Method for preparing cellulose microsphere by taking ionic liquid as solvent

A technology of cellulose microspheres and ionic liquids, applied in the fields of microsphere preparation, chemical instruments and methods, microcapsule preparations, etc., can solve the problem of high difficulty, and achieve the effects of less environmental pollution, good thermal stability and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

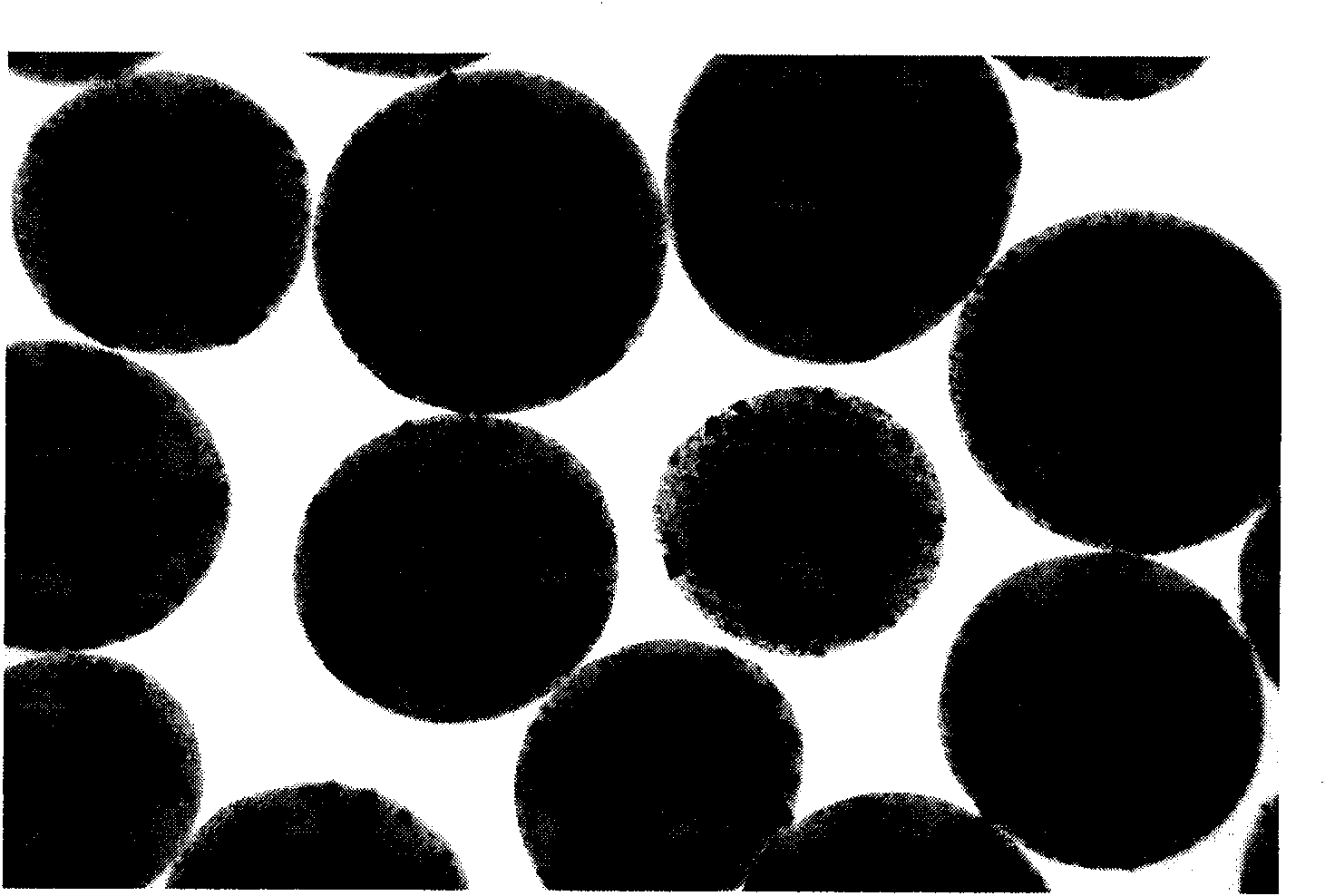

Embodiment 1

[0021] In a 500ml flask, add 38.6 g of 1-butyl-3-methyl-imidazolium chloride (BMINCl), add 1.4 g of refined cotton with a molecular weight of 190,000 Daltons, and stir at 105°C for 20 minutes to form a total weight of 40.0 g of cellulose solution. The temperature was lowered to 100°C, kept stirring, 12.0 g of tungsten carbide powder was added, and the mixture was stirred evenly. 200ml of vacuum pump oil and 4g of Tween 80 were added, the temperature was kept at 100°C, the rotational speed was adjusted to 500rpm, and the temperature was lowered after maintaining stirring for 20 minutes. The temperature was lowered to 40° C. within 120 minutes, 100 ml of absolute ethanol was added, the rotational speed was adjusted to 200 rpm, and the stirring was maintained for 20 minutes to solidify to obtain cellulose / tungsten carbide composite microspheres. The microspheres were filtered from the reaction liquid and washed three times with deionized water. Wet sieving, deionized water wash...

Embodiment 2

[0023] In a 500ml flask, add 38.8 g of 1-butyl-3-methyl-imidazolium chloride (BMINCl), add 1.2 g of refined cotton with a molecular weight of 190,000 Daltons, and stir at 110°C for 20 minutes to form a total weight of 40.0 g of cellulose solution. The temperature was lowered to 100°C, kept stirring, 10.0 g of tungsten carbide powder was added, and the mixture was stirred evenly. 200ml of vacuum pump oil and 2g of Tween 80 were added, the temperature was 95°C, the rotational speed was adjusted to 650rpm, and the temperature was started after maintaining stirring for 20 minutes. The temperature was lowered to 35° C. within 120 minutes, 120 ml of absolute ethanol was added, the rotational speed was adjusted to 200 rpm, and the stirring was maintained for 20 minutes to solidify to obtain cellulose / tungsten carbide composite microspheres. The microspheres were filtered from the reaction liquid and washed three times with deionized water. Wet sieving, deionized water washing and s...

Embodiment 3

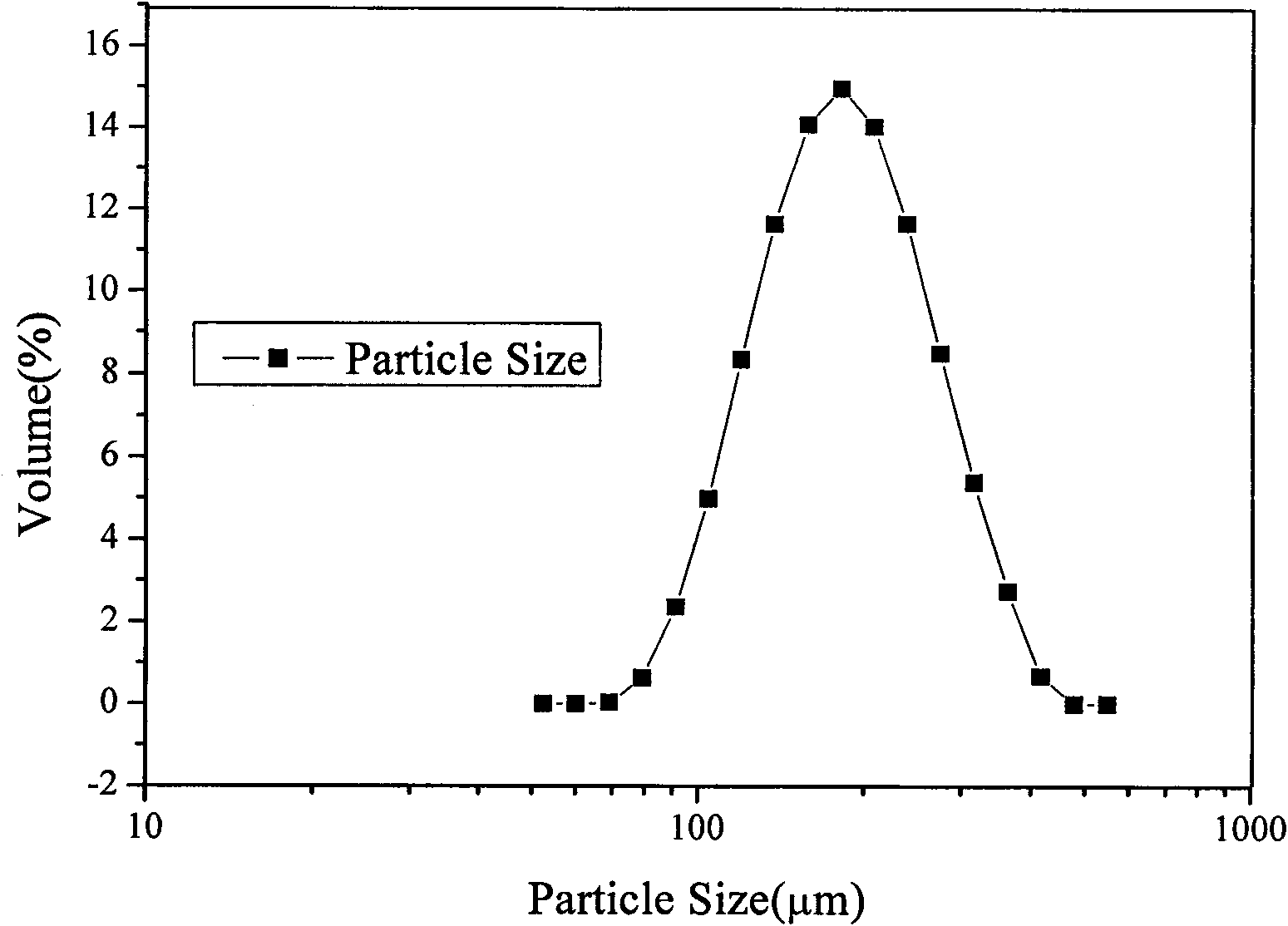

[0025]Add 38.8 grams of 1-butyl-3-methyl-imidazolium chloride (BMINCl) in a 500ml flask, add 1.2 grams of refined cotton with a molecular weight of 190,000 Daltons, stir at 90°C for 30 minutes, and form a total weight of 40.0 grams of cellulose solution. Keep the temperature at 90°C, keep stirring, add 10.0 grams of tungsten carbide powder, and stir evenly. Add 160ml of vacuum pump oil and 4g of Tween 80, drop the temperature to 85°C, adjust the rotation speed to 700rpm, keep stirring for 20 minutes, and then start to drop the temperature. Reduce the temperature to 30°C within 110 minutes, add 100ml of acetone, adjust the rotation speed to 200rpm, keep stirring for 20 minutes, and solidify to obtain cellulose / tungsten carbide composite microspheres. The microspheres were filtered from the reaction liquid and washed three times with deionized water. Wet sieving, washing and soaking in deionized water, obtained 11.3ml of cellulose microspheres with a particle size of 74-300μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com