Patents

Literature

356results about How to "Good impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

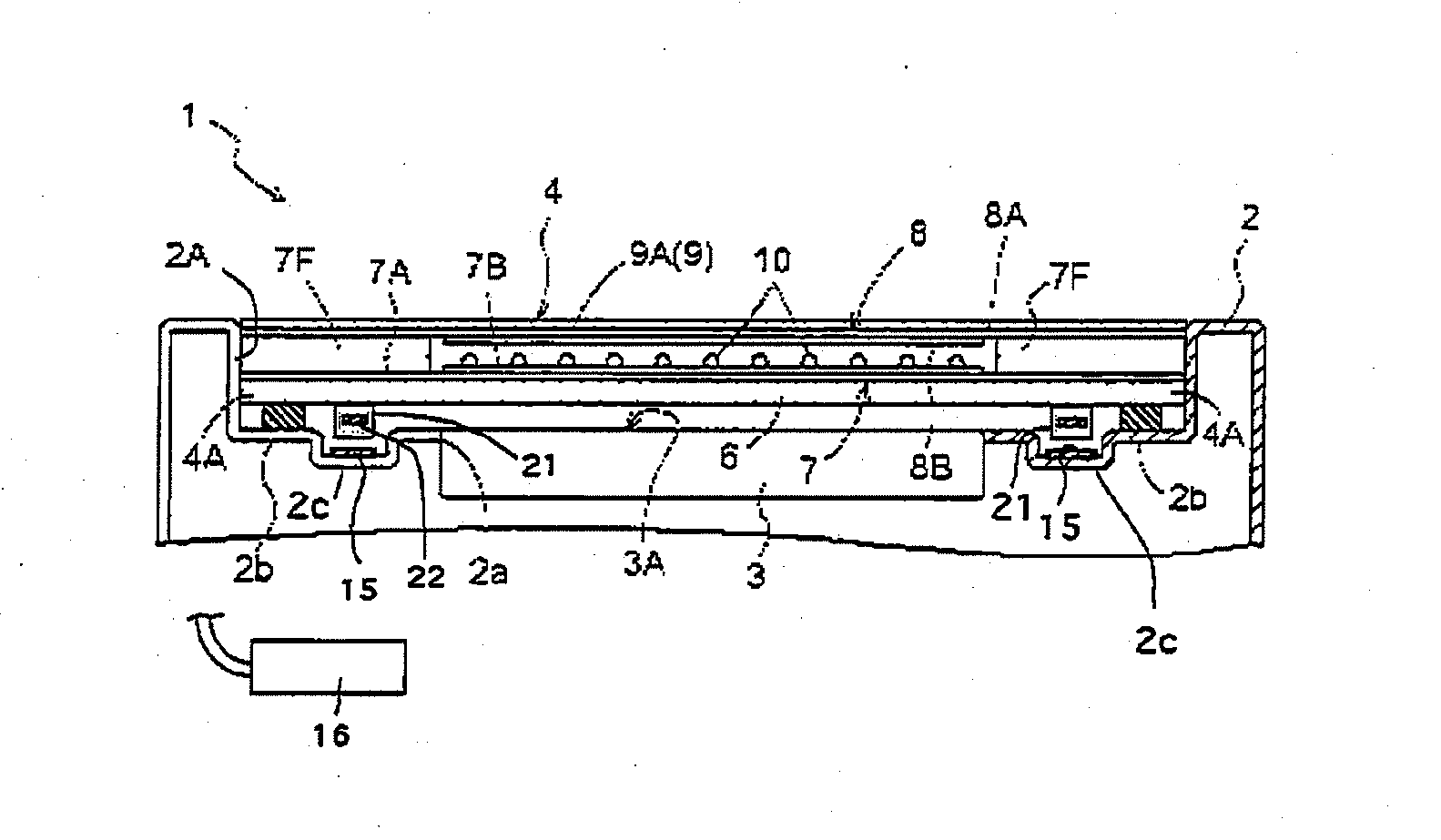

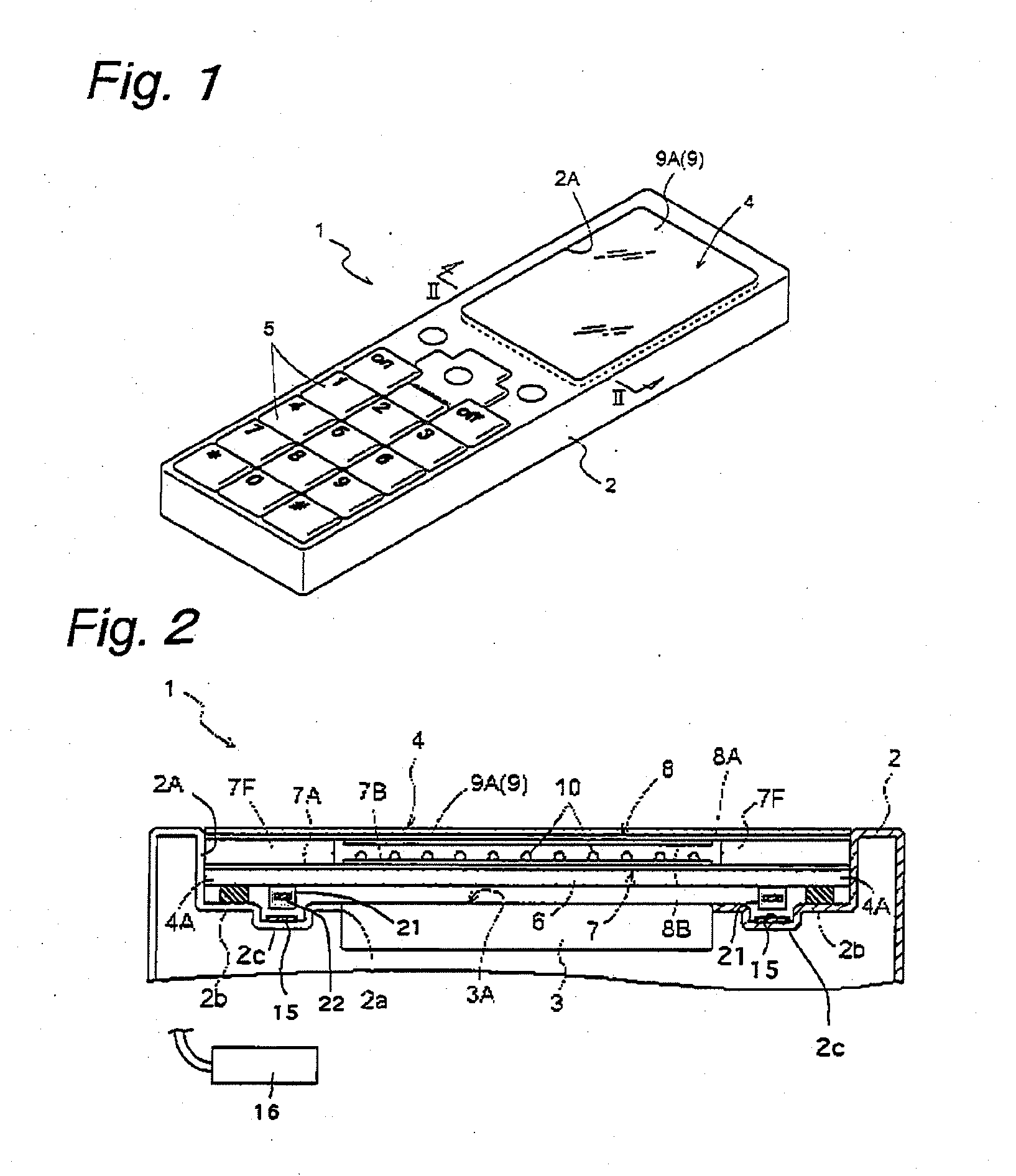

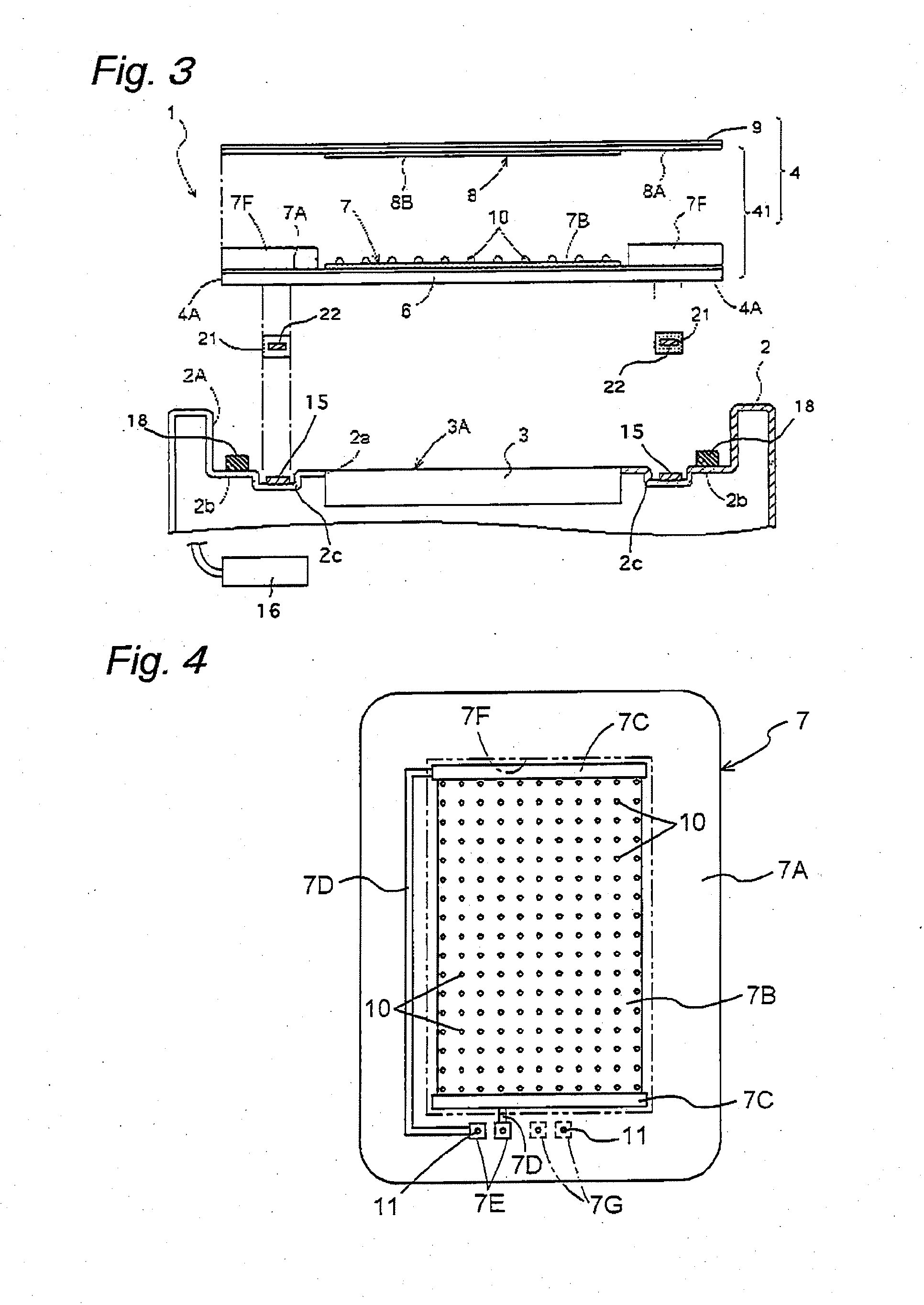

Mount structure of touch panel with vibration function

ActiveUS20120162143A1Good impact resistanceEfficiently transmittedDigital data processing detailsLoudspeakersTouch panelEngineering

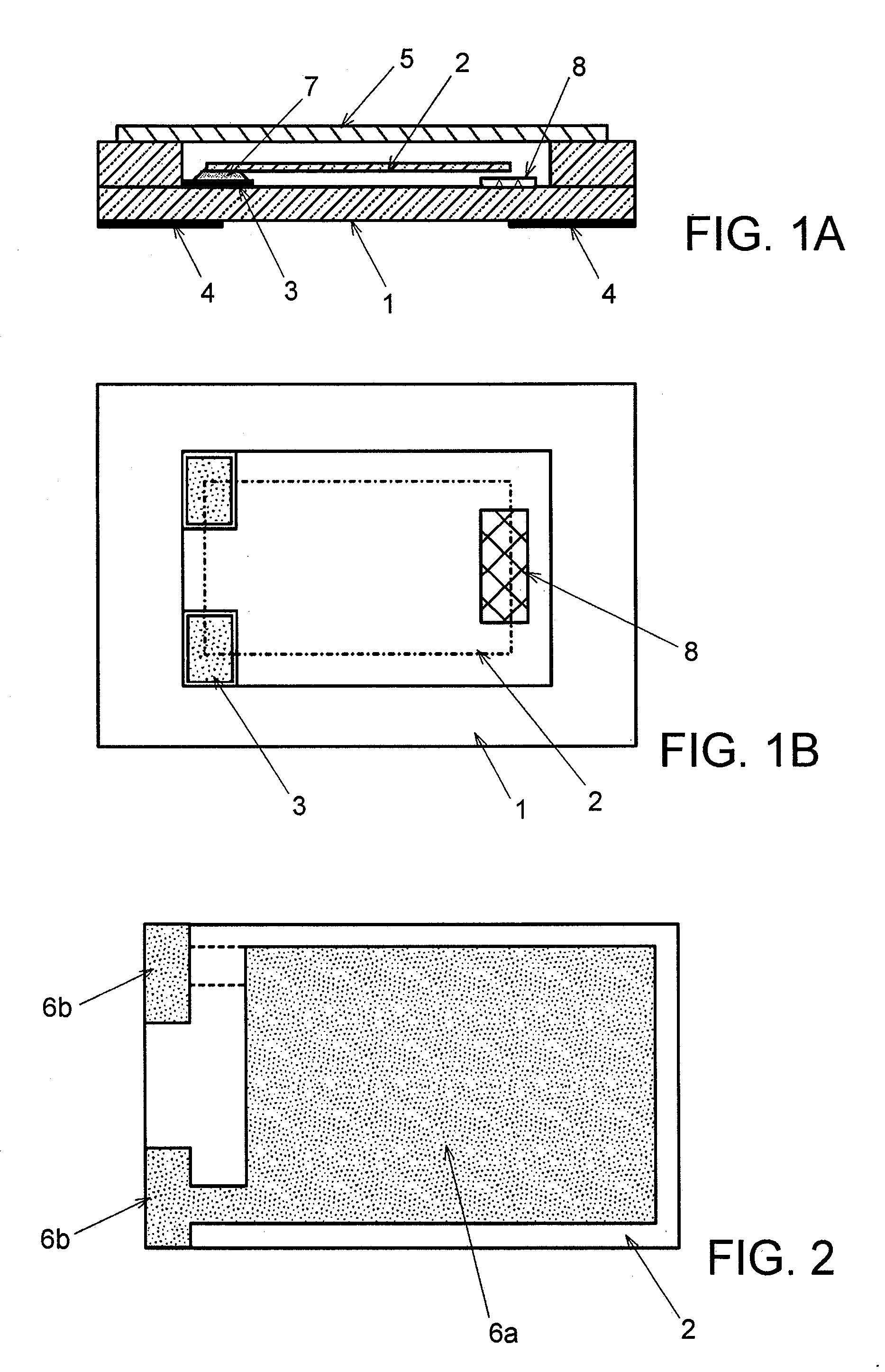

[Object] It is an object to provide a mount structure of a touch panel with a vibration function which is superior in impact resistance, dust-proofness, and drip-proofness, and can effectively transmit a vibration of a vibration element.[Solution to Problem] The mount structure of the touch panel with the vibration function is characterized by including a touch panel body, a design sheet bonded to an upper surface of the touch panel body and having a transparent window part and a decorative part surrounding the transparent window part, a vibration element formed in a back surface peripheral part of the touch panel body and hidden by the decorative part, a casing dented so as to have a level difference to allow the above parts to be externally fitted in and having a recess part or an opening part for a display device, and a frame-shaped support part to support the back surface peripheral part of the touch panel body, in its bottom surface, an elastic member frame arranged on the support part and positioned on an outer edge side of the touch panel with respect to the vibrator, and a vibration control unit arranged inside the casing to apply a drive voltage to the vibration element.

Owner:NISSHA PRINTING COMPANY

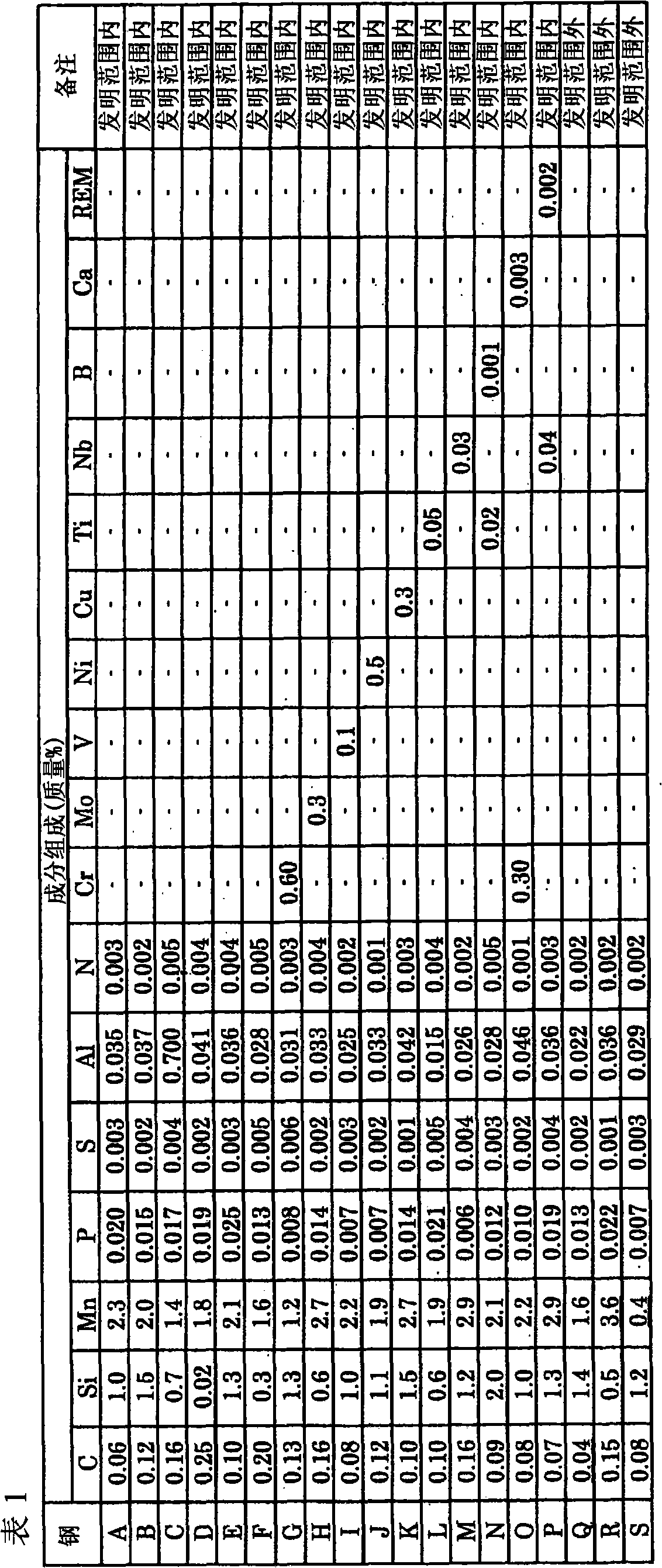

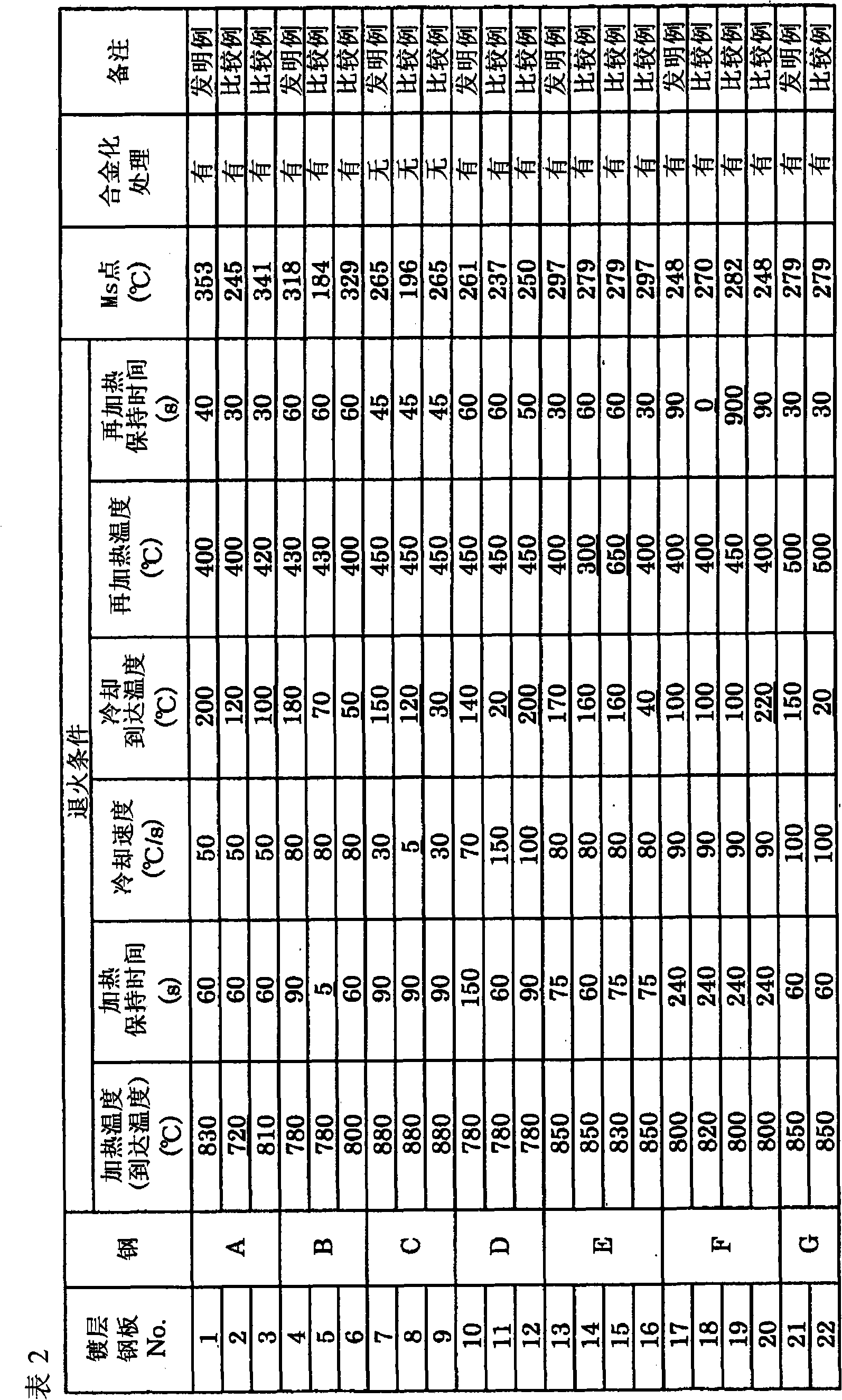

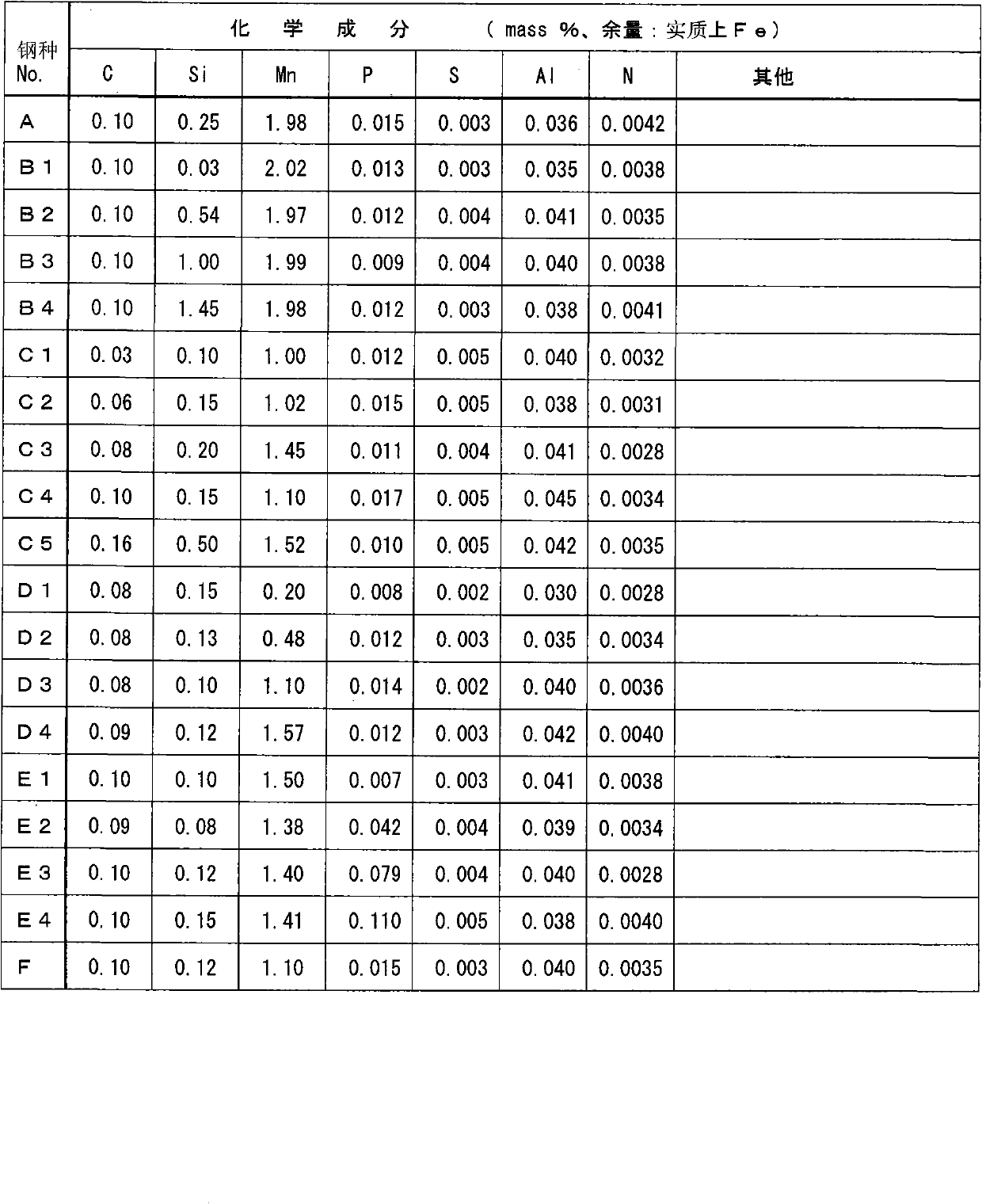

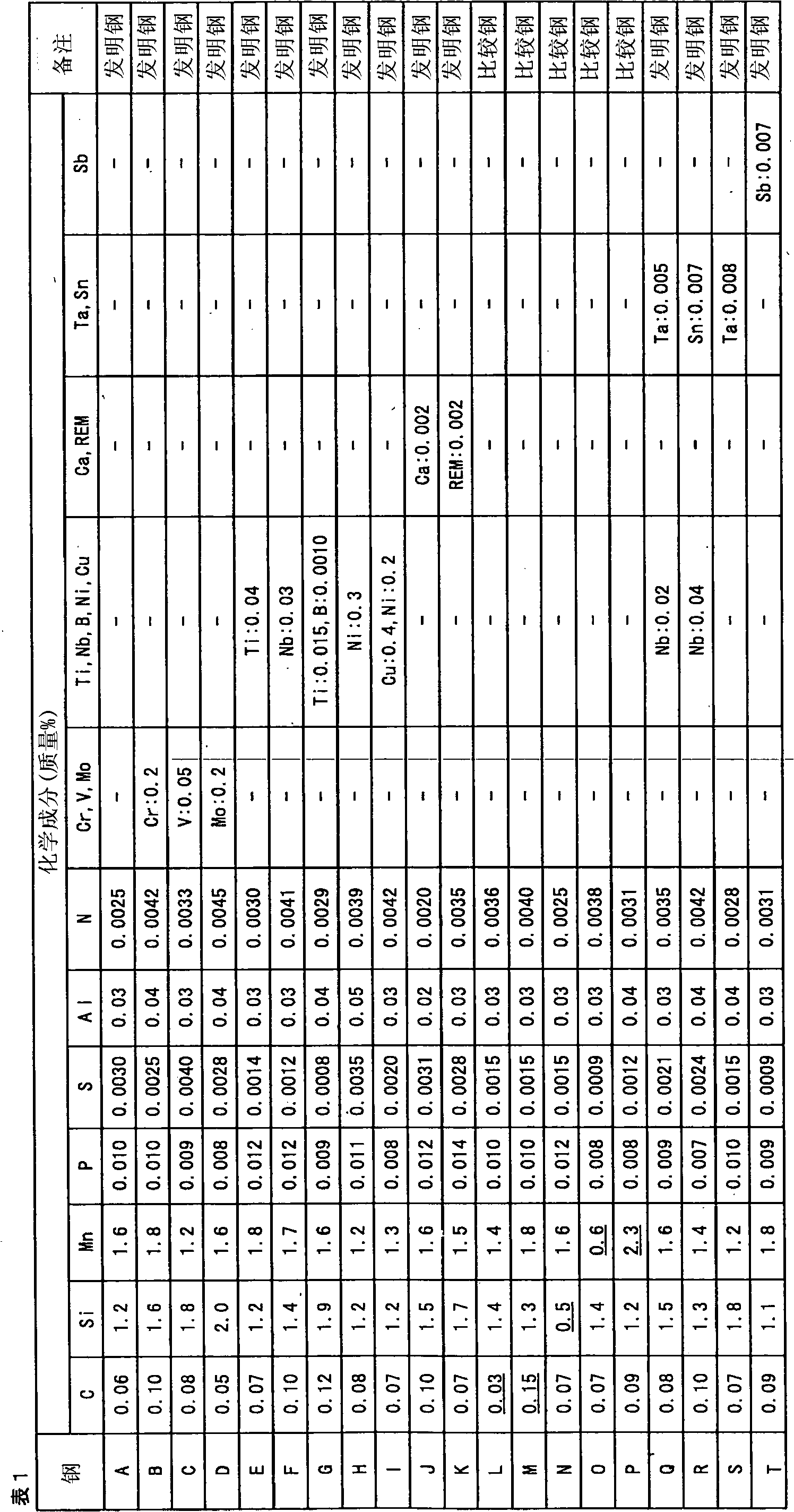

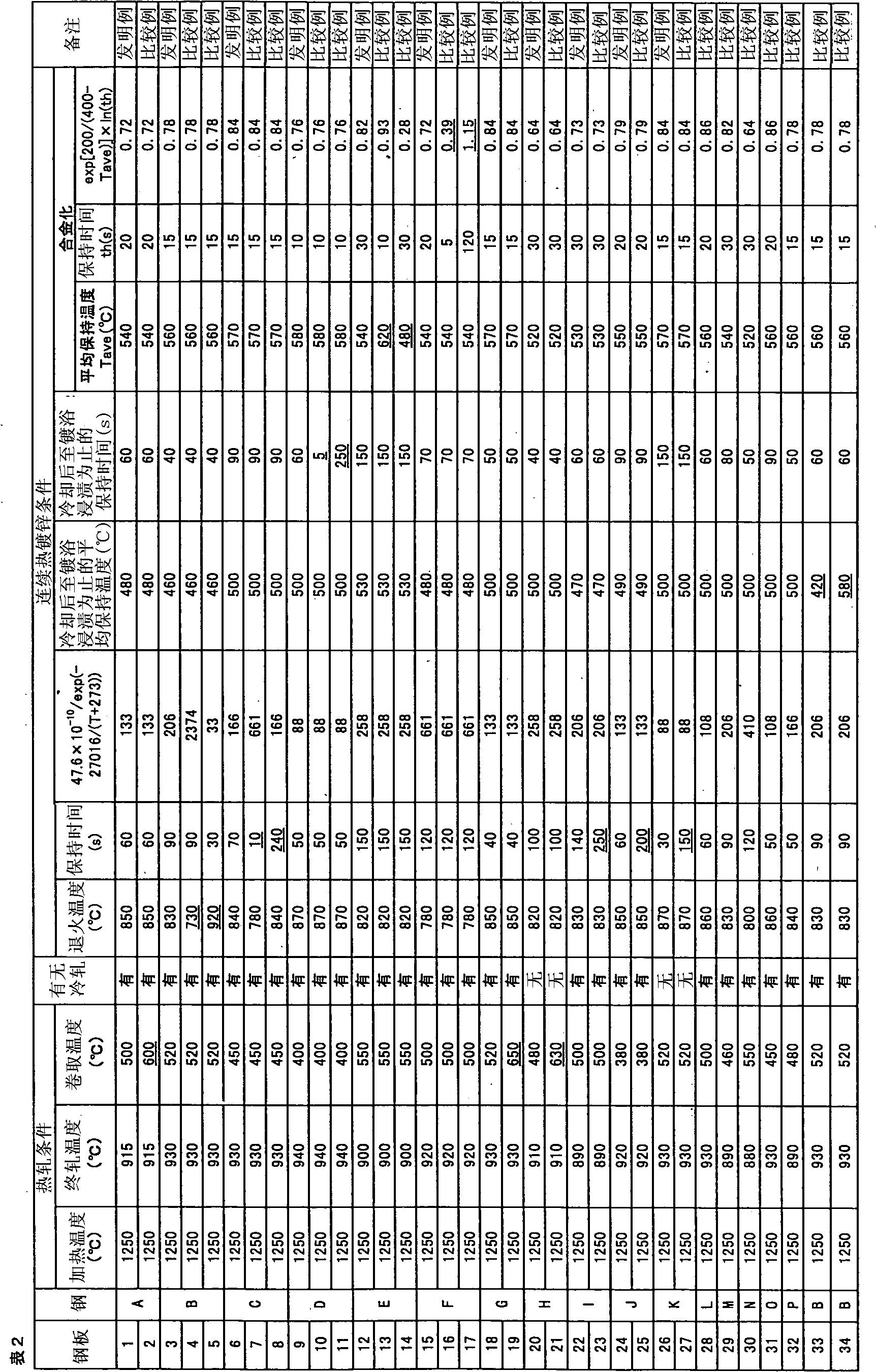

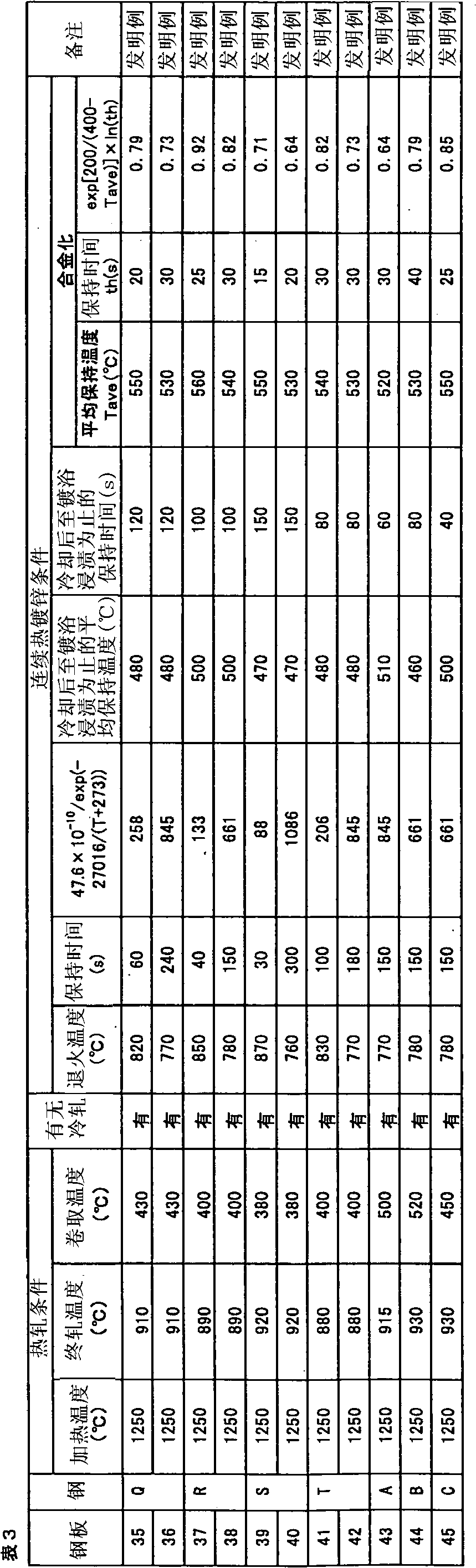

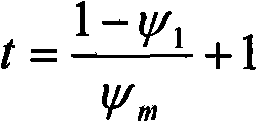

High-strength hot-dip zinc plated steel sheet excellent in workability and process for manufacturing the same

ActiveCN101821419AImprove balanceExcellent stretch flangeabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

The invention provides a high-strength hot-dip zinc plated steel sheet which exhibits high TS-El balance, excellent stretch frangeability, excellent workability due to low YR, and excellent impact characteristics, and a process for manufacturing the same. A high-strength hot-dip zinc plated steel sheet excellent in workability and impact characteristics, having a composition which contains by mass C: 0.05 to 0.3%, Si: 0.01 to 2.5%, Mn: 0.5 to 3.5%, P: 0.003 to 0.100%, S: 0.02% or below, Al: 0.010 to 1.5%, and N: 0.007% or below and further contains at least one element selected from among Ti, Nb and V in a total amount of 0.01 to 0.2% with the balance being Fe and unavoidable impurities and a microstructure which comprises, in terms of area fraction, 20 to 87% of ferrite, 3 to 10% (in total) of martensite and retained austenite, and 10 to 60% of tempered martensite and in which the average grain diameter of the second phase consisting of the martensite, retained austenite, and tempered martensite is 3[mu]m or below.

Owner:JFE STEEL CORP

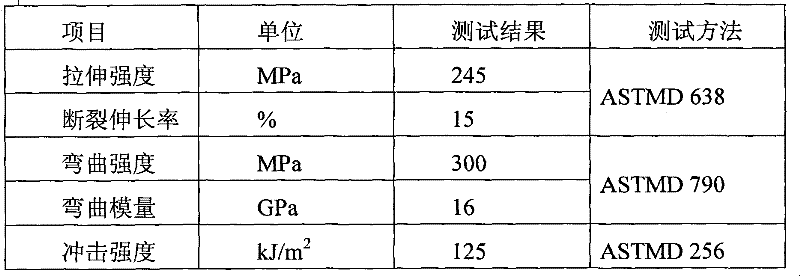

Continuous fiber reinforced thermoplastic flame retardant prepreg tape composite material and preparation method thereof

The invention relates to a continuous fiber enhanced thermoplastic antiflaming presoaking belt composite material and a preparation method thereof. The composite material is prepared from the following raw materials by weight percent: 45-55% of modified resin and 55-45% of continuous fiber. According to the preparation method in the invention, the composite material is obtained by reasonable fiber dispersion, resin impregnation and composite rolling processes based on the resin containing a flame retardant, a grafting agent, glass microsphere and other auxiliaries and the continuous fiber treated by an impregnating agent which are used as raw materials; compared with the prior art, by using the preparation method in the invention, the problem that the antiflaming resin is difficultly impregnated due to poor flowability is overcome, the produced continuous fiber enhanced thermoplastic antiflaming presoaking belt has extremely high strength, modules and impact property and has antiflaming characteristic, wherein the antiflaming grade can reach UL94 V0 grade.

Owner:LIAONING LIAOJIE SCI & TECH

Wastewater treating microbial agent and preparation method thereof

ActiveCN103374525AAdaptable and TolerableGood impact resistanceBacteriaMicroorganism based processesChemistryNitric oxide

The invention discloses a wastewater treating microbial agent and a preparation method thereof. The microbial agent contains kocuriapalustris FSDN-A, arthrobactercreatinolyticus FDN-1, flavobacteriummizutaii FDN-2, paracoccusdenitrificans DN-3 and methylobacteriumphyllosphaerae SDN-3, wherein the collection register numbers of the five strains are respectively CGMCCNo.5061, CGMCCNo.3657, CGMCCNo.3659, CGMCCNo.3658 and CGMCCNo.3660. The microbial agent can achieve removal of ammonia nitrogen, total nitrogen and CODcr in the same reactor, has a good wastewater treatment effect, and can achieve short-cut nitrification and denitrification or simultaneous nitrification and denitrification while removing COD. Kocuriapalustris FSDN-A can utilize the two nitric oxides including nitrite nitrogen and nitric nitrogen, can ensure thorough denitrification of a wastewater treatment system, is slow in appreciation in the process of competing for substrates, is favorable for reduction of sludge, and further widens the application range of the microbial agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

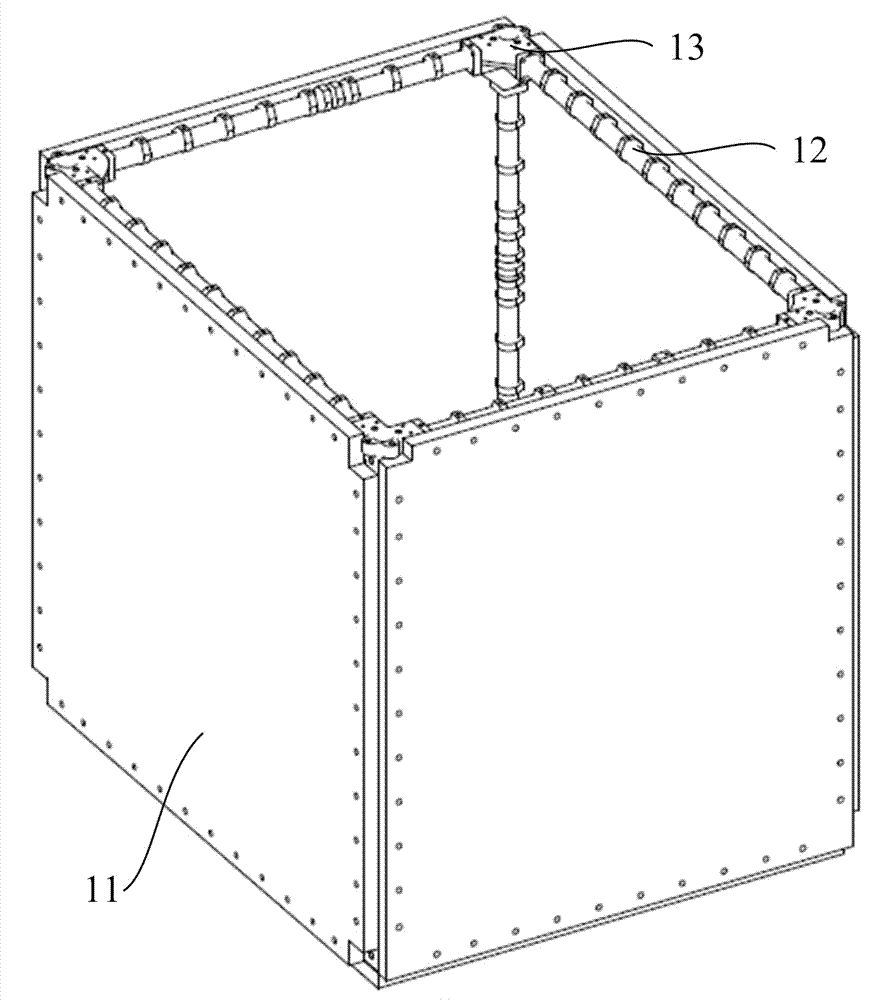

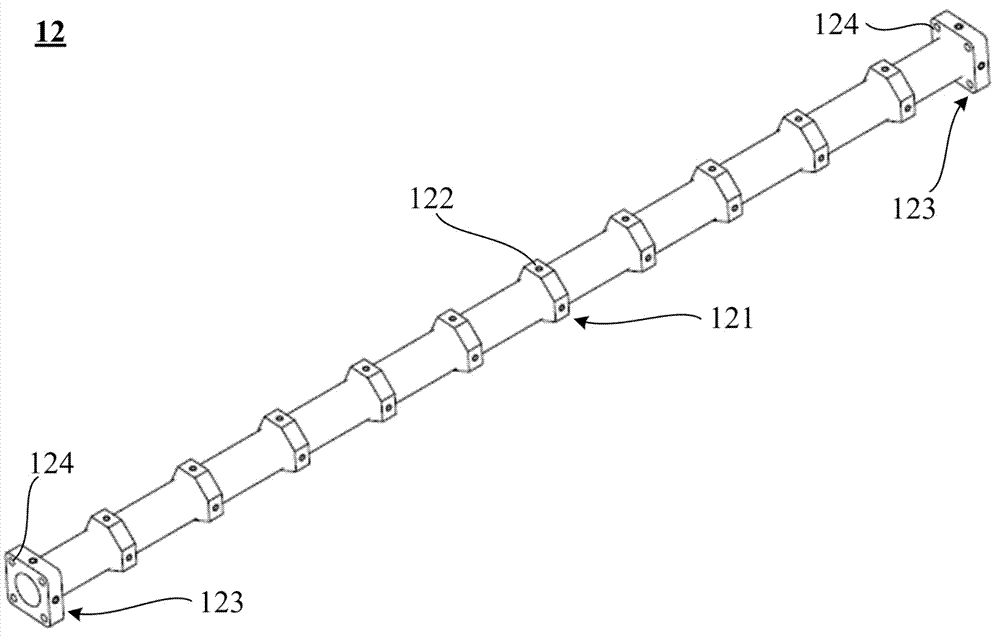

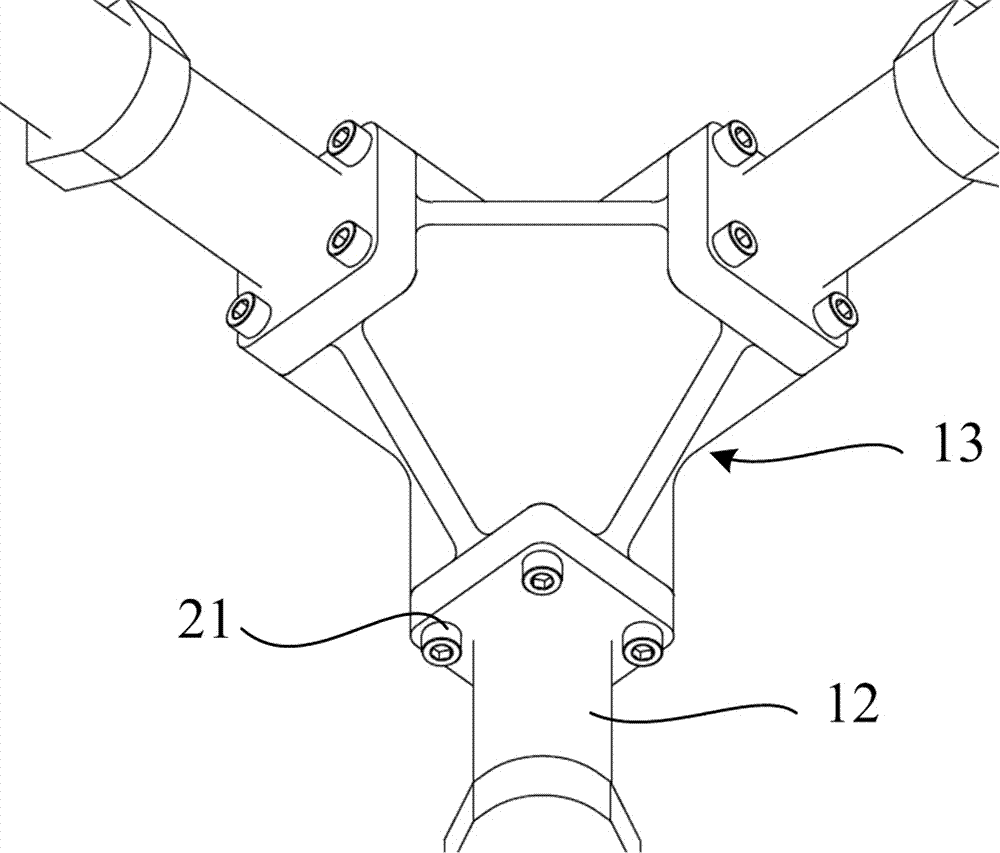

Frame panel type satellite configuration and modular satellite

InactiveCN103863577AGood heat dissipationGood impact resistanceArtificial satellitesSatelliteFastener

The invention provides a frame panel type satellite configuration and a modular satellite adopting the same. The frame panel type satellite configuration comprises a four-edge-column frame and honeycomb structure plates; the four-edge-column frame is used for bearing axial load when being connected with four connecting interfaces for carrying, wherein the four-edge-column frame comprises rod pieces and rod-piece joints; each rod piece is provided with a plurality of bosses; the bosses are provided with installing holes for connection with the honeycomb structure plates by first fasteners; a plurality of through holes are arranged in the extending surfaces of the end parts of the rod pieces and are used for connection with the rod-piece joints by second fasteners; the honeycomb structure plates provide installing surfaces for single satellite equipment and simultaneously provide in-plane shearing rigidity for the four-edge-column frame.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

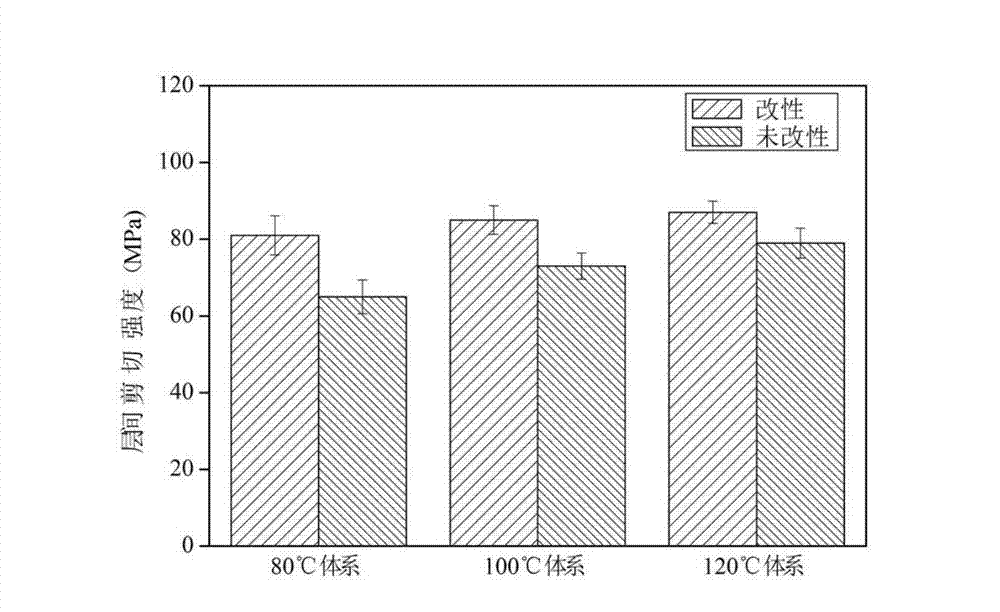

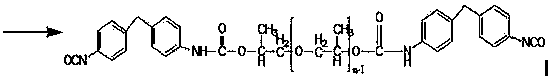

Method for improving interlaminar shear strength of medium/low-temperature cured prepreg by using polyurethane prepolymer

The invention provides a method for improving interlaminar shear strength of medium / low-temperature cured prepreg by using polyurethane prepolymer. The method comprises the following steps: firstly, reacting isocyanate with polyether polyol according to a controllable ratio to obtain a terminal isocyanate polyurethane prepolymer; grafting the terminal isocyanate polyurethane prepolymer to a bisphenol type epoxy resin, and adding a mixed epoxy resin to obtain a modified epoxy resin matrix; uniformly mixing the modified epoxy resin matrix with a curing agent and an accelerant to obtain a resin system for prepreg; and finally, preparing the resin system into a rubber film, compounding the rubber film with reinforced fibers or fabrics so as to prepare the medium / low-temperature cured prepreg with excellent adhesiveness. The prepreg preparation process is reasonable, the bonding strength of the resin system and fiber is high, the interlaminar shear strength of the composite material is obvious improved, and the method is particularly suitable for low-temperature cured prepreg.

Owner:中威北化科技有限公司

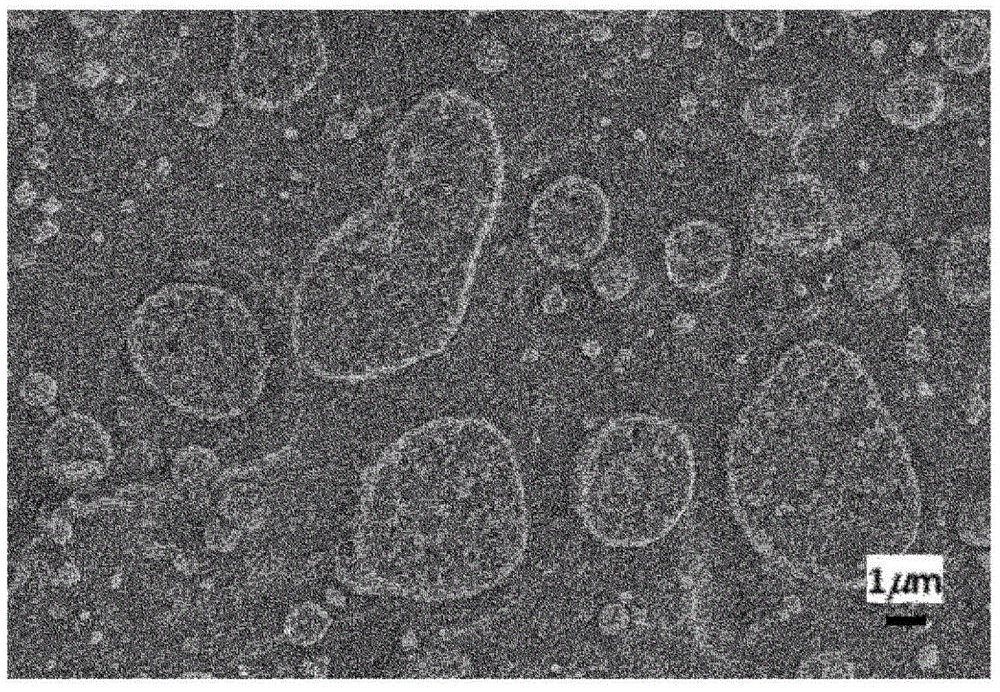

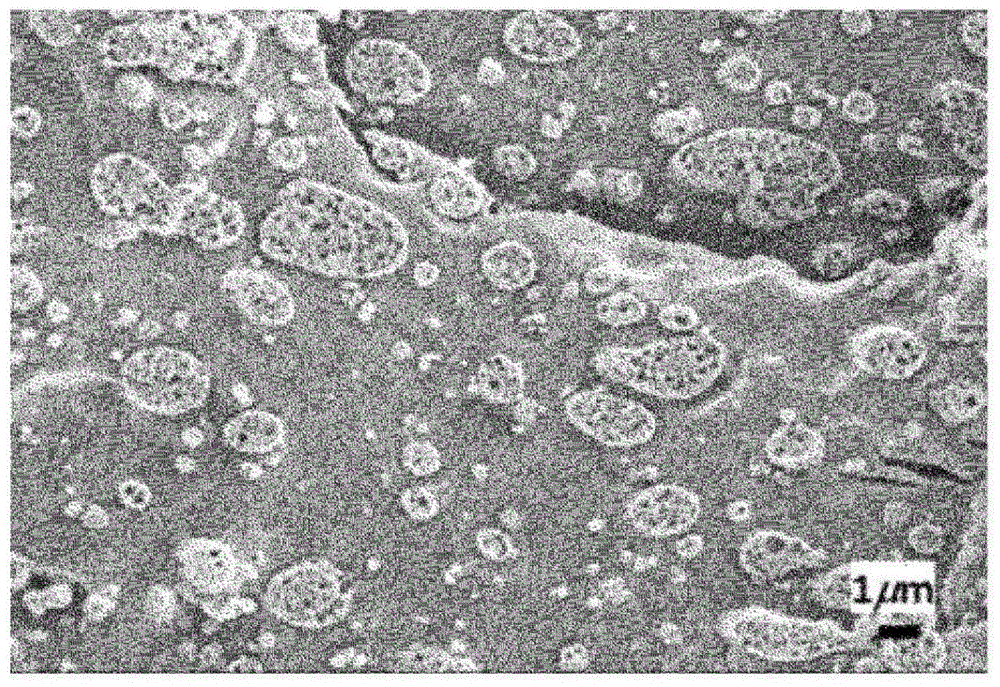

Thermoplastic resin composition and method for producing same

The purpose of the present invention is to provide a thermoplastic resin composition having excellent rigidity and impact resistance and a method for producing the same. The thermoplastic resin composition is obtained by mixing a polyolefin resin (such as a polypropylene resin), a polyamide resin (such as nylon 11 resin), and a compatibilizer (such as maleic anhydride-modified EPR, maleic anhydride-modified EBR). The thermoplastic resin composition is characterized in having a resin phase separate structure as observed under an electron microscope, wherein the resin phase separate structure consists of a continuous phase and a disperse phase dispersed in the continuous phase, there is a microdisperse phase in the disperse phase, and the average diameter of the microdisperse phase is 5 to 1,200 nm.

Owner:TOYOTA BOSHOKU KK

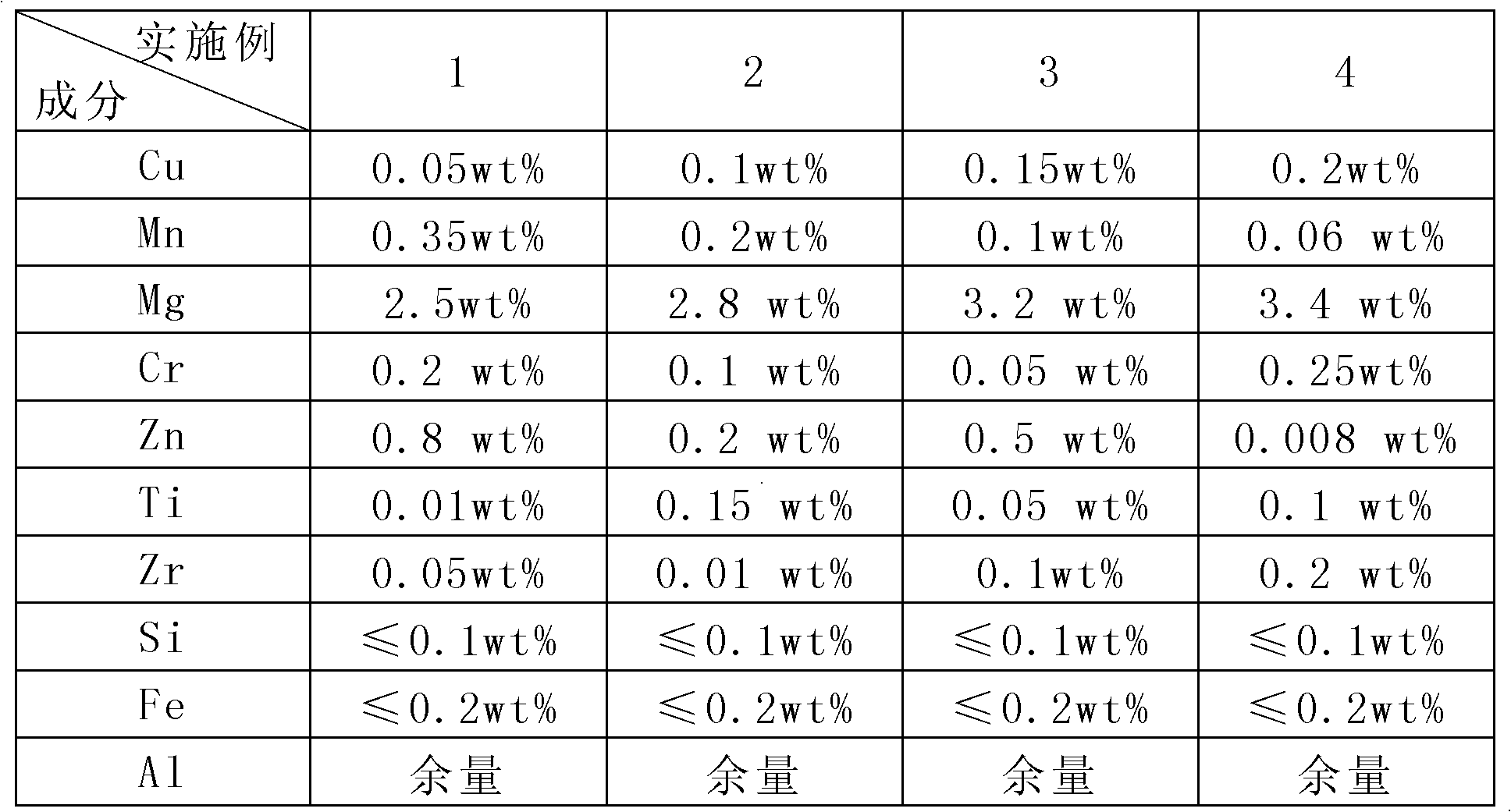

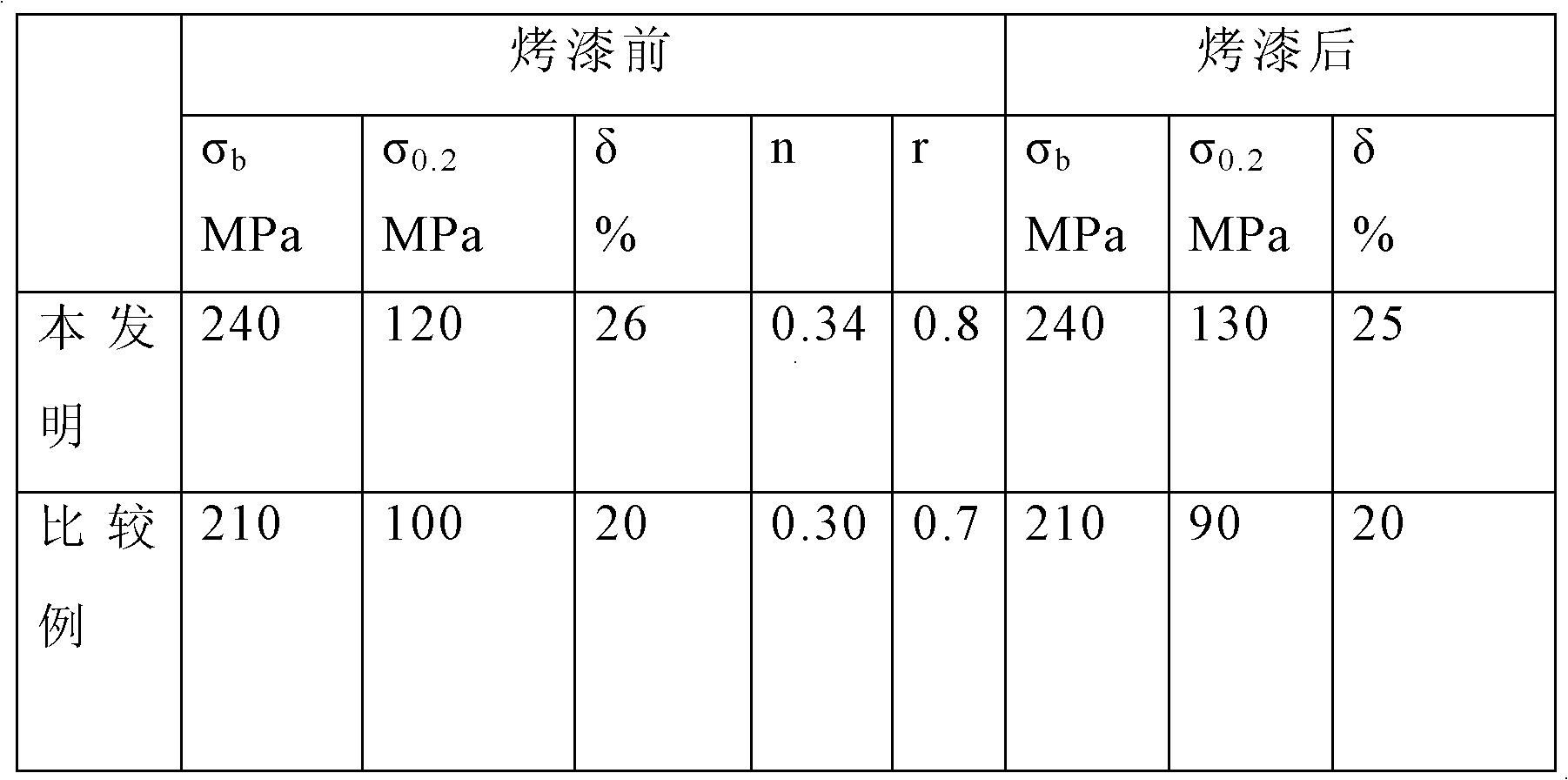

Al-Mg alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880803AImprove corrosion resistance and plasticityGood impact resistanceMg alloysAluminium alloy

The invention provides Al-Mg alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the problem that the existing 5754 series alloys have poor strength and impact resistance. The alloys comprise the following components in percentage by weight: 0.001-0.25wt% of Cu, 0.05-0.35wt% of Mn, 2.5-3.5wt% of Mg; 0.005-0.25wt% of Cr, 0.008-0.8wt% of Zn, 0.01-0.15wt% of Ti, 0.001-0.2wt% of Zr, not more than 0.2wt% of Si, not more than 0.3wt% of Fe and the balance Al. The alloys have the advantages of good impact resistance and plasticity and strong feasibility, and the manufacturing method has the advantage of realizing the aims of energy conservation and emission reduction in the process of machining.

Owner:ZHEJIANG GKO IND CO LTD

High-transparency high-flowability toughened polypropylene material and preparation method thereof

The invention relates to a high-transparency high-flowability toughened polypropylene material and a preparation method thereof. The high-transparency high-flowability toughened polypropylene material contains the following raw materials by weight percent: 20-70 percent of polypropylene, 10-30 percent of m-LLPE, 5-10 percent of ethylene-octene copolymer, 3-10 percent of compatilizer, 5-15 percent of SEBS, 5-30 percent of white oil and 0.1-0.5 percent of antioxygen. The preparation method comprises that the raw materials are weighed according to the weight proportions; the SEBS and the white oil are put into a high-speed mixer and are evenly mixed first, other raw materials are added and are mixed for 2-5 minutes, and the obtained mixture is discharged; and the evenly mixed raw materials are put into a screw extruder and are extruded for granulation. The toughened polypropylene material has the advantages that the mechanical property is excellent, and the flowability and the transparency are better than the flowability and the transparency of common PP toughened materials. The toughened polypropylene material can be used to manufacture high-transparency high-toughness tools and functional parts of shells of instruments and gauges.

Owner:SHANGHAI SUNNY

Composite stressed-skin construction for fuselage and technique of preparing the same

InactiveCN101219587AReduce weightGood impact resistanceSynthetic resin layered productsEfficient propulsion technologiesAirplaneSkin structure

The invention discloses a composite skin structure used in the airframe of the airplane, which is characterized in that: the skin structure comprises an internal wall layer, an internal carbon fiber reinforced plastic layer, a foam-core layer, and an external fiber reinforced plastic layer and an external protective layer in sequence. The invention also discloses a technique for preparing the composite skin structure used in the airframe of the airplane. The invention has the advantages of light weight, good impact resistance property and is applicable to being used in producing the airframes of the large airplanes.

Owner:TONGJI UNIV

Preparation method of impact-resistant artificial leather

InactiveCN102839547AGood impact resistanceImprove impact resistancePattern makingSynthetic resin layered productsPlasticizerProcess agent

The invention discloses a preparation method of an impact-resistant artificial leather, comprising the following steps of: stirring 100 parts of polrvinyl chloride resin, 30-100 parts of plasticizer, 10-80 parts of filler, 0.5-1 part of lubricant, 2-5 parts of heat-resistant stabilizer, 3-5 parts of pigment, 1-10 parts of regulating agent and 3-15 parts of processing agent for 100-200 seconds at the temperature of 120-130DEG C through a high-speed dispersing mixer; charging the mixture obtained in the former step into an internal mixer to mix for 200-300 seconds at the temperature of 130-150DEG C; and charging the product obtained in the former step into a rubber fining mixer for plastication for 10-20 minutes at the temperature of 120-130 DEG C; calendaring into a sheet material with 0.3-0.5mm by a calendar at the temperature of 150-170 DEG C, and fitting the sheet material and a calendaring base material, wherein a fitting pressure is larger than or equal to 1T; and charging into a foaming machine and heating to 190-205 DEG C, foaming, embossing and shaping in a cooling way. The surface of the impact-resistant artificial leather prepared by the method is good in an impact-resistant effect, so that the application range of the impact-resistant artificial leather prepared by the preparation method in the shoemaking and the ball products can be effectively expanded.

Owner:KUSN ACHILLES ARTIFICIAL LEATHER

Long-life anti-corrosive layer for transmission tower and method for making same

ActiveCN101725268AImprove anti-corrosion performanceGood impact resistanceMolten spray coatingAnti-corrosive paintsSolventChemical industry

The invention relates to a long-life anti-corrosive layer for a transmission tower and a method for making the same. The long-life anti-corrosive layer has a composite structure consisting of metal, non-metal and organic matter, wherein a thermally zinc-sprayed bottom layer is sprayed by electric arc by using zinc alloy; an epoxy zinc-rich heavy anti-corrosion enclosed middle layer comprises epoxy resin, zinc powder, a curing agent and a thinner, and is implemented via a high-pressure airless sprayer; a modified acrylic nano surface layer comprises isocyanate additive, modified acrylic resin, a mixture of pigment and filler, the curing agent and a solvent; and a coating method adopts conventional methods such as a brushing method, a rolling method, a spraying method and the like. The invention has the following beneficial effects that: the epoxy zinc-rich heavy anti-corrosion enclosed middle layer is used to enclose a zinc-sprayed layer instead of chromate, and has excellent anticorrosive property; the technology can replace hot galvanizing, lower the production cost, save energy source, eliminate pollution of the three wastes, and prolong the service life to more than 50 years for primary treatment; and the technology is applicable for the fields of electric power, transportation, chemical industry and the like, and has remarkable economic benefit and social benefit.

Owner:辽宁万事达电力股份有限公司

Toughening modified polylactic acid composite material and method for producing the same

InactiveCN101508831AImproved flexibility and formabilityGood impact resistancePliabilityPolylactic acid

The invention discloses a toughened polylactic acid composite and a preparation method thereof. The composite consists of the components with the weight proportion as follows: 72-98 percent of polylactic acid, 1-25 percent of toughener, 0.4-0.6 percent of antioxidant, 0.1-0.5 percent of lubricant and 0.5-2 percent of other processing promoter. In the invention, thermoplastic polyurethane is taken as the toughener, thereby improving the flexibility and the molding processability of PLA obviously and improving the shock resistance and the breaking elongation of the polylactic acid to a great extent.

Owner:ANHUI KEJU NEW MATERIALS

A preparation method of a polyurethane/epoxy resin composite material

ActiveCN103524703AImprove rigidity and comprehensive mechanical propertiesImprove bonding performancePolyureas/polyurethane adhesivesIsocyanateChemistry

A preparation method of a polyurethane / epoxy resin composite material comprises a step of adding a polyether polyol into a reactor to be treated, adding a diisocyanate and heating, controlling the mass content of free -NCO, and obtaining an A component after vacuum deaeration; a step of heating a binary aromatic amine, adding dropwise the liquid epoxy resin and heating again, and reacting to obtain a B component; and a step of stirring and mixing uniformly the A component and the B component stoichiometrically, and reacting and curing to obtain the polyurethane / epoxy resin composite material. When being used as an adhesive, the composite material has good bonding strength, high-temperature resistance, low-temperature resistance, impact resistance and flexibility. The composite material has a wide application scope, and can be prepared into a high-hardness polyurethane elastomer composite material to be applied.

Owner:太原英可奥笔墨科技有限公司

High-strength steel plate with excellent impact resistance and manufacturing method of same

The invention provides a high-strength steel plate with excellent impact resistance in case of no harm to stamping formability and a manufacturing method of the same. The high-strength steel plate is characterized by being composed of the following components in percentage by mass: 0.05-0.20% of C, less than 2.0% of Si, 0.3-3.0% of Mn, less than 0.1% of P, less than 0.1% of Al, and the balance of Fe and inevitable impurities, and has the two phase structures of a martensite phase and the balance of substantially ferritic phase, wherein the volume fraction of the martensite phase is 5-30%; and the ratio Hv(M) / Hv(F) of the hardness Hv(M) of the martensite phase to the hardness Hv(F) of the ferritic phase is 2.4-4.5.

Owner:KOBE STEEL LTD

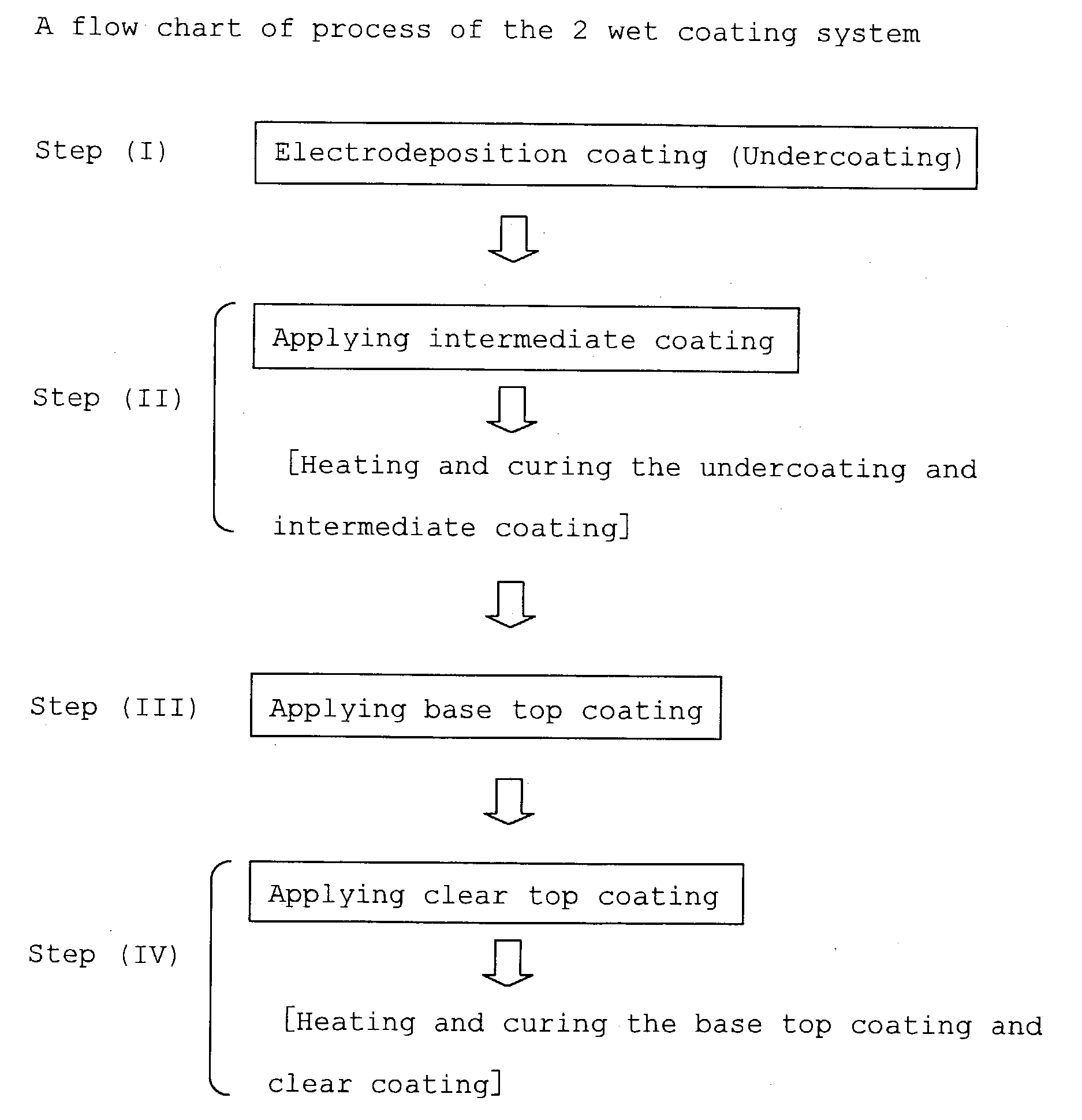

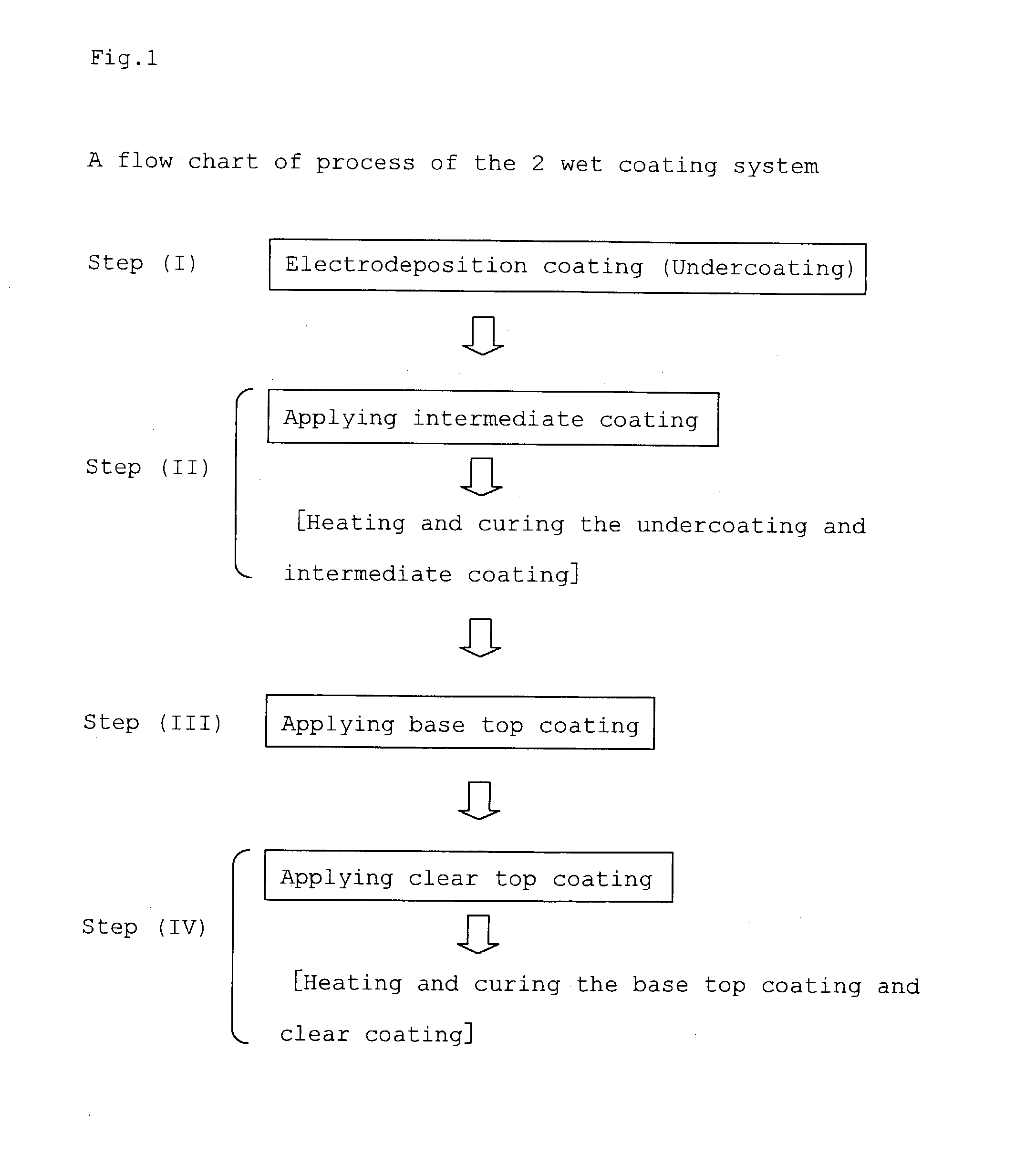

Process for forming multi layered coated film and multi layered coated film

InactiveUS20040011657A1Good impact resistanceChipping resistancePretreated surfacesPolyurea/polyurethane coatingsCoating systemElectrically conductive

The present invention provides an improved 2 wet coating system. The present invention relates to a process for forming a multi layered coated film comprising the steps of: forming an uncured electrodeposition coated film on an electrically conductive substrate, applying an intermediate coating on the electrodeposition coated film, and then simultaneously heating and curing the uncured electrodeposition coated film and an uncured intermediate coated film, forming an uncured base coated film on the intermediate coated film, applying a clear top coating on the base coated film, and then simultaneously heating and curing the uncured base coated film and an uncured clear coated film; wherein the electrodeposition coating forms a self-stratifying coated film, and a dynamic glass transition temperature of a resin layer (alpha) in direct contact with the electrically conductive substrate and that of a resin layer (beta) in direct contact with the intermediate coated film are controlled.

Owner:NIPPON PAINT CO LTD

Method for biologically denitrifying high-salinity sewage generated in production process of catalysts

ActiveCN103373767AAdaptable and TolerableGood impact resistanceWater contaminantsBiological water/sewage treatmentHeterotrophic bacteriaEnvironmental chemistry

The invention discloses a method for biologically denitrifying high-salinity sewage generated in the production process of catalysts. The method is implemented by adding nitrobacteria and denitrifiers with nitrites as electron acceptors to sewage, wherein the high-salinity sewage treatment temperature is 18-40 DEG C; the dissolved oxygen is 0.2-3mg / L; and the pH value is 7.5-8.5. The method adopts autotrophic bacteria and heterotrophic bacteria which are subjected to combination of superiority to serve as reinforced microorganisms for treating sewage, adopts different addition modes, can achieve removal of ammonia nitrogen, total nitrogen and CODcr in the same reactor, has a good wastewater treatment effect, and truly achieves biological denitrification of the high-salinity sewage generated in the production process of catalysts by being combined with high-efficiency devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

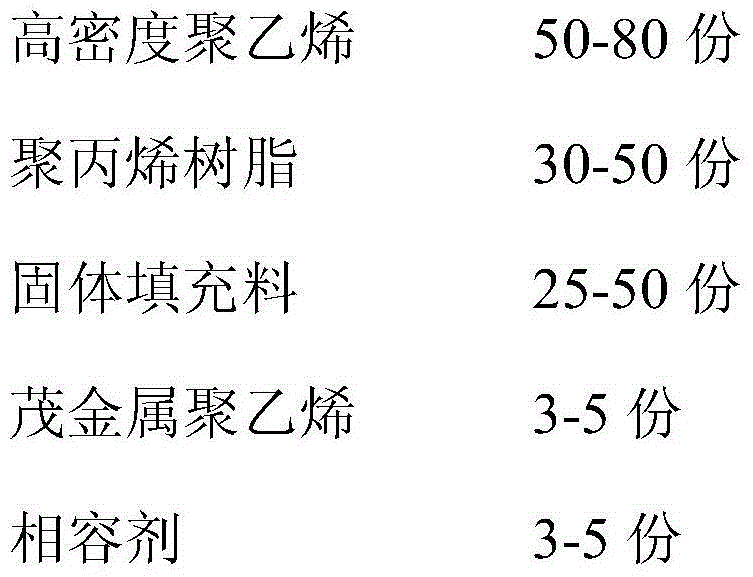

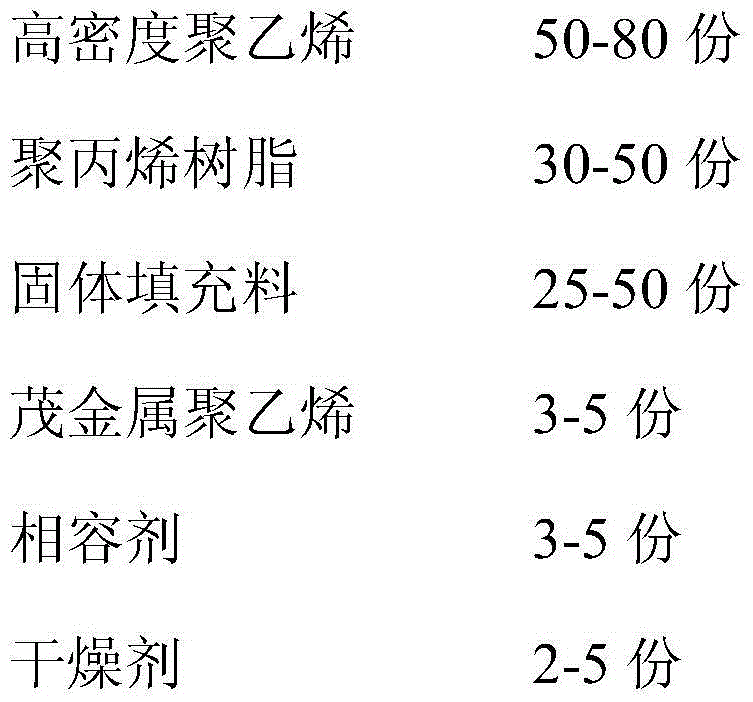

High-density polyethylene double-wall corrugated pipe

InactiveCN104910483AHigh melt strength and rigidityGood impact resistanceFlexible pipesLight pipePolypropylene

The present invention relates to the field of engineering plastic processing manufacturing, and discloses a high-density polyethylene double-wall corrugated pipe, which comprises an outer pipe and an inner pipe, wherein the materials of the outer pipe comprise 50-80 parts of high-density polyethylene, 30-50 parts of a polypropylene resin, 25-50 parts of a solid filling material, 3-5 parts of metallocene polyethylene, 3-5 parts of a compatibilizing agent, and 2-5 parts of a drying agent, and the materials of the inner pipe comprise 50-80 parts of high-density polyethylene, 30-50 parts of a solid filling material, and 2-5 parts of a drying agent. According to the modified high-density polyethylene double-wall corrugated pipe of the present invention, the inner pipe and the outer pipe have characteristics of high melt strength, high rigidity and good impact resistance, such that the double-wall corrugated pipe has characteristics of high ring rigidity, good compression resistance, and light pipe weight; the metallocene polyethylene is added to the materials of the outer pipe, such that the ring flexibility of the outer pipe is increased, and the toughness is good; and the high-density polyethylene double-wall corrugated pipe can be widely used in non-pressure plastic underground drainage and sewage drain pipelines, and has good application prospects and market competitiveness in the fields of plastic pipelines.

Owner:浙江中财管道科技股份有限公司

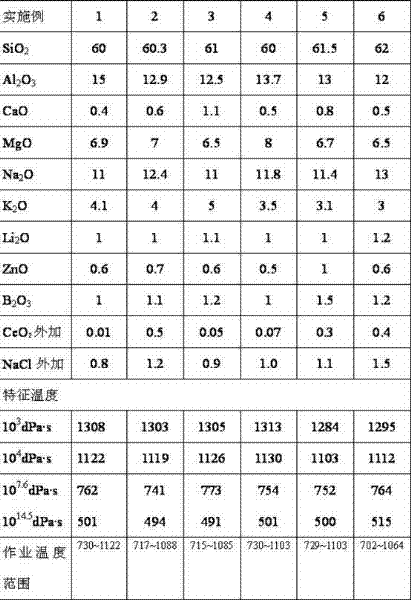

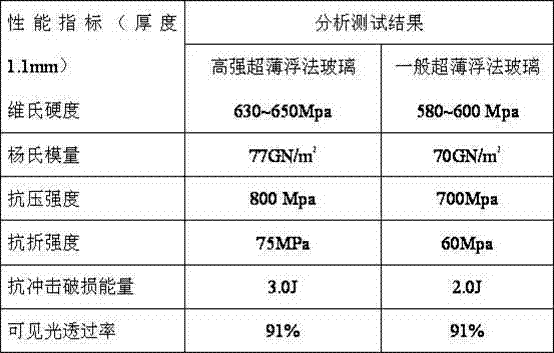

High strength ultrathin float glass

Owner:CLFG LONGHAI ELECTRONICS GLASS

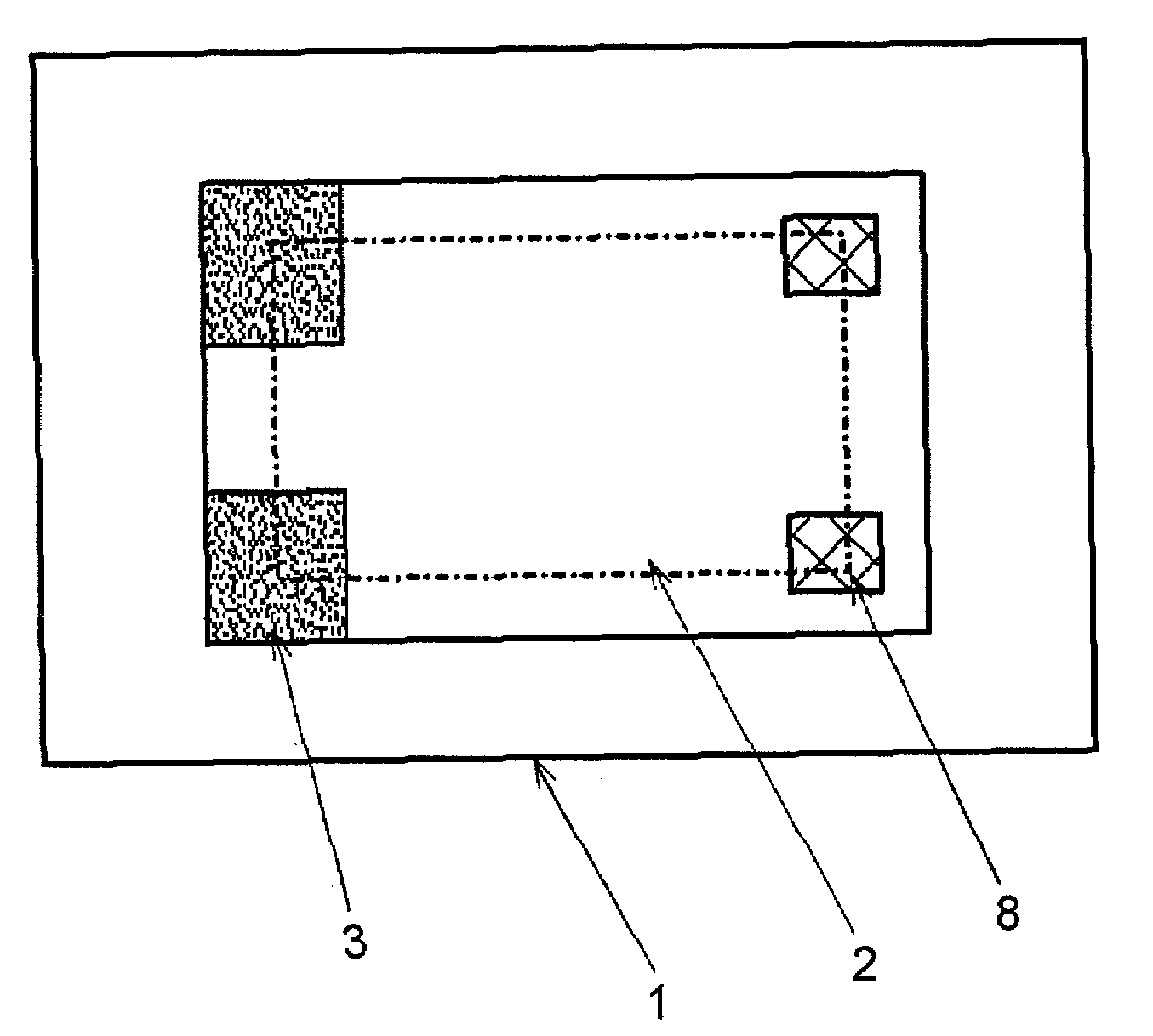

Quartz crystal device for surface mounting

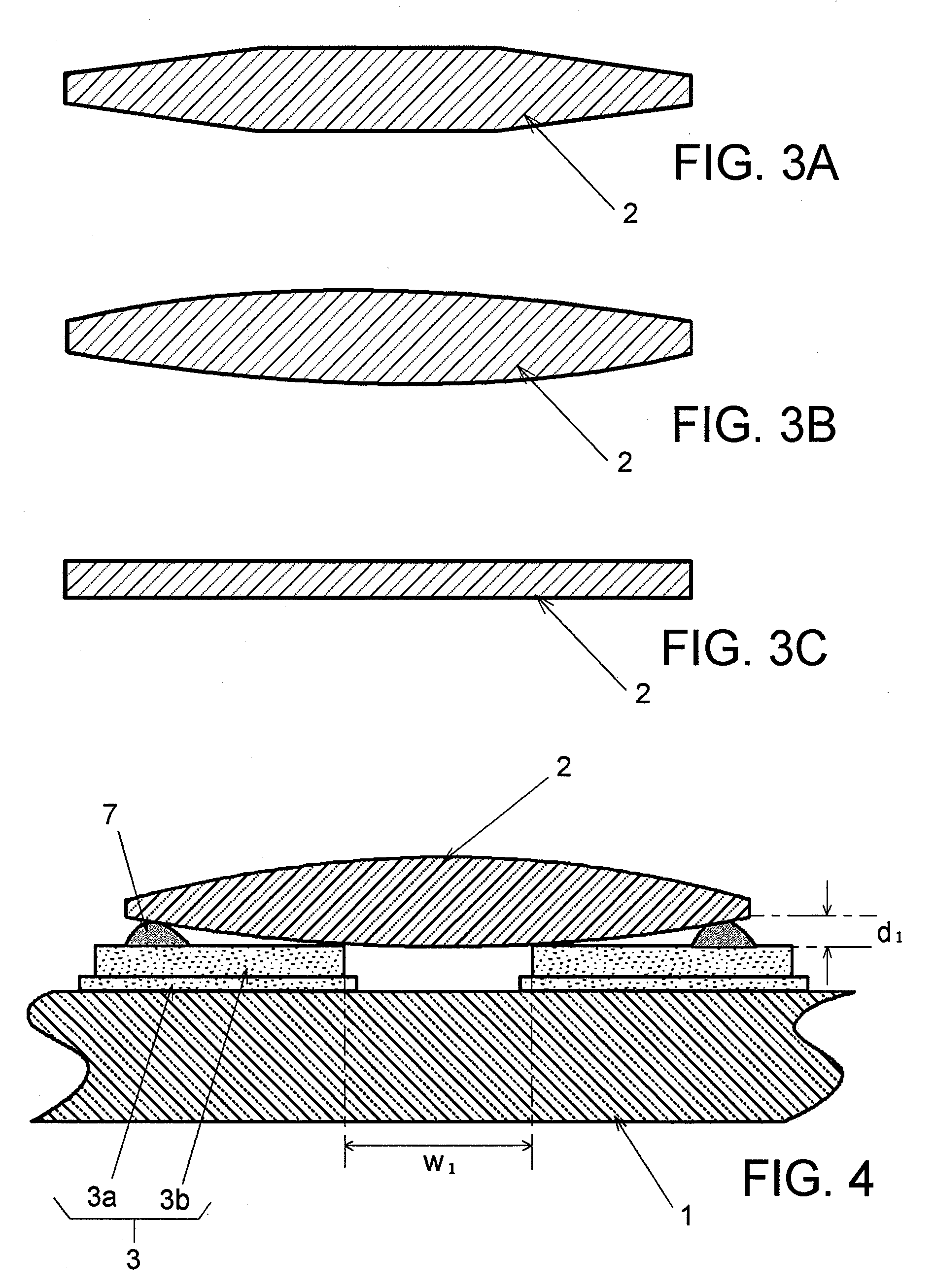

InactiveUS20090102322A1Shorten the separation distanceLarge thicknessPiezoelectric/electrostriction/magnetostriction machinesImpedence networksSurface mountingAdhesive

The quartz crystal device includes a container body having: a recess; a pair of holding terminals formed on an inner bottom surface of the recess; and a crystal blank, both principal surfaces of which are provided with excitation electrodes with lead-out electrodes extending from the pair of excitation electrodes toward both sides of one end of the crystal blank. Both sides of one end of the crystal blank are fixed to the holding terminals using a conductive adhesive. Pillow members are provided on the inner bottom surface of the recess at positions corresponding to corners on both sides of the other end of the crystal blank, and the two pillow members are independent of each other. Alternatively, each holding terminal includes a first region formed near the facing holding terminal and a second region having a greater thickness than the first region formed far from the facing holding terminal.

Owner:NIHON DEMPA KOGYO CO LTD

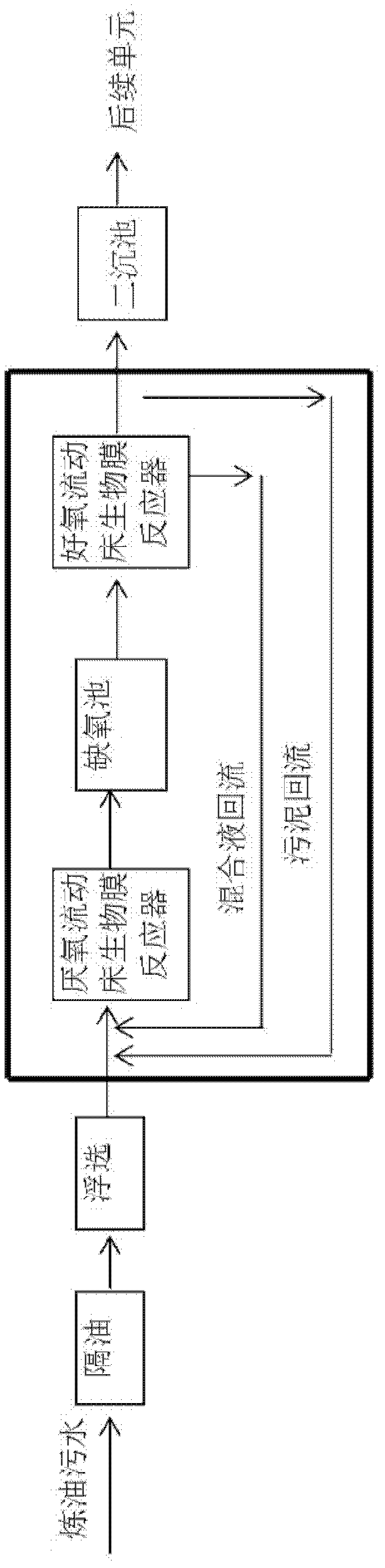

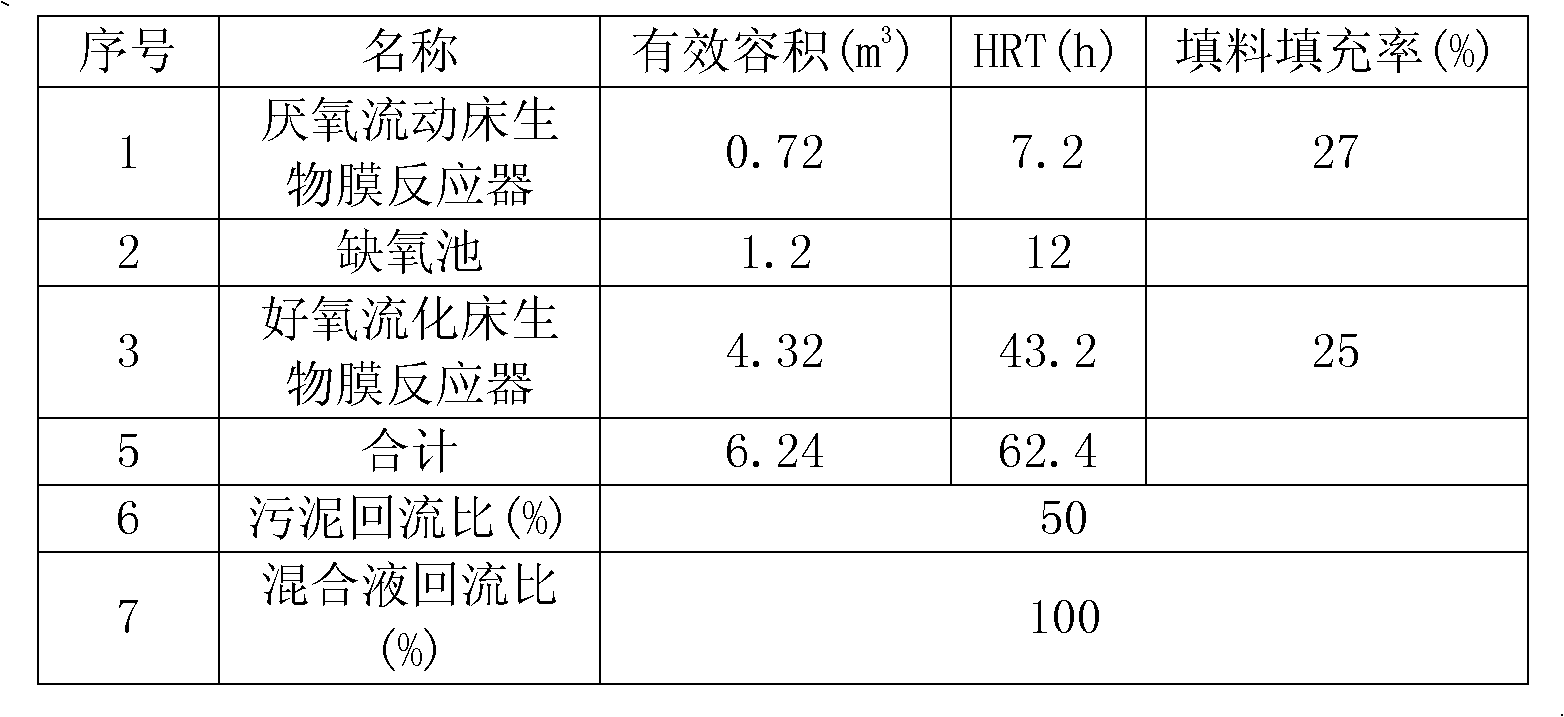

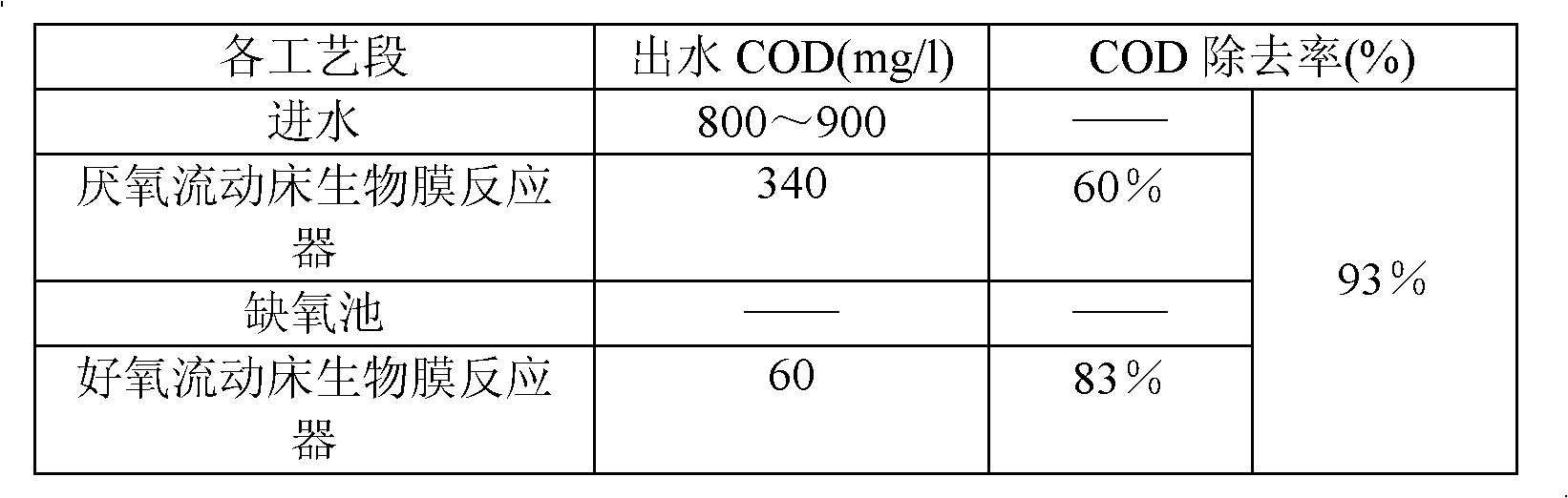

Method for biochemically treating and discharging refinery wastewater within controlling index of national standard

ActiveCN102249499AGood impact resistanceSafe and reliable operationMultistage water/sewage treatmentWater/sewage treatment by flotationTreatment effectSalt resistance

The invention provides a biochemically treating and discharging refinery wastewater within controlling index of national standard. The method comprises oil removal, floatation and biochemical treatment, wherein the biochemical treatment is performed in sequence through an anaerobic flow bed biofilm reactor, an anoxic basin and an aerobic flow bed biofilm reactor; and a part or all of mixed liquidflowing out of the aerobic flow bed biofilm reflows into the anaerobic flow bed biofilm reactor. According to the method, refinery wastewater is treated by adopting an 'aerobic flow bed biofilm reactor-anoxic method-aerobic flow bed biofilm reactor' process which has high impact resistance and is safe during running. High instantaneous impact resistance is achieved, and the treatment effect is hardly influenced. The entire biochemical system has high salt resistance, and the treatment effect is hardly influenced by the change of temperature. The refinery wastewater does not need to be subjected to subsequent further oxidation after being treated with the process, the effluent COD (Chemical Oxygen Demand) meets the national primary discharge standard less than or equal to 60 mg / l, and investment cost and running cost are saved. The entire system has a compact structure, so that the floor space is reduced.

Owner:DASMART ENVIRONMENTAL SCI & TECH (BEIJING) CO LTD

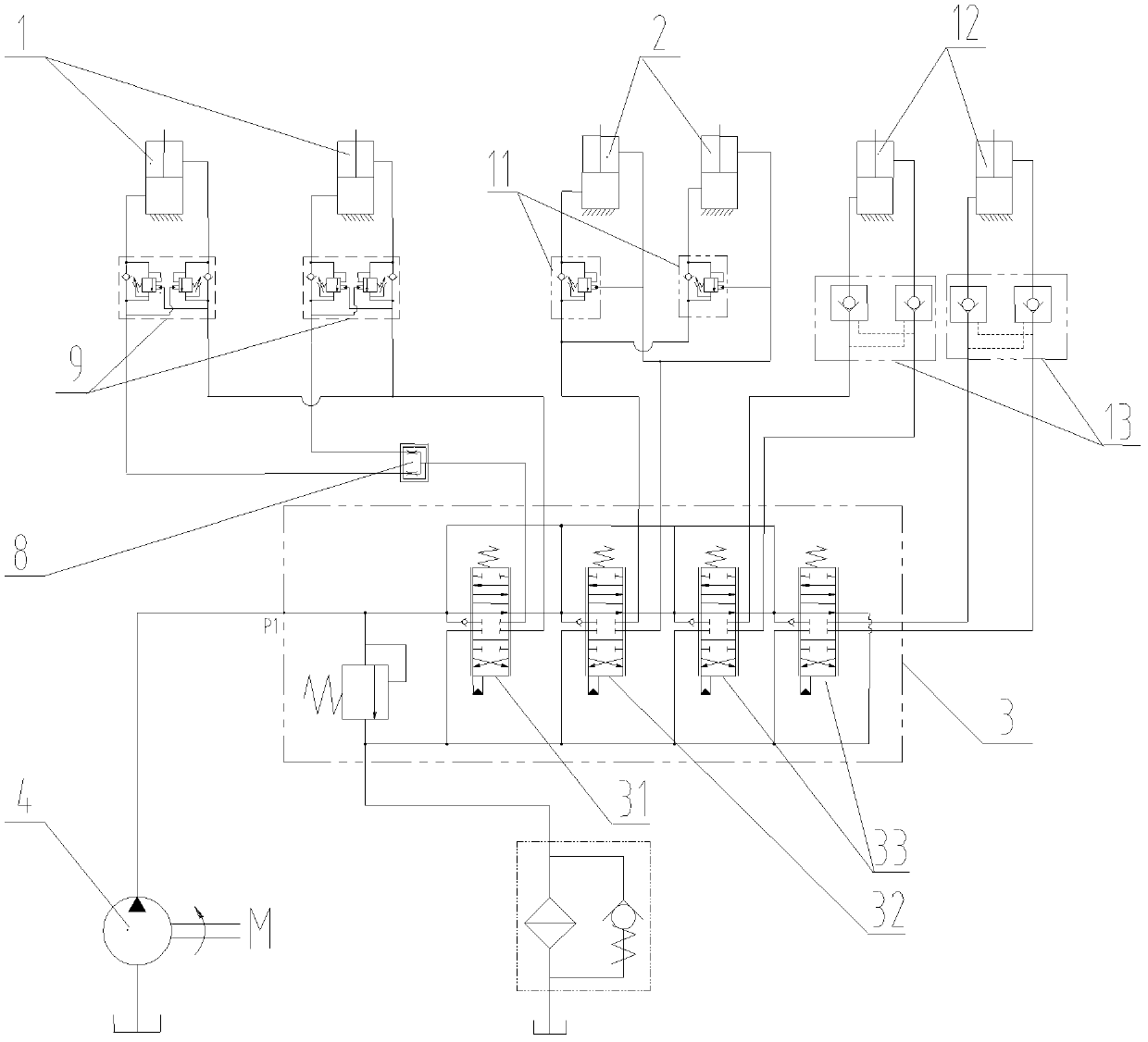

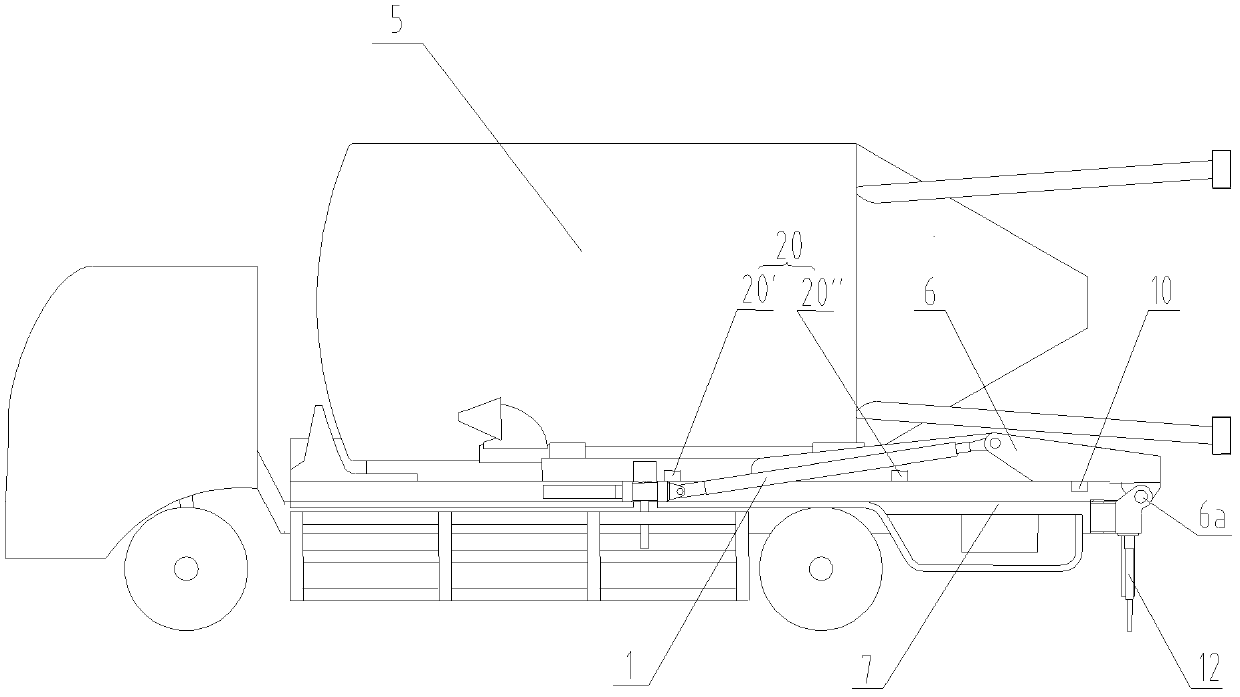

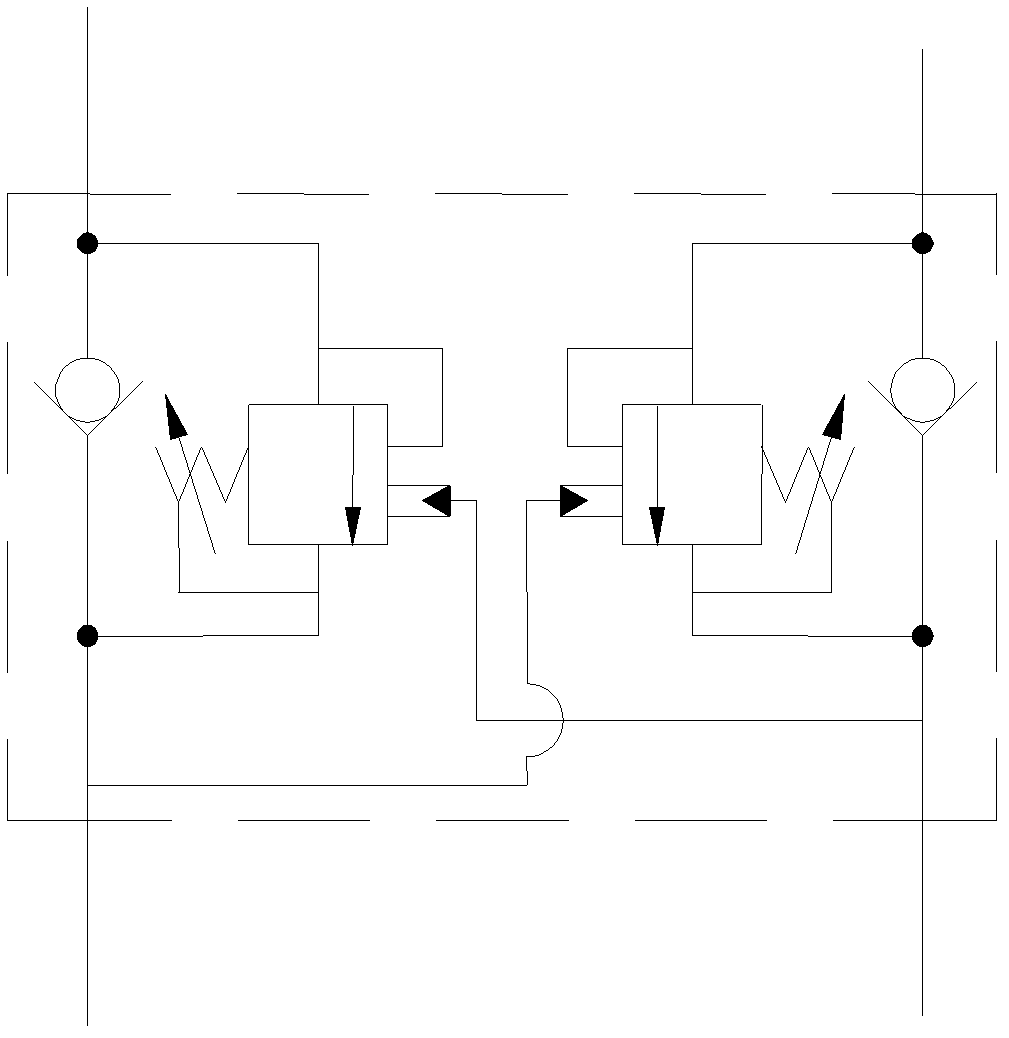

Demountable tanker truck and hydraulic system thereof

InactiveCN102381230AAnti-stall movementImproved speed stabilityTank vehiclesVehicle with tipping movementHydraulic pumpTruck

The invention provides a demountable tanker truck and a hydraulic system thereof. The hydraulic system comprises a hydraulic pump, wherein the hydraulic pump supplies oil to a main oil cylinder and a moving oil cylinder through a multi-way valve, the multi-way valve at least comprises a main oil cylinder reversing valve and a moving oil cylinder reversing valve, and the hydraulic system also comprises a first position detection device and / or a second position detection device. The moving state of the main oil cylinder can be controlled according to the first position detection device, and the moving state of the moving oil cylinder can be controlled according to the second position detection device. The synchronism of the operation process of the main oil cylinder can also be ensured, and in addition, the protection on a main oil path can also be realized. The demountable tanker truck and the hydraulic system thereof have the advantages that misoperation can be reduced, the synchronism is high, the anti-impact performance is good, and the like.

Owner:SANY HEAVY IND CO LTD (CN)

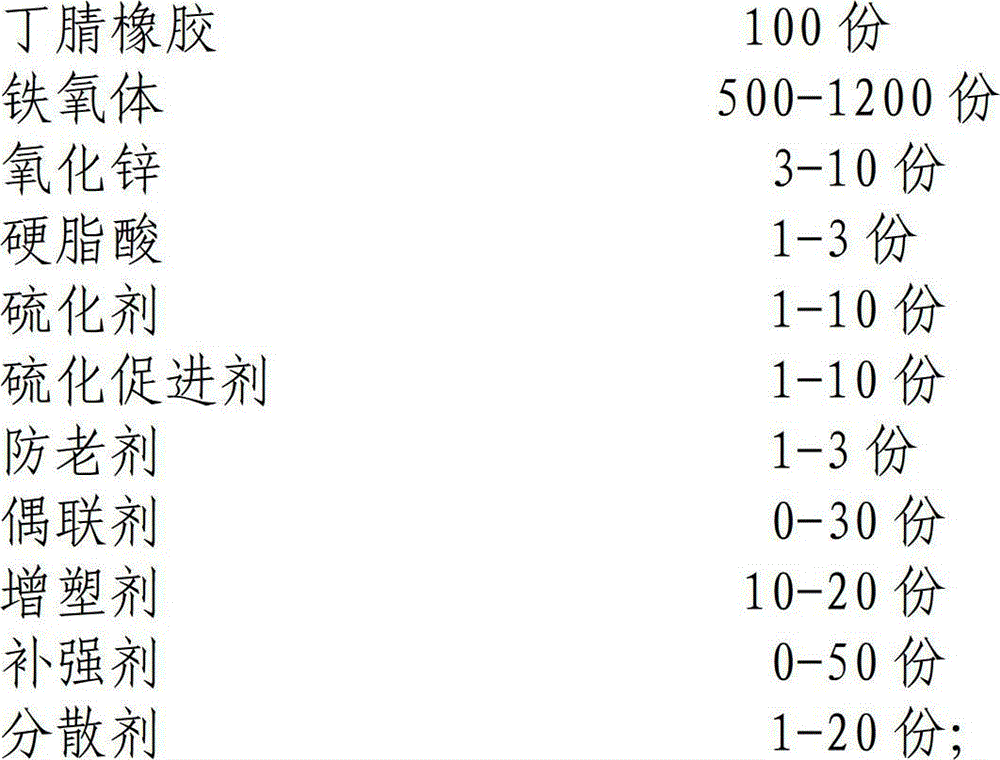

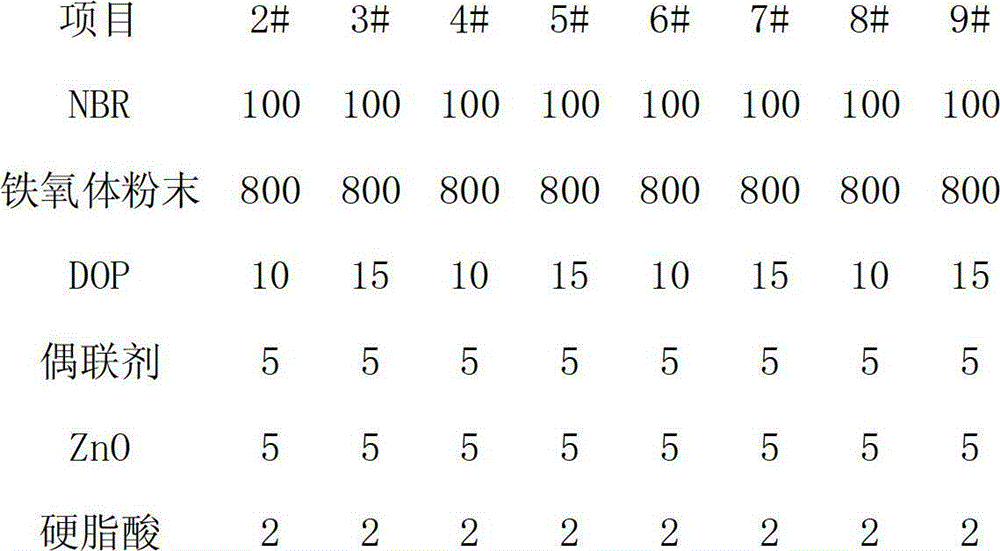

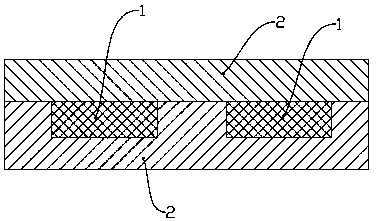

Magnetic composite material for multistage magnetic encoder and preparation method thereof

ActiveCN102942719AGood corrosion resistanceGood impact resistanceOrganic/organic-metallic materials magnetismCorrosionAnti-lock braking system

The invention relates to the field of composite materials, and provides a magnetic composite material for a multistage magnetic encoder and a preparation method thereof. The magnetic composite material mainly comprises nitrile rubber and ferrite, and is prepared by banburying and mixing by an internal mixer and vulcanization molding. The magnetic composite material has good corrosion resistance, impact resistance and good thermal stability, and especially highly uniform magnetic induction intensity, and change rate of magnetic induction less than 2% after multistage magnetizing. The magnetic composite material can be used in the production of an anti-lock braking system (ABS) magnetic encoder.

Owner:QINGDAO UNIV OF SCI & TECH +2

Polyformaldehyde composition and preparation method thereof

The invention discloses a polyoxymethylene composition and a method for preparing the same, wherein the composition includes 20-95 percent of POM, 4-80 percent of ABS, 0.1-20 percent of compatibilizer, 0.1-1.0 percent of lubricant, and 0.1-1.2 percent of antioxidant in weight proportion ( percent). Compared with conventional TPU toughening POM system, when the POM / ABS system of the invention achieves the same impact property, the mechanical comprehensive property of the invention is obviously better than the conventional TPU toughening POM system, and the heat resistance is greatly improved. The alloy material has simple preparation technology, and has advantages of dimensional stability, good appearance, high flowability, drug resistance and easy processing forming, which can be widely used to manufacture automobile, electronic and electric components. The invention improves the POM impact toughness and greatly enriches the use of polyoxymethylene in automobile, electronic and electric components through blending with the ABS material.

Owner:SHENZHEN KEJU NEW MATERIAL

Elastic shape memory material with shear thickening performance, and preparation method and applications thereof

PendingCN108424649AIncrease the scope of applicationGood impact resistanceSmart materialImpact resistance

The invention belongs to the field of smart material manufacturing and application, and relates to an elastic shape memory material with shear thickening performance, and a preparation method and applications thereof. The elastic shape memory material with shear thickening performance comprises, by weight, 10 to 95 parts of an elastic shape memory polymer material, and 5 to 90 parts of a shear thickening material; the elastic shape memory polymer material and the shear thickening material are combined to form an integral body through blending or combination; the elastic shape memory polymer material is capable of providing an obtained material with elasticity and thermal driving shape memory characteristics; and the shear thickening material is capable of providing the obtained material with shear thickening characteristics. According to the preparation method, the shear thickening material and the elastic shape memory polymer material are combined, so that the obtained elastic shape memory material is capable of adapting different structure shapes through heating deformation, the suitable range is widened, and excellent impact resistance and anticollision performance are achieved.

Owner:NANJING SKY LONG PHARMA +3

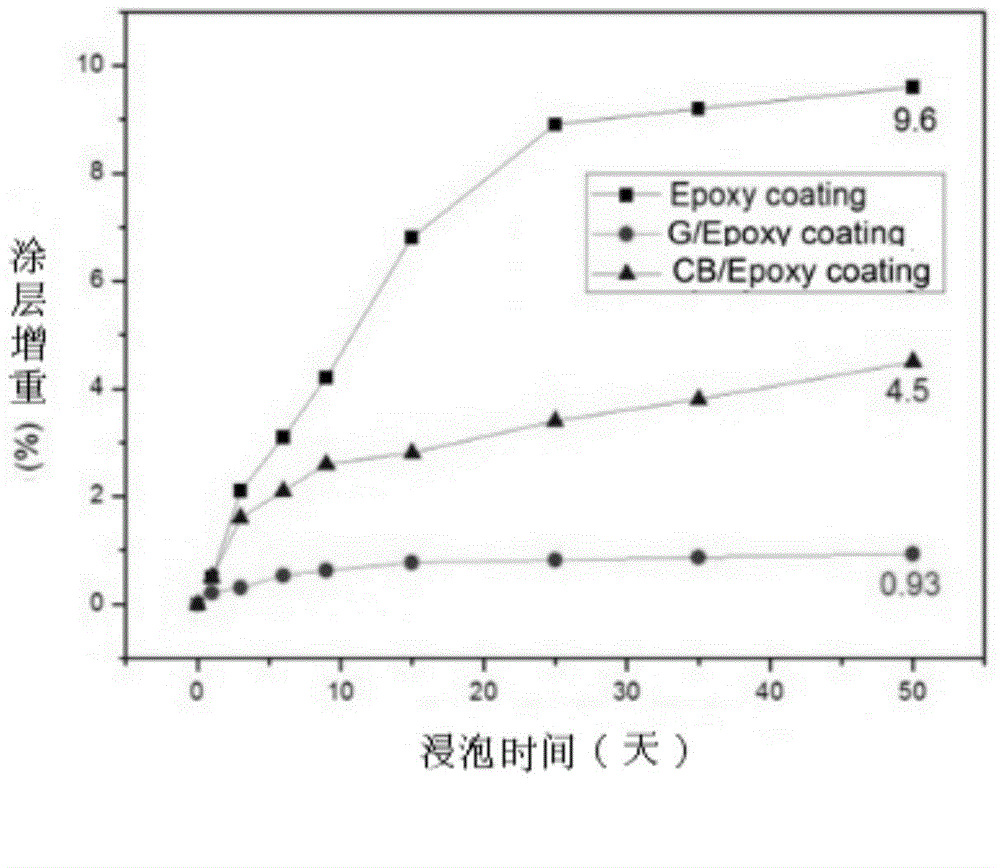

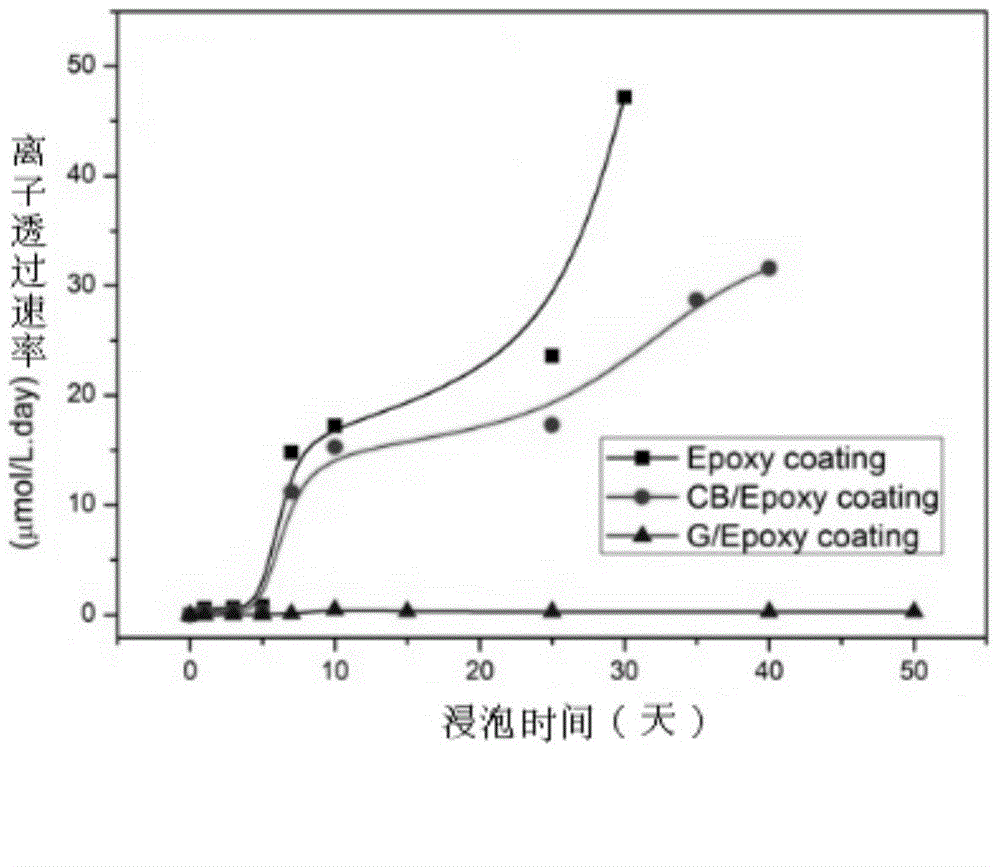

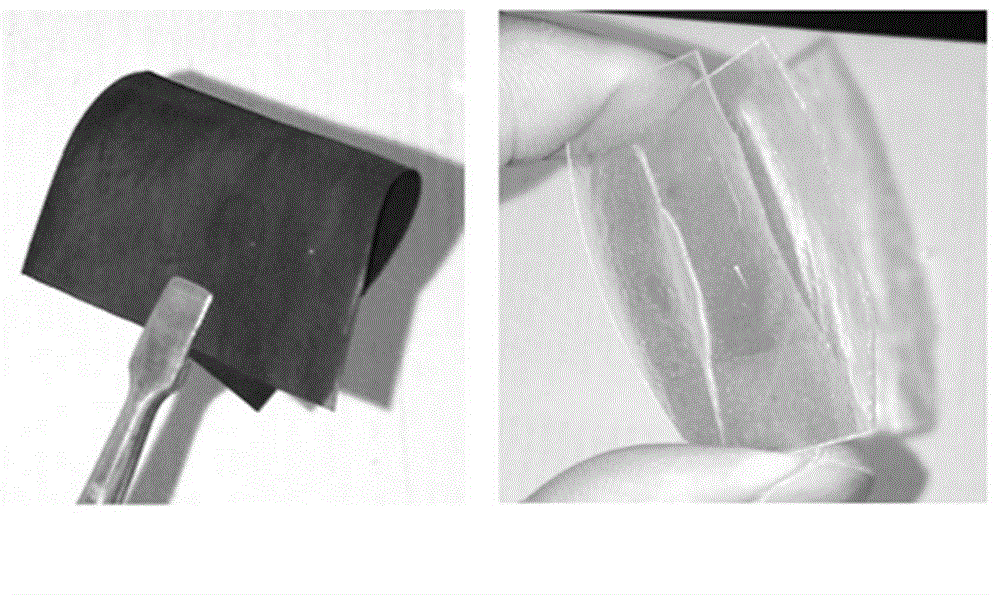

Graphene/epoxy resin composite anticorrosive paint with high isolation and preparation method

ActiveCN105647338AAvoid reunionHigh quality dispersionAnti-corrosive paintsEpoxy resin coatingsEpoxyHigh isolation

The invention relates to the field of metal corrosion protection, in particular to a graphene / epoxy resin composite anticorrosive paint with high isolation and a preparation method. A graphene / epoxy resin masterbatch with a graphene content of 5wt% is added into common epoxy resin, then a diluent and an assistant are added and stirred to disperse uniformly to form a component A; and a component B is a curing agent. By weight percentage, the component A accounts for 53-93%, and the component B accounts for 7-47%. In the component A, the content of graphene is 0.03-2.3wt%. The two components are mixed evenly to obtain the graphene / epoxy resin composite paint, which is applied and dried by a conventional method so as to obtain a corrosion prevention coating with high isolation. Compared with the prior art, the graphene / epoxy coating prepared by the method provided by the invention consumes little graphene, also can realize uniform dispersion of graphene in the composite coating, thereby endowing the coating with the advantages of excellent water resistance, corrosion resistance, weatherability, acid-base resistance, impact resistance and artificial aging resistance, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

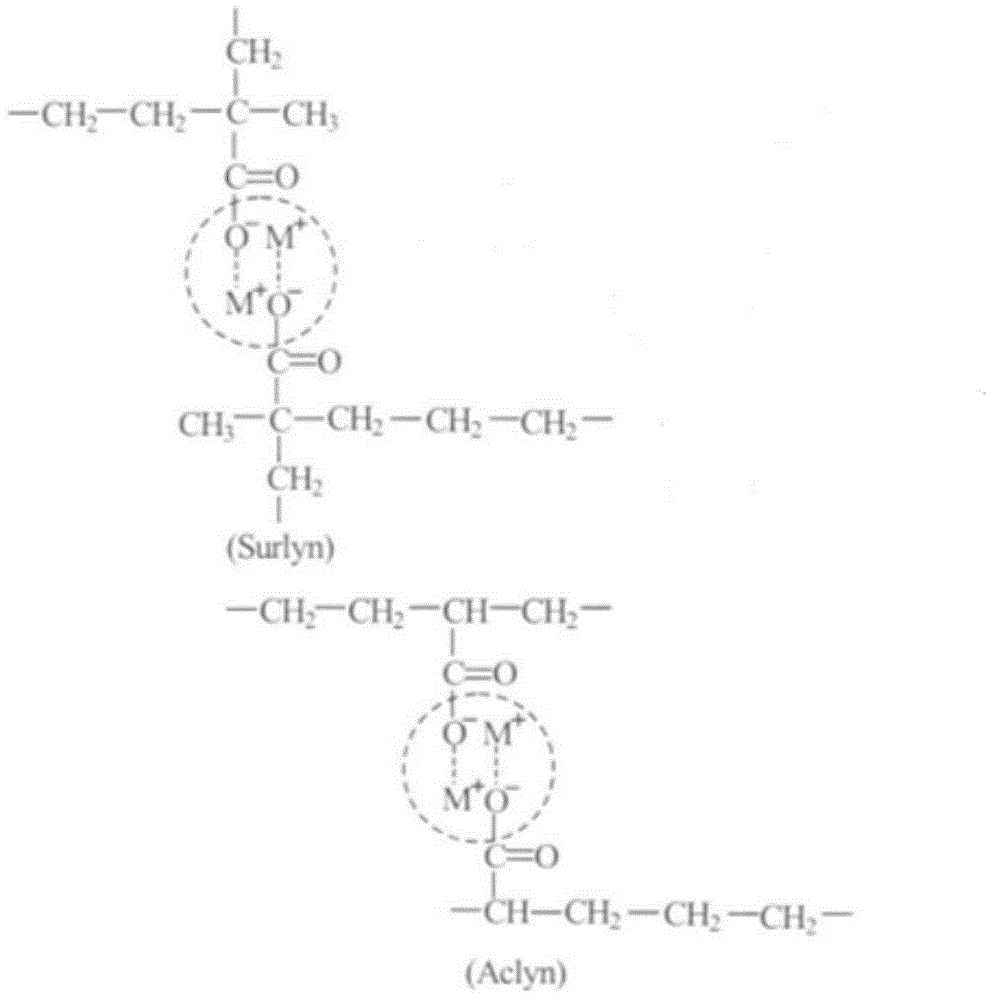

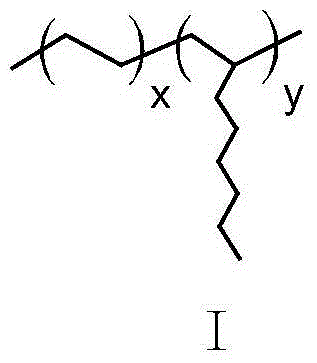

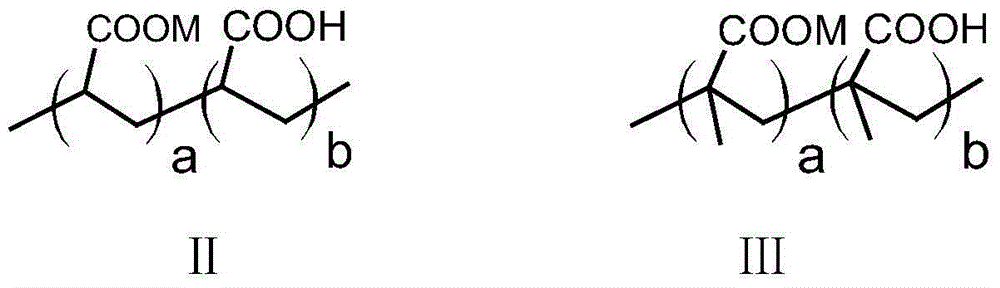

High-toughness polyester resin alloy composition and preparation method thereof

The present invention provides a high-toughness polyester alloy composition and a preparation method thereof, wherein the composition mainly comprises the following raw materials by weight: (A) polybutylene terephthalate, (B) polyethylene terephthalate, and (C) an ionomer compound using an ethylene octene copolymer as a matrix. The preparation method comprises: adding (A) polybutylene terephthalate, (B) polyethylene terephthalate, (C) an ionomer compound using an ethylene octene copolymer as a matrix and other additives to a high speed material mixer, adding to a twin-screw extruder after the mixing, and carrying out melt extrusion granulation. According to the present invention, the polyester resin alloy reinforcing material composition has good impact resistance and good fluidity, and the product prepared by using the high-toughness polyester resin alloy reinforcing material composition has characteristics of low warping, high strength and high toughness, and is suitable for vehicles, mobile phones, and notebook computer products.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

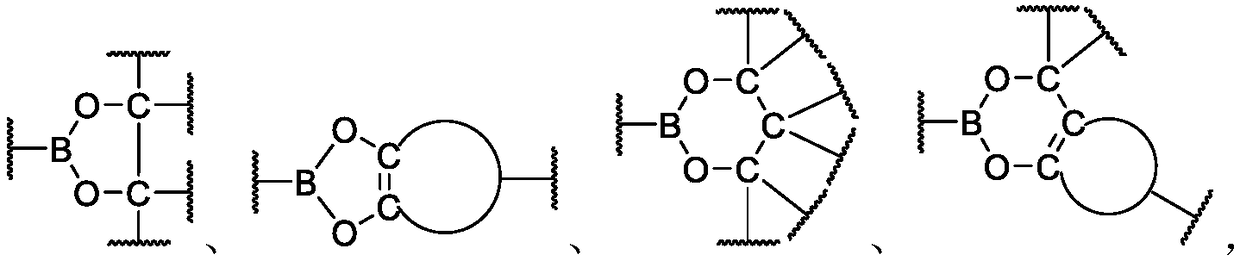

Energy-absorbing method based on dynamic polymer

InactiveCN108341944ADynamicImprove energy absorptionFibre treatmentPolyether coatingsCross-linkHydrogen

The invention discloses an energy-absorbing method based on a dynamic polymer. The method employs a dynamic polymer containing a cyclic organic borate bond and an optional supramolecular hydrogen bondfor energy-absorption, wherein the cyclic organic borate bond exists as a polymeric chain joint and / or cross-linked chain joint for the dynamic polymer and is a necessary condition for the formationor maintenance of the structure of the dynamic polymer. Due to dynamic reversibility of the cyclic organic borate bond, the dynamic polymer has an energy dissipation characteristic; as an energy-absorbing material, the dynamic polymer can provide the good functions of damping, shock absorption, sound insulation, noise abatement, impact resistance and the like; and the dynamic polymer is especiallyapplicable to the body protection of people during exercises, daily life and working, the body protection of the military police, explosion prevention, protection in airborne landing and aerial delivery, collision prevention of automobiles, anti-impact protection of electronic products and electric appliances, etc.

Owner:厦门逍扬运动科技有限公司

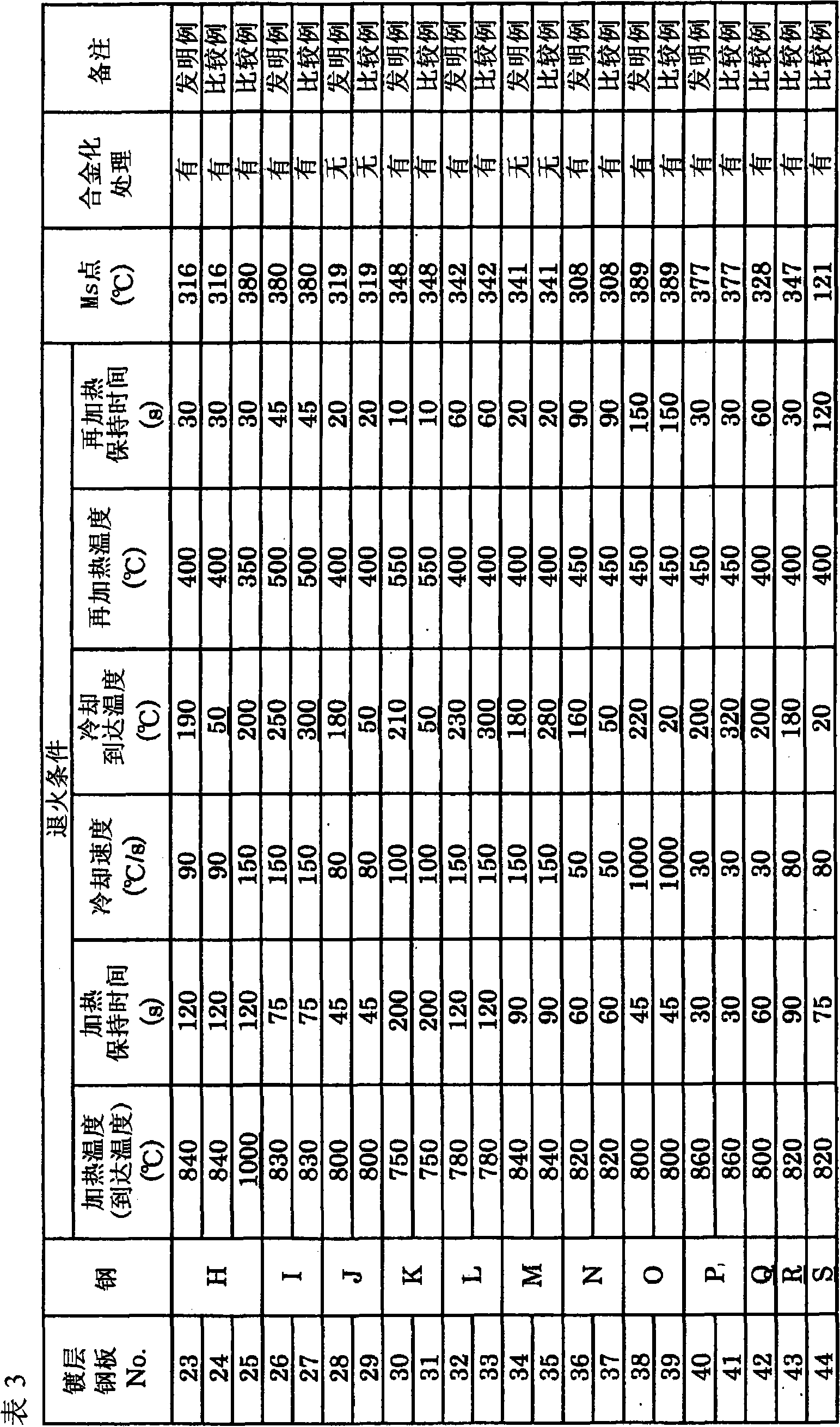

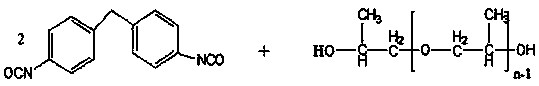

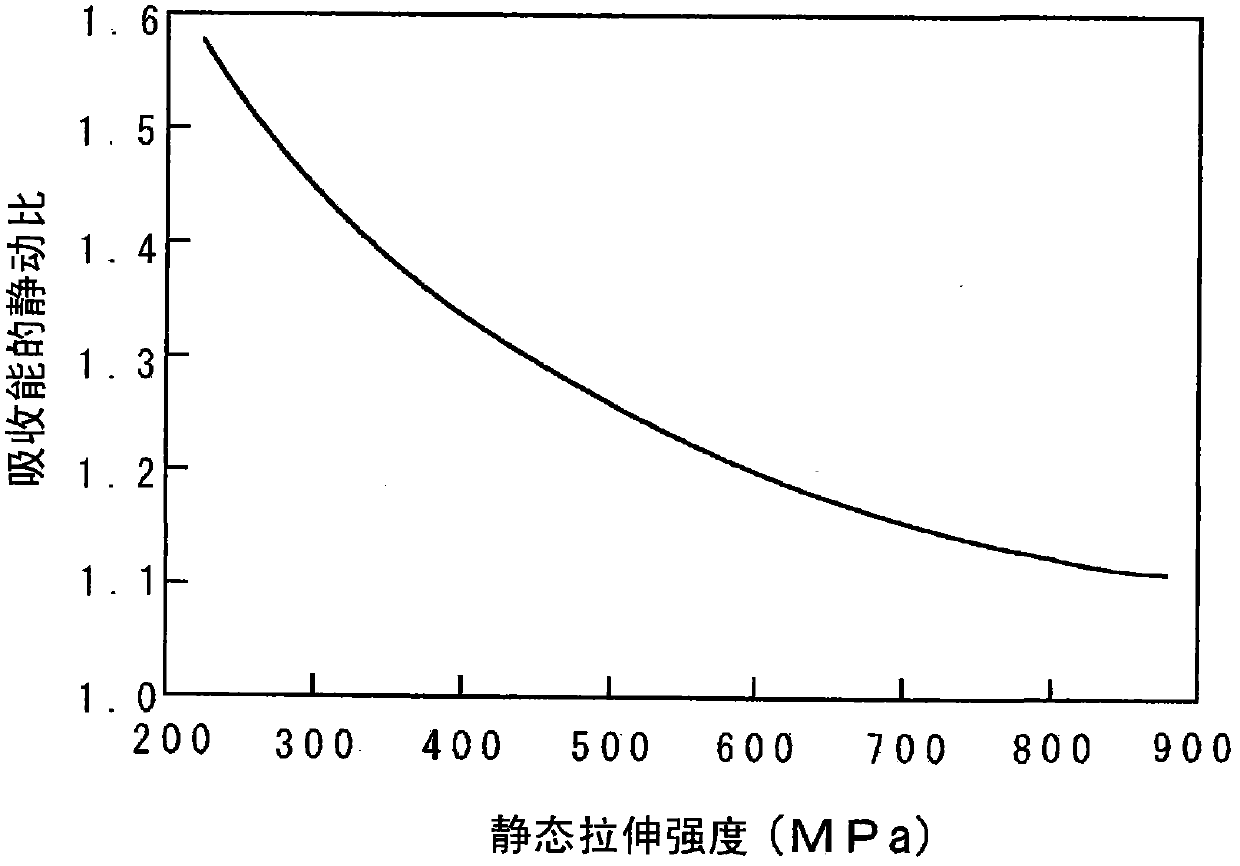

High-strength hot-dip galvanized steel sheet with excellent processability and impact resistance and process for producing same

ActiveCN102712977AGood impact resistanceImprove impact resistanceHot-dipping/immersion processesFurnace typesAbsorbed energyHigh intensity

Provided is a hot-dip galvanized steel sheet which has a tensile strength TS of 590 MPa or higher and excellent processability and which, even when no strain is introduced thereinto by pressing, highly absorbs energy in a low-strain range up to about 5% and has excellent collision resistance. Also provided is a process for producing the steel sheet. The galvanized steel sheet has a composition which contains, in terms of mass%, 0.04-0.13% C, 0.7-2.3% Si, 0.8-2.0% Mn, up to 0.1% P, up to 0.01% S, and 0.01-0.1% Al, with the remainder comprising iron and incidental impurities, and has a structure which comprises, in terms of areal proportion, at least 75% ferrite phase, at least 1% bainitic ferrite phase, and 1-10% pearlite phase, has a martensite phase content of up to 10% in terms of areal proportion, and satisfies (areal proportion of martensite) / ((areal proportion of bainitic ferrite)+(areal proportion of pearlite))<=0.6, and in which the ratio of the Mn concentration in the ferrite phase to the Mn concentration in the second phase is 0.70 or above.

Owner:JFE STEEL CORP

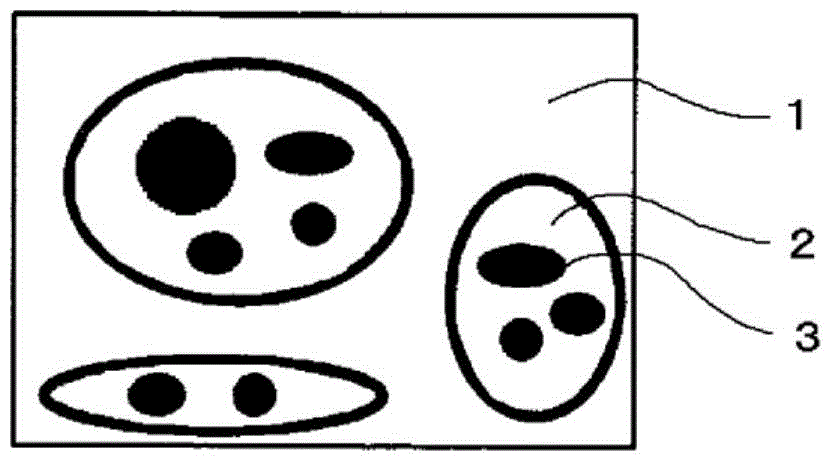

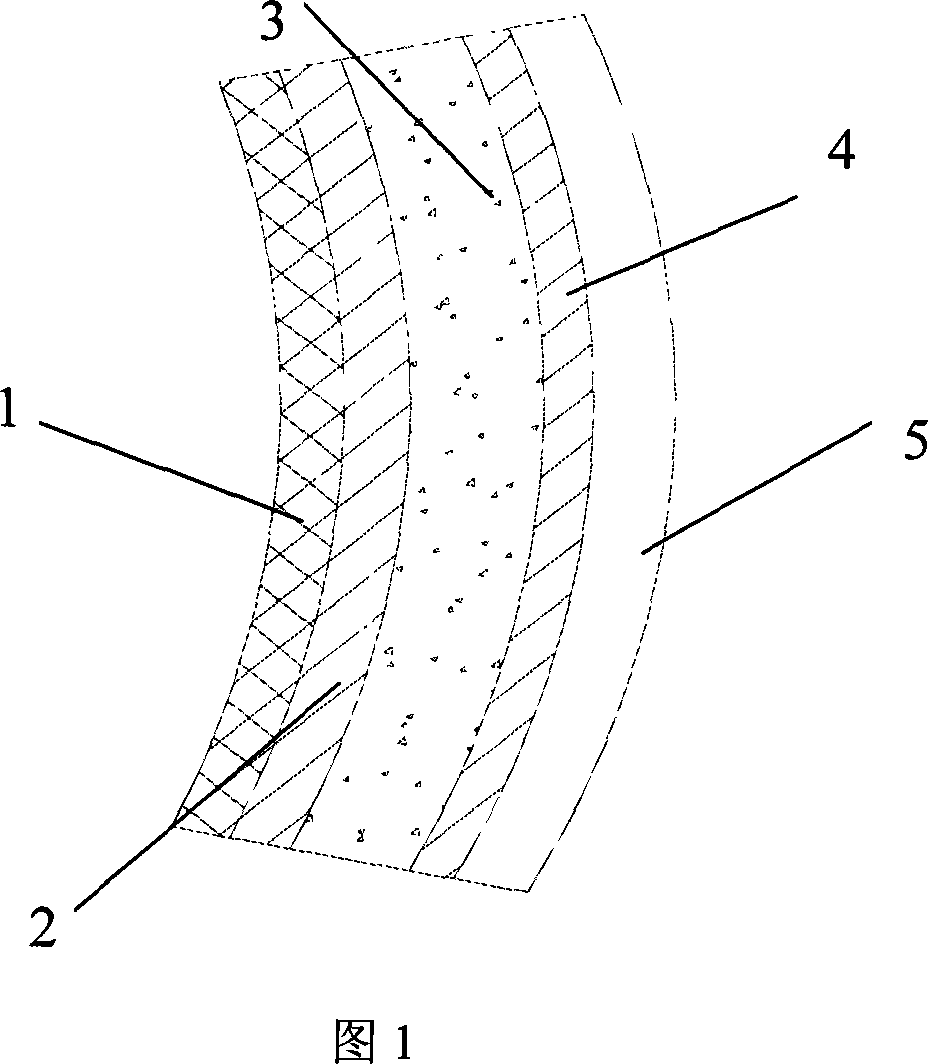

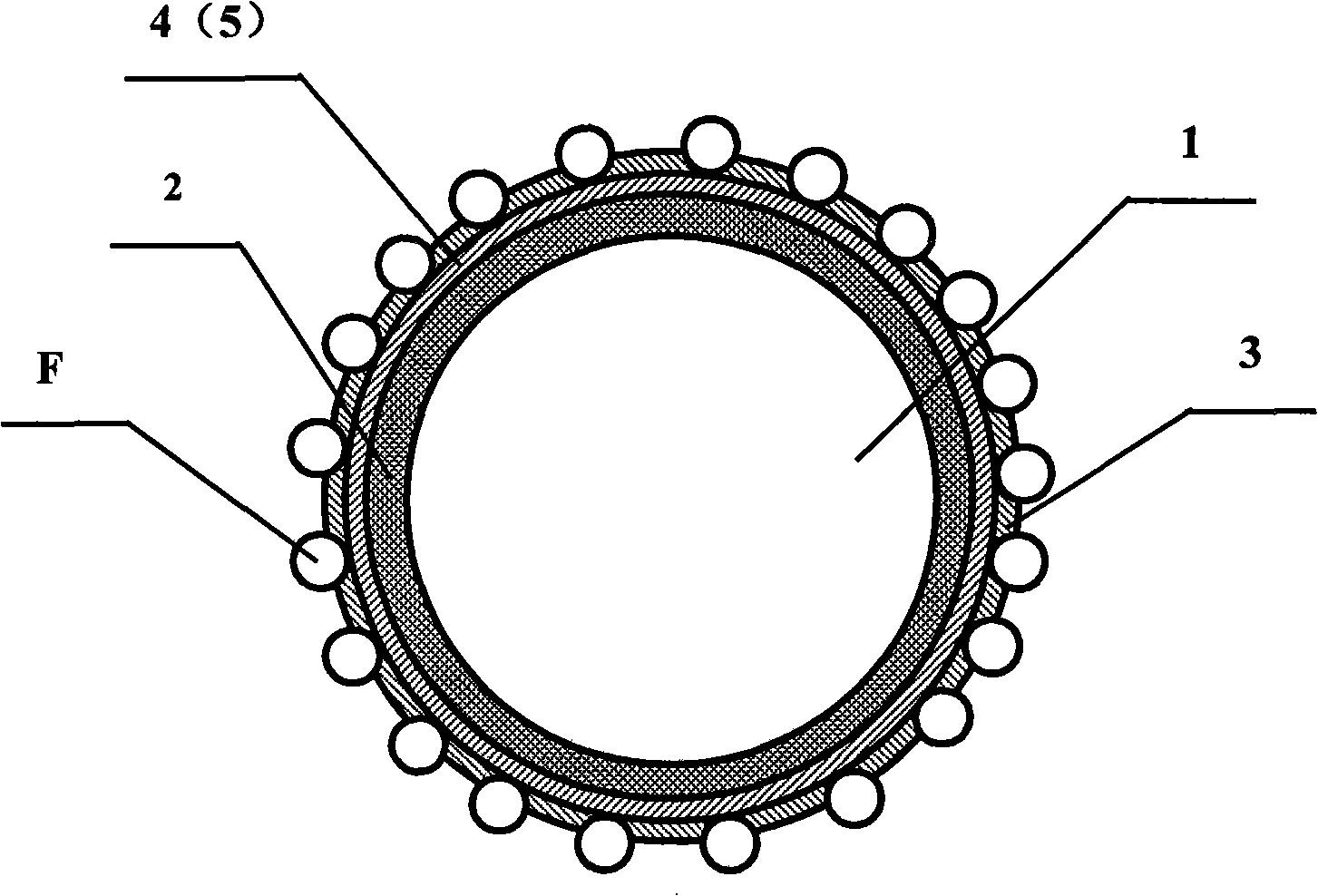

Environment friendly sulfur coating type sustained-release chemical fertilizer

InactiveCN101343204AGood impact resistanceNot easy to breakFertilizer mixturesFertilizerPolyvinyl alcohol

The invention discloses an environment-friendly sulfur-coated slow release fertilizer. The environment-friendly sulfur-coated slow release fertilizer is composed of a fertilizer core 1 and an outer envelope of the fertilizer core, the envelope comprises (a) a sulfur film layer 2, (b) a degradable polymer-organic polymer powder compound film layer 3, with or without (c) a degradable polymer film layer 4; wherein, the sulfur film layer is an inner layer or an intermediate layer of the whole envelope, the outer layer of the envelope is the degradable polymer-organic polymer powder compound film layer, and the external surface of the envelope is a rugged surface with raised organic polymer powder. The degradable polymer can be one or more of amido resin, polyvinyl alcohol and acetal resin of copolymer, unsaturated oil resin, biodegradation type polyester and natural polymer as well as derivates. The organic polymer powder is one or more of plant powder, animal powder and synthetic polymer powder. The sulfur-coated slow release fertilizer has advantages of stable release period and non pollution or low pollution to the environment of the enveloped body.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com