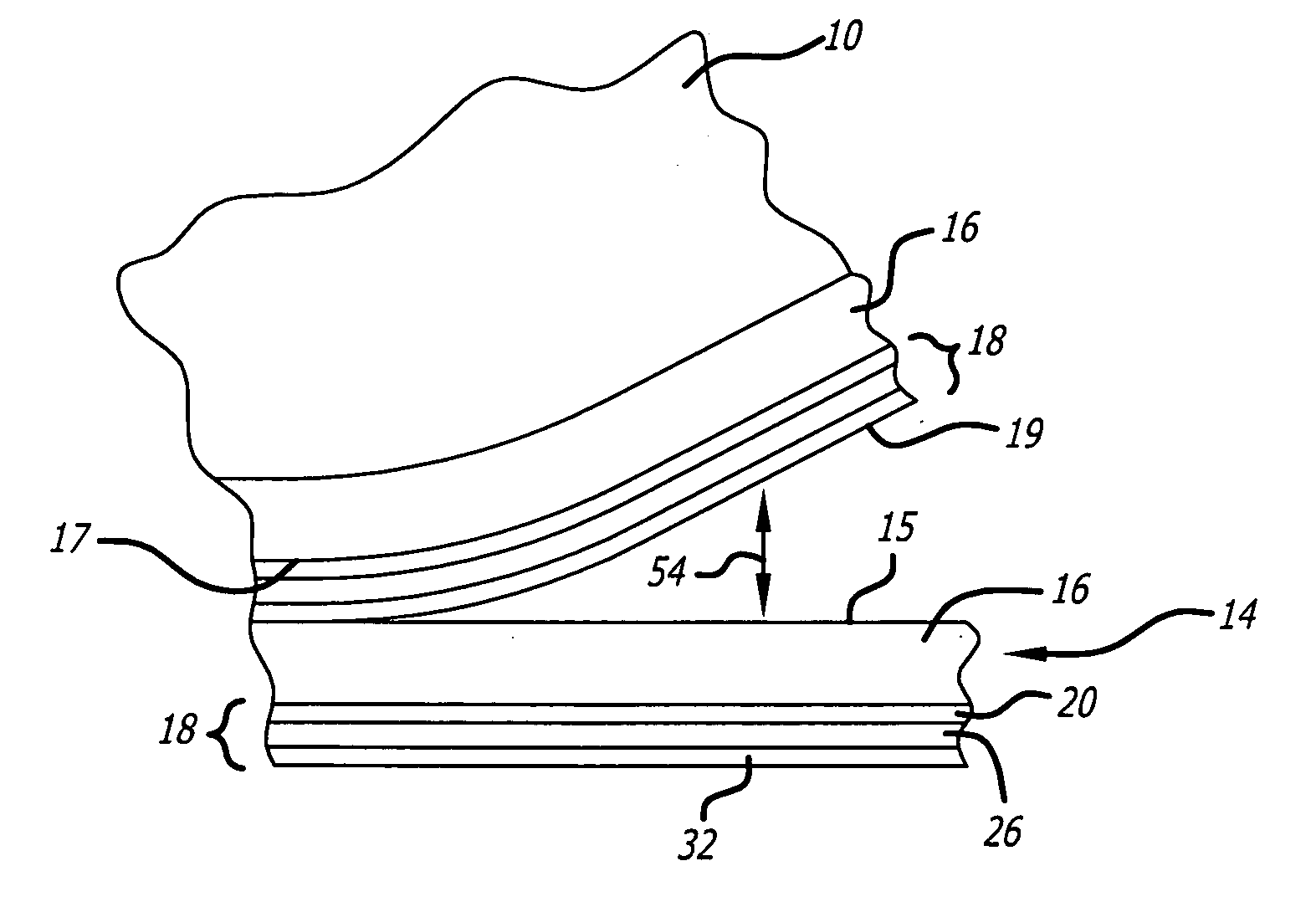

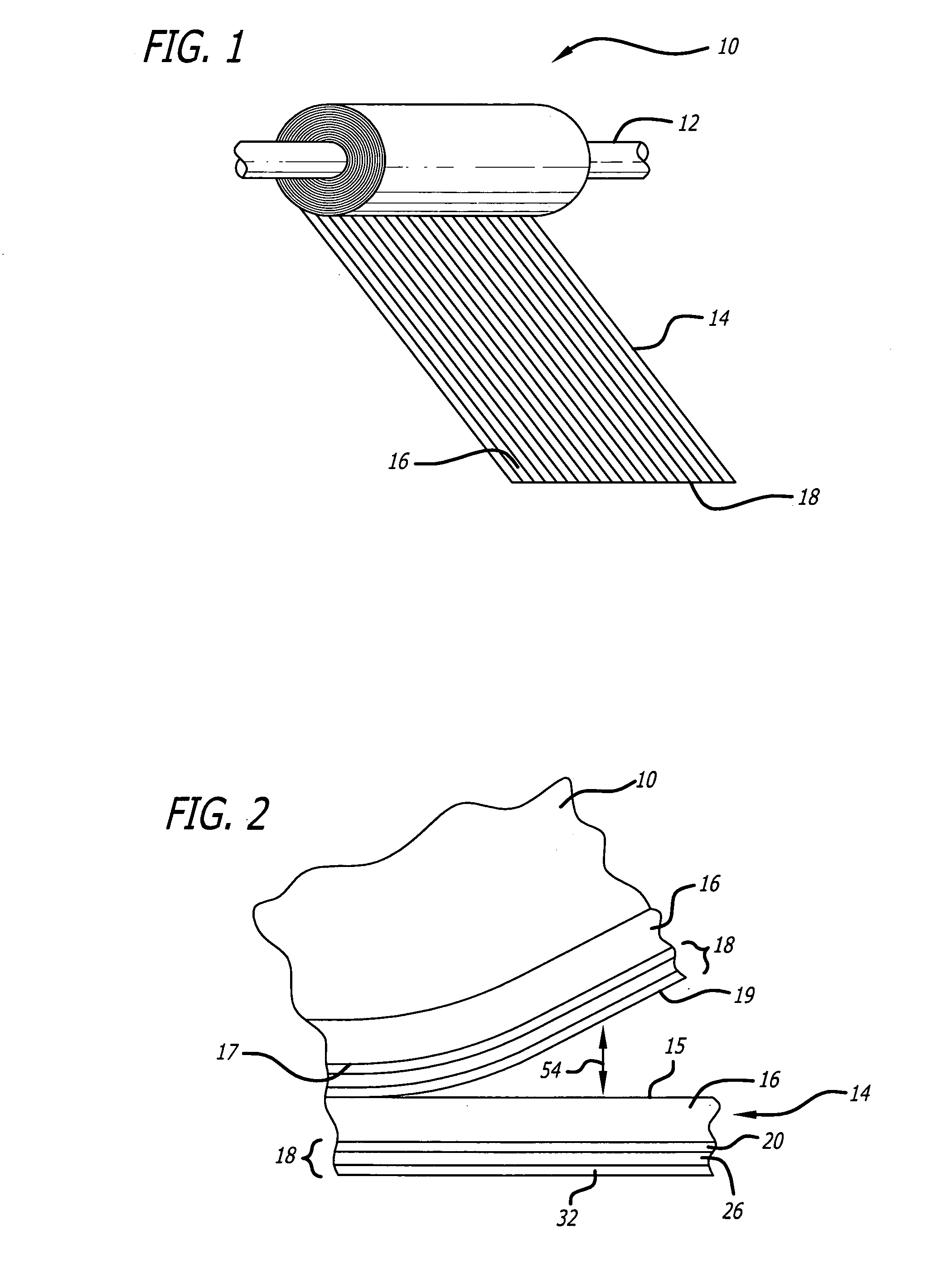

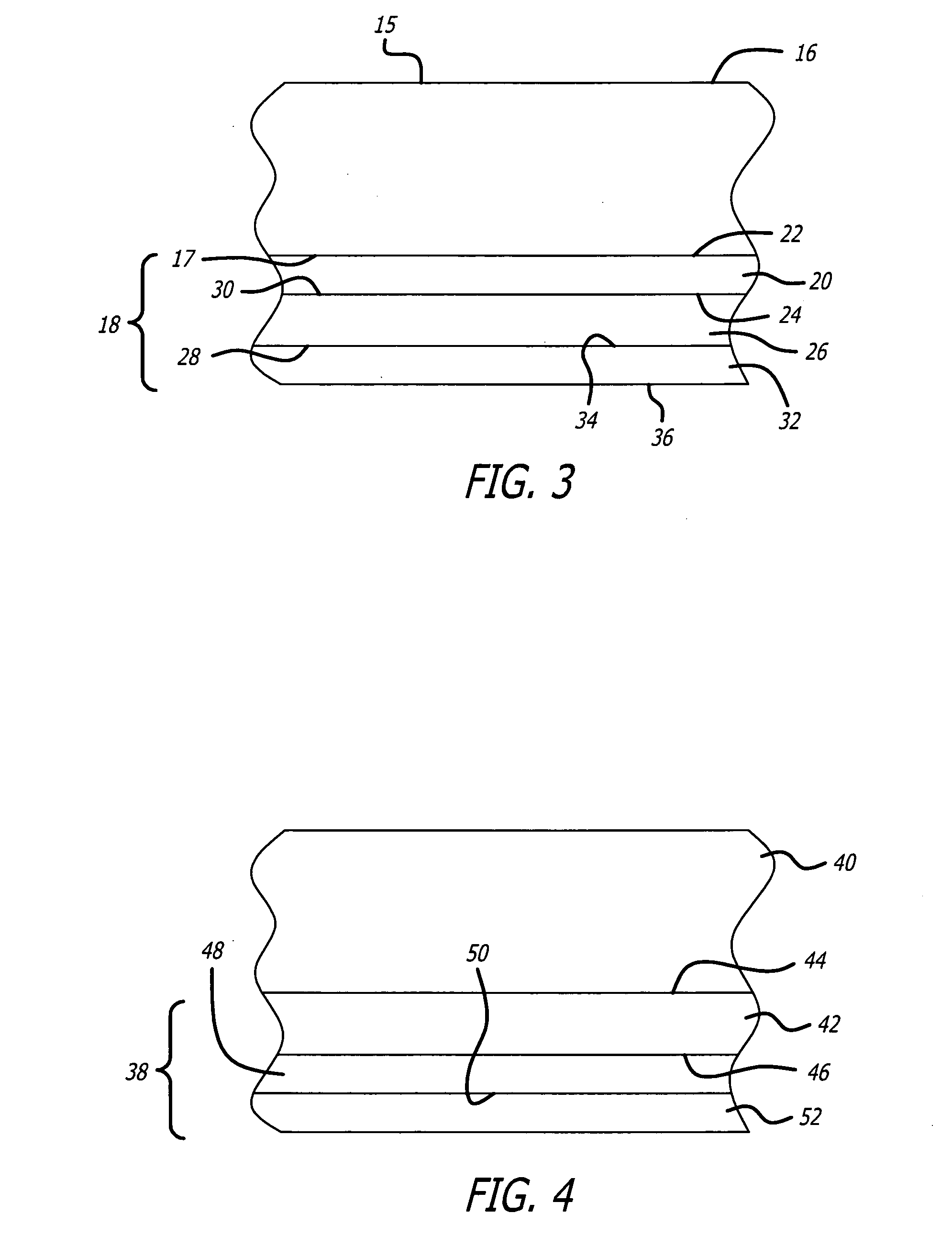

Composite Tape For Use In Tape Laying Machines

InactiveUS20100282404A1Easy to cleanFacilitated releaseDecorative surface effectsAdhesive articlesResin matrixEngineering

A tape for use in automated tape laying machines that includes a multi-layer substrate composed of a plastic layer that includes at least one plastic film having an outer film surface and an inner film surface. The plastic film is adhered to a fibrous layer so that the inner surface of the fibrous layer is bonded to the inner film surface. An uncured composite material layer composed of a fibrous reinforcement and an uncured resin matrix is releasably adhered to either the plastic layer surface or the outer fiber layer surface to provide a tape suitable for use in an automatic tape layer.

Owner:HEXCEL COMPOSITES LTD (GB)

Biodegradable quasi dry cutting oil and preparation method thereof

InactiveCN102002419AGood lubricityGood extreme pressure and anti-wear propertiesLubricant compositionChemistryPolyester

The invention relates to the technical field of chemistry, in particular to biodegradable quasi dry cutting oil and a preparation method thereof. The biodegradable quasi dry cutting oil is characterized in that the cutting oil is prepared from the following raw materials in percentage by weight: 30 to 40 percent of diester, 30 to 40 percent of polyol ester, 20 to 30 percent of poly alpha-olefin PAO20, 5 to 6 percent of zinc dialkyl dithiophosphate (ZDDP), 2 to 3 percent of polyester and 1 to 2 percent of N-laurel acyl alanine. Compared with the prior art, the cutting oil has good lubricating property and extreme pressure abrasion resistance, is biodegradable, and reduces the environmental pollution to minimum.

Owner:上海通快实业有限公司

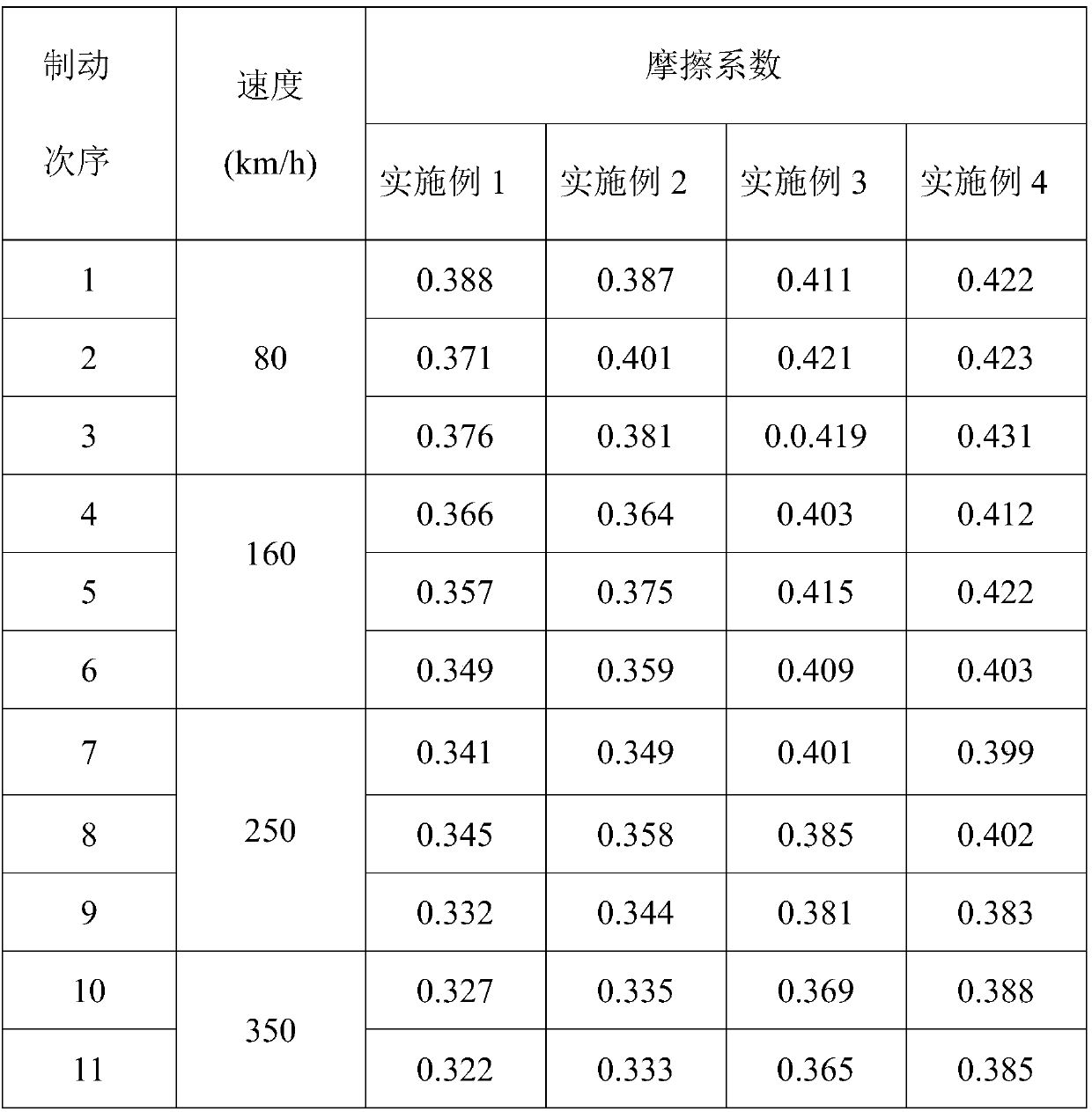

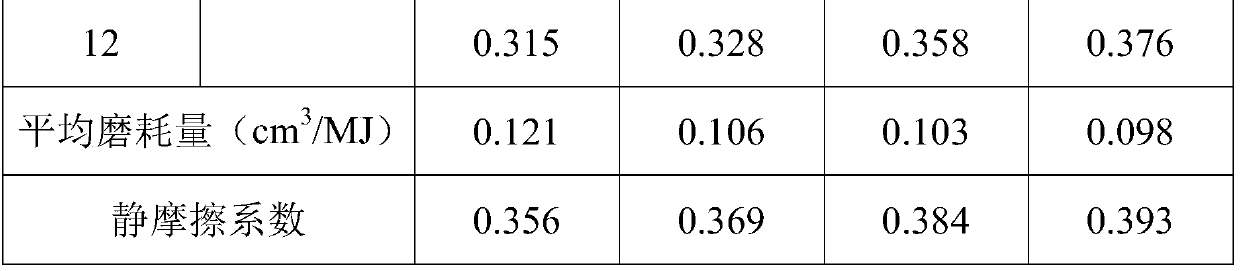

Powder metallurgy friction material for high-speed train braking and preparation method of powder metallurgy friction material

InactiveCN109518100AImprove high temperature friction performanceImprove self-shear strength and compressive strengthPowder metallurgyCopper plating

The invention relates to the technical field of brake materials, in particular to a powder metallurgy friction material for high-speed train braking and a preparation method of the powder metallurgy friction material. The powder metallurgy friction material is prepared from the following raw materials: copper powder, iron powder, copper-plated flake graphite, copper-plated graphite granules, chromium iron powder, molybdenum disulfide powder and alumina fiber through a powder metallurgy process. The powder metallurgy friction material has good mechanical properties, and is stable in friction coefficient, small in abrasion loss and good in thermal failure resistance; through the adopted raw materials and the ratio, the friction material with excellent properties can be prepared at the relatively-low sintering pressure and temperature, energy consumption is saved, a preparing process is simple and easy to control, the performance is excellent, and good application prospects are achieved.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

A negative plate lead paste used for starting and stopping lead-carbon super batteries with high performance and a preparation method thereof

ActiveCN109103426AImprove conductivity and capacitive activityImprove stabilityElectrode manufacturing processesLead-acid accumulatorsCarbon compositesGraphene

The invention belongs to the technical field of lead-acid batteries, in particular to a negative plate lead paste used for starting and stopping lead-carbon super batteries with high performance and apreparation method thereof. The carbon material used in the negative plate lead paste prepared by the invention is graphene, the homogeneous dispersion of graphene, lead powder and hydrogen evolutioninhibitor in lead paste is achieved by using aniline oligomer derivative as graphene dispersant and ball milling process. The graphene agglomeration is avoided, and a good lead-carbon composite structure is established, and the hydrogen evolution reaction of lead-carbon negative electrode is inhibited. The negative plate lead paste prepared by the invention adds xanthan gum or sodium alginate tocompletely or partially replace the traditional polyester fiber as a binder, so that the emulsifying stability, adhesion and adhesion of the negative electrode lead paste are effectively improved, andthe problems of serious water loss and easy shedding of active materials in the cycle process of lead-carbon batteries are solved, and the charging acceptance and cycle life of the lead-carbon batteries are remarkably improved.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

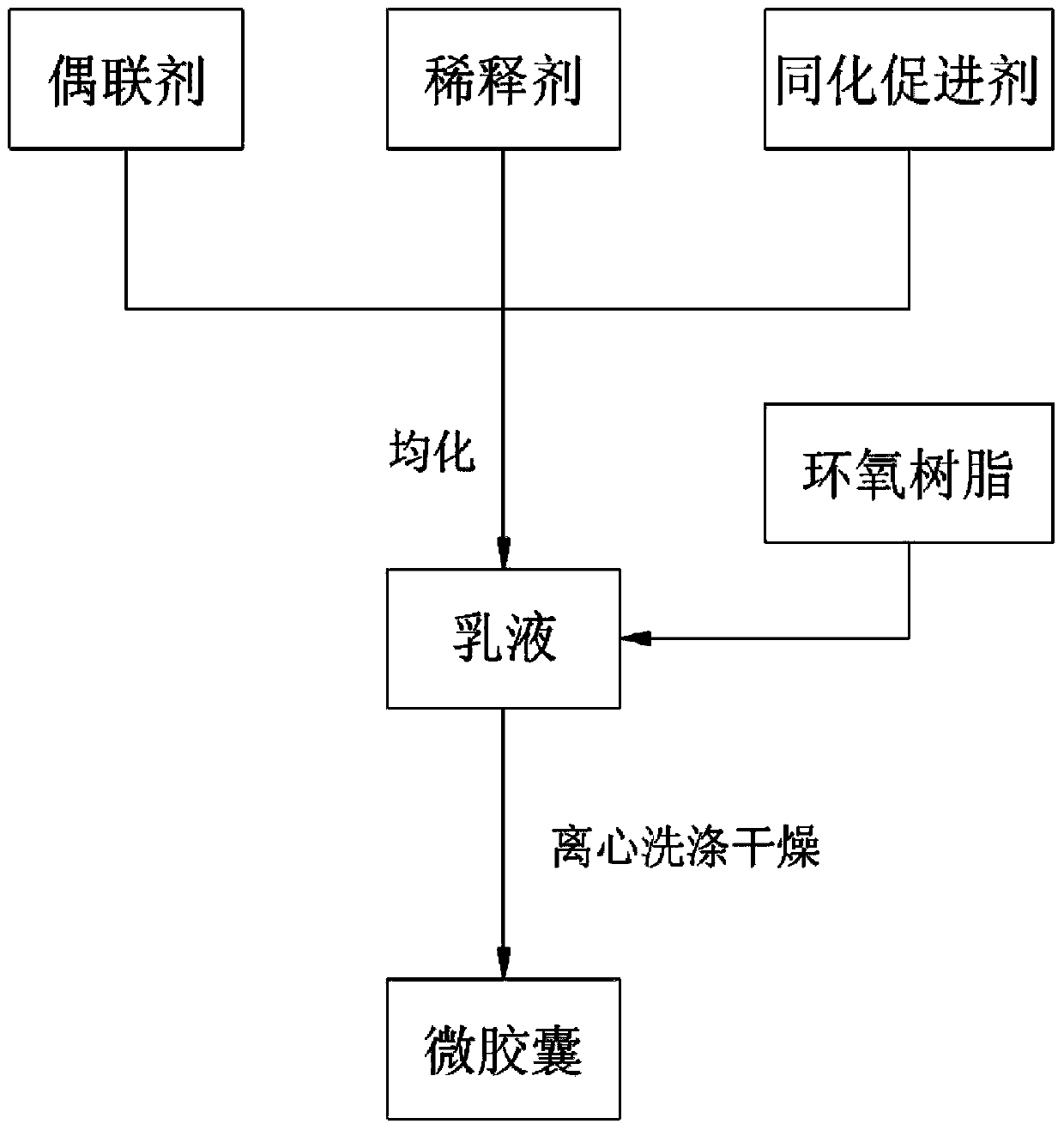

Bituminous concrete crack self-healing microcapsule and preparation method of same

The invention discloses a bituminous concrete crack self-healing microcapsule and a preparation method of the same. The bituminous concrete crack self-healing microcapsule is composed of epoxy resin film forming matter and repairing liquid, and the weight ratio of the film forming matter to the repairing liquid is 3:1, wherein the repairing liquid is composed of 10-20% of coupling agent, 50-75% of curing agent and 18-30% of curing accelerator by weight. The preparation method of the microcapsule comprises the following steps of: orderly adding the coupling agent, curing agent and curing accelerator into a reaction kettle, stirring evenly by a high-speed shearing emulsifying machine, adding the film forming matter, namely the epoxy resin, and by means of internal phase vaporization, suspension centrifuging, washing and drying, thus obtaining the microcapsule product. The microcapsule provided by the invention can obviously enhance the bitumen self-healing capability and prolong the service life of pavement.

Owner:杨林江

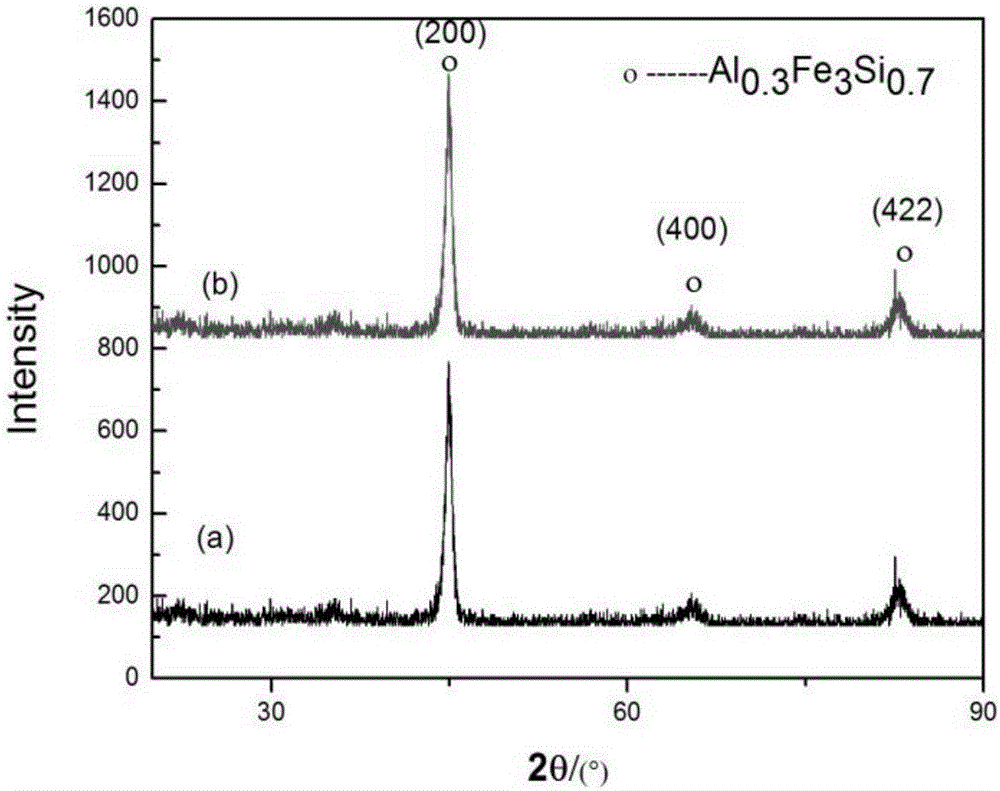

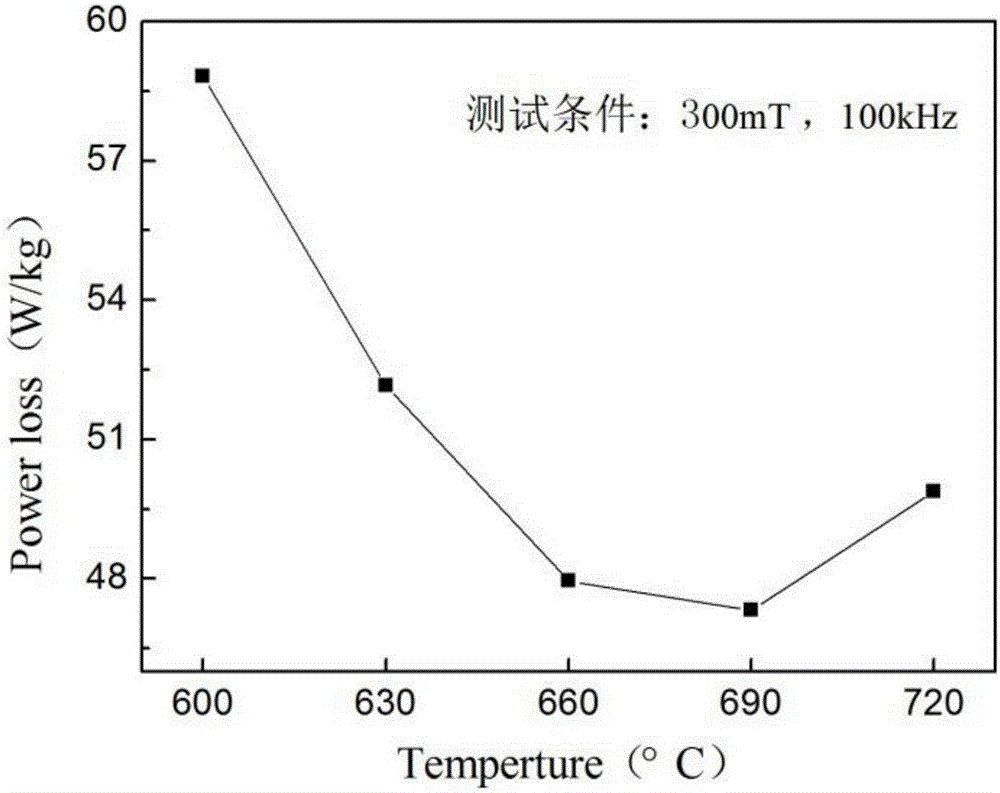

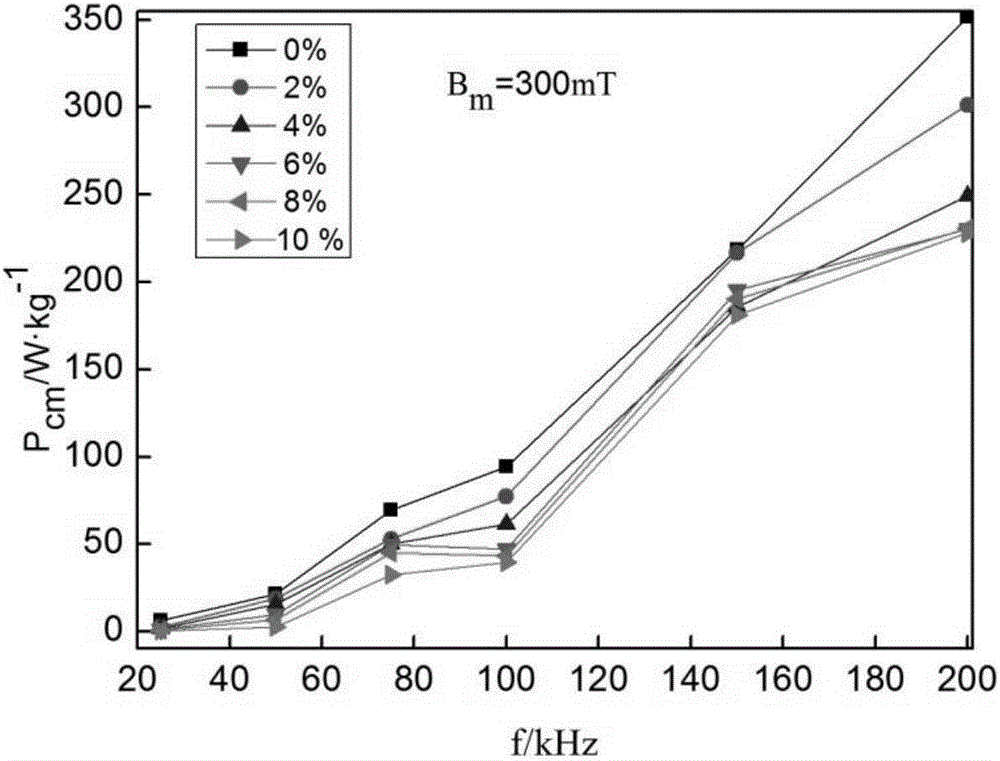

Preparation method of FeSiAl/Mn-Zn ferrite composite magnetic powder core

InactiveCN106373697AHigh temperature stabilitySolve the magnetic dilution problem of non-magnetic phaseTransportation and packagingMetal-working apparatusEpoxyManganese

The invention discloses a preparation method of an FeSiAl / Mn-Zn ferrite composite magnetic powder core. The method comprises the steps of carrying out in-situ synthesis on a ferric salt, a zinc salt and a manganese salt as raw materials and an NaOH solution as a precipitant through a chemical codeposition method on the surface of FeSiAl magnetic powder at 50-80 DEG C to form an Mn-Zn ferrite precursor and carrying out high-temperature roasting to obtain FeSiAl / Mn-Zn ferrite composite magnetic powder; and mixing the FeSiAl / Mn-Zn ferrite composite magnetic powder with epoxy resin and magnesium stearate evenly and then preparing the FeSiAl / Mn-Zn ferrite composite magnetic powder core through cold press molding. According to the method, a uniform and complete ferrite coating layer is formed on the surface of the FeSiAl magnetic powder, so that electric contact among metal magnetic powder particles is blocked; the resistivity of the composite magnetic powder core is improved; the eddy current loss of the composite magnetic powder core at a high frequency is effectively reduced; the prepared magnetic powder core is low in loss and high in magnetic conductivity; and the application field of the FeSiAl magnetic powder core is expanded.

Owner:GUANGDONG UNIV OF TECH

High temperature anti-slag anti-coking coating

The invention discloses a high temperature anti-slag anti-coking coating comprising the components (by weight ratio) of zirconium dioxide 20-50 parts, aluminum oxide 14-20 parts, magnesium oxide 14-20 parts, fluorosilicate 3-5 parts, metal powder 3-5 parts, rare-earth oxide 2-3 parts, soluble silicate 30-50 parts, orthophosphates 3-5 parts.

Owner:JIANGXI HENGDA HI TECH CO LTD

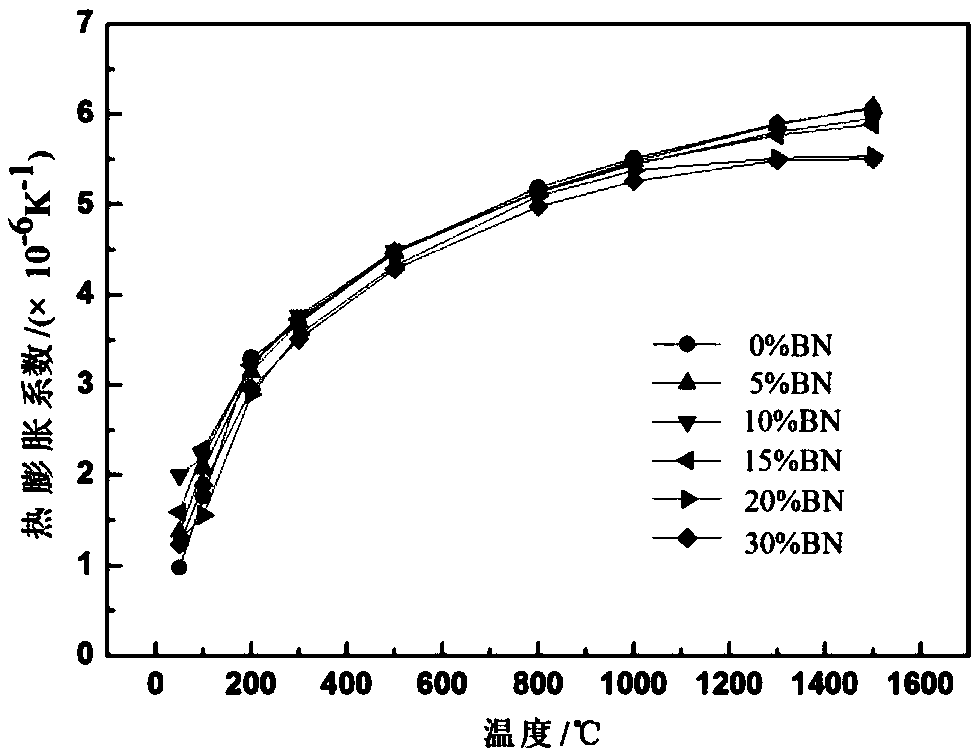

High-temperature phase-changing composite heat storage ceramic matrix material and preparation method thereof

InactiveCN108017403ALarge latent heat of phase changeHigh temperature stabilityProductsReagentsFiberEnergy conversion efficiency

The invention belongs to the technical field of heat storage materials and particularly discloses a high-temperature phase-changing composite heat storage ceramic matrix material and a preparation method thereof. The material is prepared from raw materials in parts by weight as follows: 10-15 parts of a ceramic matrix, 20-30 parts of lithium carbonate, 20-30 parts of potassium carbonate, 30-40 parts of sodium carbonate, 1-2 parts of high-thermal-conductivity carbon fiber and 1-2 parts of doped graphite. The prepared high-temperature phase-changing composite heat storage ceramic matrix materialhas the advantages of large phase change latent heat, high high-temperature stability, low toxicity, small corrosion and the like and can be used as a phase-changing heat storage material, and the energy conversion efficiency is improved; the thermal conduction performance is higher, and the heat absorption and release speed is higher; the appearance of the material cannot be changed during phasechanging, and leakage can be effectively prevented.

Owner:TIANJIN QIZHEN ENERGY SAVING TECH CO LTD

Composition of anode of low-polarization thermal battery

The invention discloses a composition of an anode of a low-polarization thermal battery. The composition of the anode of the thermal battery comprises the following components in percentage by weight: 50-88 percent of pyrite, 1-15 percent of lithium oxide and 5-30 percent of low melting point eutectic salt. In the invention, two functional materials are added to an anode active substance so as to improve the electrochemical property of the thermal battery anode and the stability of battery output voltage, wherein one functional material is used for enhancing the wetting property of the anode and electrolyte and reducing polarization, while the other functional material is used for carrying out thermal protection on the anode active substance, improving the conducting property of the anode and reducing the polarization.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

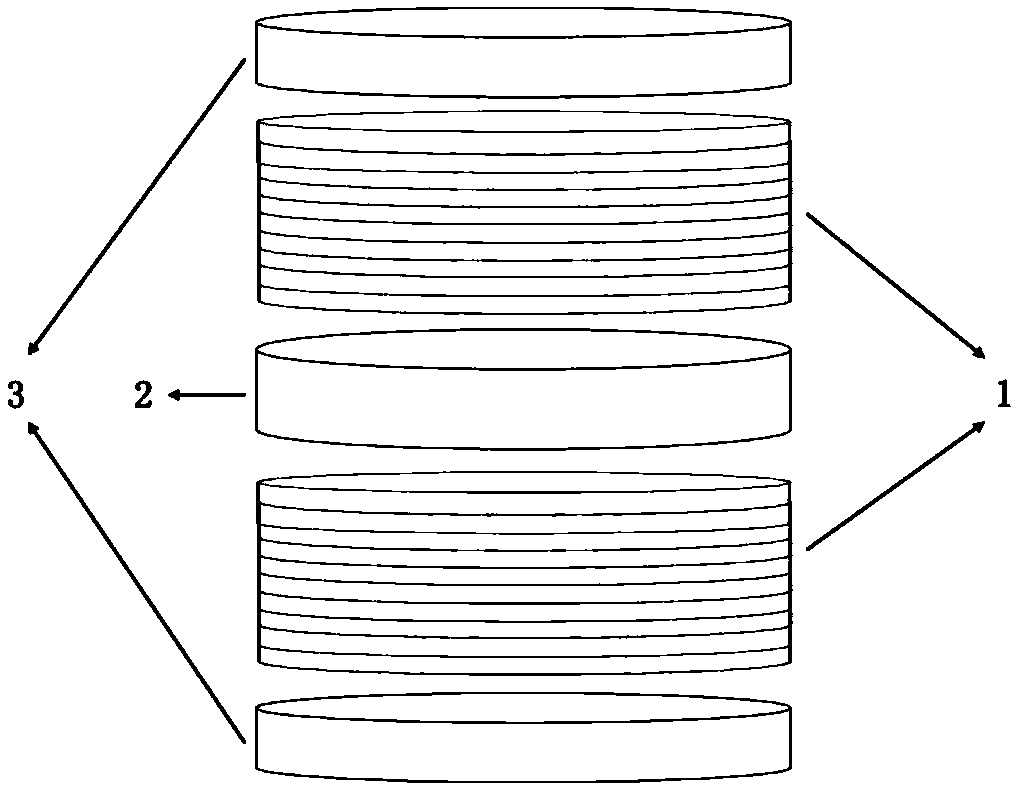

Ceramic/metal high-temperature packaging material of gradient structure and preparing method thereof

The invention relates to a ceramic / metal high-temperature packaging material of a gradient structure. A ceramic material comprises one or a plurality of nitrides (A1N, Si3N4, BN and the like), carbides (SiC, ZrC, TiC and the like) and oxides (Al2O3, SiO2, ZrO2 and the like). A metal material comprises one of high-melting-point metals, such as W, Mo, Ta, Cr and Nb. The preparing method of the material comprises the following steps: fully mixing required metal and ceramic powder according to designed gradient components, gradient layer number and the content of each component in each layer so asto obtain required raw materials for each gradient layer; stacking all layers and carrying out pressing forming; enabling the mass percent of ceramic powder to symmetrically and continuously vary ina gradient manner between 100 % and 0 % from the inner side to the outer side in the axial direction; utilizing a powder metallurgy and hot pressing co-firing technology, and finally obtaining the ceramic / metal high-temperature packaging material of the gradient structure. The helium leakage rate is smaller than 1x10<-11> Pa.m<3> / s, the bending strength is larger than 200Mpa, and the electric resistivity is larger than 6x10<9> omega.cm.

Owner:WUHAN UNIV OF TECH

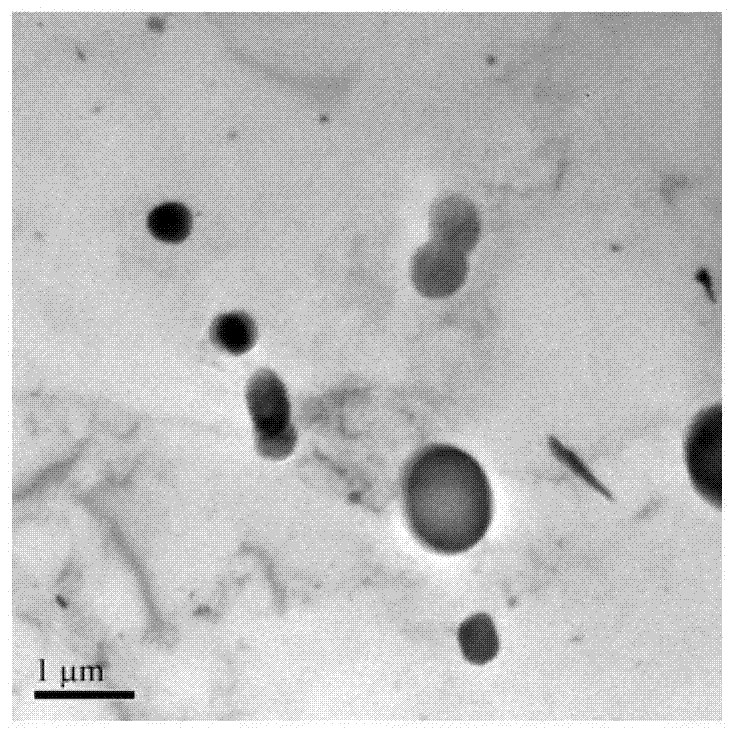

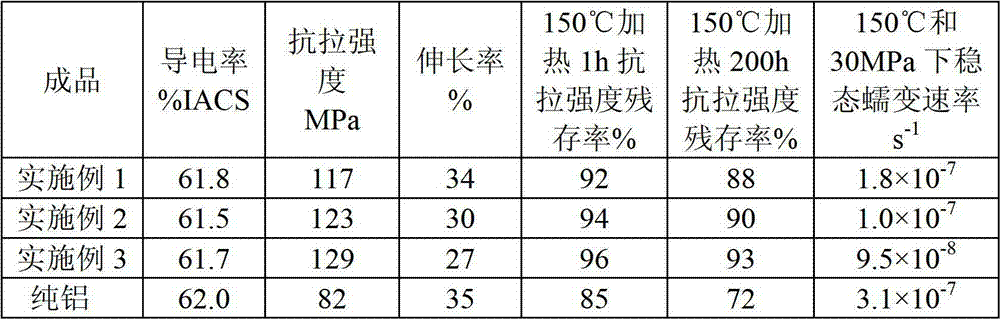

High-conductivity creep-resistant aluminium alloy cable conductor containing Hf and Ce and preparation method thereof

ActiveCN102760508AImproved heat resistance and creep resistanceImprove high temperature performanceMetal/alloy conductorsCable/conductor manufactureAlloy elementElectric energy

The invention discloses a high-conductivity creep-resistant aluminium alloy cable conductor containing Hf and Ce and a preparation method thereof. The aluminium alloy cable conductor disclosed by the invention is composed of the following constituents in percentage by mass: 0.3-1.1% of Fe, 0.1-0.5% of Cu, 0.01-0.2% of Hf, 0.01-0.05% of B, 0.02-0.1%, and the balance of Al. The preparation method comprises the following steps of: proportioning according to the designed alloy constituents, smelting and pouring, homogenizing-annealing and hot-extruding, cold-drawing and annealing to finally obtain the aluminium alloy cable conductor. The aluminium alloy cable conductor prepared by the preparation method disclosed by the invention has an elongation after fracture being greater than 25%, tensile strength being greater than 110 MPa, and conductivity being 61.0-62.5%. By using the conductor manufactured by the preparation method disclosed by the invention, transmission capacity can be increased and electric energy loss can be reduced due to the introduction of other alloy elements; and moreover, many high-temperature stable phases are distributed on the crystal boundaries and in the crystals of alloys, so that the high-temperature performance and the creep-resistant performance of the alloy conductor can be improved, thus guaranteeing the service life and safety of the conductor.

Owner:CENT SOUTH UNIV +1

Biological type micro lubricating oil and preparation method and application thereof

InactiveCN101654636AImprove the lubrication effectImprove extreme pressure performanceAdditivesBase-materialsPhosphatePollution

The invention belongs to the technical field of lubricating oil, in particular to biological type micro lubricating oil which comprises the following raw materials in percentage by weight: 62-70 polyalpha olefin (PAO), 24-30 of composite synthetic ester, 1-2 N-lauroyl alanine, 1-2 composite phosphate and 1-2 dispersant. Compared with the prior art, the invention not only has better lubricating property and extreme pressure property so that few lubricating agents can meet high-end requirement of metal processing, but also can reduce the consumption of the lubricating agent to less than 5 percent of the previous consumption, reduces the harm to the environment and worker, can be degenerated biologically, and lowers the pollution to the environment to be maximum.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

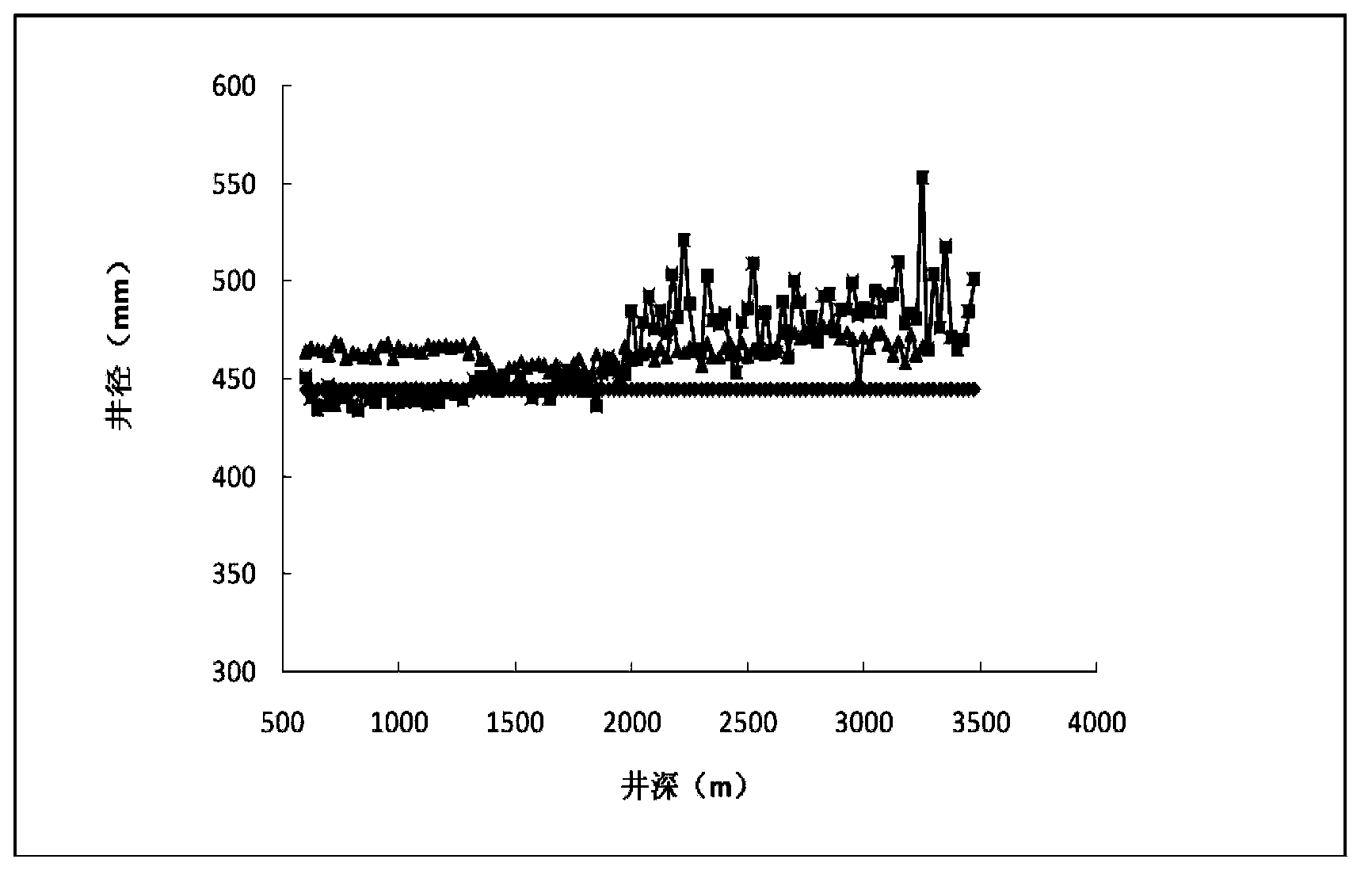

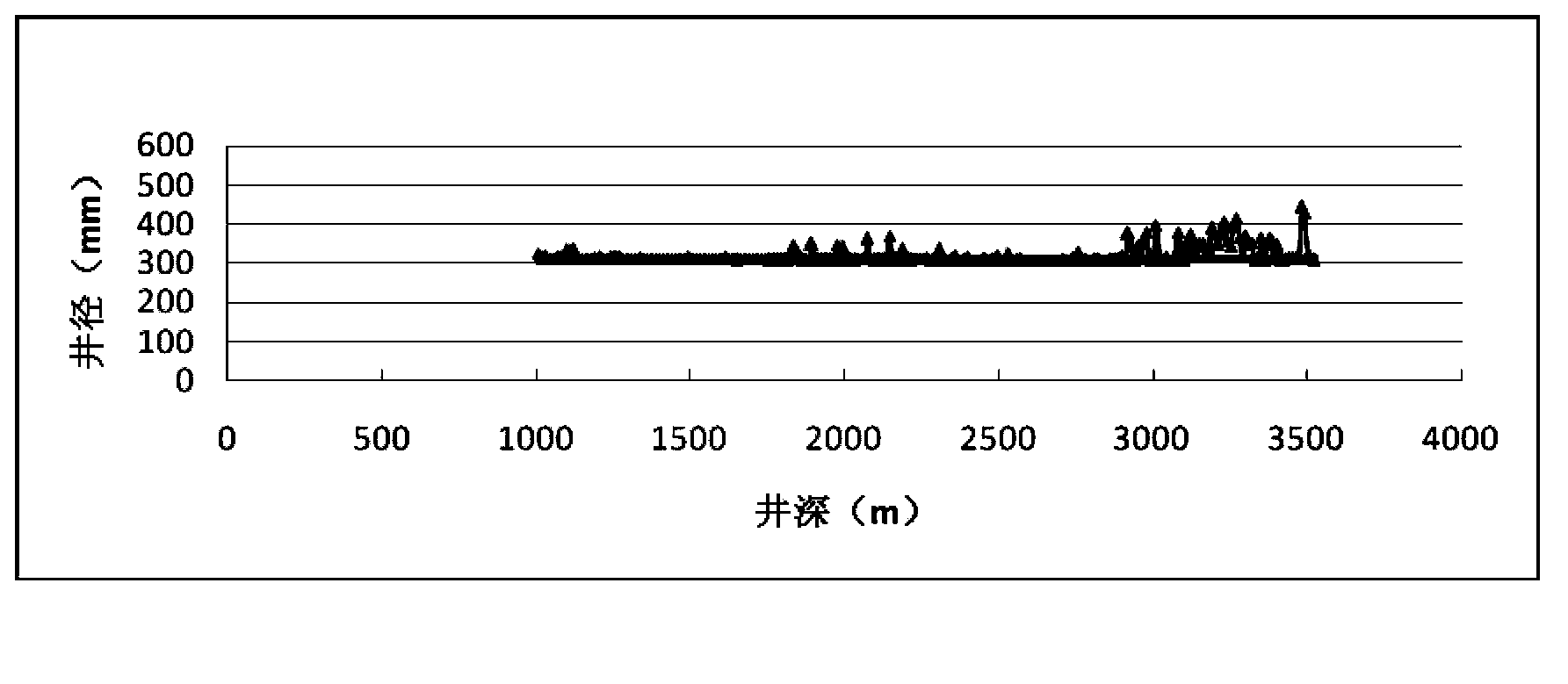

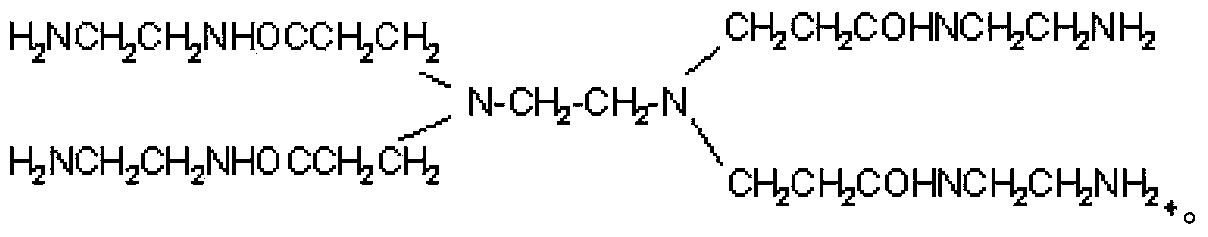

Dendritic multi-amino polymer drilling fluid used for mud rock well drilling

ActiveCN104130758AEnhanced inhibitory effectReduce plasticityDrilling compositionPotassiumWell drilling

The invention relates to a dendritic multi-amino polymer drilling fluid used for mud rock well drilling. The drilling fluid is characterized by consisting of a dendritic multi-amino polymer, drilling fluid bentonite, sodium carbonate, a polymer coating agent, potassium polyacrylate, a hydrolyzed polyacrylonitrile ammonium, a bit balling resistant lubricant and water. The dendritic multi-amino polymer drilling fluid can improve an inhibitive performance of the drilling fluid, can greatly improve the inhibitive performance on clay and drilled chips of the drilling fluid, can reduce plasticity of daub rock, can avoid water-absorption swelling and dispersing of the daub rock, can reduce friction resistance, can prevent bit balling, can increase a penetration rate and can ensure safety of a downhole operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rare earth ceramic reinforced molybdenum alloy and preparation method thereof

ActiveCN102690984ARaise the recrystallization temperatureLower plastic-to-brittle transition temperatureRare earthAlloy

The invention discloses a rare earth ceramic reinforced molybdenum alloy and a preparation method thereof. The molybdenum alloy comprises the following components by weight percent: 1.2-6.4% of alumina, 0.5-2.5% of lanthana and the balance of molybdenum and inevitable impurities. Concerning the molybdenum alloy, the recrystallization temperature reaches 1350 DEG C, the high-temperature creep resistance is 1.5-2 times that of the rare earth molybdenum alloy, the high-temperature hardness is 1.5-2 times that of the TZM molybdenum alloy and the wear resistance is 2-4 times that of the TZM molybdenum alloy. The preparation process is simple and is easily controlled; and the molybdenum alloy has fine and more uniformly distributed reinforced grains and the composite can be prepared under the condition of the process for producing the molybdenum alloy through conventional powder metallurgy; and therefore the molybdenum alloy has very extensive application prospect.

Owner:HENAN UNIV OF SCI & TECH

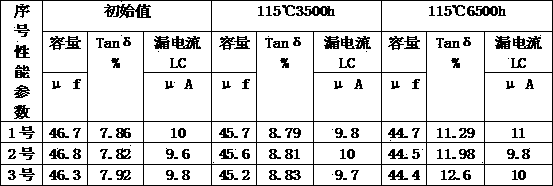

Working electrolyte for ultrahigh-voltage aluminium electrolytic capacitor and manufacturing method thereof

InactiveCN104240956AMeeting urgent needsExtend your lifeElectrolytic capacitorsElectrolytic agentUltra high voltage

Disclosed in the invention is a working electrolyte for an ultrahigh-voltage aluminium electrolytic capacitor. The working electrolyte comprises the following raw materials, by mass percent: 49 to 76% of a main solvent, 5 to 20% of a secondary solvent, 6 to 25% of a solute, and 3 to 10% of a property-modifying additive. According to the manufacturing method, the main solvent and the secondary solvent are mixed; the solute is added at the temperature of 100 to 115 DEG C, and stirring is carried out and the temperature rises 130 to 135 DEG C; heat-preservation stirring is carried out and reaction is also carried out for 10 to 40 minutes; and cooling is carried out until the temperature is reduced to 70 to 90 DEG C and then the property-modifying additive is added, thereby completing preparation. According to the invention, with application of special materials, the special preparation process is used; and on the basis of optimized formulas, the combined effect of the materials is realized. The prepared working electrolyte having advantages of reasonable cost, long service life, high high-temperature stability, and high batch stability can meet the urgent need of factories in the country, especially the need of the high-end manufacturers.

Owner:上海洪微电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com