Patents

Literature

1552results about How to "Improve suppression properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

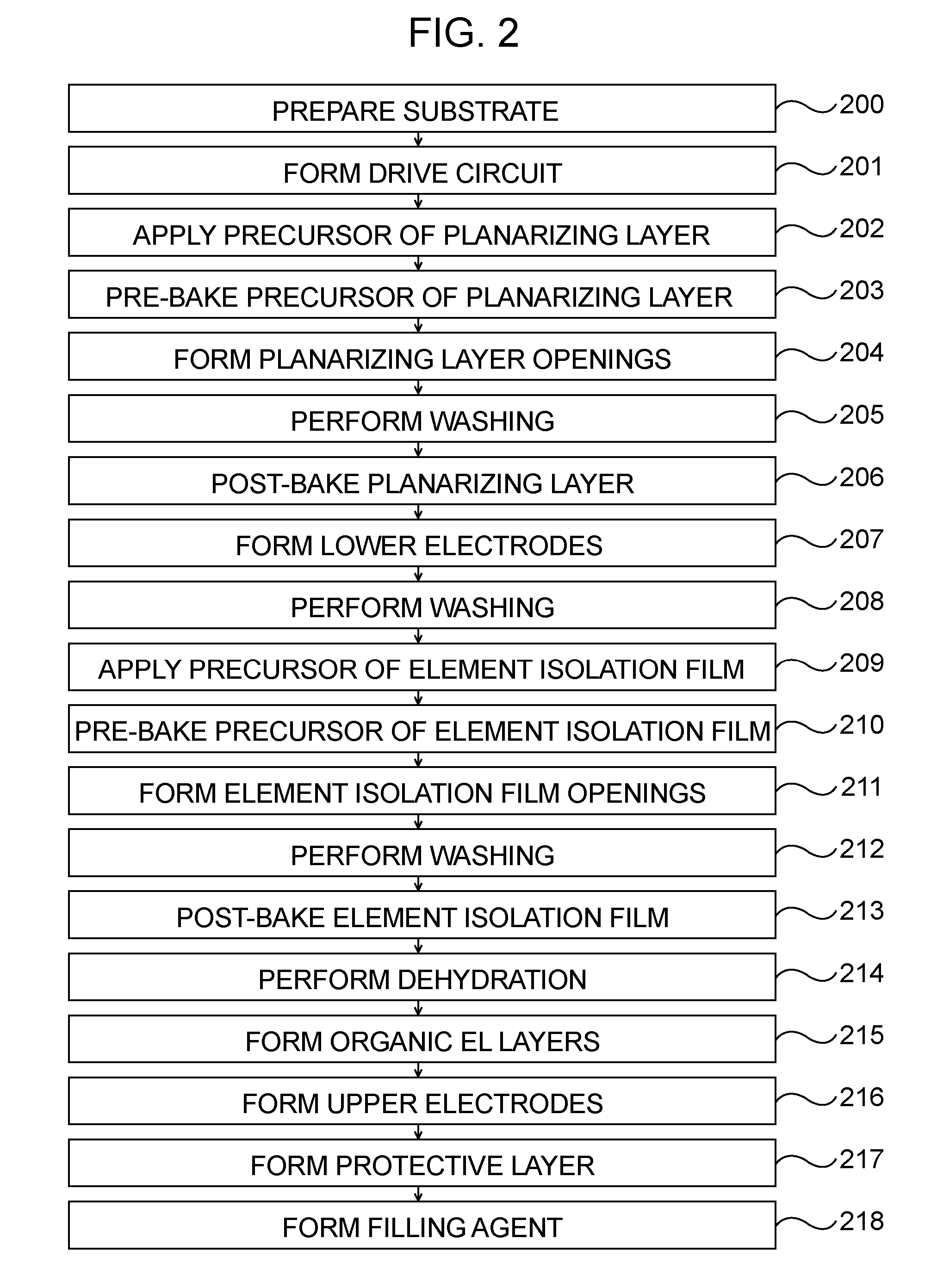

Organic electroluminescent display device and manufacturing method thereof

ActiveUS20070046191A1Maintain its level of performanceEnhance layeringDischarge tube luminescnet screensElectroluminescent light sourcesOligomerEngineering

The present invention provides an organic EL display device having a planarizing layer, which is prevented from being distorted. The above organic EL display device has a planarizing layer, which retains 5% or less the oligomer used to form this layer.

Owner:CANON KK

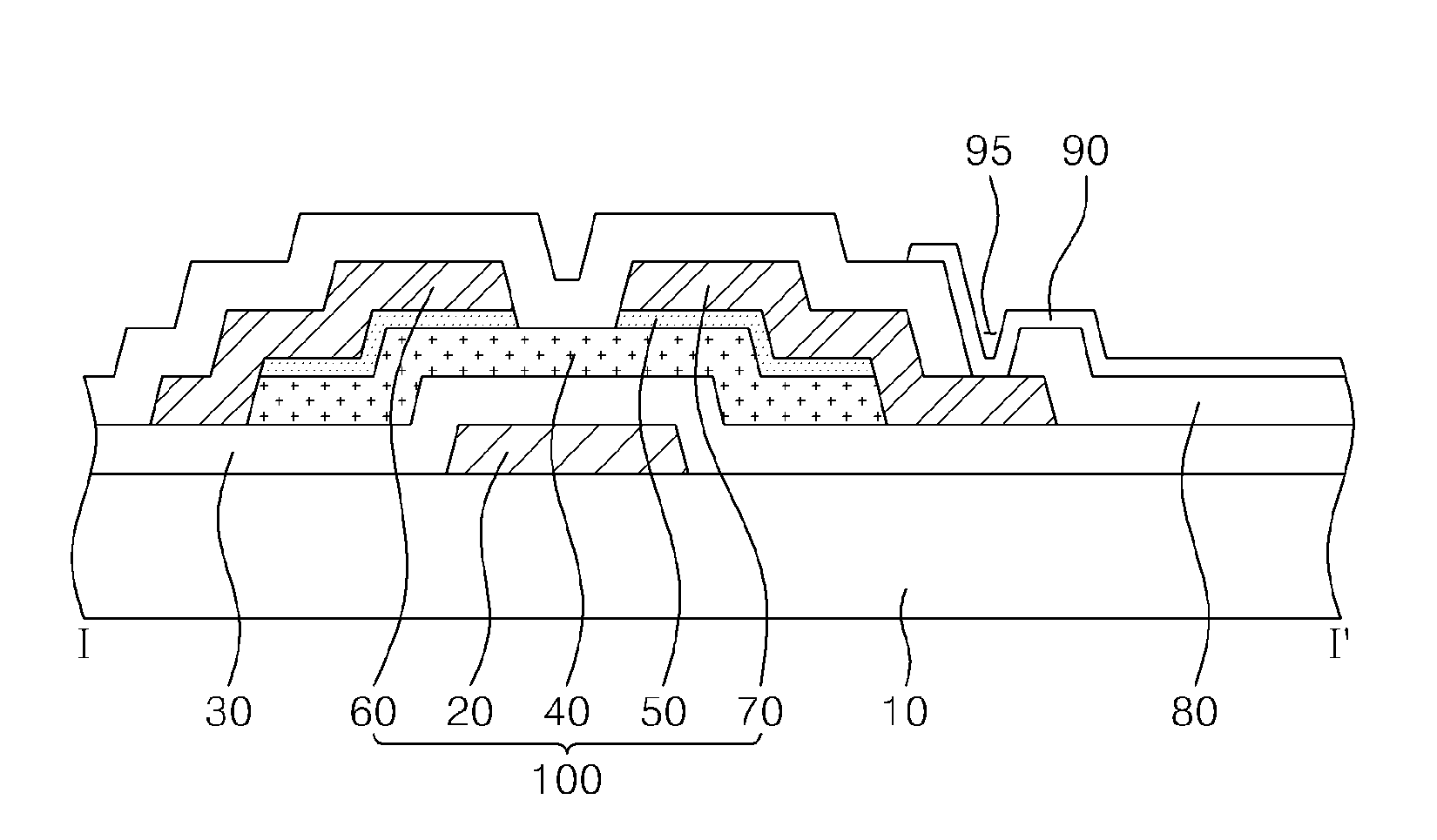

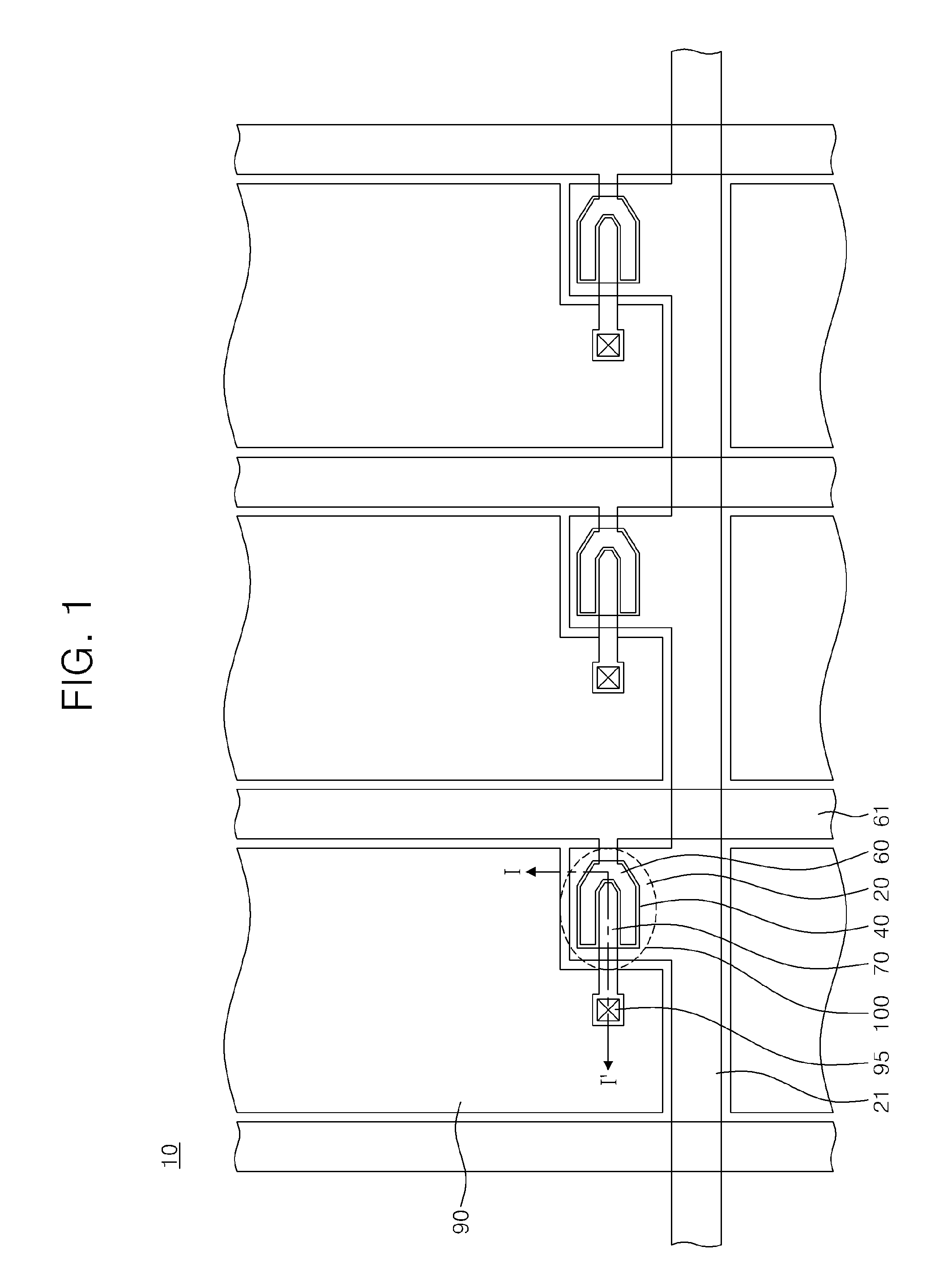

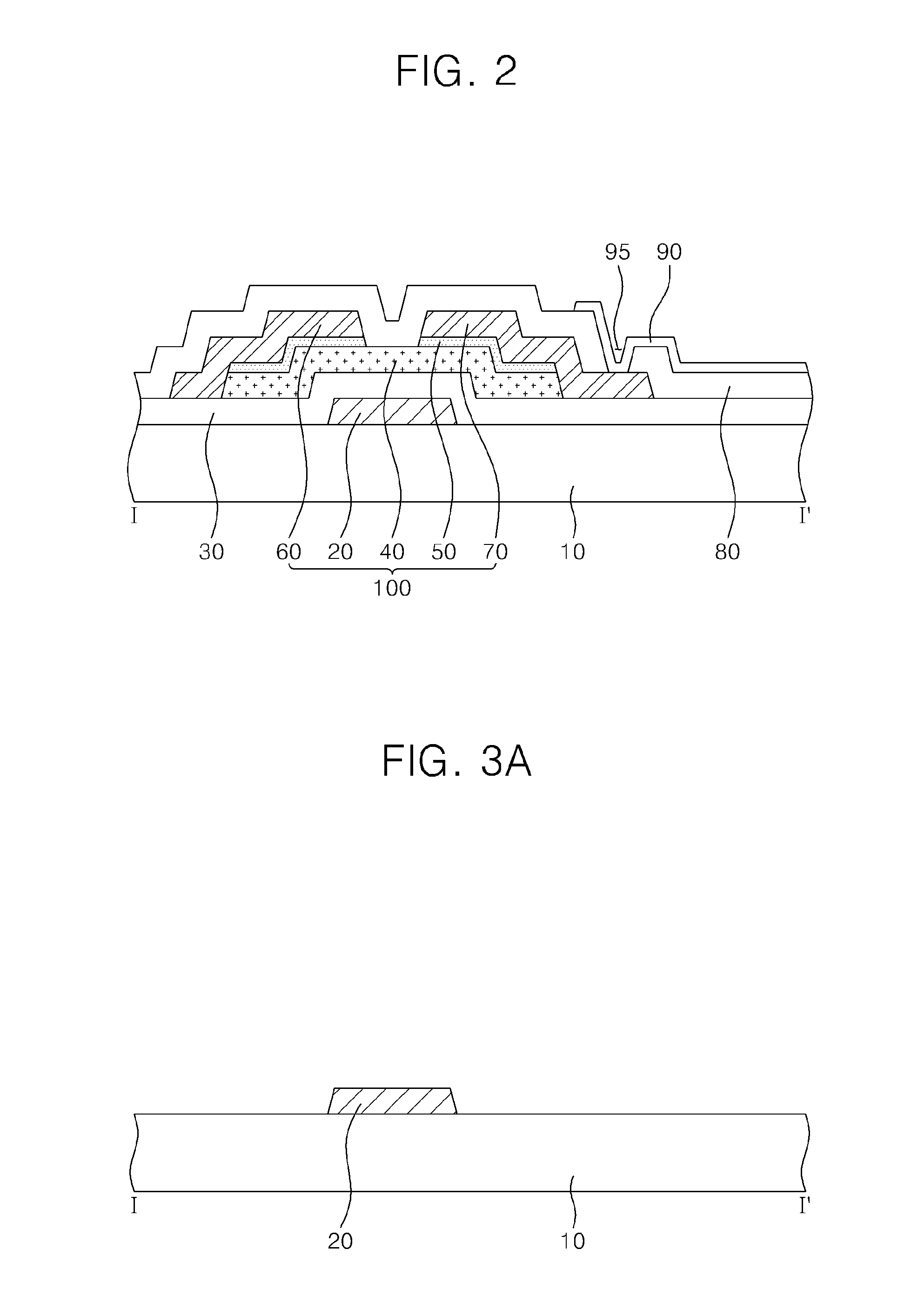

Thin film transitor substrate and method of manufacturing the same

InactiveUS20080258143A1Increases process time and leakage current and serial contact resistanceDegrading property of TFTTransistorSemiconductor/solid-state device manufacturingOxide semiconductorOxide

A method of manufacturing a thin film transistor (“TFT”) substrate includes forming a first conductive pattern group including a gate electrode on a substrate, forming a gate insulating layer on the first conductive pattern group, forming a semiconductor layer and an ohmic contact layer on the gate insulating layer by patterning an amorphous silicon layer and an oxide semiconductor layer, forming a second conductive pattern group including a source electrode and a drain electrode on the ohmic contact layer by patterning a data metal layer, forming a protection layer including a contact hole on the second conductive pattern group, and forming a pixel electrode on the contact hole of the protection layer. The TFT substrate including the ohmic contact layer formed of an oxide semiconductor is further provided.

Owner:SAMSUNG ELECTRONICS CO LTD

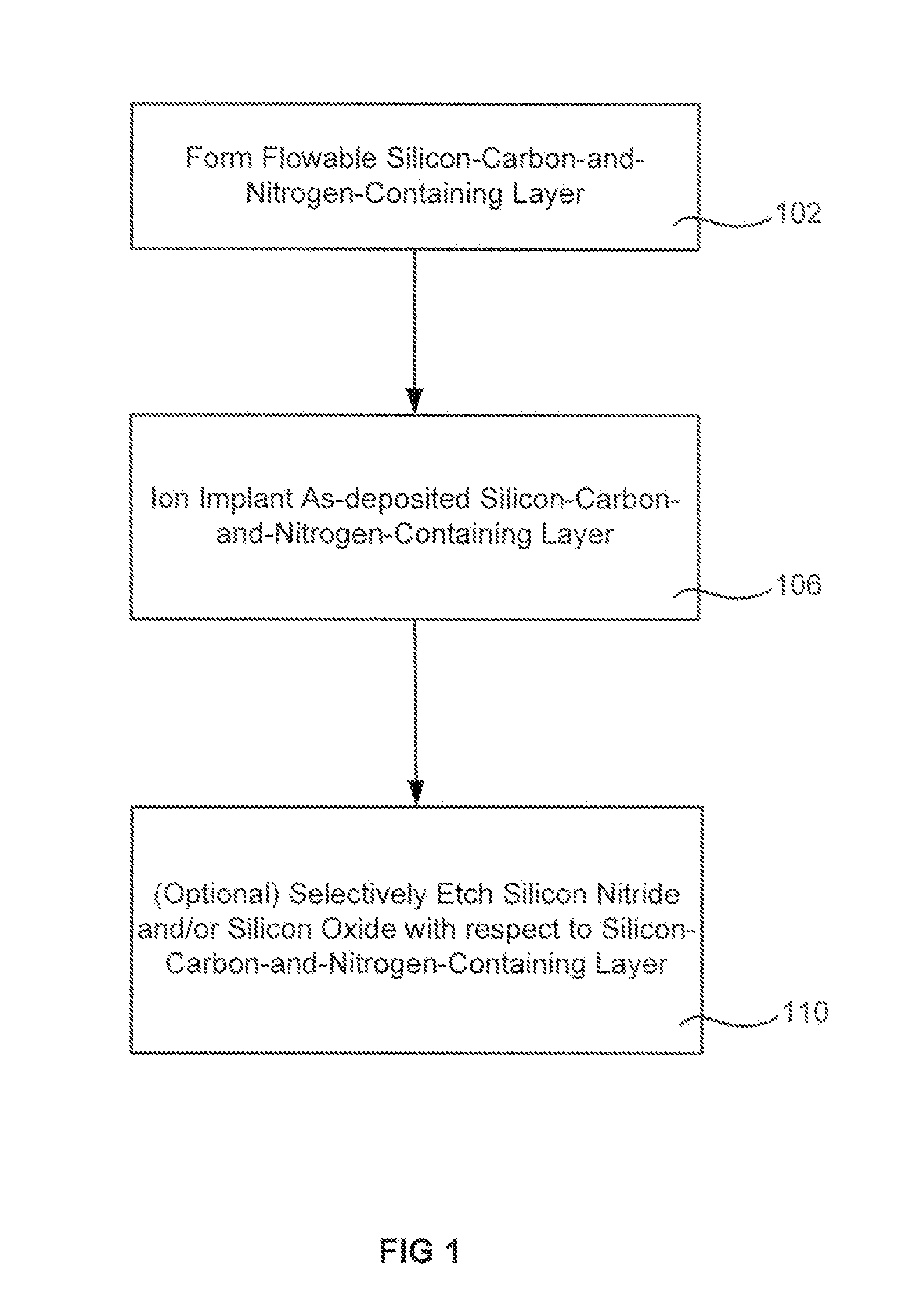

Doping of dielectric layers

InactiveUS20130217243A1Increase etch tolerancePrevent shrinkageSemiconductor/solid-state device manufacturingDeposition temperaturePhysical chemistry

Methods are described for forming and treating a flowable silicon-carbon-and-nitrogen-containing layer on a semiconductor substrate. The silicon and carbon constituents may come from a silicon-and-carbon-containing precursor while the nitrogen may come from a nitrogen-containing precursor that has been activated to speed the reaction of the nitrogen with the silicon-and-carbon-containing precursor at lower deposition temperatures. The initially-flowable silicon-carbon-and-nitrogen-containing layer is ion implanted to increase etch tolerance, prevent shrinkage, adjust film tension and / or adjust electrical characteristics. Ion implantation may also remove components which enabled the flowability, but are no longer needed after deposition. Some treatments using ion implantation have been found to decrease the evolution of properties of the film upon exposure to atmosphere.

Owner:APPLIED MATERIALS INC

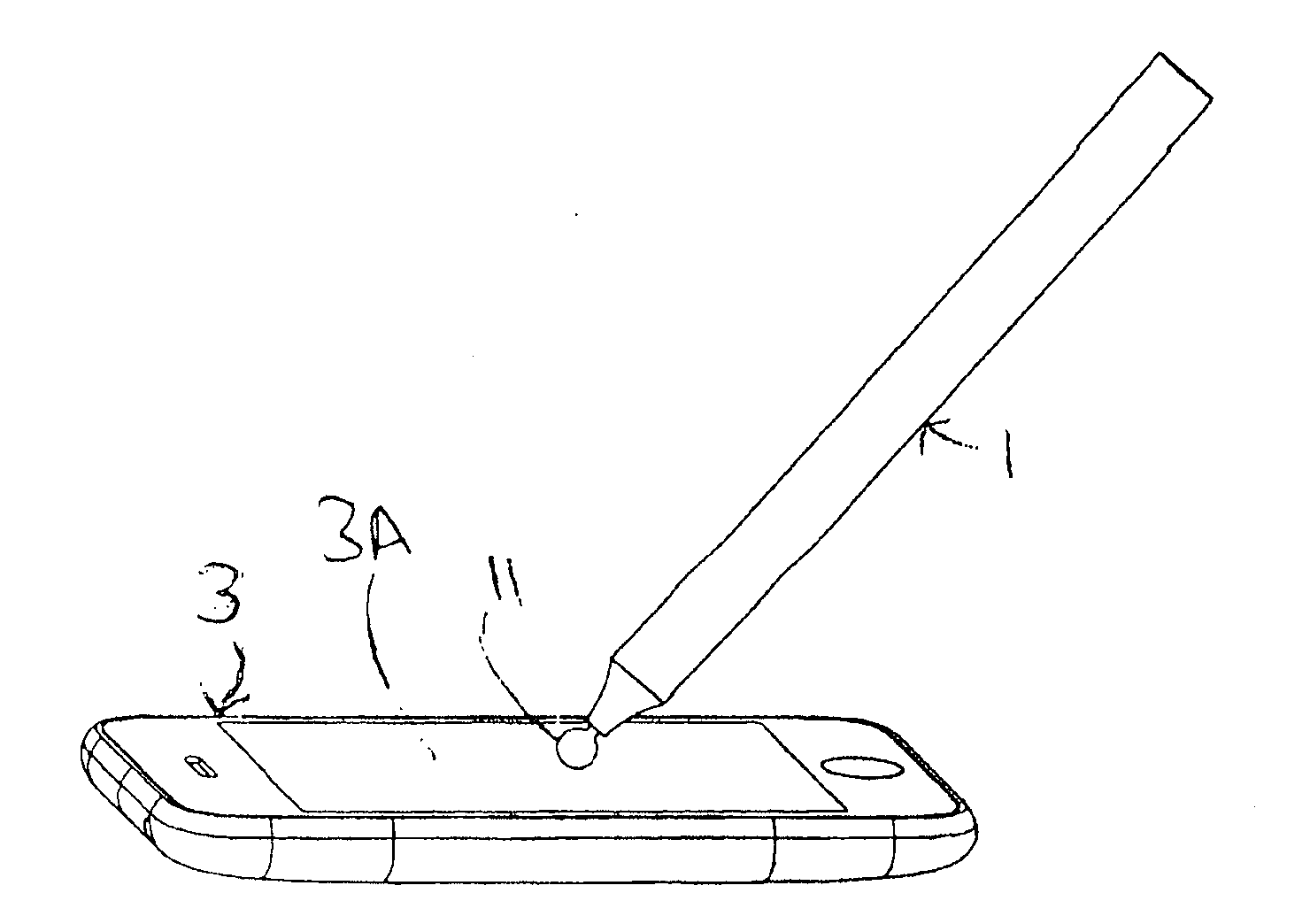

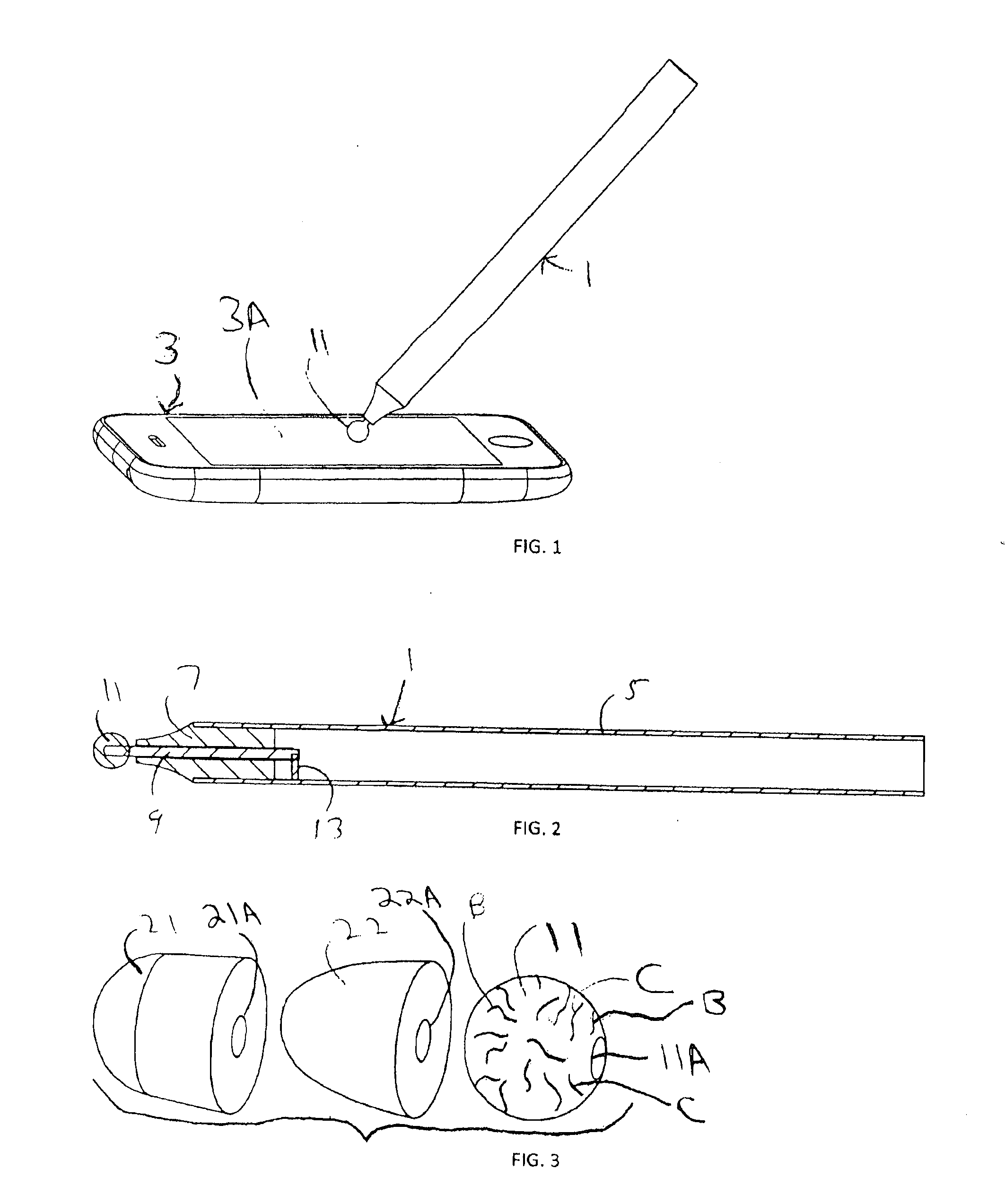

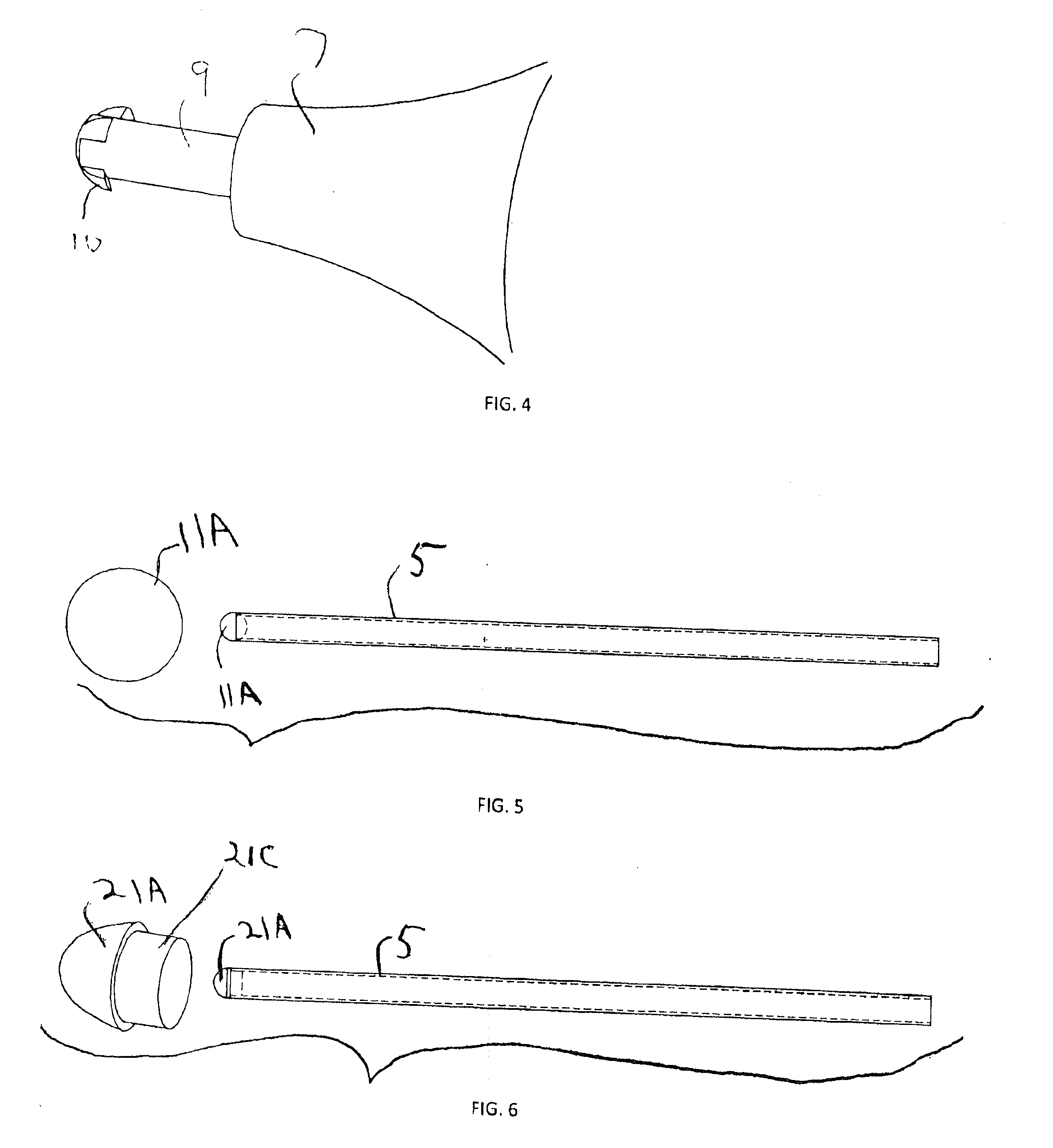

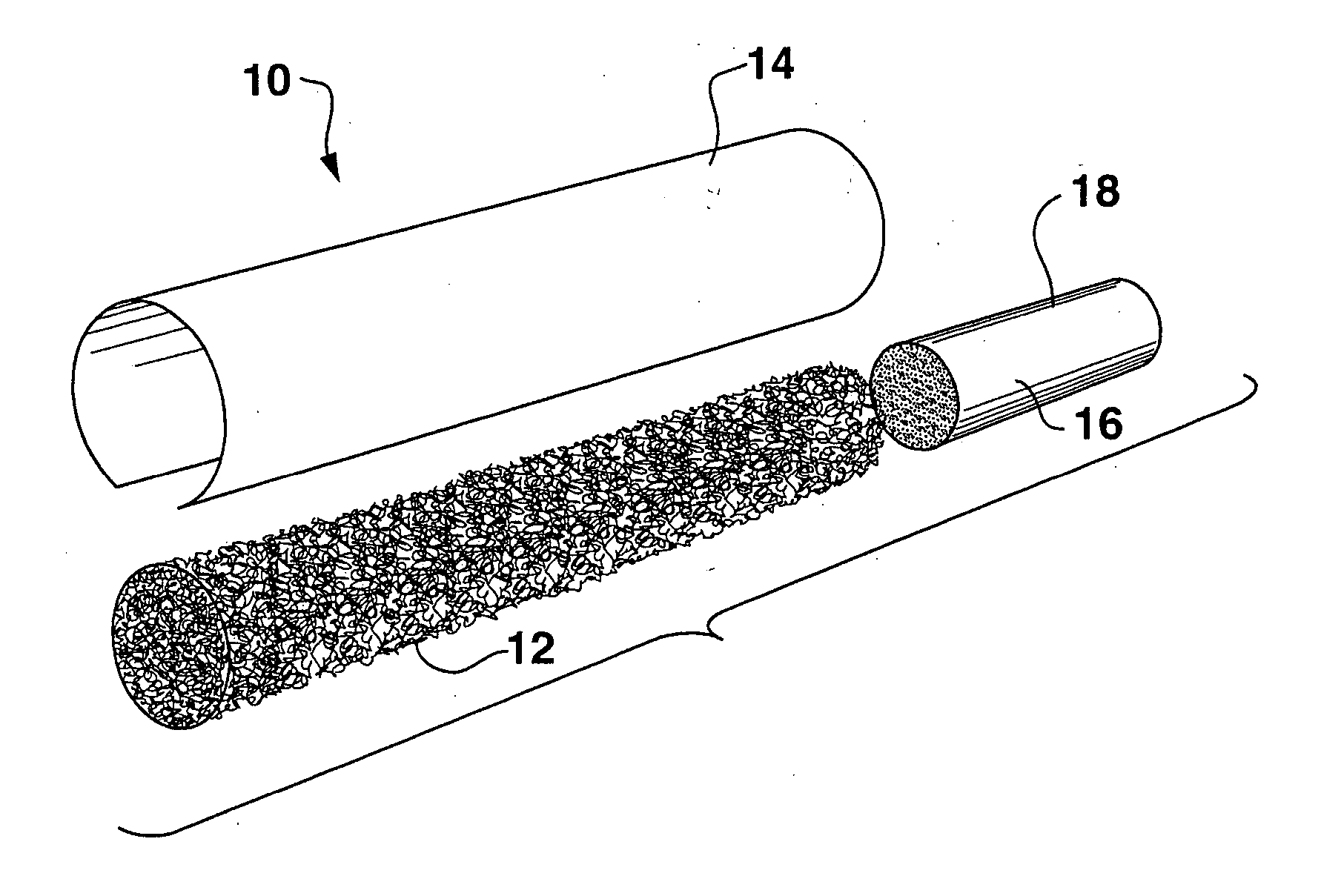

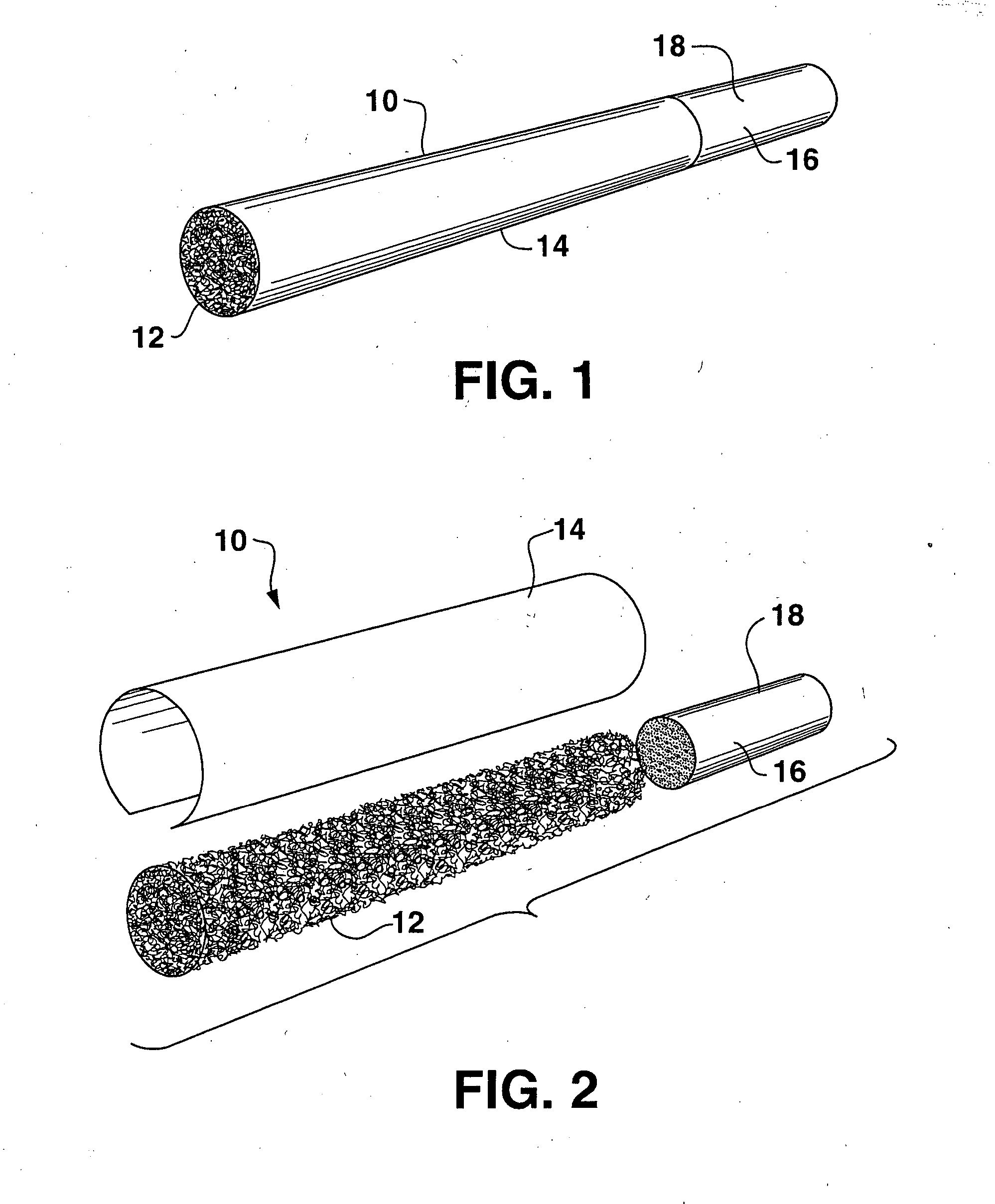

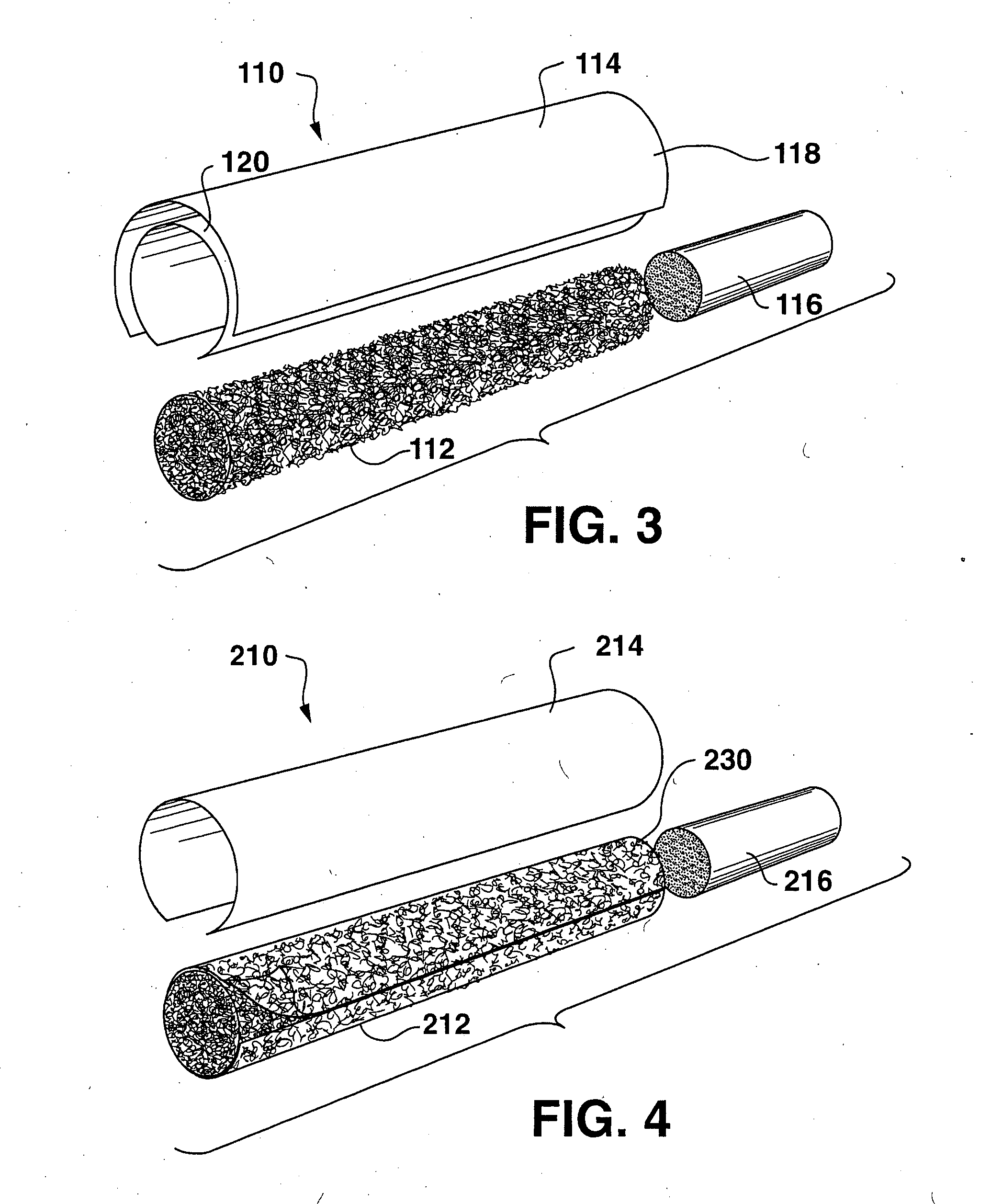

Capacitive touch screen stylus

InactiveUS20110304577A1Reduce coefficient of frictionLower impedanceInput/output processes for data processingCapacitanceFiber

In some embodiments, a stylus for providing input to a capacitive touch screen, having a tip including or consisting of conductive felt, which provides a deformable conductive surface for contacting the touch screen. The tip is produced by felting base fibers (which are typically non-conductive) with conductive fibers. In other embodiments, a capacitive touch stylus having at least a first mode of operation and a second mode of operation, and including at least one conductive tip and switched circuitry (preferably, passive circuitry) including at least one switch biased in a default state indicative of the first mode of operation but switchable into a second state indicative of the second mode of operation in response to movement of the tip (typically, in response to exertion of not less than a threshold force on the tip). In some embodiments, a stylus having a conductive tip (e.g., a conductive, felted tip) and including switched circuitry (preferably, passive circuitry) having a first state which couples a capacitance to the tip, where the capacitance is sufficient to allow a capacitive touch screen device to recognize (as a touch) simple contact of the tip on the screen of the touch screen device, and a second state which decouples the capacitance from the tip, thereby preventing the touch screen device from recognizing (as a touch) simple contact of the tip on the screen.

Owner:RB CONTROLS CO

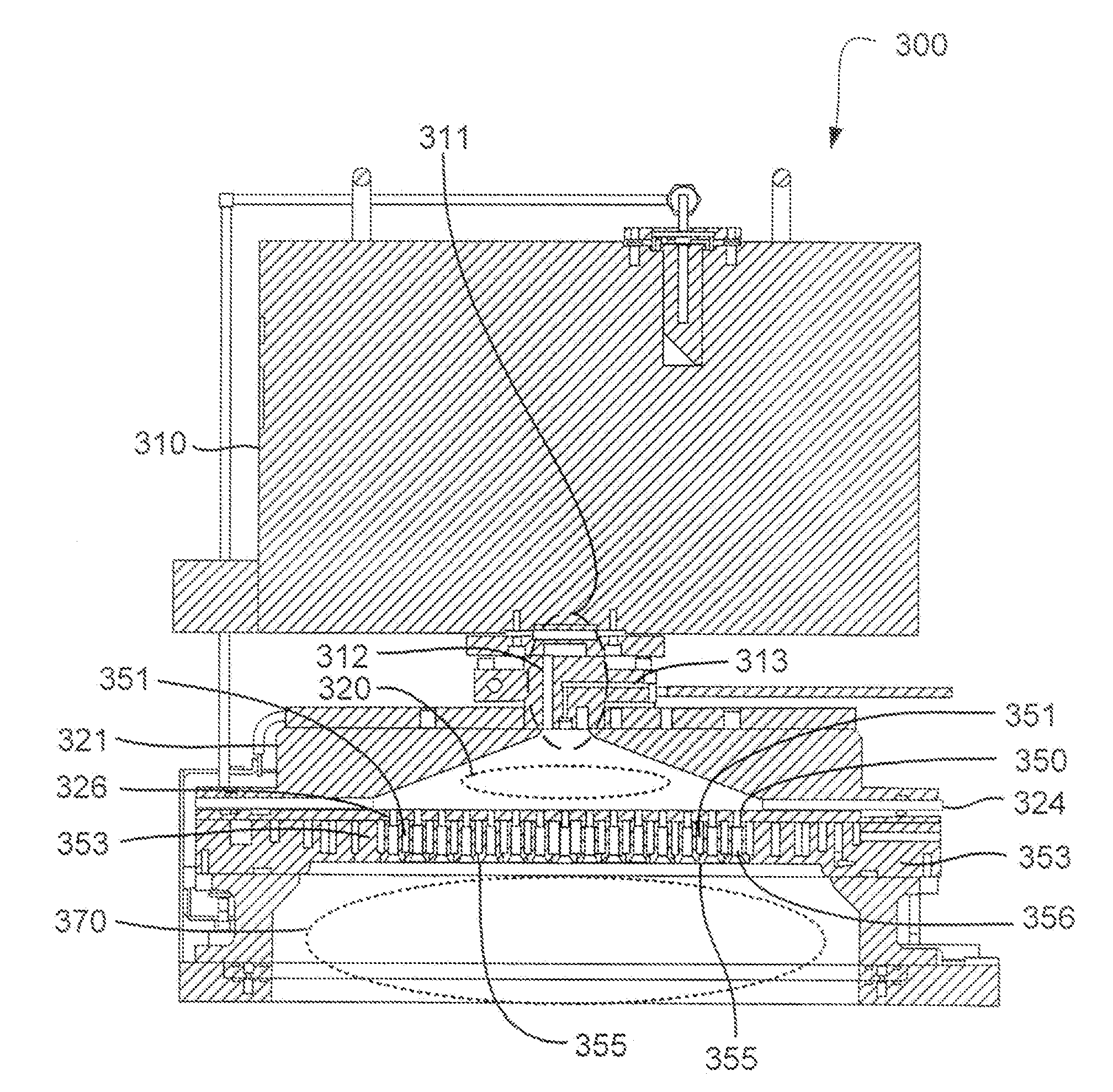

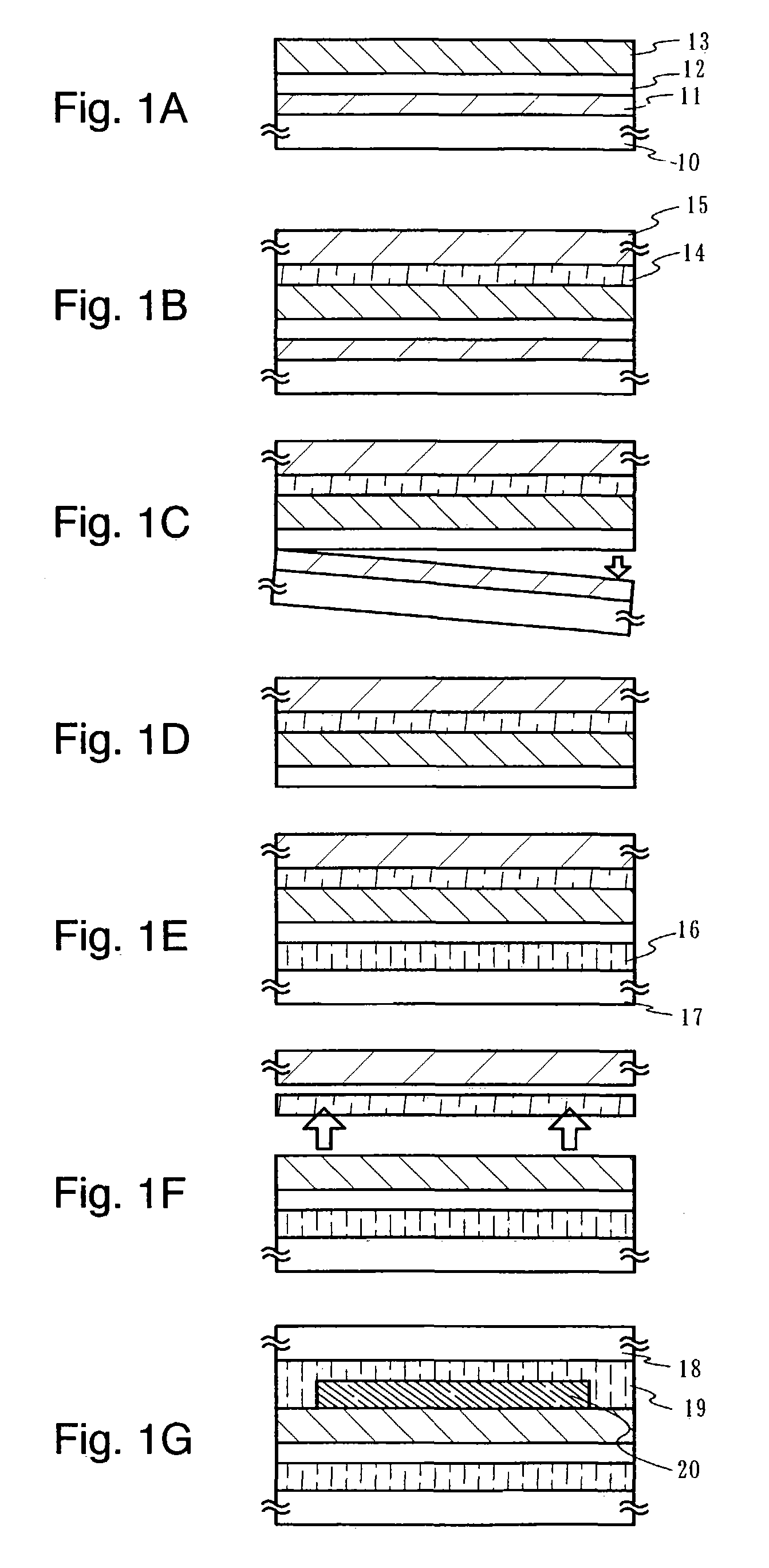

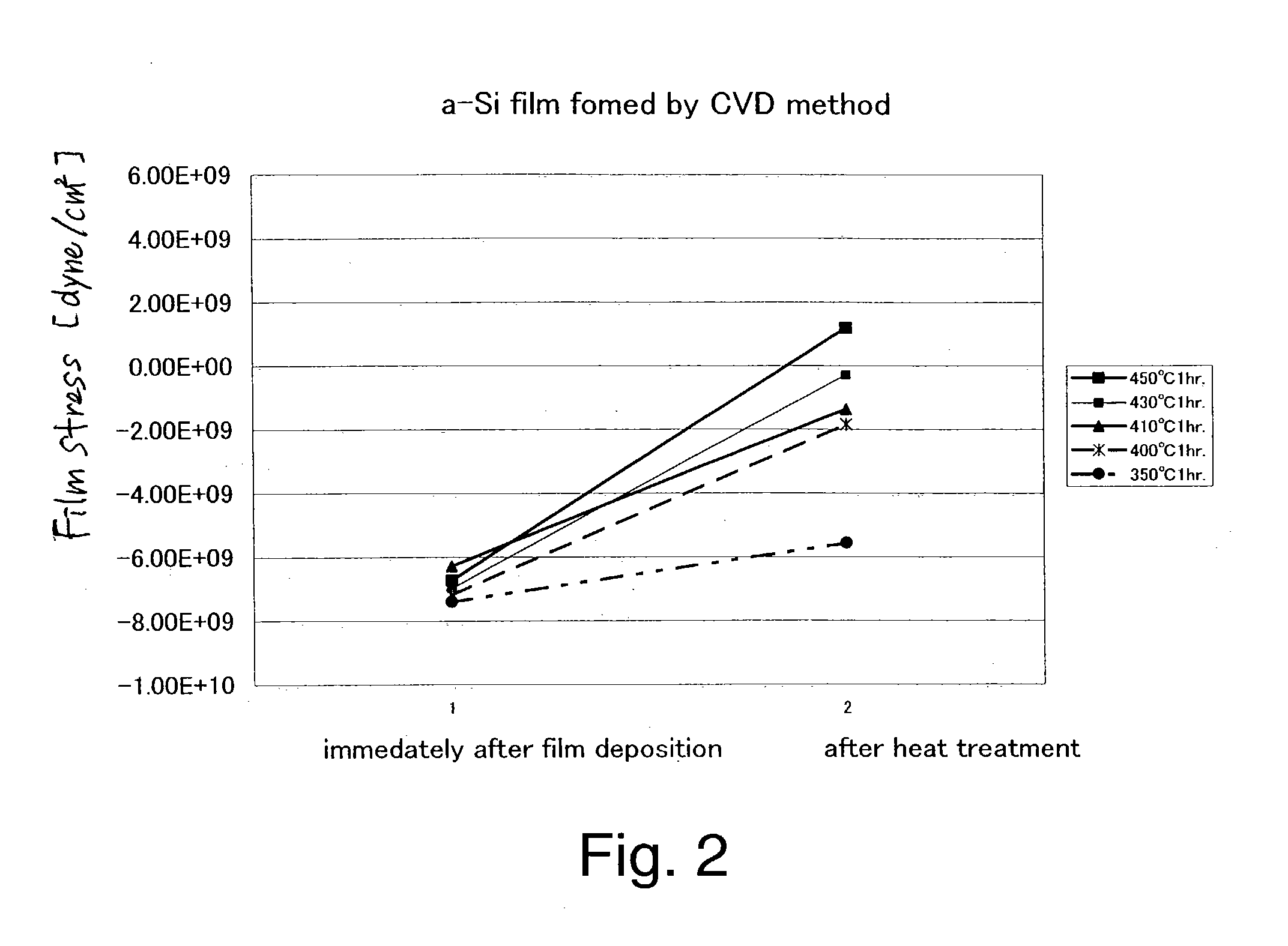

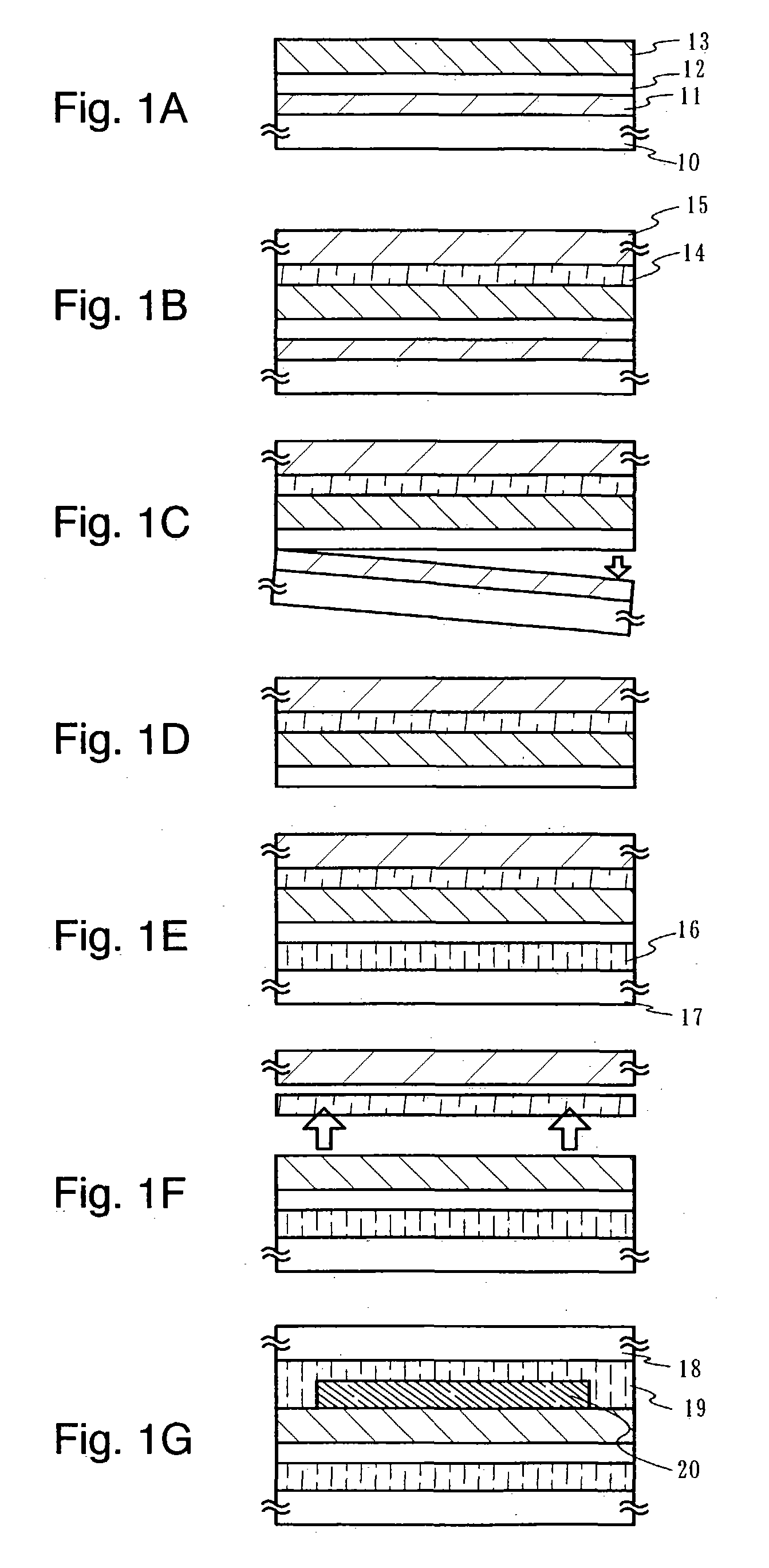

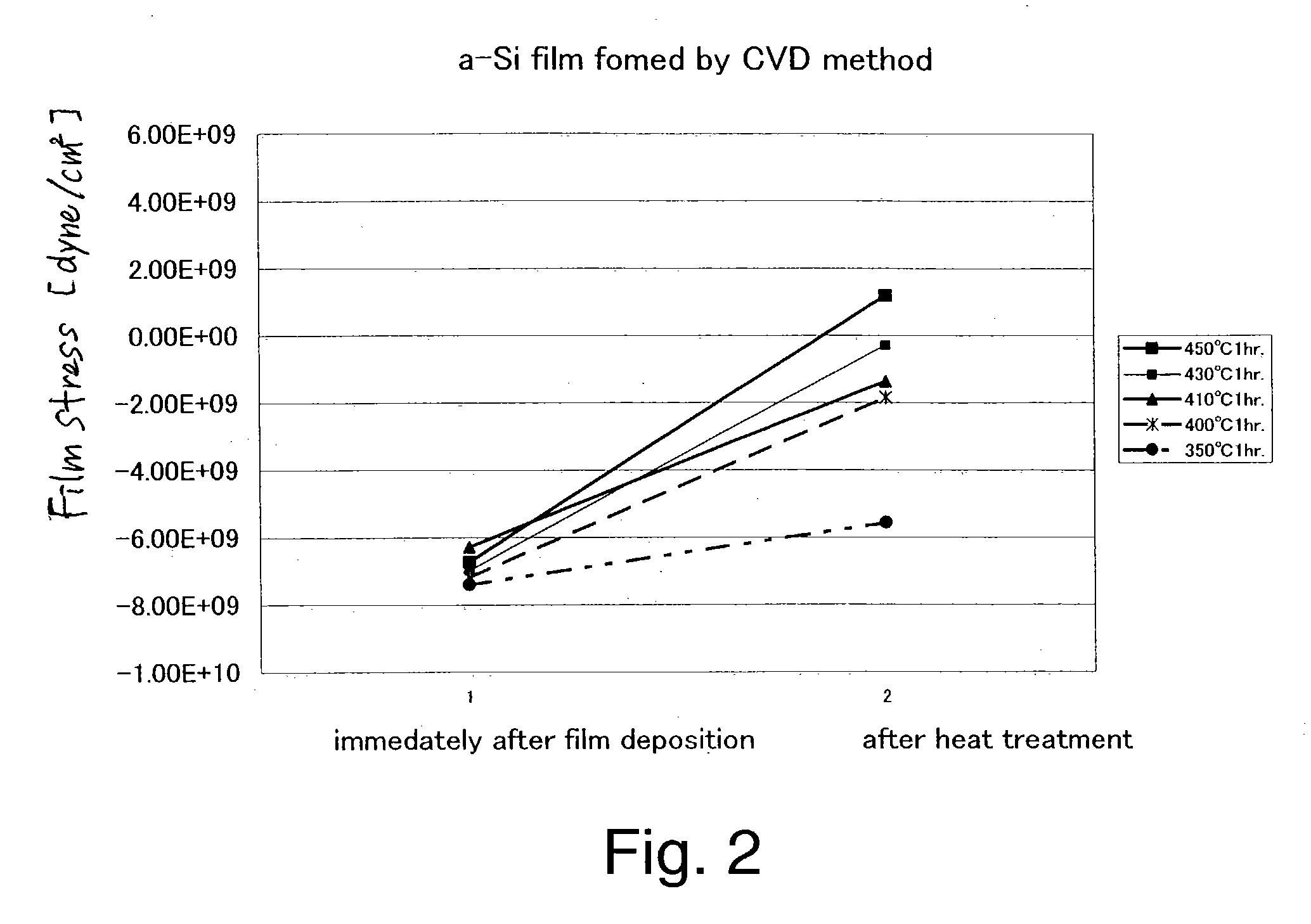

Fabrication method for a thin film semiconductor device, the thin film semiconductor device itself, liquid crystal display, and electronic device

InactiveUS6017779AImprove propertiesWell formedTransistorLinear bearingsElectronic circuitLiquid-crystal display

In order to fabricate a high performance thin film semiconductor device using a low temperature process in which it is possible to use low price glass substrates, a thin film semiconductor device has been fabricated by forming a silicon film at less than 450 DEG C., and, after crystallization, keeping the maximum processing temperature at or below 350 DEG C. In applying the present invention to the fabrication of an active matrix liquid crystal display, it is possible to both easily and reliably fabricate a large, high-quality liquid crystal display. Additionally, in applying the present invention to the fabrication of other electronic circuits as well, it is possible to both easily and reliably fabricate high-quality electronic circuits.

Owner:INTELLECTUAL KEYSTONE TECH

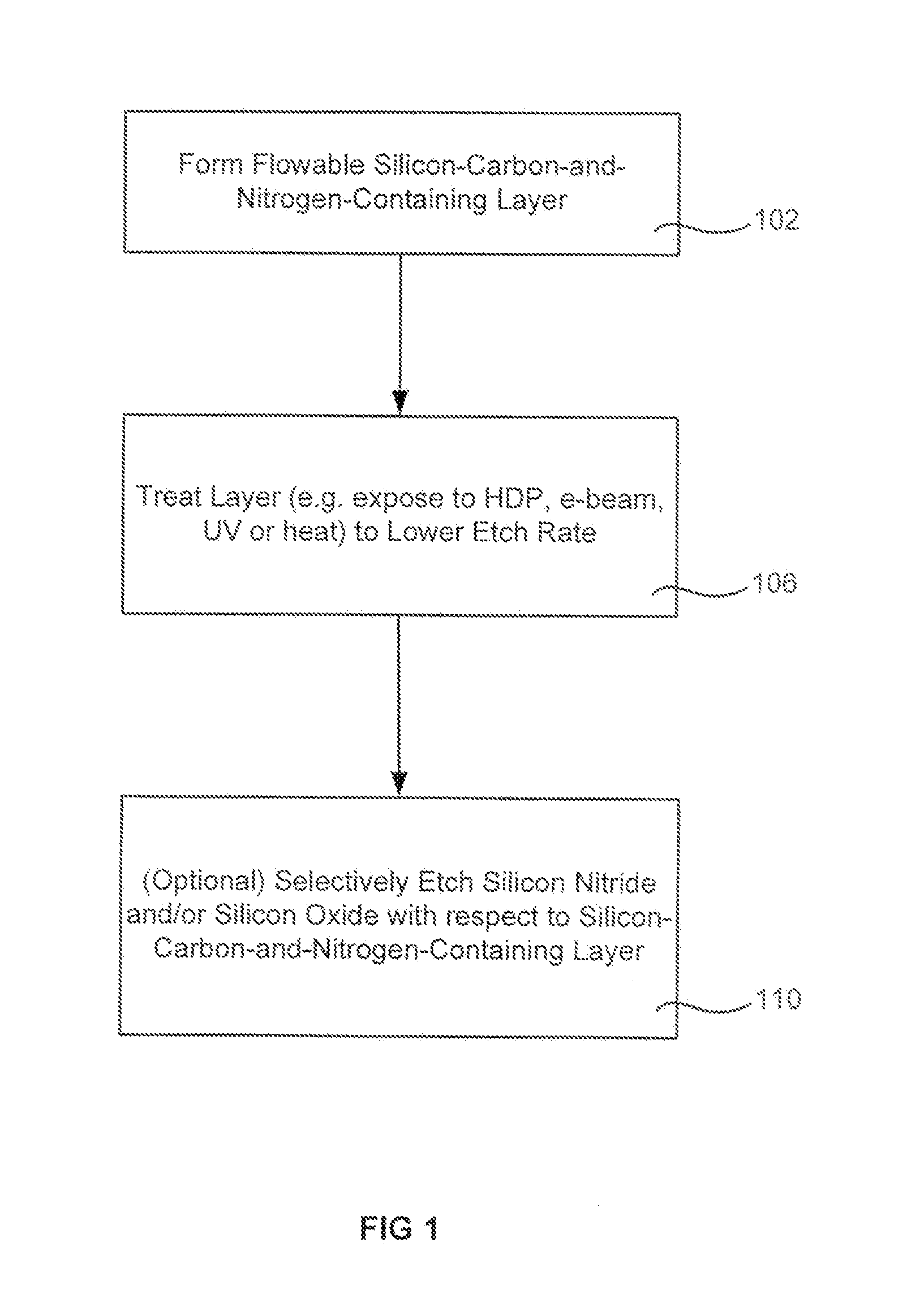

Treatments for decreasing etch rates after flowable deposition of silicon-carbon-and-nitrogen-containing layers

InactiveUS20130217241A1Excellent etch resistanceFilm property decreaseSemiconductor/solid-state device manufacturingNitrogenSemiconductor

Methods are described for forming and curing a flowable silicon-carbon-and-nitrogen-containing layer on a semiconductor substrate. The silicon and carbon constituents may come from a silicon and carbon containing precursor while the nitrogen may come from a nitrogen-containing precursor that has been activated to speed the reaction of the nitrogen with the silicon-and-carbon-containing precursor at lower deposition chamber temperatures. The initially-flowable silicon-carbon-and-nitrogen-containing layer is treated to remove components which enabled the flowability, but are no longer needed after deposition. Removal of the components increases etch resistance in order to allow the gapfill silicon-carbon-and-nitrogen-containing layer to remain intact during subsequent processing. The treatments have been found to decrease the evolution of properties of the film upon exposure to atmosphere.

Owner:APPLIED MATERIALS INC

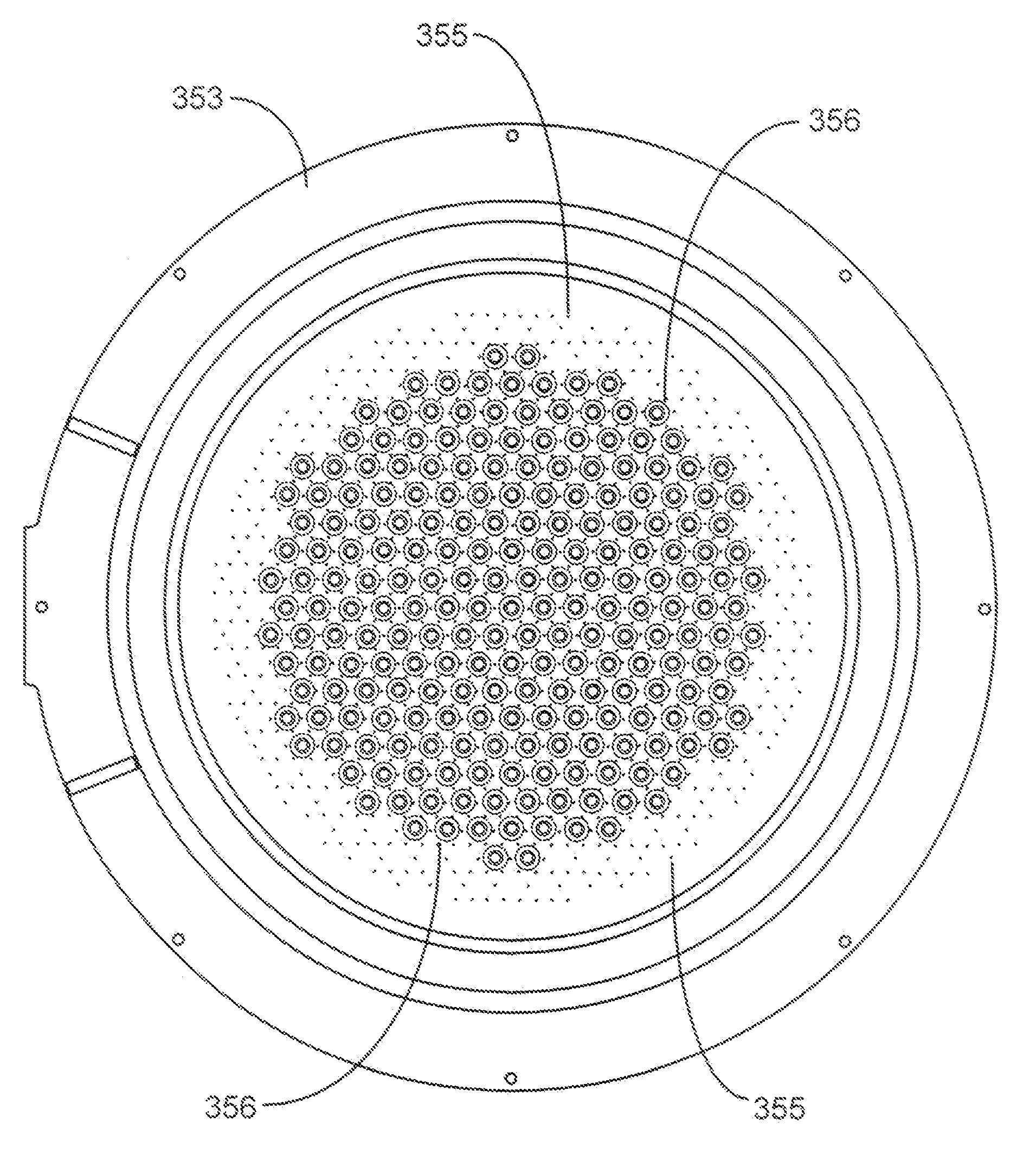

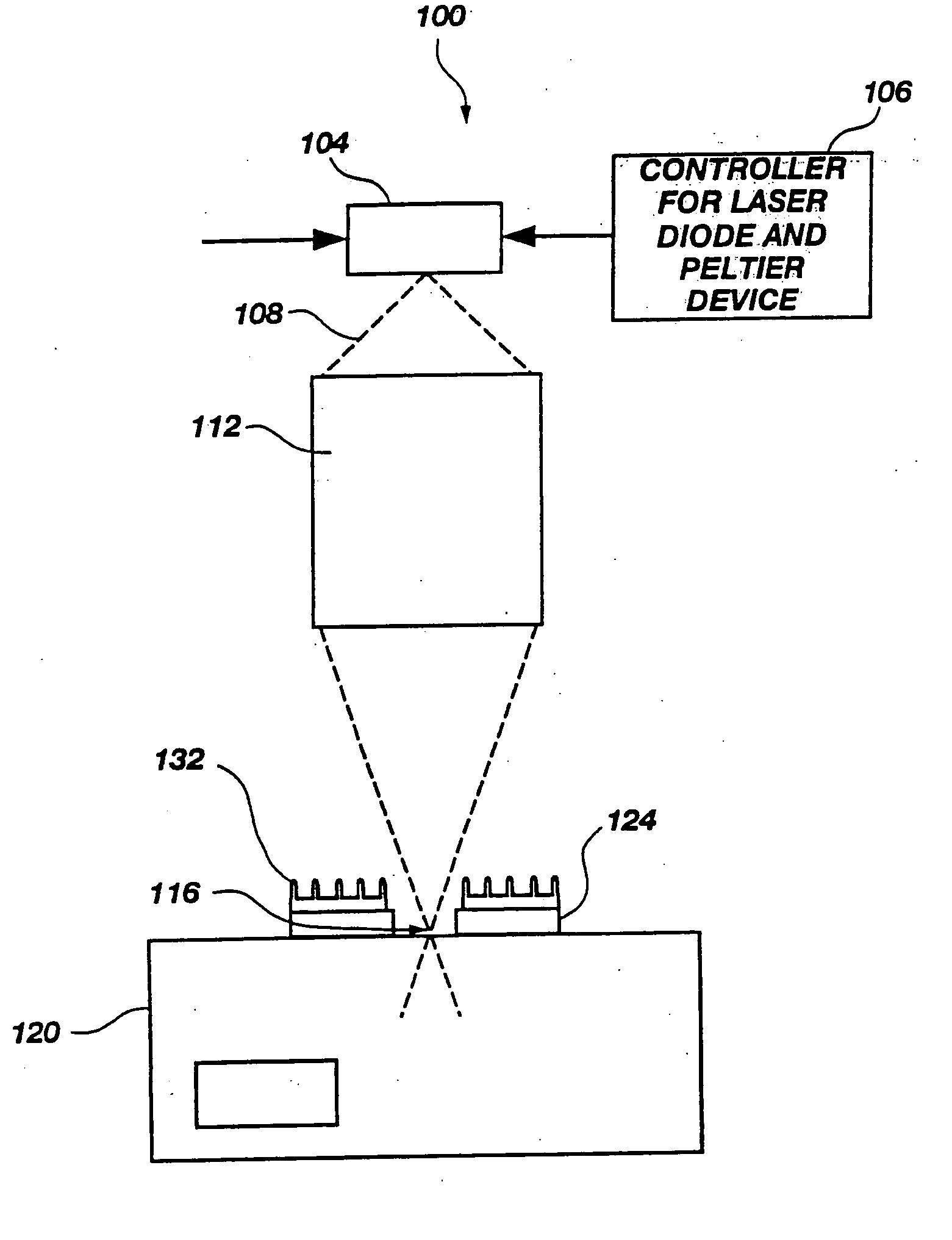

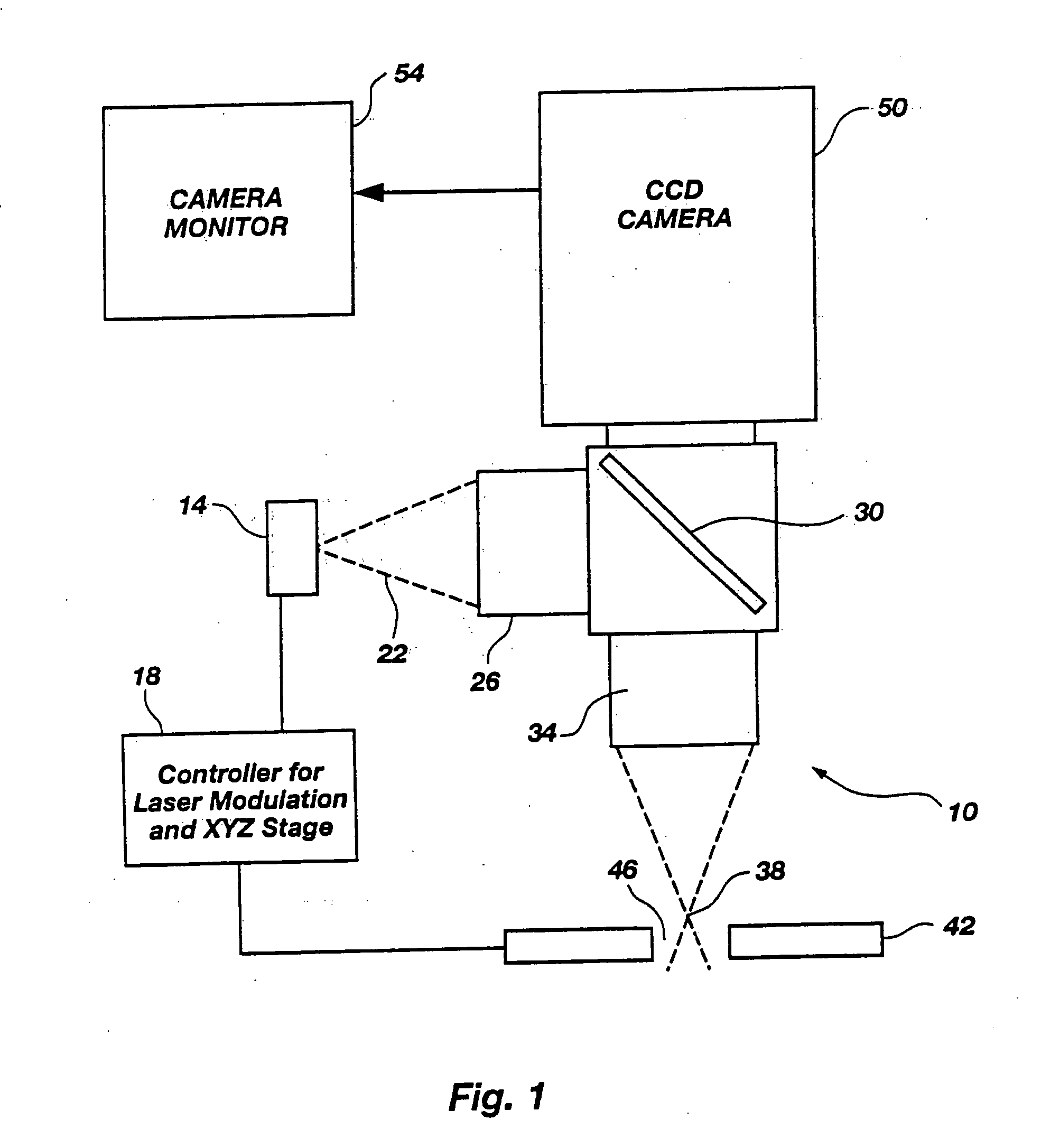

Microporation of tissue for delivery of bioactive agents

InactiveUS20050165393A1Improve throughputImprove breathabilitySonopheresisUltrasound therapyBiological bodyThermal energy

A method of enhancing the permeability of a biological membrane, including the skin or mucosa of an animal or the outer layer of a plant to a permeant is described utilizing microporation of selected depth and optionally one or more of sonic, electromagnetic, mechanical and thermal energy and a chemical enhancer. Microporation is accomplished to form a micropore of selected depth in the biological membrane and the porated site is contacted with the permeant. Additional permeation enhancement measures may be applied to the site to enhance both the flux rate of the permeant into the organism through the micropores as well as into targeted tissues within the organism.

Owner:ALTEA THERAPEUTIC CORP +1

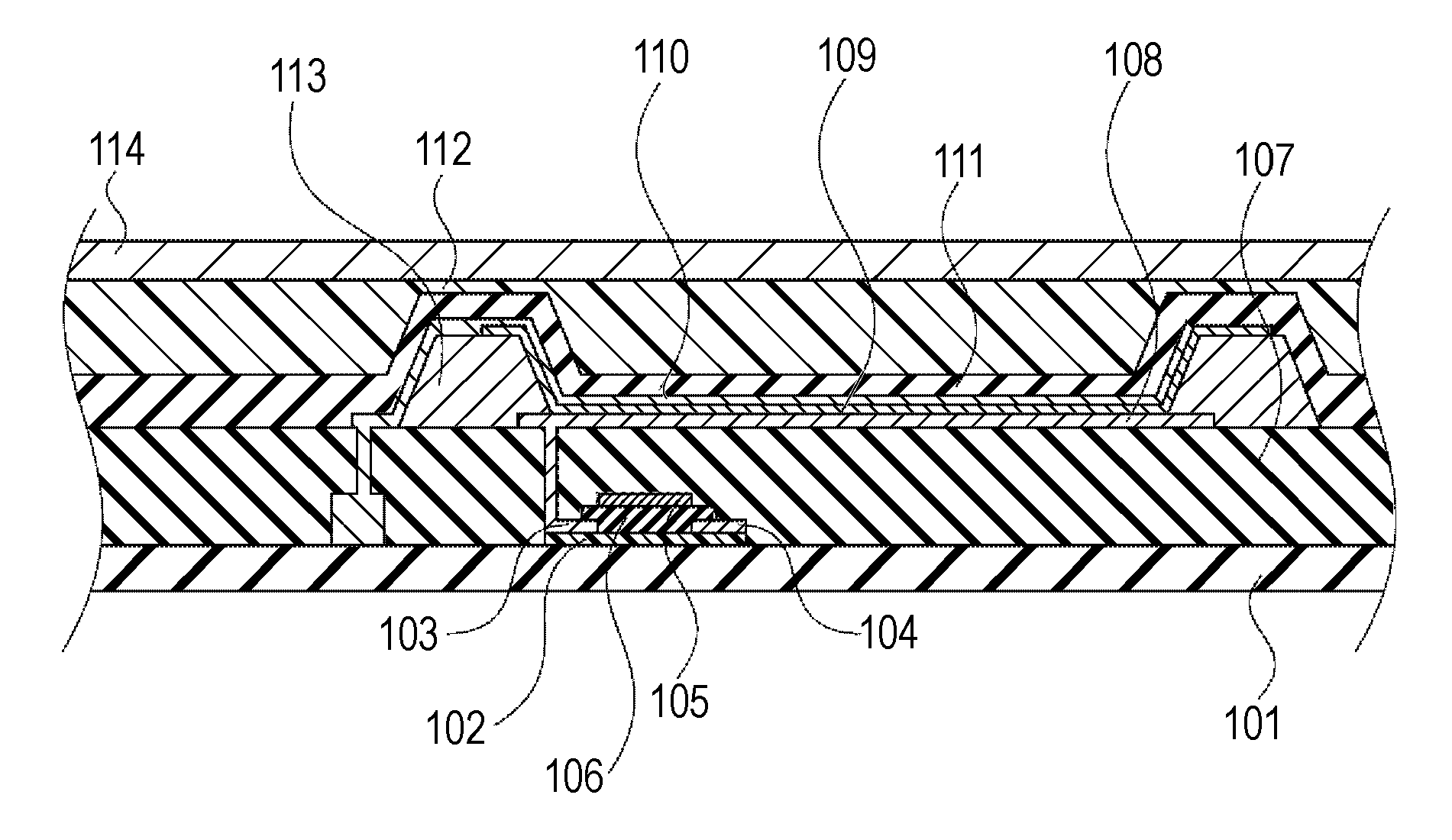

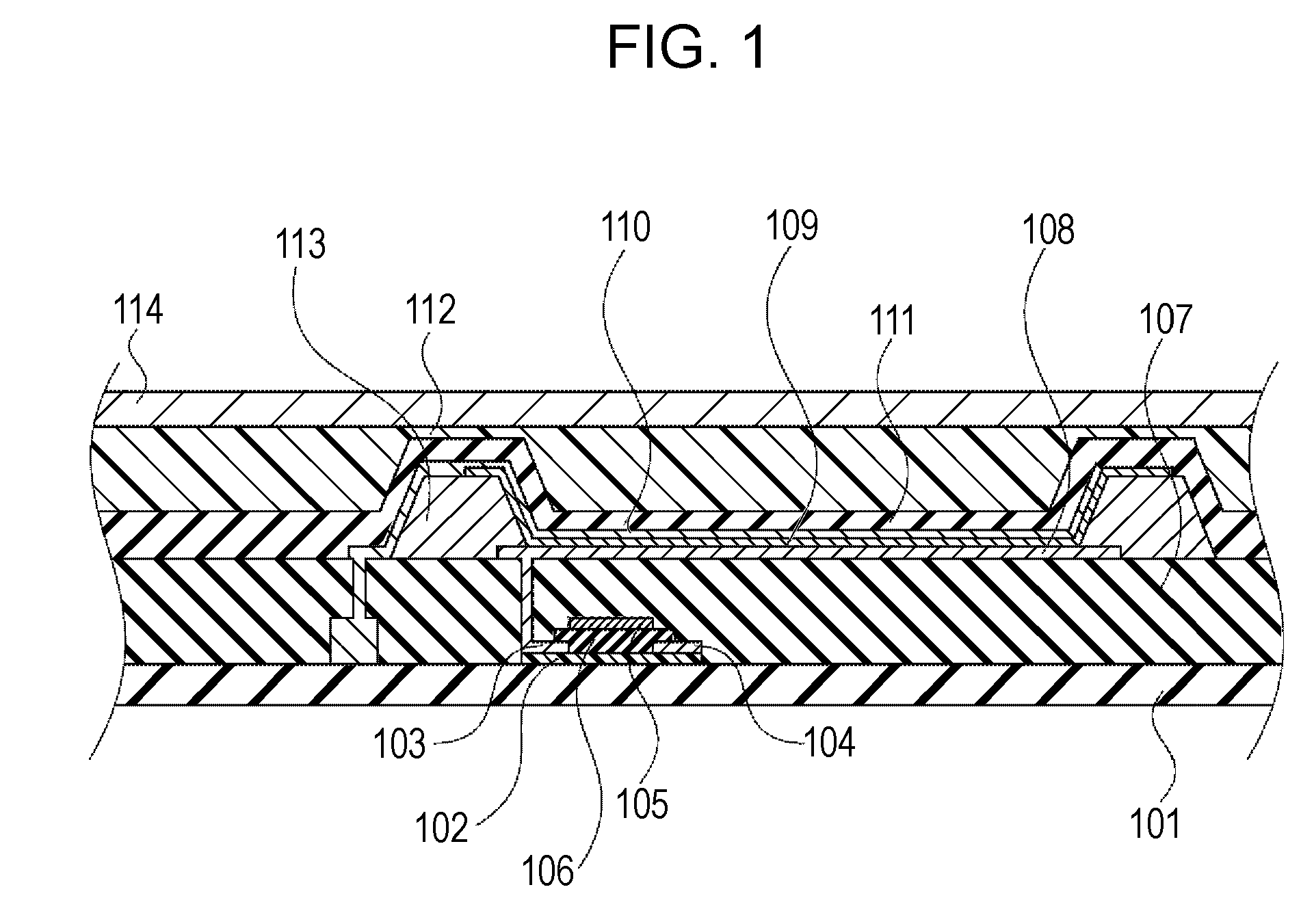

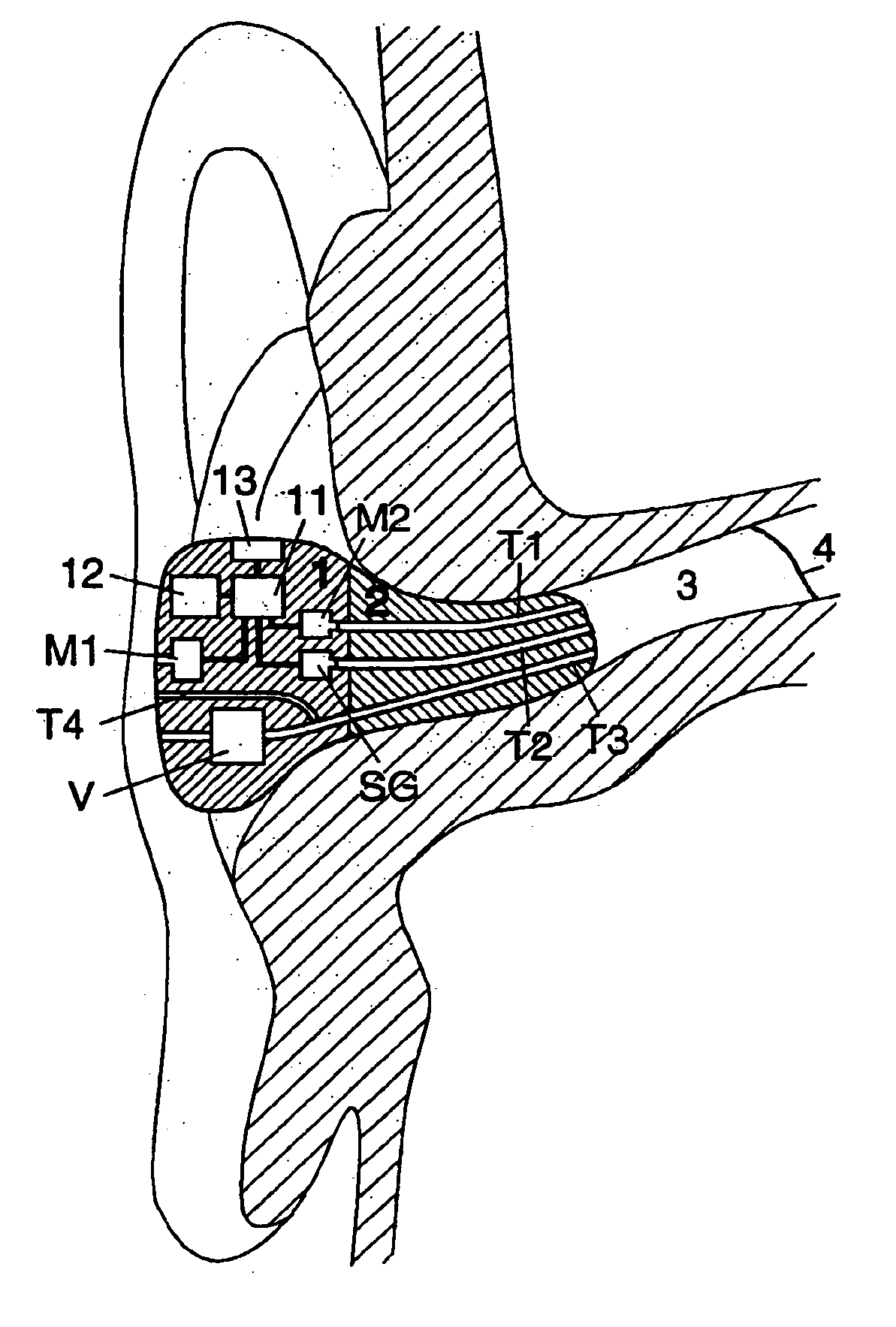

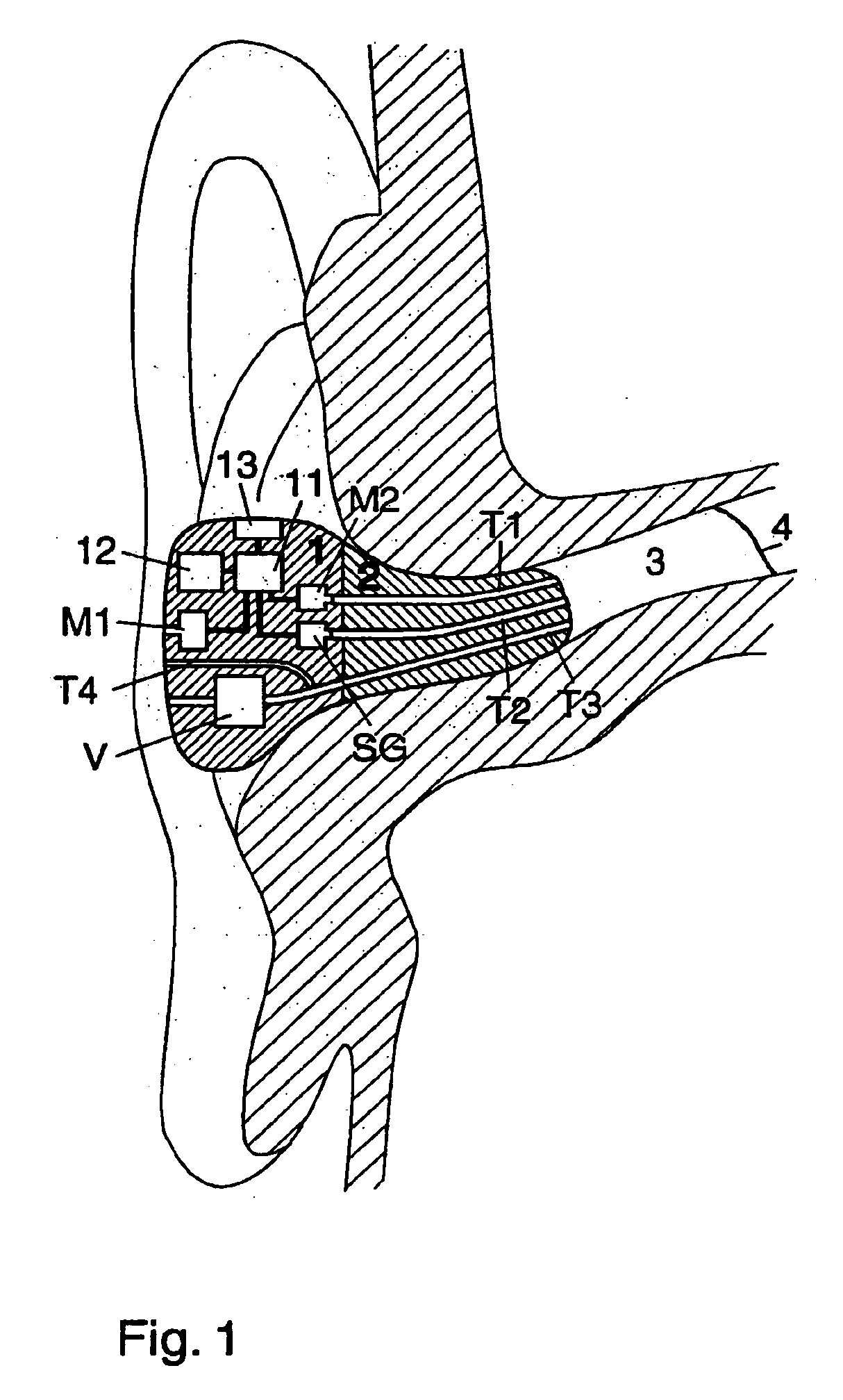

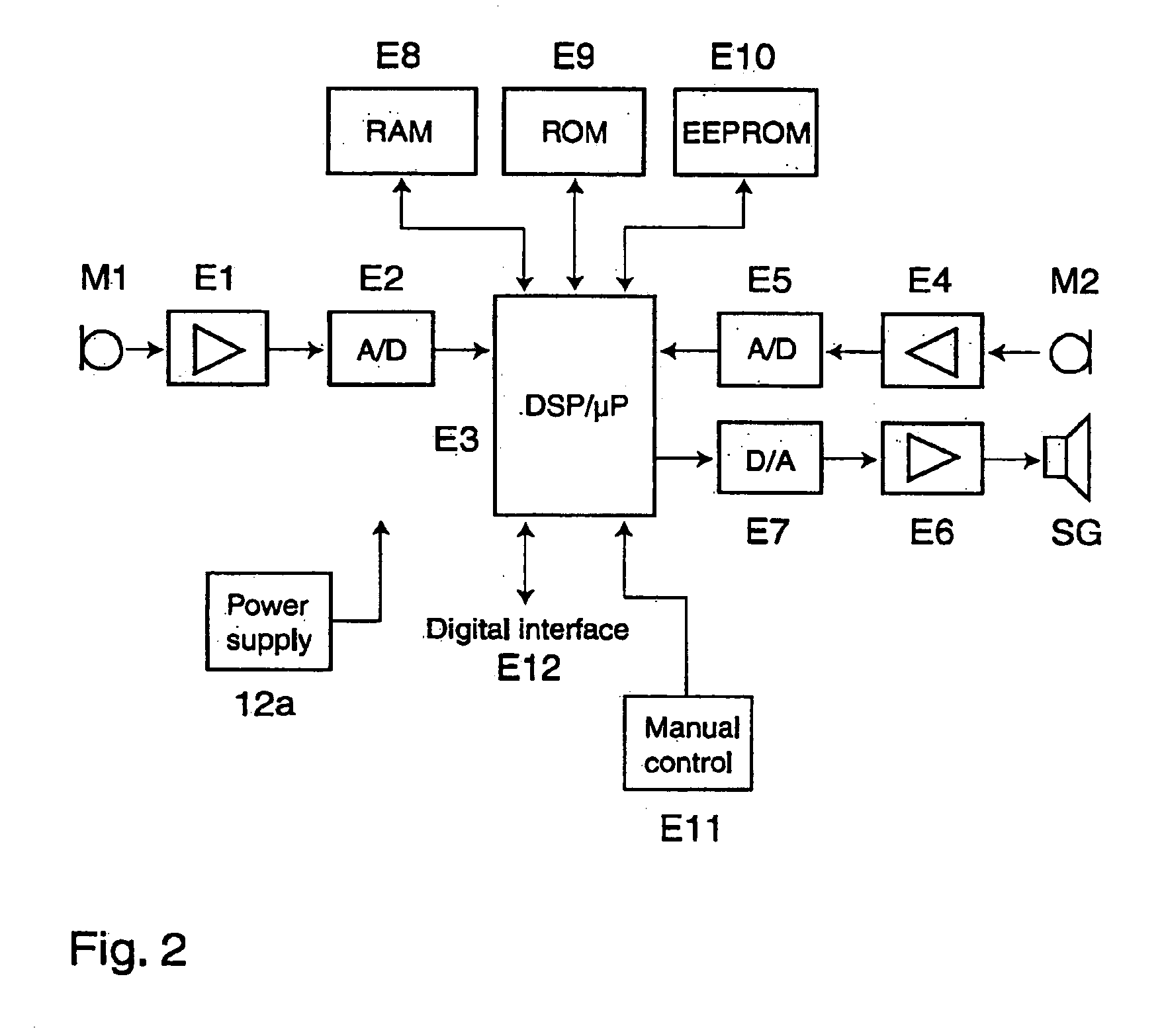

Ear terminal with microphone for voice pickup

InactiveUS6754359B1Hearing protectionQuality improvementSignal processingHearing aids signal processingEngineeringHeadphones

An ear terminal includes a sealing section arranged for use in the ear meatus of a human, with an inner microphone having a sound inlet for being directed into the meatus and an electronic unit including filtering elements coupled to the inner microphone for filtering the signal from the inner microphone, the filtering elements being programmable to transform the signals based on the sounds received in the ear by the inner microphone into sounds having essentially the characteristics of spoken sounds of the wearer of the ear terminal.

Owner:HONEYWELL HEARING TECH

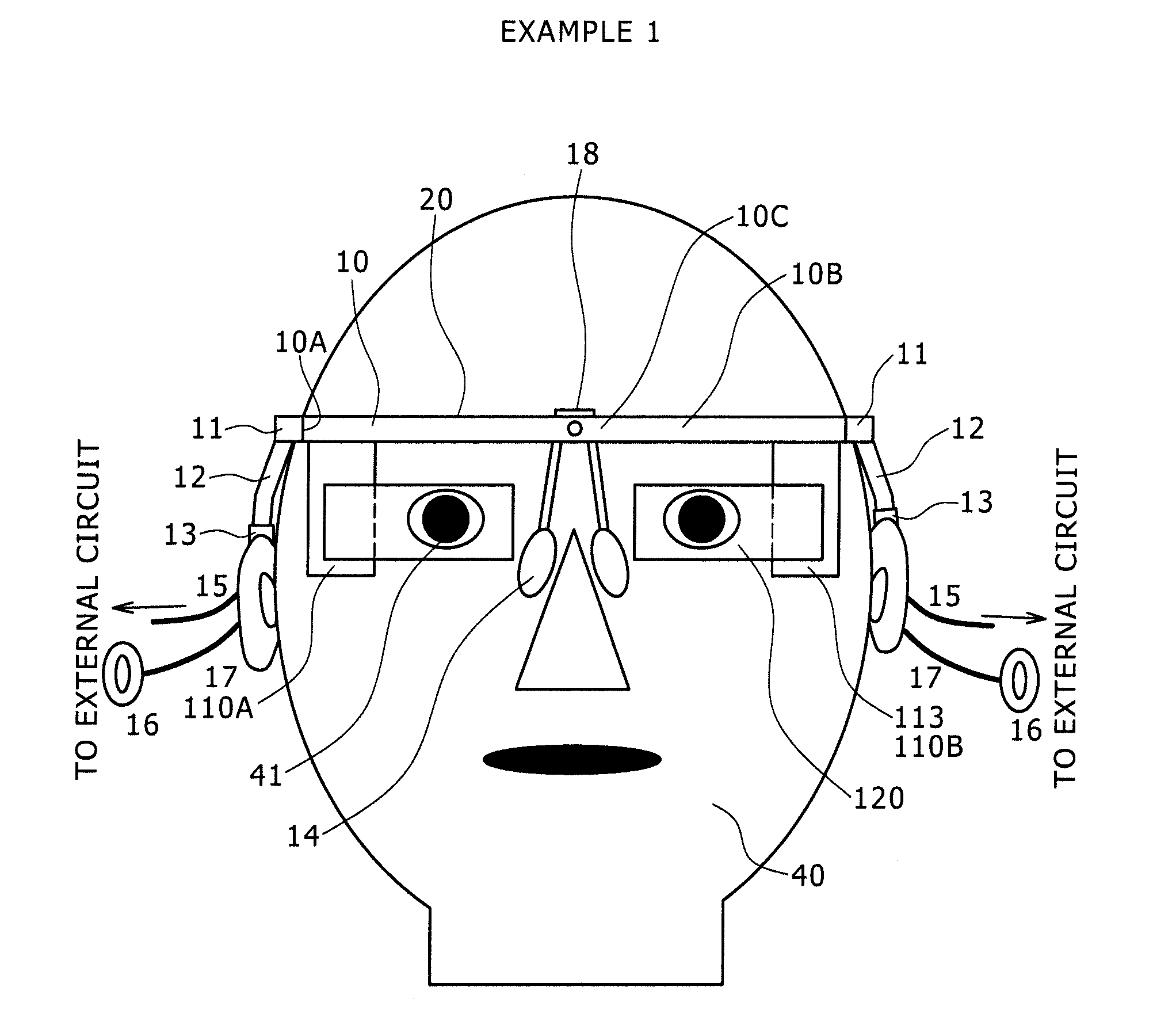

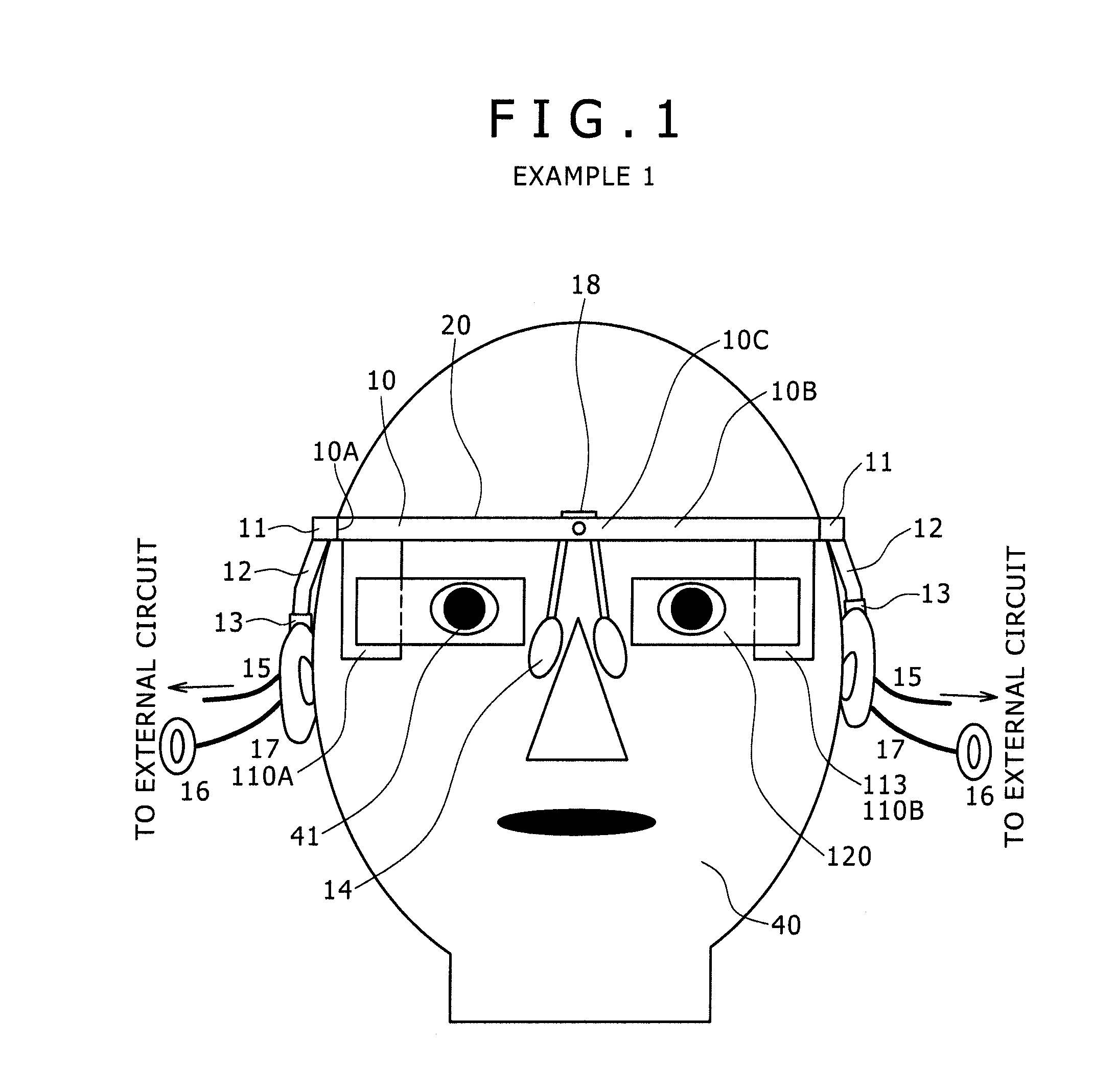

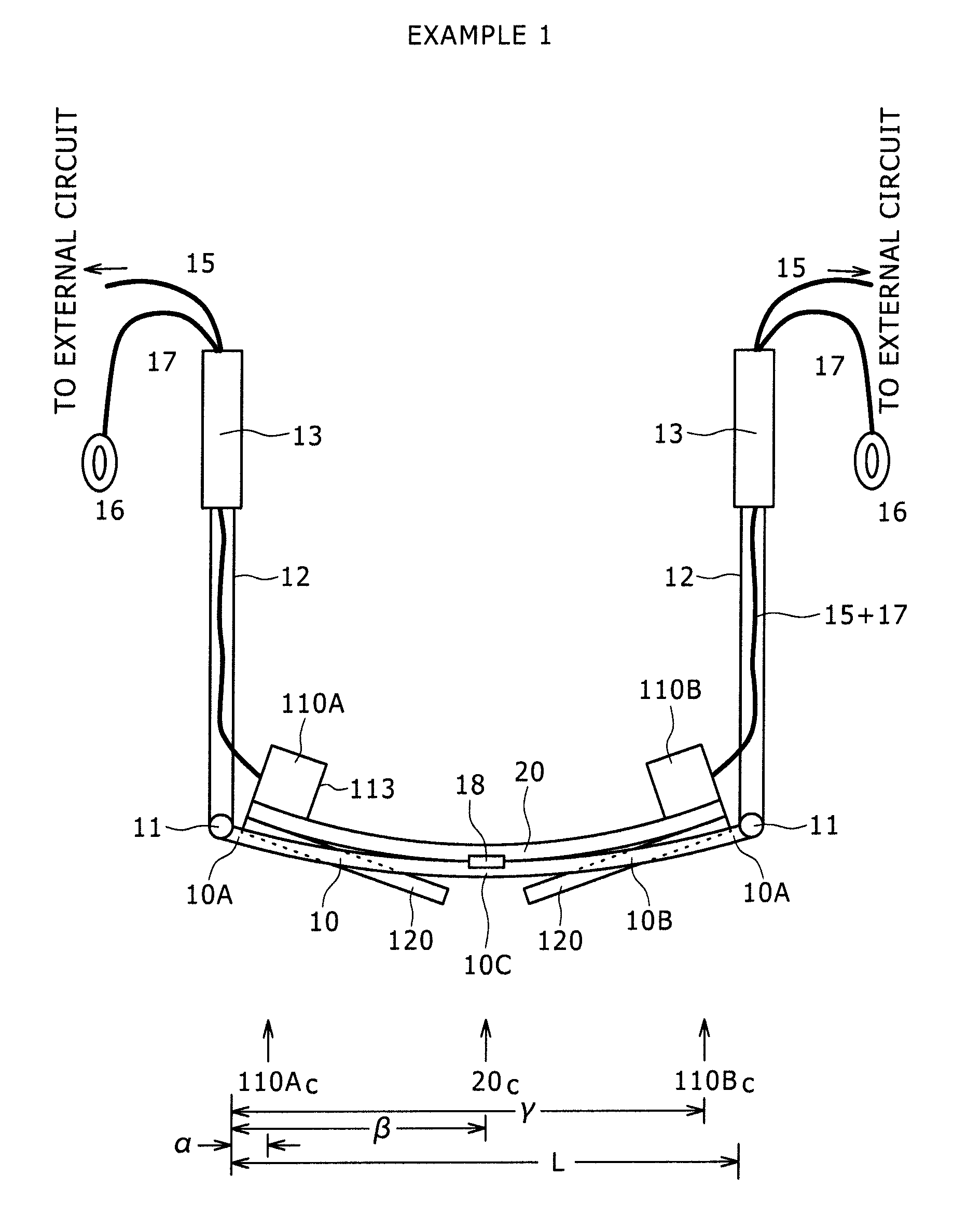

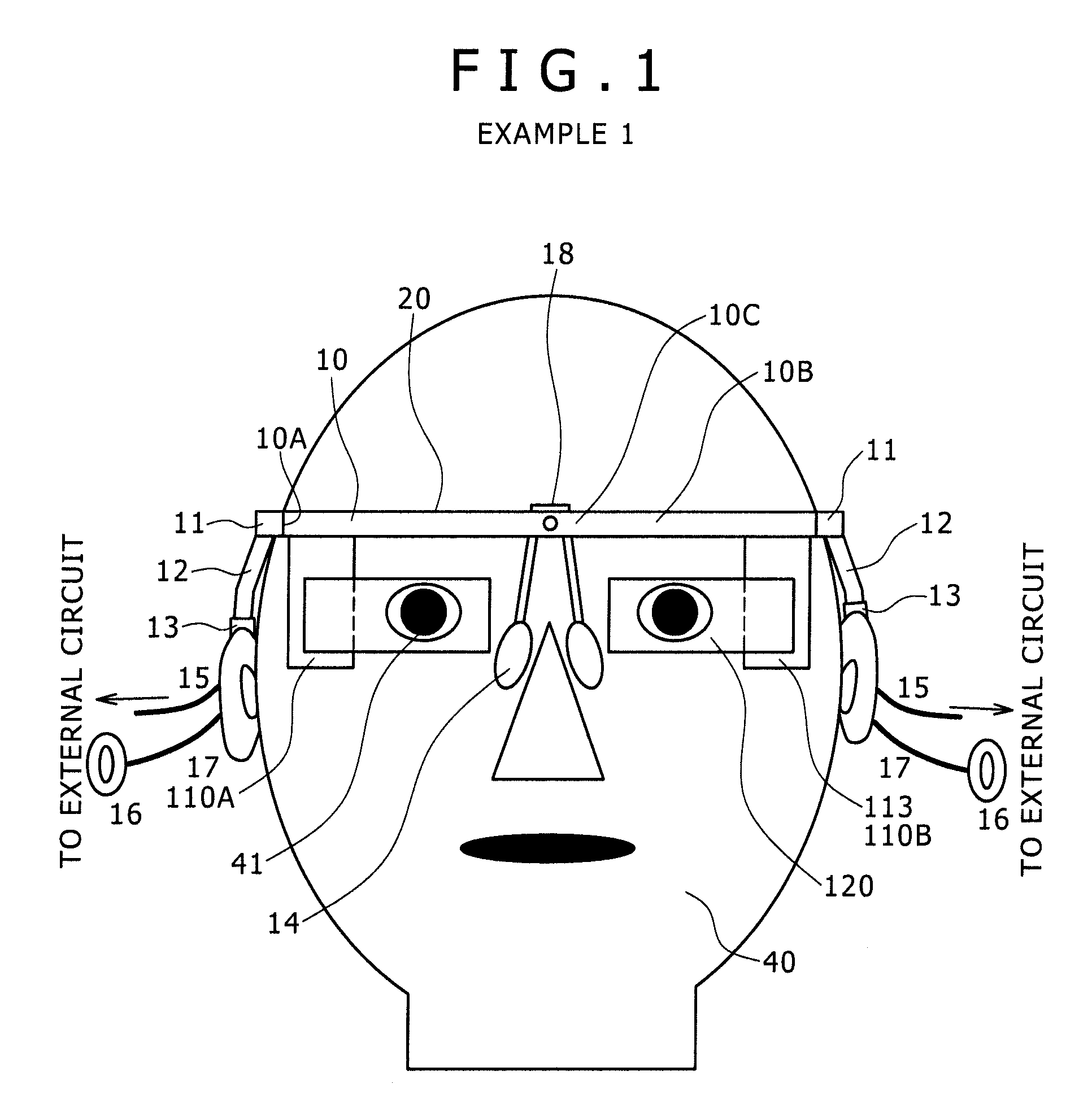

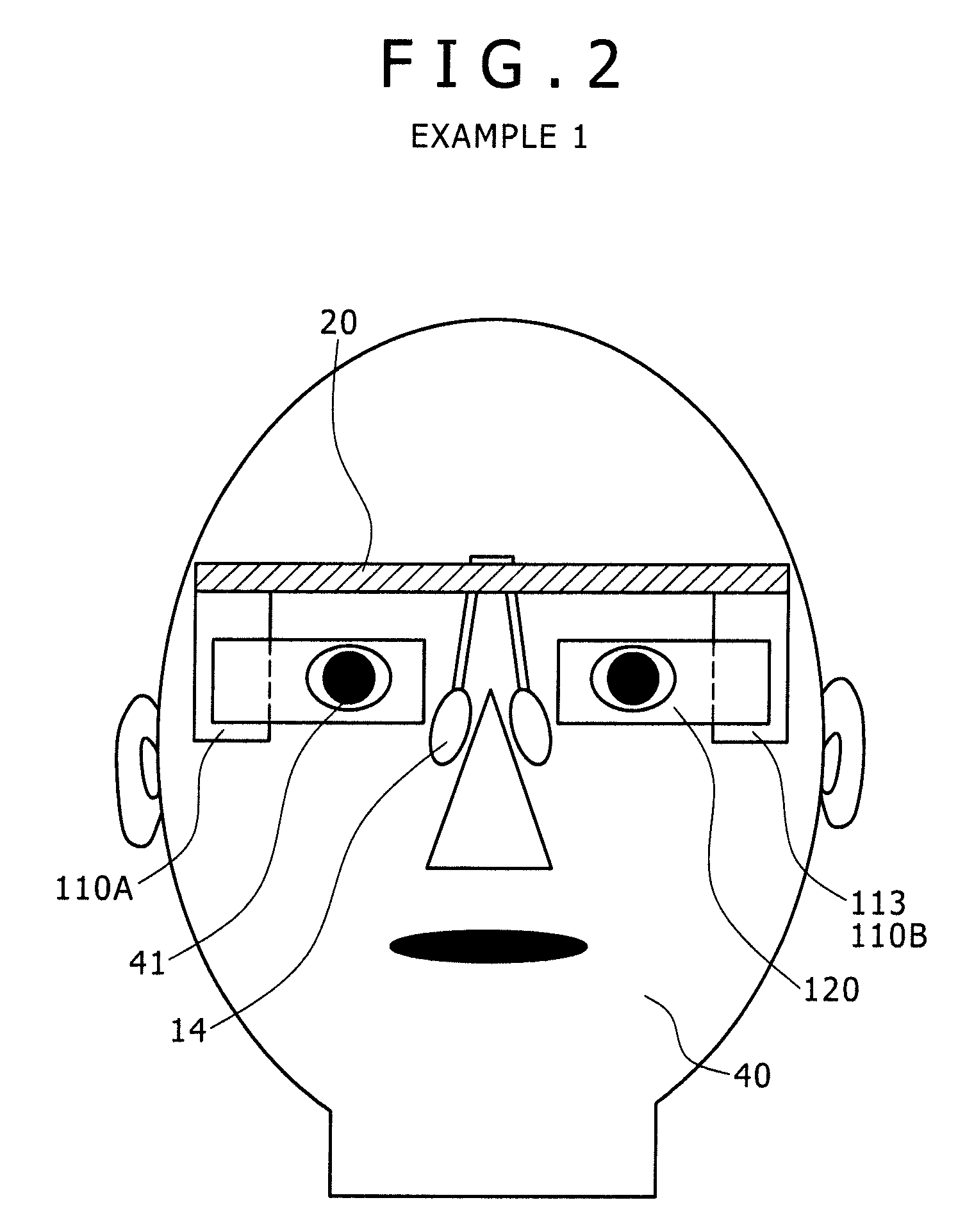

Head mounted display

ActiveUS20100157433A1Increased frame weightIncrease freedomNon-optical adjunctsProjectorsHead worn displayLight guide

Disclosed herein is a head mounted display including: an eyeglasses frame-like frame to be mounted onto an observer's head; and two image display devices, each of the image display devices including an image generating device, and light guide means which is mounted to the image generating device, which as a whole is located on the side of the center of an observer's face relative to the image generating device, on which beams emitted from the image generating device are incident, through which the beams are guided, and from which the beams are emitted toward an observer's pupil.

Owner:SONY CORP

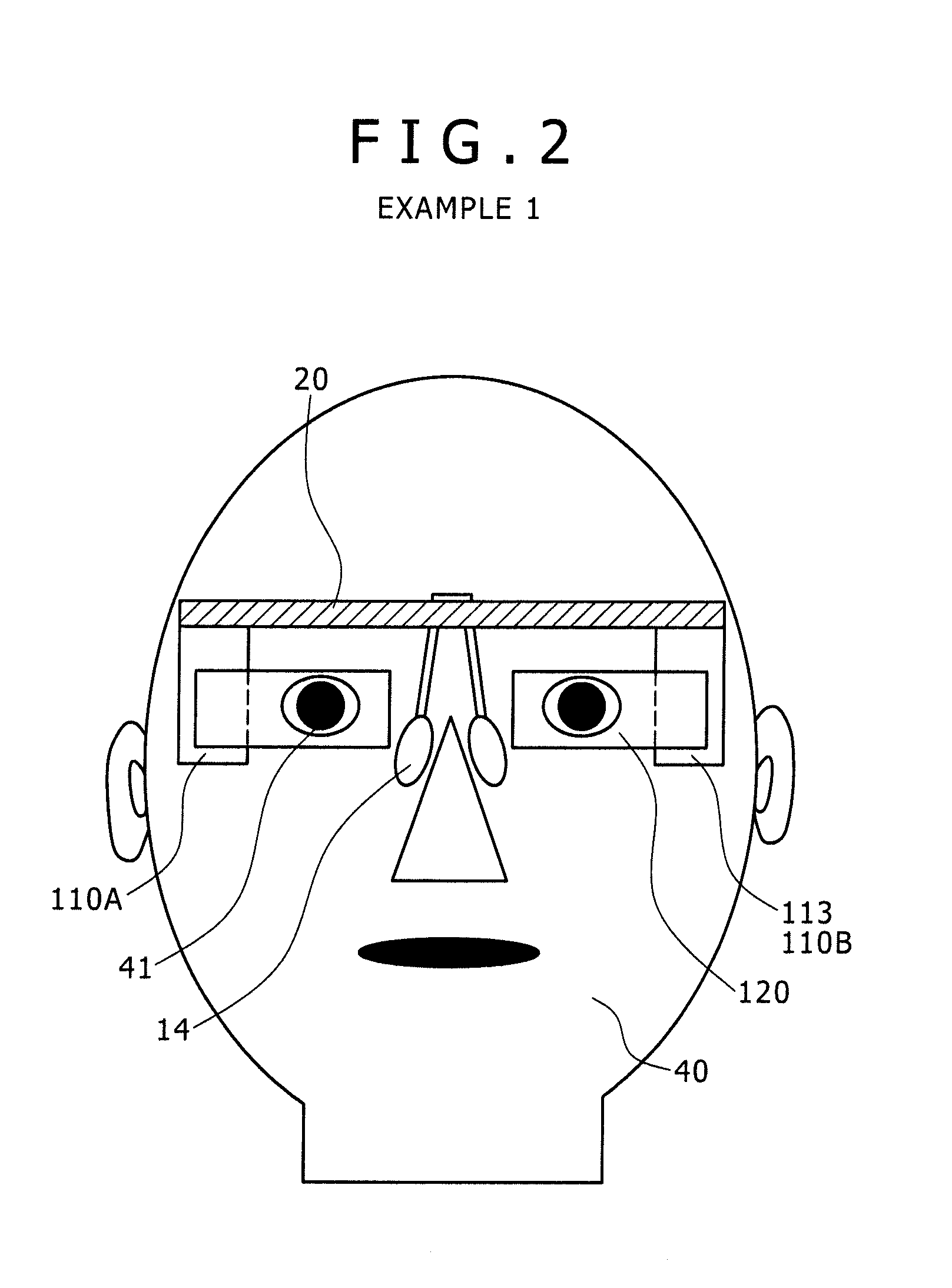

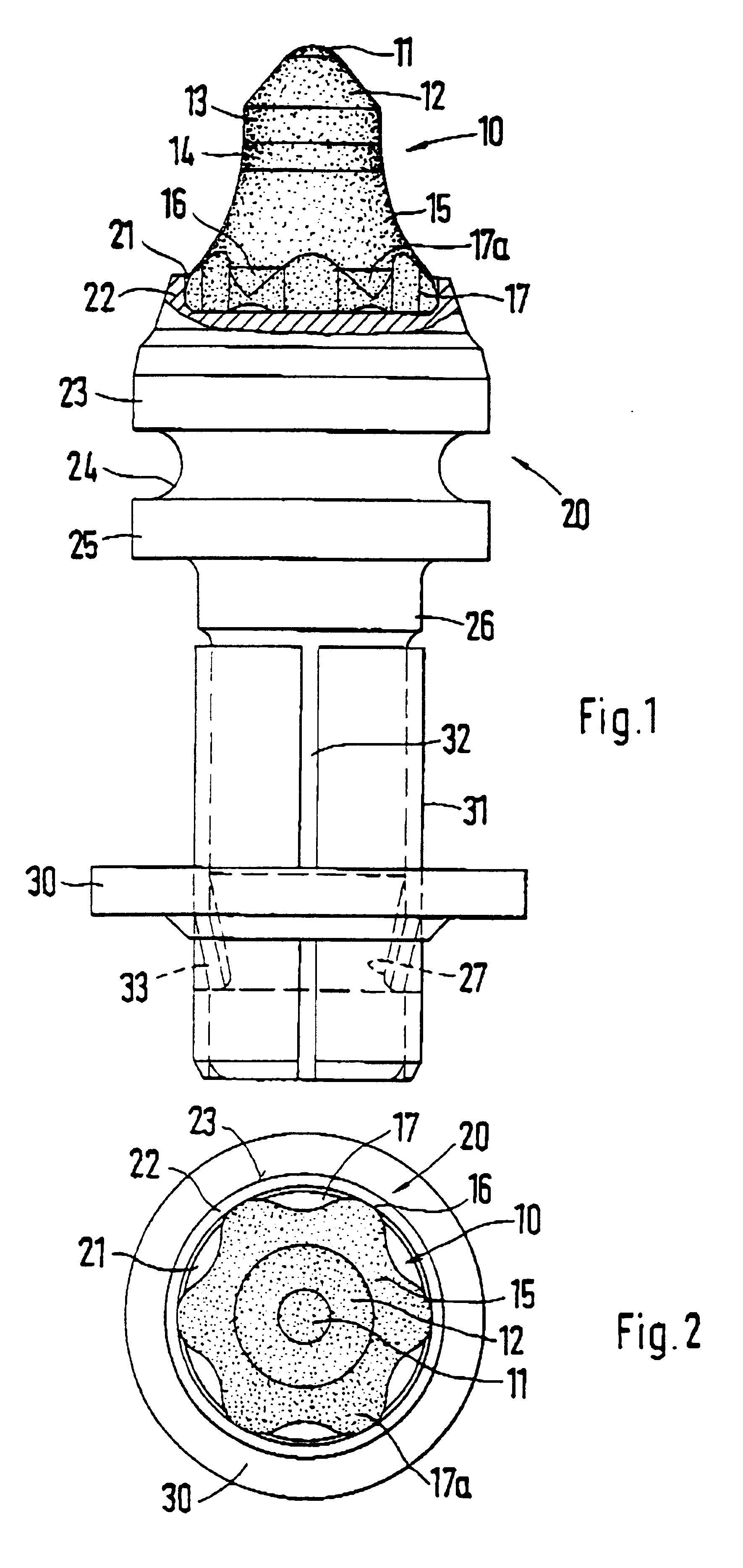

Round-shank bit for a coal cutting machine

InactiveUS6199956B1Sufficient supportLess stressPolishing machinesRevolution surface grinding machinesMaximum diameterEngineering

A round-shank bit for a coal cutting machine or the like, having a bit head and a bit shank, wherein the bit head has a bit tip, maintained by a base element in a receptacle of the bit head. Starting at the base element, the bit tip tapers in a direction toward the free end of the bit tip, wherein the base element forms a maximum diameter of the bit tip, and wherein the bit tip has recesses on its outer contour. In order to assure good rotational behavior over the entire length of the operating time, the base element has the recesses on an outer circumference forming the maximum diameter.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

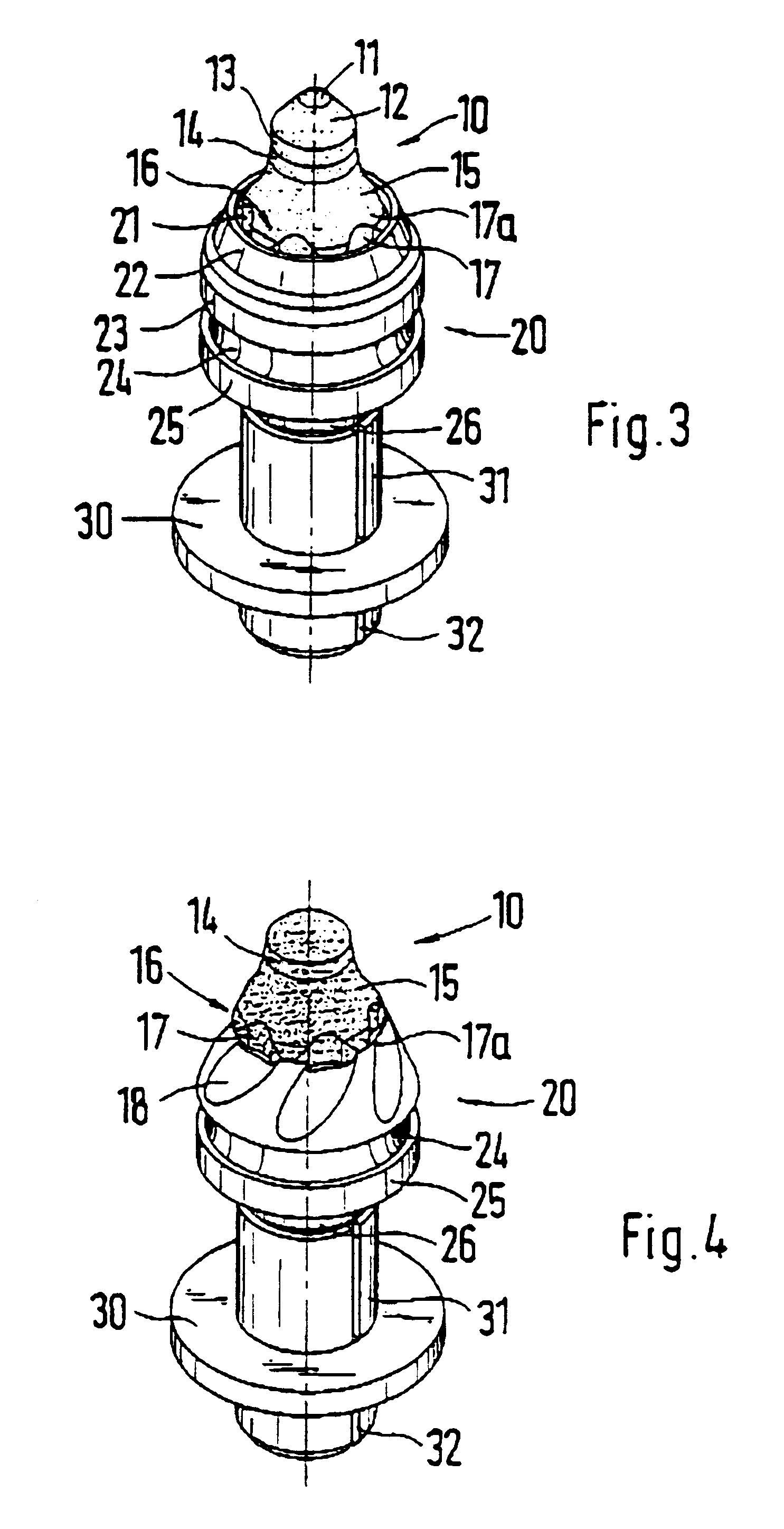

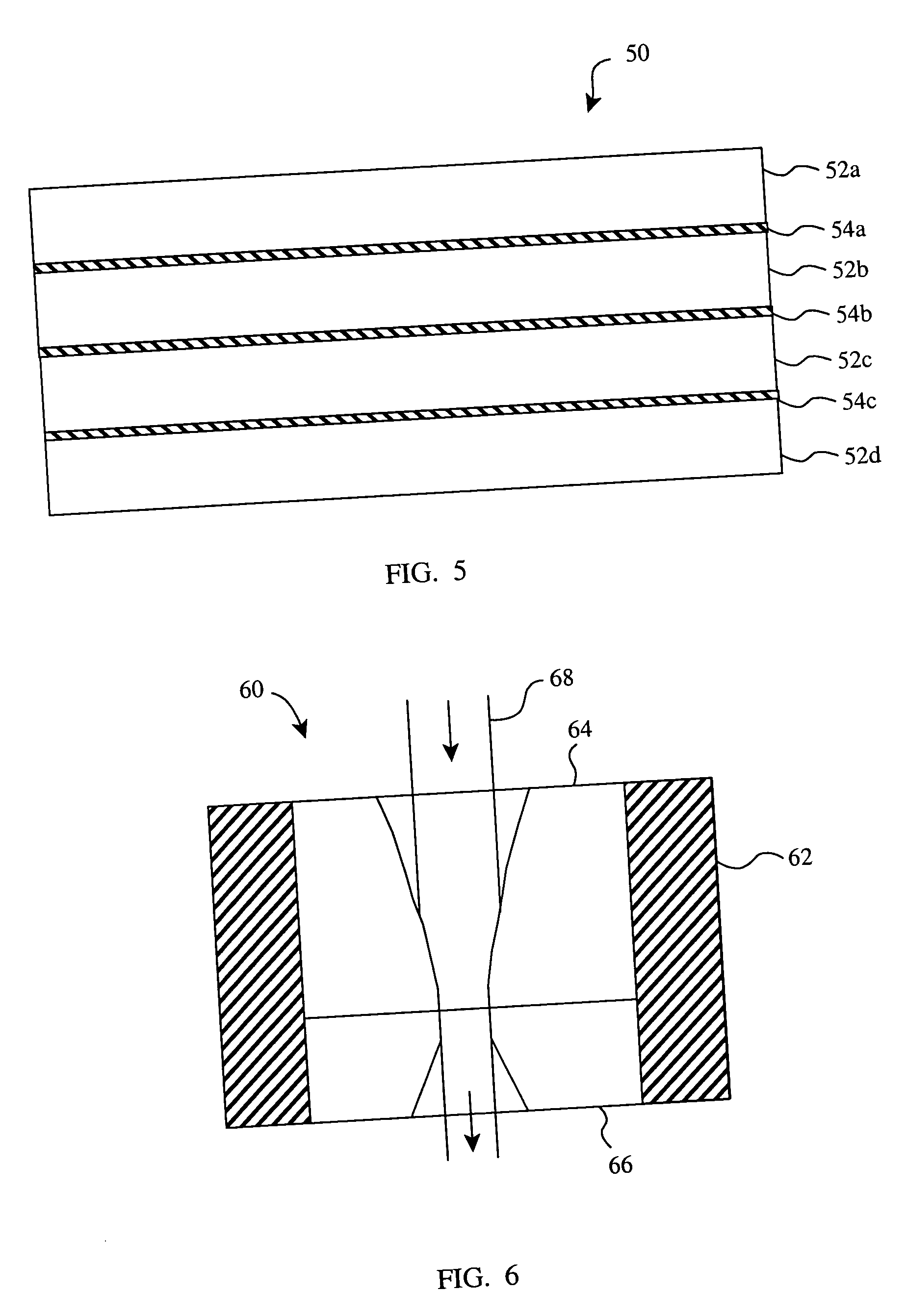

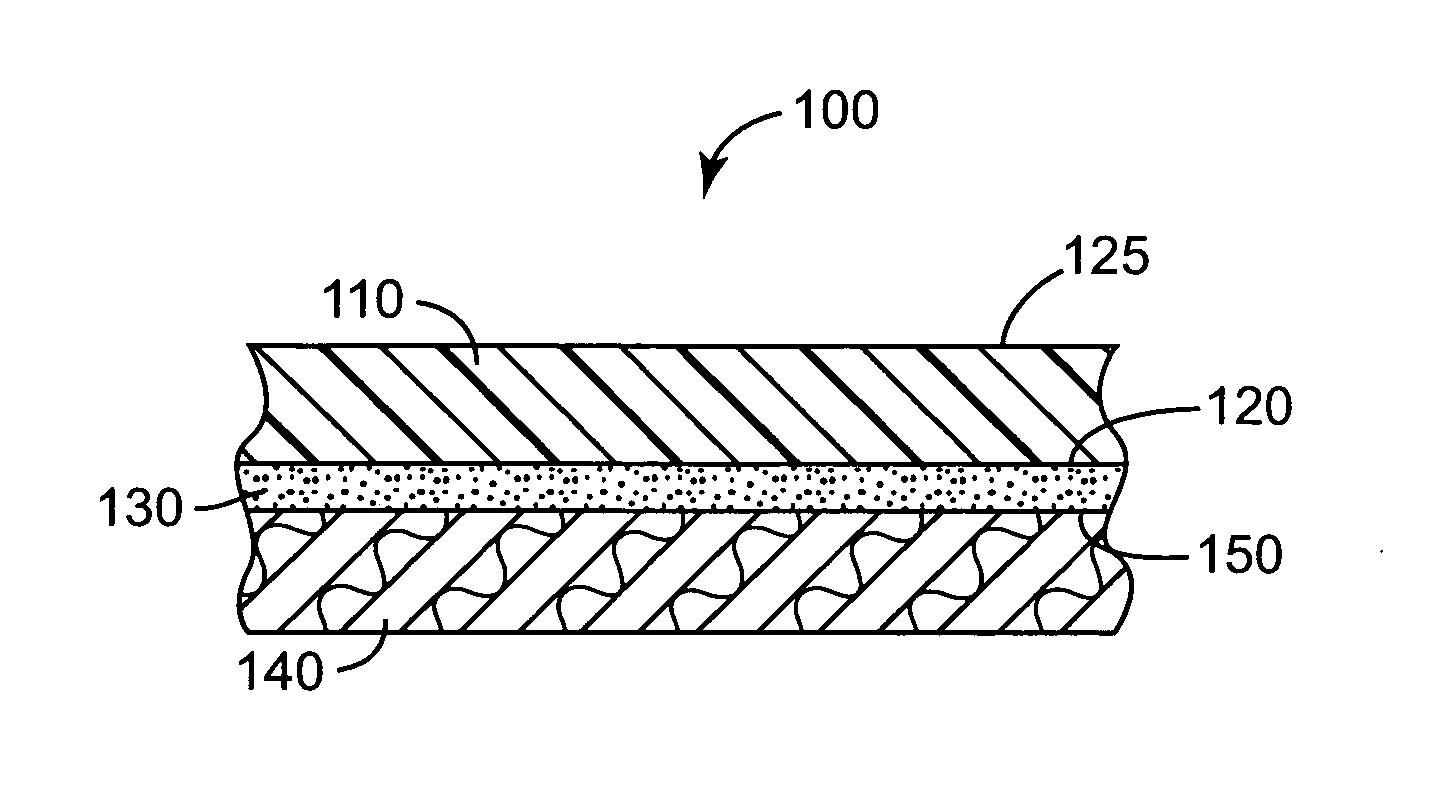

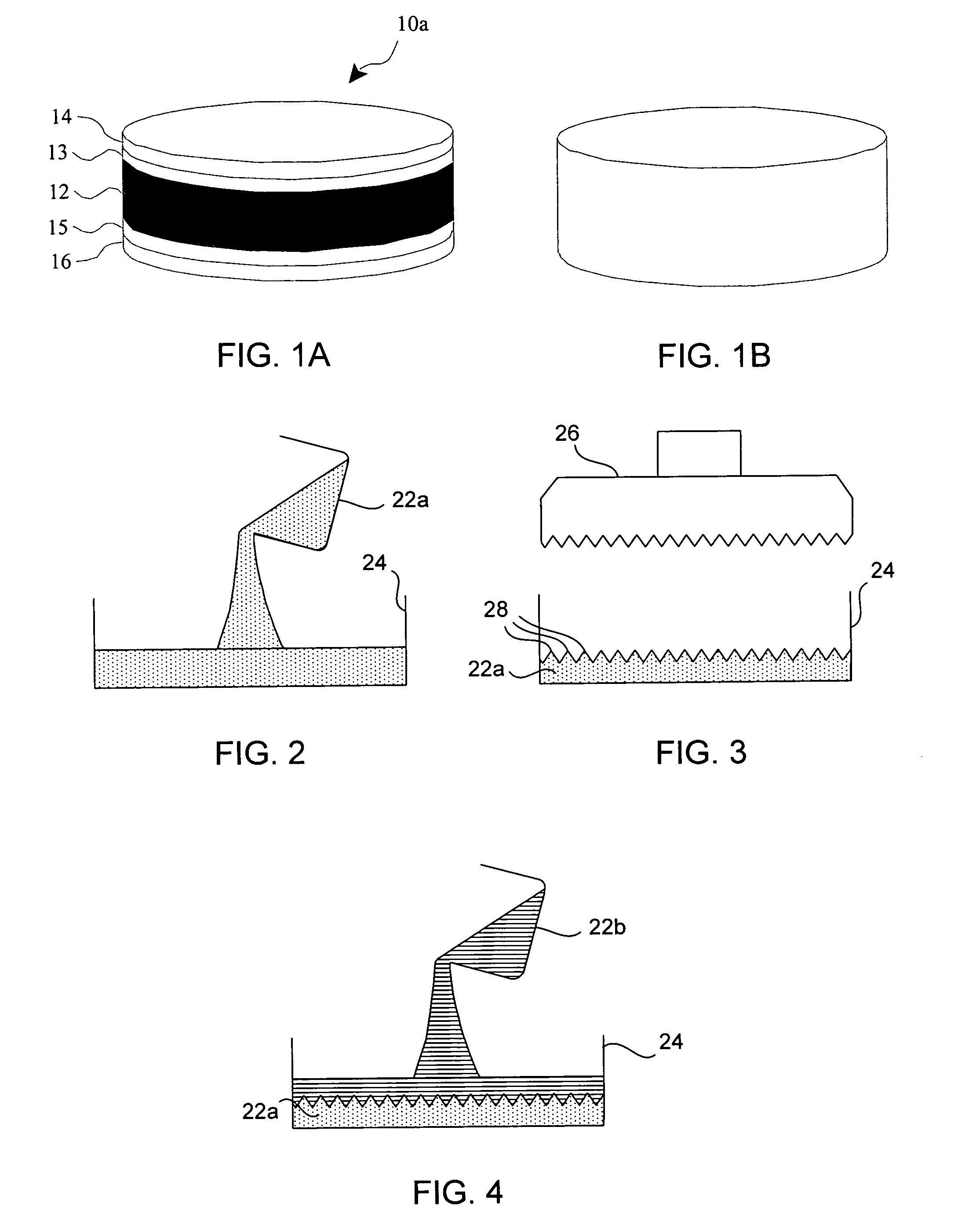

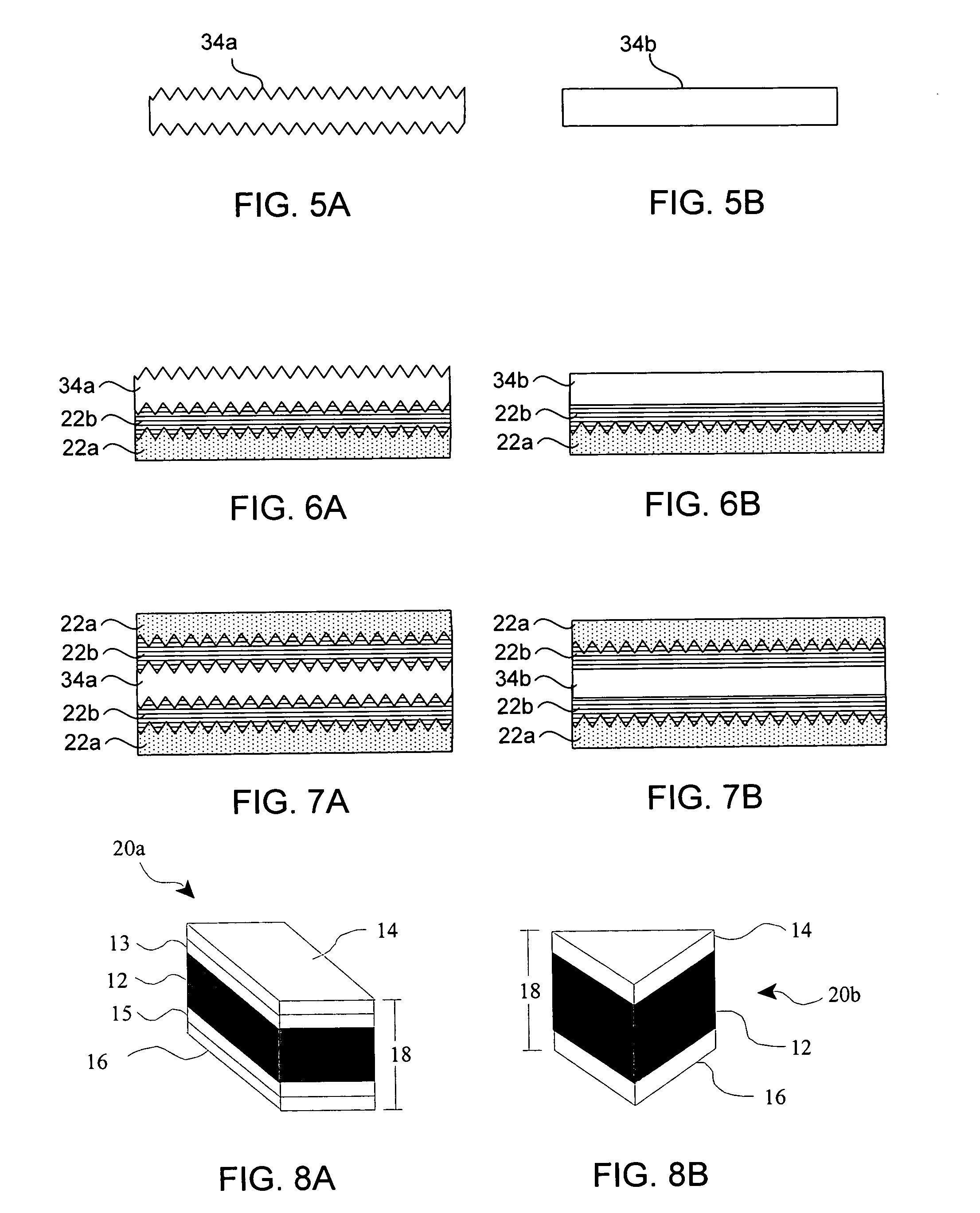

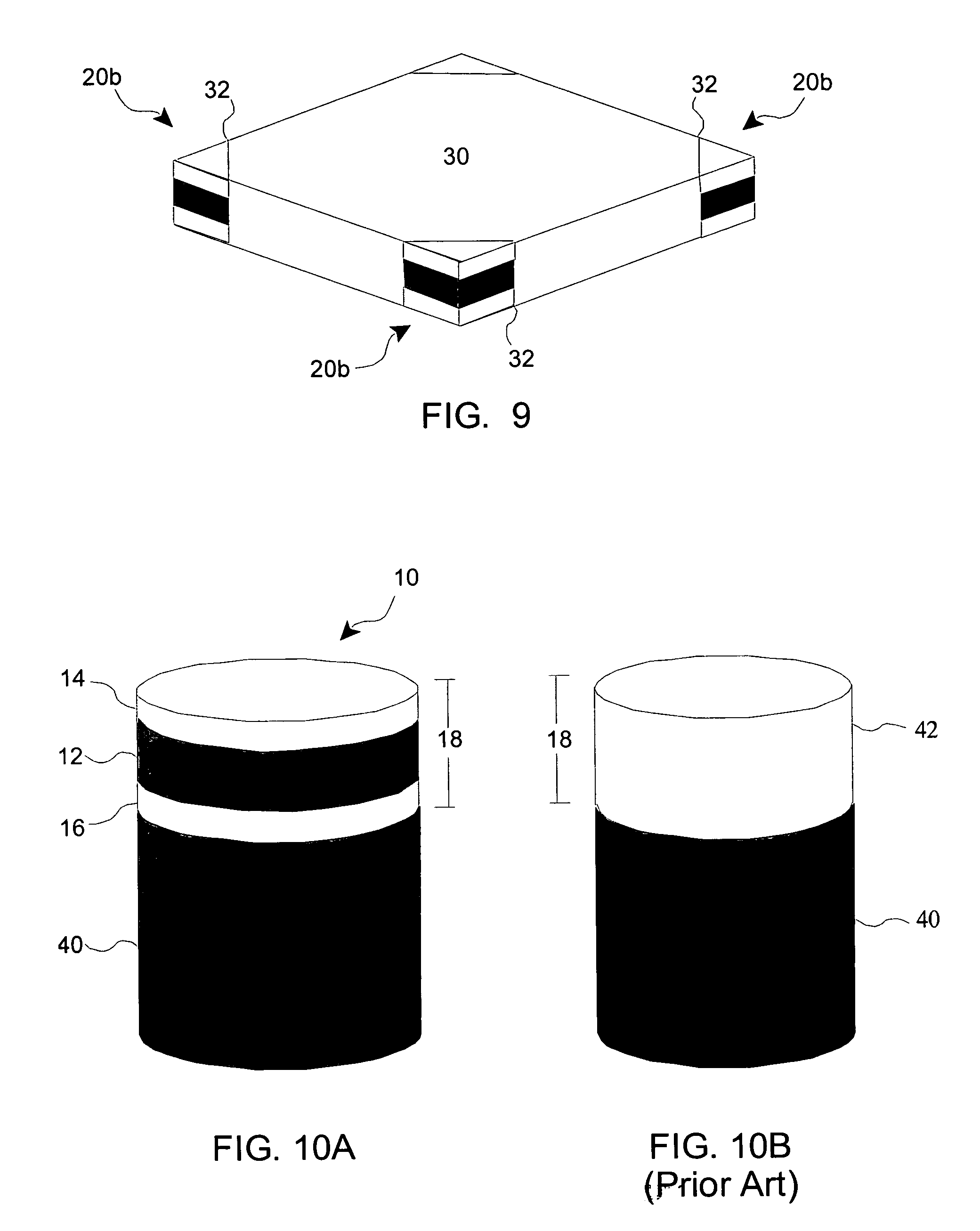

Doubled-sided and multi-layered PCD and PCBN abrasive articles

InactiveUS20050050801A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionHigh pressureMaterials science

A doubled-sided PCD or PCBN compact as well as a new multi-layered PCD and PCBN can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can include superabrasive particles bonded together by sintering or chemical bonding with an additional metal. Such double-sided PCD and PCBN compacts as well as a new multiple layered PCD and PCBN allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided and / or multiple layered PCD and PCBN compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:CHO HYUN SAM +2

Antimicrobial articles

InactiveUS20050249791A1Promote migrationEliminate the problemBiocideAdhesive dressingsWound dressingSurgical tape

An antimicrobial article is disclosed comprising a layer of a thermoplastic polymer, and an adhesive layer having a antimicrobial agent dispersed therein. The antimicrobial article is useful, for example, surgical tapes, surgical drapes and wound dressings, and as disposable surfaces for food preparation and handling.

Owner:3M INNOVATIVE PROPERTIES CO

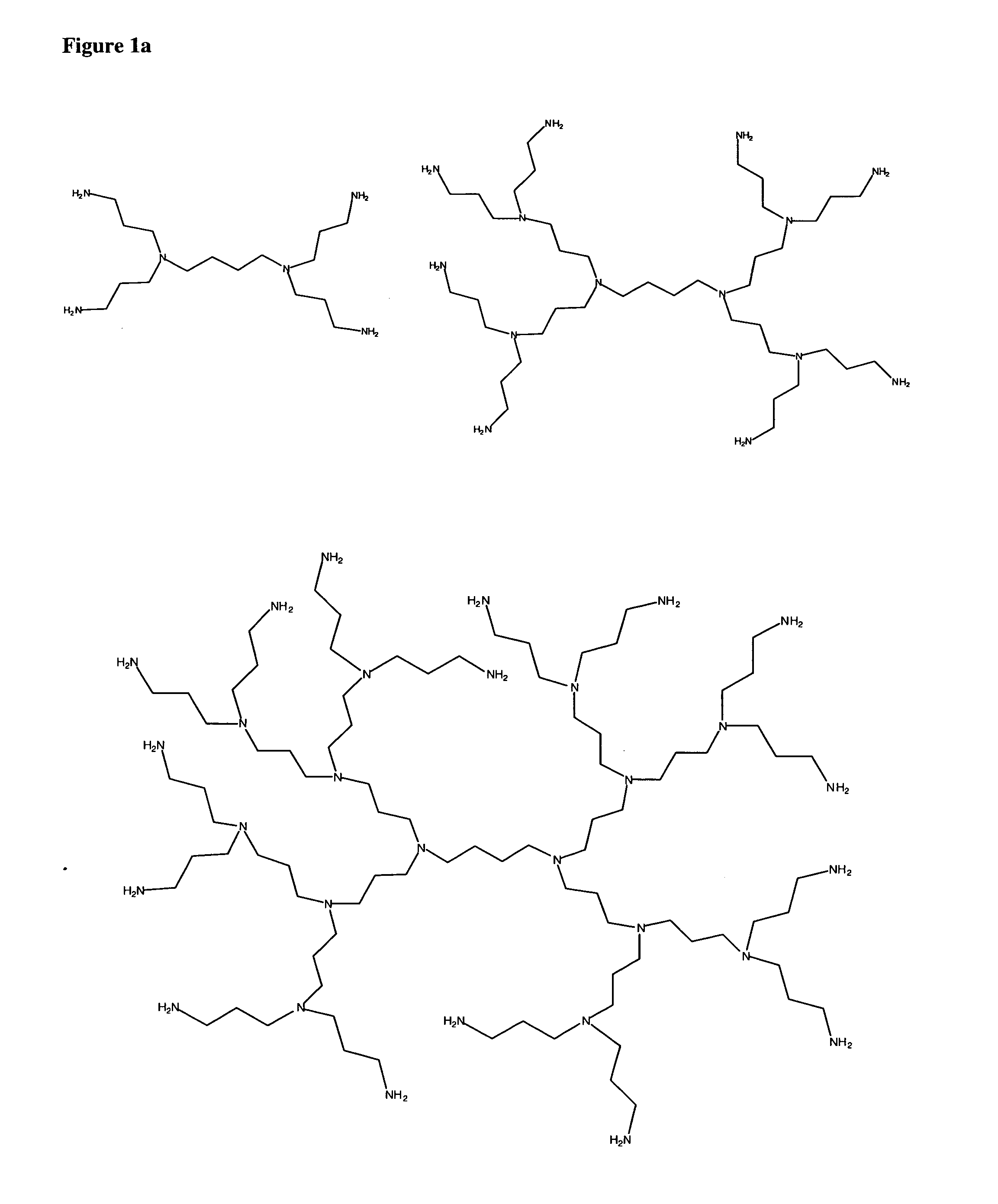

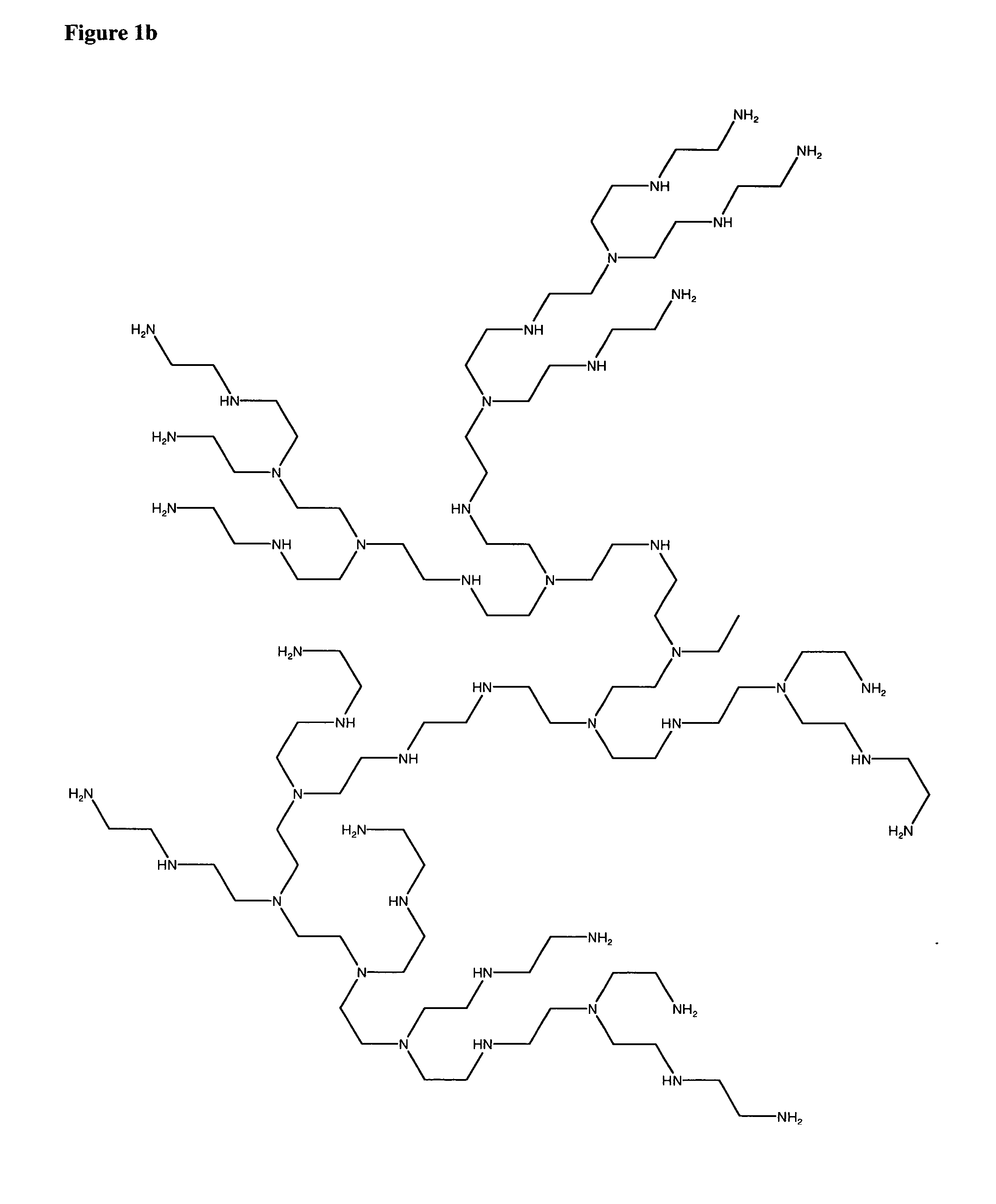

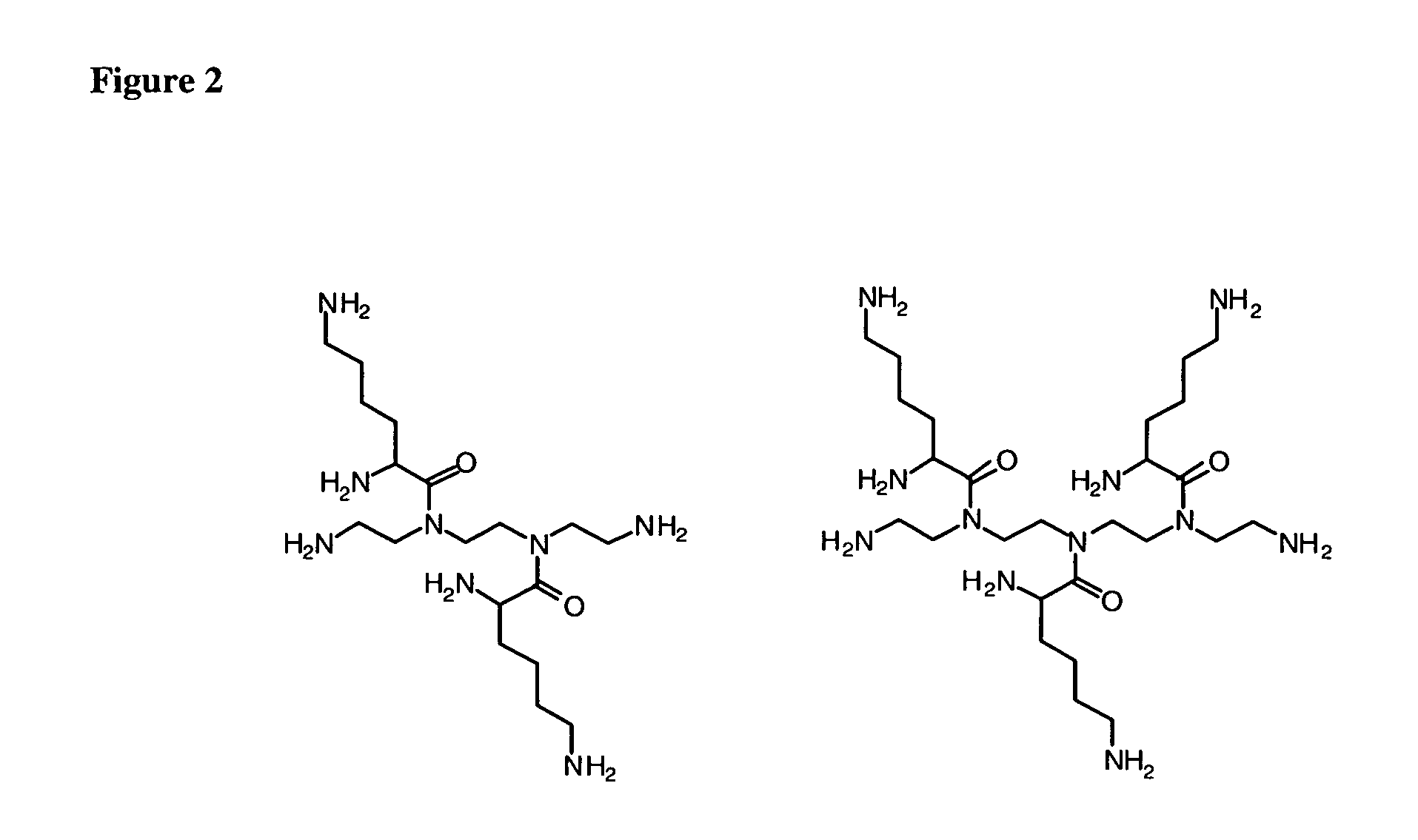

Crosslinked gels comprising polyalkyleneimines, and their uses as medical devices

ActiveUS20070196454A1Promote cell growthSoft tissue growthIn-vivo radioactive preparationsSurgical adhesivesCross-linkCysteine thiolate

One aspect of the present invention generally relates to methods of sealing a wound or tissue plane or filling a void splace. In a preferred embodiment, the wound is an ophthalmic, pleural or dural wound. In certain instances, the compositions used to seal the wound or tissue plane comprises a polyalkyleneamine. In a preferred embodiment, the polyalkyleneamine is polyethyleneimine. Treatment of the polyethyleneimine with a cross-linking reagent causes the polyethyleneimine polymers to polymerize forming a seal. In certain instances, the cross-linking reagent is a polyethylene glycol having reactive terminal groups. In certain instances, the reactive terminal groups are activated esters, such as N-hydroxy succinimide ester. In certain instances, the reactive terminal groups are isocyanates. In certain instances, the polyethyleneimine has a lysine, cysteine, isocysteine or other nucleophilic group attached to the periphery of the polymer. In certain instances, the polyethyleneimine is mixed with a second polymer, such as a polyethylene glycol containing nucleophilic groups. In certain instances, the compositions used to seal the wound or tissue plane are formed by reacting a polyalkyleneamine bearing electrophilic groups with a cross-linking reagent containing nucleophilic groups. In certain instances, the electrophilic groups on the polyalkyleneamine are activated esters, such as N-hydroxy succinimide ester. In certain instances, the compositions used to seal the wound or tissue plane are formed by reacting a polyalkyleneamine bearing photopolymerizable groups with ultraviolet or visibile light. Compositions used to seal the wound which contain PEI or a derivative of PEI are found to adhere tightly to the tissue. Other aspects of the present invention relate to methods of filling a void of a patient or adhering tissue. In certain instances, the methods use a polyalkyleneamine. In a preferred embodiment, the polyalkyleneamine is polyethyleneimine. Another aspect of the present invention relates to a polymeric composition formed by exposing a polyalkyleneamine to an activated polyalkylene glycol. In certain instances, the composition is attached to mammalian tissue.

Owner:SQUARE 1 BANK

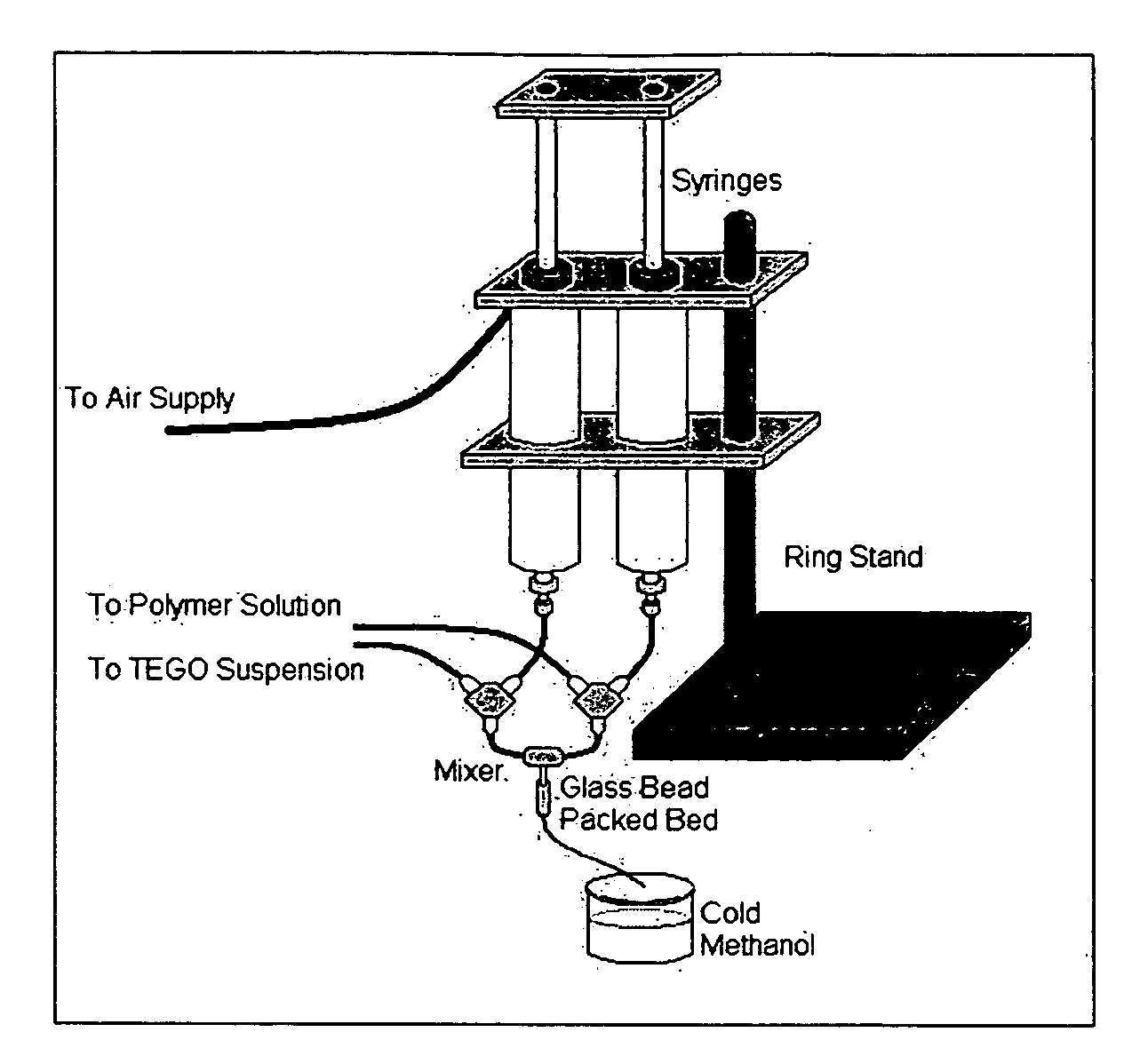

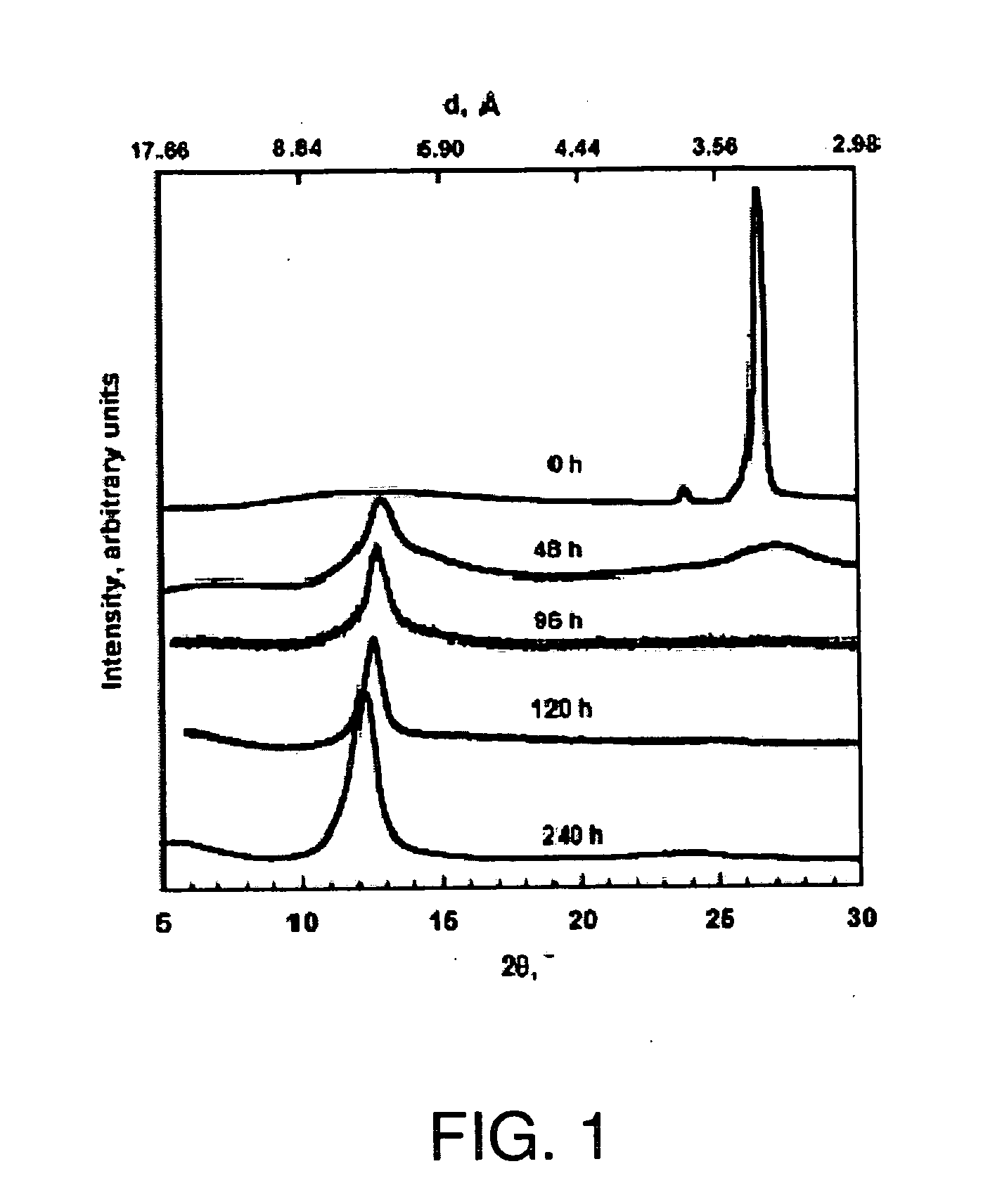

Functional graphene-polymer nanocomposites for gas barrier applications

InactiveUS20100096595A1Excellent gas barrier performanceImprove suppression propertiesMaterial nanotechnologyNanostructure manufactureNano compositesX-ray

Owner:THE TRUSTEES FOR PRINCETON UNIV

Doubled-sided and multi-layered PCBN and PCD abrasive articles

InactiveUS20050210755A1Improve propertiesIncreasing the thicknessPigmenting treatmentTool workpiece connectionWear particleHigh pressure

A doubled-sided PCBN and / or PCD compact can be produced using high pressure high temperature processes allowing for increased effective thickness of abrasive tools, decreased delamination, and increased useful service life. A polycrystalline compact can include a substrate having a first surface and a second surface which are non-contiguous. Additionally, a first polycrystalline layer can be attached to the first surface of the substrate and a second polycrystalline layer attached to the second surface of the substrate. The first and second polycrystalline layers can be attached to the substrate via an intermediate layer containing superabrasive particles. Such double-sided PCBN and PCD compacts allow for increased effective thickness of a tool without suffering from non-homogenous results typical of standard PCD and PCBN compacts, regardless of superabrasive particle size. Each polycrystalline layer can include superabrasive particles of varying particle sizes such that the final tool is tailored for specific abrading characteristics. Such doubled-sided PCBN and PCD compacts can be incorporated into a wide variety of abrasive tools for use in cutting, milling, grinding, polishing, drilling and other similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

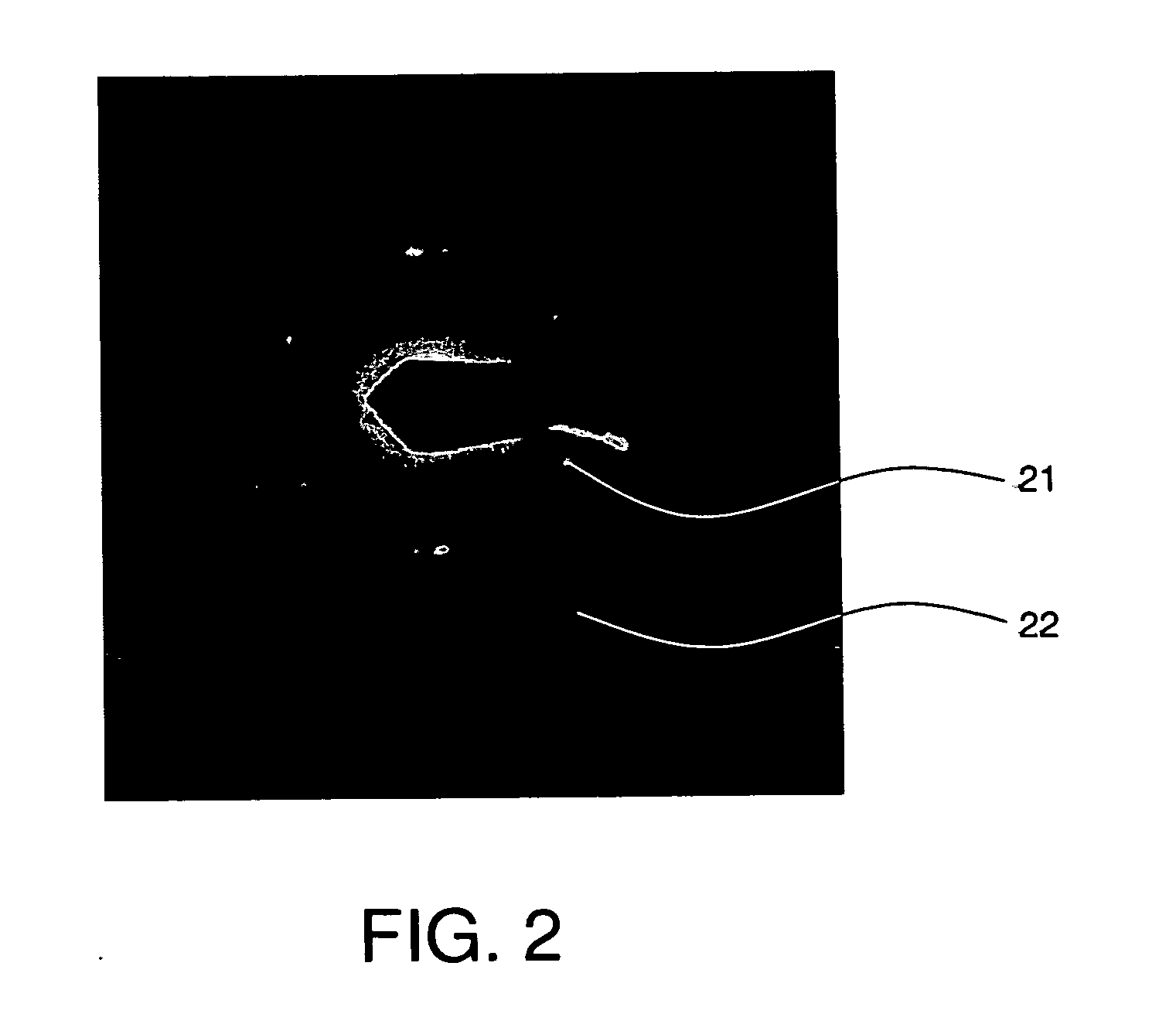

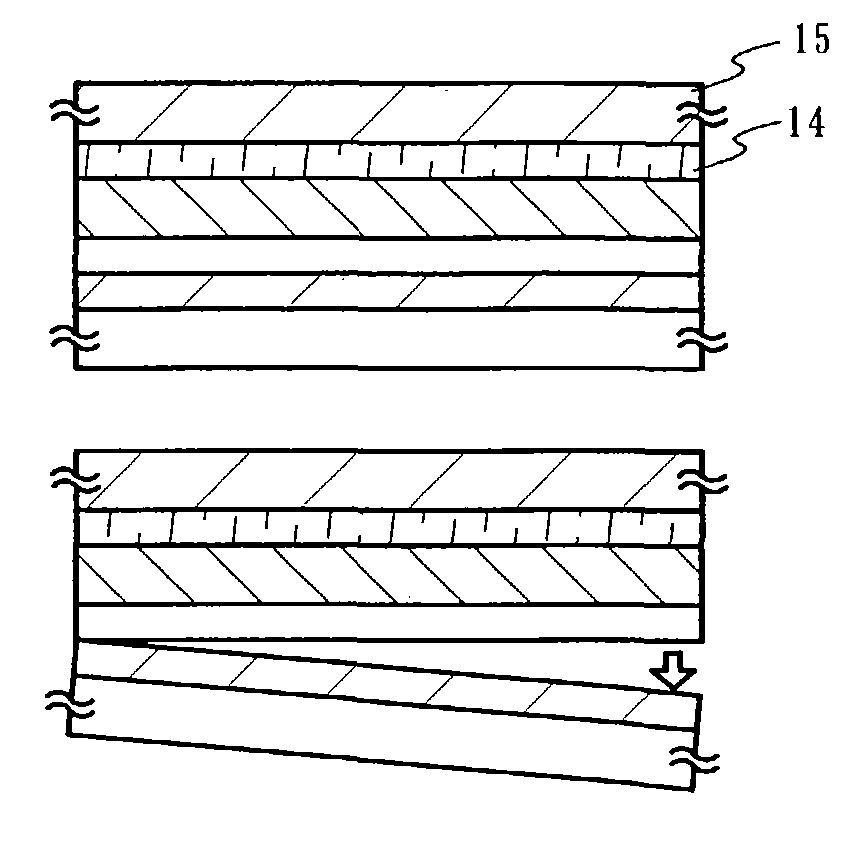

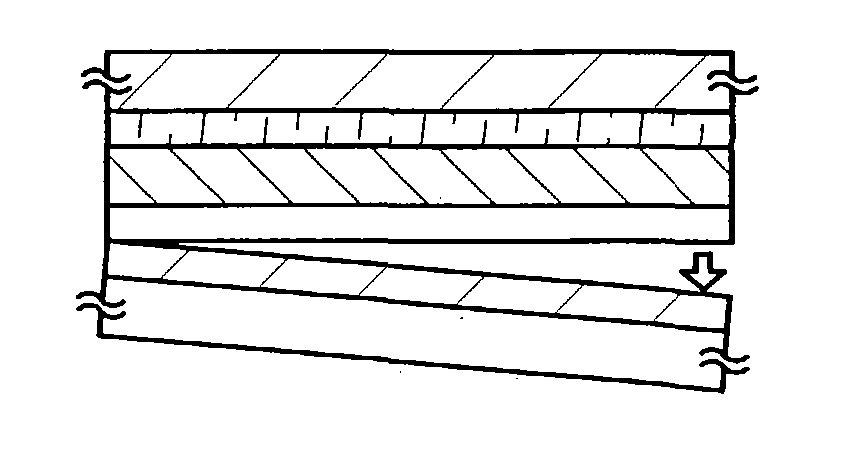

Peeling method

InactiveUS7122445B2Slow performanceImprove suppression propertiesTransistorSolid-state devicesHydrogenEngineering

Owner:SEMICON ENERGY LAB CO LTD

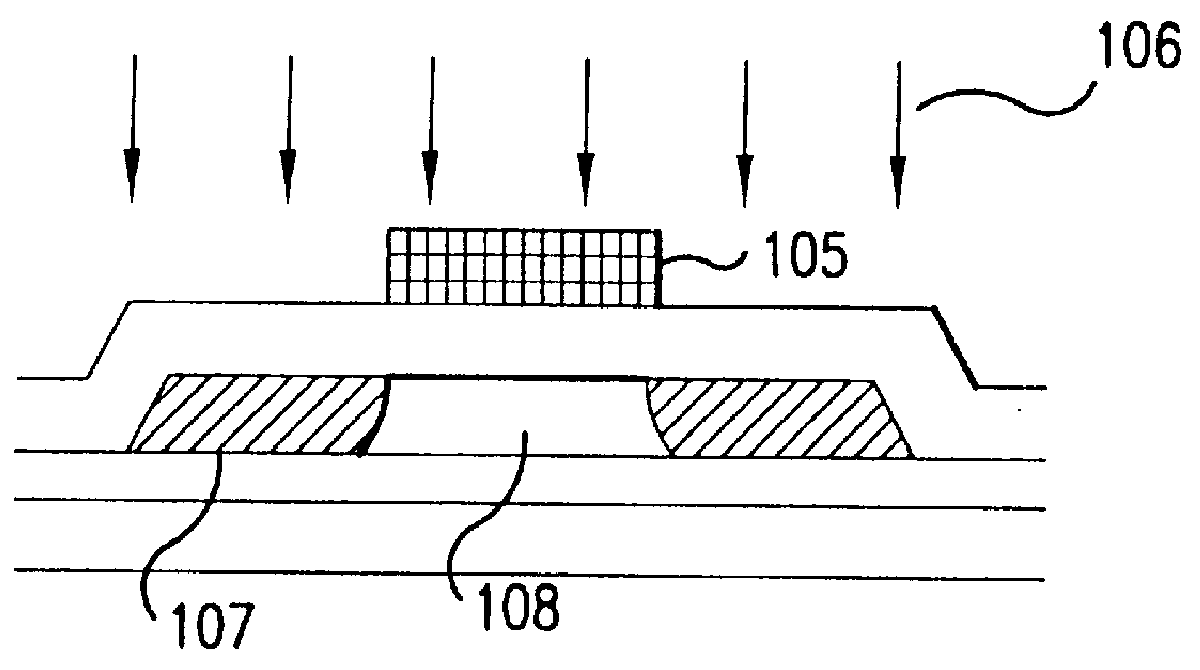

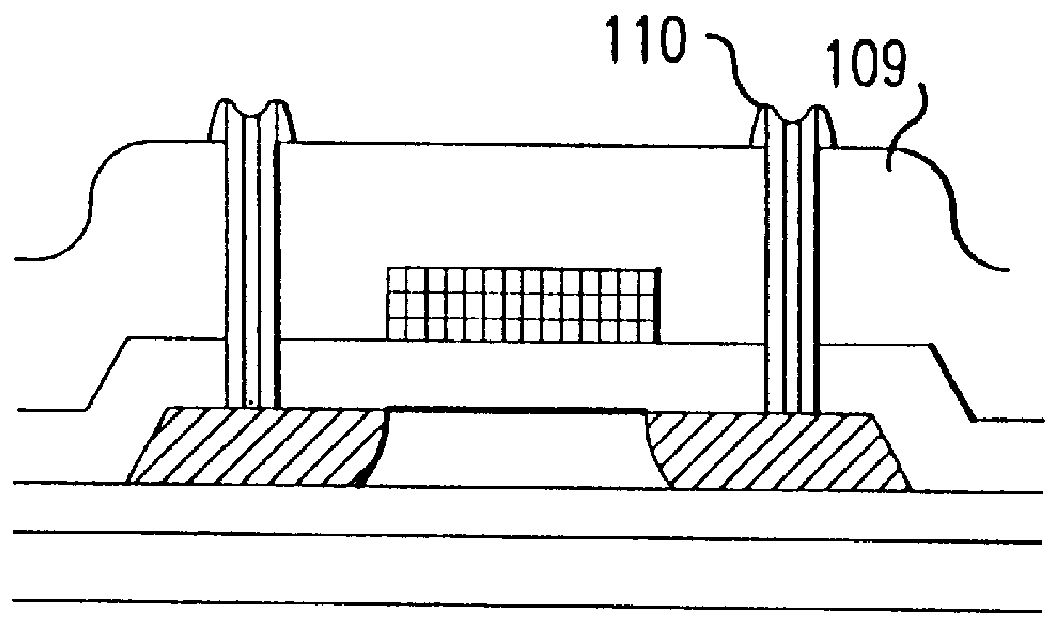

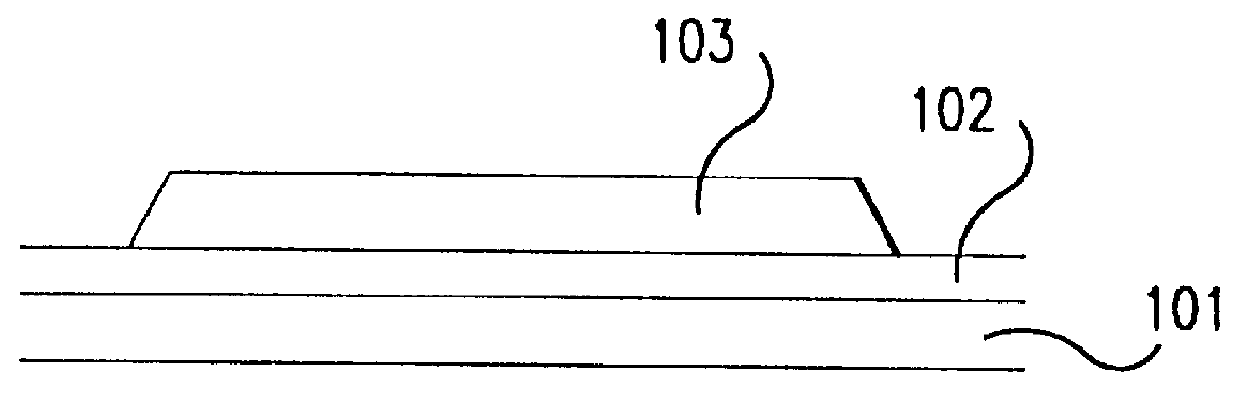

Peeling method

InactiveUS20040087110A1Slow performanceAdhesive propertyTransistorSolid-state devicesHydrogenEngineering

A peeling method is provided which does not cause damage to a layer to be peeled, and the method enables not only peeling of the layer to be peeled having a small area but also peeling of the entire layer to be peeled having a large area at a high yield. Further, there are provided a semiconductor device, which is reduced in weight through adhesion of the layer to be peeled to various base materials, and a manufacturing method thereof. In particular, there are provided a semiconductor device, which is reduced in weight through adhesion of various elements, typically a TFT, to a flexible film, and a manufacturing method thereof. A metal layer or nitride layer is provided on a substrate; an oxide layer is provided contacting with the metal layer or nitride layer; then, a base insulating film and a layer to be peeled containing hydrogen are formed; and heat treatment for diffusing hydrogen is performed thereto at 410° C. or more. As a result, complete peeling can be attained in the oxide layer or at an interface thereof by using physical means.

Owner:SEMICON ENERGY LAB CO LTD

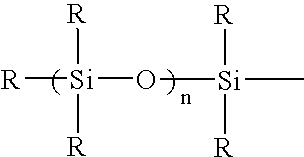

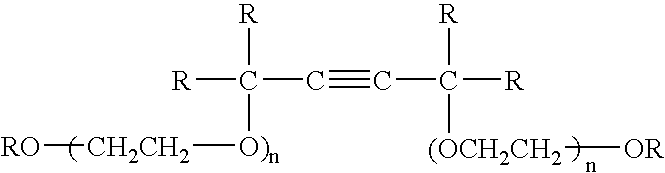

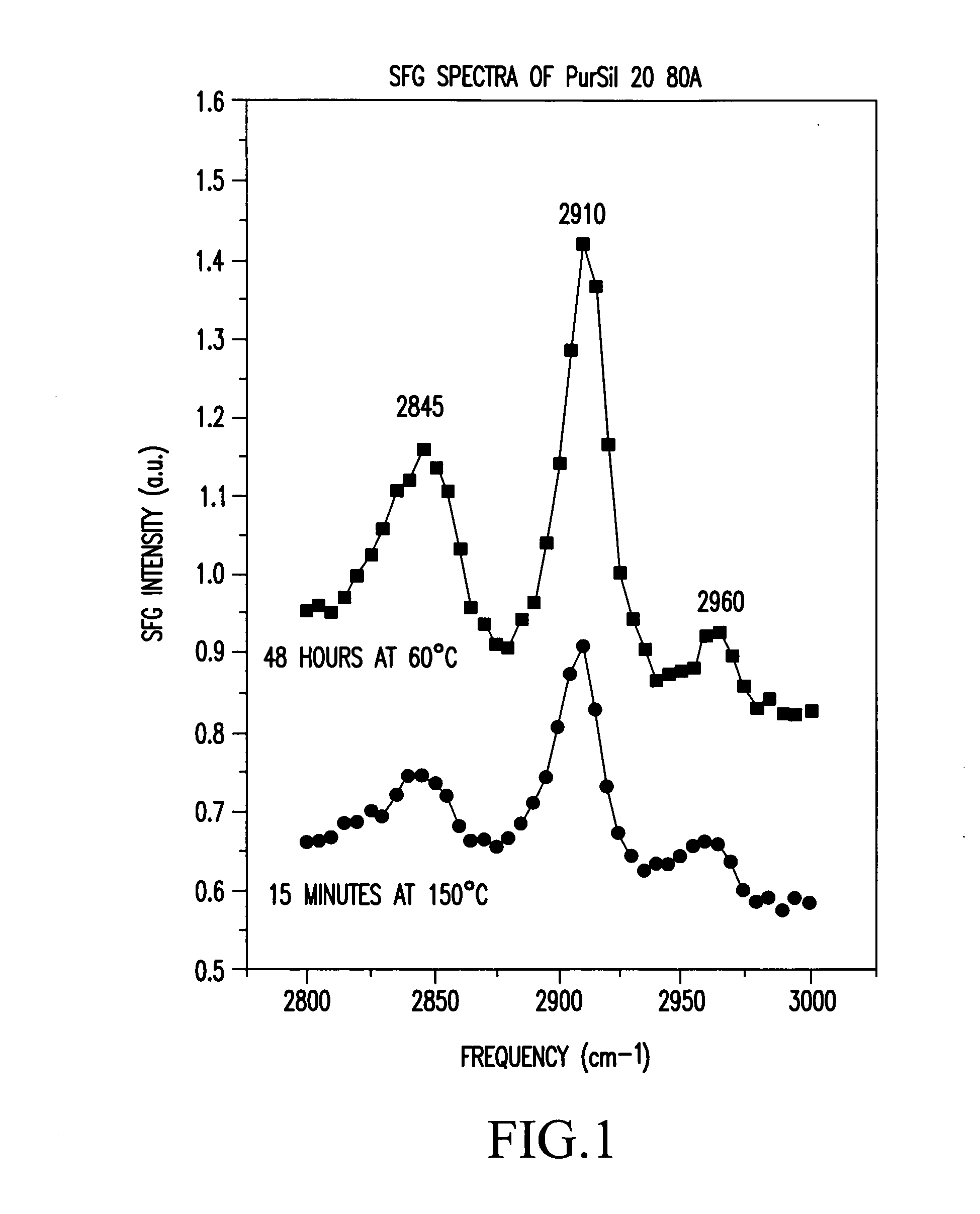

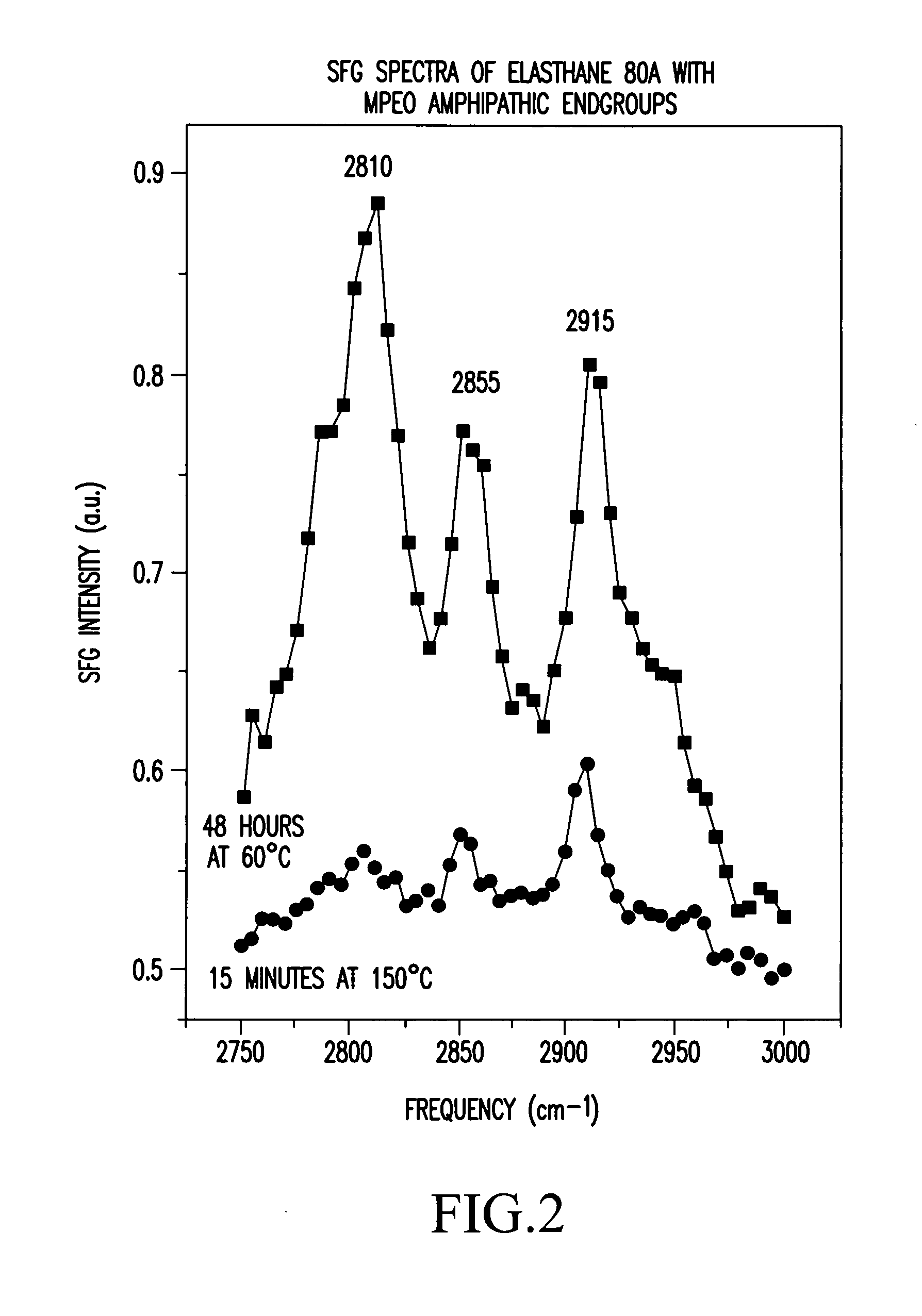

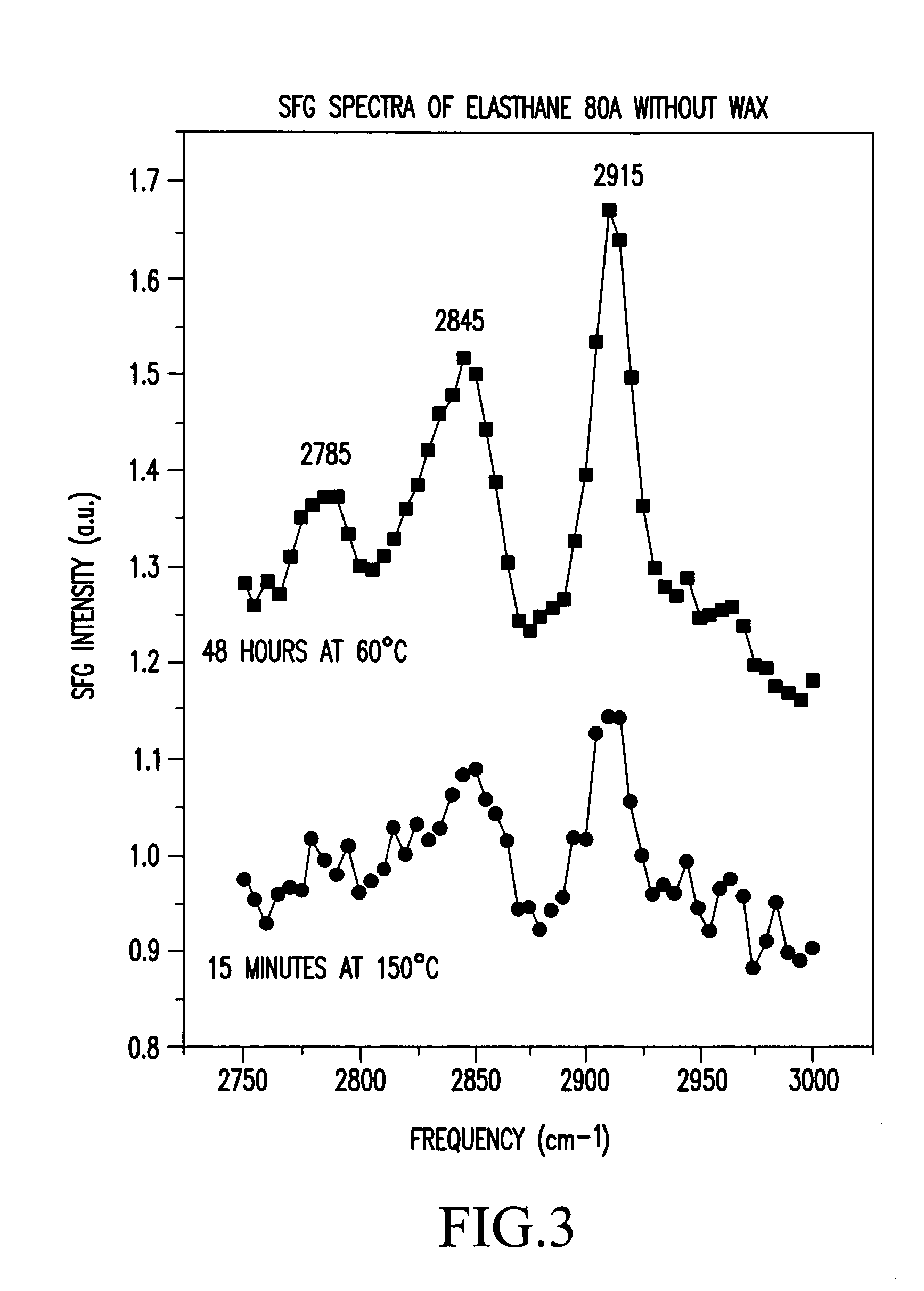

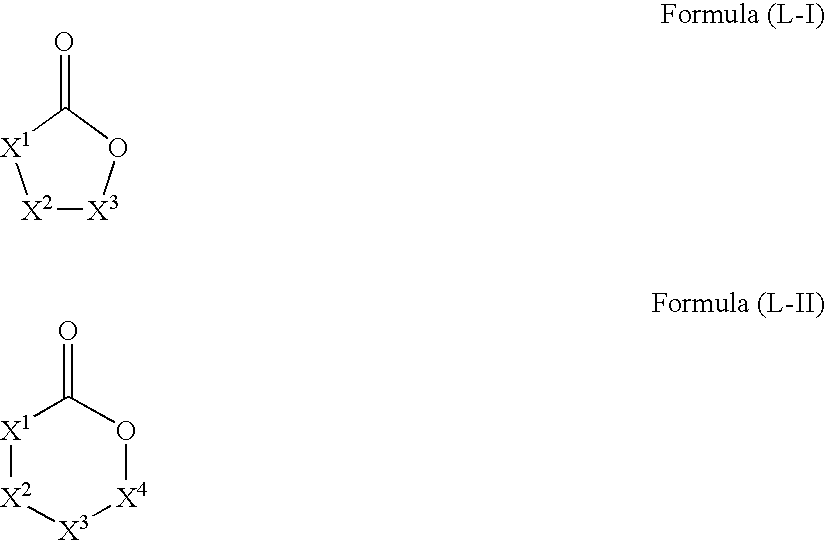

Control of polymer surface molecular architecture via amphipathic endgroups

ActiveUS20050282997A1Promote resultsReduce signal to noise ratioSurgeryCatheterPolymeric surfacePolyethylene oxide

Polymers whose surfaces are modified by endgroups that include amphipathic surface-modifying moieties. An amphipathic endgroup of a polymer molecule is an endgroup that contains at least two moieties of significantly differing composition, such that the amphipathic endgroup spontaneously rearranges its positioning in a polymer body to position the moiety on the surface of the body, depending upon the composition of the medium with which the body is in contact, when that re-positioning causes a reduction in interfacial energy. An example of an amphipathic surface-modifying endgroup is one that has both a hydrophobic moiety and a hydrophilic moiety in a single endgroup. For instance, a hydrophilic poly(ethylene oxide) terminated with a hydrophilic hydroxyl group is not surface active in air when the surface-modifying endgroup is bonded to a more hydrophobic base polymer. If the hydroxyl group on the oligomeric poly(ethylene oxide) is replaced by a hydrophobic methoxy ether terminus, the poly(ethylene oxide) becomes surface active in air, and allows the poly(ethylene oxide) groups to crystallize in the air-facing surface. In this example, immersion in water destroys the crystallinity as the poly(ethylene oxide) sorbs water and the hydrophobic methoxy group retreats below the surface of the polymer. Also disclosed are methods and articles of manufacture that make use of these polymers.

Owner:THE POLYMER TECH GROUP

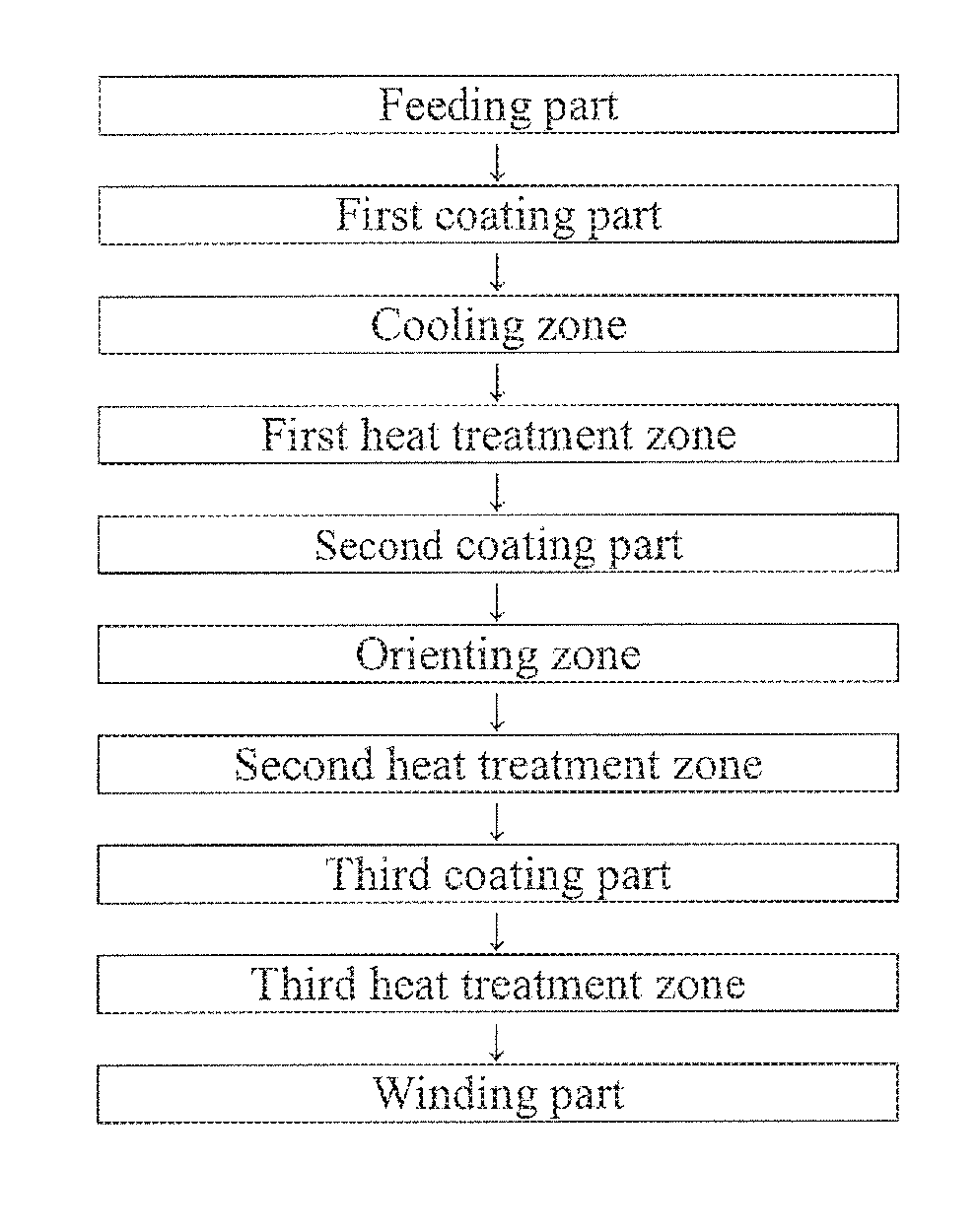

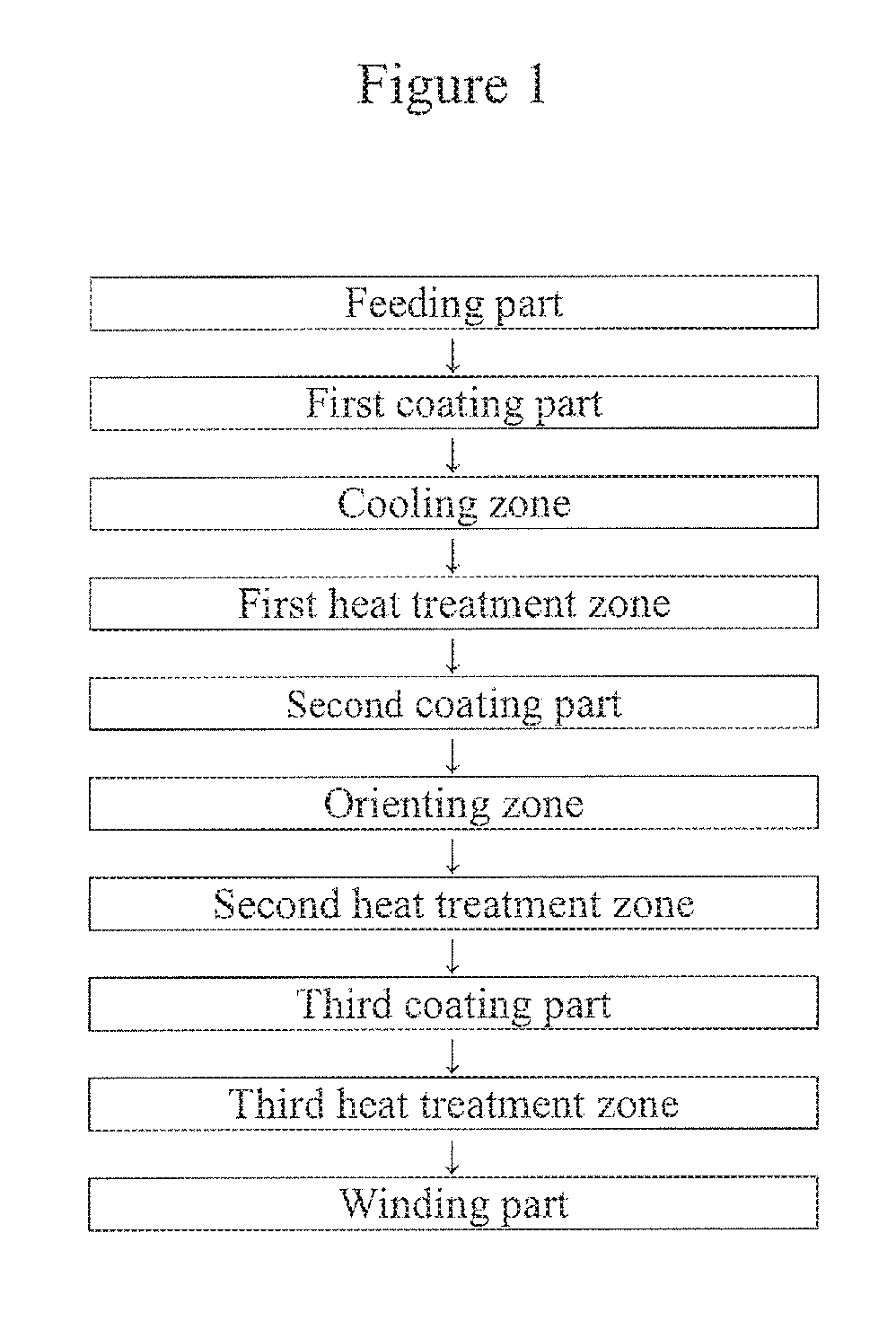

Magnetic tape, magnetic tape cartridge, magnetic recording and reproducing device, and method of manufacturing magnetic tape

ActiveUS20170178676A1Good electromagnetic characteristicShorten the timeBase layers for recording layersRecord information storagePeak areaMagnetic layer

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support, and a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer; wherein the combined thickness of the nonmagnetic layer and the magnetic layer is less than or equal to 0.60 μm, the coefficient of friction as measured on the base portion of the surface of the magnetic layer is less than or equal to 0.35, at least the magnetic layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide, and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface of the magnetic layer is greater than or equal to 45 atom %.

Owner:FUJIFILM CORP

Smoking articles having reduced carbon monoxide delivery

InactiveUS20050005947A1Reduce penetrationReduce ignition proclivityTobacco preparationNon-fibrous pulp additionCarbonateReducing agent

The present invention is directed to smoking articles having reduced carbon monoxide delivery are described. A carbon monoxide reducing agent is incorporated into the smoking article in order to reduce carbon monoxide levels in mainstream smoke. The carbon monoxide reducing agent may be, for instance, in metal oxide or in metal carbonate. The carbon monoxide reducing agent may be incorporated into a wrapper and / or into a column of smokable filler that are used to construct the smoking article.

Owner:SCHWEITZER MAUDUIT INT INC

Thermosensitive lithographic printing plate

InactiveUS7108956B2Favorable image formationHigh sensitivityPhotosensitive materialsSemiconductor/solid-state device manufacturingPolymer scienceWater insoluble

A thermosensitive lithographic printing plate comprising: a hydrophilic support; a lower layer comprising a water-insoluble and alkali-soluble resin; and an upper thermosensitive layer comprising a water-insoluble and alkali-soluble resin and an infrared absorbing dye, whose dissolution in an alkaline aqueous solution increases upon exposure, wherein a surface of the upper thermosensitive layer has protrusions caused by ununiformity of thickness of the upper thermosensitive layer in a proportion of 0.1 or more and not more than 7 per μm2 or the upper thermosensitive layer comprises at least two alkali-soluble resins having a different dissolution speed in an alkaline aqueous solution from each other, and the at least two alkali-soluble resin cause phase separation from each other.

Owner:FUJIFILM HLDG CORP +1

Head mounted display

InactiveUS7936519B2Improve rigidityIncrease the cross-sectional areaProjectorsOptical light guidesLight guideLight beam

Disclosed herein is a head mounted display including: an eyeglasses frame-like frame to be mounted onto an observer's head; and two image display devices, each of the image display devices including an image generating device, and light guide means which is mounted to the image generating device, which as a whole is located on the side of the center of an observer's face relative to the image generating device, on which beams emitted from the image generating device are incident, through which the beams are guided, and from which the beams are emitted toward an observer's pupil.

Owner:SONY CORP

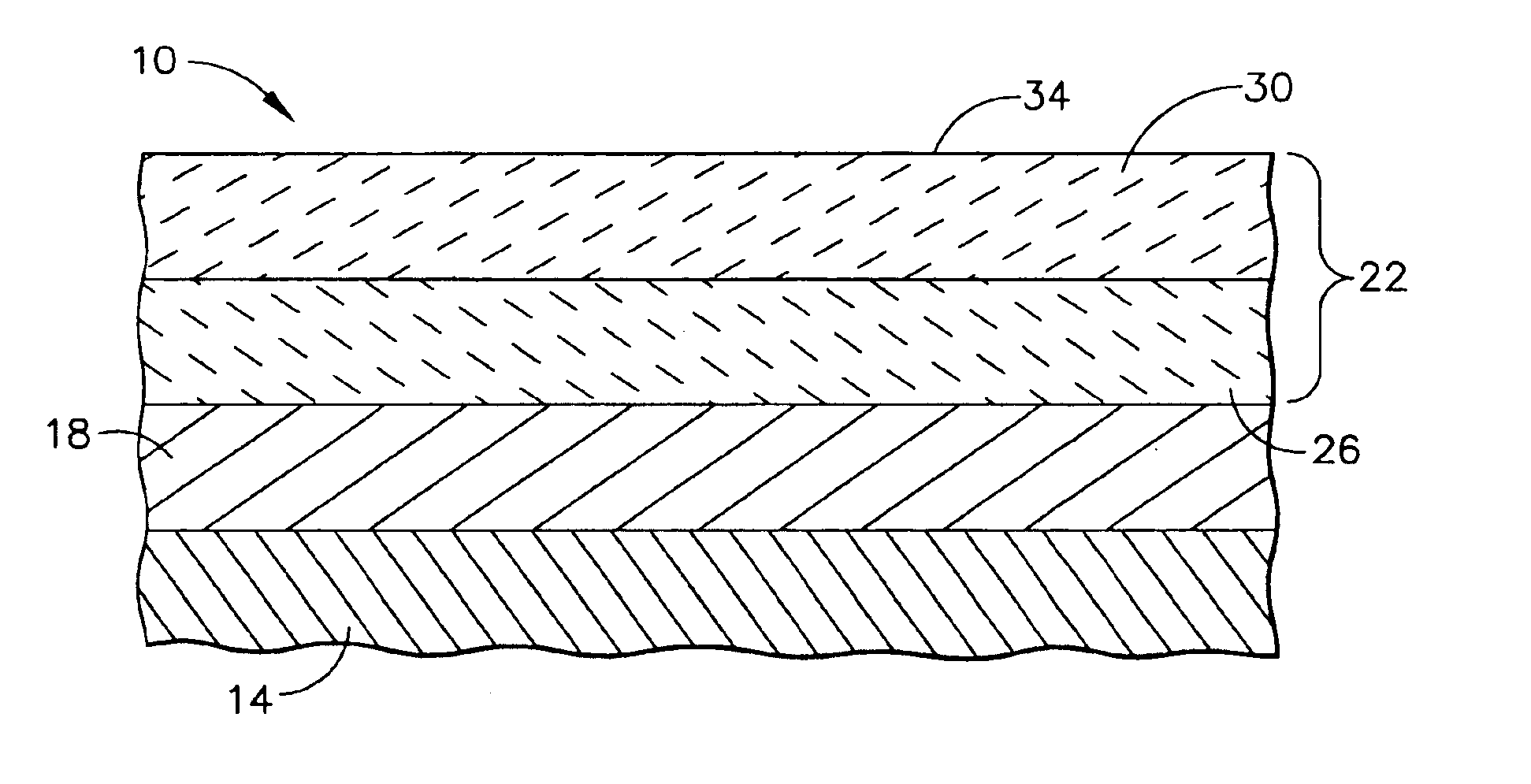

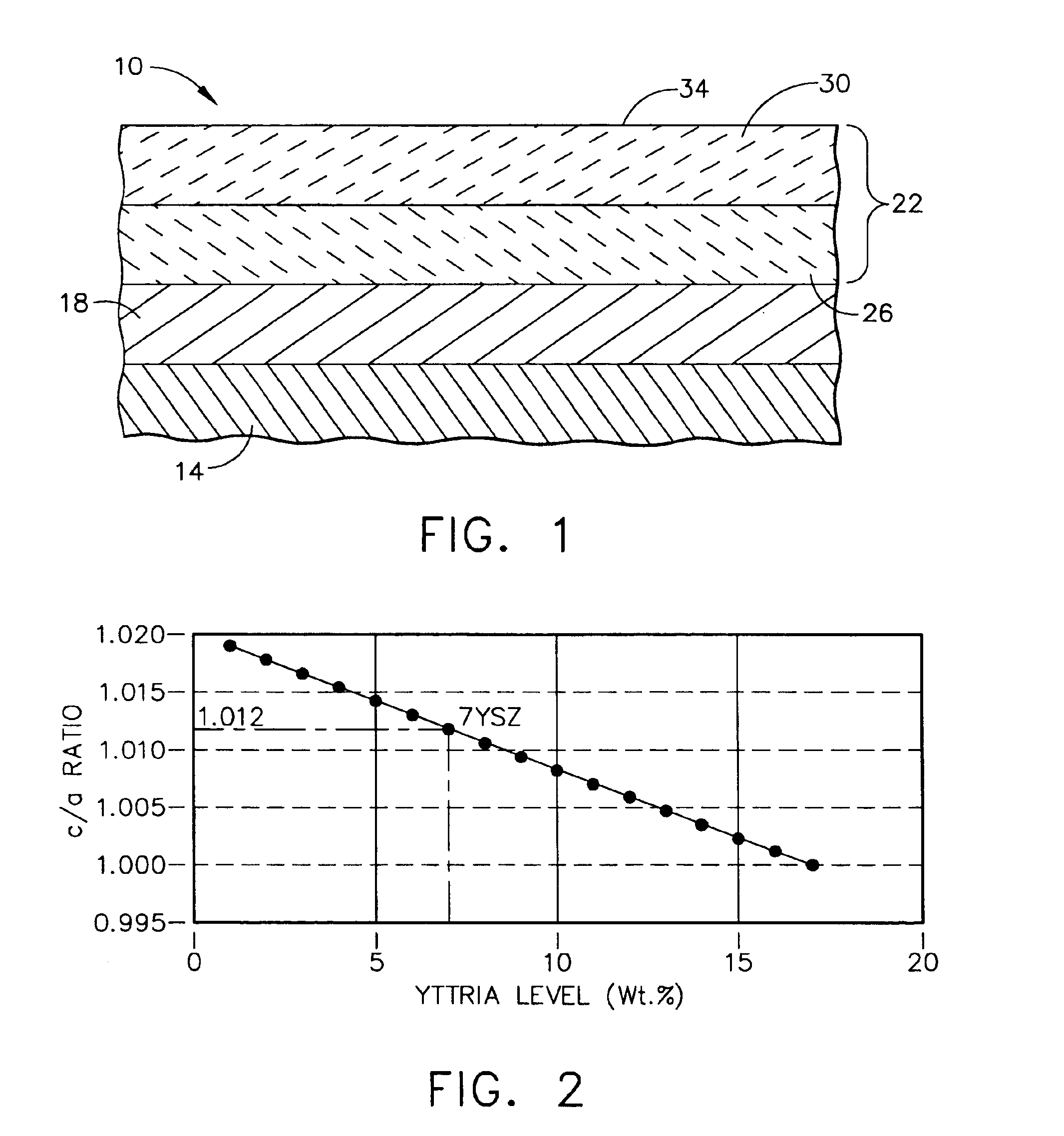

Thermal barrier coatings with protective outer layer for improved impact and erosion resistance

InactiveUS6875529B1Improve erosion resistanceImprove impact resistanceMolten spray coatingVacuum evaporation coatingBond coatMetallic substrate

A reduced thermal conductivity thermal barrier coating having improved impact and erosion resistance for an underlying metal substrate of articles that operate at, or are exposed to, high temperatures. This coating comprises an inner layer nearest to the underlying metal substrate comprising a ceramic thermal barrier coating material, as well as a protective outer layer adjacent to and overlaying the inner layer and having an exposed surface. The outer layer has a thickness up to about 5 mils (127 microns) sufficient to impart impact and erosion resistance to the thermal barrier coating, and comprises a zirconia-containing ceramic composition having a c / a ratio of the zirconia lattice in the range of from about 1.011 to about 1.016 and stabilized in the tetragonal phase by a stabilizing amount of a stabilizing metal oxide selected from the group consisting of yttria, calcia, ceria, scandia, magnesia, india, ytterbia and mixtures thereof. This coating can be used to provide a thermally protected article having a metal substrate and optionally a bond coated layer adjacent to and overlaying the metal substrate. The thermal barrier coating can be prepared by forming the inner layer comprising the ceramic thermal barrier coating material, followed by forming on the inner layer the protective outer layer.

Owner:GENERAL ELECTRIC CO

Curable composition and method of use thereof

InactiveUS6706813B2Reduce penetrationLower resistanceOther chemical processesVehicle sealing arrangementsHeat resistancePliability

To provide a curable composition excellent in flexibility and heat resistance. A curable composition which comprises (A) a block copolymer having at least one kind of block formed from an aliphatic hydrocarbon compound and (B) an isobutylene polymer having a silicon group bound to a hydrolyzable group or a hydroxyl group. That composition can be used as sealants, adhesives, pressure sensitive adhesives, compositions for gaskets, double layer glazing spacers and so on.

Owner:KANEKA CORP

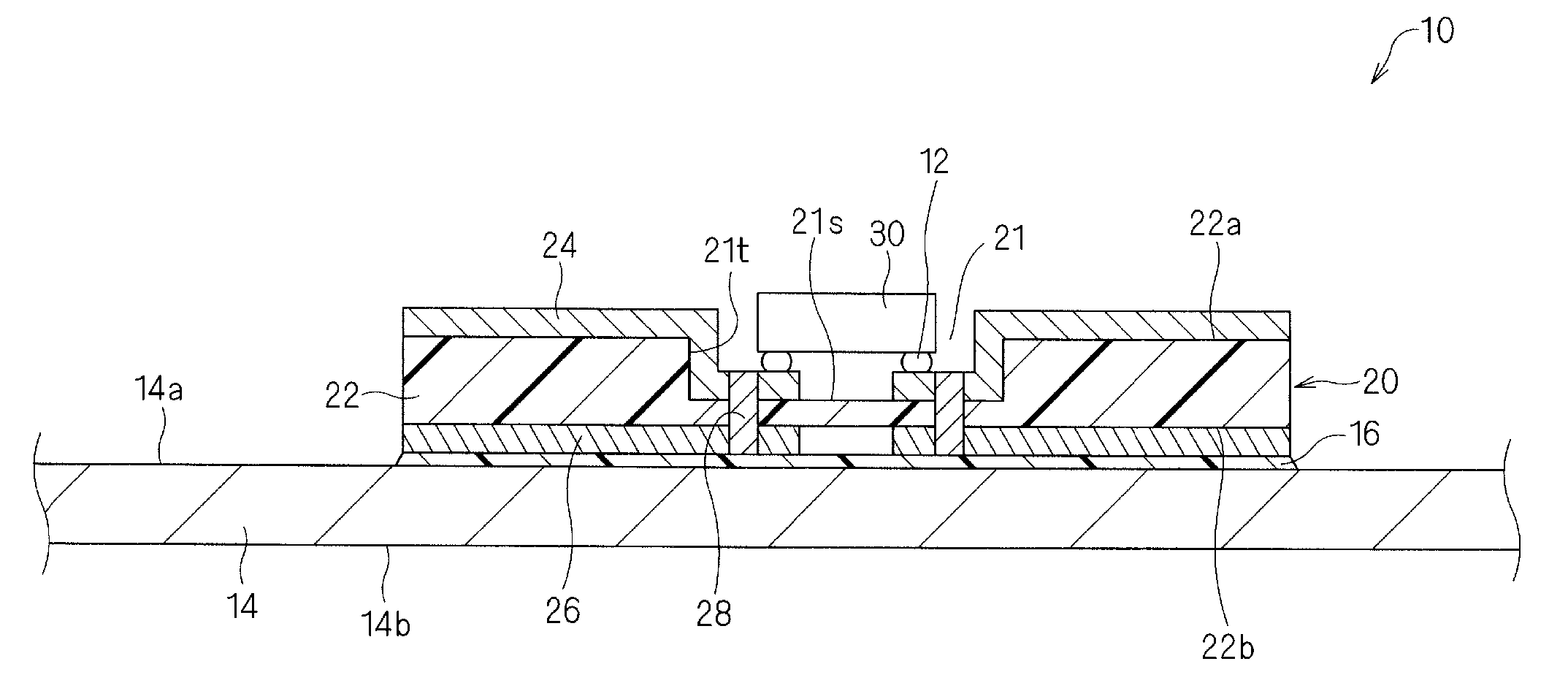

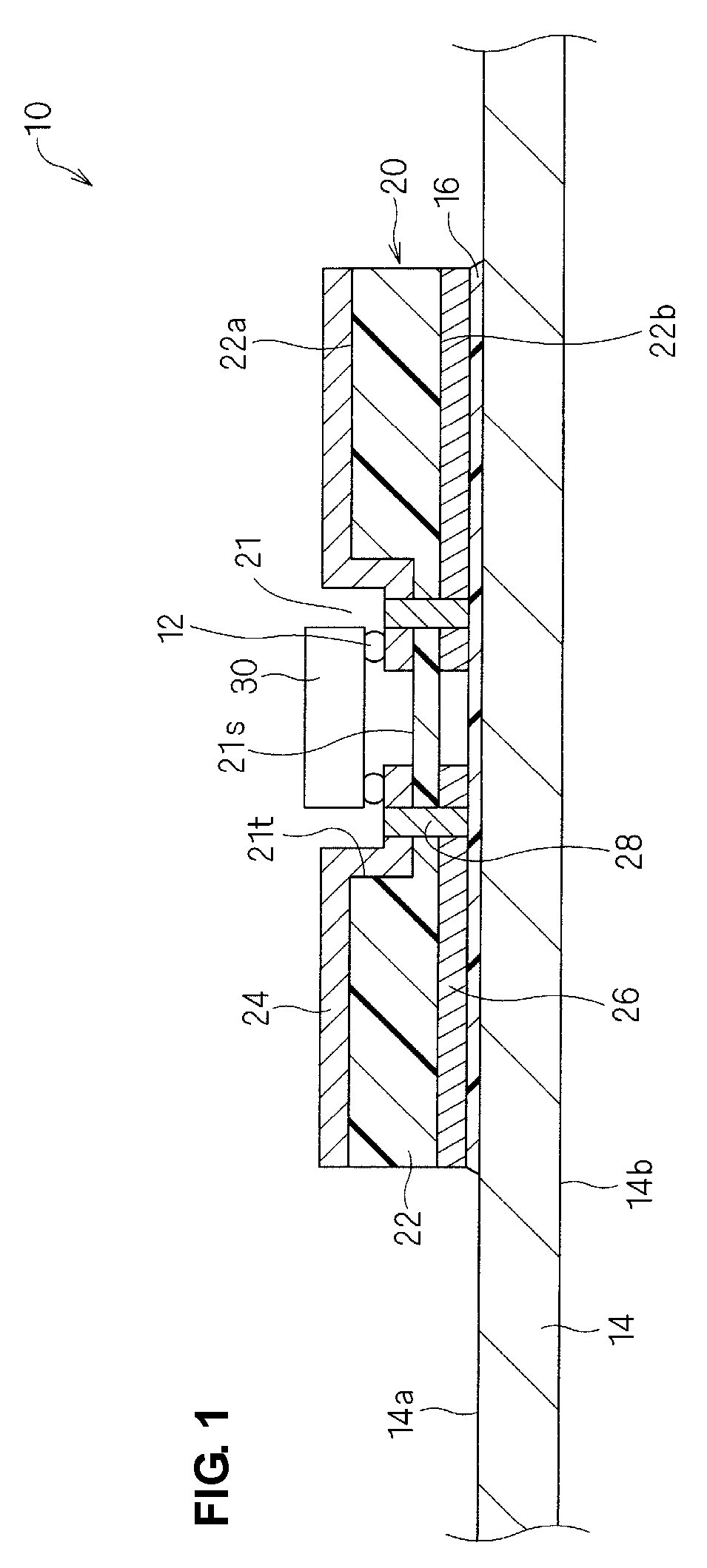

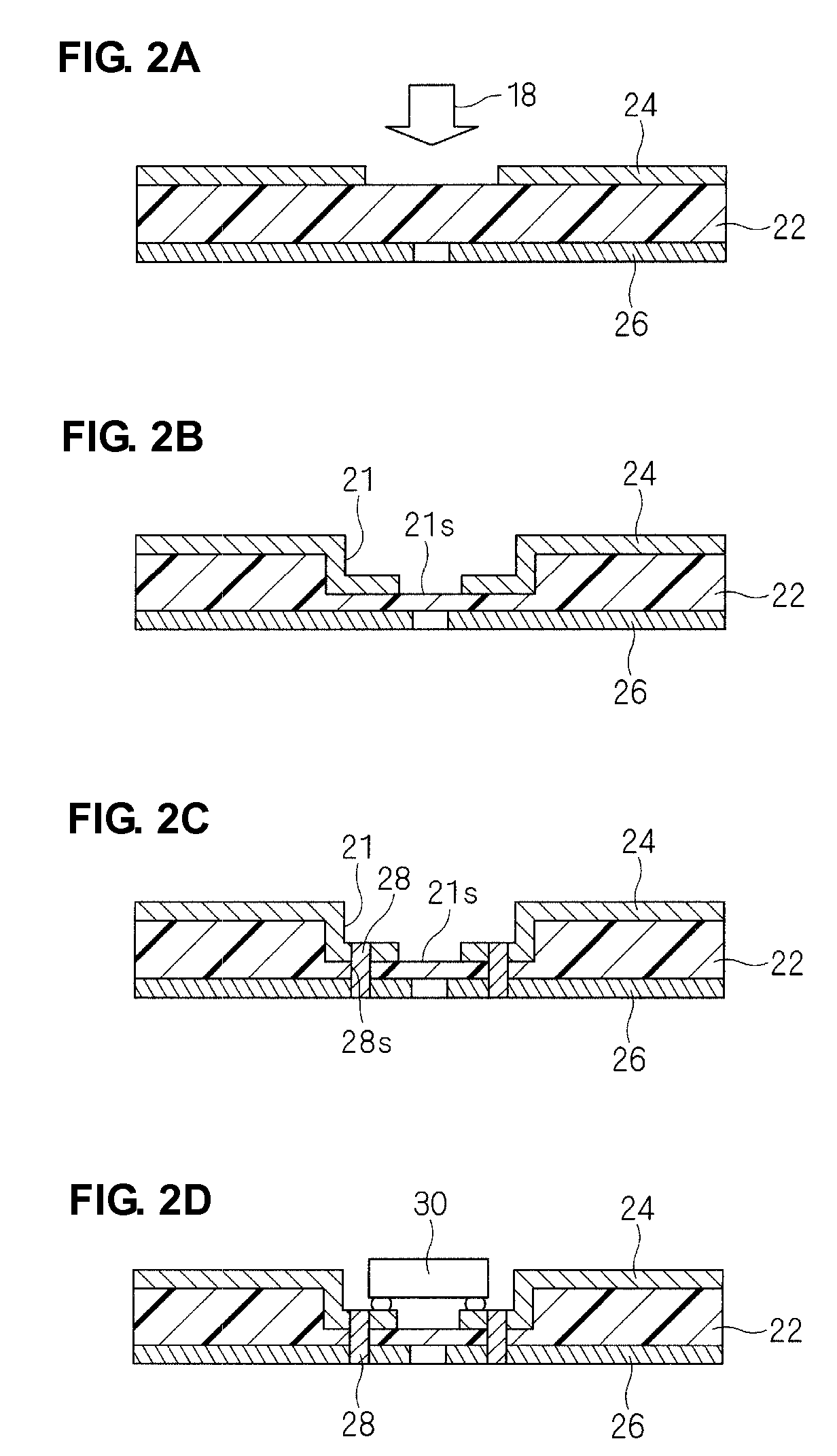

Wireless IC device and manufacturing method thereof

InactiveUS20090321527A1Low costGood electrical propertiesSemiconductor/solid-state device detailsPrinted circuit aspectsElectromagnetic couplingInductor

A wireless IC device includes a radiation plate, a wireless IC chip, and a substrate provided with a feed circuit that includes a resonant circuit and / or the matching circuit including an inductance element and that is electromagnetically coupled to the radiation plate. The substrate is made of a resin material. A recess is provided in a first main surface of the substrate. The substrate is provided with a wiring electrode arranged along a bottom surface and an inner circumferential surface of the recess and the first main surface of the substrate and electrically connected to the feed circuit, and a wedge member made of a different material from the resin material and extending between the bottom surface of the recess and a second main surface of the substrate spaced apart from the wiring electrode. The wireless IC chip is mounted in the recess and coupled to the wiring electrode.

Owner:MURATA MFG CO LTD

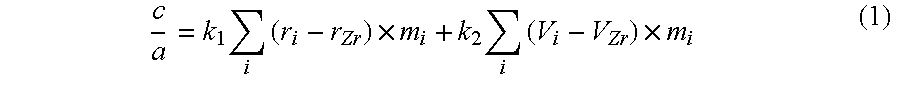

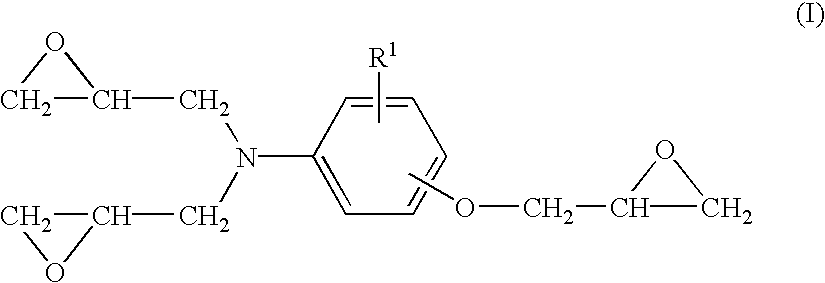

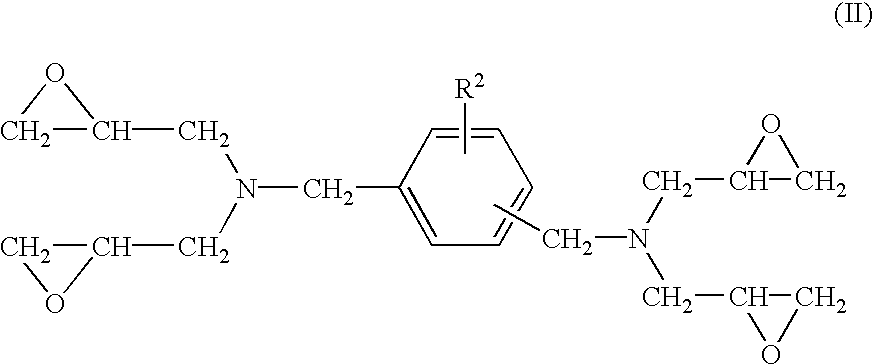

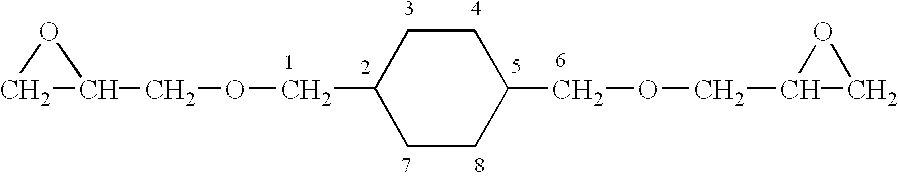

Epoxy resin compositions, epoxy resin compositions for fiber-reinforced composite materials, and fiber-reinforced composite materials comprising the same

InactiveUS6410127B1Improve heat resistanceImprove mechanical propertiesSynthetic resin layered productsYarnEpoxyCeiling temperature

An epoxy resin composition having a low viscosity around a room temperature and excellent reinforcing fiber impregnating properties provides a composite material having excellent heat resistance and mechanical properties including compressive strength. The epoxy resin composition includes an aromatic epoxy resin having at least di-functionality, an aromatic amine compound and / or an alicyclic amine compound, wherein 5 minutes after the main agent comprising the epoxy resin and the curing agent comprising the aromatic amine compound and / or the alicyclic amine compound are mixed, the composition shows a viscosity at 25° C. in the range of from 1 to 1500 mPa sec, and Tc, tc, and Tg satisfy the following equation (1):wherein k=0 when 60<=Tc<90 and k=0.35 when 90<=Tc<=200;Tc is the highest temperature (°C.) during the curing process and is defined by the formula 60<=Tc<=200;tc is the retention time (min) at the highest temperature and is defined by the formula 1<=tc<=120; andTg is the glass transition temperature of the epoxy resin composition after a lapse of tc (min) at Tc (°C.).

Owner:TORAY IND INC

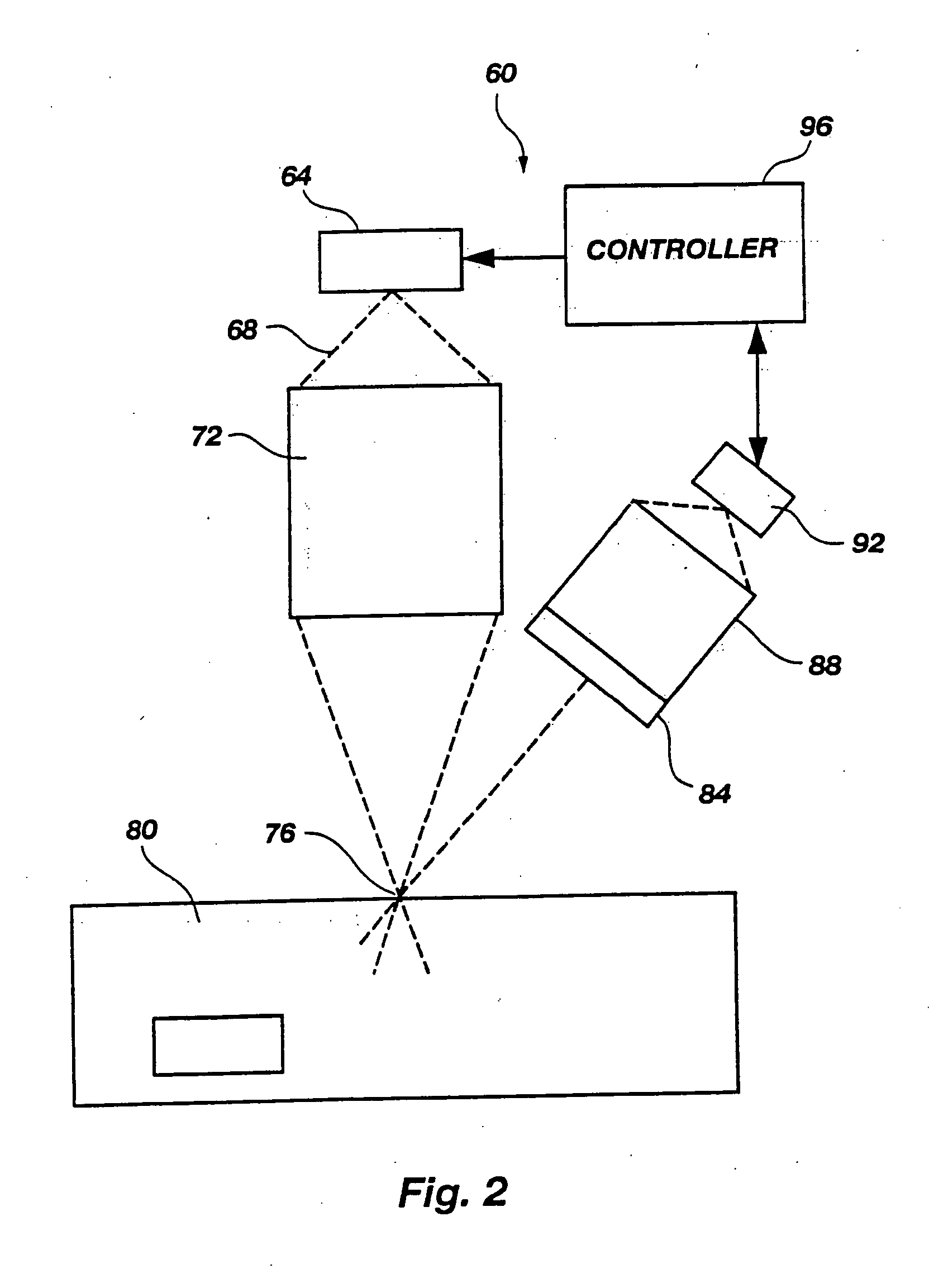

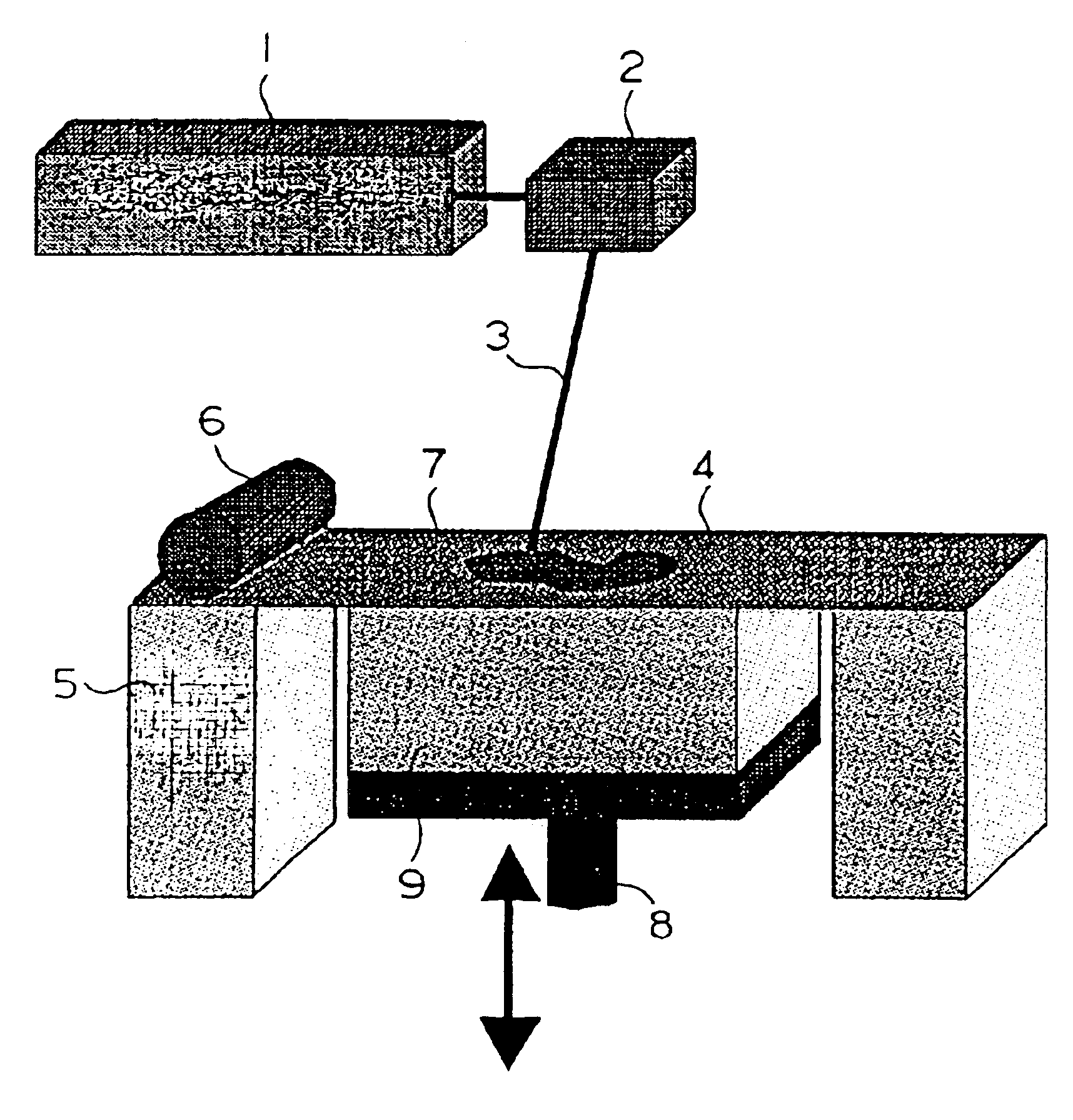

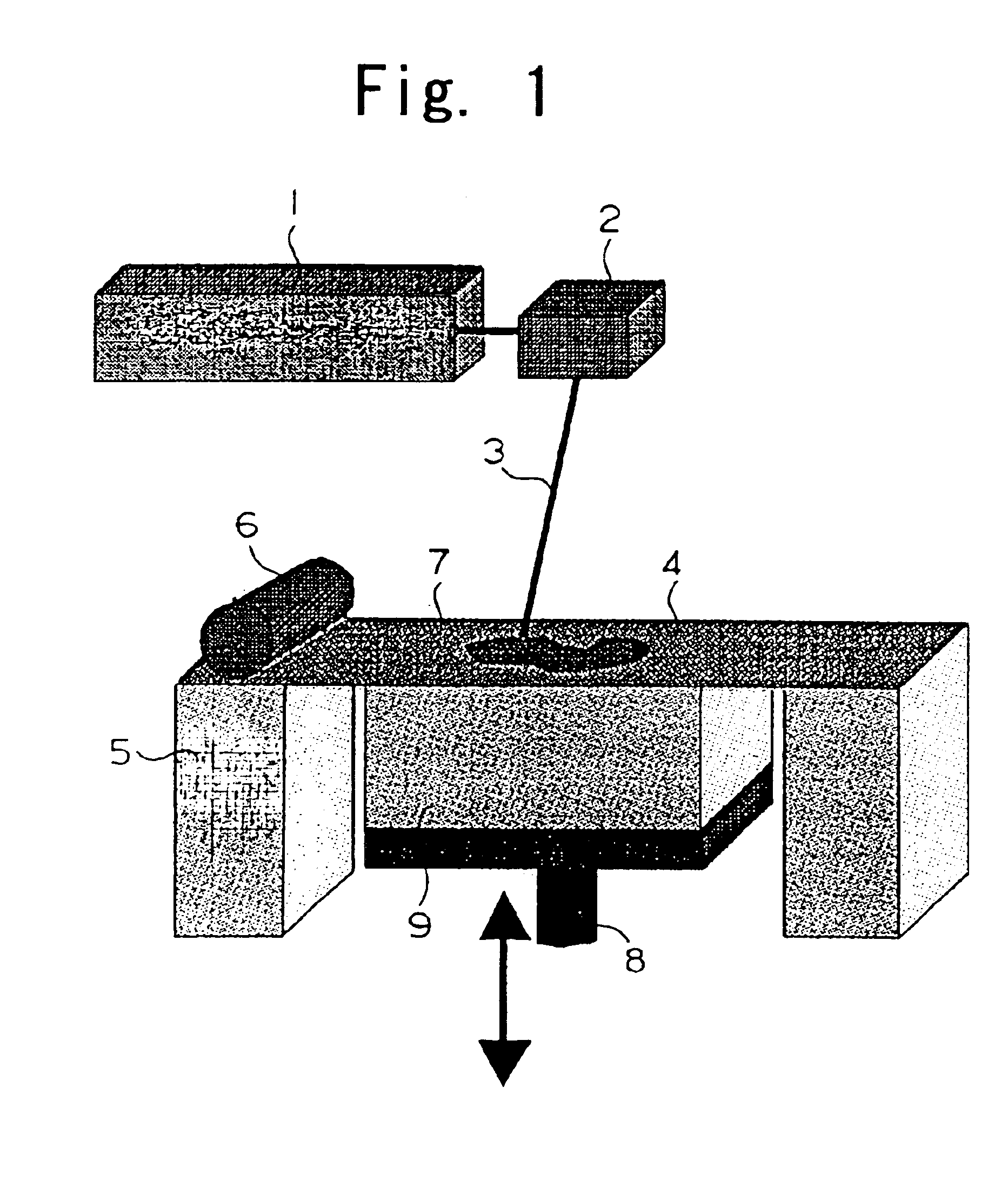

Process for producing an artificial bone model and an artificial bone model produced by the process

ActiveUS6932610B2Improve skillsEasy to getAdditive manufacturing apparatusPharmaceutical delivery mechanismHuman bodySurgical operation

A process for producing an artificial bone model in accordance with the selective laser sintering process which comprises extending a powder material for sintering comprising 30 to 90 parts by weight of powder of a synthetic resin and 10 to 70% by weight of an inorganic filler to form a thin layer and irradiating a portion of the thin layer having the shape formed based on tomograpic information of a natural bone with laser light so that the irradiated portion of the thin layer is sintered. The extension of the powder material for sintering to form the thin layer and the irradiation of the thin layer with laser light for sintering are conducted repeatedly. The artificial bone model can three-dimensionally reproduce steric shapes of natural bones such as bones in the human body precisely and accurately and exhibits the property for cutting closely similar to that of natural bones. The artificial bone model can be used for educational training or for studying a plan for curing before a surgical operation.

Owner:ONO +1

Composition for denaturing and breaking down friction-reducing polymer and for destroying other gas and oil well contaminants

InactiveUS7897063B1Onset of propertyIncreases hydrogen-bonding potentialOrganic/inorganic per-compounds compounding agentsPipeline systemsPollutantChemistry

A composition and method for breaking down and denaturing friction-reducing compound introduced into the ground during the drilling of gas and oil wells and for destroying other contaminants and biohazards naturally present within and artificially introduced into hydrocarbon wells, which are formed as a result of the drilling and pumping processes. The composition includes several species of oxidizing agent compounds that are effective in breaking down hydrogen sulfide produced by bacteria as well as the friction-reducing polymer used during drilling and several other organic compounds.

Owner:FTS INT SERVICES

Colloidal silica composition

ActiveUS20040077768A1Reduce dispersionImprove suppression propertiesMaterial nanotechnologyPigmenting treatmentSilane compoundsColloidal silica

The invention relates to a method of producing a stable substantially aqueous silanized colloidal silica dispersion having a silica content of at least about 20 wt %, comprising mixing at least one silane compound and colloidal silica particles, wherein the weight ratio of silane to silica is from about 0.003 to about 0.2. The invention also relates to a dispersion obtainable by the method, and to a stable substantially aqueous silanized colloidal silica dispersion having a silica content of at least about 20 wt %, wherein the weight ratio of silane to silica is from about 0.003 to about 0.2. The invention further concerns the use of the dispersion for coatings applications and as an additive.

Owner:AKZO NOBEL CHEM INT BV

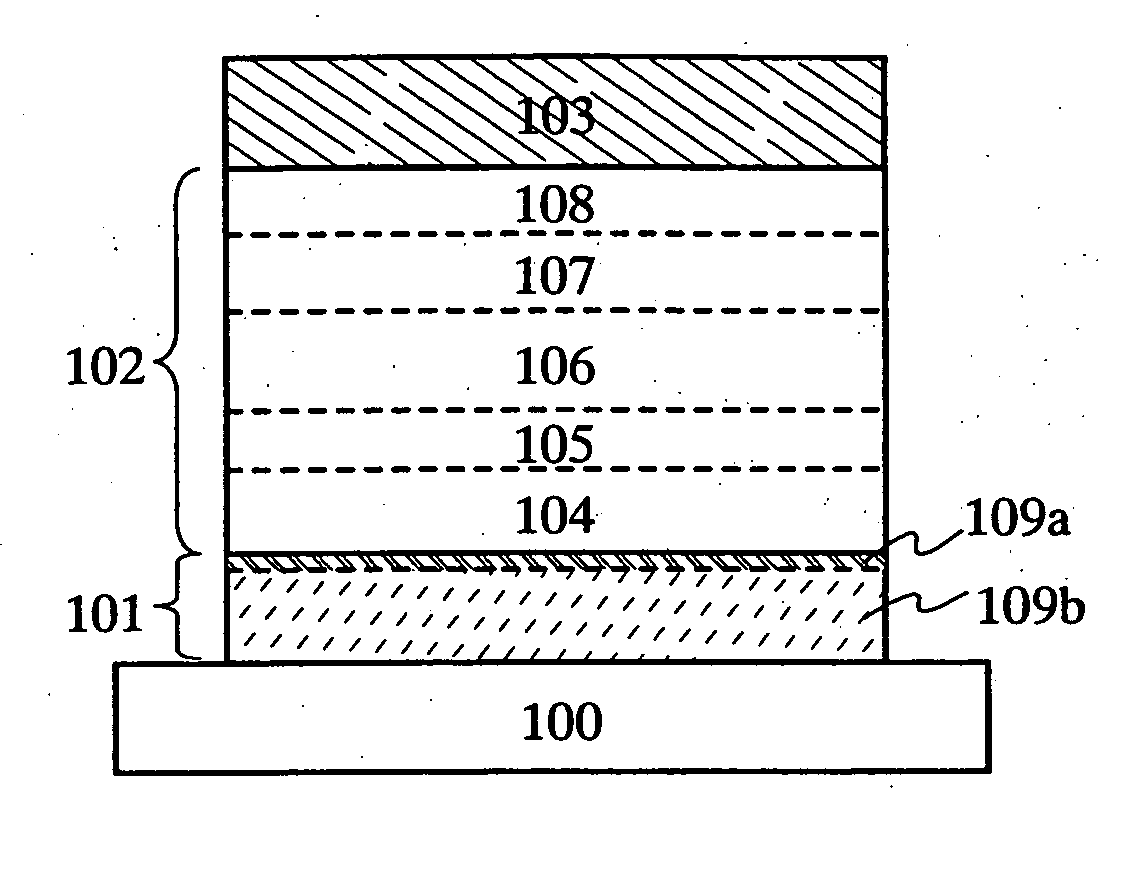

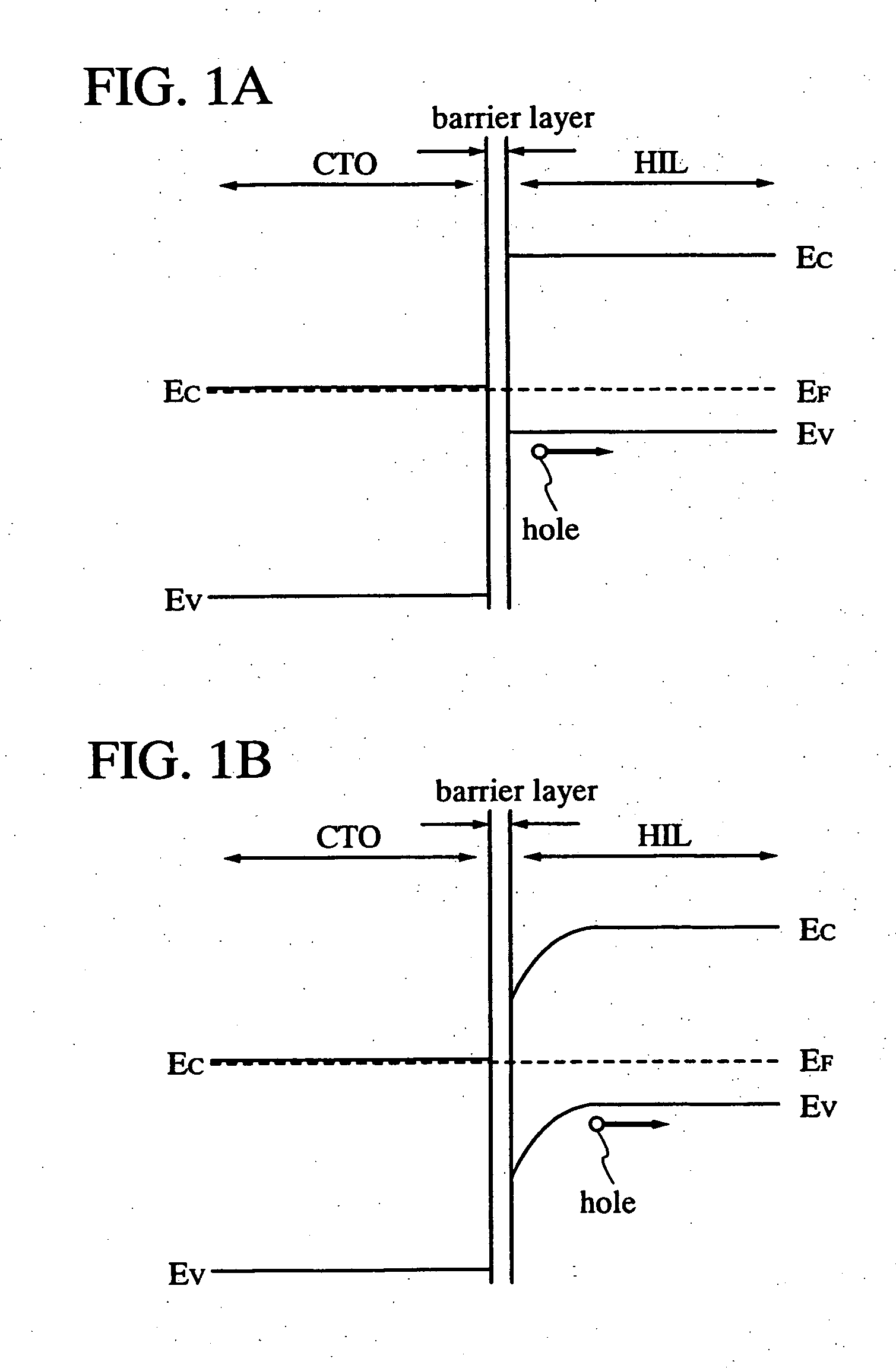

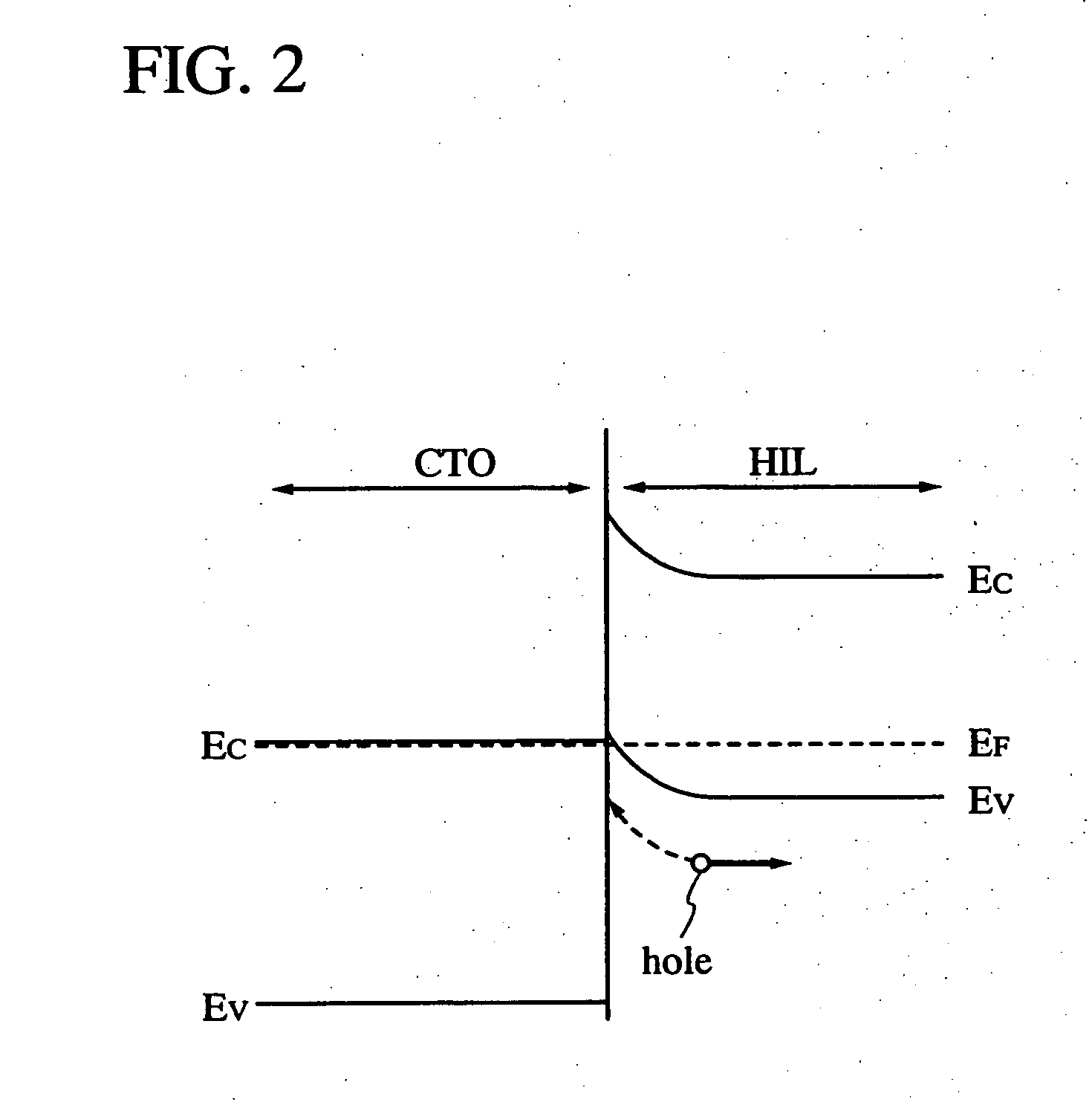

Light-emitting device and method for manufacturing light-emitting device

InactiveUS20050084994A1Improve internal quantum efficiencyPrevent lowering of hole-injecting propertySolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencySilicon oxide

It is an object of the present invention to provide a method for manufacturing a light-emitting device having high internal quantum efficiency, consuming less power, having high luminance, and having high reliability. The present invention provides a method for manufacturing a light-emitting device comprising the steps of forming a conductive light-transmitting oxide layer comprising a conductive light-transmitting oxide material and silicon oxide, forming a barrier layer in which density of the silicon oxide is higher than that in the conductive light-transmitting oxide layer over the conductive light-transmitting oxide layer, forming an anode having the conductive light-transmitting oxide layer and the barrier layer, heating the anode under a vacuum atmosphere, forming an electroluminescent layer over the heated anode, and forming a cathode over the electroluminescent layer, wherein the barrier layer is formed between the electroluminescent layer and the conductive light-transmitting oxide layer.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com