Al-Mg high magnesium alloys for automobile body sheets and manufacturing method thereof

A high-magnesium aluminum alloy and automobile body plate technology, which is applied to aluminum alloys and their manufacturing, Al-Mg series high-magnesium aluminum alloys for automobile body plates and their manufacturing fields, can solve problems such as inability to match strength, and achieve good Economic benefits, prevention of strength reduction, good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

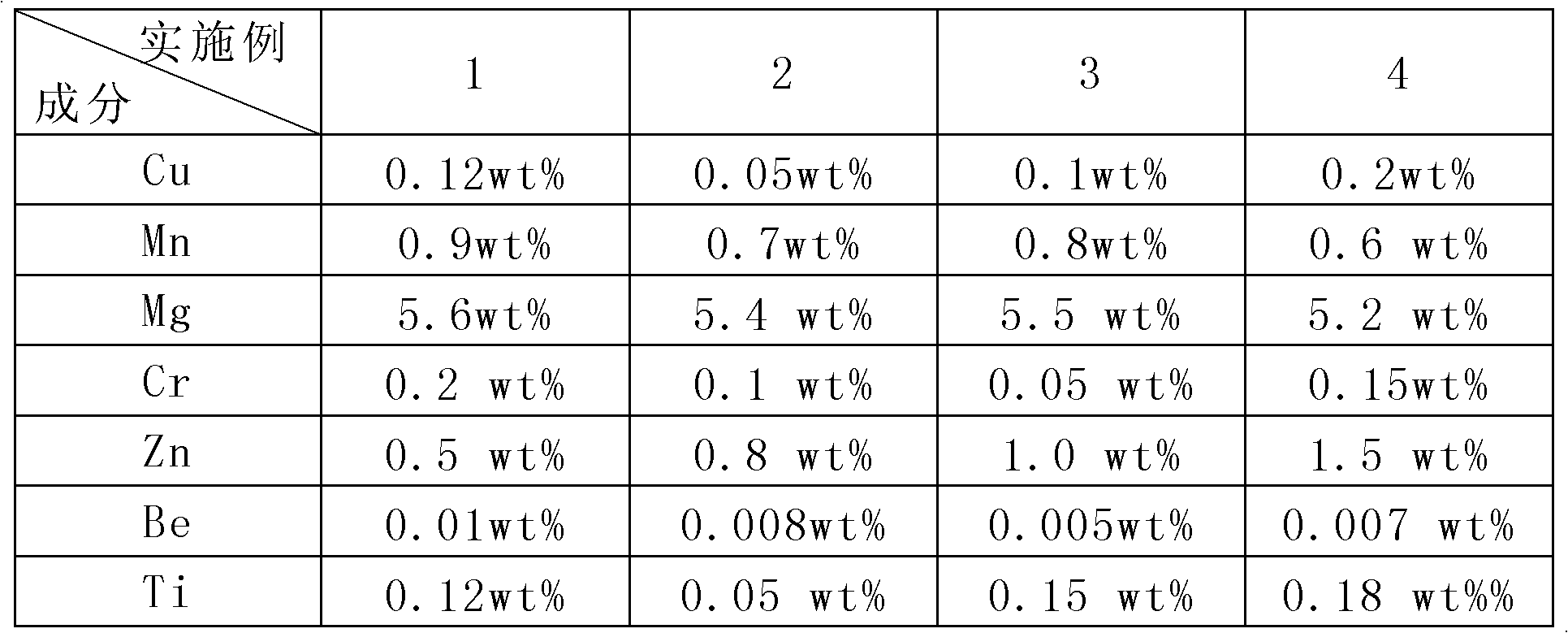

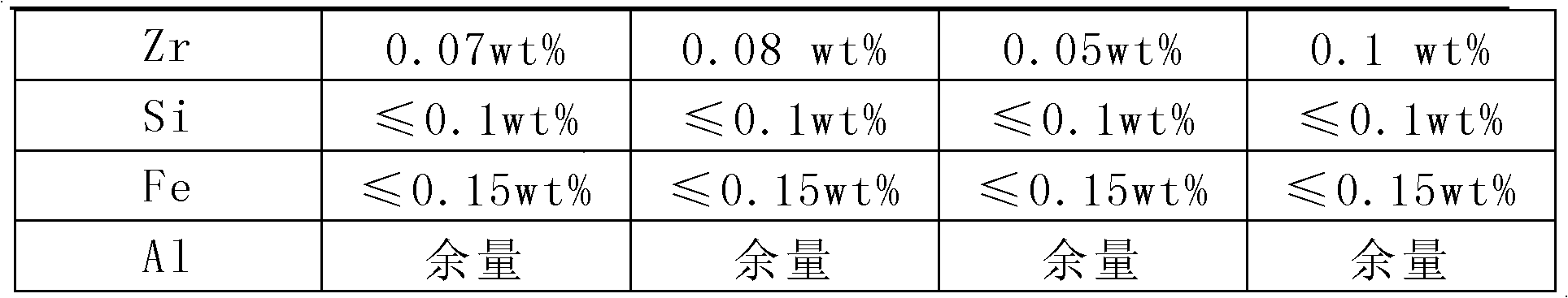

[0043] According to the mass percentage of Example 1 in Table 1, the ingredients were prepared to make aluminum ingots, master alloys AlCu50, AlMn10, AlCr4, AlBe3, AlZr4, Al-5Ti-B.

[0044] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted and the melt temperature is 720°C, add AlCu50, AlMn10, AlCr4, AlBe3, AlZr4 master alloys and stir; when the melt temperature reaches 710°C, add Mg and Zn , slag removal, and refining; when the temperature is 710°C, add Al-5Ti-B master alloy, stir and stand for 50 minutes, and cast into a cast iron mold with a temperature of 680°C;

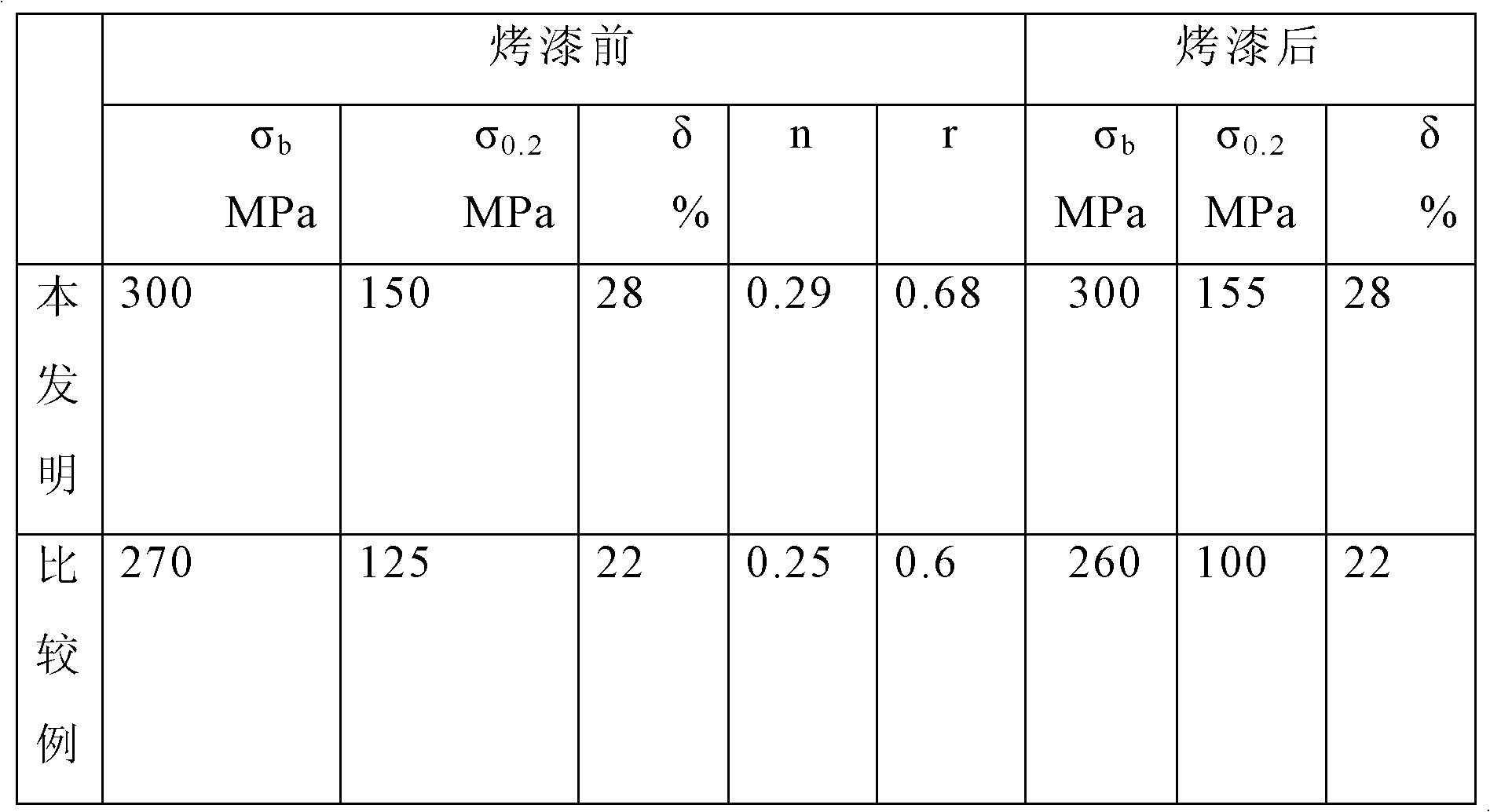

[0045] Homogenize the aluminum alloy ingots formed by casting above, the temperature of the homogenization treatment is 450°C, the treatment time is 24 hours, hot rolling at a temperature of 450°C, intermediate annealing, the intermediate annealing temperature is 400°C, and the intermediate annealing The time is 40min, and water quenching is used for rapid coolin...

Embodiment 2

[0048] According to the mass percentage of Example 2 in Table 1, the ingredients were prepared to make aluminum ingots, master alloys AlCu50, AlMn10, AlCr4, AlBe3, AlZr4, Al-5Ti-B.

[0049] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted and the melt temperature is 730°C, add AlCu50, AlMn10, AlCr4, AlBe3, AlZr4 master alloys and stir; when the melt temperature reaches 720°C, add Mg and Zn , slag removal and refining; when the temperature is 710°C, add Al-5Ti-B master alloy, stir and stand for 40 minutes, and cast into a cast iron mold with a temperature of 700°C;

[0050] Homogenize the casted aluminum alloy ingot above, the temperature of the homogenization treatment is 460°C, the treatment time is 20 hours, hot rolling at 460°C, intermediate annealing, the intermediate annealing temperature is 420°C, the intermediate The annealing time is 30 minutes, and the strong wind is used for rapid cooling after the intermediate anne...

Embodiment 3

[0053] The batching was carried out according to the mass percentage of Example 3 in Table 1 to make aluminum ingots, master alloys AlCu50, AlMn10, AlCr4, AlBe3, AlZr4, Al-5Ti-B.

[0054] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted and the melt temperature is 740°C, add AlCu50, AlMn10, AlCr4, AlBe3, AlZr4 master alloys and stir; when the melt temperature reaches 720°C, add Mg and Zn , slag removal, and refining; when the temperature is 720°C, add Al-5Ti-B master alloy, stir and stand for 30 minutes, and cast into a cast iron mold with a temperature of 700°C;

[0055] Homogenize the aluminum alloy ingots formed by casting above. The temperature of the homogenization treatment is 470°C, and the treatment time is 15 hours. The annealing time is 30min, and water quenching is used for rapid cooling after intermediate annealing. Cold rolling twice into thin plate;

[0056] Annealing the thin plate prepared above, the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com