Open caisson foundation and construction method

A construction method and caisson technology, applied in the direction of foundation structure engineering, construction, etc., can solve the problems of low stiffness of pile foundation, requirements of construction site, and difficult construction in deep water areas, etc., and achieve strong vertical bearing capacity and anti-push The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

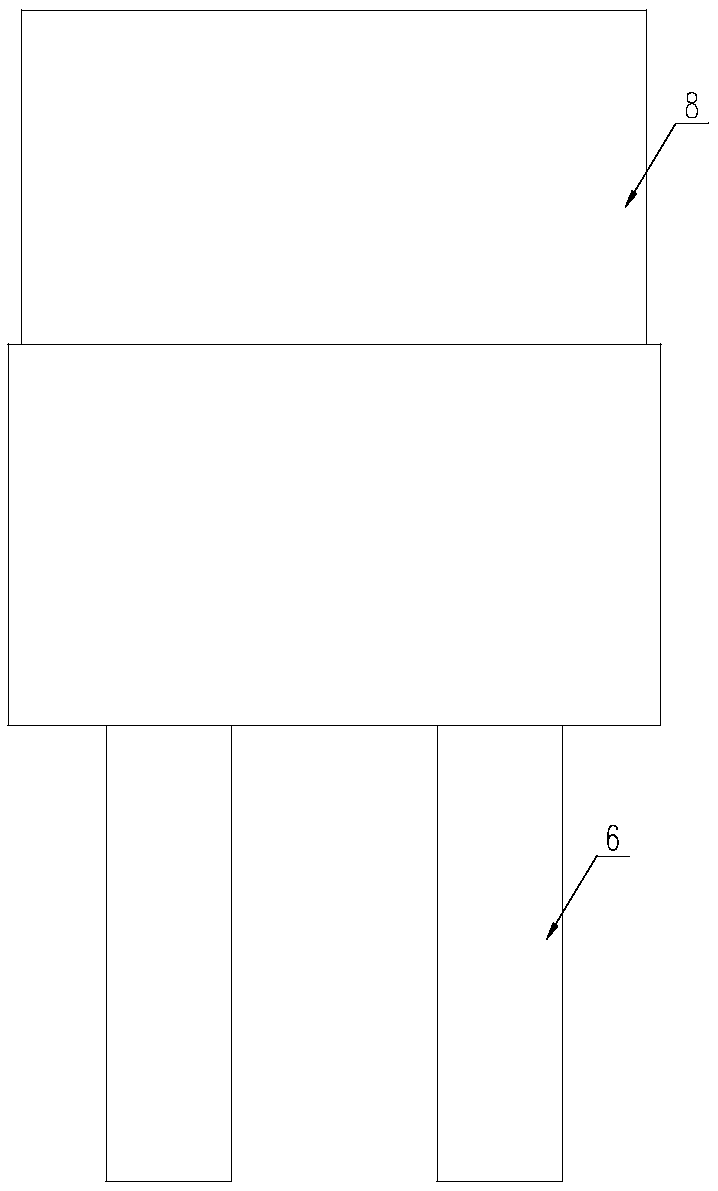

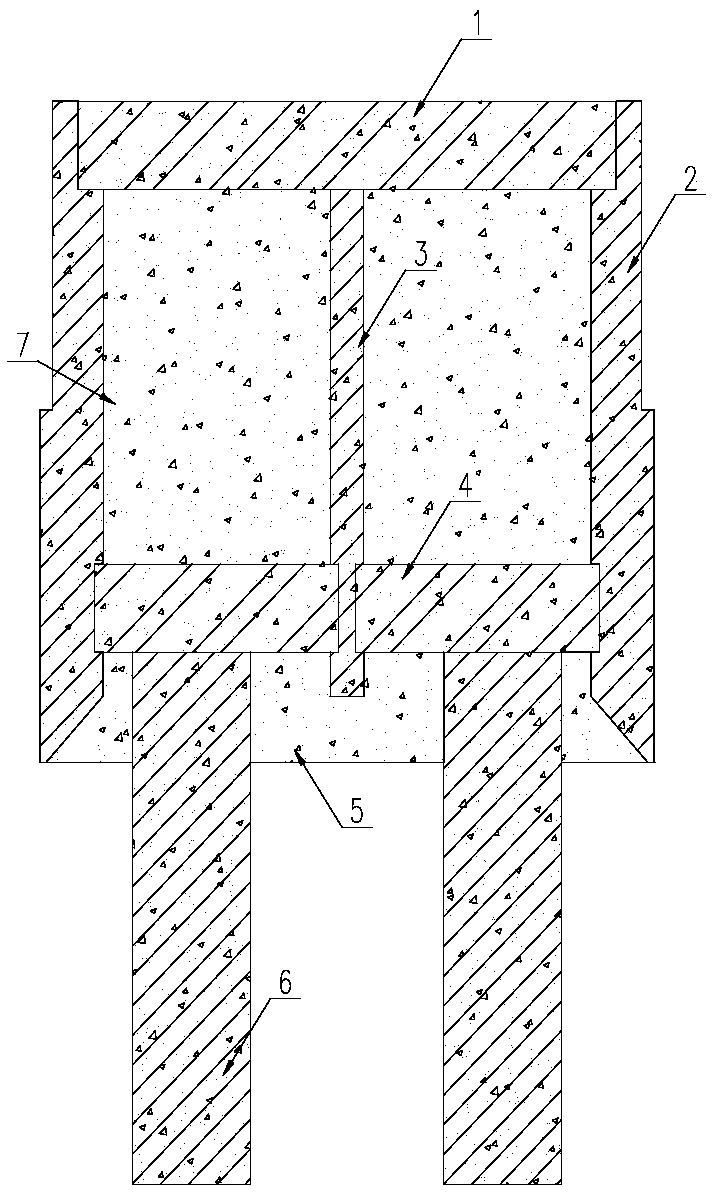

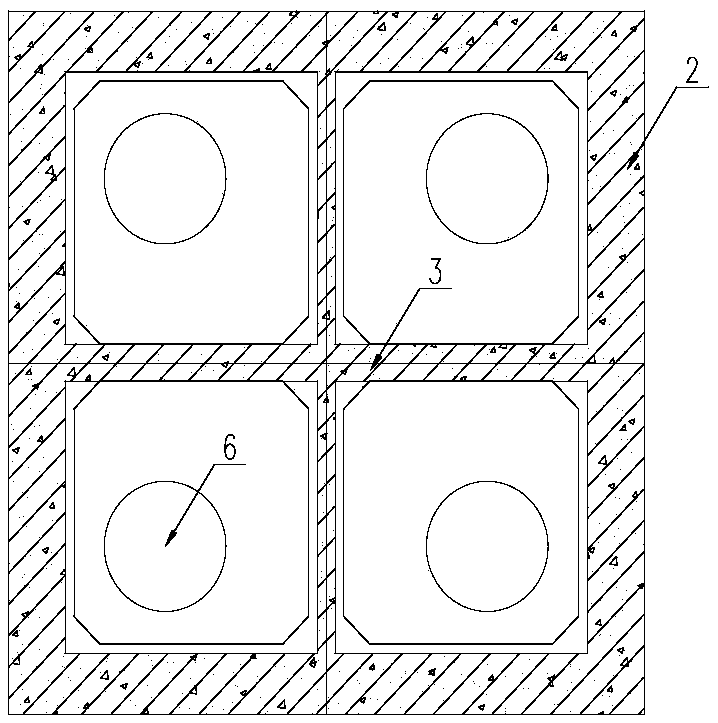

[0041] The "combined caisson foundation and construction technology in deep soft soil foundation" of the present invention is used in deep soft soil foundation. see Figure 1~3 , is a schematic diagram of the foundation of the caisson of the present invention, including a shaft 2, the bottom of which is sealed by a back-sealing concrete 5, and the top of the back-sealing concrete 5 is provided with a cap 4 fixedly connected to the inner wall of the shaft; it also includes vertically distributed concrete Pile foundation 6, the concrete pile foundation 6 is integrally connected with the bearing platform 4 after passing through the back-sealing concrete 5, the bottom-sealing concrete 5 is provided with a hole for the concrete pile foundation 6 to pass through, and the concrete pile foundation 6 is matched with the corresponding hole . The caisson structure 8 is composed of the top cover shaft, the middle partition wall, the bearing platform, the bottom sealing concrete, and the ...

Embodiment 2

[0053] The foundation structure of the caisson in this embodiment is the same as in Embodiment 1, but the construction method is different, specifically: the construction of the concrete pile foundation is preceded by the sinking of the caisson, and after the caisson is in place, the bottom concrete is poured continuously at one time 5 , Cap 4, core-filled concrete 7, to realize the firm connection between the caisson structure 8 and the concrete pile foundation 6. Such as Figure 5 As shown, the specific construction process steps are:

[0054] (a) Punching construction of the concrete pile foundation 6 at the bottom of the caisson, and pouring the concrete pile foundation 6;

[0055] (b) Arrange the vacuum deep well pump well point pipes outside the caisson, carry out pre-dewatering work in advance, and perform compaction grouting on the reinforcement area at the bottom of the caisson;

[0056] (c) The excavation of the foundation pit of the caisson to the lifting elevatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com