Patents

Literature

1782results about How to "Prevent shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

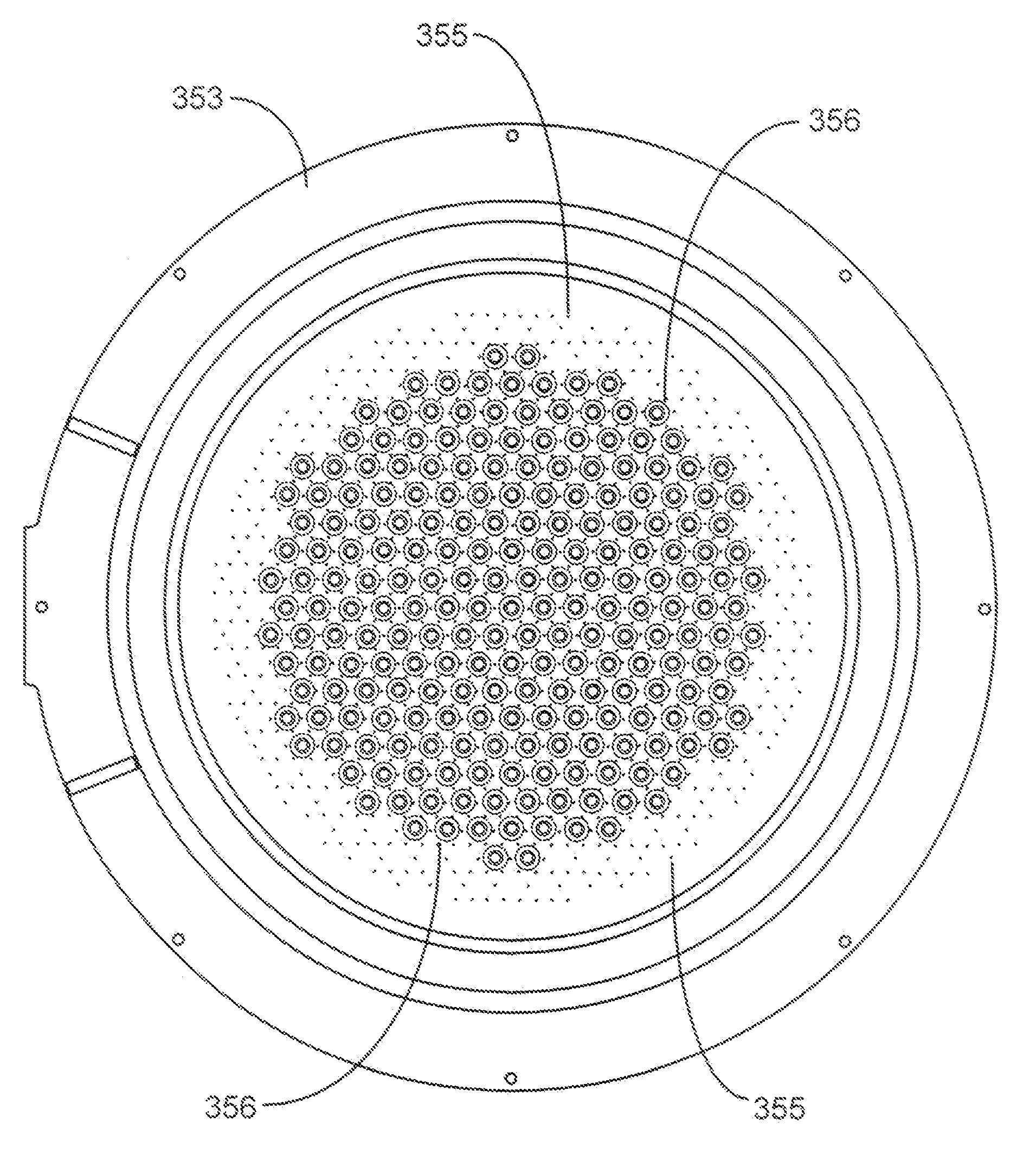

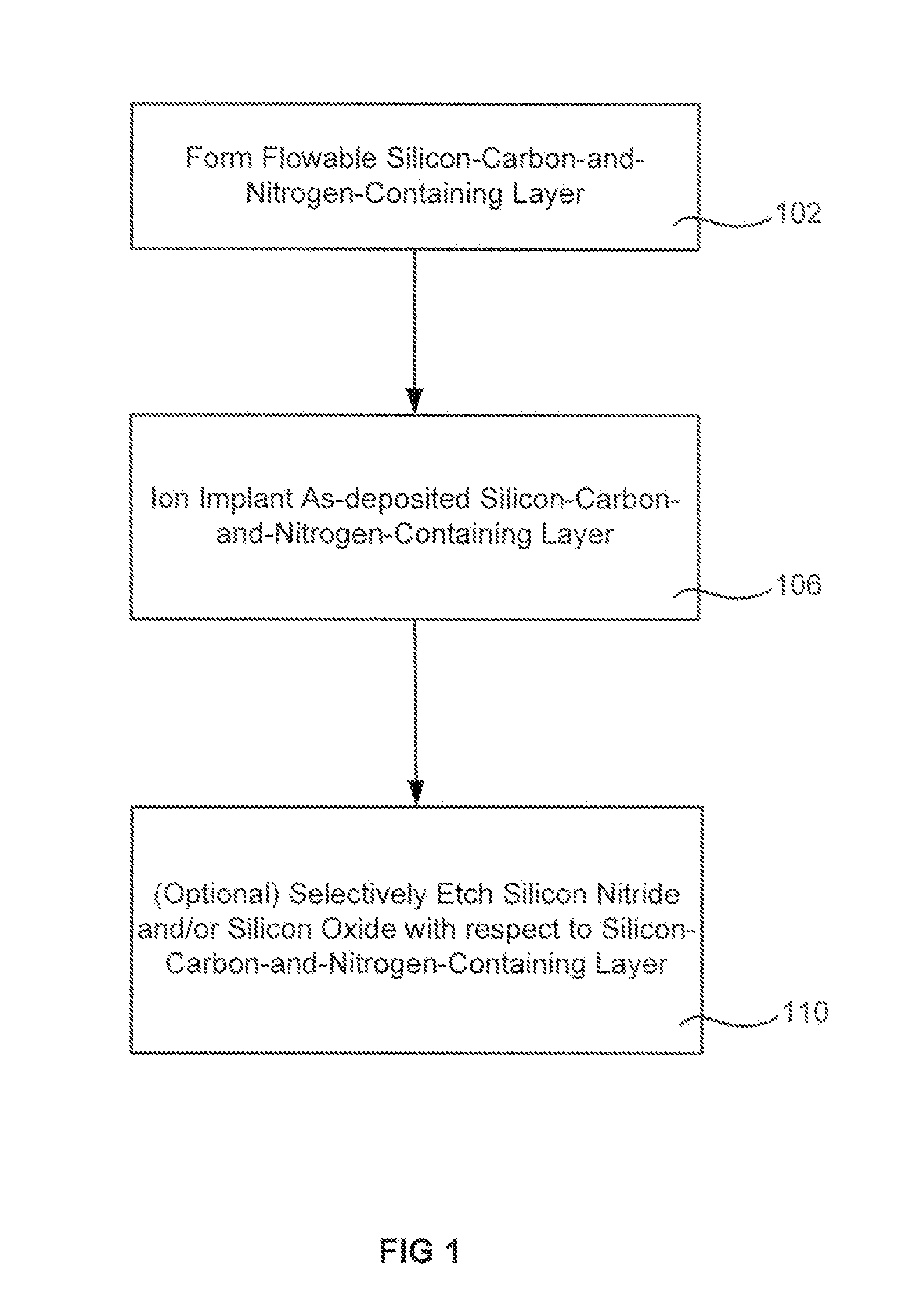

Doping of dielectric layers

InactiveUS20130217243A1Increase etch tolerancePrevent shrinkageSemiconductor/solid-state device manufacturingDeposition temperaturePhysical chemistry

Methods are described for forming and treating a flowable silicon-carbon-and-nitrogen-containing layer on a semiconductor substrate. The silicon and carbon constituents may come from a silicon-and-carbon-containing precursor while the nitrogen may come from a nitrogen-containing precursor that has been activated to speed the reaction of the nitrogen with the silicon-and-carbon-containing precursor at lower deposition temperatures. The initially-flowable silicon-carbon-and-nitrogen-containing layer is ion implanted to increase etch tolerance, prevent shrinkage, adjust film tension and / or adjust electrical characteristics. Ion implantation may also remove components which enabled the flowability, but are no longer needed after deposition. Some treatments using ion implantation have been found to decrease the evolution of properties of the film upon exposure to atmosphere.

Owner:APPLIED MATERIALS INC

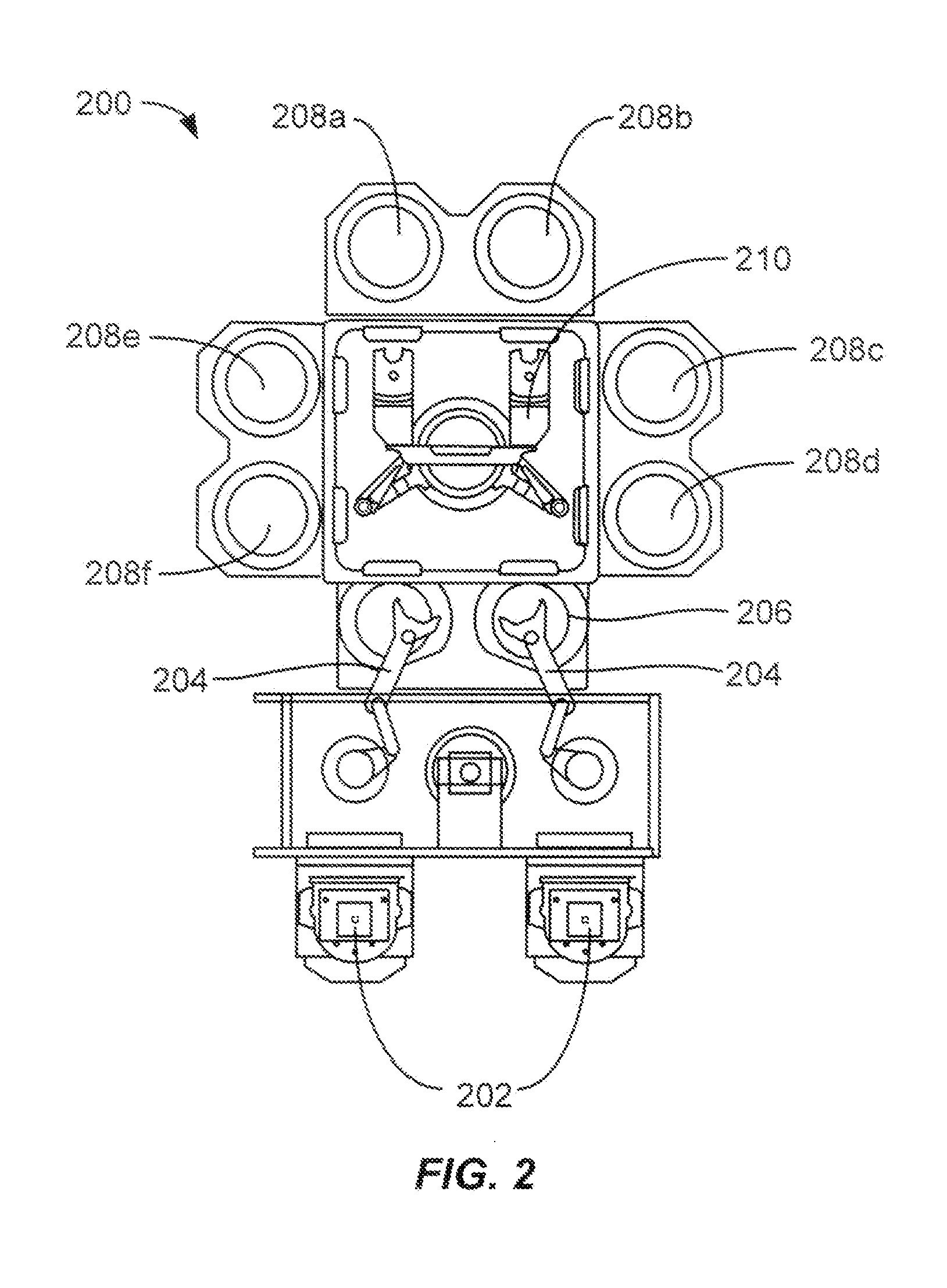

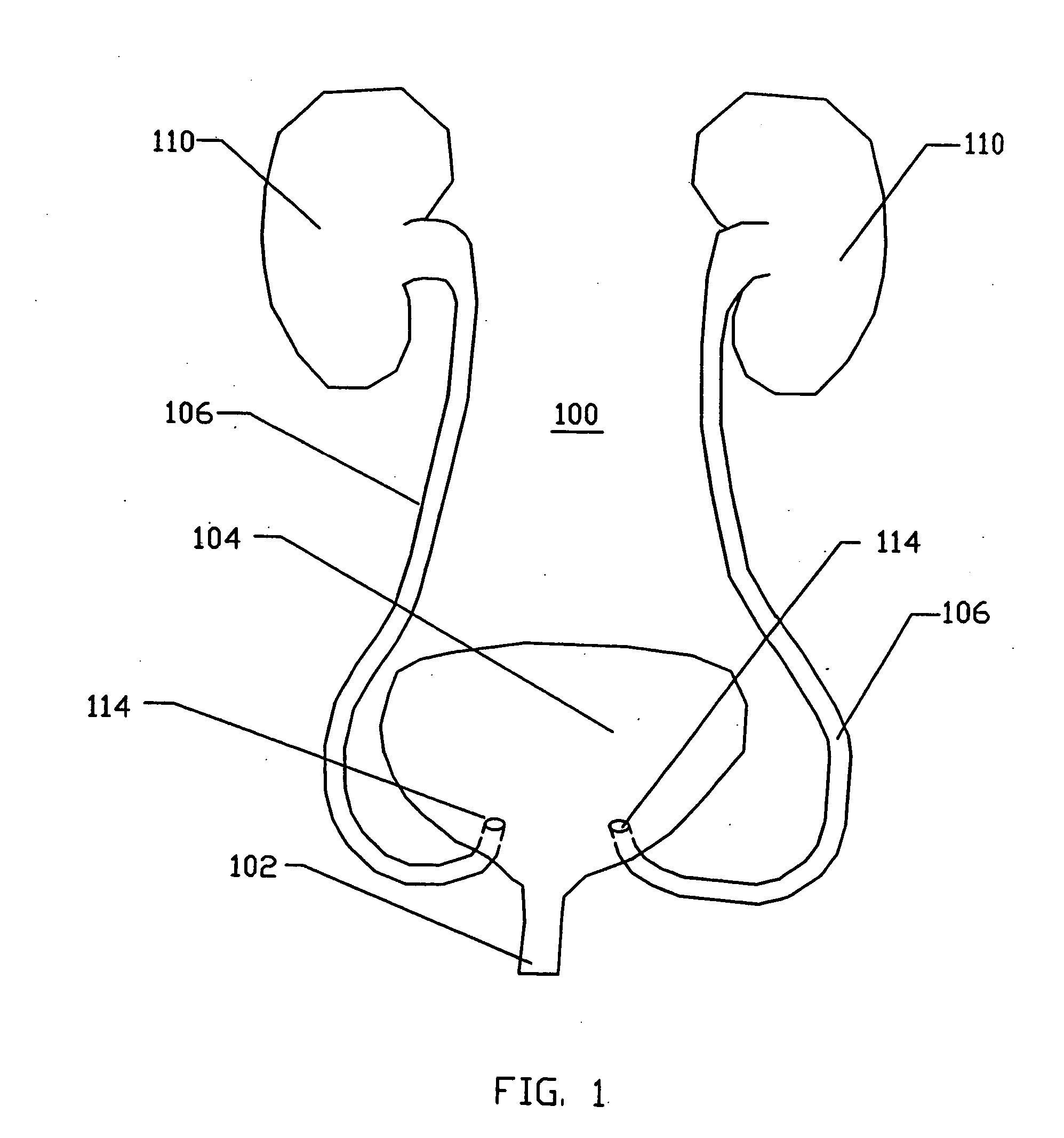

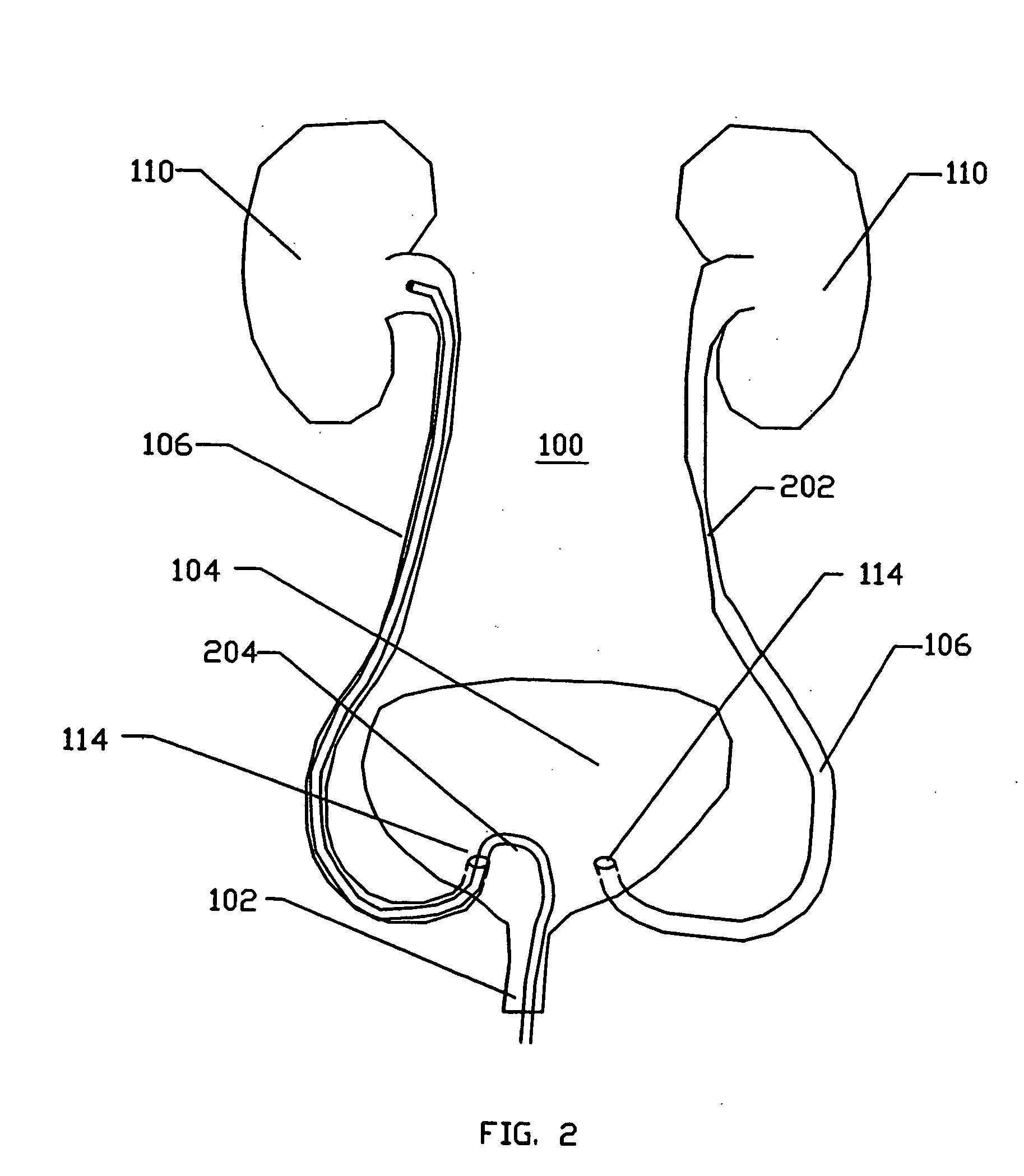

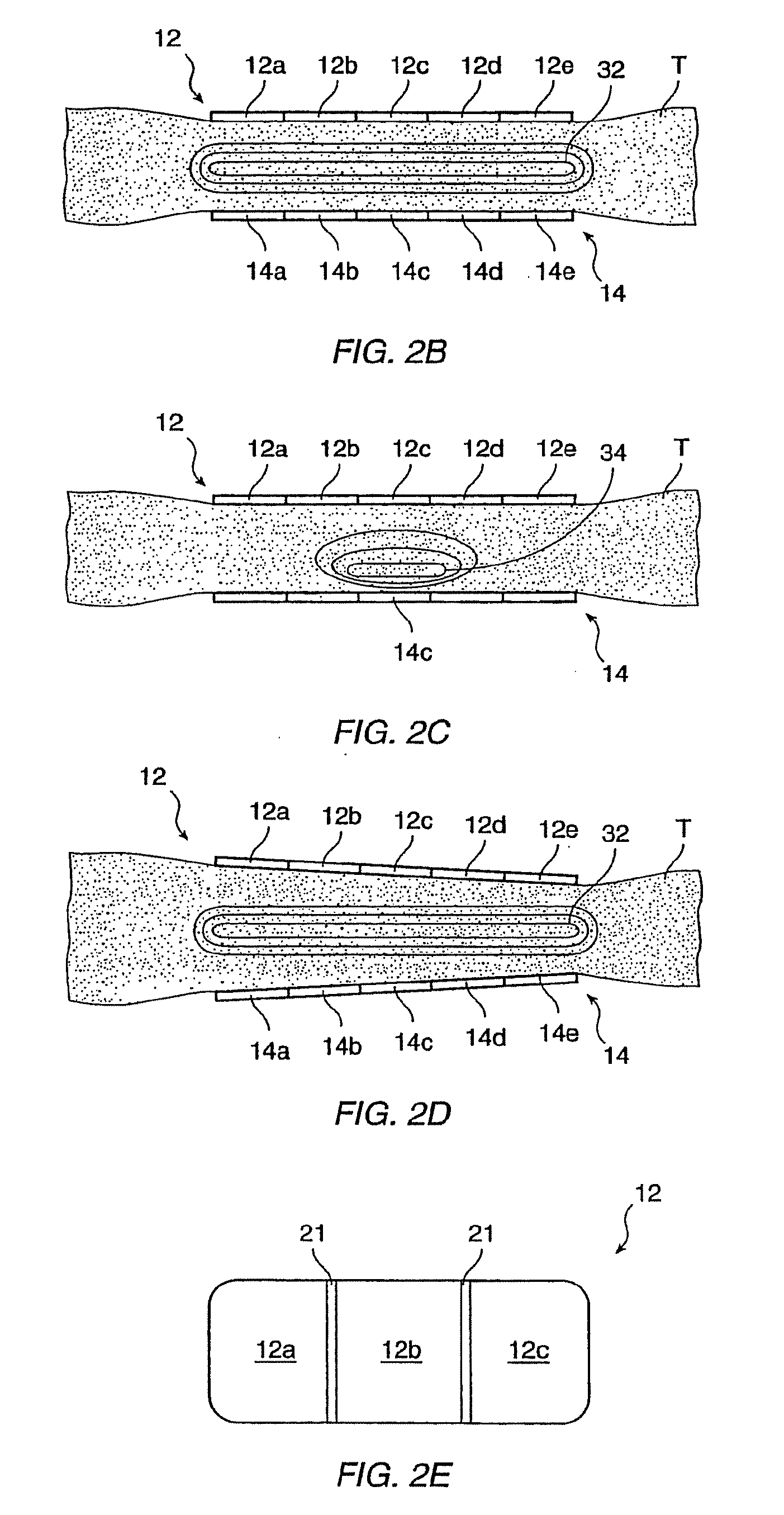

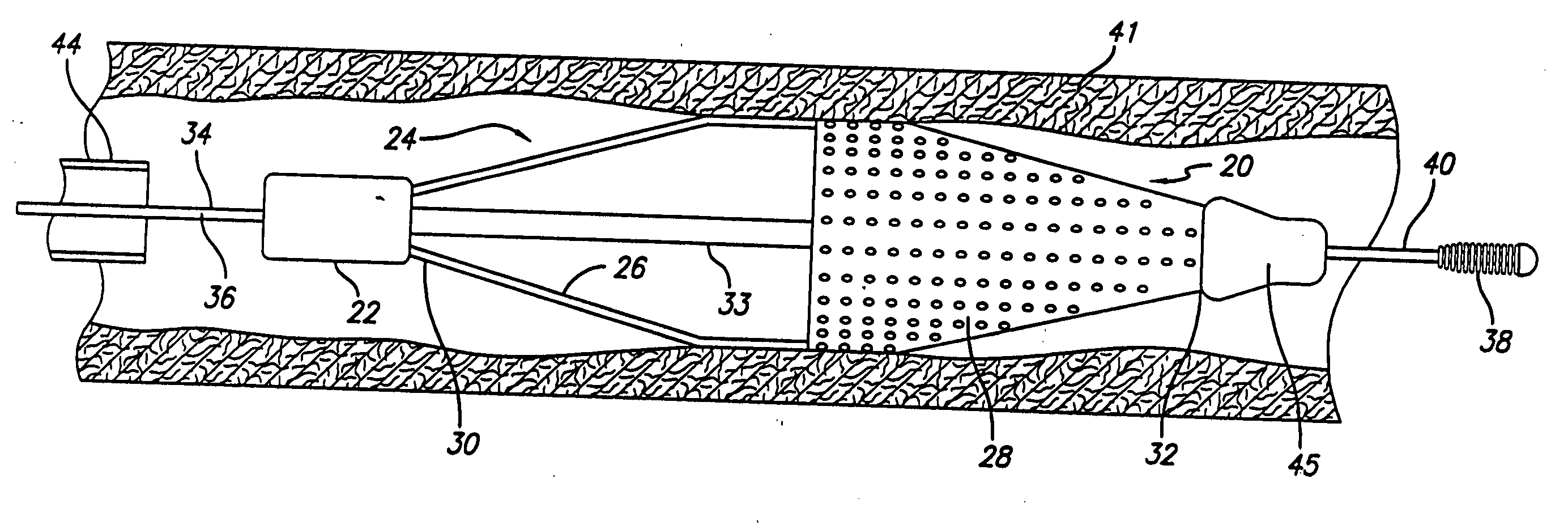

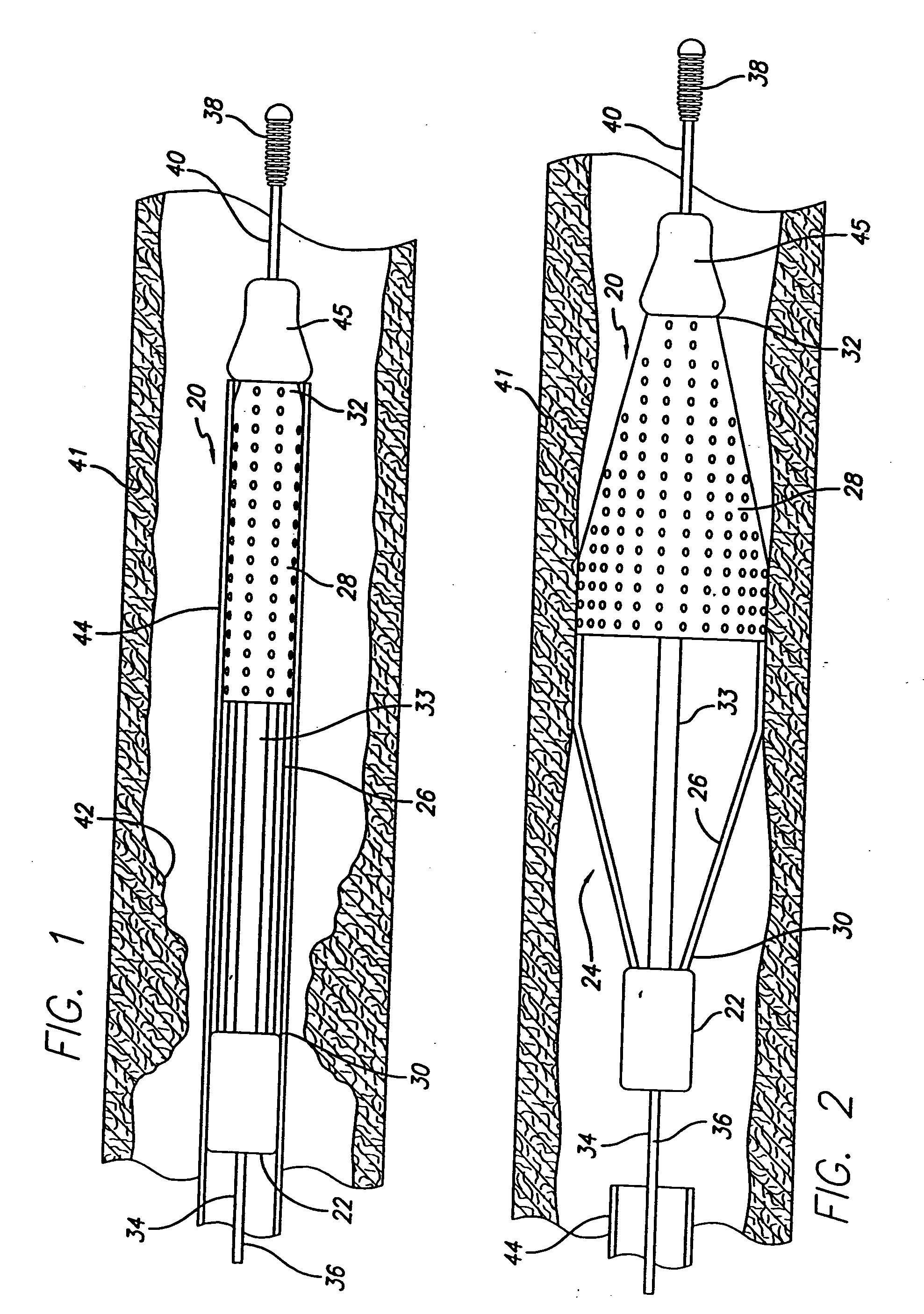

Expandable transluminal sheath

InactiveUS20060135981A1Minimize strain and catchingPrevent shrinkageGuide needlesBalloon catheterBiomedical engineeringCardiac electrophysiology

Disclosed is an expandable transluminal sheath, for introduction into the body while in a first, low cross-sectional area configuration, and subsequent expansion of at least a part of the distal end of the sheath to a second, enlarged cross-sectional configuration. The distal end of the sheath is maintained in the first, low cross-sectional configuration and expanded using a radial dilatation device. In an exemplary application, the sheath is utilized to provide access for diagnostic or therapeutic procedures such as ureteroscopy, cardiac electrophysiology, gastroenterology, and spinal access.

Owner:ONSET MEDICAL CORP

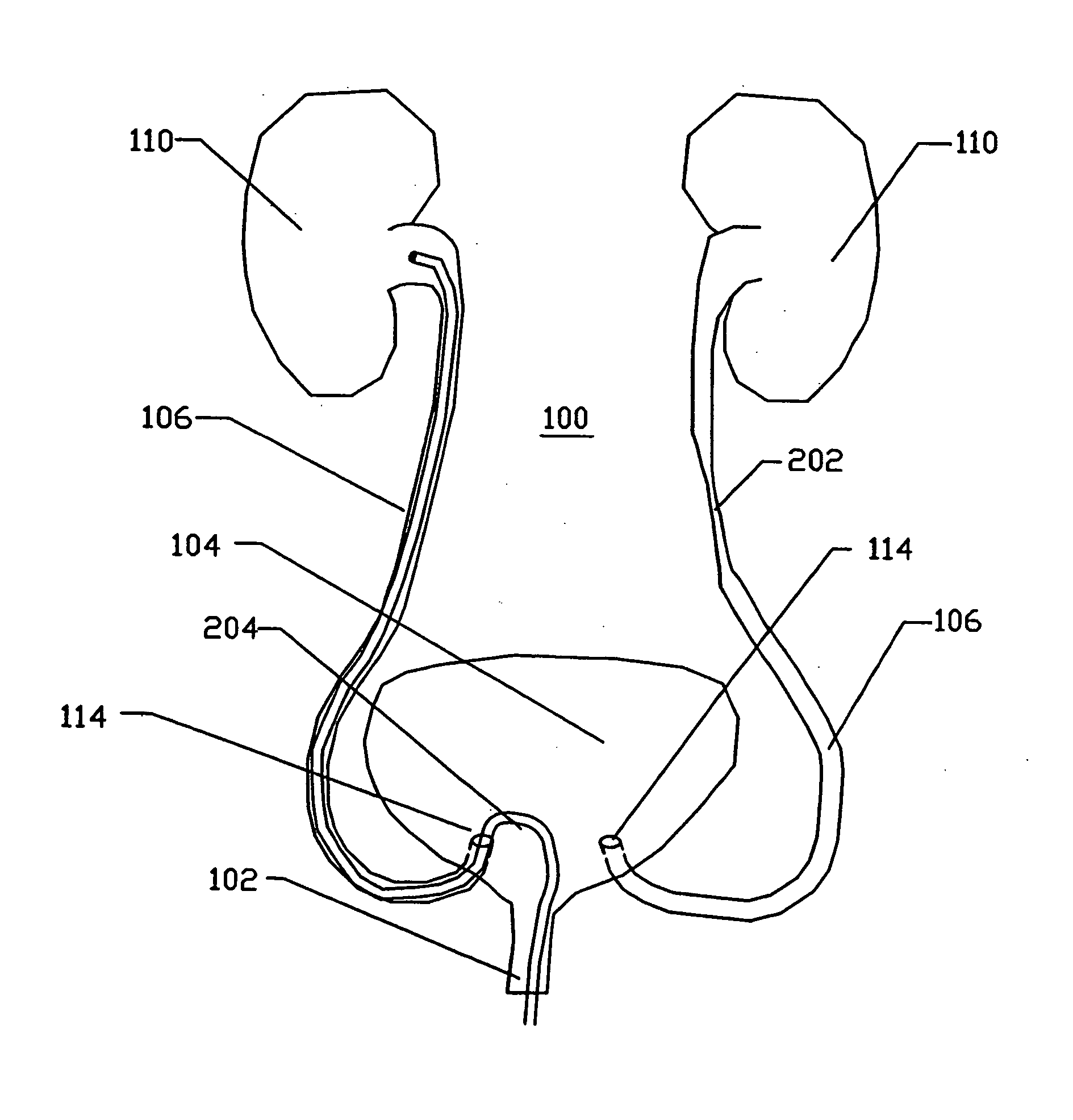

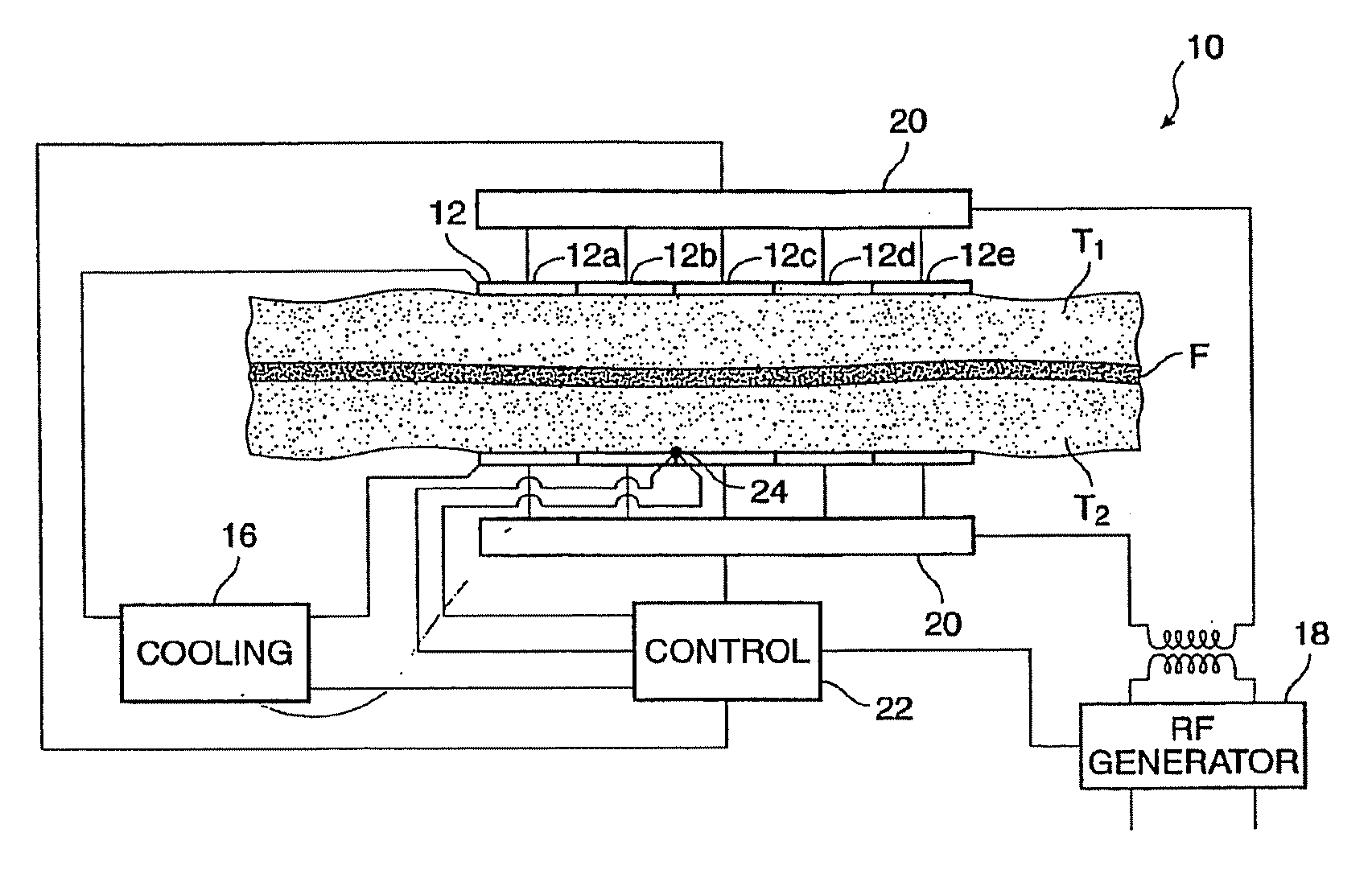

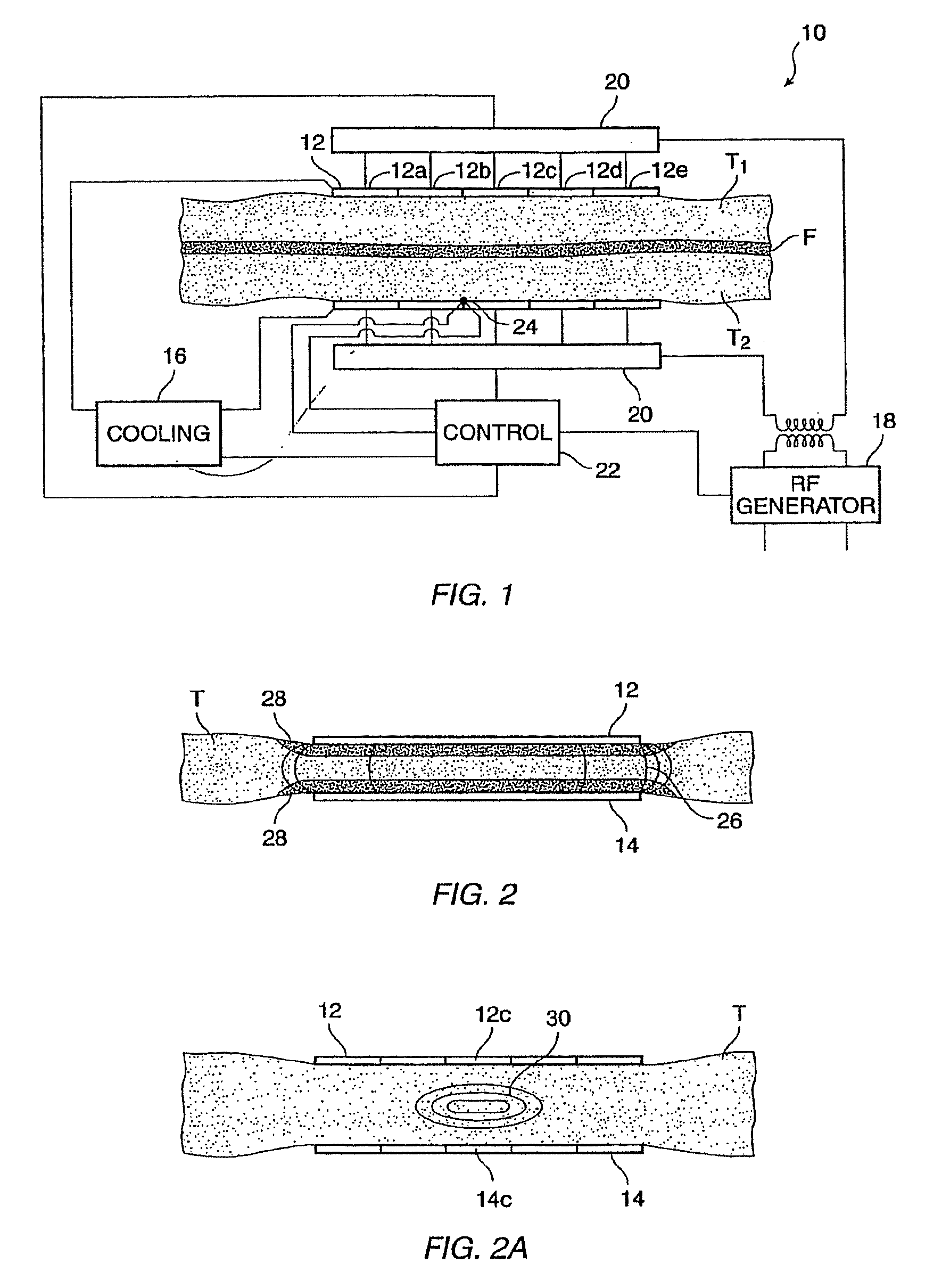

Noninvasive devices, methods, and systems for shrinking of tissues

InactiveUS20100049186A1Sufficient energyPrevent shrinkageUltrasound therapyDiagnosticsUrethraNon invasive

The invention provides improved methods for modifying collagenous tissues, particularly for treating urinary incontinence in a noninvasive manner. The methods typically include inserting a probe into a patient's urethra, transmitting electromagnetic energy from the probe to a collagneous target tissue, and cooling the tissue in the vicinity of the probe. The probe may include an expandable element at or near the distal end that is configured to expand within the patient's bladder. The expandable element may anchor the probe before or during treatment.

Owner:BOSTON SCI SCIMED INC +1

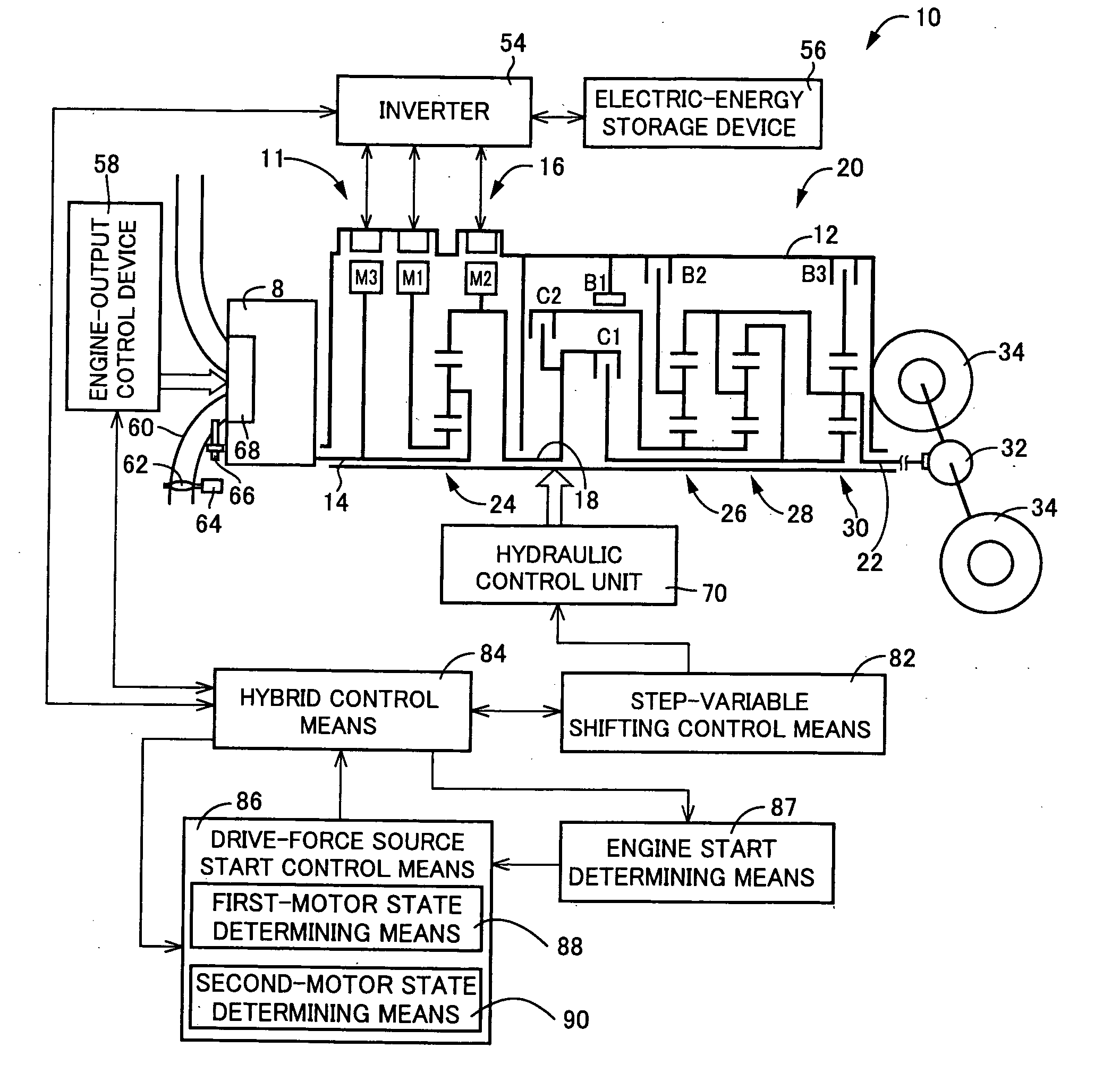

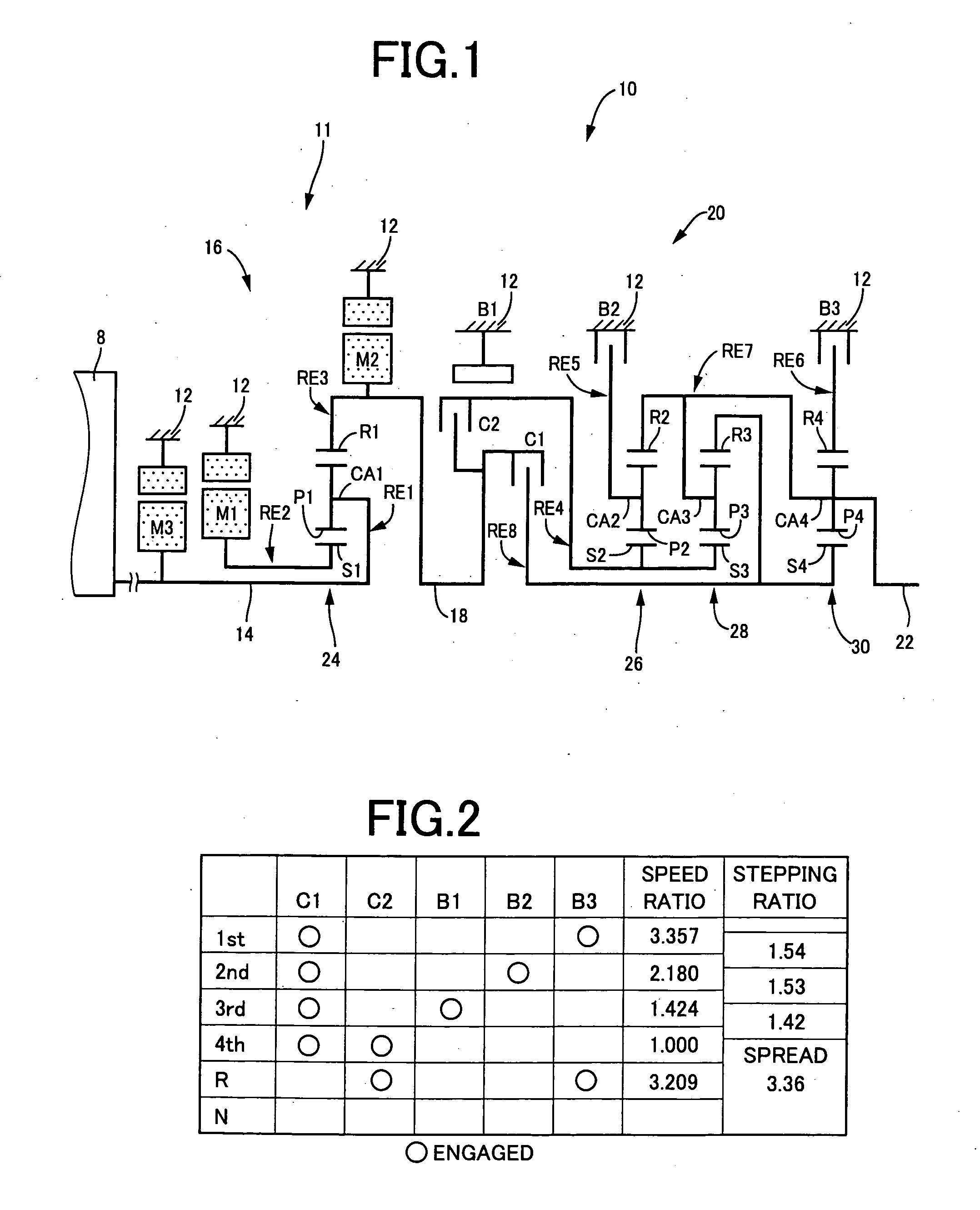

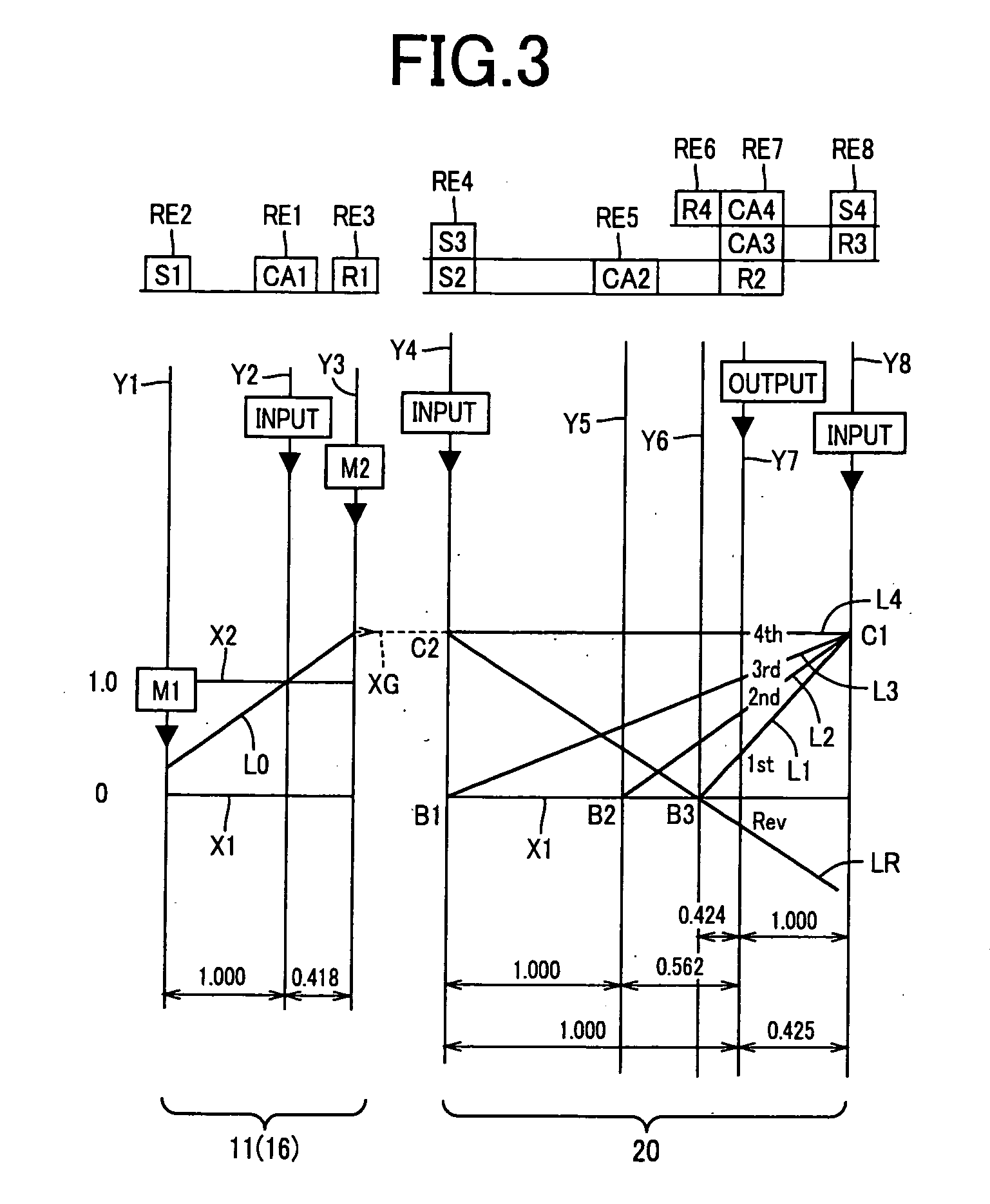

Control device for vehicular power transmitting apparatus

ActiveUS20100125019A1Inhibition of contractionAvoid reductionHybrid vehiclesDC motor speed/torque controlStart timeElectric control

In a vehicular power transmitting apparatus provided with an electrically-controlled differential portion in which controlling an operating state of an electric motor controls a differential state of a differential mechanism, a control device for starting up a drive force source in an appropriate mode depending on a vehicle condition can be provided. The control device includes drive-force source start control means 86 for switching start modes of an engine 8 depending on a vehicle condition to achieve an appropriate start mode for the engine 8 depending on the vehicle condition, so that for instance a contracted drive range by a second electric motor can be avoided.

Owner:TOYOTA JIDOSHA KK

Locking component for an embolic filter assembly

A locking component for locking a medical device onto a guide wire. Such medical devices include, for example, an embolic filter assembly used to capture embolic material that may be created and released into a patient's vasculature during a stenting or angioplasty procedure. The embolic filter assembly tracks along the guide wire, and is delivered to a treatment site where it is locked in place and deployed. The locking component enables the filter assembly to lock onto any standard guide wire, and does not require a modified guide wire that has a specially-designed fitting or stop to accomplish the locking function.

Owner:ABBOTT CARDIOVASCULAR

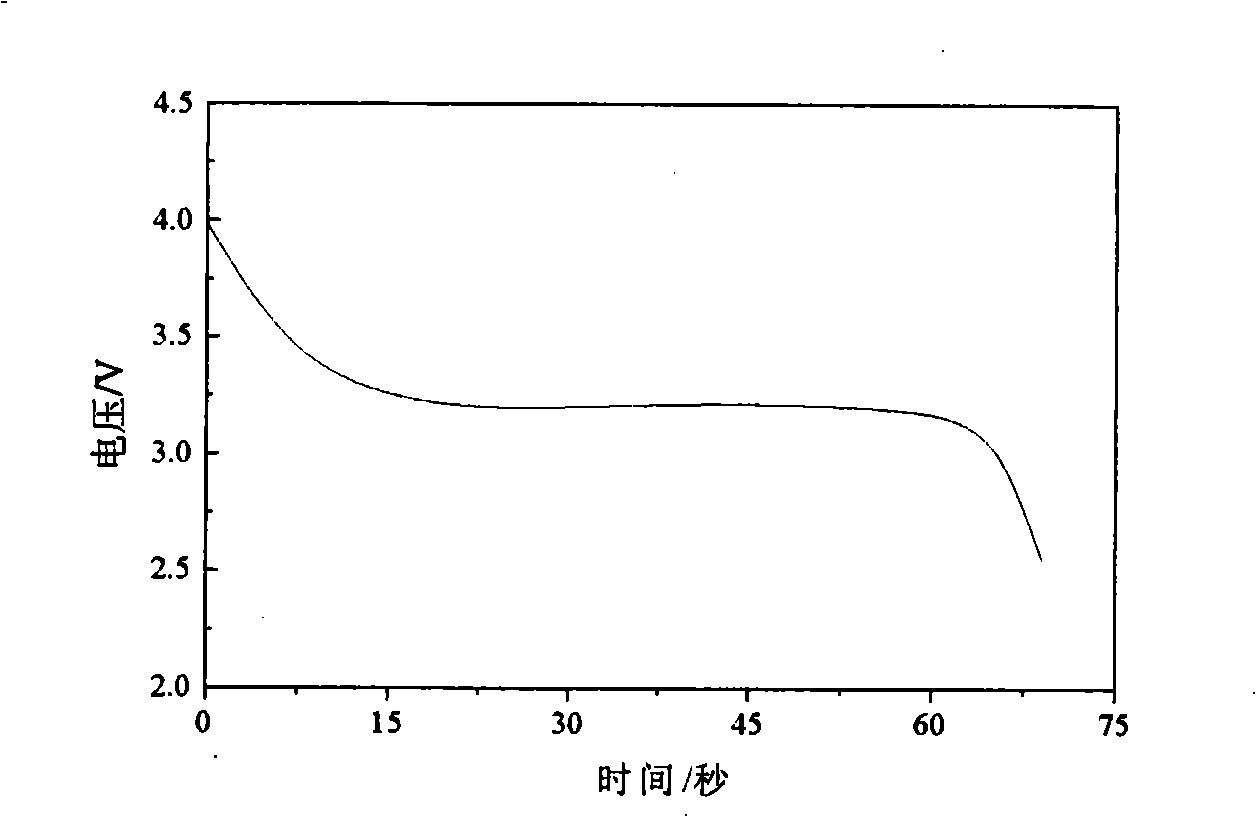

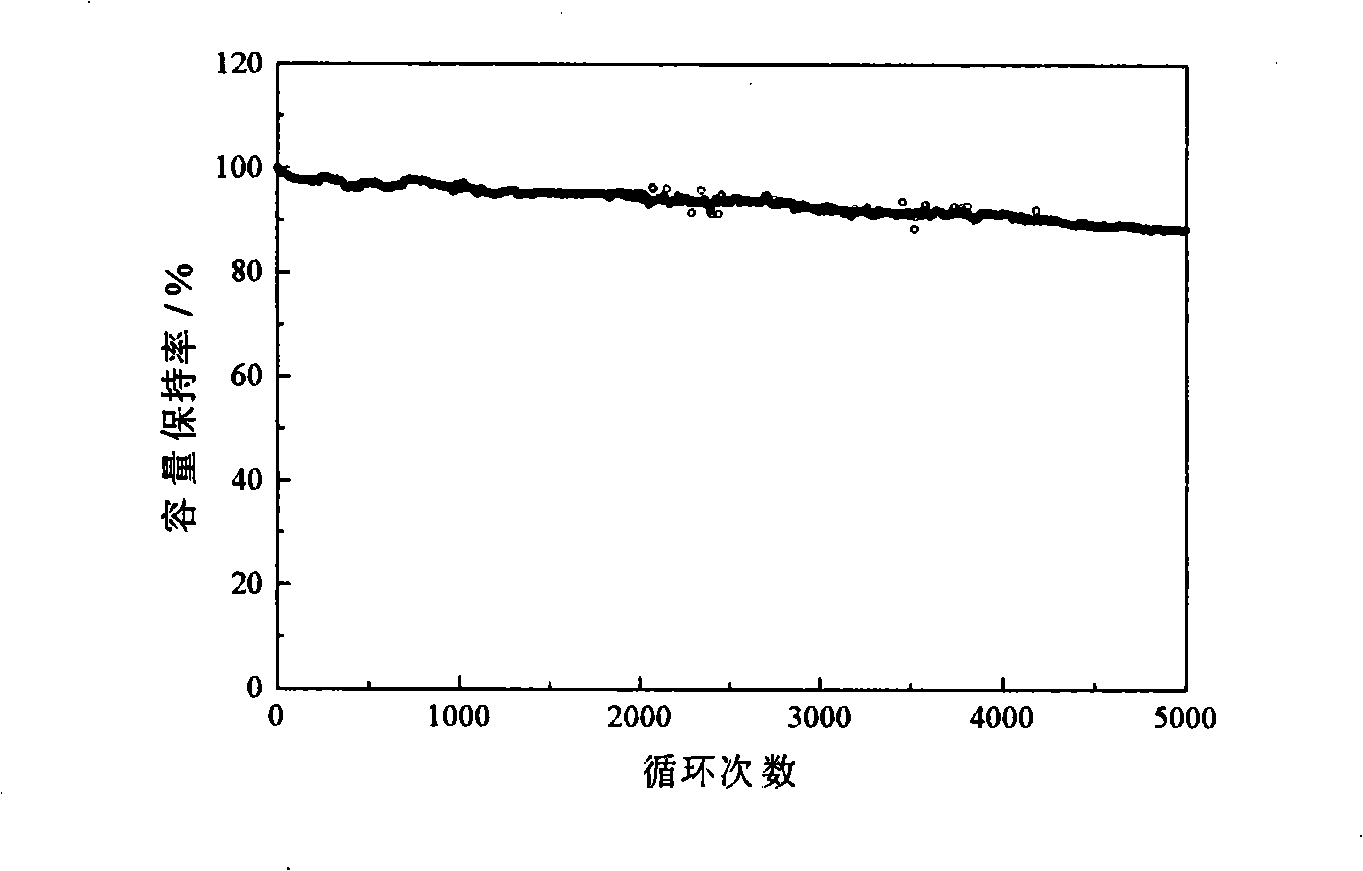

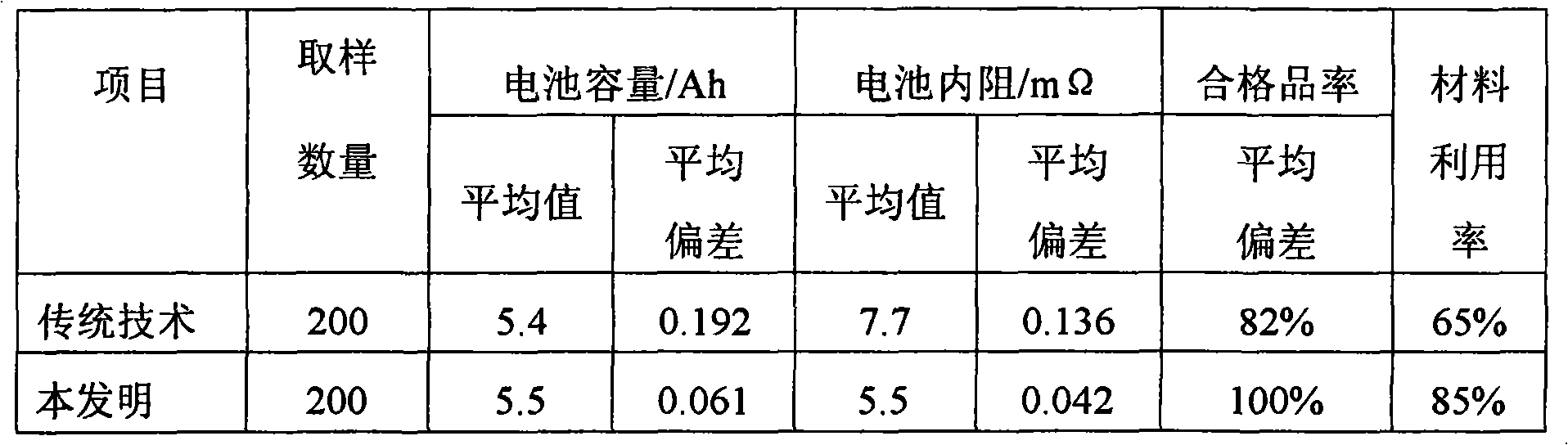

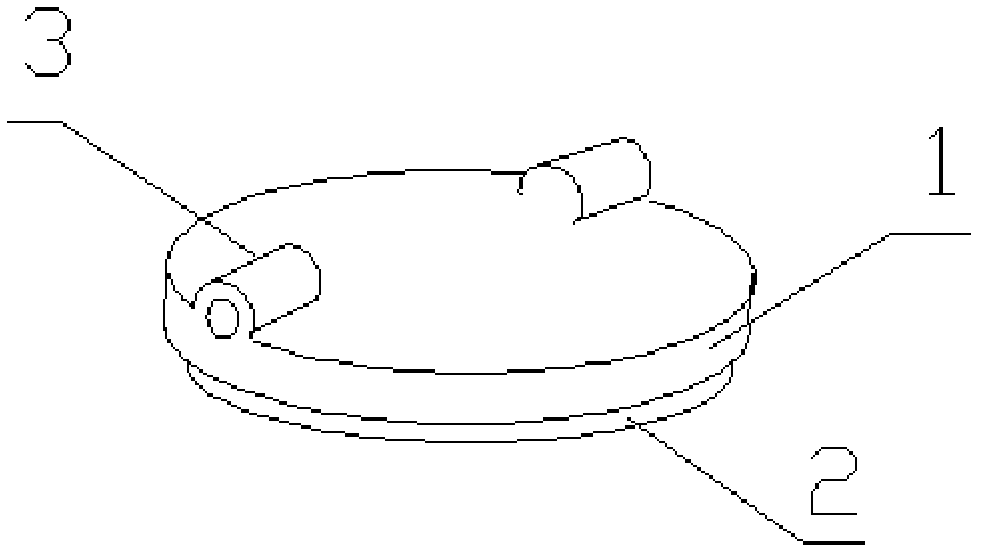

Energy storage device with both capacitor and lithium ion battery characteristics and manufacturing method thereof

InactiveCN101320821AIncrease energy densityImprove power densityFinal product manufactureActive material electrodesCapacitanceHigh energy

An energy storage device having both characteristics of super capacitor and lithium ion battery and manufacturing method thereof are provided. The invention adopts the mixture of anode material of lithium ion battery and electrode material of super capacitor or composite material as anode active substance, and uses the mixture of cathode material of the lithium ion battery and electrode material of the super capacitor or composite material as cathode active substance. In the electrode active substance, the electrode material of the lithium ion battery has a content of 20% to 95%; the electrode material of the super capacitor has a content of 5% to 80%. The electrode active substance is mixed with the bonder, conducting agent, additive and solvent etc to prepare slurry, then experience steps of coating, drying, roll forming, parting, so that the anode sheet and cathode sheet of the super capacitance battery are produced. By adopting multi-core winding parallel connection and the assembling technology of the winded wore parallel to the narrow arrangement, the anode sheet, the cathode sheet and the membrane are loaded in the battery shell and then welded, dried, dehydrated, and injected with electrolyte, then activated by electricity to obtain super capacitance battery with high energy density and high power density.

Owner:CENT SOUTH UNIV

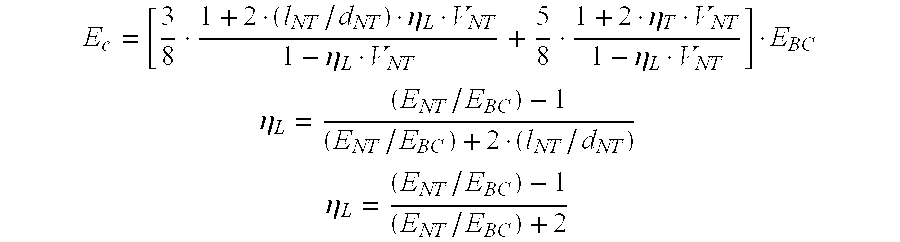

Polymethylmethacrylate augmented with carbon nanotubes

InactiveUS6872403B2Improve mechanical propertiesGood load transferBiocidePowder deliveryCarbon nanotubeSynthetic resin

An augmented synthetic resin is provided. That resin includes carbon nanotubes dispersed in a polymethylmethacrylate matrix. The method of preparing this synthetic resin includes the mixing and disaggregating of the carbon nanotubes.

Owner:UNIV OF KENTUCKY RES FOUND

Transparent, coated, shrinkable, oriented polypropylene film

InactiveUS20030157354A1Prevent shrinkageAvoid wrinklesSynthetic resin layered productsPackaging by pressurising/gasifyingWater basedEngineering

A transparent, coated, heat-shrinkable film having controlled shrinkability which includes a biaxially oriented substrate having a polypropylene blend core layer and a water based coating. The shrink during the application on packaging machines is achieved through the balanced MD-TD (machine direction and transverse direction) film retraction in and near the sealed areas. The substrate can also include outer layers of a propylene-ethylene-butylene terpolymer disposed on either side of the polypropylene core layer or on either side of additional intermediate layers that may be disposed between the outer layers and the core layer. The invention also includes a process for making this coated heat-shrinkable film. The coated film is formed under controlled temperature and tension conditions to produce a packaging film having shrinkage within a controlled shrinkability range.

Owner:EXXONMOBIL CORP (US)

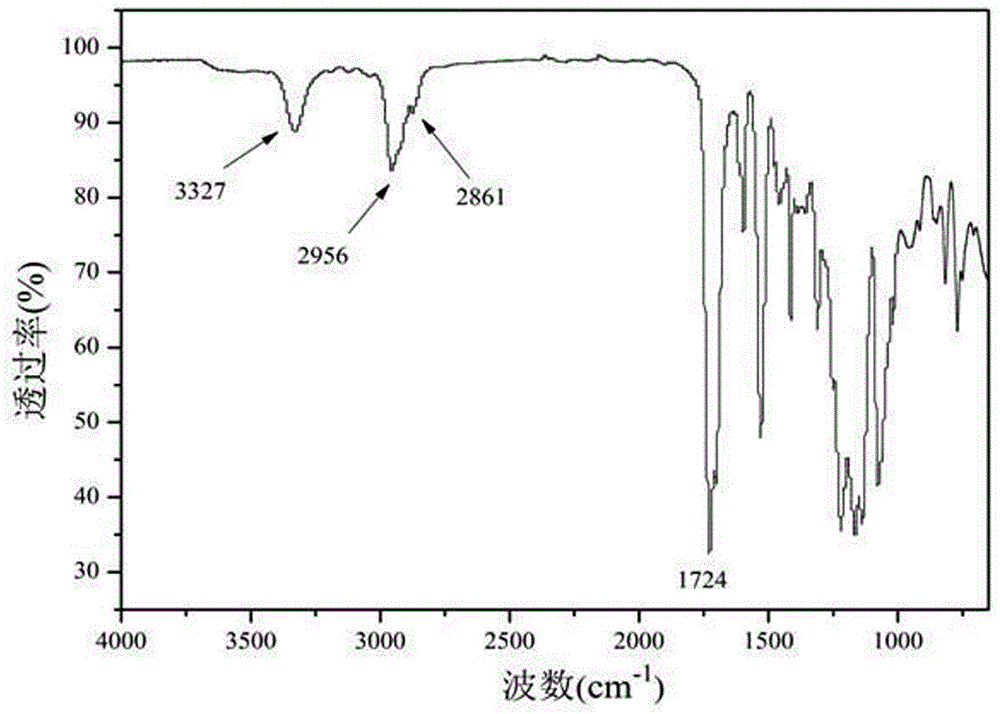

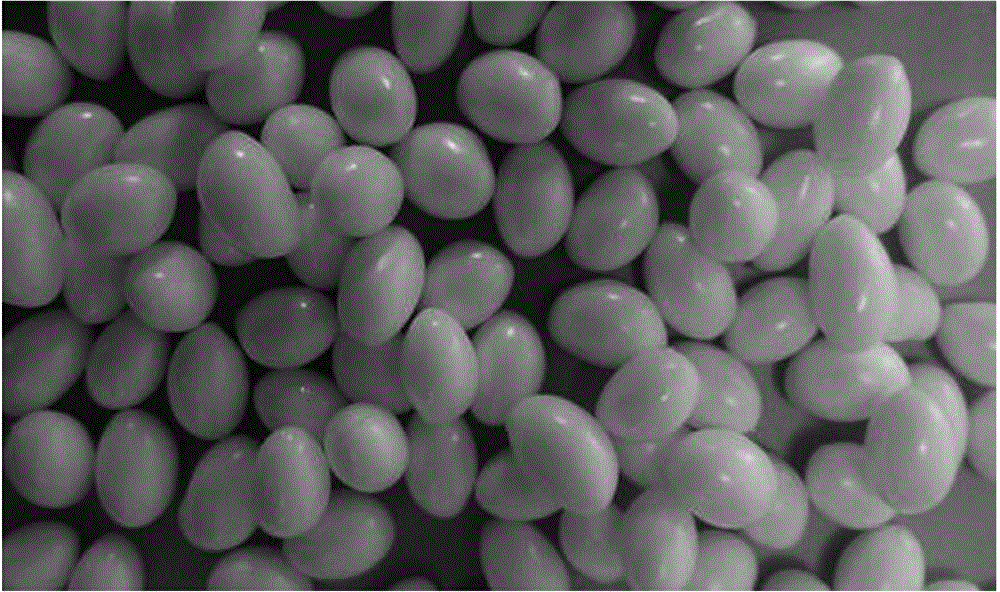

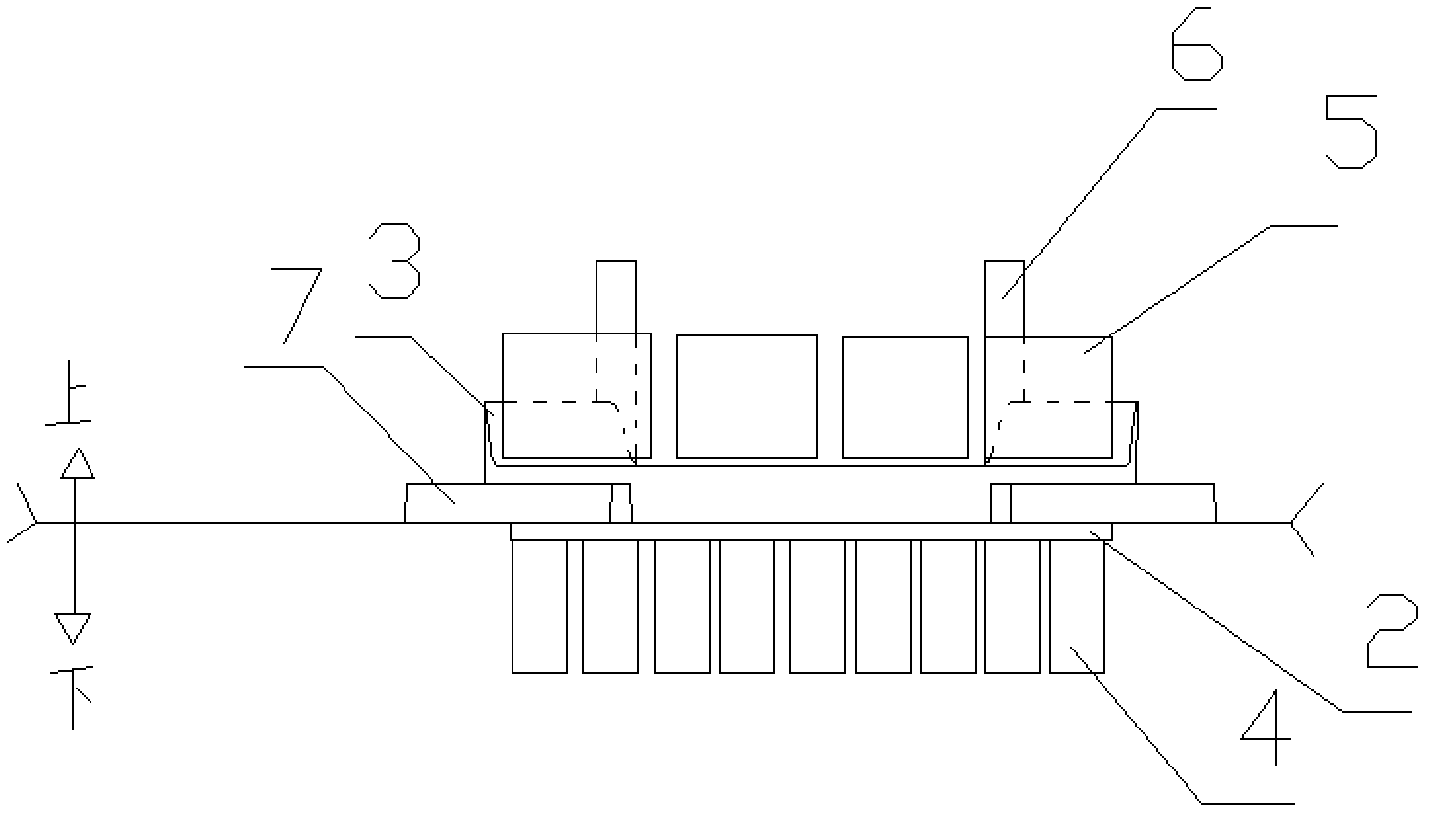

Preparation method of thermoplastic polyurethane beads and bead molding technology

The present invention discloses a preparation method of thermoplastic polyurethane beads and a bead molding technology. High foaming thermoplastic polyurethanes (TPU) beads are obtained through: melting and granulating TPU, melt viscosity modifiers, fillers and age resisters to prepare TPU co-blending granules; using clean, cheap, environmentally-friendly CO2 and / or N2 as foaming agents; and performing medium-temperature and high-pressure soakage, dissolution equilibrium, pressure relief and pre-foaming, saturated steam secondary foaming and other techniques. The obtained high foaming TPU beads are small in shrinkage ratio and smooth in surface. The invention further discloses the bead molding technology which uses a water vapor assisted mould pressing technology to prepare molded bodies of the TPU foaming beads, the prepared molded bodies of the TPU foaming beads are low in density, small in shrinkage ratio and uniform in surface texture, and also have an unique property of TPU resin. The TPU beads can be widely applied in the fields of vibration-absorptive materials, packaging materials, toys for children, sporting goods, aviation models, heat insulating materials, automotive interior materials, etc.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

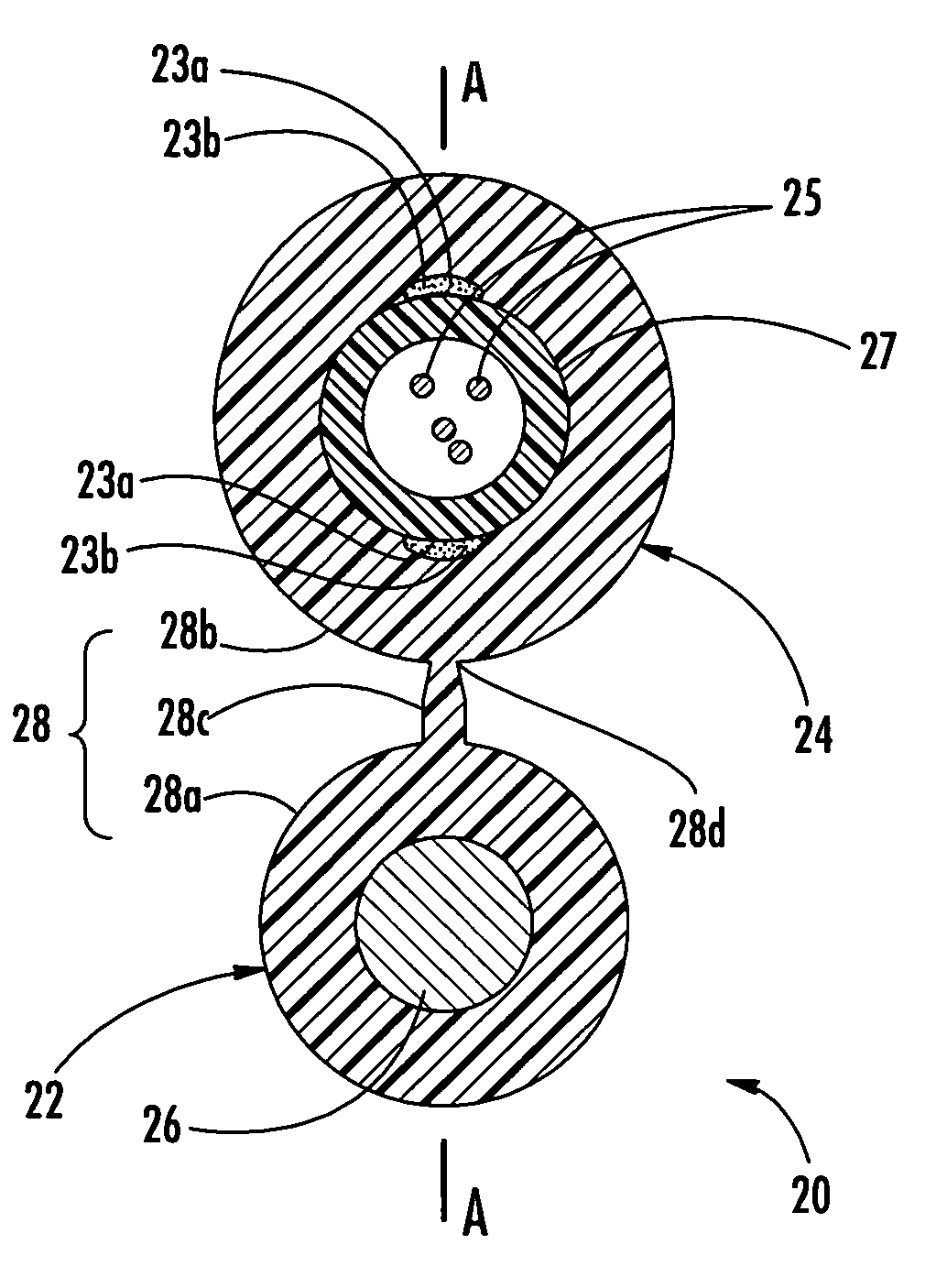

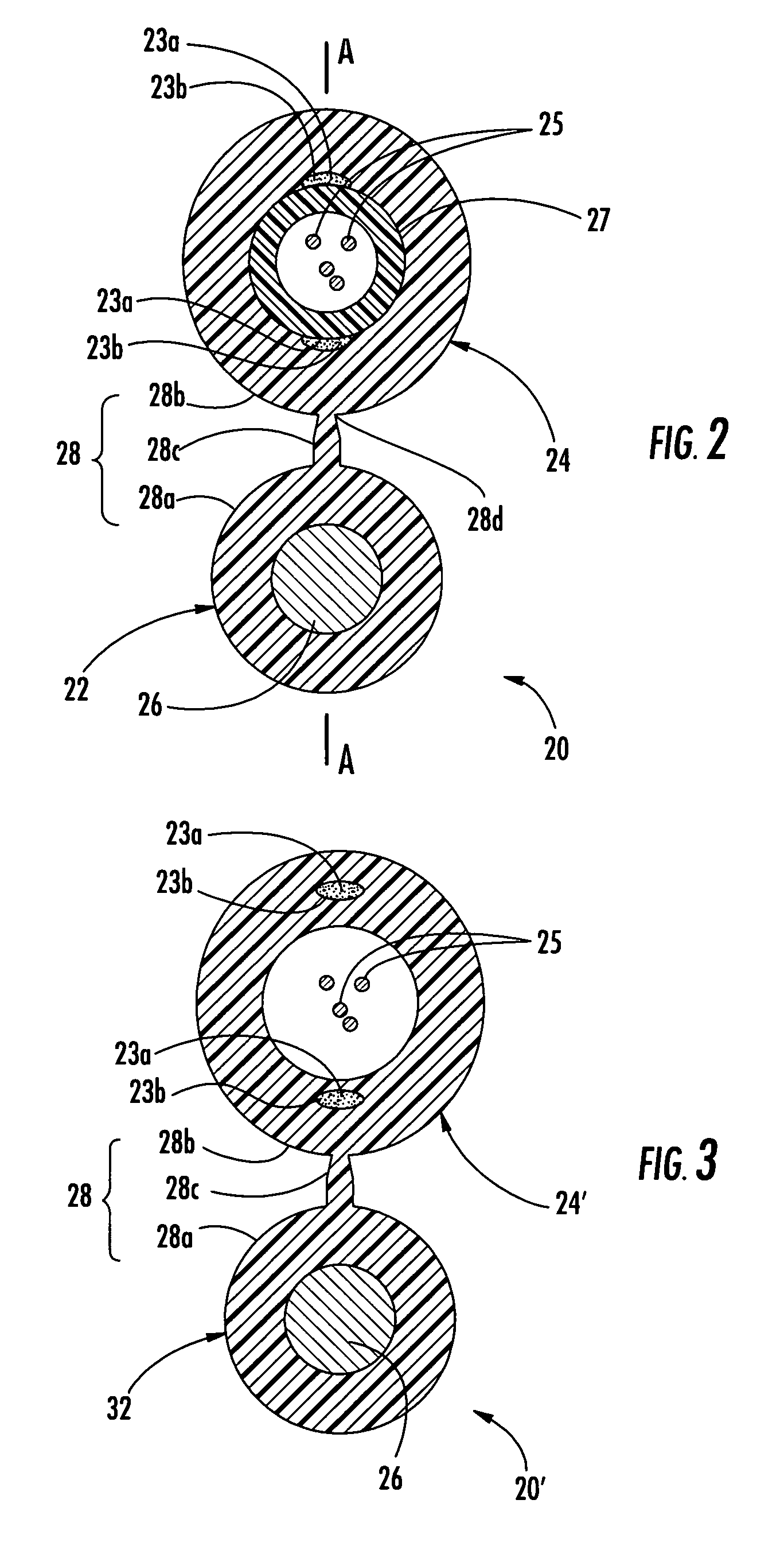

Fiber optic drop cables suitable for outdoor fiber to the subscriber applications

ActiveUS7035513B2Increase bending radiusLower Level RequirementsFibre mechanical structuresUltrasound attenuationFiber

A figure-eight fiber optic drop cable includes a messenger section and a carrier section connected by a web. The carrier section has at least one optical waveguide and at least one roving. In one embodiment, the carrier section has an average shrinkage of about 0.5% or less when separated from the messenger section during an average shrinkage test. Also the carrier section of the figure-eight fiber optic drop cable can have an average coefficient of thermal expansion (CTE) section after being separated from the messenger section of about 5.0×10−3% / ° C. or less for preserving optical performance. Furthermore, a maximum delta attenuation of the at least one optical waveguide during thermal cycling may be about 0.3 dB / 20 meters or less at a reference wavelength of about 1550 nm at a temperature of about −40° C. Other cable configurations are also possible with the invention.

Owner:CORNING OPTICAL COMM LLC

Inkjet recording sheet

InactiveUS20020176970A1Improve abilitiesGood ink absorptionCoatingsThermographyPolyvinyl alcoholAcyl group

Disclosed is an inkjet recording sheet having a colorant-receiving layer on the surface of its support, in which the colorant-receiving layer contains at least one of compounds represented by the following general formula (1) and compounds represented by the following general formula (2), and contains a vapor-phase-process silica, a polyvinyl alcohol, a boron compound, and a mordant. In the formulae, R represents a saturated hydrocarbon group having from 1 to 12 carbon atoms, an unsaturated hydrocarbon group having from 1 to 12 carbon atoms, a phenyl group, or an acyl group, and n indicates an integer of 1 to 3. <paragraph lvl="0"><in-line-formula>RO(CH2CH2O)nH (1) < / in-line-formula><paragraph lvl="0"><in-line-formula>RO(CH2CH(CH3)O)nH (2) < / in-line-formula>

Owner:FUJIFILM HLDG CORP +1

Method for evaporative pattern precise composite casting

InactiveCN101590513APrevent shrinkageAvoid shrinkage defectsFoundry mouldsFoundry coresSurface layerPolystyrene

The invention discloses a method for evaporative pattern precise composite casting. The method comprises the following steps: making a mould by polystyrene foam to form a casting system; coating a surface modifying agent on the surface of the mould; preparing a mould shell including a surface layer mould shell, a transitional layer mould shell and a back layer mould shell; taking the mould out after placing the mould in a pre-wetting agent for 2 to 3s, dipping the mould in a container filled with surface layer coating, turning the mould so as to evenly coat the mould, sprinkling zircon sand on the mould, and drying the mould for 4 to 6h to prepare a surface layer mould shell; dip-coating the surface layer mould shell by a transitional layer coating, sprinkling and drying the sand for 8 to 12h; preparing the transitional layer mould shell and the back layer mould shell by the similar method; sealing pulp by the back layer coating, and drying for 14 to 18h; roasting the mould at a temperature of between 950 and 1,050 DEG C, and keeping warm for 30 to 60min; and pouring the molten metal in the mould shell to form a casting. The method has the advantages of preparing the metallic mould without the conventional precise casting, saving processing time, lowering cost and simultaneously ensuring the product quality.

Owner:郑州神牛铸造有限公司

Aluminum silicon alloy series possessing granulated silicon phase and its process

The invention relates to an aluminum silicon alloy series possessing granulated silicon phase and its preparation process, wherein the alloy comprises the constituents of (wt%) Si 11.5-17.0, Cu 0.5-5.0, Mg 0.2-1.5, Ni 0.5-3.0, Mn 0.1-0.9, Zn<1.0, Fe<1.3, Ti 0.02-0.30, and balancing Al. The cast metallurgical structure consists of deteriorated or less-deteriorated aluminium-silicon eutecticevaporate and arborescent crystal form aluminium, and the heat treated metallurgical structure comprises aluminium matrix and adequately distributed granular silicon phase. The invention also discloses the process for preparing the alloy.

Owner:DONGHUA UNIV

Application of refractory brick in casting field

The invention relates to an application of a refractory brick in the casting field. The application of the refractory brick in the casting field provided by the invention has the advantages of low cost, long service life, obvious cooling effect and the like.

Owner:WUXI DEQIAN ENERGY EQUIP

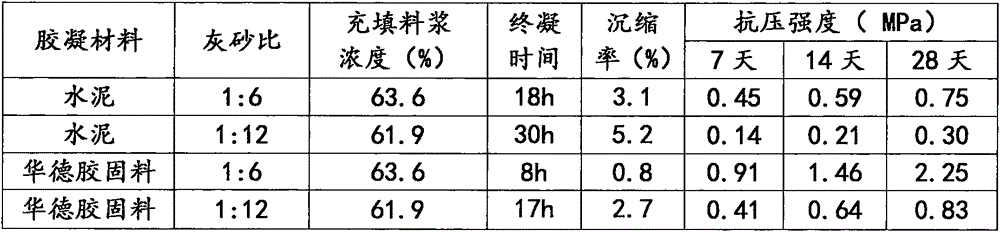

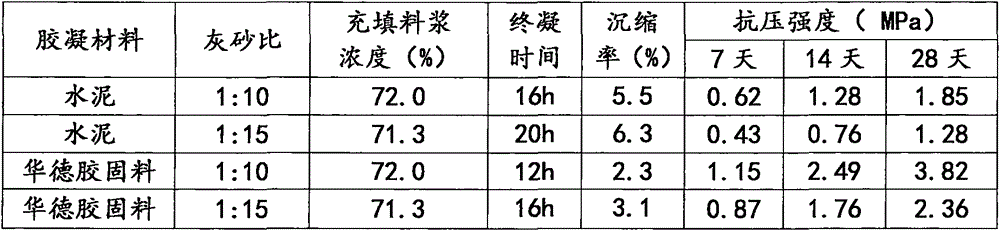

Low-shrinkage early-strength type mine filling cementing material

InactiveCN106746785AReduce surface tensionSmall shrinkageSolid waste managementCement productionGypsumSlag

The invention relates to a low-shrinkage early-strength type mine filling cementing material. The cementing material comprises the following components in percentage by weight: 50-90% of slag powder, 5-25% of cement or cement clinker, 1-30% of mineral additive, 0-10% of gypsum, 0.5-10% of alkali activator and 0.1-10% of shrinkage-reducing and cracking-resistant material. The invention solves the problem that fillers are prone to high shrinkage, cracking, slow setting and low strength when a slag-based alkali activation material is used for full tailing filling of a mine and the concentration of filling slurry is low especially in case of improper curing. The material is used instead of cement for mine filling, has favorable adaptability for tailings of different concentrations (55-80%), and has the advantages of fast filler setting, high strength and low shrinkage.

Owner:北京华德创业环保设备有限公司

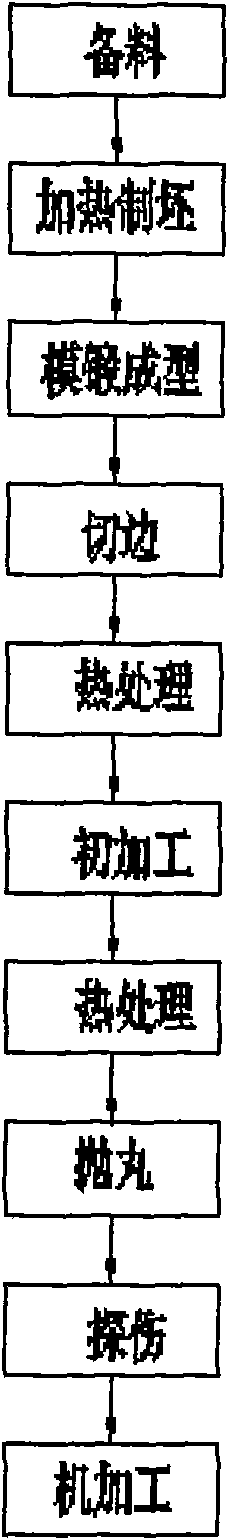

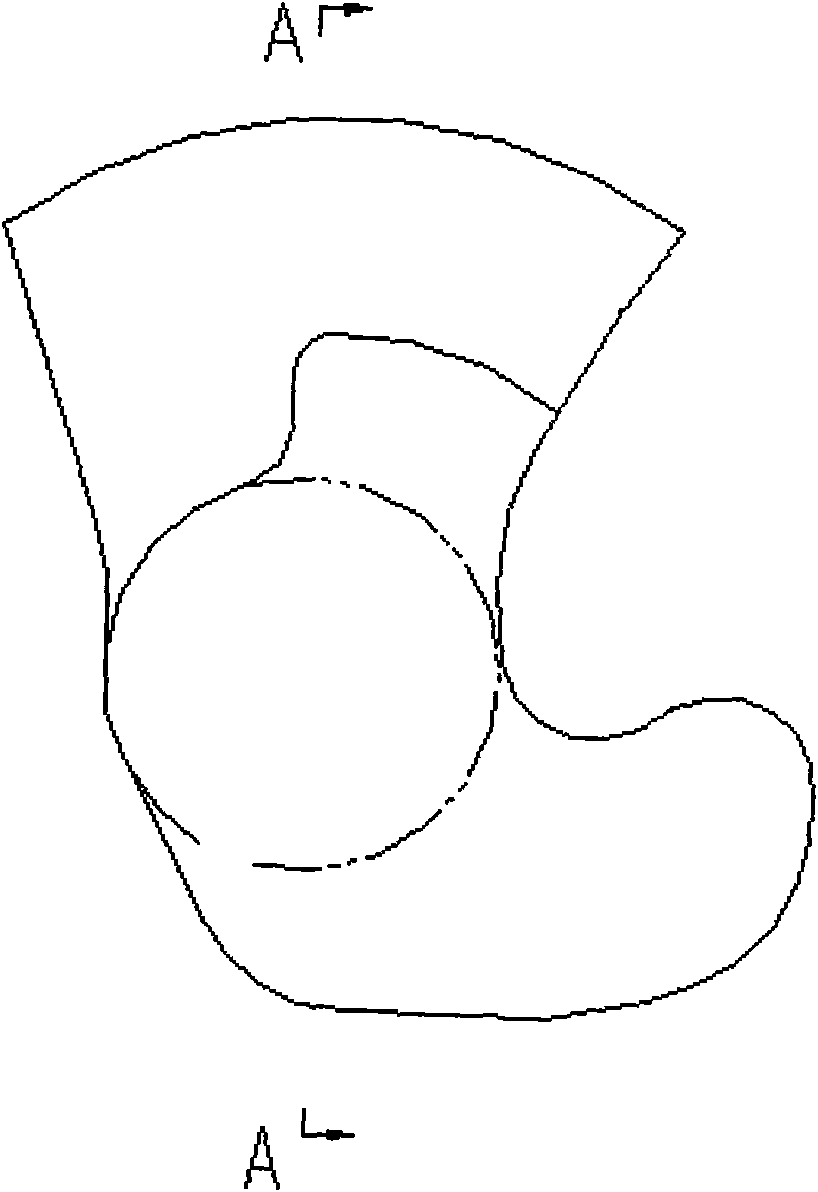

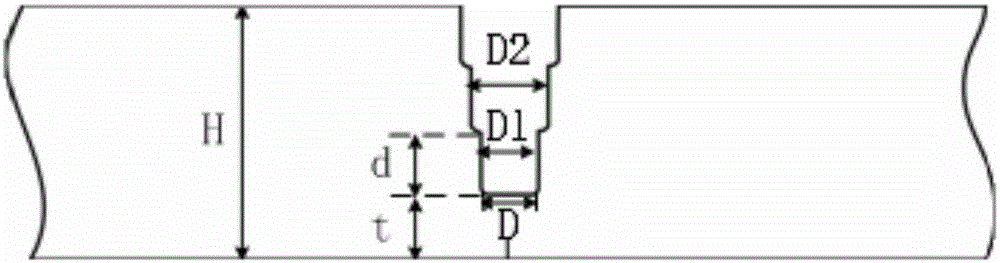

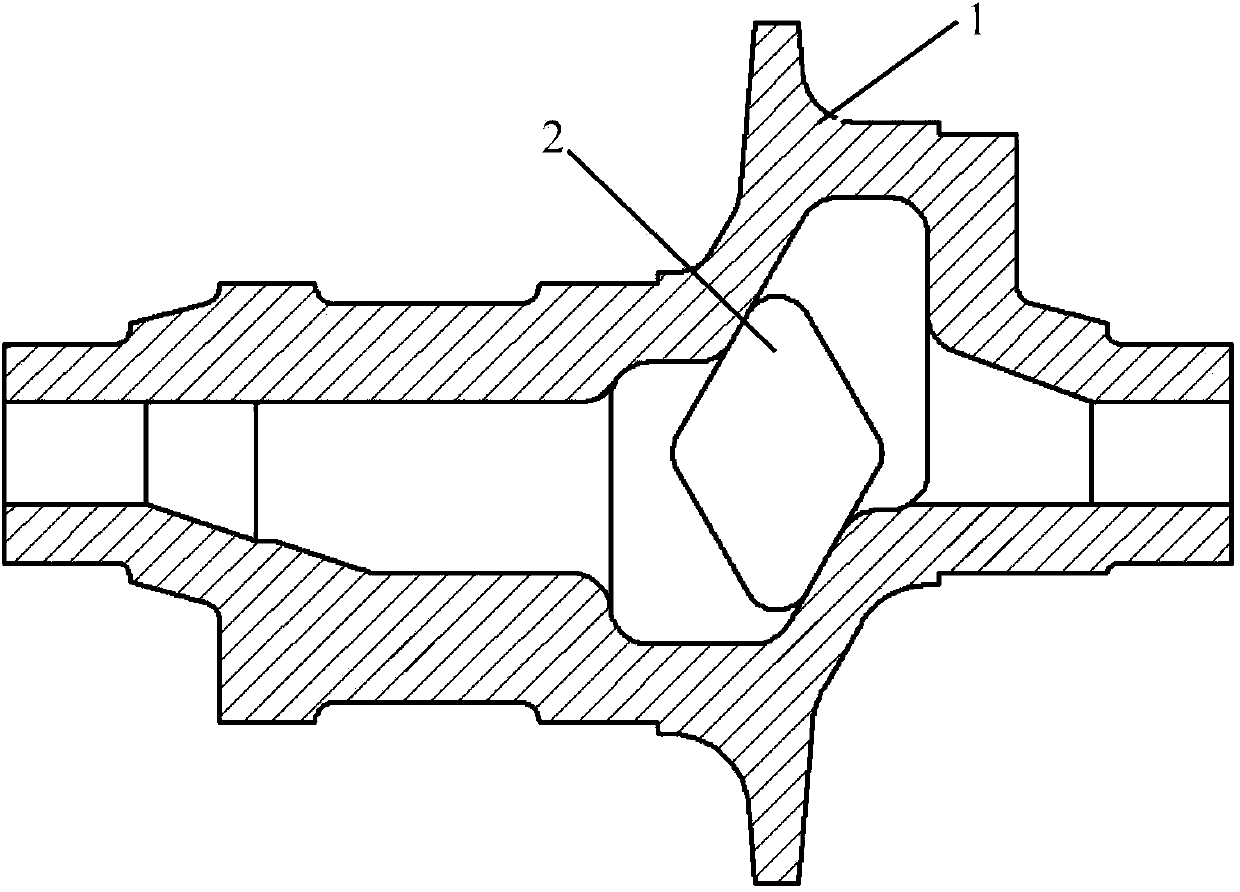

Forging method of coupler knuckle for railway vehicle

InactiveCN101559555AGood mechanical propertiesAvoid air holesOther manufacturing equipments/toolsMaterials preparationToughness

The invention discloses a forging method of a coupler knuckle for railway vehicles. The coupler knuckle for railway vehicles is formed by forging, and coupler knuckle products for railway vehicles with qualified performance and size are forged by the working procedures of material preparation, heating and blank forming, die forging and forming, trimming, heat treatment, preliminary processing, heat treatment, shot blasting, fault detecting and machining. The forging method of the coupler knuckle for railway vehicles, in which the coupler knuckle for railway vehicles has compact texture, high toughness and good fatigue performance, solves the defects of air pore, shrinkage porosity, inclusion, crack, short service life and the like of the coupler knuckle of the existing cast steel vehicle coupler.

Owner:CHONGQING CHANGZHENG HEAVY IND

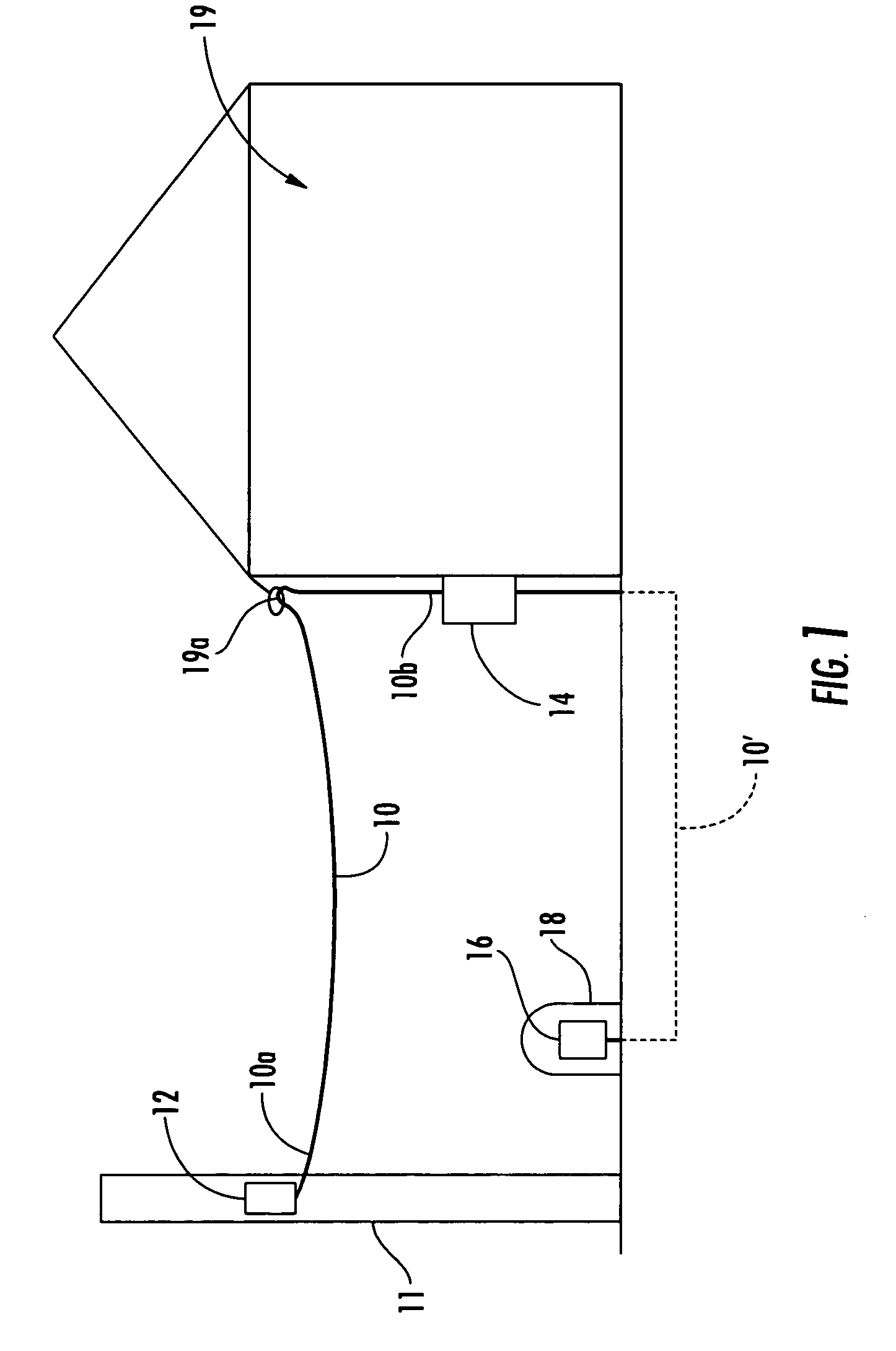

Fast clothes dryer and drying method

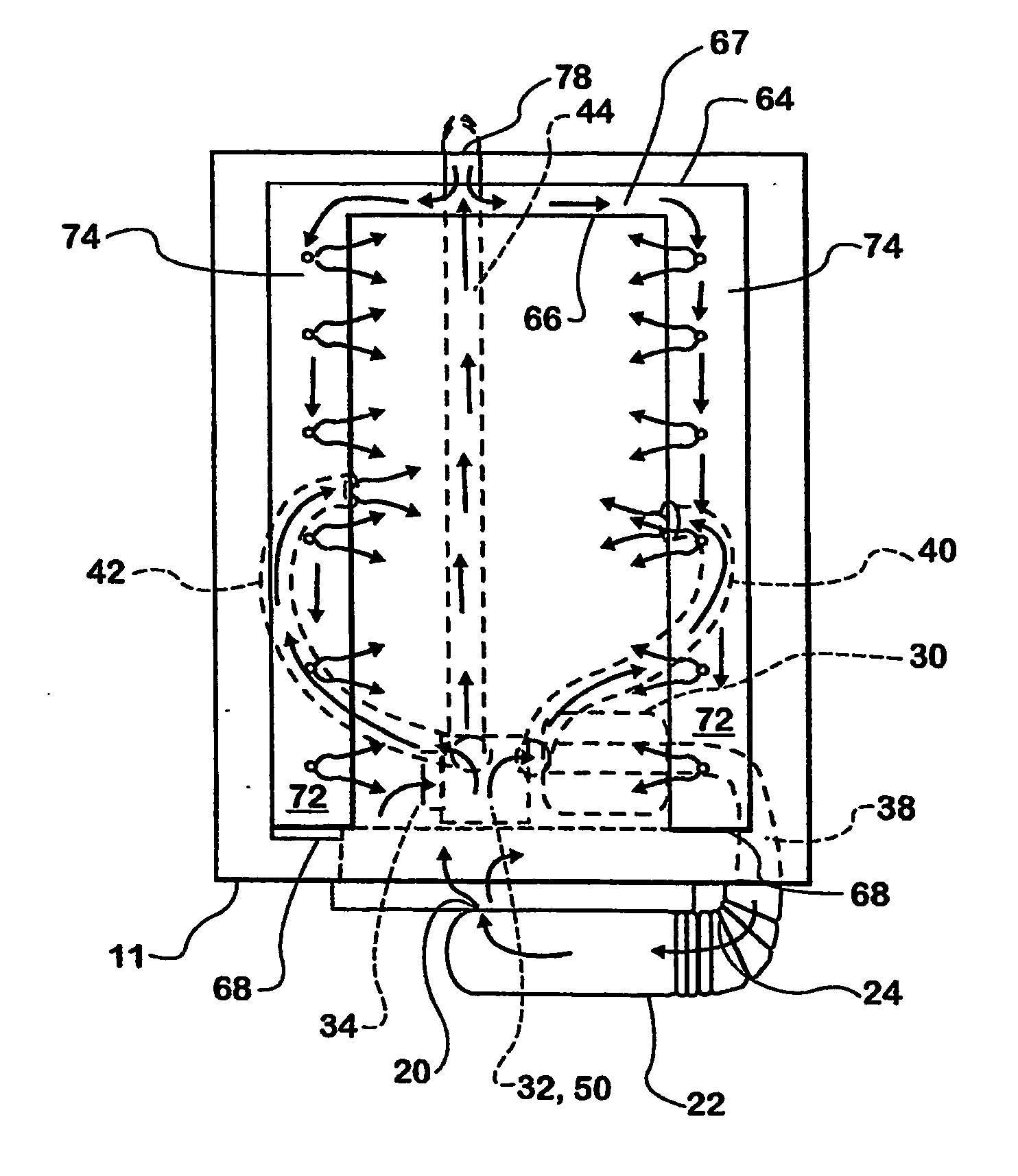

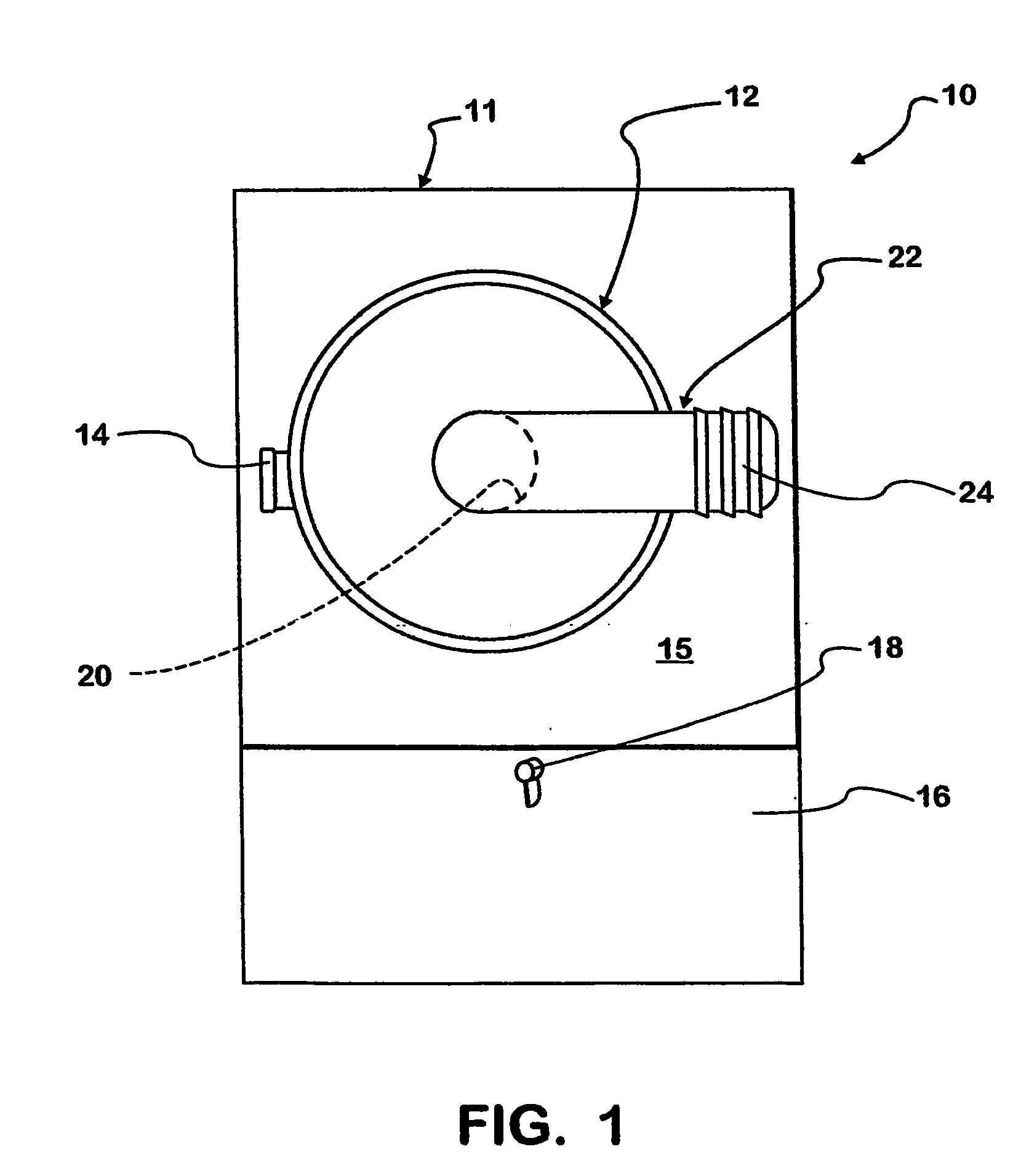

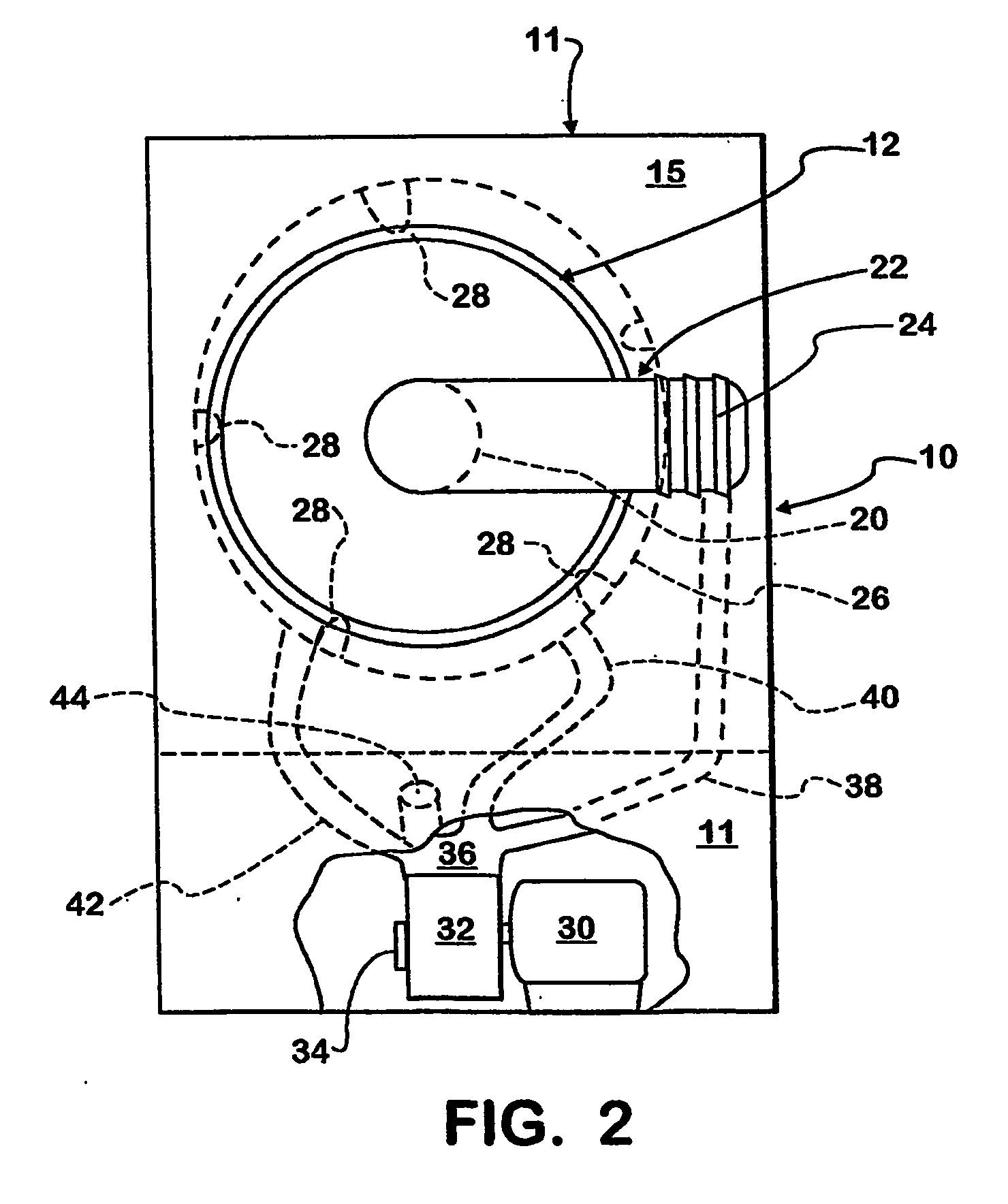

InactiveUS20060254082A1Shorten the timeShorten drying timeDrying machines with non-progressive movementsTextiles and paperCold airEngineering

A fast clothes dryer (10) is provided and has a blower (32) located after the dryer lint trap (19) to recover air, boost its velocity and then distribute it throughout the dryer, includes the dryer door (12), dryer fins (28) and dryer circumference. If additional drying is desired, the recovered air can be dehumidified before it is distributed throughout the dryer (10). The inclusion of just one of these features, the air flow through the dryer door (12) can cut drying time from say 20 minutes to 15 minutes, with less wrinkling. The dryer and method use cold air to dry clothes without shrinkage, and to avoid tumbling at initial stages of drying. The clothes may be initially dried at a warm temperature and at a speed high enough to prevent mechanical tumbling for a first period (say 20 minutes) using rotation first in one then the other direction. Then, when partially dry, cold dehumidified air is used with a lower drum rotation speed to permit very gentle tumbling with the drum rotation varying In directions for a second period of say 15 minutes. Thereafter, the clothes may be normally dried at a normal temperature and medium drum speed until done, say for another 10 to 15 minutes.

Owner:KIM SU HEON

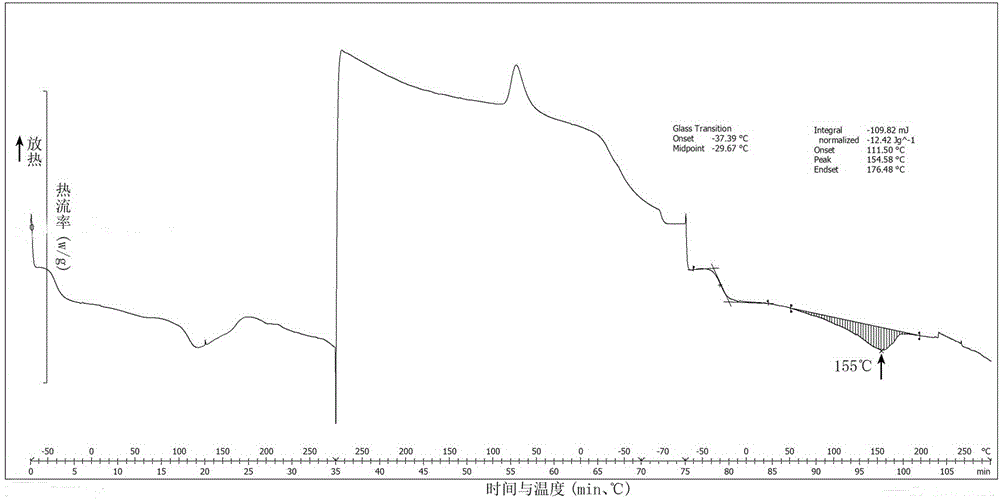

Diaphragm, preparation method of diaphragm and lithium ion battery

ActiveCN104157810AImprove heat resistanceNot easy to fall offSecondary cellsCell component detailsPolymer sciencePolymer substrate

A separator and a method for preparing the separator are provided. The separator includes a polymer substrate,a ceramic layer provided on the polymer substrate and an infiltration part formed between the polymer substrate and the ceramic layer. The polymer substrate contains a base polymer and a first curing resin. The infiltration part has at least a portion infiltrated into the polymer substrate. Each of the infiltration part and the ceramic layer independently contains ceramic particles and a second curing resin.A battery including the separator is also provided.

Owner:BYD CO LTD

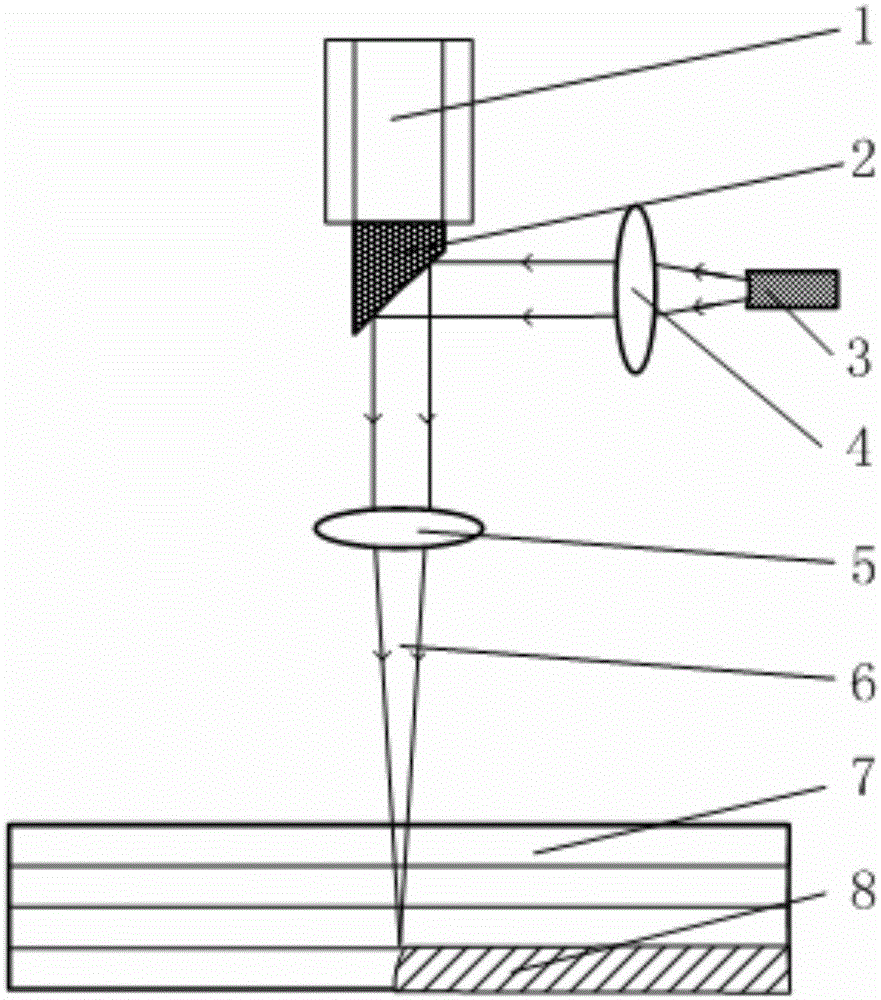

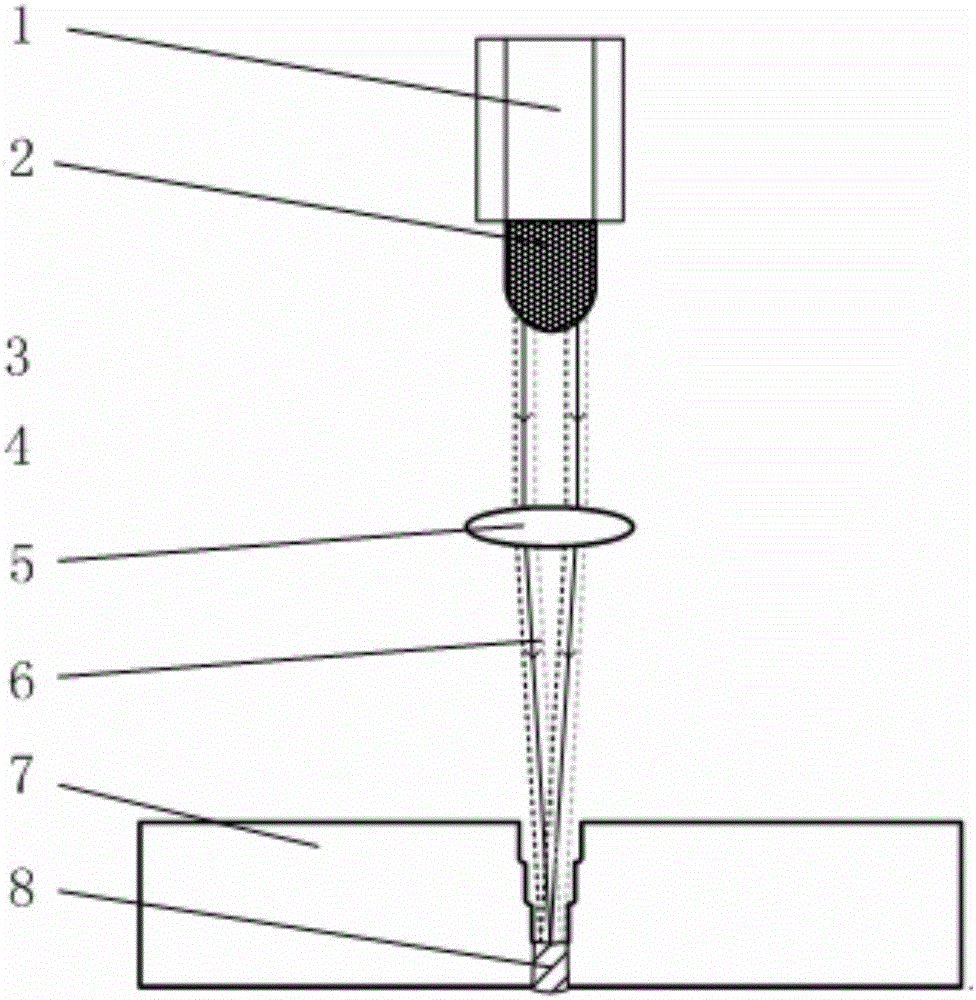

Narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials

InactiveCN105149786ASimplify the welding processPrecise control of single layer fill heightWelding/soldering/cutting articlesMetal working apparatusLaser processingThick plate

The invention belongs to the technical field of laser processing, and particularly relates to a narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials. The method aims at solving the problems that in the thick plate welding process, wire filling is difficult, and molten drop transition is not stable. According to the narrow-gap laser-scanning multi-layer self-melting welding method based on a prefabricated filling layer, a laser scanning welding technology and narrow-gap multi-layer filled welding are skillfully combined, therefore, a laser wire filling multi-layer welding mode for thick plate structure parts is converted into a laser self-melting multi-layer welding mode, and the single-layer filling height of a weld joint in a narrow-gap groove can be precisely controlled; due to the fact that the prefabricated filling layer can prevent the weld joint from shrinking, welding deformation can be further reduced, the thick plate welding process is greatly simplified, and the welding efficiency and the welding quality are improved. The method is suitable for narrow-gap laser welding of thin plates or thick plates of different thicknesses.

Owner:HARBIN INST OF TECH

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

Alkaline battery separator and alkaline primary battery

ActiveUS20090017385A1Avoid areaDenseness is improvedCell component detailsDry cellsPolymer scienceOrganic solvent

An alkaline battery separator comprising an alkali-resistance synthetic fiber, a fibrillated organic solvent-spun cellulose fiber having a Canadian standard freeness value of 10 to 280 ml, and a mercerized pulp having a Canadian standard freeness value of not less than 550 ml is prepared. In the separator, the proportion of the alkali-resistance synthetic fiber, the proportion of the fibrillated organic solvent-spun cellulose fiber, and the proportion of the mercerized pulp relative to the total amount of the separator are respectively 25 to 62% by mass, 5 to 25% by mass, and 33 to 50% by mass, provided that the total amount of the separator is 100% by mass. The alkali-resistance synthetic fiber may comprise a polyvinyl alcohol-series fiber having an average fiber fineness of not more than 1 dtex. The alkaline battery separator may further comprise a polyvinyl alcohol-series binder in a proportion of 3 to 20% by mass relative to the total amount of the separator. The alkaline battery separator of the present invention may have a shrinkage by the area of not more than 3.5% after immersing in an aqueous solution of potassium hydroxide having a concentration of 40% by mass at 80° C. for 24 hours and a stiffness strength of not less than 2 N.

Owner:KURARAY CO LTD

Process for casting thick and large nodular cast iron valve plate

The invention provides a process for casting a thick and large nodular cast iron valve plate. The process comprises the following steps of: (1) manufacturing a mould; (2) manufacturing a casting mould and a sand core; (3) drying and integrating; (4) smelting; (5) pouring; and (6) shaking out and cleaning. In the process, a large number of external chilling blocks and sand separation chilling blocks are used on upper and lower surfaces of a casting for chilling, appropriate placing positions and thickness are selected, and shrinkage cavity and shrinkage porosity of the casting are effectively avoided; meanwhile, a good graphite balling state is ensured by quickly chilling, a feeding head is avoided, the casting is easy to clean, 5 percent of molten iron using amount is saved, and production cost is reduced; a semi-closed casting system is adopted by a casting system, an ingate is uniformly distributed around the casting mould, and the casting mould is slightly scoured, and a good residue stopping effect is achieved; and under the action of chilling of chilling blocks, the thick and large nodular cast iron casting which is smelted by a cupola furnace is good in moulded surface, and meets production requirements, offscourings and sand are avoided, and process yield is improved by 5.9 percent.

Owner:TIJIN YIJI MACHINERY

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

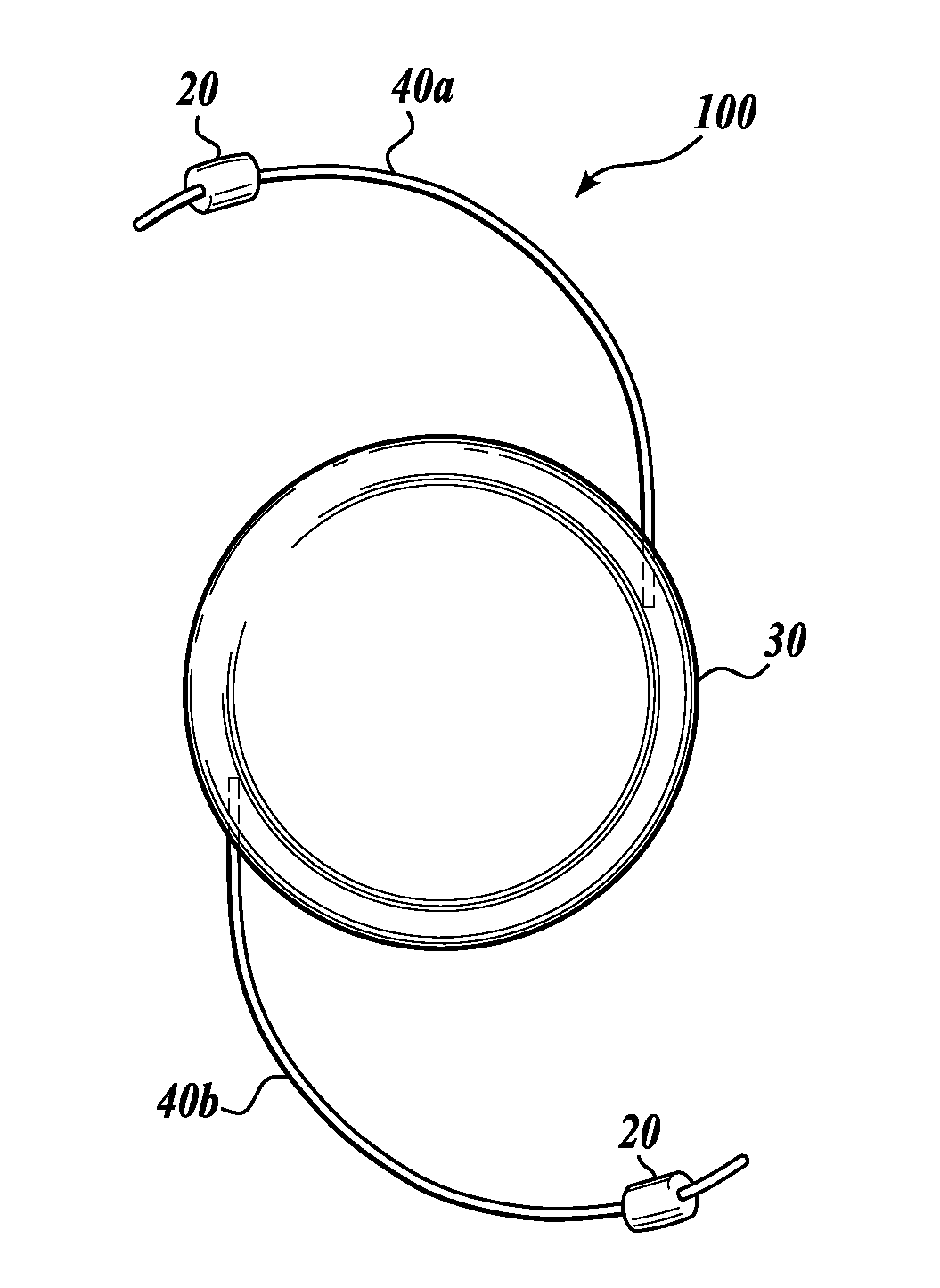

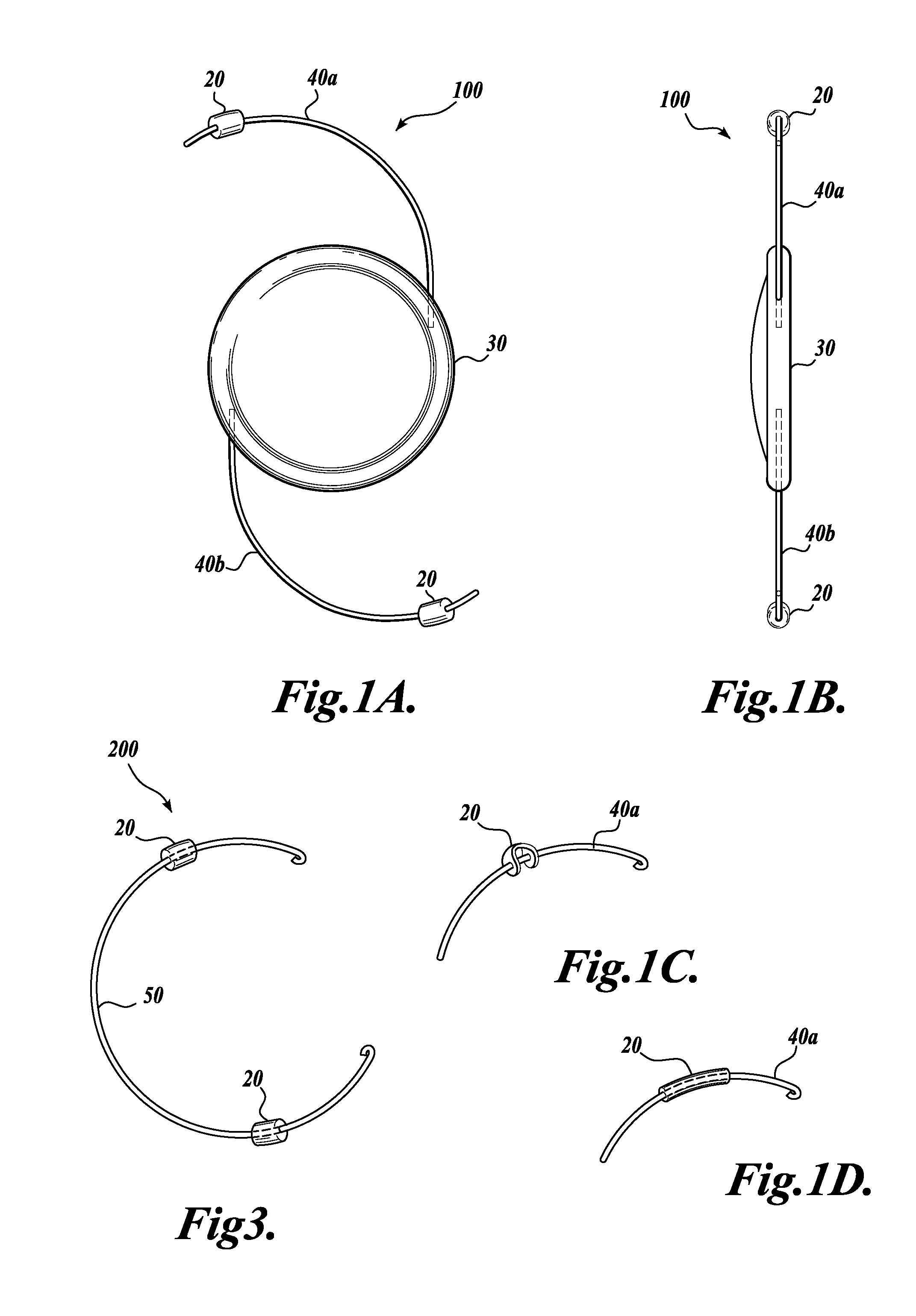

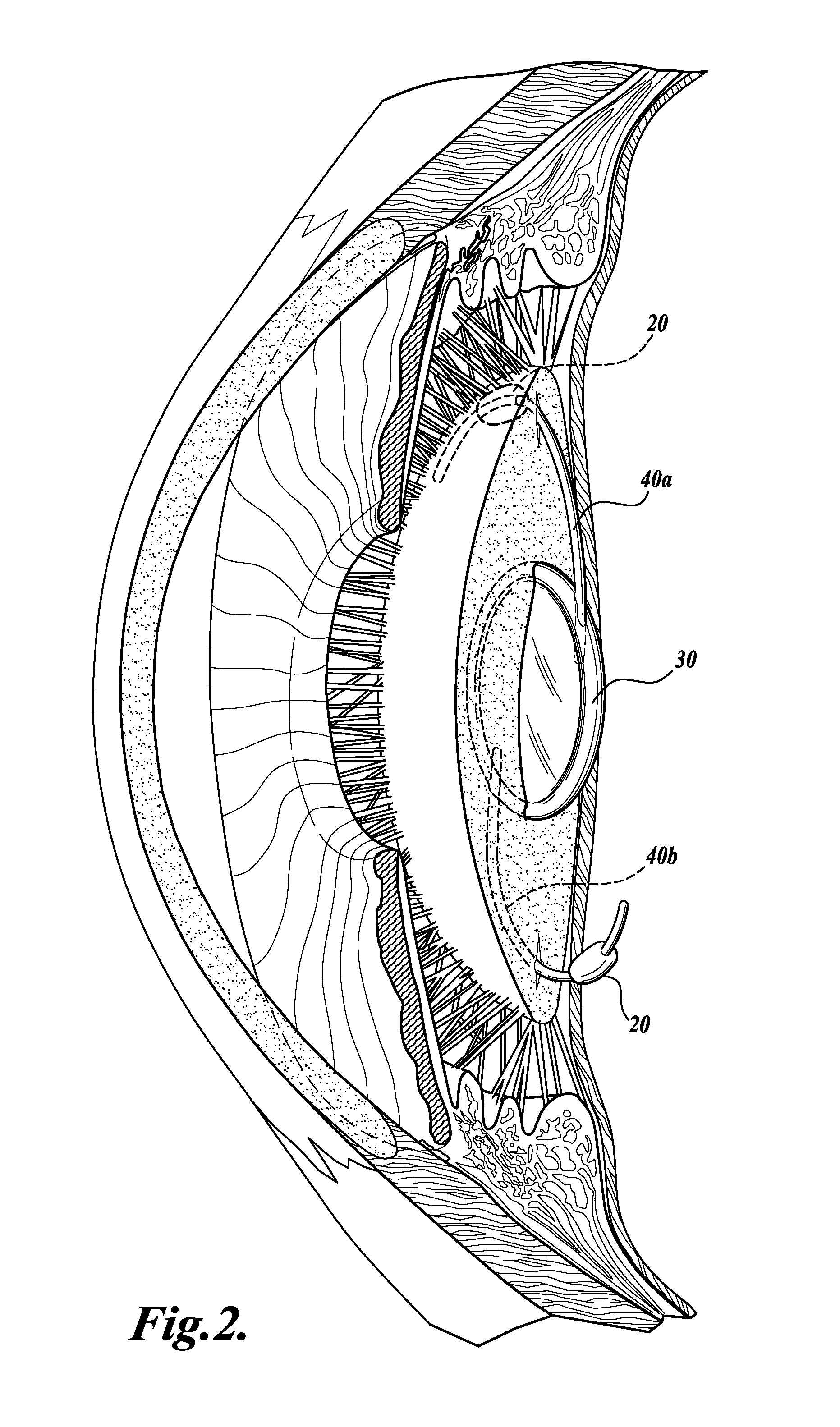

Device and method for intraocular drug delivery

InactiveUS20100074942A1Prevent shrinkagePharmaceutical delivery mechanismCarbohydrate active ingredientsOphthalmologyDrug delivery

Owner:UNIV OF WASHINGTON

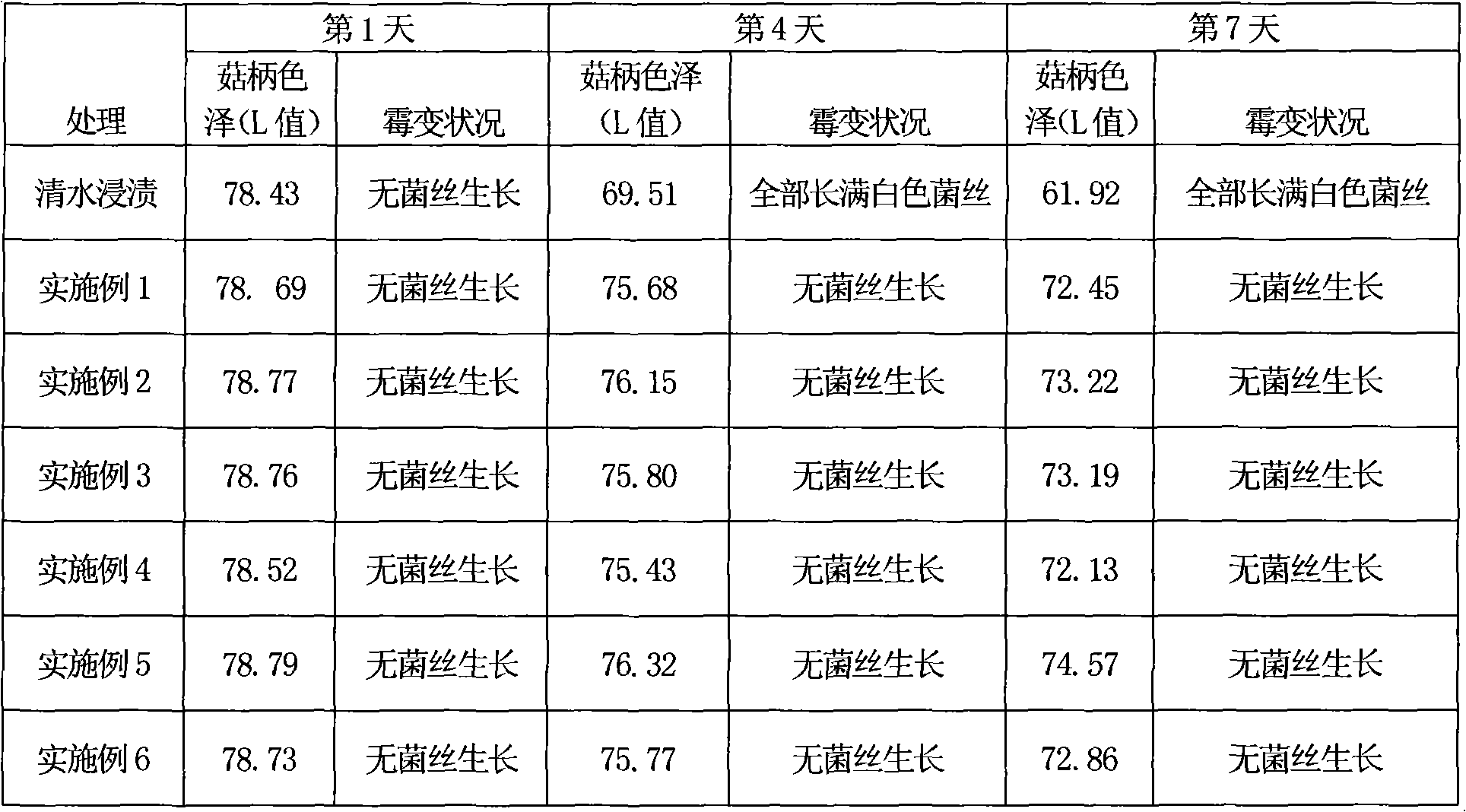

Disinfection antistaling agent containing vinegar liquid for plant and uses thereof

InactiveCN101263828AInhibitory activityAvoid gas exchangeBiocideFruit and vegetables preservationMaterial resourcesBiology

The invention relates to a sterilization and fresh-keeping agent containing the plant vinegar fluid and the application thereof, belonging to the sterilization and fresh-keeping agent technical field, which is characterized in that the sterilization and fresh-keeping agent comprises from 50% to 80% of plant vinegar fluid, from 10% to 19% of low residue germicide, from 4% to 12% of sticking agent, from 3% to 15% of mould proofing antisepsis color fixative, and from 3% to 6% of potentiating agent. The sterilization and fresh-keeping agent has the advantages of utilizing the purely natural and strong anti-pest activity vinegar as the active component, compositing the minor chemical agent, having functions of fresh-keeping, sterilization, color fixing, and strong inhibition to the bacteria, mould, and yeast, enabling to prevent the pathogeny objects from ingression, lowering the water in the fruit and vegetable to evaporate and avoiding to shrink, blocking the gas exchange of the fruit and the vegetable, decreasing the breathing intensity, restraining the activity of the enzyme inside the fruit and the vegetable, decelerating the lowering speed of the sugar acid content, extending the storage life of the fruit and vegetable. The processing method for the sterilization and fresh-keeping agent has the advantages of simple process, less equipment investment, rich material resource, higher yielding rate, energy saving, safe storage and transportation, and low production cost.

Owner:ZHEJIANG FORESTRY UNIVERSITY

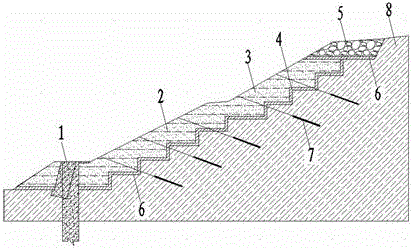

Expansive soil road cutting side slope reinforced soil back-pressure seepage-preventive supporting structure and construction method thereof

The invention provides an en expansive soil road cutting side slope reinforced soil back-pressure seepage-preventive supporting structure and a construction method thereof. The supporting structure comprises an expansive soil road cutting side slope, a slope toe retaining structure is arranged at the toe of the slope, a geomembrane seepage-preventive structure, a reinforced soil slope surface protection structure and an anchor rod system are arranged on the surface of the slope, and a slope top back-pressure seepage-preventive structure is arranged at the top of the slope. The supporting structure is simple in form, the protection structure is high in flexibility and short in construction period, the problems of stability and construction period of an expansive soil high slope can be solved effectively, and the supporting structure is an innovation for high and steep expansive soil road cutting side slope excavation scheme and supporting technology in the field of railway engineering.

Owner:KUNMING SURVEY DESIGN & RES INST OF CREEC

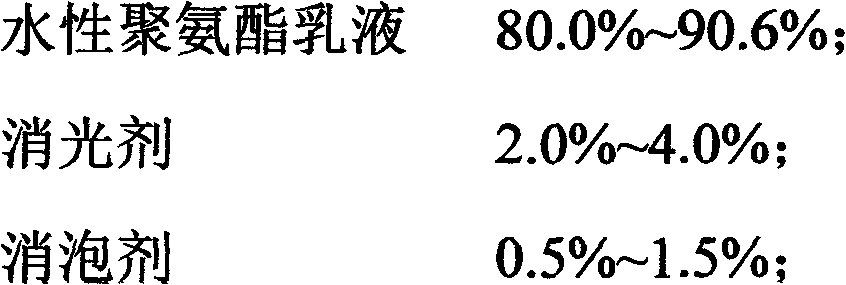

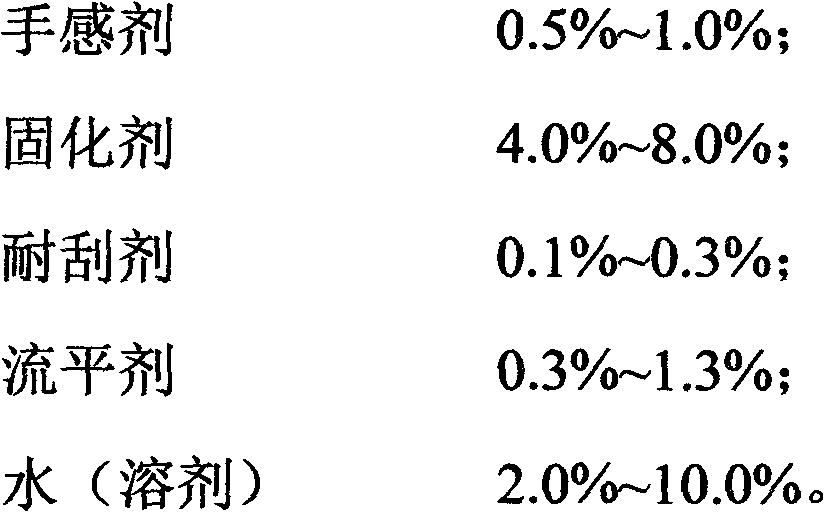

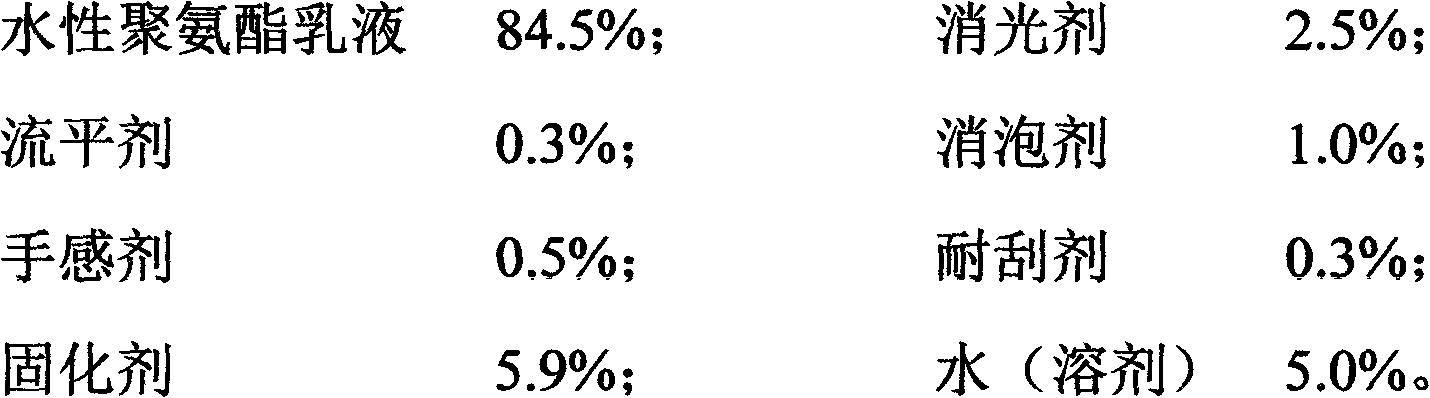

PVC (polyvinyl chloride) decorative film surface treating agent, PVC decorative film treated with same and preparation method thereof

InactiveCN102702953AGood PVC adhesionImprove smoothnessOrnamental structuresSpecial ornamental structuresWater basedEmulsion

The invention discloses a PVC (polyvinyl chloride) decorative film surface treating agent and a PVC decorative film treated with the same. The surface treating agent comprises the following components in percentage by weight: 80.0-92.0% of water-based polyurethane emulsion, 2.0-4.0% of flatting agent, 0.5-1.5% of defoaming agent, 0.5-1.0% of hand feeling agent, 4.0-8.0% of curing agent, 0.1-0.3% of scraping inhibitor, 0.3-1.3% of leveling agent and 2.0-10.0% of water. The PVC decorative film treated with the surface treating agent has the advantages of excellent matte performance, scraping resistance, favorable compatibility with other decorating materials, and the like, and feels soft.

Owner:FOSHAN TIANJIN PLASTICS

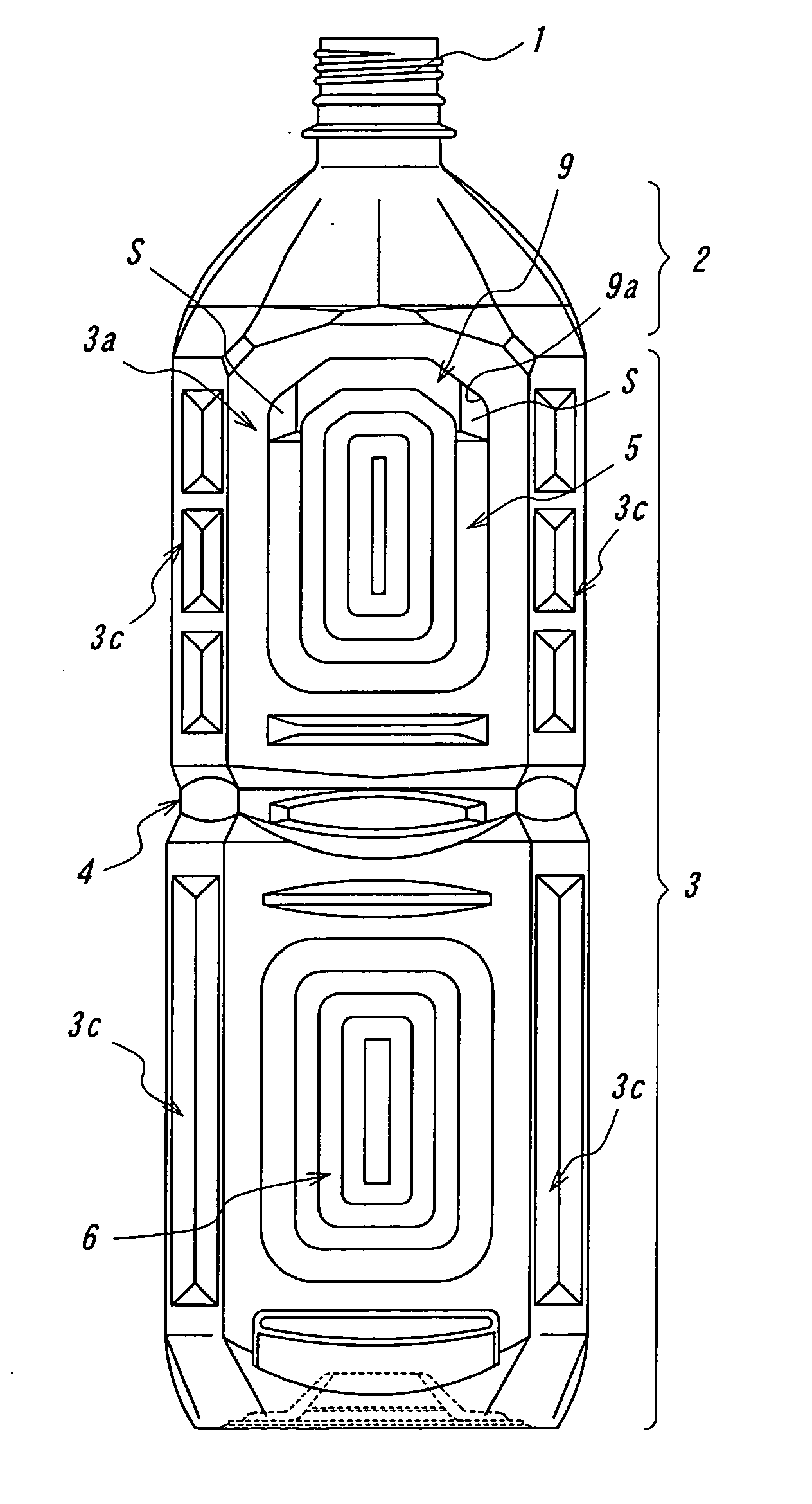

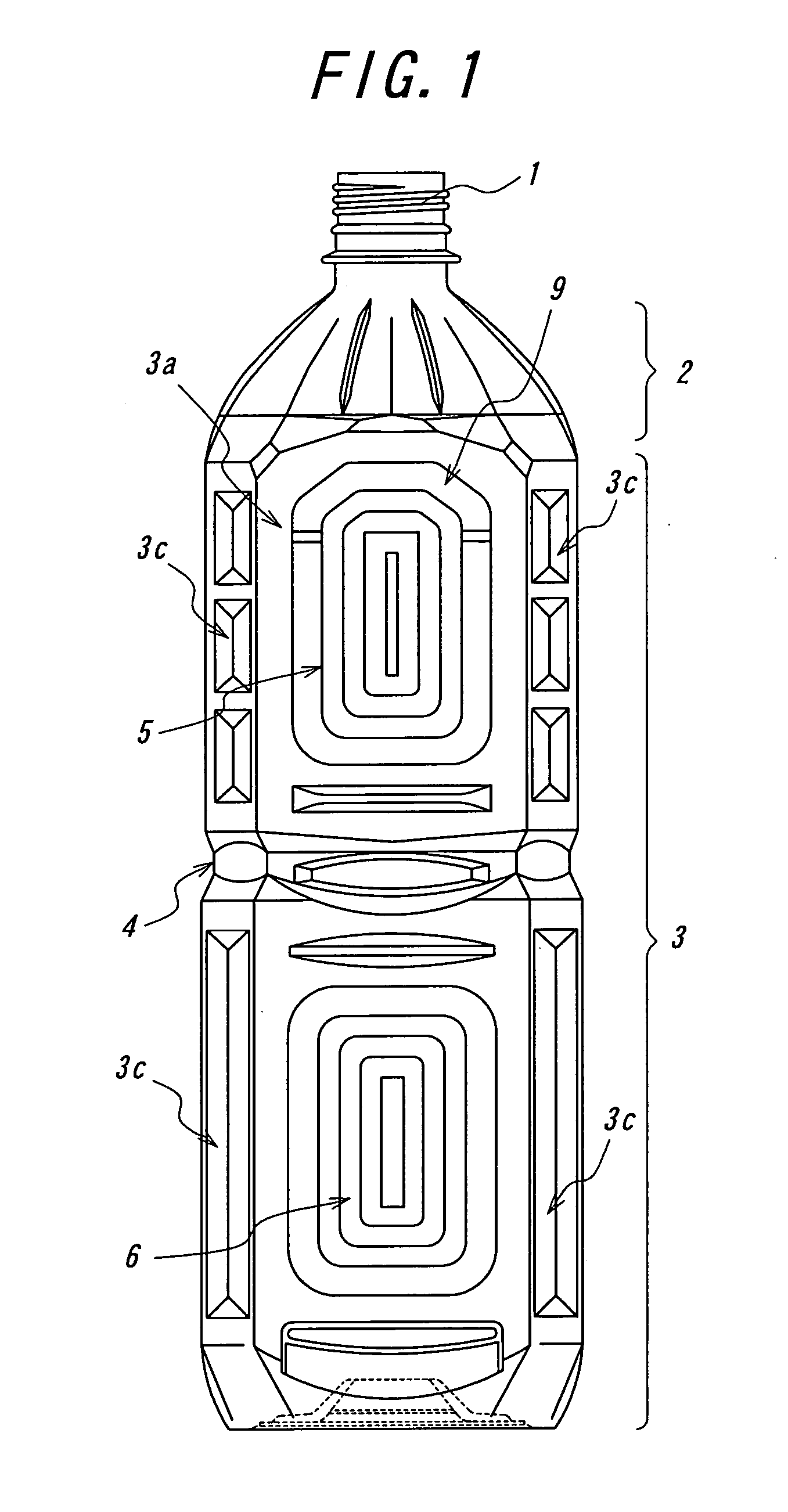

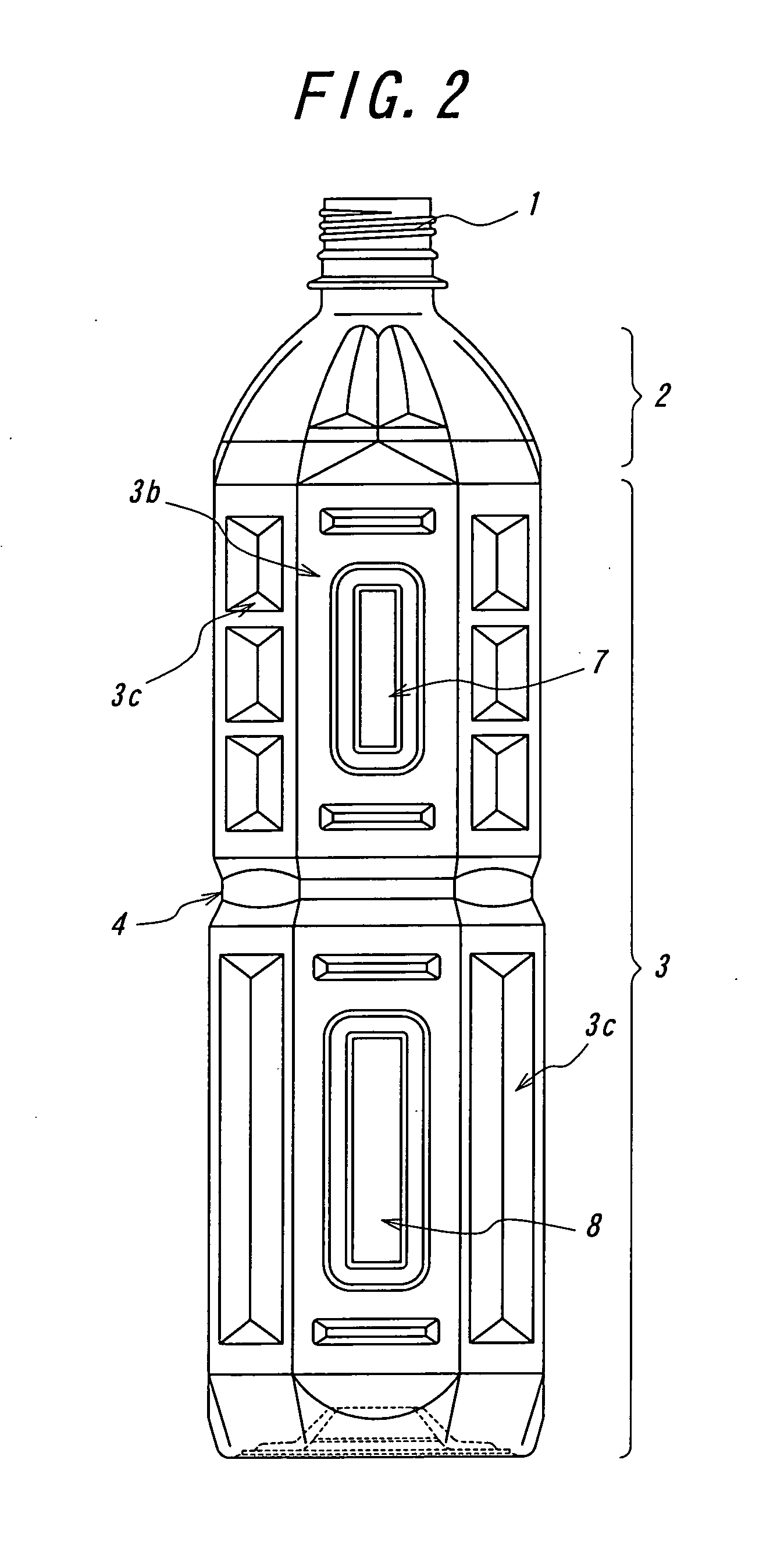

Synthetic resin bottle-type container

ActiveUS20060054587A1Avoid deformationPrevent shrinkageBottlesLarge containersEngineeringPressure reduction

A synthetic resin bottle-type container includes a shoulder portion continuous with a mouth portion through which contents can be poured out, and a body portion forms a space for accommodating the contents over an area extending to its bottom wall from the shoulder portion. The body portion includes pressure-reduction absorbing panels defined by at least one groove that projects inwards of the container. For preventing the shoulder portion from deformation due to the absorption of the pressure-reduction, the groove for the pressure-reduction absorbing panel immediately below the shoulder portion is provided with a recess extending along the groove and having a depth larger than that of the groove.

Owner:YOSHINO KOGYOSHO CO LTD

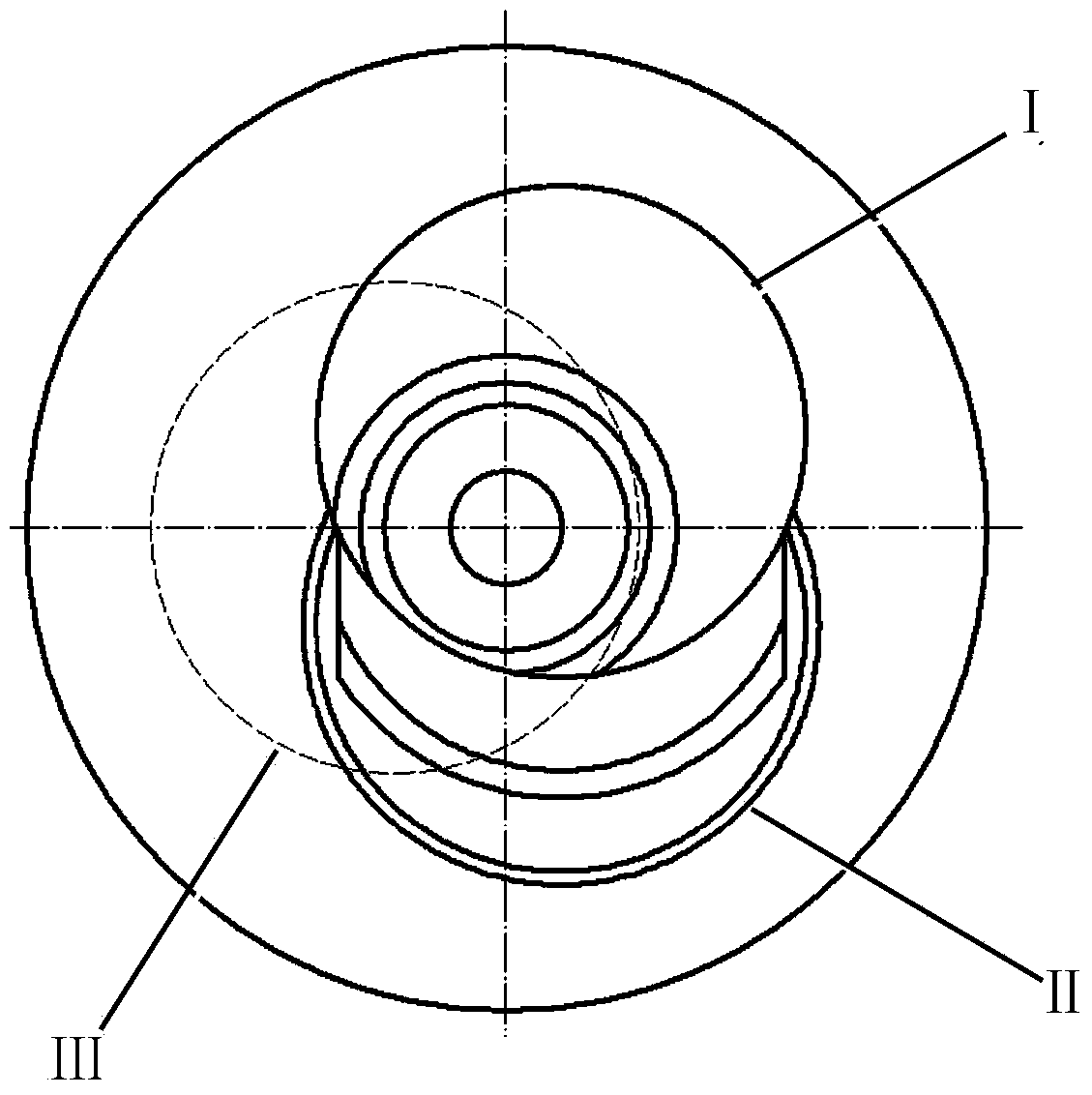

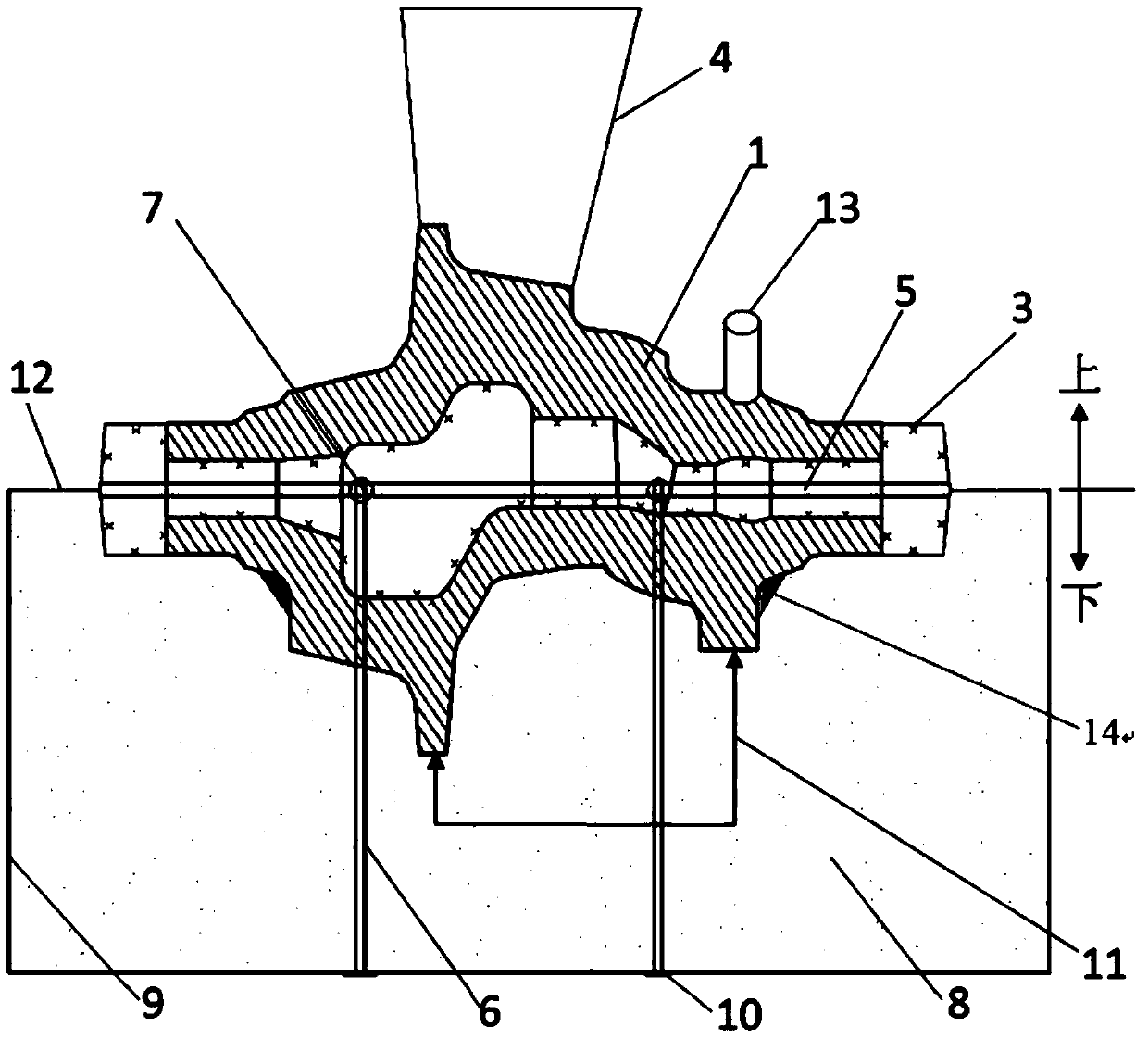

Casting method of hollow crankshaft of slurry pump

ActiveCN103624218APrevent core breakage or deformationImprove the qualified rate of flaw detectionFoundry mouldsFoundry coresRebarSlag

The invention discloses a casting method of a hollow crankshaft of a slurry pump. A casting model is utilized. The casting method comprises the following steps: manufacturing an actual sample and a core box of the hollow crankshaft; installing a sand discharge box, a large open riser, a slag collector and a pouring channel, opening open and hidden air holes in a sand mold, and arranging anti-cracking ribs in a turning part I and a turning part III; manufacturing a sand core and a core head mold body, manufacturing a core bar main rod, forming two groups of via holes in the core bar main rod, and welding a steel round positioning ring in each via hole; welding multiple reinforcing supports on the core bar main rod by reinforcing steel bars, winding a straw rope and a gas exhaust rope on the core bar main rod, putting a core bar into the core box, and filling sand for hardening; spraying paint; assembling the box; pouring; opening the box and spraying sand; polishing and repairing; normalizing; carrying out secondary sand spraying; and processing shaft holes in two end heads of the hollow crankshaft, thereby casting the hollow crankshaft of the slurry pump. The method provided by the invention can effectively prevent the structure defect of shrinkage cavity or shrinkage porosity partially.

Owner:BAOJI PETROLEUM MASCH CO LTD

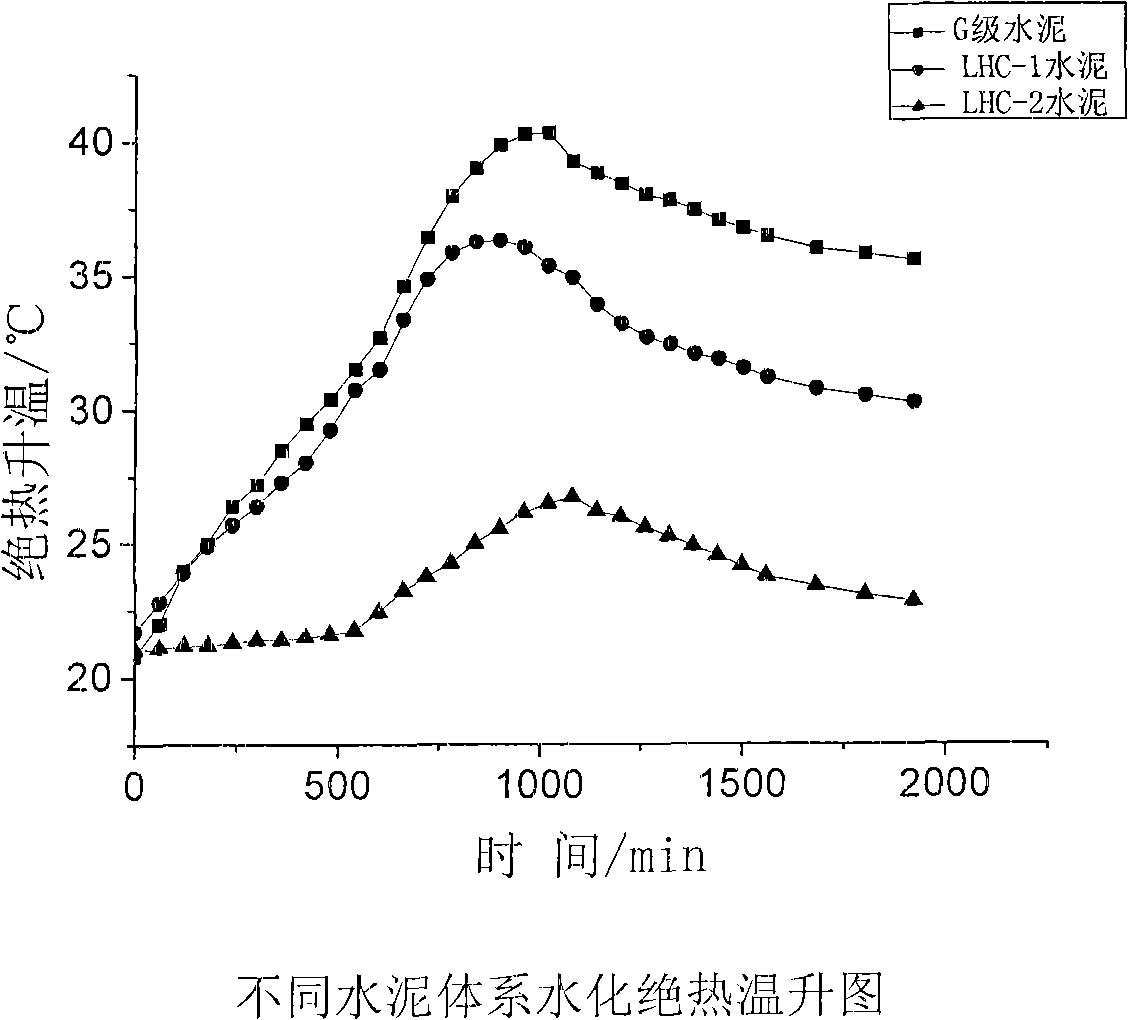

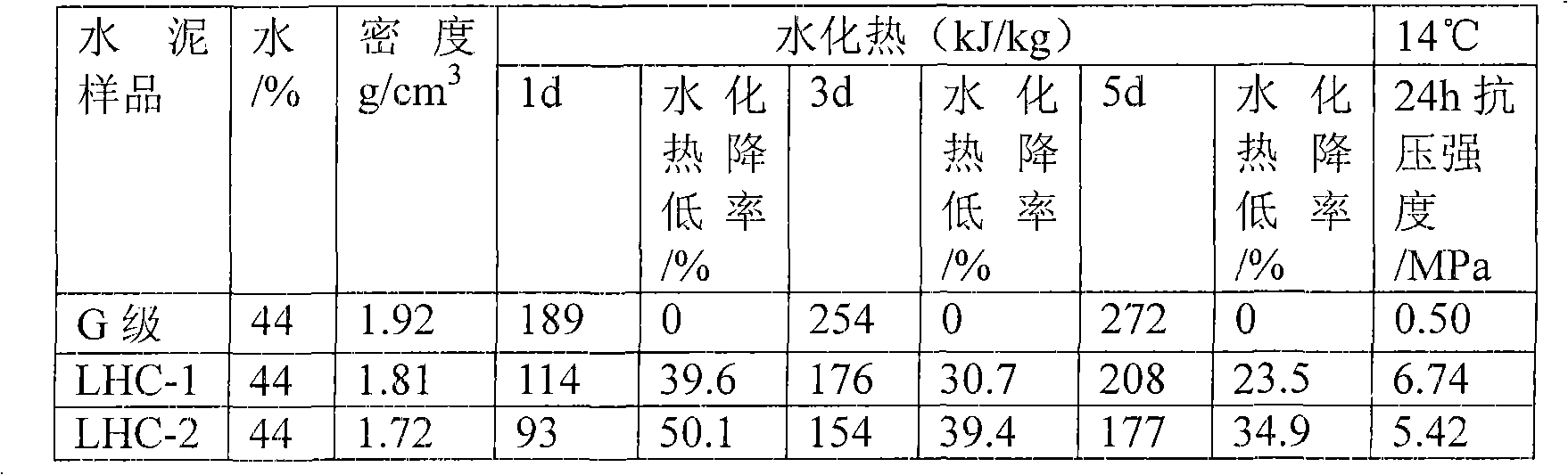

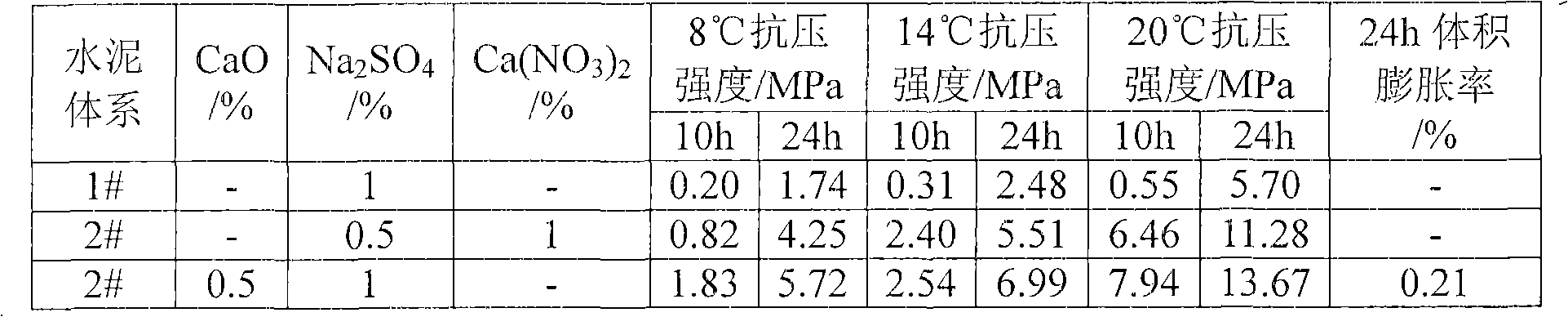

Low temperature low hydration heat cementing cement system

InactiveCN101328050AImprove performanceAvoid thermal decompositionSolid waste managementDrilling compositionSlagHydrate decomposition

The invention relates to a low temperature and low hydration heat cementing concrete system used in the natural gas hydrate layer cementing field. The objective of the invention is to effectively reduce the heat release of the cement hydration, prevent the hydrate from decomposing because of large heat and reduce the harm of the hydrate to the cementing. The whole performance of the cement under the low heat release condition is improved by adding materials which can reduce the whole hydration heat release of the cement using G grade oil well cement as base material. (1) The proper addition of superfine slag with a specific surface area between 6000 and 12000cm2 / g can make sure the strength properties of the early and later stage of the cement. (2) The hydration heat is further reduced by adding fly ash with a lower hydration activity. (3) An amount of gypsum component is added so that the cement paste has certain expansion property at a low temperature to prevent the cement paste shrinking at a low temperature. The low temperature and low hydration heat cementing concrete provided by the invention has an obvious effect for reducing the whole cement hydration heat and a good effect for preventing the deep water hydrate decomposition.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com