Patents

Literature

65results about How to "Save hoisting costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

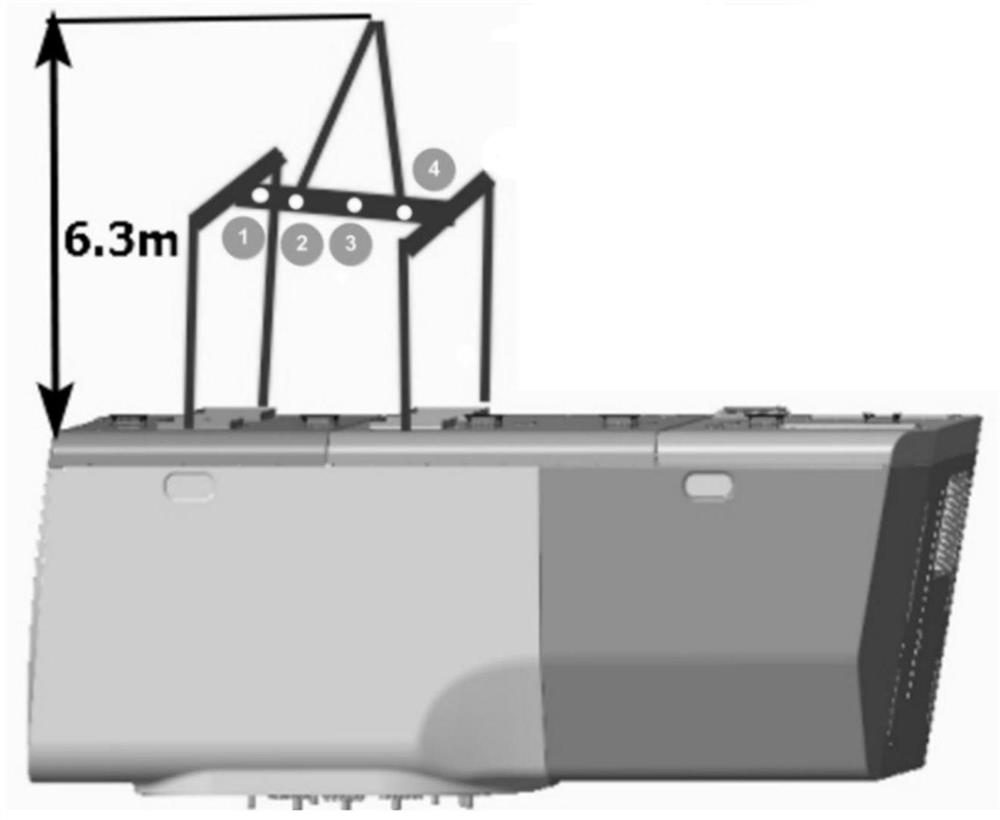

Tail device and tail dragging method

InactiveCN103058054AGuaranteed connectionStable equilibriumLoad-engaging elementsEngineeringGravity center

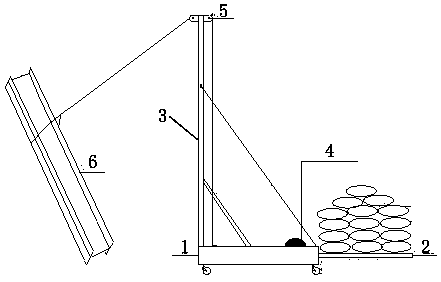

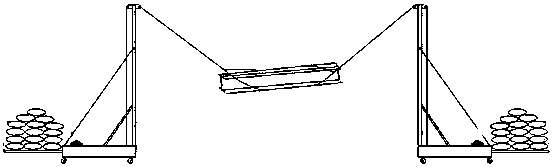

The present invention discloses a tail device and a tail dragging method. The tail device comprises: a tail end row which at least comprises a boom system, a travelling mechanism and a lifting mechanism, wherein the boom system is provided with a lifting mechanism and is supported on the travelling mechanism; and a tailstock which is used for being removably fixed to the lower part of a lifted device, and is provided with lifting holes. In the process of lifting the lifted device from the ground, the lifting mechanism is in hanging connection with the lifting holes, and the lifting holes are located at the end deviating from the ground. When the tail device is use for lifting a device, the center of gravity of the lifted device can be guaranteed to be always located below a connection line between the lifting point of main lifting equipment and the lifting point or the support point of the tail end row. The tail device has the advantages of good security, small weight borne by the tail end row, low lifting cost, etc.

Owner:SANY HEAVY IND CO LTD (CN)

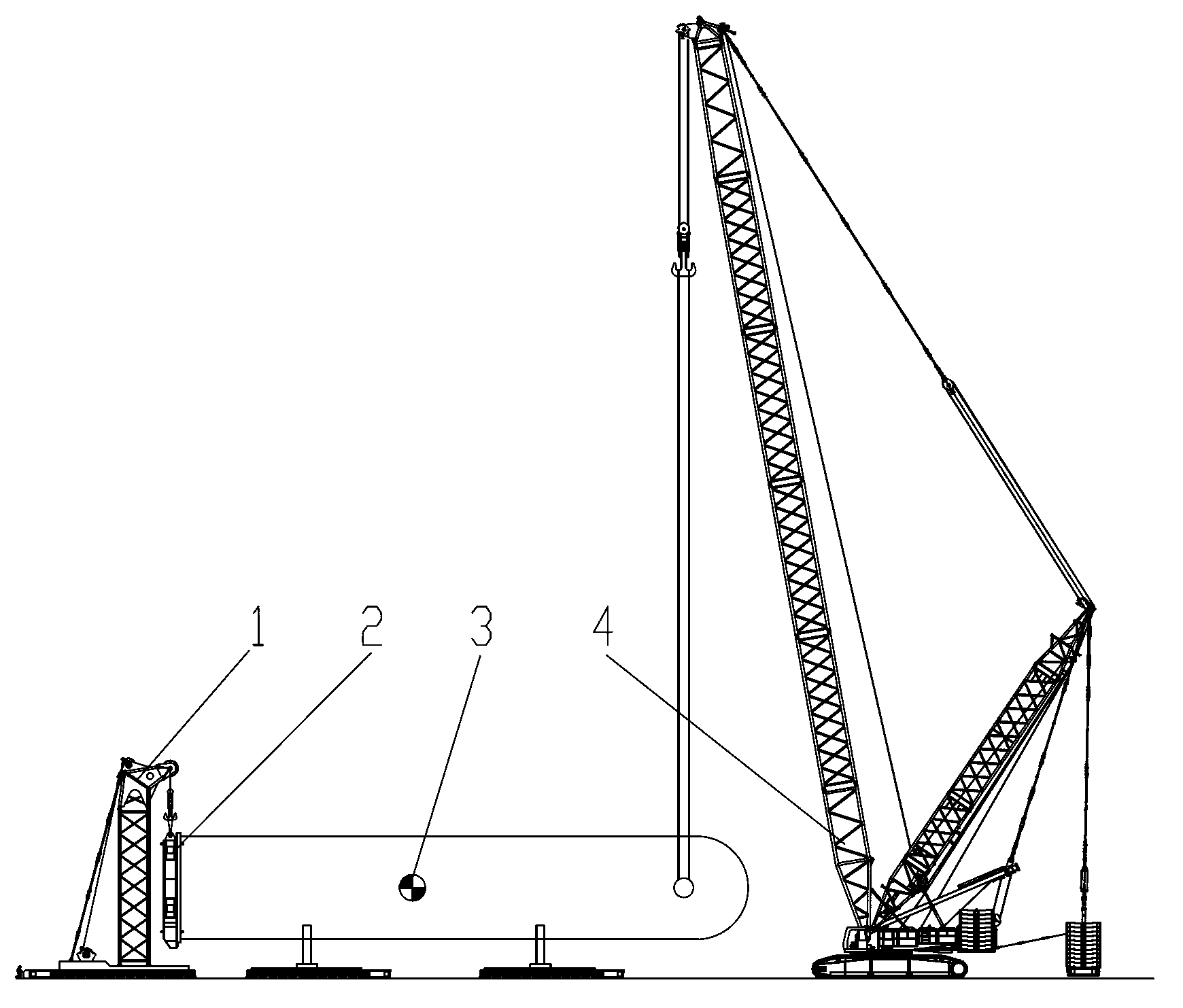

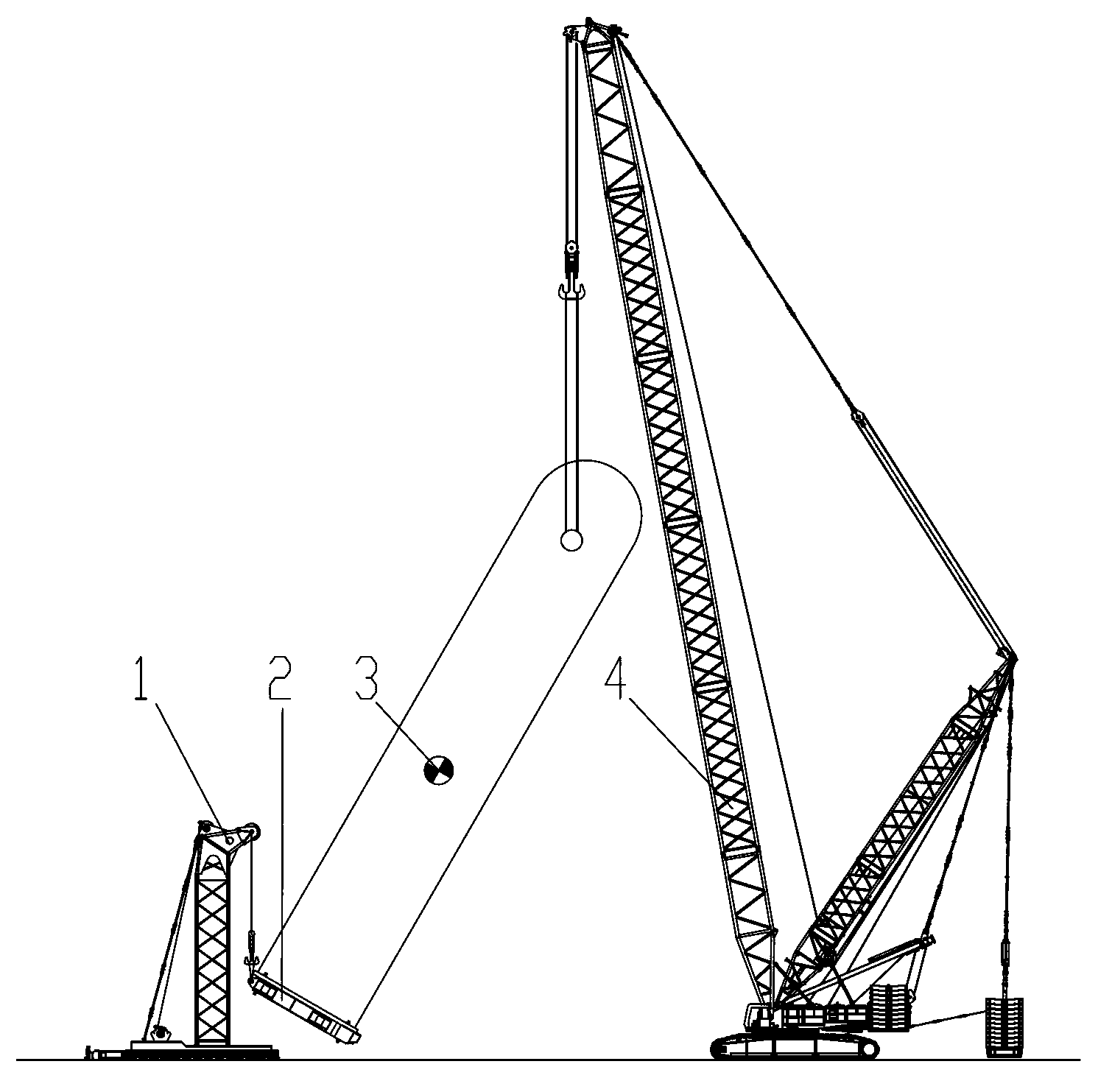

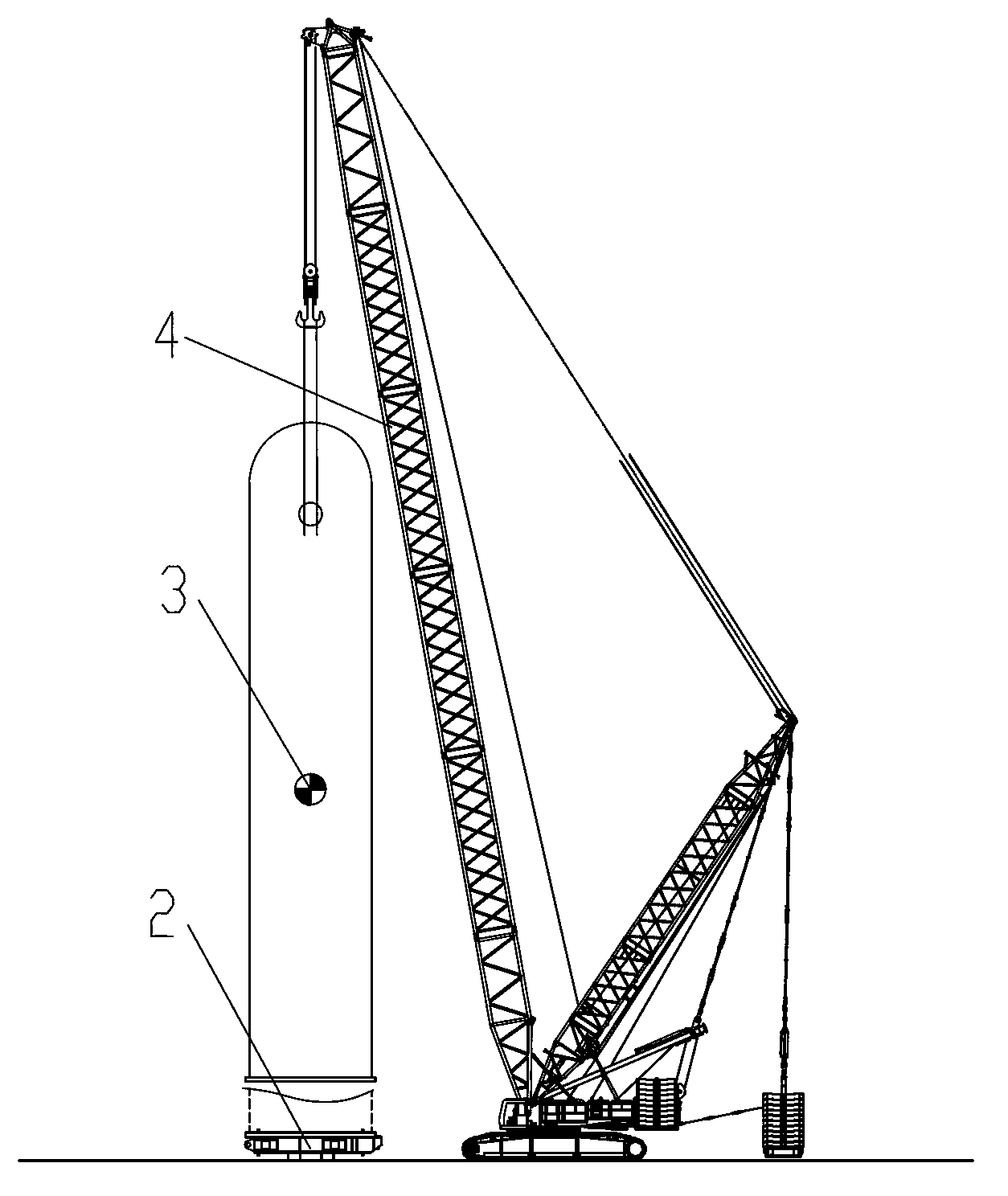

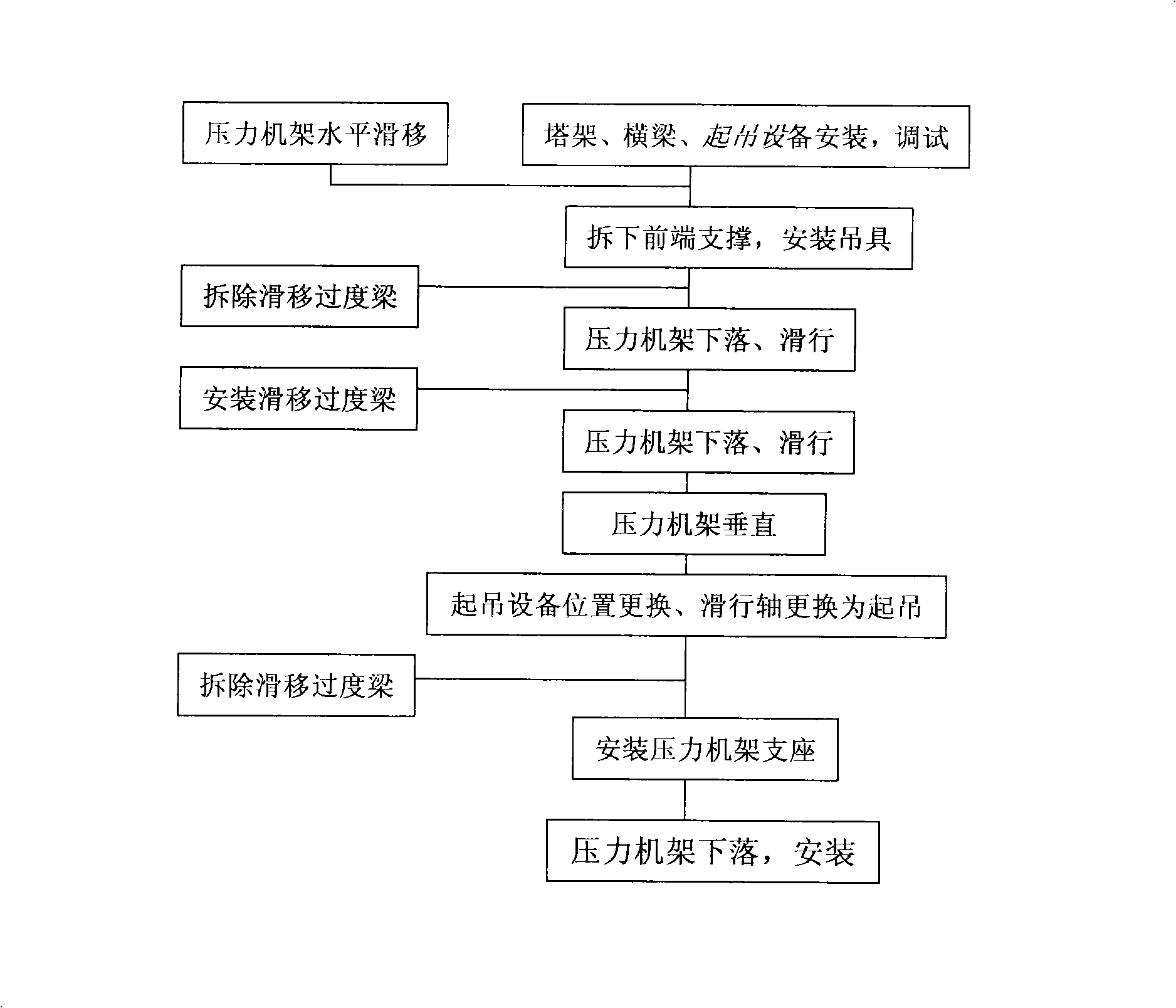

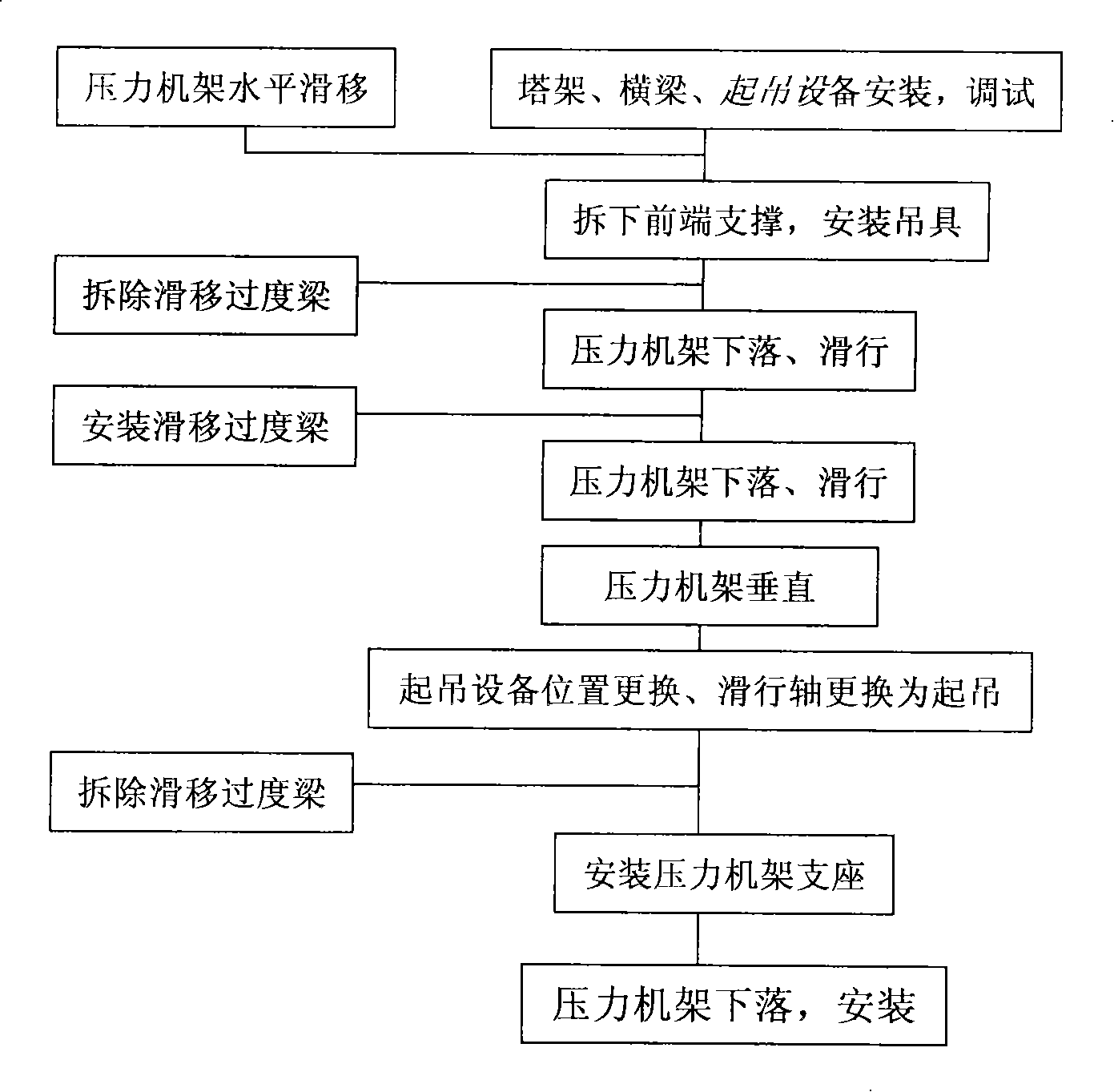

Hoisting method for framework of large tonnage pressing machine

ActiveCN101284628ALower the altitudeSolve lifting problemsTravelling cranesLoad-engaging elementsDevice placementIndustrial engineering

The invention relates to a method for hoisting large scale equipment, in particular to a method for hoisting a large-tonnage pressing machine frame. The method comprises the following steps: derrick beams are arranged on the two side of the installation position of the pressing machine frame, a large scale hoisting device is arranged thereon, a sliding shaft and a falling shaft are arranged respectively in the front and the back of the pressing machine frame, the sliding shaft is arranged at the top of the pressing machine frame in the back, and the falling shaft is arranged at the bottom in the front, the sliding shaft is slid rotationally forwards on a slideway, the falling shaft rotationally falls down, until the pressing machine frame is upright, a hoisting point is changed at the position of the sliding shaft, and the installation is finished after the pressing machine frame falls down for a certain distance. Compared with the prior hoisting method, the method of the invention has the outstanding advantages as follows: the height of the derrick is reduced, so that all the work can be done in the installed workshop; the hoisting equipment in the workshop is fully utilized, so that the hoisting problems of all the hoisting equipment are solved and the hoisting cost of the prior art is saved; the construction period is shortened, and the safety is guaranteed; and the method is suitable for the hoisting installation exercises in narrow spaces or at high altitude, underground, and in other construction situations.

Owner:CHINA 22MCC GROUP CORP

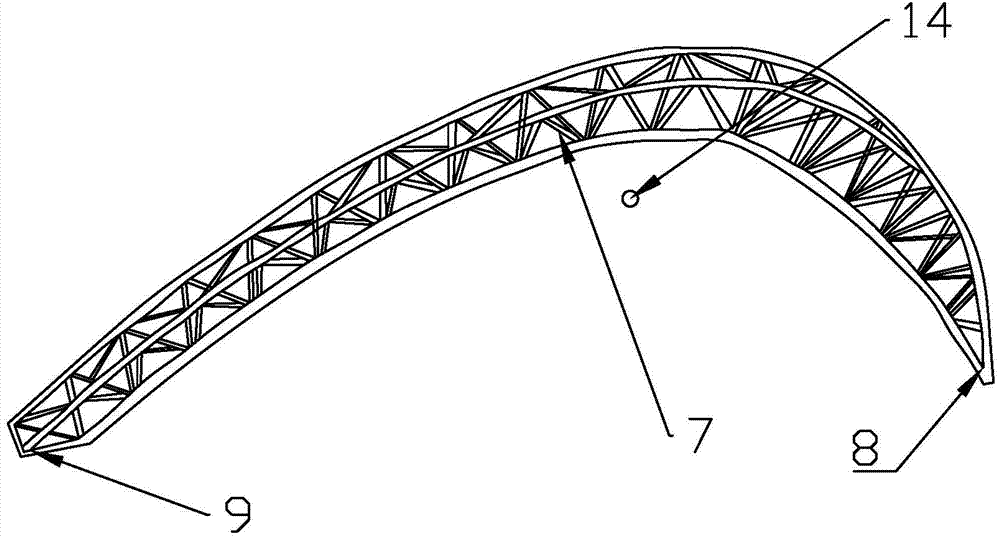

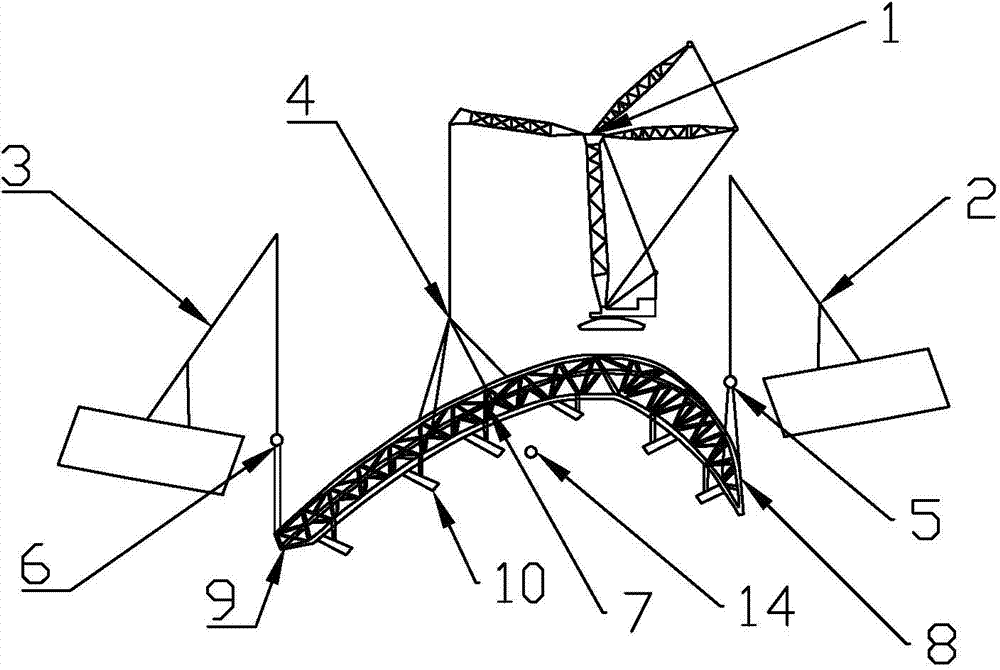

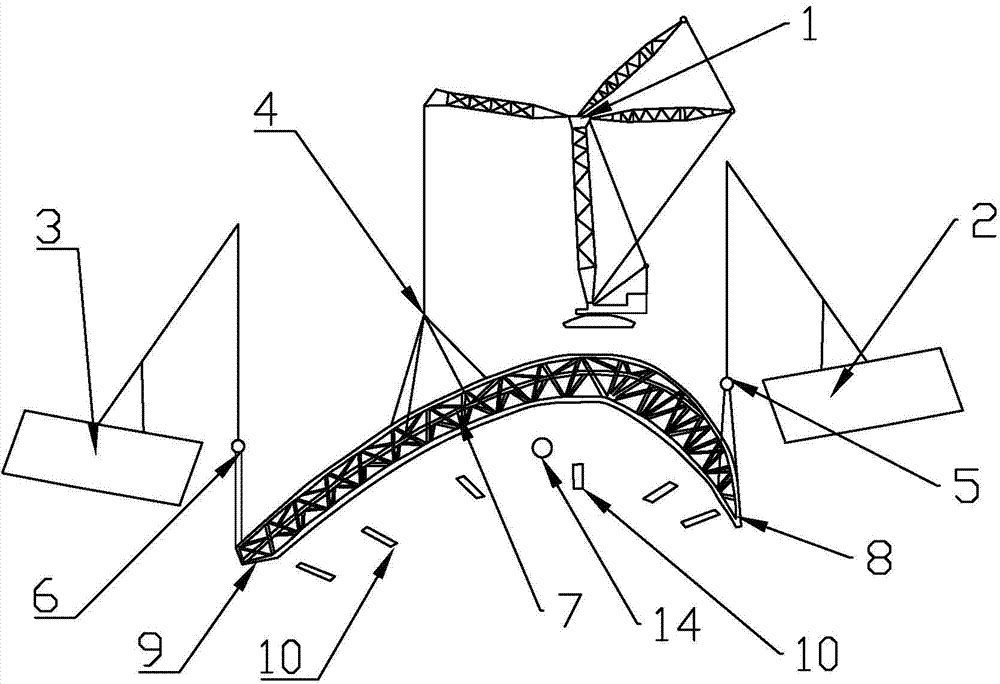

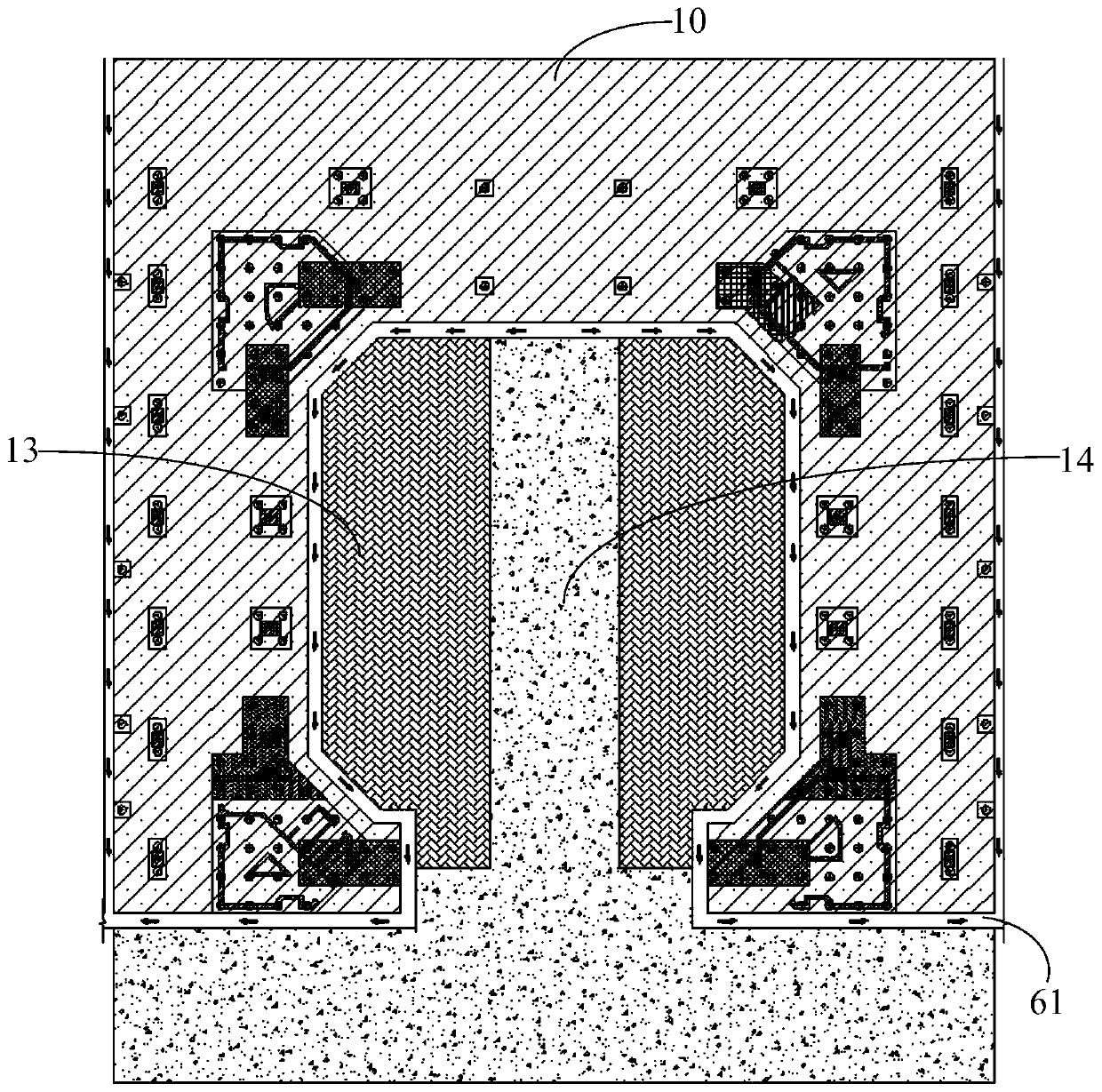

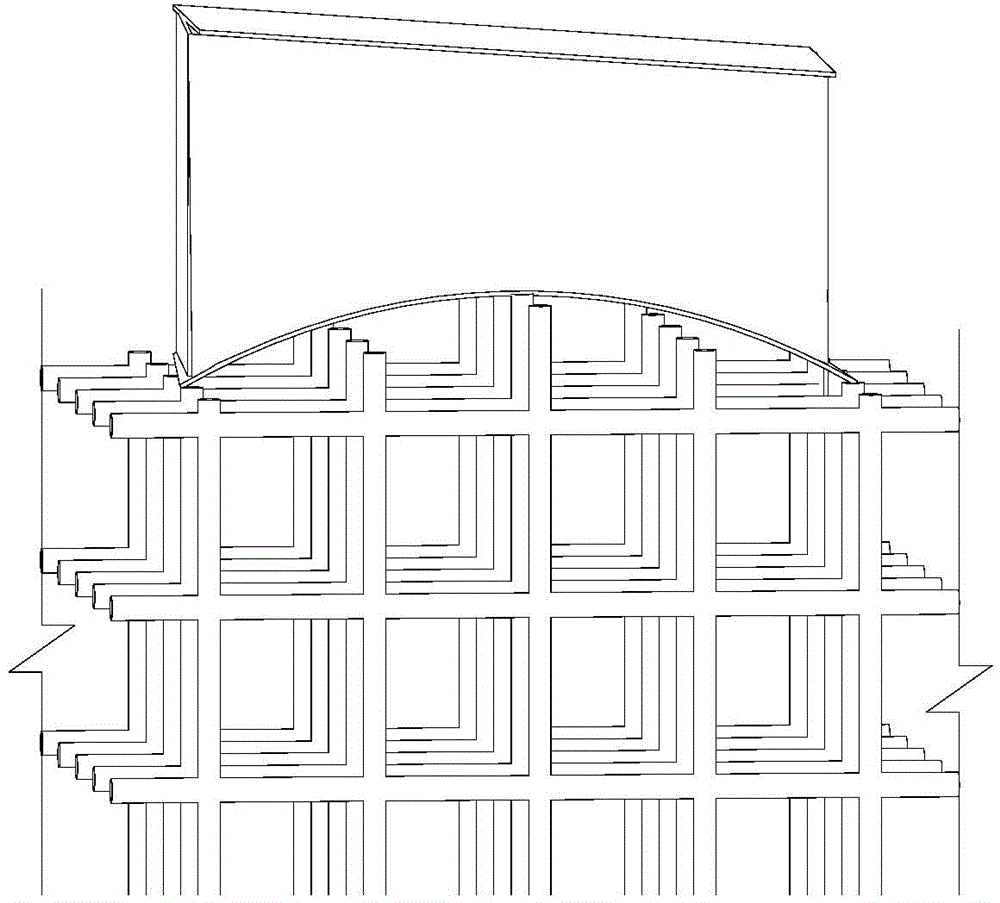

Construction method for three-crane lifting installation used for bow-shaped space truss

ActiveCN104746883ASave hoisting costsReduce split dockingBuilding material handlingButt jointGravity center

The invention discloses a construction method for three-crane lifting installation used for a bow-shaped space truss. The construction method includes the following steps of conducting simulation to determine the gravity center of the bow-shaped space truss, arranging three lifting points and three cranes, conducting separation through the three cranes, conducting carrying and correcting work after separation is completed, hoisting the bow-shaped space truss on a platform, and fixing the bow-shaped space truss to the platform. The construction method is simple, easy to achieve, high in installation efficiency, scientific, convenient and capable of saving the labor cost and greatly reducing hoisting expenses. By separating, carrying, correcting and hoisting the whole bow-shaped space truss, sectional butt joint and correction of the truss are reduced, aloft welding does not need to be conducted between sectional trusses, and therefore the installation quality and the welding quality are improved, the truss installation construction period is shortened, and truss hoisting expenses are saved.

Owner:浙江中南绿建科技集团有限公司

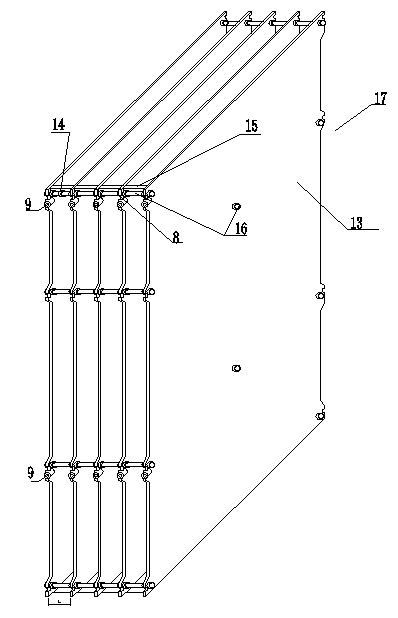

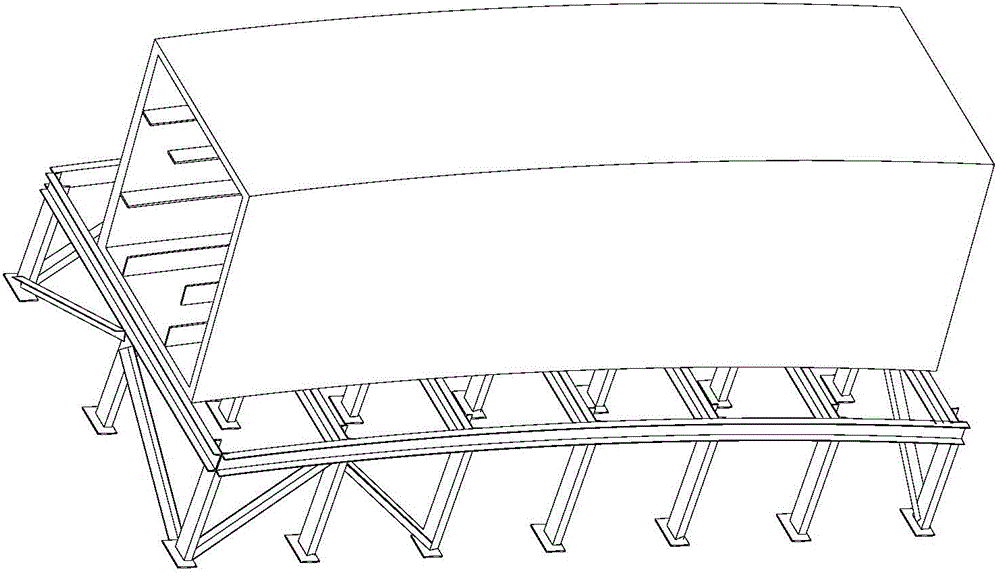

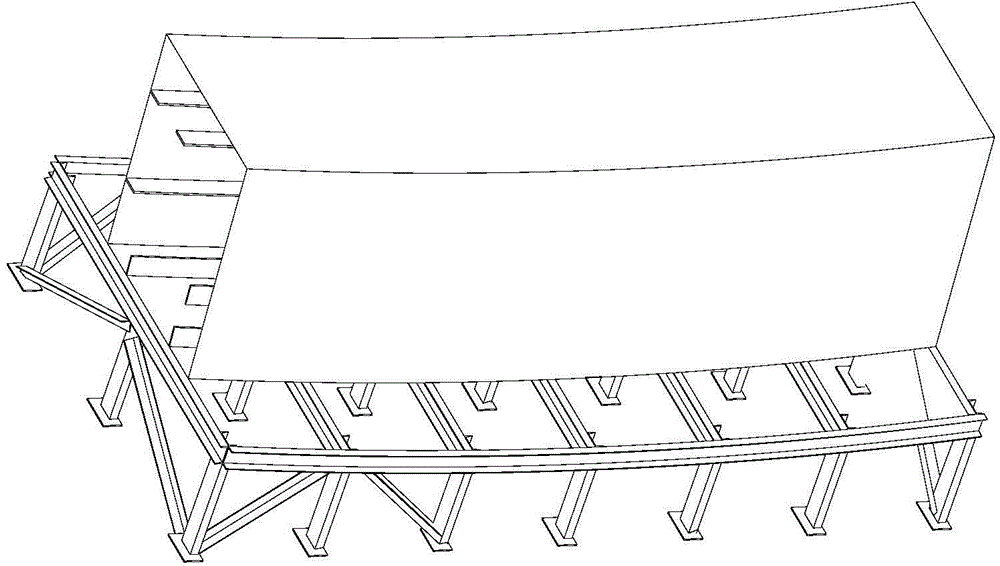

Construction method for suspended building structure

ActiveCN110616809AEnsure safetySatisfy the principle of forceFoundation engineeringGirdersStress conditionsVertical load

The invention discloses a construction method for a suspended building structure. The method comprises the following steps that S1, a peripheral core tube bearing platform foundation region is excavated, a peripheral core tube bearing platform foundation is constructed at the foundation region, and a vertical load-bearing structure is installed on the core tube bearing platform foundation; S2, a support jig is erected at a position, outside the core tube bearing platform foundation, of the foundation region; S3, a roof truss is installed above the support jig and the vertical load-bearing structure, and the support jig is removed after the roof truss is installed; and S4, a floor steel structure is installed below the roof truss from top to bottom in a layer-by-layer mode. According to themethod, construction is carried out by obeying the structure stress sequence, actual deformation and stress conditions of the suspended structure are convenient to obtain, the structure safety in theconstruction process is ensured, the construction flow and a hoisting process are optimized, a construction site is fully utilized, the construction cost is reduced, the construction efficiency is improved, moreover, the construction quality is ensured, and the method can be widely applied to construction of the suspended structure.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

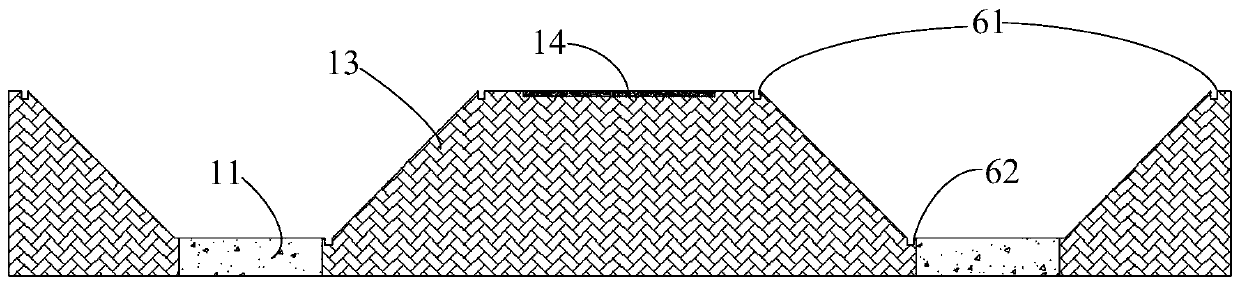

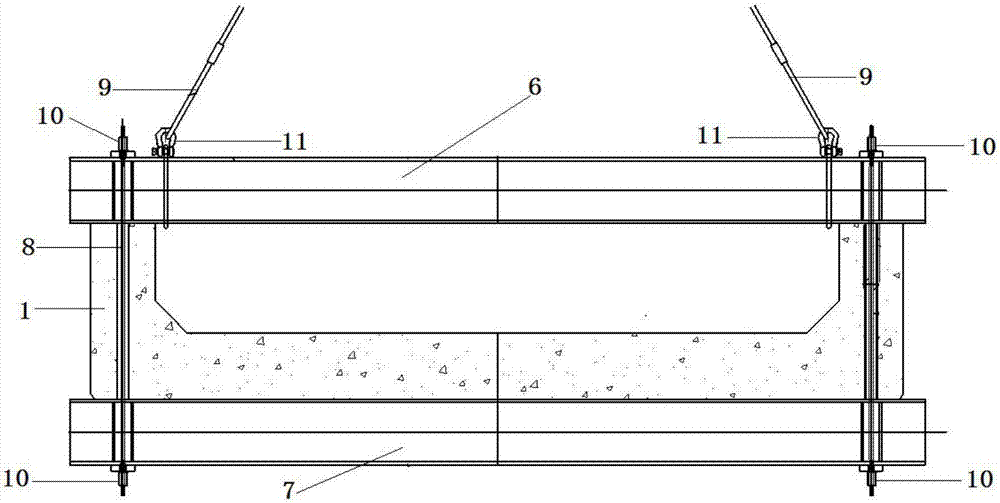

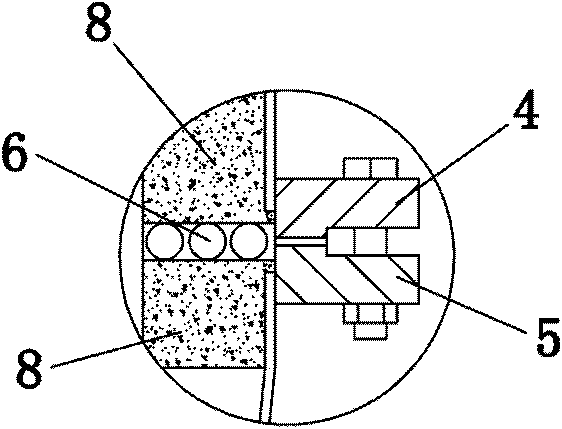

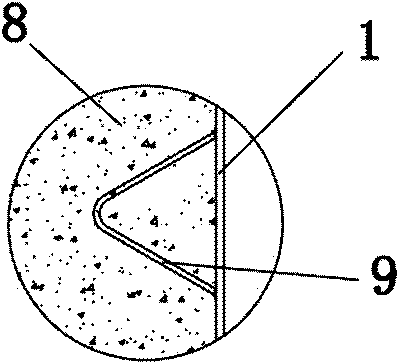

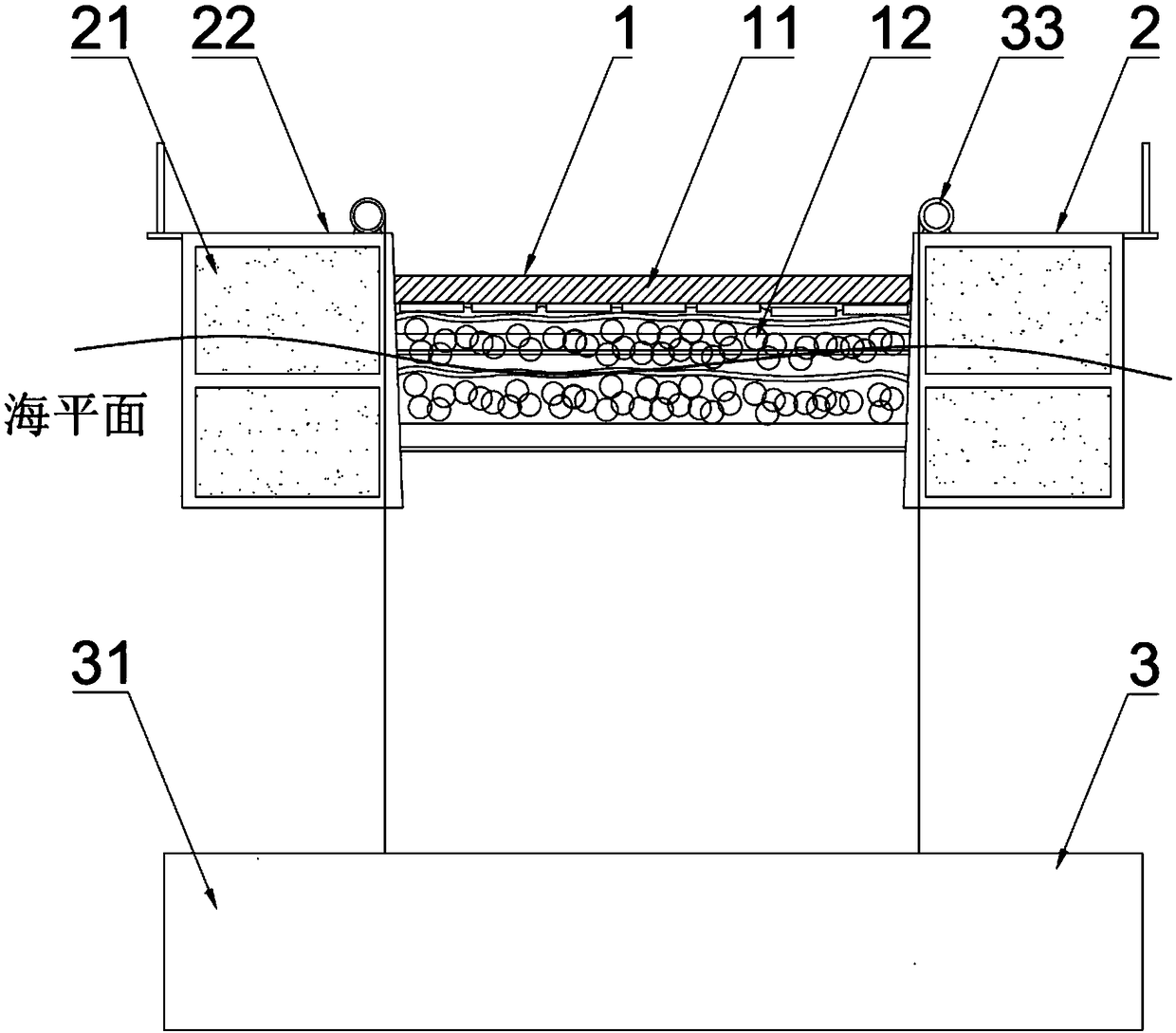

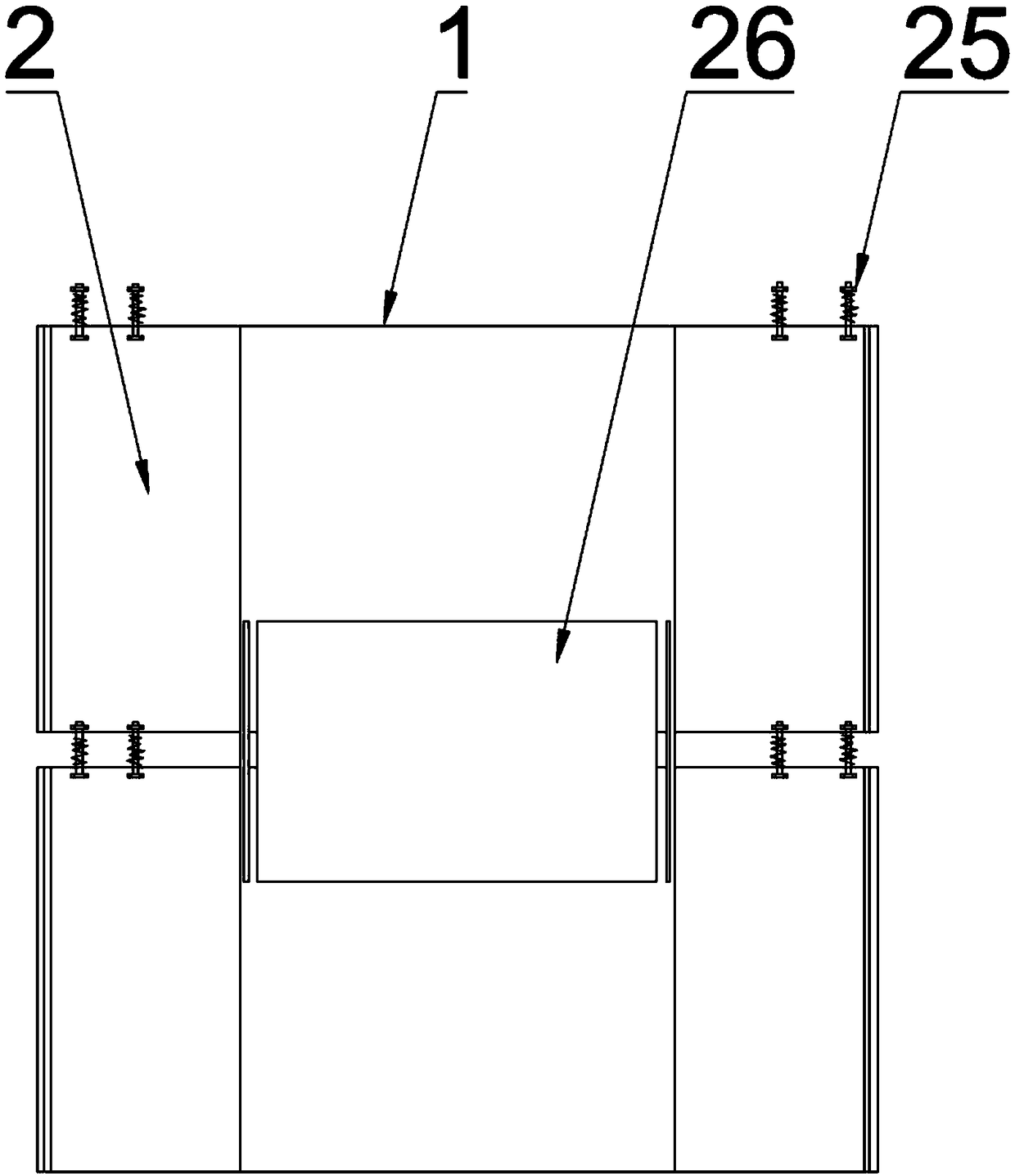

Supporting plate for flat membrane elements as well as flat membrane elements and flat membrane components

ActiveCN102512963BUniform transmembrane pressure differenceReduce consumptionSemi-permeable membranesSustainable biological treatmentEngineeringPressure difference

The invention relates to flat membrane elements and components for water treatment, which are characterized in that the front face and the back face of a supporting plate of membrane elements are respectively provided with a plurality of scattered face bosses higher than the supporting plate. The adjacent membrane elements are combined and are supported at intervals by means of the face bosses of the supporting plate. The supporting plate can not be tilted and deformed, the condition that the distance of each point between the planes of the adjacent membrane elements is unchanged is ensured, aerated scouring is uniform, and the membrane pollution is lowered. Moreover, the thickness of the supporting plate can also be obviously reduced, and the thickness is reduced from original 5.5 to 6.0mm to about 3.5mm, so that the weight and the cost of the supporting plate are lowered by about 30 percent, the bosses are arranged at intervals, the adjacent intervals of assembled membrane components can also be changed according to actual requirements, and the condition that the distance of the membrane elements can be regulated is realized. Furthermore, the method of assembling the components of the membrane elements is also changed, the function of side inserting assembly can be realized, the structure of a membrane bracket is simplified, and the versatility of a component frame is enhanced. The front face and the back face of the supporting plate are additionally provided with transverse flow passages with transverse penetration, so that the resistance of water collection and flow deflection is small, the transmembrane pressure difference of a system is small, the water output of gravitational pressure difference can be adopted for filtering, and the running energy consumption of the system can be greatly lowered.

Owner:江苏沛尔膜业股份有限公司

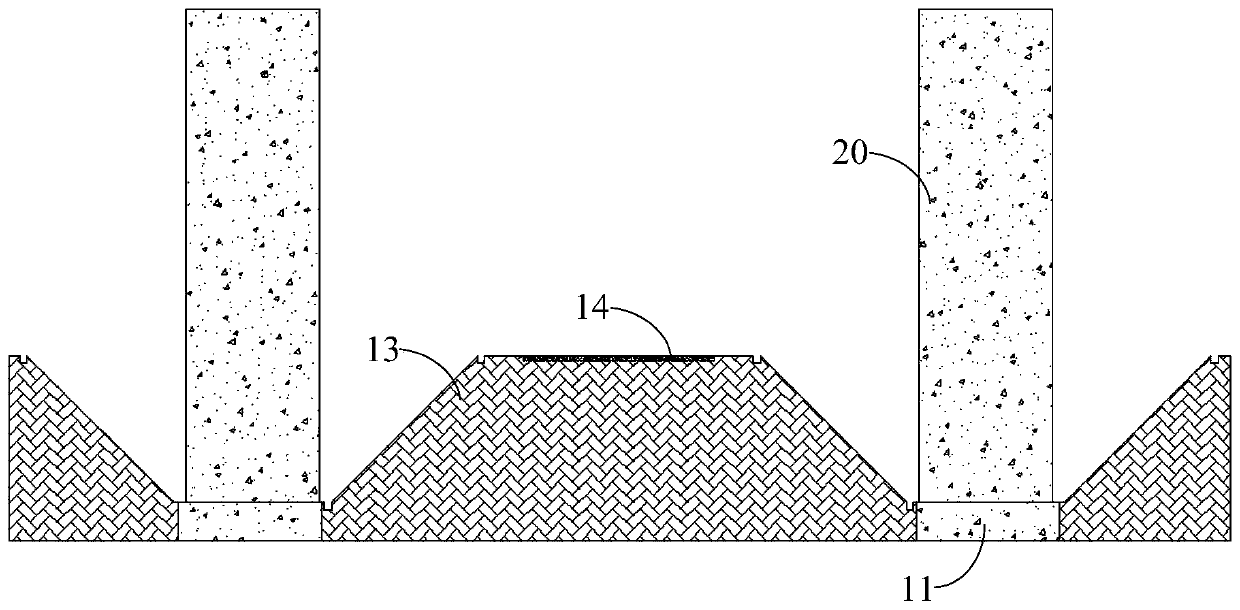

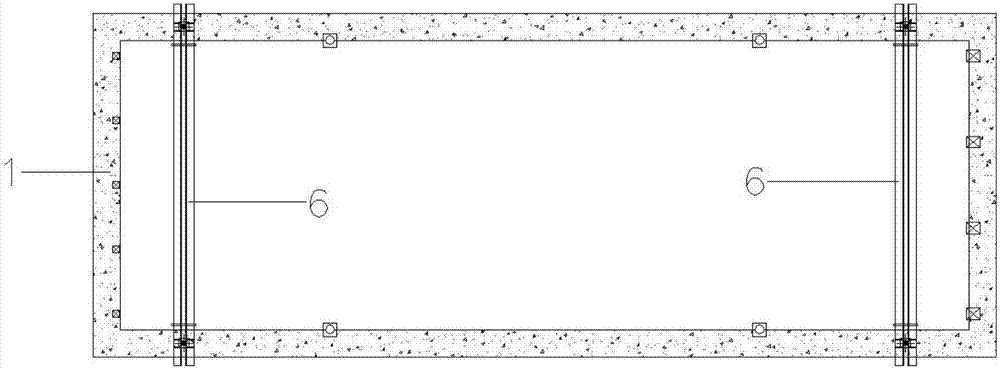

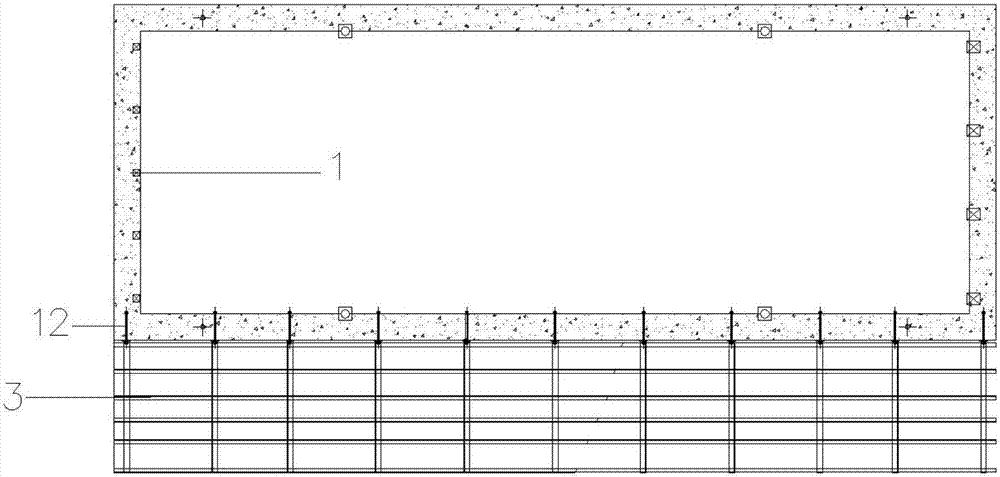

Construction method of beam body structure

InactiveCN107237270ASolve construction problemsDoes not affect the durationBridge erection/assemblyReinforced concreteMaterial consumption

The invention discloses a construction method of a beam body structure. The construction method comprises the following steps: prefabricating a U-shaped base of the beam body structure, hoisting the U-shaped base onto a bridge pier column, lapping a flange plate support and a flange plate bottom die on the left side and right side of the U-shaped base, pouring upper-part reinforced concrete of the beam body structure in a U-shaped groove of the U-shaped base based on the U-shaped base, pouring a flange plate based on the flange plate bottom die, and removing the flange plate support and the flange plate bottom die after the solidified flange plate achieves the strength requirement. According to the designed construction method, the U-shaped base is utilized as the bottom die, the support is not lapped, hoisting is conducted by utilizing a conventional crane, and the hoisting construction is easy. The on-site prefabrication can be done together with the pier column construction without the influence on the construction period of key lines, and thus the construction period is short. Auxiliary materials comprise a prefabricated pedestal and a few flange plate supports, so that the material consumption quantity is relatively small; and the installation of a beam body can be conducted by adopting a common crane, so that the hoisting cost is low. The construction method has good economy, practicability and market application values.

Owner:CCCC SECOND HARBOR ENG

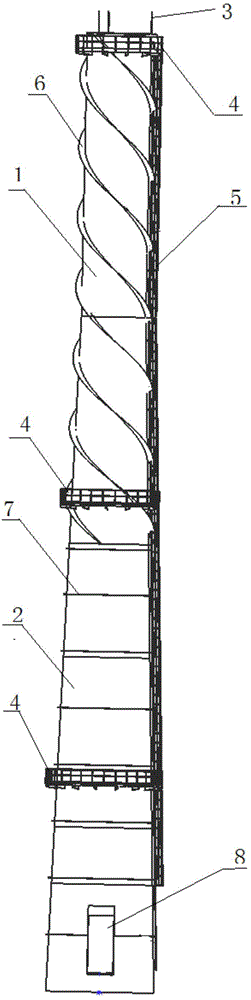

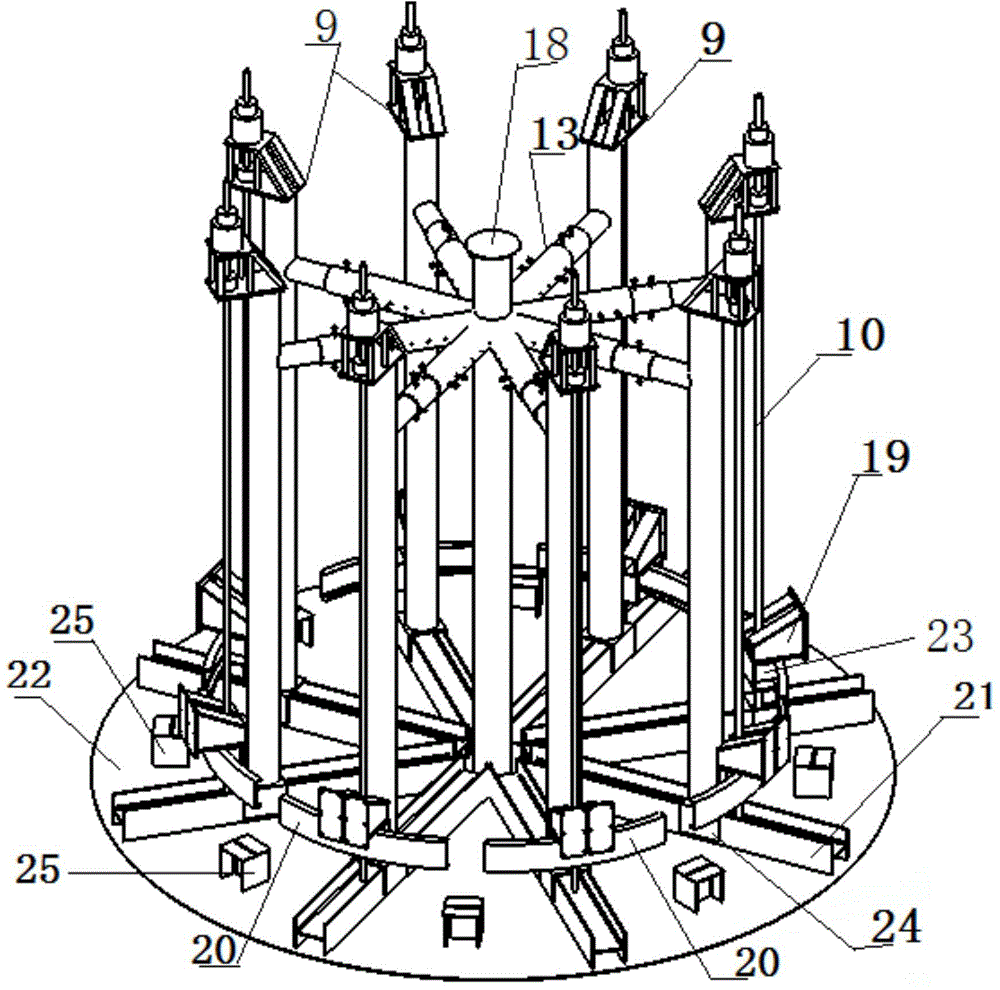

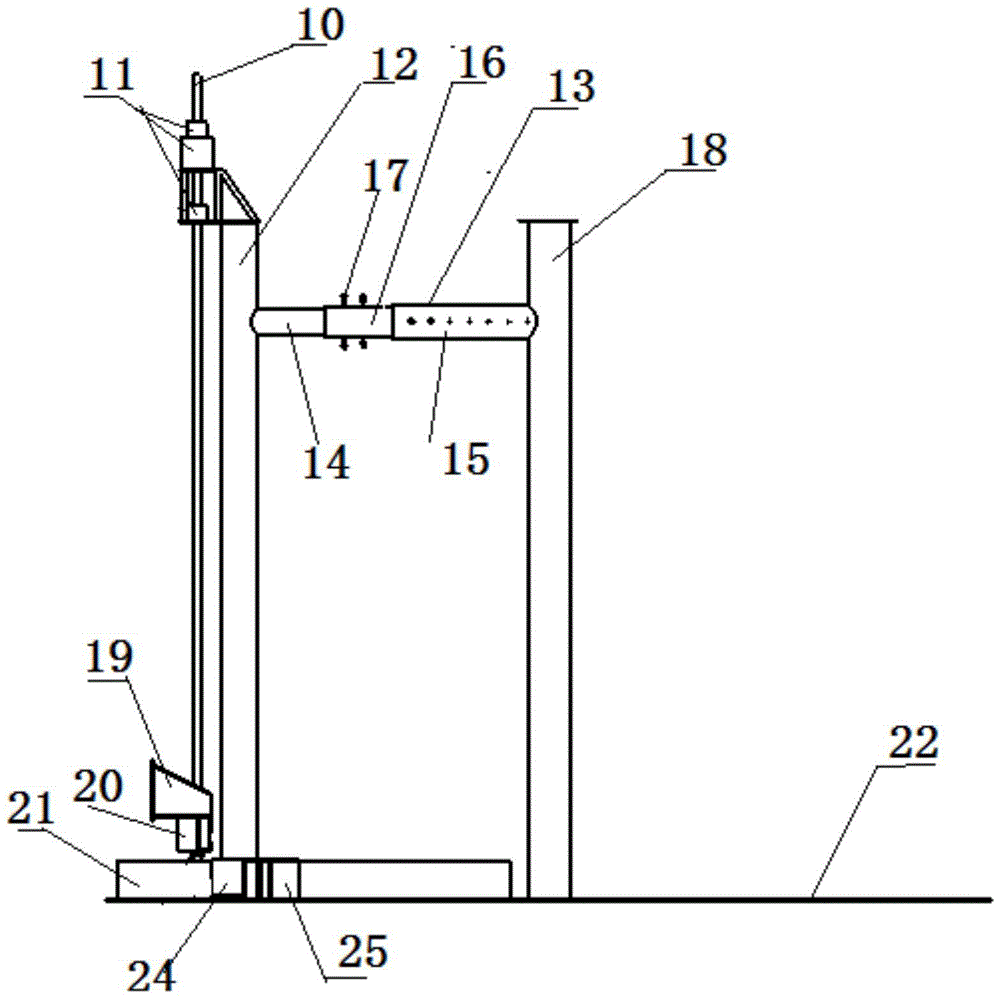

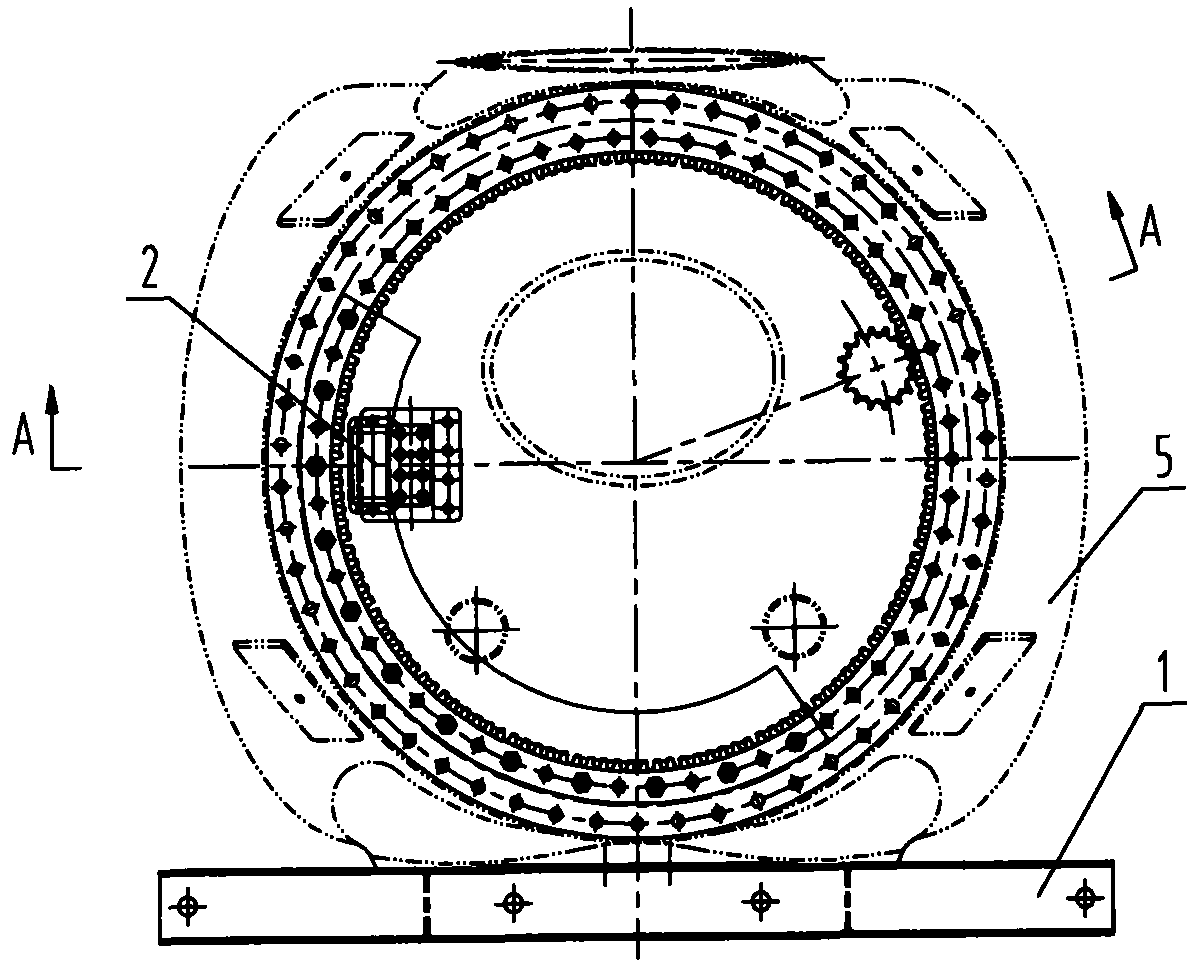

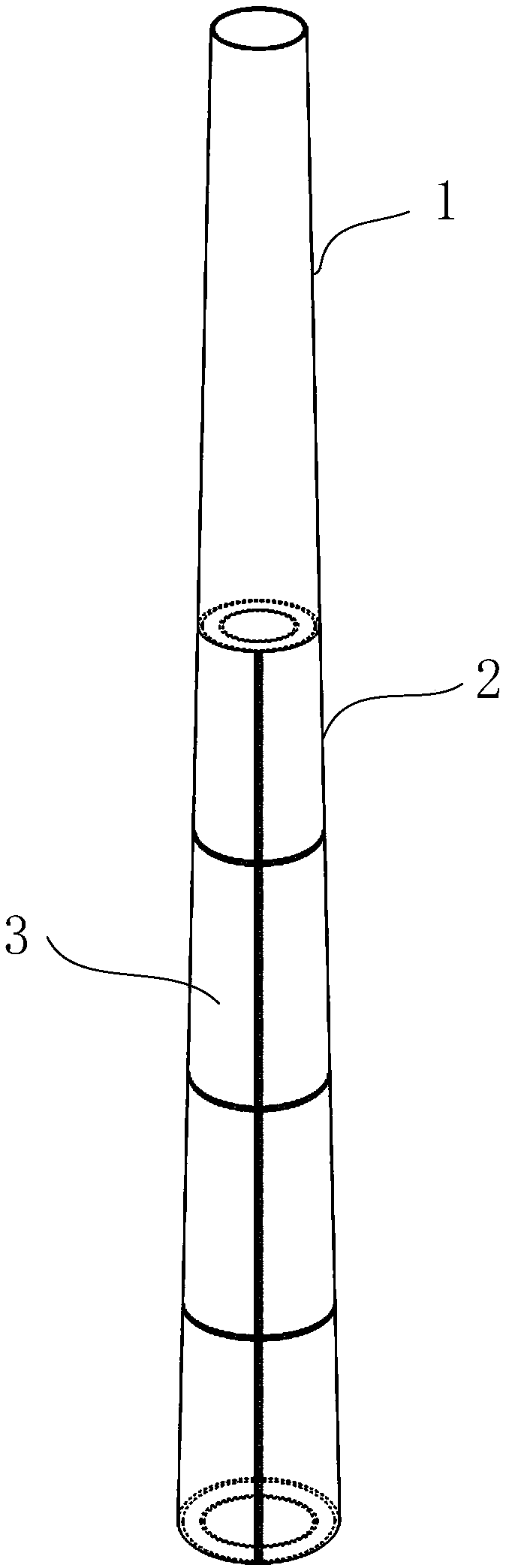

Reversed assembling method of upright cylindrical equipment

The invention discloses a reversed assembling method of upright cylindrical equipment; the upright cylindrical equipment consists of a pillar section and a tapered section; the reversed assembling method employs a hydraulic hoisting device for assembling; the hydraulic hoisting device comprises a horizontally arranged base plate, a central pillar, a plurality of cylindrical section wall plate buttresses and a plurality of hoisting mechanisms; in the process of assembling the tapered section of the equipment, the distance from the hoisting mechanisms to the central pillar needs to be adjusted based on the diameter changes of the tapered section of the upright cylindrical equipment. All assembling works of the equipment are implemented in a range of 2 meters above the ground without building up an overhead butt joint welding platform; therefore the danger of dismantling the temporary overhead platform and the potential safety hazard of work staff climbing up and down the overhead platform do not exist, thus greatly increasing the safety; the construction quality is easy to be ensured; land occupied by construction can be reduced; heavy hoisting equipment is not necessary; the construction cost is reduced; and the construction period is saved; the reversed assembling method has a wide application range.

Owner:TIANJIN 20 CONSTR

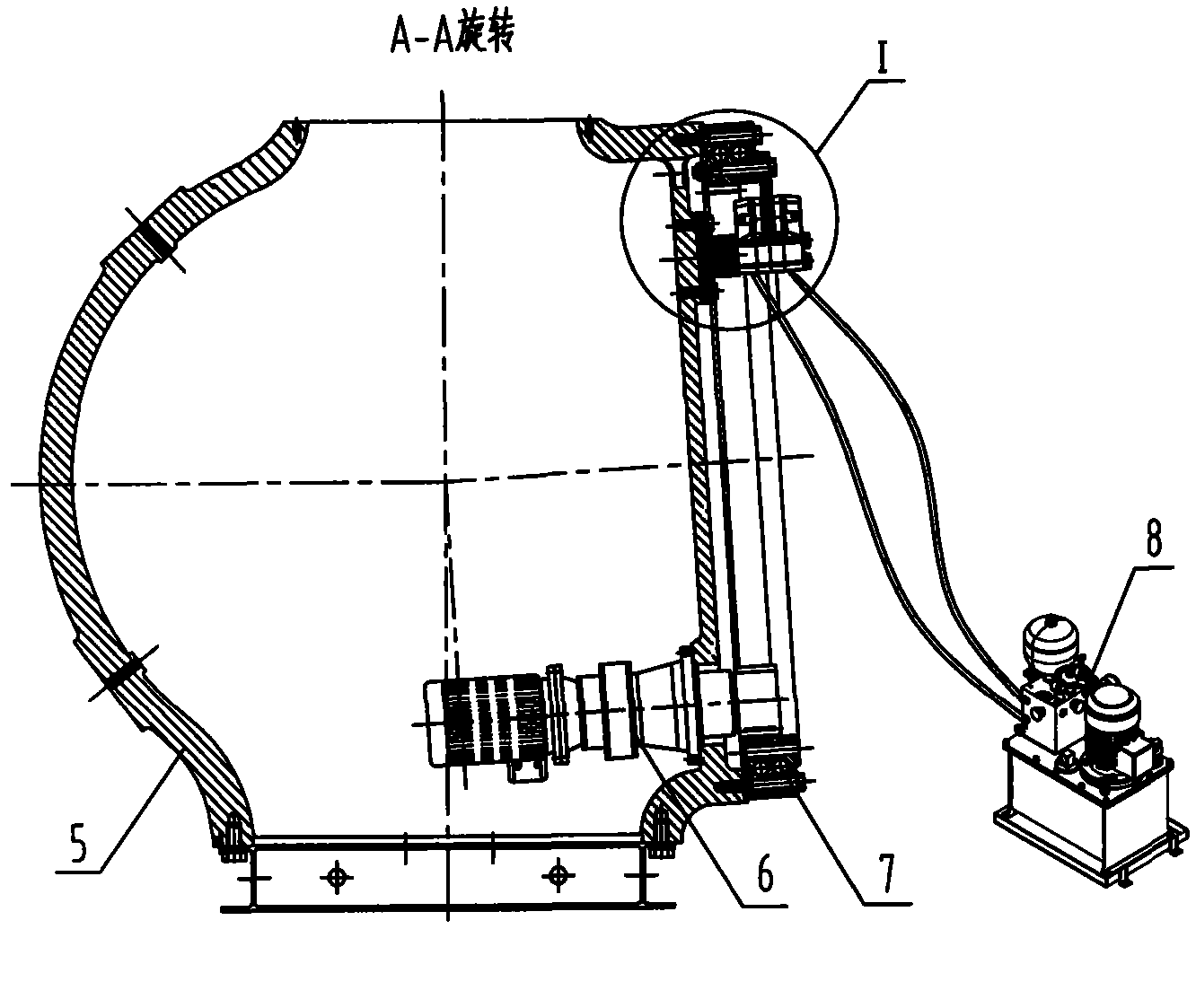

Barrel connecting method without support

The invention relates to a rotary kiln barrel, in particular to an installation method of the rotary kiln barrel. A barrel connecting method without support comprises the following steps that barrels are divided into sections, and connecting points are positioned, namely, barrel rounds are divided into sections according to the number of installing draw-in blots and lap jointed plates, and welding positions of the draw-in bolts and the lap jointed plates are positioned; a draw-in bolt base is welded, the draw-in bole base is welded to one of two sections of barrels which need to be connected according to preset positions; after the barrels are hoisted and the two sections of the barrels are hoisted and abutted, the draw-in bolts are used for positioning the welding position of the other bolt base, and welding is conducted, then the draw-in bolts are fixed through the two bolt bases, the lap jointed plates are welded to the preset positions, and a single barrel is fully welded; installation is finished, the draw-in blots bear tension, the lap jointed plates bear shear force, and all the barrels of the rotary kiln are connected together. The barrel connecting method without the support does need to manufacture a steel support, and is economical, practical, convenient to achieve and efficient.

Owner:CHINA MCC20 GRP CORP

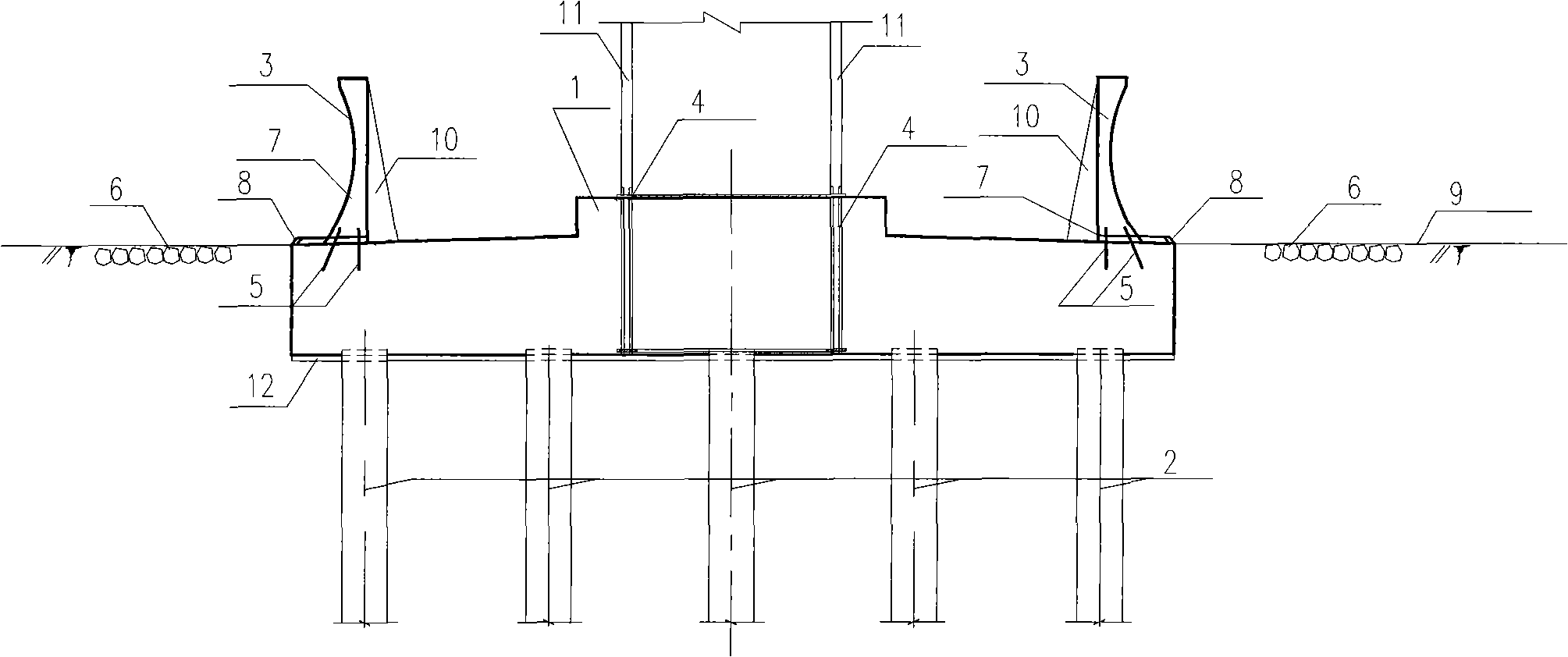

Mudflat wind electric field fan foundation structure

InactiveCN101324061ASmall amount of workImprove economyArtificial islandsUnderwater structuresTidal waterBarrel Shaped

The invention relates to a fan foundation structure in the beach wind power field, mainly comprising a fan foundation upper bearing platform, a barrel-shaped foundation structure type formed by the surrounding wave walls and a drainage facility which is arranged on the foundation surface and drains the water from interior to the exterior. The top surface elevation of the fan foundation can be appropriately lifted up according to the elevation of beach surface; the wave walls which are arranged around the foundation are used for retaining the tidewater, so as to ensure that the fan tower frame steel structure is not soaked and corroded by the seawater. During the construction of the fan foundation, the foundation construction difficulty is reduced owing to the small elevation difference of the casting surface and the beach surface; after the existing beach surface is locally levelled and structurally disposed, a fan hoisting platform can be directly formed, thus reducing the engineering quantity of cubic metre of earth and stone of the fan hoisting platform, saving the engineering investment and shortening the construction period; on the fan hoisting aspect, as the hoisting platform is basically flush with the fan foundation surface, the fan foundation structure has the advantages of smaller hoisting height, convenient hoisting, and low hoisting expense, etc. compared with the existing beach fan foundation types.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

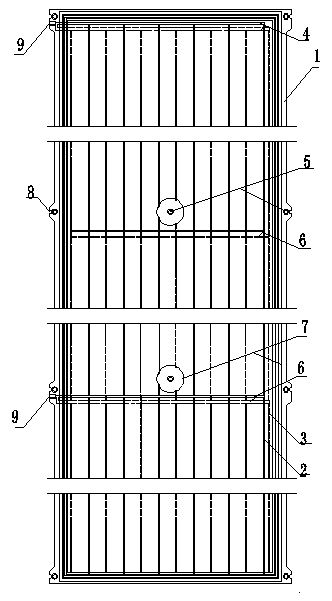

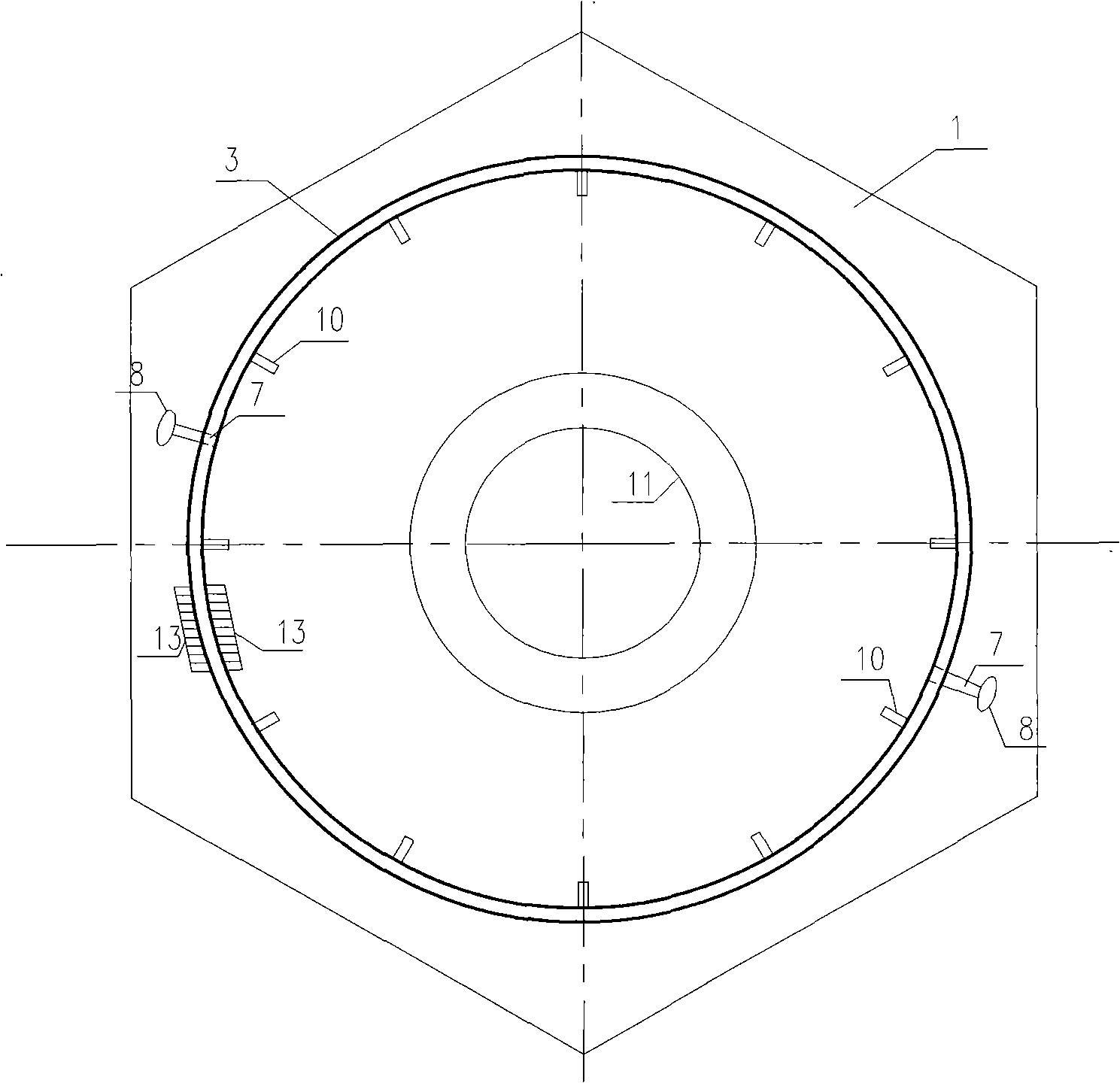

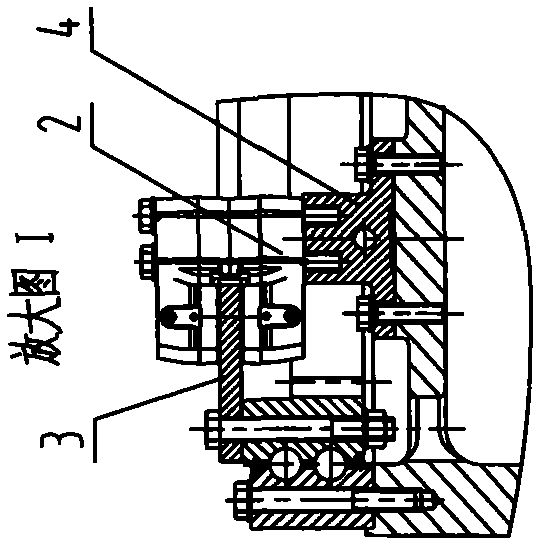

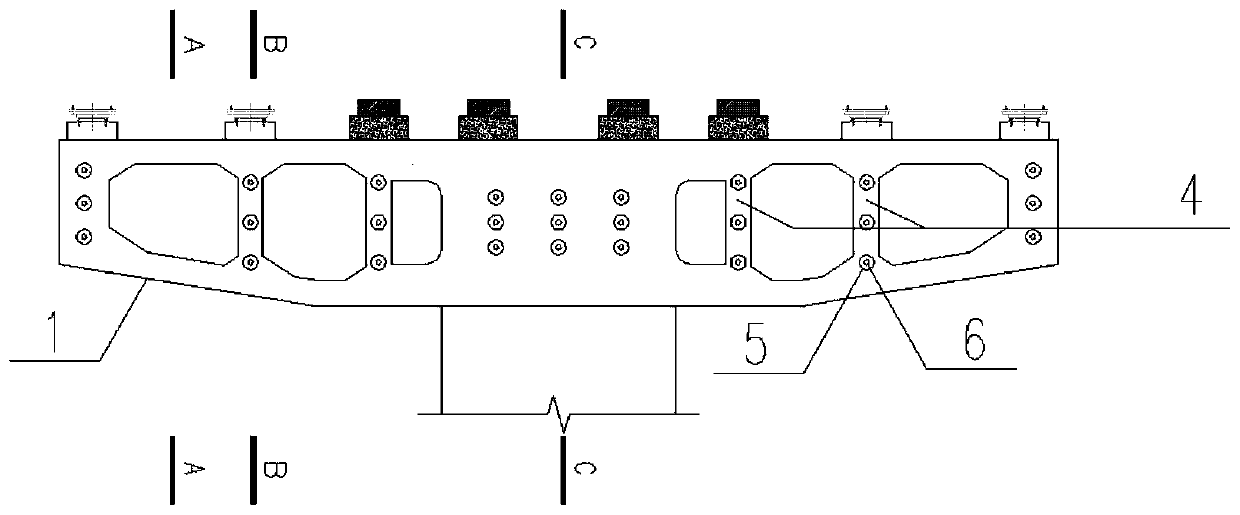

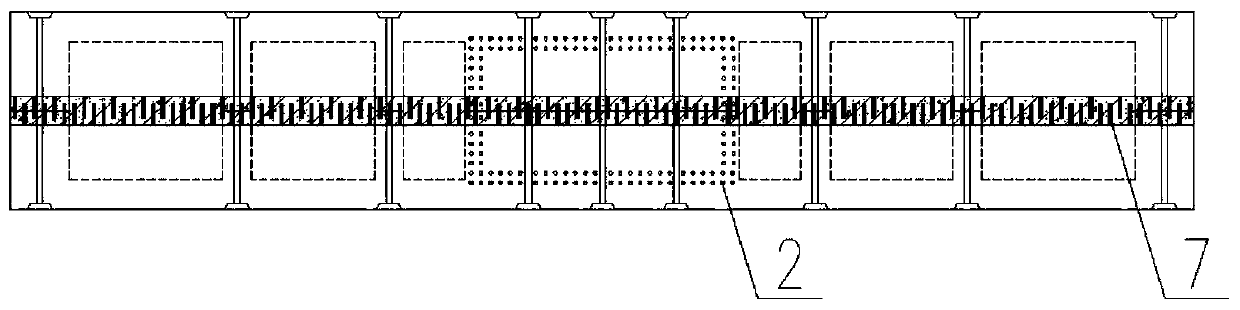

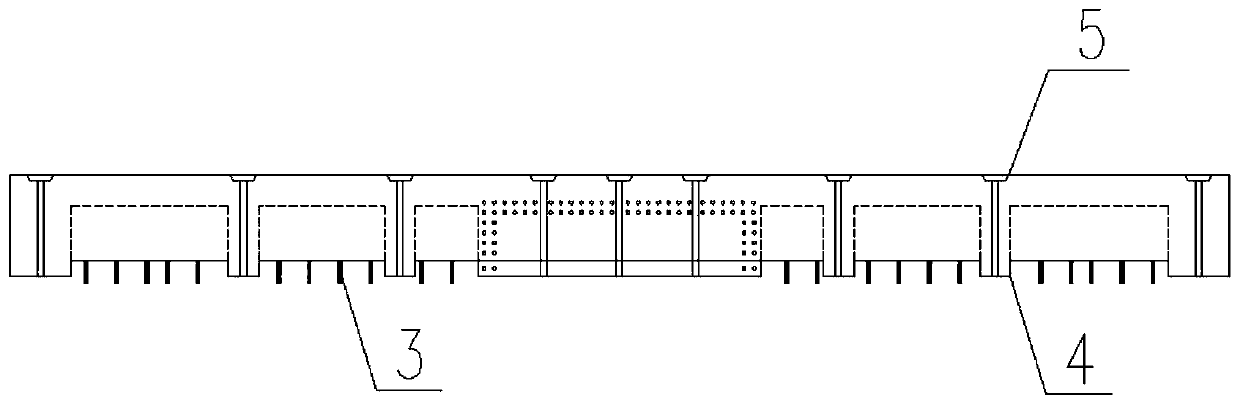

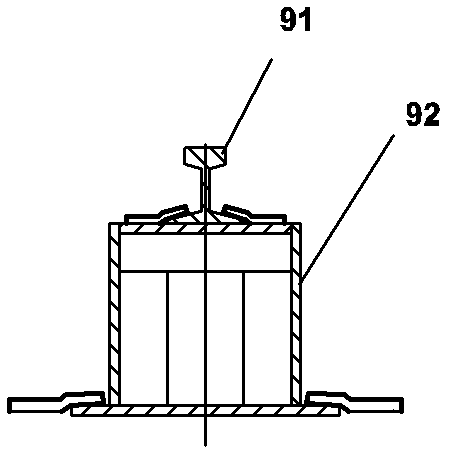

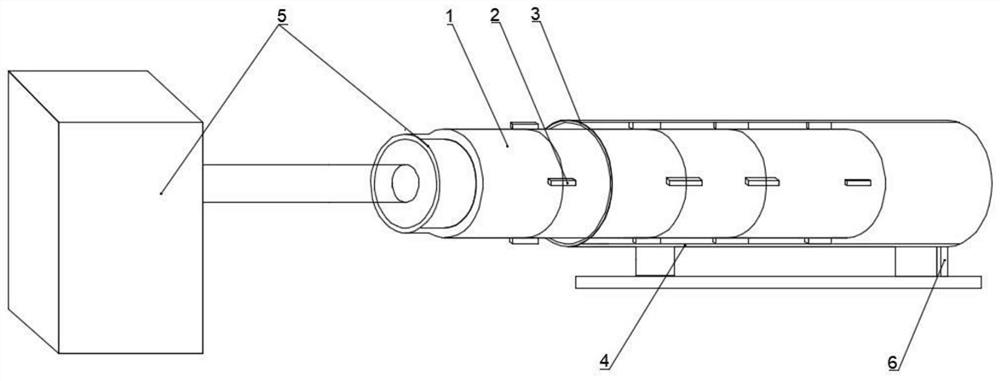

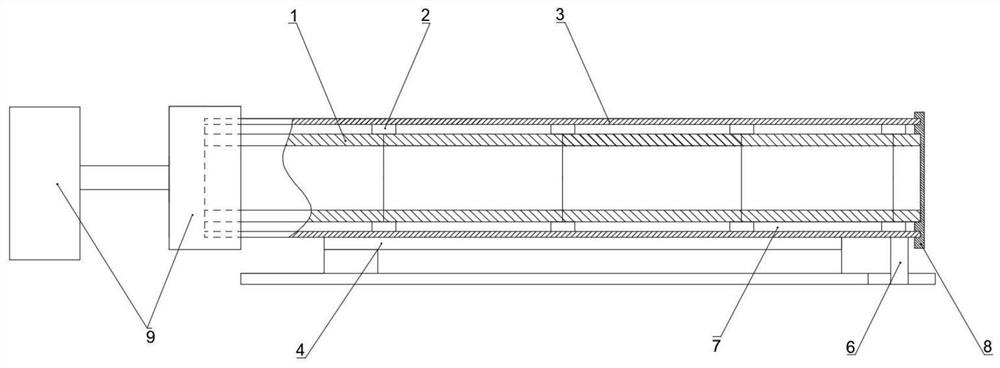

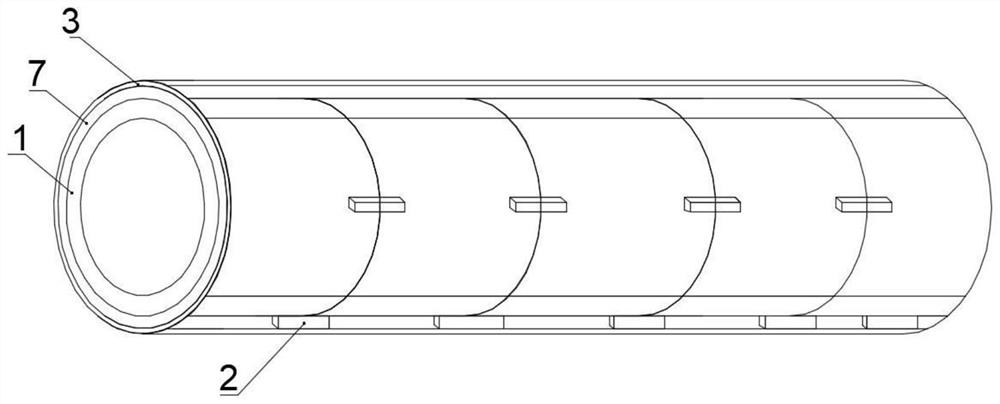

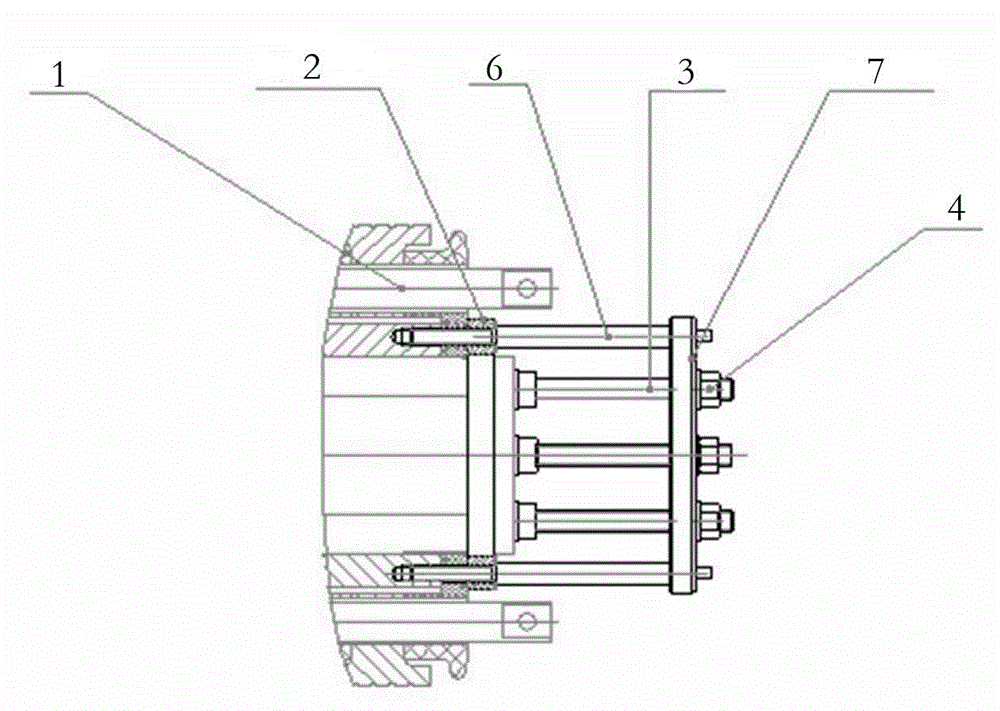

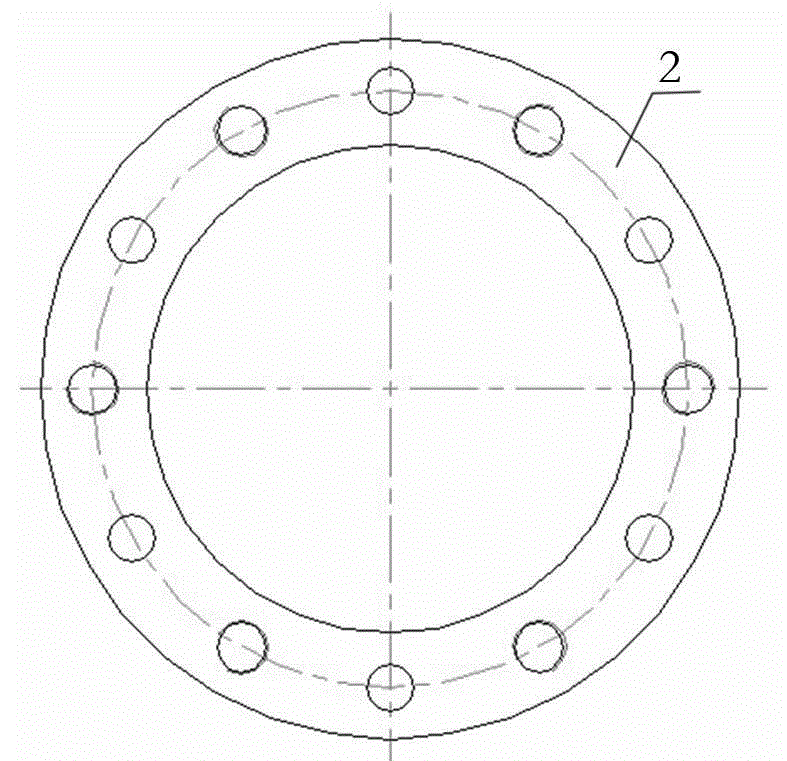

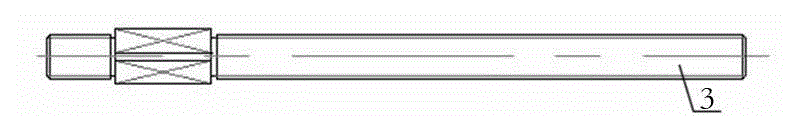

Test unit of variable-pitch system of wind generation set

InactiveCN102519720AEasy to load testSave hoisting costsMachine gearing/transmission testingMachine bearings testingWind forceGenerating unit

A test unit of a variable-pitch system of a wind generation set relates to wind generation set equipment, and solves the technical problem of difficulty in carrying out load test on the existing variable-pitch system. The test unit comprises a hub, and a variable-pitch drive assembly and a variable-pitch bearing which are installed on the hub, and is characterized in that: the variable-pitch drive assembly drives an inner ring of the variable-pitch bearing to be connected with a brake disc, and a brake is connected with the hub through a mounting seat, and is connected with a hydraulic station. The test unit tests the wind generation set and occupies a small space, the load is flexibly adjusted, the test unit not only is time saving and labor saving and has high efficiency, but also can conveniently carry out the load test on the variable-pitch system in a workshop, can timely find the defect, is beneficial to product quality improvement, and saves the hoisting cost of a fan.

Owner:TAIYUAN HEAVY IND

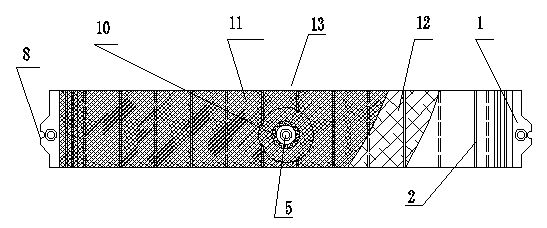

Longitudinal assembly type prestressed bent cap

PendingCN111576193ASafe and reliable structureLight weightBridge structural detailsBridge erection/assemblyEarthquake resistancePre stress

The invention discloses a longitudinal assembly type prestressed bent cap which comprises two prestressed bent cap prefabricated assemblies symmetrically arranged in the longitudinal length directionof the bent cap. Pier column main reinforcement preformed holes are formed in the range of a pier column top joint area of the assembly. Transverse prestressed ducts are formed in the side faces of the assemblies; the overhanging parts of the assemblies are C-shaped sections; transverse partition plates are arranged in the C-shaped sections; transverse prestressed ducts are reserved in the transverse partition plates; transverse prestressed steel bar assemblies tension and fix the two symmetrically-arranged assemblies through the prestressed ducts; and a post-cast strip is arranged at the abutted seam position of the two assemblies. The bent cap has the advantages that the abutted seams are arranged in the longitudinal length direction of the bent cap, internal force in the direction is small, structural weak areas are avoided, the transverse prestressed reinforcements provide a concrete hooping effect, structural bearing capacity and anti-seismic property are improved, and structuralsafety of the bent cap is guaranteed. The overhanging part of the assembly is a C-shaped section, so that a cavity is formed in the bent cap after the assemblies are symmetrically assembled, the selfweight of the bent cap body is greatly reduced, the hoisting batch is reduced, and the hoisting cost is saved.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Segmented mounting method for square raw coal hopper

ActiveCN106567548ASave large mechanical shiftsImprove construction accuracyLarge containersBuilding material handlingWork periodButt joint

The invention provides a segmented mounting method for a square raw coal hopper. The segmented mounting method for the square raw coal hopper comprises the steps that the raw coal hopper is manufactured and combined in a segmented mode; corrosion prevention is conducted on the ground where the raw coal hopper is located in a segmented mode; the raw coal hopper is transported in a segmented mode; the raw coal hopper is hoisted in a segmented mode; and assembling is conducted. By adoption of the segmented mounting method for the square raw coal hopper, the high-altitude butt joint workload is greatly reduced, the working time is shortened, the number of all-round scaffolds required when a traditional single-segment construction scheme is adopted is reduced, the cost is reduced, and the construction efficiency is improved.

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

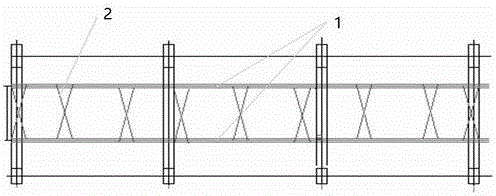

Overall horizontal assembly method for box-type steel arched girder

The invention provides an overall horizontal assembly method for a box-type steel arched girder. The method comprises the steps: firstly, dividing a single-truss box girder into a plurality of sections; then, manufacturing assembly jigs, and blanking all the sections; during the assembly of the box-type steel arched girder, firstly, laying high-side web plate units, and carrying out spot welding among all the high-side web plate units so as to achieve temporary fixation; lofting locating lines, corresponding to transverse partition plate units, on the located high-side web plate units, and locating, mounting and welding all the transverse partition plate units on the high-side web plate units; lofting locating lines, corresponding to the transverse partition plate units, on top plate units of the box girder, and locating, mounting and welding the transverse partition plate units; lofting locating lines, corresponding to the transverse partition plate units, on bottom plate units of the box girder, and carrying out locating, mounting, welding and fixing on the bottom plate units of the box girder and the transverse partition plate units; lofting locating lines, corresponding to the transverse partition plate units, the box girder top plate unit locating lines and the box girder bottom plate unit locating lines on low-side web plate units of the box girder, and locating, mounting and welding the low-side web plate units of the box girder. The method has the advantages that the overall size of the box girder and the accuracy of interface butting can be excellently guaranteed, the overall strength is high, and the stability is good.

Owner:MCC TIANGONG GROUP

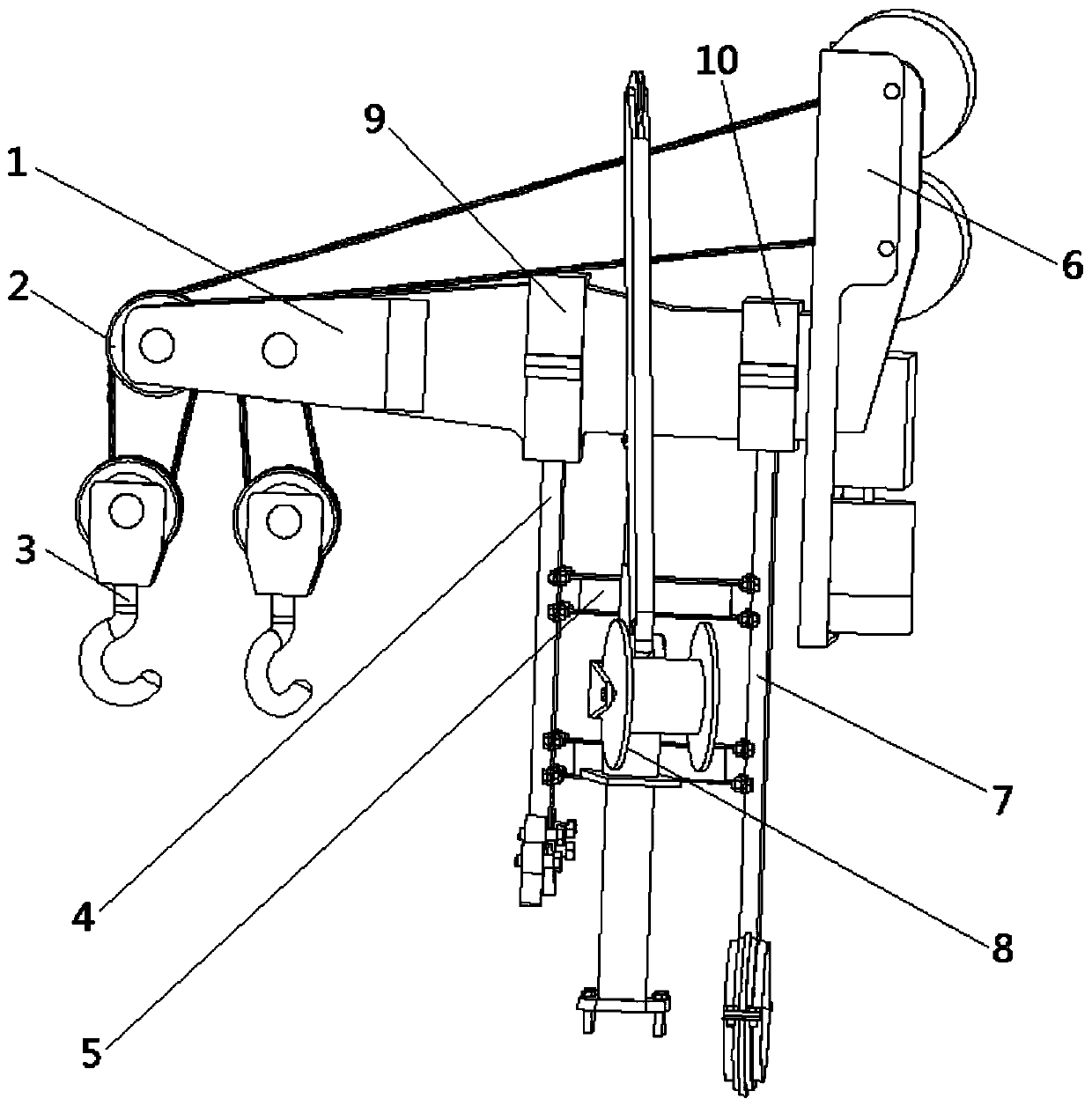

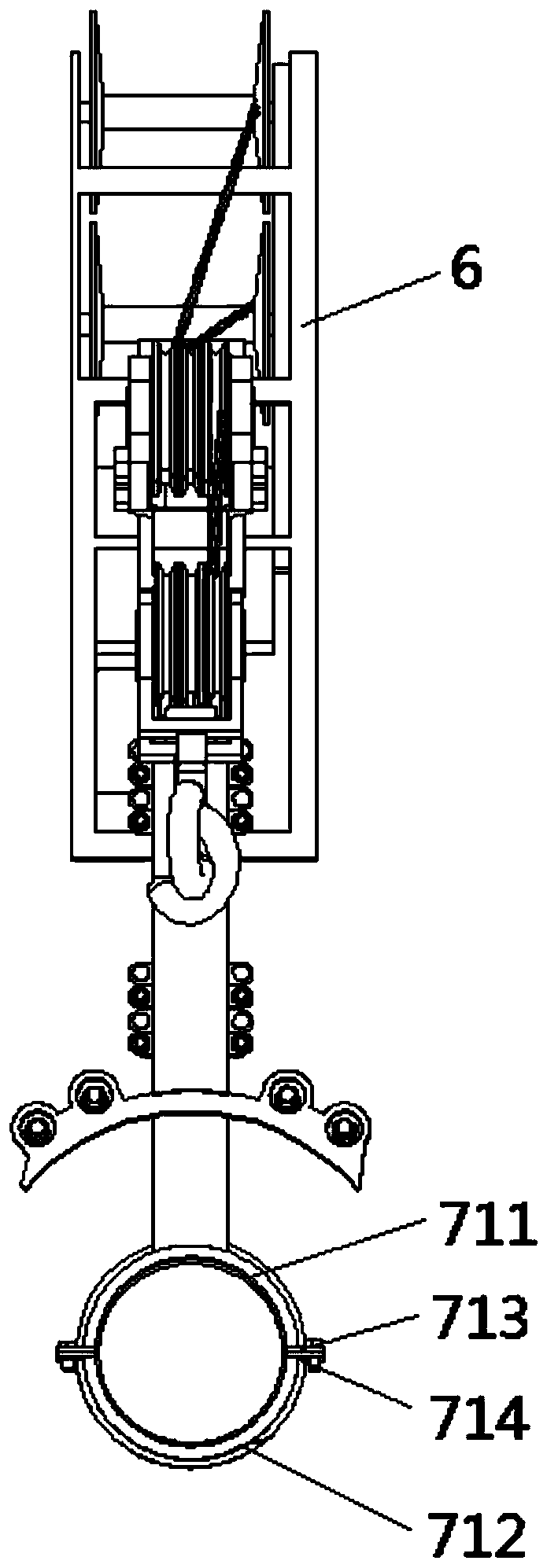

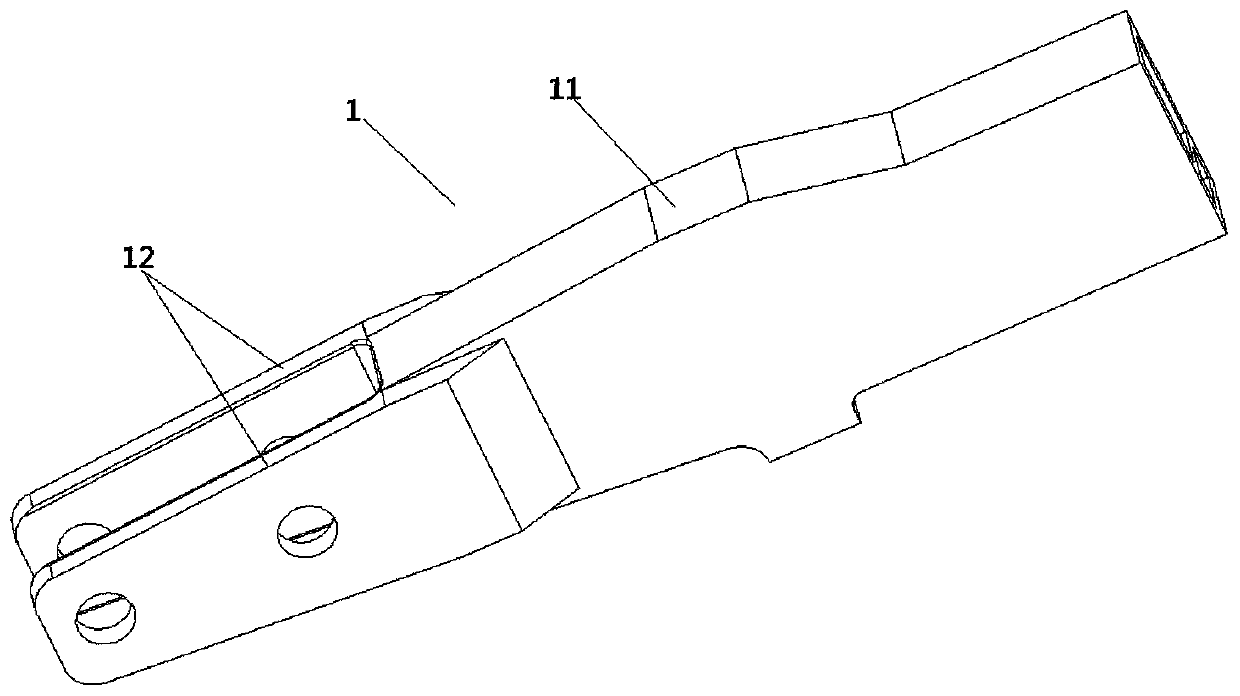

Wind wheel hoisting tool

PendingCN110356959AGuaranteed stabilityEnsure safetyLoad-engaging elementsPulleyAutomotive engineering

The invention discloses a wind wheel hoisting tool. The wind wheel hoisting tool comprises a main hoisting beam with a plurality of slide wheel assemblies, a drive mechanism which is arranged on the main hoisting beam, and a supporting beam assembly, wherein a hanger assembly which is used for hoisting a wind wheel to realize mounting or dismounting the wind wheel is wound on any slide wheel assembly; the drive mechanism is connected to all hanger assemblies, and can provide drive force; and the supporting beam assembly is used for fixedly connecting a main hoisting beam to a fan main shaft positioned below the main hoisting beam to realize supporting the main hoisting beam, and can transmit gravity of the wind wheel to the fan main shaft. The wind wheel hoisting tool is fixedly mounted onthe fan main shaft, so that the wind wheel can be hoisted and dismounted without a hoist, and therefore, hoisting cost for large part replacement can be saved; and meanwhile, the tool can realize 90-degree turnover, in air, of the wind wheel, and also cancels a tailing crane.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

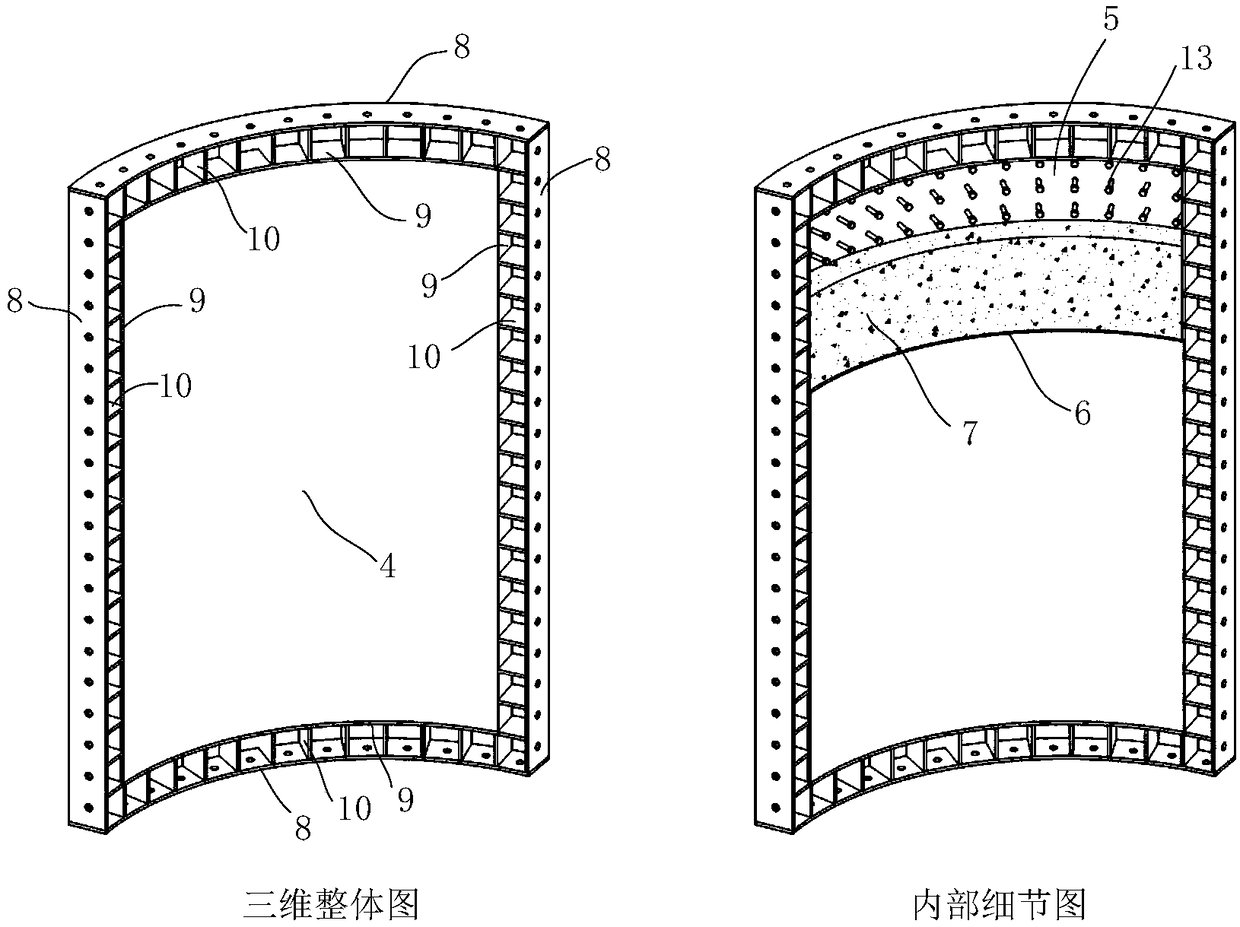

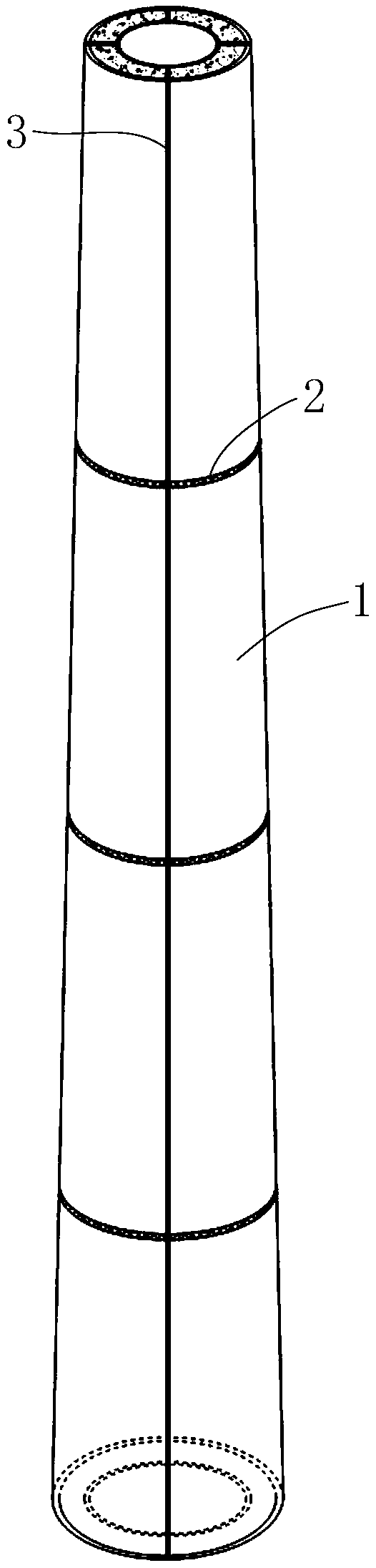

Wind power mixing tower barrel based on edge stiffening combined shell

PendingCN109404224AEasy constructionIncrease productivityWind motor supports/mountsMachines/enginesElectricityTower

The invention discloses a wind power mixing tower barrel based on an edge stiffening combined shell, and relates to the technical field of wind power generation. The upper portion of the wind power mixing tower barrel is a pure steel tower barrel, and the lower portion of the wind power mixing tower barrel is a combined tower barrel. The combined tower barrel is formed by splicing two to eight edge stiffening combined shells along the circumferential direction, and is assembled along the vertical section. The edge stiffening combined shell is composed of hollow interlayer steel tube concrete and outer end plates, inner end plates and stiffening plates arranged along the periphery of the hollow interlayer steel tube concrete. The hollow interlayer steel tube concrete is composed of an outerlayer steel tube, an inner layer steel tube and concrete. Bolts, steel angles, T-shaped steel parts or a combination of the three steel parts are welded on one side of the steel pipe in advance, andthen concrete is poured. According to the wind power mixing tower barrel, the advantages of the combined structure are brought into full play, the stress form is reasonable, the connection is reliable, all the components can be prefabricated in advance and assemblied in filed, the construction efficiency is high, the material consumption is saved, the transport is convenient, and the engineering application prospect is wide.

Owner:CHONGQING UNIV

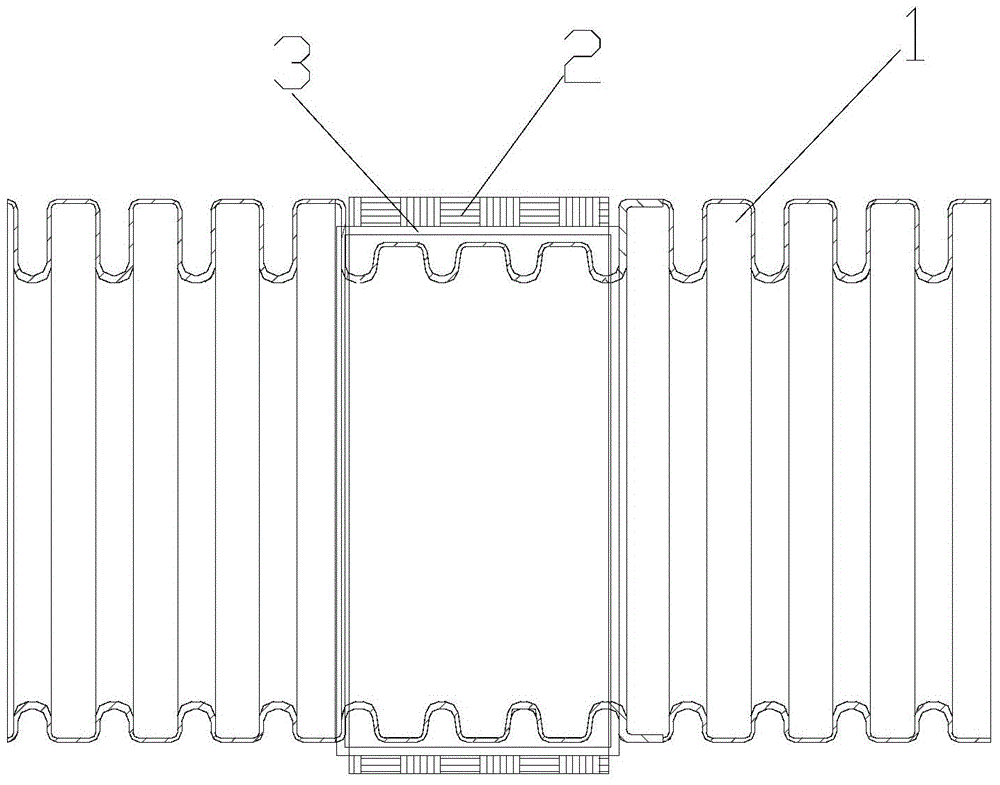

Connecting structure and manufacturing method of composite polypropylene GHFB square high-voltage cable

InactiveCN104065005AImprove insulation performanceStrong ability to resist external pressureElectrical apparatusPower cableEngineering

The invention relates to the technical field of power cable production, in particular to a connecting structure and a manufacturing method of a composite polypropylene GHFB square high-voltage cable. According to the technical scheme, pipe material bodies are included, the inner wall and the outer wall of each pipe material body are both in a corrugated shape, the two pipe material bodies are connected through a sealing ring and a clamping hoop, one end of each of the two pipe material bodies is connected into the sealing ring, the clamping hoop is arranged on the outer layer of the sealing ring in a sleeved mode, and the width of the clamping hoop is at least the width of the wave crests of three ripples of the pipe material bodies. The connecting structure has the advantages of being good in insulation performance and good in connecting sealing performance, great low-temperature shock resistance is achieved, meanwhile, materials are the lightest in all ground burying pipe materials, and conveying cost and mounting type hoisting cost can be greatly lowered.

Owner:GUIZHOU HUANRUI TECH

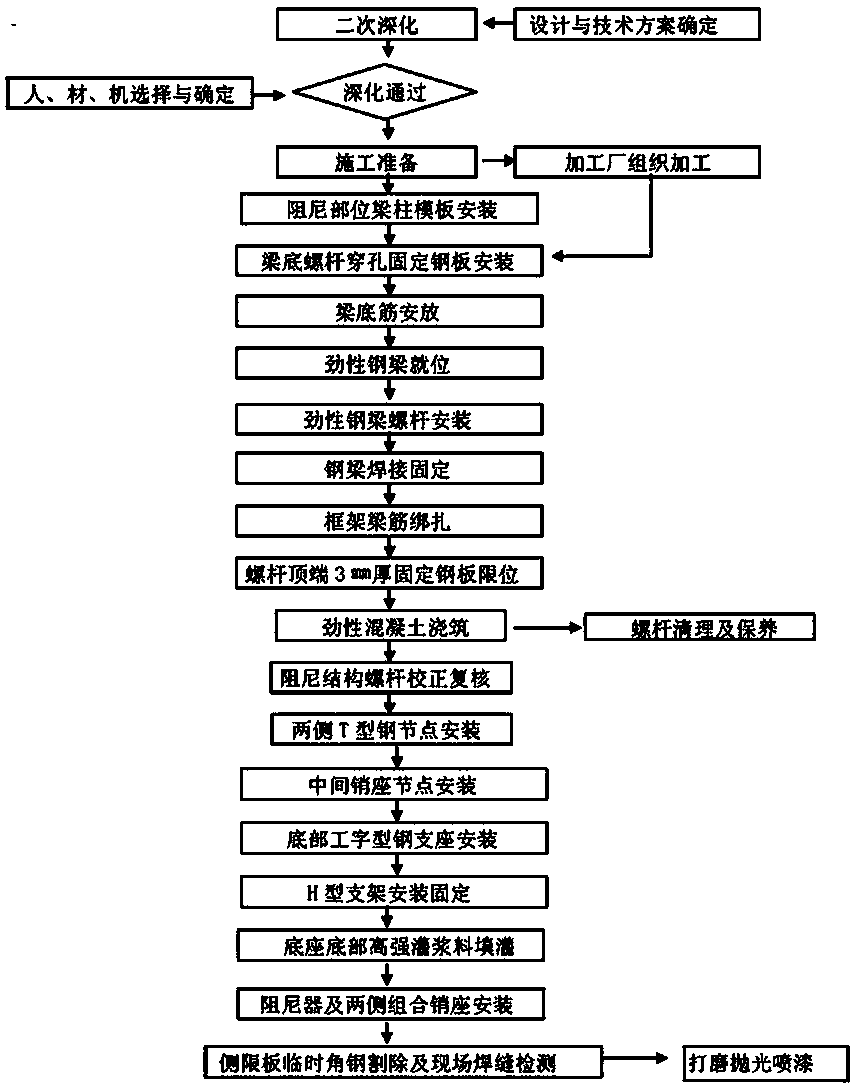

Construction method for high-rise large-span stiff damping structure

The invention discloses a construction method for a high-rise large-span stiff damping structure. The method comprises the following steps of performing secondary deepening; preparing for construction; mounting beam column templates on a damping part; mounting beam bottom screw punching fixing plates; placing beam bottom reinforcements; placing stiff steel beams in place; mounting stiff steel beam screws; fixedly welding the steel beams; binding frame beam reinforcements; performing limiting by using the 3mm-thick fixing steel plates at the top ends of the screws; pouring stiff concrete; correcting and rechecking the damping structure screws; mounting T-shaped steel joints on the two sides; mounting middle pin seat joints; mounting a bottom transverse H-shaped steel support; fixedly mounting an H-shaped bracket; filling a strong-strength grouting material at the bottom of a base; mounting a damper and combined pin seats on the two sides of the damper; cutting temporary angle steel of side limiting plates, and performing field weld joint detection. The method has the beneficial effects that compared with a conventional structure, the stiff damping structure has the advantages that the cost of an energy dissipation element is increased, but the using amounts of reinforcements, shape steel and concrete are reduced.

Owner:成张佳宁

Entire loading and transporting technology and equipment for portal crane

InactiveCN102530735ASave hoisting costsSave on-site installation spaceTrolley cranesWaste managementLifting equipment

The invention provides an entire loading and transporting technology and equipment for a portal crane. The portal crane is hoisted according to the requirements of final assembly technology and powered on for test to reach the technical requirements. The portal crane is driven to a ship through a running track, a land part temporary track and a ship part temporary track, and transported to the designated site by the ship; and the portal crane runs to the land through the ship part temporary track, the land part temporary track and the running track to finish the loading and transportation. According to the invention, the portal crane is hoisted for test on the site of the manufacturer, and any problem if discovered can be solved in time; the whole hoisting test stage does not occupy the area of the owner, the hoisting equipment of the manufacturer is sufficiently used, and the hoisting cost is saved; the equipment can be put into use quickly after arriving at the area of the owner; and the field installation area and time can be greatly saved.

Owner:ELEPHANT KING HEAVY IND

Cyclone separator for ecological oil

InactiveCN102179319AReduce maintenance rateSave replacement timeReversed direction vortexCyclonePulp and paper industry

The invention relates to a cyclone separator for ecological oil, which consists of a cylinder body positioned on the upper half part, and a tapered cylinder and a wearable layer positioned on the lower half part; a cyclone inlet is formed on the side surface of the cylinder body; the side wall of the cyclone inlet is tangential to the inner wall of the wearable layer; an air outlet is formed on the upper part of the cylinder body; a discharging port is formed on the lower part of the tapered cylinder; the separator is formed by connecting the two sections of the cylinder body and the tapered cylinder; a plurality of pins are arranged inside the wearable layer; the upper part of the cylinder body is provided with an air outlet cylinder; the air outlet is positioned on the exposed part of the air outlet cylinder; the lower end of the air outlet cylinder positioned inside the cylinder body is provided with a filter screen. The cyclone separator for ecological oil can save the replacement time and the lifting cost; the inner wall of the separator has high wearability and impact resistance; and the service life is long.

Owner:GUANGZHOU DEVOTION THERMAL TECH

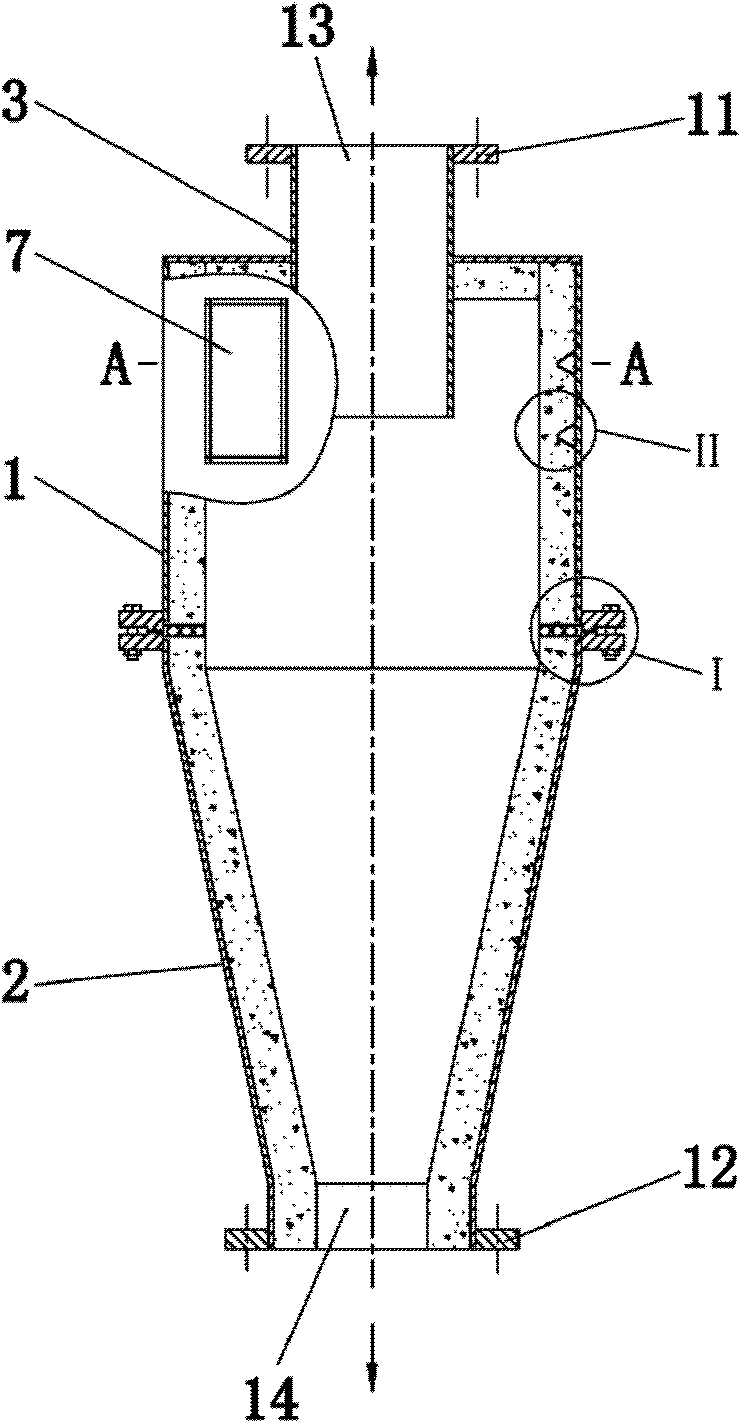

Novel combined steel open caisson

PendingCN110468864AEasy to assembleEasy to operateArtificial islandsUnderwater structuresImpact timeBolt connection

The invention provides a novel combined steel open caisson which comprises a top joint, a middle joint and a bottom joint which are sequentially spliced from top to bottom. The top joint and the middle joint are the same. The middle joint comprises a rectangular frame body structure formed by combining two first module plates and two second module plates, wherein the two first module plates are perpendicular to the two second module plates, and every two adjacent first module plate and second module plate are connected through a bolt. The bottom joint comprises a rectangular frame body structure formed by combining two third module plates and two fourth module plates, wherein every two adjacent third module plate and fourth module plate are connected through a bolt. Compared with the priorart, the novel combined steel open caisson has the beneficial effects that splicing is simple, operation is convenient, recycling can be achieved, the construction cost is saved, the construction time is saved, the self rigidity is high, the dead load is small, the construction period can be greatly shortened, the transporting and lifting cost is saved, the traffic impact time during constructionis short, seepage can be prevented, and construction is safer.

Owner:安徽省永流管道有限公司

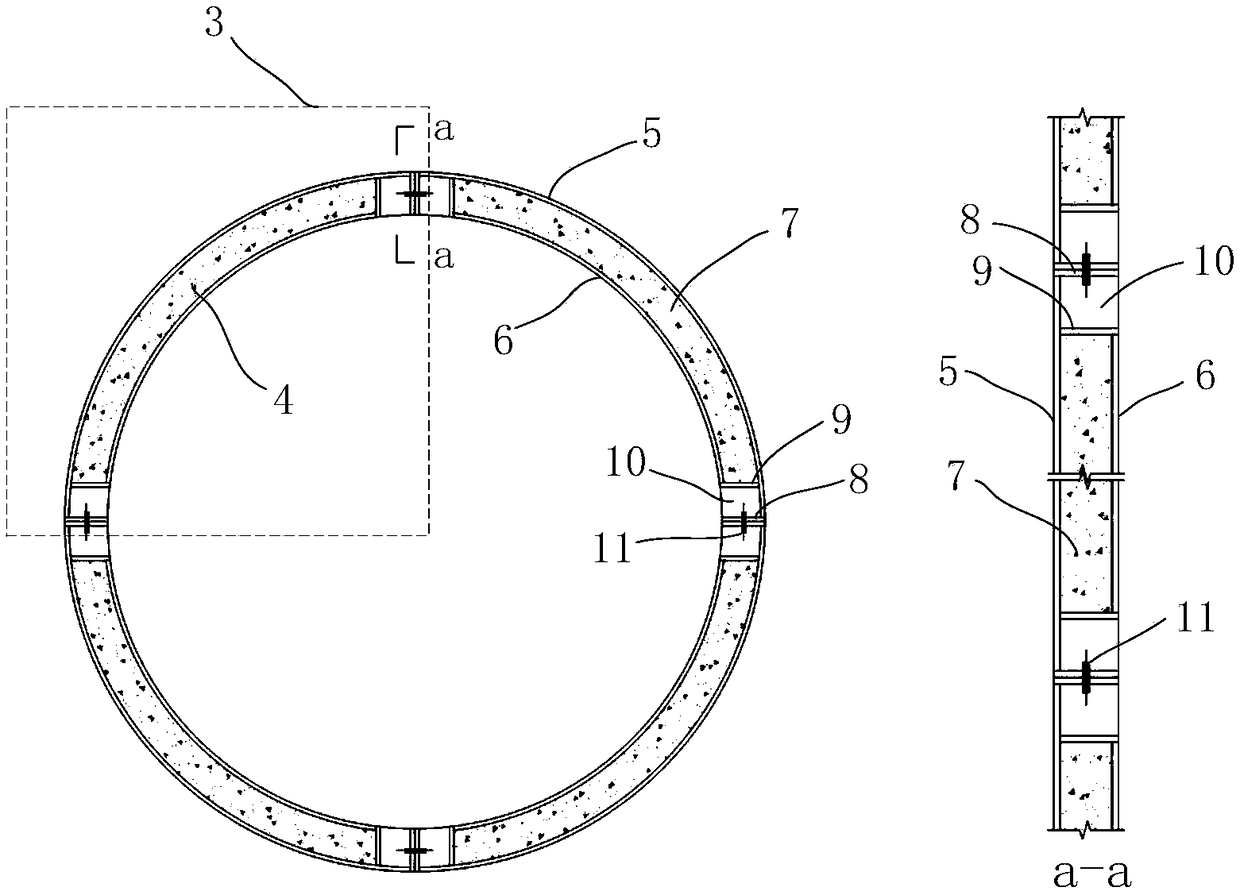

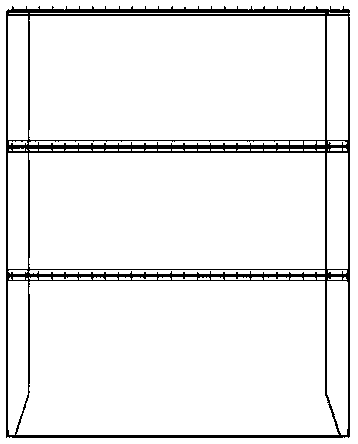

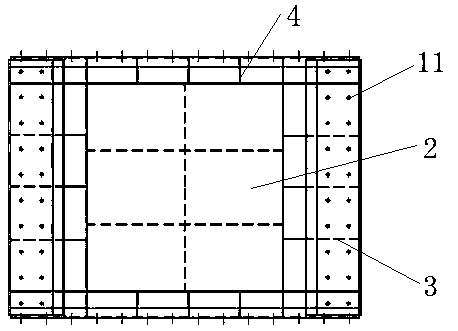

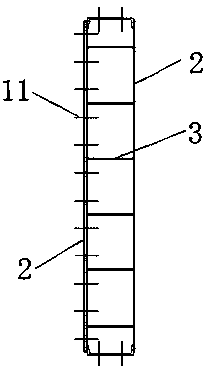

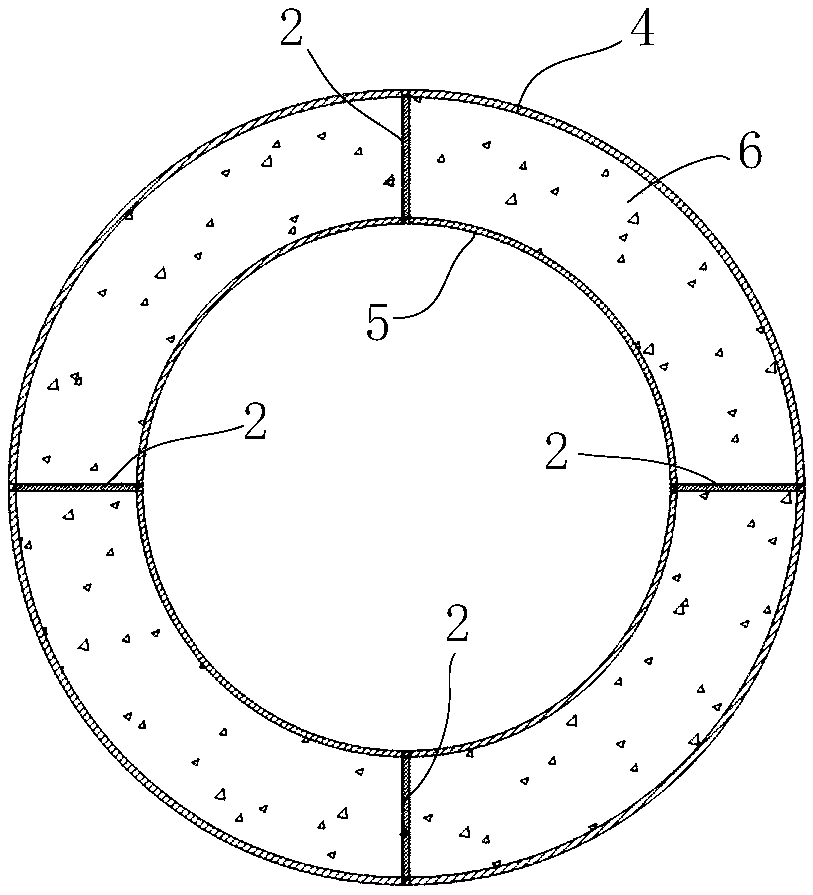

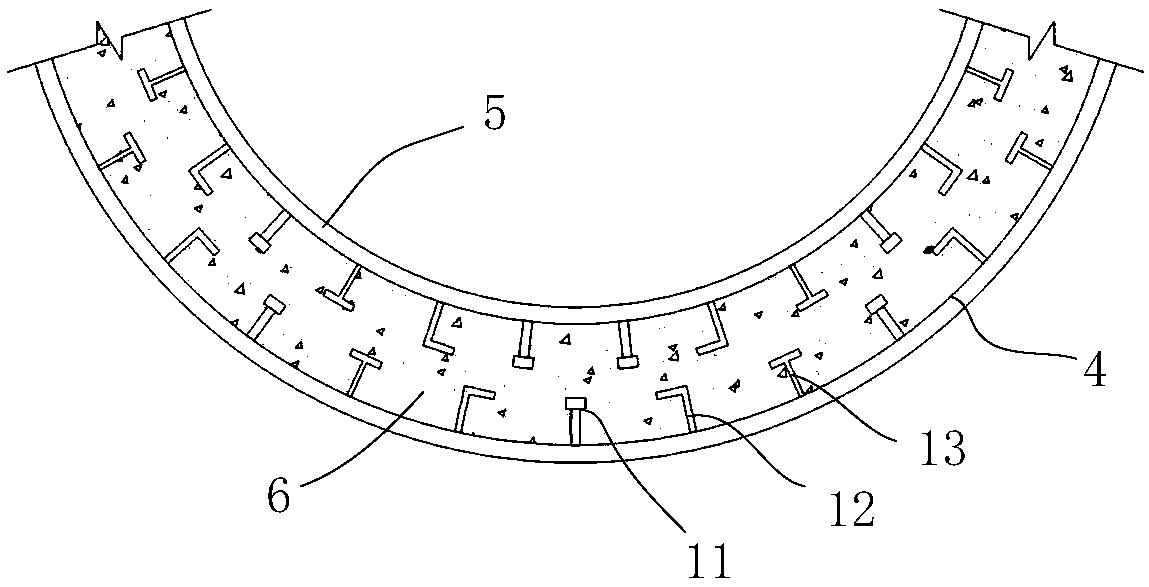

Totally-assembled type hollow interlayer steel pipe concrete combined tower barrel and joints

PendingCN109322793AReduce dosageThe form of force is reasonableWind motor supports/mountsMachines/enginesTowerMaterials science

The invention discloses a totally-assembled type hollow interlayer steel pipe concrete combined tower barrel and joints, and relates to the technical field of wind power generation. The system comprises a hollow interlayer steel pipe concrete barrel body, transverse joints, longitudinal joints and corresponding structures. The hollow interlayer steel pipe concrete barrel body is composed of an outer-layer steel pipe, an inner-layer steel pipe and concrete, studs, angle iron, T-shaped steel or the combination of the studs, the angle iron, the T-shaped steel is welded to one side of each steel pipe in advance, and then concrete pouring is conducted. The hollow interlayer steel pipe concrete barrel body is divided into 2-8 sheets in the ring direction, connection is conducted through the transverse joints, and two forms are adopted in the transverse joints. Segmented assembling of the hollow interlayer steel pipe concrete barrel body in the height direction is achieved, various segments are connected through the longitudinal joints, and two forms are adopted in the longitudinal joints. According to the system, the advantages of a combined structure are brought into full play, the stress form is reasonable, and joint connection is reliable. All the components can be prefabricated in advance, field assembling is adopted, transportation is convenient, the construction efficiency is improved, the material usage amount is reduced, and wide project application prospects are achieved.

Owner:CHONGQING UNIV

Installation method for ultra-large-area closed-type workshop roof skylight truss

ActiveCN107447931ASimple installation principleEasy to operateSky-lights/domesRoof toolsCartSkylight

The invention relates to an ultra-large-area closed-type workshop, in particular to an installation method for an ultra-large-area closed-type workshop roof skylight truss. The installation method comprises the following steps of 1, manufacturing of a transporting trolley and an installation cart, 2, rail design of the transporting trolley and the installation cart, 3, in-position of the transporting trolley and 4, installation of the skylight truss. According to the installation method for the ultra-large-area closed-type workshop roof skylight truss, the structure is simple, all materials can be taken locally, machining and manufacturing are easy, and the manufacturing cost is low.

Owner:CHINA MCC20 GRP CORP

Installation method of two-story steel structure in large-area enclosed workshops

InactiveCN107558742ASimple structureSimple and fast operationBuilding material handlingSUSPENDING VEHICLEBlock and tackle

The invention relates to steel structure construction and provides an installation method of a two-story steel structure in large-area enclosed workshops. The method comprises following steps: preparing a one-handed winch lifting truck; the one-handed winch lifting truck comprises a seat with rollers installed at the bottom, a counterweight zone at the rear of the seat, a vertical rod and an electric winch which are installed on the seat and a pulley group which is installed on the top of the vertical rod; a wire rope of the winch is connected to a free end with a fastening member of a hoisting steel structure member through the pulley group on the top of the vertical rod; the free end of the well counterweighted winch lifting truck steel rope is fastened to the steel structure member; theelectric winch which is controlled to operate and lift; a steel column of the steel structure member is positioned and set by the one-handed winch lifting truck; anchor bolts are installed and installation is completed; a steel girder of the steel structure member is installed by two one-handed winch lifting trucks; the girder is positioned and transversely fixed; connecting bolts are installed to complete the installation. The invention does not need to use a large crane or a tower crane, and saves hoisting expenses; the occurrence of site safety accidents is reduced.

Owner:CHINA MCC20 GRP CORP

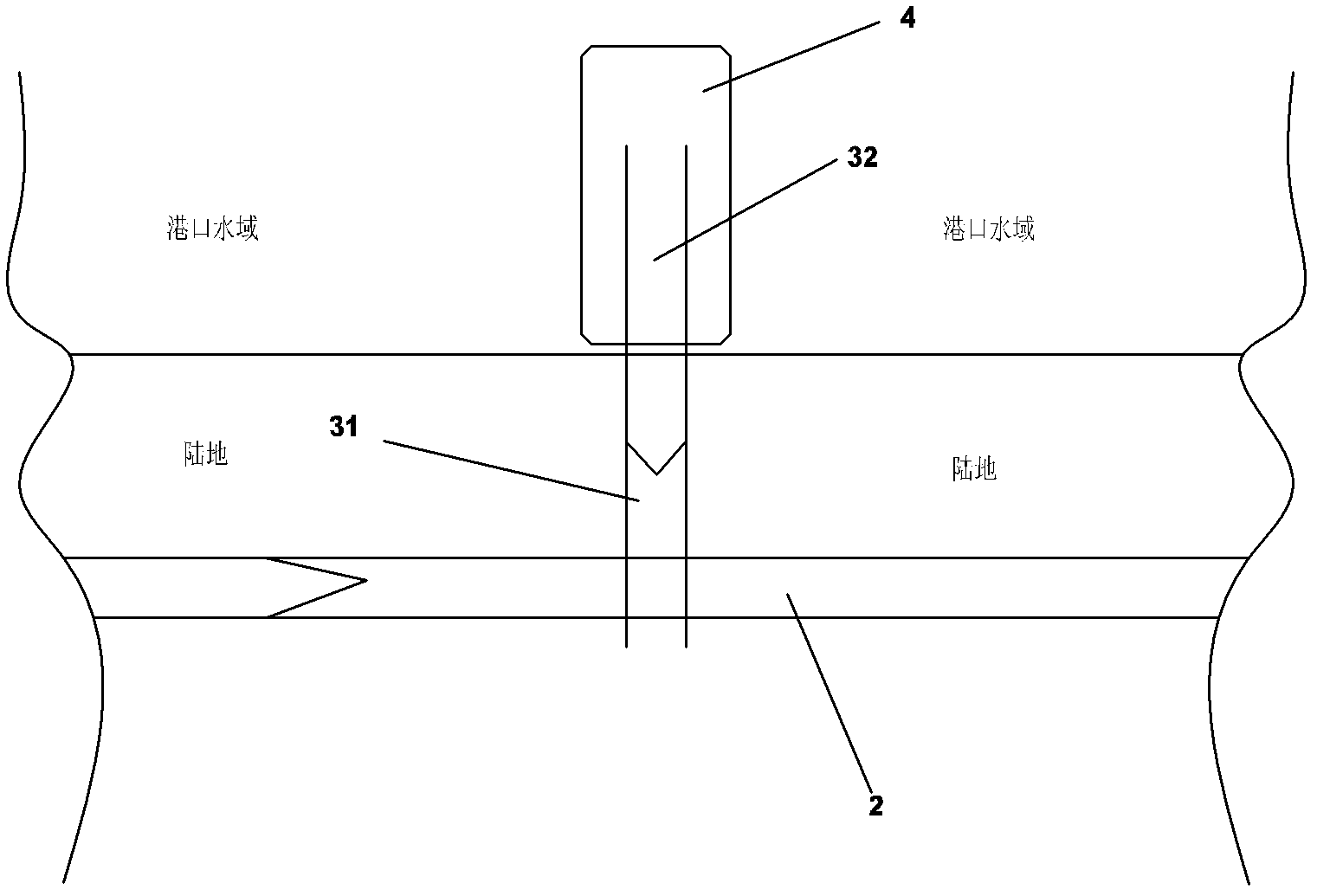

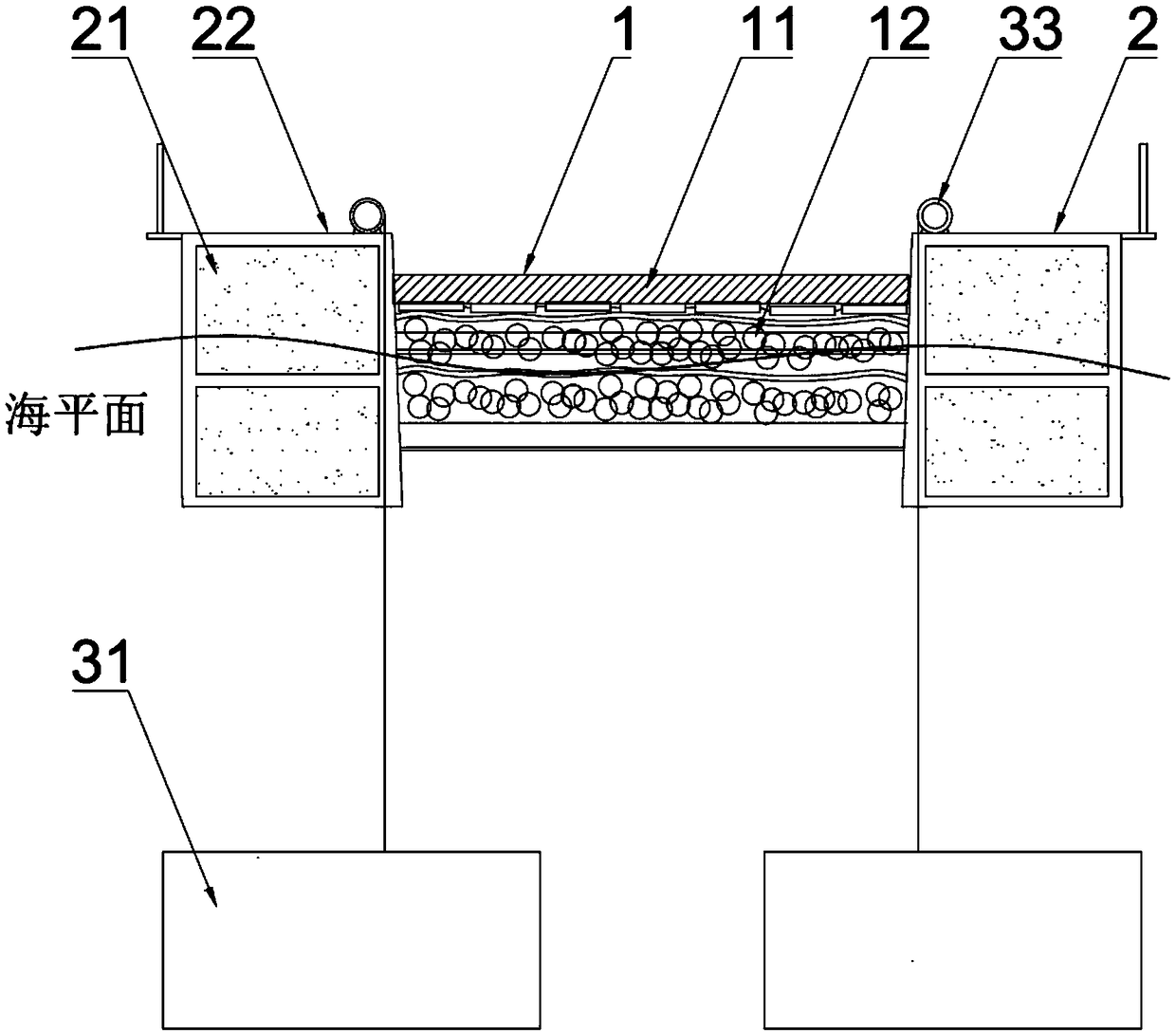

Expressway floating on sea

ActiveCN109505227AImprove subject qualityShorten the timeWaterborne vesselsTemporary pavingsOcean bottomEngineering

The invention discloses an expressway floating on the sea. The expressway is formed by sequentially connecting a plurality of suspension box bridges end to end. Each suspension box bridge comprises anexpressway body, insulating outer layers and an anchoring system, wherein the expressway body comprises a bridge surface and a floating body for providing buoyancy for the bridge surface, the insulating outer layers float on the sea surface, are arranged on the two sides of the expressway body respectively so as to clamp and limit the floating body and the bridge surface, the two insulating outerlayers are fixedly connected with each other, the anchoring system comprises a balanced gravity base sinking in the seabed, the balanced gravity base is provided with a plurality of steel wire ropeswhich are connected with the two insulating outer layers respectively, and the steel wire ropes are tightened so as to limit the vertical floating of the insulating outer layers. The suspension box bridges are high in design safety coefficient and long in service life; since each suspension box bridge is an independent unit, the suspension box bridges are easy to maintain and recyclable.

Owner:XIANGSHAN SHANGBO E COMMERCE CO LTD

Production technology of wear-resistant composite pipe filled with adhesive cement

The invention relates to a production technology of a wear-resistant composite pipe filled with adhesive cement. The technology comprises the following steps that a pipe is horizontally fed, horizontal filling of the adhesive cement is performed, an outer sleeve steel pipe is horizontally fixed to a support, one end of the outer sleeve steel pipe is tightly connected with a grouting sealing hoop, a plurality of fixing blocks are arranged on the outer walls of wear-resistant pipes, every two adjacent wear-resistant pipes are sealed and bonded, a pressure propelling device sequentially pushes all the wear-resistant pipes into the outer sleeve steel pipe through a propelling rod, a grouting cavity is formed among the outer sleeve steel pipe and the wear-resistant pipes through supporting of the fixing blocks, the grouting cavity is filled with the adhesive cement through a pressure grouting device, the outer sleeve steel pipe and the wear-resistant pipes form the wear-resistant composite pipe, the grouted wear-resistant composite pipe is maintained, the end, without the adhesive cement, of the wear-resistant composite pipe is repaired and is flush, and the outer surface of the wear-resistant composite pipe is treated. According to the technology, horizontal pipe feeding and horizontal adhesive cement filling are adopted, additional steps are reduced, the production period is shortened, the production efficiency can be improved, and the production cost can be reduced.

Owner:SGIS SONGSHAN CO LTD

Device for changing slip ring of motor

ActiveCN102013764BIncrease usageSave hoisting costsManufacturing dynamo-electric machinesWind energy generationEngineeringTower

The invention relates to a tool for changing a slip ring of a motor, specifically to a device for changing the slip ring of the motor, which is used for solving a problem of failure in changing the slip ring of a wind power generator at top of a tower for the reason of being lack of a manual device for changing the slip ring in cold state. The device for changing the slip ring of the motor is composed of a slip ring protection ring fixed to an end surface of the slip ring, a threaded pull rod in threaded connection with the slip ring protection ring or an end surface of a rotation shaft of the motor, a nut matched with the threaded pull rod, a threaded plunger connected with the end surface of the rotation shaft of the motor or the slip ring protection ring in thread manner and provided with a shaft shoulder, and a pressing board on which a threaded pull rod through hole and a threaded plunger through hole are formed. The device for changing the slip ring of the motor is particularly suitable for changing the slip ring of a high-power megawatt-class doubly-fed wind power generator, and also can be used for changing the slip rings of other motors.

Owner:CRRC YONGJI ELECTRIC CO LTD

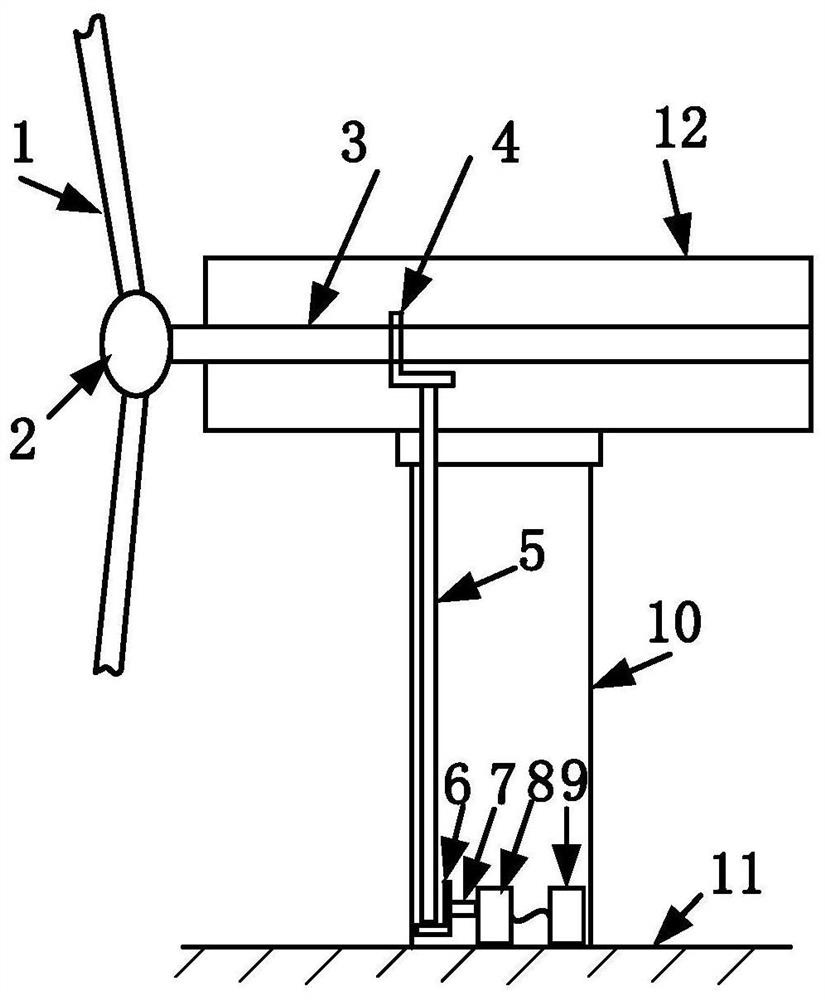

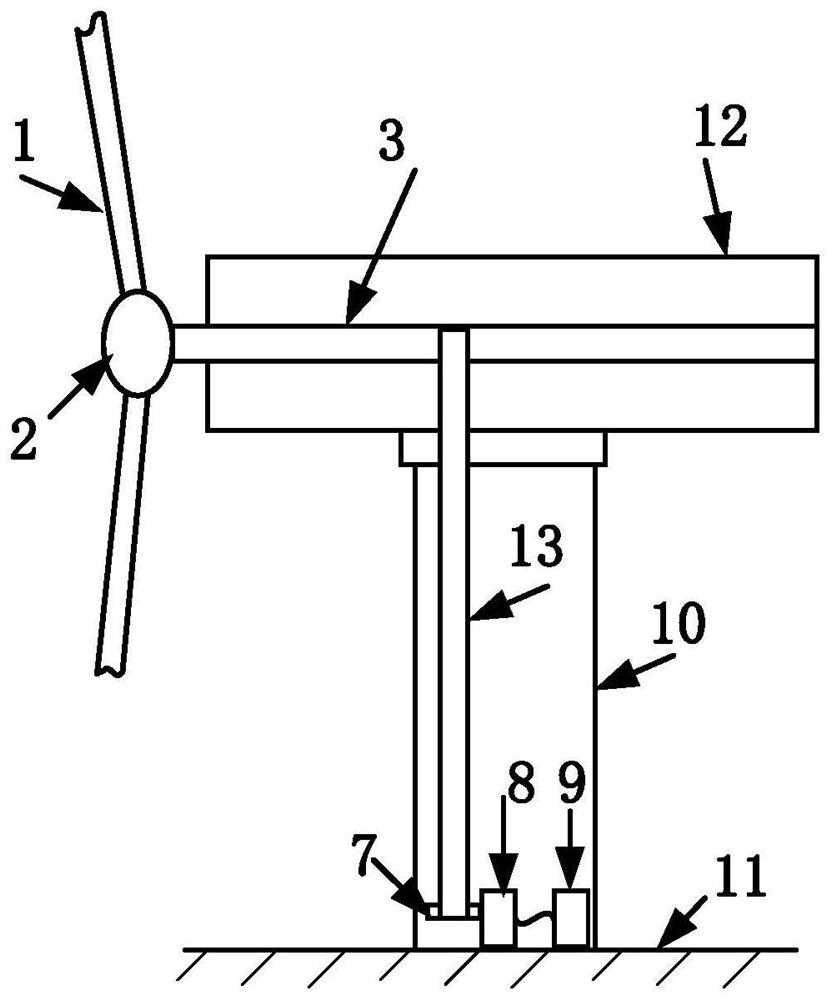

Wind power generation system capable of saving land and reducing load

PendingCN113417816AReduce cabin weightSave hoisting costsWind motor supports/mountsWind motor combinationsElectric generatorWind power generator

The invention discloses a wind power generation system capable of saving land and reducing load. A power generation part is arranged at the bottom of a tower drum, a bottom main shaft is connected with a power generator, a cabin main shaft is connected with blades through a hub, the cabin main shaft is connected with the bottom main shaft through a transmission mechanism, and a box transformer substation is arranged in the bottom of the tower drum and connected with the power generator. The generator is moved downwards from the cabin at the top of the tower drum to the bottom of the tower drum, so that the weight of the cabin is reduced, and the engineering hoisting cost is reduced; and meanwhile, the requirement of loads for the tower drum and a wind generation set foundation is greatly reduced, the engineering construction cost is further reduced, the land expropriation area for wind generation set construction is saved and the engineering land expropriation cost is reduced by arranging the box transformer substation in the tower drum, and the length of a cable between the generator and the box transformer substation is reduced by arranging the generator downwards and arranging the box transformer substation internally, and therefore, the material cost and the installation cost of engineering are further reduced.

Owner:HUANENG CLEAN ENERGY RES INST

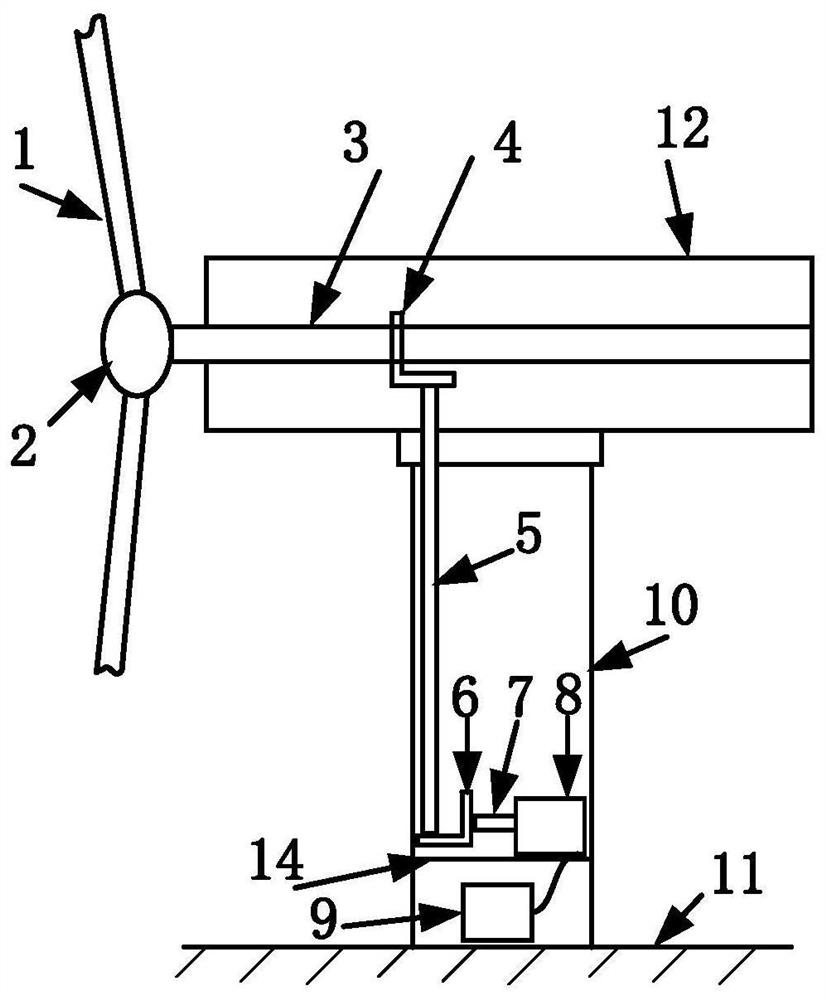

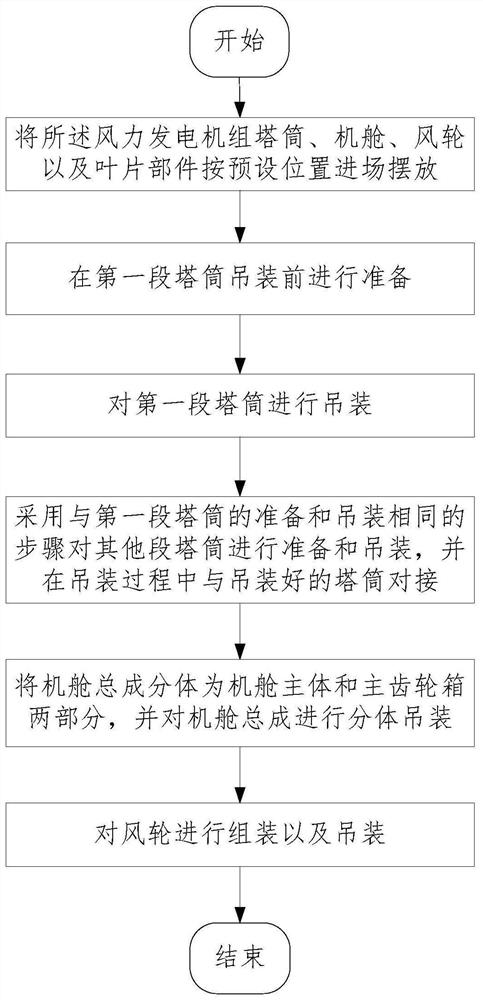

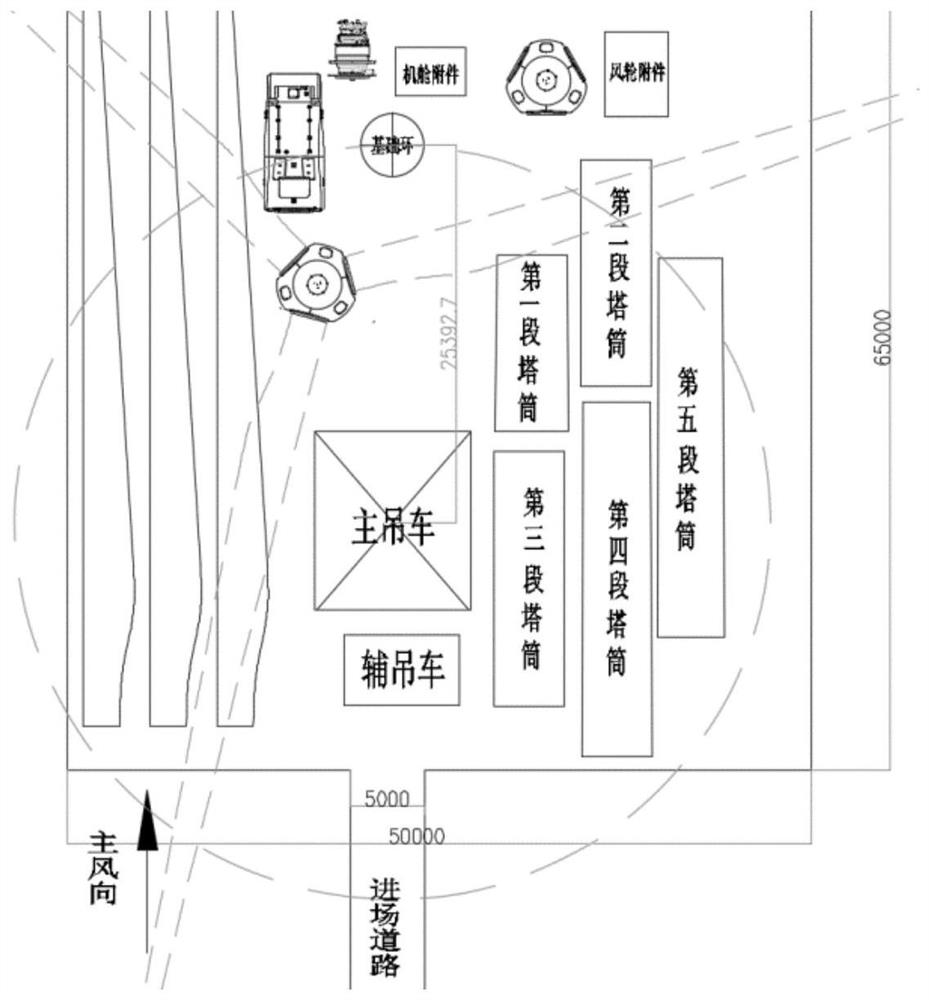

Split type hoisting method for land wind turbine generator set

ActiveCN112249874AImprove hoisting efficiencyMeet the requirements not to exceed 100tWind energy generationLoad-engaging elementsNacelleMarine engineering

The invention relates to a split type hoisting method for a land wind turbine generator set. A cabin of a 3.XMW set is divided into a cabin body and a main gear box for hoisting, so that the weight ofeach part is controlled within 80 t; and the steps of part placement, detection and the like in the hoisting process are further combined, so that split type hoisting of the wind turbine generator set is achieved, the requirement that the total weight of large single-vehicle transportation cannot exceed 100t according to the current national policy can be met, and the hoisting requirement of mainstream large cranes in the market in the prior art can also be met; and meanwhile, the hoisting frequency of a main crane is reduced, the hoisting period of the single wind turbine generator set is shortened, and the hoisting efficiency of the wind turbine generator set is improved.

Owner:XUCHANG XUJI WIND POWER TECH

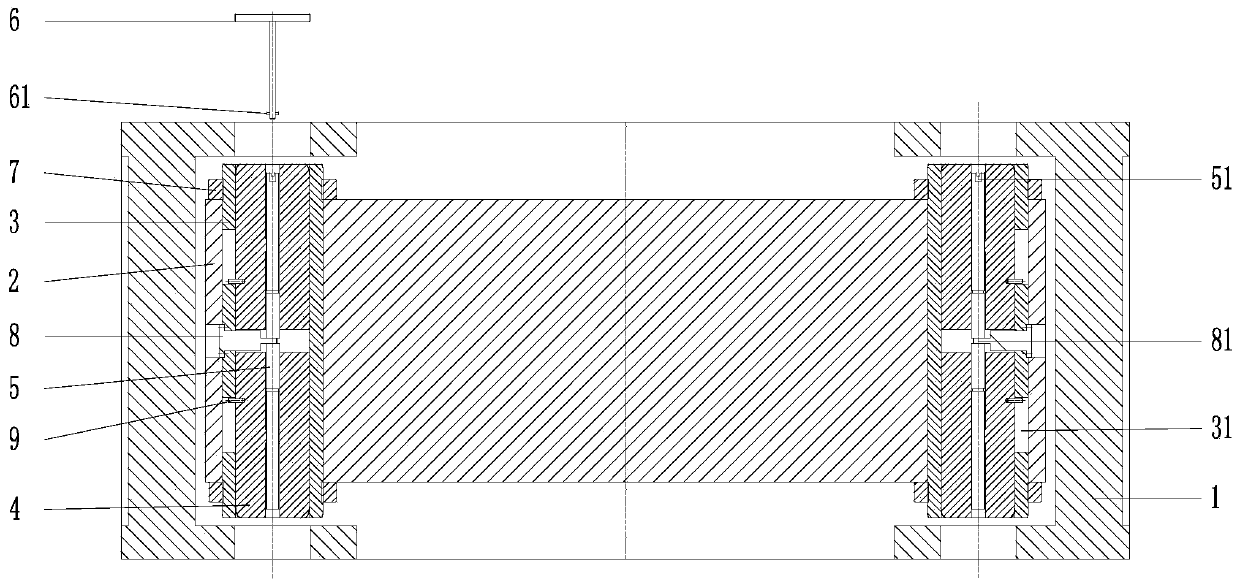

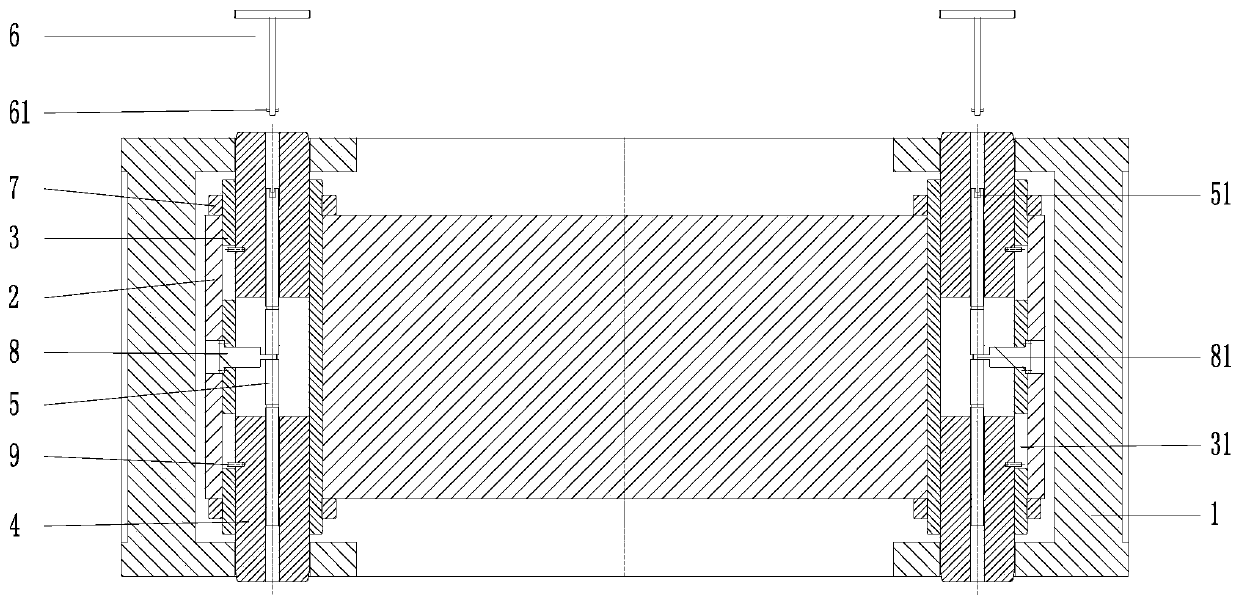

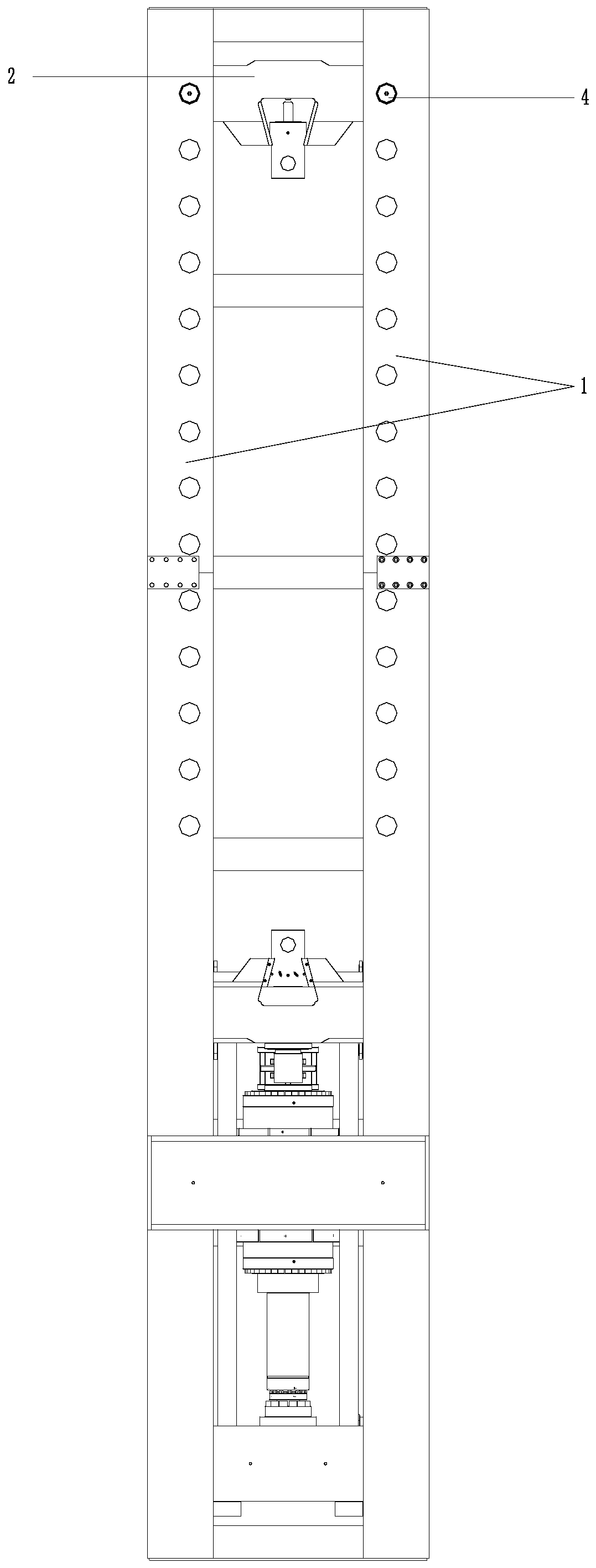

Rotary symmetric plug pin insertion mechanism and horizontal-type tension test machine

PendingCN110286034AImprove work efficiencyReduce labor costsMaterial strength using tensile/compressive forcesMetal-working hand toolsEngineeringScrew thread

The invention discloses a rotary symmetric plug pin insertion mechanism and a horizontal-type tension test machine. The rotary symmetric plug pin insertion mechanism comprises guide cylinders, plug pins, threaded rods and handles, wherein the guide cylinders are inserted and fixed into the positioning holes of a movable cross beam respectively, the plug pins are arranged in the guide cylinders respectively, the threaded rods are inserted into inner threaded holes at the central axes of the plug pins respectively, and the handles are used for driving one end of each threaded rod to rotate; and when the threaded rods rotate, the plug pins can be driven to be axially inserted into the positioning holes of a guide rail, so that a movable beam reaches a locking state relative to the guide rail. According to the rotary symmetric plug pin insertion mechanism and the horizontal-type tension test machine of the invention, by means of forward-reverse threaded rod rotation, the plug pins can be driven to be inserted into the positioning holes, so that a locking state is achieved. The rotary symmetric plug pin insertion mechanism has the advantages of great convenience, high rapidness and high accuracy. With the rotary symmetric plug pin insertion mechanism of the invention adopted, labor cost and lifting cost are decreased.

Owner:湖北万测试验设备有限公司

Hoisting method for framework of large tonnage pressing machine

ActiveCN101284628BLower the altitudeSolve lifting problemsTravelling cranesLoad-engaging elementsDevice placementTower

The invention relates to a method for hoisting large scale equipment, in particular to a method for hoisting a large-tonnage pressing machine frame. The method comprises the following steps: tower beams are arranged on two sides of the installation position of the pressing machine frame; a large scale hoisting device is arranged on the tower beams; a sliding shaft and a falling shaft are arrangedrespectively in the front and in the back of the pressing machine frame; the sliding shaft is arranged at the top of the pressing machine frame and in the back thereof, and the falling shaft is arranged at the bottom thereof and in the front thereof; the sliding shaft slides rotationally forwards on a slideway; the falling shaft rotationally falls down, until the pressing machine frame is upright; a hoisting point is changed in the position of the sliding shaft; and the installation is completed after the pressing machine frame falls down for a certain distance. Compared with the prior hoisting method, the method of the invention has the outstanding advantages that: the height of the tower is reduced, so that all work can be done in the well-installed workshop; the hoisting equipment in the workshop is fully utilized, so that the hoisting problems of all hoisting equipment are solved and the hoisting cost of the prior art is saved; the construction period is shortened, and the safety is guaranteed; and the method is suitable for the hoisting installation operations in narrow spaces or at high altitude, underground, and in other construction situations.

Owner:CHINA 22MCC GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com