Patents

Literature

764 results about "Immersed tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An immersed tube is a kind of undersea tunnel composed of segments, constructed elsewhere and floated to the tunnel site to be sunk into place and then linked together. They are commonly used for road and rail crossings of rivers, estuaries and sea channels/harbours. Immersed tubes are often used in conjunction with other forms of tunnel at their end, such as a cut and cover or bored tunnel, which is usually necessary to continue the tunnel from near the water's edge to the entrance (portal) at the land surface.

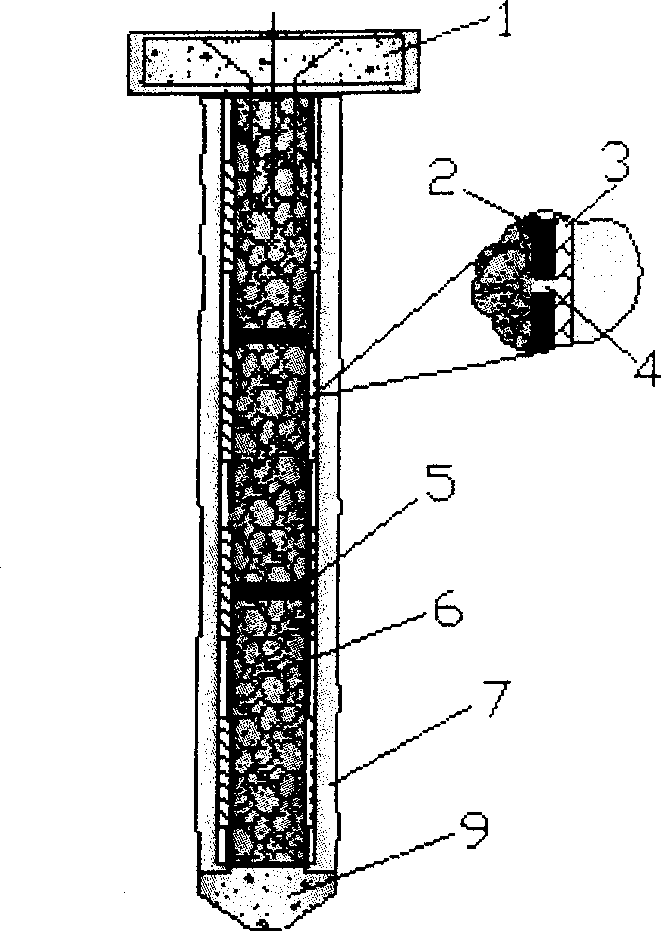

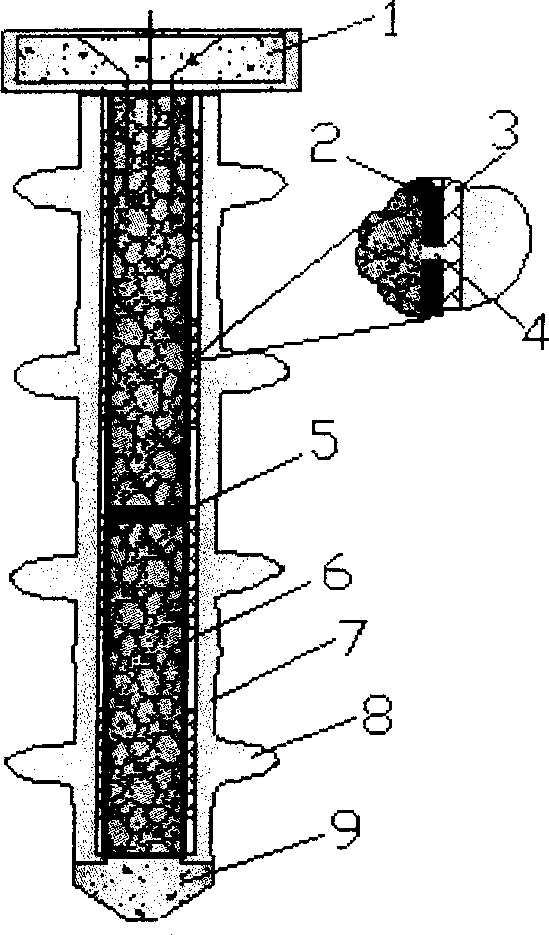

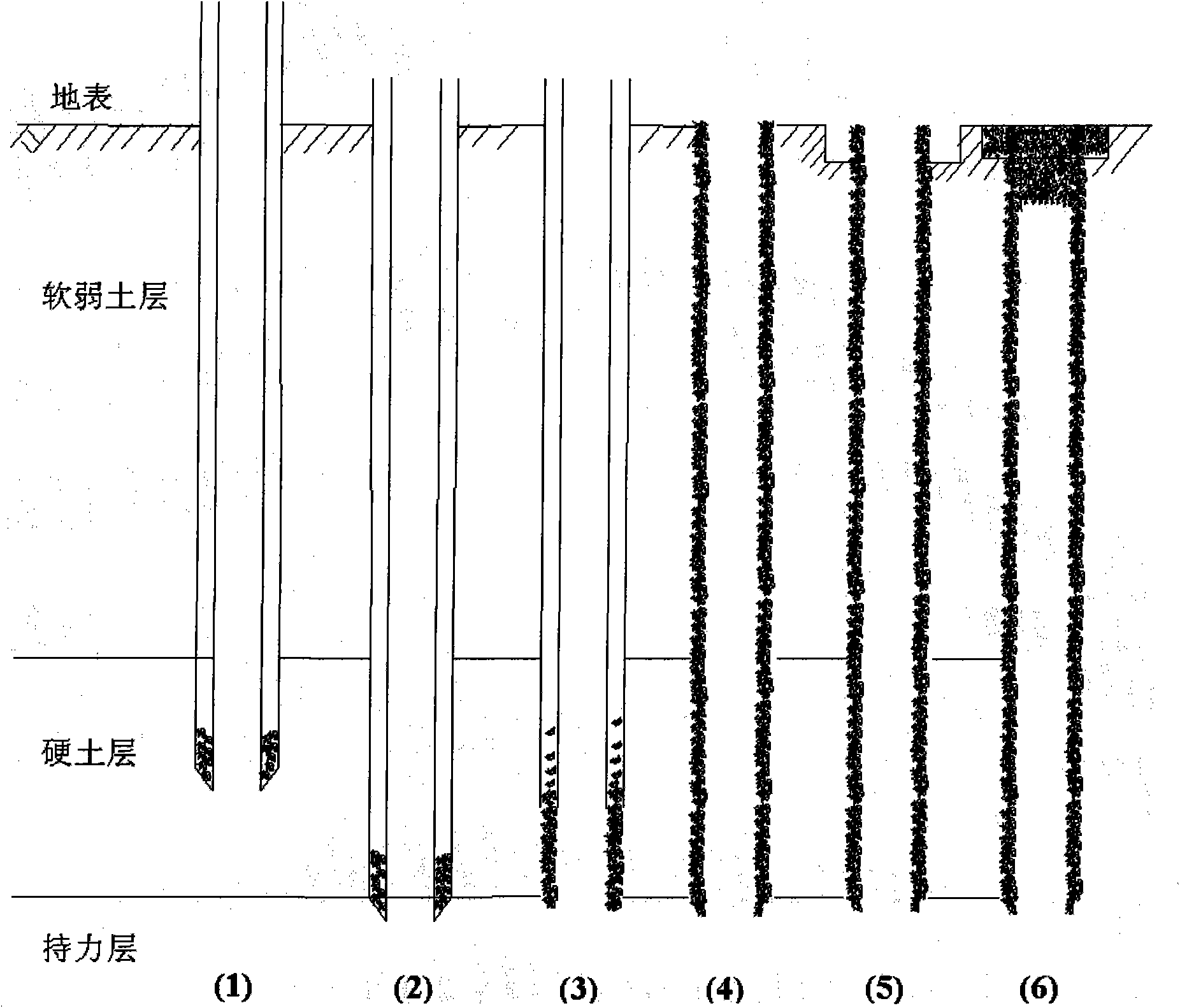

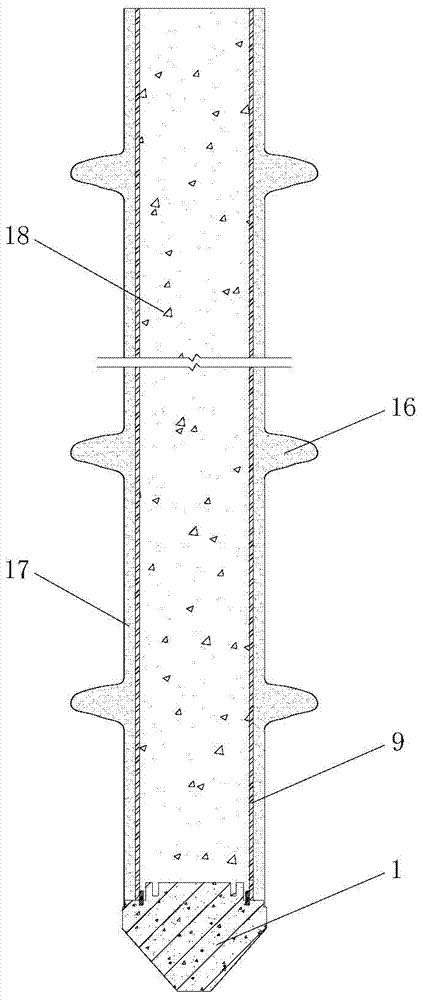

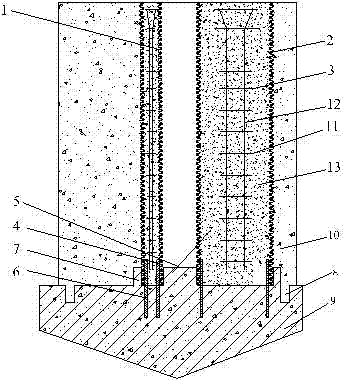

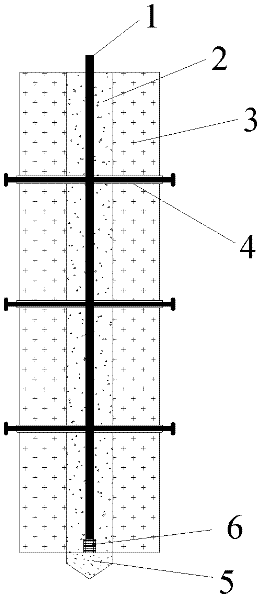

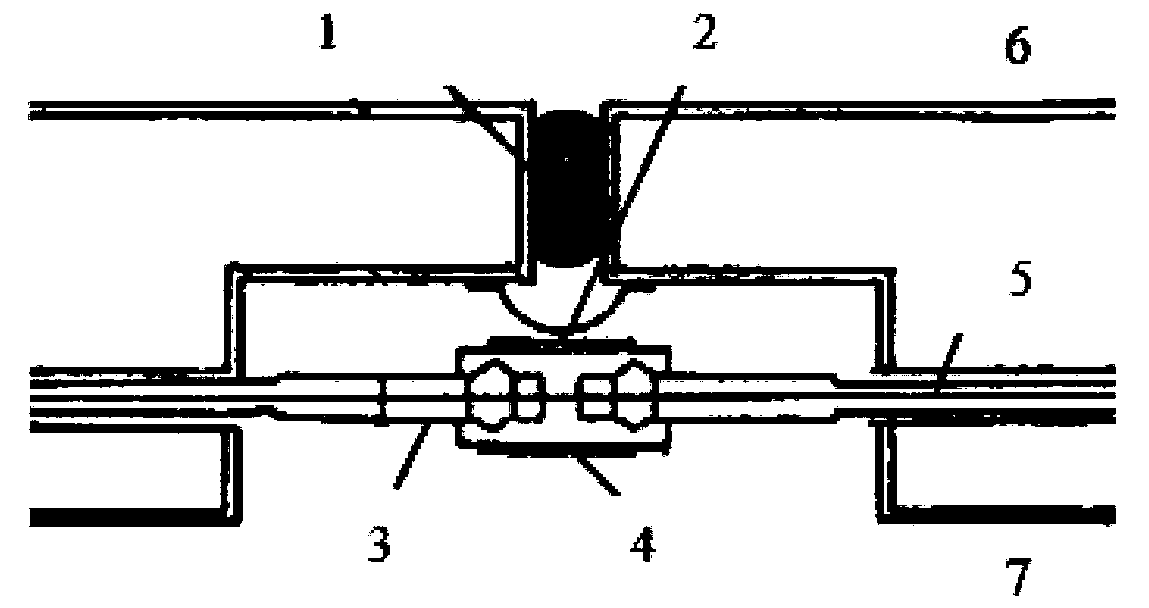

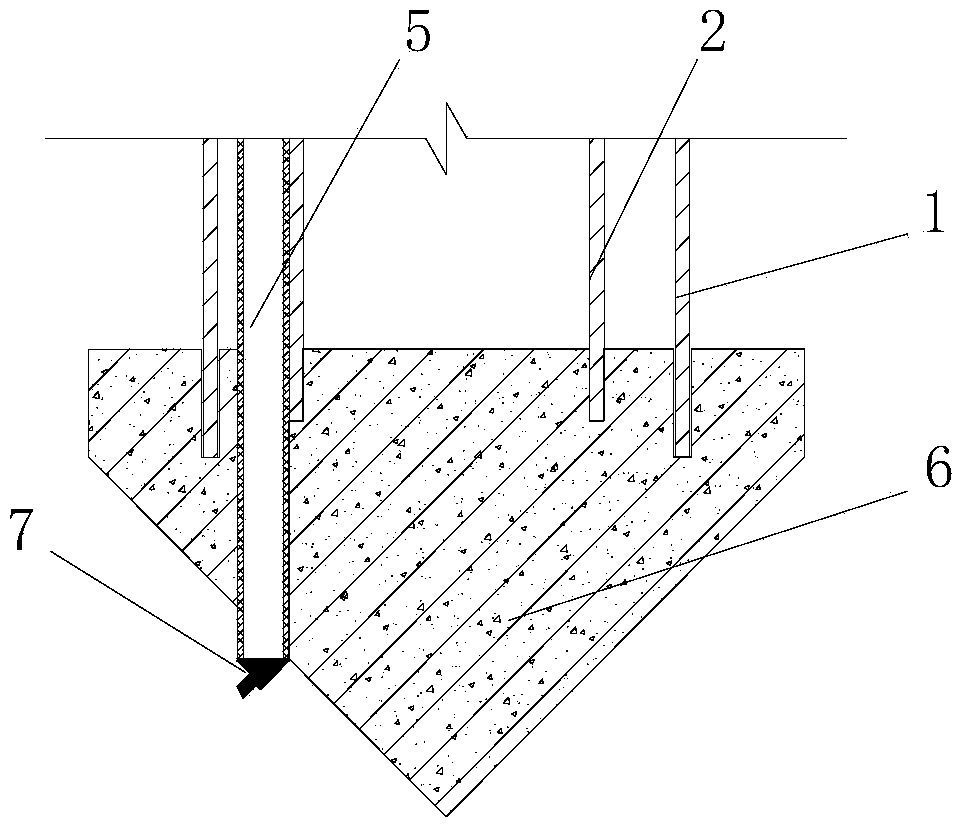

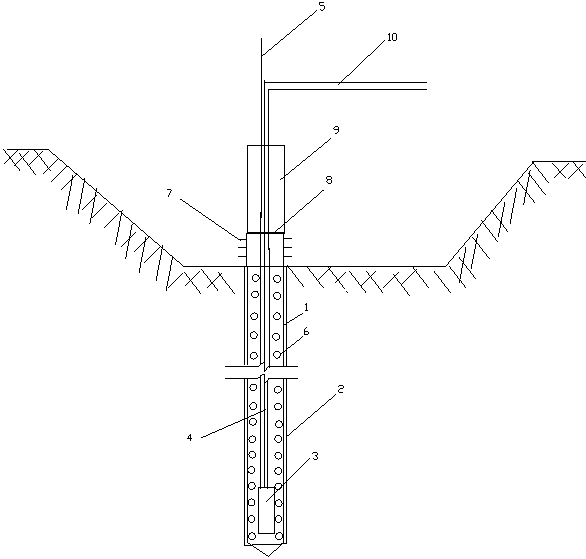

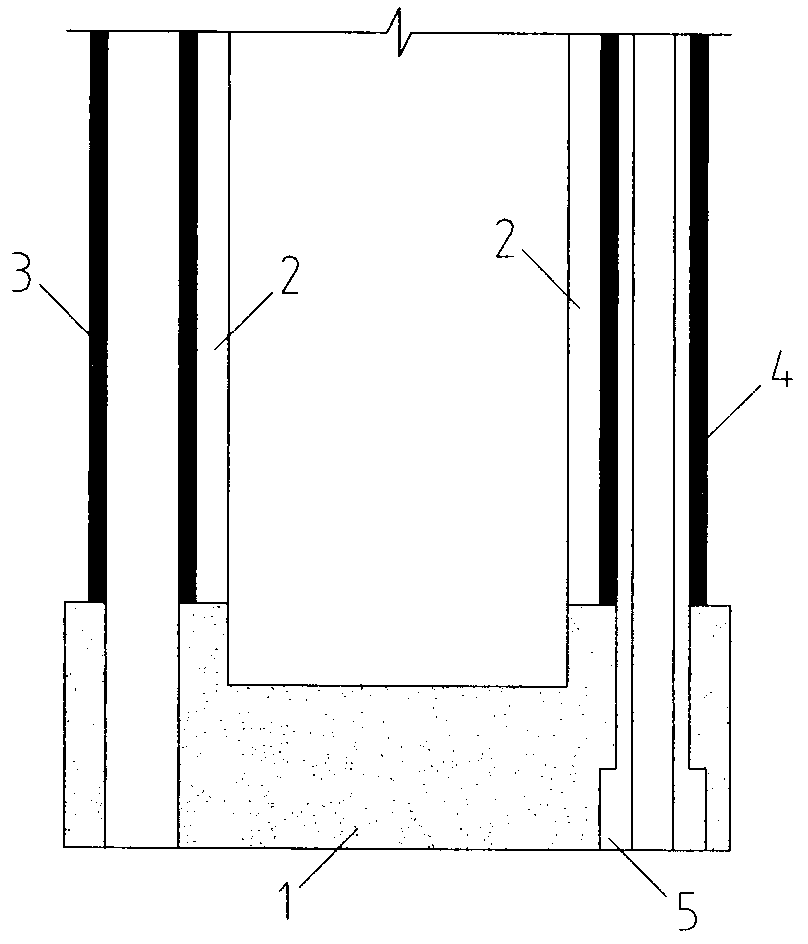

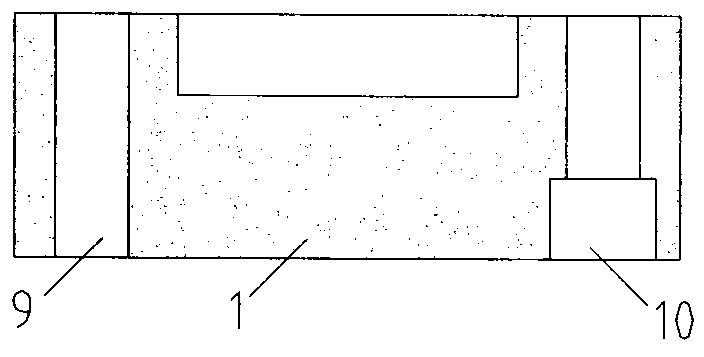

Granule grouting pile of ripple plastic sleeve with hole for strengthening soft soil foundation and strengthening method

The invention discloses a grouting pile of a plastic sleeve for strengthening a soft soil foundation and a pile-forming strengthening construction method thereof. The pile consists of a pile cap, a thread sleeve, an earthwork cloth, a joint, a pile body and a pile tip; the top of the sleeve is connected with the pile cap and the bottom of the sleeve is connected with the pile tip, the side wall of the sleeve is provided with an opening hole, the outside of the sleeve is packed by the earthwork cloth, each section of the sleeve is connected by the joint, and the sleeve is filled with granules and grouted with slurry inside so as to form the pile body and a pile periphery as a slurry spreading zone. The pile-forming strengthening method comprises: connecting the sleeve to the depth of the pile length by the joint and then to the pile tip, placing the sleeve and the pile tip into an immersed tube together, beating the sleeve into a foundation by a beating machine, leaving the sleeve and the pile tip in the foundation, feeding the granules into the sleeve and grouting the sleeve to form a slurry scattered material column, spreading a slurry liquid on the pile periphery to form a spreading zone under the grouting pressure or expanding the earthwork cloth outwards to form a gourd pile body, pouring the pile cap on the pile top, and paving a reinforced material and a gravel cushion after the pile body and the pile cap are dried so as to form a composite foundation. The pile type can strengthen the contact action between the pile and the soil, can improve the bearing capacity of the pile body greatly, and is an ideal pile type for strengthening the soft soil foundation.

Owner:HOHAI UNIV

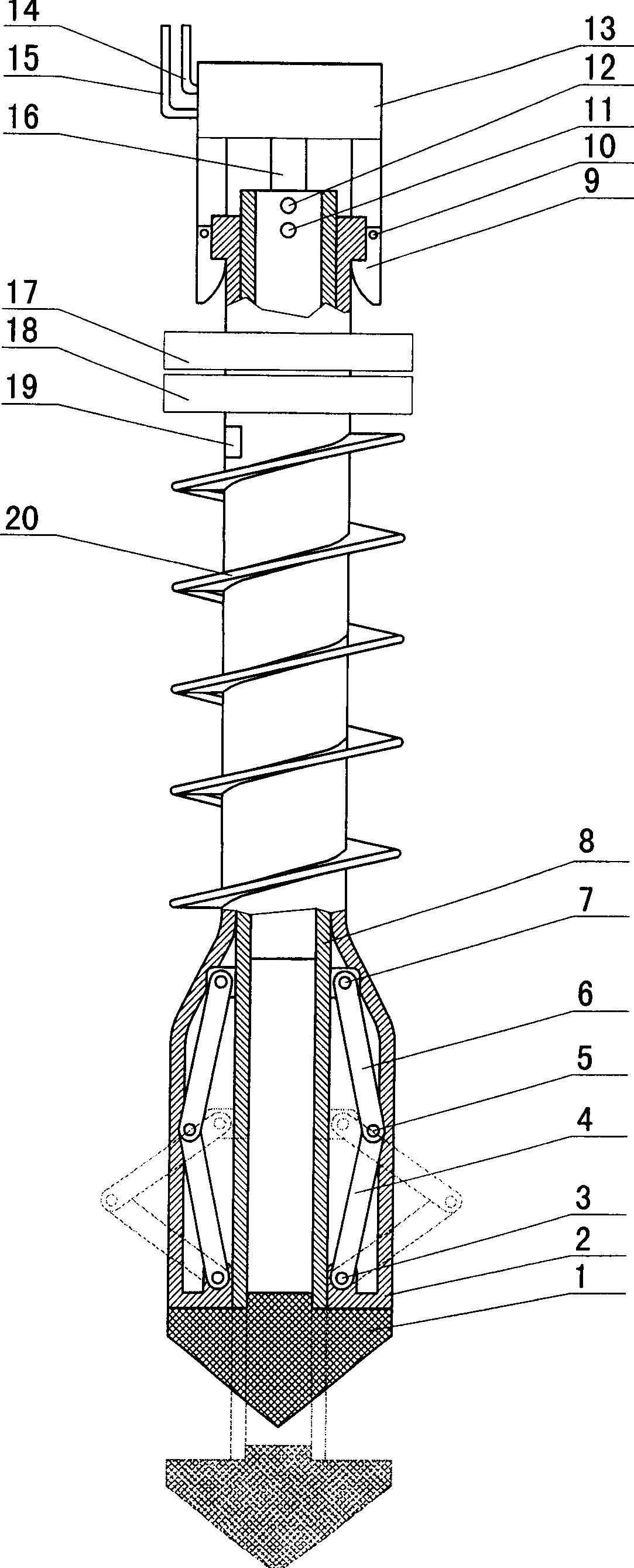

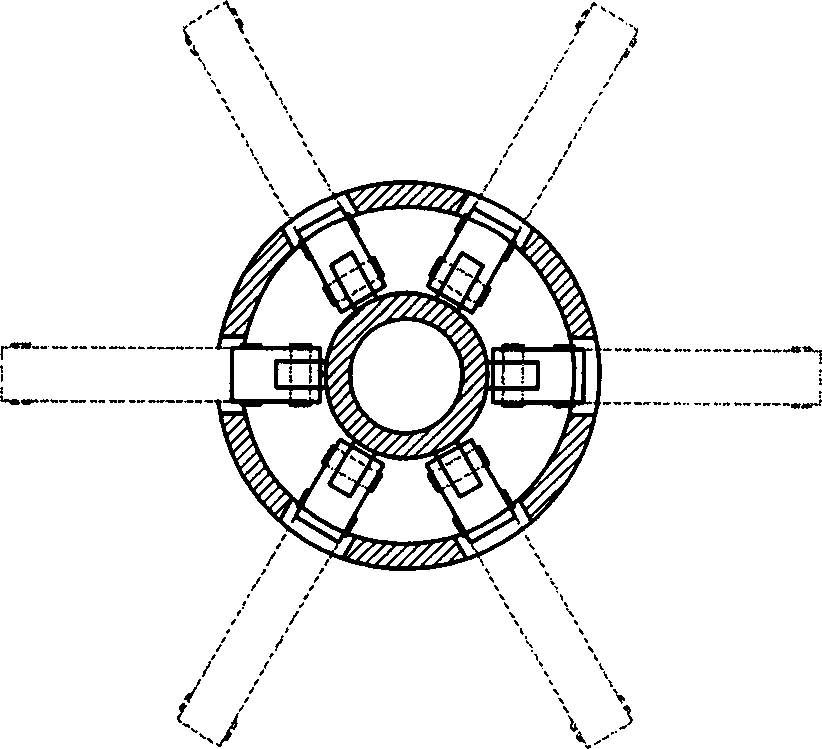

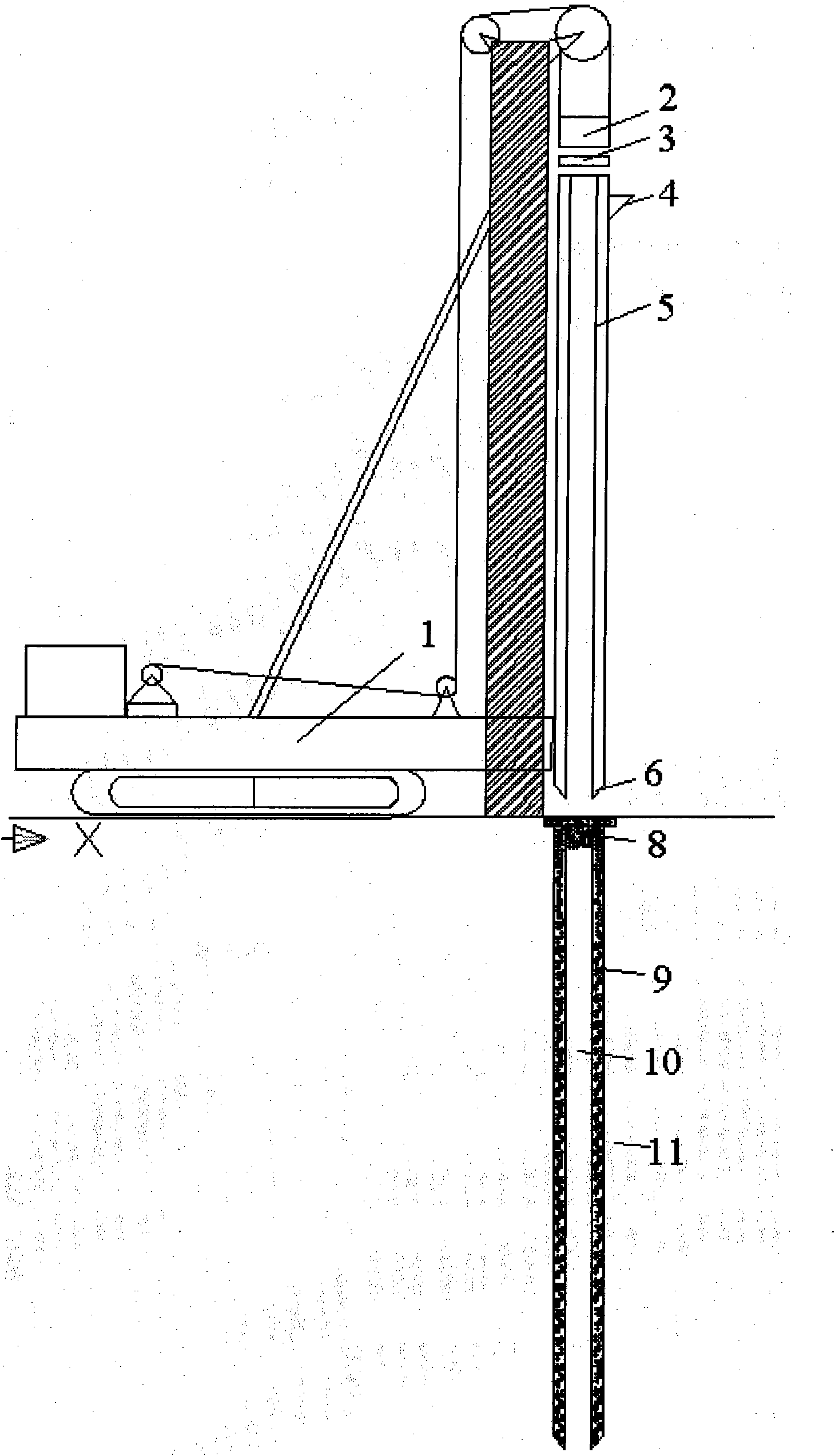

Device for knobby pushing and expanding spiral immersed tube stake and its engineering method

ActiveCN1800509AHigh strengthSolve the lack of carrying capacityBulkheads/pilesDrilling machines and methodsHydraulic motorHelical blade

The invention relates to a multi-section expansion screw pipe-deposition post, which is formed by inner pipe, outer pipe, upper and lower bow compression arms, axial pin, cylinder, hydraulic motor, vibrator and a cement head. First, entering said device into ground via vibration and rotation; lifting the steel cage into pipe; filling concrete; connecting the cylinder on the upper end of pipe to be expanded; vibration lifting the pipe to a preset height to be expanded; calling back it to be lifted and expanded again; calling it back and filling concrete and lifting the pipe from the hole to from several pipe-deposition post with multi-expanded head and multi-branch. The invention can fully utilize the bearing ability of soil, and the multi-section expanded head has strong strength of post, big distance between posts and less posts. Since the outer pipe with bigger outer diameter and the screw blades can discharge the soil, it can solve the soil-compression effect to confirm the operation quality with improved working efficiency, reduced cost and non-noise.

Owner:CHINA RAILWAY ECONOMIC & PLANNING RES INST +2

Immersed tube tunnel deformation monitoring and stress analyzing system and application method and functions of immersed tube tunnel deformation monitoring and stress analyzing system

ActiveCN104567710AImprove reflectivityEnhanced inhibitory effectForce measurement by measuring optical property variationHeight/levelling measurementFiber Bragg gratingDeformation monitoring

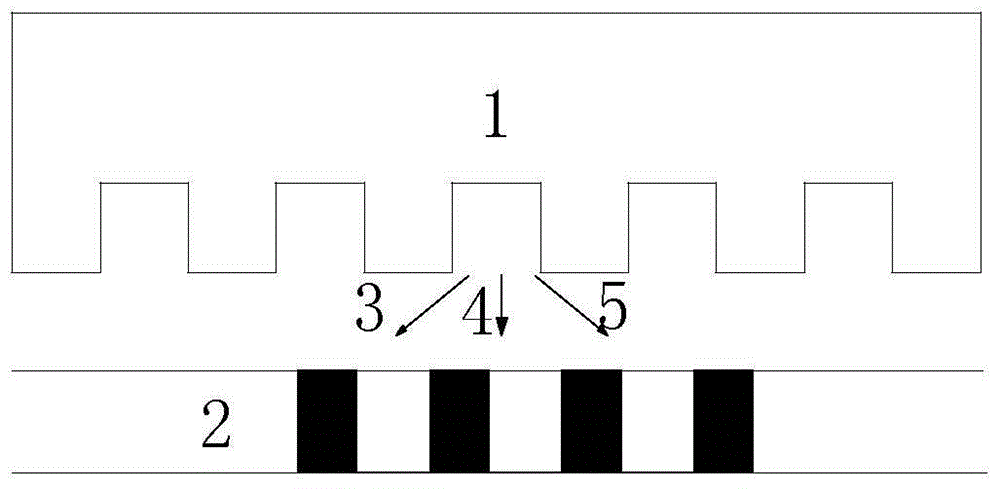

The invention relates to the field of infrastructure structure safety health monitoring, in particular to an immersed tube tunnel deformation monitoring and stress analyzing system based on optical fiber sensing and an application method and functions of the immersed tube tunnel deformation monitoring and stress analyzing system. The immersed tube tunnel deformation monitoring and stress analyzing system has the advantages of being compact in structure, high in stability and flexibility, resistant to electromagnetic interference, high in environment adaptive capacity and the like. When a fiber bragg grating in a sensor is manufactured, the duty cycle adopted for an optical fiber mask plate is 0.5, the optimal groove shape depth is 234+ / -10 nm, the zero-level diffraction efficiency of the fiber bragg grating can be as low as 2%, the diffraction efficiency of the + / -1 class can reach 36%, the manufacture fiber bragg grating has the advantages of being high in reflectivity and side-mode suppression ratio, narrow in bandwidth, and the like, and the measurement result is more accurate; monitoring data are transmitted through a wireless remote data transmission network, the advantage of remote monitoring is achieved, and the monitoring work is quite conveniently conducted.

Owner:ZHEJIANG UNIV CITY COLLEGE

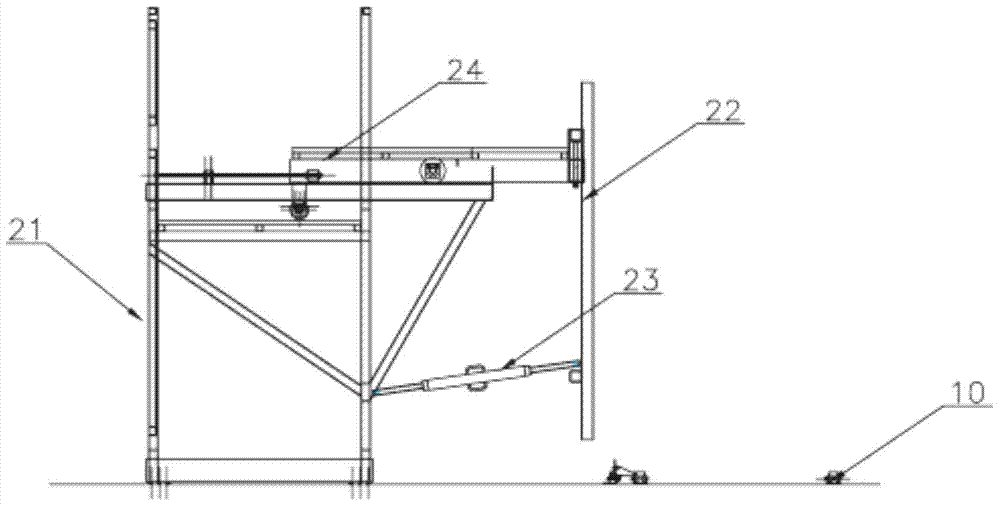

Construction method for prefabricating immersed tube tunnel tubulation adopting mobile dry dock

InactiveCN1884723AAvoid demolition difficultiesAvoid land acquisition difficultiesArtificial islandsUnderwater structuresEngineeringImmersed tube

The invention relates to a method for constructing movable dry dock preformed sink tube tunnel section, which uses semi-dive dock as movable dry dock; uses right dock to perform the sink tube tunnel section; then drawing movable dry dock to the diving position near the tunnel; separating the movable dry dock and the sink tube tunnel tube; then floating the sink tube tunnel tube to the temporary anchoring position to process secondary installment; then completing the connection of tubes. Compared with present technique, the invention has low cost and short time.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

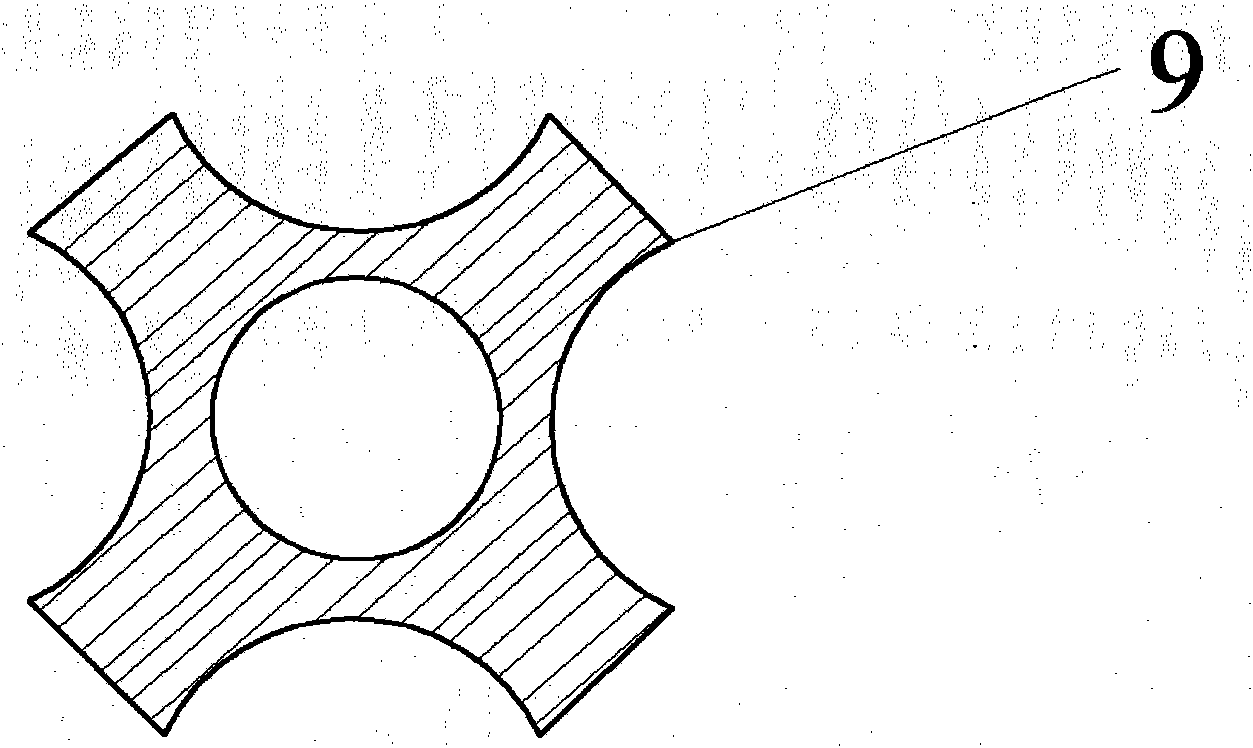

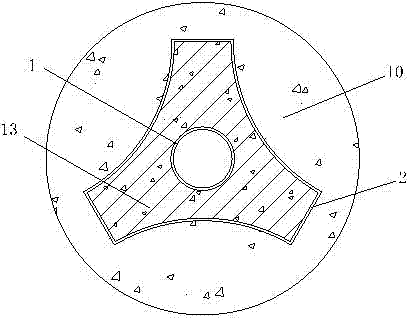

Cast-in-place X-shaped large-diameter hollow concrete pile and construction method thereof

The invention relates to a cast-in-place X-shaped large-diameter hollow concrete pile. The cast-in-place X-shaped large-diameter hollow concrete pile is formed by driving an X-shaped hollow concrete pile die into a foundation till a designed depth in an immersed tube vibrating mode, then casting concrete into a cavity of a pile die immersed tube and vibrating and drawing the tube, wherein the X-shaped hollow concrete pile die comprises the pile die immersed tube with an X-shaped outer profile, the pile die immersed tube consists of inner and outer sleeves, the section of the outer sleeve is X-shaped and the section of the inner sleeve is circular. The invention also relates to a construction method for the concrete pile. The new pile form of the invention can improve the strength and utilization of unit materials and reduce the construction cost on the premise of ensuring the integral performance of the pile body; and the vertical bearing capacity and the horizontal bearing capacity are effectively improved by using the special-shaped effect of the cross section and the improvement effect of the pile core soil on the friction force of the pile side. The construction method for the pile is simple, has strong operability and is convenient for quality control and detection; and the single pile has high bearing capacity.

Owner:HOHAI UNIV +1

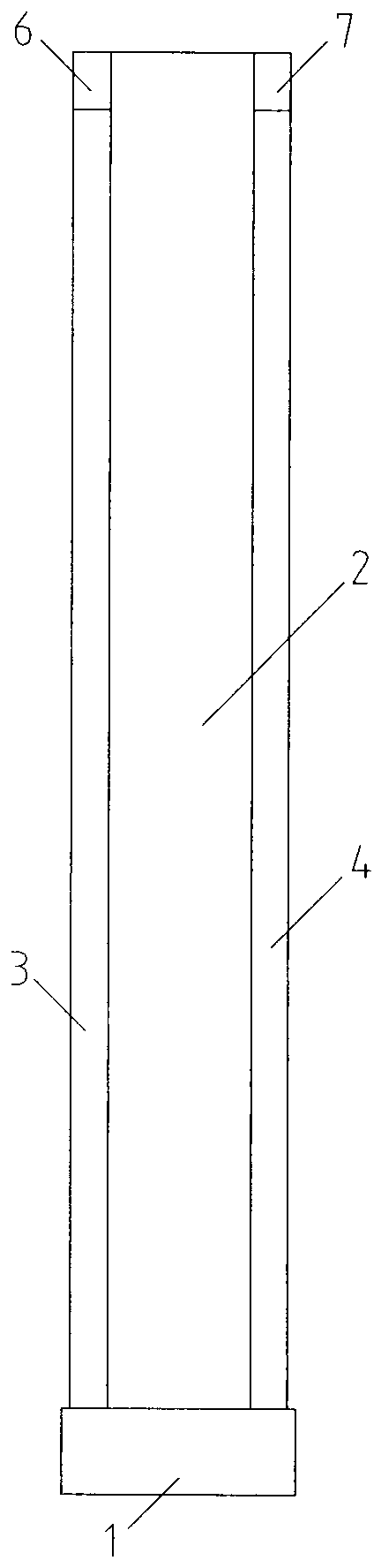

Plastic sleeve concrete pile and method thereof for reinforcing soft soil foundation

The invention relates to a plastic sleeve concrete pile and a construction method thereof. the plastic sleeve concrete pile comprises a cover board, plastic sleeves, pile tips, concrete and sleeve joints, wherein the top of each plastic sleeve is connected with the cover board and the lower part is connected with each pile tip, every two plastic sleeves are connected by the sleeve joint, and the concrete is poured in the plastic sleeves. The construction method comprises the following steps: connecting the prefabricated pile tips with the plastic sleeves, pulling the plastic sleeves together with the pile tips into an immersed tube after lifting the immersed tube at a certain height, starting a plastic sleeve concrete pile driver to drive the plastic sleeves with the pile tips together into the pile length designed depth, lifting the immersed tube after filling water into the plastic sleeves until 1 / 2-2 / 3 of pile length but remaining the plastic sleeves and the pile tips into the foundation, pumping filled water in the plastic sleeves, and pouring a concrete pile body and the cover board into the plastic sleeves to be made into the plastic sleeve concrete pile. The plastic sleeve concrete pile has small soil extrusion action, uneasy broken pile, flexible and rapid construction, easy control of pile body quality, higher bearing capacity of single pile and good cost performance; and the pouring is not influenced by outside.

Owner:HOHAI UNIV

Immersed tube tunnel construction monitoring system and construction technology thereof

ActiveCN104807497AGuaranteed reliabilityArtificial islandsMeasurement devicesRelative displacementMonitoring temperature

The invention relates to the field of immersed tube tunnels, and discloses an immersed tube tunnel construction monitoring system. The immersed tube tunnel construction monitoring system is characterized in that adjacent tube sections of an immersed tube tunnel are provided with first test sensors used for testing the opening-closing degree between the test tube sections, a second test sensor used for monitoring relative displacement changes between the tube sections in the horizontal direction and third test sensors used for monitoring differential displacement between the tube sections in the vertical direction; the adjacent sections are provided with fourth test sensors therebetween used for measuring the opening-closing degree of a gap between the sections; an end sealing door is provided with stress sensors used for testing the maximum bearing stress and fifth test sensors used for testing maximum deformation conditions; and the adjacent tube sections are provided with sixth test sensors used for monitoring settlement changes of the tube sections, seventh test sensors used for monitoring displacement changes of the tube sections and temperature sensors used for monitoring temperature changes in the immersed tube. The invention further provides a construction technology. The immersed tube tunnel construction monitoring system and the construction technology thereof are comprehensive in monitoring, and capable of ensuring monitoring data to be reliable, timely and effective.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG

Cloth bag squeezing concrete branch pile and construction method

The invention relates to a cloth bag squeezing concrete branch pile. The bottom of a branch pile body is connected with a prefabricated pile point, the pile body is composed of a concrete stiffness core, a reinforced body, a geotechnical cloth bag slurry pressing body, a geotechnical cloth bag, a branch squeezing cloth bag slurry pressing body, branch squeezing cloth bags and a cement soil pile from the inside to the outside. The branch squeezing cloth bags are arranged on a geotechnical cloth bag body at intervals. The geotechnical cloth bag slurry pressing body is formed by injecting slurry into the geotechnical cloth bag in a high-pressure mode, and the branch squeezing cloth bag slurry pressing body is formed by injecting slurry into branch squeezing cloth in a high-pressure mode. The reinforced body is composed of a vertical main rib and an annular hoop rib. A geotechnical cloth bag connecting body, a reinforced body vertical main rib connecting body and a limit groove of an immersed tube are sequentially arranged on the top face of the prefabricated pile point from the outside to the inside. By means of the pile, rigid and flexible compound pile effects are achieved, damage of a soil squeezing effect on concrete and mortar which are not initially set is reduced, and pile quality is guaranteed. In addition, common loading performance of flexible piles and rigid piles is improved by means of the branch pile.

Owner:德州市公路工程总公司

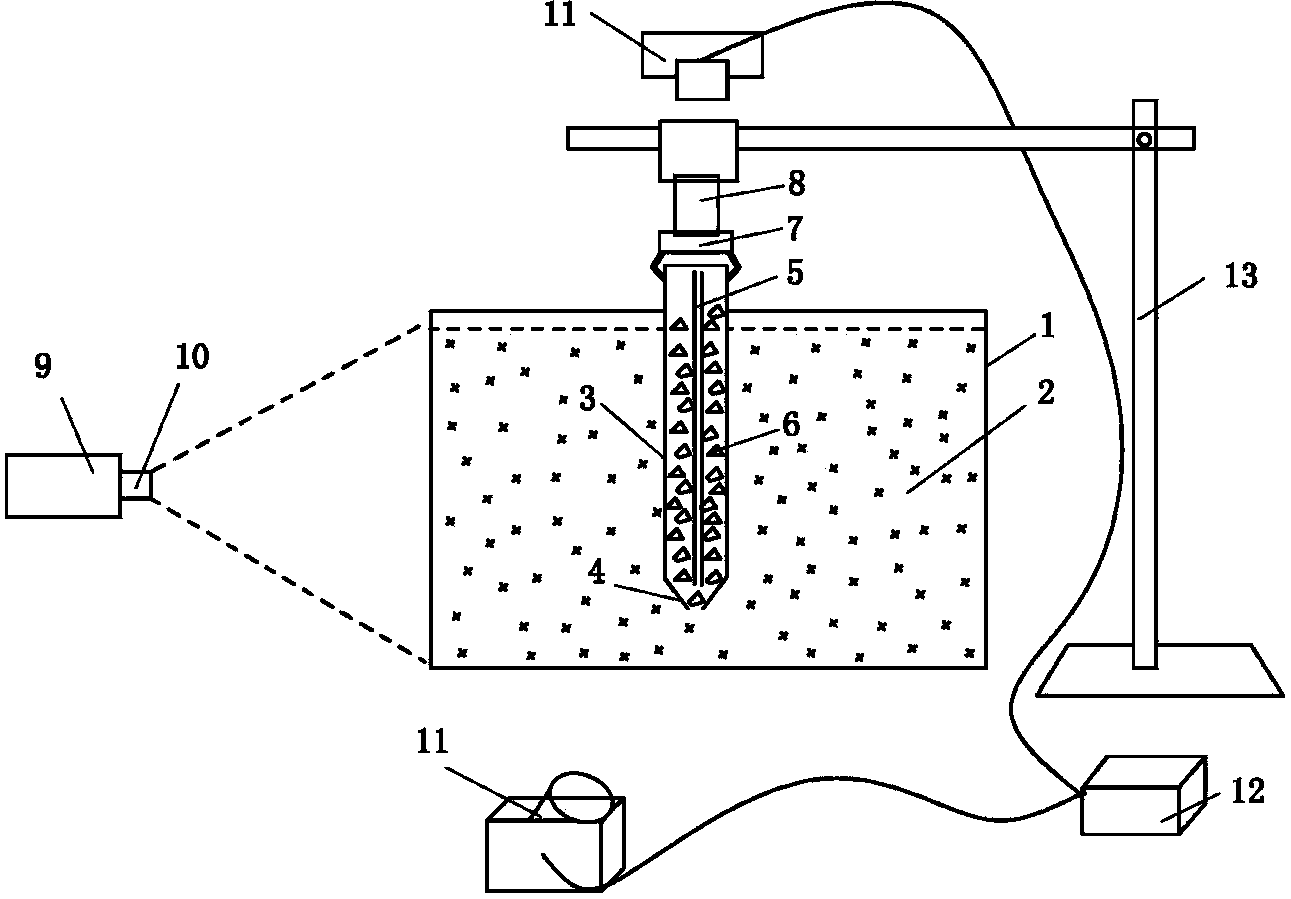

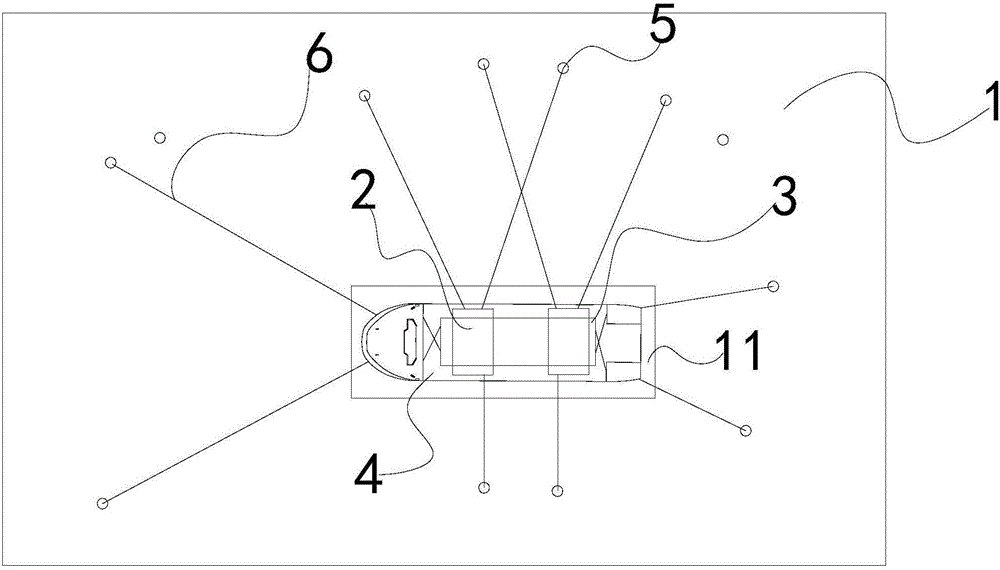

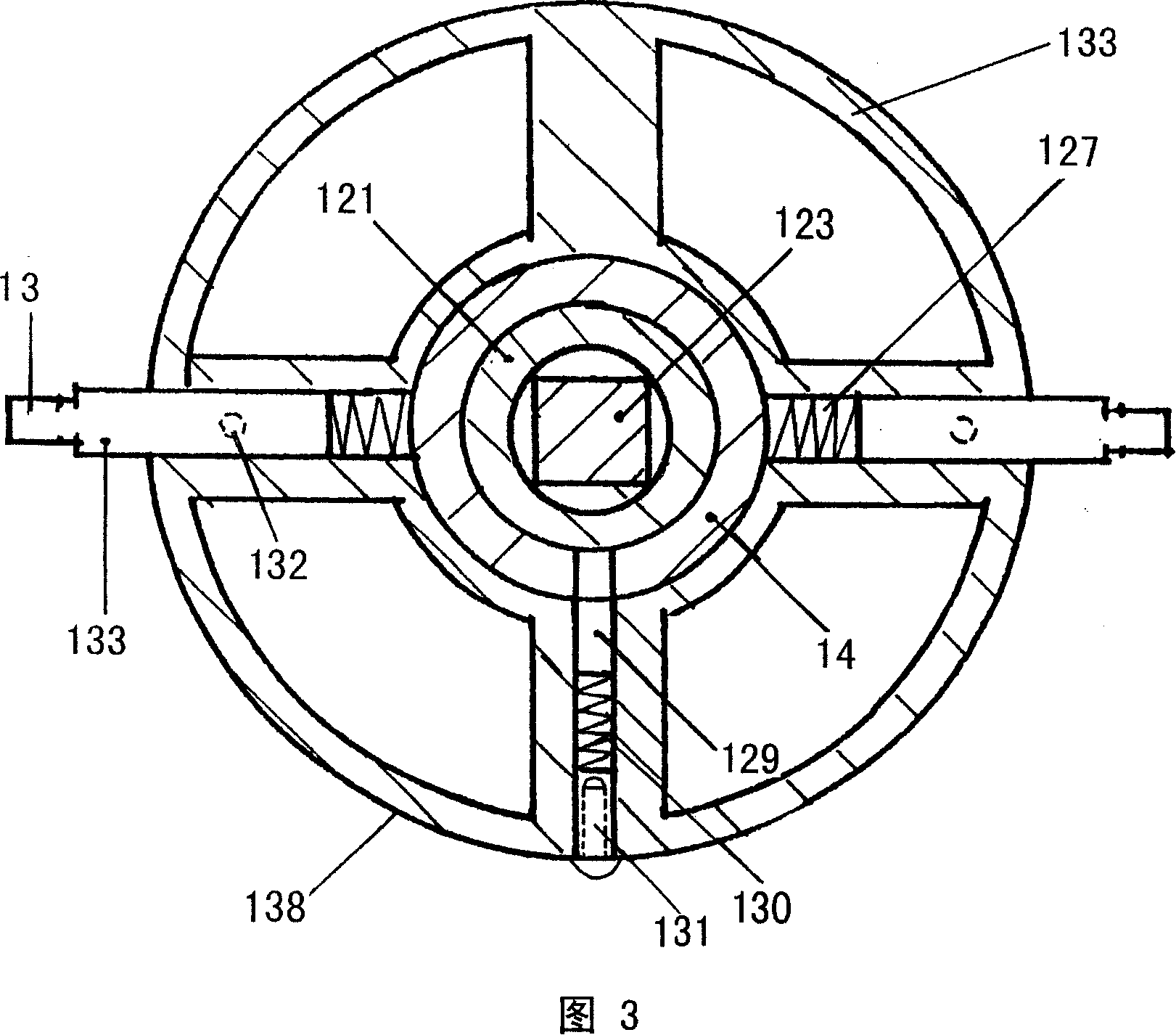

Vibration immersed tube compaction pile model test device and test method

InactiveCN103938661AHigh transparencySimple and fast operationFoundation testingEngineeringModel test

The invention discloses a vibration immersed tube compaction pile model test device and a test method. The vibration immersed tube compaction pile model test device is characterized by comprising a transparent model groove, transparent soil for simulating soil around a pile and an immersed tube with pile shoes are arranged in the transparent model groove, a grouting pipe is arranged in the center of the immersed tube, and a pile sinking mechanism mounted on a support is arranged above the transparent model groove. A laser source is arranged on one side outside the transparent model groove, digital cameras capable of observing a transparent model groove space are arranged on a front view face and a top view face of the outside of the transparent model groove, and the digital cameras are connected with a processing device through data lines. The vibration immersed tube compaction pile model test device is easy and convenient to operate and high in repeatability; the prepared transparent soil and natural soil are good in soil nature similarity; according to the test method, the squeezing effect of a vibration immersed tube compaction pile under the conditions of different natures of the soil around the pile, different immersed tube section forms, different pile diameters and different pile lengths can be observed and measured in a visual mode; the vibration immersed tube compaction pile model test device and the test method have important significance in design and construction for guiding influences on surrounding buildings by pile-forming construction of vibration immersed tube piles.

Owner:HUNAN CITY UNIV

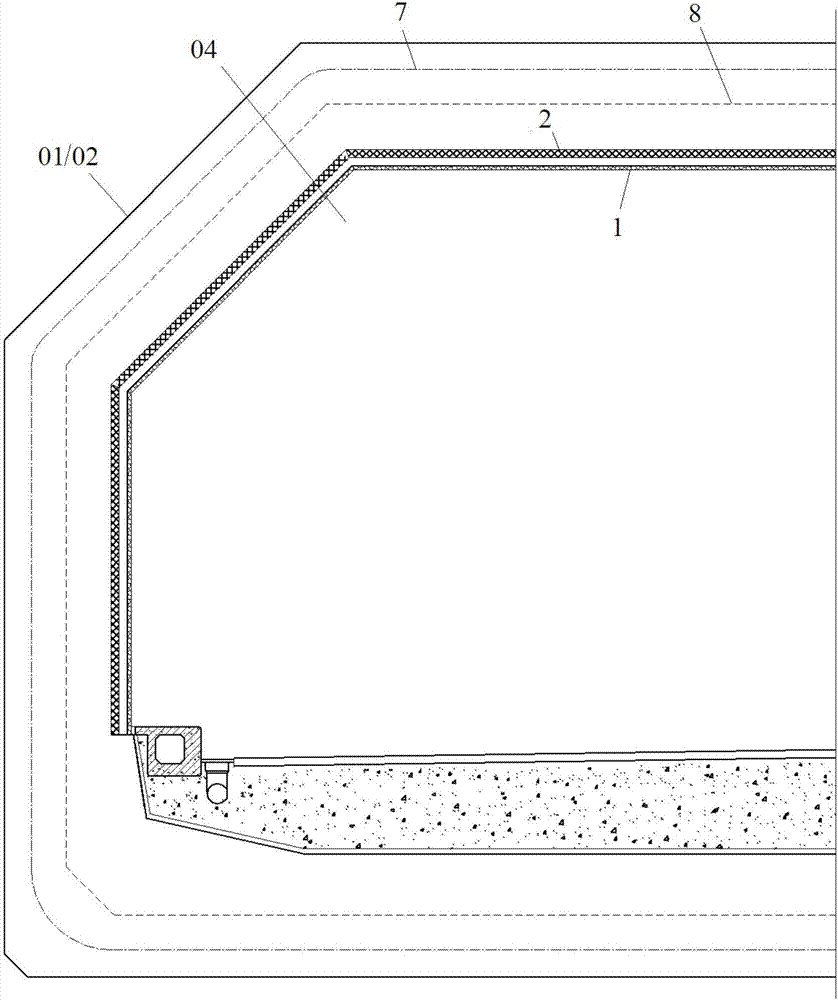

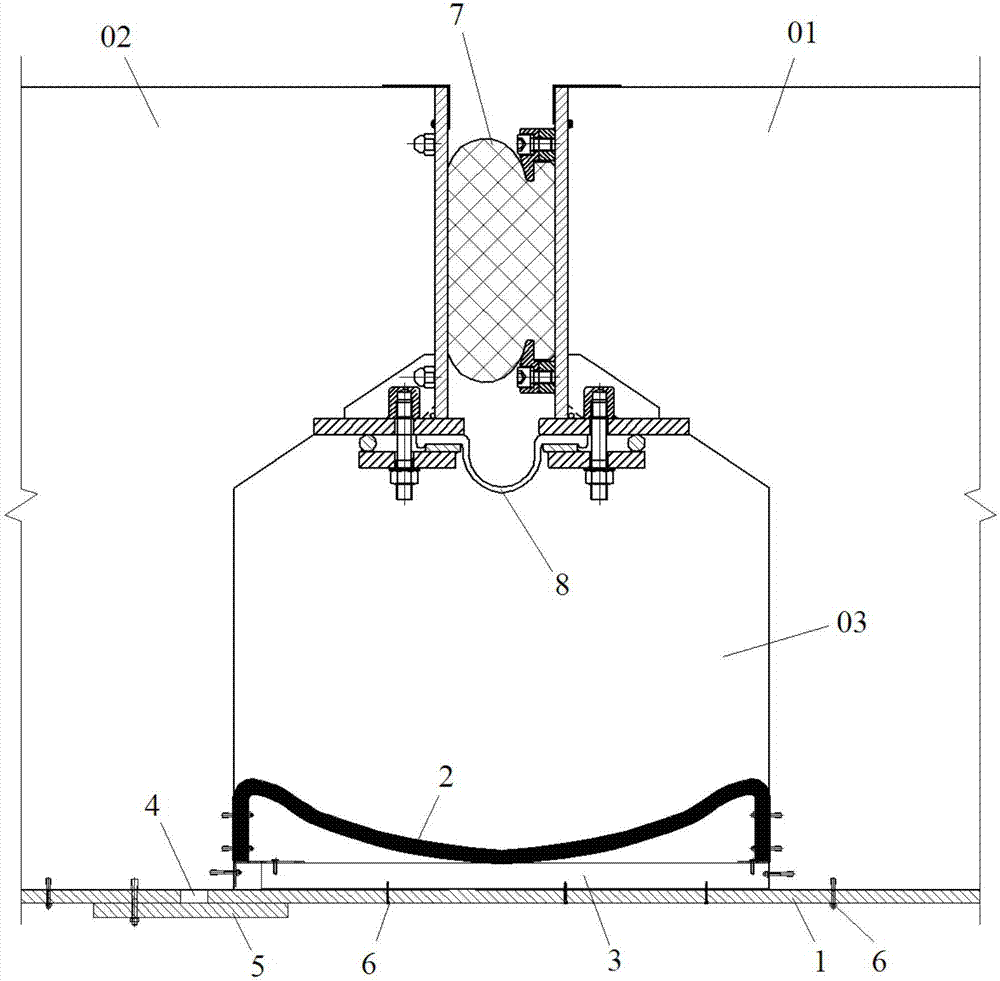

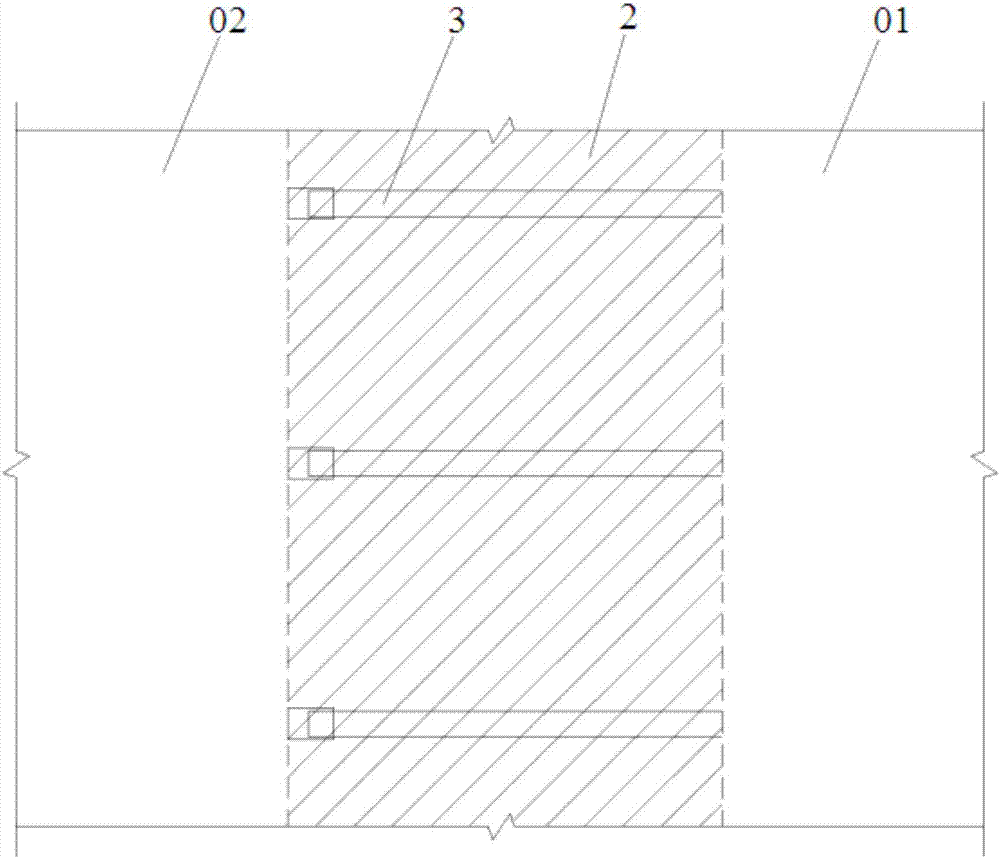

Tube section joint fire-protection structure for immersed tube tunnel and construction method

ActiveCN107023037AFlexible adaptation to deformation situationsPlay a protective effectArtificial islandsUnderwater structuresFire protectionEngineering

The invention discloses a tube section joint fire-protection structure for an immersed tube tunnel and a construction method. The tube section joint fire-protection structure comprises a first protection component and a second protection component. The first protection component is a rigid structural component; and one end of the first protection component is used for being fixed to one side of the end of a first tube joint, and the other end of the first protection component is used for being movably connected to one side of the end of a second tube joint. The second protection component is a flexible structural component; and one end of the second protection component is used for being fixed to one side of the end of the first tube joint, and the other end of the second protection component is used for being fixed to one side of the end of the second tube joint. According to the construction method, the second protection component is mounted in the first place, and then the first protection component is mounted. According to the fire-protection structure for the immersed tube joints, two joint fire-protection structure bodies which combine rigidity and flexibility are formed through the first protection component and the second protection component; effectiveness and reliability of fire protection and heat insulation achieved during the operation period can be effectively improved; furthermore, the tube section joint fire-protection structure can be flexibly adapted to deformation of the tube section joints; during the construction period and the operation period, the tube section joint fire-protection structure can play the effective protection role for tube sections; and the construction method for the fire-protection structure for the tube section joints is simple, safe and efficient.

Owner:CHINA COMMUNICATIONS CONSTRUCTION +1

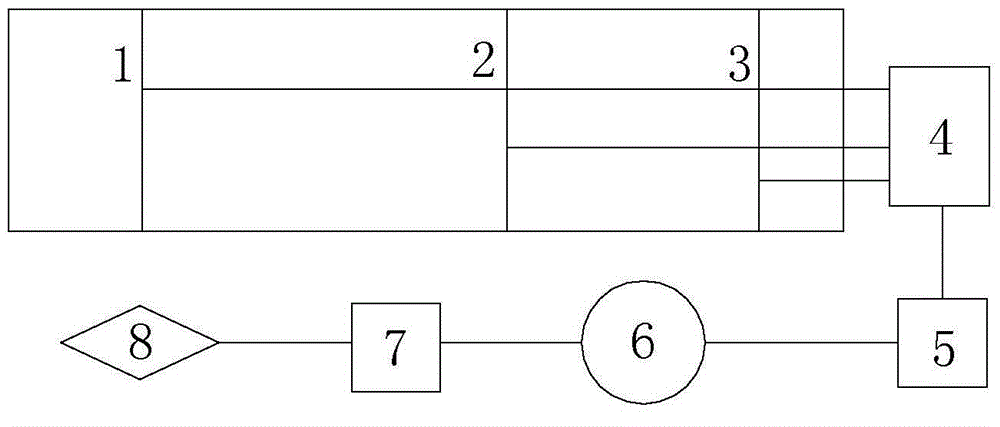

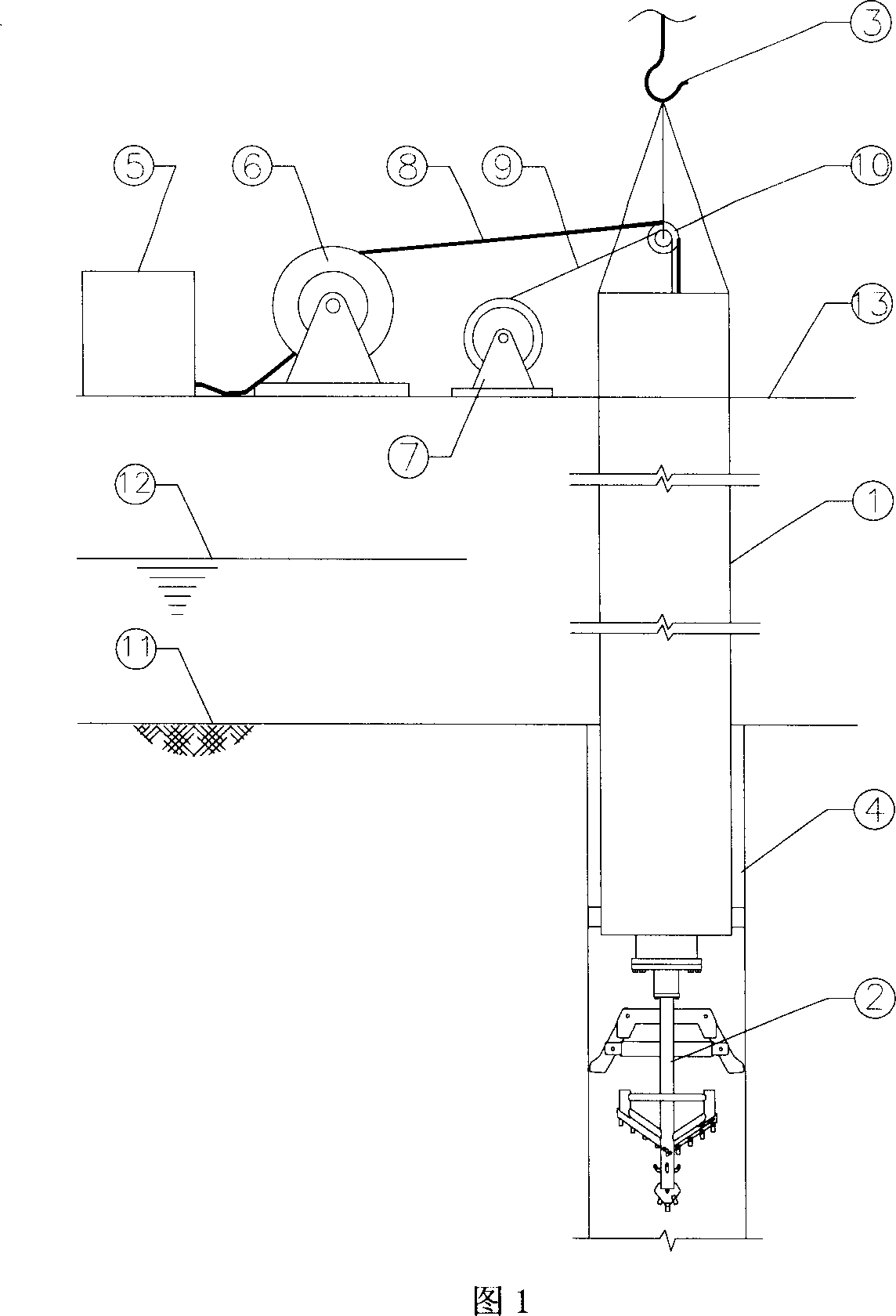

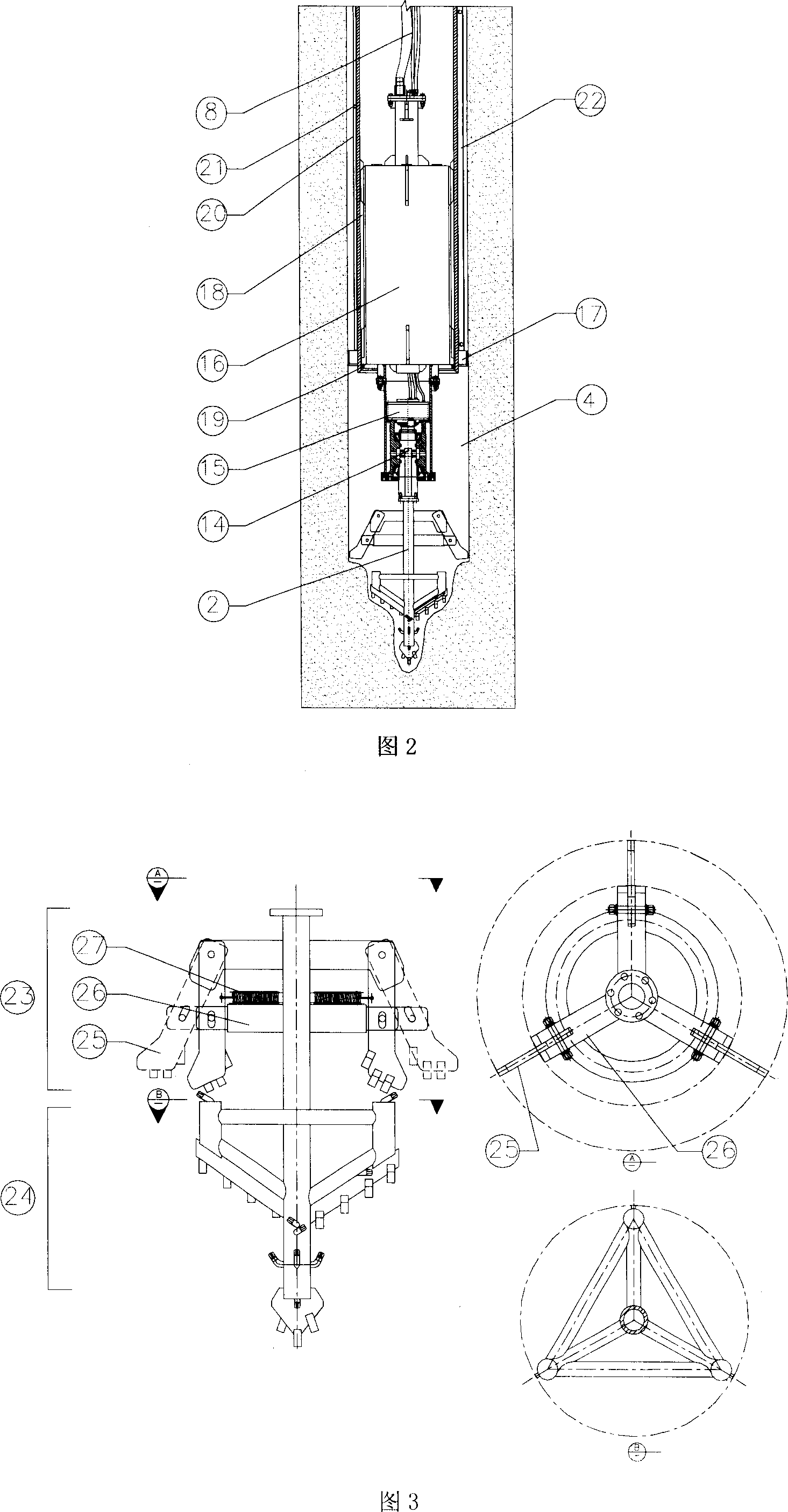

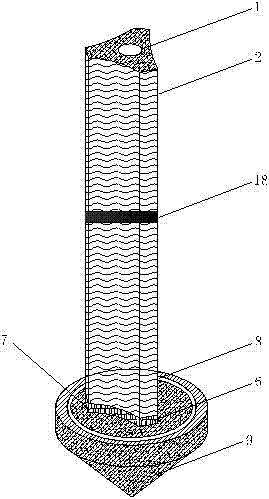

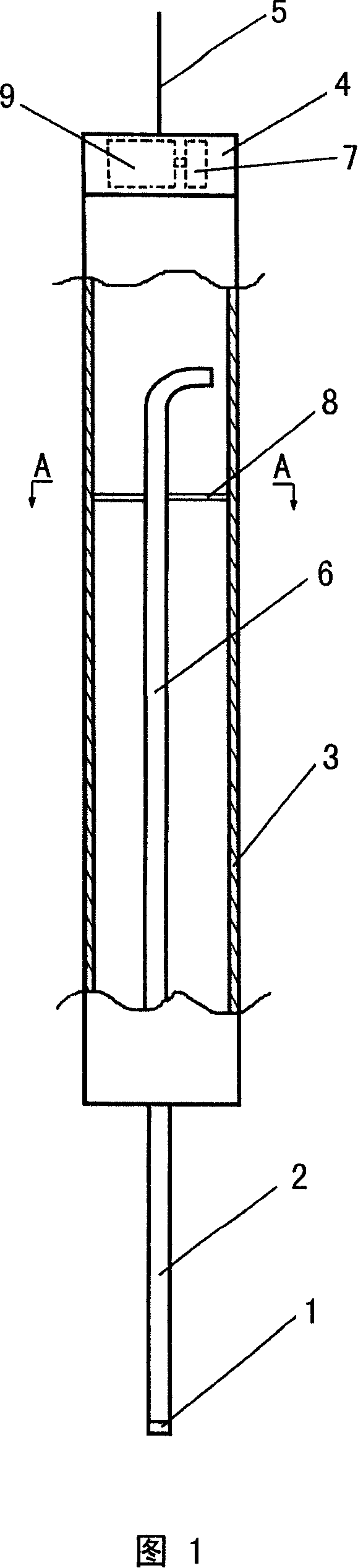

Waterproof casing mounting method-immersed tube drilling method

The invention relates to a water string installation method, namely, the immersed tube drilling method; a drill bit (2) is arranged at the lower end of a water string (1), the drill is connected with a power station (5) on a platform by a power hose bundle (8) in the water string (1), the water string (1) is hung on a large hook (3) of the platform drill and is lowered gradually, the rise and fall of the drilling tool and the power hose bundle (8) is realized by a cable winch (7) arranged on the platform and a hose winch (6), the drill bit (2) drills holes by the combination way of the mechanical drilling force and the water flushing force; the diameter of a drill hole (4) is greater than that of the water string (1), the water string (1) is inserted into the drill hole (4) together with the drill bit (2) until the design position is reached. The invention firstly proposes that the drill bit is arranged at the lower end of the water string and the well pipe is lowered during the drilling process, which avoids that the drill hole collapses and reduces the installation cost, and the invention is especially suitable for the addition of a small amount of new wells on the existing platform facility.

Owner:天津市海恩海洋工程技术服务有限公司

Bi-layer plastic-bushing inverted-arch cambered hollow special-shaped pile and construction method

ActiveCN103485334BIncrease girthImprove mechanical performanceBulkheads/pilesReinforced concreteEngineering

The invention relates to a bi-layer plastic-bushing inverted-arch cambered hollow special-shaped pile and a construction method. The pile is characterized by structurally comprising the inverted-arch cambered hollow special-shaped pile, a pile toe arranged at the bottom end of the special-shaped pile and fixed through fixing parts, and a precast reinforced concrete pile tip; a cemented soil layer is arranged on the outer side of a pile body; a cross section of the special-shaped pile is Y-shaped or X-shaped, and bushings with threads are arranged in a round hole in the center of the pile body and on the outer side of the pile body; a reinforcement cage, which is in the same shape as the pile body but slightly smaller than the pile body, is arranged in the pile body; horizontal and longitudinal tensile reinforcements are arranged in the reinforcement cage; and the fixing parts corresponding to the bushings and an immersed tube are arranged on the top face of the precast reinforced concrete pile tip. During construction, the pile toe and the inner bushing are fixed firstly, then the reinforcement cage and the outer bushing are sleeved, and concrete is poured between the inner bushing and the outer bushing as well as between the outer bushing and the immersed tube to respectively form a concrete pile core and a pile-side cemented soil layer. Area of the cross section of the pile body is small, consumption of building materials is reduced, bearing capacity is high, and the pile body is high in capability of resisting to environmental erosion.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

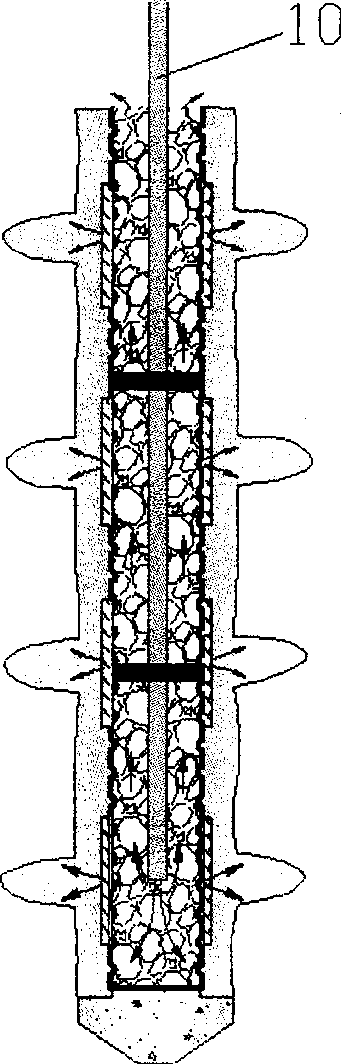

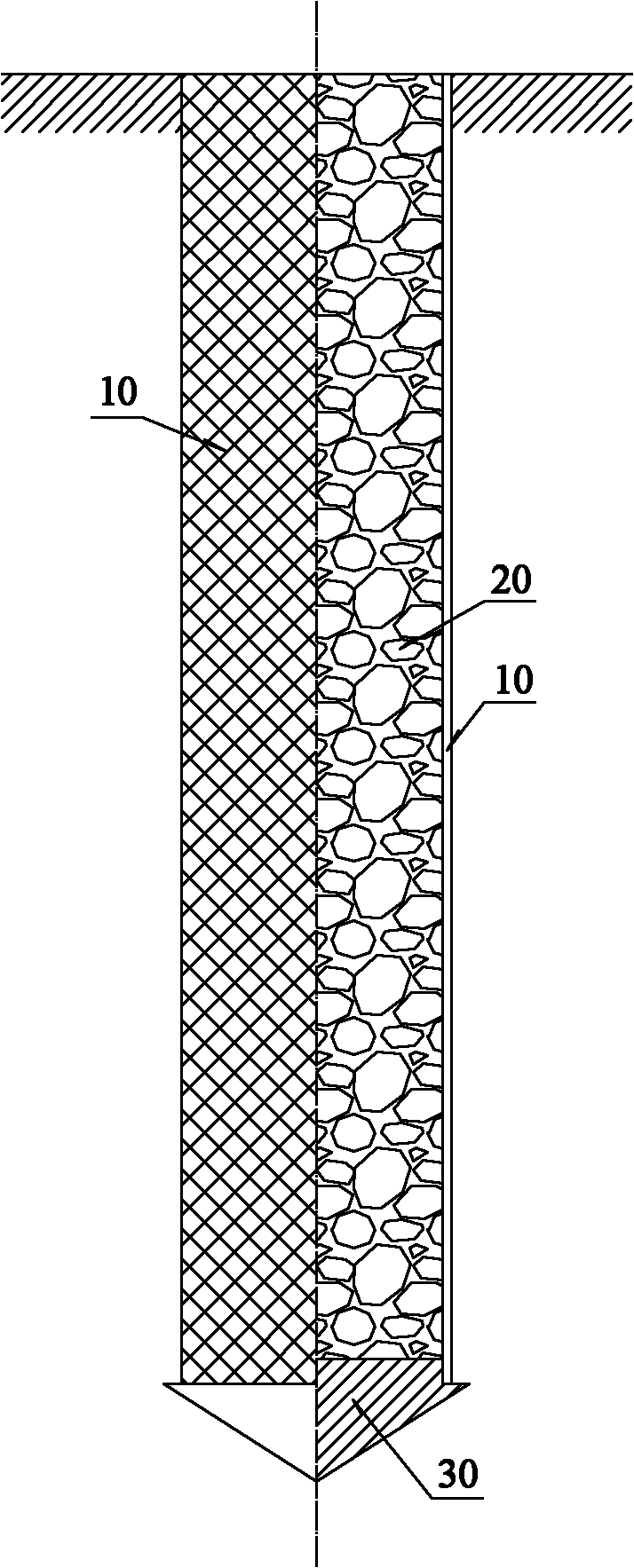

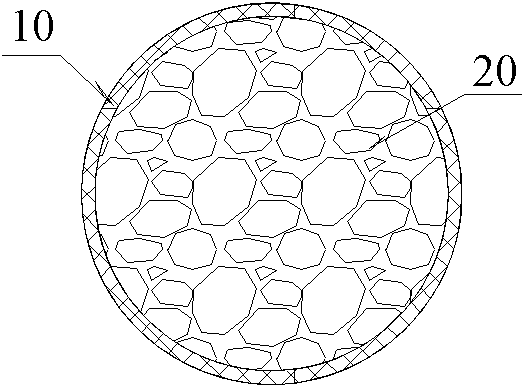

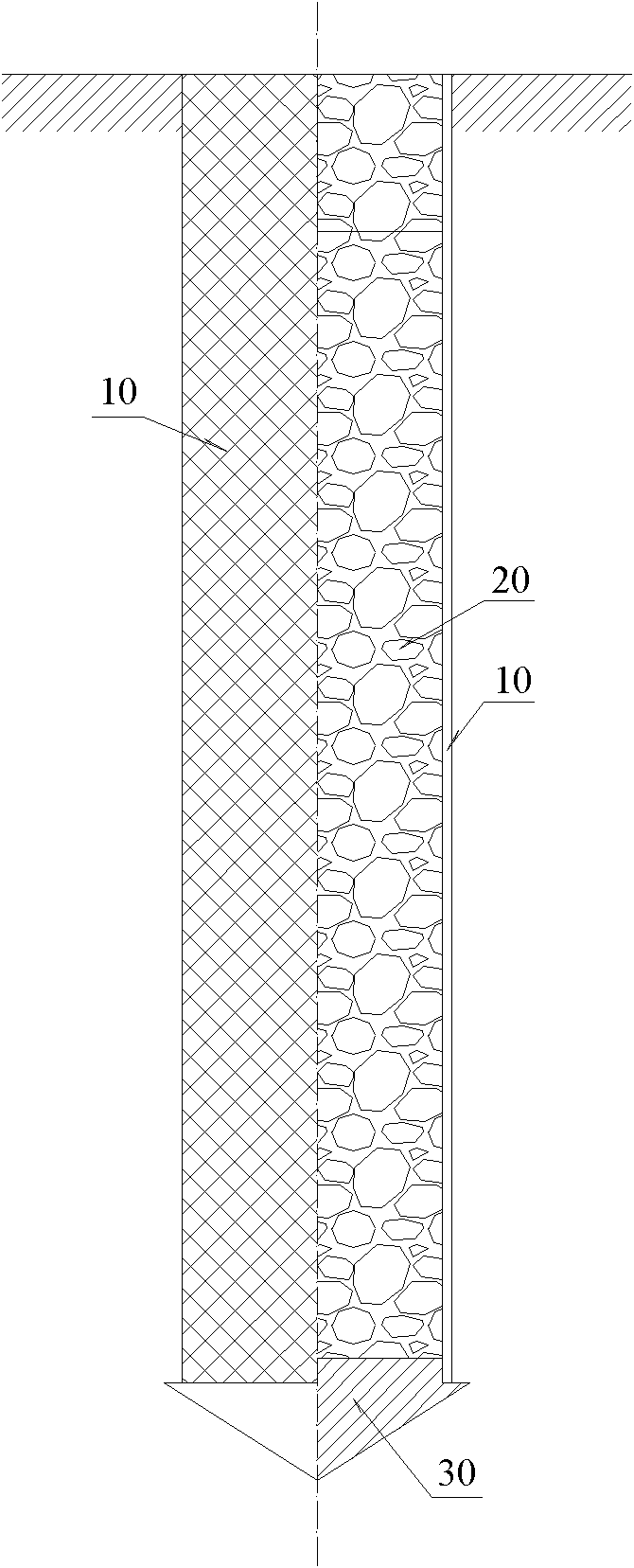

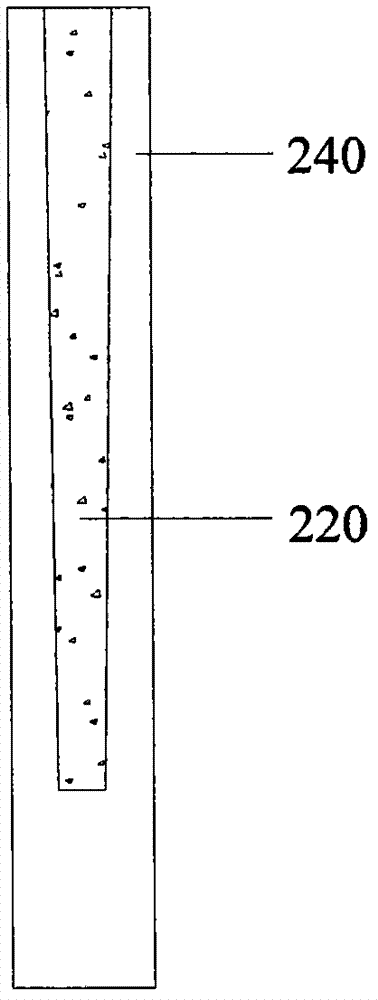

Crushed rock pile used for strengthening extremely soft soil foundation and construction method thereof

InactiveCN102155009APrevent proliferationDrainage is not affectedSoil preservationCrushed stoneEngineering

The invention relates to a crushed rock pile used for strengthening an extremely soft soil foundation and a construction method thereof, capable of effectively controlling filling quantity of crushed rock filler so as to reduce the foundation strengthening construction cost. The crushed rock pile comprises a net barrel (10) which vertically extends to a foundation supporting layer or design elevation and crushed rock filler (20) which is filled in the net barrel (10) densely, wherein the circumference of the net barrel (10) is provided with a grid structure, and the grid size of the grid structure is smaller than the grain size of the crushed rock filler (20). The construction method comprises the following steps of: mounting a pile head (30) at the lower end of an immersed tube, placing the net barrel (10) in the immersed tube; filling the crushed rock filler (20) into the net barrel (10); acting on the immersed tube by adopting static pressure or vibrating equipment so that the immersed tube is immersed into soil and reaches the foundation supporting layer or the design elevation; and vertically lifting the immersed tube upward until the immersed tube is pulled out of a pile hole. By adopting the crushed rock pile and the construction method provided by the invention, the crushed rock filler can be prevented from radially spreading outside a pile, so that the crushed rock filling quantity is bassically consistent with the volume of the pile body of the crushed rock pile, thereby well exerting the advantage of low manufacturing cost of the crushed rock pile.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

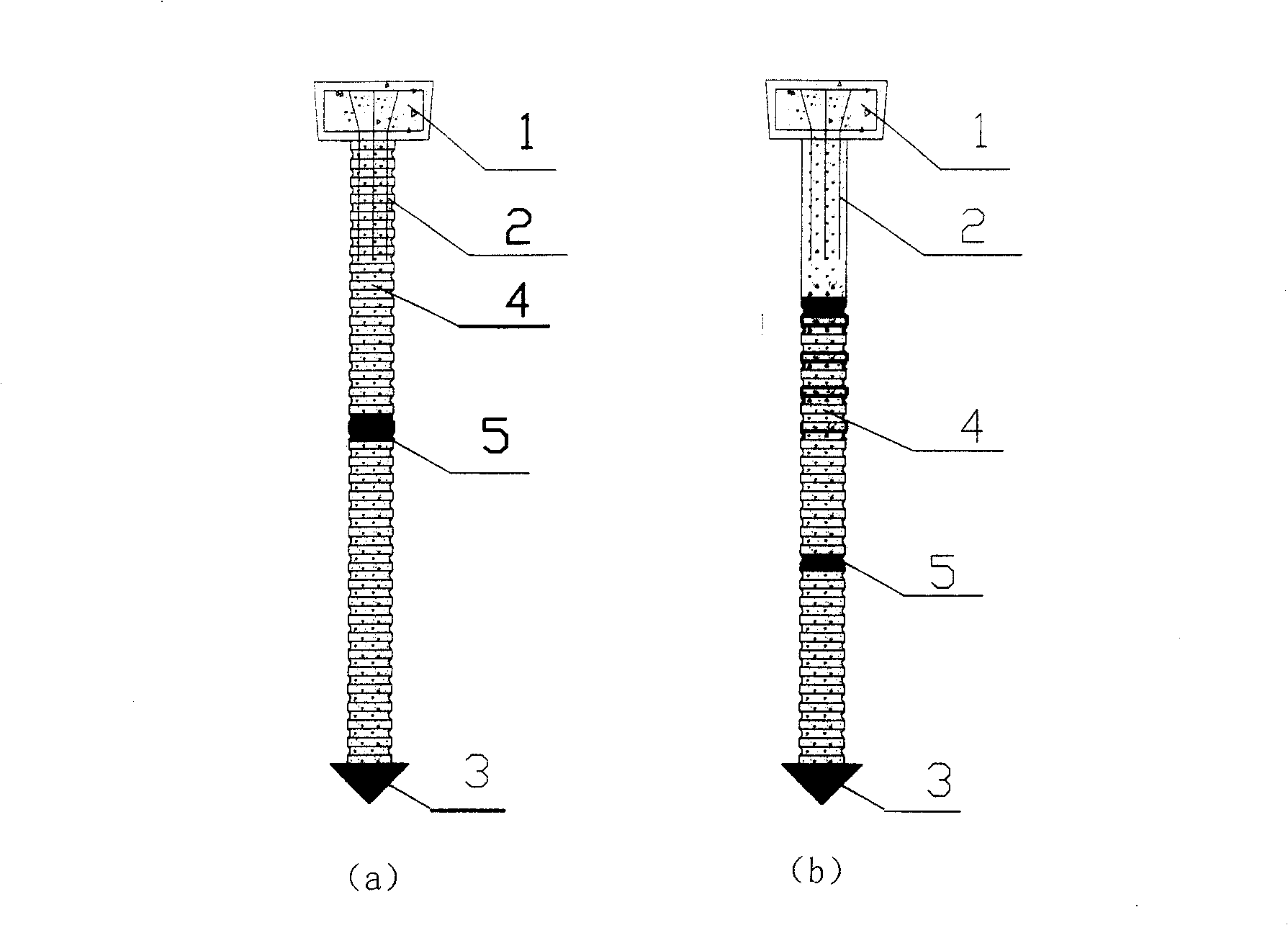

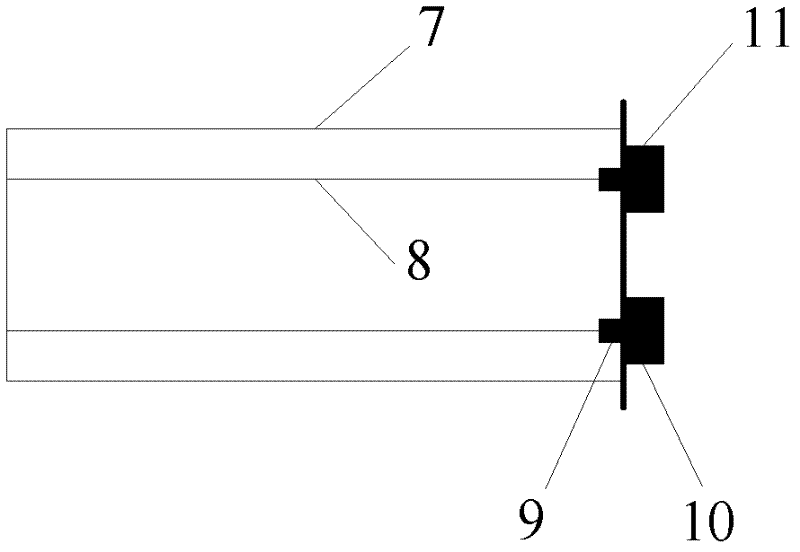

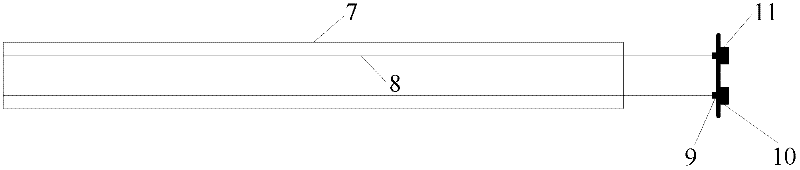

Cement mixing pile with stiffness core capable of draining and pre-pressing firstly and then grouting as well as construction method thereof

InactiveCN102650128AEasy to sinkConducive to uplift constructionBulkheads/pilesSoil preservationImmersed tubePipe

The invention relates to a cement mixing pile with a stiffness core capable of draining and pre-pressing firstly and then grouting as well as a construction method thereof. The cement mixing pile comprises a vertical draining and grouting pipe arranged in the cement mixing pile, and more than one dual-layer telescopic horizontal draining and grouting pipes arranged at intervals on the vertical draining and grouting pipe, wherein a bulk solid pile with the stiffness core is arranged in the cement mixing pile, and the length of a horizontal draining and grouting pipe in an outer layer is smaller than that of the horizontal draining and grouting pipe in an inner layer when the horizontal draining and grouting pipe is in a telescopic state. In a construction process, an upper drawn steel immersed tube is vibrated, and the horizontal draining and grouting pipe departs from the steel immersed tube and is stretched to form a horizontal draining body. According to the invention, the advantages of drainage consolidation and composite foundation methods are integrated, and foundations can be dynamically reinforced according to the construction period and the settlement requirements on the premise of lower construction cost while the bearing capacity and the processing depth of the cement mixing pile are increased.

Owner:ZHEJIANG UNIV CITY COLLEGE +2

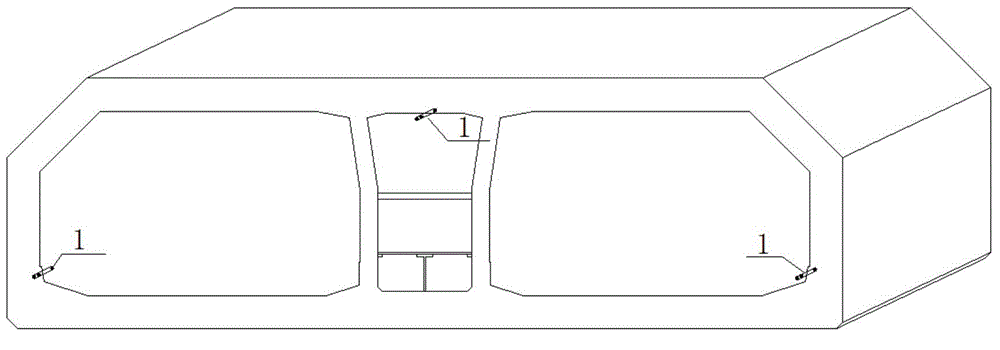

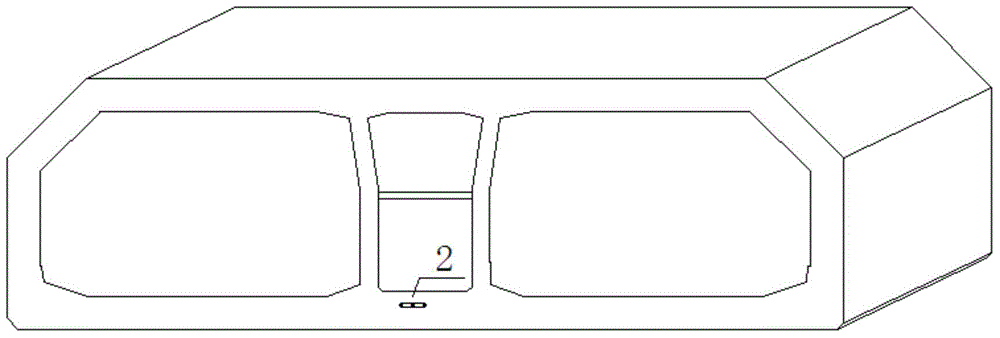

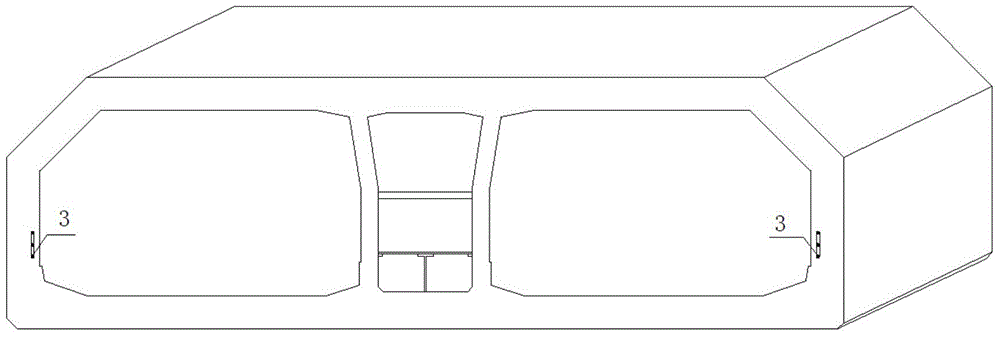

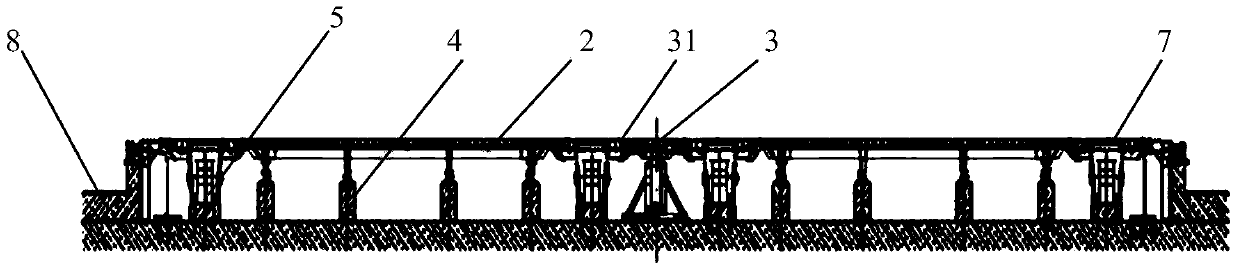

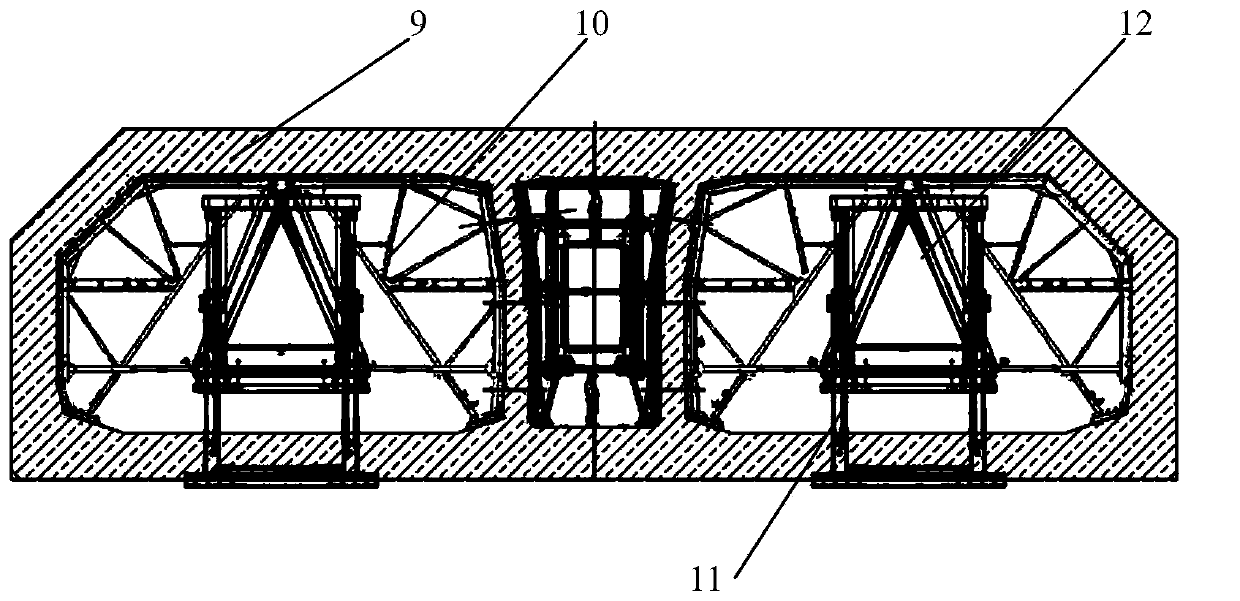

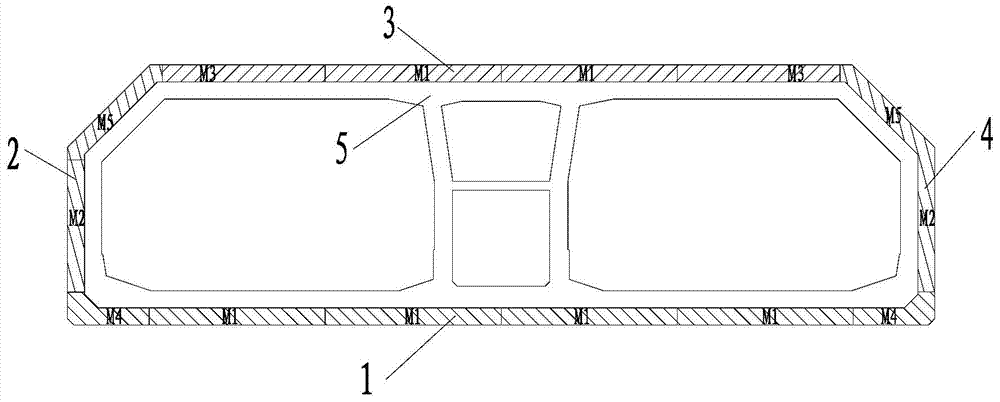

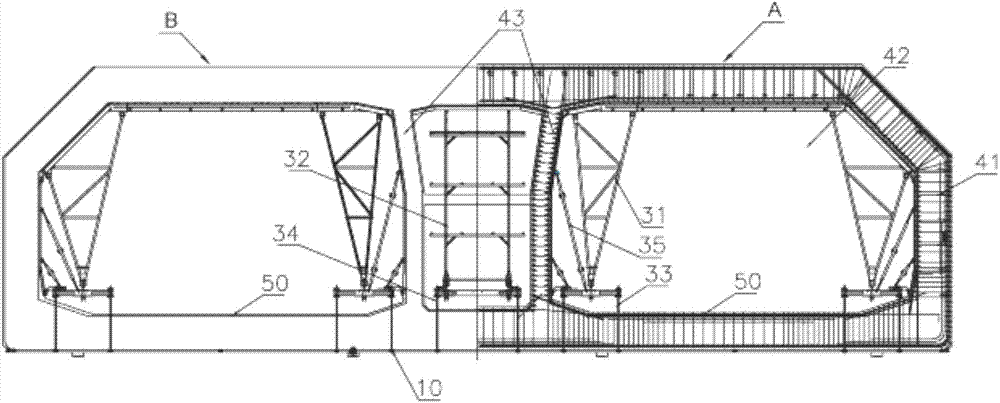

Template system used for overall pouring of large-area tunnel immersed tube

ActiveCN103726511AImprove manufacturing precisionIncrease productivityArtificial islandsUnderwater structuresImmersed tubeTunnel construction

The invention relates to the field of tunnel construction, in particular to a template system used for overall pouring of a large-area tunnel immersed tube. The template system used for overall pouring of the large-area tunnel immersed tube comprises a bottom die, side dies, an inner die, an end die and a hydraulic drive system, wherein the hydraulic drive system drives the bottom die, the side dies and the inner die to move, be released and reset. The template system used for overall pouring of the large-area tunnel immersed tube improves the production efficiency of pouring of the immersed tube, improves the manufacturing precision of the immersed tube, can effectively avoid resource waste in the process of manufacturing of the immersed tube, and saves the production cost.

Owner:CCCC FOURTH HARBOR ENG CO LTD +3

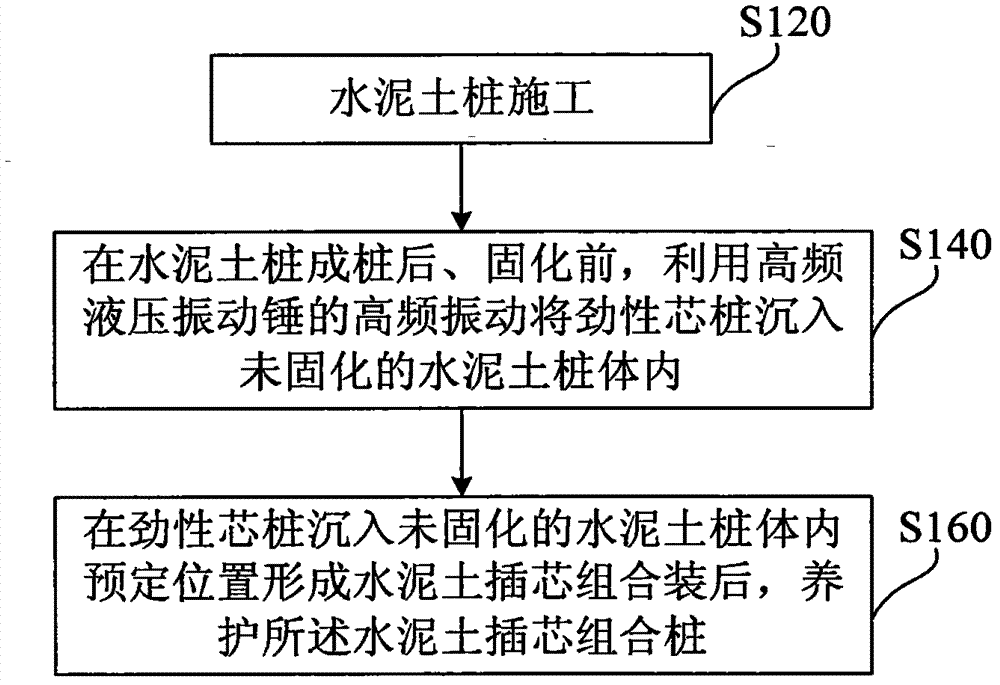

High-frequency hydraulic vibratory construction method for cement-soil core-inserted combined pile

InactiveCN102900079AImprove bearing capacityMake full use of side friction resistanceBulkheads/pilesRigid coreImmersed tube

The invention provides a high-frequency hydraulic vibratory construction method for a cement-soil core-inserted combined pile. The high-frequency hydraulic vibratory construction method is a foundation reinforcing method, and includes forming a hole in a soil squeezing mode by a traditional immersed tube or drilling a hole by long spiral equipment, and filling stirred cement-soil mixtures into the drilled hole to for a pile; or directly forming a cement-soil pile by a stirring pile machine, immersing a rigid core pile into the uncured cement-soil pile by a high-frequency hydraulic vibratory hammer after cement-soil forms the pile, and forming the novel pile comprising the cement-soil pile and the core pile which jointly bear load. Compared with the prior art, the high-frequency hydraulic vibratory construction method has the advantages that the construction speed is high, the noise and the manufacturing cost are low, pollution is prevented, the quality of the formed novel pile is stable, and the formed novel pile is high in load bearing capacity. Besides, the construction efficiency is ten times of that of a common piling machine, the cost is saved by about 30% to 50% as compared with a precast pile, and is saved by about 40% to 50% as compared with a drilled grouting pile, and the high-frequency hydraulic vibratory construction method has substantial social and economical benefits.

Owner:MCC COMM CONSTR GRP CO LTD

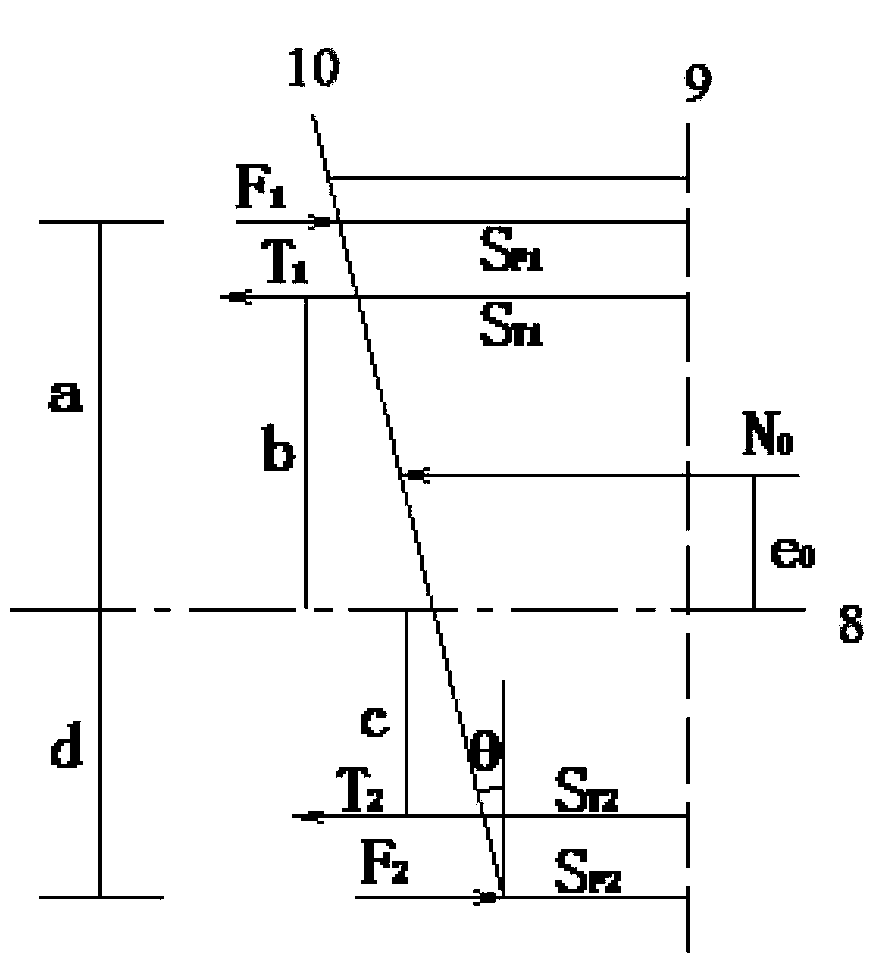

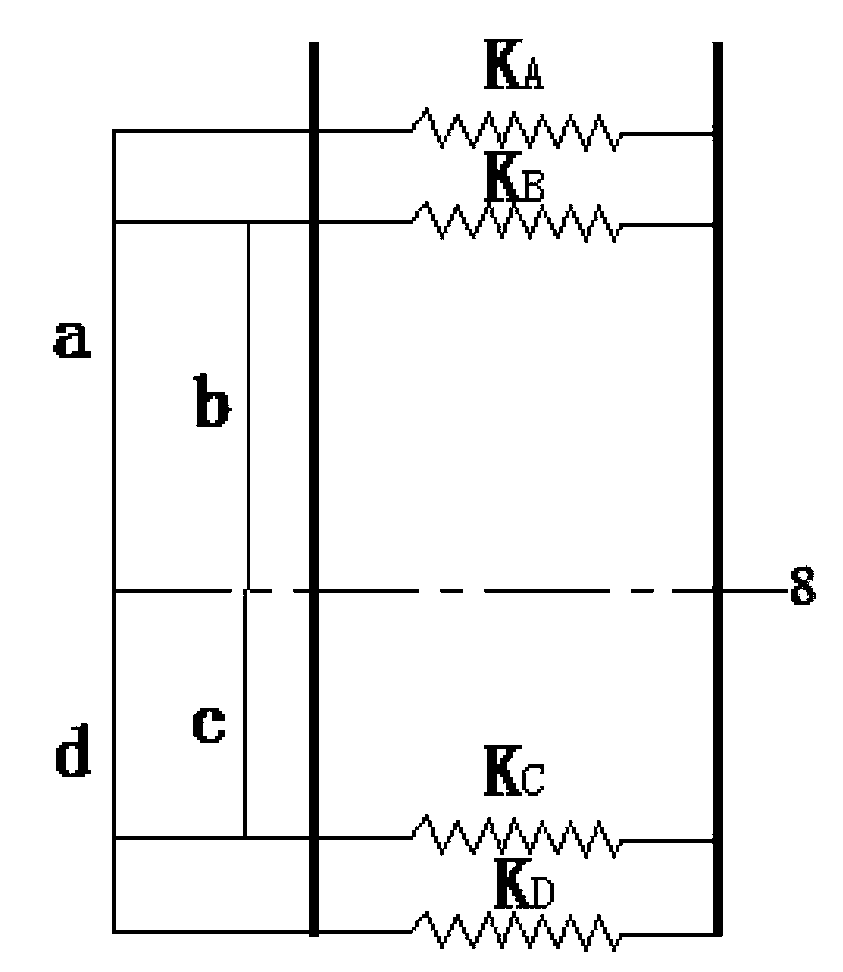

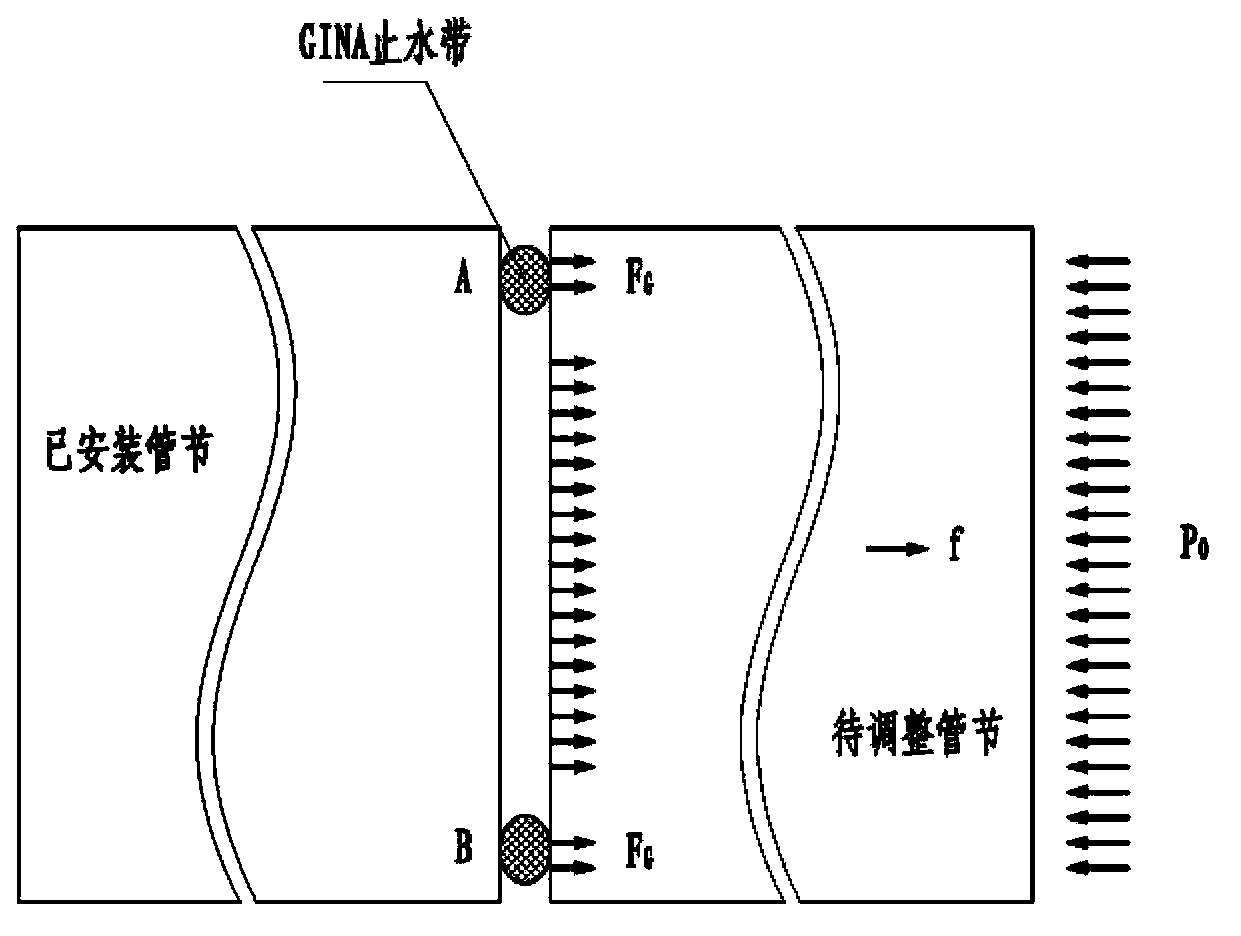

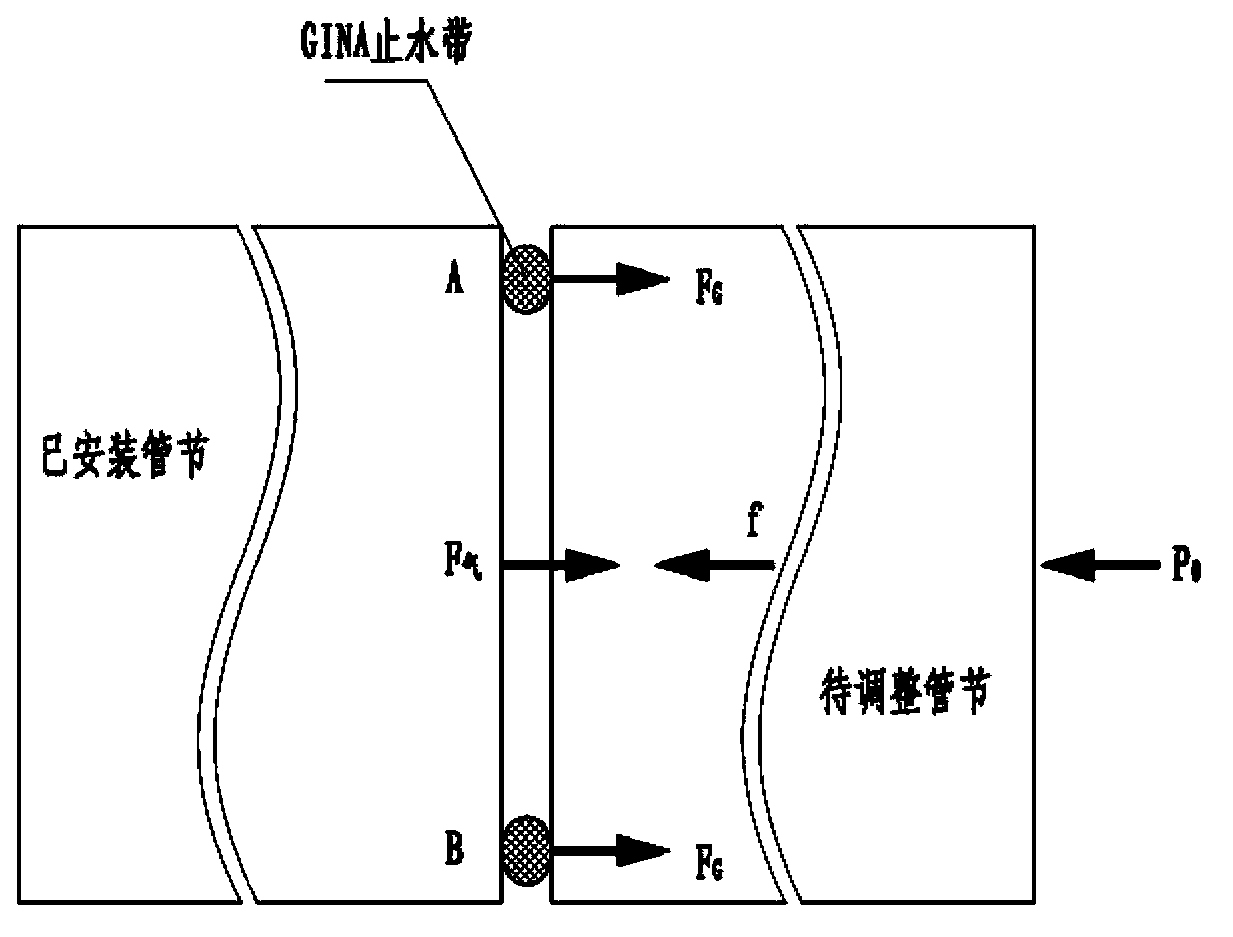

Method for measuring flexural rigidity of immersed tube tunnel joint

ActiveCN103792139AReasonable descriptionSimplifying Calculation AssumptionsMaterial strength using tensile/compressive forcesPre stressImmersed tube

The invention relates to a method for measuring the flexural rigidity of an immersed tube tunnel joint. The method comprises the following steps: 1, applying an axial external water pressure N0 to the immersed tube tunnel joint as an external force applied to a position having a distance of an initial eccentric throw e0 to the neutral axis of the immersed tube tunnel joint; 2, continuously applying prestressed cable pretensions T1 and T2 to the immersed tube tunnel joint; 3, measuring the displacement S0 and the corner theta of a GINA waterstop under the action of N0, T1 and T2; 4, using an immersed tube tunnel joint structure simplification model established by a steel plate and a spring element to calculate the compression amount SF1 and SF2 of the GINA waterstop, the prestressed cable extension amount ST1 and ST2 at a top board and a bottom board, the pressures F1 and F2 of the GINA waterstrop of the top board and the bottom board, and the pulling forces T1 and T2 of the prestressed cables of the bottom plate; and 4, calculating according to a force balancing equation to obtain the flexural rigidity Ktheta of the joint. Compared with the prior art, the method provided by the invention improves the design level and efficiency of the performance of the immersed tube tunnel joint.

Owner:TONGJI UNIV

Construction method of bamboo wood reinforcement bidirectional enhanced part-cut and part-fill weak roadbed

The invention discloses a construction method of a bamboo wood reinforcement bidirectional enhanced part-cut and part-fill weak roadbed, comprising the following steps of: (1) machining a bamboo wood; processing a bamboo sheet; and manufacturing a bamboo rib cage, a bamboo rib grid and a bamboo rib U-shaped anchor nail; (2) flattening a field and setting out a pile position; (3) utilizing a vibration shock method of a vibration immersed tube method to construct to form a bamboo rib cage crushed stone pile and paving a crushed stone cushion layer on a pile top; and (4) digging a step; paving, connecting and anchoring the bamboo rib grid; and backfilling a soil material and rolling and leveling. The construction method is characterized in that the bamboo rib cage can effectively improve the bearing capability and the stability of the crushed stone pile; the bamboo rib grid can reinforce the connection between a filling region and a digging region, the differential deposition is reduced, and sliding and instability of sliding along a filling and digging connecting face is prevented; and the construction method has the beneficial effects that a bamboo rib is used as a reinforcement material so that a construction industry is developed towards a low-carbon, energy-saving, environment-friendly and sustainable development direction, and saves the investment under the condition of meeting the requirements of roadbed bearing capability and deformation stability.

Owner:HUNAN UNIV

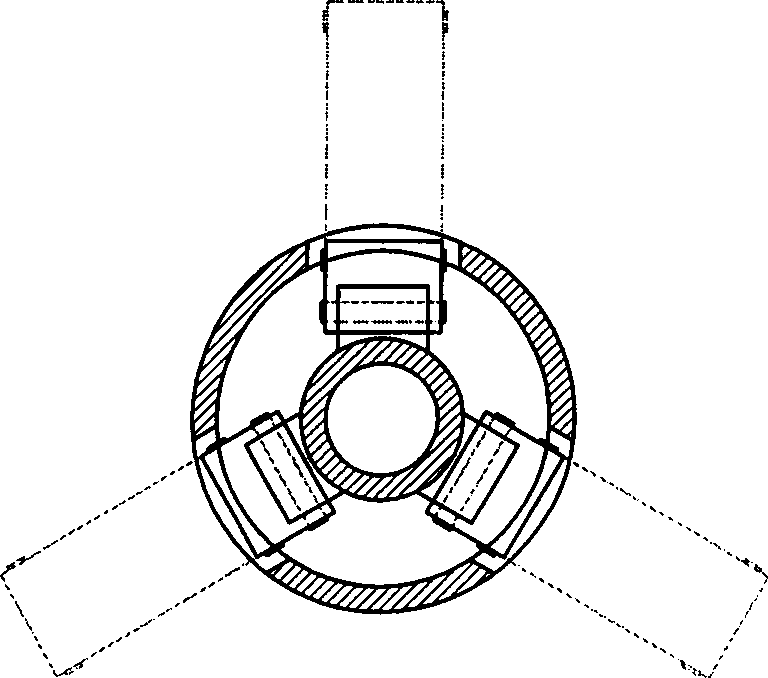

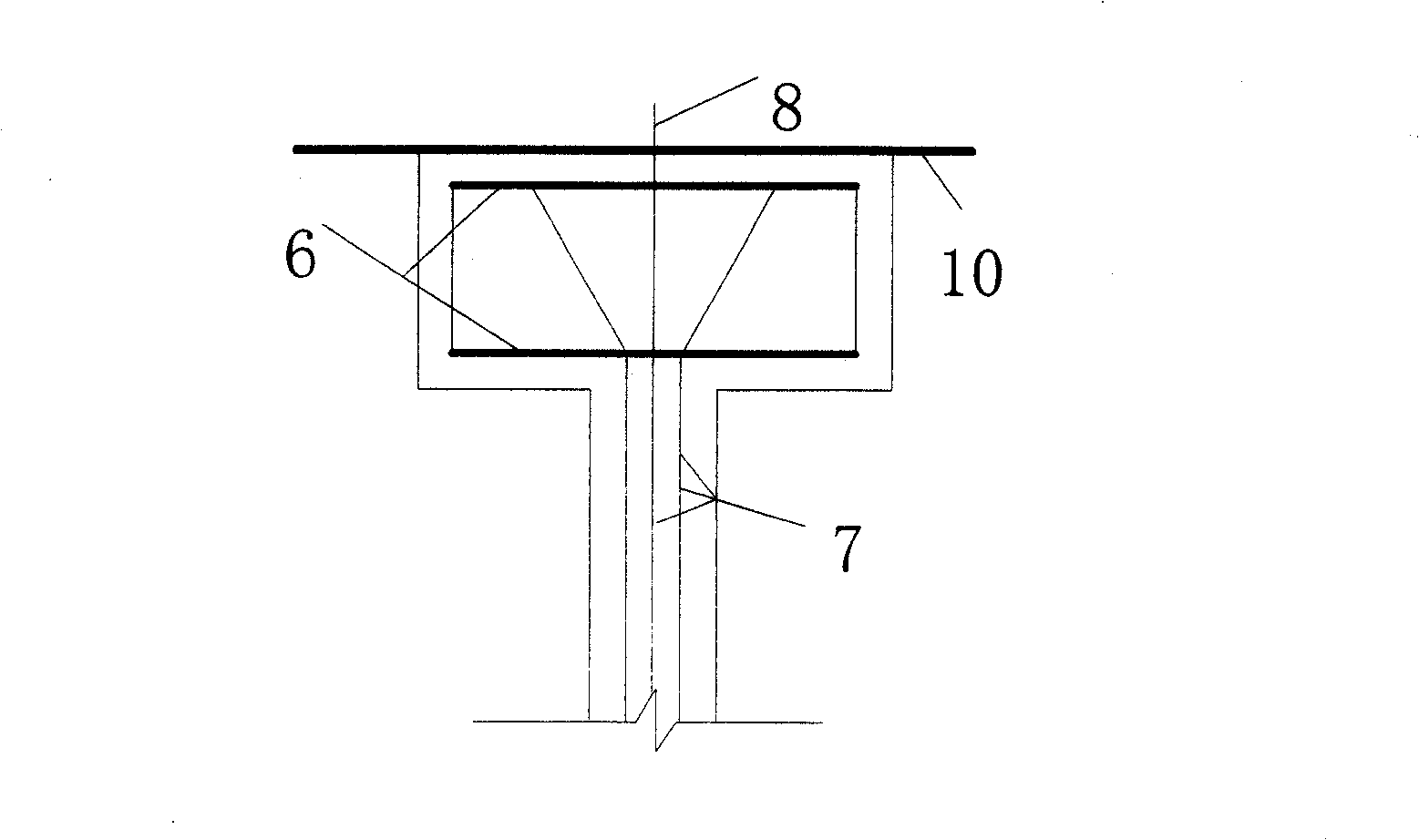

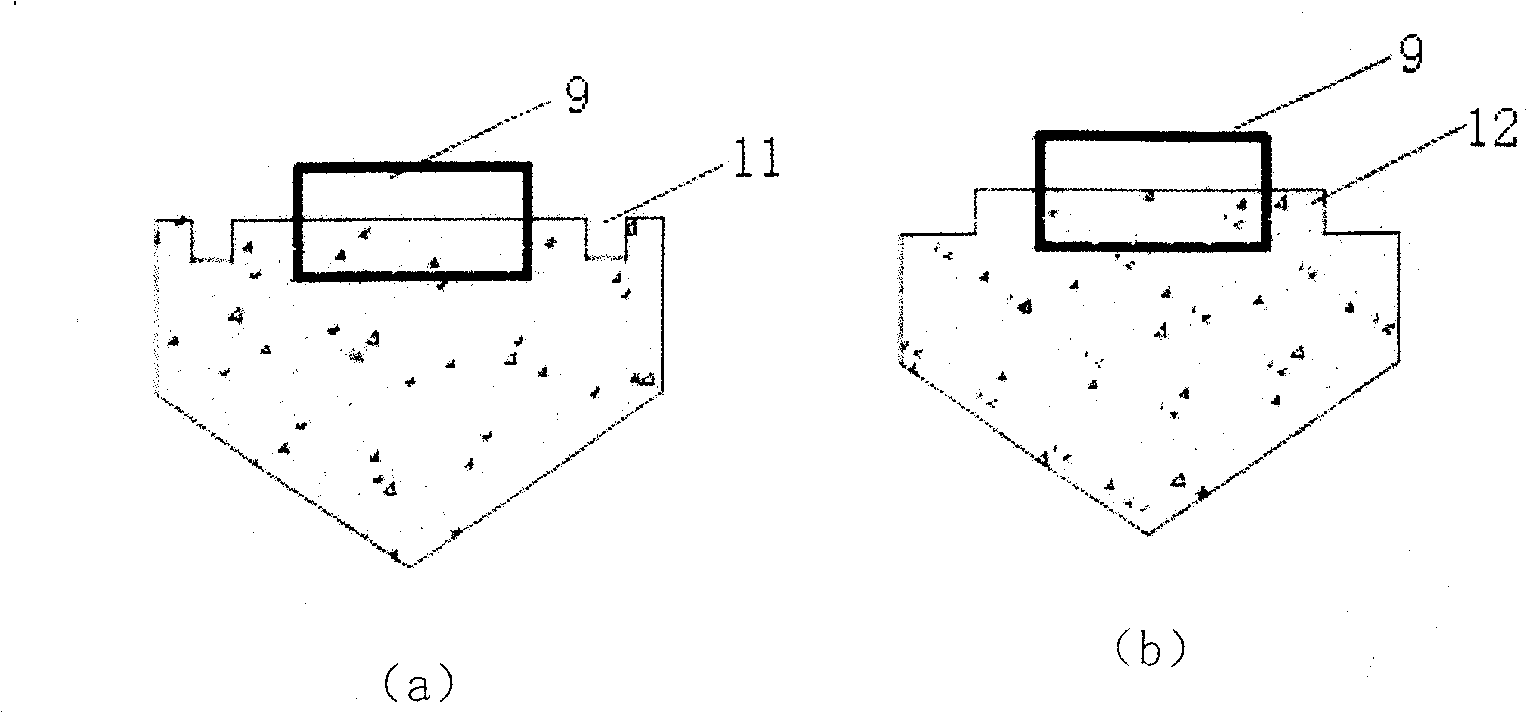

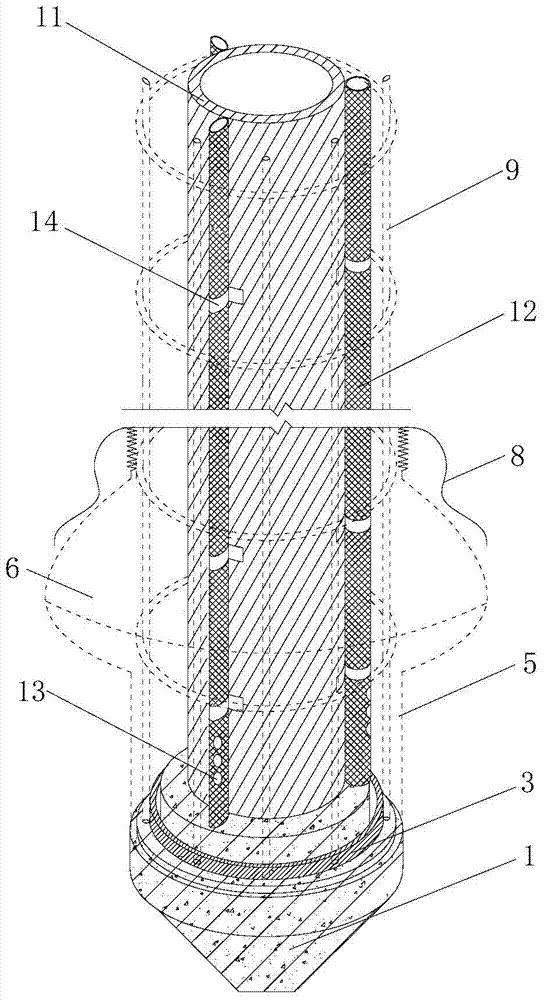

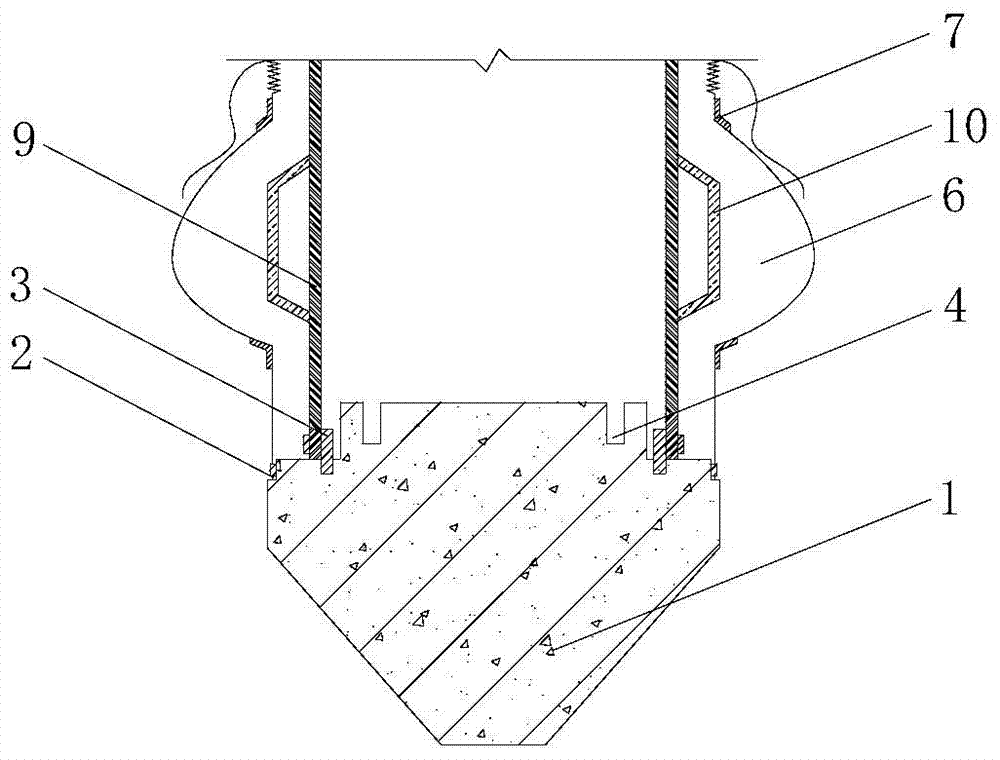

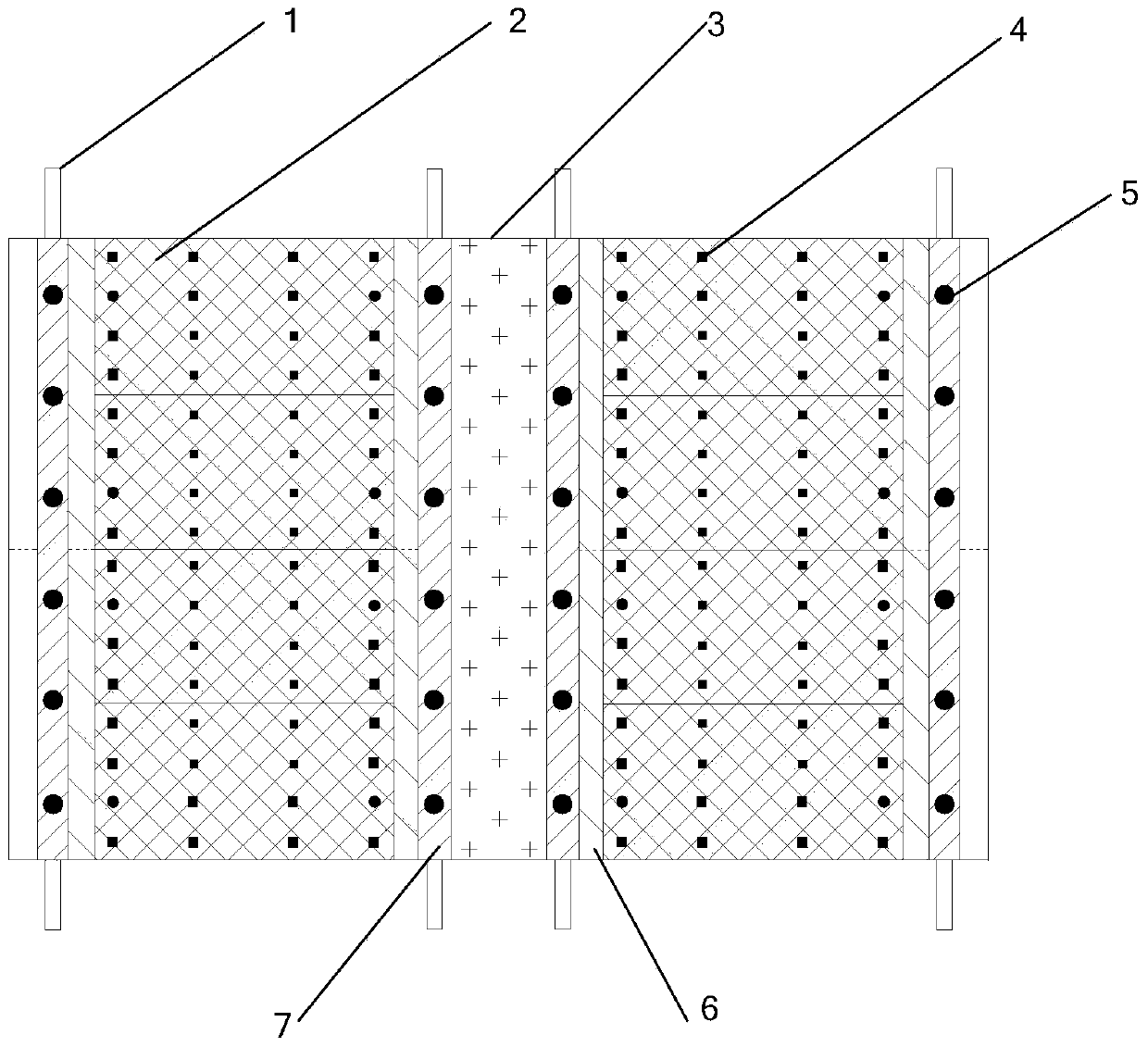

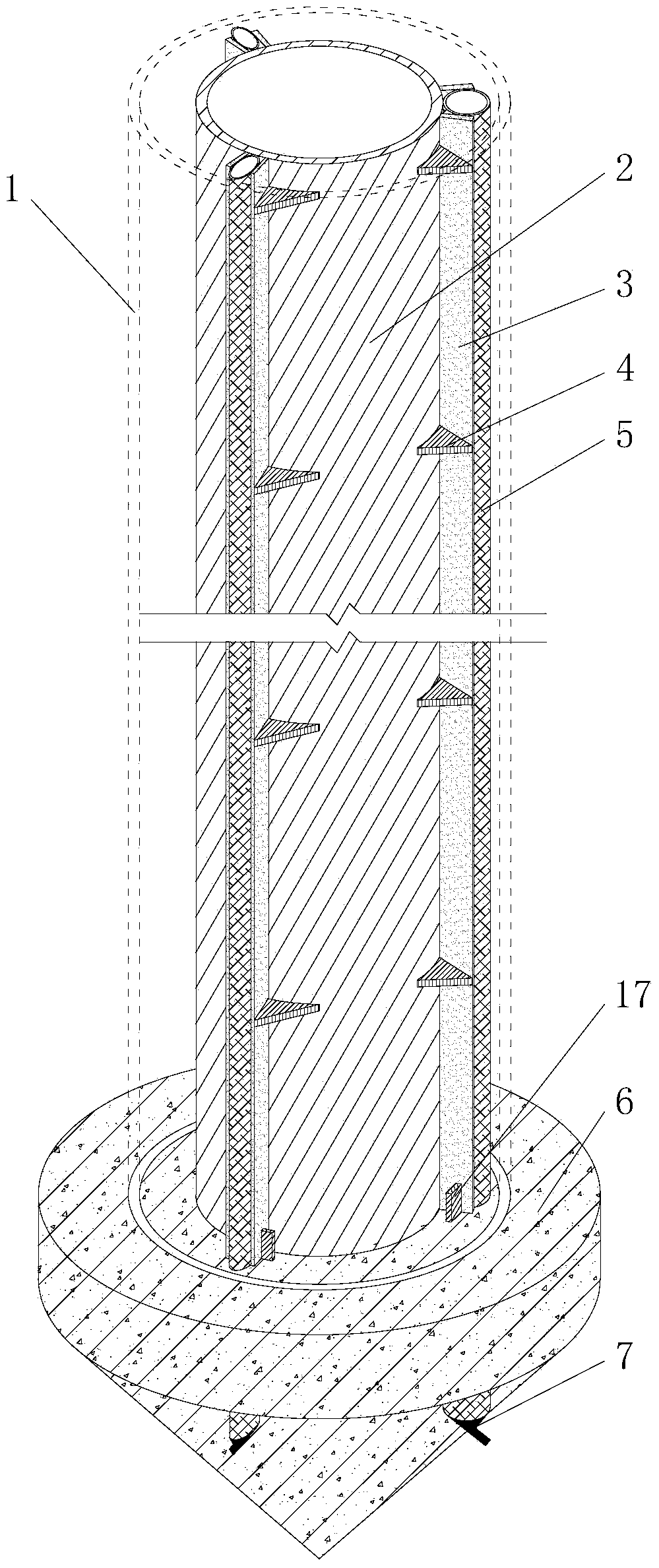

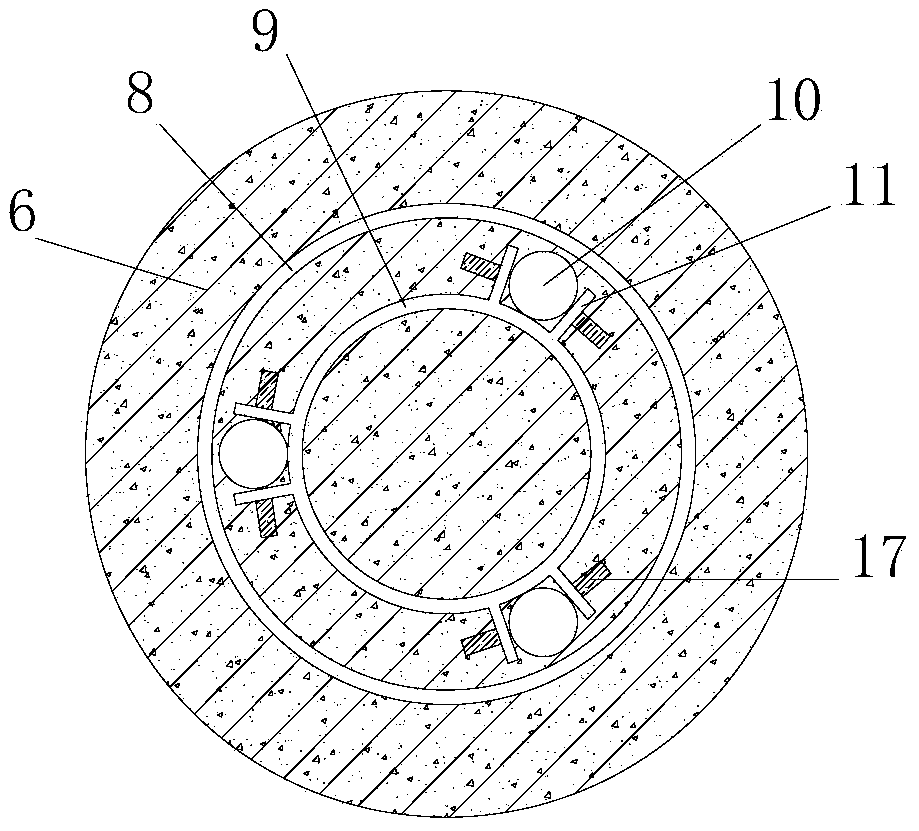

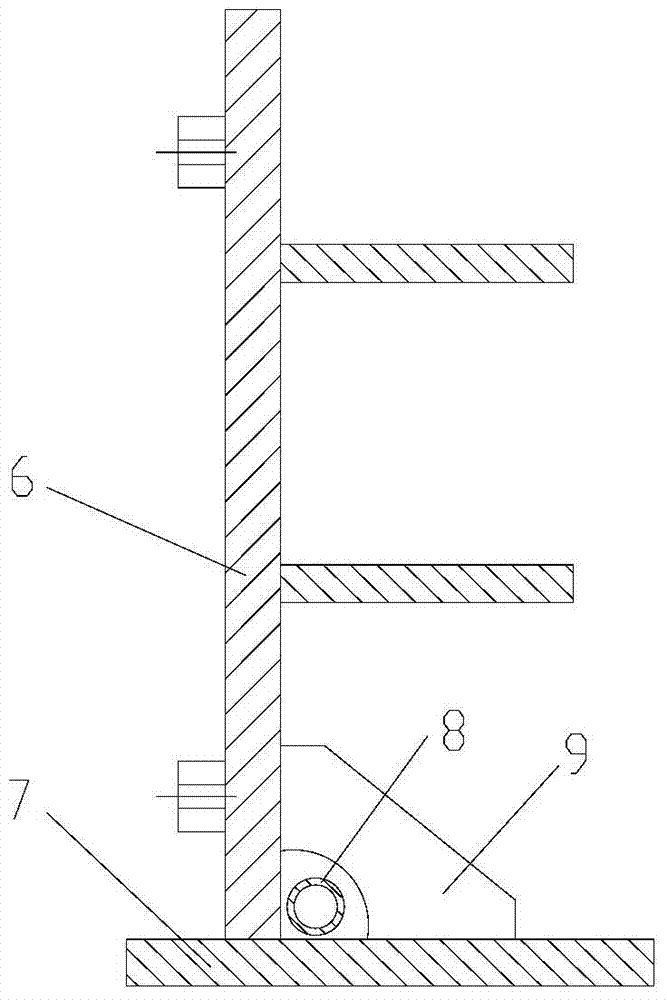

Construction device and method of pile peripheral cemented soil cast-in-place stiffness core pile

The invention relates to a construction device of a pile peripheral cemented soil cast-in-place stiffness core pile. The construction device is mainly composed of an inner immersed tube, an outer immersed tube, a precast pile toe and high-pressure guniting tubes. An outer immersed tube limiting groove, an inner immersed tube limiting groove, supporting baffle embedded grooves and torsion-resistance limiting steel plates which are used for positioning an upper portion immersed tube device are arranged on the upper surface of the precast pile toe. Hole channels which allow the high-pressure guniting tubes to pass are pre-formed inside the precast pile toe. The high-pressure guniting tubes which are provided with spraying heads at the bottom ends are evenly distributed on the outer side wall of the inner immersed tube in the circumferential direction. The two sides of each high-pressure guniting tube are respectively provided with a vertical through long supporting baffle. Stiffening ribbed plates are arranged on the outer sides of the supporting baffles in a uniformly-spaced mode. By the adoption of the construction device, the stiffness core pile can be formed inside the immersed tubes, cemented soil is formed at the periphery of the pile, the stress performance of pile body materials is brought into full play as much as possible, in the rotation sinking process of the device, high-pressure guniting is carried out on a lower portion soil body, end portion resistance and side frictional resistance can be reduced, and the sinking speed of the immersed tubes is improved. The invention further discloses a pile-forming construction method of the construction device.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

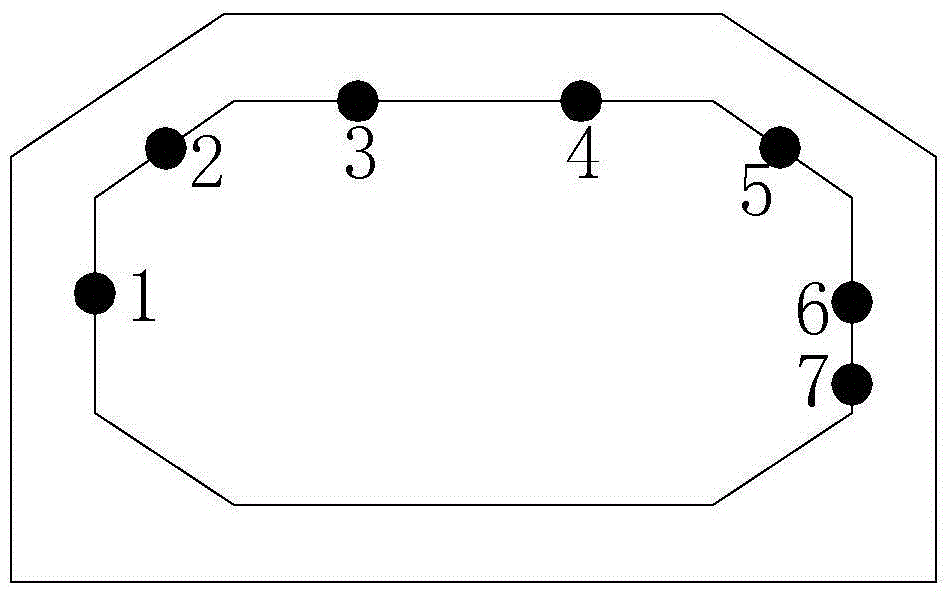

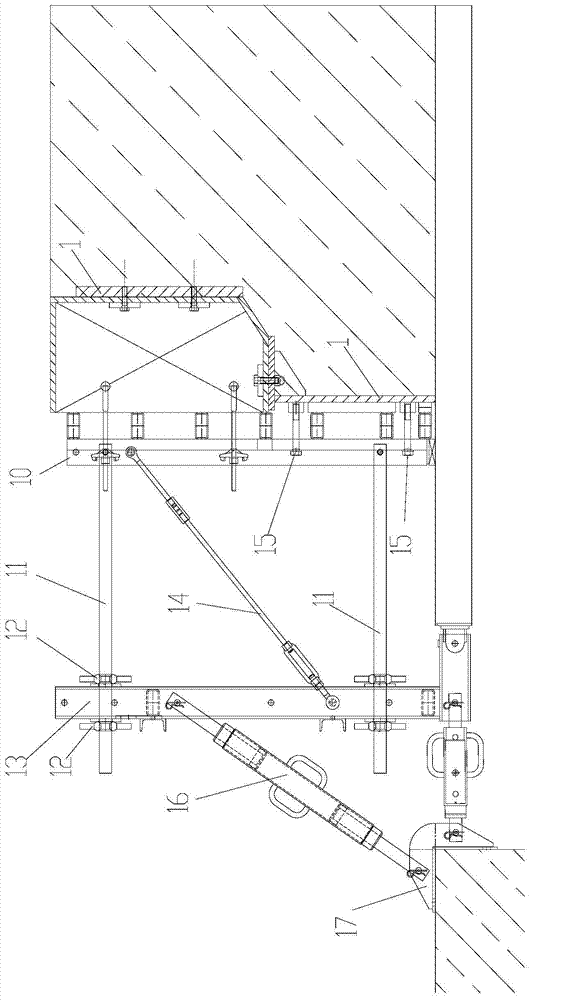

End steel shell mounting and positioning device and operation method

ActiveCN104711996AGuaranteed accuracyReduce wear and tearArtificial islandsUnderwater structuresRebarSoldering

The invention relates to the manufacturing field of subsea tunnel immersed tubes, in particular to an immersed tube end steel shell mounting and positioning device and an operating method. The end steel shell mounting and positioning device comprises an end steel shell and an end formwork unit. The end steel shell comprises a bottom plate segment, a left wall segment, a right wall segment and a top plate segment which are each formed by splicing segmented steel shell parts. The end formwork unit comprises a formwork back rack, adjusting threaded rods, a vertical frame, a telescopic rod and a fixing base, wherein the adjusting threaded rods are connected with the vertical frame and the formwork back rack; the formwork back rack is closely connected with the end steel shell; the adjusting threaded rods are provided with nuts; the telescopic rod is connected with the vertical frame and the fixing base; the end steel shell is provided with reflective pasters. Firstly, the spliced end steel shell large-segments are sequentially and initially located at the end of a bundled overall reinforcement cage, and then joint soldering is conducted; secondly, the reinforcement cage and the end steel shell are pushed into a pouring region, the end formwork unit and the end steel shell are connected and then accurately positioned and fixed; finally, the end steel shell and immersed tube sections are formed through one-time pouring, and then real-time positioning is conducted. The device is high in mounting accuracy, small in steel consumption, simple in process, high in working efficiency and low in cost.

Owner:THE SECOND ENG COMPANY OF CCCC FOURTH HARBOR ENG +3

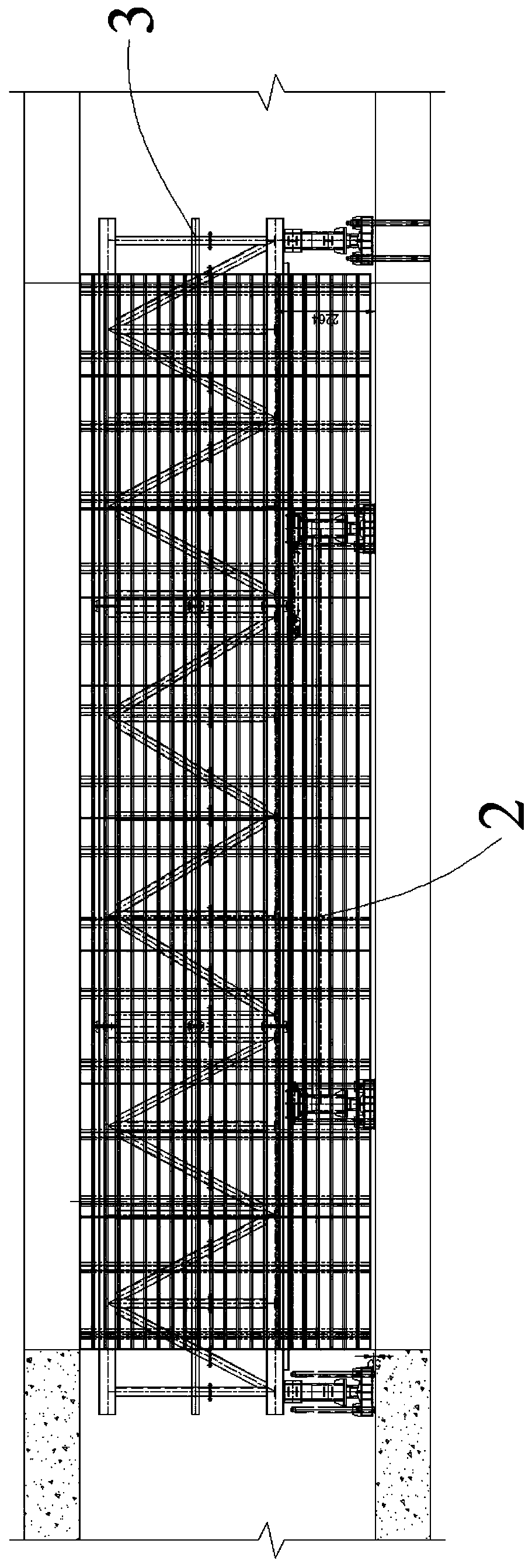

Movable reinforcement cage binding jig

InactiveCN103696440AImprove ergonomicsHigh precisionArtificial islandsShaping reinforcementsEngineeringRebar

The invention relates to the field of immersed tube tunnels, in particular to a movable reinforcement cage binding jig, which comprises a plurality of sliding tracks, an outer jig and an inner jig, wherein the sliding tracks are arranged in parallel, the outer jig is fixed out of a reinforcement cage, the inner jig is arranged in the reinforcement cage and is positioned on the sliding tracks, and the inner jig can move along the sliding tracks. The inner jig and the reinforcement cage of the movable reinforcement cage binding jig are arranged on the sliding tracks and can be removed and conveniently moved, the movable reinforcement cage binding jig is suitable for factory large-sized prefabricated parts, and a movable jig structure which can be quickly installed and removed is adopted, so that the work efficiency and the precision of binding the reinforcement cage are improved.

Owner:CCCC SECOND HARBOR ENG +3

Immersed tube drainage structure and method for handling suddenly-produced foundation pit water bursting and fountains through immersed tube drainage structure

InactiveCN103967028AReduce construction costsSimple processFoundation engineeringStopped workTube drainage

The invention discloses an immersed tube drainage structure, and further discloses a method for handling suddenly-produced foundation pit water bursting and fountains through the immersed tube drainage structure. When the water bursting phenomenon obviously occurs in a foundation pit and mud is sprayed out, landfill is conducted through original soil within the range of a core tube which has been dug, and then well digging and water pumping are conducted. A plurality of wells are formed for the core tube, and shaft bottom elevations are reduced till the shaft bottom elevations are below the natural ground and extend into high-water-content layers; after formation, a submerged pump is placed in each well to conduct water pumping; the upper openings of the wells are connected to form a water pumping network so that underground water can be pumped to a drainage system on the upper edge of the foundation pit; digging is continued after water inside the well is lowered below the foundation bottom elevations of the core tube; in the digging process, water pumping systems of the water pumps keeps working, blinding concrete pouring is conducted instantly after earth excavation conducted on the portions is completed; after pouring, the water pumping systems of the water pumps in the wells stop working after the raft foundation concrete pouring is completed and the strength reaches 75% of the designed strength. The drainage construction method is simple in process, and construction cost of foundation pit drainage construction can be effectively reduced.

Owner:JIANGSU NANTONG SANJIAN CONSTRUCTION GROUP CO LTD

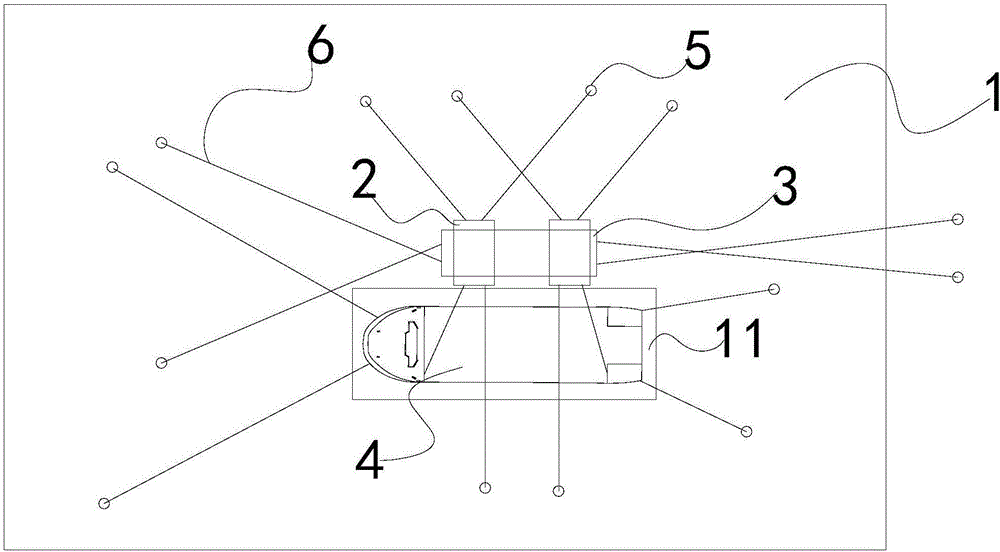

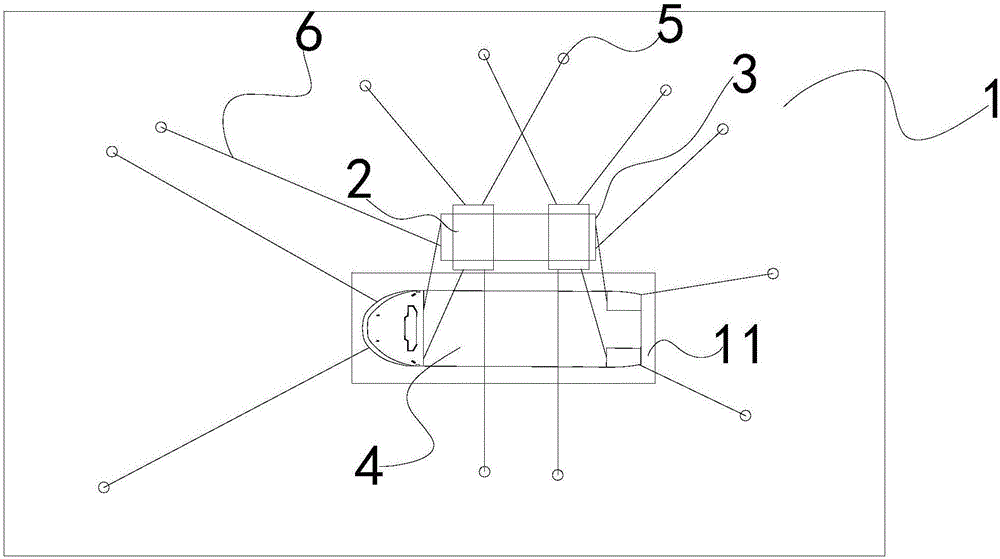

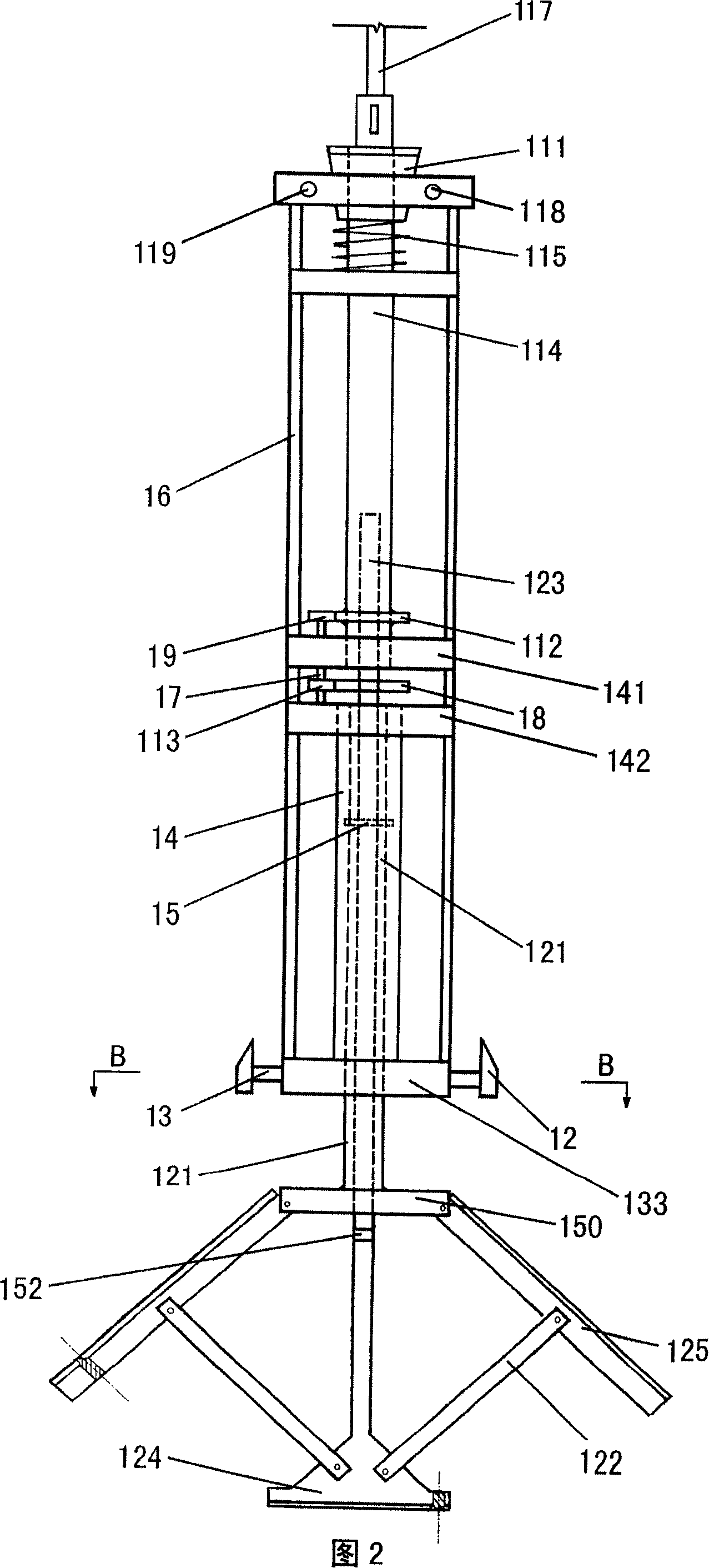

Pile machine special for immersed tube pressure filling pile, using method thereof and application thereof

InactiveCN103161155AImprovement on the method of inserting reinforcement cageGuaranteed verticalityBulkheads/pilesEconomic benefitsRebar

The invention provides a pile machine special for an immersed tube pressure filling pile and a method of using the pile machine to conduct concrete pressure filling construction and reinforcing cage post inserting construction. The pile machine special for the immersed tube pressure filling pile is provided with a concrete pressure filling system and a reinforcing cage post inserting system, uses a hollow vibratory hammer, and is provided with an inner hammer. According to the pile machine special for the immersed tube pressure filling pile and the method of using the pile machine, the quality of the concrete pressure filling construction and the quality of the reinforcing cage post inserting construction can be guaranteed, the application range of the immersed tube pressure filling pile is enlarged, and good economic benefit and technological benefit are achieved.

Owner:毕建东

Stiffening core composite pile and construction method thereof

The invention relates to a strength-core composite pile and a construction method. The outer periphery of the pile body is a granular pile, and a high-bonding strength pile core is arranged in the center of the granular pile. The construction method comprises the construction of the granular pile by the vibrating tube sinking method, and then driving the pile core with high bonding strength by the vibrating tube sinking method in the center of the granular pile. The invention can effectively reduce foundation deformation, enhance strength and rigidity of foundation soil, accelerate drainage and consolidation of soft soil, and prevent foundation soil from liquefying.

Owner:邓亚光

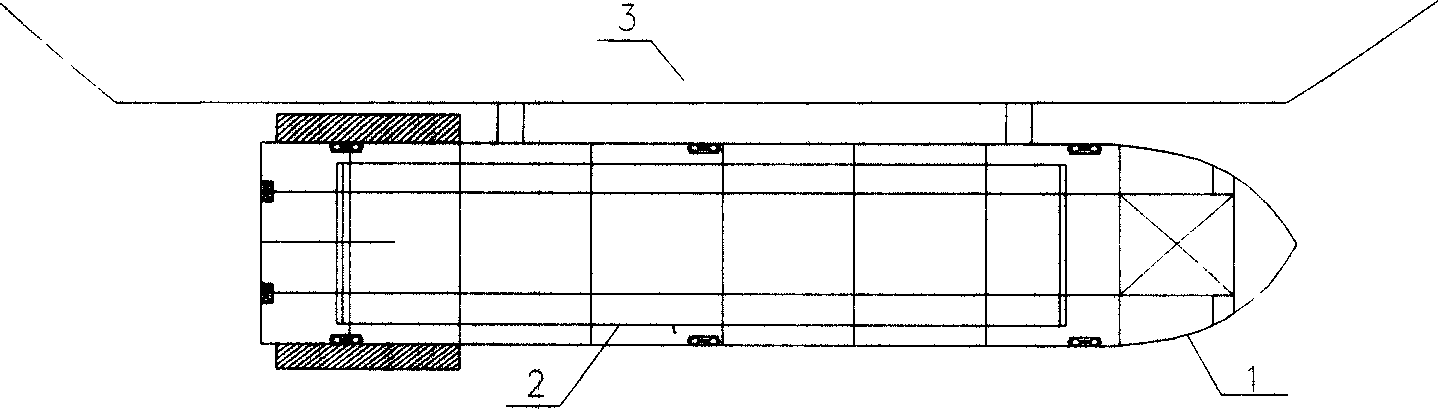

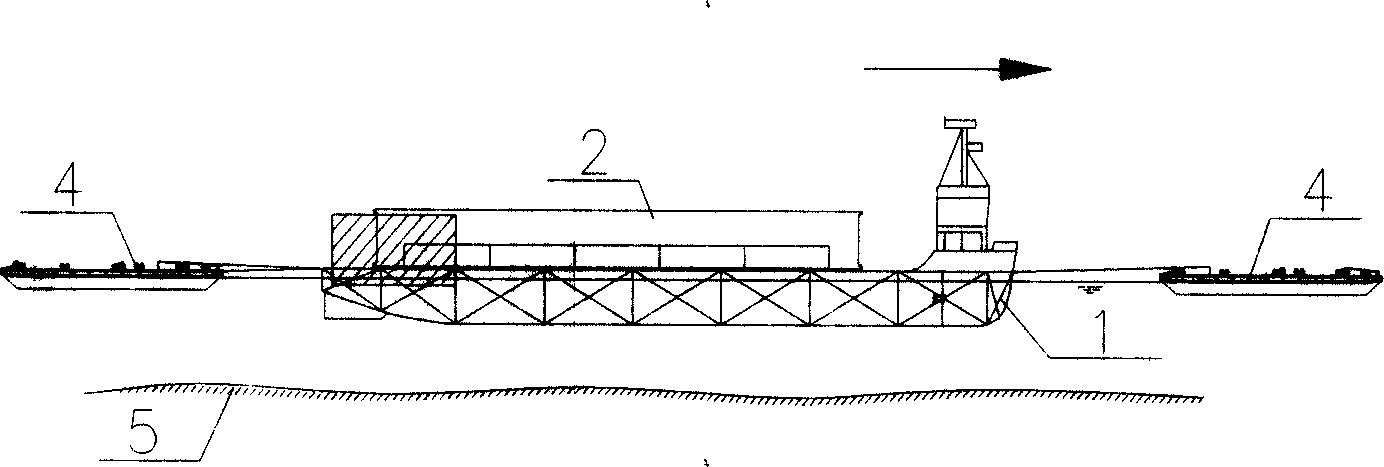

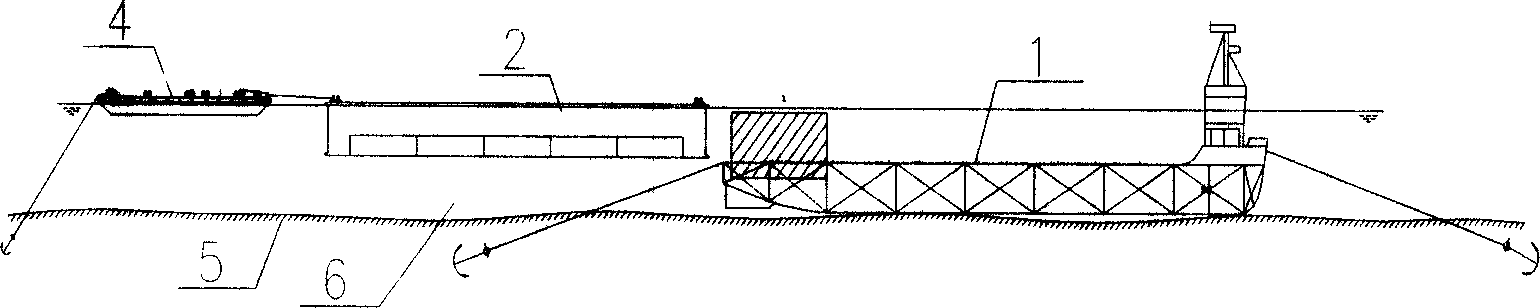

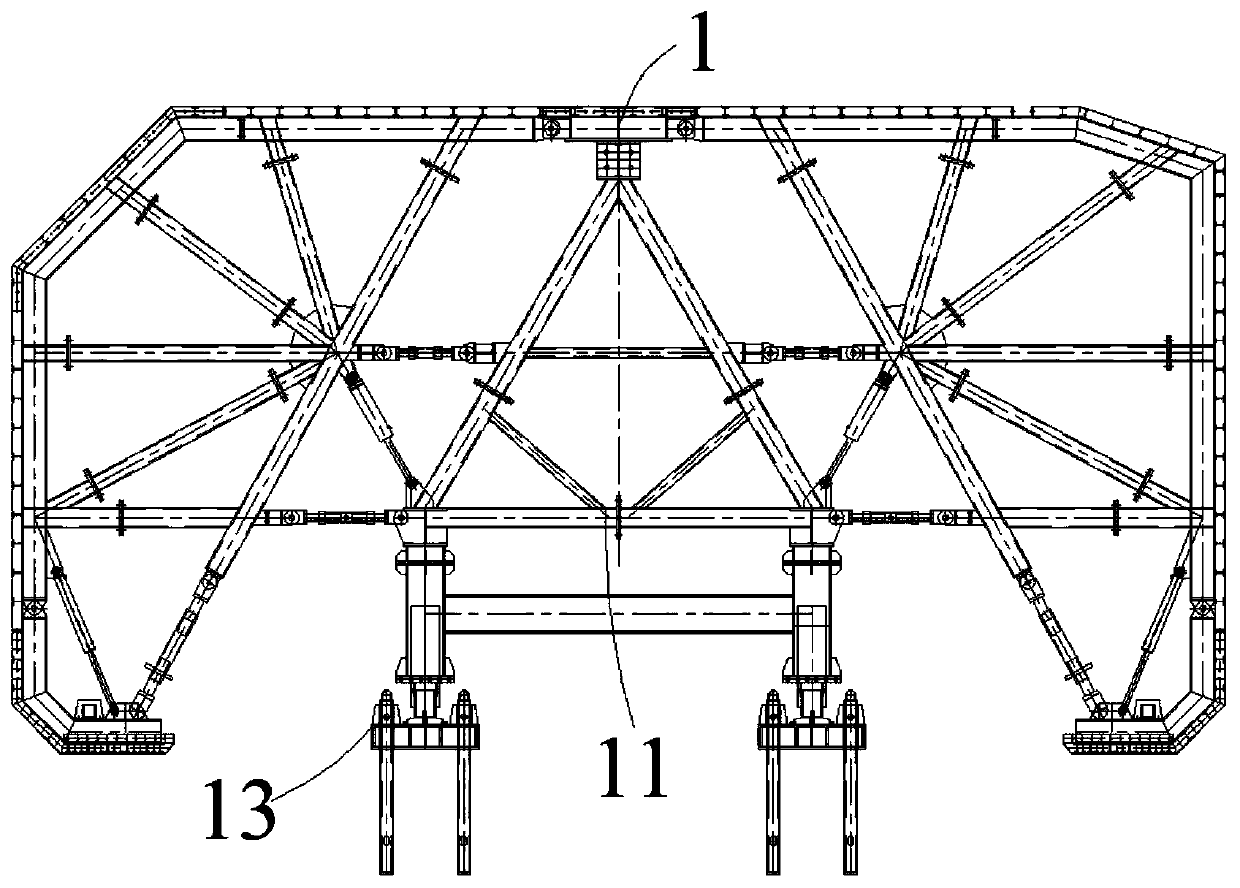

Construction technique for conveying immersed tube for long distance with self-propelling-type semi-submersible boat

ActiveCN106545031AShorten the timeReduce economyArtificial islandsUnderwater structuresEngineeringImmersed tube

The invention discloses a construction technique for conveying an immersed tube for a long distance with a self-propelling-type semi-submersible boat, and the construction technique is used for conveying the immersed tube from an immersed tube prefabrication factory to a foundation trench zone for assembly construction of the immersed tube. A first immersing operation zone is arranged in a temporary mooring zone of the immersed tube prefabrication factory; a second immersed operation zone is arranged beside the foundation trench; the immersed tube and an immersed tube assembly boat are loaded on the self-propelling-type semi-submersible boat at the temporary mooring zone and are conveyed to a turning zone; the immersed tube assembly boat and the immersed tube are unloaded in the second immersed operation zone; the immersed tube is floating-conveyed to the foundation trench zone for assembly construction of the immersed tube by tugs and the immersed tube assembly boat; and a mooring fitting-out zone does not need to be arranged beside the foundation trench, so that time and economic investment during previous preparation work is greatly reduced, and construction work efficiency is improved.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG +1

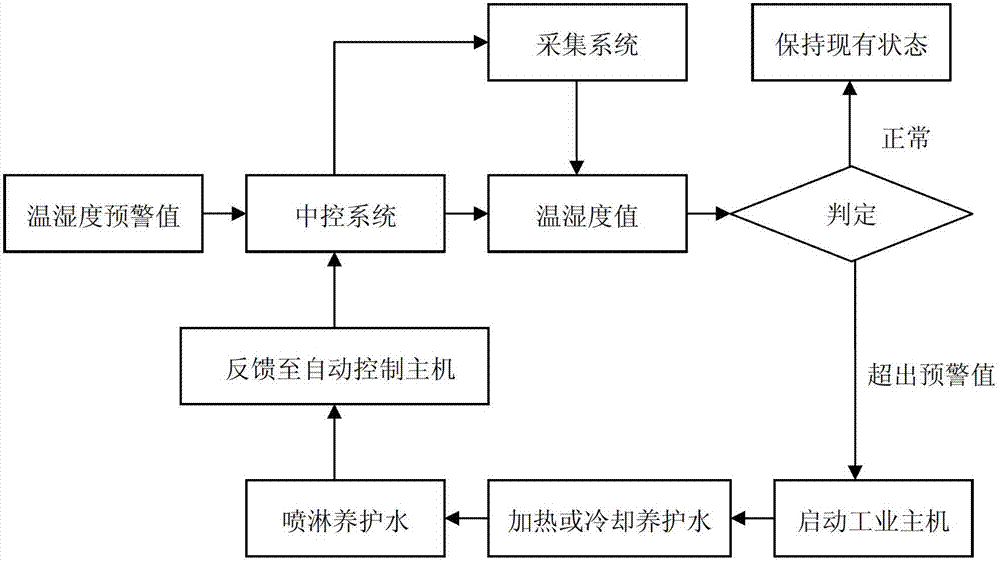

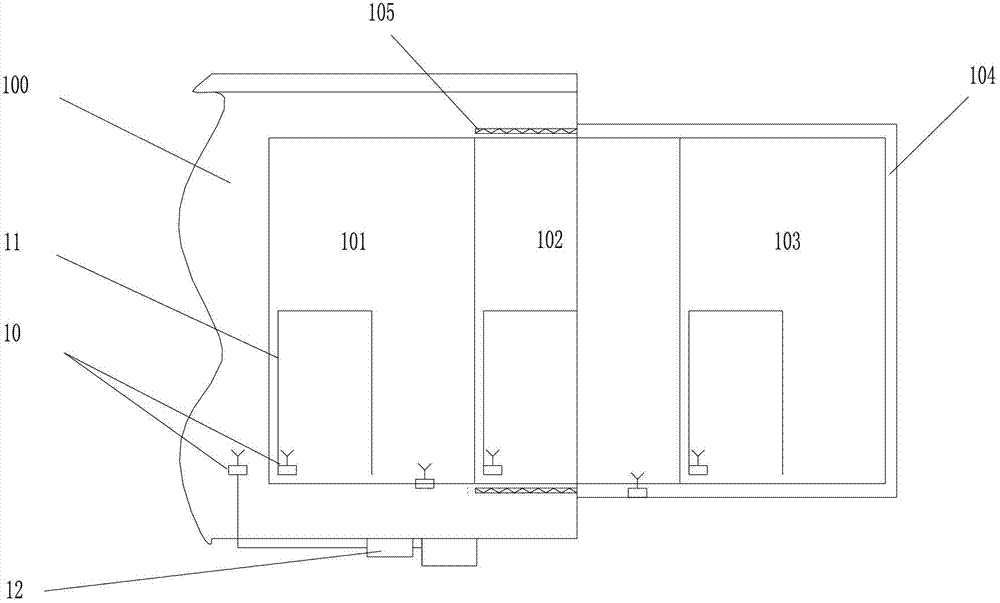

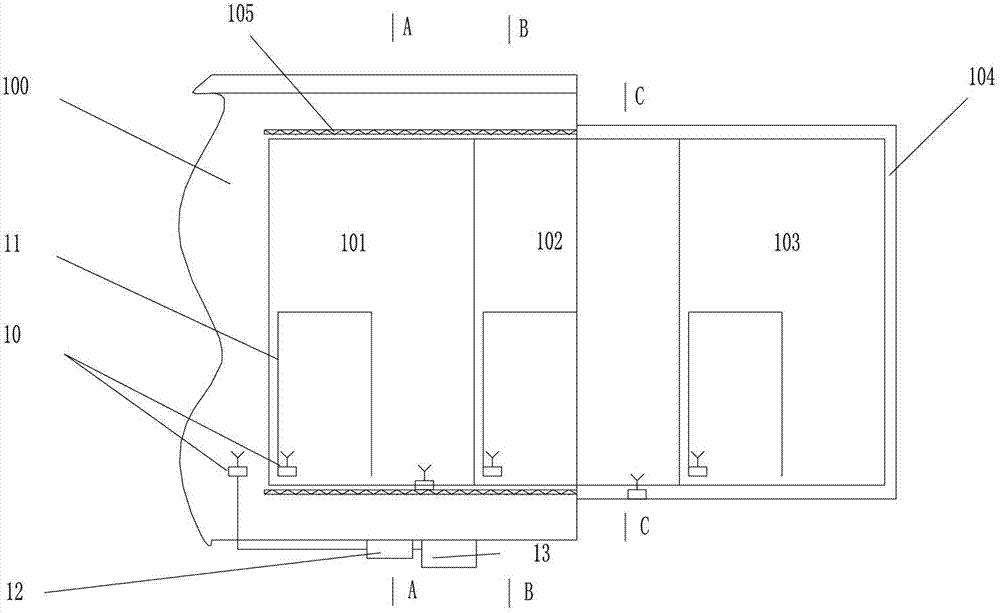

Full-automatic monitoring, early warning, temperature control, moisturizing and curing system and method for prefabricated immersed tube sections

The invention discloses a full-automatic monitoring, early warning, temperature control, moisturizing and curing system for prefabricated immersed tube sections. The system comprises a curing shed, a temperature moisture control system, a spraying system and an automatic control main machine, wherein the curing shed consists of a folding curing shed arranged in a prefabricated workshop and a fixing curing shed arranged outside the prefabricated workshop. The invention relates to a temperature control, moisturizing and curing system for prefabricated immersed tube sections, the system integrates the functions of temperature and moisture detection, early warning and automatic adjustment of ambient temperature and moisture, the immersed tube sections are subjected to heat preservation, moisture preservation and curing within 14 days after the concrete is poured in the immersed tube sections, and the curing method has incomparable advantages in curing effectiveness and timeliness against conventional curing methods.

Owner:CCCC FOURTH HARBOR ENG INST +1

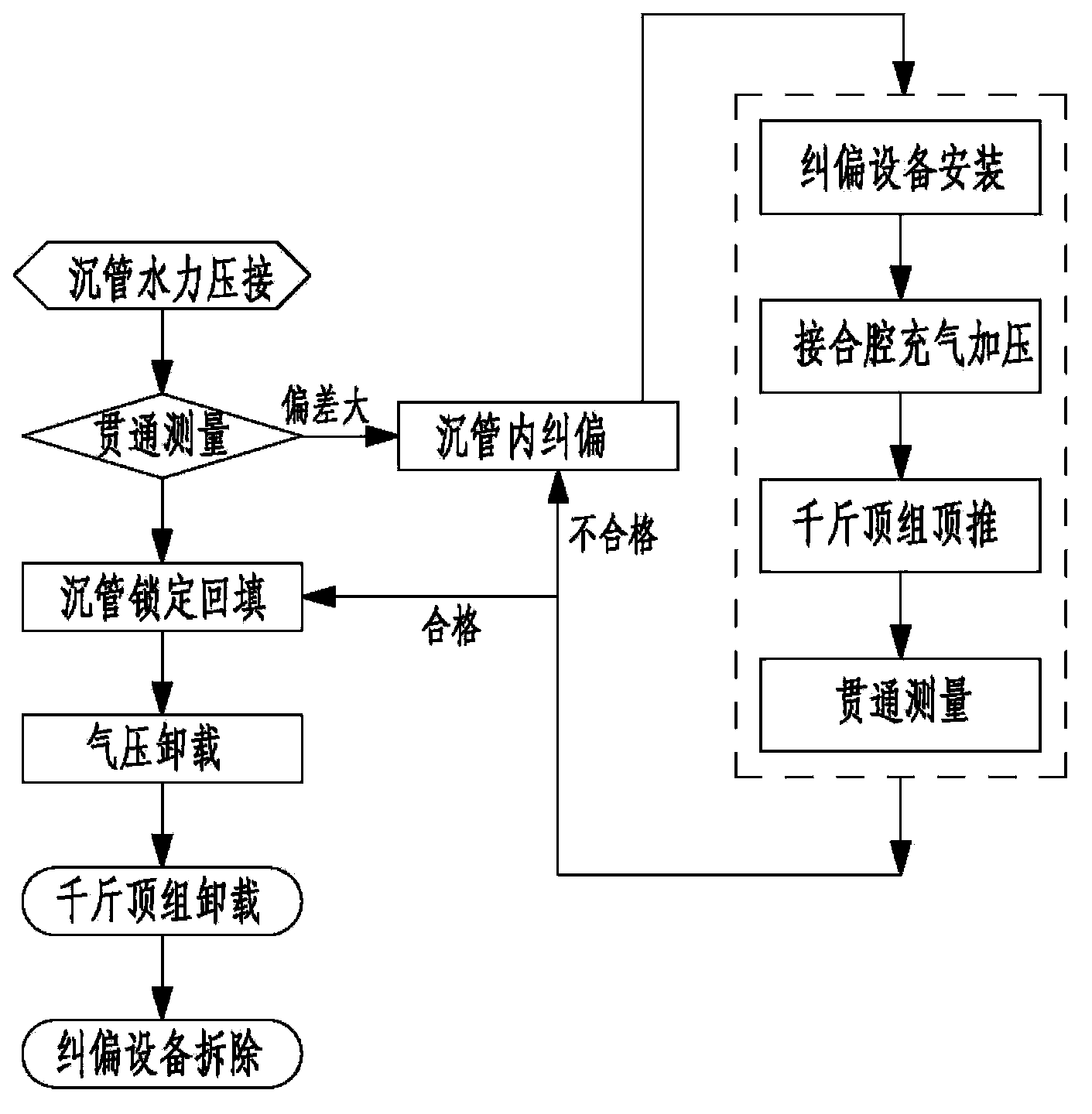

Rectification method for immersed tube tunnel

ActiveCN103912017AReduce the difficulty of correctionSimplify the construction processArtificial islandsUnderwater structuresEngineeringImmersed tube

The invention provides a rectification method for an immersed tube tunnel. The rectification method comprises a step of mounting a jack group in a joint chamber, a step of controlling the jack group to jack up a tube section to be adjusted until completion, a step of backfilling at the two sides of the immersed tube, a step of removing the jacking force of the jack group, and a step of detaching the jack group. Due to the adopted steps, the jack group is mounted in the jointed chamber to perform fine adjustment rectification on the immersed tube in the chamber, and therefore, the rectification difficulty of the immersed tube under water can be reduced, the construction cost can be reduced and the rectification precision can be improved; air can be charged into the jointed chamber so that the total pressure in the joint chamber is basically equal to the sum of water pressure outside the tube section to be adjusted and the frictional force of a foundation bed, and therefore, the tube section to be adjusted is located in a dynamic-static critical state; rectification can be realized by just applying relatively low jacking force to the immersed tube by using the jack group of a relatively small size, and therefore, the size of the jack group is effectively reduced and then the jack group can be matched with the relatively small space of the joint chamber.

Owner:CCCC FIRST HARBOR ENG +1

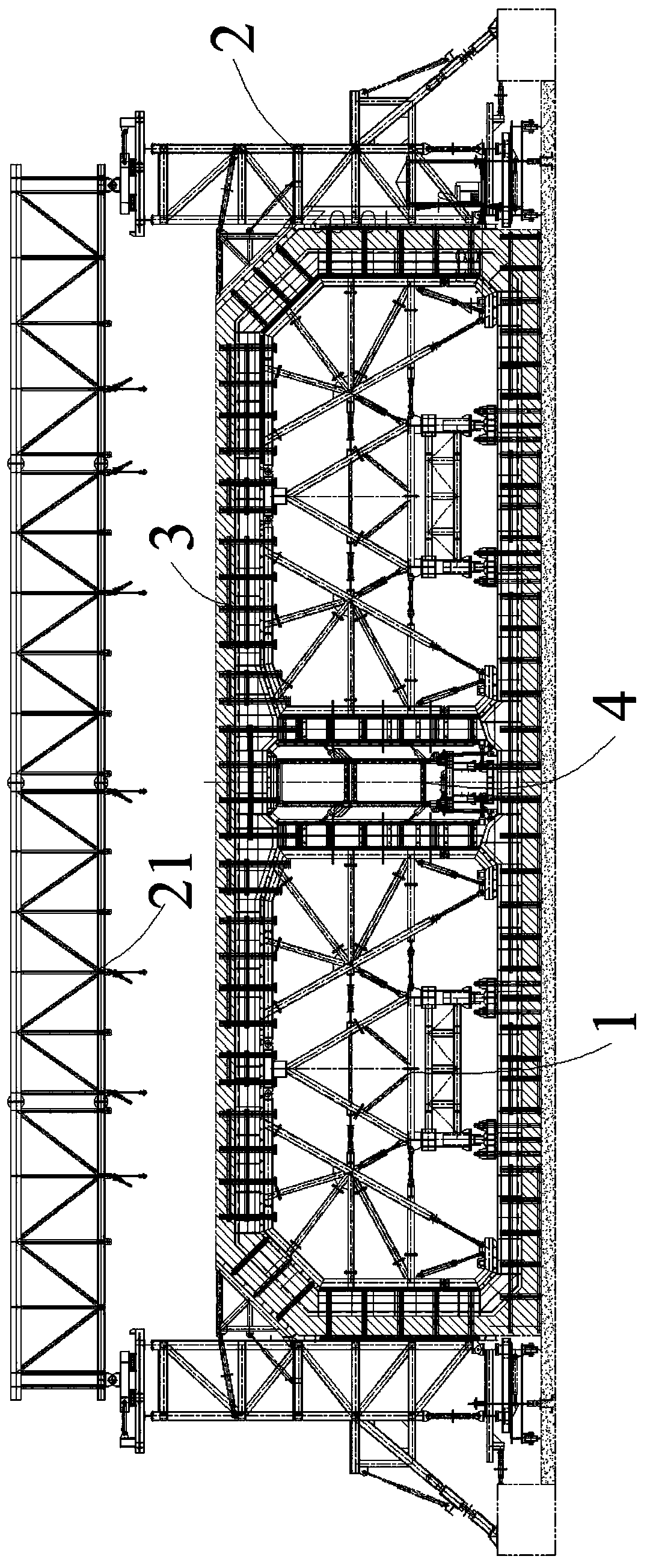

Dry dock sequential method full-section integral immersed tube prefabrication formwork system

PendingCN110076889AEasy to adjustSimple travel adjustmentDischarging arrangementMouldsSequential methodEngineering

The invention relates to the technical field of immersed tube prefabrication construction, in particular to a dry dock sequential method full-section integral immersed tube prefabrication formwork system. The system comprises an inner mold system, an outer mold system and an end mold system, wherein the inner mold system is located on the inner side of an immersed tube casting space and is connected with the outer mold system located outside the immersed tube casting space into a whole through the end mold system positioned at the longitudinal end part of the immersed tube casting space, the lower end of the inner mold system is provided with an inner mold travelling support device which is used for carrying out longitudinal, transverse and vertical position adjustment on the inner mold system, and the outer mold system is an outer side formwork structure capable of being adjusted in the longitudinal direction, the transverse direction and the vertical position. The immersed tube prefabrication method has the advantages of being accurate in position adjusting, less in main body structure damage and capable of operating all weather, so that the technical problems of sequential prefabrication, adjacent operation, compact space, longitudinal long-distance travel of an ultra-large super-heavy formwork is long, being prone to deviation and the like which occur to a sequential methodare solved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

Diving casting cast-in-place pile construction method for constructing in scree layer and sand layer

ActiveCN101196004AWarranty Strength RequirementsMeet strength requirementsBulkheads/pilesSlurry wallImmersed tube

The invention relates to a construction method for an immersed tube compaction cast-in-place concrete pile in the construction in a pebble bed, a puddingstone bed, a sand bed, and a strong weathered mudstone. Double casing pipes are hammered, simultaneously, the inner pipe is extracted from the stratum, then concrete is cast into the outer pipe, the inner pipe is positioned into the outer pipe and presses the surface of the concrete, then the outer pipe is pulled up at uniform speed, and the formation of the cast-in-place concrete pile is completed. Earth is not carried out when the hole is formed, therefore the degree of compaction of the earth among the piles is greatly enhanced, simultaneously, when the pile body concrete is cast, no hole collapse phenomenon of the outer pipe appears in the hole, even slurry wall protection is not required to be adopted, in addition, no bottom settlings exists at the bottom of the pile, thereby the characteristic that the bearing capacity of a single pile is high is ensured, and the invention has the advantages of no pollution on site and quick construction speed.

Owner:刘清洁

Bottom-expanding and piling method for immersed tube bottom-expanding pile

The invention discloses a construction pile foundation project and a method for constructing the same, in particular a method expanding bottom and forming pile by immersed tube. The method comprises the following steps that: an immersed tube with a metal pile head is pressed into a firm ground layer to a designed elevation; the metal pile head is taken out, soil body is burst by detonators, and then is absorbed; a bottom is expanded by a bottom expansion device, after a base cavity is formed at the bottom, the soil is taken out by an air absorption soil device; radial reinforcing steel bars are put into the base cavity and are hammered into the firm ground, the concretes which are prepared well on the ground are poured into the base cavity to form a concrete base; a prefabrication steel concrete pile body which is put into the concrete base and a cast-in-place concrete base are butt jointed and anchor fixed to form a whole through inserted reinforcing steel bars at the bottom of the concrete base; the immersed tube is pulled out, and a pile is formed. Compared with the prior art, the invention which uses the technical proposal has the advantages that: the process method is simple and advanced, the shape of the bottom expansion cavity is regular, soil is cleanly taken out without granular loose soil and the efficiency is high, thereby the bearing capacity of the single pile is effectively improved and reaches the designed specification, the quality of pile foundation project is ensured, the construction cost is lowered, the utilization ratio of the material strength is improved, the pile can be operated in the most economic condition and the constructing security is improved.

Owner:王国奋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com