Patents

Literature

64results about How to "Solve the lack of carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

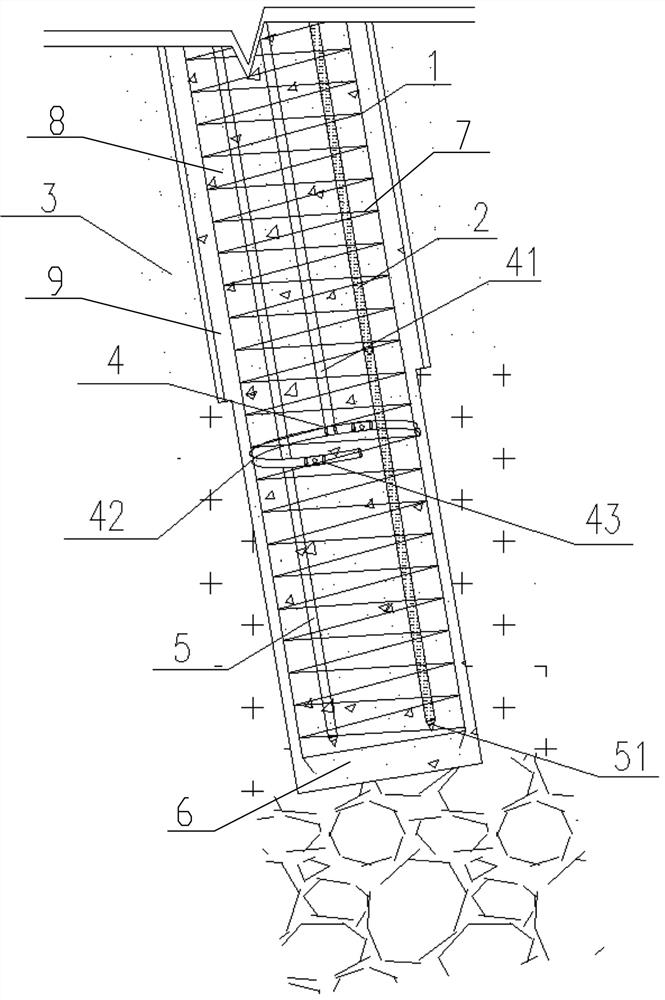

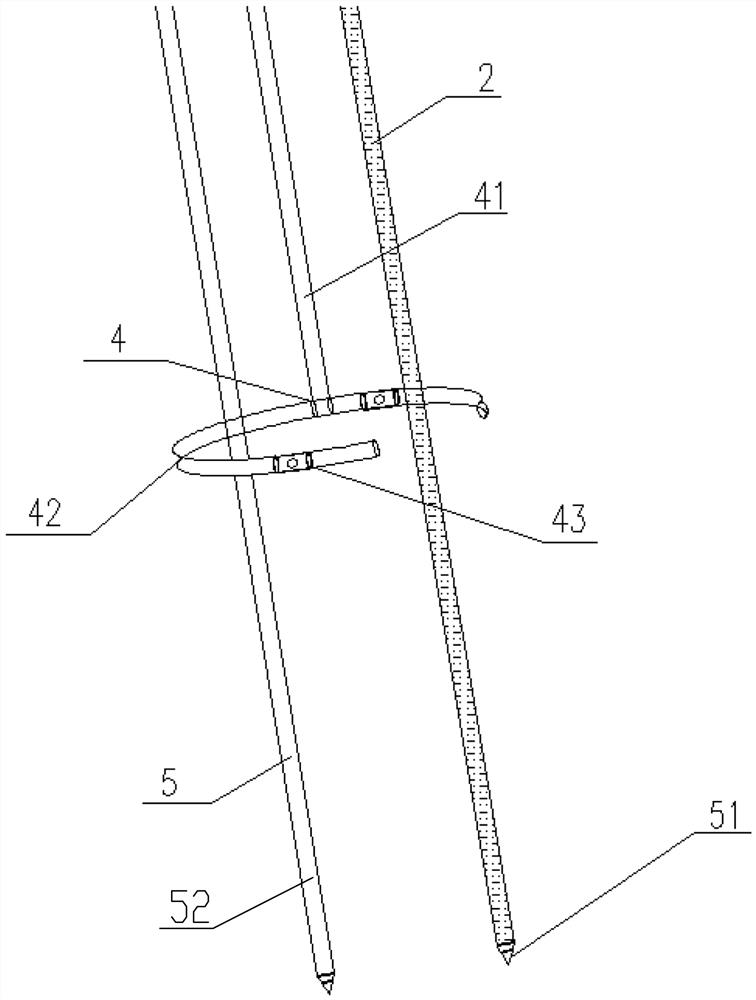

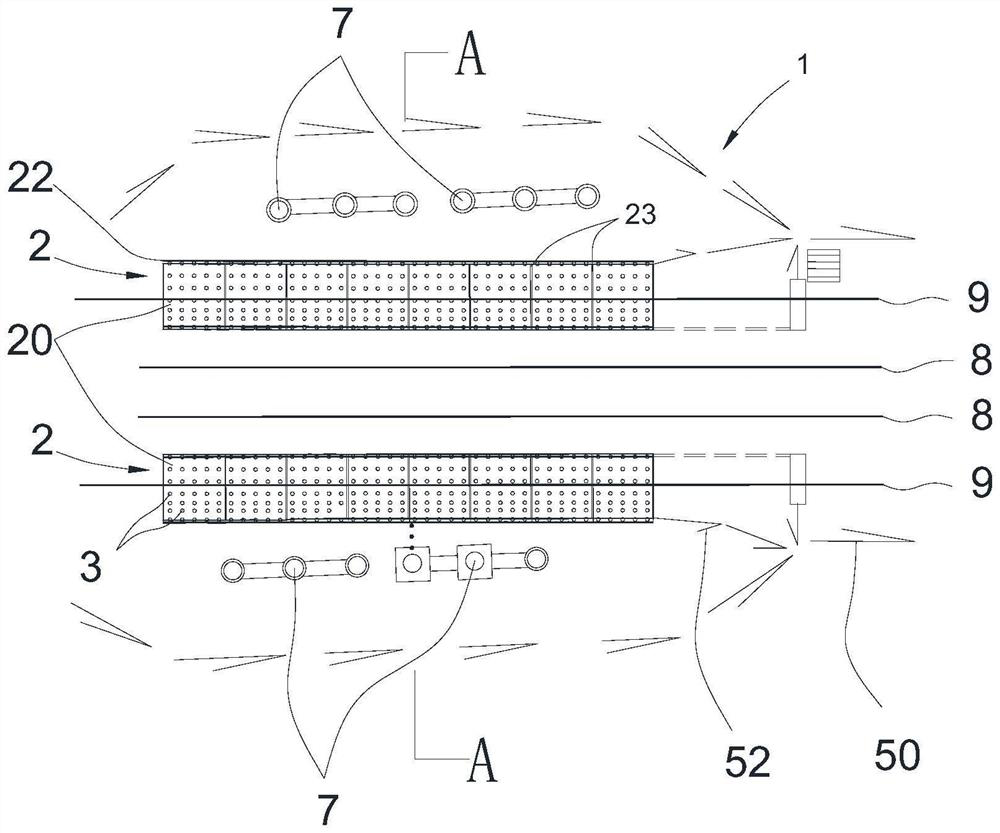

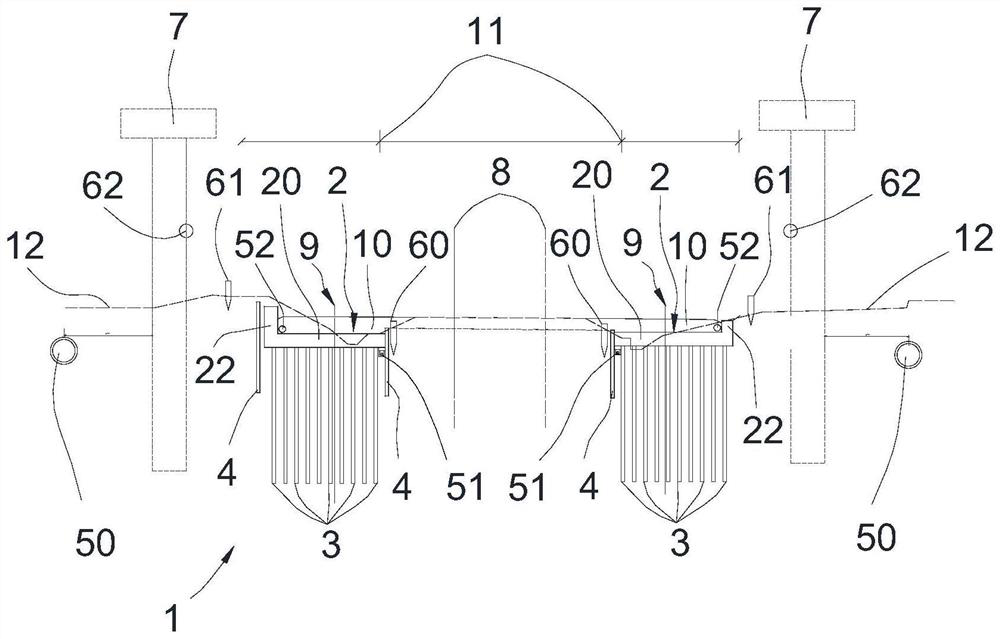

Underground excavation construction method for multilayer underground space of soft soil area

InactiveCN103775110ASolve the lack of carrying capacityRealize the purpose of the invention of multi-layer underground spaceUnderground chambersTunnel liningCarrying capacityReinforced concrete

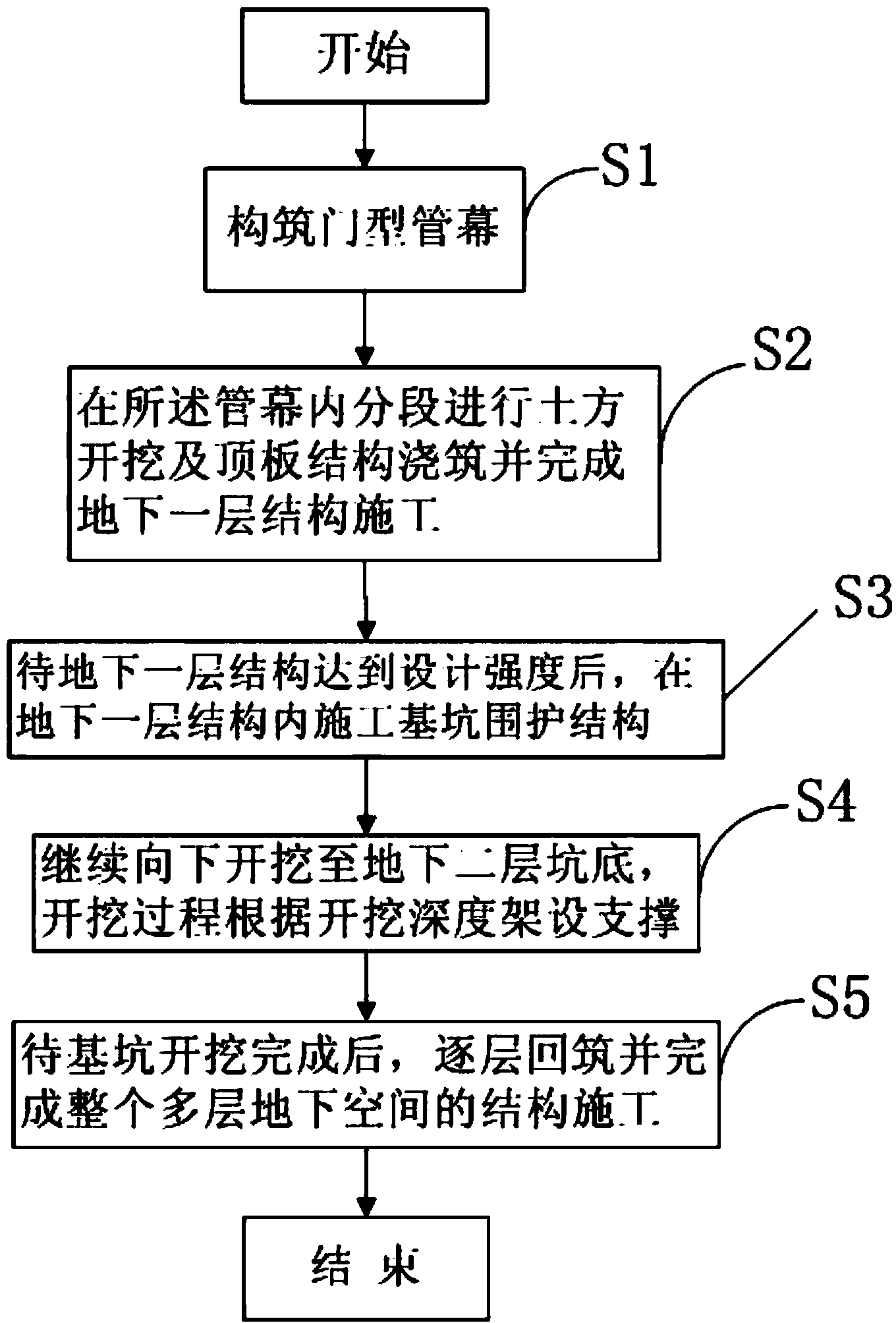

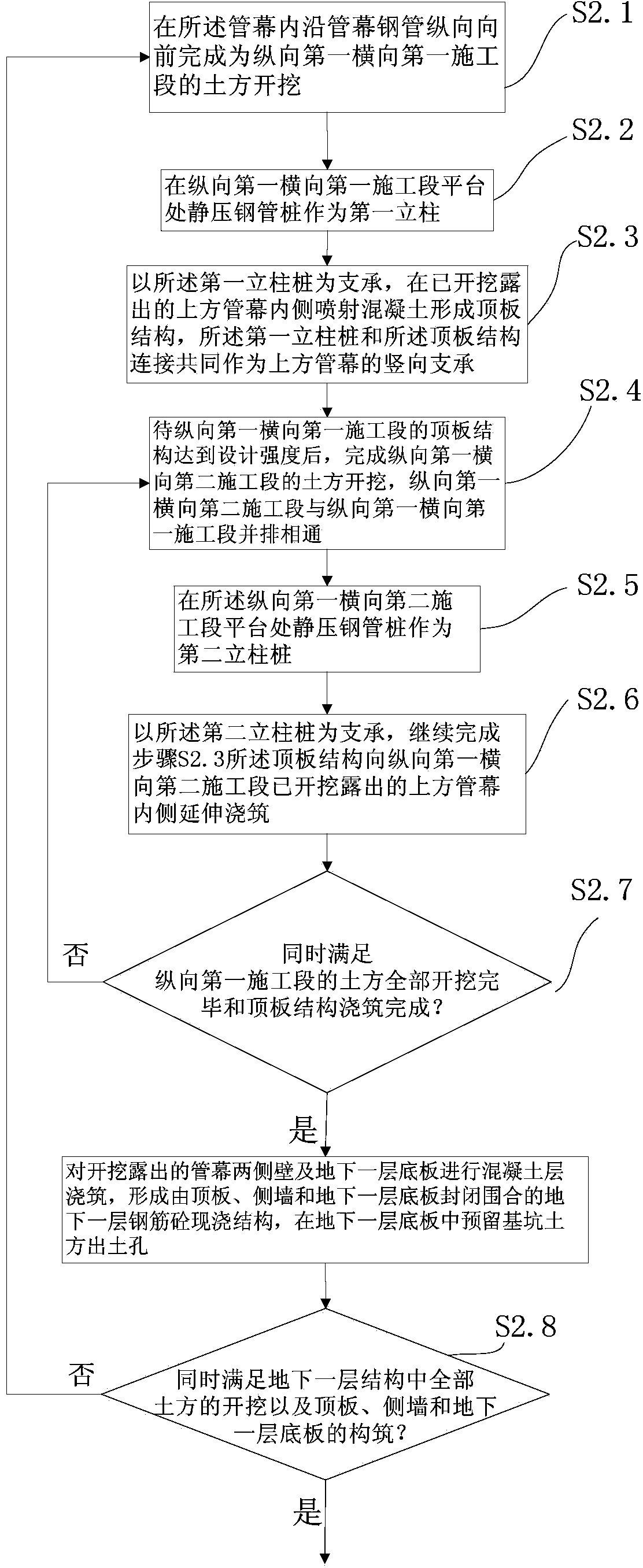

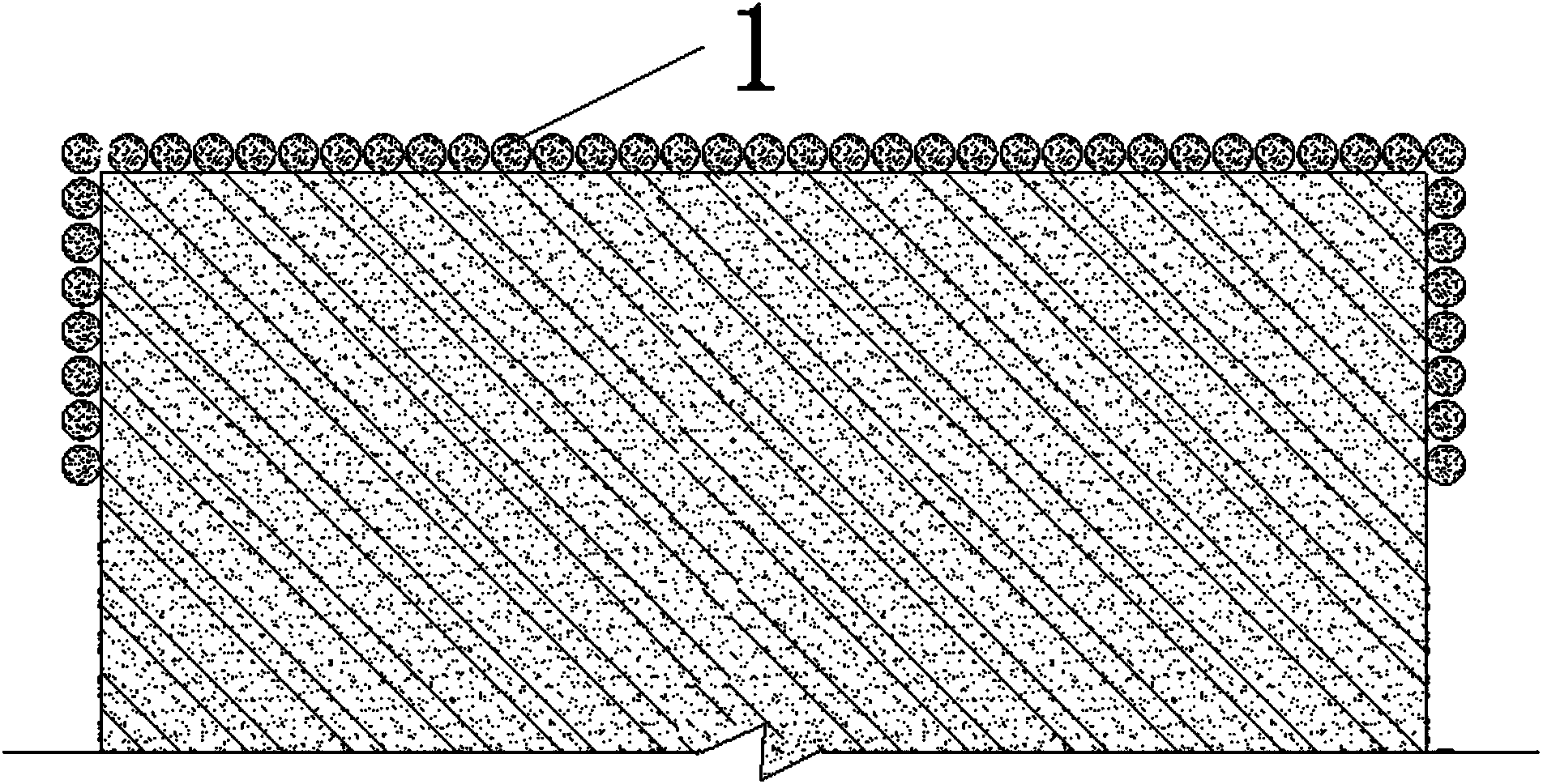

The invention discloses an underground excavation construction method for a multilayer underground space of a soft soil area. The method comprises the following steps: (1) forming a gantry pipe roof of an underground first-layer by the construction of horizontal static pressure steel pipes; (2) excavating the soil of the underground first-layer and pouring a top plate structure in different stages in the pipe roof, and forming an underground first-layer reinforced concrete cast-in-place structure which is enclosed by a top plate, side walls and a next-layer plate; (3) after the structure of the underground first-layer reaches the designed strength, constructing a plurality of layers of foundation pit support structures to be excavated in the underground first-layer; (4) continuously excavating downwards to a pit bottom; (5) performing layer-by-layer back construction, and completing the structure construction of the whole multilayer underground space. According to the method, the problem of poor carrying capacity of lateral steel pipes in a conventional pipe-roofing method when the excavation depth is large enough is solved, and the aim of constructing the multilayer underground space in the soft soil area under the limited excavation conditions is achieved.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

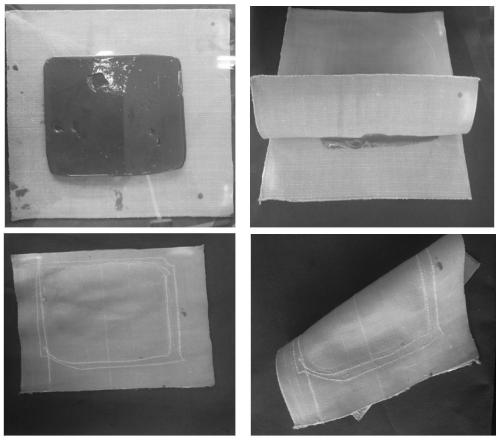

Anti-impact flexible protective composite material based on shear thickening adhesive and preparation method thereof

InactiveCN110091562AImprove isotropic performanceImprove mechanical propertiesNon-macromolecular adhesive additivesProtective equipmentAdhesiveDiluent

The invention discloses an anti-impact flexible protective composite material based on a shear thickening adhesive, and a preparation method of the composite material comprises the following steps of:(1) preparing the shear thickening adhesive; (2) preparing a shear thickening adhesive diluent and a fixed shape shear thickening adhesive; (3) preparing a shear thickening adhesive composite flexible protective fabric; and (4) placing the fixed shape shear thickening adhesive obtained in the step (2) into an interlayer of two layers of the shear thickening adhesive composite flexible protectivefabric obtained in the step (3) or interlayers of multiple layers of the shear thickening adhesive composite flexible protective fabric obtained in the step (3), and sewing and fixing the periphery ofthe interlayers to obtain the flexible protective composite material. The anti-impact flexible protective composite material not only maintains good flexibility but also has excellent antistatic property and impact resistance.

Owner:JIANGNAN UNIV

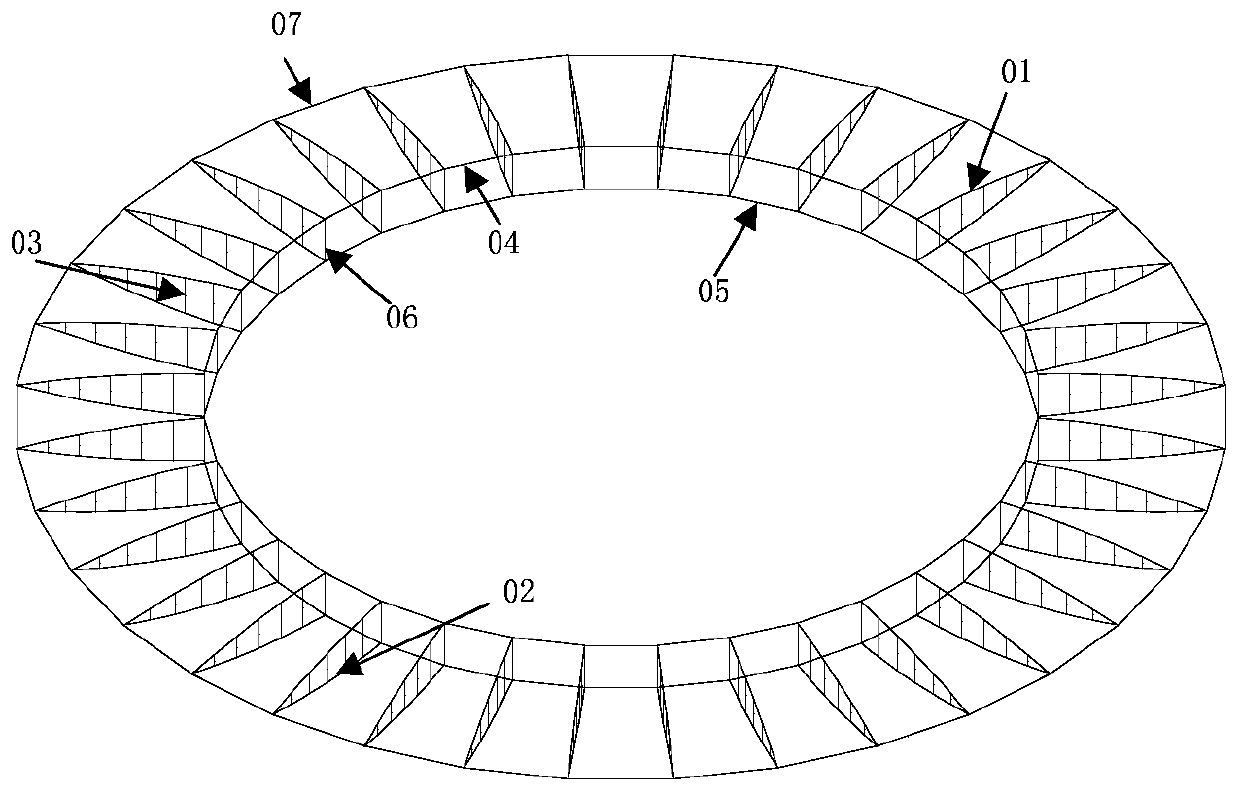

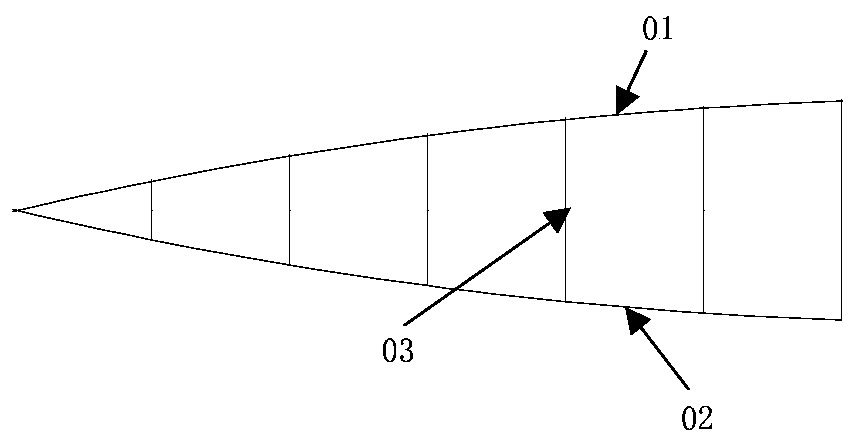

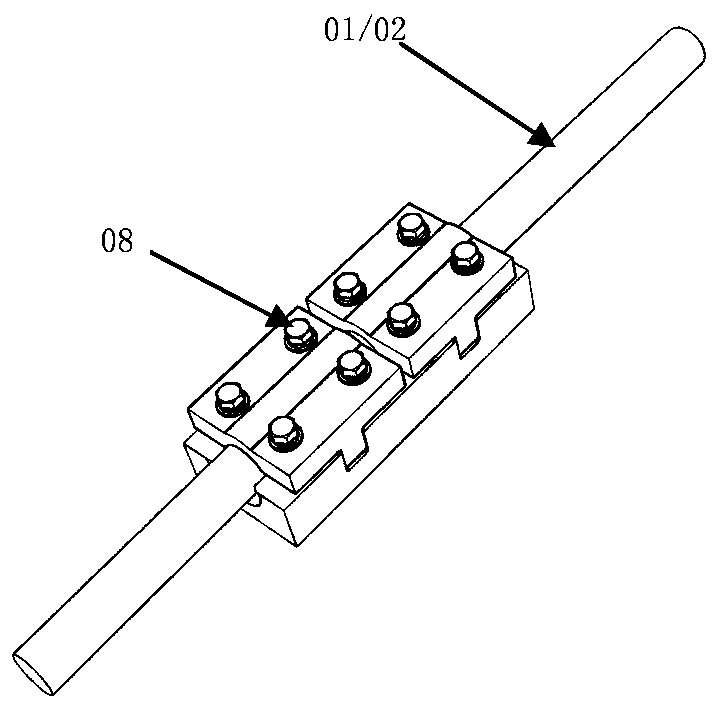

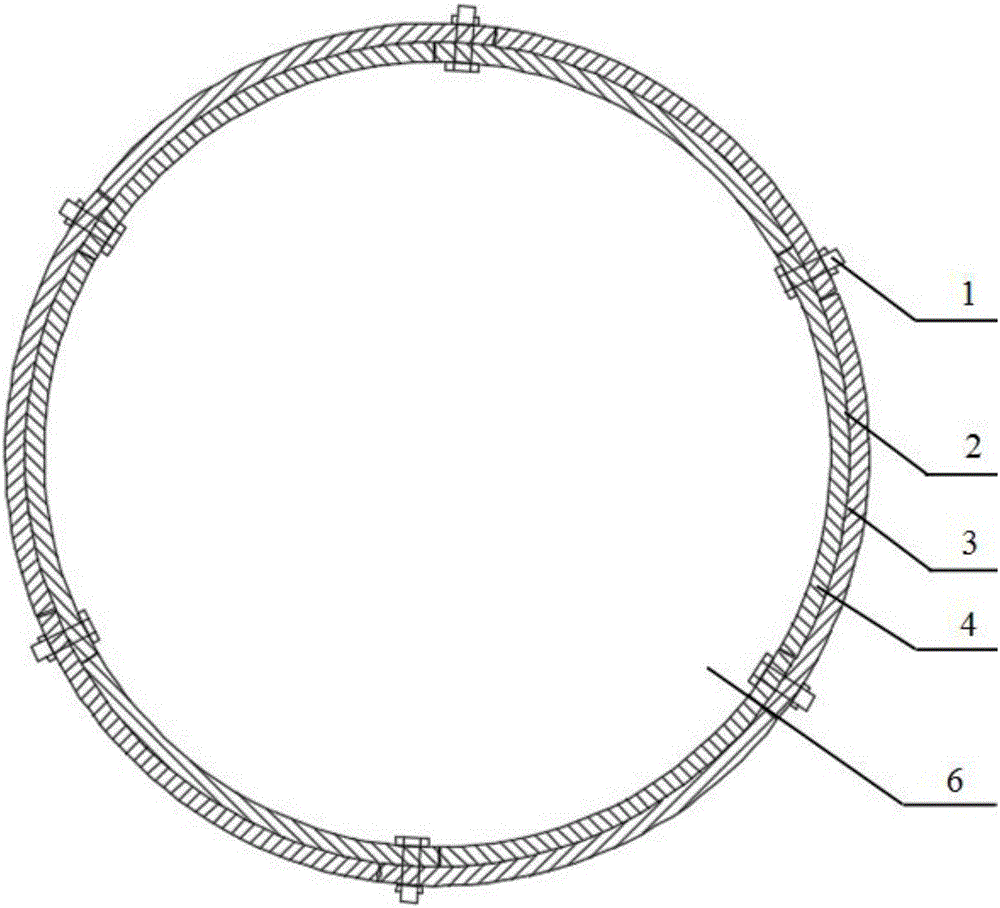

Carbon fiber cable reinforced spoke type cable truss structure

PendingCN111441477AImprove overall stiffnessDecreased static and dynamic responseBuilding roofsAwningLong span

The invention relates to the field of large-span stadium awning structures, in particular to a carbon fiber cable reinforced spoke type cable truss structure. The spoke type cable truss structure comprises a radial cable truss, an inner pull ring and an outer pressing ring, wherein the inner pull ring and the outer pressing ring are arranged at the two ends of the radial cable truss. The radial cable truss is composed of an upper radial cable, a lower radial cable and cable truss supporting rods, the inner pull ring is composed of an upper ring cable, a lower ring cable, a ring cable supporting rod and an inner ring cross cable, and the inner ring cross cable is a carbon fiber cable. According to the carbon fiber cable reinforced spoke type cable truss structure, the carbon fiber cross cable is additionally arranged in an inner ring cable plane of the spoke type cable truss structure; after the improvement, the vertical rigidity of the spoke type cable truss structure is greatly enhanced, and the response is obviously reduced under the action of wind loads and the like. The carbon fiber cable is small in section and rigidity, the influence on the inner pull ring cable force is small, the cable clamp unbalanced force can be remarkably reduced, the cable clamp structure is simplified, and therefore the problem that the cable clamp bearing capacity is insufficient is solved without additionally arranging balance cables.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

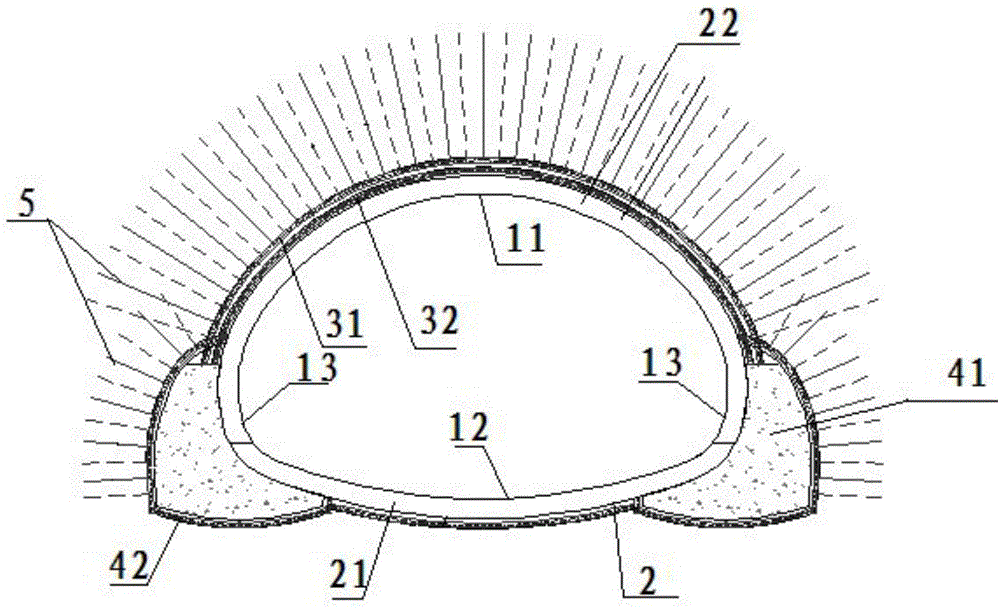

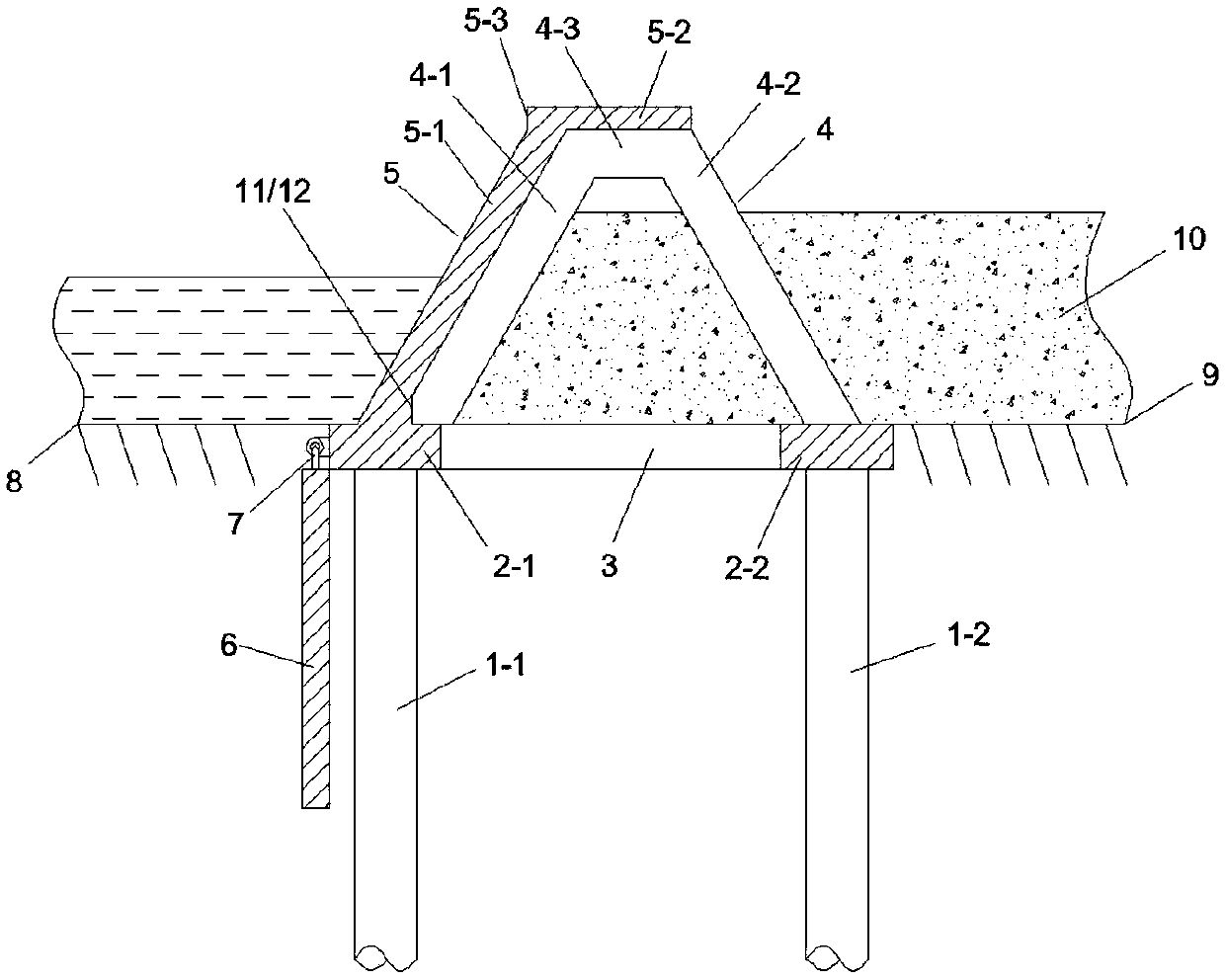

Oversized variable cross section tunnel supporting structure

ActiveCN104405411ASolve the lack of carrying capacityFirmly connectedUnderground chambersTunnel liningClerestoryEngineering

The invention provides an oversized variable cross section tunnel supporting structure. Along the ring shape of a tunnel, the oversized variable cross section tunnel supporting structure comprises a top arch crown, a bottom inverted arch, side walls on the two sides and pilot tunnels on the outer sides of the side walls. The oversized variable cross section tunnel supporting structure comprises a secondary lining of an inner layer in the radial direction of the tunnel. Pilot tunnel primary supports are arranged on the outer sides of secondary linings of the side walls on the two sides, boot-shaped large wall feet are poured between the pilot tunnel primary supports and the secondary linings of the side walls on the two sides, primary supports are arranged on the secondary lining of the arch crown and the surface of the outer side of the secondary lining of the inverted arch in the radial direction of the tunnel, an inner layer primary support is arranged between the secondary lining of the arch crown and the primary supports, the primary support of the arch crown and the inner layer primary support are supported on the boot-shaped large wall feet, and the primary support of the inverted arch is supported on the pilot tunnel primary supports. The oversized variable cross section tunnel supporting structure solves the problem of insufficiency of the soft foundation bearing capacity better and provides a stable foundation for an upper structure.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

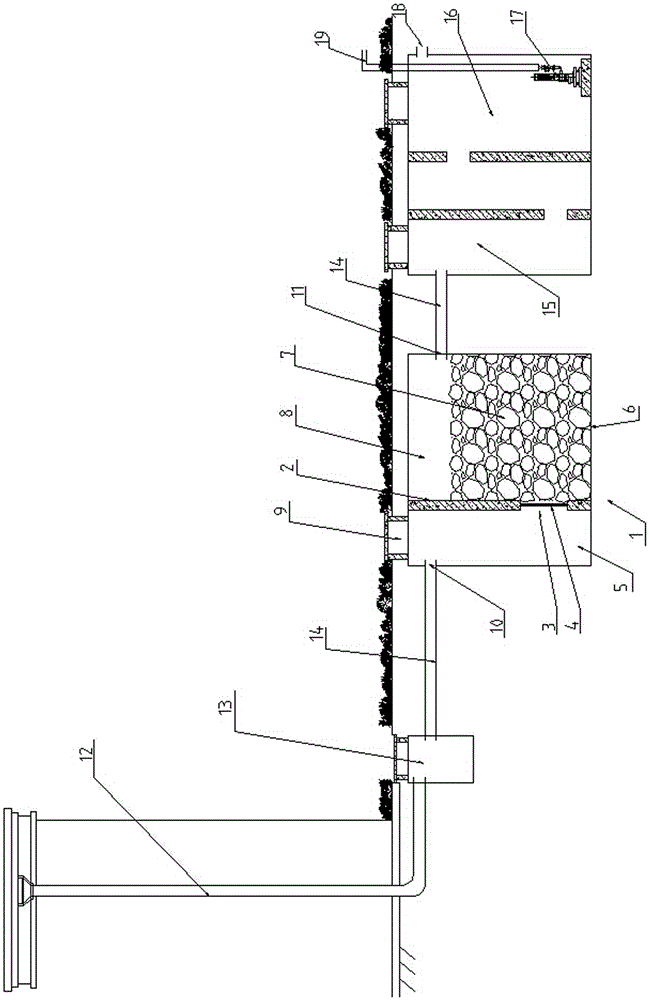

Rainwater collection and reutilization system for modern residence and application method

InactiveCN105587008AAvoid the stenchConvenient for swimmingGeneral water supply conservationService pipe systemsCollection systemEngineering

The invention provides a rainwater collection and reutilization system for a modern residence and an application method. The system comprises a rainwater collection system body, a rainwater filtration system body, a rainwater sedimentation system body and a rainwater storage system body, the rainwater filtration system body comprises a filter basin, the filter basin is internally provided with a partition wall which separates the filter basin into two cavities, a filter hole communicating the two cavities is formed in the position, close to the bottom of the filter basin, of the partition wall, the two cavities are the first cavity and the second cavity respectively, and the second cavity is filled with cobblestones. The system is provided with the simulated ecological filtration system body, long-term filtration and impurity removal can be conducted, periodic replacement is not required, natural permeation and filtration are conducted by imitating an ecological system completely, the filtering effect is good, the traditional structure that sewage is arranged at the top, a filter layer is arranged in the middle, and filtered water is arranged at the bottom is changed, construction of the filter basin is more convenient, the problem that the intermediate filter layer is insufficient in bearing capacity is effectively solved, the side surface permeation mode is adopted, the filtering effect is good, and a filter screen is long in service life.

Owner:WEIFANG DACHUAN REAL ESTATE CO LTD

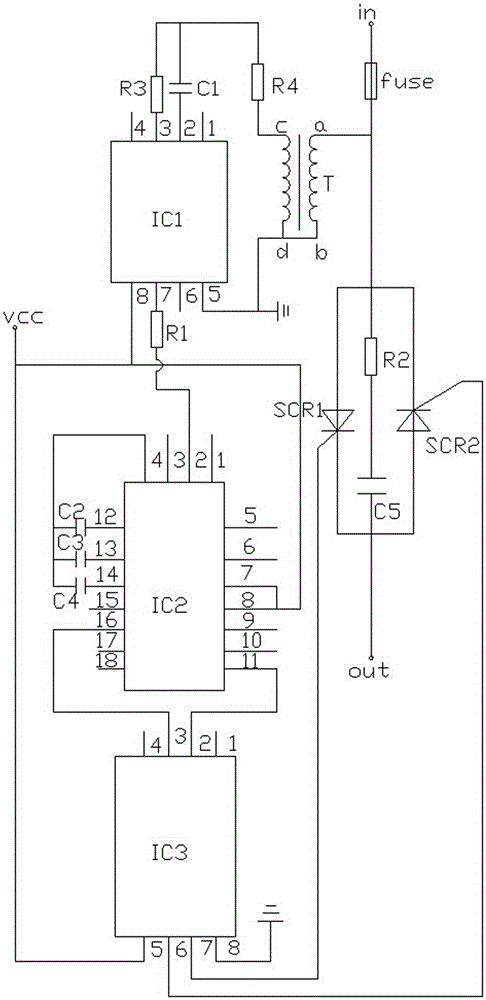

Vacuum preloading and soil body surface solidification combined processing technique

InactiveCN105064324ASolve the lack of carrying capacityImprove bearing capacitySoil preservationWork periodSurface layer

The invention discloses a vacuum preloading and soil body surface solidification combined processing technique. The vacuum preloading and soil body surface solidification combined processing technique includes the following steps that A, a vertical water discharging plate is arranged in a hydraulic reclamation mud / sludge / waste mud pit; the upper end of the vertical water discharging plate is connected with a water discharging pipeline; the water discharging pipeline is connected with the outside; sealing cloth coves the top of soil in a vacuum preloading water reduction pit and the water discharging pipeline; the edge of the sealing cloth is sealed through a sealing structure and soil; a vacuum pump is connected with the water discharging pipeline and used for pumping water in the soil; B, after vacuum preloading is finished, the vacuum sealing cloth on the surface is removed; C, curing agents are added to the soil body on the surface layer and evenly distributed in the soil body on the surface layer; D, after a period of time, the soil body is solidified. The soil body processed through the technique is high in dehydration rate, short in work period and higher in strength after the soil body is processed.

Owner:WENZHOU UNIVERSITY

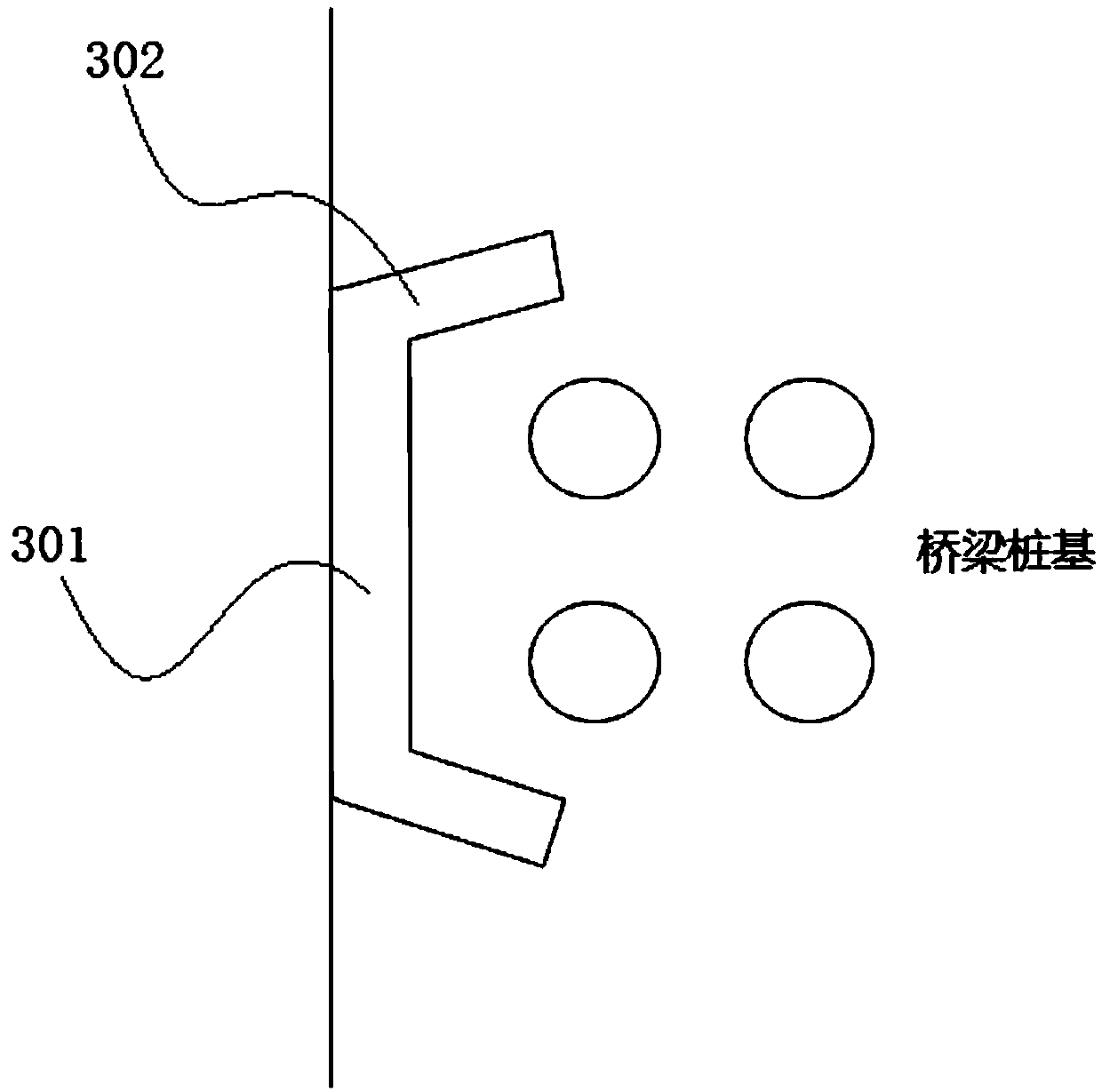

Piled drainage anchor rod retaining wall structure and construction method thereof

PendingCN109577365AAdvanced technologyImprove economyArtificial islandsUnderwater structuresCheck valveRetaining wall

The invention provides a piled drainage anchor rod retaining wall structure and a construction method thereof. The retaining wall structure comprises a pile foundation, a beam, a retaining wall and aplurality of anchor rods, the pile foundation comprises a plurality of bearing piles embedded in a bank slope stable rock soil body, the beam is arranged above the pile foundation, the retaining wallis arranged on the upper surface of the beam, and the retaining wall structure further comprises a drainage hole. The construction method includes steps: constructing the pile foundation; constructingthe beam; constructing the anchor rods; constructing the drainage hole; constructing the retaining wall; mounting a check valve. The retaining wall structure can effectively solve the problem in large reservoir hydro-fluctuation belt shoreside gully area bridge pile foundation protection technology and is advanced in technology and high in economic efficiency.

Owner:CHONGQING JIAOTONG UNIVERSITY

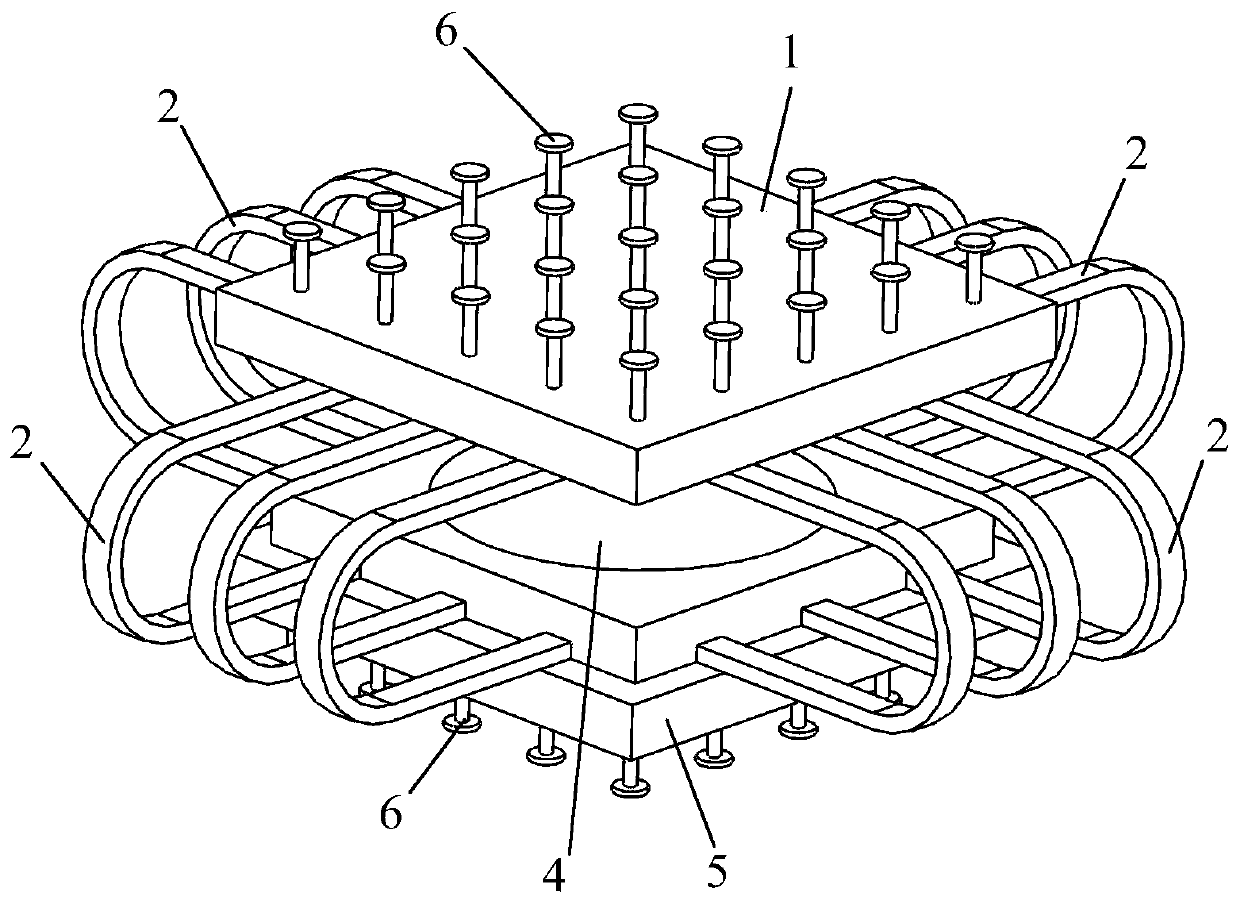

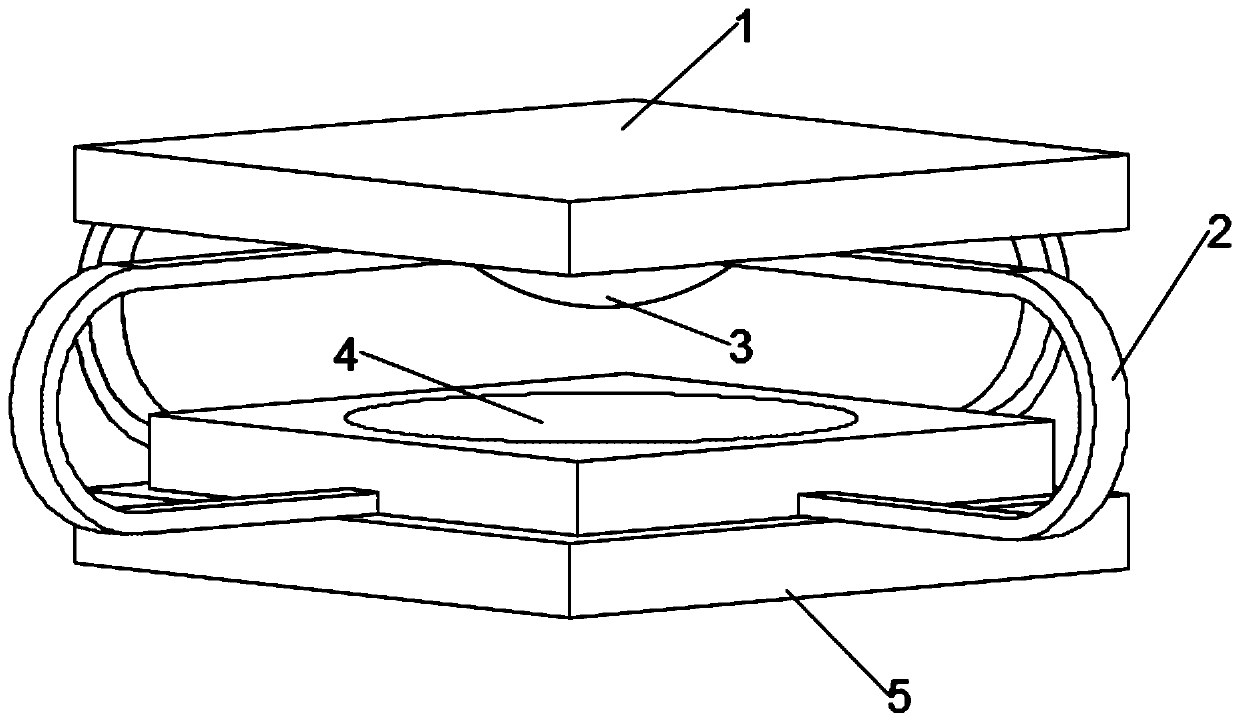

High-bearing-capacity tensile energy dissipation shock insulation device

PendingCN109898681AEfficiently provideHigh bearing capacity characteristicsProtective buildings/sheltersShock proofingEngineering structuresBearing capacity

The invention discloses a high-bearing-capacity tensile energy dissipation shock insulation device, and belongs to the technical field of building engineering structure shock insulation. The shock insulation device comprises an upper connecting plate, a plurality of U-shaped supports, a spherical sliding block, a lower sliding groove, a lower connecting plate, and tensile and shear resistance connectors. The tensile and shear resistance connectors are arranged on one face of the upper connecting plate, and the spherical sliding block is arranged on the other face of the upper connecting plate.According to the movement energy dissipation radius of the spherical sliding block, the lower sliding groove is determined, the lower sliding groove is in rigid connection with the lower connecting plate, the multiple U-shaped supports are arranged, the U-shaped supports are then evenly distributed on the front, back, left and right parts of the spherical sliding block, wherein upper legs of theU-shaped supports are arranged on the upper connecting plate, lower legs of the U-shaped supports are arranged on the lower connecting plate, and the tensile and shear resistance connectors are arranged on the lower connecting plate. The high-bearing-capacity tensile energy dissipation shock insulation device has the characteristics of high bearing capacity, good horizontal shock isolation and tensile energy dissipation, being economical and practical, and environmental protection.

Owner:HUAZHONG UNIV OF SCI & TECH

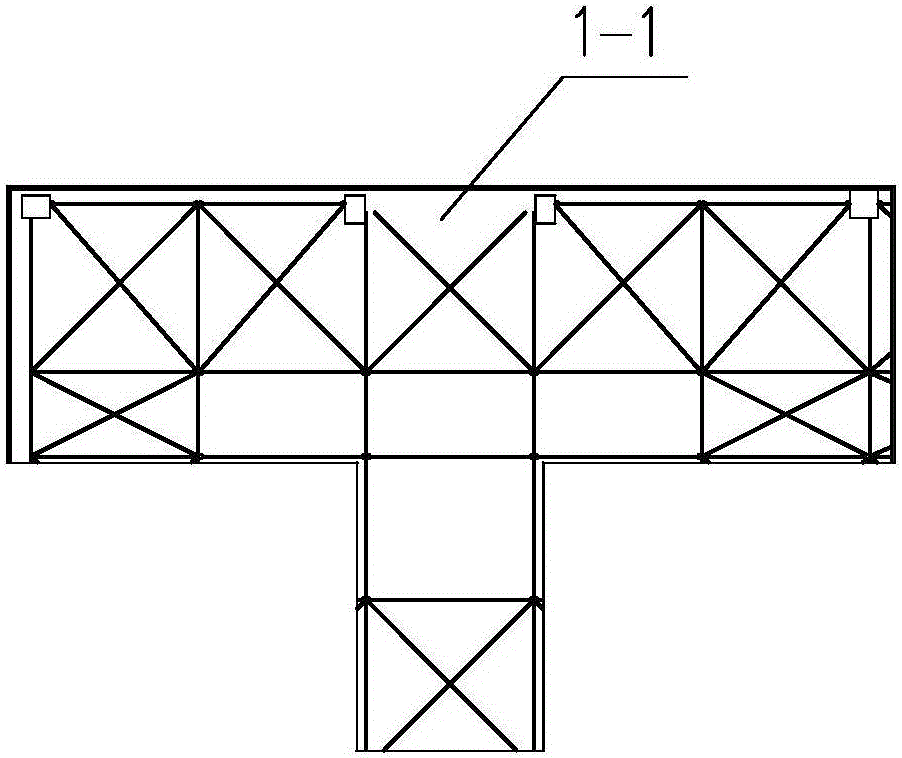

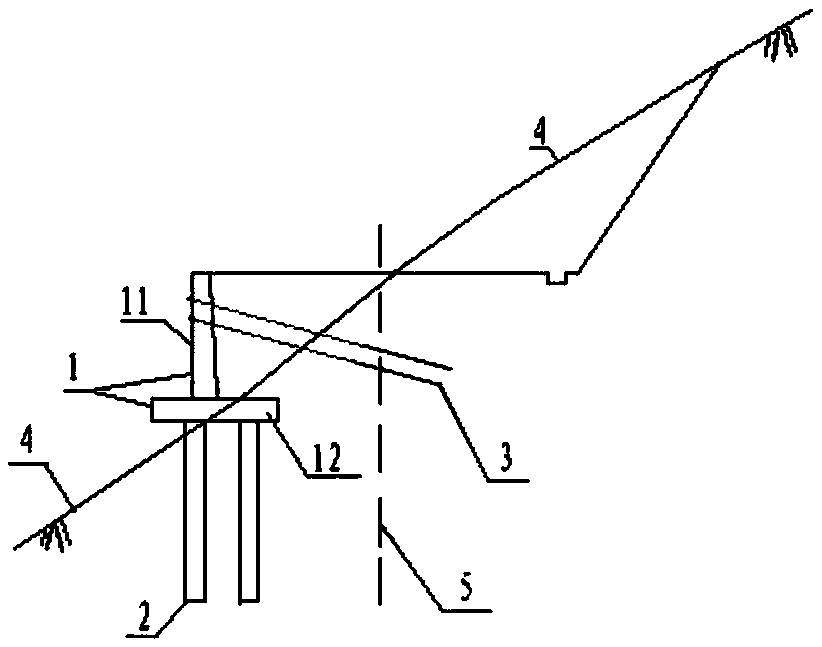

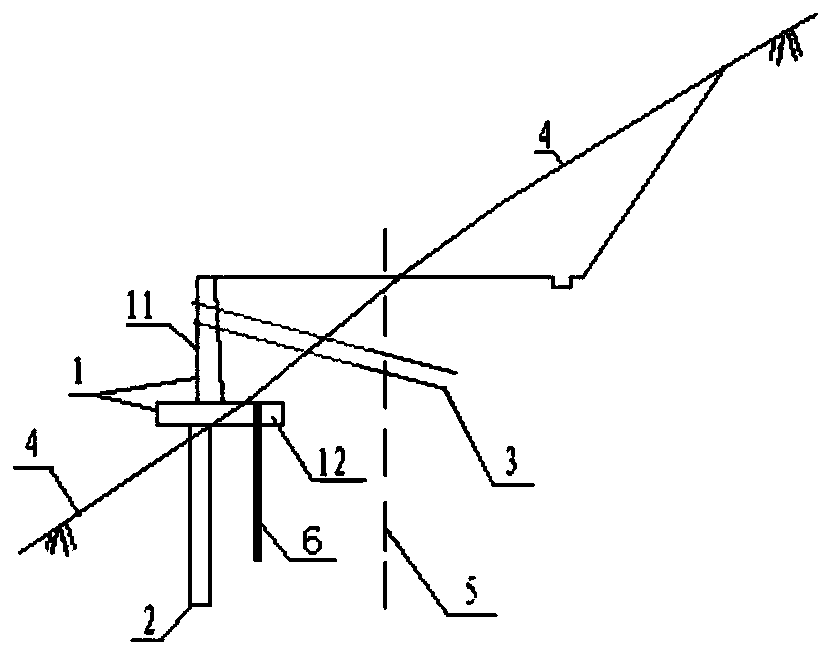

Construction method for long-span overhung specially-shaped limit exceeding structure steel corridor

ActiveCN106013419AStrong targetingSave man hoursBuilding material handlingArchitectural engineeringEngineering

The invention discloses a construction method for a long-span overhung specially-shaped limit exceeding structure steel corridor. The method includes the following steps that firstly, the steel corridor is divided into construction units, wherein the inner part of a corridor structure and middle strip blocks of an upper steel structure of a corridor overhung part are classified as the first construction unit, the remaining part of the corridor overhung part is classified as the second construction unit, and a corridor suspension part is classified as the third construction unit; secondly, a high-altitude bulk assembly method and a cantilever installation method are adopted for finishing construction of the first construction unit on a floor panel of a tower A; thirdly, construction of the second construction unit is finished through integral lifting; and fourthly, construction of the third construction unit is finished through sliding after integral lifting. The high-altitude bulk assembly technology, the integral lifting technology, the sliding after integral lifting technology and the like are applied, work hours are reduced, the material cost and equipment cost are saved, and the requirements for integral control over multiple aspects of the construction process, the quality, the safety, the schedule, the cost and the like are met.

Owner:中建六局第一建设有限公司 +1

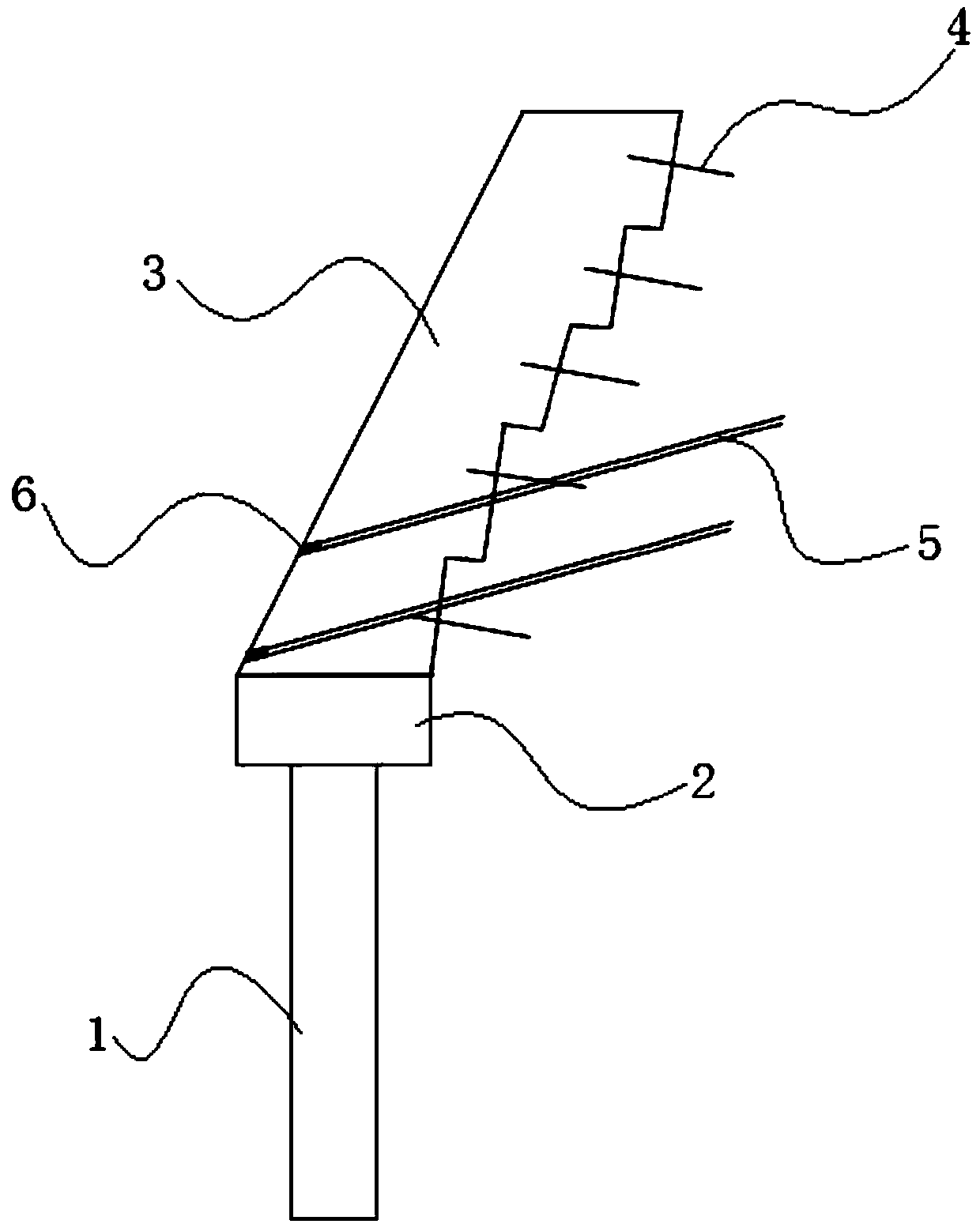

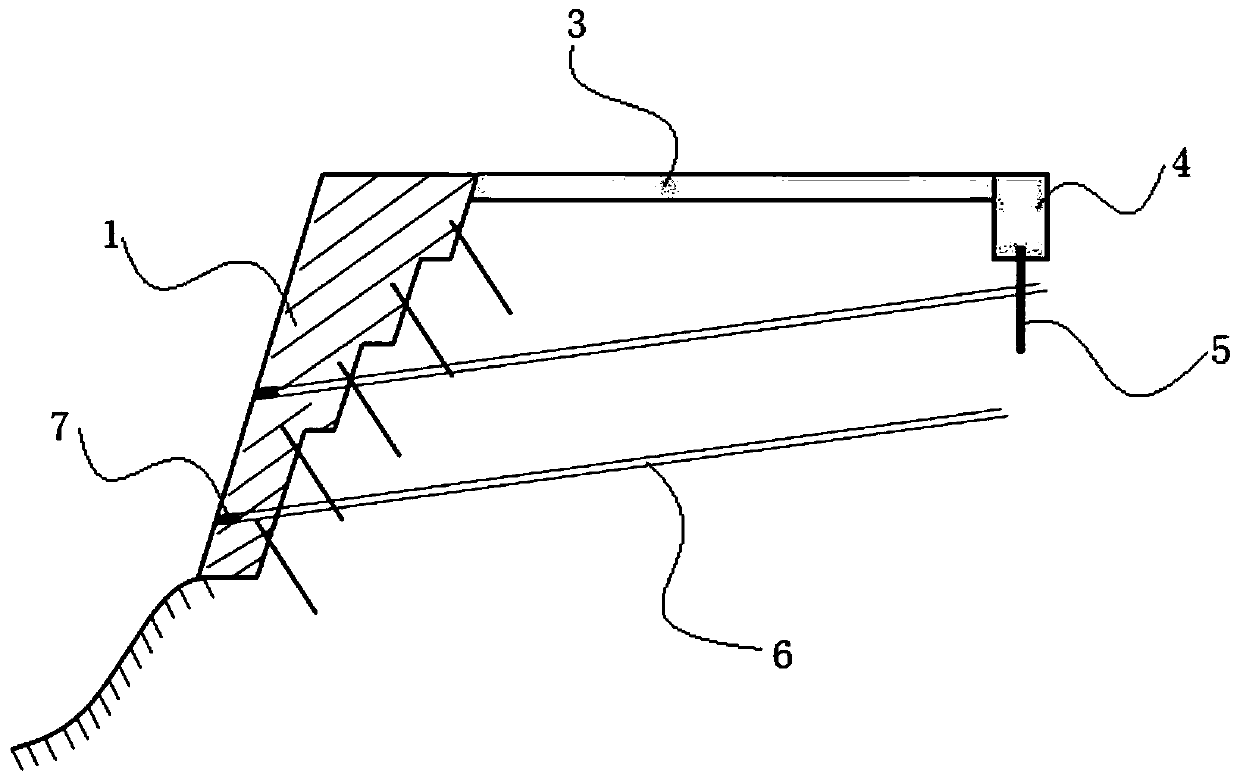

Steep slope embankment supporting and blocking structure and construction method thereof

PendingCN109403371AImprove anti-overturn performanceImprove slip resistanceArtificial islandsRoadwaysSteep slopeEngineering

The invention relates to the field of steep slope roads and discloses a steep slope embankment supporting and blocking structure and a construction method thereof. The steep slope embankment supporting and blocking structure comprises a cantilever-type soil retaining wall, a foundation pile and an anchor cable; and the cantilever-type soil retaining wall comprises a bottom plate and a vertical wall located on the bottom plate, the foundation pile is arranged on the lower part of the bottom plate, the bottom of the foundation pile is inserted into a slope body, a first anchor cable hole is formed in the vertical wall, one end of the anchor cable is connected with the vertical wall at the first anchor cable hole, and the other end of the anchor cable is inserted into a second anchor cable hole in the slope body and fixed into a stable soil layer or base rock of the slope body. According to the steep slope embankment supporting and blocking structure and the construction method thereof, apile foundation is arranged to support the cantilever-type soil retaining wall so that the problem of insufficient bearing capacity of a foundation can be solved, and the anti-overturning capabilityand the anti-sliding capability of the supporting and blocking structure are improved; and the anchor cable is arranged to connect the vertical wall with the slope body, the soil pressure of the wallback of the soil retaining wall can be partially counteracted, and the anti-overturning capability of the soil retaining wall and the overall stability of the supporting and blocking structure are further improved.

Owner:CHINA RAILWAY SIYUAN GRP SOUTHWEST SURVEY & DESIGN CO LTD +1

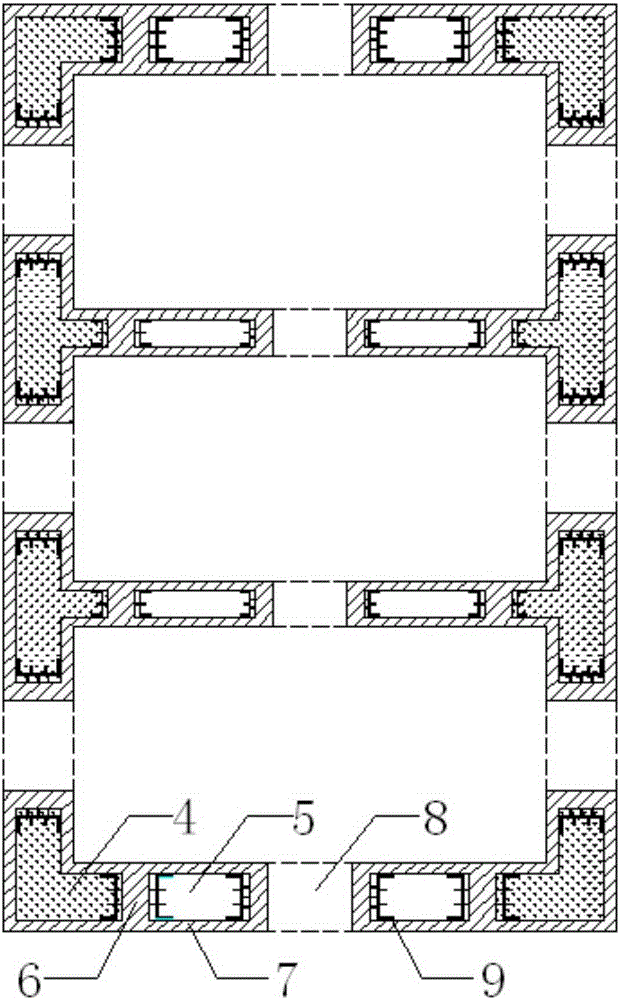

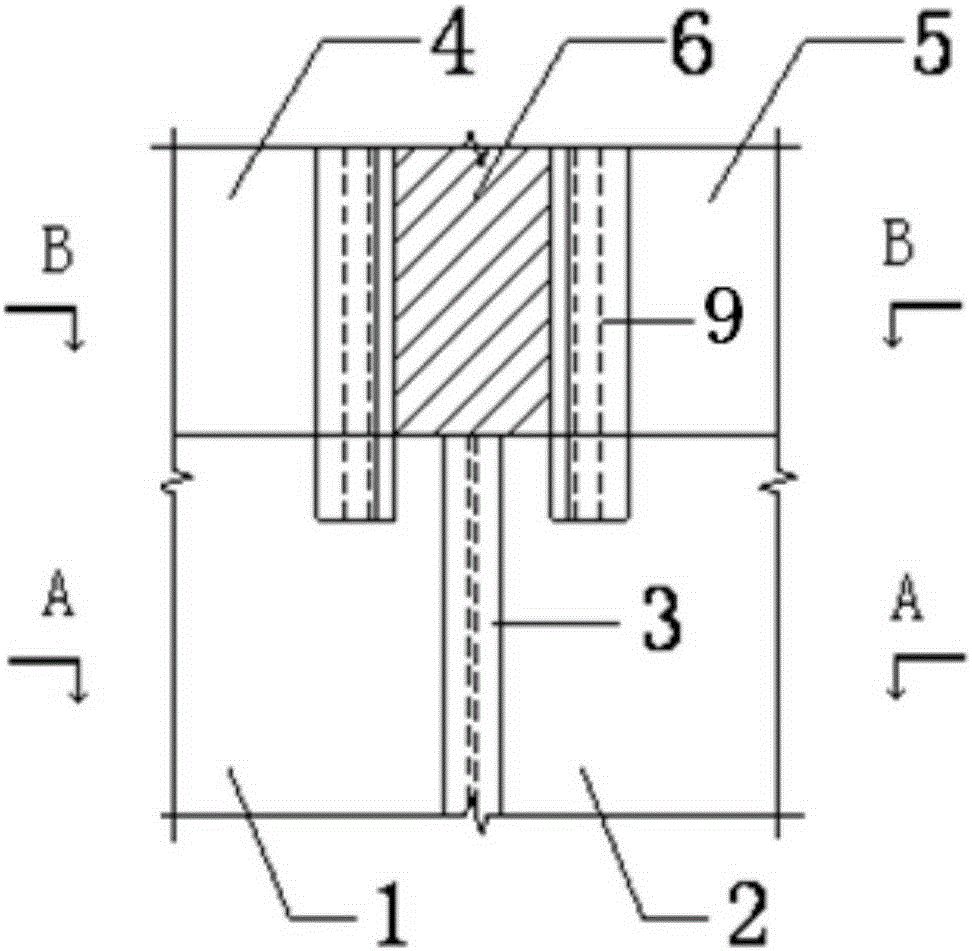

Core tube inverse superimposed underground diaphragm wall and construction method thereof

ActiveCN105275013ASolve the lack of carrying capacityImprove integrityArtificial islandsUnderwater structuresSlurry wallCarrying capacity

The invention discloses a core tube inverse superimposed underground diaphragm wall. The core tube inverse superimposed underground diaphragm wall comprises a core tube underground diaphragm wall body below a raft top elevation and a core tube underground diaphragm wall body above the raft top elevation. The underground diaphragm wall body below the raft top elevation comprises first advance width sections and first follow-up width sections. The underground diaphragm wall body above the raft top elevation comprises second advance width sections, second follow-up width sections, connecting beams, post-pouring gap sections arranged at the connecting positions of the second advance width sections and the second follow-up width sections and the connecting positions of the width sections and the connecting beams, and outer lining walls arranged at the outer sides of the width sections and the post-pouring gap sections. Wall body lacing wires and stirrups are pre-embedded in the two side edges of steel reinforcement cages of the second advance width sections and the second follow-up width sections respectively. Box irons are pre-embedded in the end portions of the two sides of the second advance width sections and the second follow-up width sections, and the box irons stretch into the underground diaphragm wall body below the raft top elevation. The invention further discloses a construction method for the core tube inverse superimposed underground diaphragm wall. According to the core tube inverse superimposed underground diaphragm wall, the outer lining walls are arranged additionally on the two sides of the underground diaphragm wall body above the raft top elevation, and the problem that an existing underground diaphragm wall is insufficient in carrying capacity is solved; in addition, two different underground diaphragm wall connecting modes are adopted, so that not only are requirements for stressing and constructing met, but also the shear performance of the underground diaphragm wall is guaranteed.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

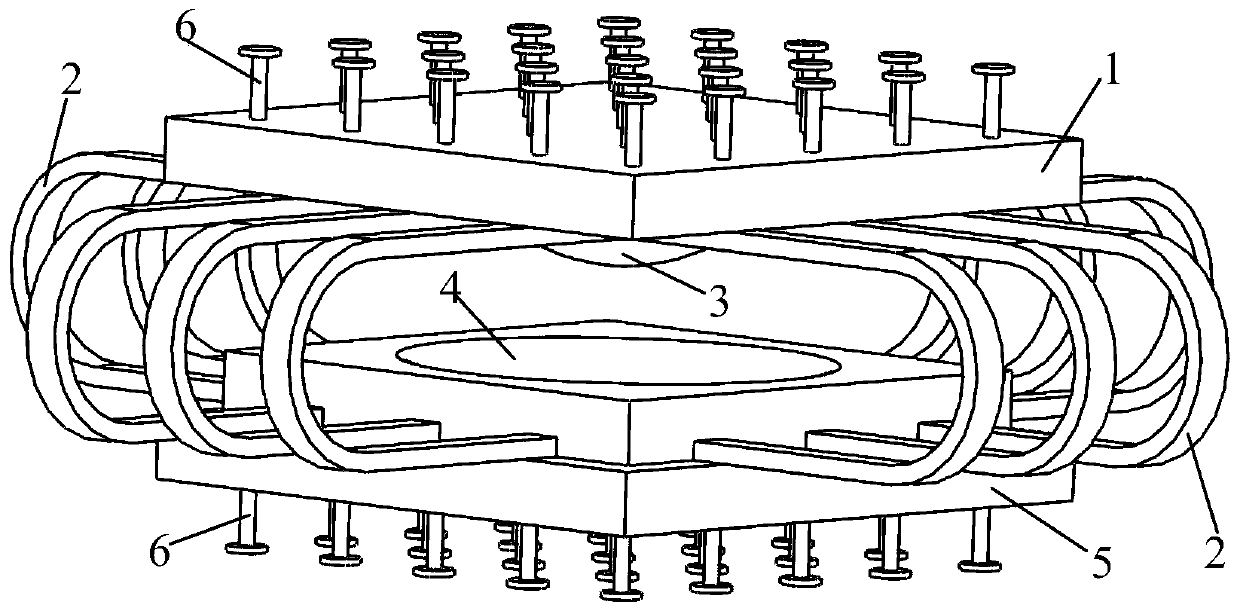

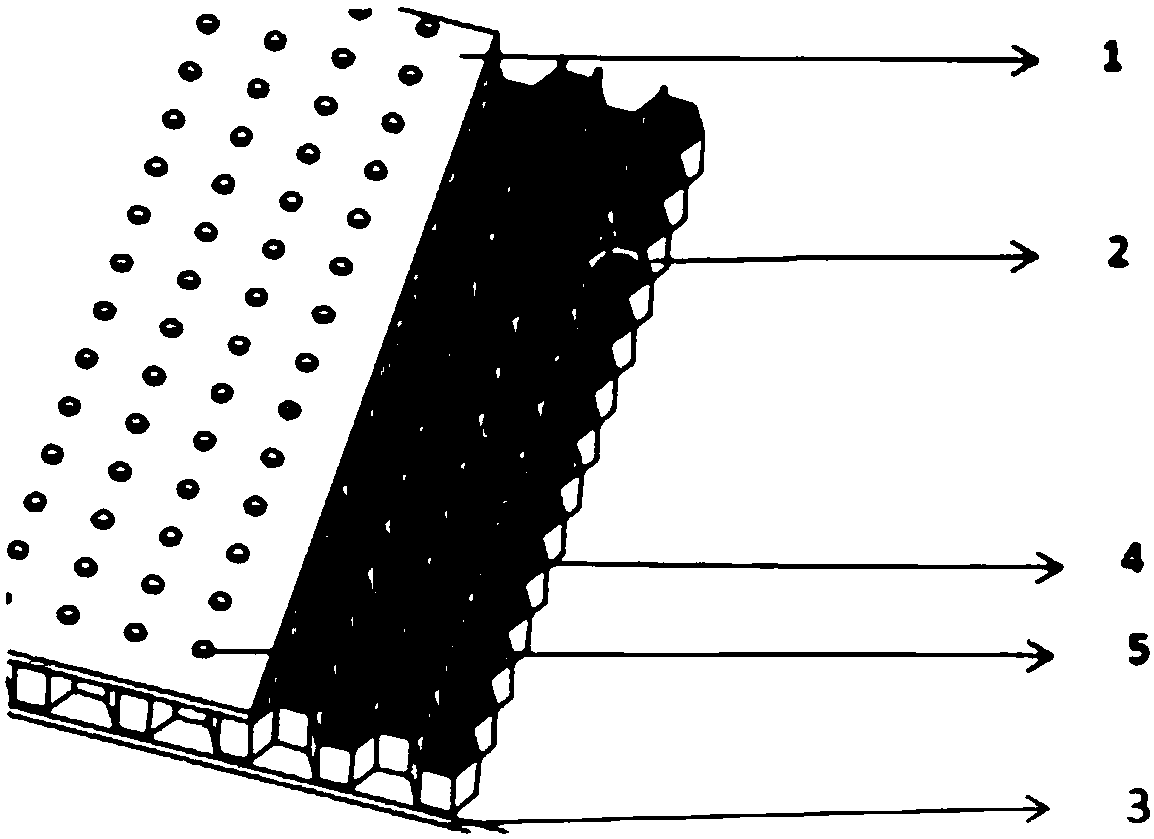

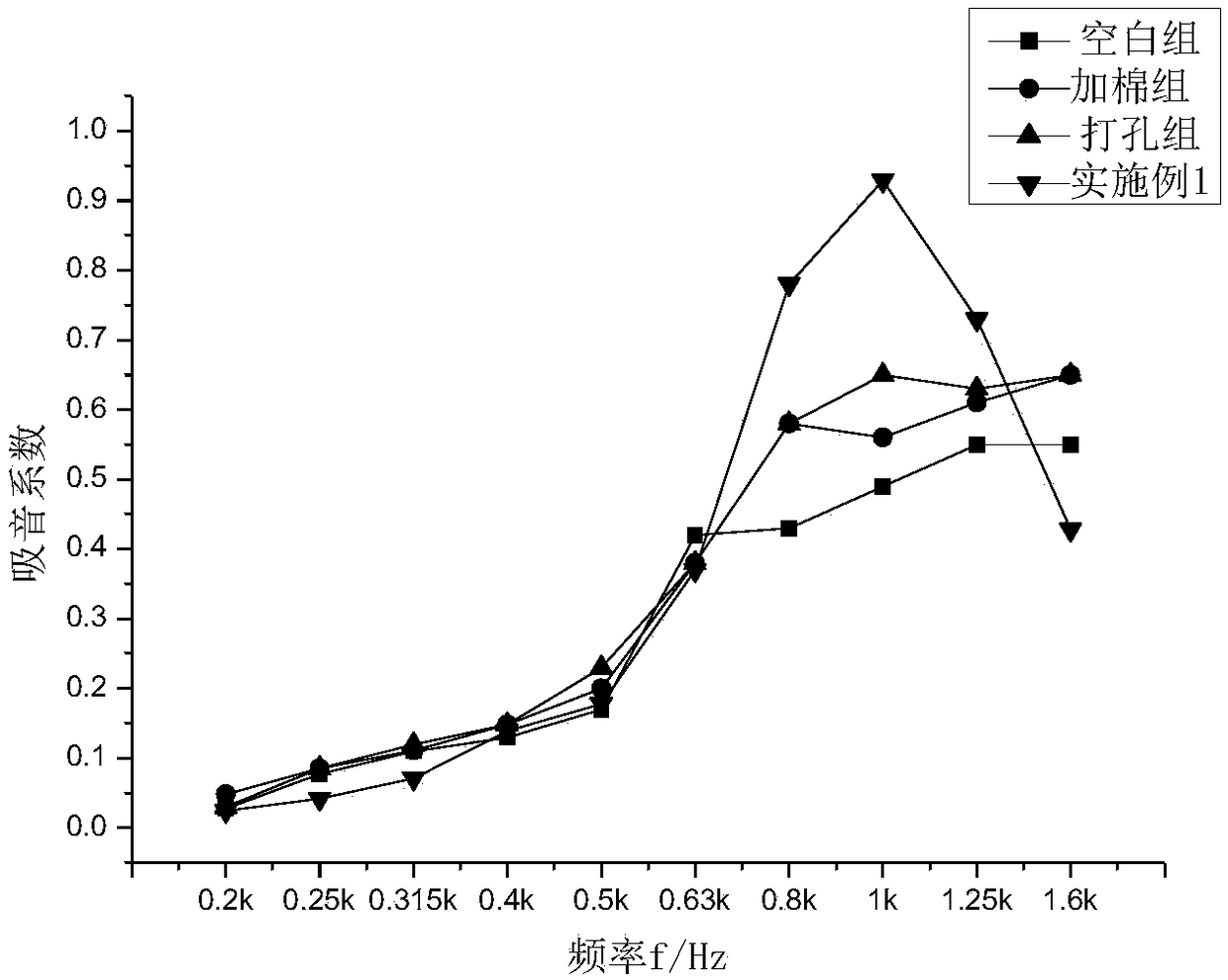

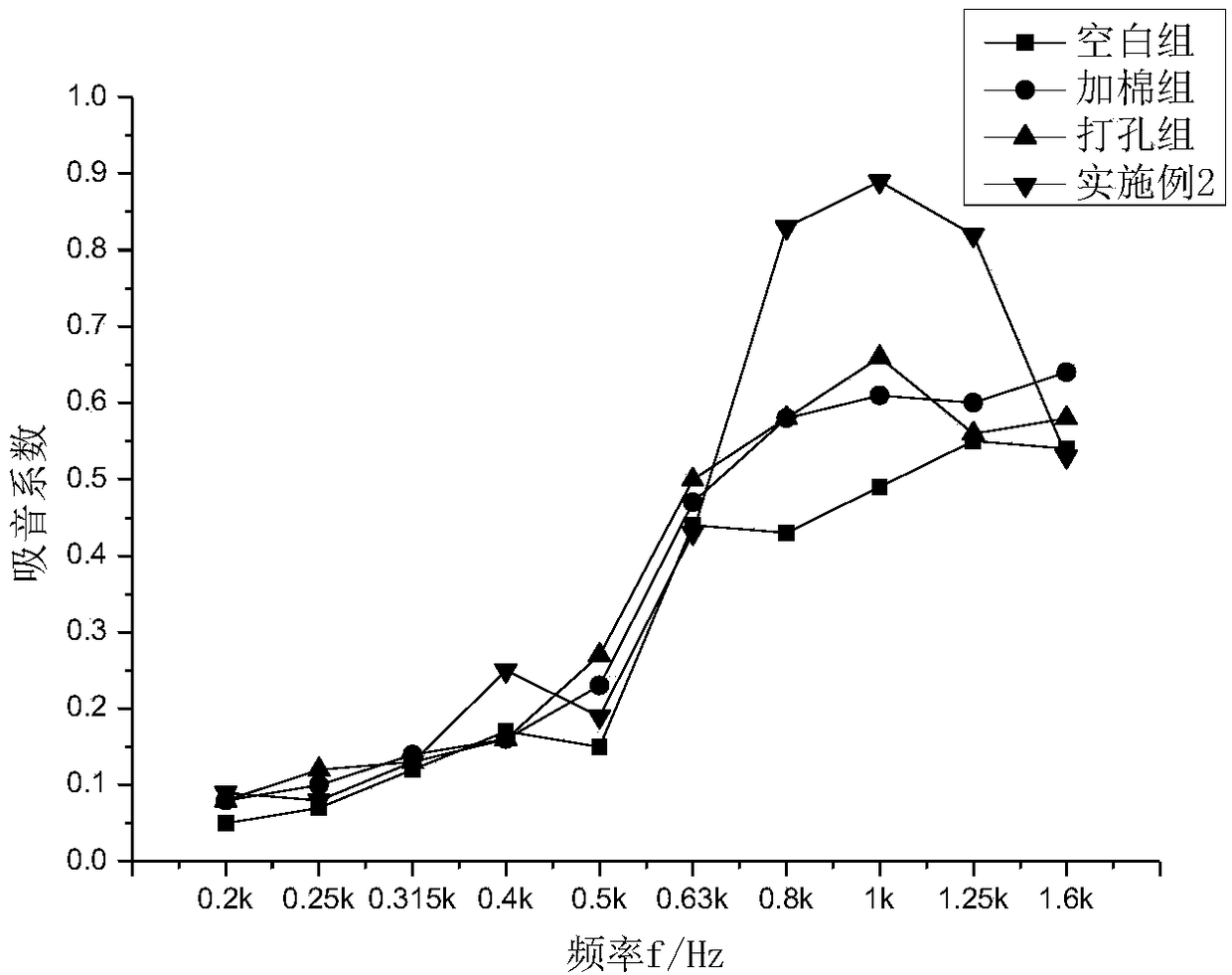

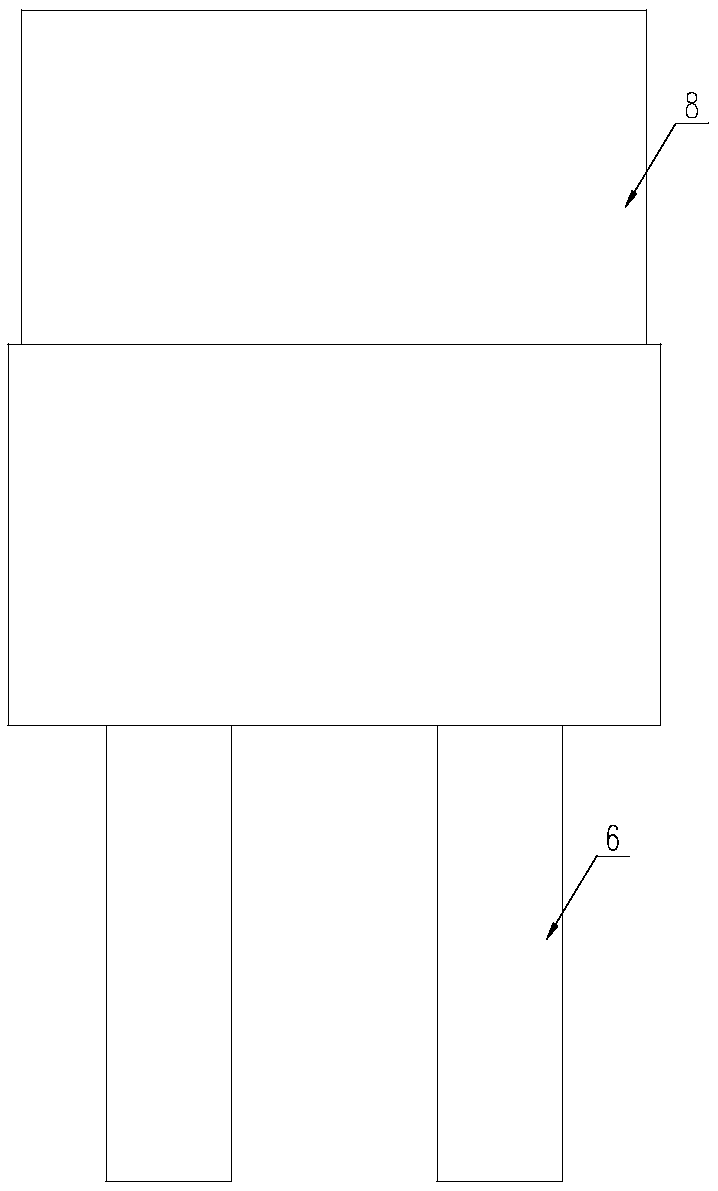

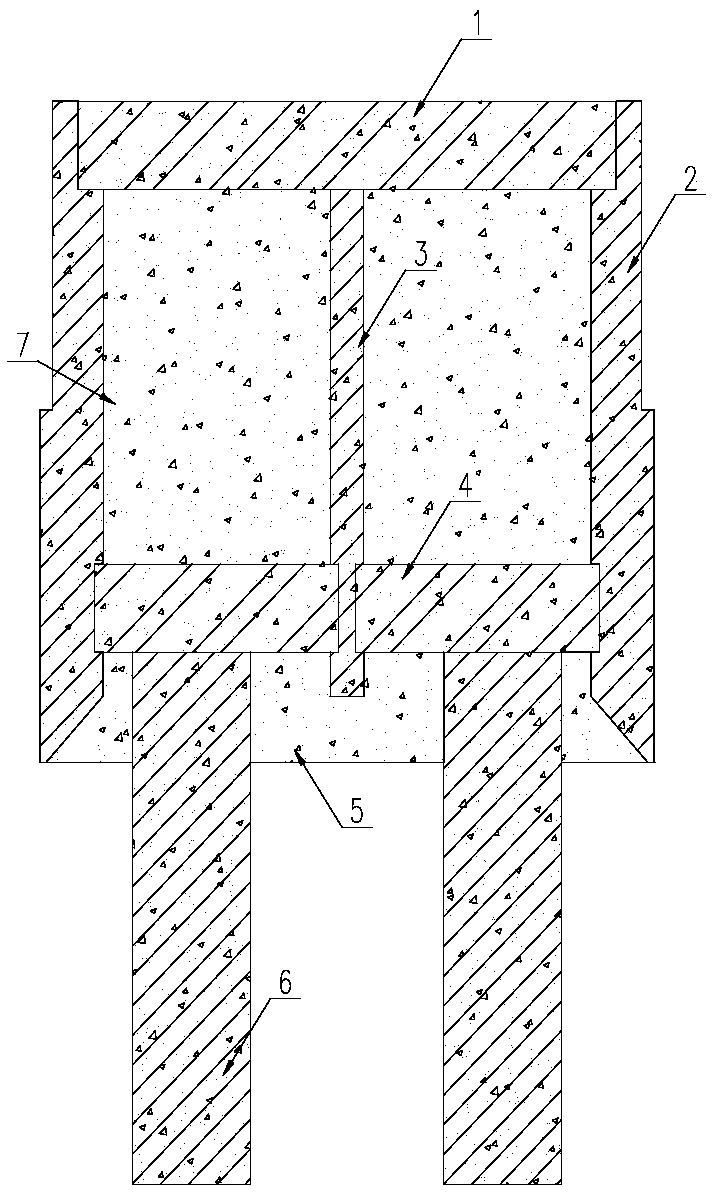

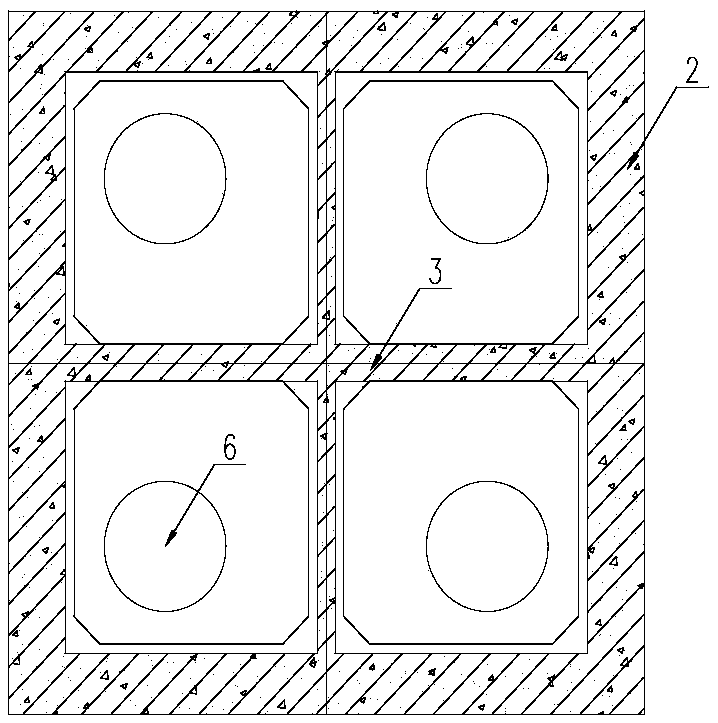

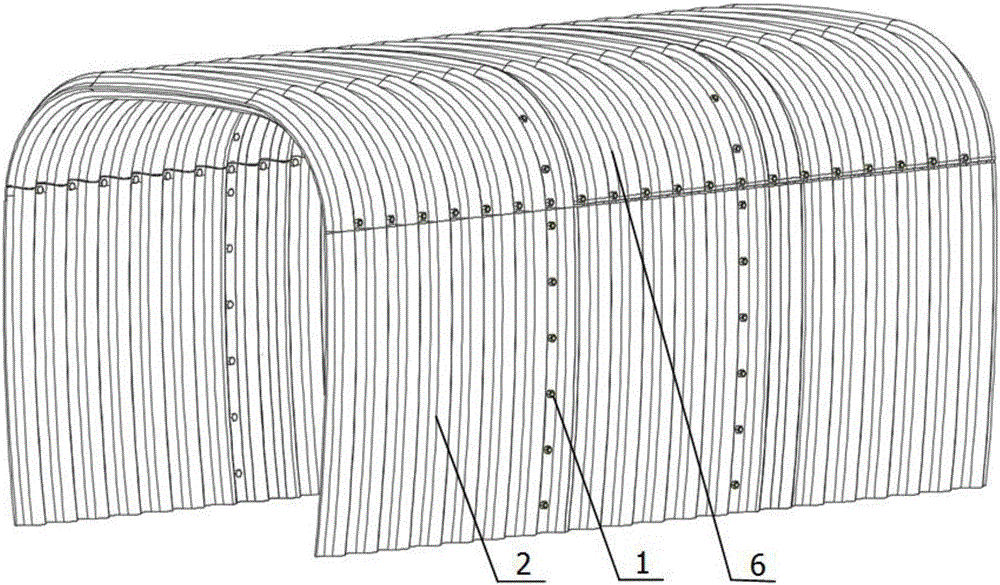

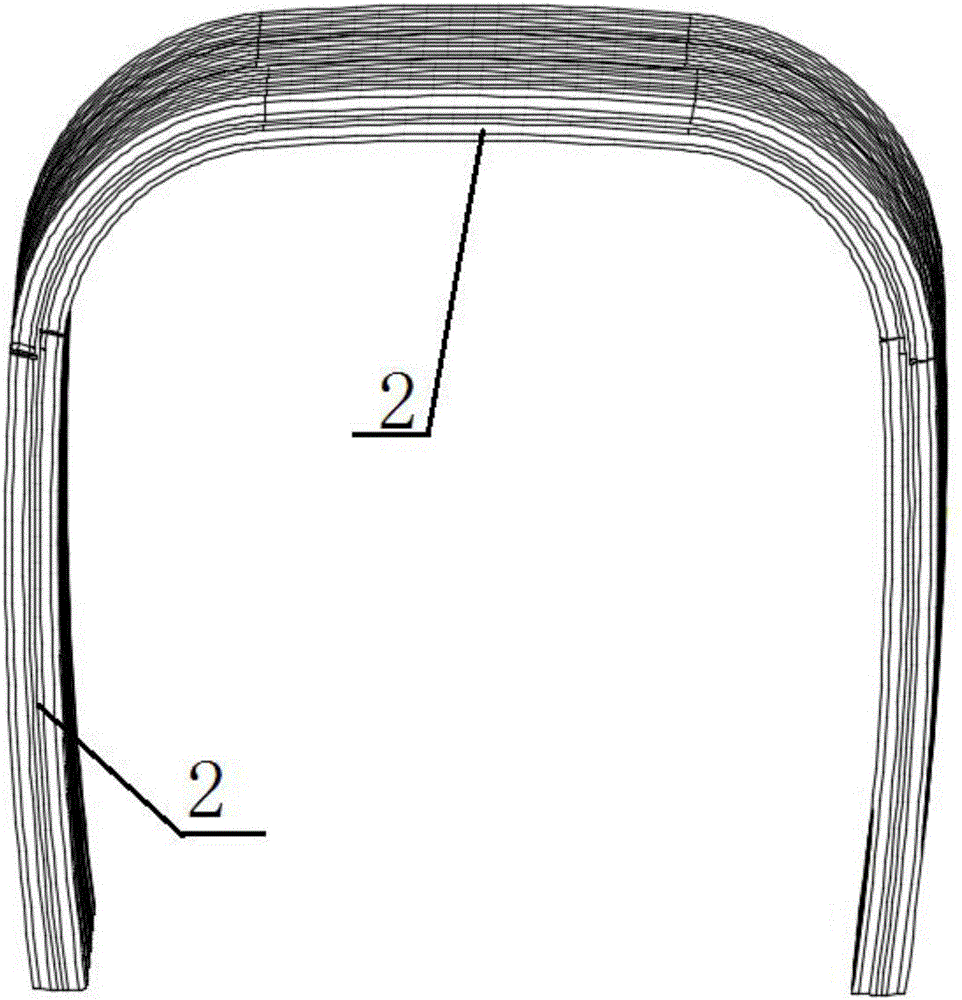

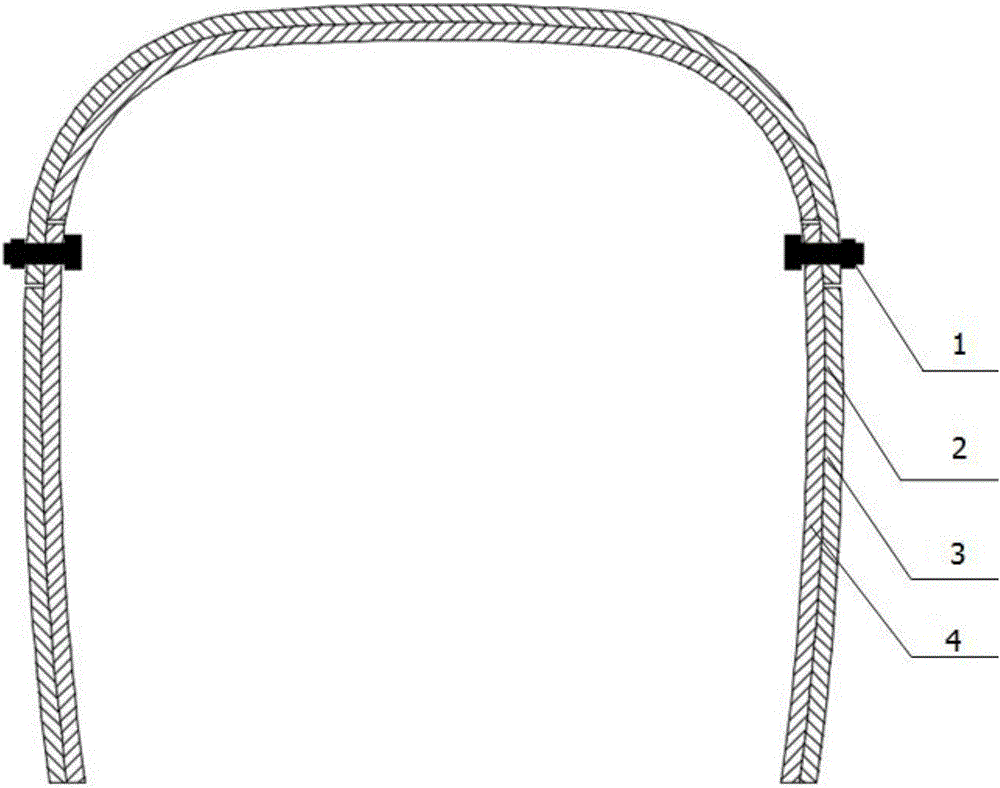

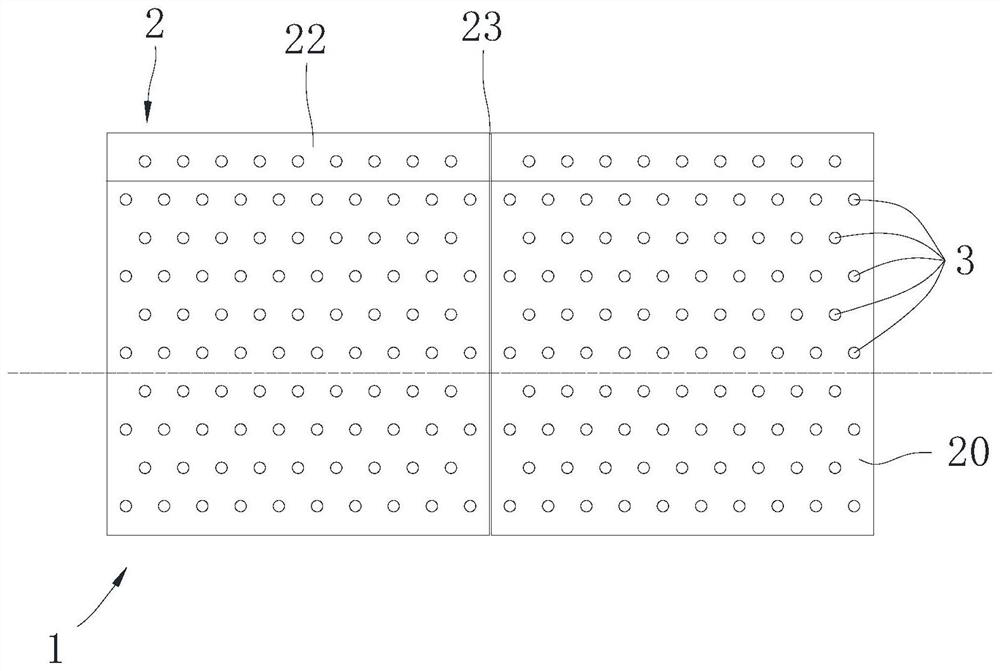

Honeycomb sandwiched sound absorbing and noise reducing structure filled with porous fibers and method of preparing same

InactiveCN108437588ASolve the lack of carrying capacitySimple structureSynthetic resin layered productsLaminationAdhesiveHeavy load

The invention relates to a honeycomb sandwiched sound absorbing and noise reducing structure filled with porous fibers and a method of preparing same. The structure includes an upper skin (1), a honeycomb sandwich core (2), a lower skin (3), PP / PET bi-component porous fibers (4) packed in cells in the honeycomb sandwich core, and micropores (5) uniformly distributed in the upper skin (1). The preparation method includes the steps of: a) preparing a resin base body and manufacturing the upper skin and the lower skin with the composite material, and performing gel solidification; b) uniformly smearing a layer of adhesive on the upper surface of the lower skin, placing the honeycomb sandwich core, pressing the structure with a weight, and performing heating for gel solidification; c) uniformly packing the PP / PET bi-component porous fibers uniformly in the cells in the honeycomb sandwich core, and uniformly smearing a layer of adhesive on one surface of the upper skin, and adhering the upper skin to the honeycomb structure with solidification; d) forming the pores in the upper skin by certain distance. The structure is simple and is light in weight and high in strength, has excellent sound absorbing effect in medium / high frequency, and has great application prospect.

Owner:WUHAN UNIV OF TECH

Open caisson foundation and construction method

PendingCN108755731AImprove vertical load carrying capacityHigh thrust resistanceFoundation engineeringBearing capacityFrictional resistance

The invention relates to an open caisson foundation and a construction method. The open caisson foundation comprises a shaft and vertically-distributed concrete pile foundations. The bottom of the shaft is sealed through bottom sealing concrete, and the top of the bottom sealing concrete is provided with a bearing table fixedly connected with the inner wall of the shaft. The concrete pile foundations are integrally connected with the bearing table after penetrating the bottom sealing concrete. The bottom sealing concrete is provided with holes for the concrete pile foundations to penetrate, and the concrete pile foundations are in clearance fit with the corresponding holes. The open caisson foundation is clear in stress, the concrete pile foundations arranged at the bottom of an open caisson are used for solving the problem that the foundation bearing force is insufficient, the open caisson and the concrete pile foundations have the beneficial effect of mutual supplementing, all foundation dead loads are transmitted to a foundation, the open caisson bottom frictional resistance action is brought into play to the maximum degree, and the structure horizontal thrust exerted on the tops of the concrete pile foundations is obviously reduced.

Owner:POWERCHINA ZHONGNAN ENG

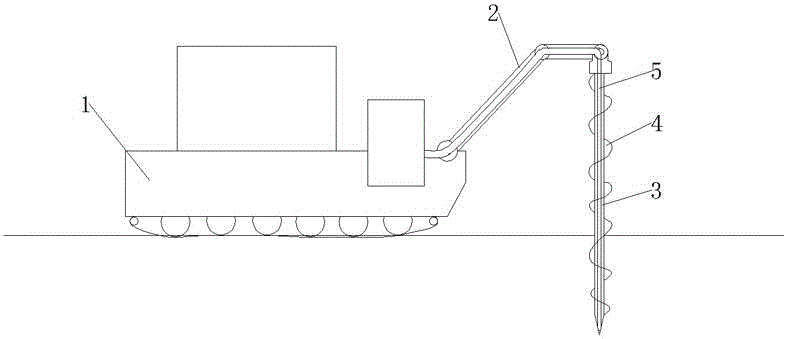

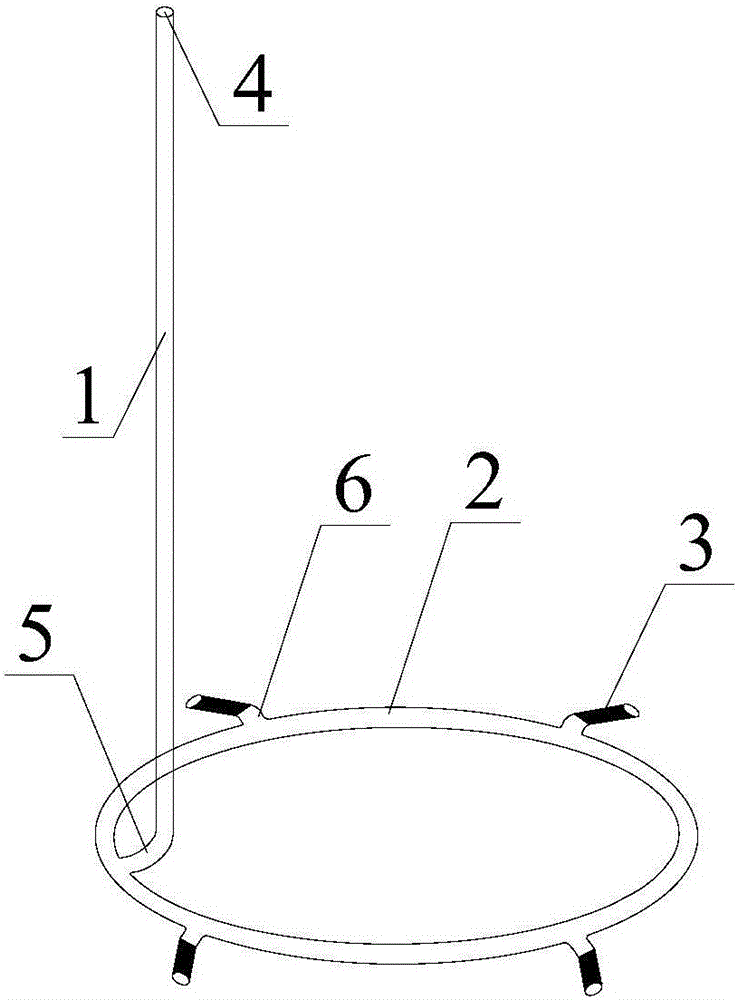

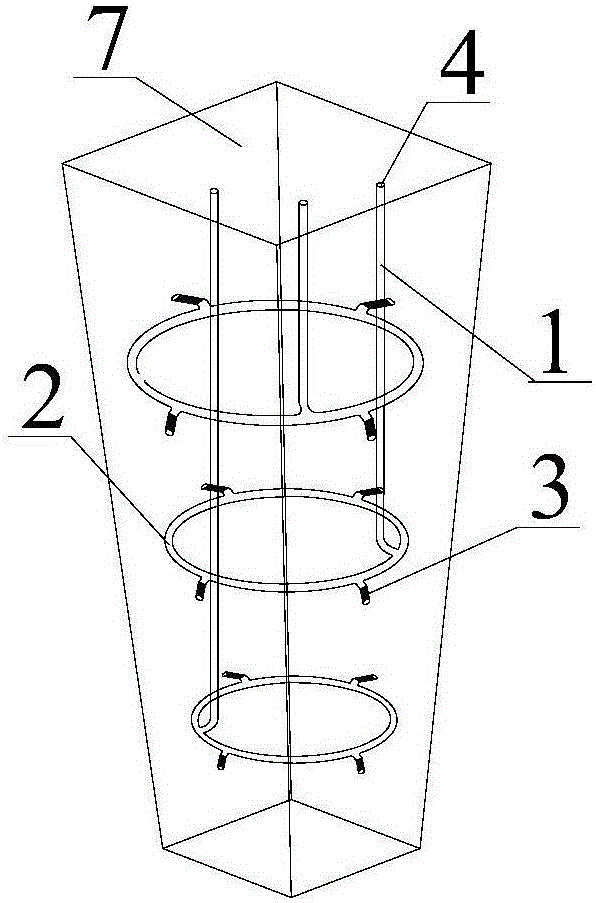

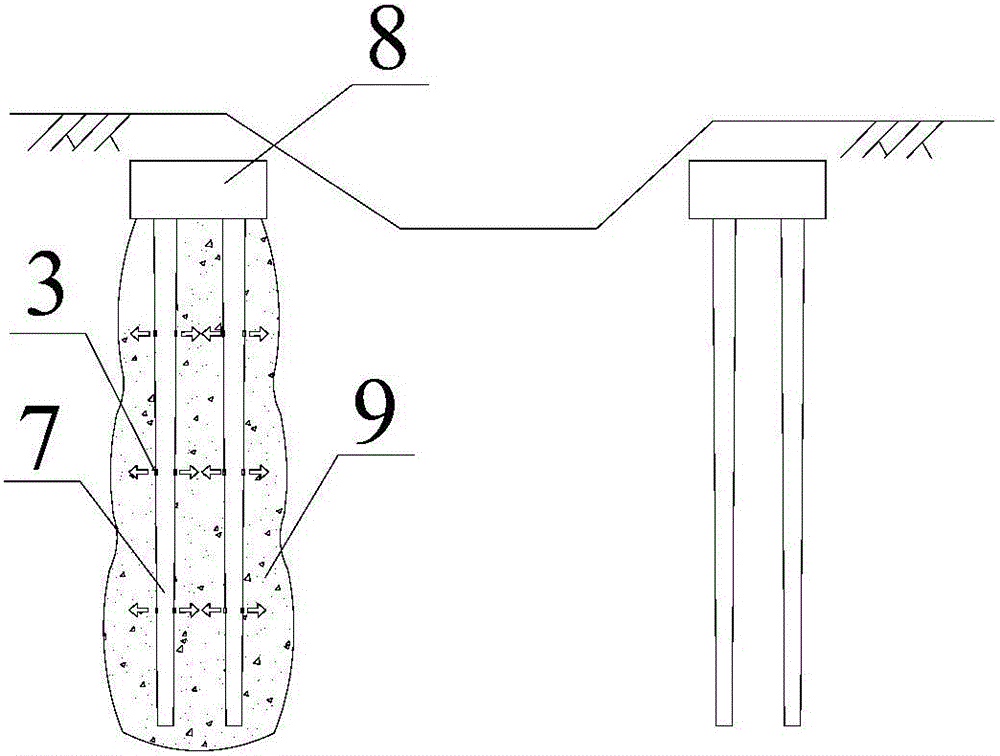

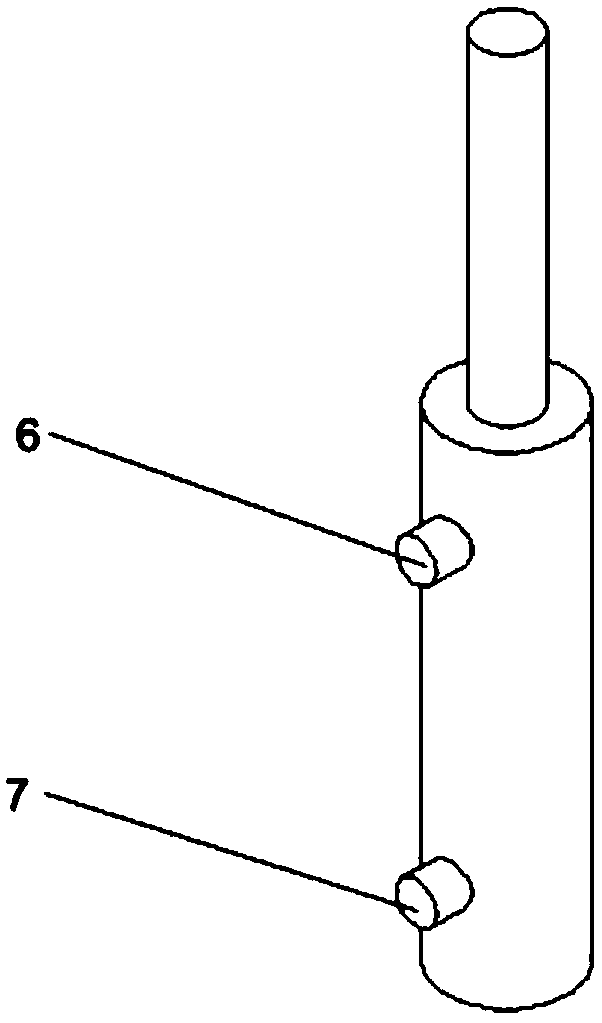

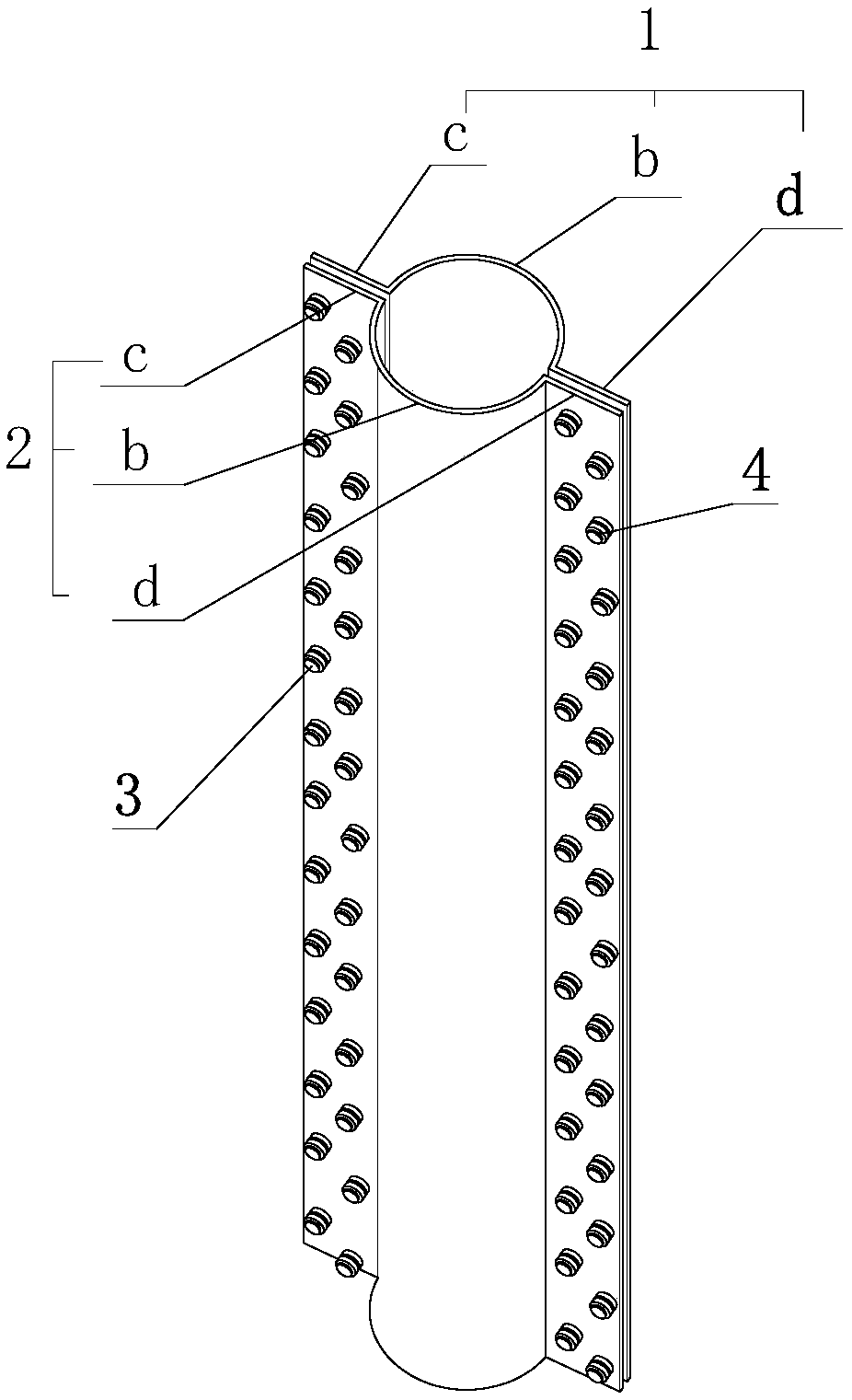

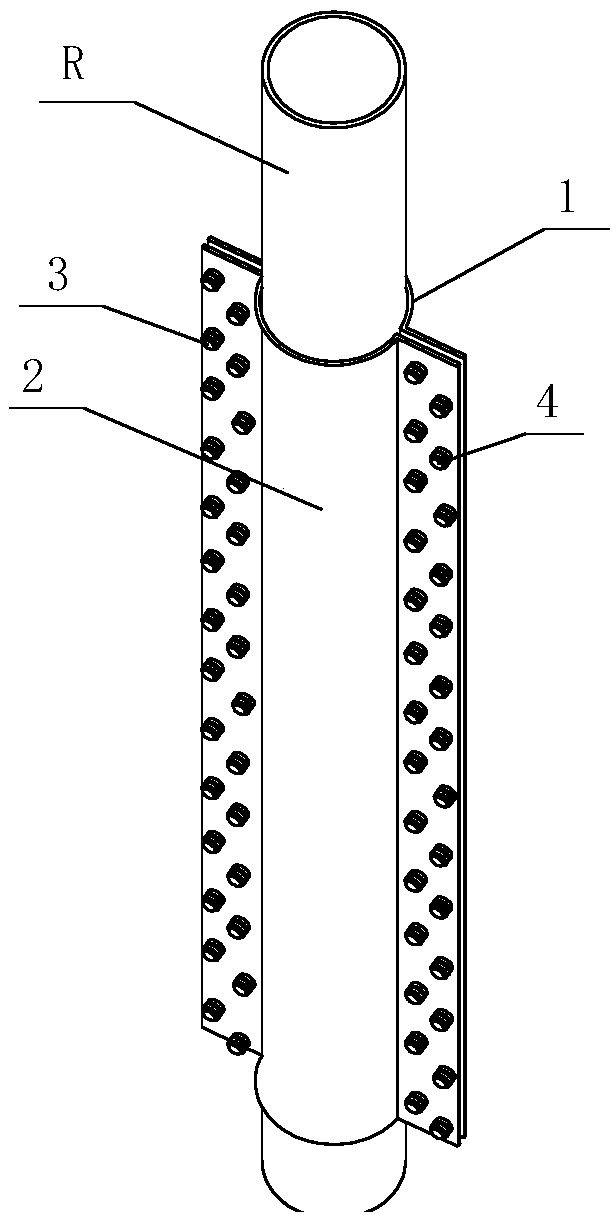

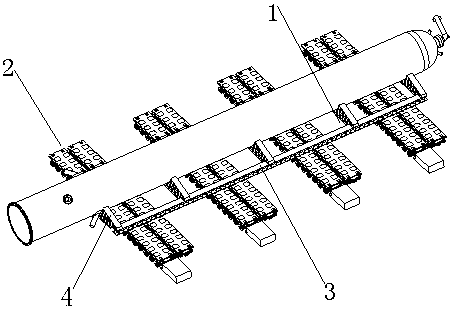

Grouting pipeline device, conical special-shaped pile and application method thereof

InactiveCN105804083ASolve the lack of carrying capacityAdaptableBulkheads/pilesEngineeringGuide tube

The invention discloses a grouting pipeline device. The grouting pipeline device comprises a longitudinal grouting pipe, an annular pipe, grouting machines, a first arc guide pipe and a second arc guide pipe; the longitudinal grouting pipe is arranged on the inner side of the annular pipe in the axial direction of a pile body, and a grouting port is formed in the top of the pile; the annular pipe is perpendicular to the axial direction of the pile body, and is communicated with the longitudinal grouting pipe through the first arc guide pipe; the grouting machines are symmetrically arranged in the center positions of the side surfaces of the pile in the peripheral annular direction of the pile; one side is communicated with the annular pipe through the second arc guide pipe; and the other side is communicated with the external of the pile body. The invention further discloses a conical special-shaped pile for prefabricating the grouting pipeline device and an application method thereof. The grouting pipeline device performs the targeted grouting section setting, grouting scheme selection and parameter design according to different engineering environments and specific working conditions, has such advantages as safety, reliability, high adaptability and flexibility, economy and environmental protection, can effectively compensate the pile side friction resistance of the conical special-shaped pile, reduces the difficulty of secondary construction for improving the bearing capacity of the special-shaped pile, and saves the construction cost.

Owner:TONGJI UNIV

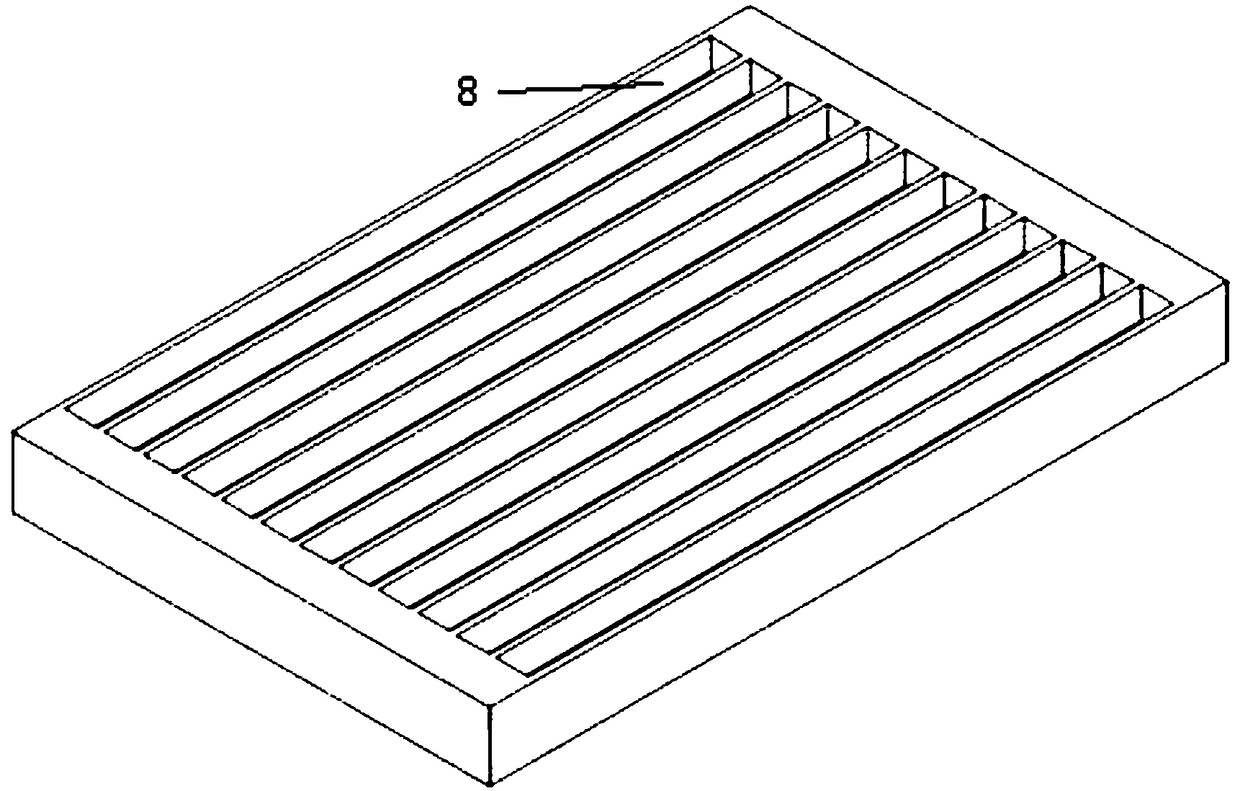

Bearing and deformation integrated pressure-charging oil tank skin

ActiveCN108639357AOvercome the shortcomings of not being able to deformReduce consumptionPower plant fuel tanksFuel tankAirplane

The invention discloses a bearing and deformation integrated pressure-charging oil tank skin. The bearing and deformation integrated pressure-charging oil tank skin comprises a pressure-charging cavity. An outer skin body is arranged on the outer side wall of the pressure-charging cavity, and an inner skin body is arranged on the inner side wall of the pressure-charging cavity; a plurality of strip-shaped grooves which are parallel mutually and penetrate through the pressure-charging cavity are formed between the outer side wall and the inner side wall of the pressure-charging cavity; partition plates for partitioning the strip-shaped grooves into outer side grooves located in the outer side of the pressure-charging cavity and inner side grooves located in the inner side of the pressure-charging cavity are arranged in the strip-shaped grooves; pressure-charging pipes are arranged in the outer side grooves and the inner side grooves correspondingly, wherein the axes of the pressure-charging pipes correspond to the extending directions of the strip-shaped grooves; the two ends of the pressure-charging pipes are connected with the groove walls of the strip-shaped grooves correspondingly, and air inlets are formed in the pressure-charging pipes; and the bearing and deformation integrated pressure-charging oil tank skin further comprises a plurality of supporting air columns with the upper ends being hinged to the inner skin body. According to the bearing and deformation integrated pressure-charging oil tank skin, the defect that a traditional oil tank skin cannot deform is overcome; and along with consumption of fuel, the bearing and deformation integrated pressure-charging oil tank skin can generate inwards bending deformation, the air resistance of the bearing and deformation integrated pressure-charging oil tank skin is reduced, accordingly, the flight performance of an airplane is improved, and fuel consumption is also reduced.

Owner:DALIAN UNIV OF TECH

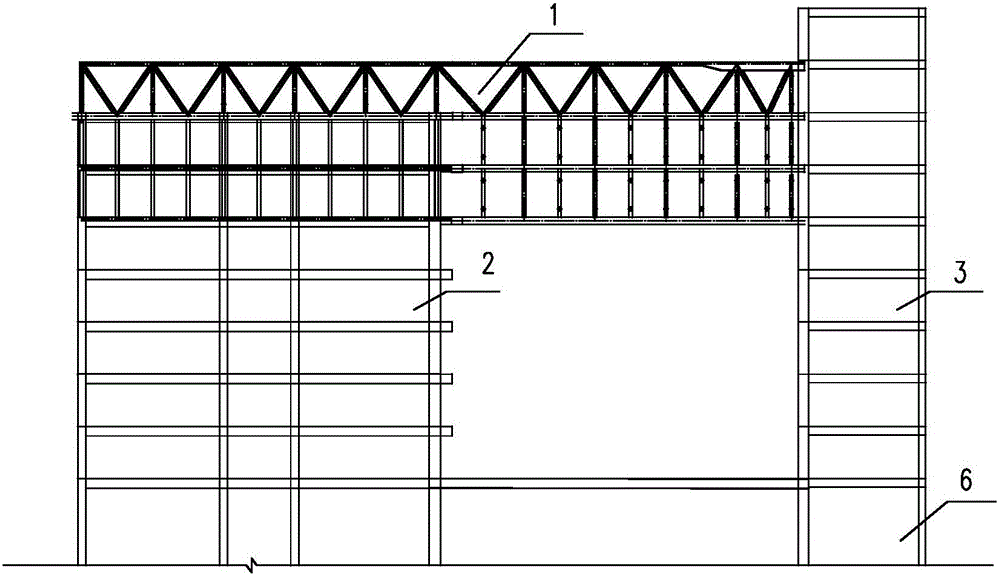

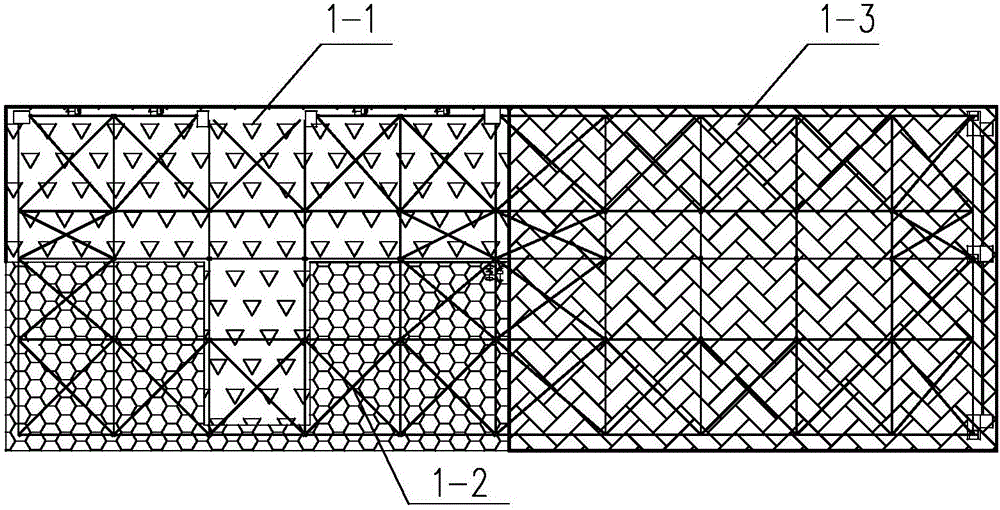

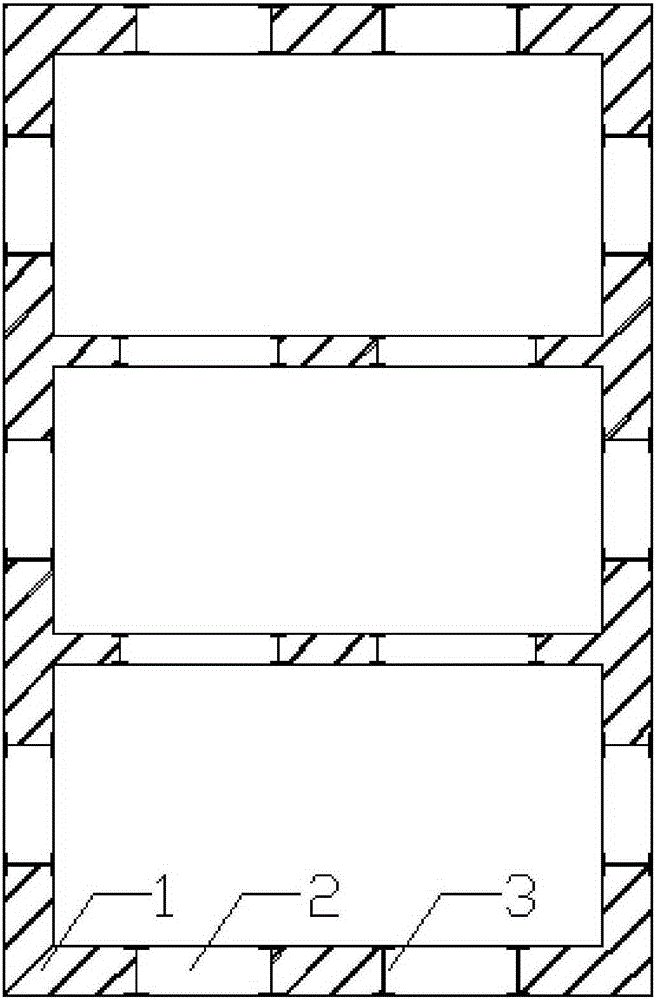

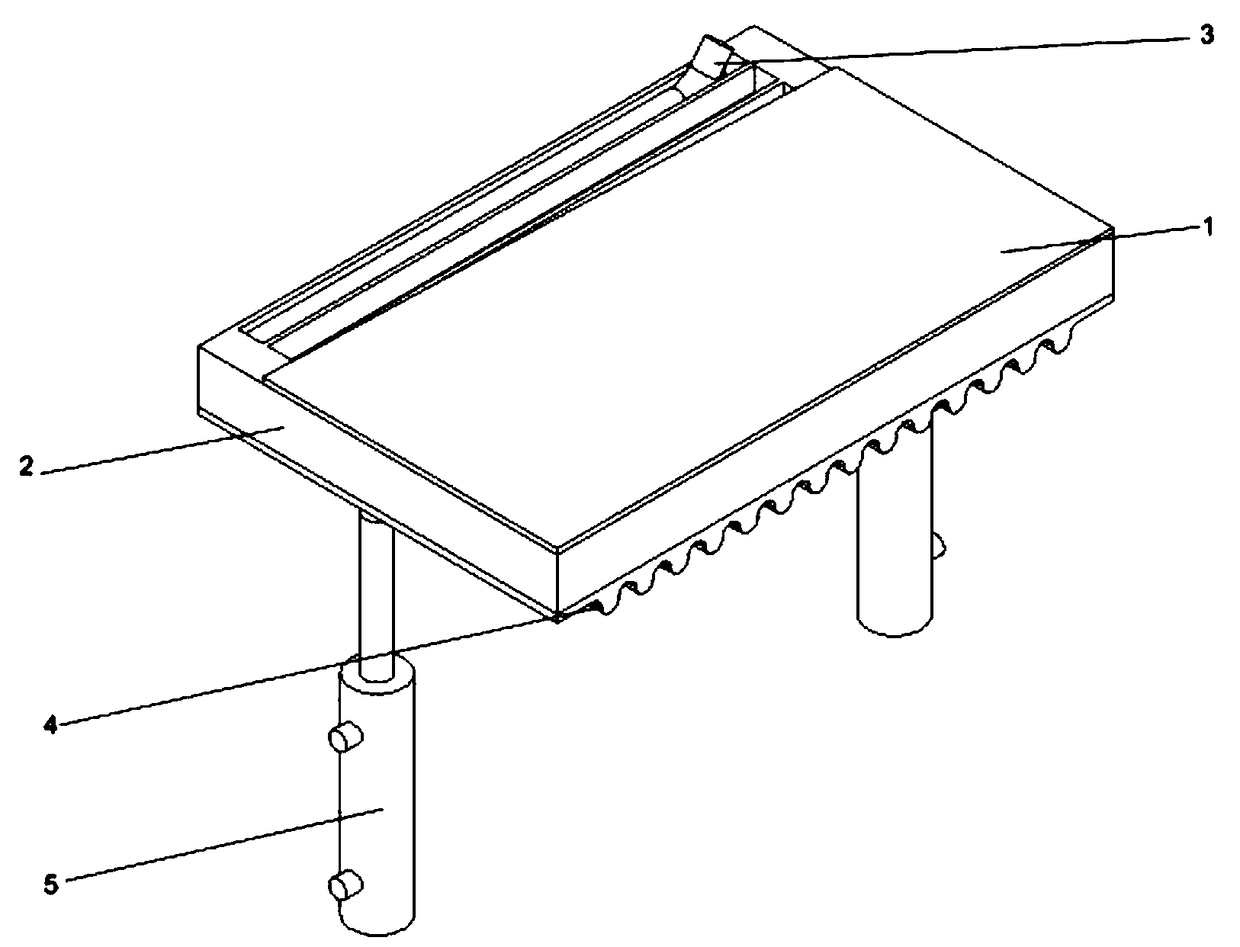

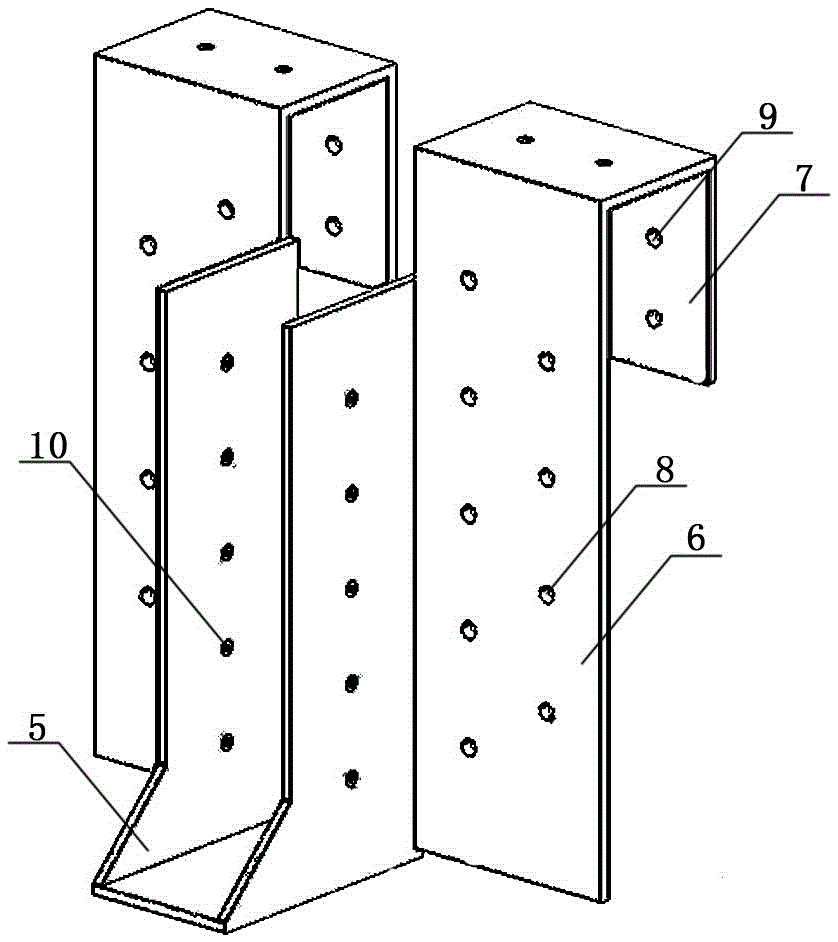

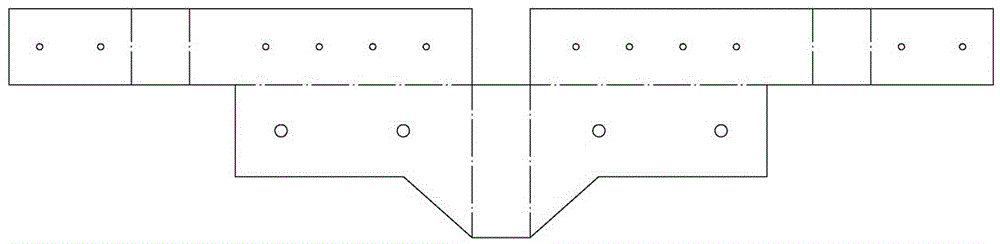

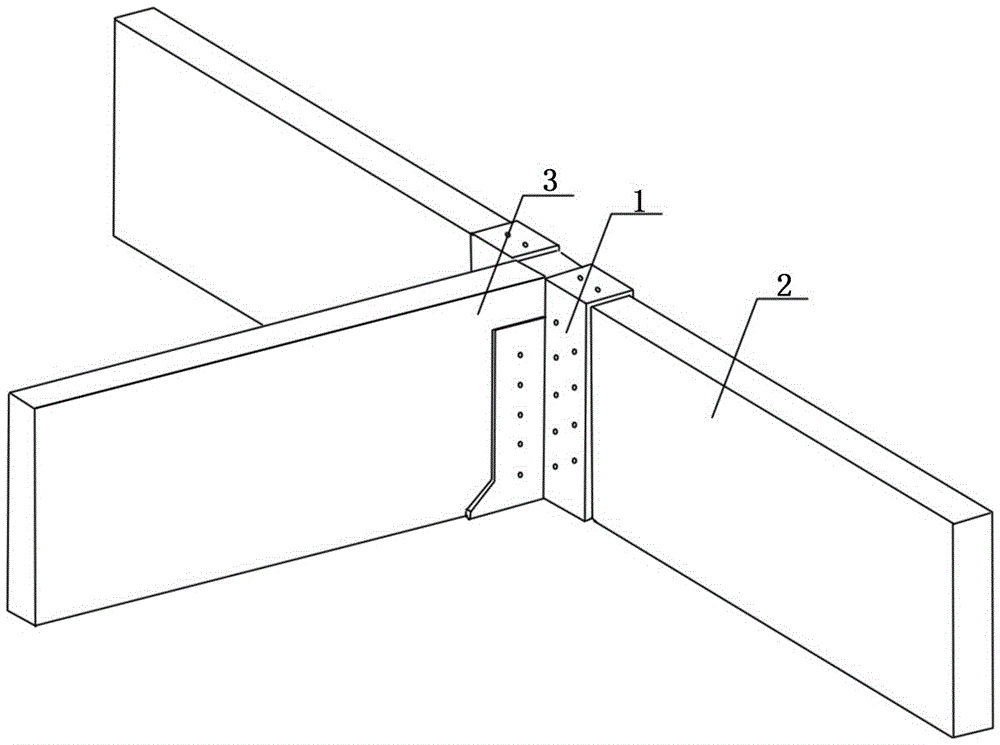

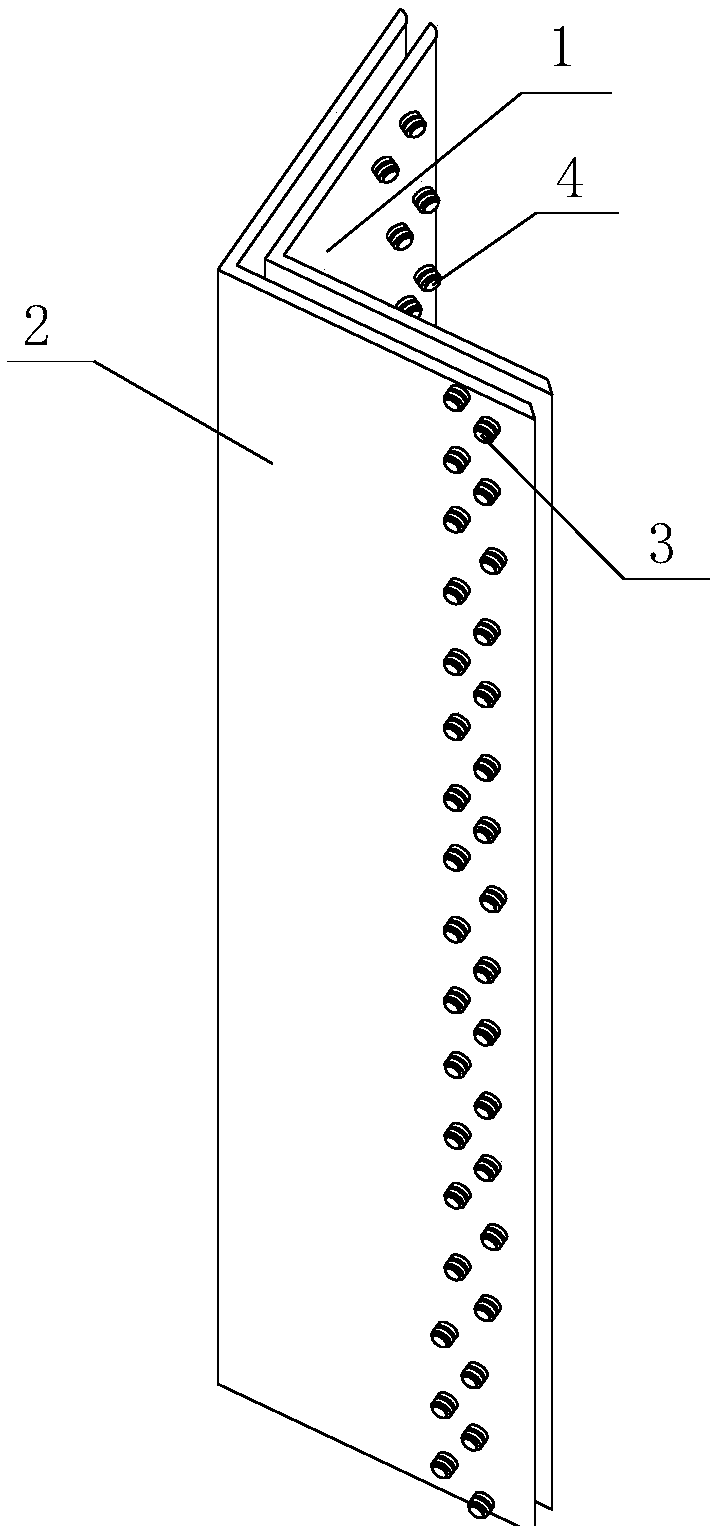

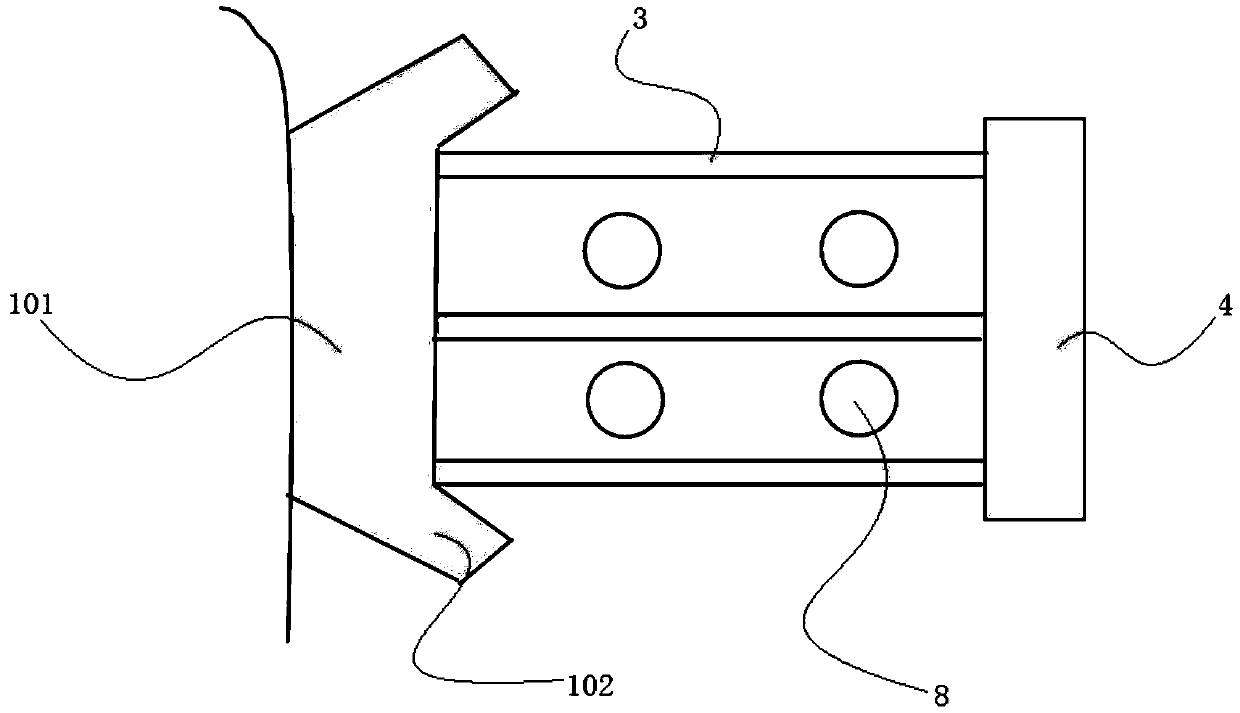

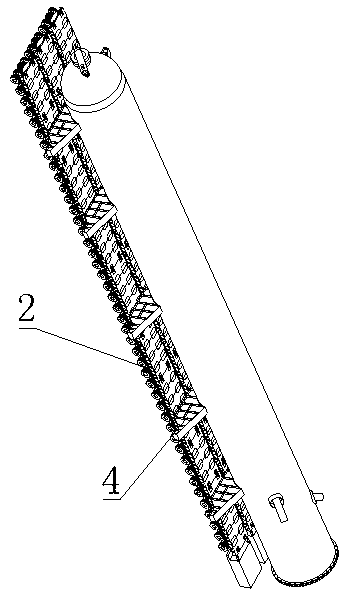

Wood structure anti-shearing connecting element, connecting structure, box body platform structure and construction method

ActiveCN105525681AImprove connection integritySolve the lack of carrying capacityFloorsEngineeringMetal

The invention relates to a wood structure anti-shearing connecting element, a connecting structure, a box body platform structure and a construction method. The connecting element is of an integral structure formed by sequentially and vertically bending a metal plate, and comprises a U-shaped web plate, flanges and hook heads, wherein the flanges symmetrically extend out from the two side surfaces of the web plate; the hook heads are formed by bending from the upper end parts of the flanges in a direction of being opposite to the web plate; and connecting holes are formed in each of the web plate, the flanges and the hook heads. The box body platform structure can be used as a lower part support structure for transforming the ground of a stadium into an ice surface; on the premise of not damaging the original field, the temporary transformation in the functional aspect can be fast completed by using the box body structure; and a technical feasible scheme is provided for transforming the existing ordinary stadium into a winter event stadium. By using the connecting element, the stability of the box body structure is ensured; and the reliability of the structure as a whole lower part supporter is ensured; the construction is simple and fast; the time and the labor are saved; and the construction efficiency and the construction quality can be effectively improved.

Owner:BEIJING NAT AQUATICS CENT CO LTD +3

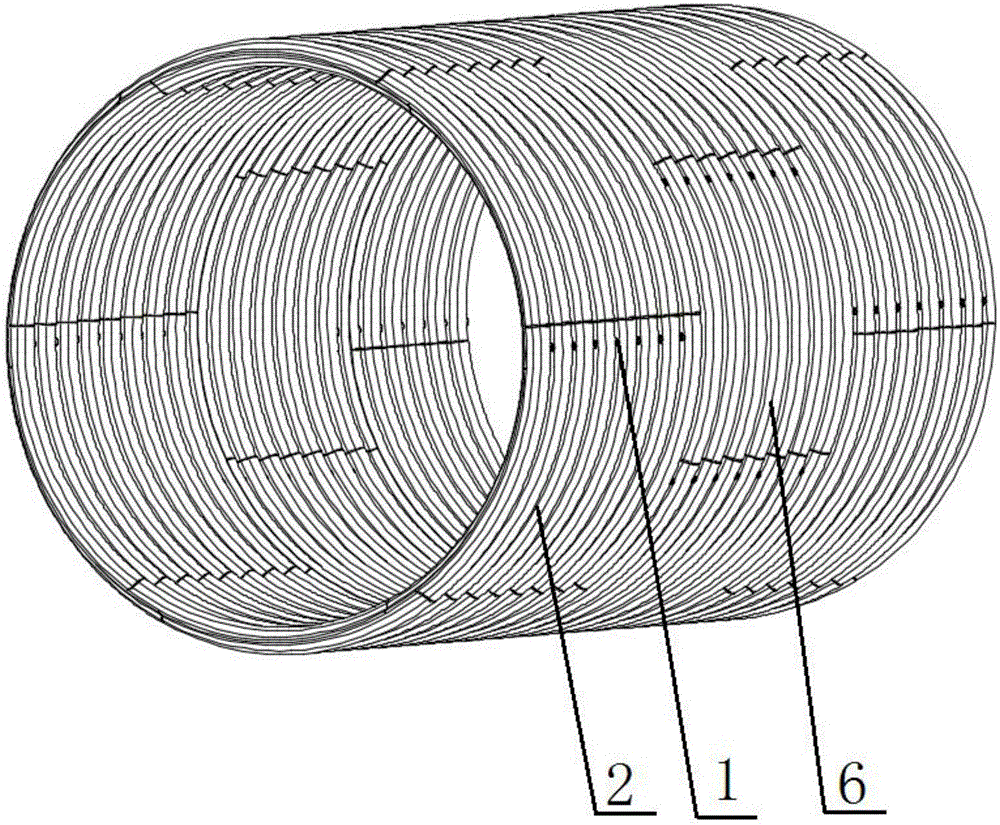

Circular assembling type double-wall corrugated closed steel corrugated culvert pipe

PendingCN106120581AAdapt to deformationSolve the problem of culvert damageGround-workCarrying capacityDouble wall

A circular assembling type double-wall corrugated closed steel corrugated culvert pipe comprises closed double-wall corrugated pipe segments. Each closed double-wall corrugated pipe segment is composed of two corrugated shaped steel plates, and the two corrugated shaped steel plates are welded to form the closed double-wall corrugated pipe segment and serve as an outer wall and an inner wall of the corresponding closed double-wall corrugated pipe segment respectively; six closed double-wall corrugated pipe segments are mutually spliced to form a circular pipe ring, the outer walls and the inner walls of every two adjacent closed double-wall corrugated pipe segments are mutually spliced, and the splicing positions are fixed through a row of bolts; and multiple circular pipe rings are mutually spliced to form an integral corrugated culvert pipe. The circular assembling type double-wall corrugated closed steel corrugated culvert pipe has the characteristics of high strength, high carrying capacity and the like, and as the body of a culvert and a bridge, when being compared with a concrete pipe culvert, the circular assembling type double-wall corrugated closed steel corrugated culvert pipe has the advantages of simpleness in construction, convenience in maintenance, long in service life, high ability of adapting to the foundation deformation and the like, and is worth popularizing.

Owner:河北驰特轨道交通设备有限公司

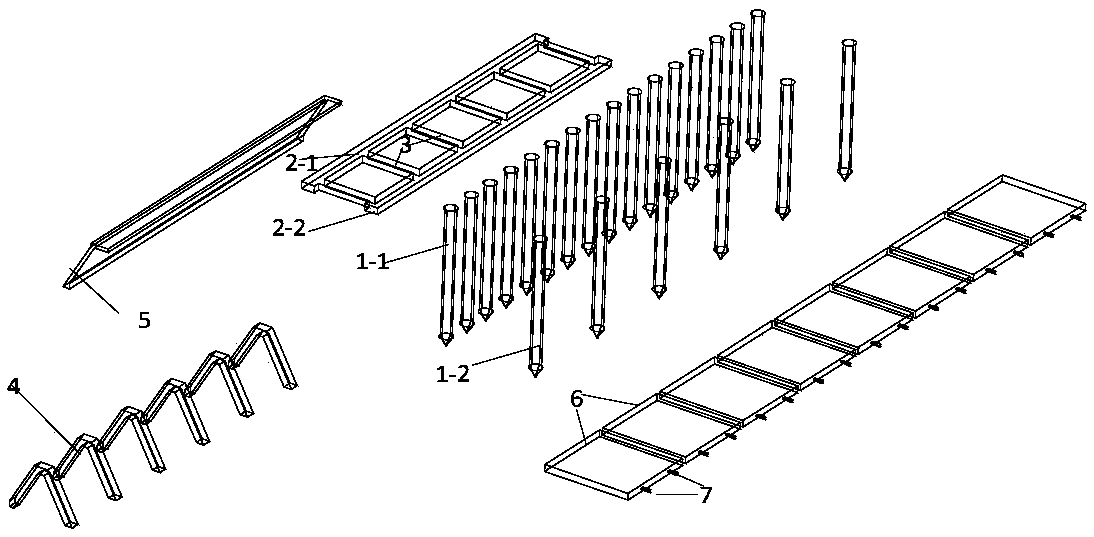

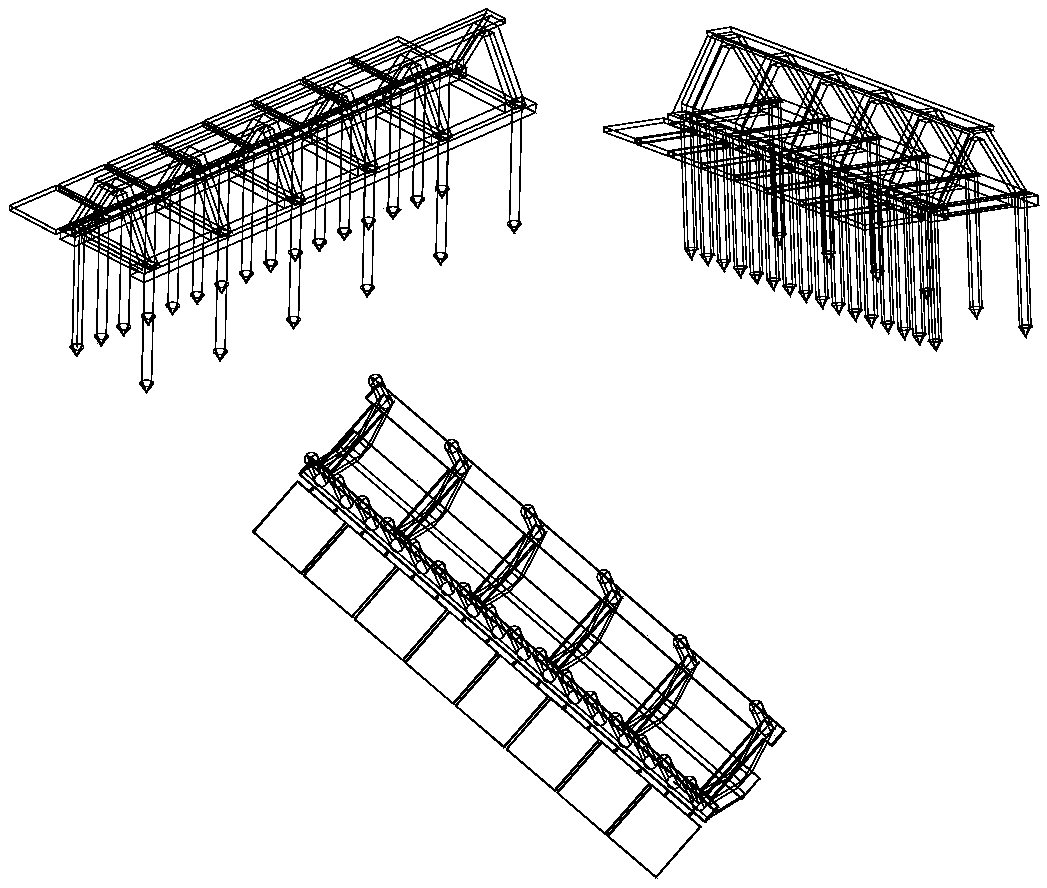

Novel structure of flood control dam on silty-fine sand stratum

PendingCN109594530AImprove bearing capacityImprove stabilityFoundation engineeringEarth-fill damsRebarFlood control

The invention provides a novel structure of a flood control dam on the silty-fine sand stratum. The novel structure comprises an underground sunken pile structure and an overground water retaining damstructure, two rows of sunken piles are driven underground with a water jetting method, and the overground structure and the underground structure are connected through reinforcing steel bar pouringor connected by prefabricated socket nesting and addition of fasteners; #-shaped ring beams are connected with upper ends of the sunken piles and extend in the configuration direction of the sunken piles, water retaining panels are arranged on floor beams located on one side of an upstream face, a plurality of supporting beam units are arranged on the side, away from a riverway, of each water retaining panel, the supporting beam units are arranged at certain intervals in the configuration direction of the sunken piles, and impingement plates are arranged on the outer sides of the row of sunkenpiles close to the riverway. The sunken piles are taken as the foundation, a flood control dam main body with the reinforced concrete plate slab and girder structure is added, so that dead load of engineering is reduced, overall bearing capacity and foundation stability of the structure are improved, the problem of insufficient bearing capacity of a soft foundation can be solved, and with the adoption of the water jetting method, operation is easy and the sunken piles are not damaged during mounting.

Owner:新疆水利水电规划设计管理局

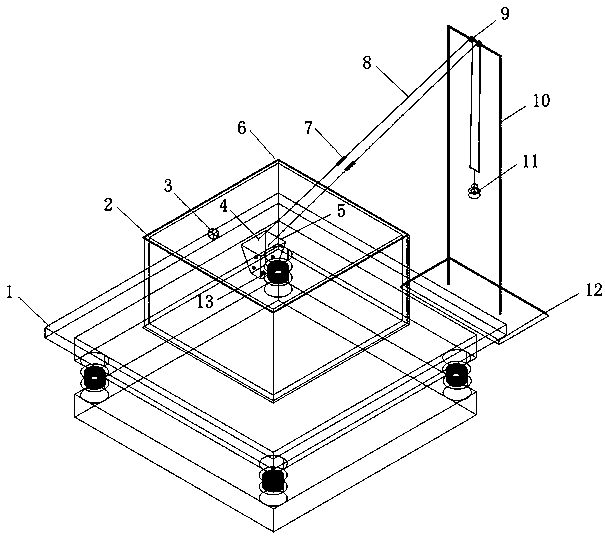

Model test system and method for gravity type anchorage stability research under earthquake load

PendingCN111537217AImprove adaptabilityEffective simulationMachine part testingVibration testingTest chamberModel test

The invention discloses a test system and method for simulating gravity type anchorage stability research under earthquake load. The system comprises an anchorage system, a load system and a measurement system. The anchorage system is composed of a test box, a similar rock-soil layer, an anchorage body and a steel strand; the load system comprises a static load system and a dynamic load system; and the measurement system comprises a precision dynamometer, an angle measuring device, a miniature pressure box, a laser range finder and a sound wave vibration meter. The specific operation of the test system comprises the steps of manufacturing a test model, arranging a monitoring system, loading the test model, debugging the monitoring system, testing a model test and recording data. Dynamic measurement of dynamic response data such as internal force, displacement and vibration speed of the anchorage body and surrounding rock-soil bodies of the anchorage body in the dynamic load loading process is achieved, and a test basis and a research method are provided for further revealing gravity type anchorage stability evaluation under the earthquake load effect.

Owner:四川路桥华东建设有限责任公司

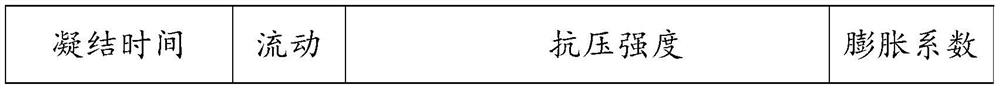

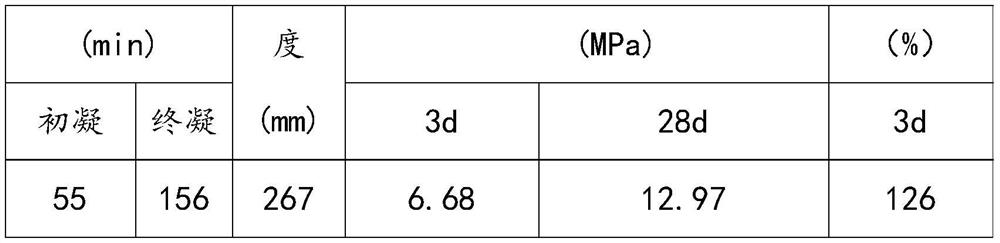

Solid waste foundation grouting material suitable for reinforcing bearing capacity of existing pile foundation and preparation method

The invention discloses a solid waste foundation grouting material suitable for reinforcing the bearing capacity of an existing pile foundation and a preparation method of the solid waste foundation grouting material. Red mud is adopted as a main material and cooperates with other multi-source solid waste, potassium hydroxide, carbide slag and quick lime are adopted as excitants, and the multi-source solid waste foundation grouting material suitable for reinforcing the bearing capacity of an existing pile foundation of reconstruction and extension engineering is prepared. The preparation method is simple, and the prepared grouting material is short in setting time, high in early strength, large in expansion coefficient, high in pile-soil interface cementing strength, suitable for reinforcing the bearing capacity of an existing pile foundation, capable of guaranteeing safety construction of highway reconstruction and extension projects, relieving solid waste stacking pressure and solving the problem of environmental pollution caused by red mud and suitable for large-scale popularization and application. And high-added-value comprehensive utilization of solid waste is promoted.

Owner:SHANDONG UNIV +1

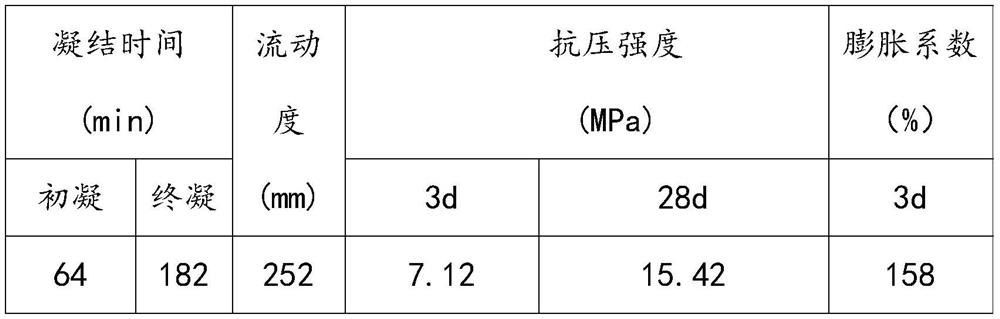

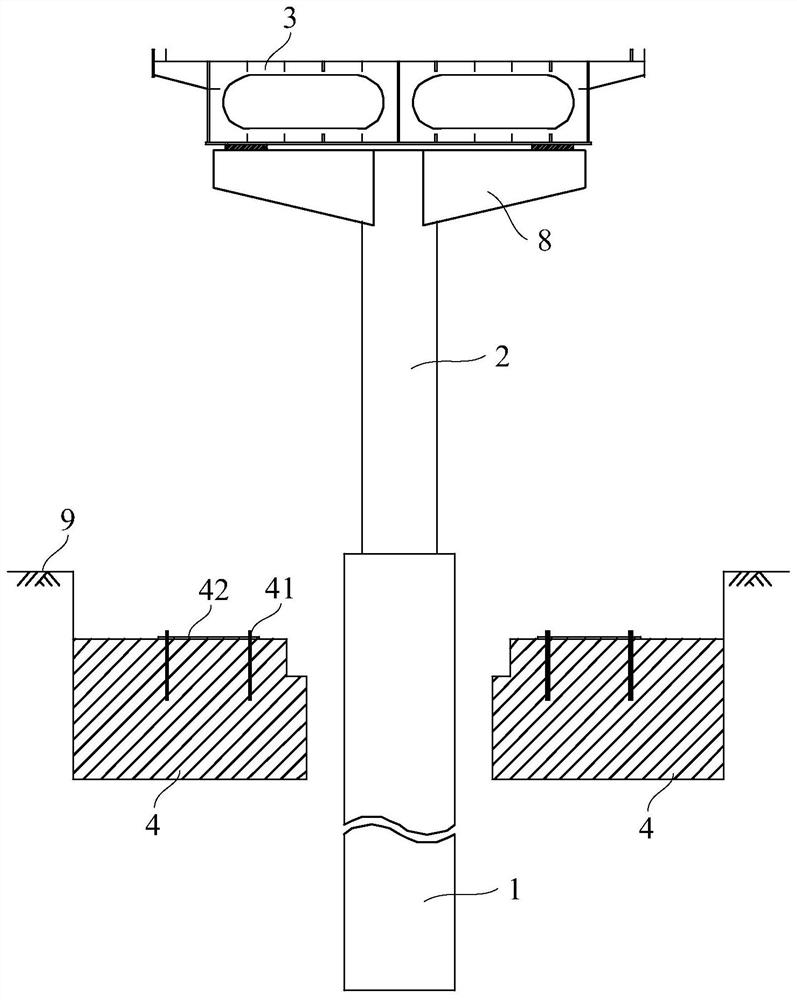

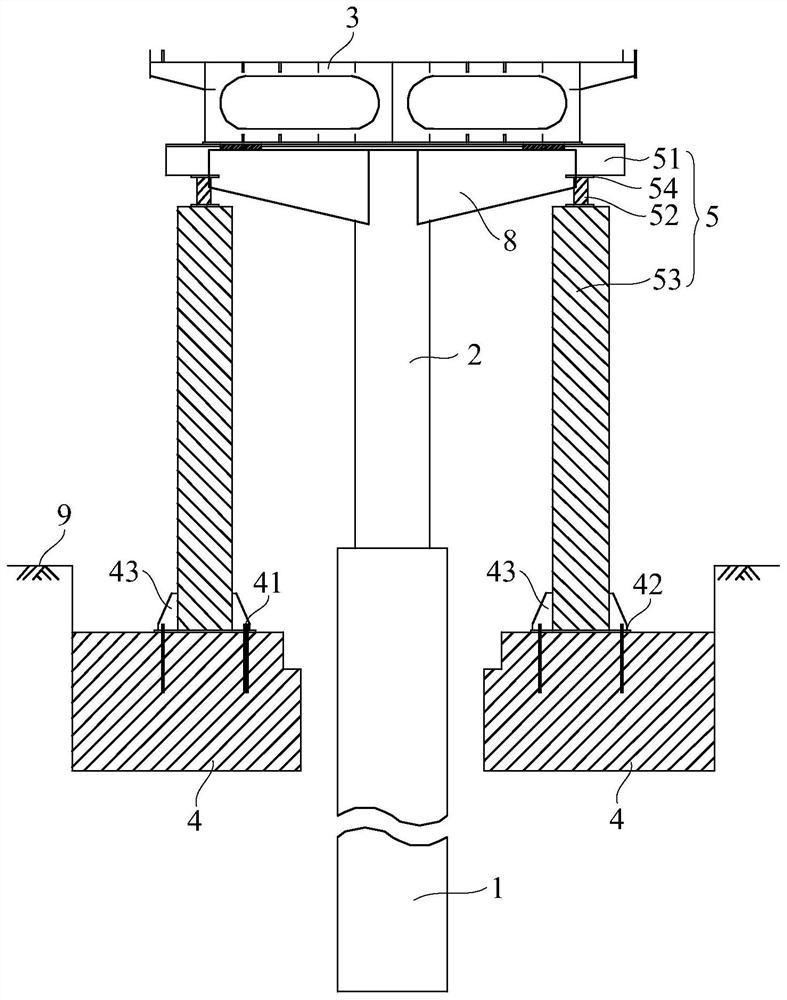

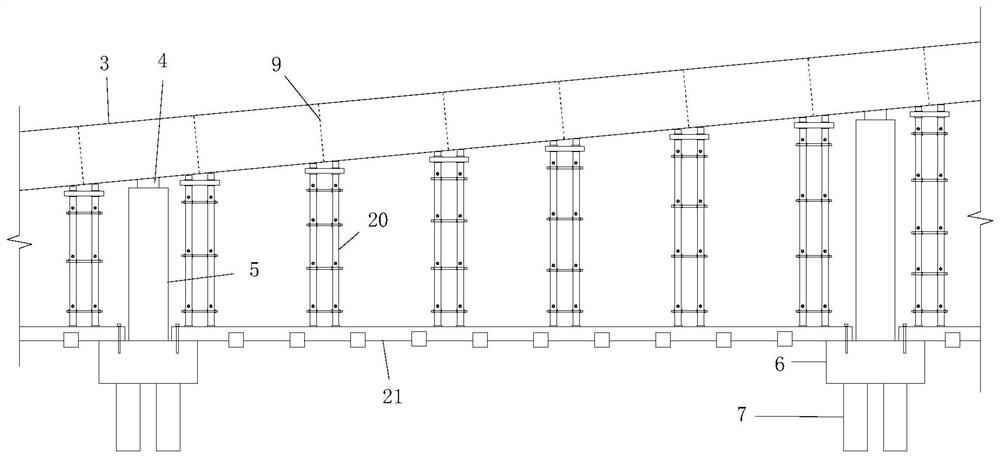

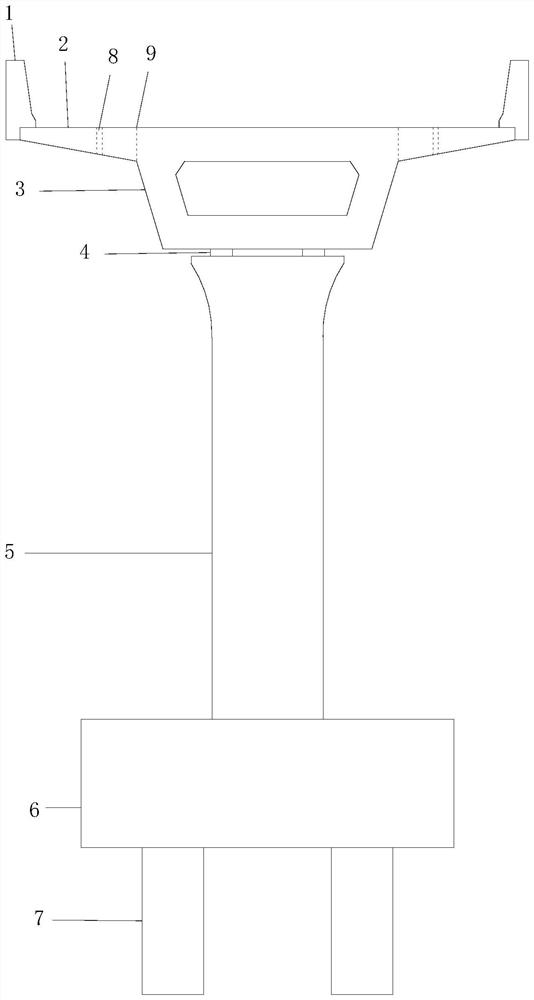

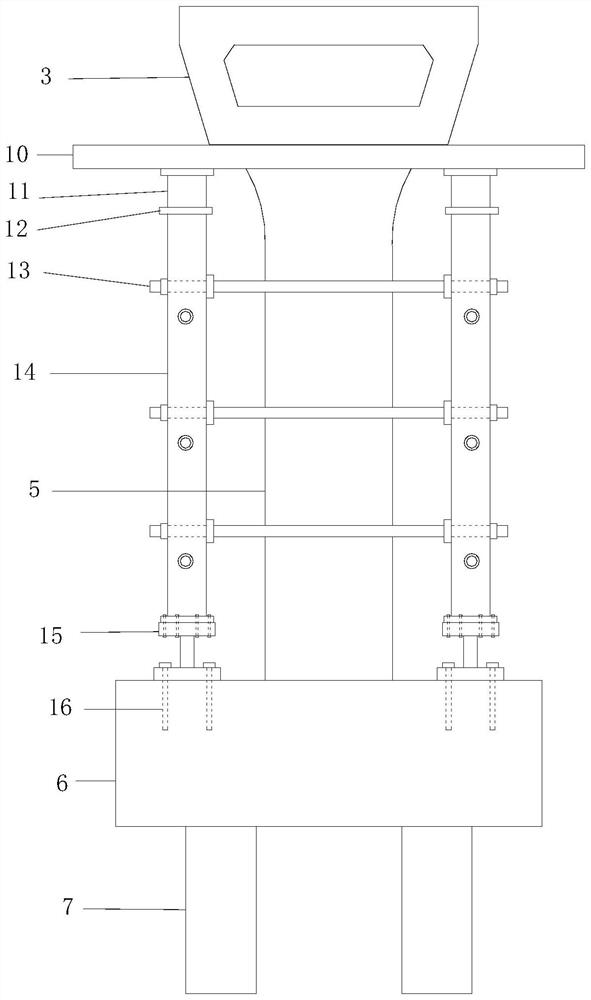

Pile foundation conversion method and structure for bridge

PendingCN111636464AAchieve structural adjustmentImprove stabilityBridge structural detailsFoundation engineeringArchitectural engineeringPier

The invention relates to the technical field of constructional engineering, in particular to a pile foundation conversion method and structure for a bridge. The pile foundation conversion method comprises the steps that expanded pile foundations are newly built on the two sides of an existing pile foundation, and the two expanded pile foundations are arranged in the width direction of the bridge;a temporary supporting structure is constructed between the expanded pile foundations and a main beam; an existing pier column and the existing pile foundation are dismantled; and a pile foundation isnewly built between the two expanded pile foundations, a pier column is newly built between the newly-built pile foundation and the main beam, and the newly-built pile foundation and the expanded pile foundations are connected into a whole. The pile foundation conversion method can be completed before subway crossing on site, has the advantages of being convenient to construct and easy to convert, can break the original pile foundation conflicting with a subway interval structure, avoids adverse effects on a subway structure, and meanwhile solves the problem that the existing bridge pile foundation is insufficient in bearing capacity.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

Reinforcing device for reinforcing steel member in communication tower

PendingCN109653528AImprove carrying capacityEasy to installBuilding repairsTowersCarrying capacityEngineering

The invention discloses a reinforcing device for reinforcing a steel member in a communication tower. The reinforcing device comprises a first reinforcing body and a second reinforcing body. The firstreinforcing body is detachably connected with the second reinforcing body through a connecting mechanism, and while the first reinforcing body is connected with the second reinforcing body, the firstreinforcing body and the second reinforcing body are oppositely arranged and a holding cavity for holding the steel member is formed between two parties. An inner contour shape of the holding cavityis matched with an outer contour shape of the steel member, so that in a reinforcing state of the steel member, the inner wall of the holding cavity contacts with the outer wall of the steel member. Alength of the holding cavity is matched with a length of the steel member, so that in the reinforcing state of the steel member, the length of the holding cavity is greater than 2 / 3 of a total lengthof the steel member. The reinforcing device is capable of solving a problem that carrying capacity of an original steel member of the communication tower is not enough, and conveniently installing, and providing a type of guarantee for using stock communication tower resources better.

Owner:ANHUI TELECOMM PLANNING & DESIGNING

Up ramp dismantling system and construction method

ActiveCN114319159AAvoid pollutionSolve the lack of carrying capacityUsing liquid separation agentClimate change adaptationButtressArchitectural engineering

The invention relates to an ascending ramp dismantling system and a construction method thereof. According to the scheme, the ascending ramp dismantling system comprises a temporary buttress system and a construction fence spraying system; the temporary buttress system comprises a steel pipe support and a support foundation. The steel pipe support comprises a main beam, a distribution beam, steel pipe stand columns and high-strength split bolts. The support foundation comprises a foundation longitudinal beam with the top connected with the steel pipe stand column and a longitudinal beam sleeper fixed to the bottom of the foundation longitudinal beam through a connecting part, and the foundation longitudinal beam is fixed to the bearing platform through an anchor bolt. The construction fence spraying system comprises fence stand columns fixed to the ground, fences arranged between every two adjacent fence stand columns and pipelines arranged at the tops of the fence stand columns and the fences. The fence stand columns and the fence form a circle of construction fence, and a temporary opening is formed in any side of the construction fence. A plurality of water mist nozzles facing the interior of the construction fence are arranged on the pipeline. The construction method has the advantages that the dismantling difficulty and the dismantling cost are reduced, the construction period is shortened, and accumulated water pollution is avoided.

Owner:杭州萧山交通建设管理有限公司

High-rigidity three-translation redundant drive parallel mechanism

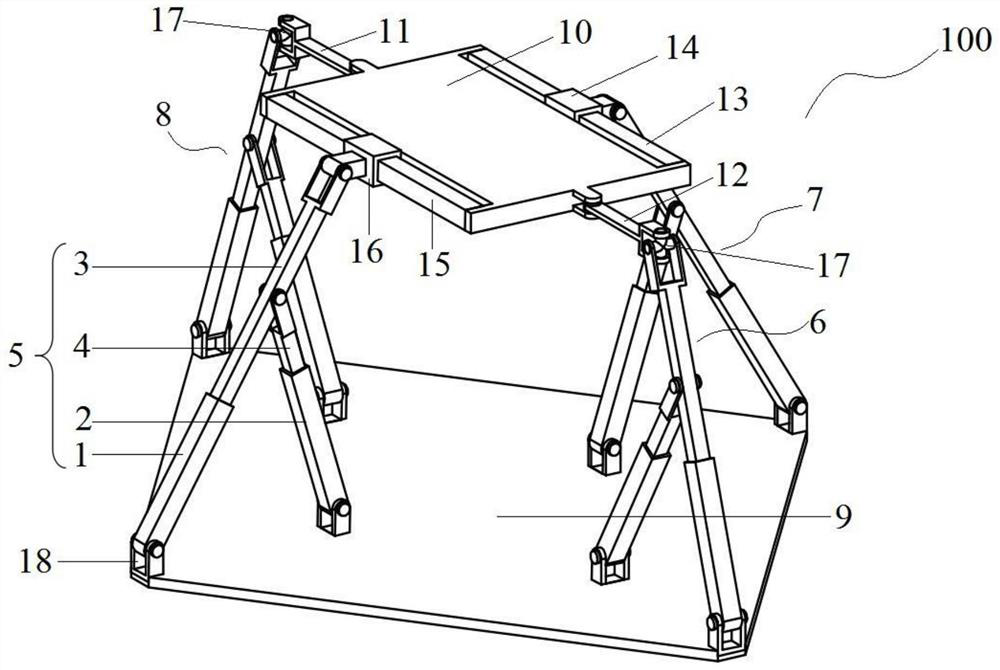

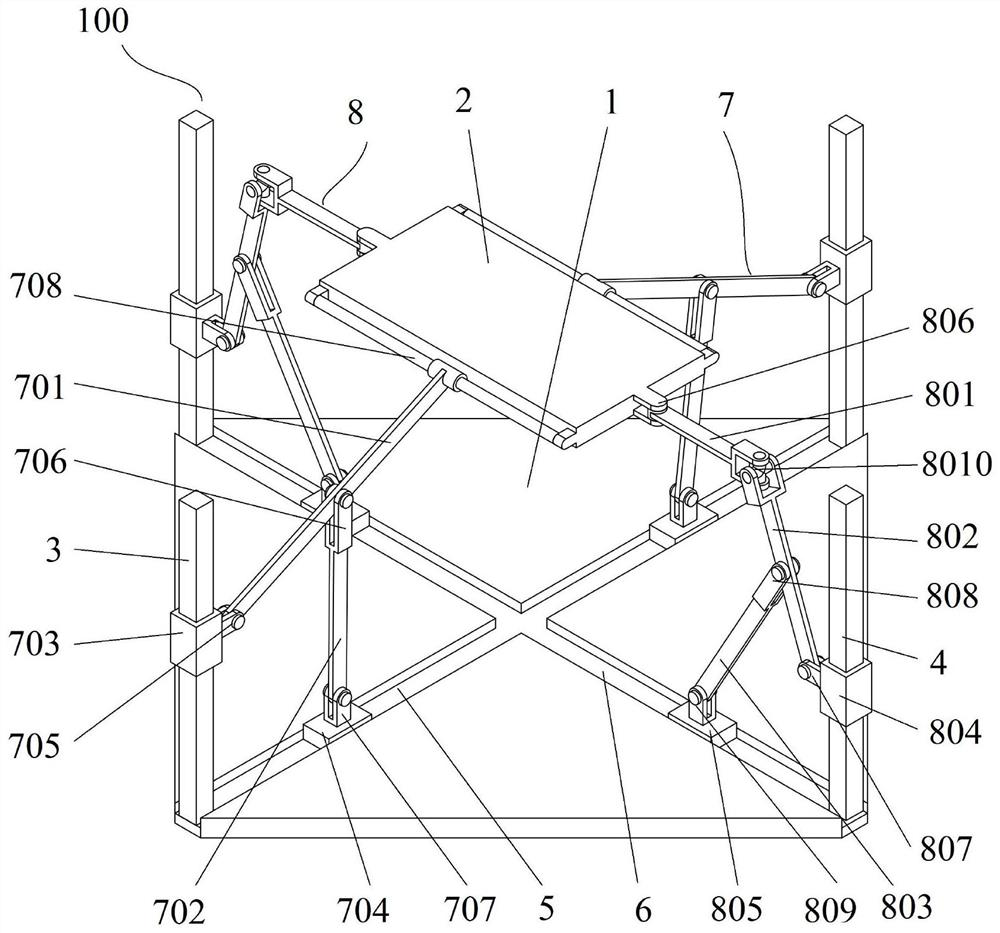

InactiveCN113370189AIncrease stiffnessImprove carrying capacityProgramme-controlled manipulatorStructural engineeringMechanical engineering

The invention discloses a high-rigidity three-translation redundant drive parallel mechanism which comprises a fixed platform, a movable platform and four branch chain units. Each branch chain unit comprises a first connecting rod, a second connecting rod, a third connecting rod and a fourth connecting rod; the bottom end of each first connecting rod and the bottom end of each second connecting rod are hinged to the fixed platform; each third connecting rod is in sliding fit with the corresponding first connecting rod; each fourth connecting rod is in sliding fit with the corresponding second connecting rod; the top end of each fourth connecting rod is hinged to the middle of the corresponding third connecting rod; the two non-adjacent side edges of the movable platform are each provided with a middle connecting rod in a hinged mode; the other two non-adjacent side edges of the movable platform are each fixedly provided with a fixing rod; each fixing rod is provided with a sliding block in a sliding mode; the two branch chain units are hinged to the two sliding blocks correspondingly; and the other two branch chain units are rotationally connected with the two middle connecting rods correspondingly. According to the high-rigidity three-translation redundant drive parallel mechanism provided by the invention, the rigidity and the bearing capacity of the three-translation parallel mechanism are improved.

Owner:YANSHAN UNIV

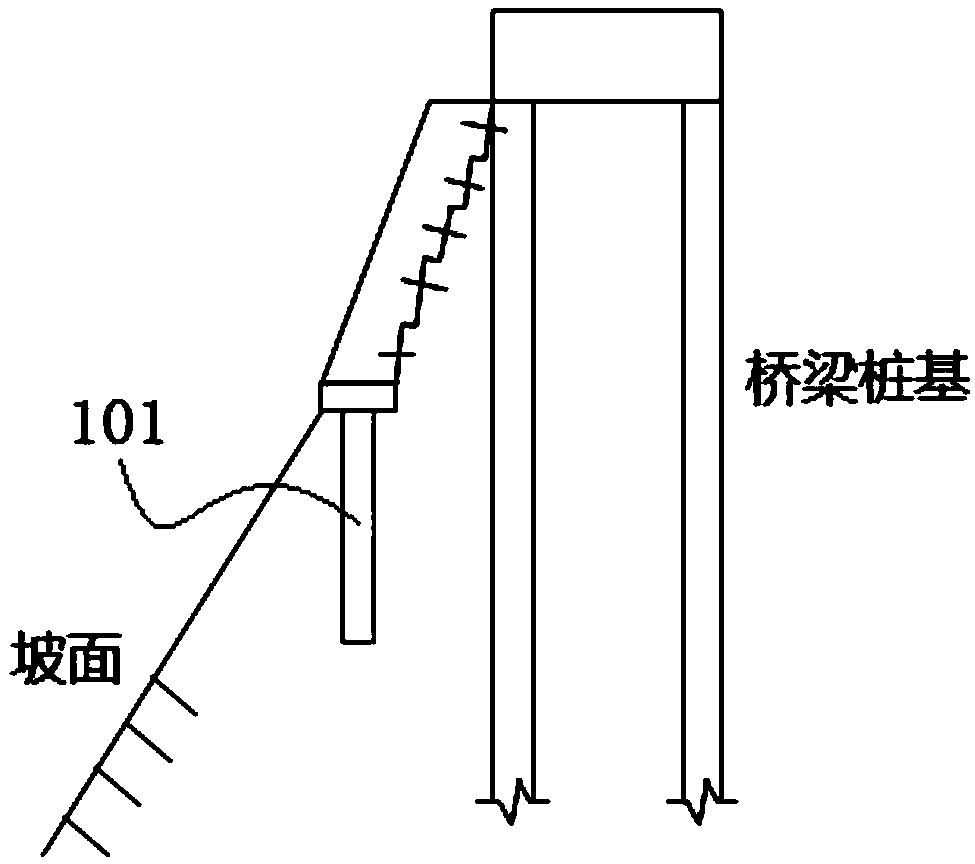

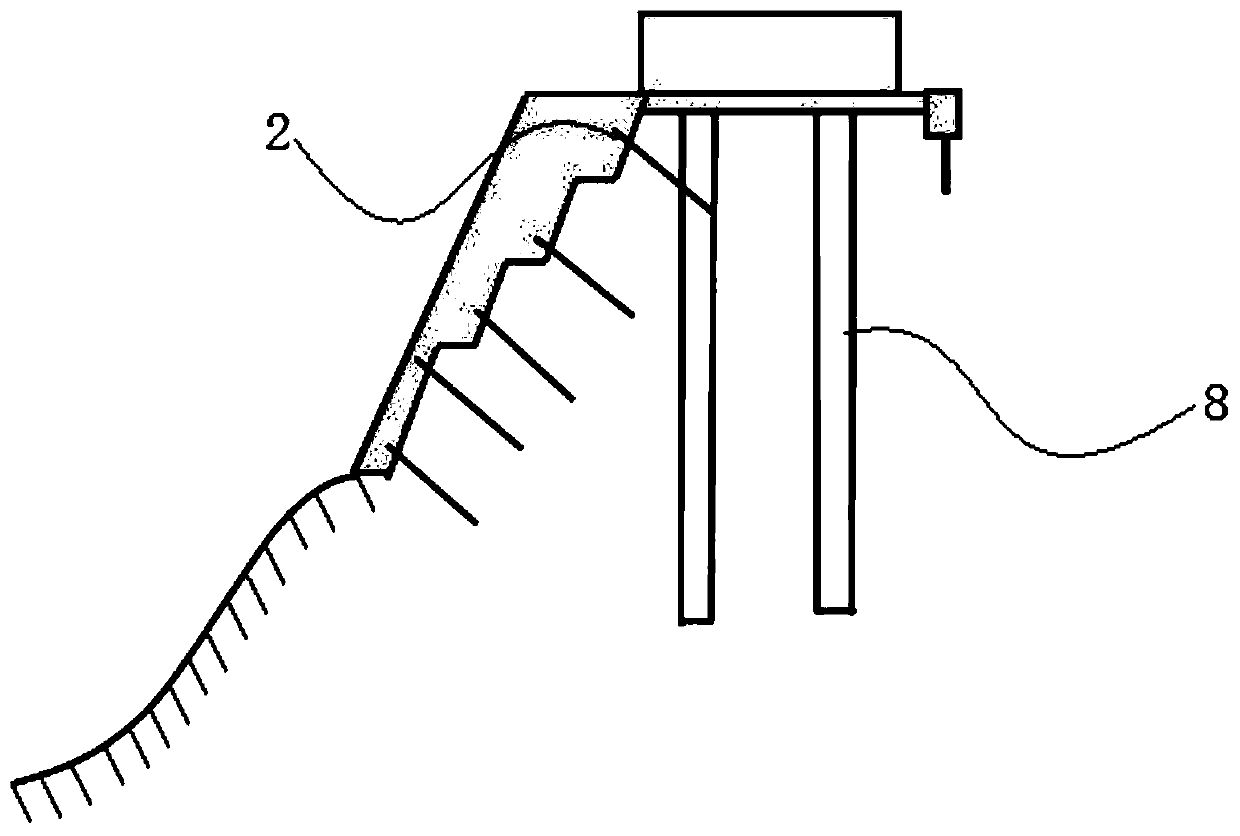

Wall-mounted draining anchor rod barricade structure and construction method thereof

ActiveCN109577277AAdvanced technologyImprove economyArtificial islandsClimate change adaptationEngineeringWall mount

The invention provides a wall-mounted draining anchor rod barricade structure and a construction method thereof. The barricade structure comprises a longitudinal beam embedded in the top of a bank slope, a barricade and an anchor rod. The barricade is arranged at a by-water side of the bank slope. The longitudinal beam is positioned at a fundamental inner side of a protected bridge pile foundation. A plurality of cross beams is connected between a barricade body and the longitudinal beam. The construction method for the barricade structure comprises steps of constructing the anchor rod, constructing a draining hole, constructing the barricade, constructing an anchor pile, constructing the longitudinal beam, constructing the cross beams and installing a cut-off valve and the like. The barricade structure is capable of effectively solving problems existing in a large-scale reservoir hydro-fluctuation belt bank side cleugh area bridge pile foundation protecting technology, and advanced intechnology, and well in economy.

Owner:CHONGQING JIAOTONG UNIVERSITY

Three-translation redundant drive parallel mechanism comprising closed-loop units

InactiveCN113386111AIncrease stiffnessStrong rigidityProgramme-controlled manipulatorControl engineeringStructural engineering

The invention discloses a three-translation redundant drive parallel mechanism comprising closed loop units, and relates to the technical field of robots. The three-translation redundant drive parallel mechanism comprises a fixed platform, a movable platform, two first branch chains and two second branch chains, wherein two first horizontal slide rails, two second horizontal slide rails, two first vertical slide rails and two second vertical slide rails are arranged on the fixed platform, the movable platform is located above the fixed platform, the two first branch chains are symmetrically arranged on the two sides of the movable platform, and the two second branch chains are symmetrically arranged on the other two sides of the movable platform. The first branch chains and the second branch chains each comprise the closed loop unit, so that the structure is compact, the rigidity is high, eight moving pairs are arranged in the two first branch chains and the two second branch chains in total, the moving pairs are all driving pairs, and the eight driving pairs drive the movable platform to achieve translational motion in three spatial directions relative to the fixed platform, so that redundant drive is achieved, the bearing capacity, driving stability and overall rigidity of the mechanism are improved, and control is convenient.

Owner:YANSHAN UNIV

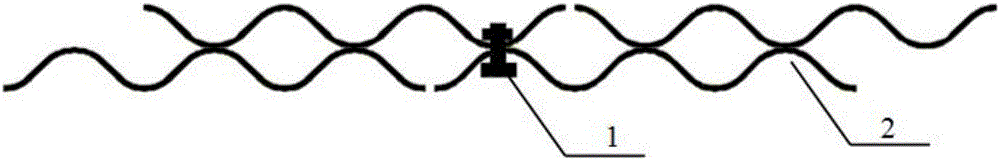

U-shaped assembling type double-wall corrugated closed steel corrugated culvert pipe

PendingCN106120583AAdapt to deformationSolve the problem of culvert damageGround-workDouble wallUltimate tensile strength

A U-shaped assembling type double-wall corrugated closed steel corrugated culvert pipe comprises closed double-wall corrugated pipe segments. Each closed double-wall corrugated pipe segment is composed of two corrugated shaped steel plates, and the two corrugated shaped steel plates are welded to form the closed double-wall corrugated pipe segment and serve as an outer wall and an inner wall of the corresponding closed double-wall corrugated pipe segment respectively; three closed double-wall corrugated pipe segments are mutually spliced to form a U-shaped pipe ring, the outer walls and the inner walls of every two adjacent closed double-wall corrugated pipe segments are mutually spliced, and the splicing positions are fixed through a row of bolts; and multiple U-shaped pipe rings are mutually spliced to form an integral corrugated culvert pipe. The U-shaped assembling type double-wall corrugated closed steel corrugated culvert pipe has the characteristic of high strength, uniform stress and the like, as a reinforcement body of a culvert, when being compared with the reinforcement of a concrete square culvert, the U-shaped assembling type double-wall corrugated closed steel corrugated culvert pipe has the advantages of being large in sectional area and small in occupied original culvert space, is especially suitable for the reinforcement of the square culvert, can be used as a lining, and is worth popularizing.

Owner:河北驰特轨道交通设备有限公司

Grouting system for enhancing bearing capacity of offshore wind power pile foundation and construction method

InactiveCN112900440ASolve the lack of carrying capacityImprove bearing capacityBulkheads/pilesOffshore wind powerSeabed

The invention provides a grouting system for enhancing the bearing capacity of an offshore wind power pile foundation and a construction method. The grouting system comprises a pipeline installation structure used for installing the grouting system, the grouting system comprises a pile side grouting system used for conducting grouting on the outer side wall of a cast-in-place pile and a pile bottom grouting system used for conducting grouting on the pile bottom of the cast-in-place pile, the pile side grouting system is connected to the grouting system, grout is injected into a pile side gap between the outer side wall of the cast-in-place pile and a seabed foundation layer, the pile bottom grouting system is connected to the grouting system and injects the grout into a pile bottom gap between the pile bottom of the cast-in-place pile and the seabed foundation layer. By the adoption of the grouting system, secondary grouting can be conducted after pouring of the cast-in-place pile is completed, permeation and splitting effects are generated on a pile body and a nearby soil body through the grout, then solidification is conducted, and therefore the effect of increasing the bearing capacity is achieved.

Owner:CHINA THREE GORGES NEW ENERGY CO LTD +1

Roadbed protection structure

PendingCN111893829AImprove stabilityImprove carrying capacityRoadwaysRailway tracksArchitectural engineeringStructural engineering

The invention discloses a roadbed protection structure, the roadbed is located between an existing railway and an existing building, the protection structure comprises a plate girder, the plate girderis laid on the roadbed, and the plate girder has an optimization effect on the stress load of the roadbed; and micro piles which are arranged below the plate girder, at least part of the micro pilesare located in the plate girder, and the micro piles provide supporting force for the plate girder. The roadbed protection structure has the advantages of being high in bearing capacity and high in stability.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

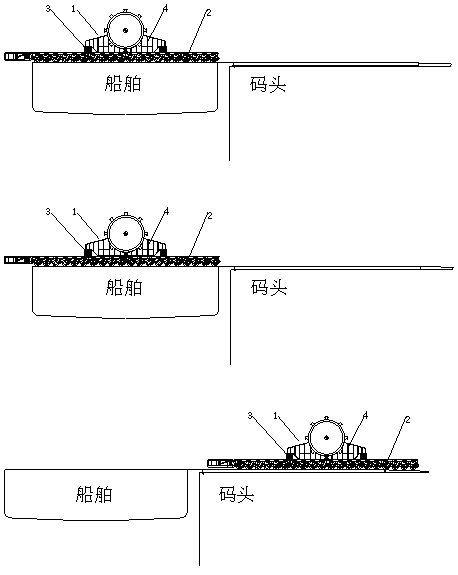

Transverse rolling loading method for chemical tower device

ActiveCN110451081ASolve the problem that the width of the water area is insufficient and the normal berthing operation cannot be carried outEasy replacementPackaging vehiclesContainers for machinesButtressMode of transport

The invention provides a transverse rolling loading method for a chemical tower device. The method comprises the steps that a ship is transversely abutted against a wharf; a transport saddle is designed; the chemical tower device is arranged on the transport saddle; yellow sand is laid on the front edge of the wharf; a subgrade box is laid on the yellow sand; a transport cart bears the transport saddle to roll and be unloaded to the wharf; and after the transport saddle reaches the wharf, temporary support is carried out on the transport saddle by the aid of equal-height buttresses, and the loading mode of the transport cart is changed from the transverse loading to the longitudinal loading. According to the method, the ship is transversely abutted against the wharf for butt joint, so thatthe problem that an existing wharf front edge water area is insufficient in width and cannot meet the requirement for longitudinal rolling loading and docking can be solved; the transport saddle which meets the longitudinal transportation mode and the transverse transportation mode of the chemical tower is designed, the transverse rolling loading is carried out on the chemical tower device, a yellow sand layer and the subgrade box are further adopted for cooperation, so that pressure intensity of the transport cart to the ground is evenly distributed, so that the problem of insufficient bearing capacity of the wharf is solved; and the temporary support is carried out by utilizing the buttresses, a supporting point of the transport cart on the transport saddle is changed, so that transportation and reloading can be completed, and the reloading operation is simple and convenient.

Owner:郭斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com