Patents

Literature

453results about How to "Improve the wrapping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

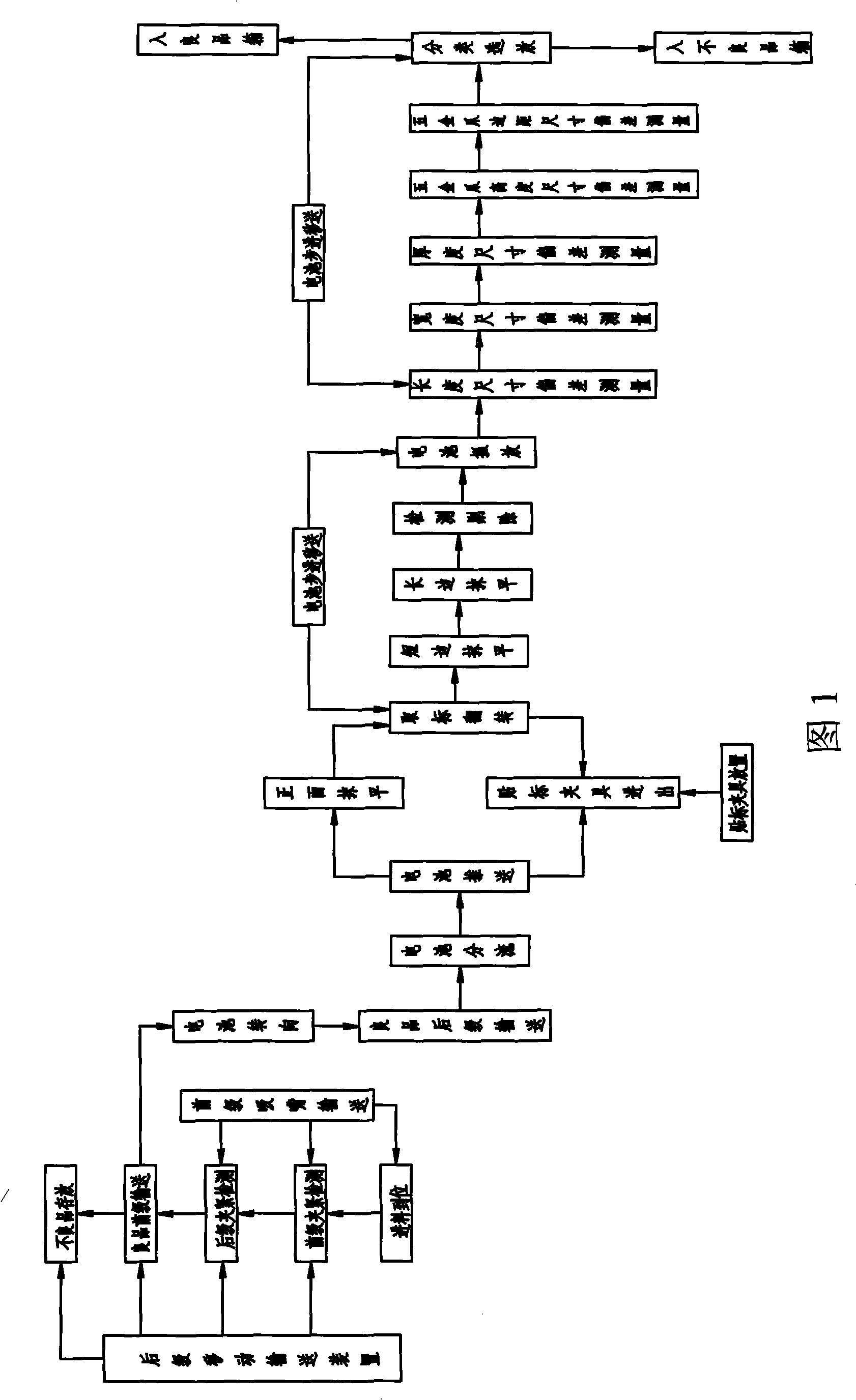

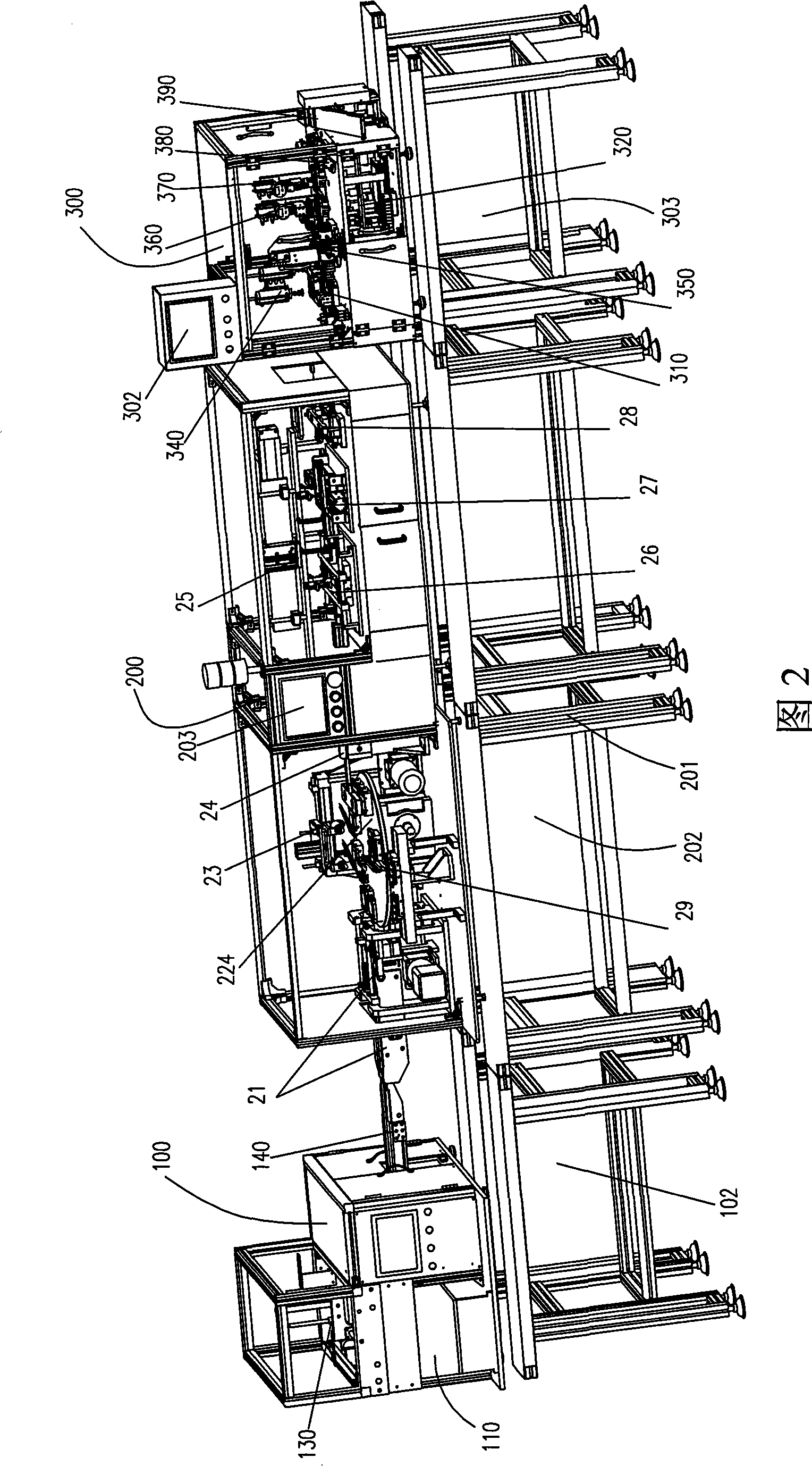

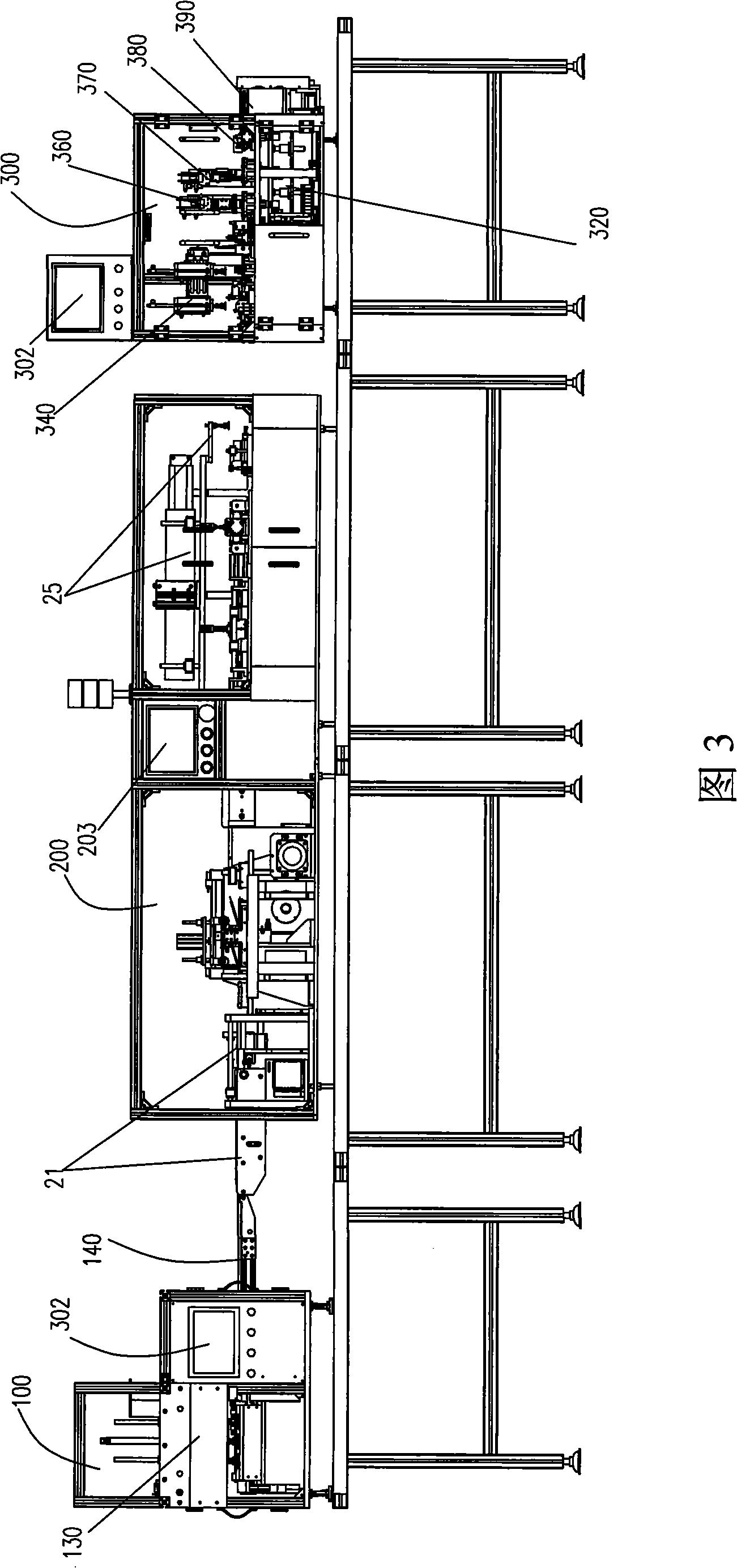

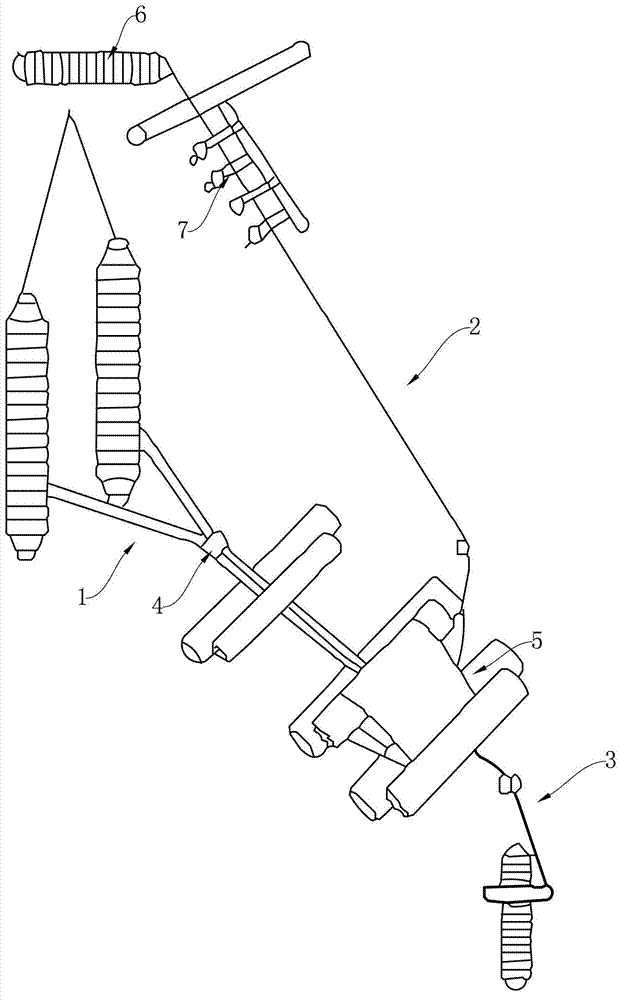

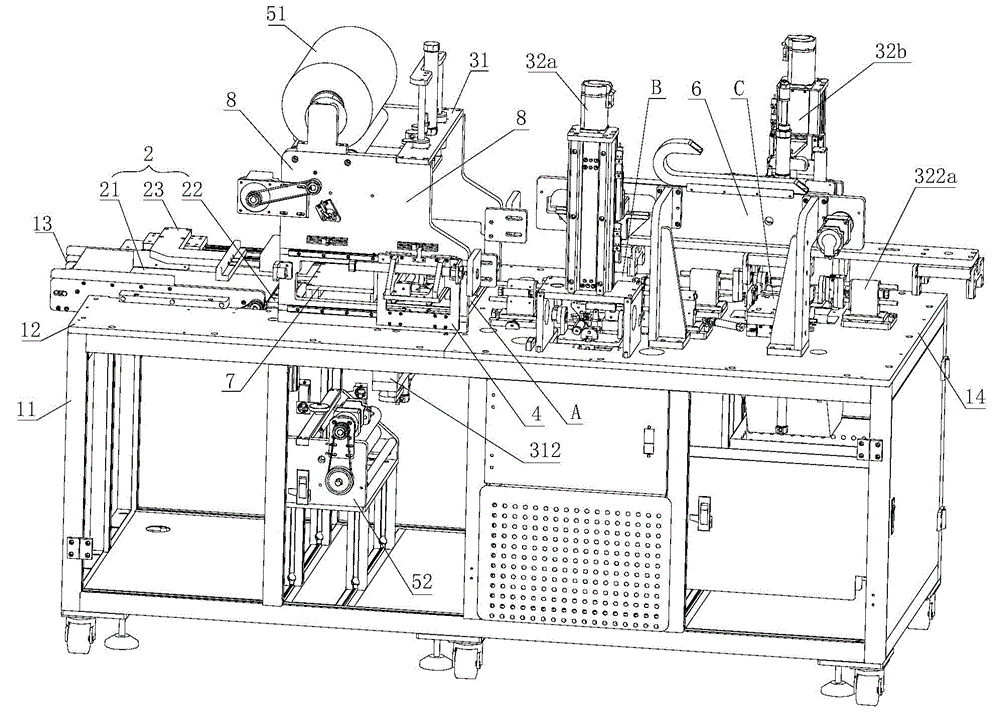

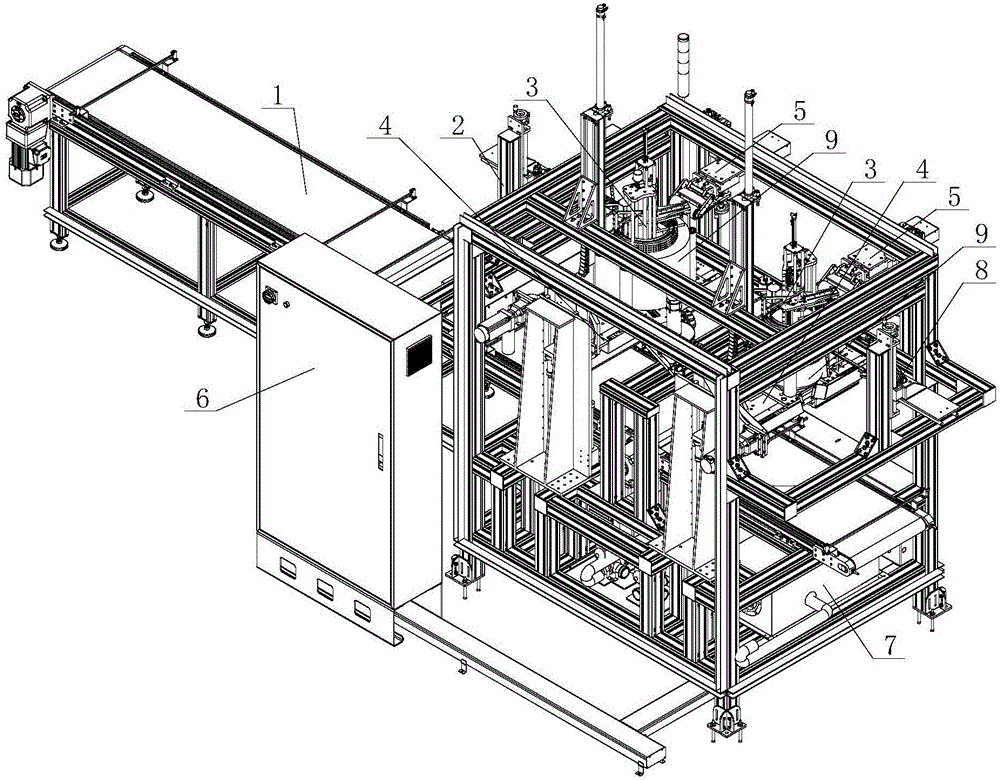

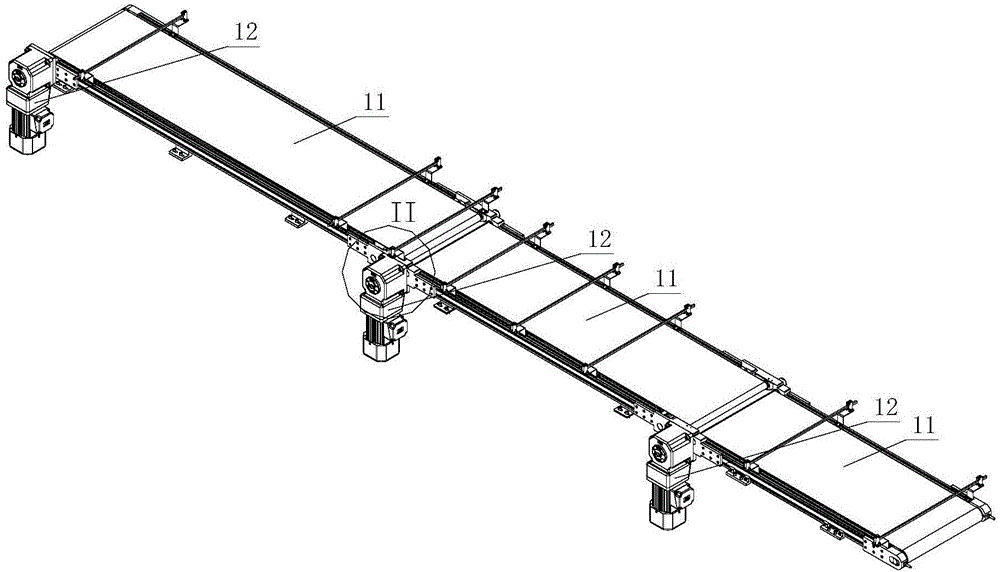

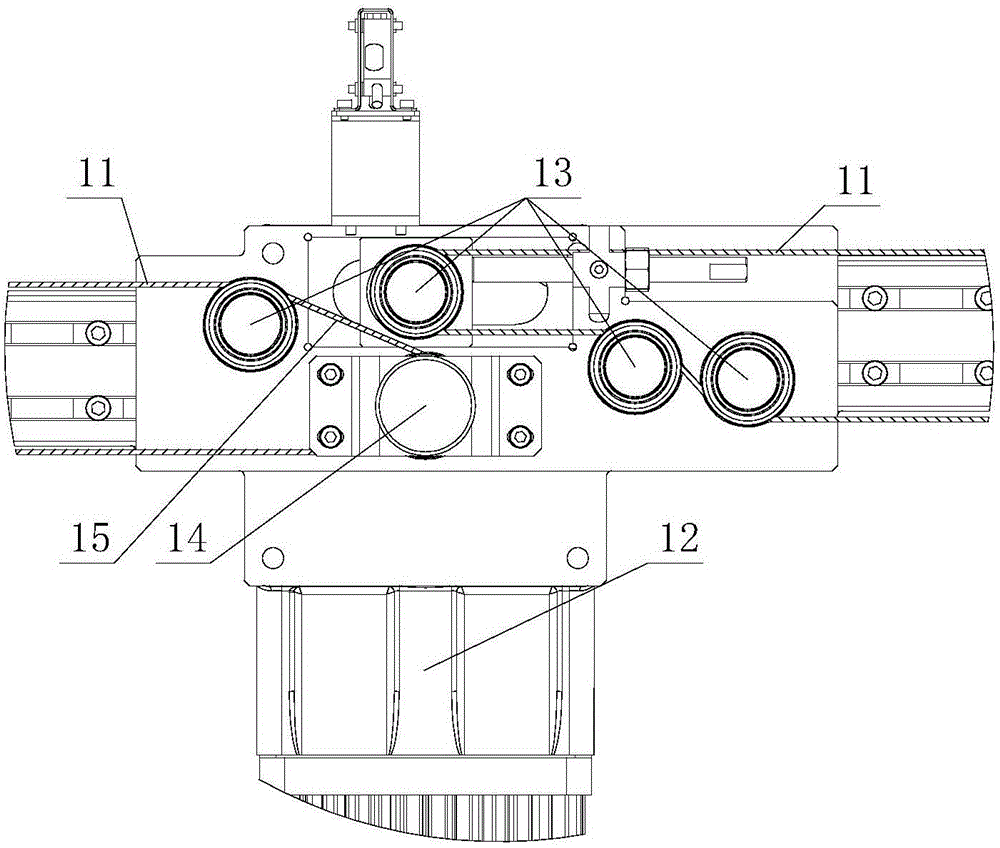

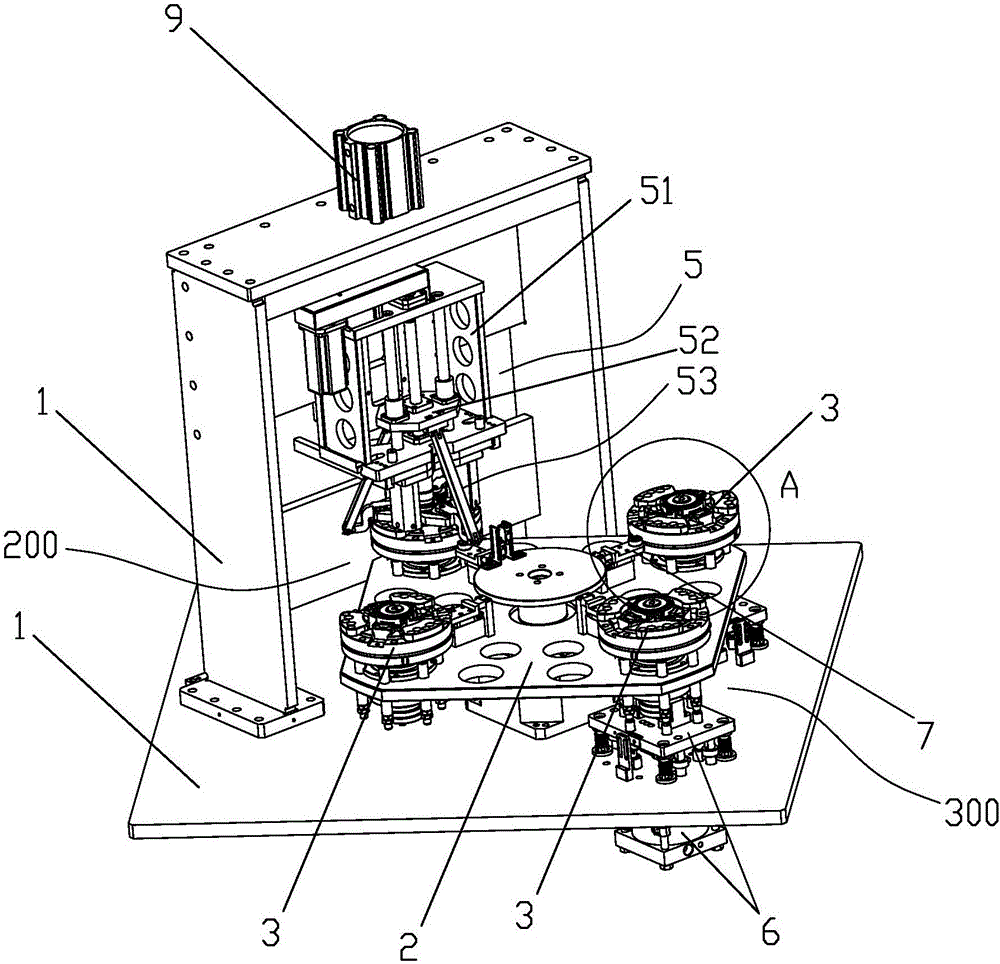

Detection, mark-wrapping, measurement automatic production line and process flow of mobile phone cell

InactiveCN101276929AReduce labor intensityImprove the wrapping effectFinal product manufacturePrimary cellsEngineeringAutonomation

The invention relates to a mobile phone detecting, mark wrapping, measuring automatic product line and technical flow. The product line comprises an orderly arranged mobile phone inside parameter automatic detector, a mobile phone automatic mark wrapper and a mobile phone cell size difference automatic measurer. A discharge port end of the mobile phone inside parameter automatic detector is connected with an inlet point end of the mobile phone automatic mark wrapper. A discharge port end of the mobile phone automatic mark wrapper is connected with an inlet point end of the mobile phone cell size difference automatic measurer that is connected electrically. In the invention, the cell feed in, position, clamp detection, mark wrapping and difference measurement after the mark wrapping are completed automatically. The mark wrapping effect is good, stable, and strongly reliable. The invention is simple in operation, high in efficiency and automatic level, which reduces the product manufacturing cost greatly and improves product quality and manufacturing speed, work efficiency as well as lightens labor intensity of the workers and improves labor capacity.

Owner:GRAND TECH SHENZHEN

Modified epoxy mortar abrasion-resistant patching material

The invention relates to a modified epoxy mortar abrasion-resistant patching material which comprises a component A and a component B. The mass ratio of the A component and the B component is 4:1. The A component comprises, by weight, 15-20 parts of epoxy resin, 1.5-2 parts of flexibilizer, 1.5-3 parts of reactive diluent and 75-82 parts of abrasive aggregates. The B component comprises, by weight, 18-24 parts of hardening agent, 1-1.5 parts of coupling agent and 75-80 parts of abrasive aggregates. The abrasive aggregates are quartz-sand-class aggregates or diamond-sand-class aggregates. The mass ratio of aggregates with the particle diameter of 10-20 meshes to aggregates with the particle diameter of 20-40 meshes to aggreates with the particel diameter of 40-70 to aggreates with the particel diameter of 100-200 meshes is 0-1 to 1-2 to 0-2 to 0-1. The hardening agent is a polyether amine hardening agent. According to the modified epoxy mortar abrasion-resistant patching material, the abrasion-resistant strength and the anti-impact strength are improved, the hardening reaction speed is lowered and micro cracks in the early stage of epoxy mortar are avoided.

Owner:WUDA JUCHENG STRUCTURE CO LTD

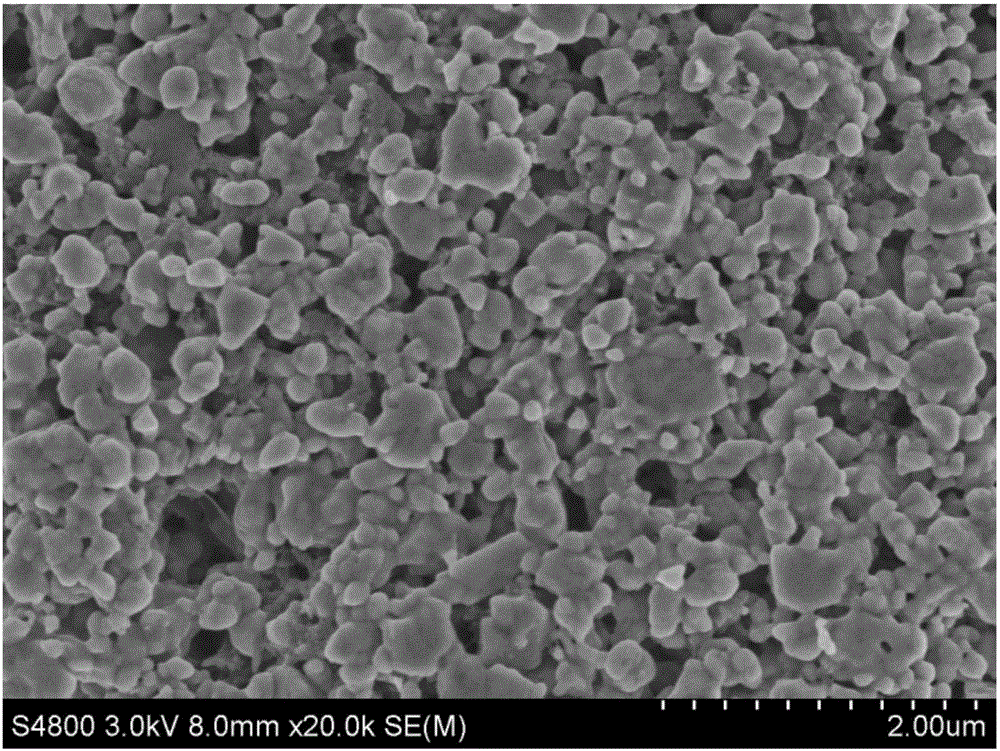

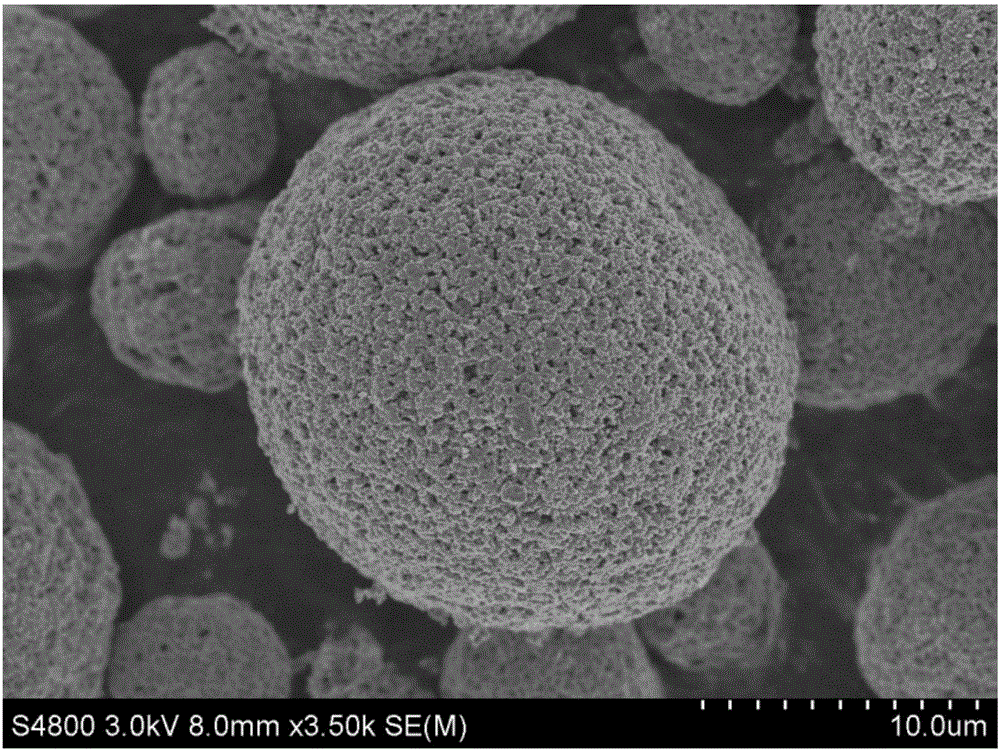

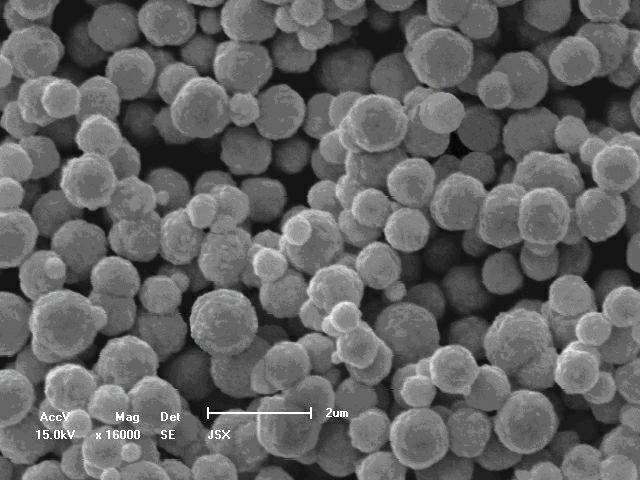

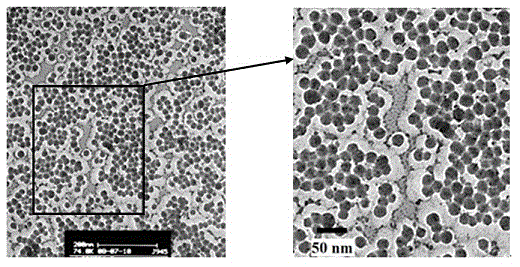

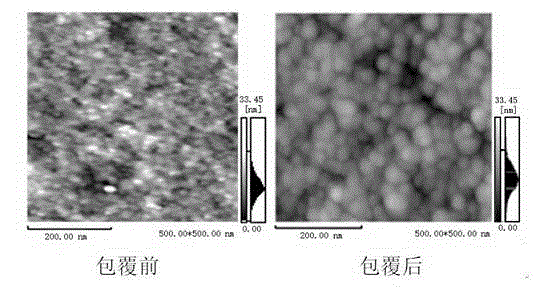

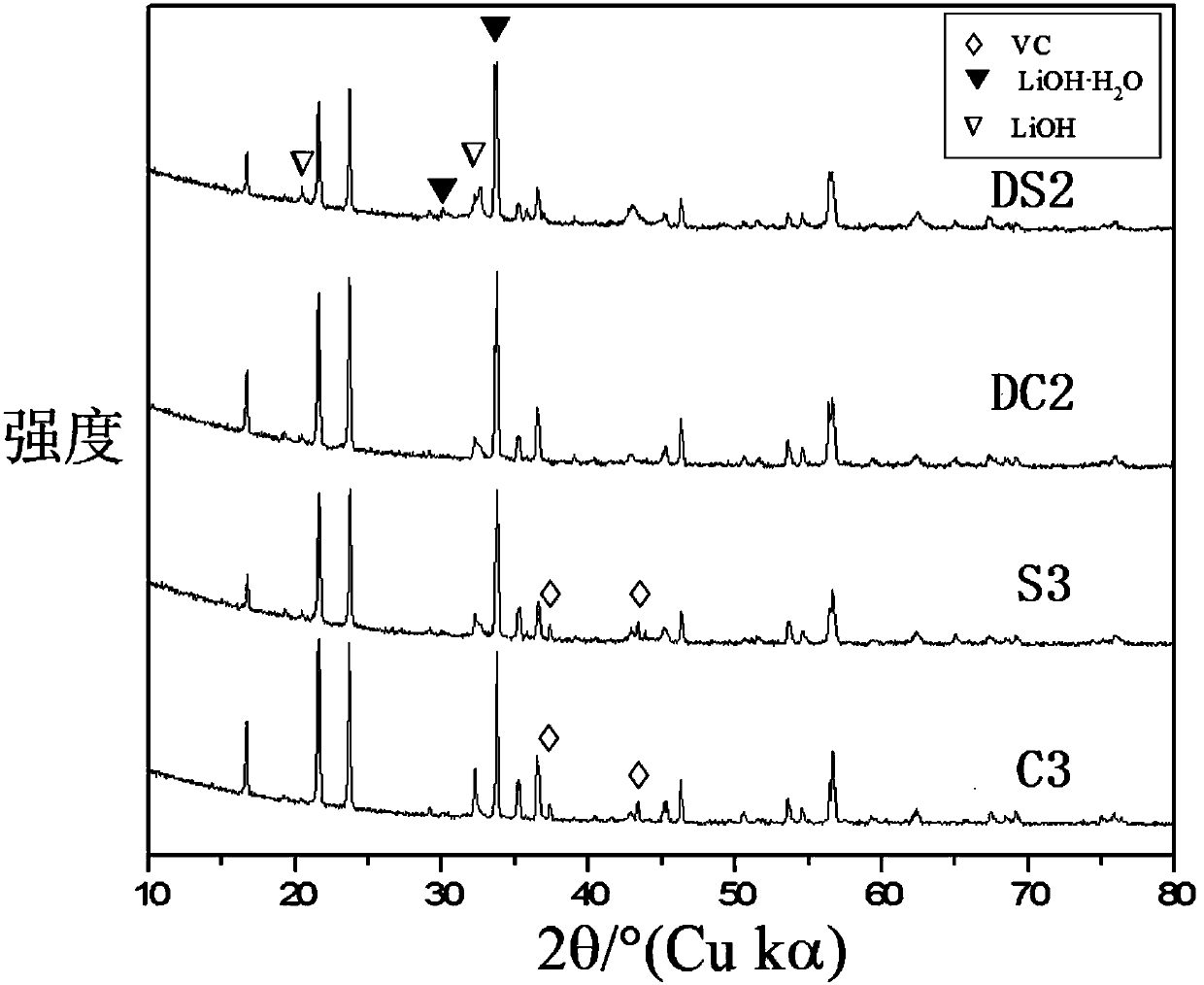

Sodium-titanium phosphate/carbon composite material and preparation method and use thereof

InactiveCN106784696AUneven solutionImprove uniformityCell electrodesSecondary cellsCarbon layerCarbon coating

The invention belongs to the field of electrode material synthesis, and relates to a sodium-titanium phosphate / carbon composite material and a preparation method and use thereof. The sodium-titanium phosphate / carbon composite material comprises secondary particles formed by clustering primary particles, the primary particles comprise sodium-titanium phosphate particles and carbon layers coated on the surfaces of the sodium-titanium phosphate particles, and the carbon layers are prepared through two times of carbon coating. According to the sodium-titanium phosphate / carbon composite material and the preparation method and use thereof, by means of preparing a precursor of the sodium-titanium phosphate and then adopting a spray drying method to carry out primary carbon coating and secondary carbon coating, the sodium-titanium phosphate / carbon composite material having a uniform and compact coating carbon layer is prepared, and the problem that the coating carbon layer obtained by the primary carbon coating is not uniform is solved. The composite material is good in stability, electrodes prepared from the sodium-titanium phosphate / carbon composite material and assembled batteries have excellent electrochemical properties, the discharge capacity is above 115mAh / g, and the capacity retention ratio is above 95% after 500 weeks of circulation.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Spinning process of covering yarn with high hollowness degree, prepared covering yarn and process for weaving towel by utilizing covering yarn

ActiveCN102888686AIncrease warmthHigh hollownessBiochemical fibre treatmentBleaching apparatusCotton fibreEngineering

The invention provides a spinning process of covering yarn with high hollowness degree, a prepared covering yarn and a process for weaving towel by utilizing the covering yarn. The spinning process comprises the following steps of: compositing and twisting two crude cotton yarns and water-soluble vinylon filament with number of 4.1-7.3 tex to prepare a spun yarn with cotton fiber covering the water-soluble vinylon filament; and hydrolyzing the water-soluble vinylon filament to obtain the covering yarn with the high hollowness degree. The strength and the hollowness degree of the covering yarn with the high hollowness degree, prepared by the spinning process disclosed by the invention, are higher than the strength and the hollowness degree of a common hollow covering yarn with the same yarn count, the overing yarn with the high hollowness degree is soft and fluffy and has strong water absorbability and improved heat insulation performance; and the woven towel prepared by the process of the invention is light and fluffy, and has good heat insulation performance and resilience, high water absorption speed, large unit-area water absorption amount and high drying speed.

Owner:SUNVIM GROUP

Method for displacement chemical silver plating on copper powder

InactiveCN101709461AIncrease profitHigh activityLiquid/solution decomposition chemical coatingAcid etchingSilver plate

The invention discloses a method for displacement chemical silver plating on copper powder. The method comprises the following steps of: cleaning and oil removal, water washing, acid etching, water washing, catalytic liquid treating, chemical silver plating and the like. In the method, a catalytic liquid capable of preplanting catalytic mass points is developed; the surface of the copper powder is preplanted with discretely distributed palladium mass points after the copper powder is treated by the catalytic liquid at a room temperature by controlling components, pH value and treatment time of the catalytic liquid; and the preplanted palladium mass points can catalyze and promote the silver ion reduction to improve precipitation speed and to retard copper-ammonia complex ions to be absorbed on the copper surface so as to obtain a sliver plating layer with good cladding performance in the chemical silver-plating process for the copper powder. Compared with the conventional method of displacement chemical silver plating, the method realizes surface activation of the copper powder by pretreating the catalytic liquid, a silver content of the silver plating copper powder is greatly improved, the problems of poor cladding performance of replacement type chemical silver plating and the like are solved, and the method is simple in process and convenient to operate and has good application prospect.

Owner:GUANGDONG UNIV OF TECH

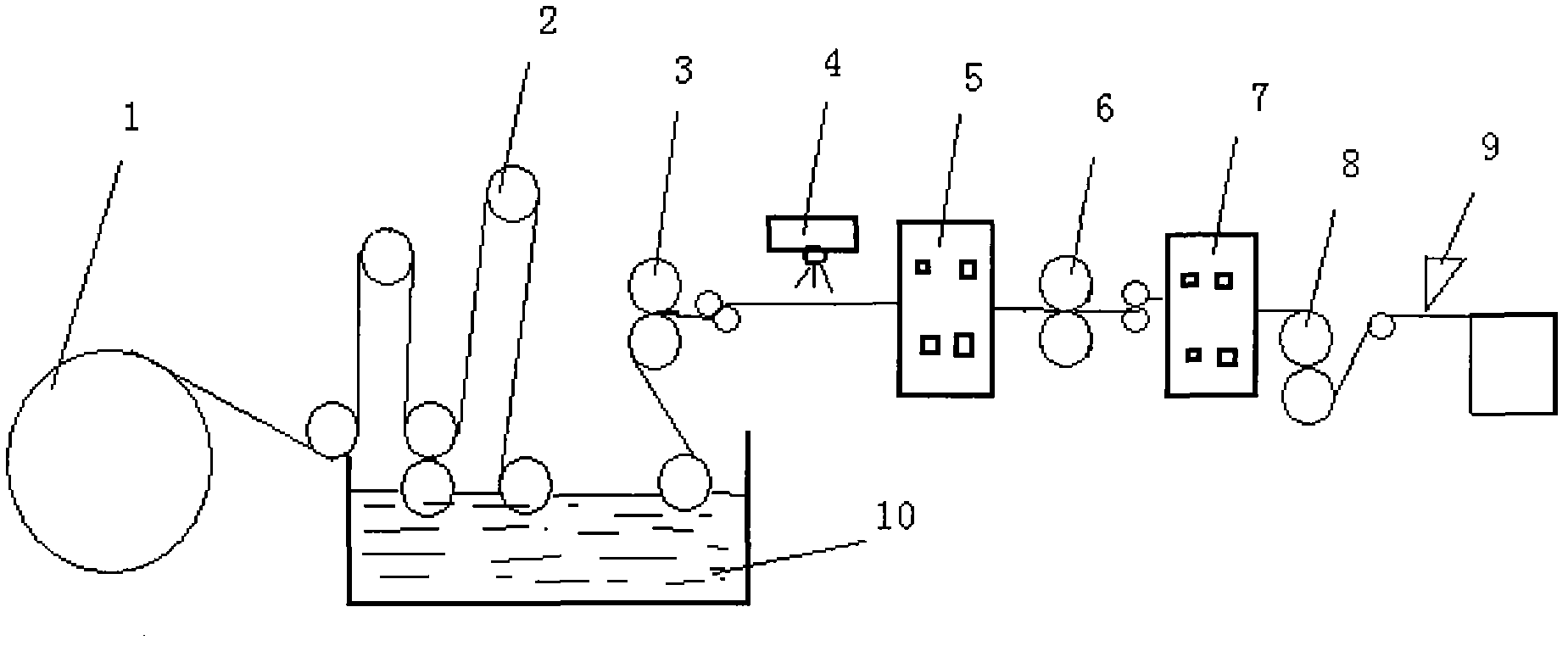

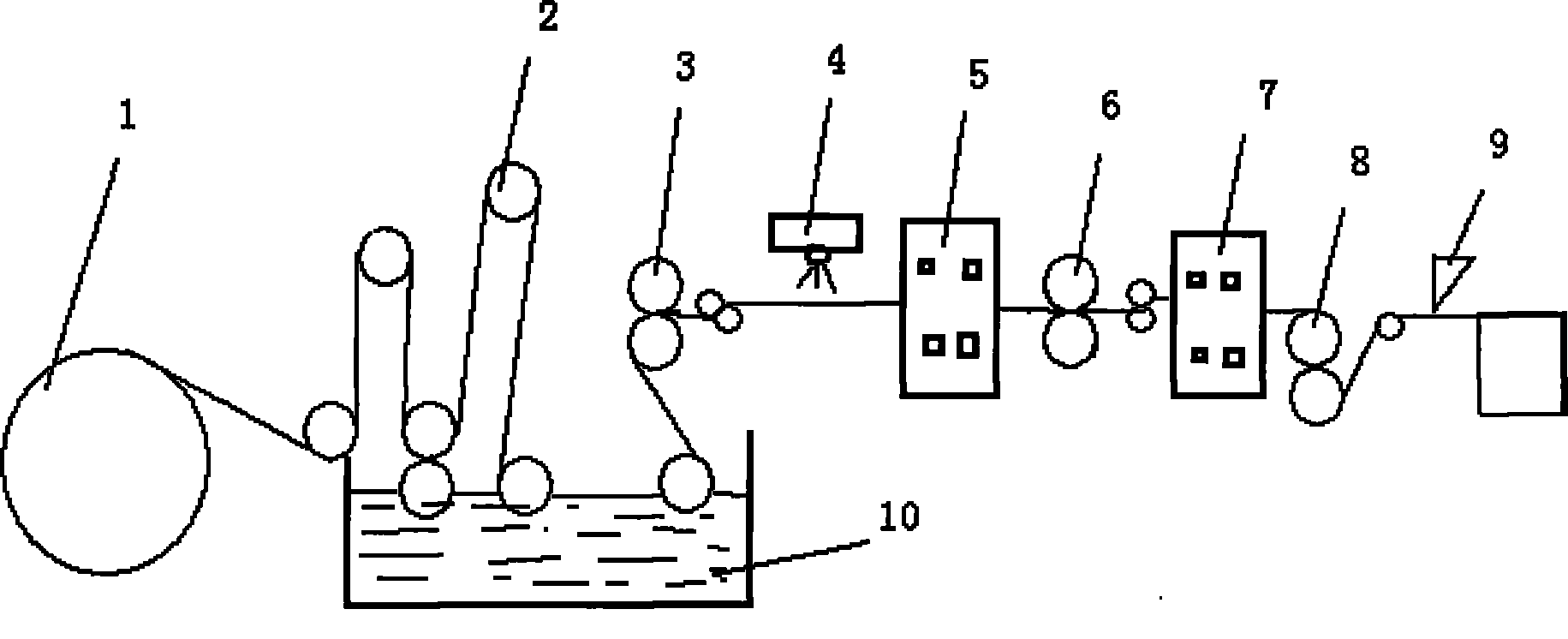

Method for manufacturing surface wear-resisting impregnated paper of laminate floor by dry-spraying Al2O3

ActiveCN102086616AImprove wettabilityImprove the wrapping effectNon-fibrous pulp additionPaper coatingRolling paperMelamine formaldehyde

The invention relates to a method for manufacturing surface wear-resisting impregnated paper of a laminate floor by dry-spraying Al2O3. The method comprises the following steps: impregnating pure wood pulp roll paper with a melamine-formaldehyde (MF) resin liquid; uniformly spraying the Al2O3 on the surface of the impregnated paper by utilizing a dry sprayer; allowing the impregnated and sprayed paper to enter a first oven for drying at the temperature of 100-150 DEG C; roll-coating 300-500% (relative to the weight of the paper) of the MF resin liquid on the paper surface after preliminary drying; and allowing the roll-coated paper to enter a second oven for drying at the temperature of 100-150 DEG C, controlling the whole-course running speed of the paper at 10-12m / minute, cooling, adjusting the temperature of the oven and machine speed so as to reach 6.0-7.5% of volatile matters and 40-60% of pre-curing degree, cutting and packaging. By means of the method, the defects of the prior art are overcome, and the spray quantity of the Al2O3 can be adjusted by controlling the dry sprayer so as to obtain the surface wear-resisting impregnated paper with reliable quality according to different wear-resisting requirements; and the method has the advantages of reasonable process and obvious effect, and is simple in operation, thus effectively improving the product quality.

Owner:天津市瑞鸿装饰材料销售有限公司

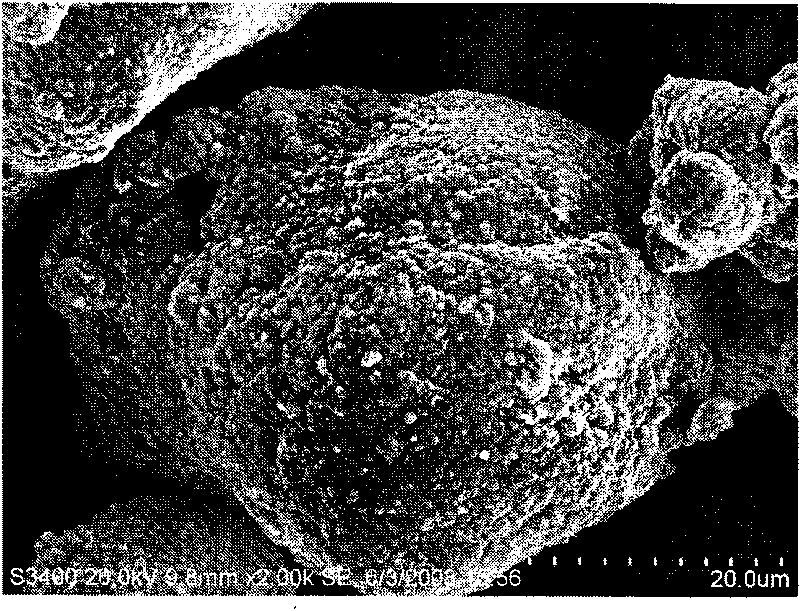

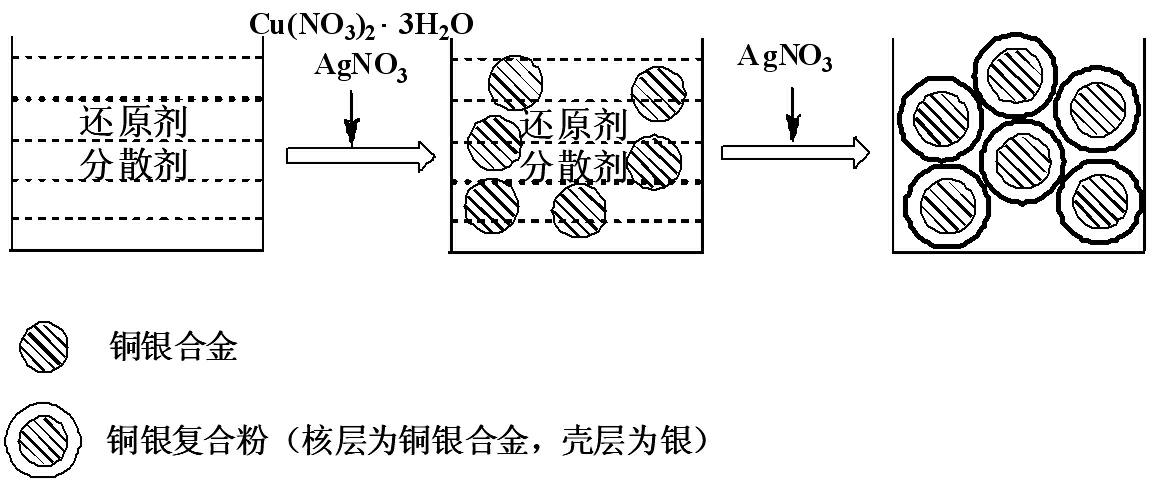

Preparation method of copper-silver composite powder

InactiveCN102161104AInhibition of spontaneous nucleation growthImprove efficiencyAqueous solutionReducing agent

The invention relates to a preparation method of copper-silver composite powder. The copper-silver composite powder has a coated nuclear-shell structure; a nuclear layer is made of copper-silver alloy, and the shell layer is made of silver. The preparation method comprises the steps: firstly, adding a mixed aqueous solution of AgNO3 and Cu(NO3)2.3H2O into a mixed aqueous solution consisting of a reducing agent and a dispersing agent to obtain a copper-silver alloy solution containing the reducing agent; then adding an AgNO3 aqueous solution into the copper-silver alloy solution containing the reducing agent, and leading silver to be deposited and coated on the surface of the copper-silver alloy; and then obtaining the 0.3-3mum copper-silver composite powder after filtering, cleaning, drying and surface densified treatment. In the obtained copper-silver composite powder, the coating of the outer-layer silver is uniform, the compact density is high, the conductivity is good, and the high-temperature oxidation resistance is strong.

Owner:SOUTHEAST UNIV

High-elastic denim fabric and production process thereof

InactiveCN105401307AMeet the needs of moderate exerciseReduce consumptionMercerising of indefinite length fabricsSingeingYarnFiber

The invention provides a high-elastic denim fabric, wherein PTT fiber filaments and spandex filaments are adopted as core yarns. Fasciated yarns are spun into double stretch yarn core-spun yarns, and then the double stretch yarn core-spun yarns are weaved in a three-upward one-downward right twill-weave mode to form cotton roves. After that, the high-elastic denim fabric is prepared successively through the steps of spinning double stretch yarn core-spun yarns, warping, starch dyeing, singeing, desizing, mercerising and washing finished products. The tensile elastic elongation rate of the high-elastic denim fabric prepared by the above method is up to 53.5% and the tensile elastic recovery rate thereof is up to 92.7%. Meanwhile, through setting the ratio of two types of stretch yarns, stretch yarns of different elastic performances can be obtained to meet different elastic requirements. The current situation that the conventional male denim fabric is not elastic can be changed. Meanwhile, the physical and chemical properties and the wearing comfortness of male denim clothes are improved to a certain degree. The fabric is soft and comfortable in hand feeling, good in shape-retaining ability, high in degree of dyeing and good in color fastness, thereby meeting the moderate sport requirement of men when wearing denim clothes. At the same time, the fabric does not unduly fit, thus having a good development prospect and a large value space.

Owner:FUJIAN SEPTWOLVES IND

Formula of water glass modifying additive and production process and using method thereof

InactiveCN101885035AImprove adhesionImprove sand performanceFoundry mouldsFoundry coresEmulsionMetallurgy

The invention relates to a water glass modifying additive for casting and a production process and a using method thereof. The modifying additive consists of the following components in percentage by mass: 40 to 65 percent of styrene-acrylate emulsion, 0 to 10 percent of urea resin, 0.1 to 0.5 percent of quaternary ammonium salt and 25 to 55 percent of water. Used water glass sand is subjected to dry reclamation, the residual Na2O content of the used sand is controlled in a certain range and the water galls with ultra-low modulus is matched with the modifying additive so that the available time for preparing molding sand by mixing all or partial reclaimed sand can be prolonged and the molding sand has good process performance; and the reclamation rate of the used water glass sand can reach over 85 percent. The water glass modifying additive is directly added into the water glass at normal temperature and stirred uniformly without a fussy heating-cooling process so as to facilitate the operation on a molding site.

Owner:深圳市景鼎现代科技有限公司

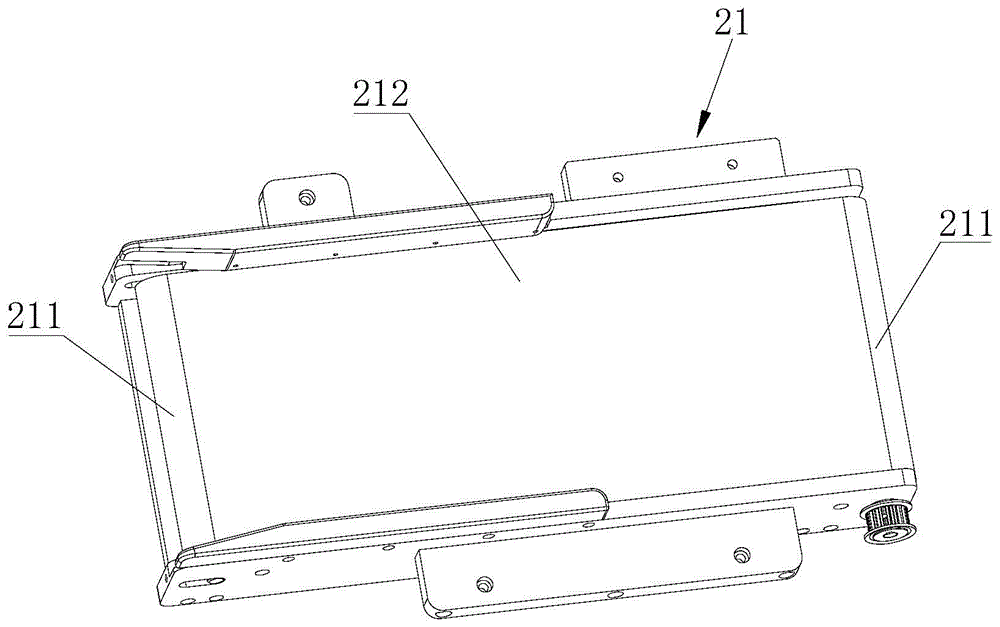

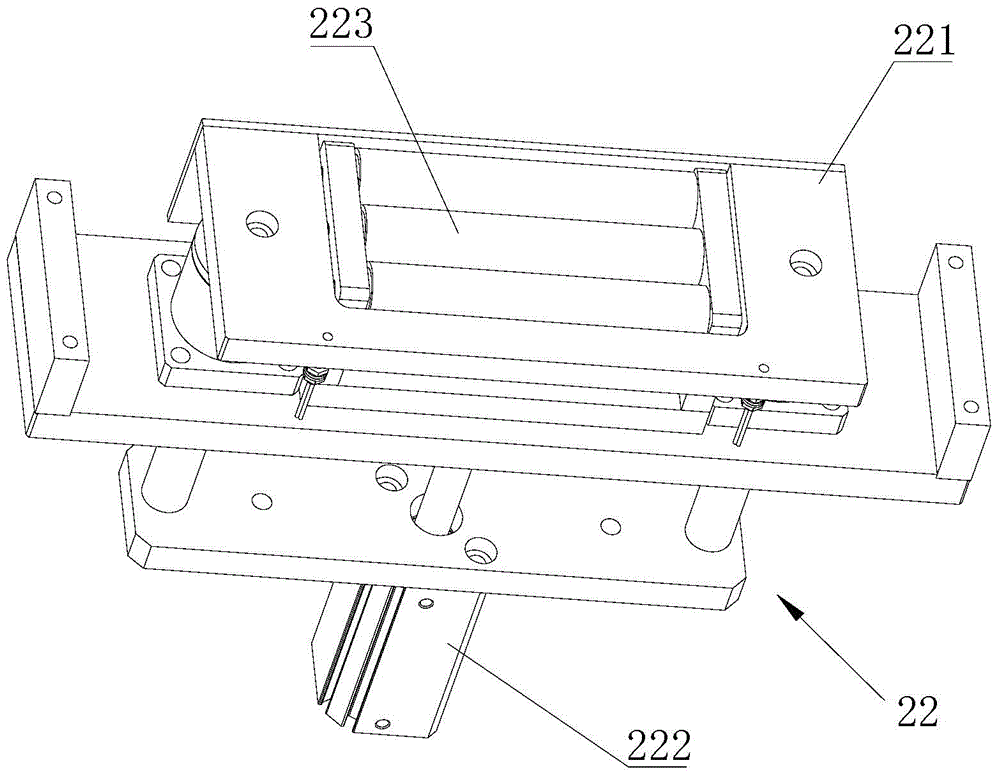

Square box thin film sealing and cutting machine

ActiveCN104925320AImprove aestheticsImprove the wrapping effectWrapper twisting/gatheringThin membraneEngineering

The invention belongs to the field of thin film packaging equipment, and discloses a square box thin film sealing and cutting machine which comprises a machine frame and a mounting plate arranged on the machine frame. One end of the mounting plate is a box inlet end, and the other end of the mounting plate is a box outlet end. A film wrapping assembly is arranged on the mounting plate and located between the box inlet end and the box outlet end. The film wrapping assembly comprises a box feeding assembly, sealing and cutting assemblies and a transferring assembly. The sealing and cutting assemblies comprise the first sealing and cutting assembly, the second sealing and cutting assembly and the third sealing and cutting assembly. A thin film roller is arranged above the first sealing and cutting assembly, the thin film transferring direction is perpendicular to the square box conveying direction, and the thin film penetrates through the portion between the box feeding assembly and the first sealing and cutting assembly. A first station is arranged at the position, where the first sealing and cutting assembly is arranged, of the mounting plate. A second station is arranged at the position, where the second sealing and cutting assembly is arranged, of the mounting plate. A third station is arranged at the position, where the third sealing and cutting assembly is arranged, of the mounting plate. According to the square box thin film sealing and cutting machine, sealing-cutting packaging can be carried out at the positions of corner lines of boxes, and thin film sealing and cutting lines are more invisible, so that the overall wrapping effect is greatly improved, and attractiveness is good.

Owner:深圳市道元实业有限公司

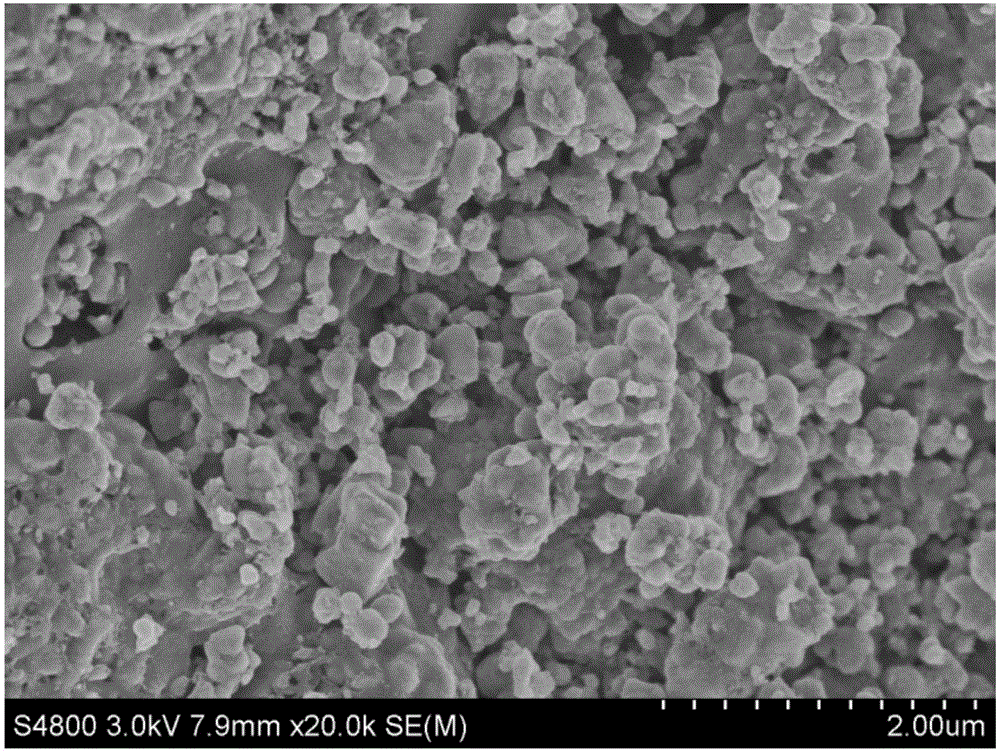

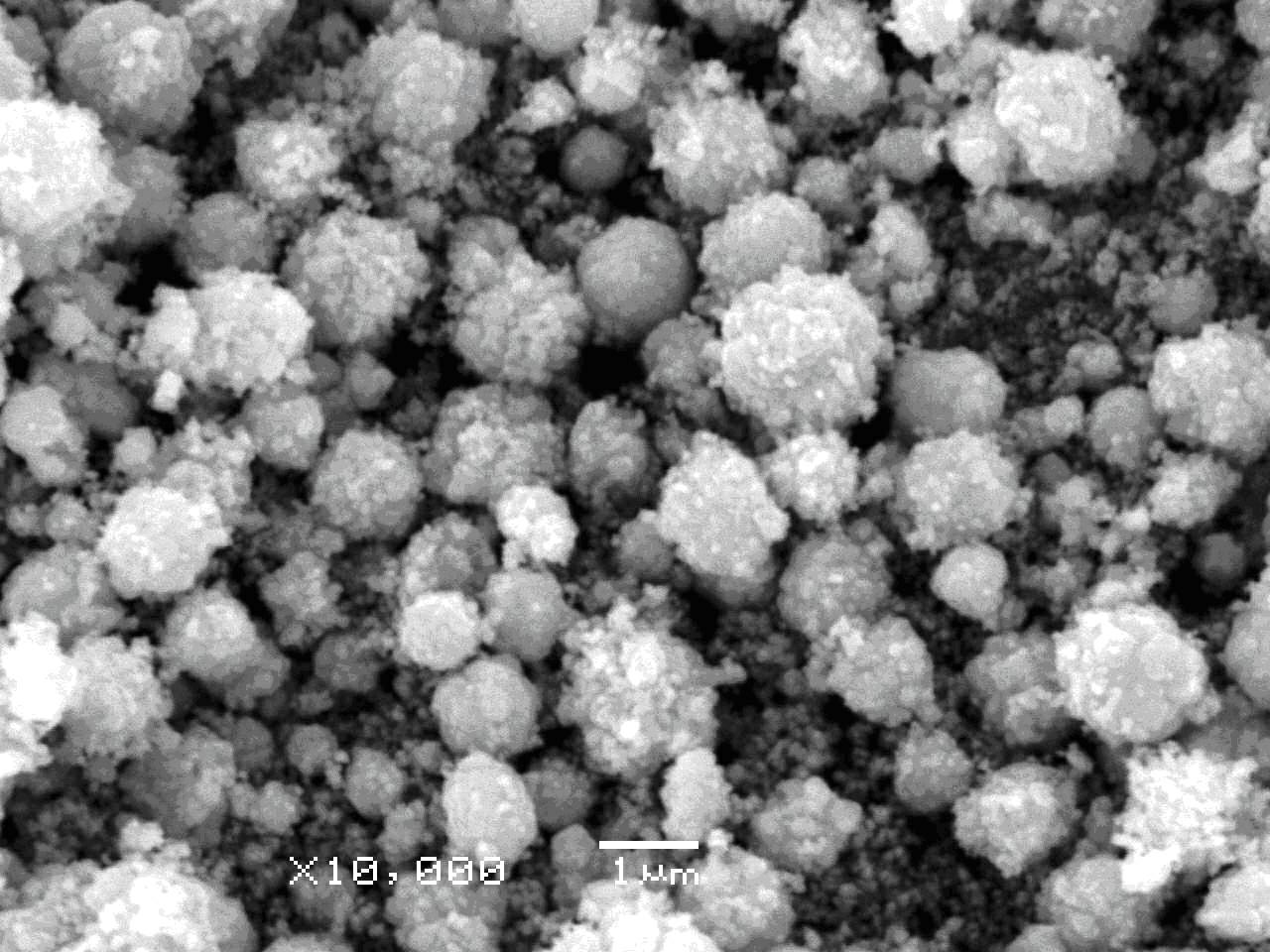

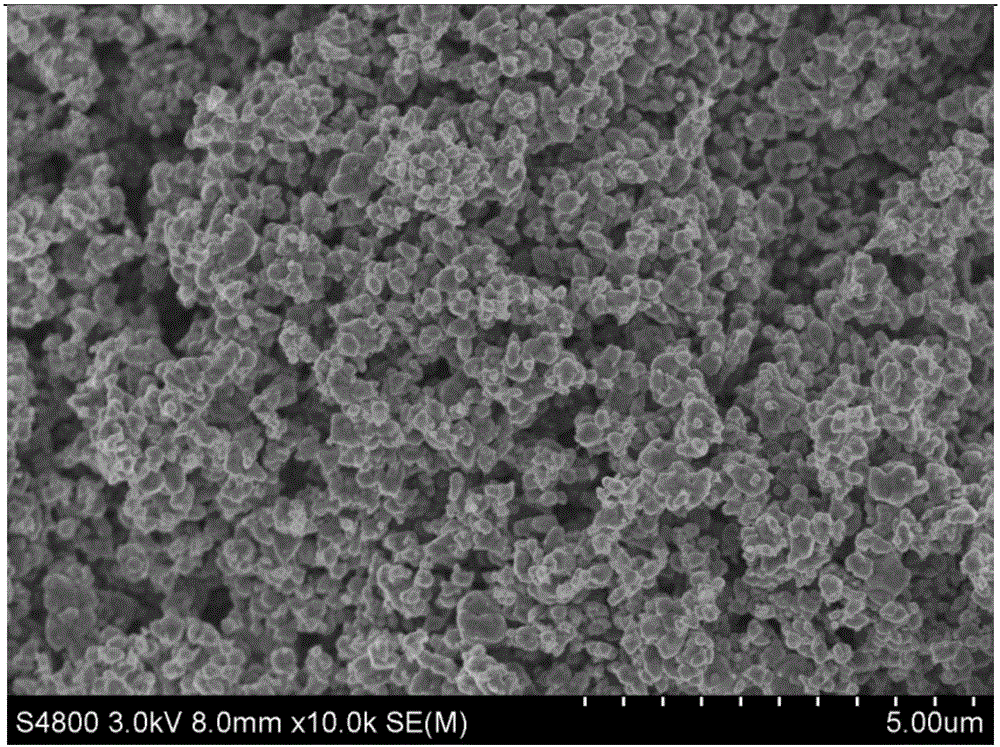

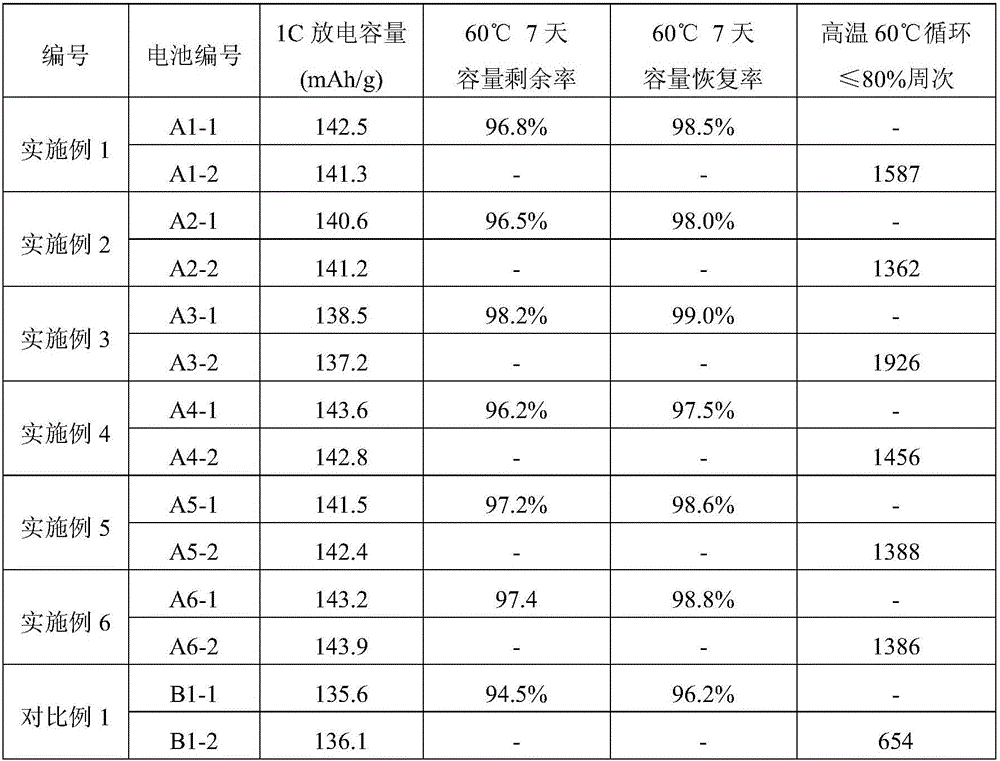

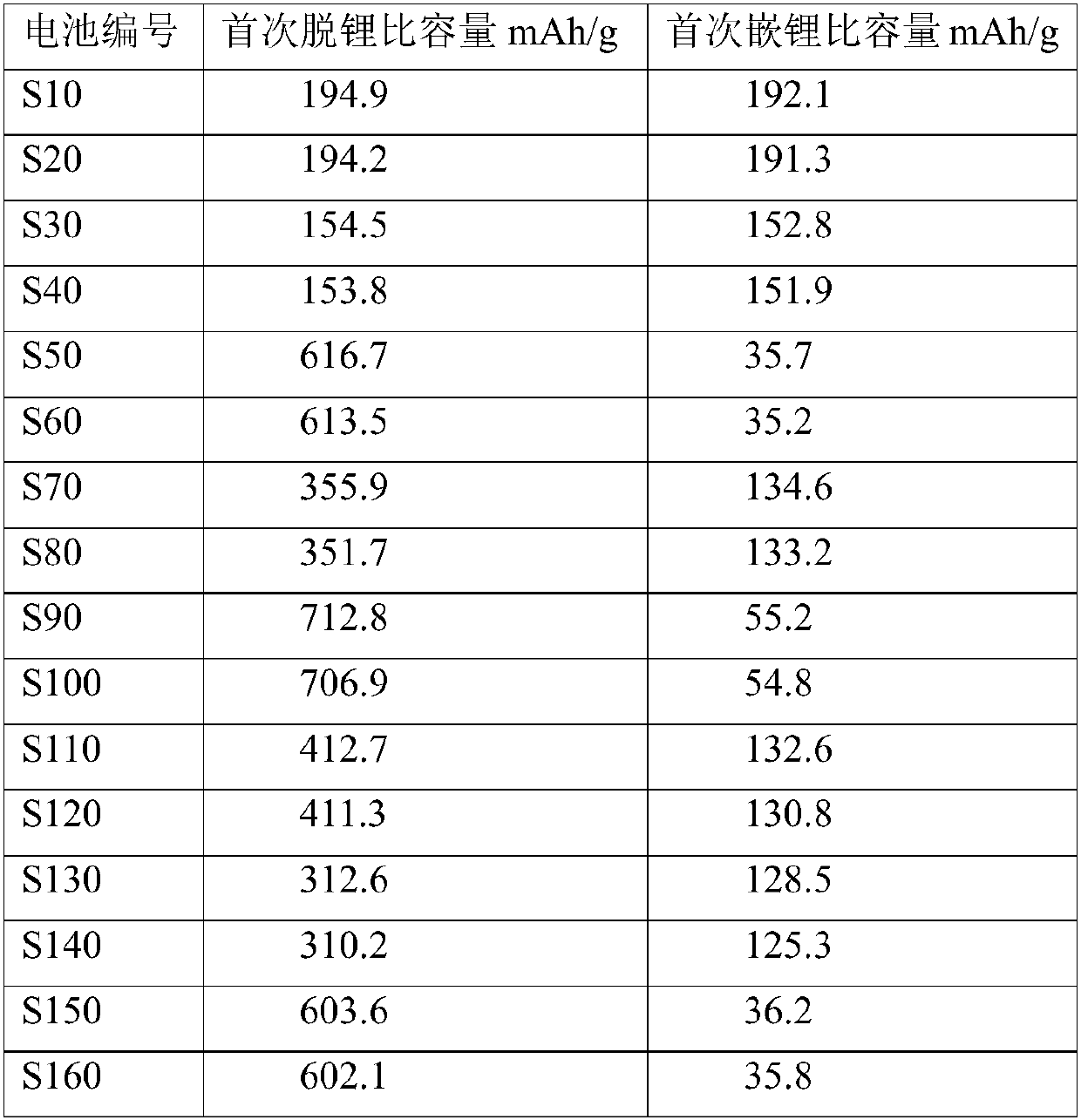

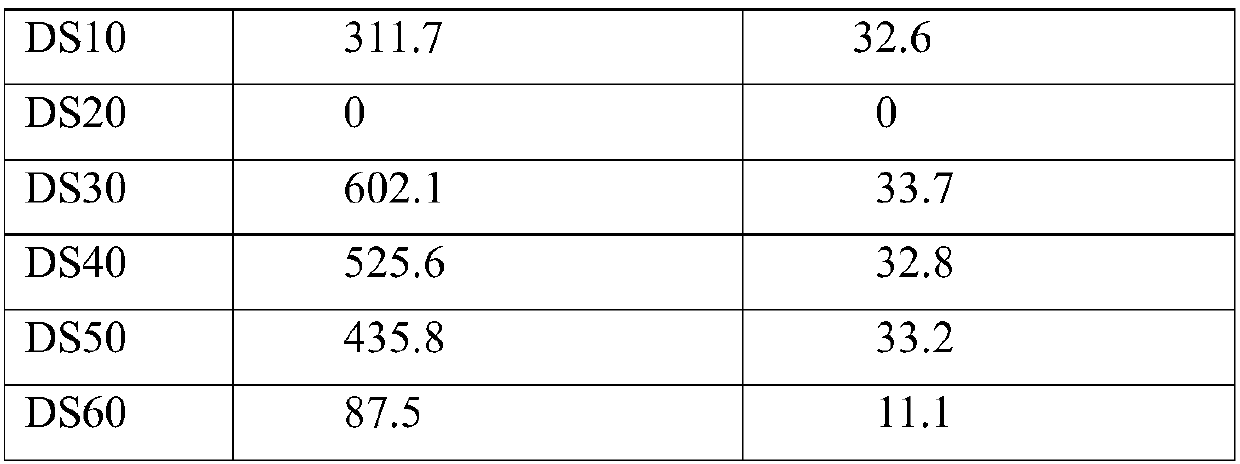

Lithium iron phosphate/carbon composite material for power battery, and preparation method and application of lithium iron phosphate/carbon composite material

InactiveCN106532013AAlleviate growth phenomenonImprove the wrapping effectCell electrodesSecondary cellsCarbon filmPower battery

The invention discloses a lithium iron phosphate / carbon composite material, and a preparation method and application thereof. The lithium iron phosphate / carbon composite material is formed by lithium iron phosphate and a complete and compact carbon film coating the surface of the lithium iron phosphate. The method comprises the steps of (1) mixing a lithium source, an iron source, a carbon source and an optional doping element source and adding a solvent for grinding and drying to obtain a precursor; (2) crushing the precursor until the particle sizes D50 are 2-8 microns; (3) carrying out roasting under the condition of introducing a gaseous organic carbon source and an inert gas to obtain a first coated product; (4) crushing the first coated product until the particle sizes D50 are 1-6 microns; and (5) carrying out roasting under the condition of introducing the gaseous organic carbon source and the inert gas to obtain a second coated product, namely the lithium iron phosphate / carbon composite material. Through coordination of process steps and control of parameters, the complete and compact carbon film can be formed on the surfaces of lithium iron phosphate particles, side reaction of the particles and an electrolyte is effectively relieved and the high-temperature performance of a battery is significantly improved.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

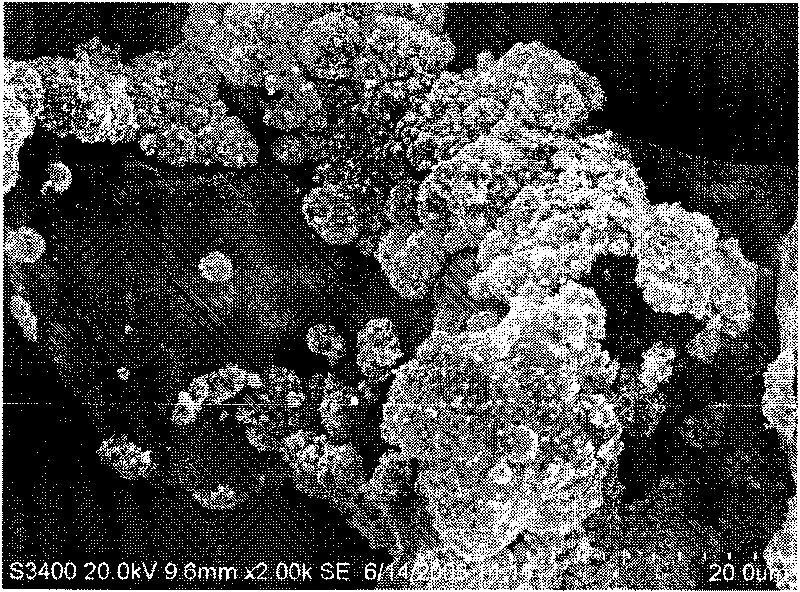

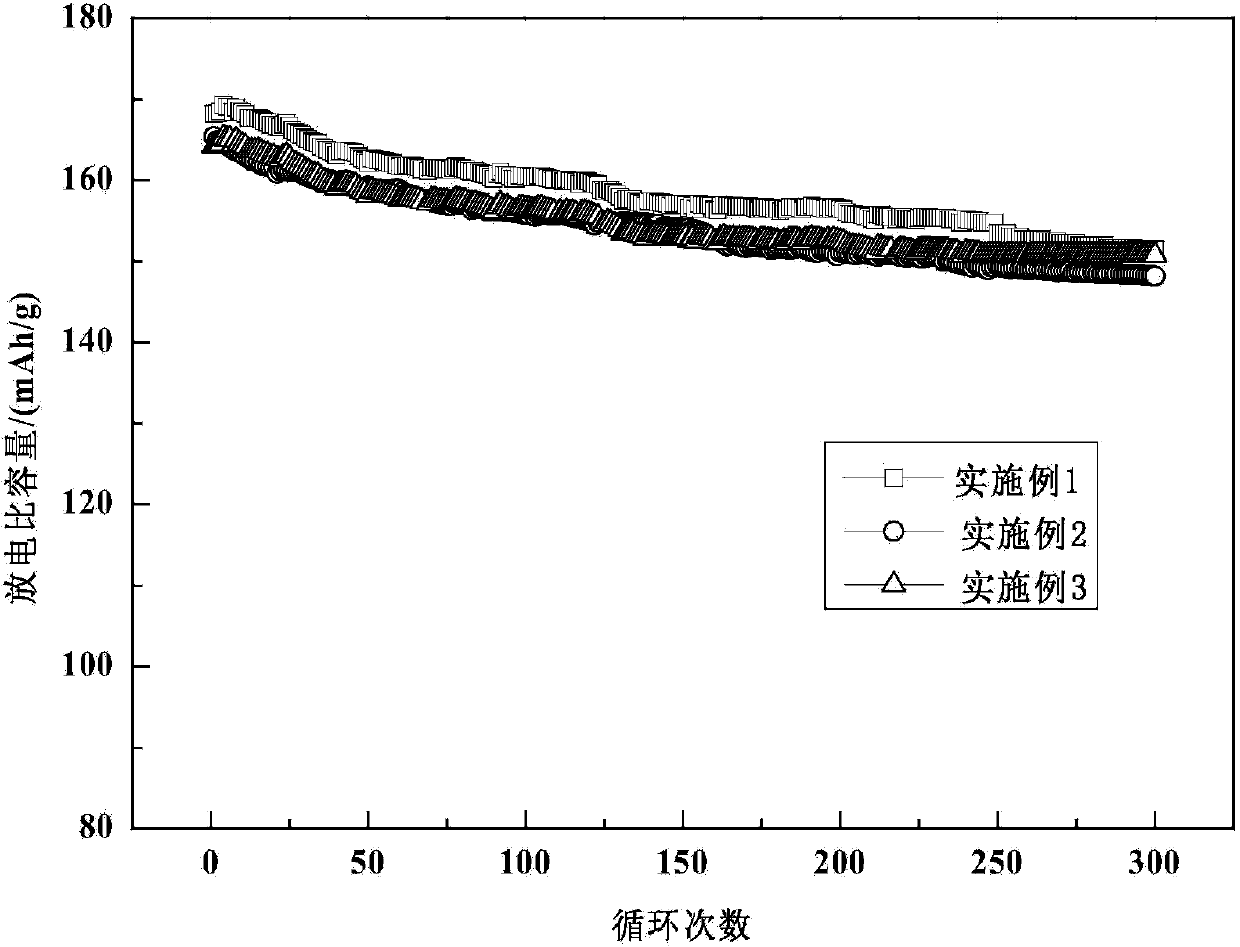

Pretreatment method of cobaltosic oxide for preparing high-voltage lithium cobalt oxide, high-voltage lithium cobalt oxides anode material and preparation method of high-voltage lithium cobalt oxide

The invention discloses a pretreatment method of cobaltosic oxide. The method comprises the steps of mixing a titanium-containing organic matter with an organic solvent so as to obtain a mixed liquid; adding cobaltosic oxide powder into the mixed liquid under a stirring condition so as to form a turbid liquid, adding deionized water into the turbid liquid, adequately stirring the turbid liquid and the deionized water until a uniform pulp-shaped fluid material is formed, and drying the uniform pulp-shaped fluid material so as to obtain a cobaltosic oxide compound. The high-voltage lithium cobalt oxide can be obtained by adequately mixing the obtained cobaltosic oxide compound, a lithium source and a dopant to obtain a mixture, and performing solid sintering and covering on the mixture at a high temperature. The tap density of the prepared high-voltage lithium cobalt oxide is more than 3.0g / cm<3>, the compaction density is more than 4.2g / cm<3>, the primary discharge gram capacity in the range of 2.8V to 4.34V can reach more than 164mAh / g, and the circulating capacity retention rate in 300 weeks is more than 89 percent. The prepared high-voltage lithium cobalt oxide has the advantages of good processing performance, high tap density, good circulating performance, high specific capacity and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

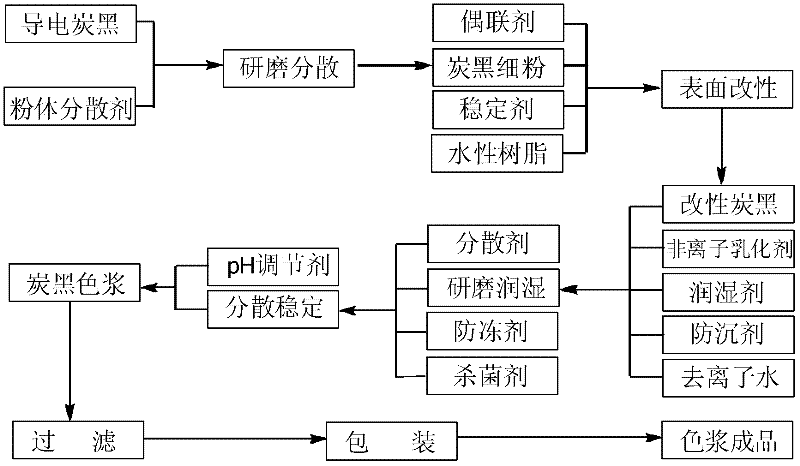

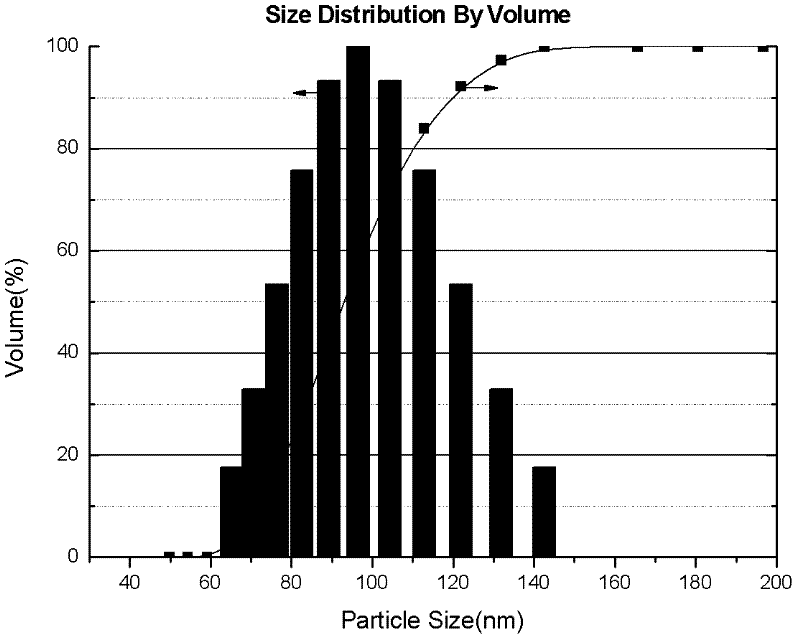

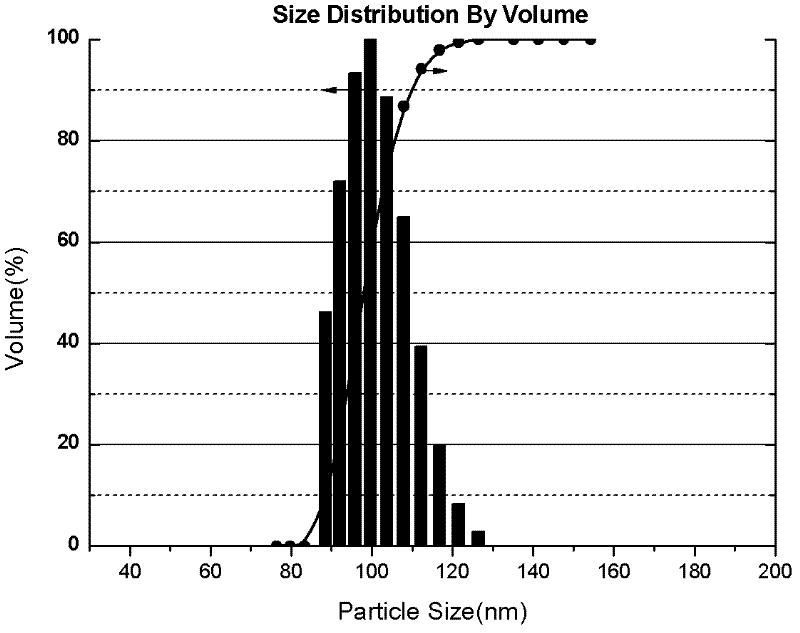

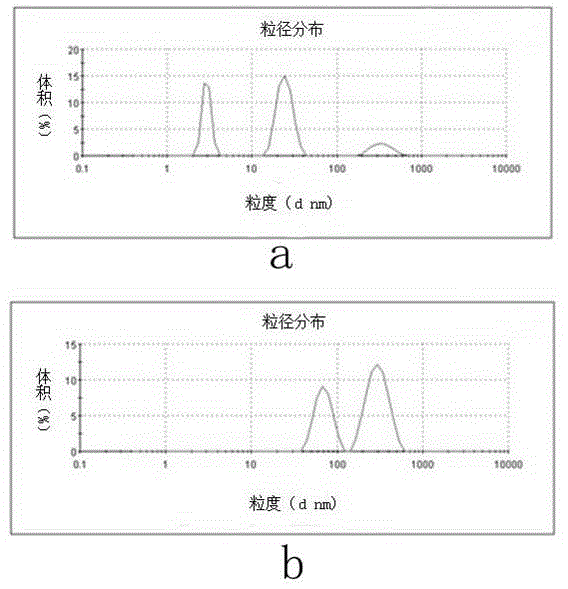

Nano aqueous conductive carbon black color paste and preparation method thereof

ActiveCN102532975ALarge particle sizeGood dispersionAntifouling/underwater paintsPaints with biocidesParticle-size distributionSurface modification

The invention provides a nano aqueous conductive carbon black color paste which comprises the following components by weight percent: 18.0-30.0% of conductive carbon black, 0.35-1.4% of powder dispersing agent, 0.7-2.0% of coupling agent, 0.02-0.24% of stabilizing agent, 0.35-1.4% of water-soluble resin, 2.0-5.5% of dispersing agent, 1.0-3.2% of wetting agent, 0.04-0.26% of anti-sedimentation agent, 0.3-1.3% of nonionic emulsifying agent, 0.002-0.008% of pH regulating agent and 55-75% of deionized water. According to the invention, the conductive carbon black color paste is prepared through a method of combing physics and chemistry by adopting dry grinding and dispersing, dry surface modification and wet grinding technologies, thus the problem that the conductive carbon black is difficult to disperse is solved, the particle size distribution of the color paste is narrow, the color paste has good compatibility with adhesive resin and is high in carbon black content, filmed paint can reduce the resistance of a coating to the greatest extent, and the prepared conductive color paste is good in stability.

Owner:GUANGDONG LEPUTAI NEW MATERIAL TECH

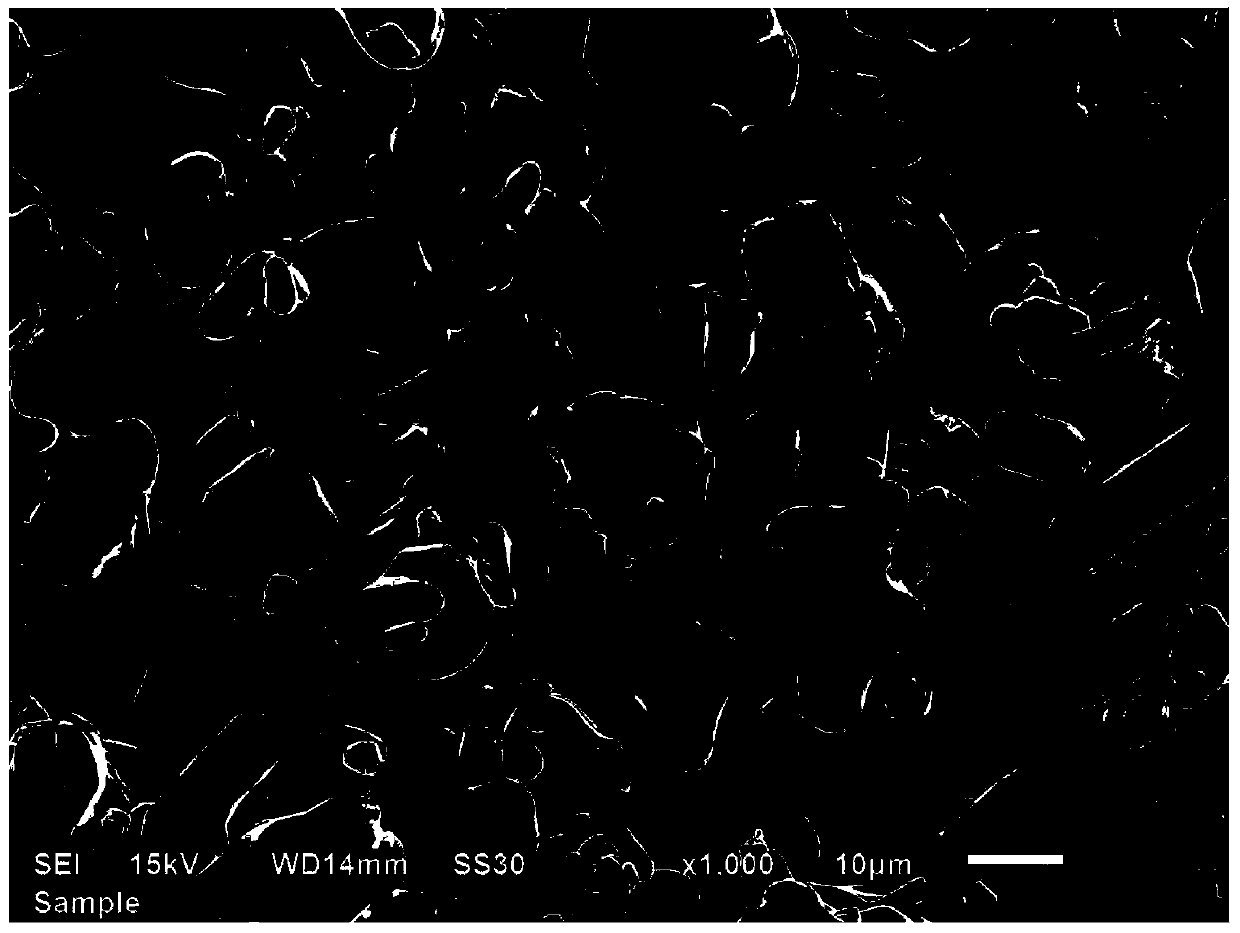

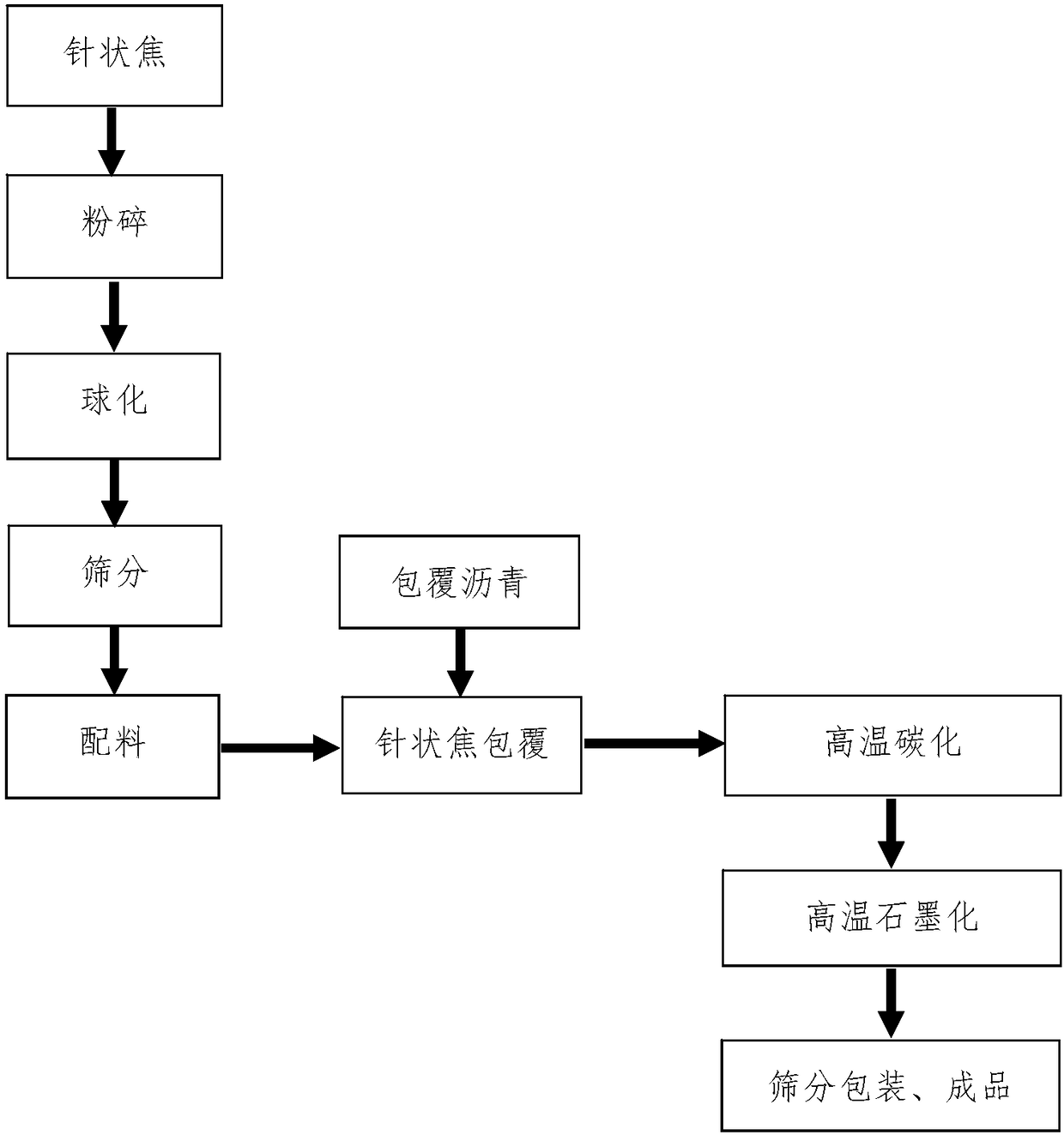

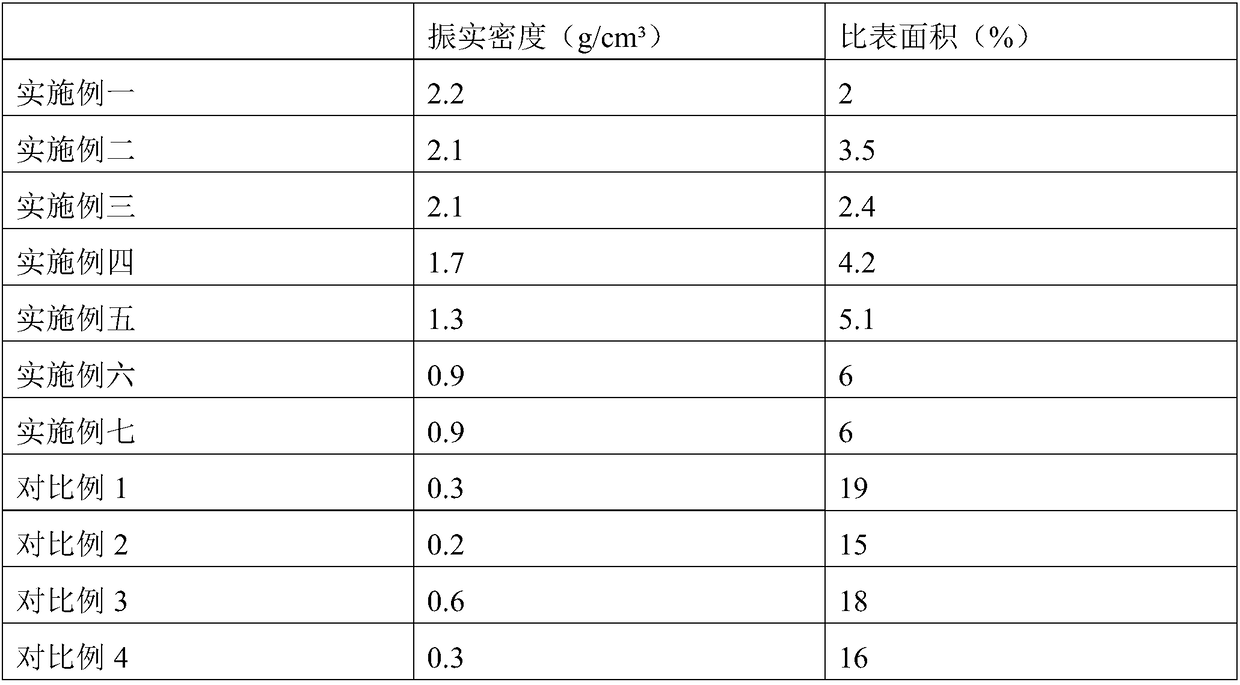

Method for producing graphite negative-electrode material by using needle coke, and negative-electrode material

ActiveCN108328613AExcellent preparation performanceLarge specific surface areaCarbon compoundsCell electrodesLithiumGraphite

The invention specifically relates to a method for producing a graphite negative-electrode material by using needle coke, and the negative-electrode material, belonging to the field of graphite negative-electrode materials. According to the method, needle coke is subjected to crushing, spheroidizing, screening, batching, coating, graphitization and screening successively so as to obtain the graphite negative-electrode material. In the step of batching, 10 to 15 parts of needle coke with a particle size in a range of 10 to 15 [mu]m, 50 to 55 parts of needle coke with a particle size in a rangeof 15 to 25 [mu]m and 20 to 35 parts of needle coke with a particle size in a range of 25 to 30 [mu]m. The invention has the beneficial effects that needle coke with three different particle sizes isused for preparing the carbon negative-electrode material, and small-particle-size needle coke which is large in specific surface area, short in the path that lithium ions take to enter particle centers and small in resistance is mixed with larger-particle-size needle coke which is small in specific surface area, long in the path that lithium ions take to enter particle centers and large in resistance, so the advantages of the small-particle-size needle coke and the larger-particle-size needle coke complement each other; and thus, the coated integral needle coke has large tap density and smallspecific surface area, and better facilitates preparation of the negative-electrode material with excellent performance.

Owner:衢州市衢发瑞新能源材料有限公司

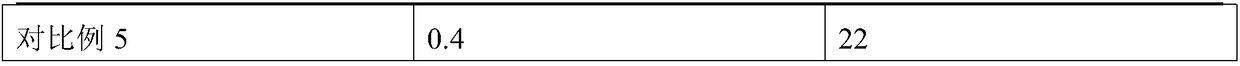

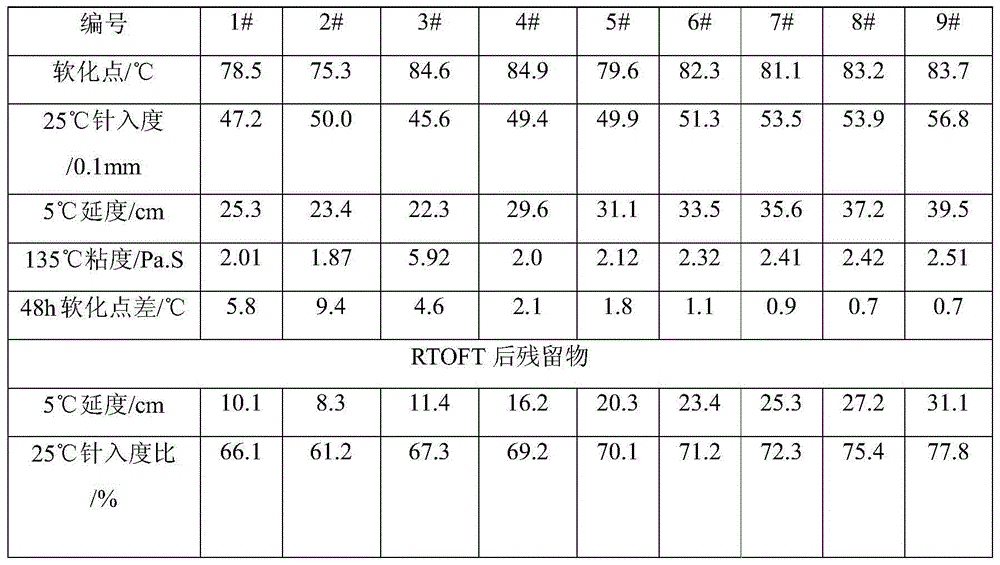

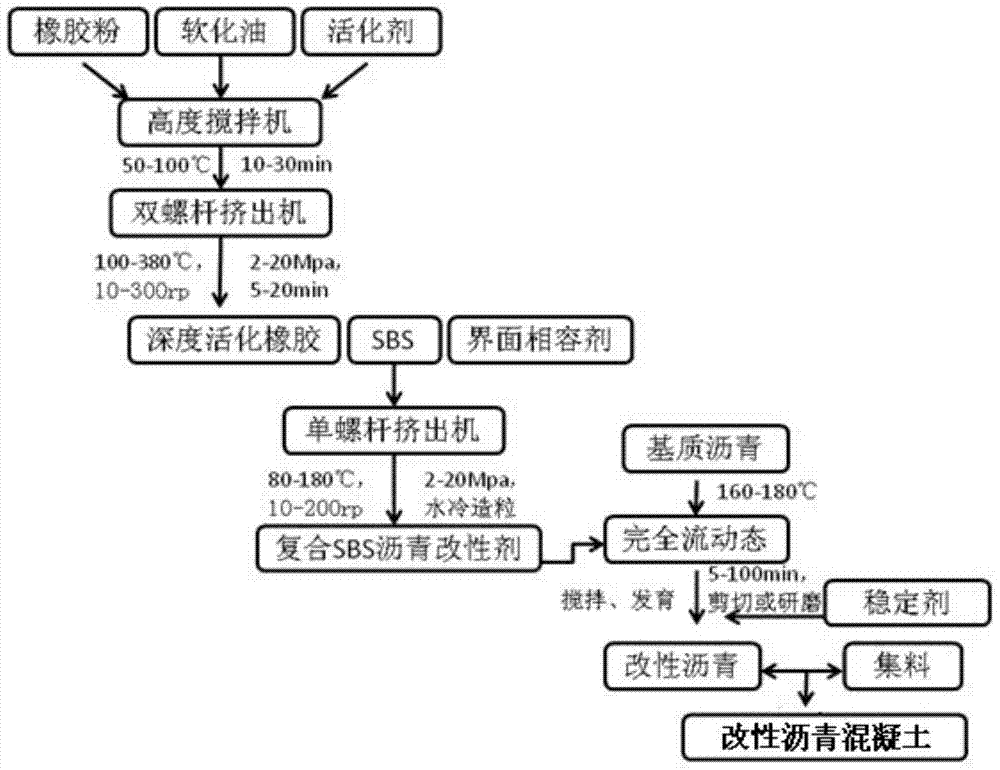

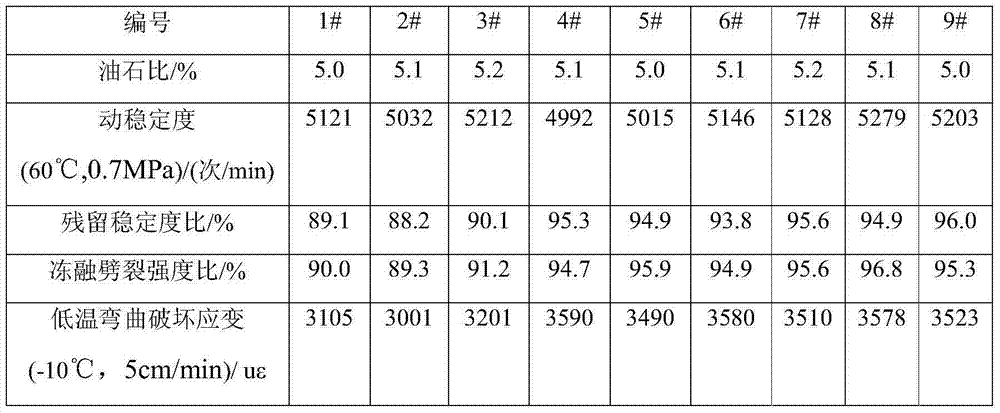

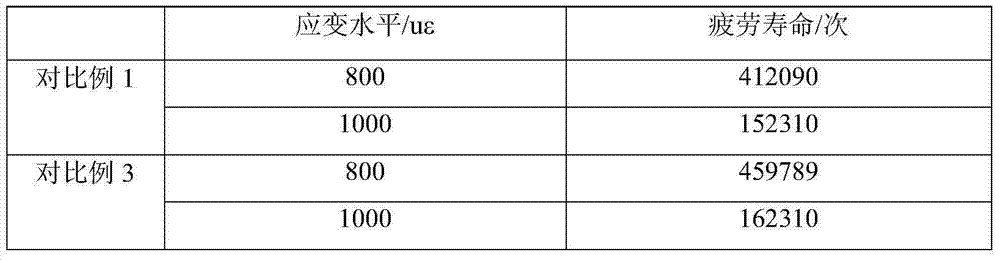

Composite-SBS (Styrene Butadiene Styrene block polymer)-particle asphalt modifier with storage stability and aging resistance and preparation method thereof

ActiveCN104693819AControl "Secondary Pollution"Low costBuilding insulationsPolymer scienceAging resistance

The invention relates to composite-SBS (Styrene Butadiene Styrene block polymer)-particle asphalt modifier with storage stability and aging resistance and a preparation method thereof. The composite-SBS-particle asphalt modifier contains the ingredients in percentage by mass: 15-38% of SBS, 56-82% of deep-activated rubber powder and 3-6% of an interface compatibilizer, wherein the deep-activated rubber powder consists of rubber powder, softening oil and an activator. The method comprises the steps: preparing the deep-activated rubber powder from waste rubber powder by using the high-temperature and high-shear action of a twin-screw extruder; thoroughly mixing the SBS particles and the deep-activated rubber powder by using the blending action of screws, and granulating, thereby preparing the asphalt modifier. Compared with asphalt modified by ordinary SBS modifiers, asphalt prepared by using the composite-SBS-particle asphalt modifier disclosed by the invention has the advantages that the ageing resistance is excellent, and heat storage does not separate out basically. Waste / used tires can be massively consumed, so as to relieve black pollution. According to the asphalt modifier, urban noise pollution and road surface microstructure can be lowered, road surface drainage is facilitated, water splashing is reduced, and the safety performance of driving is improved.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

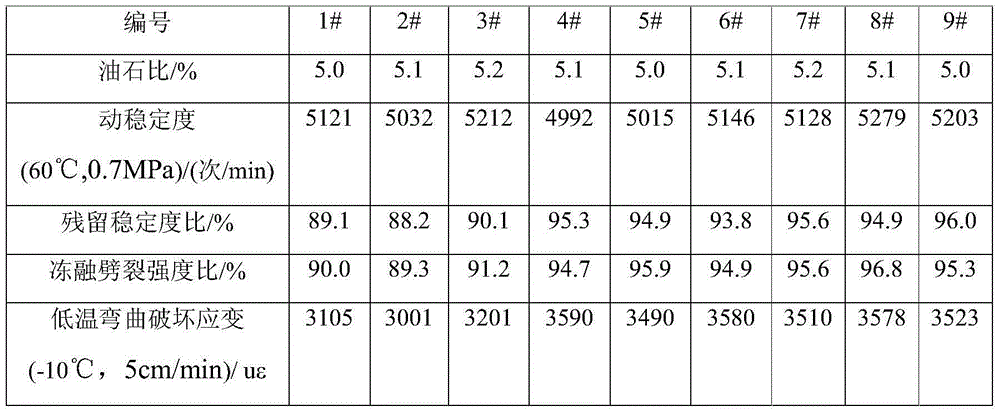

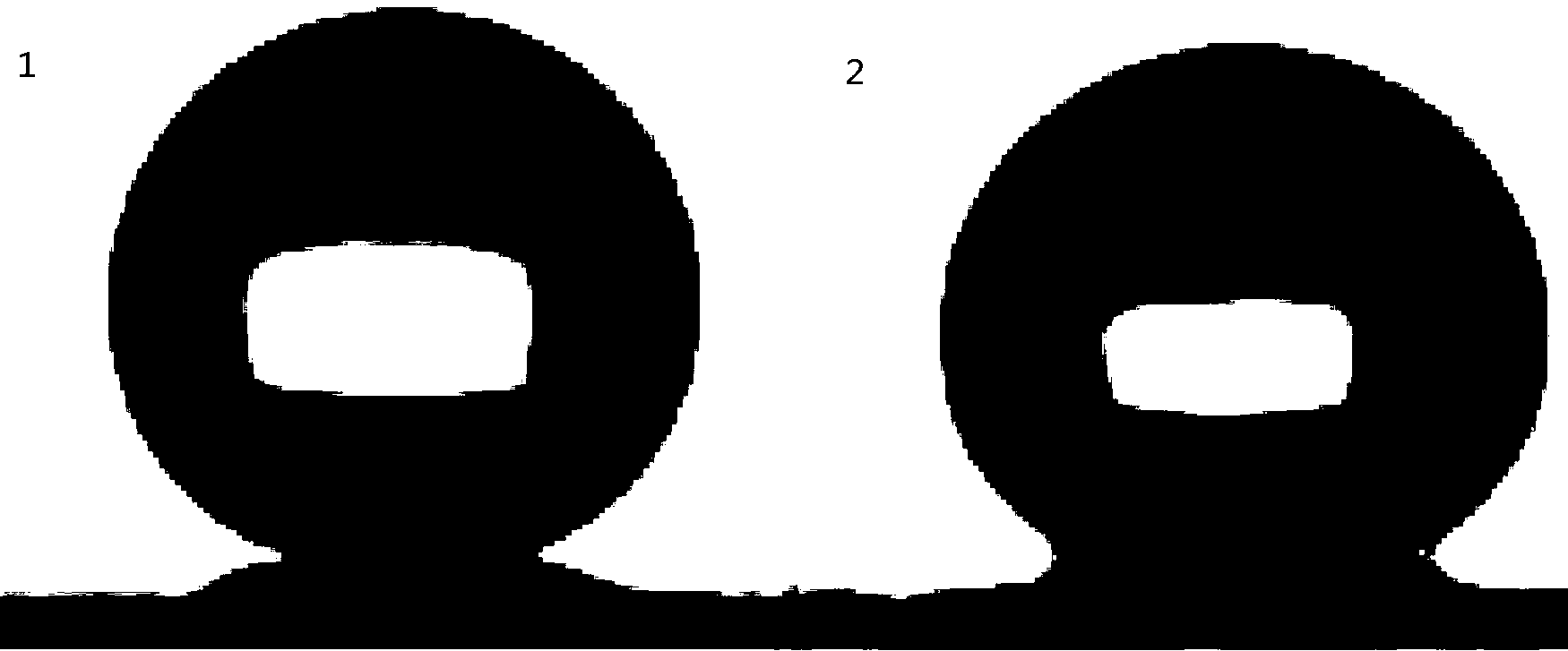

Super-hydrophobic super-oleophobic anti-reflection glass surface layer and preparation method thereof

The invention discloses a super-hydrophobic super-oleophobic anti-reflection glass surface layer and a preparation method thereof, which belong to the field of novel materials and particularly belong to the field of self-cleaning optical materials. The preparation method comprises the following steps: firstly, etching the surface of a glass body by CF3 / O2 plasma to construct a submicron coarse structure; secondly, chemically bonding a SiO2 nano porous layer; adjusting the space packing factor by means of adding a pore-foaming agent so as to construct a double-stage coarse glass surface with a suspended structure; and finally fluoridizing for modification so as to reduce surface free energy. The obtained glass surface layer achieves super-hydrophobic and super-oleophobic self-cleaning standards and has excellent light transmission. As the lower layer submicron structure in a micro-nano composite structure required by super-amphiphobic performance is directly constructed from the glass body and then a nano porous layer is chemically bonded, so that the double-layer loose structure in the prior art is avoided and the mechanical strength of the surface layer is enhanced greatly; the glass surface is high in stability and excellent in durability, thereby having significant practical application value.

Owner:JIANGNAN UNIV

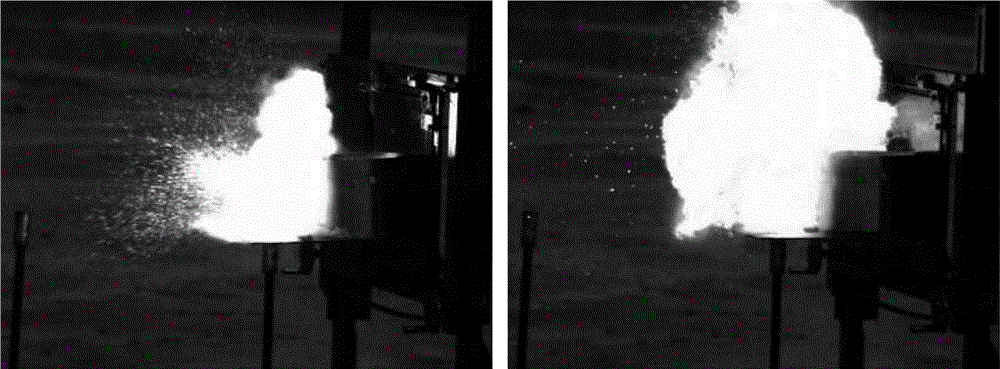

Energy-containing fragment on basis of nanometer Al/M<x>O<y>/oxidizing agents

InactiveCN105753616AHigh mechanical strengthGuaranteed penetration effectExplosivesChemical reactionFerrocene

The invention relates to an energy-containing fragment with nanometer Al / M<x>O<y> / oxidizing agents.The energy-containing fragment comprises, by weight, 10-30% of nanometer aluminum powder, 30-60% of transition metal oxide (the M<x>O<y>), 10-40% of the oxidizing agents, 1-5% of ferrocene, 1-7% of high explosive and 3-8% of mixed binders.The energy-containing fragment has the advantages that the energy-containing fragment is high in energy density and fire setting capacity, good in safety performance and easy to ignite, immediate reaction can be prevented when the energy-containing fragment is driven by explosive, but violent chemical reaction can be carried out in penetration procedures, extremely high-temperature heat can be released, and high-temperature hot reaction products with flowability can be generated.

Owner:ZHONGBEI UNIV

Preparation method of antifogging and antireflection film coating liquid

The invention discloses a preparation method of an antifogging and antireflection film coating liquid. The preparation method comprises the following steps: (1) dispersing nano silica in deionized water to prepare a dispersion liquid with mass percent concentration of 0.1-30%, adding a silane coupling agent to the dispersion liquid, heating to raise the temperature, and reacting for 0.2-1 hour; (2) adding a mixed solution which is formed by acrylic acids and acrylic esters and is diluted by a diluent to the solution in the step (1), stirring and mixing the solutions at 50-80 DEG C for 30-40 minutes, then adding an initiator, reacting for 5-10 hours, and cooling to obtain a nanocomposite dispersion liquid; (3) diluting the nanocomposite dispersion liquid in the step (2) into a solution with concentration of 0.1-50wt%. The preparation method has the beneficial effects that an in-situ free radical polymerization method is adopted, the coating effects are better, the coating can be ensured to have good apparent properties, and the coating is high in drying speed and has excellent antireflection and anti-dazzle effects.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

Preparation method for flake-like aluminium powder pigment

The invention discloses a preparation method for a flake-like aluminium powder pigment, and the method comprises the following steps: putting 1-1.5 tons of steel balls of which the diameter is 0.8-1.5mm, 1-10mu m of spherical aluminium powder, 150#or 200# solvent oil and accessory ingredients into a ball mill at a certain ratio; introducing nitrogen for protection; after the ball mill carries outball milling at a higher speed for 5-7 hours, slowing the revolving speed to carry out ball milling for 1.5-3 hours; after ball milling is finished, adding 80-120kg of 150# or 200# solvent oil for diluting; pressing out the diluted aluminium slurry by virtue of an air pump; screening and grading by virtue of a vibrating screen; carrying out filter pressing by a use of a plate and frame type filter press; separating solid and liquid to obtain a filter cake of which the solid content is 70-80%; adding a 150#or 200# diluted phenolic antioxidant; kneading in a kneader for 40-60 minutes; and packaging. By utilizing the preparation method disclosed by the invention, silver dollar type flake-like metal particles with even particle diameter can be obtained, the product performance is improved, the coating effect of the aluminium particle is improved, the phenomenon of silver drop can be solved, the surface of the aluminium particle is smooth and flat, and the welding, burr and the like of thealuminium particle can be reduced.

Owner:HEFEI SUNRISE PIGMENTS

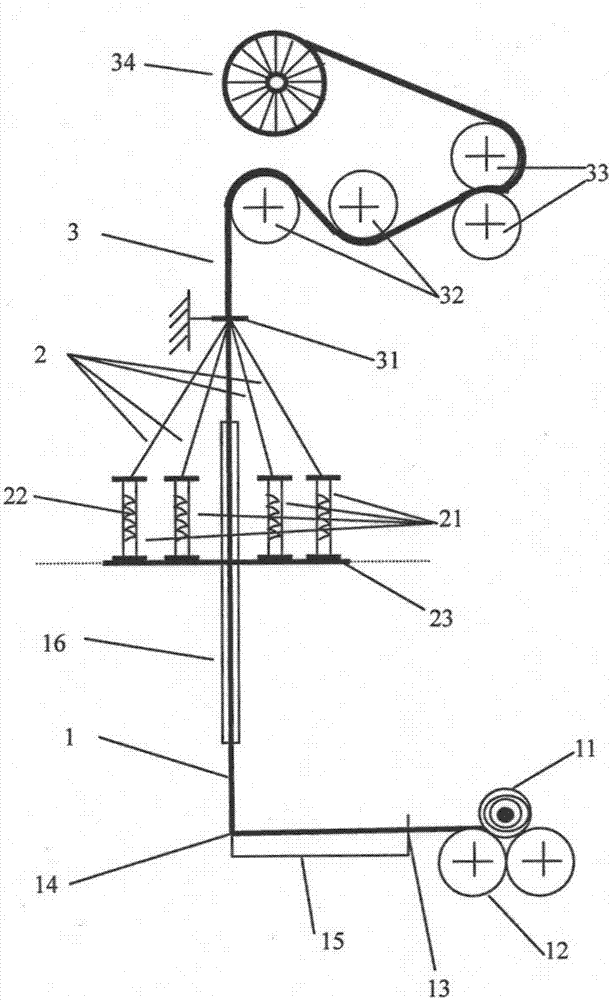

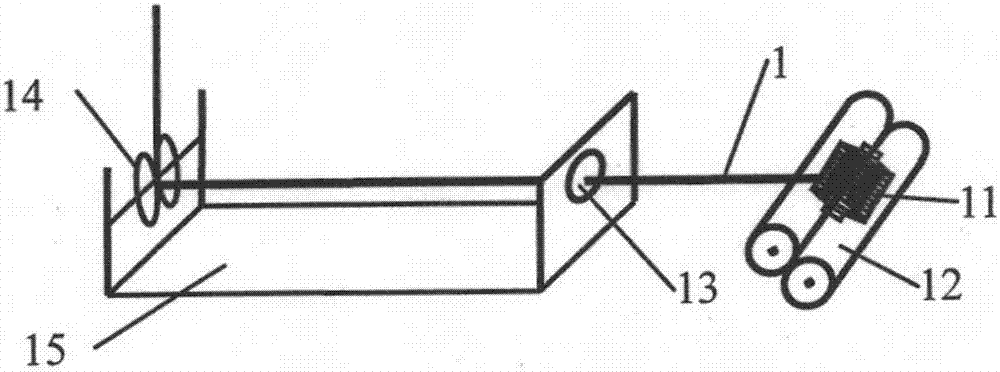

Stable structure stretching composite yarn, and preparation device, method and use thereof

The invention provides a stable structure stretching composite yarn, and a preparation device, a method and use thereof. The stable structure stretching composite yarn is characterized by comprising wrap yarns and elastic core yarns, the wrap yarns are twisted on the surfaces of the elastic core yarns in an intercrossing manner and have a Poisson ratio effect. The stretching composite yarn is good in formation, stable in structure, unique in performance and obvious in stretching effect, a proper raw material can be selected to apply to human body protection fabrics, biomedical materials, engineering materials and the like, meanwhile the spinning device is refitted based on a miniature knitting machine, and the spinning method is easy to operate, is convenient to implement, low in cost and is suitable for continuous production and application.

Owner:DONGHUA UNIV

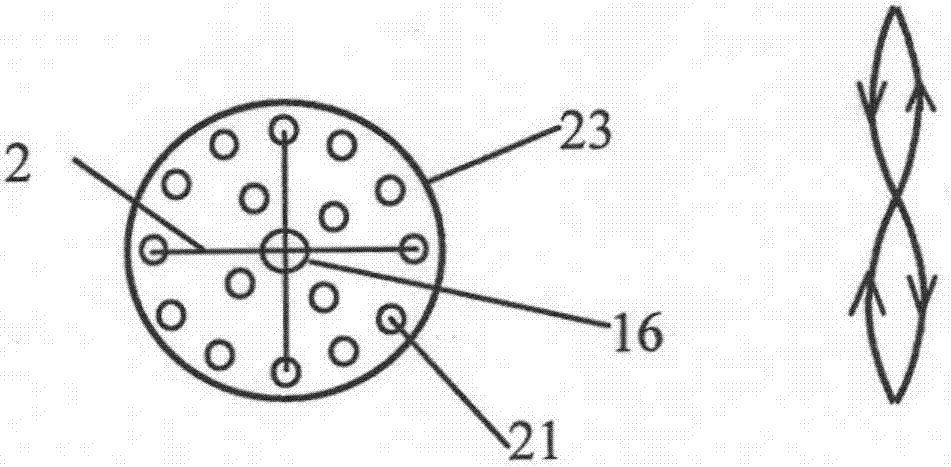

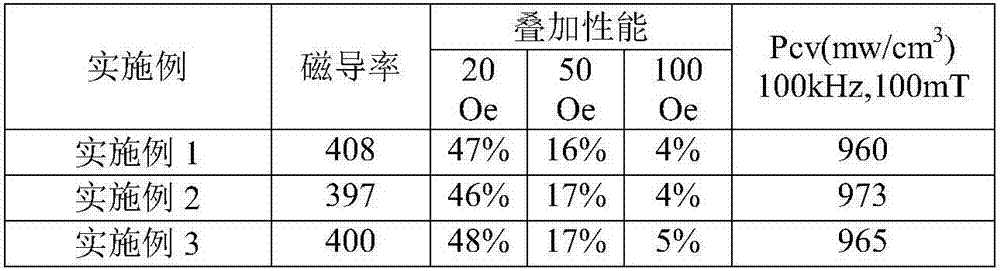

Preparation method of iron-nickel-molybdenum metal magnetic powder core with magnetic permeability mu = 400

ActiveCN107578873AImprove permeabilityReduce dosageInorganic material magnetismBiological activationHeat treated

The invention relates to the technical field of metal soft magnetic material manufacture, in particular to a preparation method of an iron-nickel-molybdenum metal magnetic powder core with the magnetic permeability mu = 400. The preparation method comprises the steps of 1, weighing material; 2, gas atomization pulverizing; 3, granularity combination; 4, heat treatment; 5, activation treatment; 6,once insulating coating; 7, twice insulating coating; 8, compression molding; 9, core annealing; 10, immersion spraying. According to the preparation method of the iron-nickel-molybdenum metal magnetic powder core, before the insulating coating, the surface of the magnetic powder is activated by using an activator, the coating effect is increased, the formed coating layer is more uniform, and theprepared core is not easy to break; organic reagent is not used, and the preparation process is greener and more environmentally friendly; a high temperature release agent is adopted, the heat treatment temperature is high, the forming pressure is low, the magnetic permeability of the magnetic core is improved; the whole method is simple in process, easy to implement and strong in operability.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Flexible glue for coating ABS material and method for producing the same

The invention discloses a soft plastic used for coating ABS material and a preparation method thereof. The soft plastic comprises the components according to the weight percentage: 30-60% of PU, 5-25% of white oil, 15-25% of SEBS, 10-20% of ABS resin, 3-5% of compatilizer, 0.2-0.4% of antioxidizer and 0.5-1% of other accessory ingredients. The invention has the advantages that the raw materials are environment-friendly and sanitary, so that the prepared soft plastic is sanitary and environment-friendly; besides realizing high intensity and elasticity as well as good abrasion resistance, oil proof property, low temperature resistance and aging resistant performance, the soft plastic has high flexibility and comfort; due to good adhesive bonding property with the ABS material, the coating effect between the soft plastic and the ABS base material can be improved. The preparation method provided by the invention is simple in technique.

Owner:徐东

Preparation method of coated bismuth vanadate pigment

ActiveCN103525128AImprove acid resistanceImprove the wrapping effectPigment physical treatmentEnvironmental chemistryAcid resistance

The present invention provides a method for preparing a coated bismuth vanadate pigment, comprising steps of: providing a bismuth vanadate substrate of a specified particle size; adding pure water to the bismuth vanadate substrate of the specified particle size to formulate a basic coating slurry; heating the basic coating slurry, carrying out a chemical reaction for coating, adjusting the pH, and carrying out filtering, washing, drying, sintering, wet milling, filtering and washing after the coating reaction is complete, to obtain coated bismuth vanadate; and adding pure water to the obtained coated bismuth vanadate to formulate a basic coating slurry, and repeating the previous step for a specified number of times, to obtain a final coated bismuth vanadate pigment. Through the method for preparing a coated bismuth vanadate pigment of the present invention, acid resistance, alkali resistance and temperature resistance of the obtained coated bismuth vanadate pigment can be improved, thereby avoiding interference between different layers in the multilayer coating process.

Owner:昆明先导新材料科技有限责任公司

Film-coating method for glass fiber yarn cluster

ActiveCN106586060ATransport impactImprove coating efficiencyWrapper folding/bending apparatusWrapping with article rotationGlass fiberYarn

The invention discloses a film-coating method for a glass fiber yarn cluster, and belongs to the technical field of glass fiber production equipment. The invention aims to provide the film-coating method for the glass fiber yarn cluster, and the coating method is relatively good in coating effect and is high in film-coating efficiency. The film-coating method comprises the following steps: step I: conveying yarn clusters; step II: grabbing the yarn clusters; step III: pressing the yarn clusters; step IV: coating a film, wherein a coating film is pushed to a specific position through a film feeding device, a gas blowing tube of a film cutting mechanism of the film feeding device works to blow the coating film; and the coating is adhered on the yarn cluster in a sticky mode, and the coating film is pressed onto the yarn cluster through a film-pressing thin sheet of the film pressing device; a clamping rotating device drives the yarn cluster to rotate, the coating film is continuously guided out and is coated on the cluster yarn; and the film is cut off through a blade of a film cutting mechanism; step V: pushing a film, wherein the film pressing device moves upwards and the film pressing device works to level the coating film exceeding the upper end surface of the yarn cluster to the upper end surface of the yarn cluster; and step VI: outputting finished products. The film-coating method is a film-coating method suitable for coating a layer of film outside the glass fiber yarn cluster.

Owner:福德机器人(成都)有限责任公司

Automatic spinning-necking equipment

The invention discloses automatic spinning-necking equipment. A rotating disk is arranged on a rack; fixture assemblies are arranged on the rotating disk; power assemblies capable of driving the fixture assemblies to rotate are arranged on the rack; a spinning assembly is arranged above a spinning station and comprises a lifting frame capable of being lifted relative to the rack; a lifting plate capable of being lifted relative to the lifting frame is arranged on the lifting frame; a spinning piece is connected onto the lifting plate and comprises at least three spinning connecting rods hinged to the lifting plate in the circumferential direction; spinning forks are hinged to the spinning connecting rods; each spinning fork comprises a main body section and bifurcated sections, the main body section is hinged to the spinning connecting rod, ends of the bifurcated sections are hinged to stand columns arranged on the lifting frame, and a necking wheel is arranged on the spinning fork and is located between the two bifurcated sections; an abutting piece which can rotate relative to the lifting frame and abut against a workpiece is arranged on the lifting frame and located among the stand column; and an unlocking assembly for unlocking the fixture assemblies is further arranged on the rack. The equipment is simple in structure, high in production efficiency and good in workpiece necking effect.

Owner:ZHONGSHAN XINHUI PRECISION TECH CO LTD

Storage-stable and ageing-resistant composite SBS particle modified asphalt concrete and preparation method thereof

ActiveCN104710134AControl "Secondary Pollution"Low costBuilding insulationsNoise pollutionMicrostructure

The invention discloses a storage-stable and ageing-resistant composite SBS particle modified asphalt concrete and a preparation method thereof. The composite SBS particles comprise 15%-38% of SBS, 56%-82% of deep activation rubber powder, and 3%-6% of an interface compatibilizer, wherein the deep activation rubber powder consists of rubber powder, softening oil and an activating agent. According to the storage-stable and ageing-resistant composite SBS particle modified asphalt concrete and the preparation method thereof, waste rubber power is processed through a double-screw extruder under the high-temperature and high shearing condition to obtain the deep activation rubber powder; and besides, the blending effect of screw rods is utilized to fully mix SBS particles with the deep activation rubber powder to prepare the composite SBS particles through granulation, and the composite SBS particles are utilized to prepare modified asphalt concrete; Compared with a common SBS modifying agent, the composite SBS particle modified asphalt concrete is better in ageing resistance, and has no heat storage evolution; junked tires can be excessively consumed, the black pollution is reduced, city noise pollution is reduced, and the surface drainage is facilitated, water splattering is alleviated, and the traffic safety performance is improved through the pavement surface microscopic structure.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

Ternary positive electrode material doping and coating method, ternary positive electrode material and lithium ion battery

ActiveCN112993258AStable structureSave abrasiveSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention discloses a ternary positive electrode material doping and coating method, a ternary positive electrode material and a lithium ion battery. The method comprises the following steps: 1) preparing a ternary positive electrode material precursor by adopting silicate doped with metal source, a nickel source, a cobalt source and a manganese source through a one-stepco-precipitation method, and performing primary sintering to obtain a ternary positive electrode material core co-doped with silicon and doped metal elements; and 2) cleaning the inner core of the ternary positive electrode material by using a saturated solution of silicate as a base solution, adding metal salt in the cleaning process to perform precipitation coating, and performing secondary sintering after dehydration to obtain the doped and coated ternary positive electrode material. The method disclosed by the invention is simple to operate, the doping and coating uniformity is guaranteed, and meanwhile, the cost is properly reduced. The prepared positive electrode material is good in doping and coating effect, the problem of gas production can be effectively solved, and the cycle performance is improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

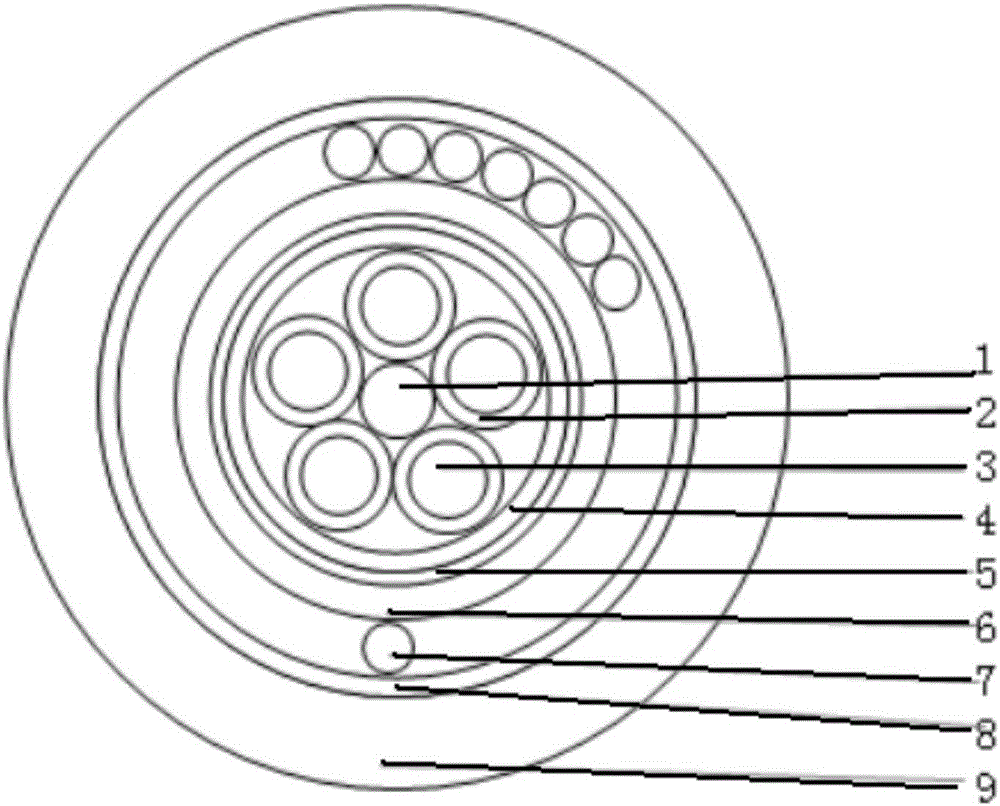

High-grade flame-retardant fireproof optical cable

ActiveCN106125216AHigh viscosityGood compatibilityClimate change adaptationFibre mechanical structuresFiberLow smoke zero halogen

The invention discloses a high-grade flame-retardant fireproof optical cable. The high-grade flame-retardant fireproof optical cable comprises a layer stranded type cable core, the layer stranded type cable core is wrapped by a double-face synthetic mica tape layer, the double-face synthetic mica tape layer is wrapped by a steel plastic composite band layer, the steel plastic composite band layer is externally plastically extruded by a low-smoke halogen-free inner sheath, the low-smoke halogen-free inner sheath is externally provided with at least one armored layer, the armored layer is externally provided with a fireproof layer and a low-smoke halogen oversheath, the low-smoke halogen-free inner sheath and the low-smoke halogen-free oversheath are both prepared by low-smoke halogen-free ceramic polyolefin, and the low-smoke halogen-free ceramic polyolefin comprises 60-70% of matrix polyolefin and 30-40% of an auxiliary agent, wherein the auxiliary agent comprises a plasticizer, white carbon black, 3% of micro-encapsulated red phosphorus, siloxane, 15-28% of a gas-phase fire retardant and 5-7% of a special fire retardant. The ceramic polyolefin is a halogen-free high-oxygen index sheath material and is easily ceramic during high-temperature combustion to form a compact protection layer so as to obstruct flames and heat transfer and accordingly prevent fibers from high-temperature damage.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

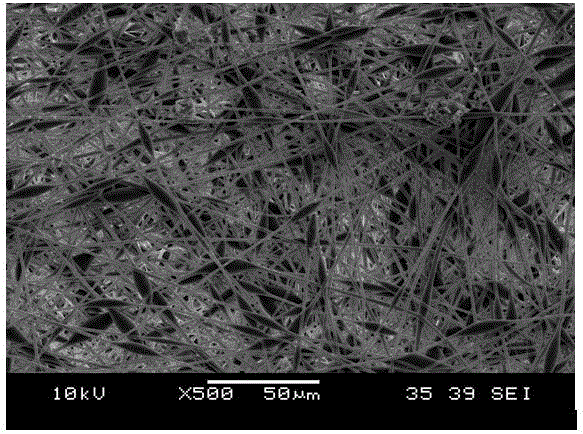

Method for preparing phase-changing fiber having core-shell beaded structure

InactiveCN106048757AFew preparation stepsHigh energy storage densityFilament/thread formingConjugated synthetic polymer artificial filamentsFiberOrganic solvent

The invention discloses a method for preparing phase-changing fiber having a core-shell beaded structure. The method includes: dissolving phenolic resin and polymer component in an organic solvent to form a resin solution, and putting the resin solution in an injector connected to a spinning head skin layer; putting a lower temperature phase changing material in an injector connected to a spinning head core layer; acquiring phase-changing nascent fiber on a rotation or flat plate receiving device; and putting the obtained phase-changing nascent fiber in a curing solution to be cured, and washing and drying the cured phase-changing nascent fiber to obtain the phase-changing fiber having the core-shell beaded structure. The beaded phase-changing fiber having a special structure is prepared through a single-step coaxial electrostatic spinning method, and the preparation steps of the phase-changing fiber are reduced; the connected core-shell structure is obtained through the coaxial electrostatic spinning method, secondary load can be reduced, the energy density of the phase-changing fiber is improved, and the efficacy of the phase-changing fiber can be improved; and skin and core beads prepared by the electrostatic spinning method can coat the phase-changing material well, and the coating performance of the phase-changing fiber can be improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Positive active material, preparation method thereof, positive electrode and battery

PendingCN110299515AImprove stabilityInsulation erosionCell electrodesSecondary cellsCarbideLithium-ion battery

The present invention provides a positive active material comprising a core material and a coating layer. The core material comprises a lithium salt which is one or more selected from the group consisting of LiFeBO3, Li2FeSiO4, Li5FeO4, Li6CoO4, Li6MnO4, Li2NiO2 and Li2CuO2. The coating layer coats the core material and comprises carbon and metal carbide. The invention also provides a positive electrode containing the positive active material and a lithium-ion battery, the coating layer of the positive active material can isolate the influence of water in the air on the core material, the stability and conductivity of the material are improved, and the electrical conductivity and stability of the battery are improved.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com