Patents

Literature

1005results about How to "Uniform adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

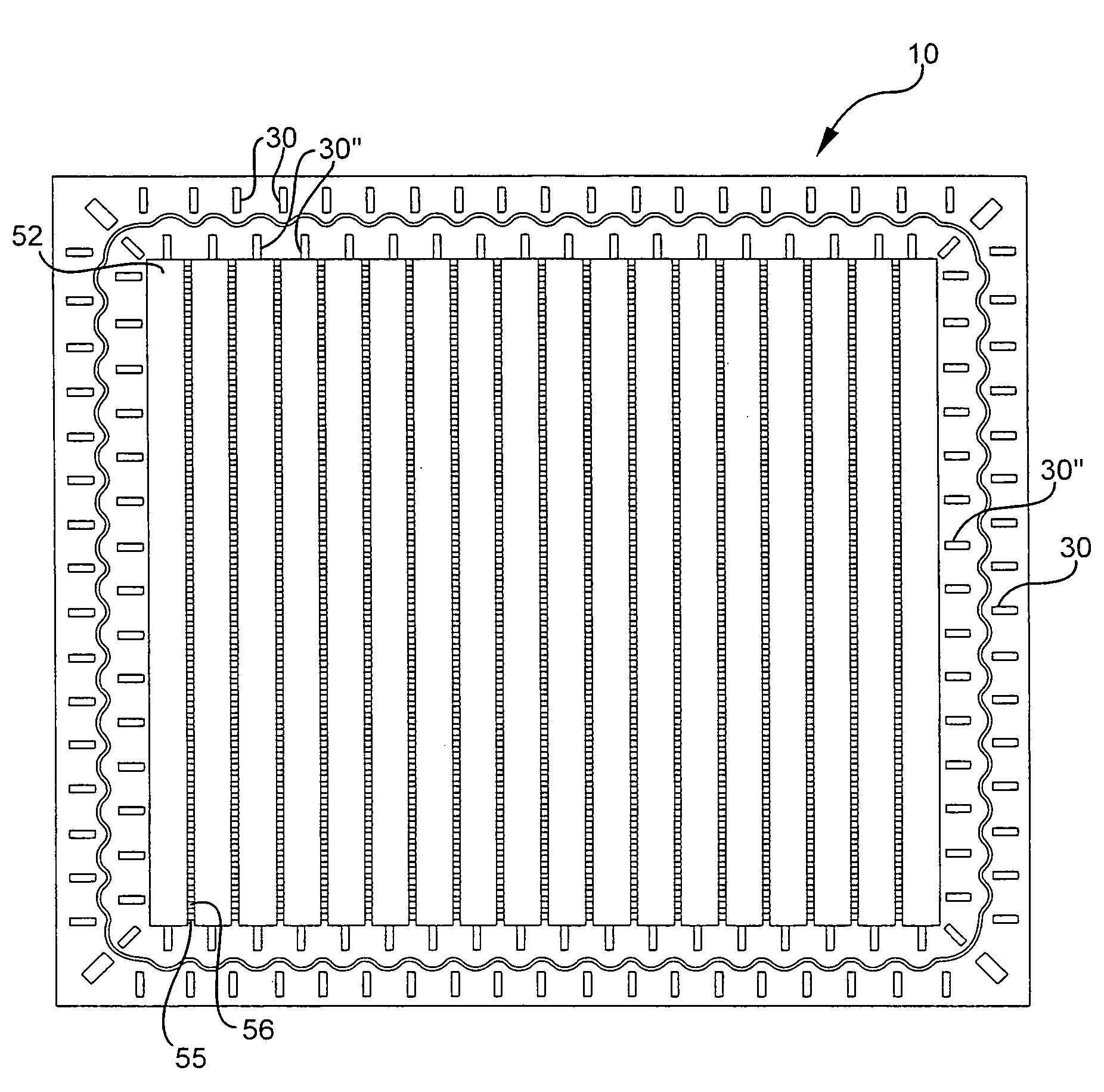

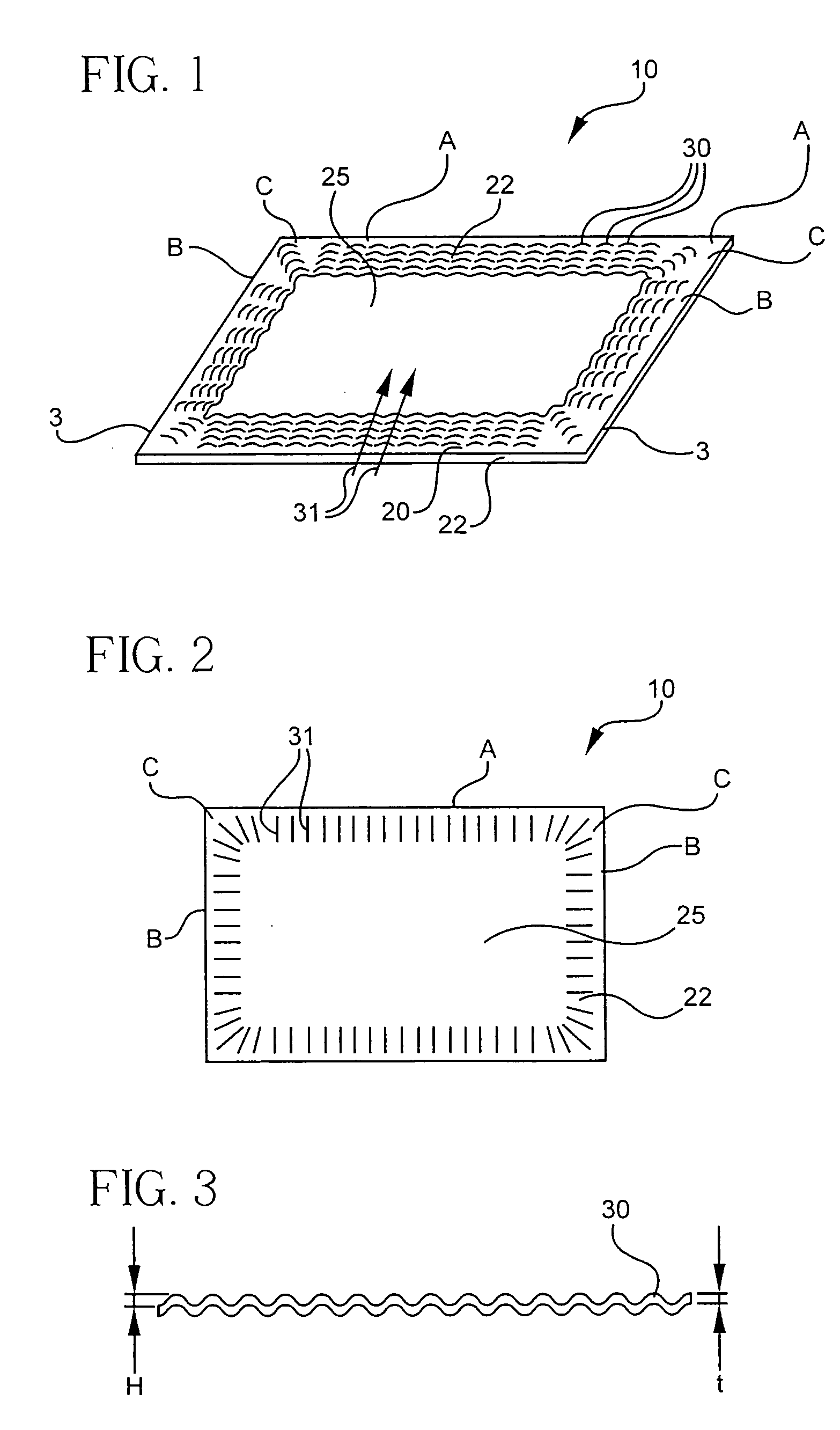

Electrolyte sheet with a corrugation pattern

ActiveUS20060003213A1Increased multi-axial strain toleranceImproving and maintaining structural strengthFuel cells groupingFinal product manufactureEngineeringStress relief

An electrolyte sheet comprises a substantially non-porous body and has at least one stress-relief area on at least a portion of the electrolyte sheet. The stress-relief area has a surface with a plurality of folds. The plurality of folds are arranged around and directed longitudinally toward a common central area.

Owner:CORNING INC

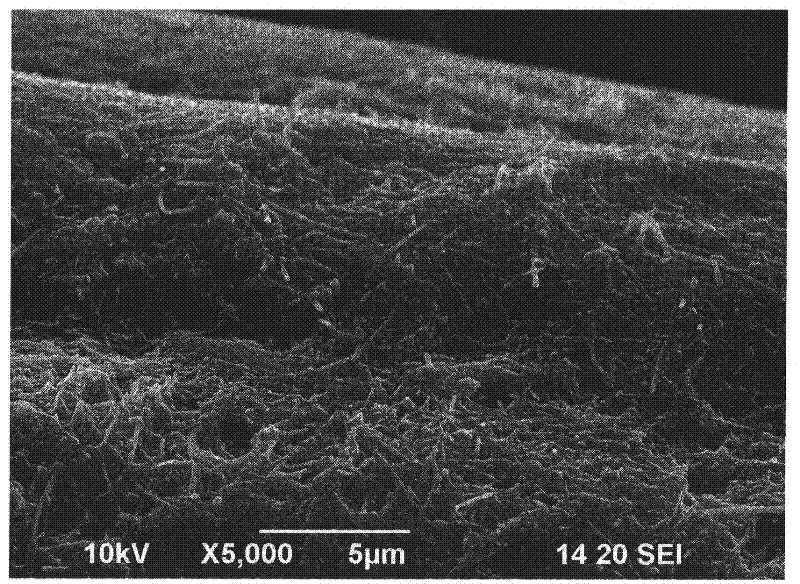

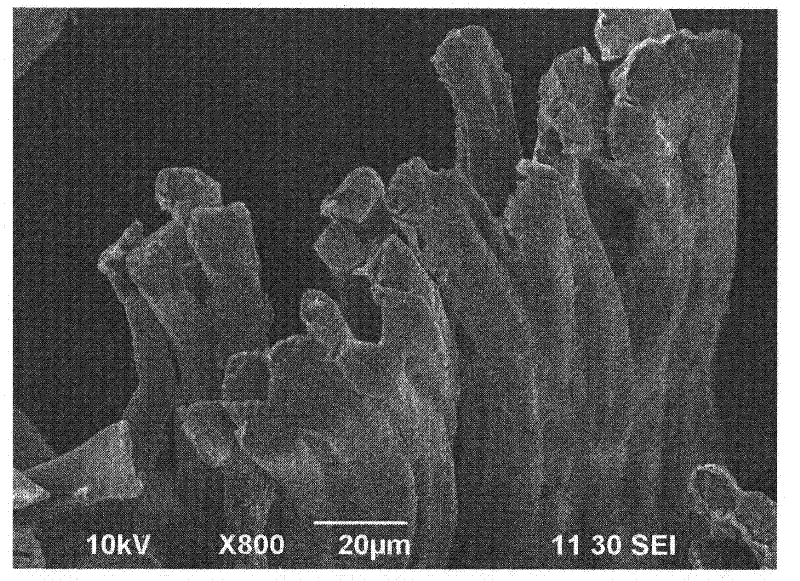

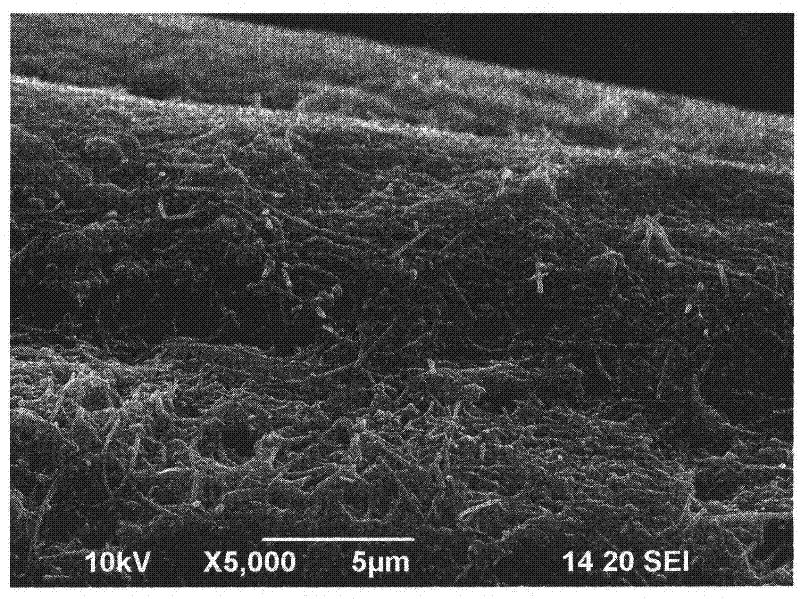

Electroconductive fibers with carbon nanotubes deposited thereon, electroconductive threads, fiber structure, and process for producing same

ActiveCN102131980AImprove conductivityGood flexibilityFibre typesUltrasonic/sonic fibre treatmentPolymer scienceMicrometer

Owner:HOKKAIDO UNIVERSITY +1

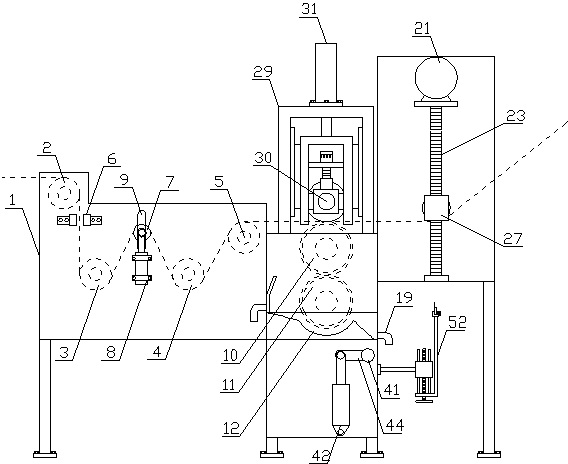

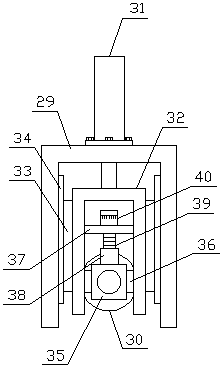

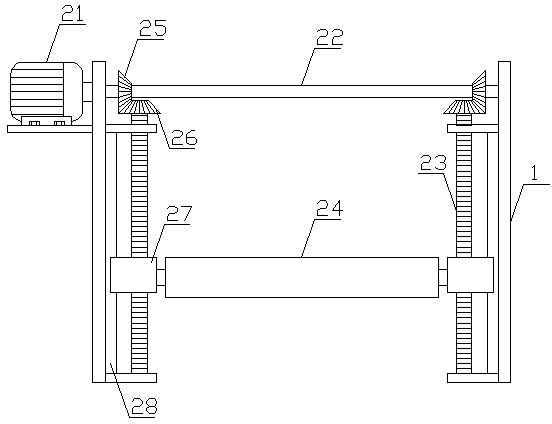

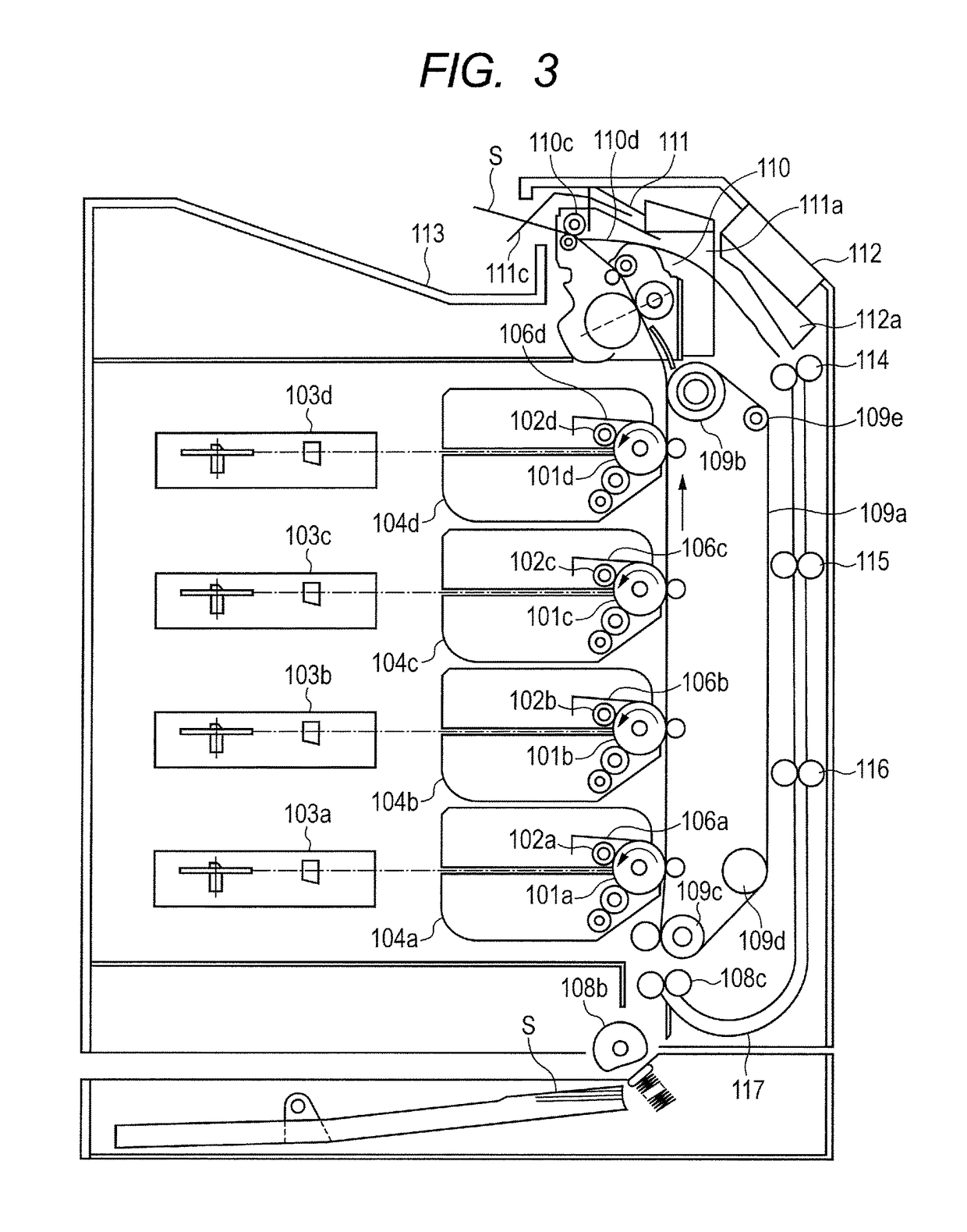

Thin film conveying gluing device

ActiveCN104163356AAdjustable tensionGuarantee stabilityArticle deliveryWebs handlingDrive shaftEngineering

The invention discloses a thin film conveying gluing device and belongs to the field of thin film processing equipment. The thin film conveying gluing device comprises a main support, a film guide mechanism, a film gluing mechanism and a film discharging mechanism, wherein the film guide mechanism, the film gluing mechanism and the film discharging mechanism are sequentially arranged on the main support in the thin film conveying direction. The film guide mechanism comprises a first film guide roller, a second film guide roller, a third film guide roller and a fourth film guide roller, wherein the first film guide roller, the second film guide roller, the third film guide roller and the fourth film guide roller are sequentially connected to the main support horizontally and rotationally in the thin film conveying direction. A static electricity eliminating board is arranged between the first film guide roller and the second film guide roller. A tension adjusting roller is arranged between the second film guide roller and the third film guide roller. The film gluing mechanism comprises a film pressing mechanism, a gluing roller, a glue feeding roller and a film gluing groove, wherein the film pressing mechanism, the gluing roller, the glue feeding roller and the film gluing groove are sequentially arranged from top to bottom. The surface of the gluing roller is attached to the surface of the glue feeding roller. The film gluing groove is an arc-shaped groove matched with the glue feeding roller in shape. The film discharging mechanism comprises a driving motor, a driving shaft, a driving screw and a film discharging roller. The thin film conveying gluing device is simple in structure, thin films can be glued rapidly, efficiently and evenly, and the requirement for production is met.

Owner:浙江耀阳新材料科技有限公司

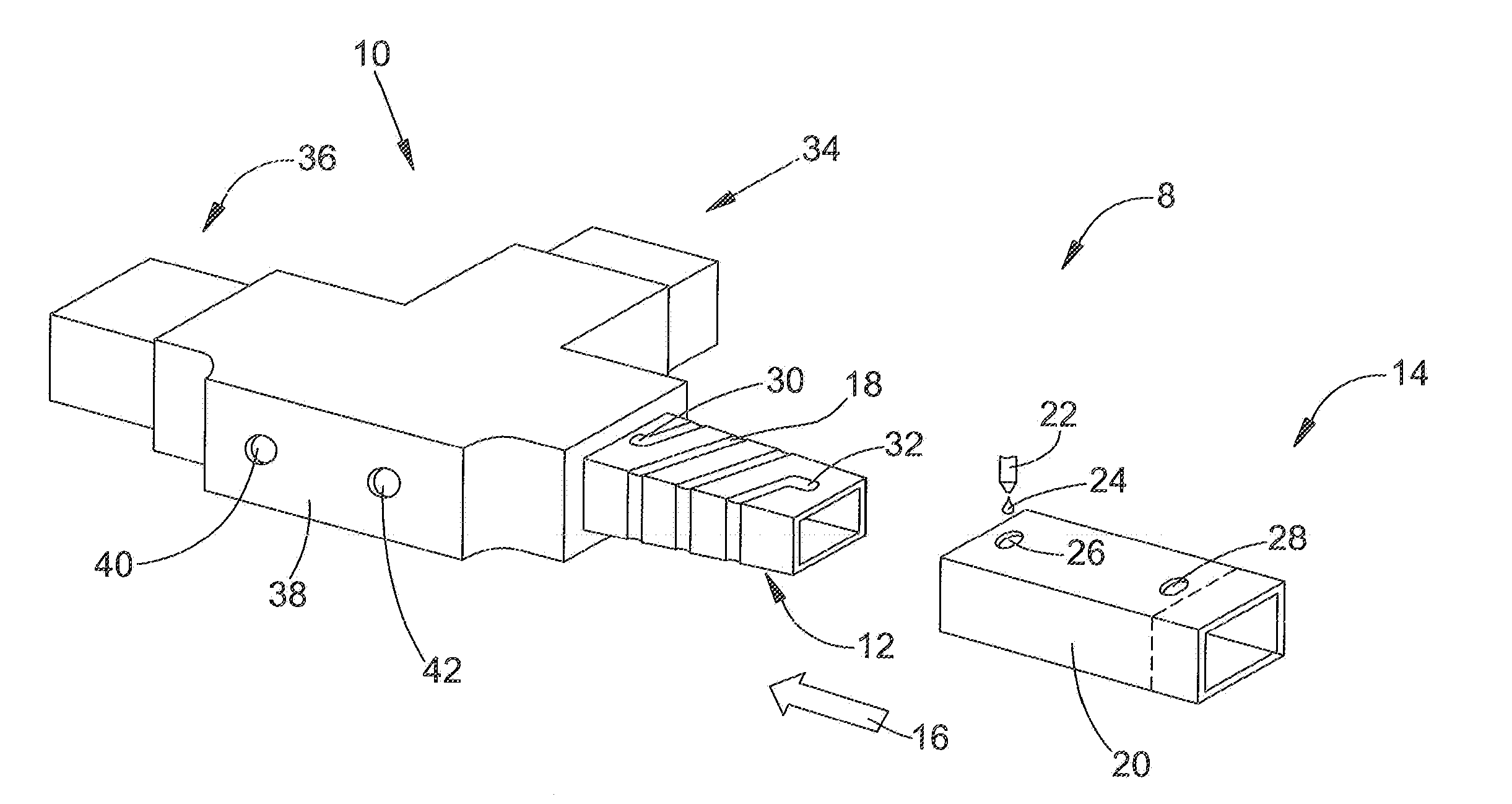

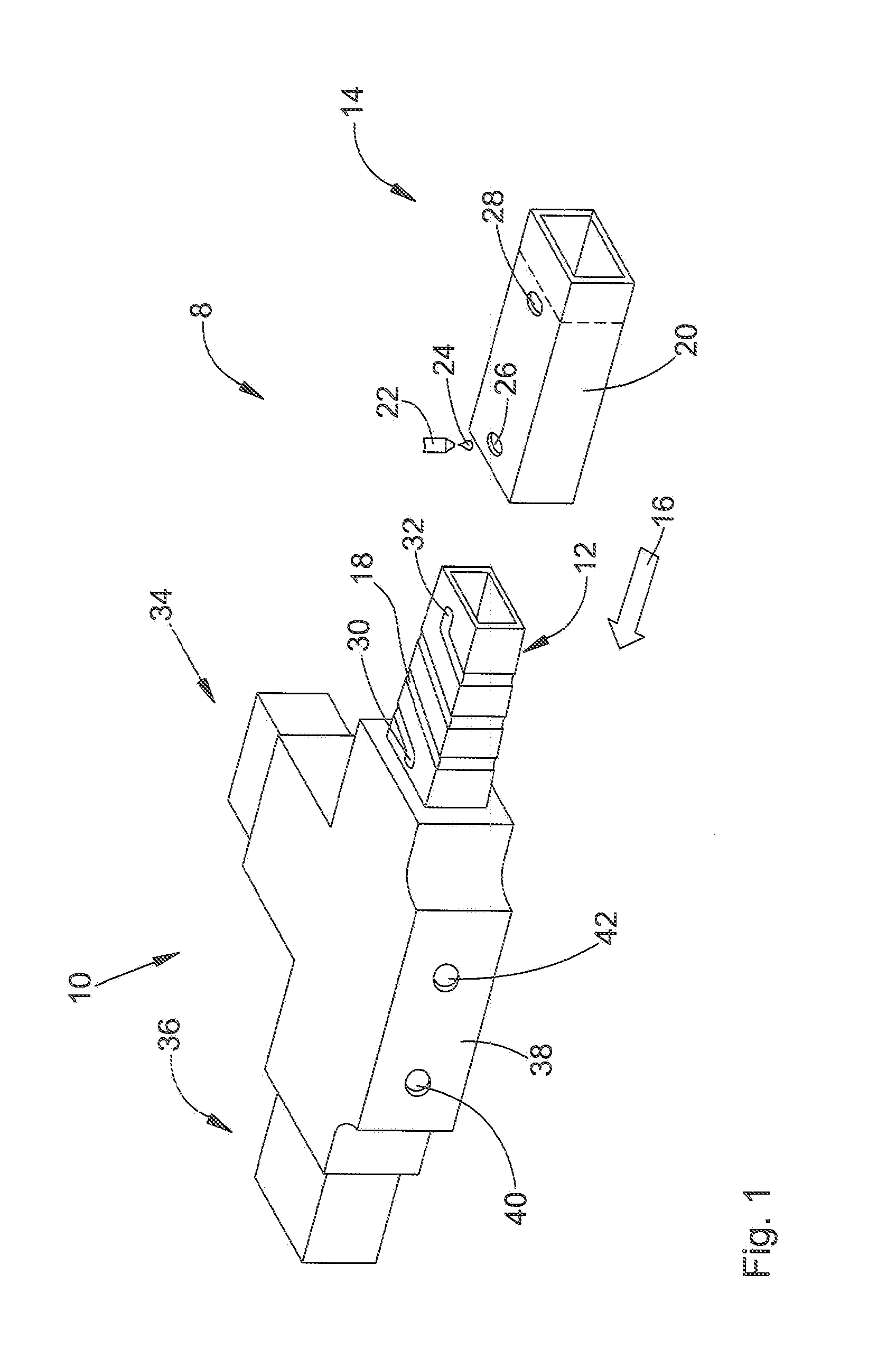

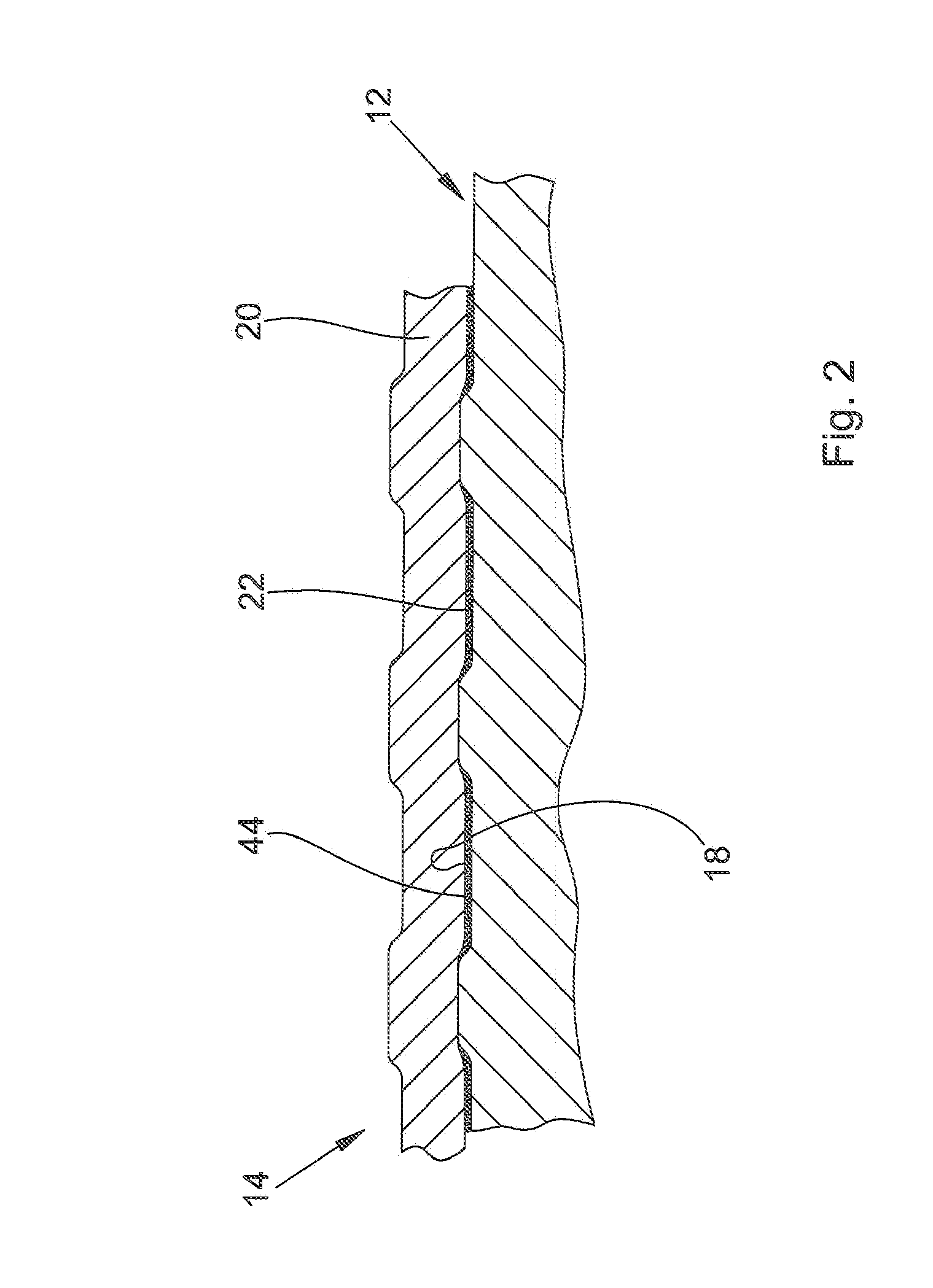

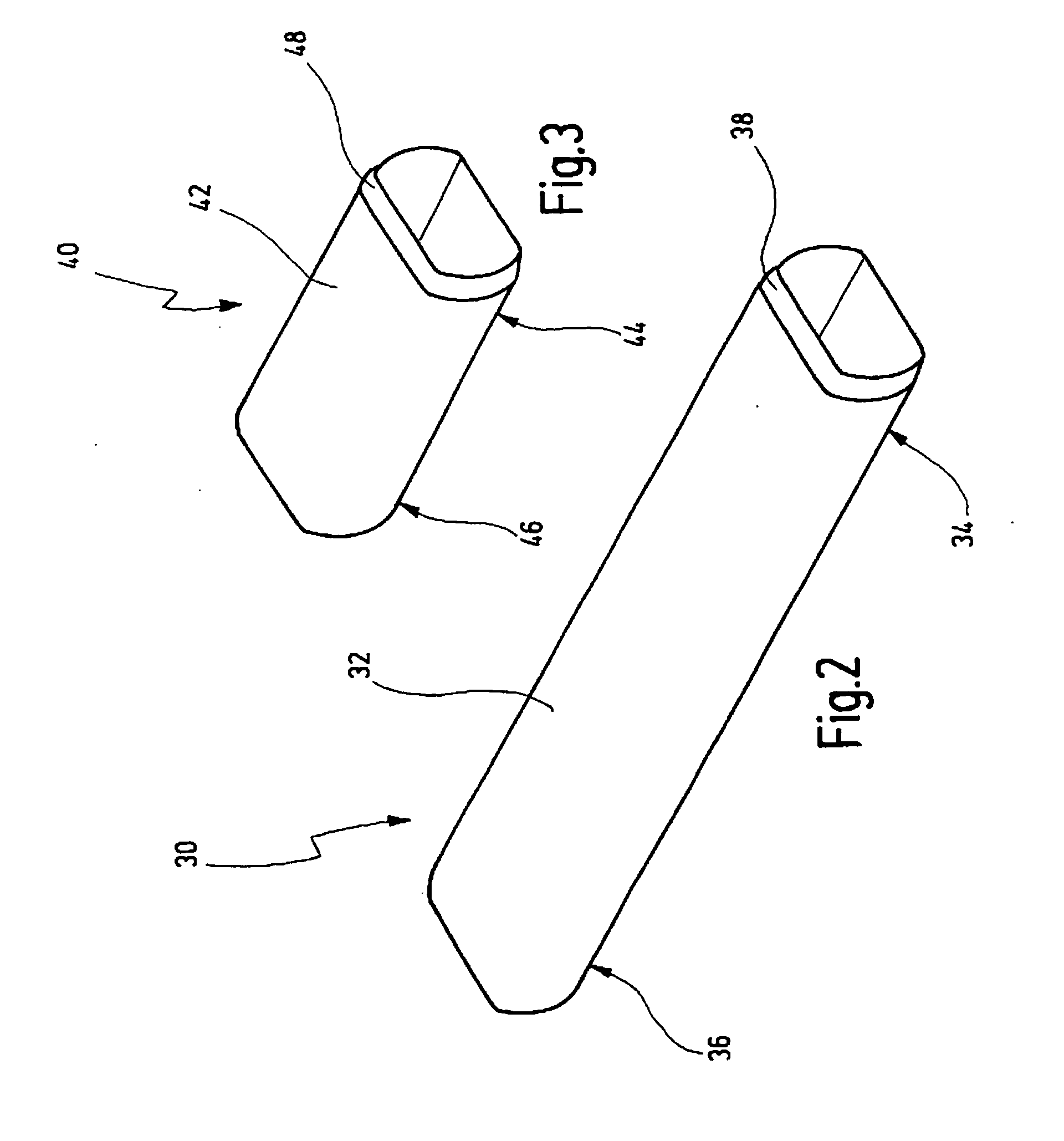

Nodal Member For A Frame Structure Nodal Assembly

InactiveUS20110158741A1Simple pre-assemblyUniform adhesionMaterial gluingLaminationAdhesiveEngineering

A nodal assembly, such as for a frame structure, includes a nodal member which has a fastening flange for connecting to a hollow frame member. An adhesive channel runs helically around an outer surface of the fastening flange, substantially transversely to a pushing-on direction of the frame member. The frame member is pushed onto the flange, and an adhesive is injecting into the adhesive channel via an adhesive injection opening formed in the frame member.

Owner:DEERE & CO

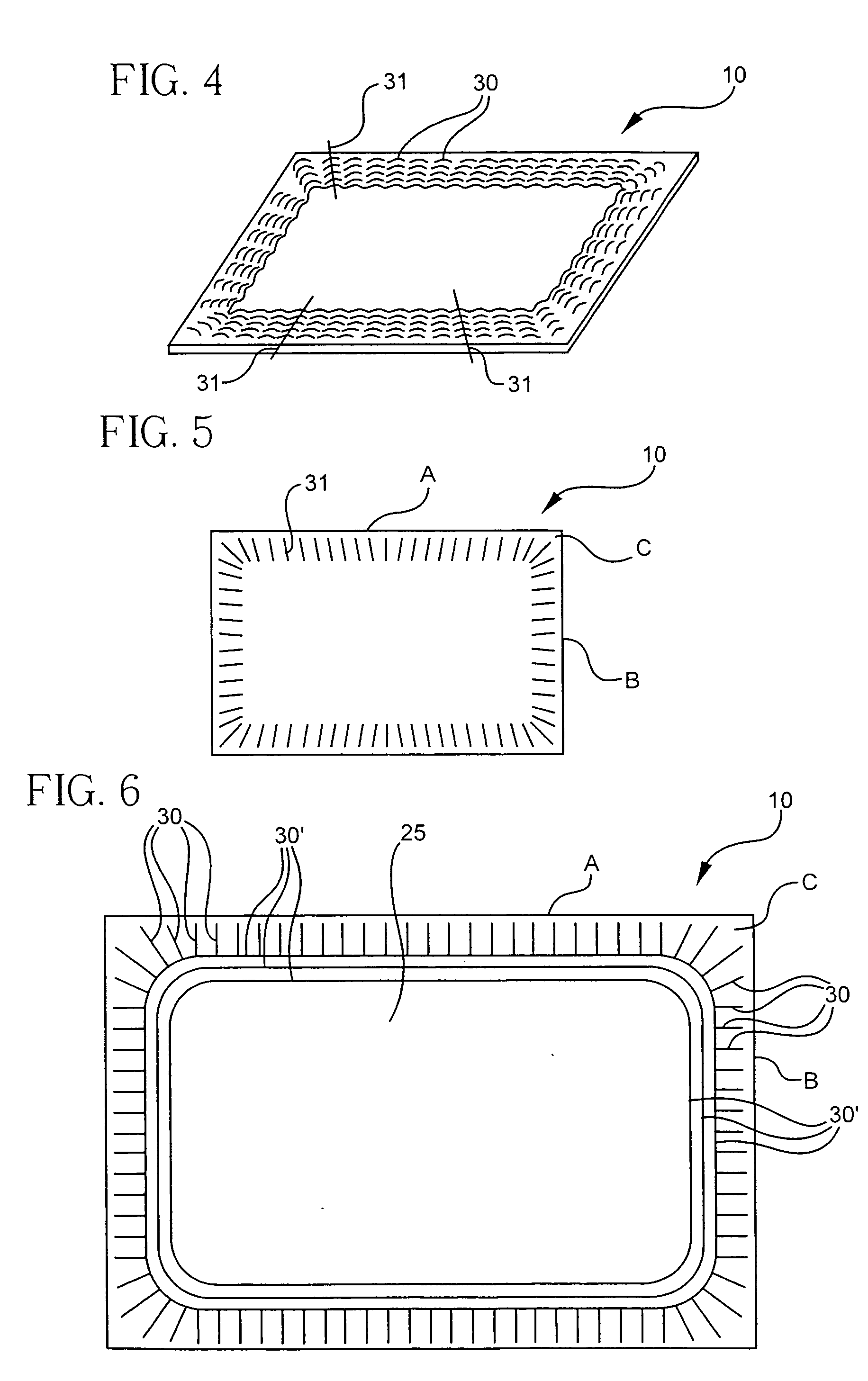

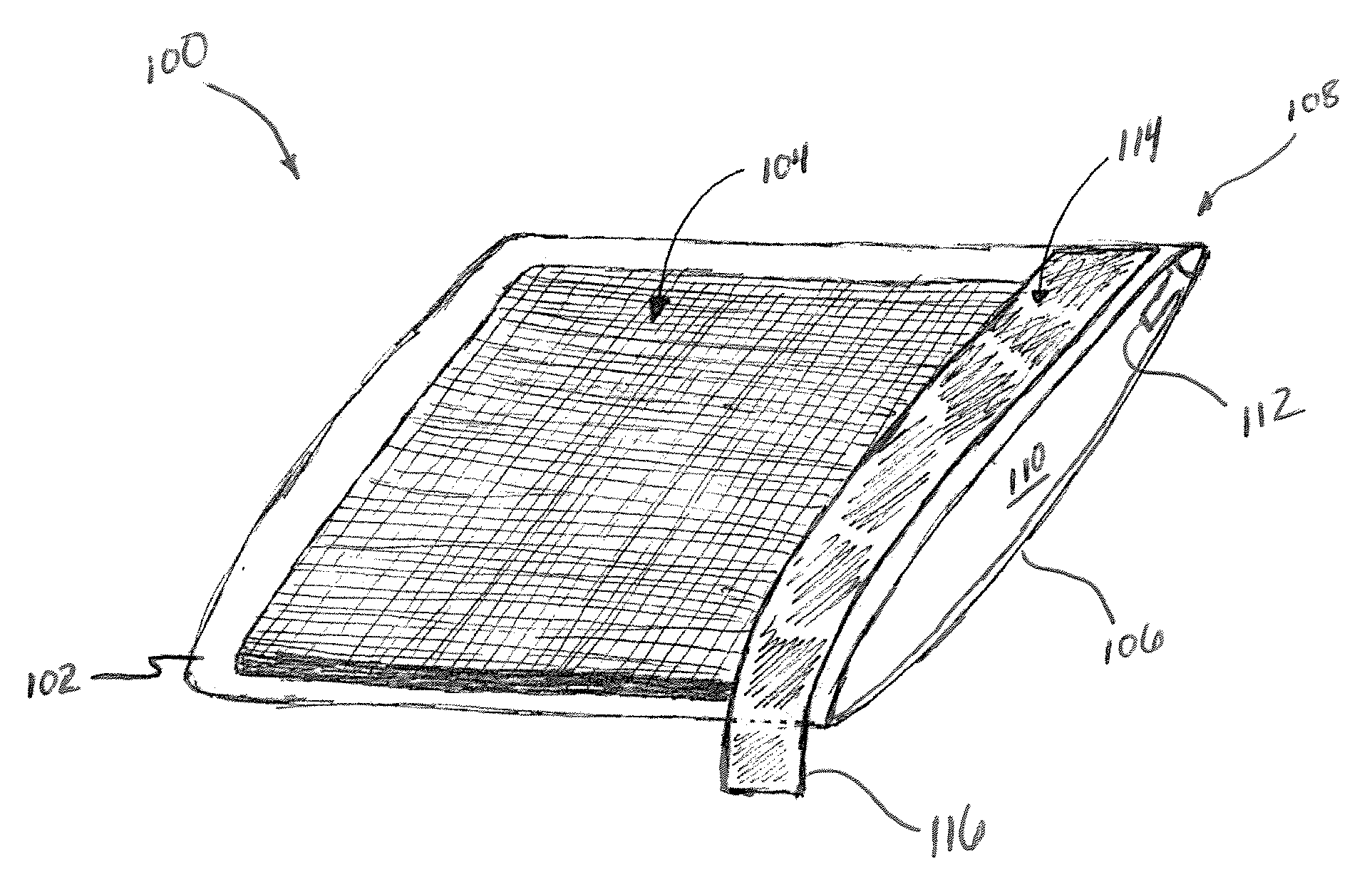

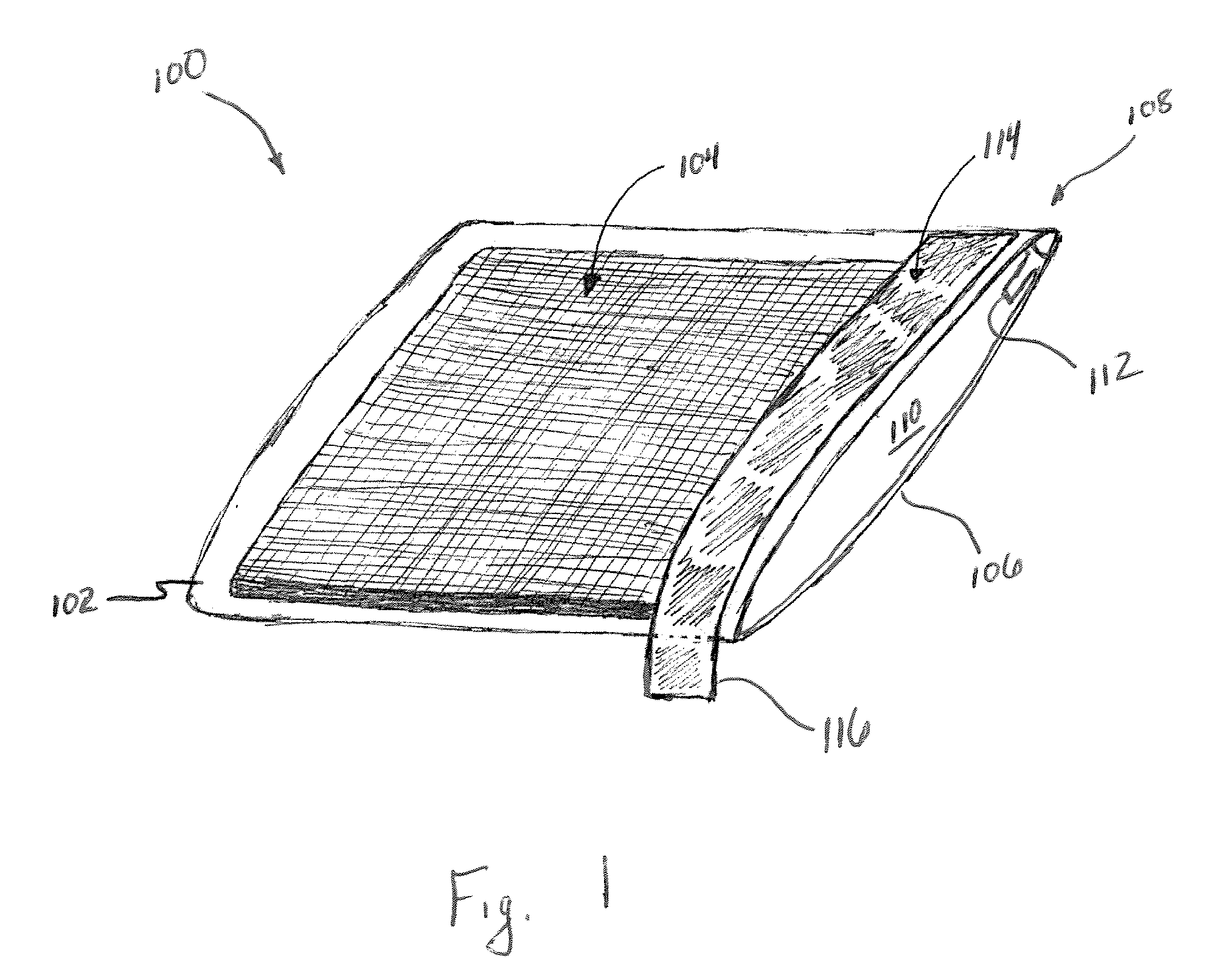

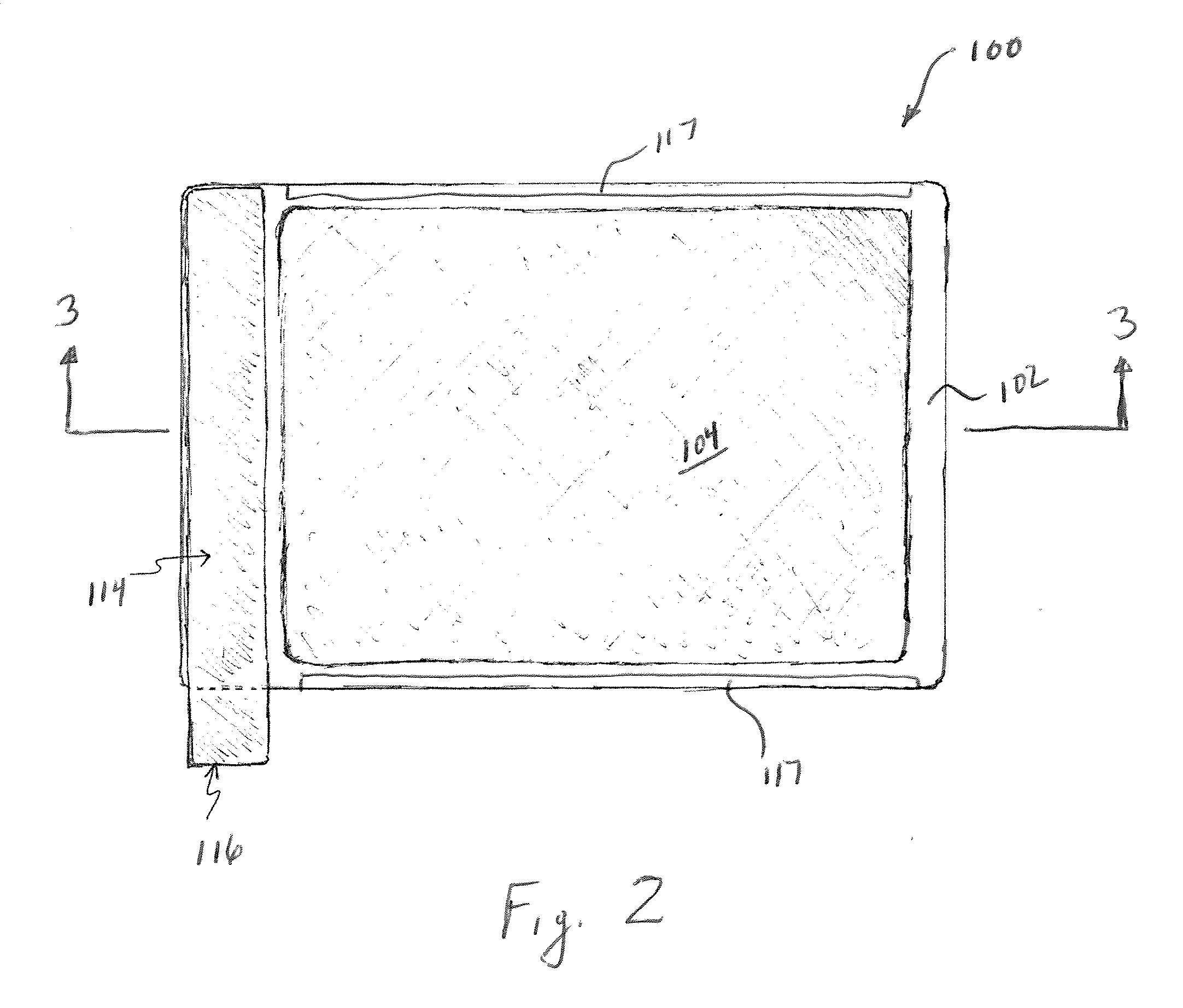

Surgical depilatory device

InactiveUS20070078467A1Avoid lostProtect the epidermisSurgical furnitureDiagnosticsSurgical operationBiological waste

A depilatory device includes flexible sheets that are coupled together to define a pouch. At least one side of the pouch is at least partially covered with an adhesive layer. Before or during a surgical operation, a user places their hand in a pocket formed in the pouch and then places the pouch in contact with a patient's skin to remove potential contaminants, such as hair, debris, and other particulates. The flexibility of the pouch permits it to readily conform to various contours of the patient. The pouch, after picking the aforementioned contaminants, can then be inverted (e.g., flipped inside-out) and sealed to keep the contaminants within the inverted pouch and not allow them back into the surgical environment. The inverted pouch can then be disposed of in a biological waste bin, for example.

Owner:MULLEN GARY J

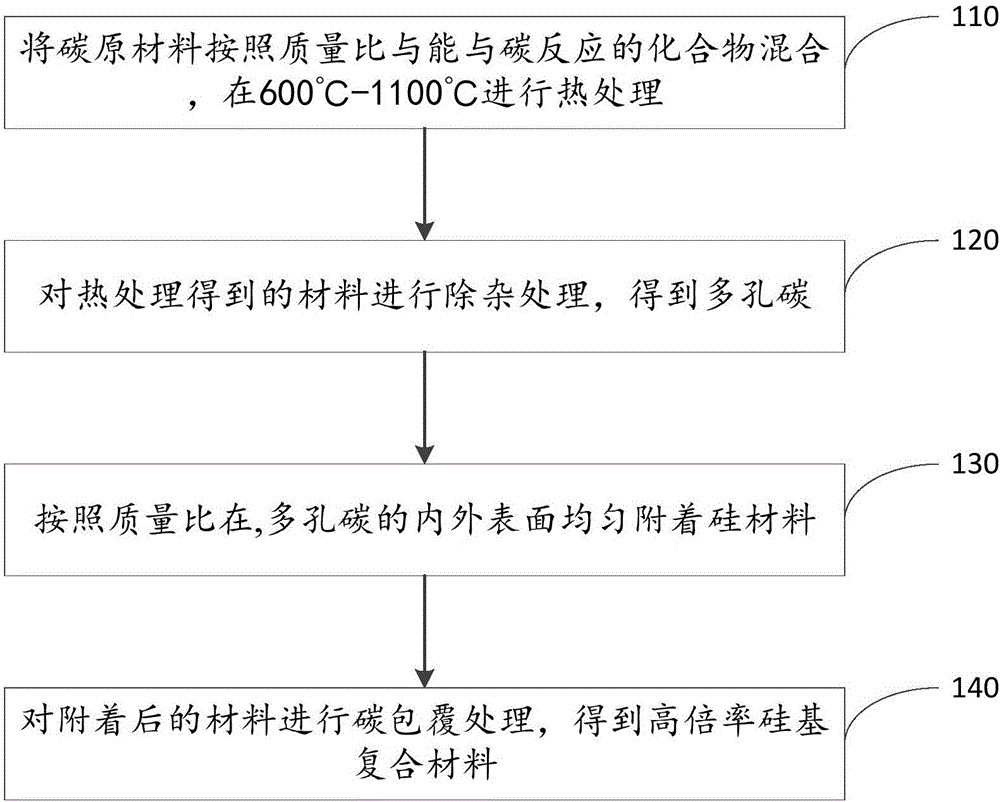

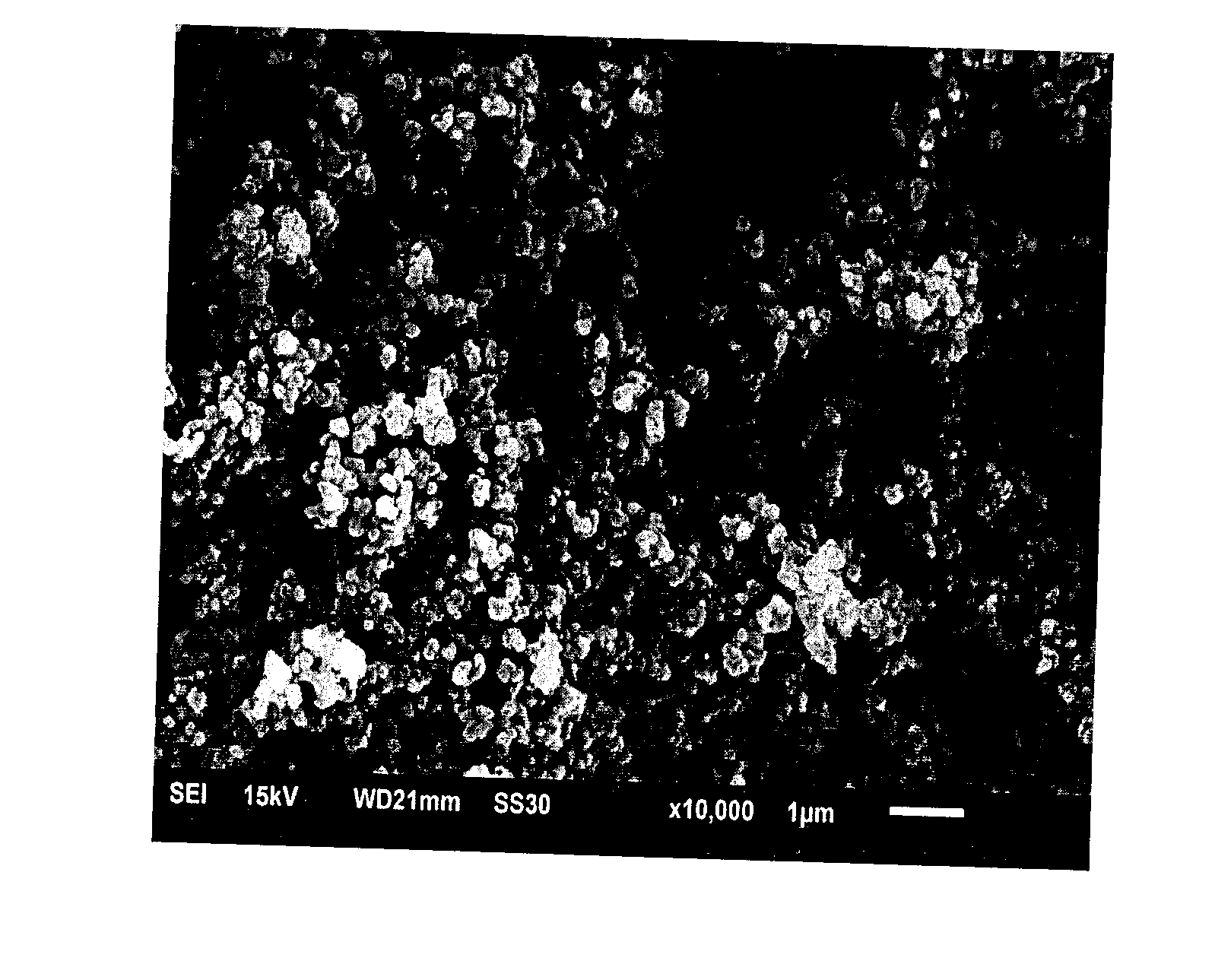

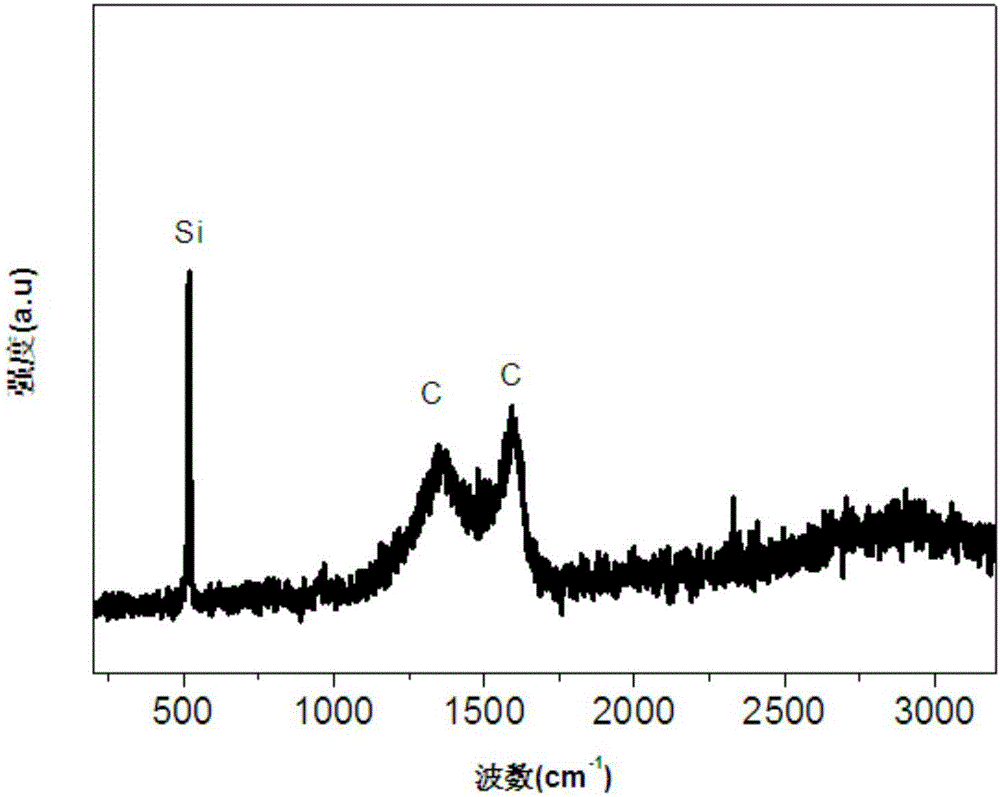

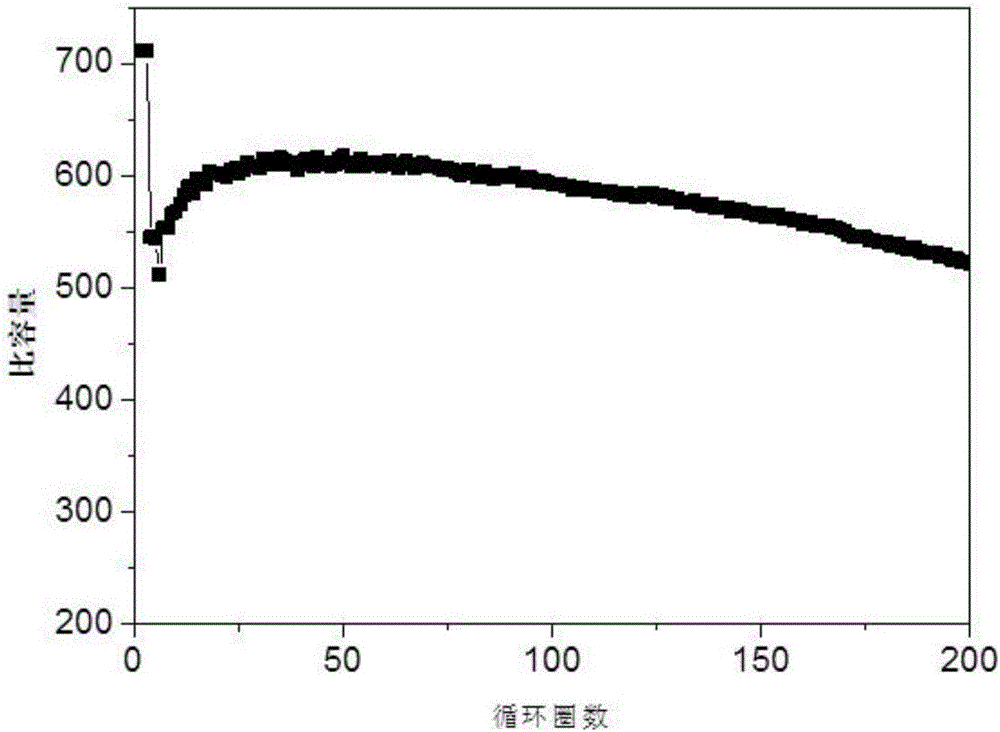

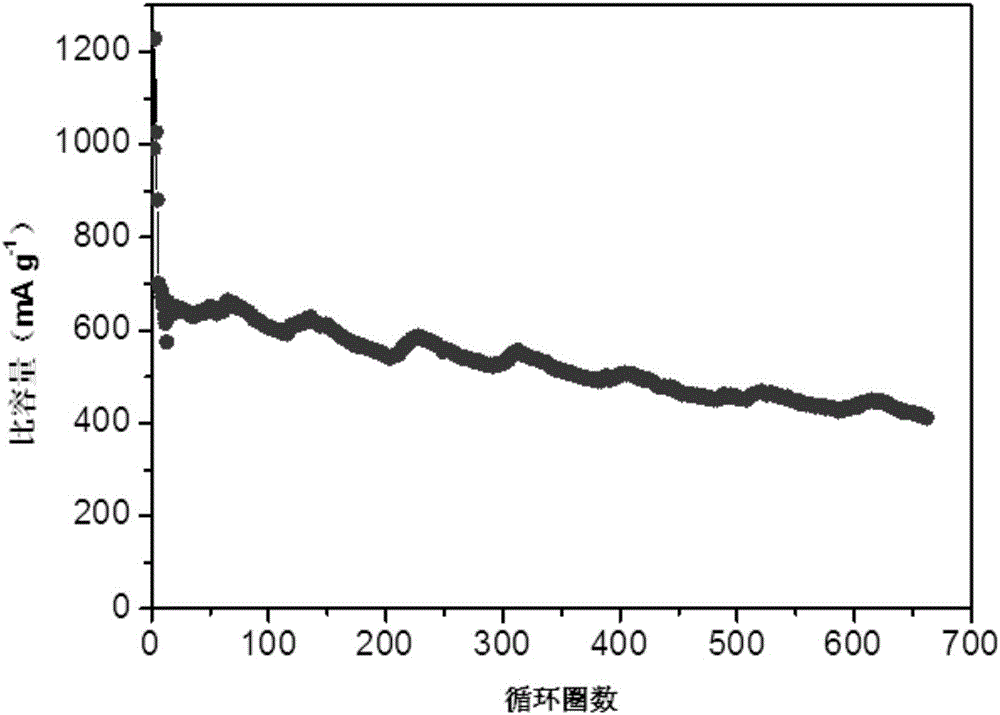

Preparation method of composite high-magnification silicon-based material, cathode material and lithium battery

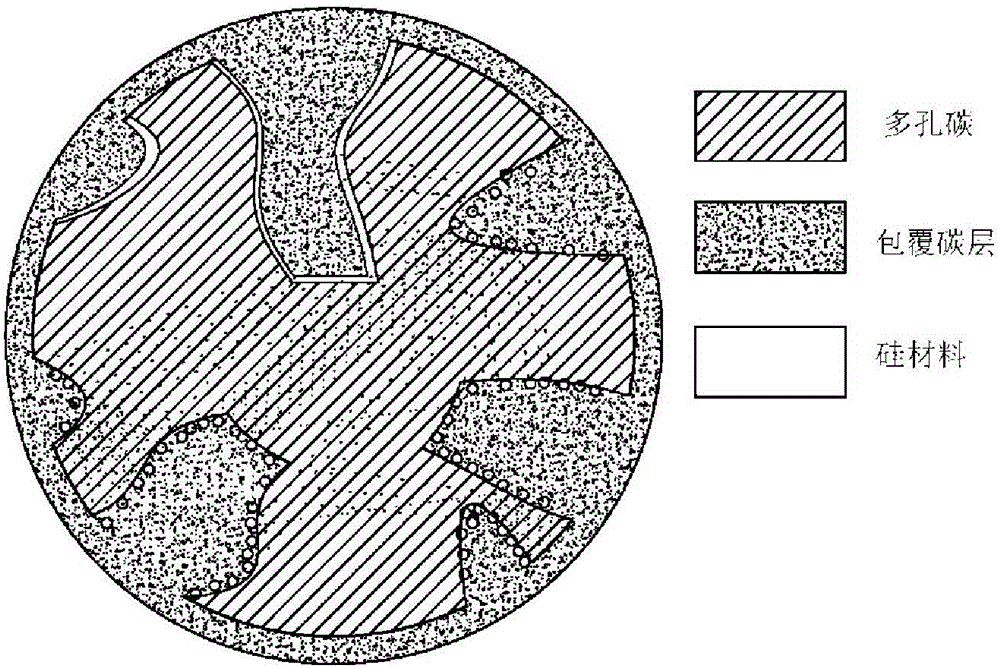

InactiveCN105680023AUniform adhesionReduce strainCell electrodesSecondary cellsCarbon coatingPorous carbon

The invention discloses a preparation method of a composite high-magnification silicon-based material, a cathode material and a lithium battery. The preparation method comprises the following steps: mixing a carbon raw material and a first compound according to a mass ratio, and carrying out the heat treatment, wherein the first compound is a compound capable of reacting with carbon; removing impurities in the heat-treated material to obtain porous carbon; uniformly attaching a silicon material on the inner surface and outer surface of the porous carbon according to a mass ratio; and coating the attached material with carbon to obtain the composite high-magnification silicon-based material, wherein in the composite high-magnification silicon-based material, the mass percent of the porous carbon is 10 to 90 percent, and the specific surface area is 10m<2> / g to 500m<2> / g; the mass percent of the silicon material is 1 to 60 percent; and the mass percent of the carbon coating layer is 20 to 80 percent.

Owner:SHANGHAI PUTAILAI NEW ENERGY TECH CO LTD +2

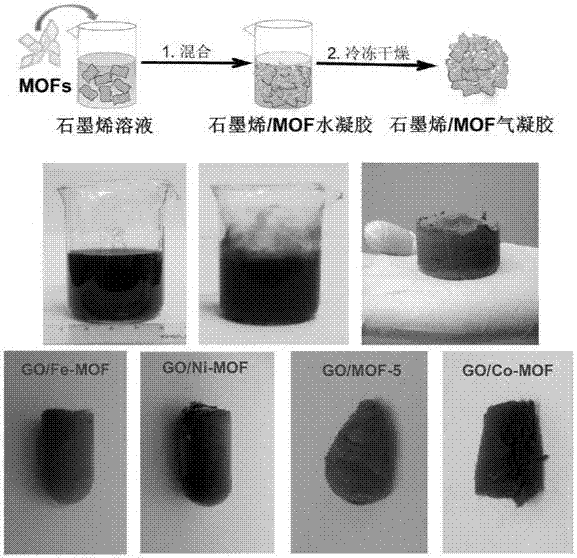

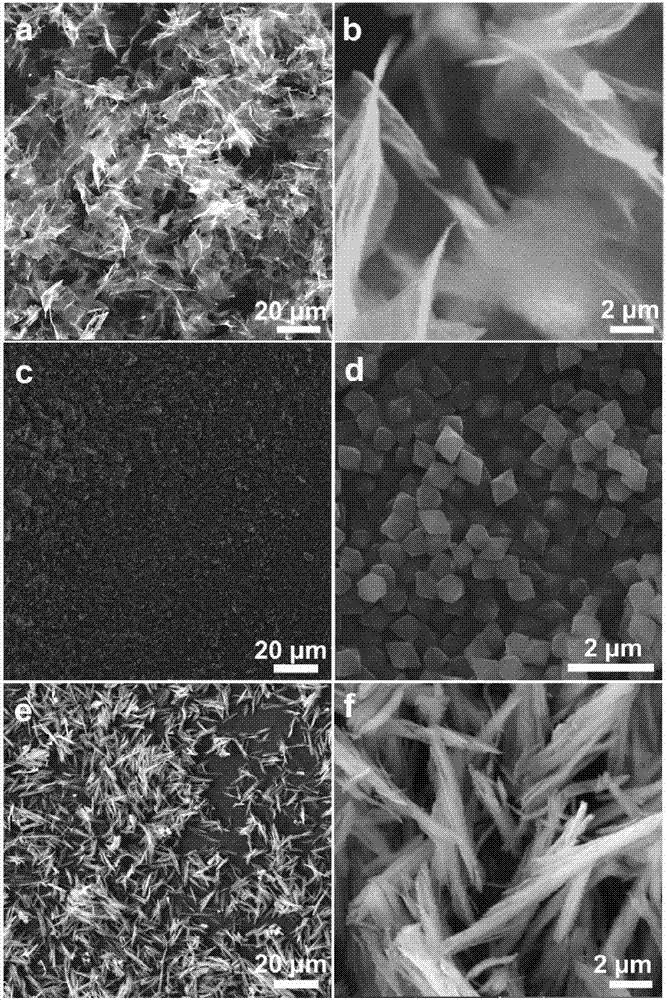

Method for preparing graphene/MOF (metal-organic framework) porous composite material aquagel and graphene/MOF porous composite material aerogel

The invention discloses a method for preparing a graphene / MOF (metal-organic framework) porous composite material aquagel and a graphene / MOF porous composite material aerogel. The method comprises the following steps: taking a clean container, adding a graphene or graphene oxide dispersion solution into the container, adding MOFs crystal powder into the container until the mass ratio of the MOFs crystal powder to the graphene or graphene oxide is (1:100)-(100:1), sealing the container, and performing oscillation or stirring to promote the formation of a graphene or graphene oxide self-assembled three-dimensional framework structure and the uniform compounding between the MOFs crystals and graphene sheets or graphene oxide sheets, thereby obtaining the graphene / MOF porous composite material aquagel; and finally, performing freeze-drying to obtain the graphene / MOF porous composite material aerogel. The graphene / MOF porous composite material aerogel has a self-supporting porous structure, and maintains the structural integrity of the graphene or graphene oxide and MOFs. The preparation method is mild in conditions and simple to operate, and can effectively prevent the graphene sheets or graphene oxide sheets and the MOFs crystals from aggregation.

Owner:ZHEJIANG UNIV OF TECH

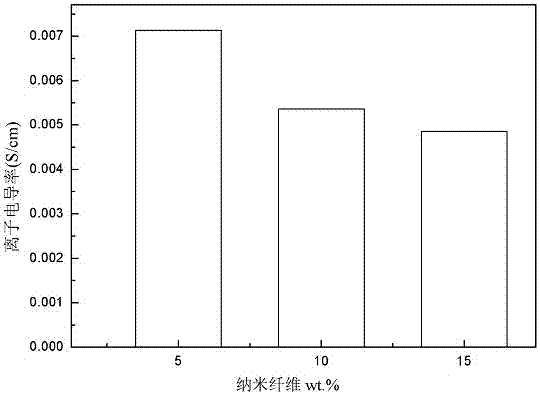

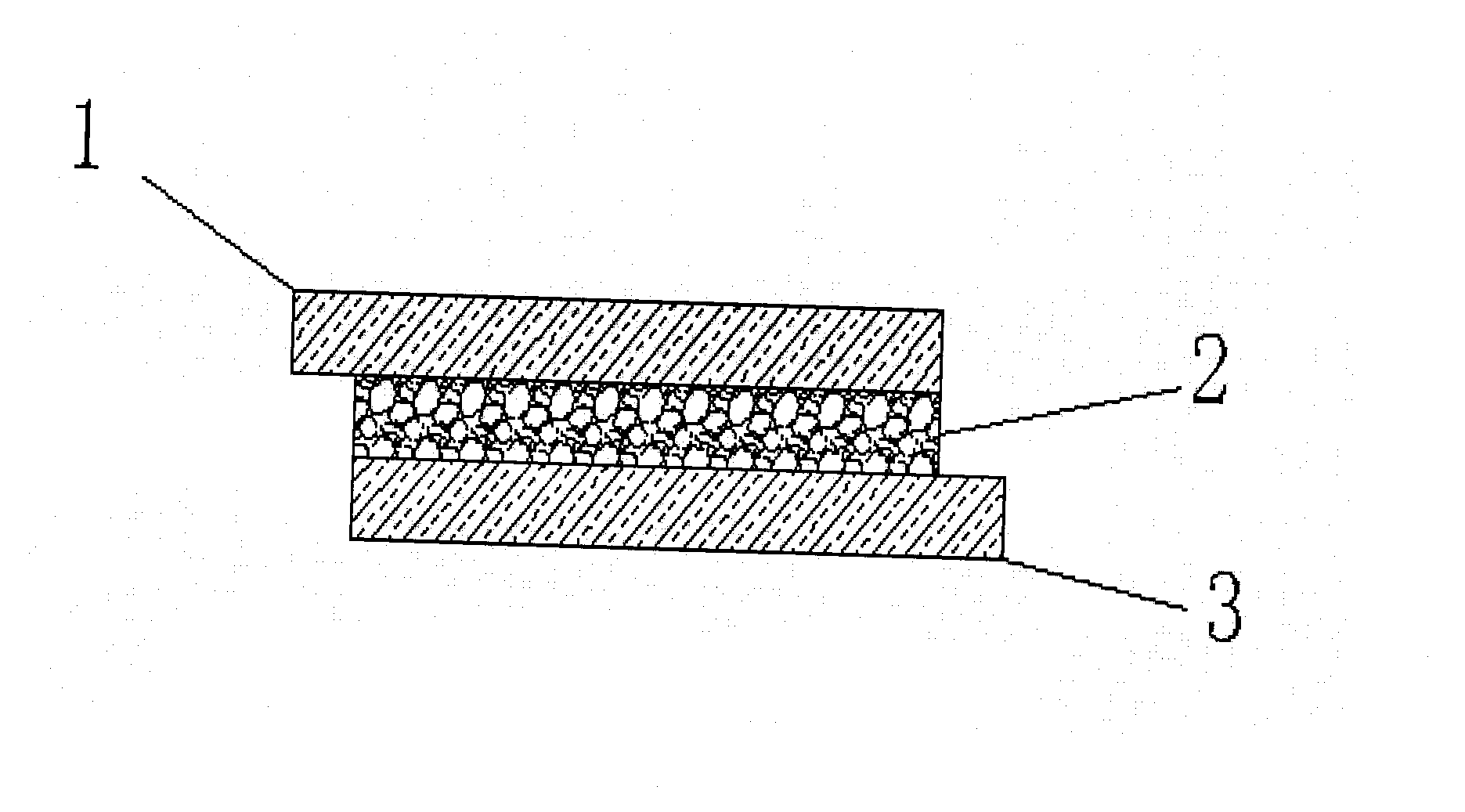

Method for preparing flexible three-dimensional solid electrolyte membrane

ActiveCN107887554AImprove ionic conductivityExcellent electrochemical stability and flexibilitySolid electrolytesSecondary cellsSolventCeramic particle

The invention belongs to the technical field of lithium ion batteries and relates to a method for preparing a flexible three-dimensional solid electrolyte membrane. The method comprises the followingsteps: adding nano fibers into a solvent to prepare nano fiber suspension; adding lithium-ion conductive ceramic particles into the nano fiber suspension, stirring at high speed, and performing freezedrying so as to obtain a ceramic particle / nano fiber three-dimensional porous composite scaffold; adding lithium salt into an acetonitrile solution of polyethylene oxide, and stirring at high speed so as to obtain a lithium salt-polyethylene oxide mixed solution; soaking the ceramic particle / nano fiber three-dimensional porous composite scaffold into the lithium salt-polyethylene oxide mixed solution, drying and performing hot-pressing treatment, thereby obtaining the flexible three-dimensional solid electrolyte membrane. According to the method disclosed by the invention, the lithium-ion conductive ceramic particles are uniformly attached onto the nano fibers to form the three-dimensional porous scaffold, so that the transmission path of lithium ions in a polymer matrix is lengthened, and the solid composite electrolyte membrane has high ionic conductivity, excellent electrochemical stability and flexibility at room temperature.

Owner:柔电(武汉)科技有限公司

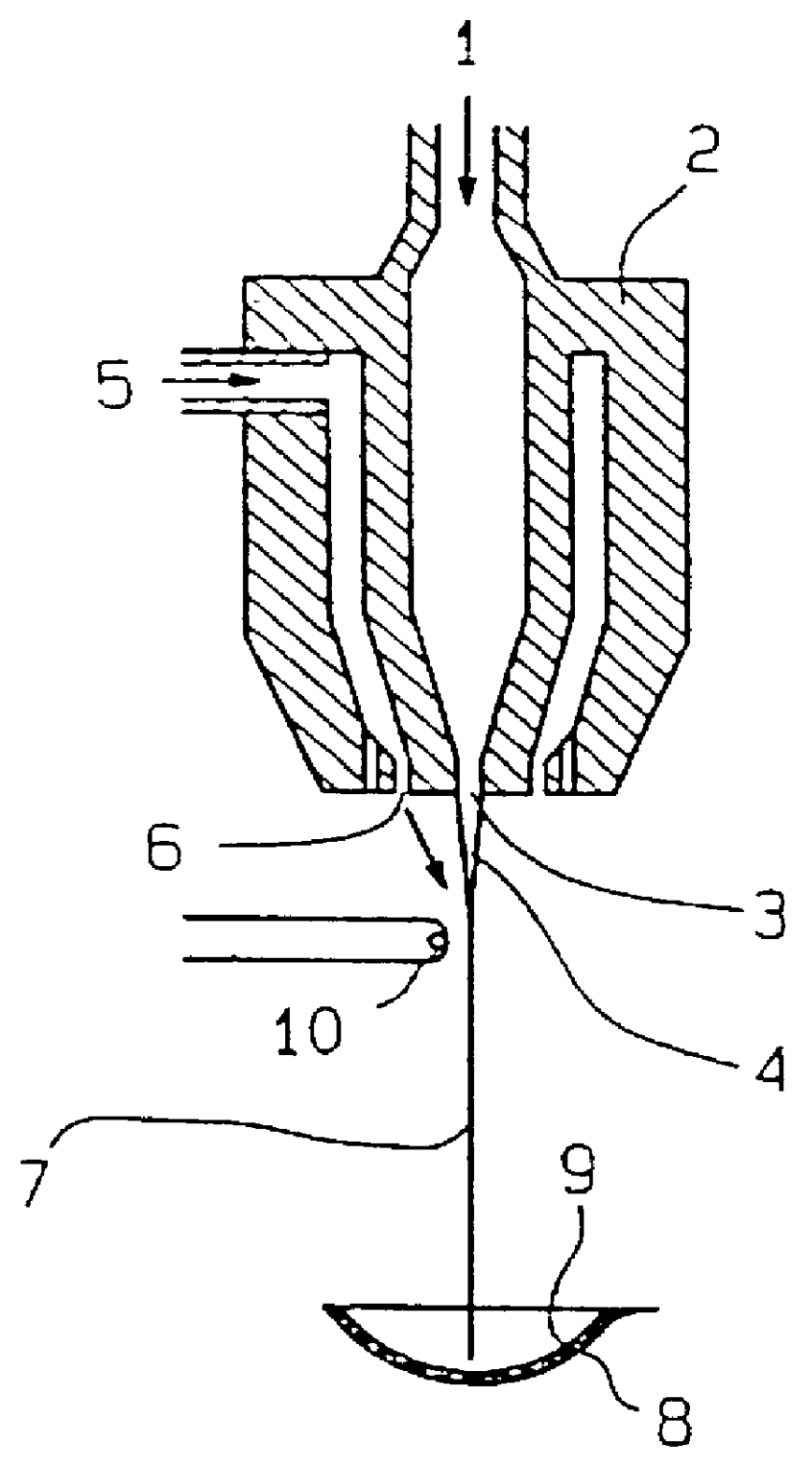

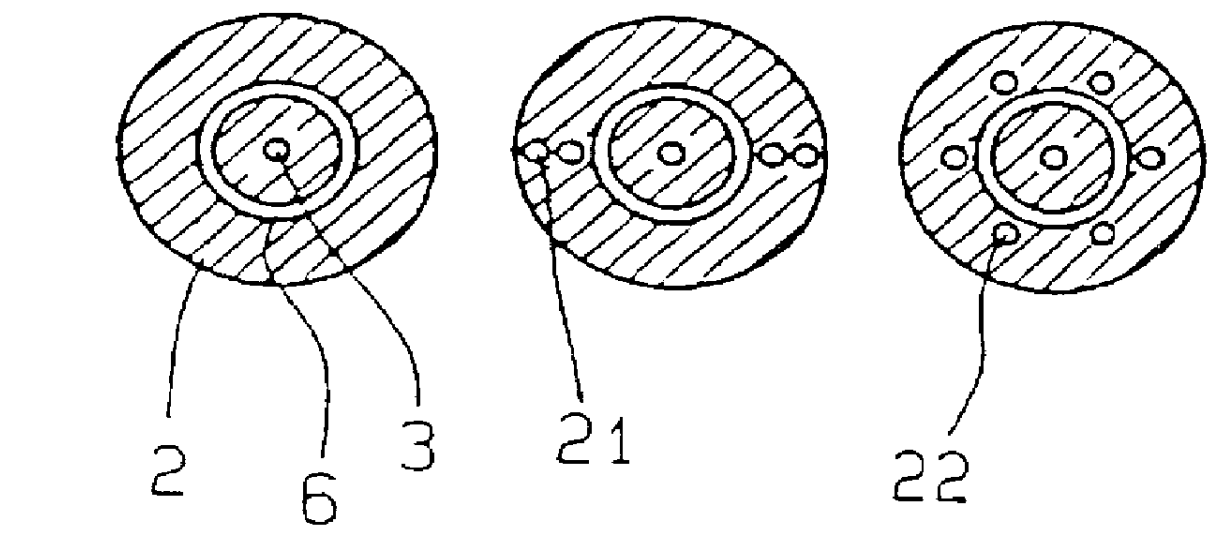

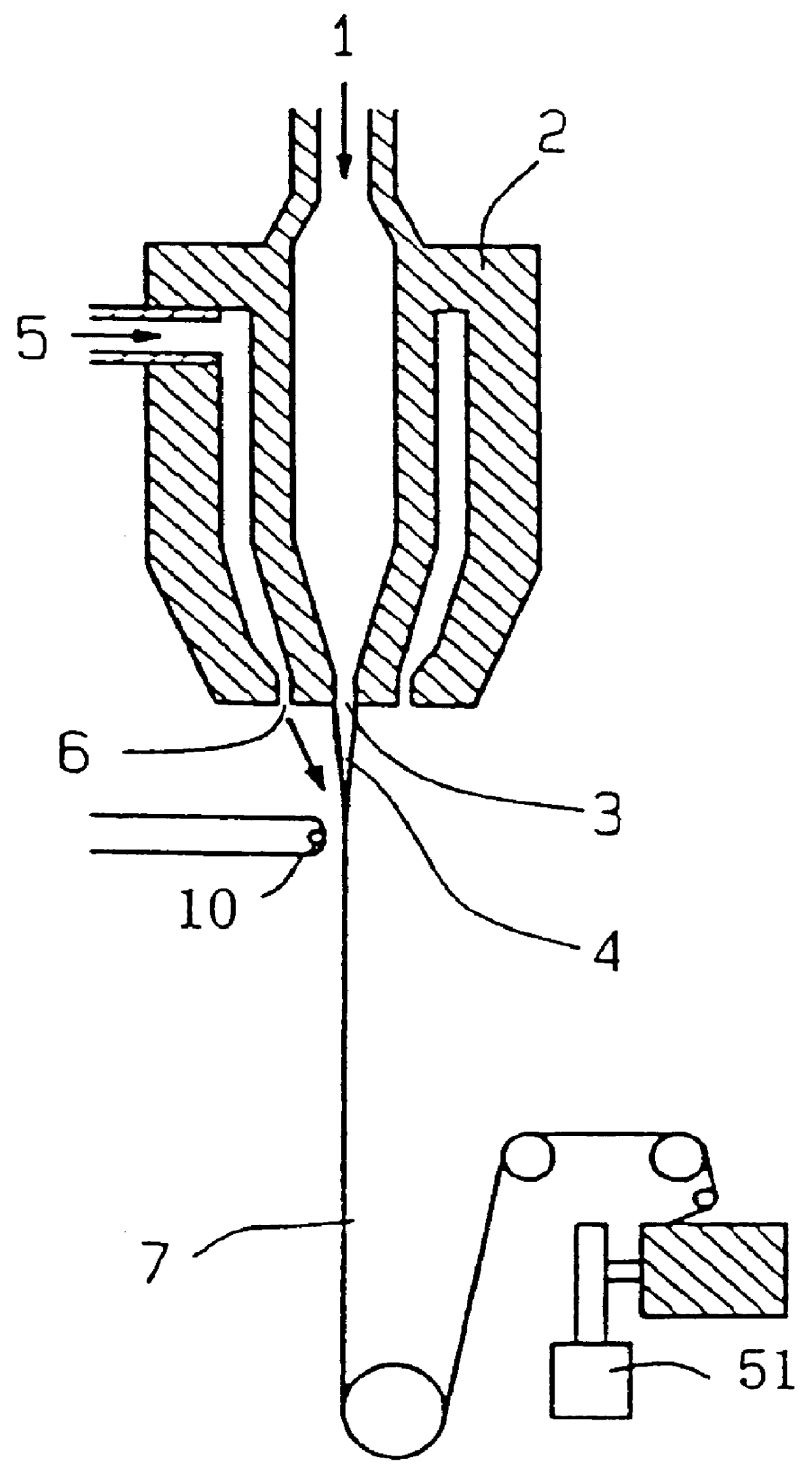

Process for producing filament and filament assembly composed of thermotropic liquid crystal polymer

InactiveUS6051175ALow costHigh strengthAdditive manufacturing apparatusMonocomponent synthetic polymer artificial filamentPolymer sciencePolymer

PCT No. PCT / JP94 / 01454 Sec. 371 Date May 3, 1995 Sec. 102(e) Date May 3, 1995 PCT Filed Sep. 2, 1994 PCT Pub. No. WO95 / 06765 PCT Pub. Date Mar. 9, 1995A process for producing a filament assembly composed of a thermotropic liquid crystal polymer, includes the step of melt extruding a thermotropic liquid crystal polymer through an orifice nozzle into a high-speed fluid to thereby hold filaments spun right under the spinning nozzle at a high temperature, so that the filaments are taken up at a high draft ratio by the frictional force of the high-speed fluid.

Owner:POLYMER PROCESSING RES INST

High-temperature glaze coating, preparation method thereof, binder and using method of coating

The invention discloses a high-temperature glaze coating, a preparation method thereof, a binder and a using method of the coating, and aims at solving the problems of poor high-temperature resistance, low emissivity and absorptivity in a high-temperature zone, instability, and easiness of attenuation of the existing far-infrared energy-saving coating. The high-temperature glaze coating has the characteristics of good radiation heat transfer effect, high external blackness (the emissivity is greater than 0.95) and the like, and has the advantages of stable emissivity and absorptivity, non-attenuation performance and long service life in a long-term use process. Meanwhile, the coating can be tightly combined with a basal body by matching with the binder disclosed by the invention; the adhesive force is increased; a glazed ceramic polymer can be formed on the basal body after high-temperature sintering; the high-temperature glaze coating has the advantages of hardness, abrasive resistance, and long service life, and does not fall off; and the coating disclosed by the invention can also evenly coat the surface which cannot be covered by general coatings.

Owner:四川科达节能技术有限公司

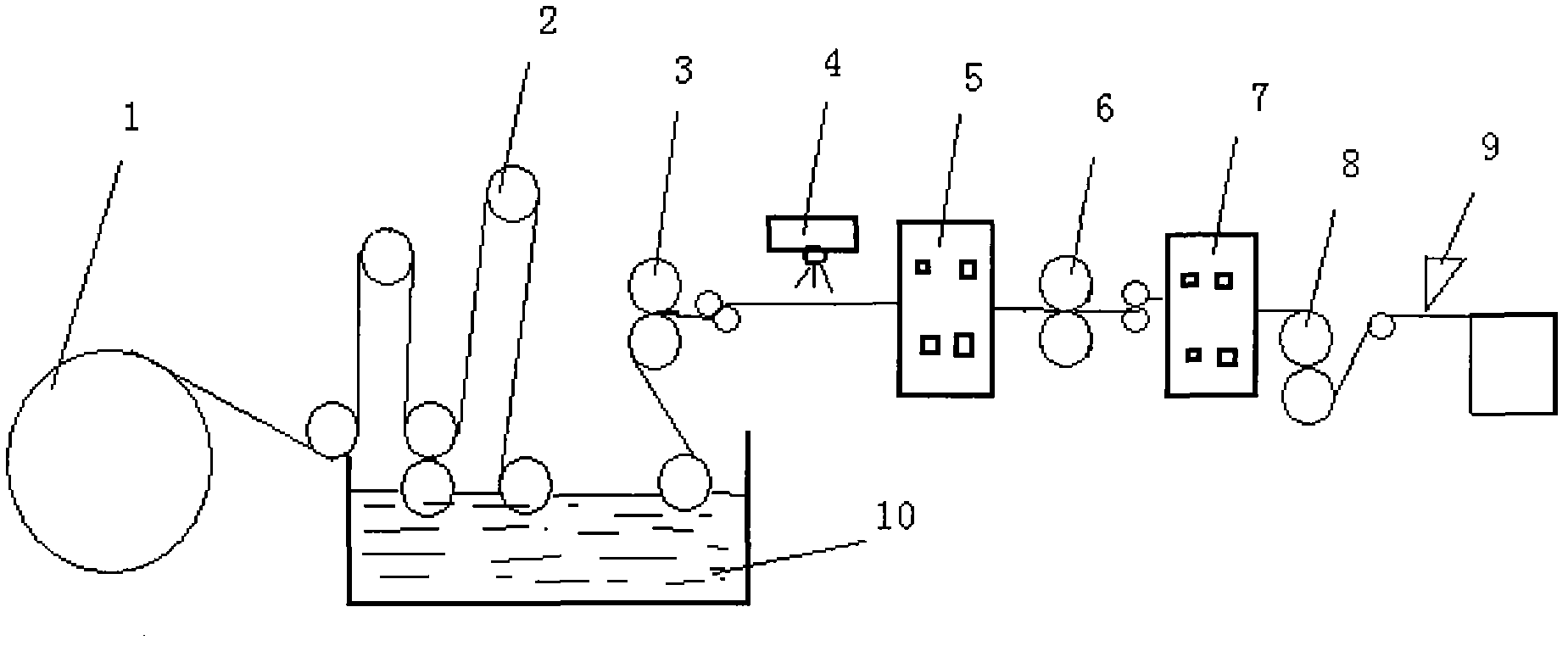

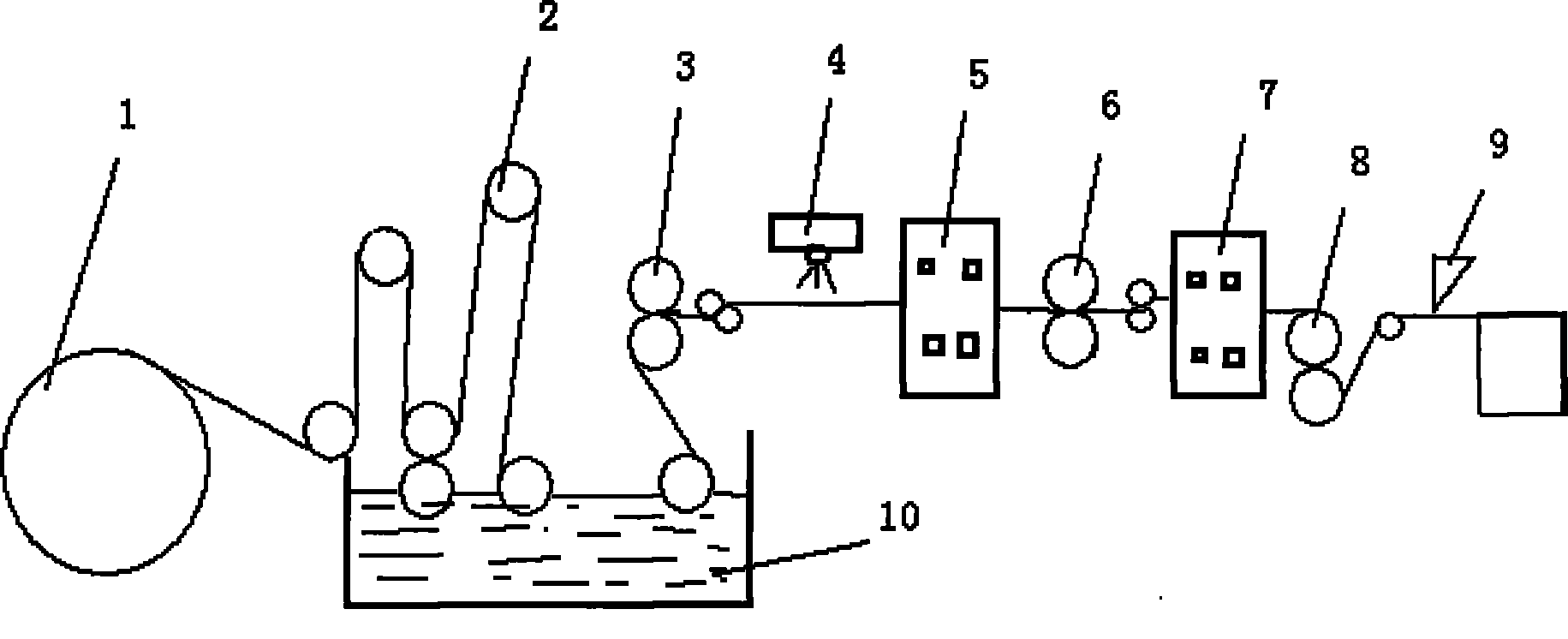

Method for manufacturing surface wear-resisting impregnated paper of laminate floor by dry-spraying Al2O3

ActiveCN102086616AImprove wettabilityImprove the wrapping effectNon-fibrous pulp additionPaper coatingRolling paperMelamine formaldehyde

The invention relates to a method for manufacturing surface wear-resisting impregnated paper of a laminate floor by dry-spraying Al2O3. The method comprises the following steps: impregnating pure wood pulp roll paper with a melamine-formaldehyde (MF) resin liquid; uniformly spraying the Al2O3 on the surface of the impregnated paper by utilizing a dry sprayer; allowing the impregnated and sprayed paper to enter a first oven for drying at the temperature of 100-150 DEG C; roll-coating 300-500% (relative to the weight of the paper) of the MF resin liquid on the paper surface after preliminary drying; and allowing the roll-coated paper to enter a second oven for drying at the temperature of 100-150 DEG C, controlling the whole-course running speed of the paper at 10-12m / minute, cooling, adjusting the temperature of the oven and machine speed so as to reach 6.0-7.5% of volatile matters and 40-60% of pre-curing degree, cutting and packaging. By means of the method, the defects of the prior art are overcome, and the spray quantity of the Al2O3 can be adjusted by controlling the dry sprayer so as to obtain the surface wear-resisting impregnated paper with reliable quality according to different wear-resisting requirements; and the method has the advantages of reasonable process and obvious effect, and is simple in operation, thus effectively improving the product quality.

Owner:天津市瑞鸿装饰材料销售有限公司

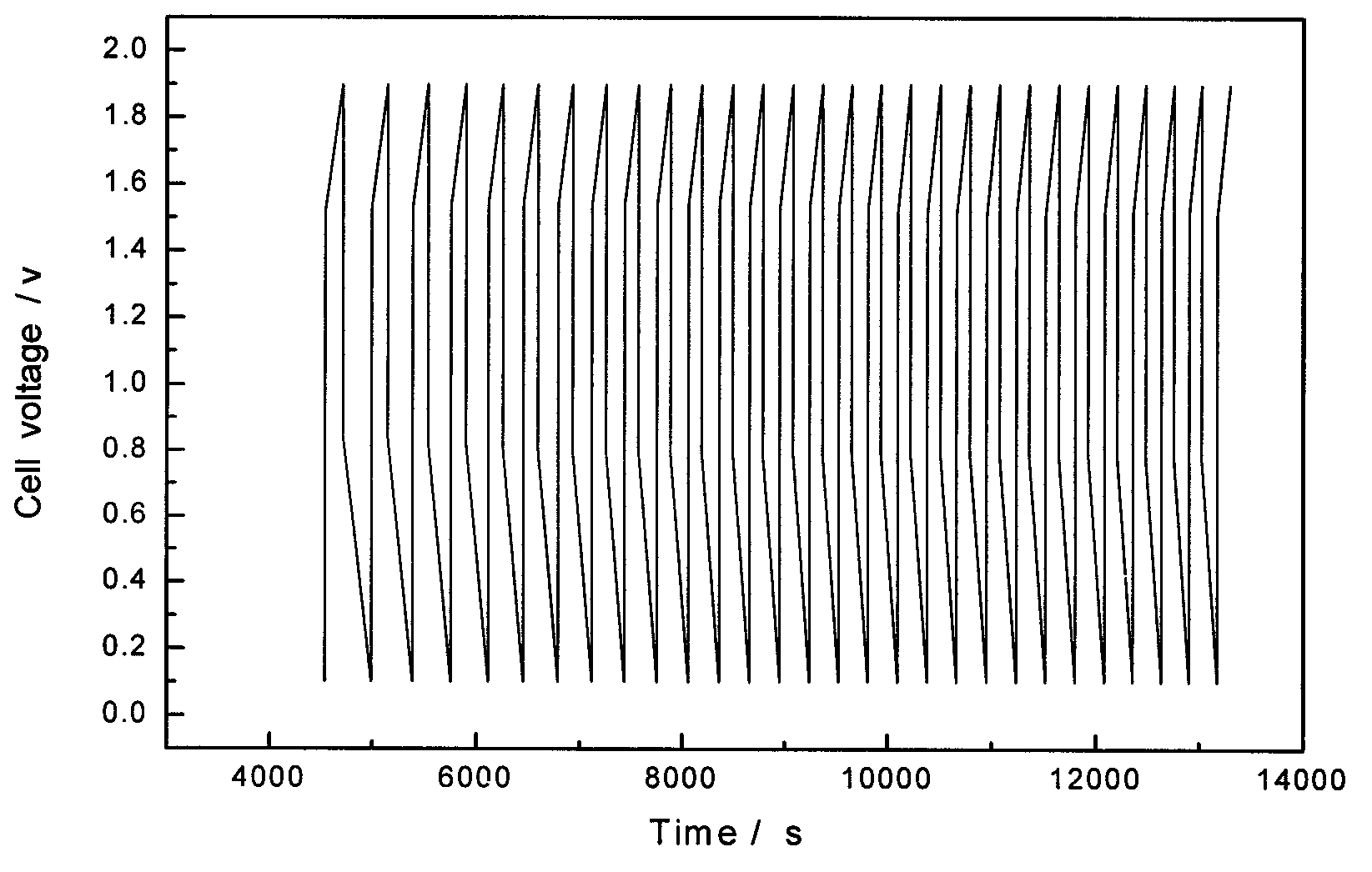

Fabric morphological polymer battery and preparation method thereof

InactiveCN103066314AUniform adhesionIncrease loadFinal product manufactureSecondary cells manufactureCapacitanceCharge rate

The invention relates to a fabric morphological polymer battery and a preparation method thereof, and belongs to the technical field of batteries. The fabric morphological polymer battery takes non-conductive fabric as flexibility base materials, conductive macromolecule is polymerized and deposited on the base materials, conductive fabric is obtained, and then the conductive fabric is used for machining two electrodes of a battery and is assembled to the battery with an electrolyte layer. Condition of the preparation method is easy to control, and the preparation method is simple in operation, low in raw material cost, small in energy consumption and suitable for large-scale industrialization production. The prepared fabric morphological polymer battery is light in weight, simple in structure, good in flexibility, pollution-free, high in safety, high in battery specific capacitance, good in circulation stability and rapid in charging rate. The fabric morphological polymer battery can be applied to certain flexibility electronic products and wearable electronic clothes.

Owner:WUHAN TEXTILE UNIV

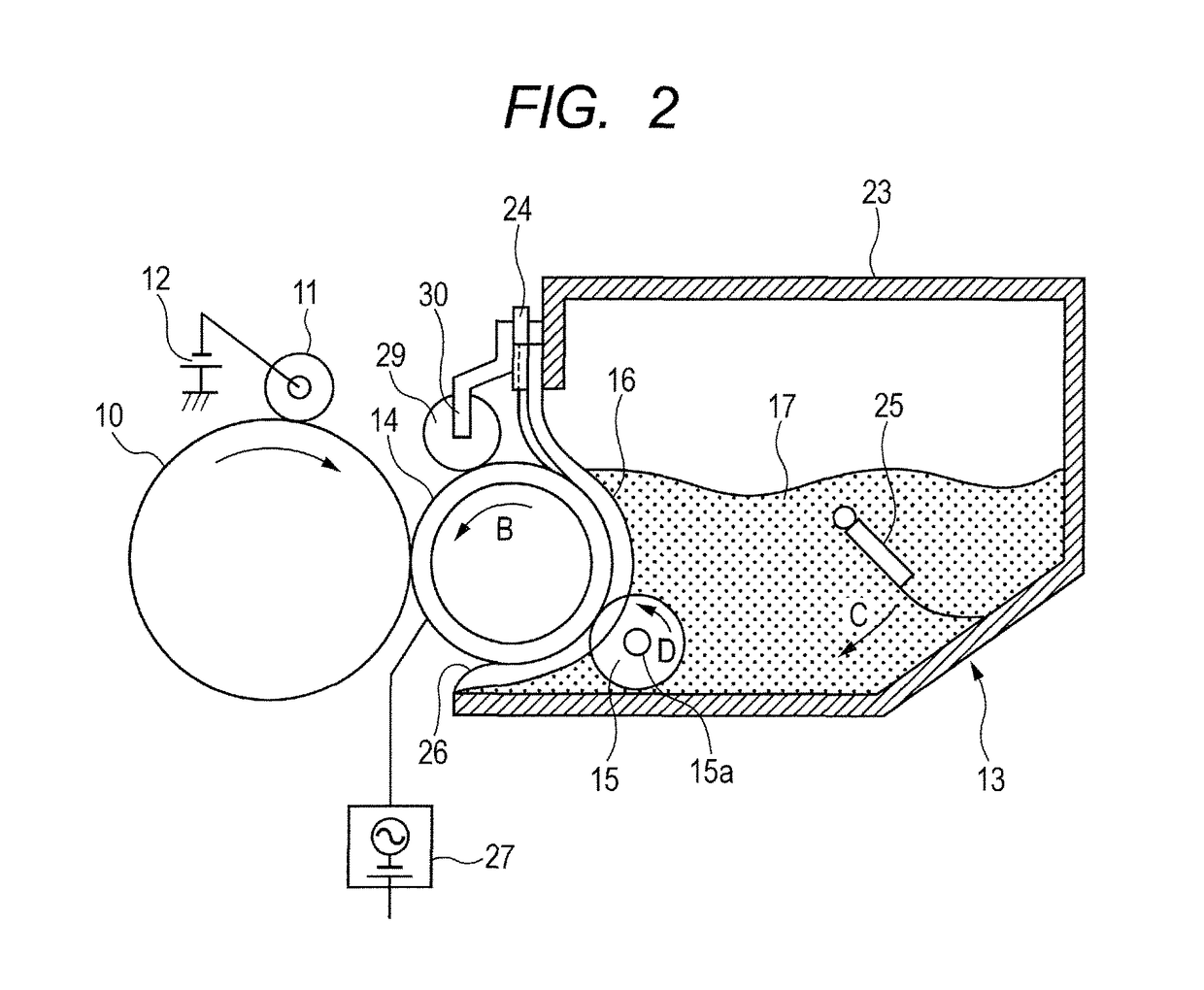

Toner and method for producing toner

The present invention is directed to providing a toner having no environmental difference in charging performance, and having high stability of images after output of a large number of copies under environments at high temperature and high humidity in a higher-speed one-component developing system, and a method for producing the toner, and the toner comprises a toner particle including a toner base particle containing a binder resin, a colorant and a releasing agent; and a resin particle adhering to the surface of the toner base particle, wherein the resin particle contains a resin A, and the resin A has an ionic functional group and an acid dissociation constant pKa of 7.0 or more and 9.0 or less, and the resin A has a monovalent group a represented by Formula (1):

Owner:CANON KK

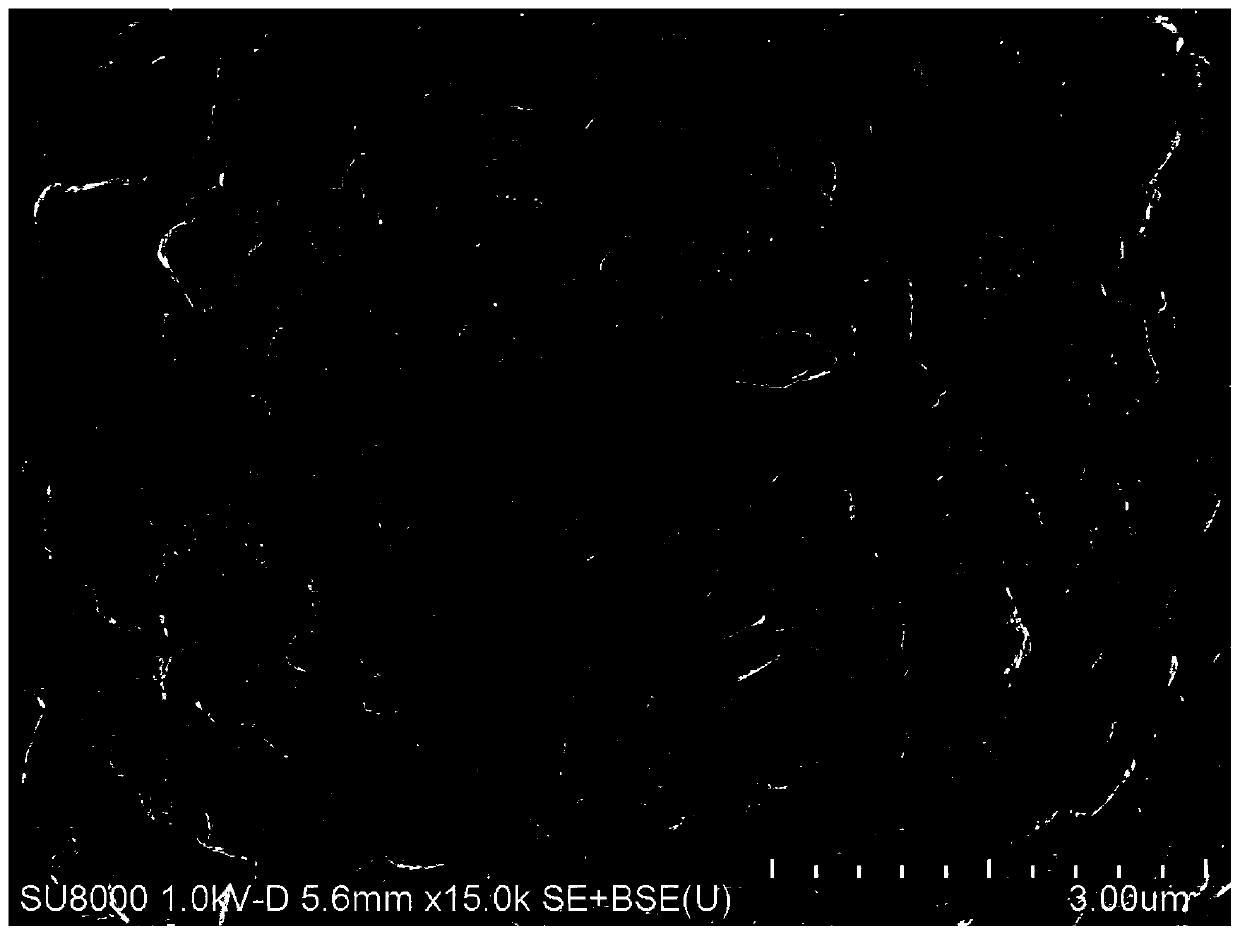

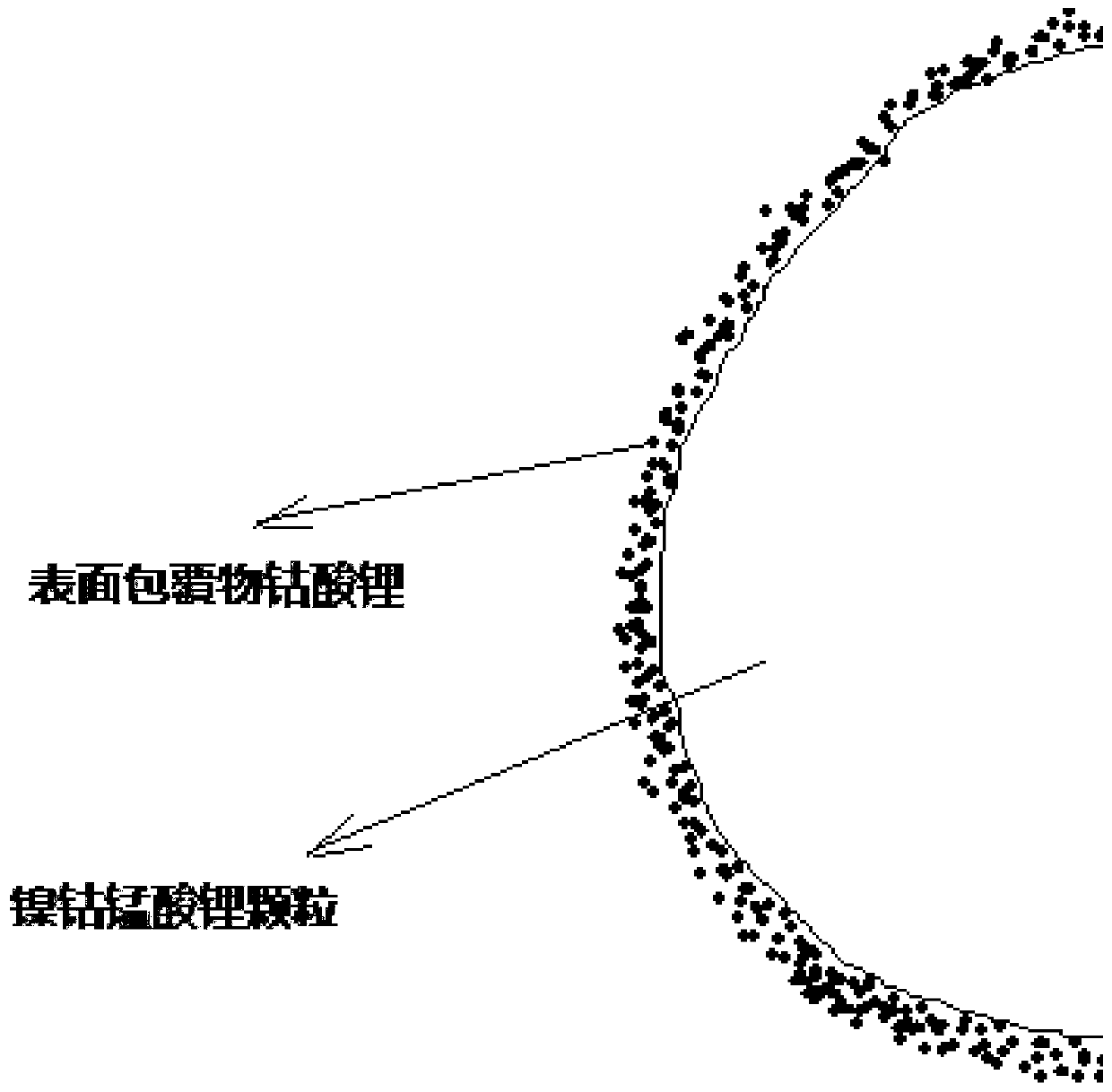

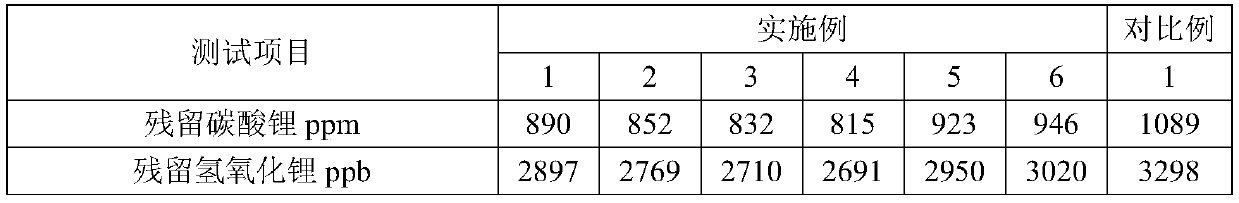

Lithium cobaltate-coated high-nickel ternary positive electrode material and preparation method thereof

InactiveCN110247031AAvoid direct contact with airReduce surface residual alkaliCell electrodesLithium carbonateChemistry

The invention relates to a lithium cobaltate-coated high-nickel ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps of: mixing a high-nickel ternary precursor, nano cobaltosic oxide, and a lithium source, and calcining the mixture at 750-820 degrees centigrade to obtain the lithium cobaltate-coated high-nickel ternary positive electrode material, wherein the mass ratio of the nano cobaltosic oxide to the high-nickel ternary precursor is 0.05 to 0.2:1. The surface of the high-nickel ternary positive electrode material is uniformly coated with a layer of lithium cobaltate material, thereby protecting the reticular structure of the high-nickel ternary positive electrode material, reducing the nickel-lithium ion mixing, improving the electronic conduction, the cycle performance and the rate performance of the material, additionally avoiding direct contact between the surface of high-nickel ternary positive electrode material and the air, reducing the water absorption of the material and the formation of surface lithium hydroxide and lithium carbonate, reducing residual alkali on the surface of the material, and optimizing the processing properties of the material.

Owner:RUYUAN DONGYANGGUANG MAGNETIC MATERIAL

Brazing clad material used for metal surface

ActiveCN104907725AWon't fall offReduce stressWelding/cutting media/materialsSoldering mediaEpoxyAtomic diffusion

The invention discloses a brazing clad material used for a metal surface, wherein the clad material is powder particles that is constituted of the follow components with weight percent; Ni tungsten carbide powder ( WC-10 Ni) is within 48 percent to 62 percent; Ni powder is within 7 percent to 11 percent; NiCrBSi alloyed powder (AWS BNi-2) is within 27 percent to 45 percent; binder occupies the rest percentage; the size of the Ni tungsten carbide powder particle is within 5 to 15 micro-meter; the size of the Ni powder particle is within 30 to 45 micro-meter; the NiCrBSi alloyed powder particle is within 25 to 35 micro-meter; and the degree of the metal bonding phase between Ni tungsten carbide powder particles is less or equal to 0.3 micro-meter. According to the invention, under the effect of the organic silicon resin binding material and the epoxy resin binding material, the component of the brazing material is uniform and has specific binding property; and the brazing clad material won't be fell off, thus facilitating to the atomic diffusion and the interface reaction during the high temperature connection process and improving the wetting ability of the clad material and the performance of the metal surface.

Owner:无锡腾达海川新材料有限公司

Preparation method for antibacterial and stinking-proof fabric

This invention relates to a method for preparing an antibiotic stinking-proof textile, which comprises the following steps: 1) preparing A finishing liquid including AgNO3, penetrant and dispersing preservative; 2) immersing the textile in the A liquid by pad mangle; 3) preparing B finishing liquid including reducer and dye leveler; 4) immersing the textile in the B liquid by the pad mangle and reacting to generate the nanometer silver particles; 5) cleaning the finishing liquid not reacted; 6) drying and shaping. The penetration, dispersing protection, reduction and equalizing technology are all proceeding in the liquid, by which the compounded nanometer silver particles can be absorbed and penetrated in the surface and gap of the textile evenly.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Method for producing liquid-fumigated duck tongue snack food

The invention relates to the technical field of meat product deep-processing, and in particular relates to a method for producing a liquid-fumigated duck tongue snack food. The method comprises the following steps of: defreezing duck tongues, pre-treating the refrozen duck tongues, performing kneading pickling and static pickling, paving, baking, cooling, performing vacuum package and performing multi-stage heating and sterilizing. The method has the characteristics that a liquid fumigating agent and a pickling seasoning liquid are mixed for pickling the duck tongues; and then the combined control is realized by using a baking technology and a multi-stage heating and sterilizing process, so that the liquid-fumigated duck tongue snack food is high in chewing property and high in duck tongue yield. Compared with the prior art, for method disclosed by the invention, the produced liquid-fumigated duck tongue snack food has the advantages that the nutrient component is low in loss, pickling materials are uniformly penetrated, a unique fumigating flavor is realized, the food shelf life is long and the like.

Owner:TENGQIAO POULTRY

Process for the production of variously painted and/or decorated artefacts by means of the technique of transfer from a sublimable color support

InactiveUS7077926B2Reduce in quantityImprove reliabilityLamination ancillary operationsDecorative surface effectsPlastic materialsPolyvinyl alcohol

Process for the production of variously decorated artefacts, comprising the steps of: preliminary preparation of the surfaces of the artefact, possible application of preliminary painting cycles or other surface treatments; covering or tight-wrapping up of the artefact with a transfer support bearing the decorations desired, realized from gas-tight thermoformable plastic material such as polyvinyl alcohol; creation of a vacuum between said transfer support and the artefact covered by the same, so that the support adheres to the shape of the artefact; and heating for the transfer of the decoration and the polymerization of the colors.

Owner:DECORAL SYST USA CORP

Preparation method and application of silicon-carbon composite material

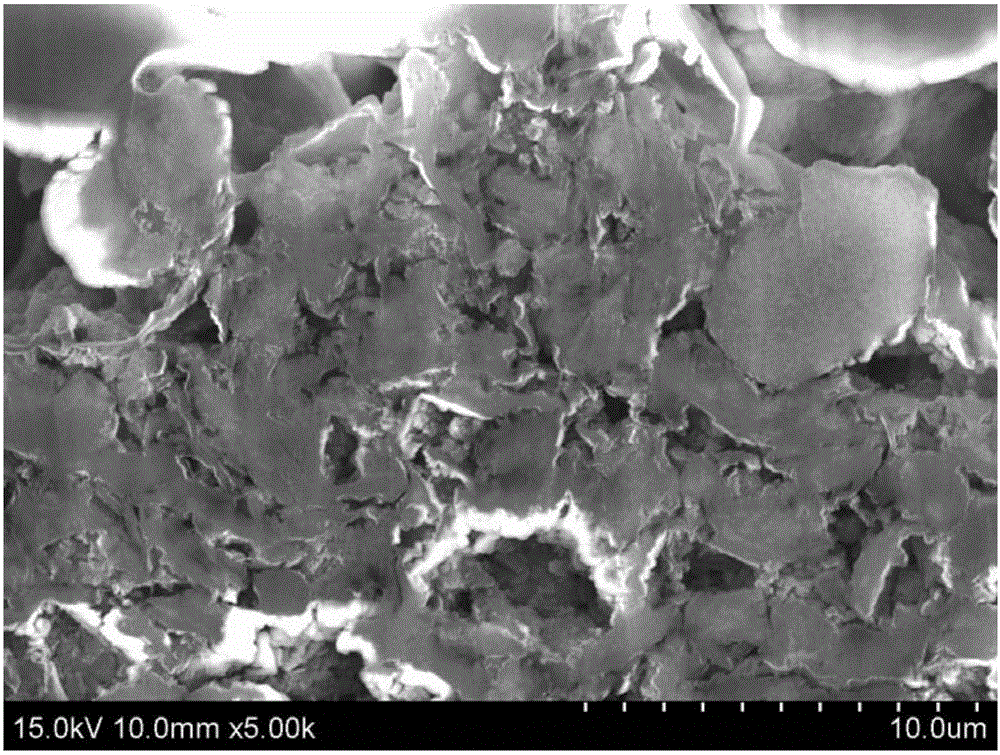

InactiveCN106549149AImprove coating efficiencyUniform adhesionCell electrodesSecondary cellsCarbon coatingCarbon composites

The invention discloses a preparation method and application of a silicon-carbon composite material, belonging to the technical field of preparation of composite materials. The preparation method comprises the following steps of: (1), grinding silicon-based alloy into powder, and performing acid pickling to obtain a porous silicon material; and (2), mixing the porous silicon material with an organic polymer carbon source and a solvent, performing ball-milling to obtain a homogenate type mixture, and performing thermal treatment after drying so as to obtain the silicon-carbon composite material. According to the preparation method and application disclosed by the invention, when carbon coating is carried out, the organic polymer carbon source (such as polyvinylidene fluoride) having high viscosity is mixed with a little solvent, so that thick colloid is prepared; then, matched with ball-milling, the organic polymer carbon source is adhered to the surface of porous silicon effectively and uniformly; the carbon coating efficiency is relatively high; in addition, the use amount of the organic solvent is low; energy consumed by solvent evaporation is saved; therefore, the production cost is reduced; the preparation process is simple, and suitable for large-scale production; the silicon-carbon proportion in the prepared silicon-carbon composite material is reasonable; the volume strain capacity is better; and the electrochemical performance of a lithium ion battery is improved.

Owner:TIANNENG SAFT ENERGY JOINT CO

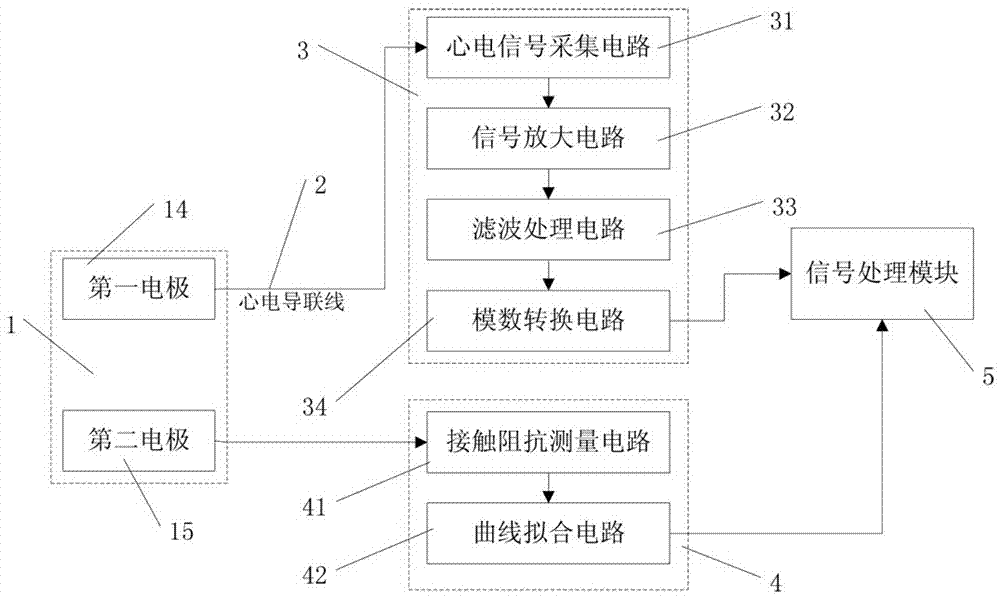

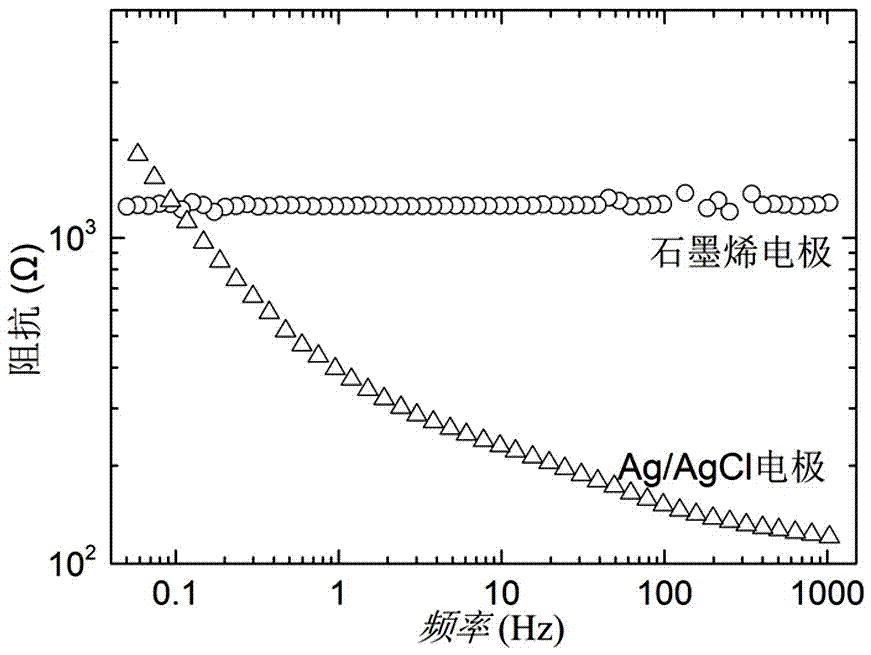

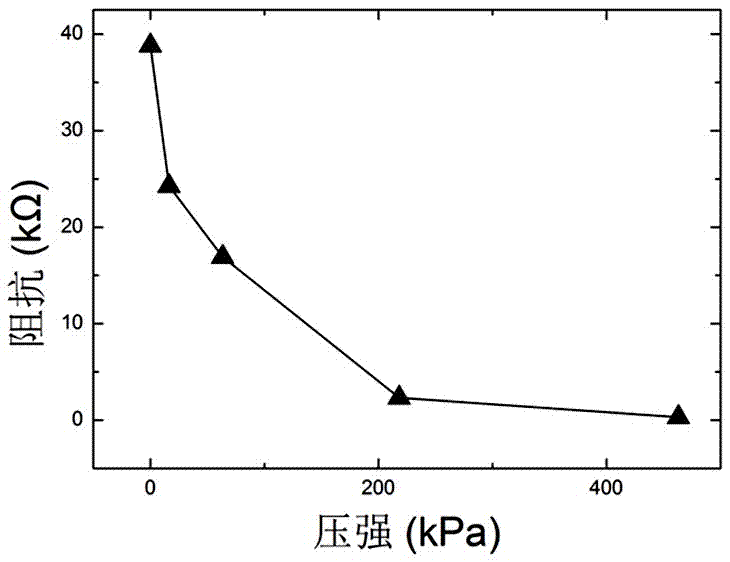

Anti-interference electrocardiograph detection system, detection method, special flexible graphene electrode, and preparation method and application of special flexible graphene electrode

ActiveCN107049299AGuaranteed real-timeGuaranteed accuracyDiagnostic signal processingSensorsEcg signalGraphene electrode

The invention provides an anti-interference electrocardiograph detection system, a detection method, a special flexible graphene electrode, and a preparation method and the application of the special flexible graphene electrode. The anti-interference electrocardiograph detection system comprises the flexible graphene electrode, an electrocardiosignal acquiring and processing module, an impedance measurement module, an electrocardiographic wire and a signal processing module, can measure an electrocardiosignal and a motion artifact signal, and removes the motion artifact in the electrocardiosignal. The flexible graphene electrode is formed in a way that a graphene material is adhered on a sponge layer through negative pressure deposition to obtain a graphene-sponge conductive composite, a fastener is additionally added on the graphene-sponge conductive composite, and the electrocardiographic wire is fixedly connected to the graphene-sponge conductive composite through the fastener. The anti-interference electrocardiograph detection system and the detection method effectively overcome the interference of the motion artifact on the electrocardiosignal, and guarantees the instantaneity, the accuracy and the reliability of the electrocardiographic examination result; the preparation flow of the flexible graphene electrode is simple, the biological compatibility of the flexible graphene electrode is good, the service life of the flexible graphene electrode is long, and the flexible graphene electrode can be used in the anti-interference electrocardiograph detection system.

Owner:HEBEI UNIVERSITY

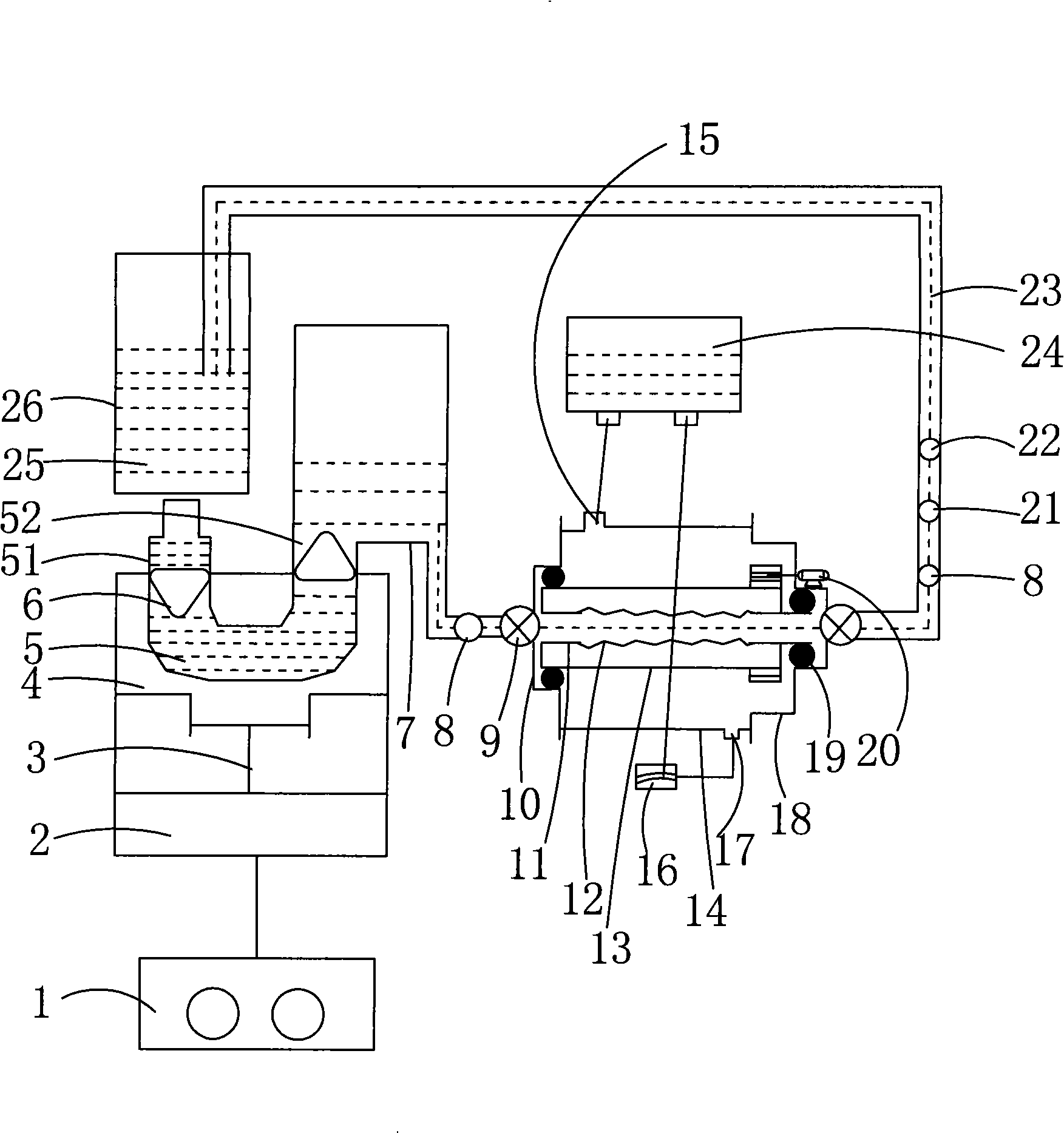

Bioreactor for vascellum tissue engineering

InactiveCN101294131APromote growthRealize internal rotation inoculationBioreactor/fermenter combinationsBiological substance pretreatmentsHuman bodyHemodynamics

The invention discloses a bioreactor in vascular tissue engineering, which comprises a hemodynamics simulating device, a 3D bracket and culture chambers. The hemodynamics simulating device is a pulsating flow control device; the culture chambers are serially connected with each other in the pulsating flow control device and include hermetically matched rotary devices and a sealed cavity; the rotary device includes a rotary rod having the 3D bracket fixed thereon and a drive device for rotating the rotary rod; and the rotary rod is located in the sealed cavity. The bioreactor can provide a pulsating flow simulating environment of human body facilitating growth, proliferation and differentiation of cells by adopting the pulsating flow control device for providing the dynamic effect simulating human heart. In the culture chambers, cells are inoculated in the internally-rotating 3D bracket, and secondary cell inoculation can be further executed to achieve convenient taking and dropping of cells, so that the cells can uniformly adhered on the 3D bracket, thus obviating the contamination of the reactor connected with the 3D bracket, on which the cells are inoculated through rotation.

Owner:NAT INST FOR THE CONTROL OF PHARMA & BIOLOGICAL PROD

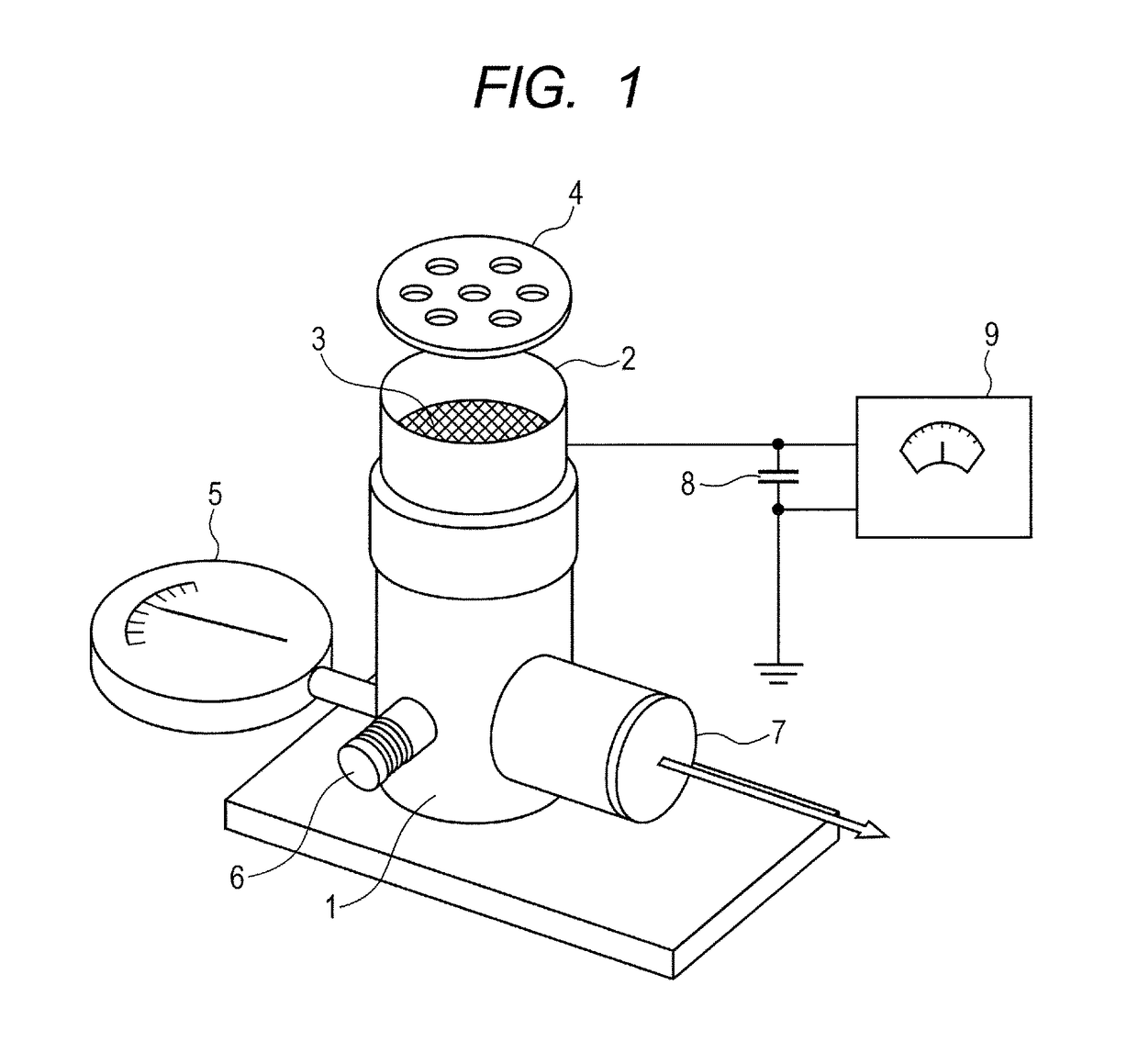

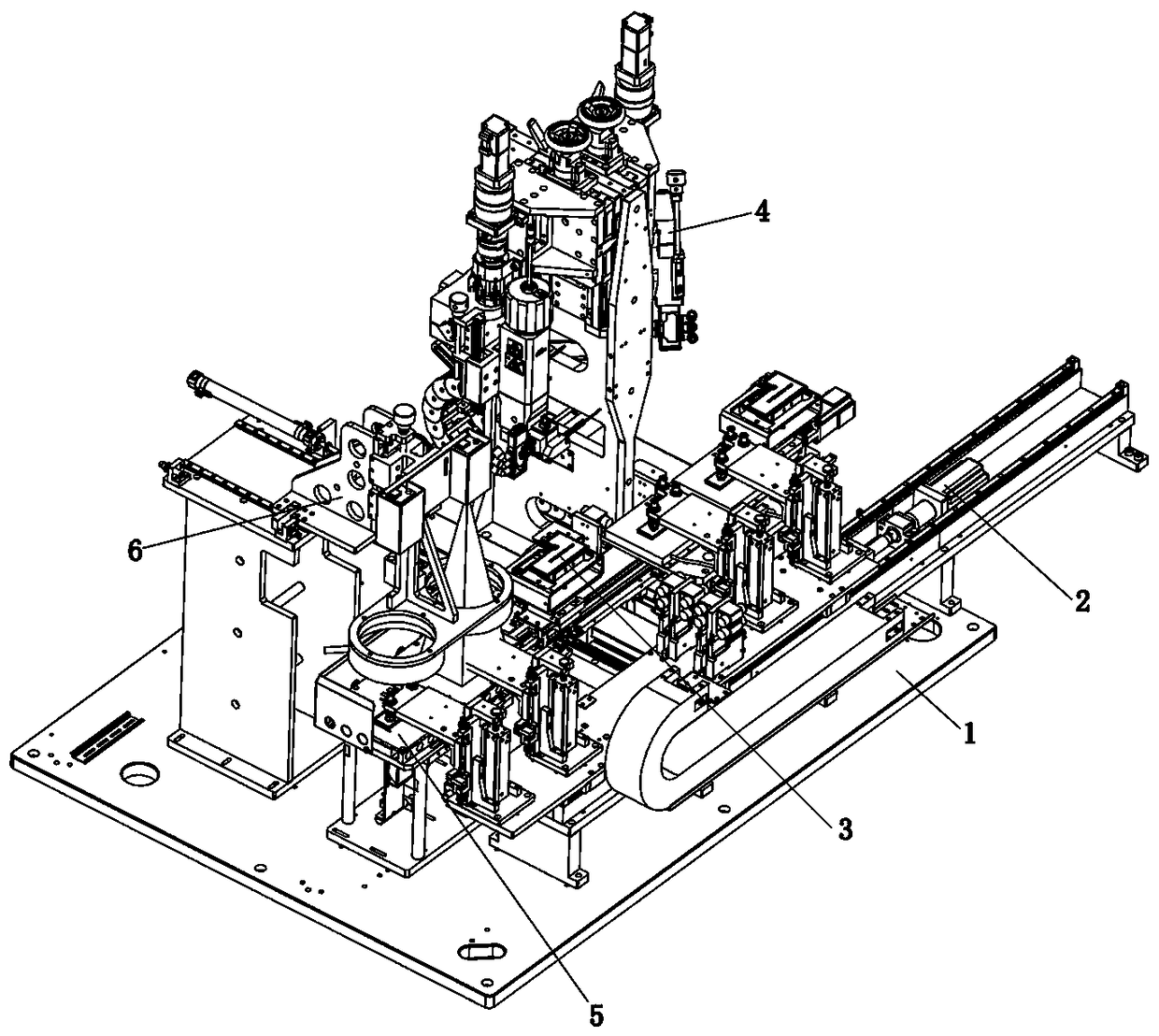

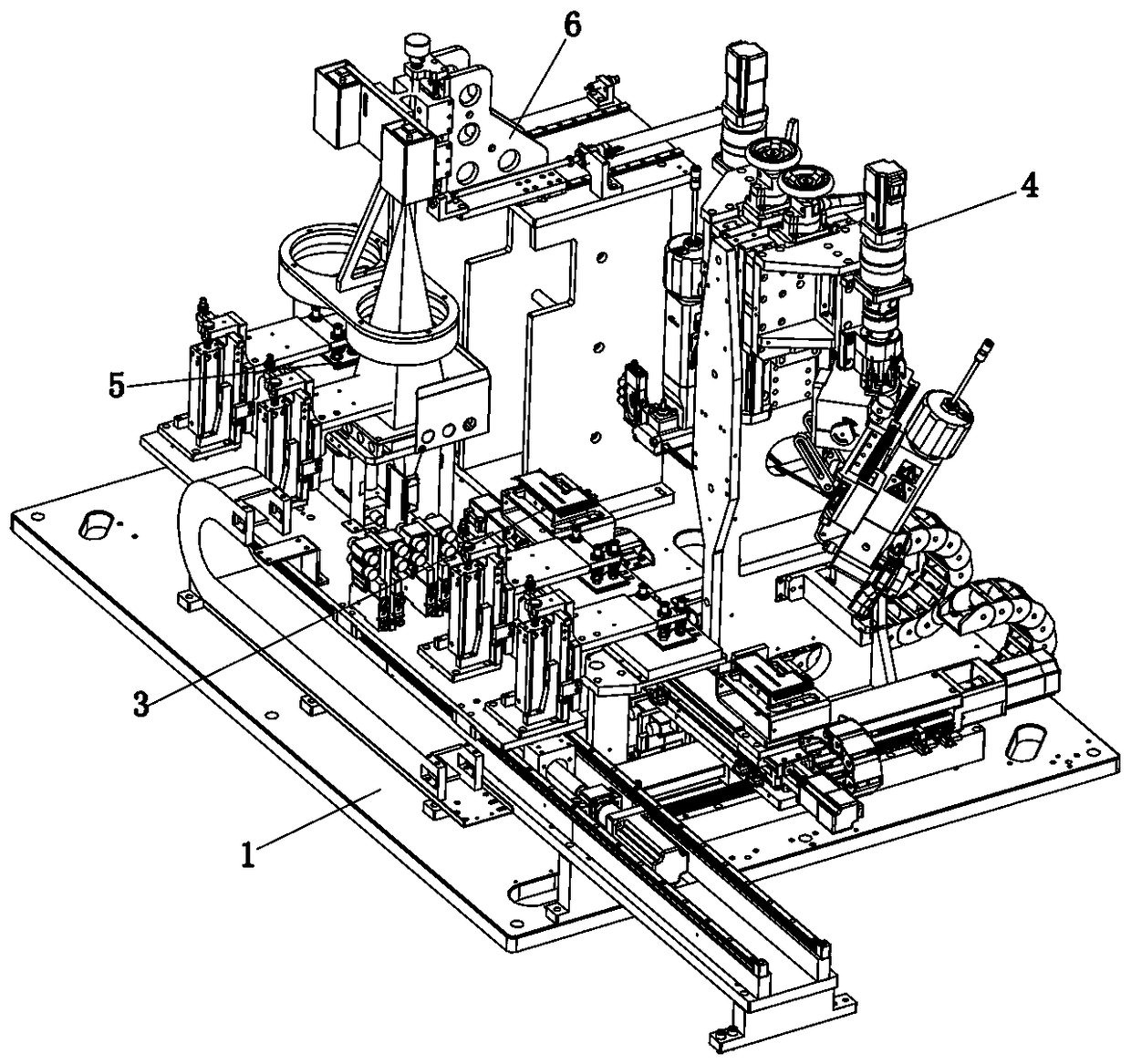

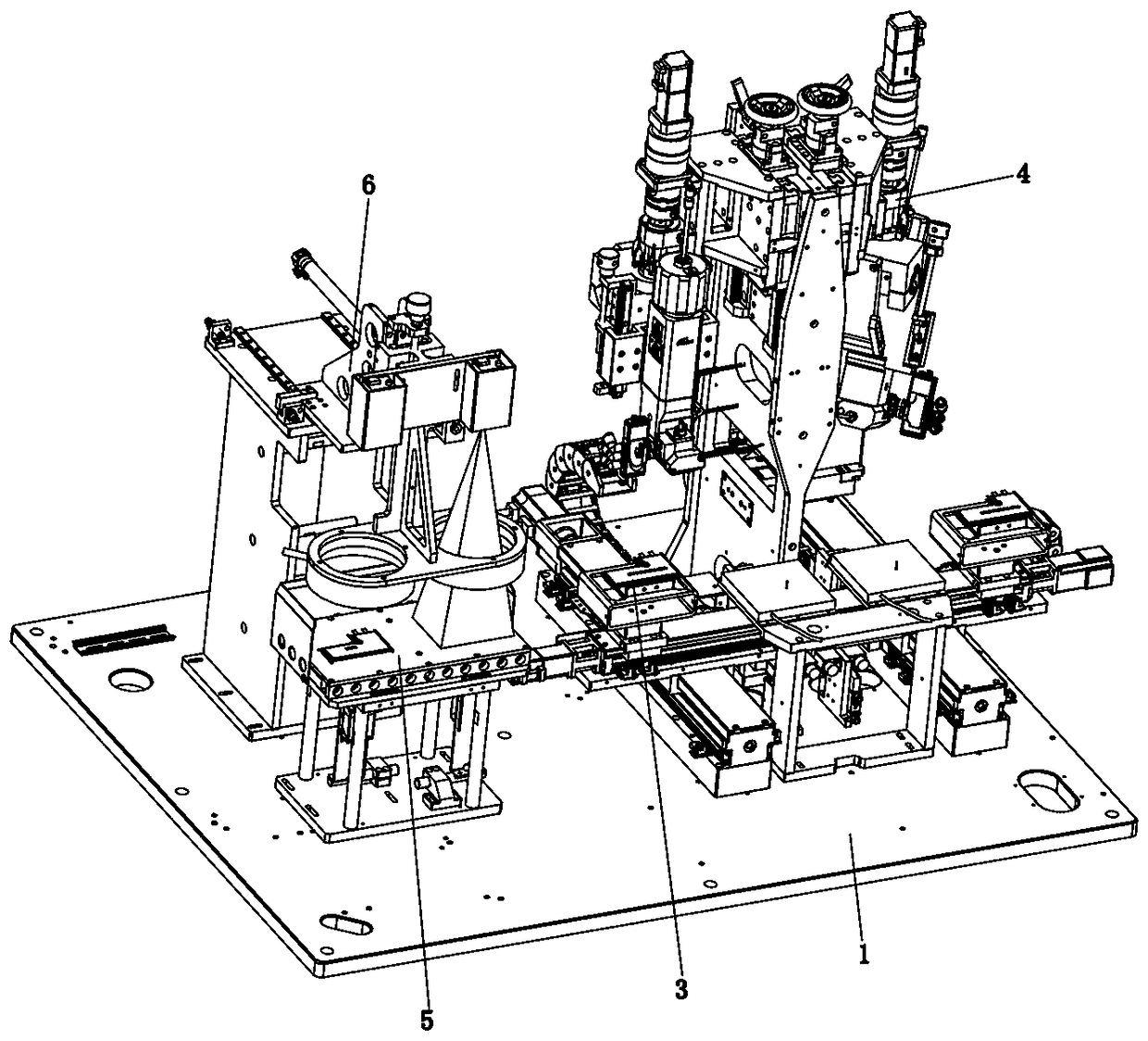

Automatic dispensing and glue point detection device and dispensing and detection technology thereof

PendingCN108465612AAutomatic even adhesionUniform adhesionLiquid surface applicatorsCoatingsLinear motionEngineering

The invention discloses an automatic dispensing and glue point detection device and a dispensing and detection technology of the device. The device comprises a machine table, a transfer mechanism, a dispensing platform, a dispensing mechanism, a detection platform and a CCD mechanism. The transfer mechanism transfers electric cores to be dispensed and dispensed electric cores to the dispensing platform and the detection platform synchronously; a dispensing gun of the dispensing mechanism is aligned to an aluminum plastic film edge on one side of an electric core center line, the aluminum plastic film edge does linear motion relative to the dispensing gun, and the dispensing gun dispenses glue to the aluminum plastic film edge on one side of the electric core center line; the dispensing gunis rotated by 90 degrees to the other side of the electric core center line, and the dispensing gun carries out uniform interval dispensing on the aluminum plastic film edge on the other side; afterdispensing is finished, the CCD mechanisms scans the contour of the aluminum plastic film edge and glue points on the aluminum plastic film edge, and a code scanning assembly of the detection platformscans and records two-dimensional codes at the bottom of the electric cores. Automatic, uniform and precise dispensing is achieved for narrow edge aluminum plastic films, uniform sticking of glue isensured, the dispensing efficiency is improved, and the dispensing and follow-up encapsulation yield is improved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Lead-free silver electrode size and preparation method thereof

InactiveCN101609724AUniform adhesionImprove conductivityConductive materialCable/conductor manufactureSilver electrodeMaterials science

The invention relates to a lead-free silver electrode size and a preparation method thereof. The invention is characterized in that the size comprises the following compositions in portion by weight: 60 to 75 weight portions of ultrafine silver powder, 2 to 10 weight portions of lead-free glass binder, 2 to 5 weight portions of oxide and 10 to 30 weight portions of organic binder. The lead-free silver electrode size can completely replace a conventional leaded glass size; and the lead-free silver electrode size can be fused through sintering at a temperature of 600 DEG C and has good fluidity, can be wetted with a ceramic substrate and shows stable performance and good electric performance.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

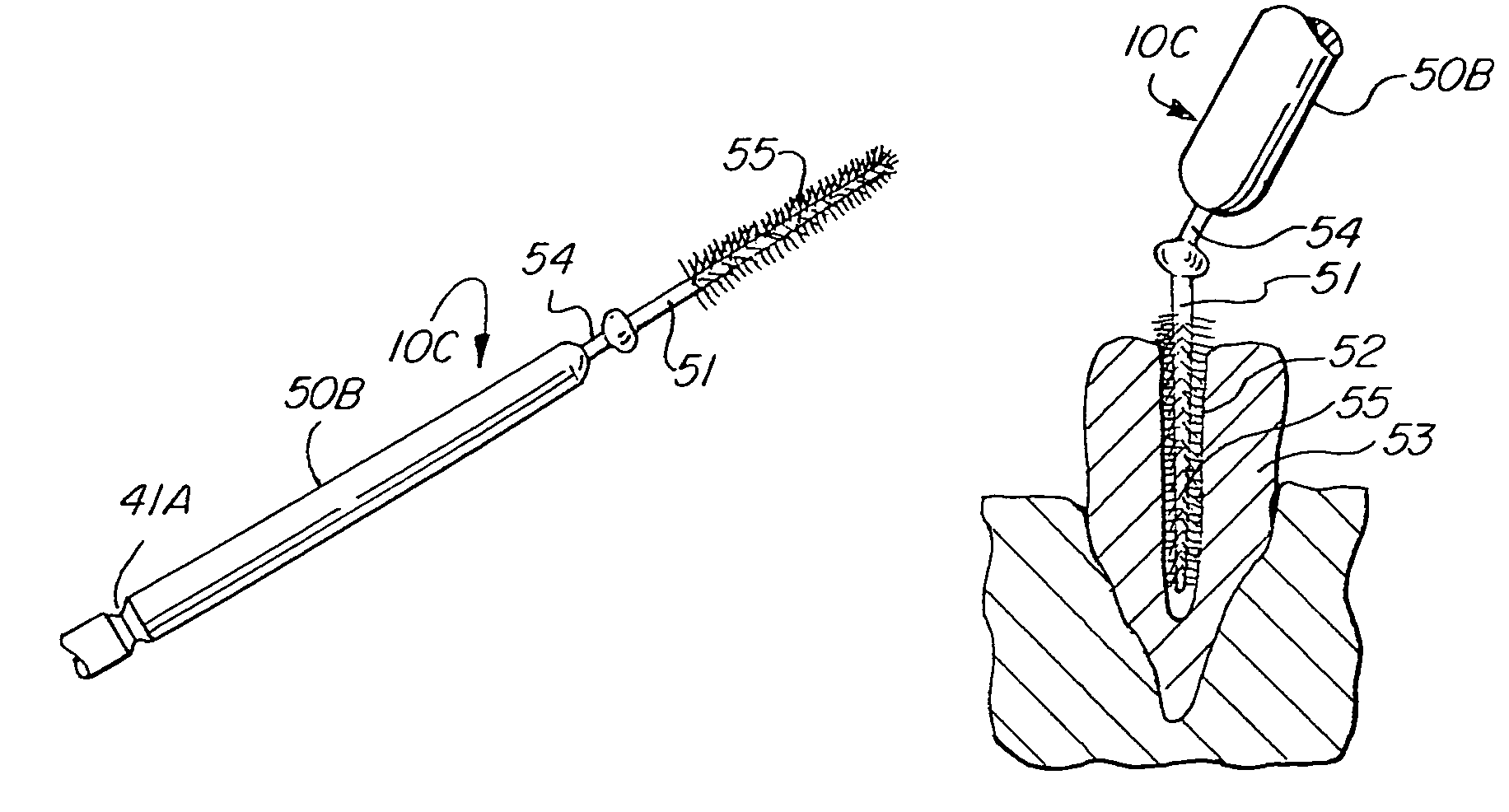

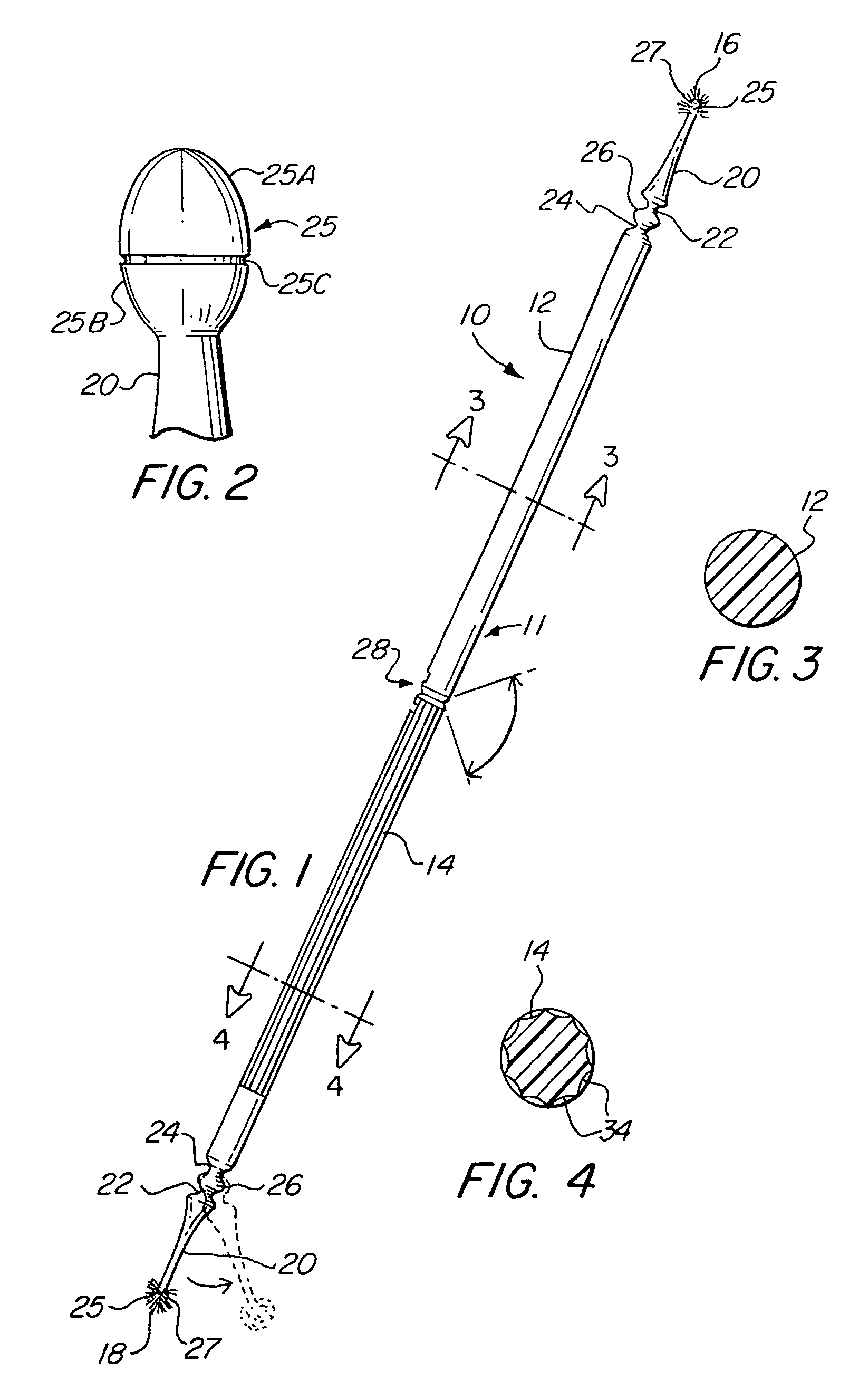

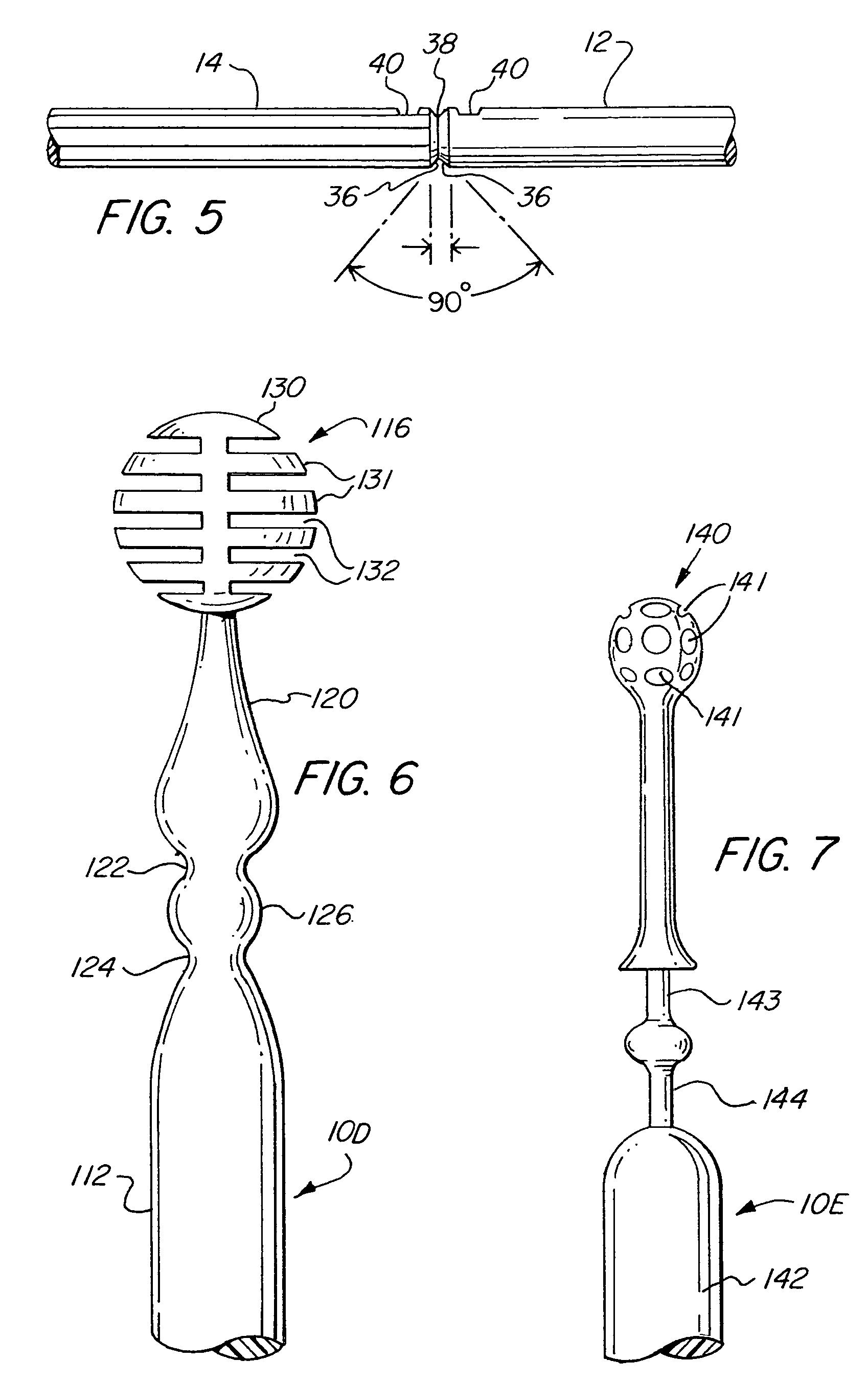

Disposable dental applicator

InactiveUS7882588B2Promotes even distributionIncrease surface areaLiquid surface applicatorsBrush bodiesBiomedical engineeringDental applicator

An applicator principally for use in the dental profession, for the placement of different materials as may be required. The applicator includes an elongated handle having an applicating end portion formed at the opposed ends thereof which may be either of like or unlike construction, i.e. formed as a brush and / or a flocked applicating end portion. The flock may extend from the distal end a predetermined longitudinal distance over an extended portion. Intermediate the opposed applicating end portion, the elongated handle is provided with a circumscribing groove to define a frangible area by which the user, at his or her option, can cleanly sever the applicator handle to form two separate and distinct applicators. The applicator is also provided with a hinging arrangement adjacent the opposed applicating end portions whereby the applicating end portions may be angularly bent relative to the elongated handle at the option of the user.

Owner:CENTRIX

High-strength painted bundling belt and manufacturing method thereof

InactiveCN102978512ANot perishableSpeed up evaporationFlexible elementsLead bismuthChemical composition

The invention discloses a high-strength painted bundling belt. The high-strength painted bundling belt comprises the following chemical components by weight percent: 0.12-0.20% of C, 0.2-0.6% of Si, 1.2-2.0% of Mn, less than or equal to 0.025% of P, less than or equal to 0.02% of S and 0.01-0.05% of Nb. The high-strength painted bundling belt is prepared by the steps of smelting, casting a blank, and then carrying out hot-rolling to form coils; carrying out acid cleaning; carrying out cold rolling; uncoiling, splitting and conducting deburring; carrying out tempering treatment in a lead-bismuth furnace; carrying out water cooling; painting by adopting a dip-coating wiping mode and carrying out sectional baking; and waxing and drying by adopting hot air. The high-strength painted bundling belt disclosed by the invention has the advantages that since a proper amount of Nb is added, the influence on crystal lattice distortion caused by overlarge volume mismatching of enhanced element atoms and Fe atoms is overcome, namely a value sigma b is increased, the overhigh yielding-to-tensile ratio can be restrained, and a steel belt with high strength, good elasticity, excellent mechanical property is produced; and the energy consumption is low, the process is simple, the painted surface is uniform, the anti-rusting performance is good and the process is simple.

Owner:武钢集团有限公司

Preformed liner adhered to a pipe with an adhesive

InactiveUS20070089797A1Eliminate voidsImprove shrinkageUnderground chambersSynthetic resin layered productsParaffin waxAdhesive

The present invention relates to a preformed liner adhered to the surface of a pipe, and in particular, an oil well pipe, by an adhesive. The liner comprises a polymer, preferably a fluoropolymer. The present invention also relates to a process for adhering the preformed liner to the interior surface of a pipe, and in particular by applying adhesive to the preformed liner. The liner is preferably treated prior to applying the adhesive. A suitable treatment includes etching. The pipe is heated to adhere the preformed liner to the interior surface of the pipe, without buckling the liner. The interior surface of the preformed fluoropolymer liner reduces the deposition of at least one of 1) asphaltenes, 2) paraffin wax, and 3) inorganic scale by at least 40% as compared to the interior surface of the oil pipe without the preformed liner being present.

Owner:EI DU PONT DE NEMOURS & CO

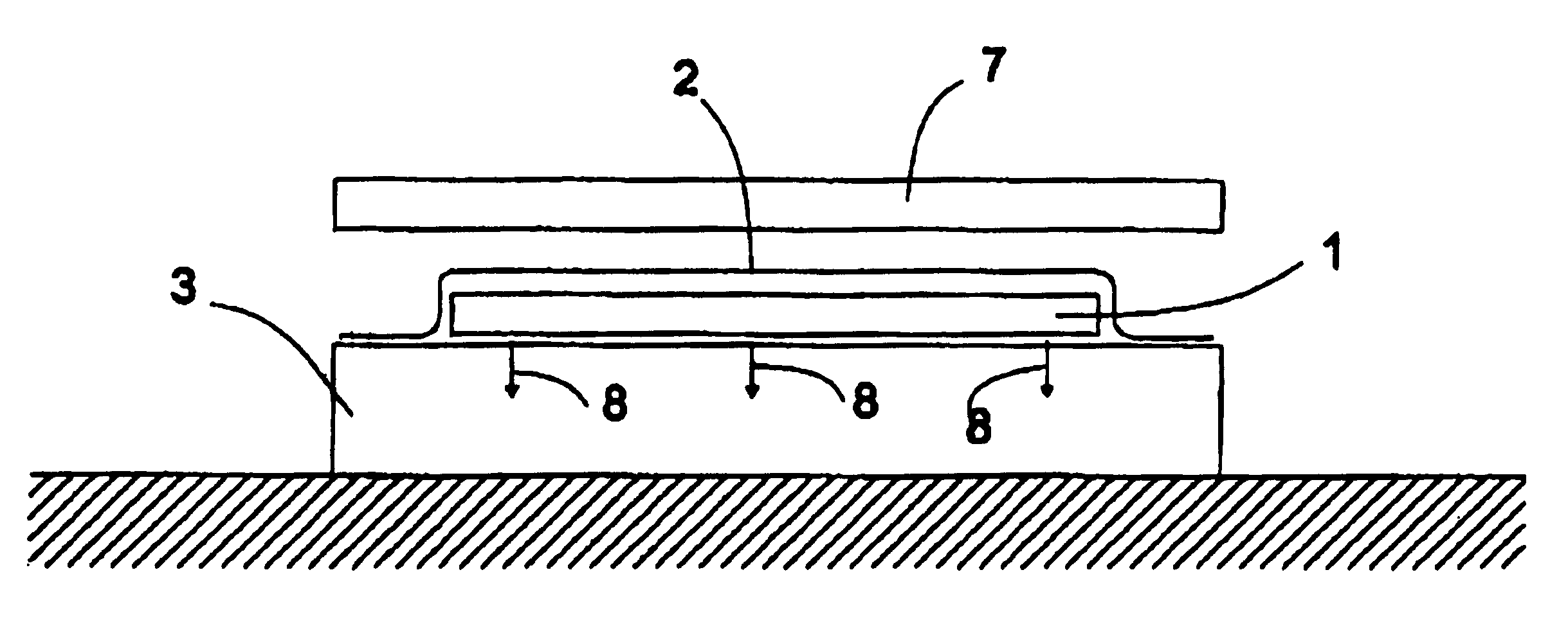

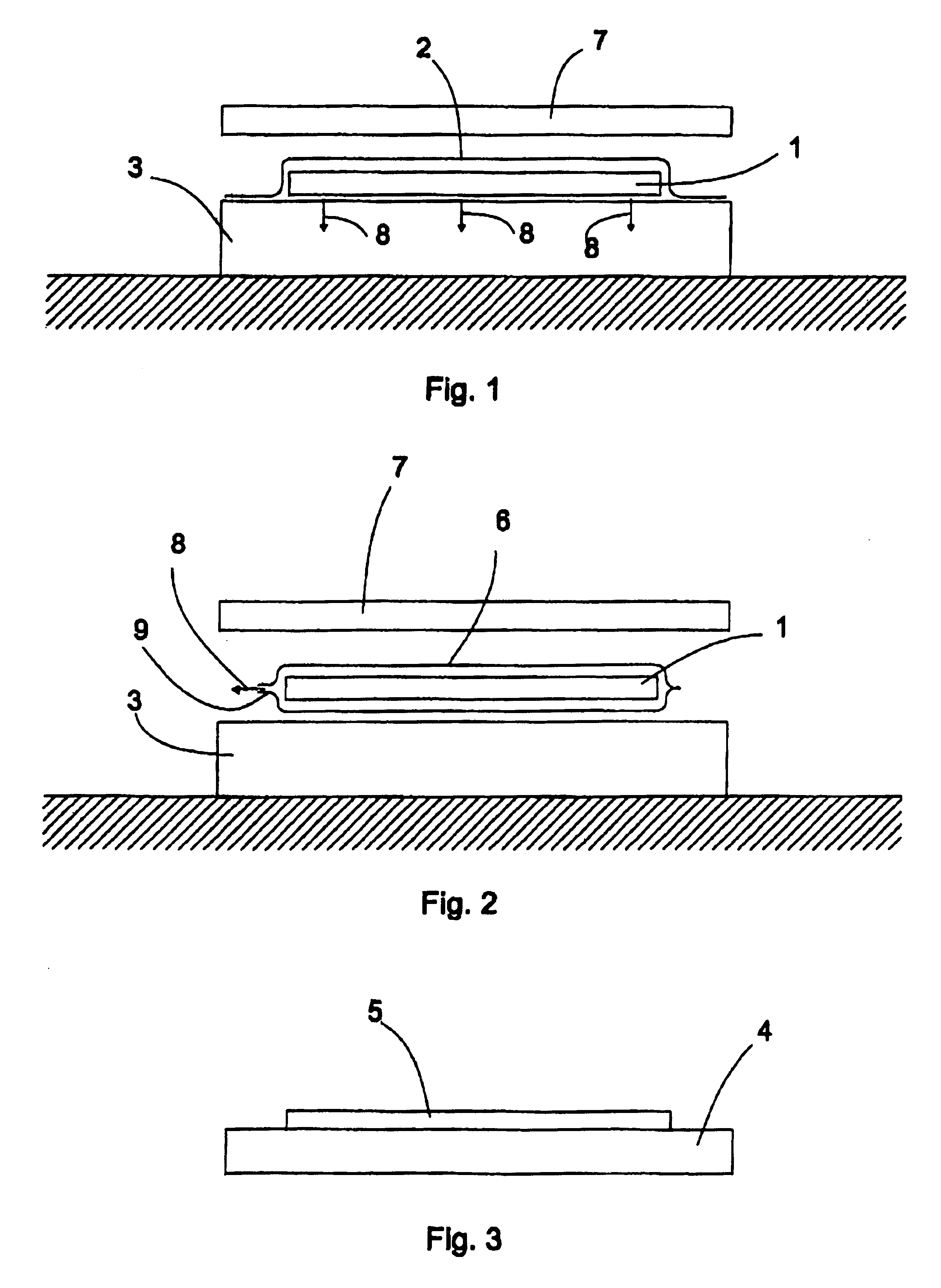

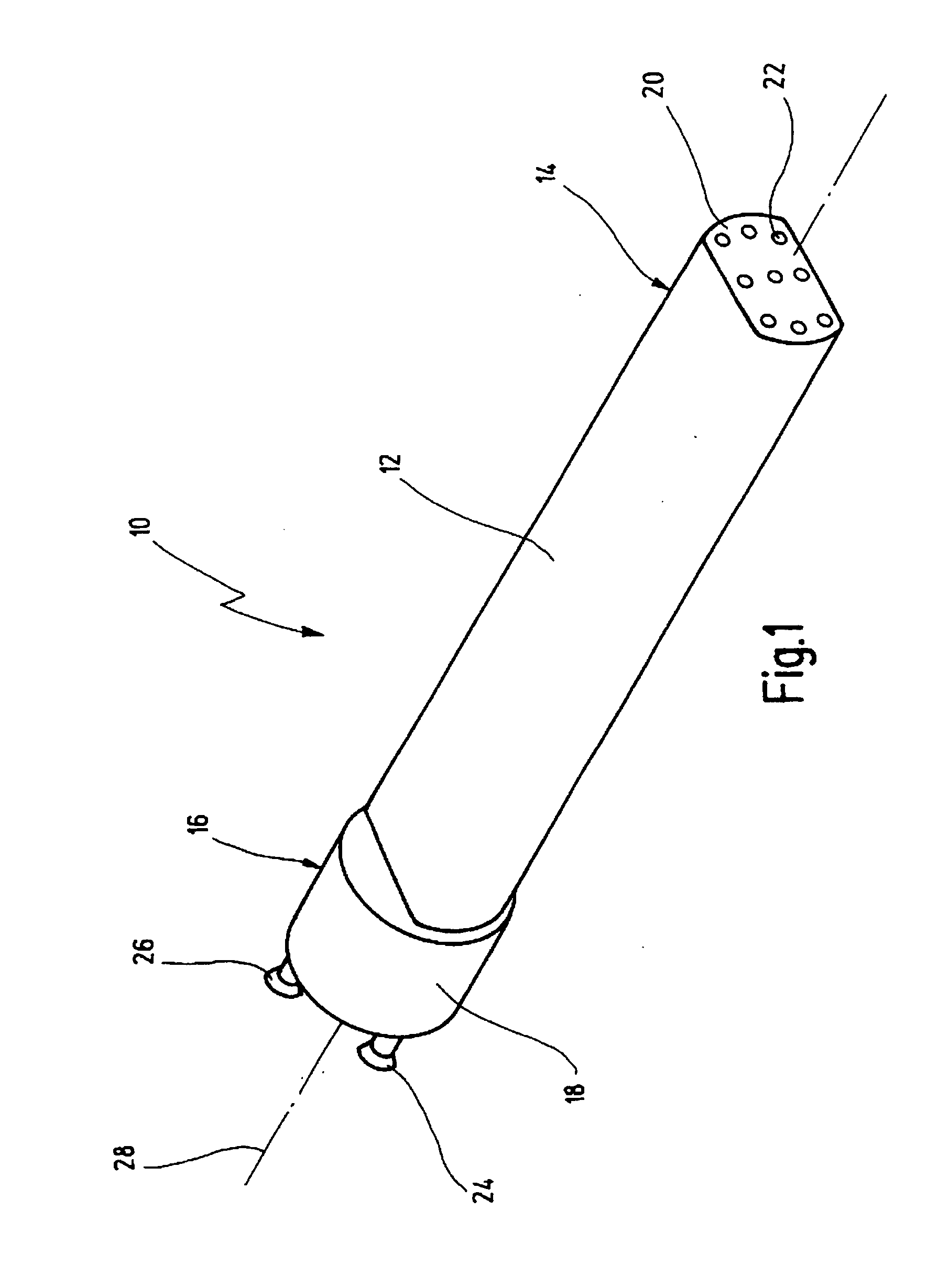

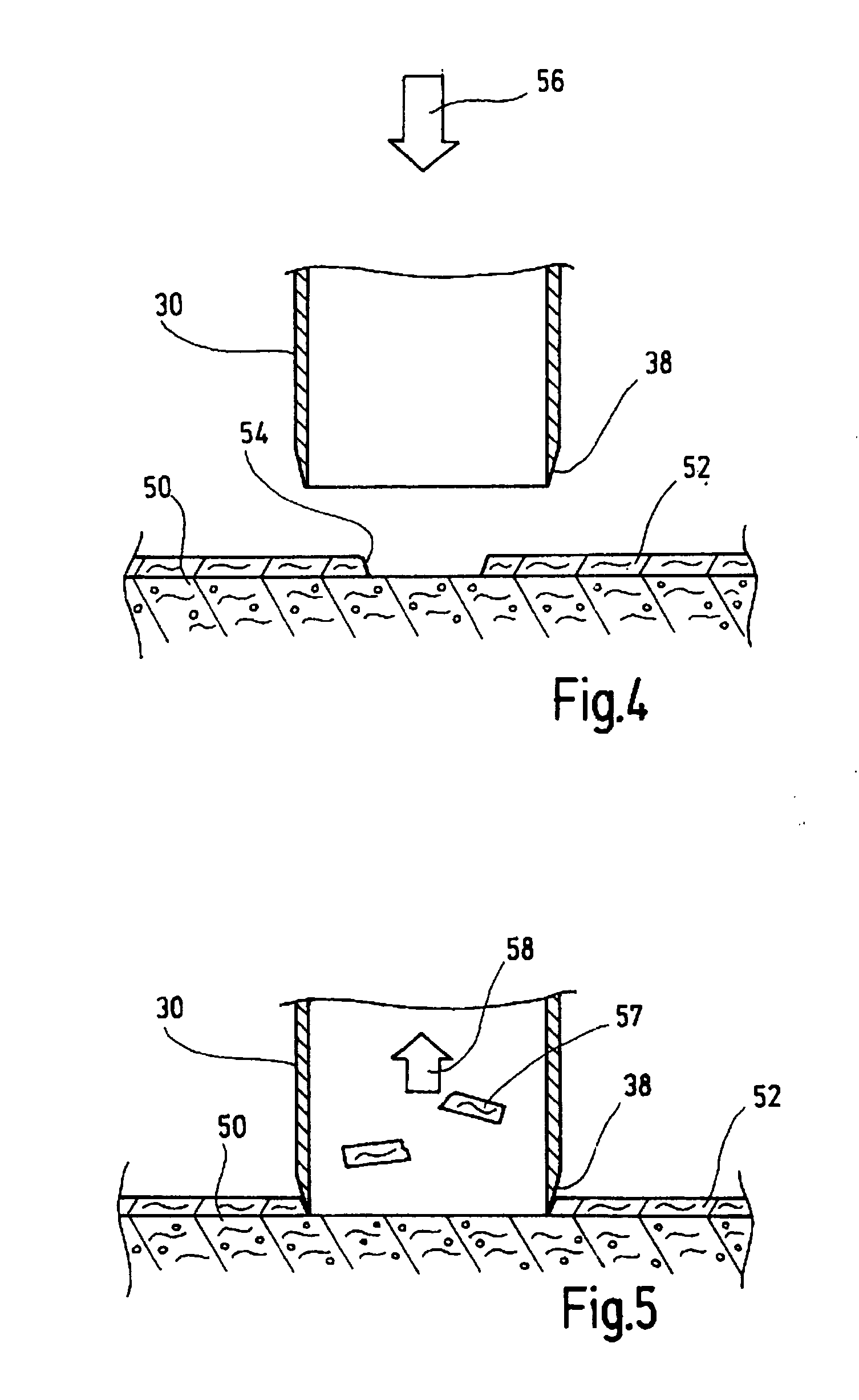

Medical instrument for autologous chondrocyte transplantation

InactiveUS20060198877A1Accurate insertionHold steadySurgerySheet deliveryTransplantationMedical instruments

A medical instrument for autologous chondrocyte transplantation comprises a stamp for introducing an implantable nonwoven into a cartilage. This stamp has, on a distal end face, at least one opening to which an underpressure can be applied.

Owner:KARL STORZ GMBH & CO KG

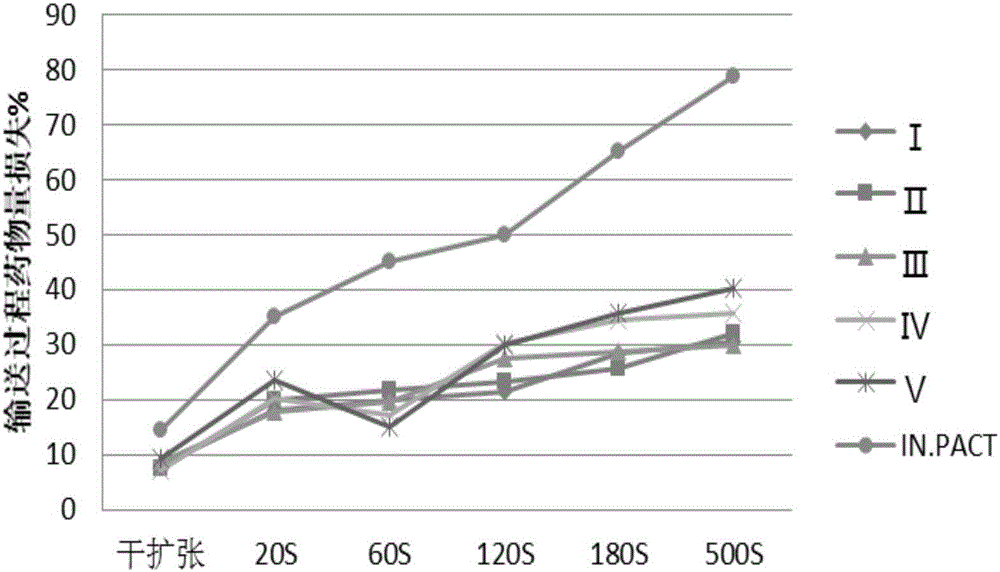

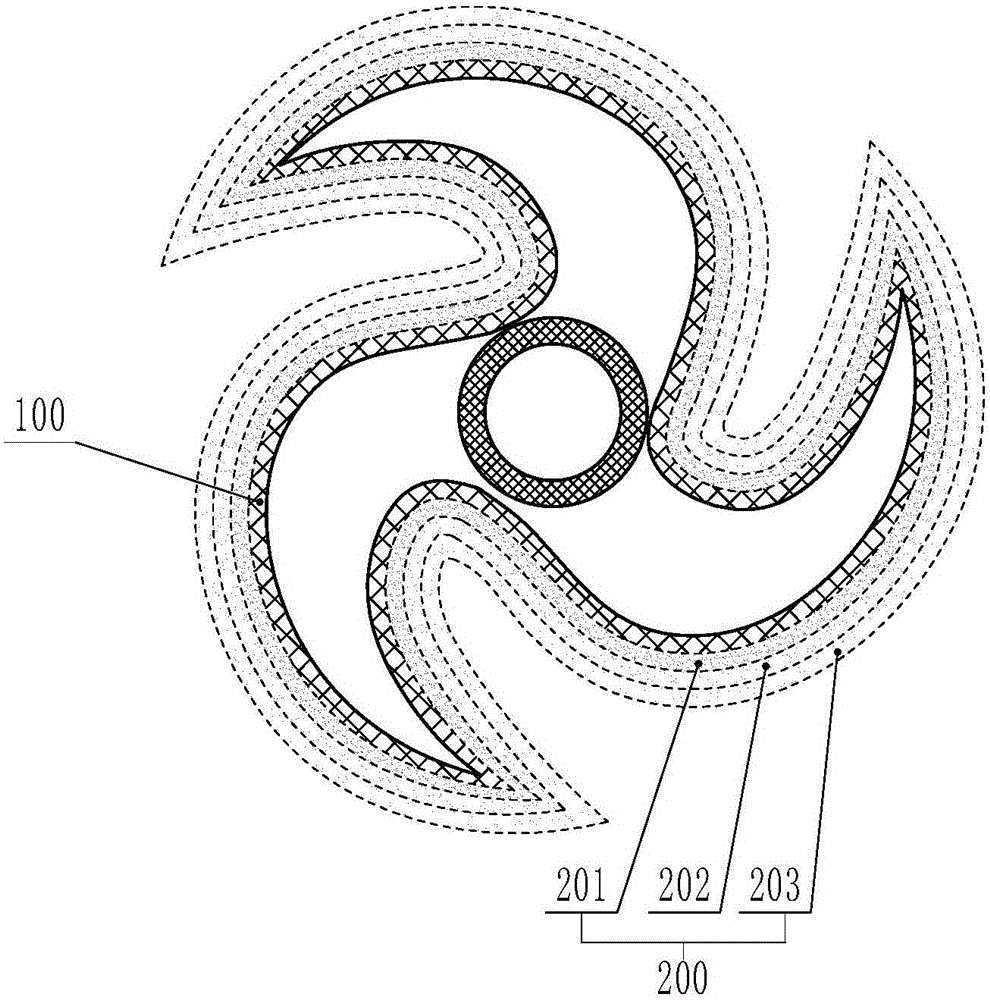

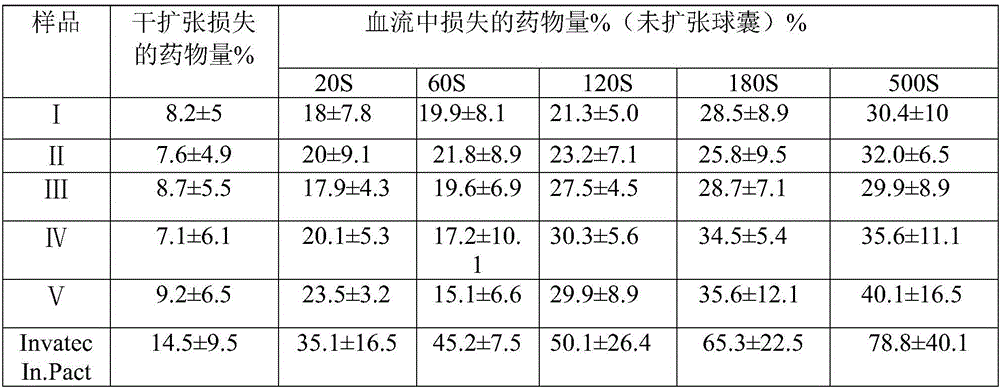

Drug-loaded saccule and manufacture method thereof

InactiveCN106075703AFacilitated releasePromote absorptionBalloon catheterMedical devicesDrugs solutionSaccule

The invention discloses a drug-loaded saccule and a manufacture method thereof. The drug-loaded saccule comprises a saccule with a multivalve structure, wherein a drug-coated crystal layer is adhered to the surface of the saccule, and comprises an active drug and a drug mixture; the content of the active drug in the drug-coated crystal layer is gradually reduced from the surface of the saccule outward, while the content of the drug mixture is gradually increased from the surface of the saccule outward. The manufacture method comprises the following steps: firstly, folding the surface of the saccule; preparing drug-coating solutions with different proportions by using the active drug, the drug mixture and solvent as raw materials; then, sequentially coating the drug-coating solutions to the surface of the saccule according to a decreasing sequence of the content of the active drug, drying and crystallizing to obtain a multi-layer drug-coated crystal layer having the content of the active drug in a gradient descending shape inside-out; and finally, rolling and pressing the saccule to obtain the final drug-loaded saccule. The drug-loaded saccule has an excellent drug-loading performance, strong adhesion soundness and strong washing resistance.

Owner:HANGZHOU WEIQIANG MEDICAL TECH CO LTD

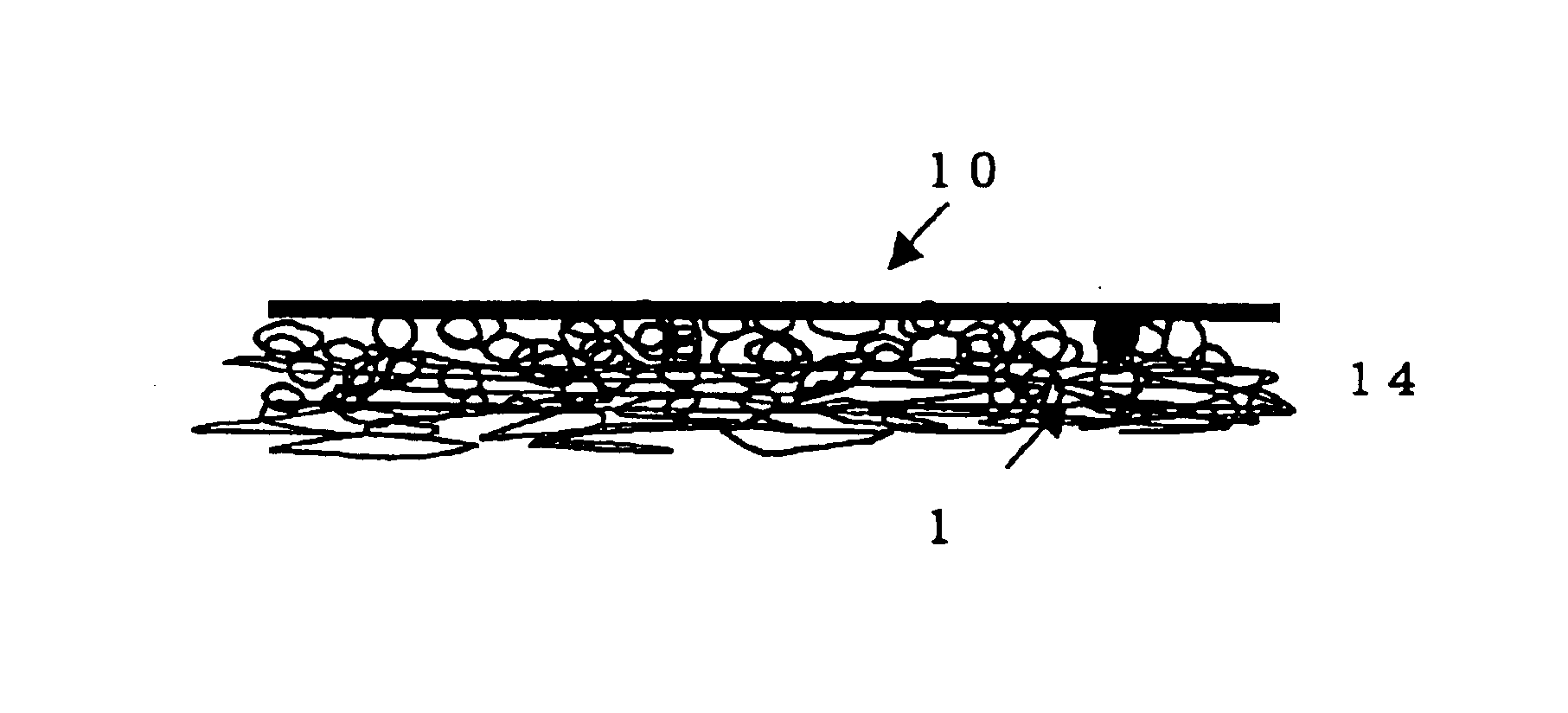

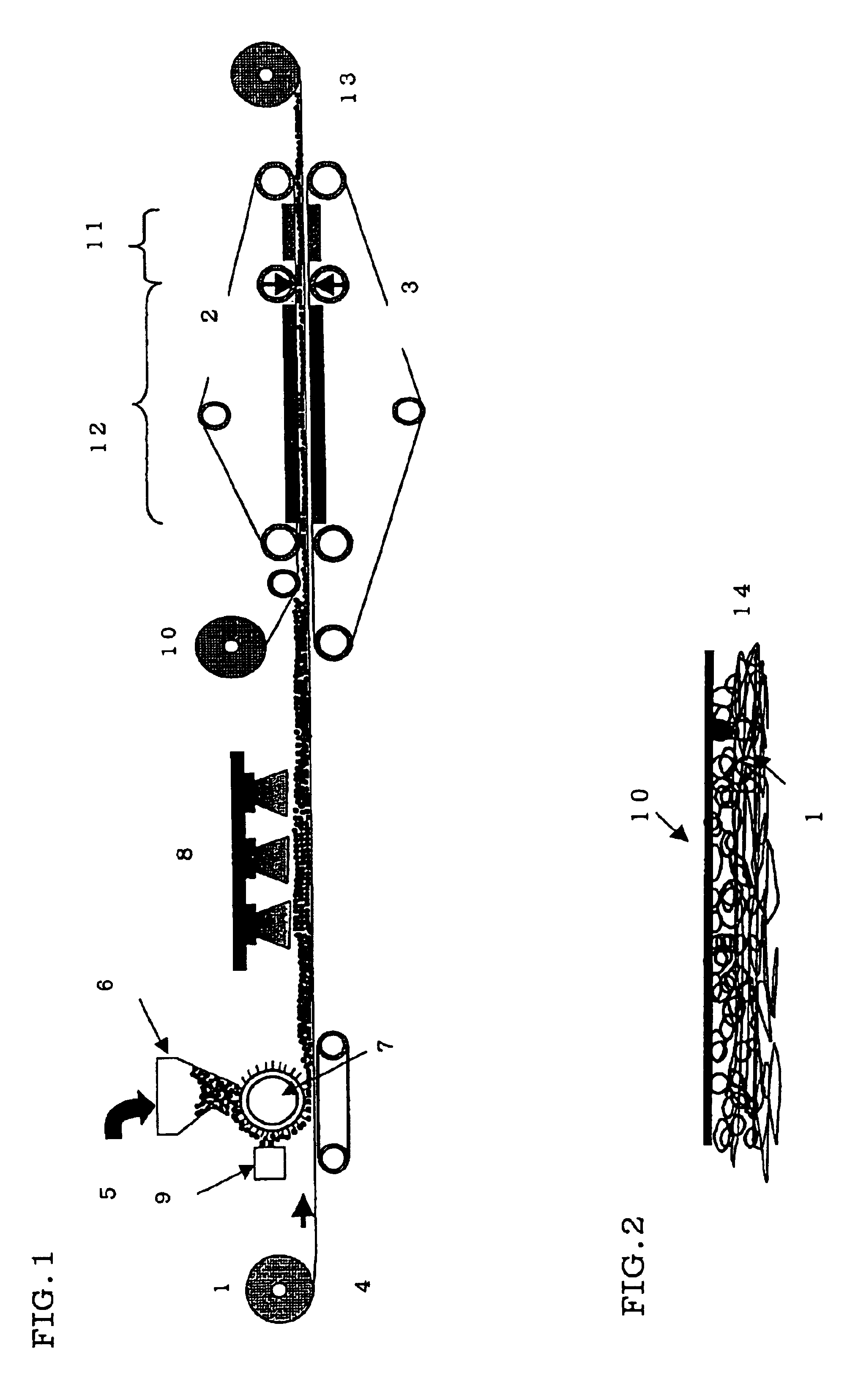

Adsorptive sheet and filter for clarifying air

InactiveUS6936094B2Improve adhesionGood dispersionDispersed particle filtrationIsotope separationThermoplasticActivated carbon

Provided are an adsorption sheet and an air-purifying filter, which can have low air-flow resistance and high deodorizing performance and be resistant to clogging by dust, from which a powdered adsorbent can hardly drop off, and in which any attached agent can hardly lose its effect. Such a product can be obtained by a process including the steps of: sufficiently premixing an agent-bearing activated carbon powder and a powdered thermoplastic resin to form a mixed powder; then spreading the mixed powder on a base sheet having a certain bulkiness and bearing an agent; stacking an air-permeable sheet thereon; and hot-pressing them.

Owner:TOYOBO CO LTD

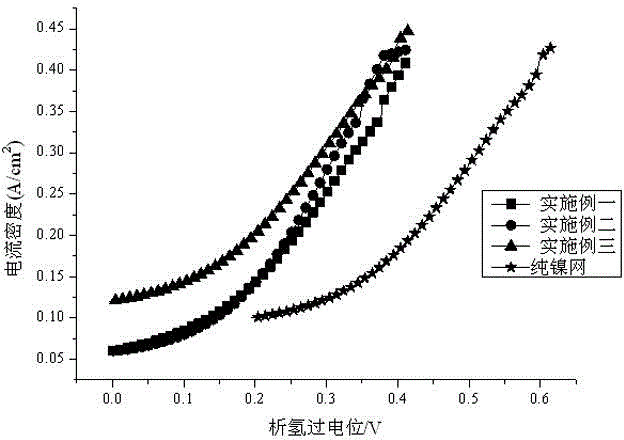

High-catalytic-activity amorphous metal oxide hydrogen evolution electrode and preparation method thereof

The invention discloses a high-catalytic-activity amorphous metal oxide hydrogen evolution electrode and a preparation method thereof. The electrode comprises an active coating made from an amorphous metal oxide, which is selected from any one or more of amorphous nickel oxide, amorphous ruthenium oxide, amorphous molybdenum oxide, amorphous cerium oxide, and amorphous strontium oxide. The preparation method comprises: step1, pre-treating a nickel screen to form a porous transition nickel oxide layer; step2, preparing an active coating precursor solution and coating the nickel screen with the precursor solution; and step3, performing thermal decomposition and laser-cladding assisted solidification to obtain the hydrogen evolution electrode. The preparation method is simple and is low in thermal decomposition temperature. The prepared hydrogen evolution electrode is high in catalytic activity and is not prone to polarize in a high current density. A catalyst firmly combines with a matrix and is not prone to fall off. The hydrogen evolution electrode has excellent anti-reverse-current performance. Compared with a conventional nickel screen, in a high current density of 4000A / m<2>, the electrode can reduce the hydrogen evolution overpotential by 250 mV. In a situation of frequent startup and shutdown, the voltage of an electrolytic bath is stable, and the fluctuation amplitude is small.

Owner:派新(上海)能源技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com