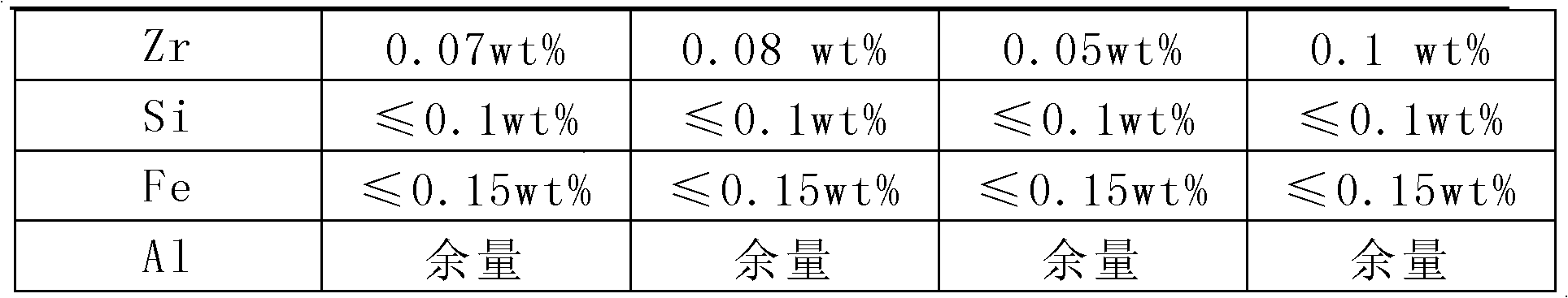

Patents

Literature

722results about How to "Reduce plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

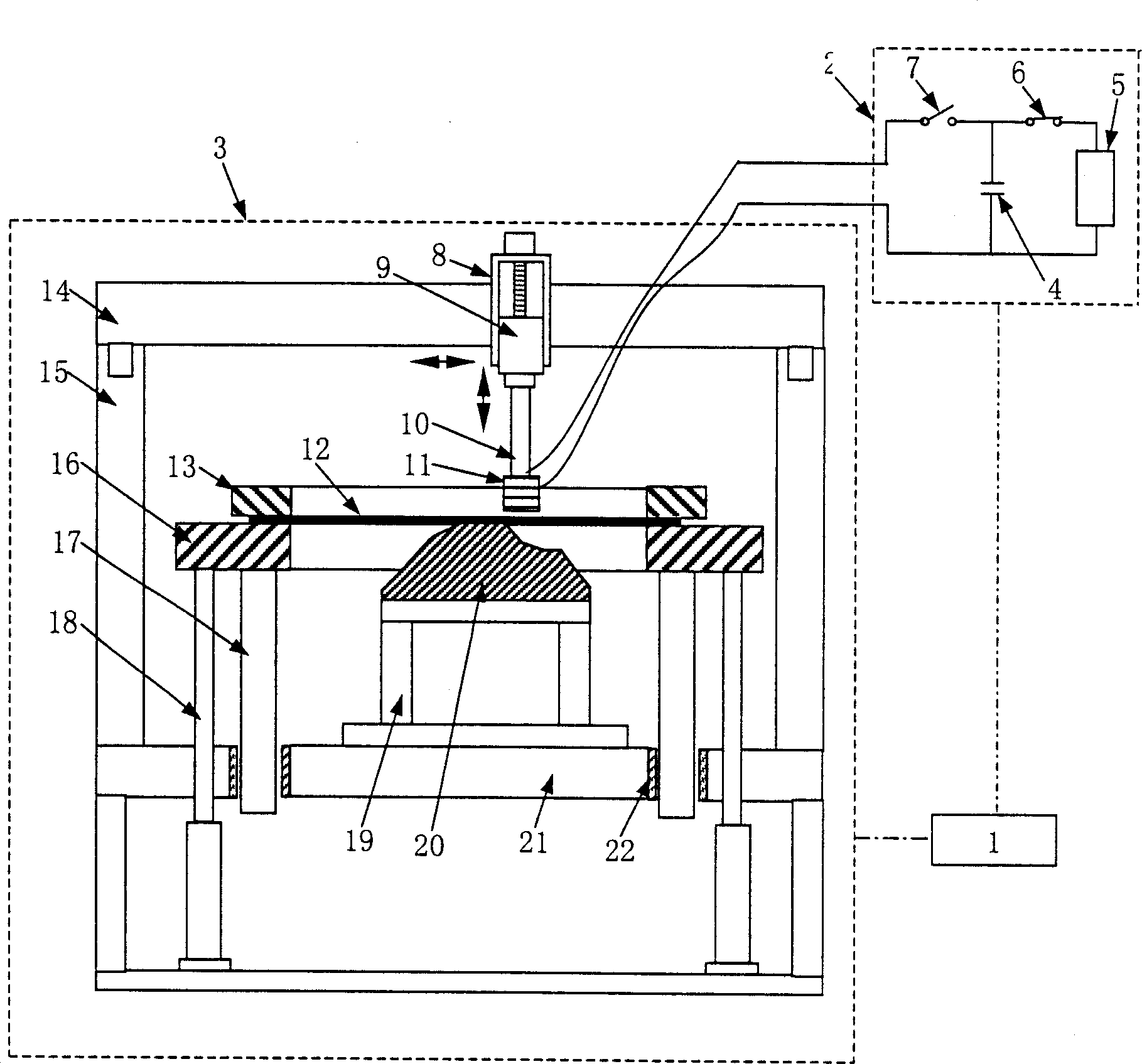

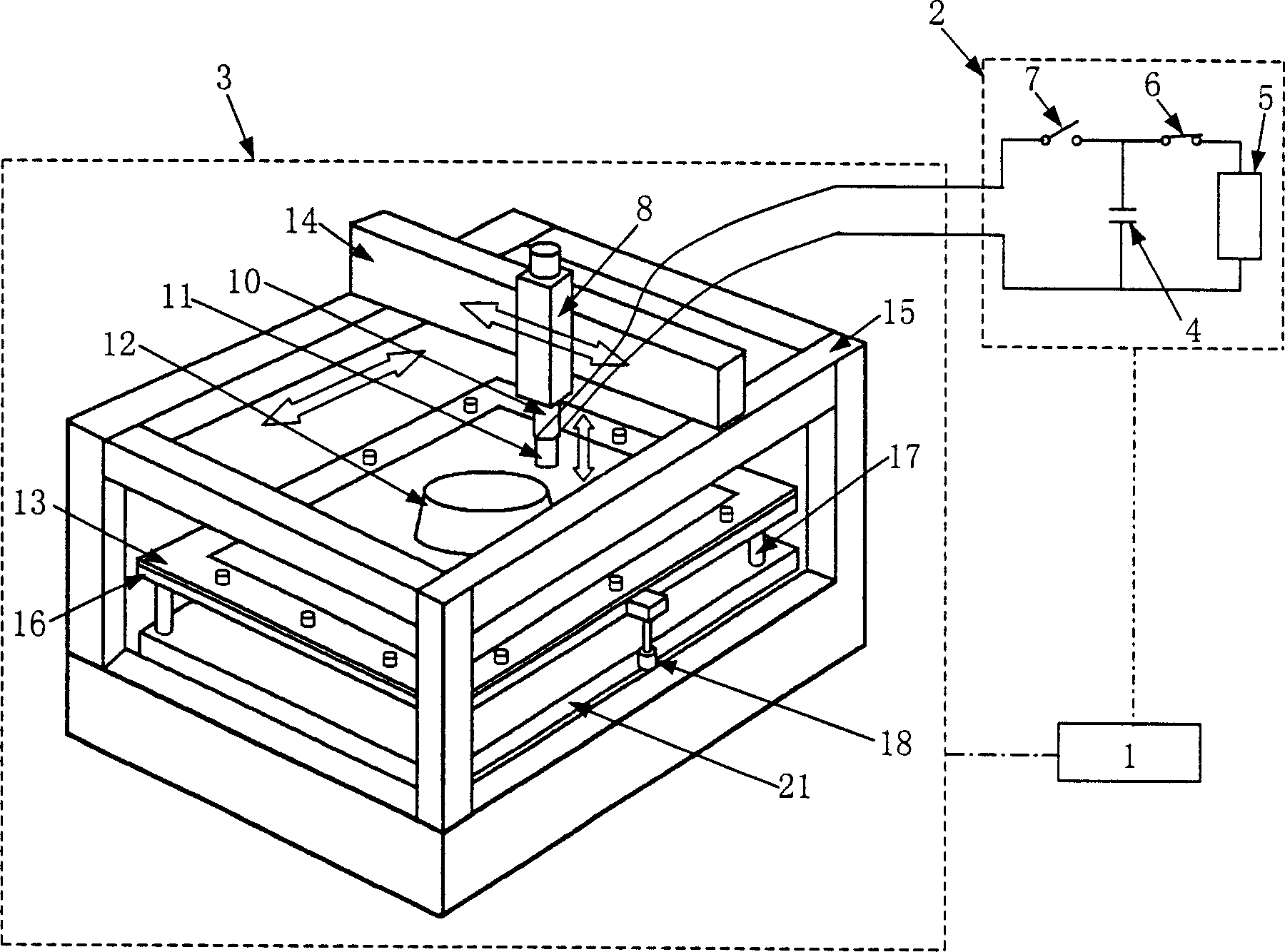

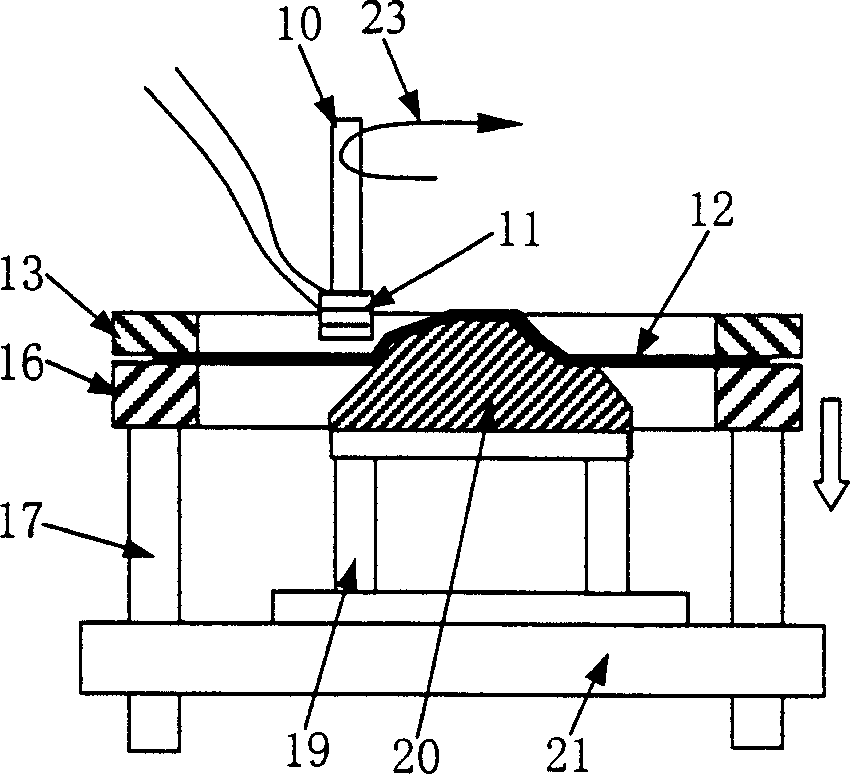

Electromagnetic inching forming method and its device for plate moving coil

InactiveCN1821910AGood repeatabilityEasy energy control and automated productionProgramme controlComputer controlEngineeringElectromagnetic pulse

This invention relates to an electromagnetic progressive shaping method for plate moving coils and a device, in which, said device includes a computer control system, an electromagnetic force generation system and a three-shaft digital control shaping system including a plate clamping elevating device, a supporting model frame and an electromagnetic shaping clamping rod, in which, the computer controls the coil to move downward along the contour of a model profile from the top according to the contour data of the model profile and the plate is formed partly relying on the magnetic force of coil till to the bottom of the model and finish the entire process.

Owner:HUAZHONG UNIV OF SCI & TECH

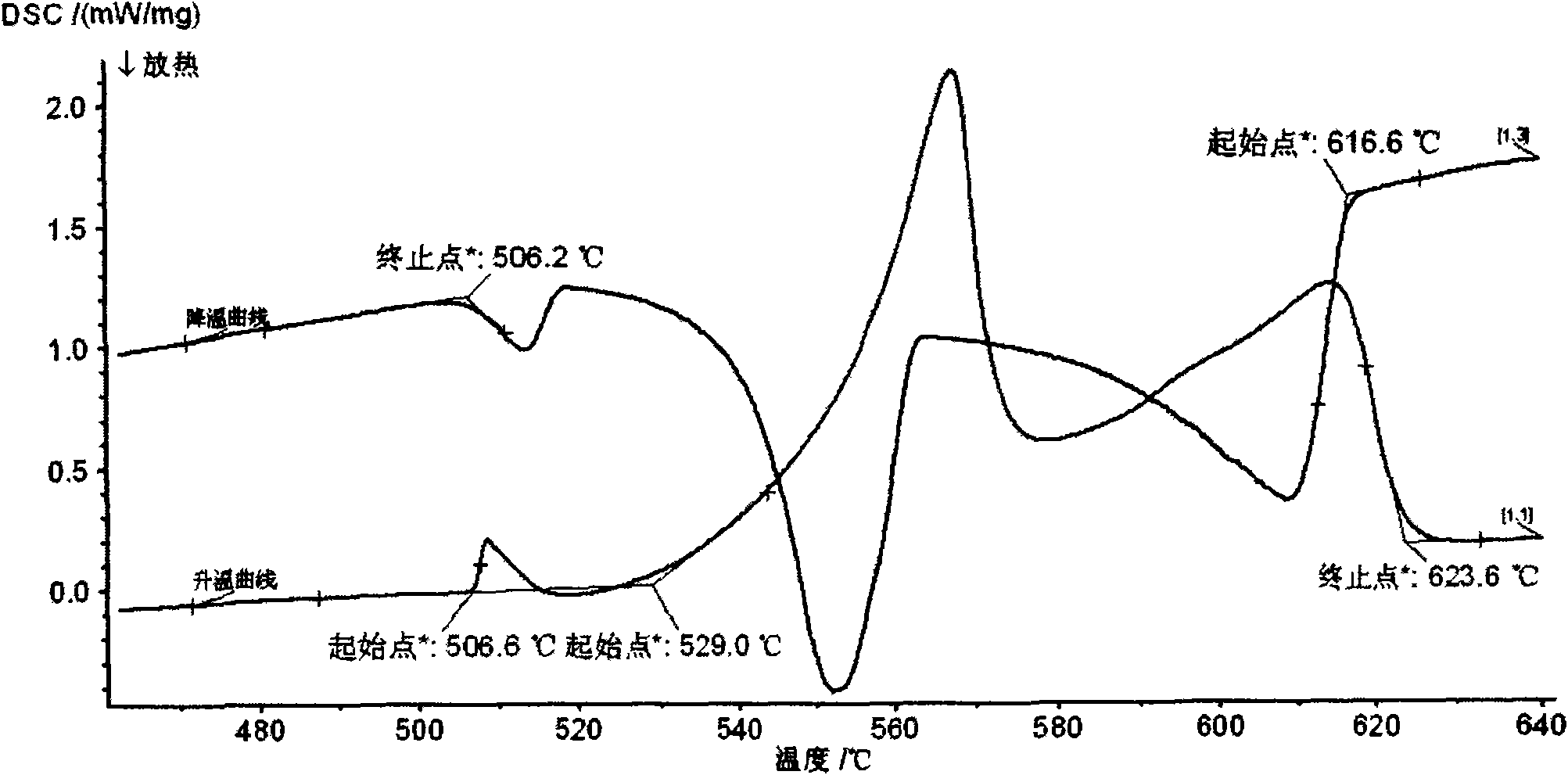

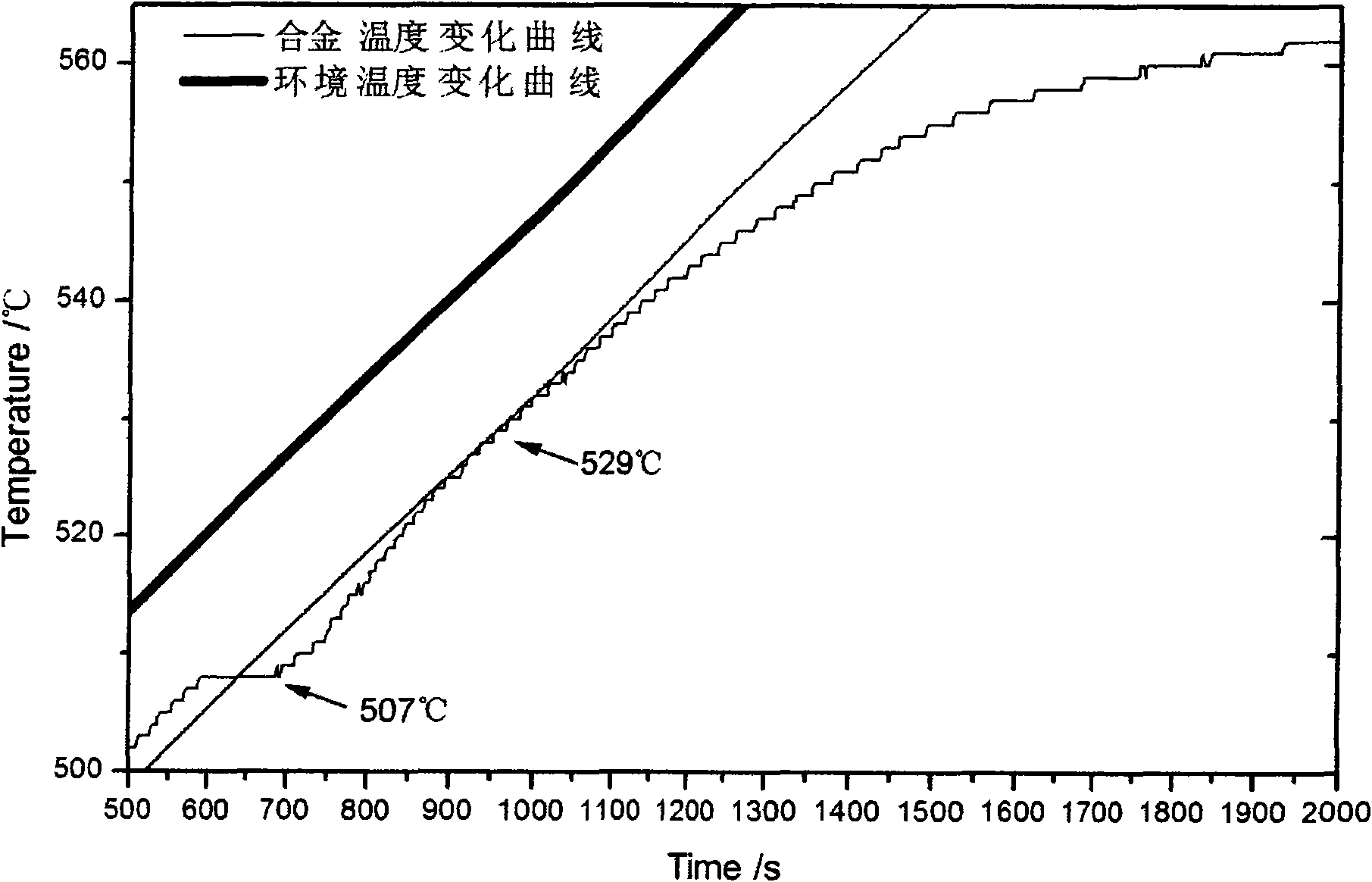

Cast aluminum-silicon alloy for engine cylinder head and heat treatment process

InactiveCN102071341AImprove room temperature performanceHigh tensile strengthChemical compositionSilicon alloy

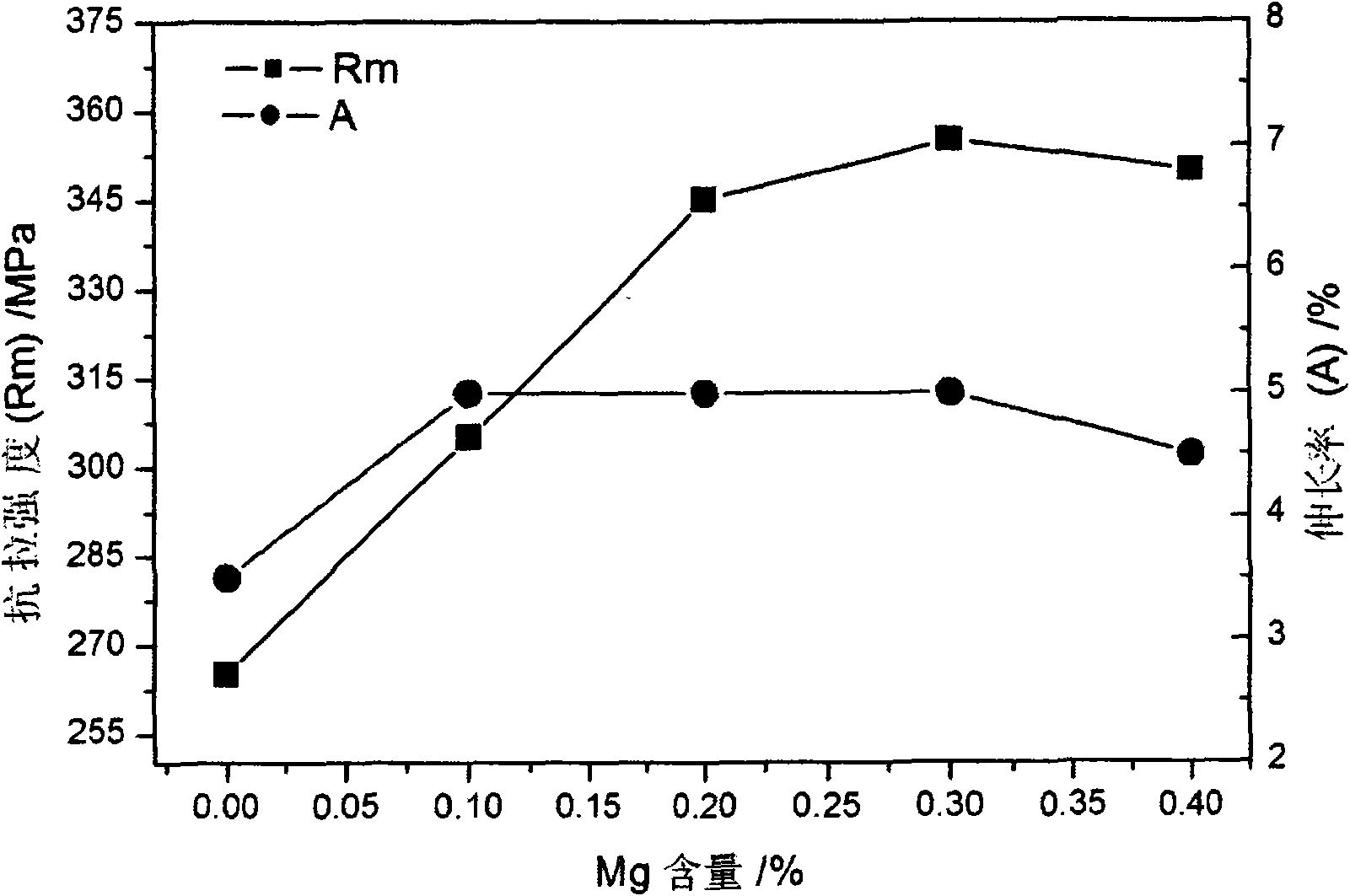

The invention relates to a cast aluminum-silicon alloy for an engine cylinder head and a heat treatment process. The alloy comprises the following chemical ingredients in percentage by weight: 5.0 to 7.0 percent of Si, 3.0 to 4.0 percent of Cu, 0.2 to 0.4 percent of Mg, 0.1 to 0.3 percent of Mn, 0.10 to 0.20 percent of Zr, 0.15 to 0.25 percent of Ti, 0.01 to 0.05 percent of B, 0.02 to 0.09 percent of Sr, 0.1 to 0.3 percent of rare earth (RE), less then 0.3 percent of Fe and the balance Al, wherein the rare earth (RE) adopts mixed rare earth. The heat treatment process comprises the following steps: carrying out primary solution at a temperature between 490 DEG C and 505 DEG C, and carrying out heat insulation for 4 to 6h; carrying out secondary solution at a temperature between 510 DEG C and 525 DEG C, carrying out heat insulation for 6 to 10h, and carrying out quenching by hot water of 60 to 80 DEG C; and carrying out aging treatment with parameters of the aging temperature being 155to 165 DEG C and the heat insulation time being 5 to 9h, and carrying out cooling in the air. All alloy elements of the cast aluminum-silicon alloy provided by the invention are reasonably matched, good mechanical performance is realized, at a normal temperature, the tensile strength reaches 325 to 355MPa, the tensile stretch is 2.5 to 5.5 percent, at a high temperature of 250 DEG C, the tensile strength reaches 240 to 270MPa, and the tensile stretch is 3.0 to 5.5 percent, after the heating processing technology, the heat resistance performance of the alloy is improved, and the casting defect is reduced.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

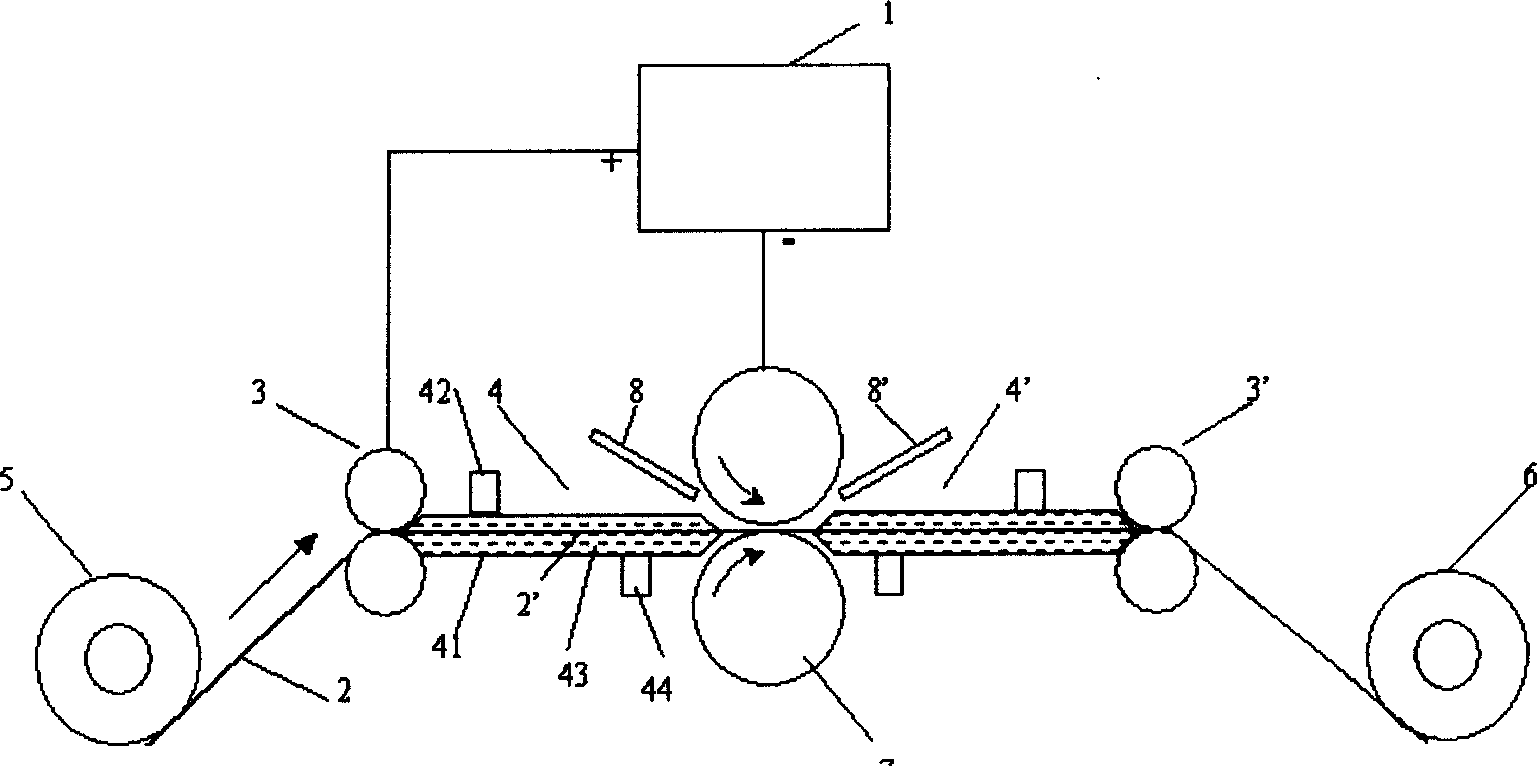

Electroplastic rolling method and apparatus for deformable magnesium alloy sheet, band and wire rod

This invention relates to an electro-plastic rolling method and a device for deformed Mg alloy thin plates, strips and wires including: inducing the deformed Mg alloy plates, strips and wires in single-way instant high energy continuous pulse current directly in the process of rolling, the current passes through a pair of electric contact devices with their distance adjustable to apply on the moving Mg materials, and the roller is the negative in it, necessary cooling and lubrication measures should be taken when rolling, this time, the rolling deformation ability of the Mg material is increased greatly and the resistance is reduced to avoid high temperature oxidation and poor accuracy in size.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

Low-carbon ultra-deep punching cold-rolling steel sheet and production method thereof

The invention relates to a low-carbon ultra-deep punching cold-rolling steel sheet and a production method thereof, belonging to the technical field of steel smelting and calendaring. The steel sheet comprises the following chemical components in weigh percentage: 0.006%-0.012% of C, 0.15%-0.20% of Mn, 0.030%-0.070% of Als, 0.015% of Si or less, 0.012% of P or less, 0.010% of S oe less, not more than 0.0030% of N or less, 0.0035% percent of O or less and the balance of Fe and inevitable impurities. Based on a ZSP sheet blank continuous casting and rolling process, the production method comprises the following working procedures of steel smelting, continuous casting, heating, hot rolling, cooling and curling, acid washing and cold rolling, and annealing and flattening. The steel sheet has excellent mechanical property and stamping forming property and simple chemical component and is suitable for punching products needing ultra-deep punching, such as fuel tank caps of automobiles; and the production method has the advantages of easy operation, low production cost, energy saving and consumption reduction and is beneficial to generalization and application.

Owner:TANGSHAN GUOFENG IRON & STEEL

Sandwich system

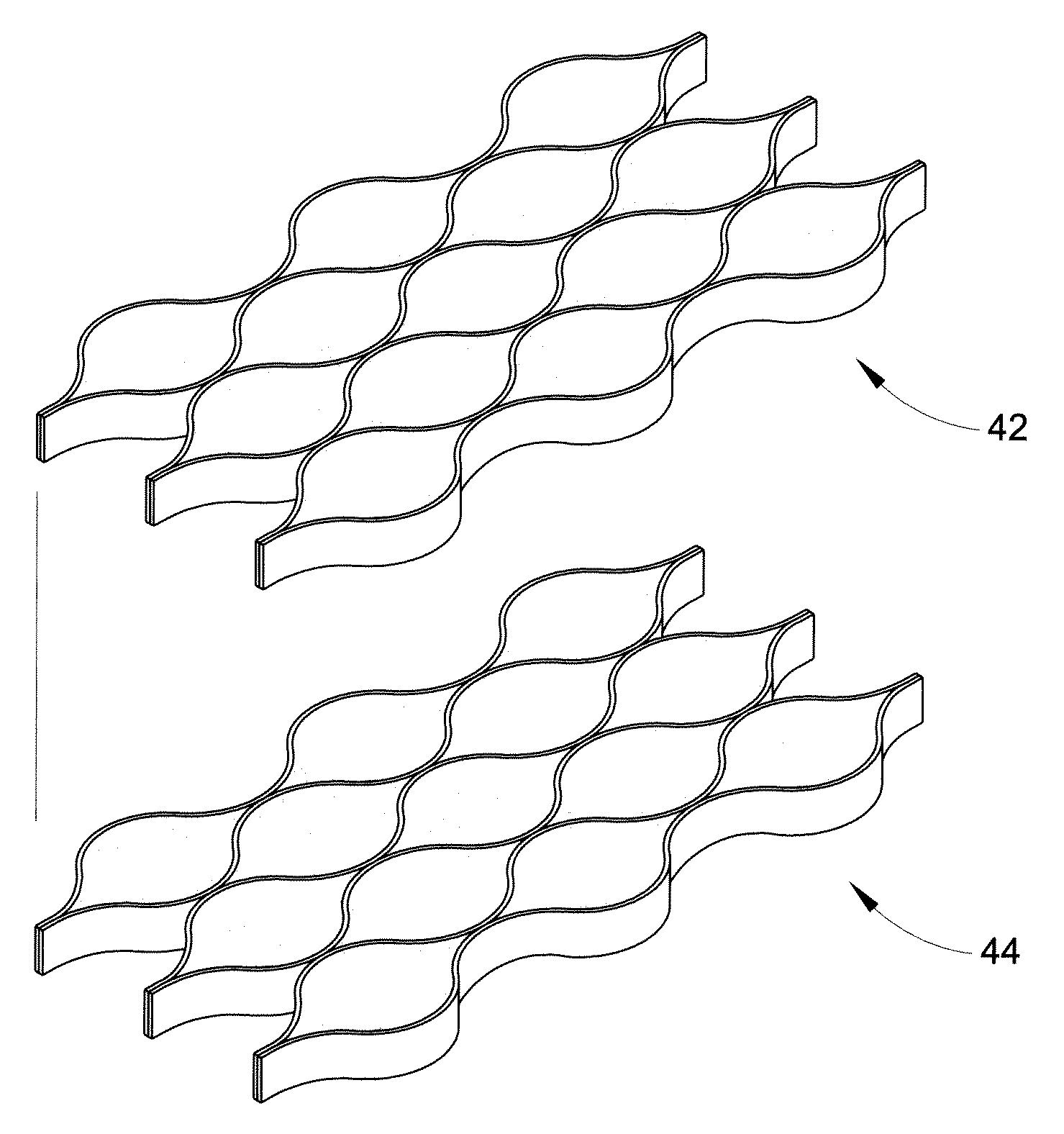

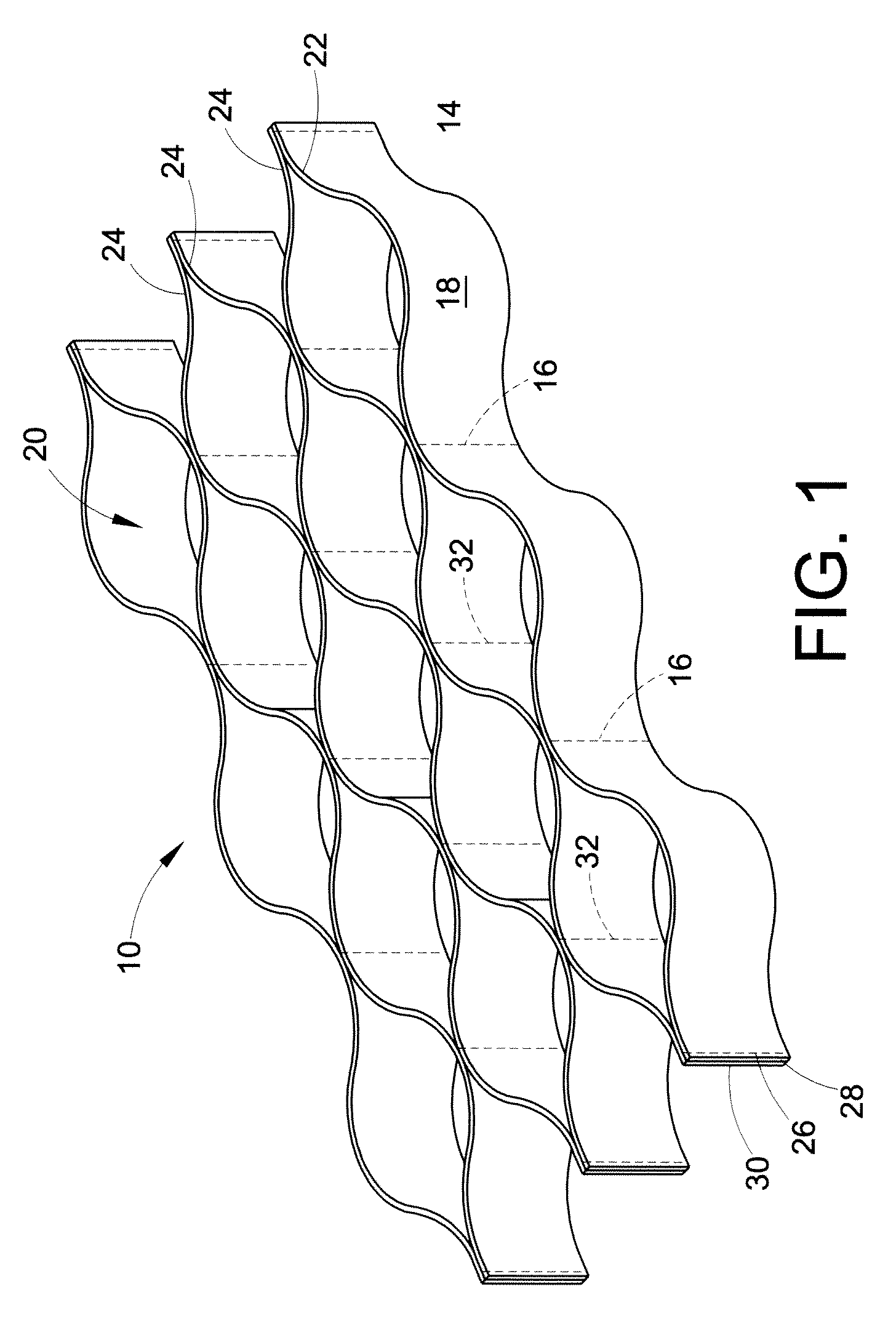

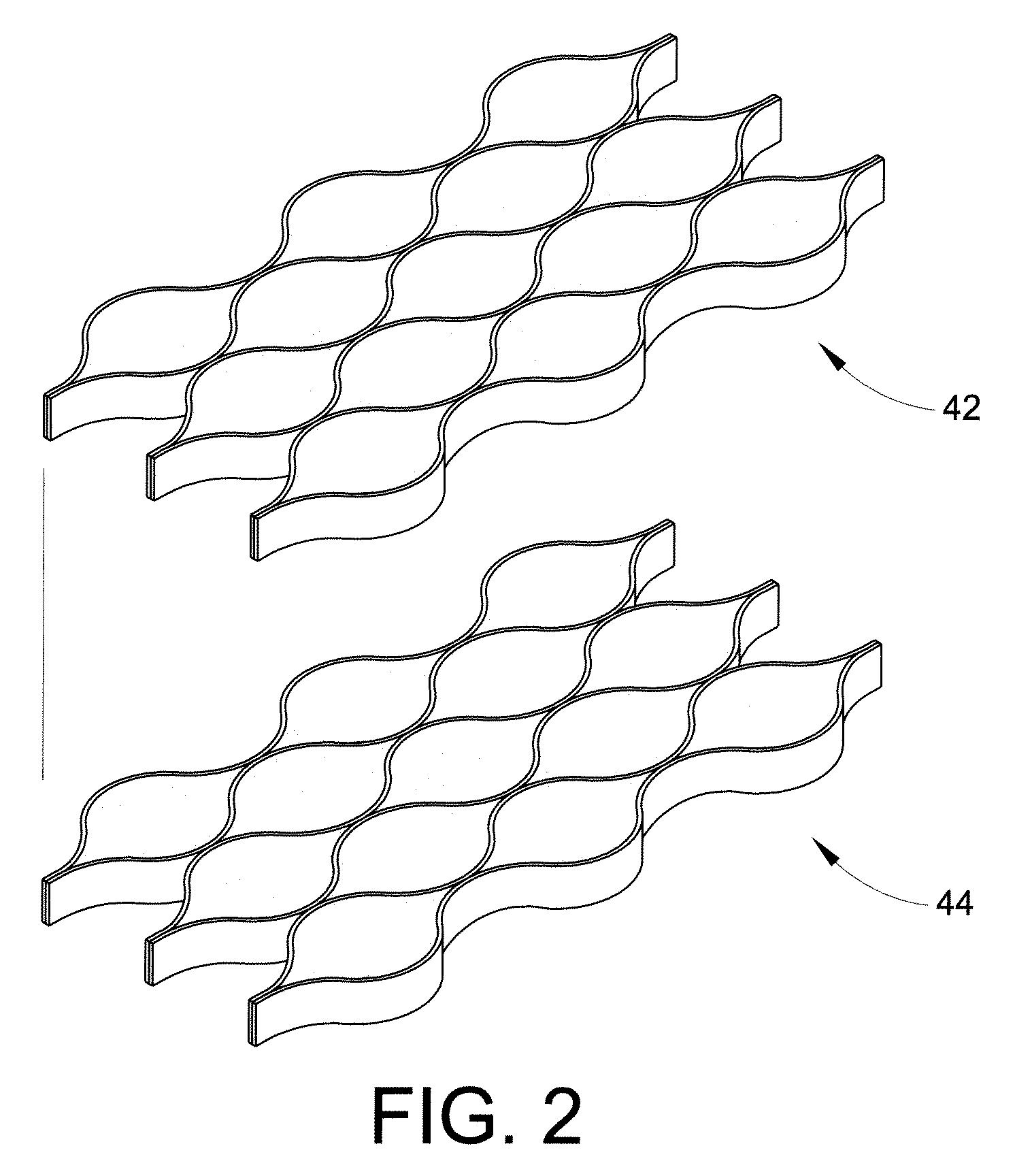

InactiveUS20090142542A1Reduce and preventIncrease loadArtificial islandsLayered productsGeocellsEngineering

A composite system comprises a base layer, a capping layer, and at least one core geocell layer. The base layer and capping layer are stacked below and above the core geocell layer, which is infilled with a low quality material. In specific embodiments, the base layer and capping layer are each geocells infilled with a high quality material. This composite system meets engineering specifications economically.

Owner:GEOTECH TECHNOLOGIES LTD

B-P-T steel tube and preparation method thereof

The invention discloses a B-P-T steel tube and a preparation method thereof. The steel tube comprises carbon, manganese, chromium, silicon, aluminum, sulphur, phosphorus and ferrum. The preparation method comprises steps of performing alloying for above components, producing a Bainite steel tube through a converter, refining and rolling and obtaining the B-P-T steel tube through a P process and a B process. The plastic property of the steel tube can be increased by more than 50% compared with former plastic property, the steel tube can be applied in the field of conveying of high-performance and high-abrasion steel tubes and the current technical problem of low plastic property is solved. The process is simple, the cost is low and the product quality is good.

Owner:攀枝花贝氏体耐磨管道有限公司

Economical high-strength binding strip steel with tensile strength more than or equal to 1,000 MPa, and manufacturing method thereof

The invention discloses economical high-strength binding strip steel with tensile strength more than or equal to 1,000 MPa, and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.25 to 0.42 percent of C, 1.0 to 2.0 percent of Mn, less than or equal to 0.45 percent of Si, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, less than or equal to 0.08 percent of Al, and the balance of Fe and inevitable impurities. The manufacturing method comprises a steelmaking process for clean steel smelting controlled in inclusion forms, a hot rolling process, a cold rolling process and a bluing-annealing process. The manufacturing method can realize the clean production of high-strength binding strip steel, reduces production processes, improves the production efficiency, and can obtain the economical high-strength binding strip steel with well matched strength and plasticity and the tensile strength more than or equal to 1,000 MPa while significantly reducing production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

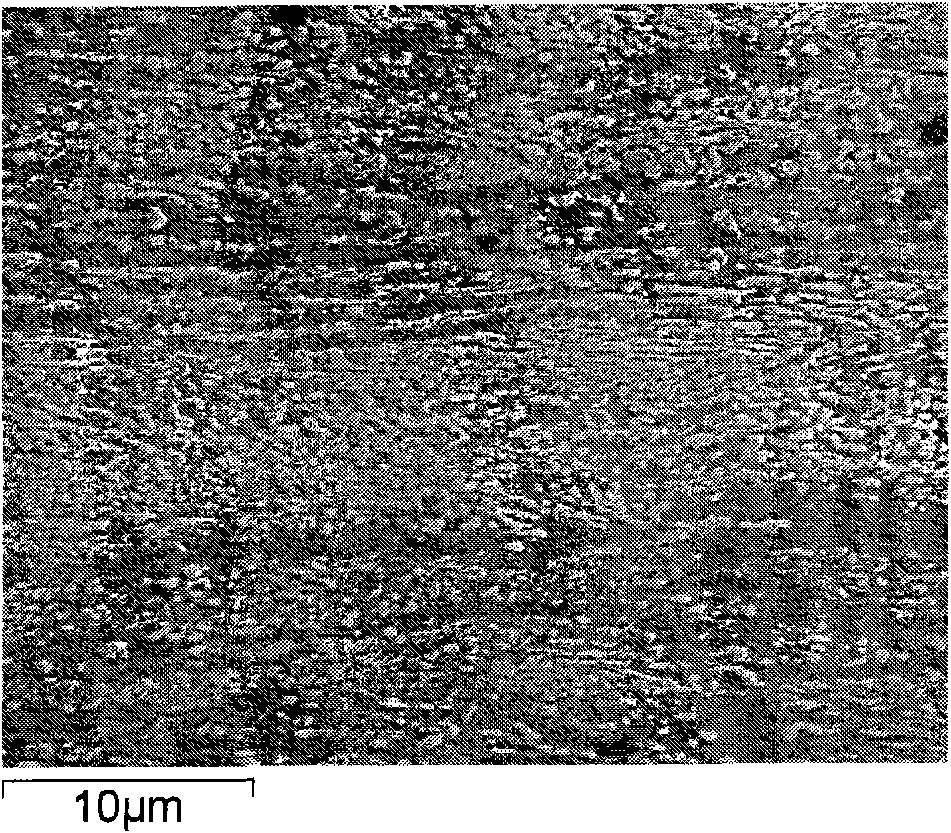

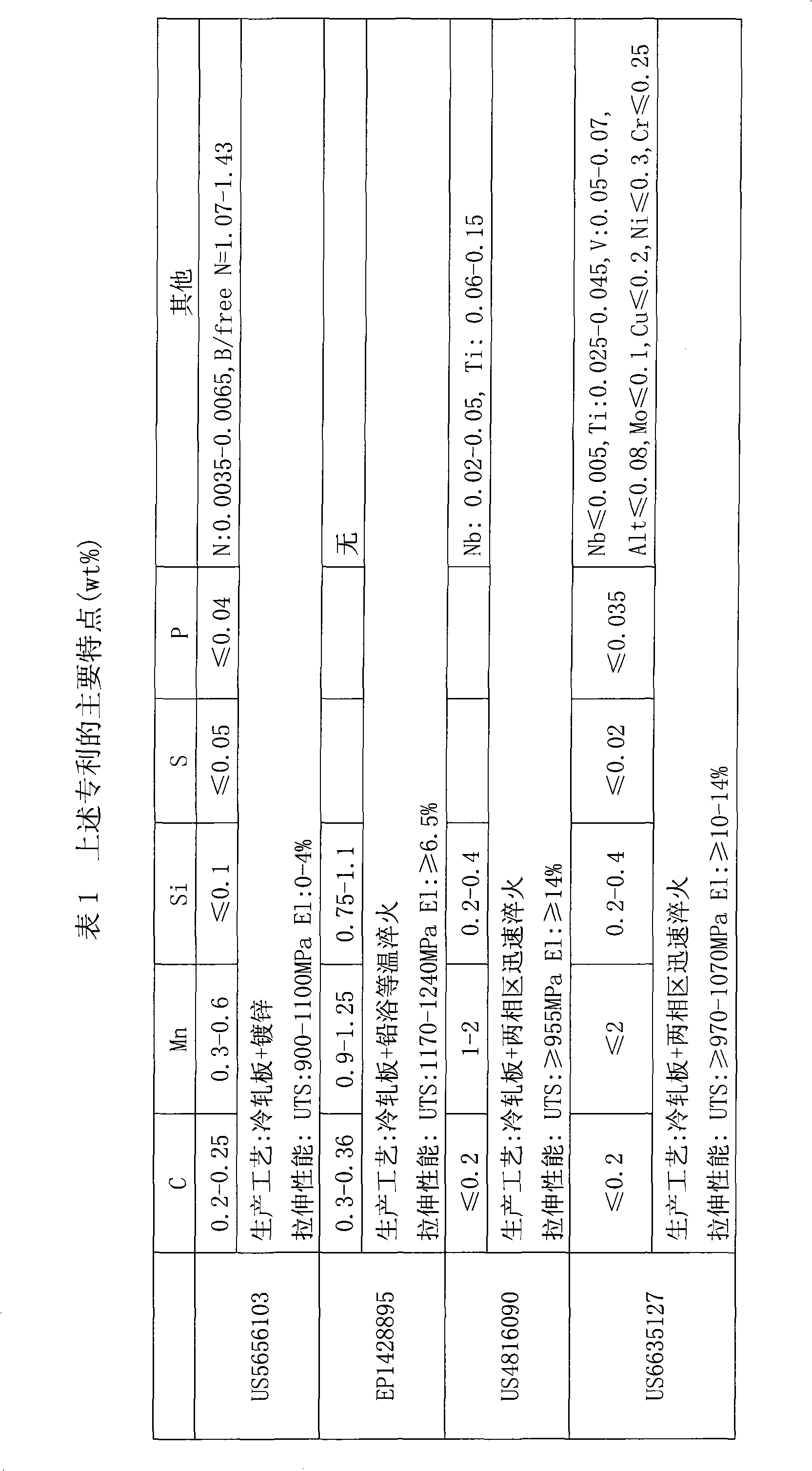

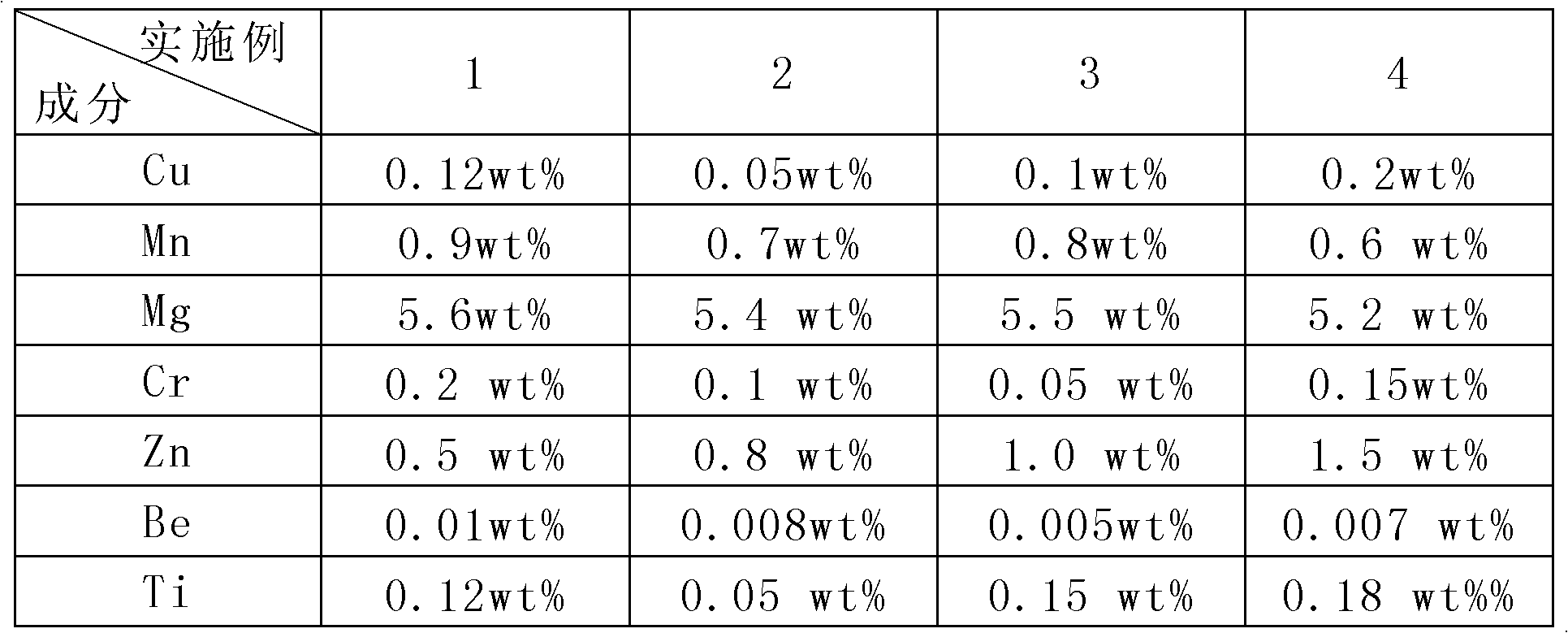

Al-Mg high magnesium alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880802AImprove corrosion resistance and plasticityGuaranteed StrengthHigh magnesiumCorrosion

The invention provides Al-Mg high magnesium alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the following problem: the existing 5083 series alloys have insufficient strength and poor impact resistance and surface quality when being used for the automobile bodies. The alloys comprise the following components in percentage by weight: 0.01-0.2wt% of Cu, 0.6-0.9wt% of Mn, 4.9-5.6wt% of Mg; 0.05-0.2wt% of Cr, 0.1-1.5wt% of Zn, 0.005-0.01wt% of Be, 0.05-0.2wt% of Ti, 0.05-0.2wt% of Zr, not more than 0.2wt% of Si, not more than 0.3wt% of Fe and the balance Al. The alloys have the advantages of high strength and good plasticity and corrosion resistance.

Owner:ZHEJIANG GKO IND CO LTD

Hot-work die steel for extrusion wheel and manufacturing method thereof

InactiveCN102534391AImprove hardenabilityReduced temper softening resistanceMetal-working apparatusTemperingThermal fatigue

The invention relates to hot-work die steel for an extrusion wheel and a manufacturing method of the die steel. The invention adopts the technical scheme that the manufacturing method comprises the following steps: hot-forging after scrap steel or molten iron and scrap steel are smelted in an electric furnace and are subjected to electroslag remelting or vacuum induction melting and then carry out spheroidizing annealing at a temperature of 700-880 DEG C; quenching at a temperature of 1,020-1,120 DEG C and tempering at a temperature of 530-650 DEG C, wherein the hot-work die steel has a hardness of up to 40-52HRC and a tensile strength of up to 1,850-1,955MPa. The hot-work die steel comprises the following chemical components in percentage by weight: 0.30-0.50wt% of C, 0.80-1.20wt% of Si, 0.2-0.5wt% of Mn, 3.00-5.00wt% of Cr, 1.00-1.50wt% of Mo, 0.70-1.20wt% of V, 0.005-0.03wt% of N and less than 0.030wt% of P, less than 0.030wt% of S and the balances of Fe and inevitable impurities. The steel has the characteristics of low cost, good thermal fatigue property, high heat stability and excellent comprehensive property and can be used for manufacturing the extrusion wheel of a continuously-extrusion-molded coating machine and other hot-work dies.

Owner:WUHAN UNIV OF SCI & TECH

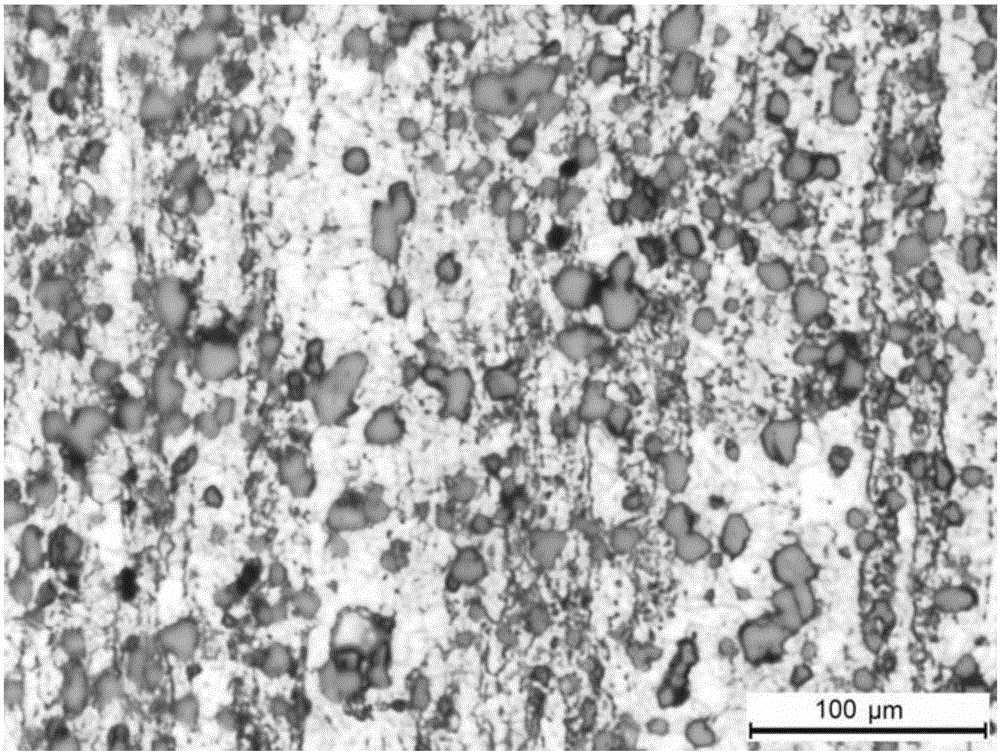

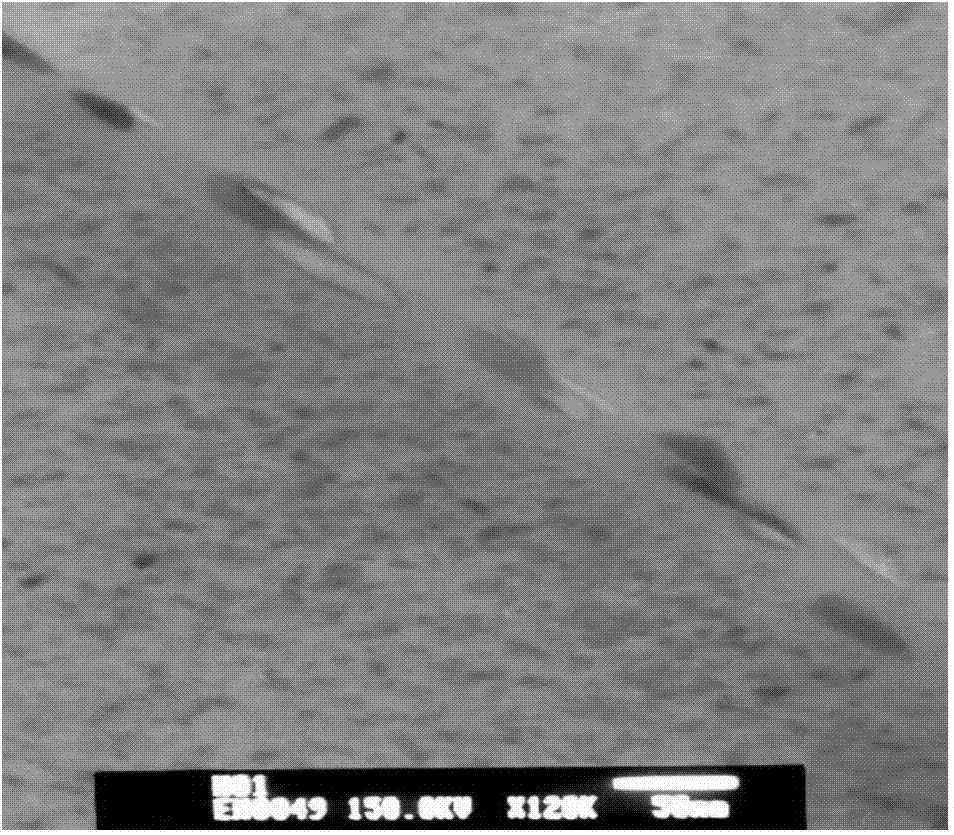

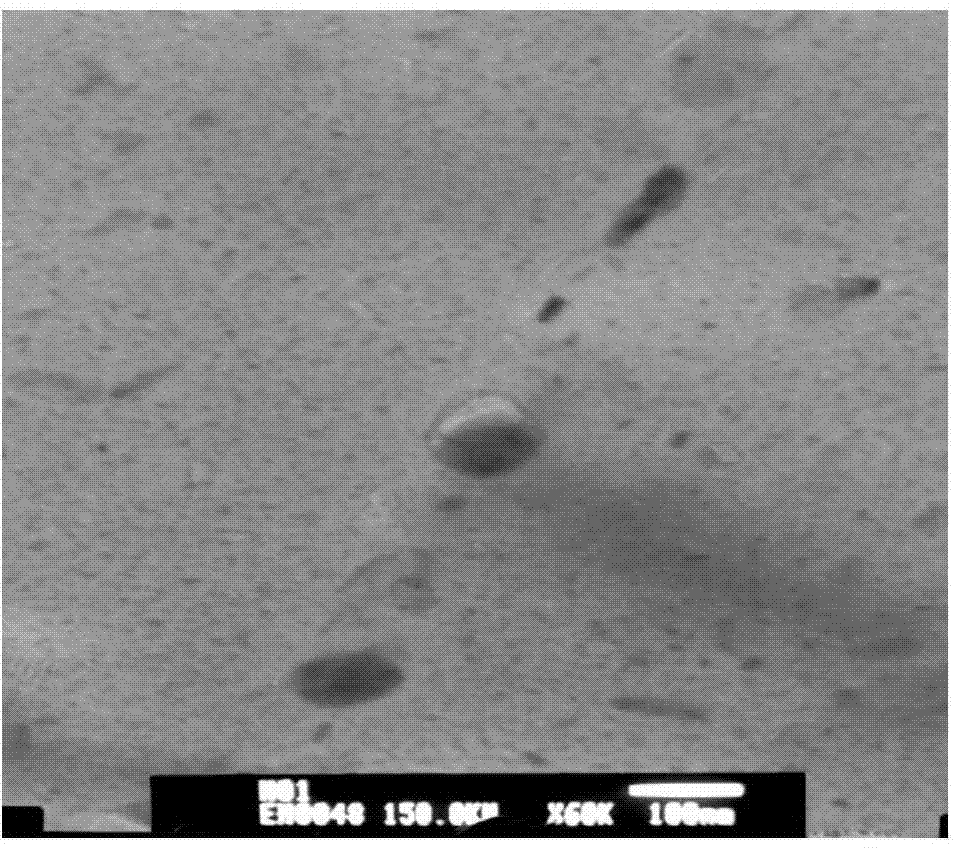

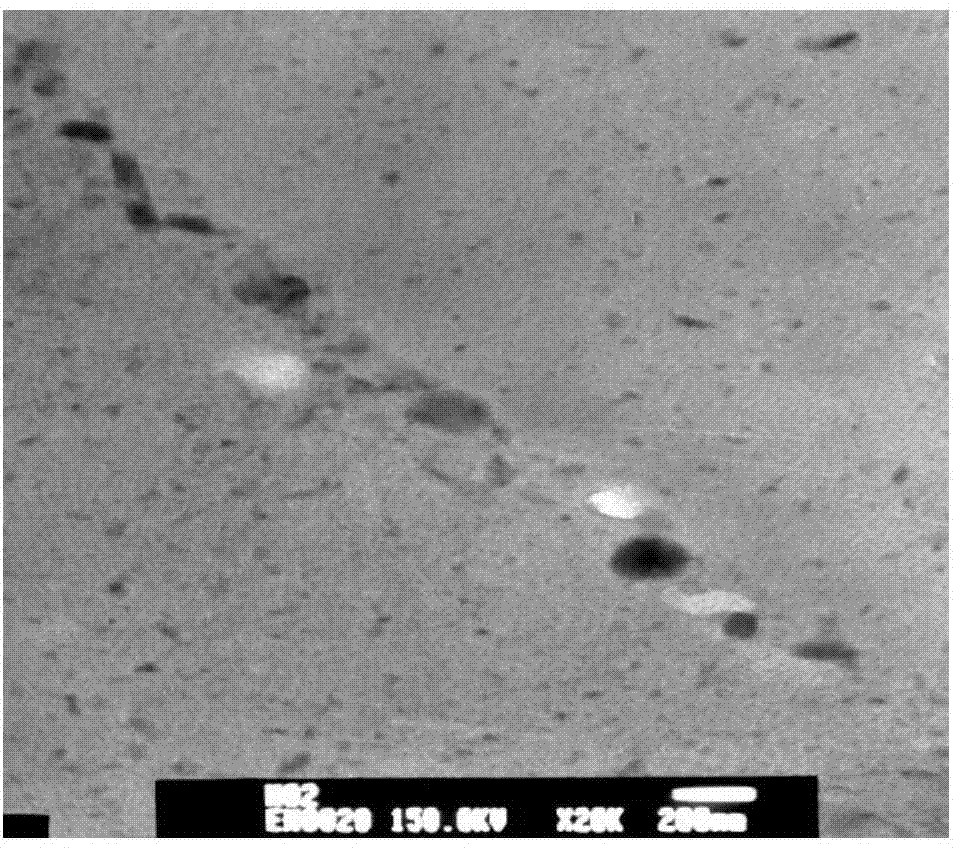

Silicon carbide particle reinforcement aluminum-based composite for train brake disc and preparation method

Disclosed are a silicon carbide particle reinforcement aluminum-based composite for a train brake disc and a preparation method. The composite includes the following components of, by mass percentage, 15-25% of SiC particles, 18-24% of Si, 0.6-3.5% of Mg, 0.15-0.35% of Zr, 0.12-0.45% of Sc, and the balance Al and unavoidable impurities. According to the preparation method, SiC, Mg, Si, Zr and Sc with the particle size being 10-15 [mu]m are added into molten aluminum in the form of intermediate alloy, SiC with the particle size being 15-25 [mu]m is added into the molten aluminum in the form of particles, and thus the silicon carbide particle reinforcement aluminum-based composite is obtained. The SiC thin particles are added in the form of Mg-SiC, so that the problems of uniform dispersing difficulty of silicon carbide particles in a matrix and poor interface bonding are effectively solved, the particle reinforcement effect is fully played, and the toughness of alloy is improved. Meanwhile, transitional element zirconium and rare earth element scandium are added to replace titanium fine grains, the roughness and heat resistance of the aluminum-based composite are remarkably improved, and occurrence of heat fatigue cracks is restrained. In addition, the added rare earth scandium has a good modification effect on the interfacial compatibility of the silicon carbide particles and aluminum alloy.

Owner:湖南中南智造新材料协同创新有限公司

Corrosion resistant niobium-titanium alloy, and method for manufacturing plates and pipes with the same

InactiveCN102703757AImprove corrosion resistanceExpand the range of corrosion resistanceSolid solution strengtheningTitanium alloy

The invention relates to a corrosion resistant niobium-titanium alloy, and a method for manufacturing plates and pipes with the corrosion resistant niobium-titanium alloy, wherein the corrosion resistant niobium-titanium alloy contains the following components by weight: 0.1-4.9% o Nb, not more than 0.08% of C, not more than 0.03% of N, not more than 0.012% of H, not more than 0.1% of O, not morethan 0.1% of Fe, and the balance of Ti. In Ti-(0.8-6%) Nb alloy pipes disclosed by the invention, titanium is as a matrix; little niobium is added; mechanical property of the niobium is improved by asolid-solution strengthening way; shearing strength and tensile strength of the alloy are higher than pure titanium; the tensile strength is increased by 10-20%; good plasticity and formability are kept; cold working performance is excellent; the niobium is added to further increase corrosion resistance of titanium and enlarge corrosion resistant range of titanium, so that the corrosion resistantniobium-titanium alloy is a good easily-formed corrosion resistant material.

Owner:NINGXIA ORIENT TANTALUM IND

Post-rolling cooling control method for small-size high-Cr 82B wire rods

ActiveCN104001741AGuaranteed uniformityAvoid it happening againTemperature control deviceWork treatment devicesWire rodTemperature control

The invention relates to a post-rolling cooling control method for high-Cr (the alloy content accounts for 0.30 percent-0.35 percent) SWRH82B wire rods. The method comprises the steps that post-rolling spinning temperature, cooling speed before spinning phase change, phase-transition temperature range, phase-transition cooling speed, Stelmor roller speed, fan delivery and Jialing air distribution are combined and controlled, and production equipment is adjusted to stabilize spinning mode so that the purpose of the stable production can be achieved. The spinning temperature is controlled to range from 860 DEG C to 880 DEG C. The cooling speed before post-rolling phase-transition is controlled to range from 10.0 DEG C / s to 14.0 DEG C / s. The phase-transition temperature is controlled to range from 580 DEG C to620 DEG C. The cooling speed in a phase-transition area is controlled to range from 1.5 DEG C / s to 3.0 DEG C / s. The base speed of the inlet segment of a Stelmor roller bed is controlled to range from 0.6 m / s to1.0m / s. After the technical scheme of the post-rolling cooling control of the wire rods is applied and implemented, it can be guaranteed that high strength is achieved, and plasticity does not decrease but is improved. Moreover, the situation that as cleaning rods are cooled in a non-uniform mode, so that the local positions produce low-temperature shift tissue such as martensite is avoided, and the uniformity of the cleaning rod tissue and the mechanical performance is guaranteed.

Owner:张家港联峰钢铁研究所有限公司

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

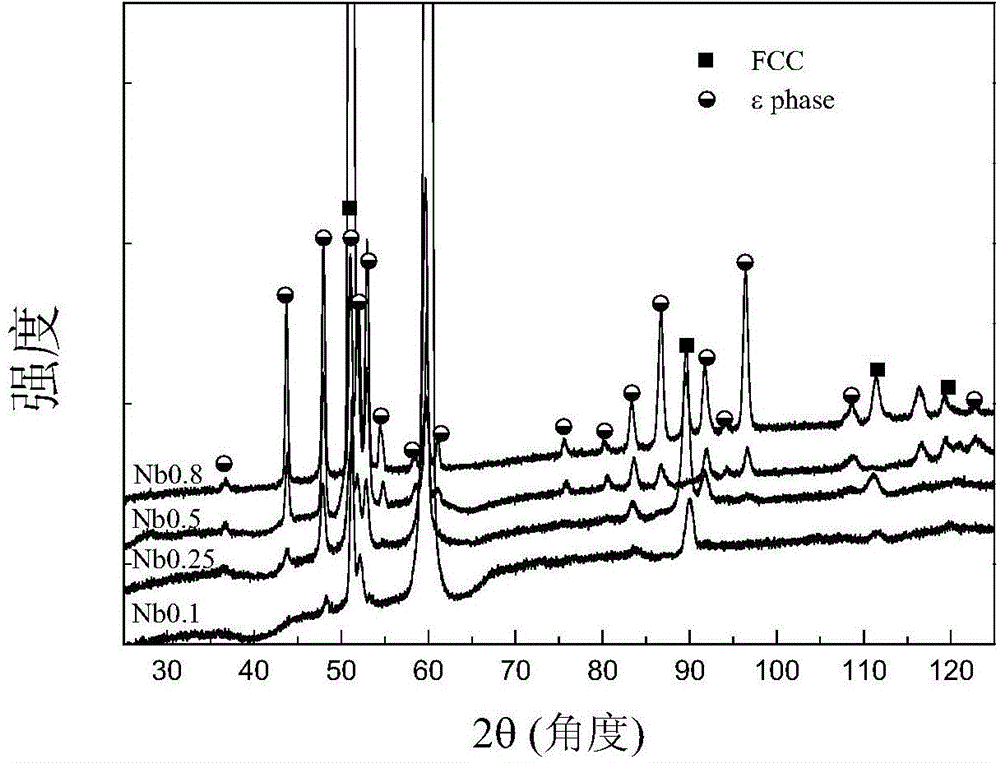

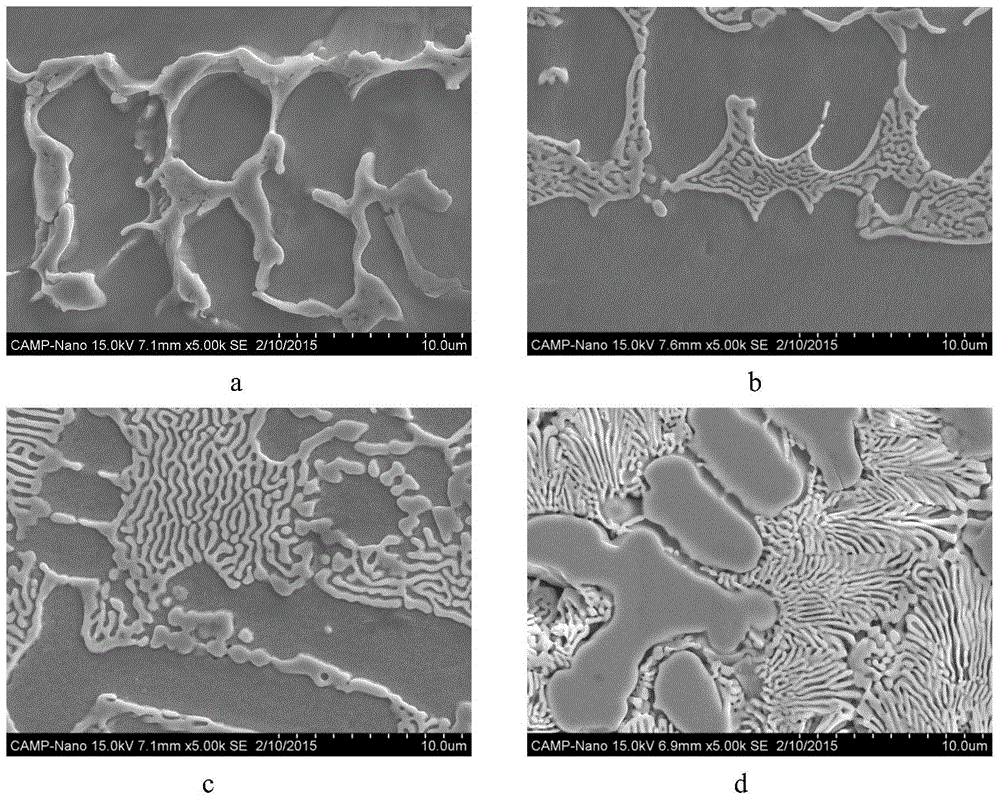

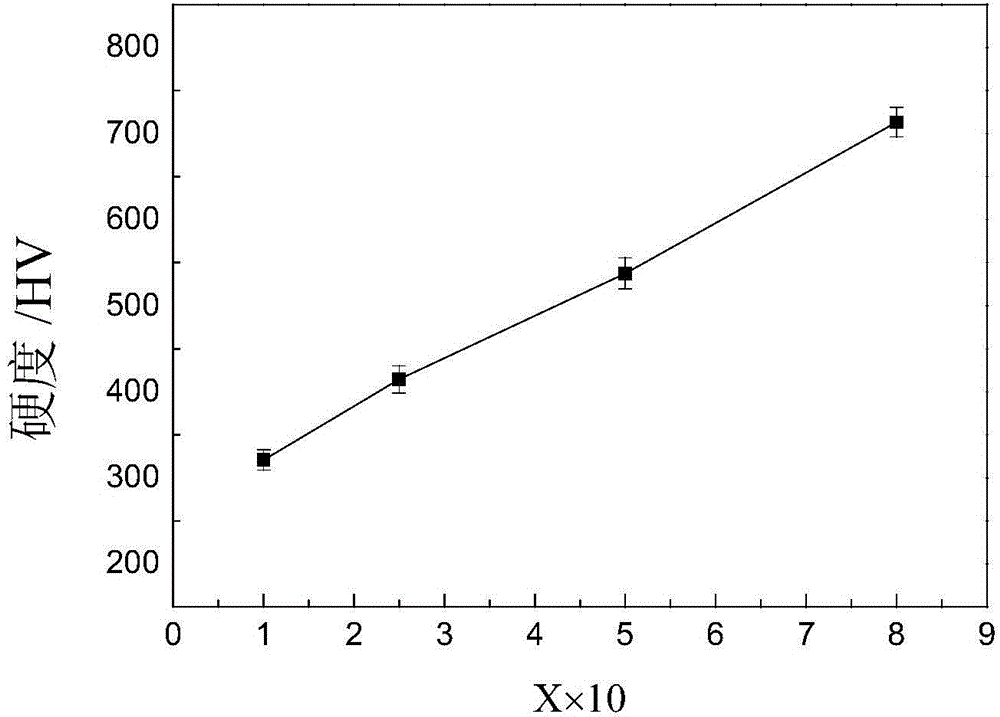

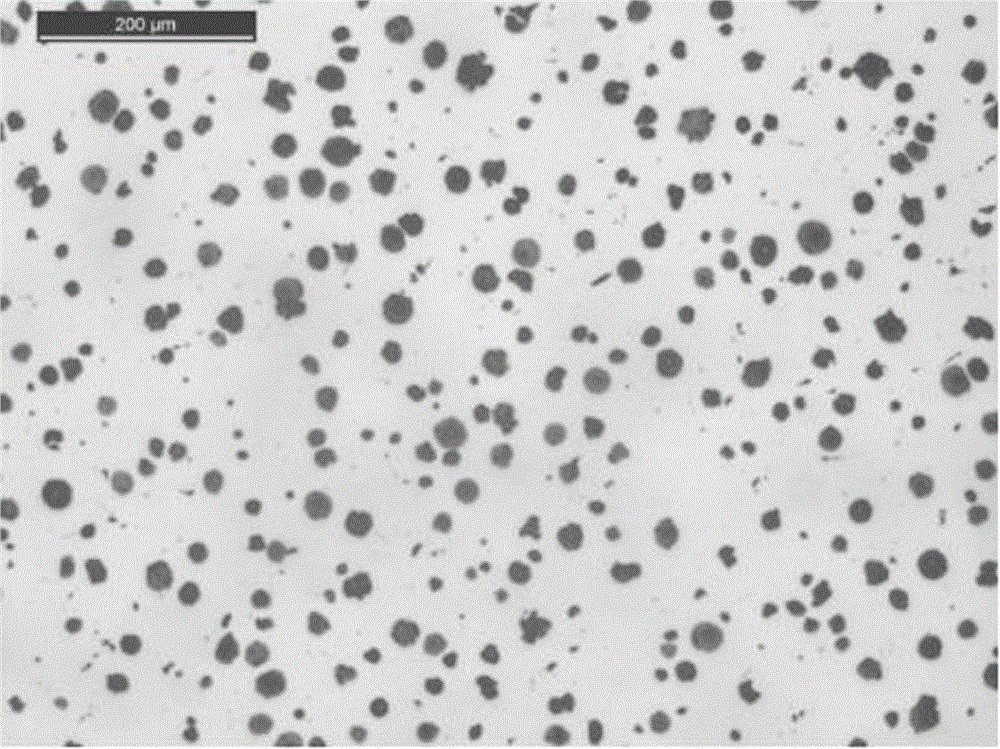

CrFeCoNiNbx high-entropy alloy and preparation method thereof

The invention discloses a CrFeCoNiNbx high-entropy alloy and a preparation method thereof. The CrFeCoNiNbx high-entropy alloy comprises Cr, Fe, Co, Ni and Nb, wherein x ranges from 0.1 to 0.8; the content of Nb is 2.4%-16.7%; Cr, Fe, Co, and Ni are equal in content; and the proportion is mole percentage. An Nb element is added to a Cr-Fe-Co-Ni quaternary alloy, a precipitated phase is formed in single FCC (face-centered cubic) solid solution phase, precipitation strengthening is performed, and the high-entropy alloy has a face-centered cubic structure, high hardness, high strength, good compression plasticity and better mechanical properties.

Owner:东莞市三航军民融合创新研究院

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

600 MPa level automobile axle housing steel and production method thereof

The invention discloses 600 MPa level automobile axle housing steel and a production method of the 600 MPa level automobile axle housing steel. Compositions of the steel comprise, by weight, 0.21 percent to 0.26 percent of C, 0.51 percent to 0.6 percent of Si, 1.1 percent to 1.5 percent of Mn, 0.01 percent to 0.06 percent of Al, P smaller than or equal to 0.02 percent, S smaller than or equal to 0.01 percent, 0.05 percent to 0.06 percent of V, 0.012 percent to 0.016 percent of N, and the balance Fe and inevitable impurities. The ratio of V to N is smaller than or equal to 5:1. According to the method, the accurate V content, the accurate N content and the controlled rolling and controlled cooling process window are designed, hot rolling strip steel for a 600 MPa level automobile axle housing is produced, the strip steel has the good strength and toughness, and meanwhile various mechanical performance indexes of the axle housing after hot forming at the temperature more than 800 DEG C can be ensured. The method can be applied to automobile axle housing production, the thickness of materials can be effectively reduced, and on the premise that the safety of an automobile is ensured, the lightweight aim can be effectively achieved.

Owner:SHOUGANG CORPORATION

Low-density ultrahigh-strength steel and preparation method thereof

ActiveCN106244927ALow costIn line with the development concept of energy saving and emission reductionChemical compositionCarbide

The invention relates to low-density ultrahigh-strength steel and a preparation method thereof, and belongs to the field of metal materials. The steel comprises the following chemical components in percentage by mass: 0.6 to 1.6 percent of C, 5 to 10 percent of Al, 15 to 30 percent of Mn, 0.01 to 0.2 percent of Nb, 0.1 to 3 percent of Mo, less than or equal to 5 percent of Cr, less than or equal to 0.5 percent of Ti, less than or equal to 2 percent of Si, less than or equal to 0.6 percent of B, and the balance of Fe and unavoidable impurity elements. According to the low-density ultrahigh-strength steel and the preparation method thereof, a NbMoC phase which is finely dispersed precipitates by compounding and adding the Nb and the Mo; precipitation is strengthened by cooperating with a kappa-carbide; the tensile strength reaches over 1,350 MPa, the elongation reaches over 10 percent and the density is 6.8 to 7.0 g / cm<3>; the low-density ultrahigh-strength steel is low in cost, is suitable for light weight of traffic transportation tools, such as vehicles and airplanes, and meets the development concept of energy conservation and emission reduction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

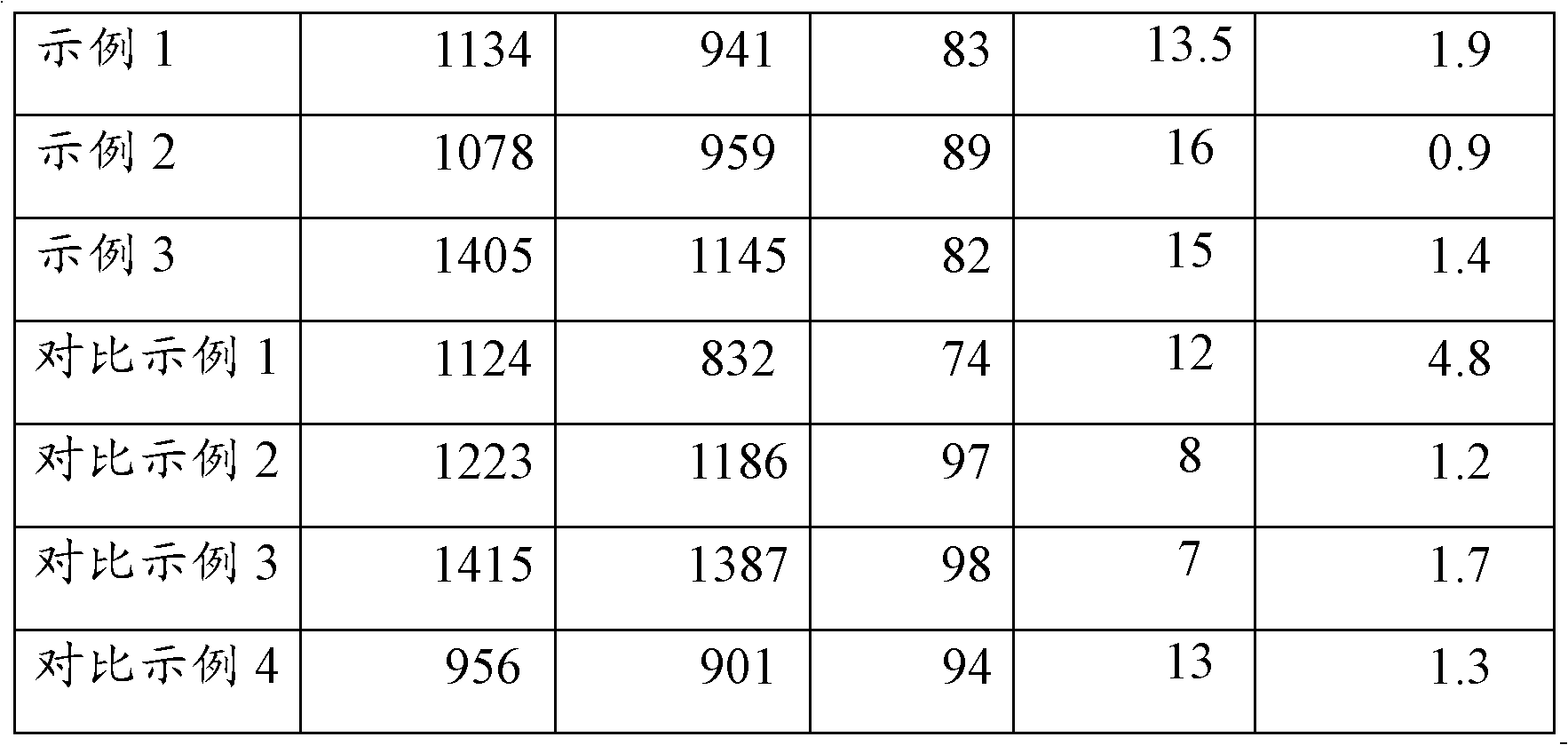

Superlarge thickness hydrogen chromium molybdenum steel plate for hydrogenation equipment and manufacture method thereof

The invention relates to a superlarge thickness hydrogen chromium molybdenum steel plate for hydrogenation equipment and a manufacture method thereof, and belongs to the technical field of ferrous metallurgy. A technical scheme is as below: the steel plate comprises the following components by weight: no more than 0.15% of C, no more than 0.10% of Si, 0.300.60% of Mn, no more than 0.007% of P, no more than 0.005% of S, 2.00-2.50% Cr, 0.90-1.10% of Mo, no more than 0.02% of Nb, no more than 0.20% of Cu, no more than 0.20% of Ni, no more than 0.003% of Sb, no more than 0.005% of Sn, no more than 0.016% of As, no more than 0.003% of O, N no more than 0.008%, no more than 0.0002% of H, no more than 0.03 of Ti and the balance of Fe and unavoidable impurities; a round steel ingot with piece weight of 80 tons is produced by electric arc furnace smelting and casting; and the steel ingot is subjected to forging cogging, rolling and a heat treatment process including normalizing, accelerated cooling and tempering to prepare the superlarge thickness chromium molybdenum steel plate with a maximum thickness of 256mm for hydrogenation equipment. A finished steel plate has maximum single weight reaching 60 tons, good cold bending property, no cracking during material manufacture and good resilience. The method provided by the invention reduces labor intensity, saves time and improves the utilization rate of materials.

Owner:WUYANG IRON & STEEL +1

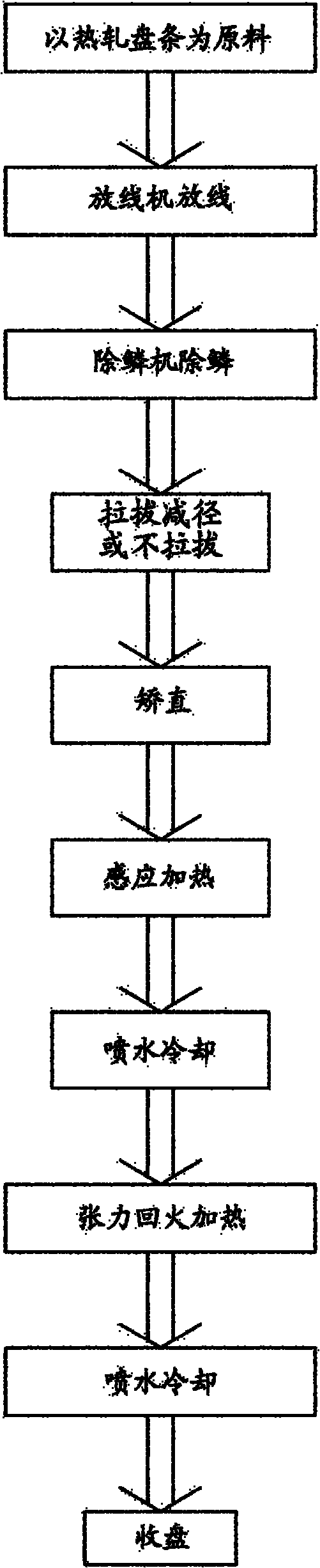

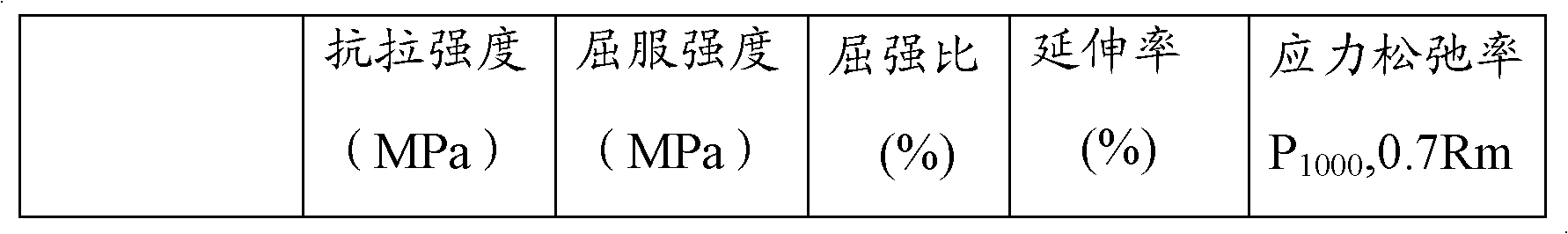

Production process of rebar for concrete

The invention discloses a production process of rebar for concrete. The production process comprises the following steps of: removing scales on a hot rolling steel wire rod; straightening the hot rolling steel wire rod after forming with die drawing or roller die drawing, or directly straightening the hot rolling steel wire rod without drawing; leading the hot rolling steel wire rod to continuously pass through a heating ring and a cooling water ring by a high-medium frequency induction furnace; heating the rebar to Ac1 above so as to carry out austenization; quenching and cooling the rebar by spraying water; executing drawing temper, and applying tension on the rebar when tempering; and cooling the rebar by spraying water to obtain the rebar for the concrete.

Owner:CHINA IRON & STEEL RES INST GRP +1

Thick chromium-molybdenum steel plate for hydrogenation equipment and production method thereof

InactiveCN102181806AImprove toughnessDoes not reduce weldabilityRoll mill control devicesMetal rolling arrangementsSheet steelIngot

The invention discloses a thick chromium-molybdenum steel plate for hydrogenation equipment, and also discloses a production method of a steel plate. The steel plate comprises the following components by weight percent: 0.12%-0.15% of C, 0.02%-0.07% of Si, 0.50%-0.60% of Mn, less than or equal to 0.007% of P, less than or equal to 0.005% of S, 2.35%-2.50% of Cr, 0.95%-1.10% of Mo, 0.012%-0.02% ofNb, less than or equal to 0.20% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.003% of Sb, less than or equal to 0.005% of Sn, less than or equal to 0.016% of As, less than or equal to 0.003% of O, less than or equal to 0.008% of N and less or equal to 0.0002% of H, the balance of Fe and inevitable impurities. For the steel plate, an electroslag remelting technology is adopted,electroslag ingot with the maximum piece weight being 50t is melted, and the maximum thickness of the produced thick chromium-molybdenum steel plate for the hydrogenation equipment can achieve 198mm,and the maximum piece weight of the single-piece finished steel plate can achieve 37.2t by a heating-rolling technology and thermal-processing production equipment of normalizing plus accelerated cooling plus tempering.

Owner:WUYANG IRON & STEEL +1

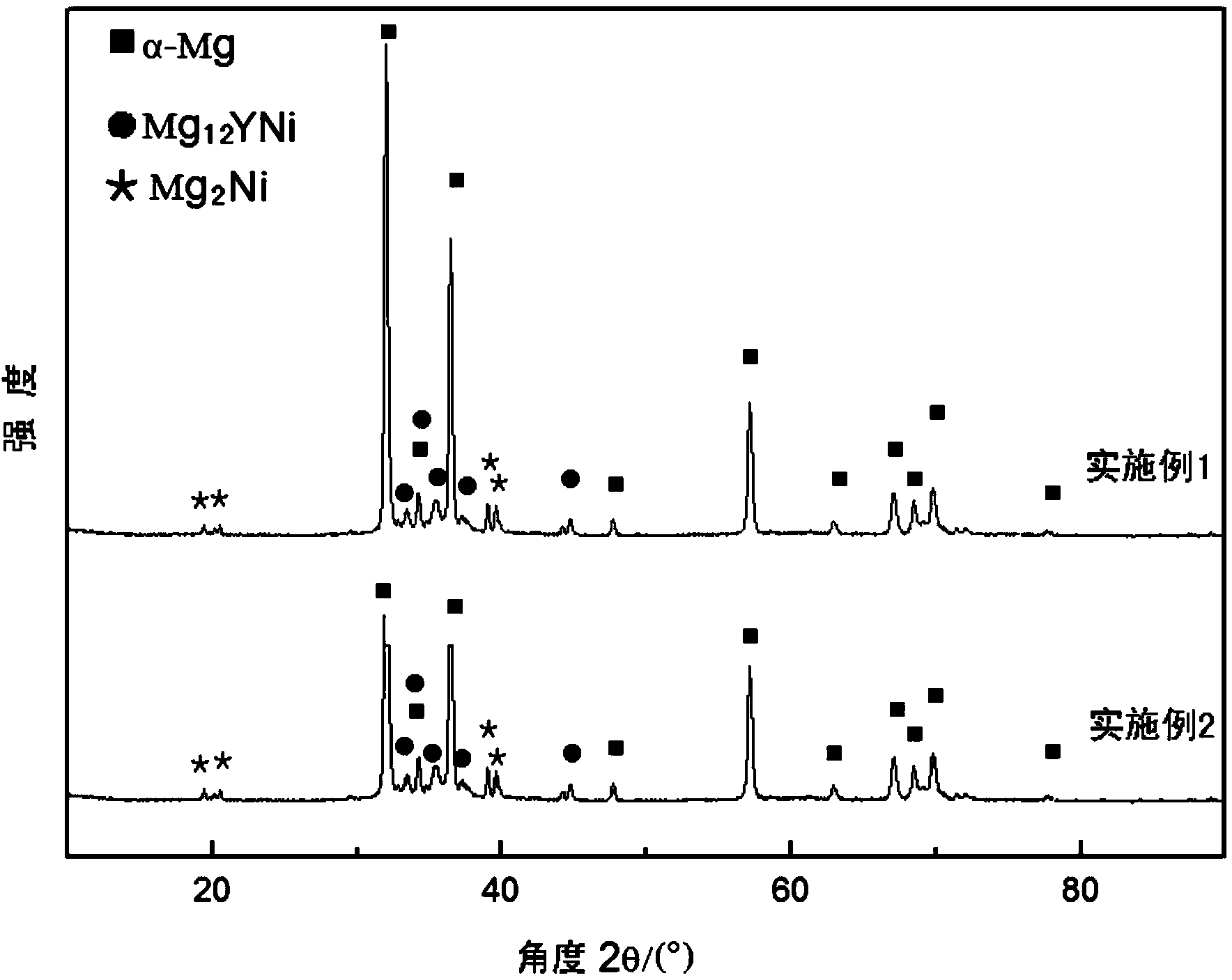

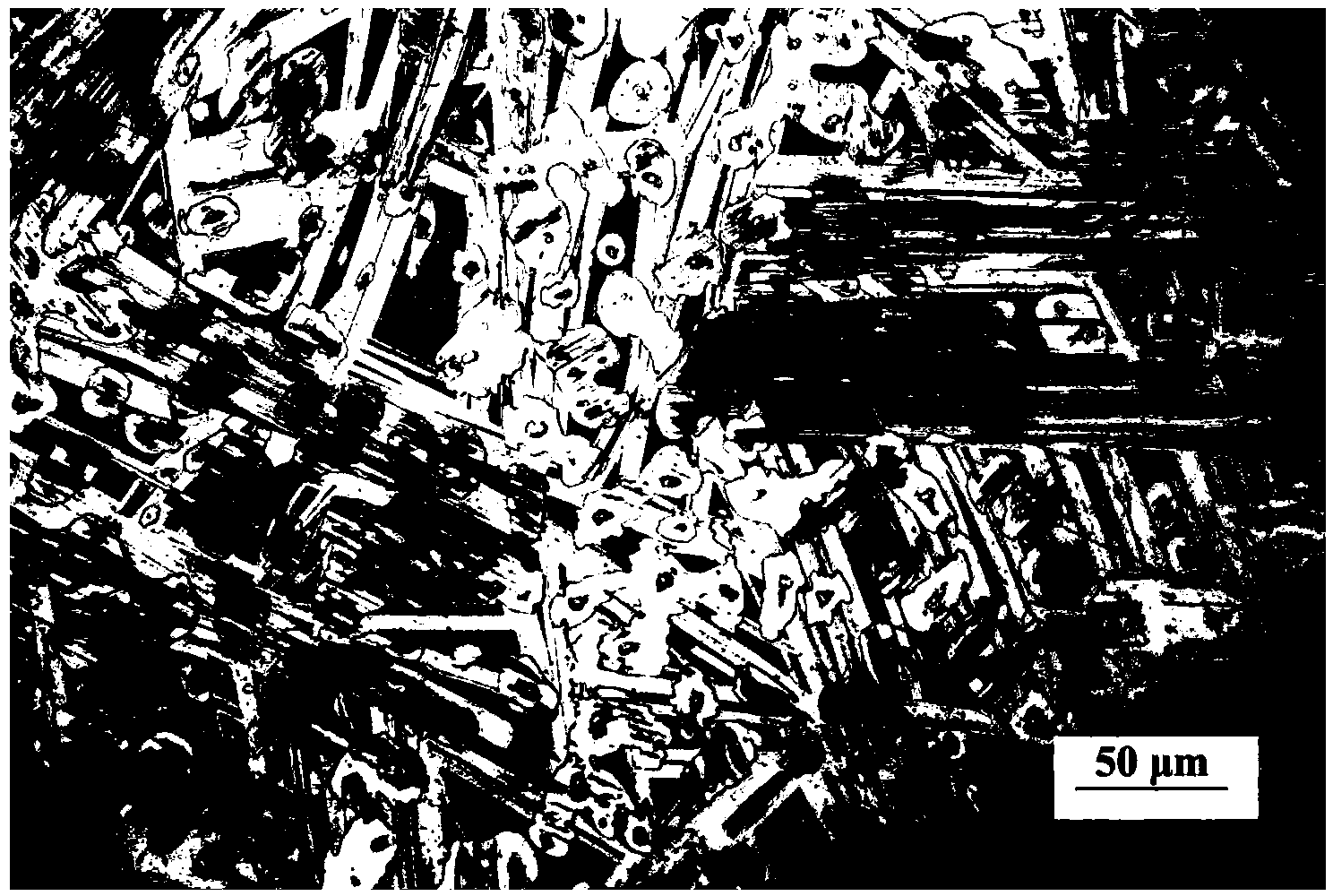

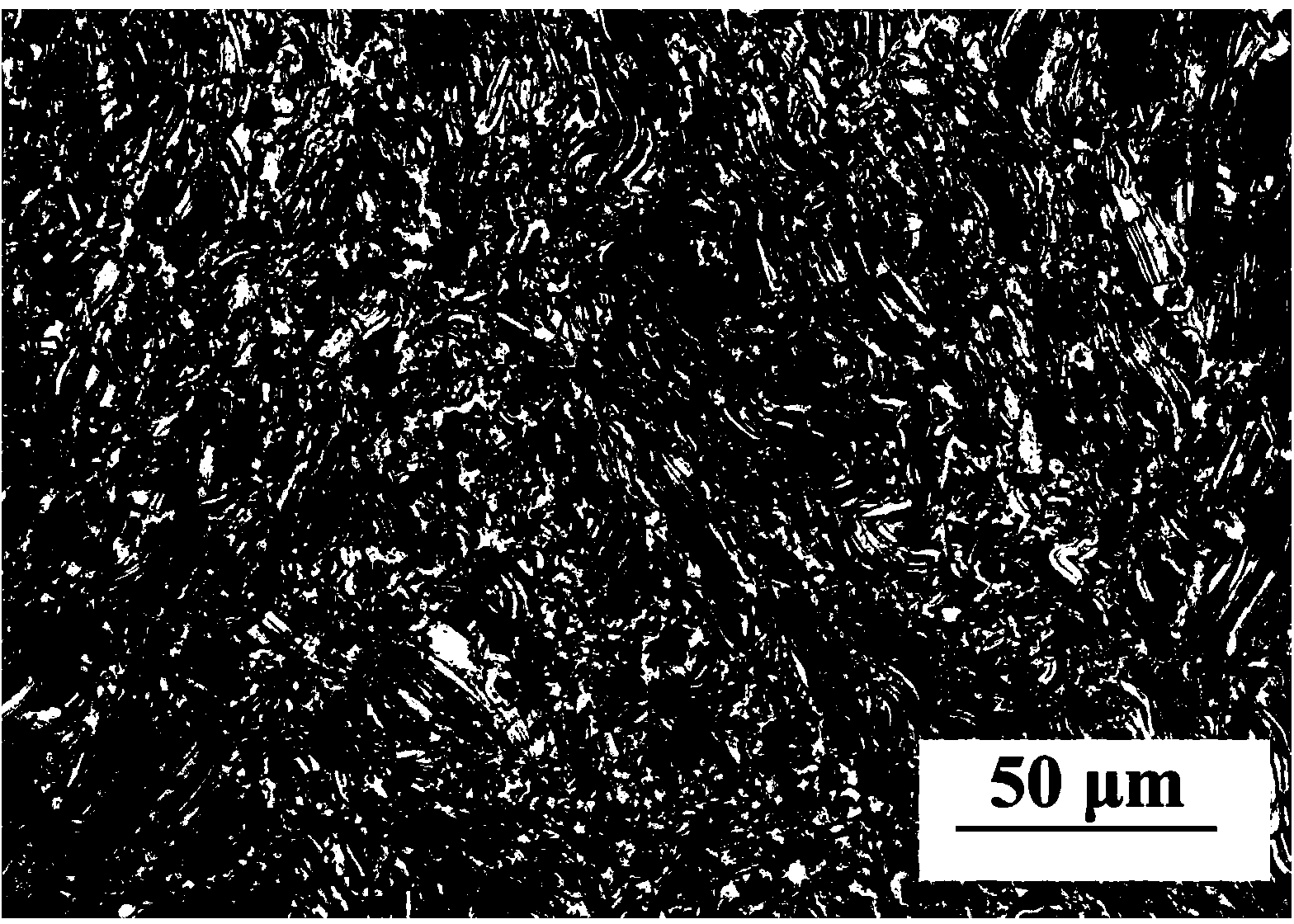

High-strength and high-plasticity magnesium alloy

The invention discloses a high-strength and high-plasticity magnesium alloy. The high-strength and high-plasticity magnesium alloy comprises the following components in percentage by mass: 3.0-4.5% of Ni, 4.0-5.0% of Y, 0.01-0.1% of Zr, not more than 0.15% of inevitable impurities and the balance of magnesium. According to the high-strength and high-plasticity magnesium alloy disclosed by the invention, Y and Ni elements are simultaneously added into a magnesium matrix, and in the smelting and molding process of the alloy, Y and Ni form Mg2Ni and Mg12YNi phases with the magnesium matrix, wherein the Mg12YNi phase is a long-period stacking ordered structure (LPSO), so that the strength of the alloy can be improved, and the plasticity of the alloy can also be improved; and Mg2Ni can improve the strength of the alloy by a strengthening mechanism of the second phase. According to the high-strength and high-plasticity magnesium alloy disclosed by the invention, an appropriate amount of Zr element is further added into the alloy, and zirconium can be dispersed and distributed in the matrix in an elemental form by controlling the smelting and molding process to play a role in refining grains.

Owner:CHONGQING ACADEMY OF SCI & TECH

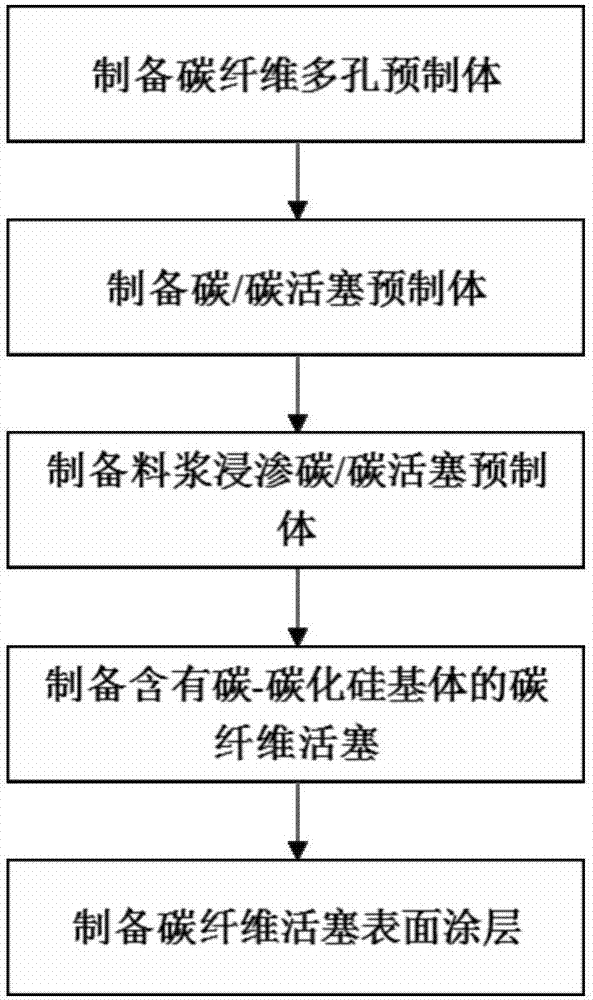

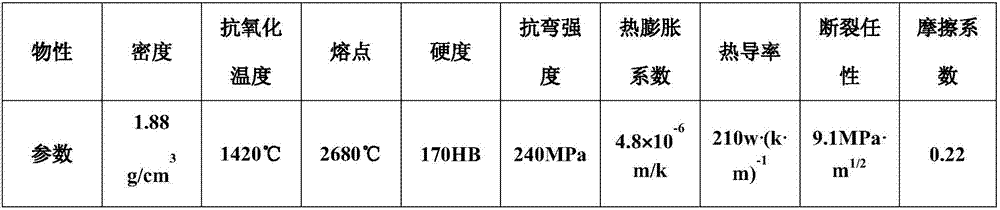

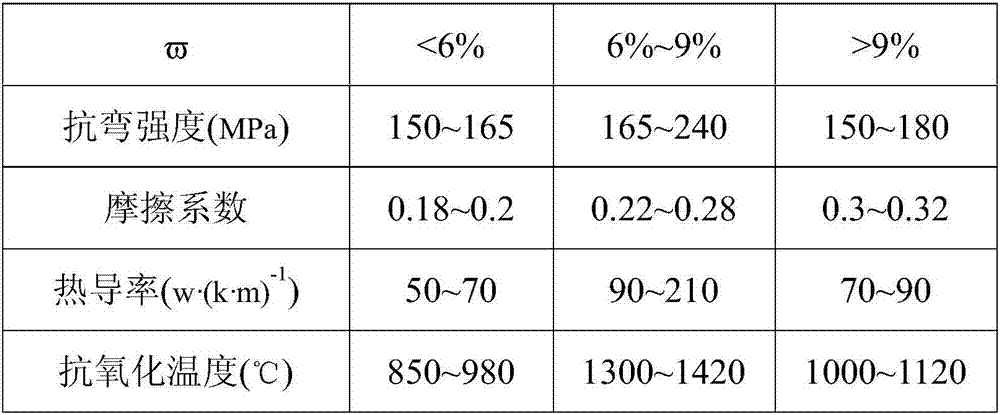

Cf/C-SiC composite material as well as preparation method and application thereof

The invention designs a composite material. The composite material comprises carbon-fiber perform, matrix carbon, filler and diamond-like carbon, wherein the matrix carbon is uniformly adhered on the carbon fiber of the perform to form the carbon-fiber perform with the matrix carbon; the filler fills the inside of the carbon-fiber perform with the matrix carbon and coats the outside of the carbon-fiber perform with the matrix carbon to form a semifinished product; the diamond-like carbon comprises a diamond-like carbon layer coated on the semifinished product; and the filler contains a Ti element, a Si element, a C element and a Mo element. The composite material has the advantages that a method of combining four processes of CVI, SI, RMI and PECVD to prepare a finished product with the advantages of high compactness, low thermal expansion coefficient and friction coefficient, high self-lubricating property, high thermal conductivity, oxidation resistance, thermal shock resistance, ablation resistance, wear resistance, high strength and toughness and the like; and simultaneously, the process is simple, the preparation period is short, the equipment requirement is low, the cost is low, net shaping can be realized and convenience is brought for large-scale industrial application.

Owner:XIANGTAN UNIV

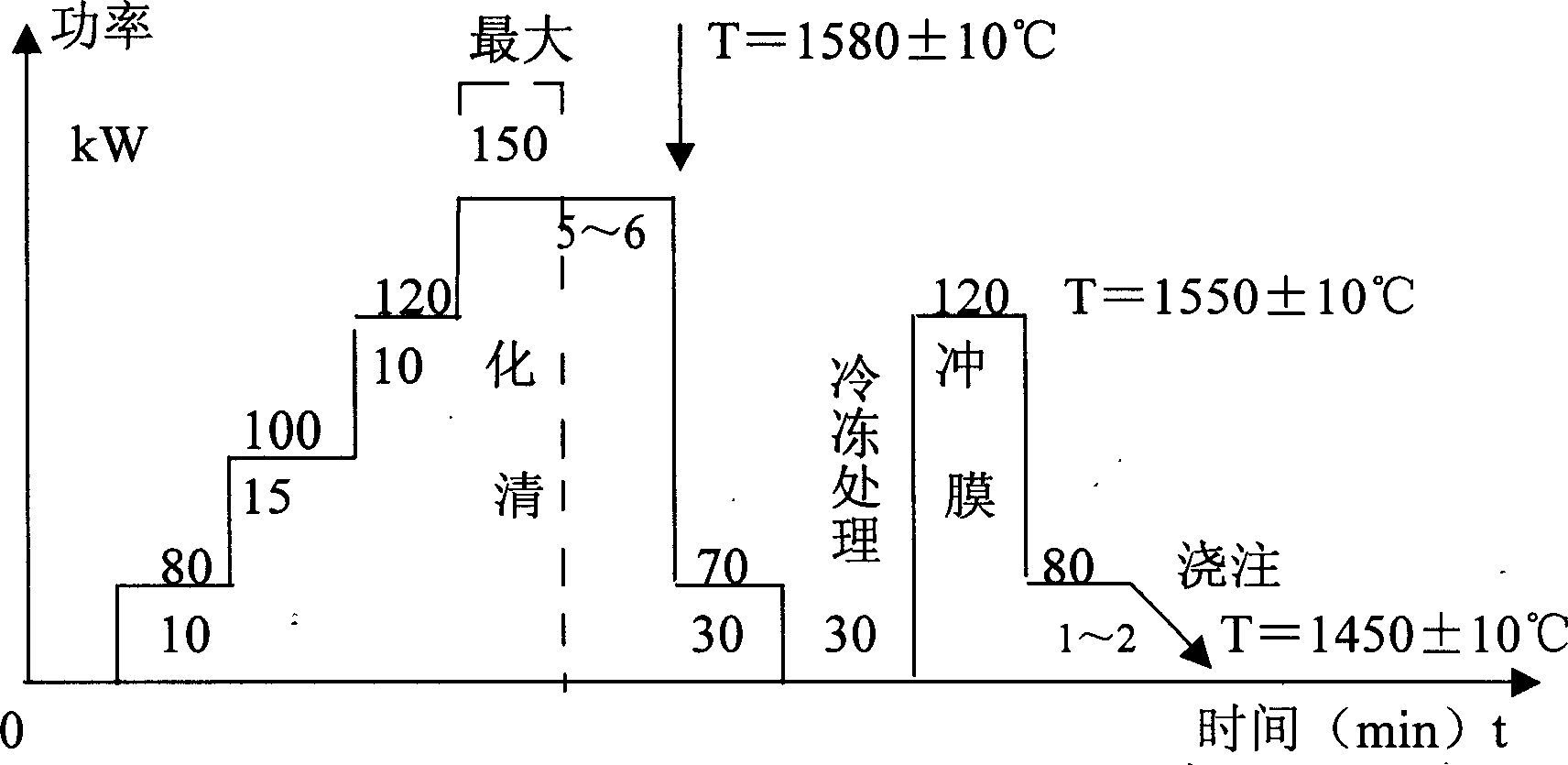

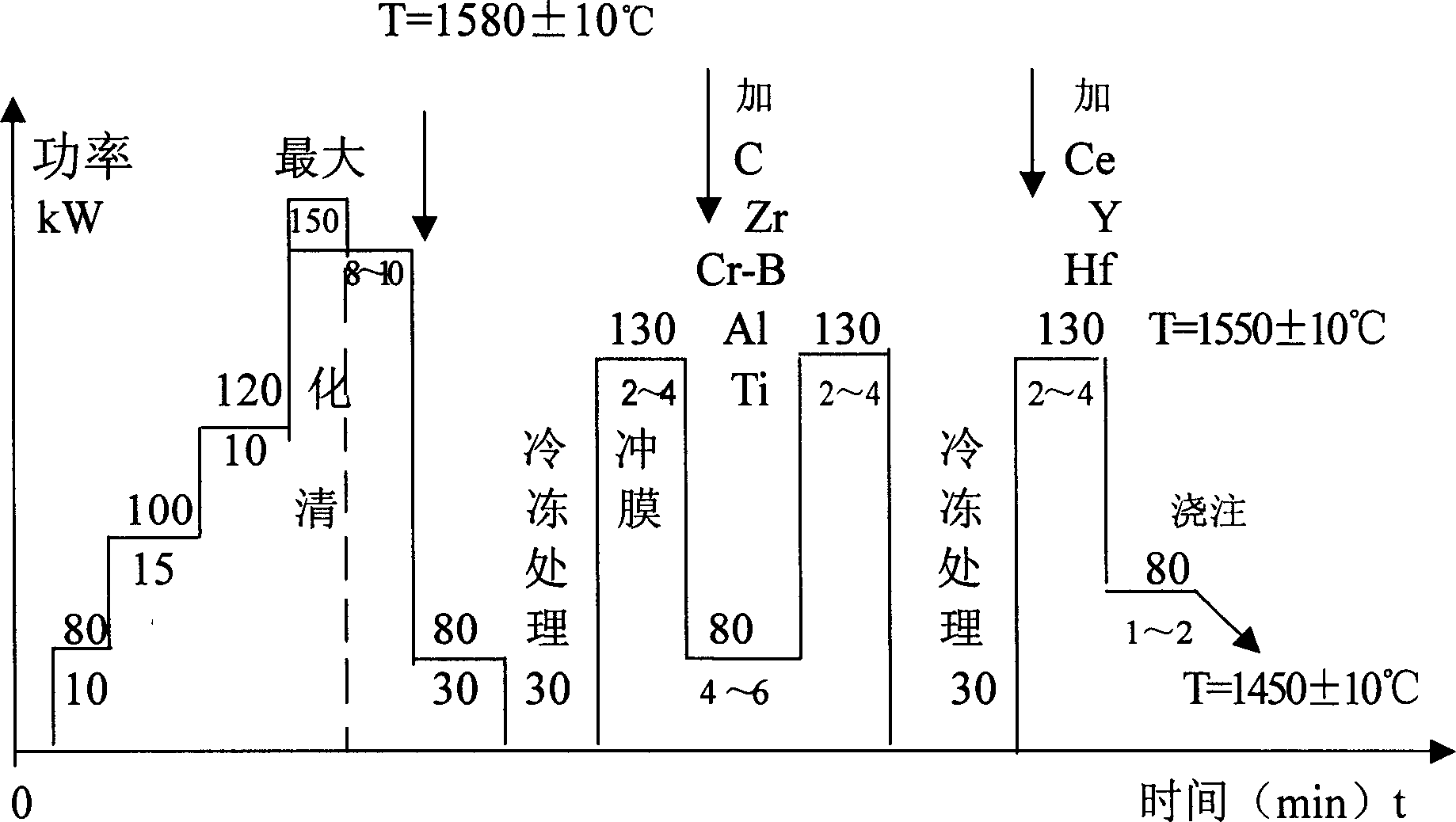

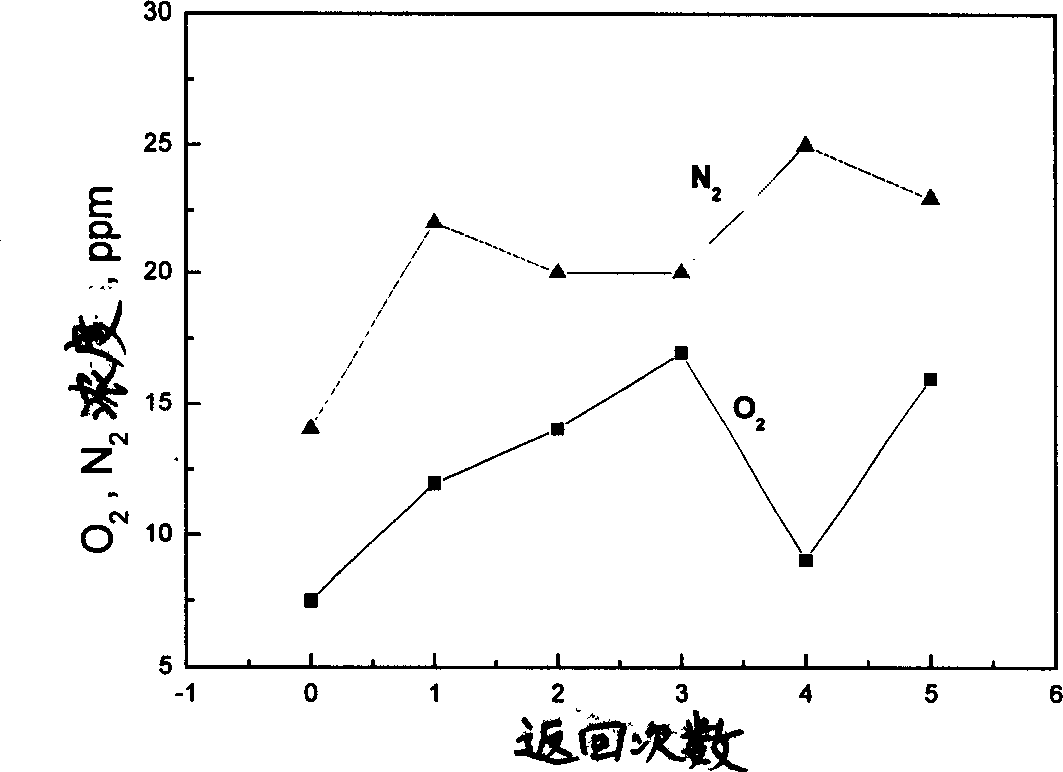

Vacuum smelting technology of hafnium containing nickel base casting high temperature alloy K488 reverse material alloy

InactiveCN1786228ADecreased tensile strength at room temperatureLower yield strengthRare-earth elementChemical composition

The invention relates to hafnium containing nickel base casting high temperature alloy K488 reverts alloy vacuum melting technique. It includes the following steps: melting reverts; pouring after melting, fining, cooling; using alumina ceramics filter screen to do the first filtration for alloy solution while pouring; adjusting the alloy solution component; mixing in proportion of 50% reverts and 50% fresh material; doing the first alloying treatment after melting, fining, cooling; adding dope material C, Cr-B inter-alloy, Al, Ti, Zr; doing the second alloying treatment after cooling; adding Ce, Y, Hf; and using alumina ceramics filter screen to do the second filtration for alloy solution while pouring to gain product. The technique adopts adding rare earth element method to purify reverting alloy. After many times returning melting, all of the alloy capability, chemical component, and impurity content can reach technical condition demand Q / 3B 1376-2005. The N content is far lower than 100ppm.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Low silver copper base medium temperature brazing filler metal

ActiveCN101524798AConserve limited resourcesReduce use costWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention relates to a low silver copper base medium temperature brazing filler metal applicable to braze welding of workpieces such as copper and copper alloy, copper and steel, belonging to the field of medium temperature brazing material. The formula and content of the low silver copper base medium temperature brazing filler by weight percentage is as follows: Ag: 1.8-5%, P: 5.5-7.5%, In: 0.5-2.5%, Ni: 0.01-1%, the rest: Cu. The invention has the advantages of rational design of formula, low manufacture cost, relatively low melting temperature of the brazing filler metal when welding copper and copper alloy and copper and bundy tubes, good wetting property and fluidness, smooth and bright surface of soldered connection, high mechanical strength, fine processing property of braze welding, stable quality and good uniformity and capability of replacing noble metal silver brazing filler metal BAg25CuZnSn.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Tinning substrate for deep-punching food can and production method thereof

The invention relates to a steel metallurgical material, in particular to a tinning substrate for deep-punching food cans and a production method thereof. The tinning substrate comprises the following chemical element compositions in percentage by weight: less than or equal to 0.04% of C; less than or equal to 0.02% of Si, 0.20-0.25% of Mn, less than or equal to 0.02% of P, less than or equal to 0.018% of S, 0.005-0.040% of Als, and the balance iron and unavoidable inclusion. The production method comprises the following processes: smelting, continuous casting, heating, hot rolling, cooling and reeling, pickling and cold rolling, and annealing and leveling, wherein the heating temperature is 1210 DEG C, the primary rolling temperature is 1100-1150 DEG C, the final rolling temperature is 890+ / -10 DEG C, the reeling temperature is 560+ / -15 DEG C, the annealing temperature is 670-690 DEG C, and others are performed as conventional processes. The invention has small production control difficulty, low cost, stable performance and high can manufacturing percent of pass, and is suitable for manufacturing deep-punching food cans and can covers with more complex transformation.

Owner:TANGSHAN GUOFENG IRON & STEEL

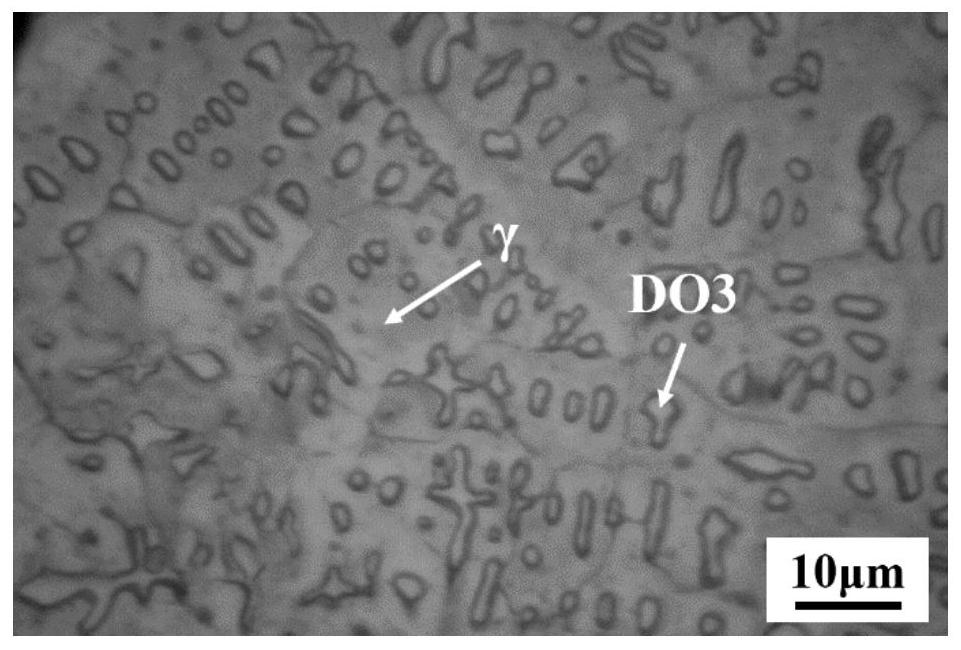

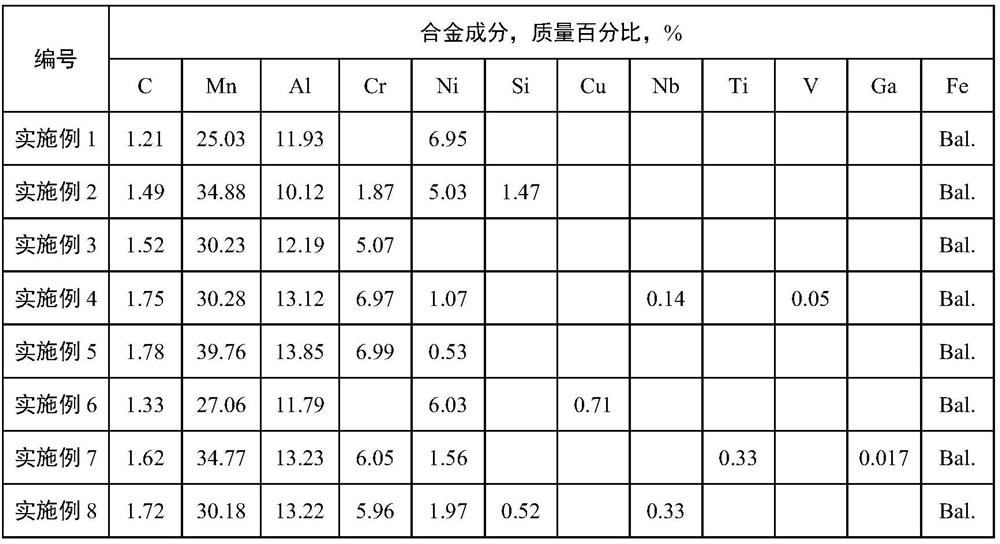

Fe-Mn-Al-C series high-strength low-density steel and preparation method thereof

The invention provides a Fe-Mn-Al-C series high-strength low-density steel and a preparation method thereof. The high-strength low-density steel comprises the following element components in percentage by mass: 1.0 to 2.0% of C, 20 to 40% of Mn, 10 to 14% of Al, more than or equal to 2% and less than or equal to 15% of Ni and Cr, and the balance of Fe. According to the preparation method, after the steps of steel smelting, solidification casting, hot working (forging / rolling) and the like are carried out, a steel plate is subjected to solution treatment for 10 min to 6 h within the temperature range of 1100 DEG C to 1200 DEG C and then cooled to the room temperature, and the high-strength low-density steel is obtained. According to the Fe-Mn-Al-C series high-strength low-density steel and the preparation method thereof, the austenite-based high-strength low-density steel with a uniform structure is finally obtained by regulating and controlling alloy components and a processing technology, the yield strength of the austenite-based high-strength low-density steel is larger than or equal to 1000 MPa, and the density is 6.0-6.6 g / cm < 3 >.

Owner:UNIV OF SCI & TECH BEIJING

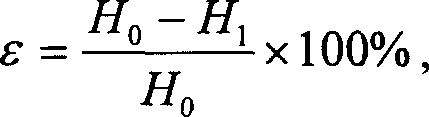

Preparation method of thin-wall tubular product of particle-reinforced aluminum-based composite material

ActiveCN101737574AReduce plasticityFix production issuesRigid pipesSolution treatmentRoom temperature

The invention relates to a preparation method of a thin-wall tubular product of a particle-reinforced aluminum-based composite material, which comprises the steps of: 1, preparing a tube blank by adopting a mixing and casting process and a powder metallurgy process; 2, homogenizing the tube blank, turning and stripping, carrying out a high-temperature compression deformation test to obtain a suitable processing deformation condition; 3, spinning the tube blank for finite element number value simulation, optimizing process parameters, and thermally spinning and warmly spinning; and 4, carrying out solution treatment on the obtained tubular product, and ageing after water hardening at room temperature. The tubular product prepared by the invention has larger diameter wall thickness ratio, smooth internal surface and outer surface without defects, uniform wall thickness and better interface combination between reinforced particles and a base body of the thin-wall tubular product. The method has short procedure, labor saving of the processing mode, energy saving and environmental protection, simple process, low raw material cost, suitability for large-scale production and better popularization value, and can be widely applied to the preparation of high-strength light tubular products in the fields of aerospace, vehicles, advanced weapons and the like.

Owner:有研金属复材技术有限公司

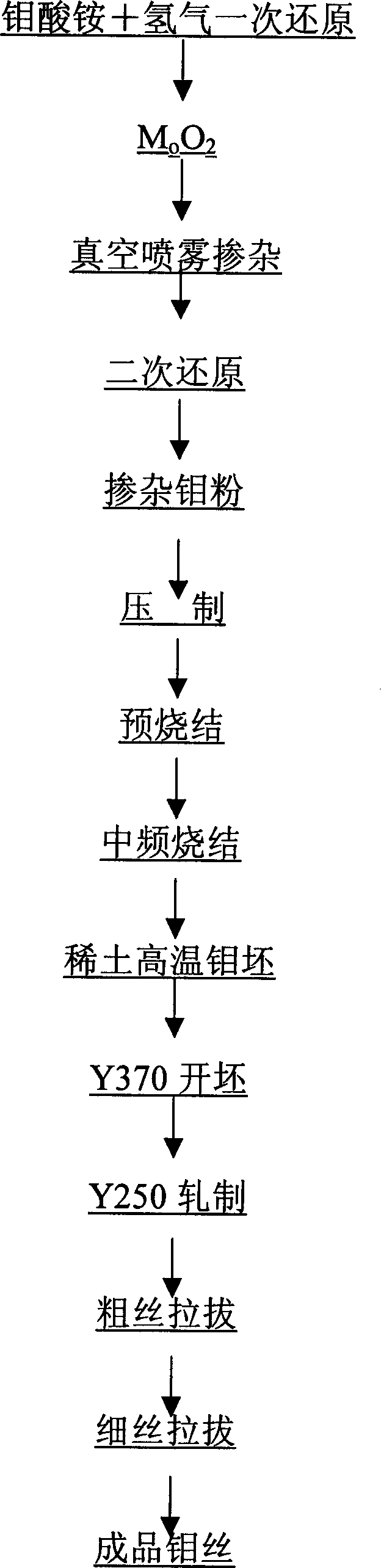

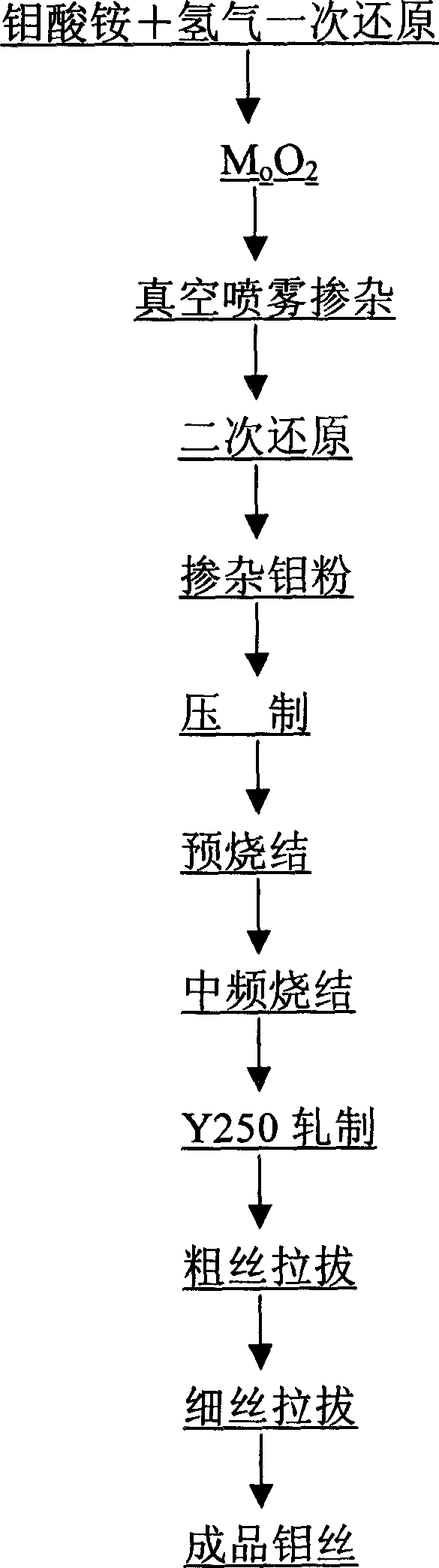

Rare earth molybdenum alloy wire and preparation method thereof

InactiveCN1876875ARaise the recrystallization temperatureHigh strengthTemperature control deviceHeat treatment process controlRare earthAlloy

The invention relates to a rare-earth molybdenum alloy wire and its process for preparing. The invention is characterized in that the said alloy wire contains two rare-earth oxides including lanthanum oxide and Y oxide(mass %) which is 0.4 %-1.0% of the alloy amount and the proportion by weight of lanthanum oxide and Y oxide is 4:1. The process for preparing is different from the traditional powder metallurgy productive technology, which includes performing double-cone vacuum drying and liquid-solid doping at molybdenum dioxide stage, then performing secondary reduction to prepare binary rare-earth doping molybdenum powder, finally preparing rare-earth doping molybdenum wire with Mo-La-Y of 0.5-0.8mm diameter by impression, agglomeration and pressure processing procedure. Compared with the pure molybdenum, the product is of good high-temperature behavior and high recrystallization temperature which increases by 300-500 DEG C than the pure molybdenum, and is of high intensity and abrasive resistance, low ductility and long durability, which has wide application in the mechanical process industry.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Mo-La-Ce rare earth molybdenum alloy wire and preparation method thereof

InactiveCN1876874ARaise the recrystallization temperatureHigh strengthTemperature control deviceHeat treatment process controlCerium nitrateHigh rate

The invention relates to a Mo-La-Ce rare-earth molybdenum alloy wire and its process for preparing. The invention is characterized in that the said molybdenum alloy wire contains 0.4 %-1.0% lanthanum oxide and cerium oxide(mass %) and the proportion by weight of lanthanum oxide and cerium oxide is 4:1. The process for preparing is different from the traditional powder metallurgy productive technology, which includes performing vacuum drying and liquid-solid doping for molybdenum dioxide, lanthanum nitrate and cerium nitrate solution, then performing secondary reduction to prepare binary rare-earth doping molybdenum powder, finally preparing rare-earth doping molybdenum wire with Mo-La-Ce of 0.5-0.8mm diameter by impression, agglomeration and pressure processing procedure. The raw materials of this invention is cheap and facile, and the prepared molybdenum wire is of high tensile strength, strong abrasive resistance and simple process and is inflexible, and has high rate of finished products, good compatibility and long durability.

Owner:JINDUICHENG MOLYBDENUM CO LTD

ER70S-6 hot rolled wire rod and preparation method thereof

ActiveCN104498818AHigh in calciumLower calcium levelsProcess efficiency improvementWire rodThermal insulation

The invention relates to the technical field of steel and iron materials and in particular relates to an ER70S-6 hot rolled wire rod and a preparation method thereof. In the process steps, deoxidation treatment is performed on the liquid steel by use of a non-calcium alloy material to avoid the increase of the calcium content in the steel, and furthermore, splashing in the process of welding is avoided. The carbon content in the steel is reduced so that the strength of the wire rod can be reduced; the percentage of area reduction and the percentage elongation of the wire rod are increased, in other words, the plasticity of the wire rod is improved, and consequently, the wire rod can be drawn into a welding wire directly without annealing and the production cost of a welding wire factory is reduced; besides, in the preparation process, the quality of the ER70S-6 hot rolled wire rod is improved by controlling the contents of various elements, such as carbon, silicon and magnesium, so that the welding property of the welding wire is improved; in the cooling process of rolling, draught fans on an air cooling line are all turned off and thermal insulation covers are all closed so that the highest tensile strength of the wire rod does not exceed 550MPa and the plasticity of the wire rod is good.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com