Patents

Literature

79results about How to "Good load transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

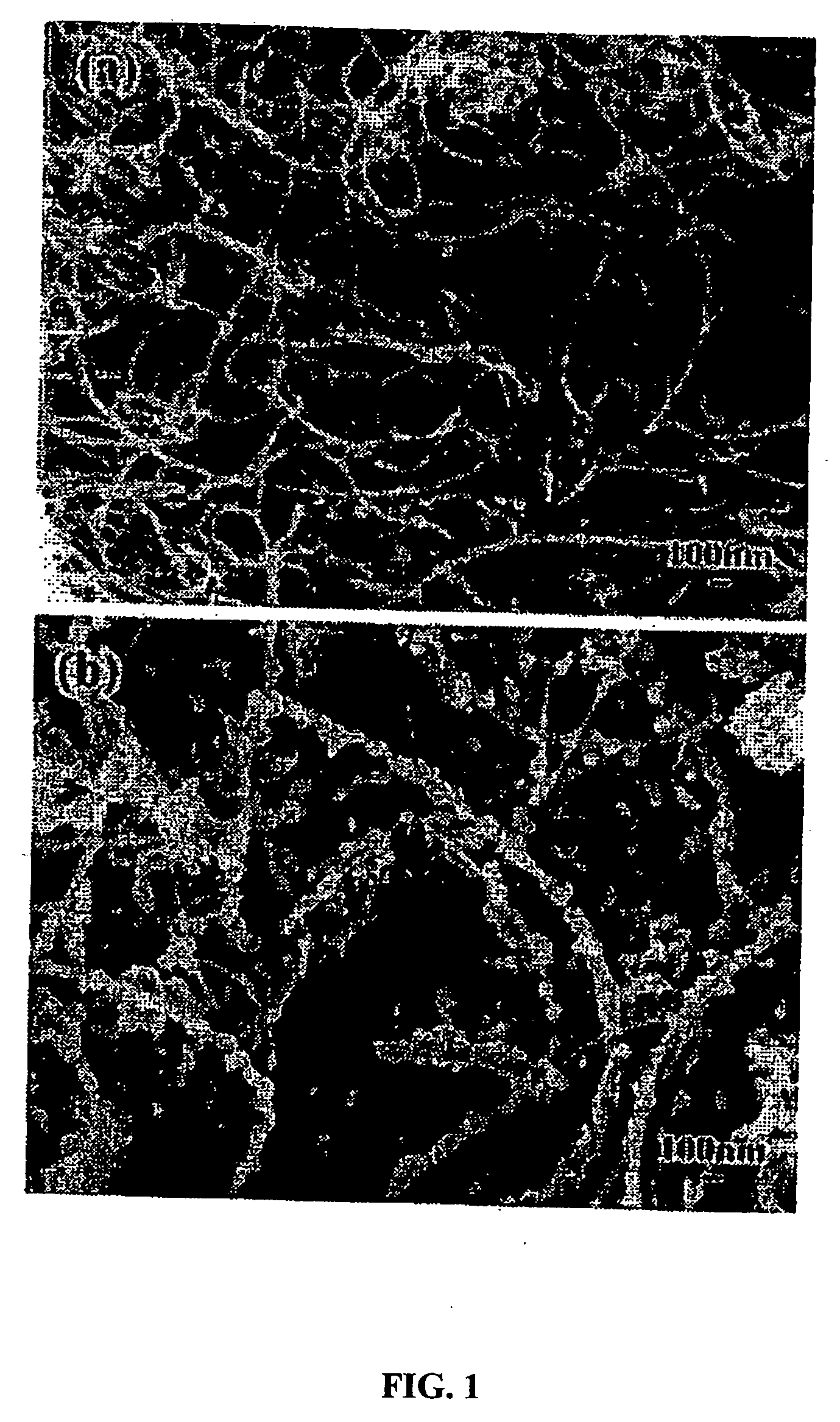

Polymethylmethacrylate augmented with carbon nanotubes

InactiveUS6872403B2Improve mechanical propertiesGood load transferBiocidePowder deliveryCarbon nanotubeSynthetic resin

An augmented synthetic resin is provided. That resin includes carbon nanotubes dispersed in a polymethylmethacrylate matrix. The method of preparing this synthetic resin includes the mixing and disaggregating of the carbon nanotubes.

Owner:UNIV OF KENTUCKY RES FOUND

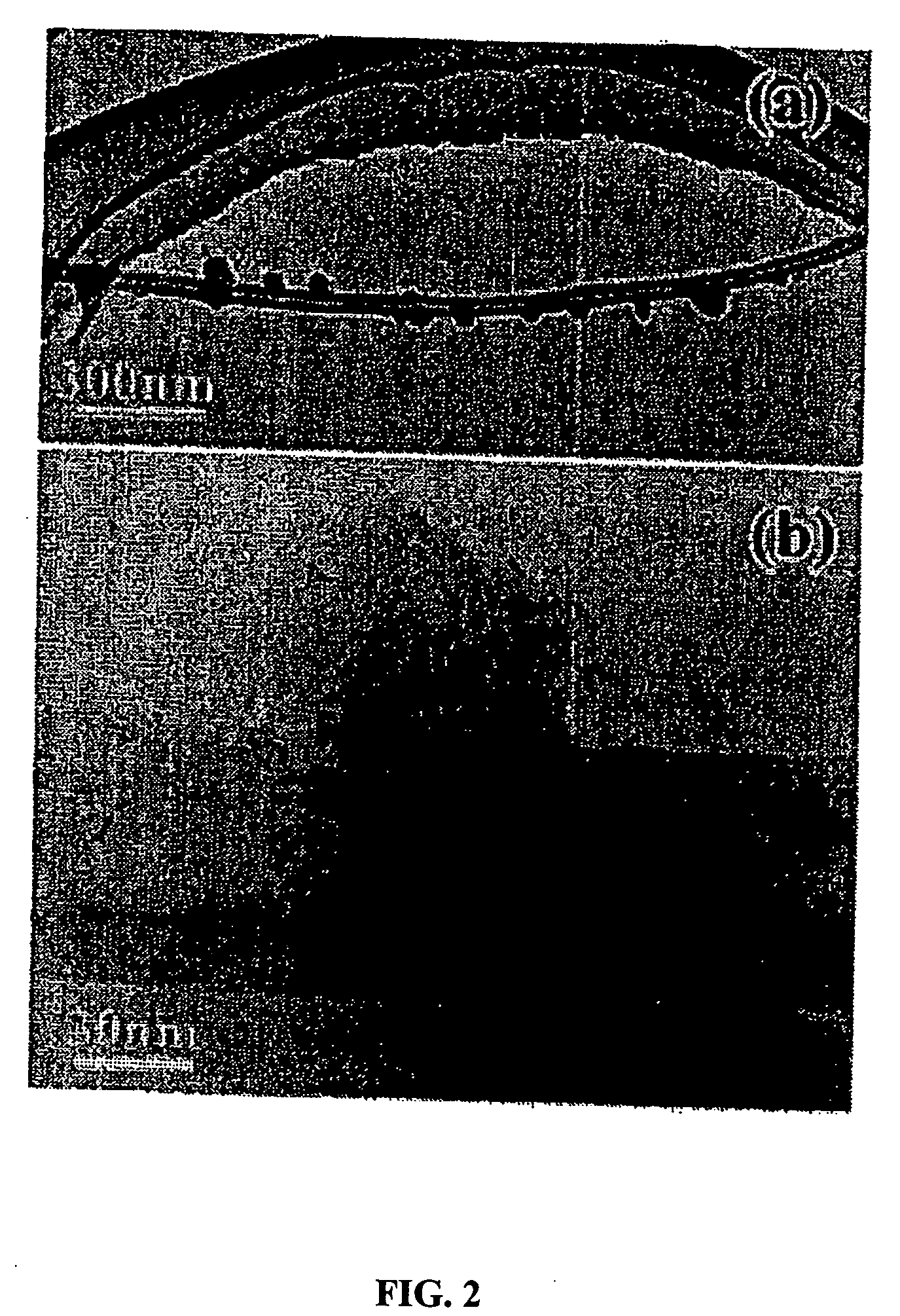

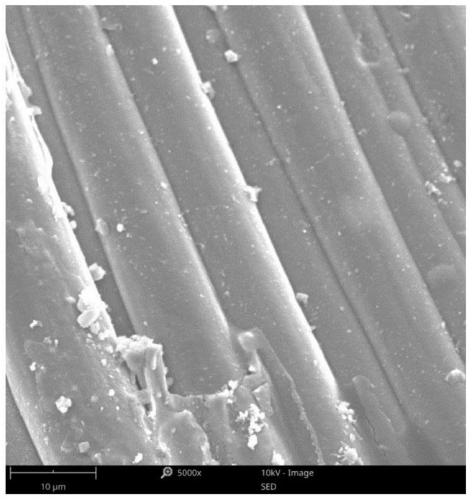

Reinforced carbon nanotubes

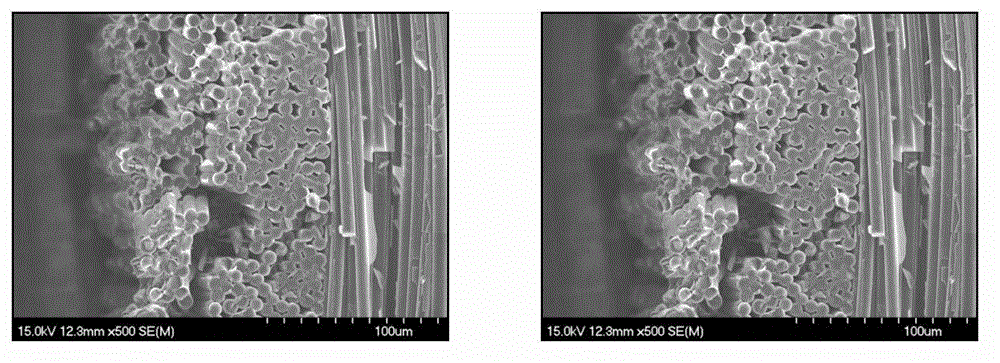

InactiveUS6911260B2Improve mechanical propertiesHigh strengthMaterial nanotechnologyLiquid surface applicatorsCarbon nanotubeBoron carbide

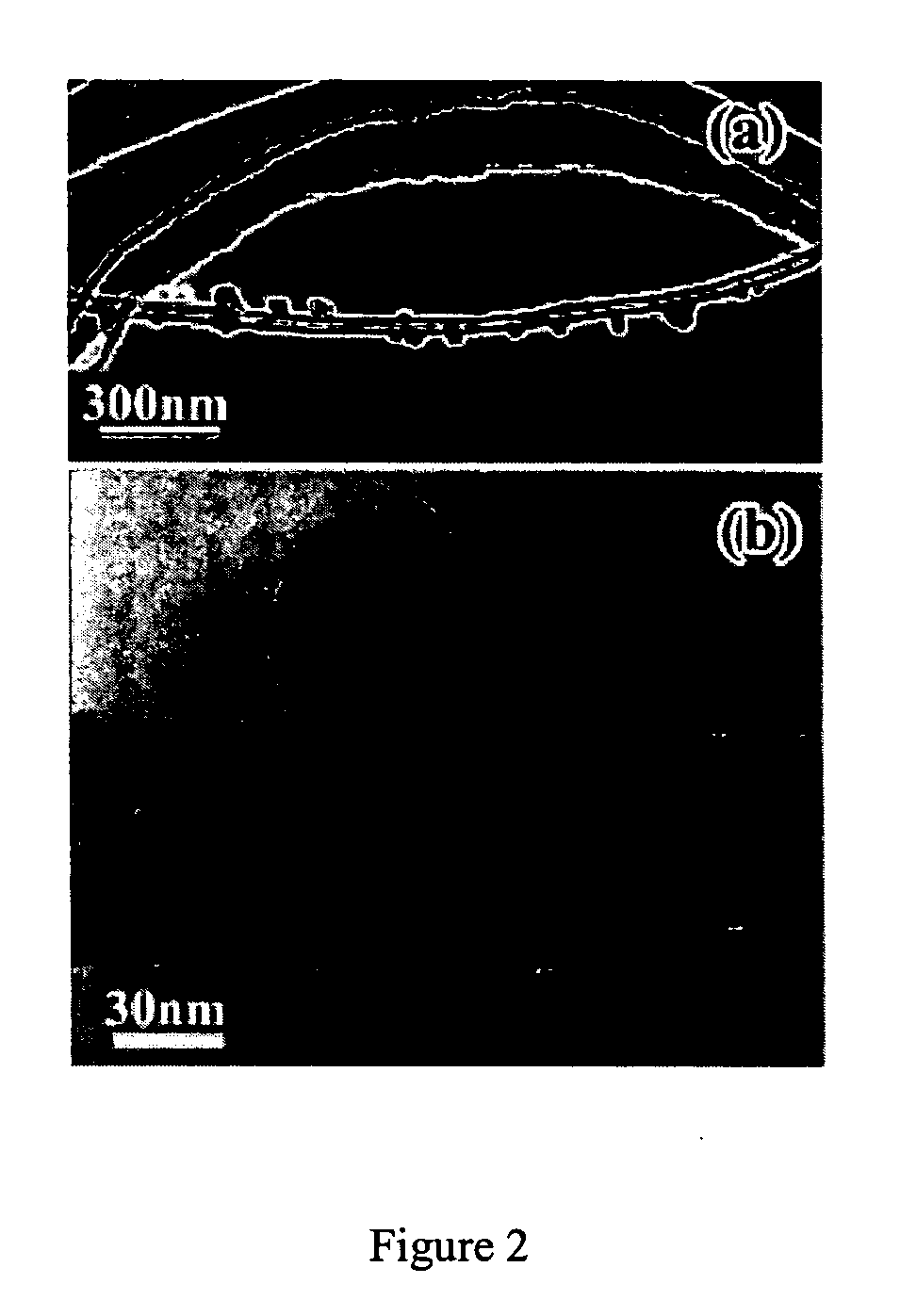

The present invention relates generally to reinforced carbon nanotubes, and more particularly to reinforced carbon nanotubes having a plurality of microparticulate carbide or oxide materials formed substantially on the surface of such reinforced carbon nanotubes composite materials. In particular, the present invention provides reinforced carbon nanotubes (CNTs) having a plurality of boron carbide nanolumps formed substantially on a surface of the reinforced CNTs that provide a reinforcing effect on CNTs, enabling their use as effective reinforcing fillers for matrix materials to give high-strength composites. The present invention also provides methods for producing such carbide reinforced CNTs.

Owner:BOSTON COLLEGE

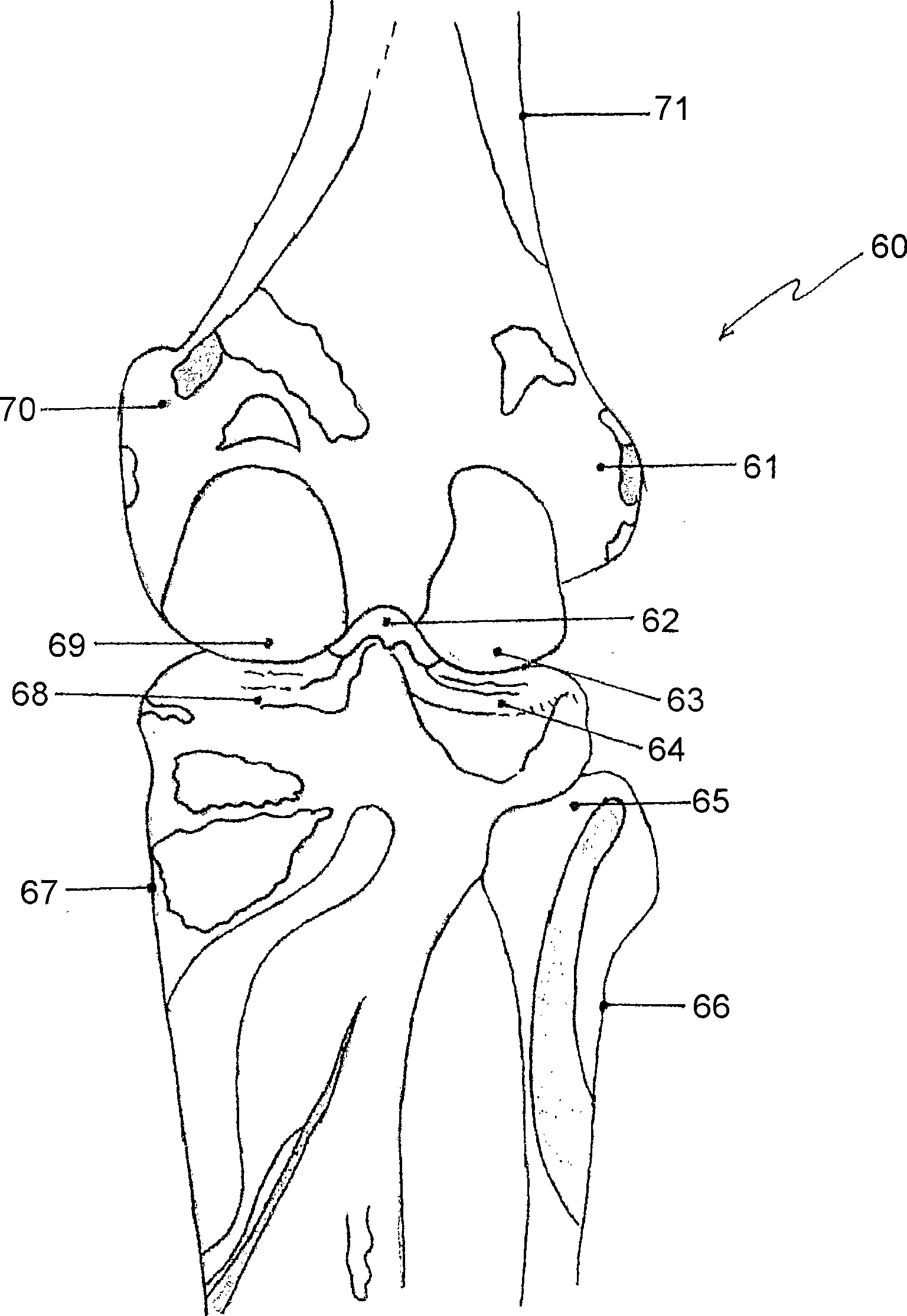

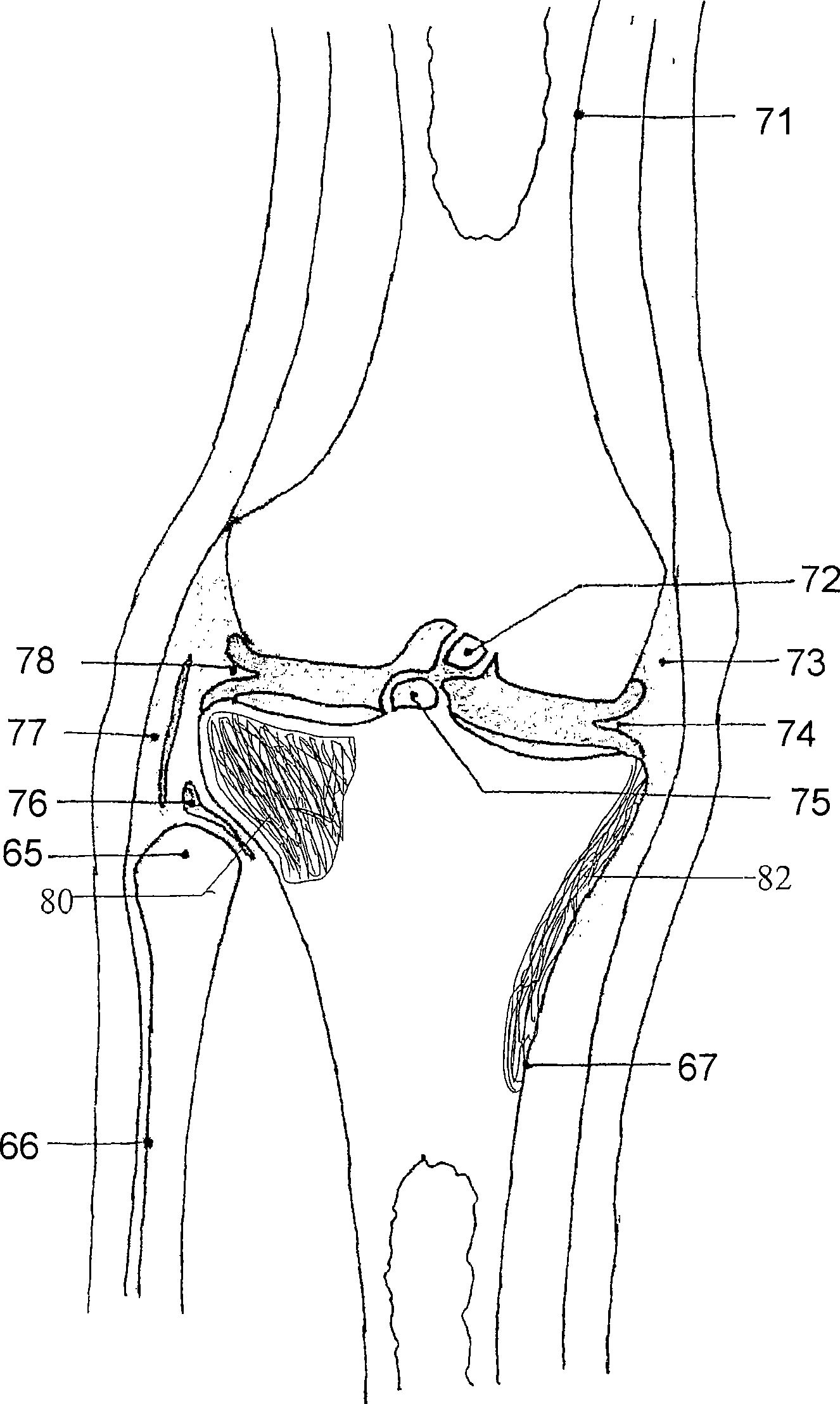

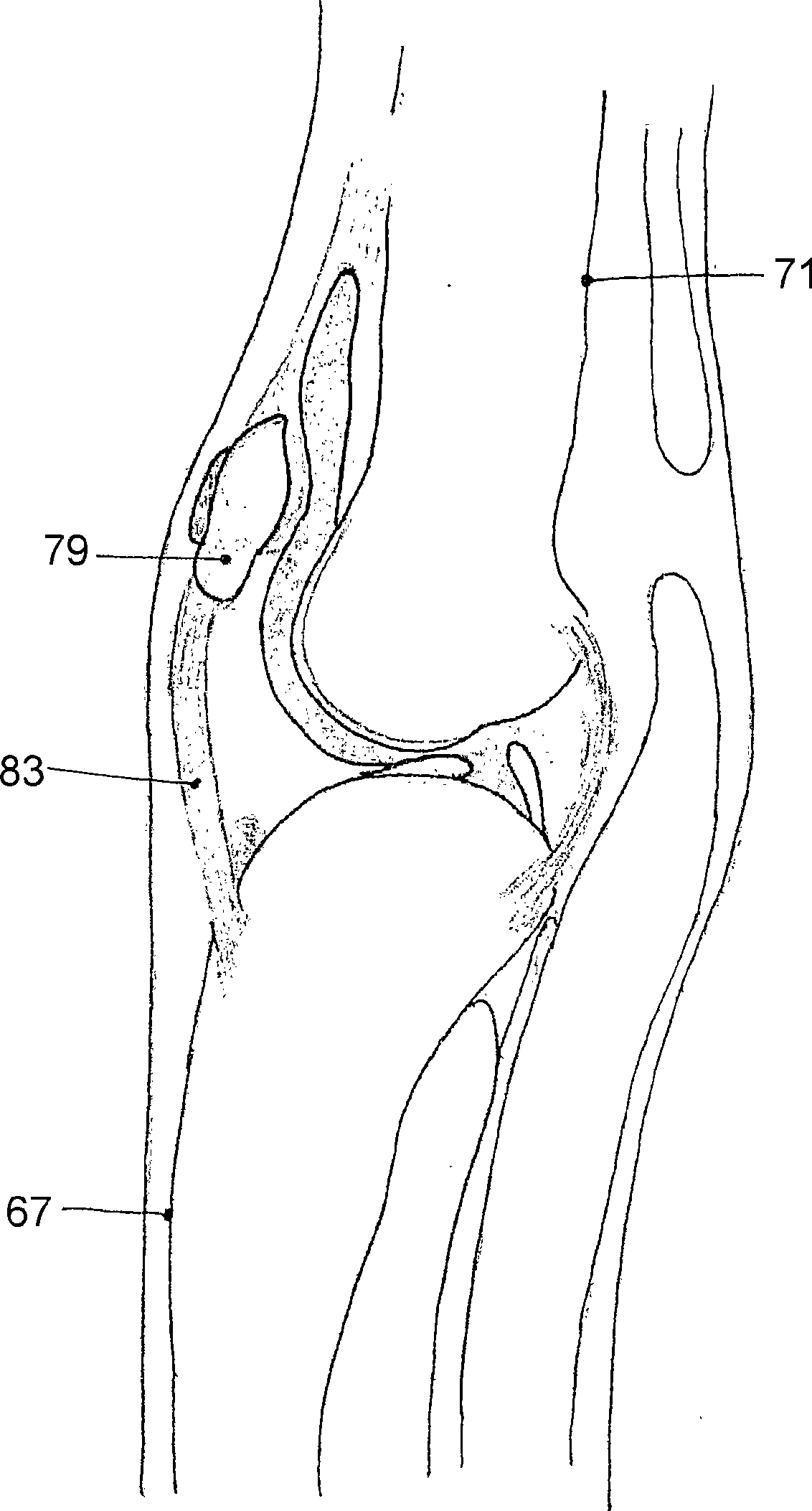

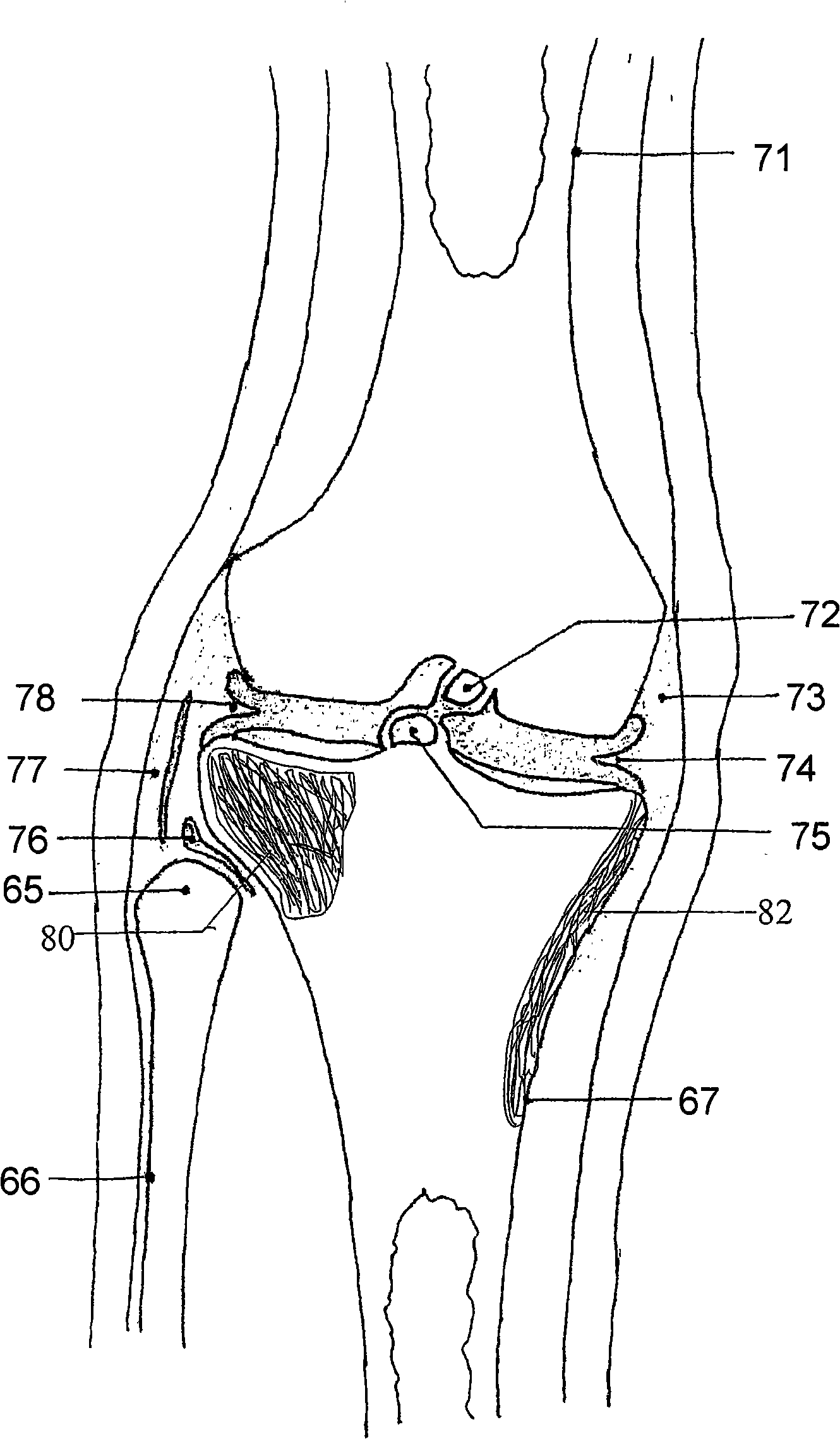

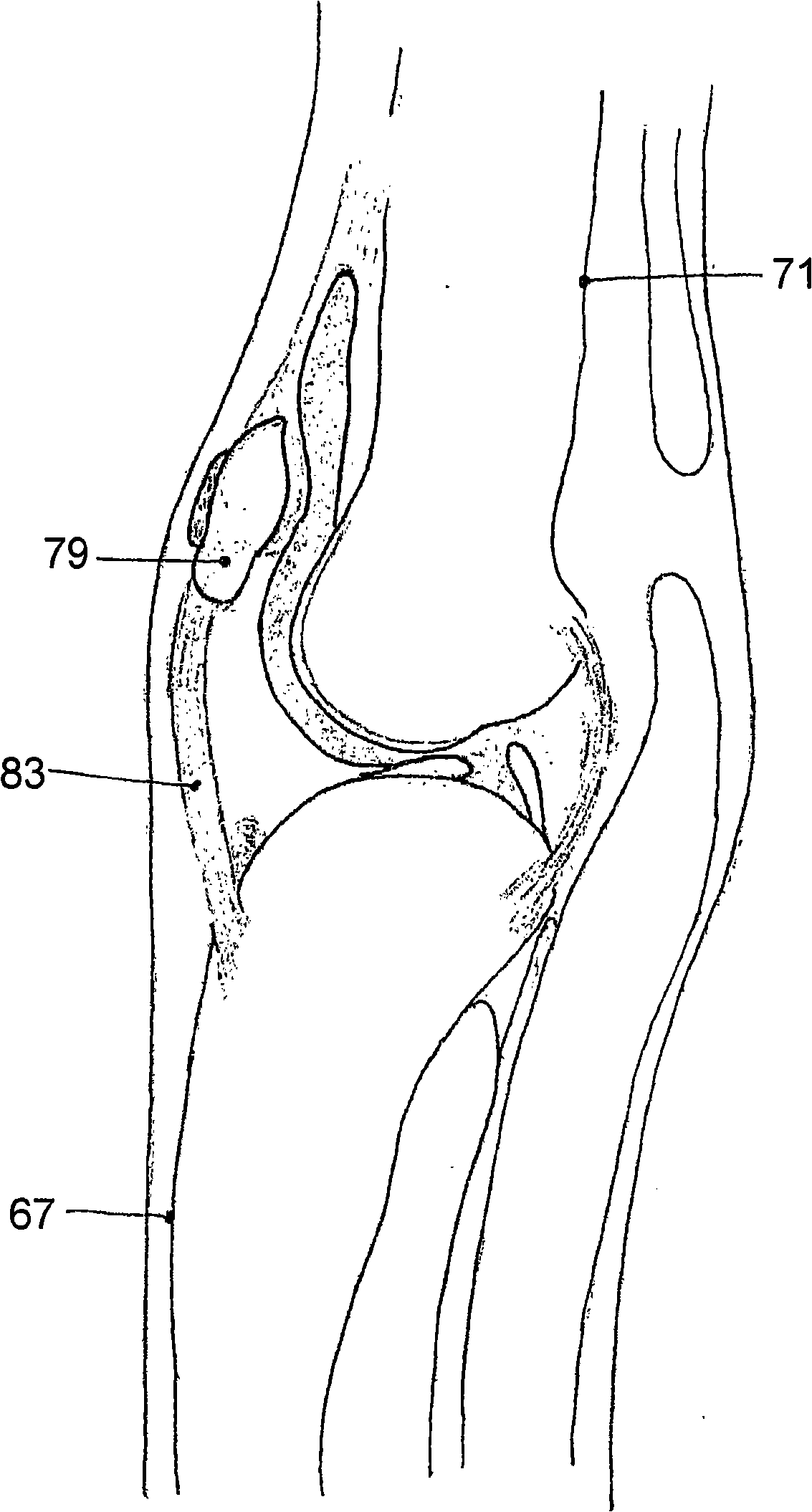

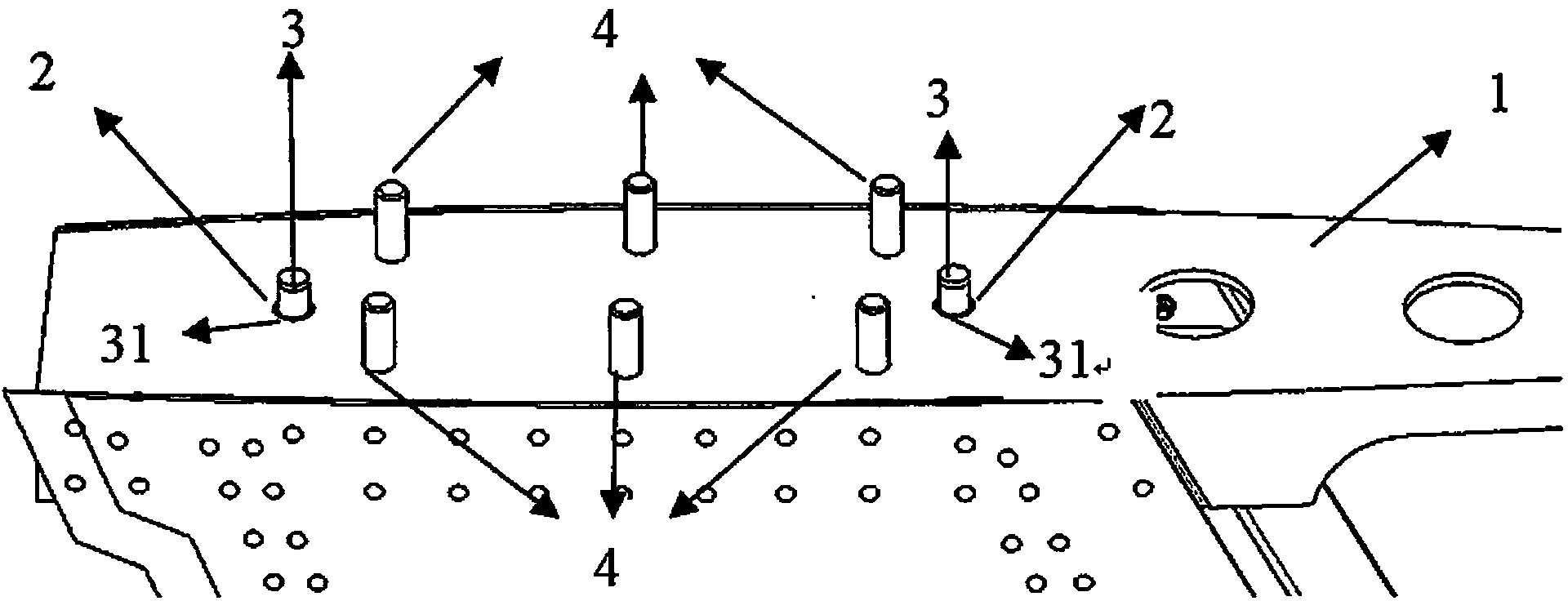

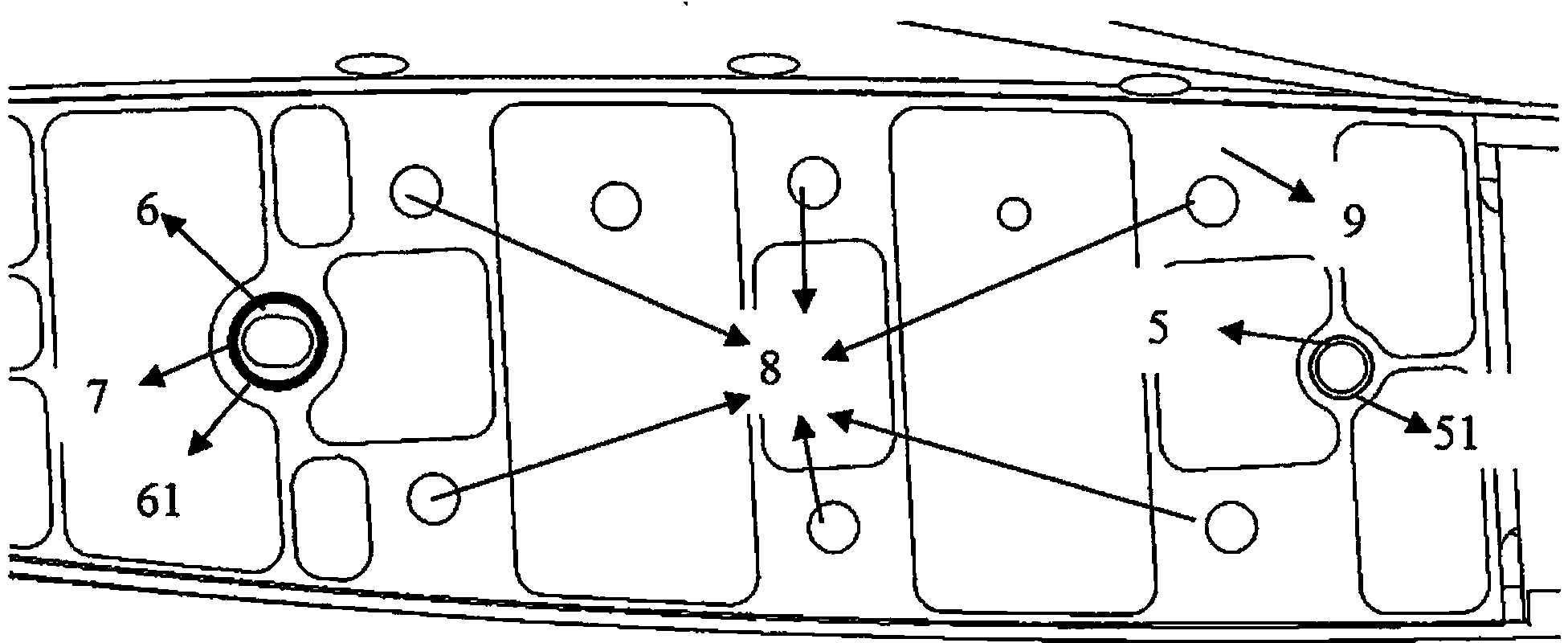

Knee joint prosthesis

InactiveCN101361684ASmooth rotationResist dislocationJoint implantsKnee jointsKnee JointFemoral component

The invention discloses a knee joint prosthesis which includes a thighbone assembly (31) and a tibia assembly (32). The tibia assembly (32) includes a tibia platform element (44) provided within a tibia tray element (40). A half-side winch-shaped bridging member (112) is provided between duplicated condyles on the thighbone assembly (31). A strut in a particular shape is provided between reniform meniscus recesses of the tibia platform element (44). The bridging member (112) is cooperative with the strut to form an additional joint for transferring loads in a kinetic configuration in the process of deeply bending the prosthesis.

Owner:坎蒂拉尔·哈斯蒂马尔·桑切蒂

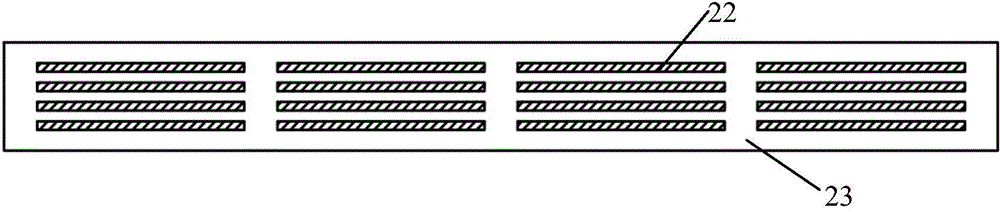

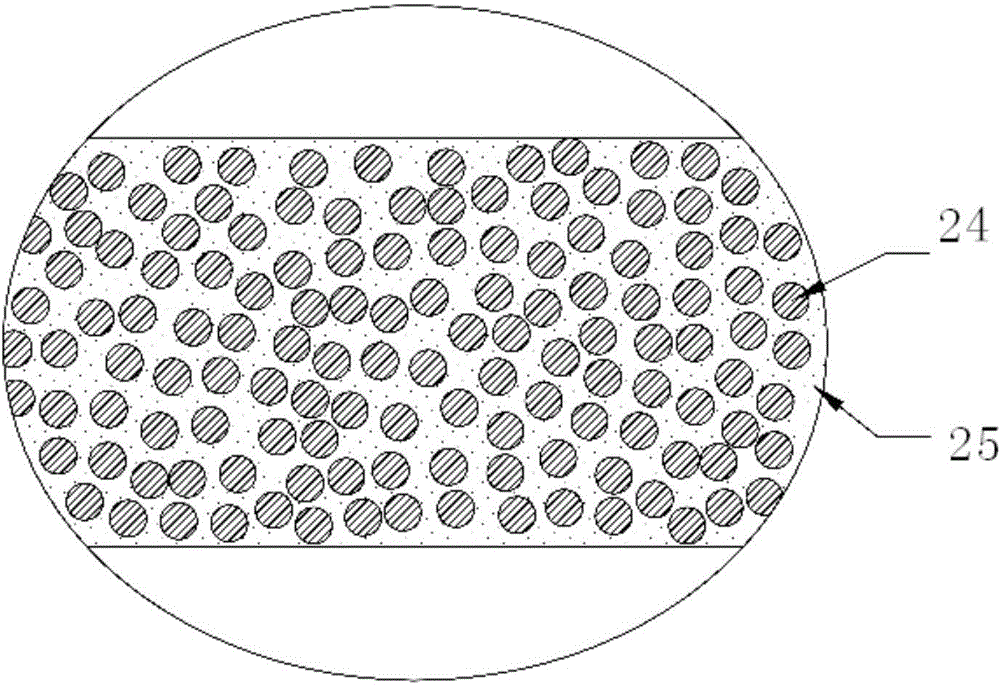

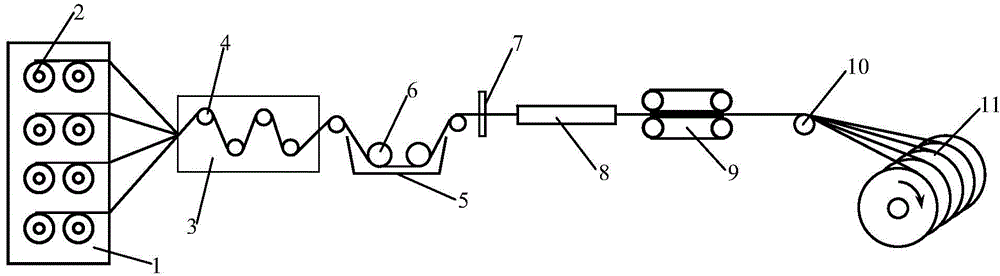

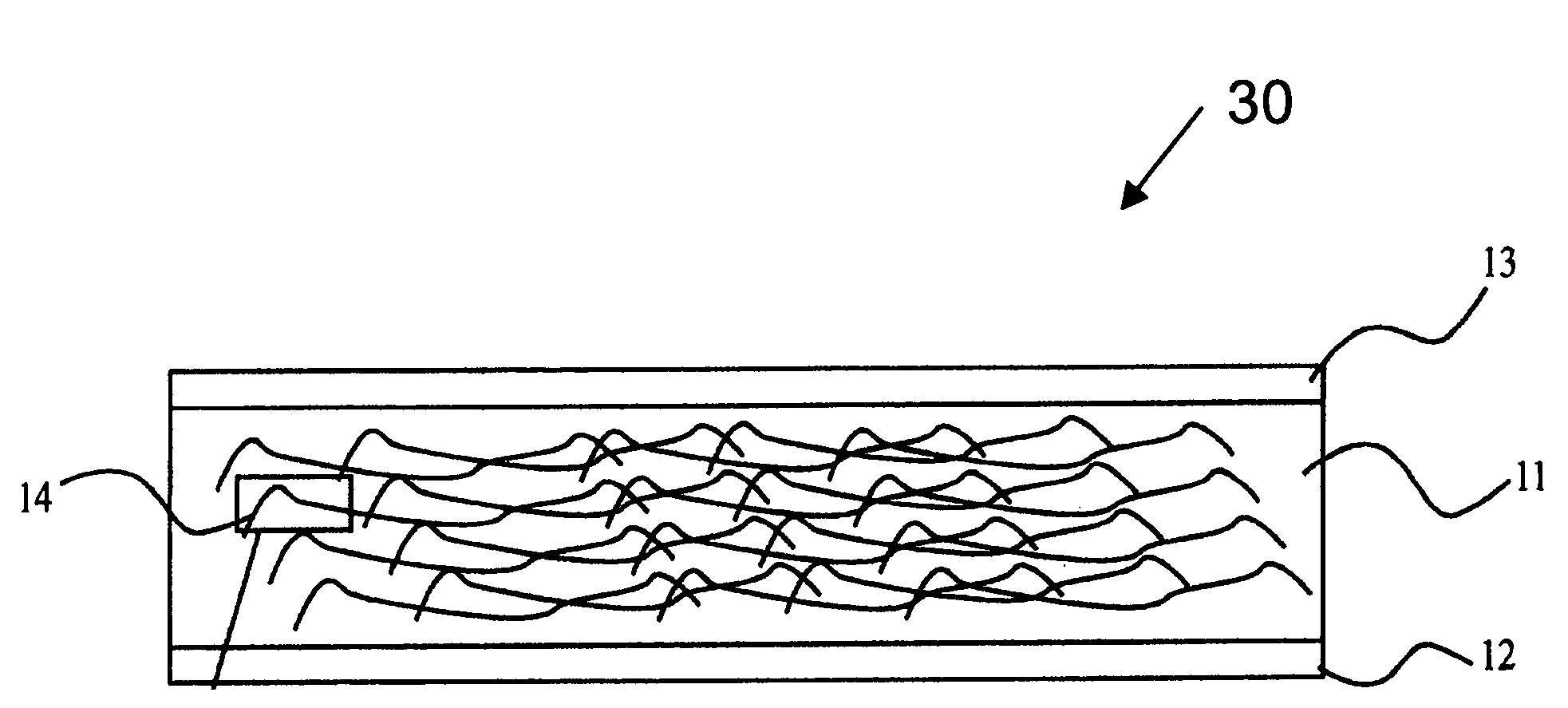

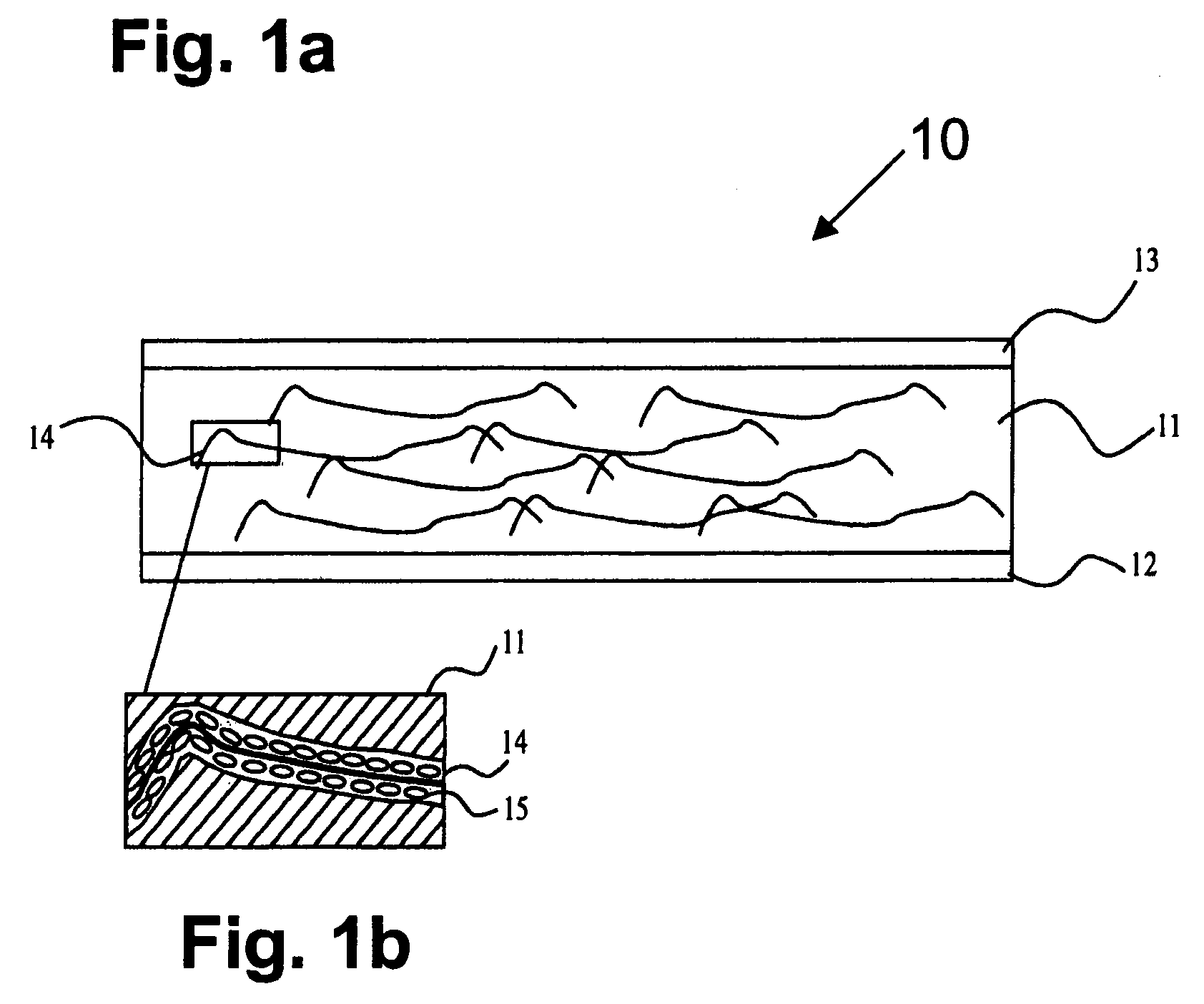

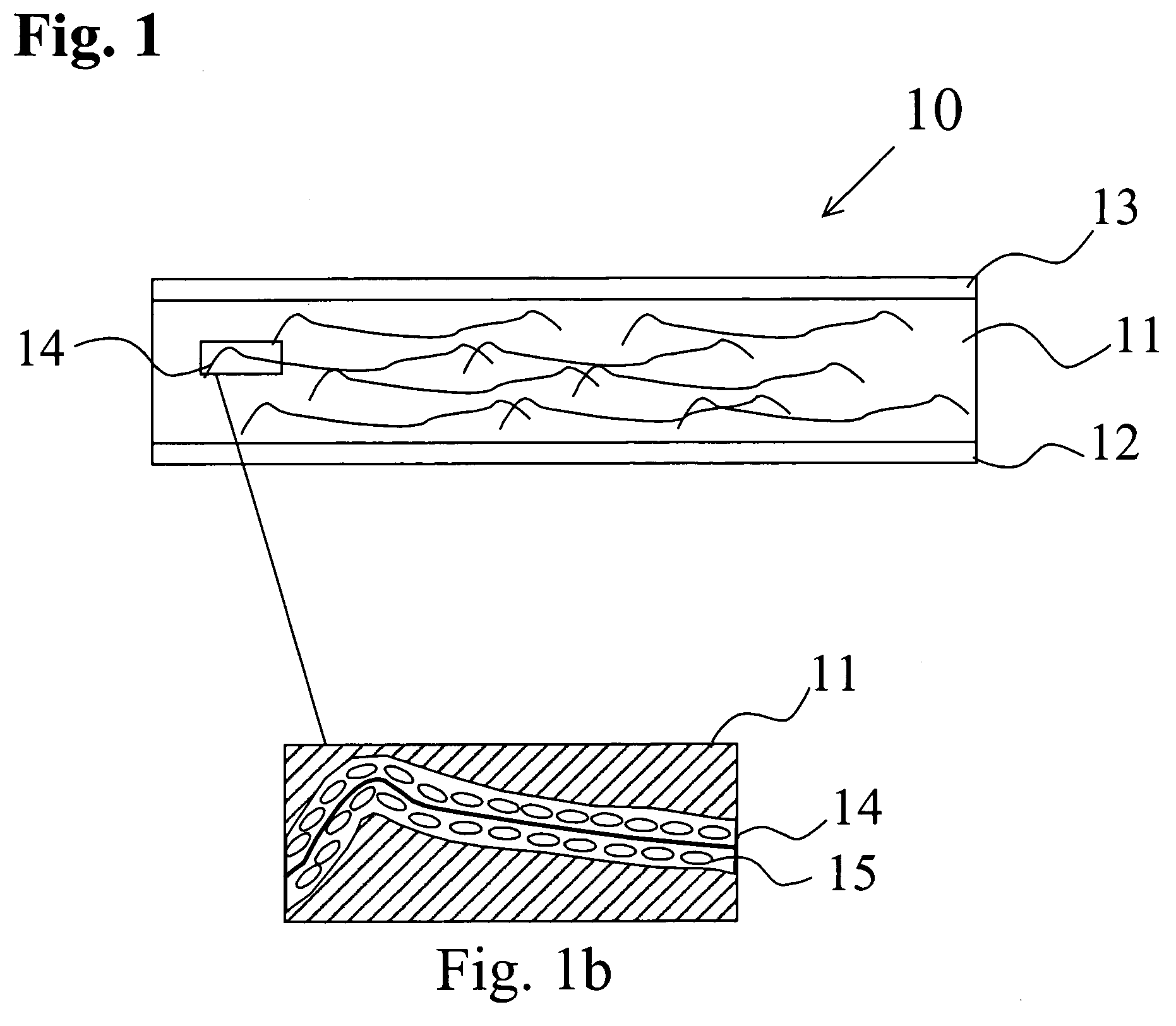

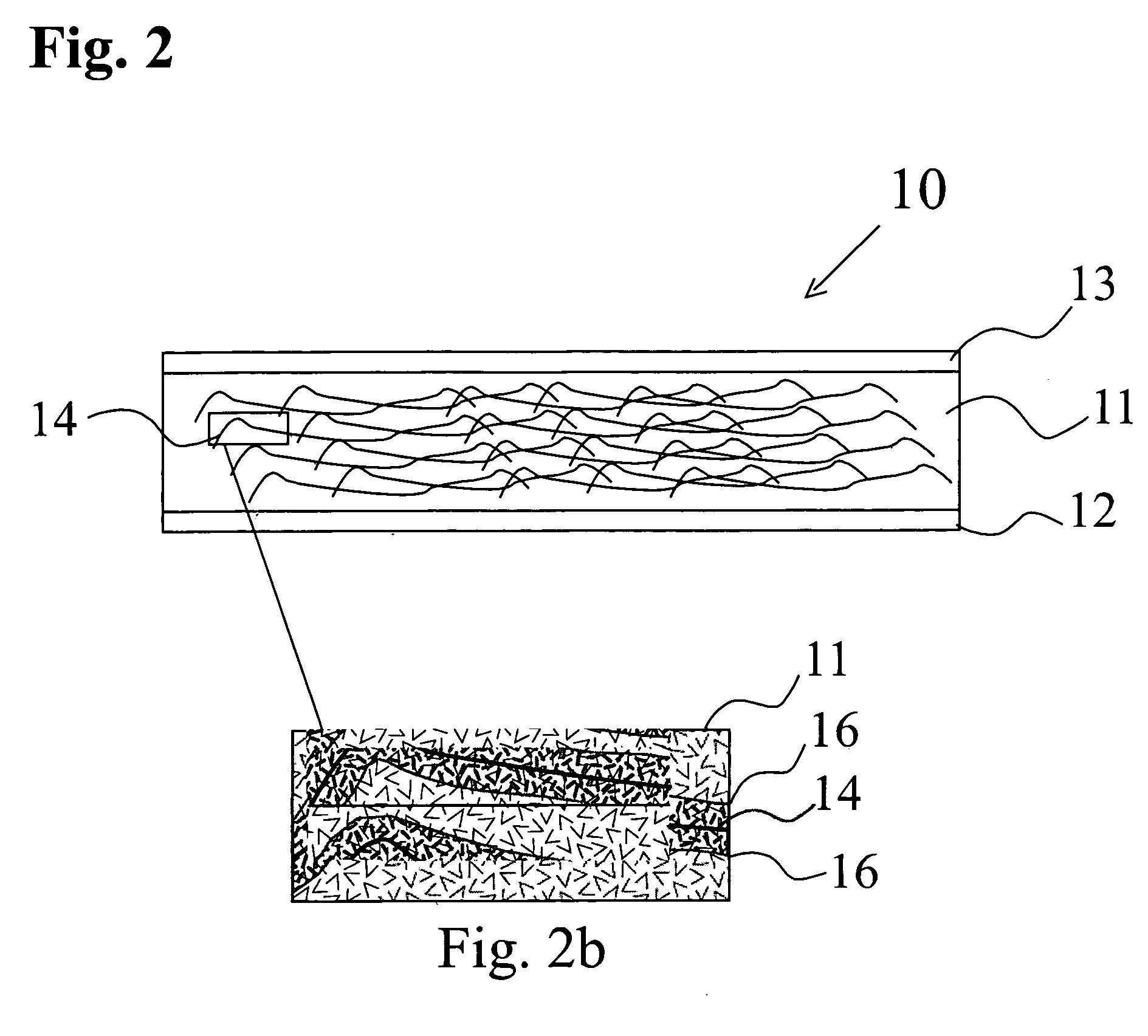

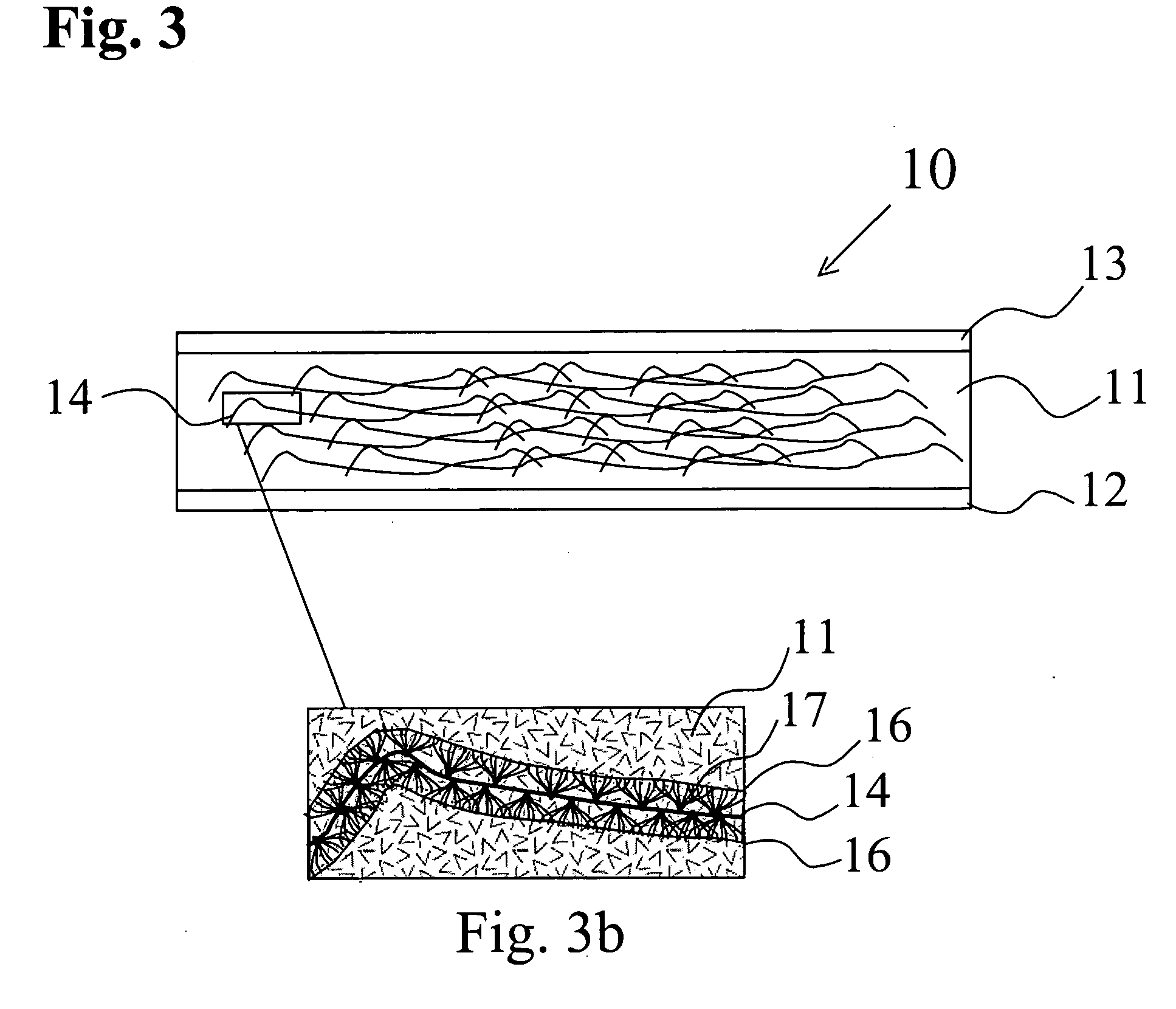

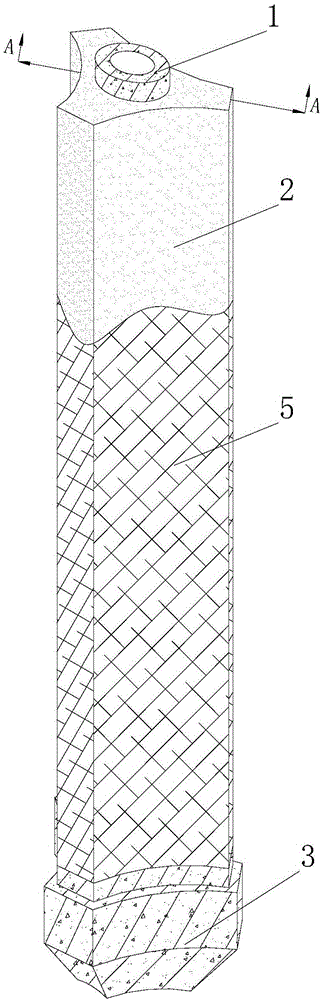

Preparation method and preparation system for ultralight composite traction belt

ActiveCN104552988AReduce internal defectsImprove tensile propertiesRope making machinesBeltsYarnAgricultural engineering

The invention discloses a preparation method and a preparation system for an ultralight composite traction belt, and provides a preparation method and a preparation system for the ultralight composite traction belt with uniform bearing and long service life. The preparation method comprises the following steps: a twist-free continuous monofilament is led out of a fiber yarn group, unfolded uniformly, and introduced into an impregnation tank for impregnation, wherein the impregnation tank is added with a glue solution, then arrangement is performed, and composite enhanced pieces are obtained after pultrusion and curing; the composite enhanced pieces are led out respectively, preheated and introduced into a head die of an extruder, an extruding die core corresponding to the section of the traction belt is arranged in the head die, the composite enhanced pieces are uniformly coated with molten thermoplastic resin in the head die and led out of the head die of the extruder, preliminary forming is realized, and the traction belt is obtained after cooling setting and cooling. The prepared traction belt is light in weight, high in strength, easy to bend, anti-fatigue, long in service life, low in maintenance cost and more applicable to a long-distance elevator.

Owner:TIANJIN GOLDSUN WIRE ROPE

Synthesis of boron carbide nanoparticles

InactiveUS20060057050A1Improve mechanical propertiesHigh strengthMaterial nanotechnologyMulti-walled nanotubesNanoparticleCarbide

The present invention relates generally to reinforced carbon nanotubes, and more particularly to reinforced carbon nanotubes having a plurality of microparticulate carbide or oxide materials formed substantially on the surface of such reinforced carbon nanotubes composite materials. In particular, the present invention provides reinforced carbon nanotubes (CNTs) having a plurality of boron carbide nanolumps formed substantially on a surface of the reinforced CNTs to reinforce the CNTs, enabling their use as effective reinforcing fillers for matrix materials to give high-strength composites. The present invention also provides methods for producing carbide reinforced CNTs.

Owner:TRUSTEES OF BOSTON COLLEGE THE

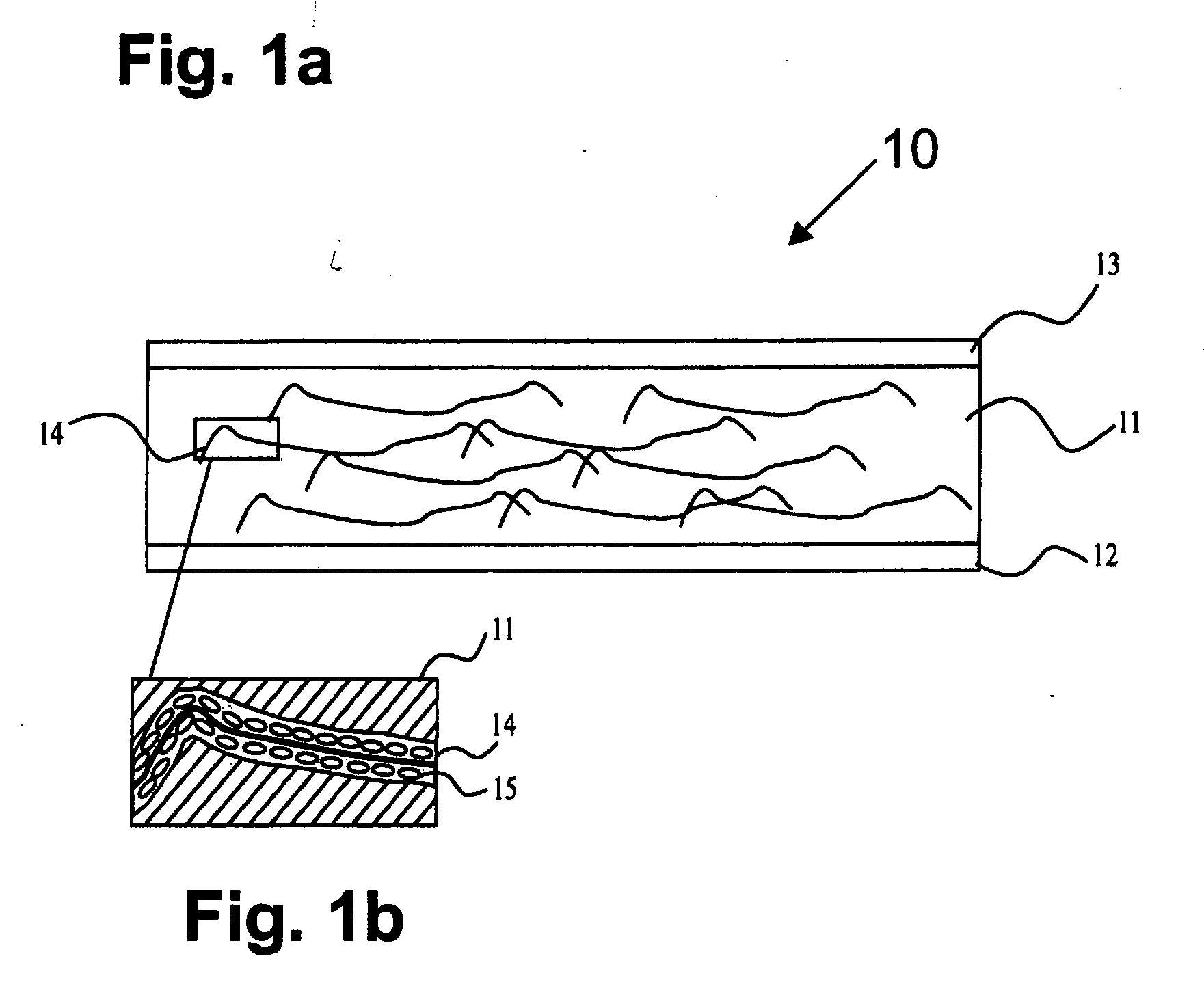

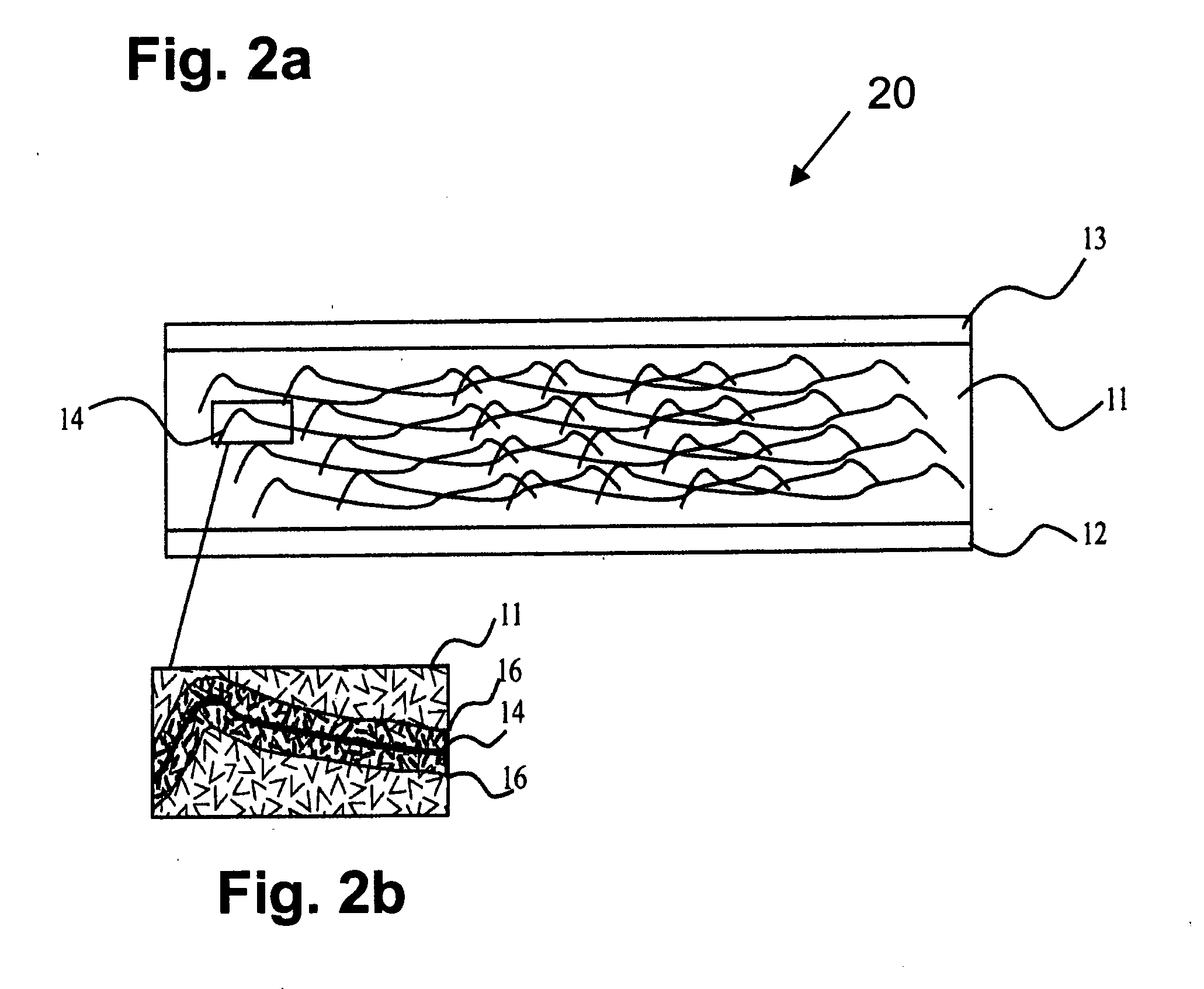

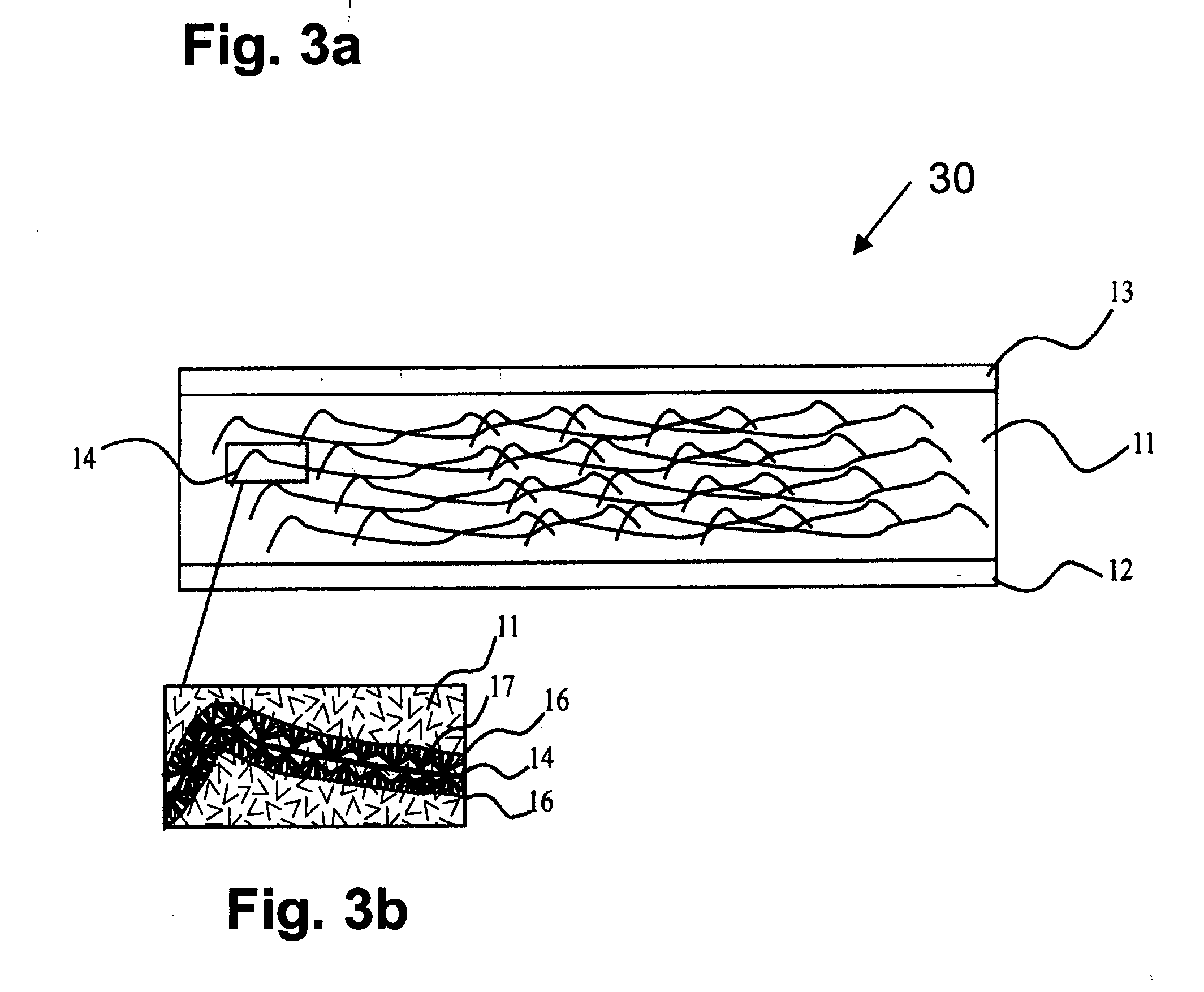

Composite materials using novel reinforcements

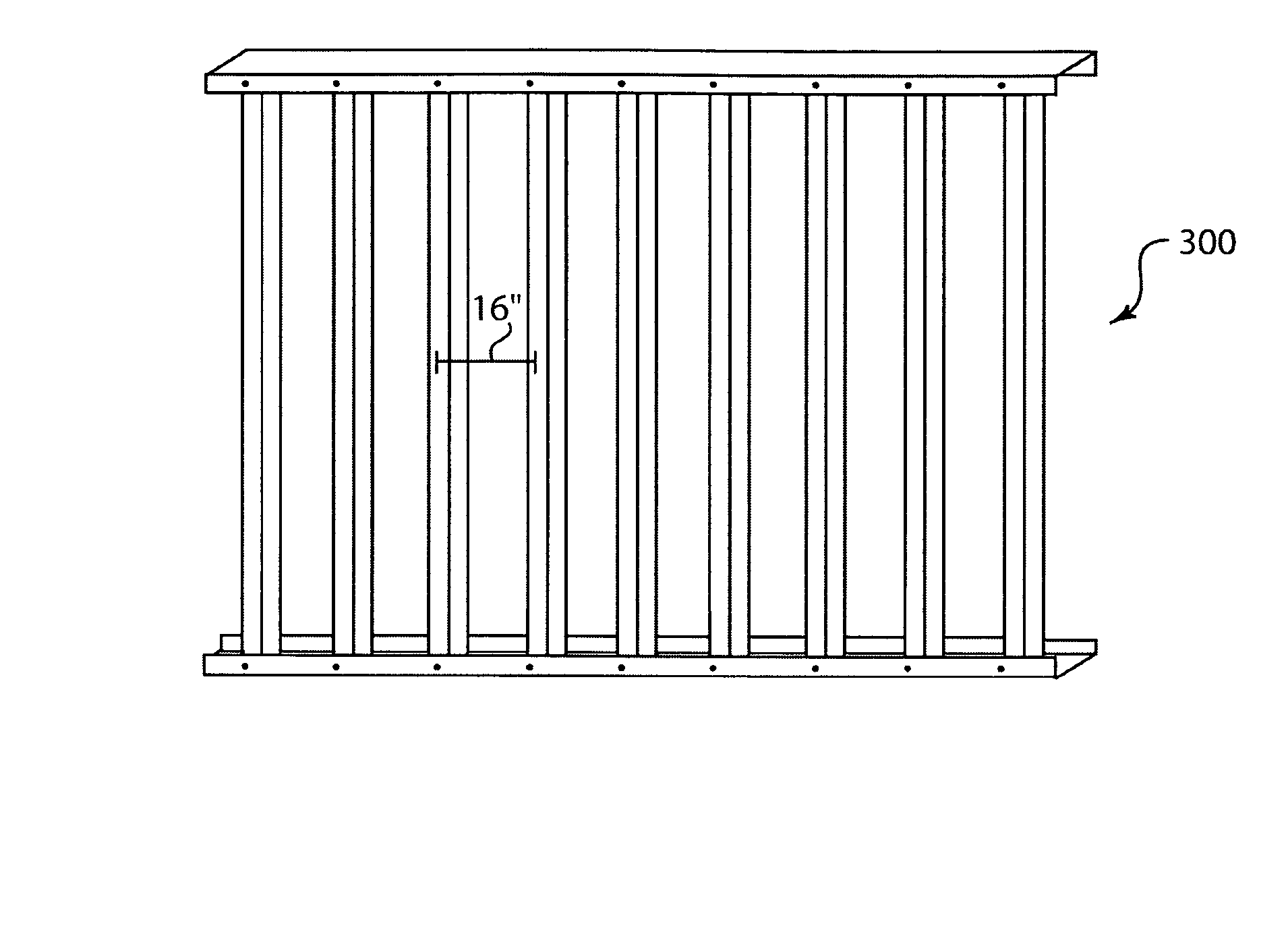

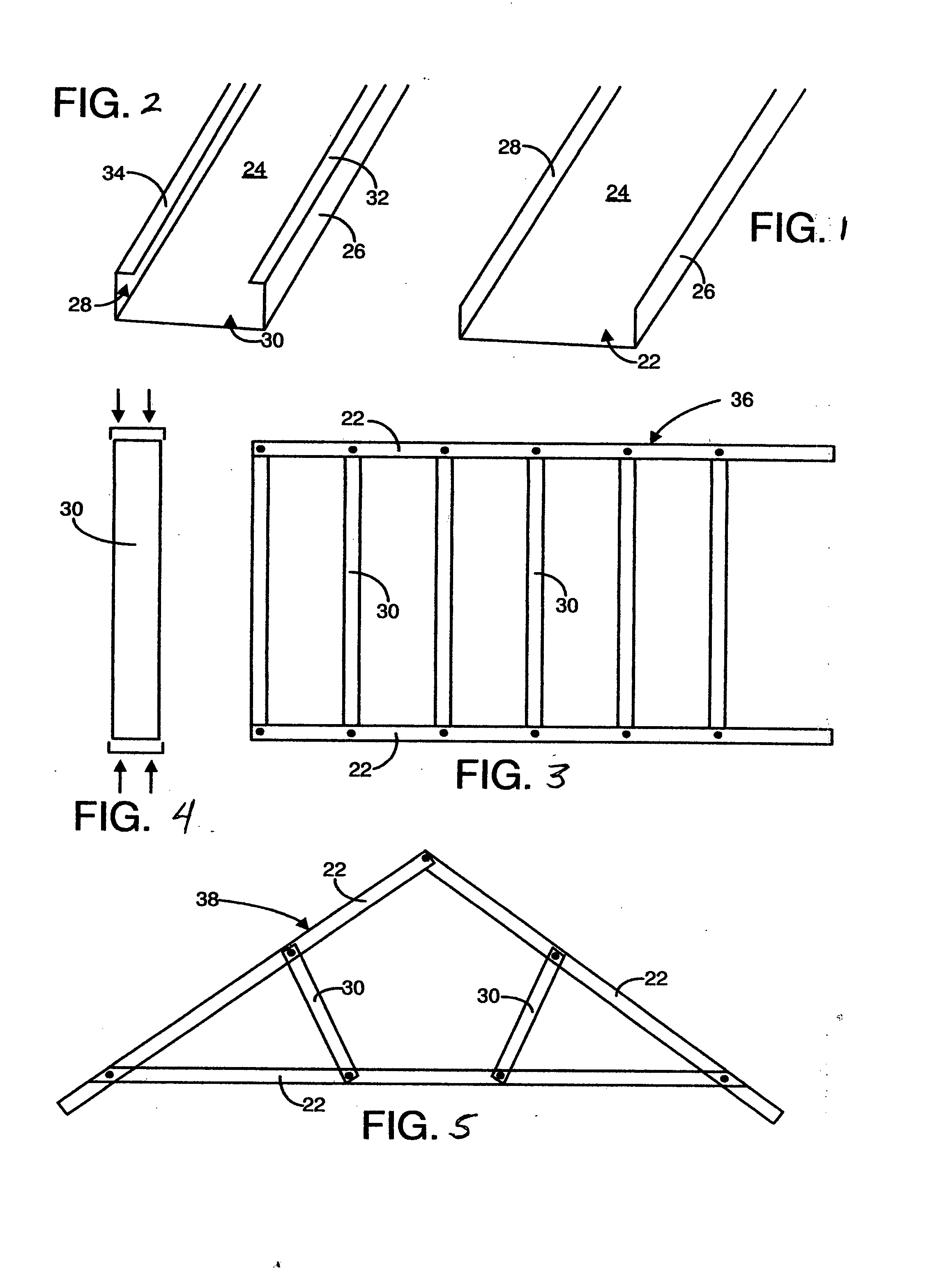

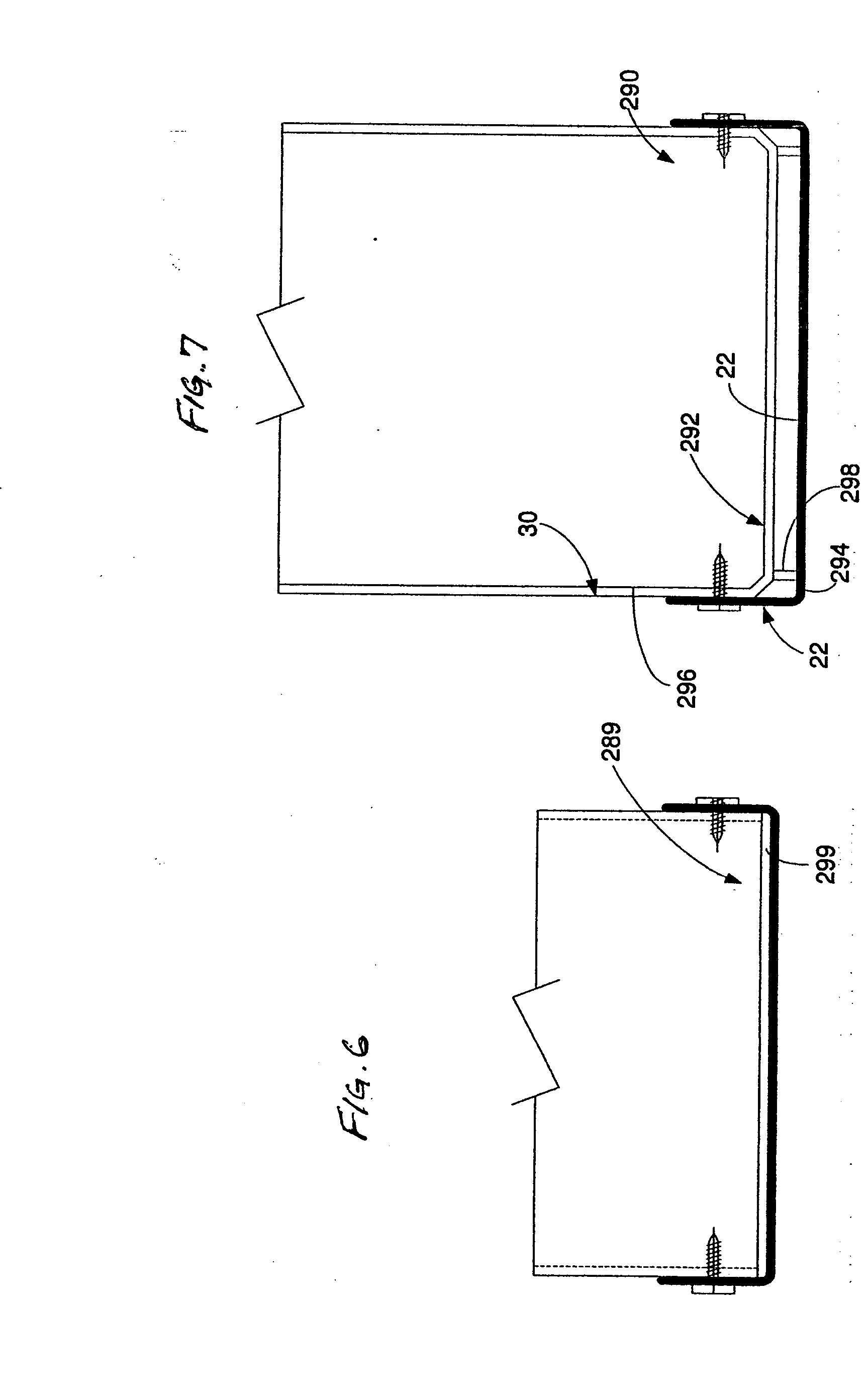

InactiveUS20030188667A1Low costEfficient preparationBuilding reinforcementsThin material handlingFiberBuilding product

The present invention relates to materials used for building products, construction projects, structural objects, mechanical devices and other materials applications. Specifically, the invention concerns composite materials made with reinforcing elements in a binder matrix material. A method of strengthening materials is described that uses high volumes of reinforcing elements, which can be easily dispersed and uniformly distributed, consisting of large diameter fibers, miniature rods or other similar geometric shapes with a diameter or thickness between 0.05 mm and 20 mm where the reinforcements are incorporated either as short, randomly distributed elements or long, continuous aligned arrays.

Owner:KIRBY WAYNE BEARD

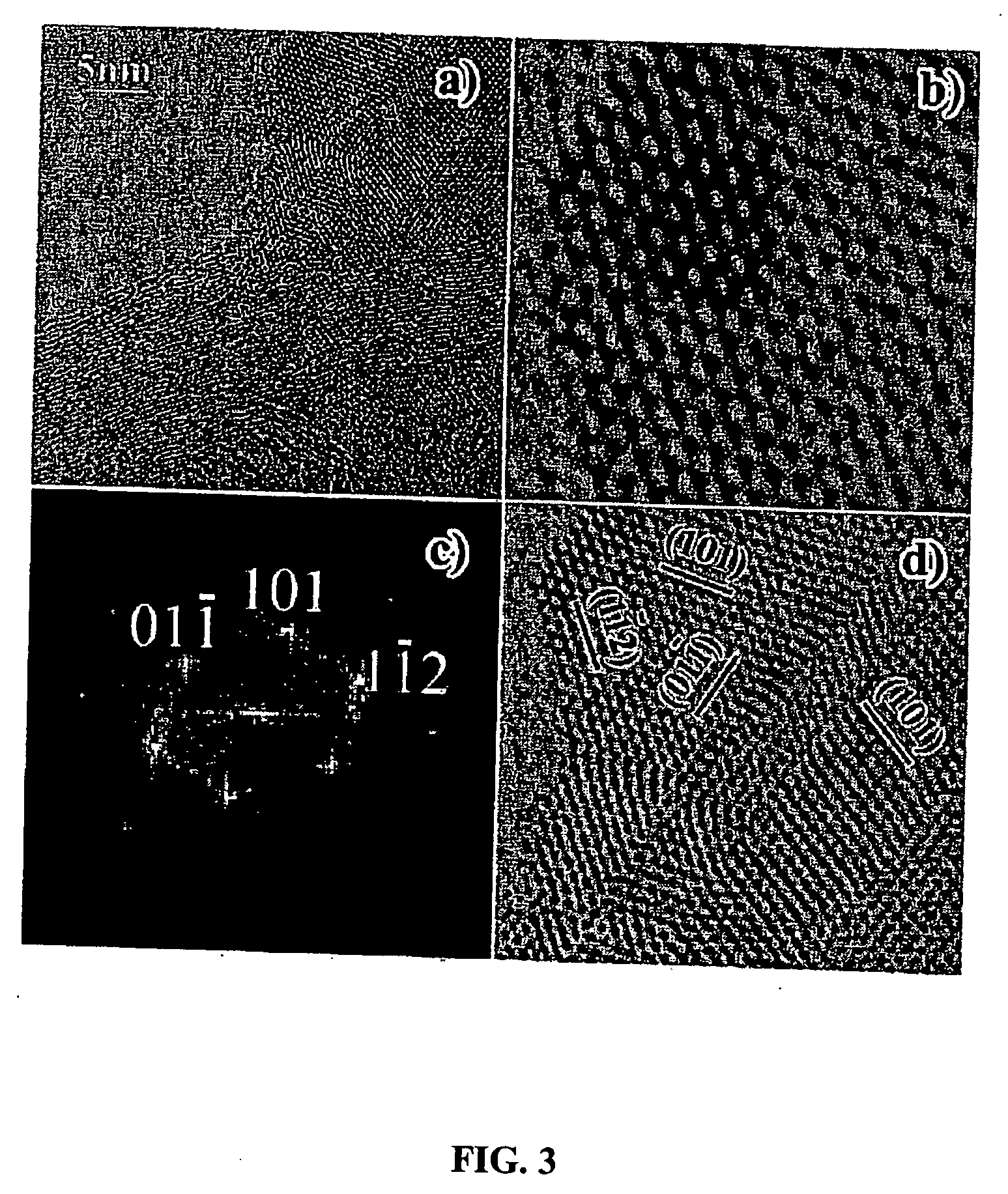

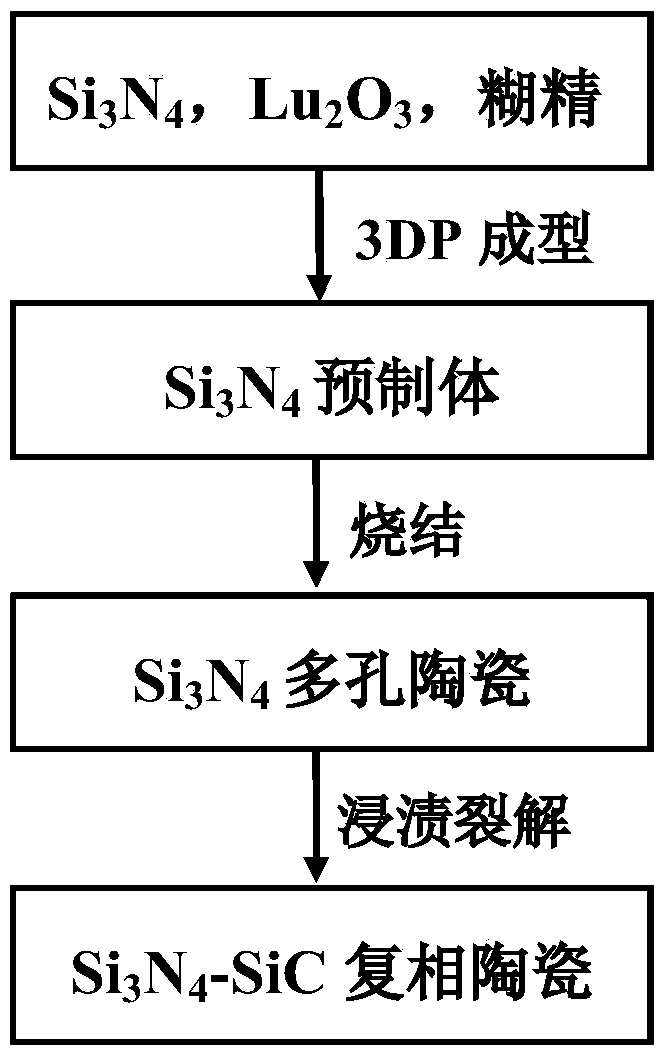

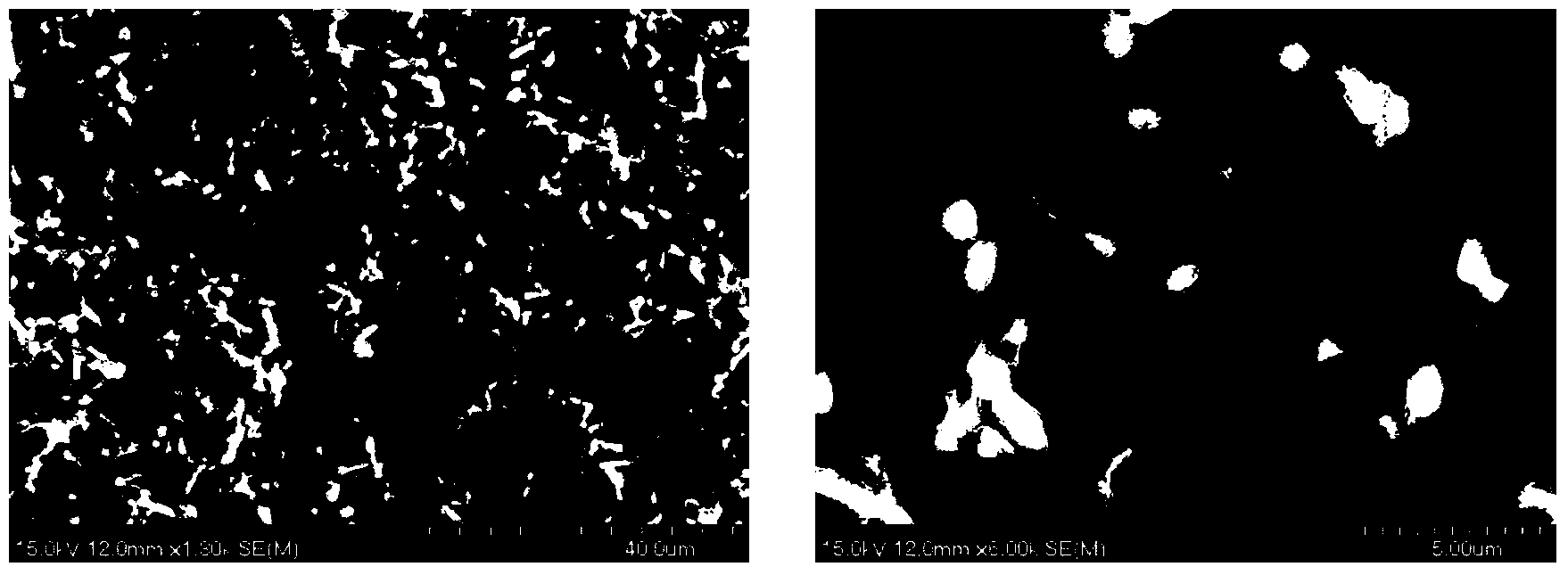

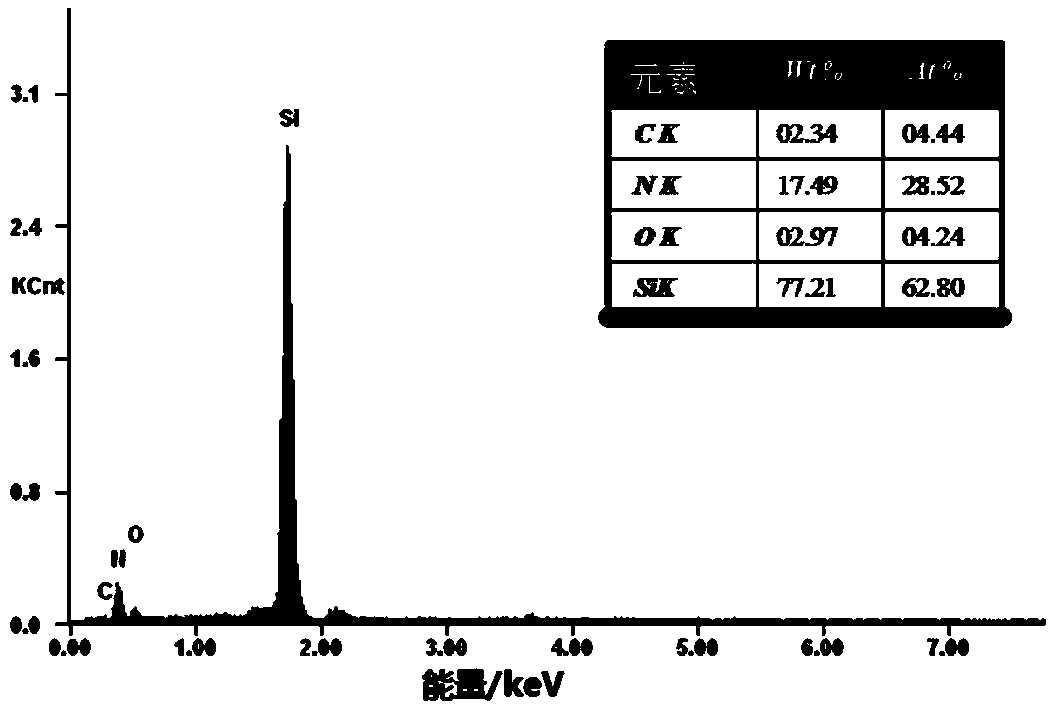

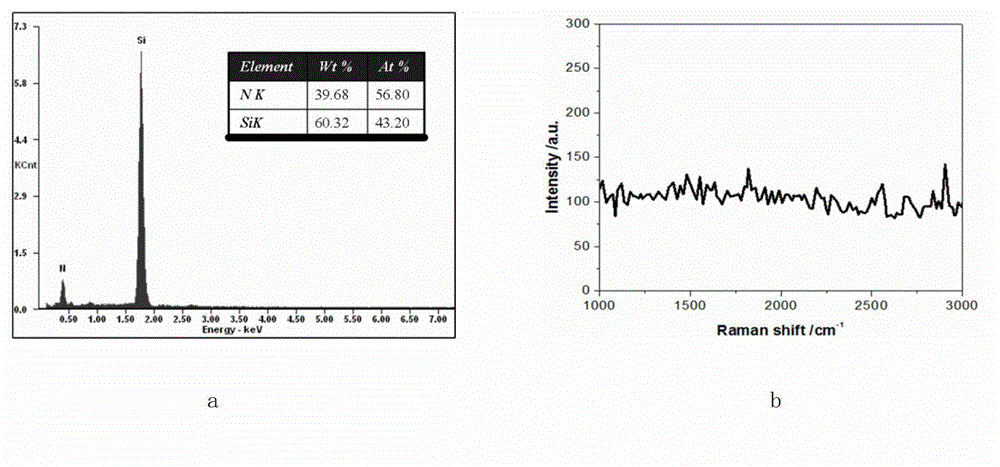

Near shape preparation method of multiphase ceramic Si3N4-SiC

ActiveCN103833370AAddressing inhomogeneityImprove absorbing performanceCeramic shaping apparatusNanowireComposite ceramic

The invention relates to a near shape preparation method of multiphase ceramic Si3N4-SiC, which completes component molding directly by bonding between particles through a three-dimensional printing method, needs no dies, and is capable of molding components with complex shapes. The Si3N4-SiC multiphase ceramic prepared by 3DP combined with PIP methods solves the problem of nonuniformity of CVI methods, and SiC nanocrystallines and SiC nanowires are uniformly distributed in a Si3N4 substrate. The Si3N4-SiC composite ceramic which is continuous, compact, free of impurities, good in uniformity and stable in wave absorbing property is obtained by using Si3N4 powder and polycarbosilane as raw materials through steps of three-dimensional printing, sintering, dipping, curing, cracking and heat treatment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Foldable metal wall frame assemblies for use in residential and commercial structures

Owner:BH LEGACY

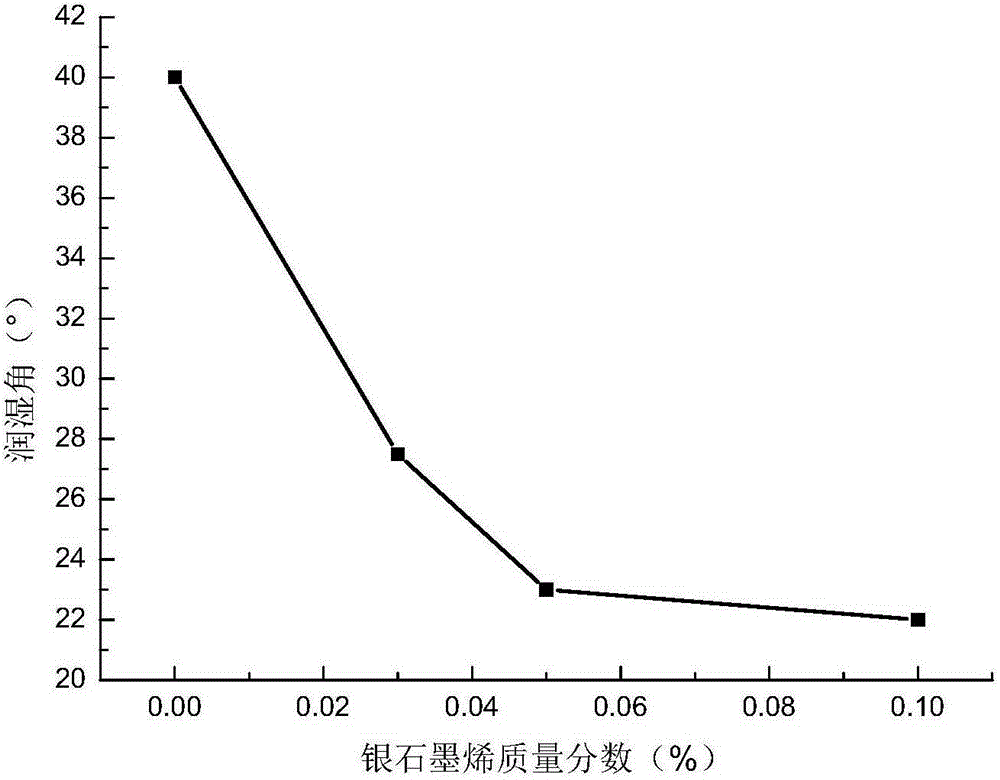

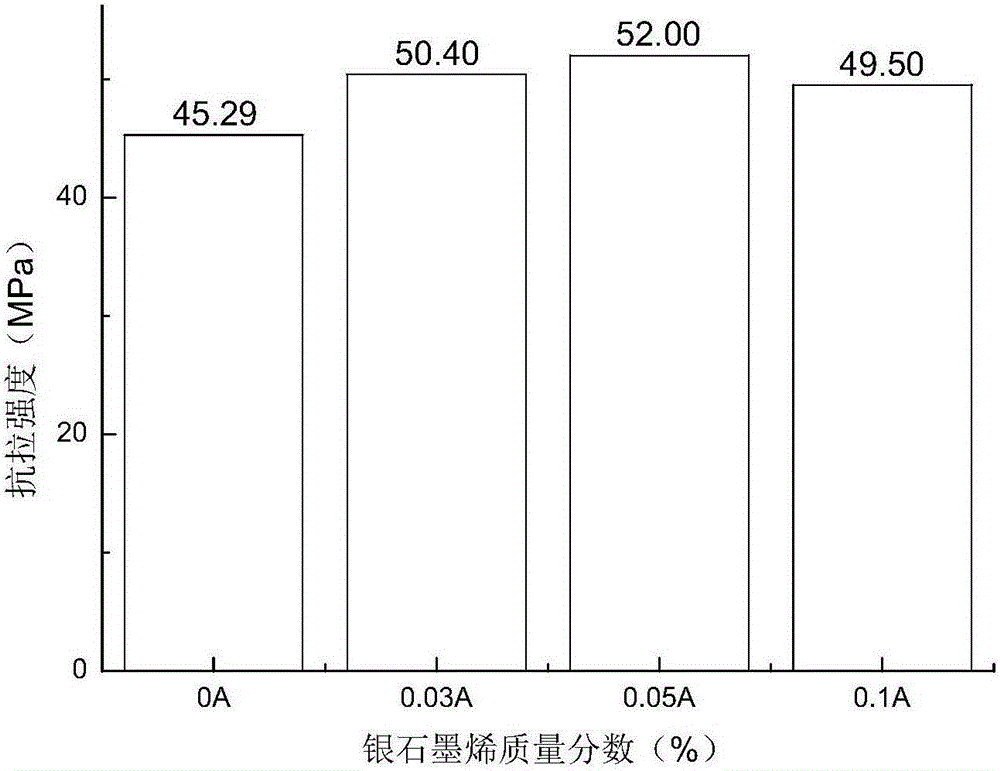

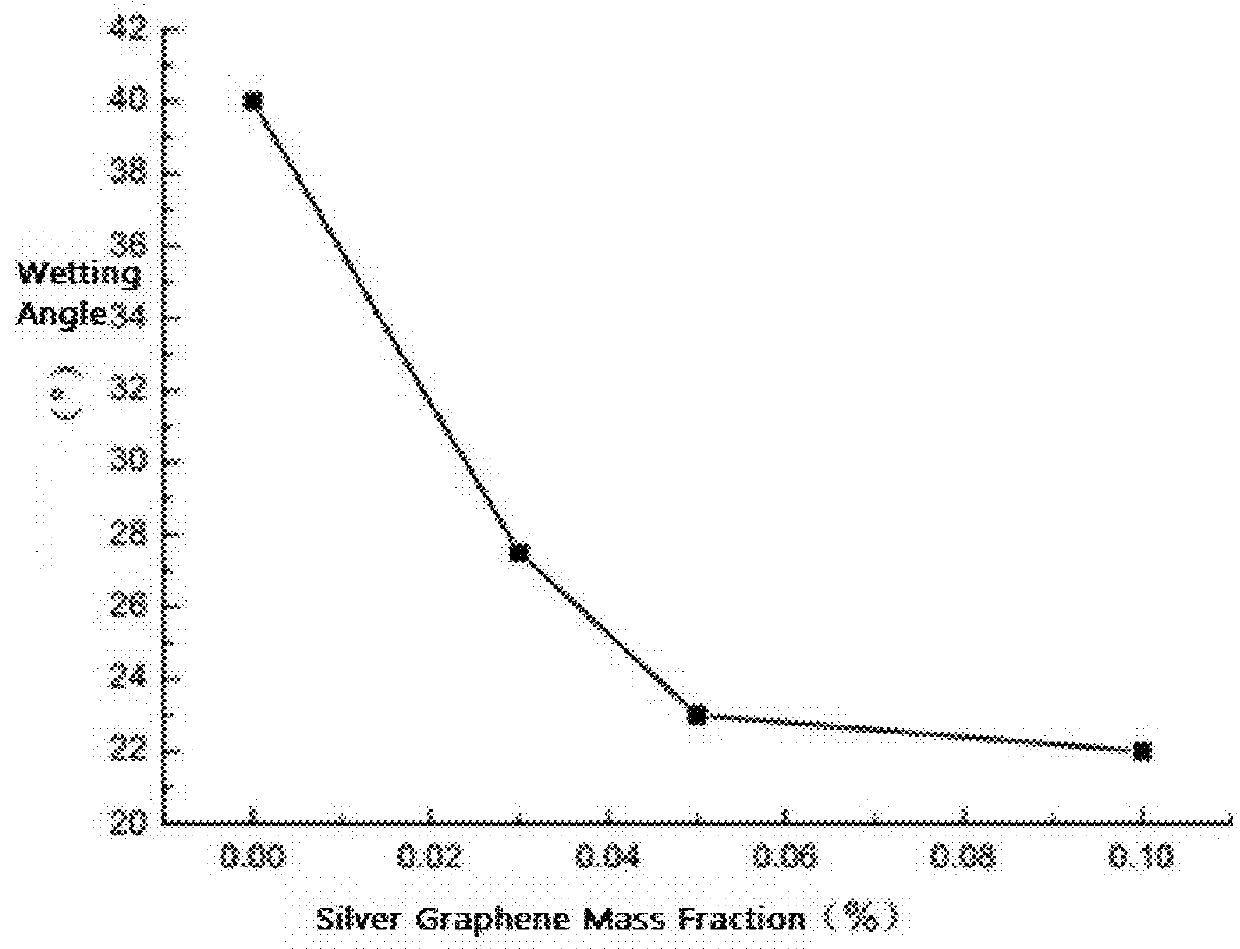

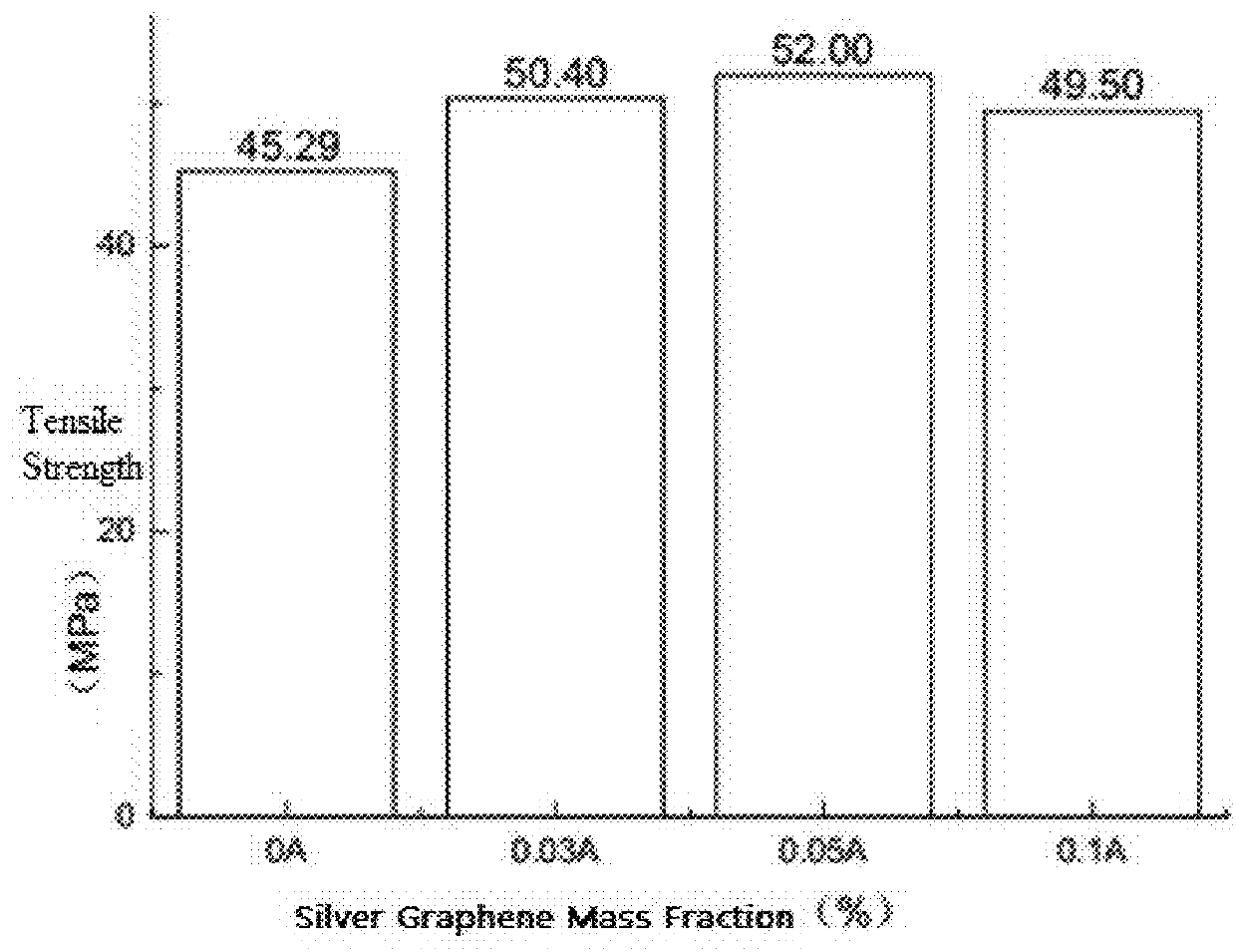

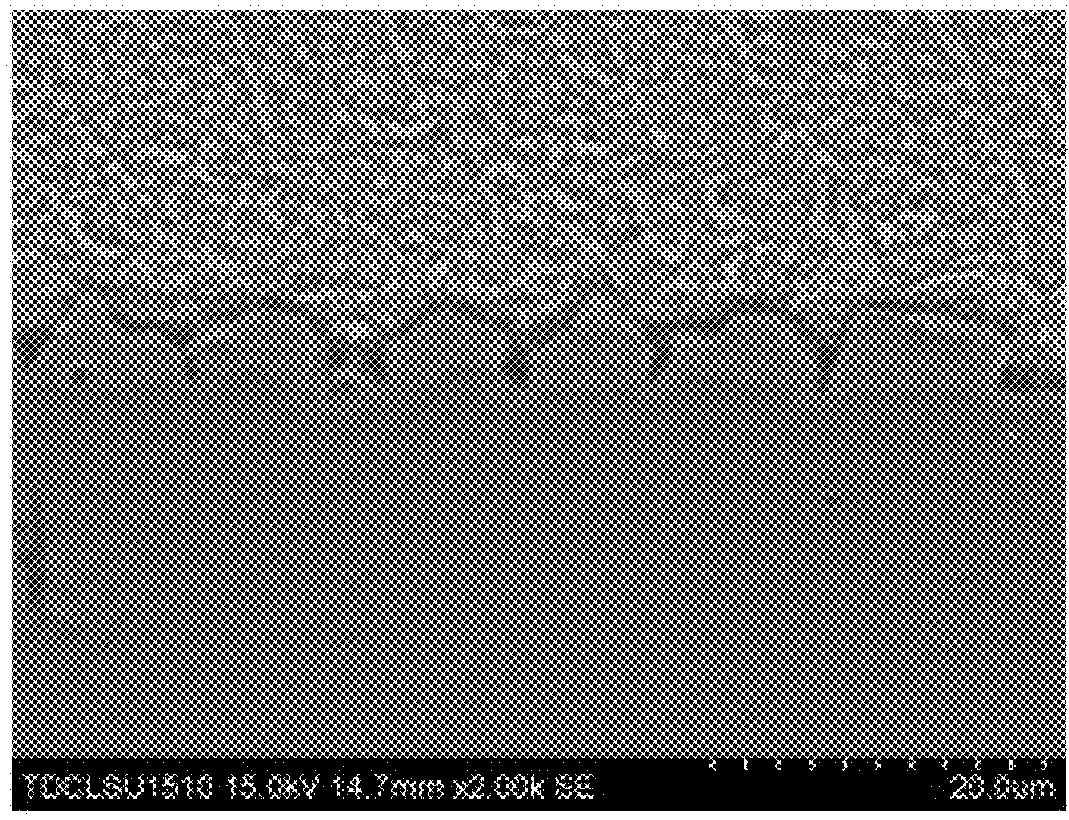

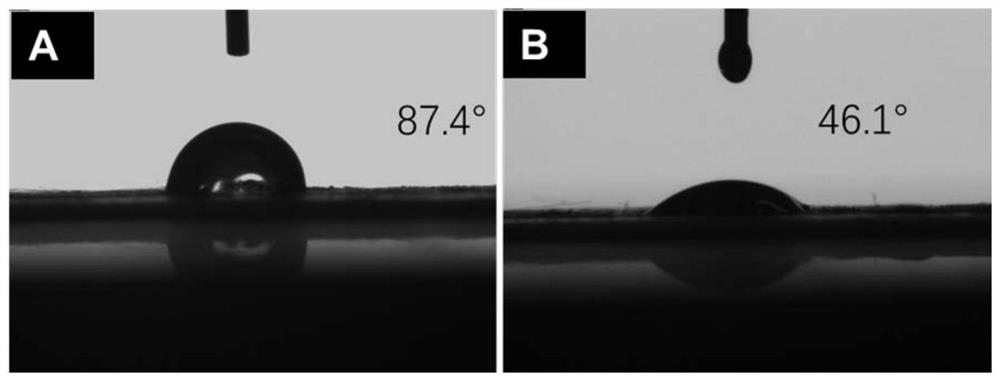

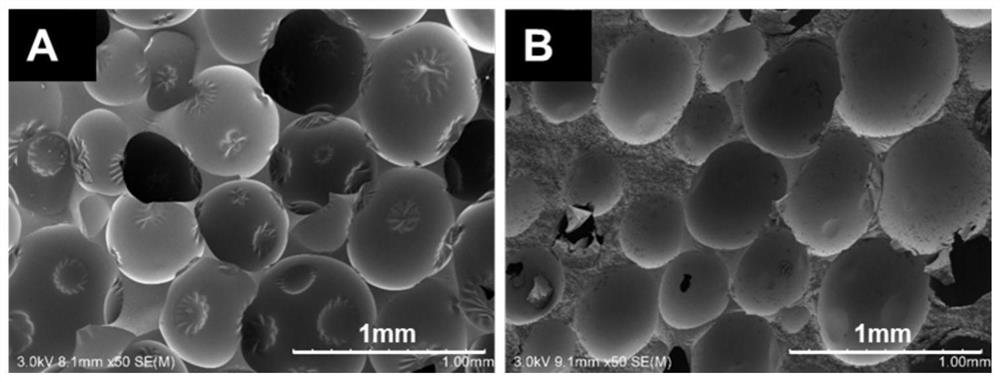

Preparation method of tin-based silver graphene lead-free composite solder

InactiveCN105171277AImprove distribution uniformityUniform compositionTransportation and packagingWelding/cutting media/materialsSolder matrixRoom temperature

The invention discloses a preparation method of tin-based silver graphene lead-free composite solder. The method comprises the steps that a certain amount of graphene and lauryl sodium sulfate are mixed, then a certain amount of dimethylformamide is added, ultrasonic treatment is performed for 2 h, a certain amount of silver nitrate is added into a mixed solution, ultrasonic treatment is performed continuously, and finally a self-made silver graphene nanosheets are obtained; and required solder matrix powder is weighed according to different graphene mass fractions and poured into a ball milling tank for ball milling for 5 h, the powder is placed into a stainless steel mold after being dried and placed under a hydraulic machine to be pressed and molded at the pressure of 500 Mpa, and then a cylinder obtained through cold pressing is placed into a high-vacuum tubular resistance furnace for vacuum sintering for 2 h at the temperature of 175 DEG C and placed under the hydraulic machine after being cooled to the room temperature to obtain a cylinder through impact extrusion. According to the preparation method, Ag-particle-modified graphene is selected as a strengthening material so as to improve load transmitting between the nano-silver-modified graphene and a Sn matrix, and therefore the better strengthening effect is achieved.

Owner:TIANJIN UNIV

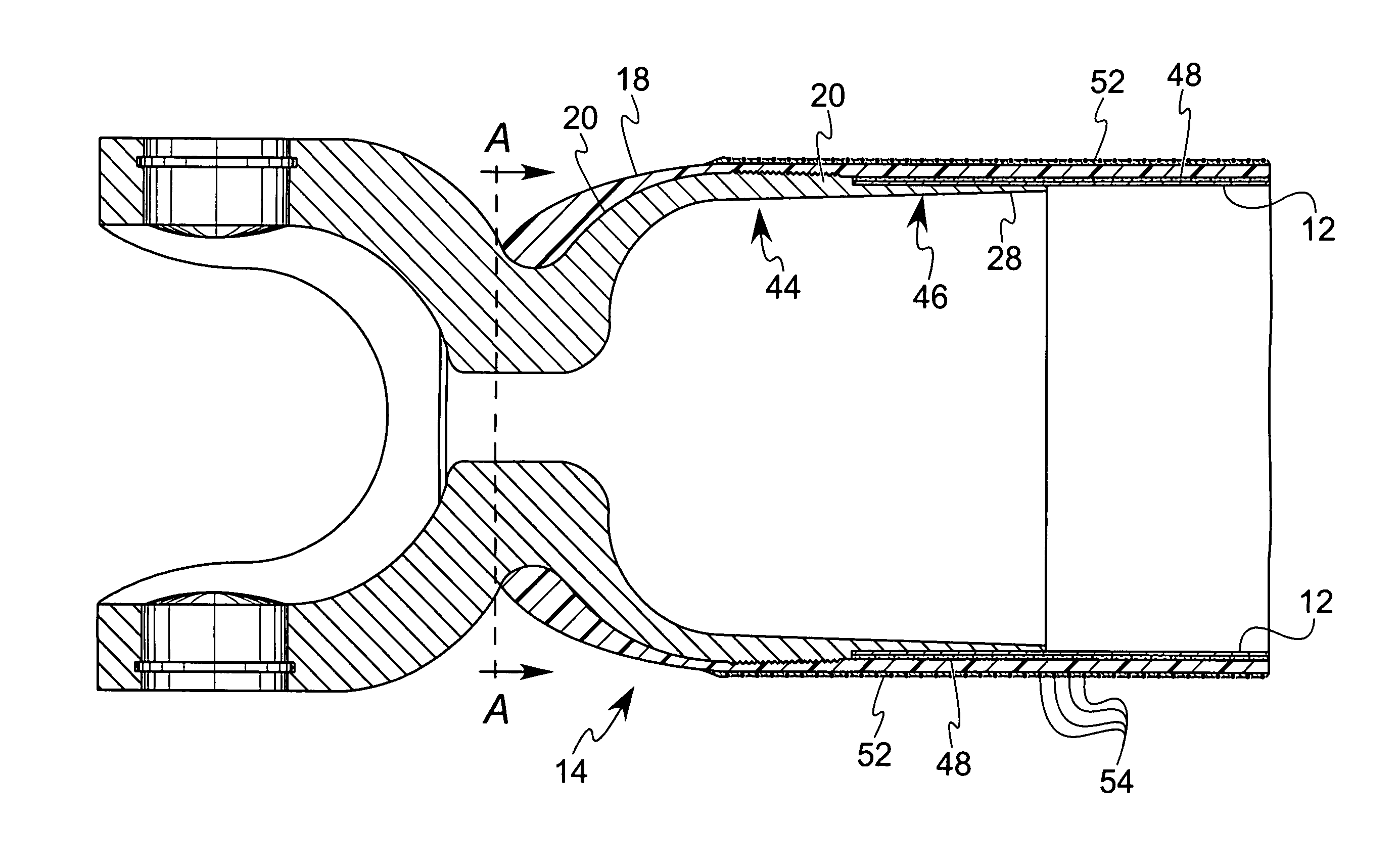

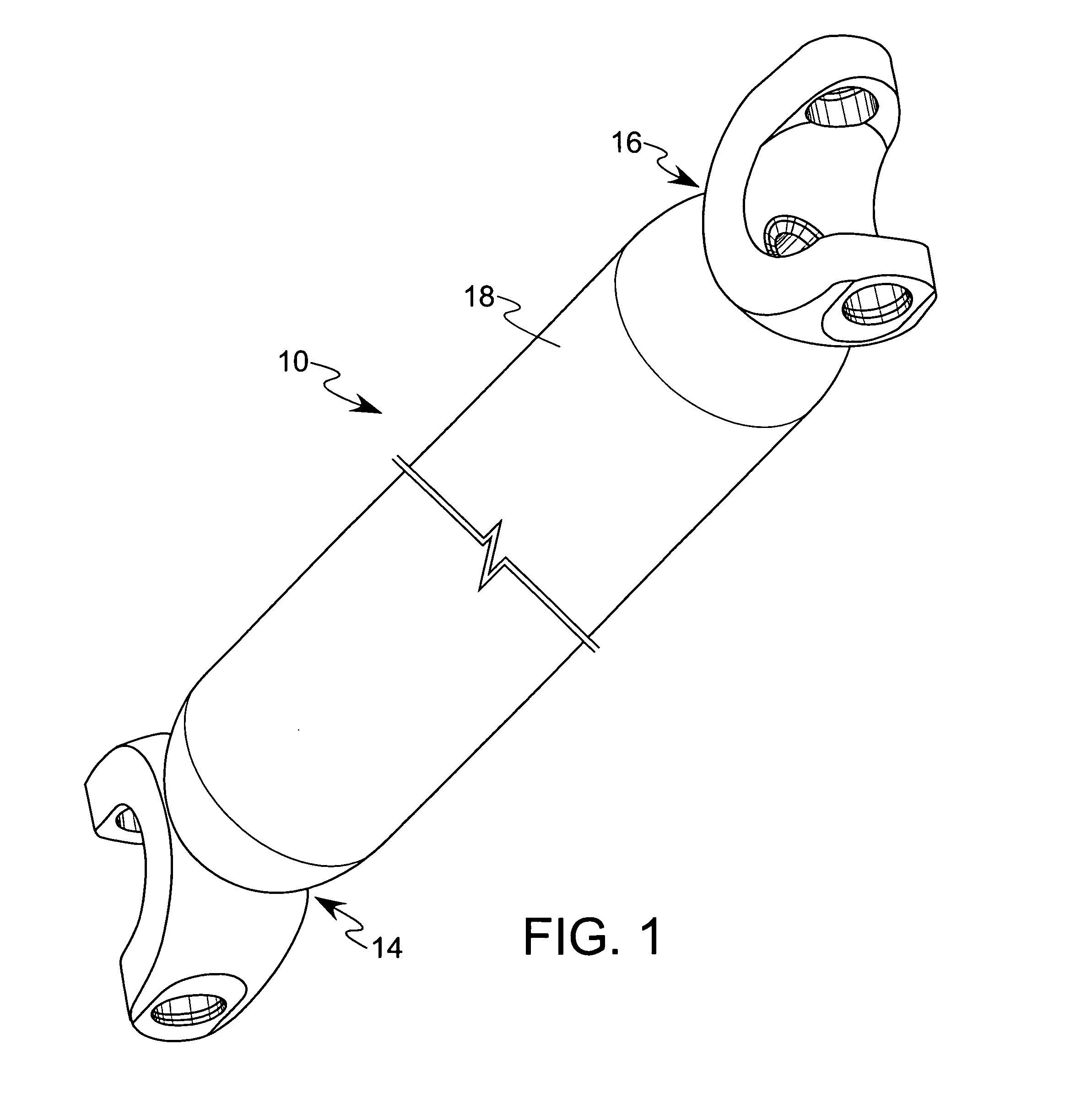

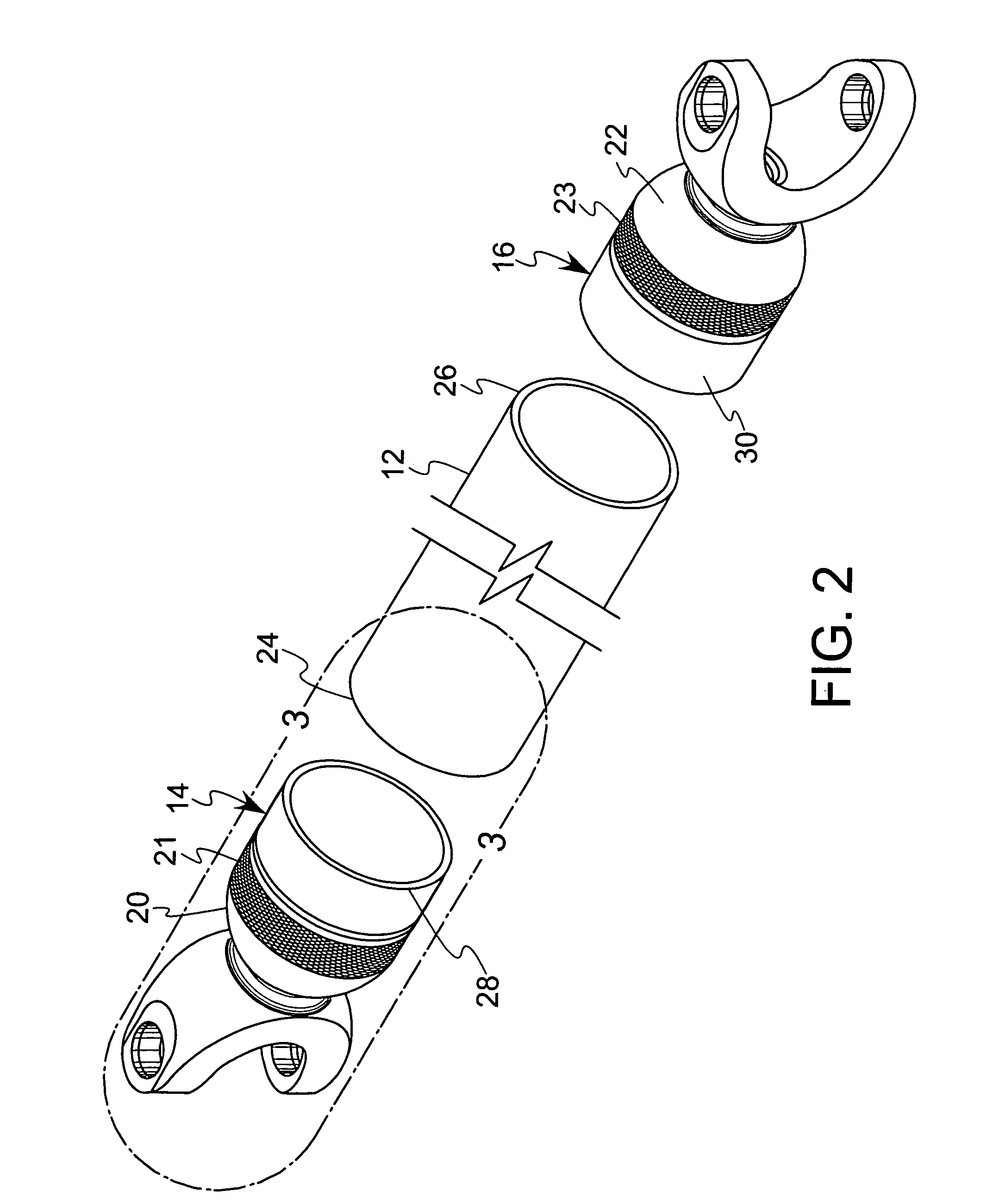

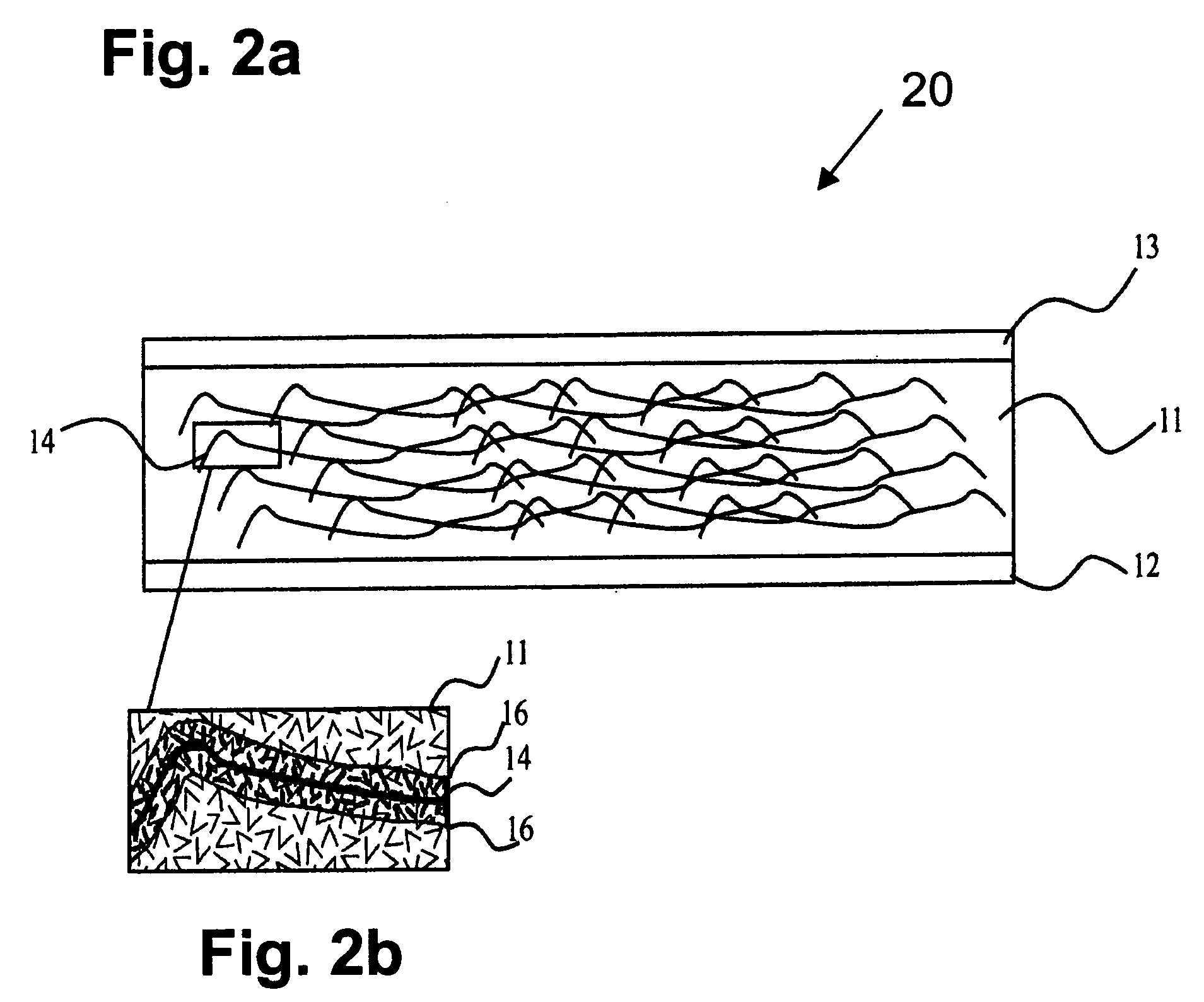

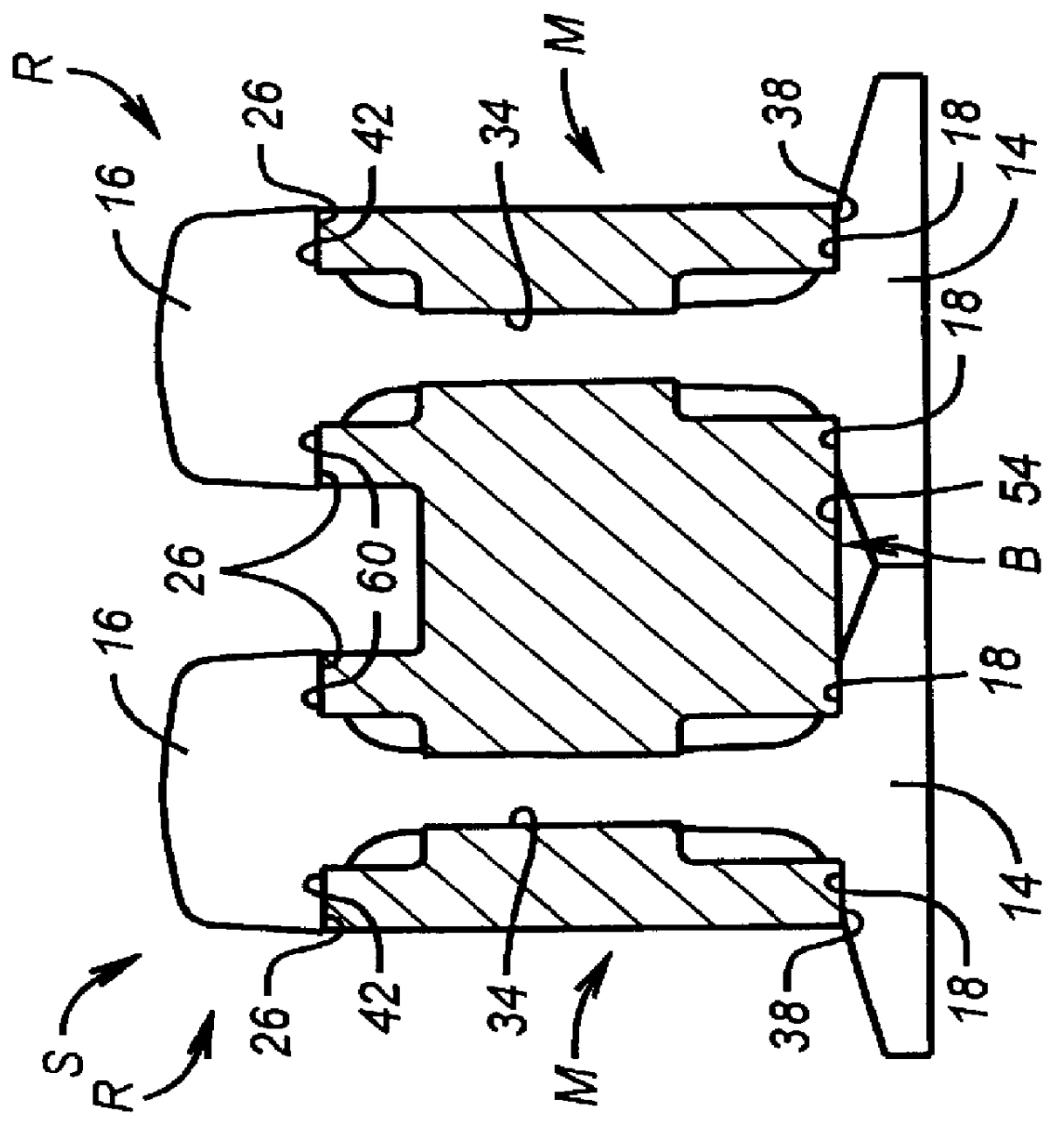

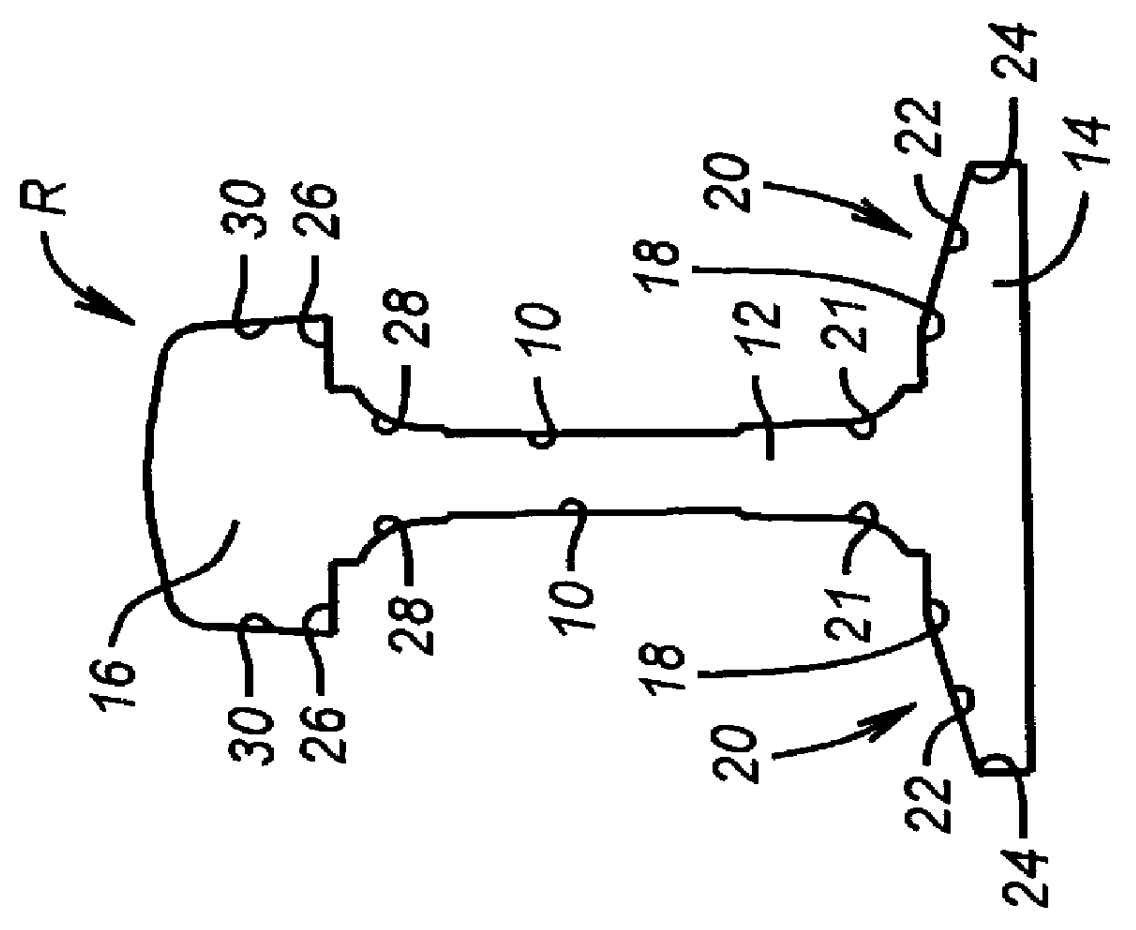

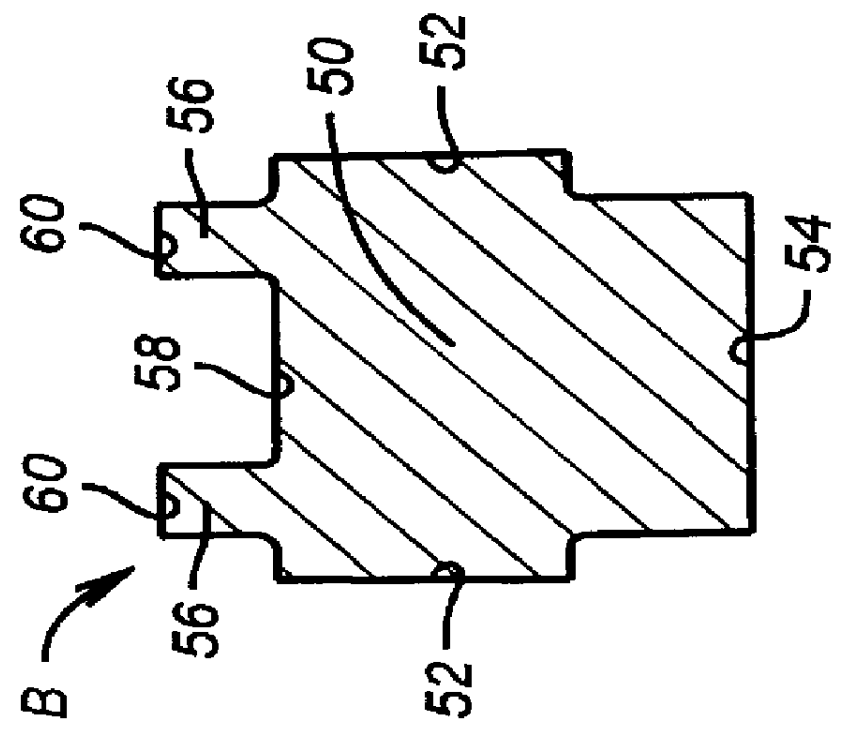

Load sharing composite shaft

InactiveUS7427237B2Good load transferImprove structural strengthYielding couplingShaftsTorsional ForcesEngineering

A composite shaft for transmitting torsional forces between end pieces of the shaft. The shaft includes an inner tube member with an end piece mounted at each end of the tube. A composite material is provided covering the inner tube member and at least a portion of the end pieces. The composite material includes elongated fibers oriented at a predetermined angle which optimizes the strength of the shaft for a desired shaft performance, and the shaft is constructed to provide multiple load paths between the end pieces.

Owner:BURKETT JERALD S

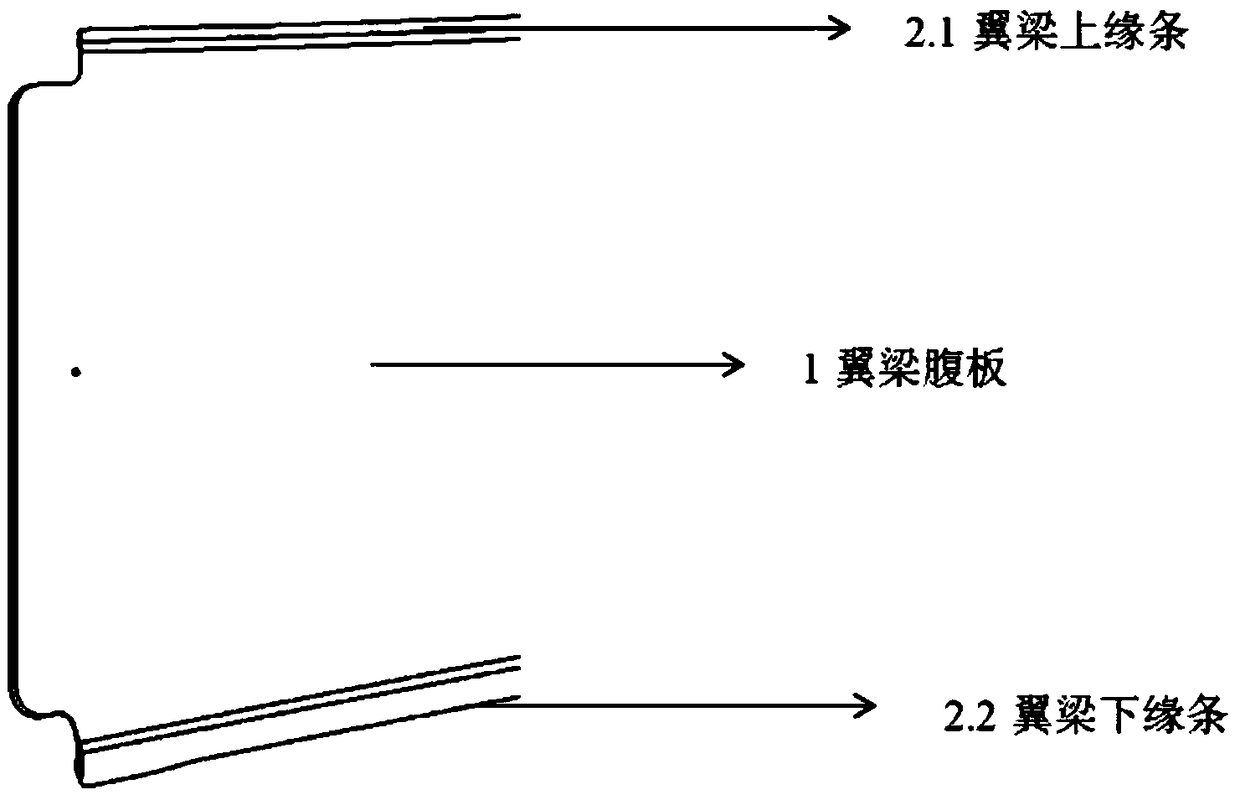

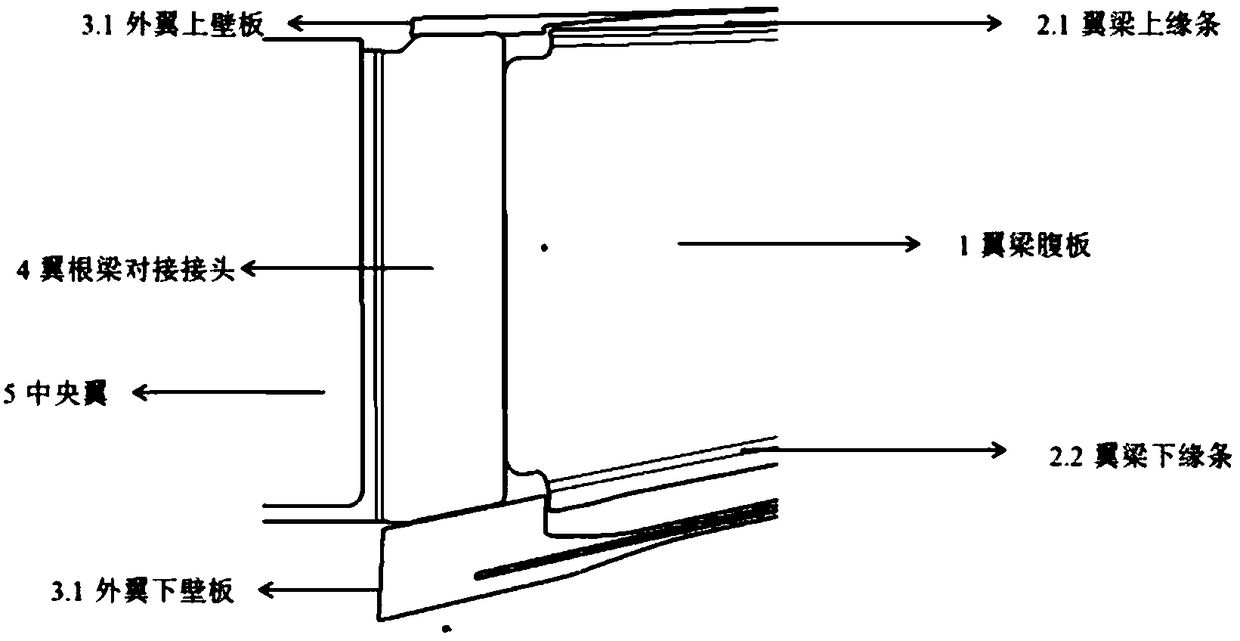

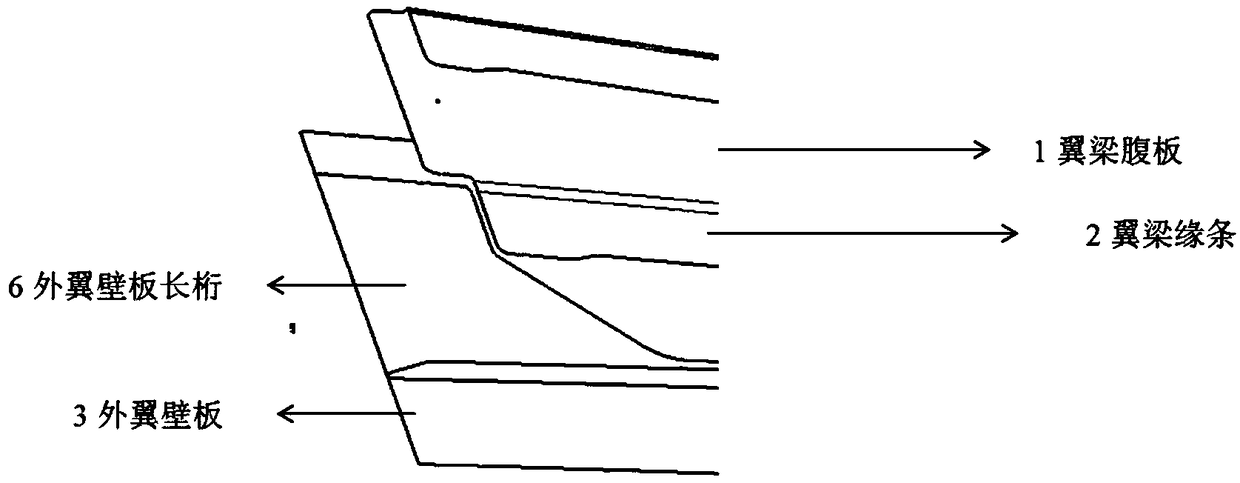

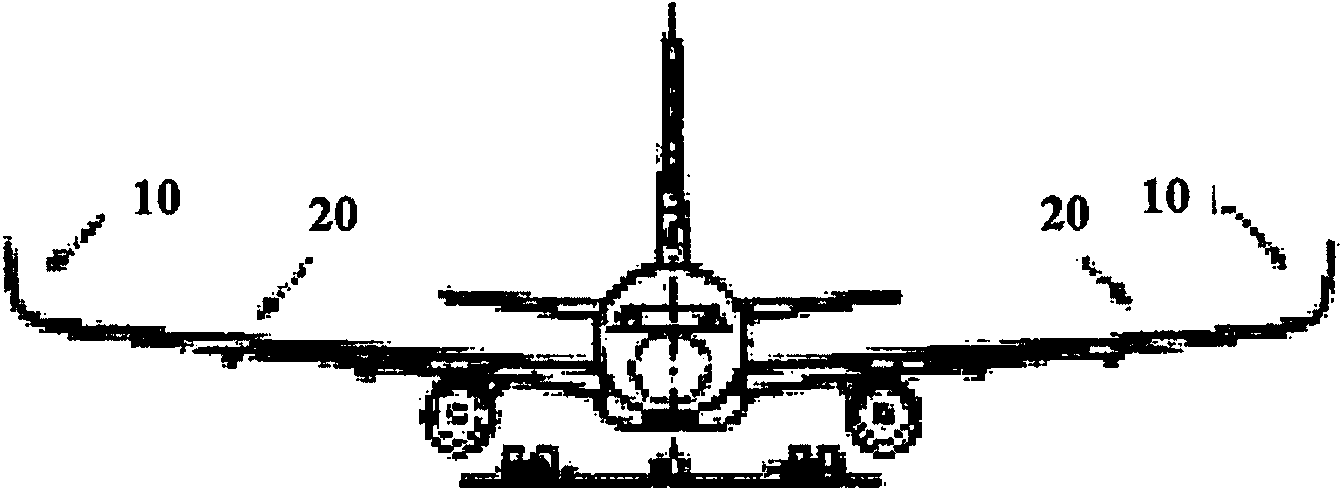

Aircraft composite material wing spar and wing butt zone connection structure

ActiveCN109484624ASimplify the power transmission pathSimplify efficiencySpars/stringersStress concentrationFiber

The invention provides an aircraft composite material wing spar and wing butt zone connection structure. In the structure, a wing spar has a C-type configuration, and is formed by a spar web, a spar upper flange and a spar lower flange; the composite material wing spar is prepared by adopting processes of manual pasting, automatic tape-laying with thermal diaphragm forming, automatic fiber-placement and the like; the wing spar is connected with an outer wing wall plate and a connection joint by adopting fastening parts; and the wing spar is arranged at the joint of a wing butt, is stopped in advance according to the butt joint requirement, is not directly butted with a wing butt, a wing rib or center wing spar, can be used for cutting an end socket to avoid stress concentration caused in avariable cross-section zone when load is transferred, and can perform fillet treatment on an edge zone.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

Reinforced carbon nanotubes

InactiveUS20060043649A1Improve mechanical propertiesHigh strengthMaterial nanotechnologyCeramic shaping apparatusCarbon nanotubeCarbide

Owner:BOSTON COLLEGE

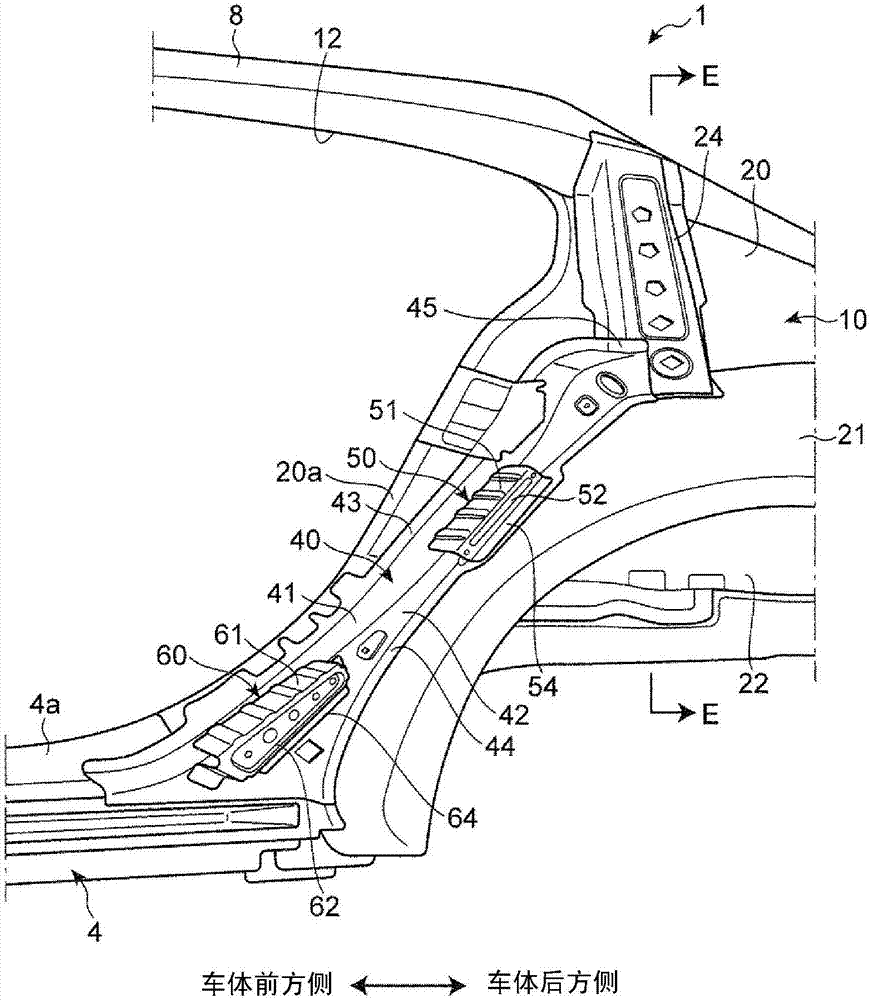

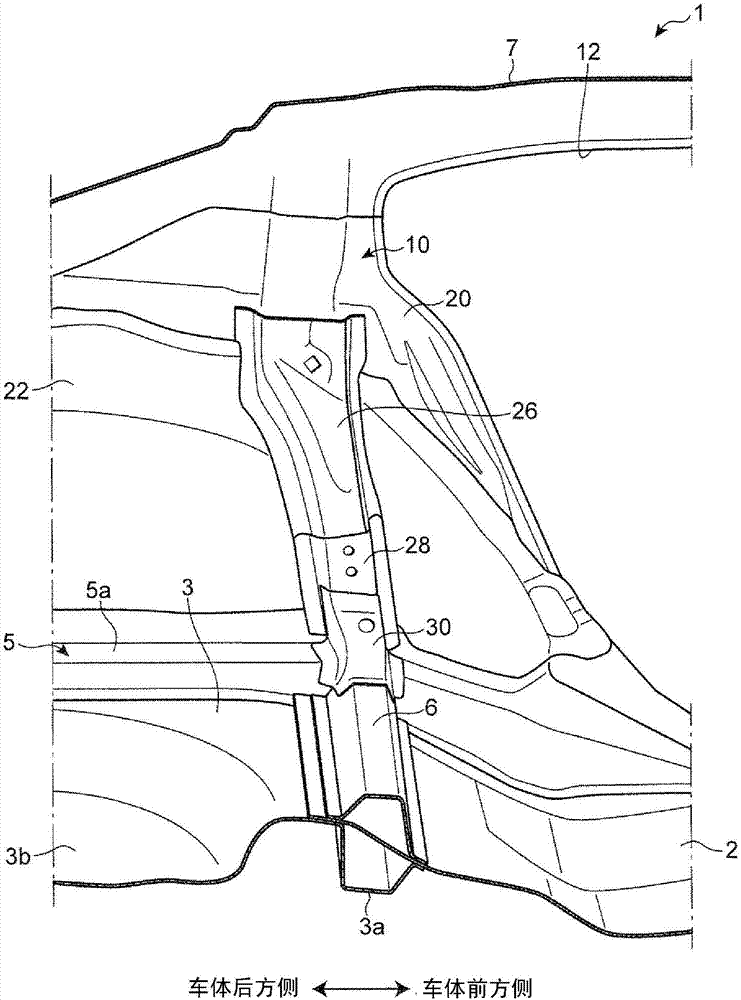

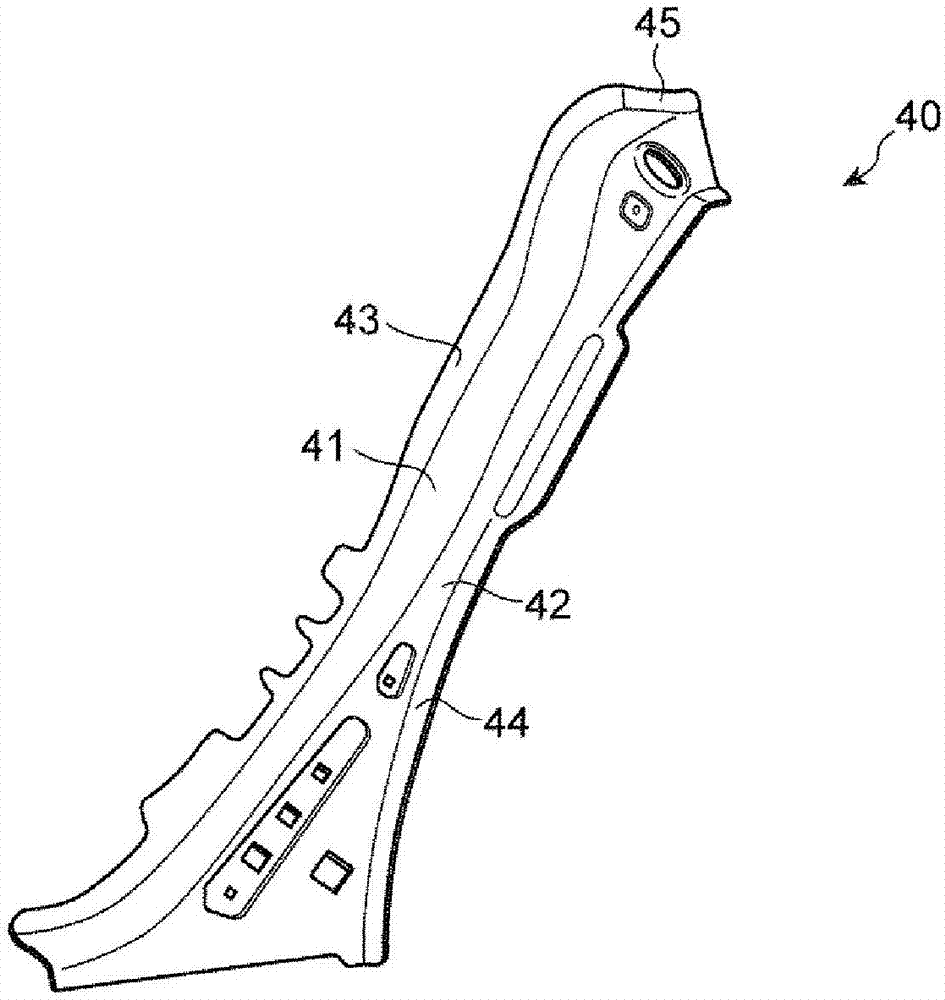

Side vehicle-body structure of automotive vehicle

ActiveCN107031731AReduce the size of the vehicle width directionInhibition of local bucklingUnderstructuresSuperstructure subunitsControl theoryMechanical engineering

The invention provides a side vehicle-body structure of an automotive vehicle. The side vehicle-body structure can increase the effects of impact absorption when an impact load is input to a side door from a vehicle body side and the effects of load diffusion to each part of the vehicle body. The side vehicle-body structure includes: a side door which is formed on a side surface part of the vehicle body and opens and closes an opening part for getting on and off from a rear seat; an anti-collision pole which is disposed on the side door in a manner that the anti-collision pole extends along the front and rear direction of the vehicle body; a side plate internal side member which constitutes a vehicle side part which includes a peripheral part on vehicle body rear side of the opening part for getting on and off; a first reinforcing part which extends along the peripheral part on the vehicle body rear side of the opening part for getting on and off and engages the outside of a compartment of the side plate internal side member so as to form a first closed cross section with the side plate internal side member; a second reinforcing member which is configured such that the second reinforcing member is partly overlapped with the anti-collision pole when the side door is closed if viewed from the vehicle body side and the second reinforcing member engages the outside of the compartment of the first reinforcing member so as to form a second closed cross section with the first reinforcing member.

Owner:MAZDA MOTOR CORP

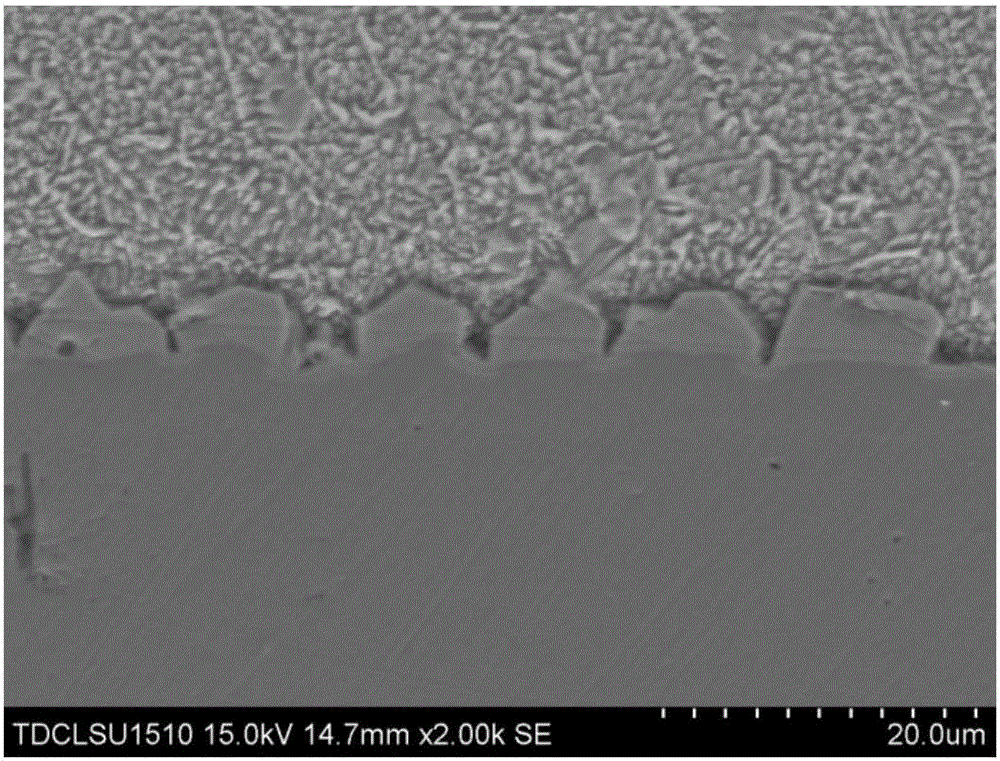

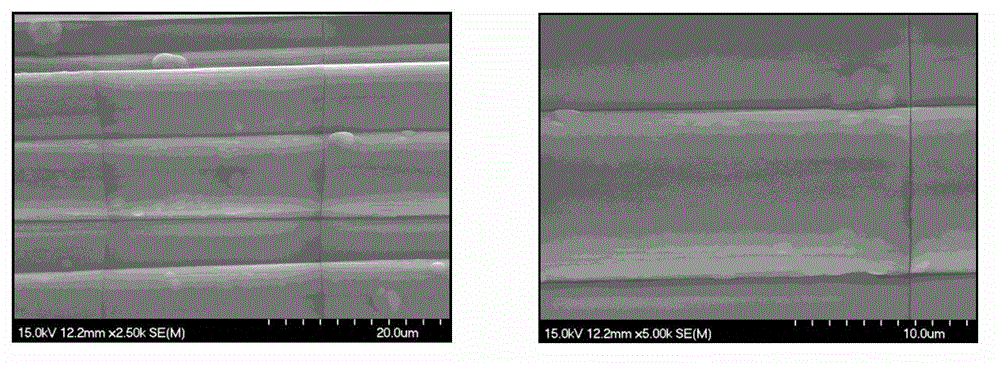

Polymeric bonding of glass fiber reinforcements with silane based coatings in gypsum board

ActiveUS7235288B2High strengthImprove bending resistanceSynthetic resin layered productsCeramic layered productsCross-linkSilanes

A bond is created between a gypsum matrix formed from an aqueous acidic gypsum slurry comprising a monomer mixture. The monomer mixture is composed of a monomer having acidic functionality and a monomer having hydroxyl or amine functionality. A silane-based sizing composition is coated onto glass fibers causing a cross-linking network of silane and monomer mixture to form during curing of the gypsum board. Hydrophilic water extraction at the gypsum matrix-sizing interface reduces void formation and promotes bonding with the crosslinked monomer mixture and growth of smaller gypsum crystals within larger crystals in microstructurally identifiable regions adjacent to the glass fiber. A bond is created between a gypsum matrix formed from an aqueous acidic gypsum slurry comprising a monomer mixture. The monomer mixture is composed of a monomer having acidic functionality and a monomer having hydroxyl or amine functionality. A silane-based sizing composition is coated onto glass fibers causing a cross-linking network of silane and monomer mixture to form during curing of the gypsum board. Hydrophilic water extraction at the gypsum matrix-sizing interface reduces void formation and promotes bonding with the crosslinked monomer mixture and growth of smaller gypsum crystals within larger crystals in microstructurally identifiable regions adjacent to the glass fiber. Alternatively, the silane based sizing composition has branched chains that diffuse into a wet gypsum mix containing the monomer mixture. During gypsum cure, the diffusion and crosslinking of monomer mixture triggers formation of interpenetrating pseudo polymeric networks within a microstructurally identifiable region adjacent to the glass fiber. Bonds formed between the gypsum matrix and the silane based sizing composition increase the strength, flexure resistance and nail pull out resistance of the gypsum board.

Owner:JOHNS MANVILLE CORP

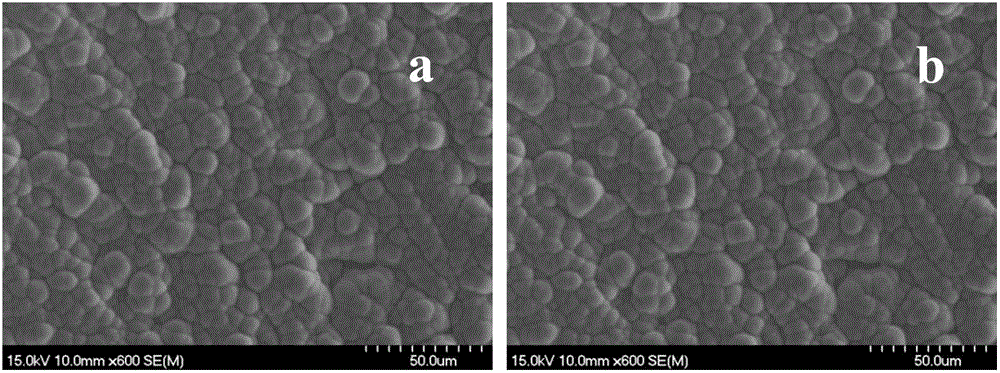

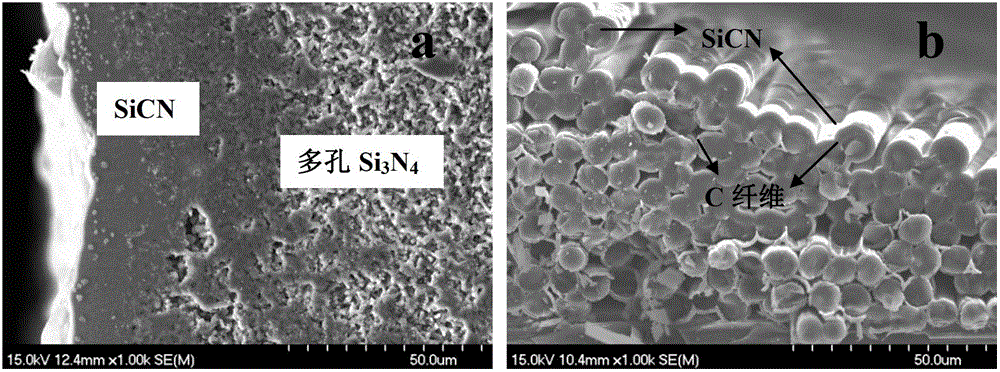

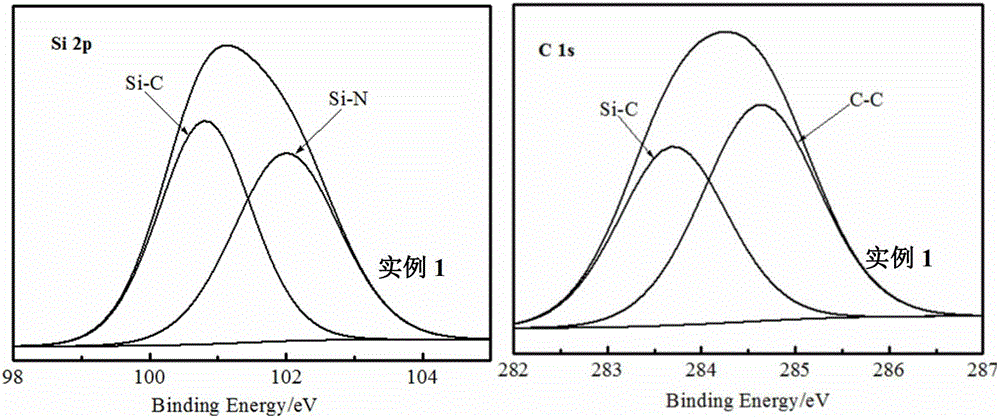

Preparing method of silicon-carbon-nitrogen wave absorbing ceramic base composite materials

The invention relates to a preparing method of silicon-carbon-nitrogen (SiCN) wave absorbing ceramic base composite materials. The preparing method includes: adopting chemical vapor deposition (CAD) or chemical vapor infiltration (CAI) technology, using SiC14, SiHC13 or other chlorine silicon compounds or silicane as a silicon source, using CH4, C3H6, C2H2 or other alkane, olefin or alkyne as a carbon source, using NH3 or N2 as a nitrogen source, using H2 as a carrier gas and a reaction gas, using argon as a diluting gas, synthesizing SiCN on substrate materials in situ, and obtaining a SiCN matrix and a coating which are uniform and compact, without impurities, and with devisable compositions and wave absorbing properties. The preparing method overcomes the shortcoming that CFCC-SiC prepared by adopting the prior art is insufficient in wave absorbing performance, and simultaneously facilitates achieving control of compositions, permeability, thickness and wave absorbing performance of a wave absorbing matrix.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Flat and planar match system between rails and fillers to railroad turnouts and crossings

InactiveUS6119988AEase of alignmentSolve the quick installationRail switchesEngineeringUltimate tensile strength

Owner:RIVAS ARTURO A ORTIZ

Preparation method for silicon nitride matrix

The invention relates to a preparation method for a silicon nitride matrix, which is mainly used for the preparation of fiber toughening ceramic matrix composite materials and porous ceramic material matrixes. The preparation method comprises the following steps of depositing a silicon nitride matrix / coating on the inner side / surface of a substrate material by a chemical vapor infiltration / chemical vapor deposition technology; and adjusting the deposition velocity, the deposition thickness and the infiltration uniformity of a ceramic matrix by controlling process parameters. According to the preparation method, the prepared silicon nitride matrix has the characteristics of deep deposition and infiltration depth, good combination with the substrate, high performance and the like by means of the advantages of a chemical vapor infiltration / chemical vapor deposition process. Combined with the ware transmission property of the silicon nitride matrix, the preparation method has the advantage that a foundation of integration design of structures and functions of the continuous fiber toughening ceramic matrix composite material is laid.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Silane based coatings on glass fiber reinforcements in gypsum board

InactiveUS20050202227A1High strengthImprove bending resistanceBuilding componentsNon-woven fabricsGlass fiberSilanes

A bond is created between a gypsum matrix and a silane-based sizing composition coated onto a glass fiber and gypsum matrix during manufacture of gypsum board. Hydrophilic water extraction at the gypsum matrix-sizing interface reduces void formation and promotes the growth of smaller calcium sulphate dihydrate crystals within larger calcium sulphate dihydrate crystals in microstructurally identifiable regions adjacent to the glass fiber. The resulting gypsum board exhibits excellent strength, flexure resistance and nail pull out resistance. An alternative approach utilizes a silane based sizing composition having branched chains that diffuse into a wet gypsum mix. During gypsum cure, the diffusion triggers formation of pseudo polymeric networks in a microstructurally identifiable region adjacent to the glass fiber. Bonds formed between the gypsum matrix and the silane based sizing composition increase the strength, flexure resistance and nail pull out resistance of the gypsum board.

Owner:JOHNS MANVILLE CORP

Preparation of Sn-based silver-graphene lead-free composite solders

InactiveUS20180272476A1Improve load transferImprove reliabilityTransportation and packagingWelding/cutting media/materialsCvd grapheneSonication

This invention discloses a method for preparing a kind of Sn-based silver-graphene lead-free composite solder, including mixing a certain amount of graphene with sodium dodecyl sulfate, then adding a certain amount of dimethylformamide, sonicating for 2 hours, adding a certain amount of silver nitrate to the mixture, continuing the sonication and finally obtaining the homemade. The solders matrix powder is weighed according to different silver-graphene mass fraction required, then poured into a ball-milling tank milling for 5 h. The powder is poured into a stainless steel mold after drying, then placed under hydraulic pressure to 500 Mpa for pressure forming. Later, the cold-pressed cylinder is placed in a high vacuum tube resistance furnace and sintered at 175° C. for 2 hours. After cooling to room temperature, it is formed into a cylinder under the hydraulic press. In this invention, graphene modified with Ag particles is selected as a strengthening material so as to improve the load-transfer between the graphene modified by nano-silver and the Sn matrix, aiming to achieve better strengthening effect.

Owner:TIANJIN UNIV

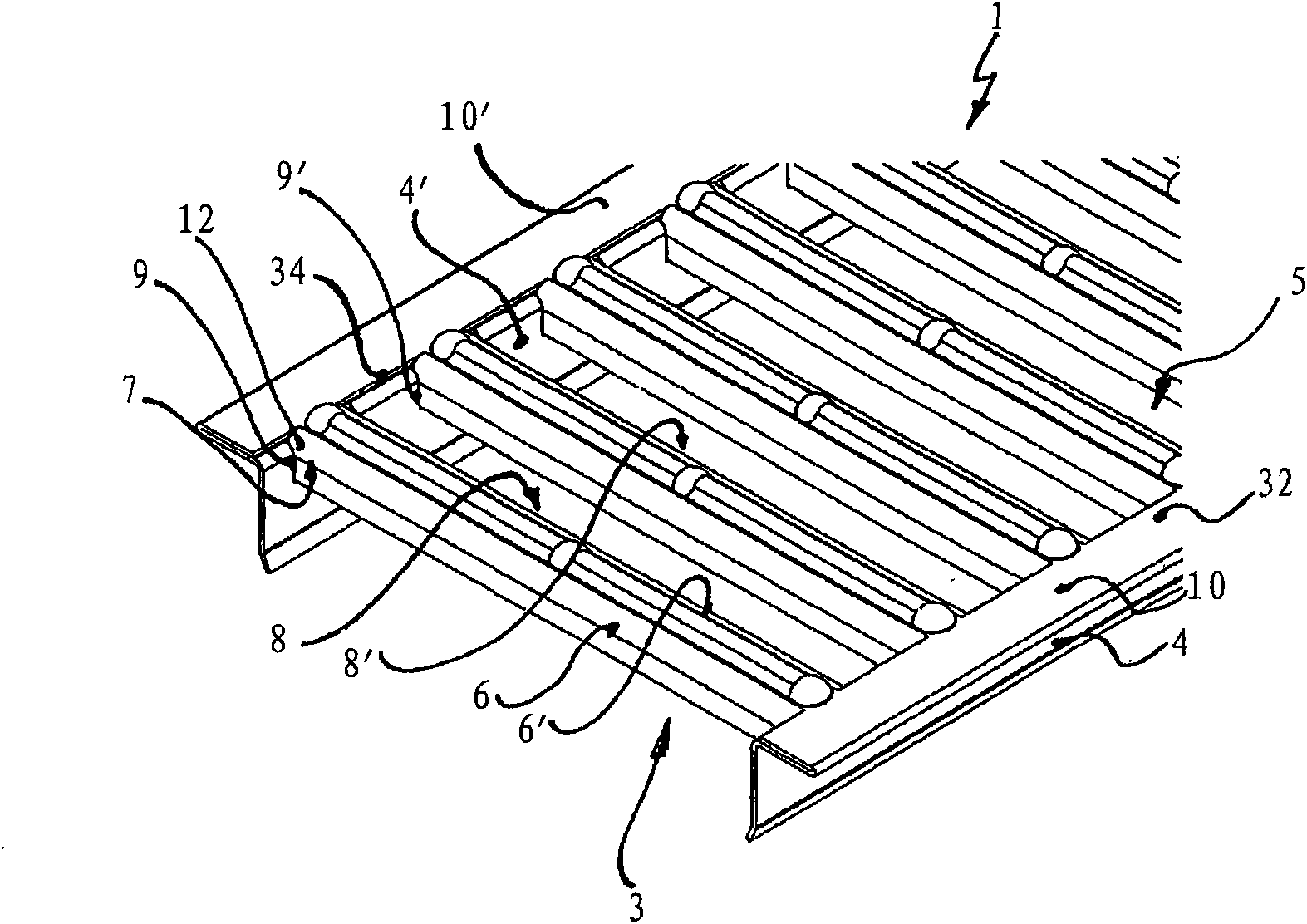

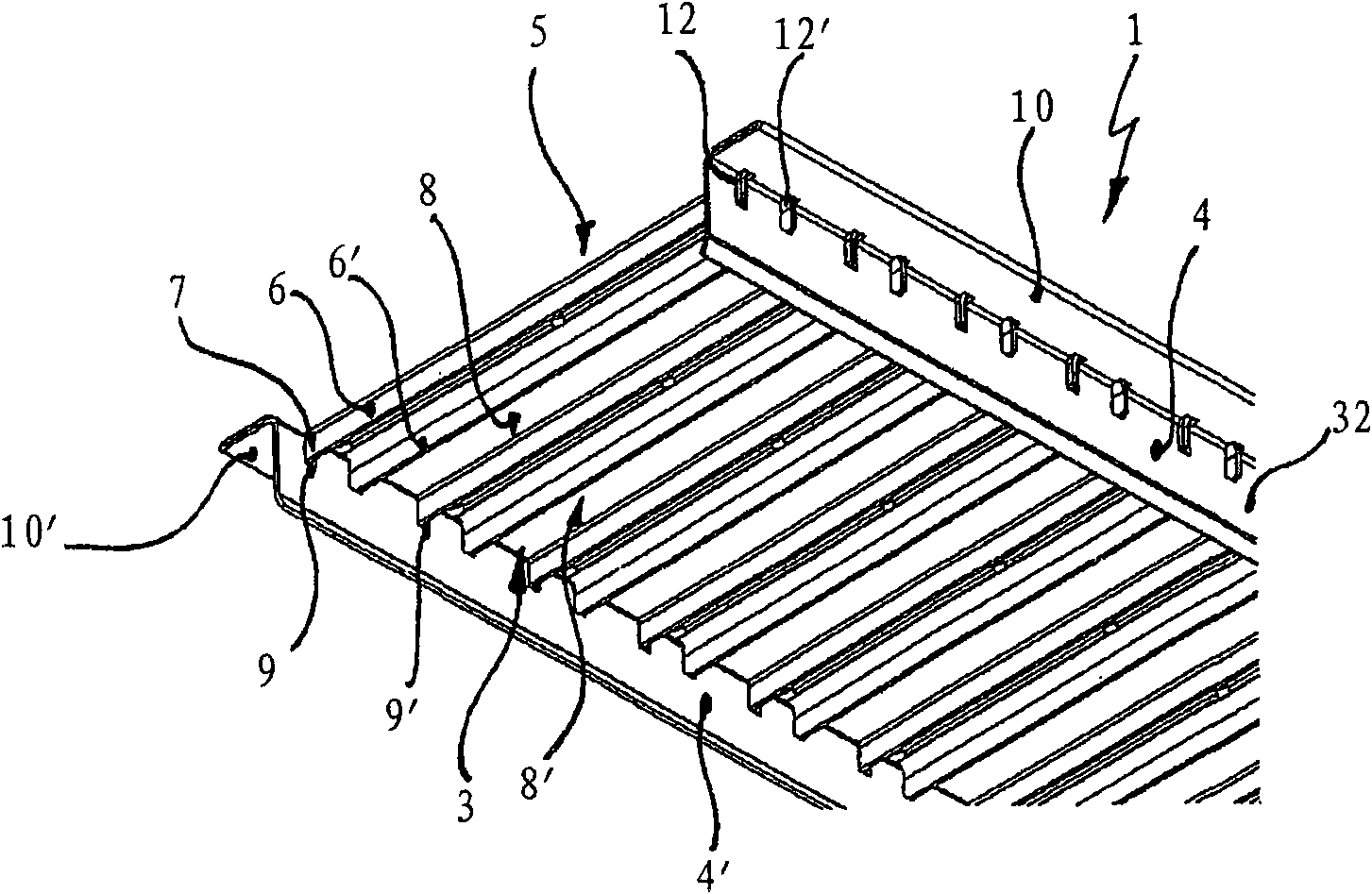

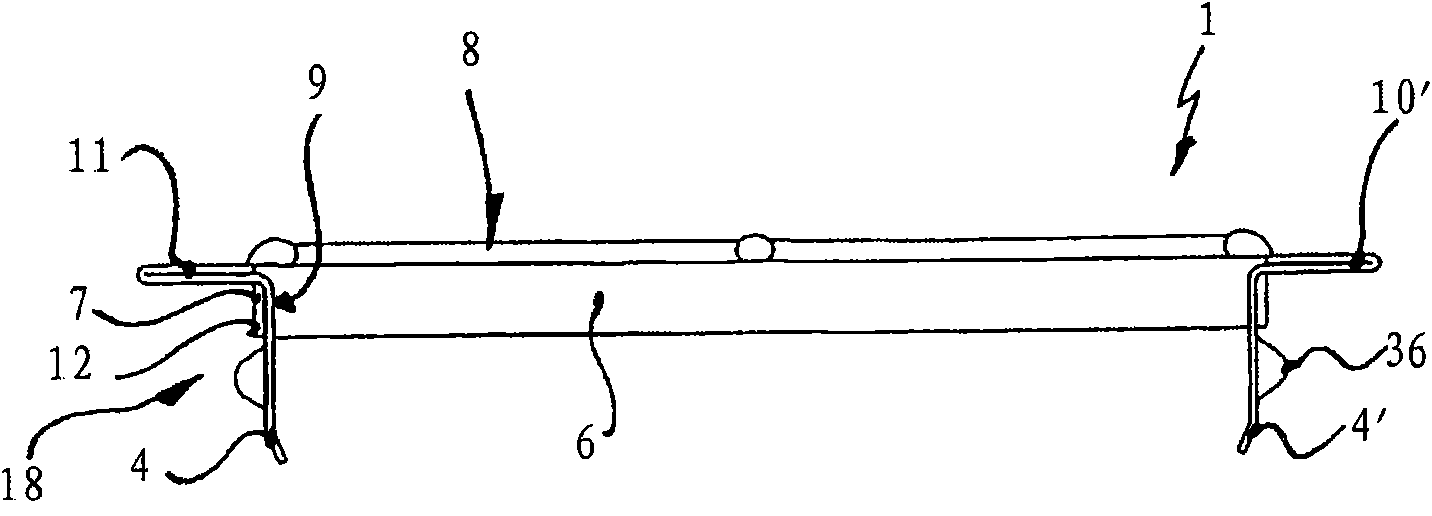

Grating

A cover grating for a drainage channel (20) or a similar hollow body which can be installed in the ground is presented, comprising at least two longitudinal webs (4) extending on a lower side (3) of the cover grating (1) and inlet slots (8) formed in the cover grating (1) between these longitudinal webs (4), and comprising transverse webs (6) resulting from the slot-forming operation and extending on the lower side (3) of the cover grating (1), wherein the transverse webs (6) are provided at each of their end regions (7) with at least one receiving projection (12) which at least partially engages into a respective complementarily formed receiving slot (9) in the longitudinal web (4).

Owner:ACO SEVERIN AHLMANN GMBH & CO KG

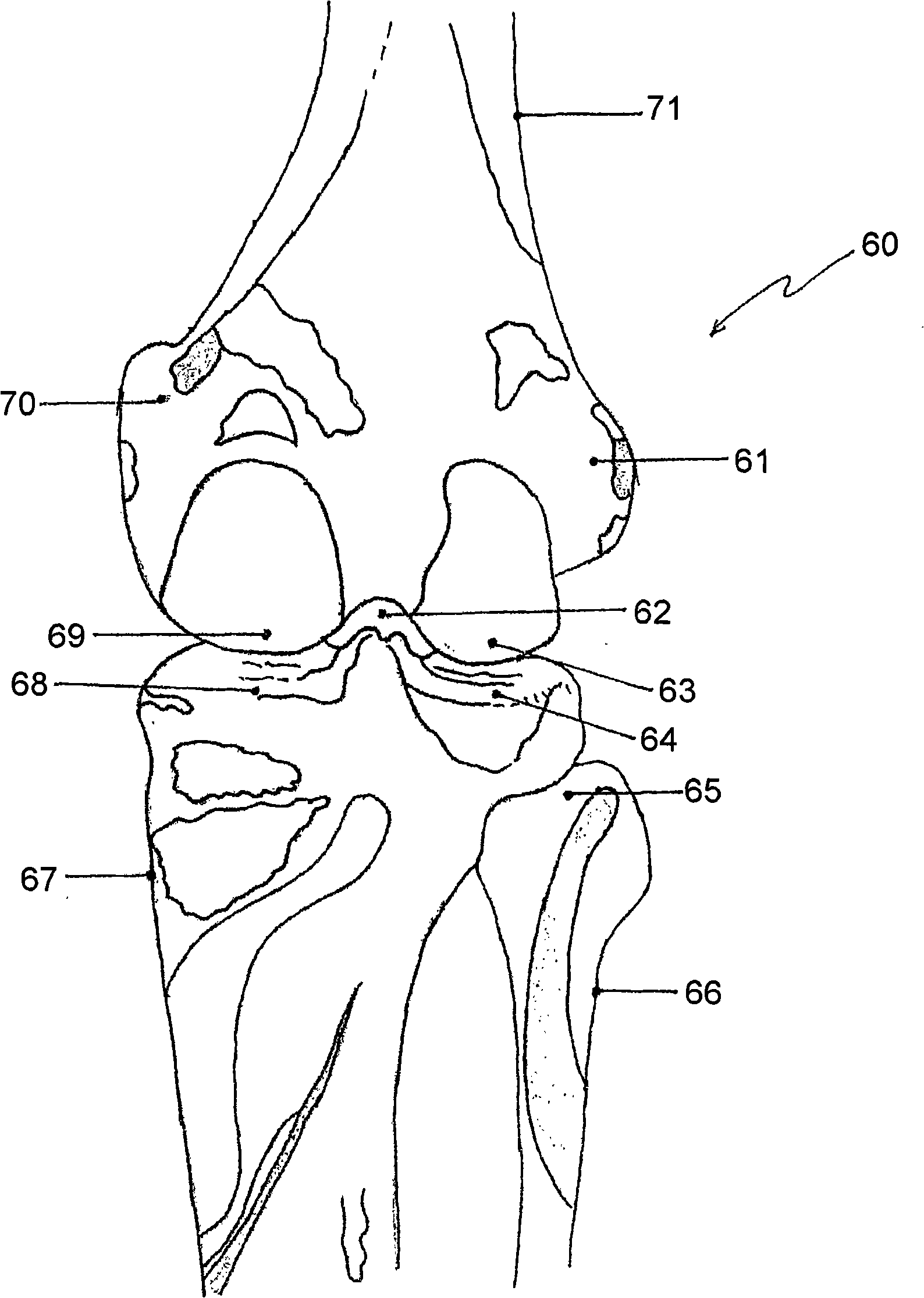

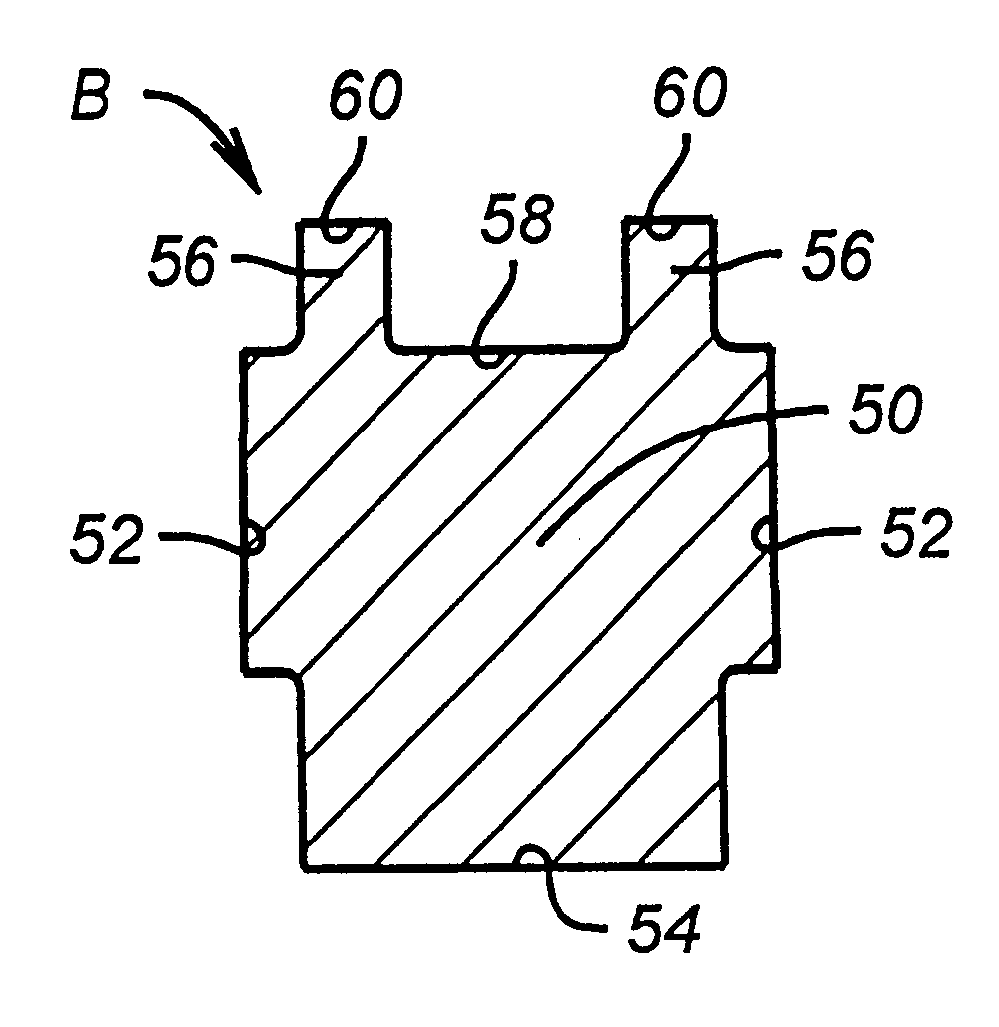

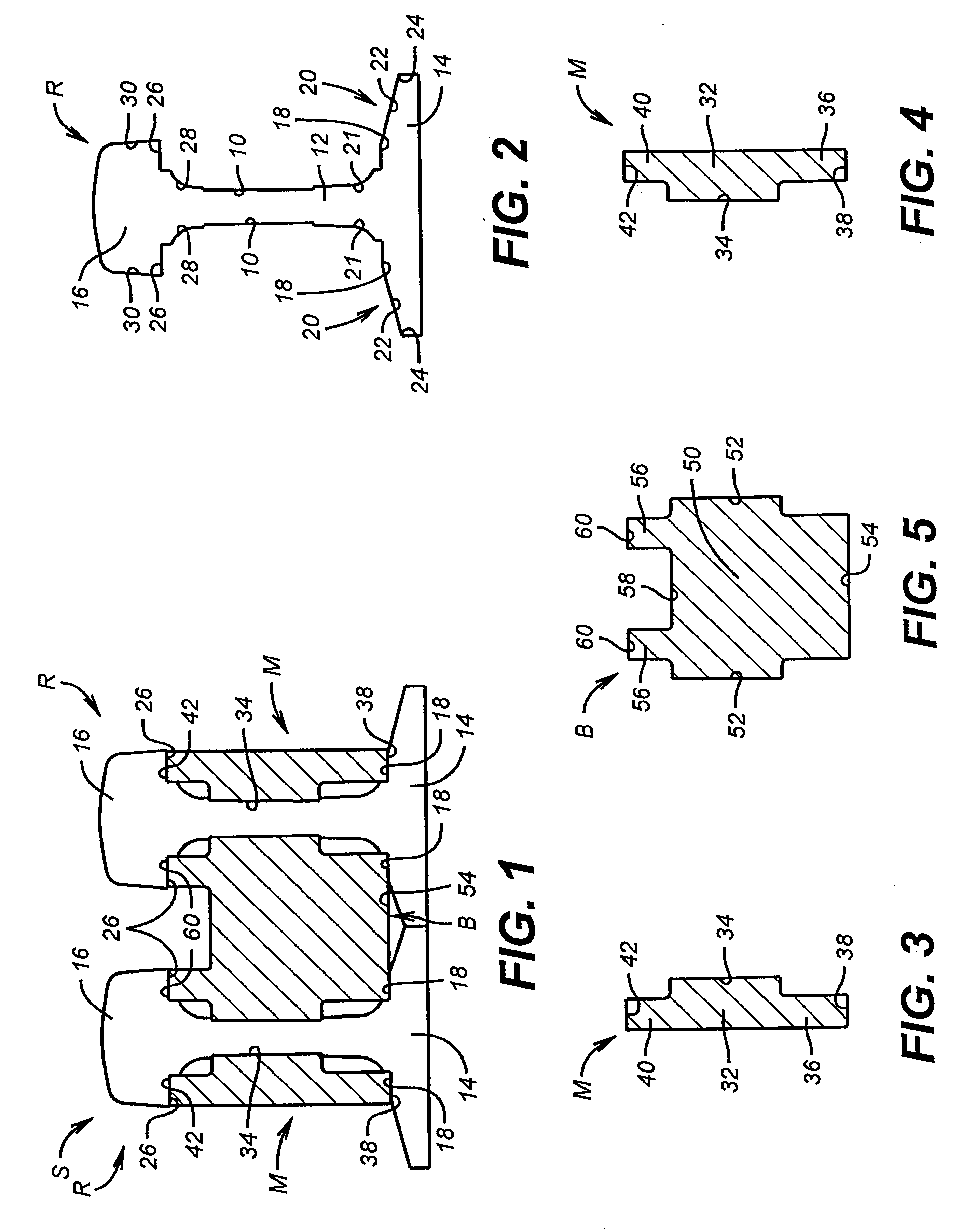

Knee joint prosthesis

A knee joint prosthesis is disclosed. The prosthesis has a femoral component and a tibial component. The tibial component has a tibial plateau element fitted in a tibial tray element. A hemi capstan shaped bridge member is provided between replicated condyles on the femoral component. A specially shaped post is provided between kidney shaped meniscal depression on the tibial plateau element. The bridge member and the post act together to form an additional joint for load transfer during deep flexion of the prosthesis in its operative configuration.

Owner:坎蒂拉尔·哈斯蒂马尔·桑切蒂

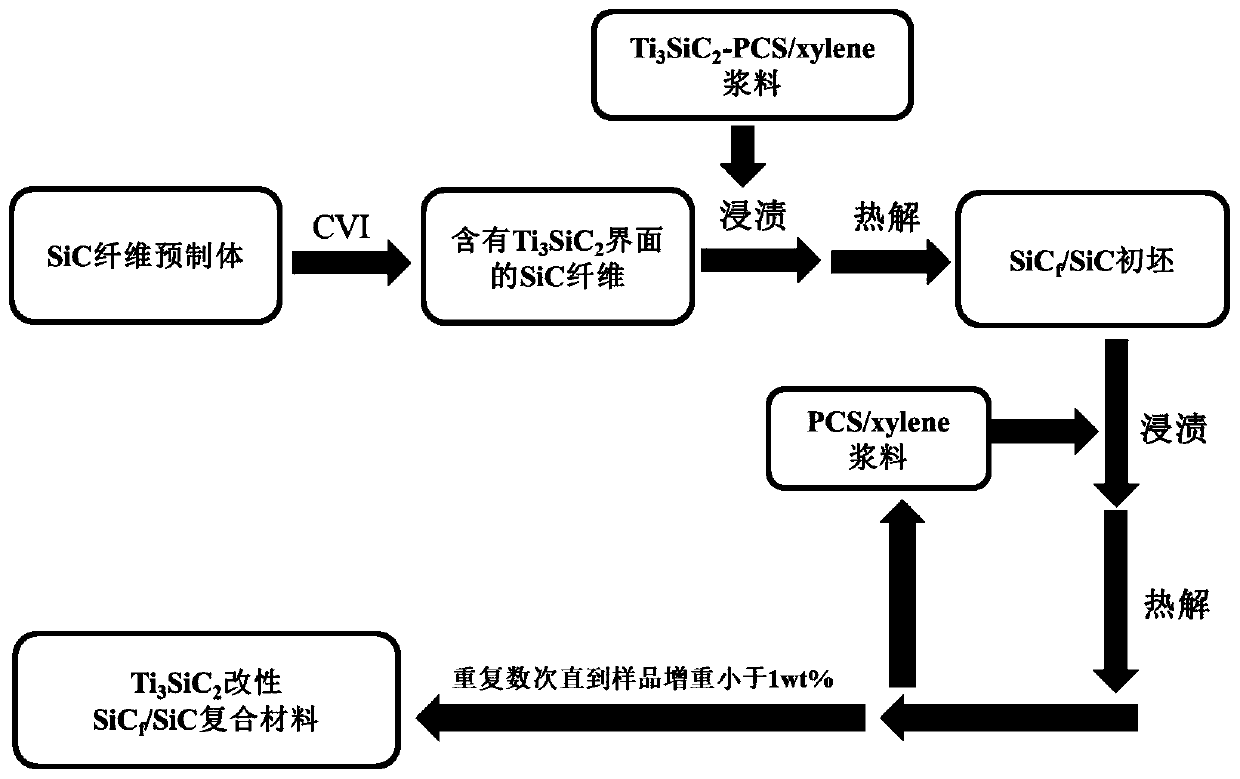

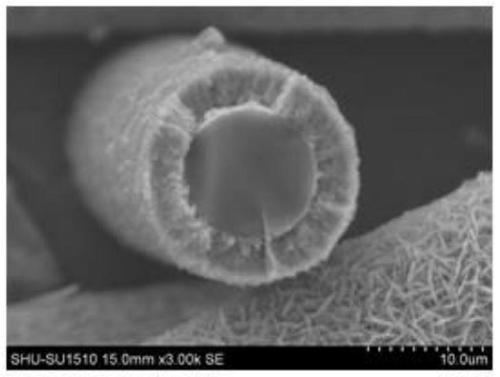

Titanium-silicon-carbon interface modified SiCf/SiC wave-absorbing composite material and preparation method thereof

ActiveCN111592371AReduce particle agglomerationReduce clumpingMagnetic/electric field screeningCarbide siliconSic fiber

The invention discloses a titanium-silicon-carbon interface modified SiCf / SiC wave-absorbing composite material and a preparation method thereof. The preparation method comprises the steps: putting asilicon carbide fiber prefabricated body in a constant-temperature area of a CVD furnace, and depositing a titanium-silicon-carbon interface layer on the surface of silicon carbide fibers through a chemical vapor infiltration method within a proper temperature range; and soaking in slurry containing polycarbosilane and titanium silicon carbon to be impregnated; and preparing the ceramic matrix composite material through a precursor impregnation pyrolysis method (PIP). The SiCf / SiC composite material containing the Ti3SiC2 interface is prepared, the process is simple, the cost is low, the dielectric constant of the wave-absorbing composite material is effectively regulated and controlled, and a good wave-absorbing effect is achieved.

Owner:SHANGHAI UNIV +1

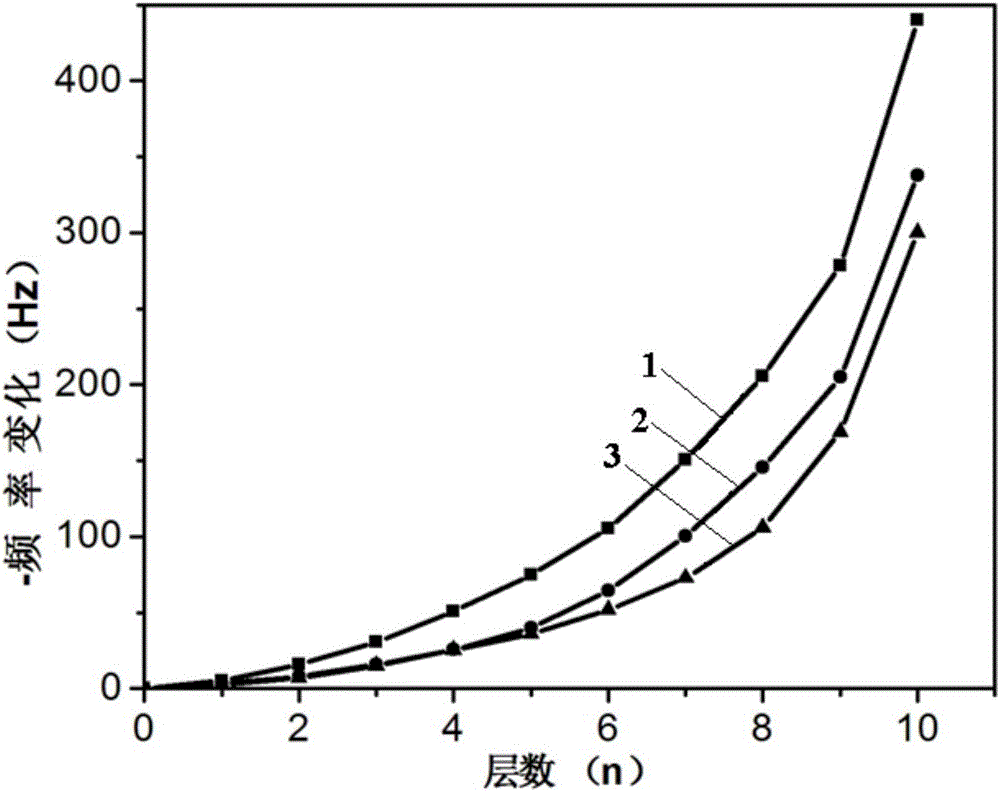

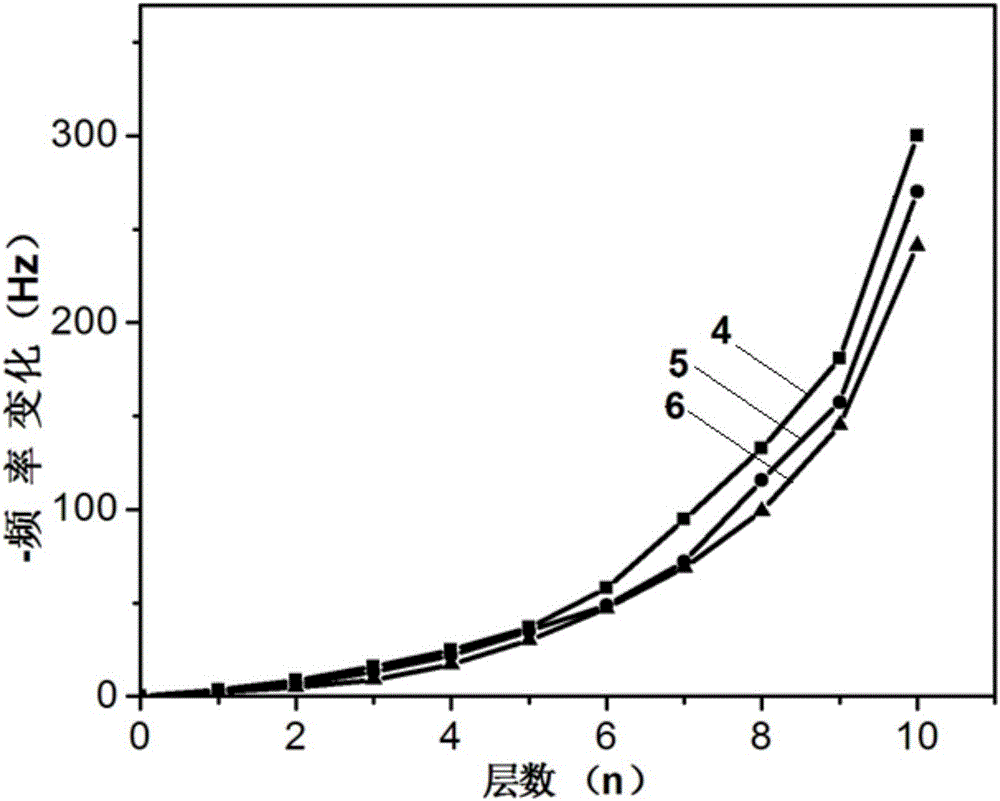

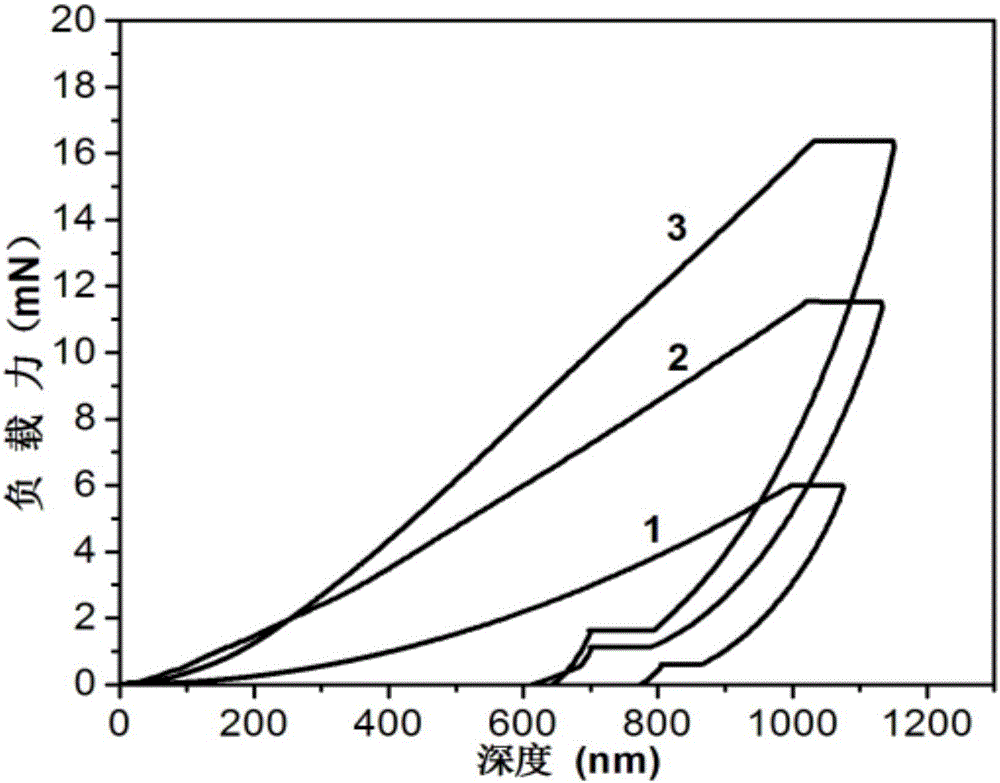

Preparation method of high-strength, antibacterial and self-repairing boron nitride layer-by-layer self-assembly composite film

The invention relates to a preparation method of a self-assembly composite film, in particular to a preparation method of a high-strength, antibacterial and self-repairing boron nitride layer-by-layer self-assembly composite film and aims to solve the problems that existing self-repairing materials are easily damaged during usage due to weaker mechanical strength and low immune capacity. The method comprises steps as follows: 1, dispersion of boron nitride; 2, dispersion of polyvinyl alcohol; 3, preparation of the boron nitride layer-by-layer self-assembly composite film. The method is used for preparing the high-strength, antibacterial and self-repairing boron nitride layer-by-layer self-assembly composite film.

Owner:HARBIN INST OF TECH

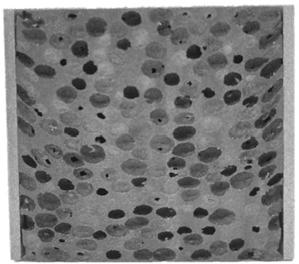

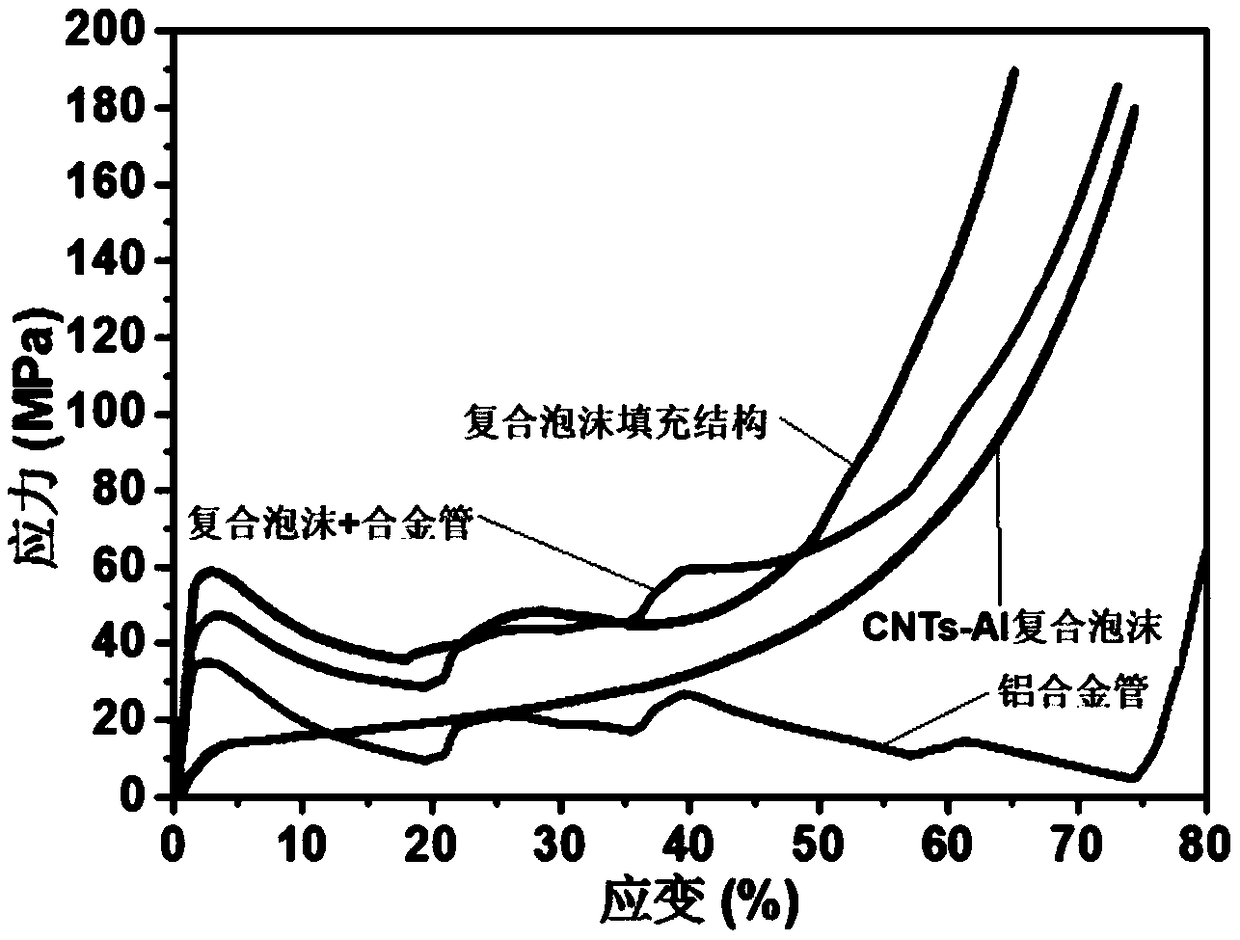

Preparation method of carbon nano-tube reinforced foamed aluminum filled aluminum alloy pipe composite structure

The invention relates to a preparation method of a carbon nano-tube reinforced foamed aluminum filled aluminum alloy pipe composite structure. The preparation method is implemented through the following steps of preparing composite powder uniformly loaded with carbon nano-tubes on the surface of aluminum powder; conducting mechanical ball milling; evenly mixing the ball-milled composite powder with urea and then conducting cold press molding; conducting water bathing on a cold pressed sample under 60-80 DEG C for 6-8 h to remove urea and then putting the sample in a drying oven to be dried after water bathing; putting the dried sample in a tube furnace to be heated to 650 DEG C under argon shielding of 200-300 ml / min at the rate of 5 DEG C / min, conducting sintering for 2-4 h, and then conducting furnace cooling to the indoor temperature after completion of sintering to obtain the carbon nano-tube reinforced foamed aluminum filled aluminum alloy pipe composite structure.

Owner:TIANJIN UNIV

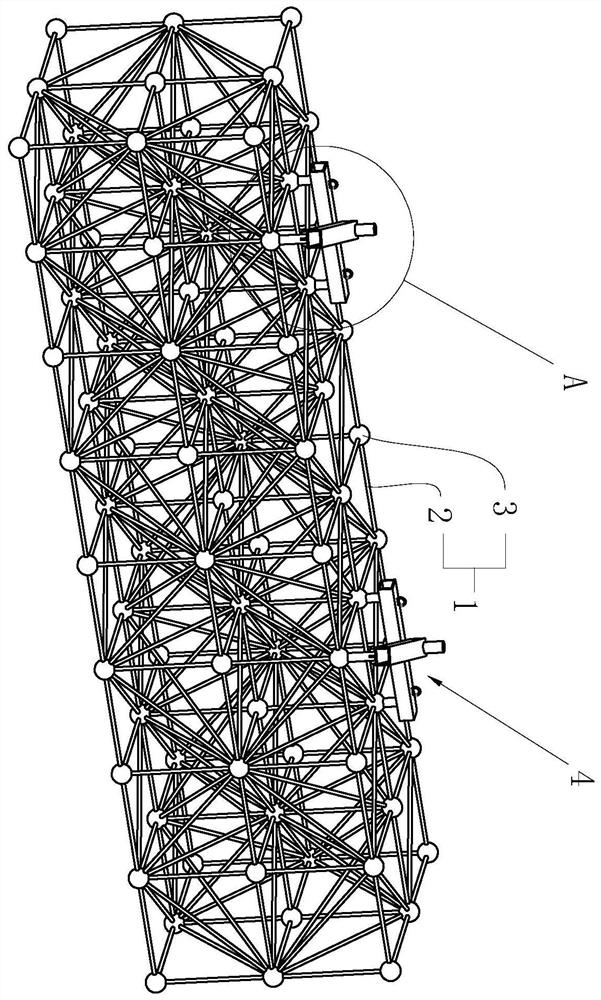

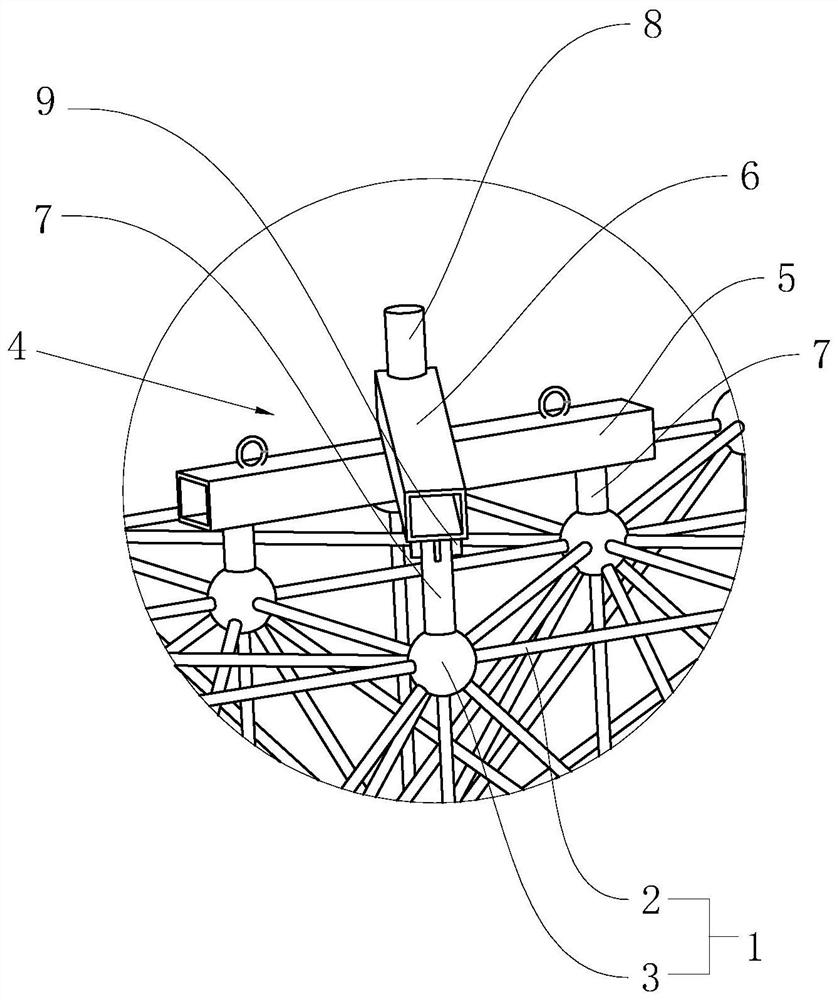

Large-span unequal-height steel structure net rack integral lifting temporary lifting point construction method

InactiveCN111779274AReduce usageReduce lossBuilding material handlingArchitectural engineeringUllage

The invention relates to a large-span unequal-height steel structure net rack integral lifting temporary lifting point construction method. The large-span unequal-height steel structure net rack integral lifting temporary lifting point construction method comprises the following steps of S1, construction preparation, and specifically, stress calculation is conducted on an assembled hangar gate truss firstly; S2, the structure of a temporary lifting point support and the form of a lifting point are determined; S3, the positions and the number of a lifting frame are determined according to the overall structure of a net rack of a hangar hall, and the positions and the number of the temporary lifting point support are determined; S4, the temporary lifting point support is arranged at the upper end of the hangar gate truss, an actual stress state is known by monitoring the stress of a component in a lifting process, and if the actual stress state exceeds the limit or is abnormal, a reasonis found, regulation and control are conducted. The large-span unequal-height steel structure net rack integral lifting temporary lifting point construction method has the effects that the assembled hangar gate truss is used as the support for the temporary lifting point support, the use amount of the temporary support is reduced, material loss is reduced, and the construction cost is reduced.

Owner:GUANGZHOU XIEAN CONSTR ENG

Polymeric bonding of glass fiber reinforcements with silane based coatings in gypsum board

ActiveUS20050202228A1High strengthImprove bending resistanceSynthetic resin layered productsCeramic layered productsCross-linkSilanes

A bond is created between a gypsum matrix formed from an aqueous acidic gypsum slurry comprising a monomer mixture. The monomer mixture is composed of a monomer having acidic functionality and a monomer having hydroxyl or amine functionality. A silane-based sizing composition is coated onto glass fibers causing a cross-linking network of silane and monomer mixture to form during curing of the gypsum board. Hydrophilic water extraction at the gypsum matrix-sizing interface reduces void formation and promotes bonding with the crosslinked monomer mixture and growth of smaller gypsum crystals within larger crystals in microstructurally identifiable regions adjacent to the glass fiber. A bond is created between a gypsum matrix formed from an aqueous acidic gypsum slurry comprising a monomer mixture. The monomer mixture is composed of a monomer having acidic functionality and a monomer having hydroxyl or amine functionality. A silane-based sizing composition is coated onto glass fibers causing a cross-linking network of silane and monomer mixture to form during curing of the gypsum board. Hydrophilic water extraction at the gypsum matrix-sizing interface reduces void formation and promotes bonding with the crosslinked monomer mixture and growth of smaller gypsum crystals within larger crystals in microstructurally identifiable regions adjacent to the glass fiber. Alternatively, the silane based sizing composition has branched chains that diffuse into a wet gypsum mix containing the monomer mixture. During gypsum cure, the diffusion and crosslinking of monomer mixture triggers formation of interpenetrating pseudo polymeric networks within a microstructurally identifiable region adjacent to the glass fiber. Bonds formed between the gypsum matrix and the silane based sizing composition increase the strength, flexure resistance and nail pull out resistance of the gypsum board.

Owner:MANVILLE JOHNS

Airplane wing assembly

ActiveCN104290900ASmooth assembly and disassemblyGuaranteed interchangeabilityWing adjustmentsDrag reductionInterference fitJet aeroplane

The invention provides an airplane wing assembly. The airplane wing assembly comprises a wing, a small wing and a connection piece, wherein the wing is provided with a wing box; the small wing is located at a wing tip of the wing and is connected with the wing by the wing box; the connection piece comprises a butt joint rib which is assembled with the wing box and a central connector which is assembled with the small wing; the butt joint rib is provided with a first shearing pin hole and a second shearing pin hole; a first shearing pin and a second shearing pin are pressed into the first shearing pin hole and the second shearing pin hole respectively to form interference fit; the central connector is provided with a first lining hole and a second lining hole; a first lining and a second lining are pressed into the first lining hole and the second lining hole respectively to form interference fit; and the position relation between the first shearing pin hole and the second shearing pin hole is the same as the position relation between the first lining hole and the second lining hole, so that small interference fit can be realized between the first shearing pin and the second shearing pin and between the first lining and the second lining when the small wing provided with the central connector moves towards the wing box provided with the butt joint rib and when the first shearing pin and the second shearing pin are inserted into the first shearing pin hole and the second shearing pin hole in the central connector respectively.

Owner:COMAC +2

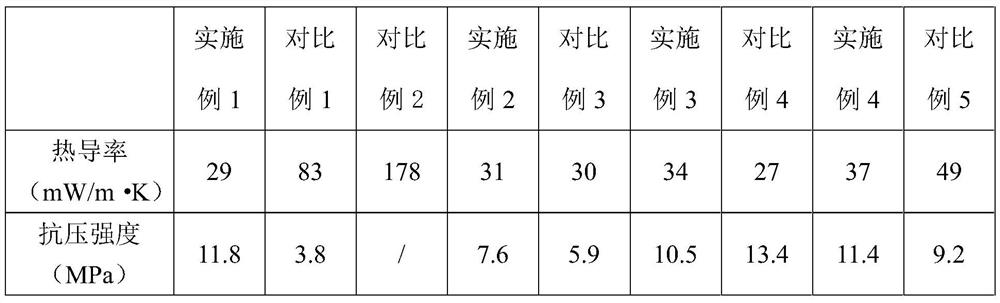

Preparation method of high-heat-insulation, high-pressure-resistance, low-density and heat-resistant composite epoxy foam

The invention relates to the technical field of epoxy resin, and mainly relates to a preparation method of high-heat-insulation high-pressure-resistance low-density heat-resistant composite epoxy foam. According to the invention, diisocyanate is selected as bridging small molecules to construct an epoxy resin-diisocyanate-graphene oxide trinity foaming precursor, so that oxazolidinone and isocyanurate rigid macrocycles are introduced into a traditional epoxy-curing agent cross-linked network to enhance the heat resistance. Then through two key procedures of curing-foaming step-by-step operation and valve opening and closing type foaming, a pre-curing stage is added in the earlier stage to enhance the melt strength so as to facilitate the growth of a foaming core, and air pressure is released in the later stage to eliminate the internal stress of foam, so that the problem that epoxy resin curing and foaming procedures are difficult to match is solved. On the other hand, graphene oxide is driven to construct a bubble wall for enhancing toughness , and the problem of bubble structure defects in a traditional preparation method of epoxy foam at present and the problem that the heat resistance and compressive strength of the epoxy foam are difficult to further improve are solved.

Owner:BEIJING UNIV OF CHEM TECH

Flat and planar match system between rails and fillers to railroad turnouts and crossings

Owner:ORTIZ RIVAS ARTURO A

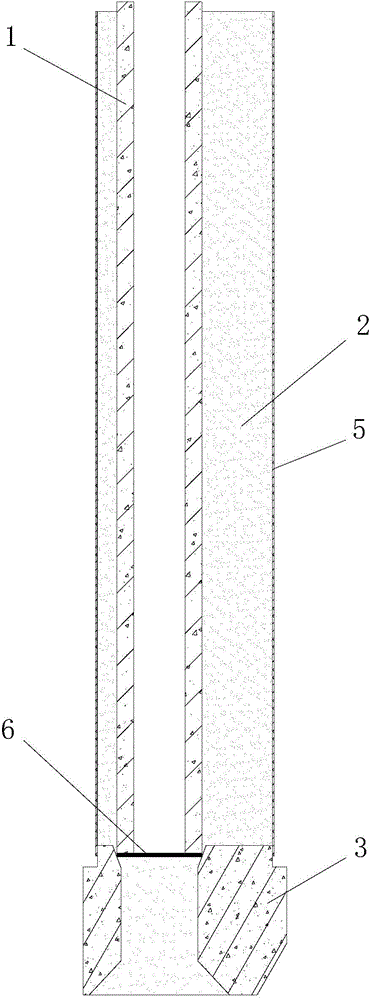

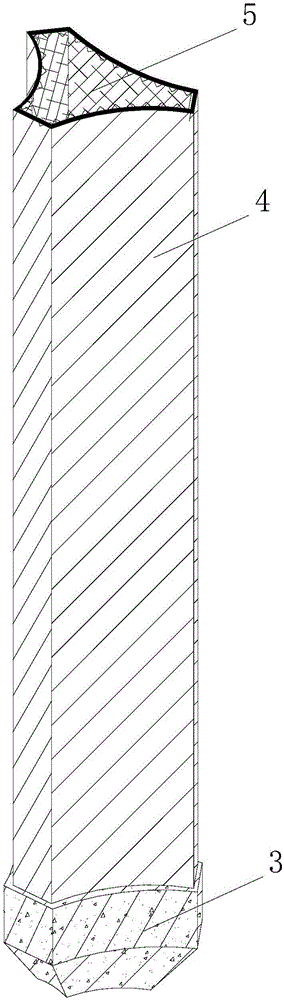

Extrusion formed precast pile stiffness core and cement soil combined Y-shaped pile and construction method thereof

InactiveCN104141304AStable formReduce the crowding effectBulkheads/pilesImmersed tubeAbnormal shaped

The invention relates to an extrusion formed precast pile stiffness core and cement soil combined Y-shaped pile. The Y-shaped pile is composed of an external cement soil cladding, a precast core pile and a precast end-open pile tip, wherein the cross section of the external cement soil cladding is Y-shaped and is formed through enclosing of a steel immersed tube in a constraint mode, the external cement soil cladding is coated with geotechnical cloth bags, and the precast core pile presses downwards perpendicularly along the center of the steel immersed tube and is embedded into a precast hollow pile tip. Back extrusion initial set type cement soil is shaped by means of the Y-shaped steel immersed tube, stability of forming of the Y-shaped pile is guaranteed, the precast core pile is inserted in the center, the advantages that the frictional resistance of the special-shaped pile side is large and the bearing capacity of the stiffness core composite pile is high are fully utilized, and technological and economical efficiency is high. The invention further discloses a construction method of the Y-shaped pile.

Owner:GUANLU CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com