Patents

Literature

826results about How to "Clear force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

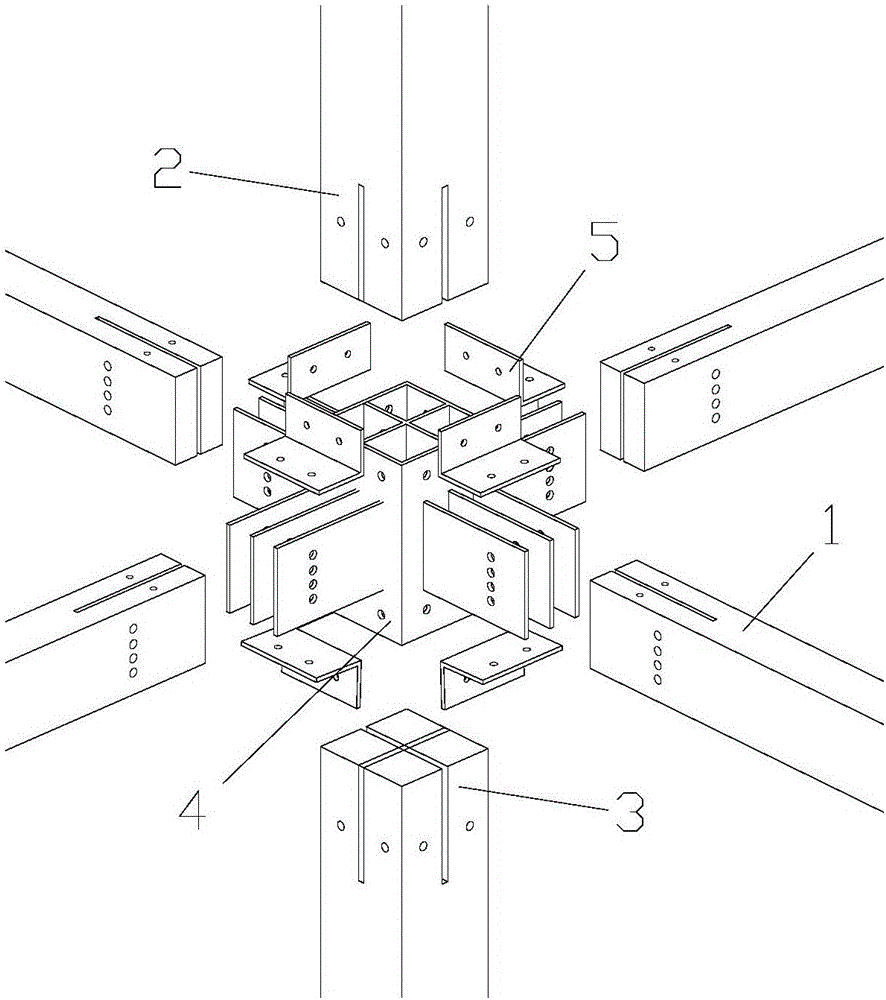

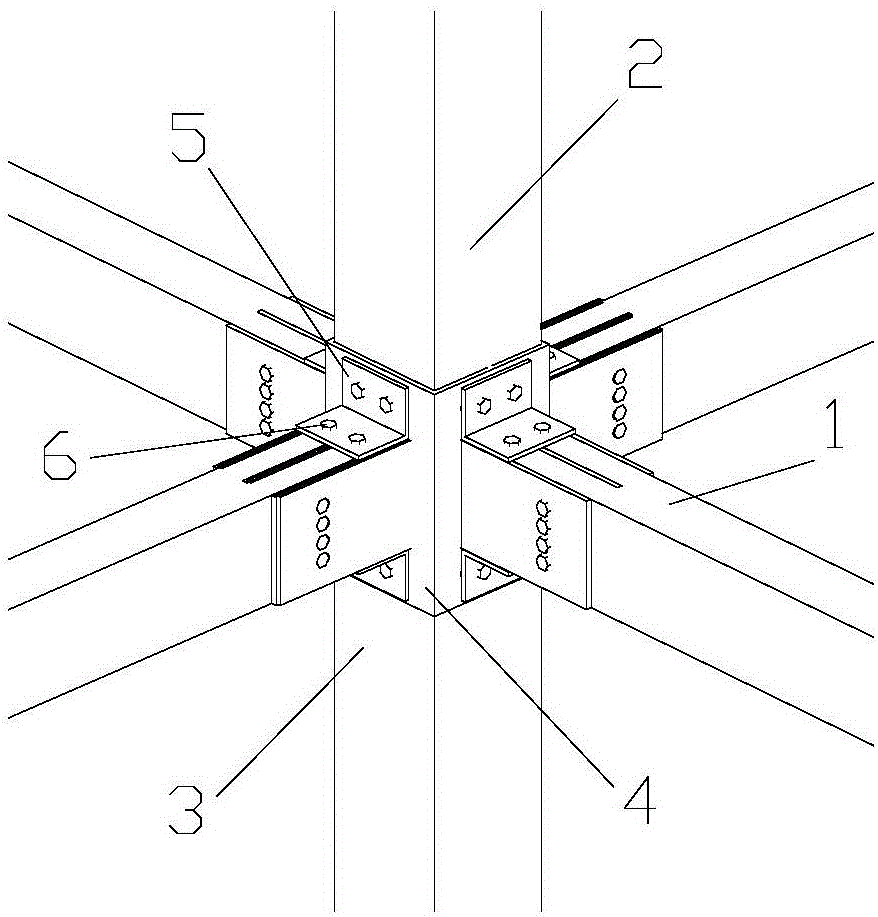

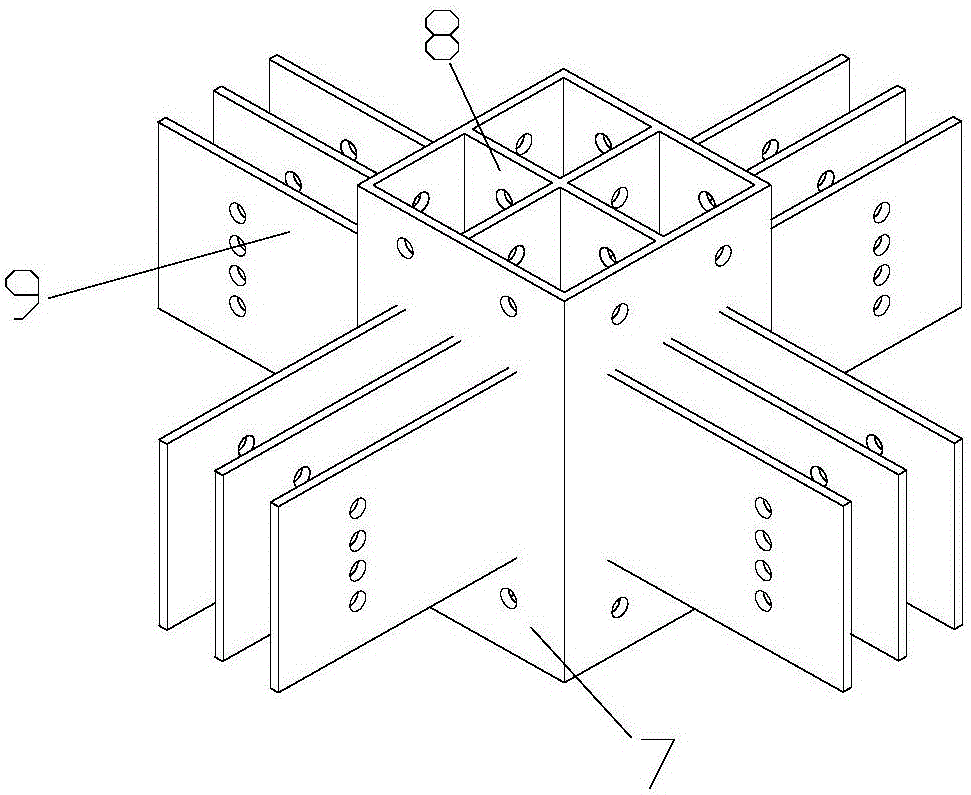

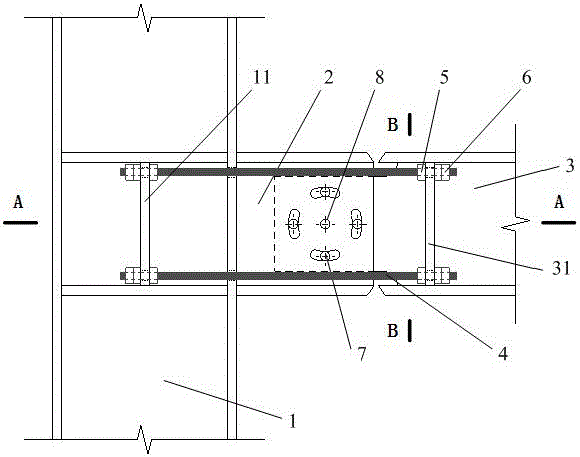

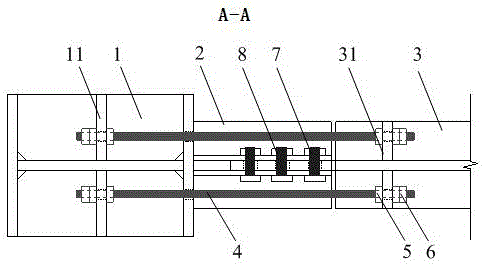

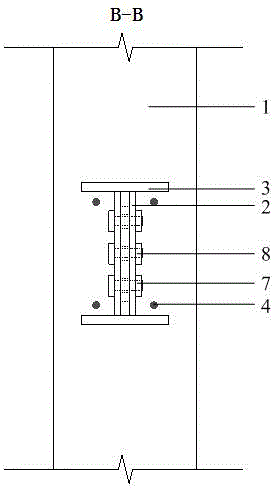

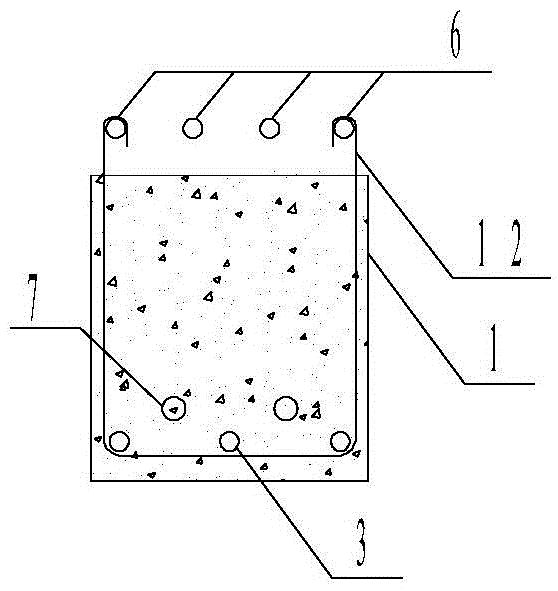

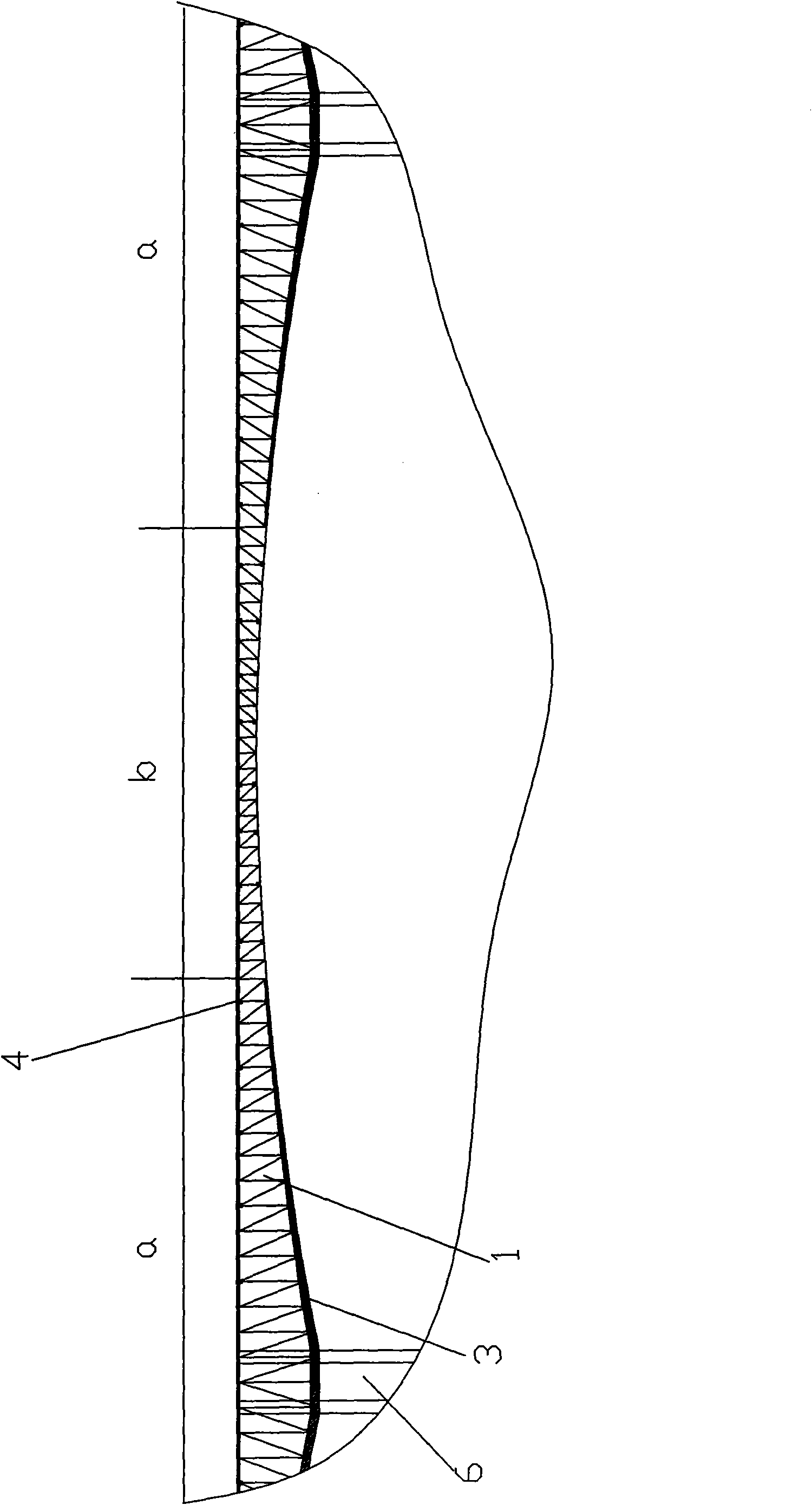

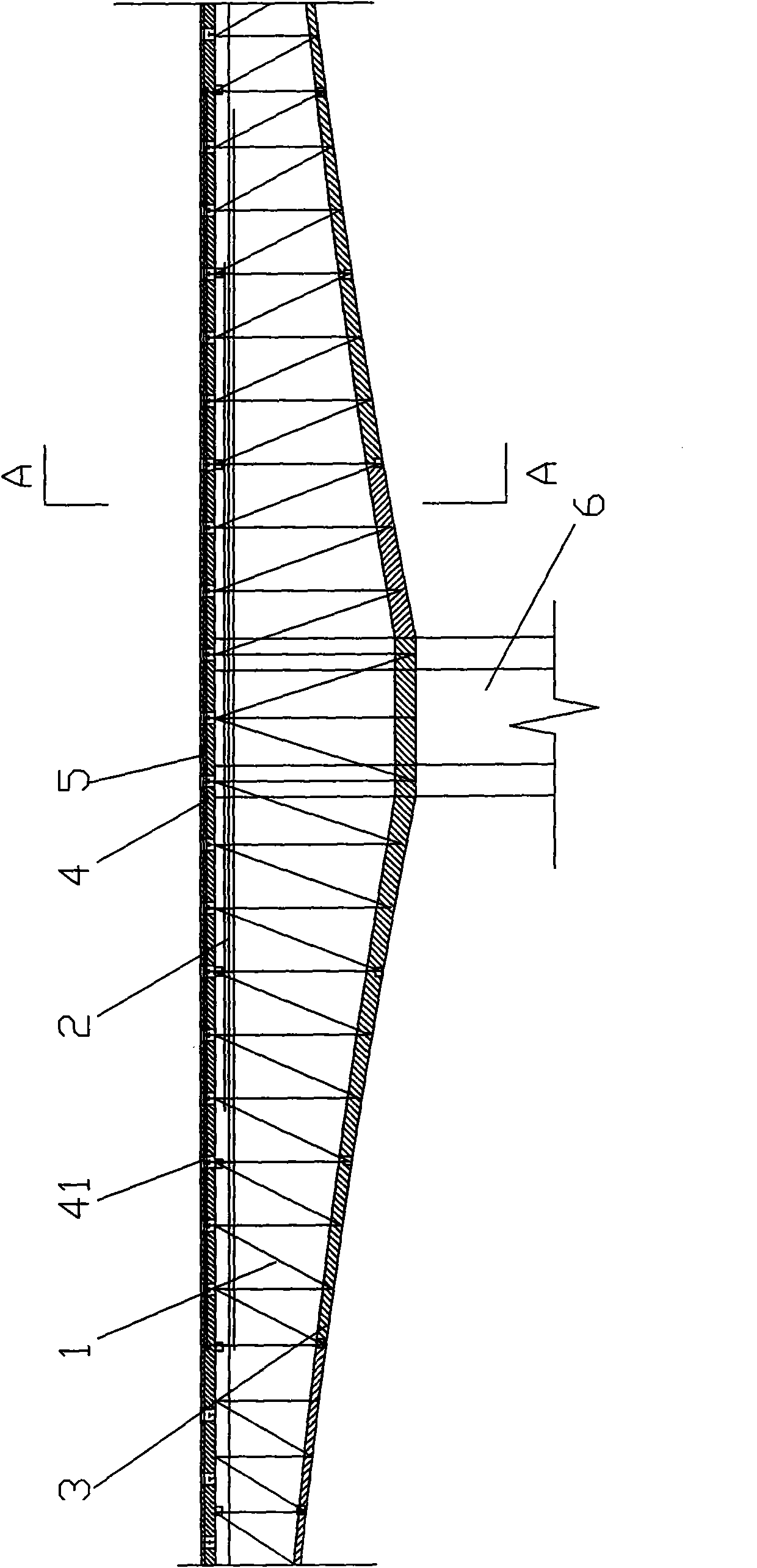

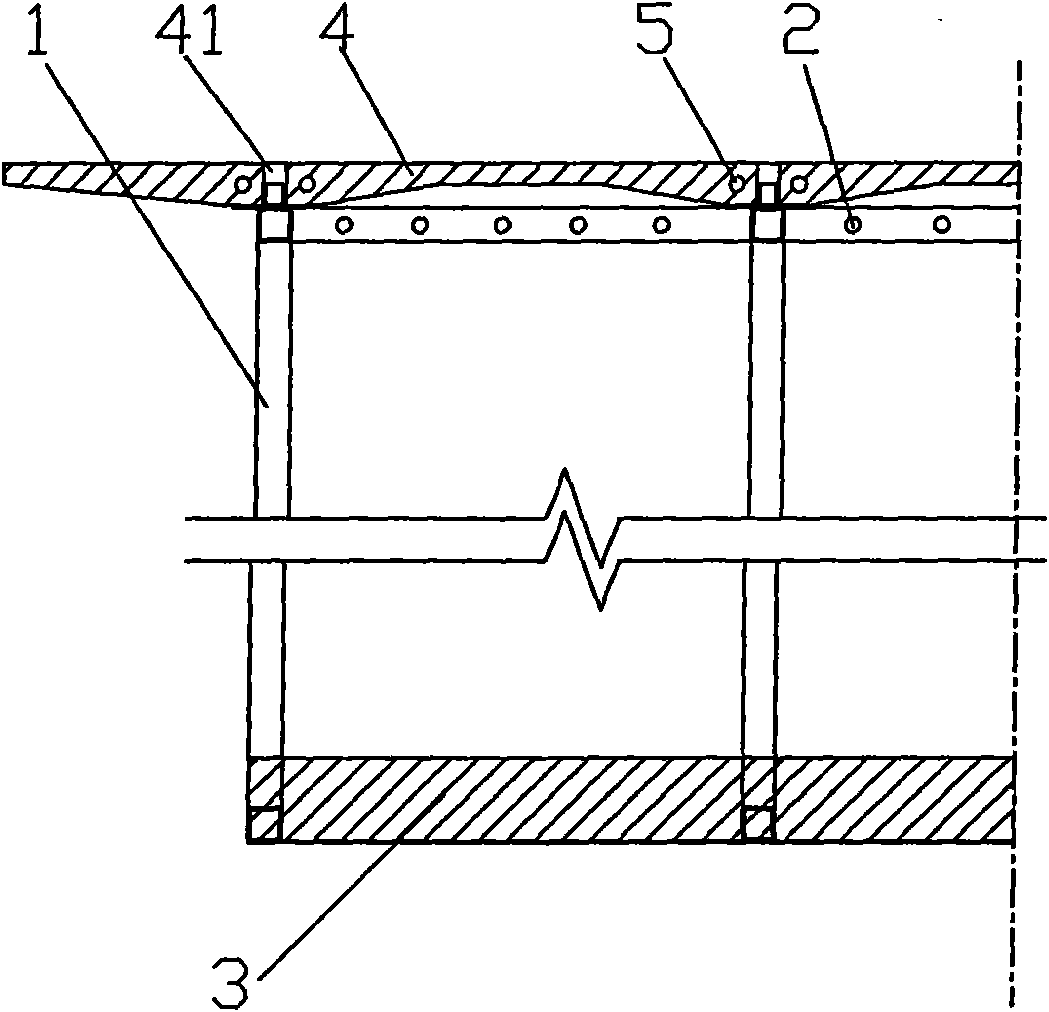

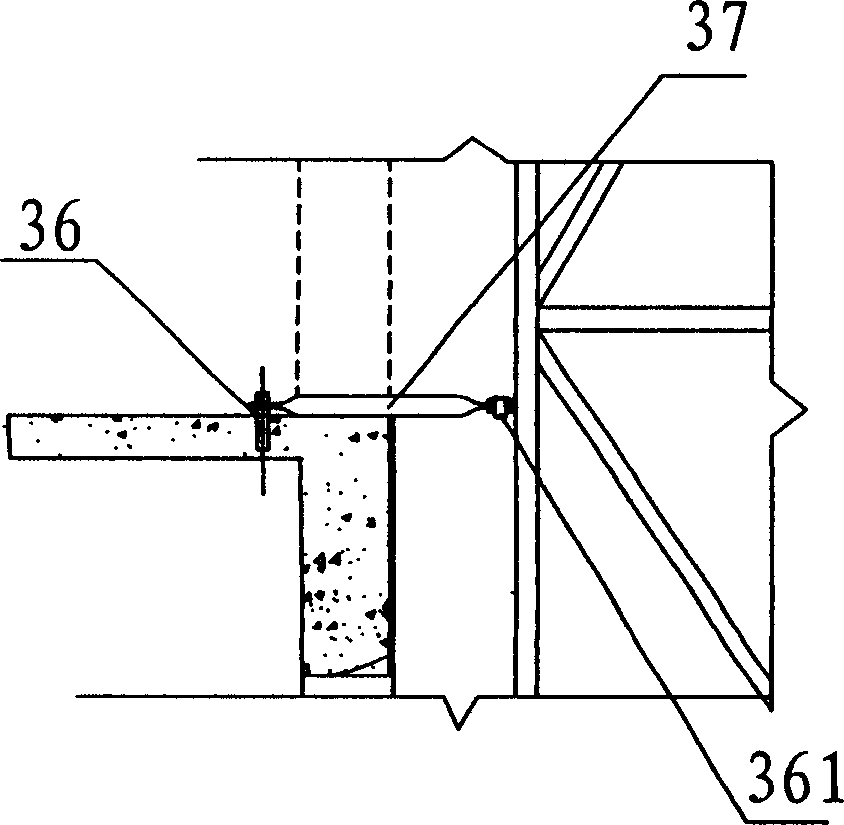

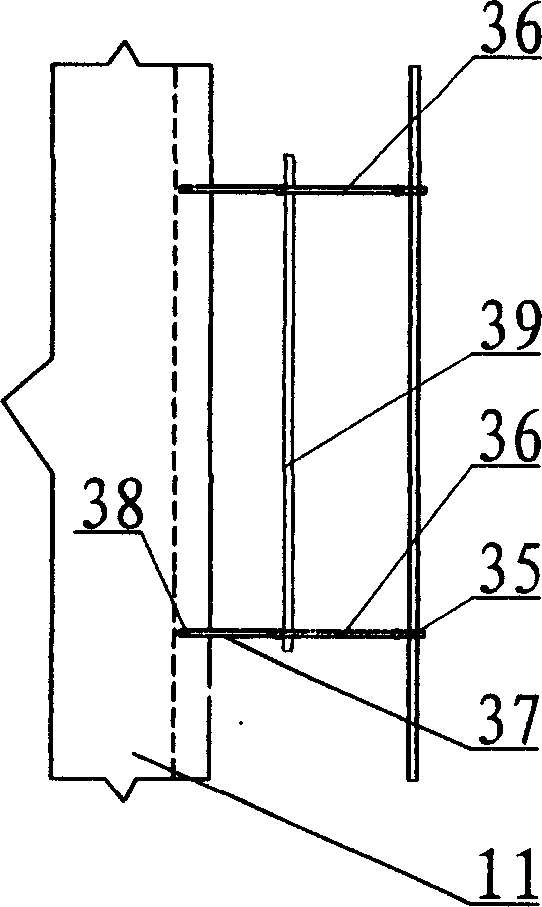

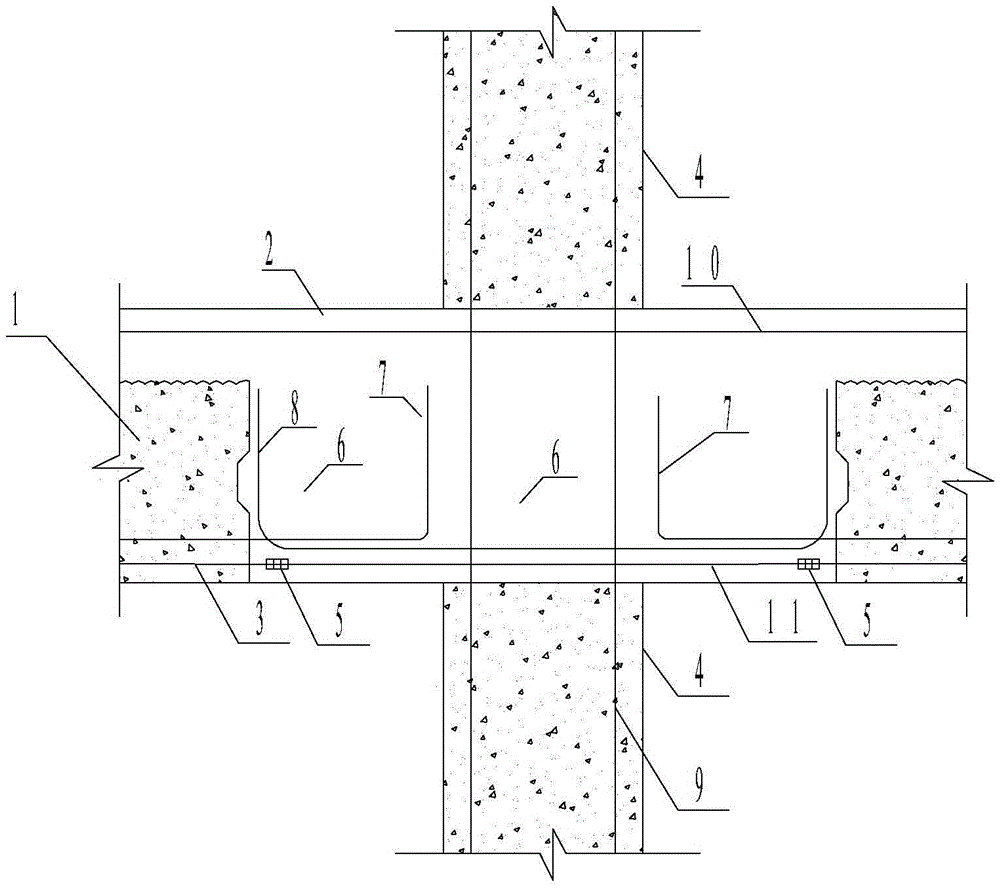

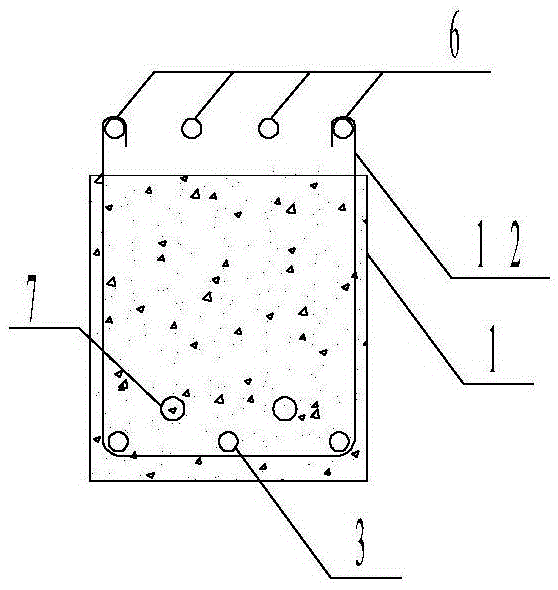

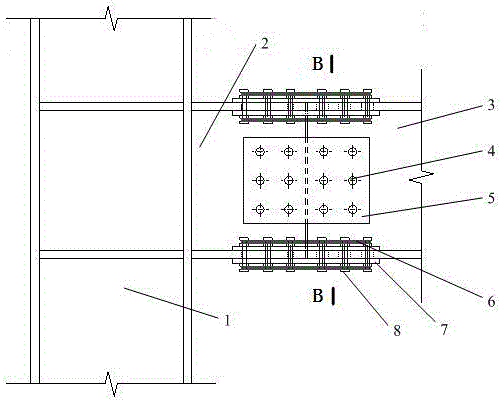

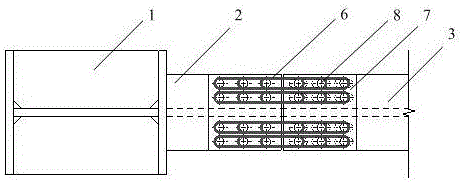

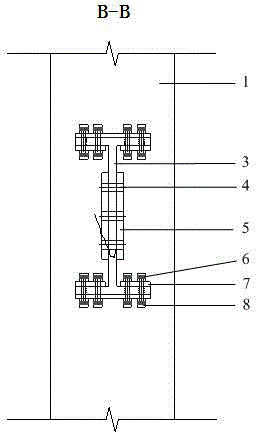

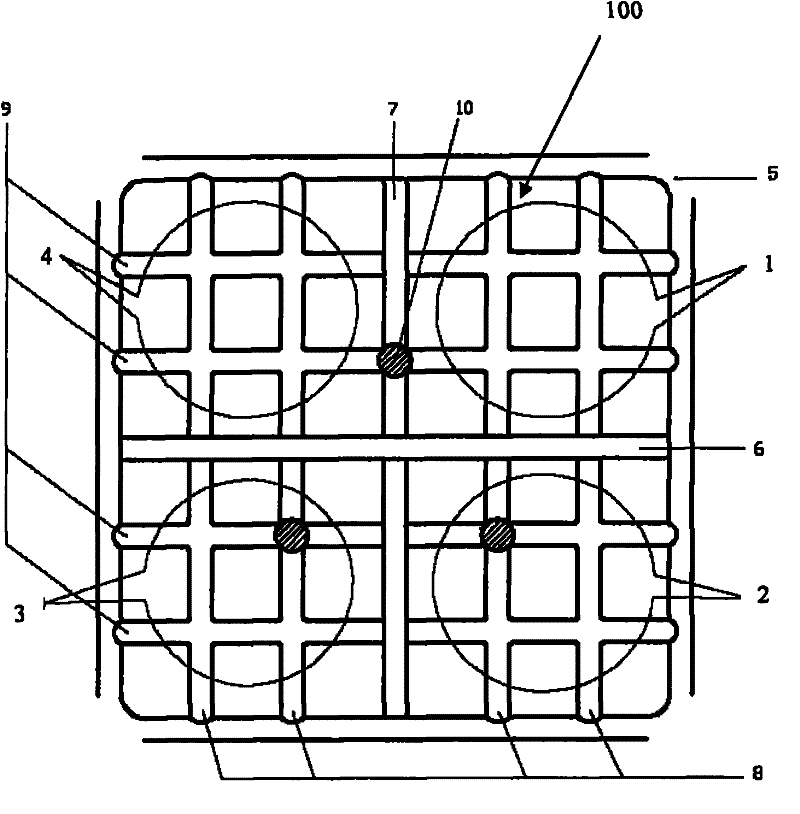

Assembly type wood frame structure beam-column joint with sleeve

InactiveCN106368315AAvoid weakeningIncrease profitBuilding constructionsAgricultural engineeringUltimate tensile strength

The invention discloses an assembly type wood frame structure beam-column joint with a sleeve. The assembly type wood frame structure beam-column joint comprises an upper wood column, a lower wood column, wood beams, a sleeve joint and reinforcing corner pieces. A middle vertical inserting groove is formed in the end of each wood beam. A cross-shaped inserting groove is formed in the upper end of the lower wood column, and a cross-shaped inserting groove is formed in the lower end of the upper wood column. The sleeve joint is provided with a column sleeve; a cross-shaped sleeve longitudinal rib plate and a sleeve middle transverse partition plate are arranged in the column sleeve; and wing type sleeve connecting plates are arranged outside the column sleeve. The column sleeve is arranged at the upper end of the lower wood column in a sleeving mode; the lower end of the upper wood column is inserted into the column sleeve; the ends of the wood beams are inserted into the wing type sleeve connecting plates; and the upper side and the lower side of each wood beam are each provided with a reinforcing corner piece. The reinforcing corner pieces, the sleeve joint, the wood beams and the wood columns are connected through bolts. The assembly type wood frame structure beam-column joint is little in wood consumption, low in manufacturing cost, high in connection strength, easy to manufacture, convenient to construct, definite in stress, and beneficial to the population and the application of assembly type wood frame structures.

Owner:TIANJIN UNIV

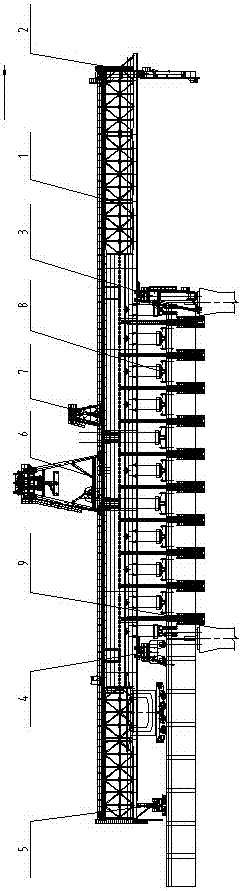

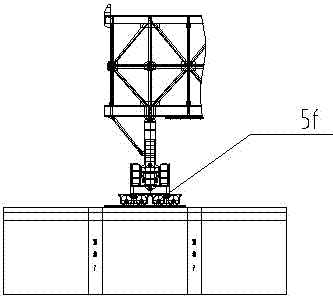

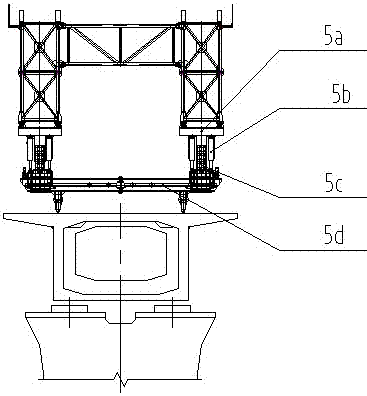

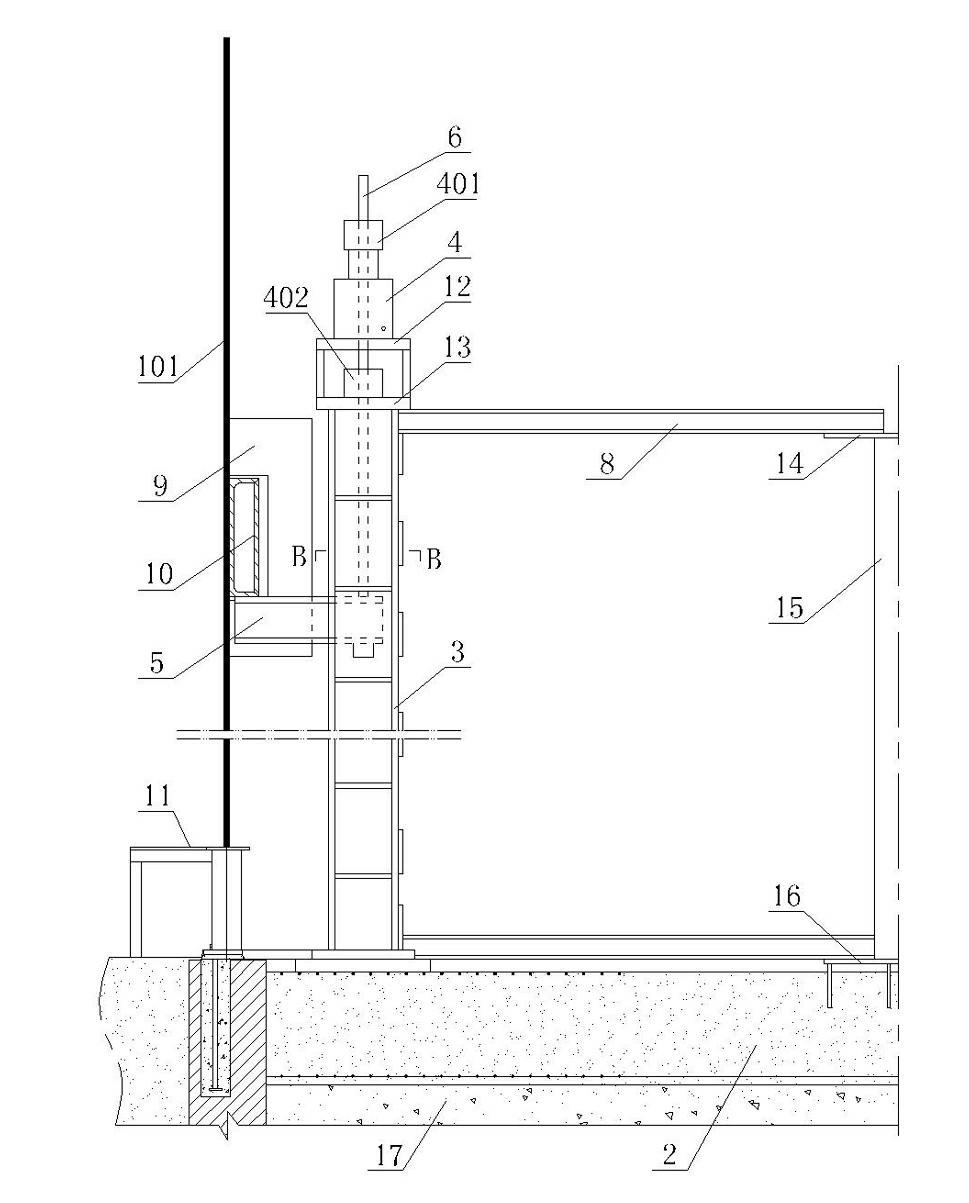

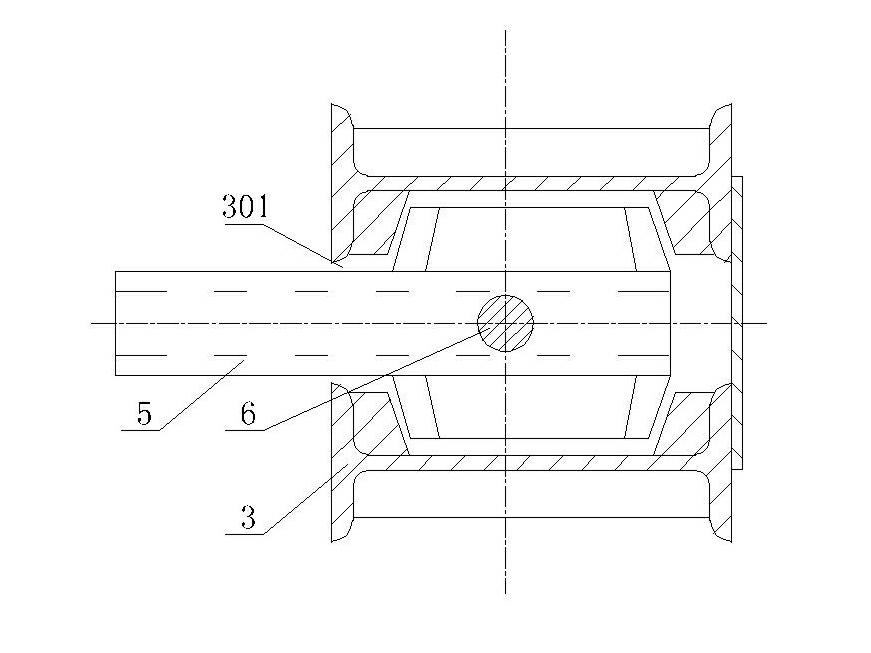

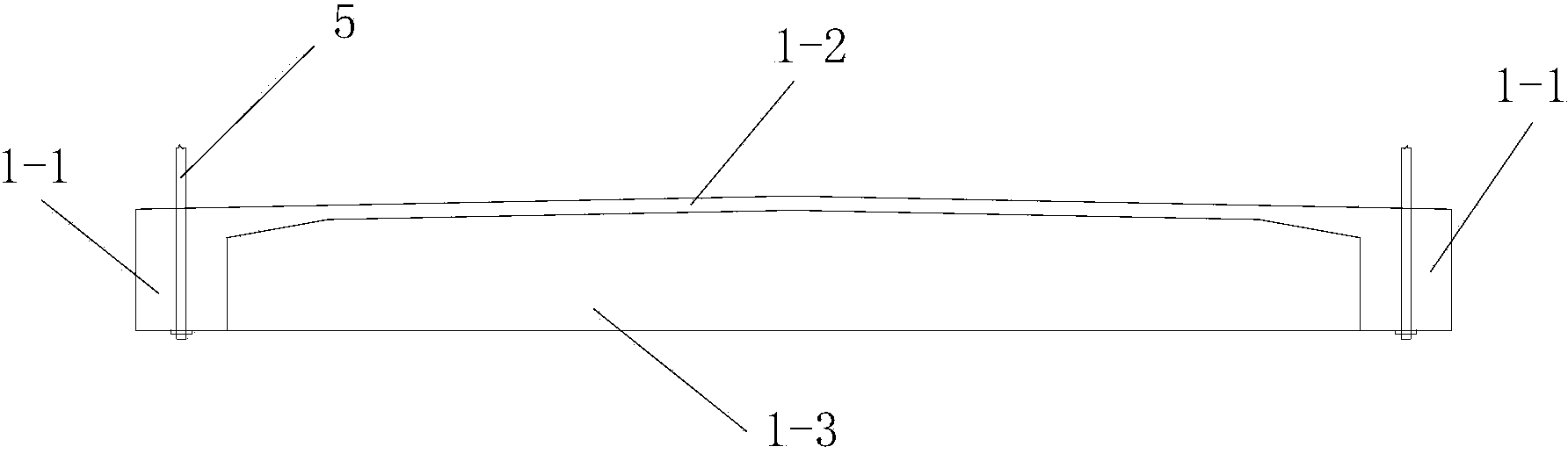

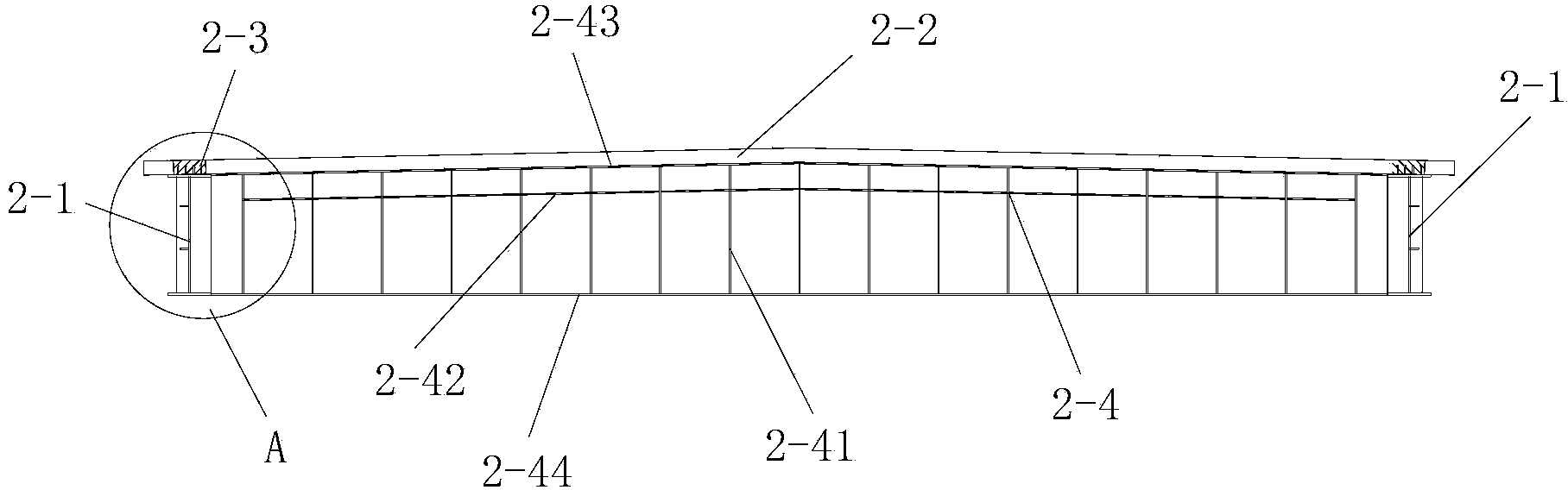

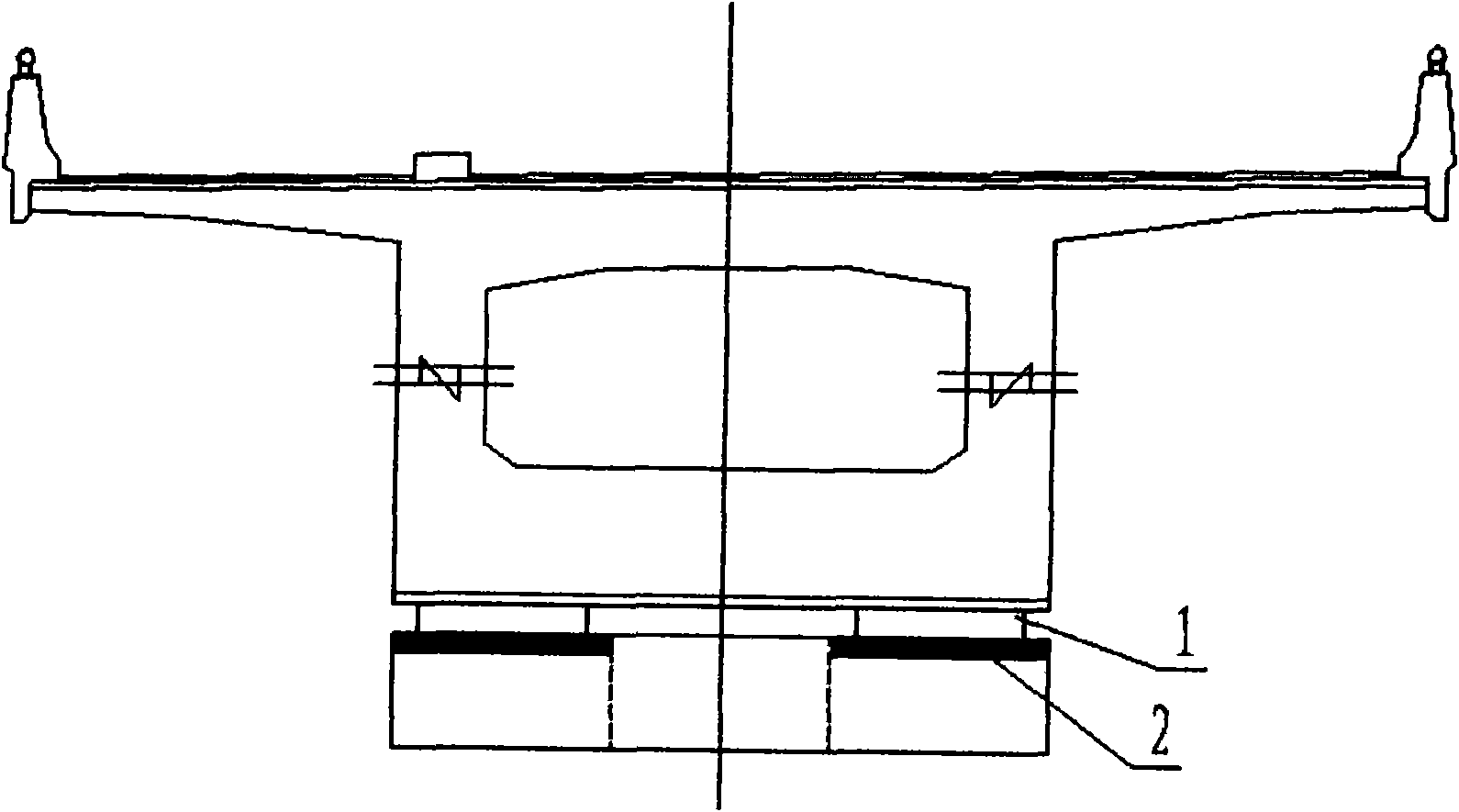

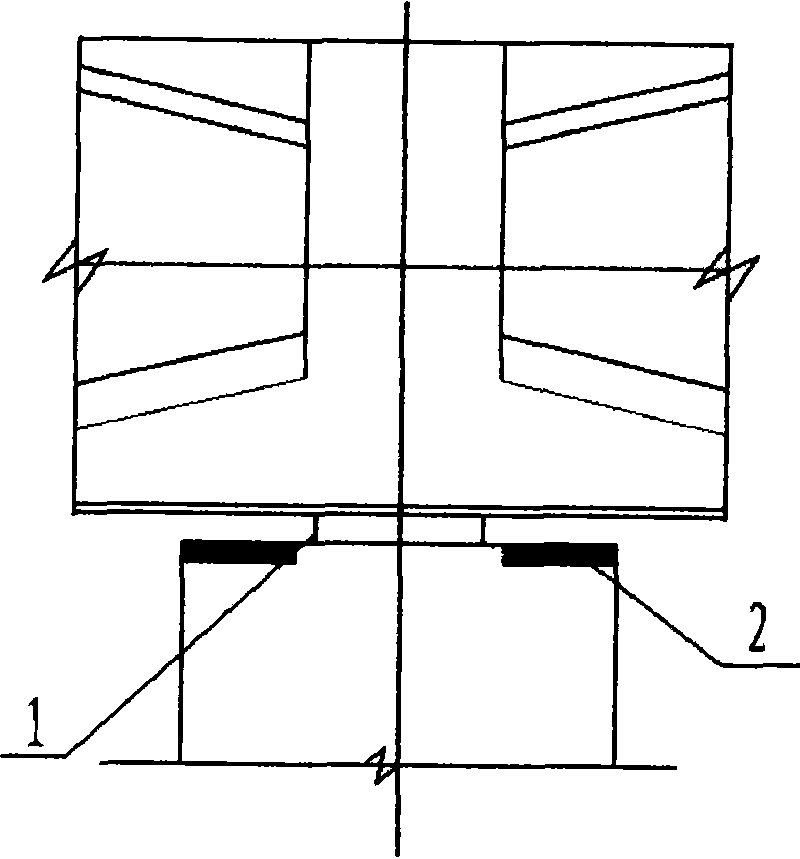

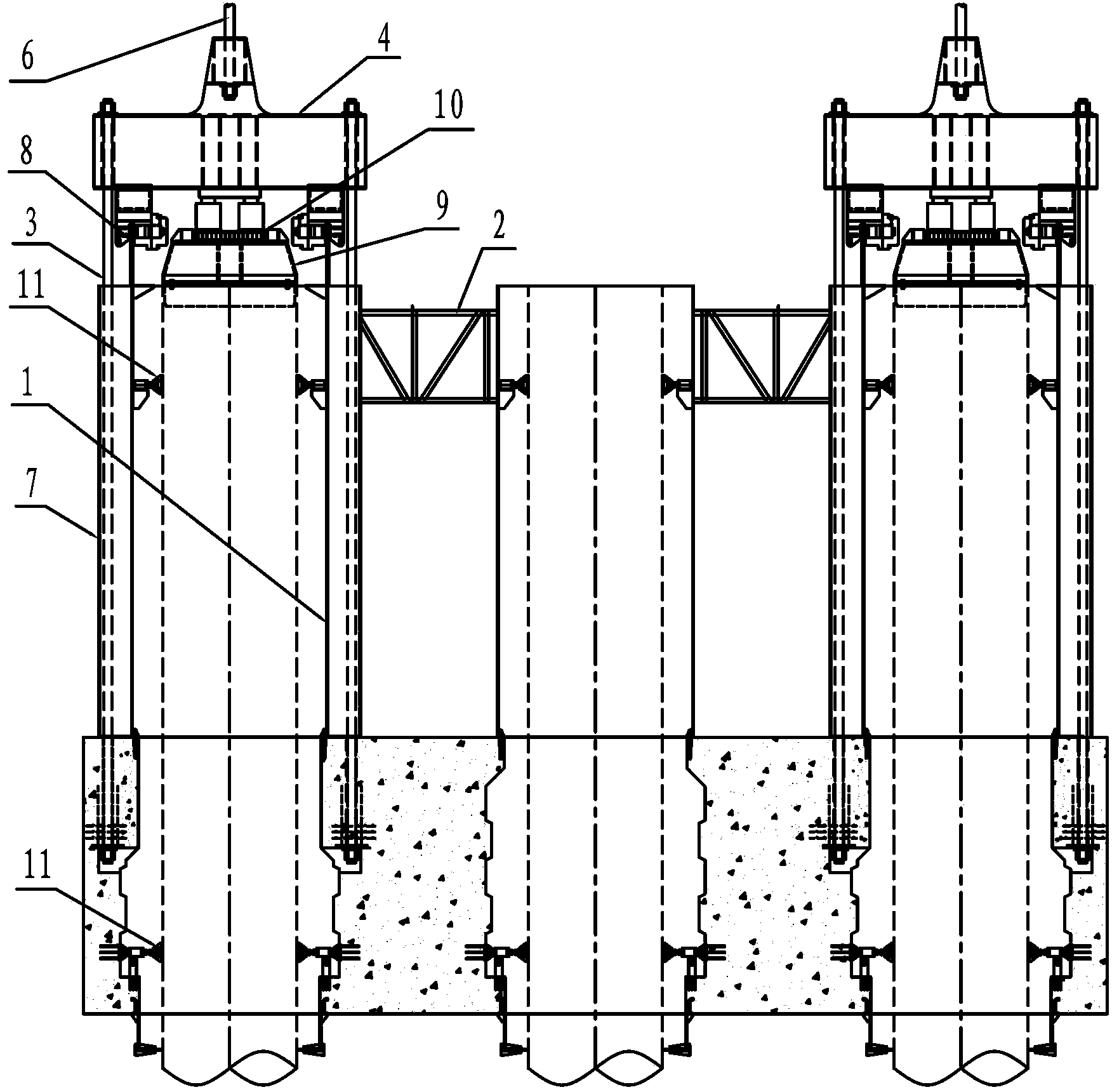

Bridge erecting machine for precast segmental beam span by span construction and construction method thereof

ActiveCN107059640ASmooth rotationNo need for staggered placementBridge erection/assemblyArchitectural engineeringHeavy load

The invention discloses a bridge erecting machine for precast segmental beam span by span construction and a construction method thereof. The bridge erecting machine for the precast segmental beam span by span construction comprises a main frame, a support leg system, a hanging system, a wet joint template system and an overhead travelling crane system. The support leg system comprises a number one support leg, a number two support leg, a number three support leg and a number four support leg, which sequentially arranged at the lower portion of the main frame from front to back, wherein the number one support leg and the number four support leg are located on two ends of the main frame as a auxiliary supporting support leg correspondingly, the number two support leg and the number three support leg are used as a heavy load supporting support leg, the hanging system is connected to the bottom of the main frame, the wet joint template system is connected to the outside of the main frame, the overhead travelling crane system is arranged on a longitudinal moving rail at the top of the main frame; and the construction method of the bridge erecting machine for precast segmental beam span by span construction comprises beam erecting process of the bridge erecting machine and bridge erecting machine through-hole process. The bridge erecting machine for the precast segmental beam span by span construction and the construction method thereof have the advantages that the construction demands of the precast segmental beam of high speed railway are met, the construction efficiency is high, and the construction is convenient and highly efficient.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

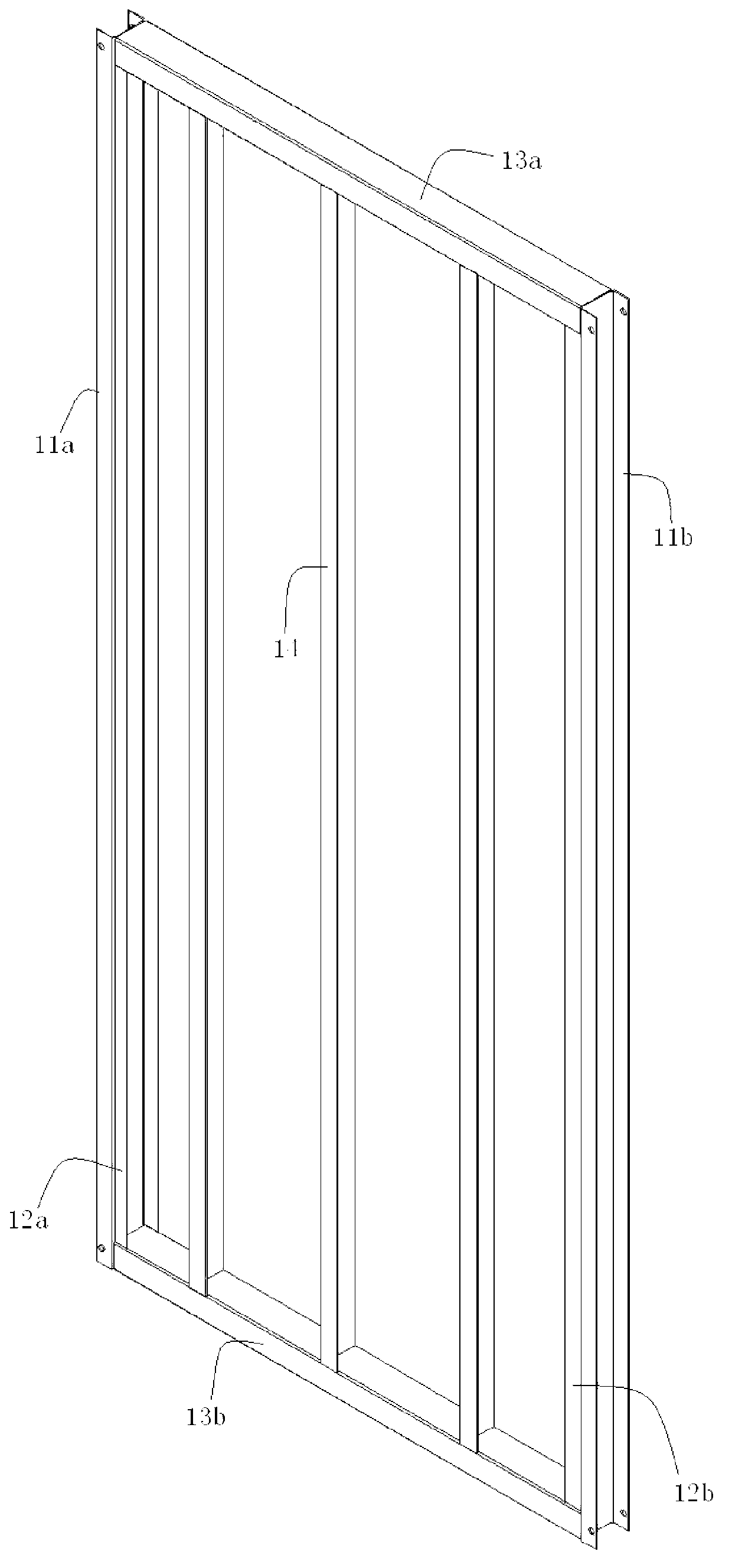

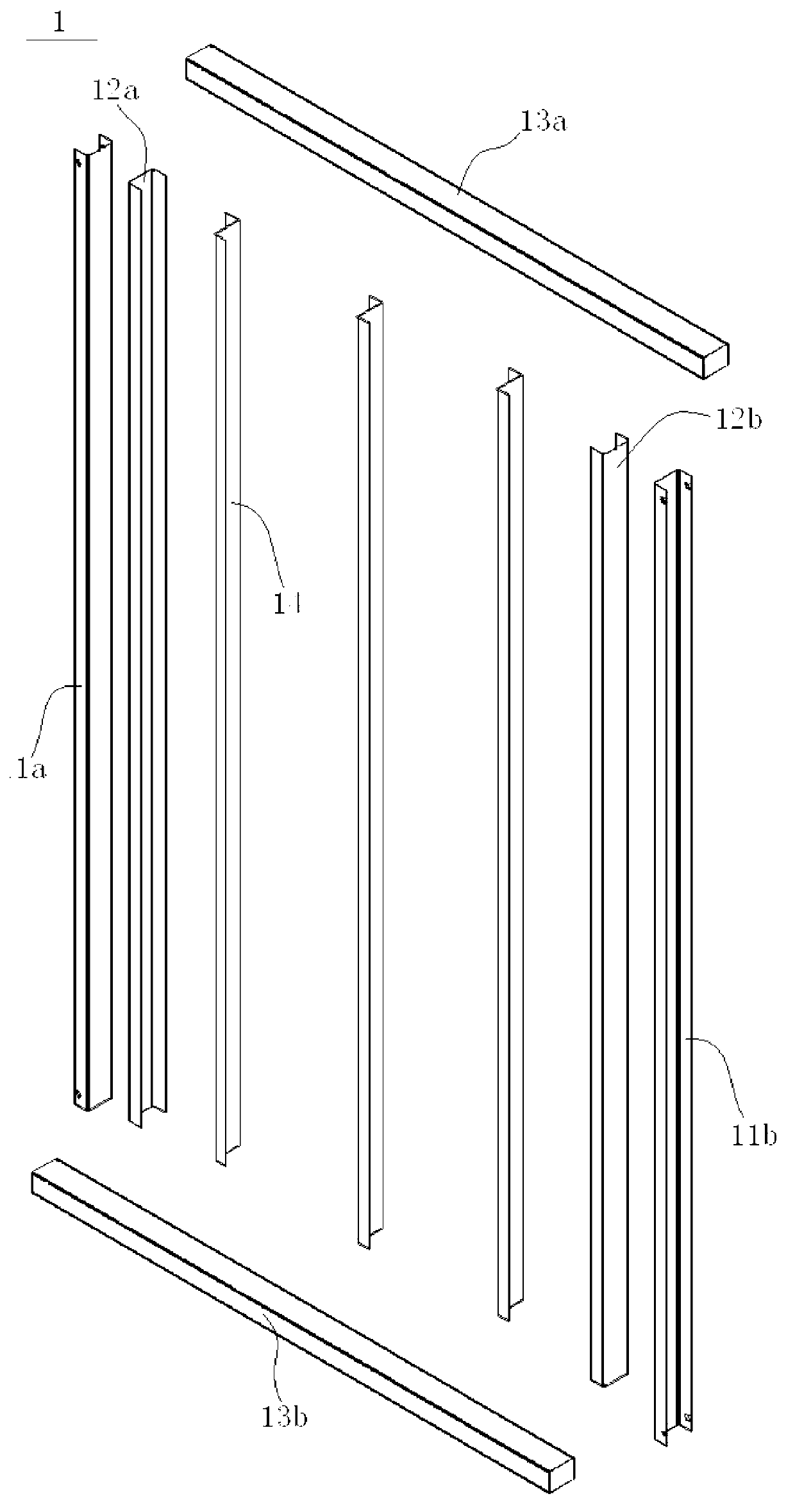

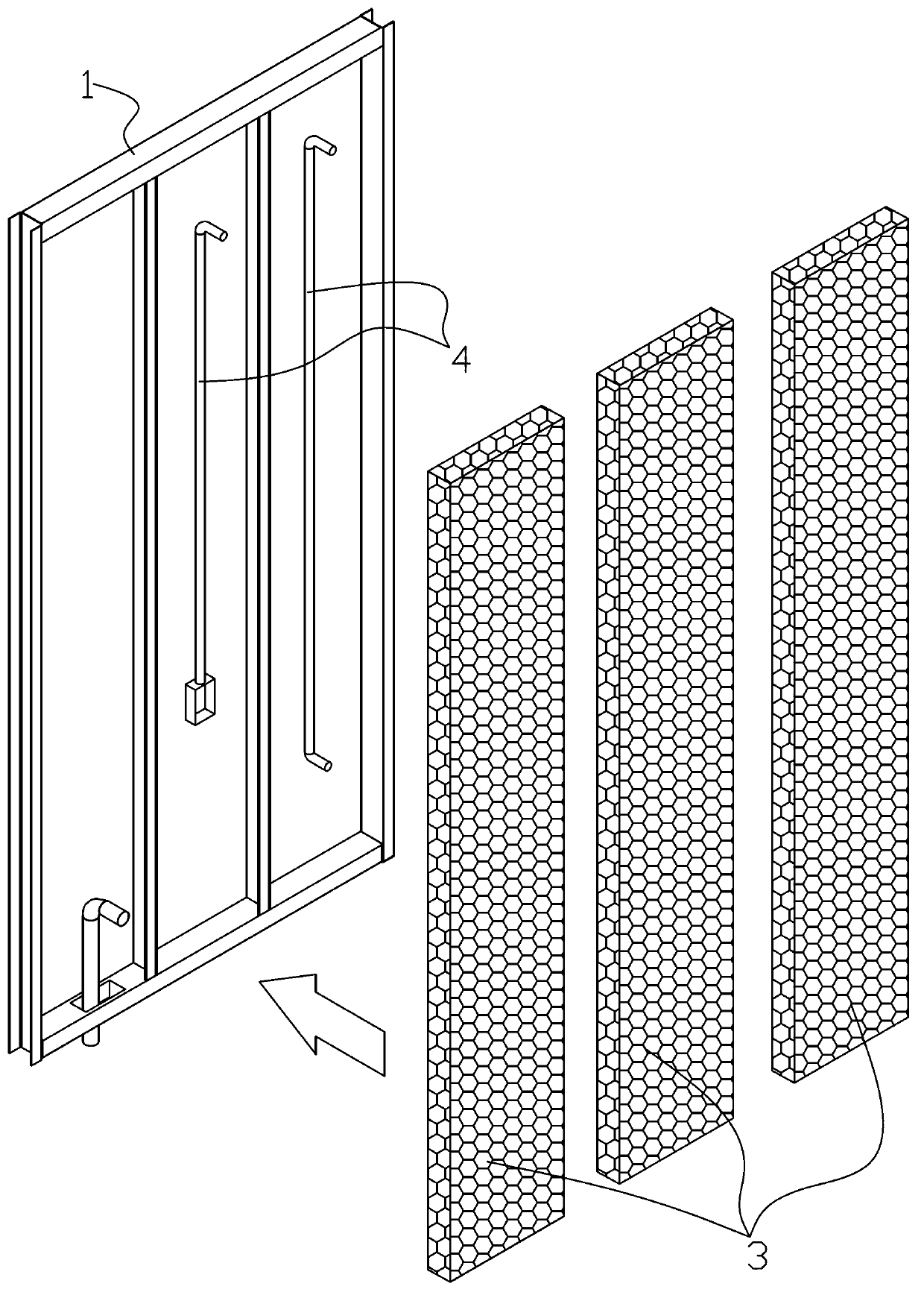

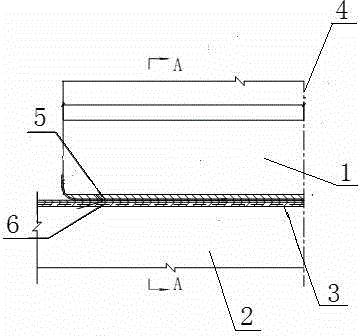

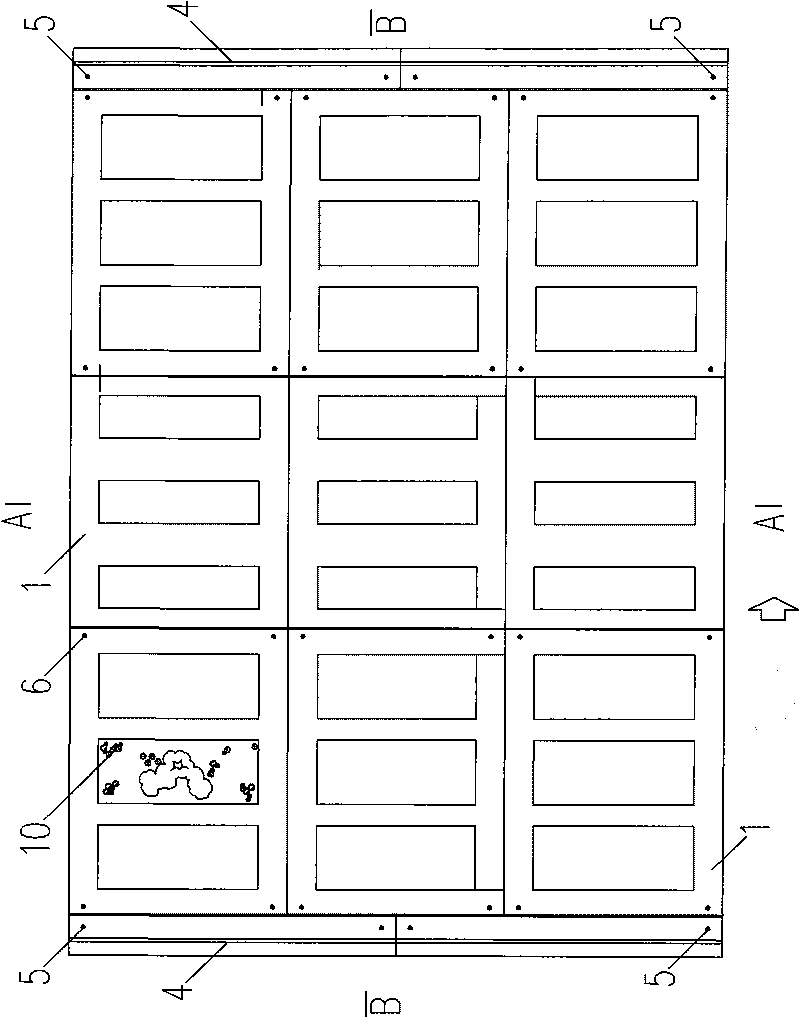

Prefabricated slab and fixed mounting structure thereof

The invention discloses a prefabricated slab and a fixed mounting structure thereof. The prefabricated slab comprises a light steel frame, a front board and a rear board, wherein the light steel frame comprises a left border, a right border, an upper border, and a lower border, which are enclosed together to form a square frame; U-shaped notches of the left border and the right border are respectively arranged towards the left and the right, so that the prefabricated slab can be inserted together with a structure member through the U-shaped notches; mounting holes through which bolts penetrate to fix the prefabricated slab on the structure member are arranged on front and rear connecting arms of the left and right borders; the front board and the rear board are respectively paved on the light steel frame as front and rear panels of the light steel frame; and the top surfaces and the bottom surfaces of the upper and lower borders are exposed outside. The light steel frame is internally built into the prefabricated slab; the light board is paved outside a skeleton by a 'stressed-skin effect' technology; the performance stronger than that of a single material is developed; and the light steel skeleton internally arranged inside the prefabricated slab is exposed at the periphery of the prefabricated slab, so that the prefabricated slab can be conveniently and effectively connected with a steel structure by the existing steel structure connecting technology.

Owner:广州市澳居科技有限公司

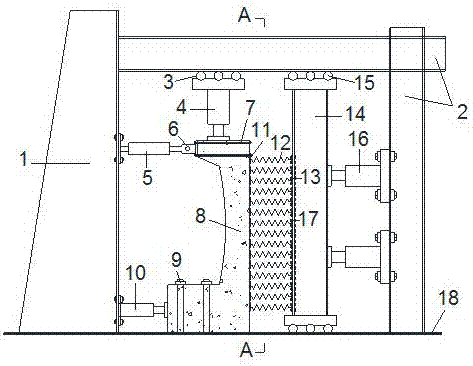

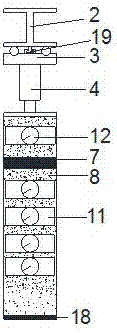

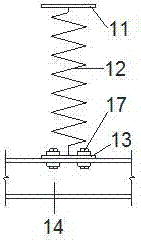

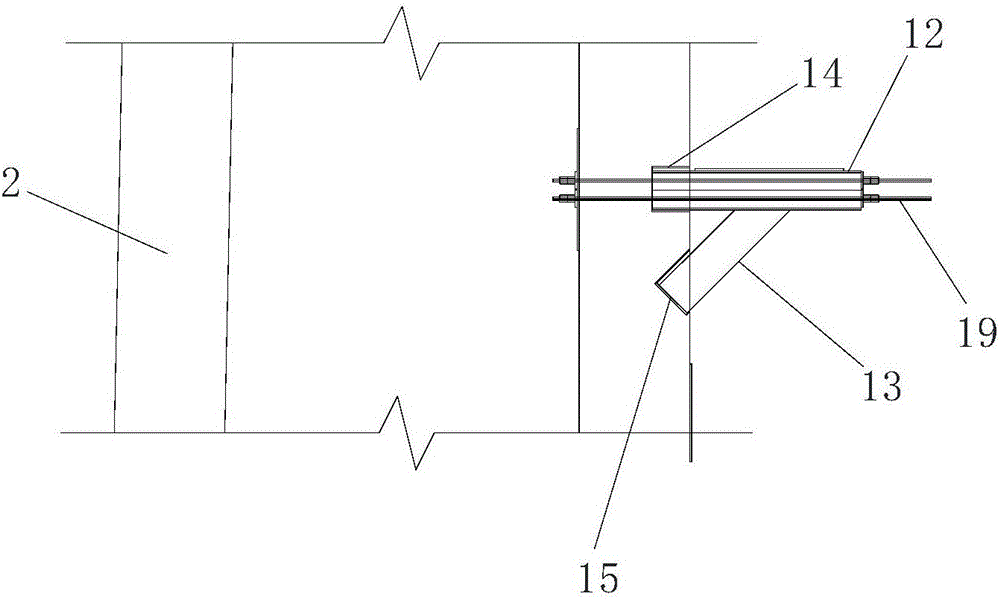

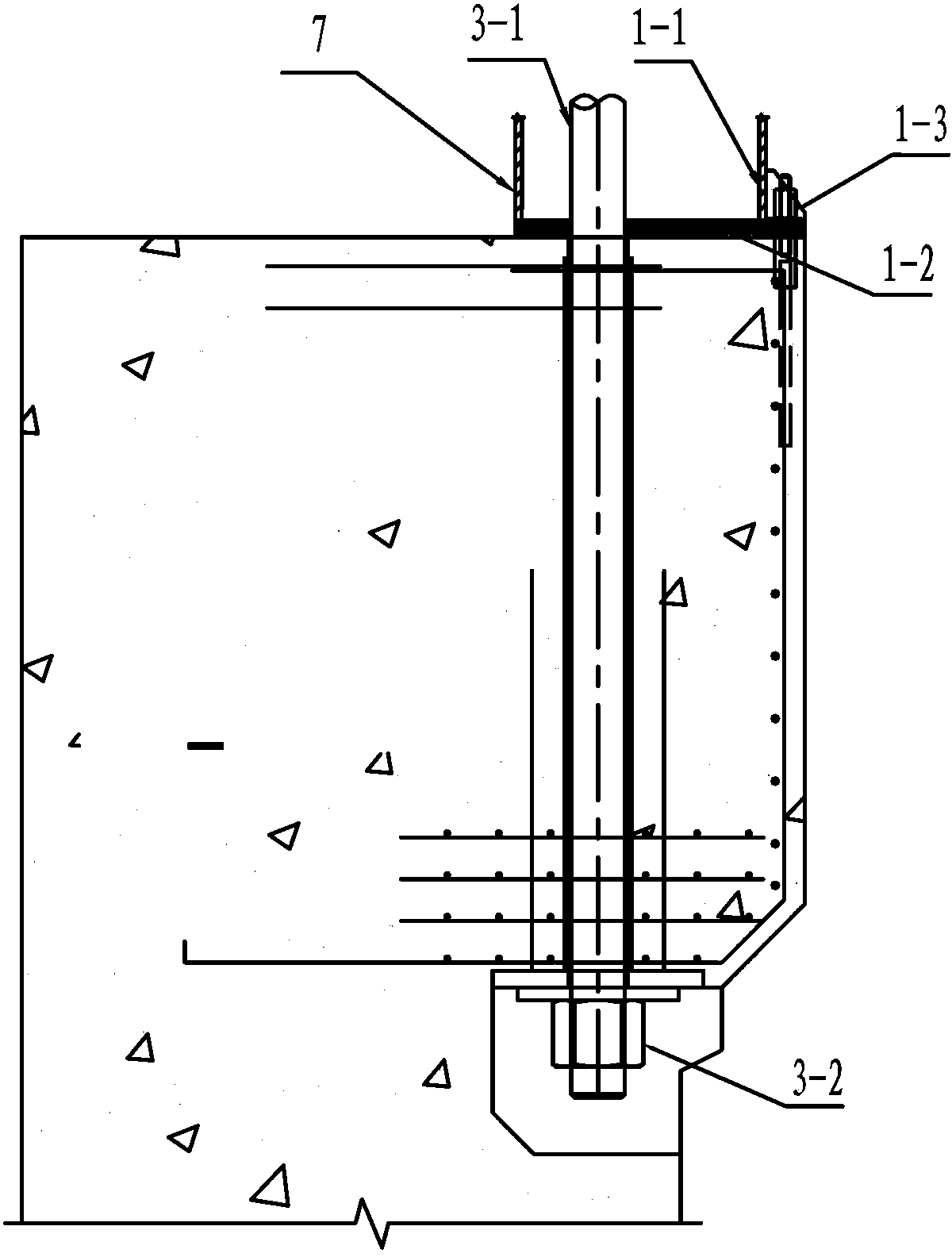

Lining member quasi-static test apparatus and lining member quasi-static test method

ActiveCN107228803ASimple structureEasy to operateMaterial strength using repeated/pulsating forcesSteel frameEngineering

The present invention discloses a lining member quasi-static test apparatus and a lining member quasi-static test method. The lining member quasi-static test apparatus comprises a reaction force device, a loading device, a lining member and a surrounding rock simulation system, wherein the reaction force device comprises a reaction force wall and a reaction force steel frame, a sliding support seat is arranged above a vertical jack, the lower portion of the vertical jack is connected to the lining member so as to apply a static load and simulate the eccentric compression state of the lining member, a horizontal actuator is connected to the top portion of the lining member so as to apply a dynamic load and simulate the action of the repeated load applied on the lining member, a spring is arranged on the right side of the lining member so as to simulate the constraint action of the surrounding rock, and by changing the type of the spring and disassembling the local spring, the different levels of the surrounding rock, the surrounding rock softening, surrounding rock voiding and other surrounding rock conditions can be simulated. According to the present invention, with the apparatus and the method, the dynamic and static coupling effect of the lining member can be simulated, the lining member back cavity and other defects can be simulated, and the advantages of test economy, simple operation, strong reliability and the like can be provided.

Owner:KUNMING UNIV OF SCI & TECH

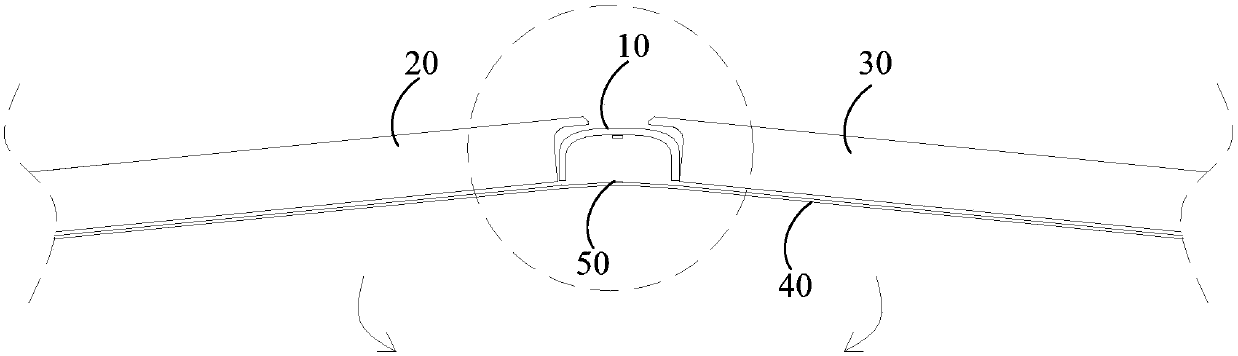

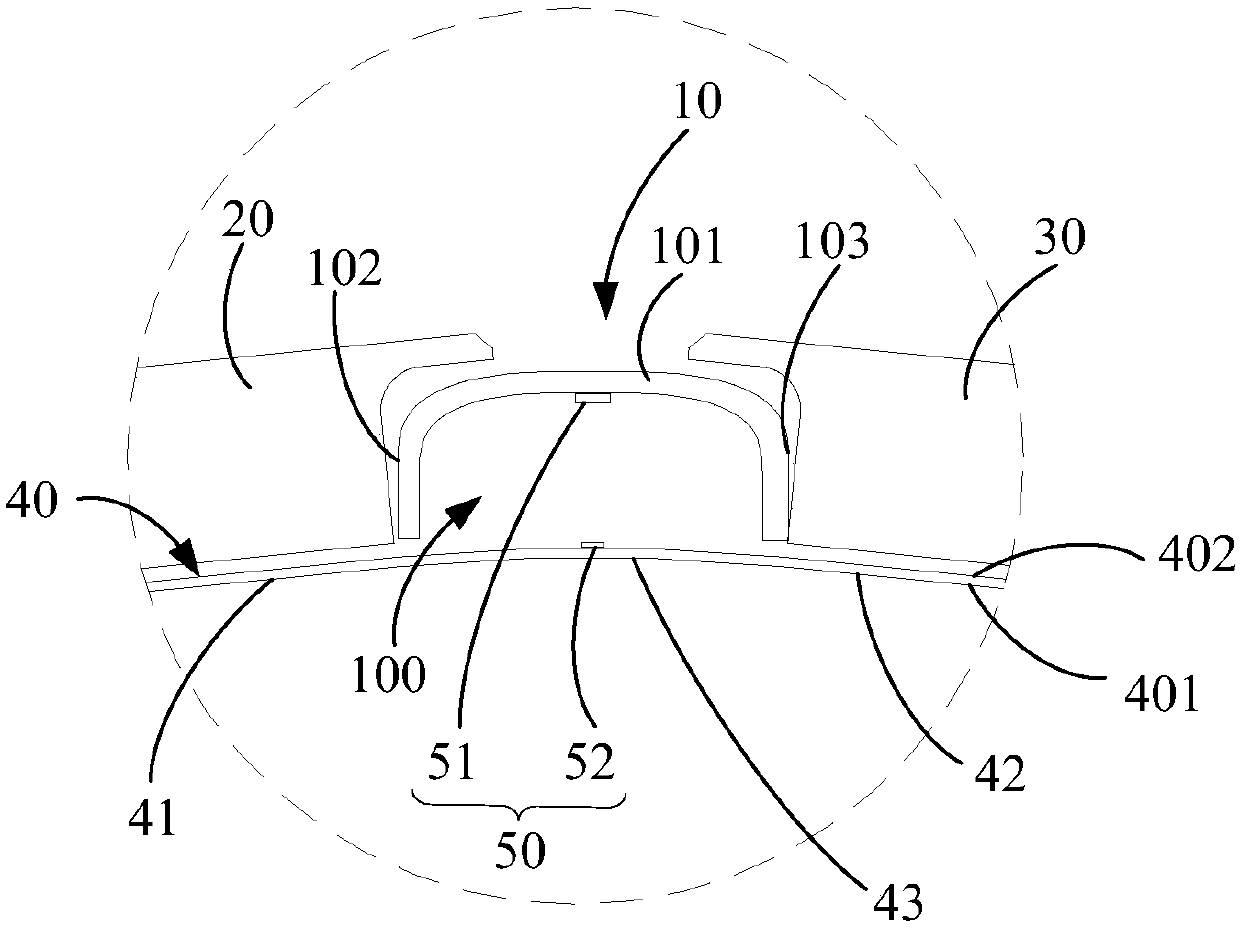

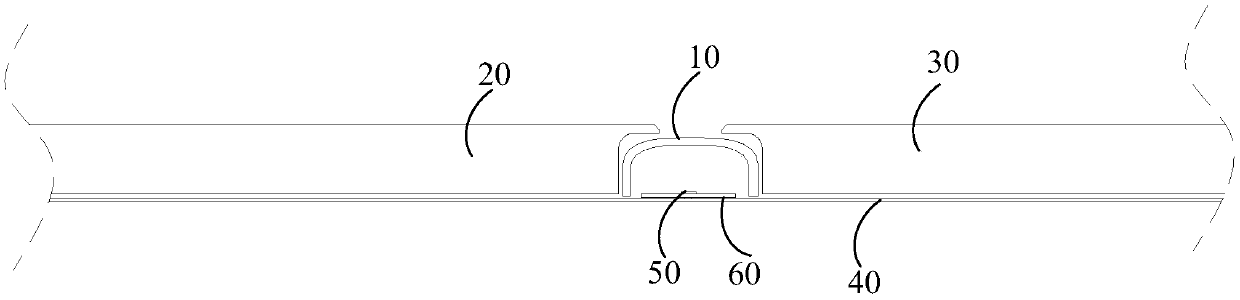

Foldable electronic equipment

PendingCN110719346AClear forceAvoid damageDetails for portable computersTelephone set constructionsStructural engineeringMechanical engineering

The invention relates to foldable electronic equipment. The equipment comprises a rotating shaft support which comprises a bottom plate, a first side plate and a second side plate, the first side plate and the second side plate are connected to two opposite sides of the bottom plate, and the bottom plate, the first side plate and the second side plate form an accommodation space; the first shell and the second shell can rotate around the rotating shaft bracket; the flexible screen comprises a first area, a middle area and a second area which are integrally arranged, the first area is combinedwith the first shell, the second area is combined with the second shell, and the middle area corresponds to the bottom plate of the rotating shaft bracket; and the guide component is arranged betweenthe middle area of the flexible screen and the rotating shaft bracket and is used for applying a guide force towards the accommodating space of the rotating shaft bracket to the middle area. In the initial stage that the foldable electronic equipment is switched from the unfolded state to the folded state, the guiding component enables the middle area of the flexible screen to be stressed clearly,then the flexible screen deforms in the preset direction, and the flexible screen is prevented from being damaged.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

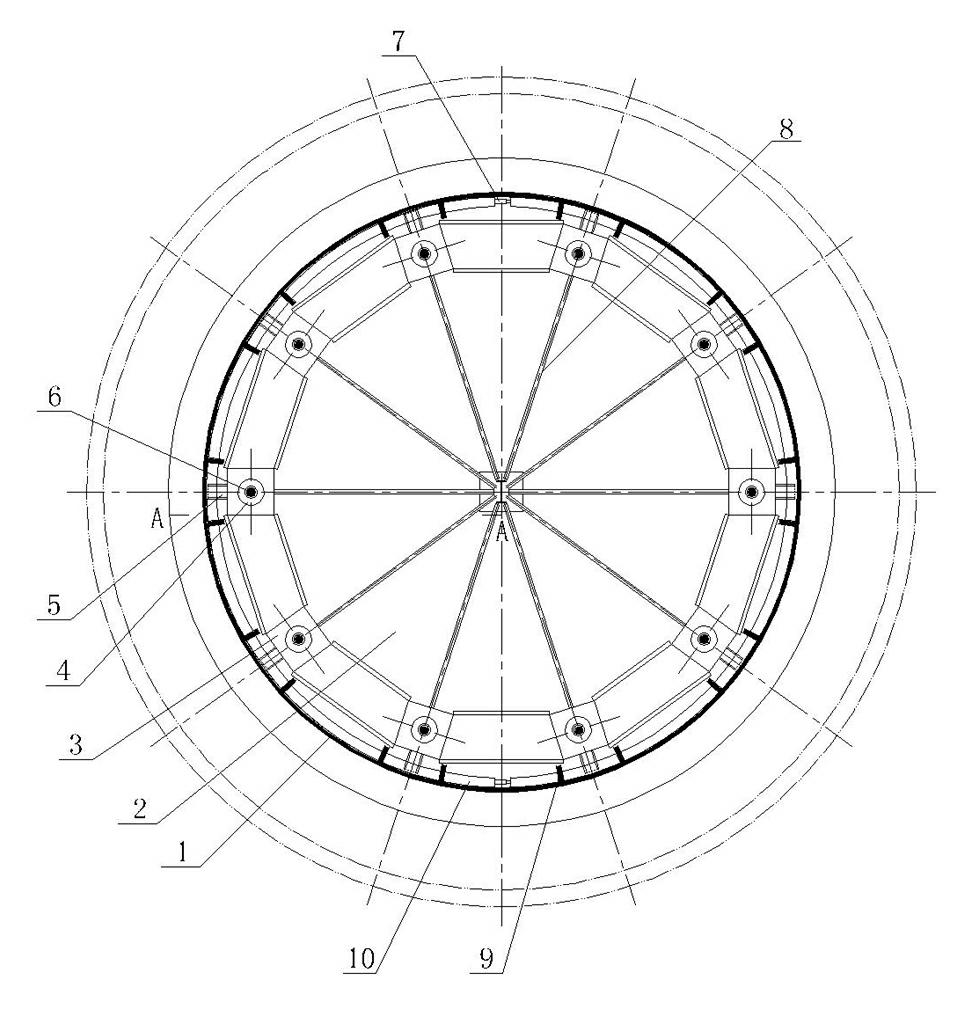

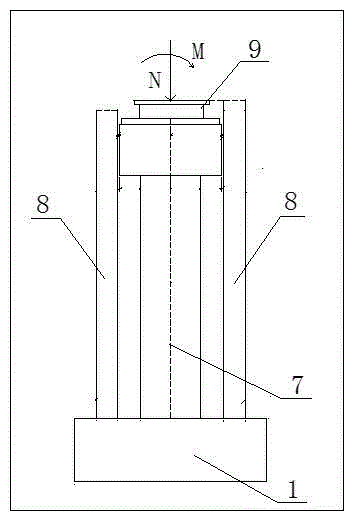

Hydraulic lifting inverted construction method for steel inner cylinder of chimney in thermal power plant

InactiveCN102108737AReduce investmentReduce construction costsBuilding constructionsTowersAnnular beamHydraulic pressure

The invention discloses a hydraulic lifting inverted construction method for a steel inner cylinder of a chimney in a thermal power plant, which comprises the following steps: (1) dividing the steel inner cylinder into a plurality of cylinder sections, and dividing each cylinder section into a plurality of cylinder sheets; (2) manufacturing a jack stand base in the steel inner cylinder, and mounting a hydraulic lifting device and a construction platform on the jack stand base; (3) beginning to assemble the first cylinder section of the steel inner cylinder, welding a plurality of sets of door-shaped clips on the inner wall of the first cylinder section along a circumferential direction, and clipping the horizontal annular beam by the door-shaped clips; (4) lifting the assembled cylinder section to the height of the first cylinder section by using the hydraulic lifting device, assembling a next cylinder section and welding the next cylinder section with the previous cylinder section; (5) cutting off the door-shaped clips and transferring and mounting the door-shaped clips and the horizontal annular beam to the corresponding position of the next cylinder section; and (6) repeatedly circulating the steps (4) and (5), and mounting the subsequent cylinder sections in turn. The method has the advantages that: the construction cost is low; the stress is definite, the operation is simple and convenient, and the safety factor is high; and the construction period is short and the project quality is high.

Owner:DONGDIAN YANTA ENG

Shape memory alloy web friction self-reset steel frame joint

The invention relates to a shape memory alloy web friction self-reset steel frame joint.The joint is composed of a column, a bracket, beams, shape memory alloy stay rope units, tensioning nuts, fixing nuts, arc hole high-strength bolts and central high-strength bolts.The bracket is welded to the side, close to the beams, of the column, a double-web mode is adopted for the bracket, and the bracket is connected with beam webs through the high-strength bolts.Arc holes are formed in the parts, at the arc hole high-strength bolts, of double webs of the bracket, the contact faces of the beam webs and the double webs of the bracket are subjected to friction treatment, friction parameters are adjusted with prestress of the high-strength bolts, the upper portions and the lower portions of the beams are connected with the column through the shape memory alloy stay rope units respectively, and the initial states of shape memory alloy stay ropes are controlled by adjusting the tensioning nuts and the fixing nuts.The shape memory alloy web friction self-reset steel frame joint has the advantages of being simple in structure, high in practicability, definite in stress, high in energy dissipation, capable of achieving self-resetting and the like.

Owner:SUZHOU UNIV OF SCI & TECH

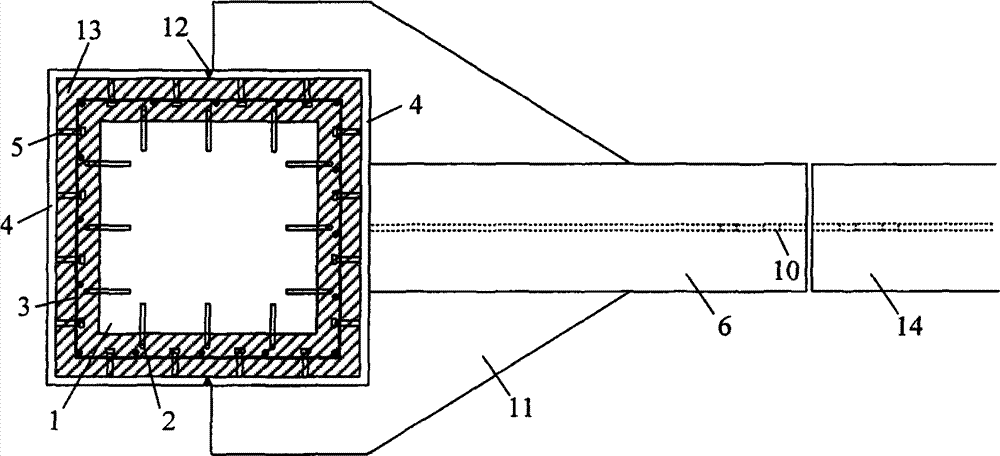

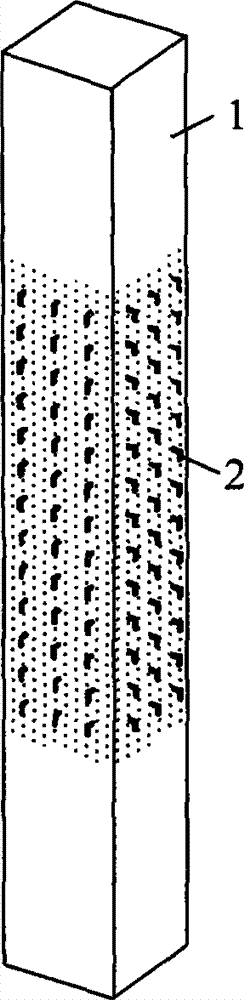

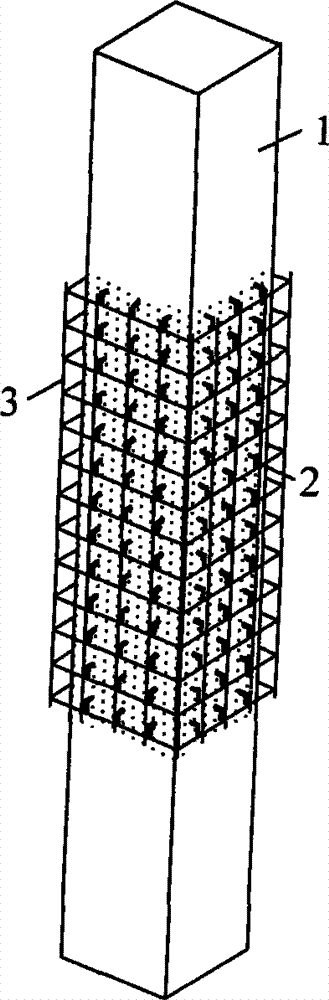

Connecting method of steel beam and existing reinforced concrete column

InactiveCN102966245AEasy to get materialsReduce wet work loadBuilding repairsReinforced concrete columnEngineering

The invention relates to a connecting method of a steel beam and an existing reinforced concrete column, which can be used for reinforced modification of an existing reinforced concrete structure, and belongs to the technical field of structural engineering. The method comprises the steps of: scabbling, planting bars and binding reinforced mesh pieces on the surface around with a node connection domain of the original reinforced concrete column; processing two pieces of channel steel and welding a stud connection piece inside; extending an extending bracket and external reinforcing plate on the channel steel connected to the steel beam; buckling the two pieces of channel steel and wrapping the original reinforced concrete column; welding in an abut manner; pouring node area concrete; and finally connecting the steel beam. The method overcomes the deficiencies of the conventional connection method, is simple in structure, quick and convenient to construct, good in stress performance of the connecting node, reliable in force transfer, and can efficiently prevent a node core area from cracking and being exposed. The core area concrete is wrapped by a steel plate so that the concrete is strongly constrained, and the quake-proof ductility of the node is good. The method has high practicality and wide application prospect.

Owner:TSINGHUA UNIV

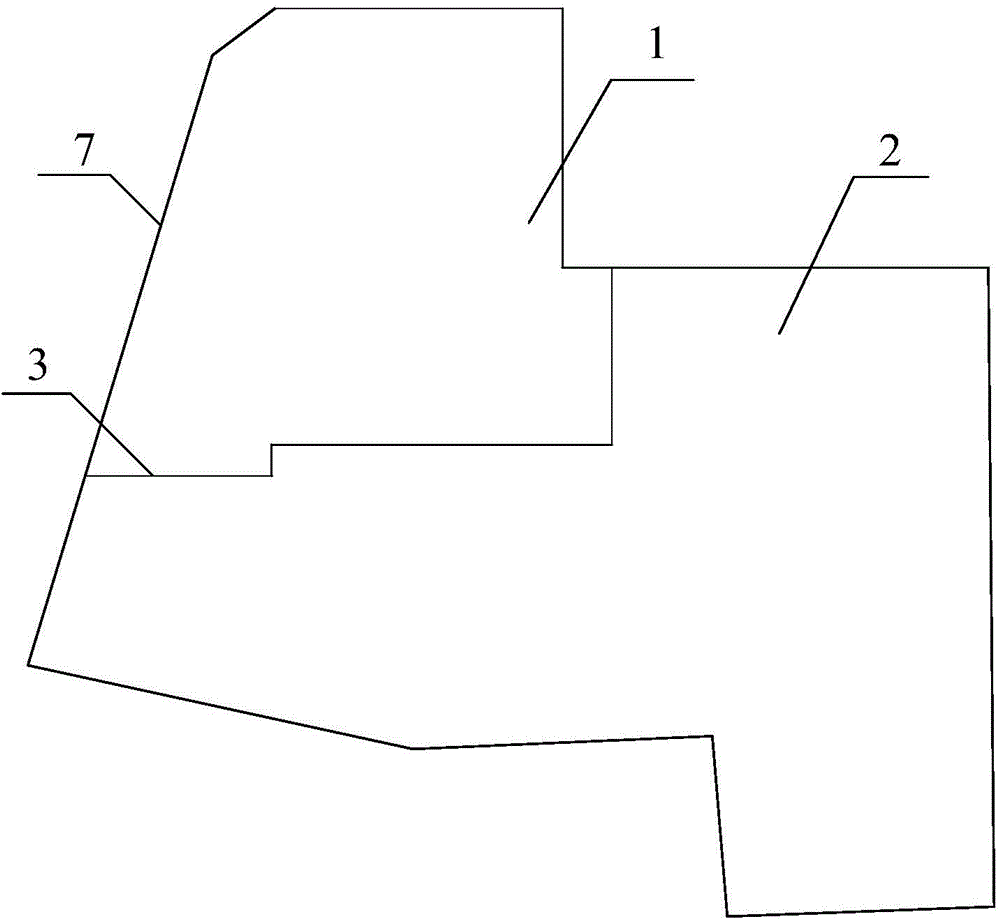

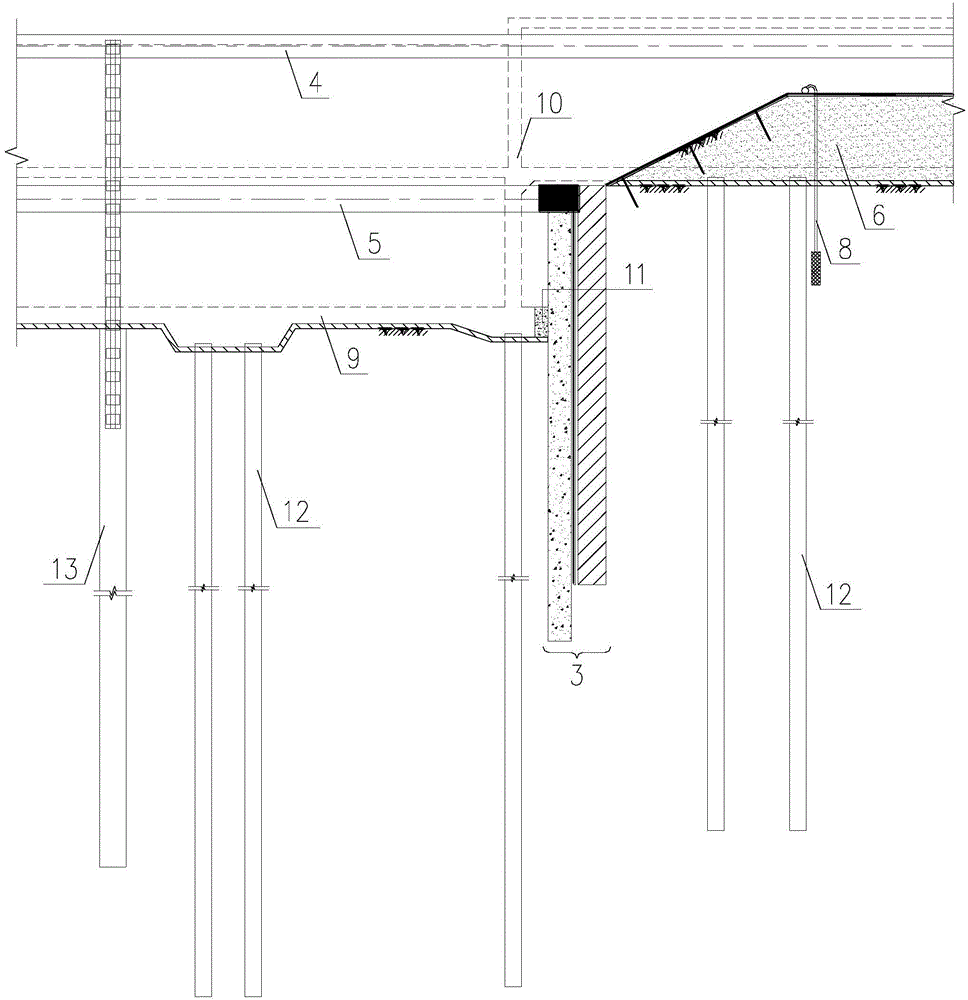

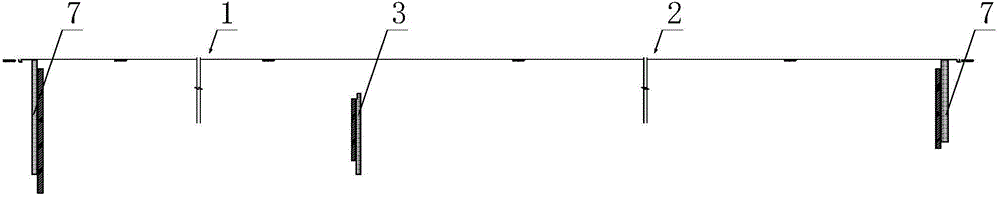

Synchronous excavation supporting system for deep and large asymmetric pit in soft soil area and implementation method of supporting system

ActiveCN104563128AControl pit deformationThe surrounding environment protection effect is goodExcavationsEnvironmental geologyStructure of the Earth

The invention discloses a synchronous excavation supporting system for a deep and large asymmetric pit in a soft soil area and an implementation method of the supporting system. The deep and large asymmetric pit consists of a deep area and a shallow area which are internally close to each other, the top elevation of an enclosure structure at the junction of the deep area and the shallow area is a substrate of the shallow area, the total pit is provided with a first horizontal support in a unified way, the deep area is additionally provided with a plurality of deep-area horizontal supports, a soil body platform used for balancing the horizontal transfer force of the deep-area horizontal supports is reserved at the junction of the interior of the shallow area and the deep area, and two sides of the soil body platform are sloped to the substrate of the shallow area, so that open excavation and bottom-up construction in the deep area and the shallow area can be synchronously carried out, the problem of imbalance of the internal force and the deformation of the pit caused by an asymmetric excavation mode due to function requirements is solved, and the asymmetric pit can be excavated in a safe, reliable, economic and environment-friendly mode; through the synchronous excavation of the deep area and the shallow area, the construction period can be effectively shortened, and the construction cost is reduced; moreover, the supporting system is definitely stressed, the horizontal force of each horizontal support additionally arranged in the deep area is reliably transferred, and the construction feasibility is high.

Owner:SHANGHAI CONSTRUCTION GROUP

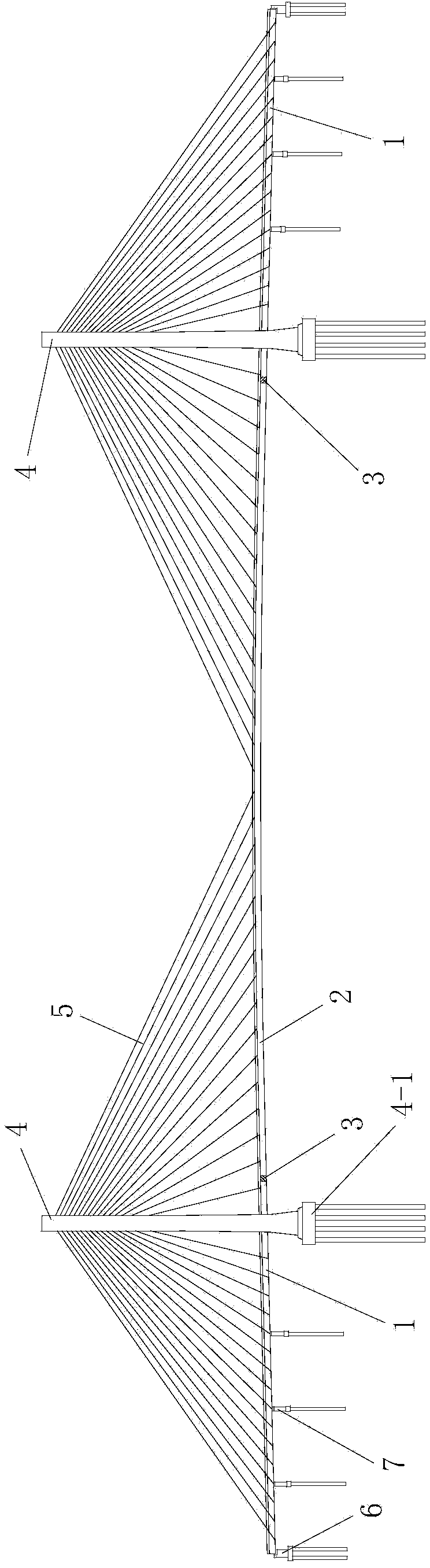

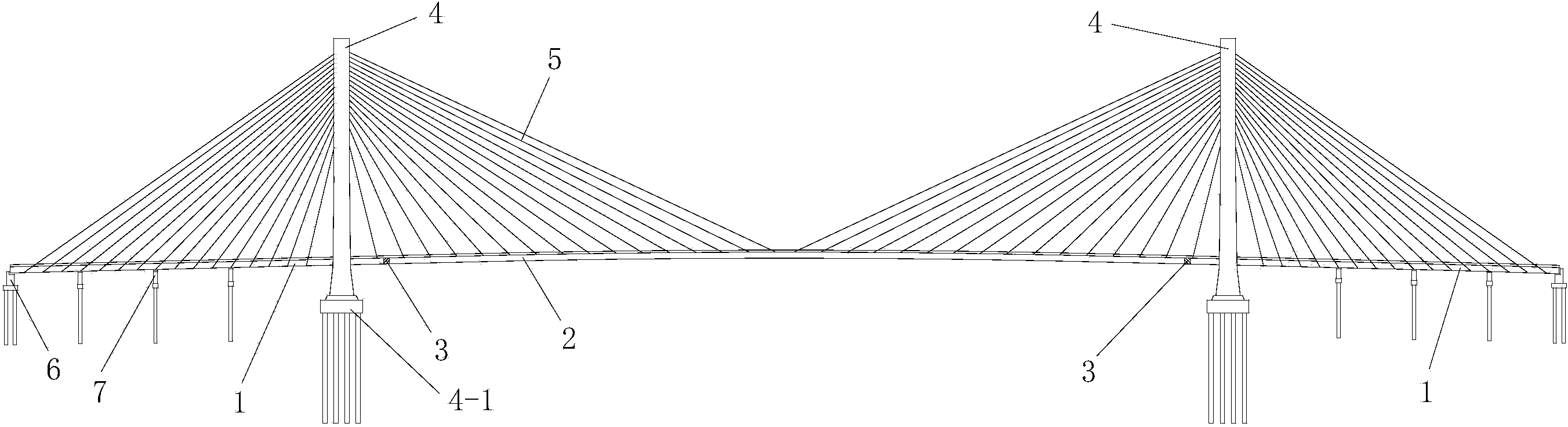

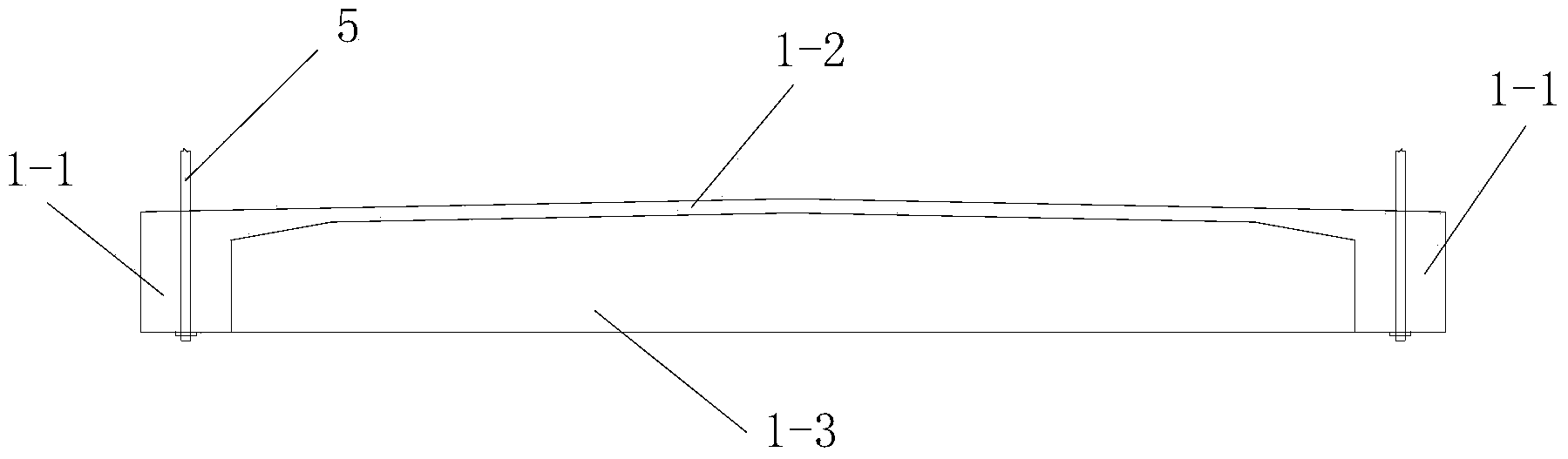

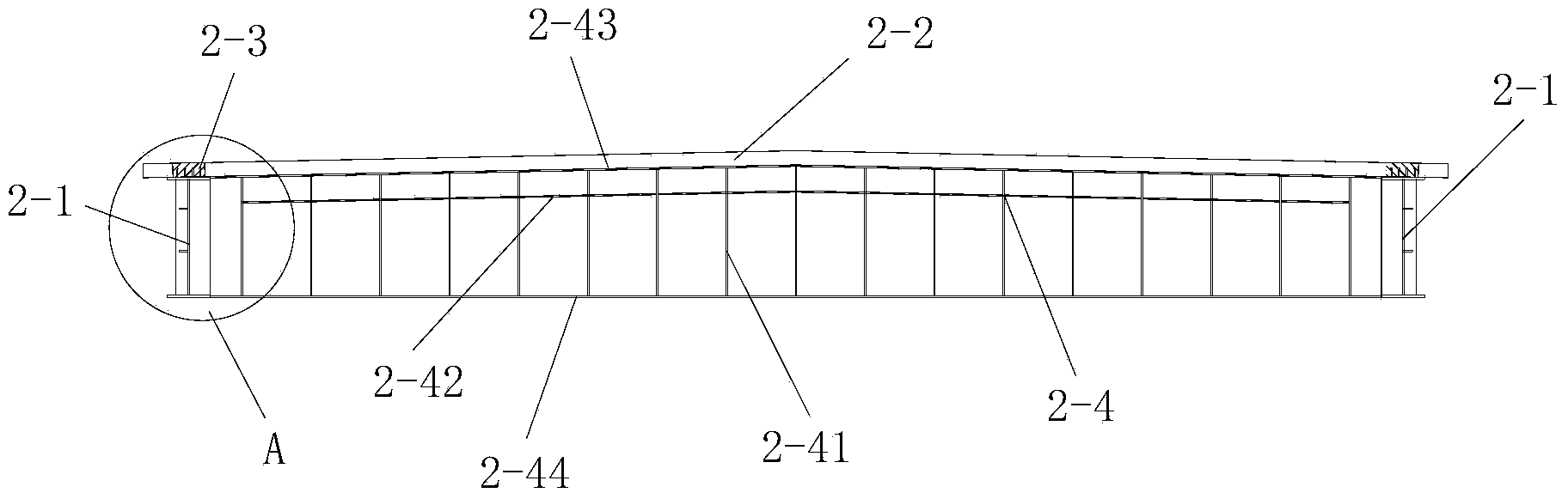

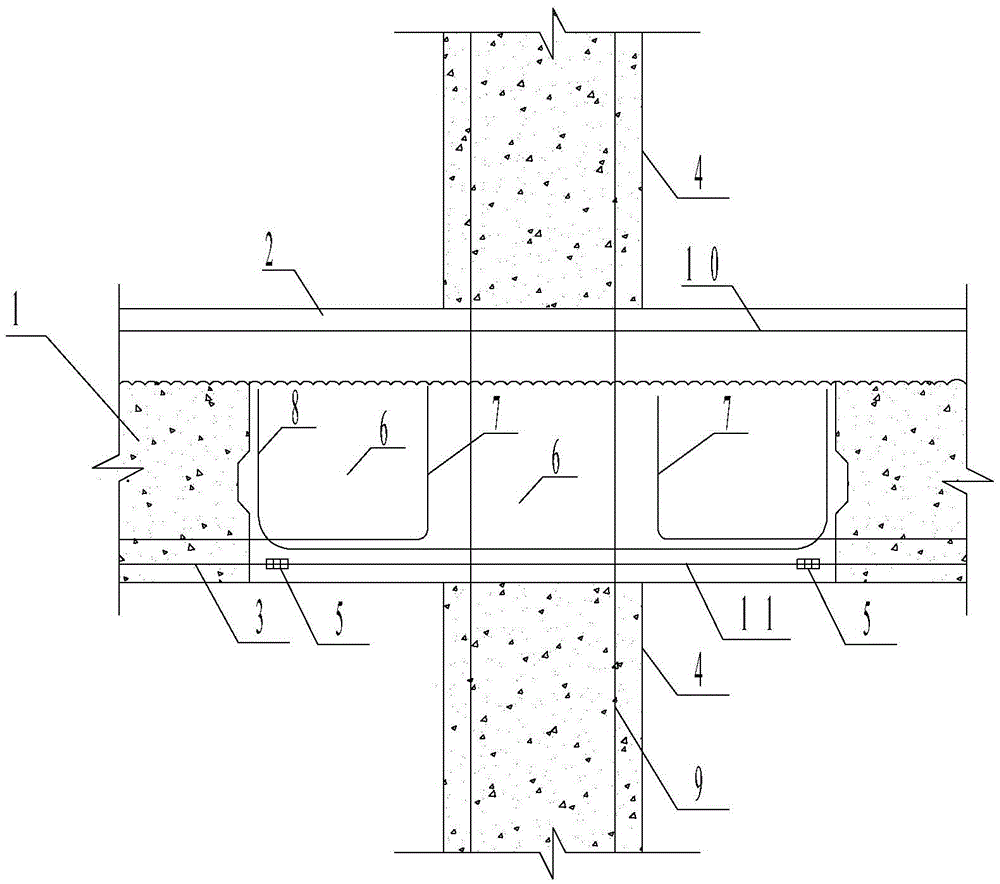

Double-tower hybrid beam cable-stayed bridge system and construction method thereof

InactiveCN104294747ASimple structureReasonable designCable-stayed bridgeBridge erection/assemblyCable stayedConcrete beams

The invention discloses a double-tower hybrid beam cable-stayed bridge system. The double-tower hybrid beam cable-stayed bridge system comprises a hybrid beam composed of a concrete beam and a composite beam. The concrete beam and the composite beam are connected through a joint section. The concrete beam is a bilateral ribbed beam and comprises two concrete beam ribs. The composite beam comprises two main steel beams, and the main steel beams are each of an I shape and each comprise a main steel beam top plate, a main steel beam bottom plate and a main beam steel web. The joint section comprises a concrete beam rib-main steel beam connection structure composed of a front pressure bearing plate, a rear pressure bearing plate and a joint section steel web, and the main steel beam top plates and the main steel beam bottom plates stretch into the concrete beam ribs. The double-tower hybrid beam cable-stayed bridge system is reasonable in structural design, convenient to construct, high in construction speed, good in use effect and good in connection effect of a steel-concrete joint part. Meanwhile, the invention further discloses a construction method of the double-tower hybrid beam cable-stayed bridge system. The construction method includes the steps of lower portion supporting structure and main tower construction and hybrid beam construction. The construction method is simple, easy to implement, short in construction period and good in construction effect.

Owner:TONGJI UNIV

Integral lifting reconstruction method for high-span overweight continuous box girder

InactiveCN101892636ASolve the problem of setting up a reliable jacking systemAddress the risk of collapseBridge structural detailsBridge erection/assemblyReconstruction methodHydraulic equipment

The invention discloses an integral lifting reconstruction method for a high-span overweight continuous box girder. The method comprises the following steps of: cutting the top of a pier; reinforcing an upper box girder; welding a limiting device on the outer side of an upright post hoop, and integrating the limiting structure and a concrete pier into a whole to limit the lifting of the girder; debugging a lifting jack and a follow-up jack; lifting formally until the girder is lifted to a position which is 1cm higher than a designed elevation, screwing up a self-threaded device of the lifting jack, disassembling the follow-up jack, arranging a support and a permanent cushion block; loosening the self-threaded device on the lifting jack and allowing the jack to drop for 1 cm to the designed elevation; and disassembling the lifting device, the hoop and the limiting device and joining the lifted pier. The method can adapt to the high-span continuous box girder with limited height at the support, heavy weight, high requirements on a lifting hydraulic device and small width at the ribbed part of the box girder and can realize safe integral lifting of the continuous box girder with an accurate position.

Owner:SHANGHAI XIANWEI CIVIL ENG

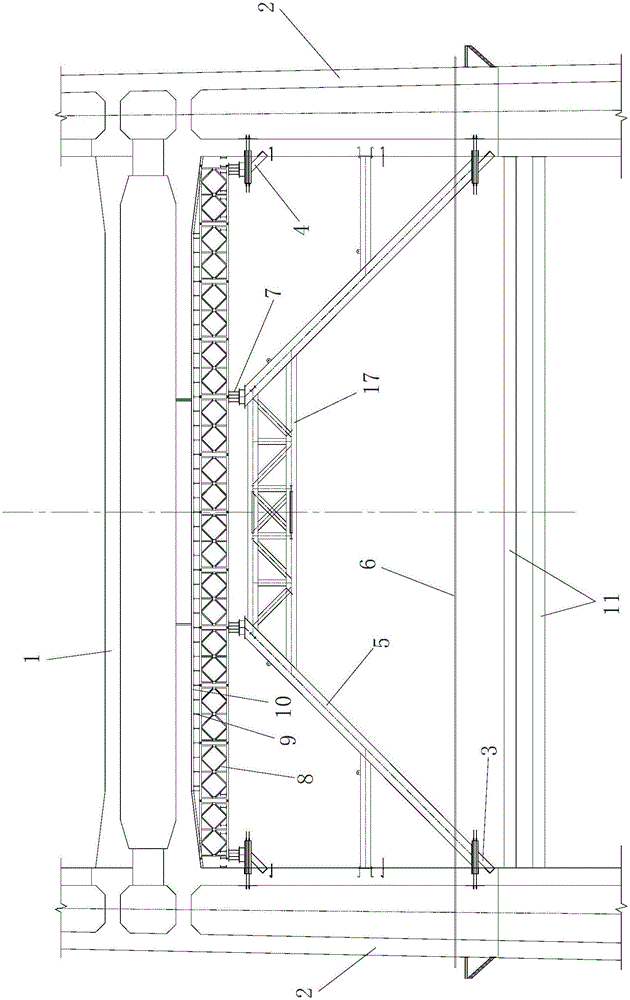

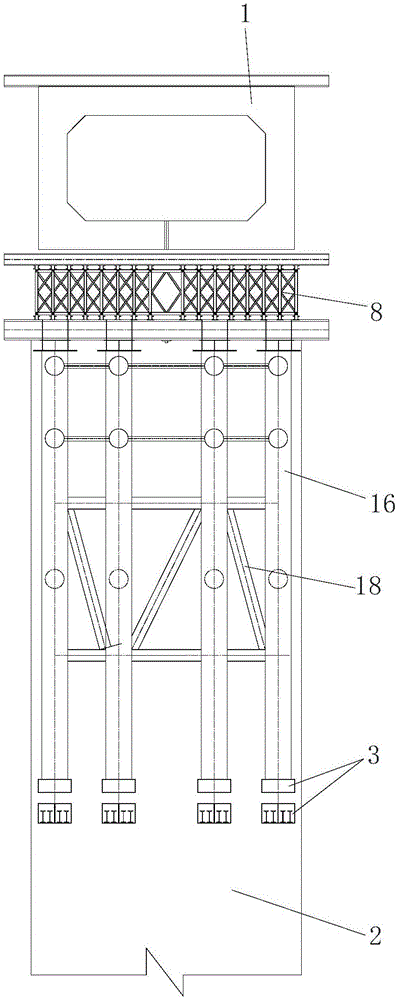

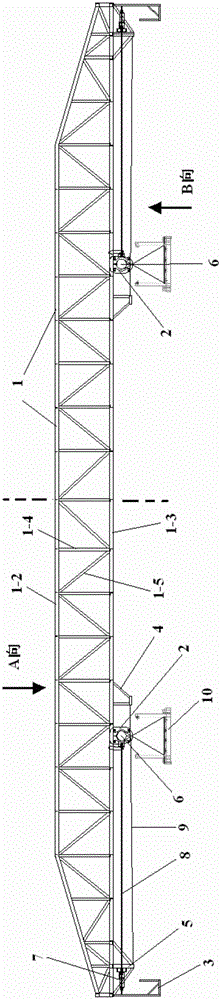

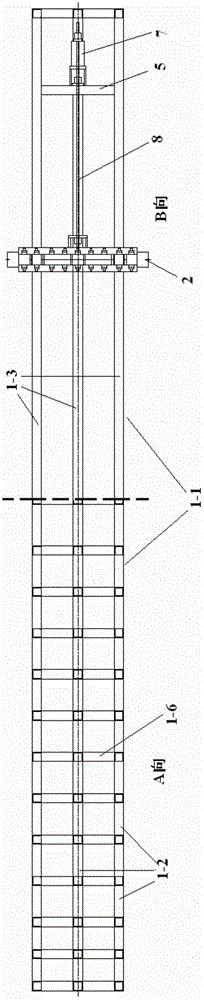

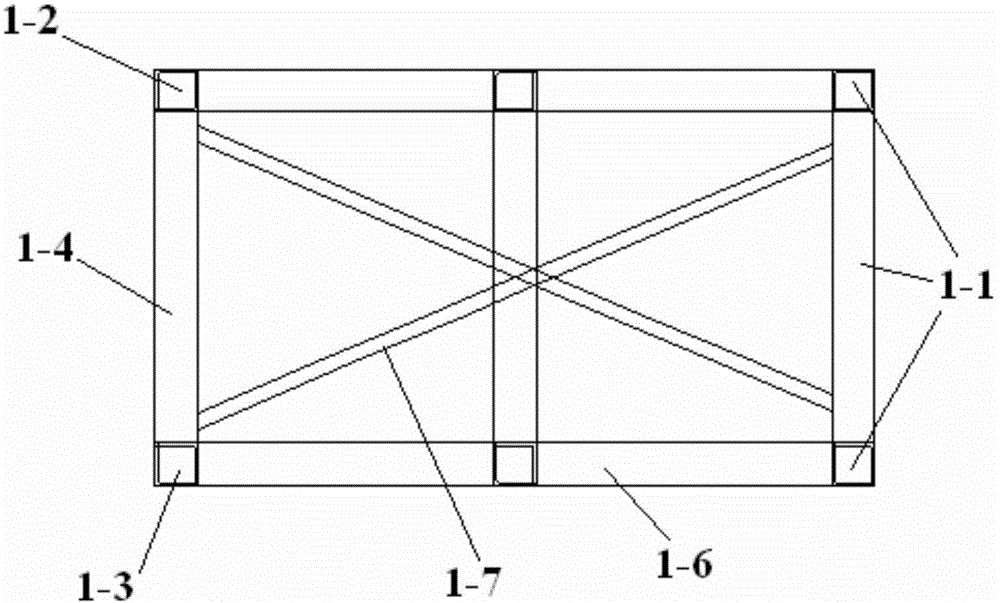

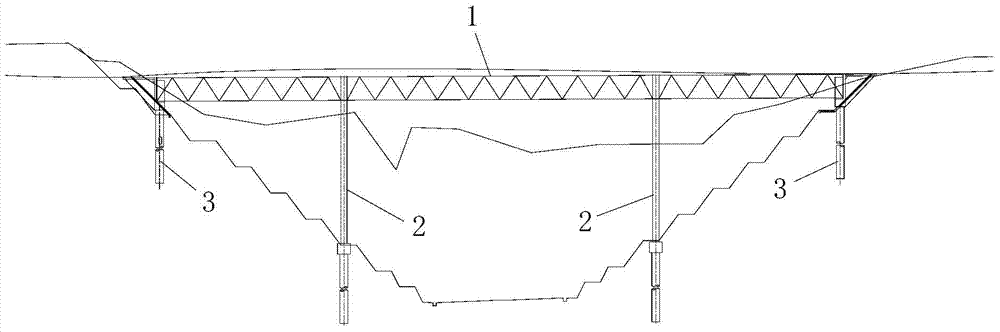

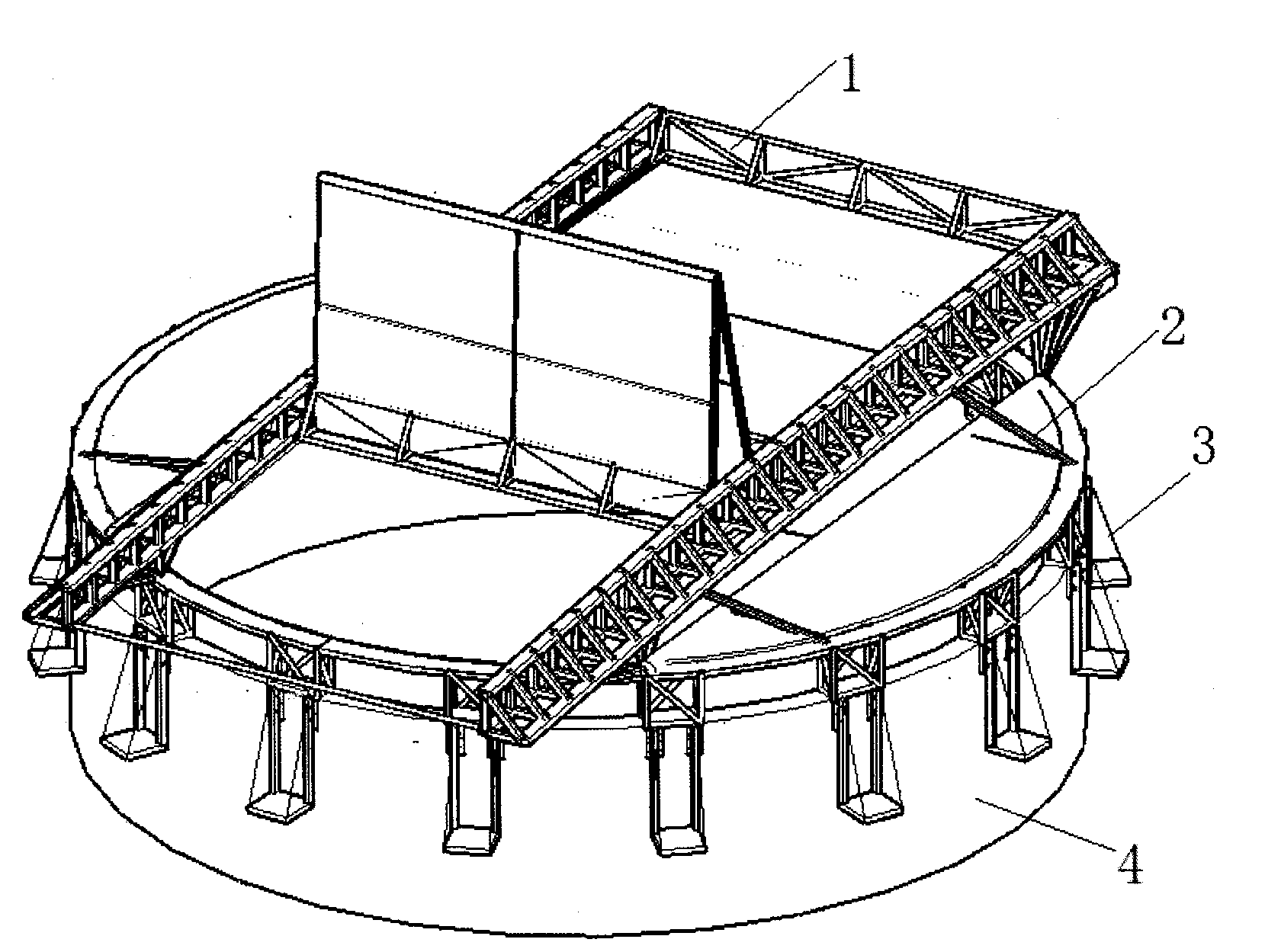

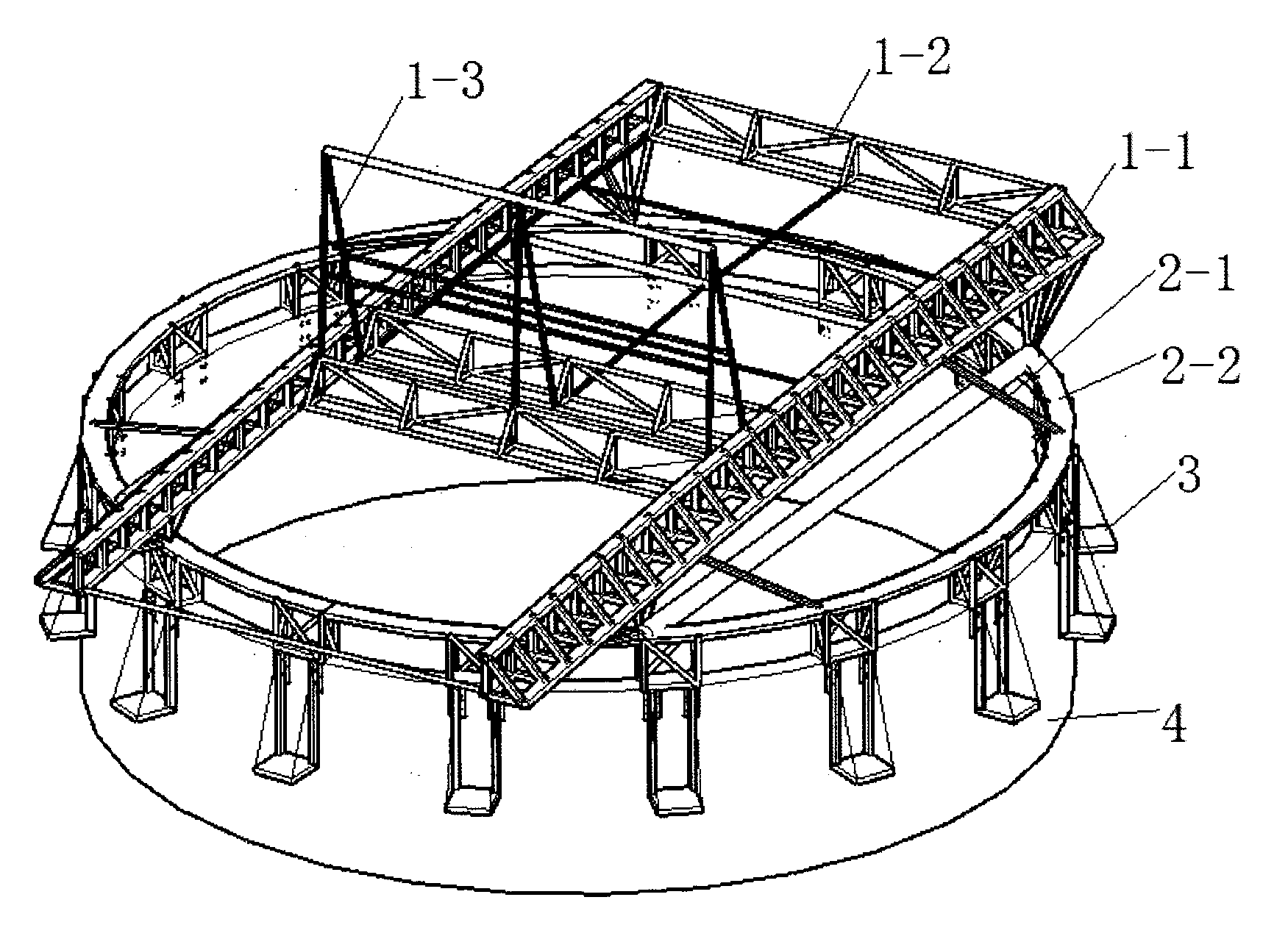

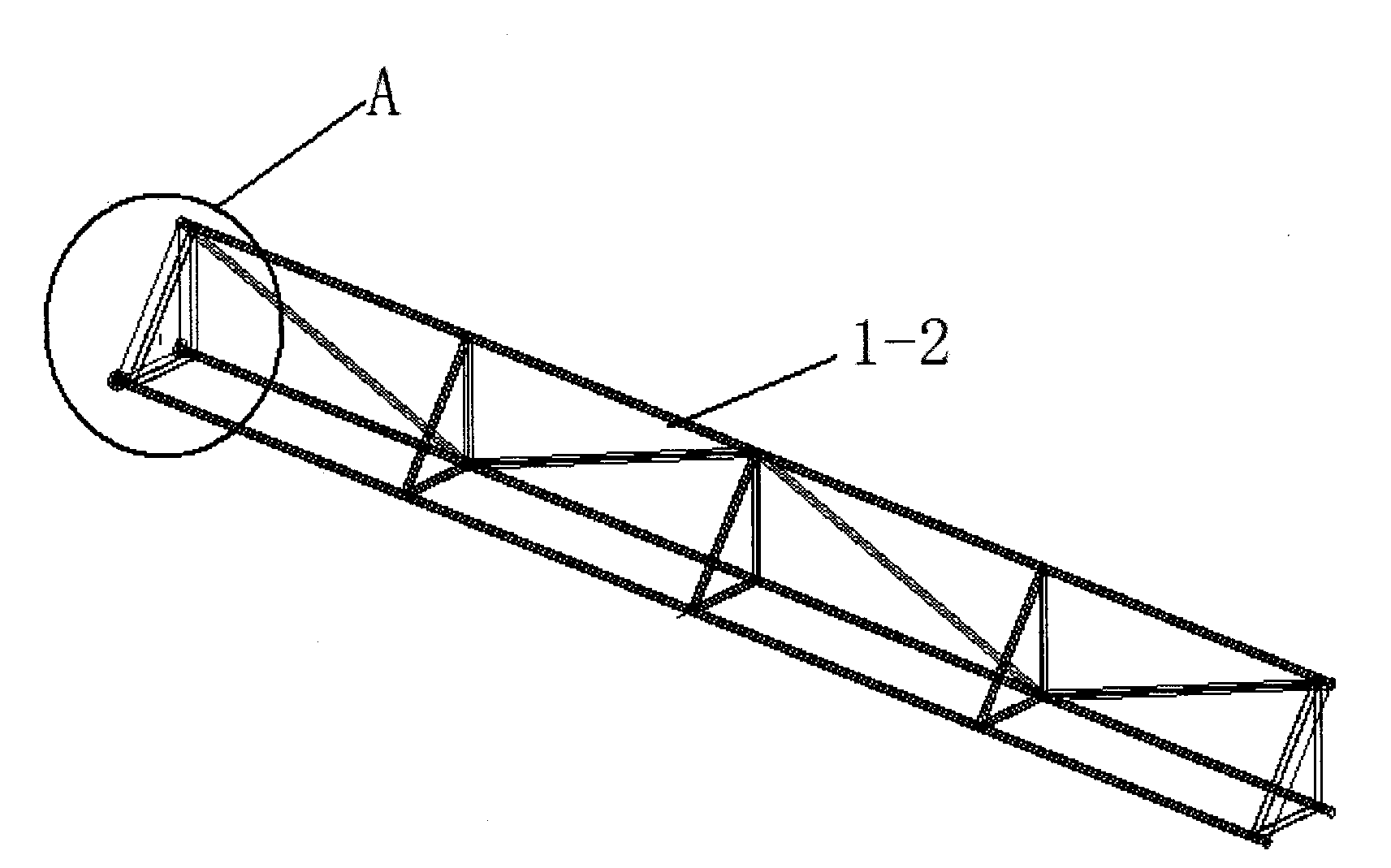

Construction support and method for overhead large-span heavy-duty cross beam

ActiveCN106677070ASimple structureEasy to processBridge erection/assemblySupporting systemPipe support

The invention discloses a construction support and method for an overhead large-span heavy-duty cross beam. The construction support comprises a lower bracket supporting structure, an upper bracket supporting structure located above the lower bracket supporting structure, and a middle supporting structure with the bottom supported on the lower bracket supporting structure. The top face of the upper bracket supporting structure is flush with the top face of the middle supporting structure, and the upper bracket supporting structure and the middle supporting structure form a temporary supporting platform for supporting the cross beam to be constructed. A load bearing structure is erected on the temporary supporting platform. The construction method comprises the steps that firstly, the lower bracket supporting structure is installed; secondly, the upper bracket supporting structure and the middle supporting structure are installed; thirdly, the load bearing structure is erected; fourthly, the support is prepressed; fifthly, the upper cross beam is constructed; and sixthly, the support is removed. According to the construction support and method, design is reasonable, construction is easy and convenient, the using effect is good, and the problems that as for an existing floor steel pipe supporting system, cost is high, the erection process is complex, the construction period is long, the construction risk is high, the requirement for supporting stability is high, and the construction progress of the upper cross beam is affected can be effectively solved.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

Joint section structure for hybrid beam cable-stayed bridge and construction method thereof

InactiveCN104294748ASimple structureReasonable designCable-stayed bridgeBridge structural detailsConcrete beamsCable stayed

The invention discloses a joint section structure for a hybrid beam cable-stayed bridge. The joint section structure comprises a concrete beam-combined beam connecting structure connected between a concrete beam and a combined beam, wherein the combined beam comprises steel girders distributed in the longitudinal direction of the bridge, the steel girders are I-shaped and comprise steel girder top plates, steel girder base plates and steel girder web plates. The steel girder top plates and the steel girder base plates extend into the concrete beam, and the concrete beam-combined beam connecting structure comprises a front pressure bearing plate, a rear pressure bearing plate and a joint section steel web plate. The joint section structure is simple, reasonable in design, high in construction speed and good in using effect, and the problems of complicated structure, poor joint effect and the like existing in a steel-concrete joint portion structure can be solved. The invention further discloses a construction method of the joint section structure. The construction method comprises the steps of 1 erecting a construction support; 2 hoisting a steel structure; 3 constructing the concrete beam-combined beam connecting structure; 4 casting concrete. The construction method is simple in step, reasonable in design, convenient to construct, high in construction speed and good in construction effect.

Owner:TONGJI UNIV

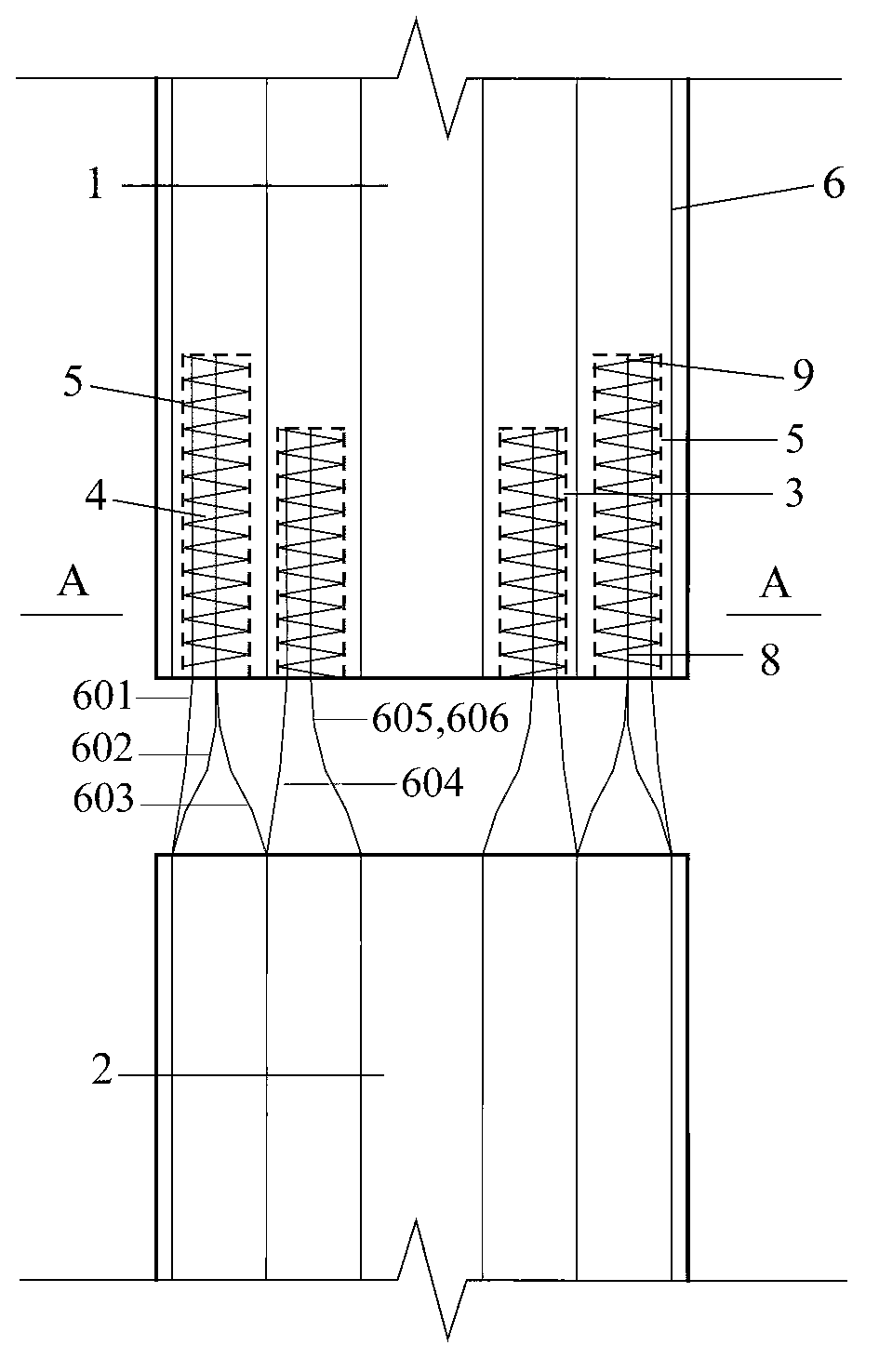

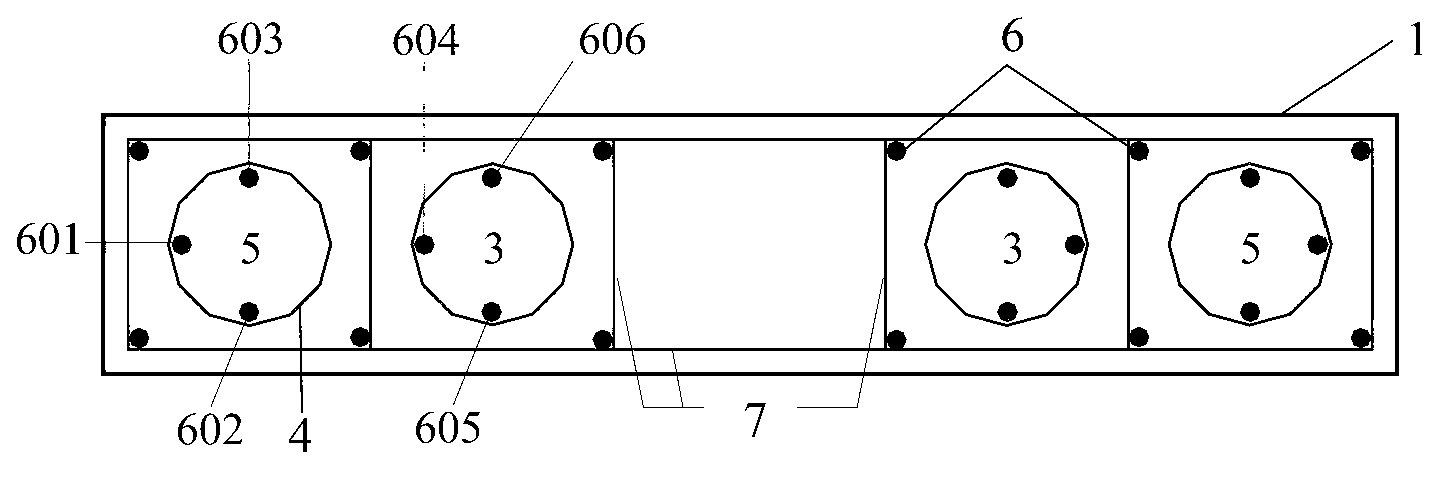

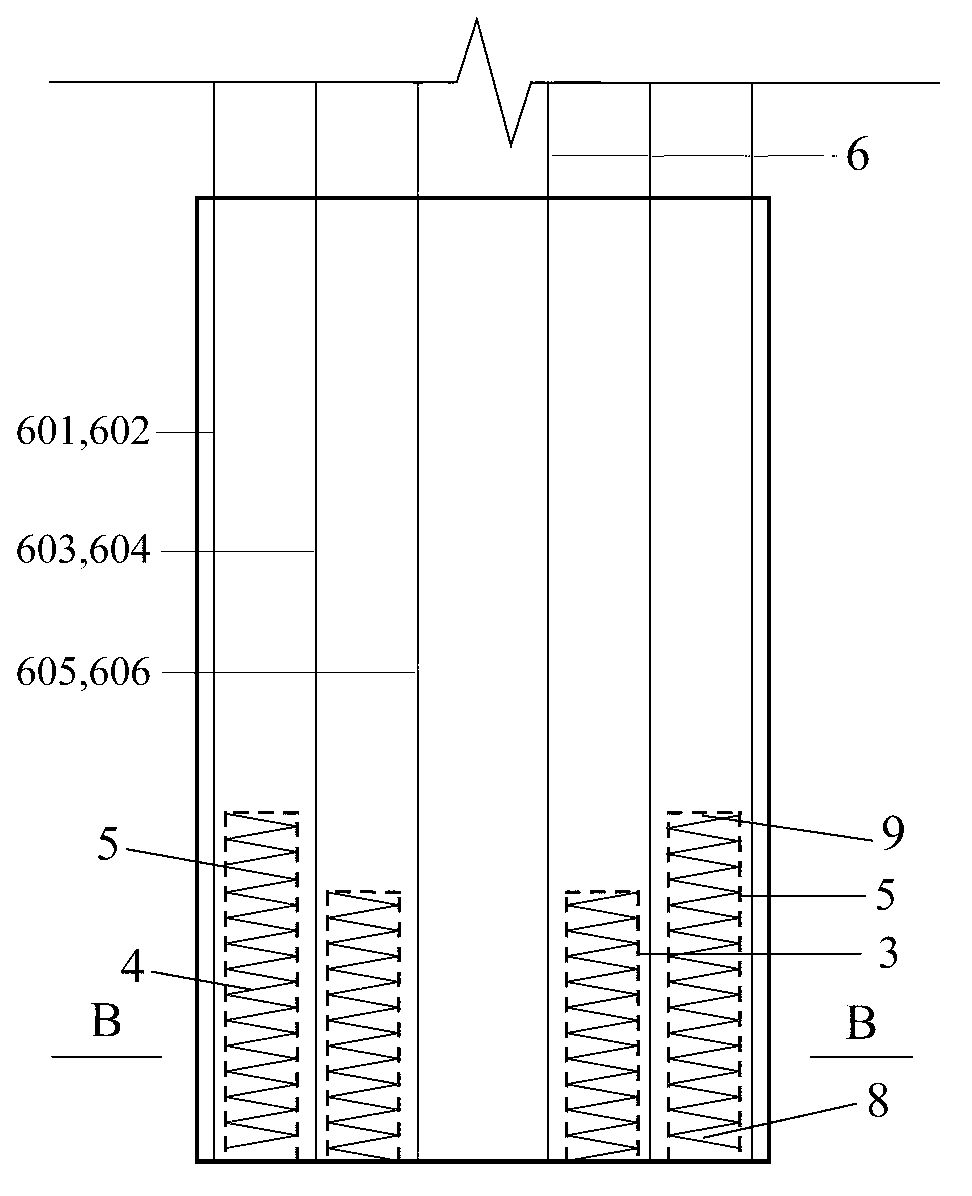

Prefabricated prestressed concrete frame beam-column joint making disparate use of high performance materials

ActiveCN105625572AReduce Beam SectionReduce steel consumptionShock proofingReinforced concrete columnConcrete beams

The invention discloses a prefabricated prestressed concrete frame beam-column joint making disparate use of high performance materials, comprising prefabricated concrete beams, prefabricated concrete columns, prefabricated beam-bottom prestressed tendons, common rebars, beam-top common rebars, in-column vertical rebars, sleeves, connecting rebars, and U-shaped rebars. Post-cast sections are reserved at two ends of the pre-fabricated beams, and the prestressed tendons fitted to the bottom of the prefabricated beams extend out of beam ends and are anchored to the beam-end post-cast sections, forming the prefabricated concrete beam-column joint with the prefabricated concrete beams and columns through post-cast concrete. In order to ensure the integrity of the beam-column joint, the beam-bottom common stressed rebars are connected with aseismic rebars through the sleeves and the U-shaped rebars are disposed in a joint post-cast area. In order to improve the energy dissipating capacity of the beam-column joint, the two ends of the prefabricated beams are made by casting high ultimate strain concrete. The invention reduces the production and construction difficulty, decreases the section height or steel usage of the prefabricated concrete beams and ensures the integrity and aseismic performance of the beam-column joint.

Owner:SOUTHEAST UNIV

Horizontal rotating construction method for steel truss beam bridge

ActiveCN104652290AReasonable structureClear forceTruss-type bridgeBridge erection/assemblyReinforced concreteConstruction engineering

The invention discloses a horizontal rotating construction method for a steel truss beam bridge. The horizontal rotating construction method comprises the following steps: constructing a reinforced concrete pile foundation, a cushion cap, a slideway, a main pier and a cap beam in a rotating system by using a conventional construction technology, and mounting a rotating spherical hinge as a core part for rotating; mounting an upper rotating plate on the slideway for construction; constructing the main pier and the cap beam; mounting a permanent support saddle of the main pier; preparing safety measures before rotating; determining a weight scheme before rotating; preparing a jack; rechecking before rotating; performing rotating construction operation. Compared with other processes, the horizontal rotating construction method for the steel truss beam bridge, provided by the invention, has the advantages of high construction speed and low construction cost. The construction of a lower structure can be synchronously finished in the manufacturing process of a steel beam in a factory; the hoisting operation of symmetrical cantilevers can be performed when a spliced site is hardened to reach the traveling strength of cranes like crawler crane; main expenses are rental expenses of the cranes, so the cost is reduced.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD +1

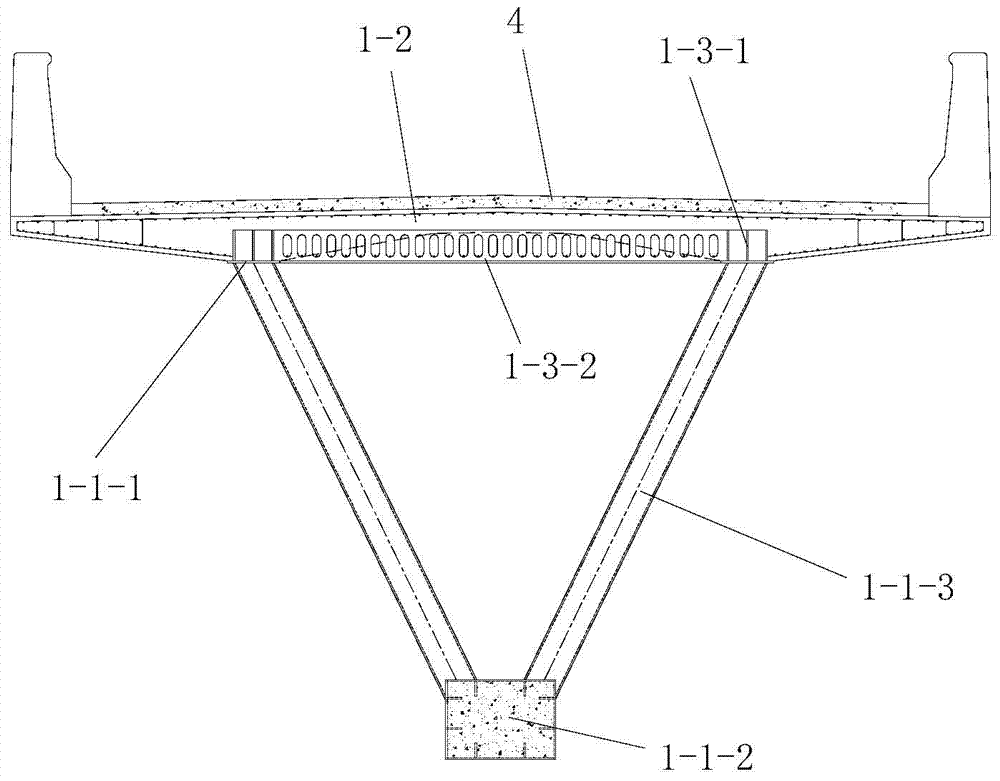

Prestress steel purlin-concrete combined continuous rigid frame bridge and construction method thereof

InactiveCN101644024ALight weightReduce size requirementsBridge structural detailsBridge erection/assemblyPurlinPre stress

The invention discloses a prestress steel purlin-concrete combined continuous rigid frame bridge and construction method thereof. A steel purlin concrete combined structure with upper and lower swingplates is adopted, girder subsection adopts different combined interfaces according to stress demand of bridge under each construction stage and operating condition, set in vitro and vivo prestress beams are timely applied in batch, and material advantages of the two are fully played; compared with the existing prestress concrete continuous rigid frame bridge, self weight of the girder is greatlyreduced, spanning capacity is obviously increased, and sub structural engineering quantity and bearing capacity requirement of foundation soil are correspondingly reduced. The invention adopts prefabricated concrete bridge road plate for splice, and the prefabricated concrete bridge road plate is joined with the steel truss girder, thus stress is clear and performance is reliable; construction isobviously simplified, quality of each parts is easy to control and check, and disease hidden troubles that the conventional prestress concrete continuous rigid frame bridge is not reliable in curve prestress long strand performance, concrete is cracked in tension and deflection is excessive for a long time caused by contraction creep are avoided.

Owner:CHONGQING JIAOTONG UNIVERSITY

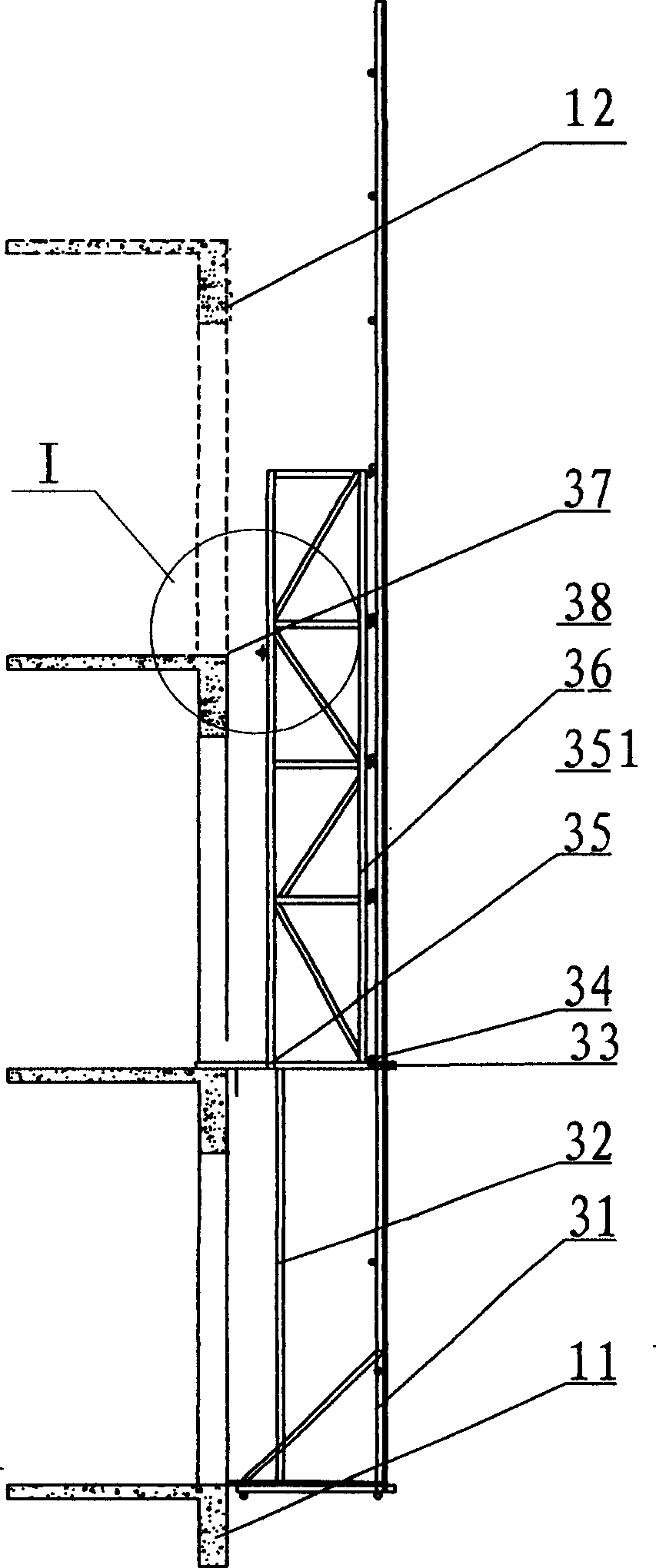

Protective frame special for construction of building main body

InactiveCN1786385ANo danger of working at heightsImprove efficiencyBuilding support scaffoldsFalseworkSafety net

The invention discloses building main body construction special prevention scaffold. It is scaffold sealed and around the building outline. It is divided into many units along length direction. Each of the units is used tower crane to lift singly. And it includes frame body and truss. The frame body is single row, formed by steel tube and fastener, and paved with safety net. And its side closed to building is connected to truss. Its features are that the truss and the building have at least two tie points; and the lower-rise tie point can bear the whole frame body dead weight and load. The invention has the advantages of safe, reliable, simple operation, and low cost.

Owner:姚康华

Prefabricated prestressed concrete frame beam column joint with U-shaped steel bar and sleeves

ActiveCN105649203AReduce Beam SectionReduce steel consumptionBuilding constructionsPre stressConcrete beams

The invention discloses a prefabricated prestressed concrete frame beam column joint with a U-shaped steel bar and sleeves. The prefabricated prestressed concrete frame beam column joint mainly comprises a prefabricated concrete beam, a prefabricated concrete column, prefabricated beam-bottom prestressed steel bars, prefabricated beam-bottom ordinary stressed steel bars, beam-top ordinary stressed steel bars, longitudinal steel bars in the column, the U-shaped steel bar and aseismic steel bars and the connecting sleeves thereof; post-casting sections are reserved at the two ends of the prefabricated beam, and the prestressed steel bars assembled at the bottom of the prefabricated beam stretch out of the beam ends and are anchored to the post-casting sections reserved at the beam ends to form the prefabricated concrete frame beam column joint with the prefabricated beam column through post-casting concrete. The ordinary stressed steel bars stretching out from the bottom of the beam are connected with the aseismic steel bars through the sleeves, the U-shaped steel bar is arranged on the post-casting area of the joint, and therefore the integrality of the beam column joint is enhanced. Accordingly, the production and construction difficulty is reduced, the section height or the steel dosage of the prefabricated concrete beam is decreased, and the integrality and aseismic property of the beam column joint are guaranteed.

Owner:SOUTHEAST UNIV

Shape memory alloy composite flange friction steel structure beam column splicing joint

The invention discloses a shape memory alloy composite flange friction steel structure beam column splicing joint.The joint is composed of a column, a bracket, a beam, a web plate bolt, a web plate splicing plate, a shape memory alloy wire, a flange splicing plate and double nuts and bolts, wherein the bracket stretches from the column in the direction of the beam, a web plate of the bracket and a web plate of the beam are spliced through a high-strength bolt, a flange of the bracket and a flange of the beam are spliced through the double nuts and bolts, and the shape memory alloy wire is wound between the double nuts and bolts.According to the joint, energy-dissipating capacity is provided through friction damping in a small earthquake, energy-dissipating capacity is provided through friction damping and superelasticity damping together in a major earthquake, the joint can recover to the original state after the earthquake, and the joint has the advantages of being simple in structure, high in practicality, definite in stress, high in energy dissipation, capable of achieving self-restoration and the like.

Owner:SUZHOU UNIV OF SCI & TECH

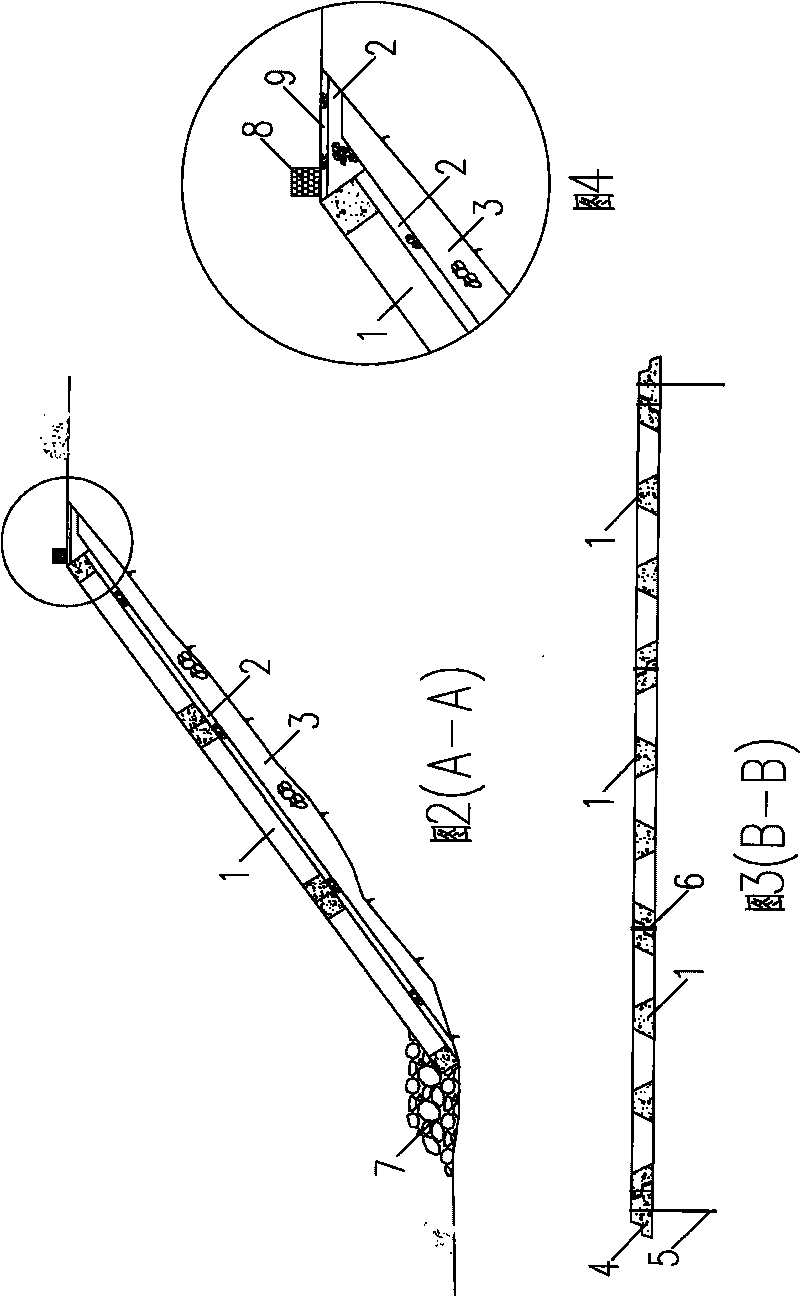

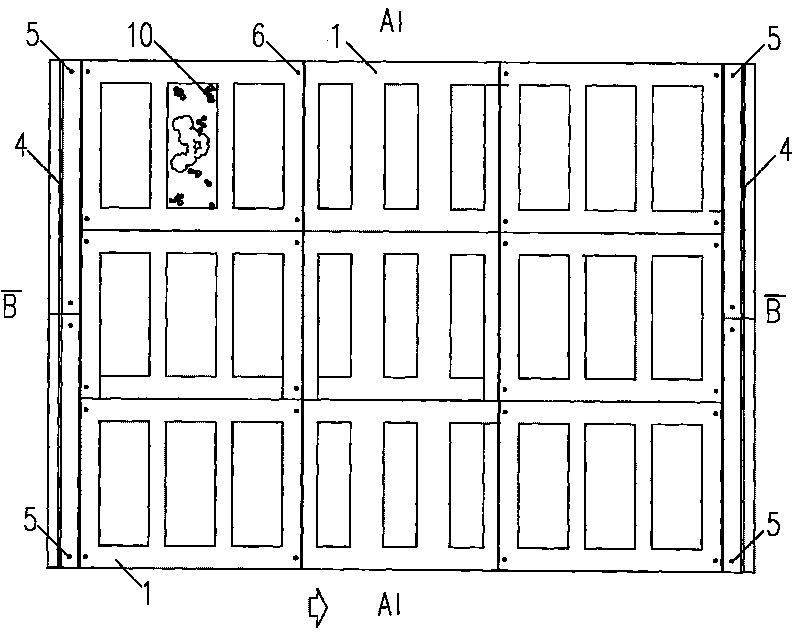

Assembled protective slope structure and construction method thereof

ActiveCN101698990ASimple construction processImprove construction progressCoastlines protectionBrickCrushed stone

The invention relates to an assembled protective slope structure and a construction method thereof. The technical problem which needs to be solved by the invention is to provide an assembled protective slope structure and a construction method thereof to solve the technical problems of short construction period, high progress requirements and difficult implementation in the side slope protection engineering. The invention has the following technical scheme for solving the problems: the structure is provided with a plurality of concrete grid plates which are embedded positively and negatively to form a protective slope with holes, and a broken stone cushion layer and a block stone cushion layer are sequentially arranged below the concrete grid plates; concrete inverted T beams which are embedded with the grid plates are respectively arranged at the left side and the right side of the protective slope formed by the concrete grid plates, and the inverted T beams are fixed with side slope rock bodies through anchor bars I; and prism protecting pins are stacked at the lower ends of the concrete grid plates near a river bed, and brick skirts are arranged at the upper ends of the concrete grid plates and are connected with shore roads by cement coating above the broken stone cushion layer. The invention is suitable for hydraulic and hydro-power engineering, marine traffic engineering, and the like.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

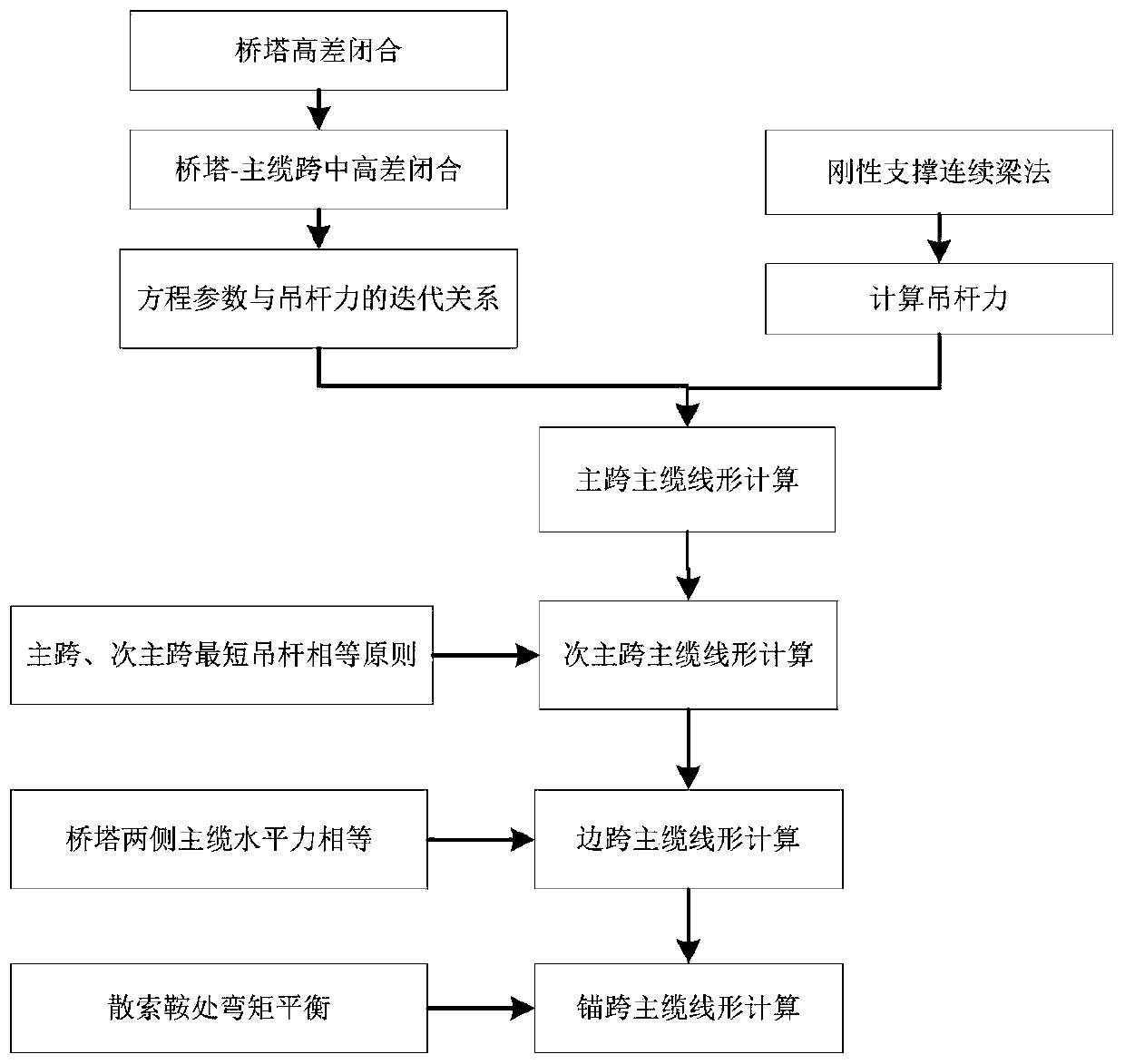

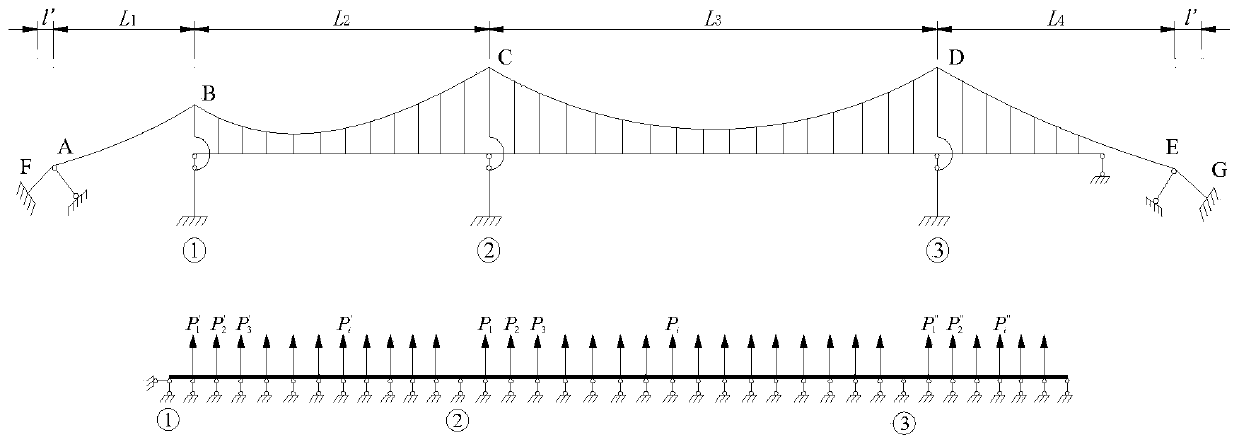

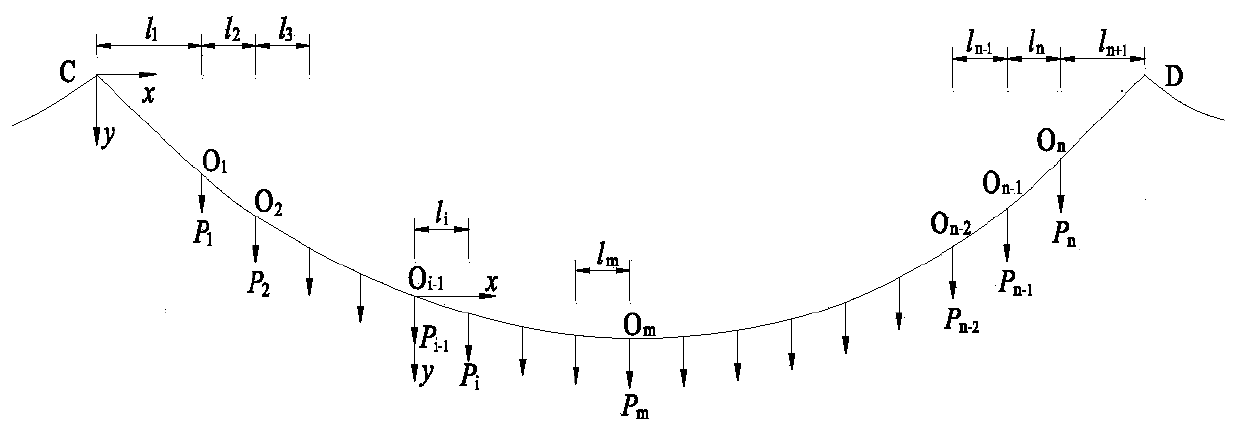

A method for constructing a main cable line shape of a three-tower suspension bridge with unequal main spans

ActiveCN109815588ANice appearanceEconomically reasonableBridge erection/assemblySpecial data processing applicationsHorizontal forceContinuous beam

The invention discloses a method for constructing a main cable line shape of a three-tower suspension bridge with unequal main spans. The method comprises the following steps of firstly, calculating suspender force by utilizing a rigid support continuous beam method; secondly, calculating the line shape of the main span main cable according to the tower top height difference closing condition of the main span two-bridge and the bridge tower top and main cable midspan height difference closing condition; according to the principle that the horizontal forces of the main cables on the two sides of each bridge tower are equal and the principle that the shortest suspenders of the main span and the secondary main span are equal, deducing the line shape of the main cable of the secondary main span and the elevation of the low tower; secondly, according to the principle that the horizontal forces of the main cables on the two sides of each bridge tower are equal, the height difference betweenside towers and cable saddle IP points is known, and deriving the main cable shapes of left and right side spans; and finally, deriving the main cable line shapes of the left and right anchor spans according to the known main cable tension at the splay saddle, the bending moment balance of the splay saddle by the dead weight of the splay saddle and the known height difference between the splay saddle IP points and the anchoring points. The structural system is attractive in appearance, clear in stress, and is economical and reasonable.

Owner:SOUTHEAST UNIV

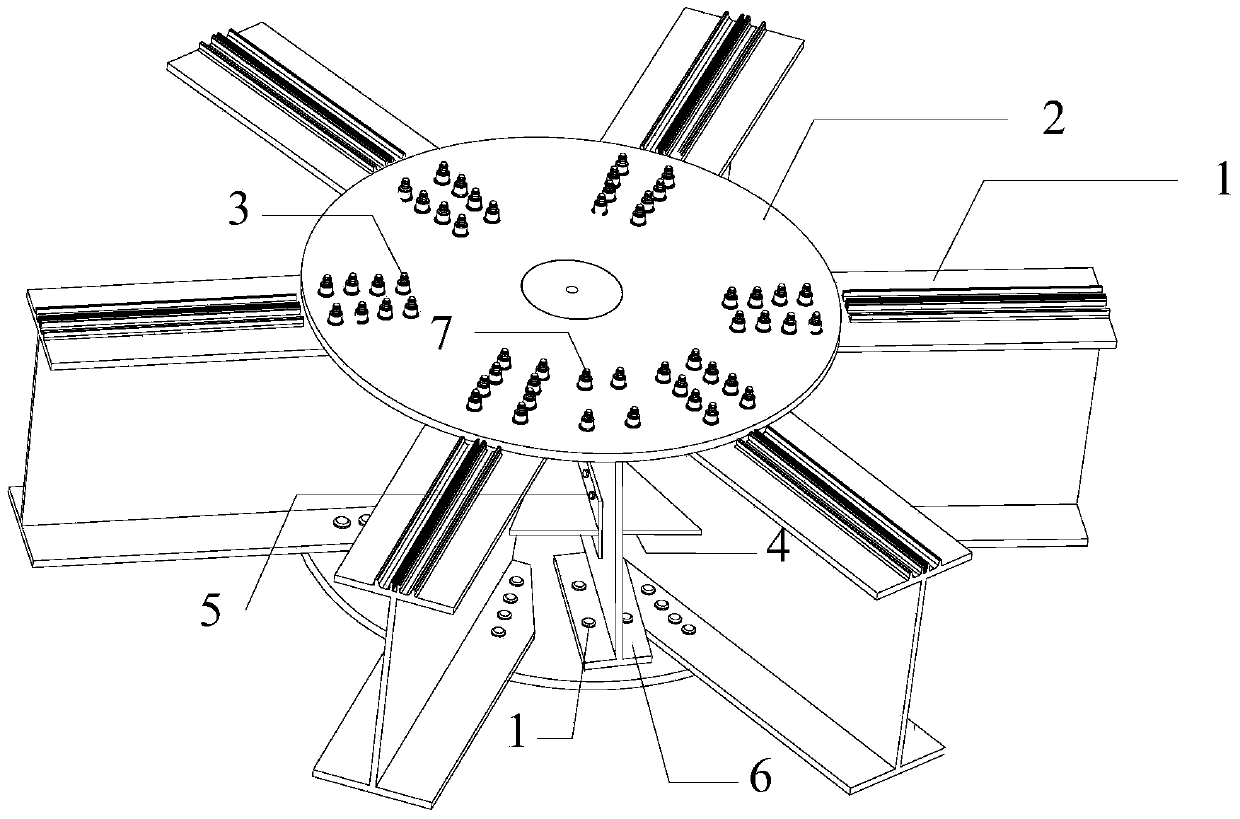

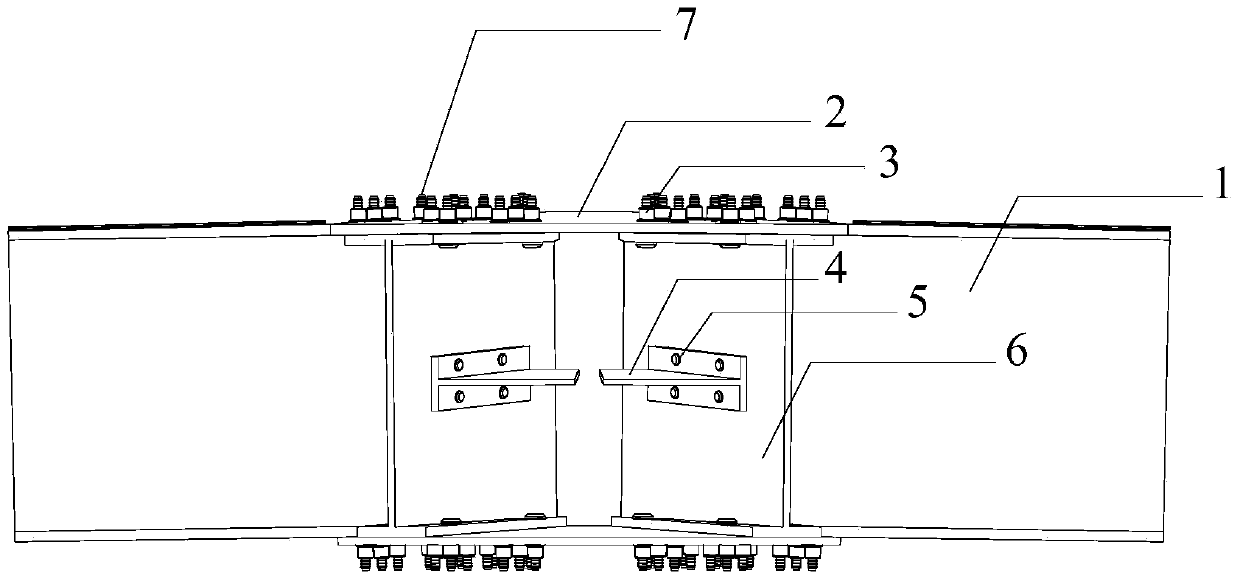

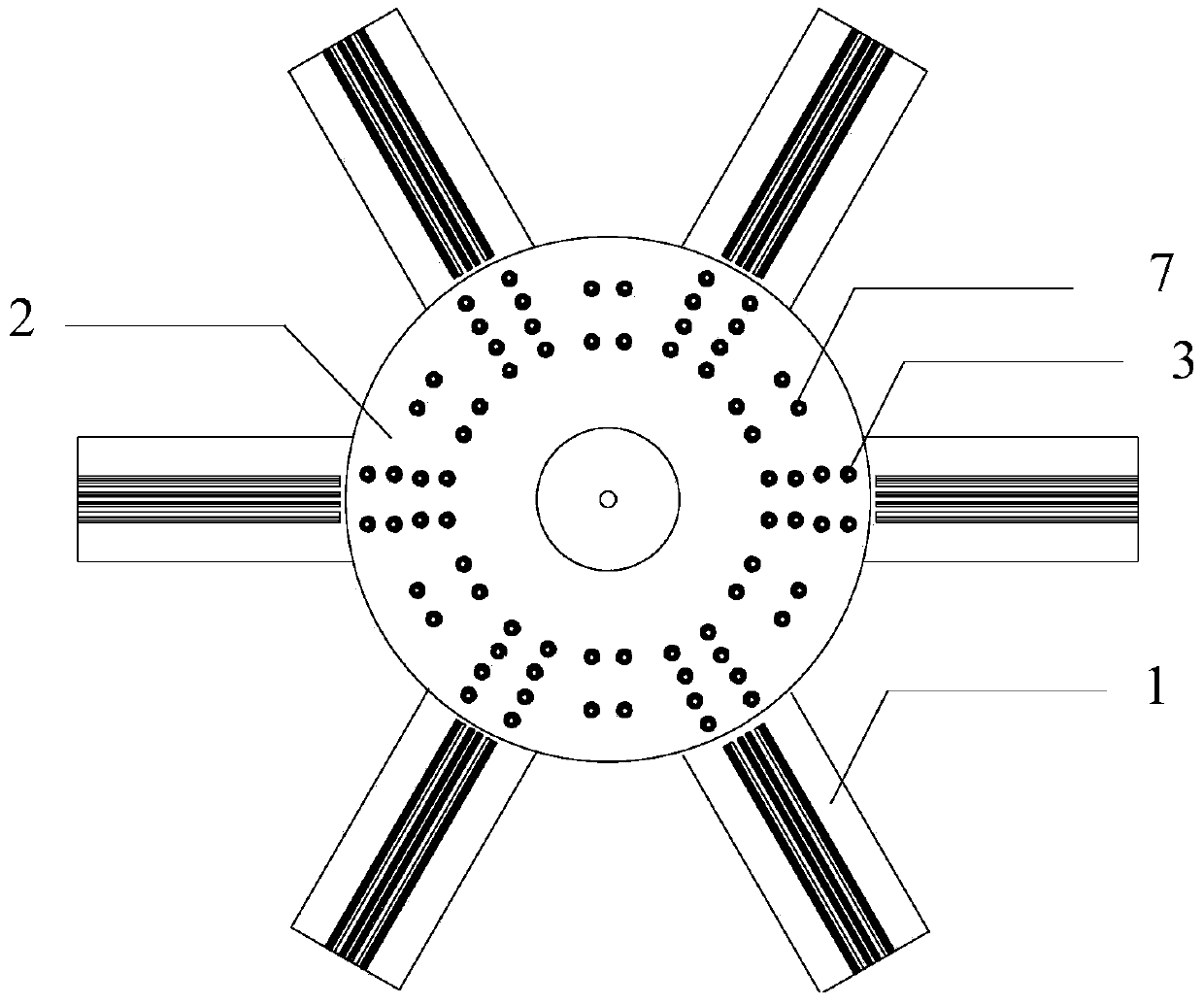

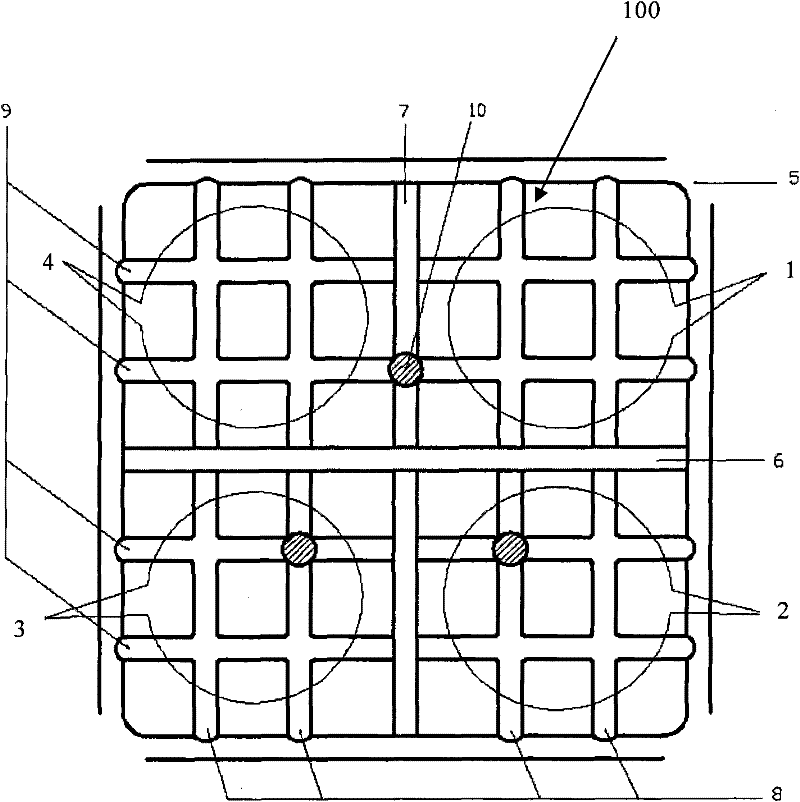

Aluminum alloy space grid structure slab rib node

InactiveCN103437427AClear forceIncreased bearing capacity and stiffnessBuilding constructionsMesh gridStructural engineering

The invention discloses an aluminum alloy space grid structure slab rib node. The aluminum alloy space grid structure slab rib node comprises two aluminum cover plates arranged up and down in parallel and at least two H-type aluminum rod pieces fixedly connected between the two aluminum cover plates through first bolts. an H-type vertical aluminum rib slab is arranged between every two adjacent H-type aluminum rod pieces, and the upper ends and the lower ends of the H-type vertical aluminum rib slabs are fixedly connected with corresponding aluminum cover plates through second bolts. According to the aluminum alloy space grid structure slab rib node, because annular rib slabs and vertical rib slabs are additionally arranged on an existing cover plate node, the internal rigidity and the external rigidity of a node plane are increased. The node distinctly bears force, the rigidity and bearing capacity of the aluminum alloy grid node can be improved, the performance of aluminum alloy is improved, some potential safety hazards can be avoided, and the safety of the aluminum alloy structure can be guaranteed.

Owner:TIANJIN UNIV

Temporary cross bracing of space cable suspension bridge and lifting-constructing method of temporary cross bracing

InactiveCN104060540AStable structureEasy to set upBridge erection/assemblyEngineeringStructural engineering

The invention provides temporary cross bracings of a space cable suspension bridge and a lifting-constructing method of the temporary cross bracing. The lifting-constructing method comprises the following steps: firstly, mounting a main cable; secondly, mounting trusses at positions of mid-span, one-fourth span, and three-fourths span to form a developed bridge space cable surface for supporting cables; thirdly, mounting cable clamps and suspension cables; finally, lifting and mounting a steel box girder. According to the method of the invention, the constructing method is adopted, that is, the main cable is erected firstly, and then a stiffening girder is lifted and mounted, so that the navigation requirement during a constructing period can be ensured and the disadvantage of erecting a temporary support can be overcome; through arranging truss cross bracings, the main cable is transited from a cable horizontal alignment shape to a developed bridge space cable shape; the cable clamps does not need to be pre-deflected in a horizontal bridge direction; all that is needed is to mount the cable clamps according to the inclined angle formed by that the suspension cables are perpendicular to a down bridge direction under the condition of the developed bridge so as to ensure that the parts between the ear plates of the cable clamps and the ear plates of the suspension cables do not bend during the lifting and mounting process of the steel box girder.

Owner:CHANGAN UNIV

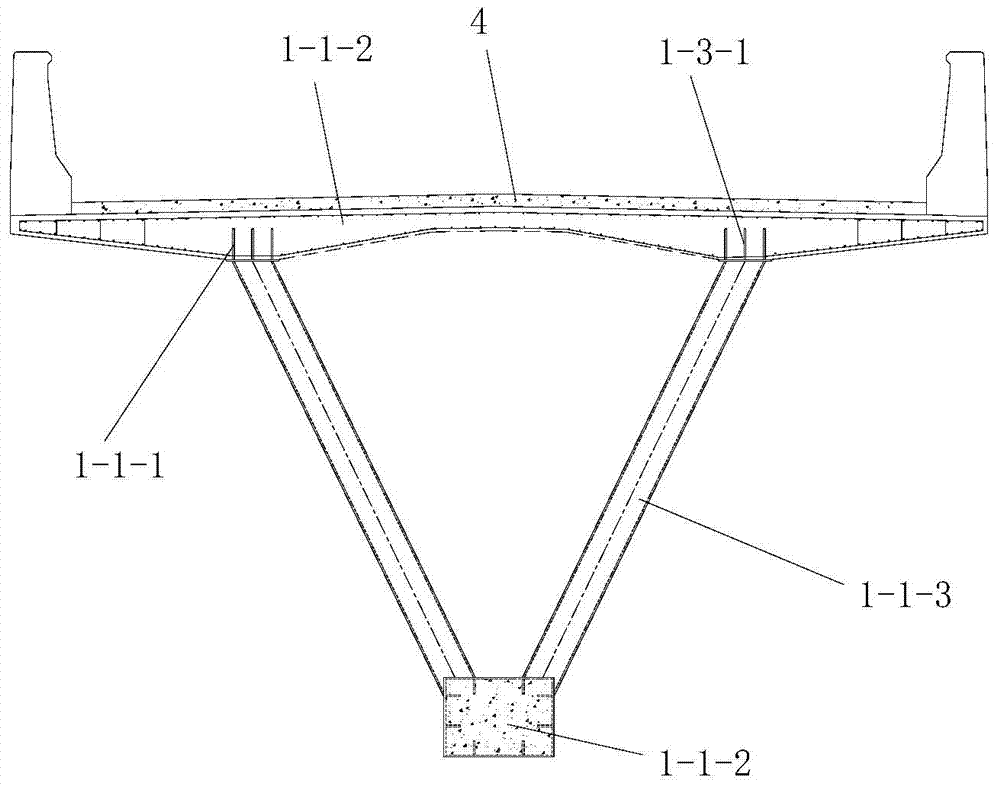

Continuous rigid frame bridge based on steel truss-concrete slab composite beam

InactiveCN103669194ALight weightImprove leaping abilityTruss-type bridgeBridge structural detailsSheet steelBridge deck

The invention discloses a continuous rigid frame bridge based on a steel truss-concrete slab composite beam. The continuous rigid frame bridge comprises a bridge substructure and the steel truss-concrete slab composite beam supported by the bridge substructure. The steel truss-concrete slab composite beam comprises a steel truss and a concrete bridge deck which is laid over the steel truss. The steel truss comprises one or more steel truss units; each steel truss unit is an inverted-triangle truss girder, wherein the inverted-triangle truss girder is composed of two upper chords, a lower chord, a left line of diagonal web members and a right line of diagonal web members, each upper chord comprises a first horizontal steel plate and a plurality of first vertical perforated steel plates evenly laid on the first horizontal steel plate, an upper chord transverse connecting system connected between the two upper chords comprises a plurality of upper chord transverse connecting pieces, and each upper chord transverse connecting piece comprises a second horizontal steel plate and a plurality of second vertical perforated steel plates evenly laid on the second horizontal steel plate. The continuous rigid frame bridge is simple in structure, reasonable in design, convenient to construct, good in stress performance, good in using effect and capable of effectively solving various problems existing in an existing continuous rigid frame bridge.

Owner:CHANGAN UNIV

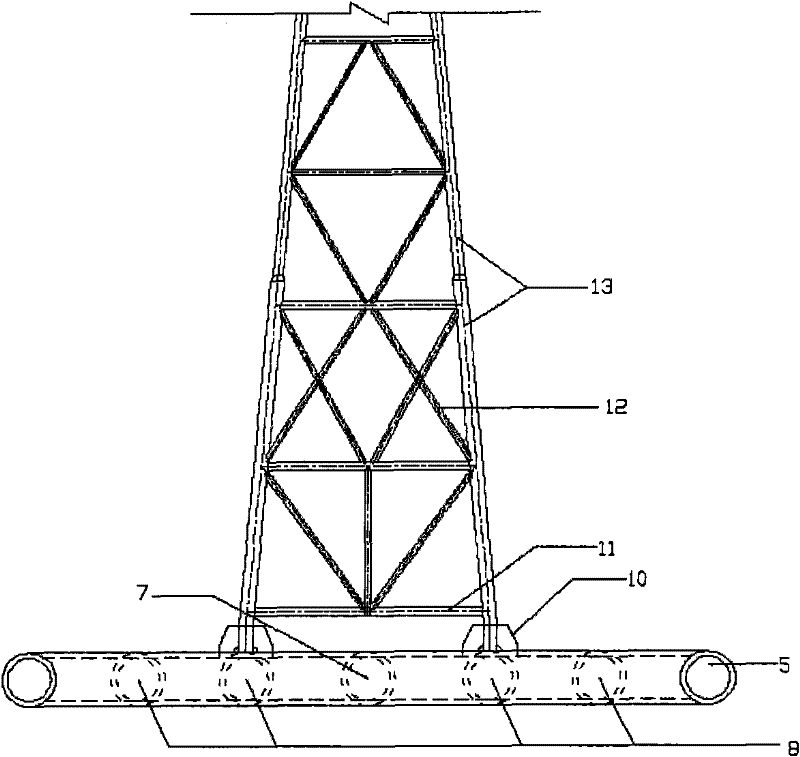

Steel row type wind measurement tower base and wind measurement tower structure

ActiveCN102182203AReduce productionEasy to understandFoundation engineeringTowersInlet valveEngineering

The invention provides a steel row type wind measurement tower base and a wind measurement tower structure. The steel row type wind measurement tower base comprises a steel row structure formed by intersecting a plurality of hollow steel pipes in a horizontal direction and a vertical direction, the periphery of the steel row structure is encircled by four hollow edge steel pipes, each edge steel pipe is provided with a steel row water inlet and a corresponding water inlet valve, and water can flow through the steel row water inlet through the outside of the water inlet valve and then flows into the hollow steel pipes of a steel row structure. The steel row type wind measurement tower base has the advantages of simple and convenient construction, low cost, favorable carrying effect, high safety and the like.

Owner:江苏道达风电设备科技有限公司

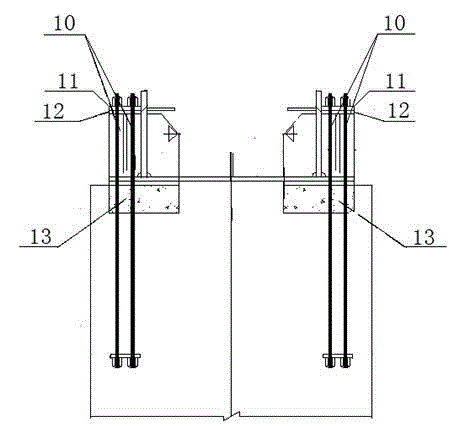

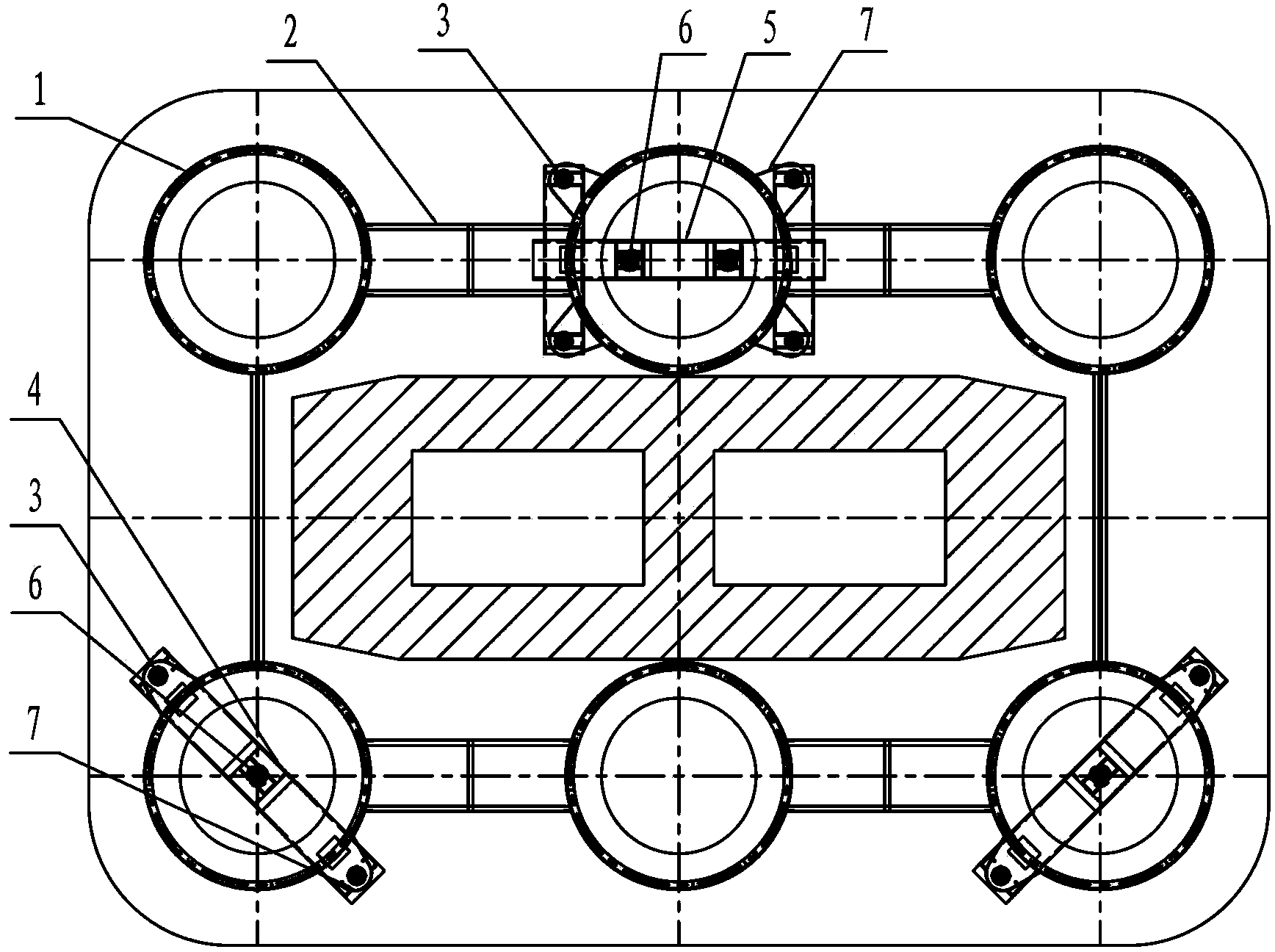

Prefabricated bearing platform mounting method

ActiveCN103362068ASmall construction impactImprove construction stabilityFoundation engineeringBridge erection/assemblyCofferdamWater flow

The invention discloses a prefabricated bearing platform mounting method and relates to the field of bridge construction. The prefabricated bearing platform mounting method comprises the following steps that a bearing platform and bottom pier bodies are prefabricated in a prefabrication field, and steel pile hole positions are reserved in the bearing platform; the bearing platform is lifted to a pile site by a large floating crane; a pile top guiding device is pre-mounted on steel piles in the pile site before the bearing platform is lifted; after the bearing platform is lifted down and is in place, a carrying pole is arranged on a pile top longitudinal direction adjusting position in a hanging manner, and the horizontal plane of the bearing platform is regulated as required; and the pouring of bottom-sealing concrete of a steel cylinder cofferdam, the water pumping, the binding of reserved hole steel reinforcing bars, and the pouring of reserved hole concrete at non-lifting points and lifting points are sequentially finished, and the steel cylinder cofferdam is detached, so that the mounting of the prefabricated bearing platform is finished. According to the prefabricated bearing platform mounting method disclosed by the invention, a small steel cylinder cofferdam replaces a large bearing platform steel cofferdam, so that the steel material can be effectively saved, the on-water operation time is shortened, and the construction cost is reduced; and meanwhile, the influence of water flow to the construction of the bearing platform is reduced, and the construction quality of the bearing platform is ensured.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Open-type dome steel structure

ActiveCN103306412ASimple structureSimple structure opening and closing methodBuilding roofsOpen typeBuilding construction

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

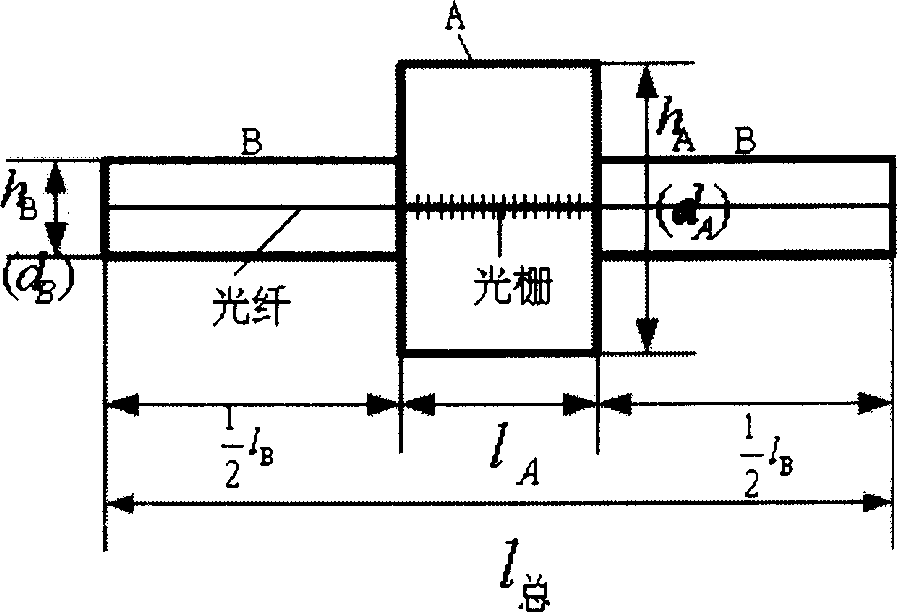

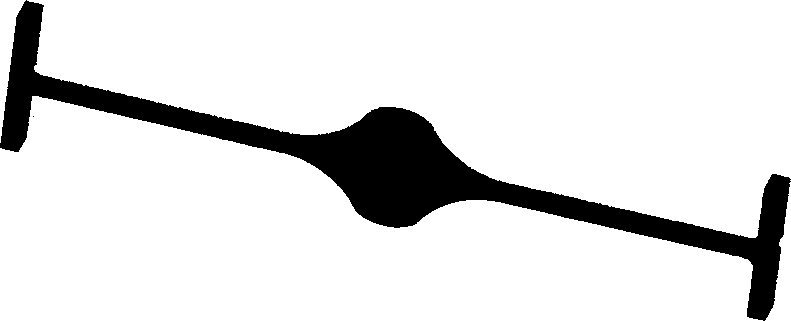

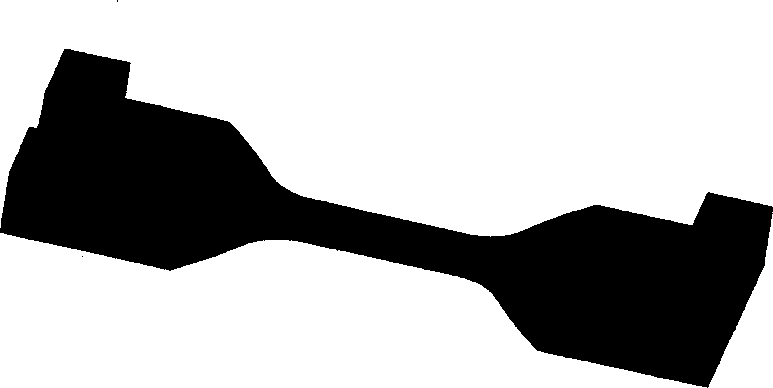

Design method and making process of fibre-optical grating sensitization strain transducer

InactiveCN1869582ASolving challenges limited by the properties of encapsulating polymersSimple structureForce measurement by measuring optical property variationUsing optical meansGratingManufacturing technology

The invention offers the designing method and manufacturing technology for the optical fiber raster fluctuating sensitive strain gage. It includes fluctuating sensitivity theoretical derivation, enhanced sensitivity coefficient definition, material selection, and structure form determination. And it has the advantages of simple structure, low cost, variable enhanced sensitivity coefficient, and good practicality etc. It ban be used to do macro-strain and high precision measuring, especially for the monitoring of the civil engineering superficial structure and concrete built-in strain.

Owner:HARBIN INST OF TECH

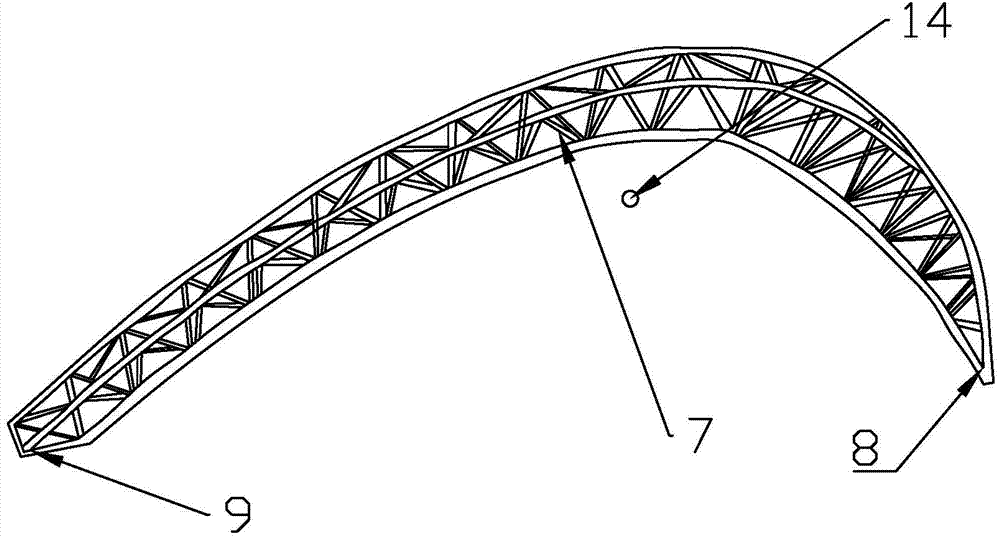

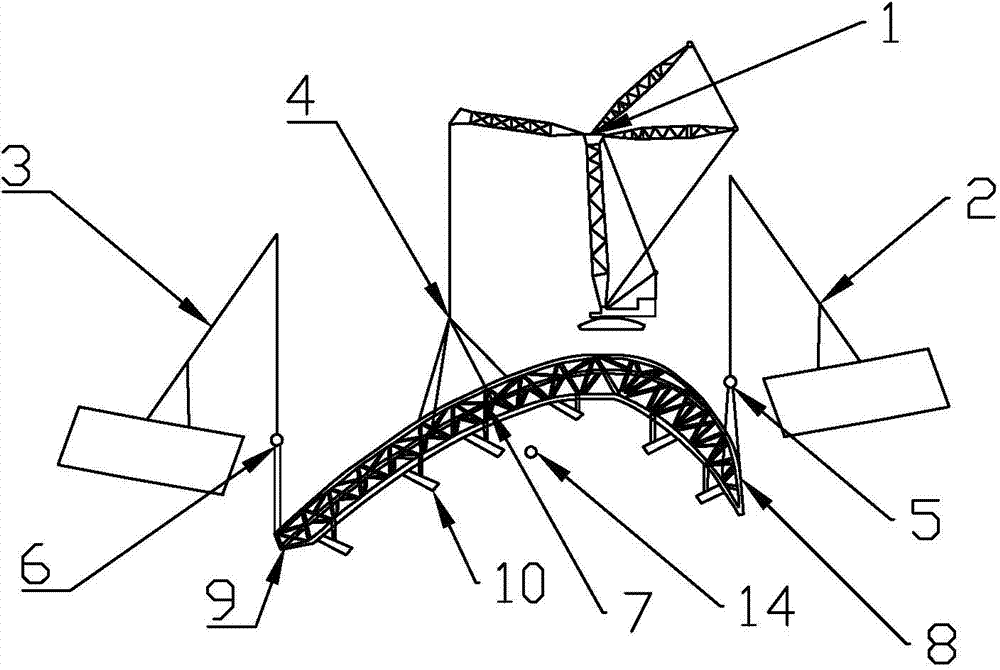

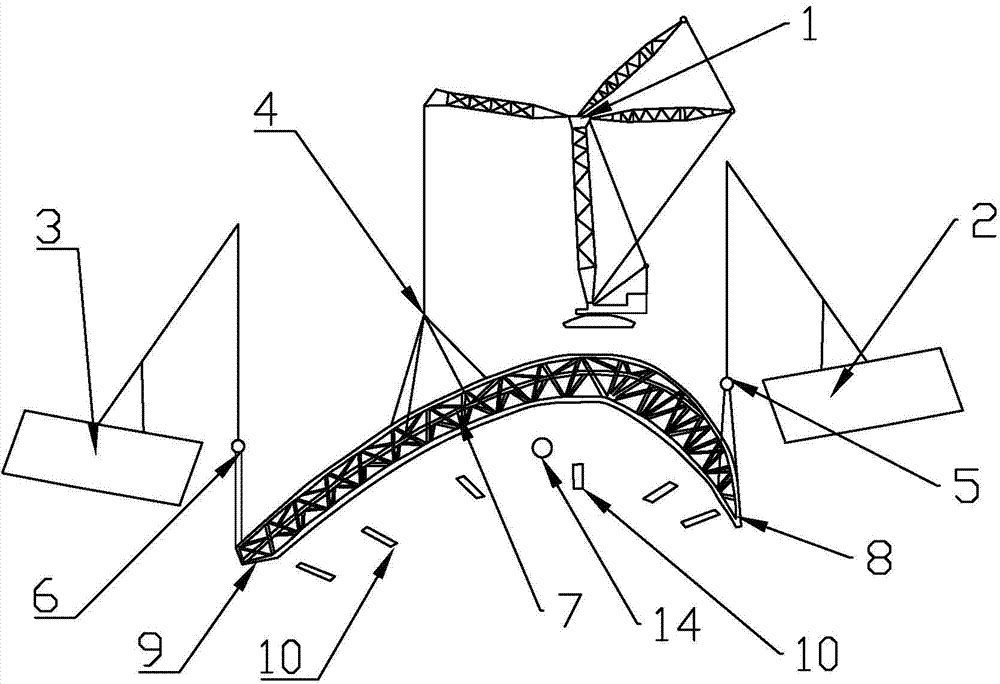

Construction method for three-crane lifting installation used for bow-shaped space truss

ActiveCN104746883ASave hoisting costsReduce split dockingBuilding material handlingButt jointGravity center

The invention discloses a construction method for three-crane lifting installation used for a bow-shaped space truss. The construction method includes the following steps of conducting simulation to determine the gravity center of the bow-shaped space truss, arranging three lifting points and three cranes, conducting separation through the three cranes, conducting carrying and correcting work after separation is completed, hoisting the bow-shaped space truss on a platform, and fixing the bow-shaped space truss to the platform. The construction method is simple, easy to achieve, high in installation efficiency, scientific, convenient and capable of saving the labor cost and greatly reducing hoisting expenses. By separating, carrying, correcting and hoisting the whole bow-shaped space truss, sectional butt joint and correction of the truss are reduced, aloft welding does not need to be conducted between sectional trusses, and therefore the installation quality and the welding quality are improved, the truss installation construction period is shortened, and truss hoisting expenses are saved.

Owner:浙江中南绿建科技集团有限公司

Prefabricated assembling whole type shear wall connected with staggered-height vertical steel bar

The invention provides a prefabricated assembling whole type shear wall connected with a staggered-height vertical steel bar, comprising an upper-layer wall body and a lower-layer wall body, wherein the two ends of the bottom of the upper-layer wall body are provided with a first reserved hole and a second reserved hole, which are vertical; the vertical height of the second reserved hole is 1.2-1.5 times as much as the vertical height of the first reserved hole; a spiral stirrup which is as high as the first reserved hole and the second reserved hole is respectively pre-buried in each one of the first reserved hole and the second reserved hole; vertical steel bars at the inner side of an edge member of the lower-layer wall body are bundled by groups; a plurality of combined steel bar bundles are respectively inserted into the first reserved hole and the second reserved hole; and concrete mortar materials are filled between the steel bar bundles and the first reserved hole, and between the steel bar bundles and the second reserved hole. According to the prefabricated assembling whole type shear wall, the concrete of a pressed region can be effectively restricted and the prefabricated assembling whole type shear wall can be used for overlapping the vertical steel bars in a prefabricated shear wall system.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com