Patents

Literature

434 results about "Magnetic phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetoresistive element and magnetoresistive random access memory including the same

InactiveUS20090080124A1High energyNanomagnetismMagnetic measurementsMagnetic phaseNuclear magnetic resonance

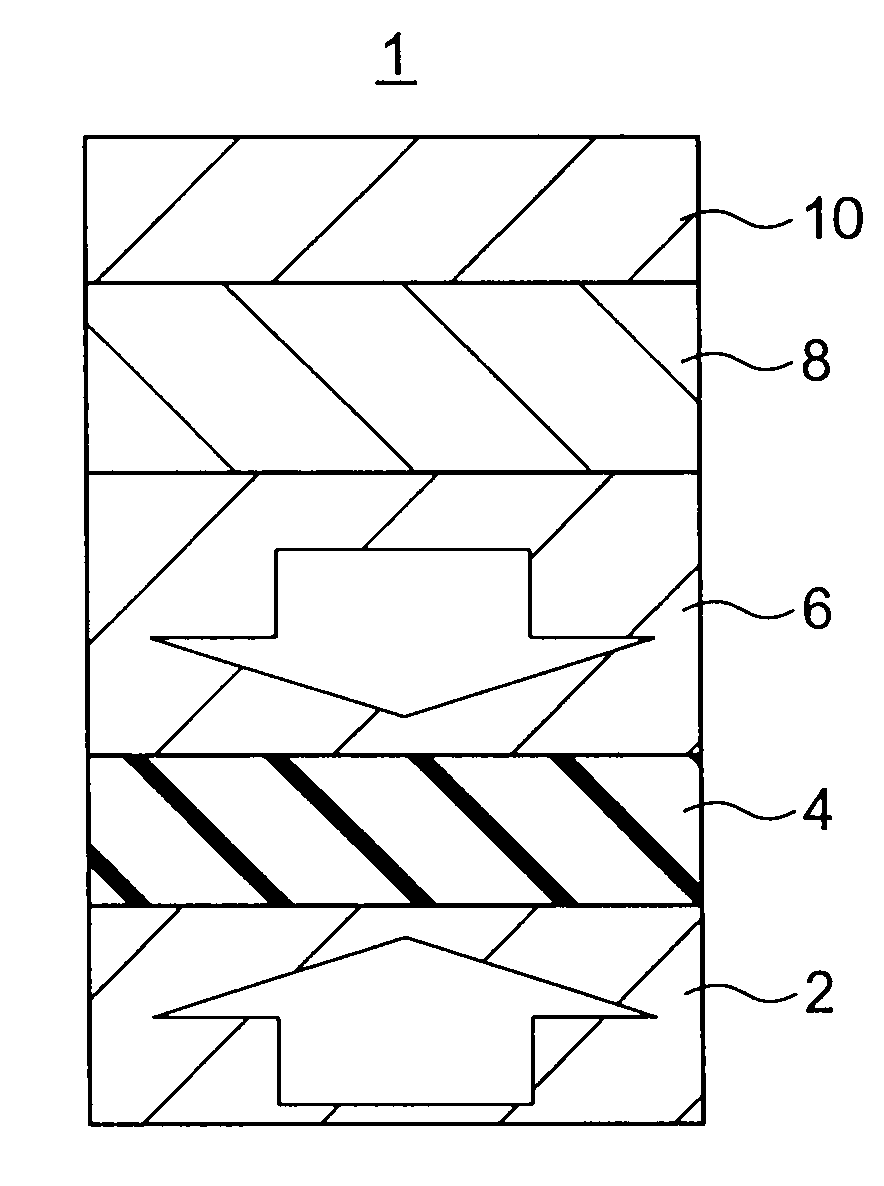

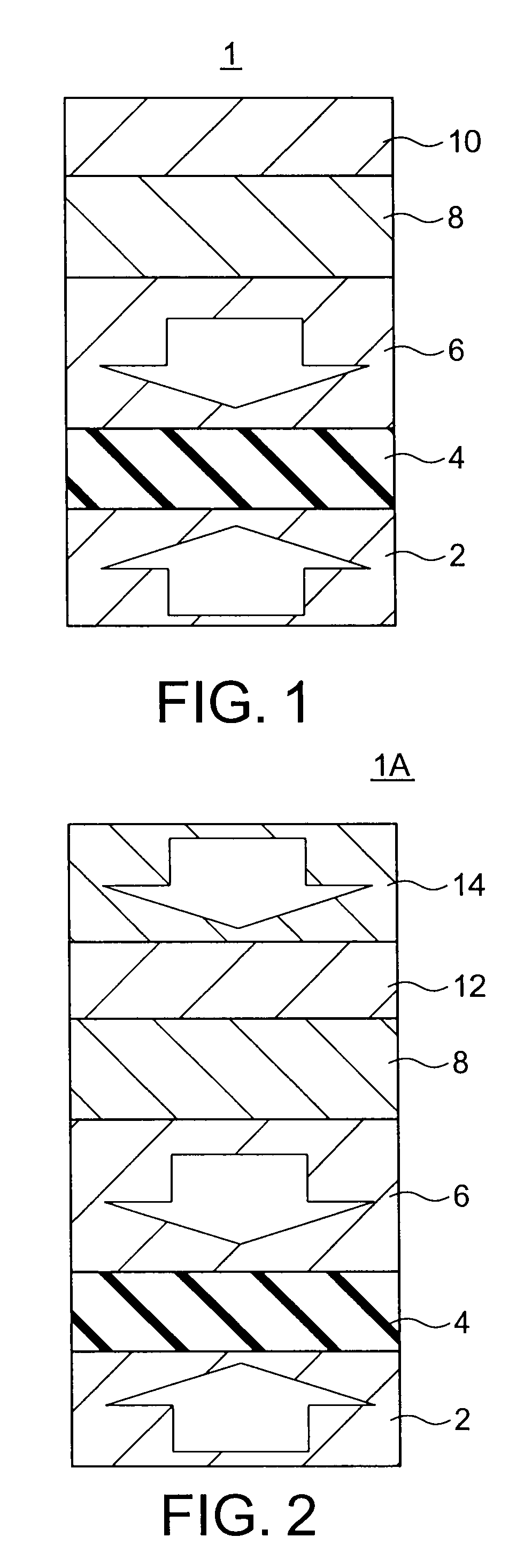

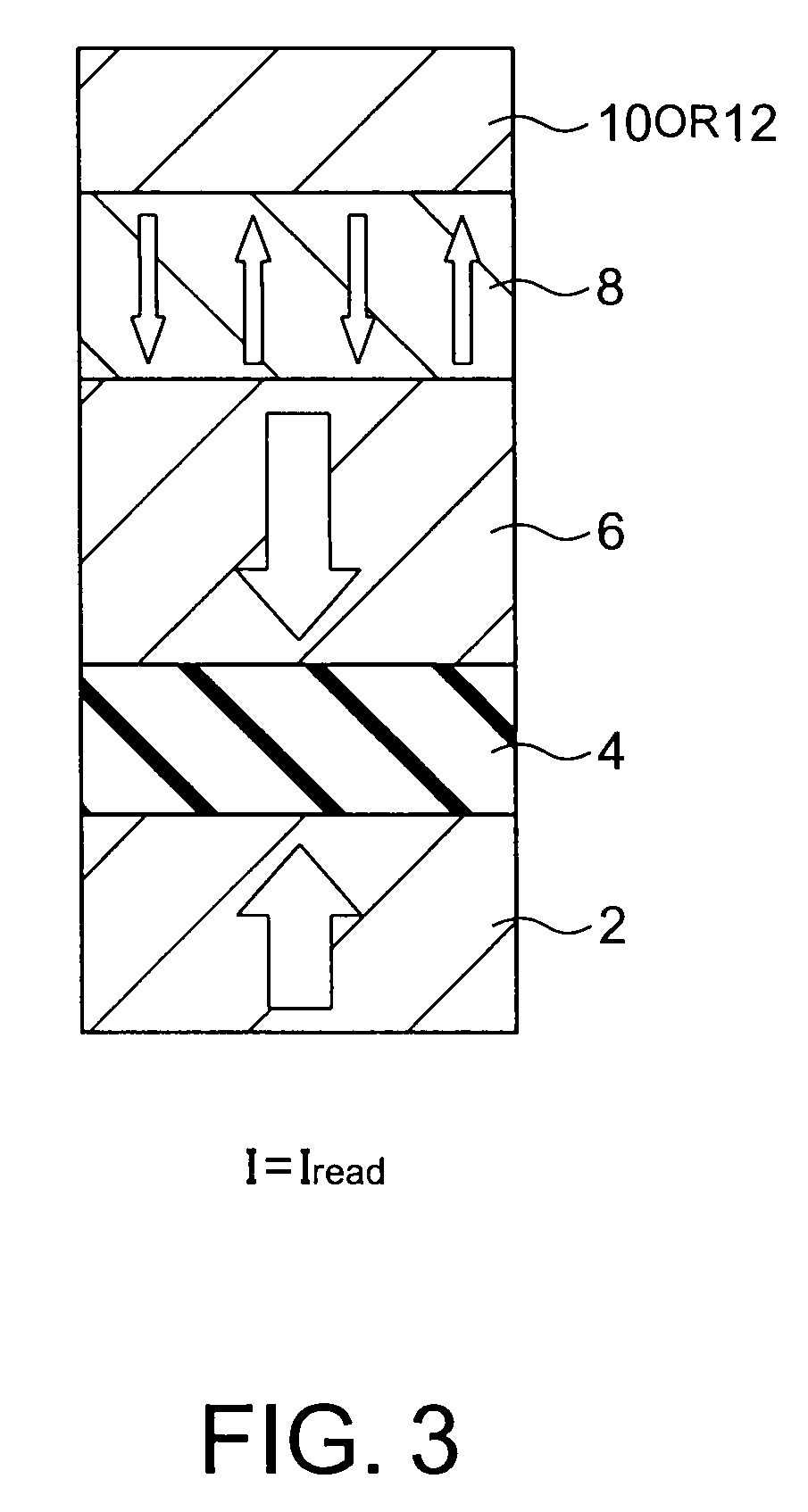

A magnetoresistive element includes: a first magnetization reference layer having magnetization perpendicular to a film plane, a direction of the magnetization being invariable in one direction; a magnetization free layer having magnetization perpendicular to the film plane, a direction of the magnetization being variable; a first intermediate layer provided between the first magnetization reference layer and the magnetization free layer; a magnetic phase transition layer provided on an opposite side of the magnetization free layer from the first intermediate layer, the magnetic phase transition layer being magnetically coupled to the magnetization free layer, and being capable of bidirectionally performing a magnetic phase transition between an antiferromagnetic material and a ferromagnetic material; and an excitation layer provided on an opposite side of the magnetic phase transition layer from the magnetization free layer, and causing the magnetic phase transition layer to perform the magnetic phase transition from the antiferromagnetic material to the ferromagnetic material.

Owner:KK TOSHIBA

Thermal generator using magnetocaloric material

ActiveUS8769966B2Energy efficient heating/coolingMachines using electric/magnetic effectsMagnetic phaseEngineering

Owner:FRANCE BREVETS SAS

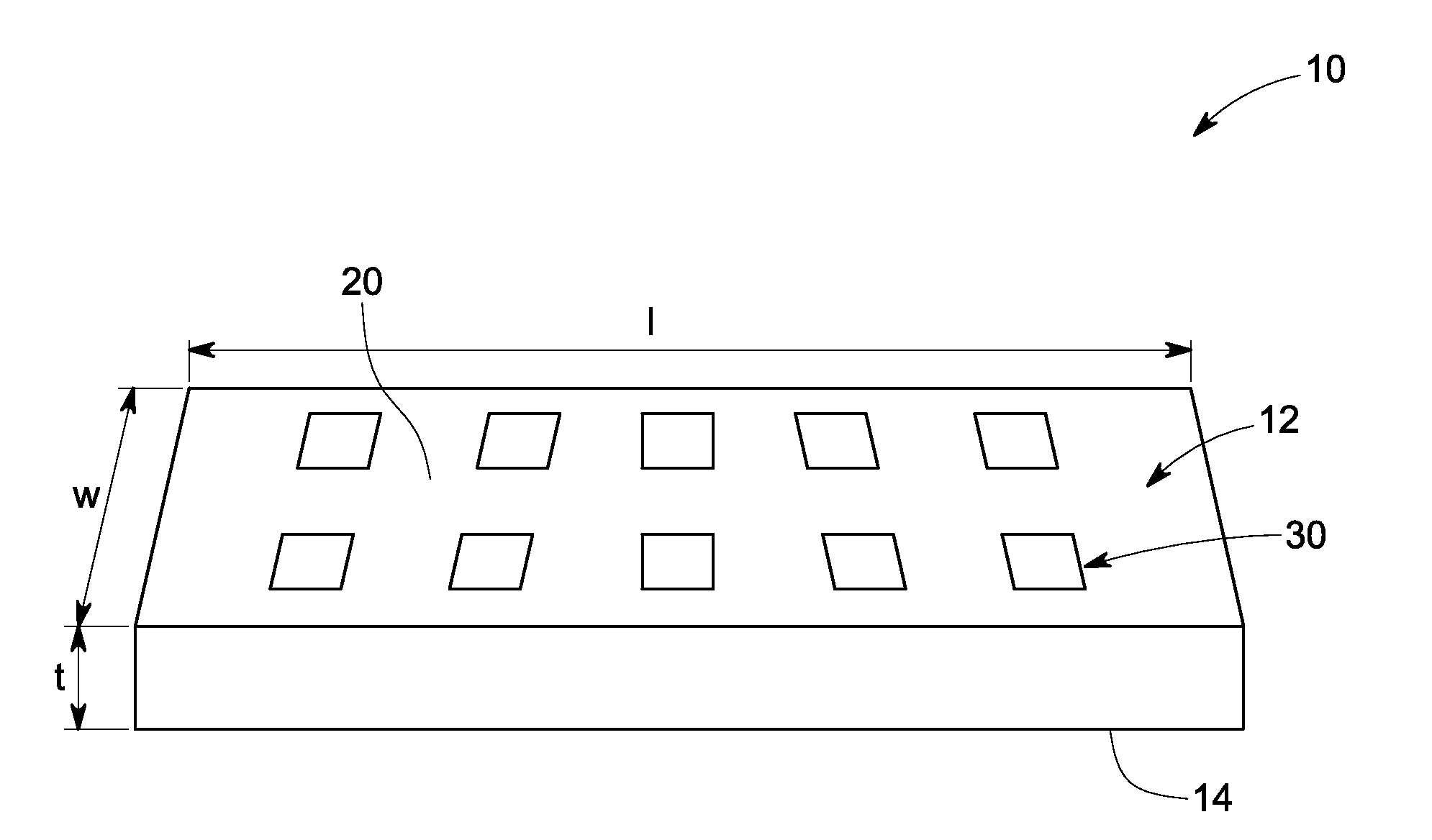

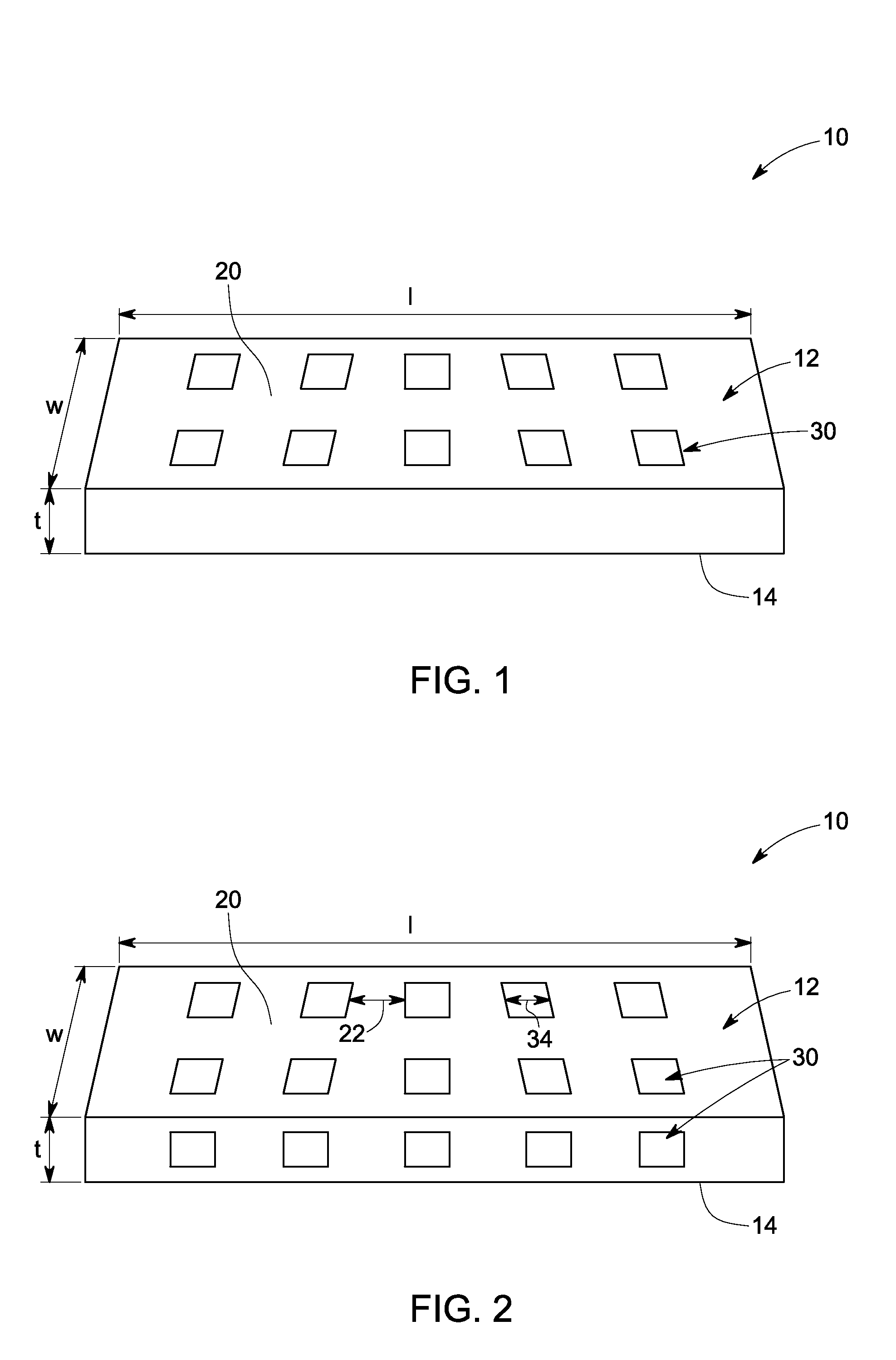

Dual phase magnetic material component and method of forming

A magnetic component having intermixed first and second regions, and a method of preparing that magnetic component are disclosed. The first region includes a magnetic phase and the second region includes a non-magnetic phase. The method includes mechanically masking pre-selected sections of a surface portion of the component by using a nitrogen stop-off material and heat-treating the component in a nitrogen-rich atmosphere at a temperature greater than about 900° C. Both the first and second regions are substantially free of carbon, or contain only limited amounts of carbon; and the second region includes greater than about 0.1 weight % of nitrogen.

Owner:GENERAL ELECTRIC CO

Anisotropic nanocrystal complex-phase compact block neodymium-iron-boron permanent-magnet material and preparation method thereof

ActiveCN102496437AAchieving macroscopic anisotropyAchieve anisotropyInductances/transformers/magnets manufactureMagnetic materialsState of artMagnetic phase

The invention relates to an anisotropic nanocrystal complex-phase compact block neodymium-iron-boron permanent-magnet material which is characterized by comprising a nanocrystal-structure hard magnetic phase and a soft magnetic phase, wherein the hard magnetic phase is a (Nd,R)2Fe17B phase, and R is selected from at least one of La, Ce, Pr, Gd, Tb and Dy; and the soft magnetic phase is at least one of alpha-Fe alpha-FeCo or Fe3B. The invention also discloses a preparation method of the permanent-magnet material. Compared with the prior art, the permanent-magnet material has the following advantages: due to the introduction of the soft magnetic phase, the coercive force of the nano complex-phase magnet is far lower than that of the single hard magnetic phase magnet, and the liquid phase is diffused into the nano complex-phase magnet and positioned at the grain boundary, thereby obviously enhancing the coercive force of the magnet.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

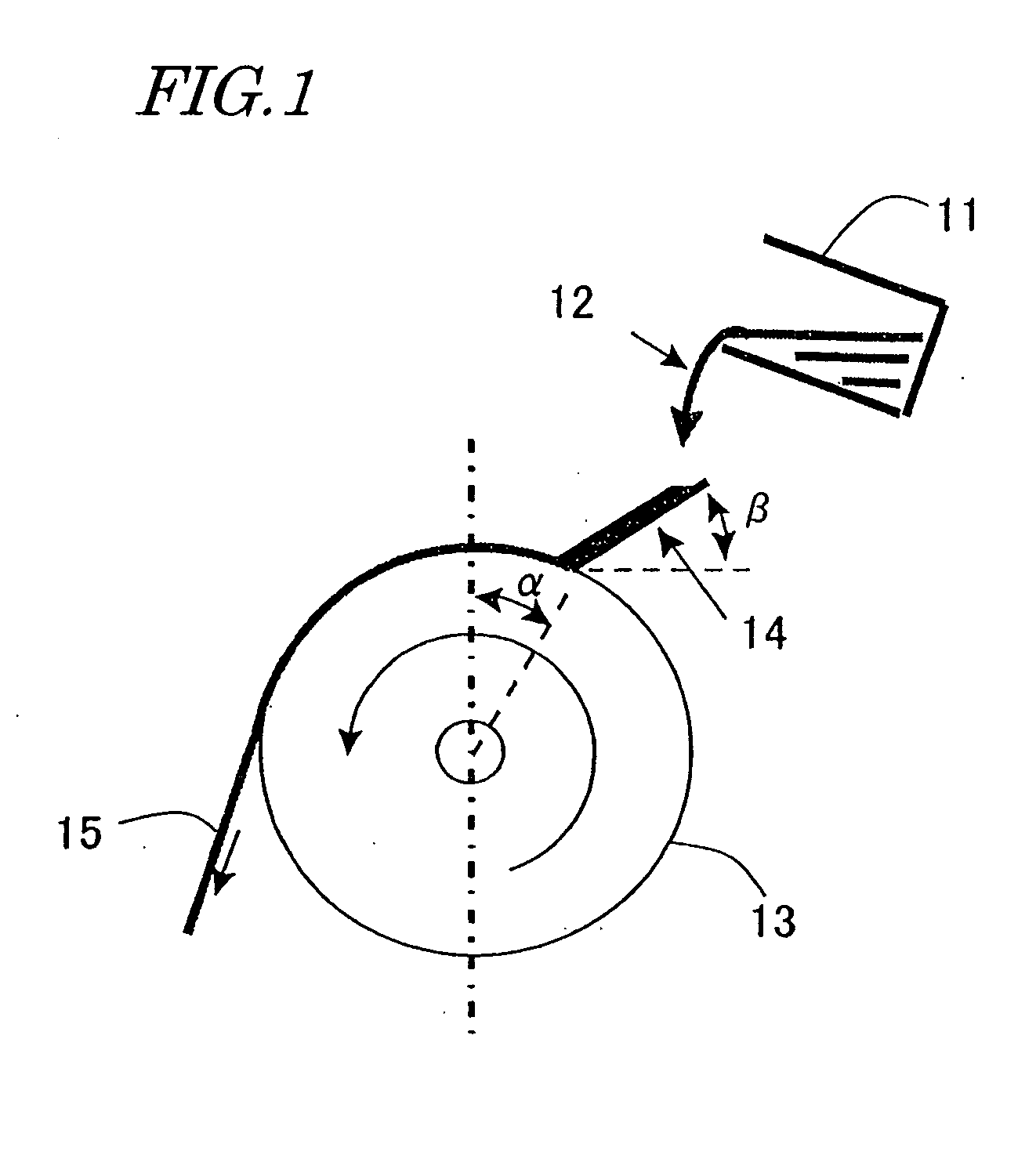

Compound for rare-earth bonded magnet and bonded magnet using the compound

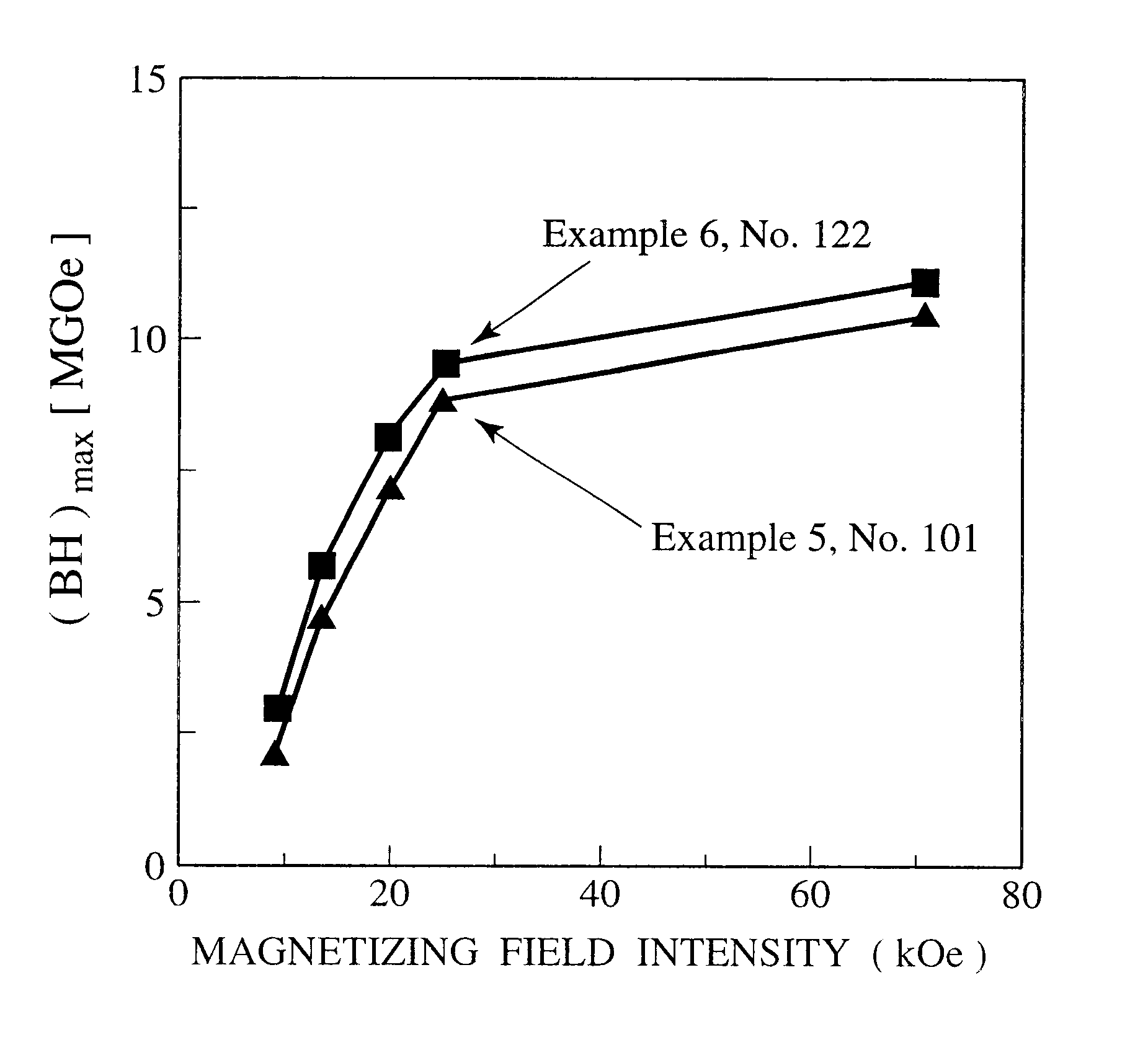

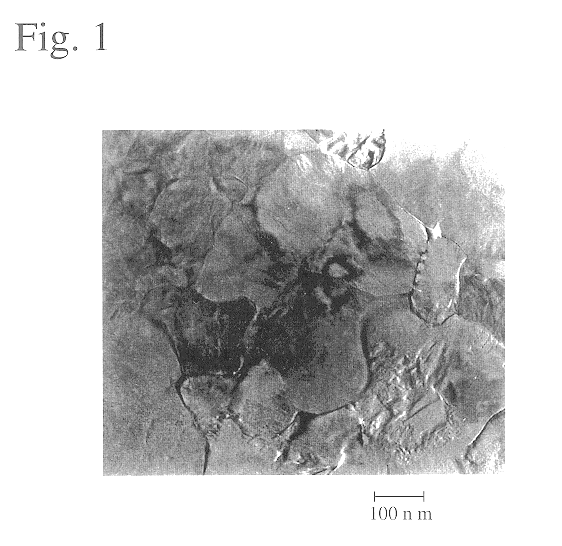

A compound for a rare-earth bonded magnet includes a rare-earth alloy powder and a binder. The rare-earth alloy powder includes at least about 2 mass % of Ti-containing nanocomposite magnet powder particles with a composition represented by (Fe1-mTm)100-x-y-zQxRyMz, where T is Co and / or Ni; Q is B with or without C; R is at least one rare-earth element substantially excluding La and Ce; M is at least one metal element selected from Ti, Zr and Hf and always includes Ti; and 10<x<=20 at %; 6<=y<10 at %; 0.1<=z<=12 at %; and 0<=m<=0.5. The particles include at least two ferromagnetic crystalline phases, in which hard magnetic phases have an average crystal grain size of about 10 nm to about 200 nm, soft magnetic phases have an average crystal grain size of about 1 nm to about 100 nm; and the average crystal grain size of the soft magnetic phases is smaller than that of the hard magnetic phases.

Owner:SUMITOMO SPECIAL METAL CO LTD

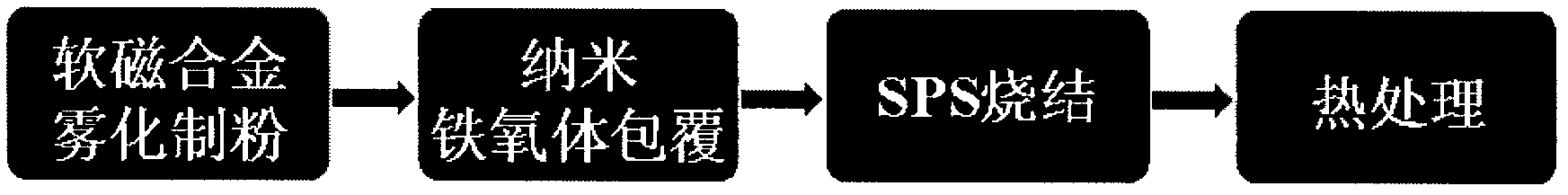

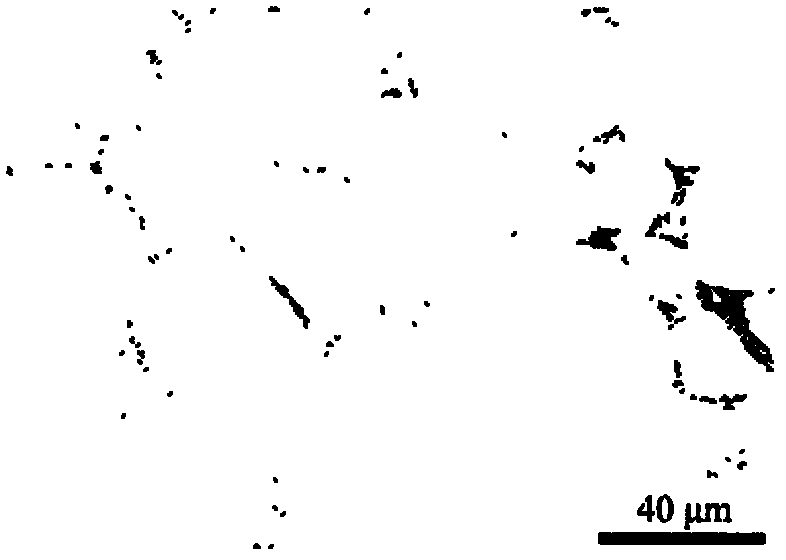

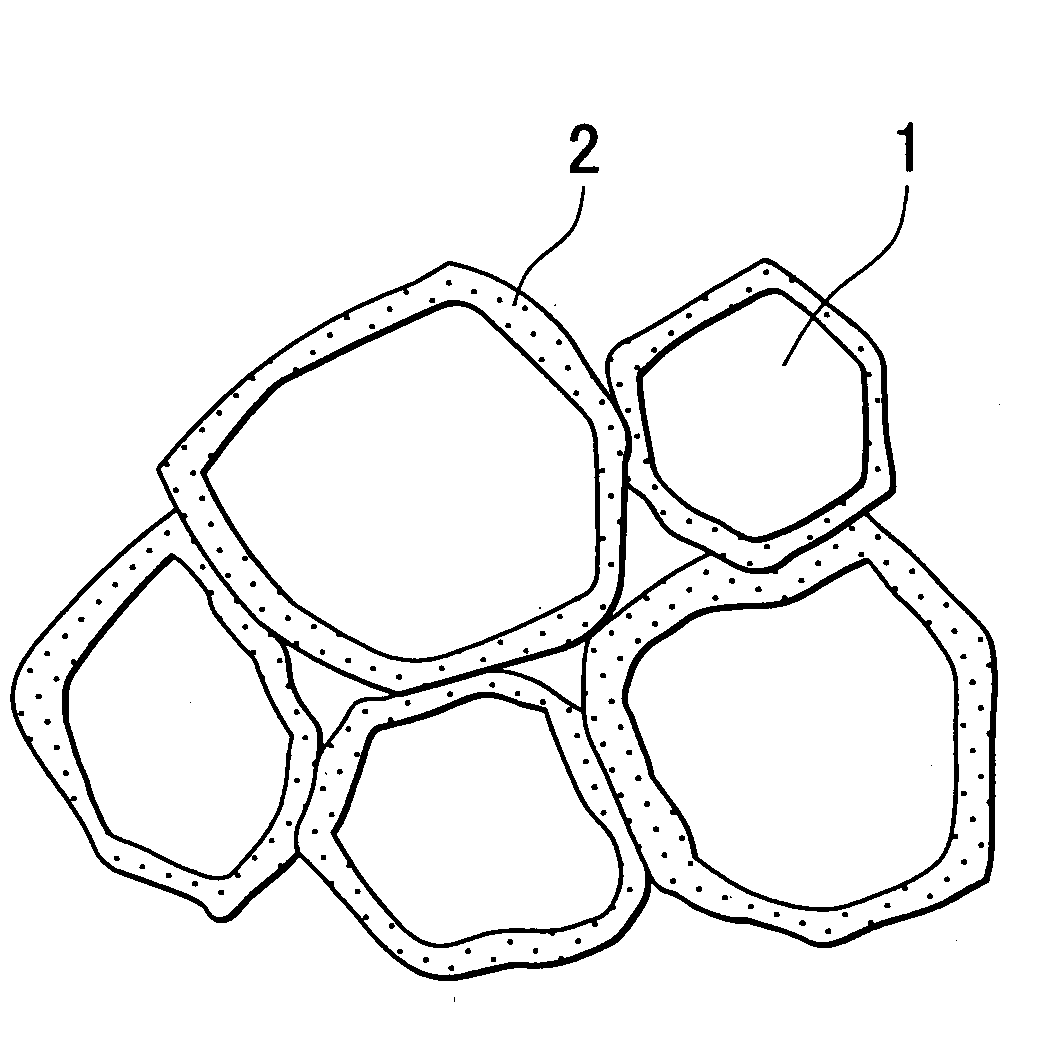

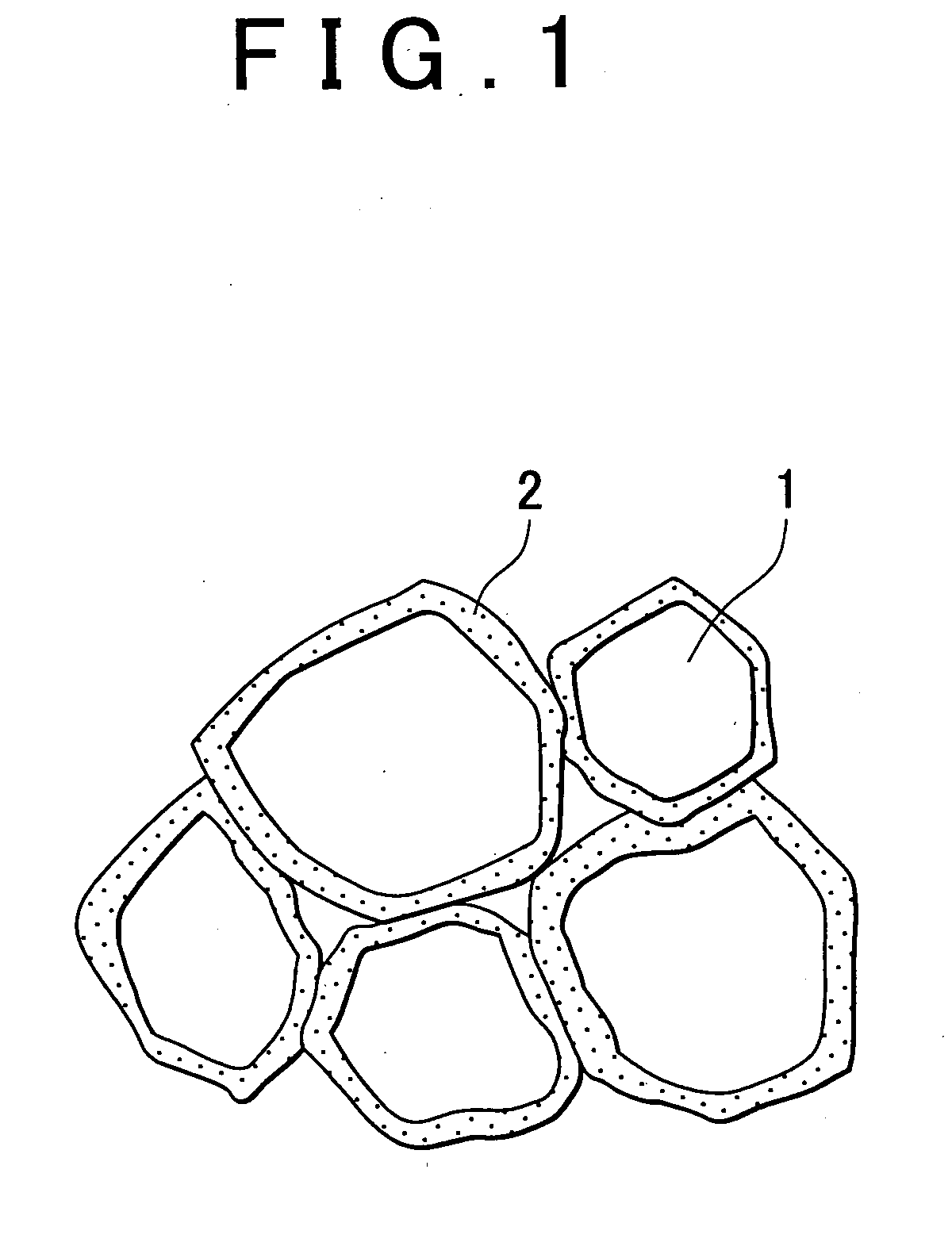

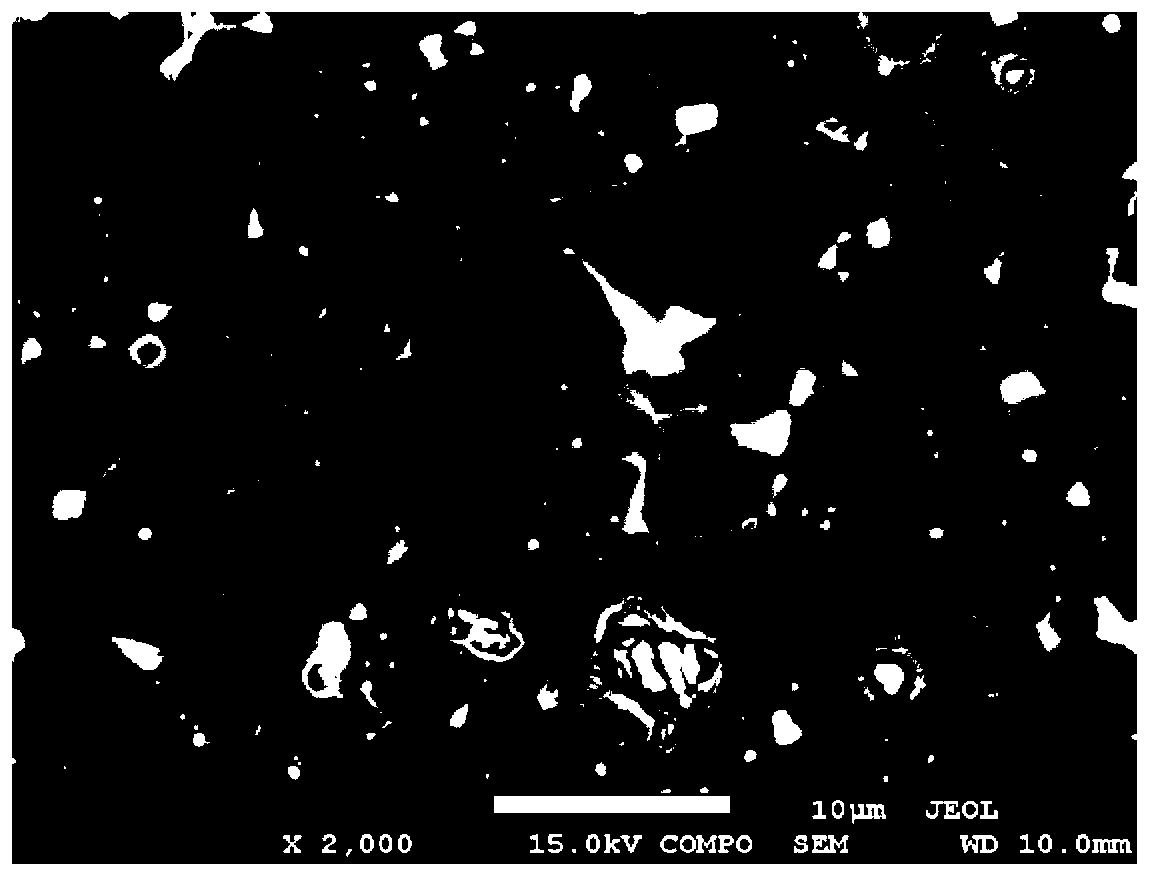

High-efficiency soft magnetic composite material and preparation method thereof

ActiveCN102136331AHigh resistivityHigh saturation magnetic inductionInorganic material magnetismMagnetic phaseAlloy

The invention discloses a high-efficiency soft magnetic composite material and a preparation method thereof. The material is in a nest wall structure composed of soft ferrite of high electrical resistivity; the ferrite in the nest wall structure completely isolates the soft magnetic metal in the nest or an alloy particle soft magnetic phase to cause the soft magnetic metal in the nest or the alloy particle soft magnetic phase to mutually isolate; the content of the soft magnetic metal or the alloy particle is 50-99wt%; and the balance is the soft ferrite. The preparation method comprises the following steps: mixing the soft magnetic metal or alloy particles and the soft ferrite powder at a ratio; causing the soft ferrite powder to completely and evenly coat the surface of the soft magnetic metal or the alloy particles; complexly sintering and shaping by spark plasma sintering densification; and finally, carrying out stress removal annealing heat treatment. The high-efficiency soft magnetic composite material has the characteristics of high-saturation induction density, high resistivity, high magnetic conductivity, low coercive force, low magnetic core loss and excellent comprehensive mechanical property. The high-efficiency soft magnetic composite material can be applied to occasions with higher working efficiency, high magnetic field and high stress. The preparation method issimple and the technological operation is convenient.

Owner:CHANGCHUN UNIV OF TECH

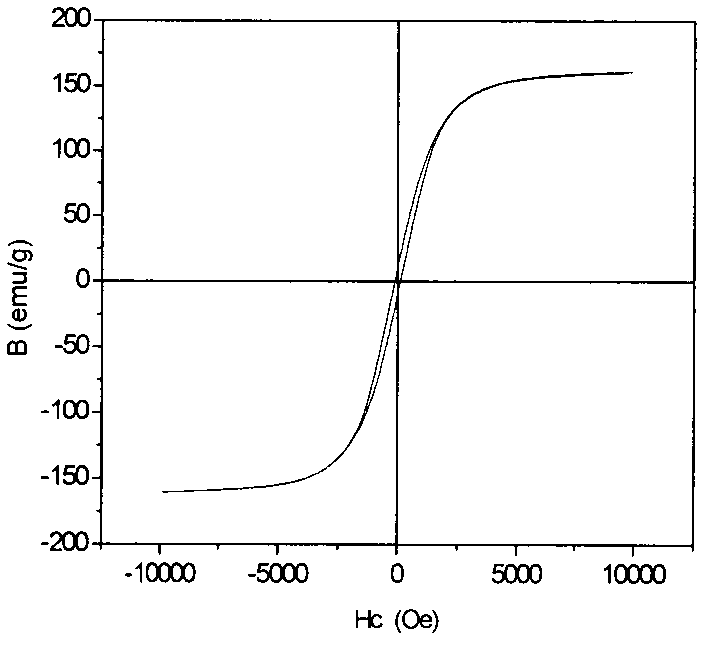

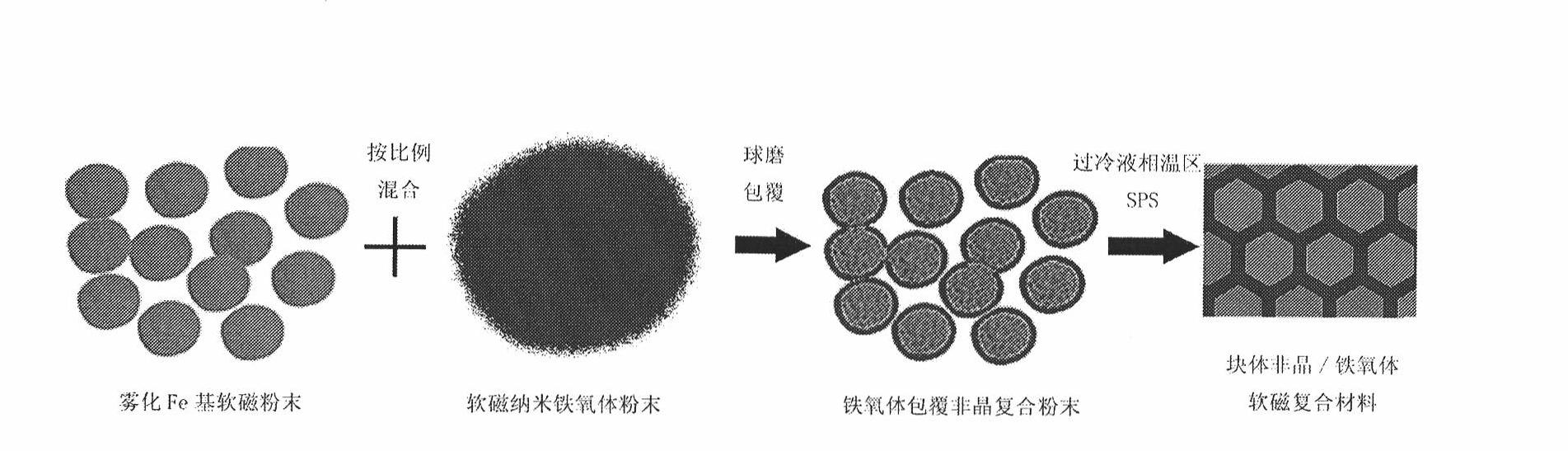

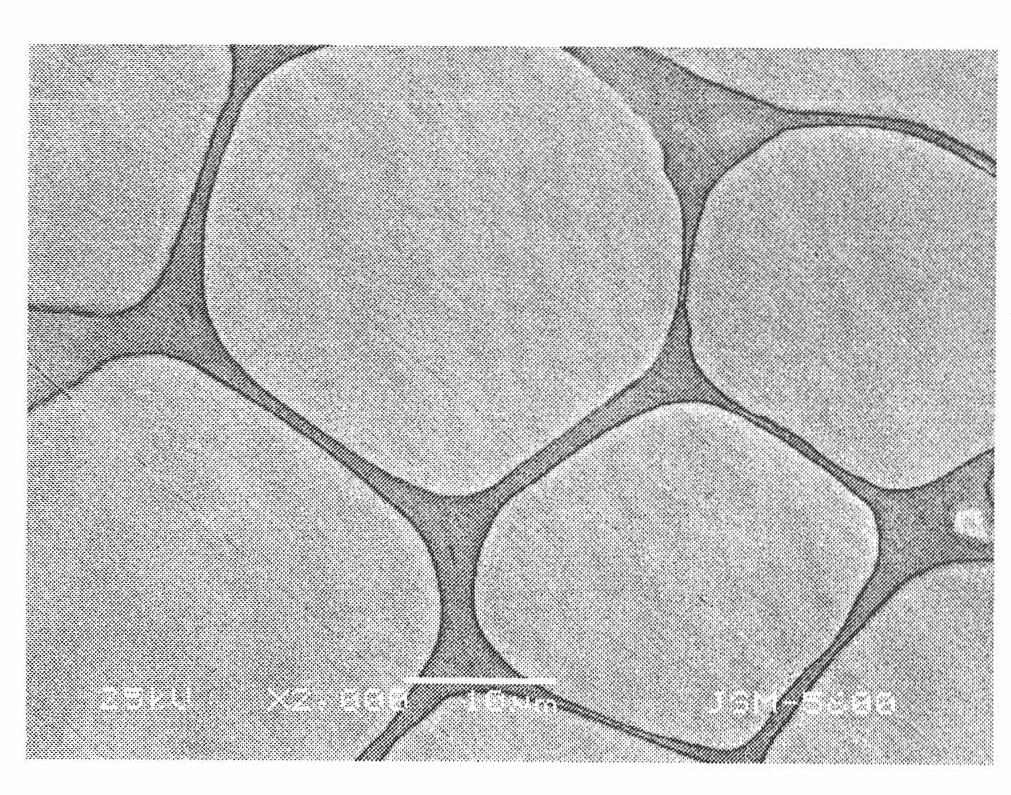

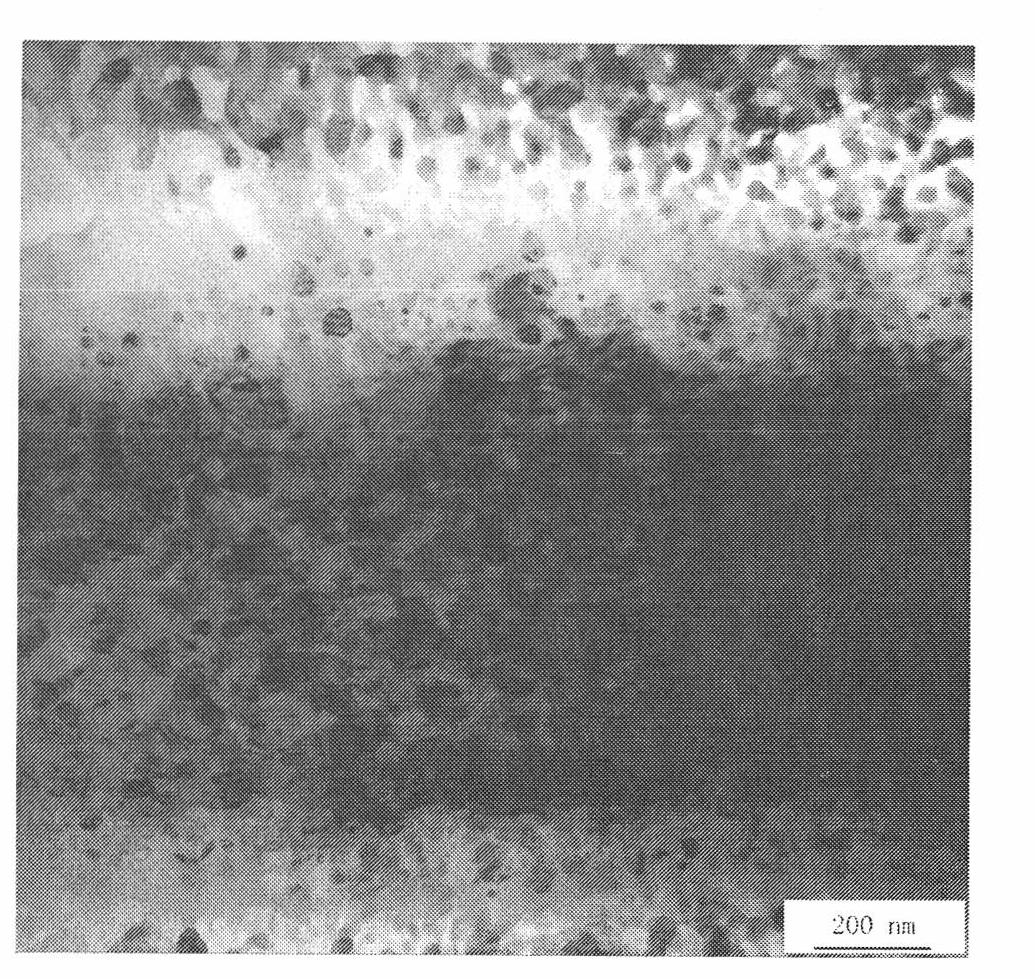

Block amorphous/ferrite soft magnetic composite material and preparation method thereof

ActiveCN102142309AHigh resistivityHigh saturation magnetic inductionInorganic material magnetismMagnetic phaseFerrite powder

The invention discloses a block amorphous / ferrite soft magnetic composite material and a preparation method for the block amorphous / ferrite soft magnetic composite material. The soft magnetic composite material is the amorphous / ferrite soft magnetic composite material having a three-dimensional honeycomb structure; a honeycomb wall structure is formed by a high-resistivity soft magnetic ferrite; the honeycomb wall ferrite encloses and completely isolates amorphous alloy soft magnetic phases which are formed by soft magnetic amorphous alloy particles in the honeycomb, so that the amorphous alloy soft magnetic phases in the honeycomb are isolated from one another; and the amorphous / ferrite soft magnetic composite material comprises 50-99 weight percent of the soft magnetic amorphous alloy particles and the balance of the soft magnetic ferrite. The preparation method comprises the following steps of: firstly, mixing the soft magnetic amorphous alloy particles with soft magnetic ferrite powder in proportion, completely coating surfaces of the soft magnetic amorphous alloy particles with the soft magnetic ferrite powder; secondly, carrying out sintering densification compound moulding on the amorphous alloy particles without crystallization by employing a discharging plasma sintering technology; and finally, carrying out de-stressing and nanometre crystallization annealing heat treatment. Compared with an amorphous alloy soft magnetic material, the block amorphous / ferrite soft magnetic composite material has the advantages that: the resistivity is remarkably improved; and the working frequency of an amorphous alloy is improved.

Owner:CHANGCHUN UNIV OF TECH

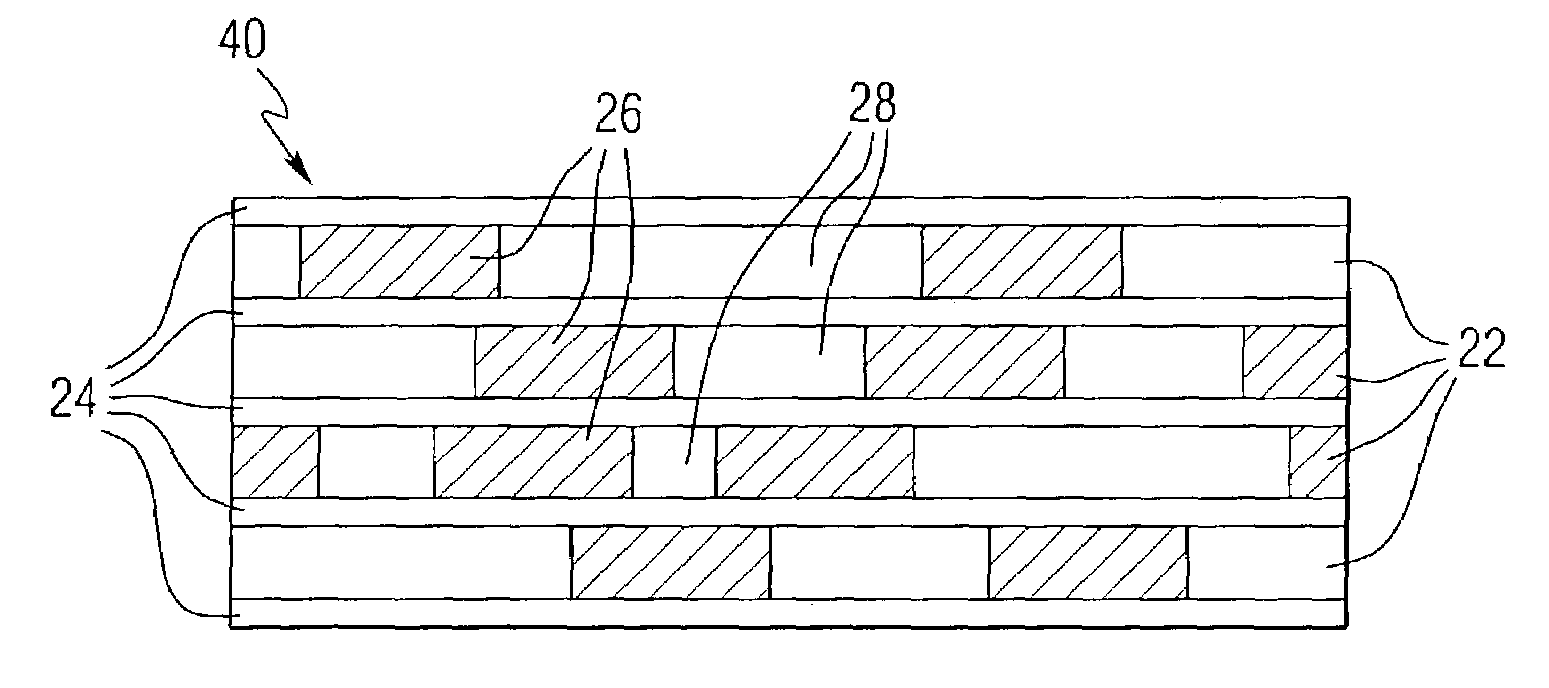

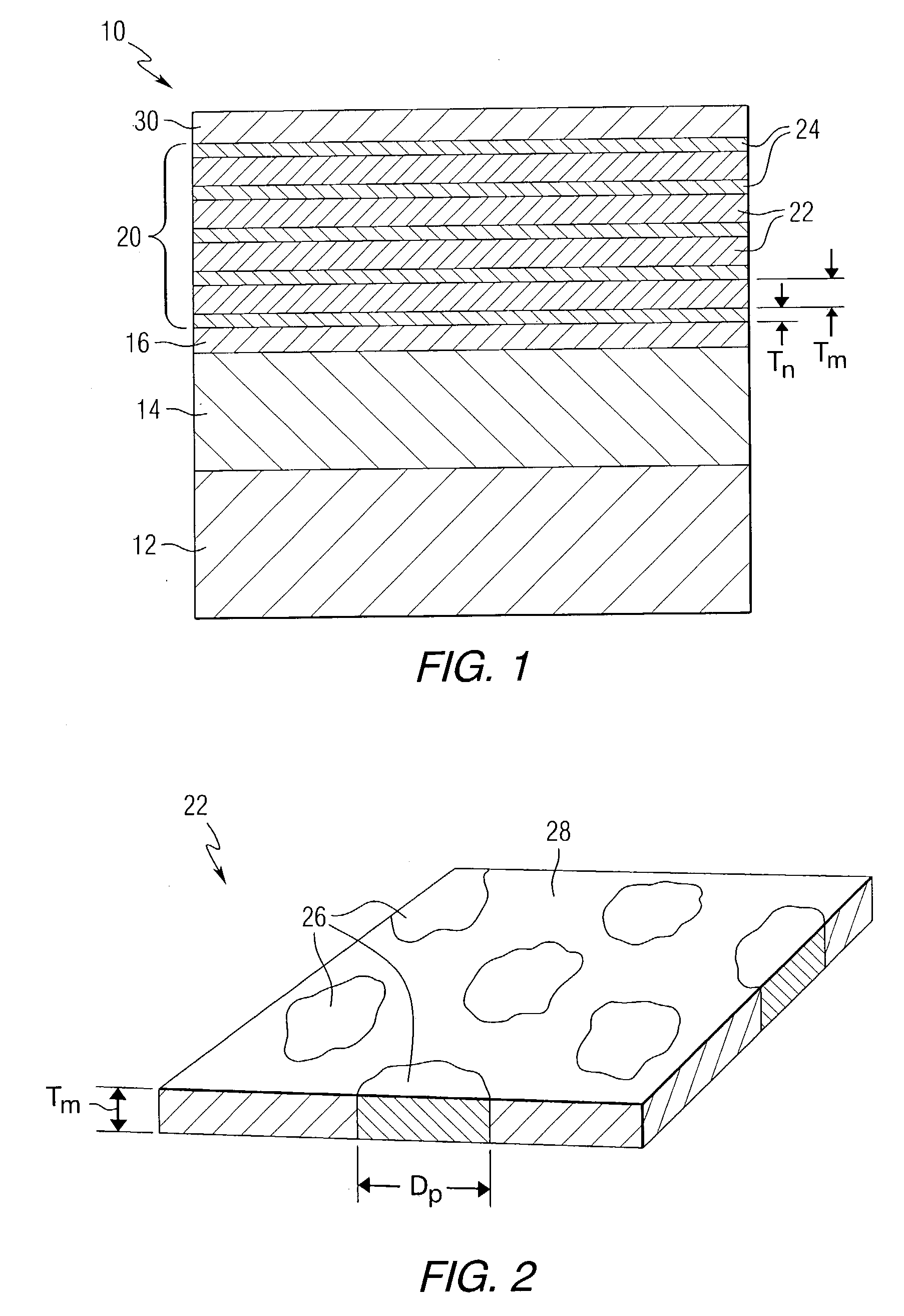

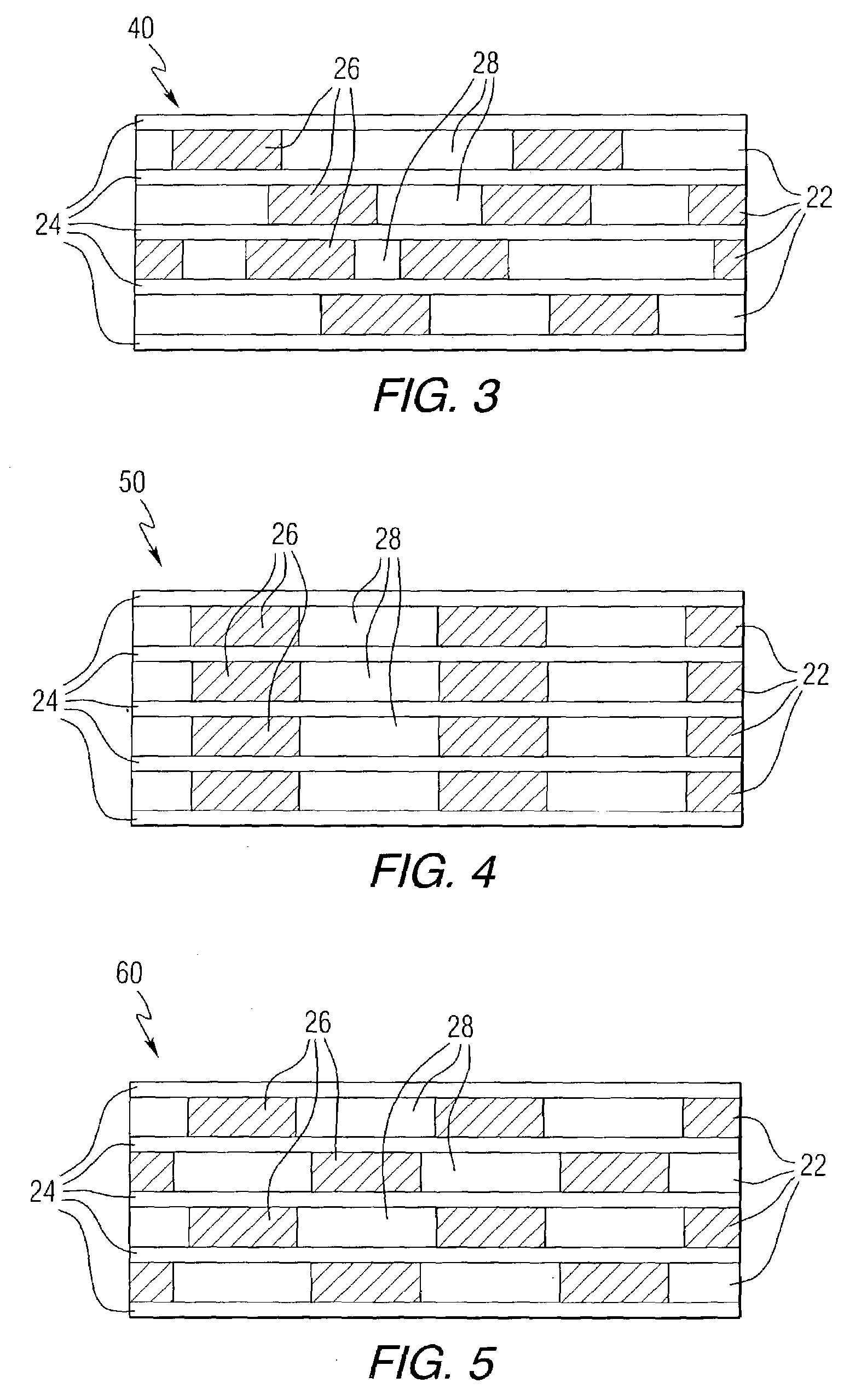

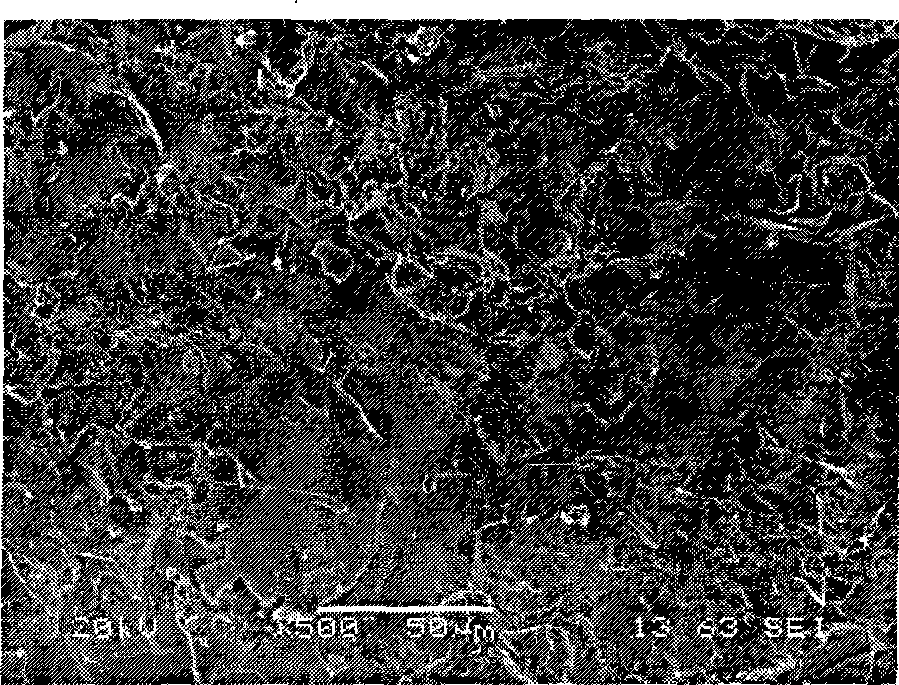

Multilayer magnetic recording media including composite layer with discontinuous magnetic phase and continuous non-magnetic phase

Multilayer magnetic structures comprising composite layers and spacer layers are disclosed. The composite layers include a discontinuous magnetic phase such as Co, Ni or Fe platelets, and a continuous nonmagnetic phase such as C, AlOx, SiOx, ZrOx, Cu, Ag and Au. The spacer layers may comprise Pt, Pd, Au or the like. The composite layers and spacer layers may be made by sputtering. The multilayer structures are useful as magnetic recording layers of magnetic recording media. In one embodiment, the recording media comprises a perpendicular magnetic recording medium including a substrate, a soft magnetic underlayer, a seed layer and the multilayer structure.

Owner:SEAGATE TECH LLC

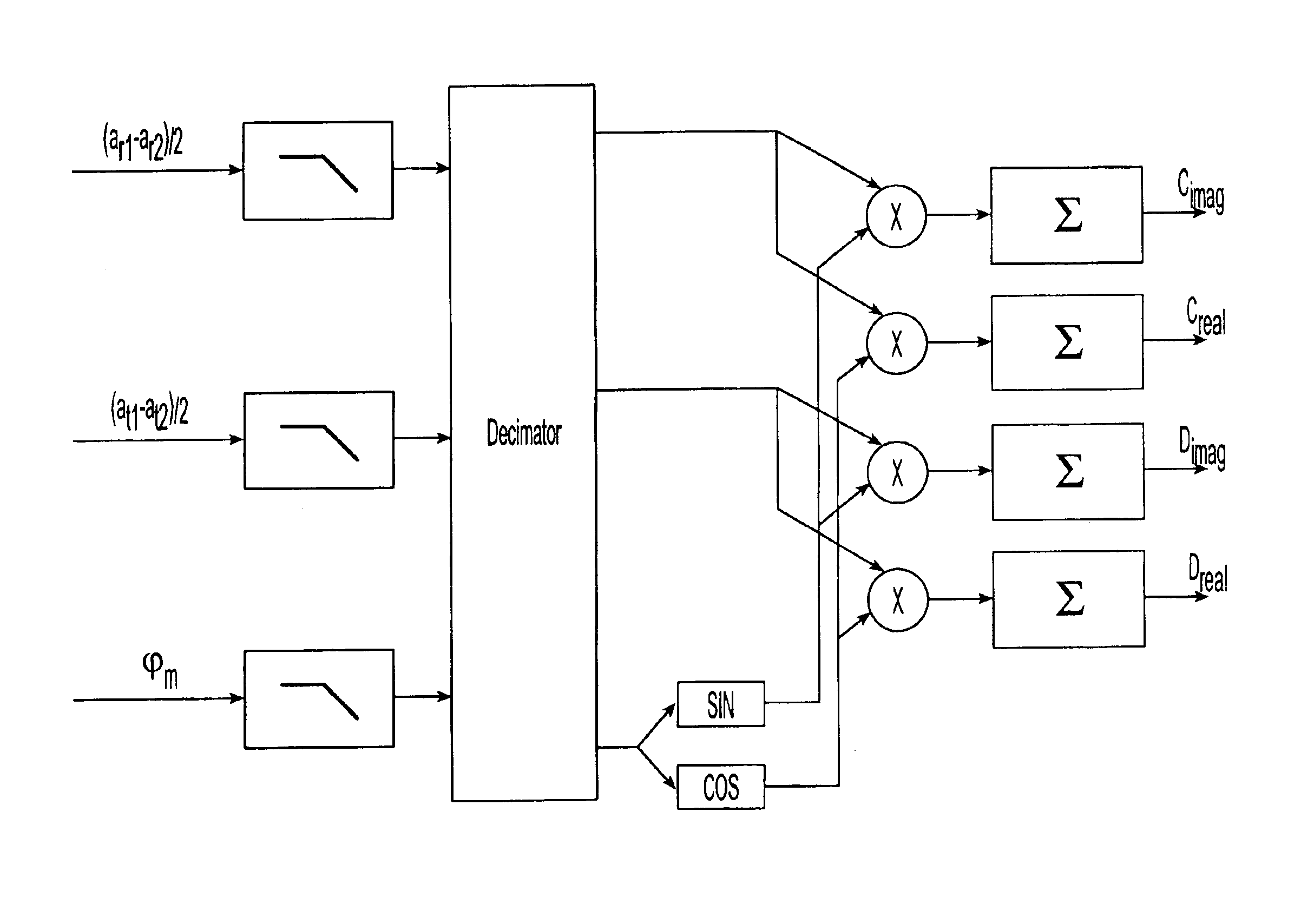

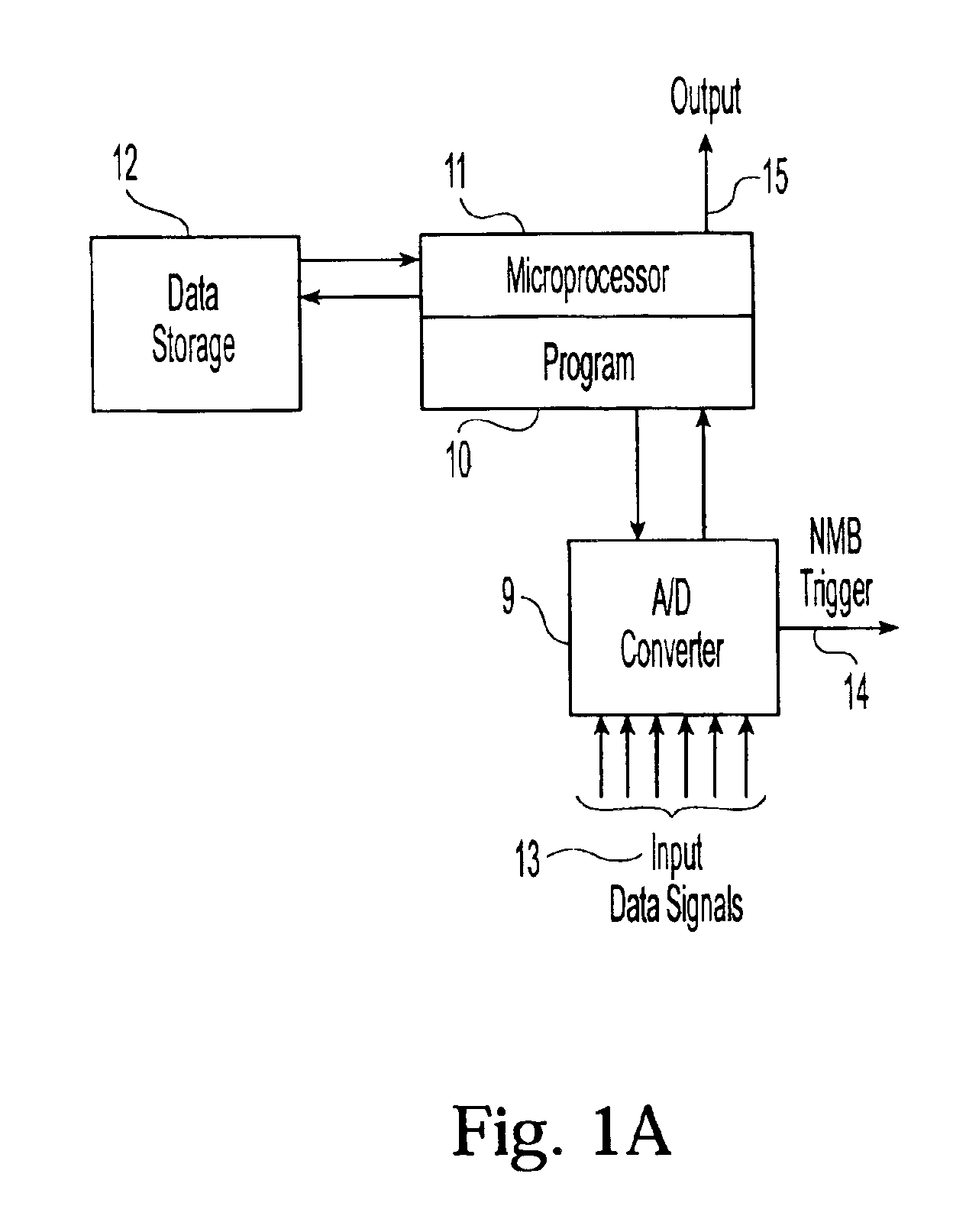

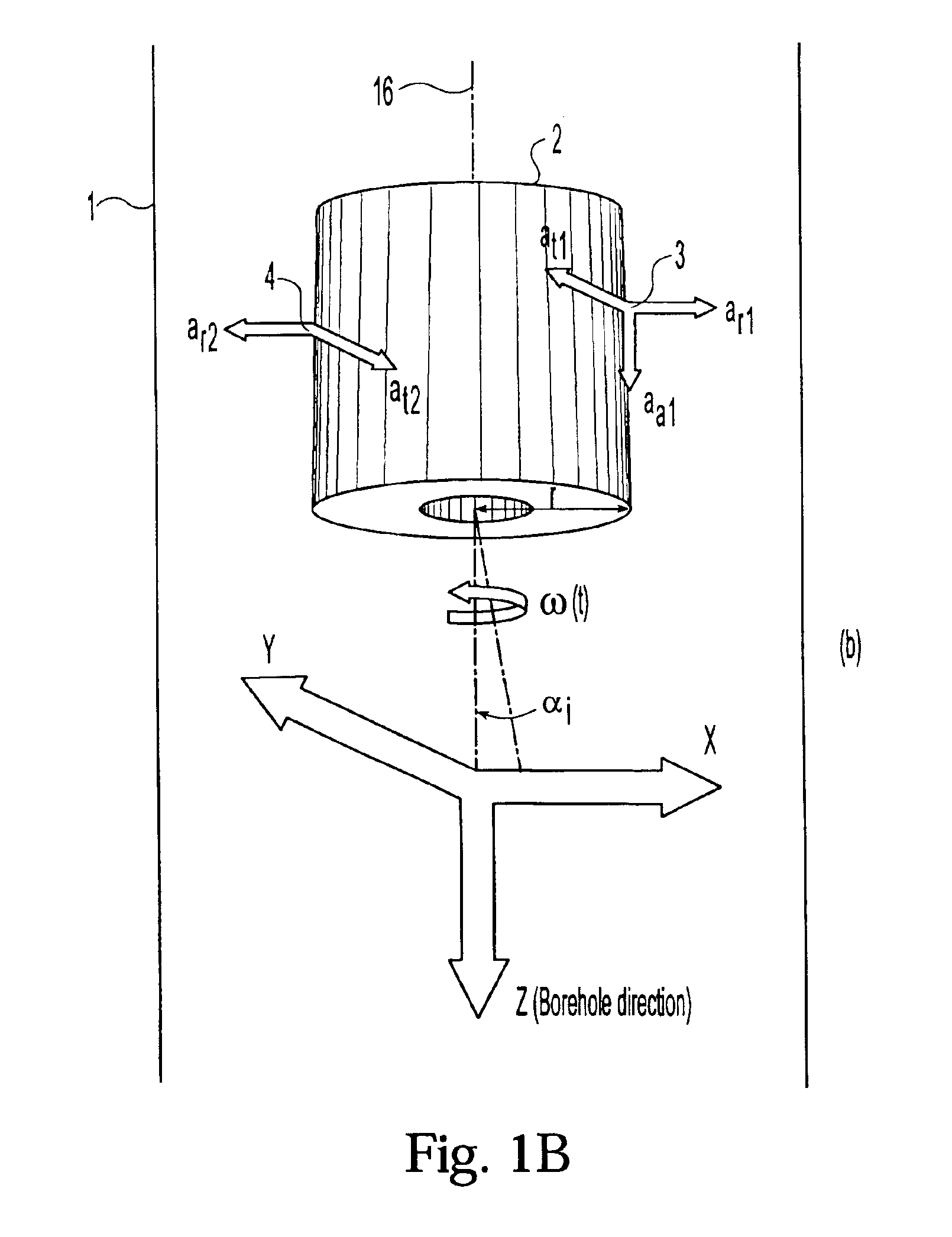

Systems and methods of determining motion tool parameters in borehole logging

A system and method for calculating the lateral velocity of a rotating drilling tool within a borehole, the system comprising: a pair of accelerometers placed oppositely across the drilling tool axis of rotation and two magnetometers. The method comprises: reading tool radial acceleration signals ar1, ar2, and tangential acceleration signals, at1 and at3, obtained with a quadrature accelerometer detection system; reading Bx and By, the tool's magnetic phase data, from two orthogonally placed magnetometers; determining the rotational phase angle of the drilling tool relative to the earth's gravity field by first determining the tool's magnetic phase, and the phase shift between the tool's magnetic phase and gravity phase; and processing the foregoing data to yield a lateral tool velocity which optionally compensates for the effect of gravity on the accelerometers, or converts the lateral tool velocity from the tool reference frame to the borehole reference frame, or does both.

Owner:HALLIBURTON ENERGY SERVICES INC

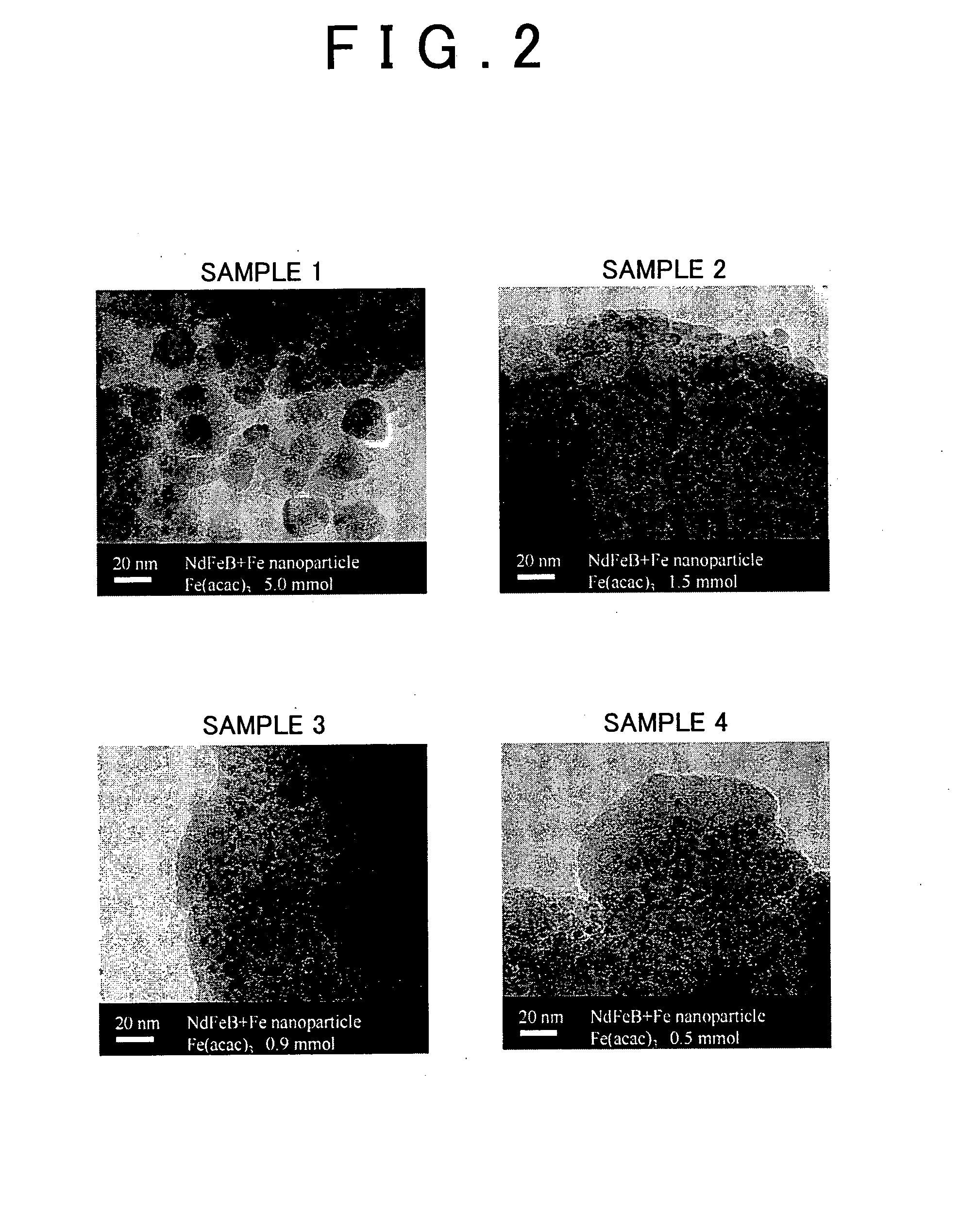

Production method for nanocomposite magnet

A nanocomposite magnet having a core-shell structure that includes a hard magnetic phase of an Nd2Fe14B compound as a core and a soft magnetic phase of Fe as a shell is produced by adding and dispersing particles of the Nd2Fe14B compound into a solvent that contains a surface-active agent, and then adding thereto an Fe precursor so as to cause Fe particles on the surface of the Nd2Fe14B compound, and drying and sintering the particles of the Nd2Fe14B compound.

Owner:TOYOTA JIDOSHA KK

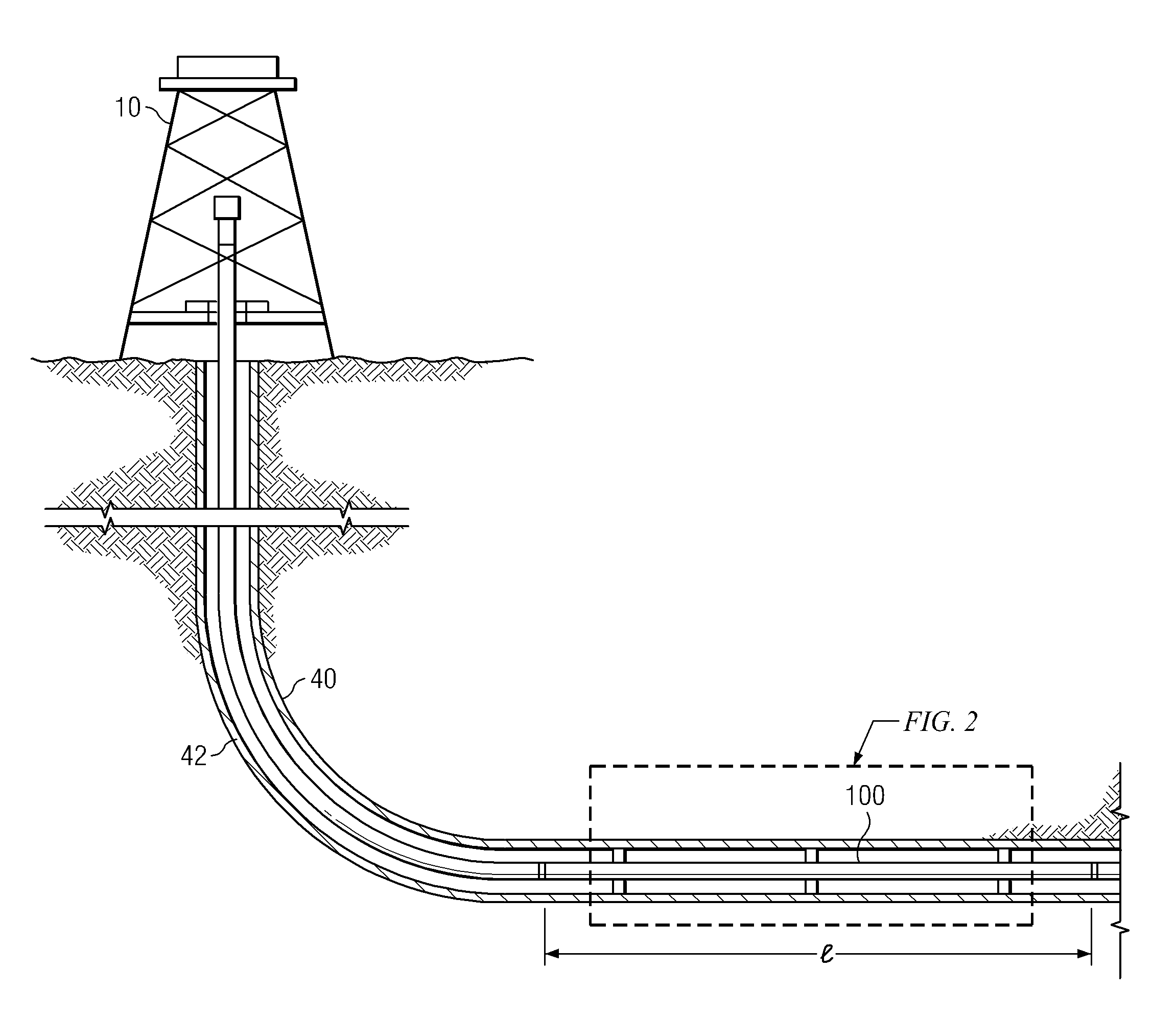

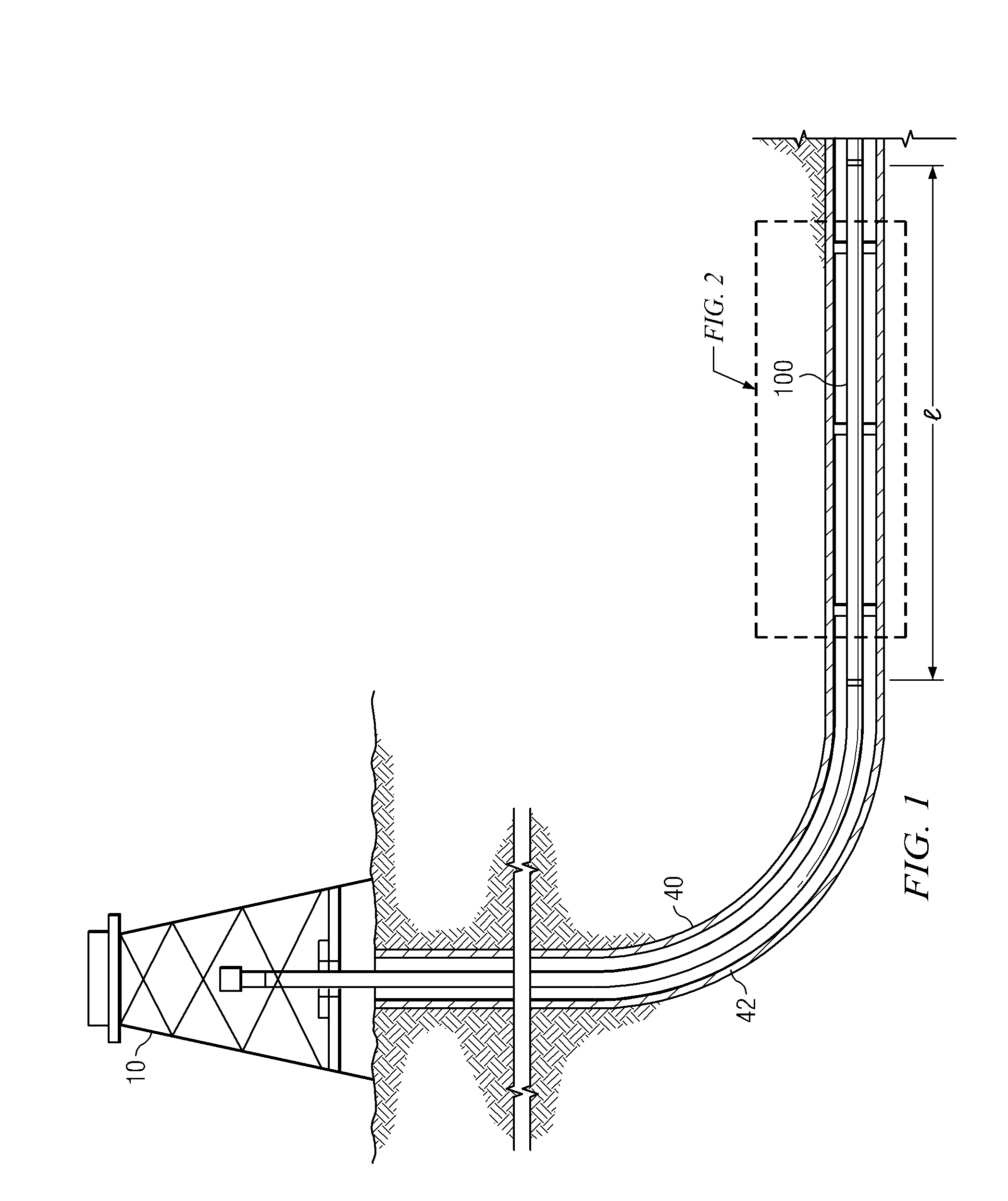

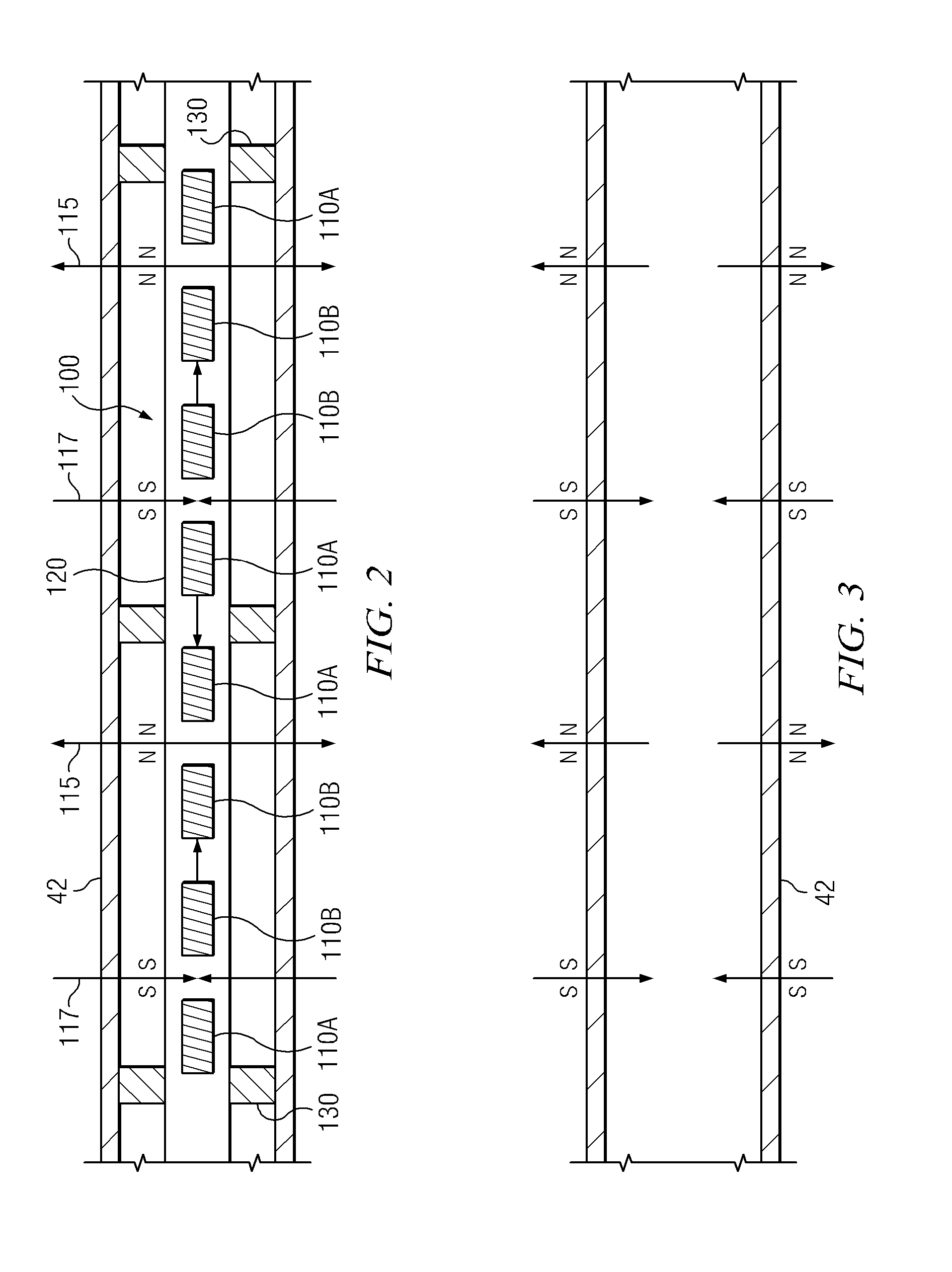

Methods for improved active ranging and target well magnetization

InactiveUS20120139543A1Simplify ranging operationShorten the timeConstructionsElectric/magnetic detectionMagnetic phaseCasing string

A method for magnetizing a portion of a pre-deployed casing string includes deploying an electromagnetic array in a cased wellbore and energizing the array. The array includes a plurality of axially spaced electromagnets and is configured to generate a magnetic field pattern having at least first and second pairs of magnetically opposing poles. Passive ranging measurements of the induced magnetic field may be advantageously utilized, for example, to survey and guide continued drilling of a twin well. The electromagnetic array may also be used in active ranging applications. An array of permanent magnets providing a similar magnetic field pattern may also be used in active ranging applications.

Owner:SCHLUMBERGER TECH CORP

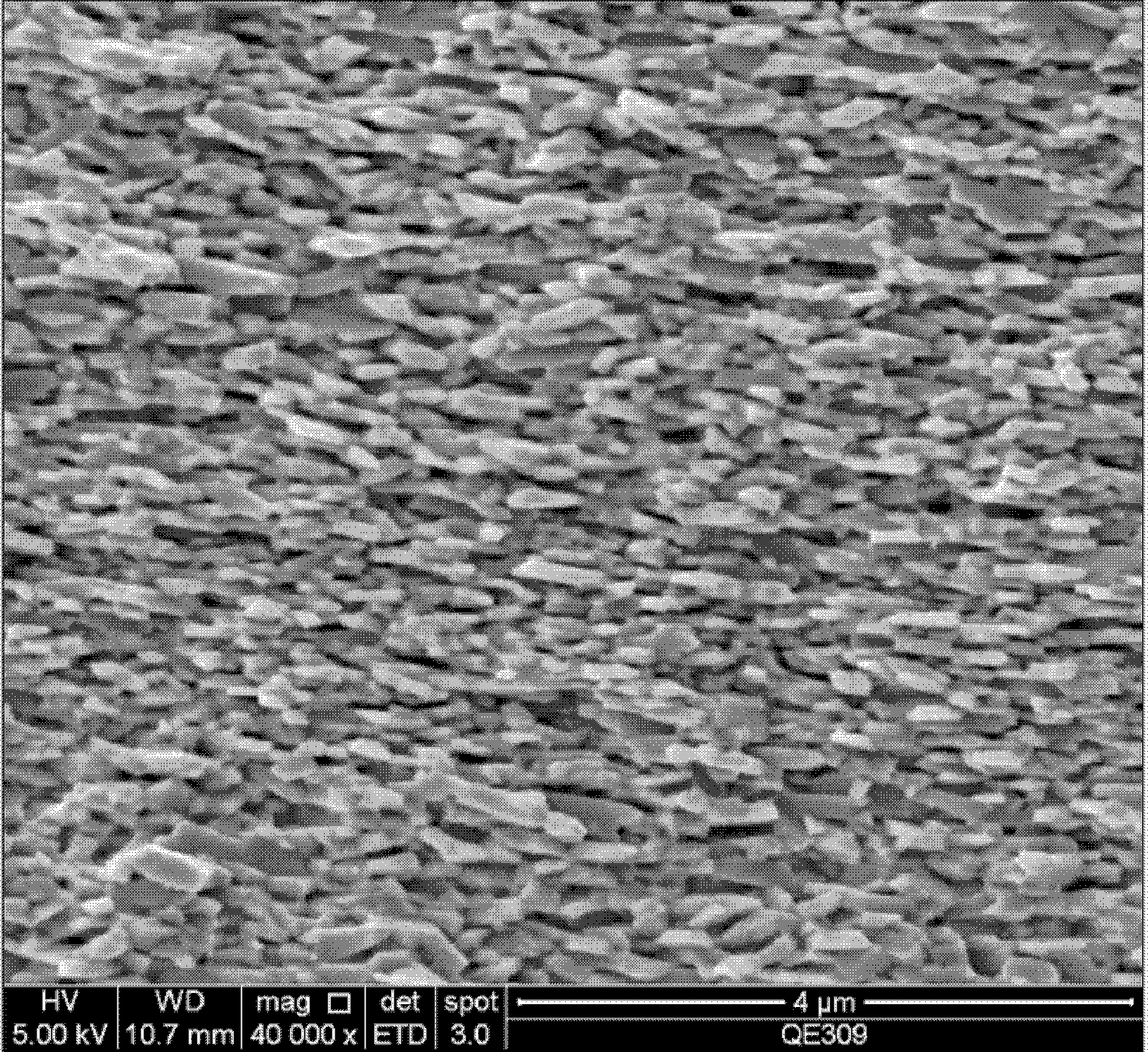

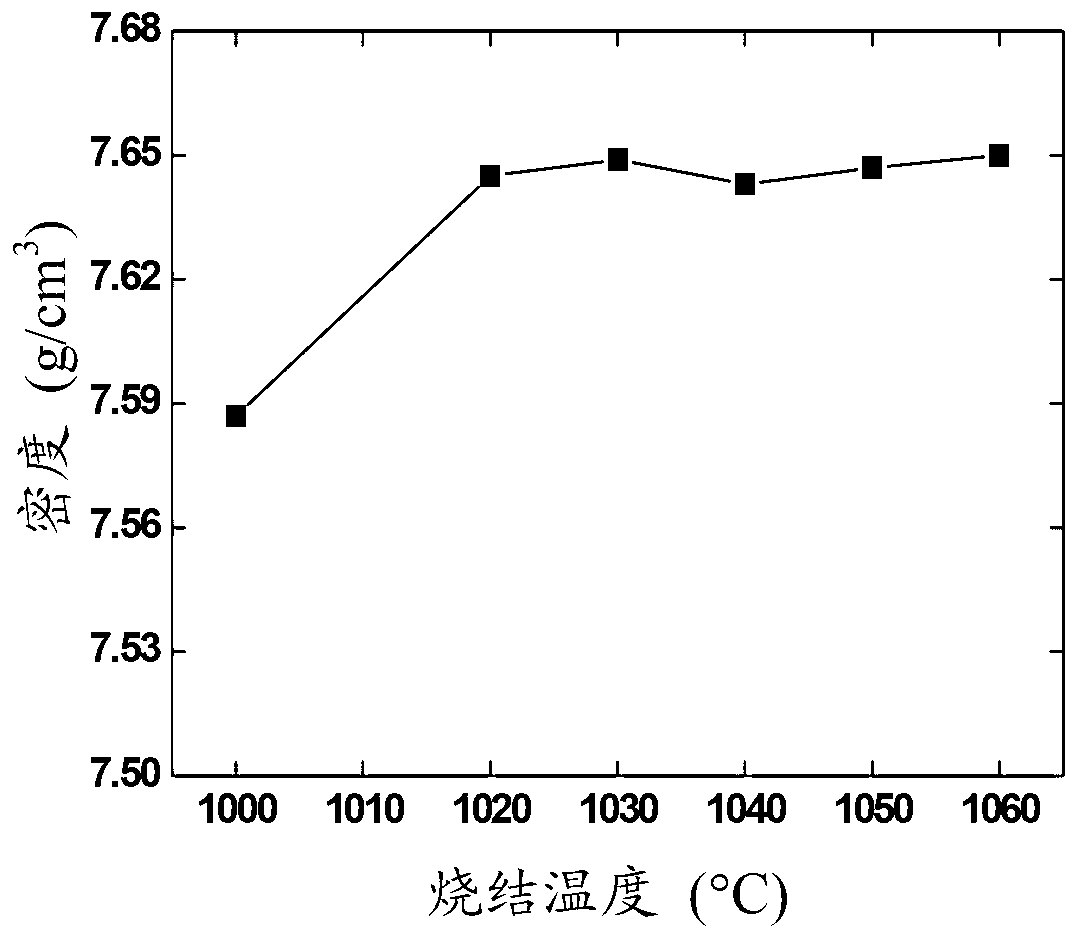

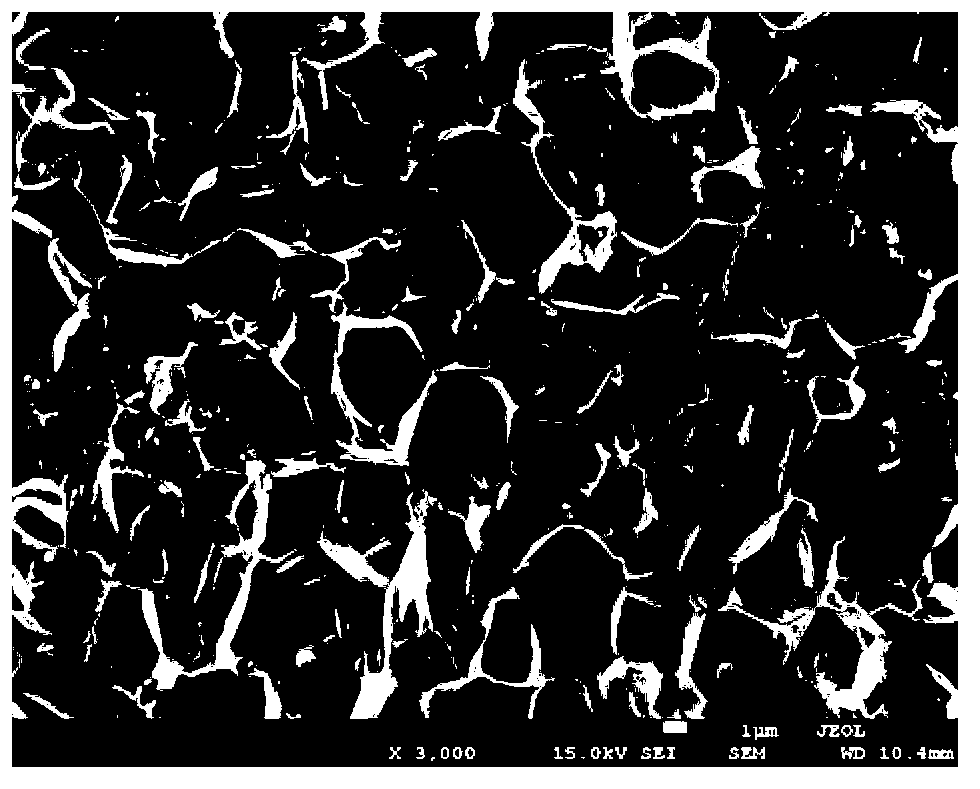

Fe-Pt-Based Ferromagnetic Material Sputtering Target

An Fe—Pt-based ferromagnetic material sputtering target comprising a metal and a metal oxide, wherein the metal has a composition in which Pt is contained in an amount of 5 mol % or more and 60 mol % or less and the remainder is Fe. An object of the present invention is to provide a ferromagnetic material sputtering target, which enables to form a magnetic recording layer composed of a magnetic phase such as an Fe—Pt alloy, and a non-magnetic phase to isolate the magnetic phase, and in which a metal oxide is used as one of the materials for the non-magnetic phase. Provided is a ferromagnetic material sputtering target wherein an inadvertent release of the metal oxide during sputtering and particle generation due to abnormal electrical discharge starting at a void inherently included in the target are suppressed, the adherence between the metal oxide and the matrix alloy is enhanced, and its density is increased.

Owner:JX NIPPON MINING& METALS CORP

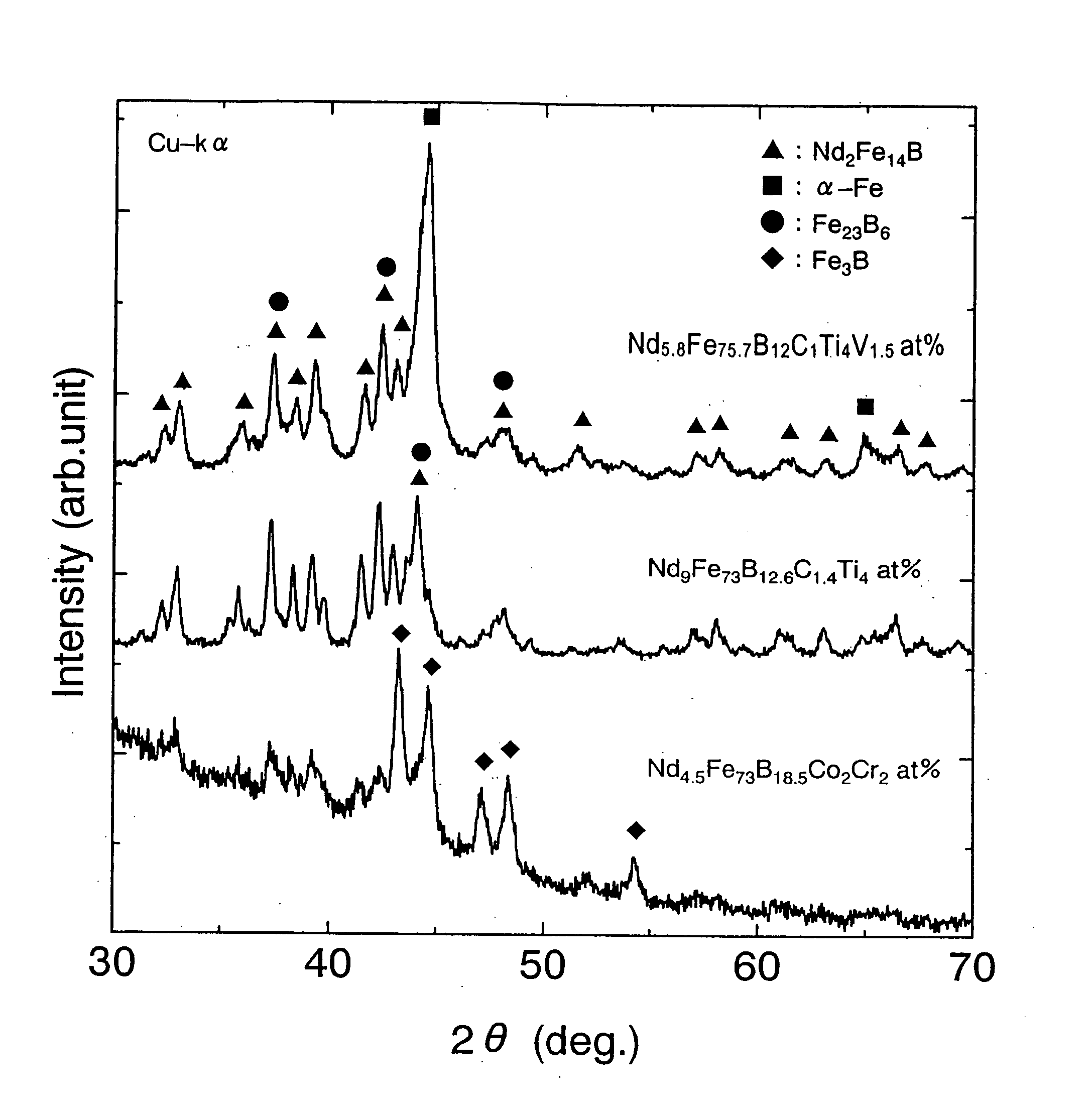

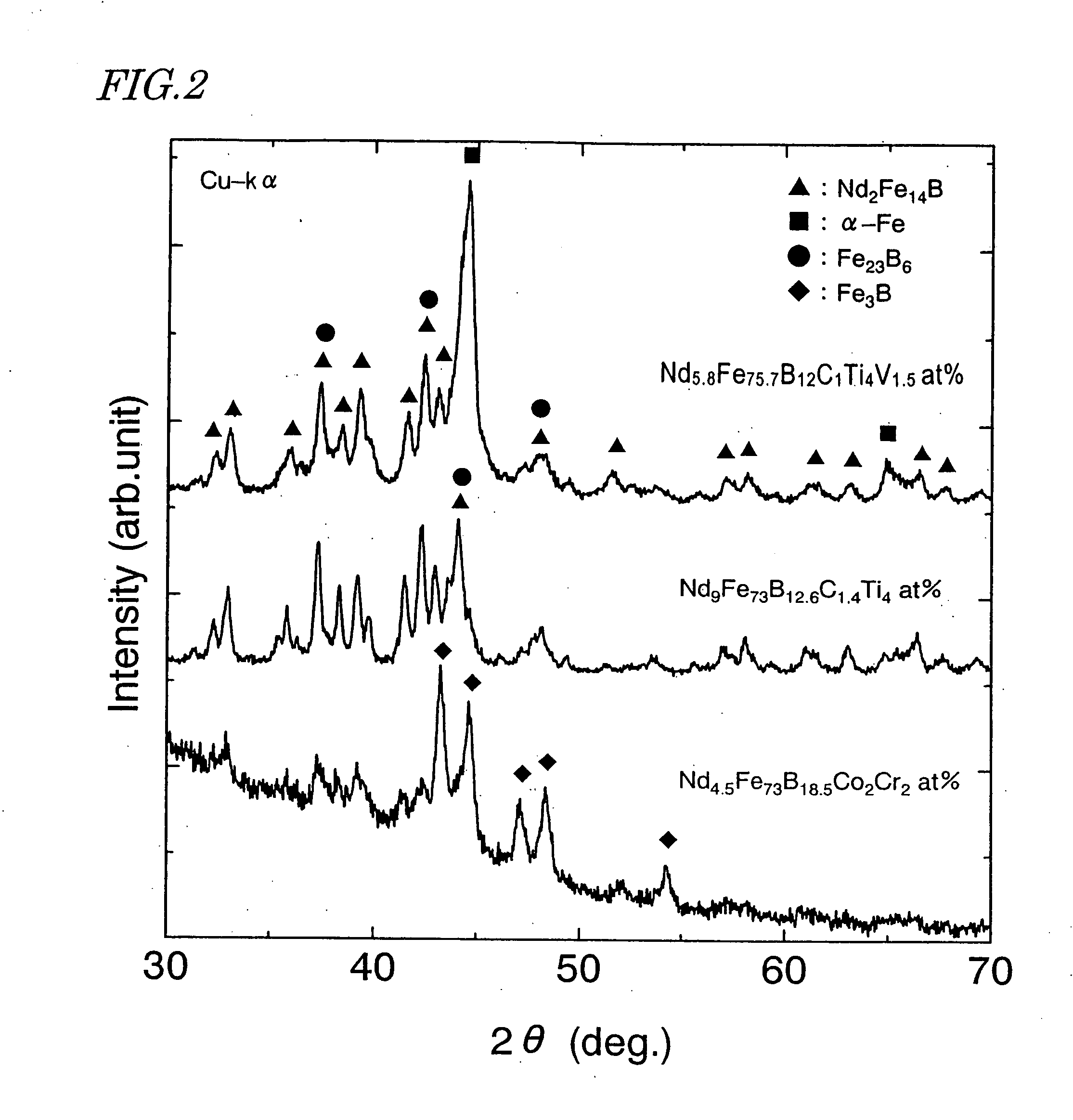

Nanocomposite magnet and method for producing the same

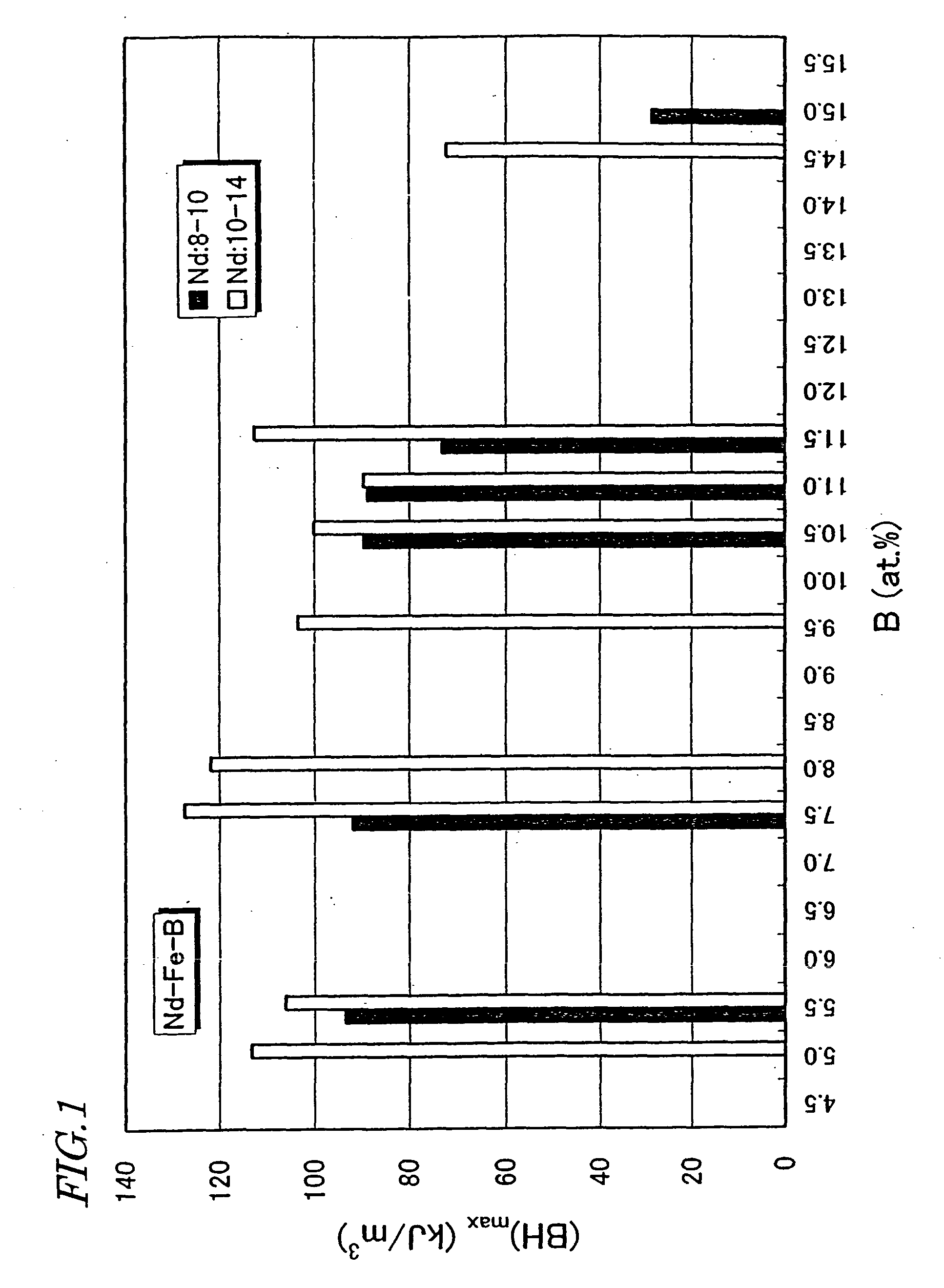

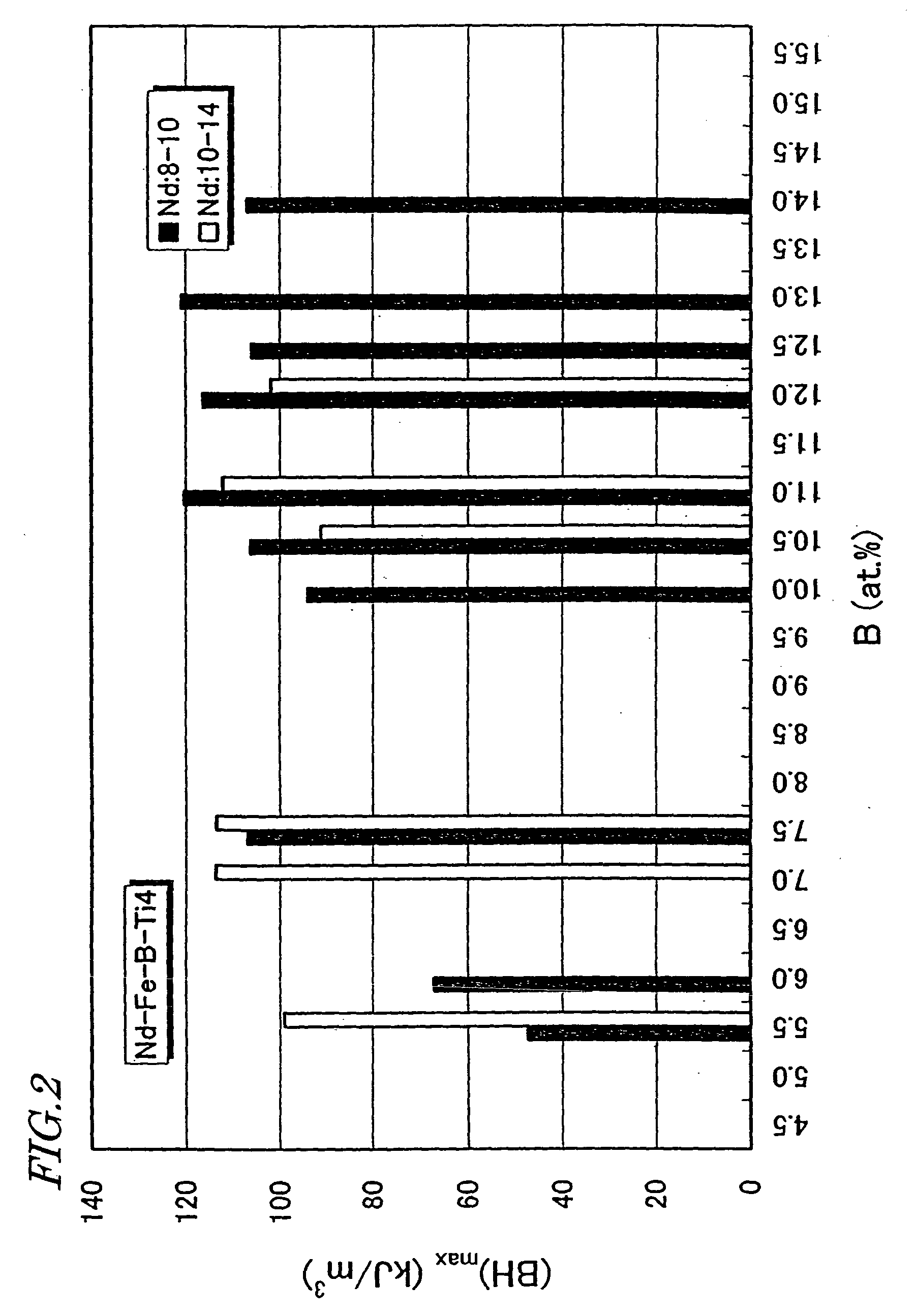

InactiveUS20050040923A1Enhanced magnetizationDecrease mole fractionNanostructure manufactureNanomagnetismRare-earth elementMagnetic phase

A nanocomposite magnet represented by the general formula: (Fe1-mTm)100-x-y-z-w-n(B1-pCp)xRyTizVwMn, where T is Co and / or Ni; R is a rare-earth element; M is at least one element selected from Al, Si, Cr, Mn, Cu, Zn, Ga, Nb, Zr, Mo, Ag, Ta and W; and x, y, z, w, n, m and p satisfy: 10 at %<x≦15 at %; 4 at %≦y<7 at %; 0.5 at %≦z≦8 at %; 0.01 at %≦w≦6 at %; 0 at %≦n≦10 at %; 0≦m≦0.5; and 0.01≦p≦0.5, respectively. The magnet includes a hard magnetic phase with an R2Fe14B type crystal structure and a soft magnetic phase. At least one of the coercivity and the maximum energy product of the nanocomposite magnet is at least 1% higher than that of a magnet including no V.

Owner:SUMITOMO SPECIAL METAL CO LTD

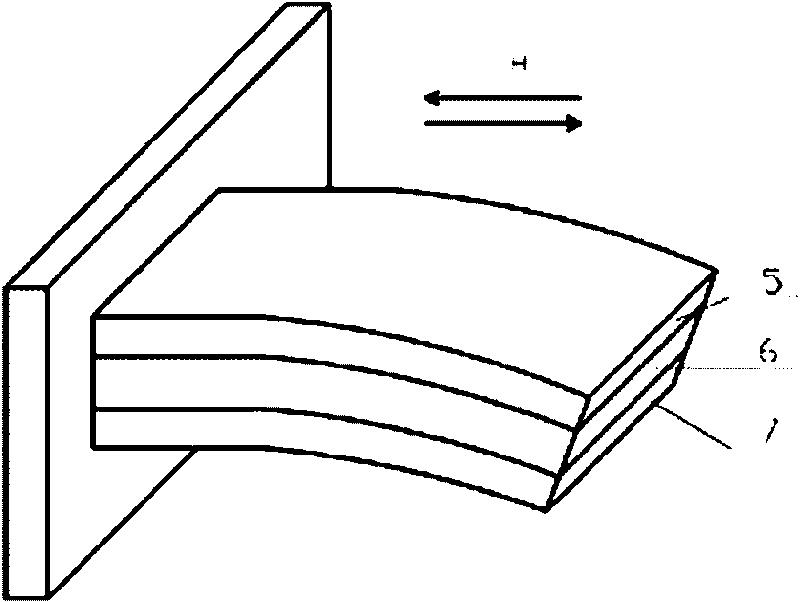

Piezoelectric giant magnetostrictive combined wideband vibration energy collector

InactiveCN101764532AIncrease output powerIncrease powerPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamEnergy technology

The invention provides a piezoelectric giant magnetostrictive combined wideband vibration energy collector, belonging to the technical field of energy. The collector comprises a frame, a bistable beam, a cantilever beam and a permanent magnet, wherein two ends of the bistable beam are fixed on the frame; the permanent magnet is attached on the bistable beam; one end of the cantilever beam is fixed on the frame, and the other end thereof is arranged by means of suspension; and a positive wire magnetostrictive layer, a piezoelectric layer and a negative wire magnetostrictive layer are connected with each other in sequence. The collector adopts a bistable structure, realizes the conversation of magnetism, machine and electricity with the product characteristic of the magnetostrictive effect of a piezomagnetic phase and the piezoelectric effect of a piezoelectric phase in composite material, and leads an MEMS energy conversation component to be capable of obtaining a lager output power under the environment of low-frequency vibration. The collector not only has simple structure, easy manufacture and small volume, but also can run in the low-frequency environment, and can output larger stable power within the range of wider environment vibration frequency.

Owner:SHANGHAI JIAO TONG UNIV

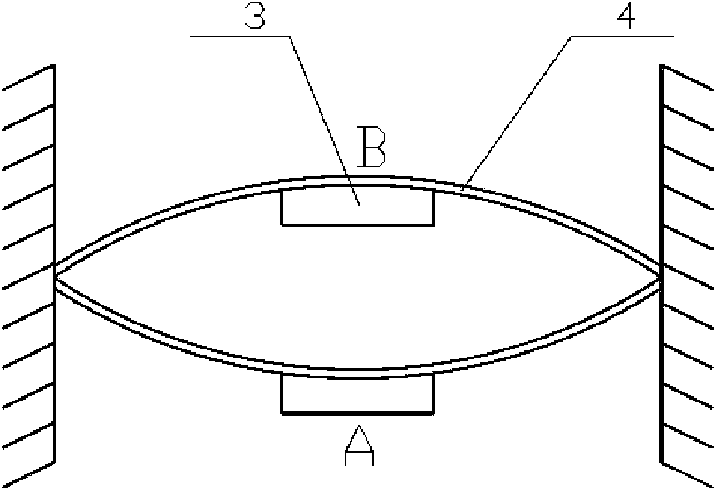

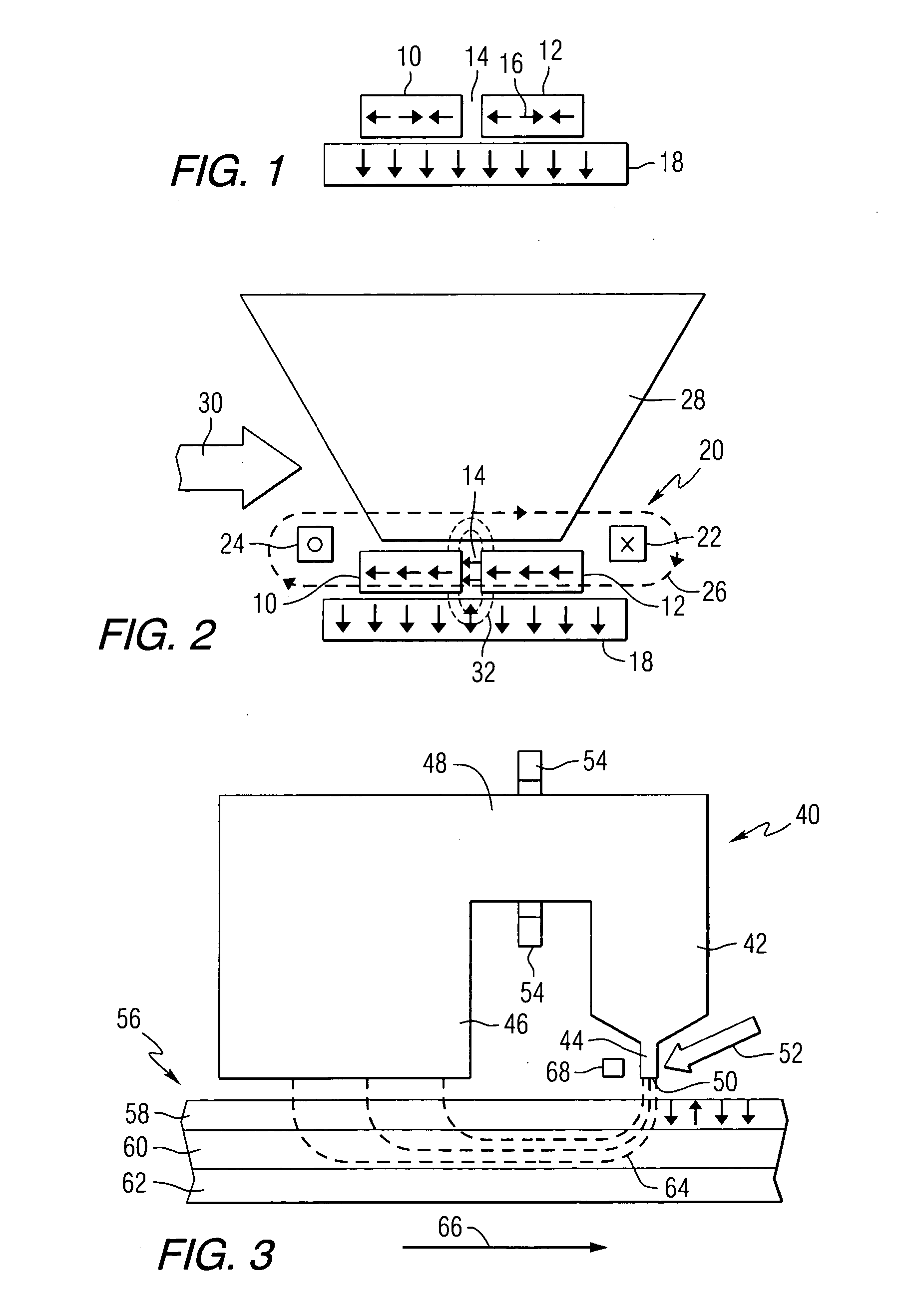

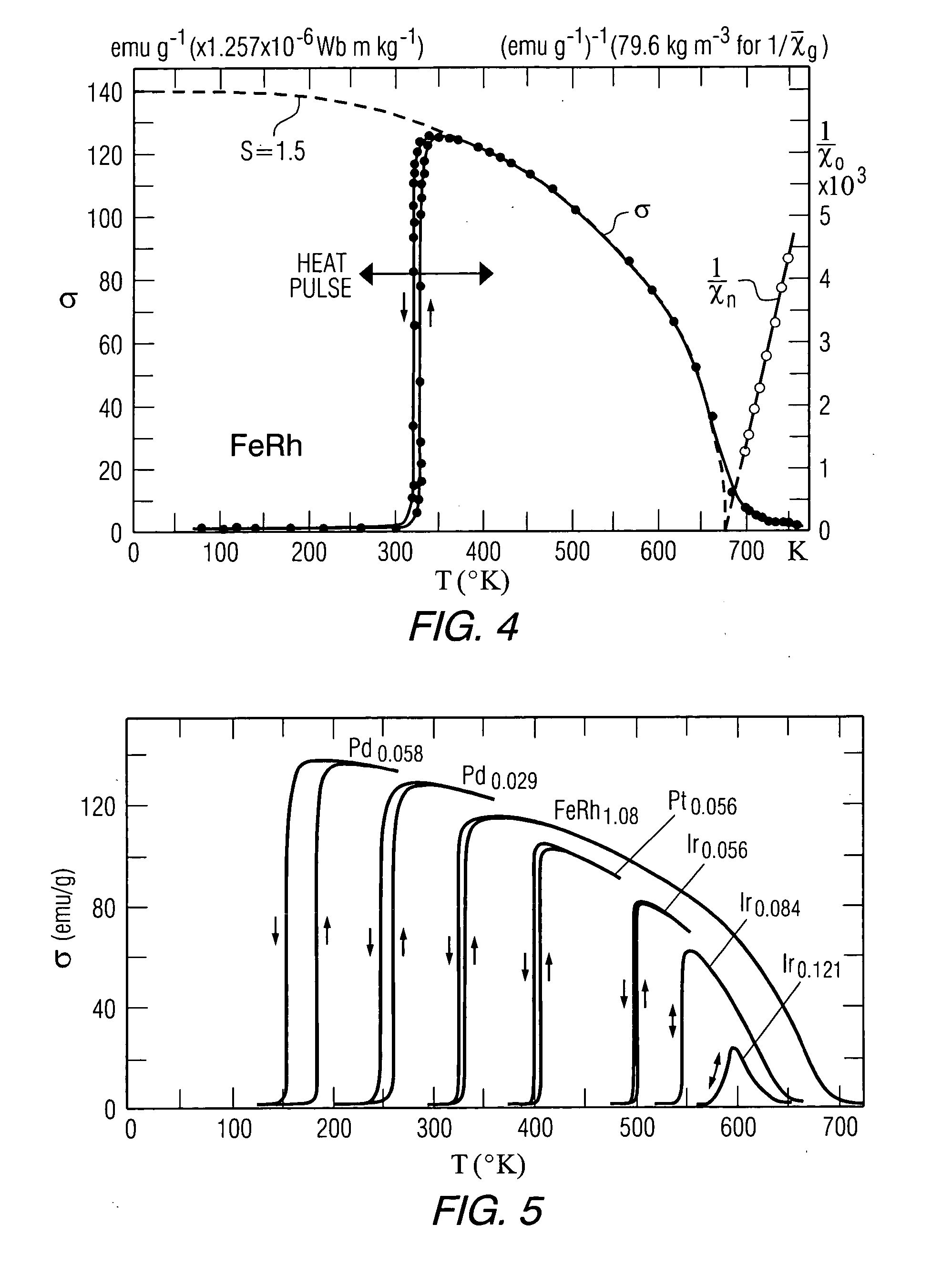

Ultrafast pulse field source utilizing optically induced magnetic transformation

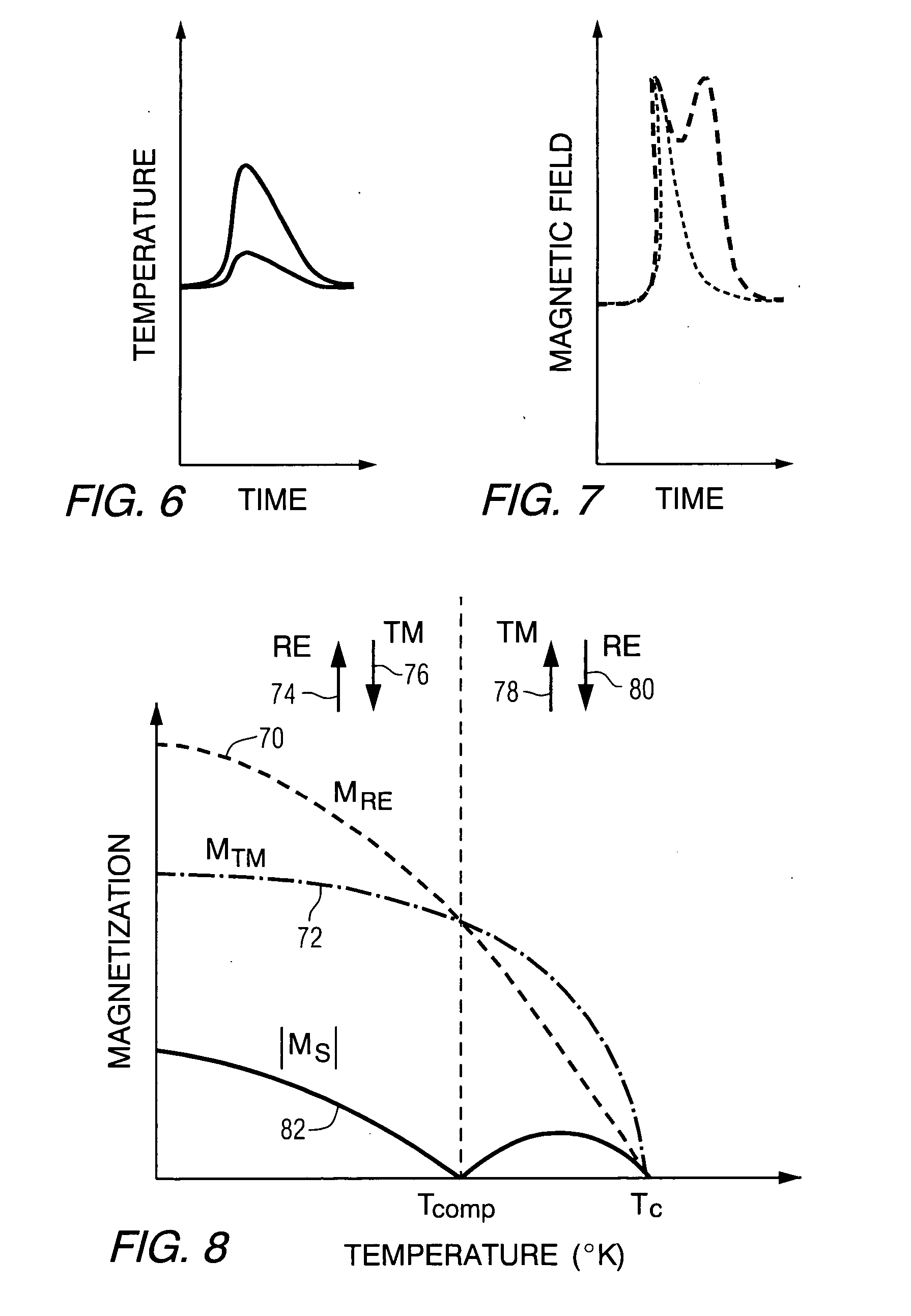

A magnetic field transducer includes a phase transition material exhibiting a change from an antiferromagnetic phase to a ferromagnetic phase when heated above a critical temperature, means for applying a magnetic bias field to the phase transition material, and means for heating the phase transition material above the critical temperature. Magnetic recording heads that include the transducer and magnetic disc drives that include the magnetic recording heads are also described. A method of producing a magnetic field pulse including applying a magnetic bias field to a phase transition material, and heating the phase transition material to cause the phase transition material to change from an antiferromagnetic phase to a ferromagnetic phase, is also provided. The phase transition material can comprise a rare earth-transition metal alloy, where the alloy is heated above a compensation temperature.

Owner:SEAGATE TECH LLC

Nitride type, rare earth magnet materials and bonded magnets formed therefrom

InactiveUS6413327B1Improve the magnetization effectImprove suppression propertiesInorganic material magnetismRare-earth elementMagnetic phase

A nitride-type, rare earth magnet material having a basic composition represented by RalphaT100-(alpha+beta+gamma+delta)MbetaBgammaNdelta (atomic %), wherein R is at least one rare earth element including Y, as a rare earth element Sm must be present, T is Fe alone or a combination of Fe and Co and / or Ni, M is at least one element selected from the group consisting of Al, Ti, V, Cr, Mn, Cu, Ga, Zr, Nb, Mo, Hf, Ta, W and Zn, 6<=alpha<=15, 0.5<=beta<=10, 0<=gamma<=4, and 4<=delta<=30, which is substantially composed of a hard magnetic phase of an R2T17-type structure having an average crystal grain size of 0.01-1 mum, an average area ratio of alpha-Fe being 5% or less.

Owner:HITACHI METALS LTD

Iron-based permanent magnets and their fabrication as well as iron-based permanent magnet alloy powders for permanent bonded magnets and iron-based bonded magnets

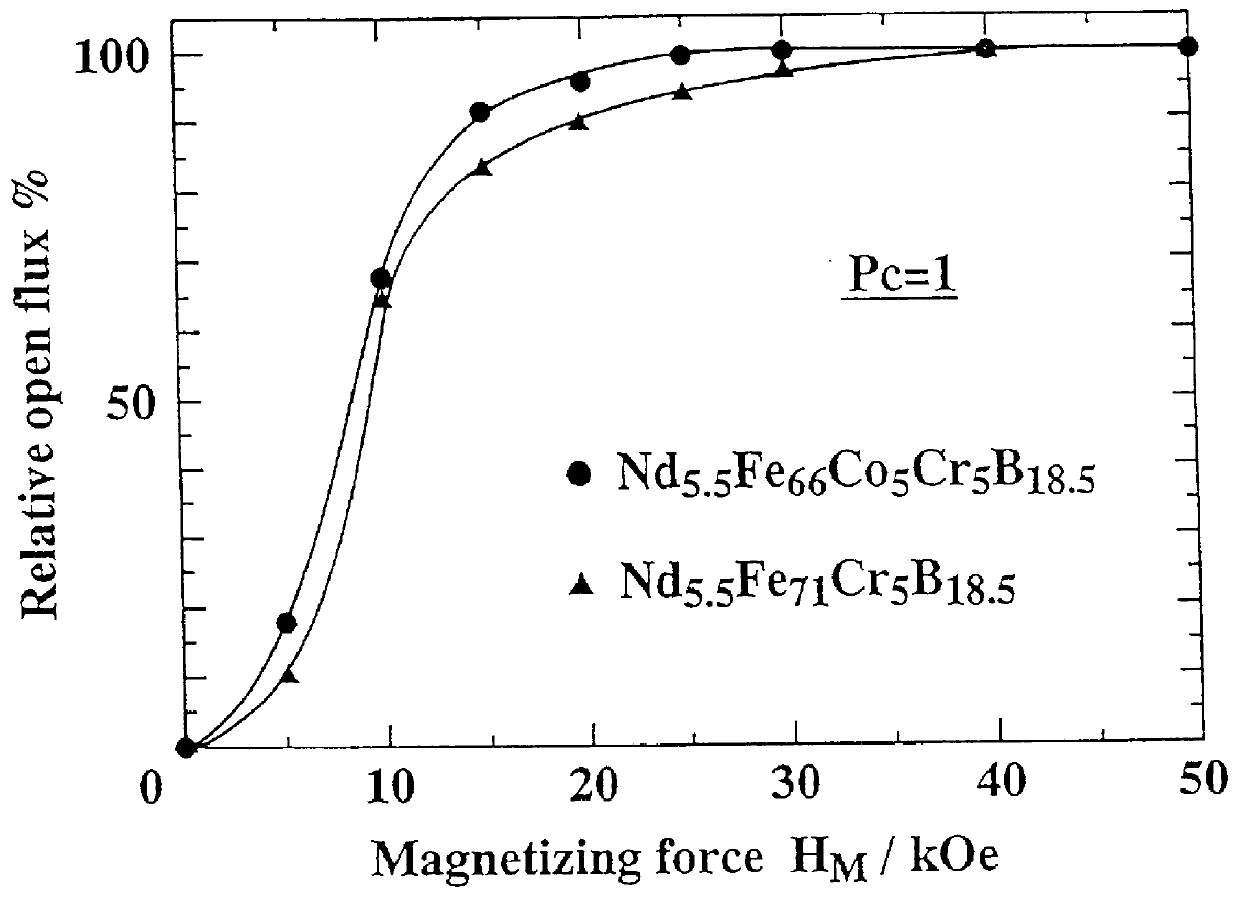

With the intention of establishing fabrication methods for cheaply produced (Fe,Co)-Cr-B-R-type bonded magnets or (Fe,Co)-Cr-B-R-M-type bonded magnets containing few rare earth elements and having a coercive force iHc above 5 kOe and a residual magnetic flux density Br above 5.5 kG matching the cost performance of hard ferrite magnets, we have obtained iron-based permanent magnets consisting of microcrystal clusters where the average crystal size of each component phase is in the range 1 nm DIFFERENCE 30 nm and where both a soft magnetic phase consisting of a ferromagnetic alloy whose main components are alpha -Fe and a ferromagnetic alloy having iron, and a hard magnetic phase having a Nd2Fe14B-type crystal structure coexist within the same powder particles, by melt-quenching of a (Fe,Co)-Cr-B-R(Pr,Nd)-type molten alloy or a (Fe,Co)-Cr-B-R-M (M=Al,Si,S,Ni, Cu,Zn,Ga,Ag,Pt,Au,Pb)-type molten alloy of a particular composition containing few rare earth elements, to obtain an essentially amorphous structure or a structure both amorphous and with small amounts of fine crystals, and by applying a crystallization heat treatment under specific conditions. By grinding this iron-based permanent magnet to an average powder particle size of 3 mu m DIFFERENCE 500 mu m and combining the resultant iron-based permanent magnet alloy powder with a resin, we can obtain an iron-based bonded magnet with good thermal and magnetic properties and with the magnetic characteristics iHc> / =5 kOe, Br> / =5.5 kG and (BH)max> / =6 MGOe.

Owner:SUMITOMO SPECIAL METAL CO LTD

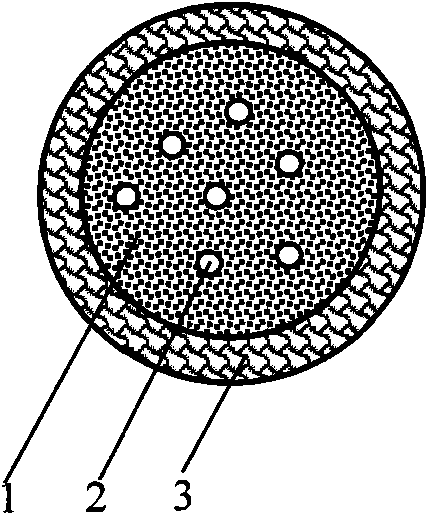

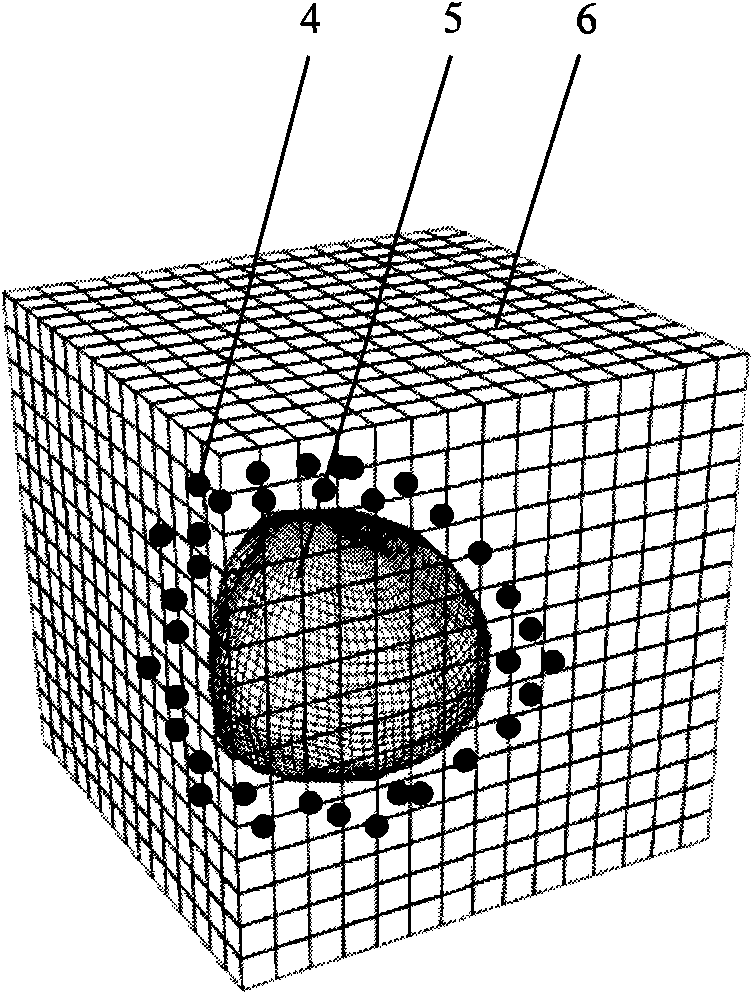

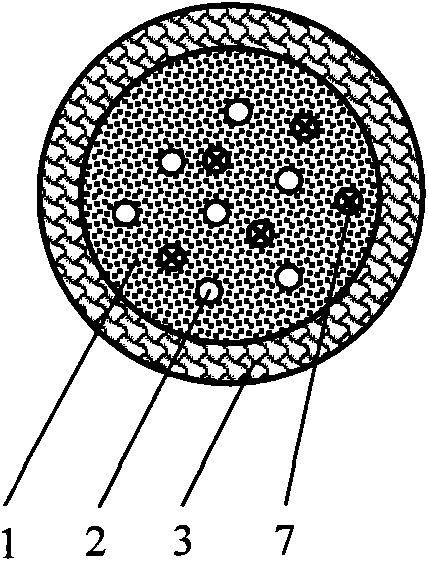

Magnetic phase-change microcapsule for performing thermal protection on normal structure in thermal physical therapy

InactiveCN101836915AGood biocompatibilityLow toxicityUltrasound therapySurgical instrument detailsMean diameterMagnetic phase

The invention discloses a magnetic phase-change microcapsule for performing thermal protection on a normal structure in thermal physical therapy. The magnetic phase-change microcapsule is a spherical microcapsule which is composed of a phase-change material (1), magnetic particles (2) and a liposome shell (3), and the mean diameter thereof is 1nm-1mm. In the invention, the phase-change material (1) is solid-liquid or / and liquid-solid phase-change material with high phase change heat and the phase change temperature at -10-0 DEG C or 38-100 DEG C according to different thermal physical therapeutic processes such as thermal therapy, cold therapy, cryosurgery or cold-heat alternating therapy and the like; the magnetic particles (2) are magnetic micro / nano-particles or magnetotactic bacteria; and a liposome is taken as a capsule carrier for lowering toxicity of the material and protecting an encapsulated material. The invention provides a safe and effective thermal protection material with novel concept. In the invention, the magnetic phase-change microcapsule can be gathered into a target organ with blood circulation under the action of an applied magnetic field; phase-change latent heat and low thermal conductivity of the phase-change material are adopted to carry out thermal protection on the normal structure; and the material is widely applied to thermal physical therapy, and the application method thereof is simple, feasible and reliable.

Owner:CHONGQING UNIV

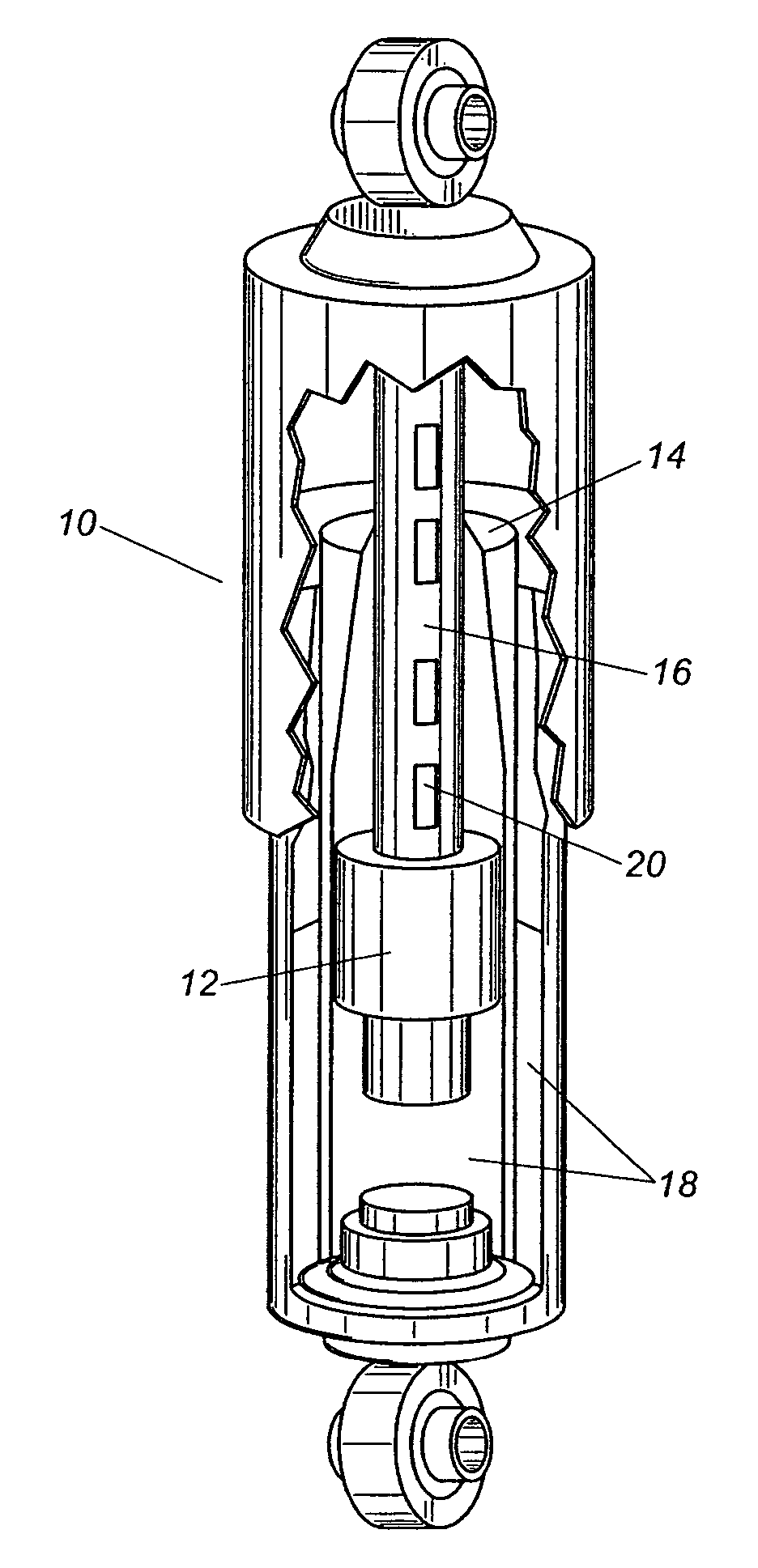

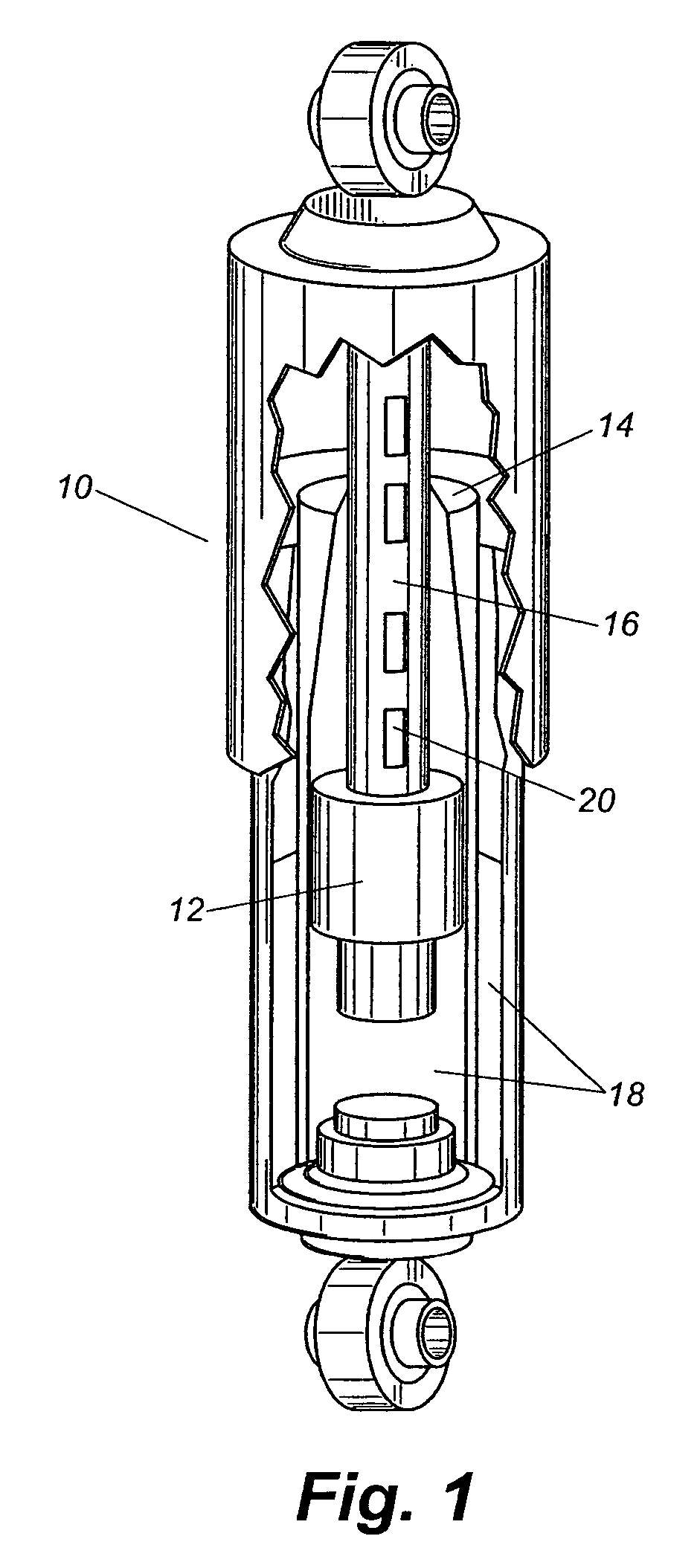

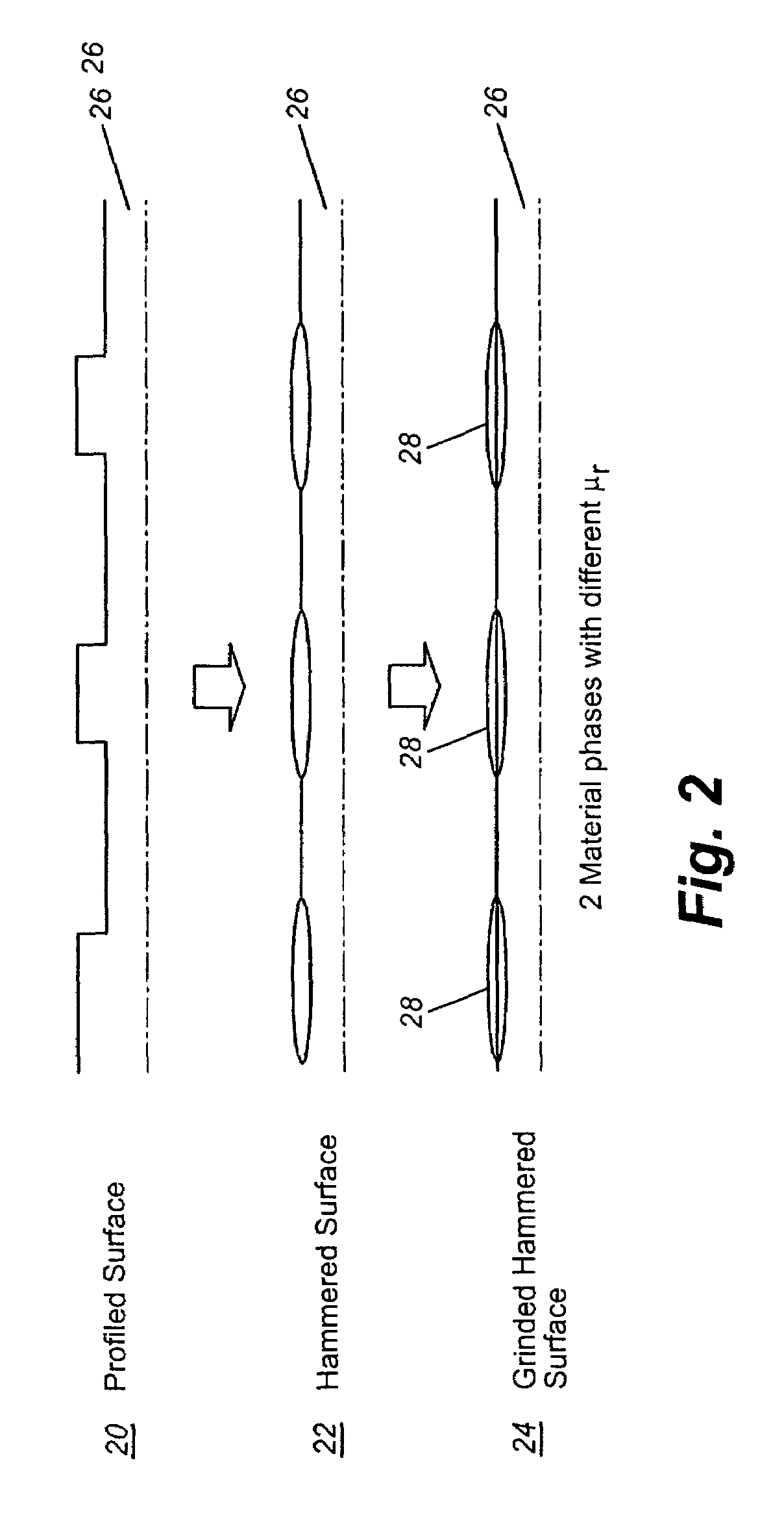

Shock absorber with integrated displacement sensor

A shock absorber include a cylinder, a piston rod coupled to the cylinder, and a piston coupled to the piston rod. The piston rod is magnetically encoded so that it includes a plurality of magnetic phase shifts. The phase shifts allow the position of the piston rod relative to the cylinder to be determined so that it can function as a displacement sensor.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

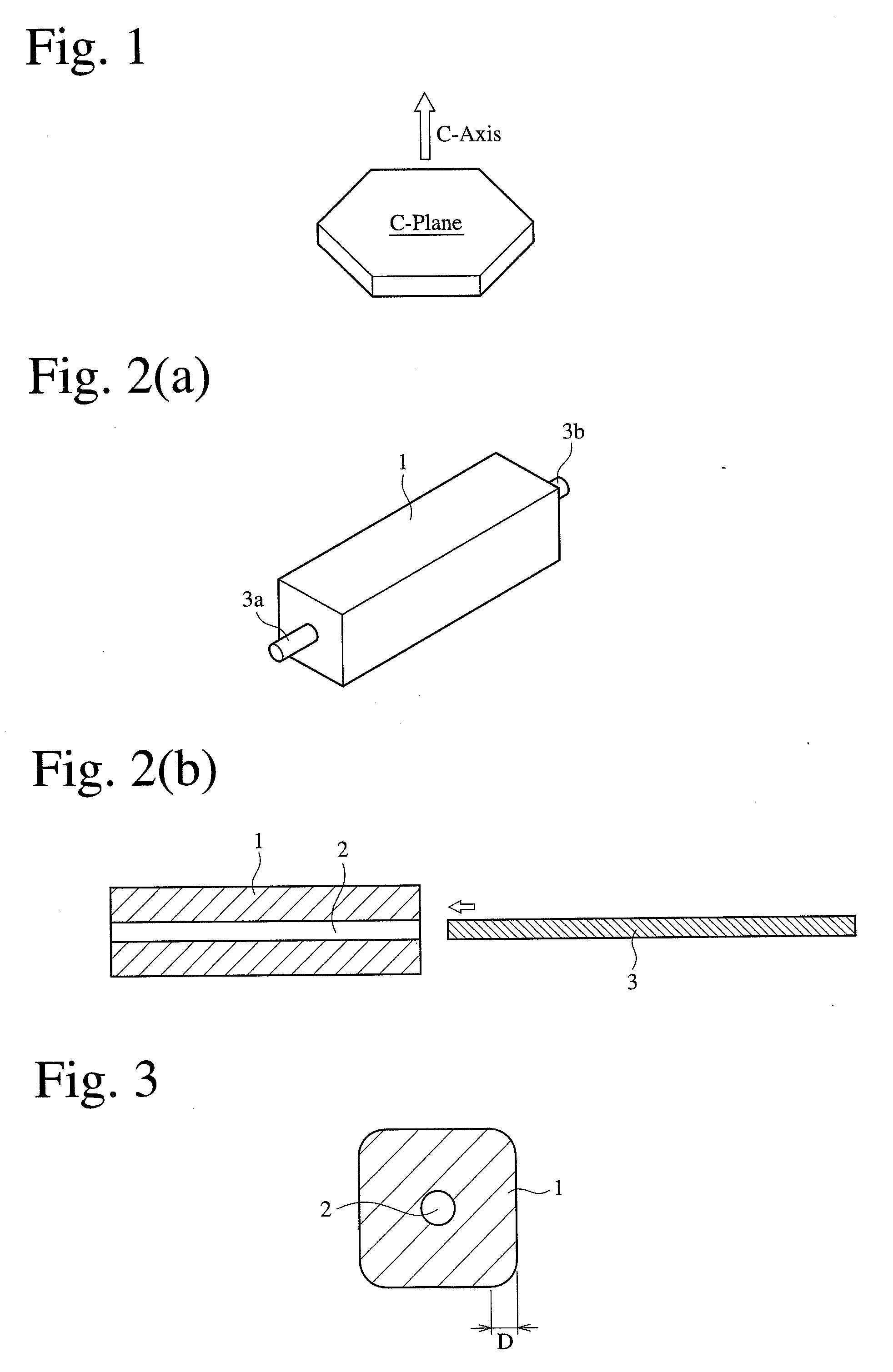

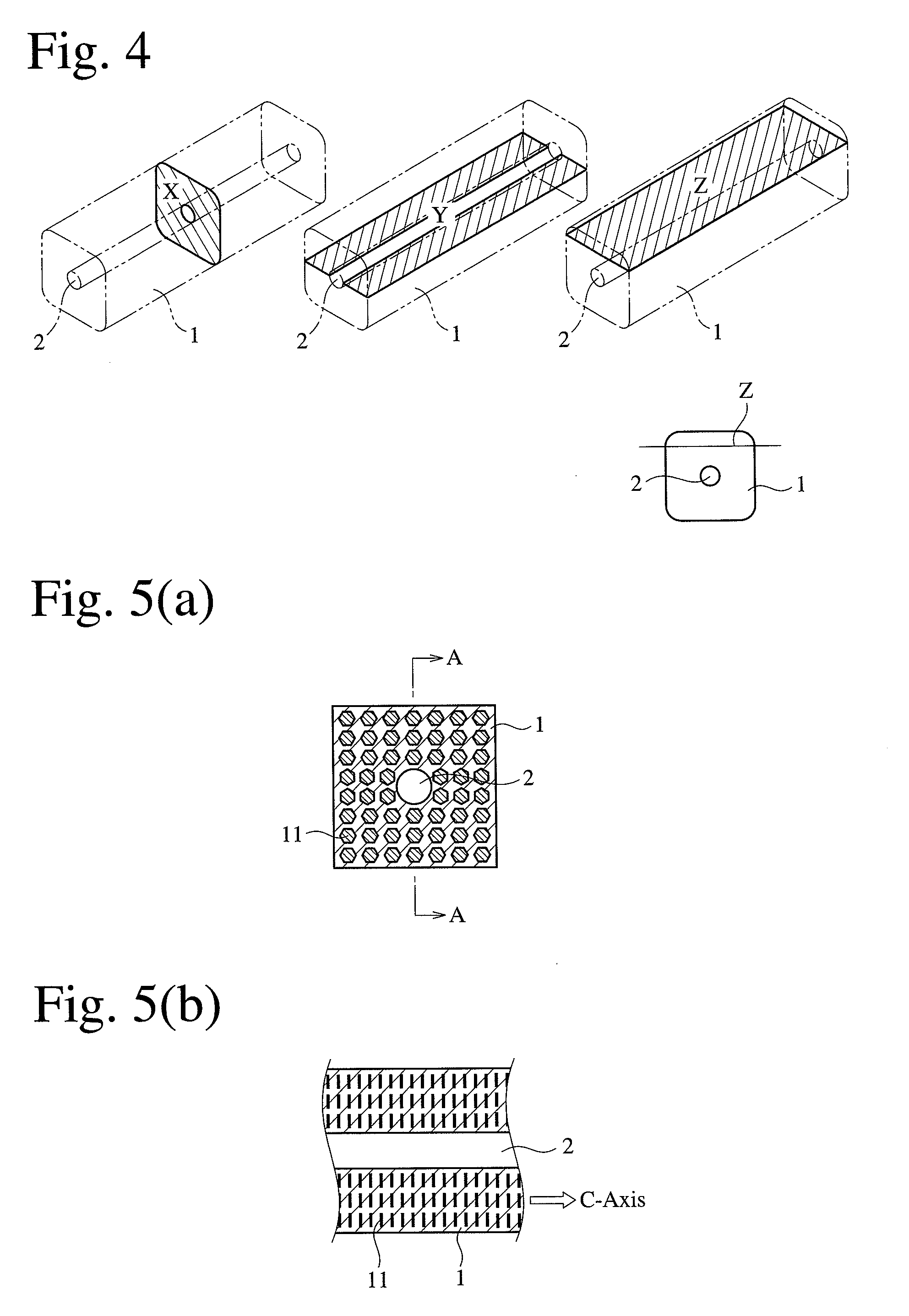

Chip antenna and its production method, and antenna apparatus and communications apparatus comprising such chip antenna

InactiveUS20100156733A1Improve reliabilityAntenna can be miniaturizedHollow filament manufactureFilament/thread formingElectrical conductorMagnetic phase

A chip antenna comprising a magnetic substrate comprising Z-type ferrite or Y-type ferrite as a main phase and having a through-hole extending linearly along a center axis, and a conductor penetrating the through-hole, the magnetic phase having a c-axis substantially parallel or perpendicular to the through-hole.

Owner:HITACHI METALS LTD

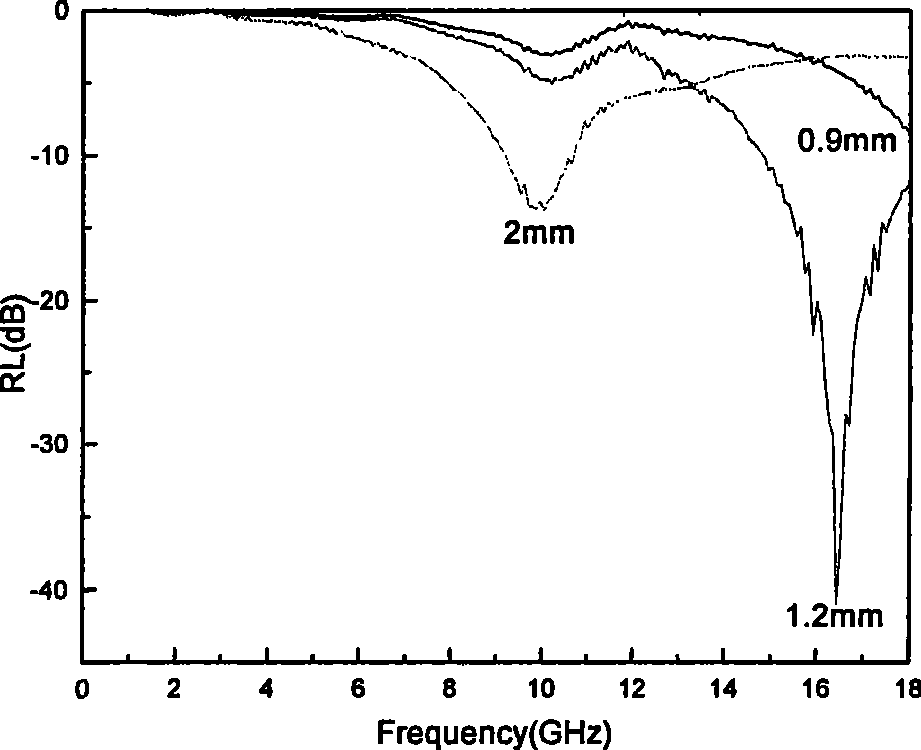

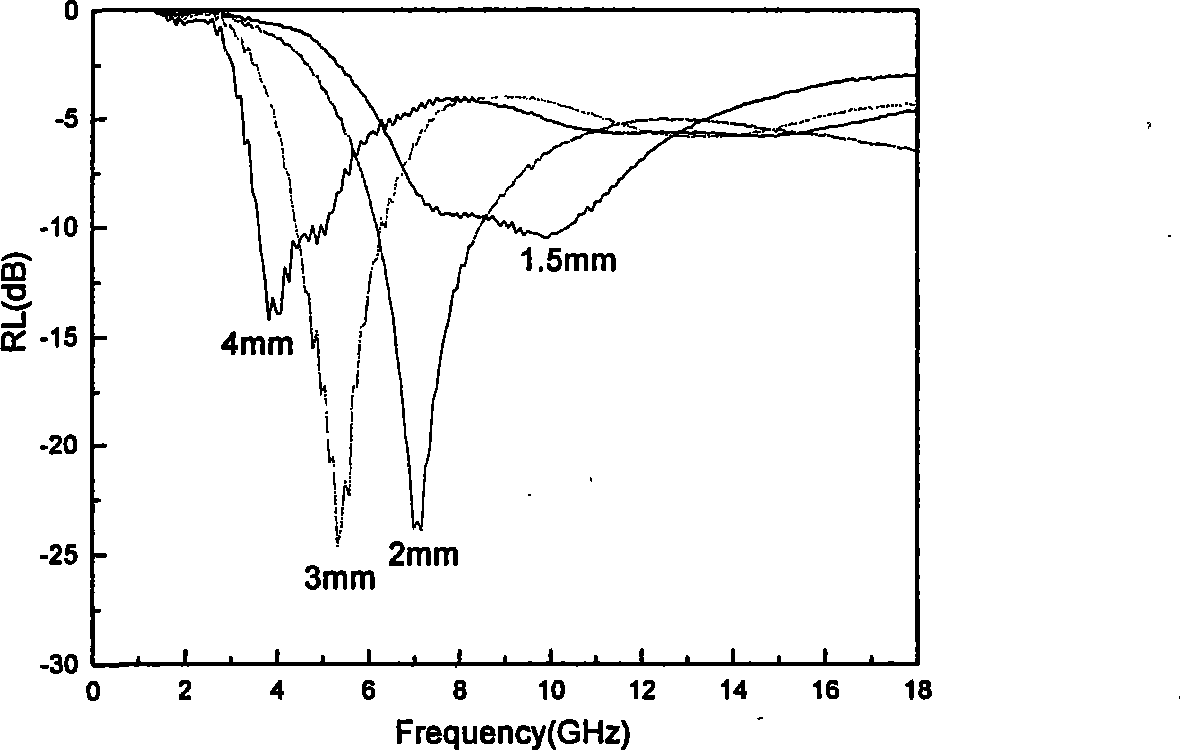

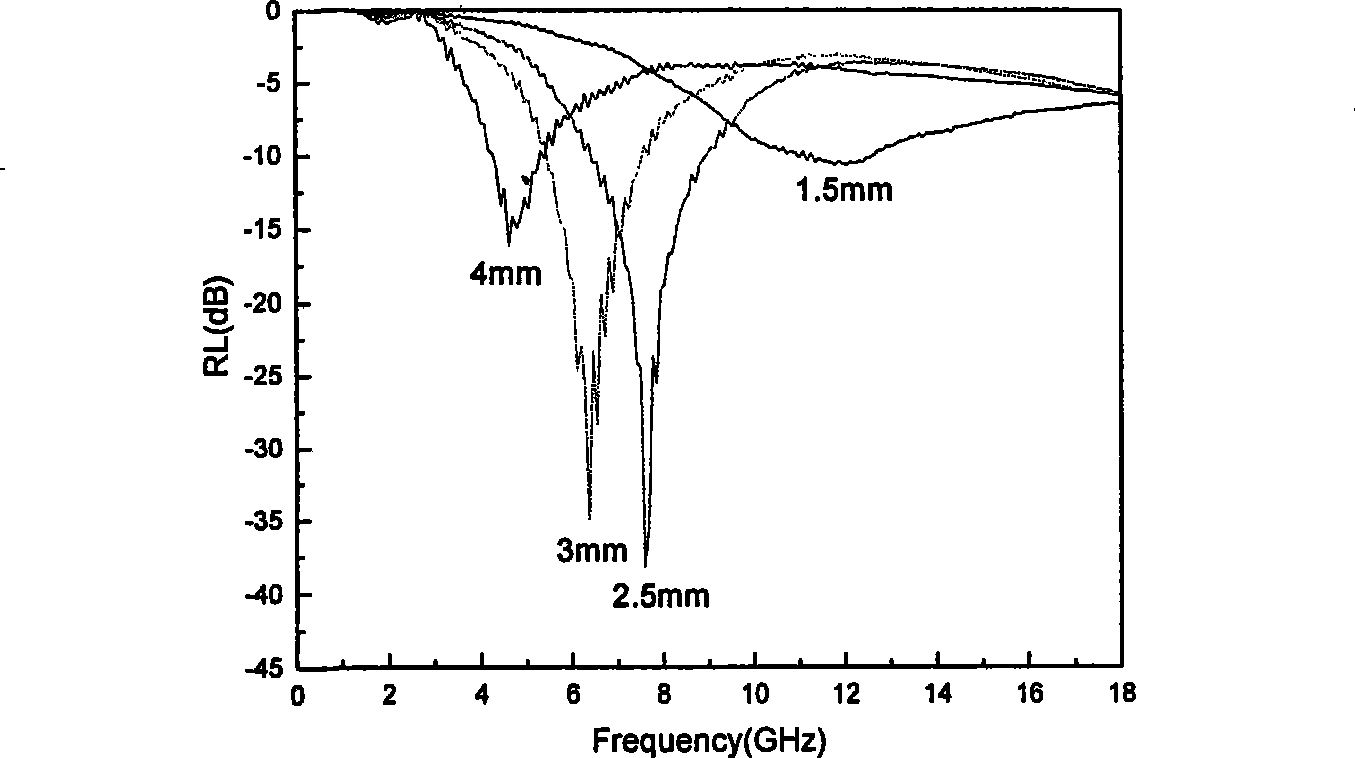

Wave suction composite material with nanocrystalline structure and method for producing the same

InactiveCN101429617AImprove absorbing performanceWide shielding bandMagnetic/electric field screeningInorganic material magnetismRare-earth elementMagnetic phase

The invention discloses a microwave absorbing composite material with a nanometer crystalline structure and a method for preparing the same. The method is characterized by comprising the following steps: smelting 2 to 70 weight portions of rare earth element, 5 to 98 weight portions of iron and 0 to 25 weight percent of microelement into cast ingots under the protection of argon gas; after heat treatment at a temperature of between 700 and 1,200 DEG C for 4 to 60 hours, reacting the prepared rare earth-iron alloy with hydrogen gas at a temperature of between 0 and 700 DEG C for 0.5 to 2 hours; crushing or ball milling the rare earth-iron alloy into fine powder; performing hydrogenation dismutation and dehydrogenation recombination on the fine powder at a temperature of between 500 and 1,000 DEG C for 1 to 5 hours; performing nitridation at a temperature of between 400 and 600 DEG C for 2 to 40 hours or performing the nitridation directly at the temperature of between 400 and 600 DEG C for 10 to 60 hours to produce rare earth iron-nitrogen magnetic powder with the nanometer crystalline structure; and heating up and decomposing the prepared rare earth iron-nitrogen magnetic powder at a temperature of between 100 and 750 DEG C for 5 to 60 minutes, or oxidizing the powder by air at a temperature of between 100 and 400 DEG C for 0.5 to 3 hours, and then preparing the powder into a three-phase coupled composite material consisting of dielectric phase rare earth nitride or rare earth oxide or rare earth oxynitride and magnetic phase alpha-Fe and rare earth hard magnetic phase with different contents through ball milling.

Owner:SICHUAN UNIV

Anisotropic rare earth sintered magnet and making method

InactiveCN102468027ASmooth topographyPermanent magnetsManufacturing dynamo-electric machinesRare-earth elementMagnetic phase

An anisotropic rare earth sintered magnet has a tetragonal R 2 Fe 14 B compound as a major magnetic phase, wherein R is Nd or a mixture of Nd with at least one rare earth element. Grains of the compound phase have two crystallographic axes, c and a-axes aligned. The biaxially aligned magnet exhibits a coercivity Hc of at least 1.6 MA / m.

Owner:SHIN ETSU CHEM CO LTD

Rare earth permanent magnetic alloy and magnetic phase composite preparation method thereof

ActiveCN103187133AImprove magnetic propertiesEfficient use ofMagnetic materialsRare-earth elementMagnetic phase

The invention relates to the technical field of a rare earth permanent magnetic material and relates to a magnetic phase composite rare earth permanent magnetic alloy and a preparation method thereof. The permanent magnetic alloy comprises the following chemical components in mass percentage: REaFe99-a-bB1Mb, wherein a is more than or equal to 28, but less than or equal to 32, b is more than 0, but less than or equal to 10, RE comprises at least two selected rare earth elements from La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, and M is one or more from Co, AL, Cu, Ga, Nb, Mo, Ti, Zr and V. Magnetic phase composite preparation is performed on the permanent magnetic alloy by crushing, mixing, sintering and thermally treating at least two rapid hardening strips with different components, wherein the rapid hardening strips are at least two 2-14-1-type magnetic main phases (RE) 2Fe14B containing different rare earths respectively. Through mutual proportioning of different proportions of rapid hardening strips, a magnet containing designed components is prepared; the magnet comprises two or more 2-14-1-type magnetic phases consisting of different rare earths, including a 2-14-1-type magnetic phase consisting of a single rare earth; and good comprehensive magnetic property is obtained on the premise of reducing the heavy rare earth content.

Owner:CENT IRON & STEEL RES INST

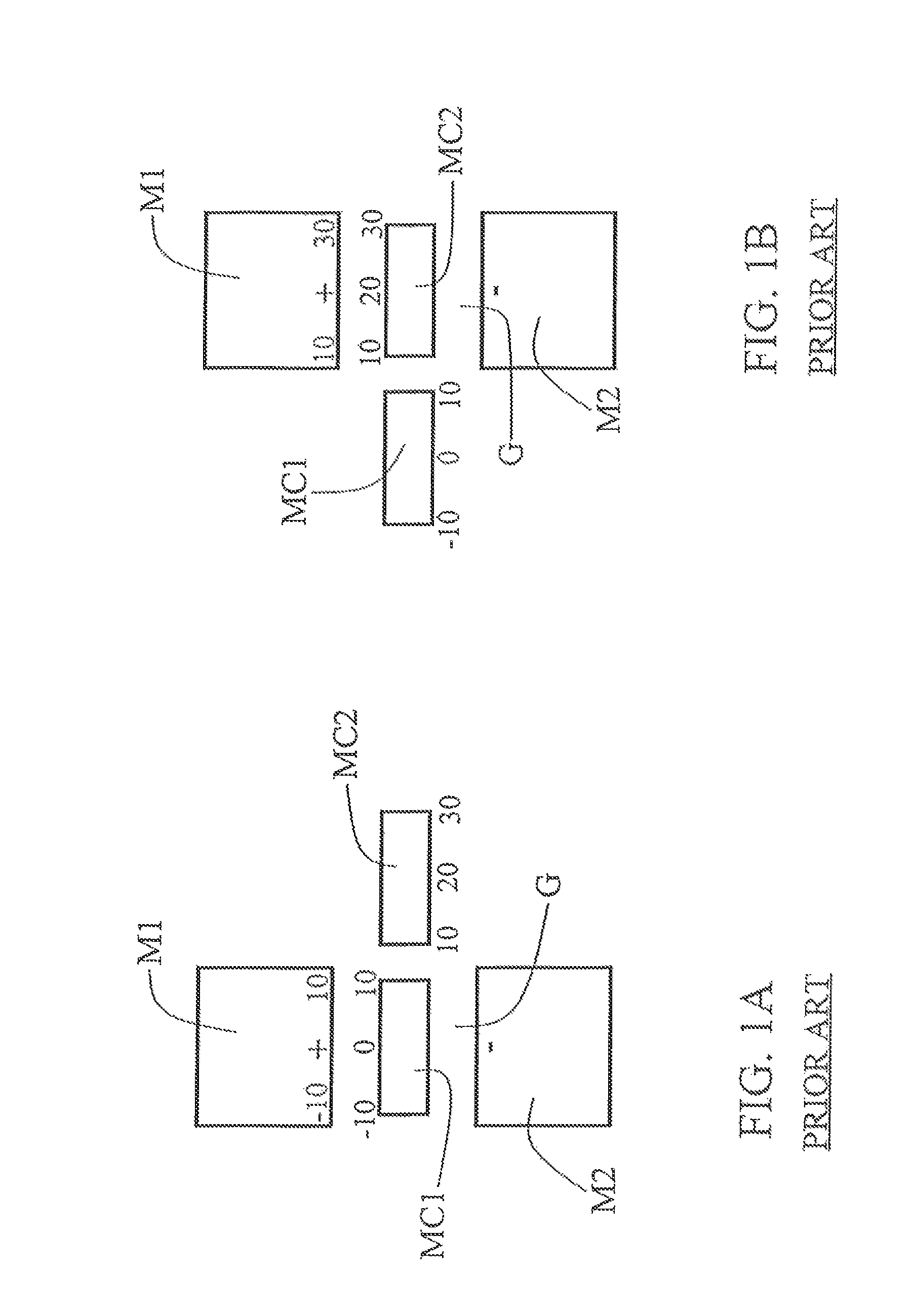

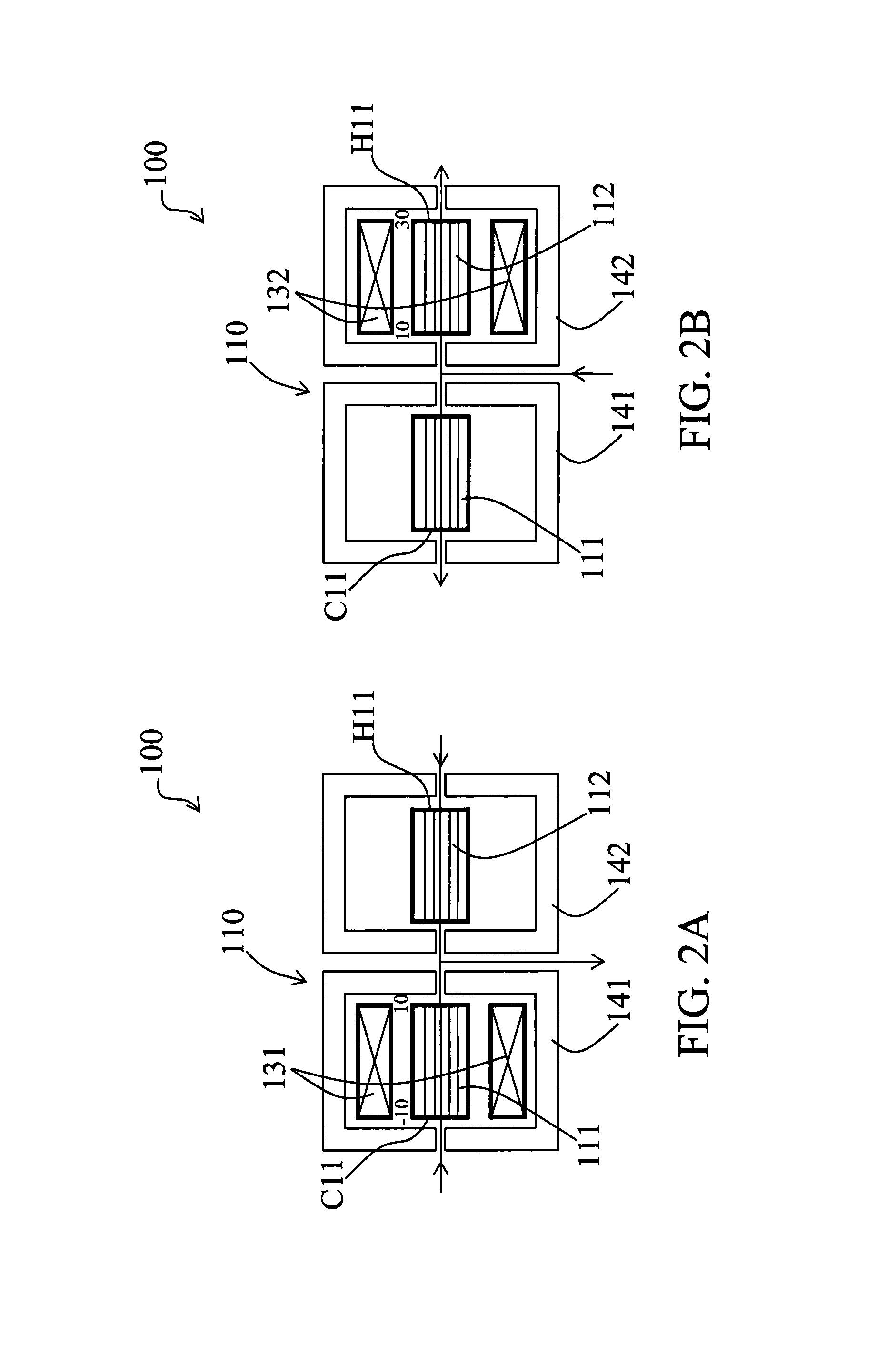

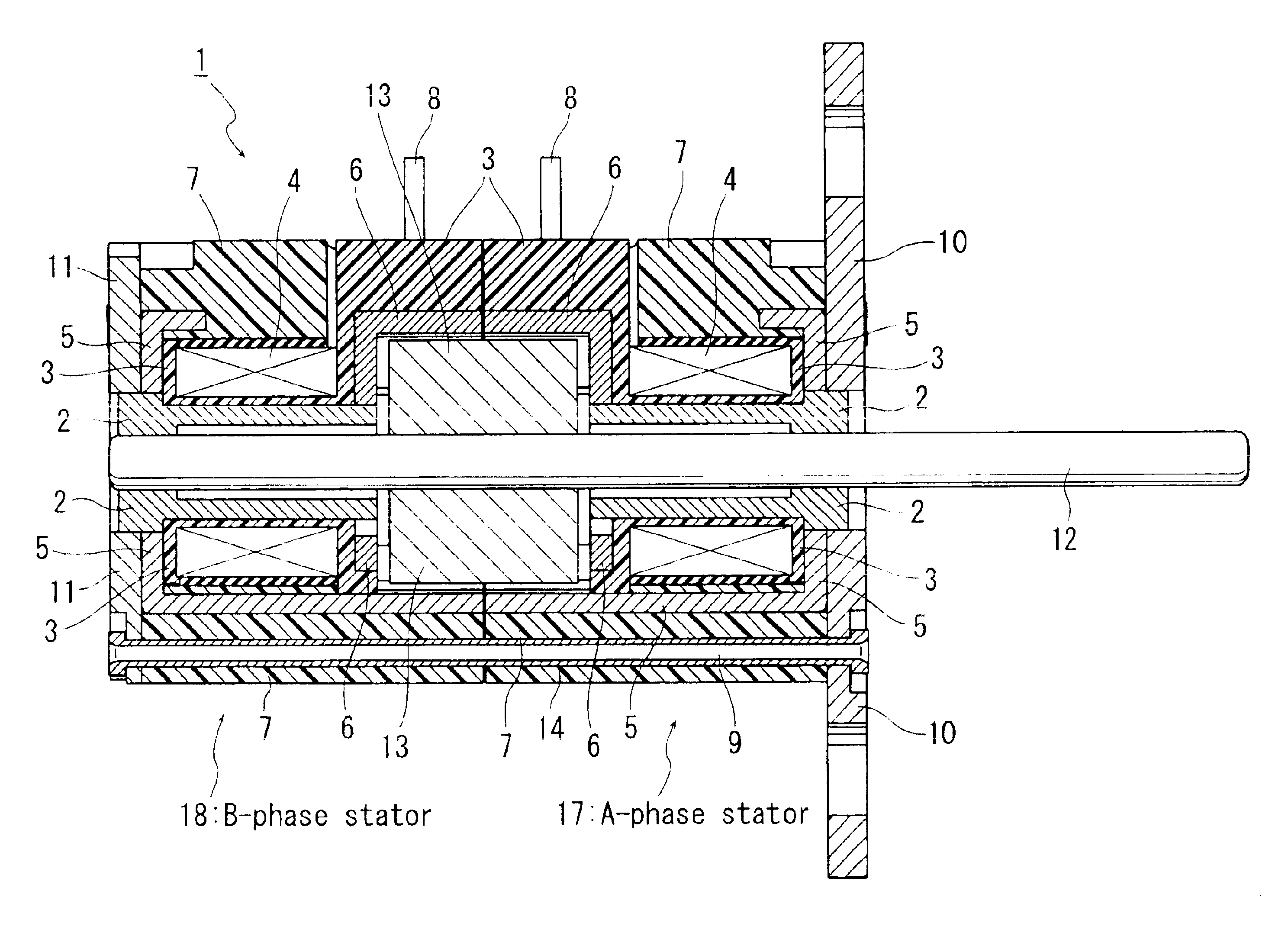

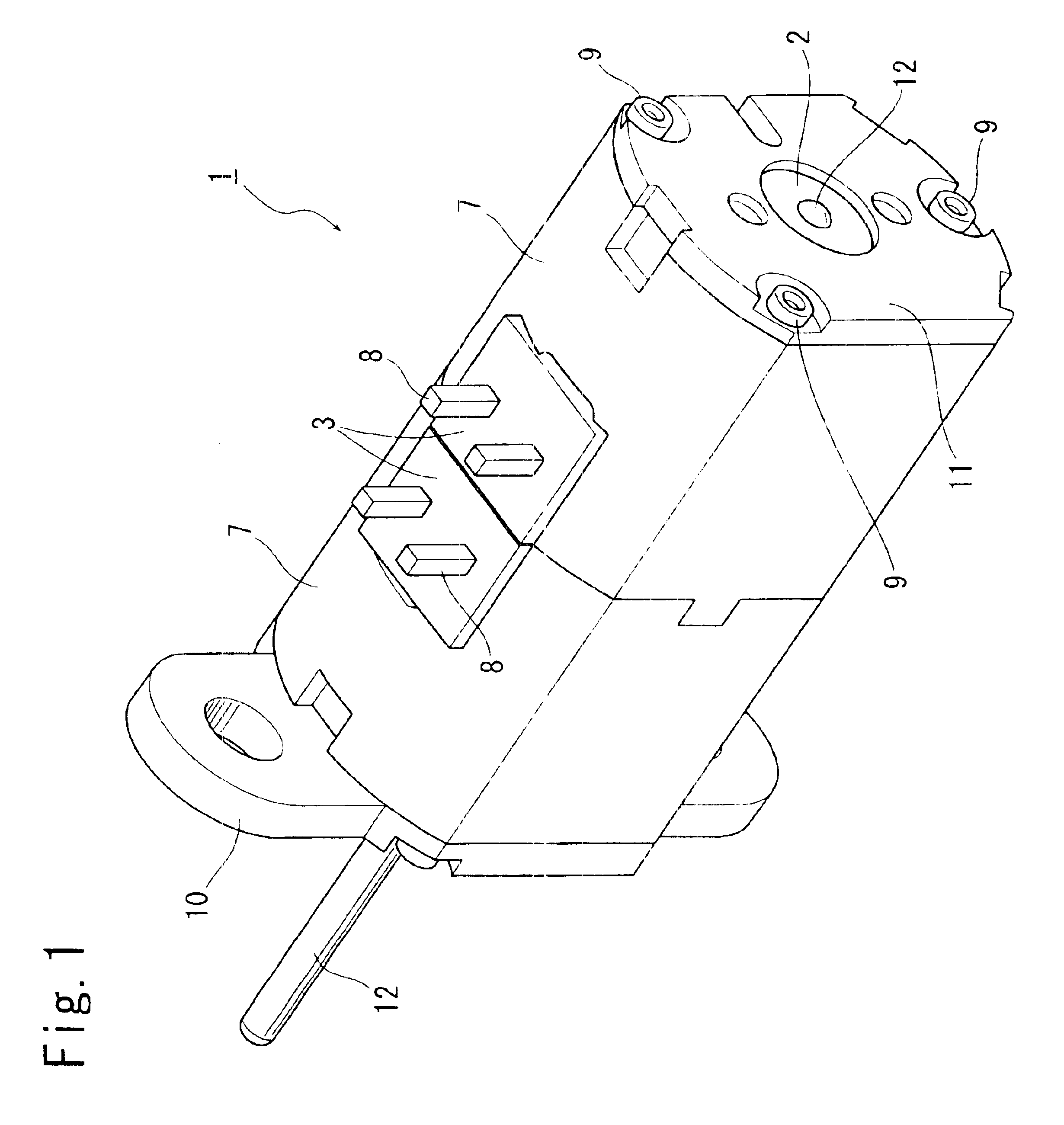

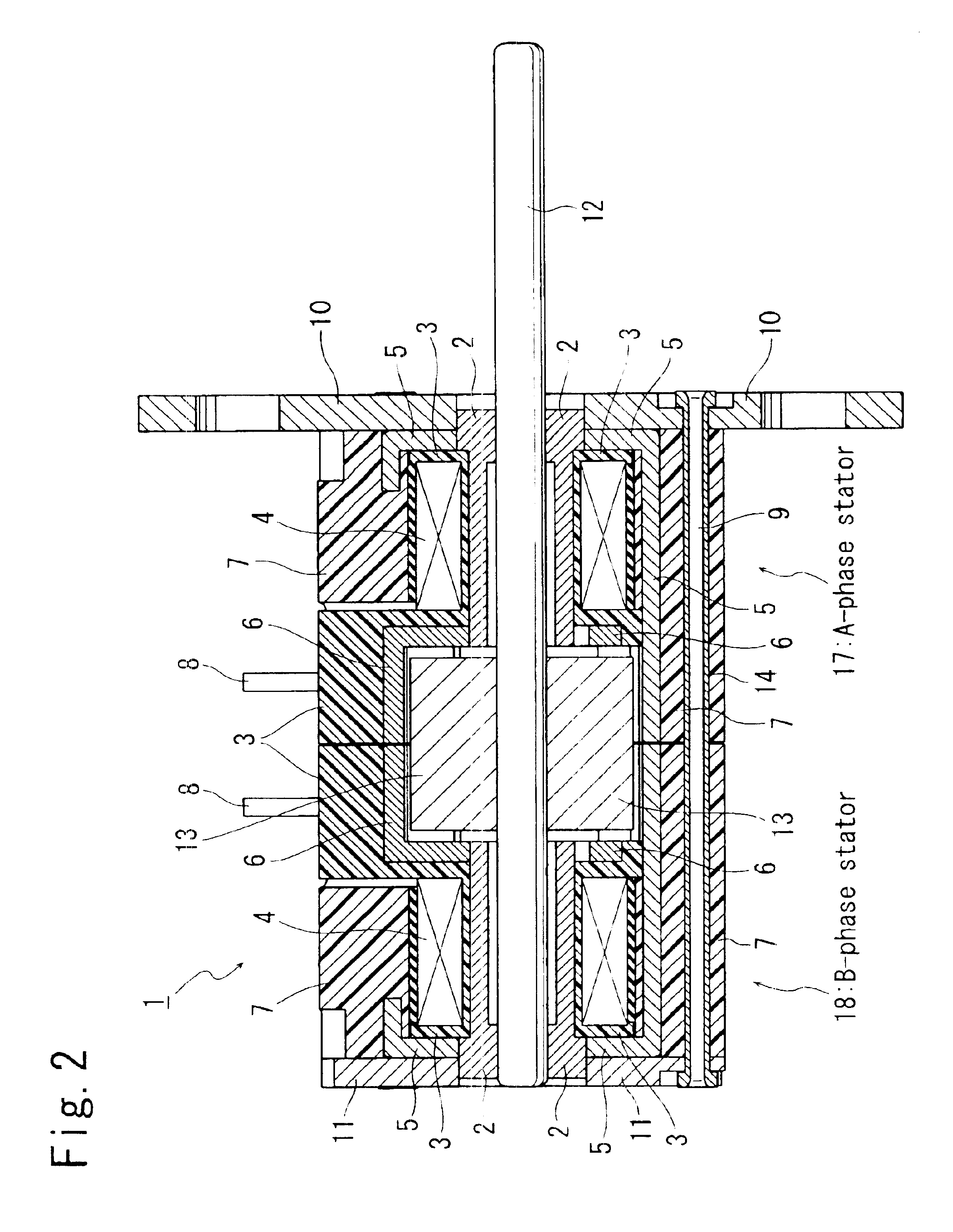

Claw-pole type stepping motor having radial dimension reduced without detriment to performance characteristic

InactiveUS6876109B2Reduces difficulty and troublesomenessReduce the overall diameterMagnetic circuit stationary partsMaster clocksMagnetic phaseStepper motor

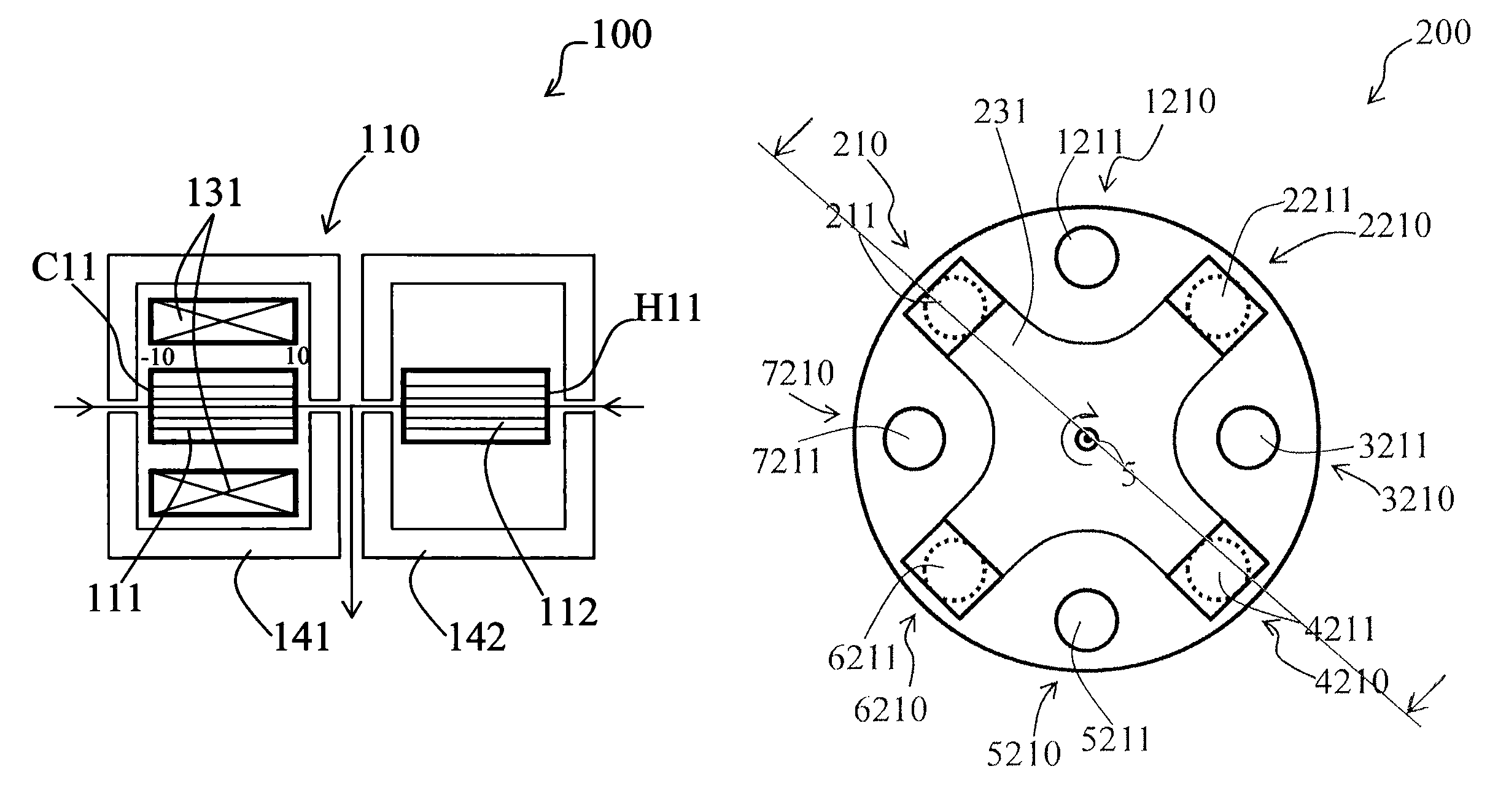

A claw-pole type stepping motor comprises: a rotor which is shaped substantially cylindrical, and which has a rotary shaft at its radial center; and two stators which are shaped like a cup, each have at least one magnetic coil, are coupled to each other so as to rotatably house the rotor with their magnetic coils located respectively toward both axial end faces of the rotor, and which each have two pole tooth arrays magnetically connected to each other such that magnetic phase difference therebetween at tips of respective pole teeth is 180 degrees in terms of electrical angle, and in the motor thus structure, three pipes of aluminum go axially through the two stators so as to hold together the two stators.

Owner:MINEBEA CO LTD

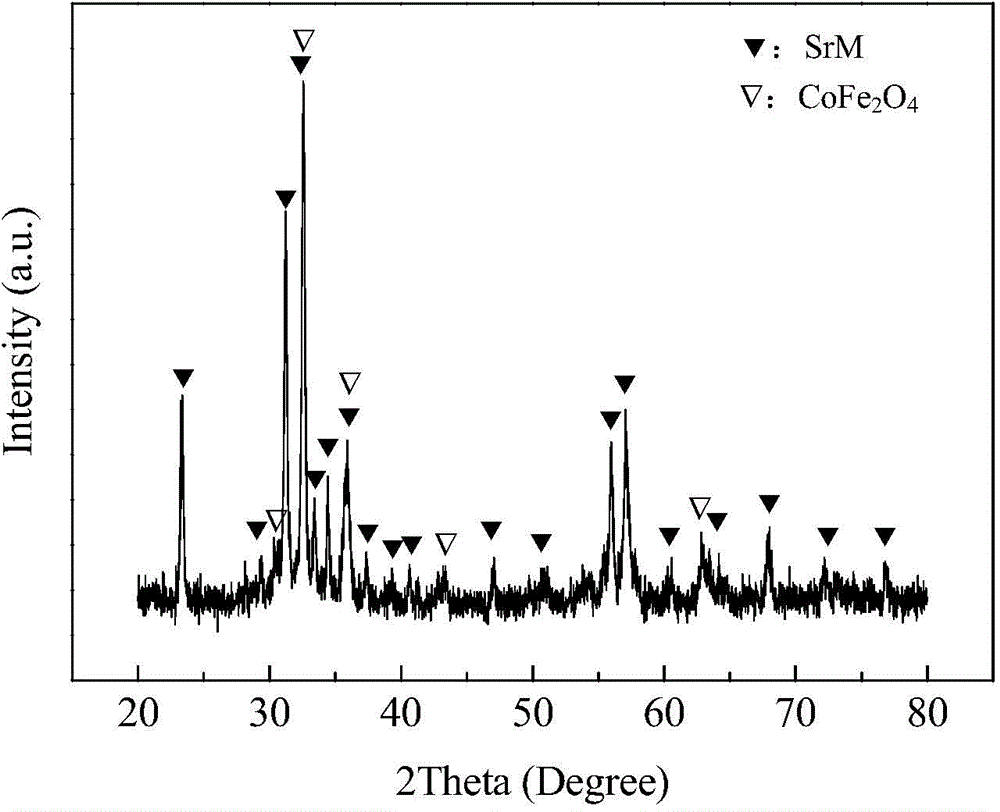

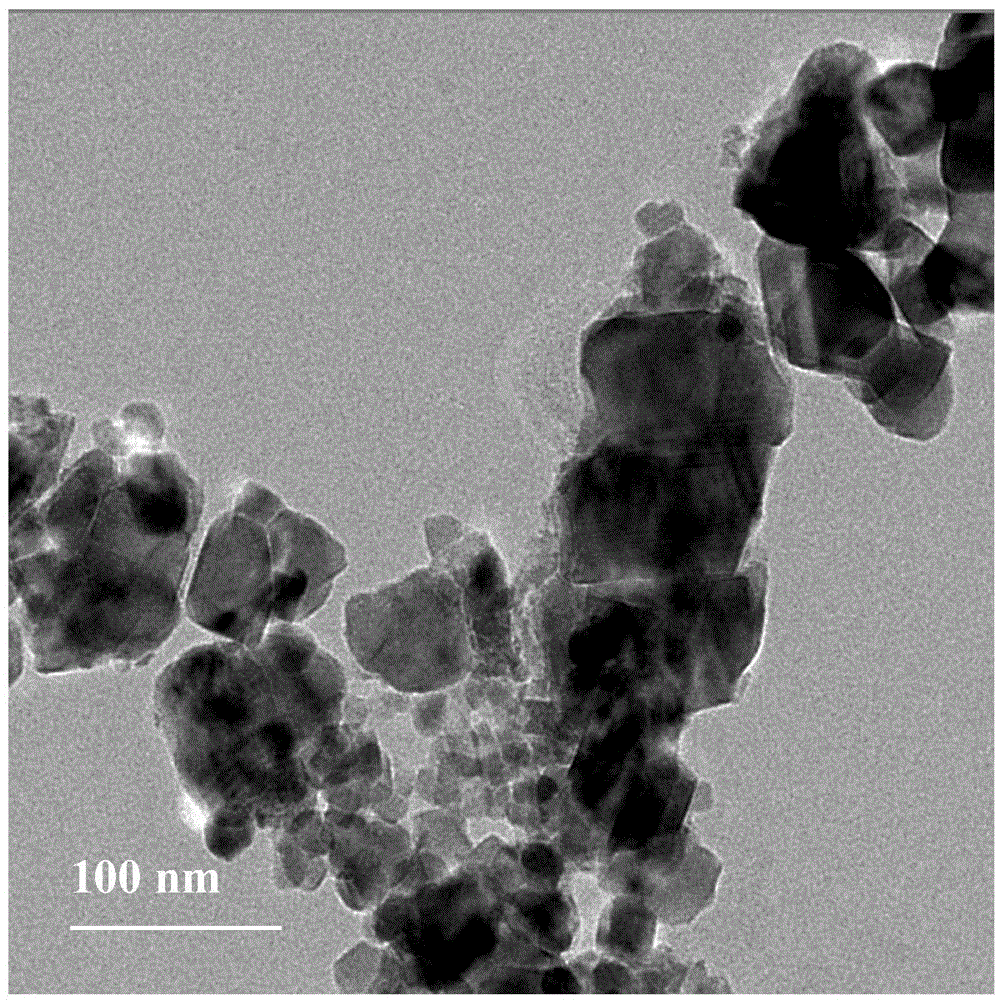

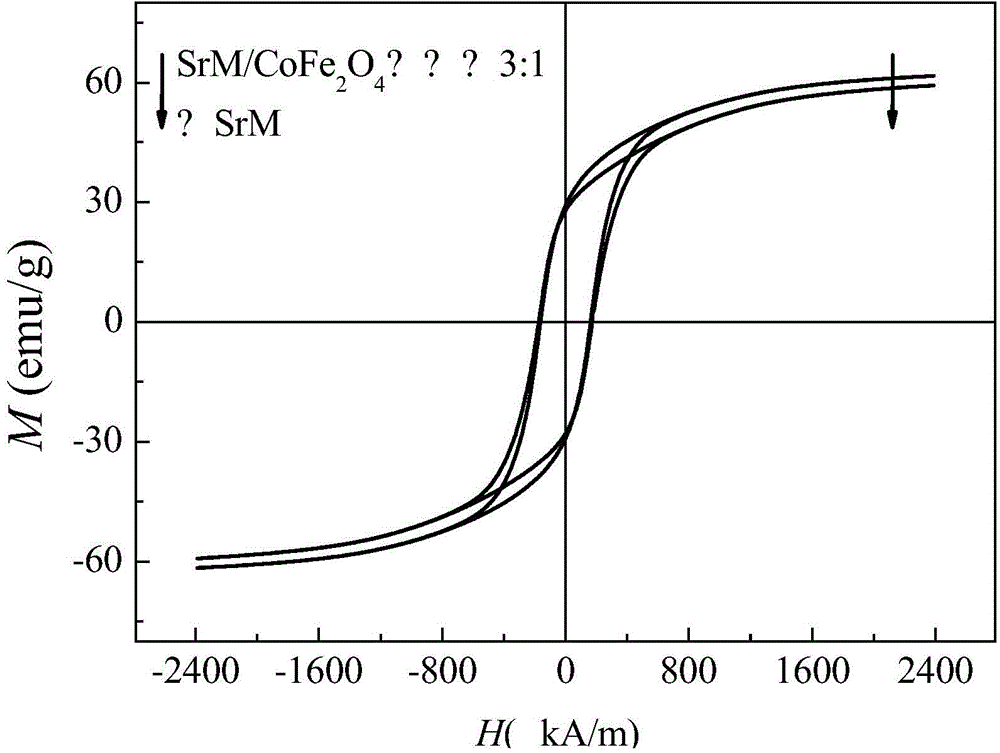

Composite permagnetferrite with functions of two-phase exchange coupling and keeping high coercive force

The invention discloses a composite permagnetferrite with functions of two-phase exchange coupling and keeping high coercive force and belongs to the technical field of preparation of magnetic ferrites. The composite ferrite is prepared by pressing SrFe12O19 ferrite nano-powder and CoFe2O4 ferrite nano-powder which are prepared by adopting a hydrothermal method alone and subjected to acid washing according to a certain mass ratio to form circular sheets, and finally calcining at the temperature of 700-900 DEG C for 2h respectively. The ferrite containing two phases displays single-phase magnetic behavior to the outside, namely the exchange coupling effect exists. As the composite ferrite adopts a CoFe2O4 ferrite with high saturation magnetization and coercive force as a 'soft magnetic phase', the composite ferrite is conductive to improving the saturation magnetization and can ensure that the composite ferrite can still keep the high coercive force which is 152.5kA / m (about 1915Oe) at least after be calcined.

Owner:扬州华翀电力电子科技有限公司

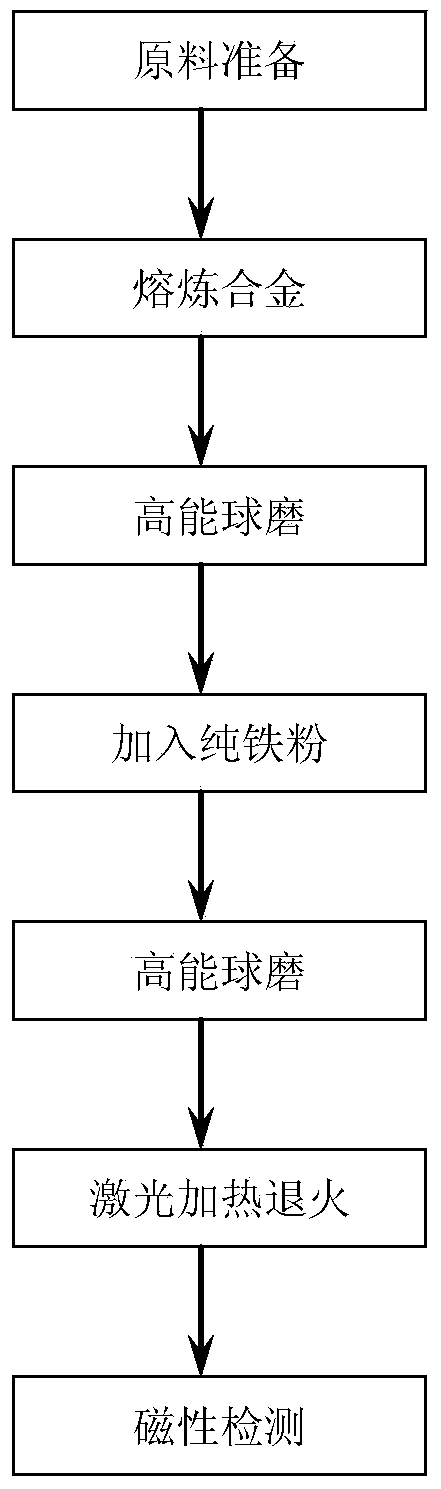

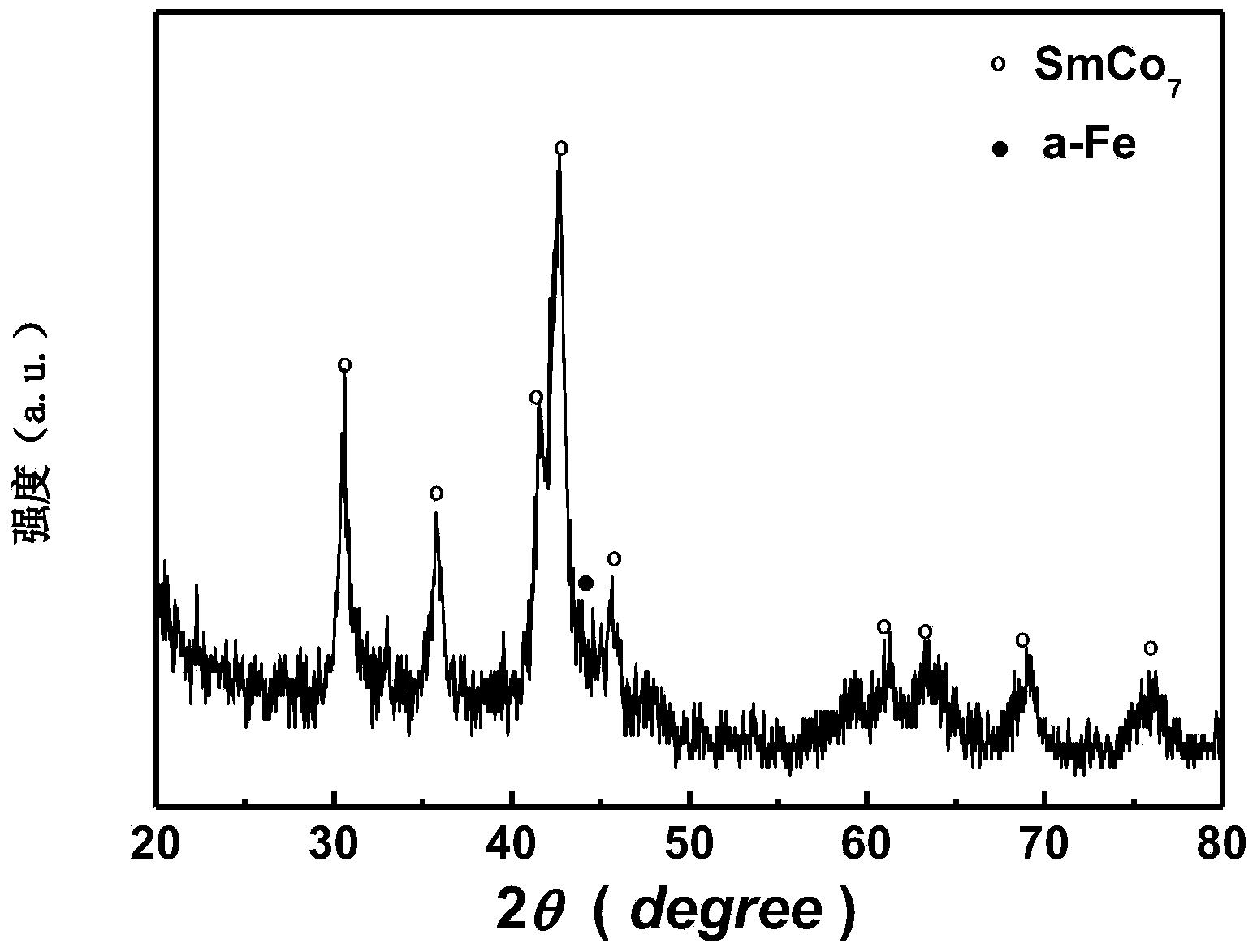

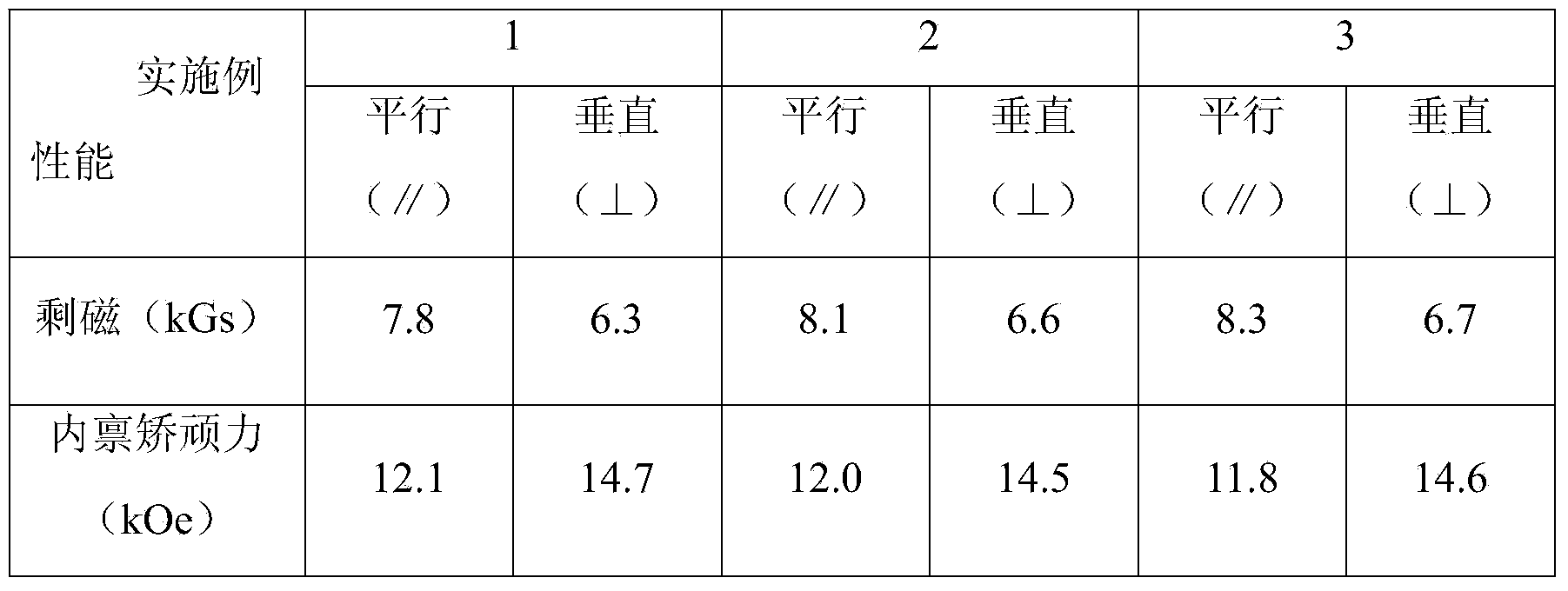

Samarium-cobalt-base nanocrystalline permanent magnet material and preparation method thereof

The invention relates to the metallurgy field and discloses novel samarium-cobalt-base nano-composite permanent magnetic material. The samarium cobalt base is (Sm, R)1(Co, Fe, Cu, Zr)7 in type and comprises a TbCu7 type structure, and Co is partially replaced by Fe, Cu and Zr; Re is any one of heavy rare earth Lu, Dy and Tb and partially replaces Sm. The preparation method includes steps that 1) mixing raw materials of the samarium cobalt base according to proportion, and smelting to obtain a 1: 7 type samarium cobalt base alloy ingot; 2) ball milling the alloy ingot through a high-energy ball milling technique, mixing with Fe powder according to proportion, and performing high-energy ball milling to obtain nanocrystalline composite magnetic powder; 3) carrying out annealing heat treatment on the nanocrystalline composite magnetic powder. According to the samarium-cobalt-base nanocrystalline permanent magnet material and the preparation method thereof, the soft / hard-magnetic phase composite magnetic powder is prepared through the high-energy ball milling, laser heat treatment and other techniques, a high magnetic energy product is obtained through exchange coupling between the nanocrystalline hard magnetic phase and nanocrystalline soft magnetic phase, and meanwhile, because rare-earth Fe phase is not used, the cost is lowered, and the operation technique is simplified.

Owner:嘉兴市鹏程磁钢有限公司 +1

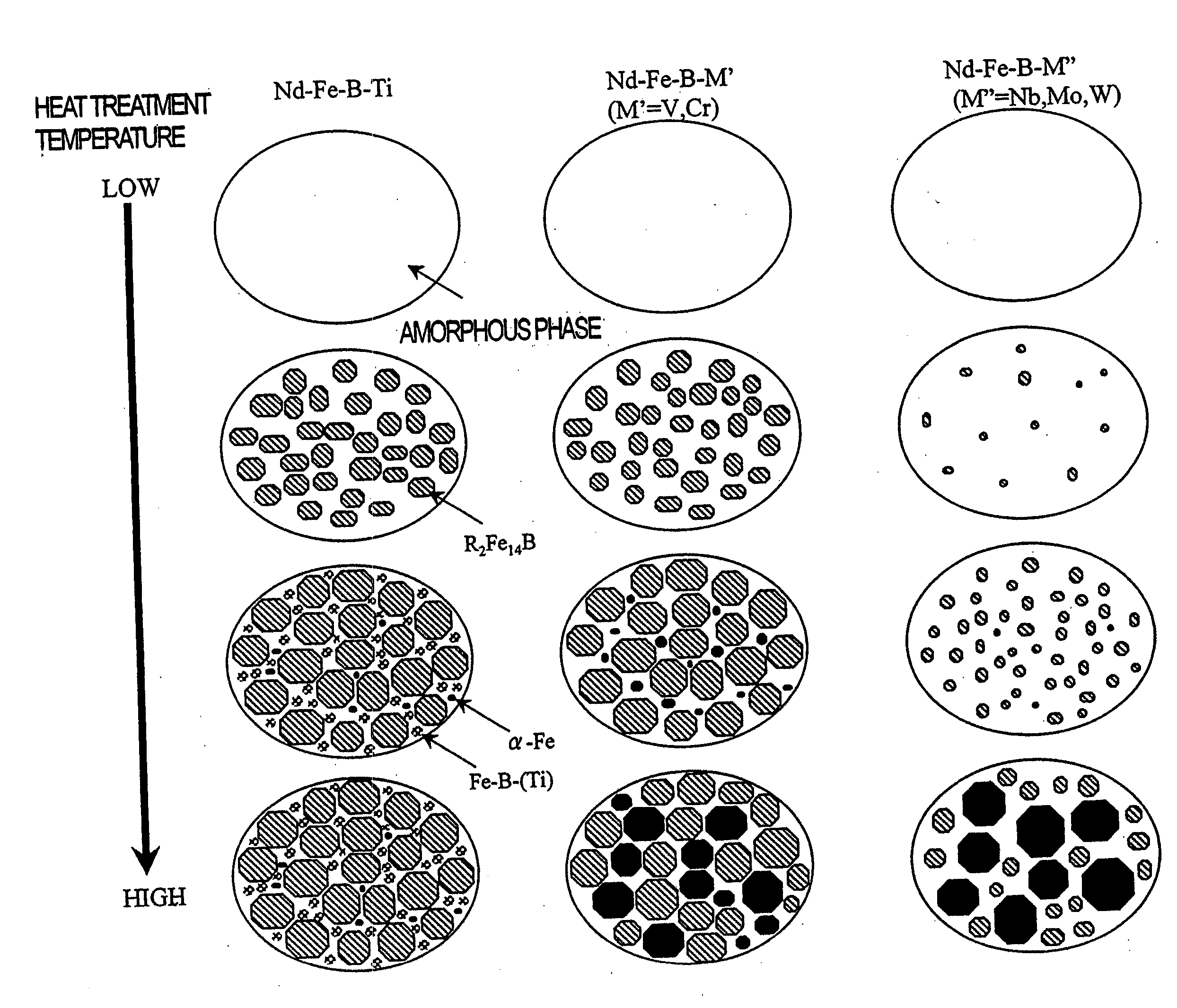

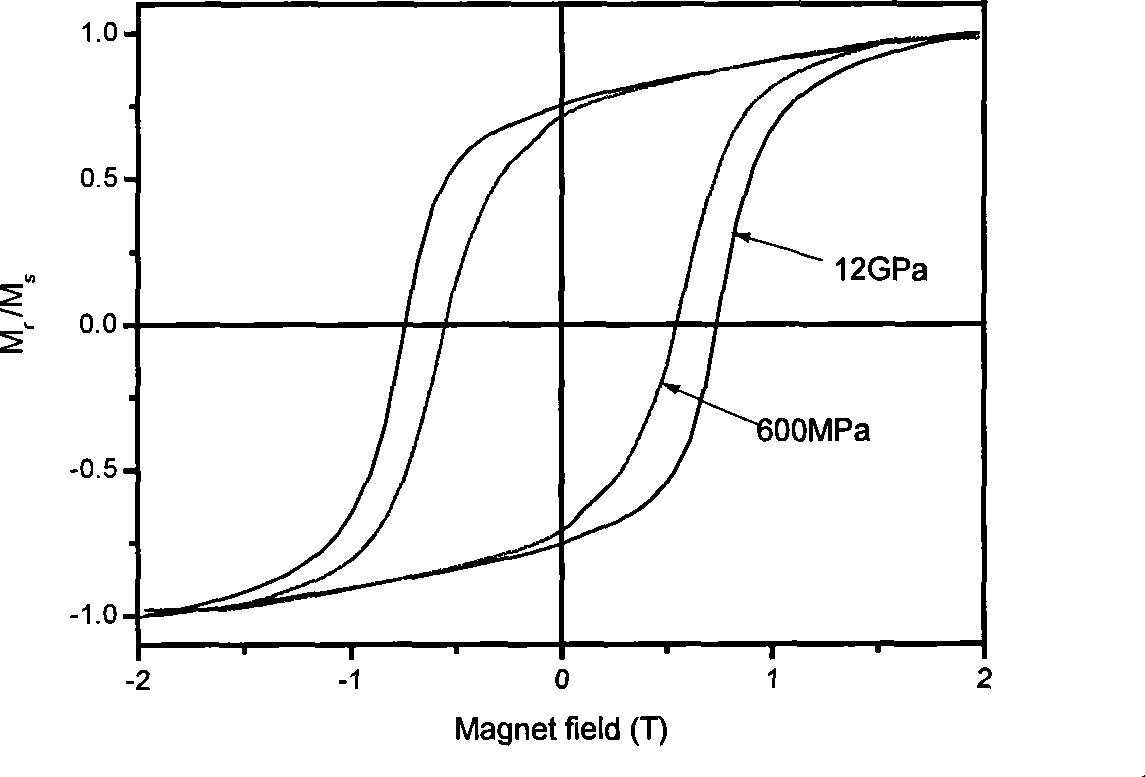

Pr/Nd based biphase composite permanent magnetic material and block body preparing method thereof

ActiveCN101425355AEnhanced exchange couplingHigh energy productMagnetic materialsMagnetic phaseUltra high pressure

The invention relates to a Pr / Nd-based two-phase nano-composite permanent magnet material and a method for the preparation of the block body thereof. The invention comprises the composing general formula of the two-phase nano-composite permanent magnet material: a (Pr, Nd)-Fe-R-Ti-QB system, wherein Pr and Nd are main rare earth components in hard magnetic phase (Pr, Nd)2Fe14B base material; R is one or more than two of Nb, Dy, Tb and Ga; Q is one or more than two of V, Mo, Zr, W and Au; the molar fraction is as follows: x is more than or equal to 4 and less than or equal to 11, y is more than or equal to 0.1 and less than or equal to 3, z is more than or equal to 0.1 and less than or equal to 4, m is more than or equal to 0 and less than or equal to 2, n is more than or equal to 6 and less than or equal to 10, w is more than or equal to 20 and less than or equal to 80, and the balance being Fe. The preparation of the block body (Pr, Nd) 2Fe14B / Alpha-Fe comprises the following steps of (1) smelting master alloy; (2) fast quenching of thin strips; (3) preparing the block body by ultra-high heat pressing, in which the thin strip alloy is put in a graphite mold and then is placed in an ultra-high pressure device, and is sintered for 1 to 30min when the temperature is heated to between 500 and 1000 DEG C at 10-50 DEG C / min, under the pressure intensity of between 1 and 12 GPa and Ar gas protective environment. The Pr / Nd-based two-phase nano-composite permanent magnet material has the advantages of low-content rare earth, low cost, good anti-saturation effect, and the like; the magnetic energy is more than 180 kJ / m3, and the density is more than 74.5 g / cm3.

Owner:浙江凯文磁钢有限公司

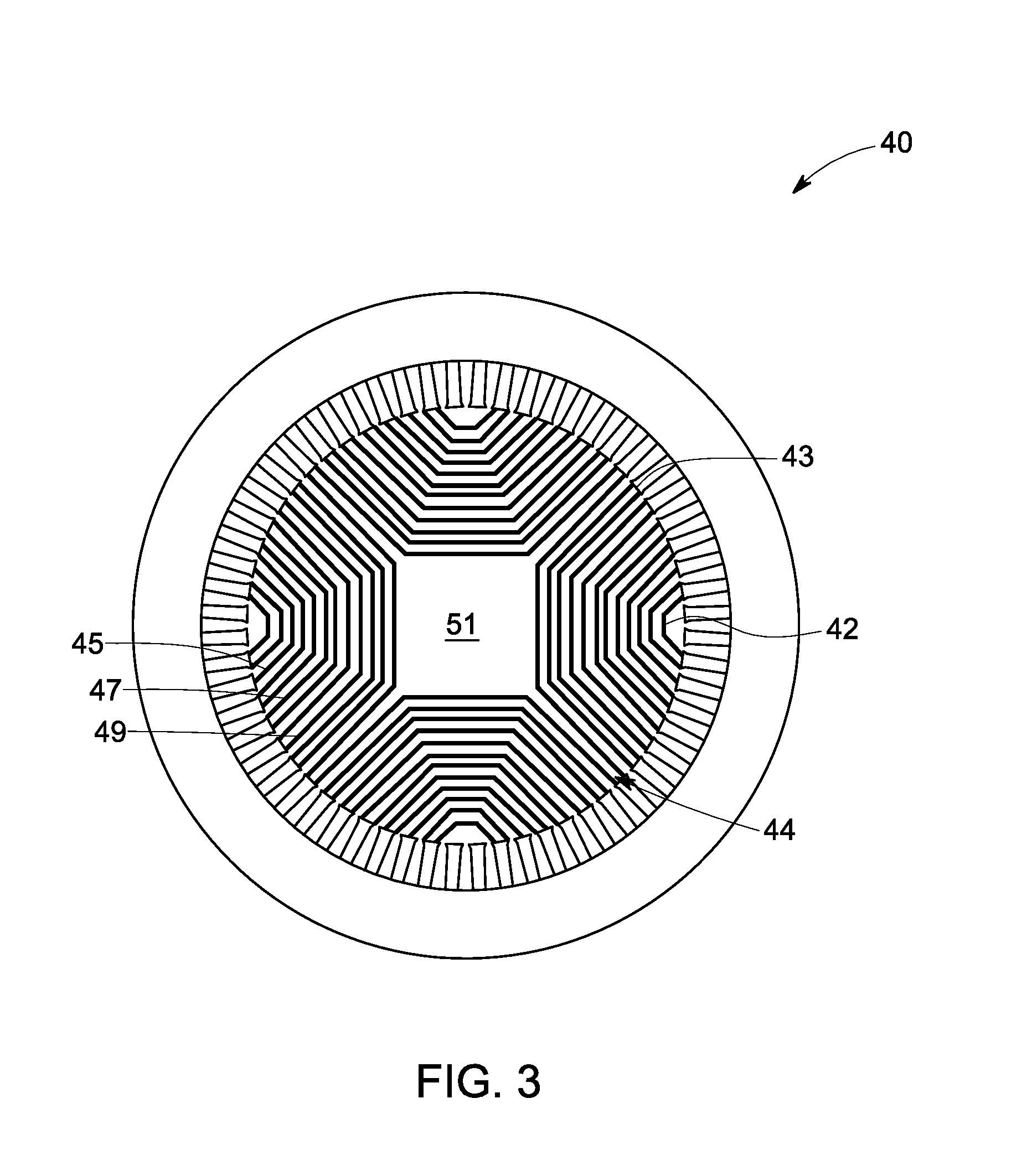

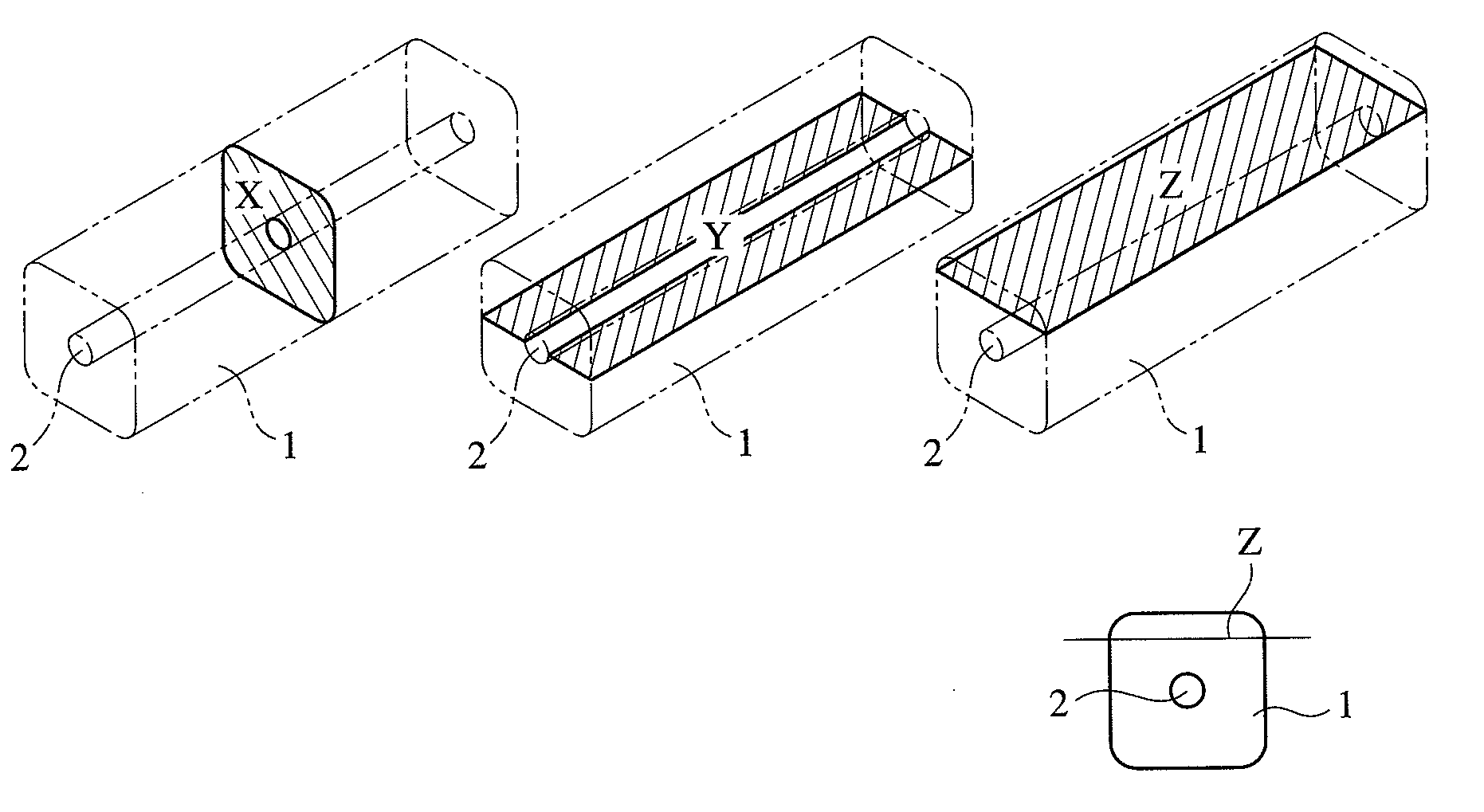

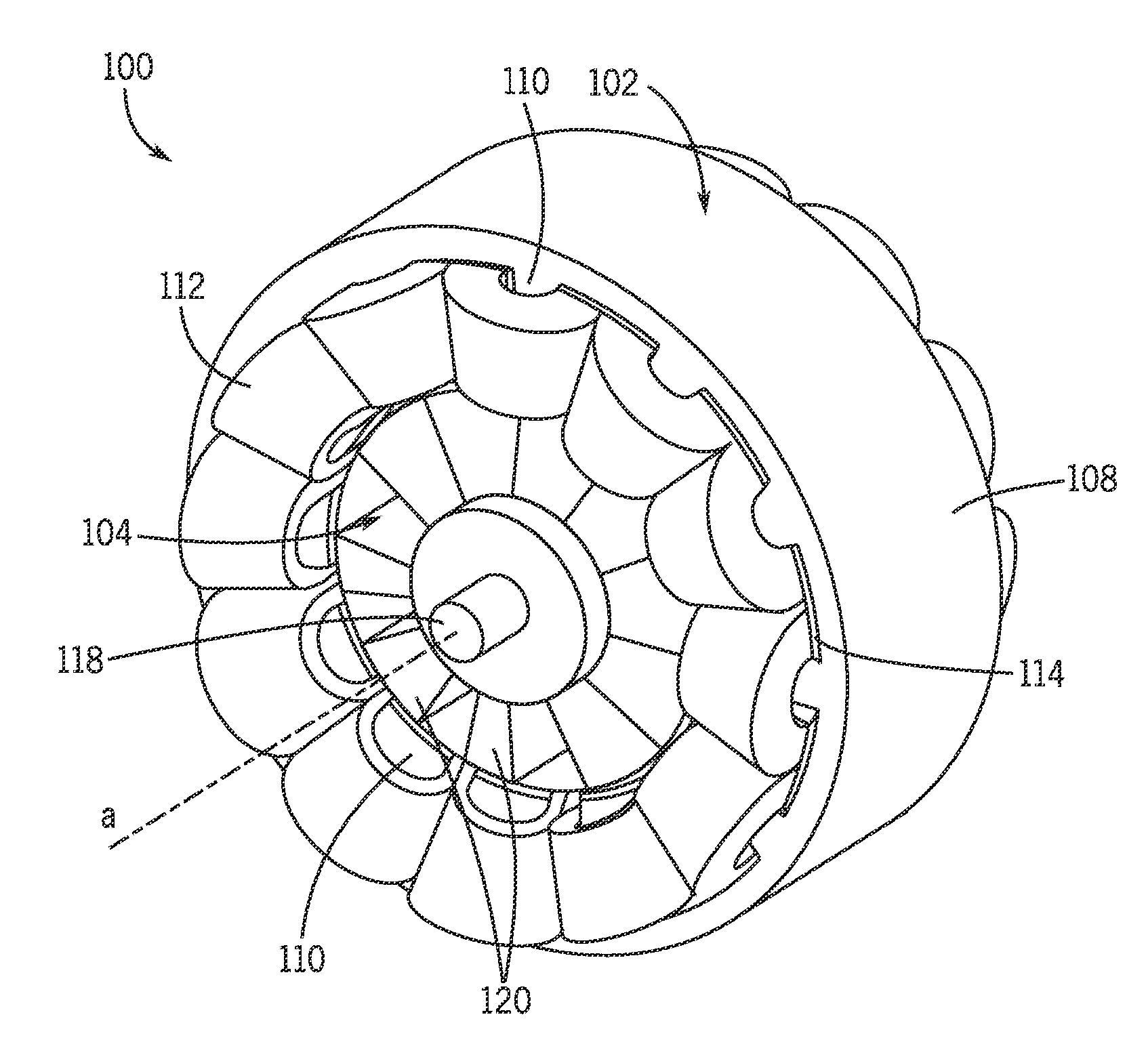

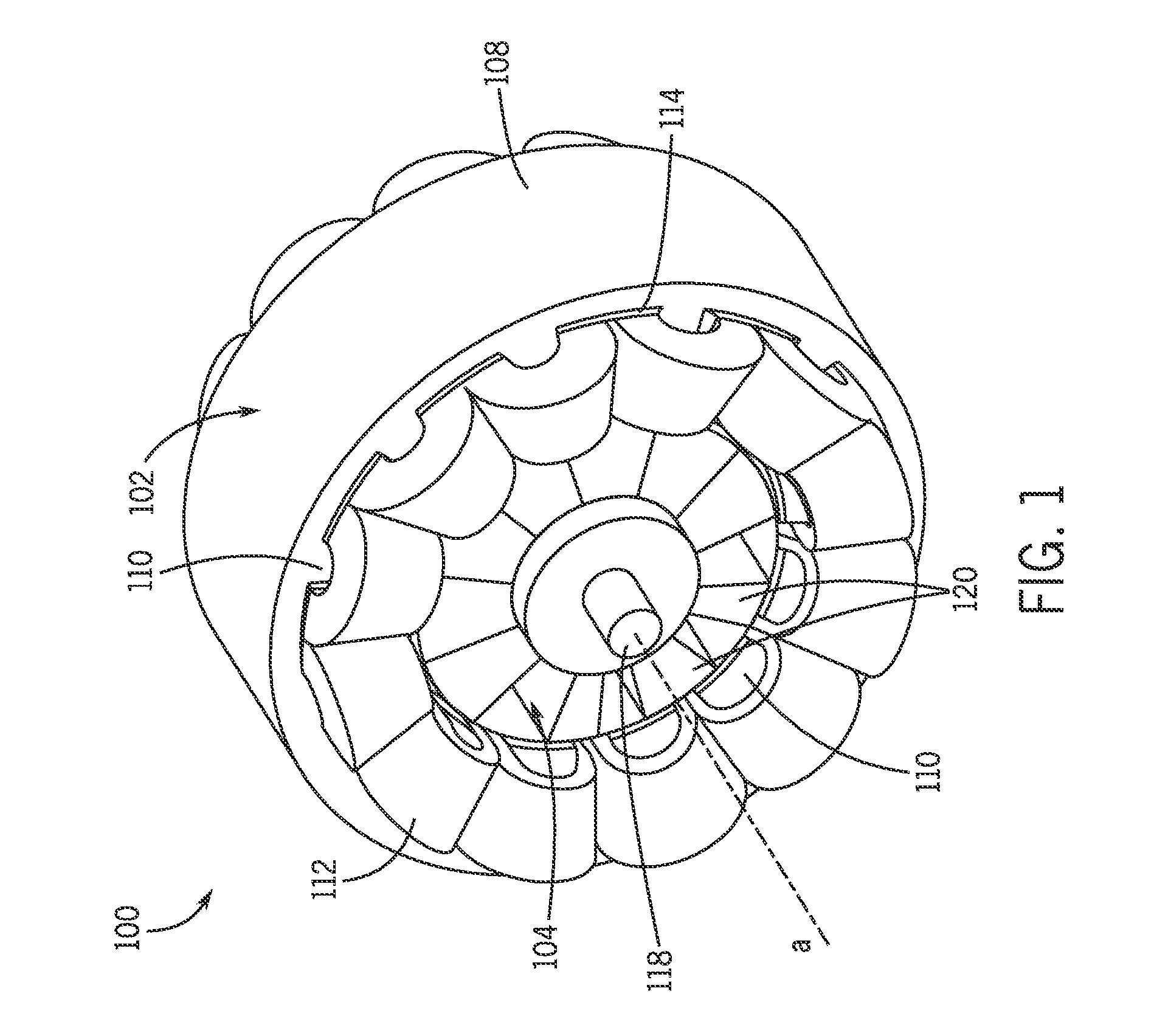

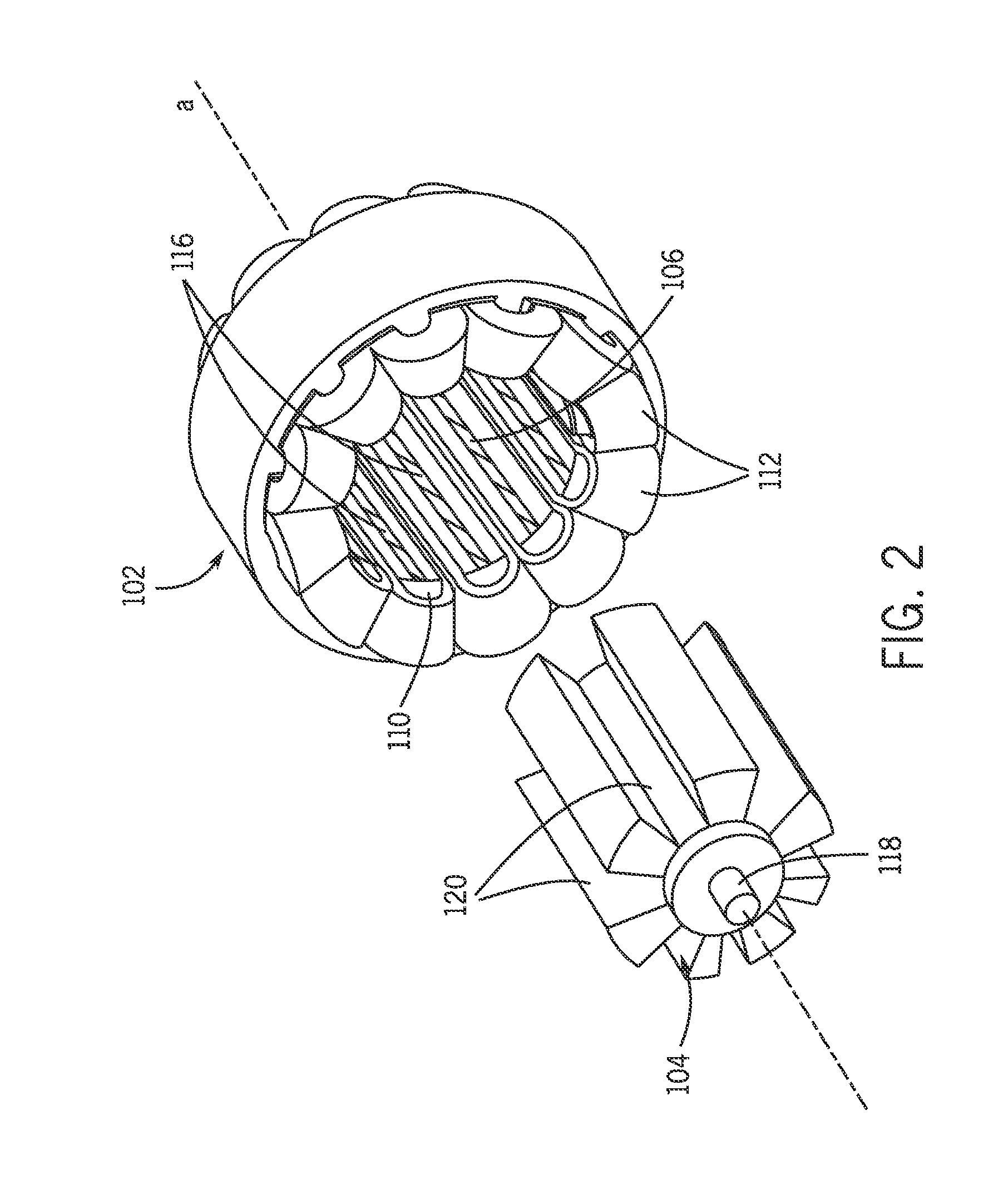

Dual magnetic phase stator laminations for stator permanent magnet electric machines

InactiveUS20140239763A1Increased power capacityProvide stabilityMagnetic circuit stationary partsManufacturing stator/rotor bodiesMagnetic phaseElectric machine

A dual magnetic phase stator lamination for use in stator permanent magnet electric machines is disclosed. The permanent magnet electrical machine includes a rotor mounted for rotation about a central axis and a stator positioned about the rotor and comprising a plurality of stator laminations, wherein each of the stator laminations is composed of a dual magnetic phase material and includes a first stator lamination portion comprising a magnetic material and a second stator lamination portion comprising a non-magnetic material, the second stator lamination portion comprising an area positioned adjacent to each of a plurality of permanent magnets embedded in the stator lamination. The second stator lamination portion comprises a heat treated portion of the stator lamination, with the heat treating of the second stator lamination portion rendering the dual magnetic phase material of the stator lamination non-magnetic at the locations of the second stator lamination portion.

Owner:GENERAL ELECTRIC CO

Alloy for use in preparation of R-T-B-based sintered magnet and process for preparing R-T-B-based sintered magnet

InactiveUS6444048B1Oxidation during the production of the sintered magnet can, therefore, be suppressedInorganic material magnetismAbnormal growthsBinary alloy

Processes for the preparation of a sintered alloy comprising R2Fe14B as a magnetic phase constituting a main phase include a binary alloy process wherein a main phase alloy having a lower R content than the above phase is mixed with a grain boundary phase alloy rich in R component and serving as a liquid phase in the sintering in order to prepare a mixture to be used as the starting material. The conventional main phase alloy has a structure comprising the R2Fe14B phase and, in addition, a large amount of an easily oxidizable lamella R-rich phase and a harmful dendrite alpha phase. On the other hand, the main phase alloy of the invention has a low dendrite a phase content and a low lamella R-rich phase and contains a lamella alpha Fe phase. This contributes to excellent oxidation resistance and improved properties of the magnet. The preparation of a sintered magnet by mixing the main phase alloy with the grain boundary phase alloy by the binary alloy method can reduce abnormal growth of crystal grains.

Owner:SHOWA DENKO KK

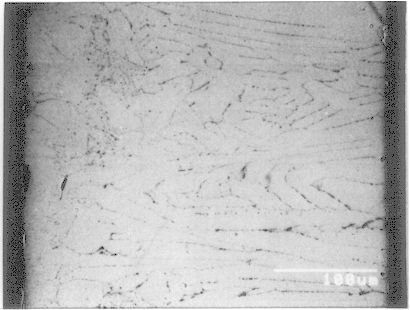

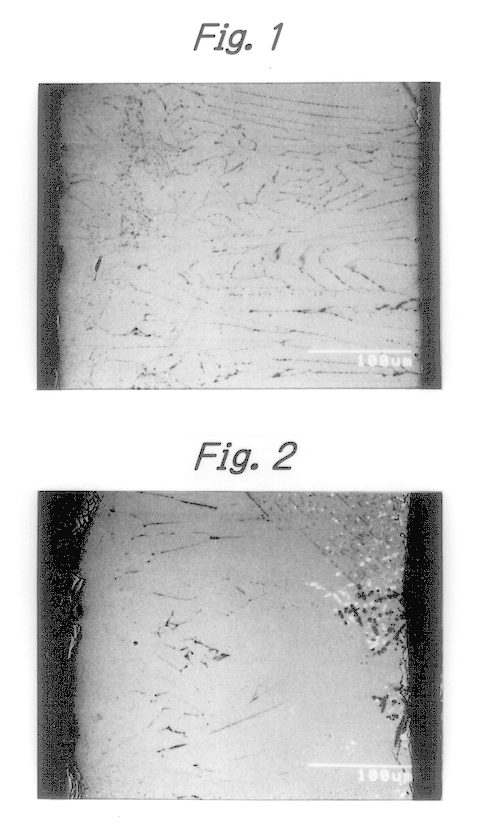

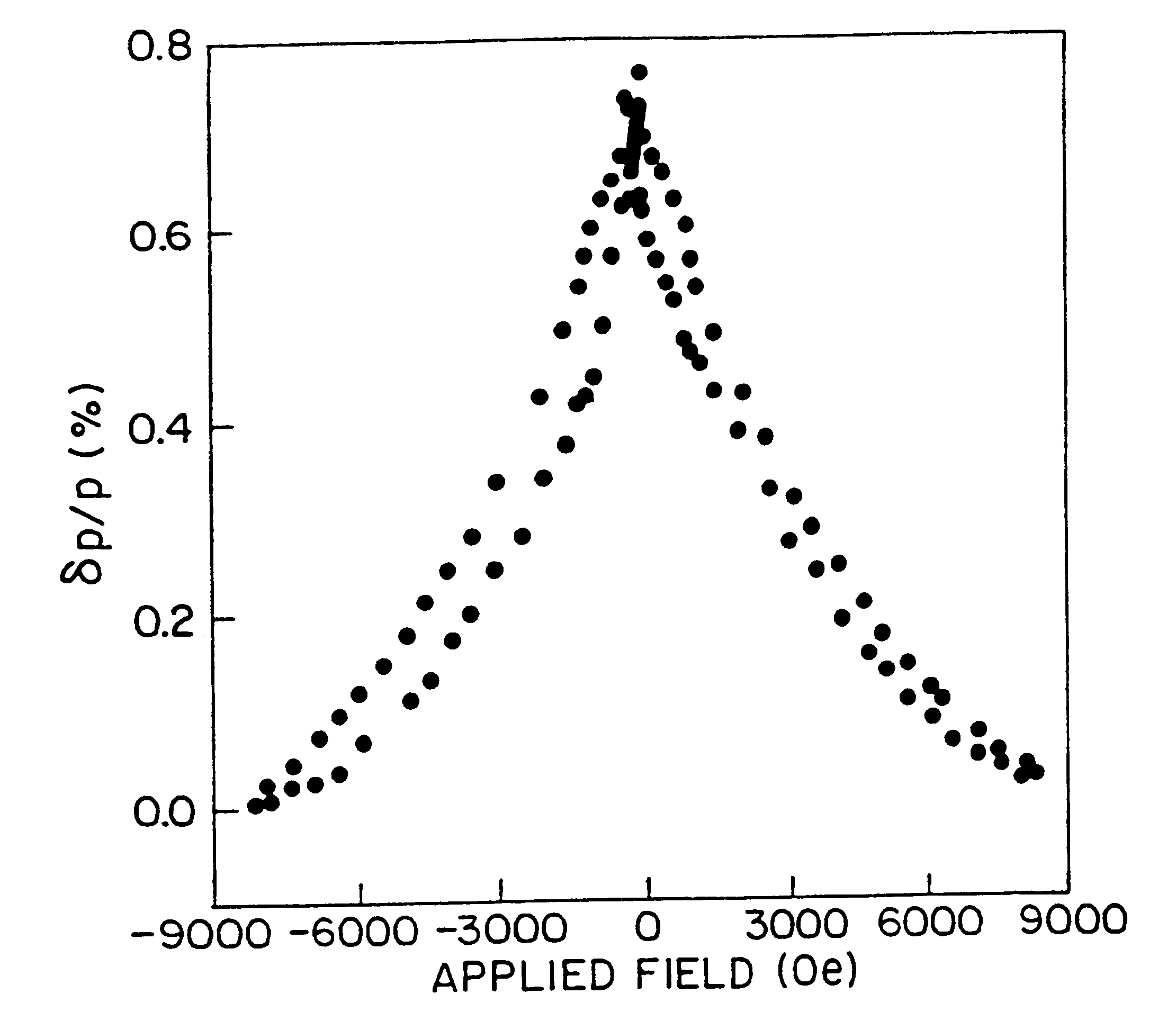

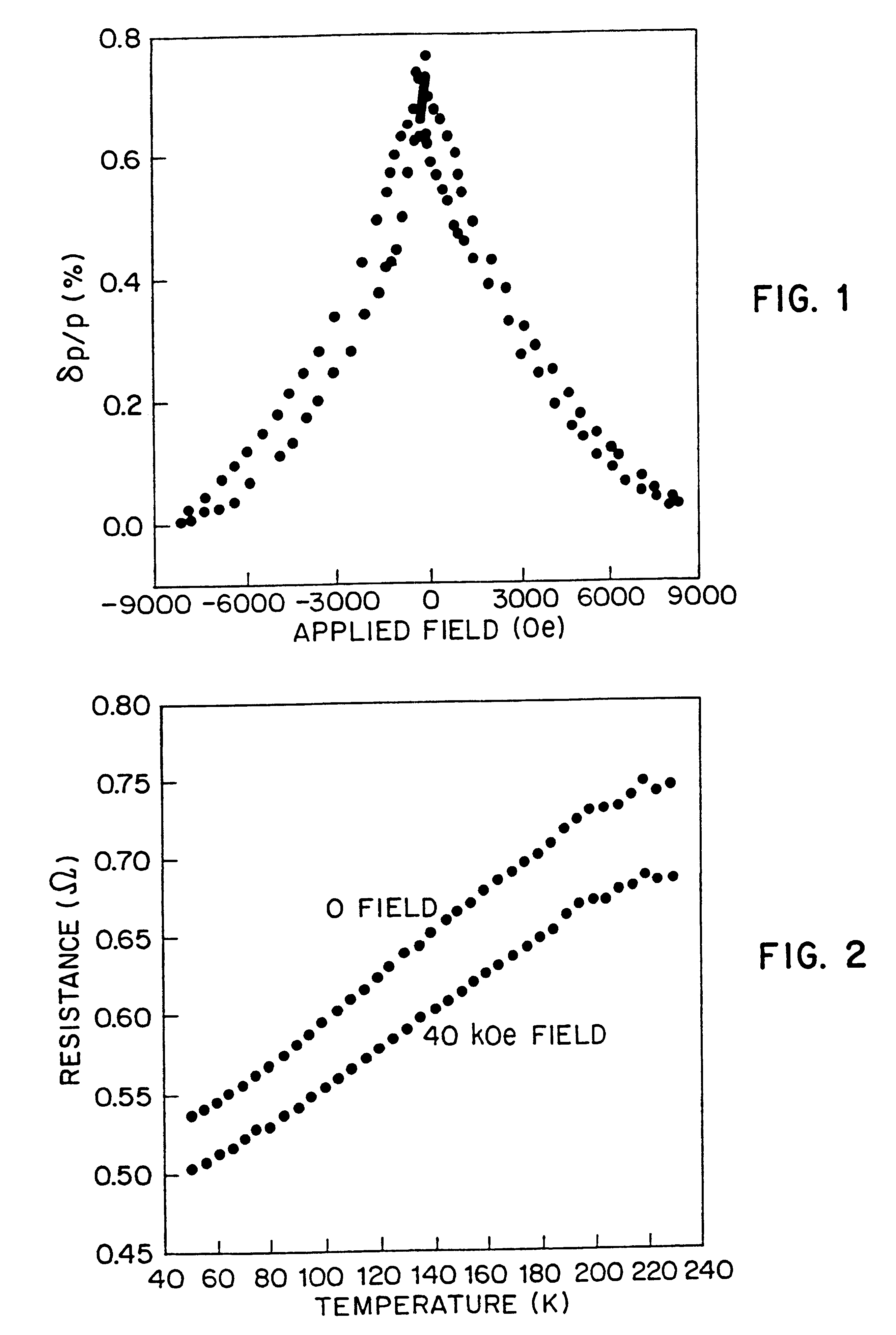

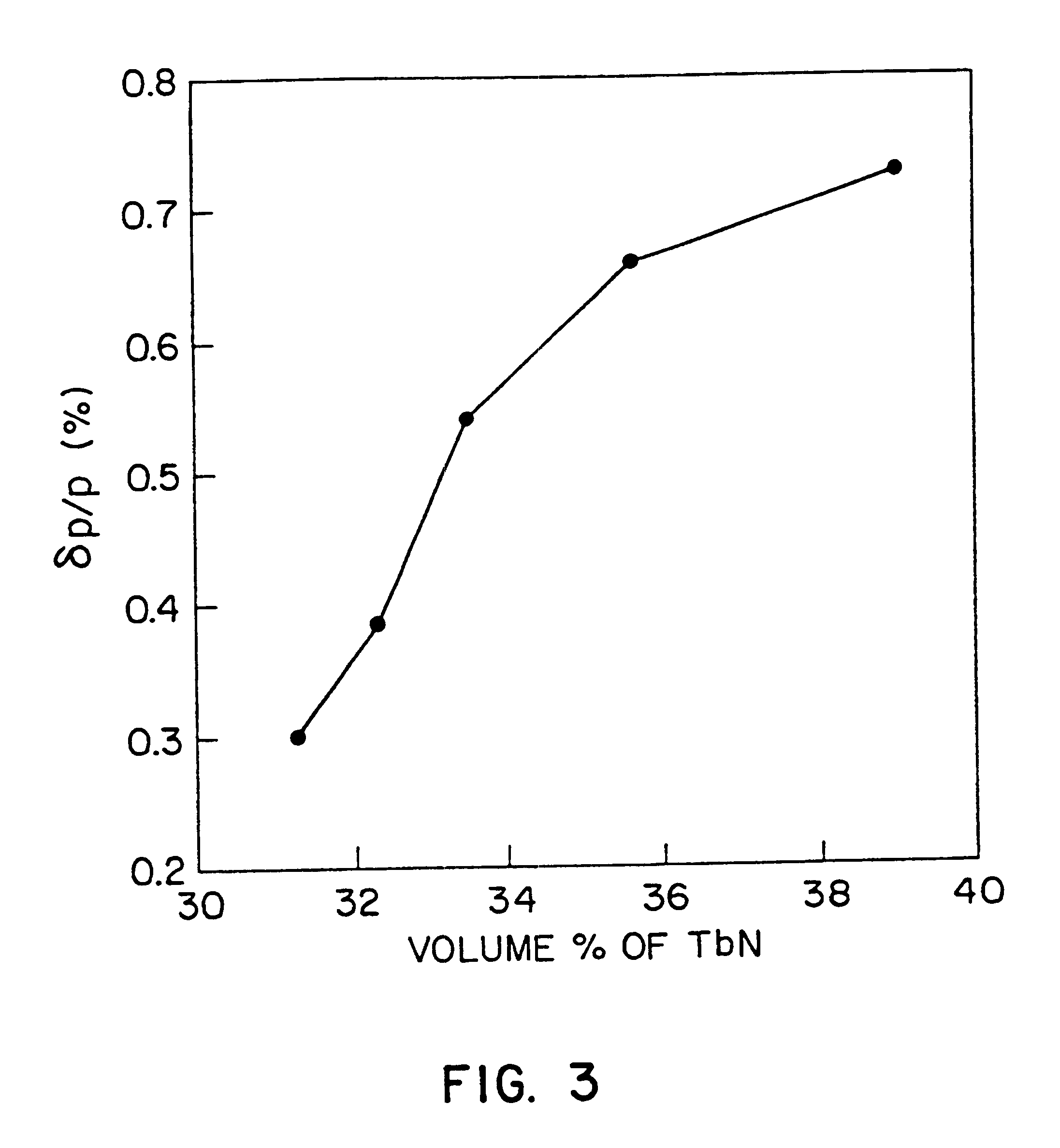

Magnetoresistive material with two metallic magnetic phases

A magnetoresistive material with two metallic magnetic phases. The material exhibits the giant magnetoresistance effect (GMR). A first phase of the material includes a matrix of an electrically conductive ferromagnetic transition metal or an alloy thereof. A second precipitate phase exhibits ferromagnetic behavior when precipitated into the matrix and is antiferromagnetically exchange coupled to the first phase. The second precipitate phase can be electrically conductive rare earth pnictide or can be a Heusler alloy. A method of manufacturing magnetoresistive materials according to the present invention employs facing targets magnetron sputtering. The invention also includes a method of detecting magnetic field strength by providing a read head including a portion of one of the magnetoresistive materials according to the invention, exposing the read head to the magnetic field of a magnetic recording medium, sensing electrical resistivity of the portion of material associated with the magnetic field of the magnetic recording medium, and converting the electrical resistivity into a signal which is indicative of the magnetic field strength of the magnetic field associated with the magnetic recording medium. A digital magnetic recording system, according to the present invention, is adapted for use with a magnetic recording medium having a characteristic coercive force and a plurality of stored bits thereon. The bits are stored by magnetic field strength levels of a magnetic field associated with the medium. The system can include a conventional write head and a controller. The system can also include a read head including a portion of magnetoresistive material according to the present invention which is located in proximity to the medium and a suitable resistivity sensor.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com