Patents

Literature

103 results about "Valence electron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a valence electron is an outer shell electron that is associated with an atom, and that can participate in the formation of a chemical bond if the outer shell is not closed; in a single covalent bond, both atoms in the bond contribute one valence electron in order to form a shared pair. The presence of valence electrons can determine the element's chemical properties, such as its valence—whether it may bond with other elements and, if so, how readily and with how many. For a main group element, a valence electron can exist only in the outermost electron shell; in a transition metal, a valence electron can also be in an inner shell.

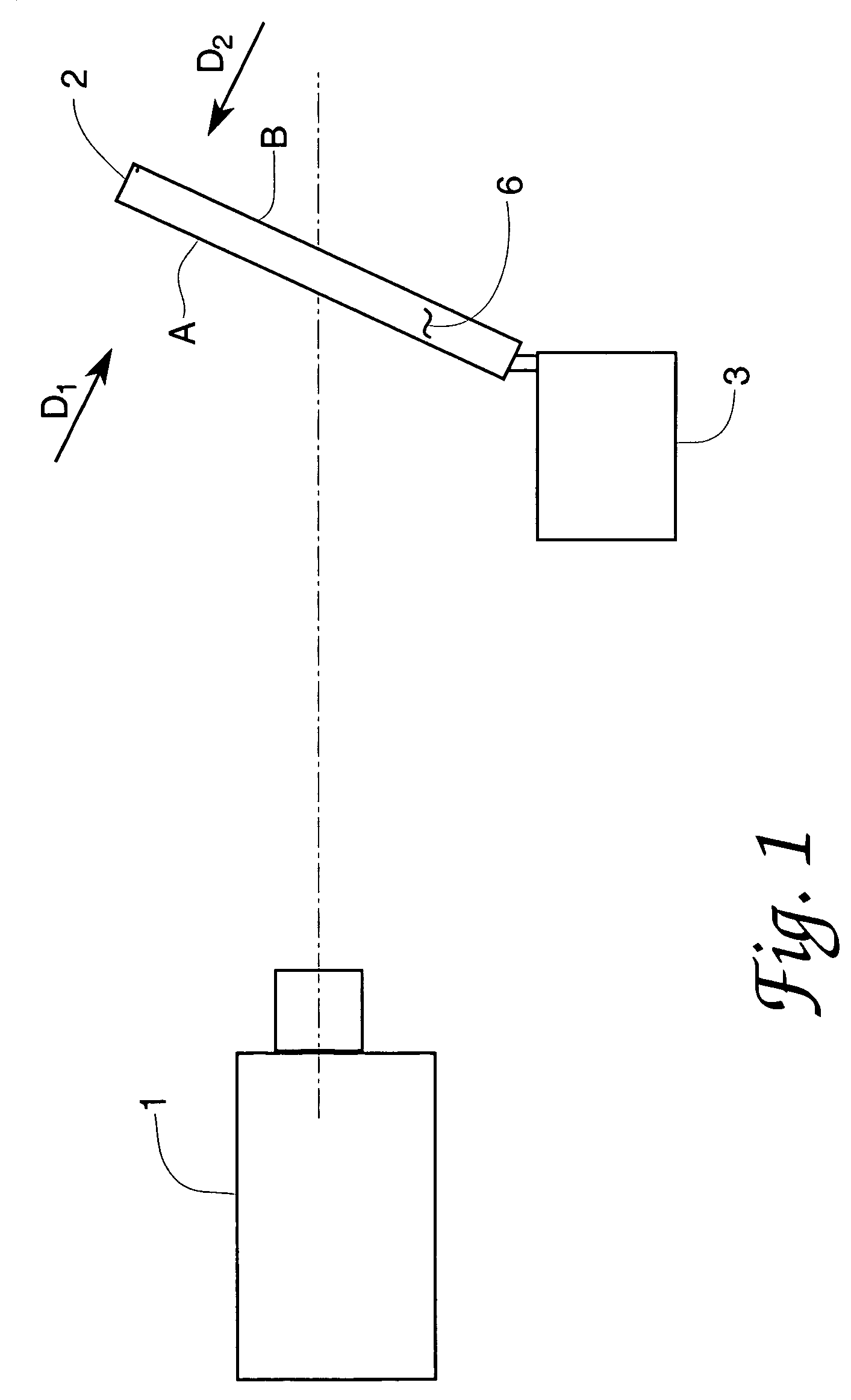

Crystallization control method for organic compound and crystallization control solid-state component employed therefor

InactiveUS6123769APolycrystalline material growthFrom normal temperature solutionsValence electronBiopolymer

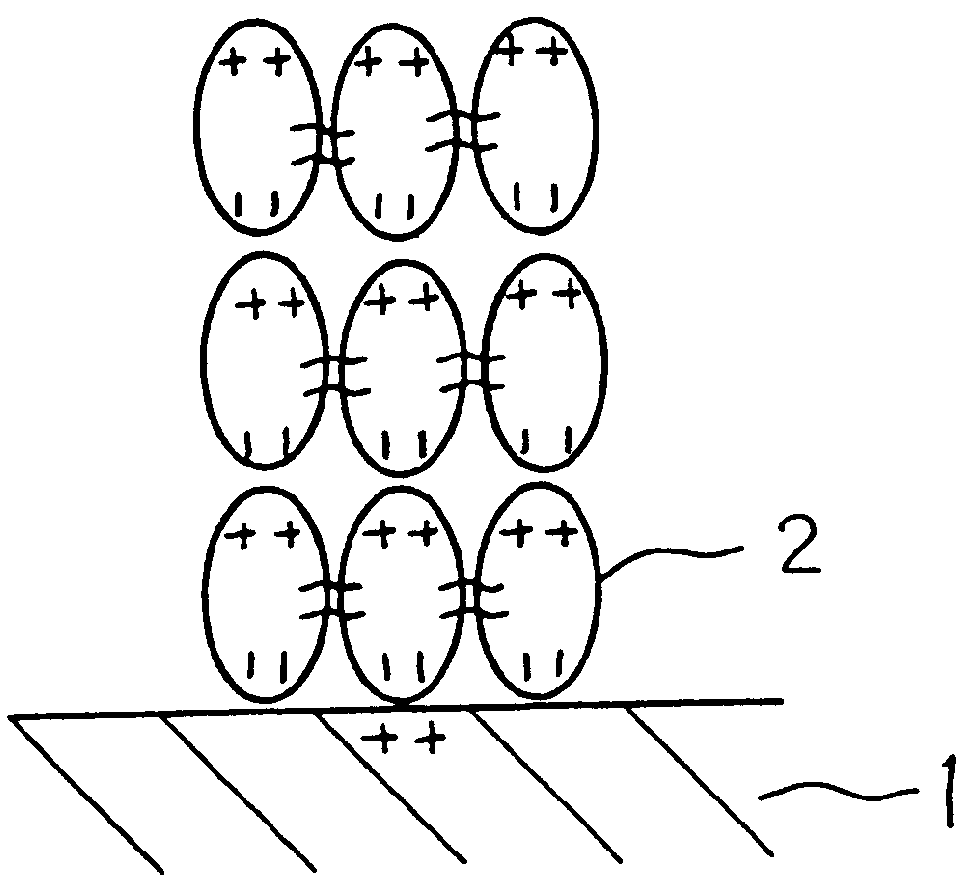

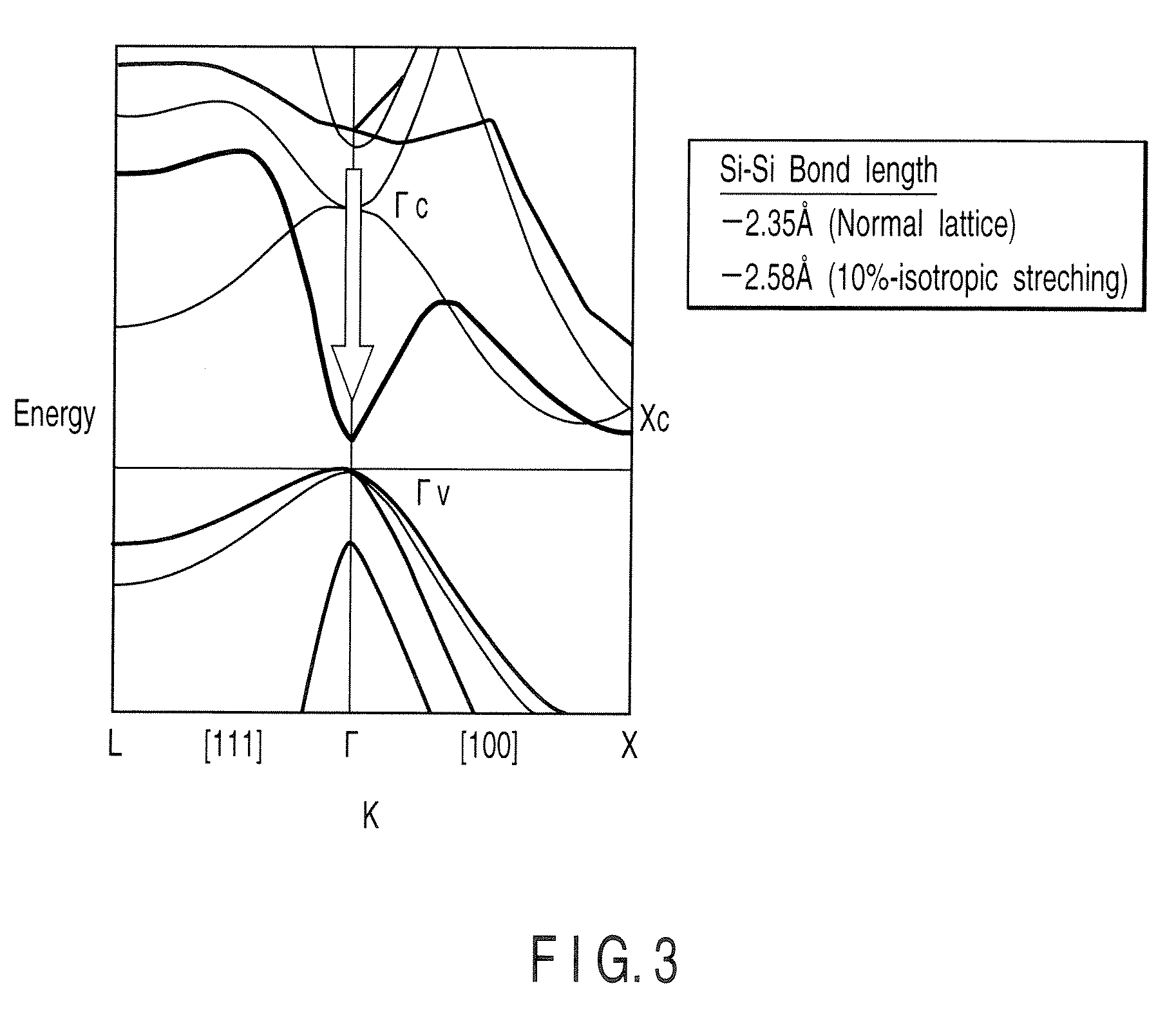

A method which can control crystallization of a biopolymer such as protein is provided. A silicon crystal (15) whose valence electrons are controlled to be capable of controlling the concentration of holes or electrons of the surface part in response to the environment of a buffer solution (14) containing the biopolymer such as protein is brought into contact with the solution (14), for getting a crystal of the biopolymer deposited on the surface of the silicon crystal (15). Crystallization is controlled by an electrical state which is generated by the controlled valence electrons on the surface of the silicon crystal (15).

Owner:SUMITOMO METAL IND LTD

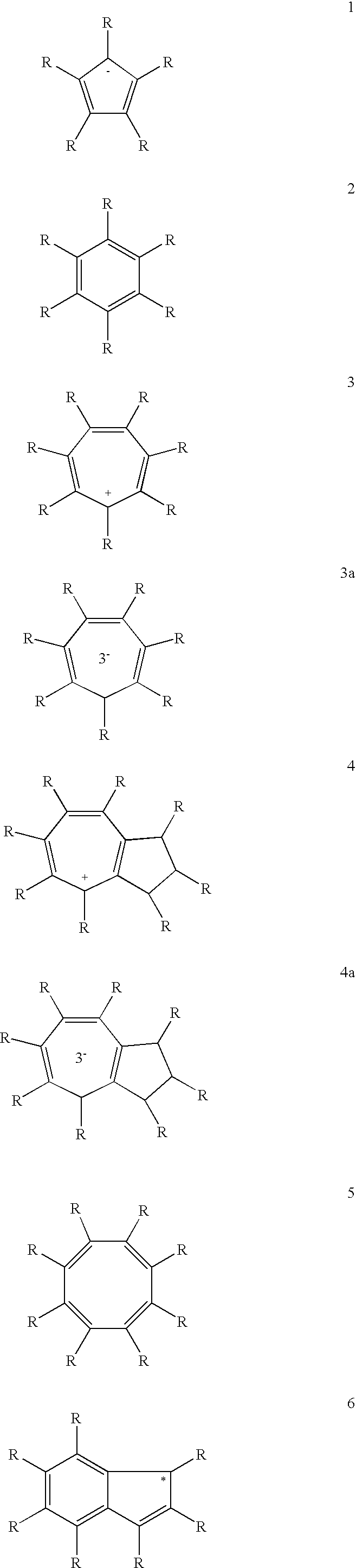

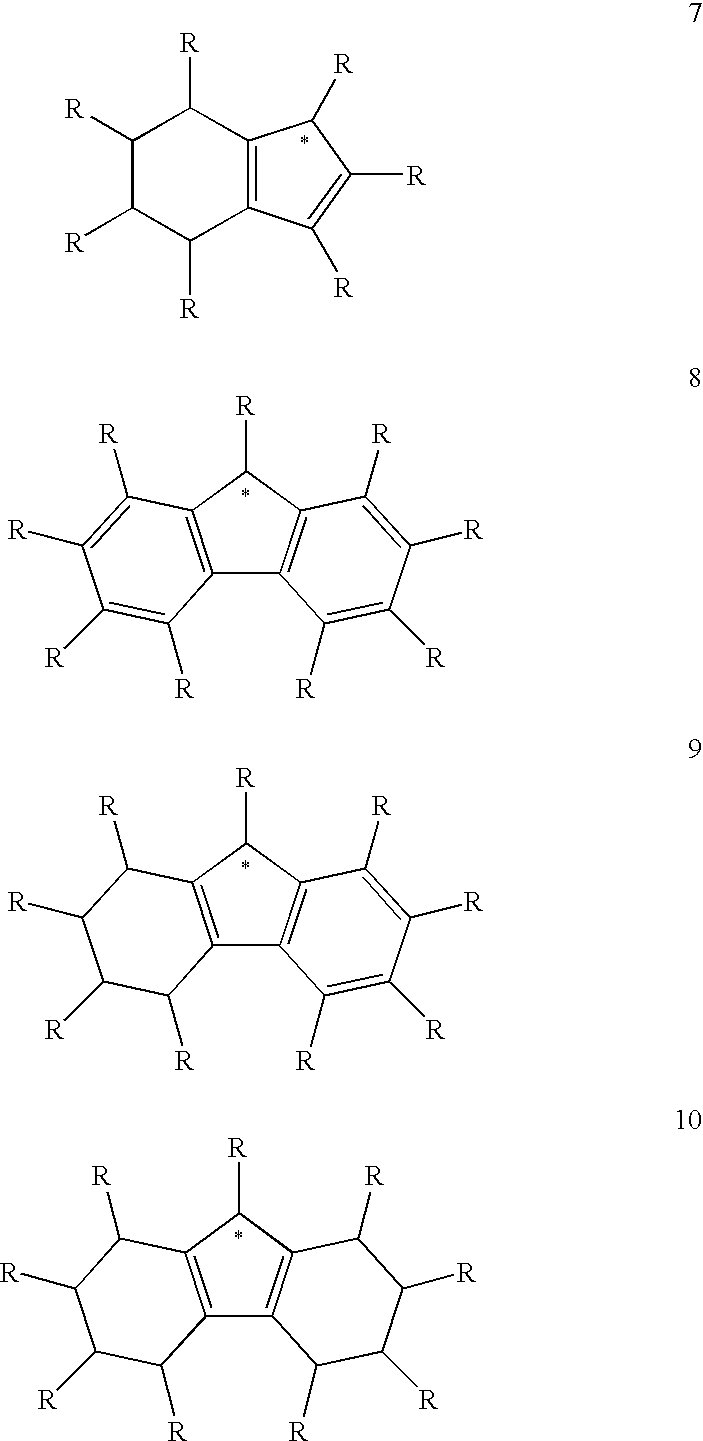

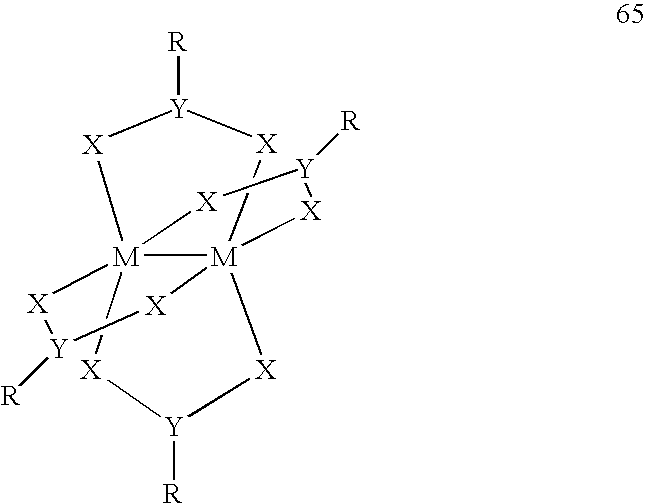

Use of a Metal Complex as an N-Dopant for an Organic Semiconducting Matrix Material, Organic of Semiconducting Material and Electronic Component, and also a Dopant and Ligand and Process for Producing same

ActiveUS20090212280A1Low oxidation potentialEasy to chargeGroup 5/15 element organic compoundsGroup 8/9/10/18 element organic compoundsCarbanionValence electron

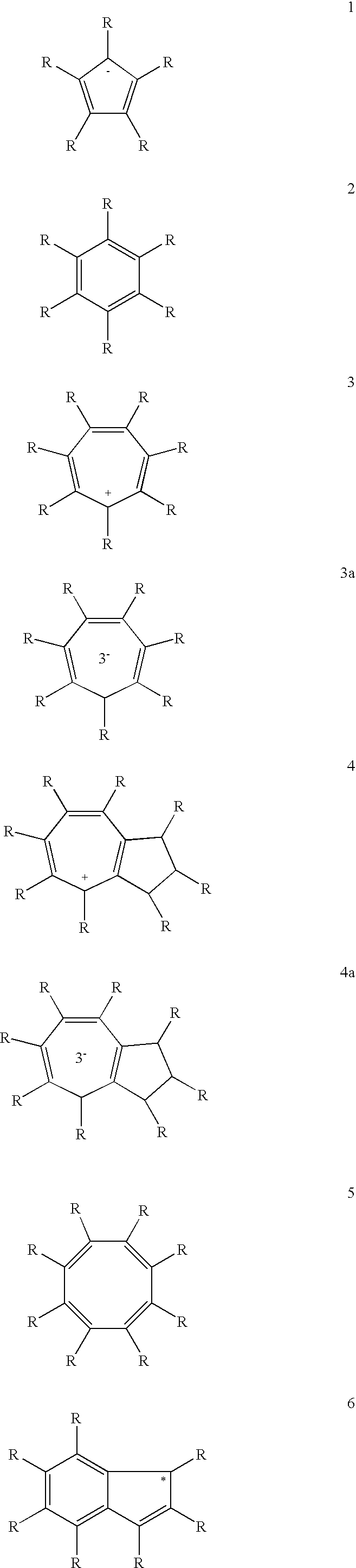

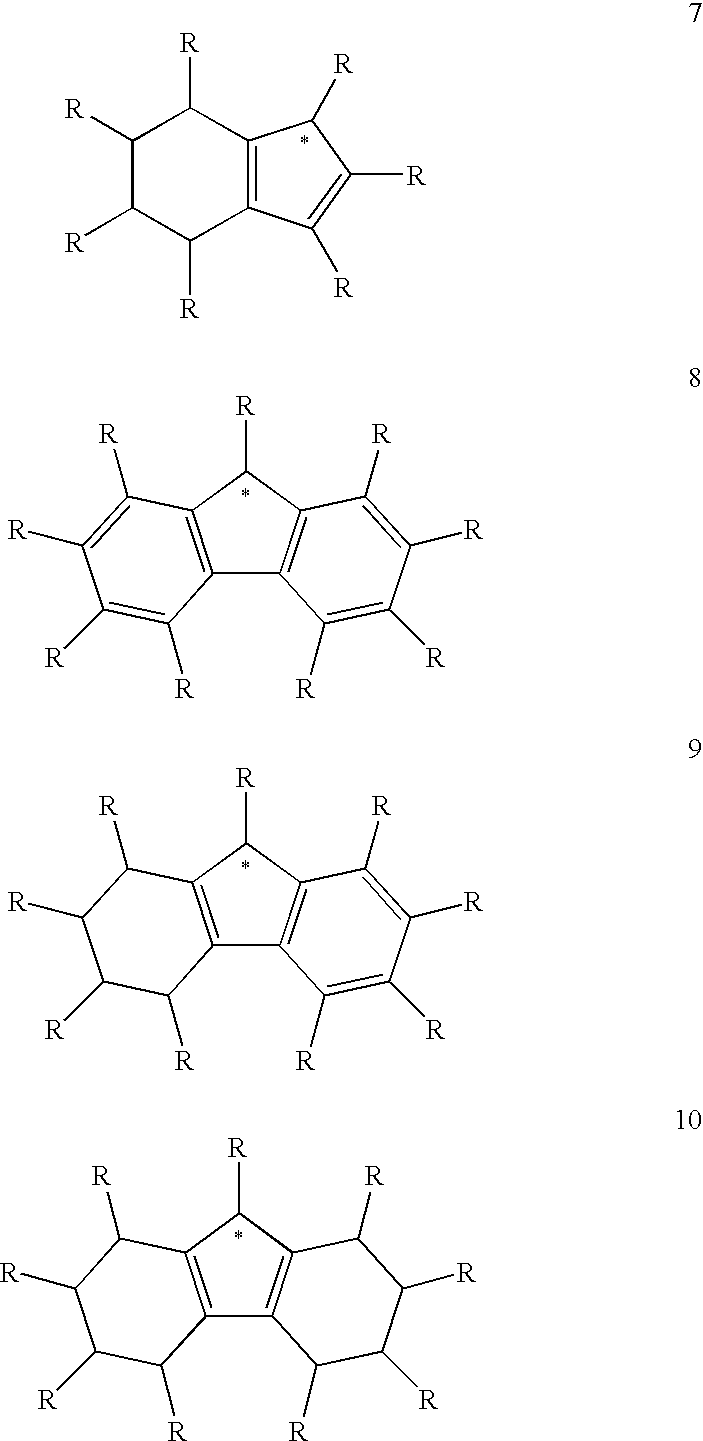

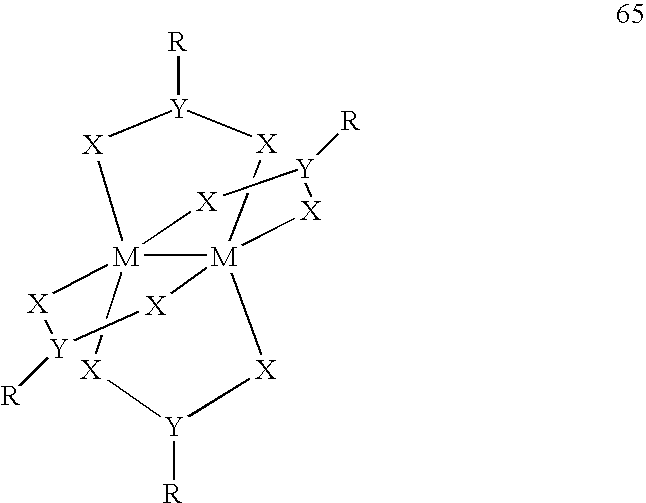

A method of using a metal complex as an n-dopant for doping an organic semiconducting matrix material in order to alter the latter's electrical characteristics is provided. In order to provide n-doped organic semiconductors with matrix materials having a low reduction potential, while achieving high conductivities, the n-dopant is a neutral electron-rich metal complex with a neutral or charged transition metal atom as a central atom and having at least 16 valence electrons. The complex can be polynuclear and can possess at least one metal-metal bond. At least one ligand can form a π complex with the central atom, which can be a bridge ligand, or it can contain at least one carbanion-carbon atom or a divalent atom. Methods for providing the novel n-dopants are provided.

Owner:NOVALED GMBH

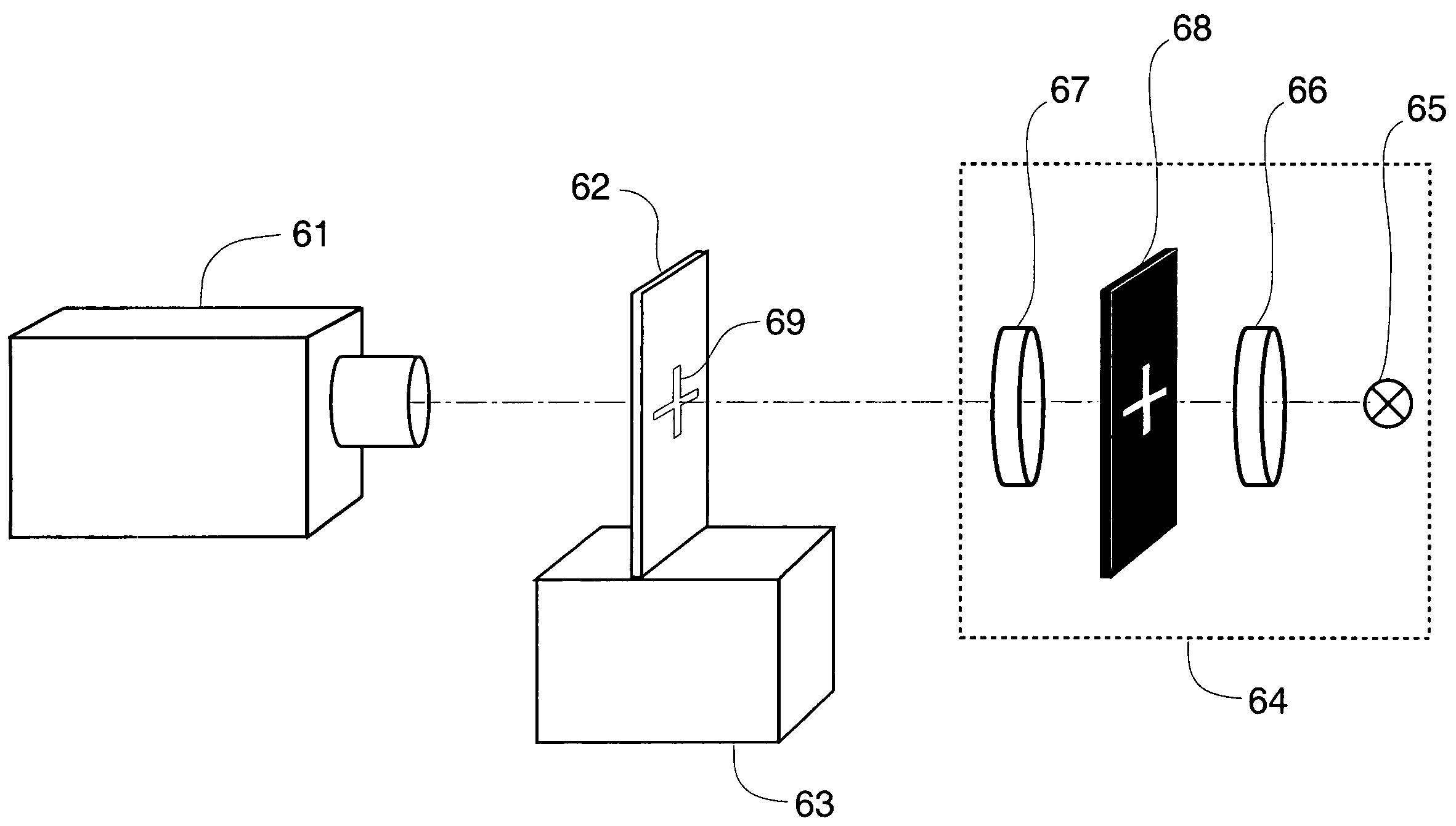

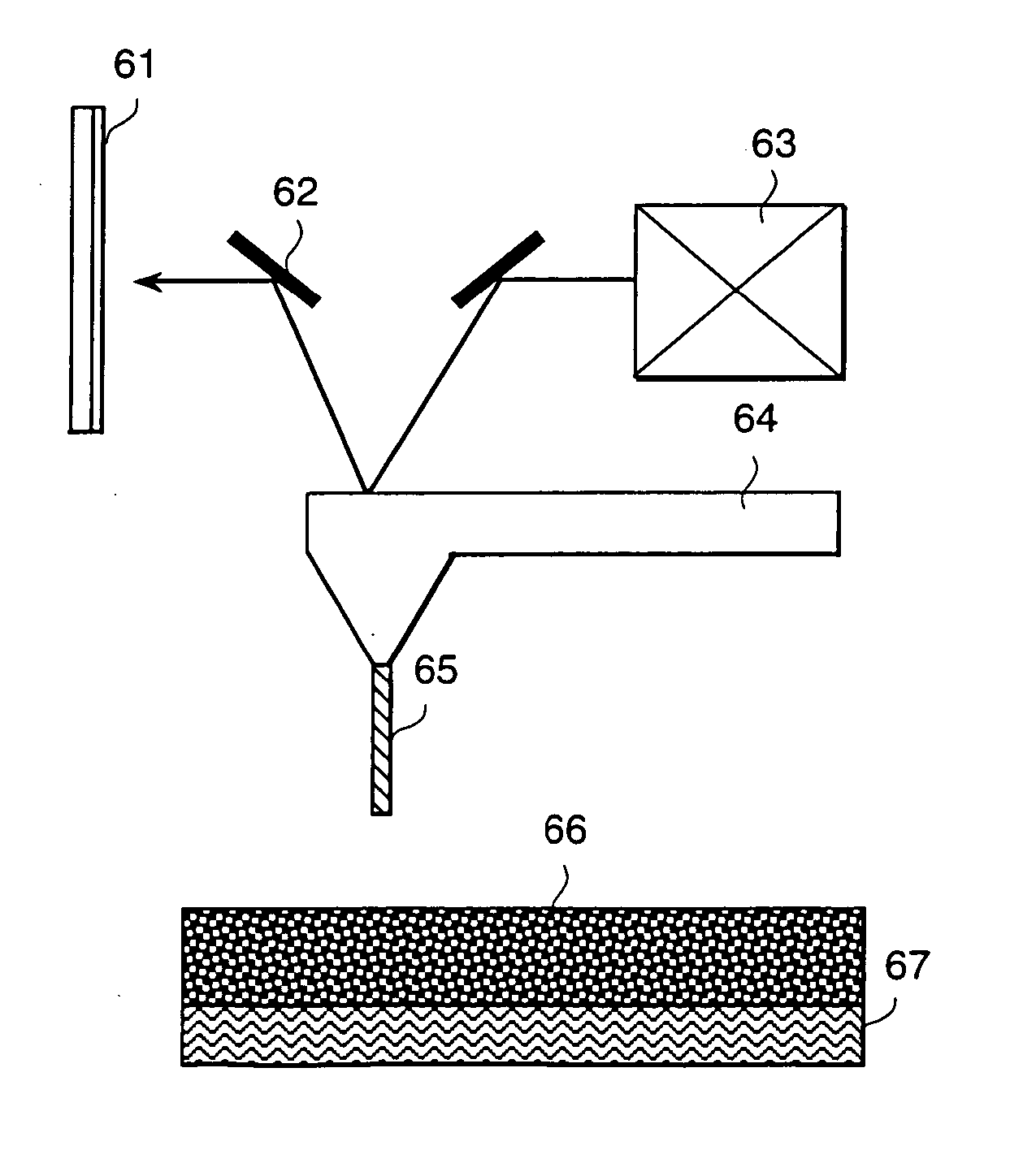

Semiconductor generation of dynamic infrared images

InactiveUS7084405B1Television system detailsSolid-state devicesSemiconductor materialsValence electron

A high-speed, high-resolution, broadband dynamic infrared scene generator based on semiconductor transducer conversion of visible spectrum scene images into infrared spectrum images. Wavelength conversion is accomplished in the semiconductor material through absorption of visible spectrum energy by valence electrons in a subsurface layer of the semiconductor material and photogeneration by valence band to conduction band electron transfer occurring within about one diffusion length of the semiconductor material surface. The semiconductor material used, for example Germanium or Silicon provides a band gap energy value that is smaller than the quantum energy level of the optical emission. Temperature of the semiconductor material may be maintained at a selected level above or below that of the infrared scene. Infrared images of higher frequency content than are achievable with conventional thermal heating infrared converters are accomplished. The invention thus includes down conversion of visible generated light in order to develop a semiconductor pixel-less Dynamic Infrared Scene Projector capable of simulating high-speed broadband IR scenery.

Owner:US SEC THE AIR FORCE THE

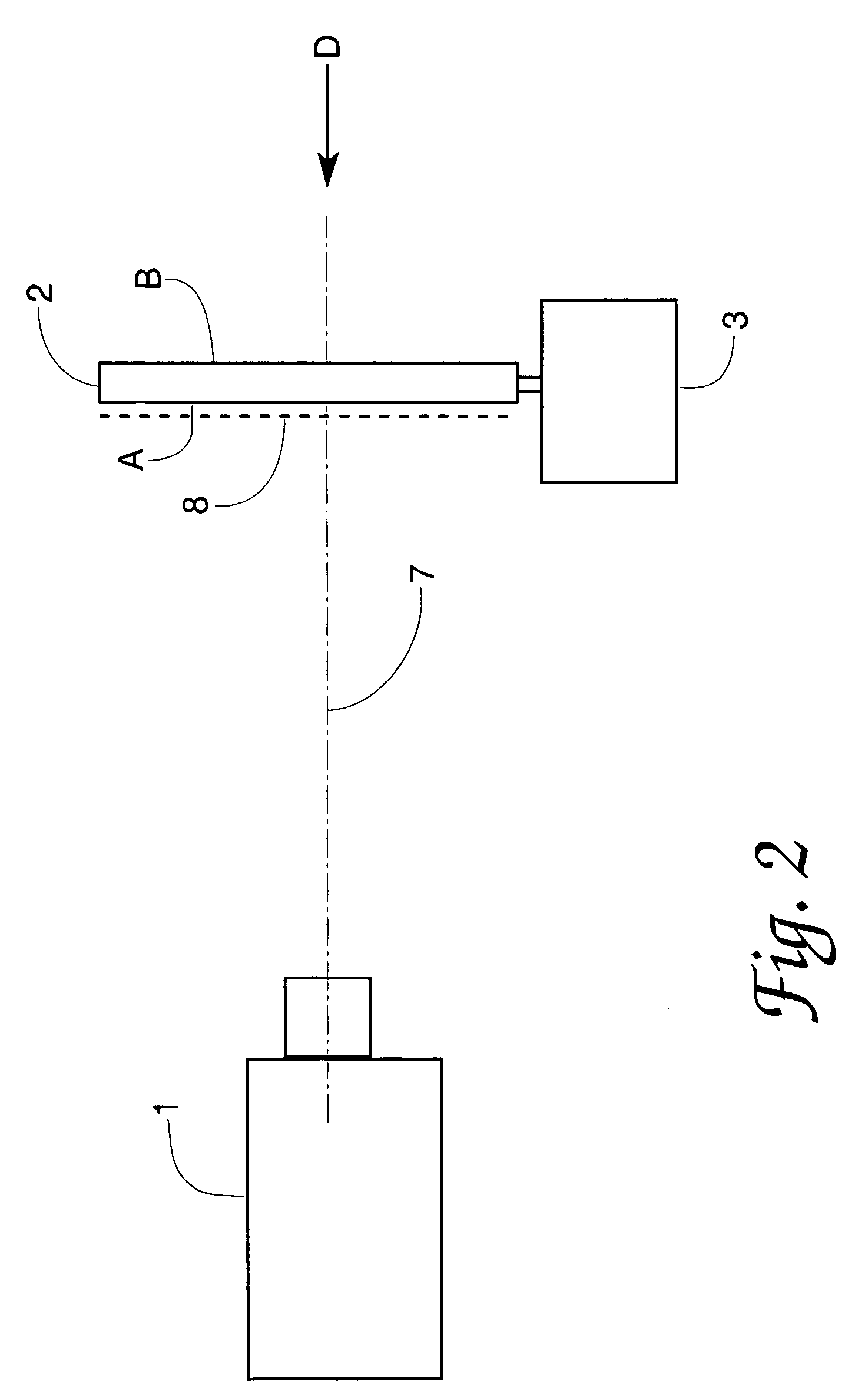

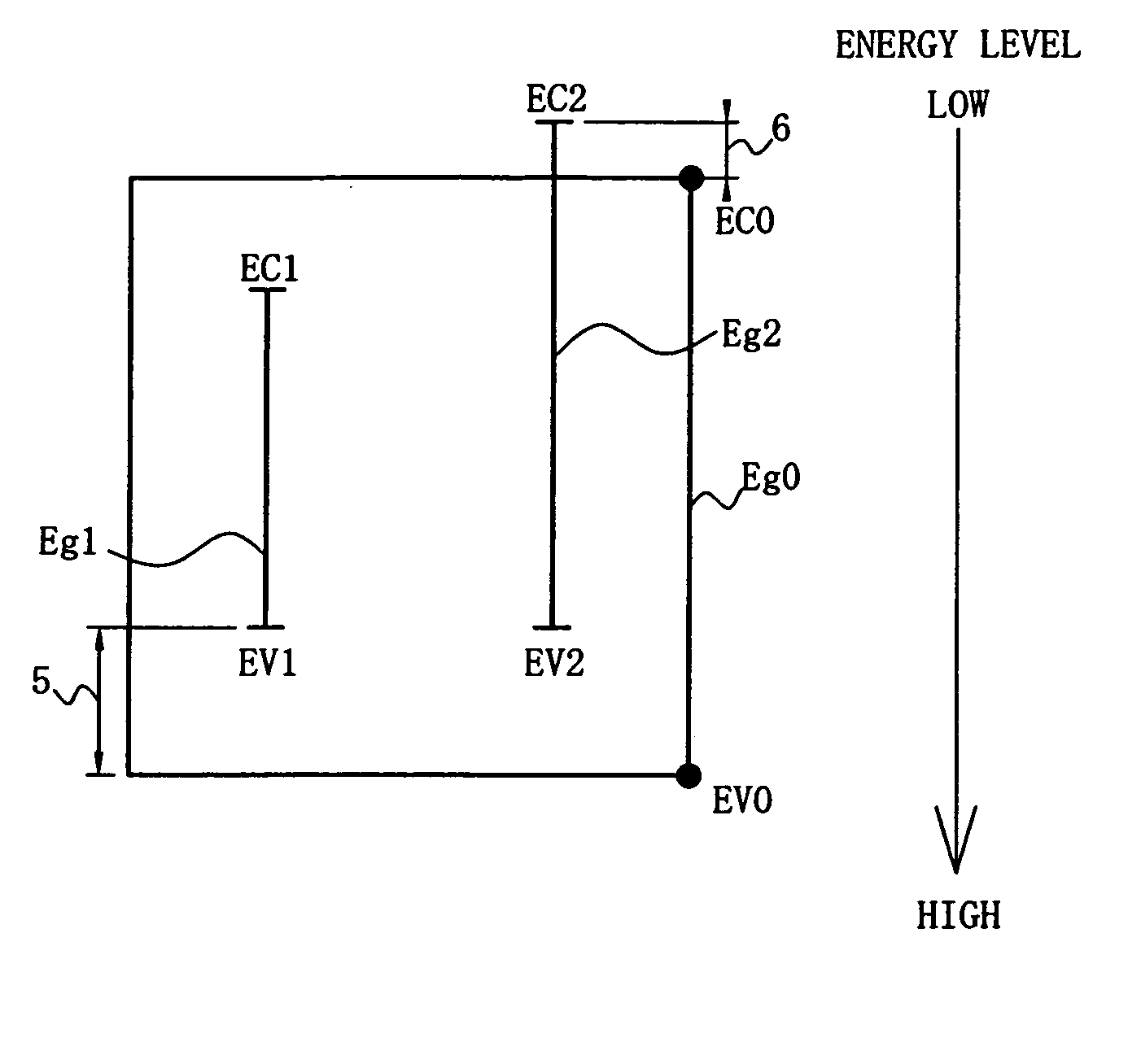

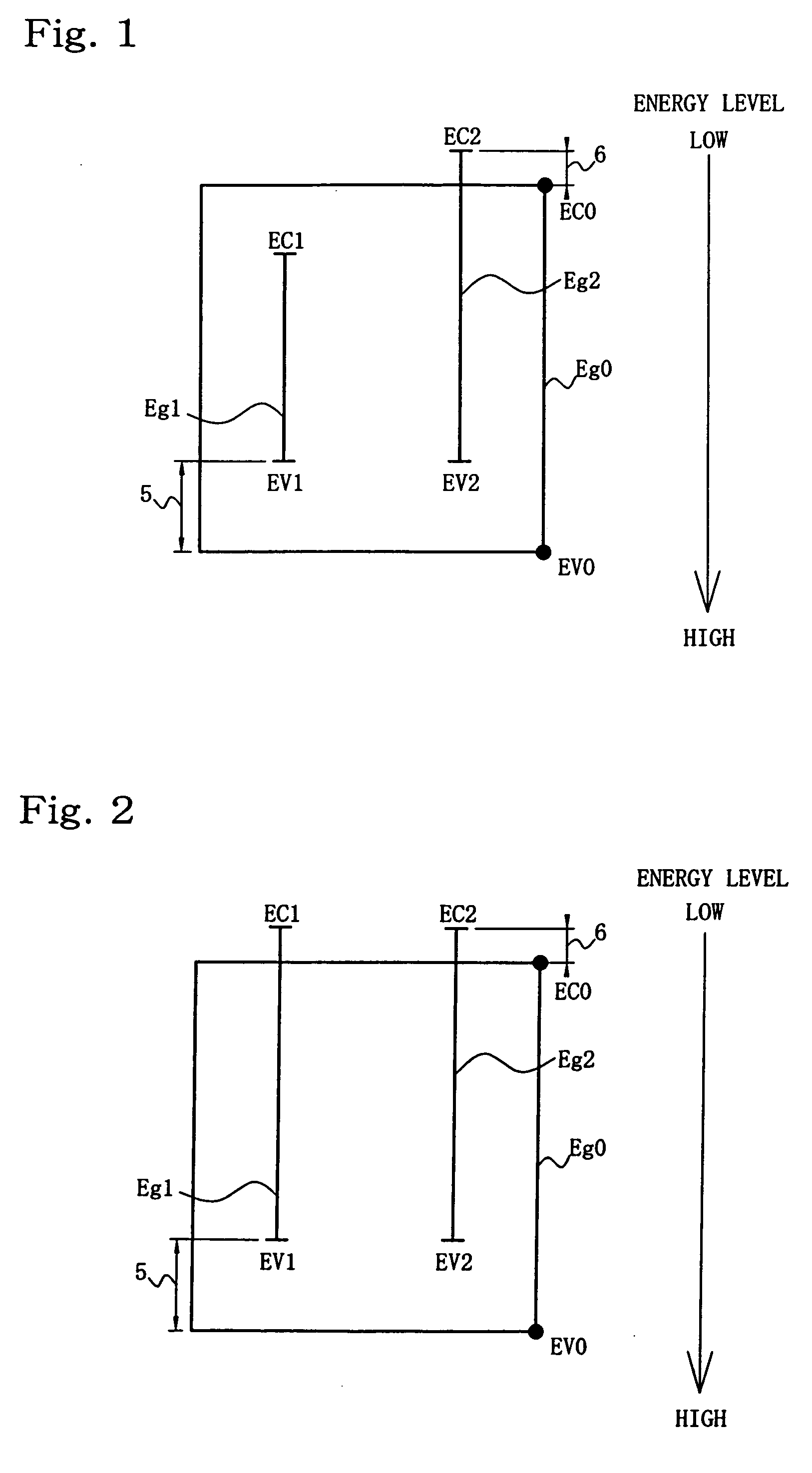

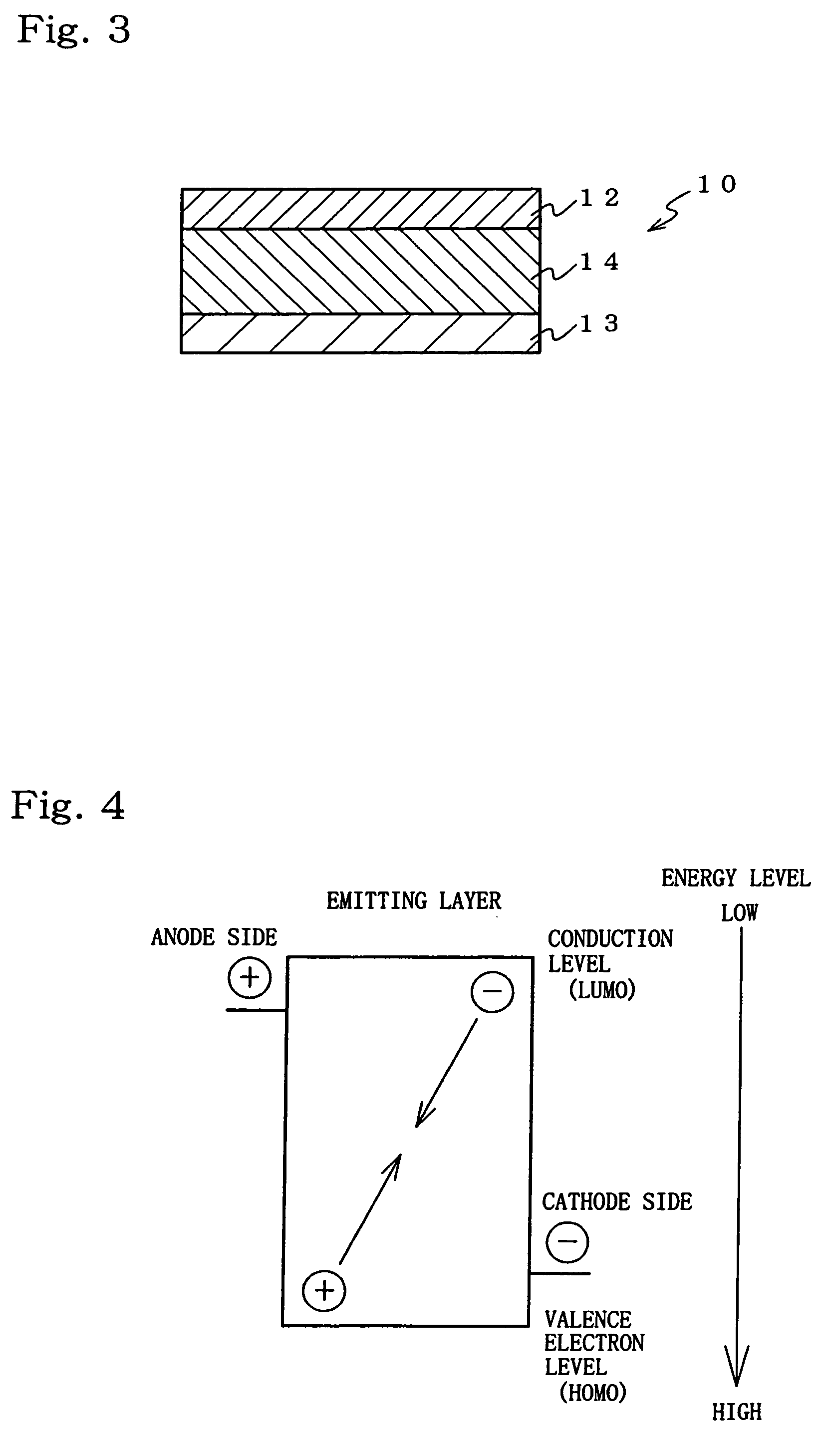

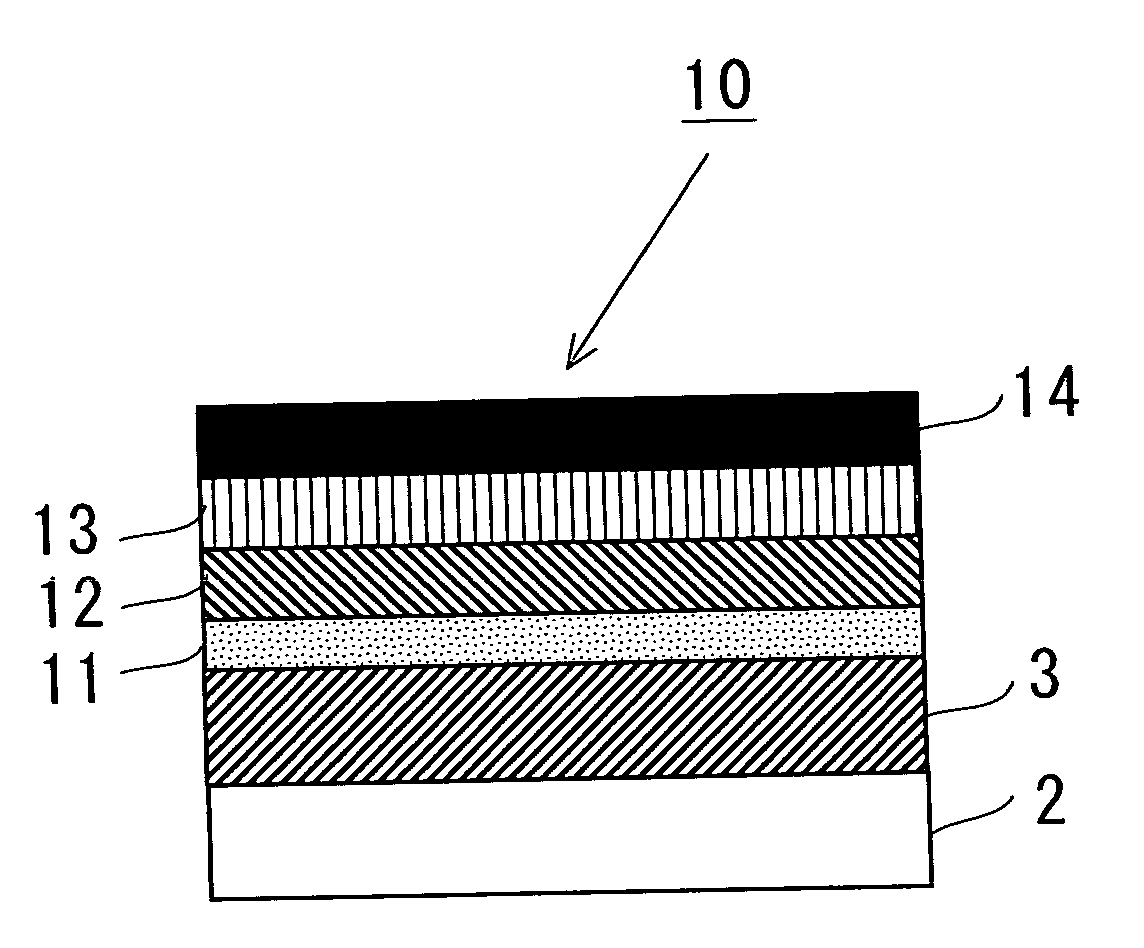

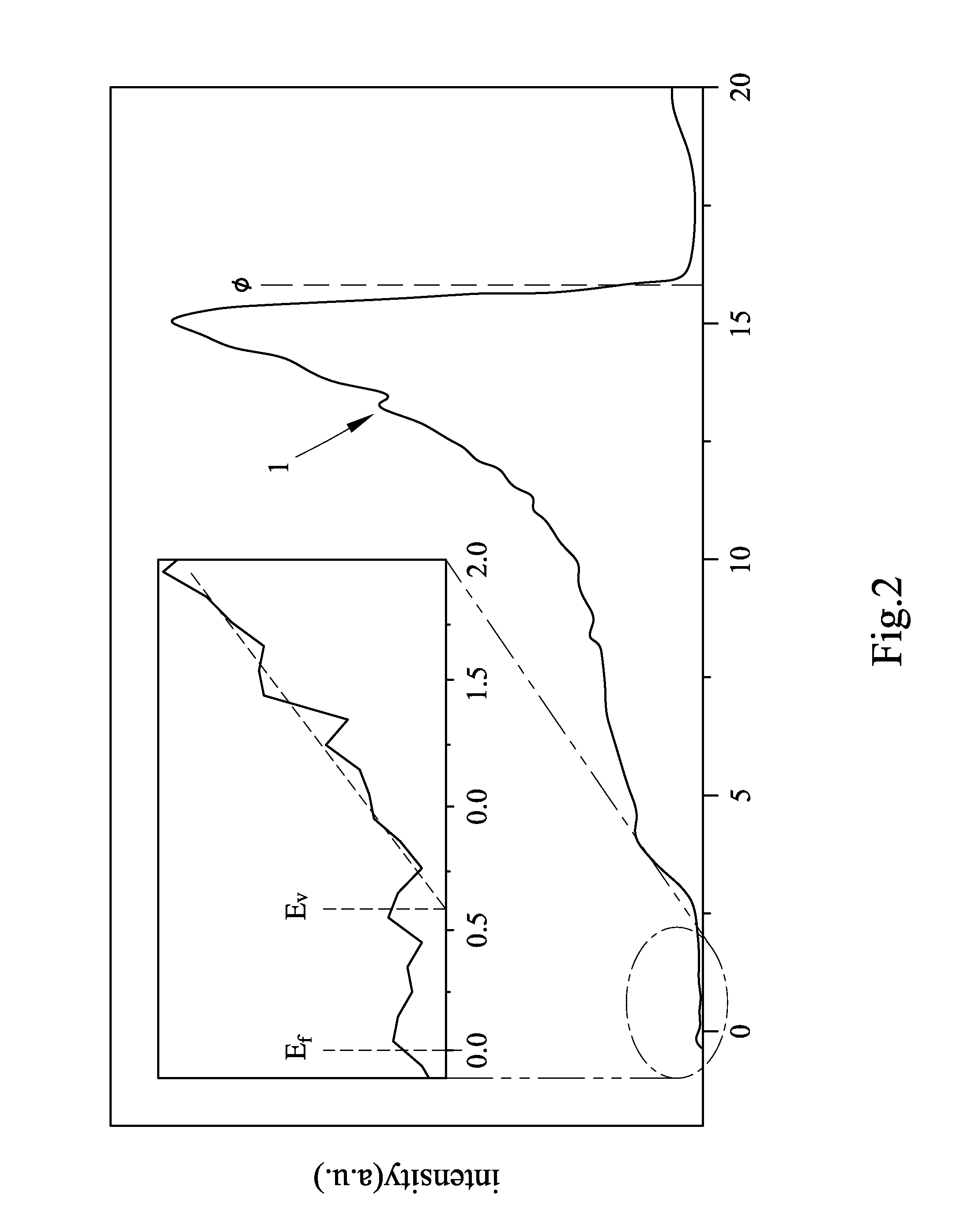

Organic electroluminescence element

InactiveUS20060055305A1Increased durabilityElectroluminescent light sourcesSolid-state devicesDopantValence electron

An organic electroluminescence element comprising: a pair of electrodes, and a light emitting layer provided between the pair of electrodes, the layer comprising a light-emitting-layer material, a first dopant and a second dopant that satisfy the following relations, EV0>EV1 and EV0>EV2 (A) EC0≧EC2 (B) EG0>EG1 and EG0>EG2 (C) wherein EV0, EV1 and EV2 are the valence electron levels of the light-emitting-layer material, the first dopant and the second dopant, respectively; EC0 and EC2 are the conduction levels of the light-emitting-layer material and the second dopant, respectively; and EG0, EG1 and EG2 are the energy gaps of the light-emitting-layer material, the first dopant and the second dopant, respectively.

Owner:IDEMITSU KOSAN CO LTD

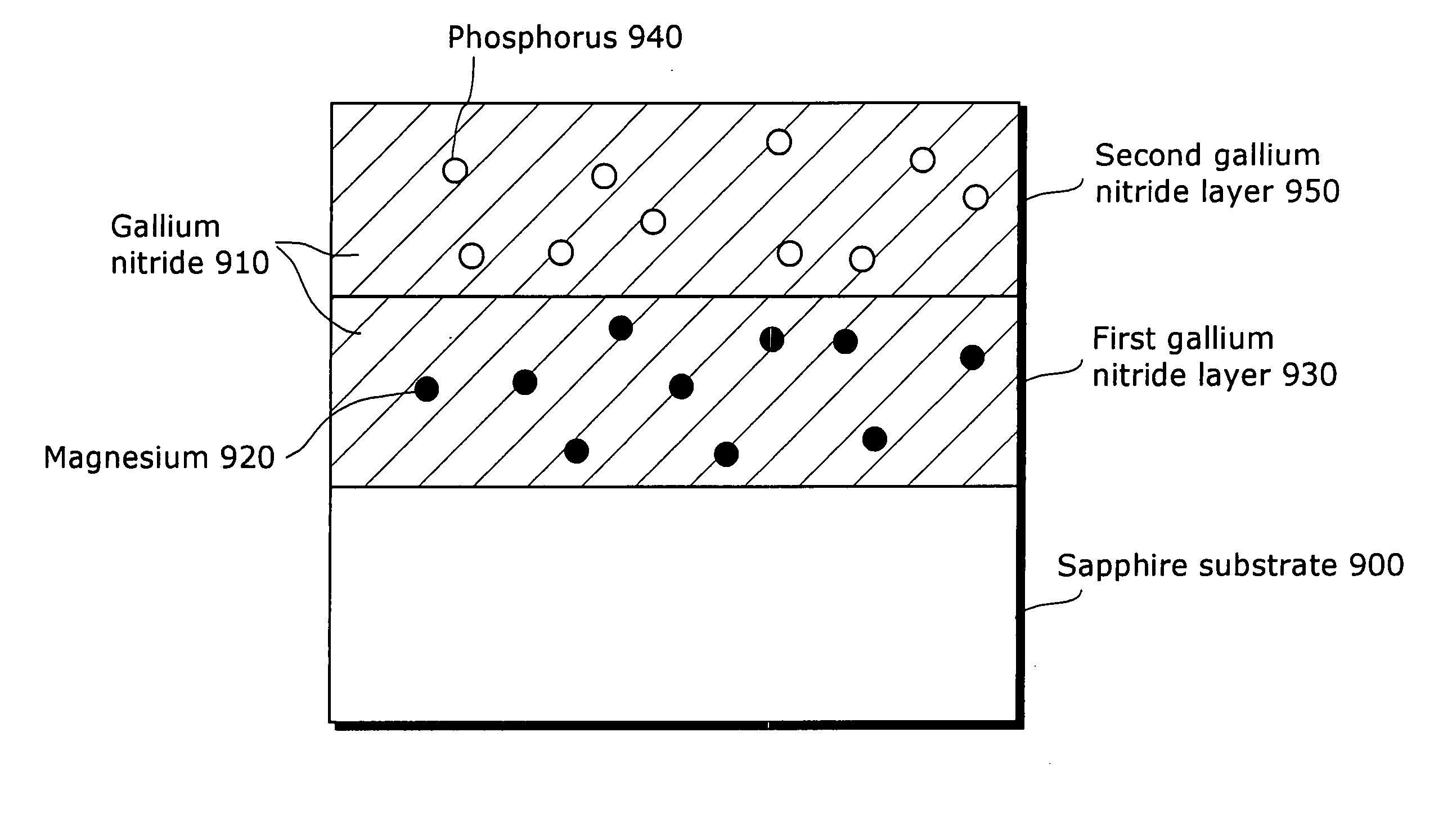

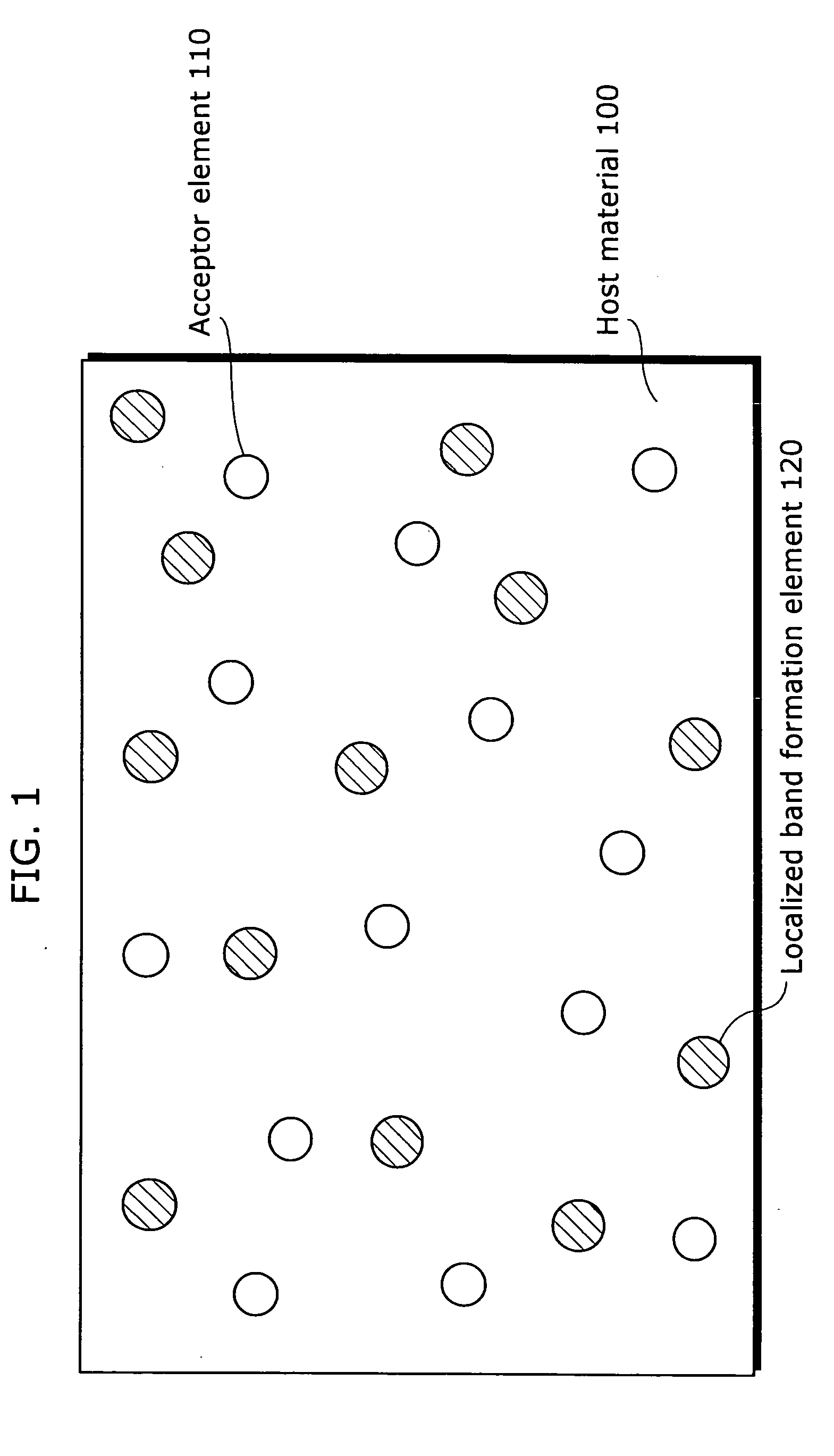

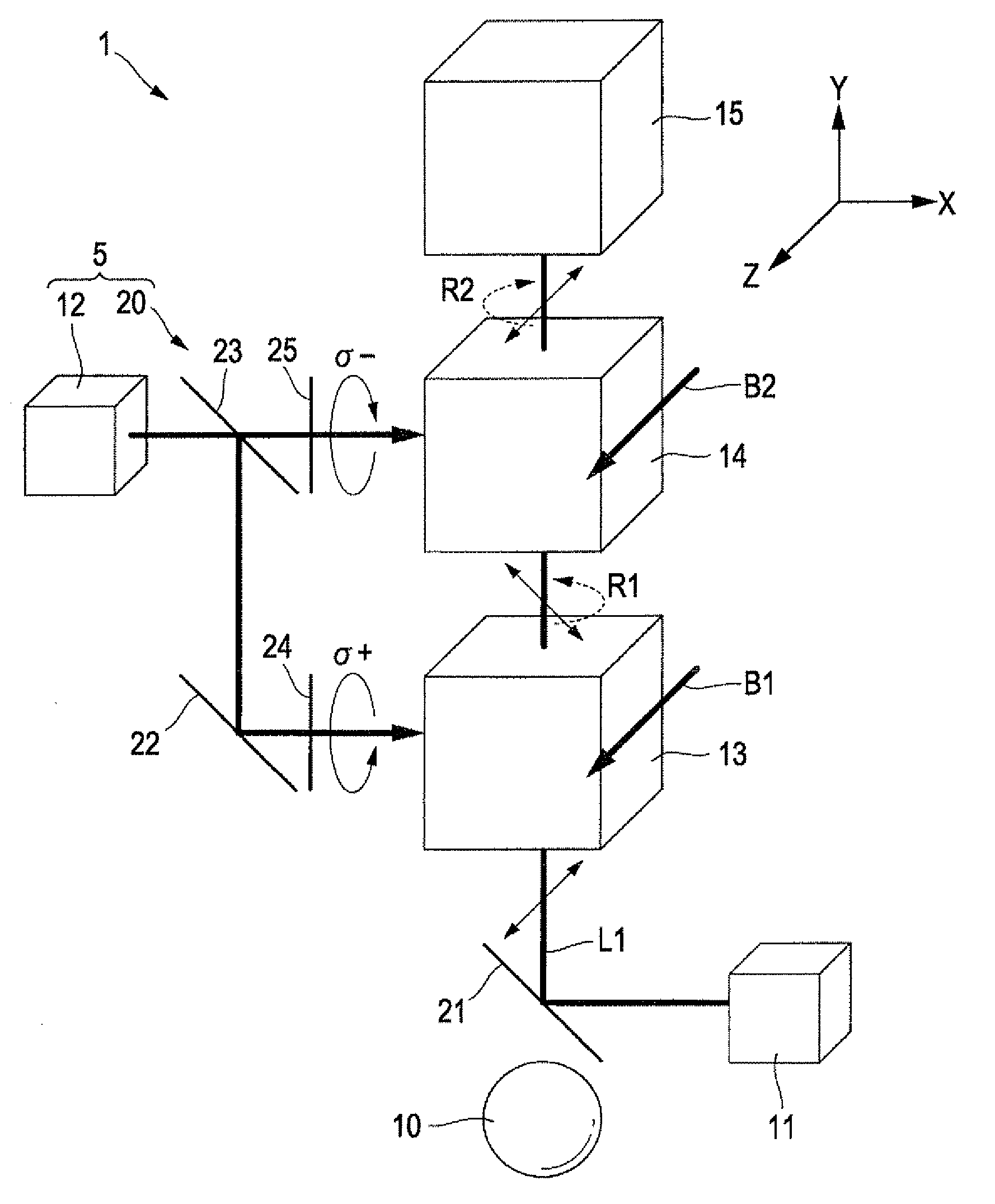

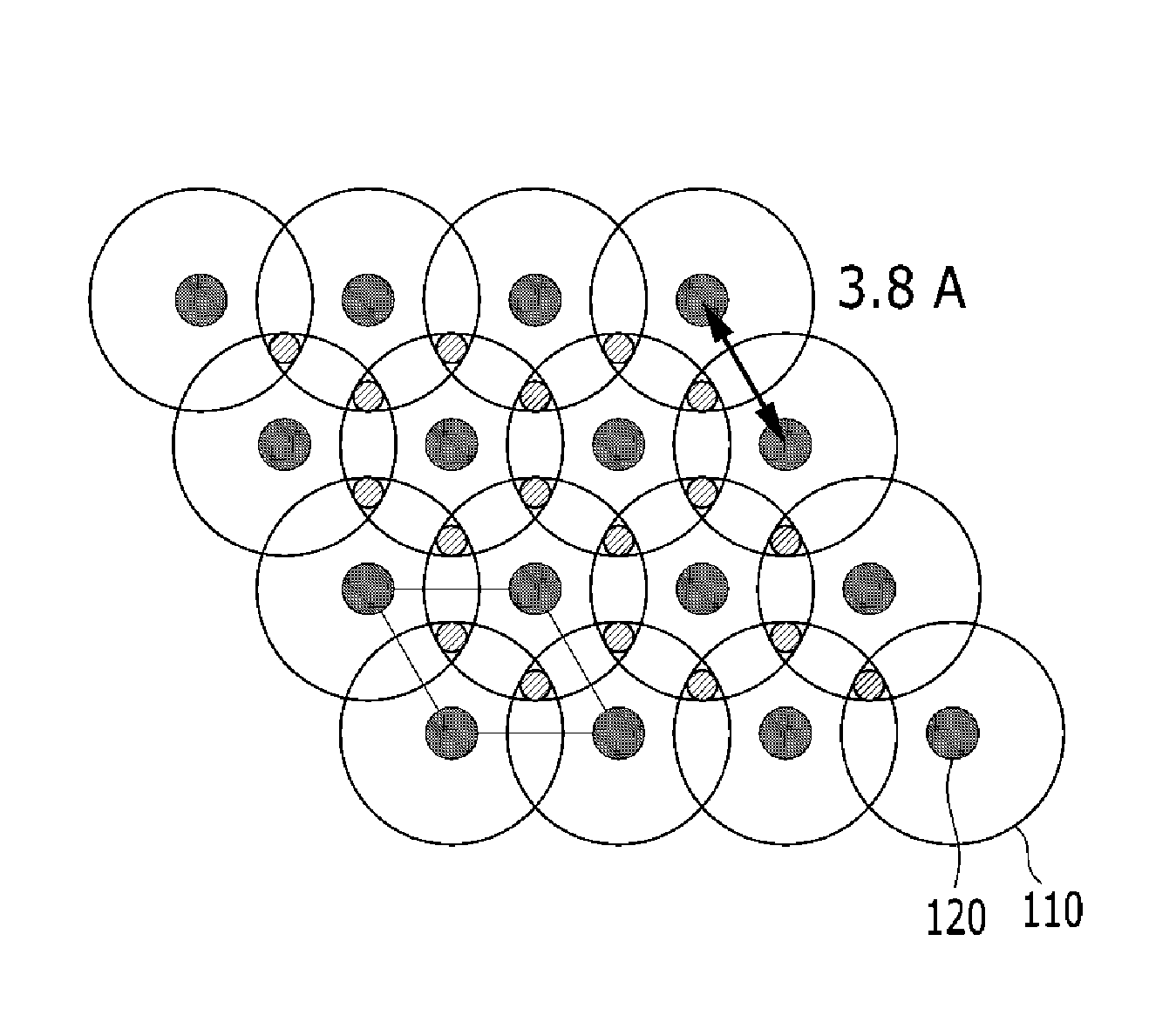

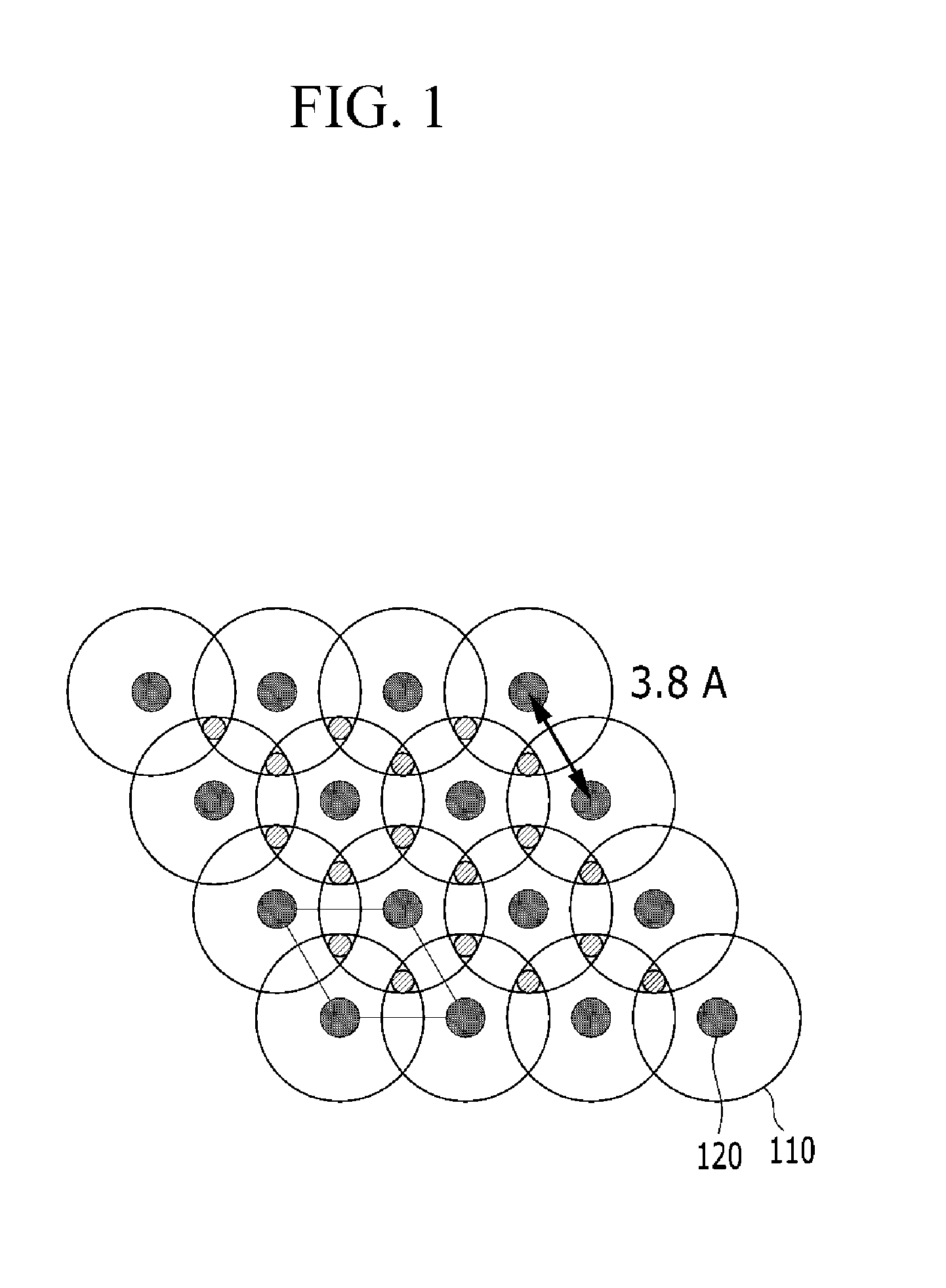

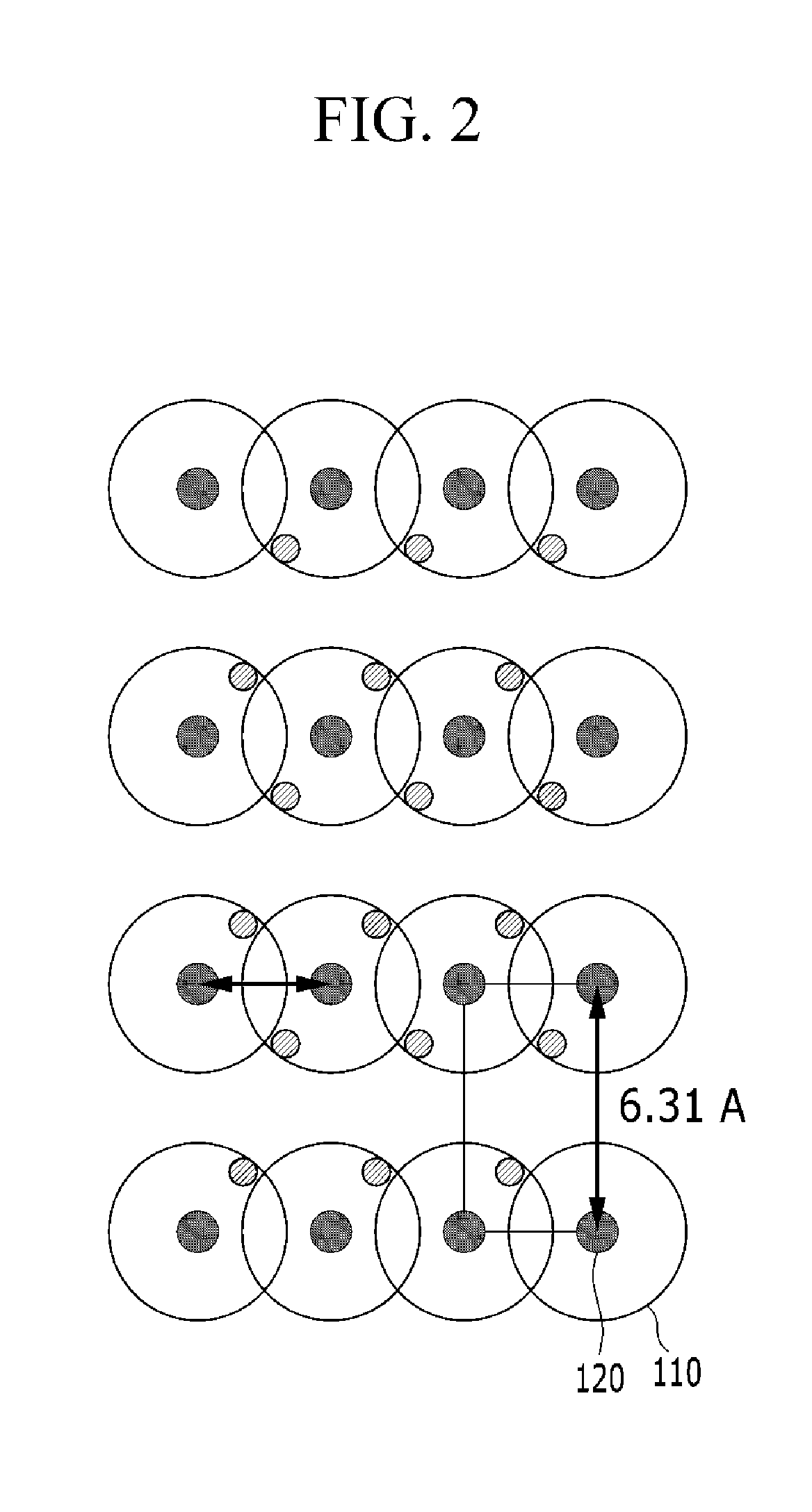

P-type semiconductor and semiconductor metero material and manufacturing methods thereof

InactiveUS20040173788A1Reduce resistanceImprove activation efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesValence electronHost material

A p-type semiconductor includes a host material 100 which is a semiconductor, an acceptor element 110 and a localized band formation element 120. Here, the acceptor element 110 is doped to the host material 100 and has fewer valence electrons than valance electrons of at least one of the elements which compose the host material 100; the localized band formation element 120 is doped to the host material 100, is isovalent with at least one of the elements which compose the host material 100 and has smaller electronegativity than the electronegativity of the element(s), and forms the localized band which activates holes of an acceptor level.

Owner:PANASONIC CORP

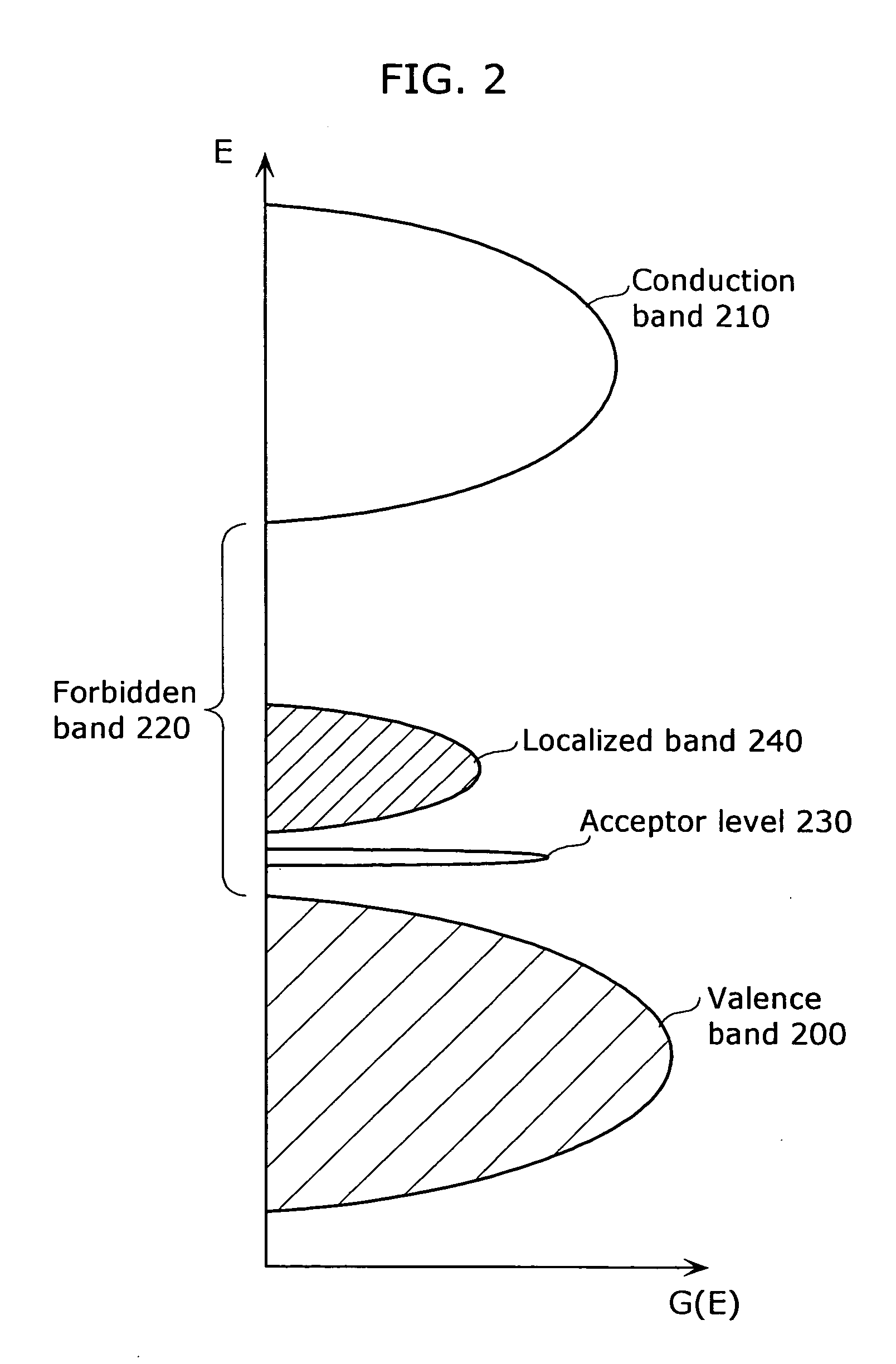

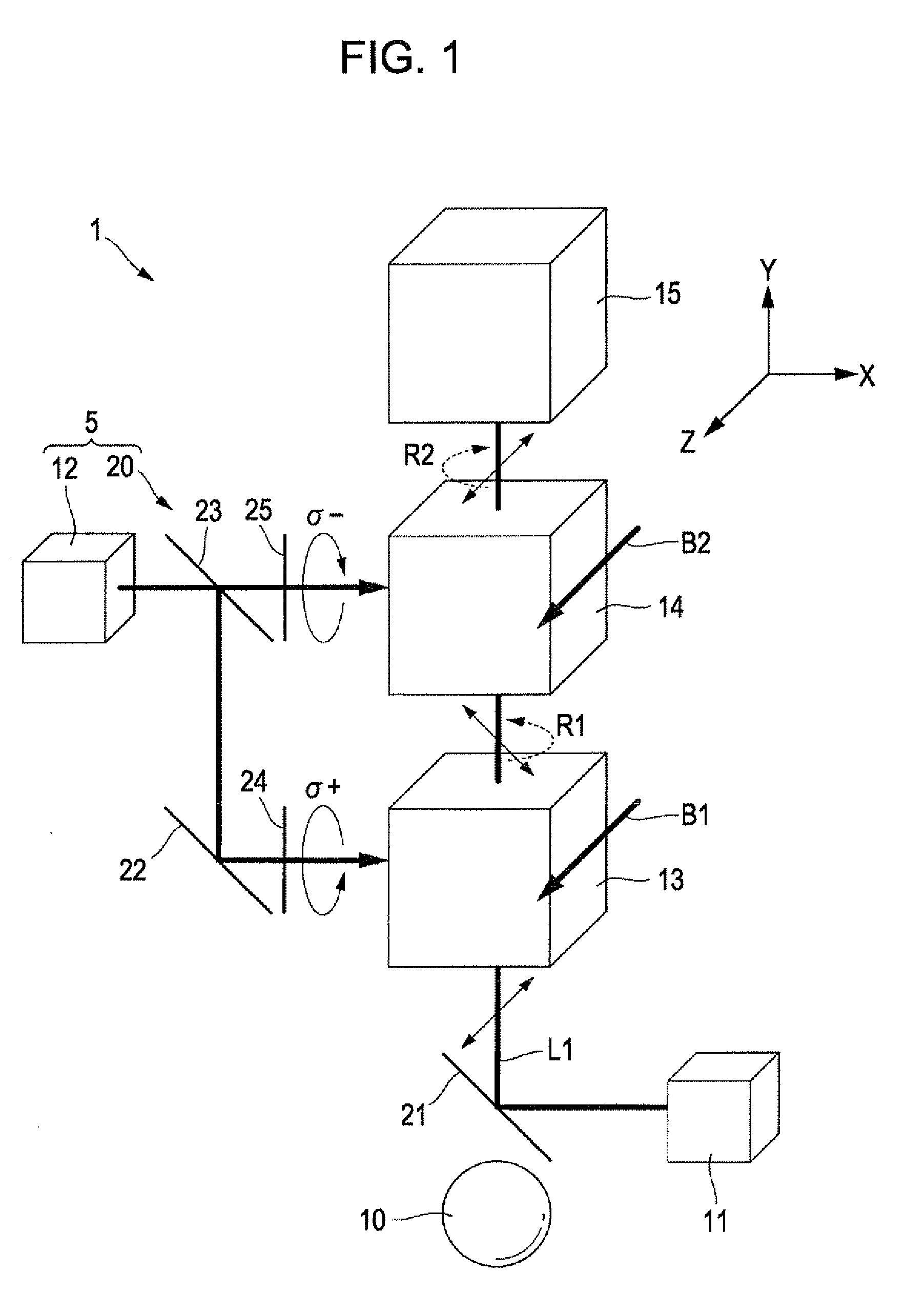

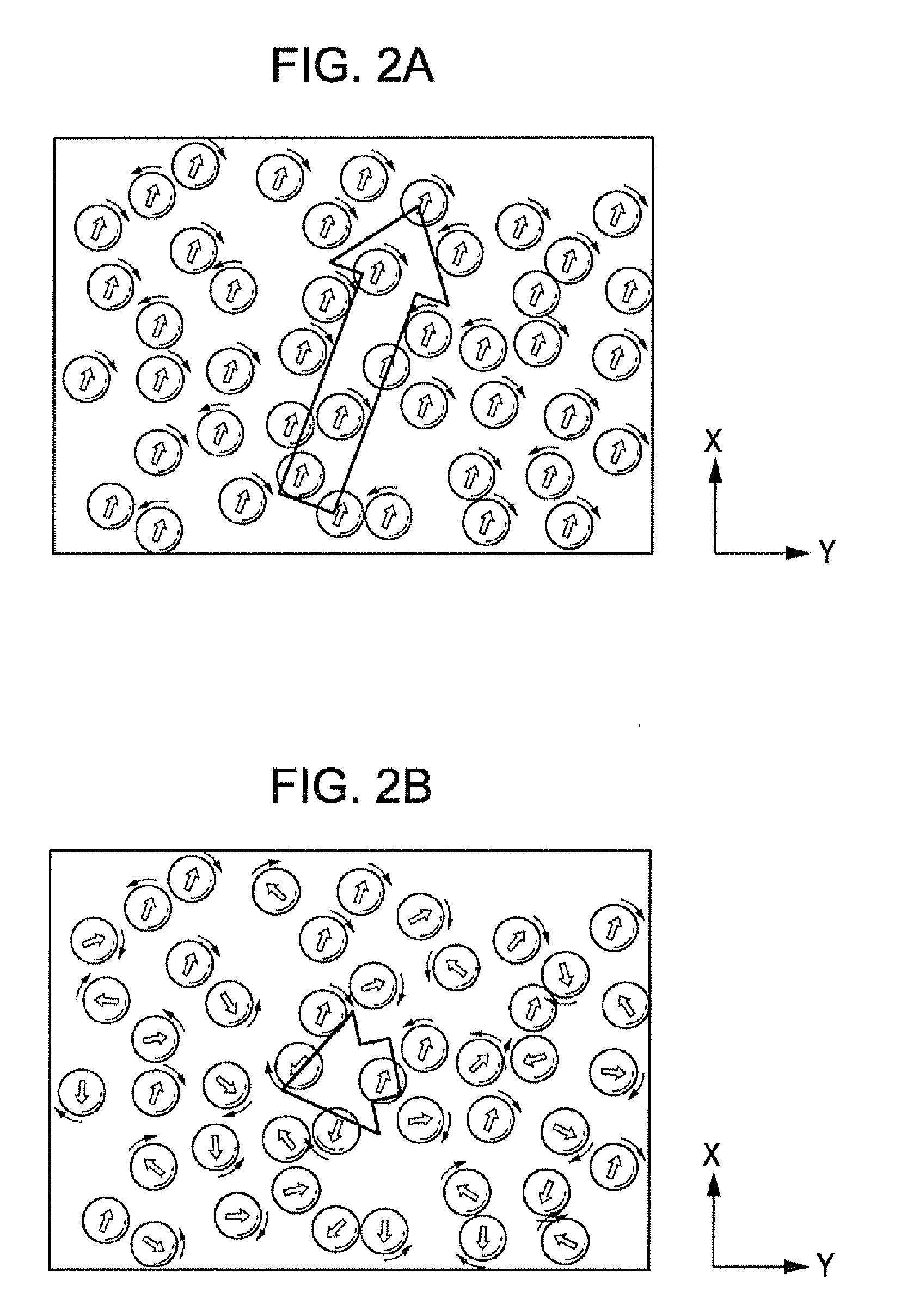

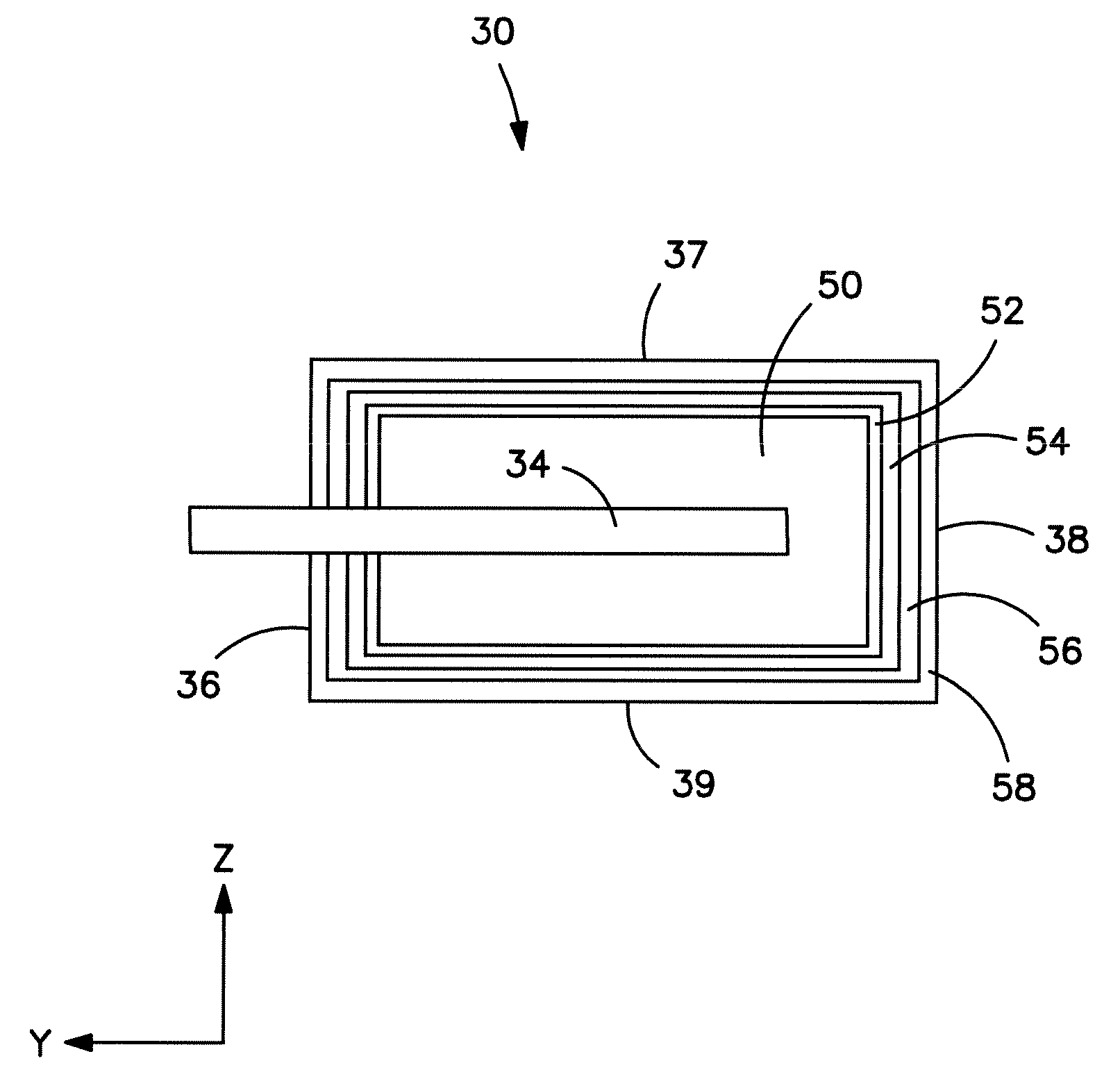

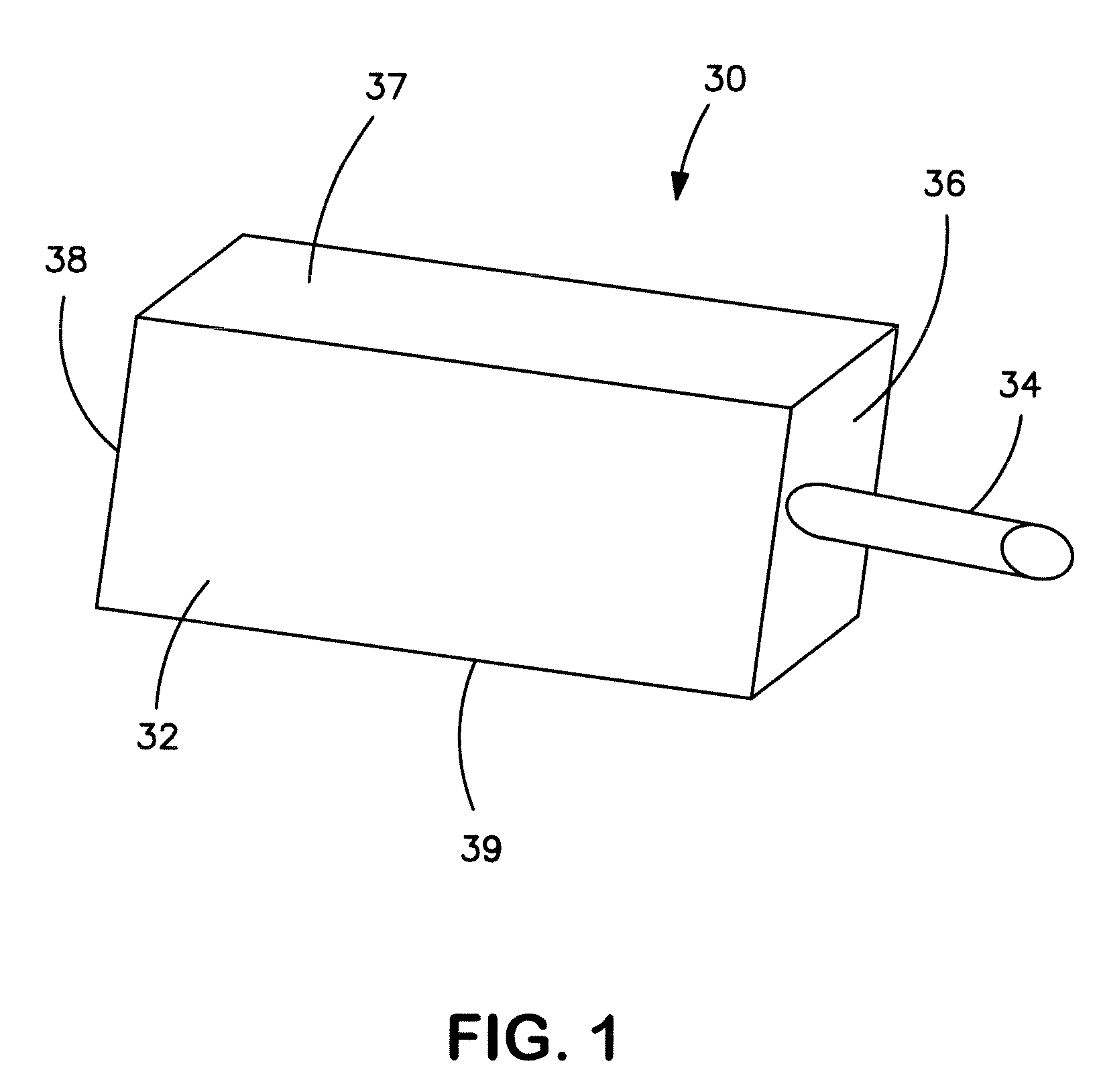

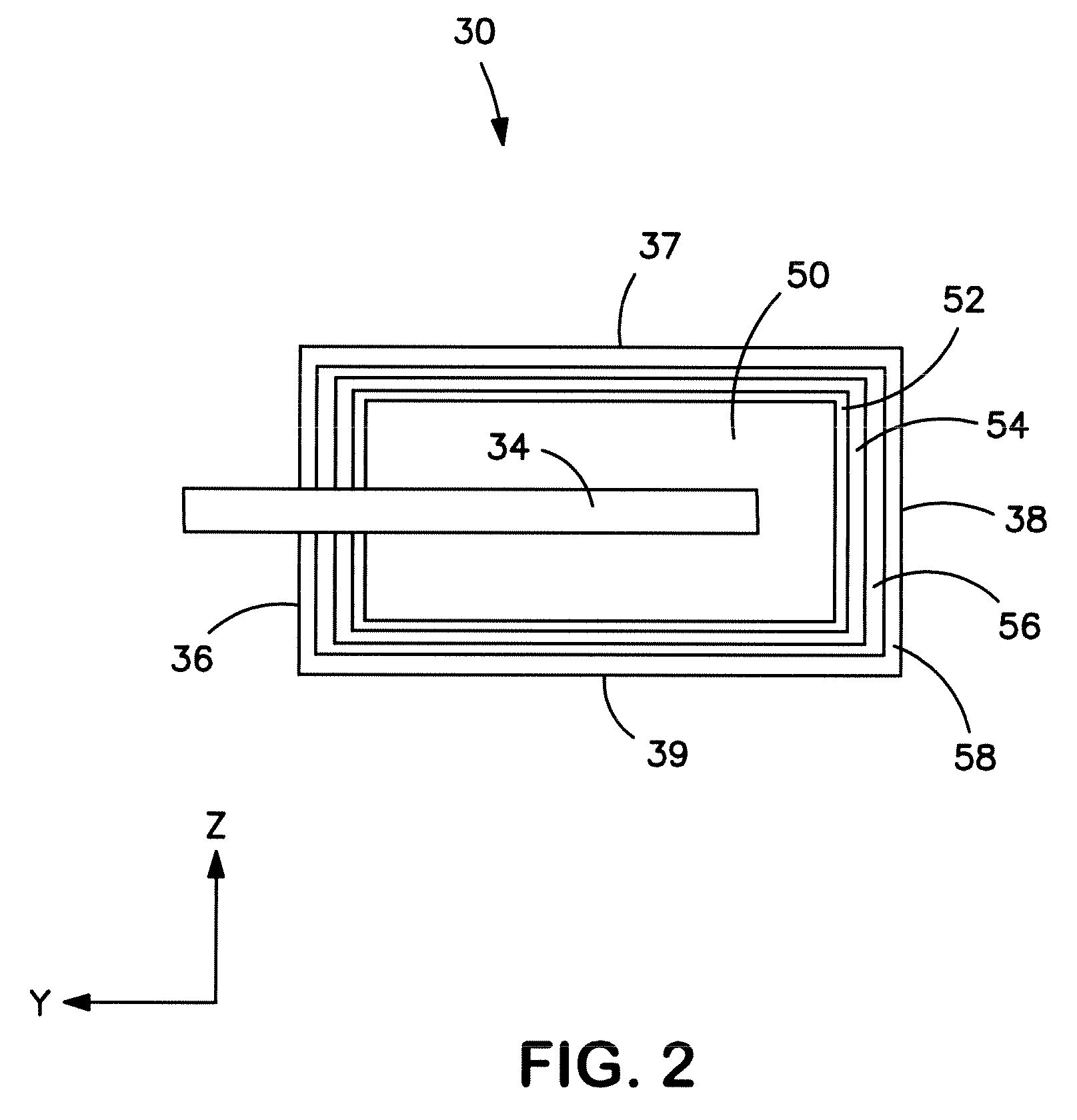

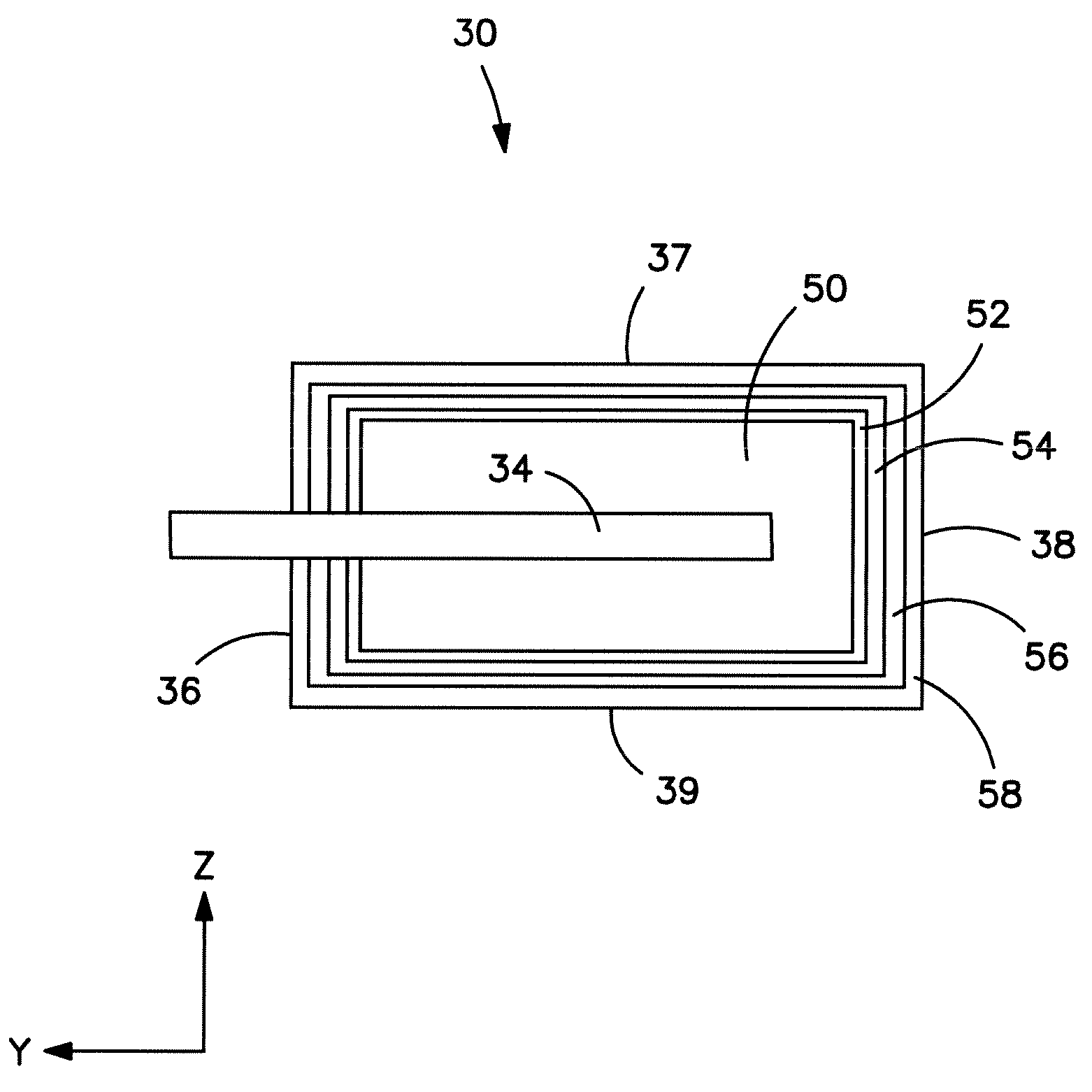

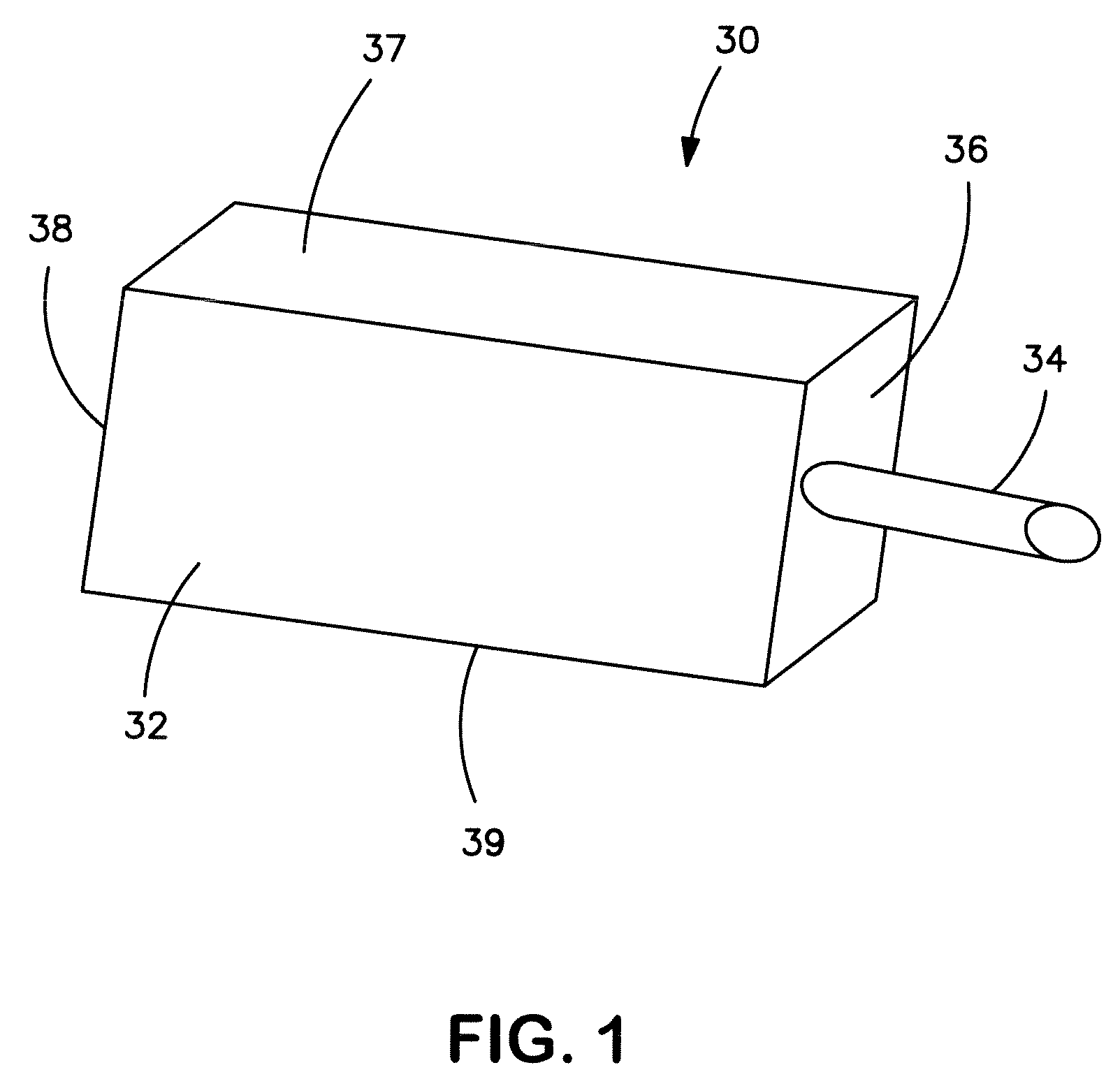

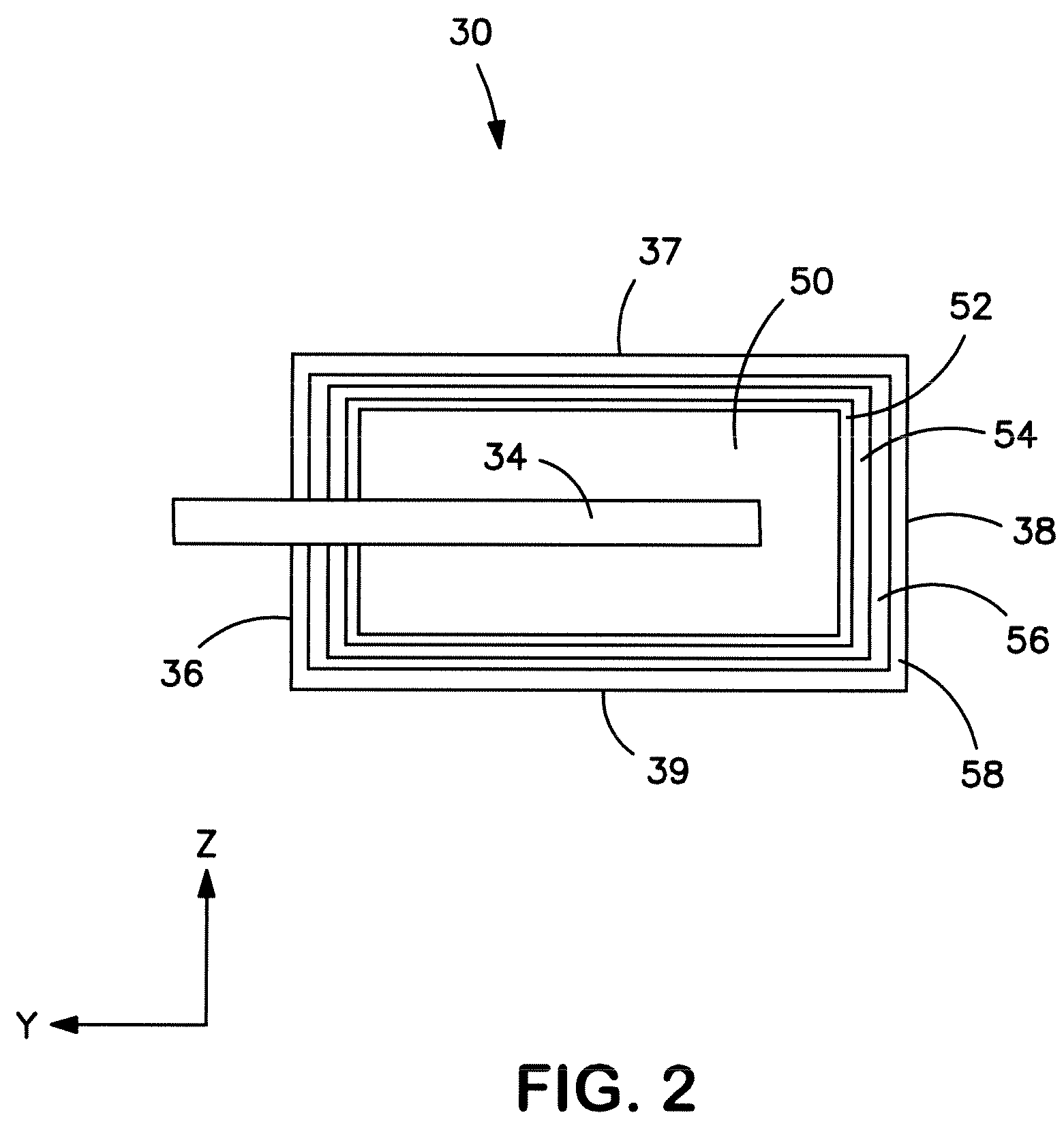

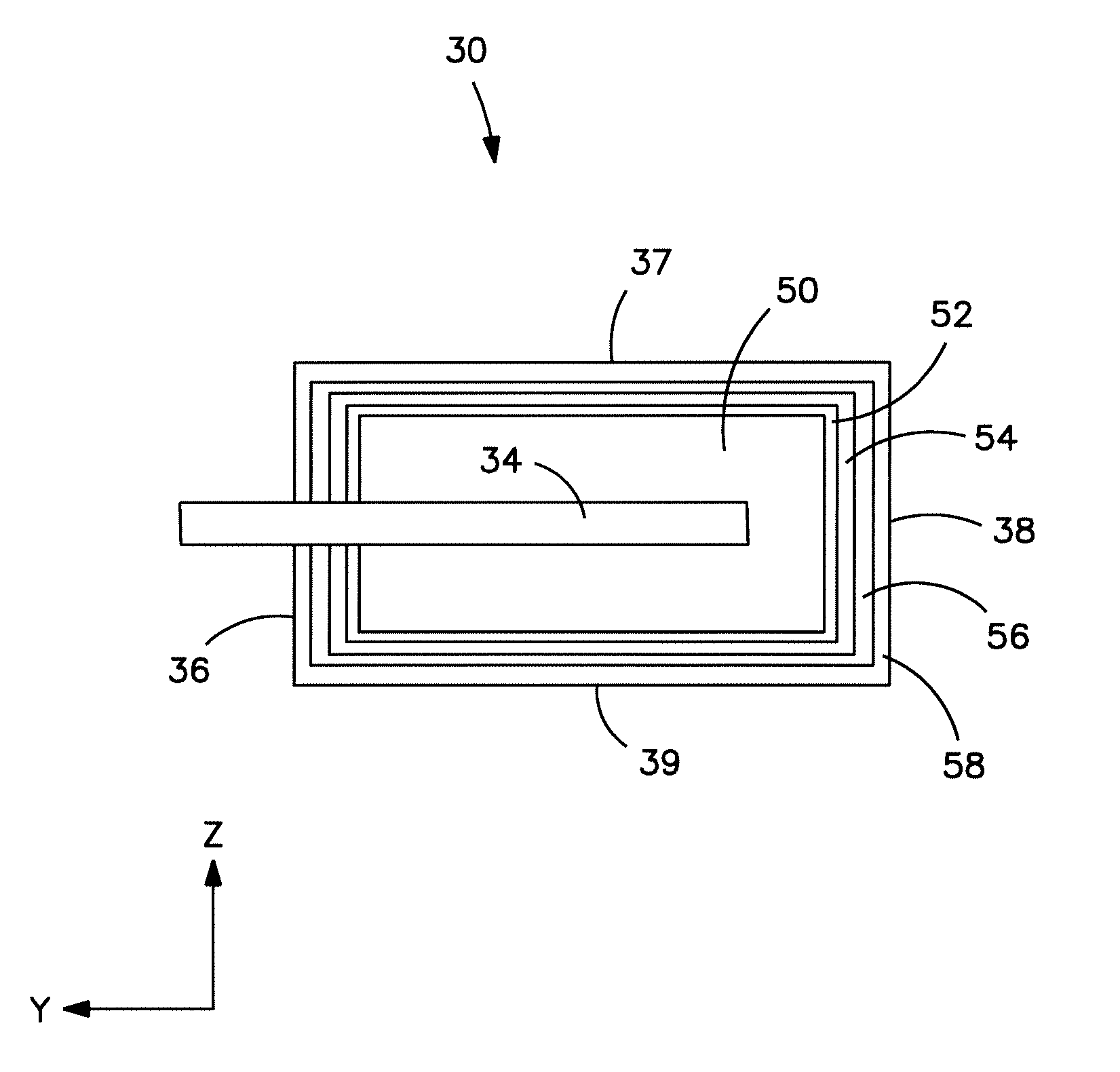

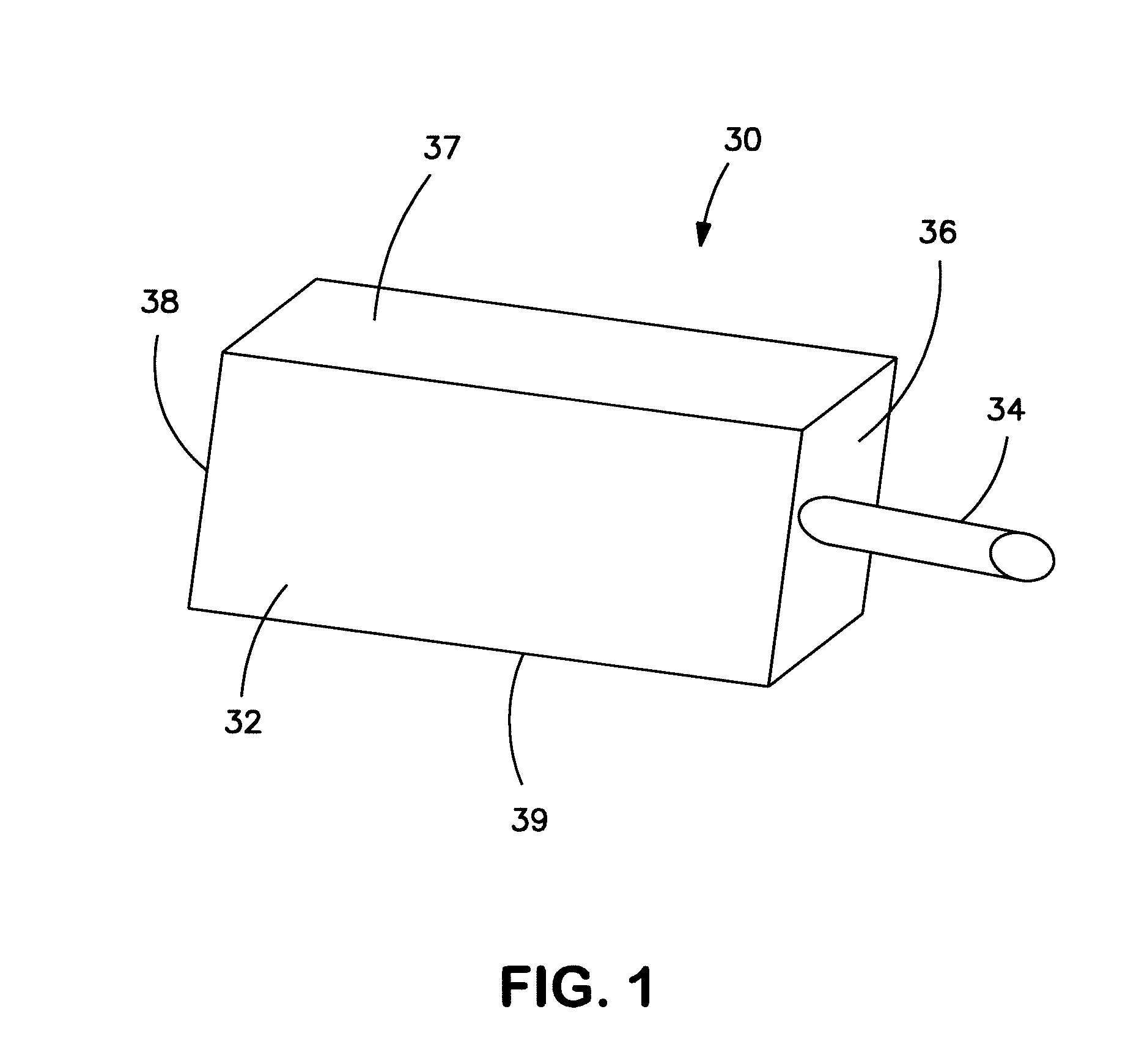

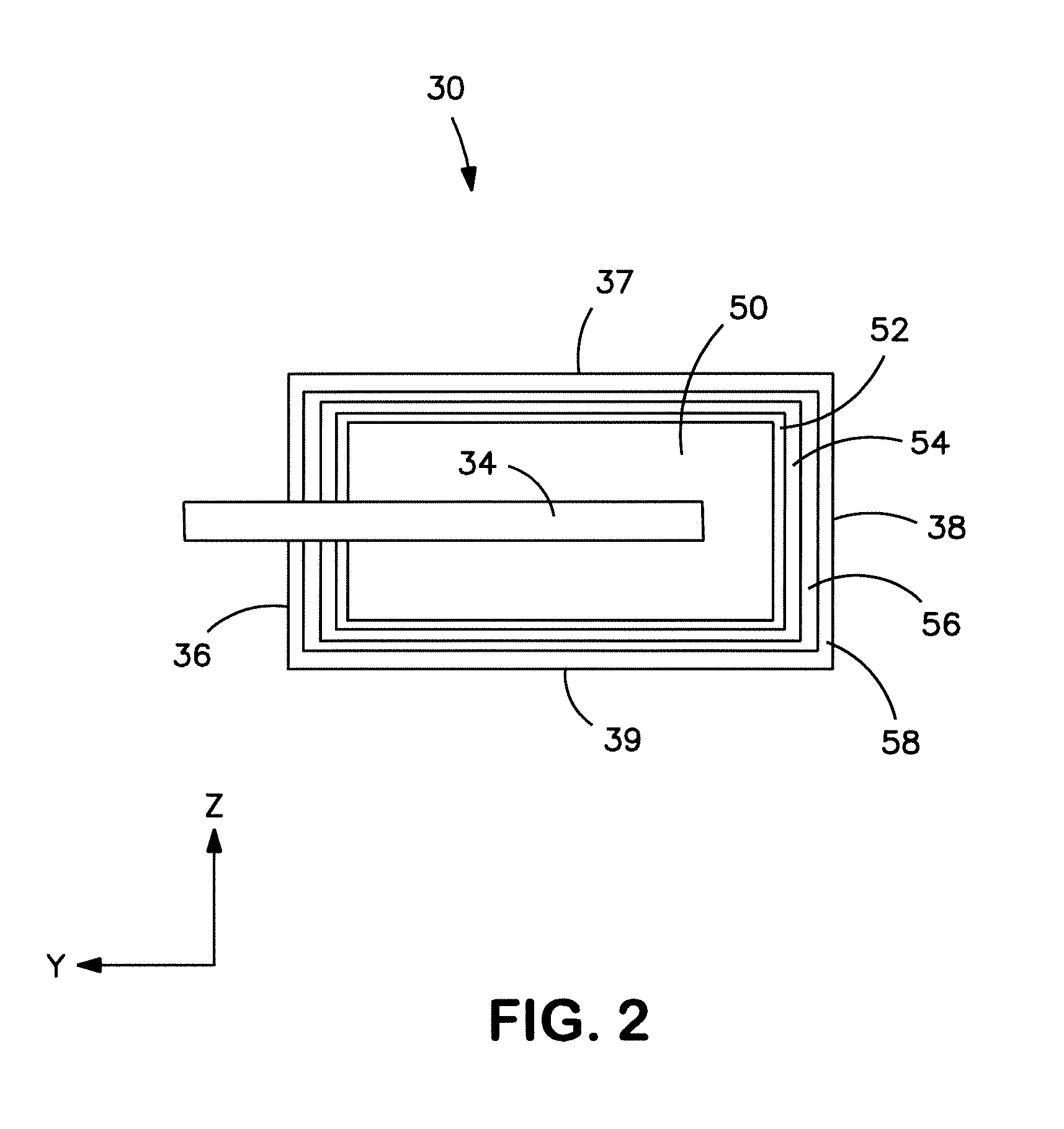

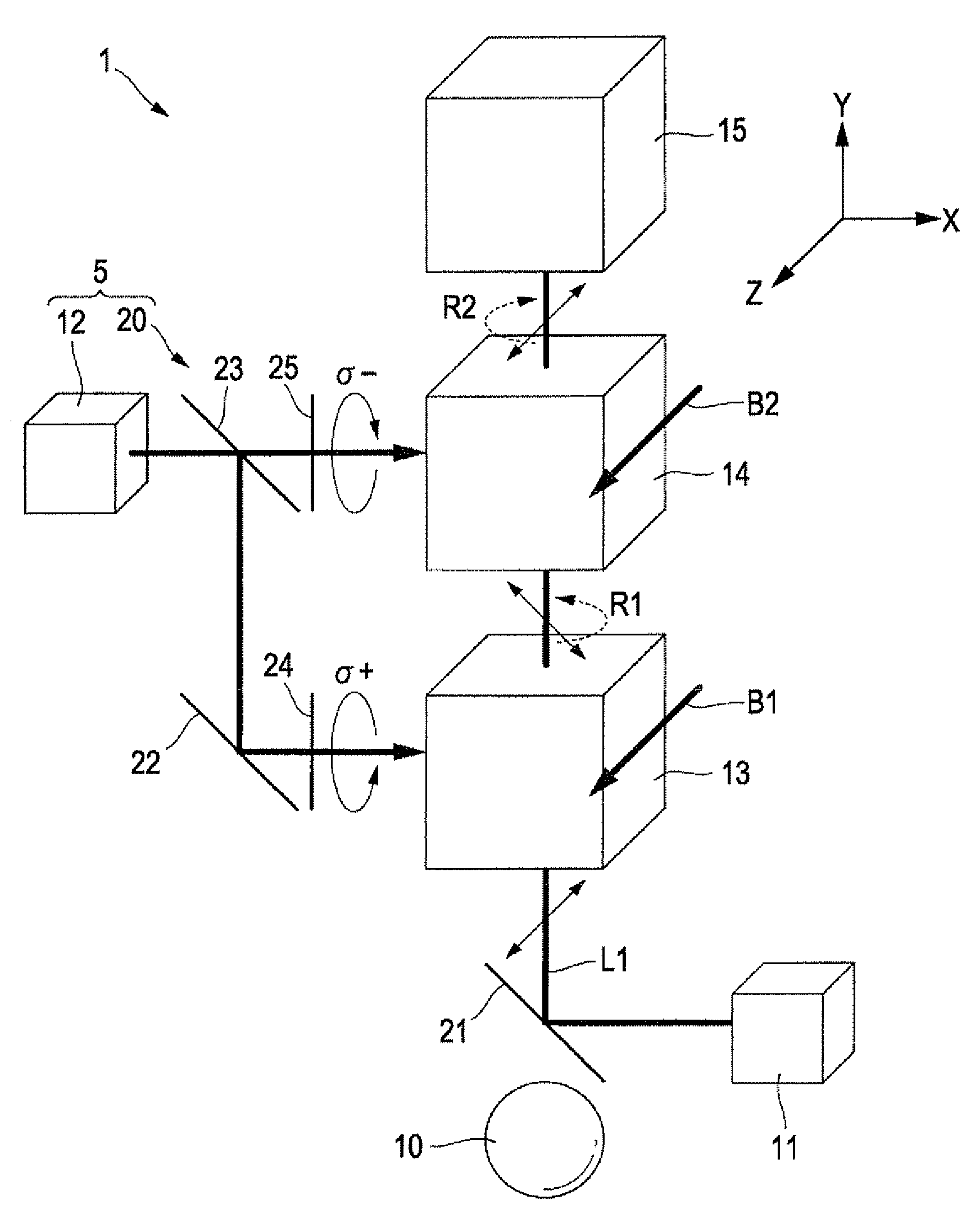

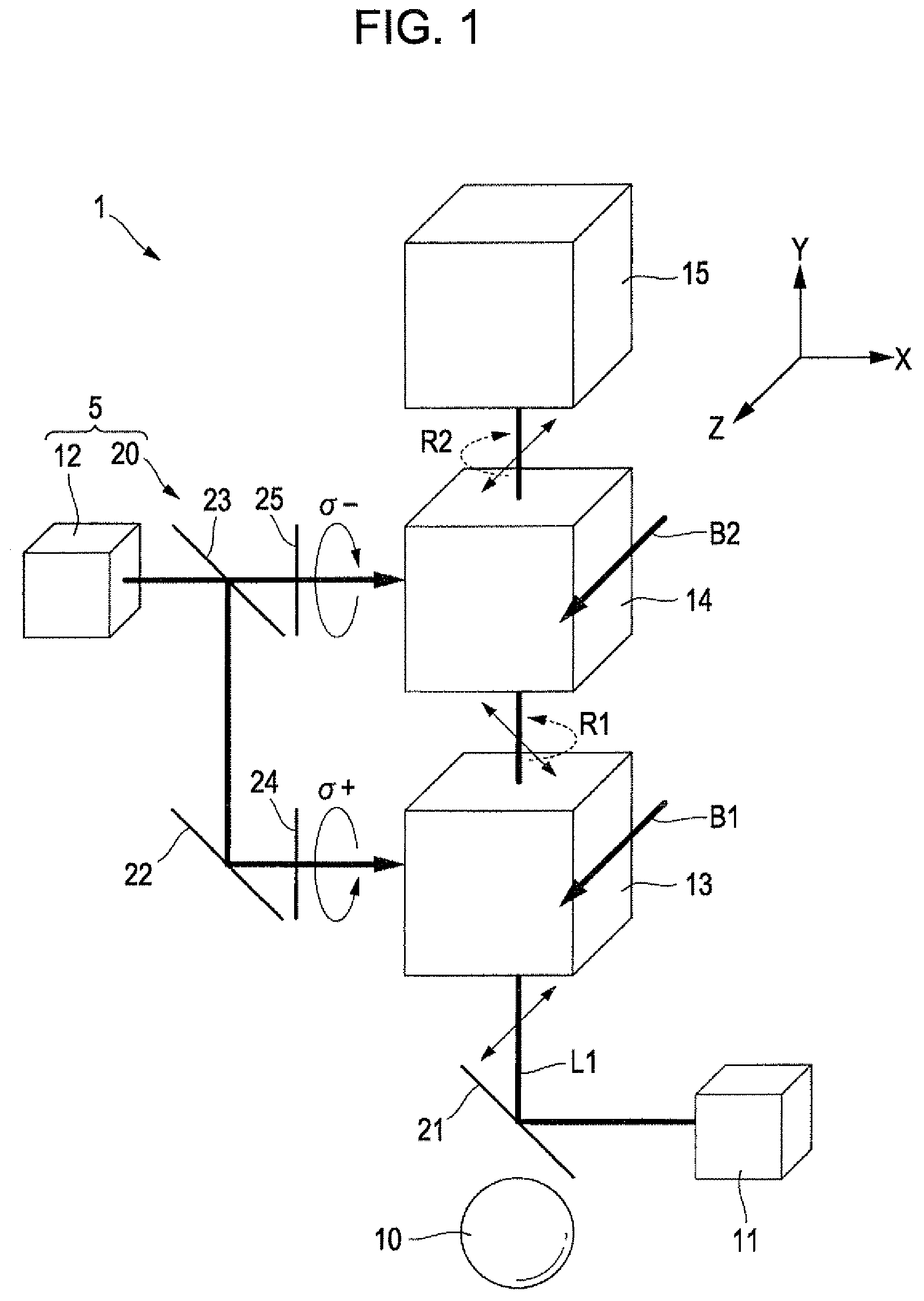

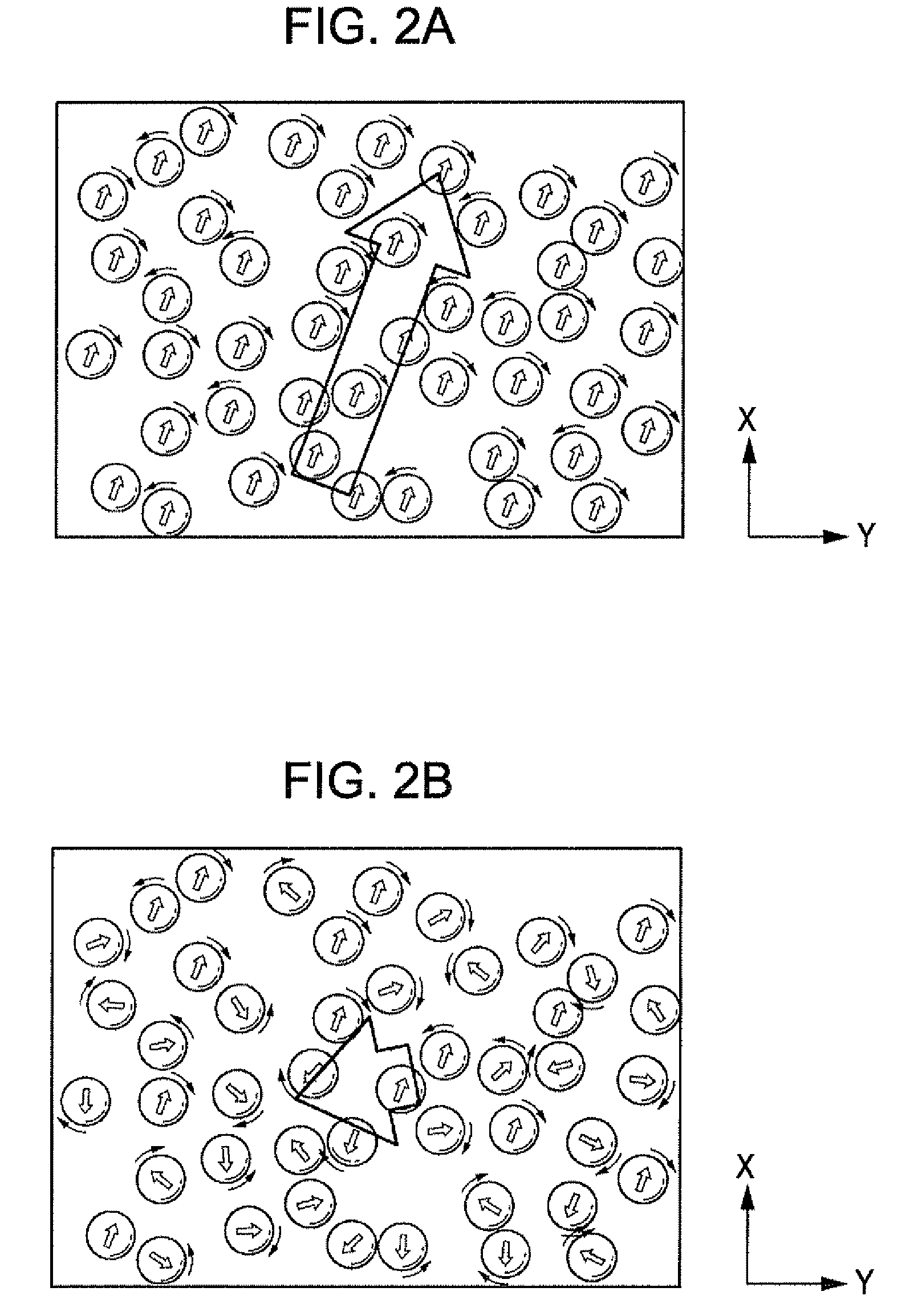

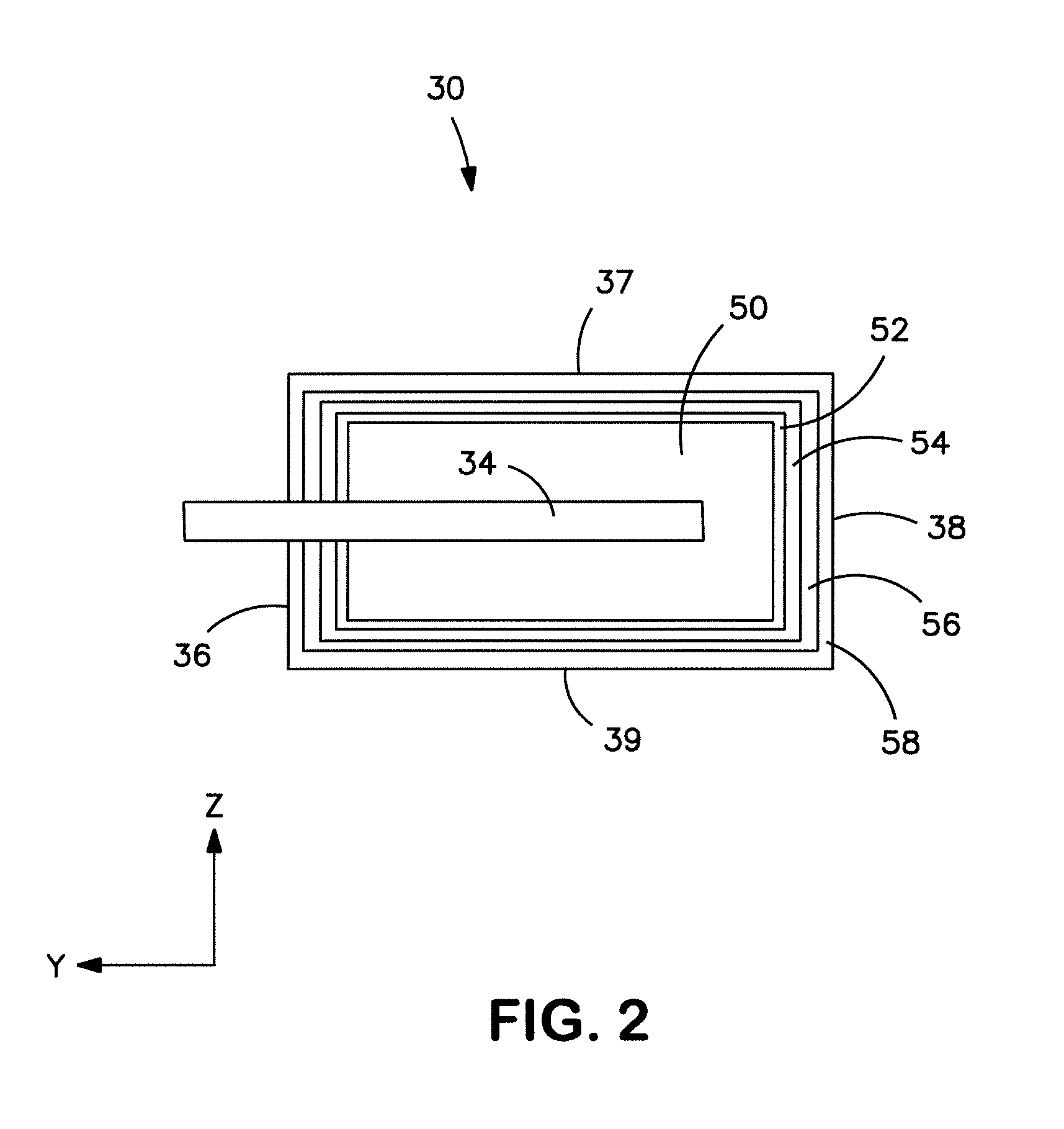

Magnetic sensor

ActiveUS20100327865A1Simple device structureEasy to set upAnalysis using optical pumpingElectric/magnetic detectionOptical pumpingValence electron

A magnetic sensor for measuring a magnetic field using an optical pumping method includes a first gas in which a valence electron is composed of an odd number of atoms or ions, a probe light incidence device which causes first probe light including straight polarized light to be incident on the first gas, a second gas in which a valence electron arranged on an optical path of second probe light that is the first probe light transmitted through the first gas is composed of an odd number of atoms or ions, a pumping light incidence device which causes first pumping light including first circular polarized light to be incident on the first gas and second pumping light including second circular polarized light to be incident on the second gas, and a detector which detects a rotation angle of a polarization plane of the first probe light and a polarization plane of third probe light that is the second probe light transmitted through the second gas.

Owner:COLUMBIA PEAK VENTURES LLC

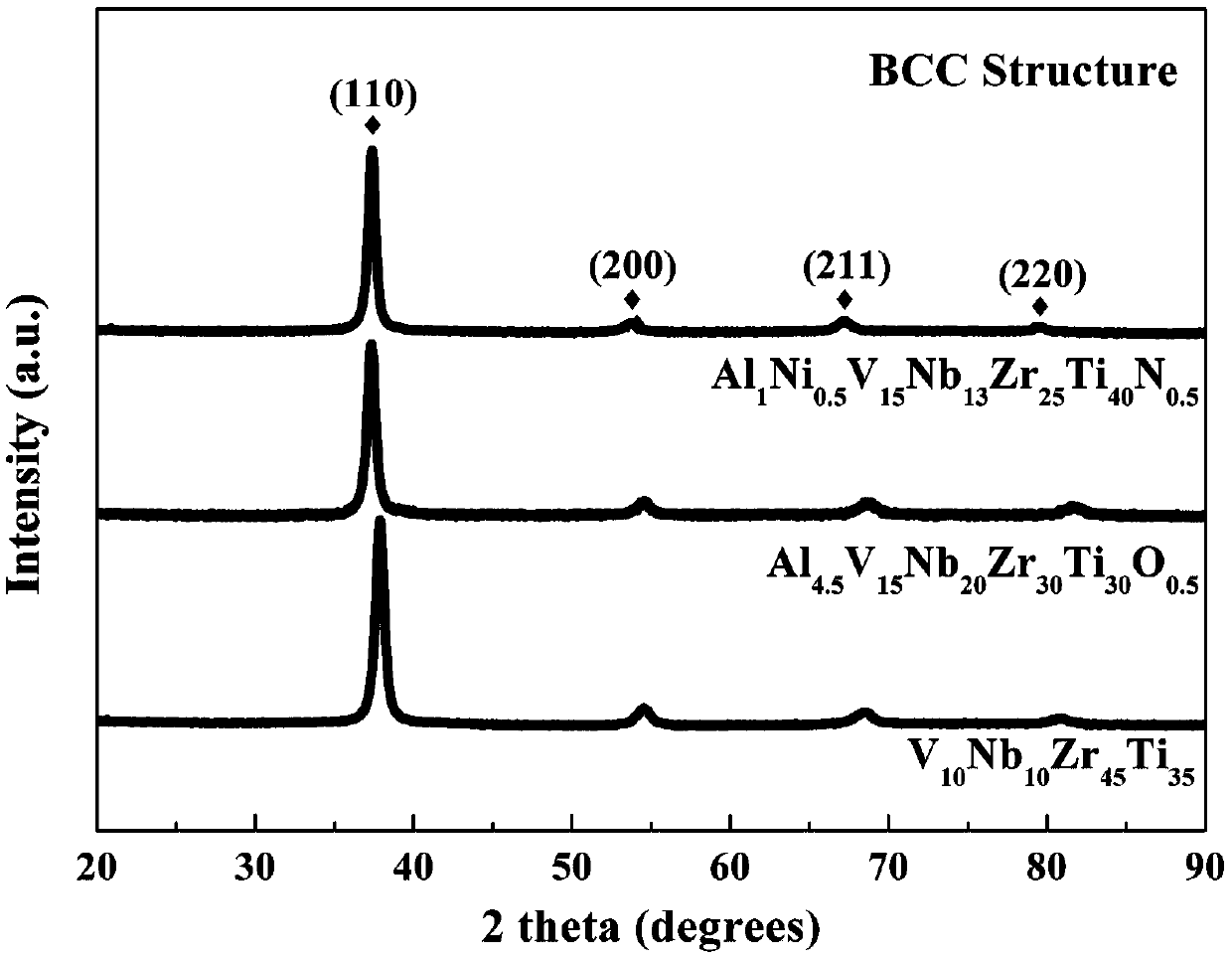

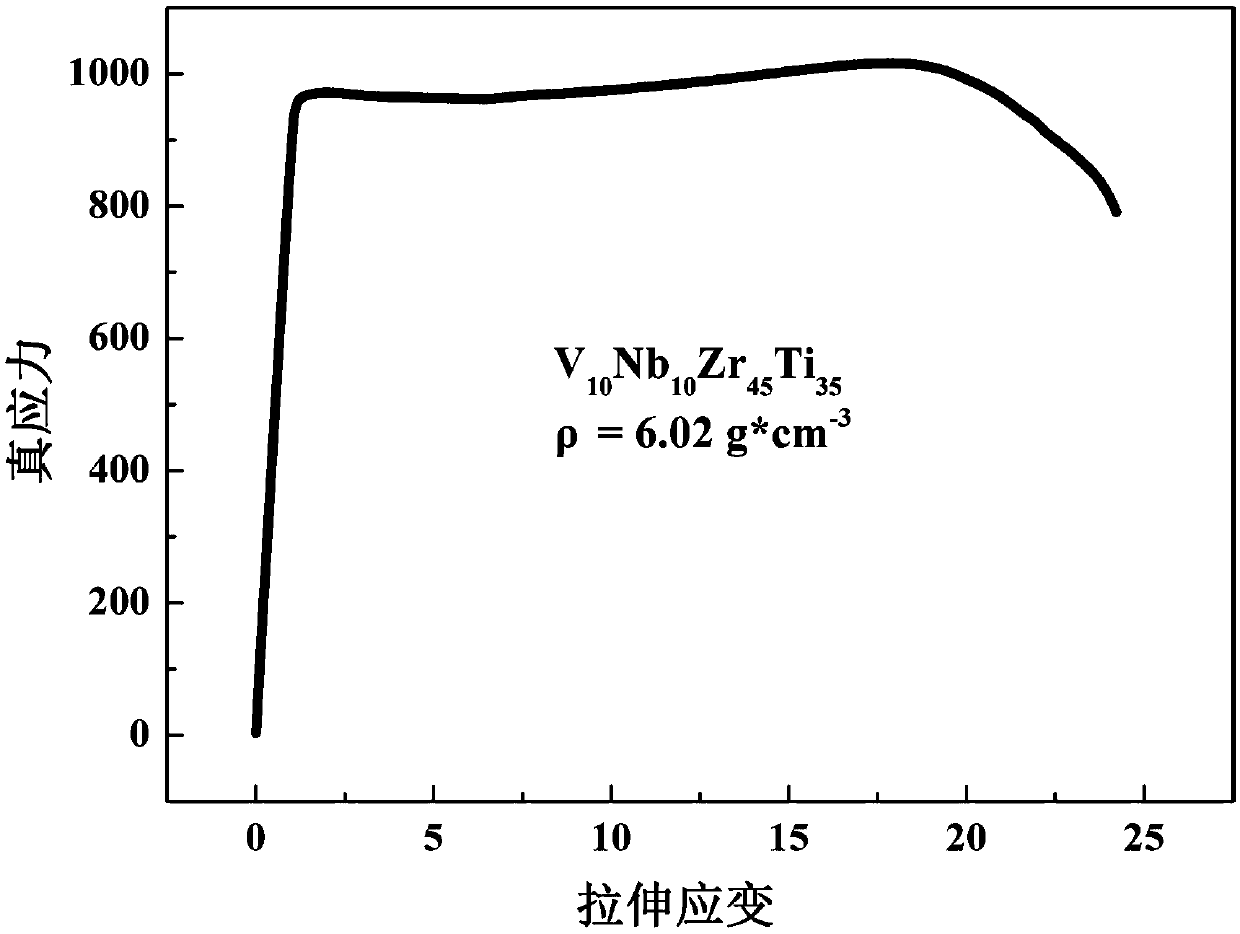

High-specific-strength high-plasticity refractory high-entropy alloy and preparing method thereof

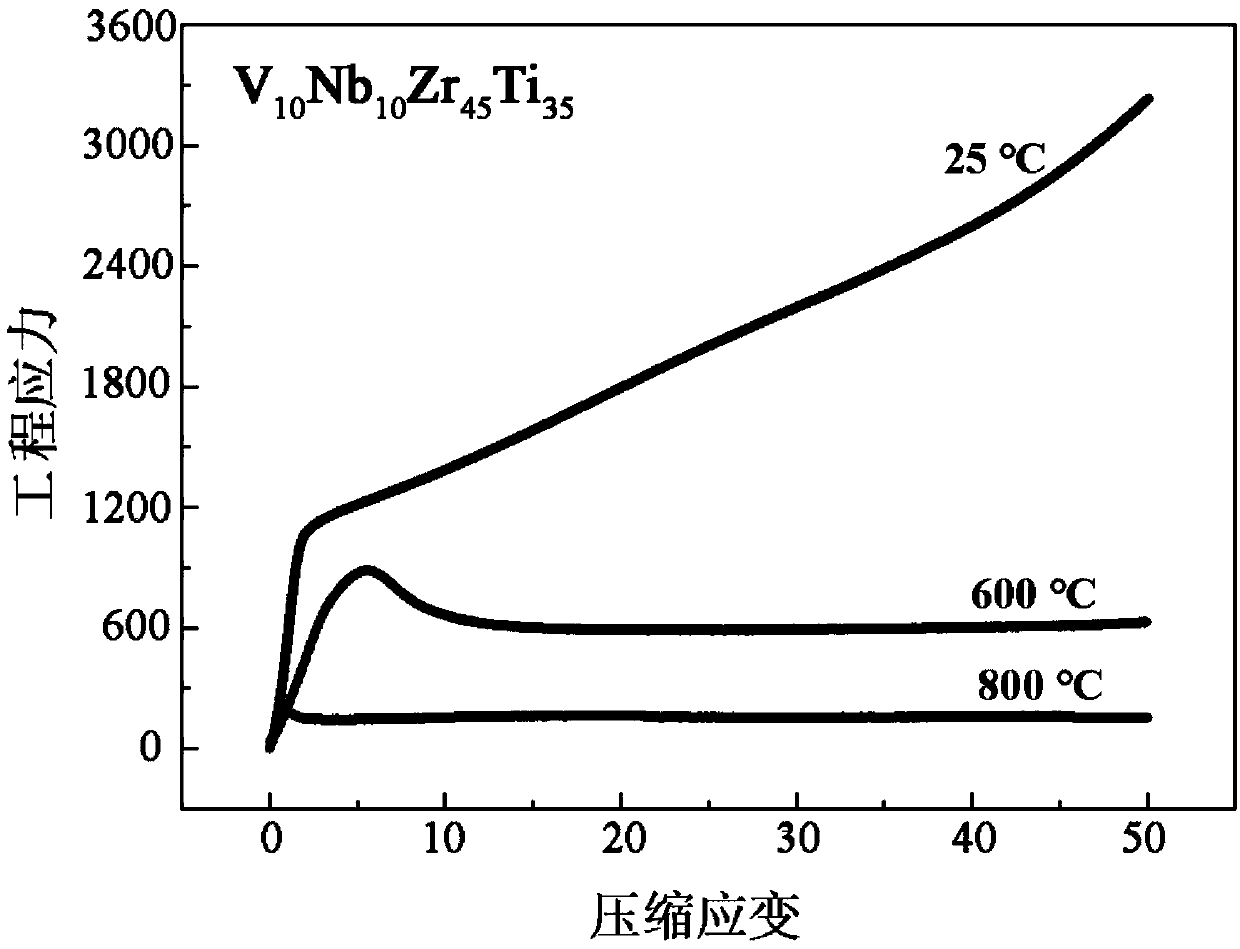

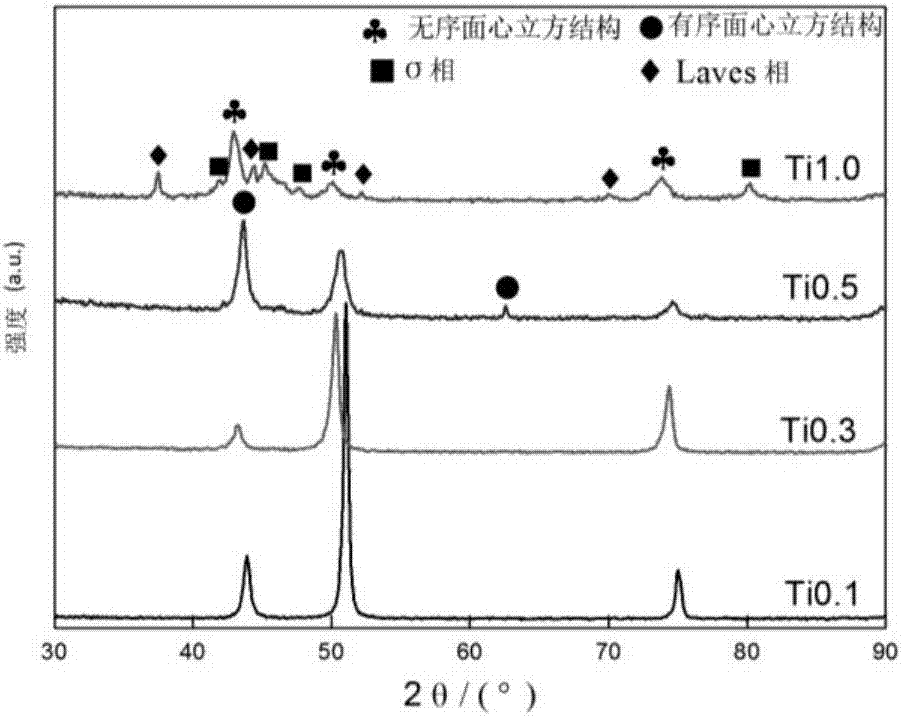

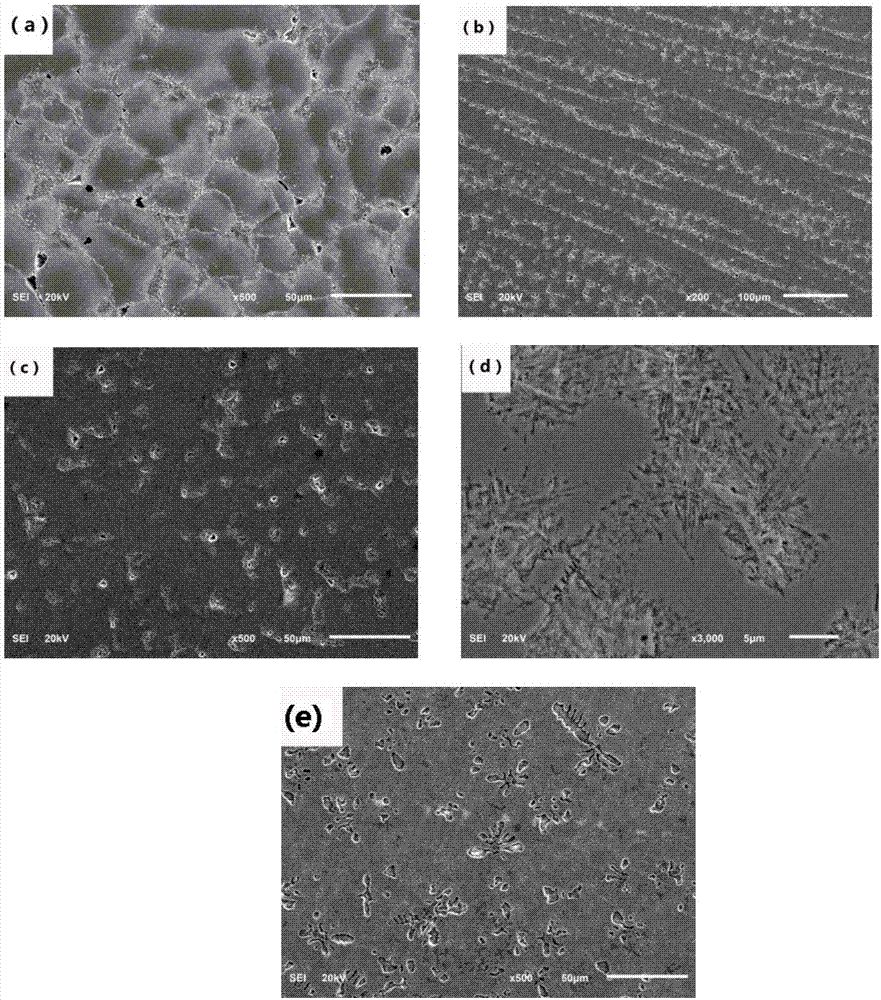

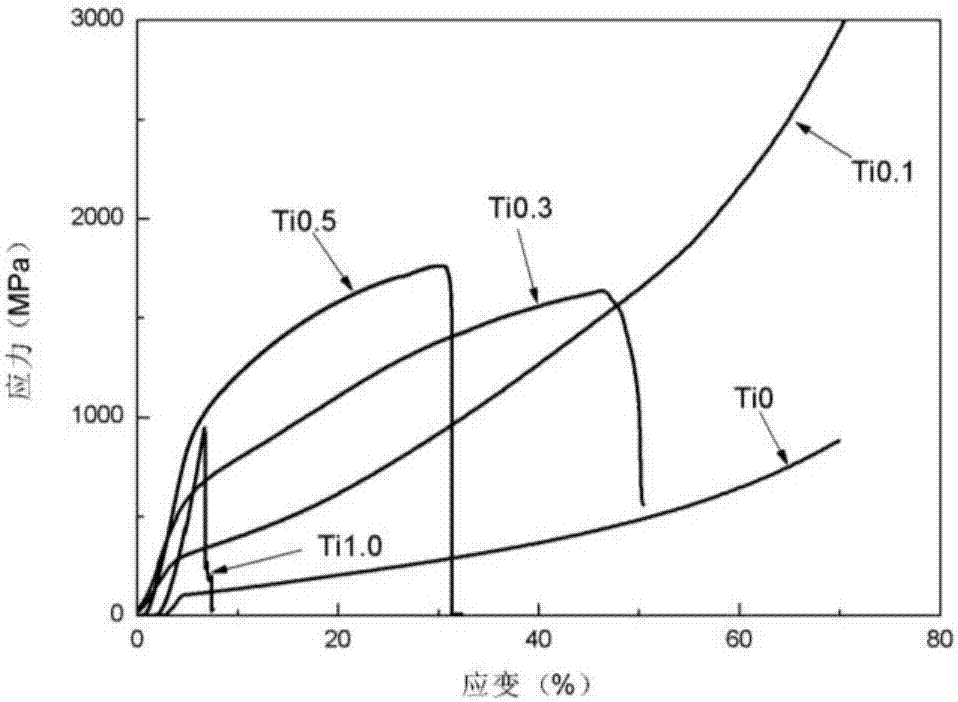

The invention relates to a high-specific-strength high-plasticity refractory high-entropy alloy and a preparing method thereof, and belongs to the technical field of metal materials. The expression isVaNbbZrcTidMeNfPg, wherein M, N, P can be the elements such as Cr, Al, Ni, Fe, Si, O, B, C, and N; a is no less than 15% and no more than 20%, b is no less than 15% and no more than 25%, c is no lessthan 30% and no more than 50%, d is no more than 30% and no less than 50%, e is no less than 0 and no more than 5%, f is no less than 0 and no more than 5%, g is no less than 0 and no more than 5%, and the sum of a, b, c, d, e, f and g is 100%; and meanwhile, the valence electron concentration VEC of the alloy is no less than 4.1 and no more than 4.4, and the atomic radius size difference Delta is no less than 5.5% and no more than 6.4%. The alloy is prepared by various methods, the density of the VaNbbZrcTidMeNfPg alloy is less than 6.5 g*cm<-3>, the room temperature tensile strength is morethan 900 MPa, the plastic deformation is more than 15%, and the high specific strength and high plasticity are achieved; and after the temperature is increased to 600 DEG C, the weakening of the material is not very obvious, after the temperature is increased to 800 DEG C, the material can still maintain a certain strength, and the alloy has a certain storage ability for H2 and can be used in thefield of energy materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Hexabasic high-entropy alloy and preparation method thereof

The invention discloses a hexabasic high-entropy alloy material. The hexabasic high-entropy alloy material is prepared from, by atomic percent, 18.18%-22.22% of Co, 18.18%-22.22% of Cr, 9.1%-11.12% of Cu, 18.18%-22.22% of Fe, 18.18%-22.22% of Ni and 2.17%-18.18% of Ti, wherein the element Ti has the large atomic radius, and the severe lattice distortion effect of the element Ti can effectively enhance a solid solution phase. In addition, the element Ti has the small valence electron concentration and tends to form a compound phase, and therefore the precipitation enhancing function is achieved. An obtained hexabasic CoCrCu0.5FeNiTi0.5 high-entropy alloy has high strength and plasticity, wherein the yield strength is 850 MPa, the compressive strength reaches 1,650 MPa, and meanwhile the plasticity reaches 31.5%. The alloy has good strength and plasticity cooperation, and a preparation method is simple and reliable. The invention further discloses the preparation method of the hexabasic high-entropy alloy material.

Owner:JIANGSU UNIV OF SCI & TECH

Anode for a Solid Electrolytic Capacitor Containing a Non-Metallic Surface Treatment

A solid electrolytic capacitor that comprises an anode, a dielectric layer overlying the anode; and a cathode that contains a solid electrolyte layer overlying the dielectric layer. The anode comprises a porous, sintered body that defines a surface. The body is treated so that the surface contains a non-metallic element having a ground state electron configuration that includes five or more valence electrons at an energy level of three or more (e.g., phosphorous).

Owner:AVX CORP

Anode for a solid electrolytic capacitor containing a non-metallic surface treatment

A solid electrolytic capacitor that comprises an anode, a dielectric layer overlying the anode; and a cathode that contains a solid electrolyte layer overlying the dielectric layer. The anode comprises a porous, sintered body that defines a surface. The body is treated so that the surface contains a non-metallic element having a ground state electron configuration that includes five or more valence electrons at an energy level of three or more (e.g., phosphorous).

Owner:AVX CORP

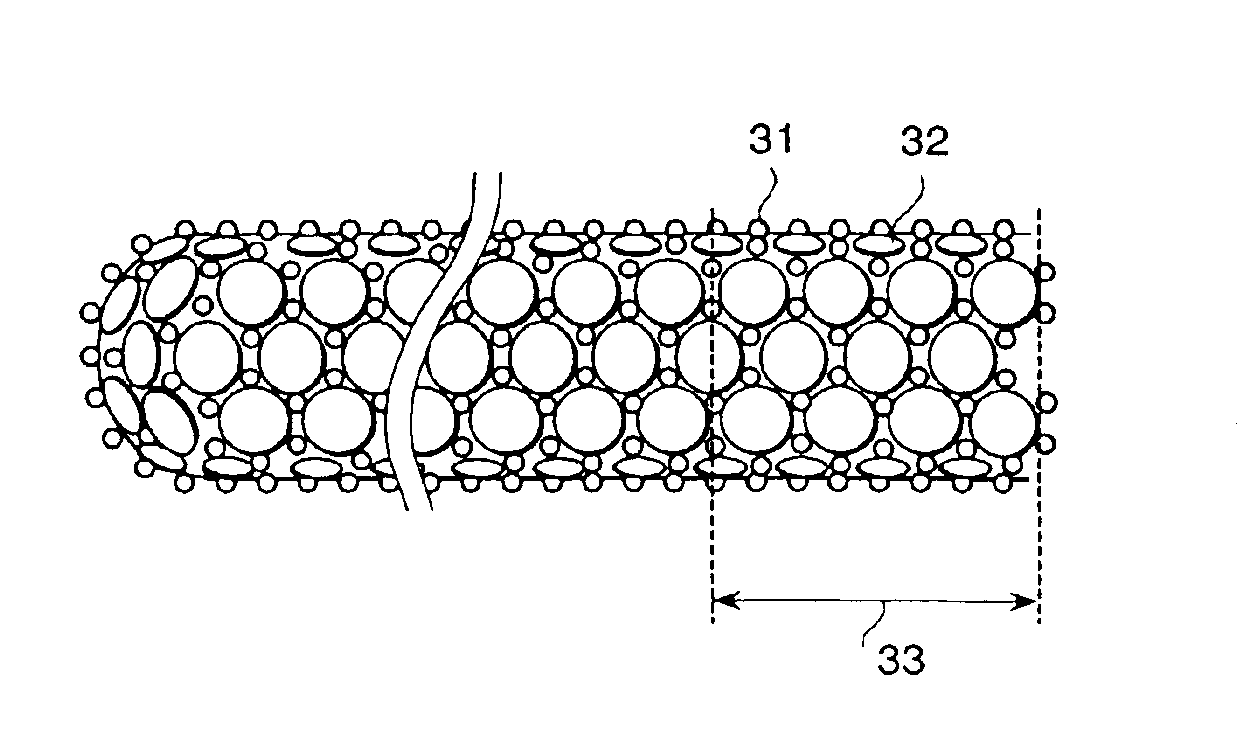

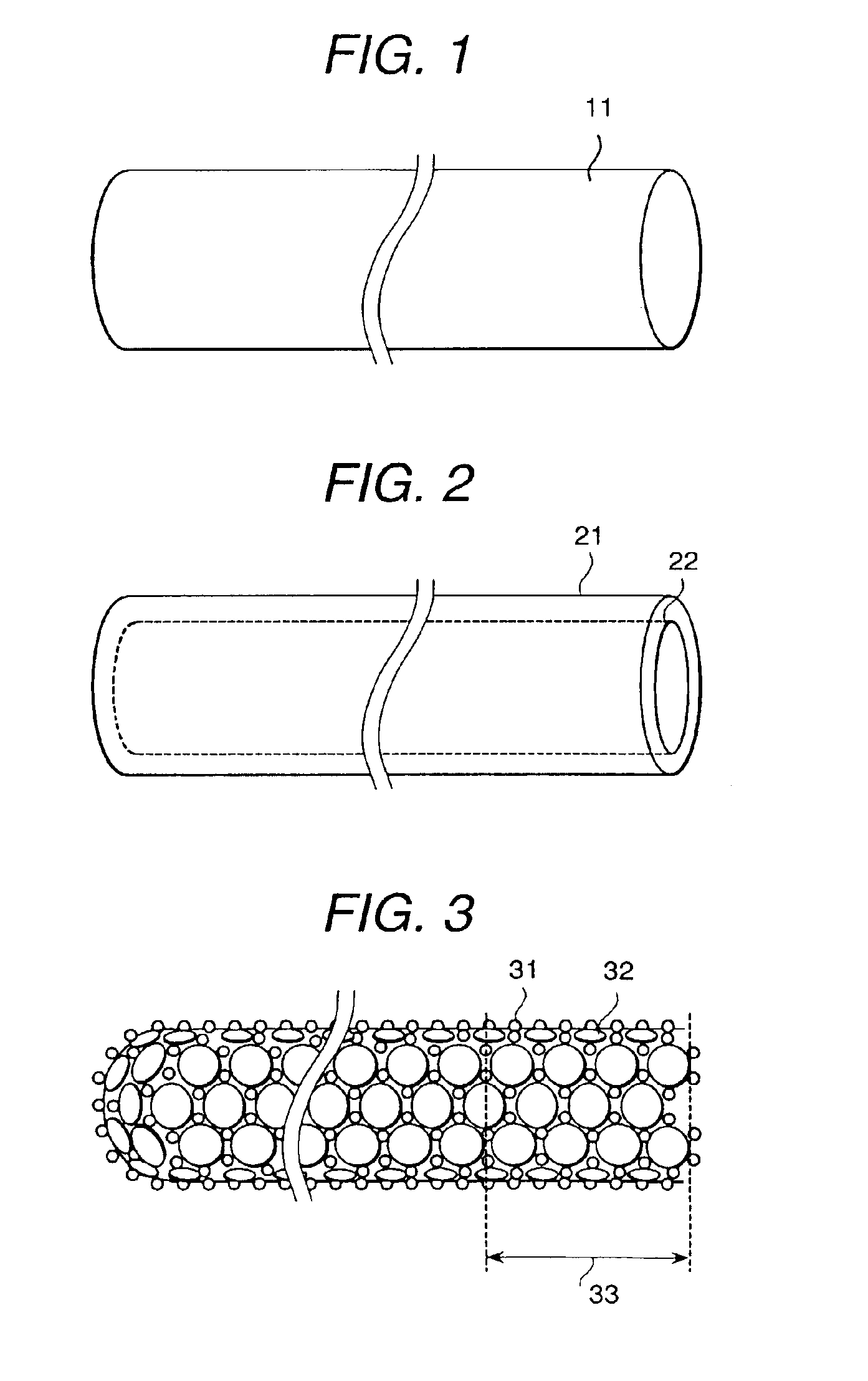

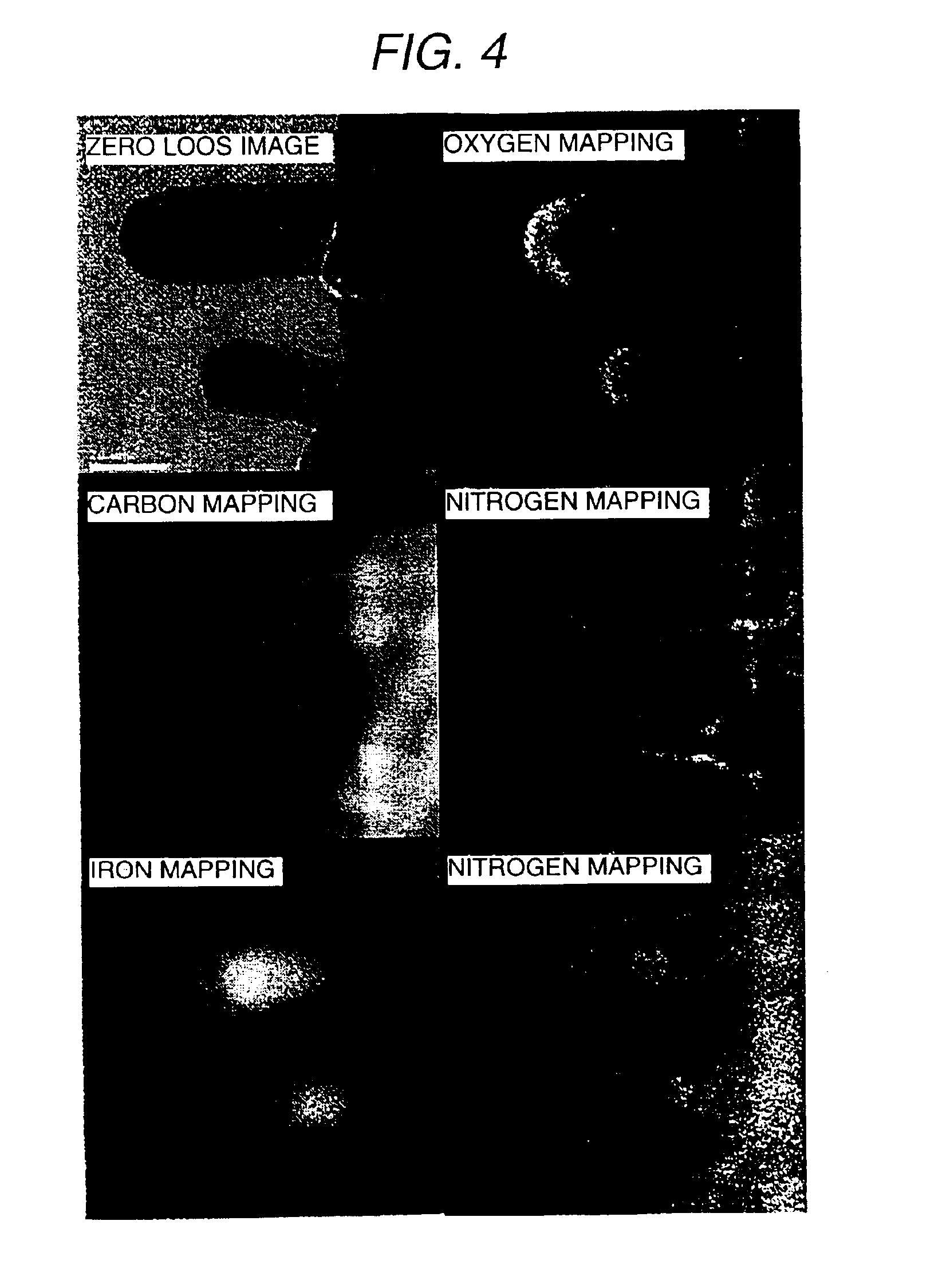

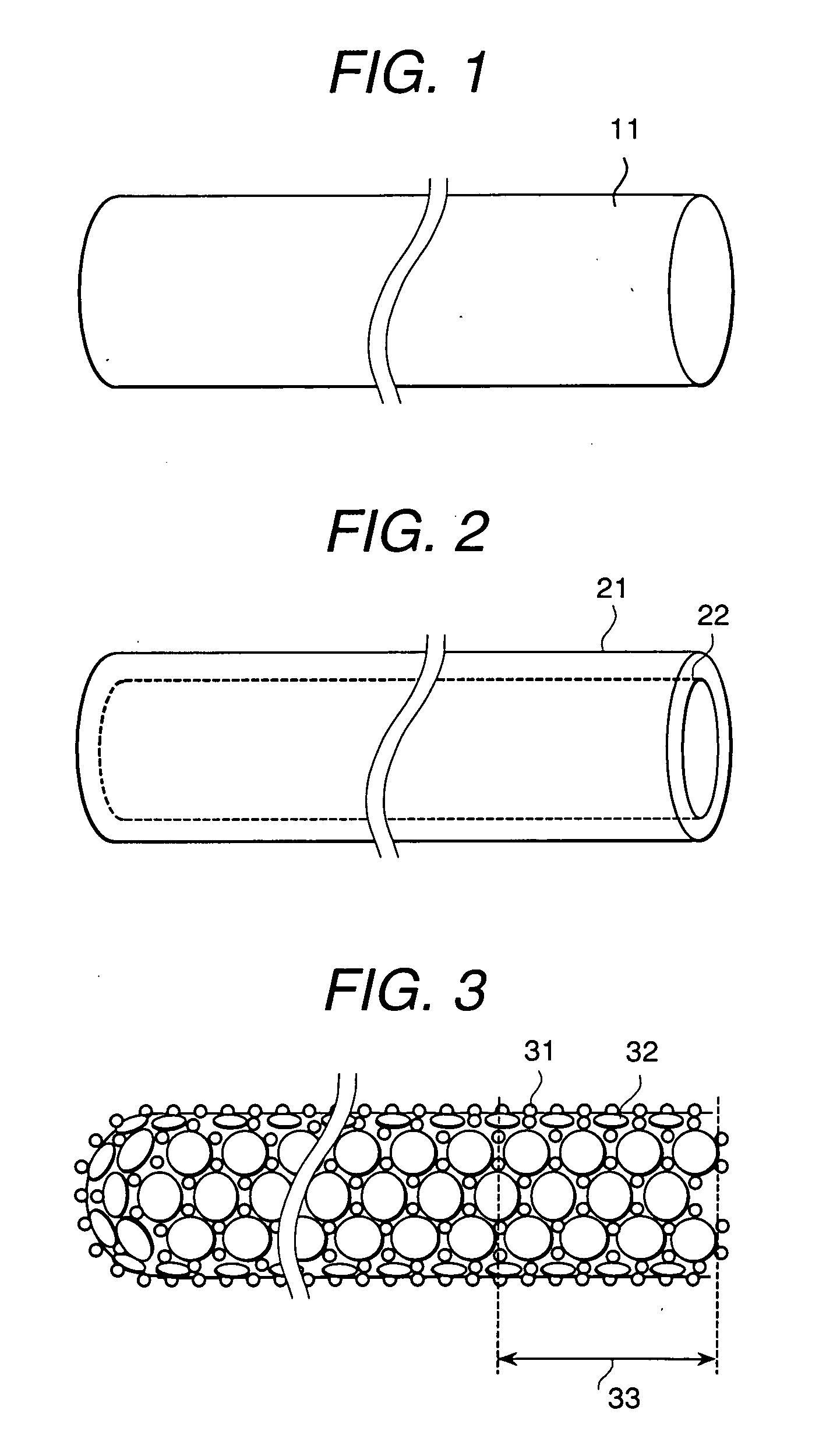

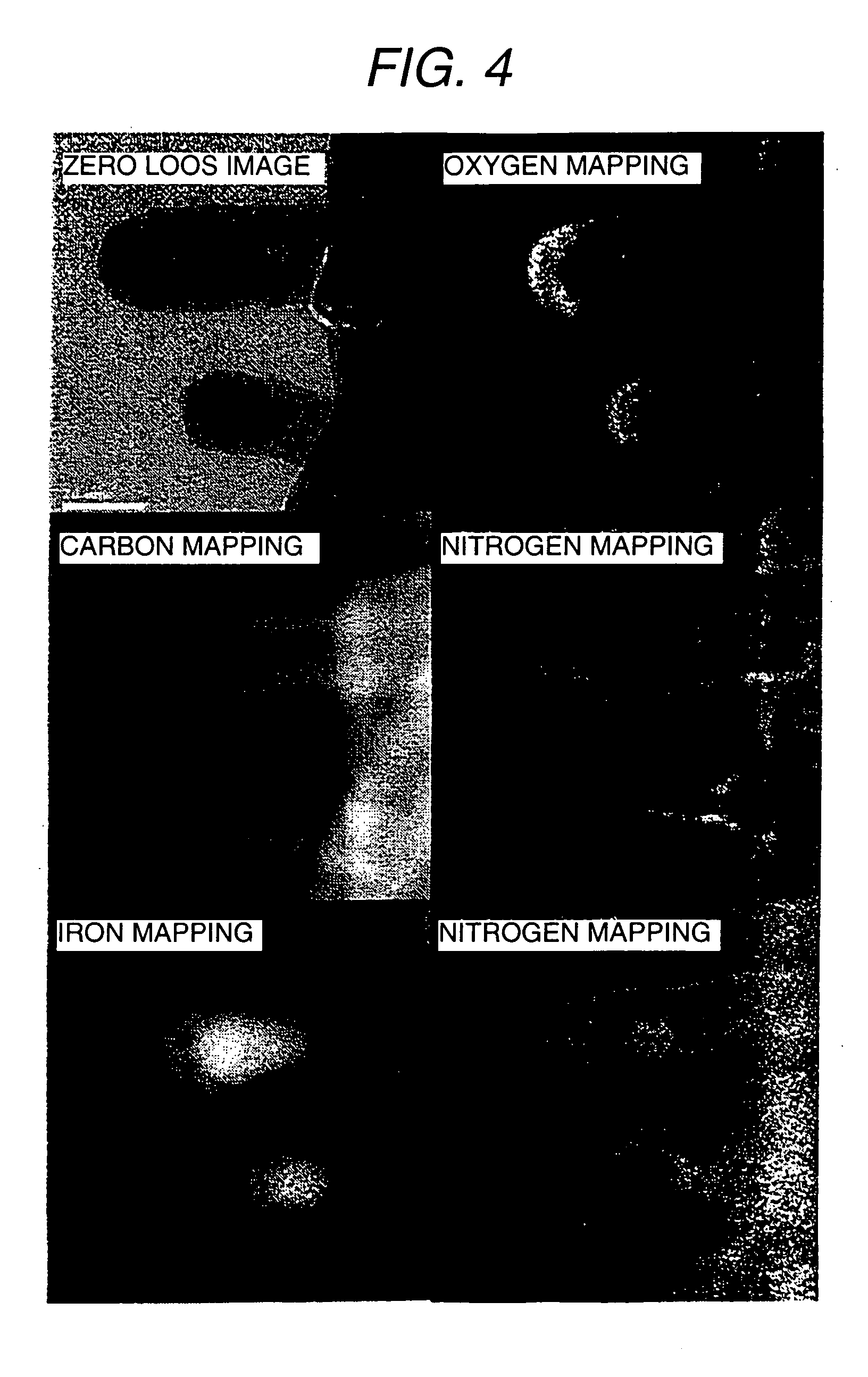

Magnetic carbon nanotube

InactiveUS6878444B2Improve thermal stabilityMaterial nanotechnologyNanomagnetismMagnetic carbonValence electron

A carbon nanotube which exhibits ferromagnetism without a ferromagnetic metal imparted thereto and also has high thermal stability is provided. The carbon nanotube is characterized by being doped with nitrogen (which differs from carbon in valence electron) such that the doped nitrogen is segregated in a strip form at one end of the carbon nanotube. The thus doped nitrogen causes the carbon nanotube to have a difference in electron density and to exhibit ferromagnetism. The present invention makes it possible to provide a carbon nanotube exhibiting ferromagnetism without the necessity of imparting any magnetic metal thereto.

Owner:HITACHI LTD

Use of a metal complex as an n-Dopant for an organic semiconducting matrix material, organic of semiconducting material and electronic component, and also a dopant and ligand and process for producing same

ActiveUS8258501B2Final product manufactureGroup 8/9/10/18 element organic compoundsCarbanionSemiconductor materials

Owner:NOVALED GMBH

Doped ceramic powder for use in forming capacitor anodes

InactiveUS7760487B2Liquid electrolytic capacitorsConductive materialValence electronElectrolytic capacitor

An electrolytic capacitor that includes an anode body formed from a powder comprising electrically conductive ceramic particles and a non-metallic element in an amount of about 100 parts per million or more is provided in one embodiment of the invention. The non-metallic element has a ground state electron configuration that includes five valence electrons at an energy level of three or more. Examples of such elements include, for instance, phosphorous, arsenic, antimony, and so forth. The capacitor also comprises a dielectric layer overlying the anode body and an electrolyte layer overlying the dielectric layer.

Owner:AVX CORP

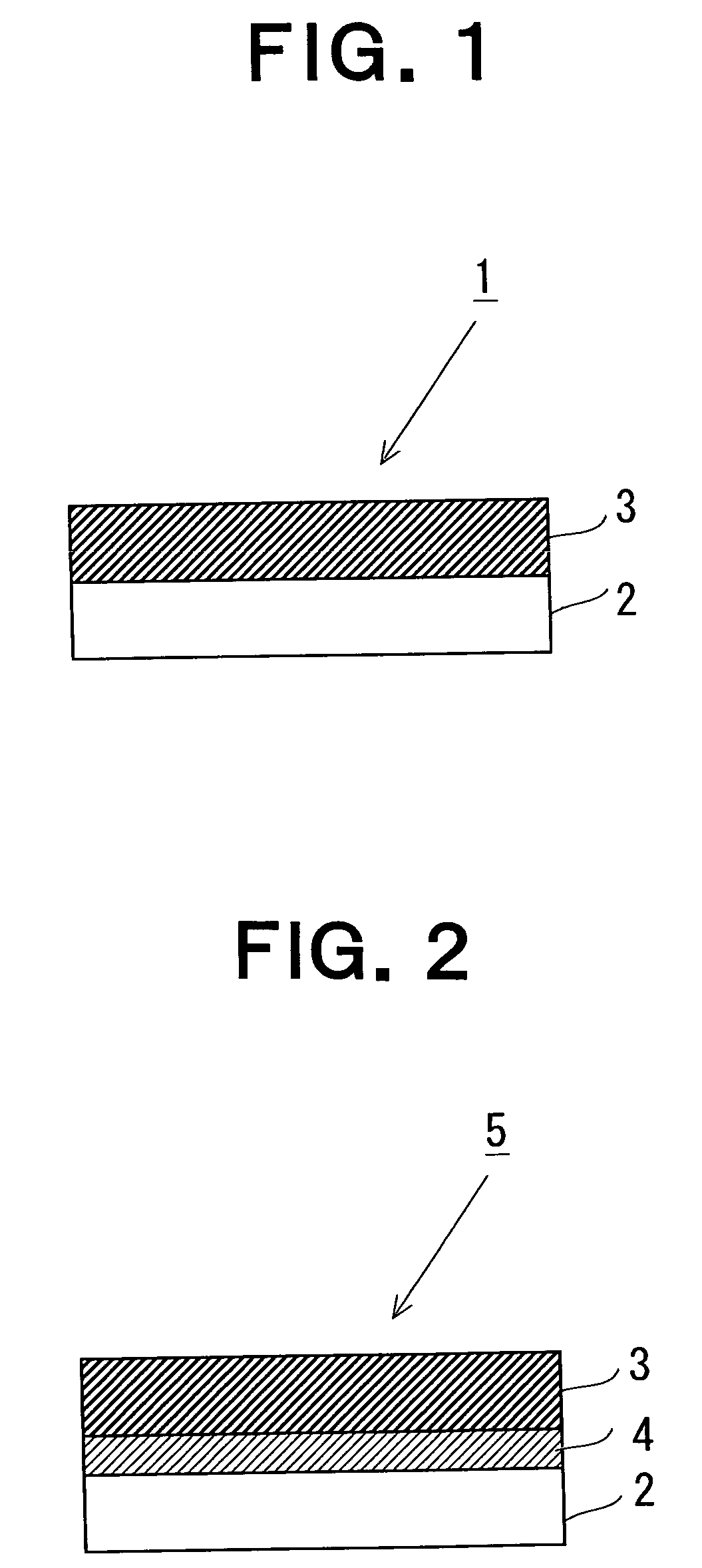

Magnetic thin film, magnetoresistance effect device and magnetic device using the same

InactiveUS20090015969A1Large capacityIncrease speedNanomagnetismChemical vapor deposition applicationGiant magnetoresistanceValence electron

Magnetic thin film having high spin polarizability and a magnetoresistance effect device and a magnetic device using the same, provided with a substrate (2) and Co2MGa1-xAlx thin film (3) formed on the substrate (2), the Co2MGa1-xAlx thin film (3) has a L21 or B2 single phase structure, M of the thin film is either one or two or more of Ti, V, Mo, W, Cr, Mn, and Fe, an average valence electron concentration Z in M is 5.5≦Z≦7.5, and 0≦x≦0.7, shows ferromagnetism at room temperature, and can attain high spin polarizability. A buffer layer (4) may be inserted between the substrate (2) and the Co2FexCr1-xAl thin film (3). The tunnel magnetoresistance effect device and the giant magnetoresistance effect device using this magnetic thin film can attain large TMR and GMR at room temperature under the low magnetic field.

Owner:JAPAN SCI & TECH CORP

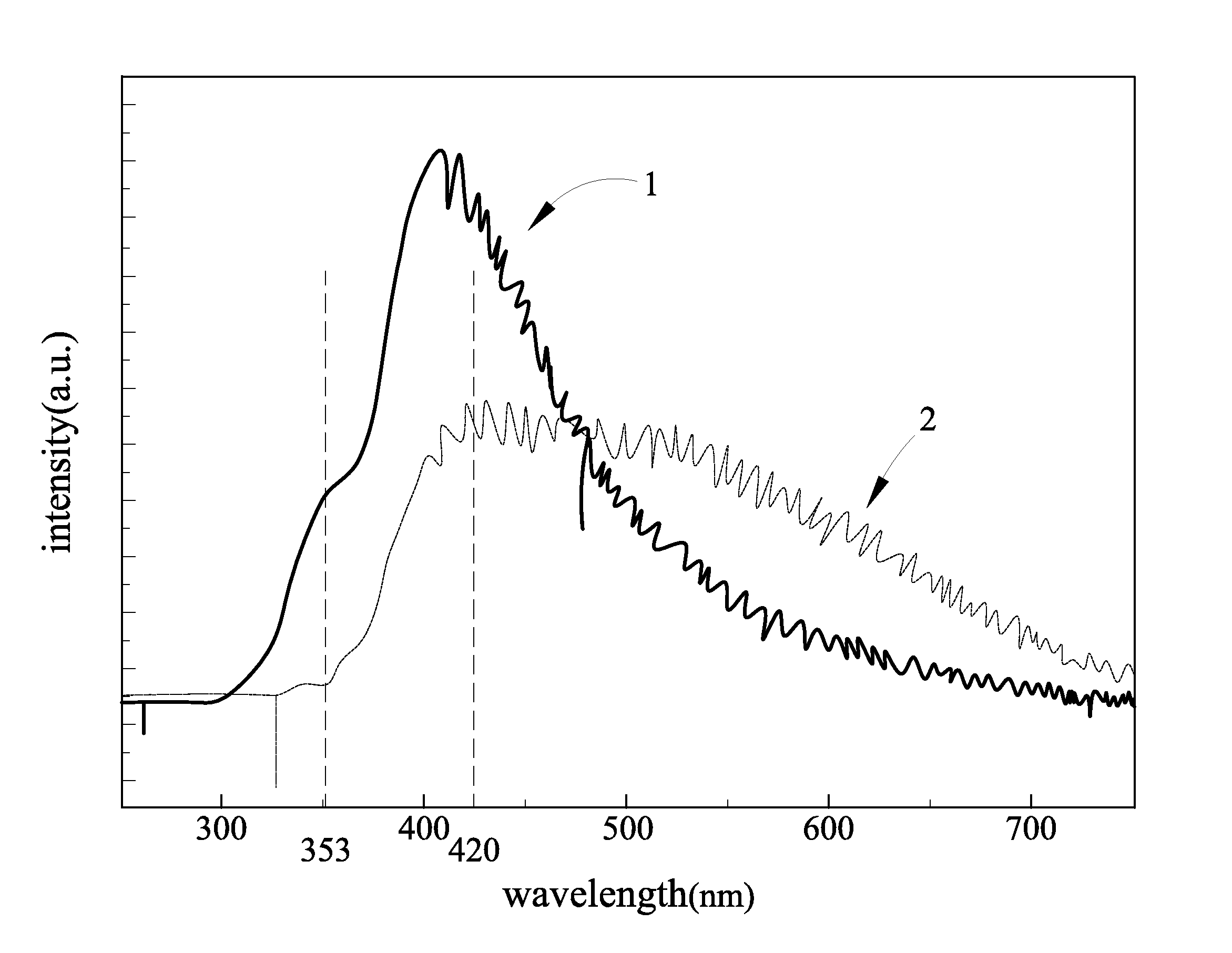

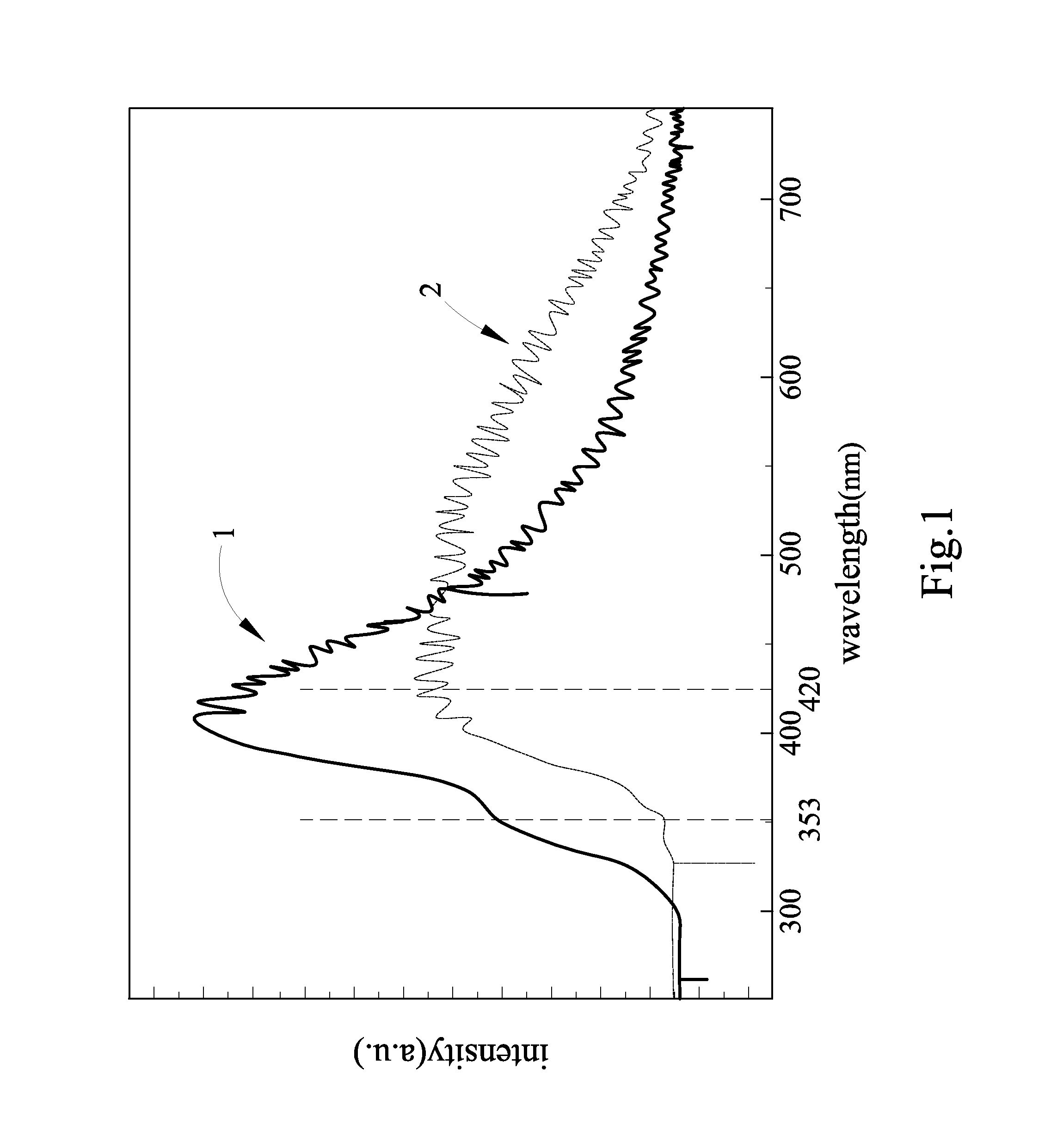

Semiconductor nanoparticle, and fluorescent labeling substance and molecule/cell imaging method by use thereof

InactiveUS20100272650A1Improve emission efficiencyHigh emission intensityUltrasonic/sonic/infrasonic diagnosticsSurgeryDopantLuminous intensity

There is provided semiconductor nanoparticles which exhibit enhanced emission efficiency, excellent emission intensity, reduced variation range of emission characteristics among lots and among particles and are excellent in stability and reproducibility. There is further provided a fluorescent labeling agent and molecule / cell imaging method by use of the same. Semiconductor nanoparticles having an average particle size of 1 to 20 nm is disclosed, comprising a dopant of a heteroatom which is identical in valence electron configuration with a main component atom forming the semiconductor nanoparticles or an atomic pair of the heteroatom, and the dopant is distributed on or near a surface of the semiconductor nanoparticles.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

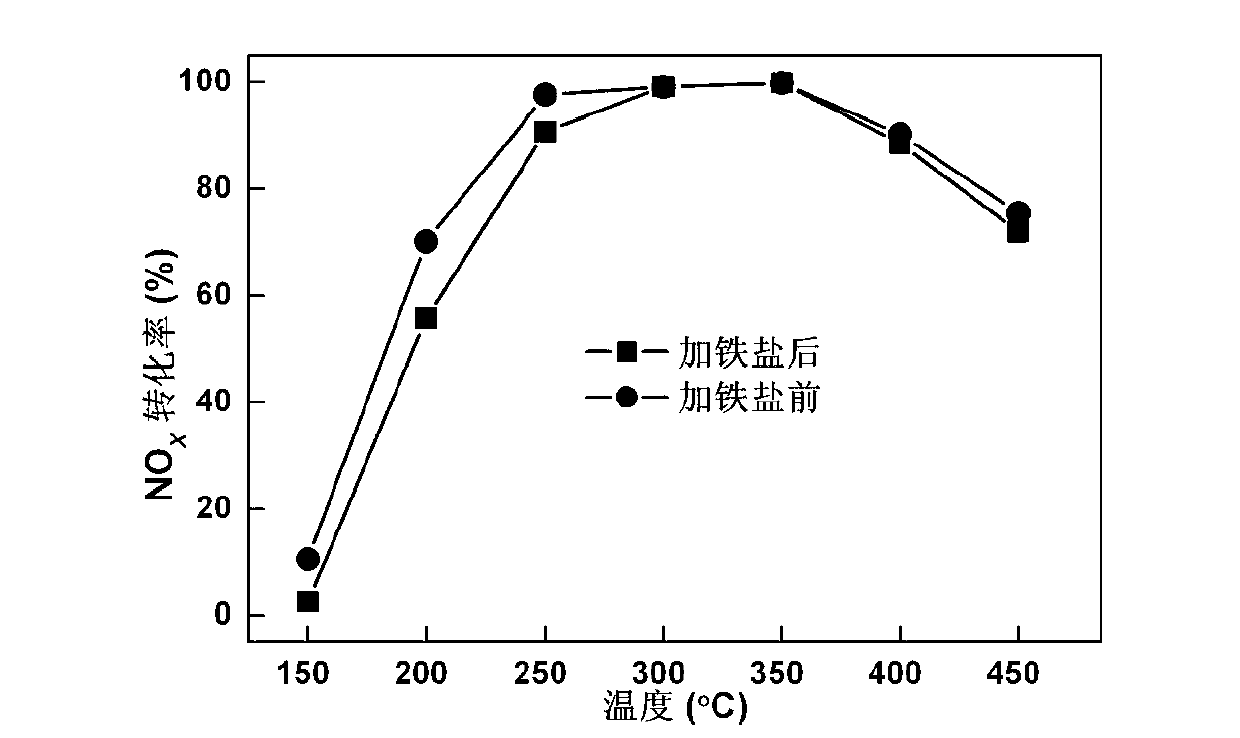

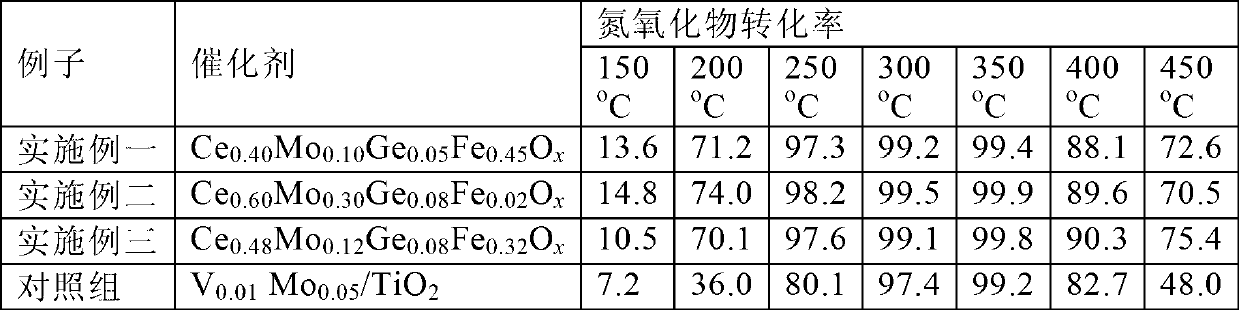

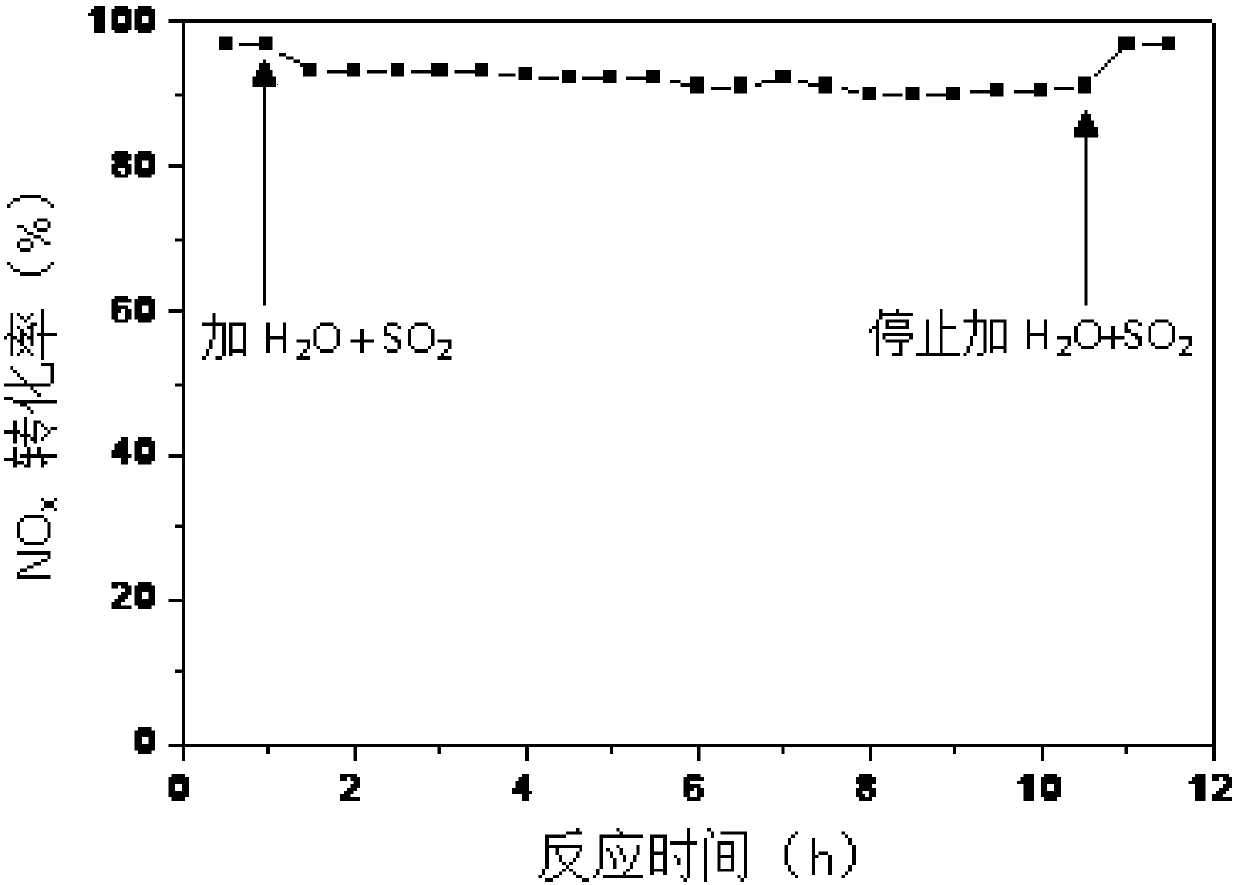

Environmentally-friendly denitration catalyst and preparation method thereof

InactiveCN102989478AGood anti-iron salt fly ash deactivation performanceNon-toxicDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsValence electronSlurry

The invention relates to an environmentally-friendly denitration catalyst which has the expression formula of CeMoGeFeOx, wherein the molar ratio among all the elements Ce, Mo, Ge and Fe is (0.40-0.65):(0.05-0.23):(0.05-0.10):(0.50-0.02), and x is confirmed by balancing positive and negative valence electrons of all atoms. A preparation method of the environmentally-friendly denitration catalyst comprises the following steps of: step 1, dissolving cerous nitrate and ammonium molybdate into water, adding a cosolvent into the solution to form a transparent solution, then dissolving germanium oxide and ferric nitrate into water, evenly stirring and then mixing; step 2, adding ammonium carbonate solution into the mixed solution dropwise and stirring to obtain slurry; step 3, putting the slurry into a centrifugal machine for centrifuge; and step 4, drying and roasting the cleaned precipitate to obtain the environmentally-friendly denitration catalyst. The environmentally-friendly denitration catalyst has the purification efficiency for the nitric oxide reaching up to 65-100% at the temperature of 200-450 DEG C; and the environmentally-friendly denitration catalyst is environmentally-friendly and free from toxic effects, and has good performances of resisting SO2 toxication and molysite class fly ash inactivation.

Owner:TSINGHUA UNIV

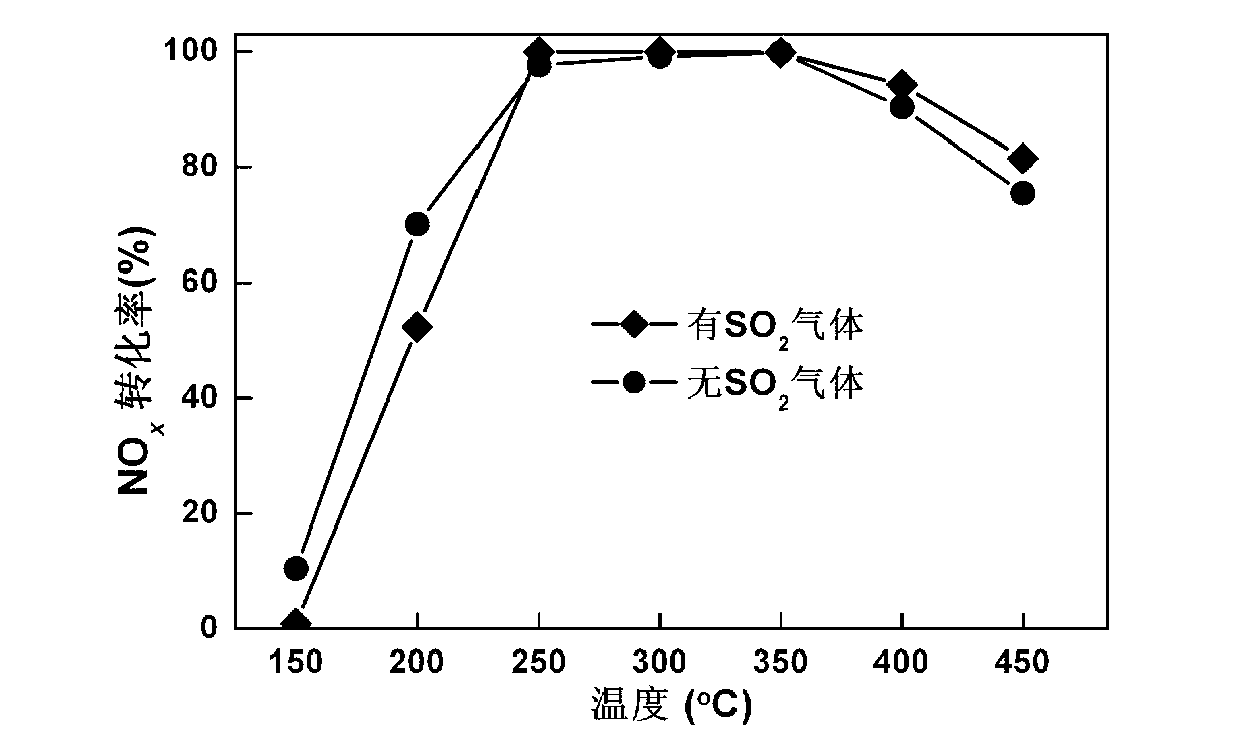

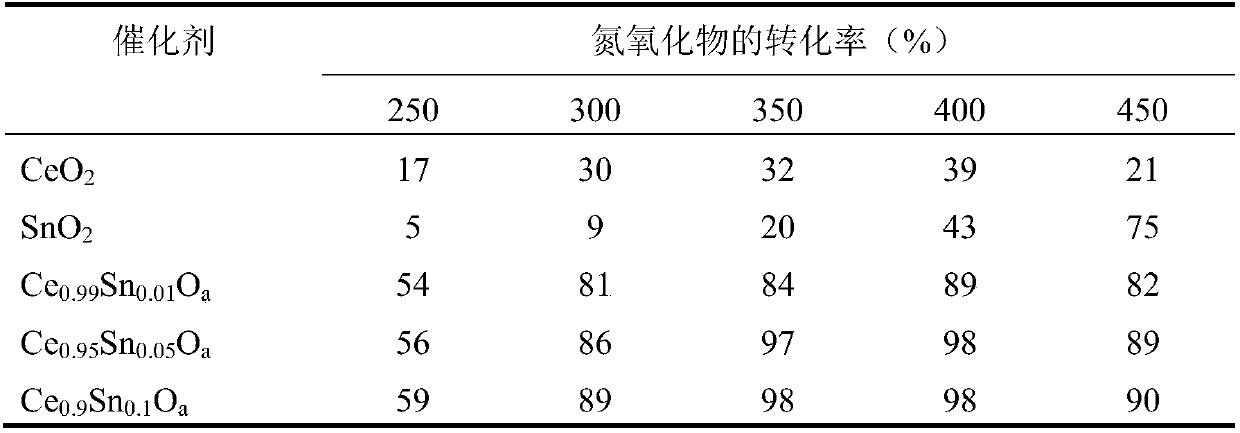

Cerium-tin composite oxide denitration catalyst as well as preparation method and application thereof

InactiveCN107649116AStrong synergistic catalytic effectHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsValence electronCerium

The invention provides a cerium-tin composite oxide denitration catalyst as well as a preparation method and application thereof. The catalyst has the following chemical composition of Ce<1-x>SnxOa, wherein x is greater than or equal to 0.01 but smaller than or equal to 0.1; a is determined by positive and negative valence electron balance. The composite oxide denitration catalyst is prepared by ahydro-thermal method; through the addition of the trace Sn, the obvious cooperated effect is achieved between Ce and Sn in the catalyst, so that the advantages of high denitration activity, strong water-resistant and sulfur-resistant performance and the like are realized. The prepared cerium and tin composite oxide denitration catalyst has the advantages that when the air speed is 12,8000h<-1>, in a range being 300 to 450 DEG C, the purification efficiency of nitrogen oxide (NOx) reaches 81 to 98 percent; the denitration catalyst can be used for purifying the NOx in the fixed source smoke gasand diesel engined car tail gas; wide application prospects are realized.

Owner:BEIJING UNIV OF CHEM TECH

Magnetic sensor

ActiveUS8362768B2Improve accuracySimple structureAnalysis using optical pumpingElectric/magnetic detectionValence electronOptical pumping

A magnetic sensor for measuring a magnetic field using an optical pumping method includes a first gas in which a valence electron is composed of an odd number of atoms or ions, a probe light incidence device which causes first probe light including straight polarized light to be incident on the first gas, a second gas in which a valence electron arranged on an optical path of second probe light that is the first probe light transmitted through the first gas is composed of an odd number of atoms or ions, a pumping light incidence device which causes first pumping light including first circular polarized light to be incident on the first gas and second pumping light including second circular polarized light to be incident on the second gas, and a detector which detects a rotation angle of a polarization plane of the first probe light and a polarization plane of third probe light that is the second probe light transmitted through the second gas.

Owner:COLUMBIA PEAK VENTURES LLC

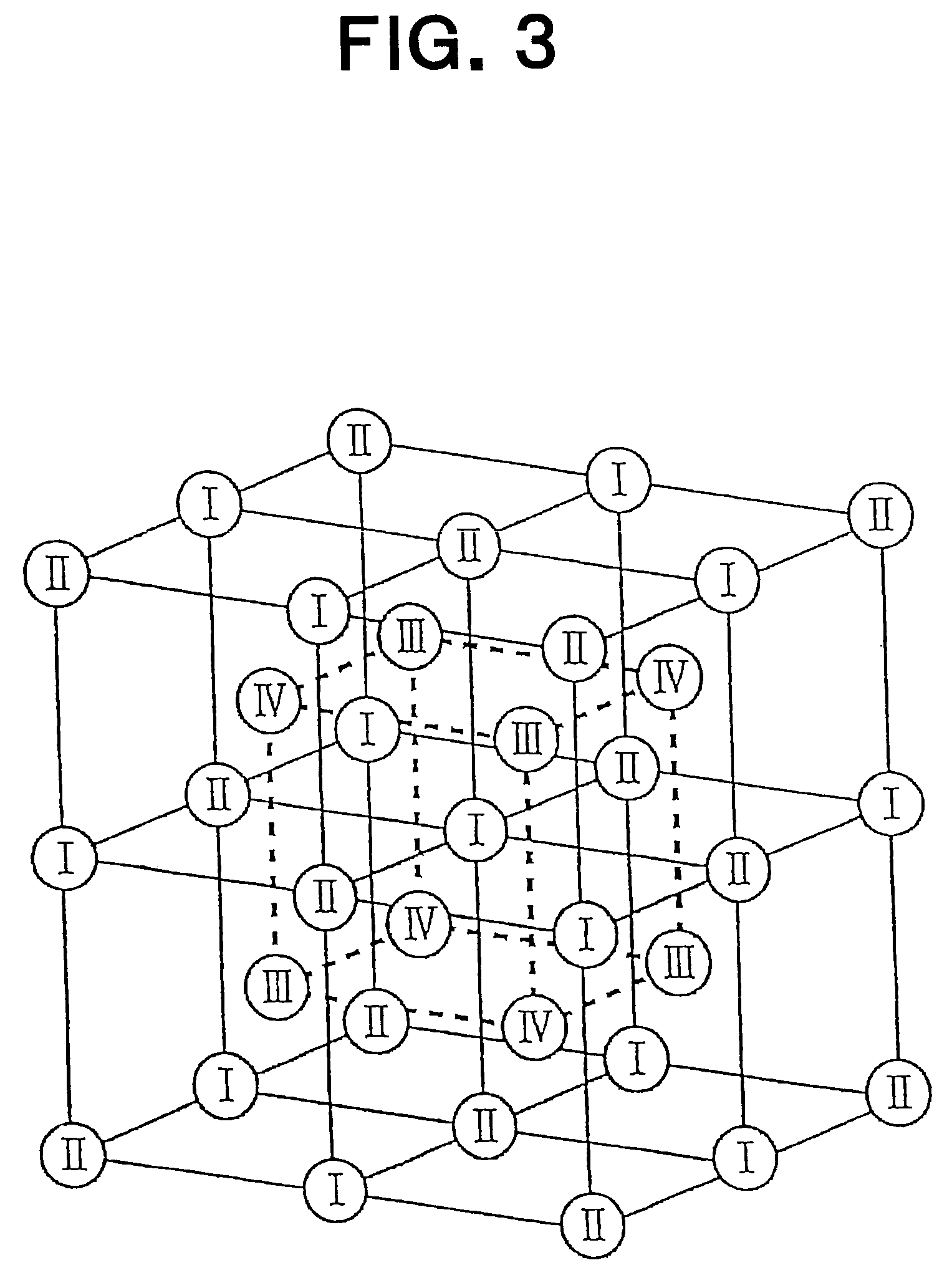

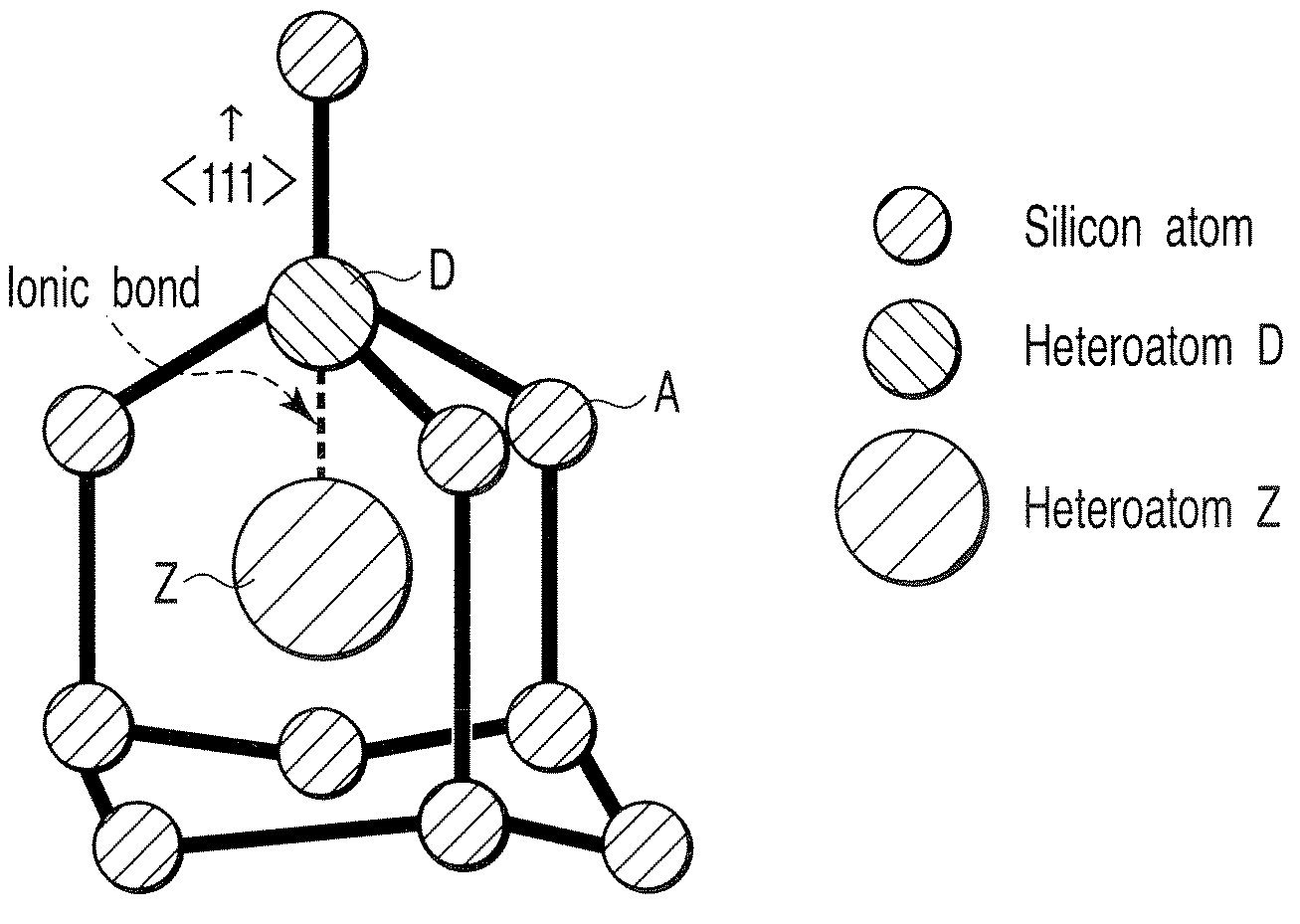

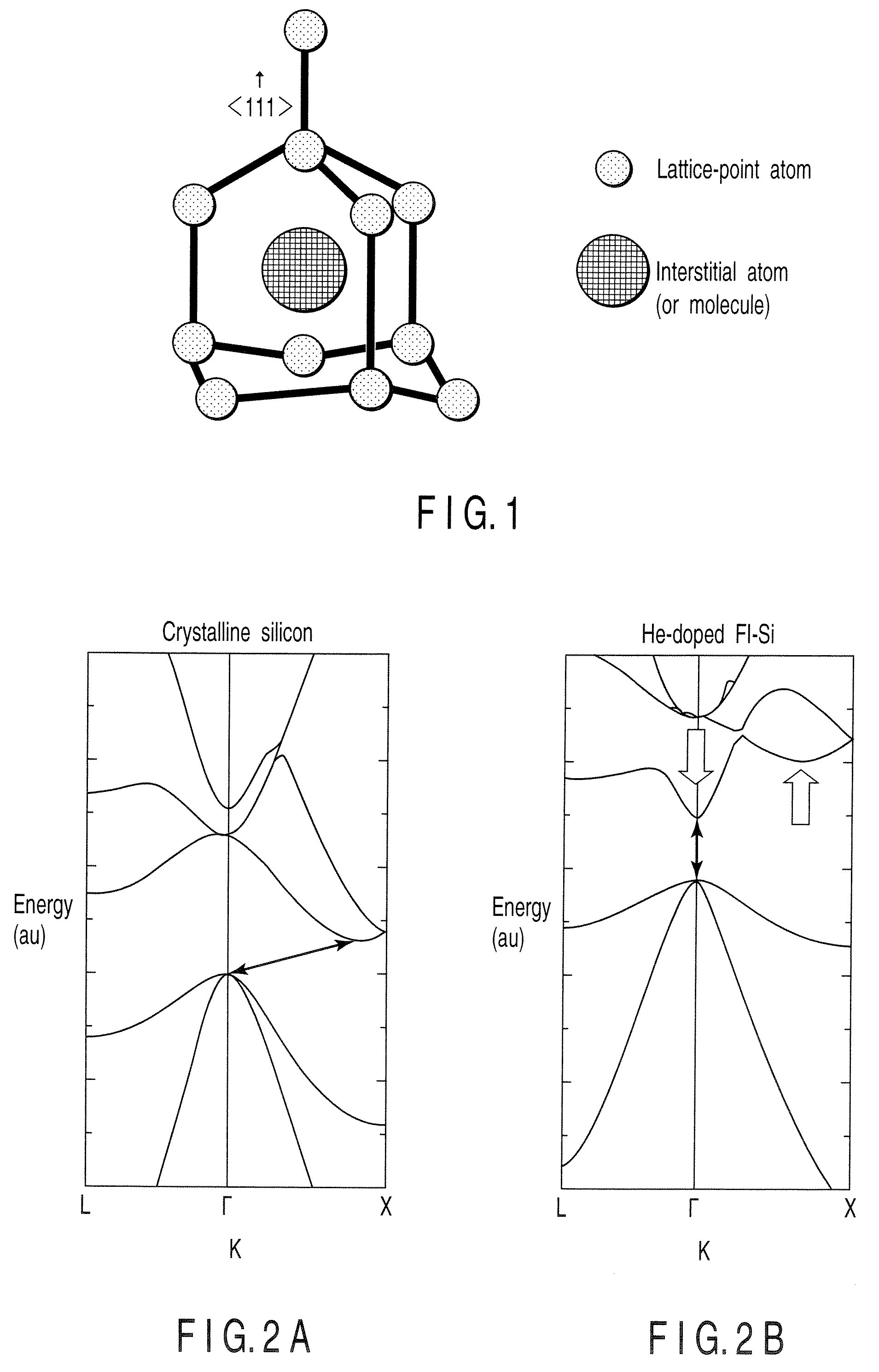

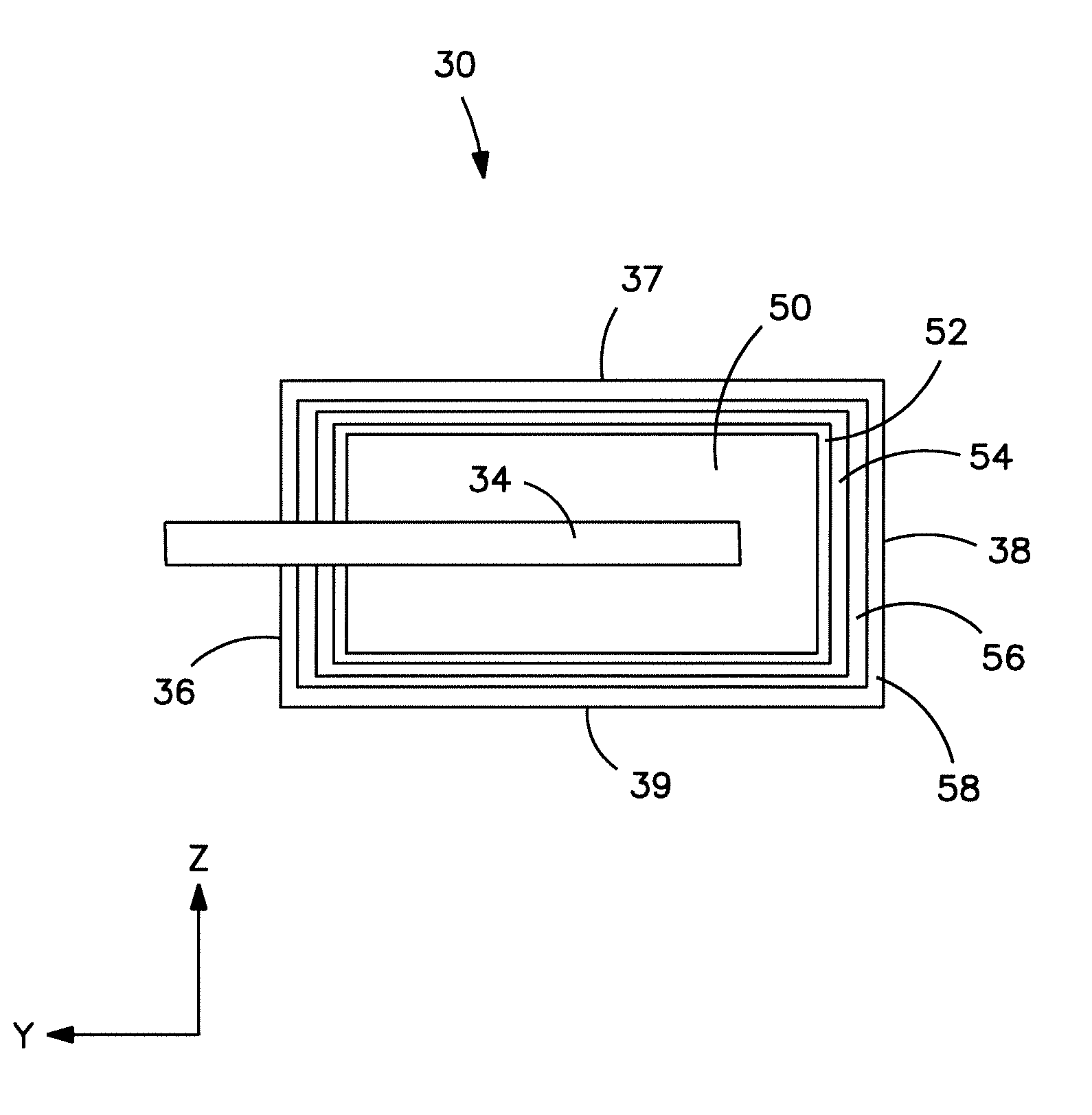

Light emitting device with filled tetrahedral (FT) semiconductor in the active layer

A light emitting device includes an active layer including atoms A of a matrix semiconductor having a tetrahedral structure, a heteroatom D substituted for the atom A in a lattice site, and a heteroatom Z inserted into an interstitial site positioned closest to the heteroatom D, the heteroatom D having a valence electron number differing by +1 or −1 from that of the atom A, and the heteroatom Z having an electron configuration of a closed shell structure through charge compensation with the heteroatom D, and an n-electrode and a p-electrode adapted to supply a current to the active layer.

Owner:KK TOSHIBA

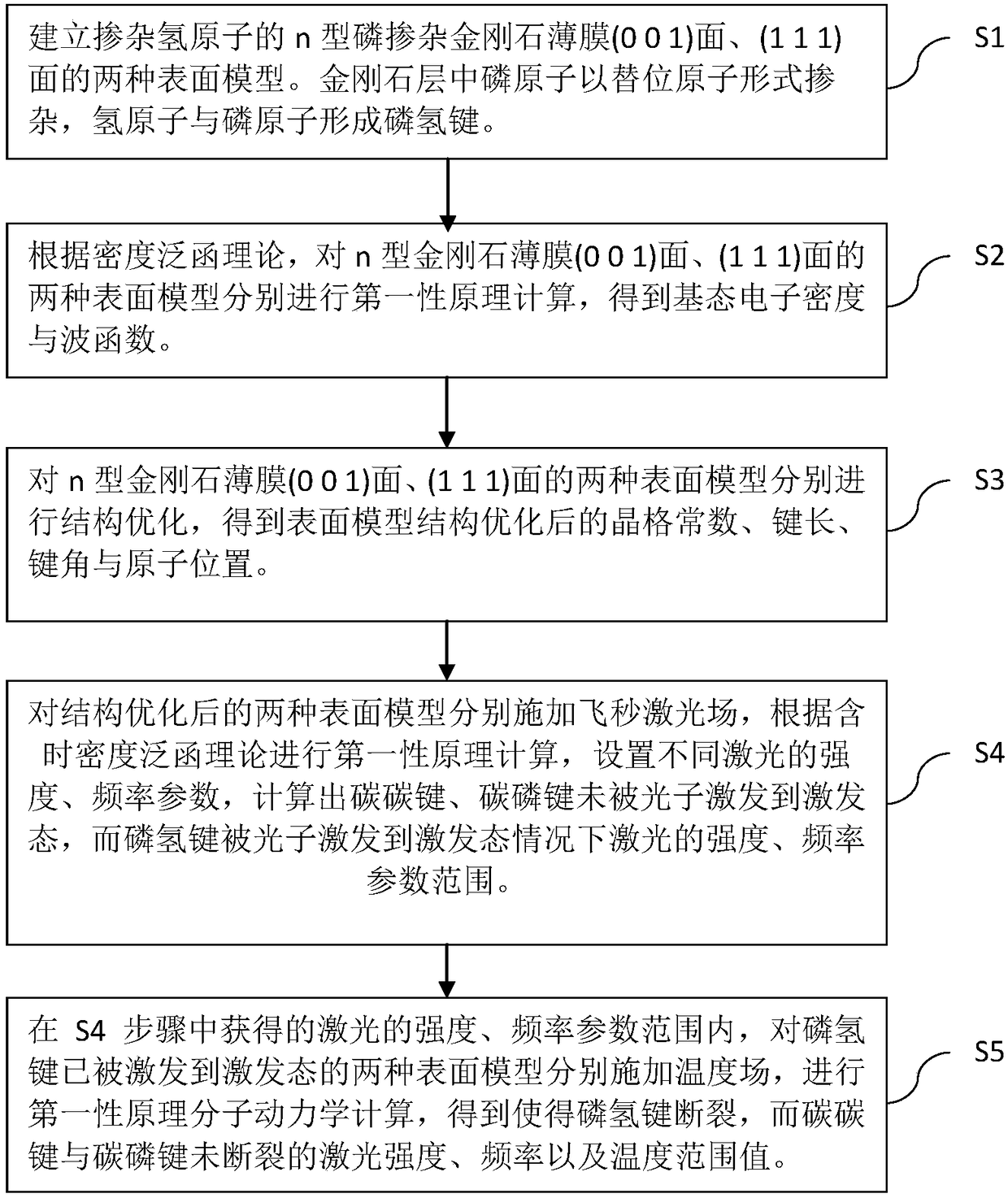

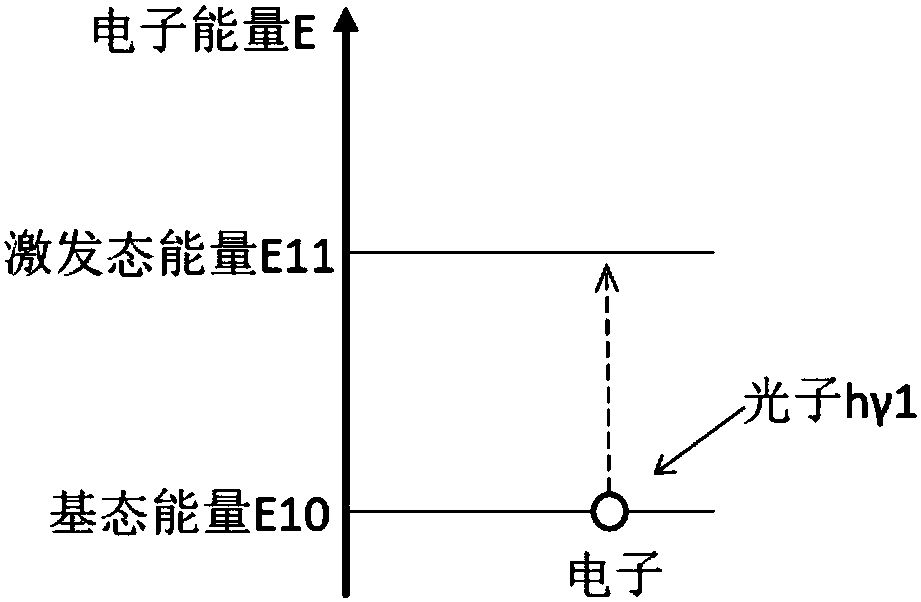

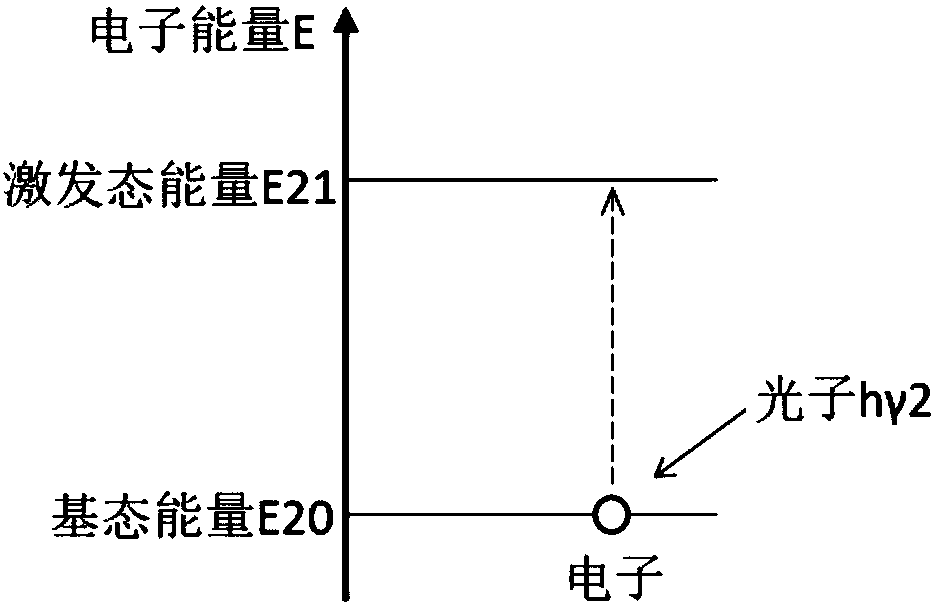

Simulation method for removing hydrogen impurity in n-type phosphorus doping diamond film

ActiveCN108425106AReduce hydrogen contentImprove electrical performanceAfter-treatment detailsChemical vapor deposition coatingValence electronFirst principle

The invention discloses a simulation method for removing the hydrogen impurity in an n-type phosphorus doping diamond film. According to time dependent density functional theory and the molecular dynamics theory, the first principle and molecular dynamics calculation is conducted on an n n-type phosphorus doping diamond film model, photon absorption, valence electron transition and chemical bond breakage in the model are simulated under a laser field and a temperature field, and the method for removing the hydrogen element impurity in the n-type phosphorus doping diamond film is further provided. The strength, the frequency and the range value of the temperature of femtosecond lasers which can break phosphorus and hydrogen bonds and remove the hydrogen impurity are calculated.

Owner:WUHAN UNIV

Electrically conductive thin films

ActiveUS20160141067A1High electron mobilityIncrease electron densityPolycrystalline material growthFrom normal temperature solutionsDopantValence electron

An electrically conductive thin film including: a material including a compound represented by Chemical Formula 1 and having a layered crystal structure,MemAa Chemical Formula 1wherein Me is Al, Ga, In, Si, Ge, Sn, A is S, Se, Te, or a combination thereof, and m and a each are independently a number selected so that the compound of Chemical Formula 1 is neutral; anda dopant disposed in the compound of Chemical Formula 1, wherein the dopant is a metal dopant that is different from Me and has an oxidation state which is greater than an oxidation state of Me, a non-metal dopant having a greater number of valence electrons than a number of valence electrons of A in Chemical Formula 1, or a combination thereof, and wherein the compound of Chemical Formula 1 includes a chemical bond which includes a valence electron of an s orbital of Me.

Owner:SAMSUNG ELECTRONICS CO LTD

Doped Ceramic Powder for Use in Forming Capacitor Anodes

InactiveUS20090103247A1Liquid electrolytic capacitorsConductive materialElectrolysisValence electron

An electrolytic capacitor that comprises an anode body formed from a powder comprising electrically conductive ceramic particles and a non-metallic element in an amount of about 100 parts per million or more is provided in one embodiment of the invention. The non-metallic element has a ground state electron configuration that includes five valence electrons at an energy level of three or more. Examples of such elements include, for instance, phosphorous, arsenic, antimony, and so forth. The capacitor also comprises a dielectric layer overlying the anode body and an electrolyte layer overlying the dielectric layer.

Owner:AVX CORP

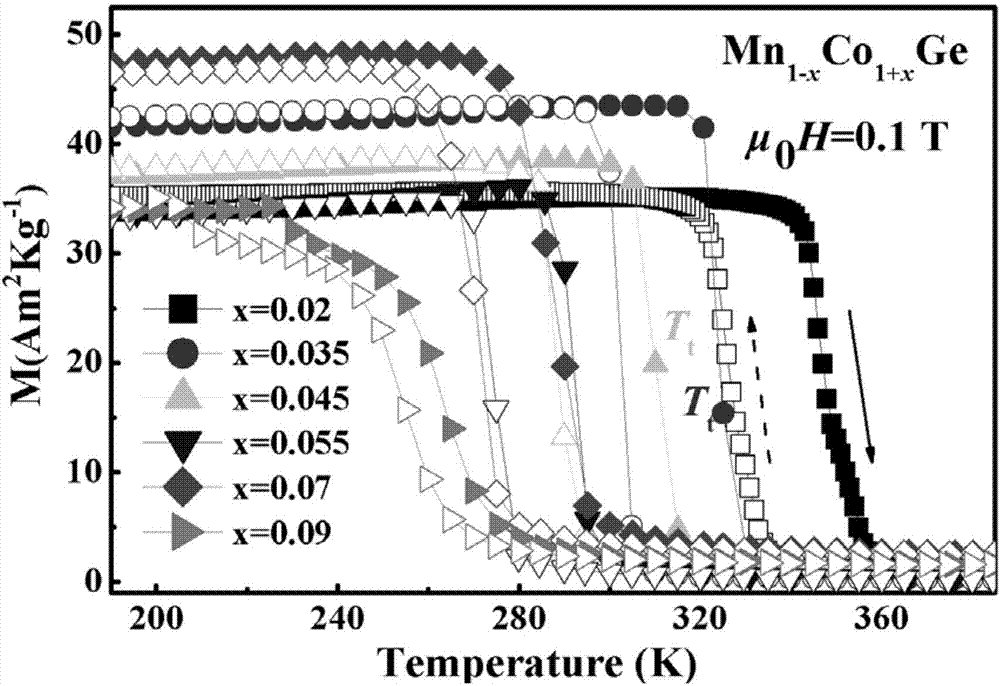

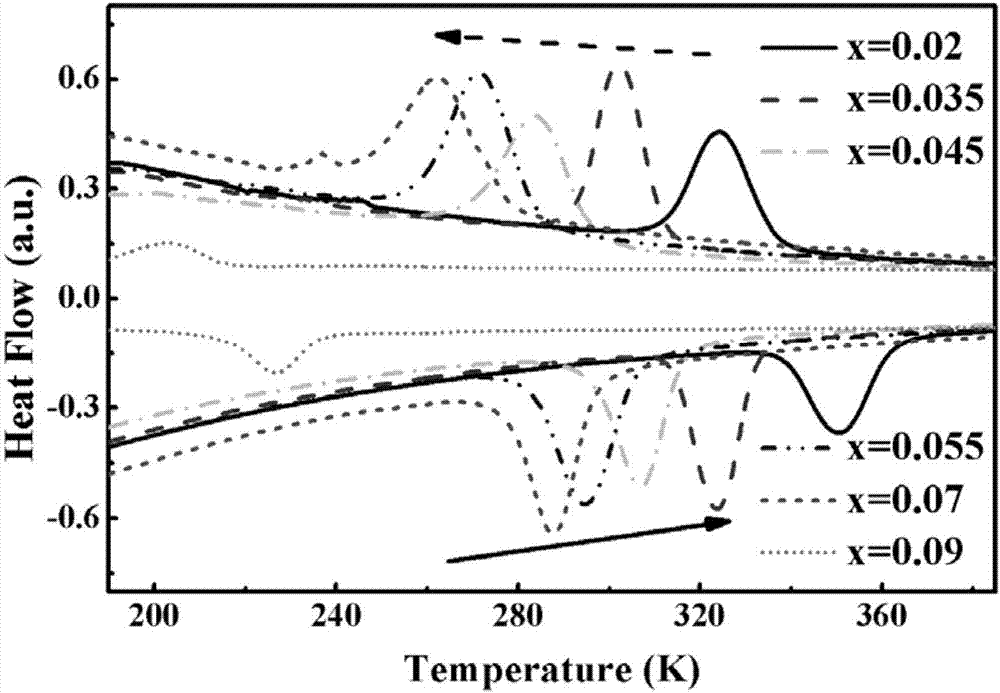

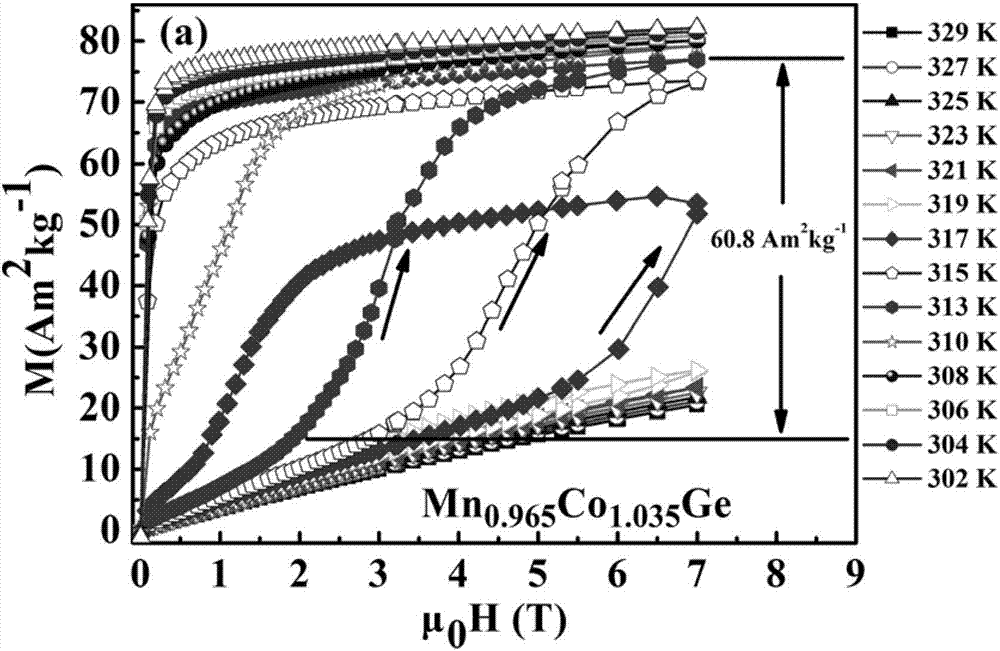

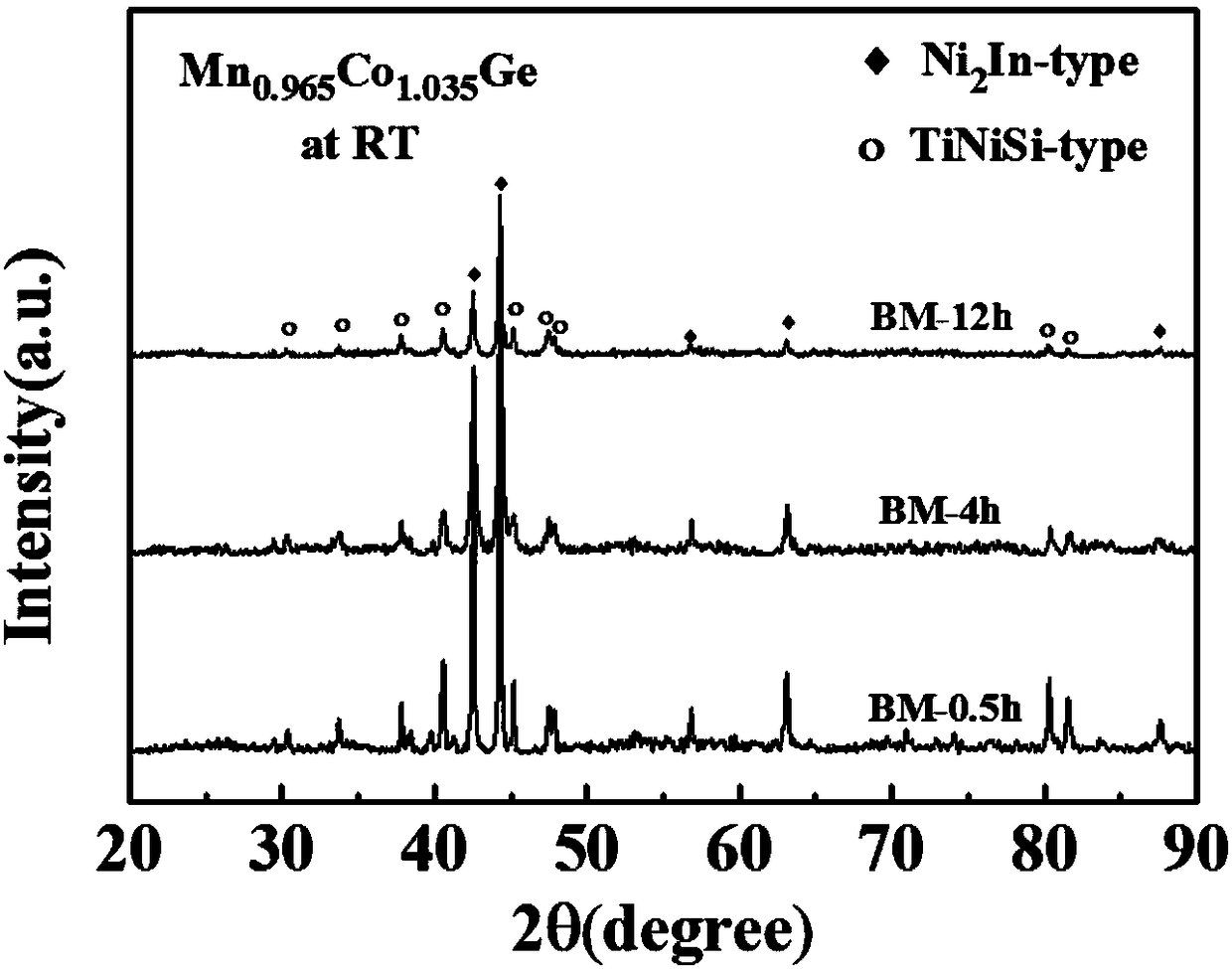

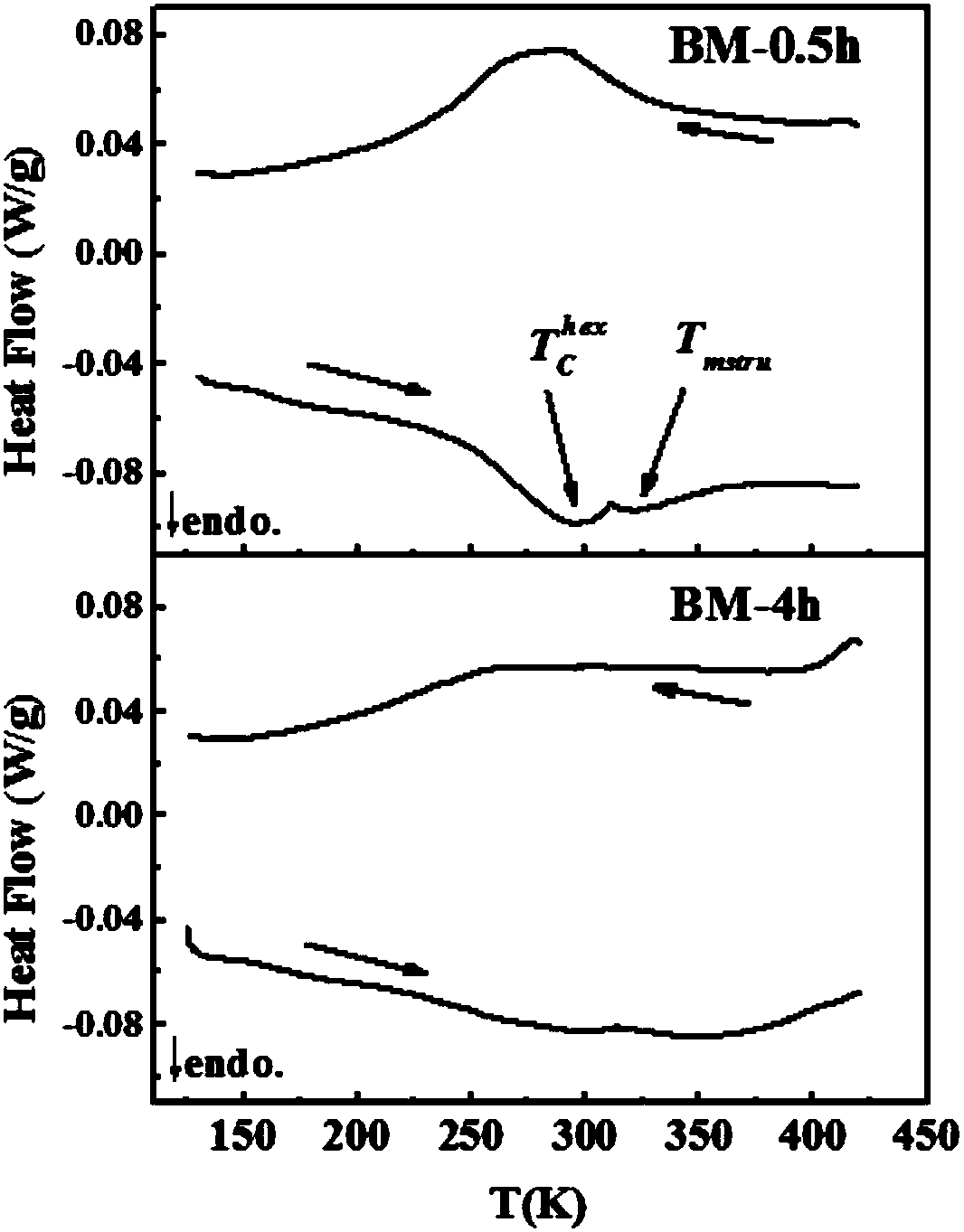

Method for achieving magnetic-field-induced metamagnetic martensite phase change in MnCoGe-based alloy

ActiveCN107164681ALower phase transition temperatureIncrease the concentration of valence electronsInorganic material magnetismMartensite transformationValence electron

The invention discloses a method for achieving magnetic-field-induced metamagnetic martensite phase change in MnCoGe-based alloy. The method specifically comprises the steps that the proportion of Co and Mn is adjusted, alloy components are designed, the concentration e / a of valence electrons of the alloy is increased, the instability of the atomic magnetic moment of Mn is increased, and therefore the sensitivity degree of the magnetic structure phase change to a magnetic field is improved, and the magnetic-field-induced metamagnetic martensite phase change is obtained. The method is simple, convenient, low in energy consumption, low in preparation cost and suitable for industrial production, and the prepared MnCoGe-based alloy has the magnetic-field-induced metamagnetic martensite phase change and excellent magnetic property.

Owner:JIANGXI UNIV OF SCI & TECH

P-type transparent conductive oxides and solar cells with p-type transparent conductive oxides

InactiveUS20120118386A1High light transmittanceIncrease the number ofMaterial nanotechnologyElectrolytic capacitorsAlkaline earth metalValence electron

A p-type transparent conductive oxide and a solar cell containing the p-type transparent conducting oxide, wherein the p-type transparent conductive oxide includes a molybdenum trioxide doped with an element having less than six valence electrons, the element is selected from the group consisting of alkali metals, alkaline earth metals, group III elements, group IV, group V, transition elements and their combinations. Doping an element having less than six valence electron results in hole number increase, and thus increasing the hole drift velocity, and making Fermi level closer to the range of p-type materials. Hence, a p-type transparent conductive material is generated. This p-type transparent conducting oxide not only has high electron hole drift velocity, low resistivity, but also reaches a transmittance of 88% in the visible wavelength range, and therefore it is very suitable to be used in solar cells.

Owner:NATIONAL TSING HUA UNIVERSITY

Magnetic carbon nanotube

InactiveUS20050151536A1Improve thermal stabilityMaterial nanotechnologyNanostructure manufactureMagnetic carbonValence electron

A carbon nanotube which shows ferromagnetism without a ferromagnetic metal imparted thereto and also has high thermal stability is provided. The carbon nanotube is characterized by being doped with nitrogen (which differs from carbon in valence electron) such that the doped nitrogen is segregated in a strip form at one end of the carbon nanotube. The thus doped nitrogen causes the carbon nanotube to have a difference in electron density and to show ferromagnetism. The present invention makes it possible to provide a carbon nanotube showing ferromagnetism without the necessity of imparting any magnetic metal thereto.

Owner:HITACHI LTD

Metallic multicomponent carbides

PendingUS20210147242A1Increase metallic characterImprove toughnessOxy/sulfo carbidesValence electronMaterials science

A multicomponent carbide has at least five transition metals, and a valence electron concentration (VEC) is greater 8.80 electrons. Preferred off-equiatomic multicomponent carbides have five transition metals and a VEC of more than 8.80. Preferred equiatomic multicomponent carbides have five transition metals and a VEC of 9.00 or greater. The valence electron configuration is important for its relationship to the mechanical properties of carbides. Since carbon forms four bonds, when there are more than four valence electrons available from the metals, there are excess electrons in the system. This increases metallic character of bonding and therefore allows for more ductility and higher toughness.

Owner:RGT UNIV OF CALIFORNIA

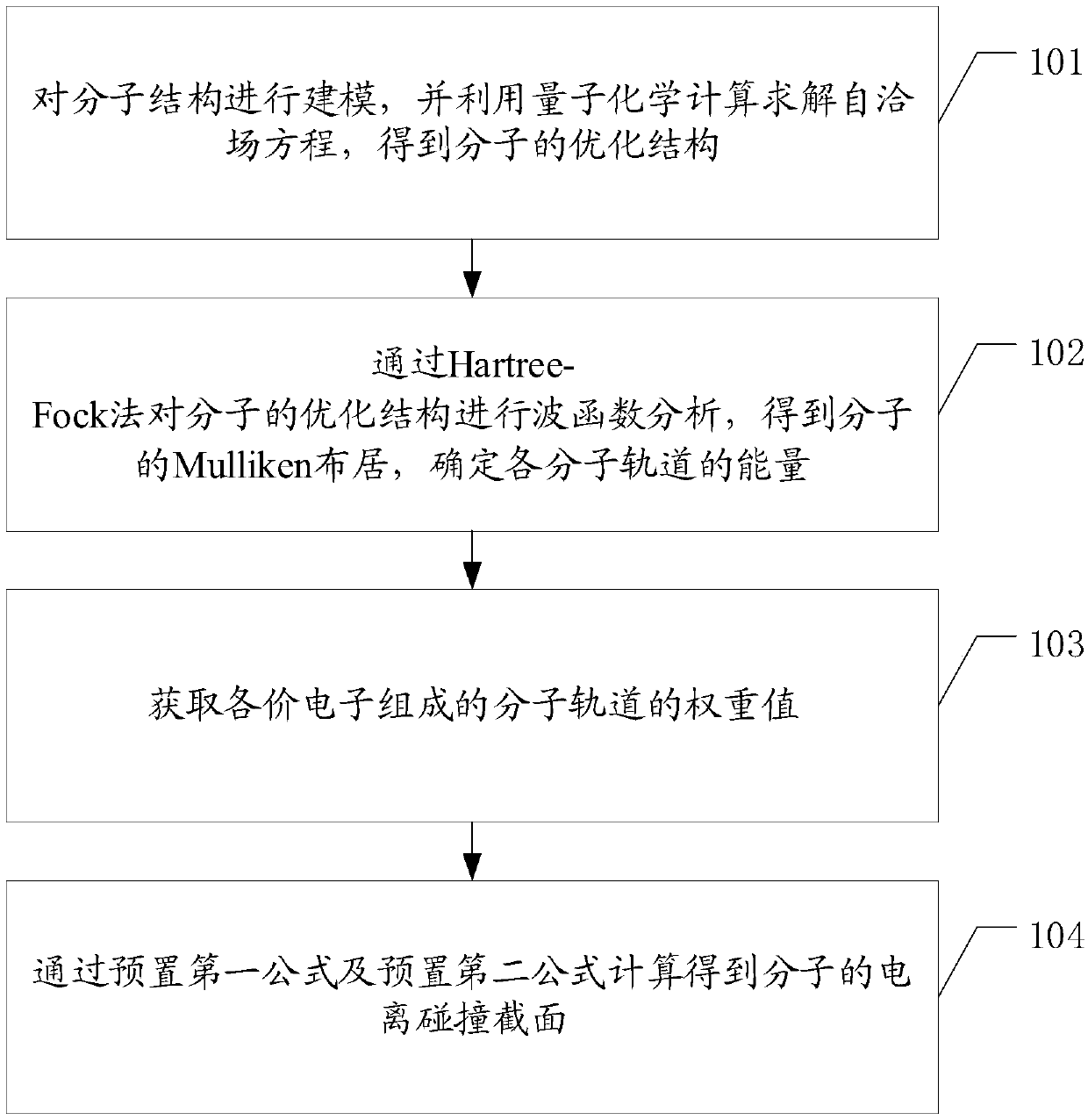

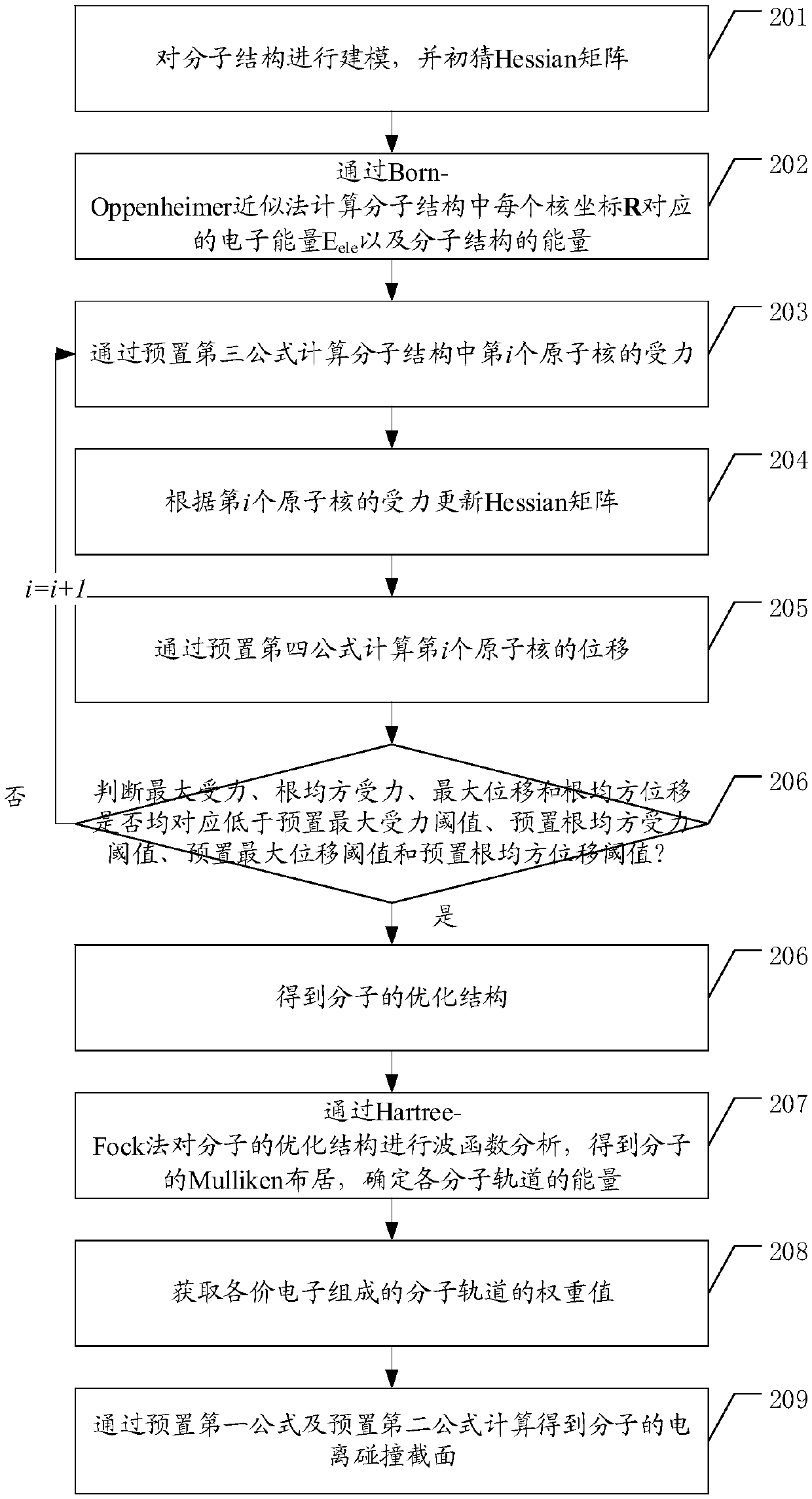

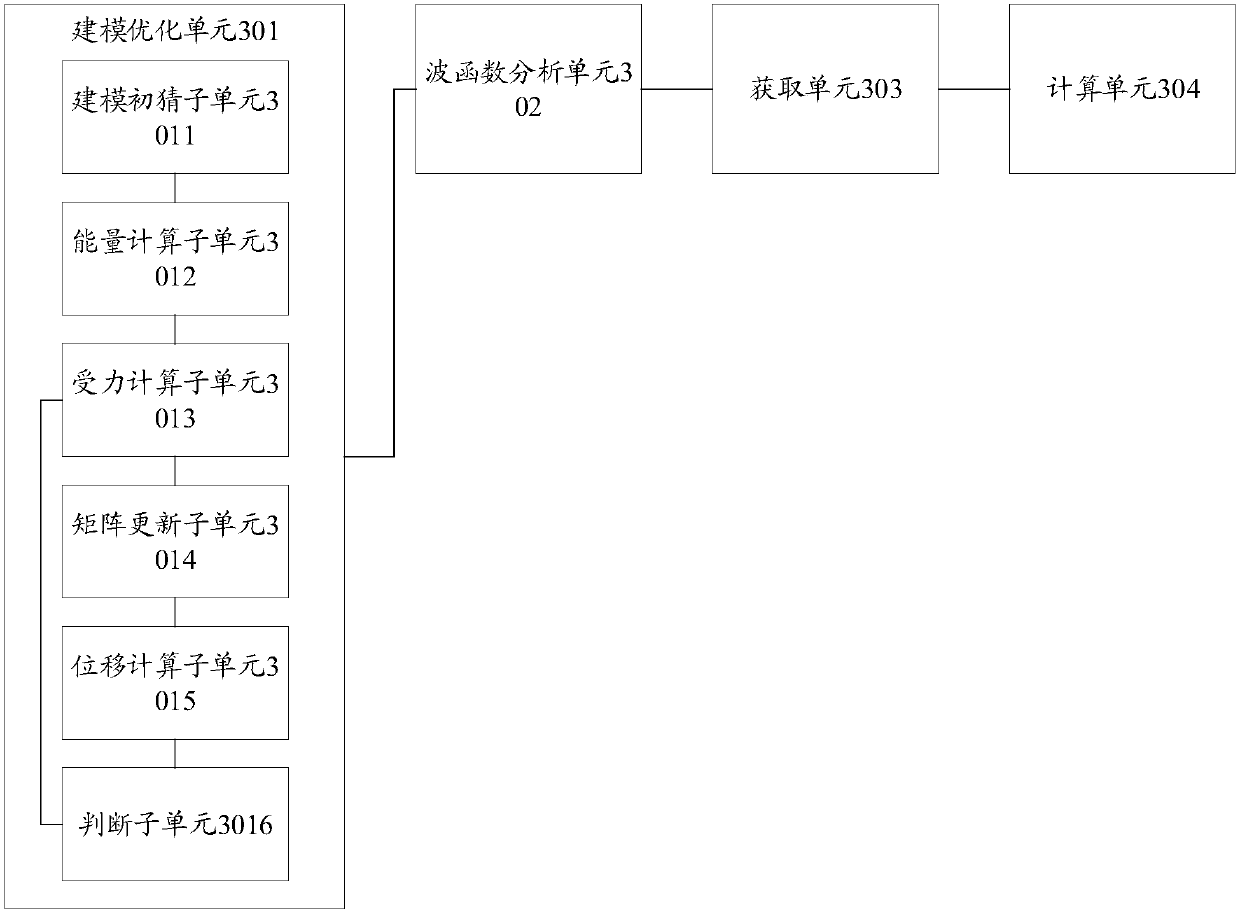

Calculation method and device for molecular ionization collision cross-section

ActiveCN108595820ASimple structureImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsValence electronSelf consistent

The invention discloses a calculation method and device for a molecular ionization collision cross-section. On the basis of a DM formula, the calculation level of quantum chemistry is determined, andan optimal method for a specific system is proposed. The method comprises the steps that S1, modeling is performed on a molecular structure, and quantum chemistry calculation is utilized to solve a self-consistent field equation to obtain an optimal structure of molecules; S2, wave function analysis is performed on the optimal structure of the molecules through a Hartree-Fock method, a Mulliken population of the molecules is obtained, and energy of each molecular orbit is determined; S3, weight values of the molecular orbits composed of all valence electrons are acquired; and S4, the ionization collision cross-section of the molecules is obtained through calculation by use of a preset first formula and a preset second formula.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

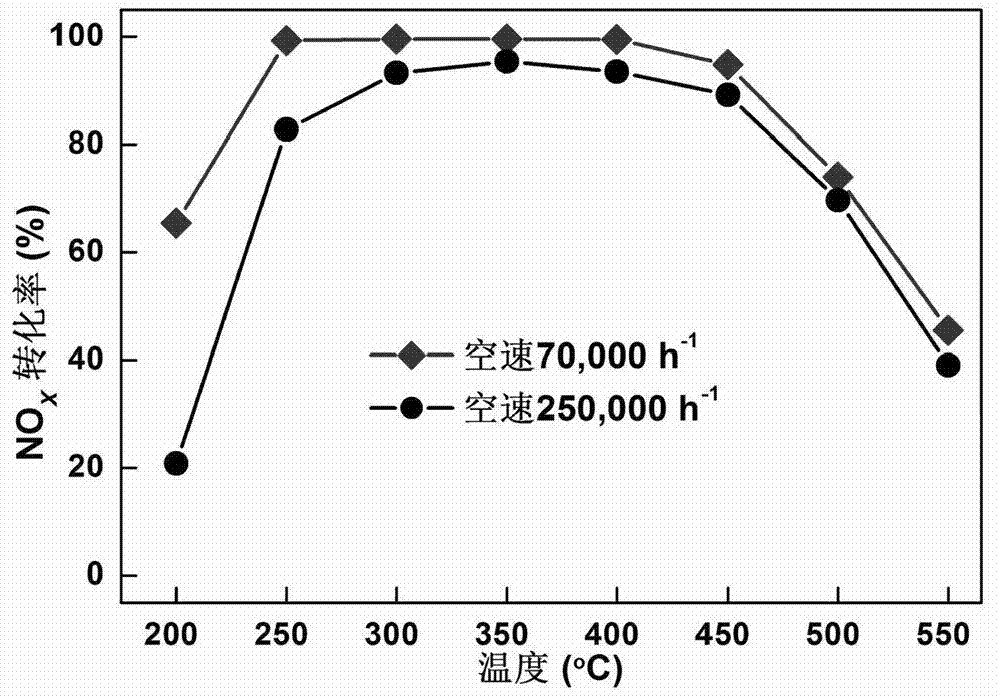

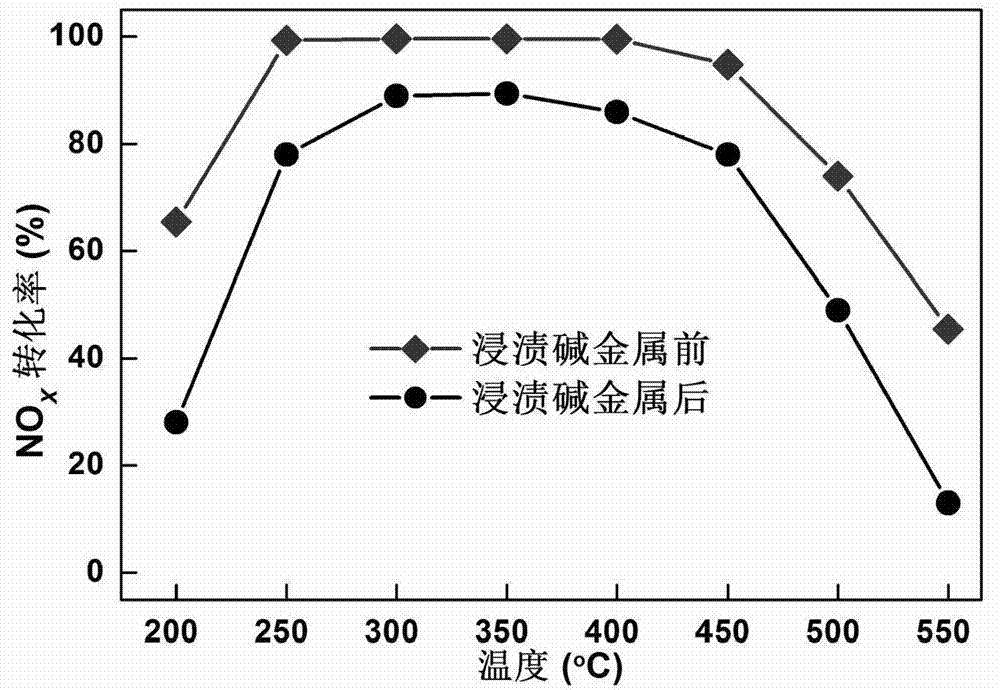

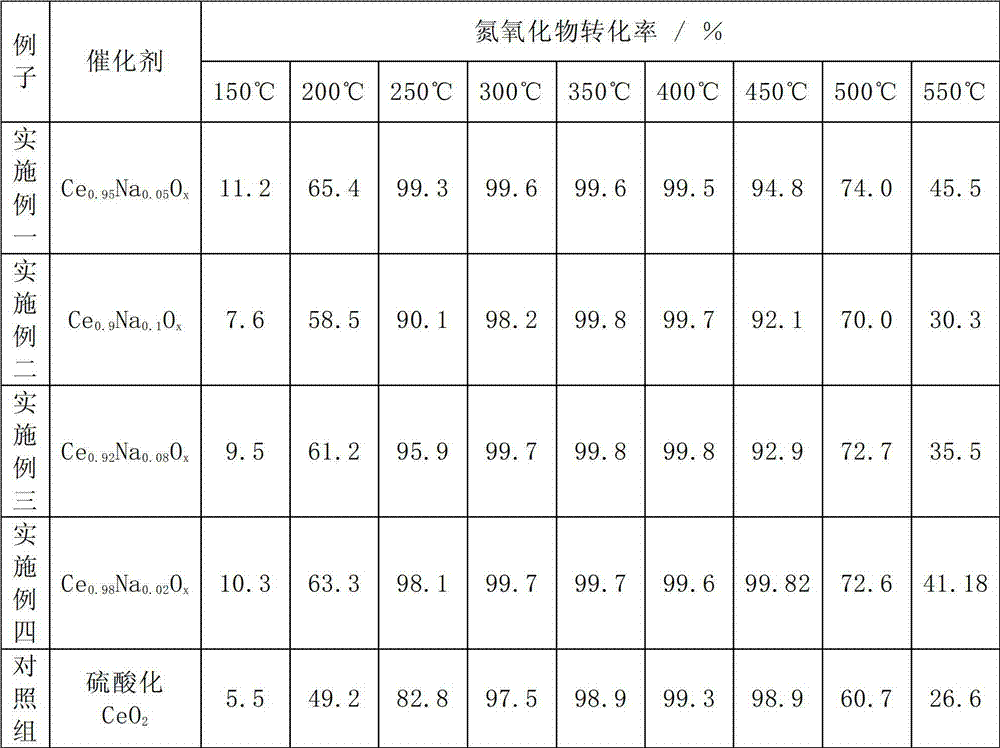

Novel cerium oxide denitration catalyst and preparation method thereof

ActiveCN103007919BImprove efficiencyLow running costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfate radicalsSodium phosphates

The invention discloses a novel cerium oxide denitration catalyst. The novel cerium oxide denitration catalyst has the expression formula of CeNaOx, wherein the molar ratio of Ce to Na is (90-98):(10-2), and x is balanced and determined by positive and negative valence electrons in each atom. The preparation method of the catalyst comprises the following steps of: 1, dissolving cerous sulfate, sodium phosphate and cerium sulfate in water at normal temperature, and stirring to form a transparent solution; 2, transferring the prepared solution into a hydrothermal reaction kettle, and adding deionized water; 3, sealing the hydrothermal reaction kettle and transferring the hydrothermal reaction kettle to an oven for heating and reacting, reducing the temperature, performing centrifugal separation, and cleaning until no sulfate radical is detected by using deionized water; and 4, drying and roasting the centrifuged precipitate, thereby obtaining the catalyst. The metallic oxide catalyst is in the range of 200-500 DEG C, and the purification efficiency of nitric oxide is 71-100 percent; and the composite oxide catalyst has high high-altitude-resistant speed and good alkali-resistant metal poisoning performance, the efficiency is greatly improved, and the operating cost can be obviously reduced.

Owner:江苏中创清源科技有限公司

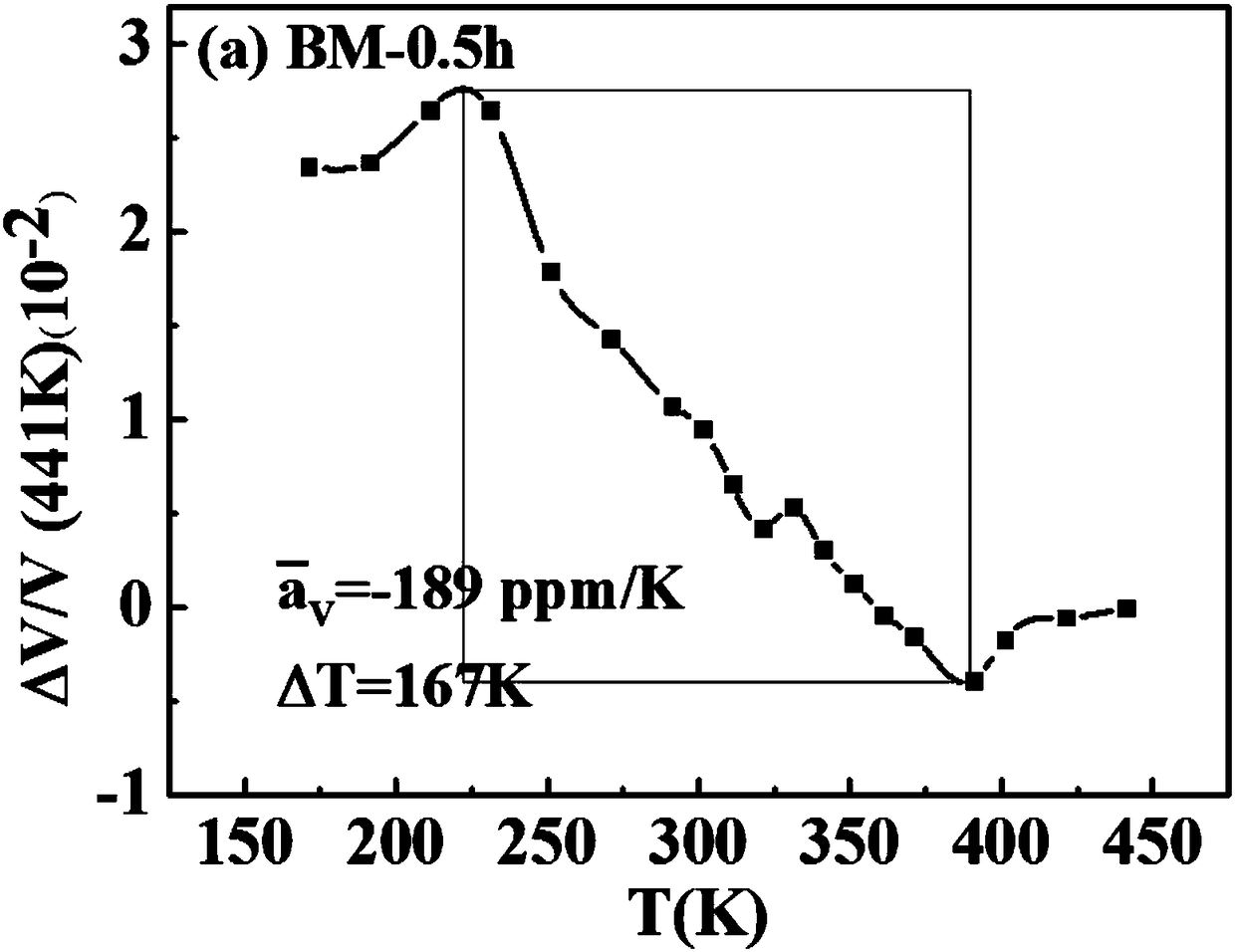

Method for realizing giant negative thermal expansion of wide temperature area in MnCoGe base alloy

The invention discloses a method for realizing giant negative thermal expansion of a wide temperature area in a MnCoGe base alloy, and belongs to the technical field of negative thermal expansion of MnCoGe base alloys. The method uses Co, Fe or Ni for replacing Mn to increase the valence electron concentration e / a; specific components Mn1-xCo1+xGe are designed, wherein c is not more than 0.15 andnot less than 0.01; the martensite phase change temperature of the alloy is lowered; the martensite phase change is coupled with the magnetic phase change to generate first-grade magnetic structure phase change at room temperature; and the method comprises the following steps: (S1) burdening is performed; (S2) arc smelting is performed to obtain Mn1-xCo1+xGe sample ingots; and (S3) aftertreatmentis performed on the Mn1-xCo1+xGe sample ingots obtained in the step (S2) to obtain Mn1-xCo1+xGe powder. The method is simple in preparation and low in cost; and obtained MnCoGe base alloy samples achieve negative thermal expansion of the wide temperature area near the room temperature.

Owner:JIANGXI UNIV OF SCI & TECH

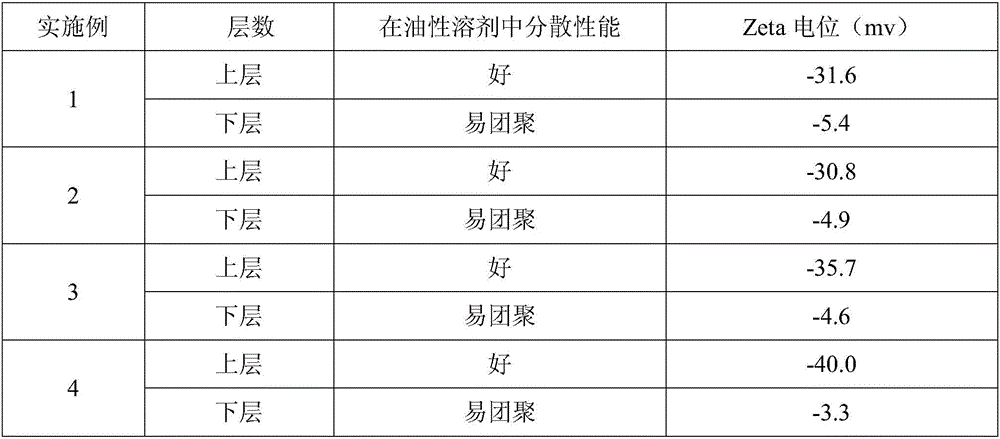

Screening method of oil soluble graphene

The invention discloses a screening method of oil soluble grapheme. The method consists of: mixing graphene, base oil and a dispersant into a uniform solution, then putting the solution in a wall breaking machine to perform processing, subjecting the processed solution to centrifugal separation to remove the sediment so as to obtain a suspension. Compared with submerged graphene, the graphene in the separated suspension can be easier to remove surface valence electrons, i.e. better realizing uniform dispersion with an oil solvent. The method disclosed by the invention can screen out oil soluble graphene capable of removing surface valence electrons, and provides an important raw material preparation process for the graphene lubricating oil preparation field.

Owner:CHONGQING DELING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com