Patents

Literature

762results about How to "Good heat dissipation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

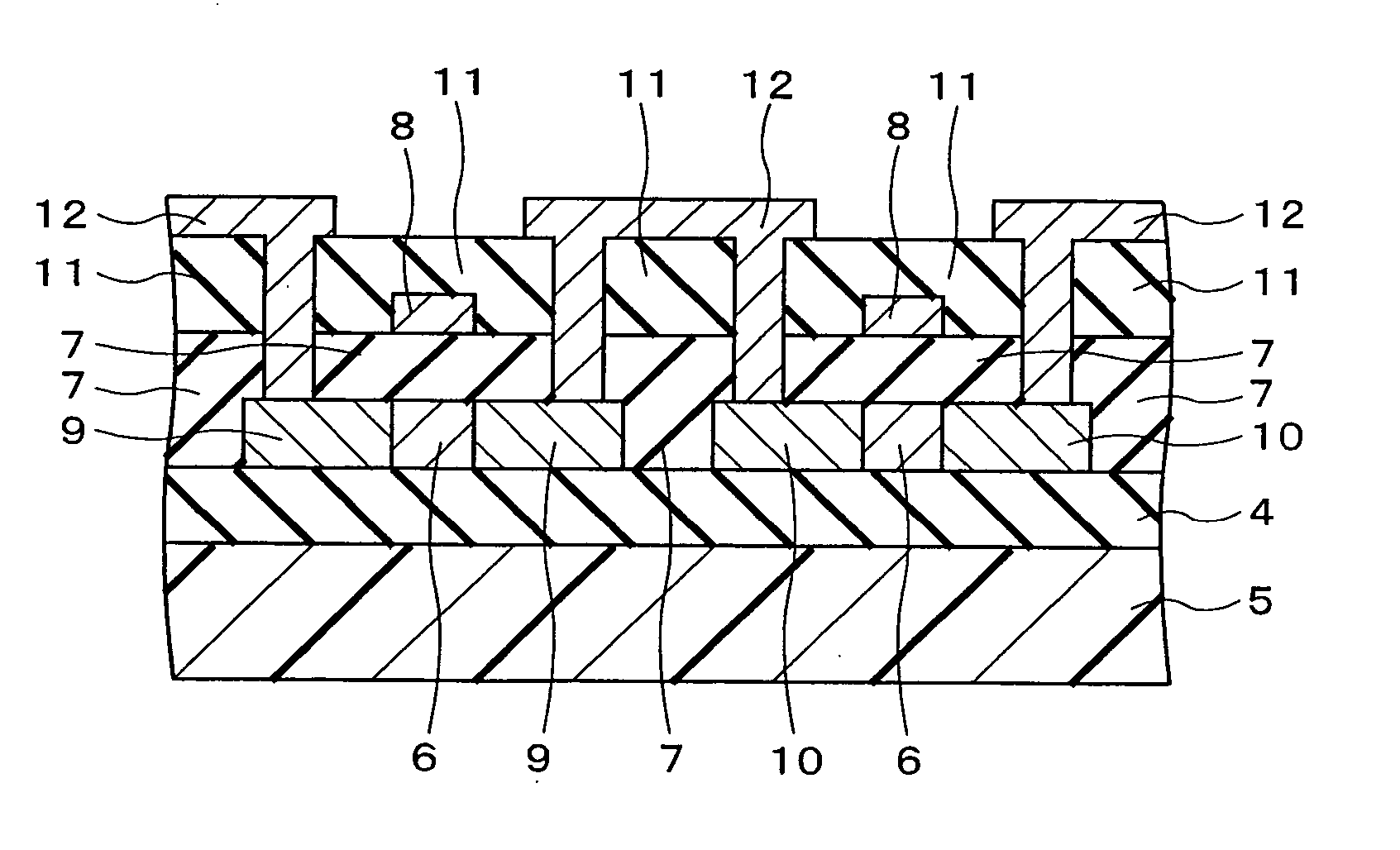

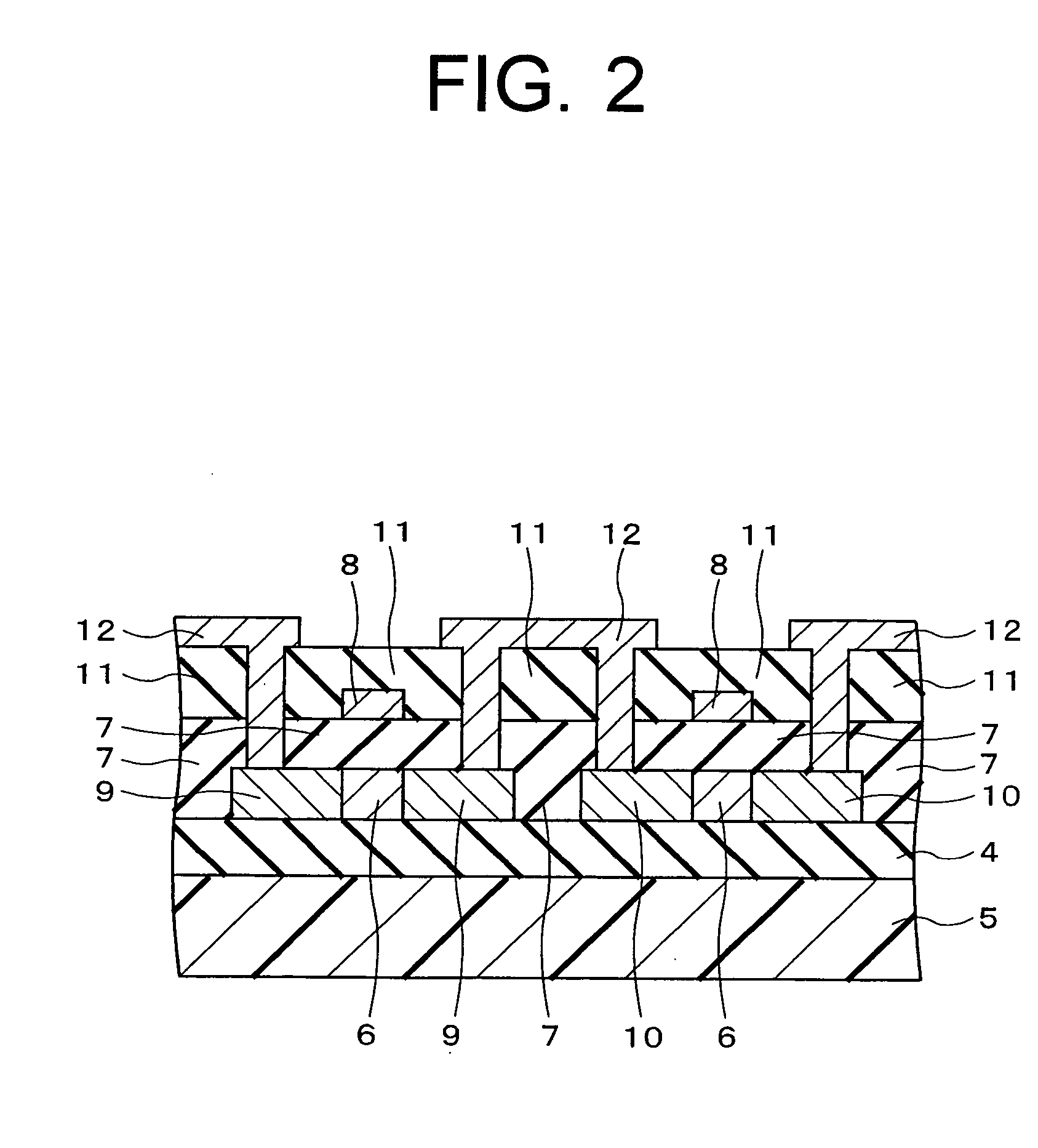

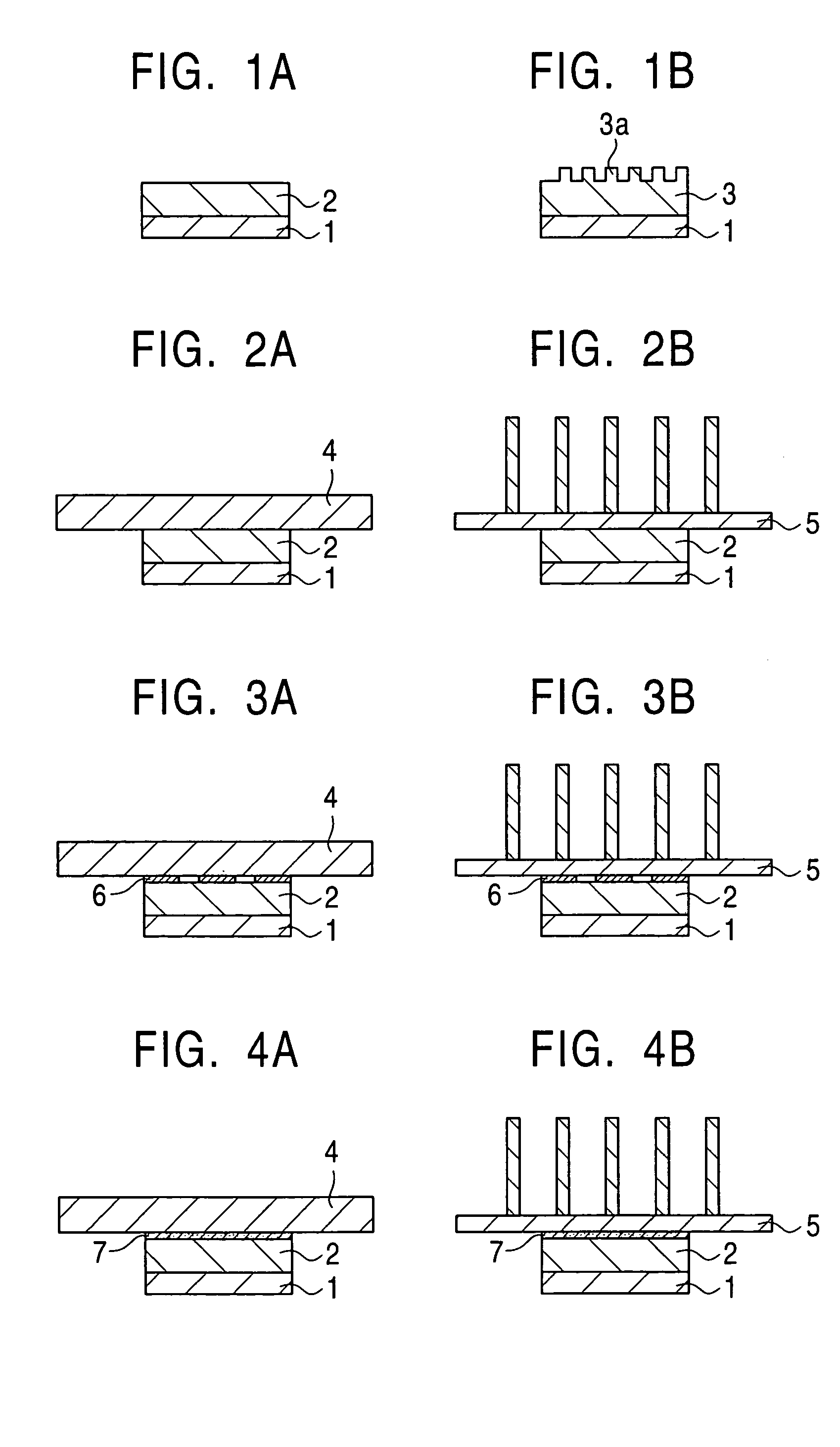

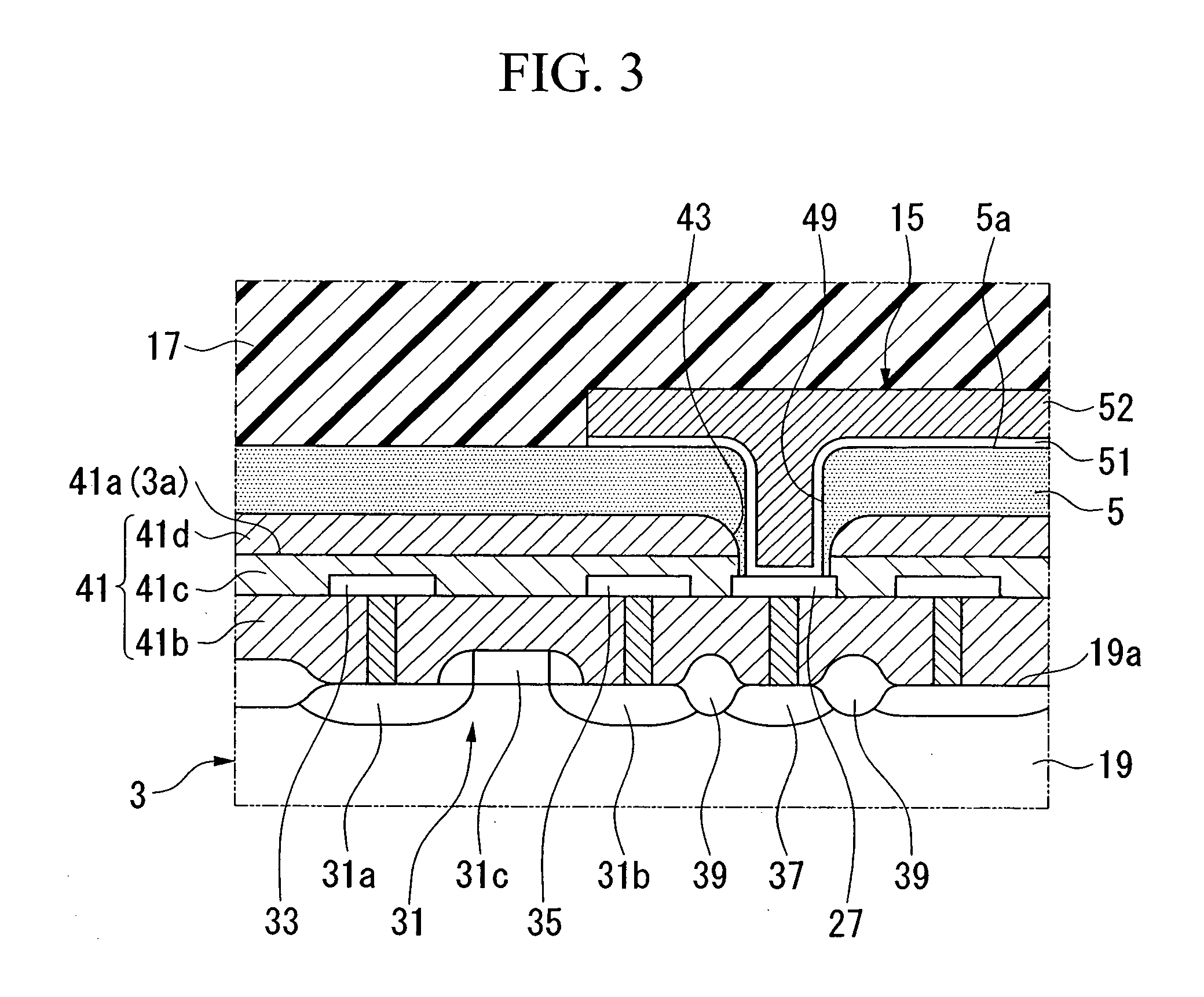

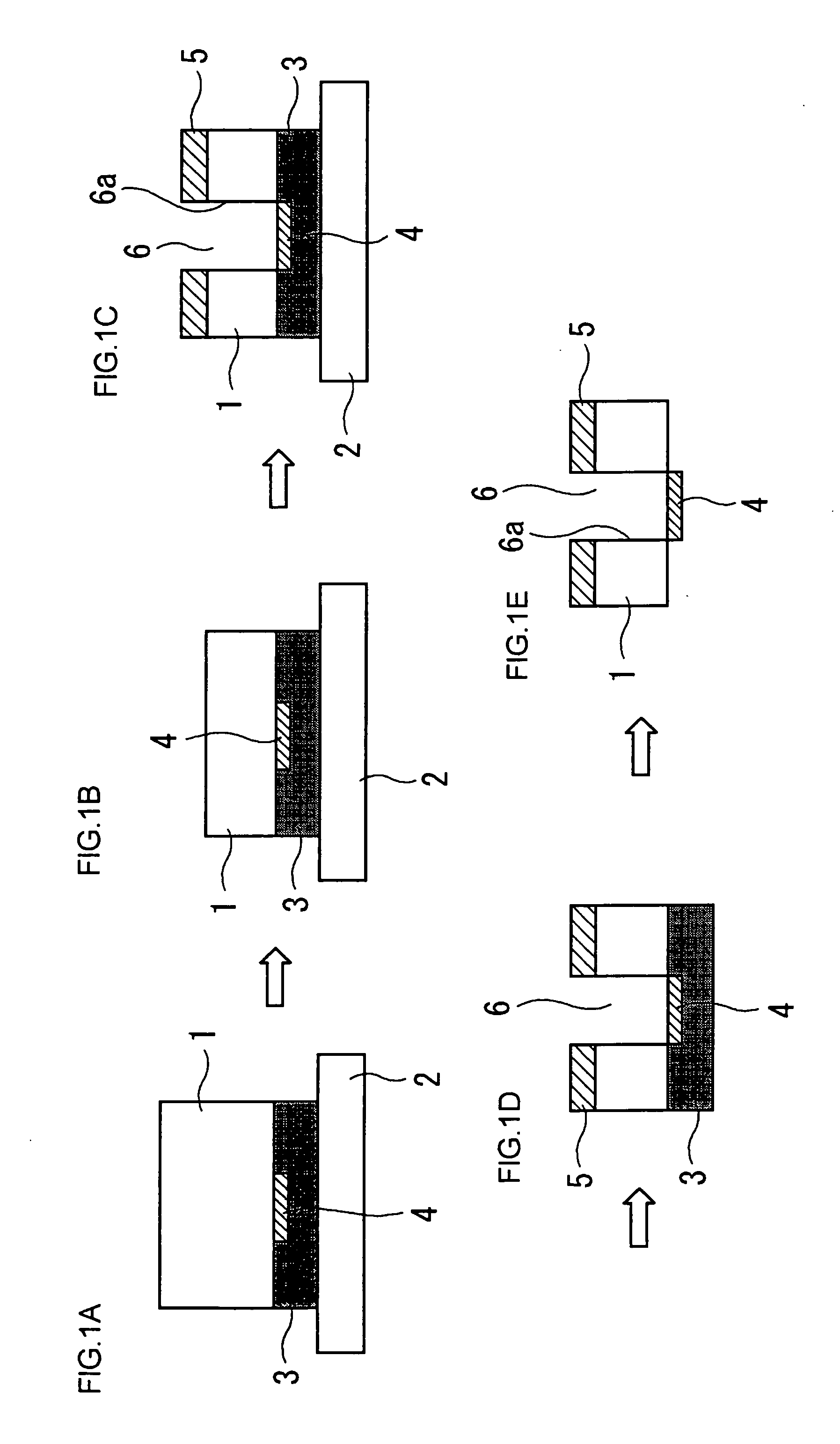

Semiconductor device

InactiveUS20050236623A1Well mixedGood heat dissipationTransistorSolid-state devicesDevice materialEngineering

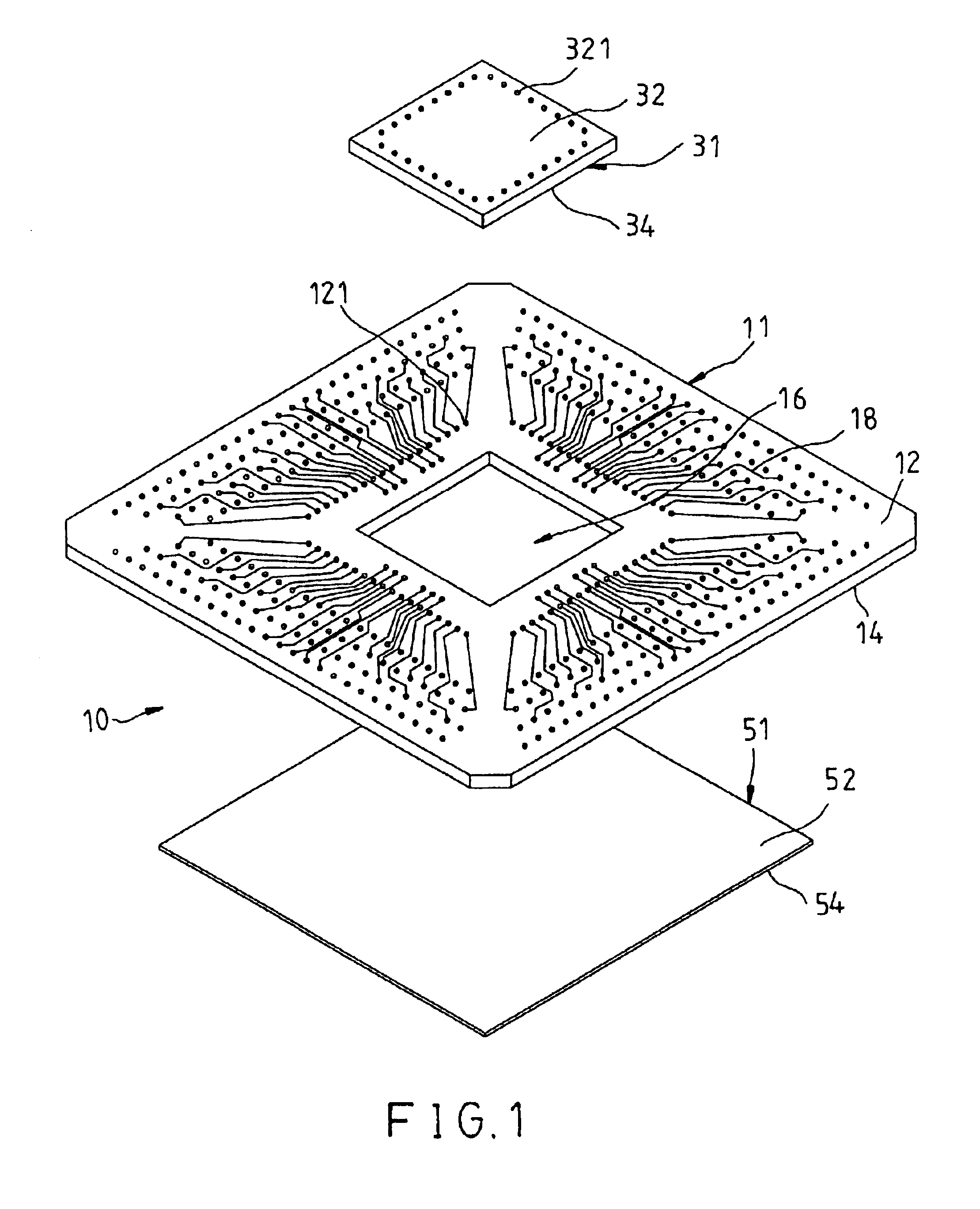

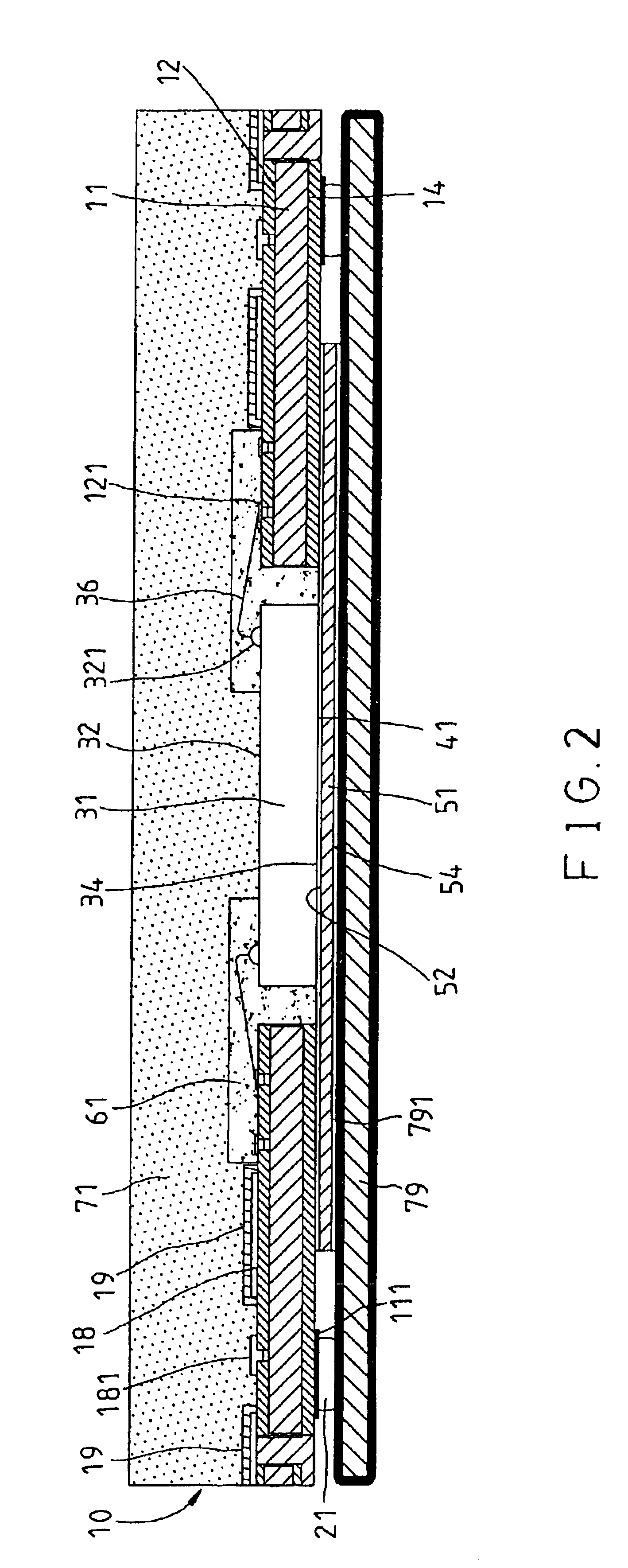

An integrated circuit is formed on a flexible substrate by using an amorphous semiconductor thin film, or a polycrystalline or a monocrystalline semiconductor thin film crystallized by laser annealing. A plurality of such flexible integrated circuit boards and mounted on a separate support substrate. This can enhance the mechanical strength of devices, such as an IC card and a liquid crystal display, and allow those devices to be manufactured at a low cost. It is also possible to provide a semiconductor device with a higher performance, on which a flexible integrated circuit board and an IC chip made from a silicon and / or glass wafer. Adhering a film substrate having a high thermal conductivity, such as a metal, to the bottom side of the flexible integrated circuit board improves the heat discharging characteristic of the integrated circuit and suppress the problem of self-heating.

Owner:NEC CORP

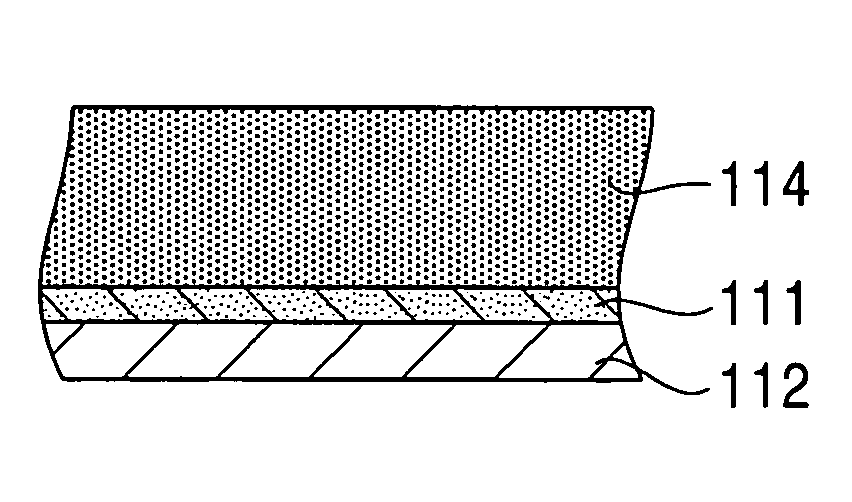

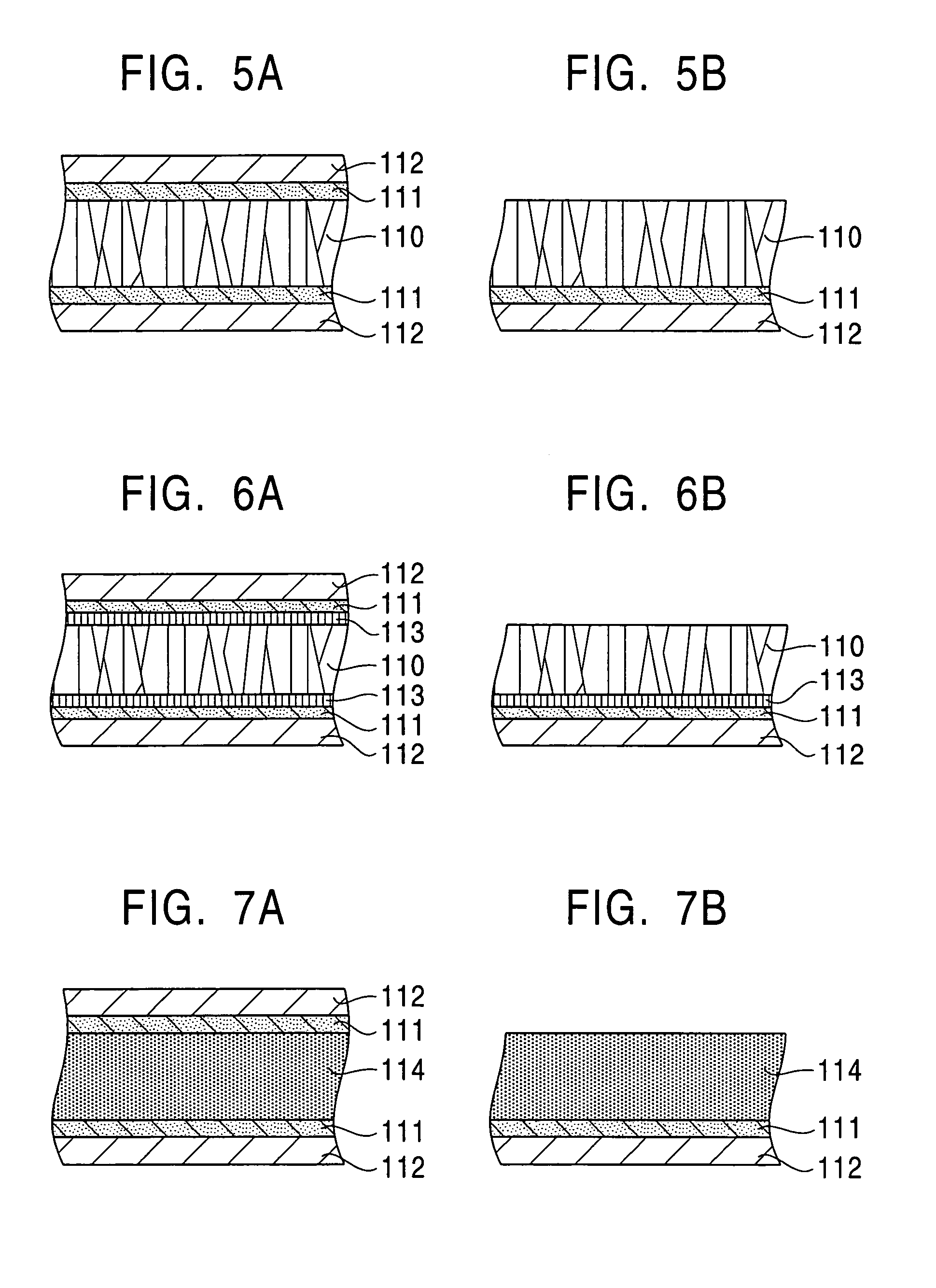

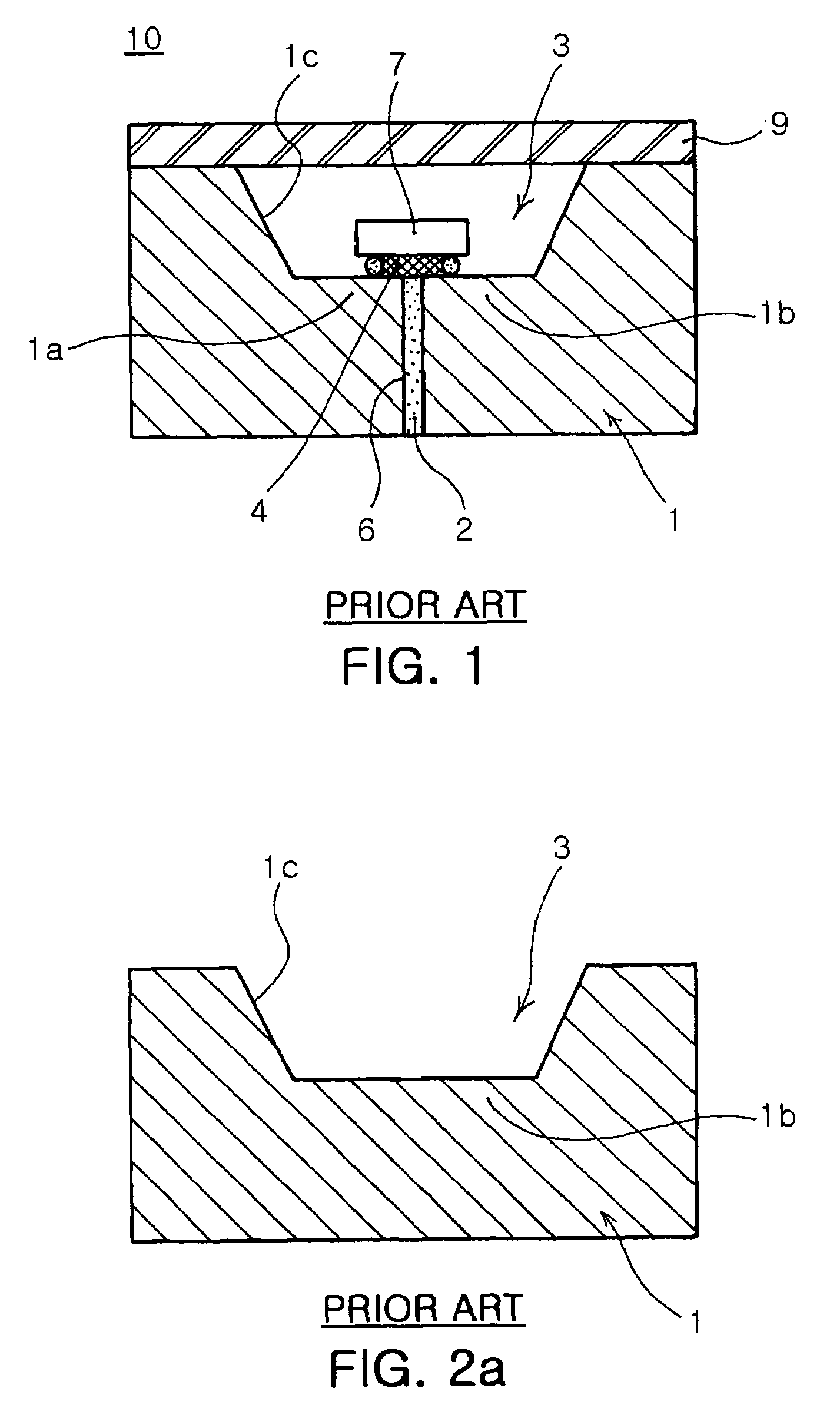

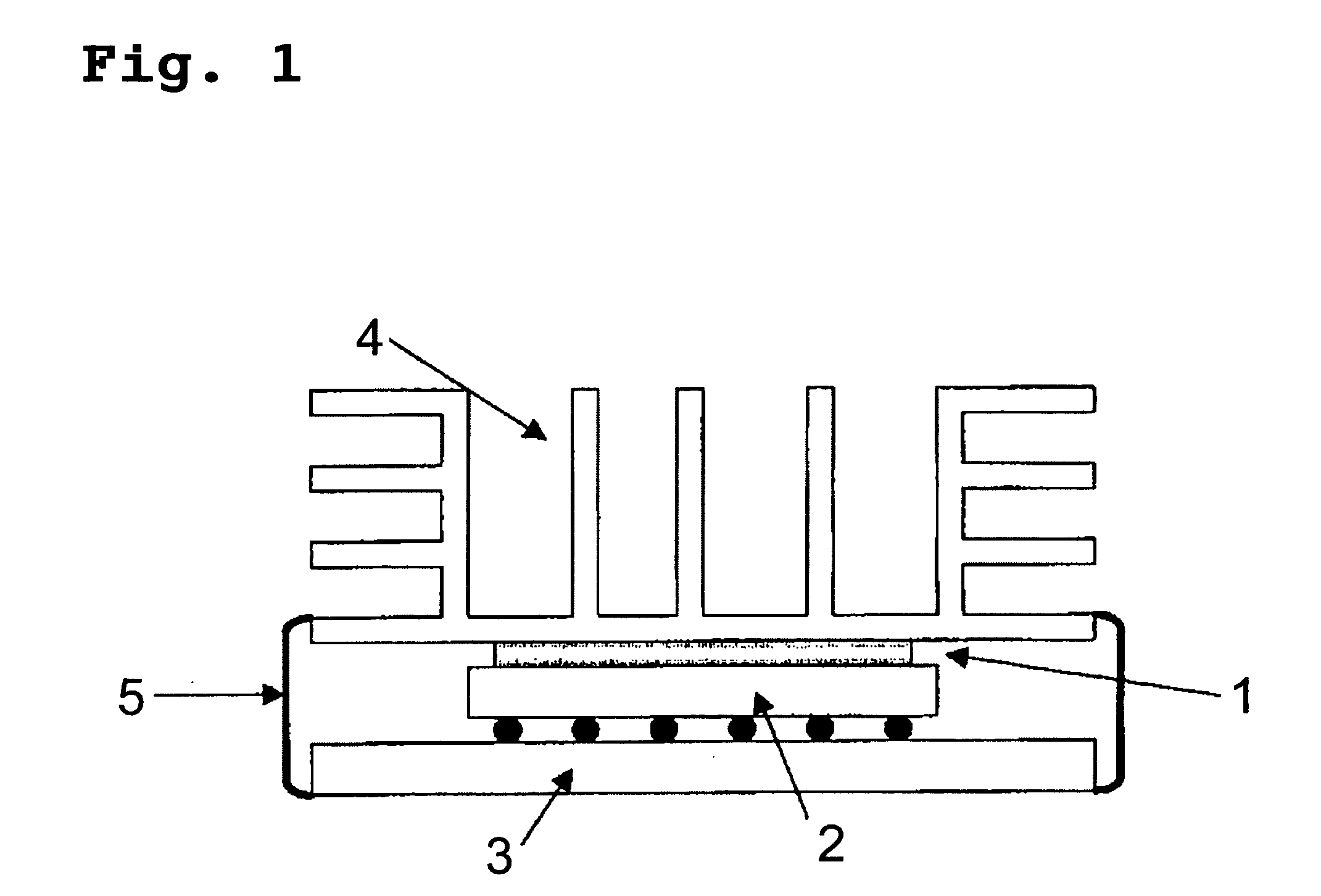

Heat spreader and semiconductor device and package using the same

InactiveUS7067903B2Improve thermal conductivityLarge thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesPolymer adhesiveCeramic

A semiconductor device and package has a heat spreader directly disposed on the reverse surface of the semiconductor device. This heat spreader includes a diamond layer or a layer containing diamond and ceramics such as silicon carbide and aluminum nitride. The heat spreader is directly formed on a substrate for the semiconductor device. In particular, the heat spreader is composed of a diamond layer and one or two metal or ceramic members, which are bonded to the diamond layer with one or two polymer adhesive layers. This diamond layer has a fiber structure across the thickness or a microcrystalline structure. Cilia are formed on a surface of the diamond layer facing the one or two metal or ceramic members.

Owner:KOBE STEEL LTD

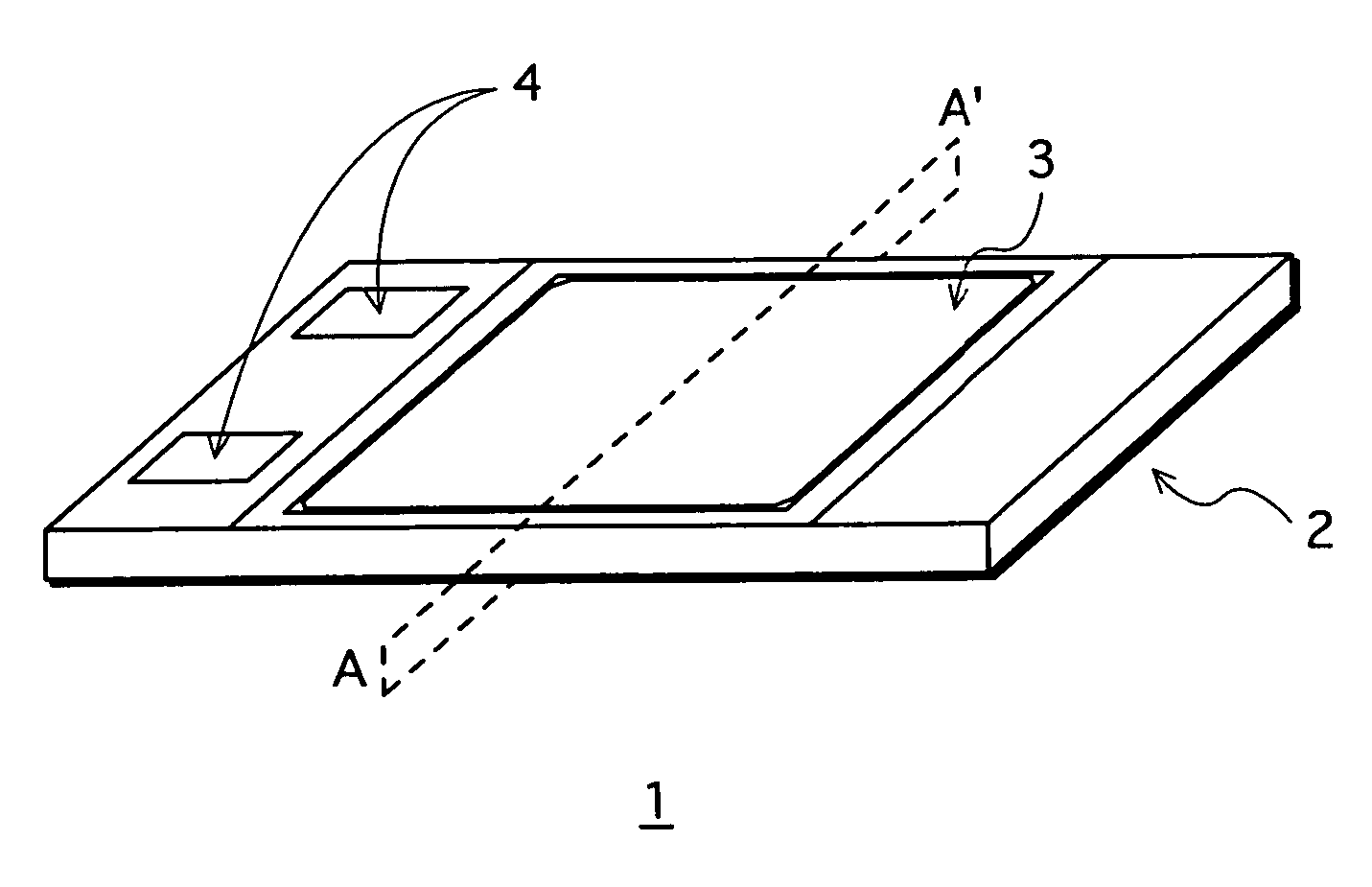

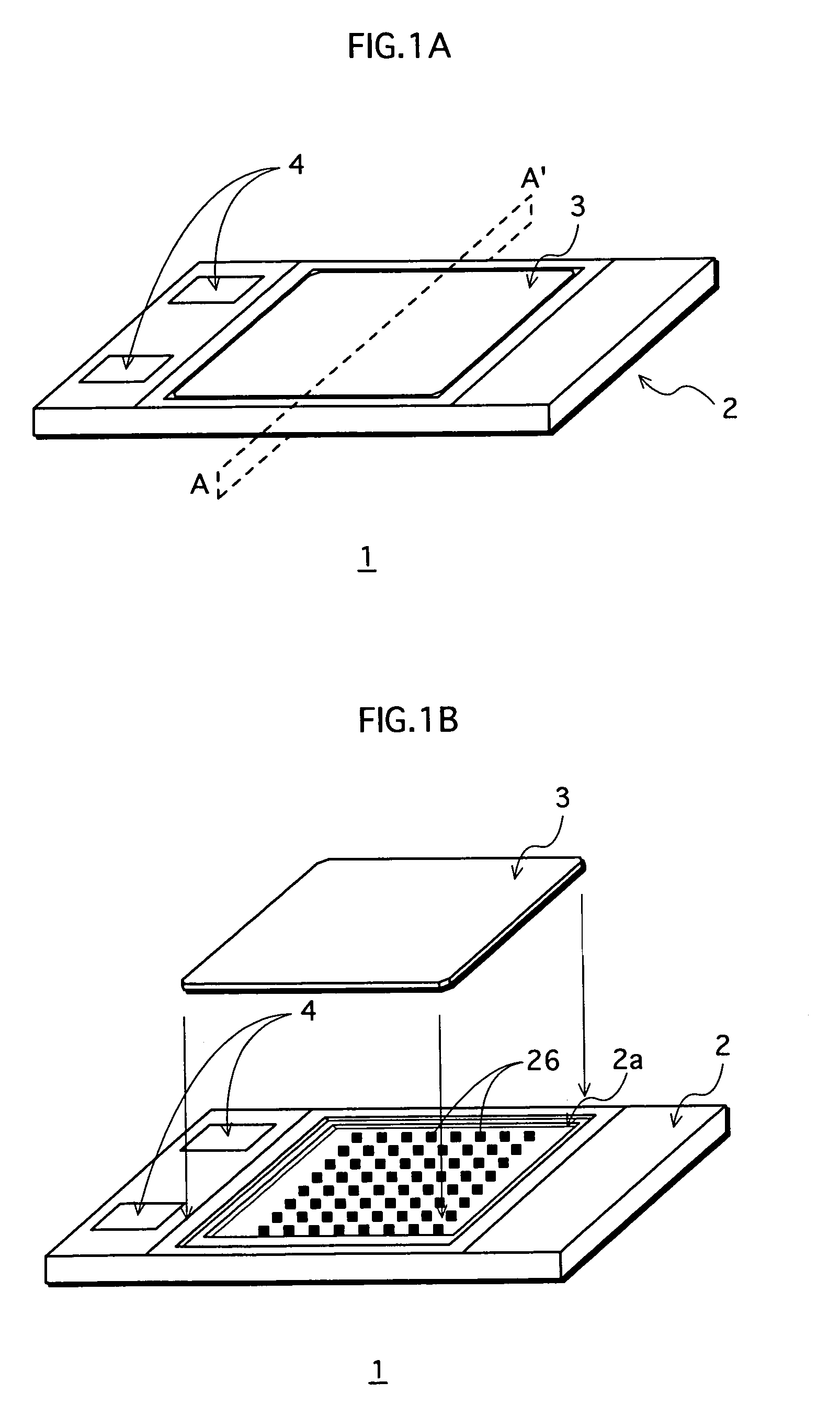

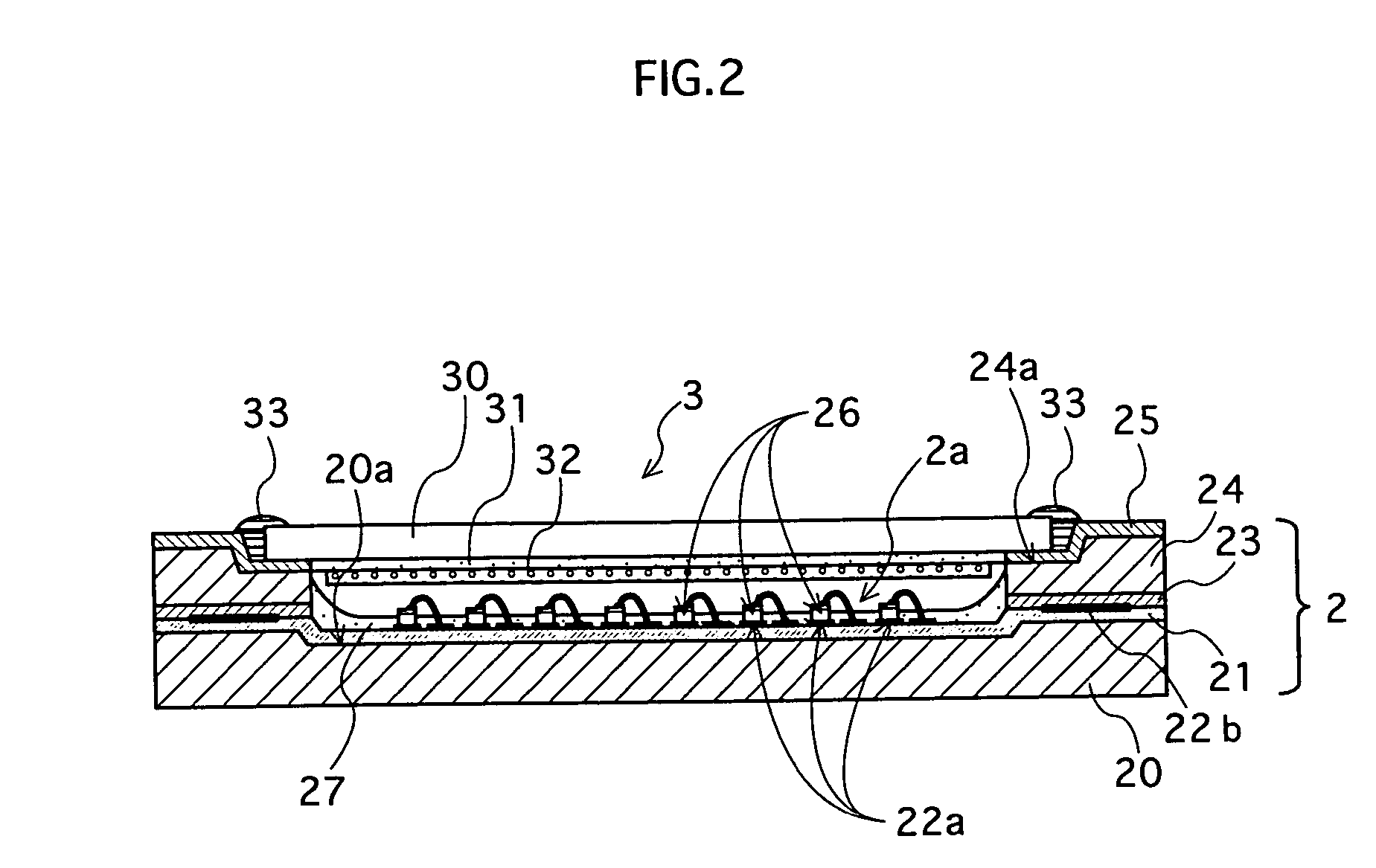

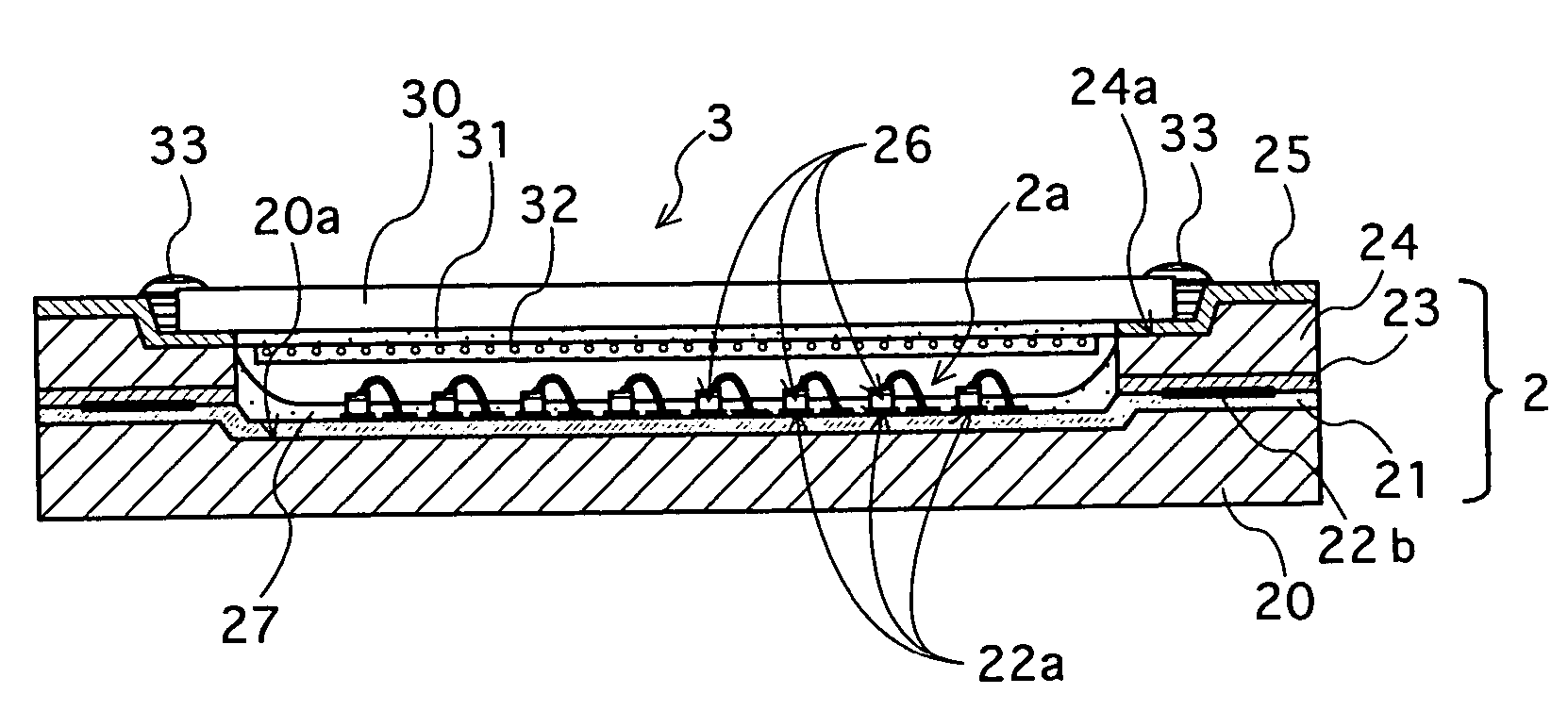

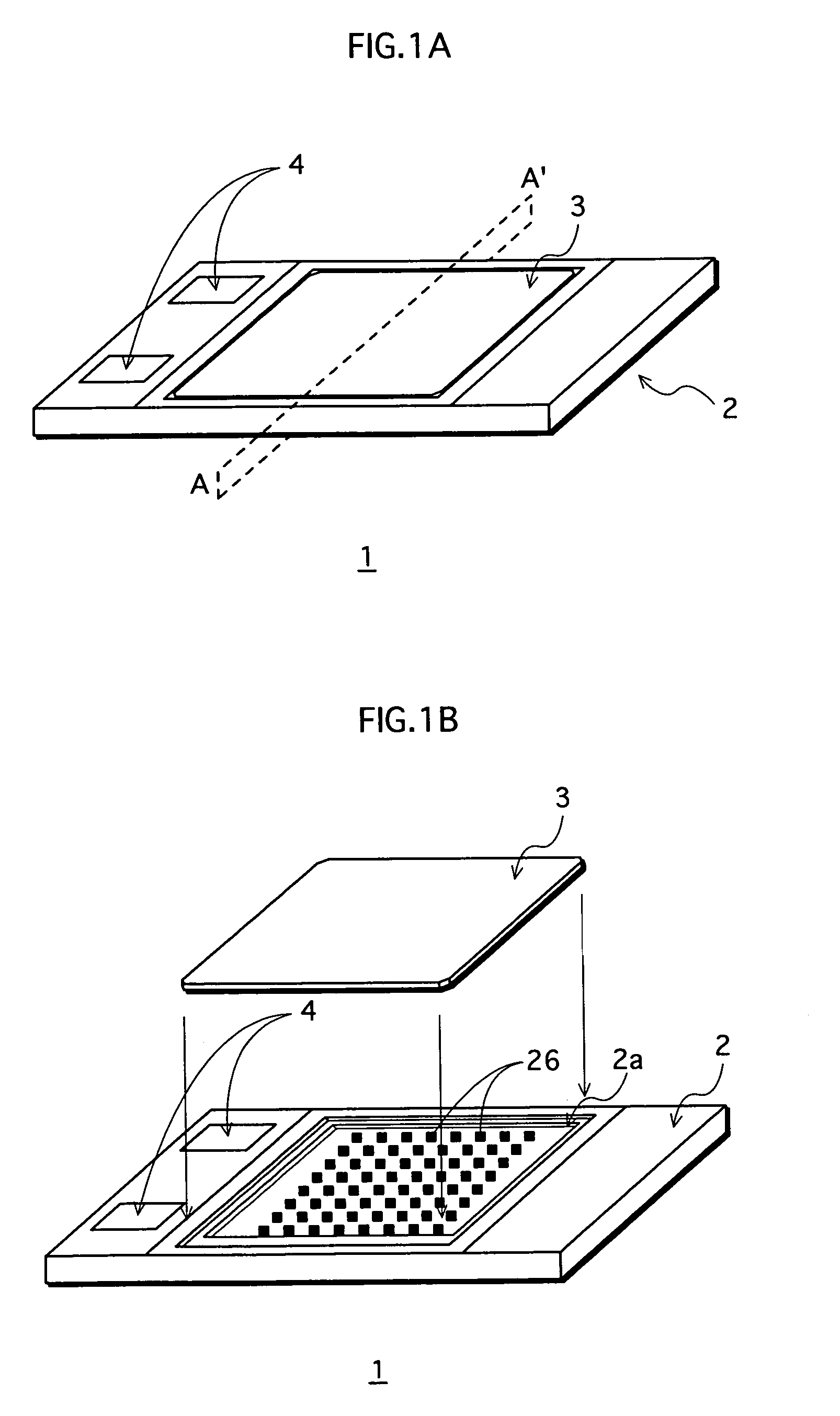

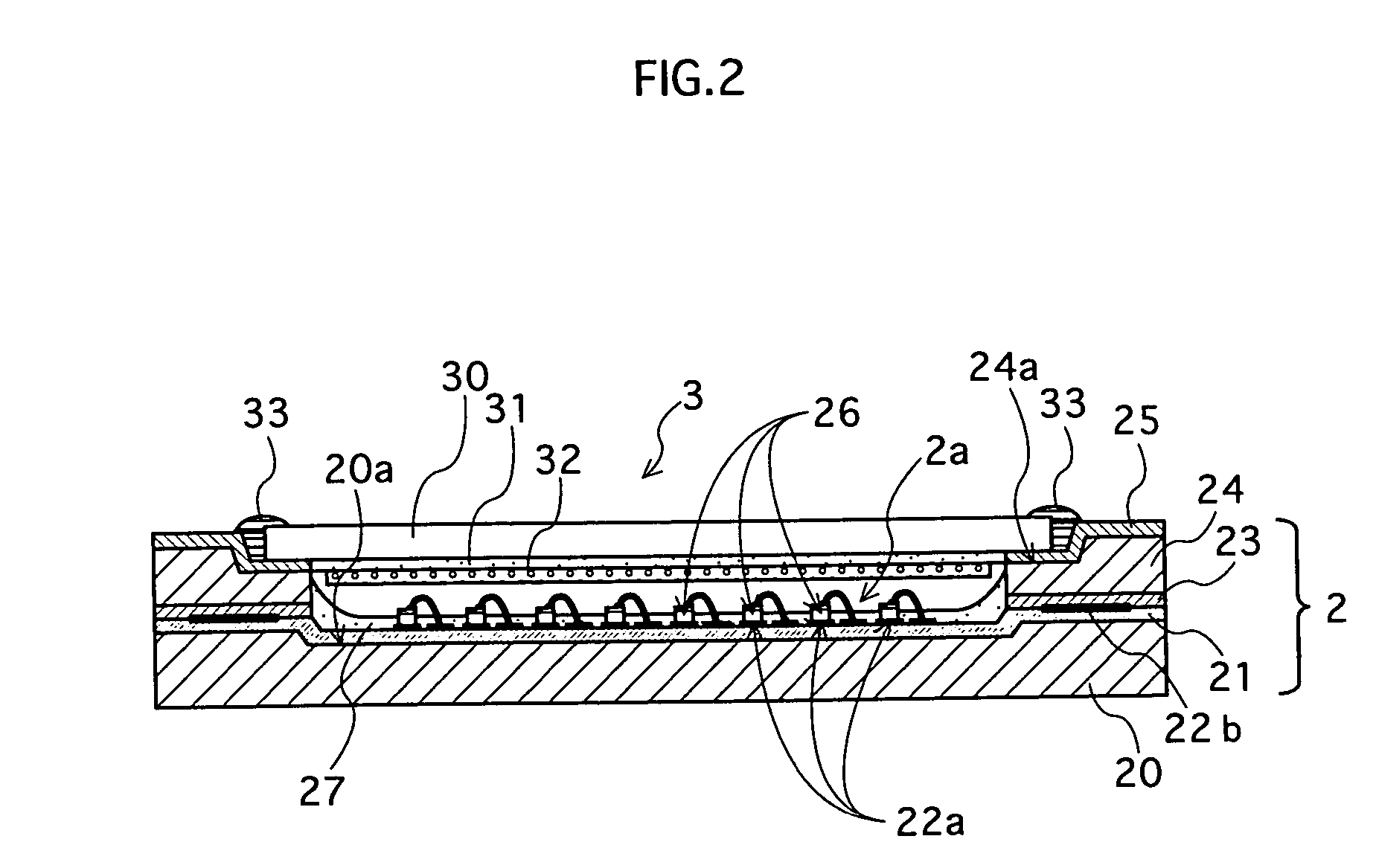

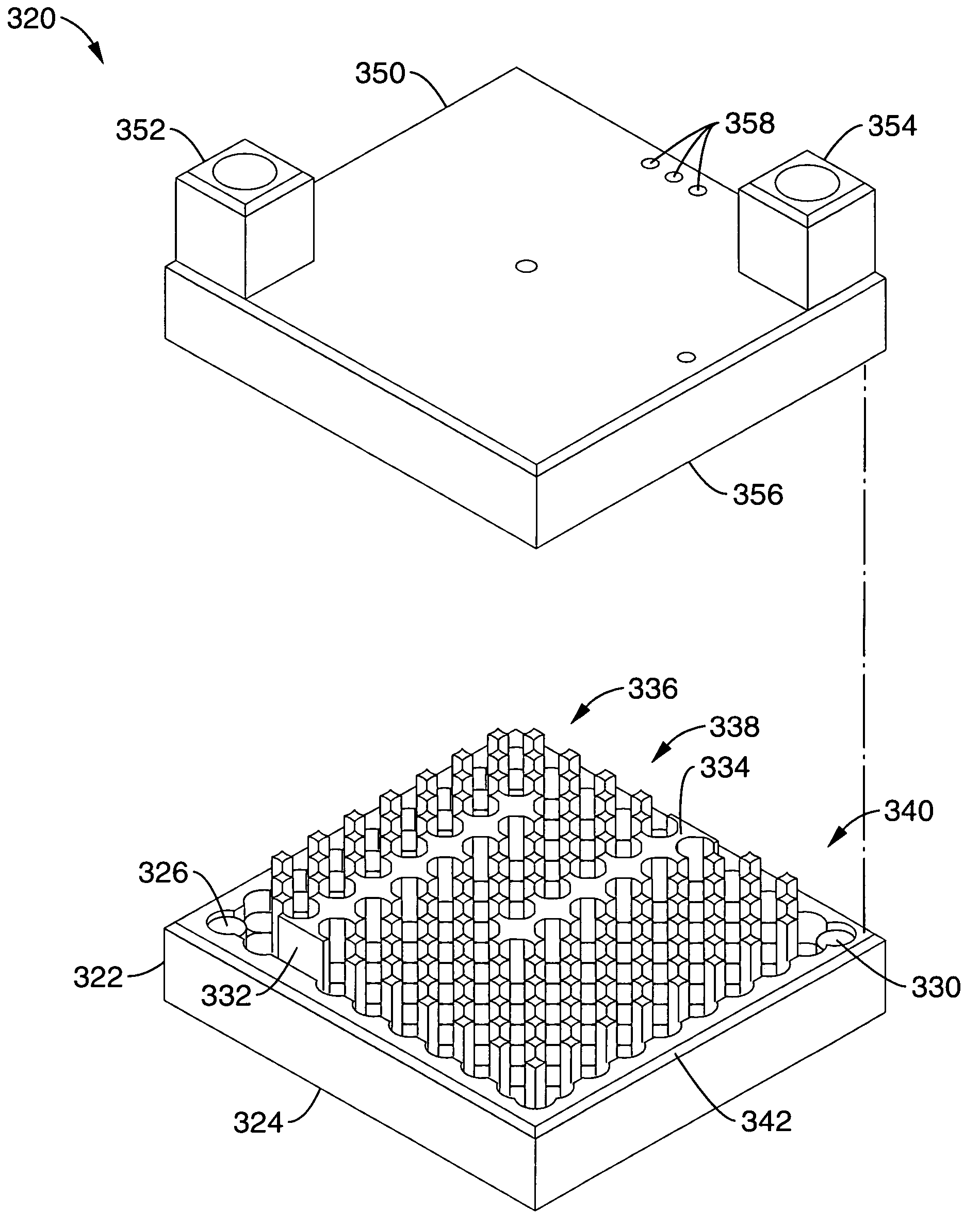

Light emission apparatus

ActiveUS20040129946A1Reduce the amount requiredDeterioration can be suppressedPlanar light sourcesLaser detailsFluorescencePhosphor

A light emission apparatus that can restrict deterioration of resin used for the light emission apparatus, and that has a reasonable structure fit for actual use is provided, in which a light reflective layer is provided to cover the side surfaces of the chips 26 provided in the concave 2a. According to this, excitation light reflected by the phosphor layer 32, such as ultraviolet light, is reflected again by the light reflective layer 27. Therefore, the excitation light will not reach the resin layer 21, thereby restraining the deterioration of the resin. Moreover, the light reflective layer 27 covers the side surfaces of the chips 26, thereby efficiently conducting the heat emitted from the chips 26 to the metal substrate 20 via the resin layer 21. This improves the heat-dissipation efficiency of the chips 26.

Owner:SIGNIFY HLDG BV

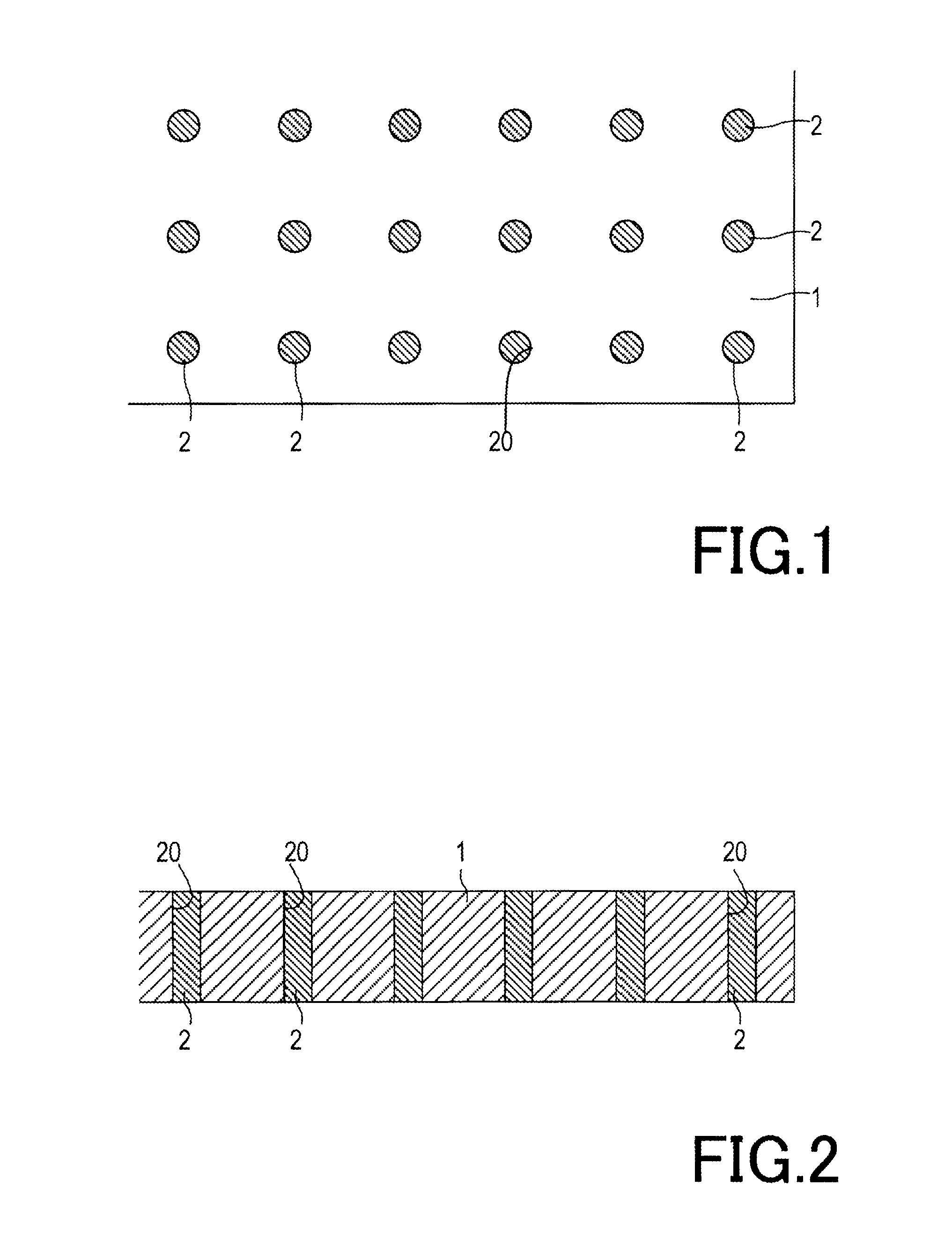

Substrate for electronic device and electronic device

ActiveUS20120168206A1Good heat dissipationSemiconductor/solid-state device detailsPrinted electric component incorporationCarbon nanotubeOptoelectronics

A substrate includes a plurality of through electrodes. The through electrode has a nanocomposite structure including a nm-sized carbon nanotube and is a casting formed by using a via formed in the substrate as a mold.

Owner:NAPRA

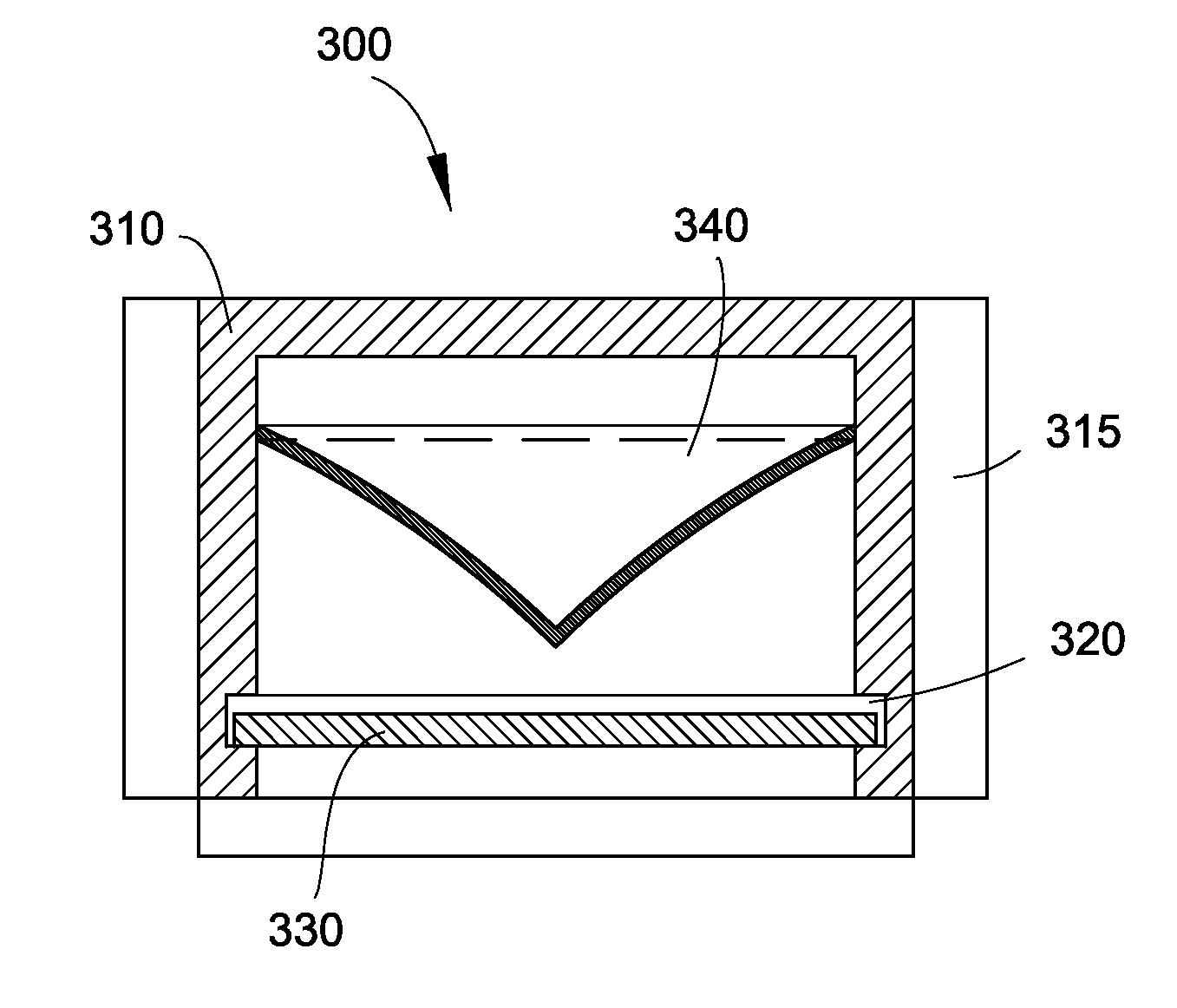

Luminescent device

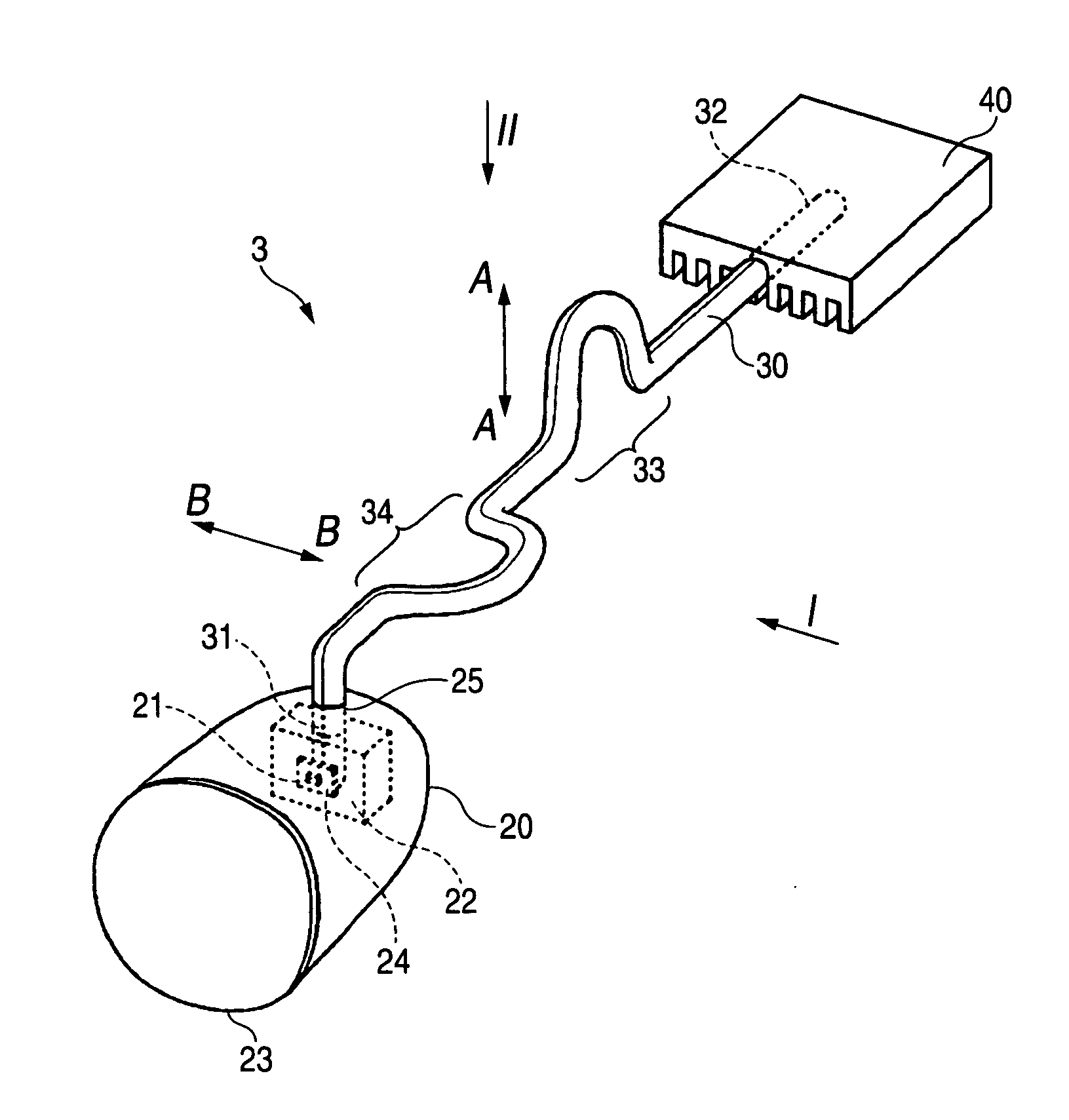

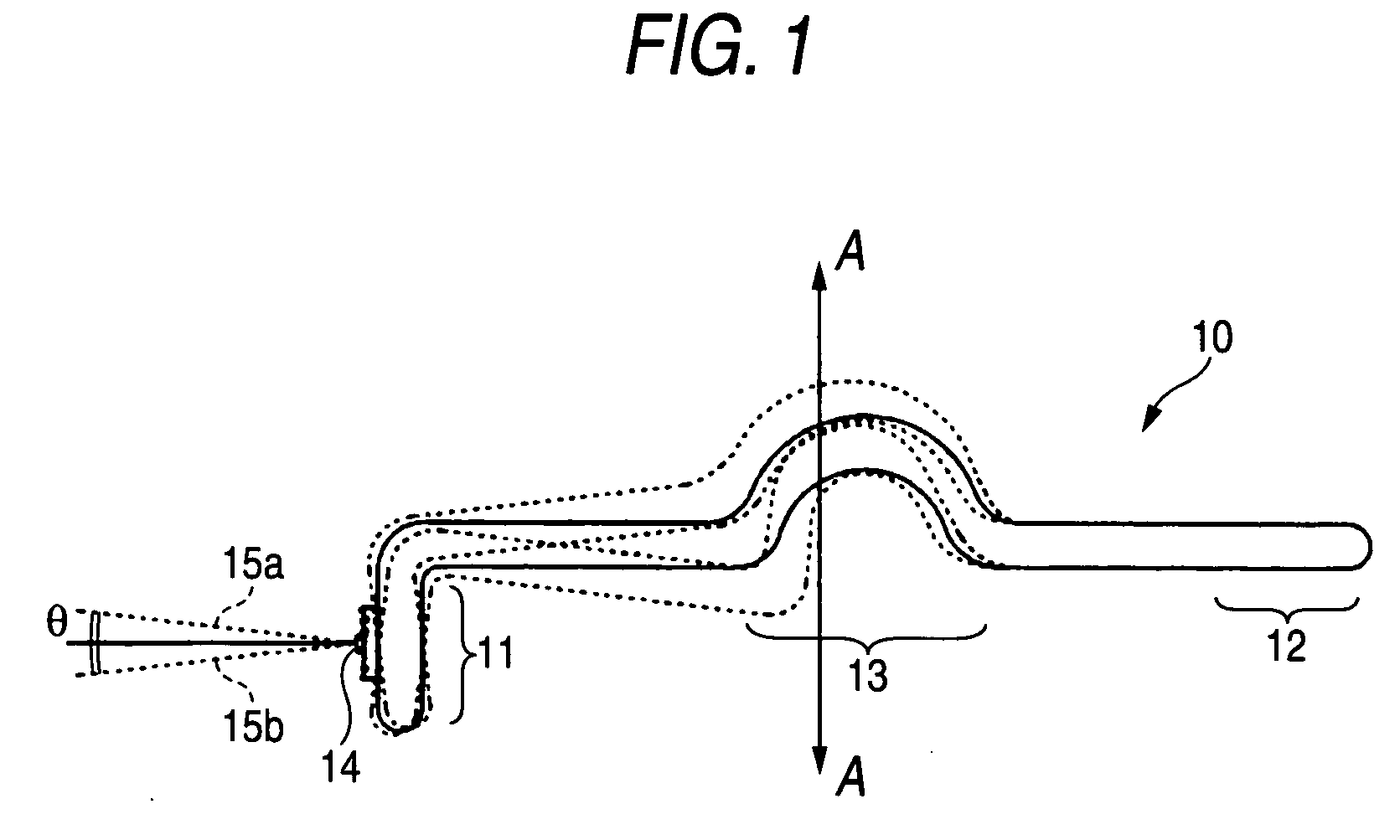

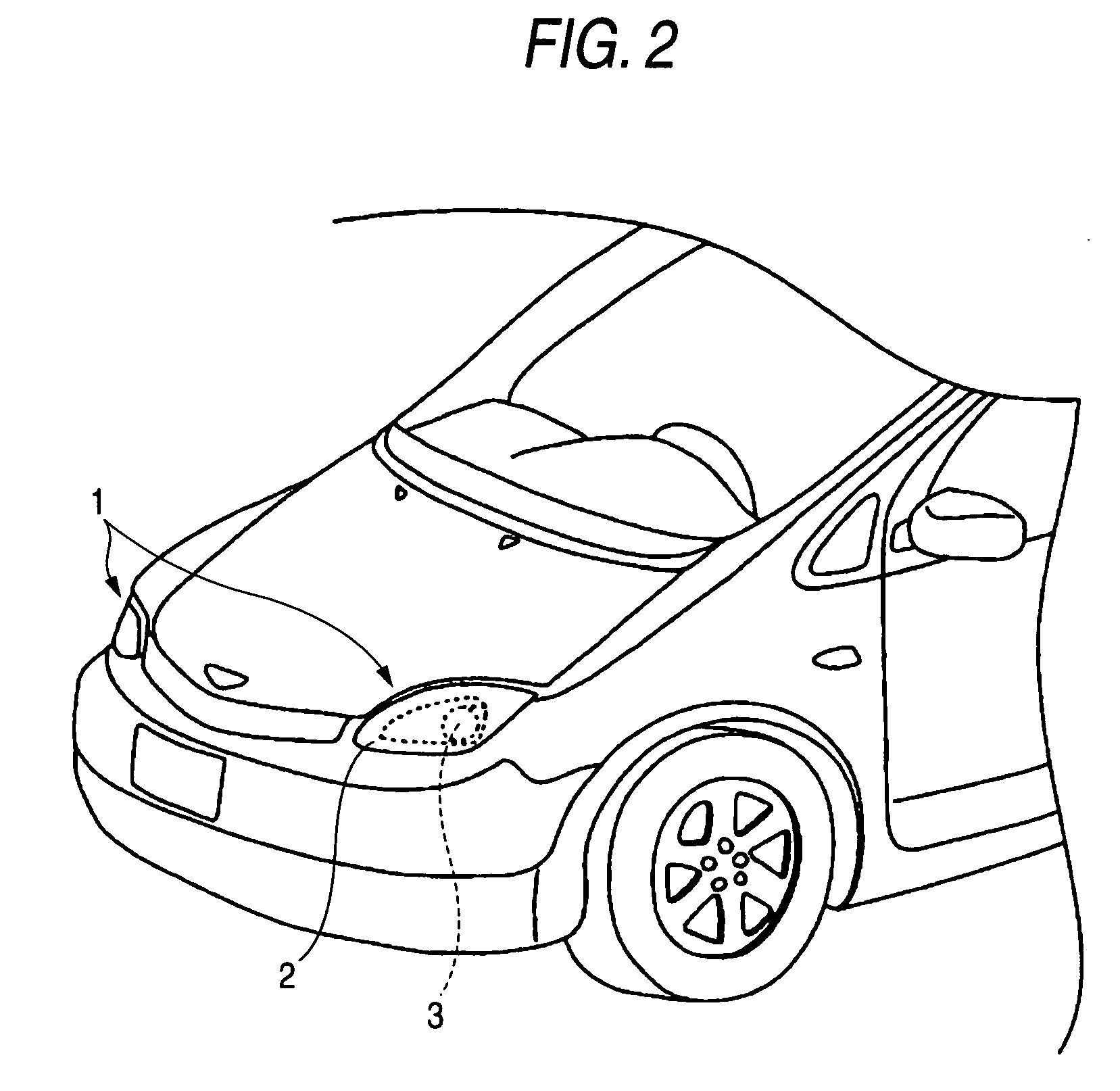

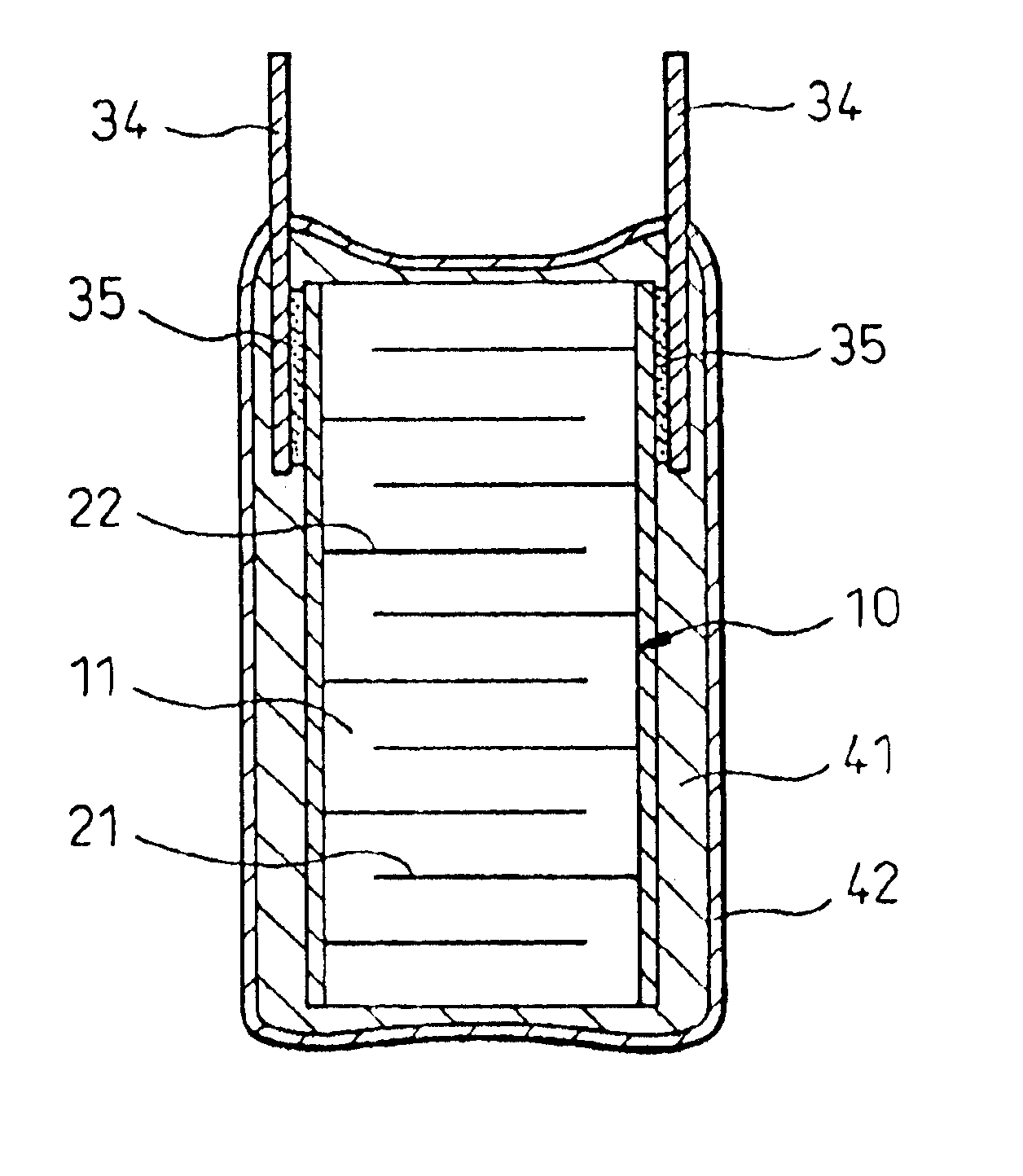

InactiveUS20080247177A1Efficient disseminationLarge heat capacityVehicle headlampsPoint-like light sourceOptical axisEngineering

A luminescent device includes: a light source; a housing for accommodating the light source, a heat discharging member including a heat transfer portion and a heat dissipation portion and passed through the housing, the heat transfer portion being mounted on the light source and the heat dissipation portion being located outside the housing; a seal portion for sealing a gap between the heat discharging member and the housing; and optical axis adjusting device for adjusting an optical axis of the light source, wherein the heat transfer portion or the seal portion is deformed so as to follow an angular change of the optical axis of the light source by the optical axis adjusting device.

Owner:TOYODA GOSEI CO LTD

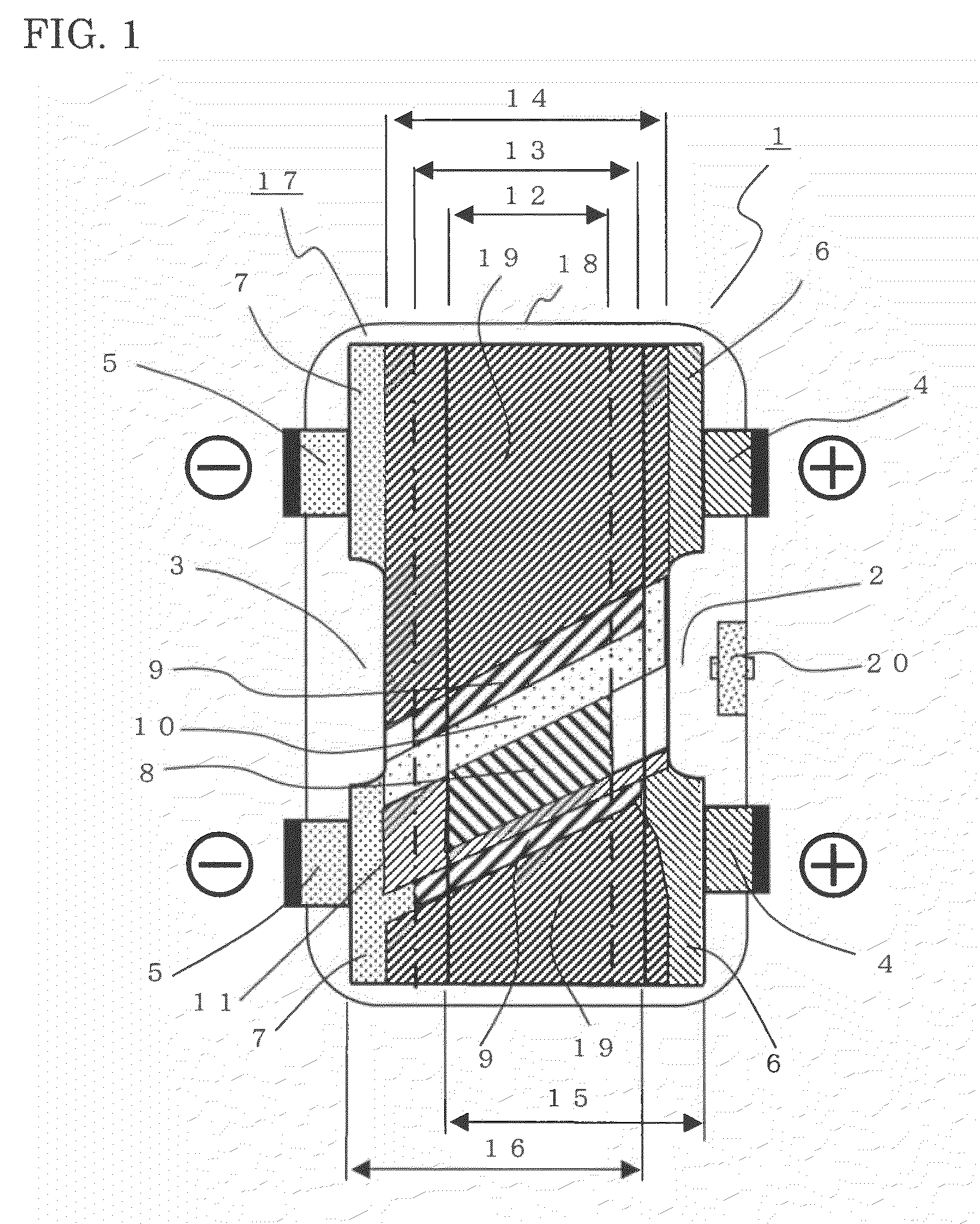

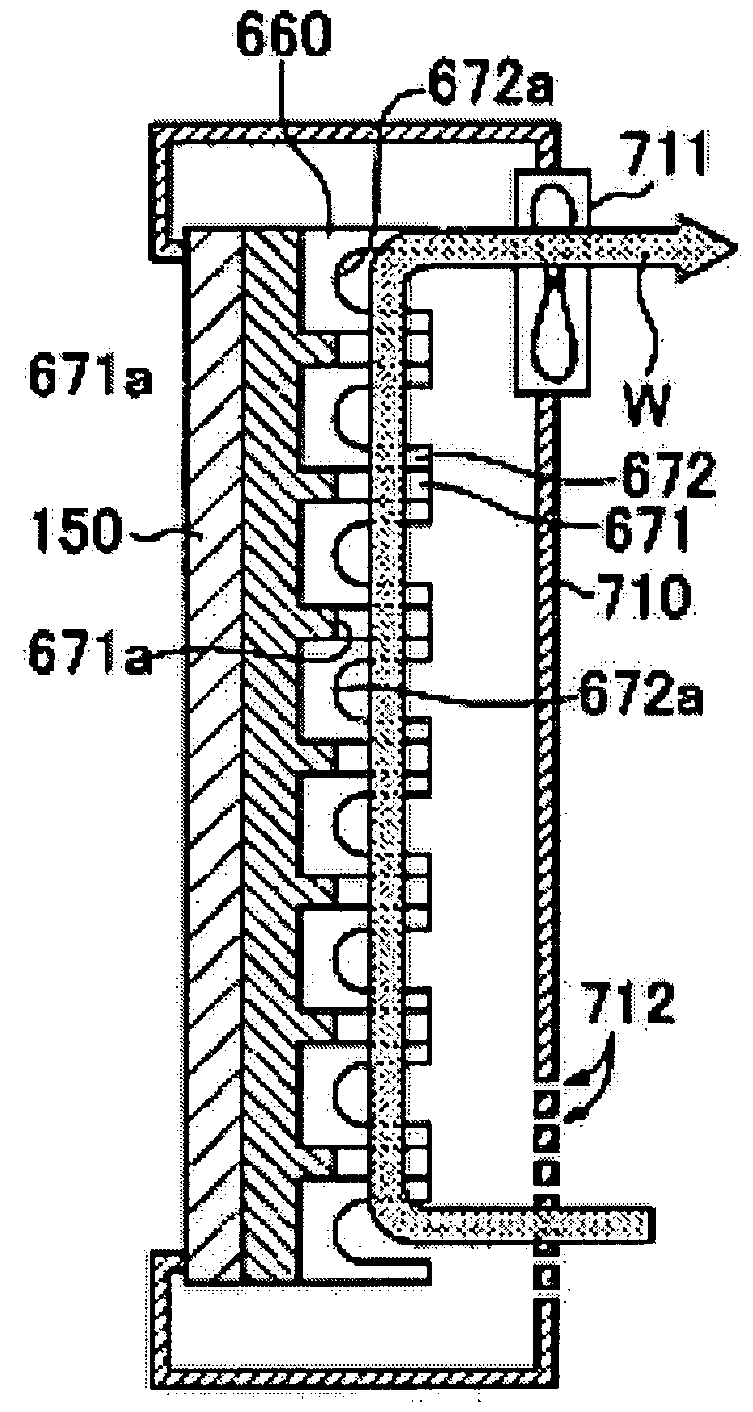

Piezoelectric element and injector using the same

InactiveUS6845920B2Good heat dissipationHighly compactPiezoelectric/electrostriction/magnetostriction machinesMovable spraying apparatusHigh humidityInorganic materials

Owner:DENSO CORP

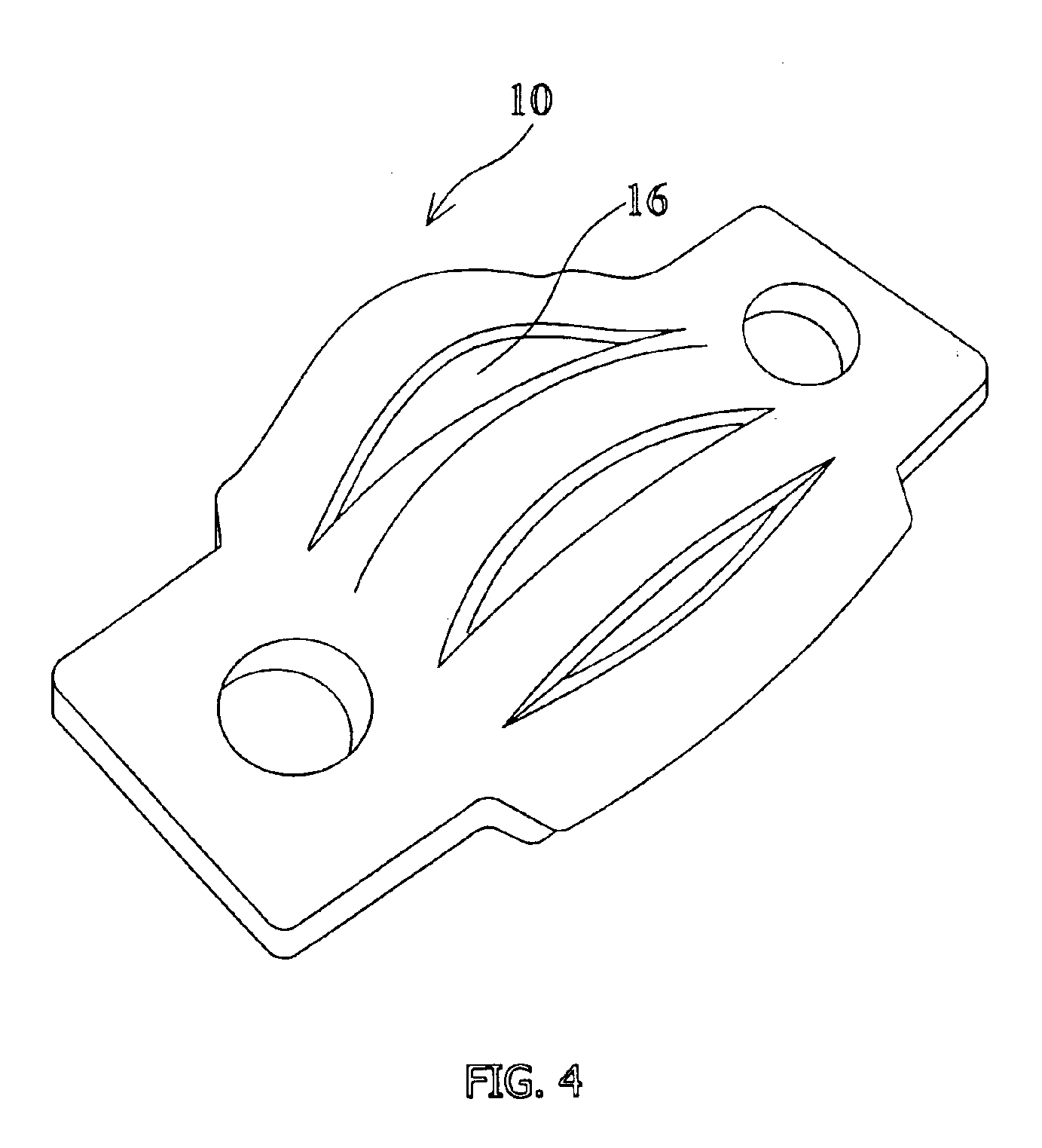

Combined electrical connector and radiator for high current applications

InactiveUS6929504B2Slow down buildingImprove heat dissipation characteristicsCoupling contact membersCell component detailsPower unitElectric vehicle

An electrical connector useful for both high-current and low-current applications including a first and a second conductive terminals, in which the terminals are interconnected by a plurality of substantially rigid and elongated conductive strips and apertures or gaps are disposed between at least some of the adjacent conductive strips. The connector provides enhanced heat dissipation characteristics and is particularly useful for high current applications such as for connecting batteries, accumulators, super-capacitors and the like storage power units for electric vehicle and other applications.

Owner:SYLVA INDS

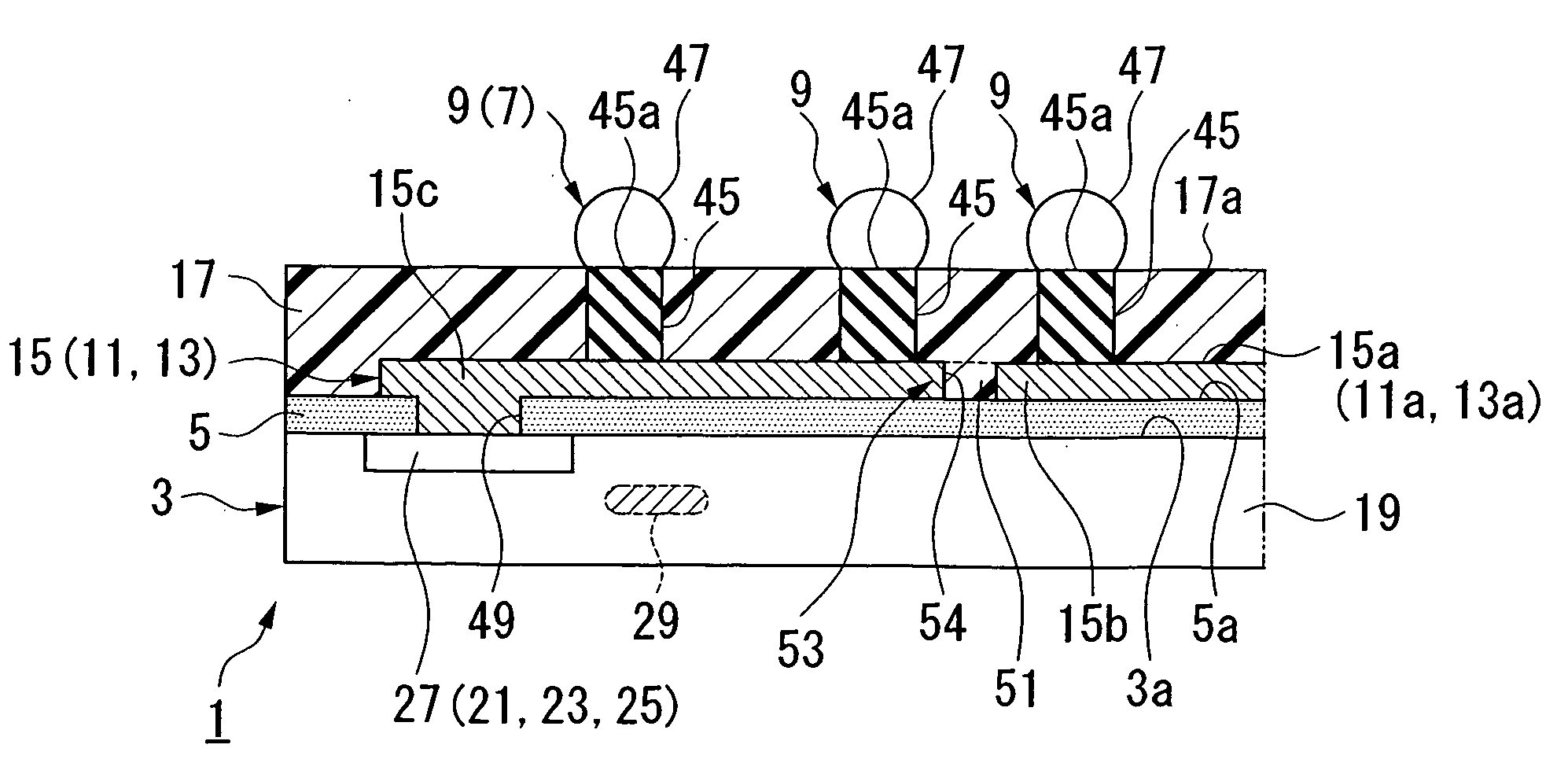

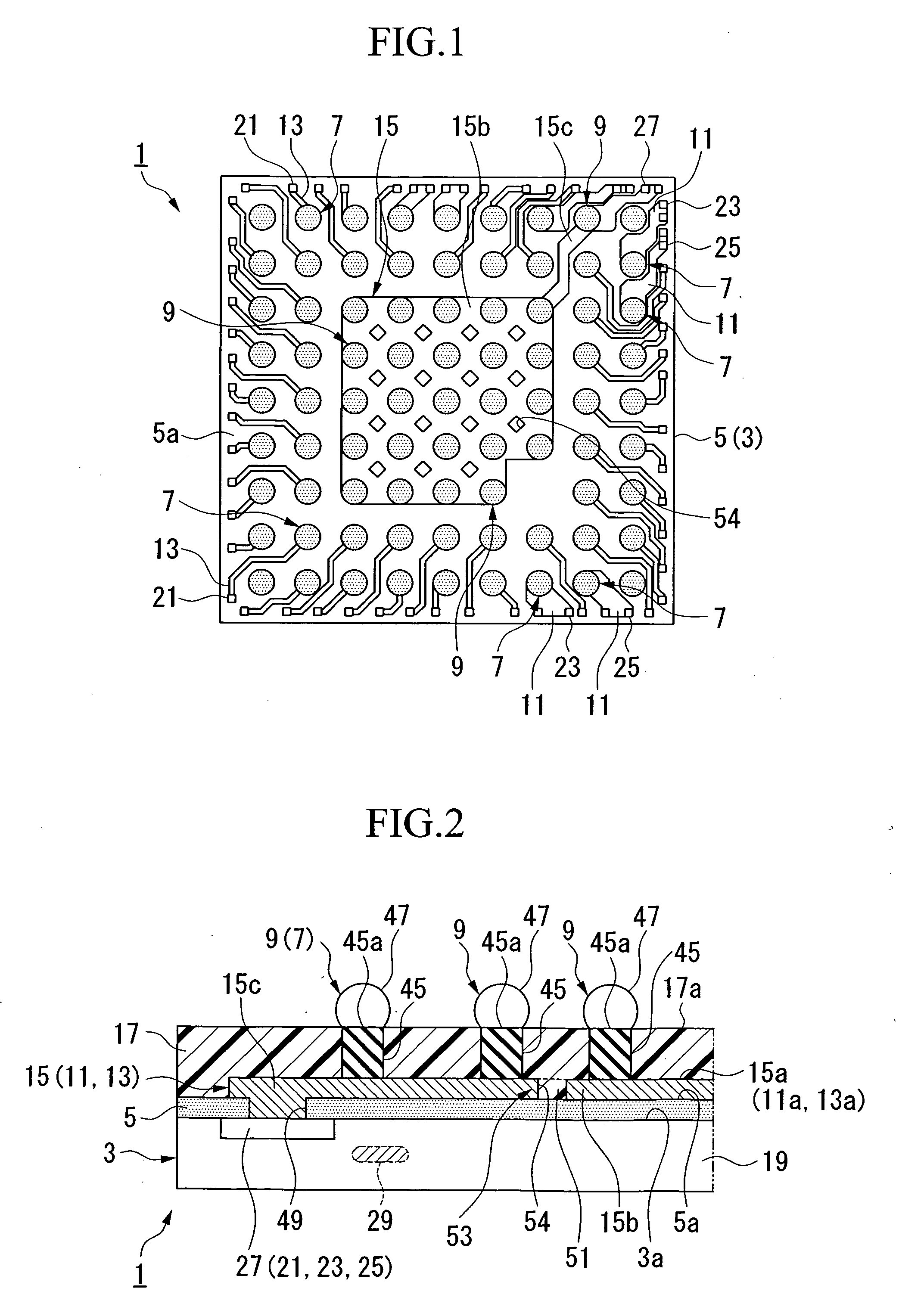

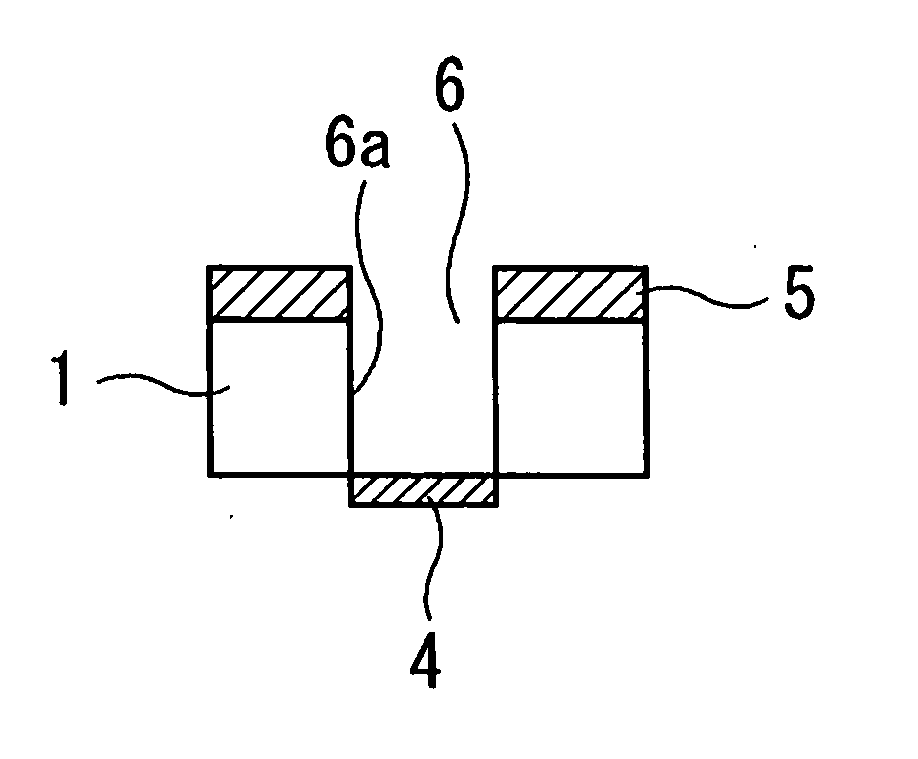

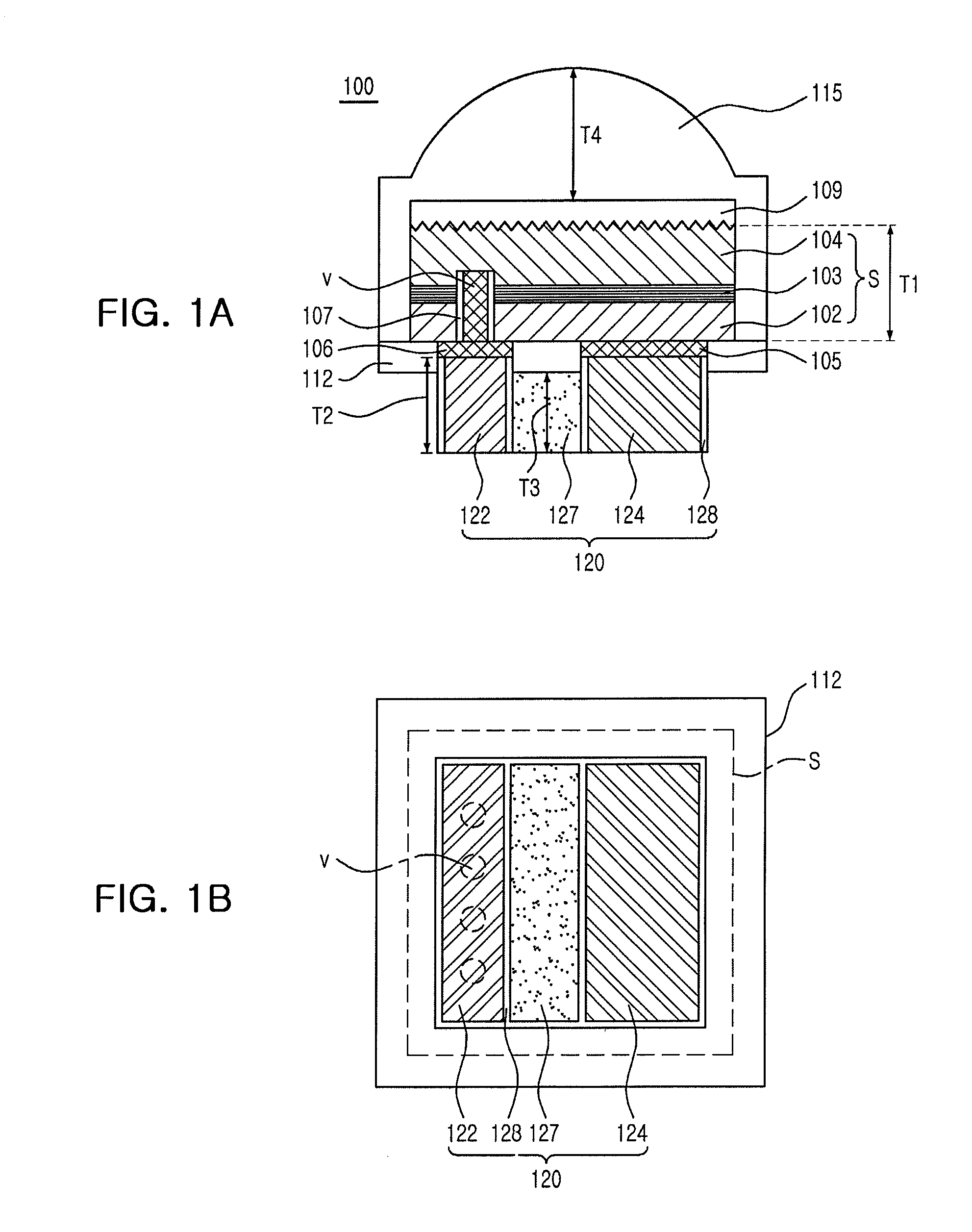

Semiconductor element and wafer level chip size package therefor

InactiveUS20050199995A1Efficiently dissipatedEasily discriminatedSemiconductor/solid-state device detailsSolid-state devicesChip sizeDevice material

A semiconductor device, encapsulated in a wafer level chip size package (WLCSP), includes a plurality of pad electrodes formed on the surface of a semiconductor chip, wherein a first insulating layer is formed on the surface of the semiconductor chip except the pad electrodes; a plurality of connection electrodes and at least one heat-dissipation electrode are formed on the surface of the first insulating layer; the pad electrodes and the connection electrodes are mutually connected via a first wiring portion; the heat-dissipation electrode is connected with a second wiring portion; and a second insulating layer is formed to enclose the electrodes and wiring portions, wherein the second wiring portion is arranged in proximity to a heating portion of the semiconductor chip and is formed on the surface of the first insulating layer except the prescribed region corresponding to the first wiring portion.

Owner:YAMAHA CORP

Light emission apparatus

ActiveUS7101061B2Reasonable structureSuitable structurePlanar light sourcesLaser detailsFluorescencePhosphor

A light emission apparatus that can restrict deterioration of resin used for the light emission apparatus, and that has a reasonable structure fit for actual use is provided, in which a light reflective layer is provided to cover the side surfaces of the chips 26 provided in the concave 2a. According to this, excitation light reflected by the phosphor layer 32, such as ultraviolet light, is reflected again by the light reflective layer 27. Therefore, the excitation light will not reach the resin layer 21, thereby restraining the deterioration of the resin. Moreover, the light reflective layer 27 covers the side surfaces of the chips 26, thereby efficiently conducting the heat emitted from the chips 26 to the metal substrate 20 via the resin layer 21. This improves the heat-dissipation efficiency of the chips 26.

Owner:SIGNIFY HLDG BV

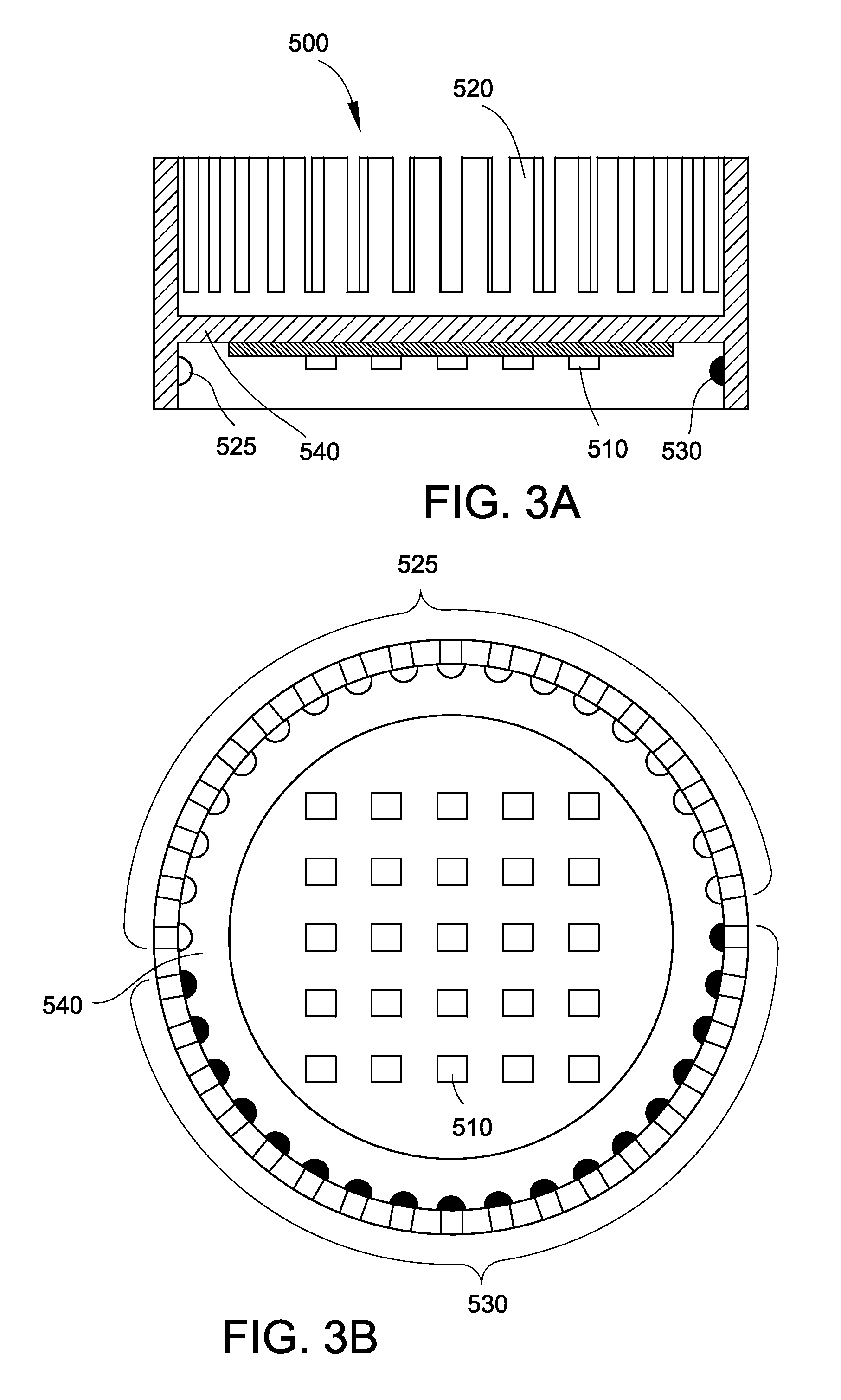

Solid-state lighting device

ActiveUS20100134016A1Improve heat dissipationGood heat dissipationPlanar light sourcesLight source combinationsHeat spreadingEngineering

A solid-state lighting device (500) includes a plurality of light-emitting elements (510, 525, 530) configured for generating light that are thermally coupled to a heat spreading chassis configured for coupling to one or more heat sinks (520). The lighting device further includes a mixing chamber which is optically coupled to the plurality of light-emitting elements and configured to mix the light emitted by the plurality of light-emitting elements. A control system is operatively coupled to the plurality of light-emitting elements, and configured to control operation of the plurality of light-emitting elements.

Owner:SIGNIFY HOLDING B V

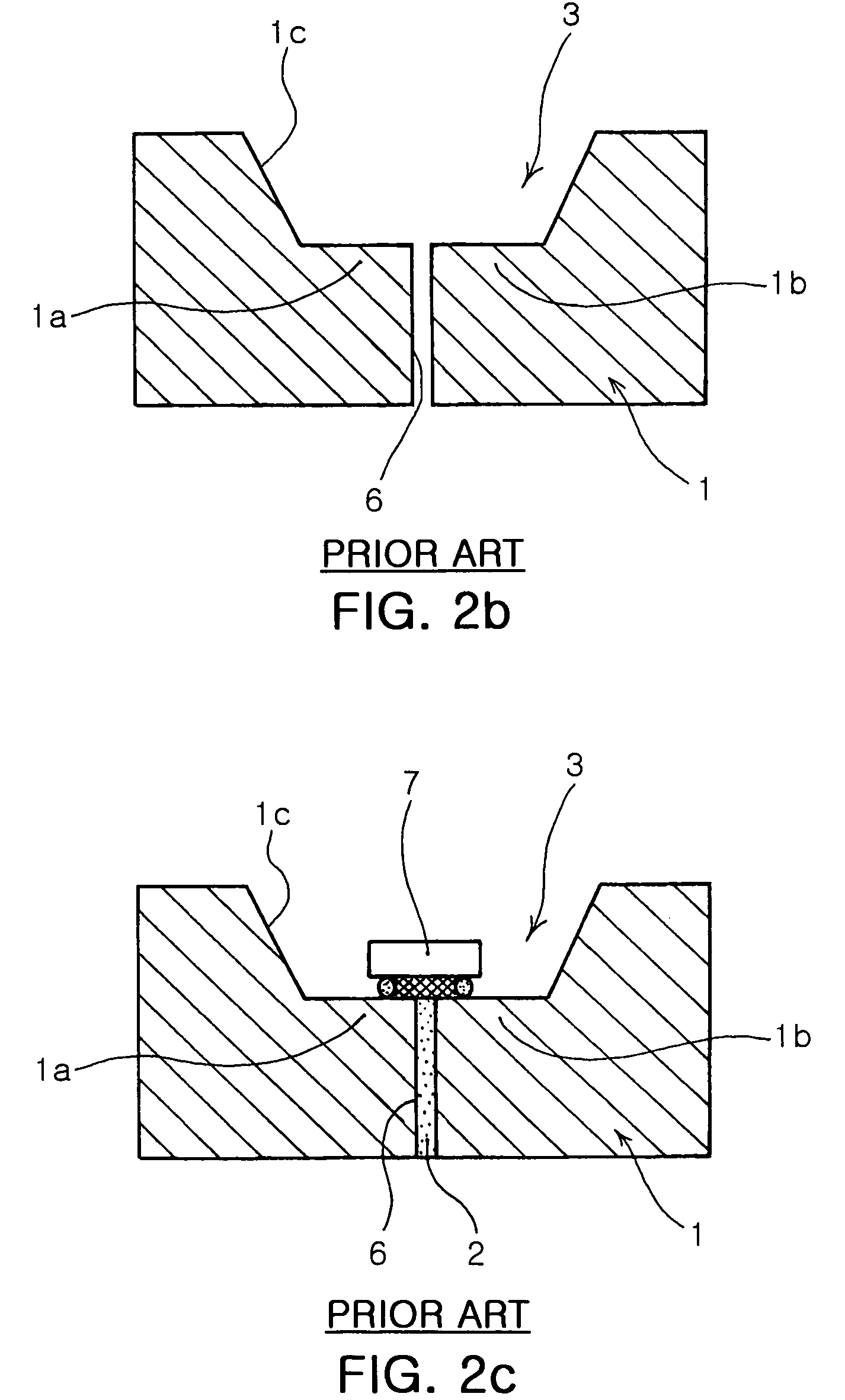

Method for manufacturing a compound semiconductor device having an improved via hole

InactiveUS20070082427A1Increase etch rateImprove verticalitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

In a method for manufacturing a compound semiconductor device, a principal surface of a SiC wafer, on which a compound semiconductor device is located, is bonded to a support substrate with an adhesive having a softening point higher than 200° C. A via hole is formed dry etching, including supplying a fluorine-containing etching gas to a rear side of the SiC wafer. Thereafter, the support substrate and the adhesive are removed. Preferably, the adhesive is formed by reacting one material coating the principal surface of the SiC wafer, and another material coating the support substrate.

Owner:MITSUBISHI ELECTRIC CORP

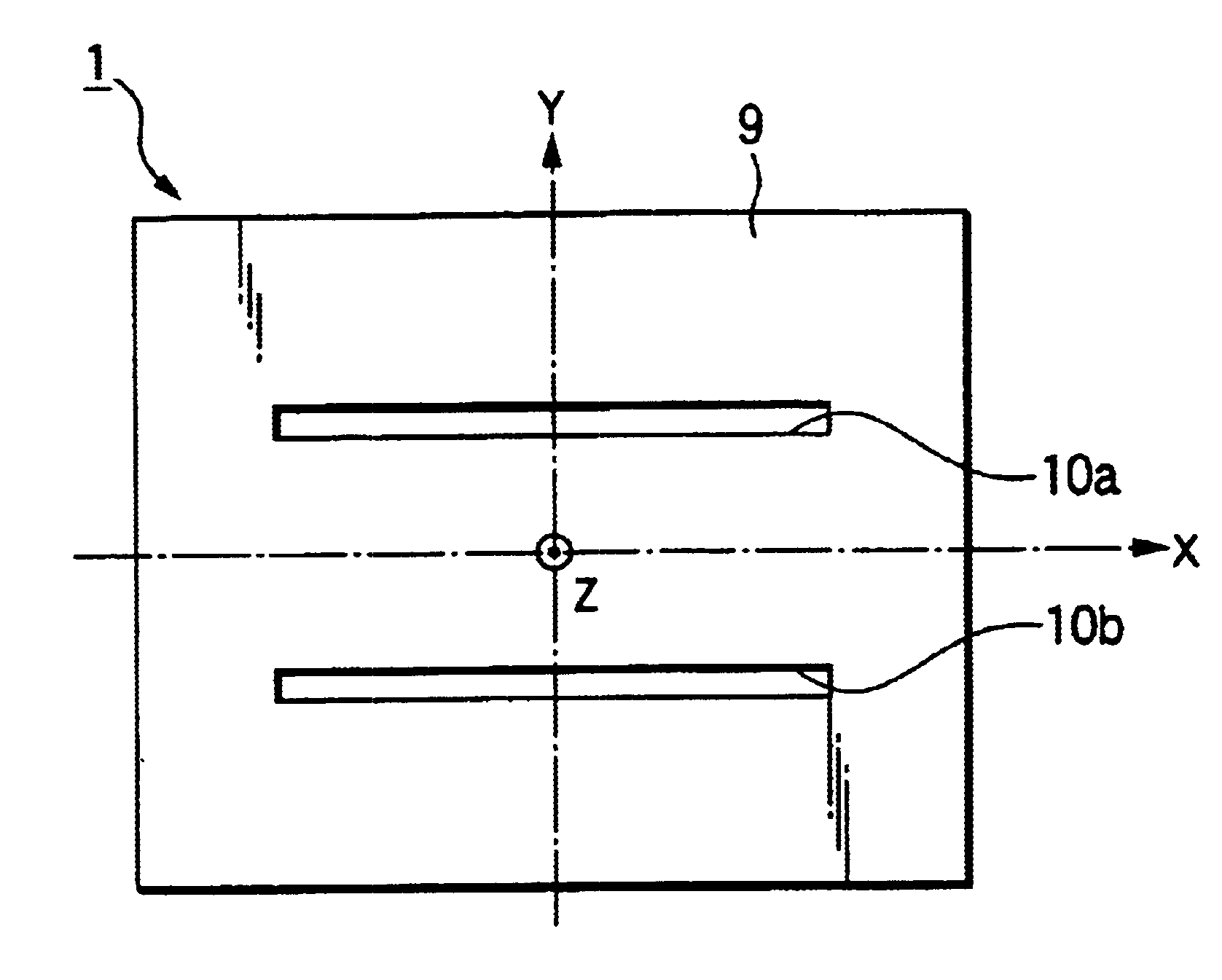

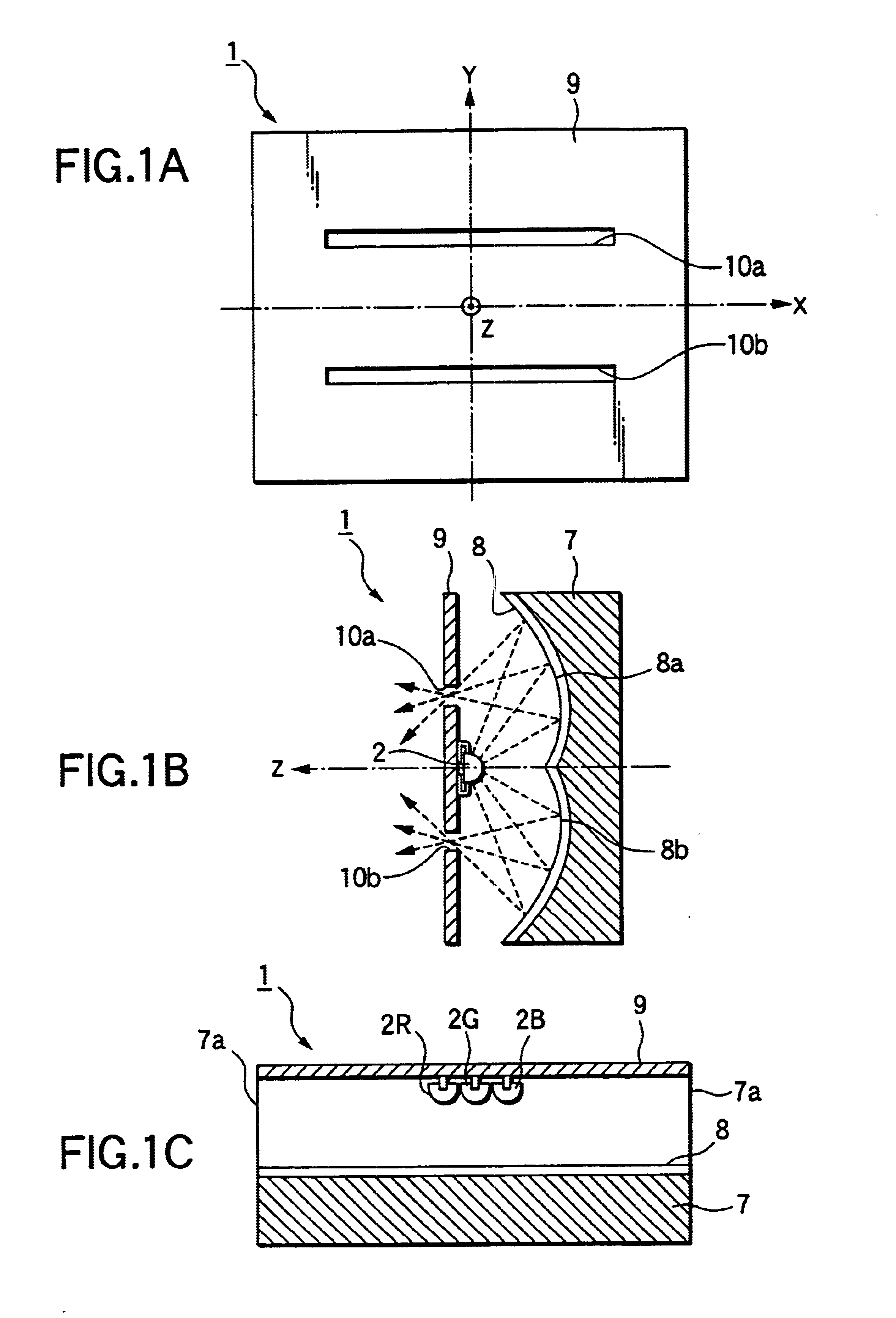

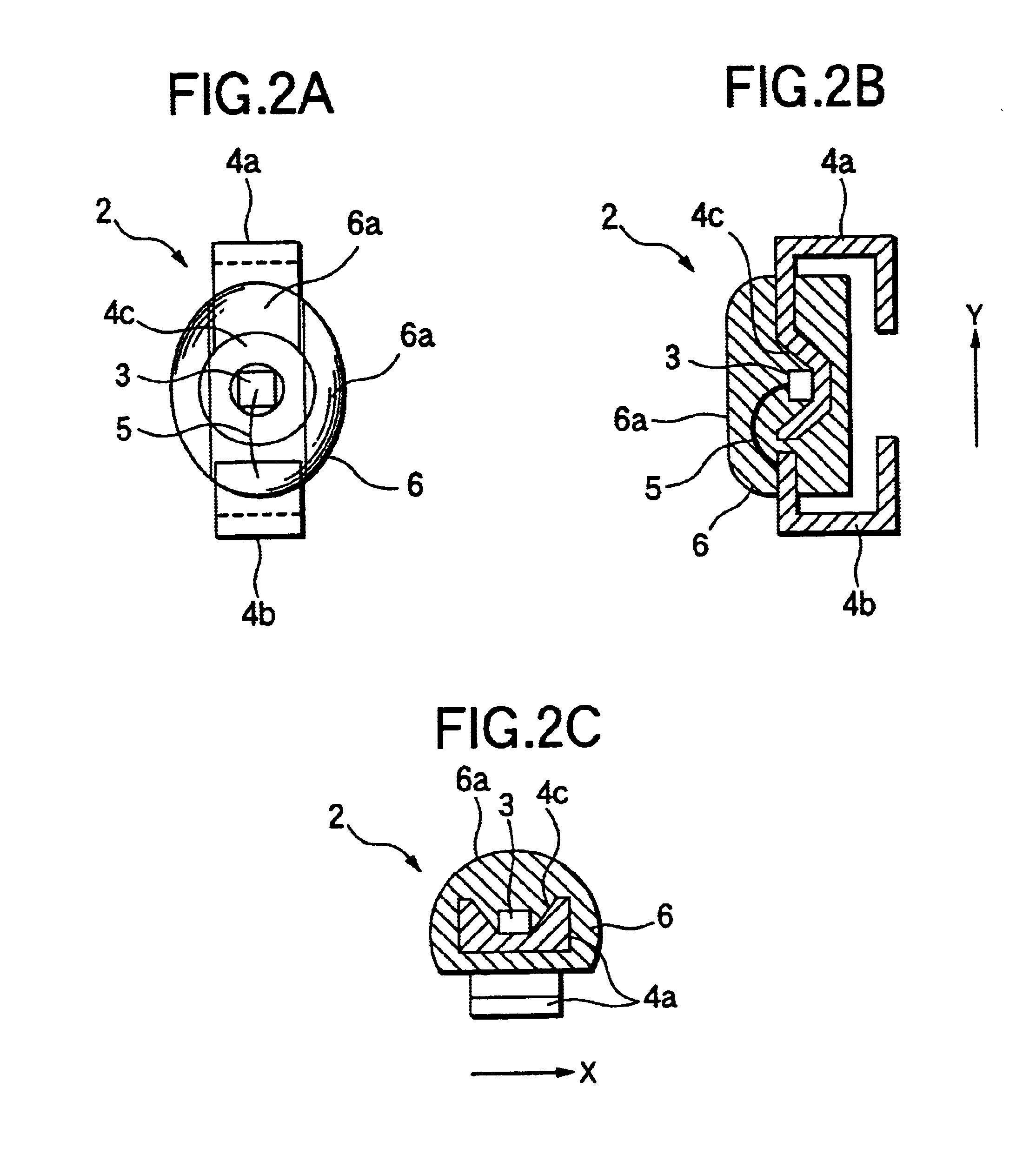

Shielded reflective light-emitting diode

InactiveUS6886962B2Reduce displayUniform intensity distributionLight source combinationsPoint-like light sourceLuminous intensitySurface mounting

In a shielded reflective LED, each of light sources can be surface-mounted substantially without being influenced by heat distortion based on the difference in thermal expansion coefficient between resin and metal because the light source is so small-sized that only one light-emitting element is sealed with a resin. Moreover, variations in luminous intensity and chromaticity of each of light-emitting elements used in three-color light sources can be examined in advance. Hence, well-matched three-color light sources can be mounted in combination so that display unevenness of a full color display can be reduced greatly. Further, the surface of the substrate portion on which the light source is fixed is silk-screen-printed in black. Hence, external light which enters the device through the optical opening portion when the device is turned off is reflected by the reflecting mirror and absorbed to the surface of the substrate portion. As a result, pseudo-lighting in which external light is radiated out again through the optical opening portion can be prevented thoroughly, so that contrast between light when the device is turned on and light when the device is turned off can be made high.

Owner:TOYODA GOSEI CO LTD

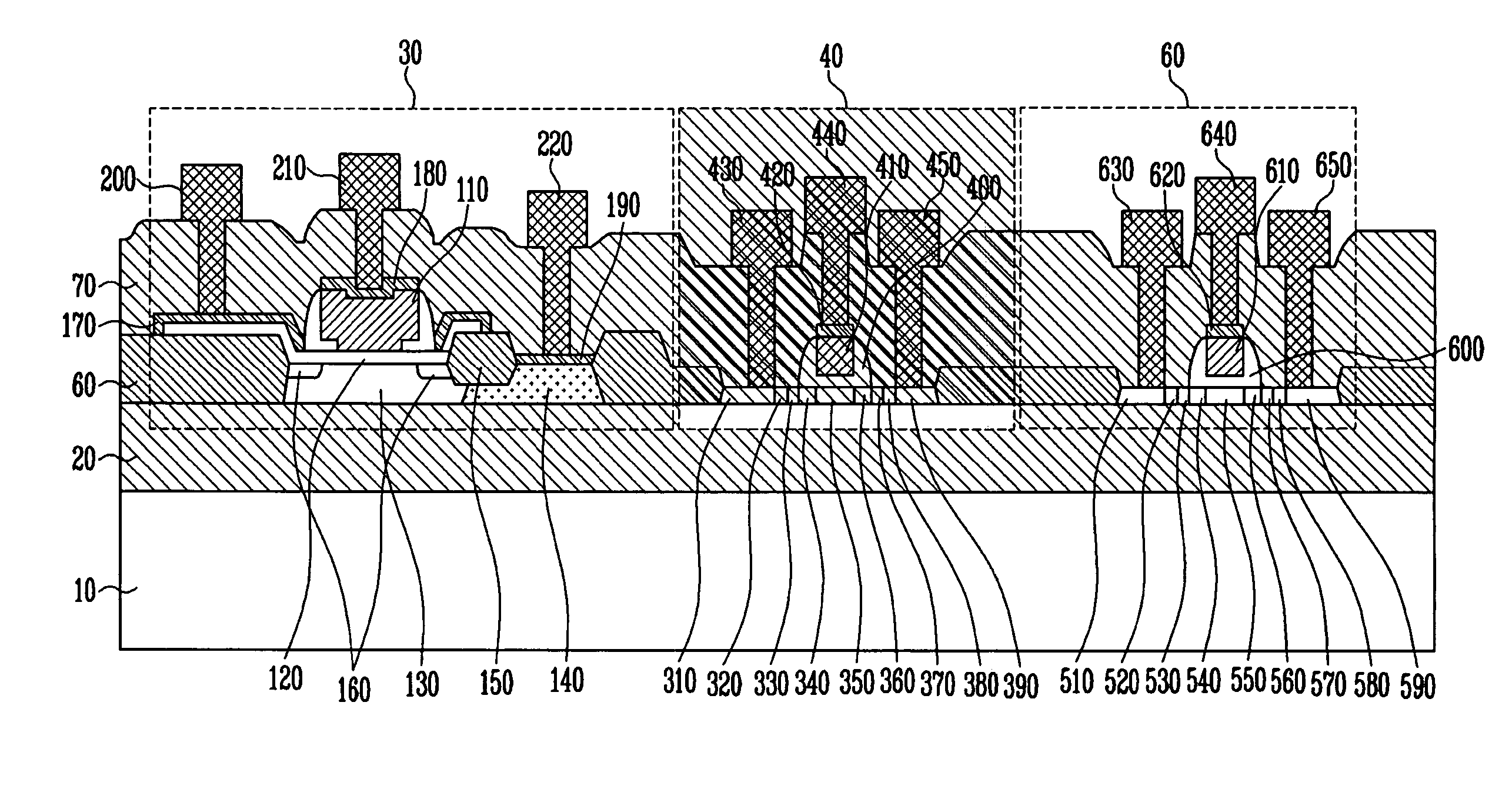

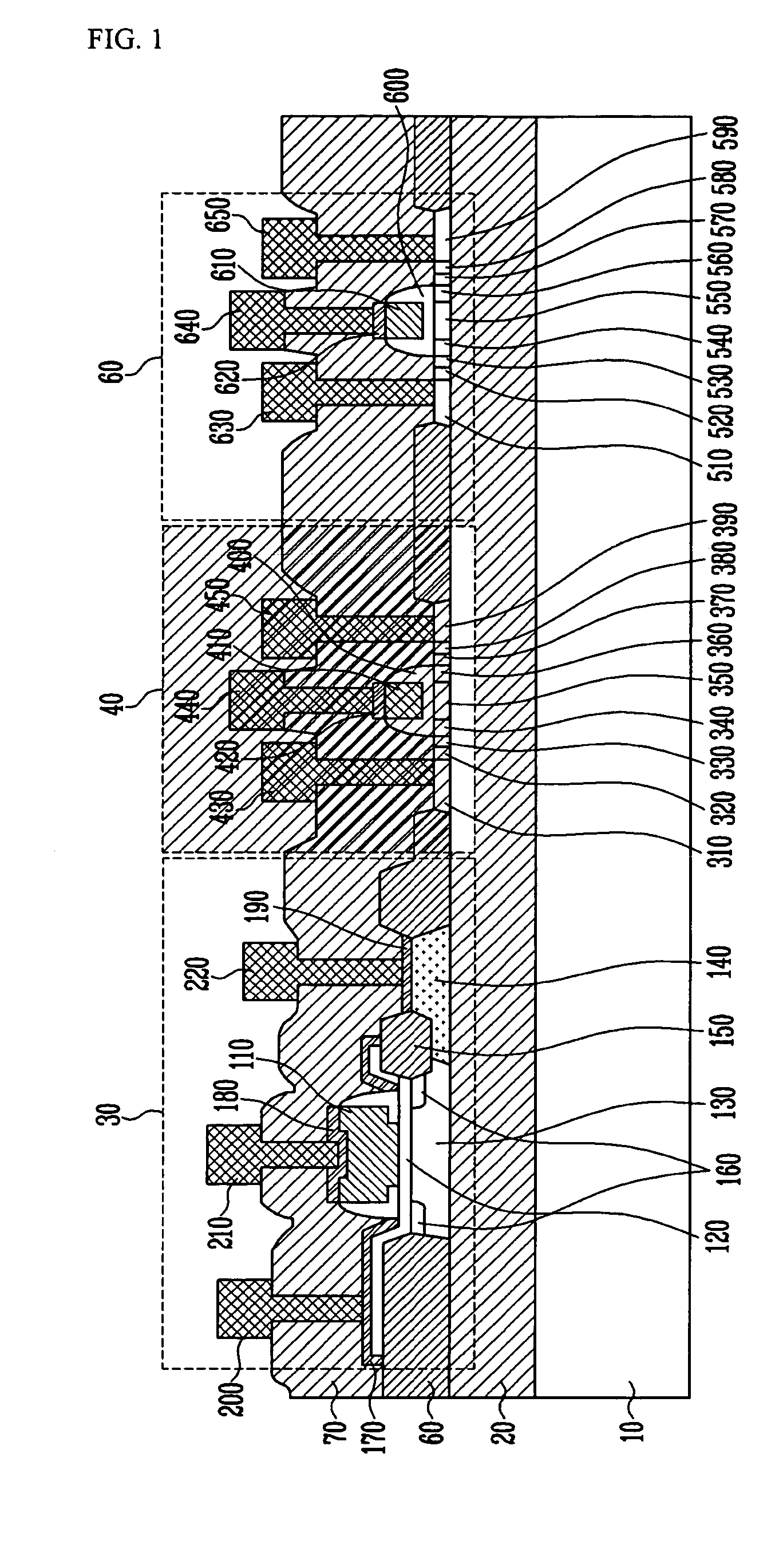

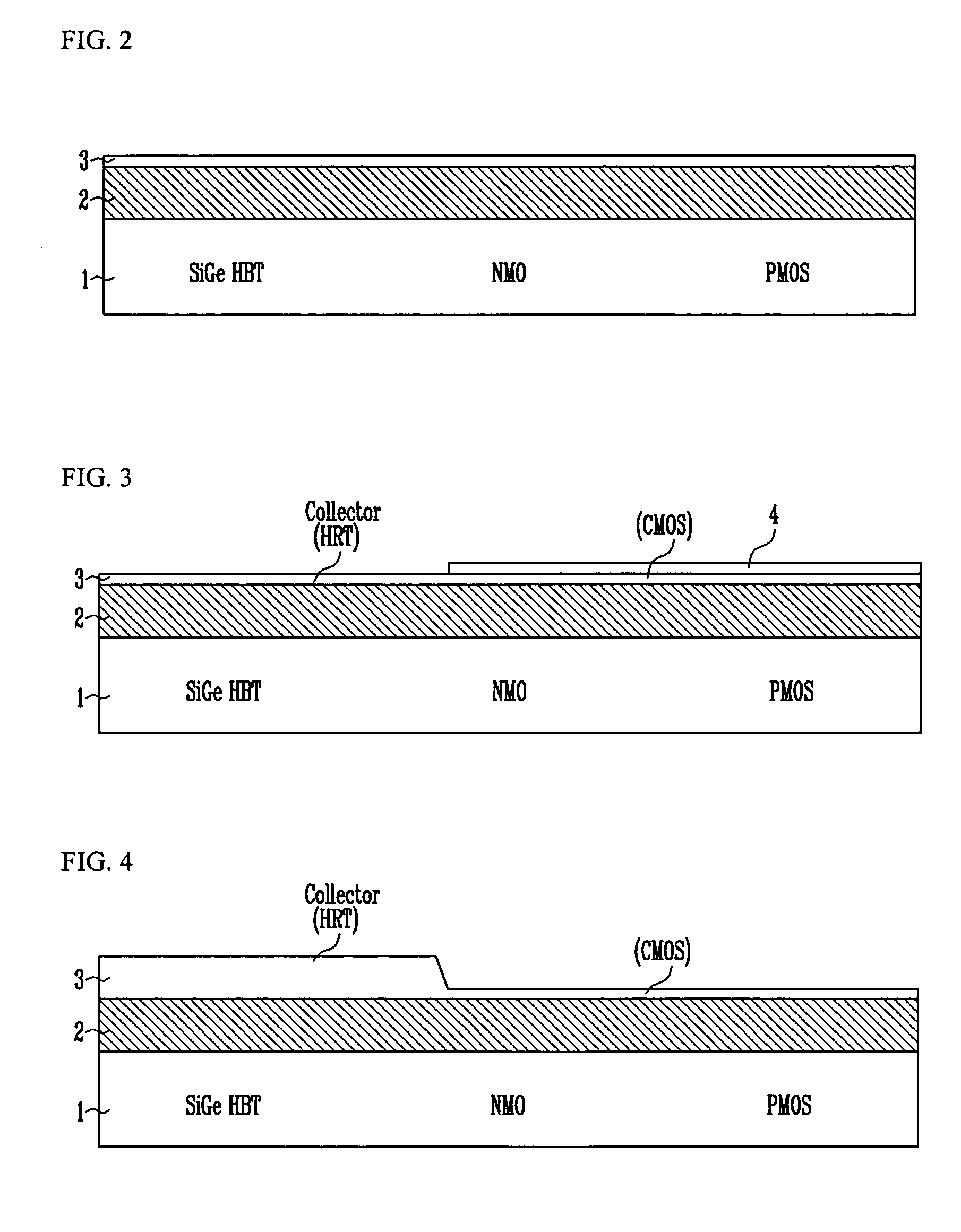

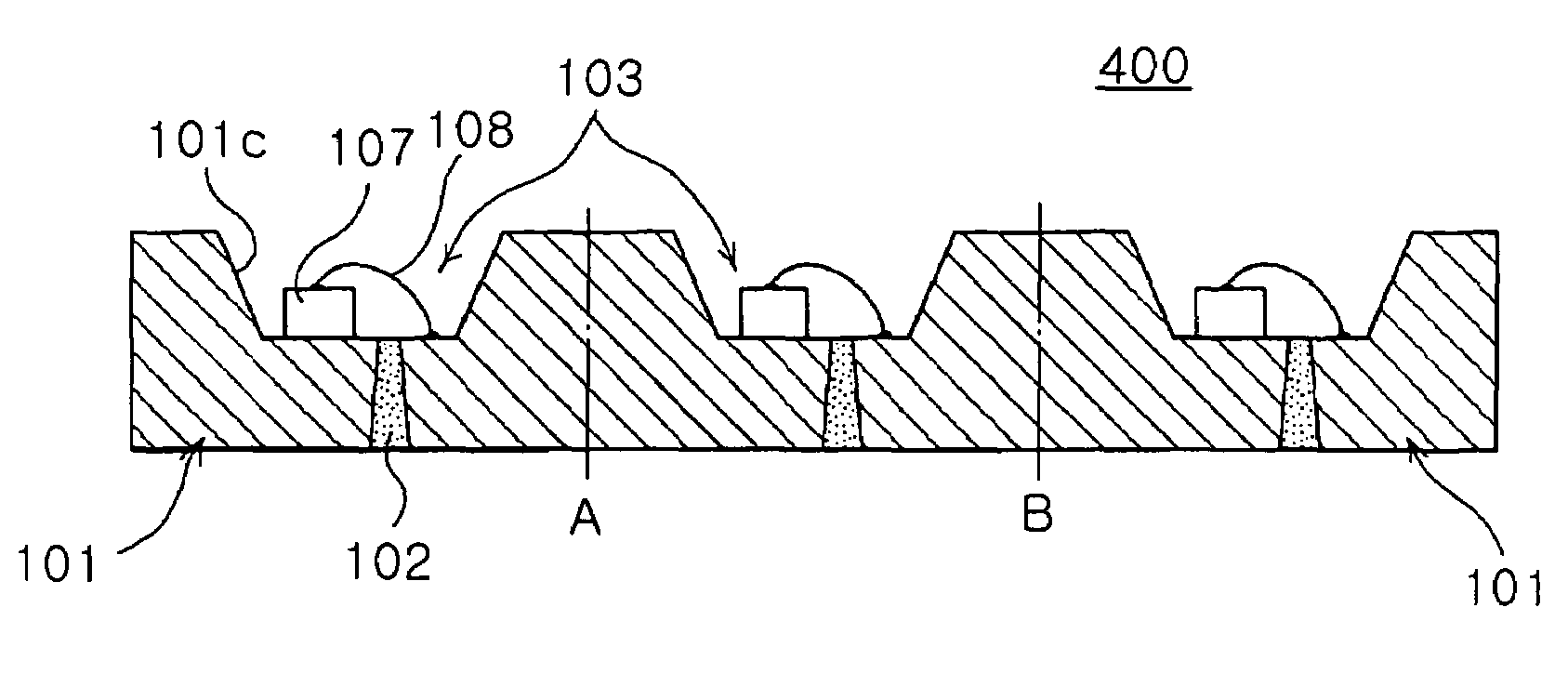

NMOS device, PMOS device, and SiGe HBT device formed on SOI substrate and method of fabricating the same

Provided are an NMOS device, a PMOS device and a SiGe HBT device which are implemented on an SOI substrate and a method of fabricating the same. In manufacturing a Si-based high speed device, a SiGe HBT and a CMOS are mounted on a single SOI substrate. In particular, a source and a drain of the CMOS are formed of SiGe and metal, and thus leakage current is prevented and low power consumption is achieved. Also, heat generation in a chip is suppressed, and a wide operation range may be obtained even at a low voltage.

Owner:ELECTRONICS & TELECOMM RES INST

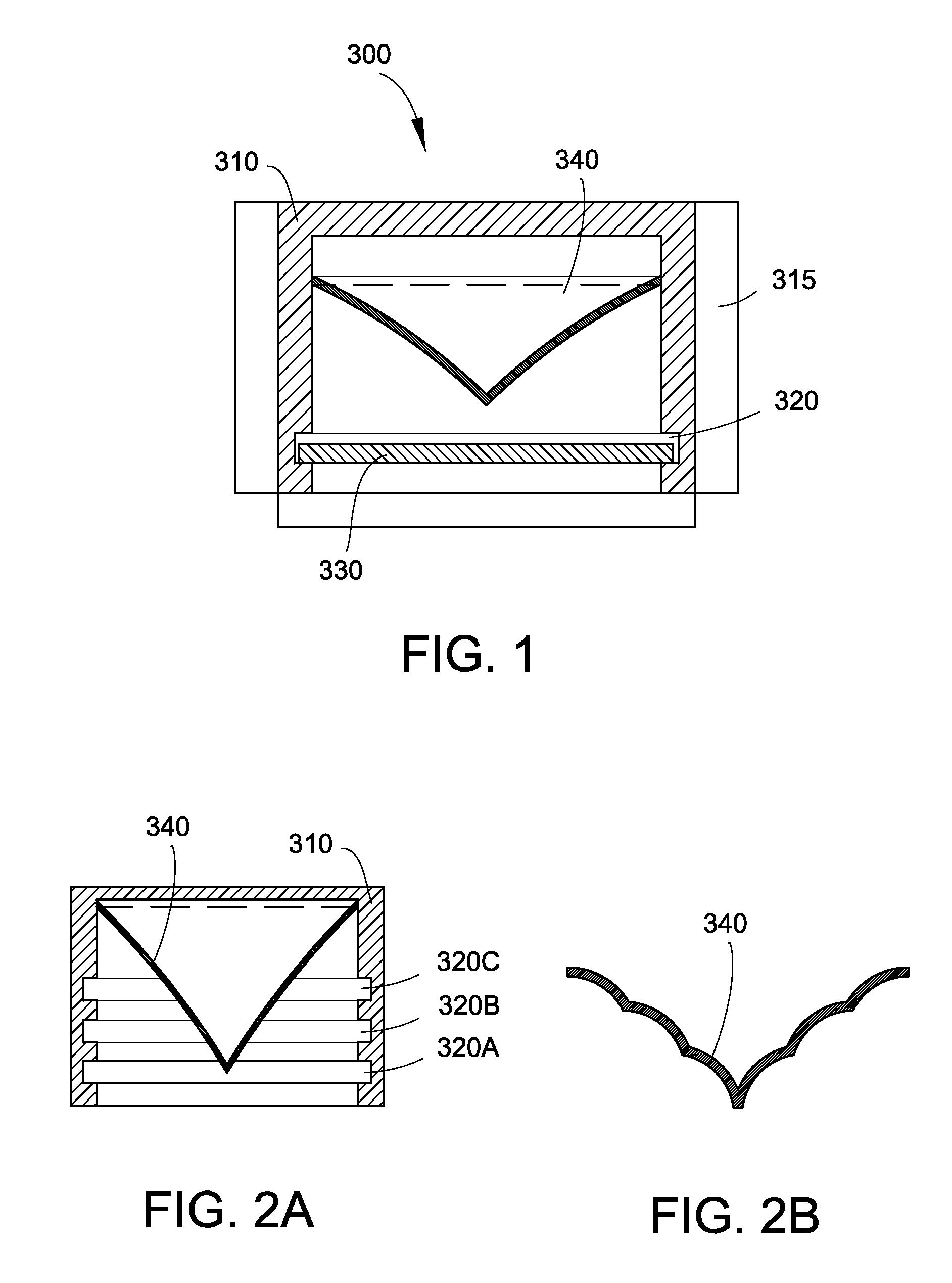

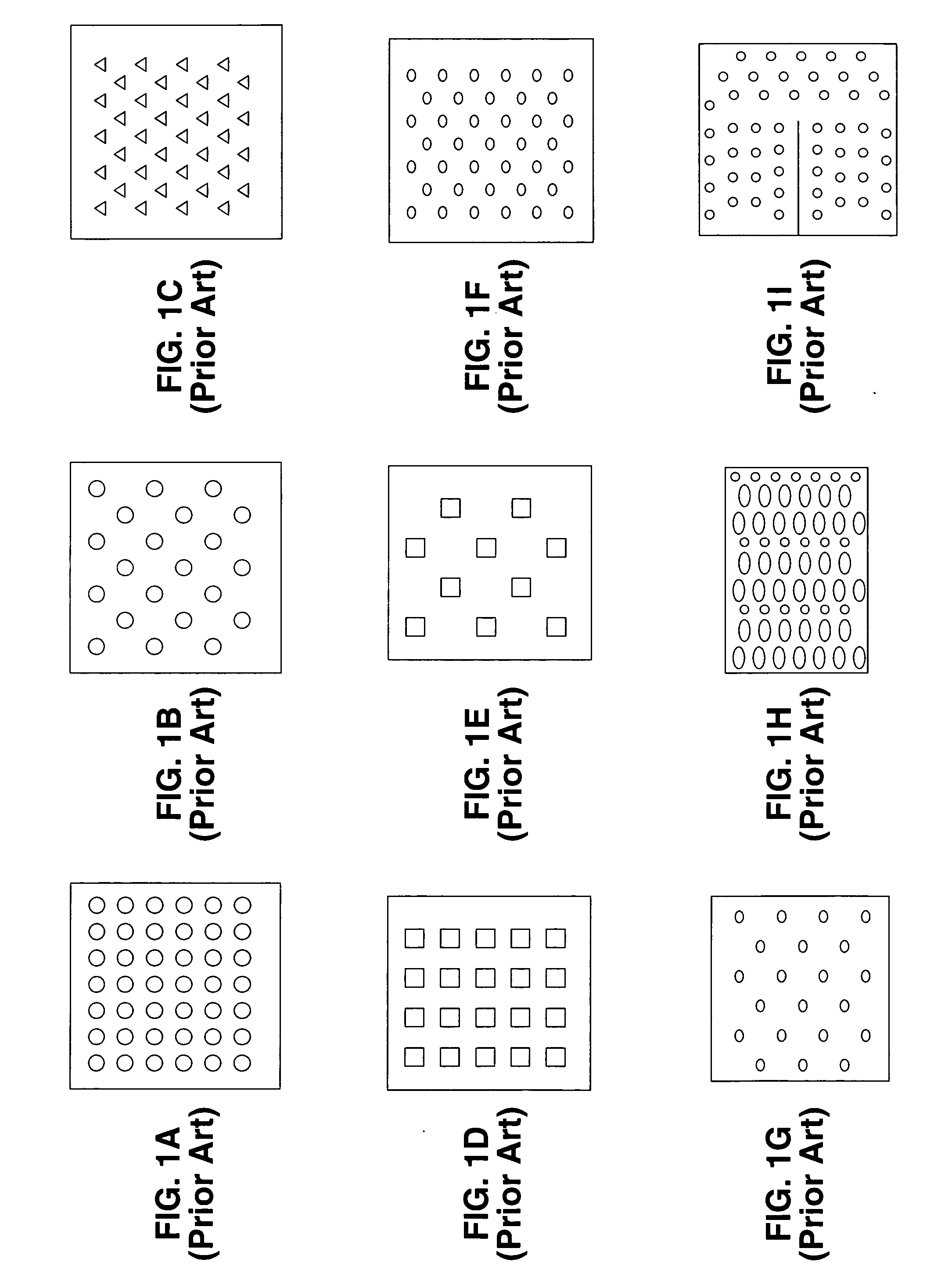

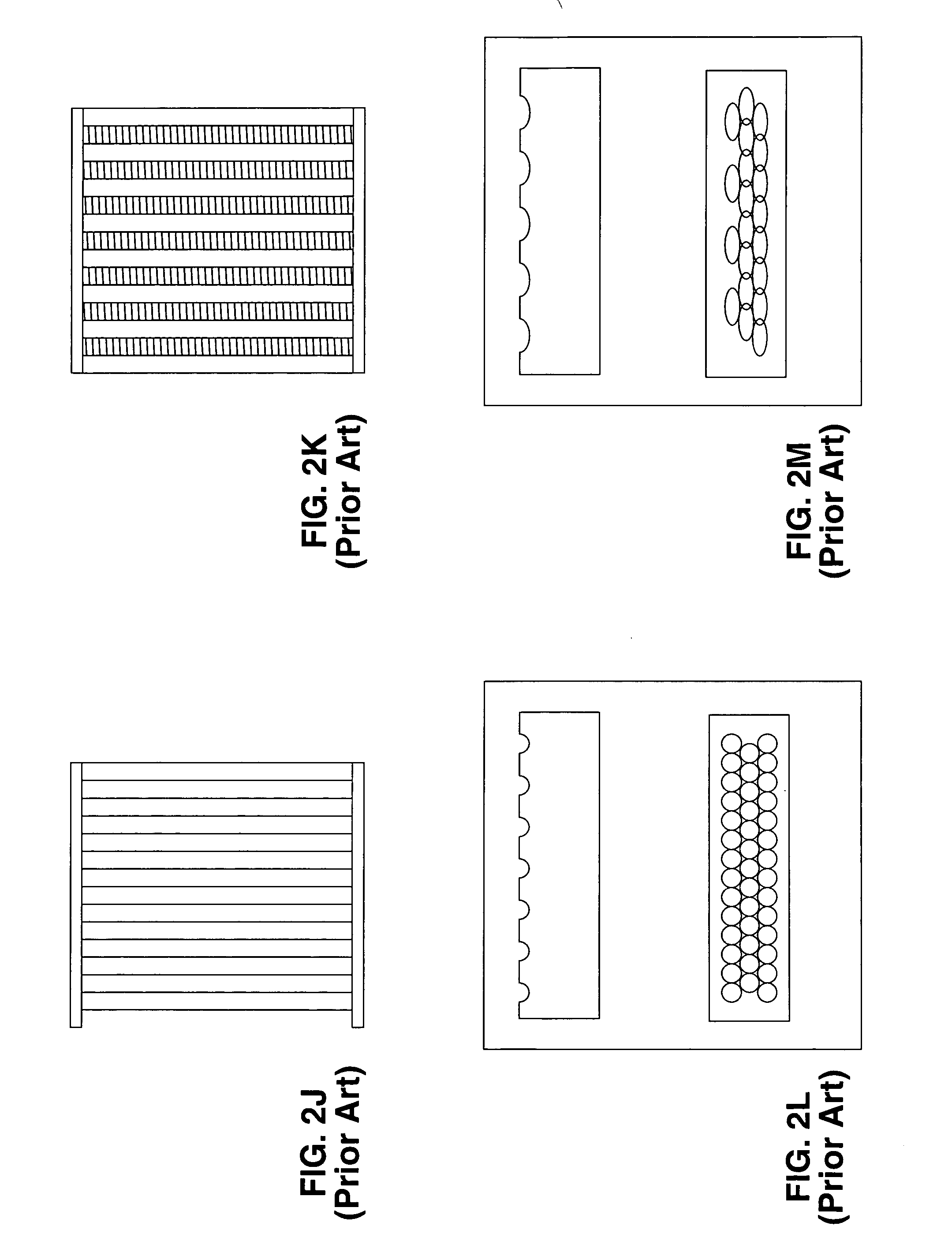

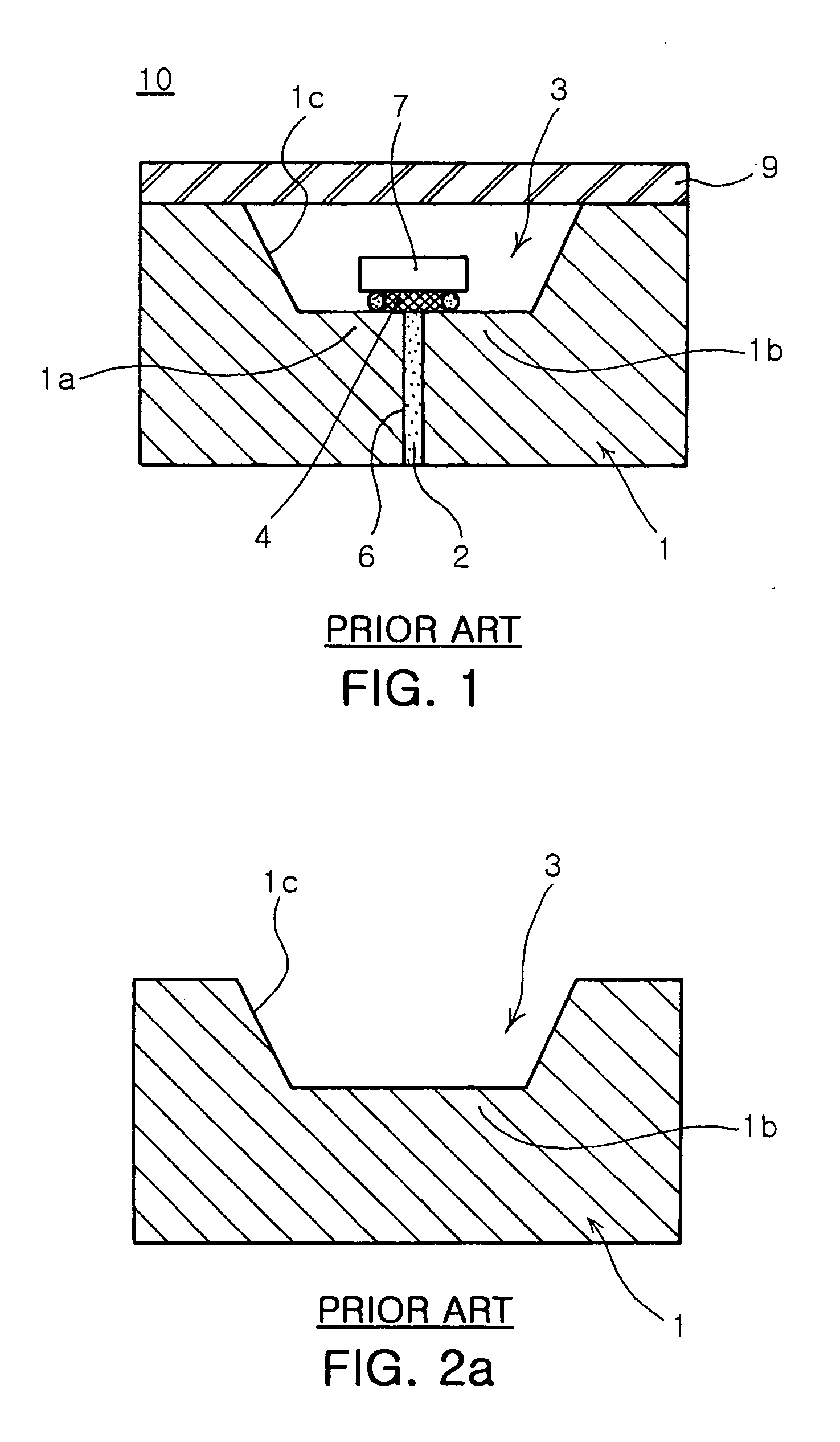

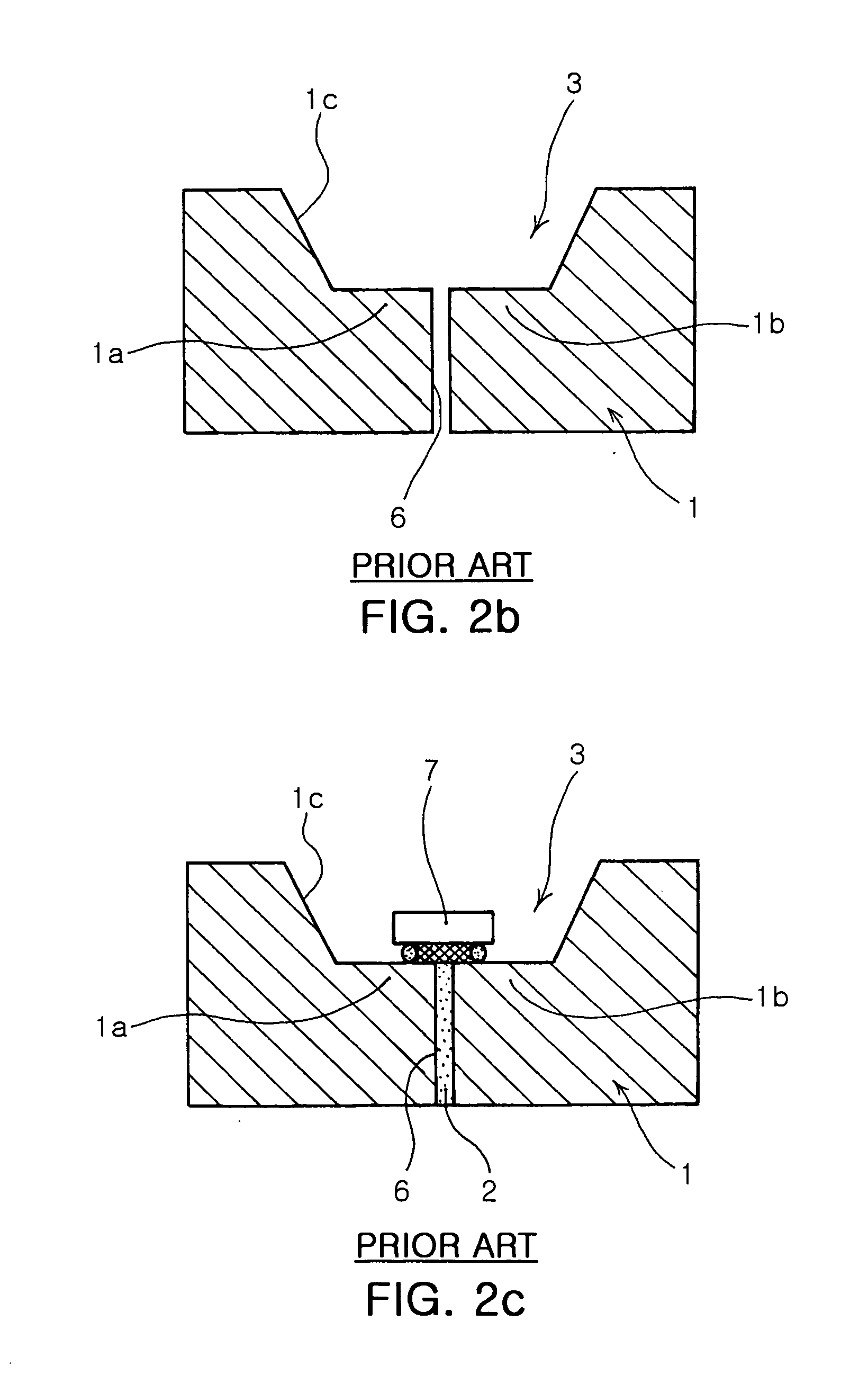

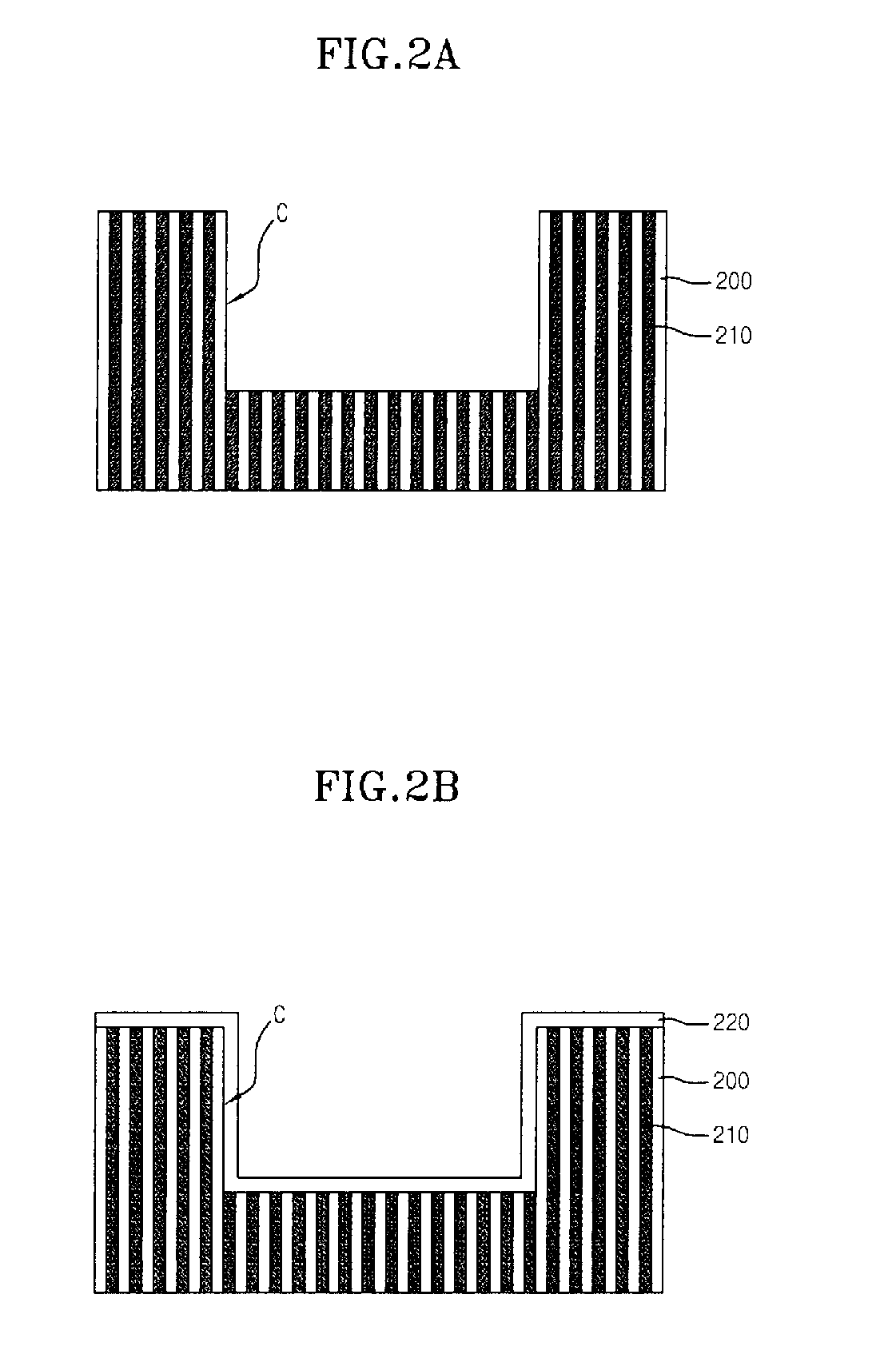

Fabrication method of light emitting diode package

ActiveUS7268014B2Good heat dissipationFabricated easily and preciselySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight emitting device

The invention provides a fabrication method of an LED package for easily fabricating LED packages of excellent heat radiation characteristics. In the method, a metallic package substrate having a recess and a reflecting surface formed in the recess is prepared, and the package substrate is selectively anodized and divided into two package electrode parts divided from each other. Then, an light emitting device is mounted on the bottom of the recess. Preferably, the package substrate is a metal substrate made of Al or Al-based metal.

Owner:SAMSUNG ELECTRONICS CO LTD

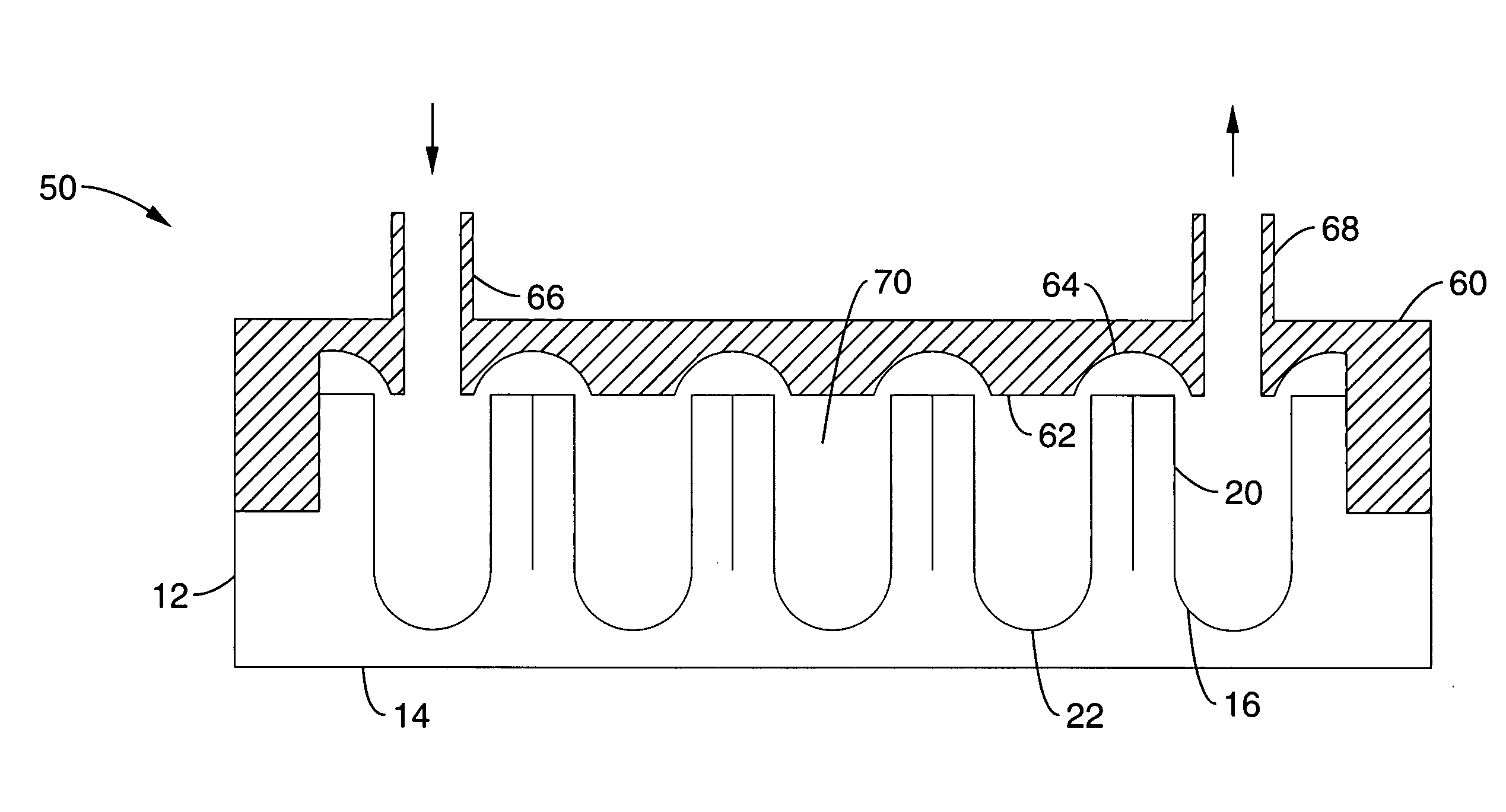

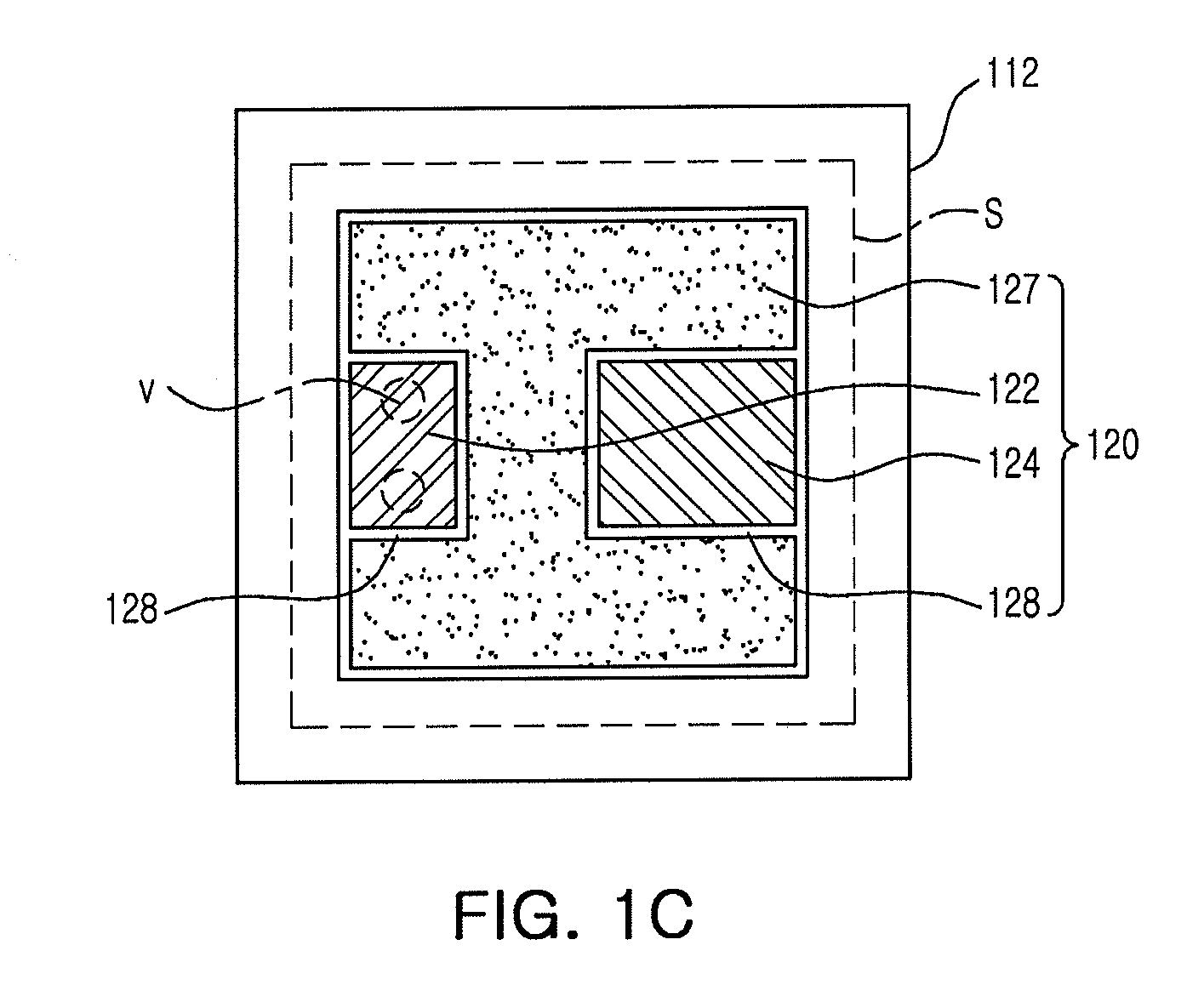

Heat dissipating device

InactiveUS20060231236A1Improve the overall coefficientIncreasing restriction of fluid flowHeat transfer modificationCooling/ventilation/heating modificationsEngineeringDistortion

A heat dissipation device with a fluid cavity that utilizes a hybrid of star pins with concave surfaces and sharp edges, and truncated dimples, which creates turbulence and a vortex phenomenon perpendicular to fluid flow transmission, and increases the heat transfer coefficient without increasing restriction of fluid flow through the device. This process increases the heat transfer along local pins which are located around each truncated dimple. This effect allows the use of taller pins than previous devices thus increasing the surface of heat transfer and thus these pins have a more efficient heat transfer coefficient along the total length of the pin, not possible previously. Star pins with sharp edges prevent the distortion of the highly efficient vortex flow which increases fluid flow and simultaneously intensifies the desired phenomena of extraordinary turbulence.

Owner:US THERMOELECTRIC CONSORTIUM

Fabrication method of light emitting diode package

ActiveUS20060246617A1Efficient use ofGood heat dissipationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

The invention provides a fabrication method of an LED package for easily fabricating LED packages of excellent heat radiation characteristics. In the method, a metallic package substrate having a recess and a reflecting surface formed in the recess is prepared, and the package substrate is selectively anodized and divided into two package electrode parts divided from each other. Then, an light emitting device is mounted on the bottom of the recess. Preferably, the package substrate is a metal substrate made of Al or Al-based metal.

Owner:SAMSUNG ELECTRONICS CO LTD

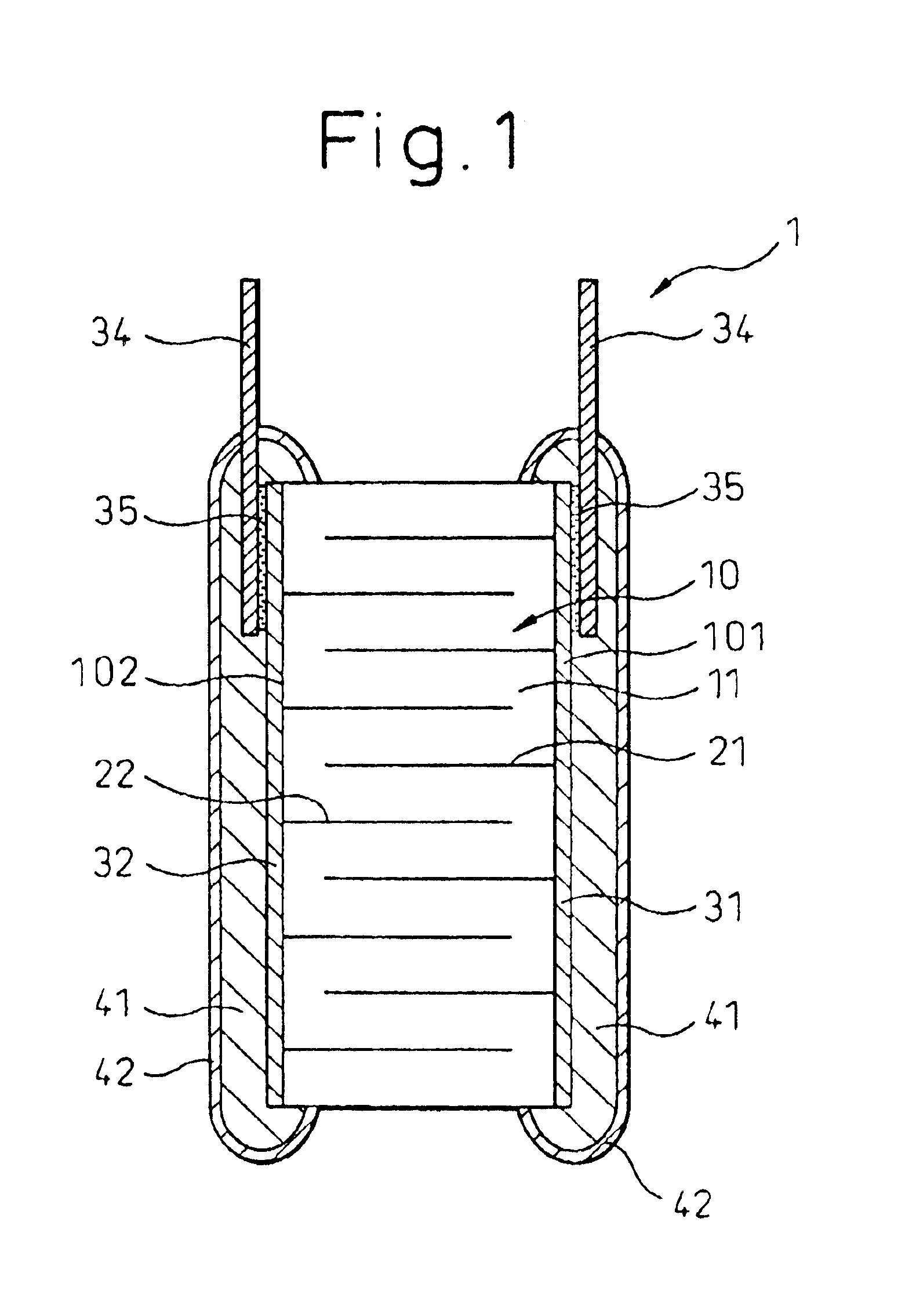

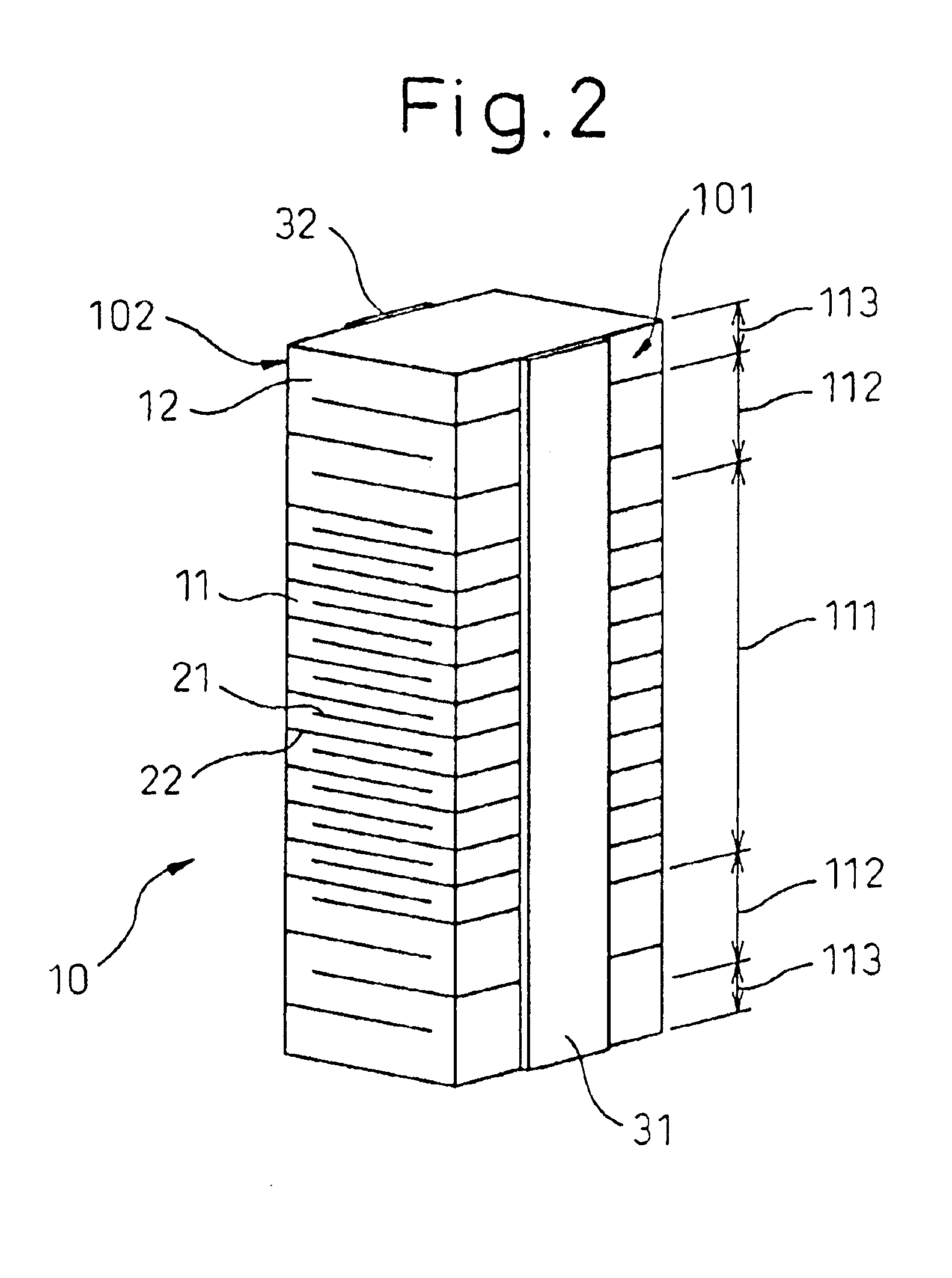

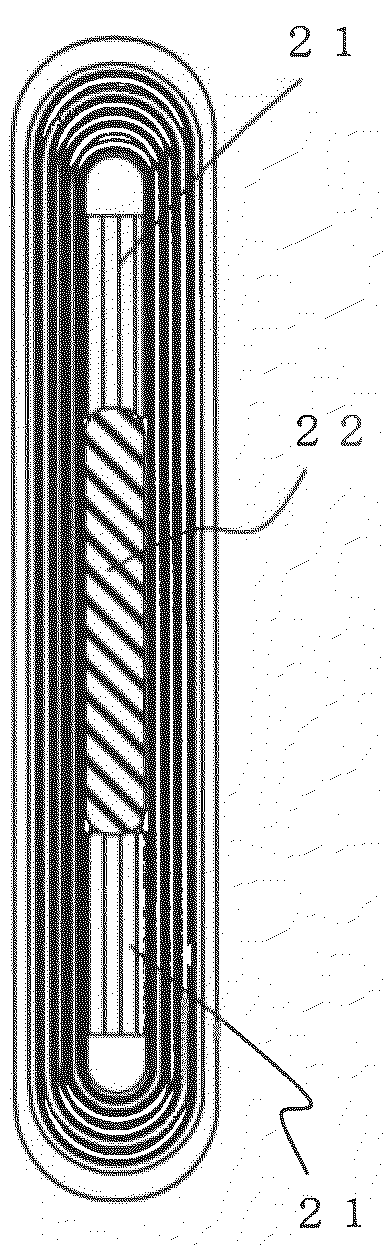

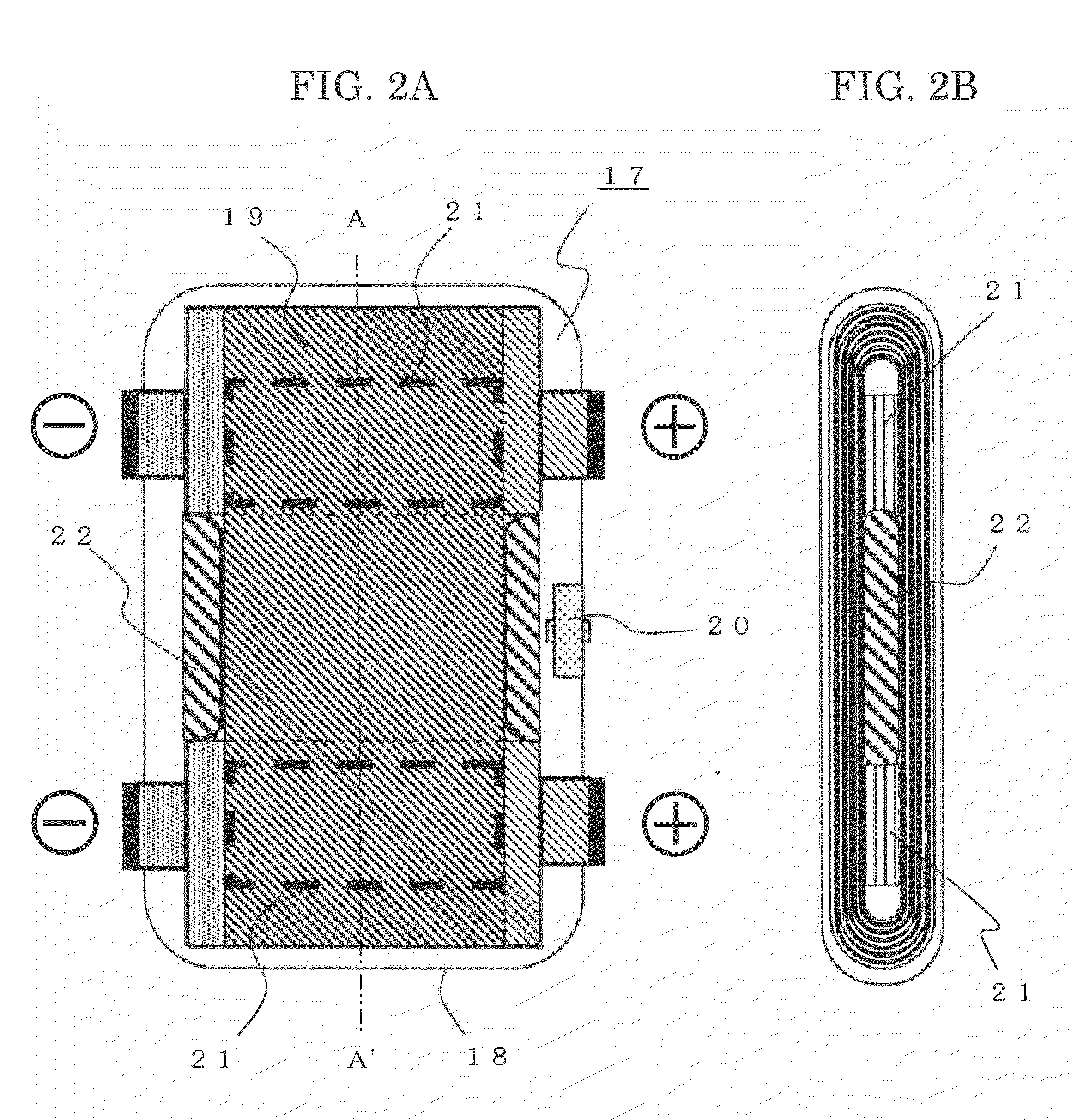

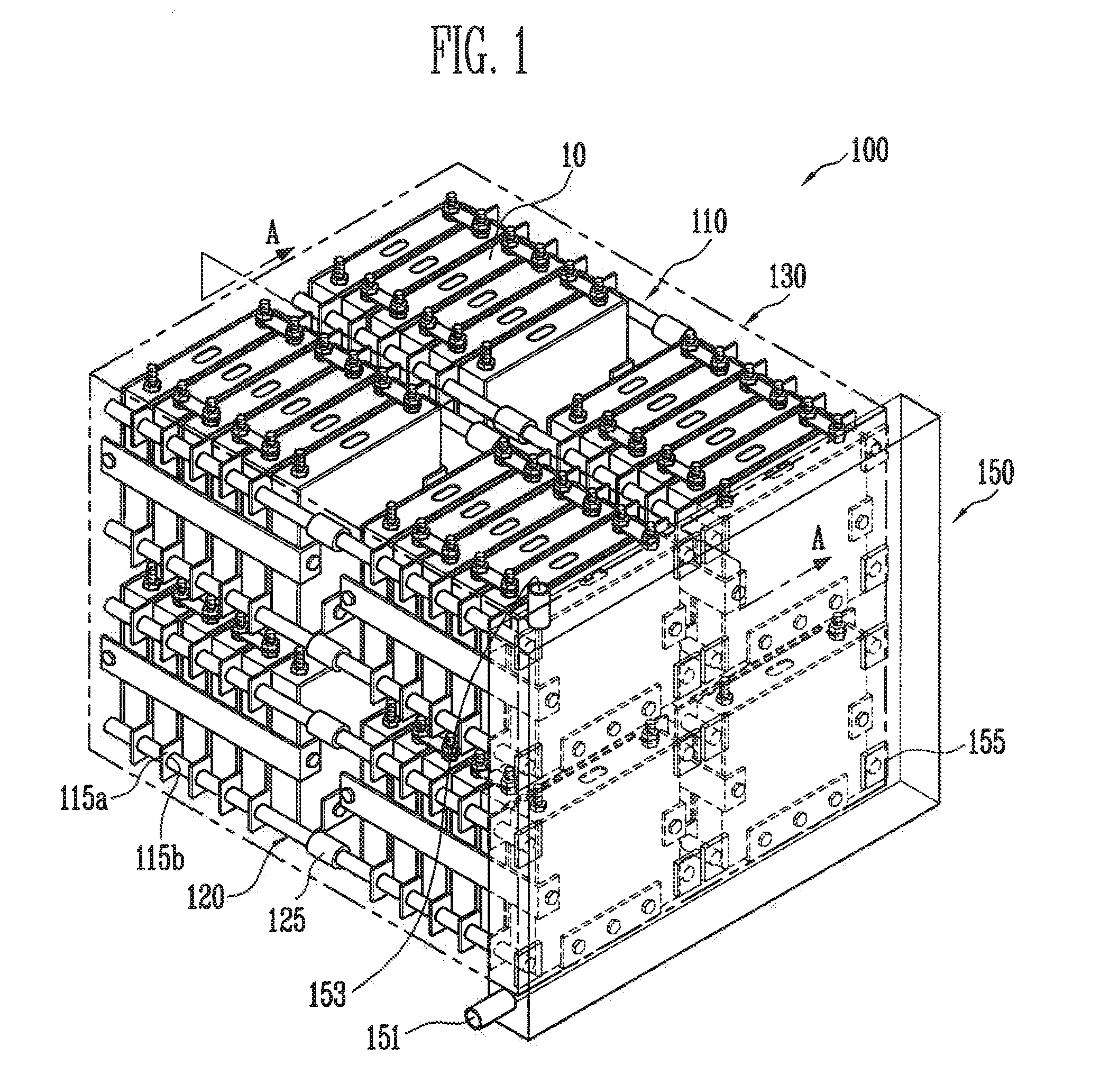

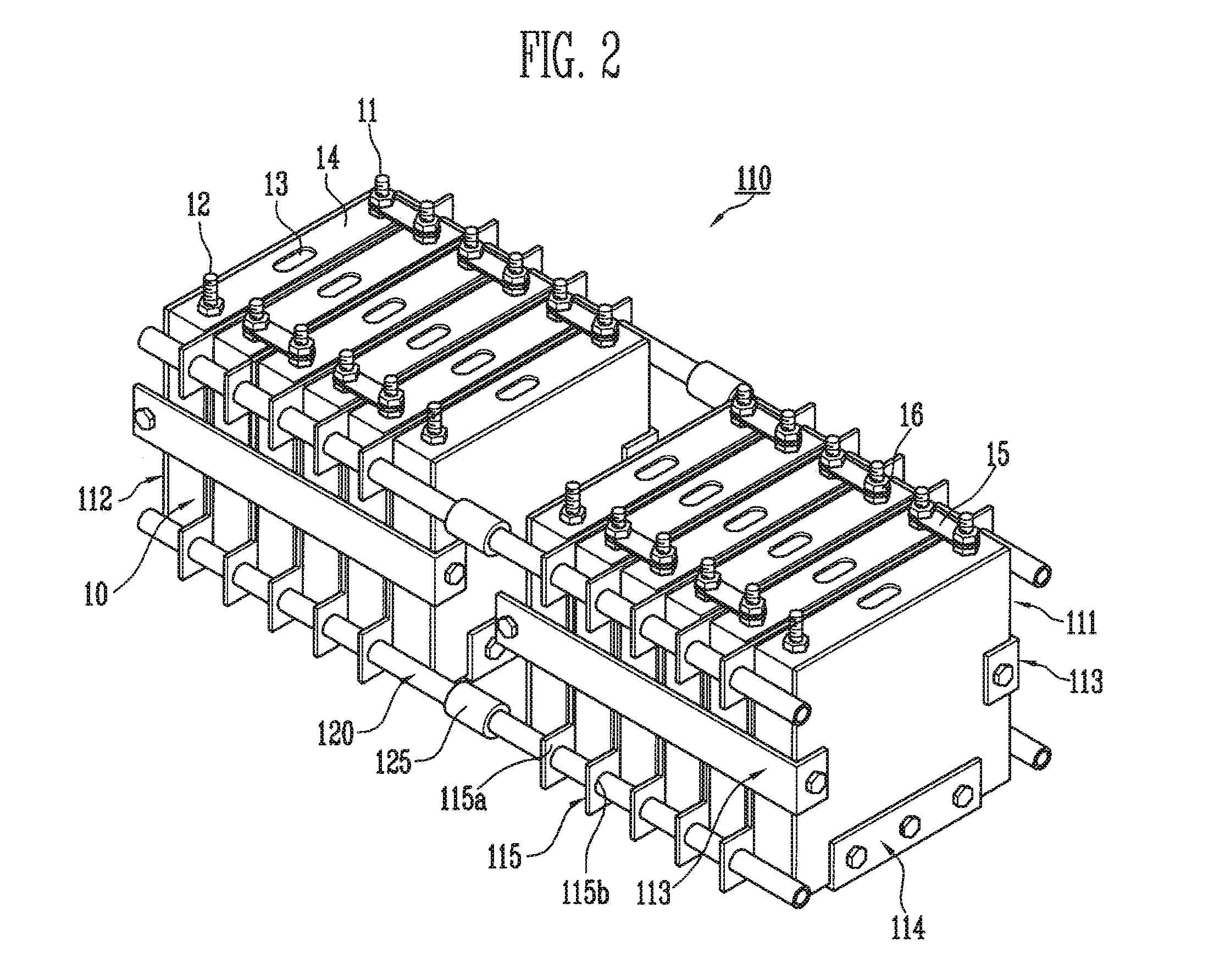

Electrical energy storage cell and electrical energy storage module including the same

InactiveUS20090136832A1Efficiently internally generated heatReduce collector resistancePrimary cell to battery groupingFinal product manufacturePositive currentStorage cell

The storage cell comprises a flat roll electrode that includes a strip of positive electrode having a positive electrode current collector foil and a positive electrode layer formed thereon, a strip of negative electrode having an electrode current collector foil and a negative electrode layer formed, and a strip of electrically insulated separator, the strip of positive electrode and the strip of negative electrode being wound into a flat roll configuration with the strip of electrically insulated separator sandwiched therebetween; a sealed casing that hermetically seals the flat roll electrode impregnated with an electrolyte; a positive terminal and a negative terminal each electrically insulated from the sealed casing, connected to the positive current collector foil and the negative current collector foil, respectively.

Owner:MITSUBISHI ELECTRIC CORP

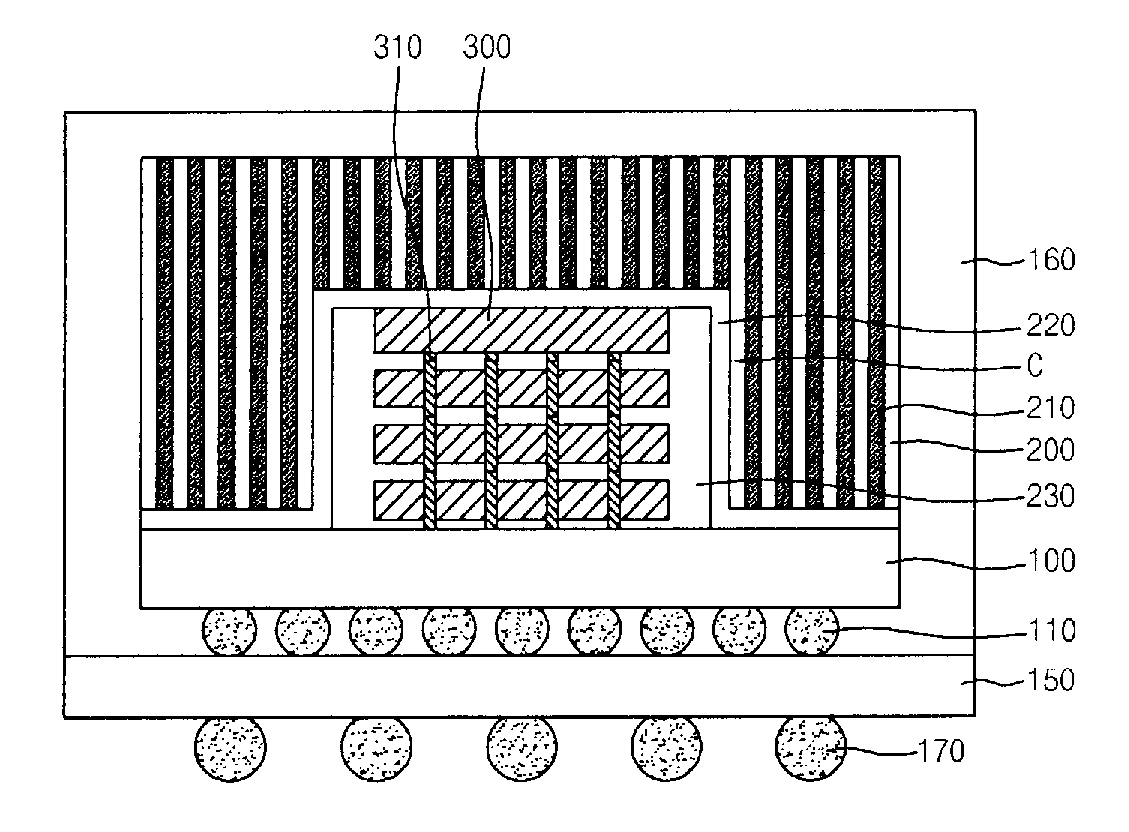

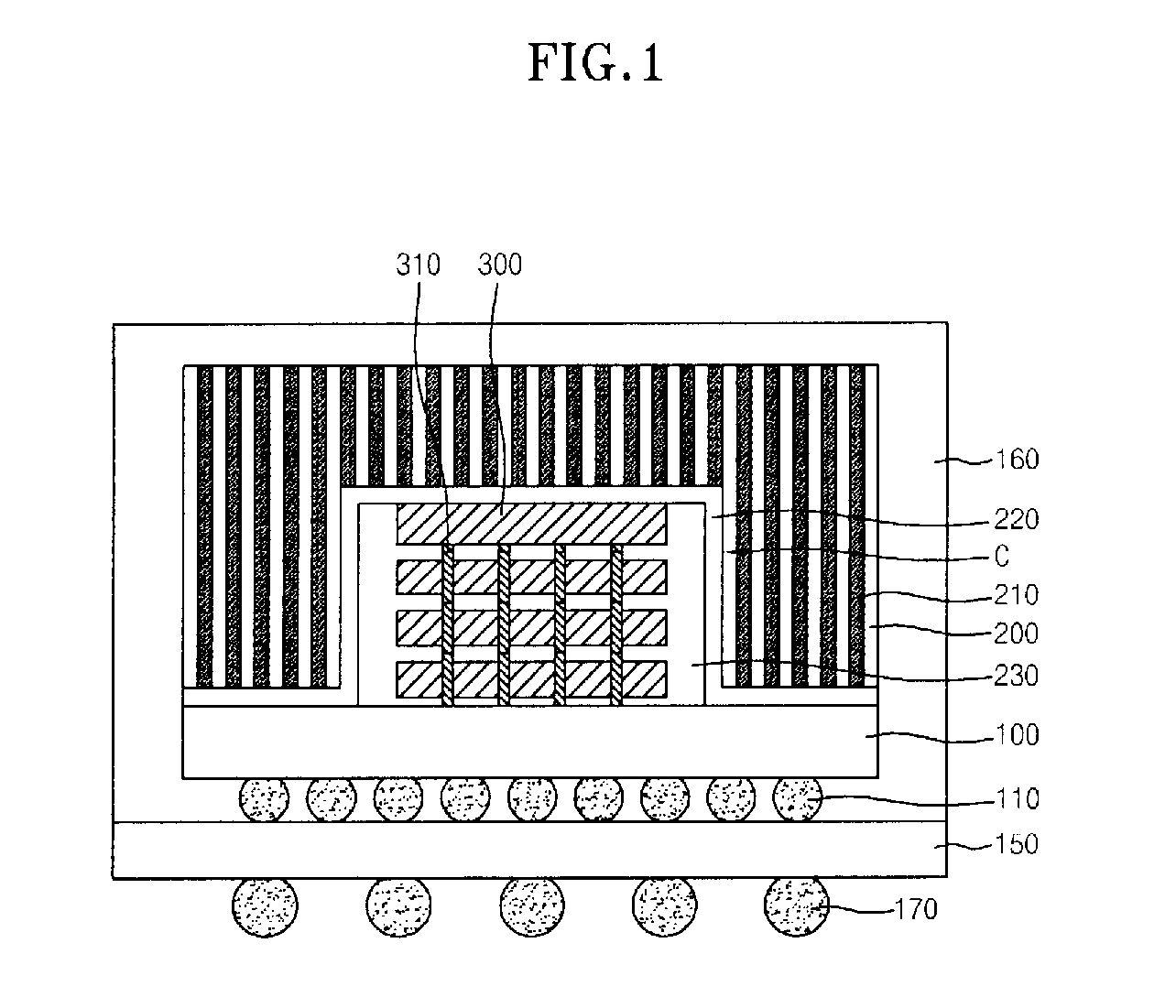

Semiconductor package with heat dissipation devices

ActiveUS20110304036A1Improve heat dissipation characteristicGood heat dissipationSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A semiconductor package includes a first semiconductor chip having a first surface and a second surface which faces away from the first surface, a heat dissipation member, defined with a cavity, disposed on the first surface of the first semiconductor chip and having a plurality of metal pillars which contact the first semiconductor chip, and one or more second semiconductor chips stacked on the first surface of the first semiconductor chip in the cavity to be electrically connected with one another and with the first semiconductor chip.

Owner:SK HYNIX INC

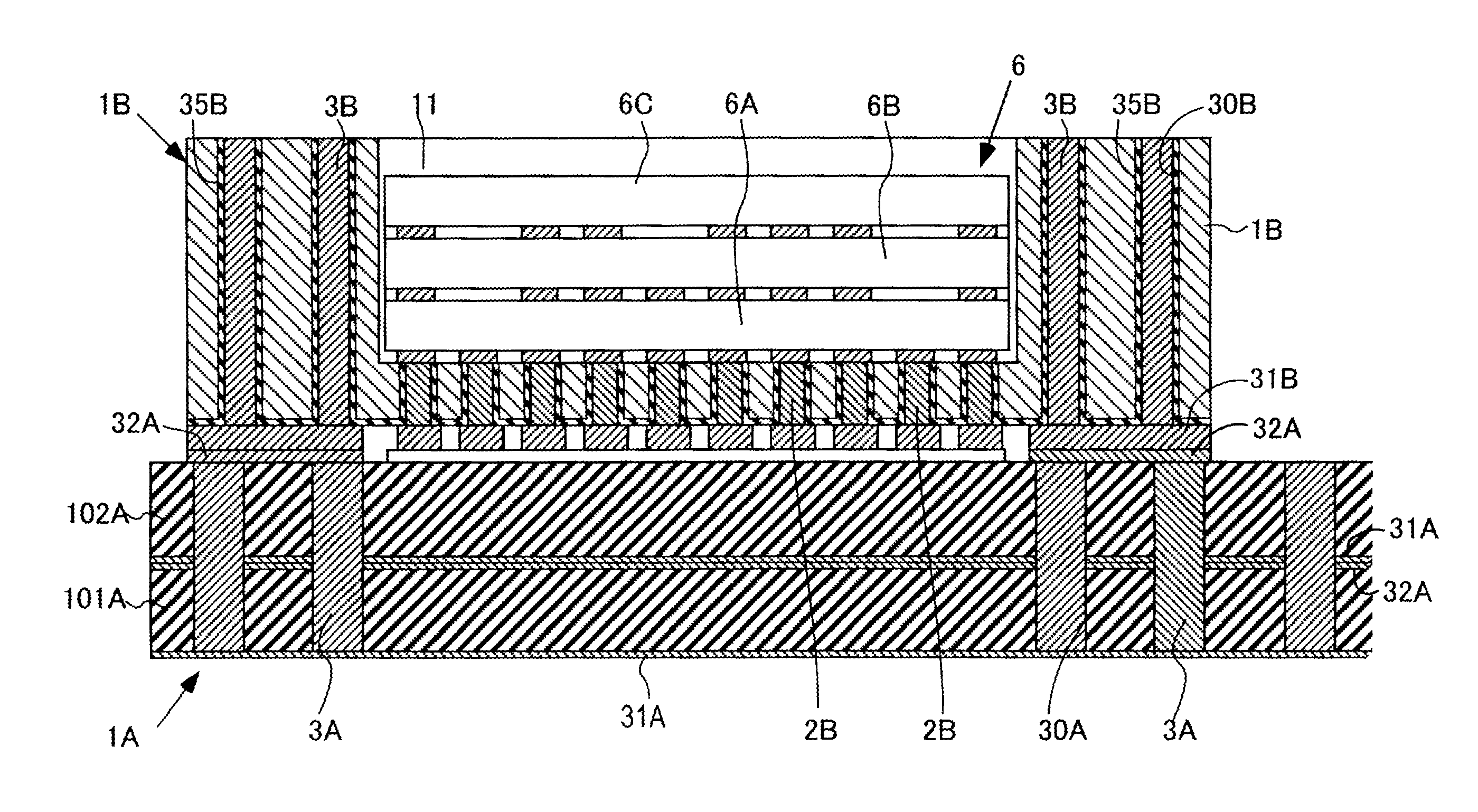

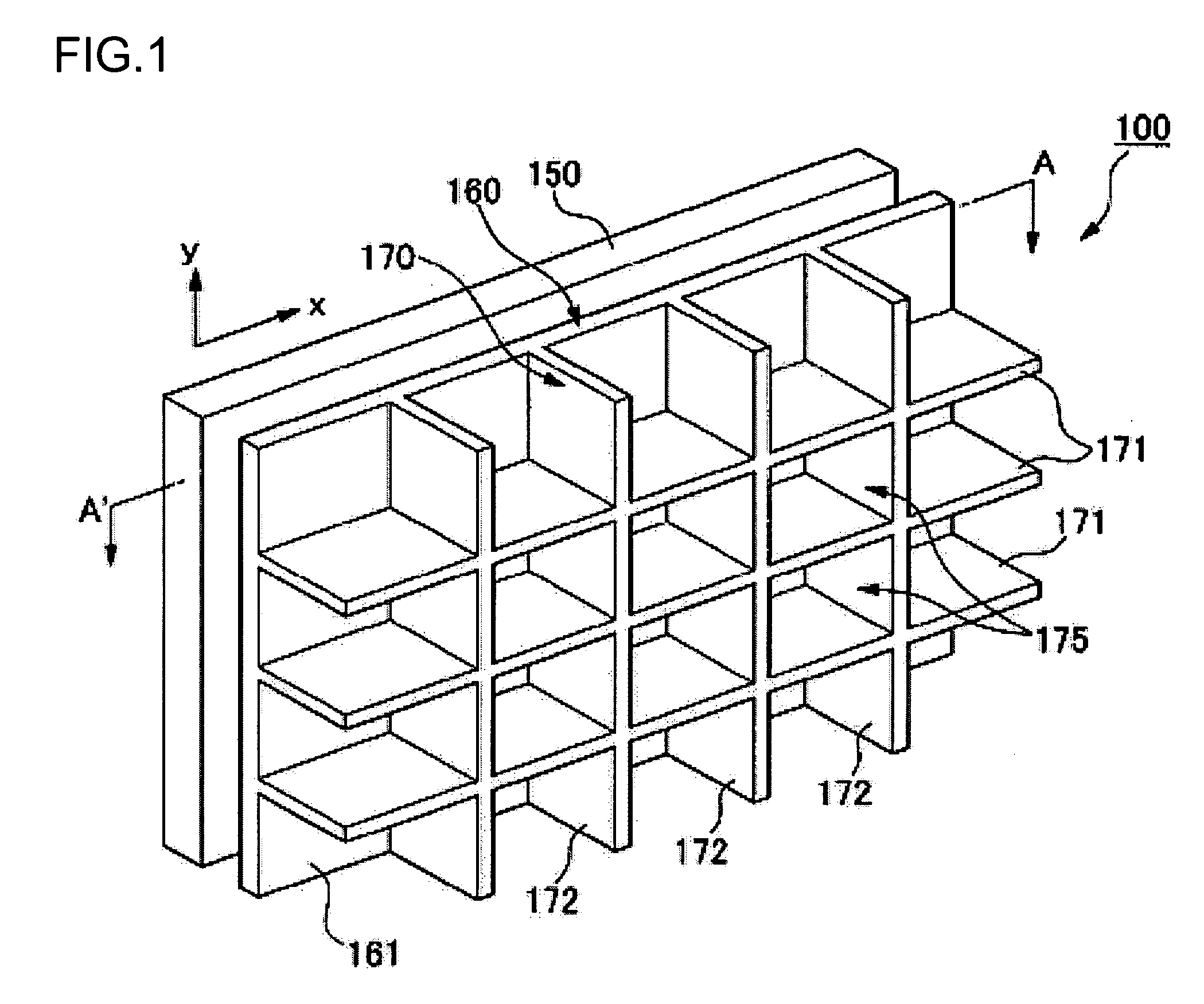

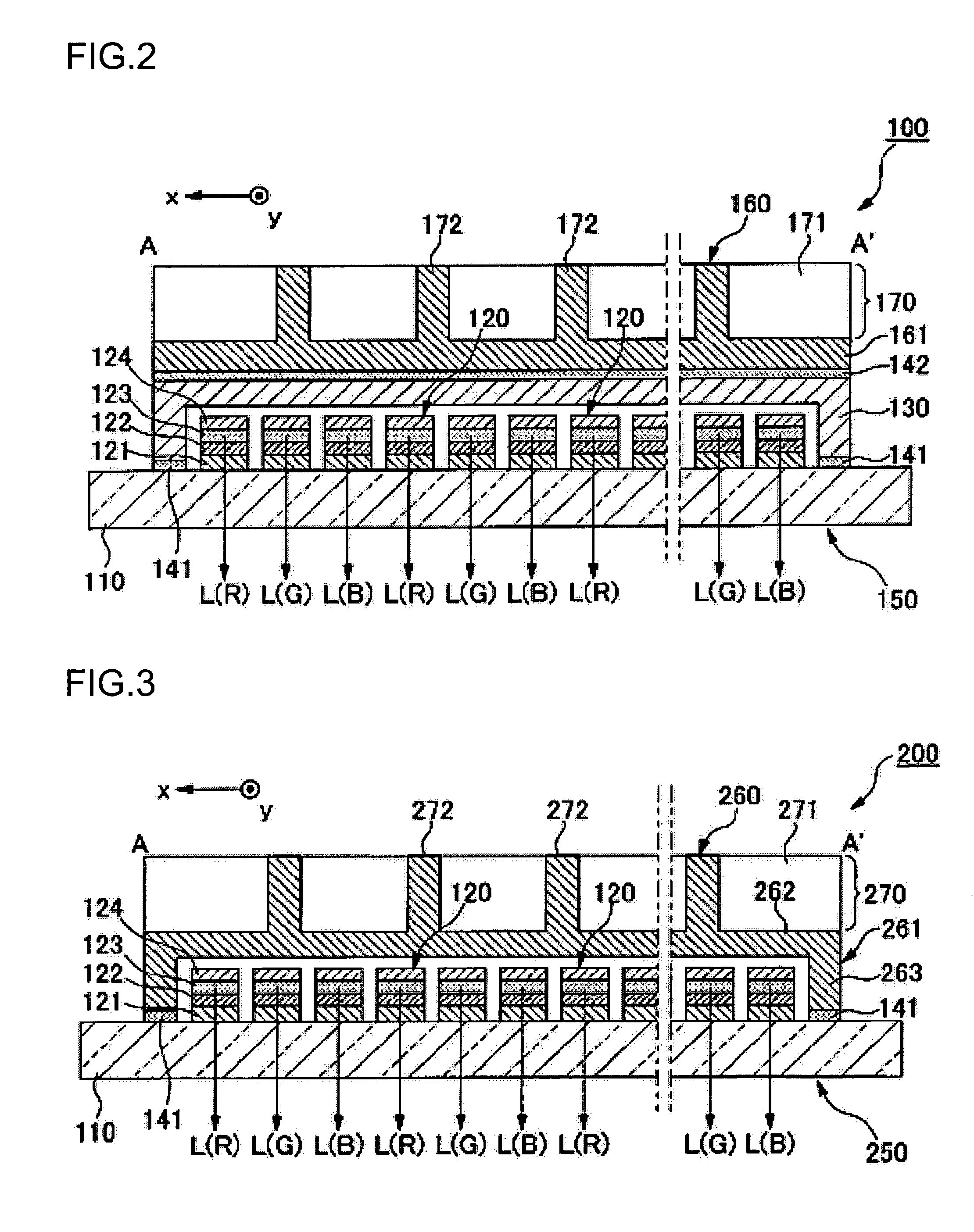

Reinforcing structure, display device, and electronic apparatus

InactiveUS20050117293A1Improve cooling efficiencyImprove reliabilityDigital data processing detailsElectroluminescent light sourcesDisplay deviceEngineering

To provide a display device with high reliability, which is capable of supporting a display panel well even when the display panel is enlarged, and capable of radiating the heat generated in the display panel well. A display device 100 of the present invention has an organic EL panel (display panel) 150 and a reinforcing structure 160 provided on the backside of the display panel 150. The reinforcing structure 160 comprises a base plate 161 forming a part adhered to a back face of the organic EL panel 150, and a heat radiation member 170 provided on the base plate 161.

Owner:SEIKO EPSON CORP

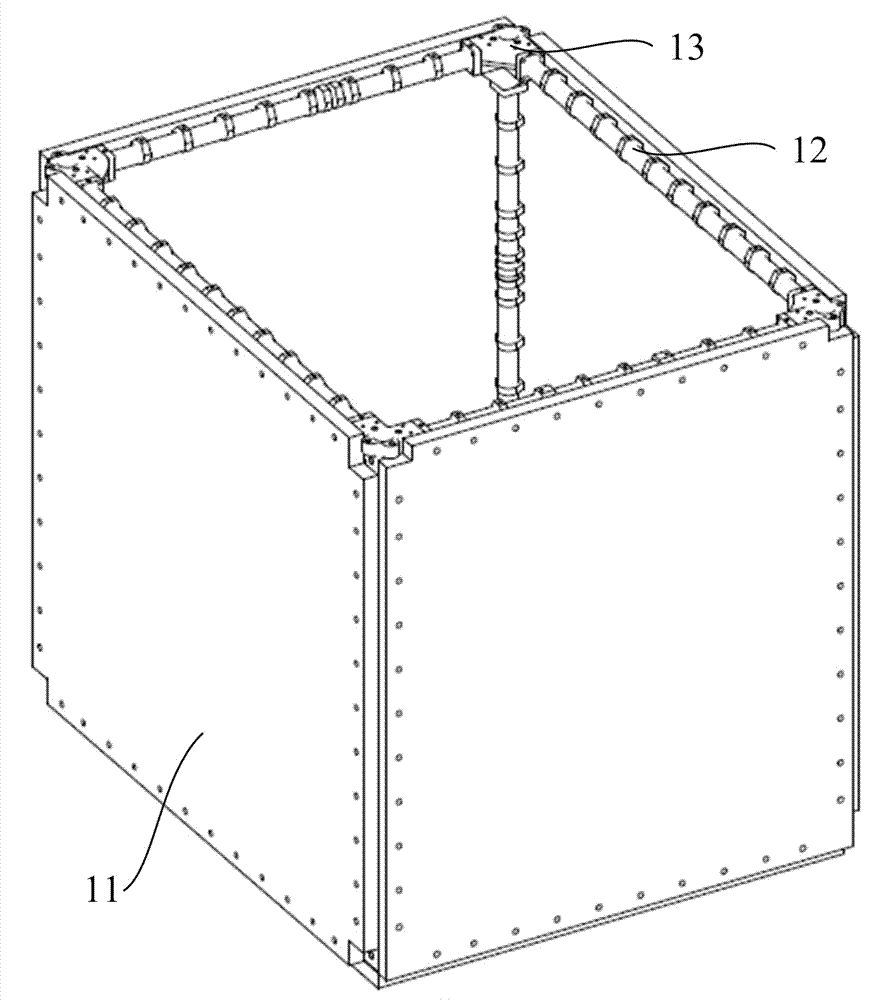

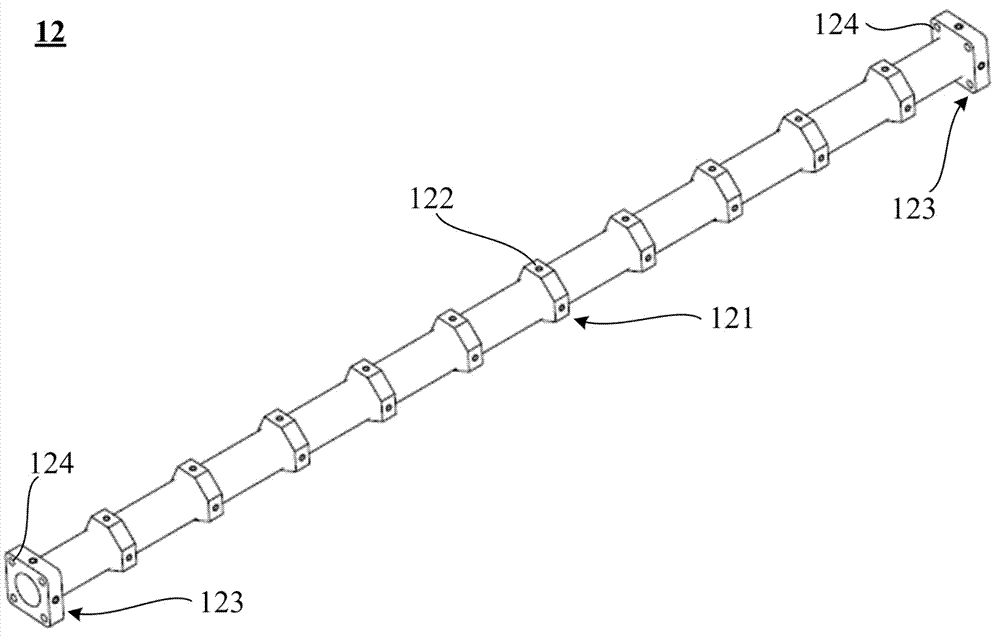

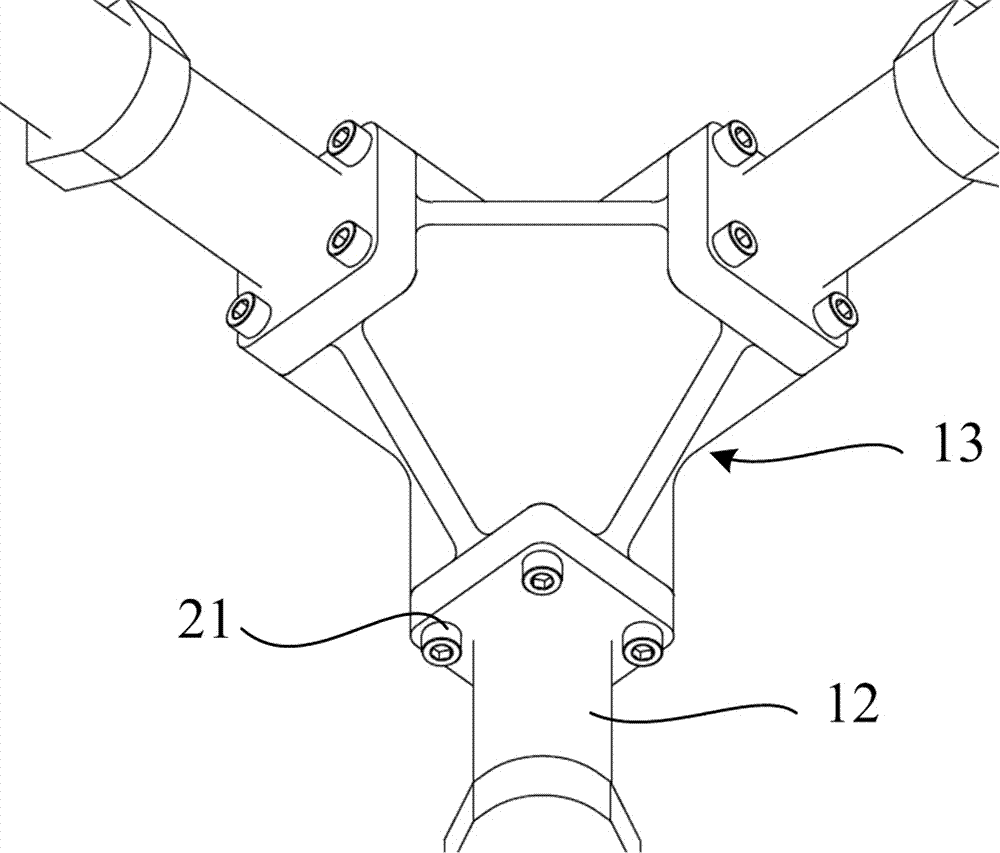

Frame panel type satellite configuration and modular satellite

InactiveCN103863577AGood heat dissipationGood impact resistanceArtificial satellitesSatelliteFastener

The invention provides a frame panel type satellite configuration and a modular satellite adopting the same. The frame panel type satellite configuration comprises a four-edge-column frame and honeycomb structure plates; the four-edge-column frame is used for bearing axial load when being connected with four connecting interfaces for carrying, wherein the four-edge-column frame comprises rod pieces and rod-piece joints; each rod piece is provided with a plurality of bosses; the bosses are provided with installing holes for connection with the honeycomb structure plates by first fasteners; a plurality of through holes are arranged in the extending surfaces of the end parts of the rod pieces and are used for connection with the rod-piece joints by second fasteners; the honeycomb structure plates provide installing surfaces for single satellite equipment and simultaneously provide in-plane shearing rigidity for the four-edge-column frame.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

Light emitting device packages and methods of forming the same

ActiveUS20140246648A1Maximizing degree of freedomGood heat dissipationSolid-state devicesSemiconductor devicesElectrodeLight emitting device

A light emitting device package, comprises a light emitting structure having first and second electrodes insulated from each other; and a support structure. The support structure comprises: a first support electrode electrically connected to the first electrode of the light emitting structure; a second support electrode electrically connected to the second electrode of the light emitting structure, the second support electrode spaced apart from, and electrically insulated from, the first support electrode; and a support connection portion between the first support electrode and the second support electrode. The light emitting structure includes a protrusion portion that protrudes in a horizontal direction beyond a sidewall of at least one of the first support electrode and the second support electrode so that a void is present below the protrusion portion and above a plane extending from bottoms of the first and second support electrodes.

Owner:SAMSUNG ELECTRONICS CO LTD

Heat dissipating device

InactiveUS7578337B2Improve the overall coefficientStrengthen restrictionsHeat transfer modificationCooling/ventilation/heating modificationsEngineeringDistortion

A heat dissipation device with a fluid cavity that utilizes a hybrid of star pins with concave surfaces and sharp edges, and truncated dimples, which creates turbulence and a vortex phenomenon perpendicular to fluid flow transmission, and increases the heat transfer coefficient without increasing restriction of fluid flow through the device. This process increases the heat transfer along local pins which are located around each truncated dimple. This effect allows the use of taller pins than previous devices thus increasing the surface of heat transfer and thus these pins have a more efficient heat transfer coefficient along the total length of the pin, not possible previously. Star pins with sharp edges prevent the distortion of the highly efficient vortex flow which increases fluid flow and simultaneously intensifies the desired phenomena of extraordinary turbulence.

Owner:US THERMOELECTRIC CONSORTIUM

Battery pack

ActiveUS20120231316A1Good heat dissipationImprove cooling efficiencyCell temperature controlHeat conductingEngineering

A battery pack having improved heat dissipation characteristics. A battery pack includes a plurality of battery modules, each including a plurality of battery cells aligned in a direction, and a plurality of barriers, each being between a respective pair of adjacent battery cells of the plurality of battery cells and including a connection portion protruded to the outside of the adjacent battery cells. The battery pack further includes a heat dissipation member connected to connection portions of the plurality of connection portions, and a heat conducting member connected to the heat dissipation member.

Owner:ROBERT BOSCH GMBH +1

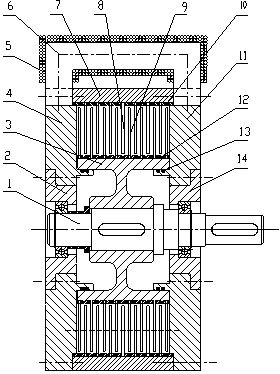

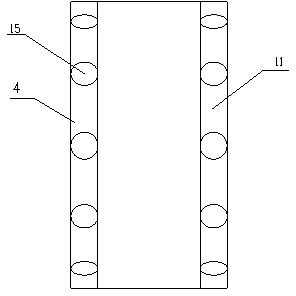

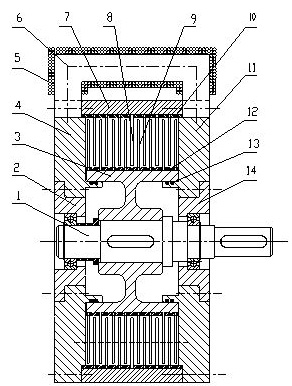

Multiple-disc type magnetorheological brake

InactiveCN102146968AGood heat dissipationImprove cooling effectLiquid resistance brakesMagnetic currentBrake torque

The invention relates to a multiple-disc type magnetorheological brake which mainly comprises a transmission shaft, a wheel hub, a drive friction plate group, a driven friction plate group, inner and outer magnetic isolation rings, an exciting coil with a U-shaped iron core, magnetic-conducting side plates and a magnetic isolation casing. A sealing ring is used for sealing magnetorheological fluid between the drive friction plate group and the driven friction plate group; the drive friction plate group and the driven friction plate group are respectively sleeved on the magnetic isolation rings and the wheel hub through splines; the drive friction plate group is separated from the driven friction plate group by the inner magnetic isolation ring and the outer magnetic isolation ring; the exciting coil with the U-shaped iron core is directly spliced in iron core jacks of the magnetic conducting side plates; and the braking torque can be changed through changing the current intensity of the coil. When the braking torque is not enough, the quantity of friction plates can be increased or the quantity of the exciting coil with the U-shaped iron core can be increased to adapt to the big torque braking. The multiple-disc type magnetorheological brake has the advantages that the structure is compact, the braking torque is big, the assembly and the disassembly are convenient, the coil is easily used for radiating the heat, and the number of turns wounded by the coil is more.

Owner:CHINA UNIV OF MINING & TECH

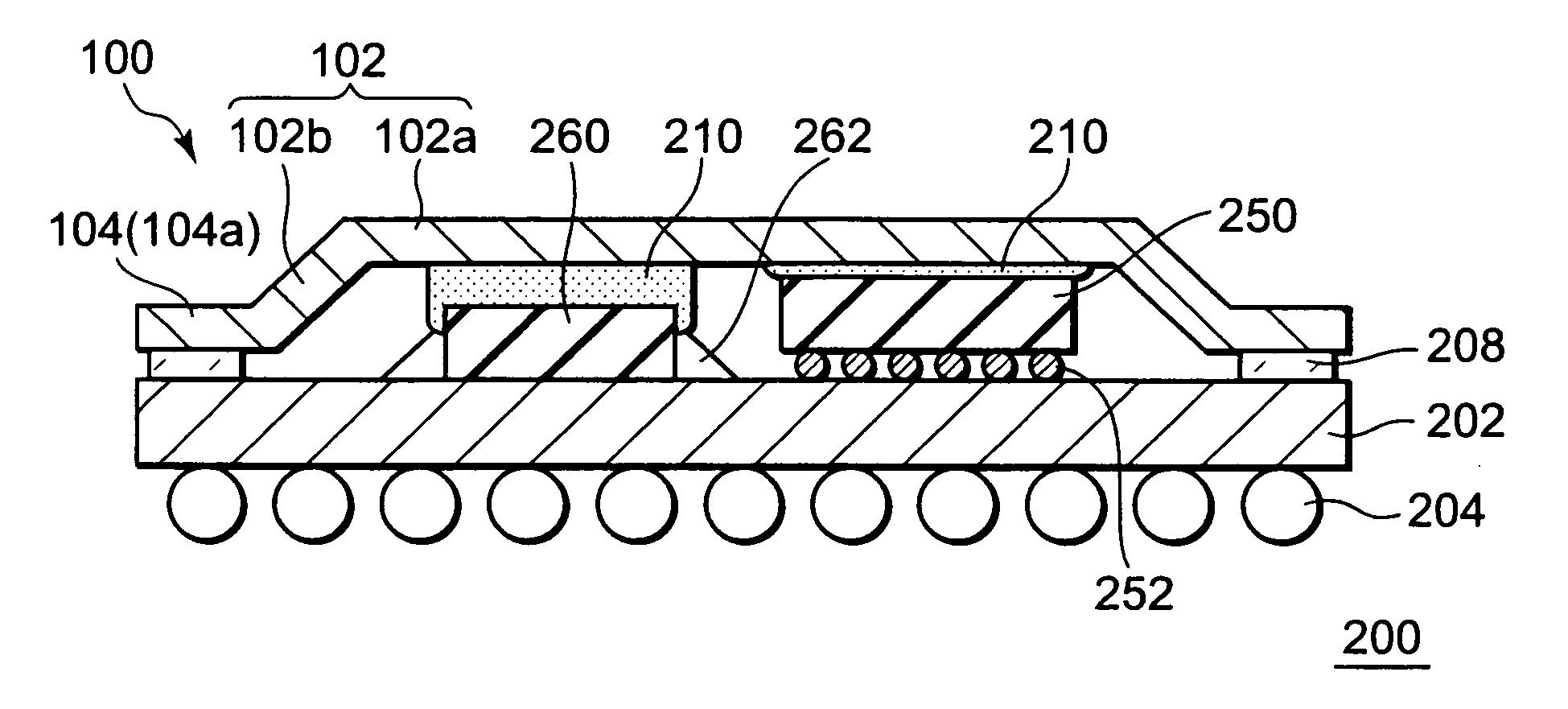

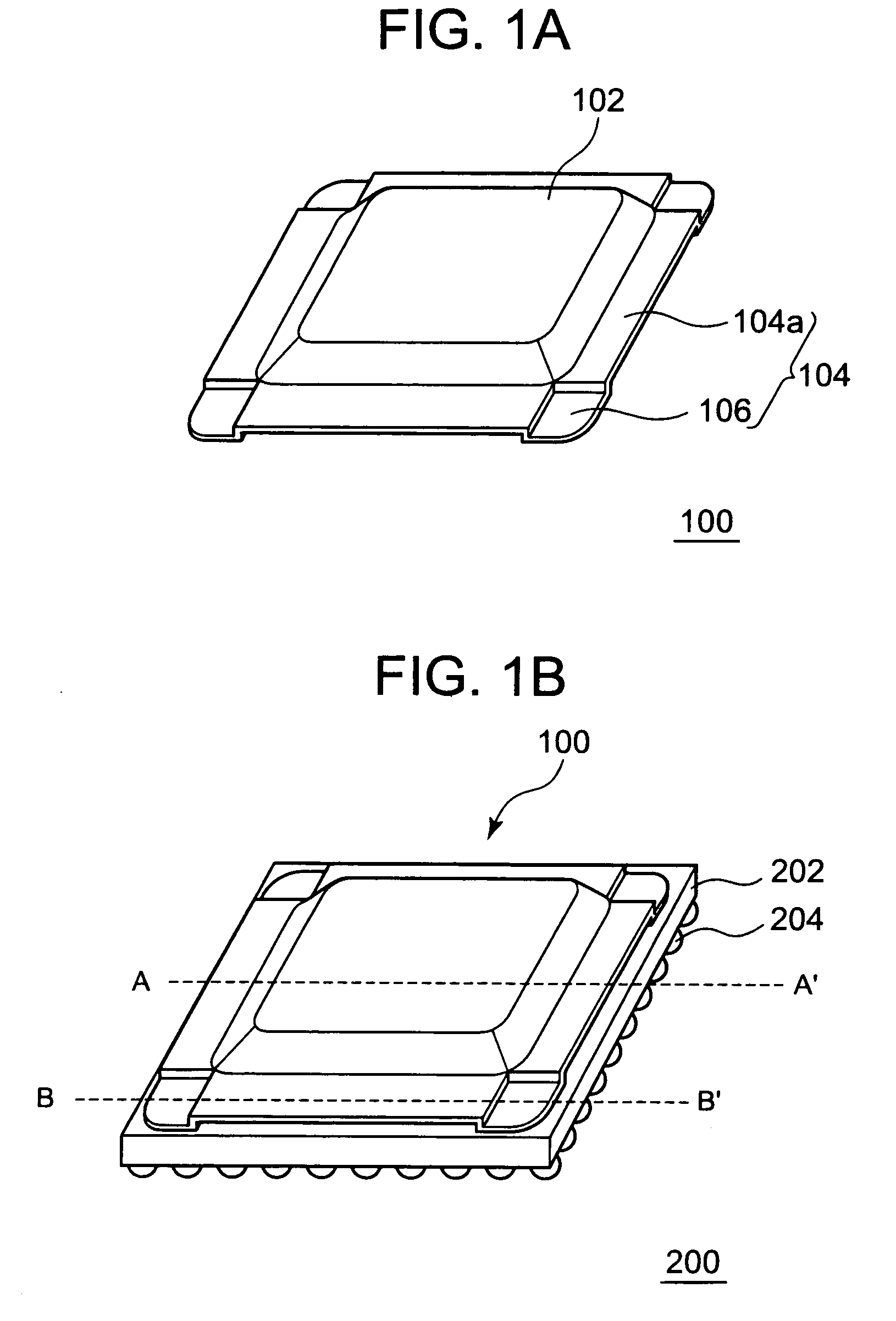

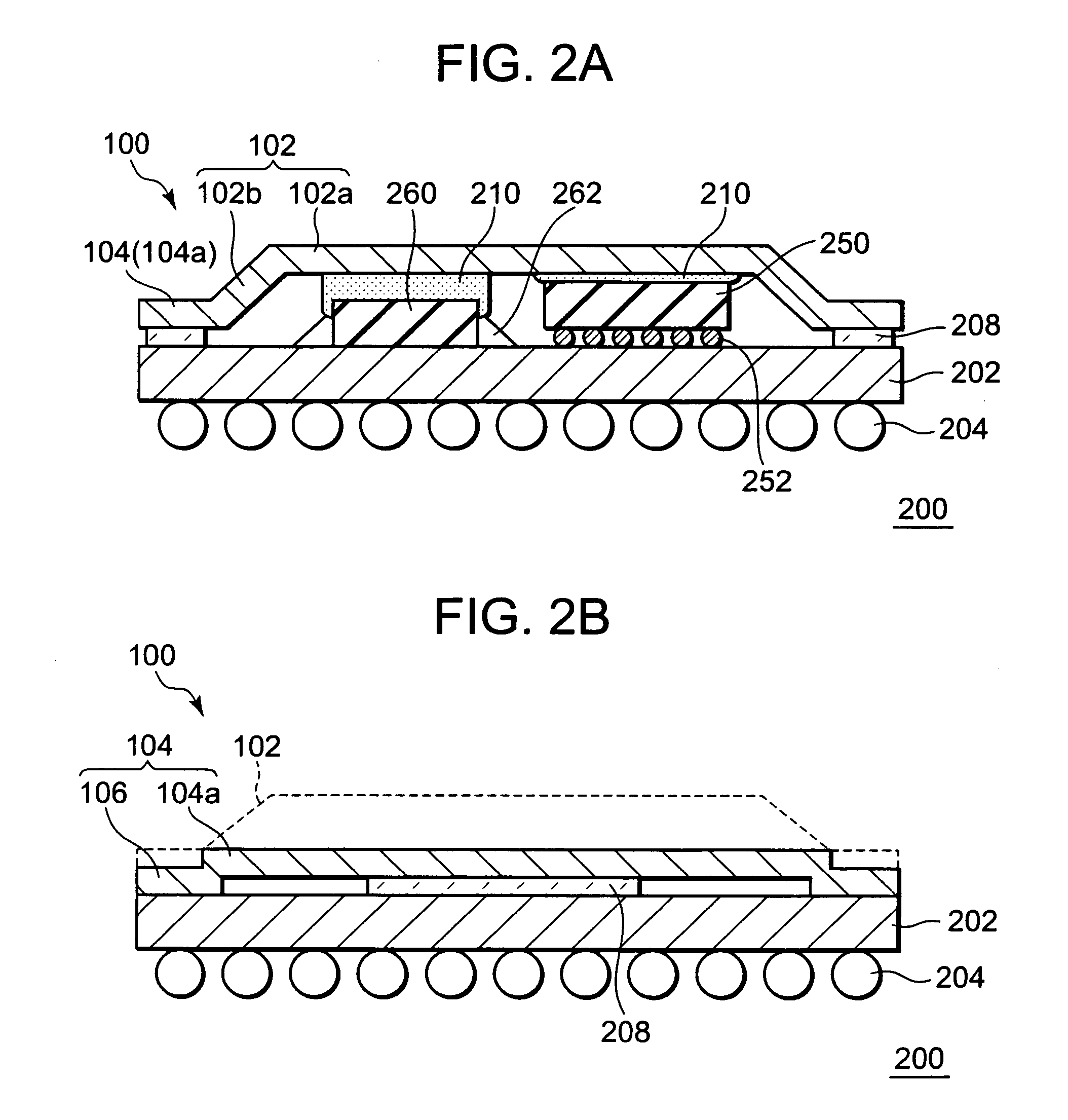

Electronic device and lid

ActiveUS20100109152A1Accurate predictionEasy to controlSemiconductor/solid-state device detailsSolid-state devicesElectronic componentFlange

The present invention can prevent a lid from tilting when the lid is attached to a substrate. An electronic device 200 includes: a substrate 202; an electronic component mounted on the substrate 202; and a lid 100 including a cover portion 102 protruding in a direction opposite the substrate 202 and covering the electronic component and a flange portion 104 arranged at the periphery of the cover portion 102 and adhered to the substrate 202. A protrusion portion 106 protruding for a predetermined height in a direction of the substrate 202 compared to other areas of the flange portion 104 is arranged on the flange portion 104 of the lid 100.

Owner:RENESAS ELECTRONICS CORP

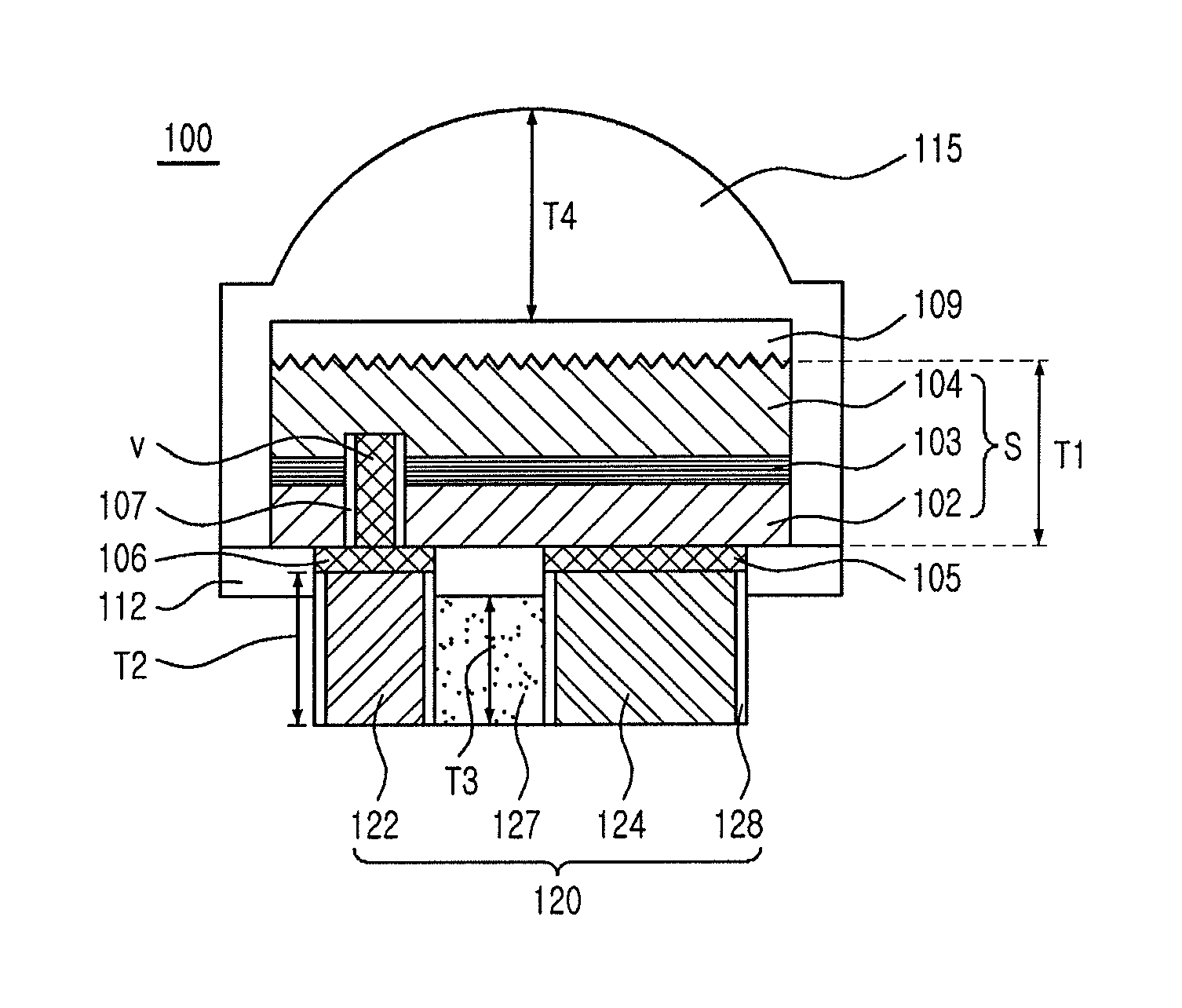

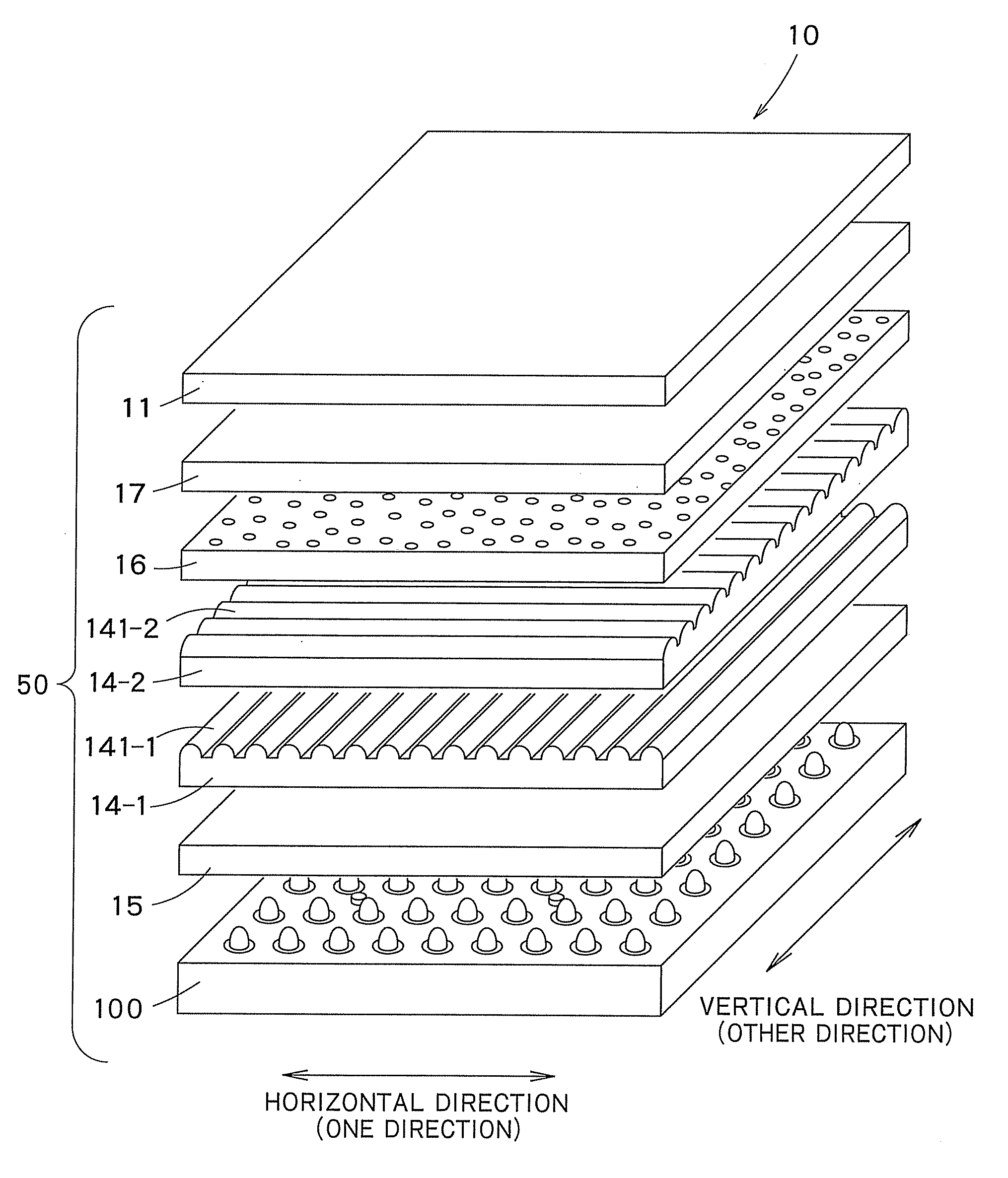

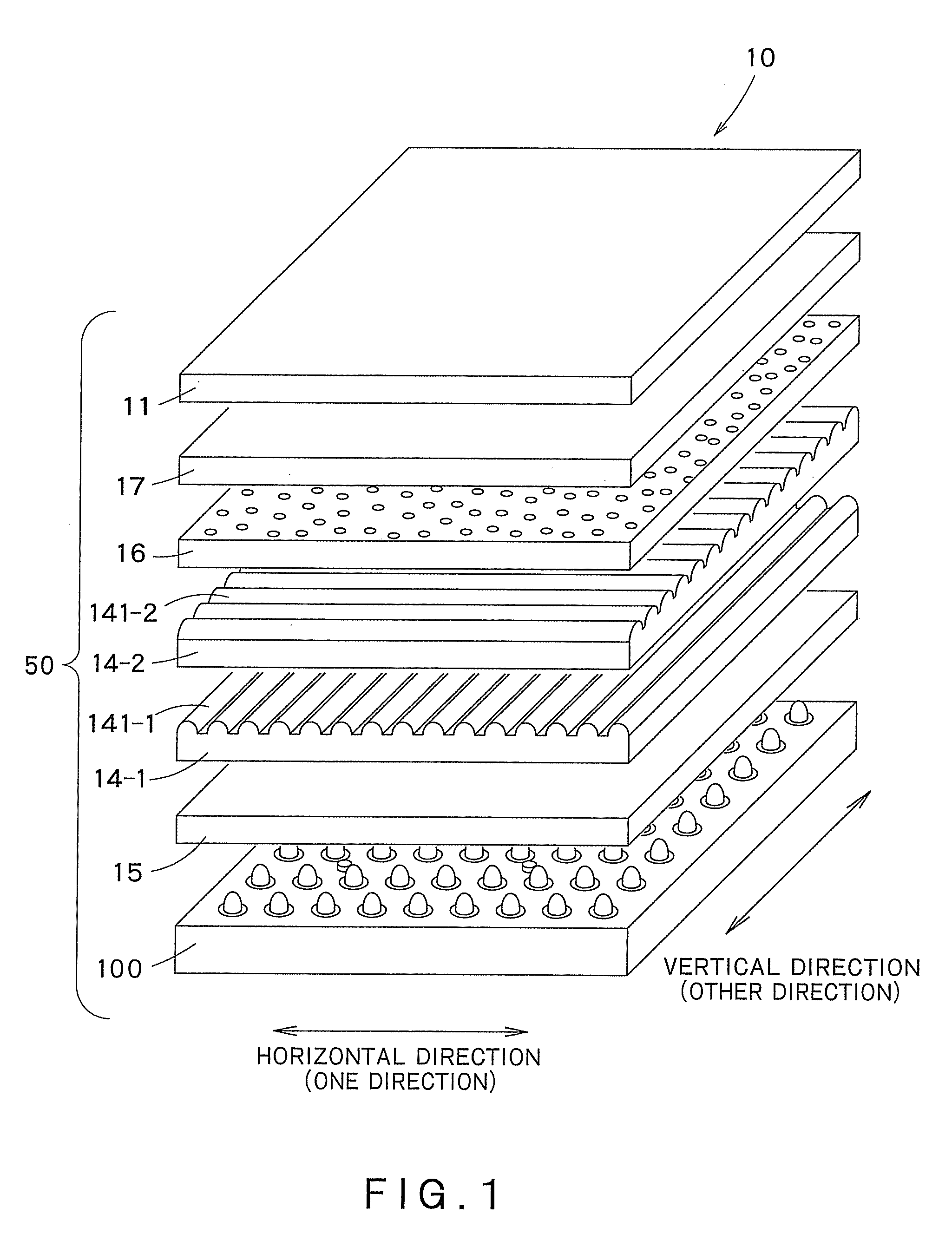

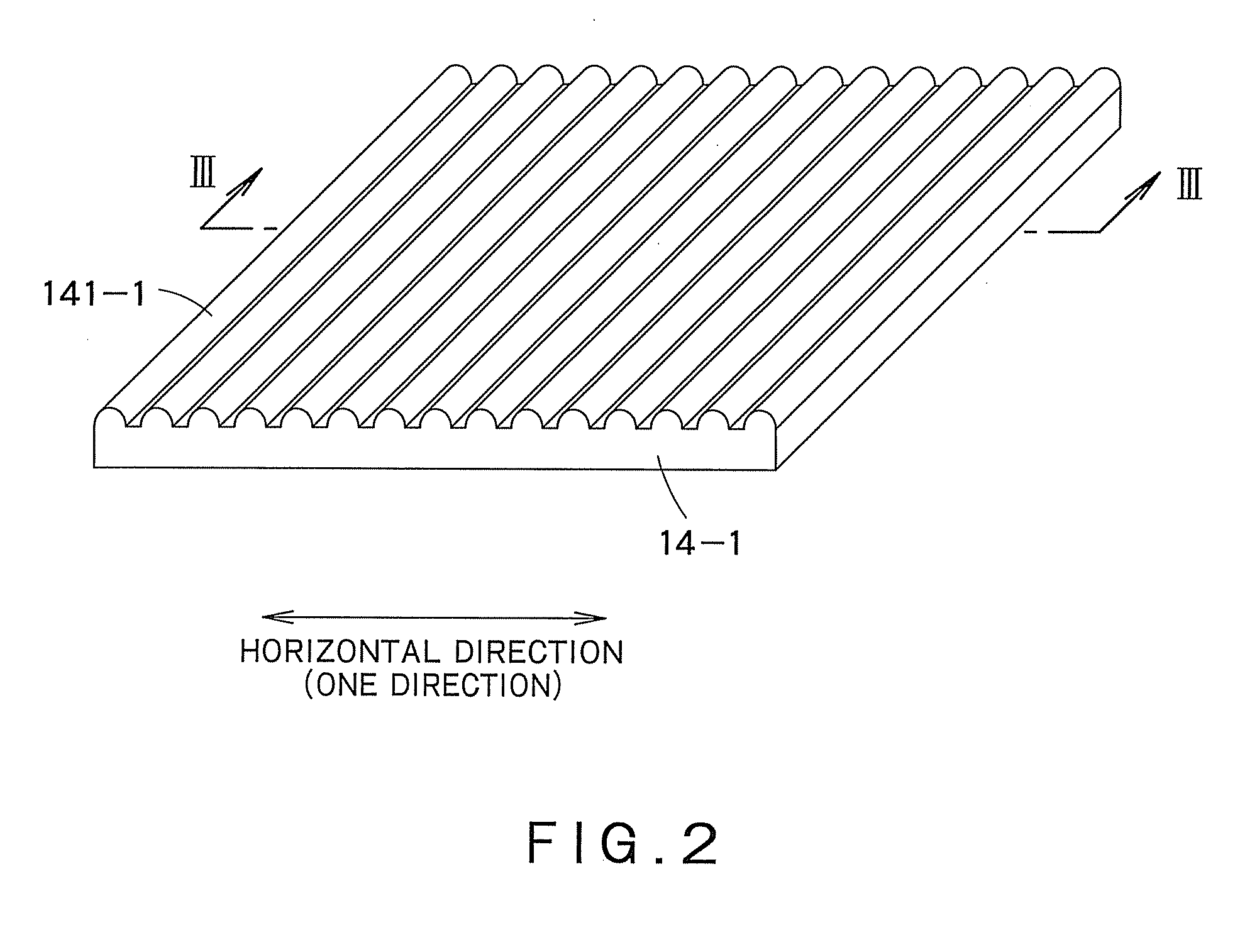

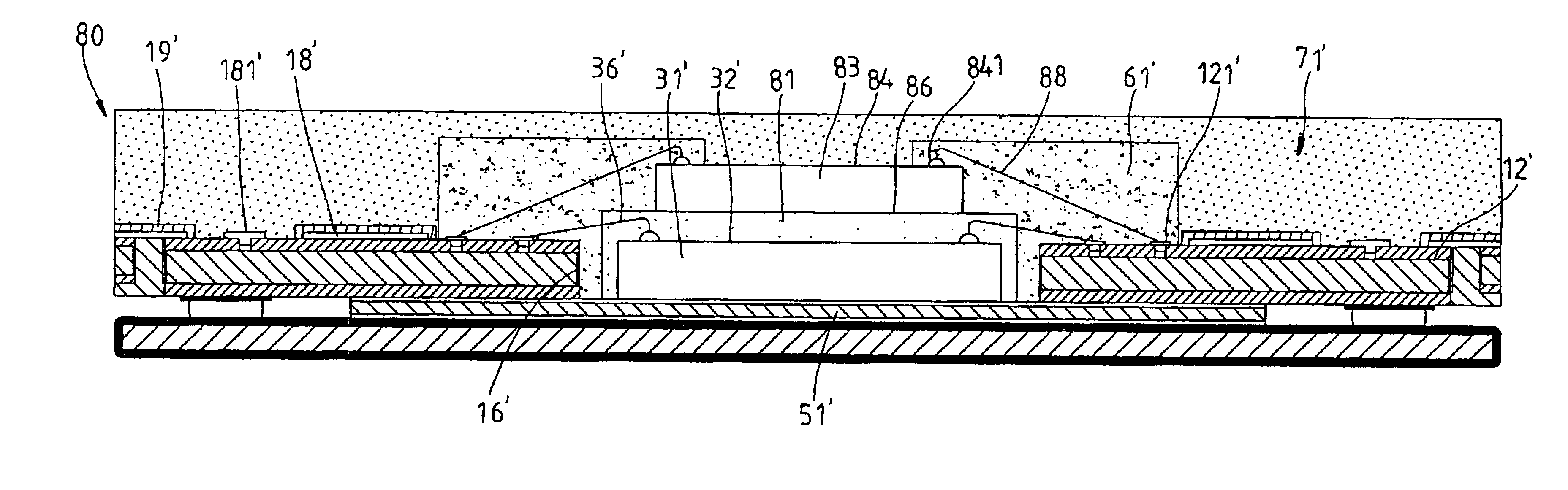

Surface light source system and light source unit

ActiveUS20090091919A1Low production costImprove energy efficiencyIlluminated signsNon-linear opticsLenticular lensLens plate

A surface light source system 50 capable of emitting light without producing non-uniform luminance and non-uniform color distributions is provided. The surface light source system 50 comprises a lenticular lens sheet 14-1 having unit lenses 141-1 with convexity on the light-exiting side, and a light source unit 100 having emission sources 101 of two types or more that are different in the wavelength range of light they emit. The unit lenses are arranged in one direction at approximately regular intervals. Emission sources of each type are arranged in the one direction at approximately regular intervals. The intervals at which the respective emission sources of two types or more arranged in the one direction are nearly the same in length.

Owner:DAI NIPPON PRINTING CO LTD

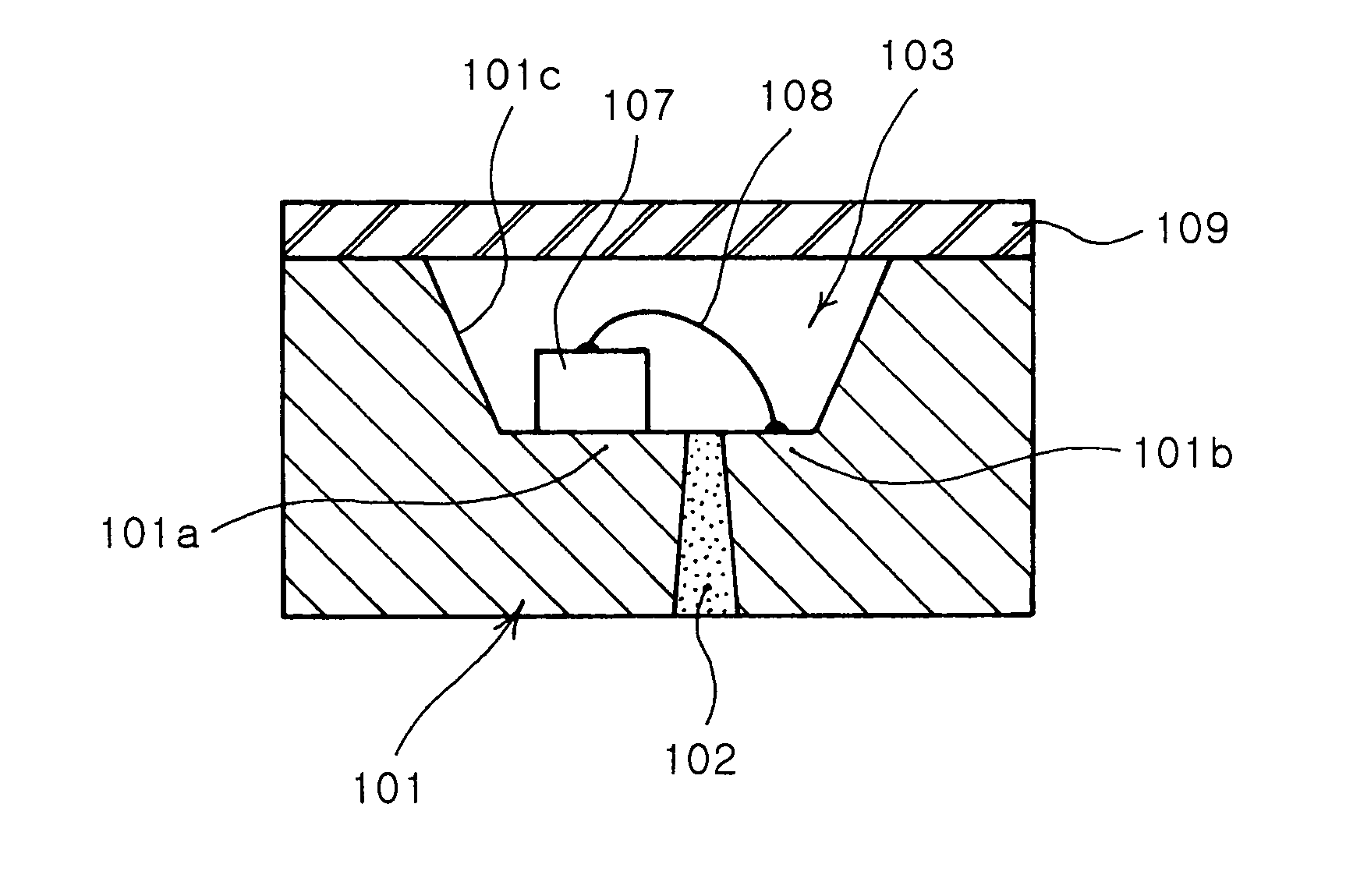

Double-sided thermally enhanced IC chip package

InactiveUS6849932B2Good heat dissipationImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringSealant

The present invention is to provide a double-sided thermally enhanced IC chip package which includes a chip being received in an opening of a substrate and electrically connected to a conductive circuit pattern on a top surface of the substrate through bonding wires. A thermally and electrically conductive planar member is attached to an inactive side of the chip through a thermally and electrically conductive adhesive layer. A portion of an active side of the chip to which the bonding wires are connected is encapsulated by a dielectric encapsulant, and the other portion of the active side of the chip is covered by a thermally and electrically conductive encapsulant. Thus, heat generated by the chip can be efficiently dissipated through the planar member and the thermally and electrically conductive encapsulant. The present invention also discloses a stacked chip package with double-sided heat dissipation capability.

Owner:UTAC HEADQUARTERS PTE LTD

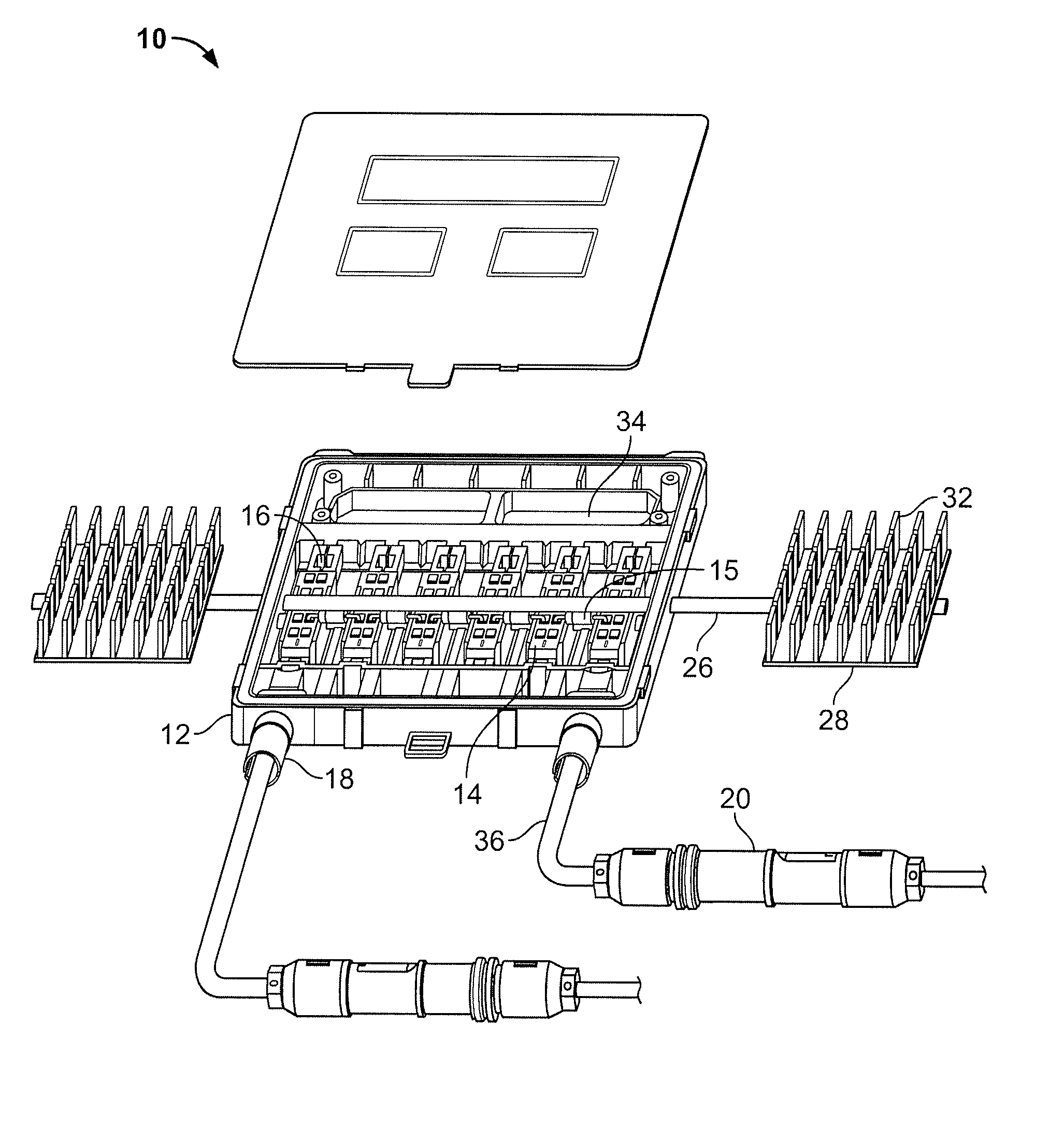

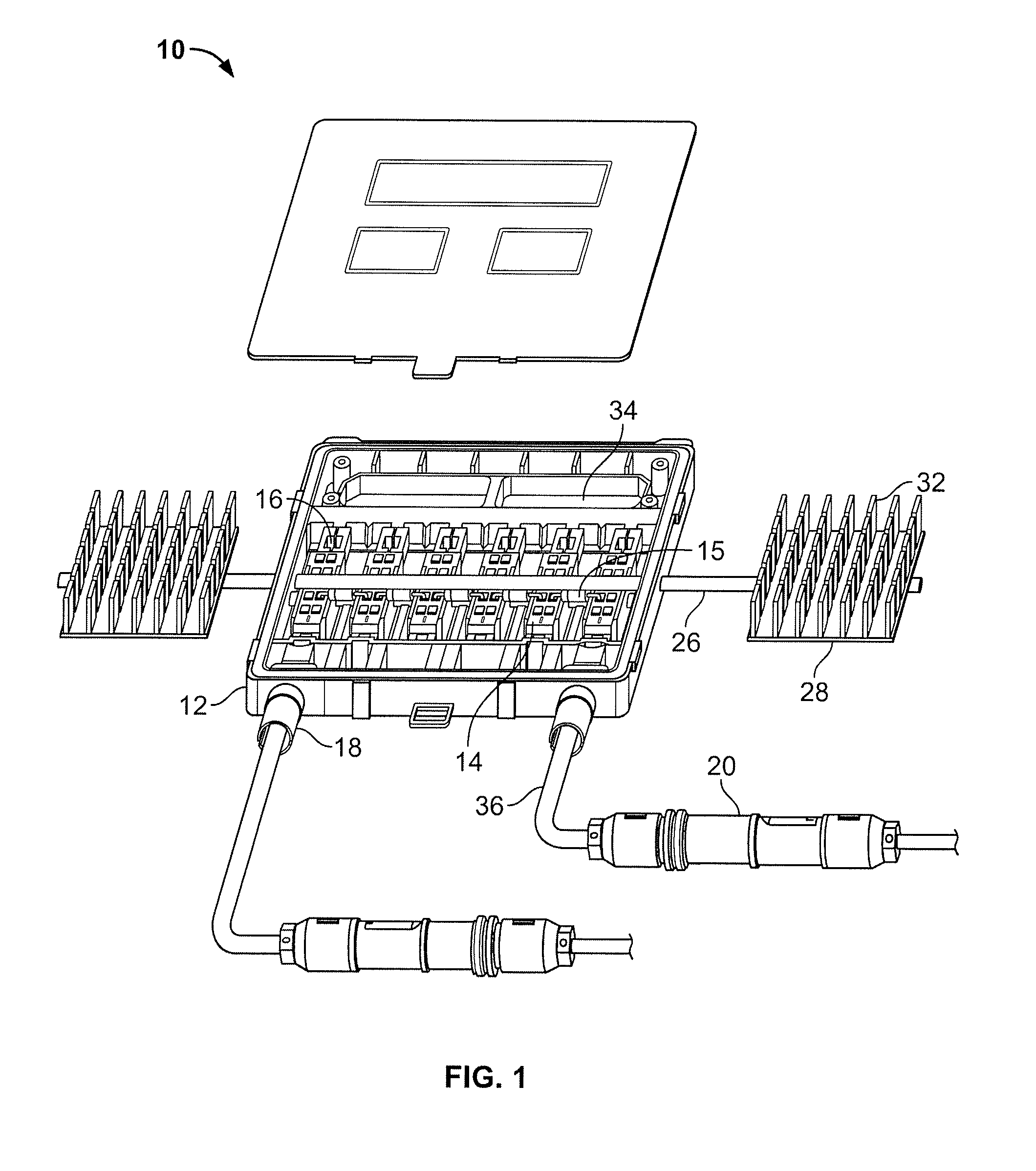

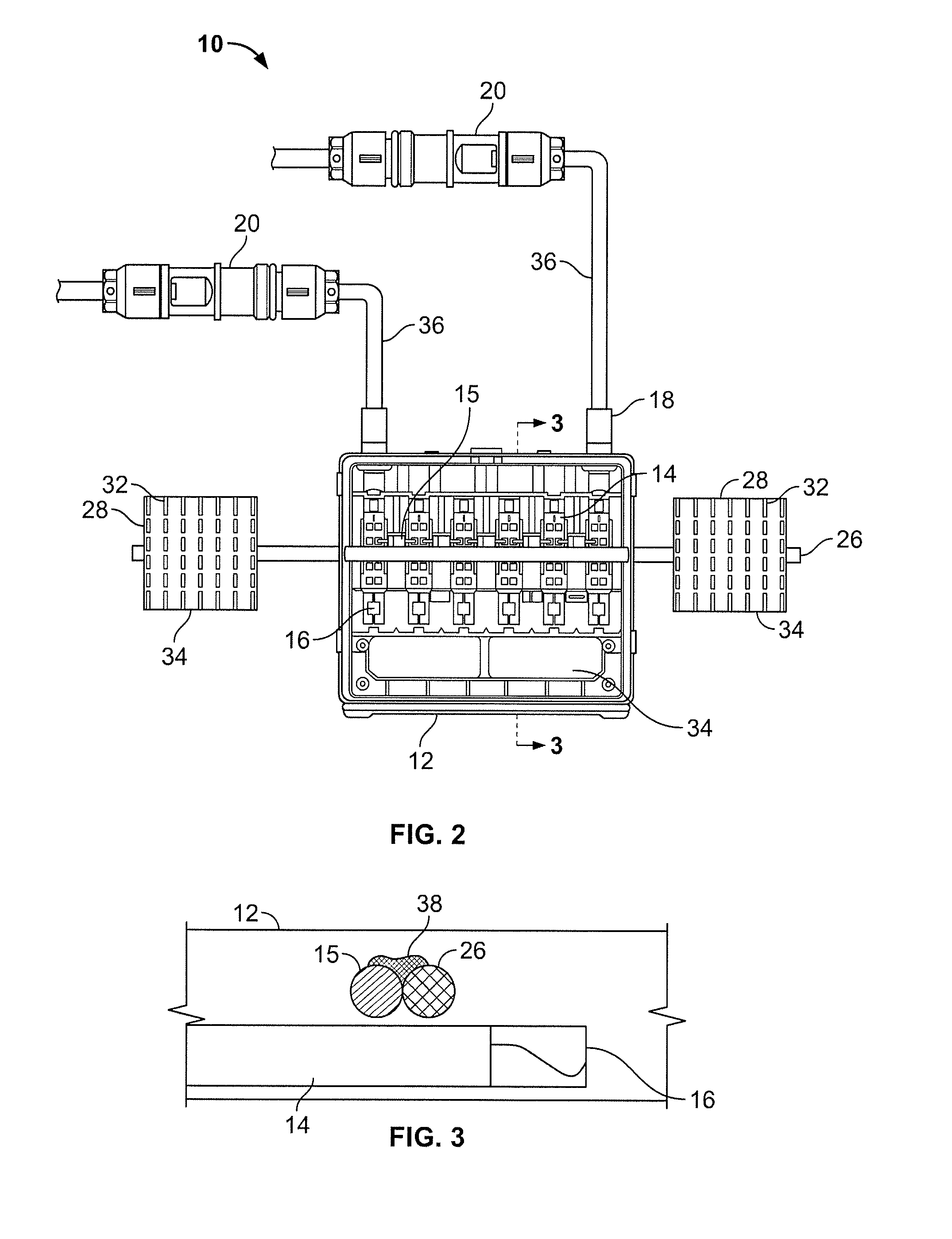

Heat dissipation system for solarlok photovoltaic interconnection system

InactiveUS20080115911A1Good heat dissipationRemove heatSolid-state devicesPhotovoltaicsEngineeringInterconnection

A heat dissipation system for a photovoltaic array (PV) interconnection system includes an enclosure containing one or more diode elements. A heat pipe system has heat sinks attached to one or both ends. The heat pipe passes through the enclosure in thermal contact with the diode assemblies. Cooling fins are arranged on the heat sink such that heat from the heat pipe is conducted into the fin and the fin dissipates the heat to the ambient atmosphere outside of the enclosure to cool the components within the enclosure.

Owner:TE CONNECTIVITY CORP

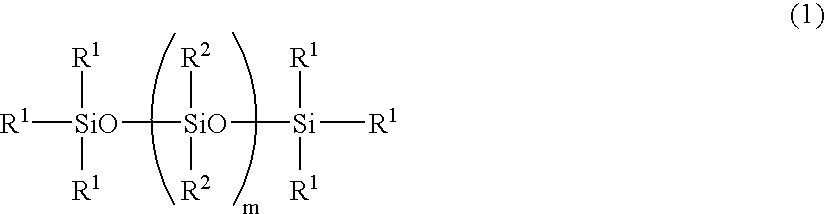

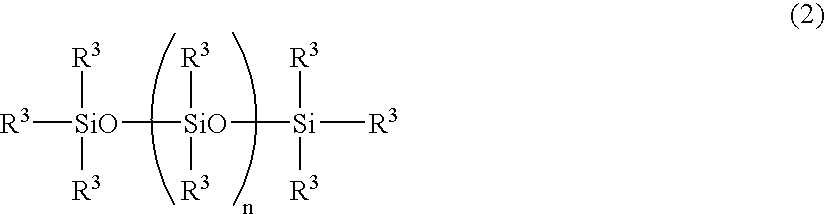

Heat conductive silicone grease composition and cured product thereof

InactiveUS20070042533A1Improve thermal conductivityReduce thermal resistanceLayered productsSemiconductor/solid-state device detailsIndiumPt element

Provided is a heat conductive silicone grease composition including (A) 100 parts by mass of an organopolysiloxane containing 2 or more alkenyl groups bonded to silicon atoms within each molecule, (B) an organohydrogenpolysiloxane containing 2 or more hydrogen atoms bonded to silicon atoms within each molecule, in sufficient quantity to provide from 0.1 to 5.0 hydrogen atoms bonded to silicon atoms within the component (B) for each alkenyl group within the component (A), (C) 100 to 2,200 parts by mass of a heat conductive filler, (D) an effective quantity of a platinum-based catalyst, and (E) an effective quantity of an addition reaction retarder, in which the component (C) includes more than 90% by mass and no more than 100% by mass of an indium powder with an average particle size of 0.1 to 100 μm. Also provided is a heat conductive silicone cured product obtained by curing the above composition by heating at a temperature equal to, or greater than, the melting point of the indium powder. Further provided is an electronic device including an electronic component, a heat radiating member, and a heat conductive member including the above cured product disposed between the electronic component and the heat radiating member. Still further provided is a method of curing the above composition. Even further provided is a method of forming a heat conductive member between an electronic component and a heat radiating member. The above heat conductive silicone grease composition generates a suitably thin cured product with excellent thermal conductivity that prevents problems such as the contamination of components other than the coated component, and the leakage of oily materials from the product if used over extended periods.

Owner:SHIN ETSU CHEM IND CO LTD

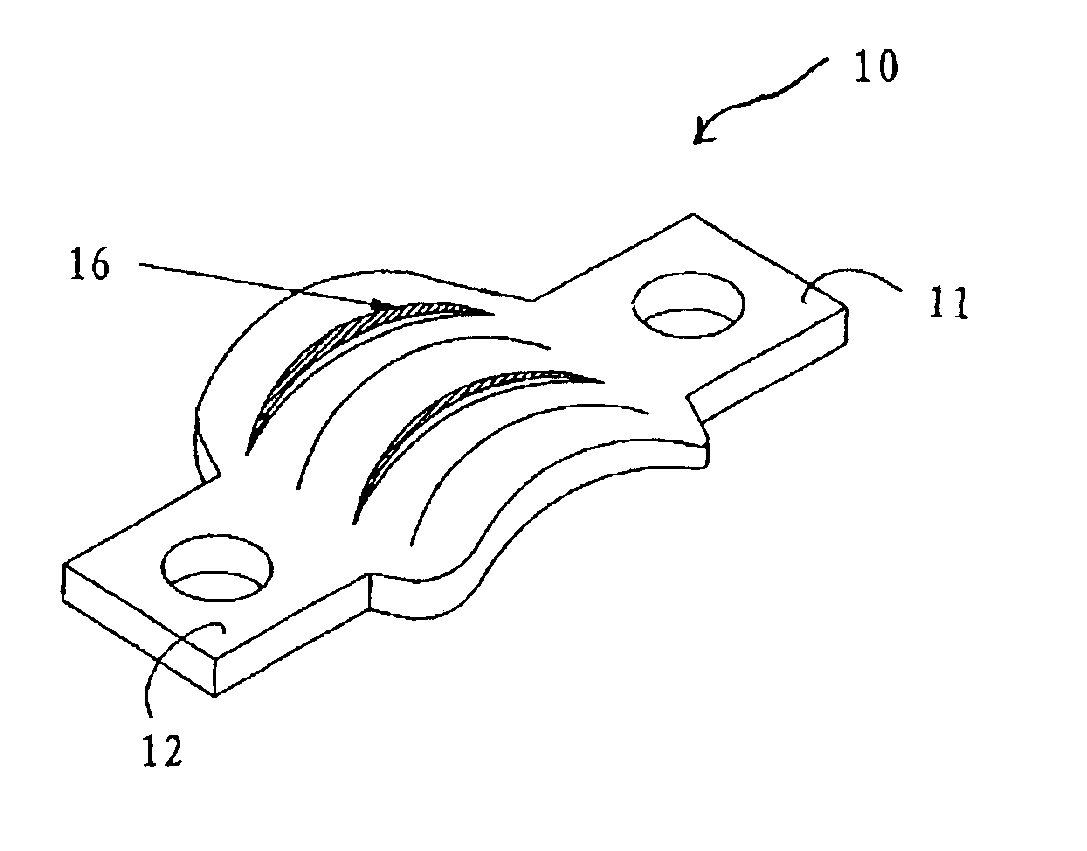

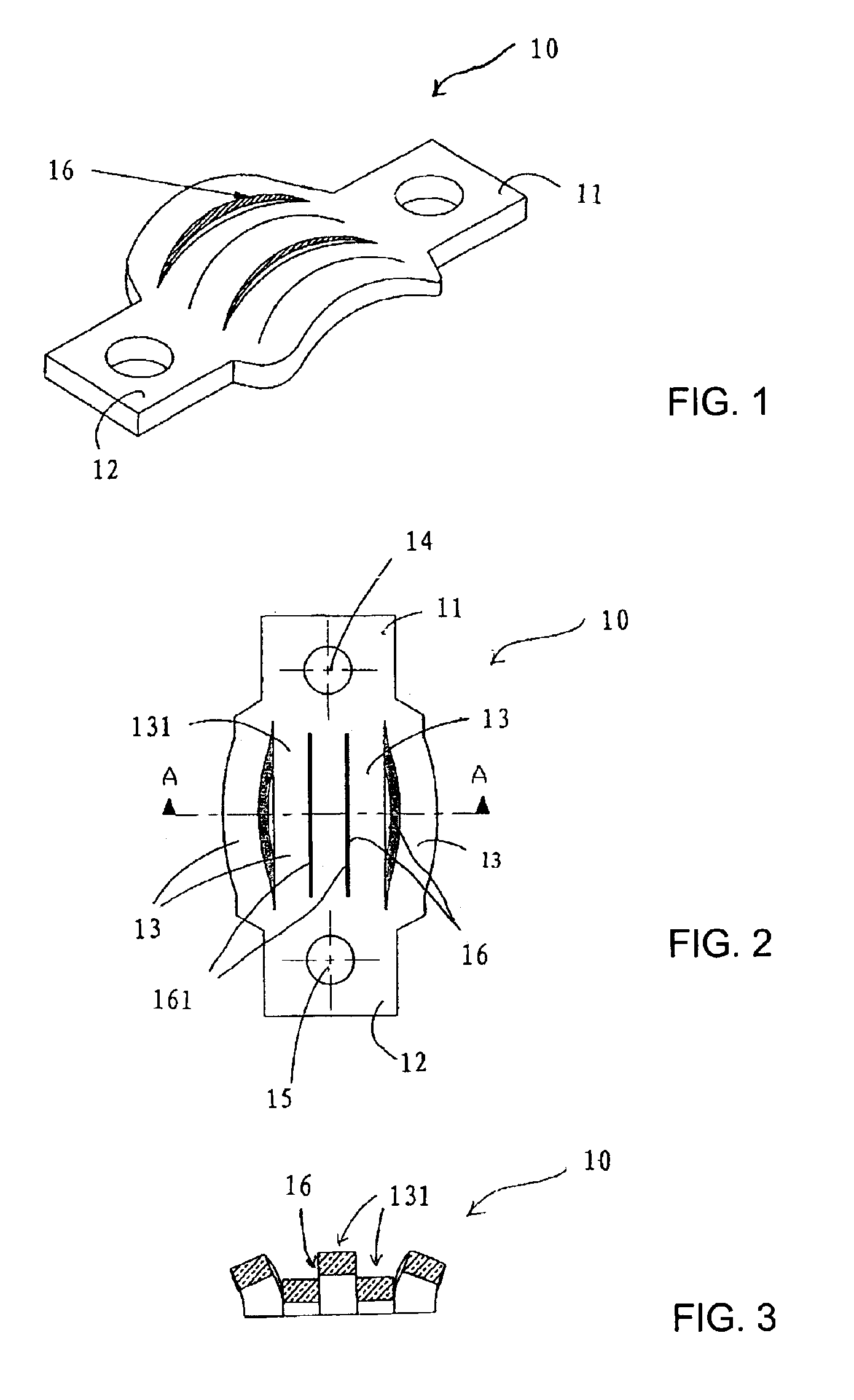

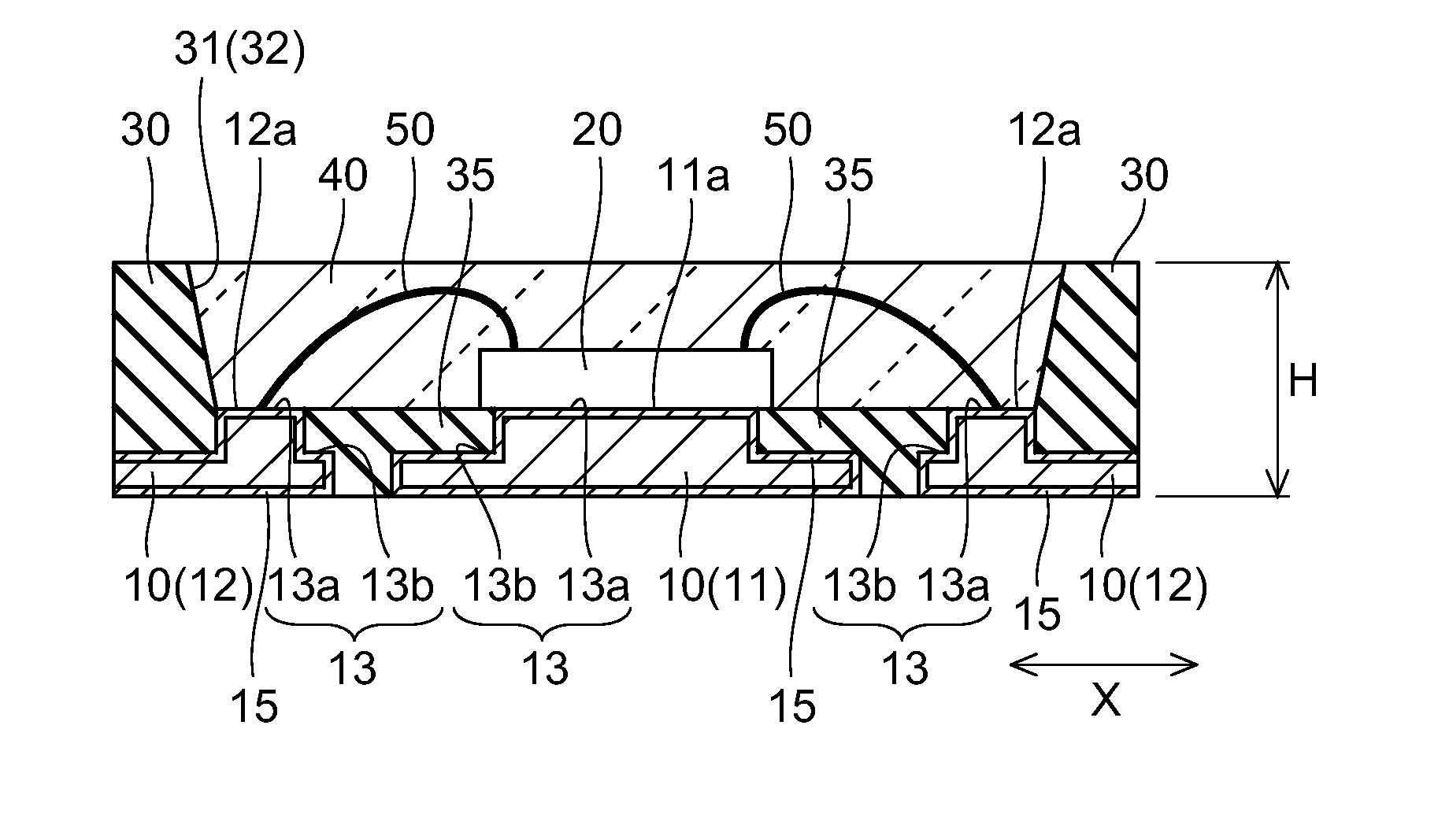

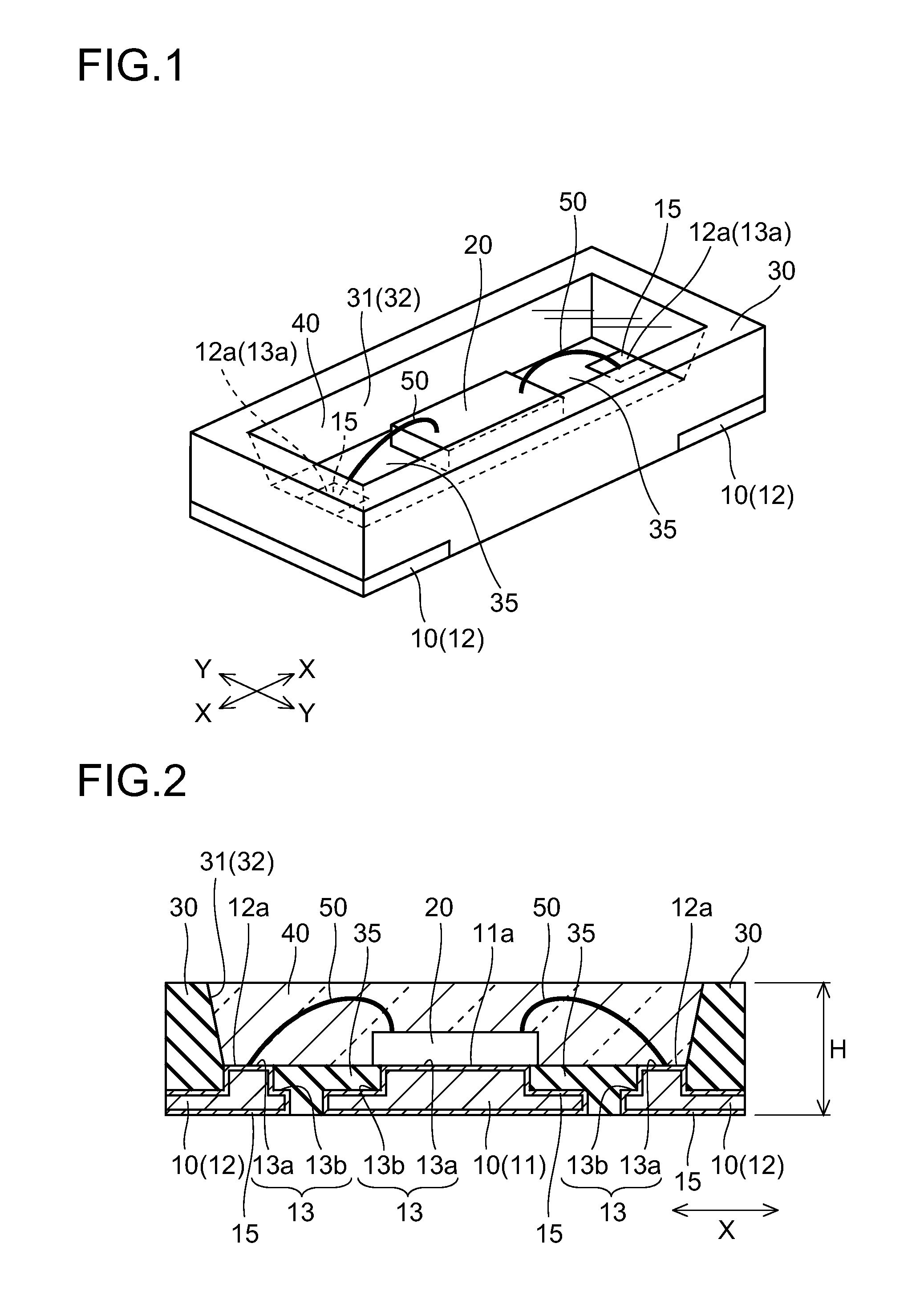

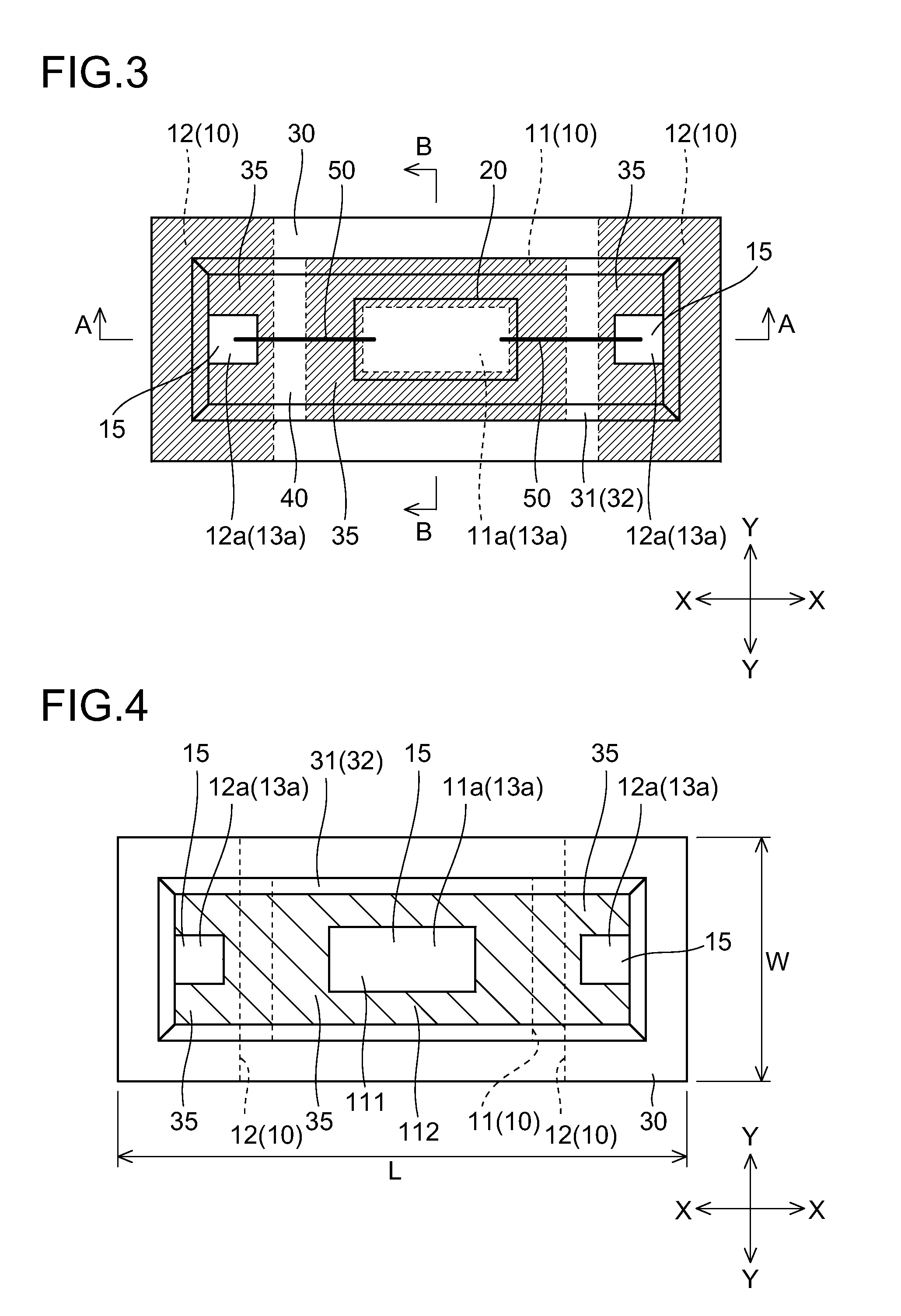

Light emitting device and method for manufacturing same

InactiveUS20130009190A1Alleviate decline in light output efficiencyGood heat dissipationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringProtection layer

A light emitting device comprises:a light emitting element (20);a first metal board (11) that includes a mount portion (111) on which the light emitting element (20) is mounted and a reflection portion (112) which is formed outside the mount portion (111) to reflect light from the light emitting element (20);a second metal board (12) that is electrically connected to the light emitting element (20) via a wire (50);a metal plated layer (15) that is formed on a surface of the metal boards (11), (12); anda seal resin (40) that is formed on the metal boards (11), (12) to seal at least the light emitting element (20); whereinat least the reflection portion (112) is provided with a protection layer (35) which is lower than the seal resin (40) in gas permeability, is transparent or has a reflectance near the metal plated layer (15).

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com