Patents

Literature

729results about How to "Large heat capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

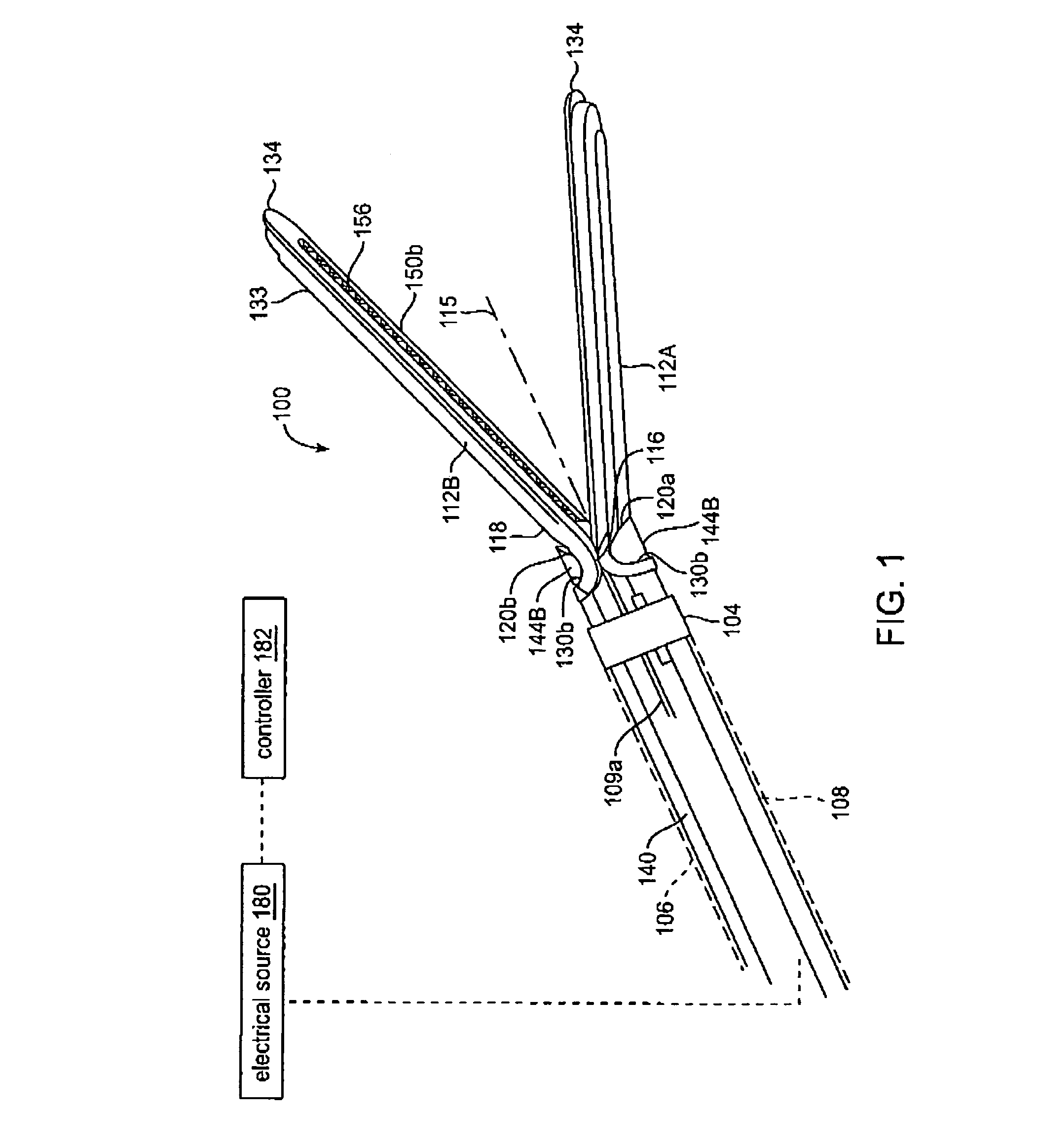

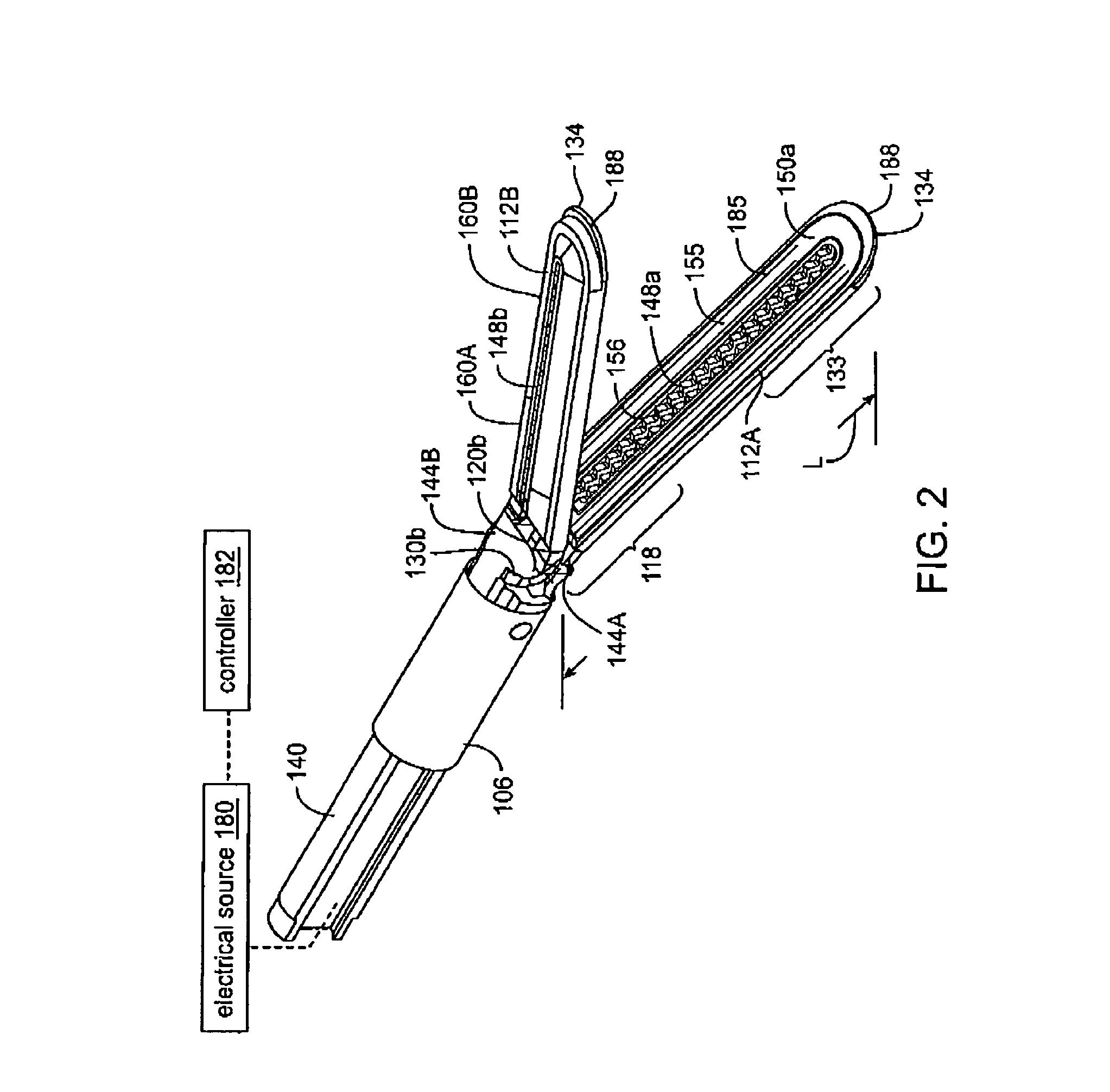

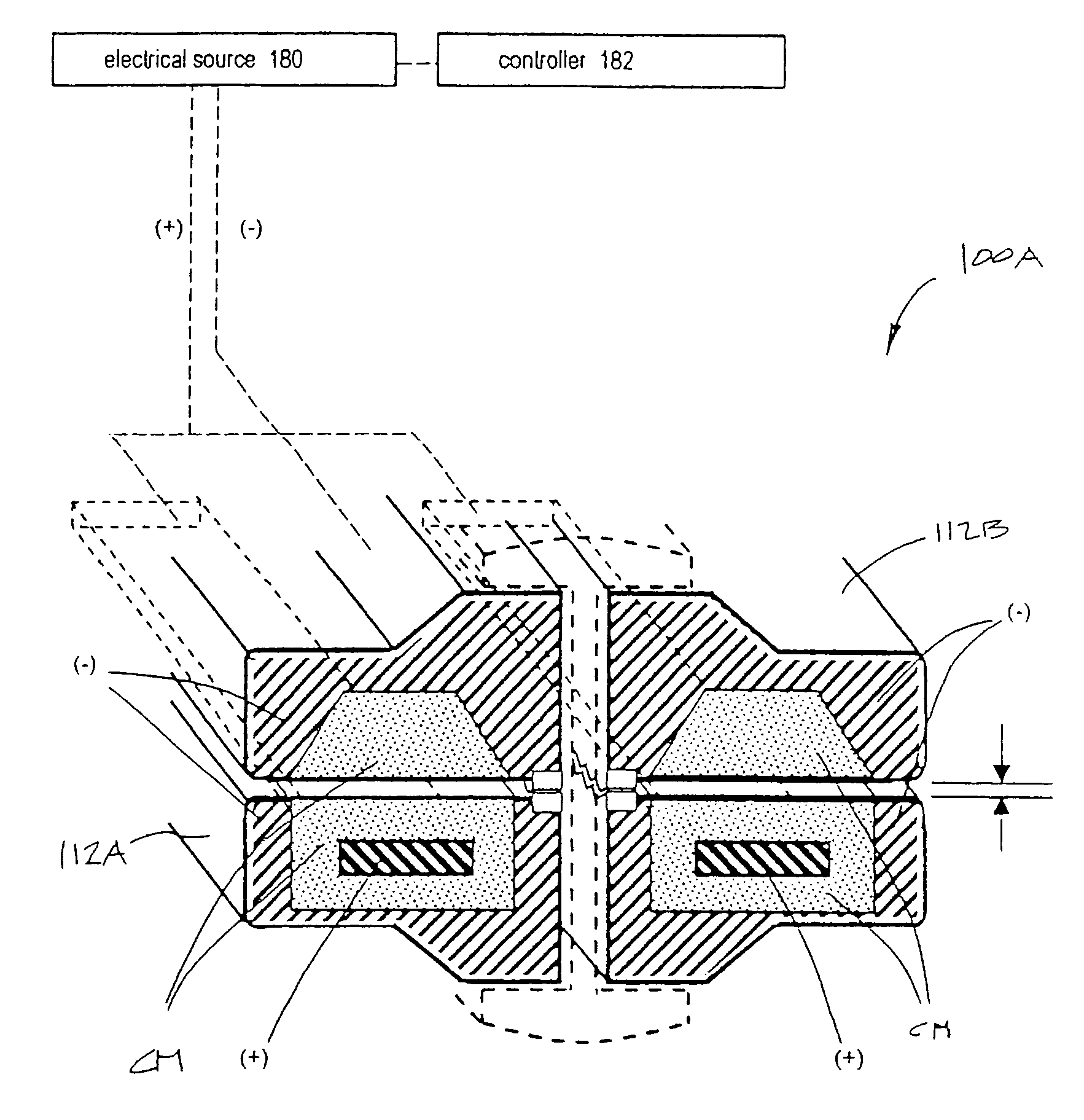

Jaw structure for electrosurgical instrument and method of use

InactiveUS7011657B2Improve the immunityEfficient weldingElectrotherapySurgical instruments for heatingTissue heatingVolumetric Mass Density

An electrosurgical medical device and technique for creating thermal welds in engaged tissue that provides very high compressive forces. In one exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying first and second surface portions that comprise (i) an electrically conductive material and (ii) a positive temperature coefficient (PTC) material having a selected increased resistance that differs at each selected increased temperature over a targeted treatment range. One type of PTC material is a doped ceramic that can be engineered to exhibit a selected positively sloped temperature-resistance curve over about 37° C. to 100° C. The 70° C. to 100° C. range can bracket a targeted “thermal treatment range” at which tissue welded can be accomplished. The engineered resistance of the PTC matrix at the upper end of the temperature range will terminate current flow through the matrix. In one mode of operation, the engagement plane cause ohmic heating within tissue from Rf energy delivery tissue PTC matrix is heated to exceed the treatment range. Thereafter, energy density in the engaged tissue will be modulated as the conductivity of the second portion hovers within the targeted treatment range to thereby provide optical tissue heating for purposes of tissue welding.

Owner:ETHICON ENDO SURGERY INC

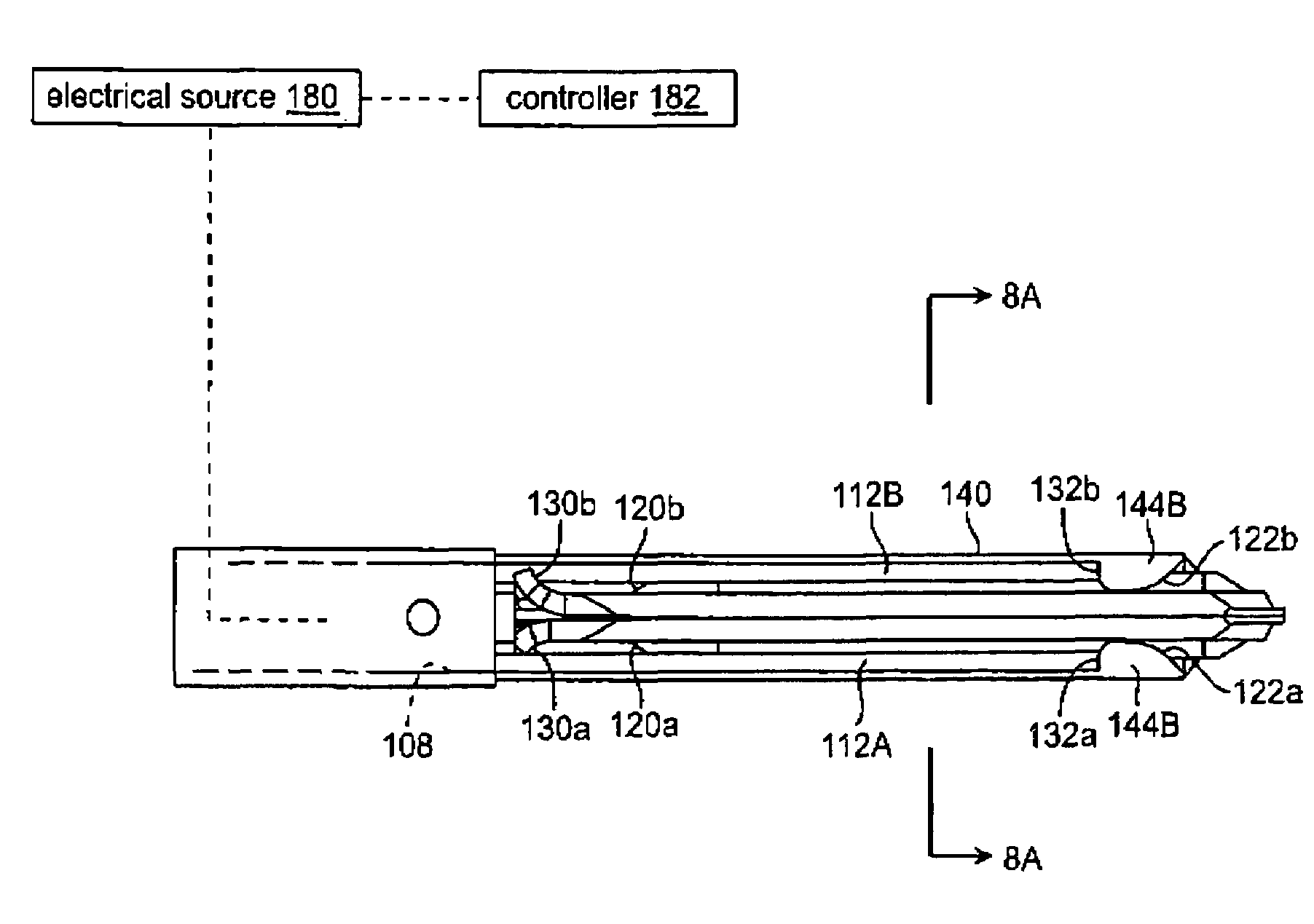

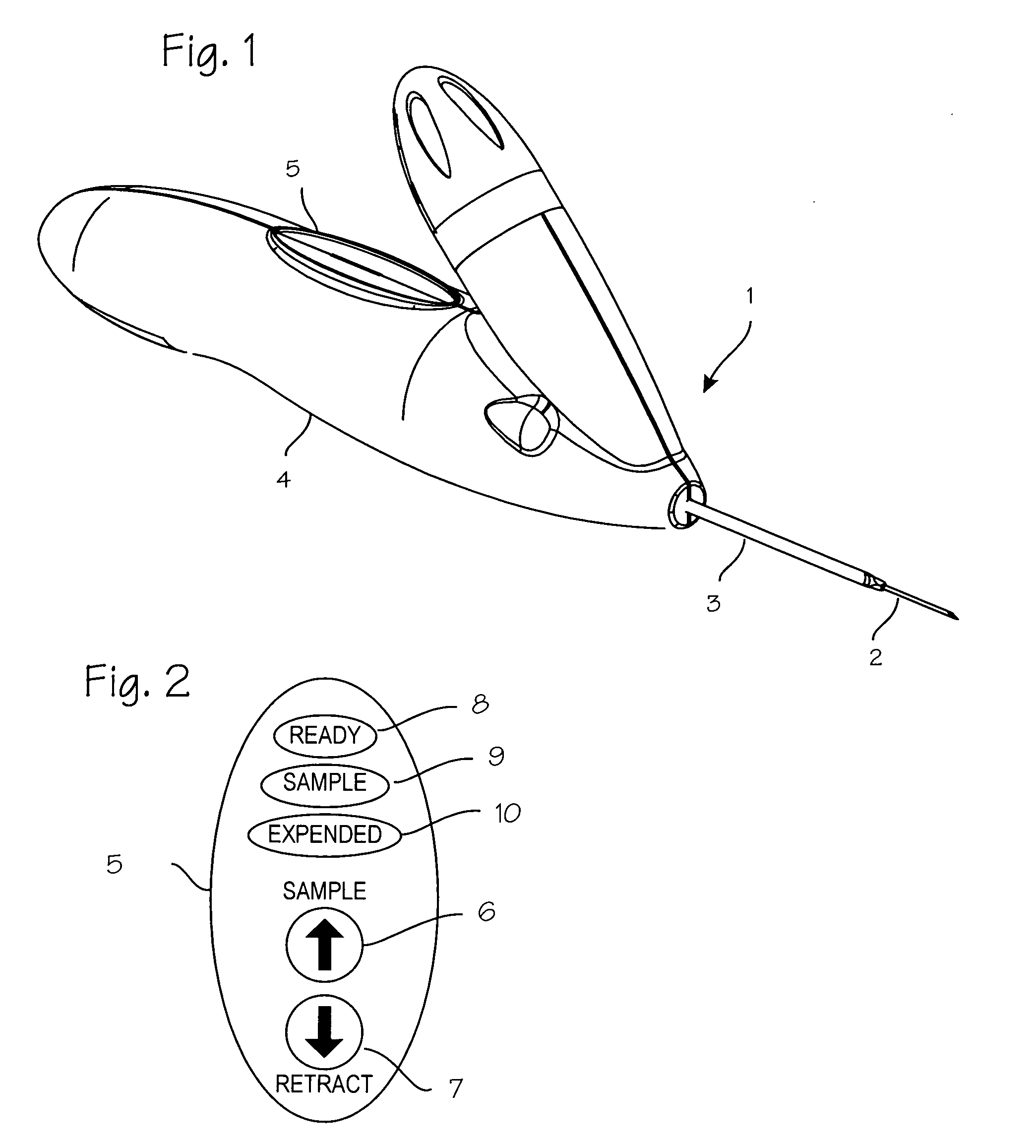

Electrosurgical instrument and method of use

ActiveUS7087054B2Reduce conductancePrevent any substantial dehydrationElectrotherapySurgical instruments for heatingEngineeringMedical device

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane that carries a recessed central portion. In another embodiment, the controller coupled to the Rf source is adapted to switch from a power control operational mode to a voltage controlled operational mode at a selected transition impedance level.

Owner:ETHICON ENDO SURGERY INC

Electrosurgical instrument and method of use

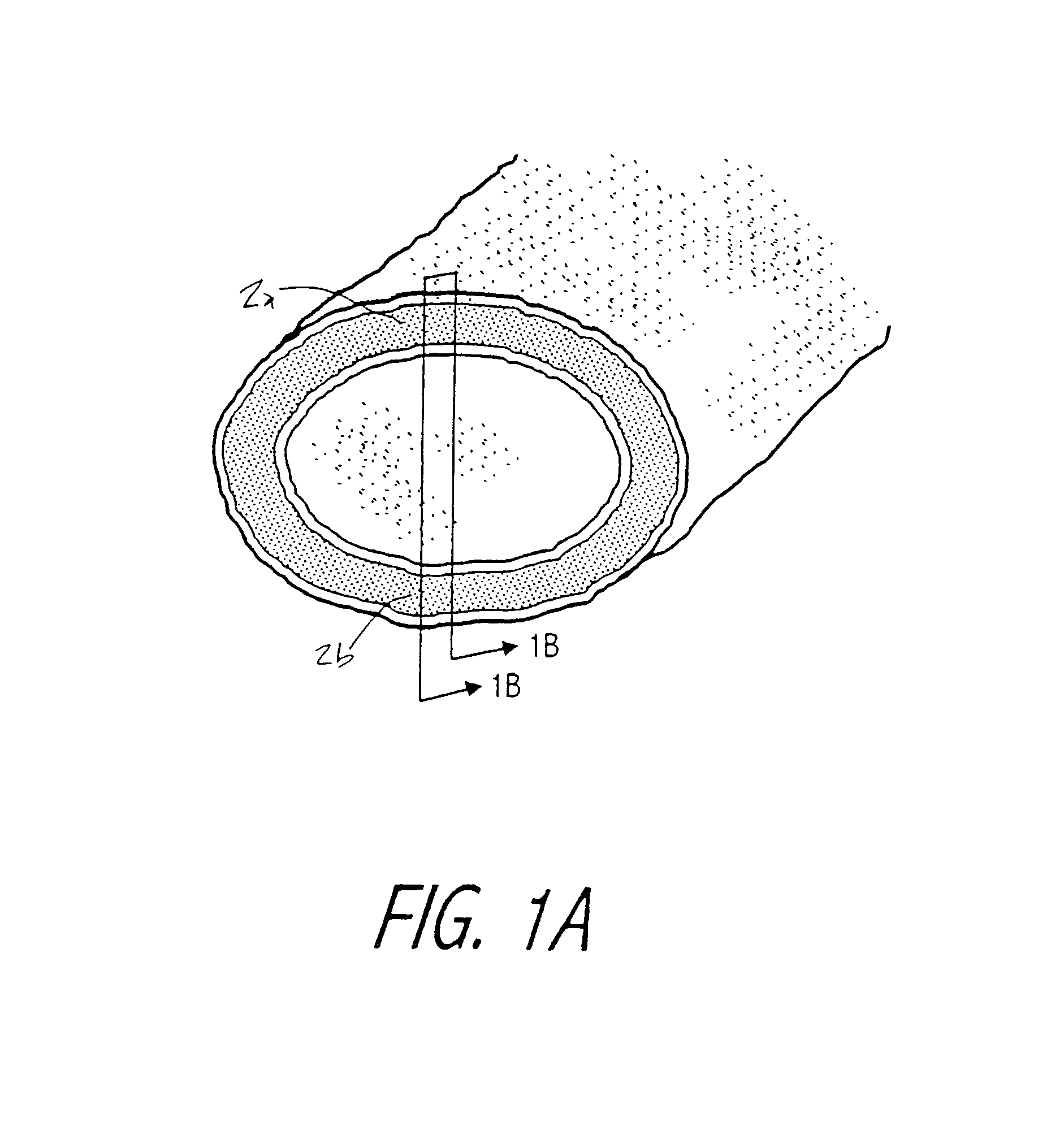

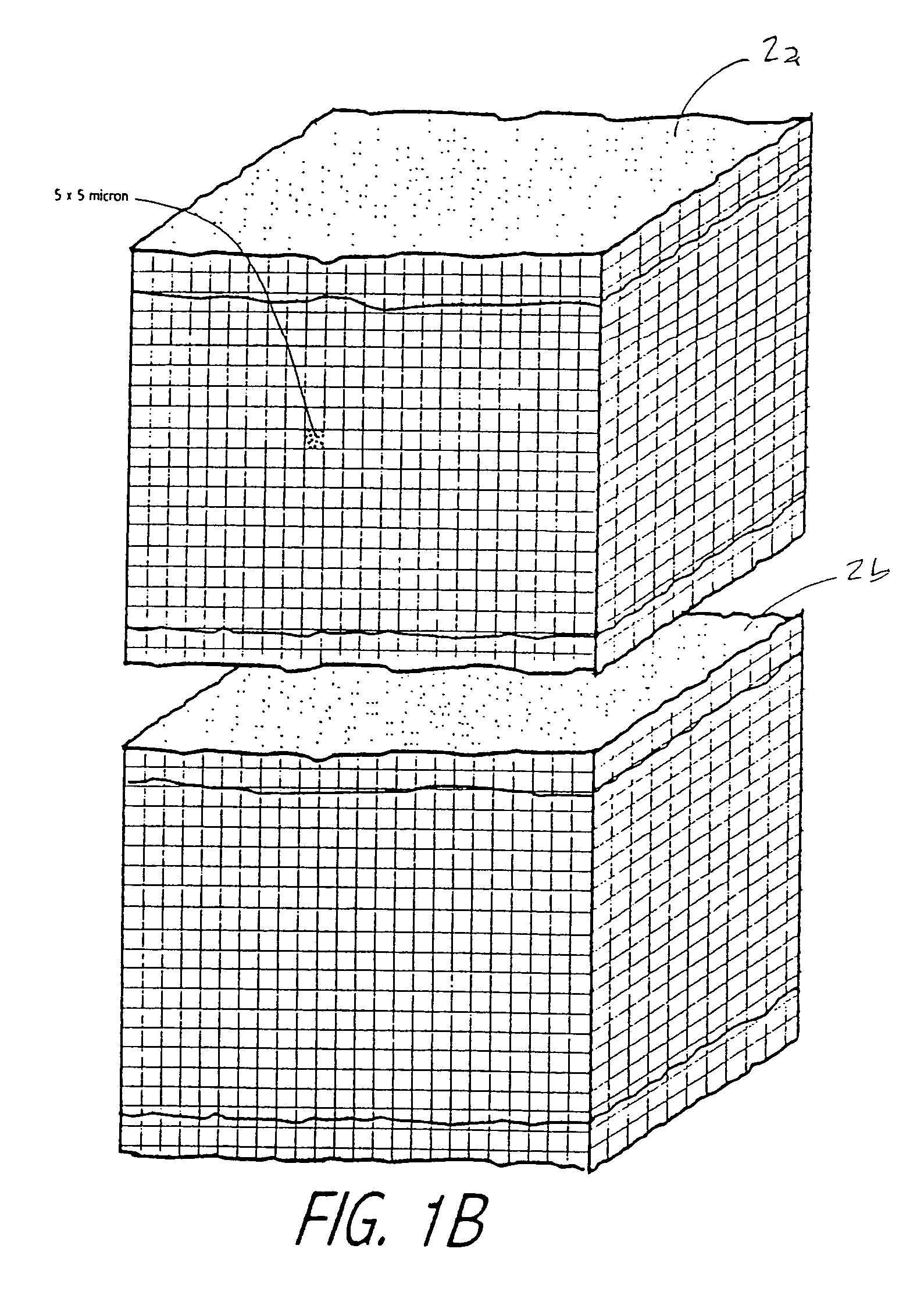

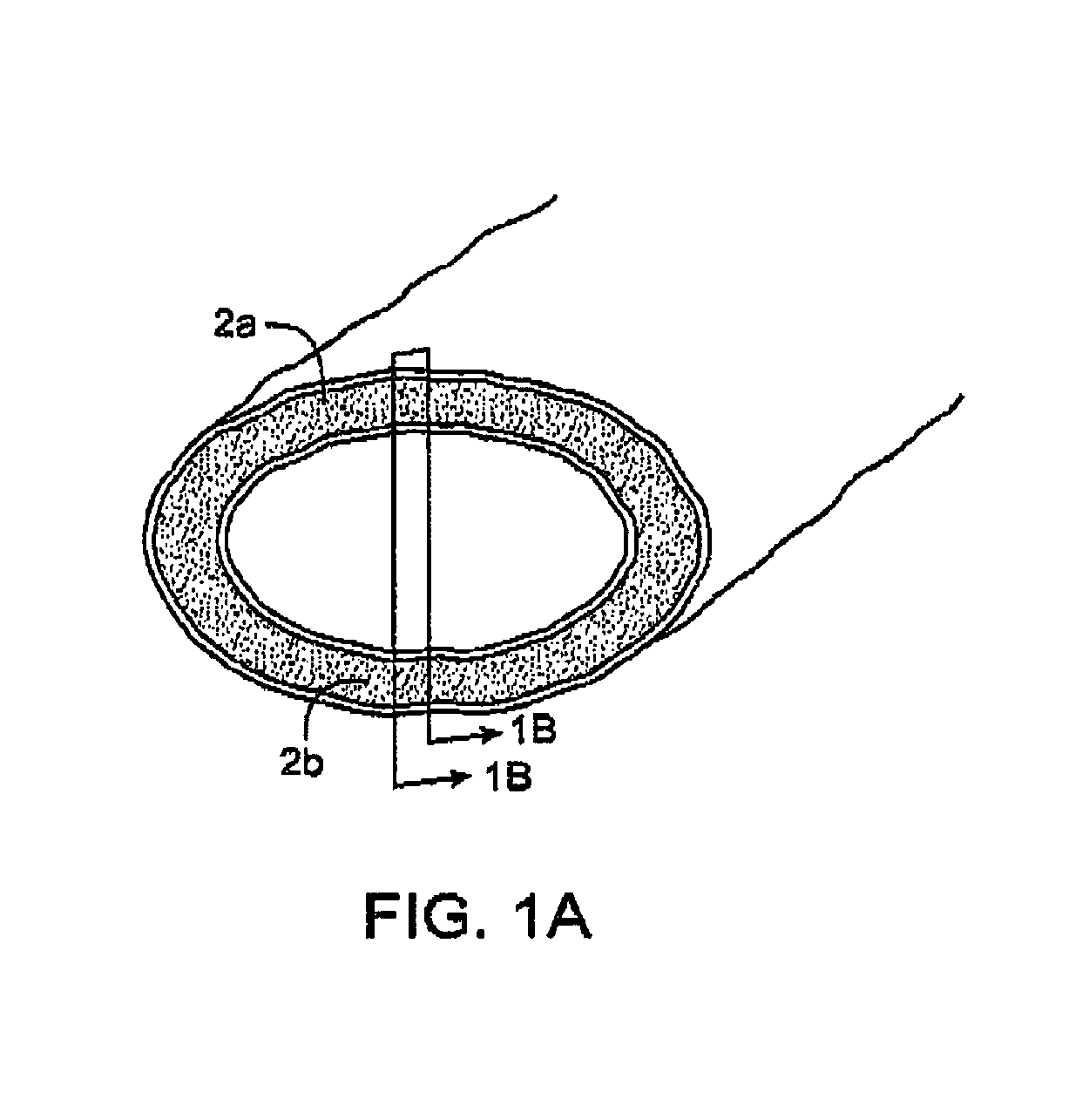

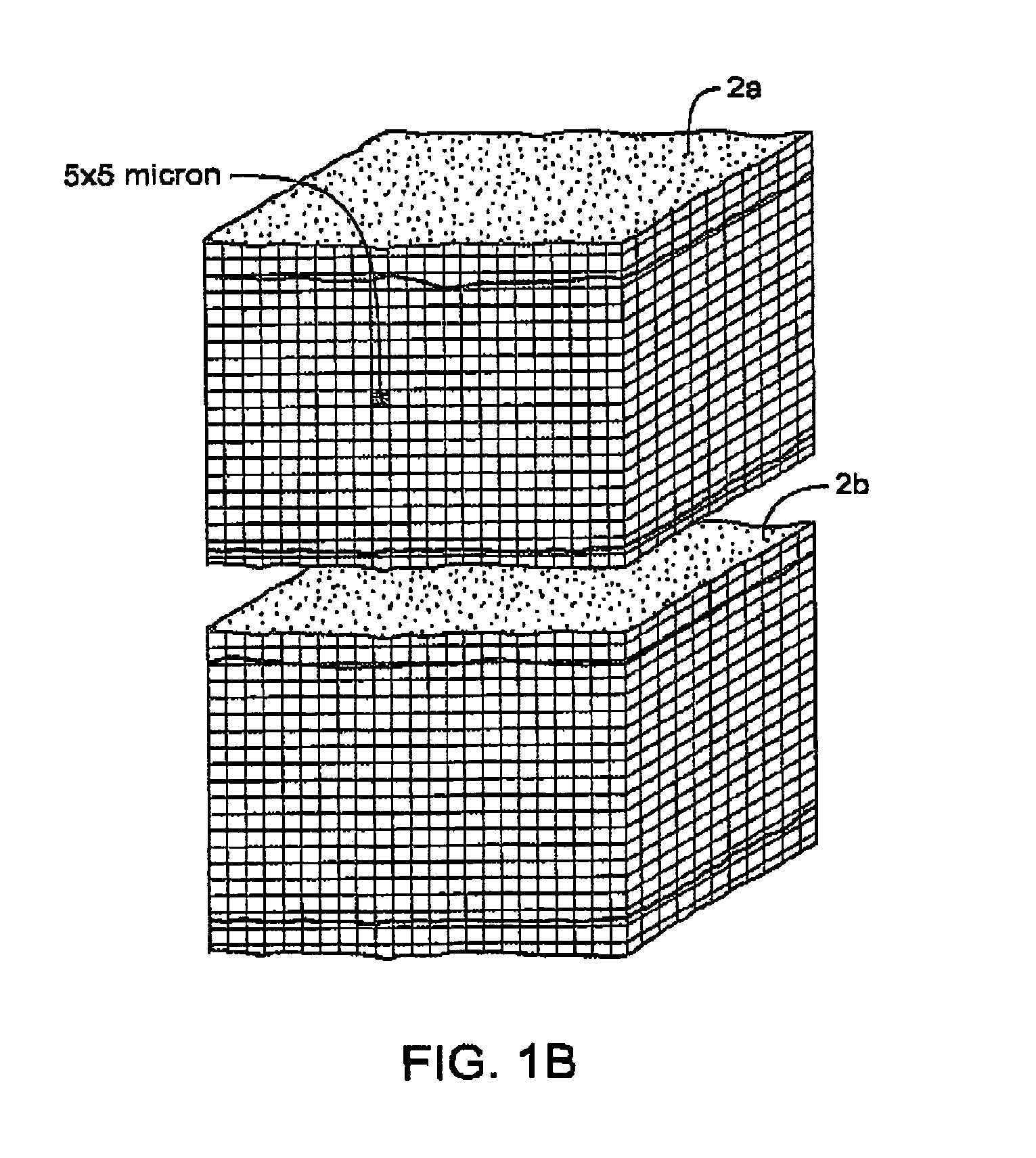

InactiveUS7083619B2Reduce conductancePrevent any substantial dehydrationSurgical instruments for heatingCoatingsMicron scaleElastomer

An electrosurgical medical device and method for creating thermal welds in engaged tissue. In one embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying a conductive-resistive matrix of a conductively-doped non-conductive elastomer. The engagement surface portions thus can be described as a positive temperature coefficient material that has a unique selected decreased electrical conductance at each selected increased temperature thereof over a targeted treatment range. The conductive-resistive matrix can be engineered to bracket a targeted thermal treatment range, for example about 60° C. to 80° C., at which tissue welding can be accomplished. In one mode of operation, the engagement plane will automatically modulate and spatially localize ohmic heating within the engaged tissue from Rf energy application—across micron-scale portions of the engagement surface.

Owner:ETHICON ENDO SURGERY INC

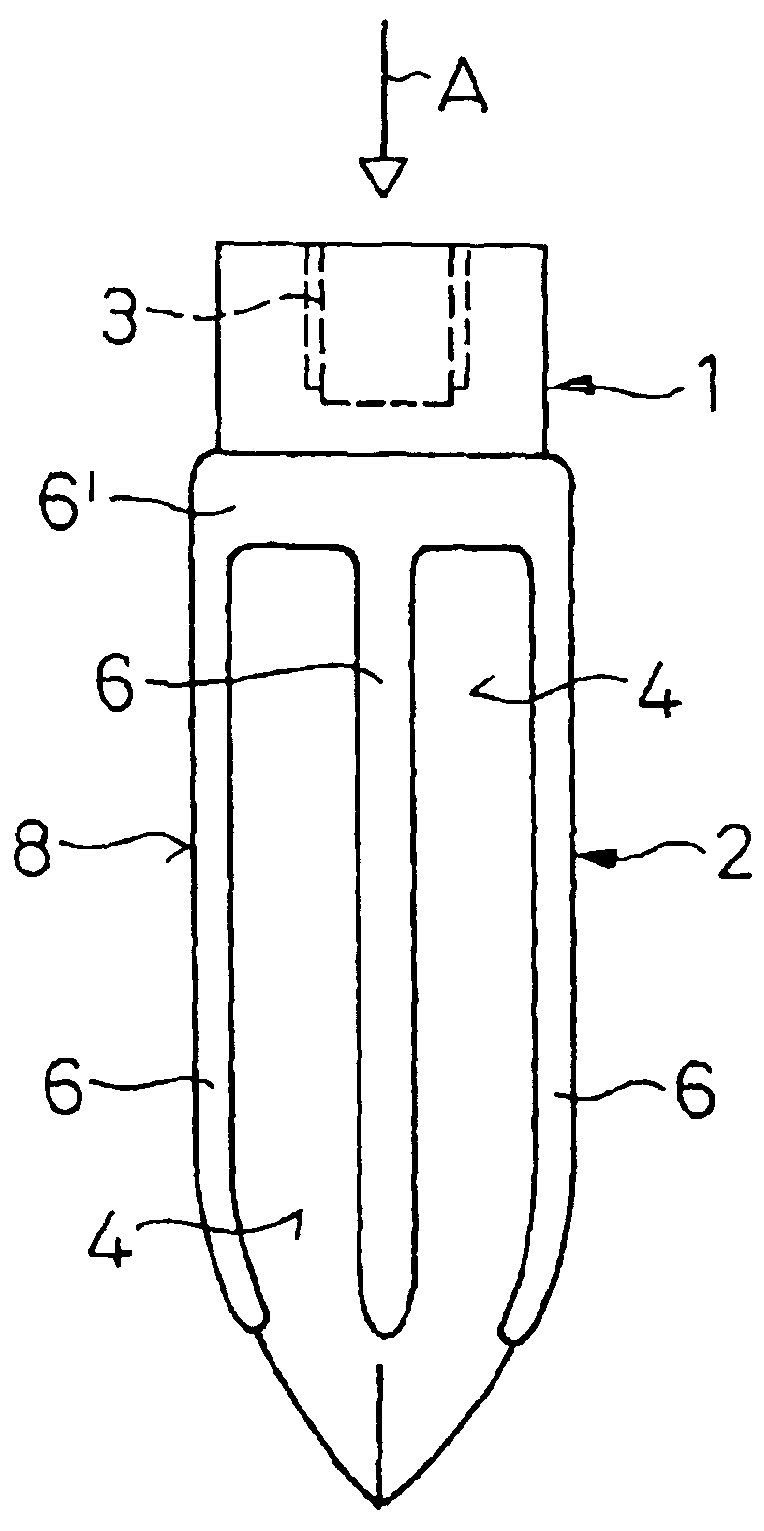

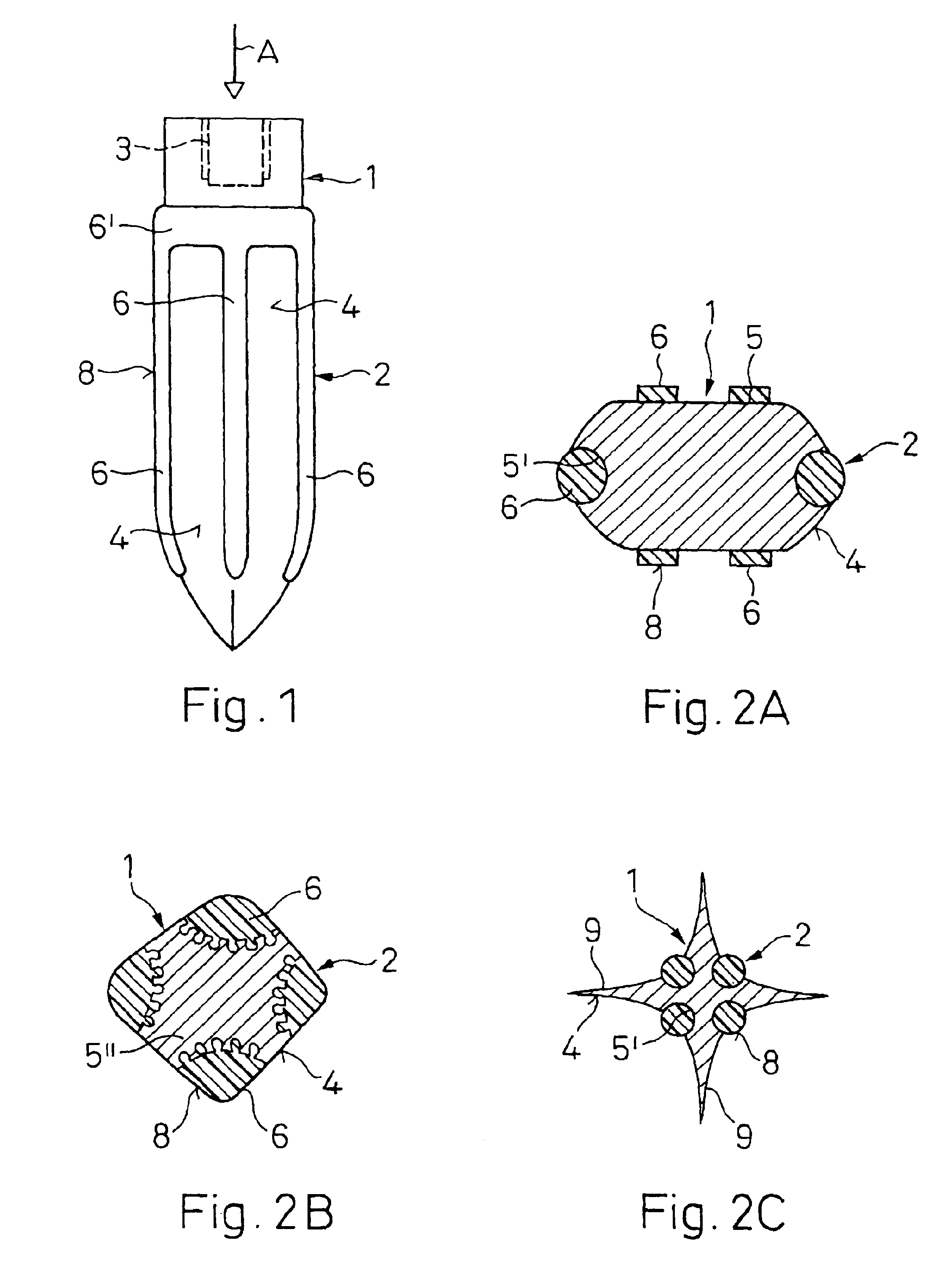

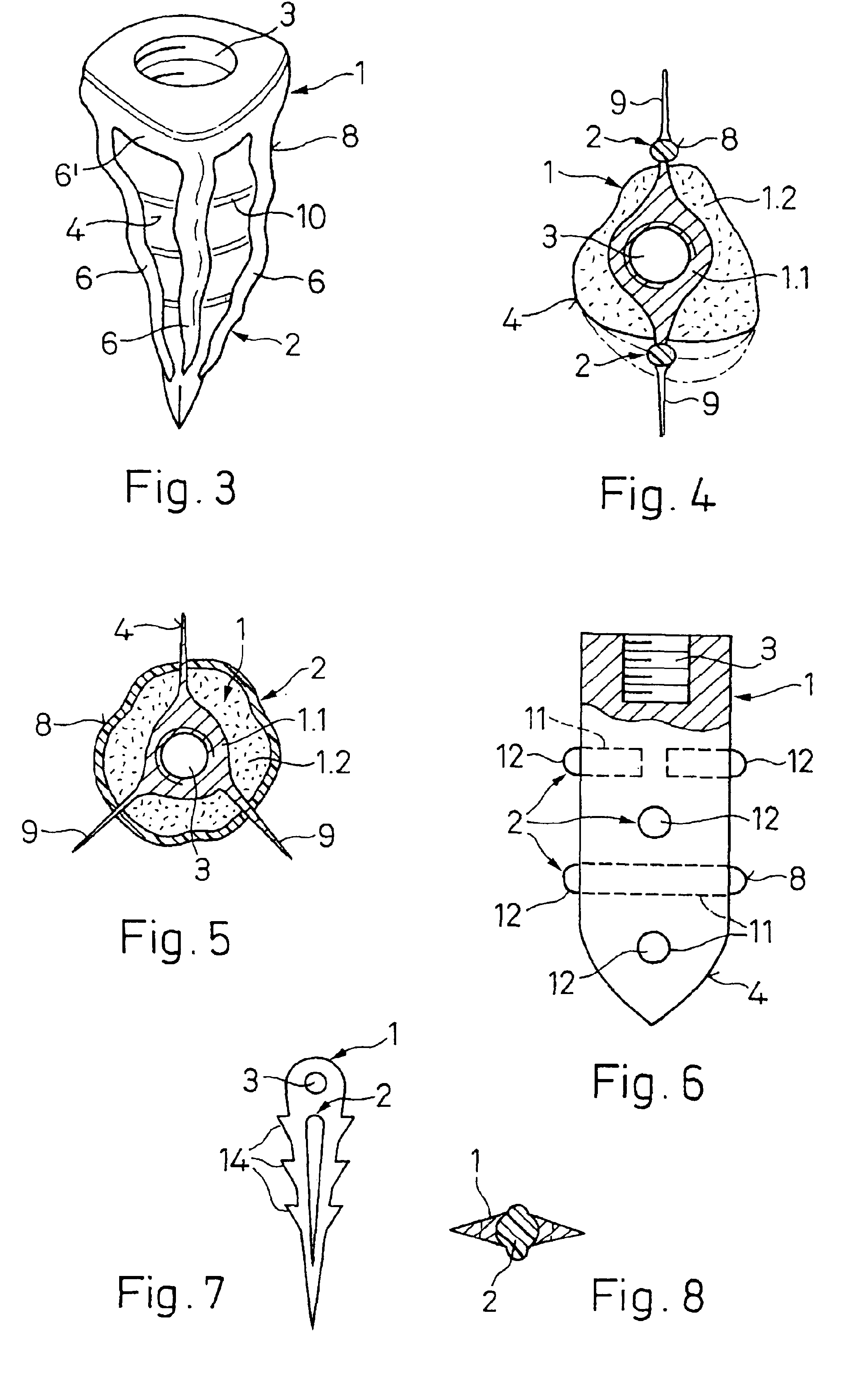

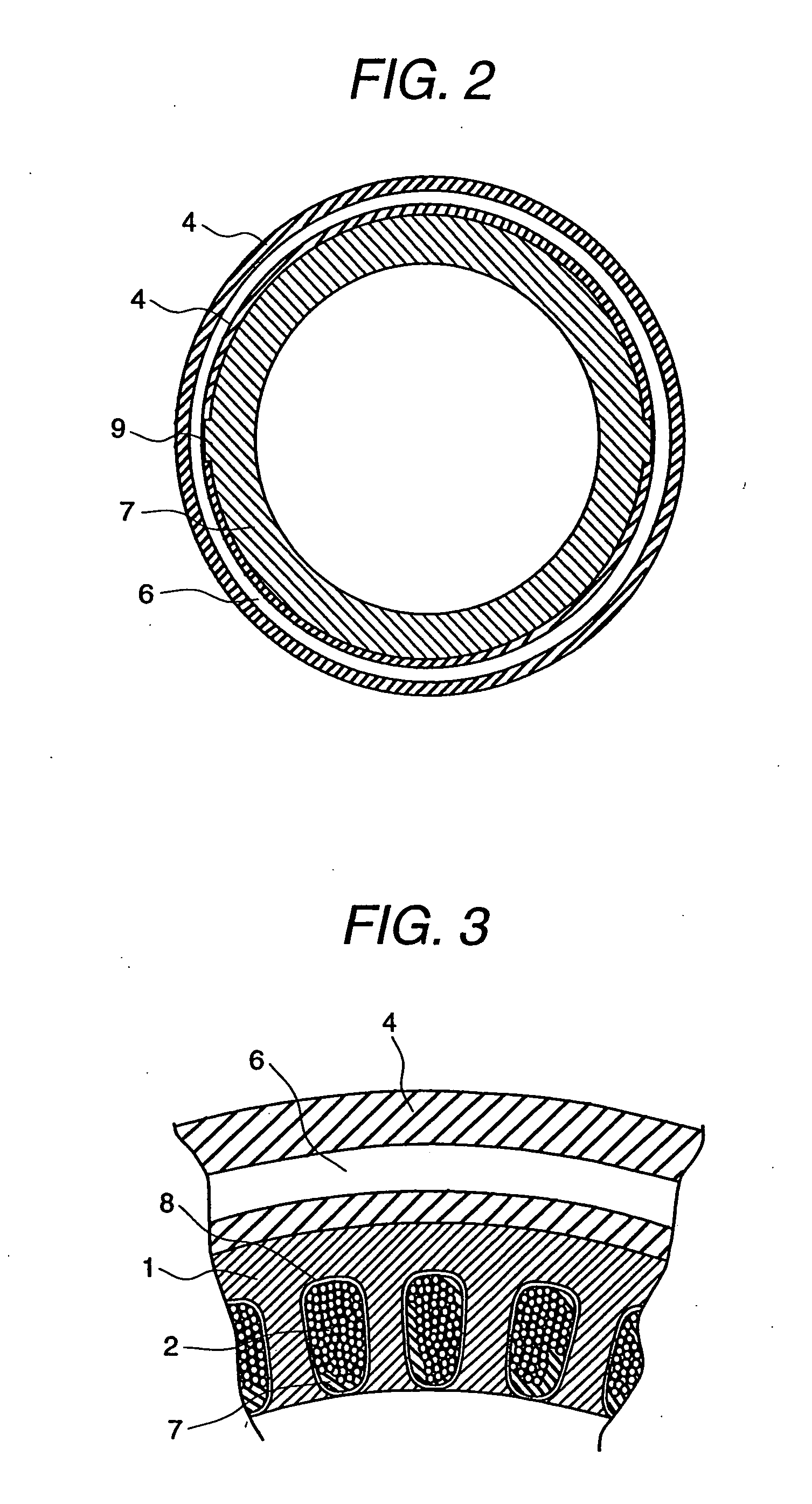

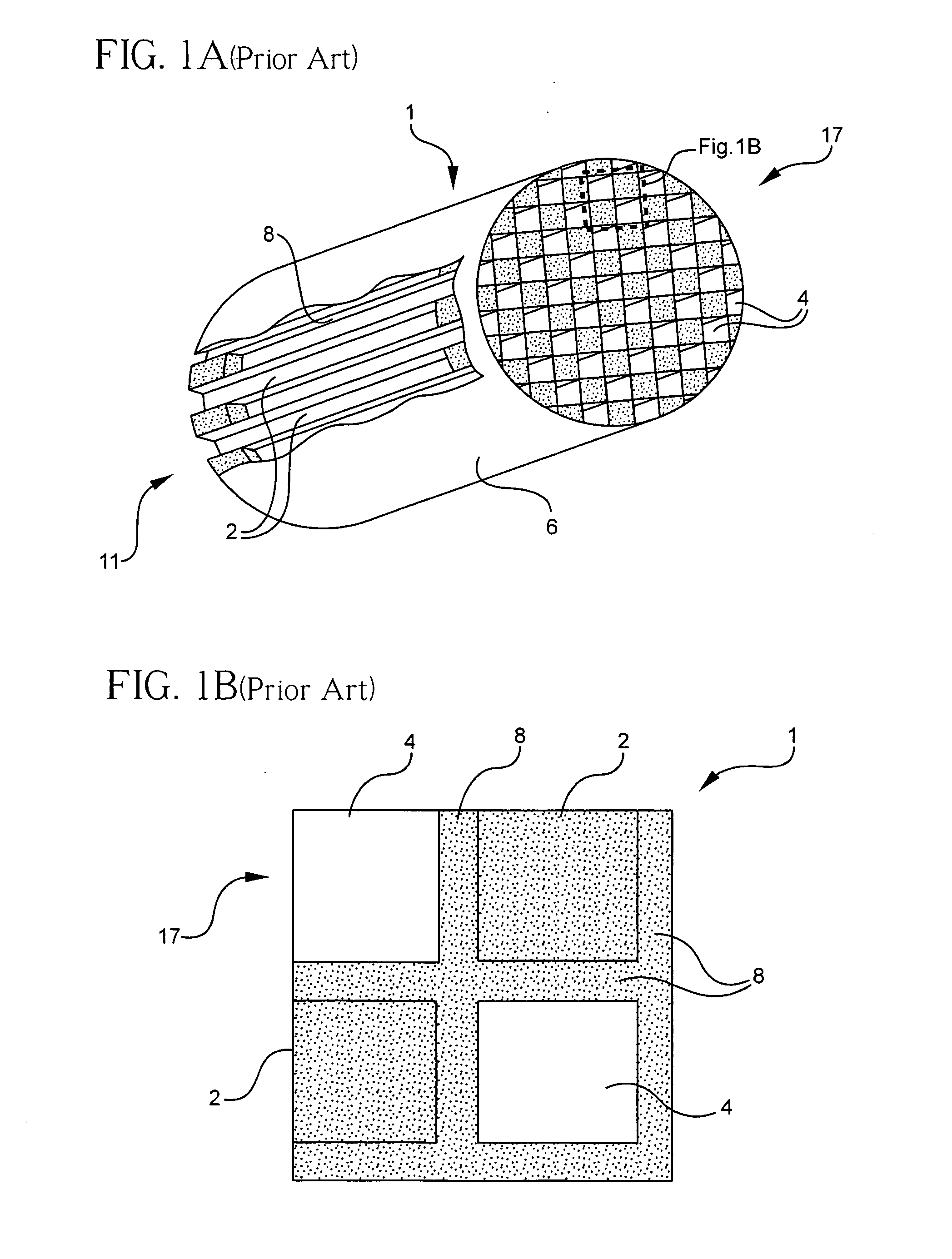

Implant to be implanted in bone tissue or in bone tissue supplemented with bone substitute material

InactiveUS6921264B2High softening temperatureLow softening temperatureDental implantsInternal osteosythesisBone tissueGrowth promoting

An implant (1) to be implanted in bone tissue, e.g. a dental implant or an implant for an orthopedic application, comprises surface regions (4) of a first type which have e.g. osseo-integrative, inflammation-inhibiting, infection-combating and / or growth-promoting properties, and surface regions (8) of a second type which consist of a material being liquefiable by mechanical oscillation. The implant is positioned in an opening of e.g. a jawbone and then mechanical oscillations, e.g. ultrasound is applied to it while it is pressed against the bone. The liquefiable material is such liquefied at least partly and is pressed into unevennesses and pores of the surrounding bone tissue where after resolidification it forms a positive-fit connection between the implant and the bone tissue. The surface regions of the two types are arranged and dimensioned such that, during implantation, the liquefied material does not flow or flows only to a clinically irrelevant degree over the surface regions of the first type such enabling the biologically integrative properties of these surface regions to start acting directly after implantation. The implant achieves with the help of the named positive fit a very good (primary) stability, i.e. it can be loaded immediately after implantation. By this, negative effects of non-loading are prevented and relative movements between implant and bone tissue are reduced to physiological measures and therefore have an osseo-integration promoting effect.

Owner:WOODWELDING

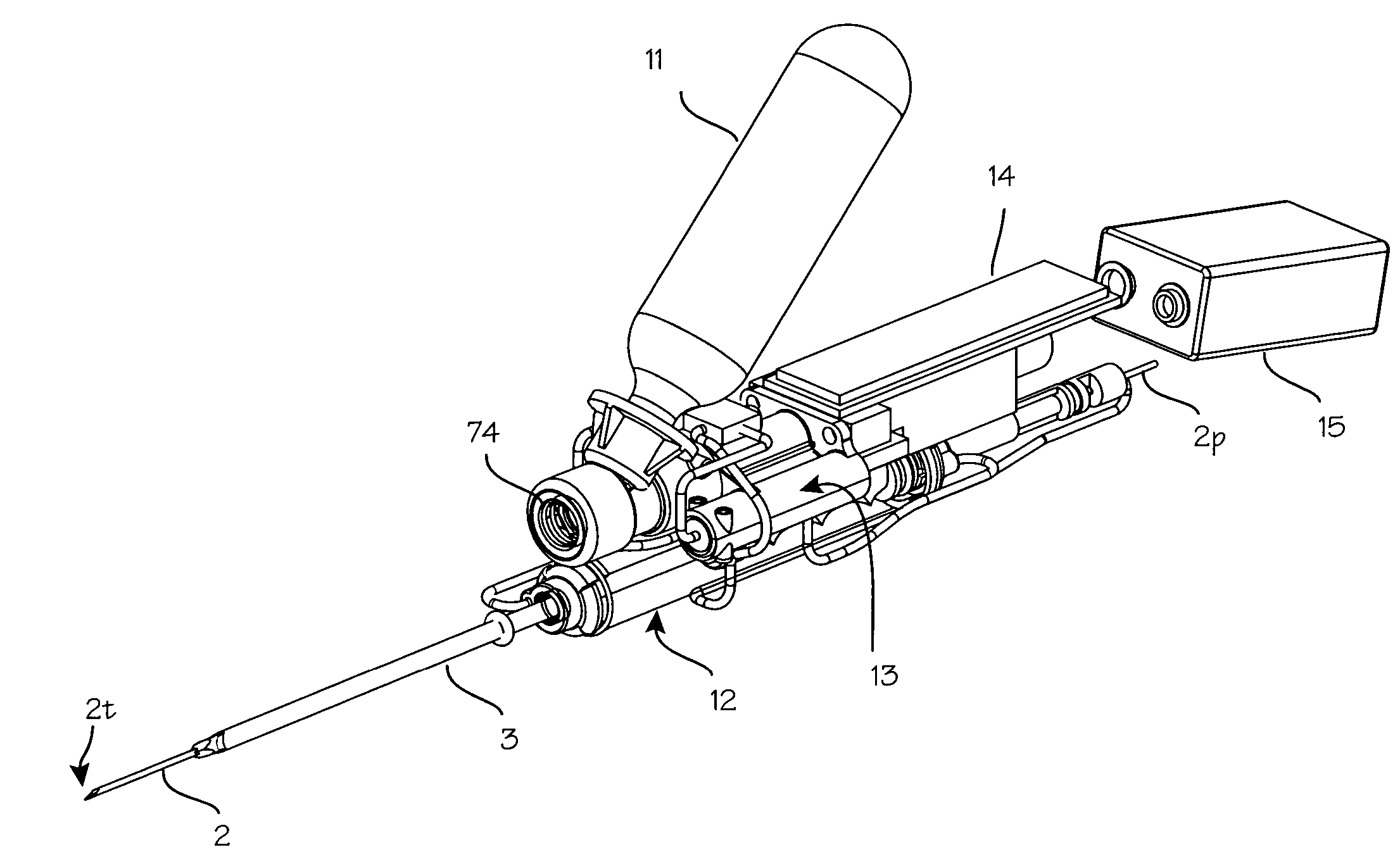

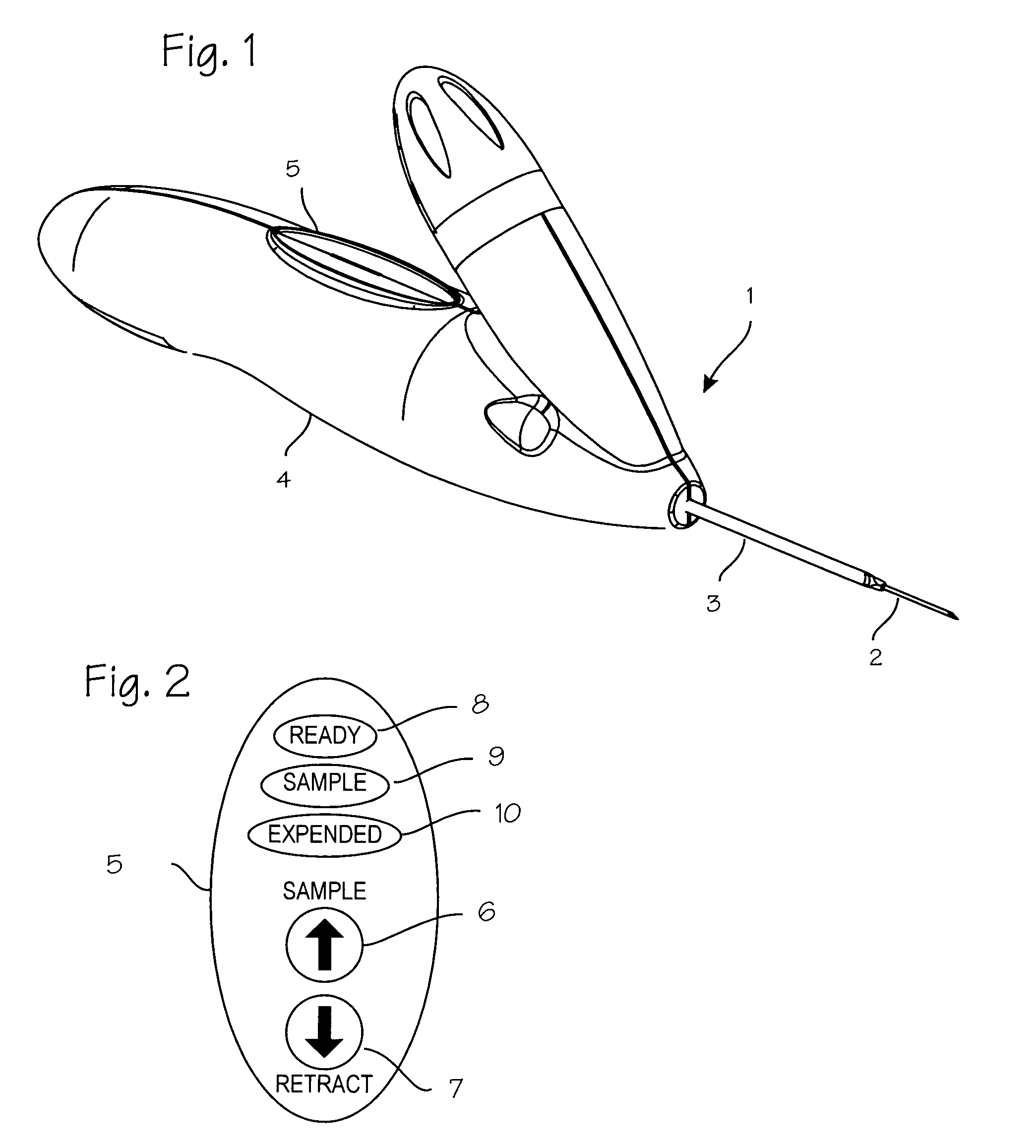

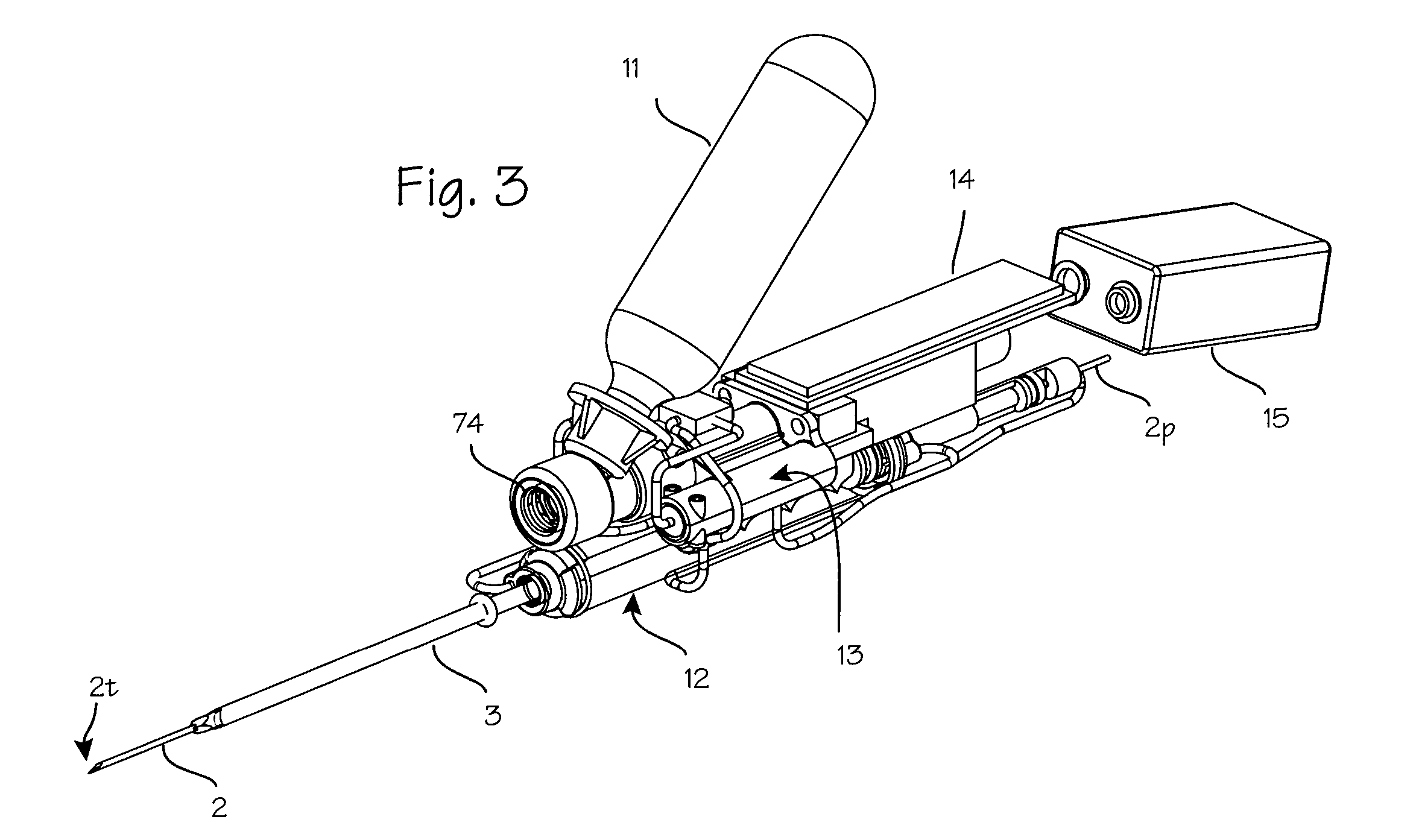

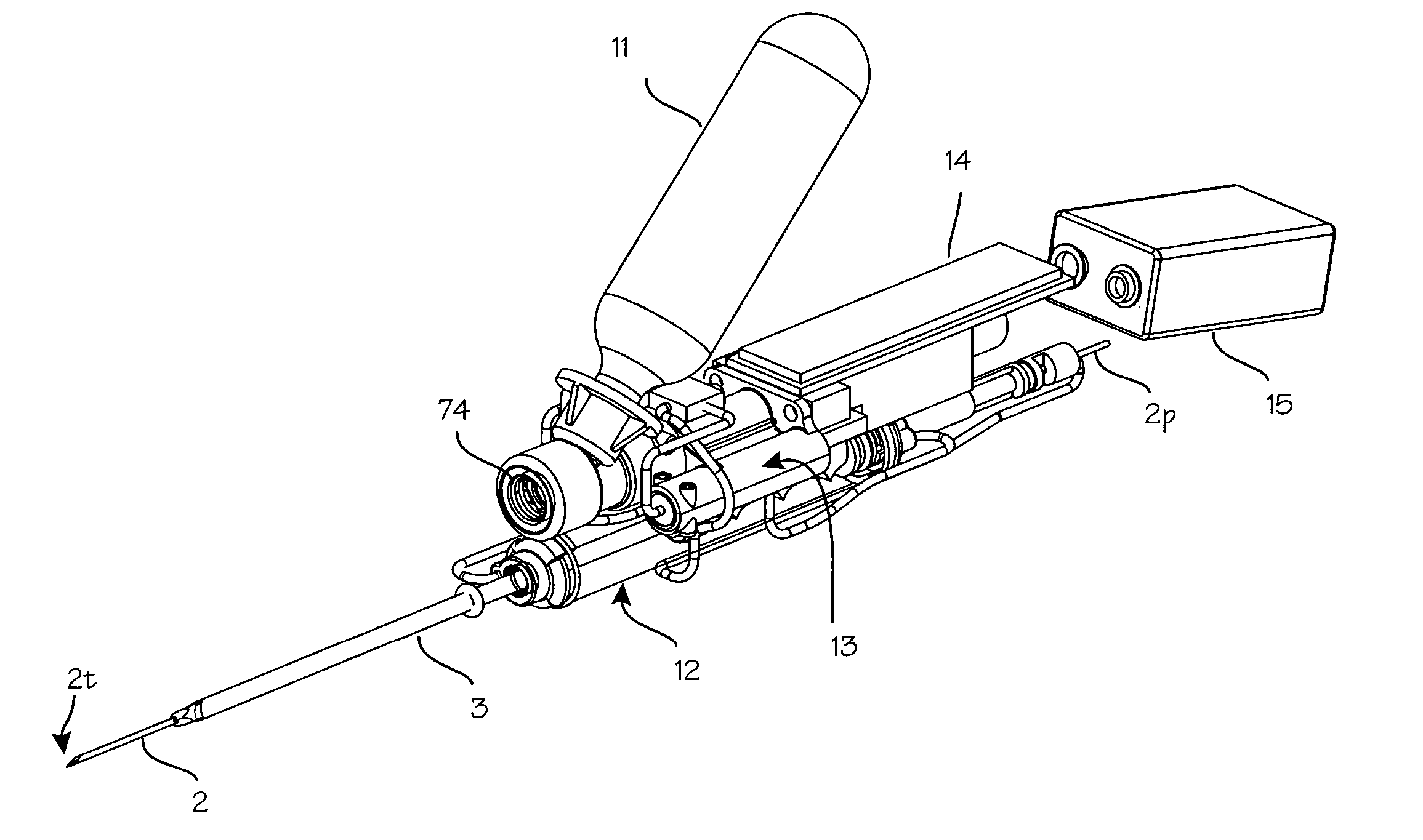

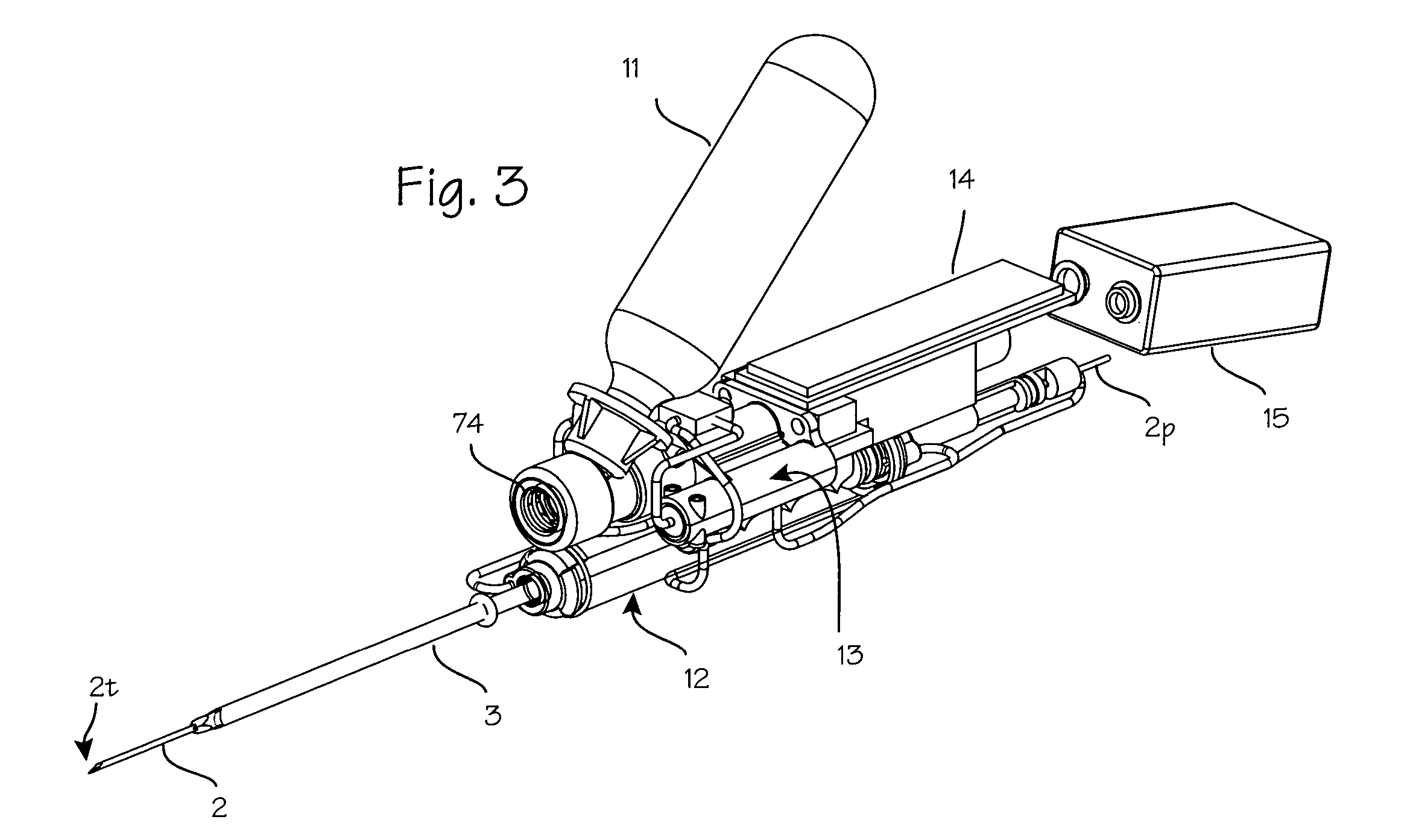

Rotational core biopsy device with liquid cryogen adhesion probe

ActiveUS7402140B2Avoid destructionReduces seedingSurgical needlesVaccination/ovulation diagnosticsControl systemBody tissue

Owner:SCION MEDICAL

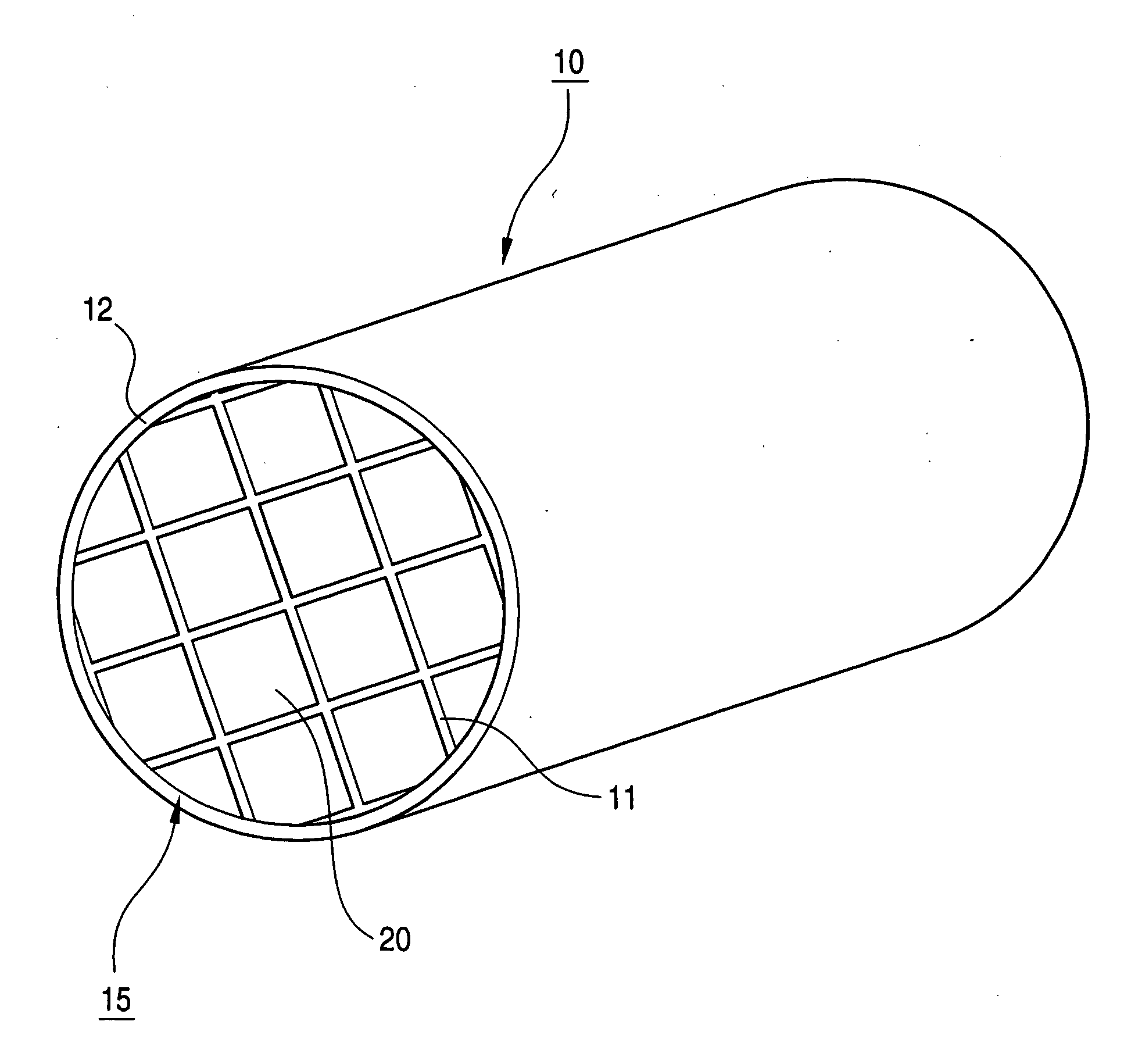

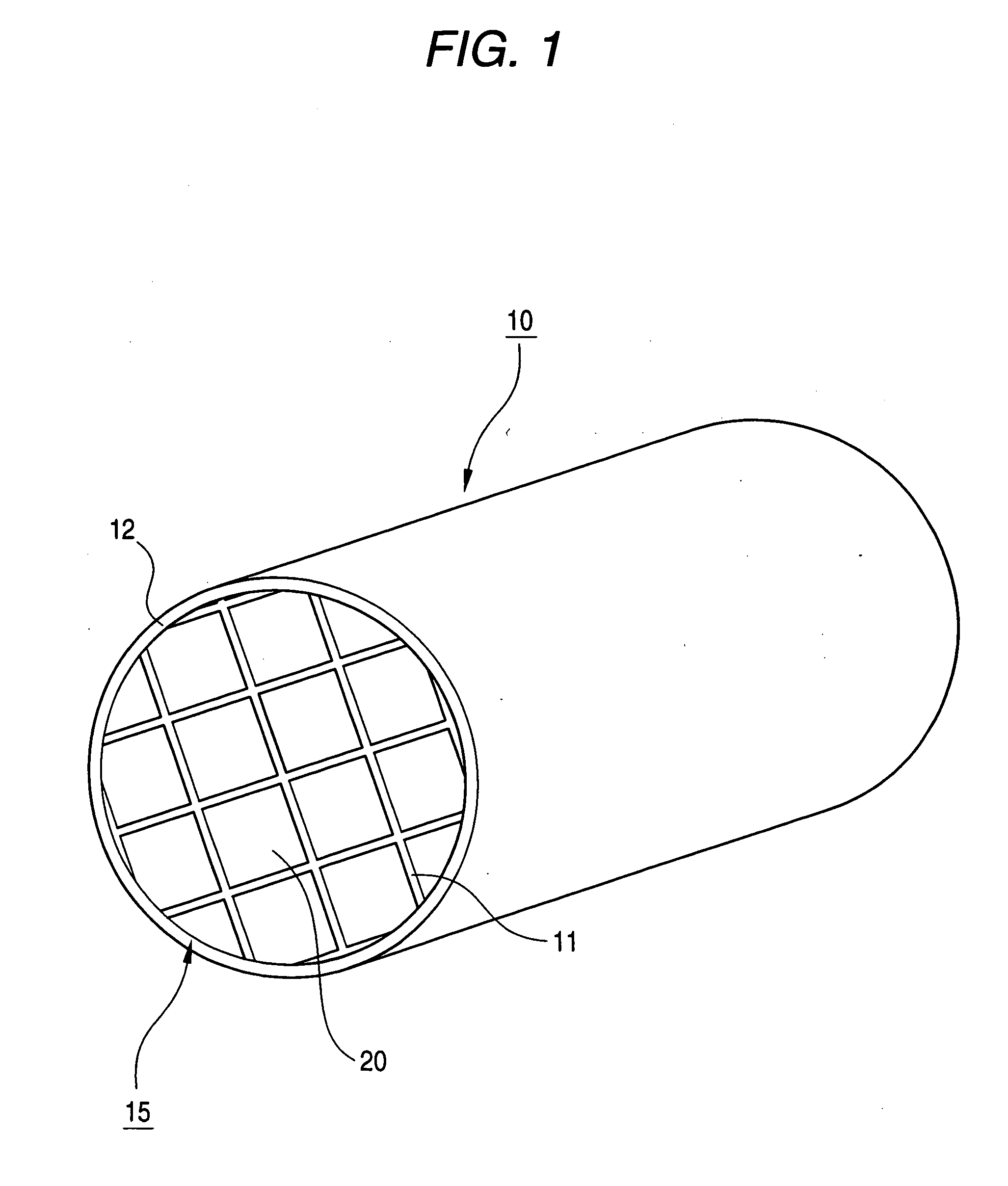

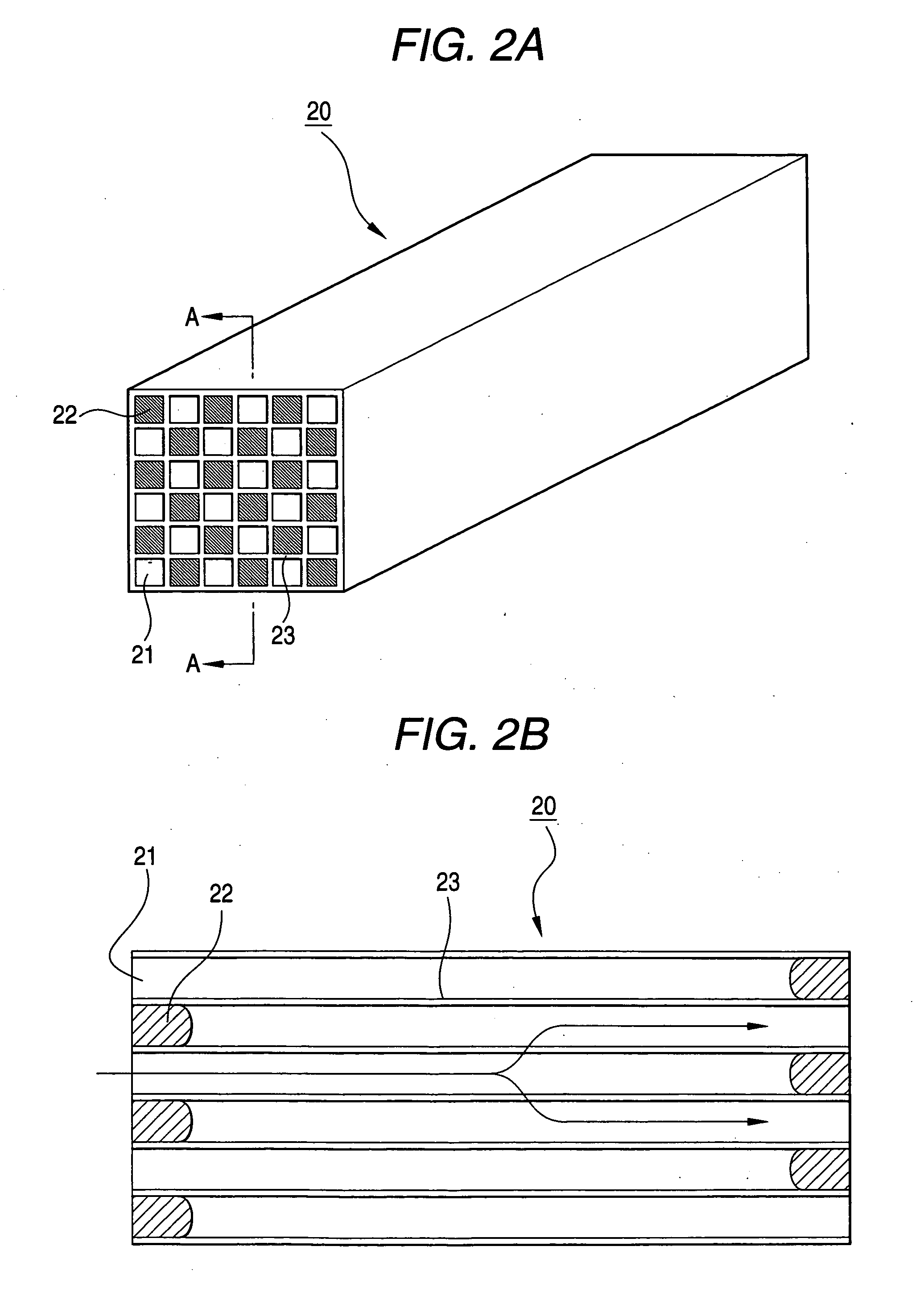

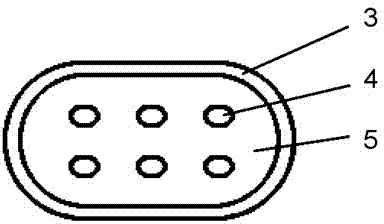

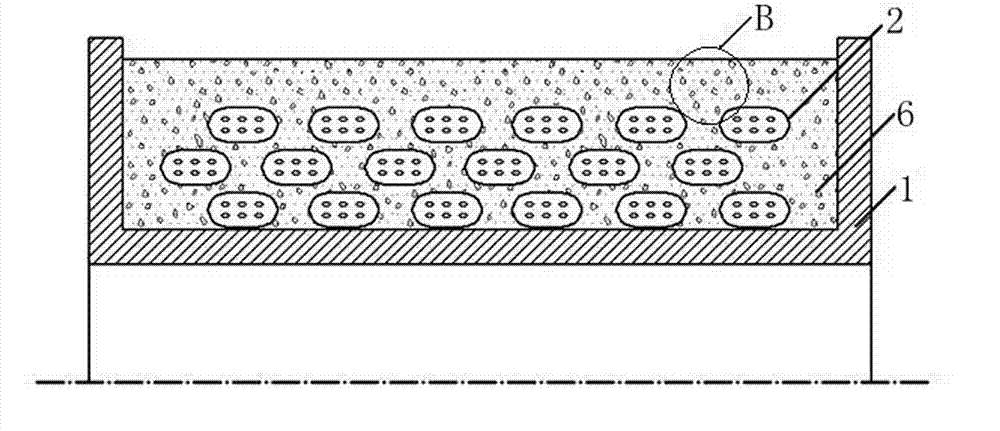

Honeycomb structure

ActiveUS20060230732A1Light weightSmall heat capacityDispersed particle filtrationOther chemical processesApparent densityYoung's modulus

A honeycomb structure including a plurality of porous ceramic members which are bonded through an adhesive layer, each of the porous ceramic members has a plurality of cells, which are arranged in parallel while being separated by cell walls. The cells extend in a longitudinal direction of the honeycomb structure. In the honeycomb structure, the following relationship is satisfied: 2≦B≦100 / 3×A−10 / 3 (1) where A (g / cm3) designates apparent density of the porous ceramic members, and B (GPa) designates Young's modulus of the adhesive layer.

Owner:IBIDEN CO LTD

Rotational core biopsy device with liquid cryogen adhesion probe

ActiveUS20050182394A1Avoid destructionReduces seedingSurgical needlesVaccination/ovulation diagnosticsControl systemBody tissue

A device for biopsy of body tissue. The device is driven by liquid CO2, and is provided with a control system to control various components to effectuate rotating core biopsies.

Owner:SCION MEDICAL

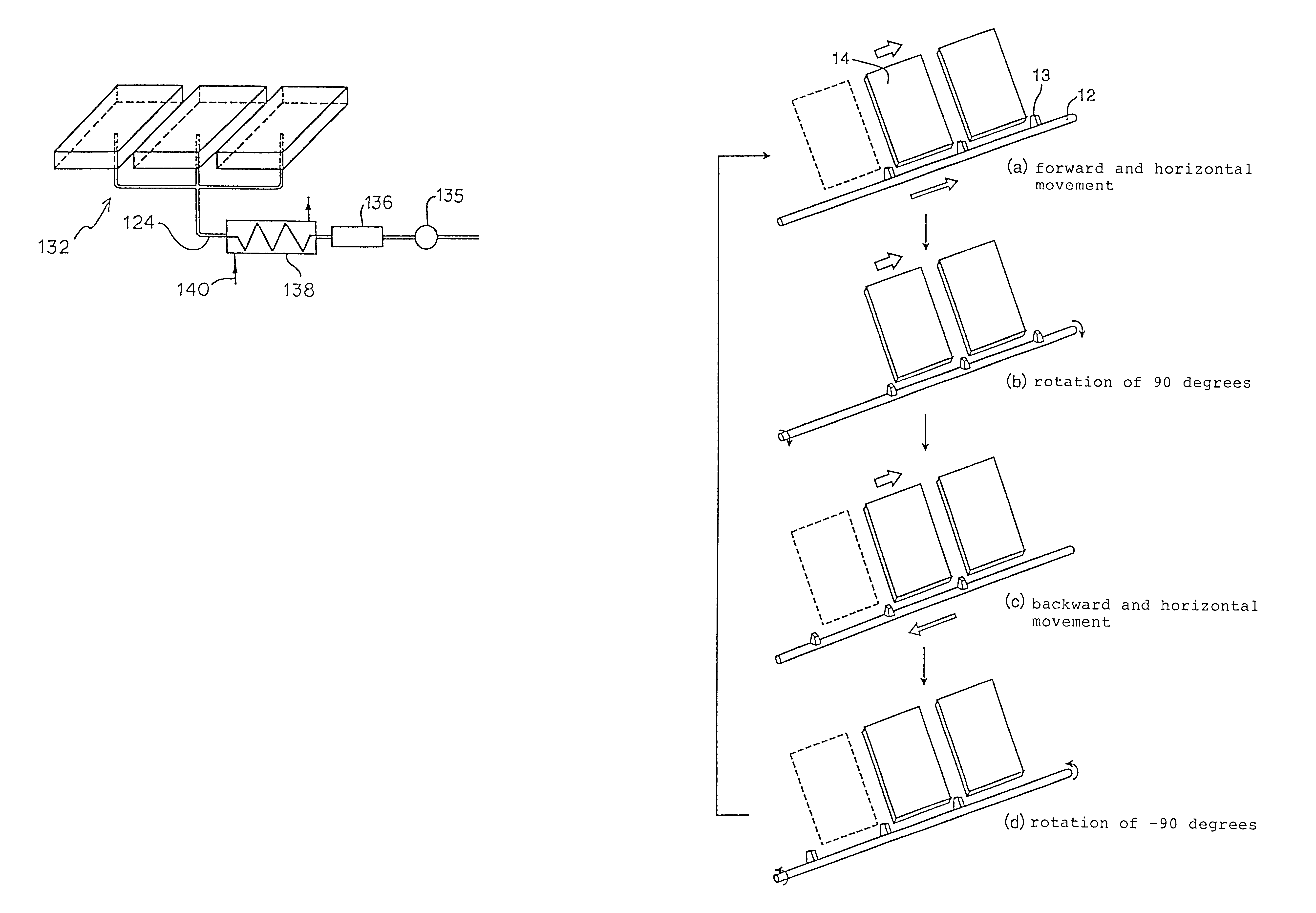

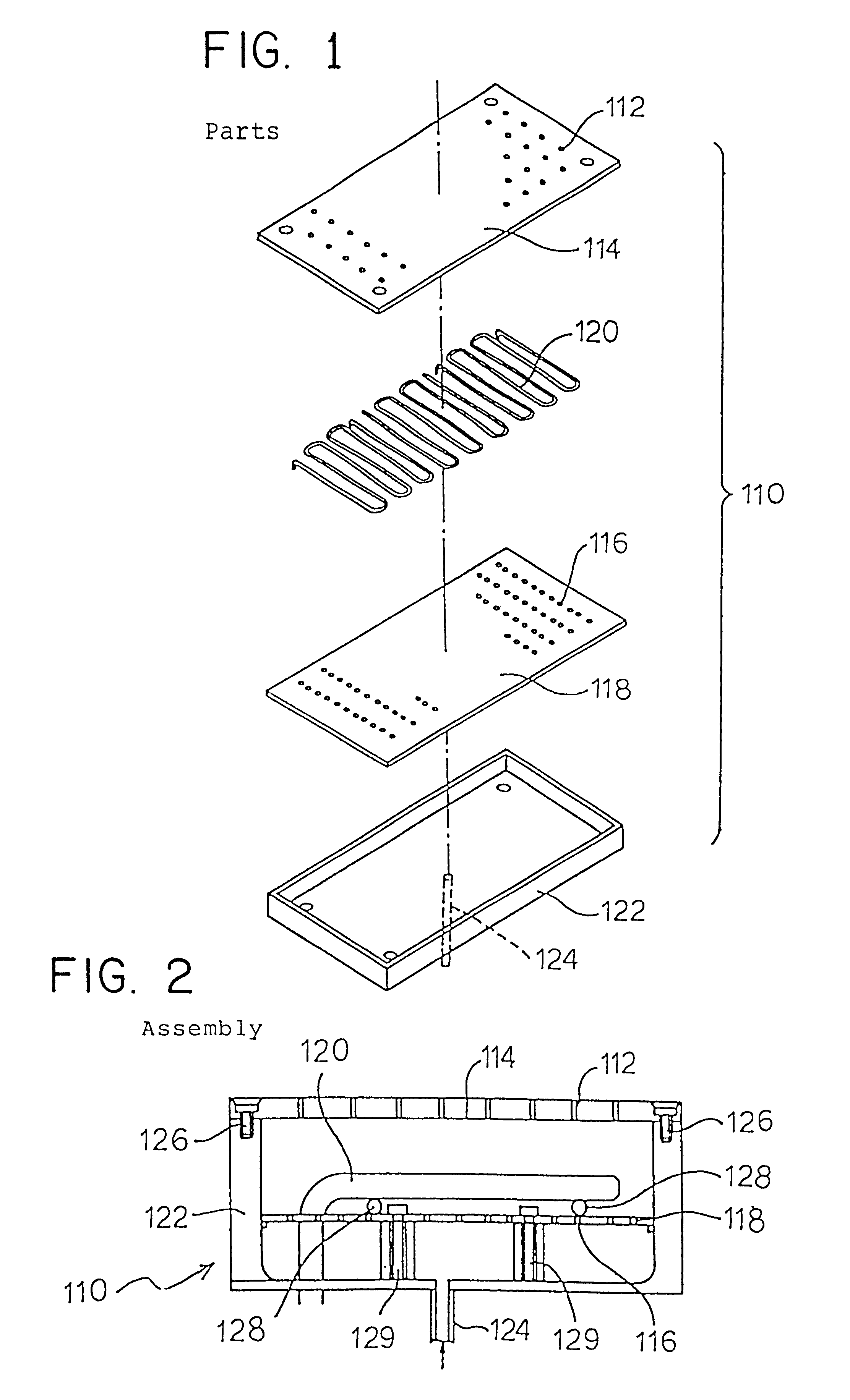

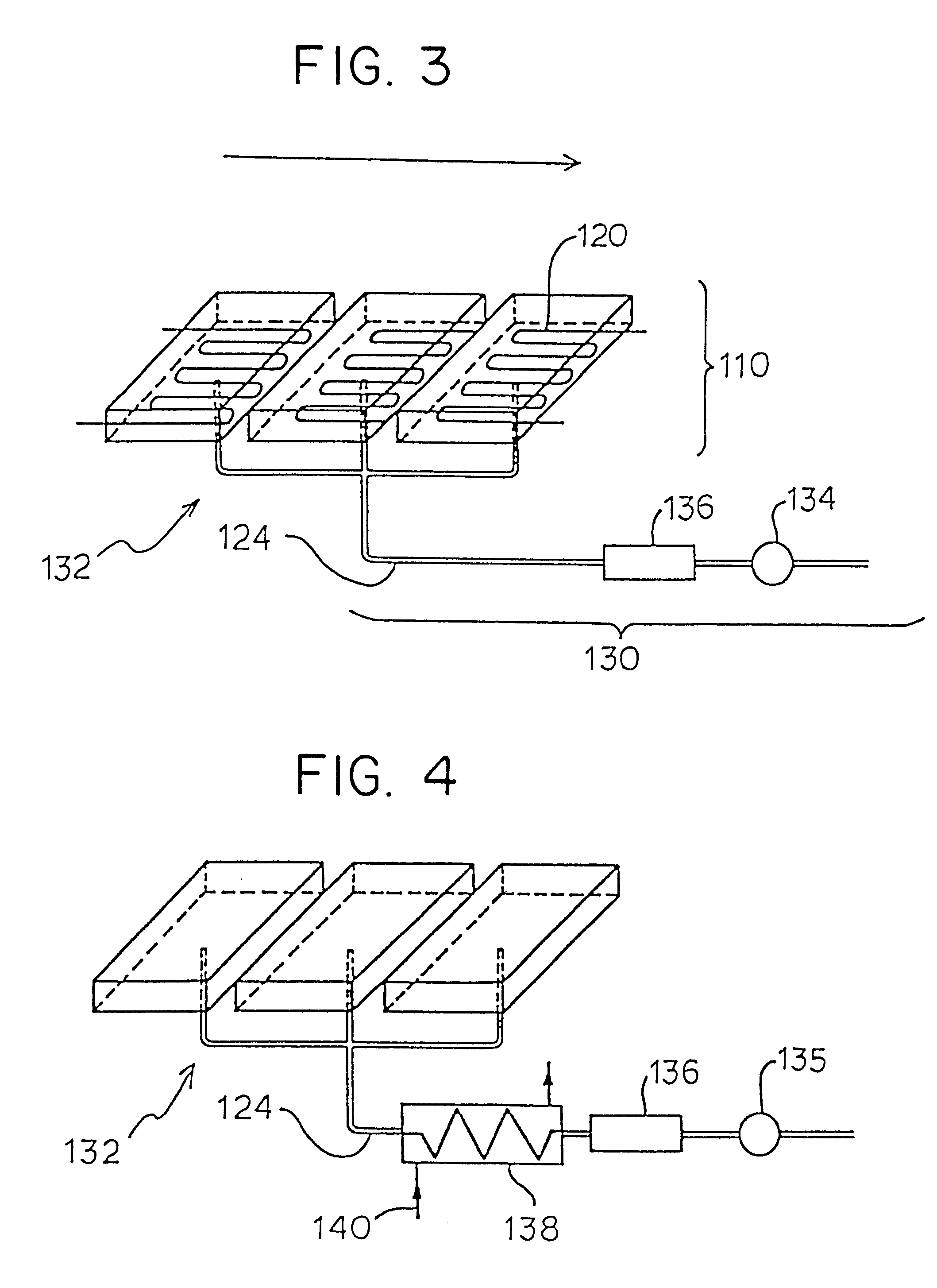

Gas floating apparatus, gas floating-transporting apparatus, and thermal treatment apparatus

InactiveUS6336775B1Large heat capacityWaste of energyGlass transportation apparatusSemiconductor/solid-state device manufacturingEngineeringThermal treatment

A gas floating-transporting apparatus transports a material to be treated along a predetermined direction in a thermal space so as to thermally treat the material to be treated. The apparatus includes a gas floating mechanism and a transporting mechanism. The gas floating mechanism includes a gas ejection device which expels the gas toward a portion of the material to be treated on which a floating force is acted so as to float the material to be treated, and a gas supply device which supplies the gas to the gas ejection means. The transporting mechanism includes an abutting member which abuts a trailing end of the floated material to be treated and moves along the predetermined direction, and which pushes the material to be treated by the movement thereof, whereby the floated material to be treated is moved along the predetermined direction.

Owner:PANASONIC CORP

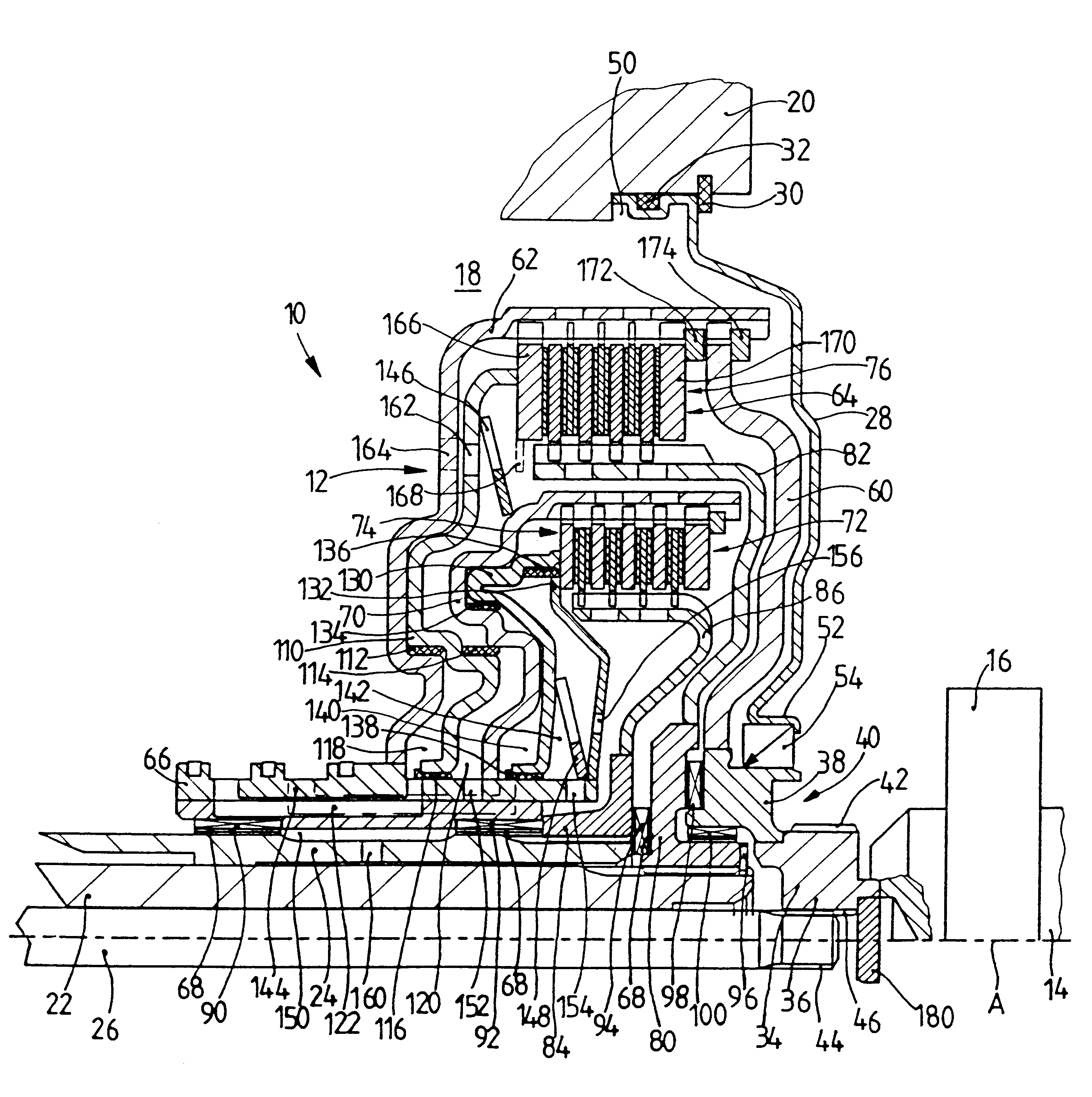

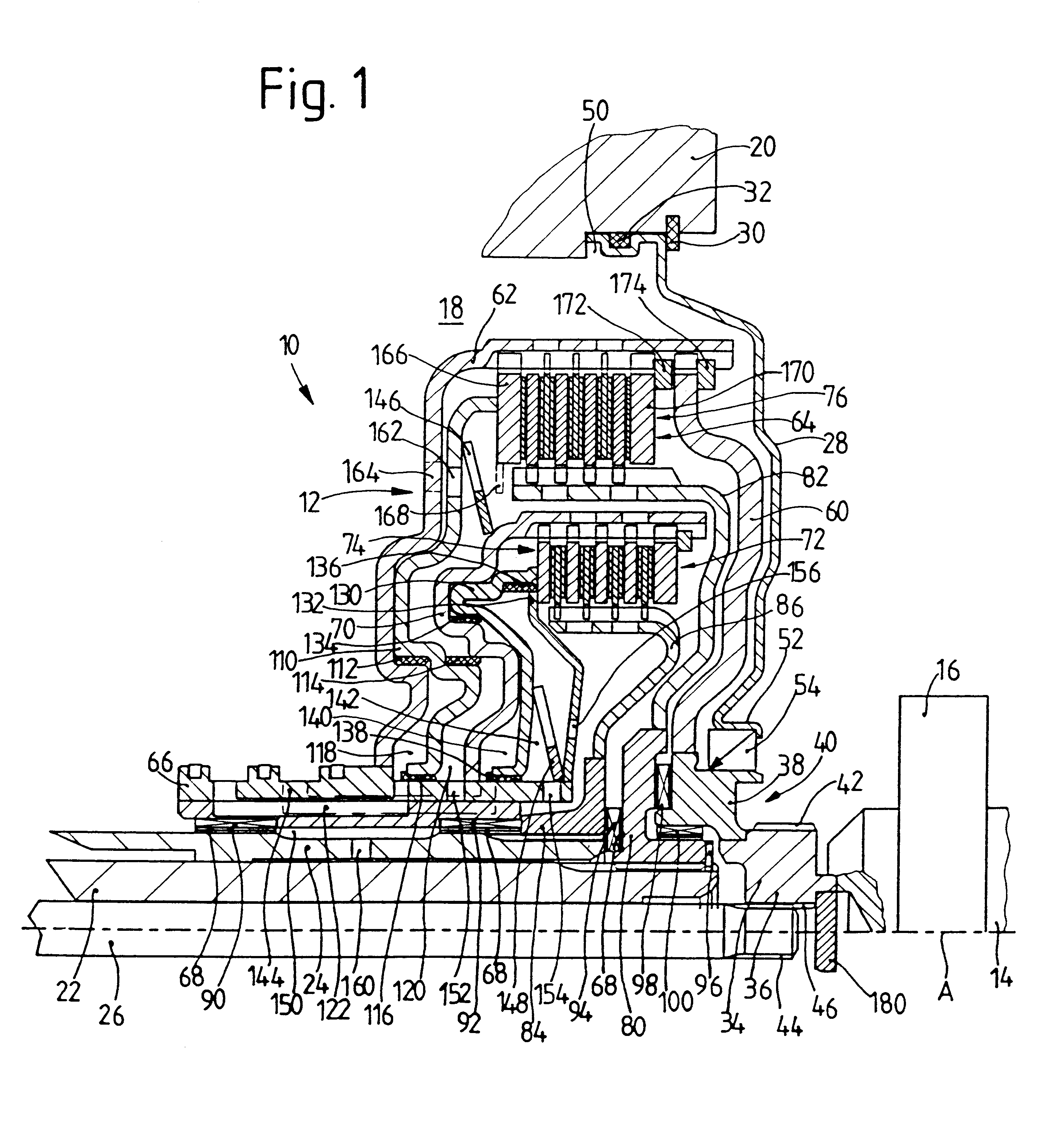

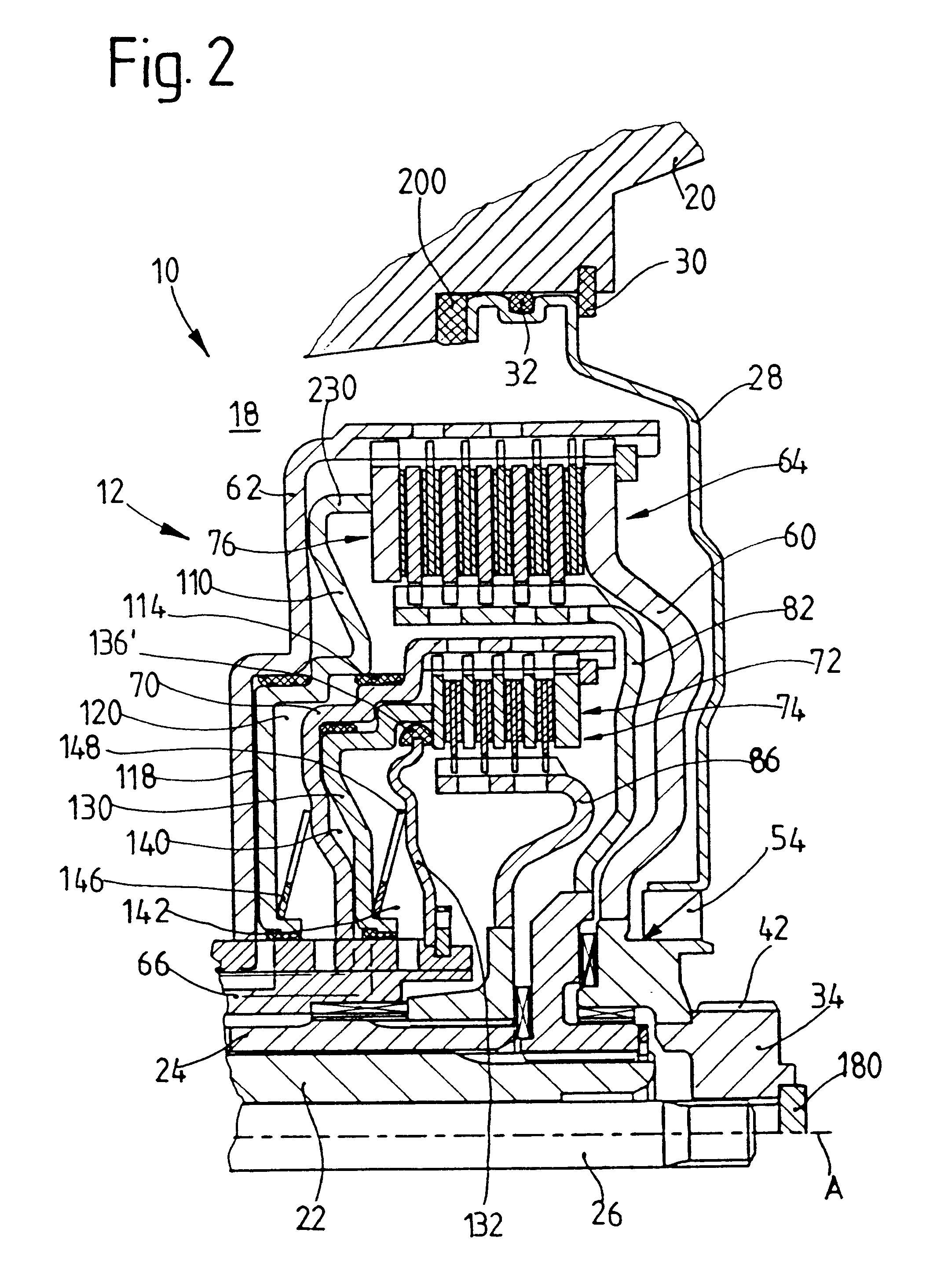

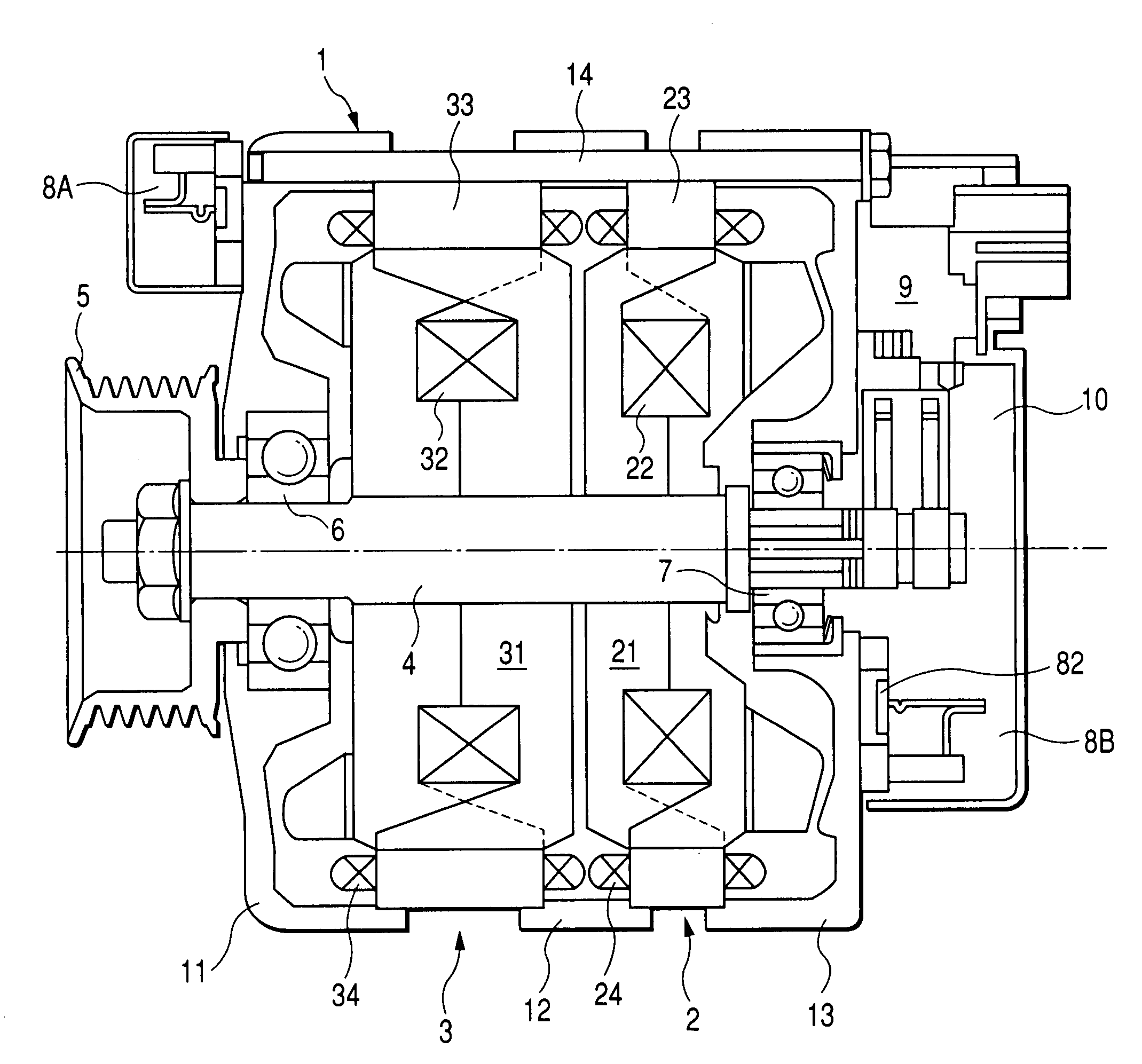

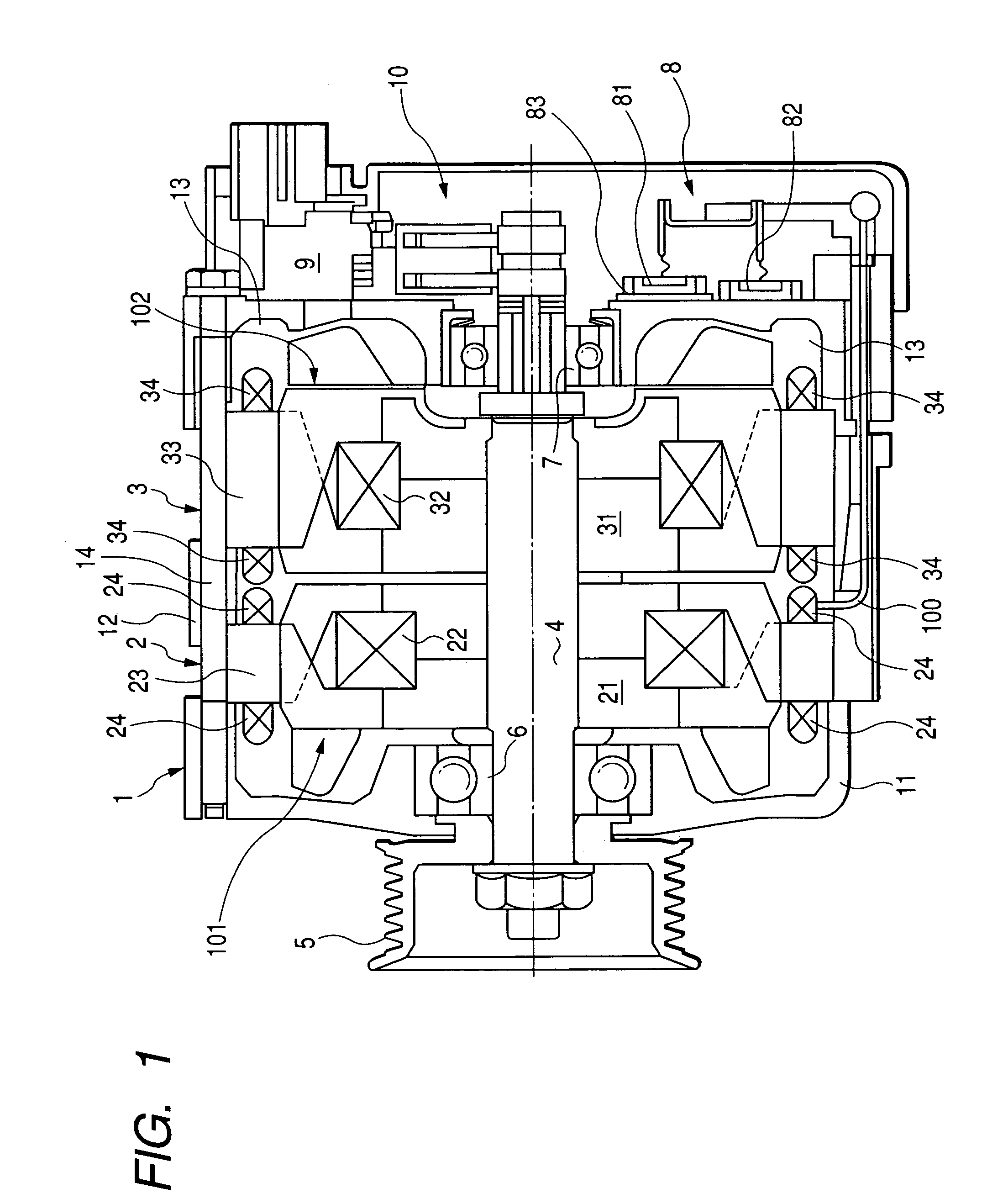

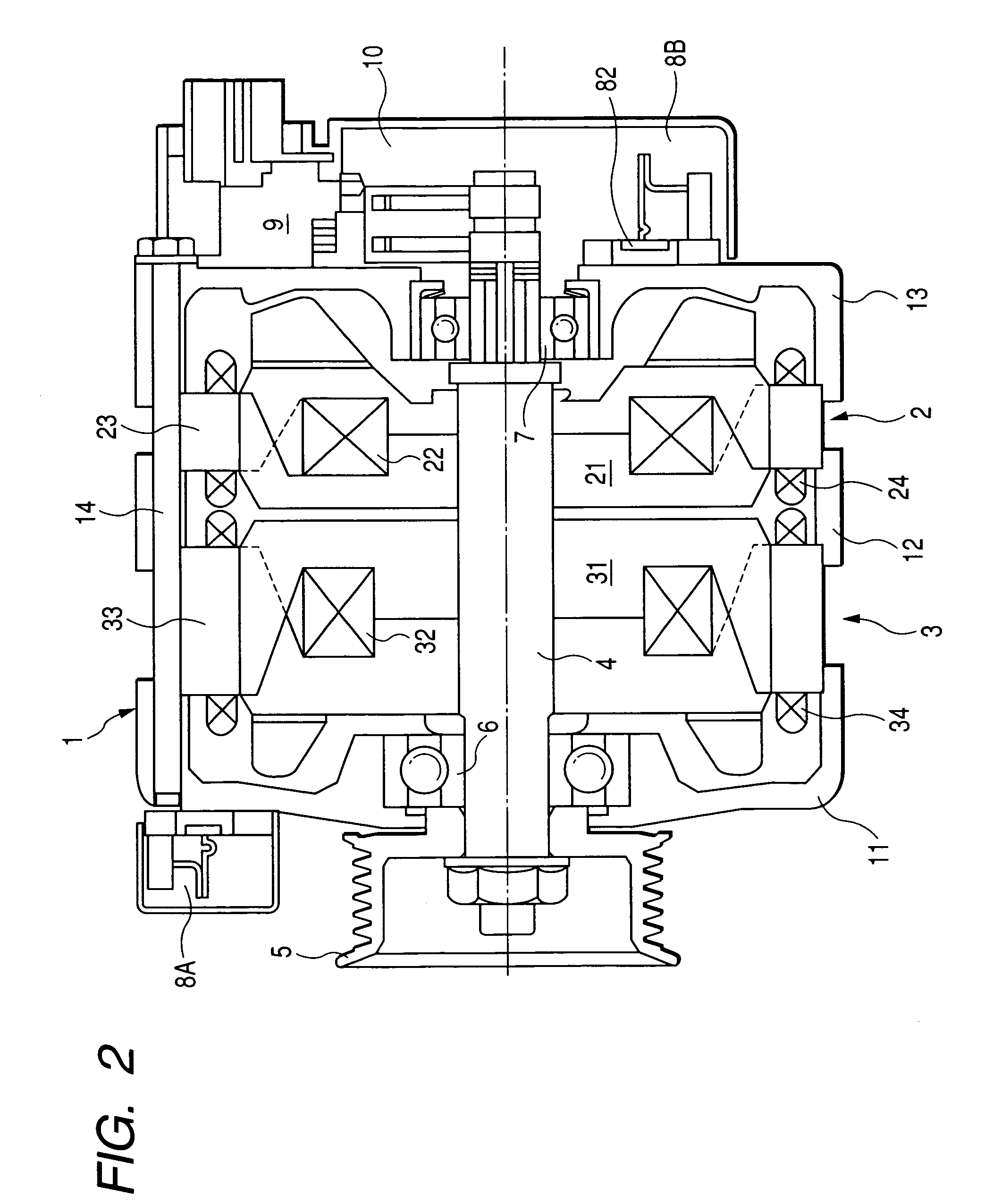

Multiple-clutch device

InactiveUS6523657B1Large massLarge heat capacityRoad transportFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that plates in a plate stack of a clutch arrangement constructed as a plate clutch arrangement which have at least one friction facing can be brought into frictional engagement with plates having no friction facing, wherein at least one of the plates not having a friction facing is thicker in axial direction than friction facing carrying elements of adjacent plates having at least one friction facing. Alternatively or in addition, it is suggested that at least one plate which has at least one friction facing of sintered material and at least one plate which has at least one friction facing made of another friction facing material are provided in the plate stack, wherein the other friction facing material has a progressive frictional coefficient curve (dlambd / dDELTAN) in relation to a slip speed (DELTAN).

Owner:ZF FRIEDRICHSHAFEN AG +1

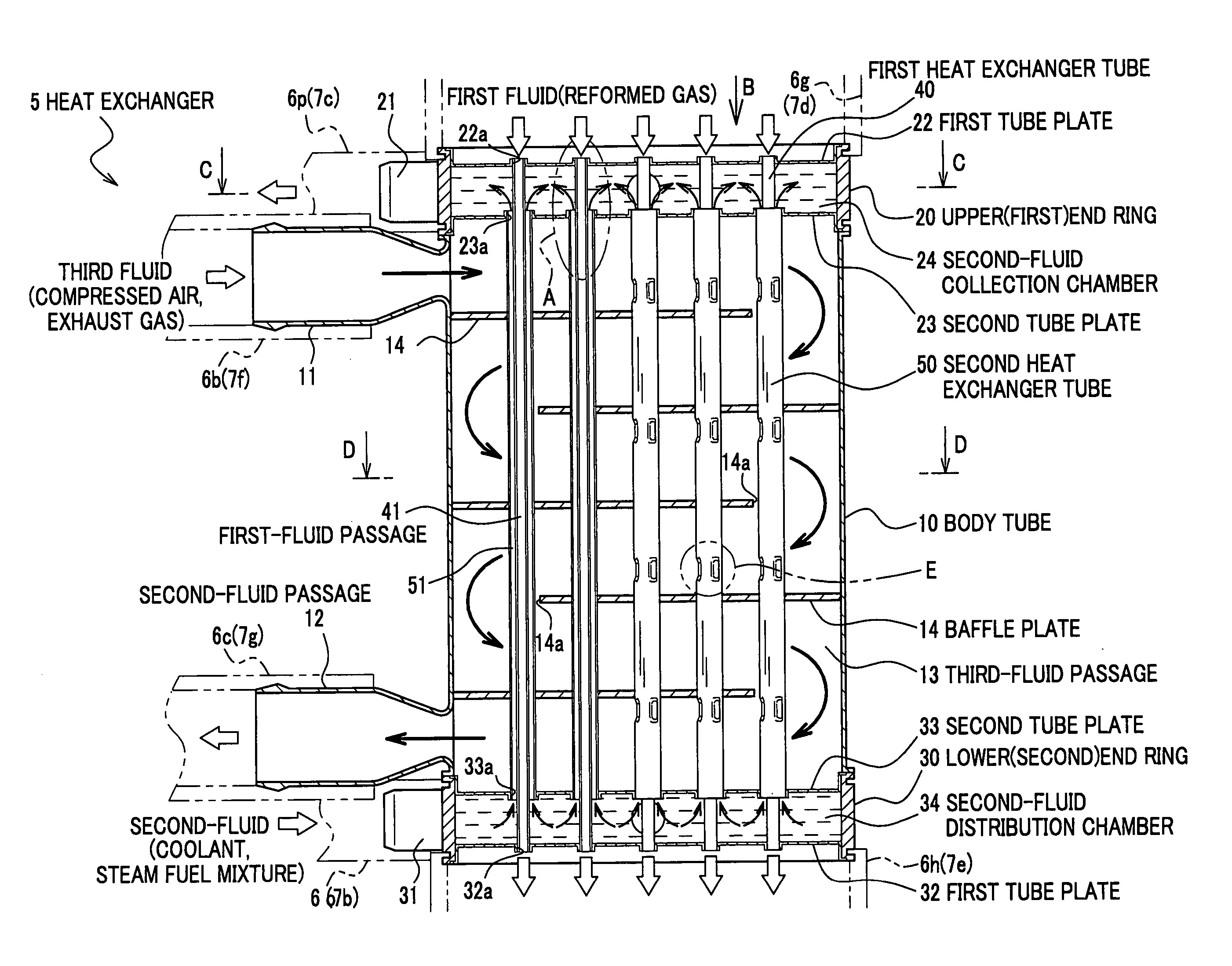

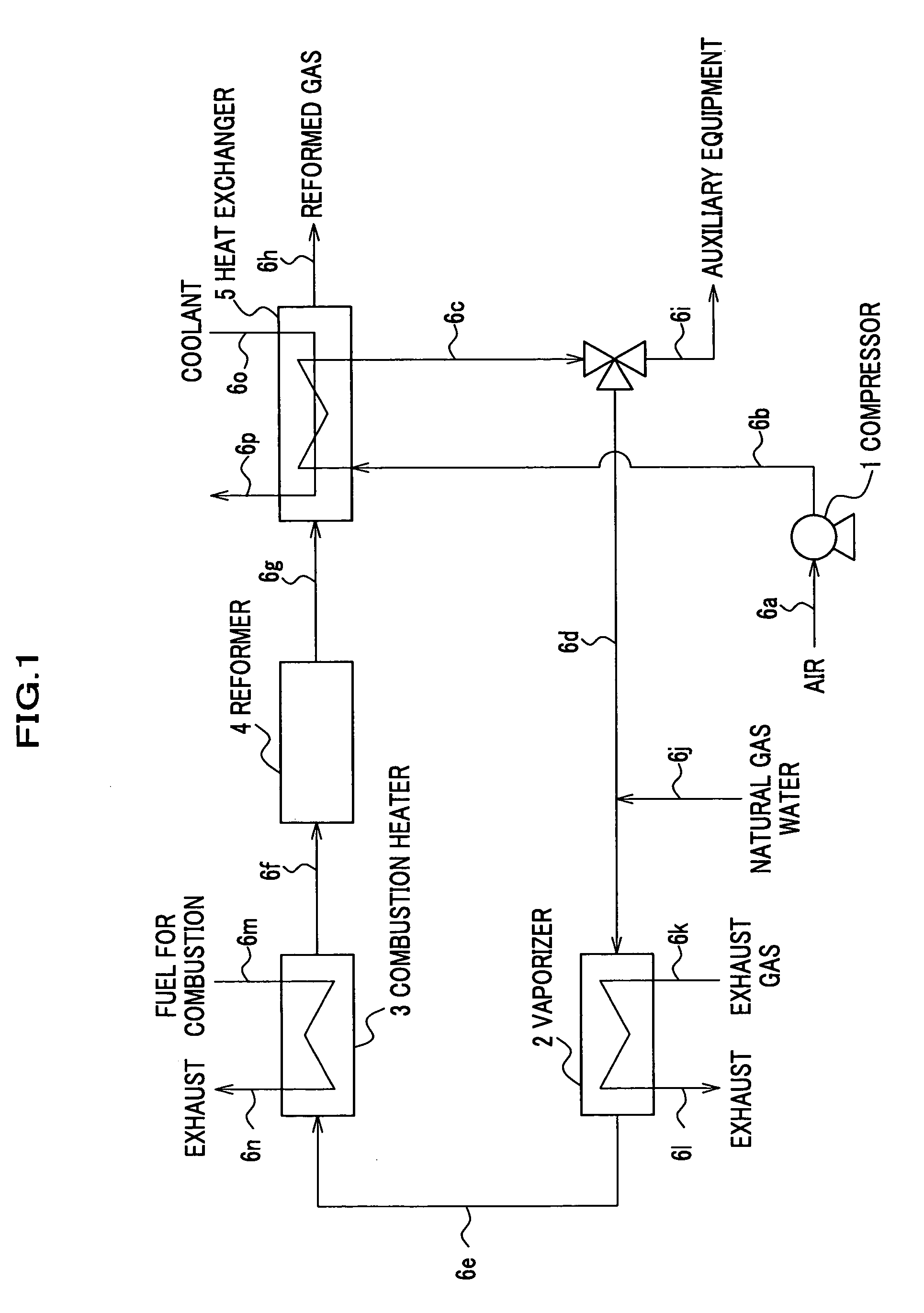

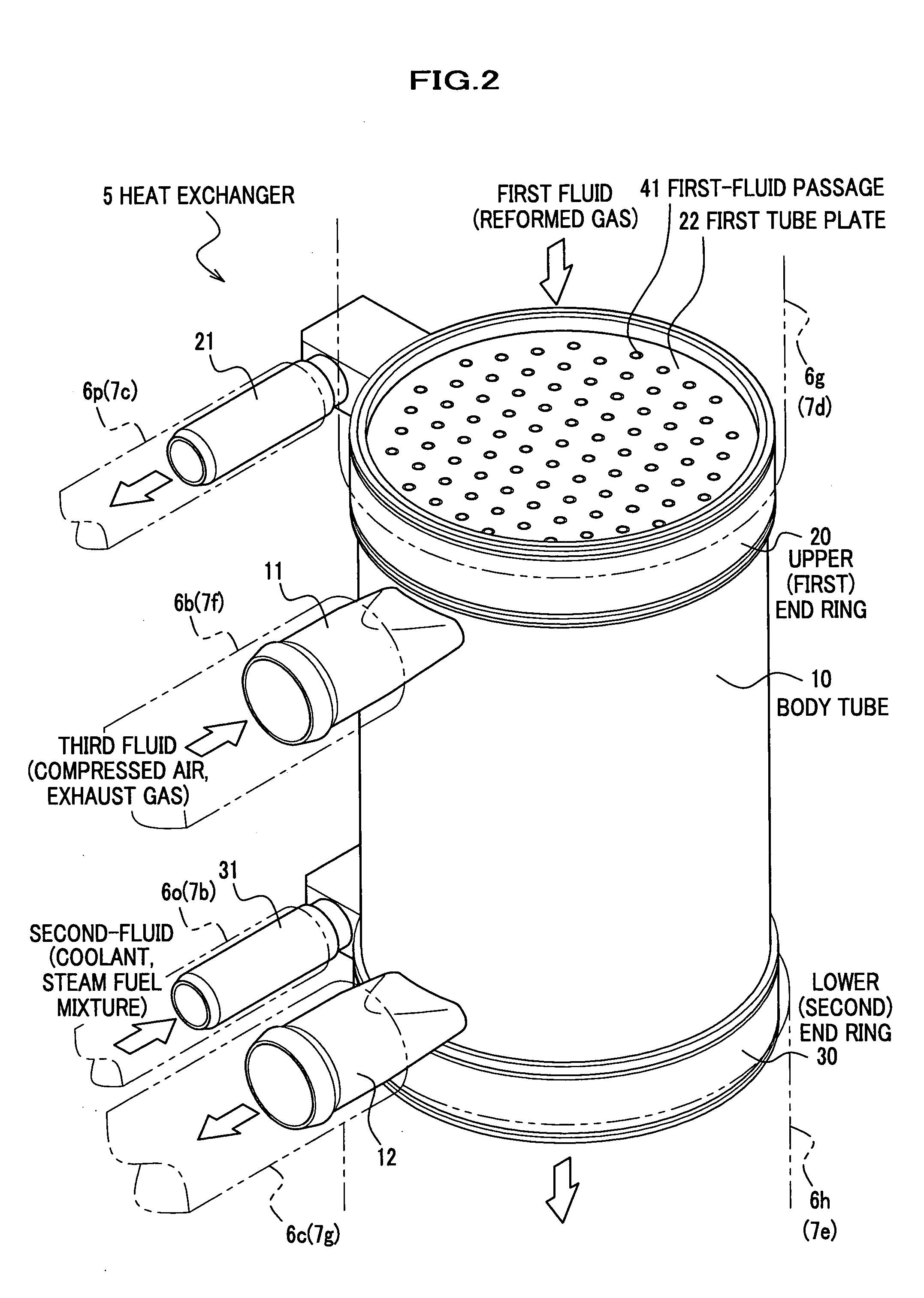

Heat exchanger

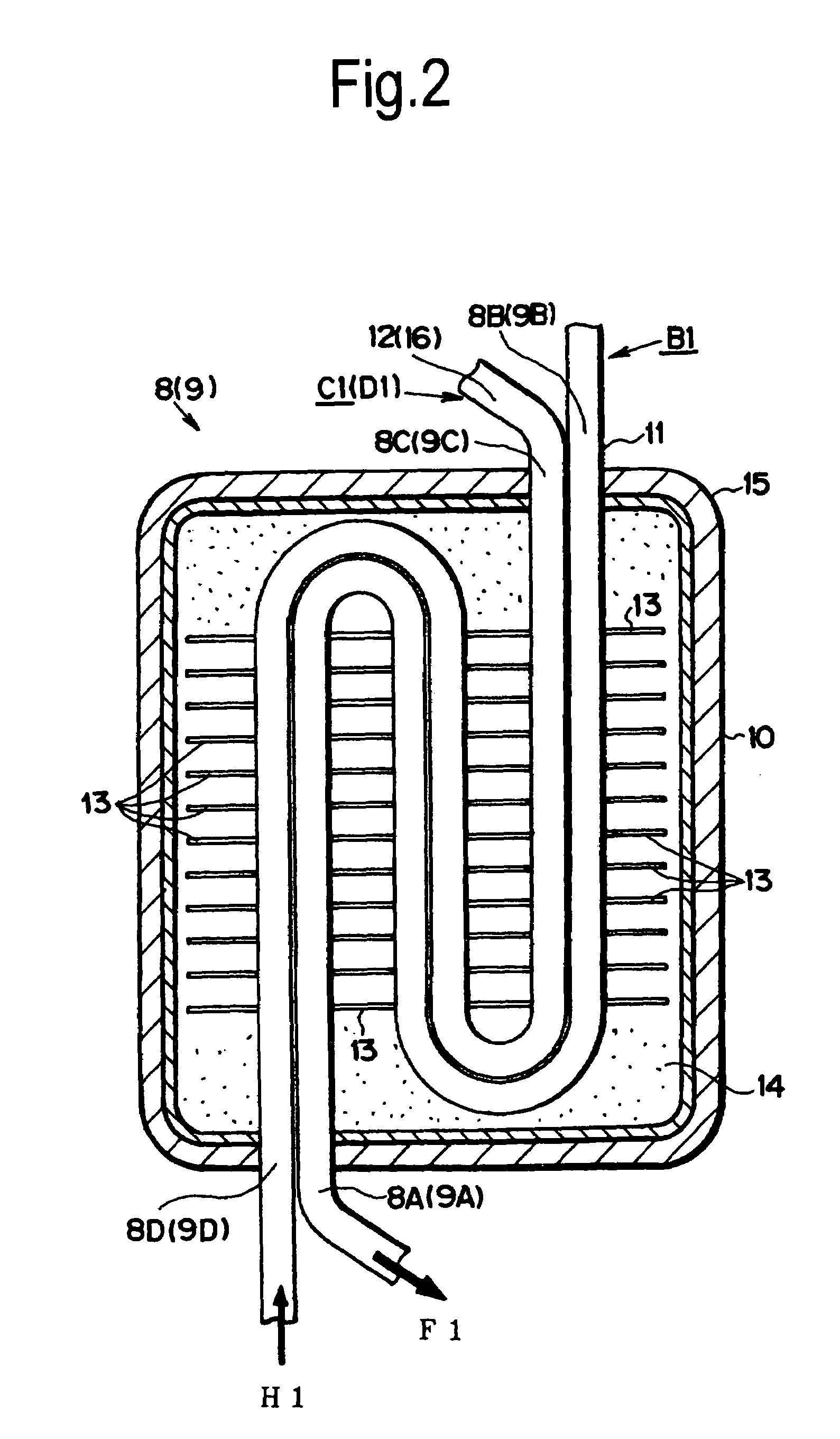

InactiveUS20050236145A1Improve heat exchange efficiencyLarge heat capacitySpacing meansHydrogenEngineeringHeat exchanger

End rings are coupled with upper and lower ends of a cylindrical body tube. A plurality of first heat exchanger tubes are fitted and held in holes provided in a pair of first tube plates. A plurality of second heat exchanger tubes are fitted and held in holes provided in a pair of second tube plates. The inside of each first heat exchanger tubes forms a first-fluid passage for carrying a reformed gas. The space defined between an outer wall of each first heat exchanger tube and an inner wall of the corresponding second heat exchanger tube forms a second-fluid passage for carrying a coolant. The space defined among an inner wall of the body tube and outer walls of the second heat exchanger tubes form a third-fluid passage for carrying compressed air.

Owner:HONDA MOTOR CO LTD

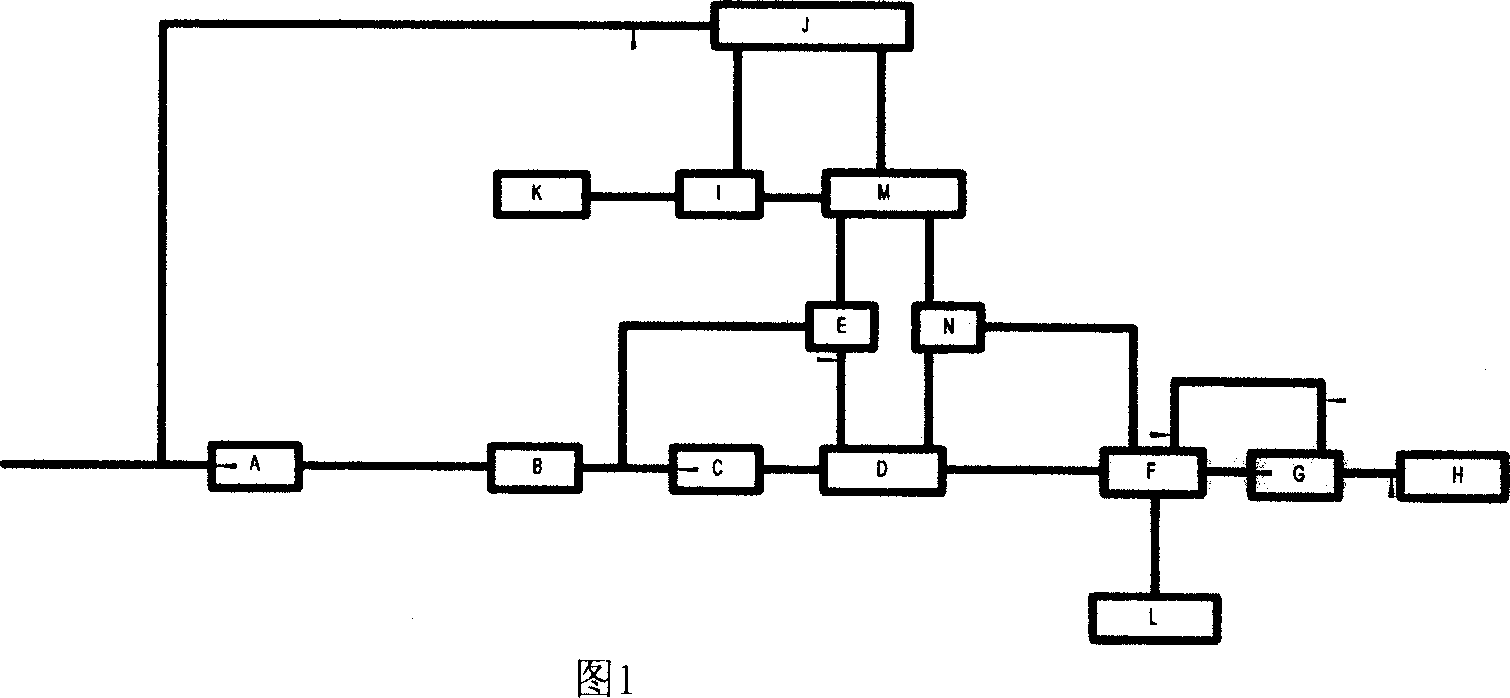

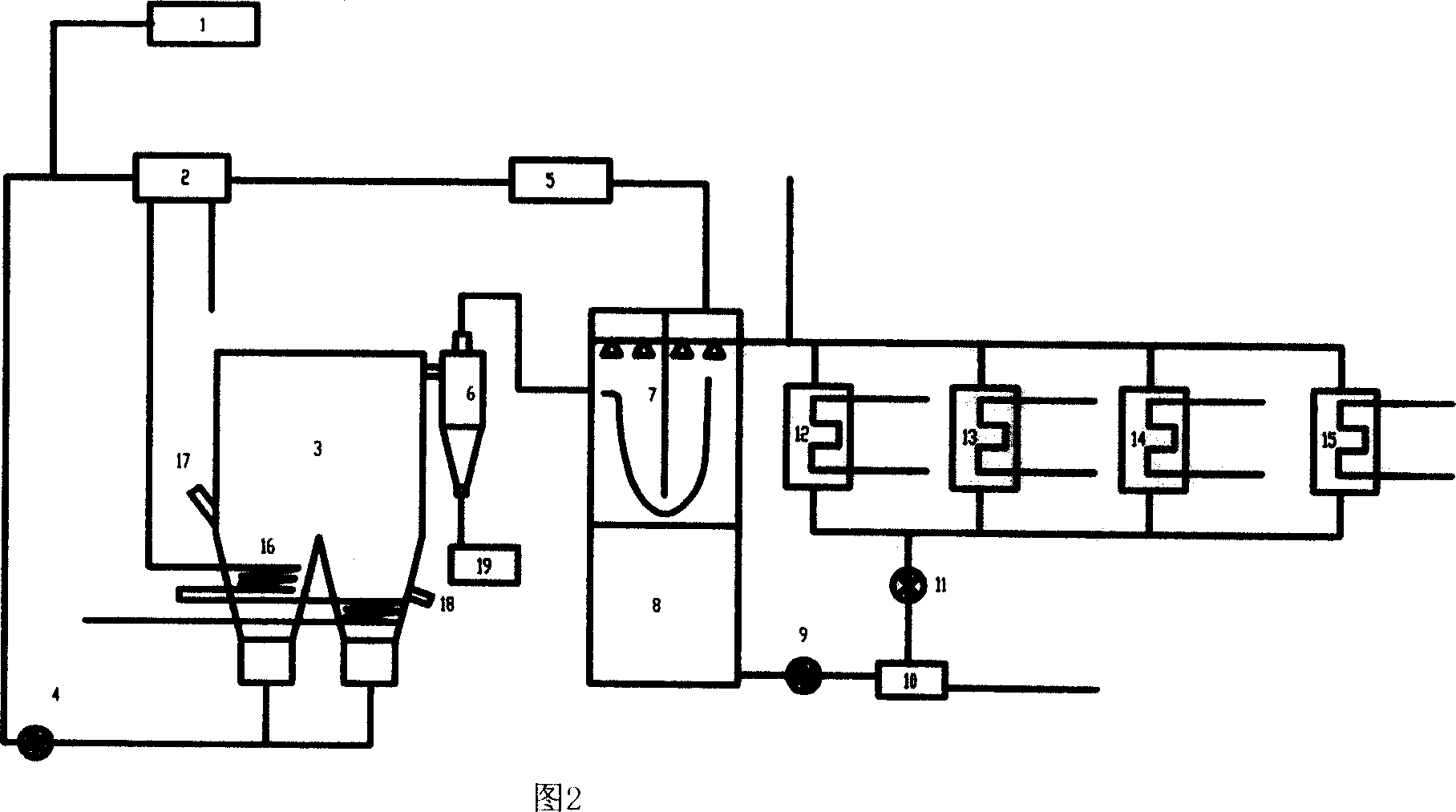

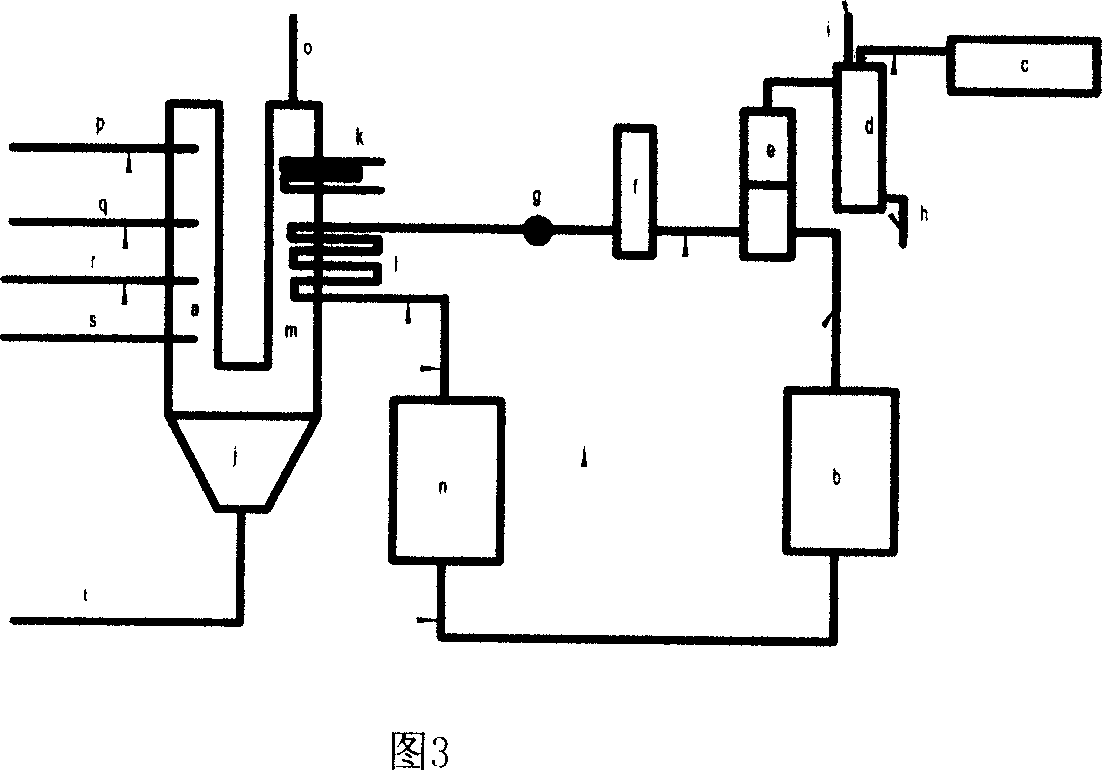

Sludge drying and incinerating treatment process

InactiveCN1931753AAvoid pollutionAvoid harmSludge treatment by oxidationByproduct vaporizationChemical compositionSludge

The present invention relates to environmental protection engineering technology, and is especially sludge drying and incinerating treatment process. The present invention has effective utilization of heat energy, no exhaust of harmful gas and bad smell, no exhaust of dangerous clinker, simple structure and high burning efficiency of the sludge incinerating system, no need of auxiliary fuel and other advantages.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

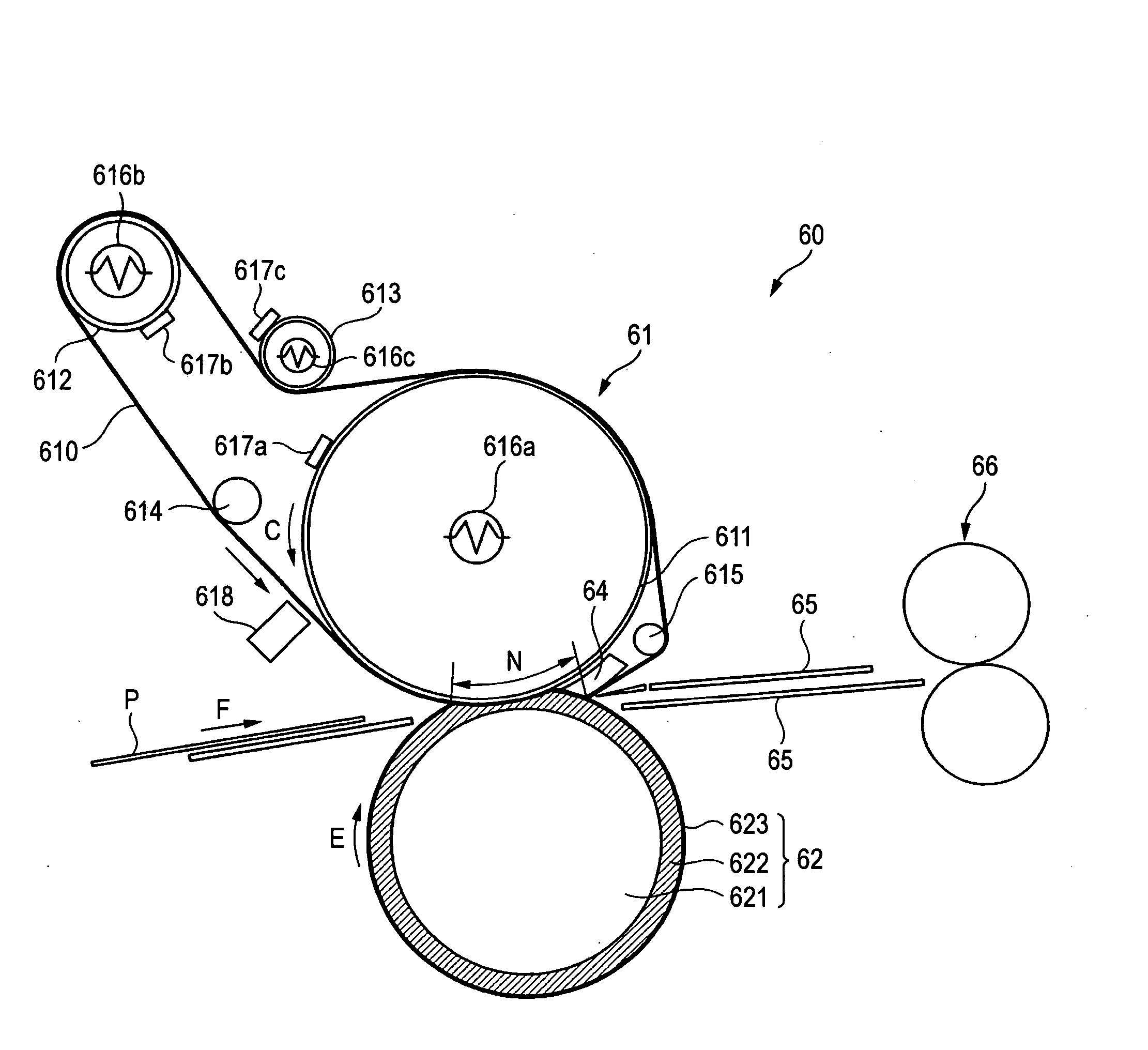

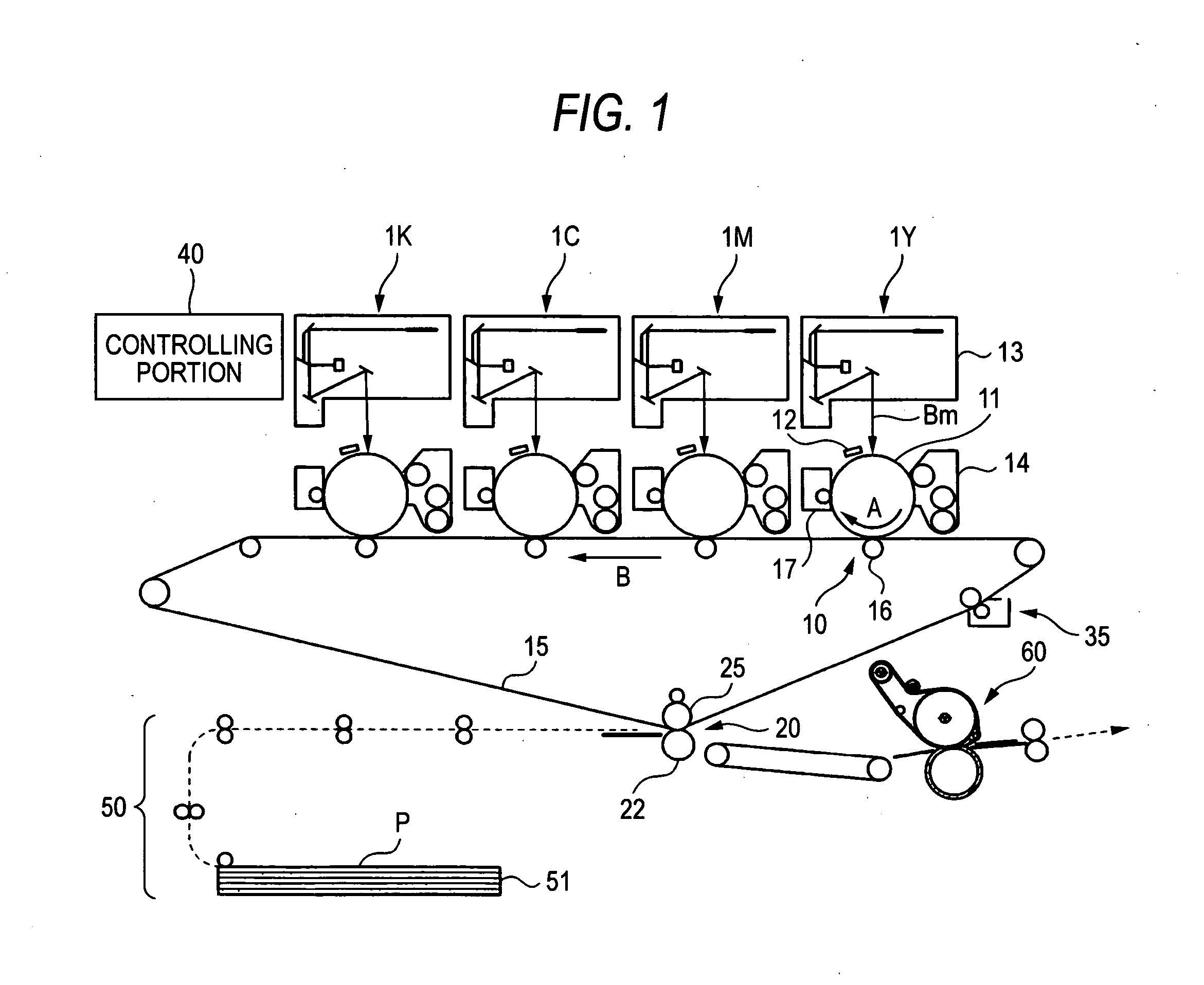

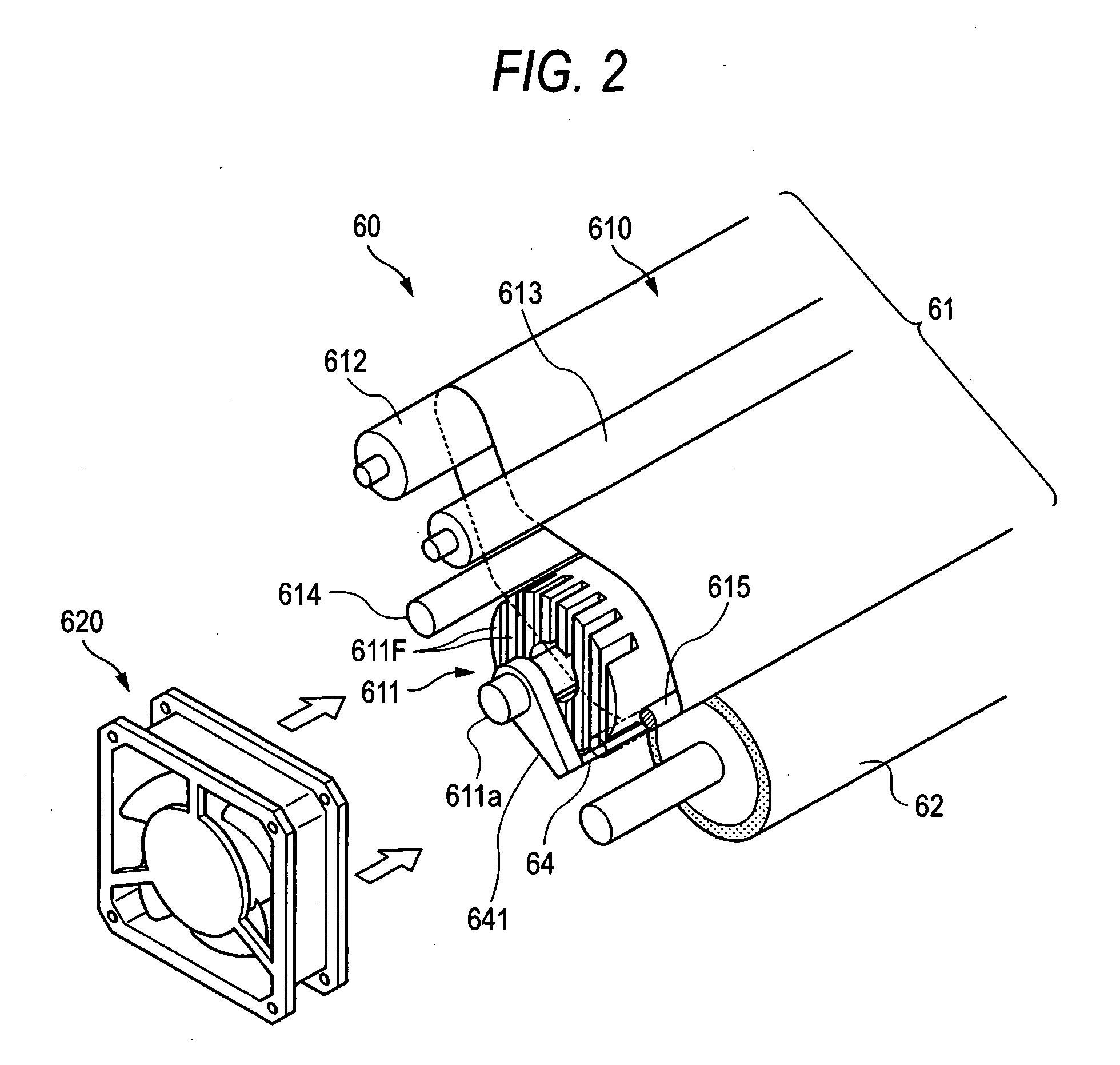

Fixing device and image forming apparatus

InactiveUS20070092277A1Avoid temperatureDifferent heat capacityElectrographic process apparatusEngineeringTemperature control

Owner:FUJIFILM BUSINESS INNOVATION CORP

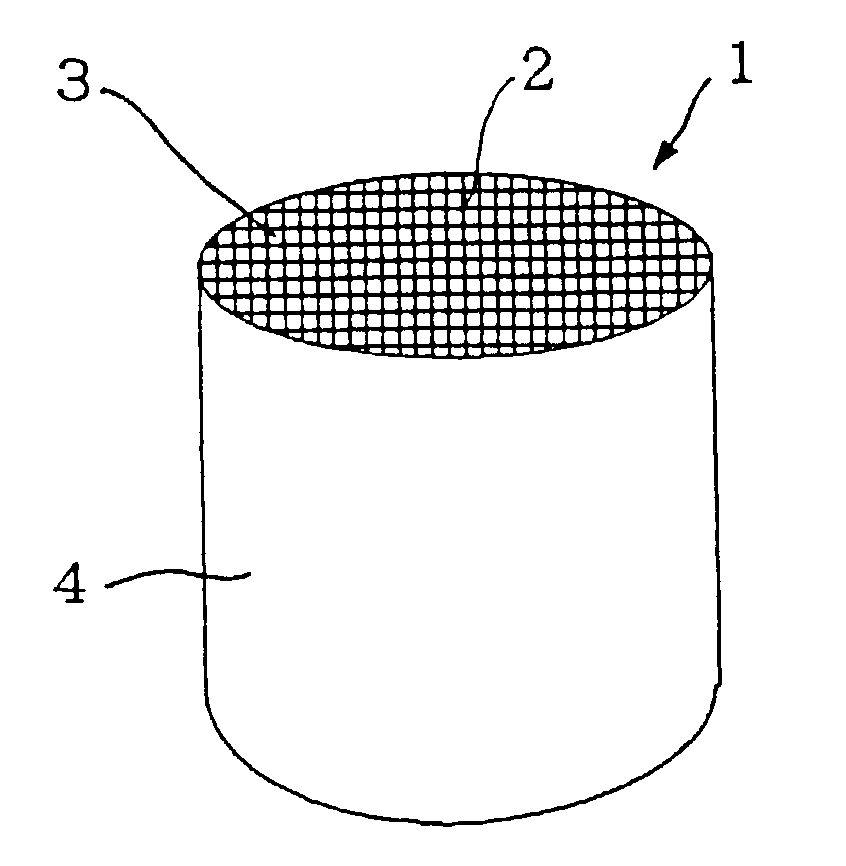

Ceramic honeycomb structure

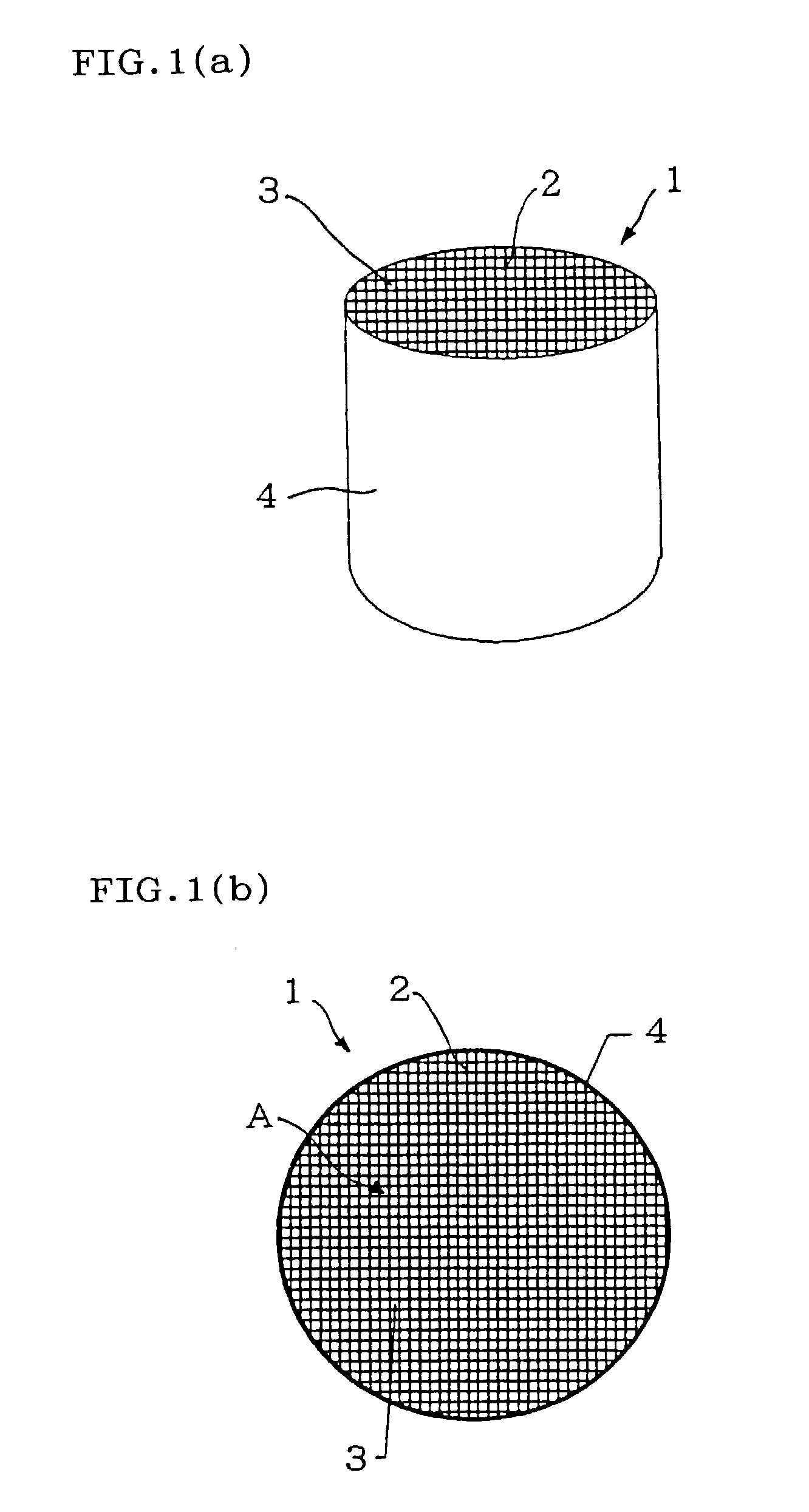

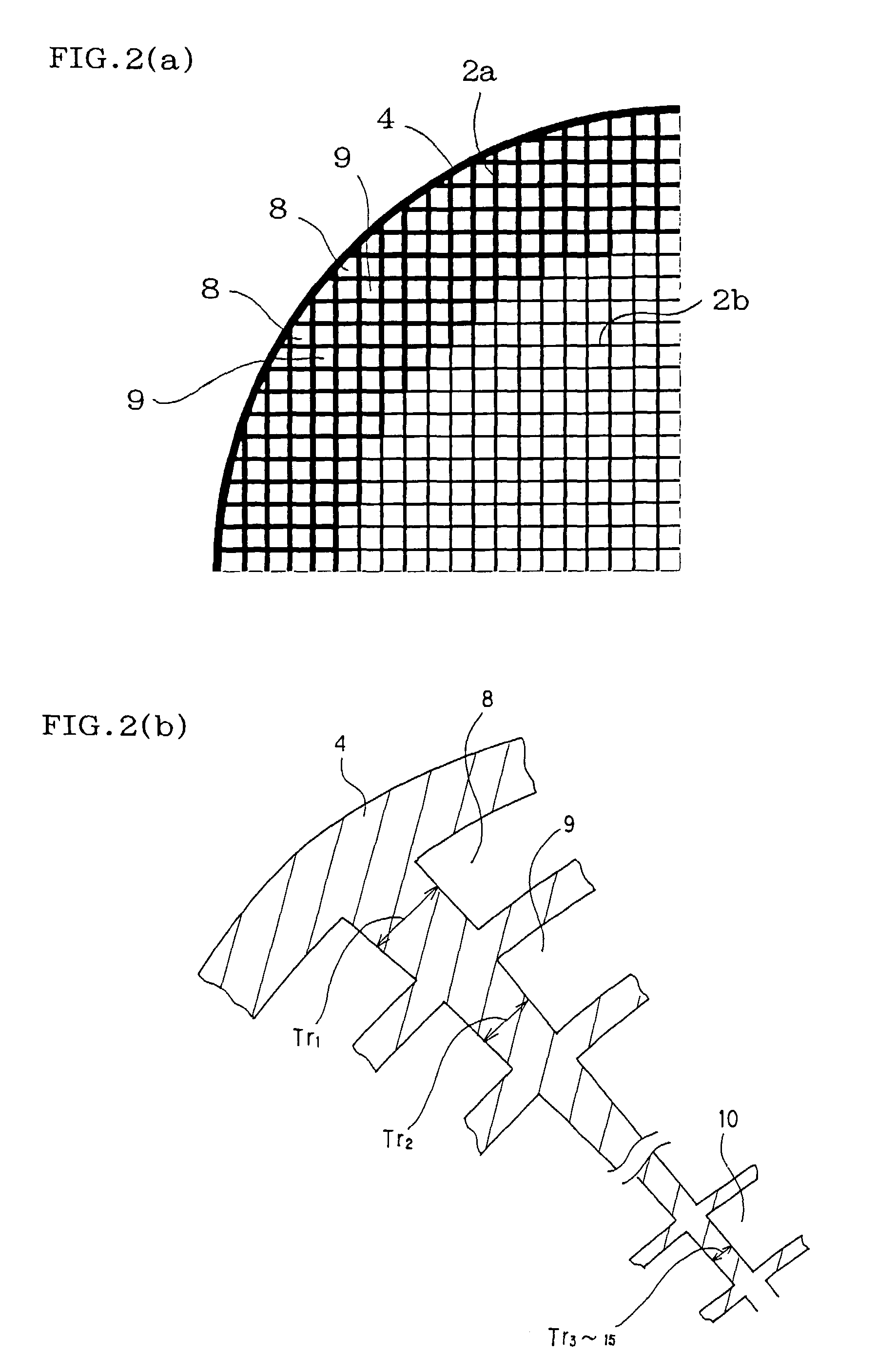

InactiveUS20020192426A1Increased pressure lossReduced thermal shock resistanceCombination devicesDead plant preservationCell wallHoneycomb structure

A ceramic honeycomb structure (1) constituted by cell walls (ribs) (2) forming a composite structure from a plurality of cells (3) being adjacent each other and a honeycomb outer wall (4) surrounding and holding the outermost peripheral cells located at the circumference of the composite structure; said composite structure satisfying the followings: the basic thickness of the cell walls (2) (the basic cell wall thickness) (Tc) is Tc<=0.12 mm, the outer wall thickness (Ts) of the honeycomb structure is Ts >=0.05 mm, and the open frontal area (P) is P>==80%, and there is a relation shown by formula: <paragraph lvl="0"><in-line-formula>1.10<=(Tr1~Tr3-20) / Tc<=3.00 < / in-line-formula>between the basic cell wall thickness (Tc) and each cell wall thickness (Tr1~Tr3-20) of cells existing between an outermost peripheral cell and any cell within a first end cell from a fifth cell to a twentieth cell extending inwardly, taking the outermost peripheral cell as a first staring cell.

Owner:NGK INSULATORS LTD

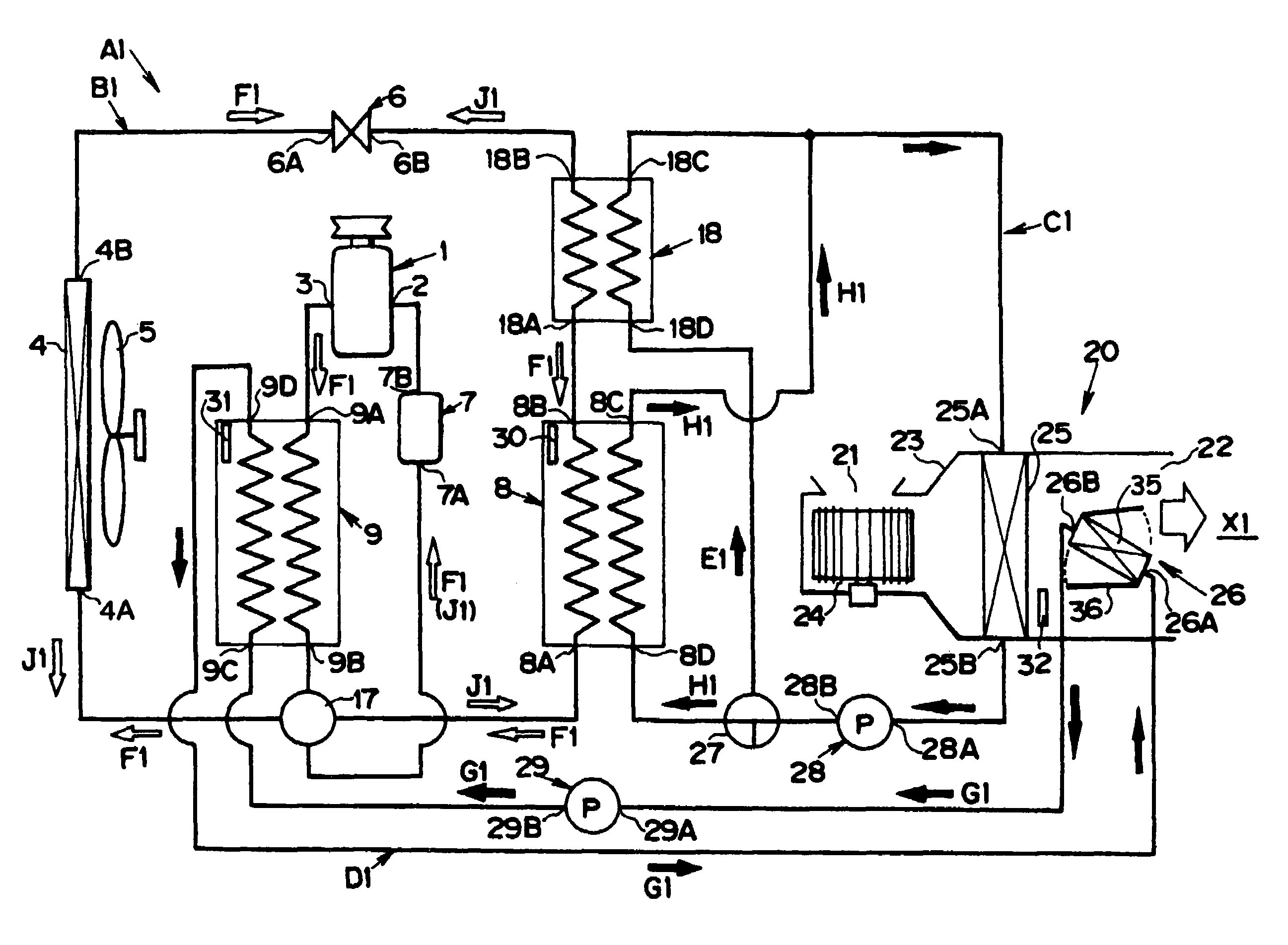

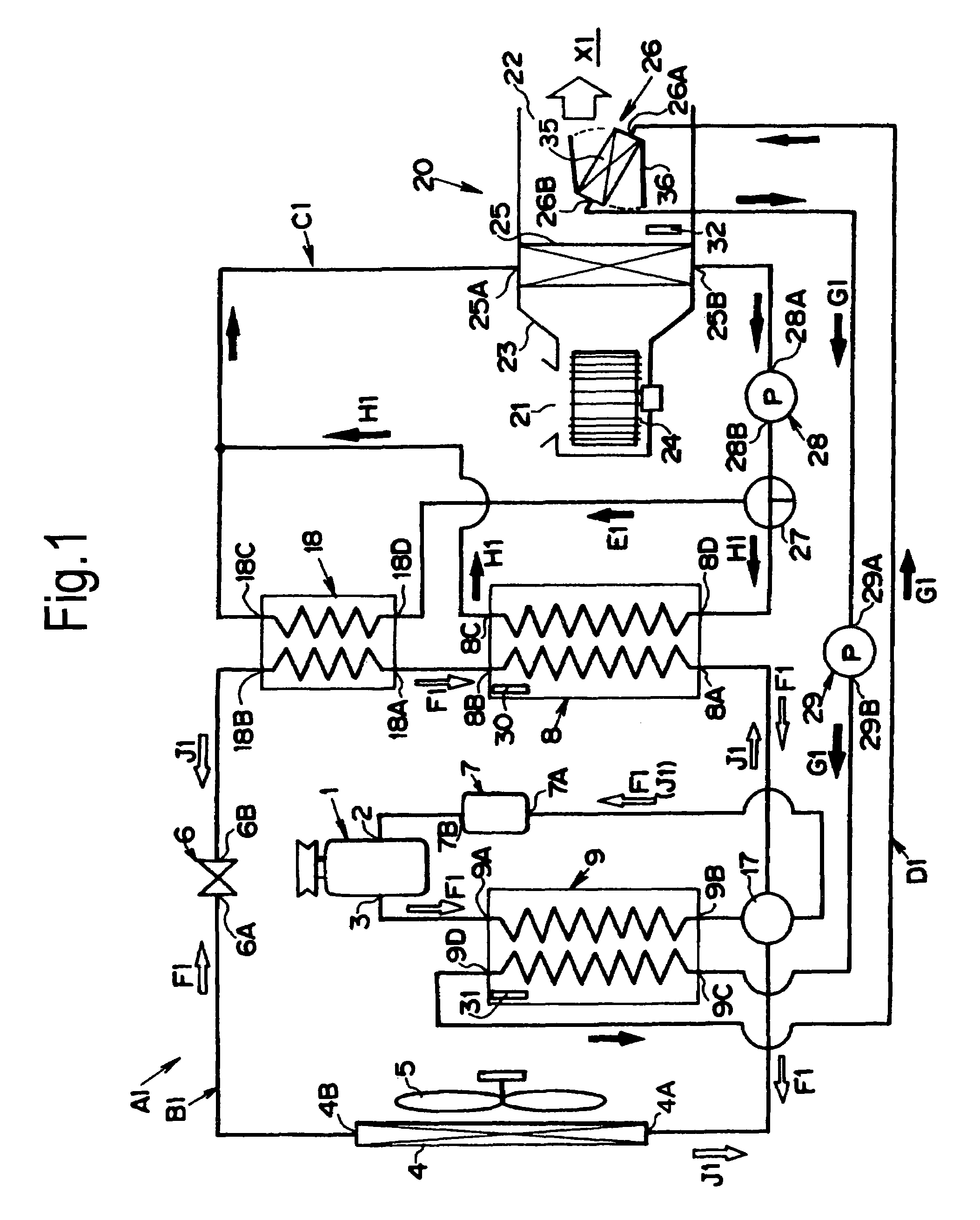

Air conditioning apparatus

InactiveUS7669647B2Increase fuel consumptionImpact engine loadOther heat production devicesHeat storage plantsEngineeringAir conditioning

An air conditioning system for cooling or heating an air, and for feeding the heated or cooled air to predetermined portions is characterized by comprising: a first circulating circuit for circulating a first heating medium; a second circulating circuit for circulating a second heating medium; a control unit for controlling the heat for executing heat exchange between the first heating medium and the second heating medium to flow through either the heat exchanger or the first heat storing device. Moreover, an air temperature is controlled by heat of the second heating medium.

Owner:TOYOTA JIDOSHA KK

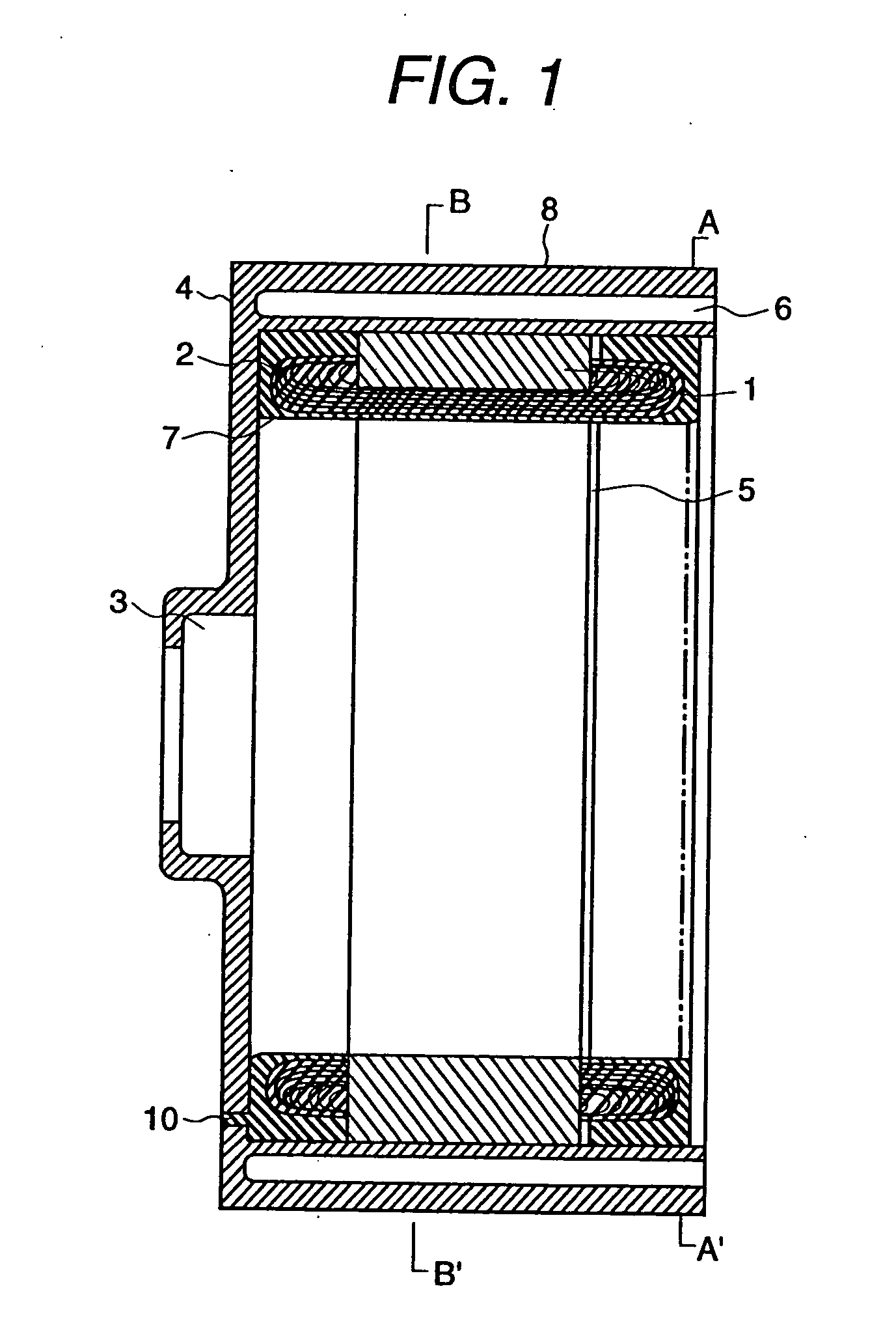

Method of manufacturing a resin-molded stator

InactiveUS20050285456A1Avoid insulation breakdownLarge heat capacityWindings insulation shape/form/constructionSynthetic resin layered productsStator coilOperation mode

A highly reliable resin-molded stator not suffering insulation breakdown between the different phases of the stator coils even when the operation mode where the output of a rotary machine using a resin-molded stator in which a stator coil wound around a plurality of slots and a stator coil provided at the stator core end are resin-molded is to be increased from the level under a stopped status to the maximum achievable level within a short time is repeated. Also disclosed is a method of manufacturing such a stator, and a rotary machine using the same. The resin-molded stator of the present invention comprises a stator core, electrically insulated stator coils wound around the plurality of slots or protrusions provided in the axial direction of the stator core, and molding resin with which are molded the stator core and the stator coils located at the aforementioned slots or protrusions and at the stator core end, wherein the resin-molded stator is characterized in that non-adhesive structure is established between the molding resin and at least one of the end faces of the stator core.

Owner:HITACHI LTD

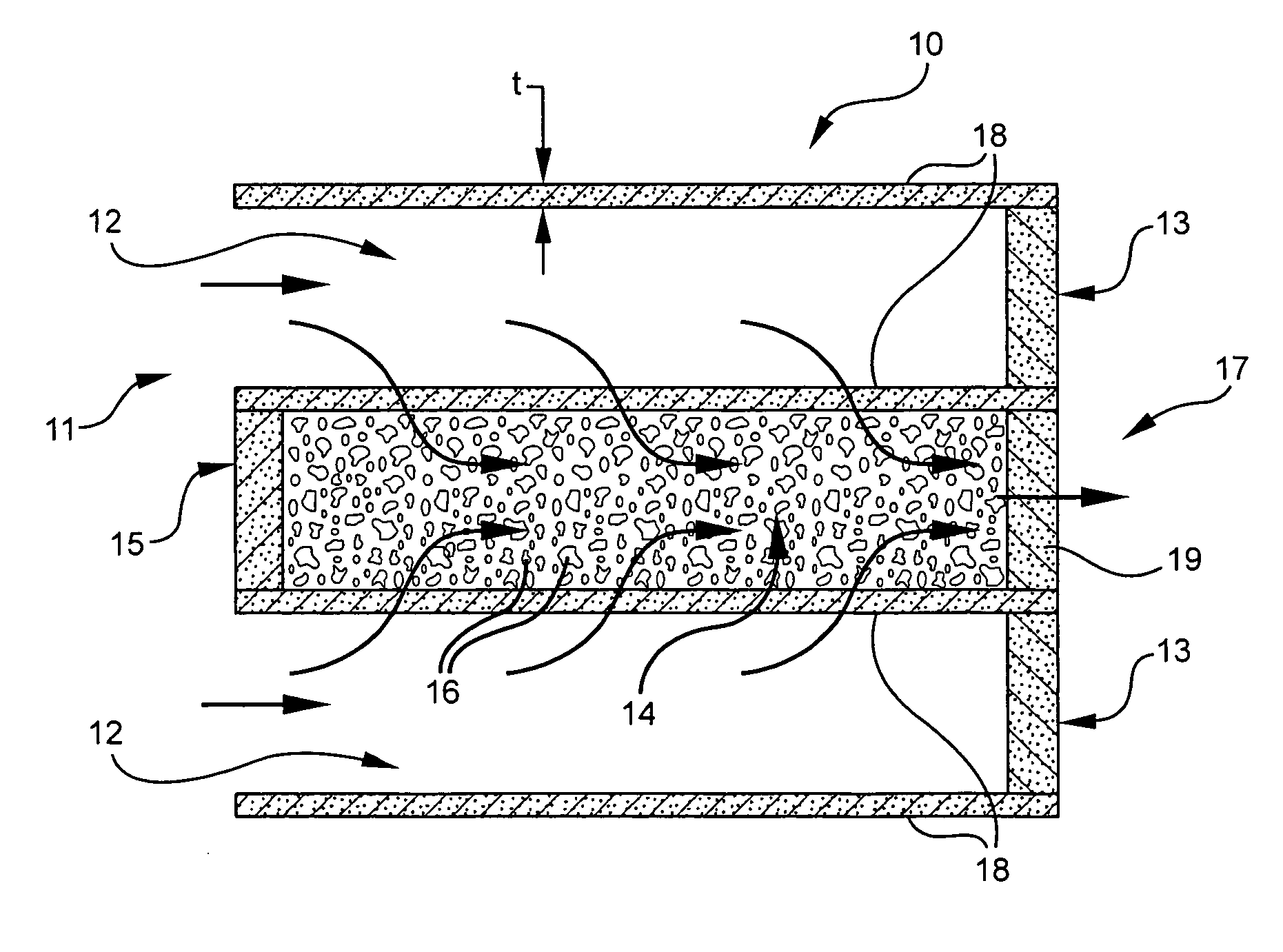

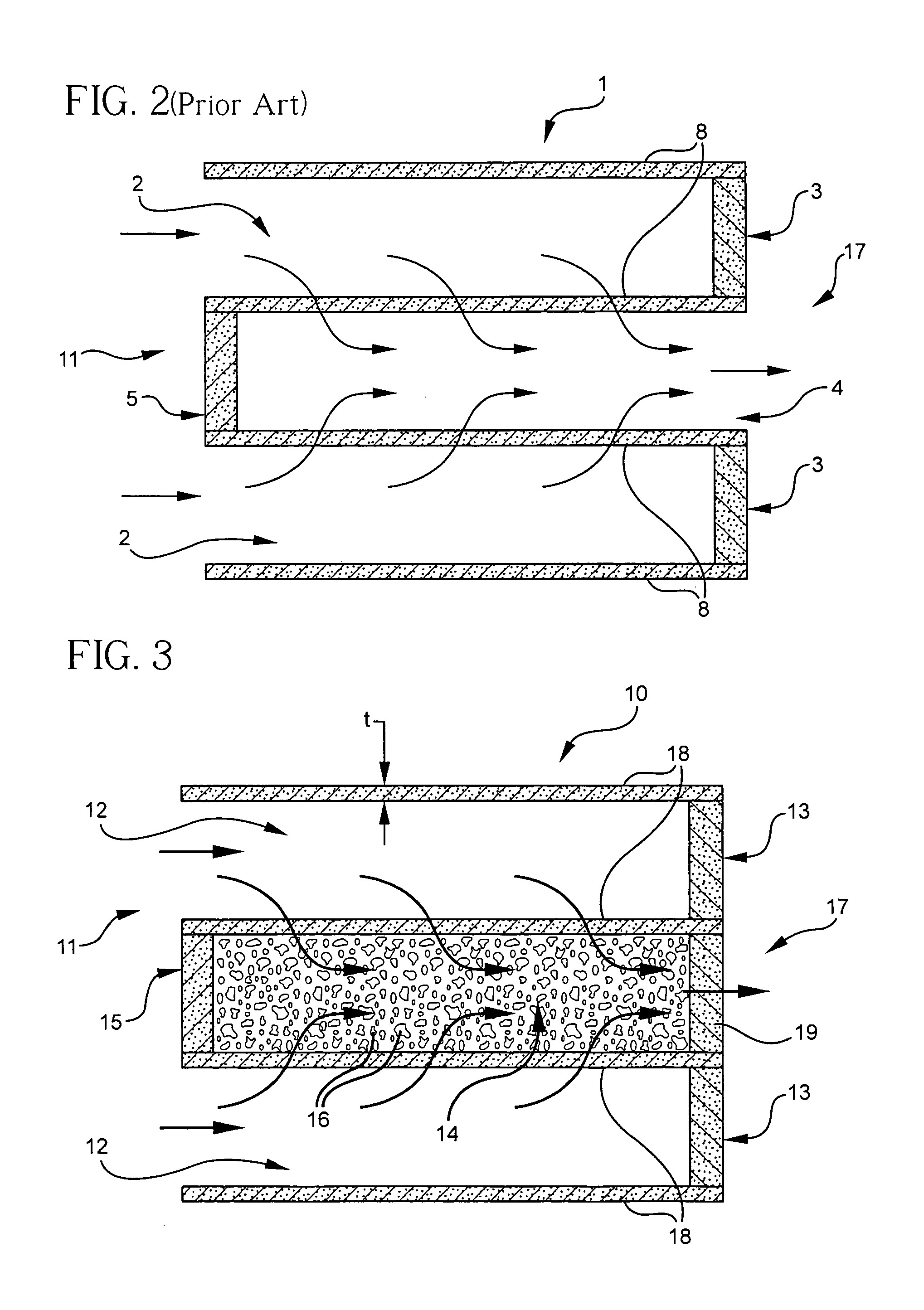

Ceramic wall-flow filter including heat absorbing elements and methods of manufacturing same

ActiveUS20060191248A1Large heat capacitySmall wall thicknessCombination devicesAuxillary pretreatmentParticulatesHeat capacity

A ceramic wall-flow filter for filtering particulate matter from gases and methods for manufacturing such wall-flow filters are disclosed. The filter includes an array of porous ceramic walls defining a pattern of end-plugged inlet and outlet cells, and heat absorbing elements disposed within at least some of the outlet cells such that a bulk heat capacity of the outlet cells is greater than a bulk capacity of the inlet cells. The heat absorbing elements increase a bulk heat capacity of the filter without substantially interfering with a flow of gas through the porous ceramic walls by allowing thinner walls. According to the method, during the step of extruding or thereafter, heat absorbing elements are formed within at least some of the outlet cells such that a heat capacity of the outlet cells is greater than the inlet cells.

Owner:CORNING INC

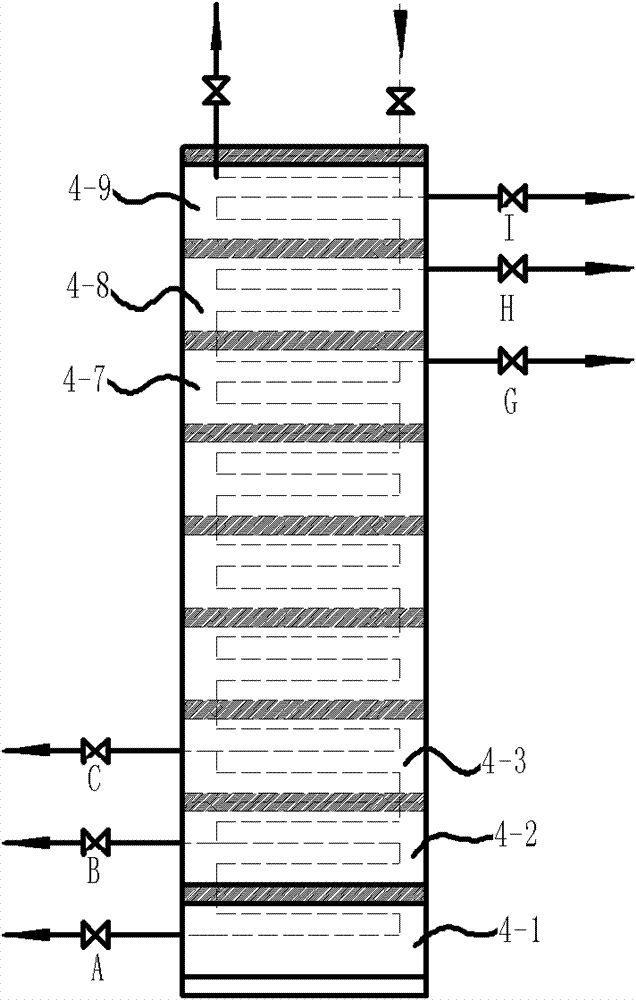

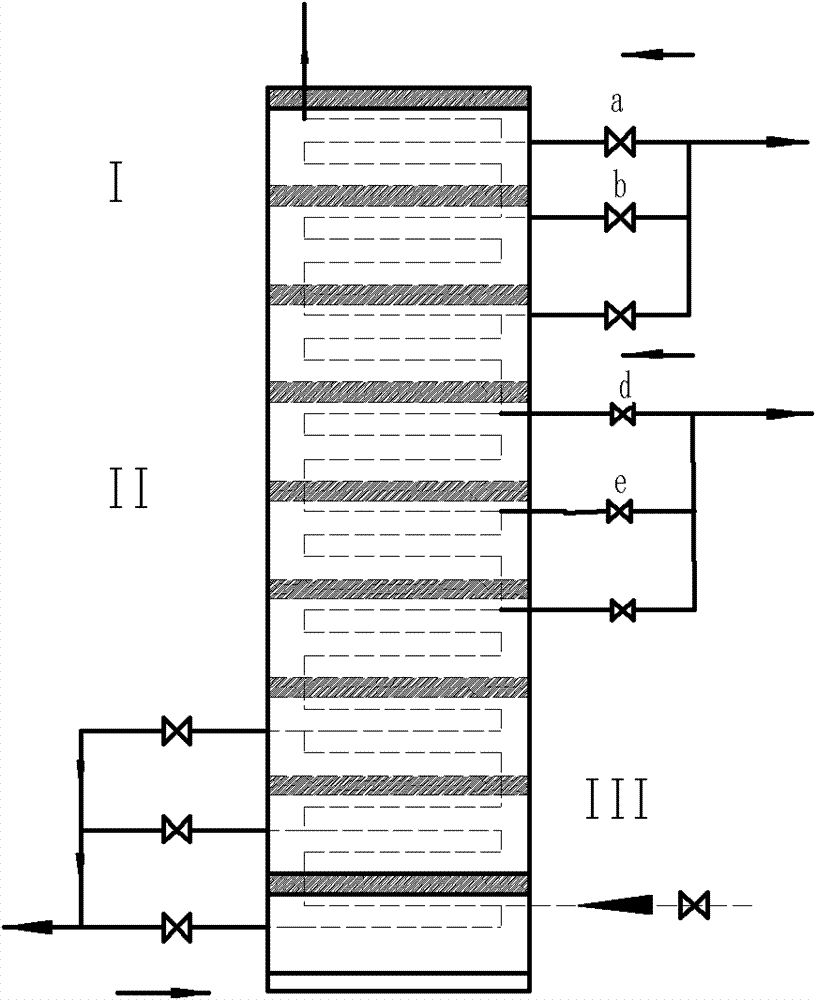

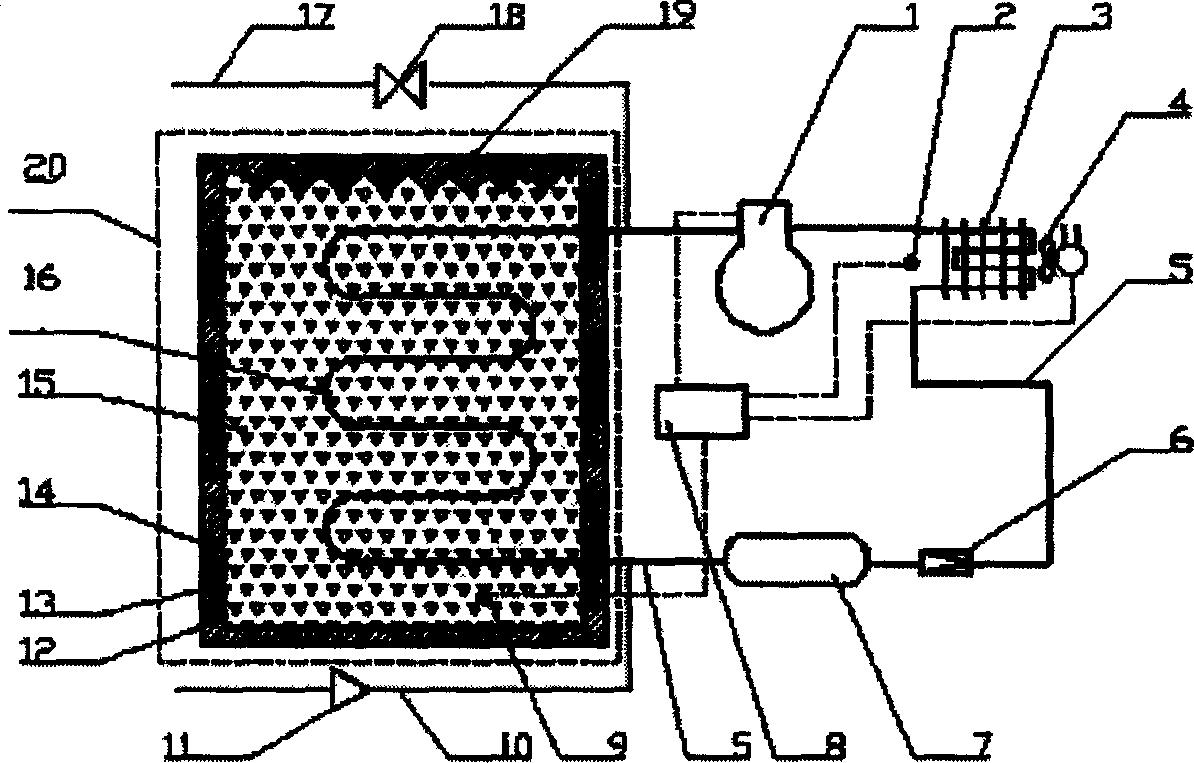

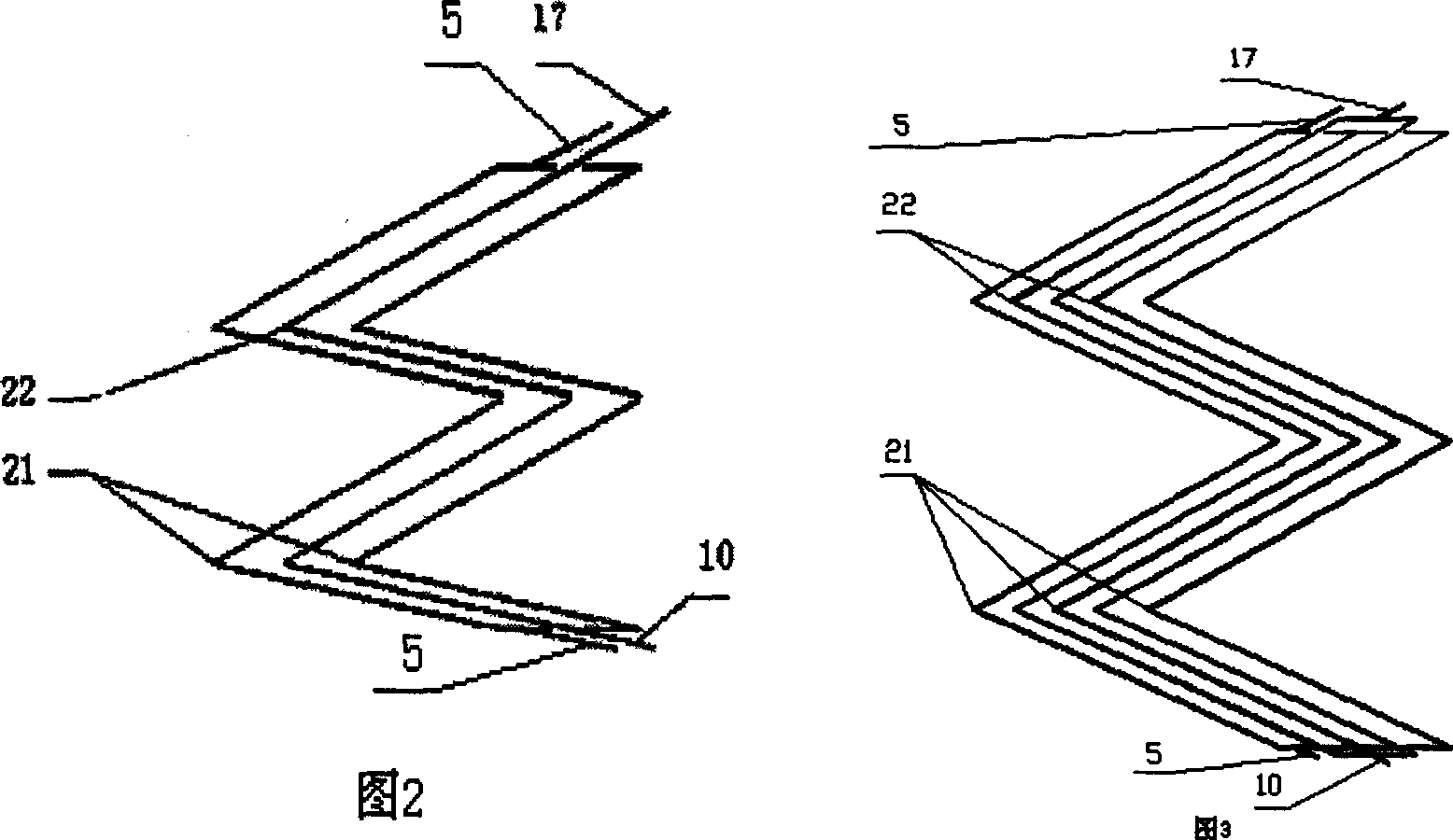

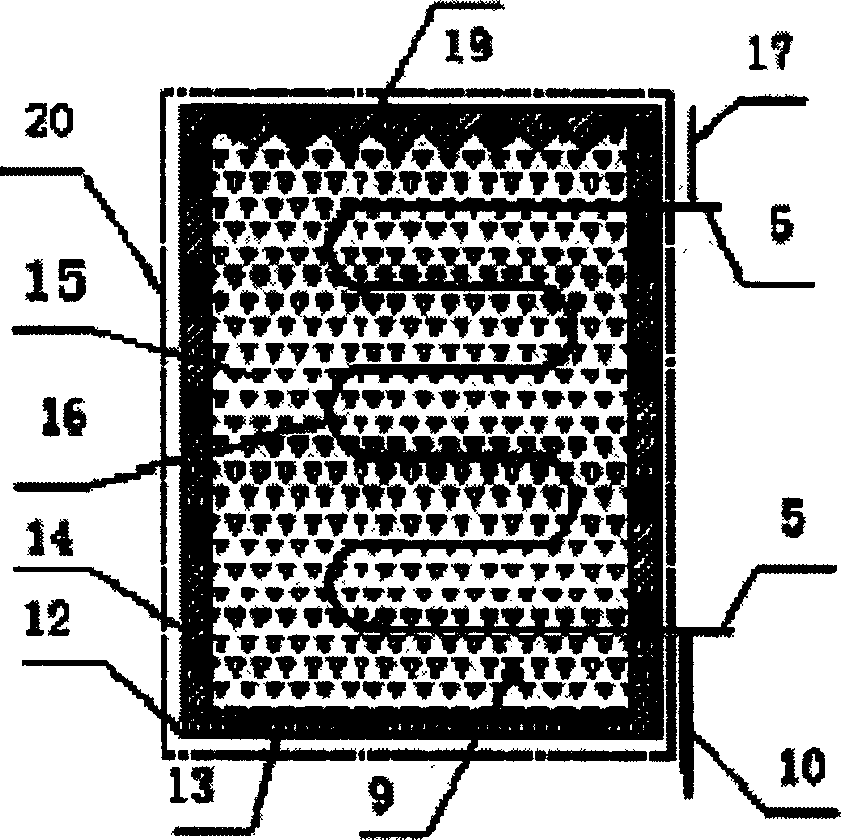

Solid heat storage device

InactiveCN102818468AGuaranteed uptimeImprove thermal conductivitySolar heating energyThermal insulationInsulation layerControl system

The invention provides a solid heat storage device which is formed by combining at least one heat storage unit in series and / or parallel. The heat storage unit comprises a casing, a solid heat storage medium arranged in the casing and a heat insulation layer arranged outside the casing. The outer surface of the solid heat storage medium is a heat exchange interface. Heat insulation layers are regularly arranged in the heat storage unit, an inclined temperature layer is arranged in the axial direction, and a layering control system is arranged in the heat storage unit to ensure high grade storage and output of heat. The heat storage unit of an array can be vertically arranged and can also be horizontally arranged with a certain inclined angle. The solid heat storage medium utilizes solid sensible heat to store heat, and is safe in running, simple to process and low in cost. The surface of the solid heat storage medium has good heat exchange efficiency and good heat storage performance and can be widely applied to various heat storage applications, especially a solar photo-thermal utilization system.

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

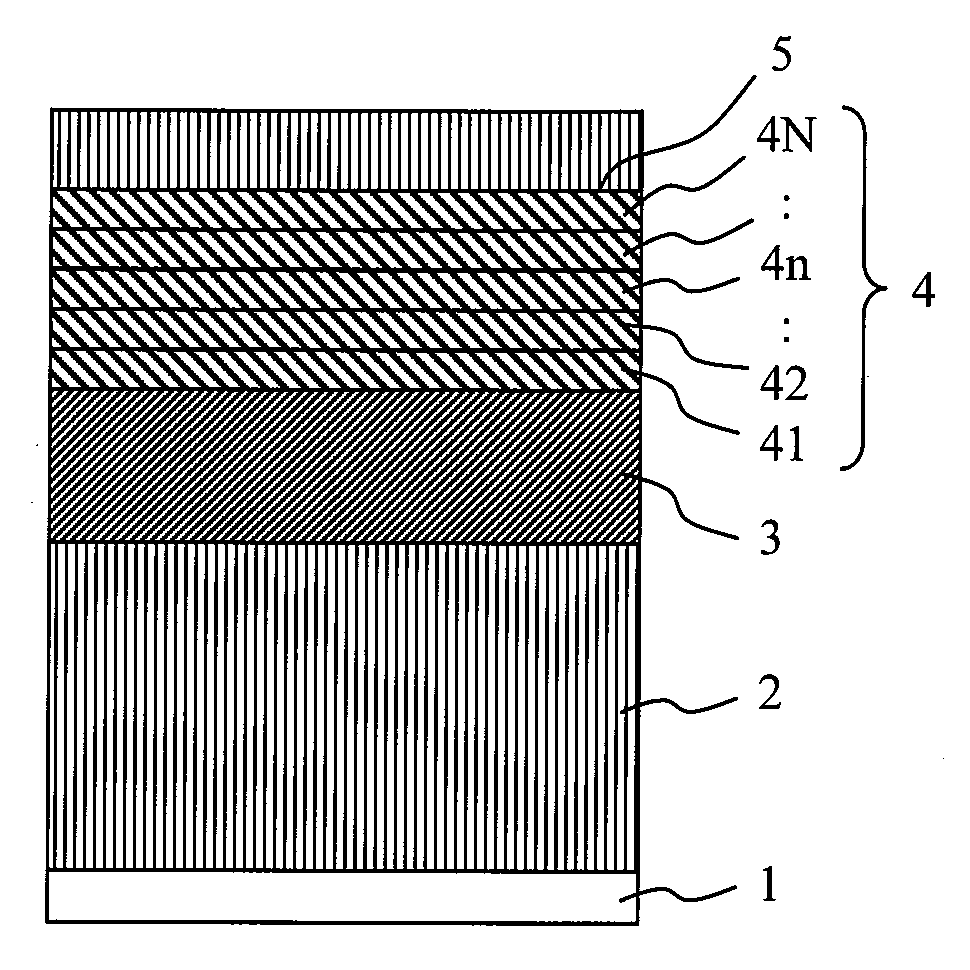

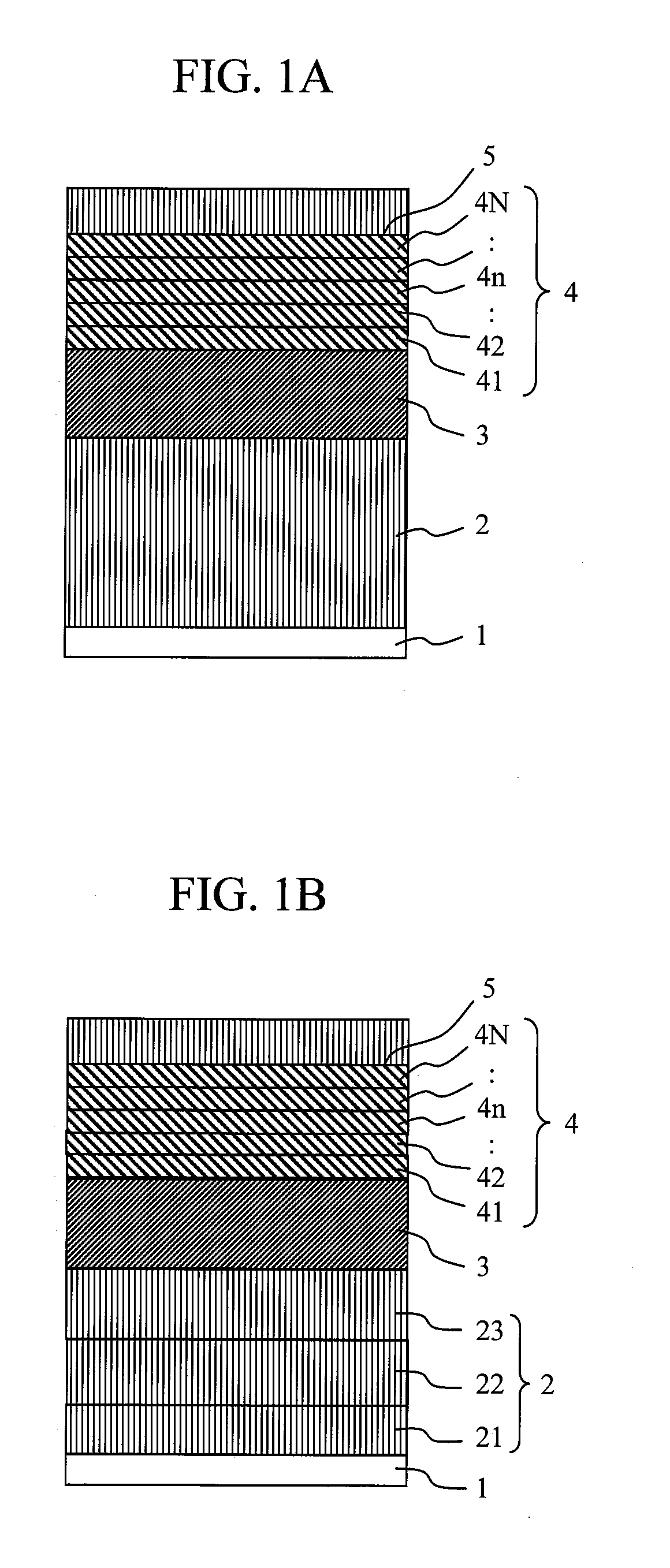

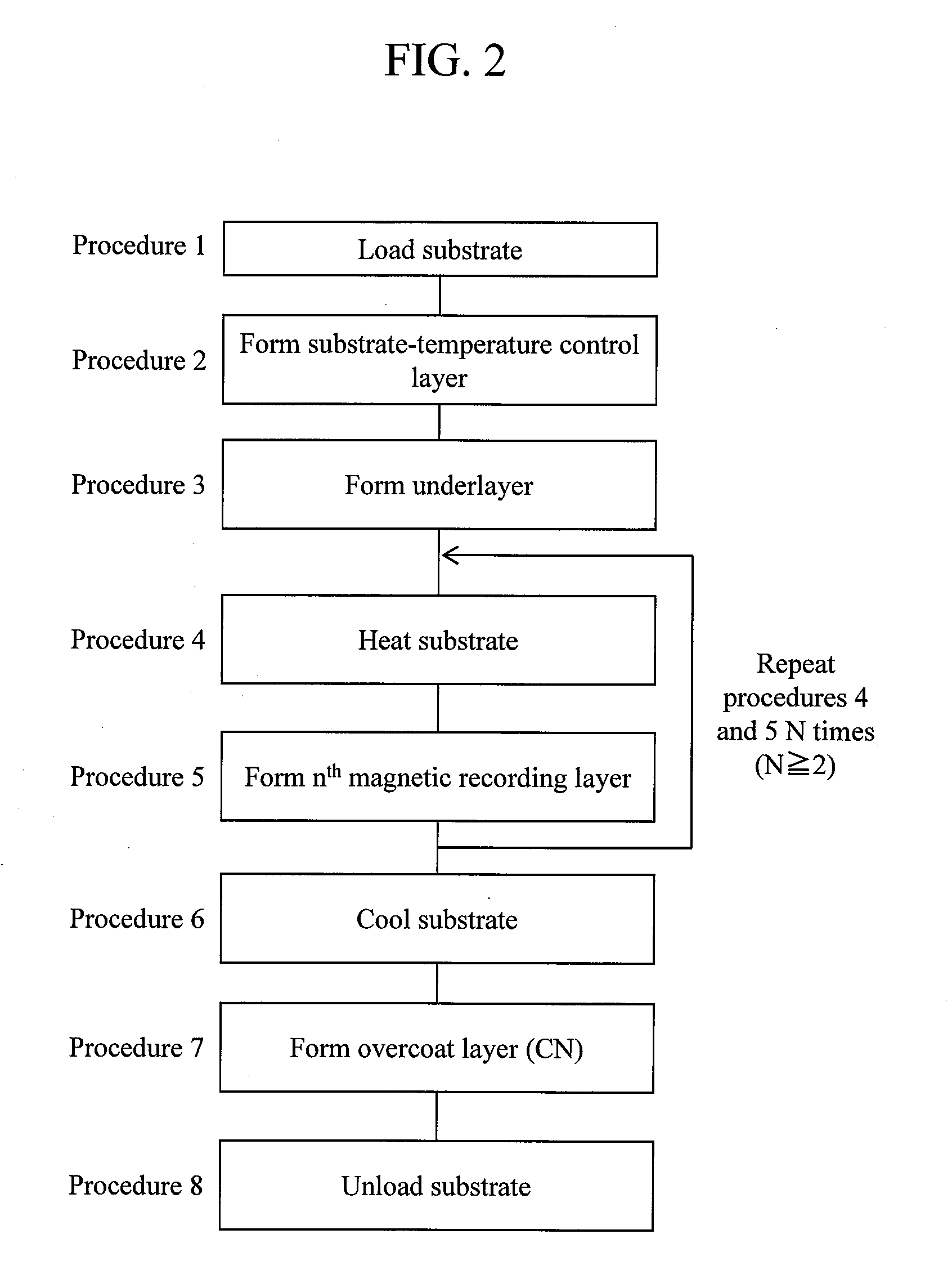

Perpendicular magnetic recording medium and manufacturing method of the same

InactiveUS20120052330A1Large heat capacityTemperature of substrate is reducedRecord information storageCoatingsPhysicsRecording density

A perpendicular magnetic recording medium having sufficient perpendicular uniaxial magnetic anisotropy energy and a crystal grain size for realizing an areal recording density of one terabit or more per one square centimeter, and excellent in mass productivity, and a manufacturing method of the same are provided. On a substrate, a substrate-temperature control layer, an underlayer and a magnetic recording layer are sequentially formed. The magnetic recording layer is formed by repeating a magnetic layer stacking step N times (N≧2), which includes a first step of heating the substrate in a heat process chamber, and a second step of depositing, in a deposition process chamber, the magnetic recording layer constituted of an alloy mainly composed of FePt to which at least one kind of non-magnetic material selected from a group constituted of C and an Si oxide is added.

Owner:HITACHI LTD

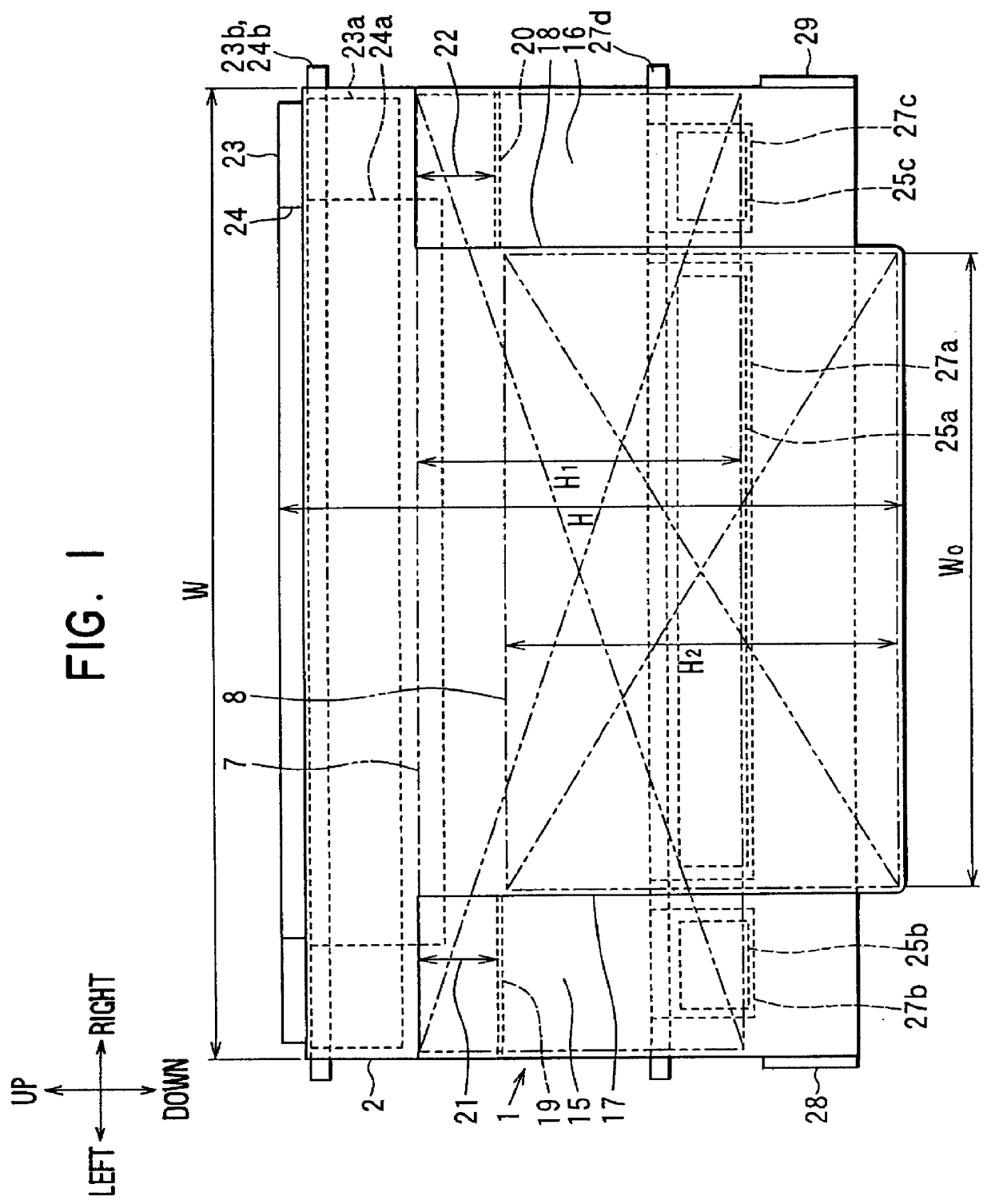

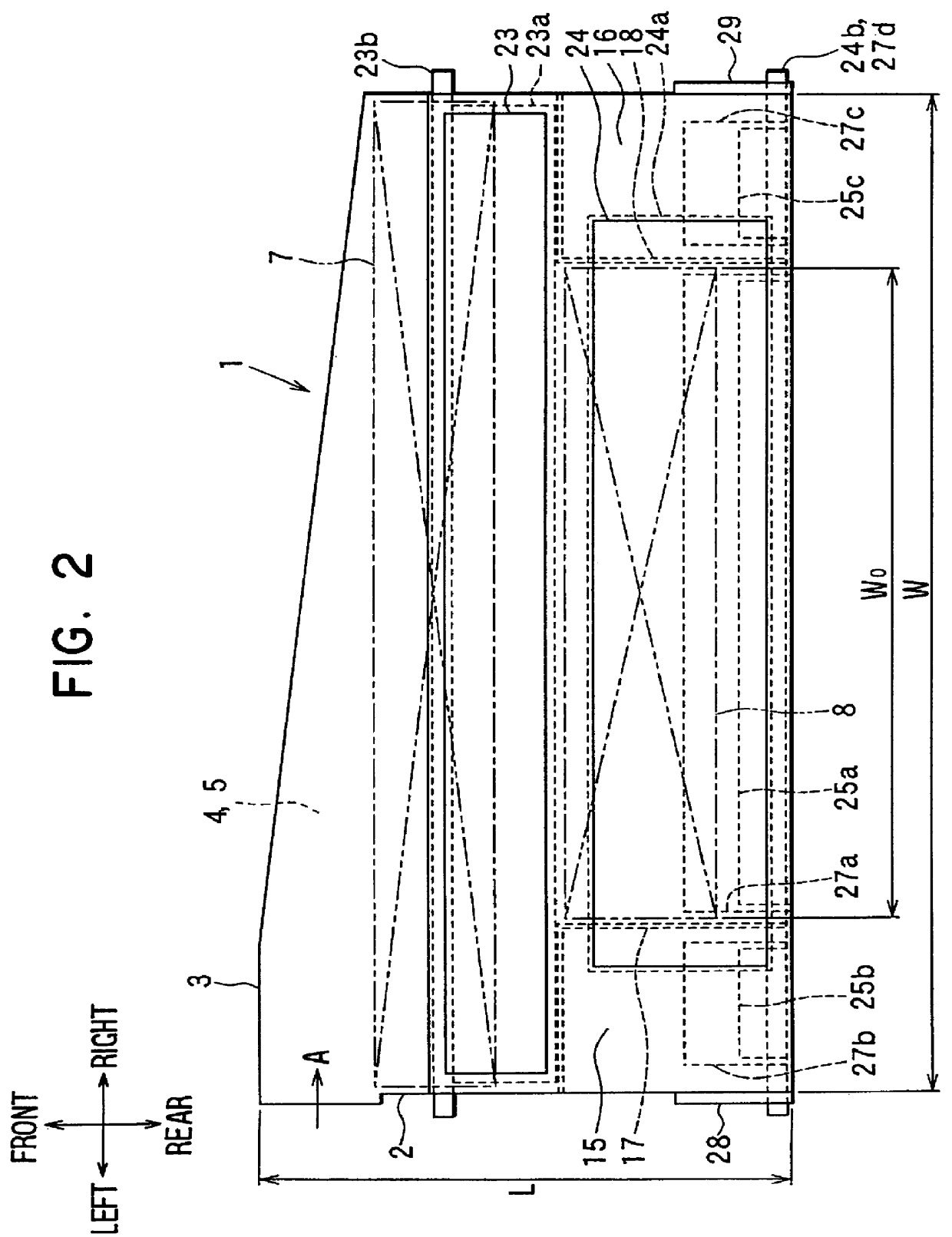

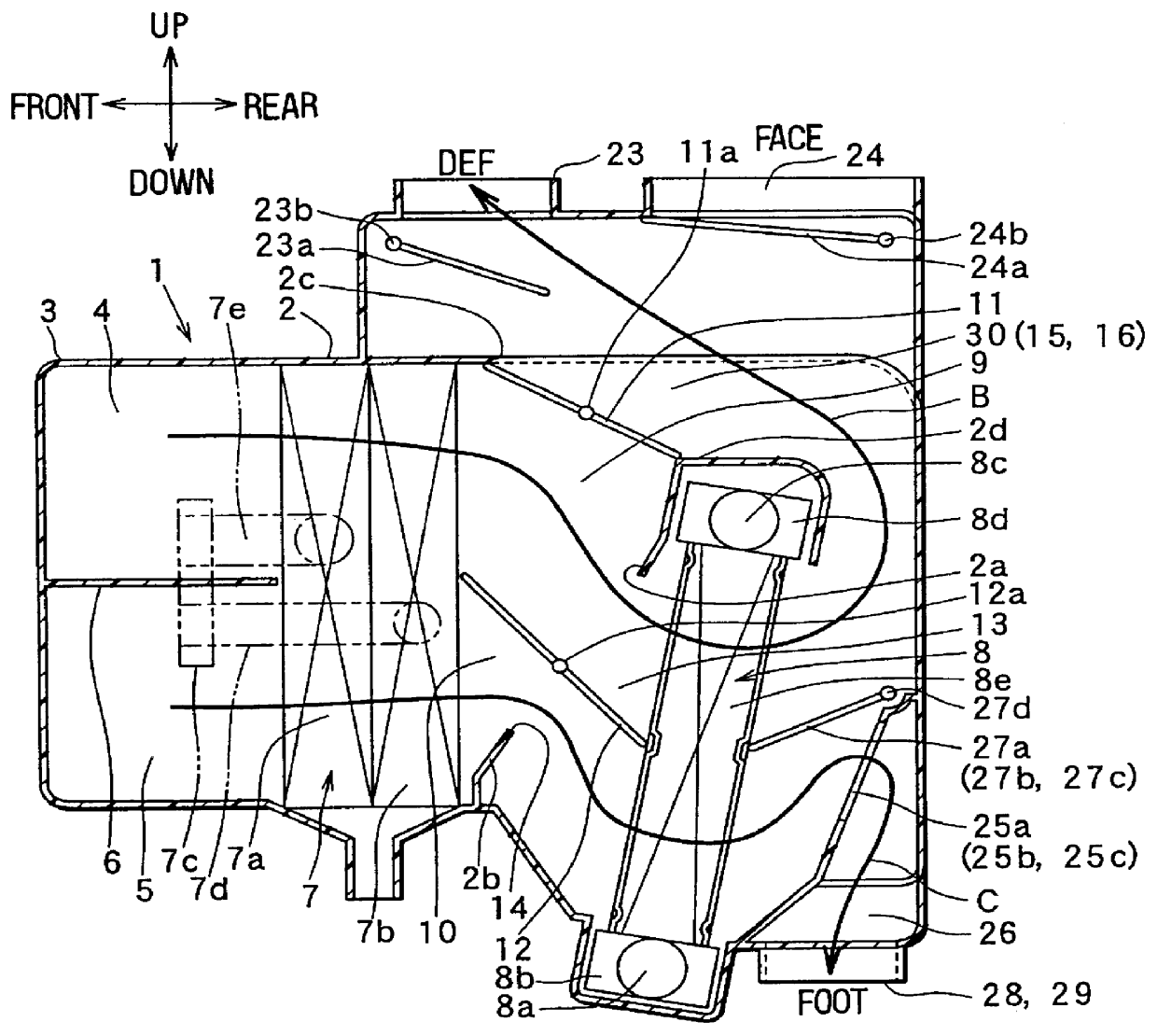

Air conditioner for vehicle

InactiveUS6092592ADistanceSmall sizeAir-treating devicesRailway heating/coolingTemperature controlEngineering

In an air conditioner for a vehicle, a temperature control unit includes a first air mixing door for adjusting an opening degree of a cool air passage through which air having passed through an evaporator bypasses a heater core, and a second air mixing door for adjusting an opening degree of an air inlet portion of the heater core. At least the second air mixing door between the first and second air mixing doors is a butterfly door having a rotation shaft at a center in a door width direction. When an inside / outside air double-layer flow mode is set, the second door partitions an air passage between the evaporator and the heater core into a first air passage through which outside air flows and a second air passage through which inside air flows while fully opening the air inlet portion of the heater core. Thus, in the air conditioner, a distance between the evaporator and the heater core is reduced while partition performance between inside air and outside air due to the second air mixing door is improved.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO +1

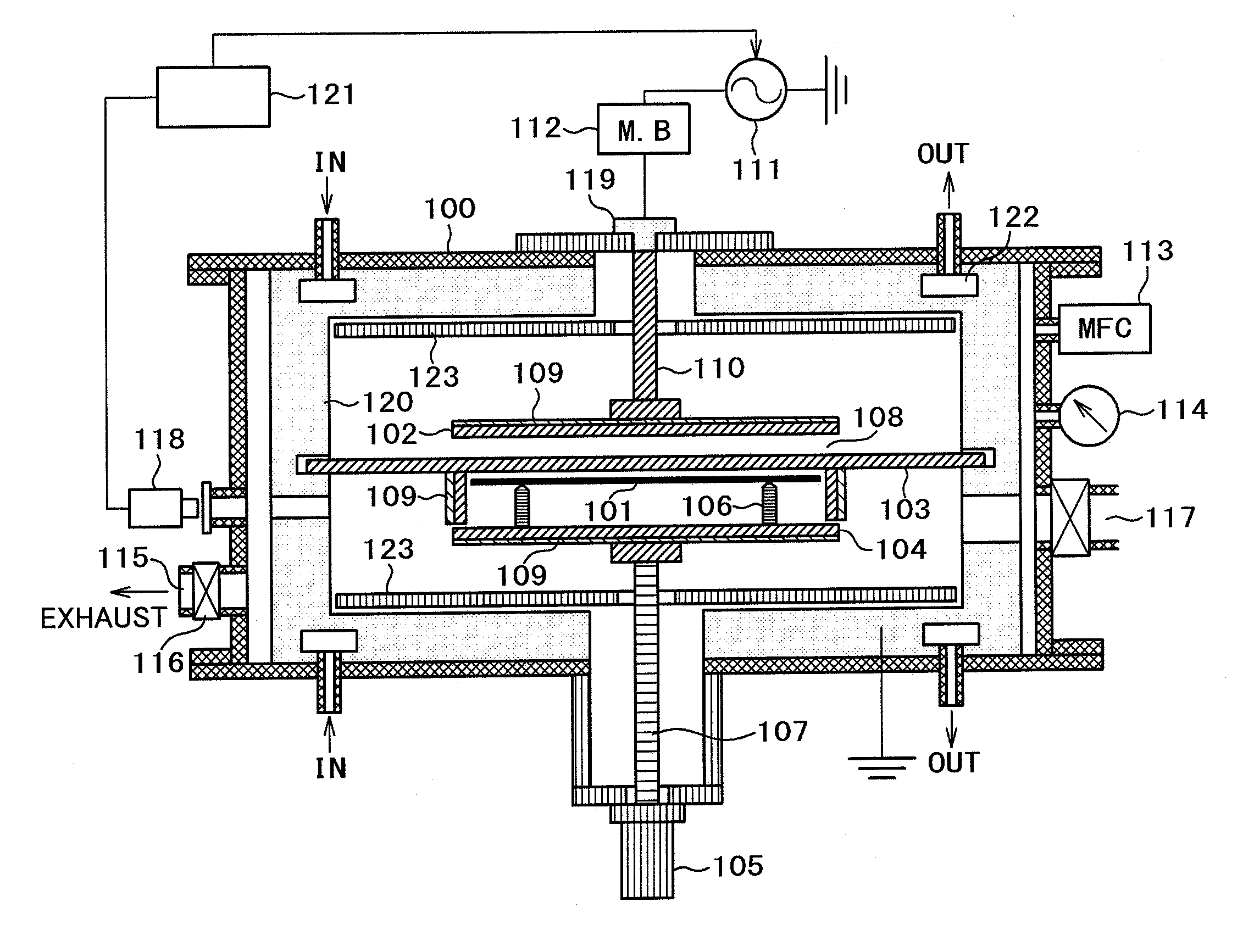

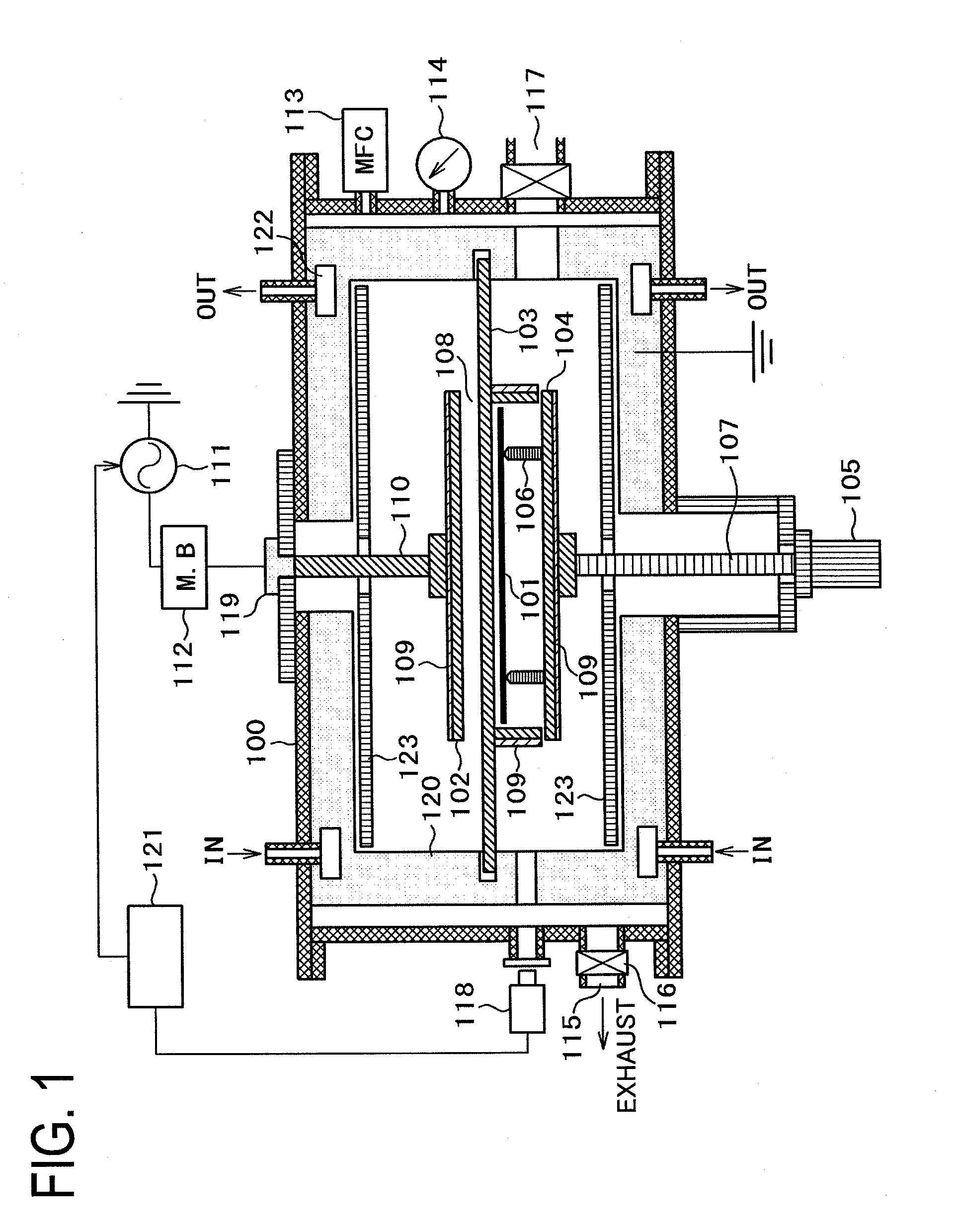

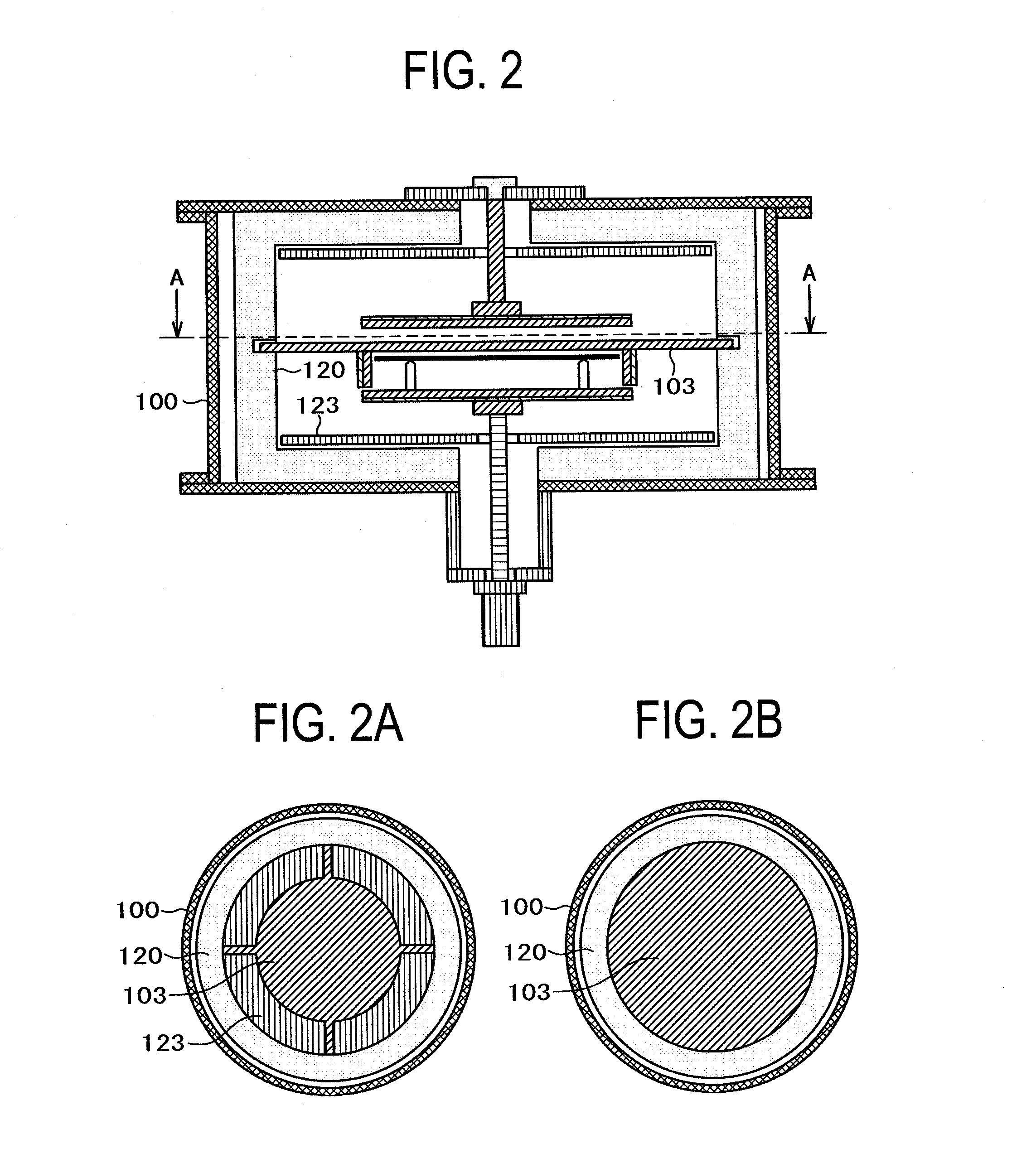

Heat treatment apparatus

ActiveUS20130112670A1High thermal efficiencyReduce surface roughnessElectric discharge tubesSemiconductor/solid-state device manufacturingSurface roughnessThermal treatment

Provided is a heat treatment apparatus that is high in thermal efficiency and can reduce surface roughness of a substrate to be treated even when a specimen is heated at 1200° C. or higher.The heat treatment apparatus heating the specimen includes a heating plate heated by plasma formed in an area of a gap to heat the specimen.

Owner:HITACHI HIGH-TECH CORP

Uninsulated superconducting magnet

InactiveCN103035354ASimple structureGive full play to the conductivitySuperconducting magnets/coilsElectrical resistance and conductanceHeat conducting

The invention belongs to the technical field of superconduction and particularly relates to an uninsulated superconducting magnet. The uninsulated superconducting magnet comprises a coil framework and a superconducting wire wound on the coil framework, wherein the surface of the superconducting wire is free from an insulating layer or is wrapped with an incomplete insulating layer, a mixture of an electroconductive material, a heat-conducting material, a curing material and a wetting material is filled among the turns of the superconducting wire, the inter-turn resistance is 0.1ohm-100kilohm, and in terms of volume percentage of all materials, the uninsulated superconducting magnet comprises 0.01-99.9% of the electroconductive material, 0-99.9% of the heat conducting material, 0-99% of the curing material and 0-5% of the wetting material. According to the uninsulated superconducting magnet disclosed by the invention, electroconductive components are filled in each turn of the superconducting coil so that the inter-turn resistance is maintained higher, not only is the inter-turn uninsulated characteristic brought into play, but also the charging excitation and the quench protection of the superconducting magnet are facilitated.

Owner:NORTHEASTERN UNIV

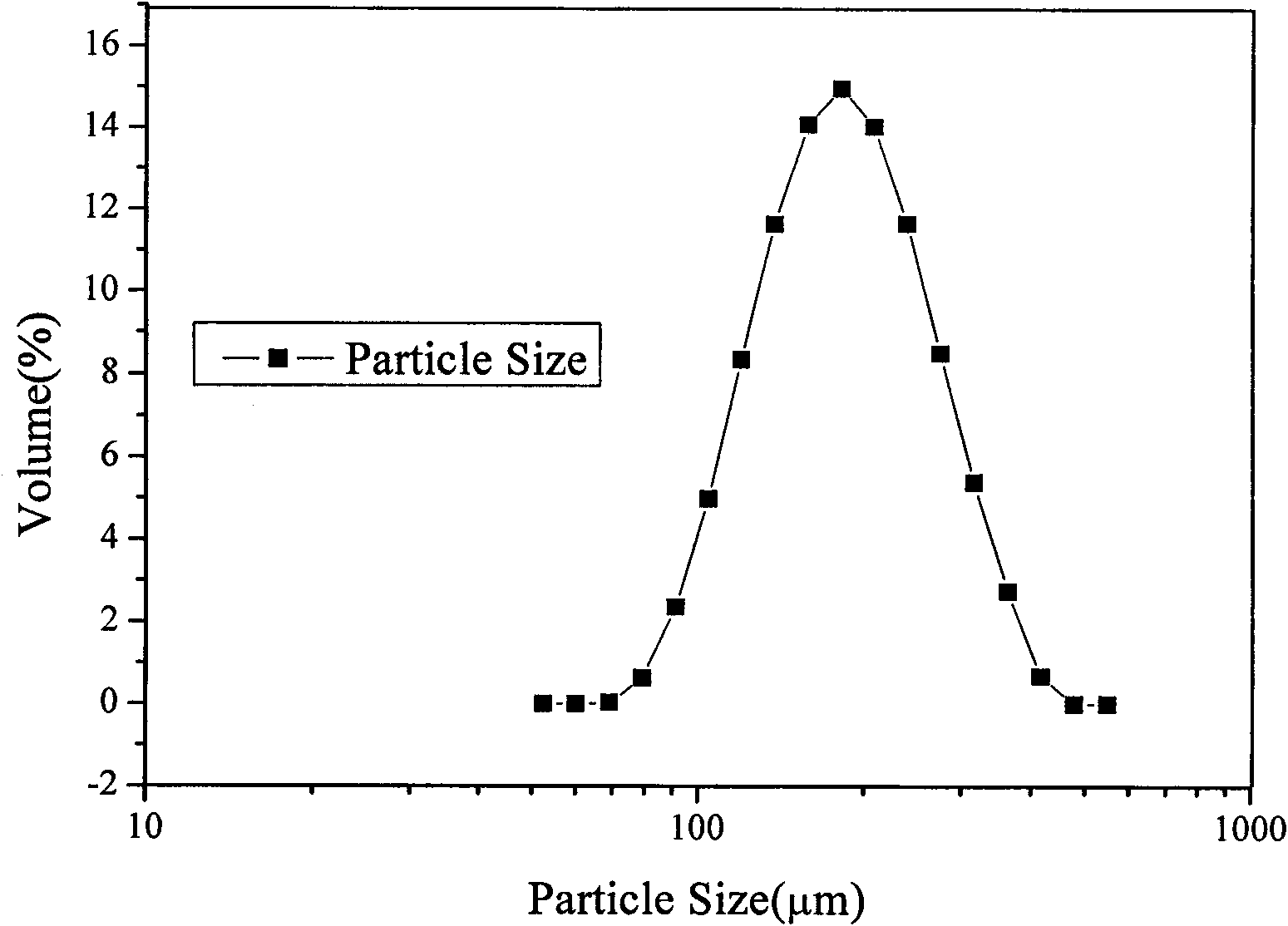

Method for preparing cellulose microsphere by taking ionic liquid as solvent

InactiveCN101612540ASolve forming problemsSolve the problem of sphericityOther chemical processesAlkali metal oxides/hydroxidesCelluloseLow speed

The invention discloses a method for preparing cellulose microspheres by taking ionic liquid as a solvent. The method comprises the steps of: 1) preparing cellulose solution as follows: dissolving the cellulose into the ionic liquid under low-speed stirring and proper temperature; 2) adding inert particles: adding proper amount of inert particles, and stirring evenly; 3) forming spheres by reversed phase suspension: adding oil phase and a surface active agent, leading the cellulose solution to be condensed into spheres by reversed phase suspension and program temperature reduction; 4) curving microspheres: adding a curving agent and curving to form the cellulose microspheres; 5) washing: using deionized water to wash and soak so as to obtain the cellulose microspheres; and 6) screening: screening in a wet state and obtaining the cellulose microspheres with a certain particle size range. The developed preparation process is simple and convenient, the used solvent is safe and non-toxic, the prepared cellulose micrsphere has porous structure and proper particle size, high sphericity and good hydropathy, can adjust density, can be used as substrate of an absorbent and has good biocompatibility.

Owner:ZHEJIANG UNIV

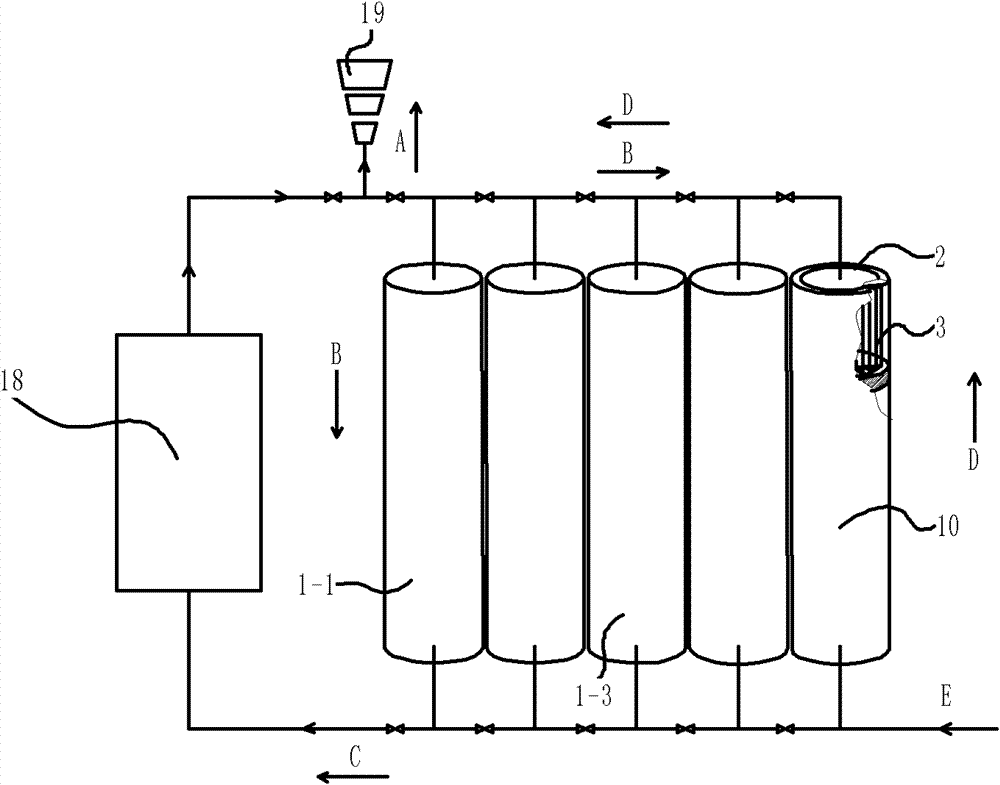

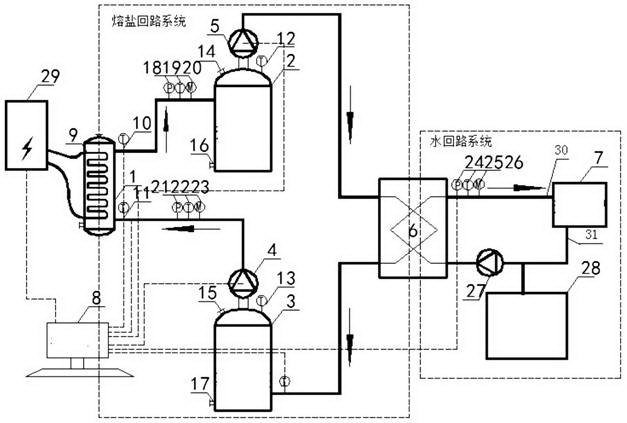

Molten salt heat storage type electric heating central heating system

ActiveCN103836703AAlleviate the peak-to-valley differenceReduce usageLighting and heating apparatusElectric heating systemWater useMaterials science

The invention relates to a molten salt heat storage type electric heating central heating system, and belongs to the technical field of heat storage. The molten salt heat storage type electric heating central heating system comprises a molten salt electric heater, a high-temperature hot salt tank, a low-temperature cold salt tank, a molten salt pump, a molten salt-water heat exchanger and a heat user. During the time period of low-price low off-peak electricity at night, the molten salt in the cold salt tank is pumped out through the molten salt pump to be conveyed to the molten salt electric heater for heating, and enters the hot salt tank after being heated up to high temperature. During the time period of a power utilization peak, the high-temperature molten salt, with accumulated heat, in the hot salt tank is pumped put through the molten salt pump to be conveyed to the molten salt-water heat exchanger and heats water used for municipal heating to produce hot water for supplying heat to residents. On the basis of a coal-fired boiler central heating system which is in general use at present, only a boiler room of the central heating system needs to be transformed into the molten salt heat storage type electric heating system, and neither a municipal heat supply pipe network nor heat supply terminal equipment needs to be transformed. Besides, the molten salt heat storage type electric heating central heating system can cut down a peak to supplement a trough and reduce the usage amount of coal, thereby playing a role in protecting the environment.

Owner:中投亿星新能源投资有限公司

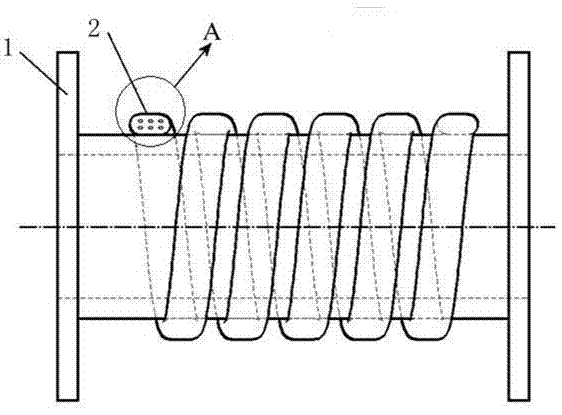

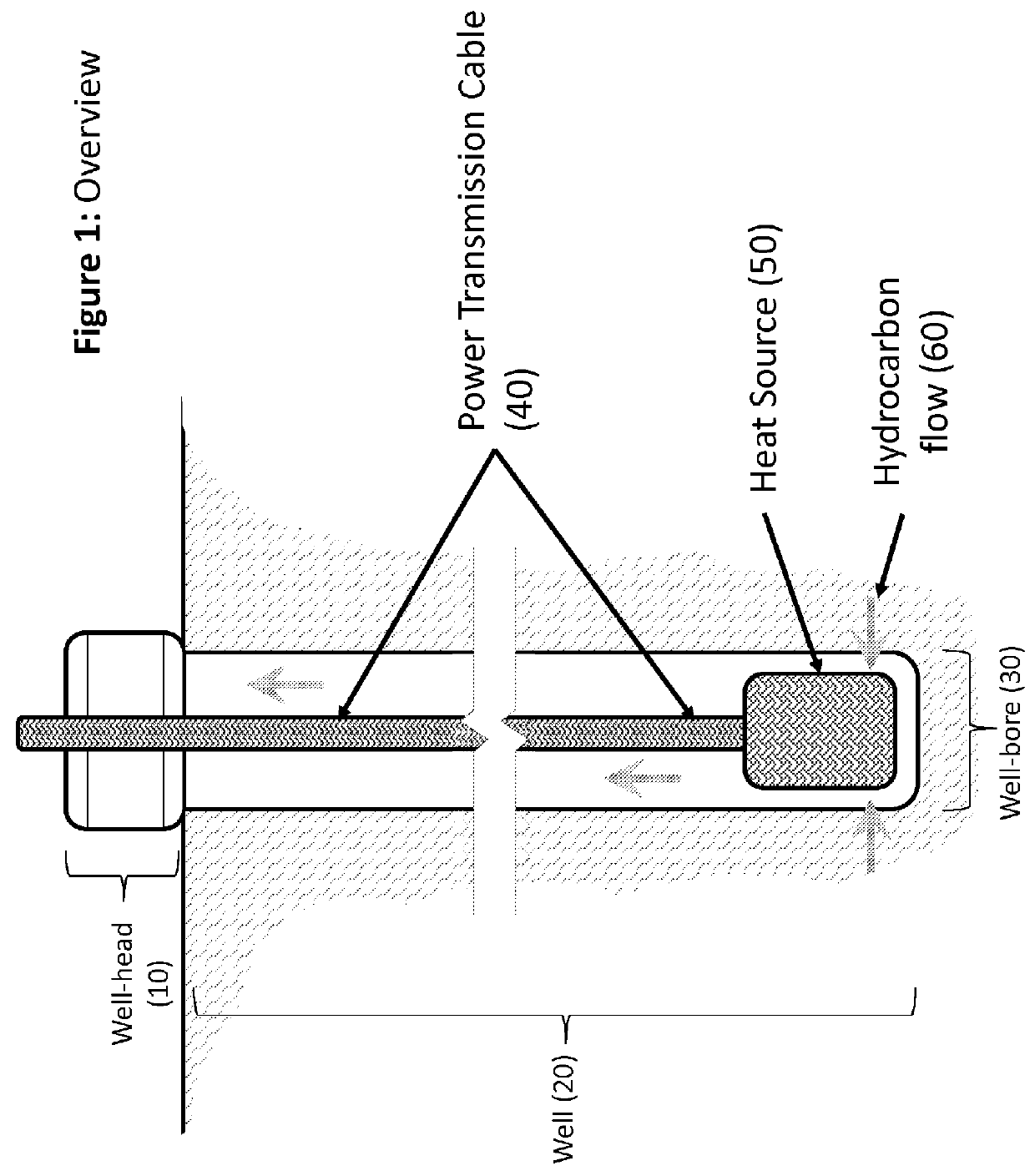

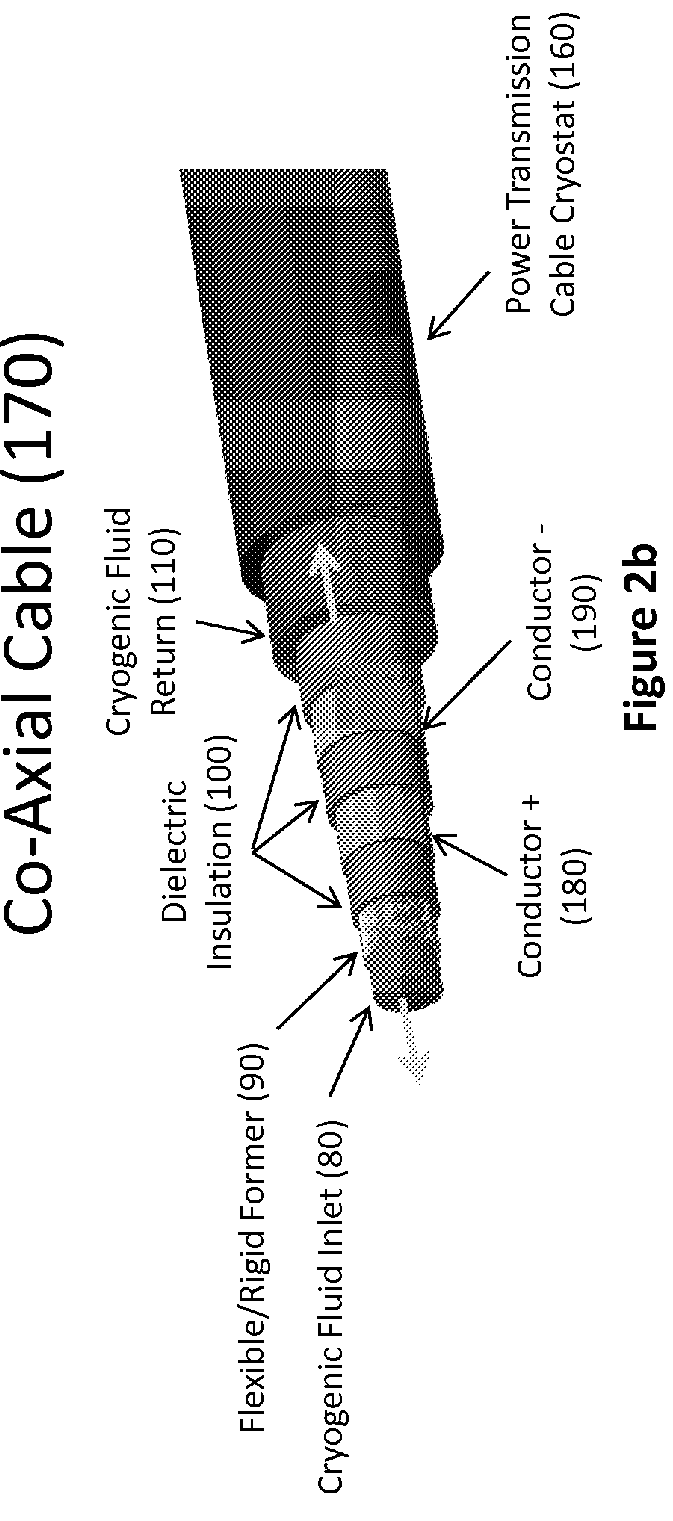

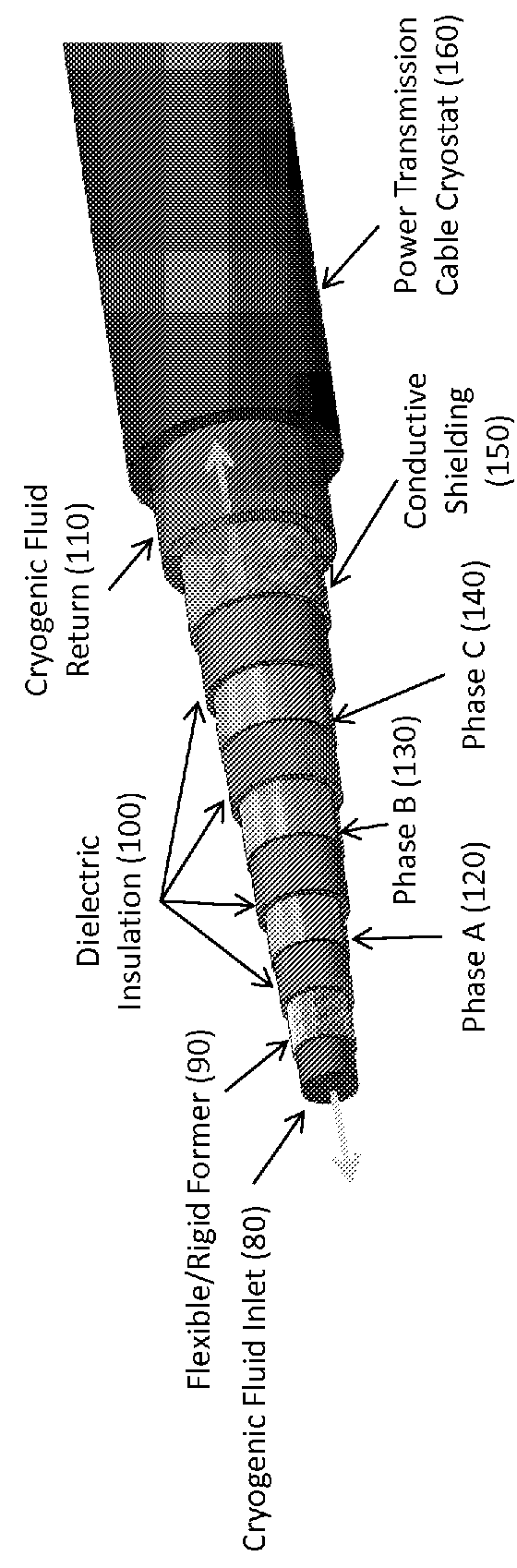

High Power Dense Down-Hole Heating Device for Enhanced Oil, Natural Gas, Hydrocarbon, and Related Commodity Recovery

ActiveUS20160053596A1Great transmission efficiencyIncreased power levelInsulationFluid removalCapital costHeating system

Electrical down-hole heating devices help enhance the recovery of thick waxy oil, heavy oil, bitumen, natural gas, hydrocarbons, and related commodities by lowering the viscosity and raising the pressures of the surrounding fluid and gas. In addition, the use of the more energy efficient electrical heat can help reduce the amount, and in some cases eliminate the use altogether, of less energy efficient steam to heat the oil. The higher power density superconducting down-hole heating system can enable the in-situ generation of steam down-hole within the confines of the well-bore. The in-situ generation of steam with this device has multiple benefits including reductions in capital costs of the above ground steam plant, increased energy efficiency, reduced greenhouse gas emission, and minimizing water usage and its corresponding reclamation costs. Common types of electrical down-hole heaters include: a) radiative type, b) inductive type, or c) resistive type. A superconducting down-hole heater has many advantages over conventional normal conducting down-hole heaters including: higher power transmission density, higher recovery fluid and gas throughput, increased energy efficiency, higher production capacity per well-bore, and more environmentally friendly fluid and natural gas extraction. Down-hole heaters involving superconductors and cryogenically cooled non-superconductors are disclosed. Additional enhancements involving coil rotation and / or vibration, well-casing rotation and / or vibration, and direct current power sources are disclosed.In addition, superconducting cables used to transmit large amounts of electric power to facilitate fracturing of shale and rock in subterranean down-hole wells is disclosed.

Owner:REY CHRISTOPHER M

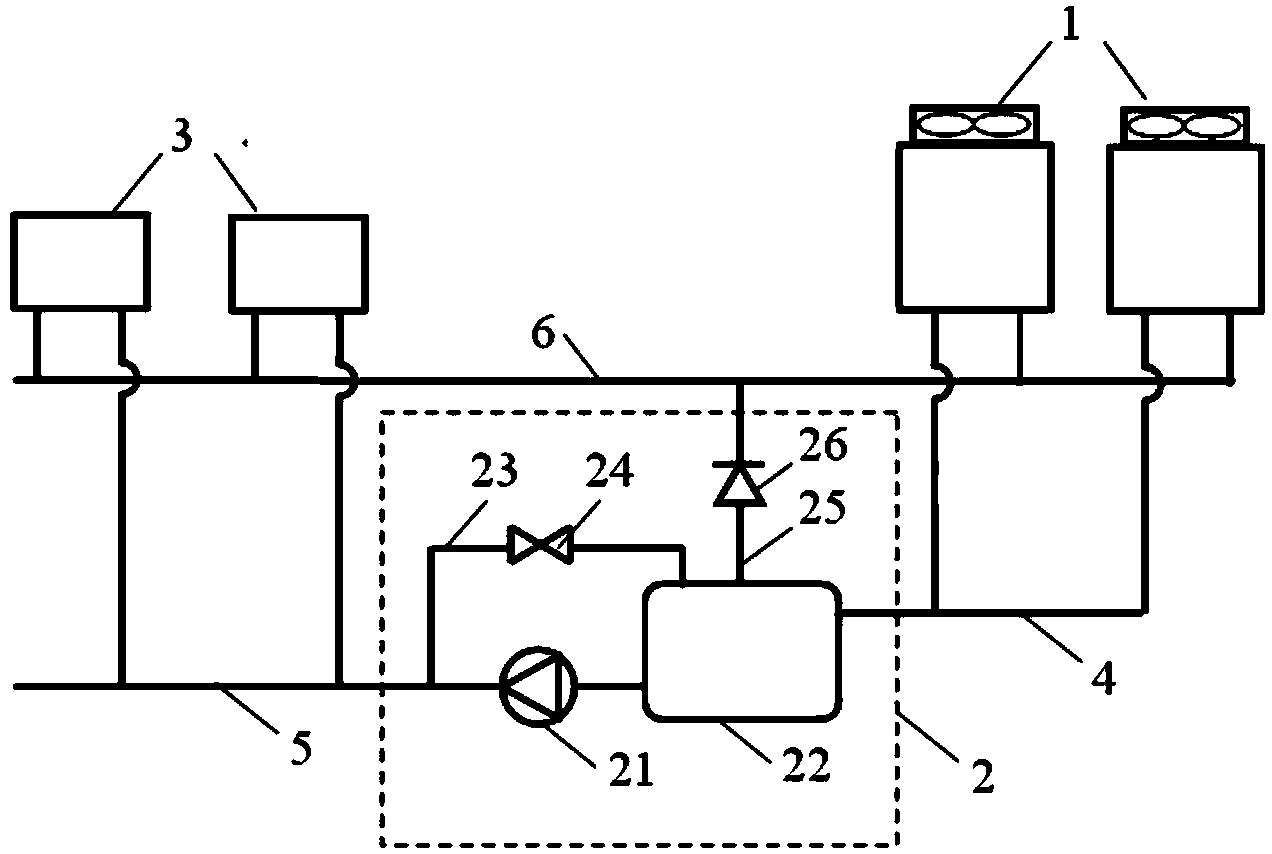

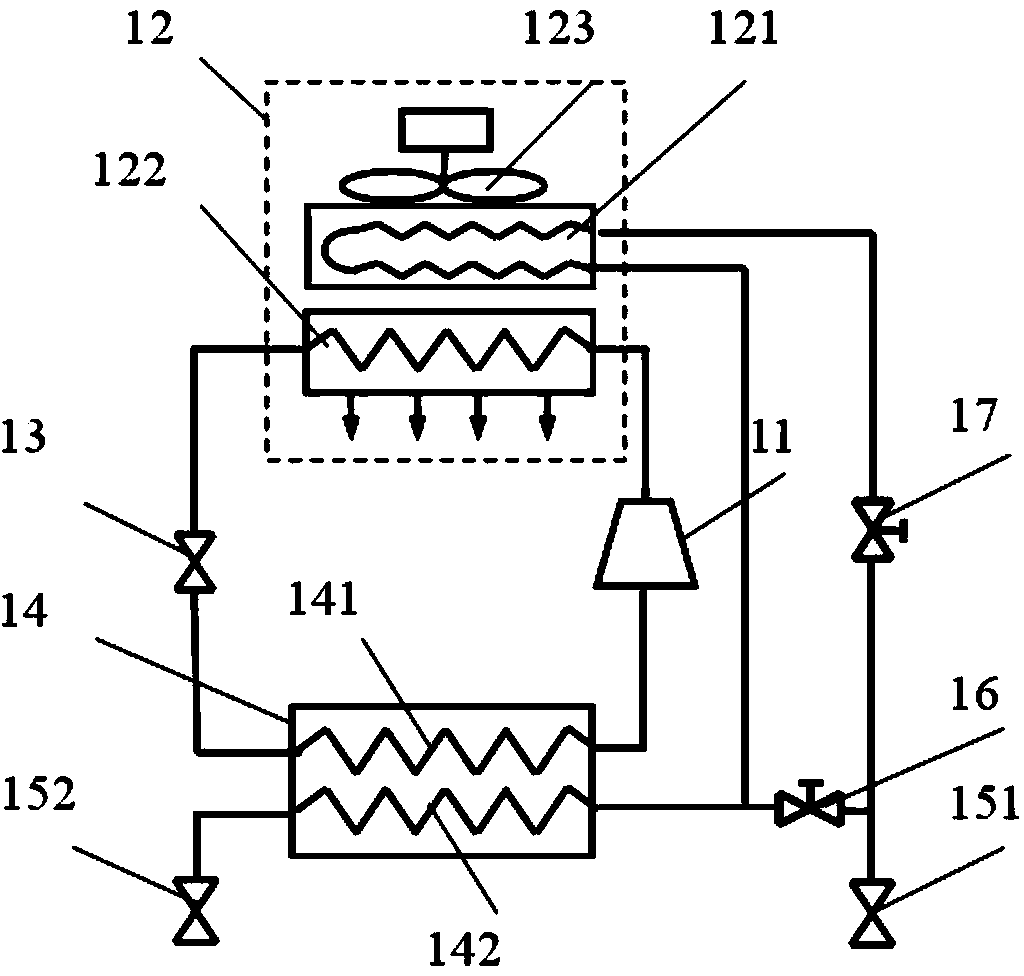

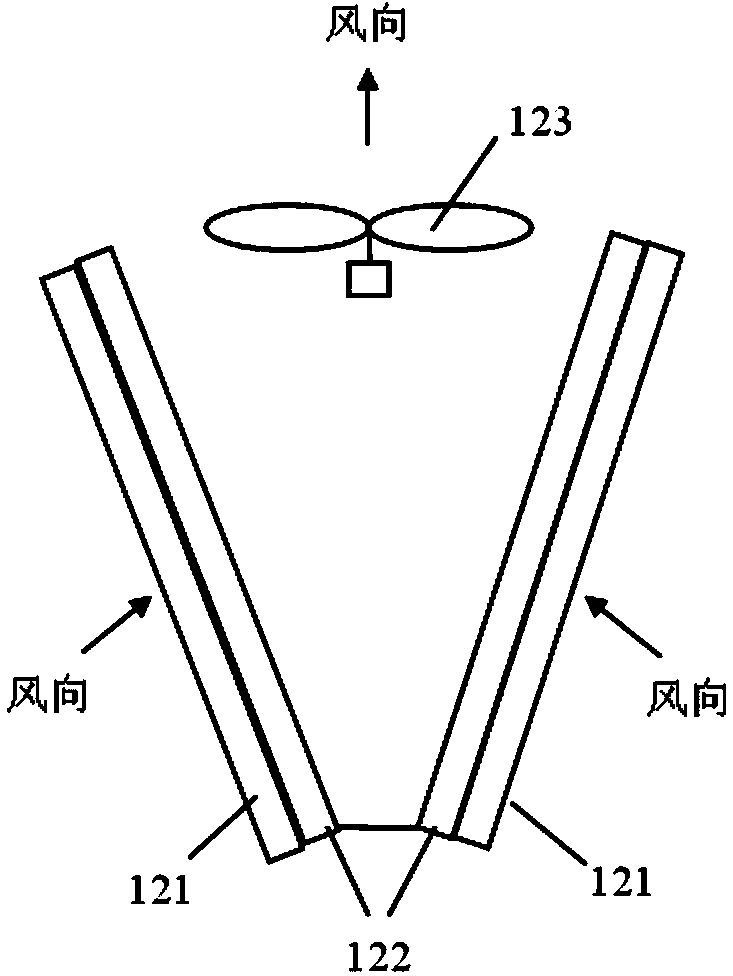

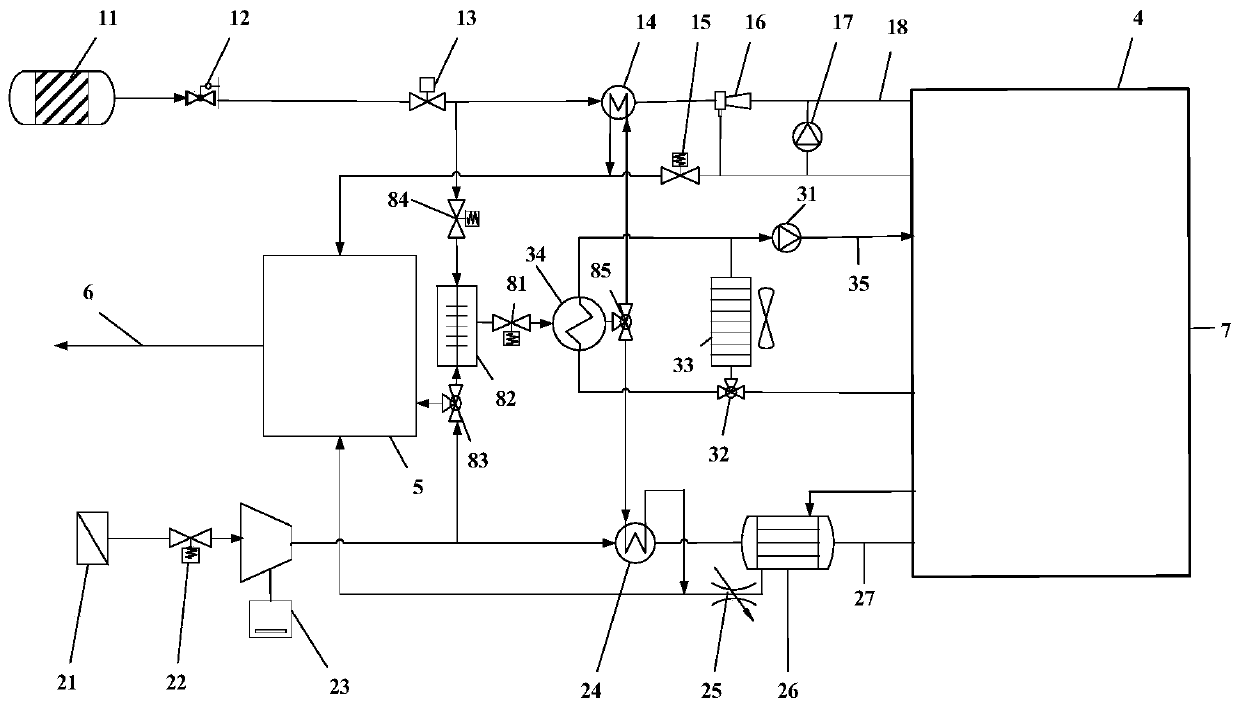

Control method for combined refrigerating multi-split air conditioner system

InactiveCN104266314ALarge working temperature zoneEasy to increase capacityMechanical apparatusSpace heating and ventilation safety systemsIndoor airTransition season

The invention discloses a control method for a combined refrigerating multi-split air conditioner system. The multi-split air conditioner system is characterized in that two or more outdoor combined refrigerating modules are arranged the outdoor side to form a cold source system of the multi-split air conditioner system, each outdoor combined refrigerating module is composed of a first refrigerant vapor compression and refrigeration circulating loop and a second refrigerant circulating loop, one or more direct evaporation type indoor air cooler modules are arranged at the indoor side, and a refrigerant storing and conveying unit is connected with the part between each outdoor combined refrigerating module and the corresponding indoor air cooler module to form a closed circulating system through a liquid collecting tube, a main liquid supply tube and a main air return tube. According to the control method for the combined refrigerating multi-split air conditioner system, the number of the indoor and outdoor modules is decided according to the designed thermal load of an air conditioner, and the control method precisely regulates the refrigerating capacity to meet the heat control needs of round-the-clock running data machine rooms and electronic equipment; the control method for the combined refrigerating multi-split air conditioner system is capable of making the maximum use of the natural cold source of the day and night, transition season and winter so as to realize the great energy conservation and emission reduction of the air conditioner system.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

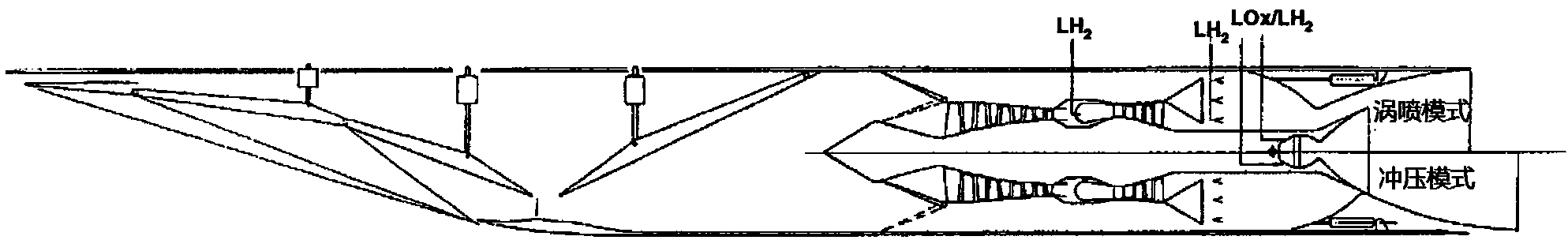

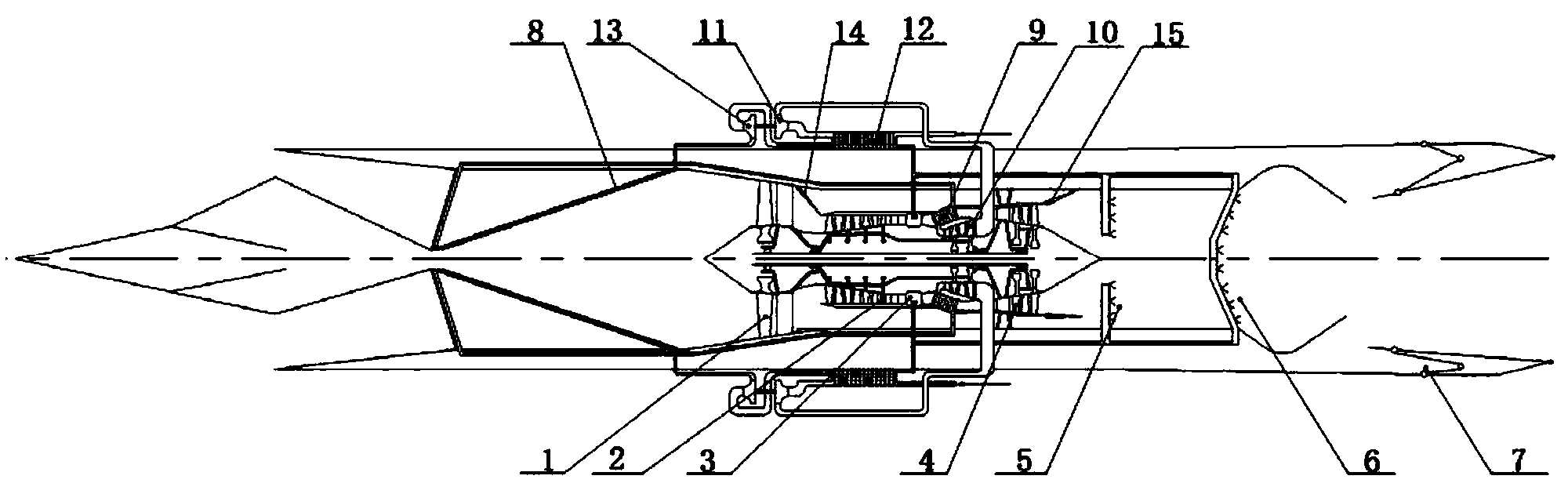

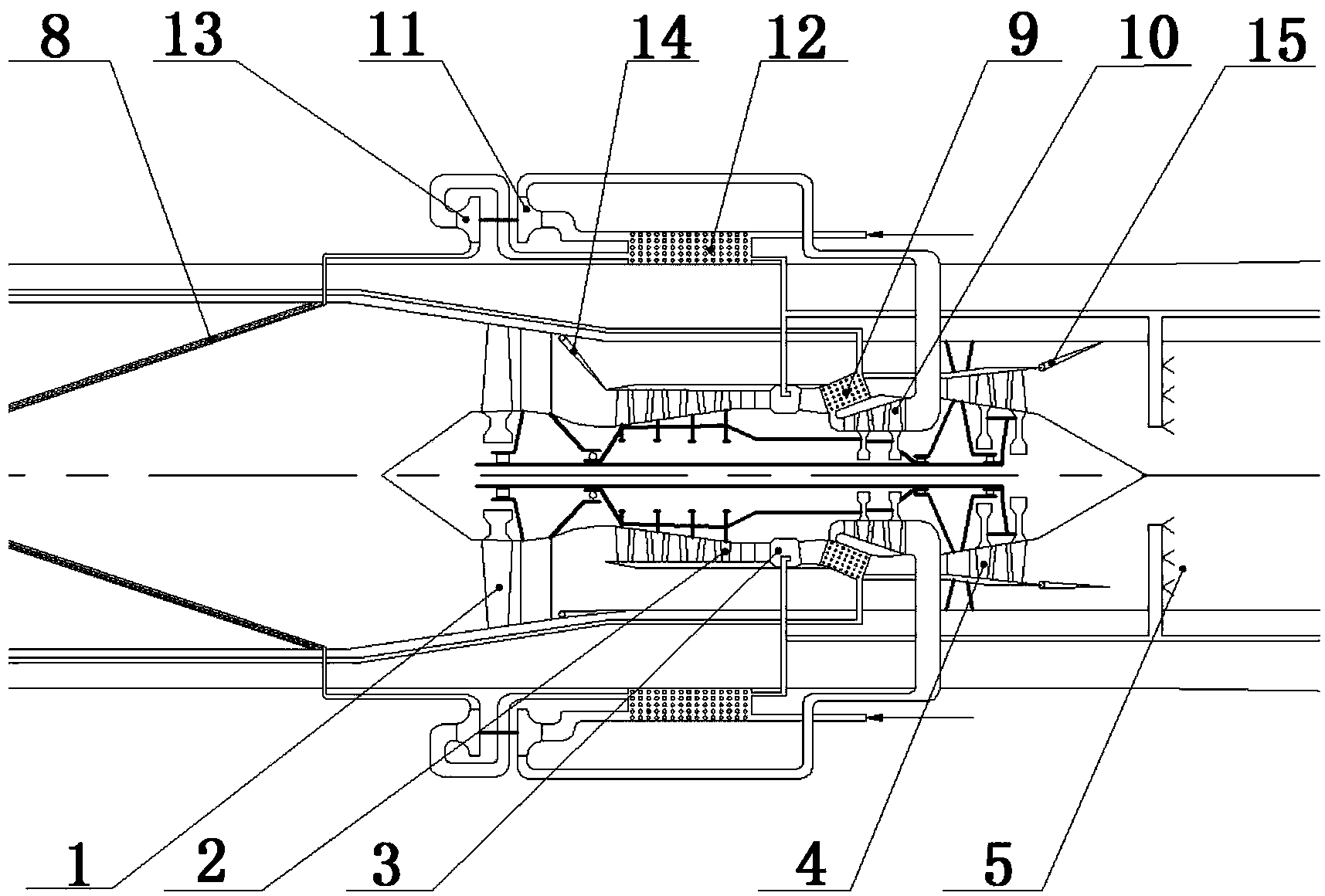

New concept high-speed aerocraft propulsion system layout method

ActiveCN104110326AEfficient cruiseLarge heat capacityRam jet enginesComposite engine plantsSpacecraft propulsionBrayton cycle

The invention provides a new concept high-speed aerocraft propulsion system layout method. Two cycles are built in a propulsion system, namely a Brayton cycle with the air as the working medium and a closed cycle with supercritical state fluid as the working medium. The two cycles are coupled through a supercritical microscopic scale heat exchange technology, a supercritical state fluid turbine and compressor power balance. By adjusting related valves, the propulsion system can be in a turbofan engine model when taking off or flying at a low speed and in a turbine rocket engine model when flying at a high Mach number, so that it is guaranteed that the aerocraft can effectively cruise for a long time in both a subsonic state and a supersonic state. Through the supercritical microscopic scale heat exchange technology, the gas flow temperature at an inlet of a compressor can be effectively reduced when the propulsion system is flying at a high speed, and when the supercritical microscopic scale heat exchange technology is applied in combination with a closed cycle technology, optical distribution of energy of the propulsion system can be achieved. By means of the method, the defects of the propulsion system of an existing high-speed aerocraft are overcome, and working performance of the high-speed aerocraft propulsion system is remarkably improved when Ma ranges from 0 to 5.

Owner:BEIHANG UNIV

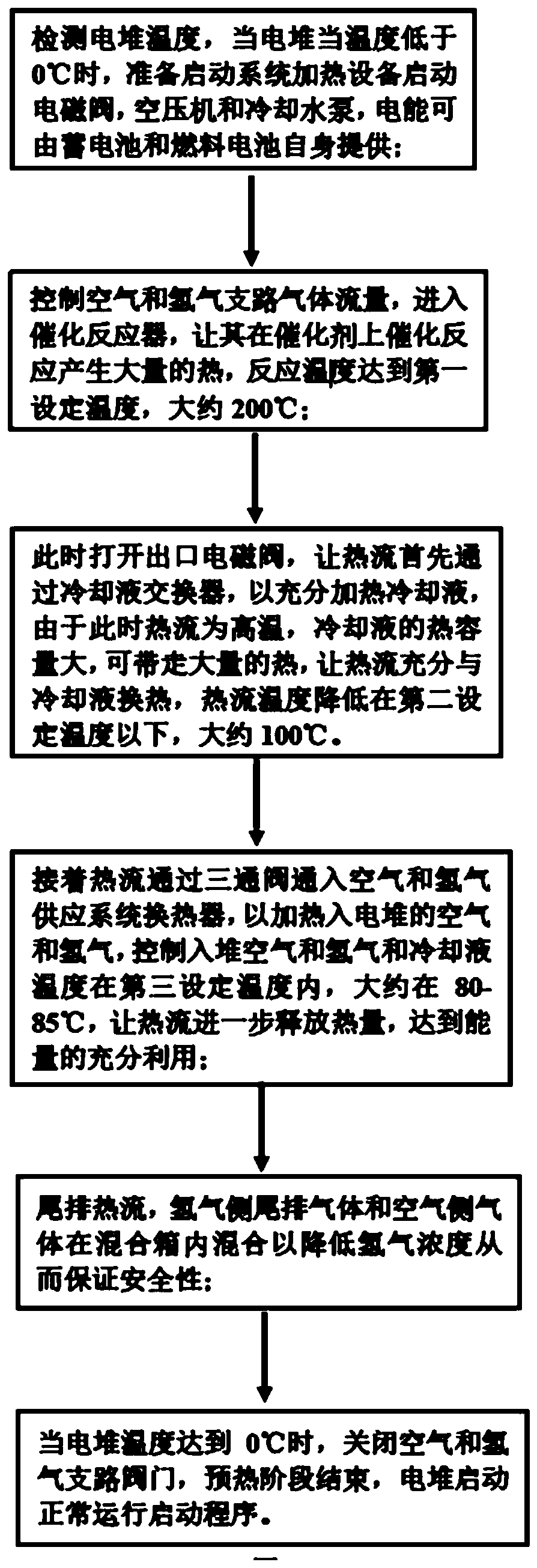

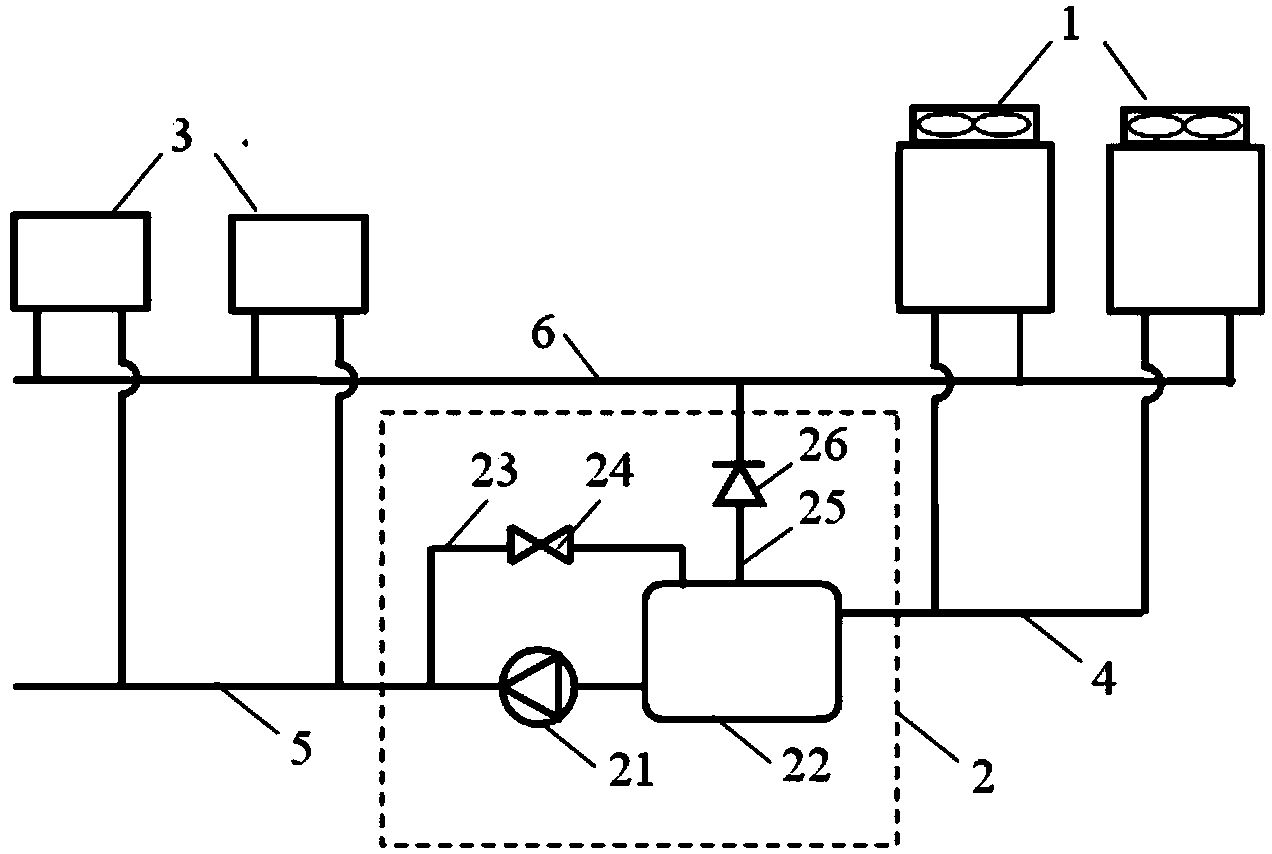

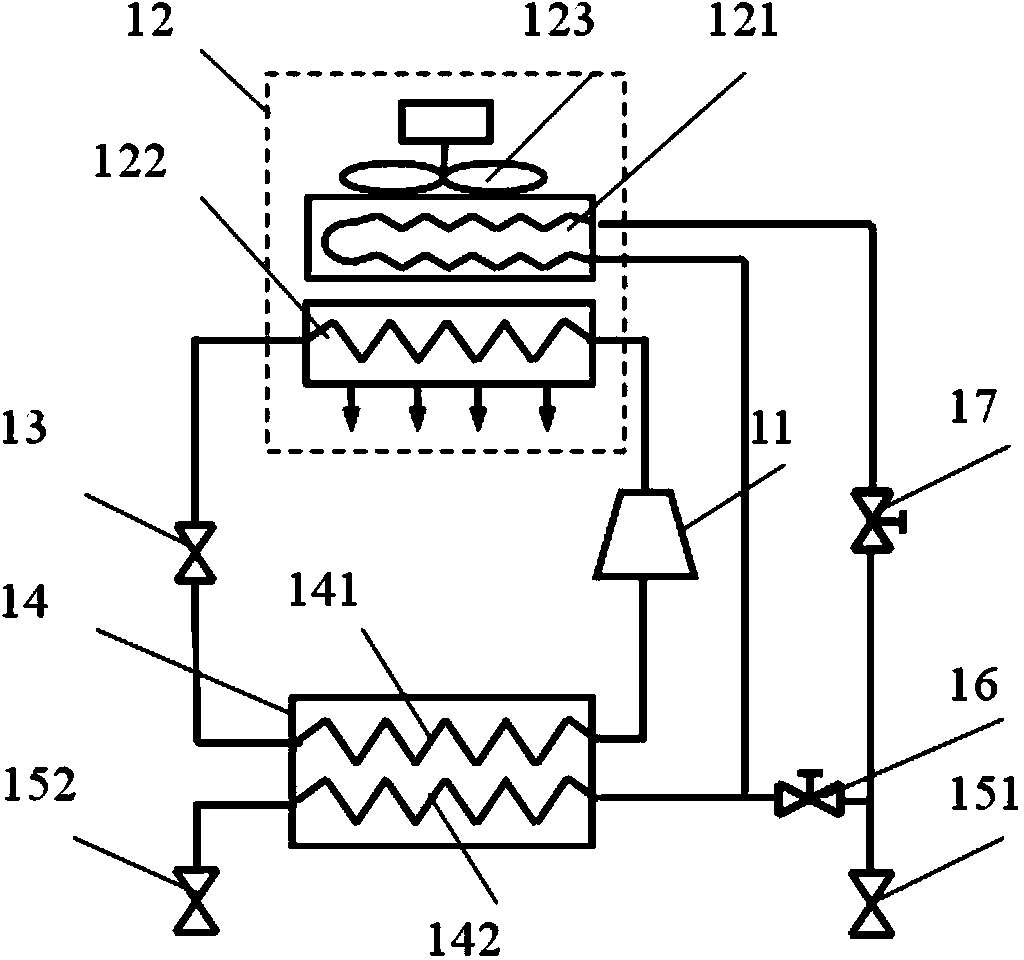

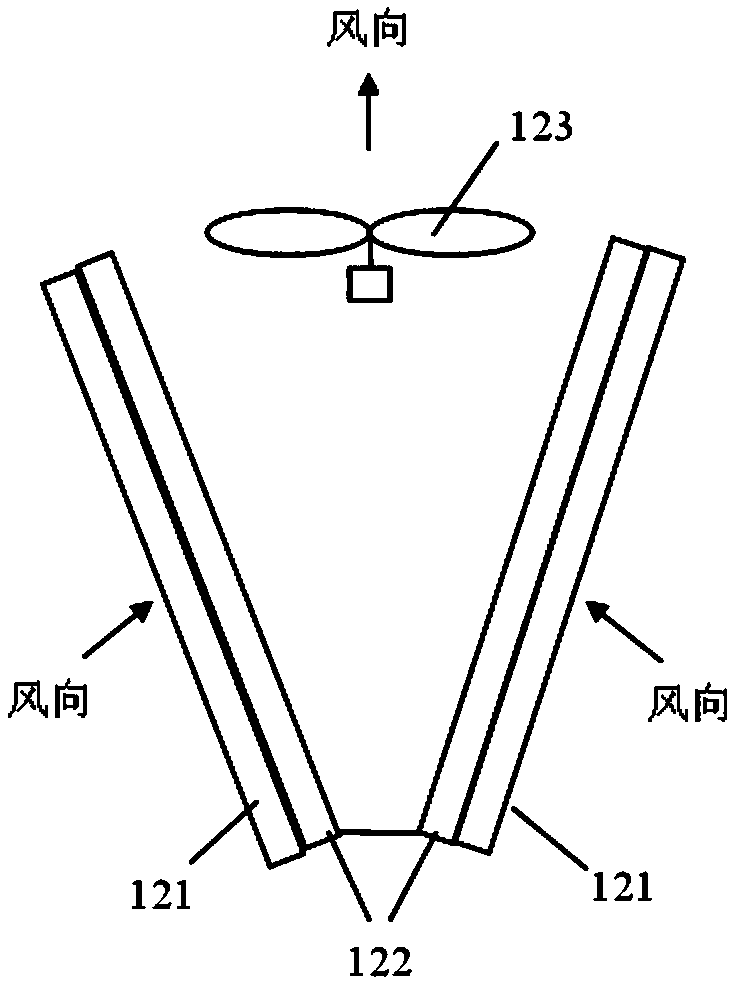

Combined heating fuel cell low-temperature starting system and working method

The invention relates to a combined heating fuel cell low-temperature starting system comprising a cooling liquid circulating pipeline, an electric pile, a waste gas mixing box, and an air supply pipeline and a hydrogen supply pipeline which are connected with the electric pile and the waste gas mixing box. The cooling liquid circulating pipeline is connected with the electric pile; the waste gasmixing box is communicated with the atmosphere to exhaust waste gas. The low-temperature starting system further comprises a heating assembly. The cooling liquid circulating pipeline comprises a cooling liquid heat exchanger; the air supply pipeline comprises an air heat exchanger, the hydrogen supply pipeline comprises a hydrogen heat exchanger, and the heating assembly is connected with the cooling liquid heat exchanger, the air heat exchanger and the hydrogen heat exchanger. Compared with the systems in the prior art, the system has the advantages that the fuel cell can be rapidly started in a low-temperature environment and the energy utilization rate is high.

Owner:TONGJI UNIV

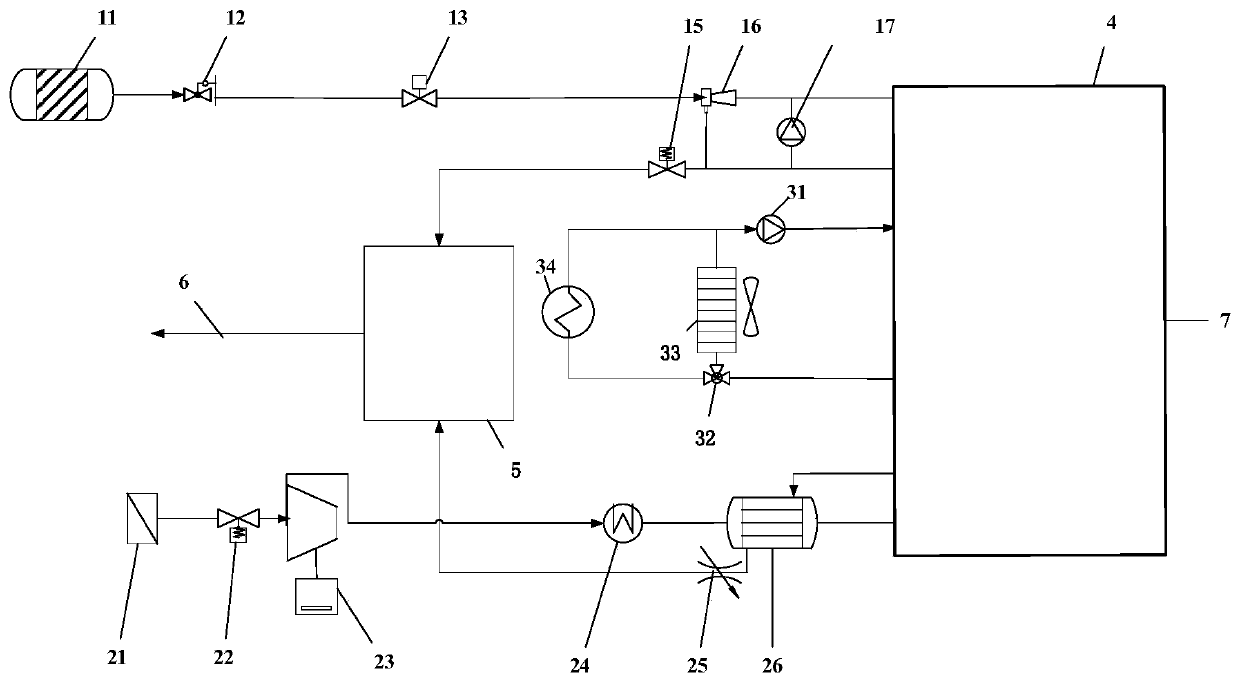

Combined type refrigeration and multi-connected air conditioning system

ActiveCN104251529ALarge working temperature zoneMaximize utilizationMechanical apparatusSpace heating and ventilation safety systemsEngineeringTransition season

The invention discloses a combined refrigeration and multi-connected air conditioning system which is characterized in that a cold source system of the multi-connected air conditioning system, which is composed of two or more than two outdoor composite refrigeration modules is arranged outdoors; each outdoor combined refrigeration module is formed by compositing a first refrigerant vapor compression refrigeration cycle loop and a second refrigerant cycle loop; one or more direct evaporative indoor air cooler modules are arranged indoors, and a refrigerant storage and transmission unit is connected between each outdoor composite refrigeration module and the corresponding indoor air cooler module to form a closed cycle system through a liquid collecting pipe, a liquid supply main pipe and a return air main pipe. According to the combined refrigeration and multi-connected air conditioning system, the number of the indoor and outdoor modules is set according to the design heating loads of air conditioning objects, refrigerating capacity is precisely regulated, the thermal control demands of various all-weather running data rooms and electronic devices are met, and natural cold sources in days and nights, transition seasons and winters can be used to the maximum extent to realize energy conservation and emission reduction of the air conditioning system.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

Critical heat accumulating heat pump water heater

InactiveCN1563812AIncrease in sizeReduce weightHeat storage plantsDomestic hot-water supply systemEngineeringPhase change

The phase change heat-accumulating heat pump water heater includes mainly compressor, evaporator, fan, throttle, filtering drier, cold water inlet pipe, hot water outlet pipe, thermal circulating pipe and phase change heat accumulator. The phase change heat accumulator consists of mainly temperature sensor, casing, insulating material, inner container, phase change heat-accumulating material and hext exchanging pipe. In the said water heater, the evaporator absorb heat from the air source, the compressor produce power by means of electric energy, and the phase change material stores heat and heats water. Some electric heater may be also set inside the phase change heat accumulator optionally as auxiliary heater. The present invention has small size, light weight, convenient use and flexible installation.

Owner:SOUTH CHINA UNIV OF TECH

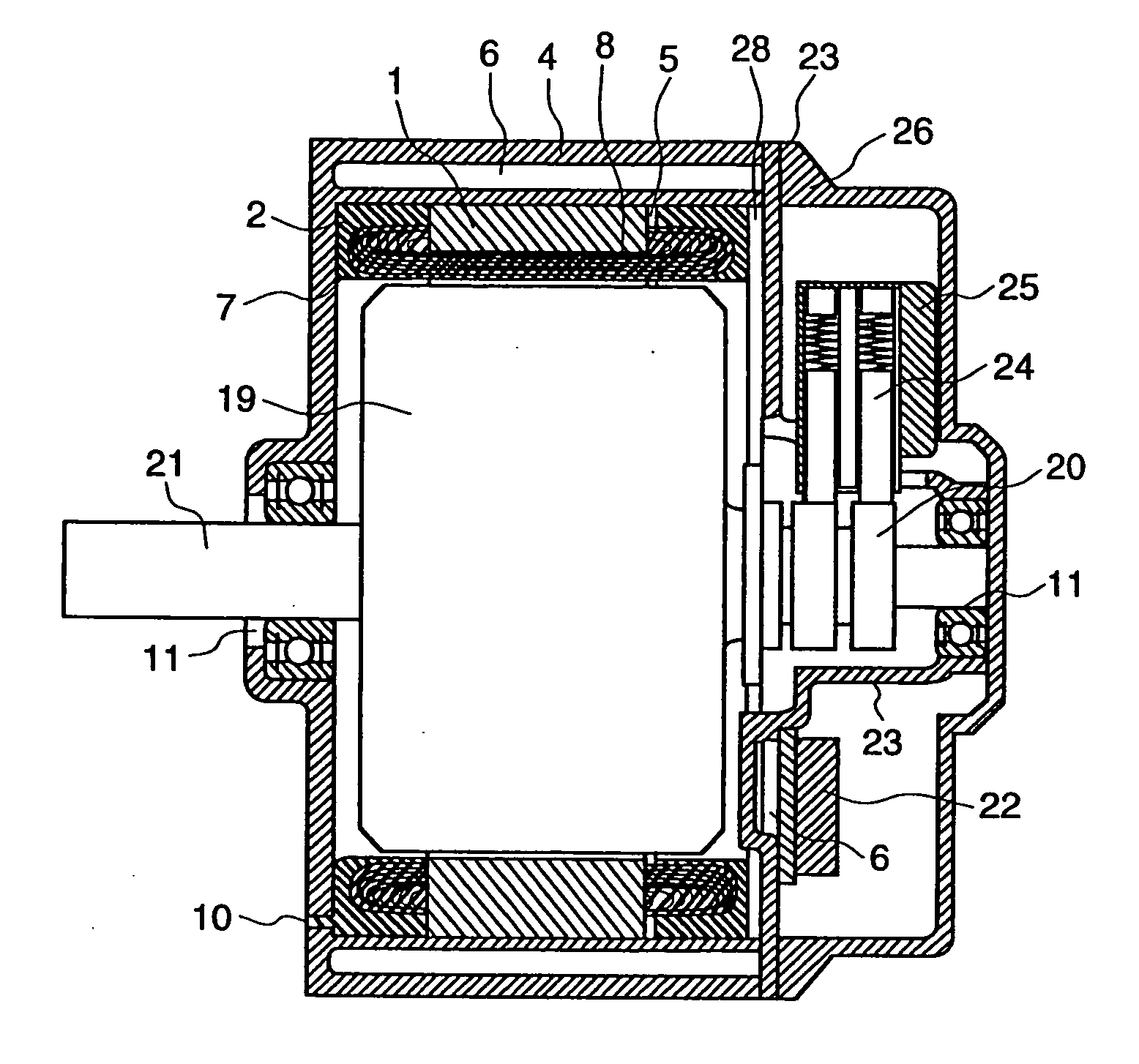

Tandem rotary electric machine

InactiveUS7397157B2Increasing total size and volume and weightImprove cooling effectSynchronous generatorsMagnetic circuit rotating partsElectric machineEngineering

A tandem rotary electric machine, to be applicable to various types of mobile bodies such as vehicles, is equipped with a primary rotary electric machine and a secondary rotary electric machine arranged in tandem mechanism. In the tandem rotary electric machine, heat energy generated by positive diodes and negative diodes forming one or more rectifier devices is dissipated to a stator core of the secondary rotary electric machine. The stator core of the secondary rotary electric machine acts as a heat sink through the housing. The stator core of the secondary rotary electric machine has a less frequency use, and a large size and a large weight than those of the primary rotary electric machine of high frequent and normal is used as a heat sink in order to prevent the temperature rise of the positive diode and the negative diode of the rectifier devices.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com