Patents

Literature

494 results about "Size difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanisms for avoiding problems associated with network address protocol translation

ActiveUS7006526B1Avoid problemsReduce morbidityError preventionTransmission systemsSize differenceSize increase

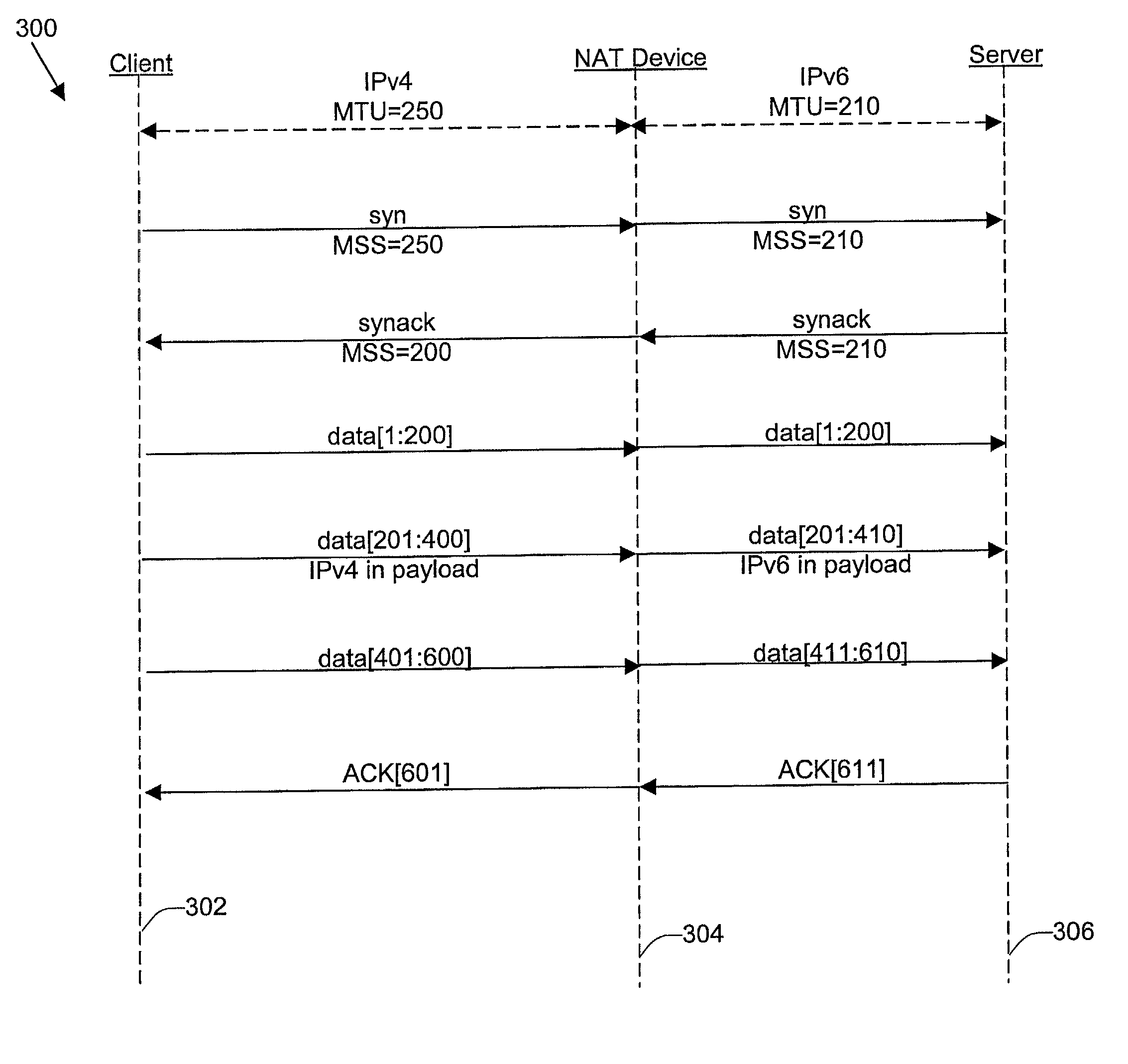

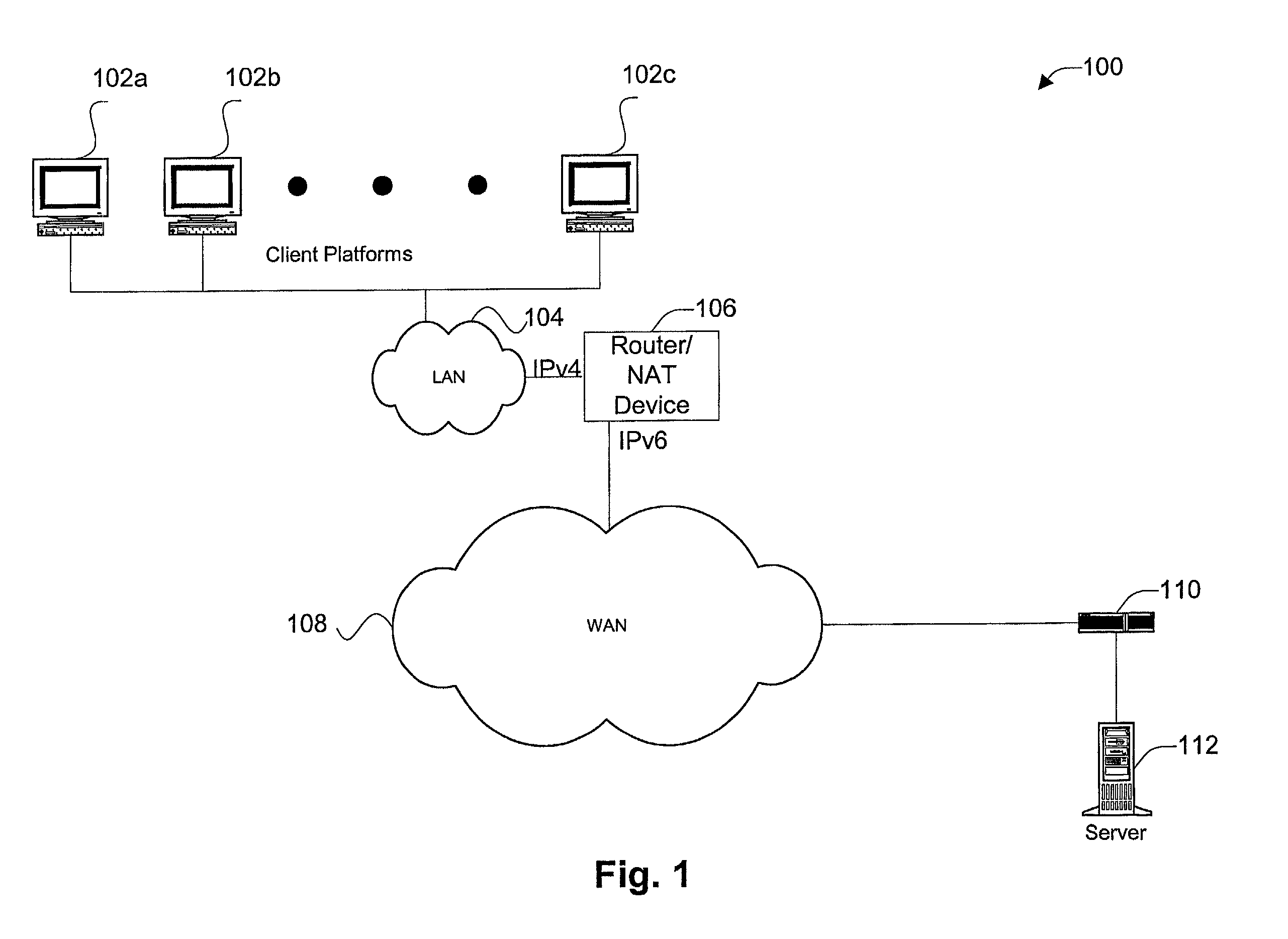

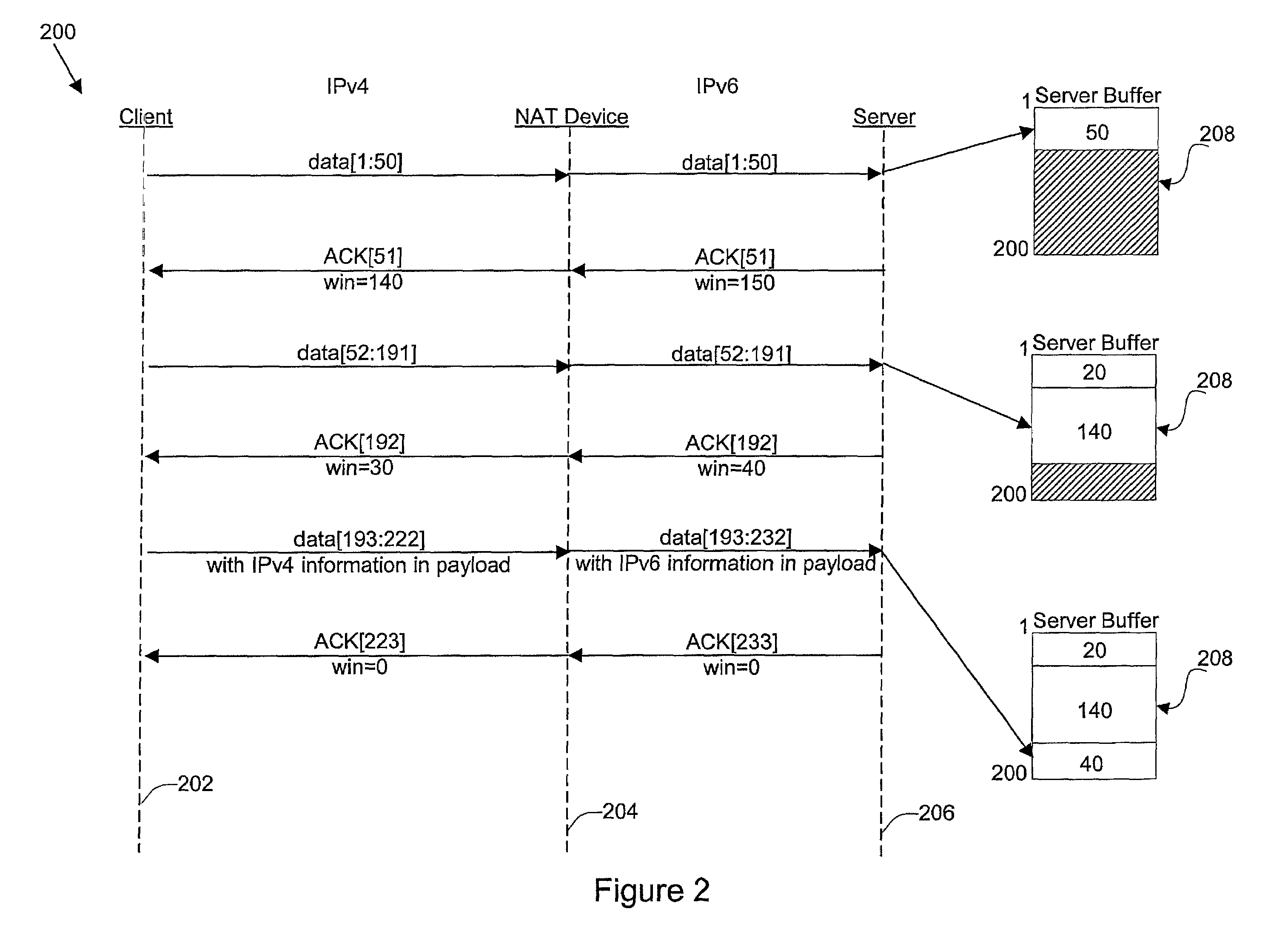

Disclosed are methods and apparatus for avoiding problems caused by converting between two different protocols, such as IPv4 and IPv6. These problems may include, but are not limited to, fragmentation of packets, dropping of packets, and retransmission of packets. Avoiding these problems will reduce the incidence of transmission delays, bandwidth degradation, and additional processing in the packet's transmission path due to such problems. In general terms, the present invention provides mechanisms for modifying a protocol parameter, such as a TCP or UDP parameter, to avoid problems associated with protocol translation, such as fragmentation. In one implementation, the protocol parameter limits the size of a particular portion of the a packet transmitted by a sending computer node or device. For example, a packet size indicator is communicated to the sending computer node so that the sending computer node sends packets limited by the packet size indicator to thereby avoid associated with the size of such packets. In specific TCP embodiments, the size indicator specifies a window size and / or a maximum segment size. For example, if packets transmitted by a sending node to a receiving node are converted from IPv4 to IPv6 and the window size indicated to the sending node (e.g., by the receiving node) is 512 bytes, the window size is adjusted to 500 bytes before reaching the sending node. The adjustment amount may be based on an estimated size increase resulting from converting from IPv4 to IPv6. In this example, the window size is decreased by 12 bytes since a conversion from IPv4 to IPv6 where one 4 byte IPv4 address is changed to a 16 byte Ipv6 address has an associated size difference of 12 bytes. In a specific embodiment, actual changes in packet size may tracked and the adjusted size indicator may be dynamically based on such tracked changes. In other embodiments, the changes in packet size are predicted, and the adjusted size is preemptively changed as needed.

Owner:CISCO TECH INC

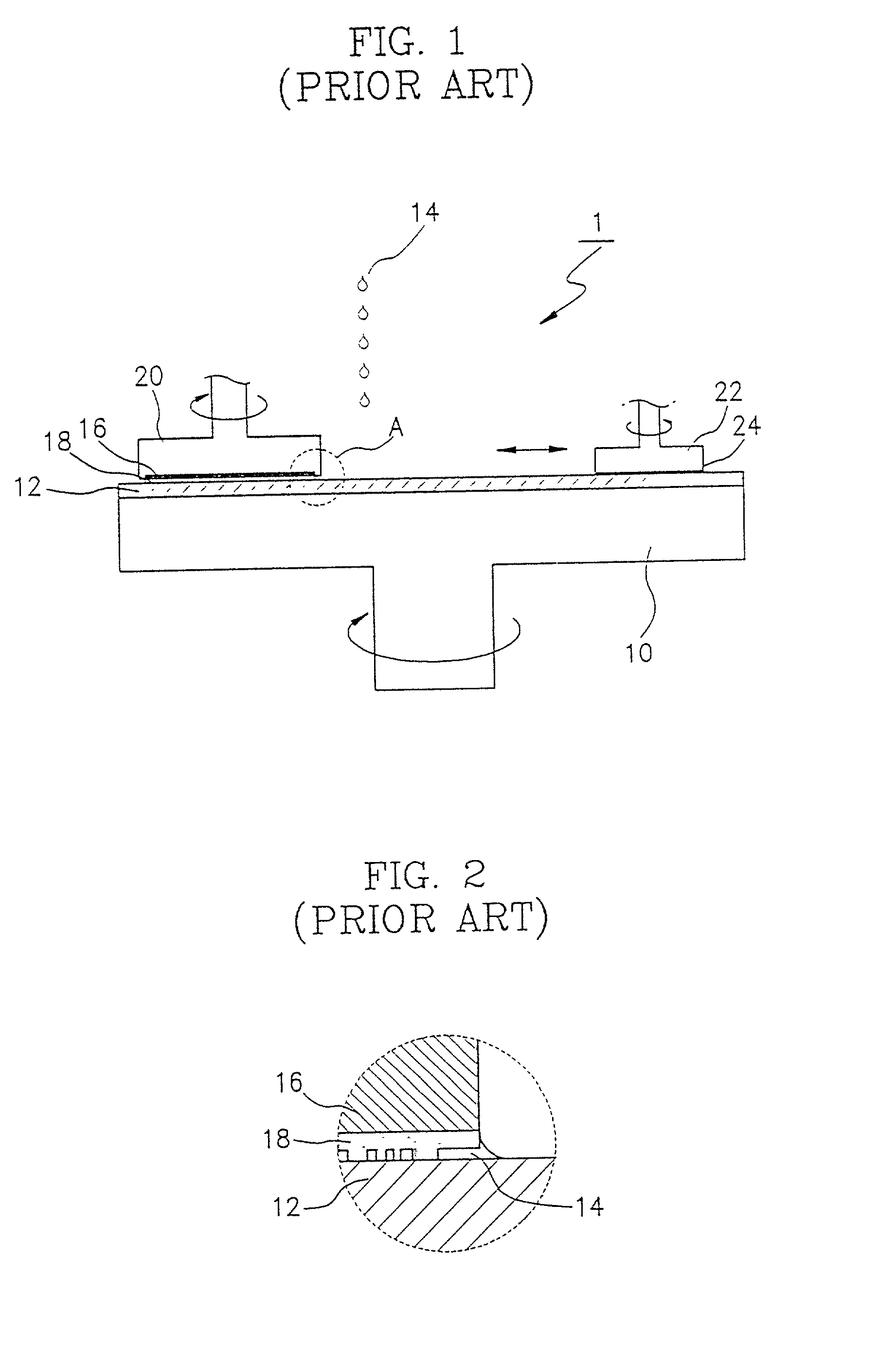

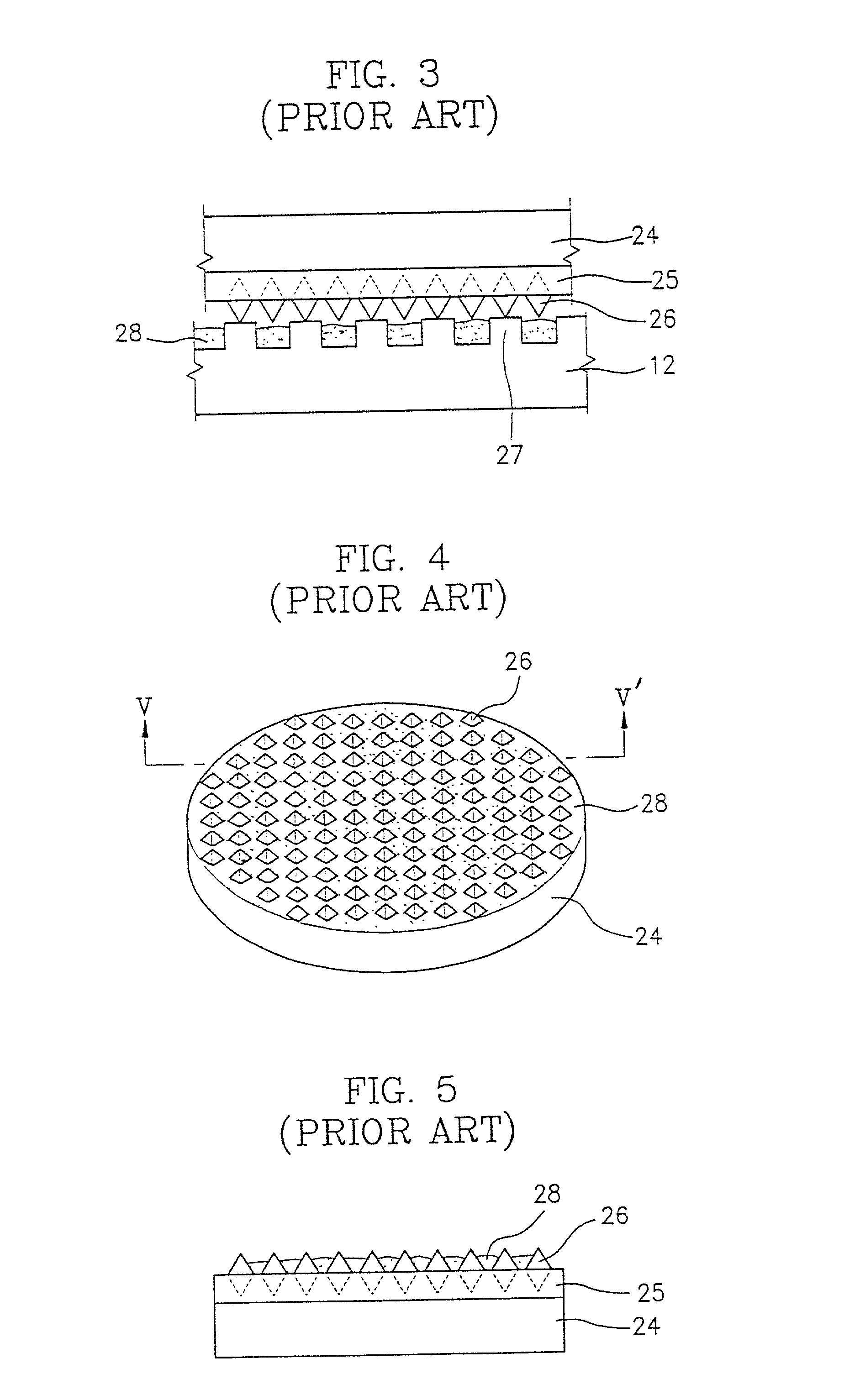

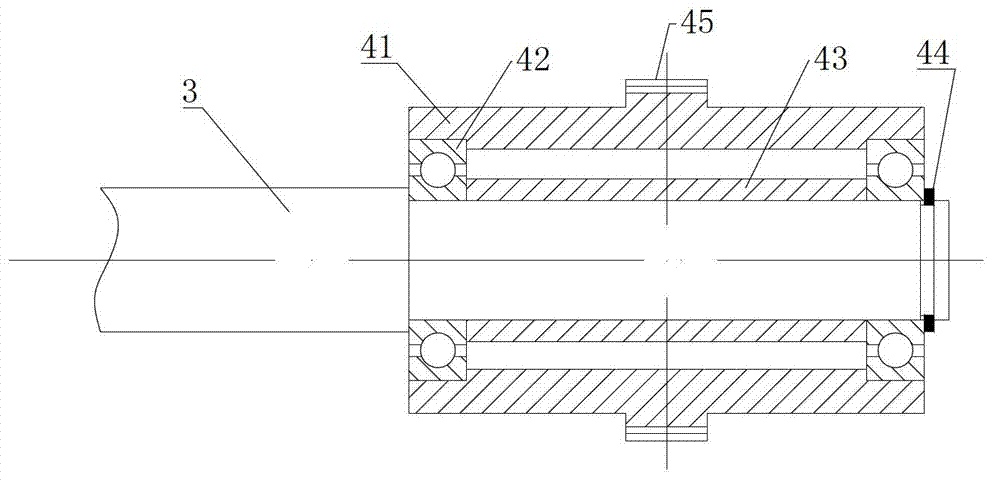

Conditioner and conditioning disk for a CMP pad, and method of fabricating, reworking, and cleaning conditioning disk

InactiveUS20020127962A1Effective conditioningProlong lifeGrinding drivesBelt grinding machinesSize differenceCleaning methods

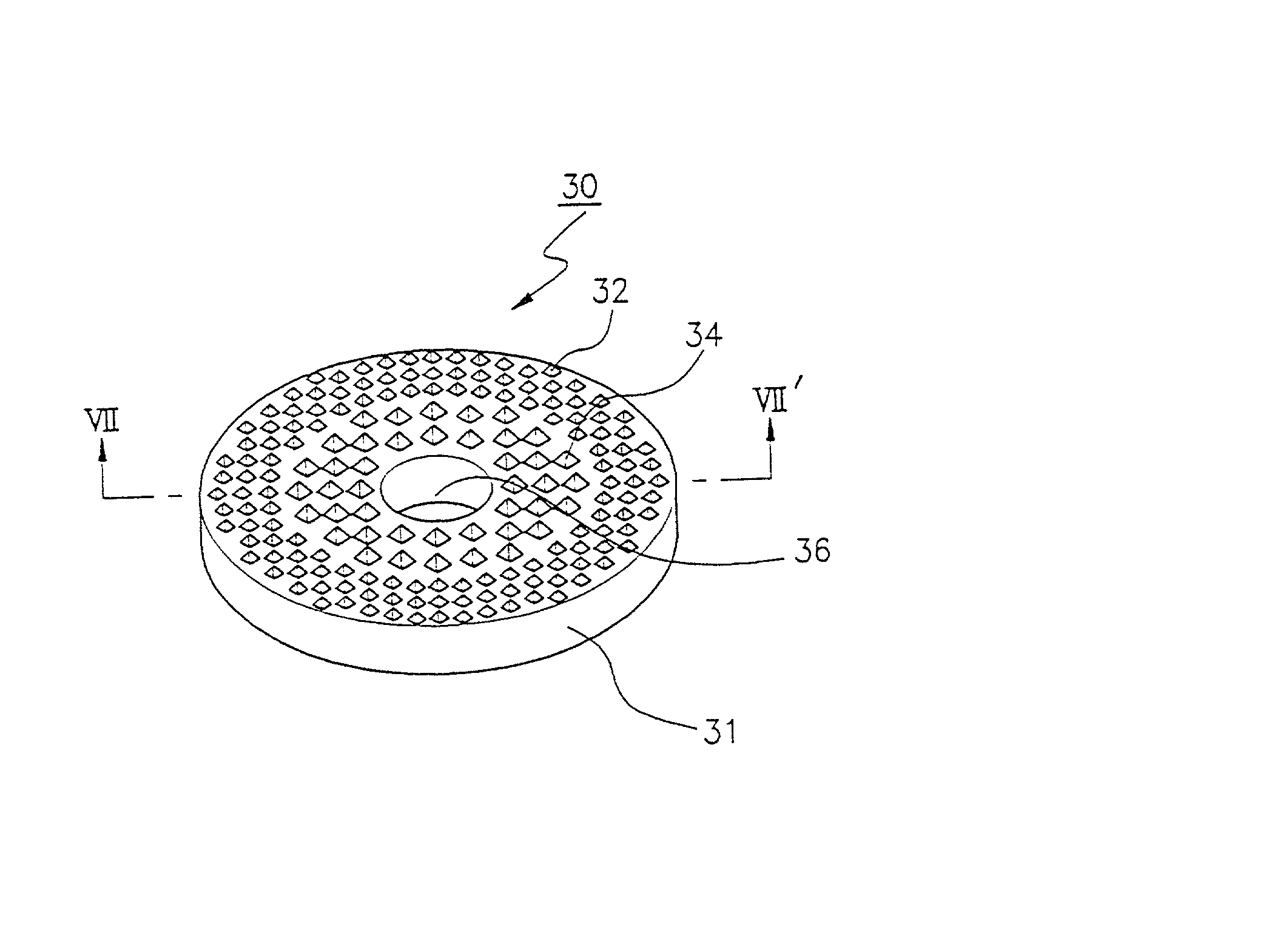

A conditioning disk and a conditioner for a chemical mechanical polishing (CMP) pad, and a method of fabricating, reworking, and cleaning the conditioning disk, are utilized to improve conditioning efficiency, and to reduce production expenses. The conditioning disk for a CMP pad is divided into regions defined by a size difference of abrasive grains formed on the body surface in each region of the conditioning disk. The method of fabricating the conditioning disk is performed by forming adhesive films for attaching the abrasive grains onto the body surface multiple times. In addition, a used conditioning disk may be reworked by detaching the abrasive grains from the body, and attaching new abrasive grains. A used conditioning disk can also be cleaned of by-products of the conditioning process by a cleaning method using a HF solution or BOE (buffered oxide etch) solution.

Owner:SAMSUNG ELECTRONICS CO LTD

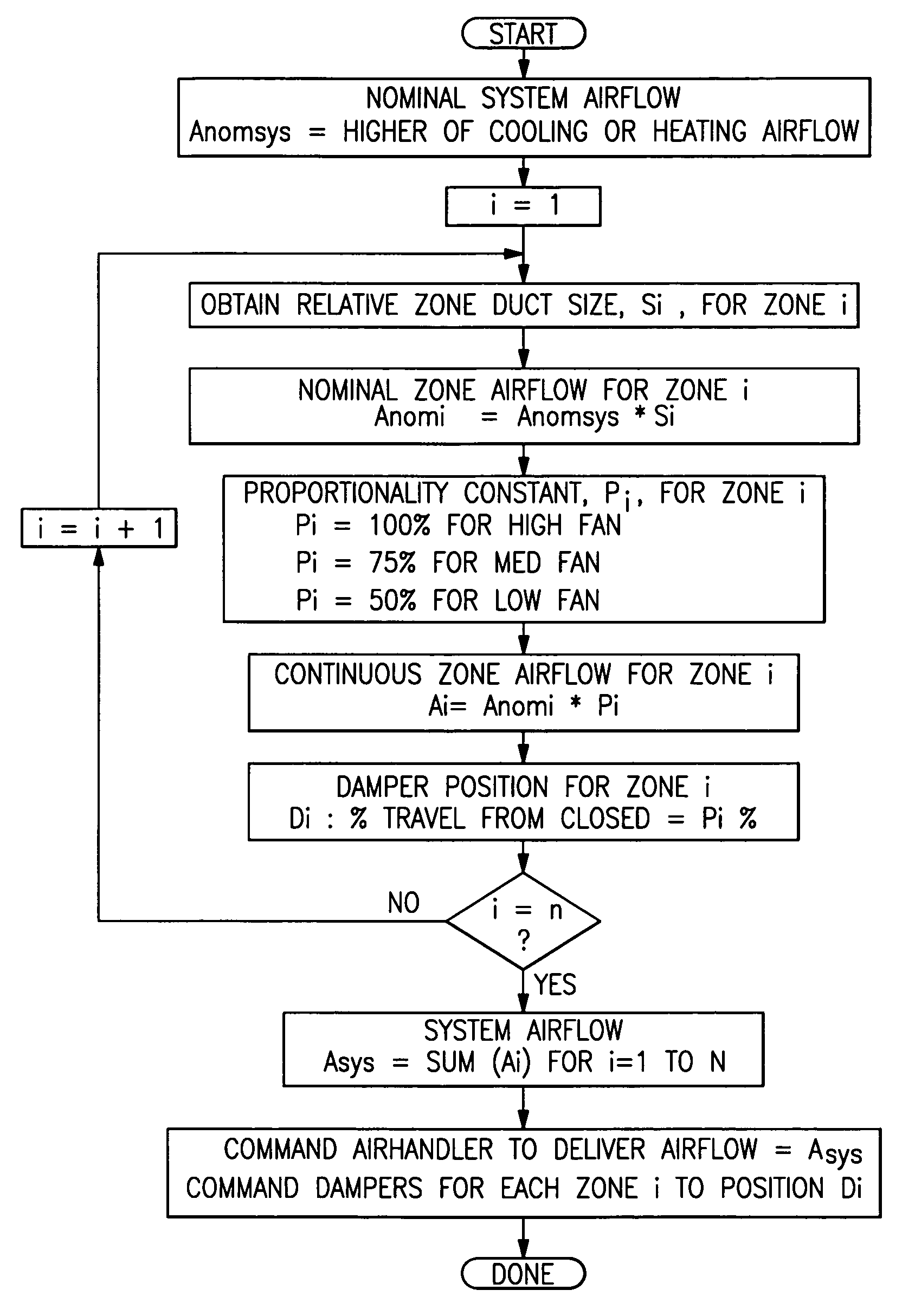

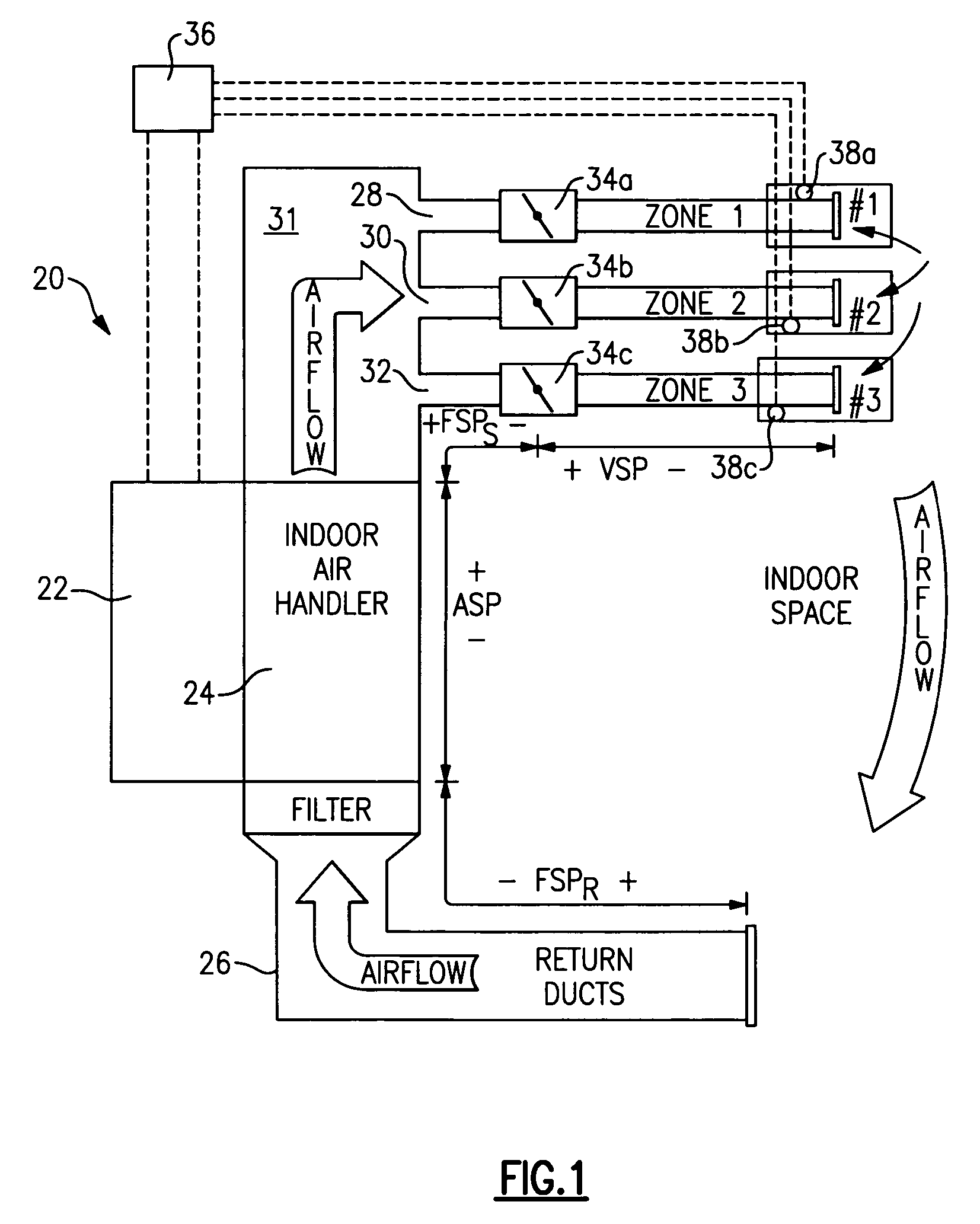

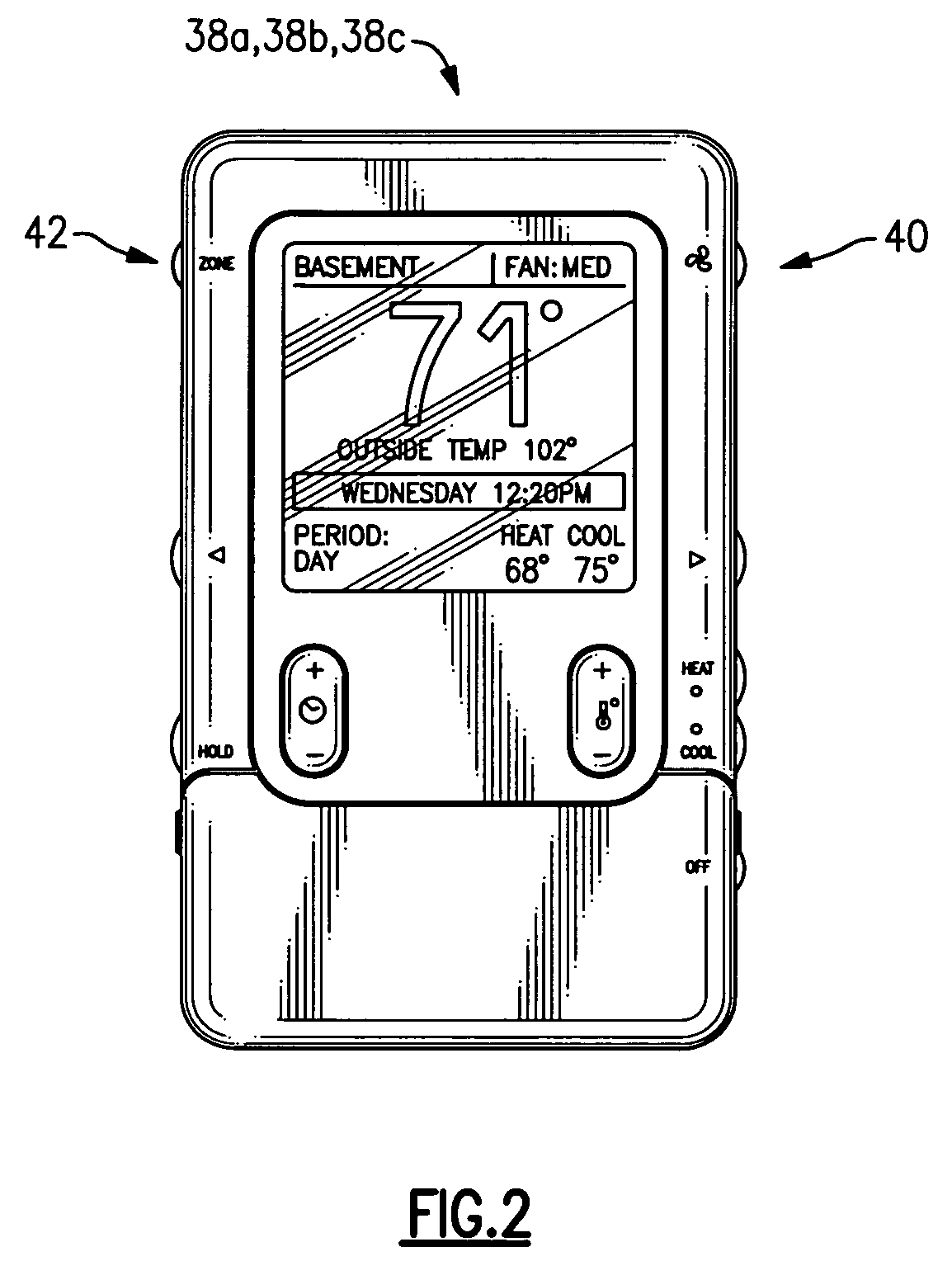

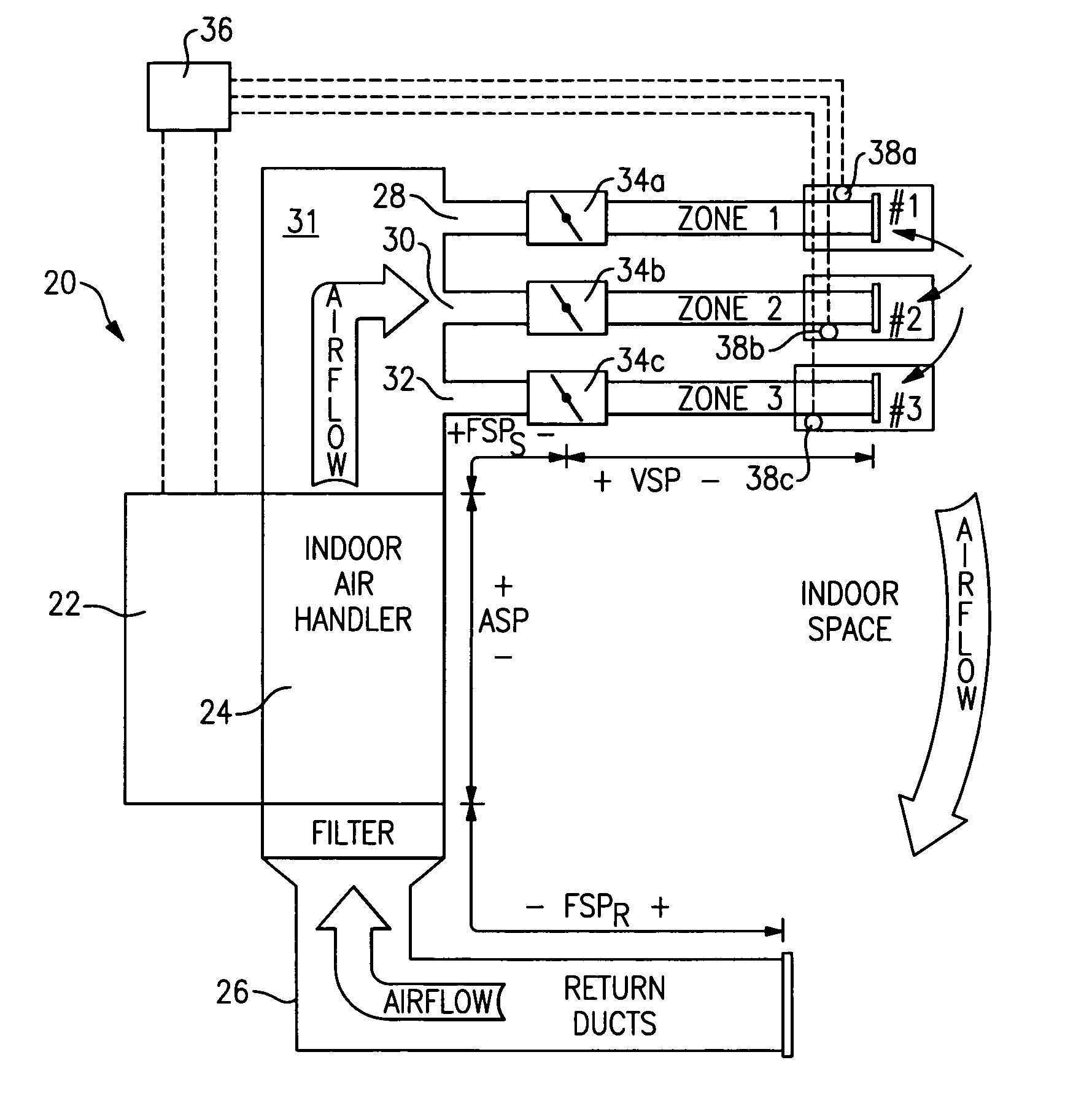

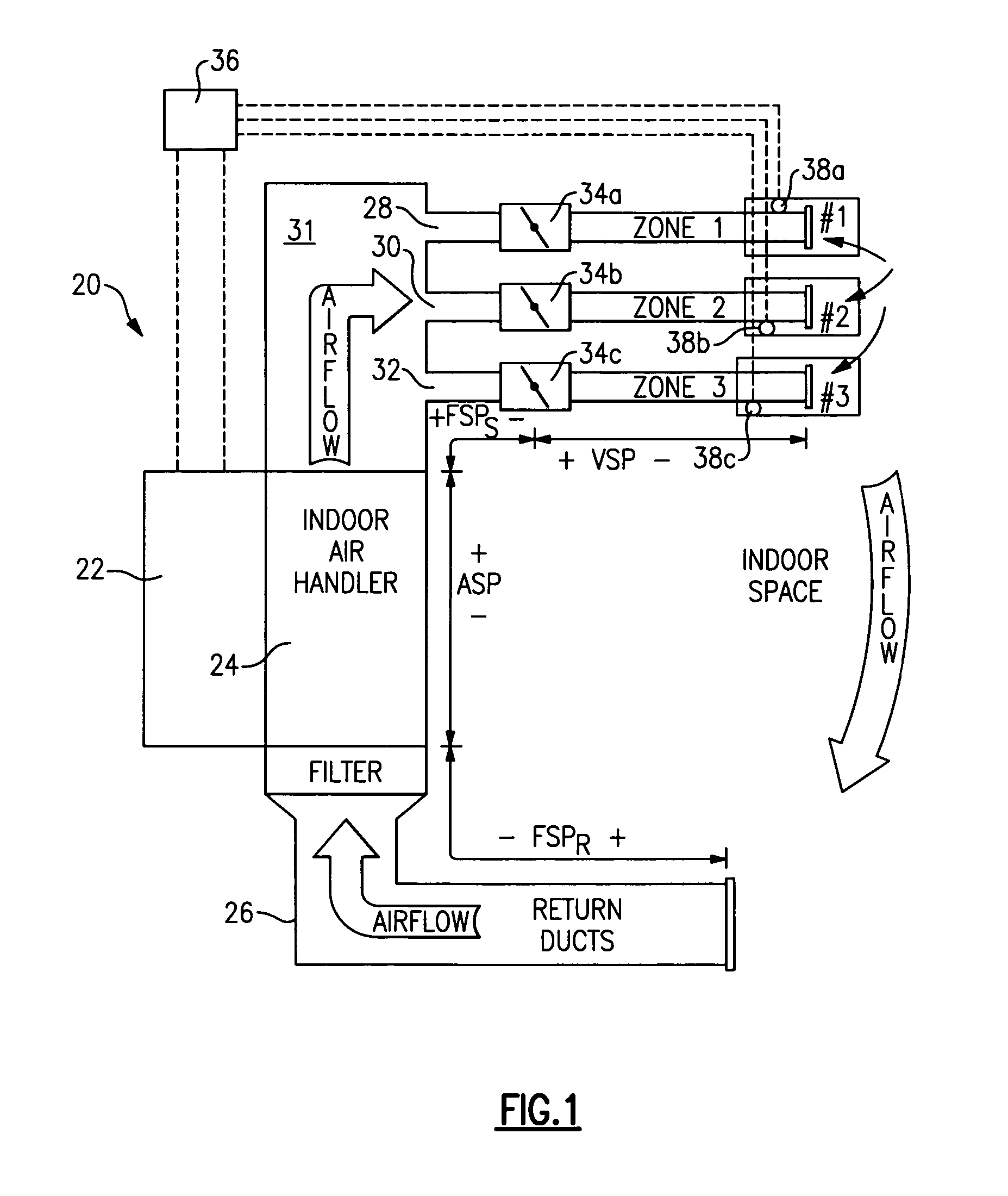

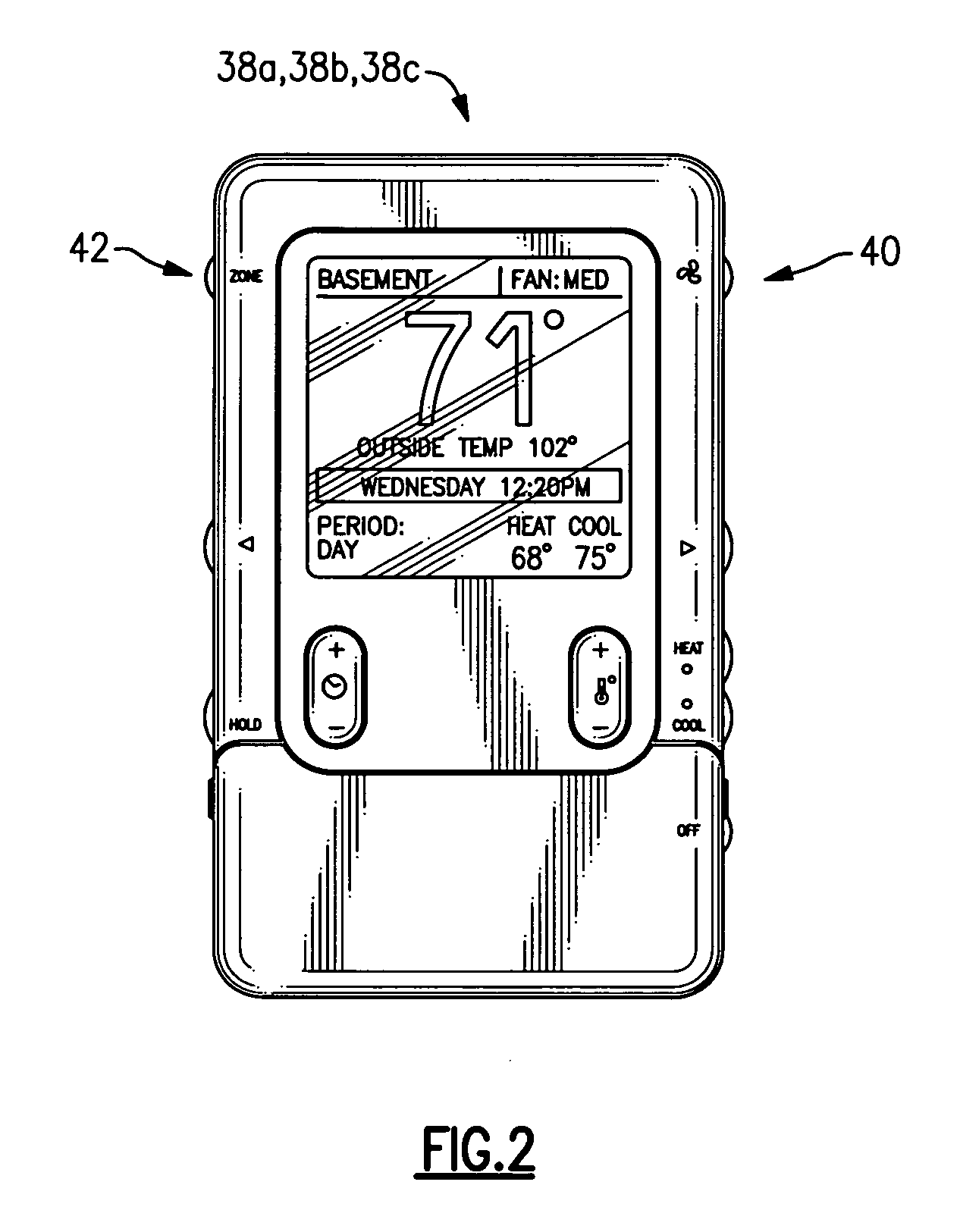

Continuous fan control in a multi-zone HVAC system

ActiveUS7036743B2Mechanical apparatusSpace heating and ventilation safety systemsSize differenceEngineering

A multi-zoned HVAC system includes a control for independently determining the amount of airflow delivered to each zone within the HVAC system. The control determines nominal zone airflow and continuous fan airflow levels for each zone based upon a user selected fan airflow level and the relative size of each zone in the HVAC system. The control determines the desired system airflow for the entire system once the continuous fan airflow levels for each zone are determined. The HVAC system provides a continuous fan airflow to each zone independently of the continuous fan airflow delivered to any other zone and irrespective of the relative size difference of the zones.

Owner:CARRIER CORP

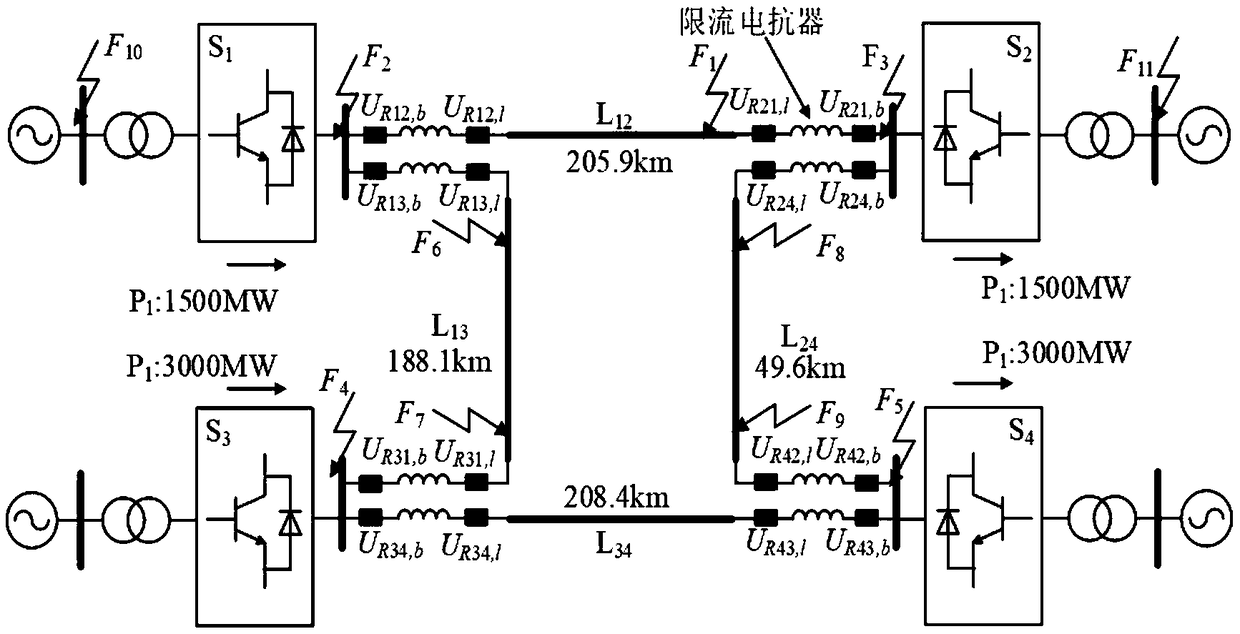

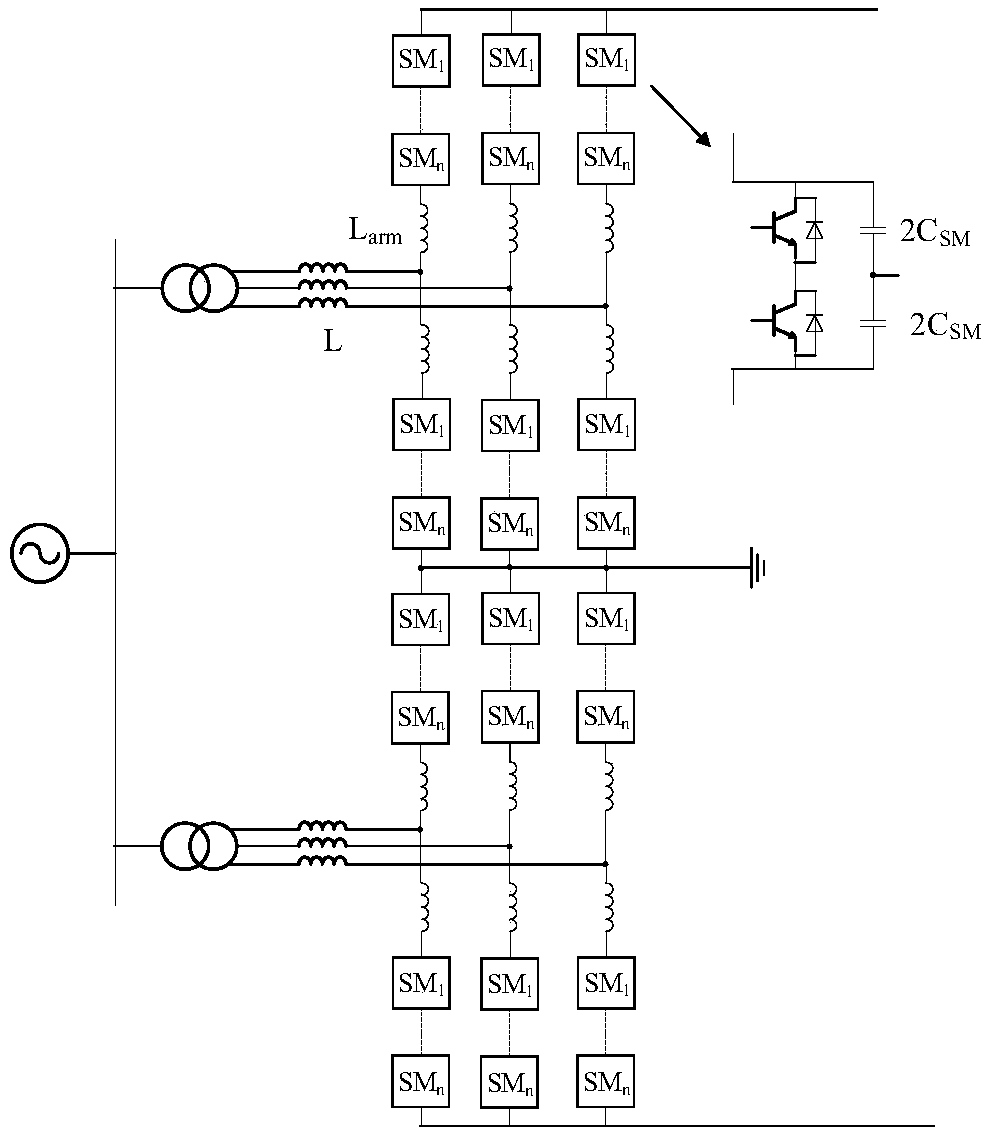

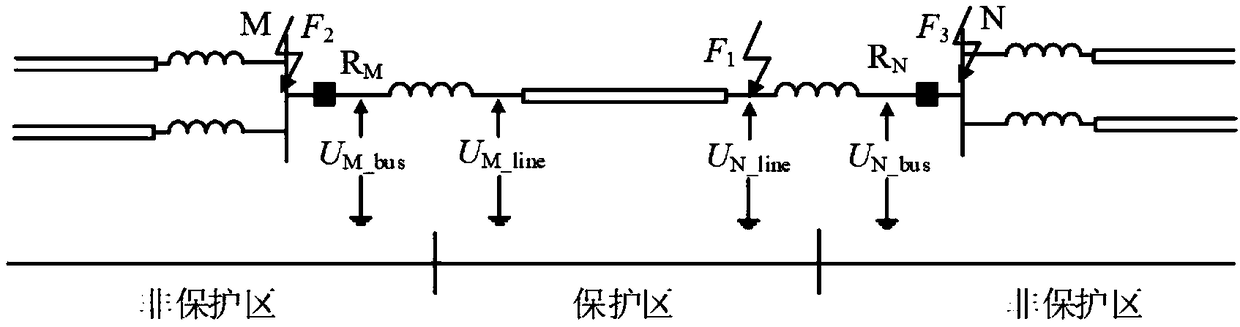

Multi-terminal flexible DC grid DC line quick protection method and system based on single-terminal voltage

ActiveCN109119977AEfficient identificationThe result of the protection judgment has no effectEmergency protective circuit arrangementsFault location by conductor typesSize differenceTerminal voltage

The invention discloses a multi-terminal flexible DC grid DC line quick protection method and system based on single-terminal voltage. The method comprises the following steps: collecting the voltagesignals on the two sides of DC positive and negative line current limiting reactors in real time; forming a low voltage starting criterion; performing wavelet transform on the calculated line mode voltage on the current limiting reactors and calculating the wavelet transform modulus maximum; performing the data validity test and recording the size and the symbol of the first wavelet transform modulus maximum meeting the data validity condition; establishing the fault identification criterion to identify the fault based on the symbol and amplitude difference of the single-terminal voltage traveling wave wavelet transform modulus maximum; and constructing the fault pole identification criterion to identify the fault pole based on the size difference of the voltage traveling wave transient energy. According to the line protection method, the fault direction can be reliably and quickly identified under various initial fault conditions, and the transition resistance, the fault location andthe fault of the AC system and other factors have little influence on the protection criterion so as to have high reliability and sensitivity.

Owner:SHANDONG UNIV +2

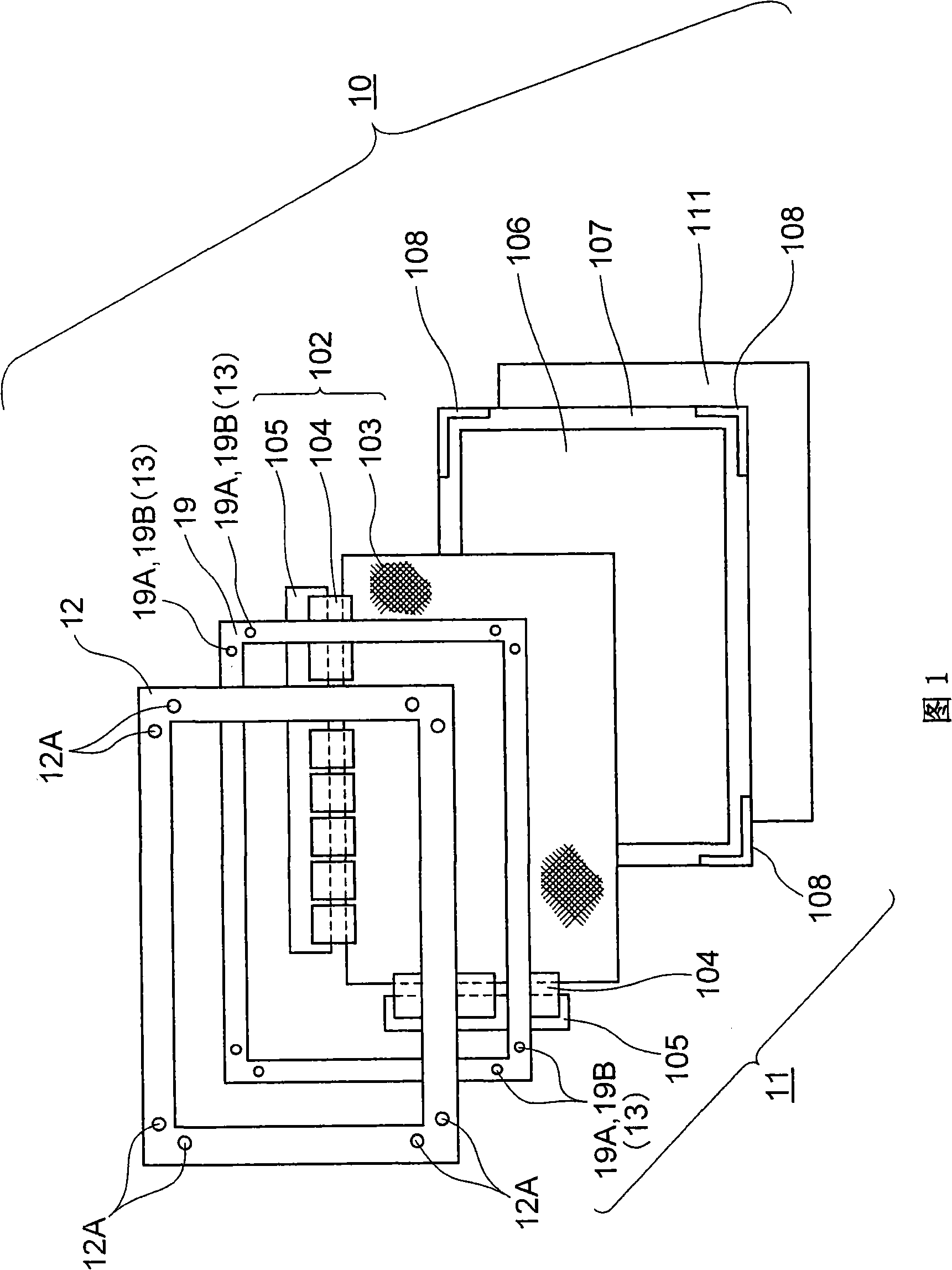

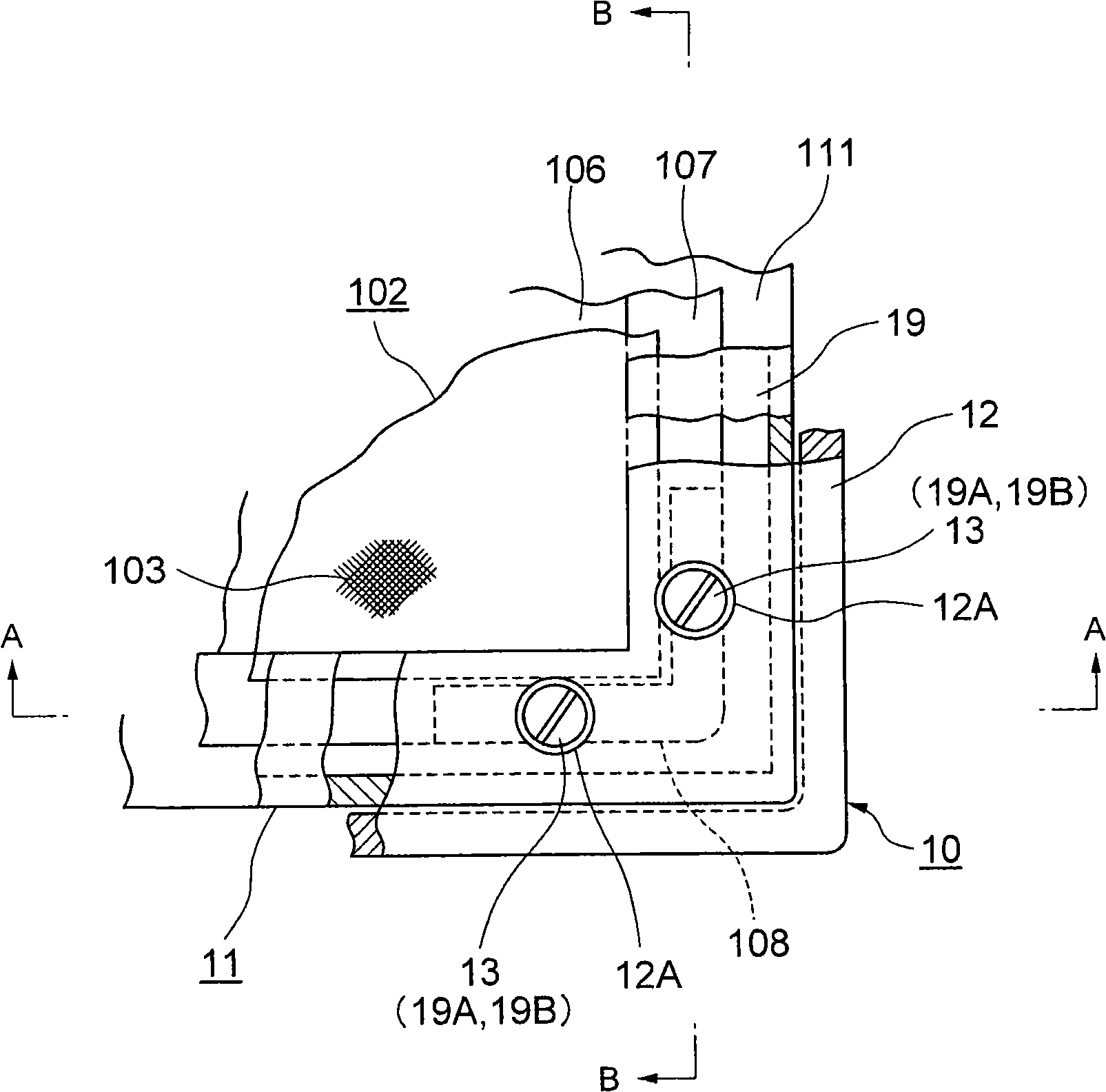

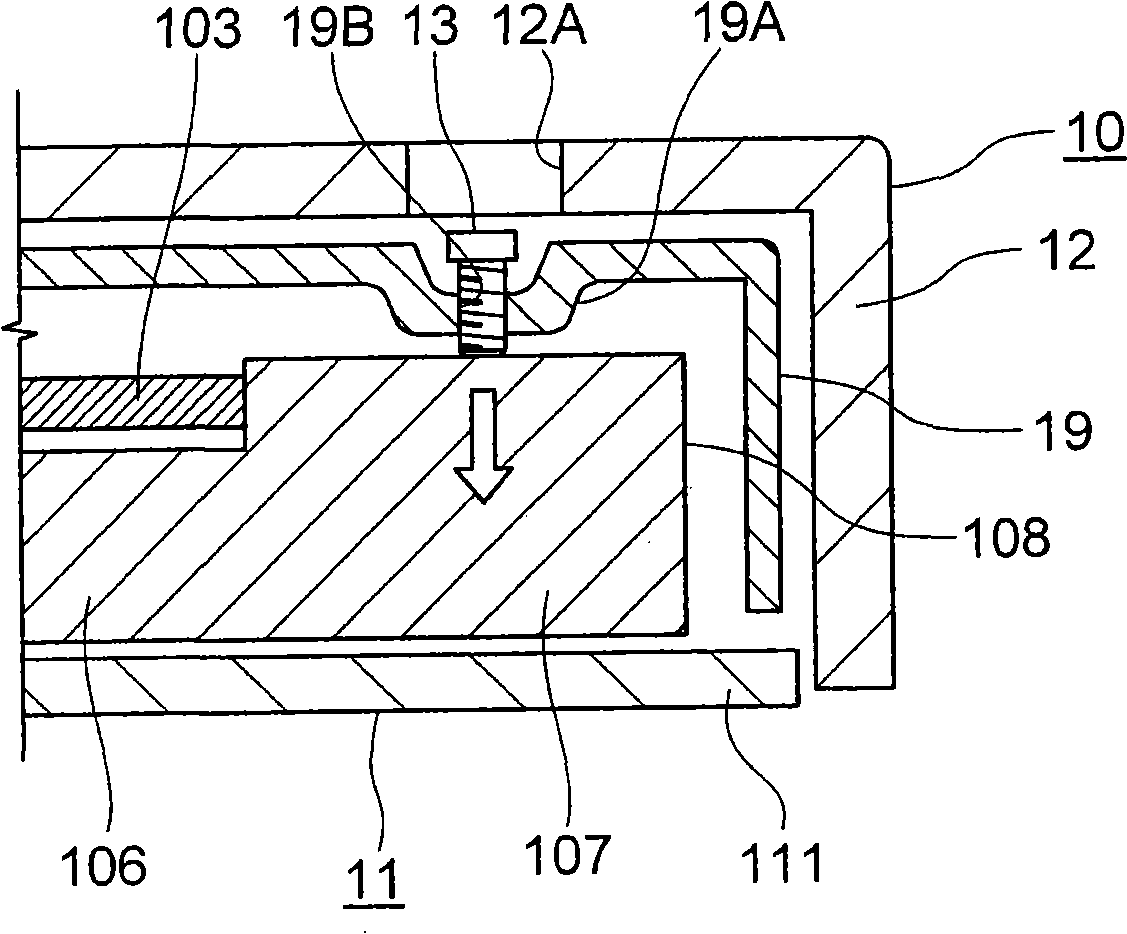

Image pickup device, focus detection device, image pickup apparatus, method for manufacturing image pickup device, method for manufacturing focus detection device, and method for manufacturing image pickup apparatus

ActiveUS20080291311A1Television system detailsTelevision system scanning detailsSize differencePhotoelectric conversion

An image pickup device includes a pixel unit which has first pixels and second pixels. A first photoelectric conversion unit is configured to generate charges corresponding to light incident upon each of the first pixels. A first control unit is connected to the first photoelectric conversion unit and configured to control the first photoelectric conversion unit. A second photoelectric conversion unit is configured to generate charges corresponding to light incident upon each of the second pixels. The second photoelectric conversion unit is smaller than the first photoelectric conversion unit. A second control unit is connected to the second photoelectric conversion unit and configured to control the second photoelectric conversion unit. The second control unit is arranged in a space which is generated due to a size difference between the first photoelectric conversion unit and the second photoelectric conversion unit.

Owner:NIKON CORP

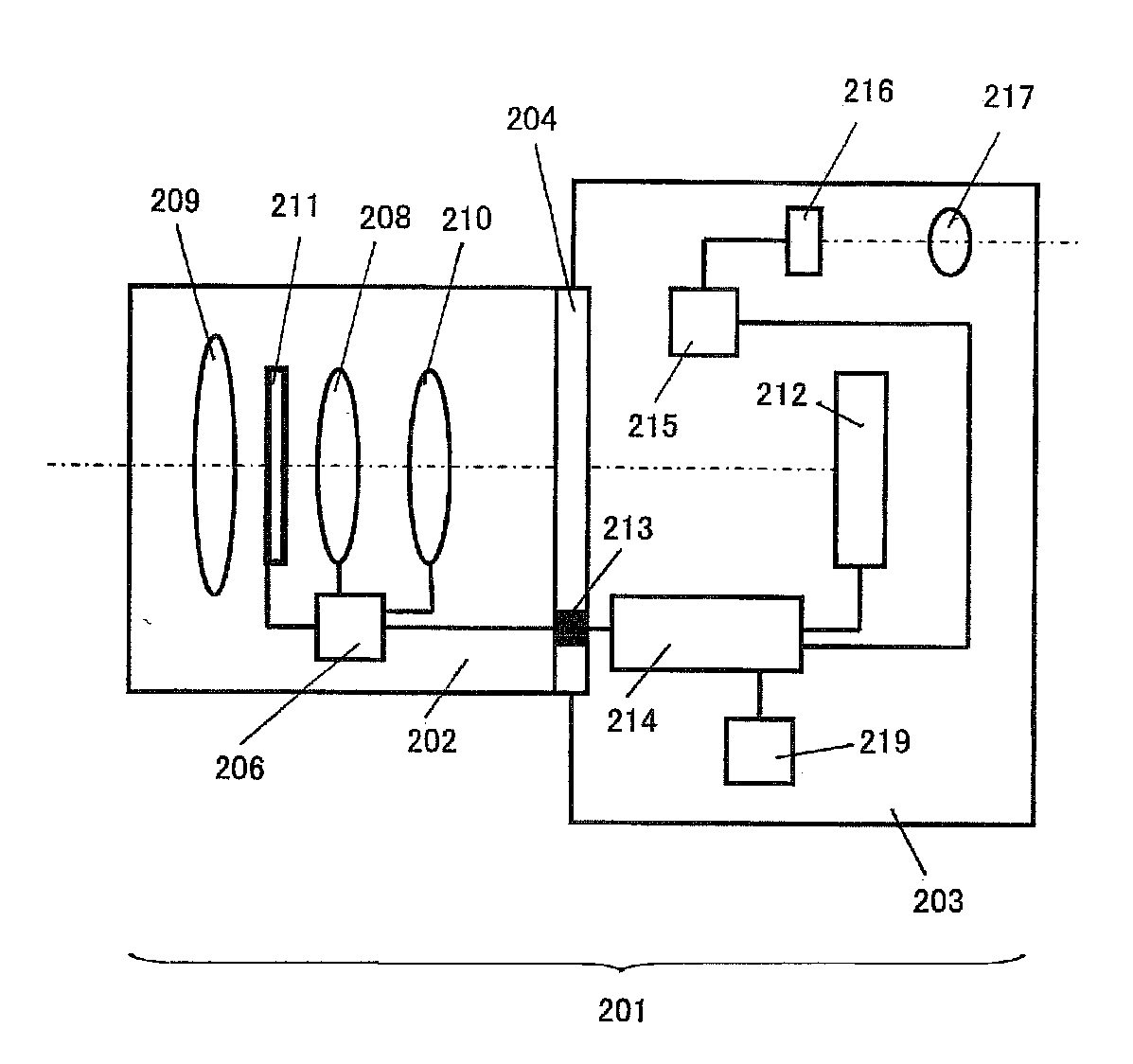

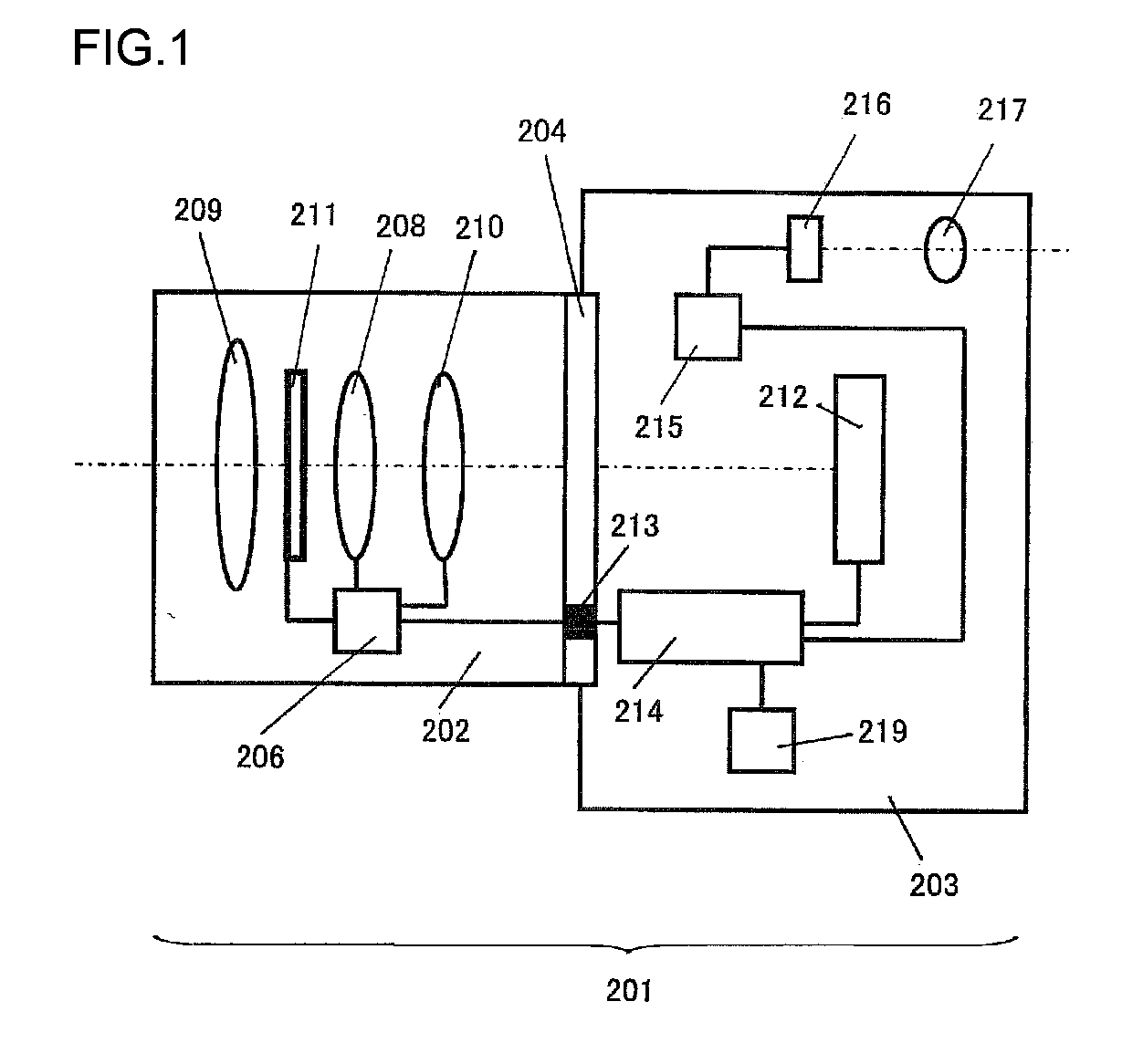

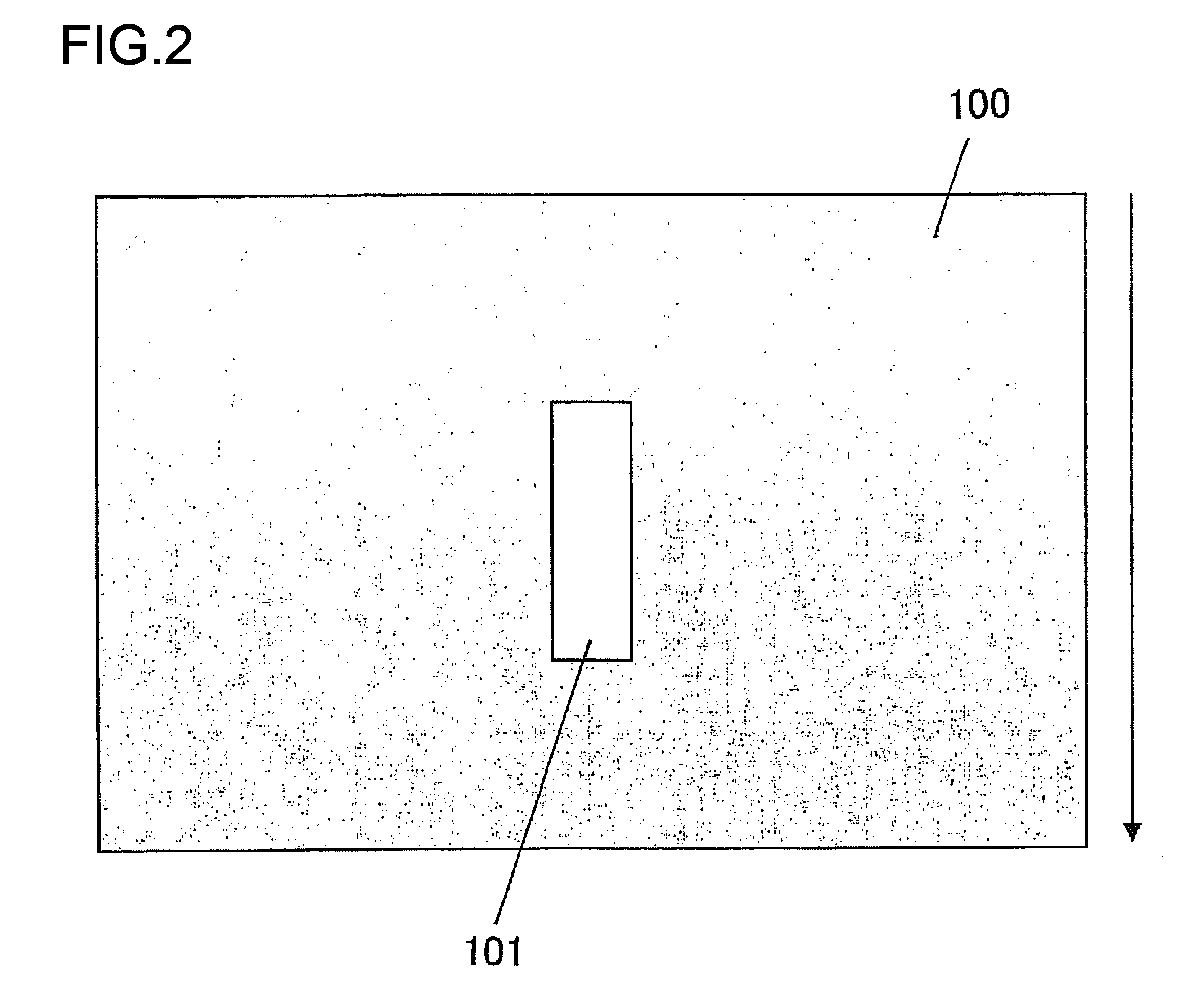

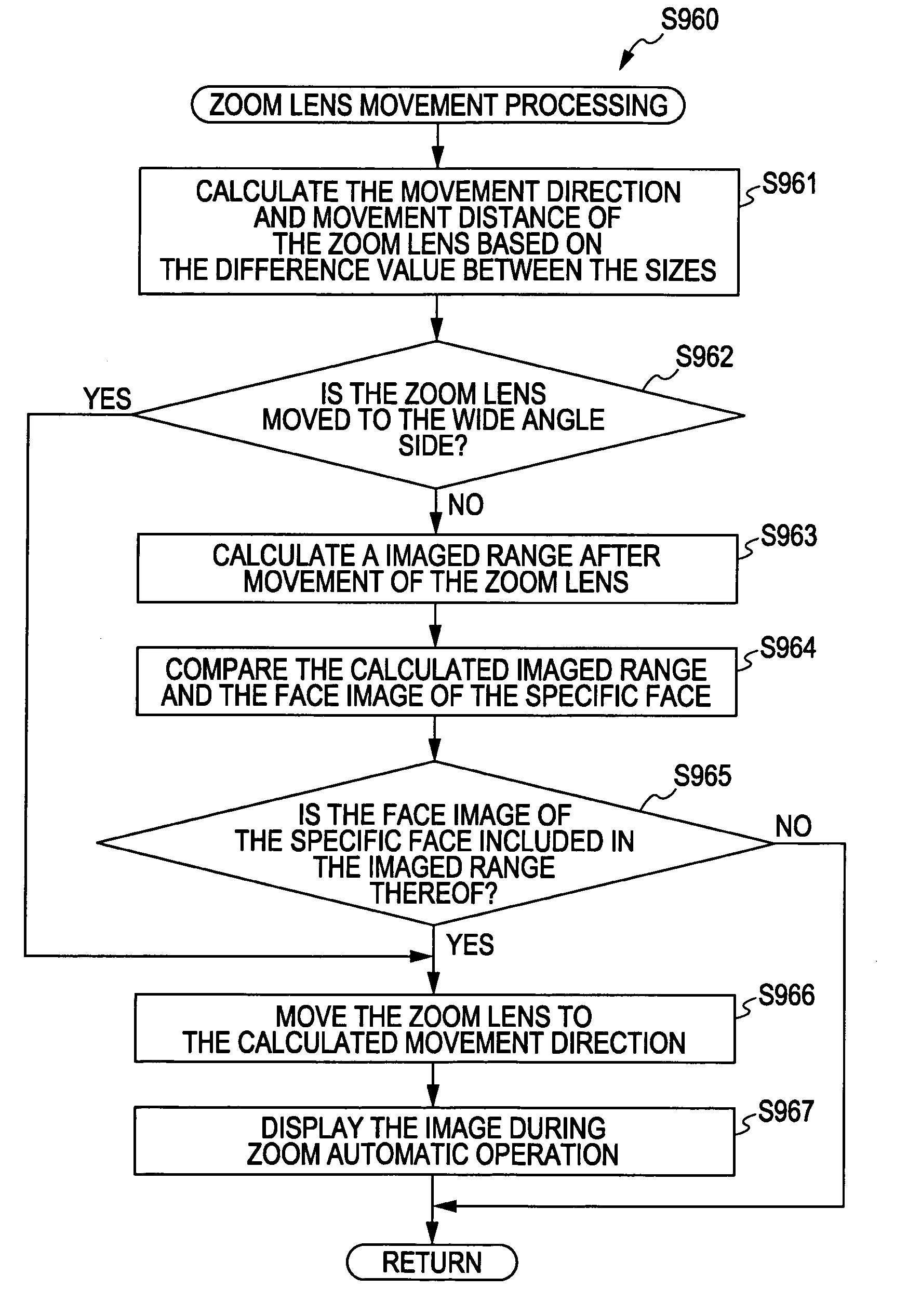

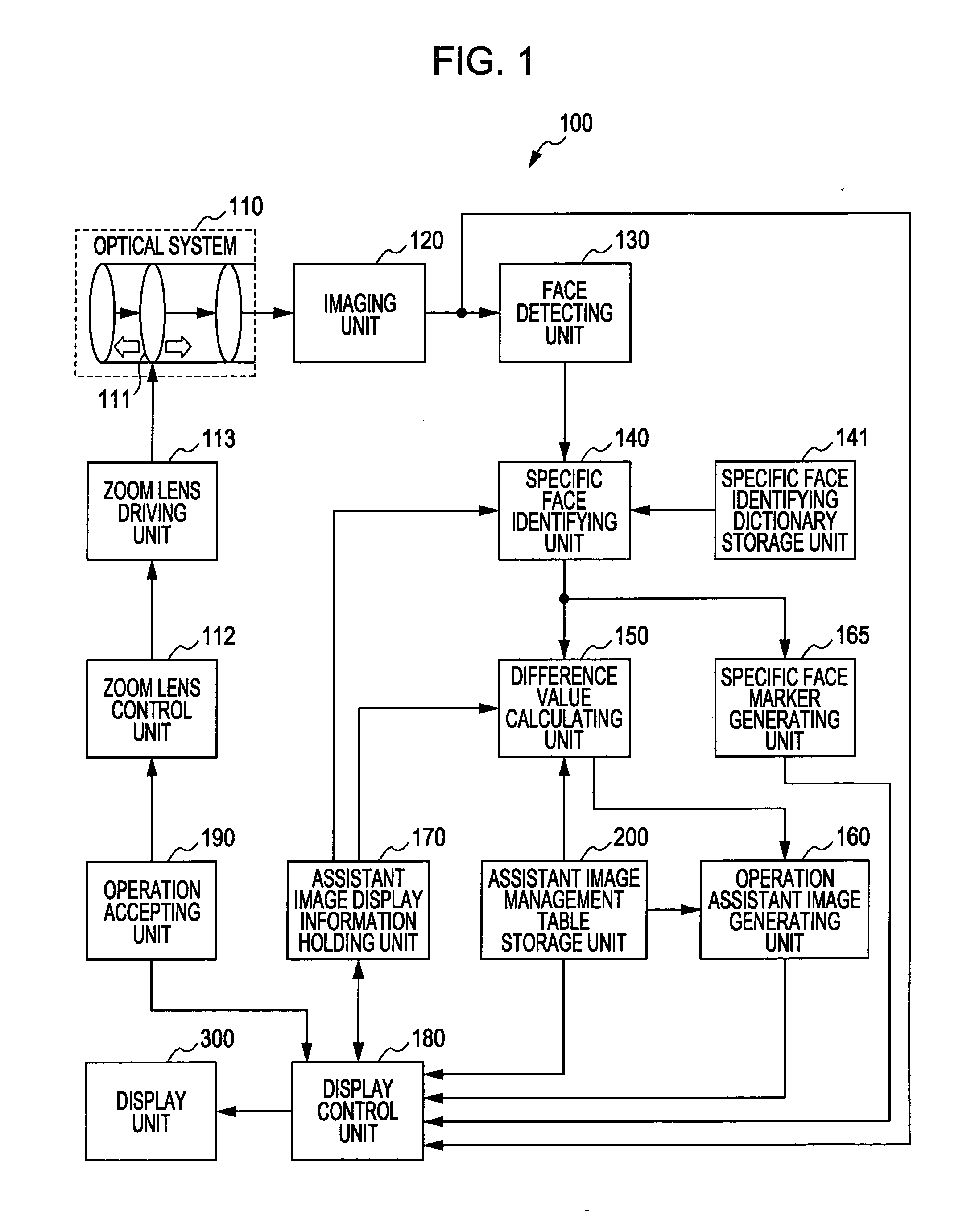

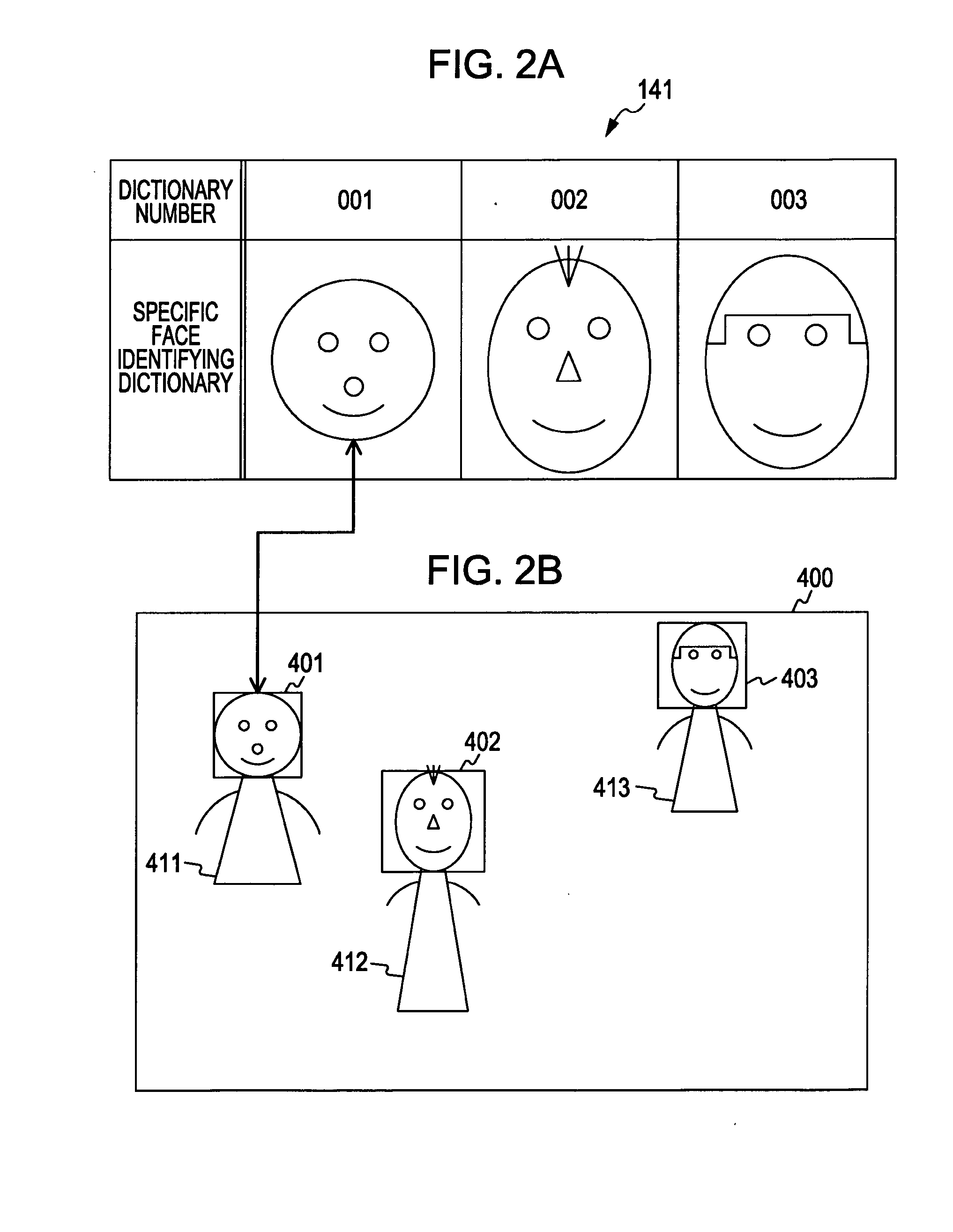

Imaging apparatus, control method thereof, and program

InactiveUS20090256933A1Easy to recordTelevision system detailsCharacter and pattern recognitionSize differenceImaging equipment

An imaging apparatus includes: a layout assistant image storage unit to store multiple layout assistant images representing position and size where an object is to be disposed within an imaging range; an imaging unit to perform imaging of a subject to generate an imaged image; an object detecting unit to detect the object from the imaged image, and the position and size of the object therein; and a display control unit to display one of multiple stored layout assistant images overlaid on the imaged image. If a position difference between the position of an object determined by the displayed layout assistant image, and a size difference between the size of an object determined by the displayed layout assistant image and the size of the detected object within the imaged image, are both within predetermined ranges, a layout assistant image other than that displayed is displayed overlaid on the imaged image.

Owner:SONY CORP

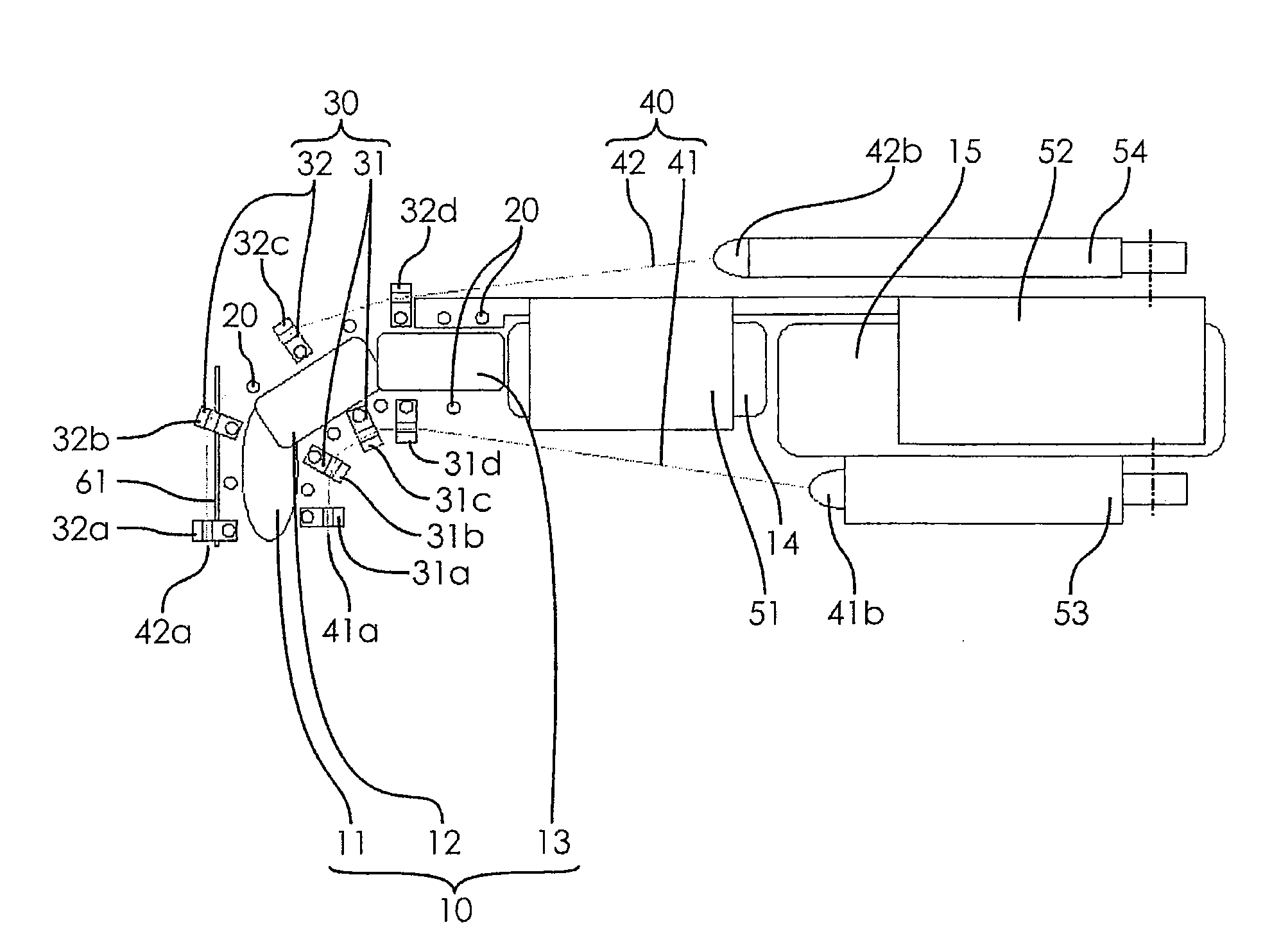

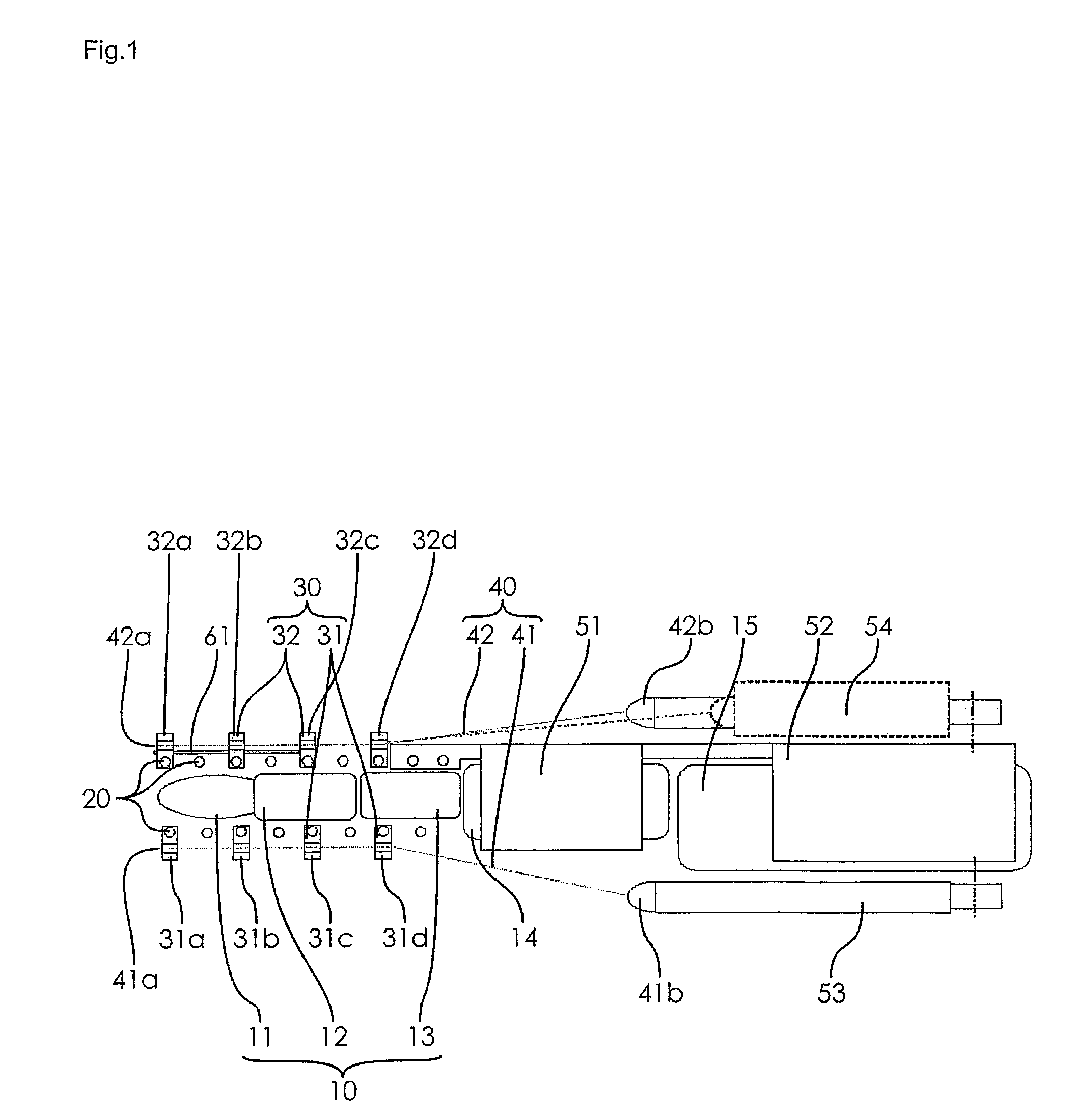

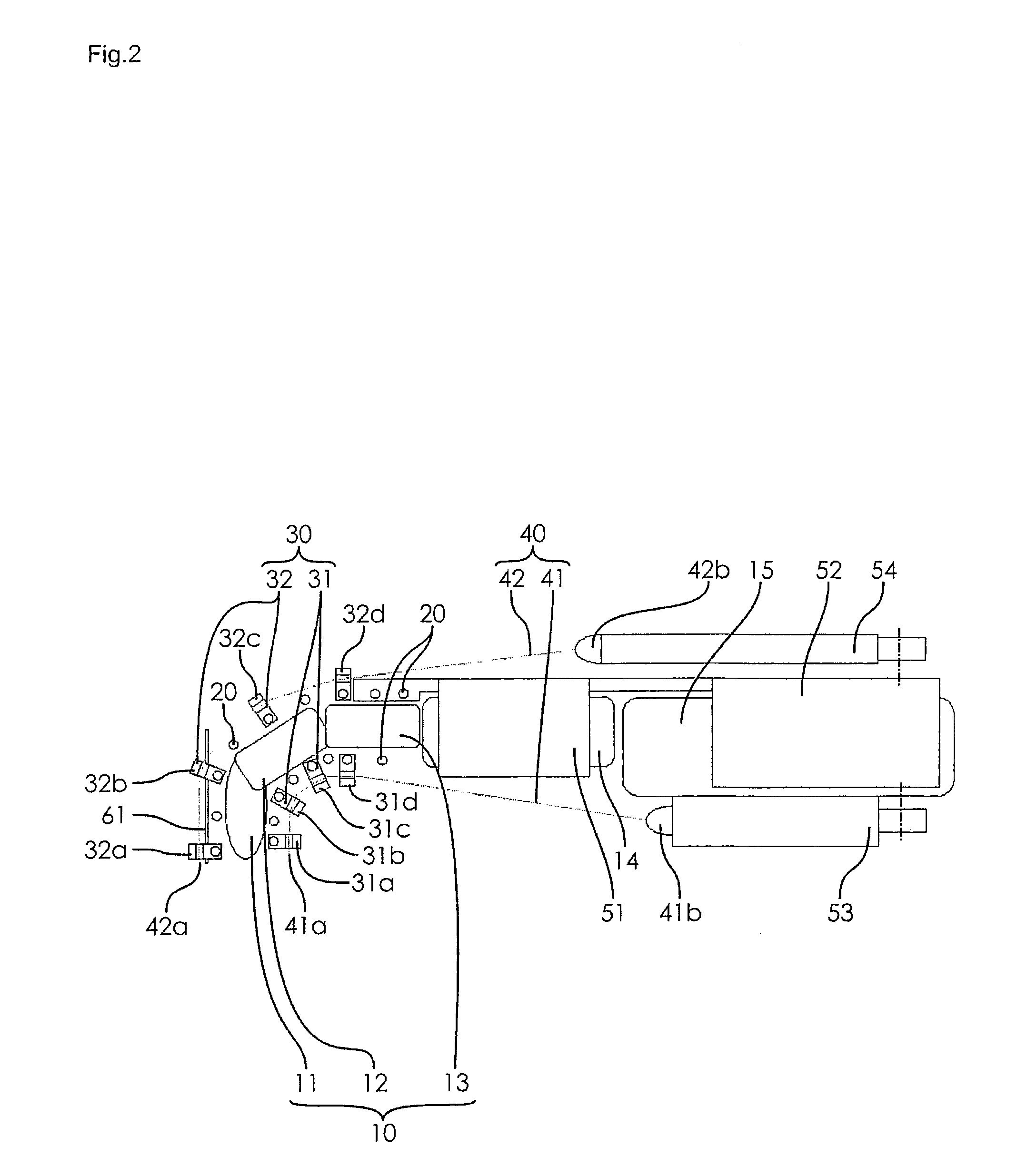

Finger motion assisting apparatus

InactiveUS20100249676A1Limit motionReliable preventionChiropractic devicesEye exercisersSize differenceEngineering

It is an object of the present invention to provide a finger motion assisting apparatus that can be attached to a user without precise positioning or aligning the mechanism parts and substantially without size-fitting operation caused by physical size difference. According to the finger motion assisting apparatus of the present invention, the wire guide group 30 includes the first wire guide group 31 located on the palm side of the phalanxes 10, and the second wire guide group 32 located on the back side of the phalanxes 10, the wire is fixed to the finger holding member 20 located on the distal phalanx, the wire 40 includes the first wire 41 inserted through the first wire guide group 31, and the second wire 42 inserted through the second wire guide group 32, and the driving unit 53, 54 loosens the second wire 42 when the first wire 41 is pulled, and loosens the first wire 41 when the second wire 42 is pulled.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

Liquid crystal module and liquid crystal display device including the same

InactiveCN101276077AEliminate or reduce unevennessStatic indicating devicesElectrical apparatus contructional detailsSize differenceLiquid-crystal display

The purpose of the invention is to eliminate or reduce unevenness on a screen display generated due to distortion stresses generated because of small size differences or the like occurred during the time of processing or assembling. A liquid crystal module includes a liquid crystal panel for displaying an image, a backlight for irradiating light to the liquid crystal panel to light up the liquid crystal panel, and a shield plate for shielding electromagnetic waves from inside and outside, wherein the backlight is mounted to a frame-type chassis and a panel holding frame for holding the liquid crystal panel is provided thereto. The frame-type chassis and the panel holding frame are structured to be capable of being displaced in a direction approaching to or isolating from the screen of the liquid crystal panel by a displacement adjusting screw that is engaged either with the frame-type chassis or with the panel holding frame.

Owner:NEC LCD TECH CORP

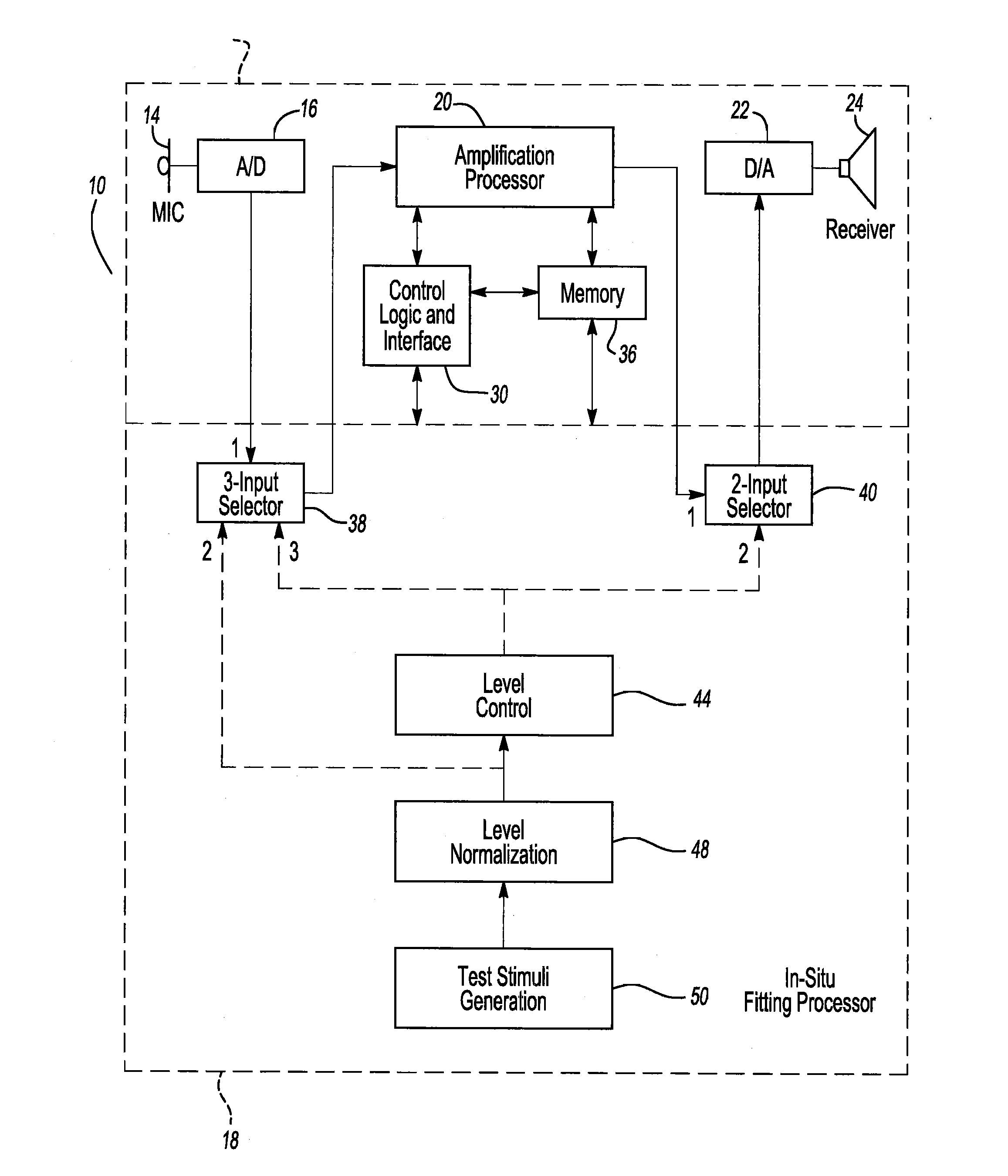

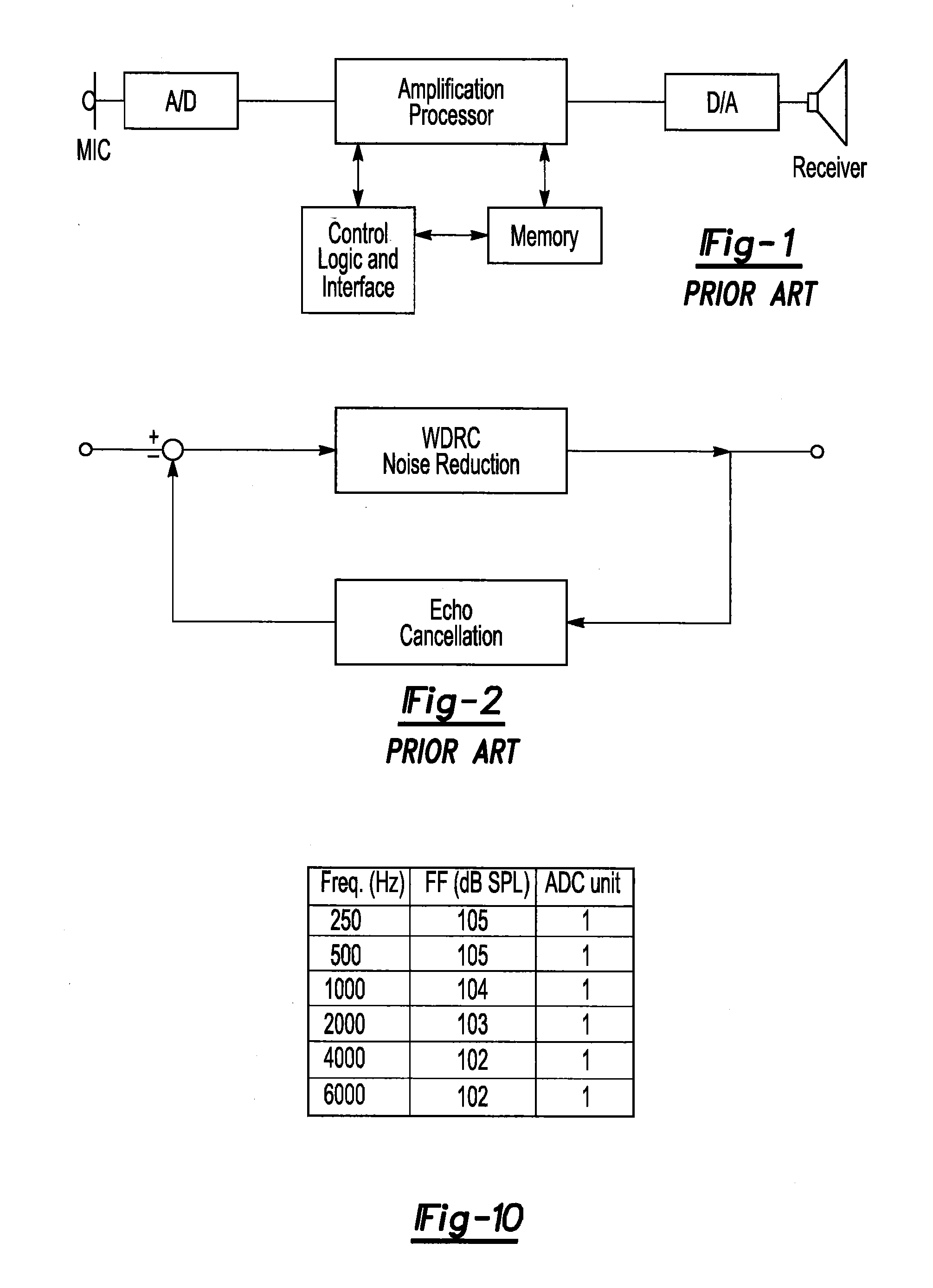

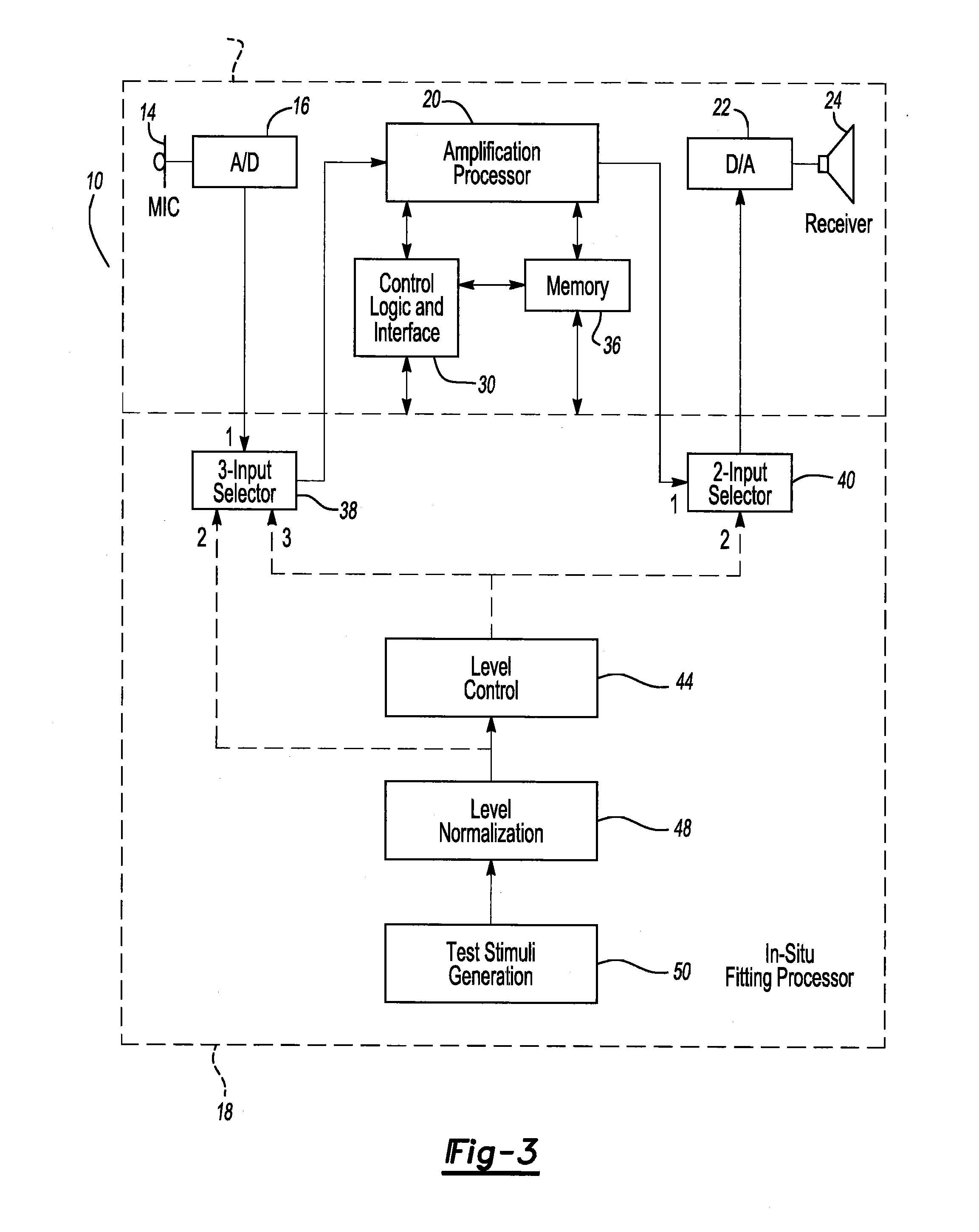

Method and apparatus for in-situ testing, fitting and verification of hearing and hearing aids

ActiveUS20120177212A1Maximize hearing aid performanceAccurate acquisitionDeaf aid adaptationNon-optical adjunctsSize differenceIndividual person

An improved multi-function hearing aid having in-situ testing, fitting and verification functions is disclosed which solves problems long standing in the art of hearing aid fitting dealing with individual size differences in the size of the pina and ear canal of the user, individual preference to sound level and frequency variation, and verification procedures.

Owner:OTOTRONIX

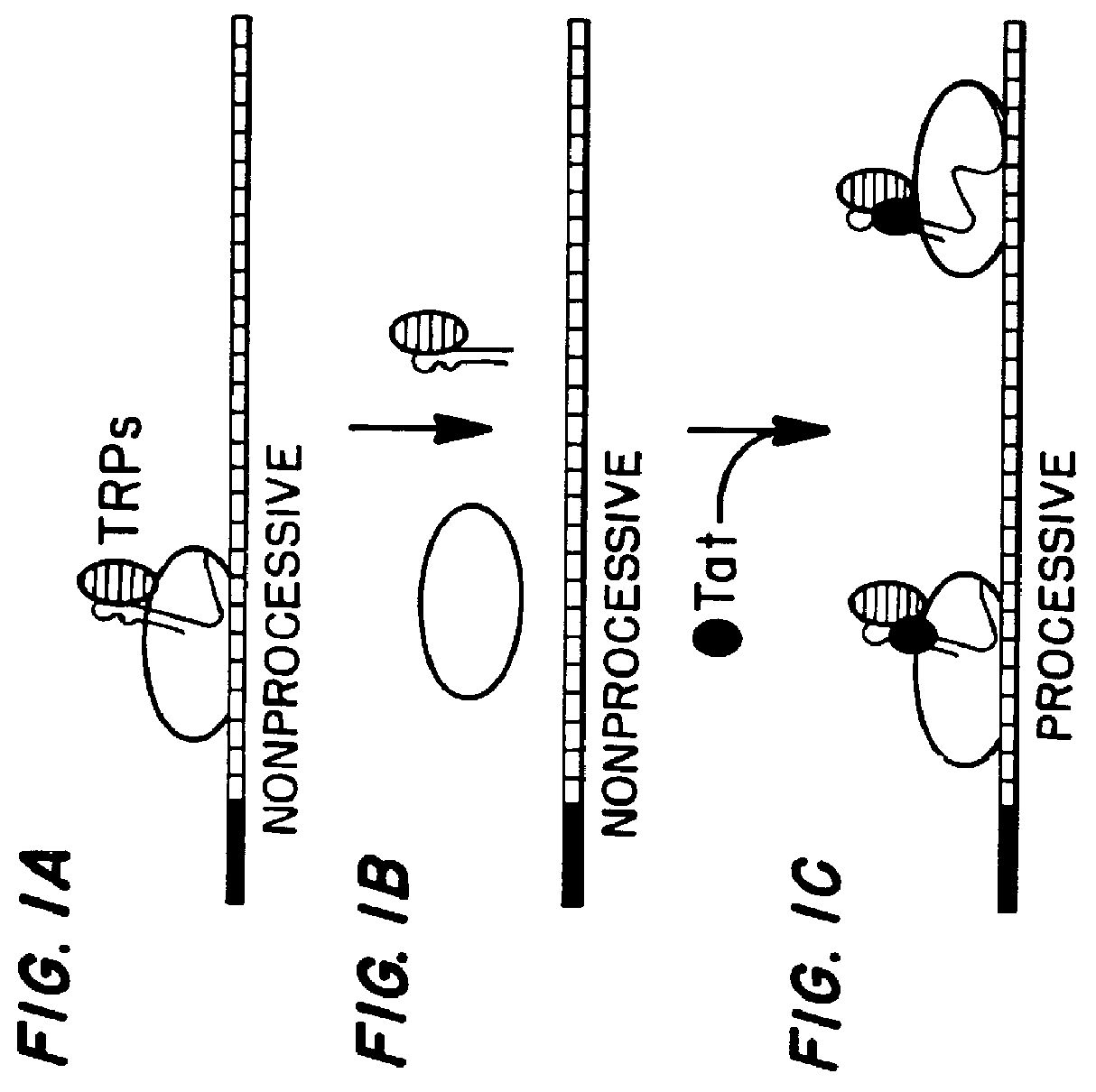

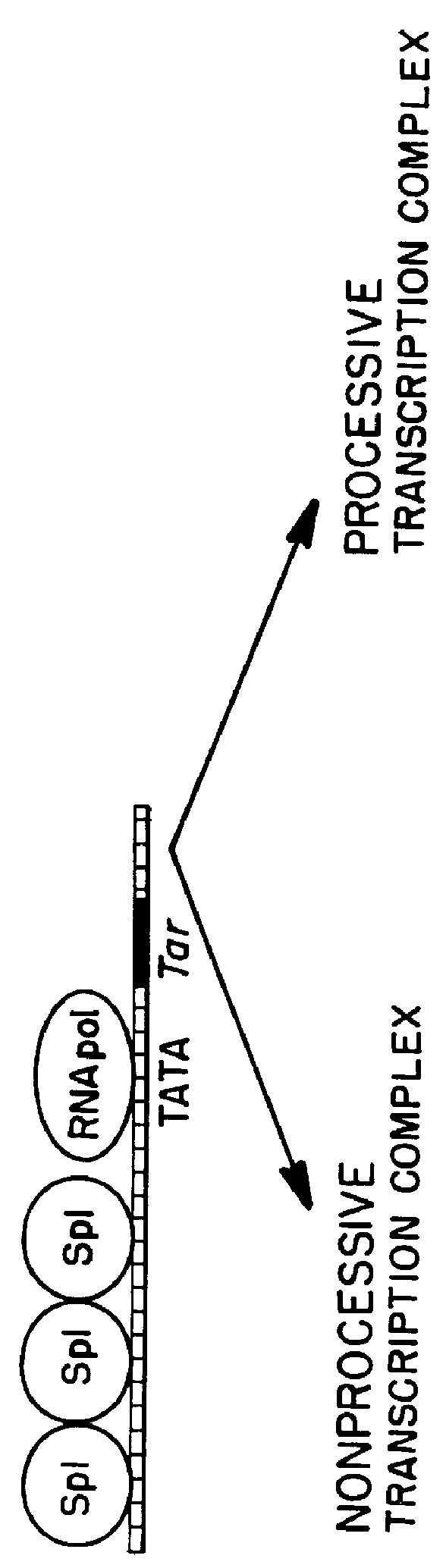

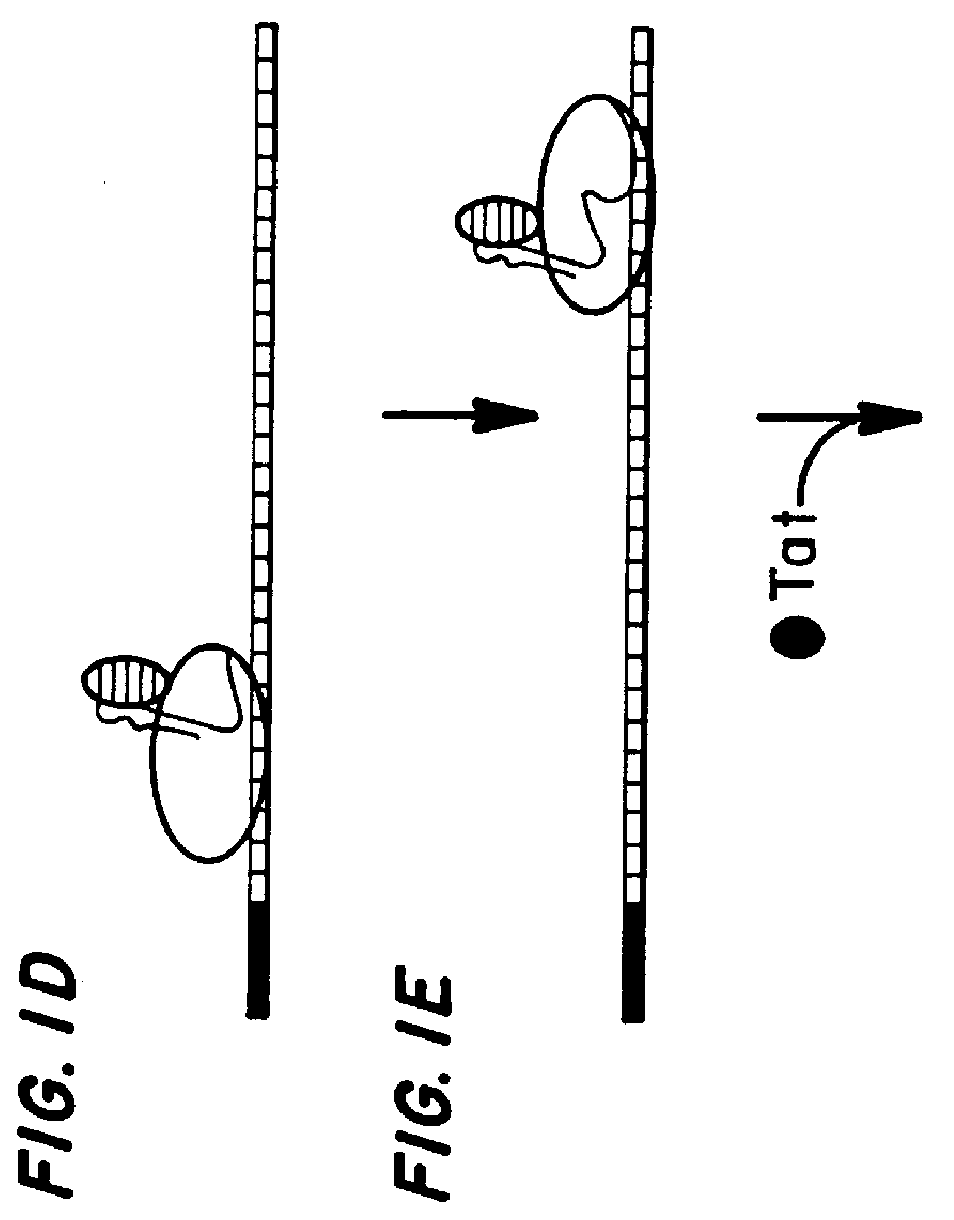

Marker, method and an assay for detection and monitoring of latency and activation of human immunodeficiency virus

A TAR marker, method for detection and monitoring of HIV latency and activation and an assay for detection of the marker. The assay sensitively detects HIV transcription and monitors HIV transcriptional activity by detecting the presence of TAR fragments and full length transcripts, quantifying both and determining the ratio of short to long transcripts. A low ratio correlates with a latent-type transcriptional activity of HIV whereas the appearance of long transcripts signifies increased efficiency of transcriptional activity of HIV and the transition from latency to activation. The size difference between the TAR fragments appearing predominantly in latency and the full length transcripts appearing predominantly during the HIV activation is detected by RT-PCR assay that utilizes novel primers and probes. The obtained ratio is a sensitive tool in detection of HIV infection, the analysis of load of latent and active virus and monitoring the transition from the latent to active state of HIV replication.

Owner:RGT UNIV OF CALIFORNIA

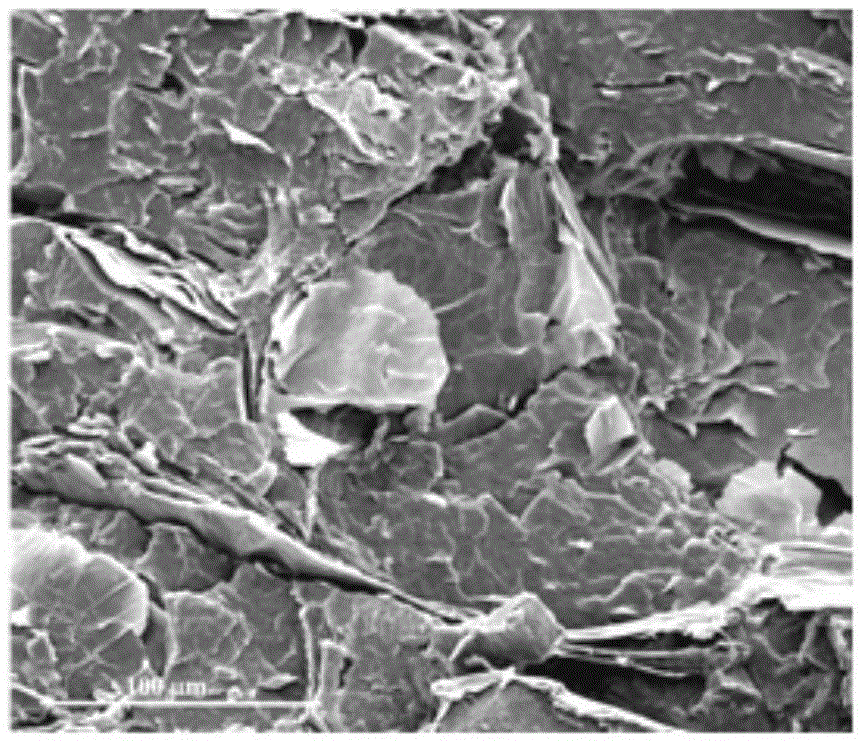

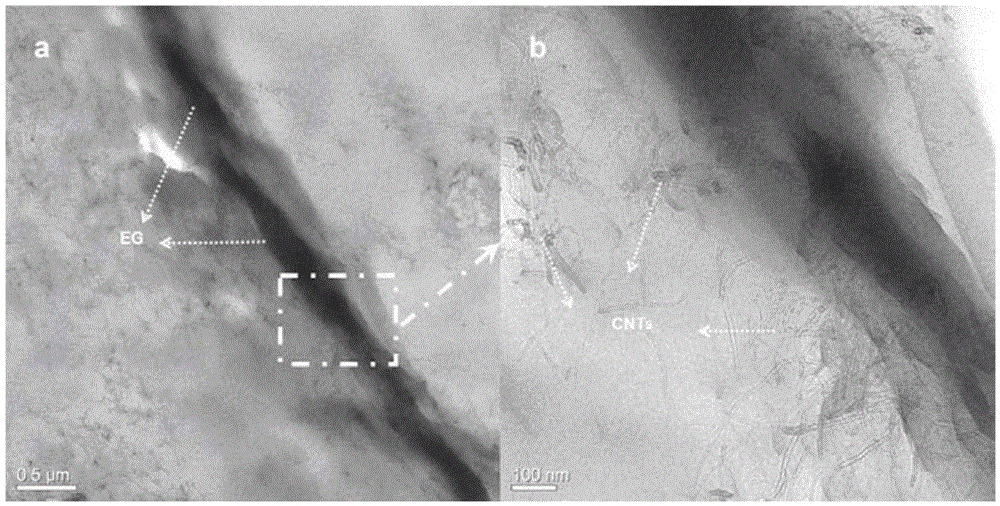

Polymer composite material with double-network structure and preparation method thereof

The invention provides a polymer composite material with a double-network structure and a preparation method thereof. The composite material contains fillers A and fillers B, wherein the size of the fillers A is 30 to 500 microns and the size of the fillers B is 1.0 to 20 microns; the size ratio of the fillers A to the fillers B is at least 20; the fillers A and the fillers B are uniformly distributed in a polymer base material, are in mutual overlap joint and penetrate through to form a conductive and heat-conducting access with a staggered network structure; the fillers B with the smaller size are distributed in grids of a loose network structure formed by the fillers A with the large size and are in mutual overlap joint to form a relatively dense network, and the inner part of the obtained composite material has a double-network structure which is good for moving electrons and reducing interface heat resistance, so that the conductive and heat-conducting performances are greatly improved at the same time. A method for constructing double networks by using the size difference of the two types of fillers has an ingenious concept and an operation method is simple; existing high molecular material modified machining equipment is used for realizing production; the method has low cost and is easy to popularize and apply.

Owner:SICHUAN UNIV

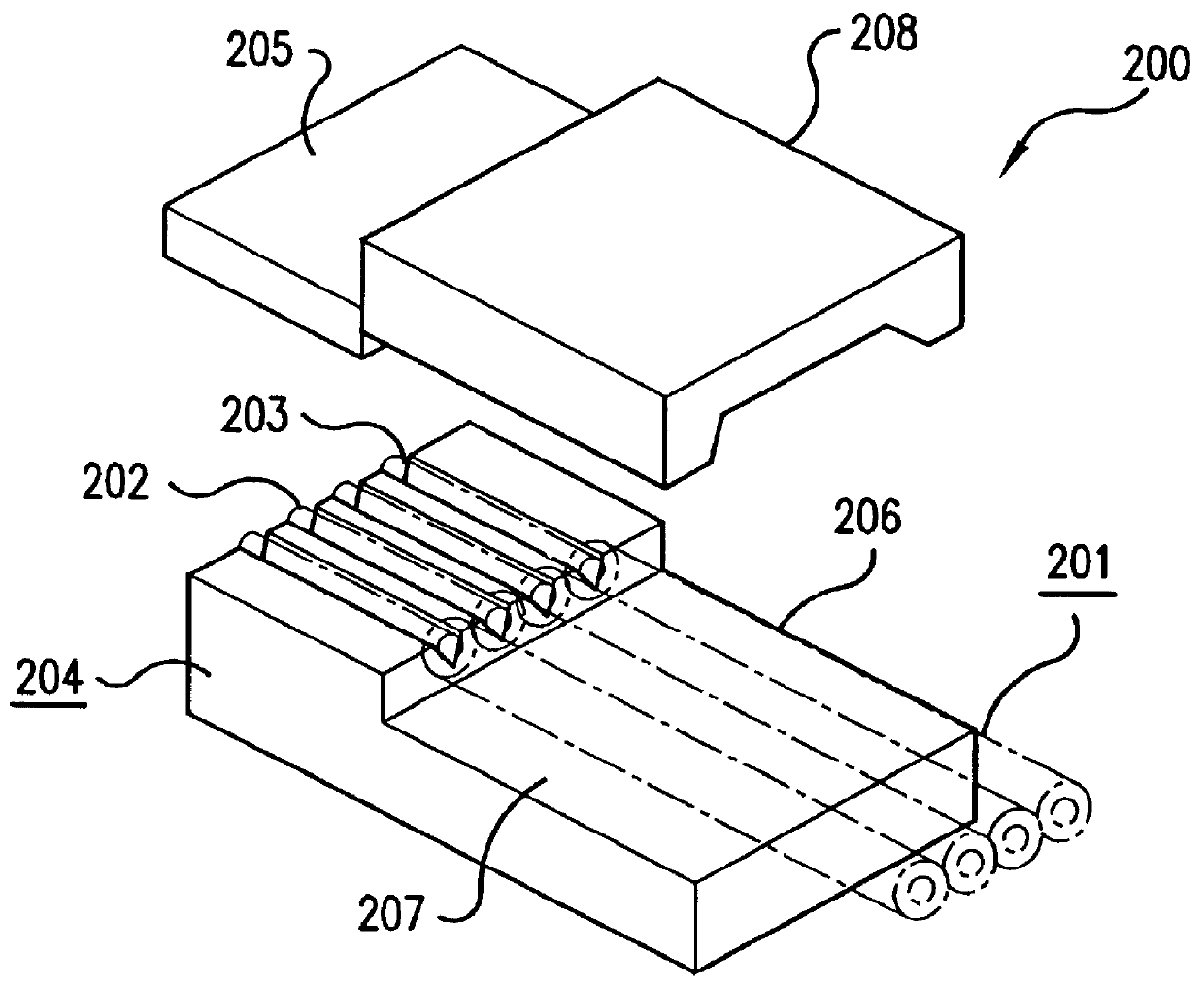

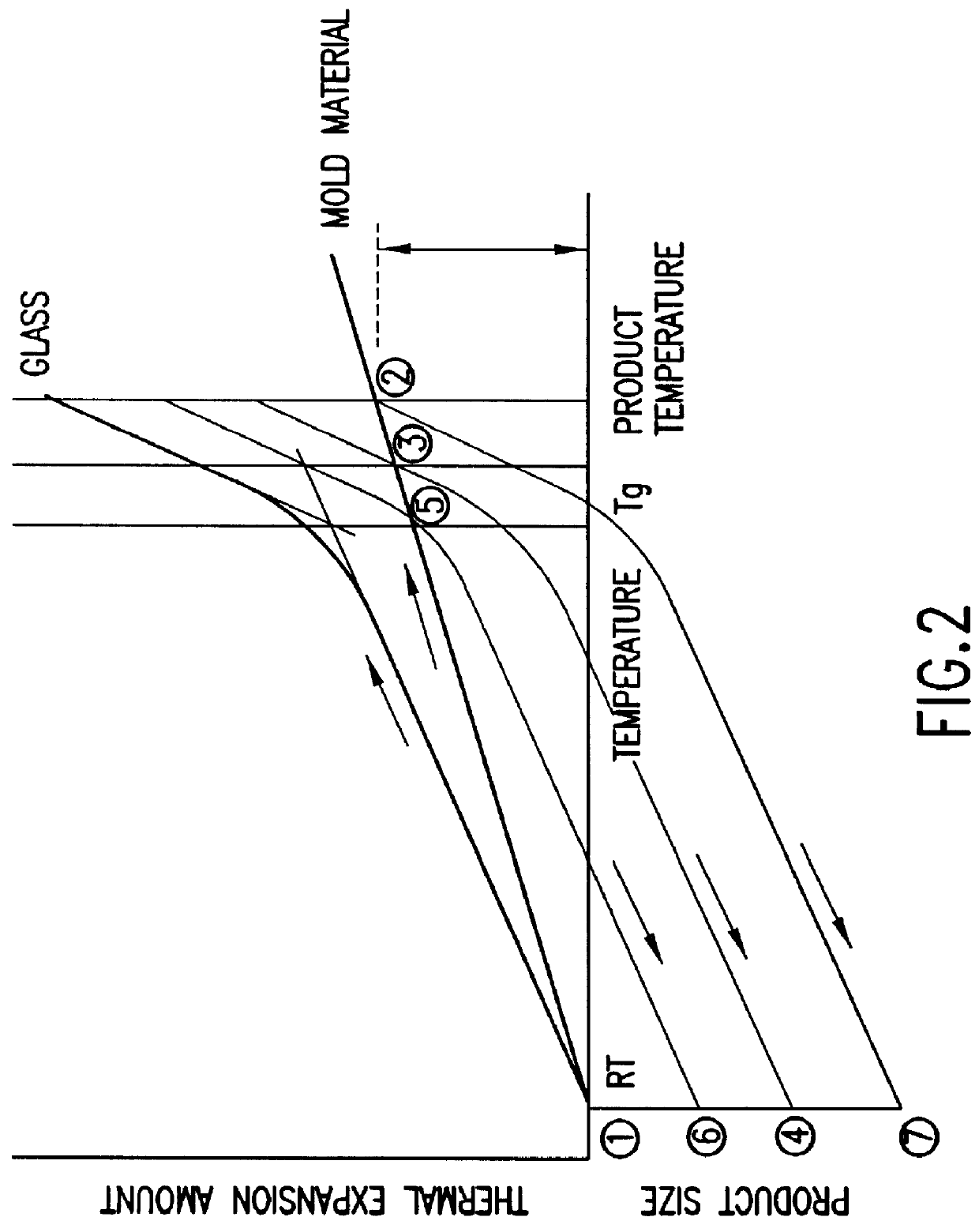

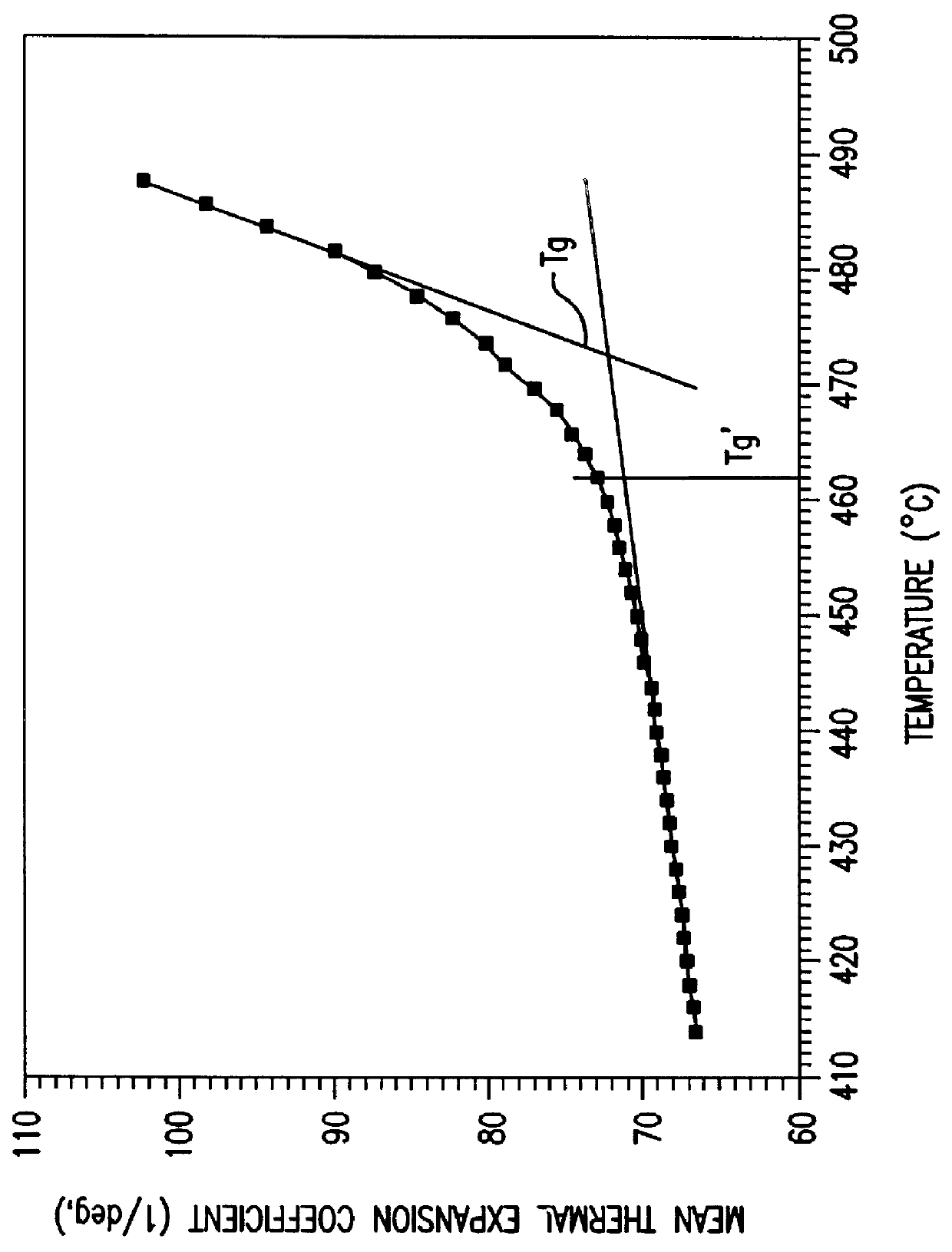

Manufacturing method for glass molded products

In a method for molding glass products having a fine structure as of an optical fiber holder with a high size precision, a mold used for the molding has the fine structure in a size such that a size difference occurring when the glass product is cooled down to a room temperature where at the end of molding with a pressure a size of the fine structure of the mold for glass product and a size of a fine structure of the glass product formed by transfer of the fine structure of the mold are the same as one another is so adjusted that a size of the fine structure of the completed glass product falls within a permissive size precision range. The mold may has a size satisfying, as a size of a fine structure at a room temperature, a formula [1+( alpha g- alpha m)x DELTA T+ alpha g'x DELTA T']xSg, wherein Sg denotes a size of a fine structure of thc glass product at the room temperature; alpha g denotes a mean thermal expansion coefficient of the glass to be molded in a temperature range from the room temperature to the glass transition temperature of the glass to be molded; alpha m denotes a mean thermal expansion coefficient of the mold in a temperature range from the room temperature to the glass transition temperature of thc glass to be molded; DELTA T denotes a difference between the room temperature and the glass transition temperature of the glass to be molded; DELTA T' denotes a difference between a temperature at which the mold's pressure exerted to the glass product is released and the glass transition temperature, in a case where the mold's pressure exerted to the glass product is released at a temperature higher than the glass transition temperature after pressing the mold with a high pressure; and alpha g' is a thermal expansion coefficient of the glass to be molded at a mean temperature of summation of the glass sag temperature and the glass transition temperature.

Owner:HOYA CORP +1

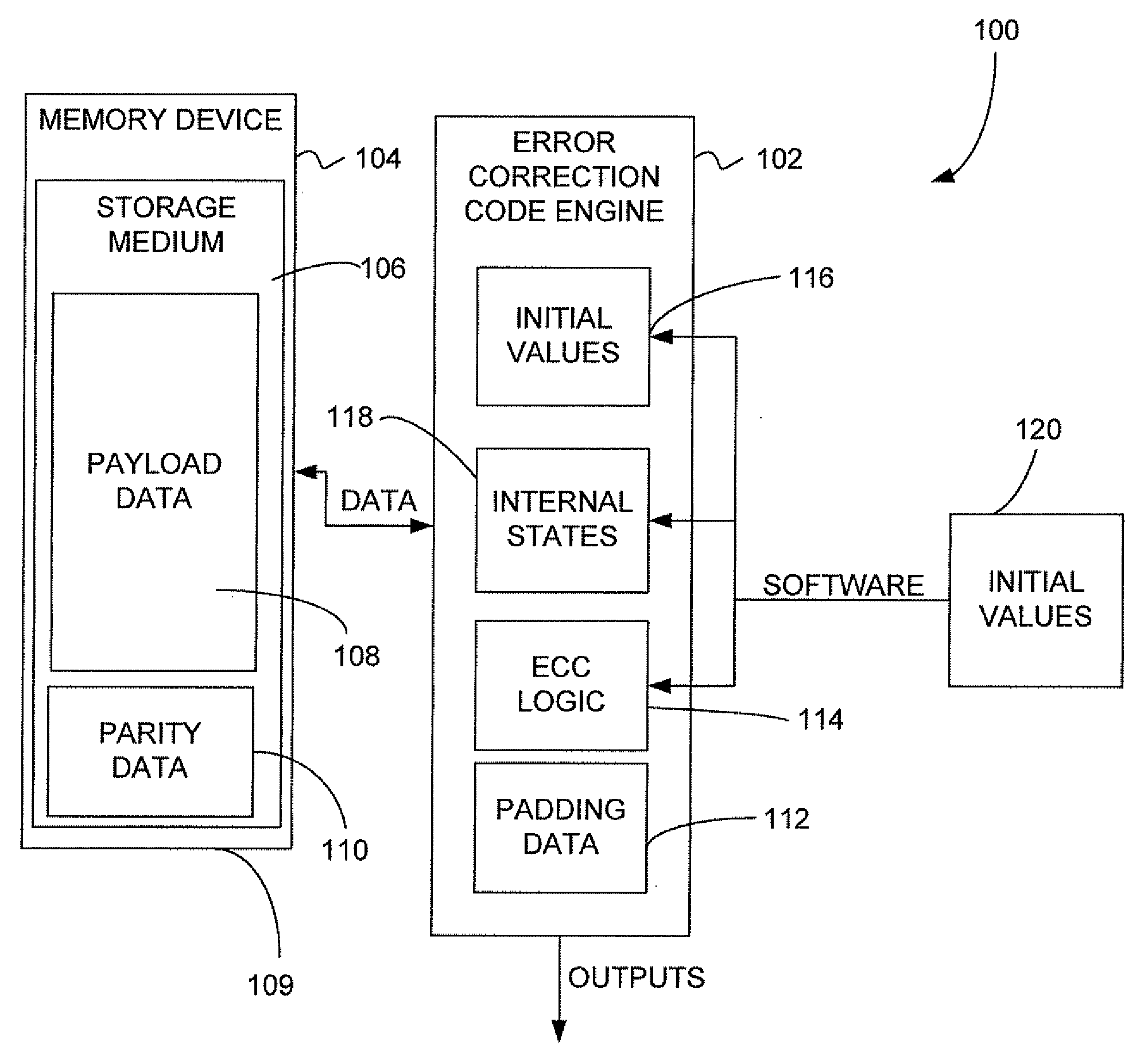

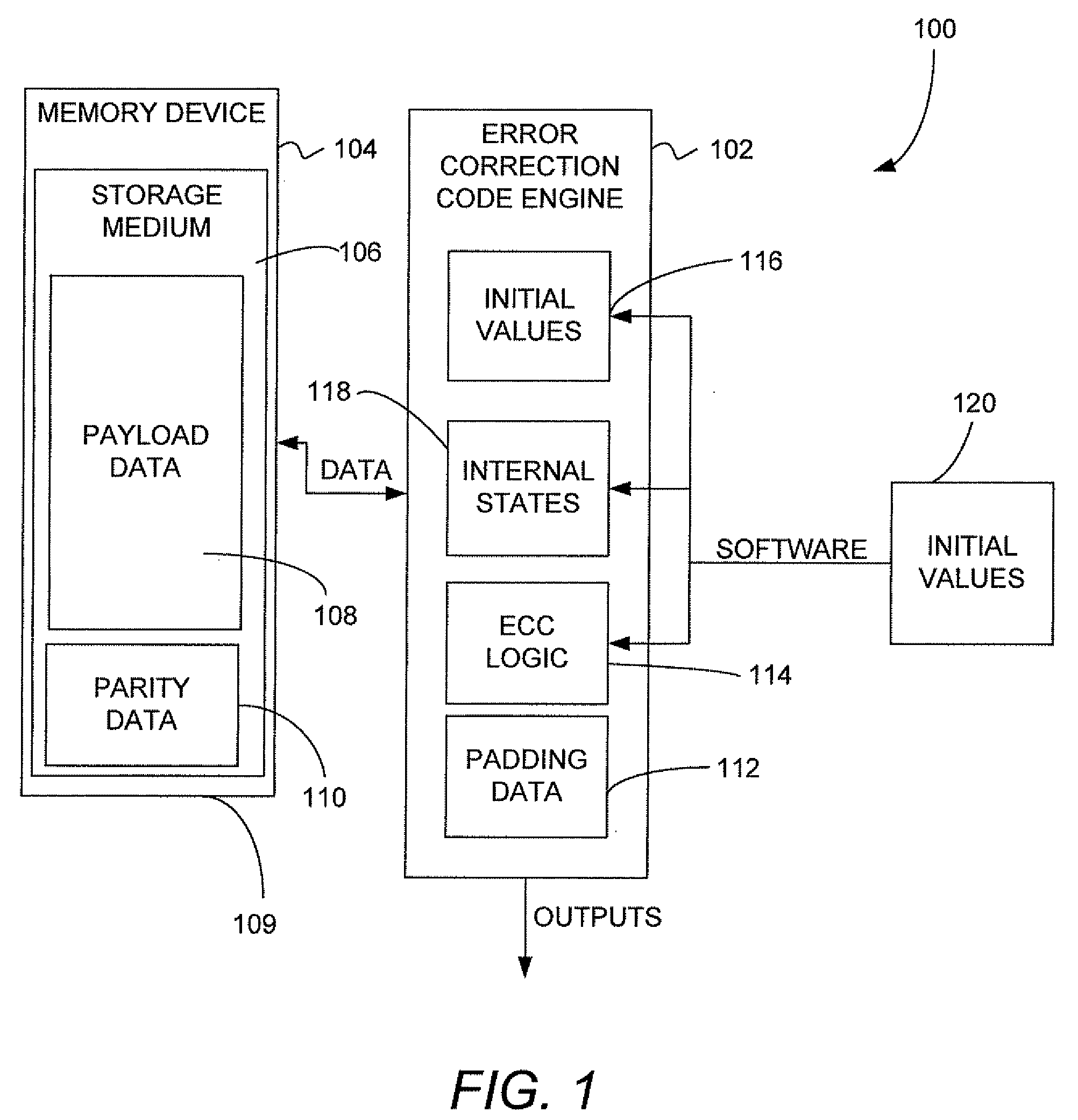

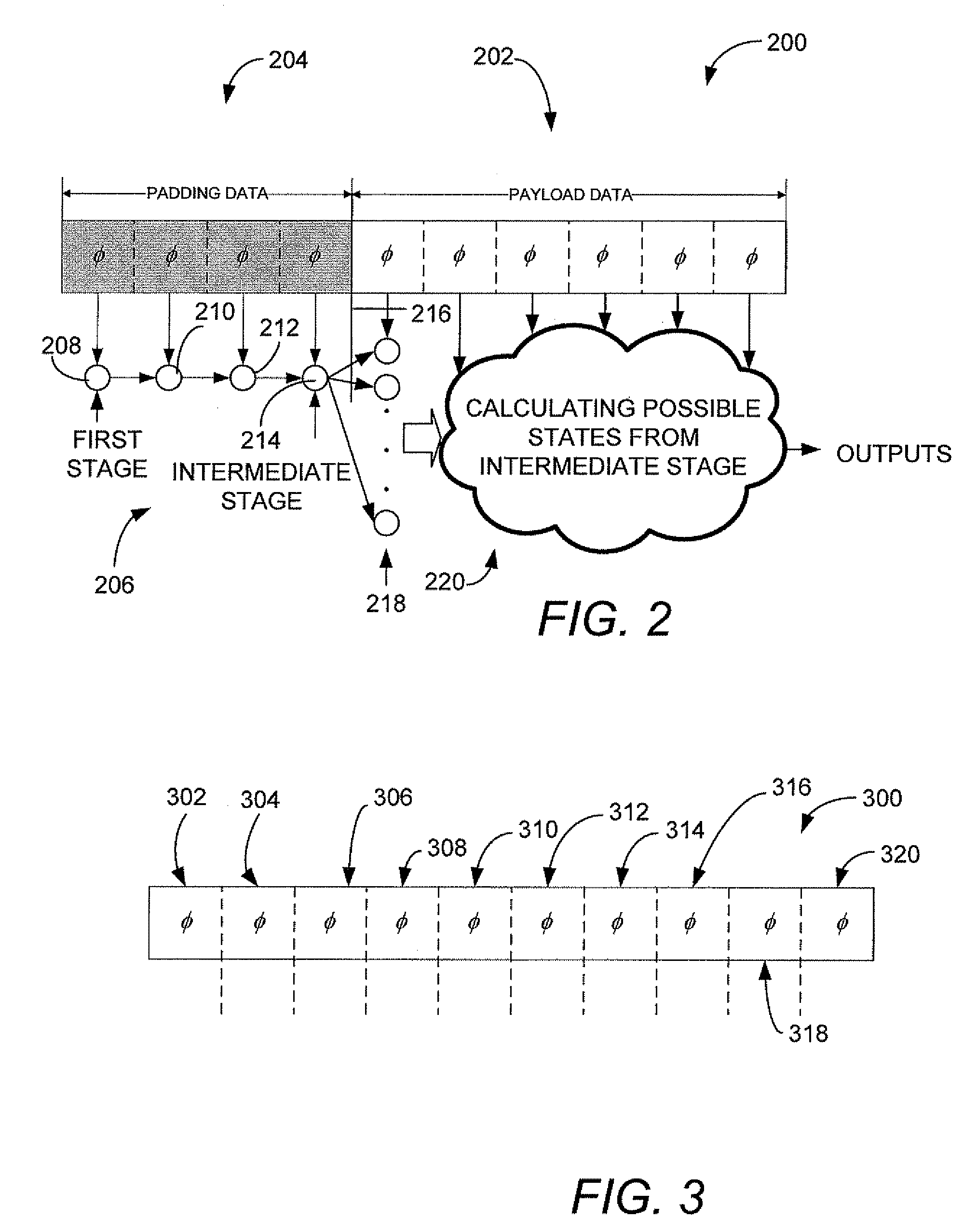

Error correction system and method

InactiveUS20080201625A1Error prevention/detection by using return channelTransmission systemsSize differenceComputer hardware

A method includes receiving payload data from a data source at error correction code (ECC) logic, where the ECC logic is adapted to process a block of data of a particular size via a plurality of stages. The ECC logic is initialized to a selected stage of the plurality of stages. The selected stage includes an initial value and an initial number of cycles. The initial value and the initial number of cycles are related to a number of symbols of padding data corresponding to a difference in size between the payload data and the block of data. The selected stage is related to a state of the ECC logic as if the number of symbols of padding data had already been processed by the ECC logic. The payload data is processed via the ECC logic beginning with the selected stage to produce parity data related to the payload data.

Owner:NORTH STAR INNOVATIONS

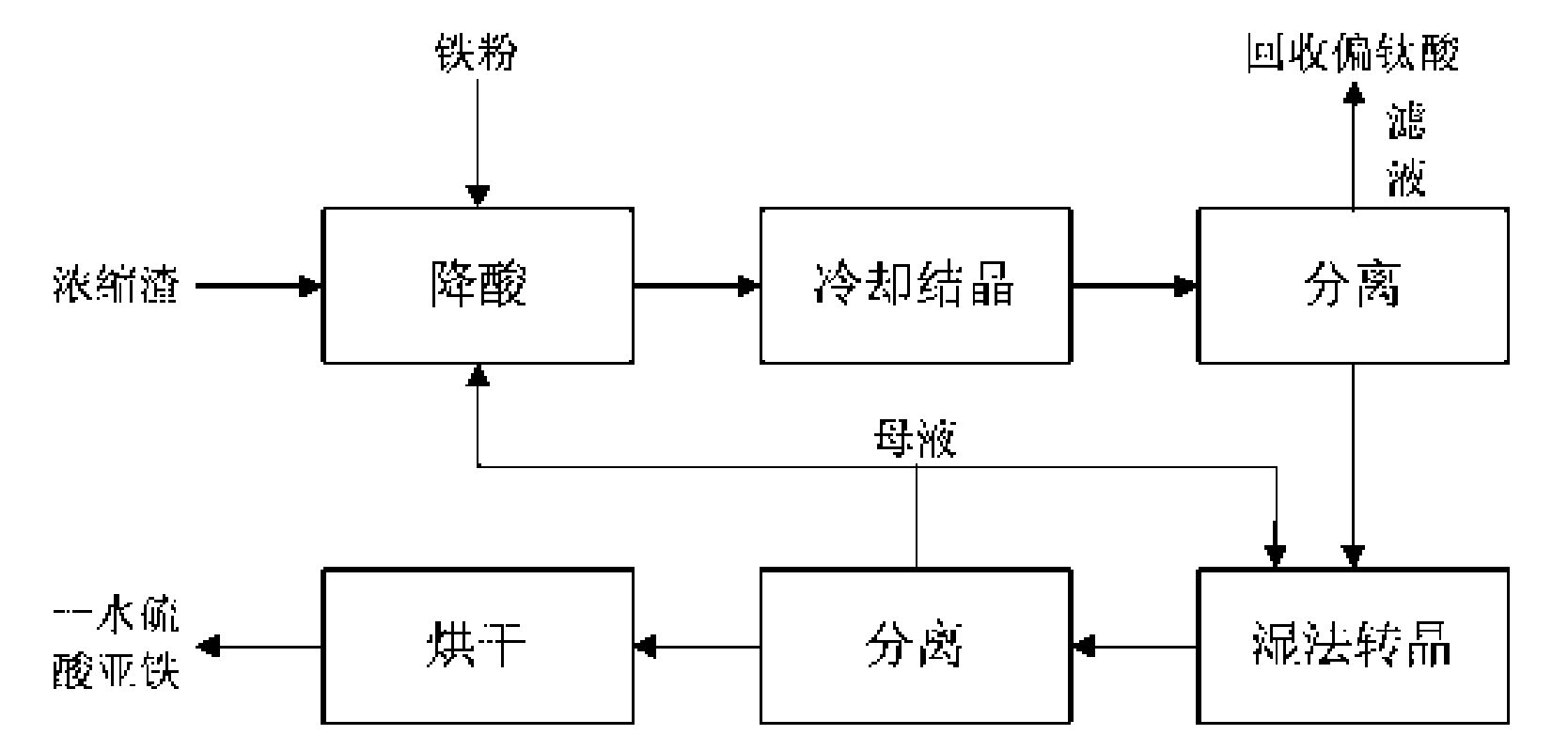

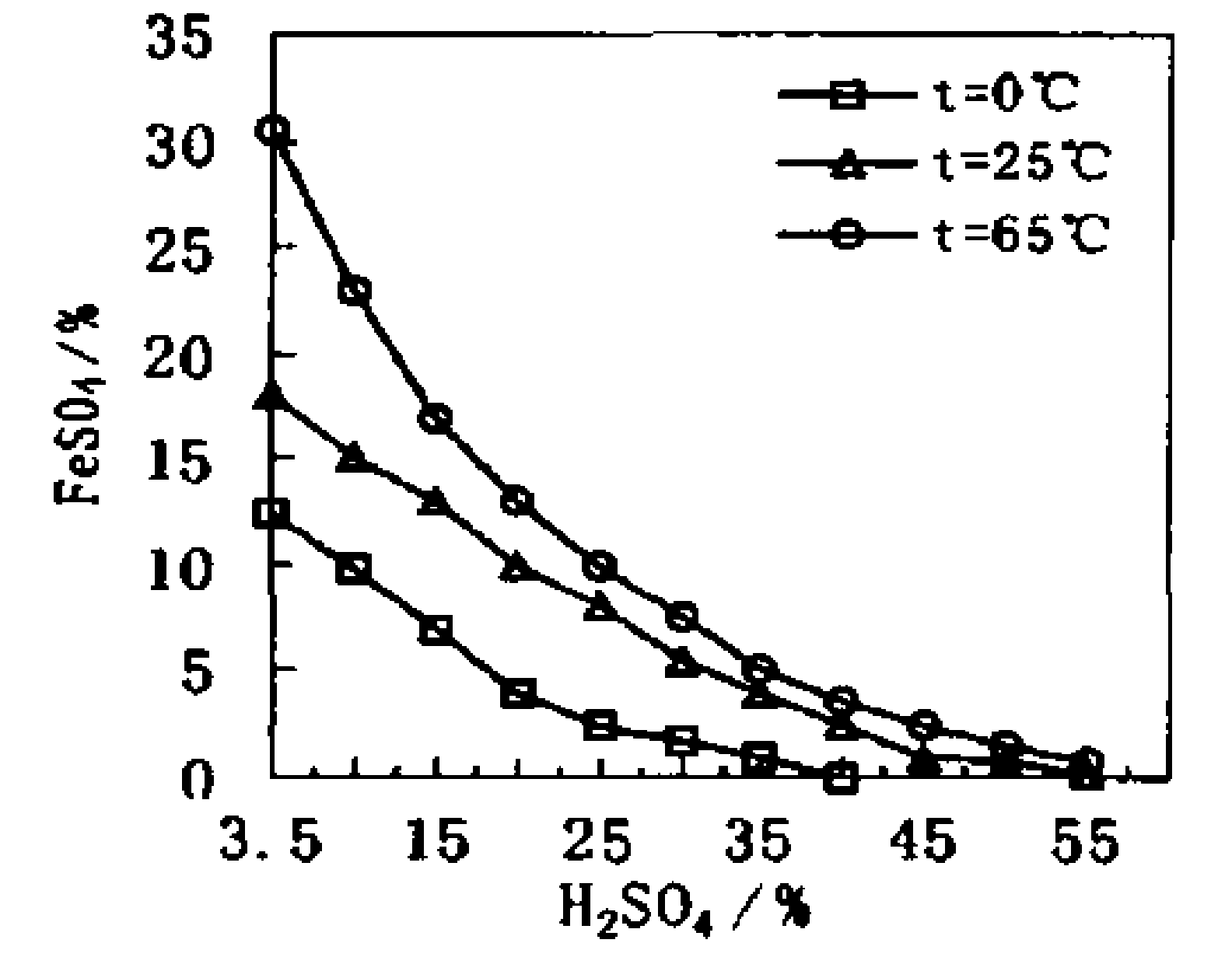

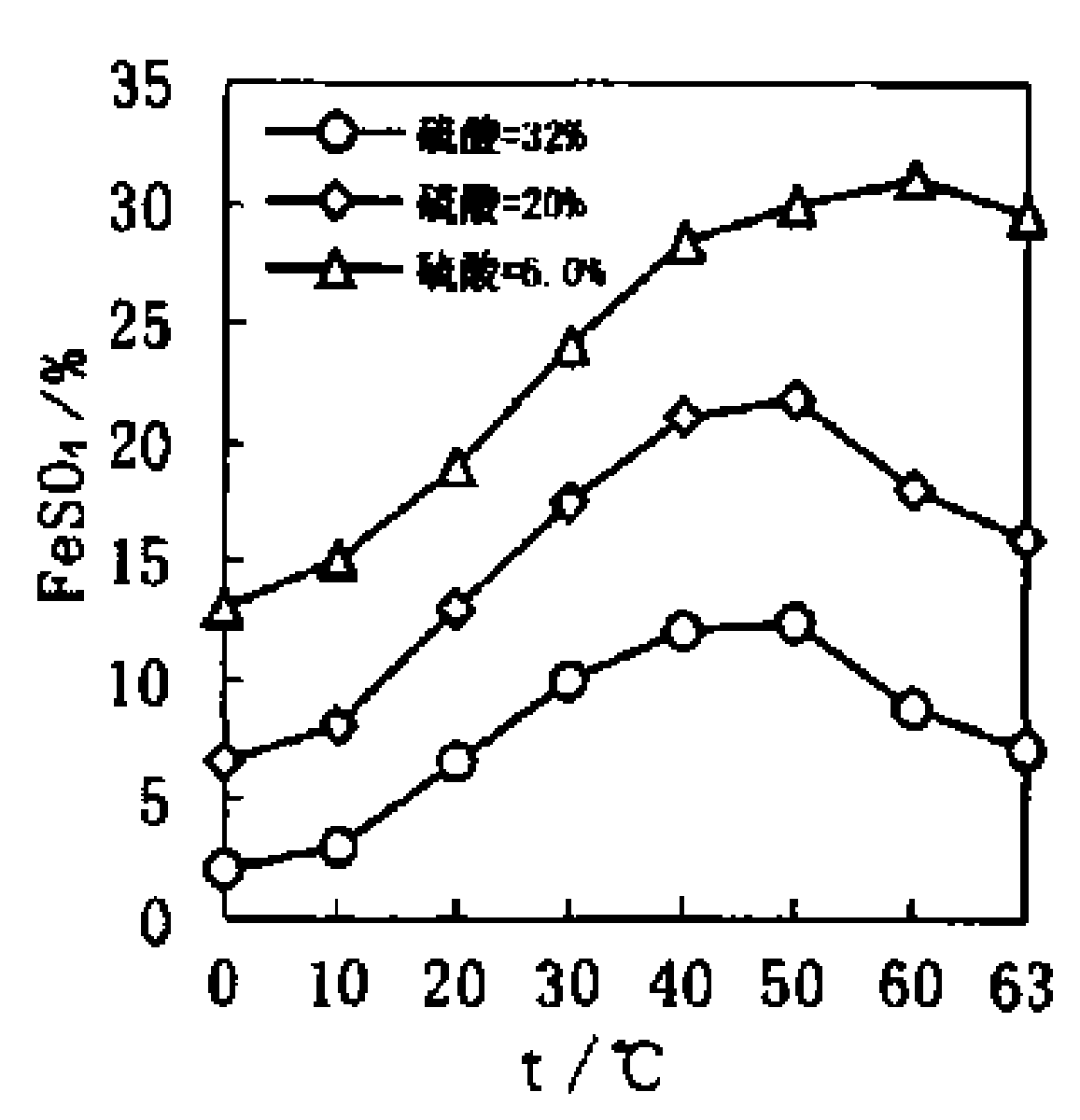

Method for producing feed grade ferrous sulfate monohydrate from titanium pigment waste acid condensed slag

The invention discloses a production method of feed grade ferrous sulfate monohydrate. Titanium white waste acid condensed slag is used as the raw material, and is subject to the processes of deacidification, pexitropy, separation, crystal transform and the like to produce the feed grade ferrous sulfate monohydrate, thereby realizing the comprehensive utilization of the titanium pigment waste acid condensed slag as the byproduct for the sulfuric acid method. The method comprises the following steps: mixing mother solutions generated in the ferrous sulfate monohydrate production processes by condensed slag and wet method, using iron powder to reduce the sulfuric acid content to 4% or so, slowly cooling and crystallizing the slurry to generatecoarse ferrous sulfate heptahydrate crystals, and separating impurities from the ferrous sulfate by using the particle size differences between the ferrous sulfate heptahydrate crystals and the impurity particles, thereby purifying the ferrous sulfate in the condensed slag and widening the application field of the condensed slag. The ferrous sulfate heptahydrate is transformed into ferrous sulfate monohydrate at high temperature to produce the qualified feed grade ferrous sulfate monohydrate in huge market demands, thereby changing the waste slag into valuable resources.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

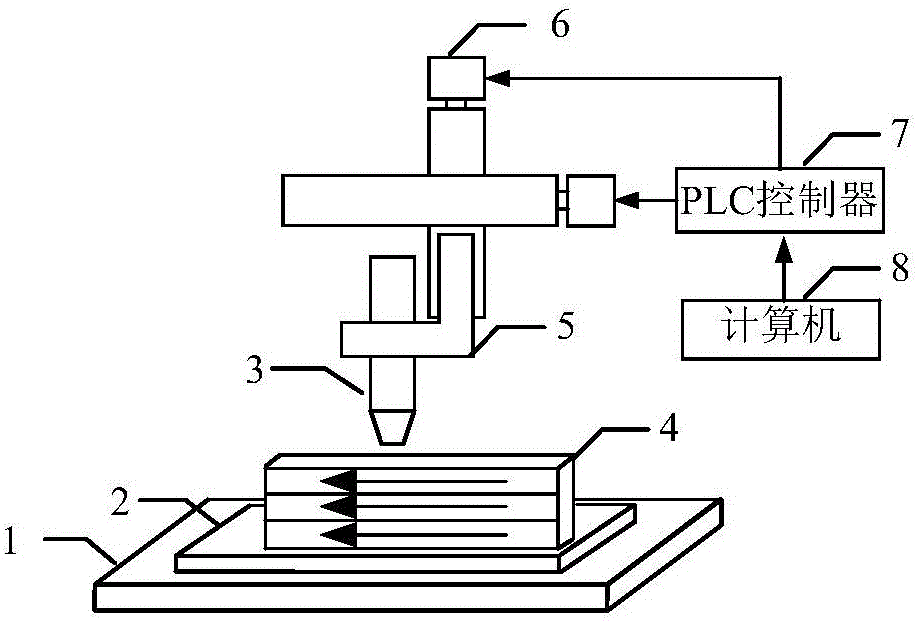

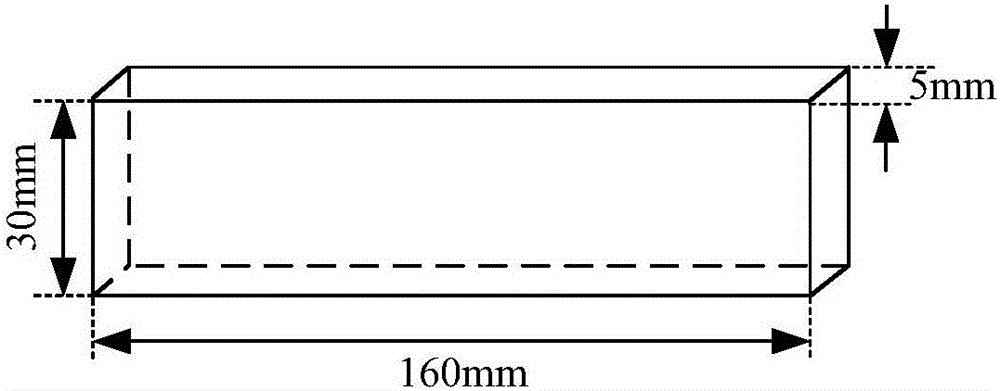

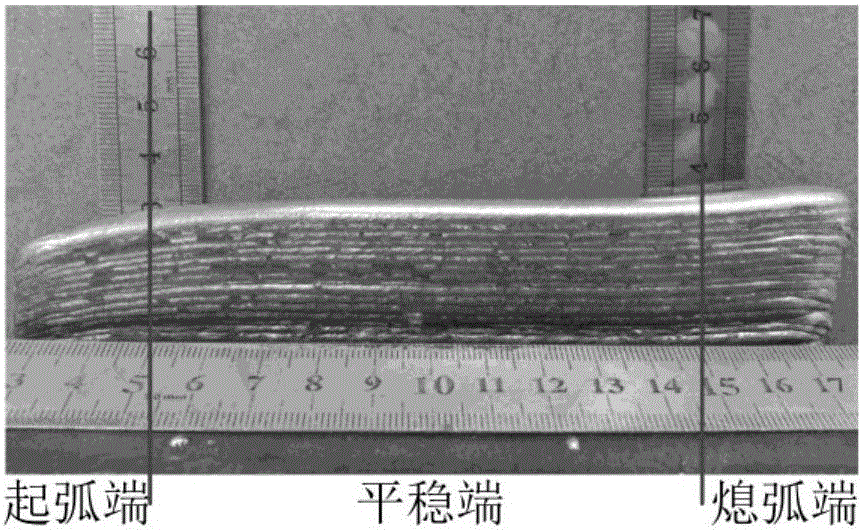

Same-direction forming mode based forming morphology control method for GMAW material increase manufacturing

InactiveCN105880808AHigh forming dimension accuracySuppression of height size differencesArc welding apparatusSize differenceQuality control

The invention provides a same-direction forming mode based forming morphology control method for GMAW material increase manufacturing. The control method includes the steps that arc starting and quenching movement I / O control and given electric signal D / A control of forming current and voltage are completed in the GMAW material increase manufacturing process, and when the forming process is close to the arc quenching end, the forming current, forming speed and forming voltage are gradually decreased within the length range of the arc quenching end; a GMAW welding gun is increased for one layer height and is controlled to return to the forming arc starting end; the upper surface temperature of a formed part is reduced to be 20-300 DEG C; forming of a residual layer is completed till the forming size of the whole structural part meets the requirements. The same-direction forming mode based forming morphology control method can effectively inhibit the height size difference produced by the part end in the same-direction forming process, decreases the defects produced in the forming process, ensures that higher forming size precision is obtained in GMAW material increase manufacturing in the same-direction forming mode and provides a reliable technical support for forming quality control of GMAW material increase manufacturing.

Owner:SOUTHWEST JIAOTONG UNIV

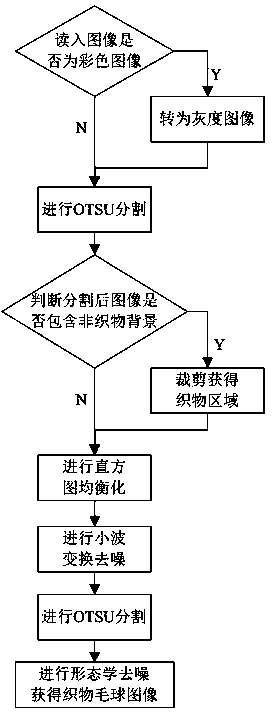

Fabric fuzzing and pilling image segmentation method based on wavelet transformation and morphological algorithm

ActiveCN104021561ARobustImprove anti-interference abilityImage analysisImage segmentationVariance method

The invention discloses a fabric fuzzing and pilling image segmentation method based on wavelet transformation and the morphological algorithm. The method comprises the steps that firstly, histogram equalization is carried out on an acquired fabric fuzzing and pilling image, and eight-stage multi-resolution wavelet decomposition is carried out; secondly, after the coefficient of a first-stage wavelet decomposition layer, the coefficient of a second-stage wavelet decomposition layer and the coefficient of an approximate wavelet decomposition layer are set to be zero, the image is reconstructed, wherein the first-stage wavelet decomposition layer and the second-stage wavelet decomposition layer express the highest-frequency information, and the approximate wavelet decomposition layer expresses low-frequency information; thirdly, binaryzation is carried out on the constructed image according to the maximum between-cluster variance method, and erosion is carried out on the image through a horizontal linear structure element, a 45-degree linear structure element, a vertical linear structure element and a 135-degree linear structure element in sequence; fourthly, dilation is carried out on the eroded image through structure elements with the sequence opposite to that of the structure elements applied to erosion, namely, the 135-degree linear structure element, the vertical linear structure element, the 45-degree linear structure element and the horizontal linear structure element in sequence. By means of the method, the influence of the texture of fabric, illumination unevenness, the surface roughness of the fabric and the size difference and shape difference of fuzzy balls on fuzzing and pilling grade assessment on the fabric can be effectively avoided.

Owner:江苏世纪燎原针织有限公司

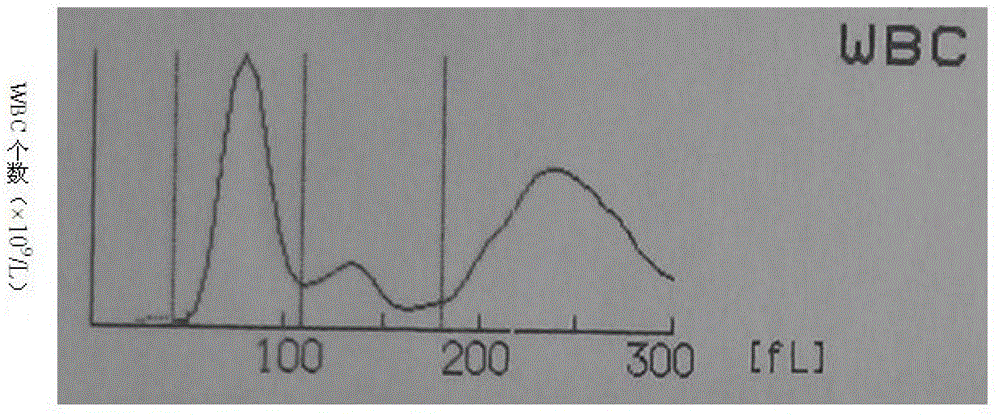

Whole blood quality control material and preparation method thereof

ActiveCN103336110AWide variety of sourcesSimple preparation processPreparing sample for investigationBiological testingSize differenceQuality control

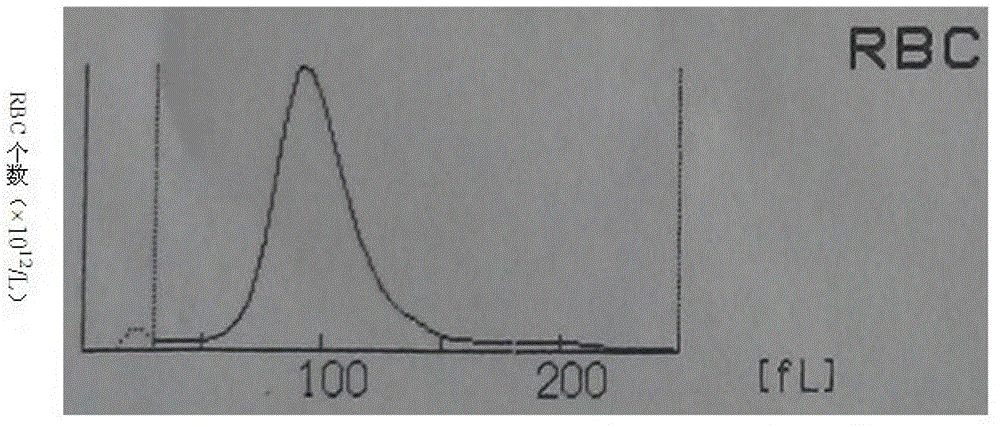

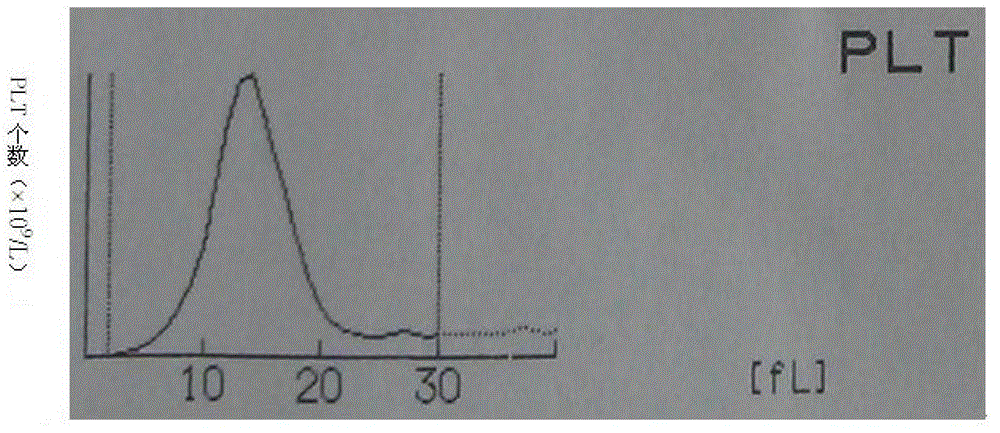

The invention discloses a whole blood quality control material. The whole blood quality control material comprises three cell simulating materials, an anticoagulation agent, white cell stationary liquid, and red cell and blood platelet stationary liquid. The invention further discloses a preparation method of the whole blood quality control material. The whole blood quality control material is wide in raw material resources and simple in preparation process; three classes of white cells can be clearly identified on a three-class blood cell instrument; the size difference of red cells and blood platelets is obvious, and the red cells and the blood platelets are easy to identify by the instrument; interferences of the small red cells on the blood platelets are small and the storage life can reach 6 months; the use requirements of clinical quality control are met.

Owner:NANJING PERLONG MEDICAL EQUIP

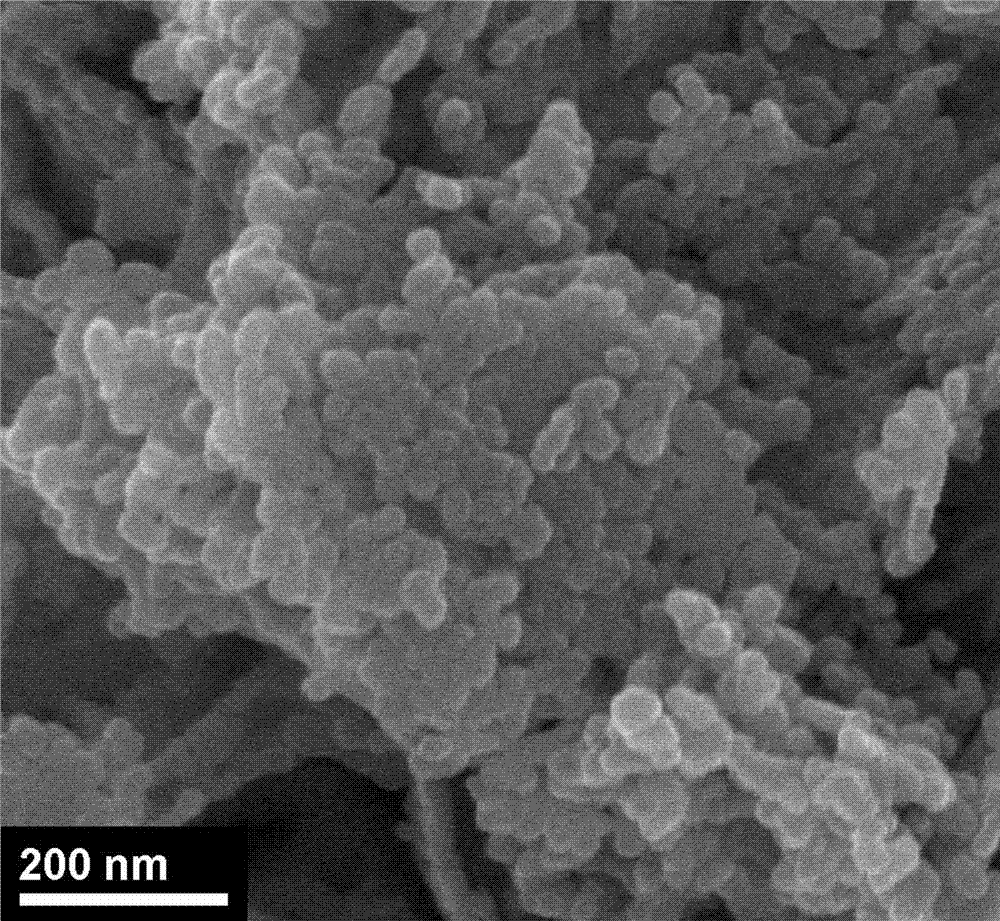

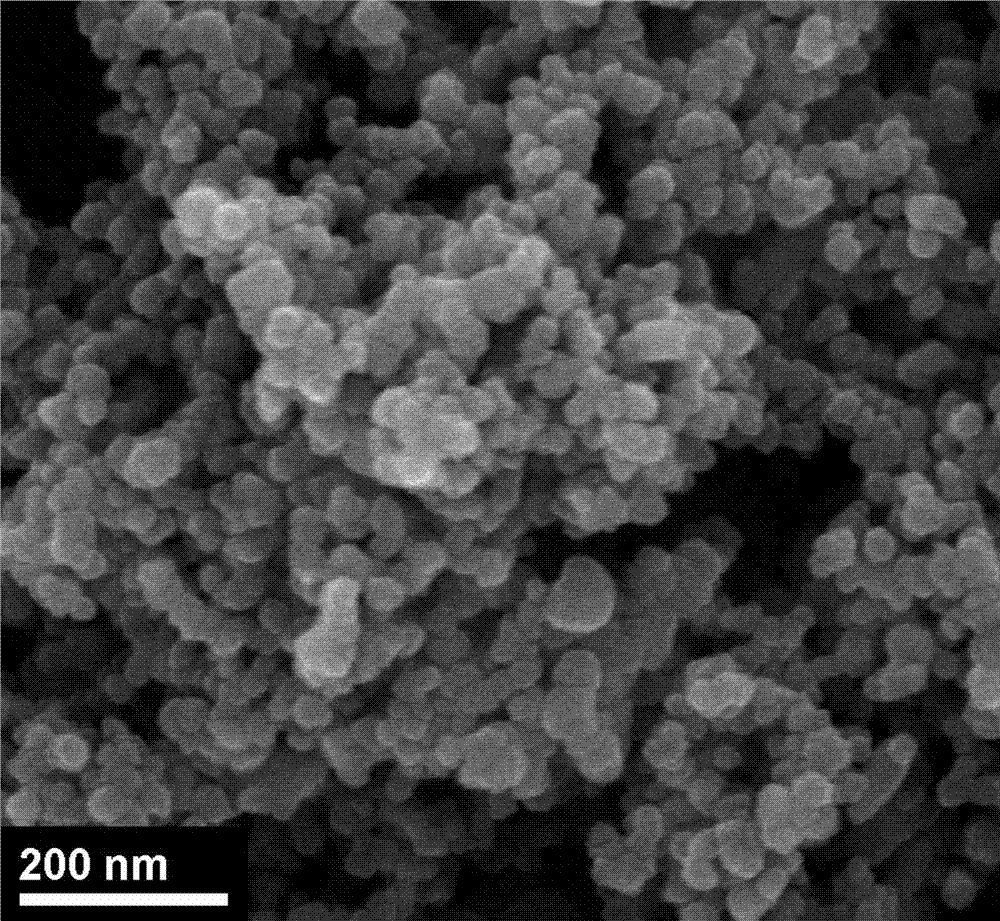

Preparation method of nanometer zinc oxide composite dispersion liquid

InactiveCN103693674AGood dispersionUniform and stable dispersionMaterial nanotechnologyZinc oxides/hydroxidesZno nanoparticlesOxide composite

The invention discloses a preparation method of a nanometer zinc oxide composite dispersion liquid. The method is characterized by comprising the following steps: mixing an oil phase component and an emulsifier according to certain proportion in an oil phase system; adding a dispersion stabilizing agent, a surfactant and a nano zinc oxide powder according to a certain ratio into water in a water dispersion system; and respectively uniformly mixing the two phases and heating to a certain temperature, rapidly stirring the two phases for homogeneous mixing, and cooling to room temperature to form a stable emulsion dispersion system. The nanometer zinc oxide composite dispersion liquid prepared by the above method, the particle size difference of zinc oxide particle and nano zinc oxide powder raw material is within 20%; in the dispersion liquid, nano zinc oxide particles are suspended in the liquid in a monodispersed form; and placing for more than 60 days, the nano zinc oxide composite dispersion liquid does not generate the phenomena of layering, demulsification or caking. Moreover, the preparation method has the advantages of simple operation, wide adjustable range of parameters, low energy consumption and short cycle, and is suitable for pilot plant test amplification and industrial large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

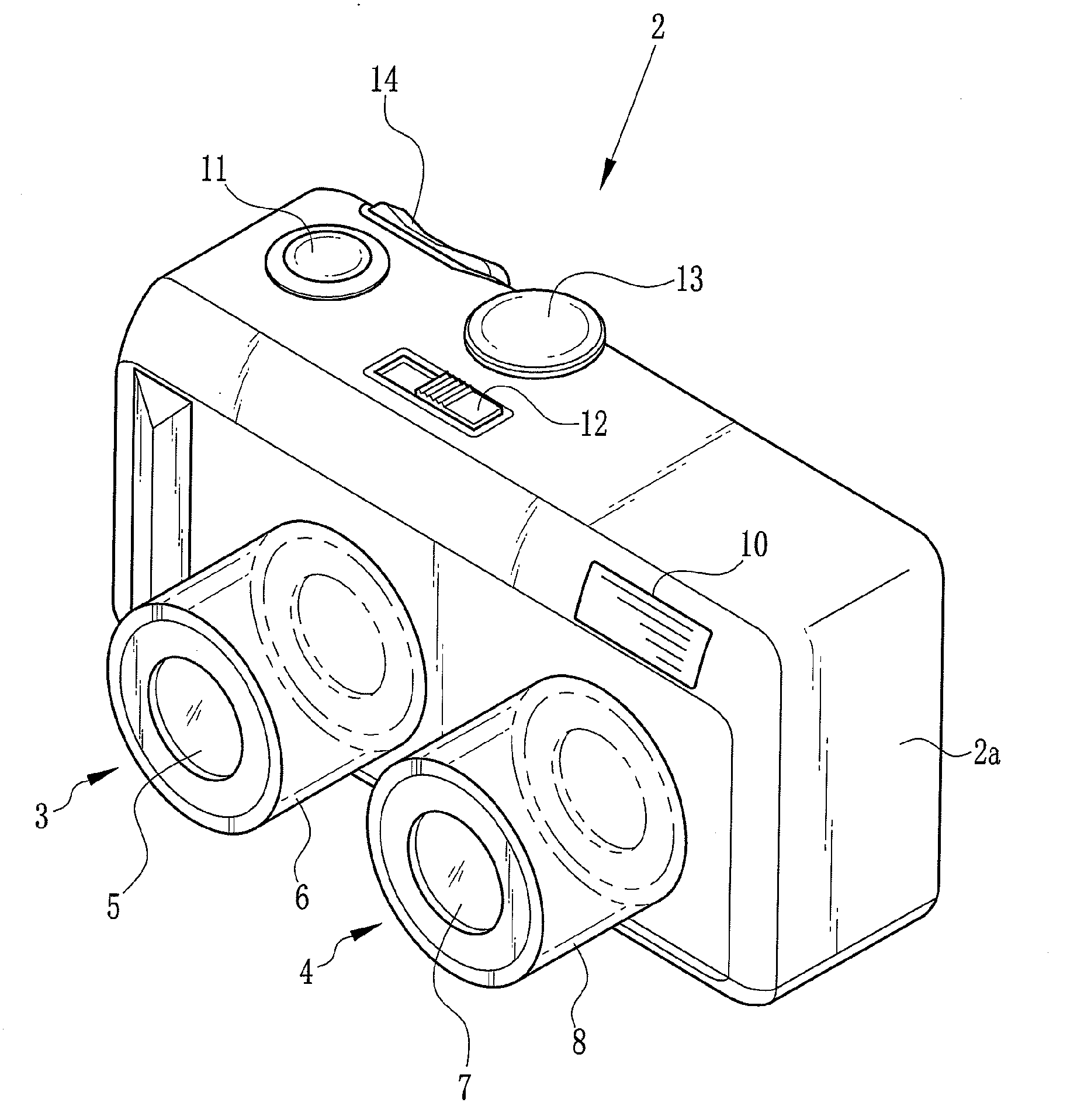

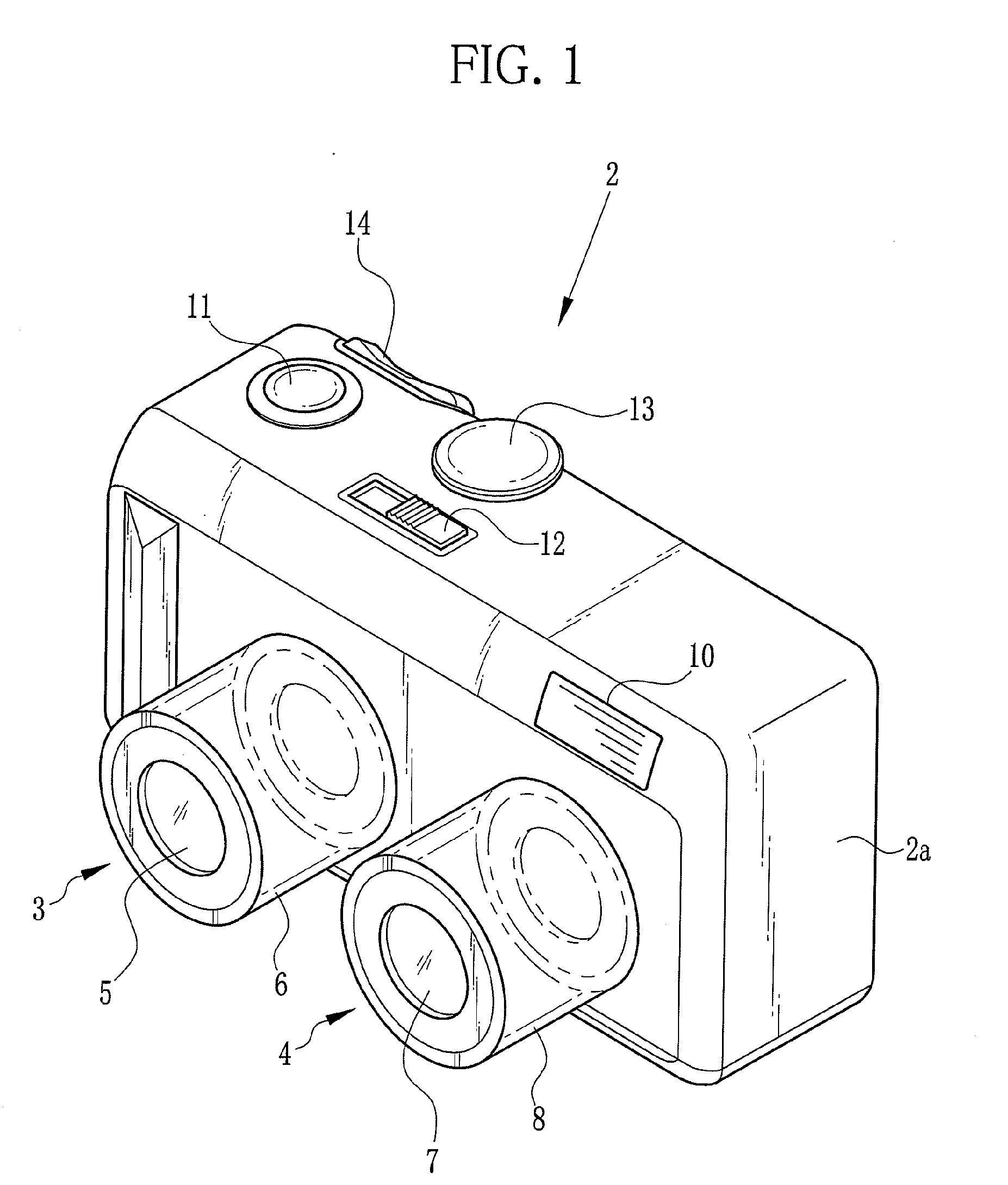

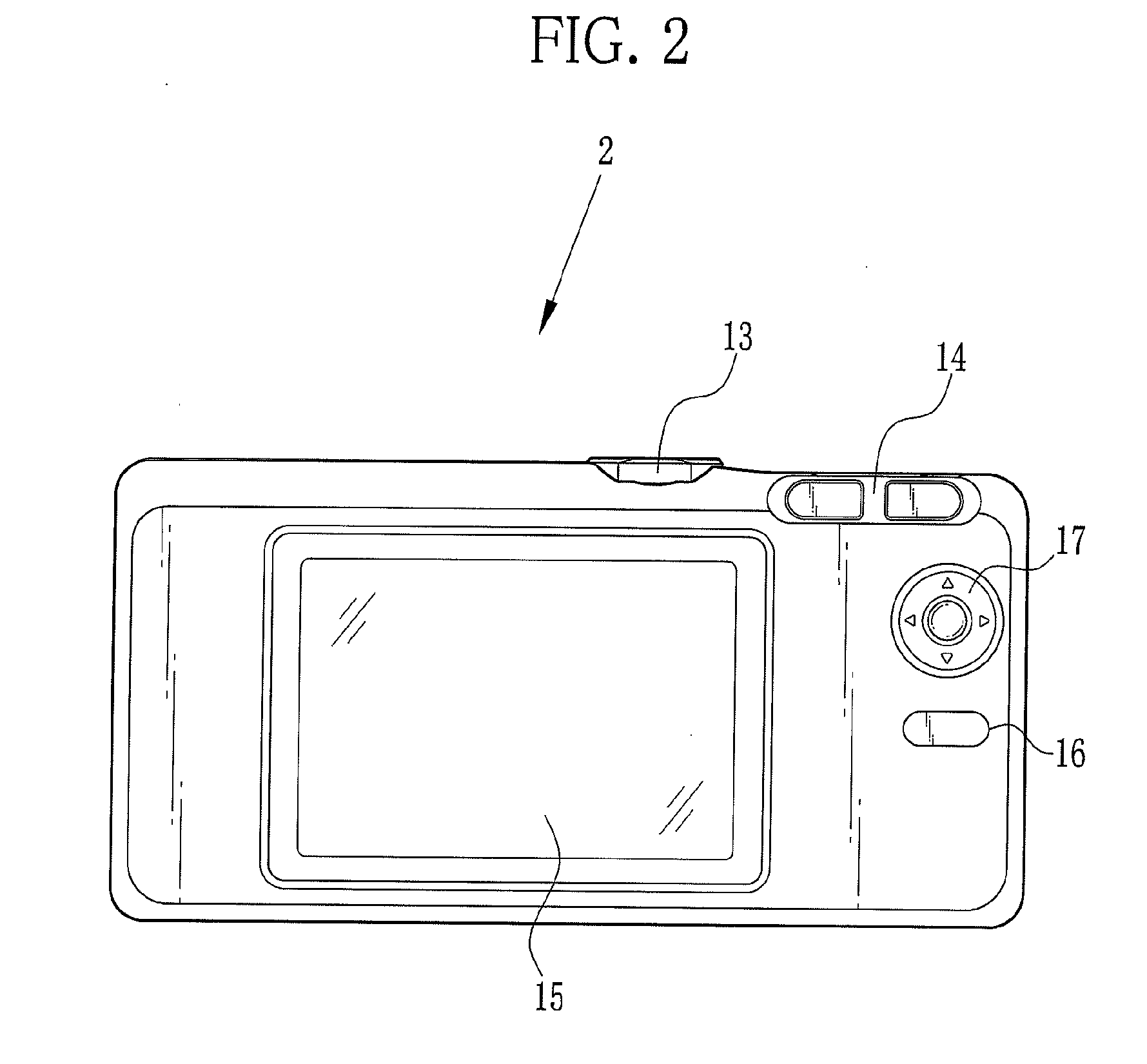

Multi-eye camera and method for distinguishing three-dimensional object

InactiveUS20110090313A1Increase costAccurate distinctionImage enhancementImage analysisSize differenceViewpoints

A stereo camera captures a pair of R and L viewpoint images. Upon a half press of a shutter release button, a preliminary photographing procedure is carried out. A binary image generator applies binary processing to each image, and a shadow extracting section extracts a shadow of a main subject from each binary image. A size calculating section calculates a size of each shadow, and a difference calculating section calculates a difference in size of the shadow between the images. If an absolute value of the difference is a size difference threshold value or more, the main subject is distinguished as a three-dimensional object suited to a 3D picture mode. Otherwise, the main subject is distinguished as a printed sheet suited to a 2D picture mode. Upon a full press of the shutter release button, an actual photographing procedure is carried out in the established 3D or 2D picture mode.

Owner:FUJIFILM CORP

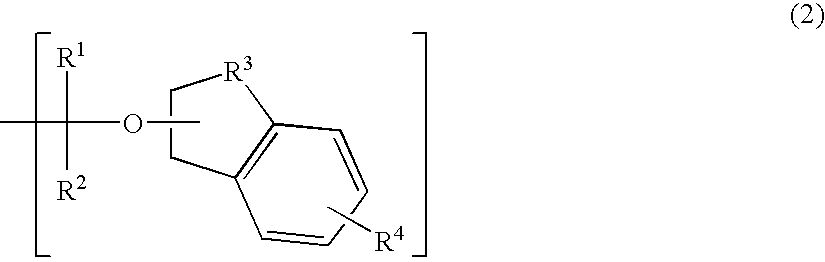

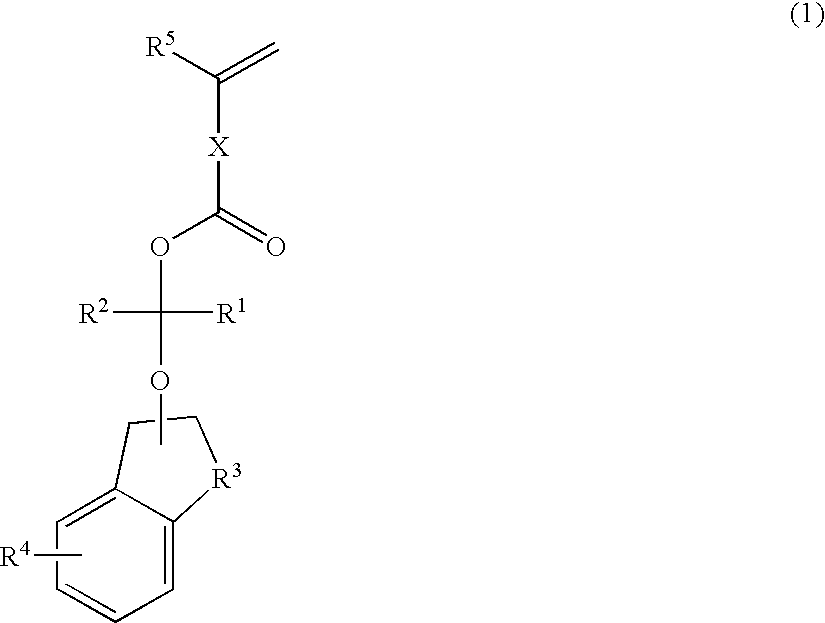

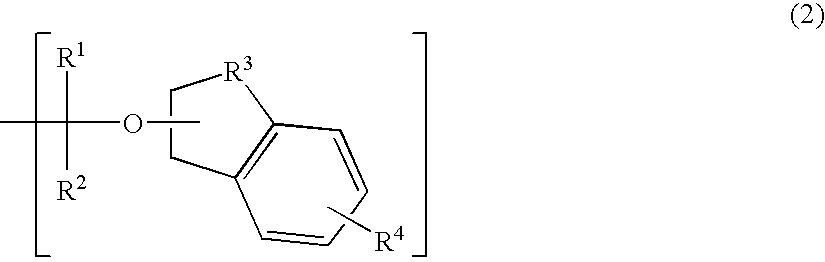

Polymerizable compound, polymer, positive resist composition, and patterning process using the same

ActiveUS20090297979A1High sensitivity and resolutionPattern configurationOrganic chemistryOrganic compound preparationResistSize difference

The present invention provides; a polymer suitable as a base resin for a positive resist composition, in particular a chemically amplified positive resist composition, having a higher resolution, a larger exposure allowance, a smaller sparse-dense size difference, a better process applicability, a better pattern configuration after exposure, and in addition, a further excellent etching resistance, than a conventional positive resist; a positive resist composition using the same; a patterning process; and a novel polymerizable compound to obtain a polymer like this.The present invention was accomplished by a polymer whose hydrogen atom of at least a carboxyl group is substituted by an acid labile group represented by the following general formula (2), a positive resist composition using the same, a patterning process, and a novel polymerizable compound to obtain a polymer like this.

Owner:SHIN ETSU CHEM IND CO LTD

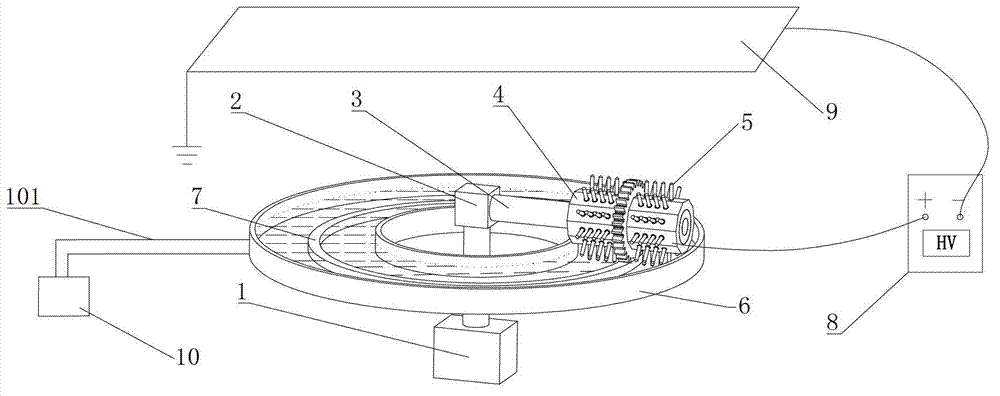

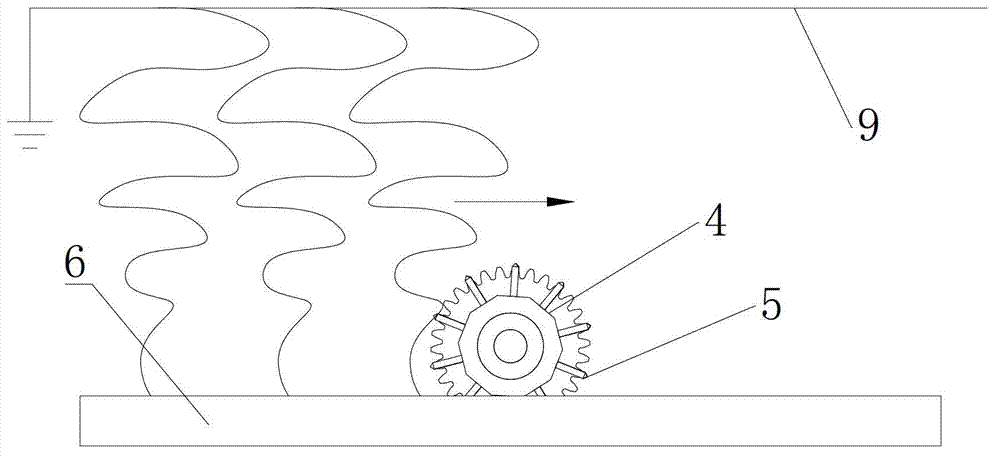

Continuous fiber-manufacturing device

InactiveCN103114347AEnsure consistencyAchieve continuous and stable manufacturingArtificial thread manufacturing machinesFilament/thread formingFiberSize difference

The invention discloses a continuous fiber-manufacturing device, relates to an electrostatic spinning device, and provides the fiber-manufacturing device capable of overcoming the shortcomings that liquid supply is not continuous and large in jet flow size difference, and surface solution solidifies and the like, and capable of guaranteeing uniformity of diameters of fiber and continuity of electrospinning nanometer fiber. The continuous fiber-manufacturing device is provided with a motor, a connector, a rotating shaft, an inducing rolling wheel, a needle tip array, an annular liquid-storage groove, a direct-current high-voltage power supply, a collection plate and a liquid-supplying device. An output shaft of the motor is connected with the rotating shaft through the connector. The inducing rolling wheel is connected with the rotating shaft in a rotating mode. Gear rings are arranged on the surface of the inducing rolling wheel. The needle tip array is arranged on the surface of the inducing rolling wheel. Annular racks are arranged inside the annular liquid-storage groove and are meshed with the gear rings of the inducing rolling wheel. The positive electrode of the direct-current high-voltage power supply is connected with an annular solution groove, and the negative of the direct-current high-voltage power supply is connected with the collection plate. The collection plate is arranged above the annular solution groove. The collection plate is grounded. The liquid-supplying device is communicated with the annular liquid-storage groove through a liquid-conveying pipe.

Owner:XIAMEN UNIV

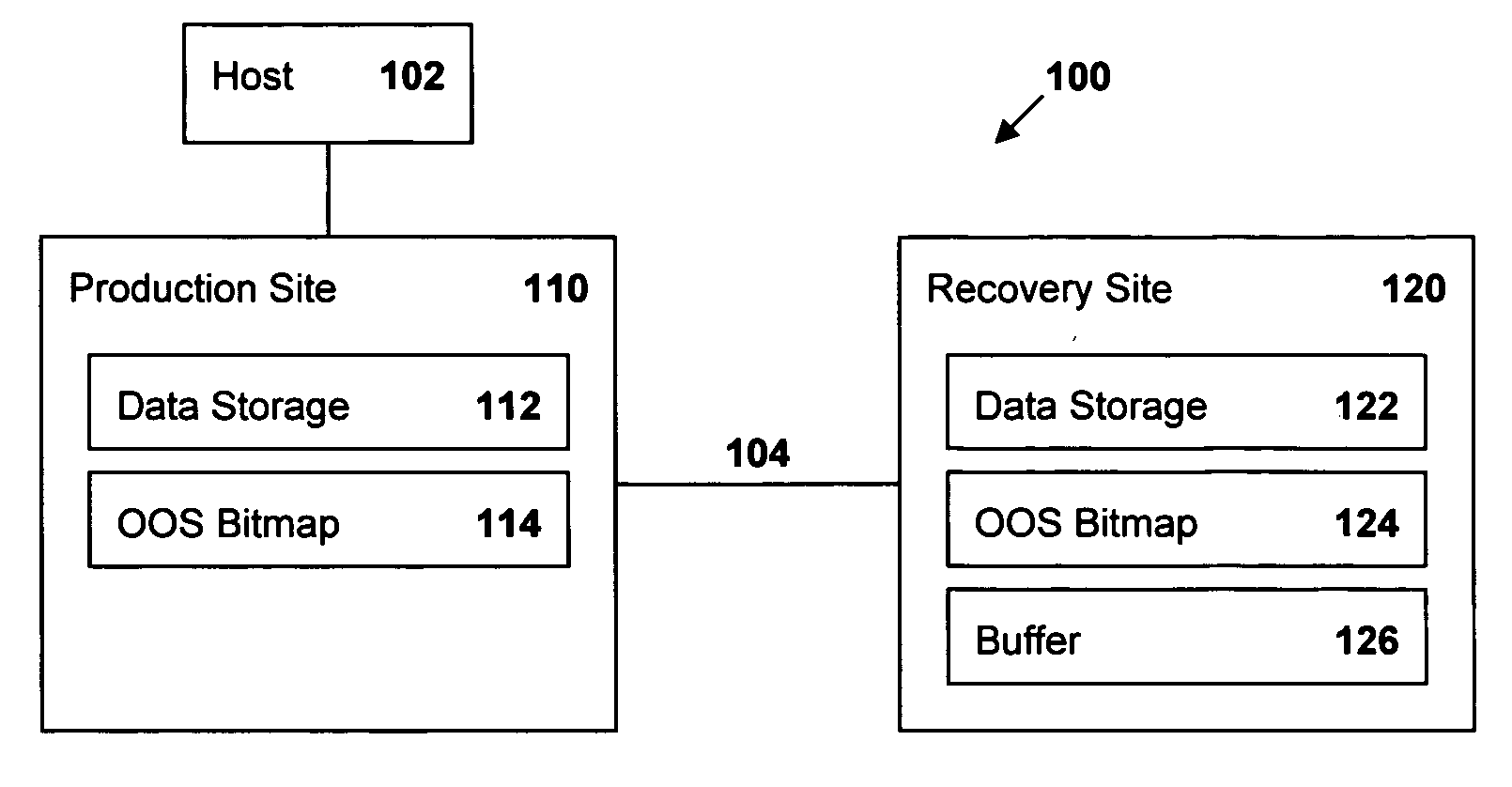

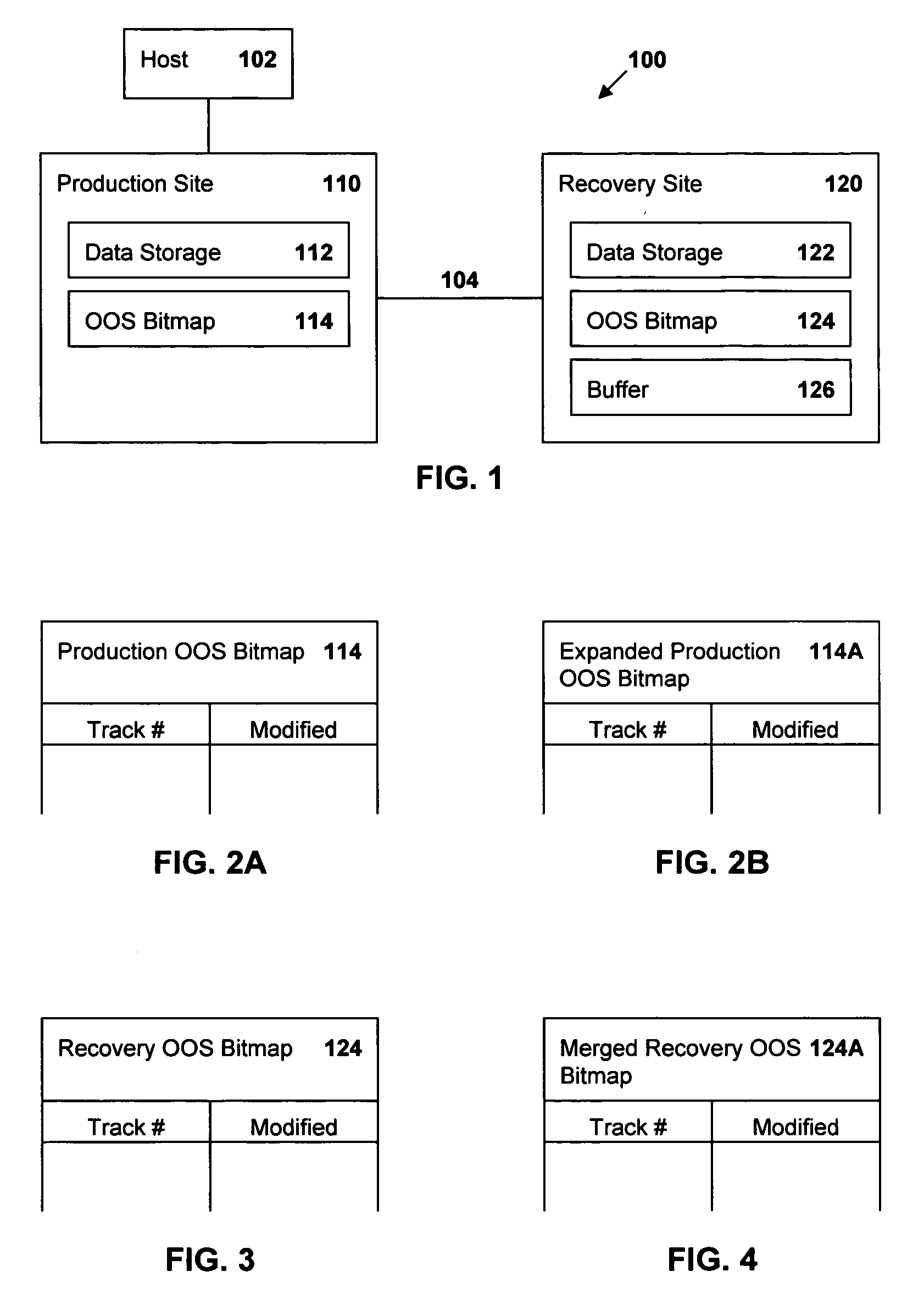

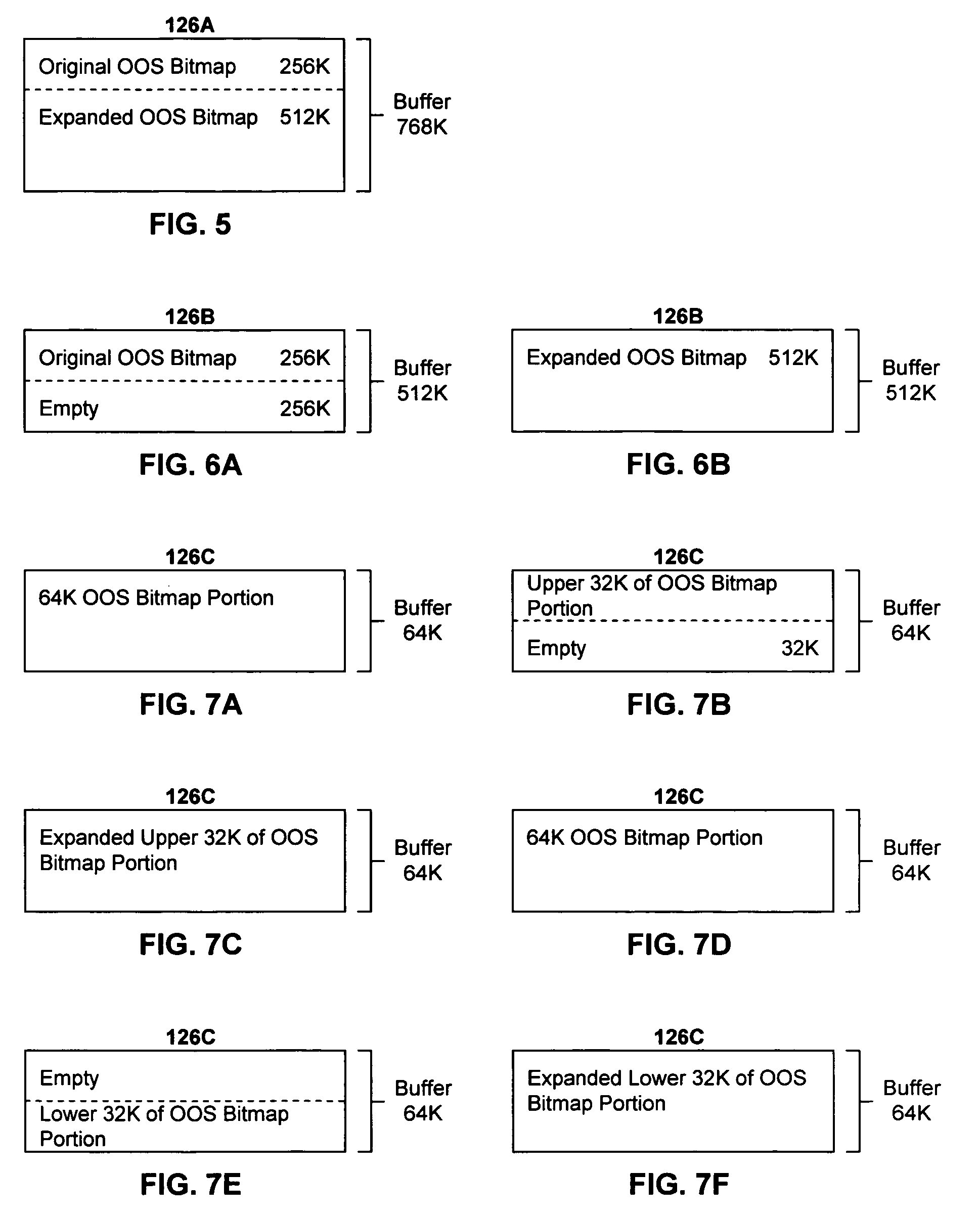

Enhanced resynchronization in a storage-based mirroring system having different storage geometries

Resynchronization of data between a primary (production) data site and a secondary (recovery) site following a failure is enhanced when the size of a data track at the production site is different from the size of a data track at the recovery site. The recovery site reads an out-of-sync (OOS) bitmap created at the production site and expands or contracts the bitmap to accommodate the size difference. The resulting production site bitmap is merged with a OOS bitmap maintained at the recovery site to indicate those tracks which are to be transferred from the recovery site to the production site. Thus, only those tracks which are required to be transferred are transferred. Buffer space may be allocated in which to expand or contract the production site OOS bitmap. Buffer space may be conserved by sequentially reading portions of the production site OOS bitmap into a small buffer. In a first operation, half of the bitmap portion is discarded and the remaining half is expanded into the buffer and merged with a corresponding section of the recovery site OOS bitmap. In a second operation, the portion is re-read into the buffer and the other half discarded. The remaining half is then expanded into the buffer and merged with the corresponding section of the recovery site OOS bitmap. The process continues until the entire production site OOS bitmap has been merged with the recovery site OOS bitmap.

Owner:IBM CORP

Construction method of slant-well pulling into main tunnel for three-line long-span tunnel

InactiveCN107605489AImprove structural stabilitySimple structureUnderground chambersTunnel liningSize differenceLong span

The invention discloses a construction method of slant-well pulling into main tunnel for a three-line long-span tunnel. The method comprises following steps: first: excavating a slant well to junctionwith a main tunnel, installing a reinforcing support at the intersection of the slant well and the main tunnel, wherein the end of the reinforcing support is provided with a door frame which is vertically provided with a connecting board; second: entering the main tunnel through top brushing upwards by means of the pilot tunnel method, obliquely upward excavating the climbing pilot tunnel until the pilot tunnel is positioned at the same elevation with the main tunnel top, continuing construction of pilot tunnel to a left sideline of the main tunnel; third: installing main line arch and constructing primary support of the main tunnel; fourth: constructing the main line tunnel according to double side wall pilot tunnel method and timely supporting and protecting temporary support to form the double side wall pilot tunnel method construction technology. Reinforcing supports are installed at the intersection of the slant well and the main tunnel; the end of the reinforcing support is provided with a door frame which is vertically provided with a connecting board; the structure at the reinforcing intersection is stable, the structure is simple, the construction is convenient, safe andreliable, which effectively solves the problems that size difference between the slant well and the main line section is large and the construction is difficult.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST +1

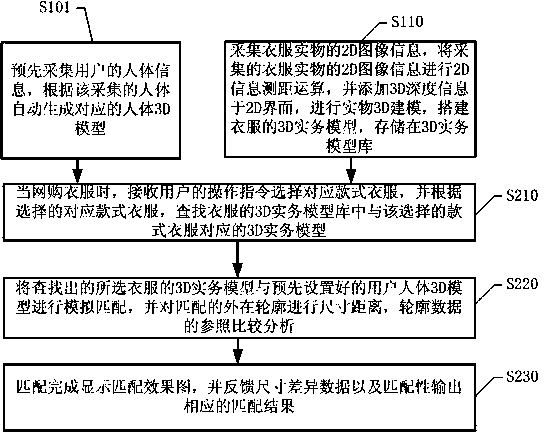

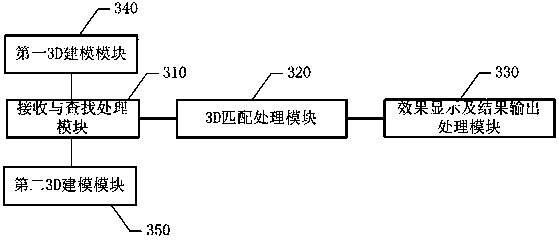

3D simulation matching processing method and system based on mobile terminal

ActiveCN103871099AAvoid the trouble of back and forth exchangeWith 3D simulation matching functionBuying/selling/leasing transactions3D modellingSize differencePhysical model

The invention discloses a 3D simulation matching processing method and system based on a mobile terminal. The method includes the steps that when a user conducts online clothes shopping, an operation instruction of the user is received to select clothes with the corresponding style, and according to the selected clothes with the corresponding style, a 3D physical model base is searched for a 3D physical model corresponding to the selected clothes with the style; simulation matching is conducted on the found 3D physical model of the clothes and a preset user physical 3D model, and the size range and contour data of the matched external contour are referred, compared and analyzed; after matching is finished, a matching effect picture is displayed, size difference data are fed back, and a corresponding matching result is output in a matching mode. By the adoption of the 3D simulation matching processing method and system, when the user conducts online shopping through the mobile terminal, matching of individual physical 3D information with an object can be synchronized, the individual 3D information is provided for simulation matching, and corresponding prompts are given; the user can buy fitted clothes without going out, and convenience is brought to the user.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

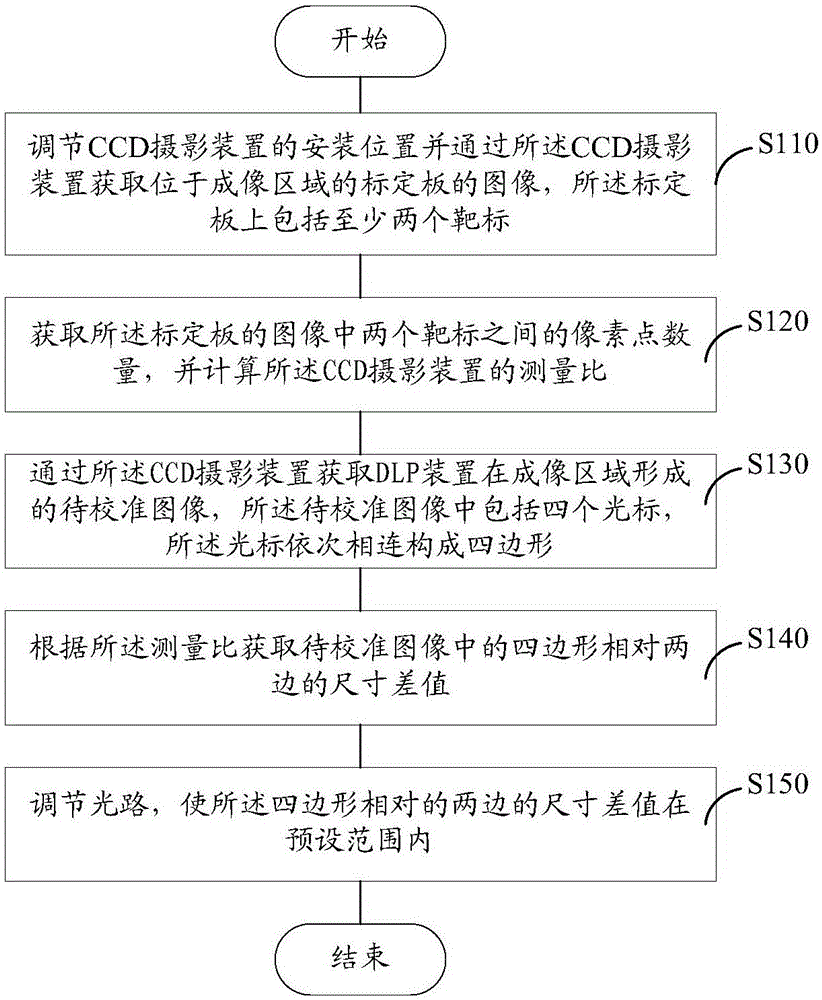

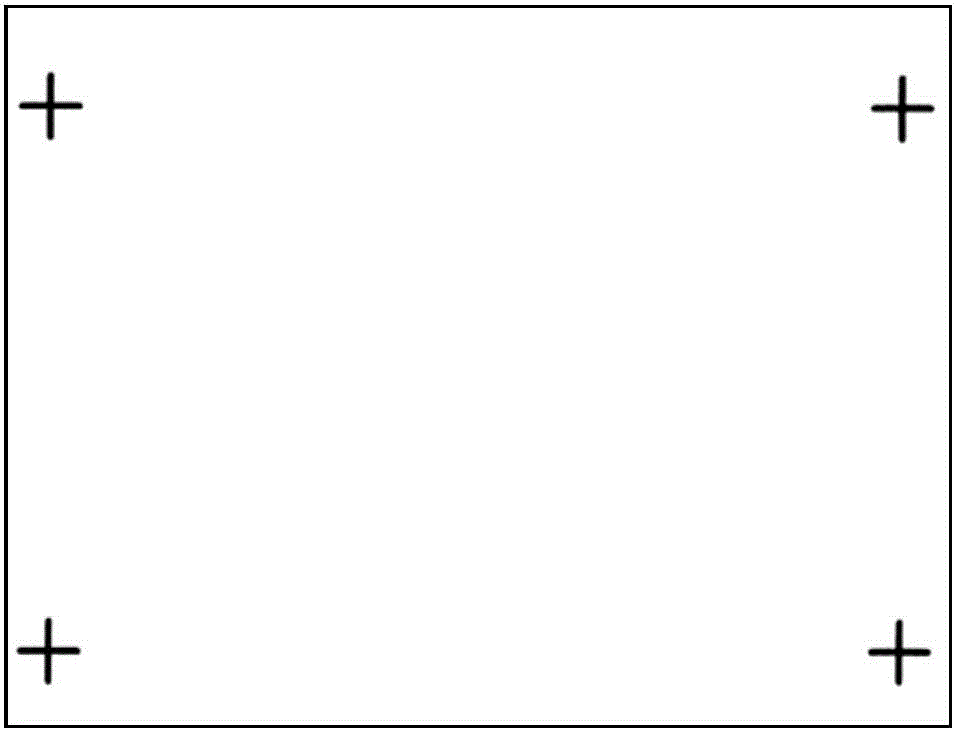

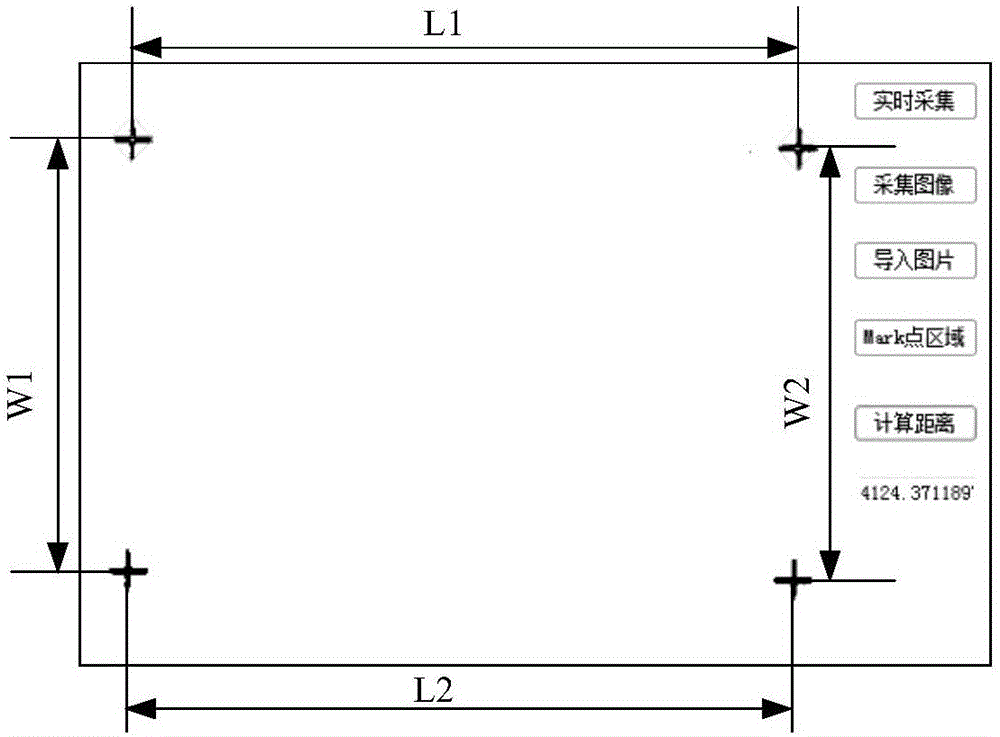

3D printing imaging calibration method and 3D printing imaging calibration system

ActiveCN106827515AAdditive manufacturing apparatus3D object support structuresSize differenceGraphics

The present invention relates to a 3D printing imaging calibration method and a 3D printing imaging calibration system. According to the 3D printing imaging calibration method, the image of a calibration plate positioned in an imaging region is acquired through a CCD imaging device; the measurement ratio of the CCD imaging device is calculated according to the acquired image of the calibration plate; according to the measurement ratio of the CCD imaging device, the size difference between the two opposite edges of a quadrilateral formed by four cursors of a DLP device in the imaging region is calculated; and by adjusting an optical path, the size difference between the two opposite edges of the quadrilateral formed by the four cursors of the DLP device in the imaging region is adjusted. With the 3D printing imaging calibration method of the present invention, the size of the projecting image of the imaging plane (exposure plane) of the DLP device can be quickly and accurately calibrated in a non-contact manner. In addition, the invention provides the 3D printing imaging calibration system.

Owner:HANS LASER TECH IND GRP CO LTD

Continuous fan control in a multi-zone HVAC system

ActiveUS20050156054A1Mechanical apparatusSpace heating and ventilation safety systemsSize differenceZone System

A multi-zoned HVAC system includes a control for independently determining the amount of airflow delivered to each zone within the HVAC system. The control determines nominal zone airflow and continuous fan airflow levels for each zone based upon a user selected fan airflow level and the relative size of each zone in the HVAC system. The control determines the desired system airflow for the entire system once the continuous fan airflow levels for each zone are determined. The HVAC system provides a continuous fan airflow to each zone independently of the continuous fan airflow delivered to any other zone and irrespective of the relative size difference of the zones.

Owner:CARRIER CORP

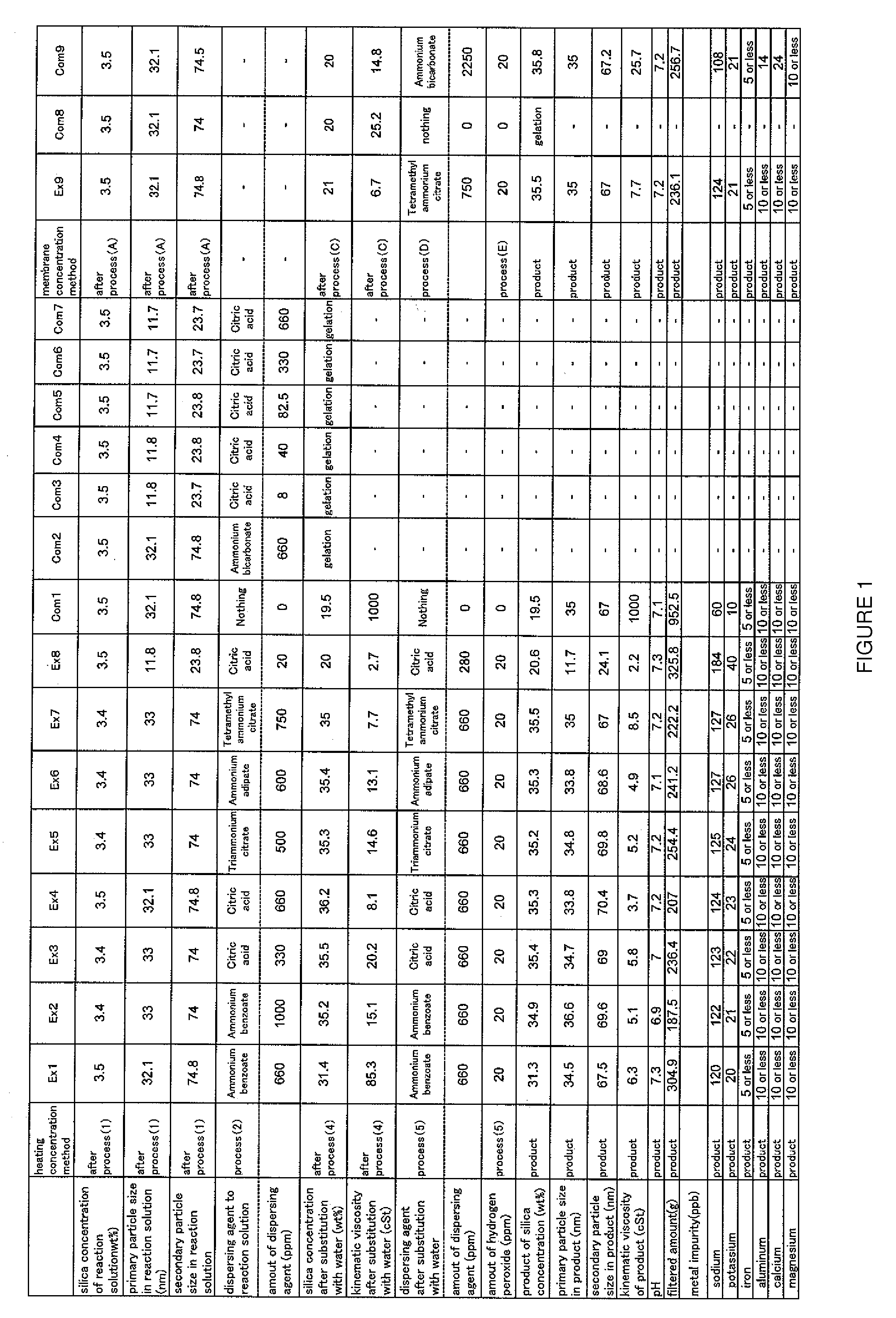

Silica sol and method for producing the same

ActiveUS20090143490A1Improve long-term stabilityImprove efficiencySilicaOther chemical processesOrganic acidSize difference

(Problem) This invention provides a high-purity, high-concentrated silica sol with long-term stability and low viscosity by preventing viscosity-increase after production, and method for producing the same. This invention provides the high-purity and high-concentrated silica sol that does not undergo a viscosity-increase or gelation in spite of any particle size differences of silica. This is obtained by adding a dispersing agent at a specific concentration to the reaction solution or solvent substitution-concentrated solution in the production process.(Means to Solve Problems) A silica sol produced by an alkoxide method, wherein said silica sol comprises at least a dispersing agent and silica, wherein said dispersing agent concentration is 10-3000 ppm with respect to the silica, wherein said dispersing agent consists of one or more compounds selected from inorganic acid, inorganic acid salt, organic acid and organic acid salt whose degradation temperature and boiling point are both 60° C. or higher, wherein said silica sol has a silica concentration of 20 weight % or higher, and method for producing the same.

Owner:FUSO CHEM

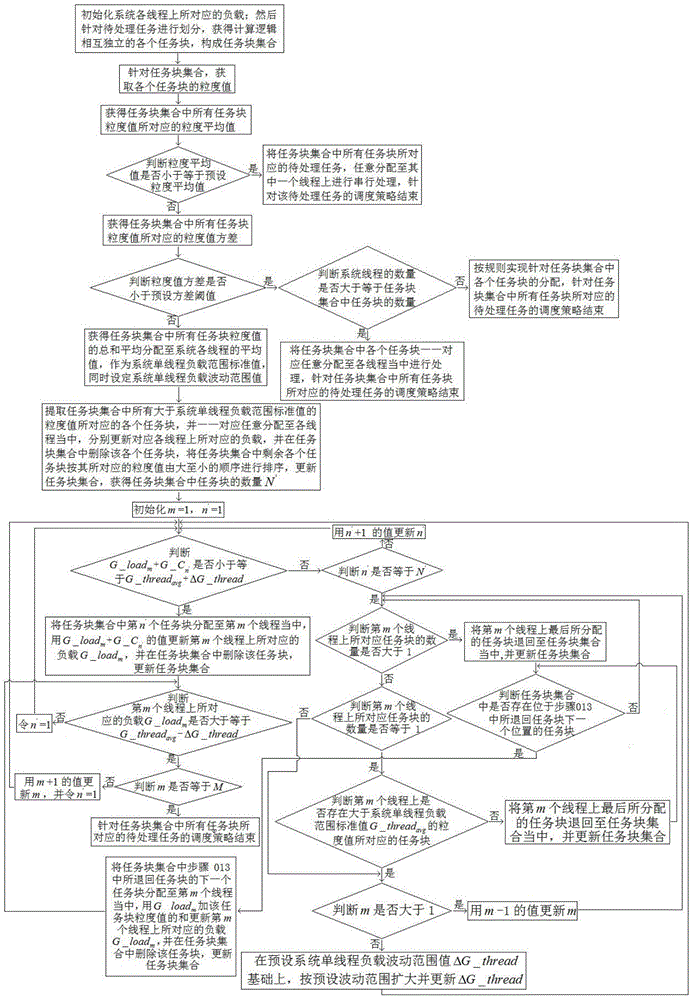

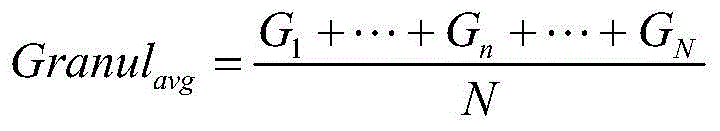

Multi-core platform oriented multithreaded division and static balancing scheduling policy

ActiveCN105700959ALoad balancingHeavy loadProgram initiation/switchingResource allocationSize differenceGranularity

The present invention relates to a multi-core platform oriented multi-threaded division and static balancing scheduling policy, and brings about the concept of a granularity parameter for assessing a size of a task acquired through decomposing. First, according to a determination condition, it is determined whether a task is really applicable to multi-threaded parallel processing; secondly, a static scheduling policy is used, and compared with that in dynamic scheduling, scheduling overheads in the operating phase do not exist; and finally, different from that in an ordinary static scheduling policy, the present invention brings about a heuristic static scheduling policy, so that the problem that during static scheduling, huge size differences between tasks acquired through decomposing cause load on threads to be extremely unbalanced is taken into account; and the task block granularity is acquired, and therefore task blocks that are greatly different can be assigned to different threads, thereby making load be balanced.

Owner:NANJING UNIV OF POSTS & TELECOMM

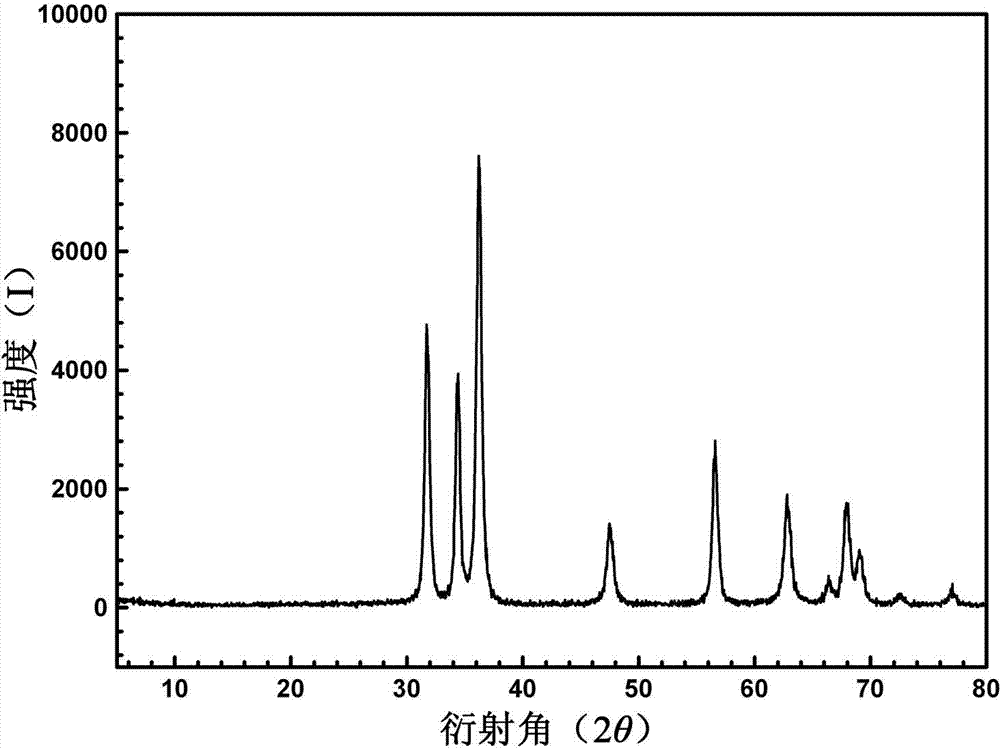

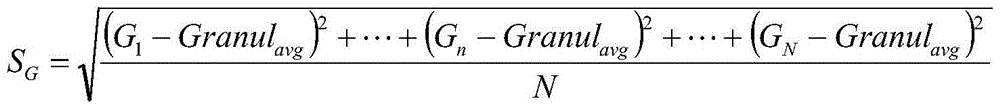

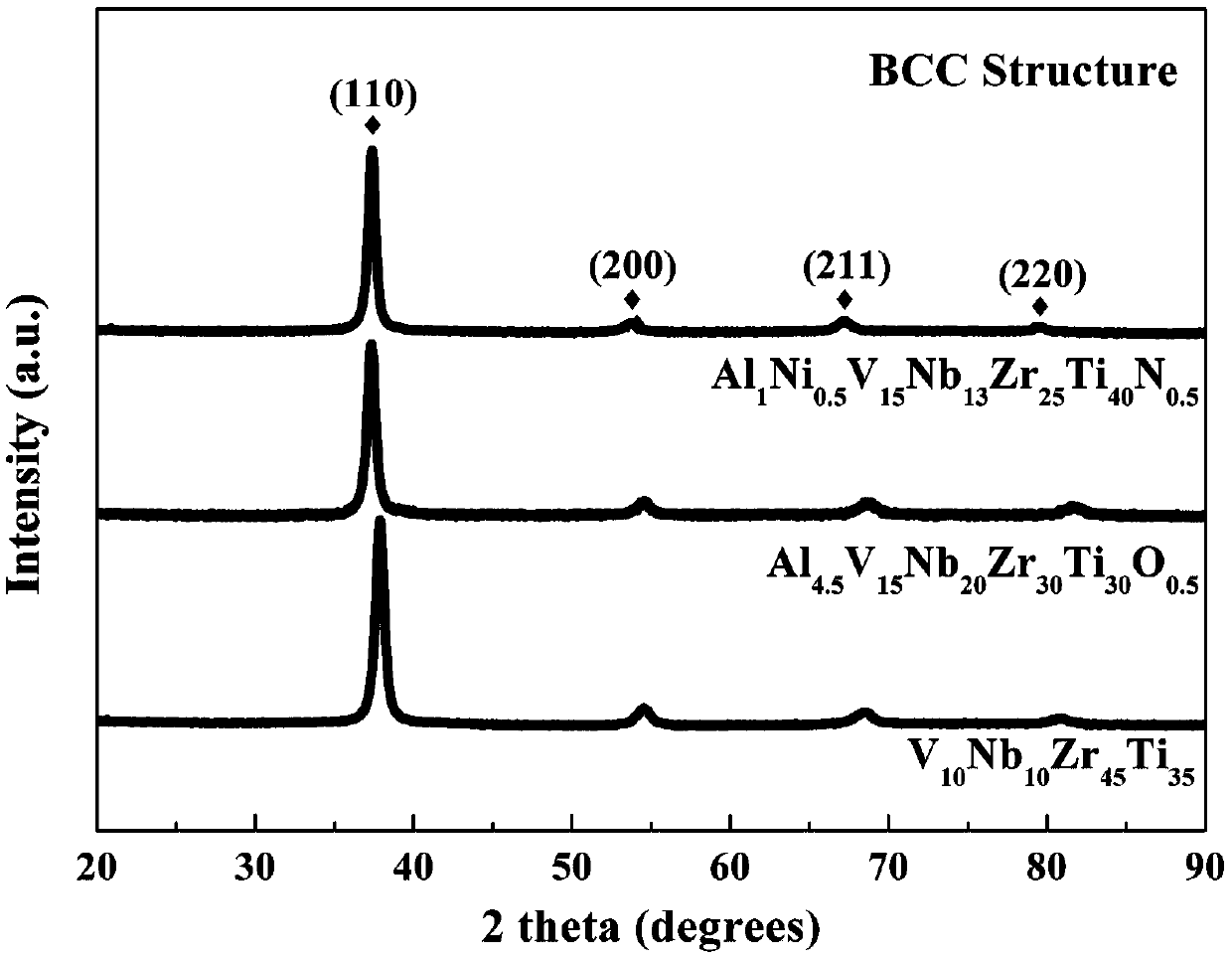

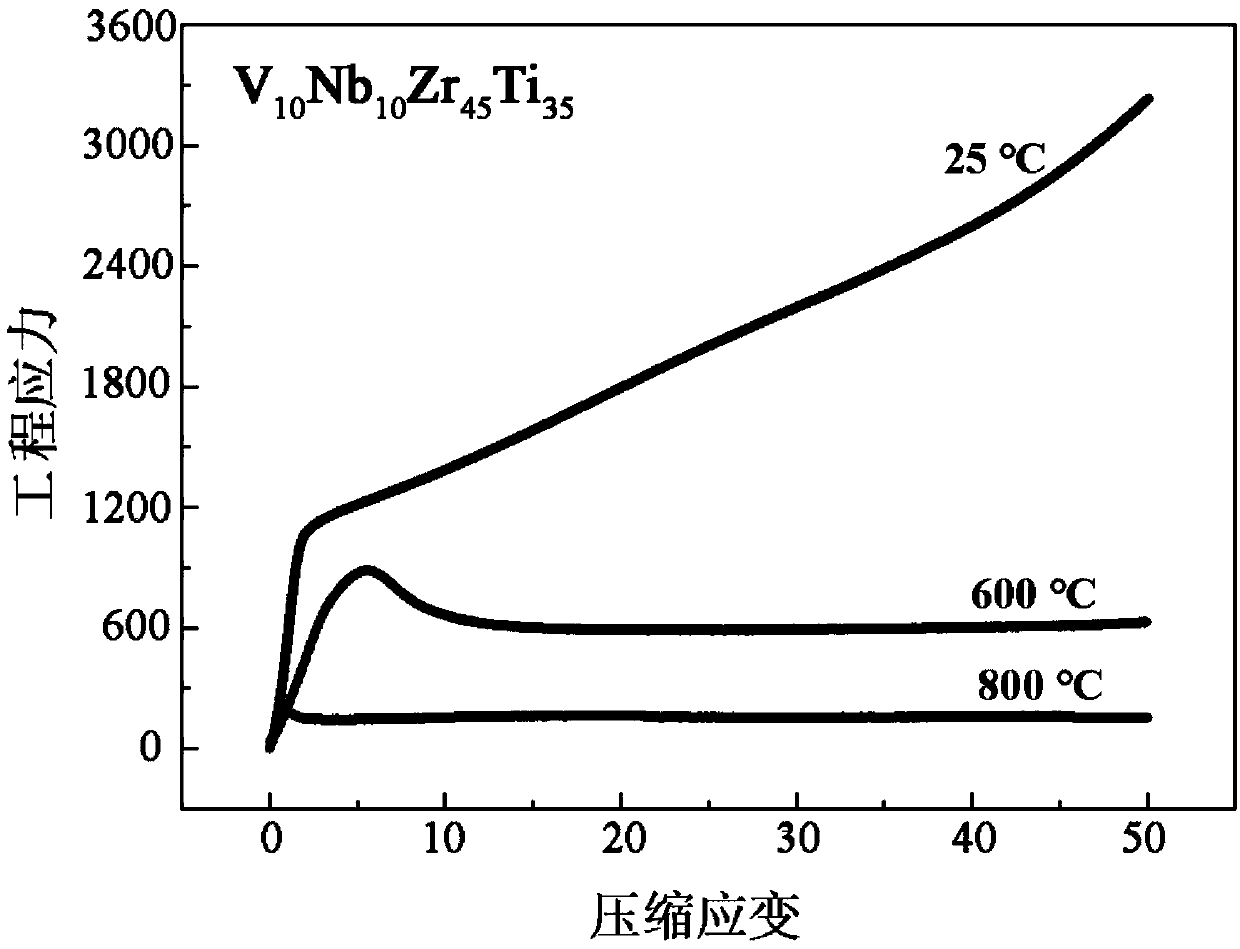

High-specific-strength high-plasticity refractory high-entropy alloy and preparing method thereof

The invention relates to a high-specific-strength high-plasticity refractory high-entropy alloy and a preparing method thereof, and belongs to the technical field of metal materials. The expression isVaNbbZrcTidMeNfPg, wherein M, N, P can be the elements such as Cr, Al, Ni, Fe, Si, O, B, C, and N; a is no less than 15% and no more than 20%, b is no less than 15% and no more than 25%, c is no lessthan 30% and no more than 50%, d is no more than 30% and no less than 50%, e is no less than 0 and no more than 5%, f is no less than 0 and no more than 5%, g is no less than 0 and no more than 5%, and the sum of a, b, c, d, e, f and g is 100%; and meanwhile, the valence electron concentration VEC of the alloy is no less than 4.1 and no more than 4.4, and the atomic radius size difference Delta is no less than 5.5% and no more than 6.4%. The alloy is prepared by various methods, the density of the VaNbbZrcTidMeNfPg alloy is less than 6.5 g*cm<-3>, the room temperature tensile strength is morethan 900 MPa, the plastic deformation is more than 15%, and the high specific strength and high plasticity are achieved; and after the temperature is increased to 600 DEG C, the weakening of the material is not very obvious, after the temperature is increased to 800 DEG C, the material can still maintain a certain strength, and the alloy has a certain storage ability for H2 and can be used in thefield of energy materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

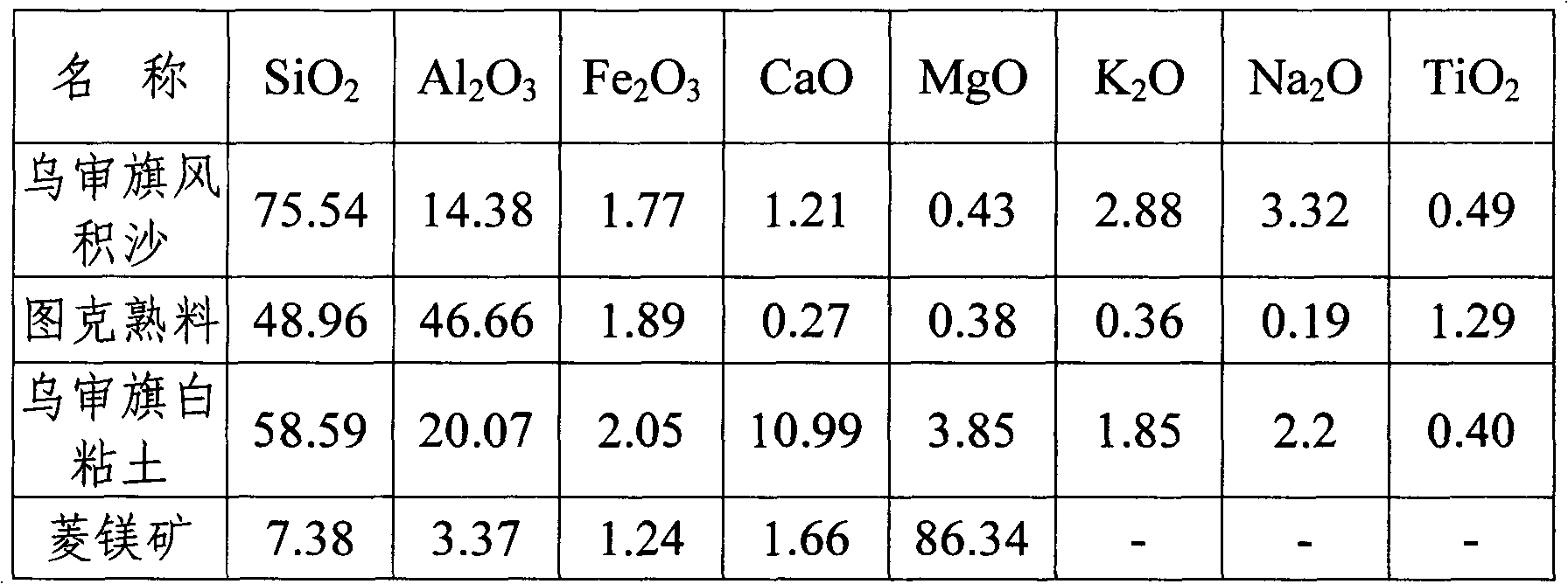

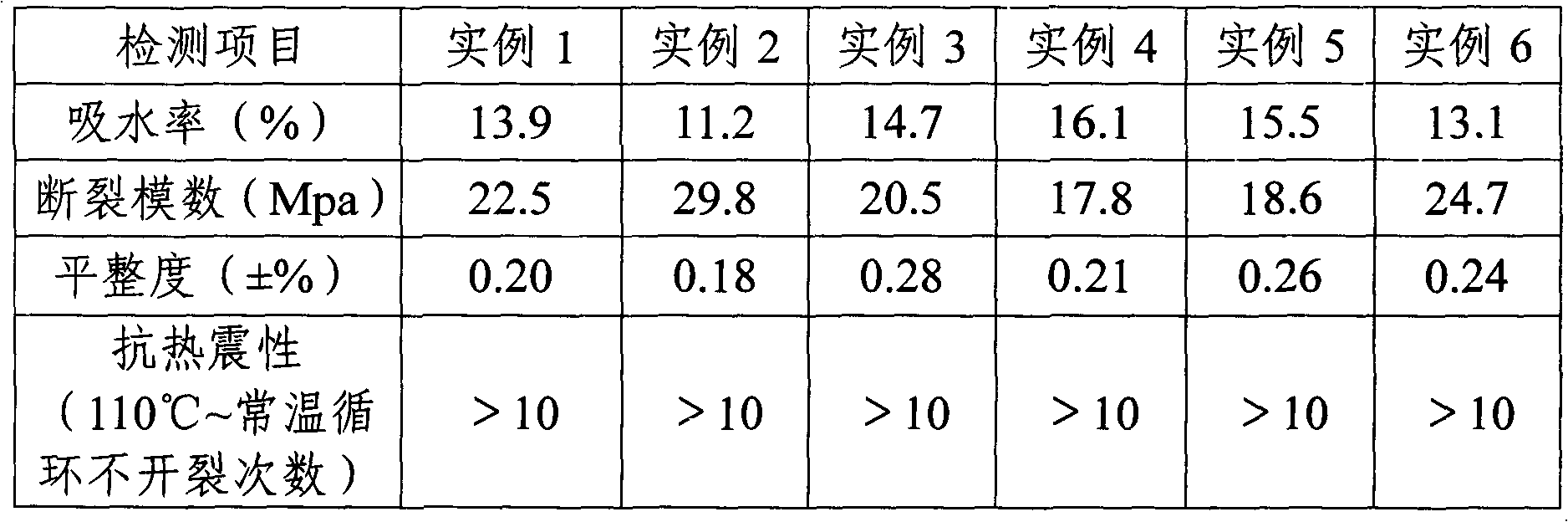

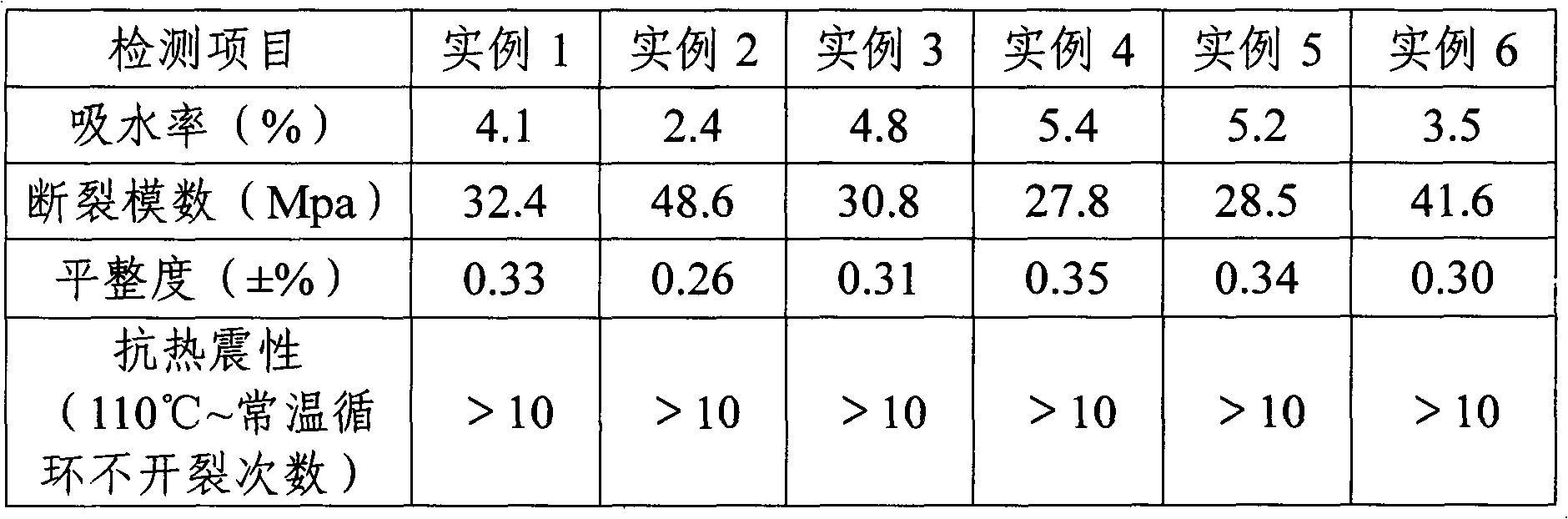

Ceramic brick prepared from aeolian sand

The invention relates to a ceramic brick prepared from aeolian sand. The ceramic brick comprises the following raw materials by weight percent: 50-60% of Uxen aeolian sand. 20-28% of Tuke clinker, 12-20% of Uxen white clay and 2-8% of magnesite. The ceramic product is prepared by the steps of ball milling, smashing, sieving, deironing, forming and firing at the temperature of 1080-1220 DGE C. According to the invention, the aeolian sand enriched in Inner Mongolia is used as a main ceramic-making material, which is beneficial to low-cost desert control and leads the production cost of the ceramic product to be greatly reduced; and the prepared ceramic product has the advantages of excellent quality, small size difference, low water absorption and high strength, and relative indexes reach the requirement of national detection standards.

Owner:马东升

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com