Patents

Literature

735results about How to "Improve construction accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

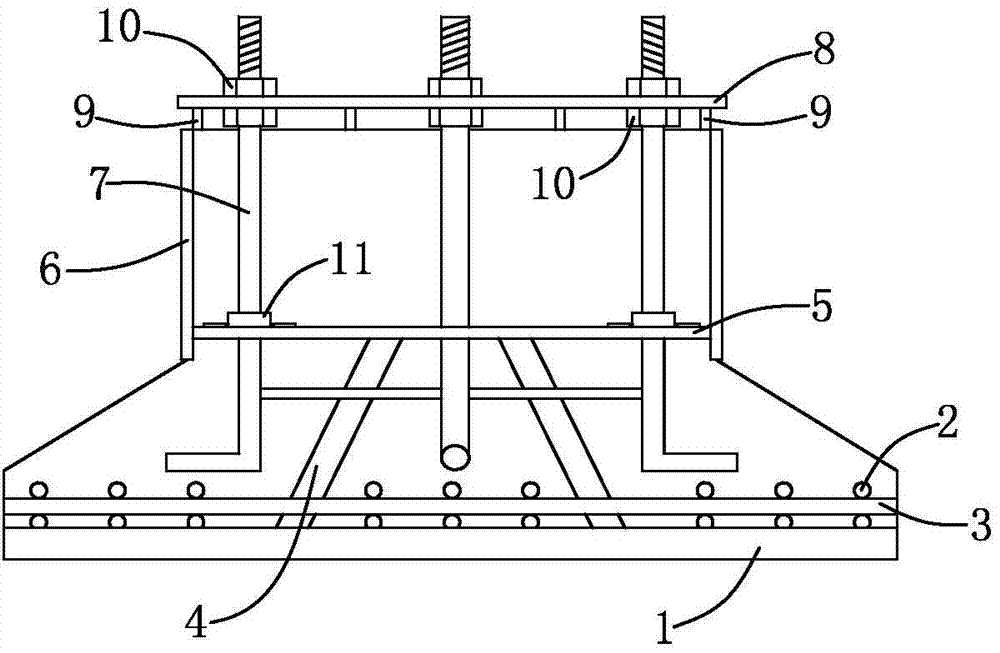

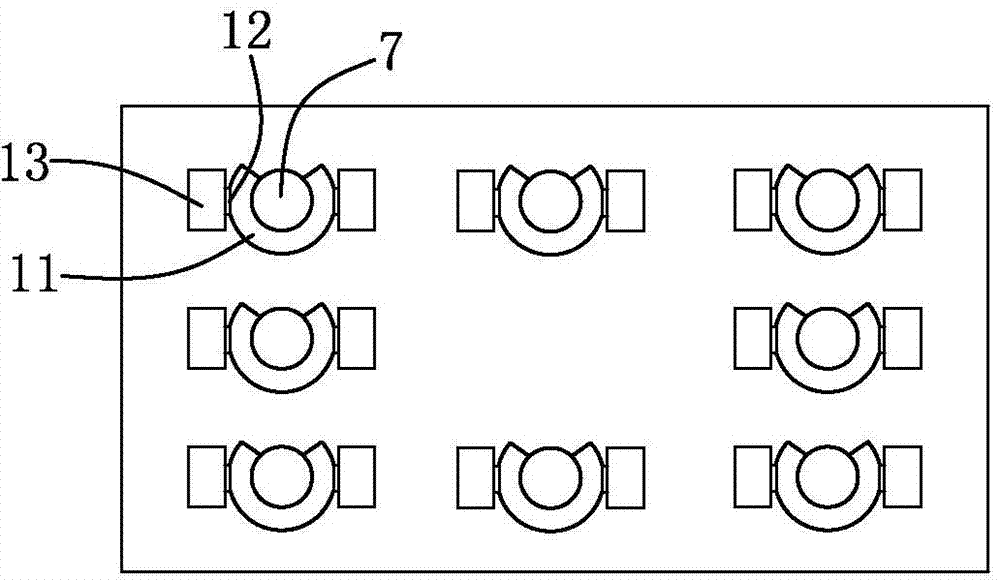

Pre-buried construction method for high-precision foundation bolts

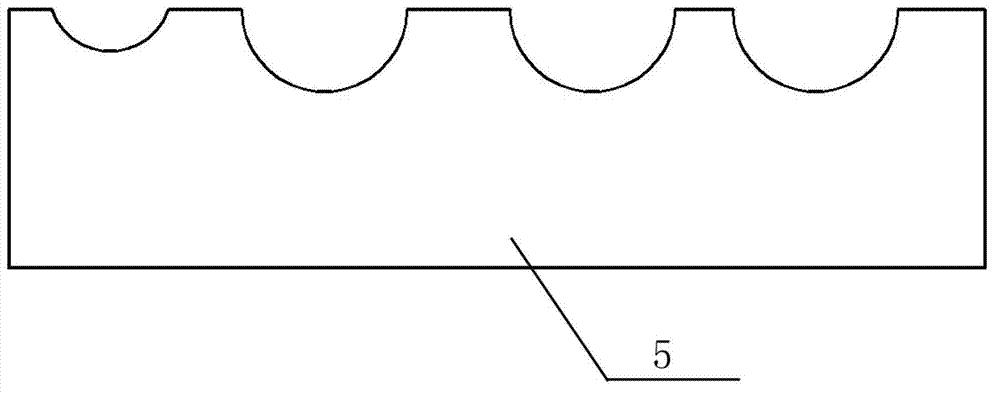

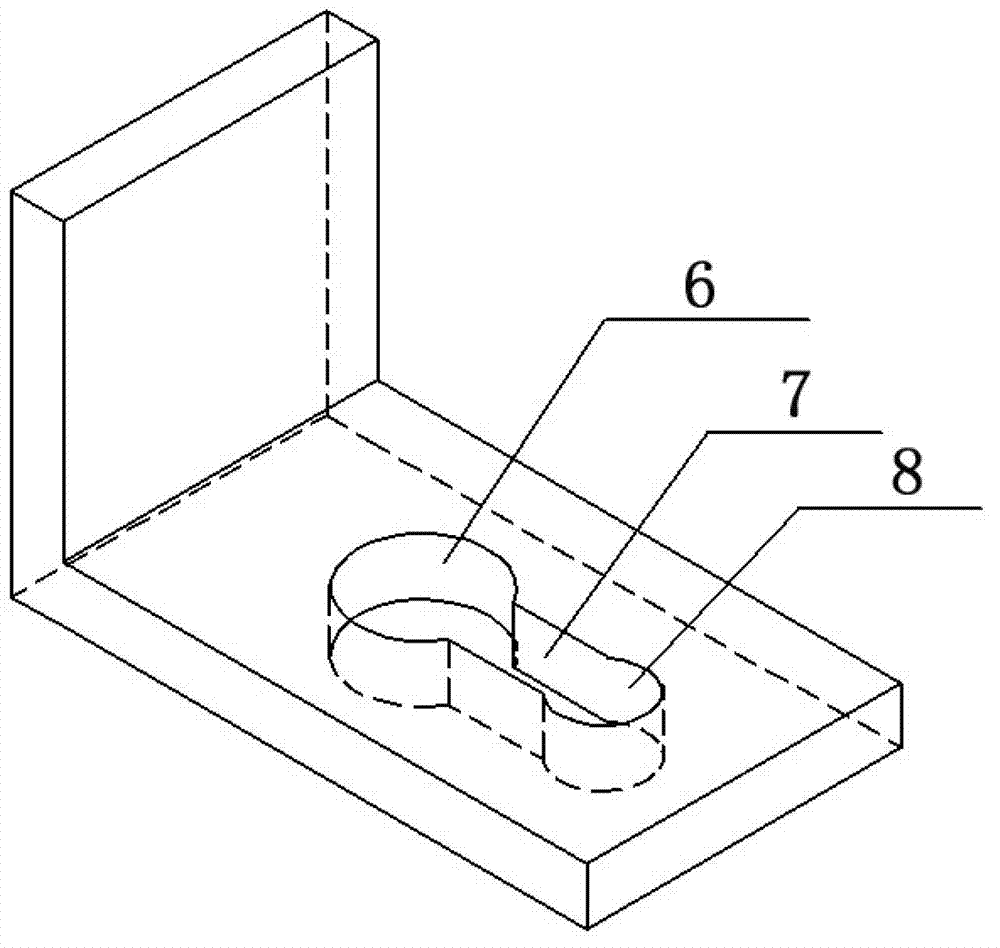

The invention discloses a pre-buried construction method for high-precision foundation bolts. The method includes the following steps that (a), construction preparation is performed; (b), a control net is established; (c), a positioning clamp and a positioning control plate are manufactured; (d), foundation steel bars are buried in advance; (e), the positioning clamp is installed; (f), the foundation bolts are installed; (g), the foundation bolts are reinforced and protected; (h), concrete pouring is performed; (i), the clamp is dismantled; (j) acceptance inspection and handover are performed to finish the pre-buried construction. The manufactured high-precision positioning clamp is adopted for performing clustering control over the pre-buried foundation bolts of each set of equipment foundations, elastic clamping tools are arranged on the outer sides of the foundation bolts, supporting legs of the elastic clamping tools are embedded into clamping holes in the positioning clamp, and the elastic clamping tools are clamped on the positioning clamp of the foundation bolts, so that the foundation bolts are further reinforced and prevented from loosening. The pre-buried construction method has the effects of being reliable in technology, high in construction precision, easy to understand and master and convenient to operate, and meanwhile is short in construction period and low in cost.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

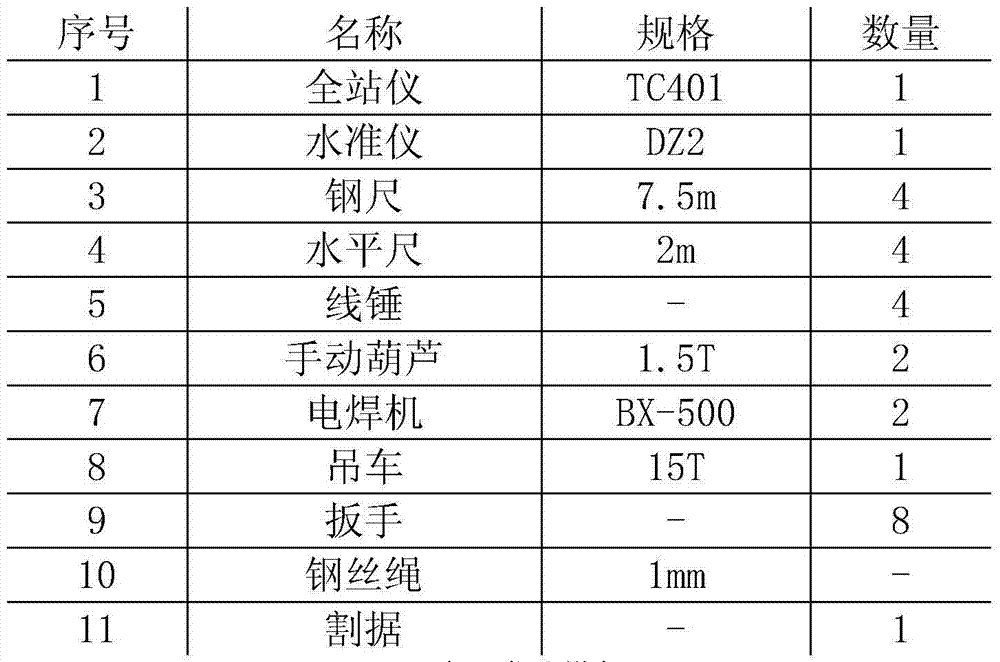

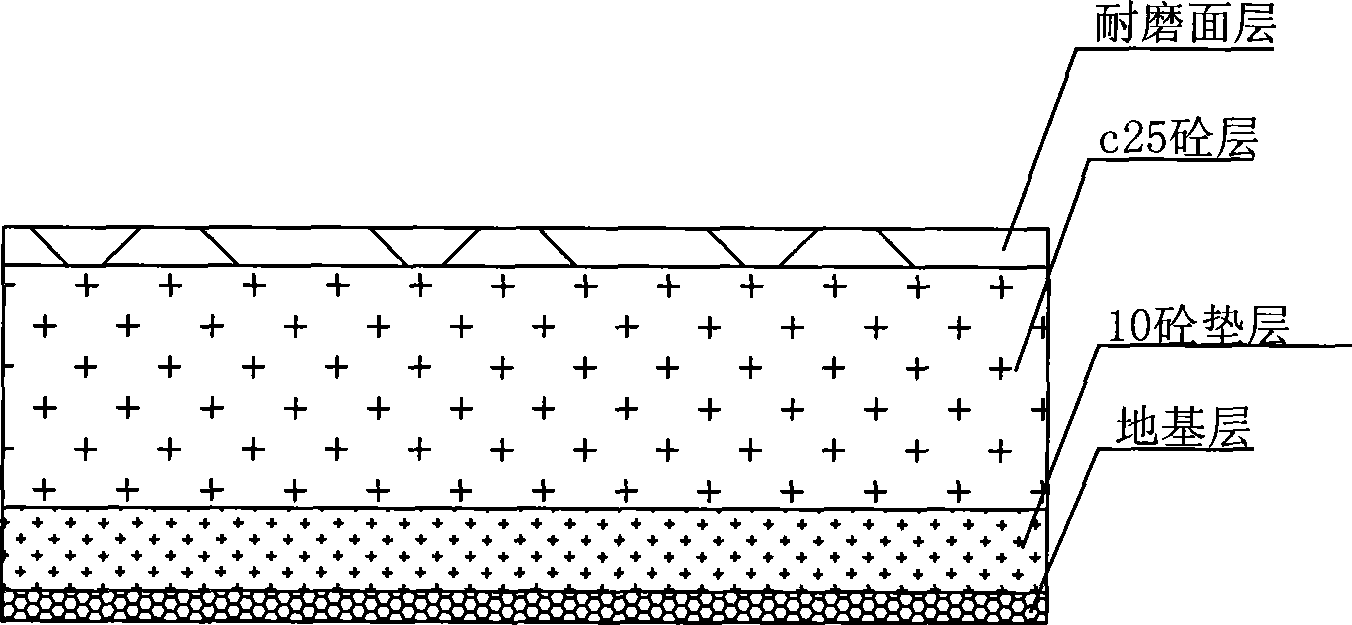

Method for controlling flatness and elevation of large area wear resistant terrace

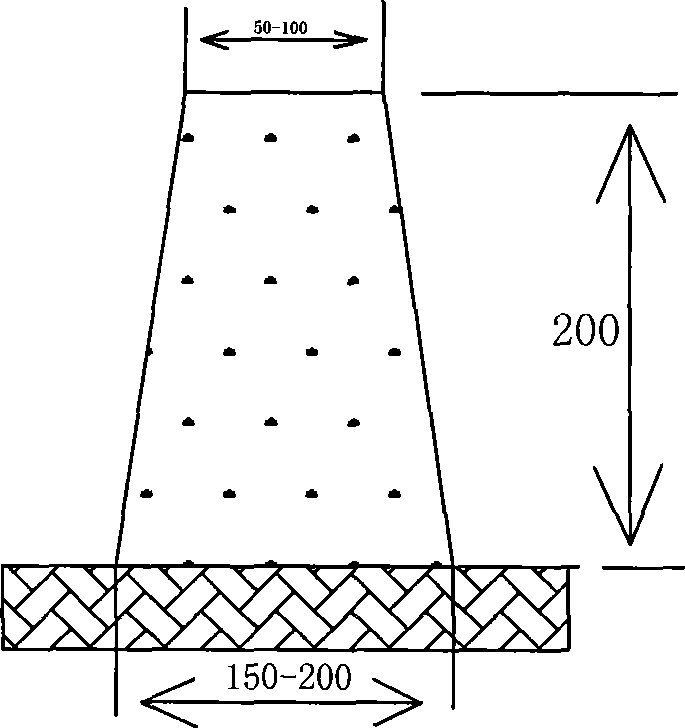

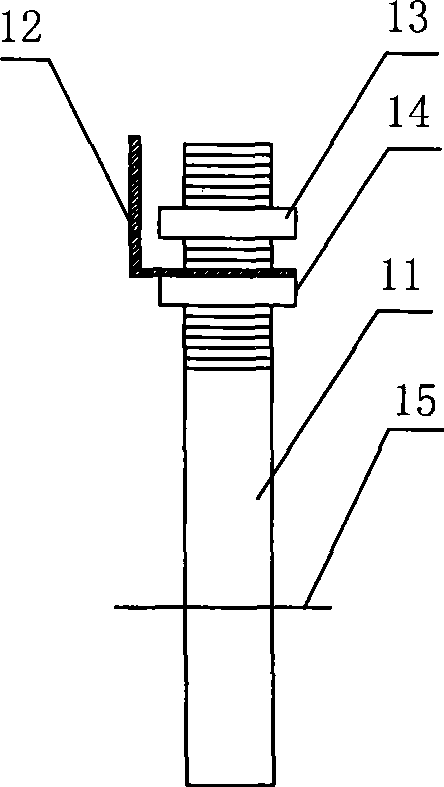

InactiveCN101440664AHigh leveling precisionHigh precision of elevation controlBuilding material handlingFlooringSurface layerWear resistant

The invention relates to a control method for evenness and elevation of large-area abrasion-resistant ground. A device for the control method comprises a bolt provided with screw thread at one end and without screw thread at the other end and welded on a bearing bar, a fixing nut, an adjusting nut, and at least two angle irons with a length of 6 meters and drilled with holes at intervals of 1,900 millimeters. The control method comprises the following steps: lofting a concrete cushion layer, drilling a hole on the concrete cushion layer according to the lofting position, nailing the end without the screw thread of the bolt in the hole of the concrete cushion layer, screwing the adjusting nut at the end with the screw thread of the bolt, sleeving the drilled angle irons on the bolt, screwing the fixing nut on the bolt, levelling the angle irons by using a level gauge, adjusting the adjusting nut to adjust the height of the angle irons, tightening the fixing nut to fix the angle irons, casting ground concrete, levelling the ground concrete cushion layer by using a guiding rule of 6 meters, removing the angle irons, paving an abrasion-resistant surface layer which is polished to be even by a fan polisher and finished by a finisher, and maintaining. The method has the advantages of simplicity, simple facilities, high precision of ground control and remarkable effect.

Owner:JIANGSU JIANGDU CONSTR GRP

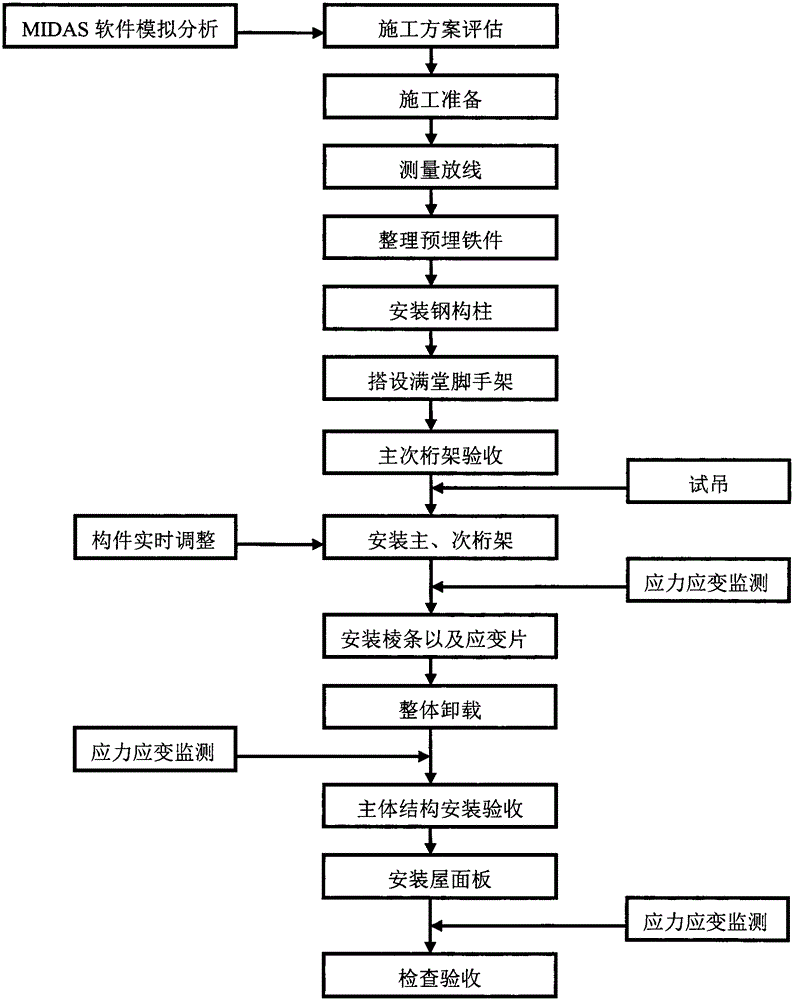

Spatial curved surface steel structure pipe truss roof installation construction method

InactiveCN105133841AClose up smoothlyImprove construction accuracyGirdersJoistsFalseworkElement model

A spatial curved surface steel structure pipe truss roof installation construction method relates to the technical field of a building construction method. The construction method comprises the following steps of elevating a scheme, making preparation for the construction, measuring and setting out, tidying a pre-buried iron member, setting up an all-around scaffold, checking and accepting a main and secondary trusses, installing the main and secondary trusses, installation ridges and stress sheets, detaching the whole, checking and accepting after main body installation, installing a roof panel plate and checking and accepting the whole. Finite element modeling for a non-linear construction phase can be achieved; construction scheme safety is evaluated according to stimulation check of component stress and strain during the construction, so practical construction can be guided; strain displacement can be monitored during the construction; real-time adjustments can be conducted to components, so construction precision can be improved and building cost can be reduced.

Owner:五洋建设集团股份有限公司

Saline-alkali soil improving method by engineering-chemistry-biology-desalination and water conservation-information technology

ActiveCN104472052AInhibit salt returnAlkaline modification takes effect quicklySoil-working methodsAlkali soilSoil science

The invention discloses a saline-alkali soil improving method by engineering-chemistry-biology-desalination and water conservation-information technology. The saline-alkali soil improving method includes steps of S1, lowering salt content in the saline-alkali soil to be treated gradually by engineering measures and isolating and discharging soluble salt in the soil; S2, reasonably utilizing water resource of the saline-alkali soil to be treated by brackish water desalination technology; S3, reasonably irrigating the saline-alkali soil to be treated by water-saving irrigation technology; S4, online detecting the saline-alkali soil to be treated by information technology; S5, improving chemical components of the saline-alkali soil to be treated by chemical measures; S6, finally improving the saline-alkali soil to be treated by biotechnology measures. The saline-alkali soil improving method provides a feasible, economic and efficient scheme for improving the saline-alkali soil in coastal regions, improvement time is short, effect is good and no backflow is caused after improvement.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

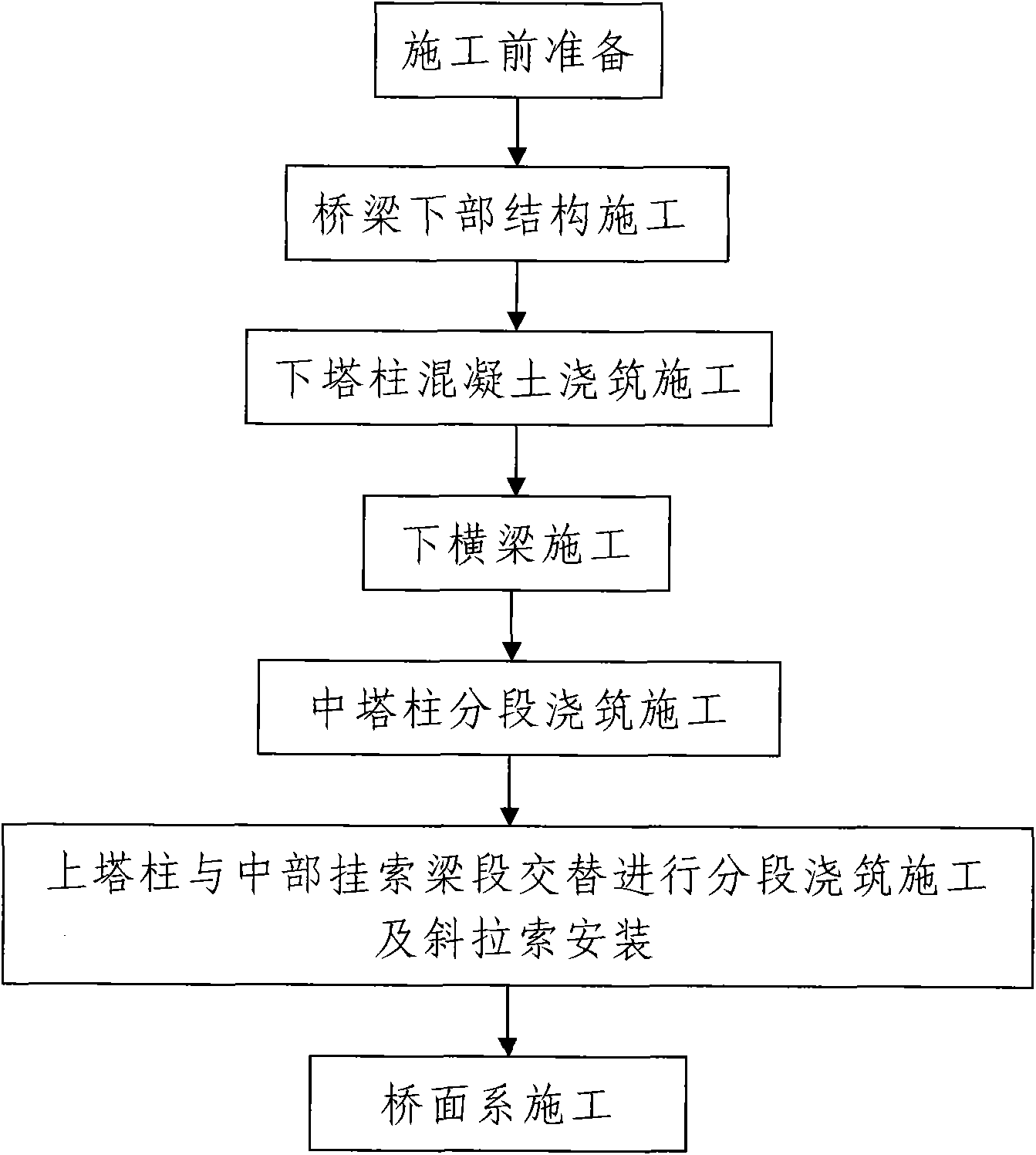

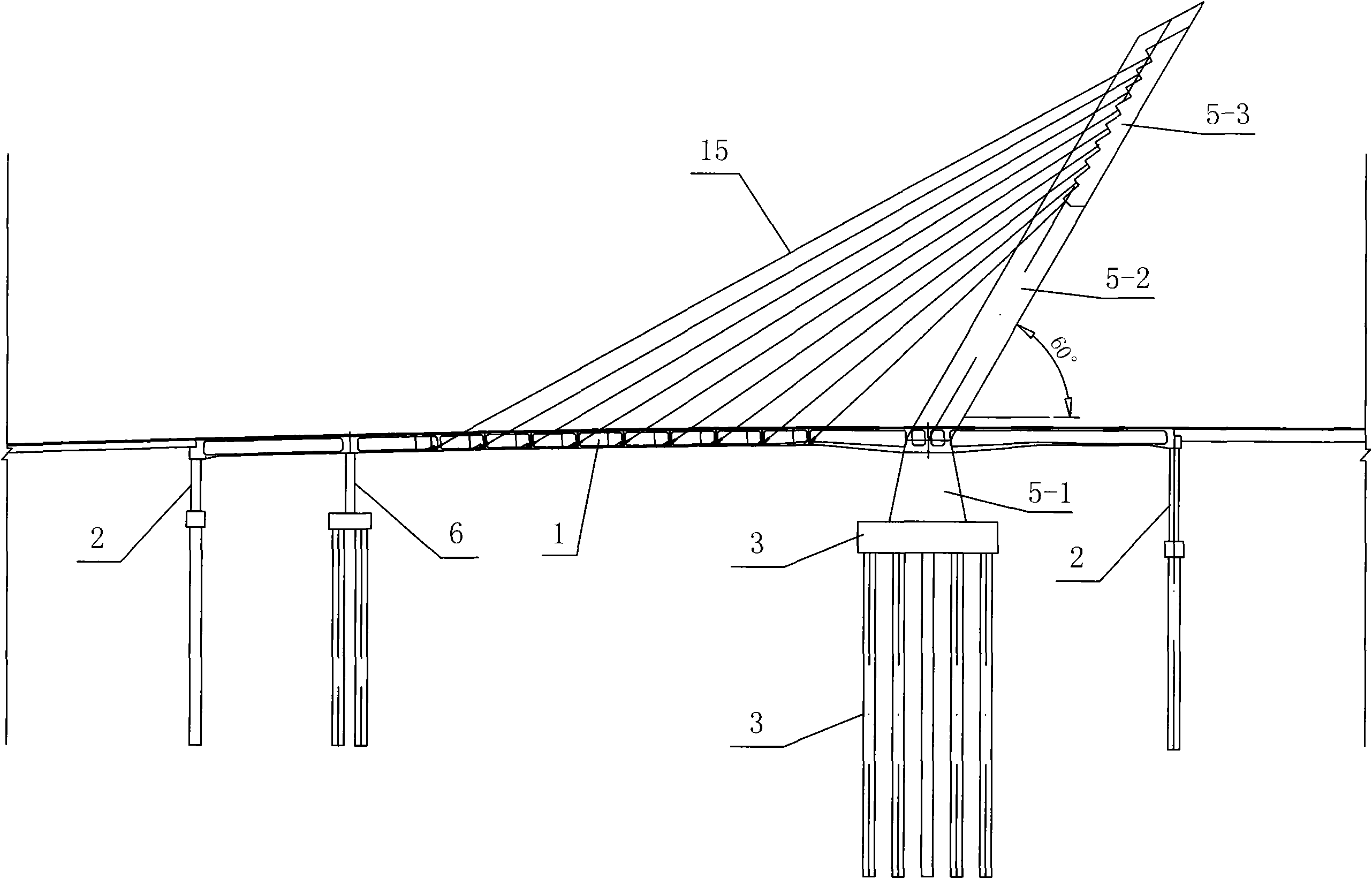

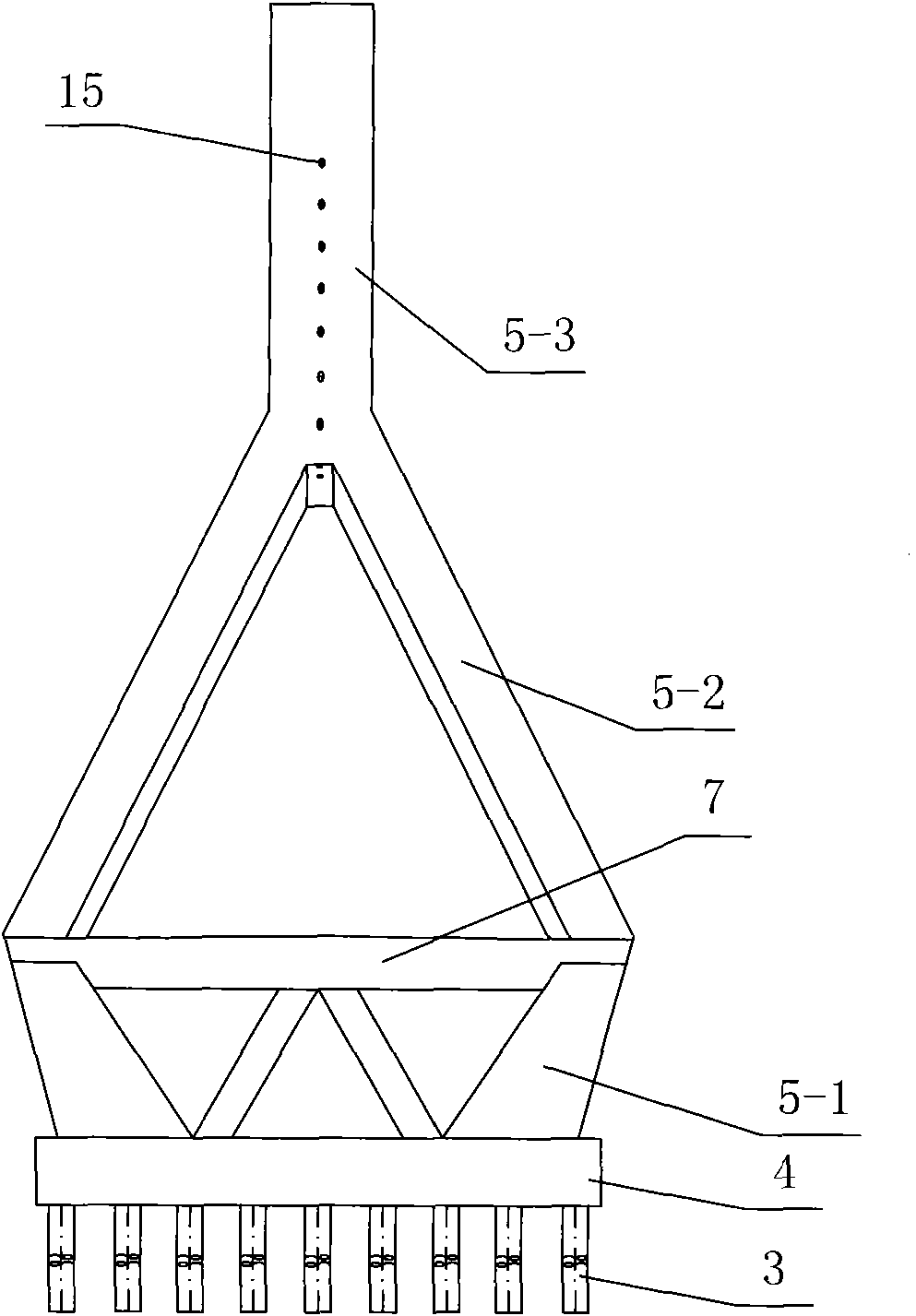

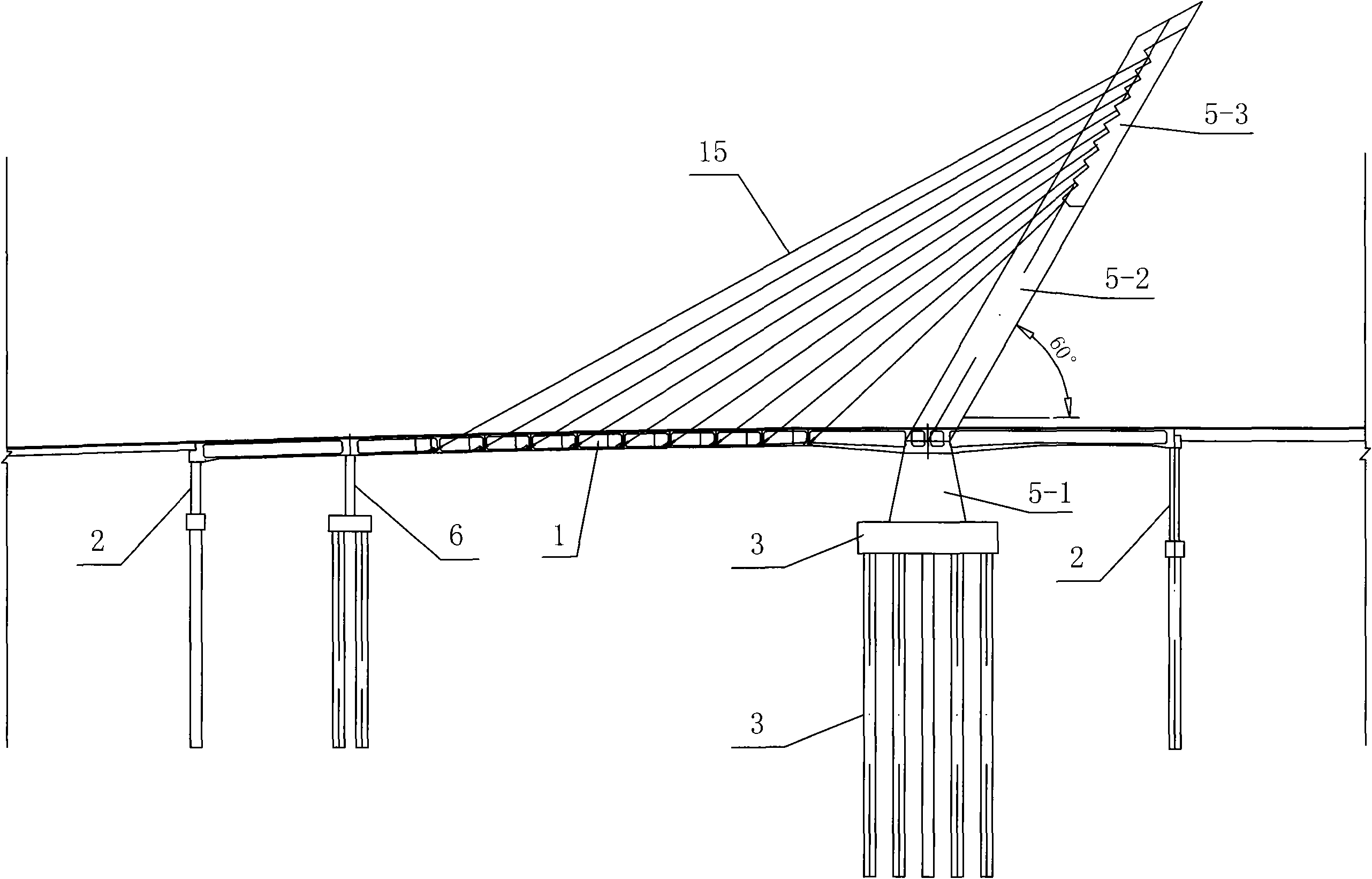

Construction method of single-pylon cable-stayed bridge without dorsal cables

ActiveCN101781879AStable structureGood construction performanceCable-stayed bridgeBridge erection/assemblyCable stayedSystem construction

The invention discloses a construction method of a single-pylon cable-stayed bridge without dorsal cables. The construction method comprises the following steps of: (1) preparation before construction; (2) lower bridge structure construction; (3) upper bridge structure construction, which comprises the following construction processes of: lower pylon concrete pouring construction, lower beam construction, middle pylon segmental pouring construction, alternate segmental pouring construction of an upper pylon and a middle suspension cable beam segment and stayed-cable mounting, wherein an integral lifting template is used for segmental construction on both the middle pylon and the upper pylon; and (4) bridge surface system construction. The construction method has reasonable step design, convenient construction, safe and reliable construction, high construction quality, short construction period and less and simple construction hardware equipment and can effectively overcomes the defects and deficiencies of complicated construction process, difficult guarantee of construction quality, various hardware equipment needed, and the like in the construction process of the single-pylon cable-stayed bridge without dorsal cables.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

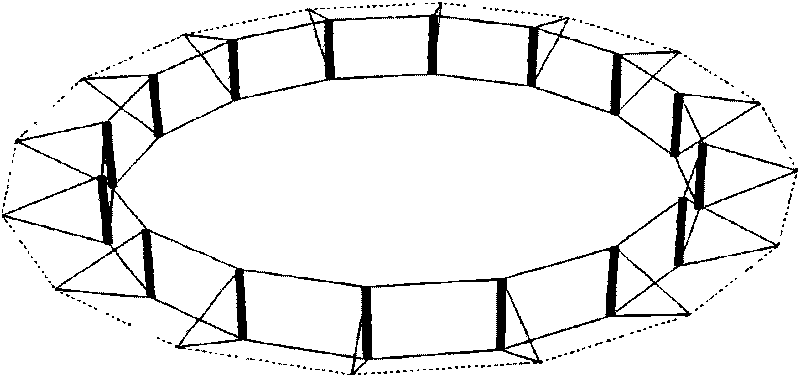

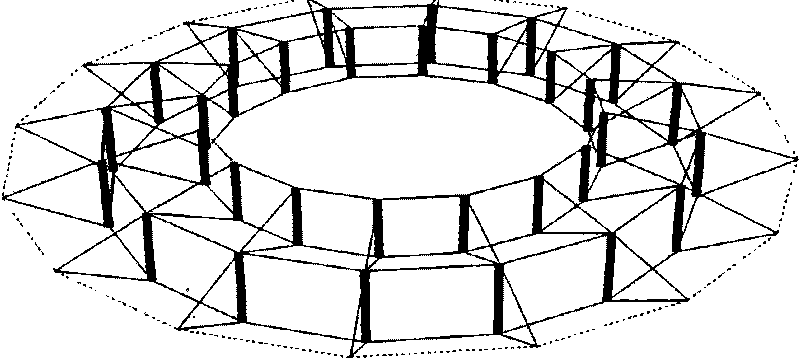

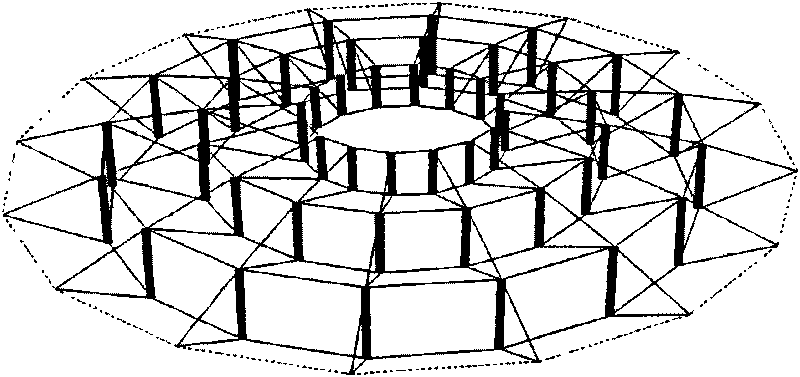

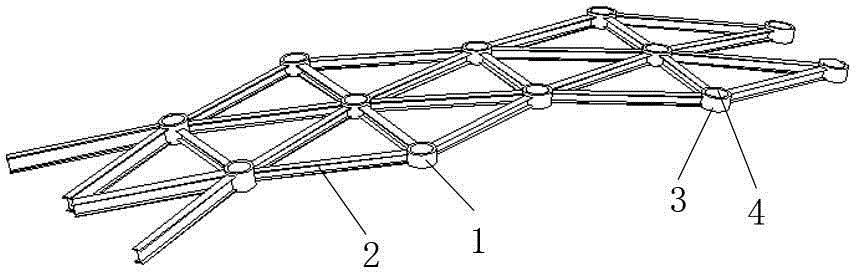

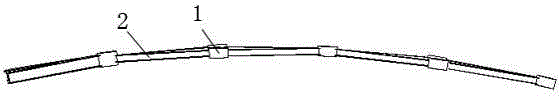

Layer-by-layer double-ring rib-ring type cable dome structure and construction forming method

InactiveCN101691791AImprove construction accuracyImprove shape coordinationBuilding roofsArched structuresRing typePre stress

The invention discloses a layer-by-layer double-ring rib-ring type cable dome structure and a construction forming method. A circle of brace struts in a vertical surface is taken as one layer, each layer other than a top layer comprises a plurality of elements which are the same in geometrical characteristic and quantity, and every two adjacent layer are arranged at equal intervals. The upper end and the lower end of one brace strut of each element are respectively provided with an upper cable strut joint and a lower cable strut joint; one side of the upper cable strut joint is connected with an upper stayed cable of the same layer, and the other side of the upper cable strut joint is respectively connected with an upper stayed cable of an upper layer, a lower stayed cable of the upper layer and an upper hoop cable through the middle of the upper cable strut joint; the lower cable strut joint at the same side of upper stayed cable of the same layer is connected with a lower stayed cable of the same layer and a lower hoop cable through the middle of the lower cable strut joint; and the top layer comprises the upper cable strut joint, the lower cable strut joint and a retractable brace strut, the upper cable strut joint is connected with all the upper stayed cables at the top layer, and the lower cable strut joint is connected with all the lower stayed cables at the top layer. The invention has the advantages of high construction accuracy, convenient construction method, low construction cost and safe structure use.

Owner:ZHEJIANG UNIV +2

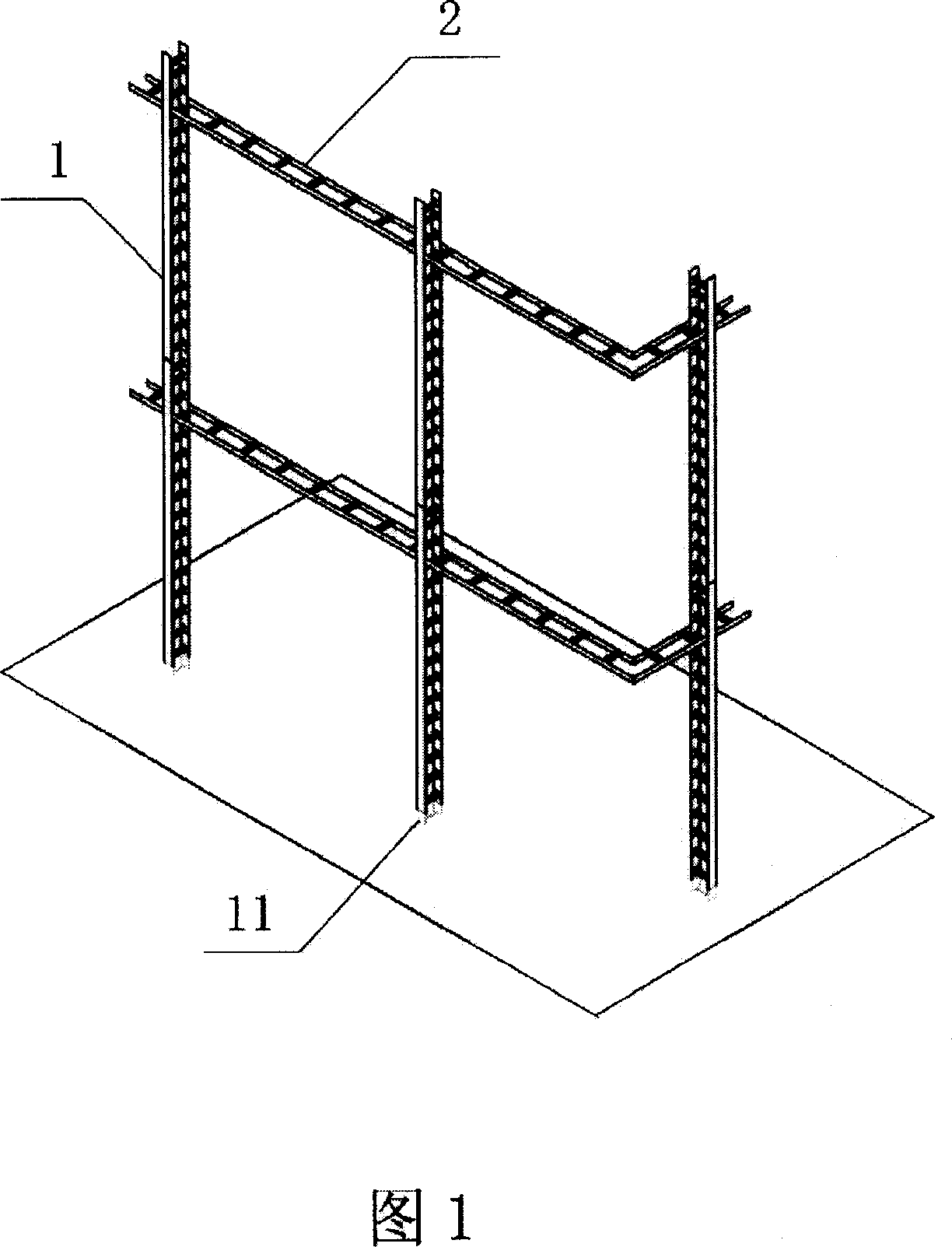

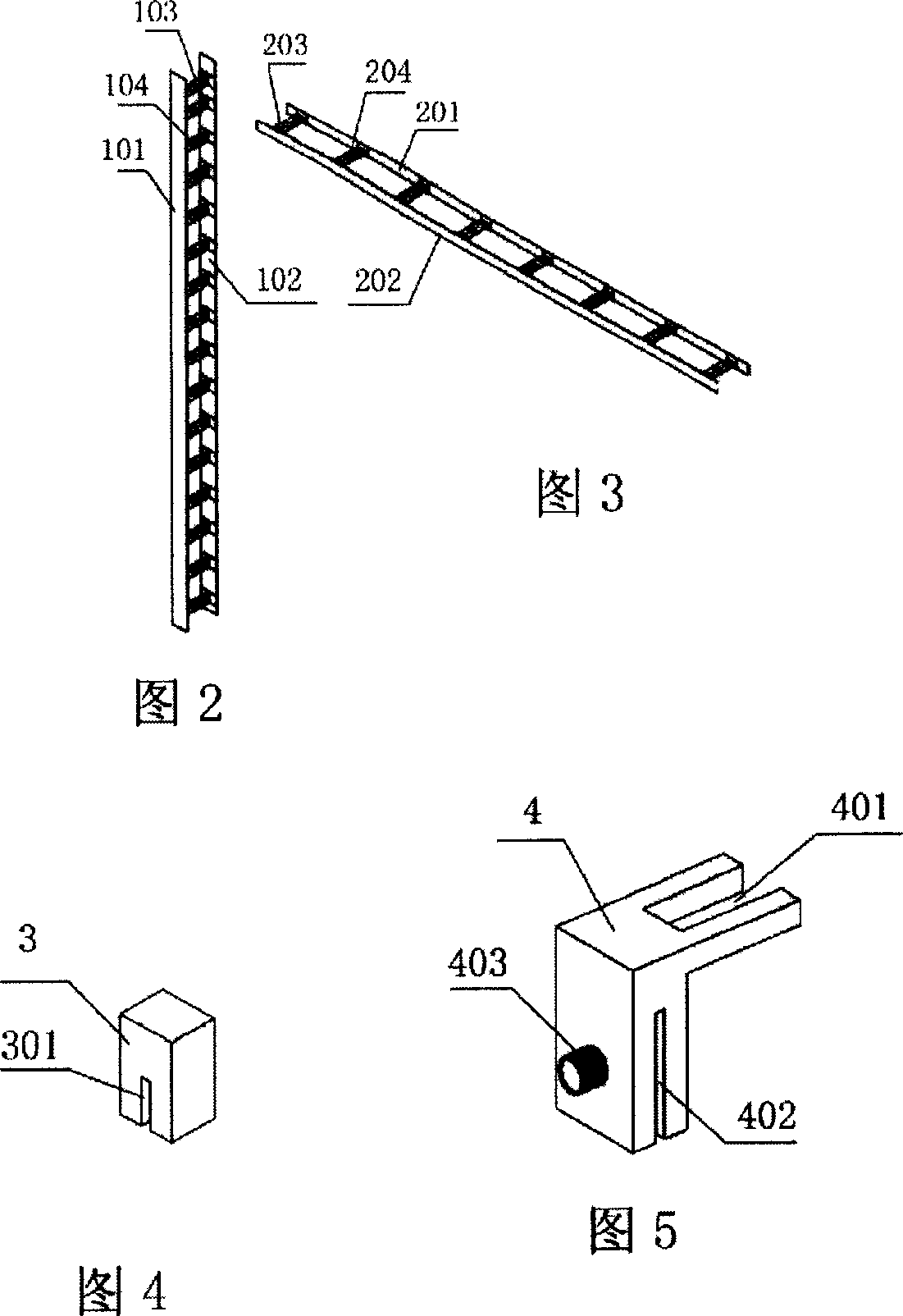

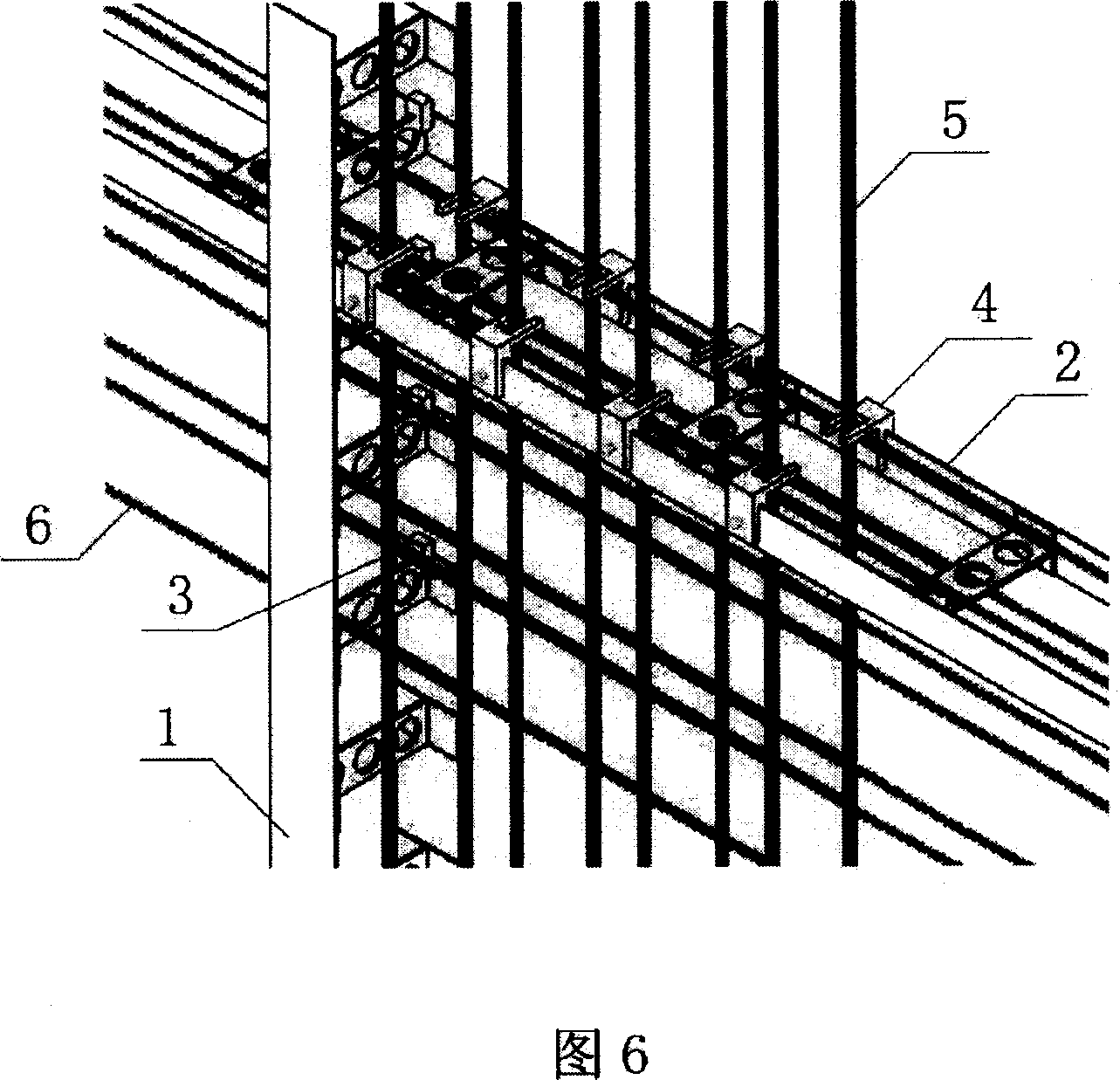

Concrete building reinforcing-bar precision positioning system and its construction method

InactiveCN1936228ANo displacementAvoid corrosionBuilding reinforcementsBuilding material handlingRebarPositioning system

The invention relates to a concrete construction reinforcing steel bar accurate locating system and the constructing method. It includes vertical localizer, horizontal positioning, vertical reinforcing steel bar locating block component, horizontal reinforcing steel bar locating block component, and pre-buried steel component. The vertical localizer is made up of inner board, external board, crosspiece fixation stairway stringer that is plumbed to vertical reinforcing steel bar and paralleled to horizontal reinforcing steel bar, and has the same thickness with wall and the same width with cavity of it. The invention could improve constructing speed and increase the constructing accuracy and entire rigidity of the reinforcing steel bar construction.

Owner:朱秦江

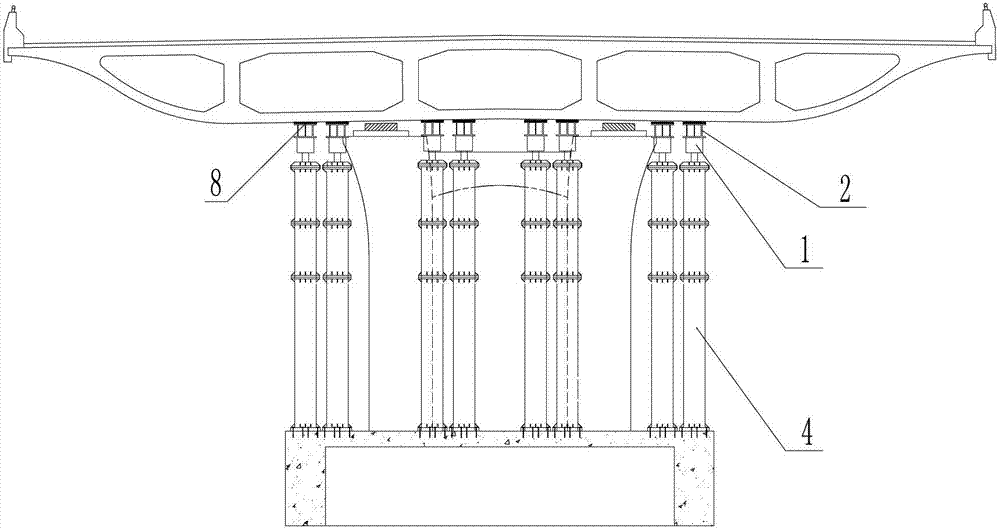

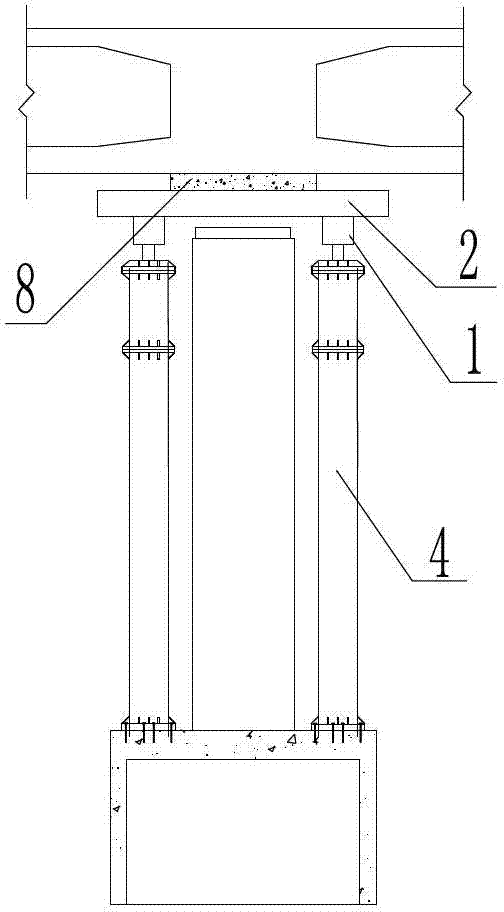

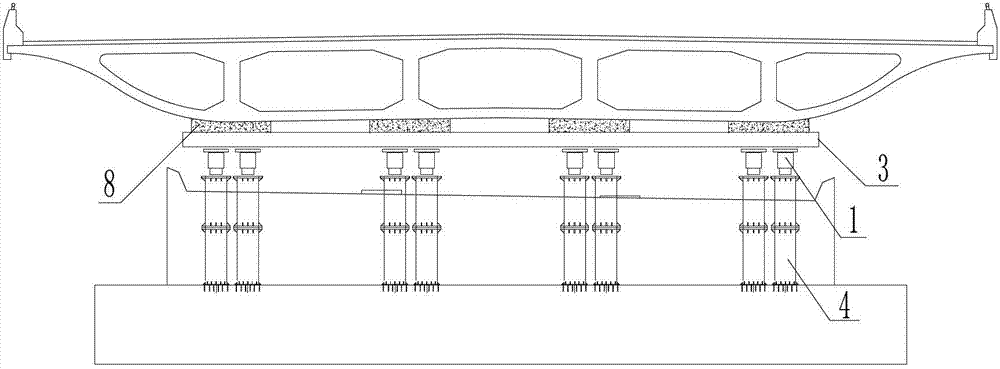

Integral synchronous rotary jacking construction method for small radius horizontal curved bridge

ActiveCN102733316AClarify the principle of structural linear displacementControl residual stressBridge erection/assemblyControl systemStructural engineering

The invention relates to an integral synchronous rotary jacking construction method for a small radius horizontal curved bridge, comprising the following steps of: arranging a steel pipe column on a bearing platform to form a pipe pile structure; arranging a longitudinal distributive girder at the girder bottom of a middle pier, and arranging a transverse distributive girder at the girder bottom of a side pier; inversely mounting a jack between the distributive girders and the steel pipe column; mounting a longitudinal limiting device and a transverse limiting device at the high end bridge head of a bridge; mounting a transverse limiting device at the lower end bridge head of the bridge, and prearranging a displacement space between the limiting devices and a girder body according to the transverse displacement value calculated according to the rotating jacking of the small radius plane curve bridge; arranging a hydraulic jacking system, a jacking control system and a stress monitoring system; and carrying out formal jacking after trial jacking is passed. The integral synchronous rotating jacking construction method for the small radius plane curve bridge provided by the invention points out the structure linear change principle during the integral synchronous rotary jacking of the small radius plane curve bridge for the first time, and the complicated successful implementation of the integral synchronous rotary jacking of the small radius plane curve bridge is ensured by adjusting the final construction precision using girder lowering gaps.

Owner:WUHAN BRIDGE SPECIAL TECH CO LTD CHINA RAILWAY MAJOR BRIDGE ENG BUREAU

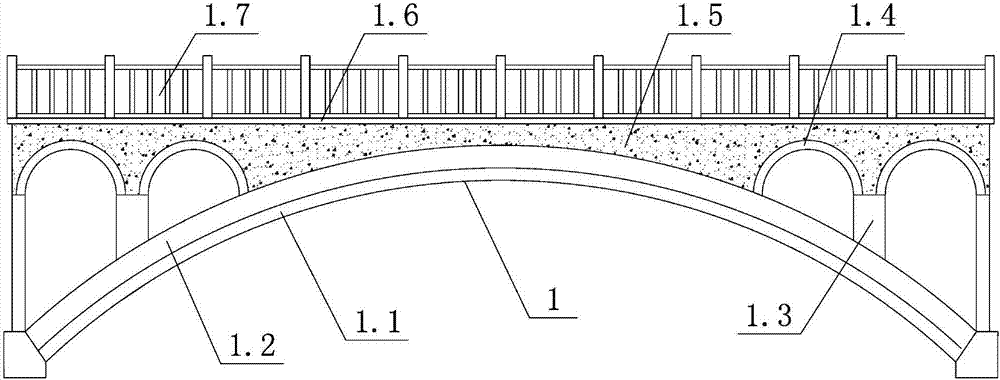

Novel reinforcement method for two-way curved arch bridge

InactiveCN106958208AIncrease weightLess weight gainBridge erection/assemblyBridge strengtheningBridge deckOperability

The invention discloses a novel reinforcement method for a two-way curved arch bridge comprising the following steps: (1) closing to traffic on a bridge deck, dismantling the bridge deck and auxiliary facilities of the bridge deck and removing fillings on arches; (2) cutting rectangular grooves along the two-way curved arch bridge on the top of an extrados corresponding to an original arch rib; (3) chipping the bottom of the rectangular grooves, planting anti-shear reinforcement bars, erecting a formwork on the extrados on the top of the rectangular grooves, assembling the anti-shear reinforcement bars and pouring concrete to form new arch ribs, of which the height is same relative to the extrados, protruding from the extrados; (4) repairing transverse walls, chipping the sections, which are at the outer side of the transverse walls along the two-way curved arch bridge, of the extrados and the new arch ribs, planting reinforcement bars on the extrados and the new arch ribs which are chipped, erecting the formwork and pouring the concrete; (5) chipping the top of the transverse walls, planting vertical reinforcement bars and erecting new columns for supporting the bridge deck; (6) newly building the bridge deck. The novel reinforcement method for the two-way curved arch bridge has the advantages of being small in dead weight of a bridge structure, good in unity of an old structure and a new structure, low in reinforcement cost, good in adaptability, not restricted by surroundings under the two-way curved arch bridge, unchanged about the original appearance of the two-way curved arch bridge, good in operability and good in application prospect.

Owner:WUHAN UNIV OF TECH

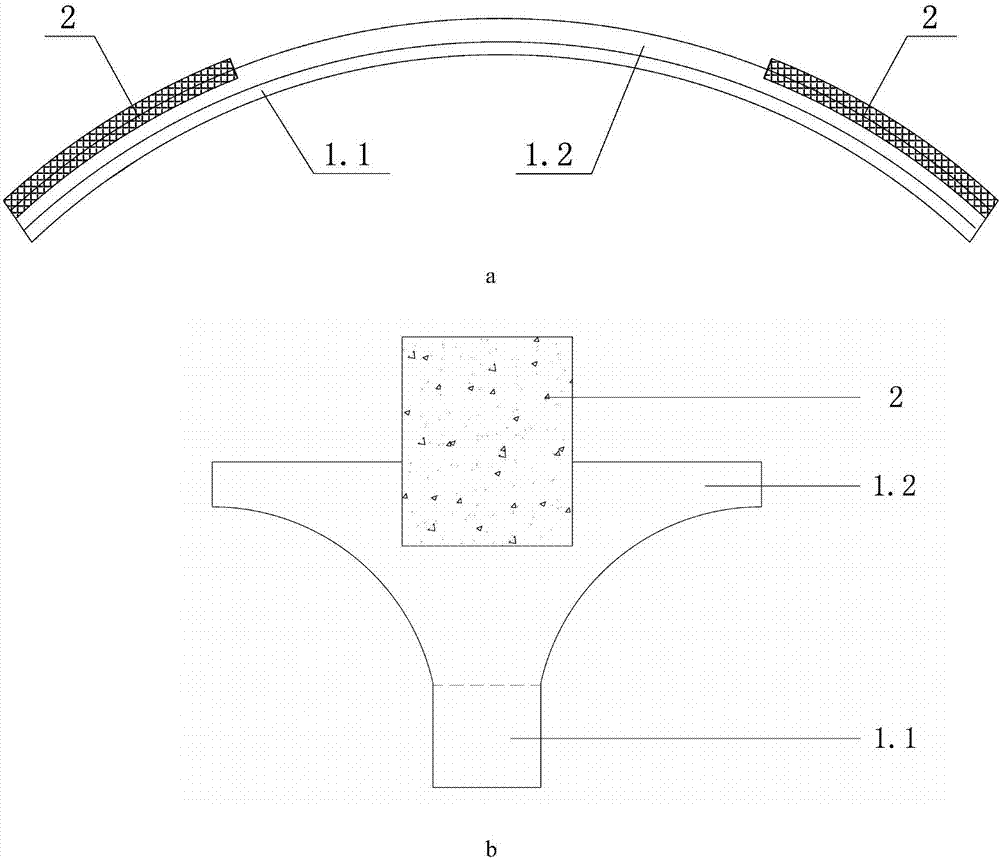

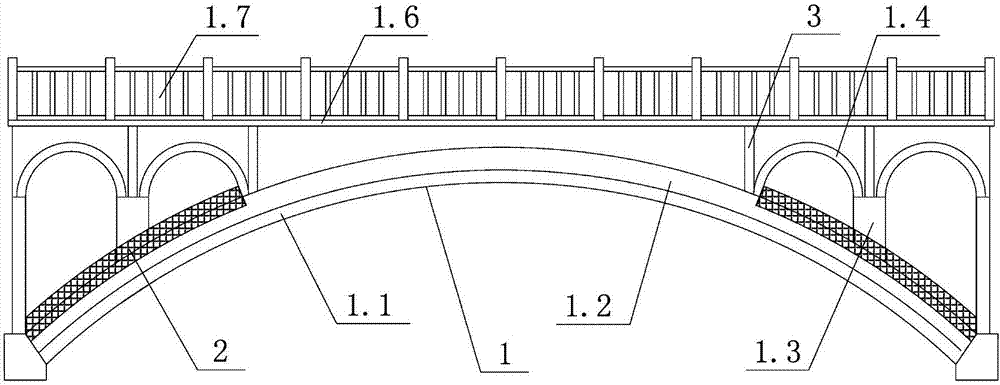

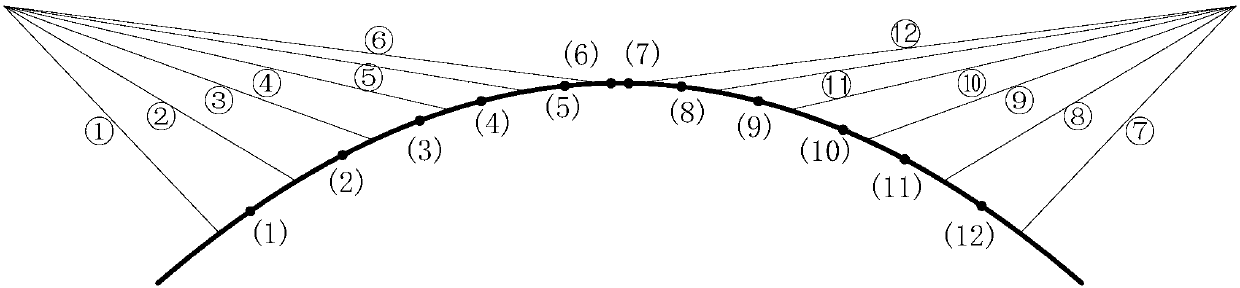

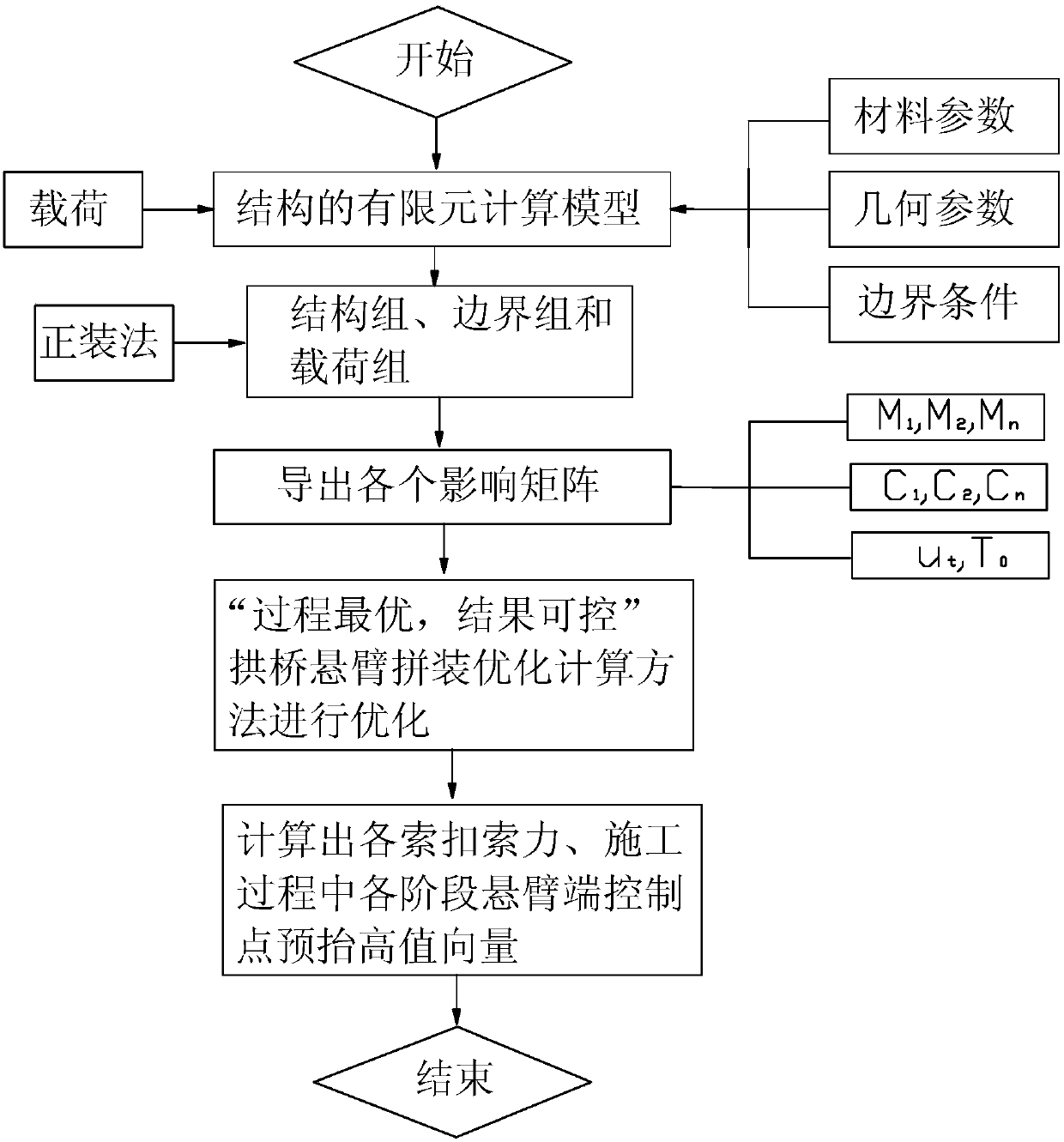

Arch bridge cantilever assembling construction optimization model and optimization calculation method

ActiveCN108038326ASmooth changeNo stress concentrationGeometric CADDesign optimisation/simulationStress concentrationConstraint control

The invention provides an arch bridge cantilever assembling construction optimization calculation method. An actual line shape and a target line shape in each construction lifting stage are strictly controlled, so that the preraised height value of each control node is changed mildly, the cable force uniformity is good, and the stress concentration phenomenon of a material in a construction process does not occur. An arch bridge cantilever assembling construction optimization model has the advantage of relatively few constraint conditions; the constraint condition that a deviation between theline shape after cable tightening and release, and the target line shape is in an allowed range mainly achieves a constraint control effect; and the problems of large buckling cable force gradient, poor uniformity and the like during adoption of a conventional method for performing construction optimization calculation are solved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

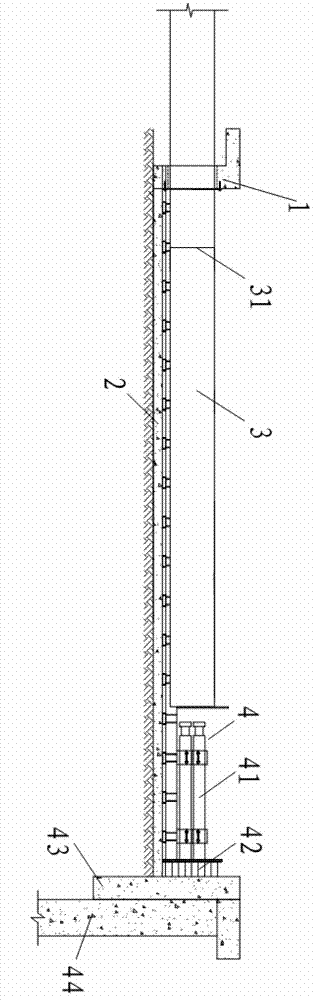

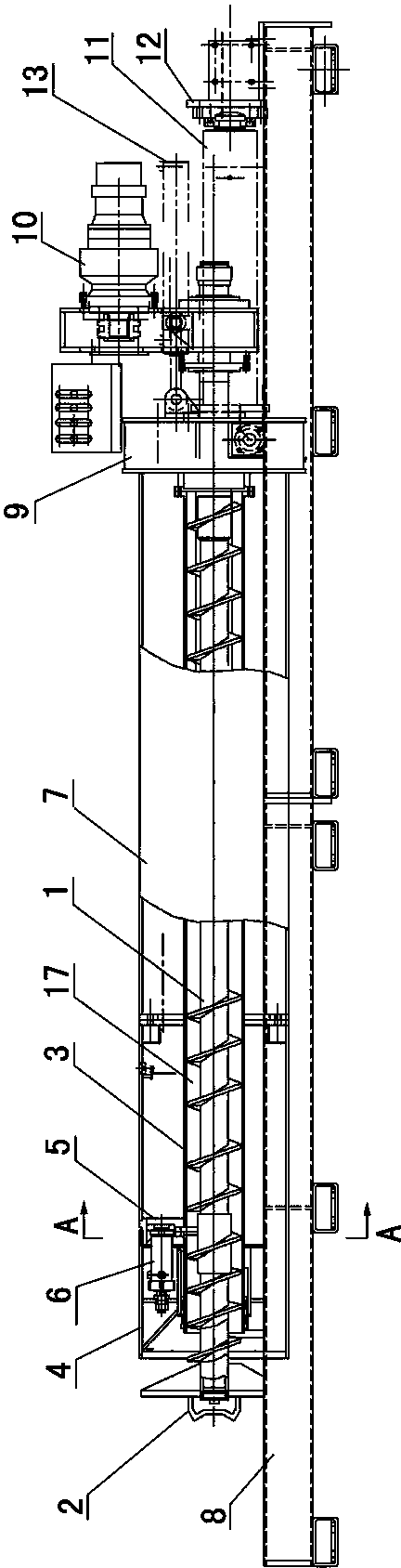

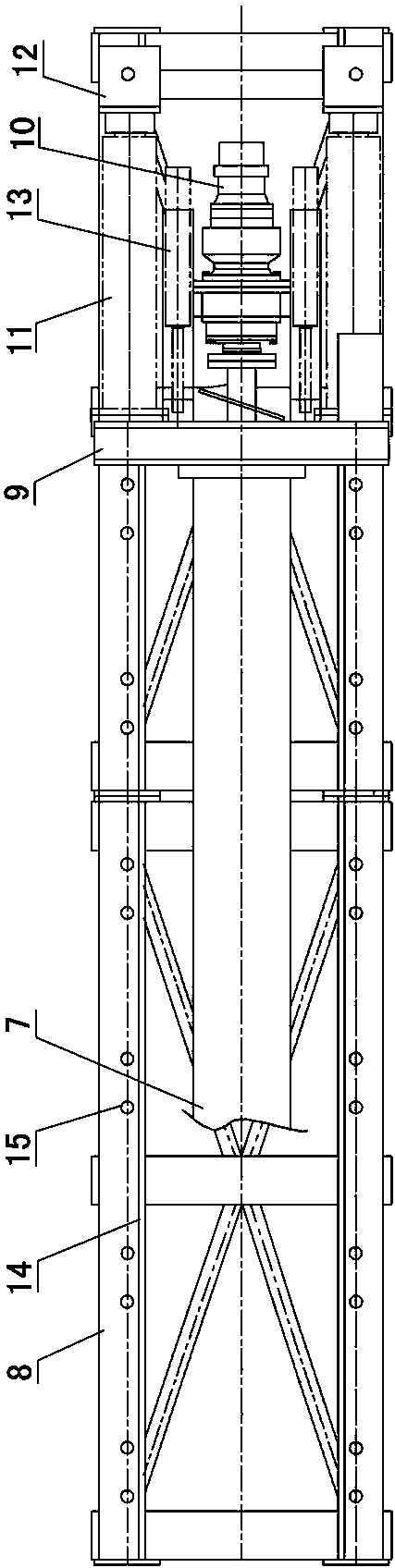

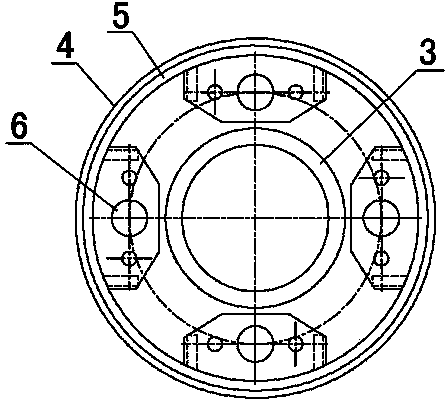

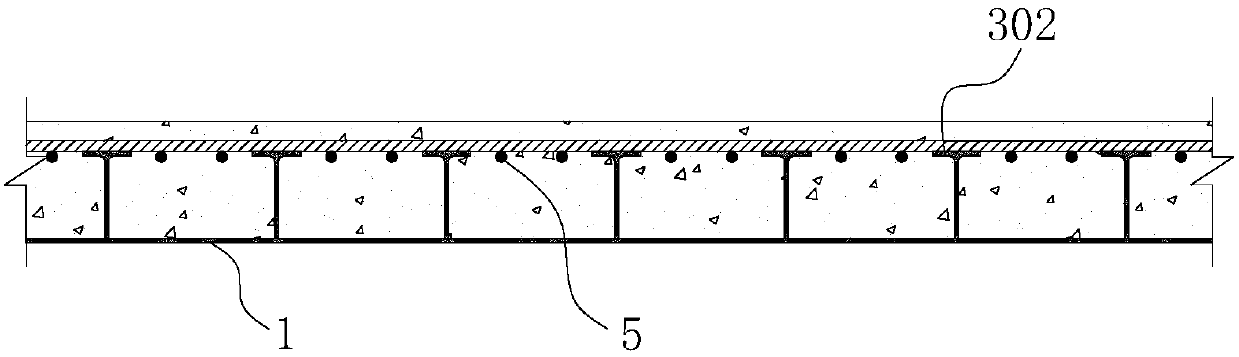

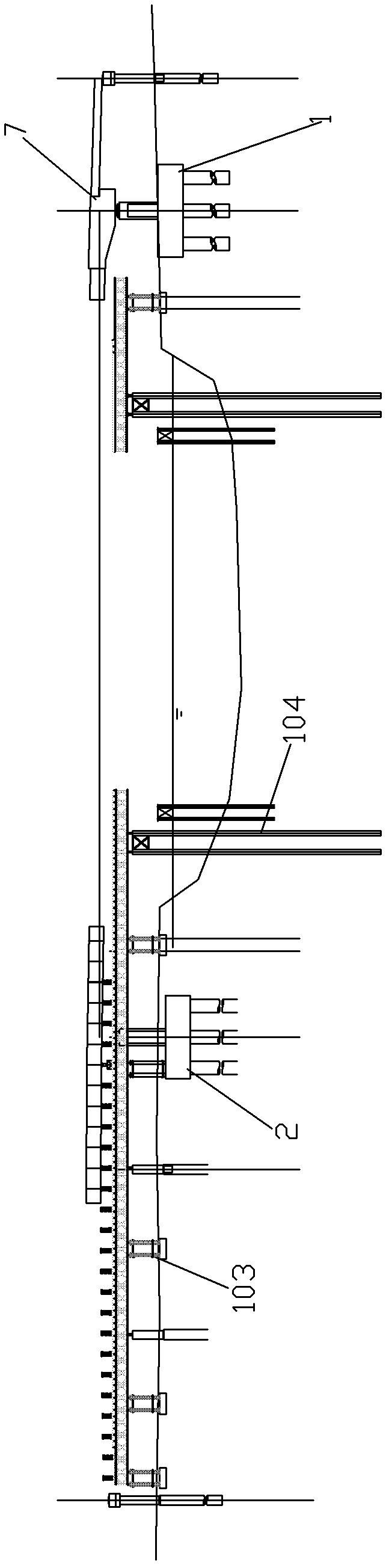

Intermediate-jacking-station-free jacking construction device of ultra-long pipe roof and method thereof

ActiveCN102777189ASolve construction difficultiesReduce usageUnderground chambersTunnel liningRubber ringSheet steel

The invention discloses an intermediate-jacking-station-free jacking construction device of an ultra-long pipe roof and a method thereof. The device comprises a tunnel portal pressurizing device and a pipe roof steel pipe, wherein the tunnel portal pressurizing device comprises a soil body, a jet-grouting pile and a grouting pipe; the jet-grouting pile and the grouting pipe are arranged outside the soil body; the jet-grouting pile is as a sealed waterproof wall; a steel protection cylinder is arranged in the jet-grouting pile; an outer end of the steel protection cylinder is orderly provided with a sealing rubber ring and a steel plate ring; a blind plate connected with the grouting pipe is arranged outside the steel plate ring. A lubricating grouting hole and a grouting connection and control device are arranged on the steel pipe of the pipe roof to reduce jacking resistance, at the same time, pressure of 0.1-0.5 mPa is formed in a 35 mm gap between a soil hole and peripheries of the pipe so as to resist deformation of a soil cave, and achieve the purpose of controlling settlement of a road face above the soil cave. The device and the method provided by the invention have the advantages that negative factors caused by an intermediate jacking station structure in use are removed on the basis of carrying out the intermediate-jacking-station-free jacking method; the problem that jacking construction of the ultra-long pipe roof is difficult is solved; the jacking force for construction is small; the construction precision is high; and the settlement degree is low.

Owner:BEIJING ENG COMPANY LIMITED OF CHINA RAILWAY URBAN CONSTR GRP

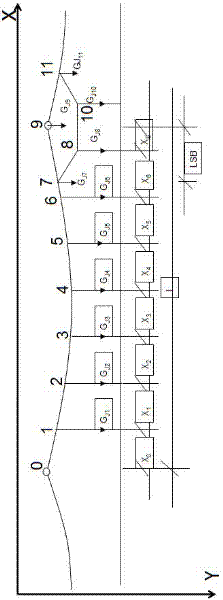

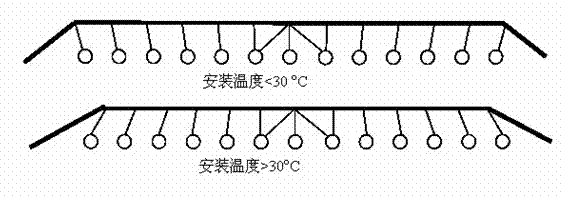

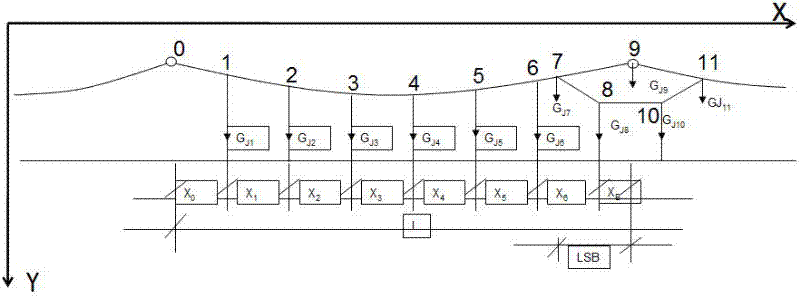

Full-compensation elastic chain hanging construction method for high-speed rail contact network

InactiveCN102381212AGuaranteed accuracyGuaranteed installation qualityTrolley linesContact networkArchitectural engineering

A full-compensation elastic chain hanging construction method for high-speed rail contact network, which comprises a construction preparing process, a construction measuring process, a software calculating process, a precasting process for sling and dropper, a mounting adjusting process for sling and dropper, and an ending process; each process is equipped with uniform and high-quality construction standards, and is assisted by modern construction meanses for satisfying with technical requirements for construction of high-speed rail contact network of 350 km / h; the software calculating process especially can obtain more accurate pre-stowage data of dropper length via a brand new calculating method finding form based on sling net, and then improve elastic chain hanging construction accuracy for high-speed rail contact net of 350 km / h. So the construction method does not only benefit for improving accuracy of sling and droppser calculation, and the construction method but also has high-quality construction standards and modern construction meanses, and is capable of improving quality and speed of construction of high-speed rail contact net of 350 km / h.

Owner:中铁建电气化局集团南方工程有限公司

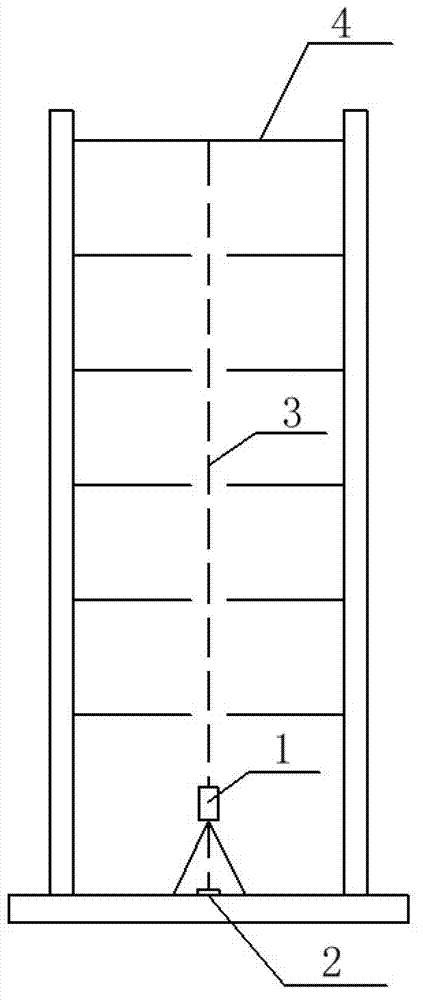

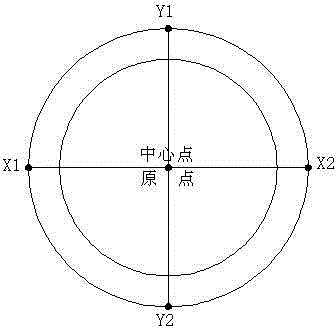

Integral setting and one-step in-position construction method for steel sleeves of inner pipelines of vertical shaft of building

The invention discloses an integral setting and one-step in-position construction method for steel sleeves of inner pipelines of a vertical shaft of a building. The integral setting and one-step in-position construction method includes drawing an integral installation planar positioning graph of sleeve stacks; manufacturing an integral positioning mold for the sleeve stacks; accurately placing the sleeves and integrally welding the sleeve stacks in advance; reserving the first-layer sleeve stack by a measuring process by the aid of a straight scale; projecting positions of center points of first-layer reference sleeves to bottoms of formworks of layers to be positioned by a laser positioning process and marking corresponding points of the bottoms of the formworks; displaying positions of center points of sleeves to be positioned on upper portions of the formworks by a process for nailing the formworks at the marked points by iron nails or a process for drilling holes at the marked points of the formworks; placing and fixing a certain sleeve stack according to the positions of the center points of the sleeves to be positioned; and sequentially placing and fixing the remaining various sleeve stacks by such analog to complete integral setting and one-step in-position operation for the various layers of sleeve stacks. The integral setting and one-step in-position construction method has the advantages that construction is easy and convenient, secondary form erecting and pipe hole pouring are omitted, the construction quality is good, the work efficiency is high, and the integral setting and one-step in-position construction method is favorable for shortening the construction period and reducing the construction cost.

Owner:广西建工第一建筑工程集团有限公司

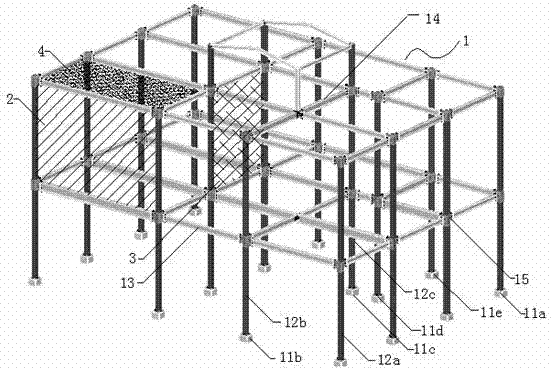

Self-lifting sliding and turnover construction system and construction method

ActiveCN104695337AReduce manual labor intensityReduce the risk of manual overmoldingBridge erection/assemblyTruckRebar

The invention discloses a self-lifting sliding and turnover construction system and a construction method. The system comprises a framework type combination crown block hanging bracket device and a semi-automatic turnover device. The construction method comprises steps as follows: construction of reinforcing steel bars of a pier body, large-area formwork bracket splicing, sliding formwork bracket splicing, self-lifting hanging bracket splicing, concrete pouring, sliding formwork bracket sliding rising, large-area formwork turnover and next stage of reinforcing steel bar construction. A self-lifting technique can be adopted, auxiliary construction by mechanical equipment such as a tower crane, a truck crane and the like can be omitted, high-pier construction is realized with the self-lifting technique, and the method guarantees the construction speed of a sliding formwork and the appearance quality of a turnover formwork without relying on external machines.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG +1

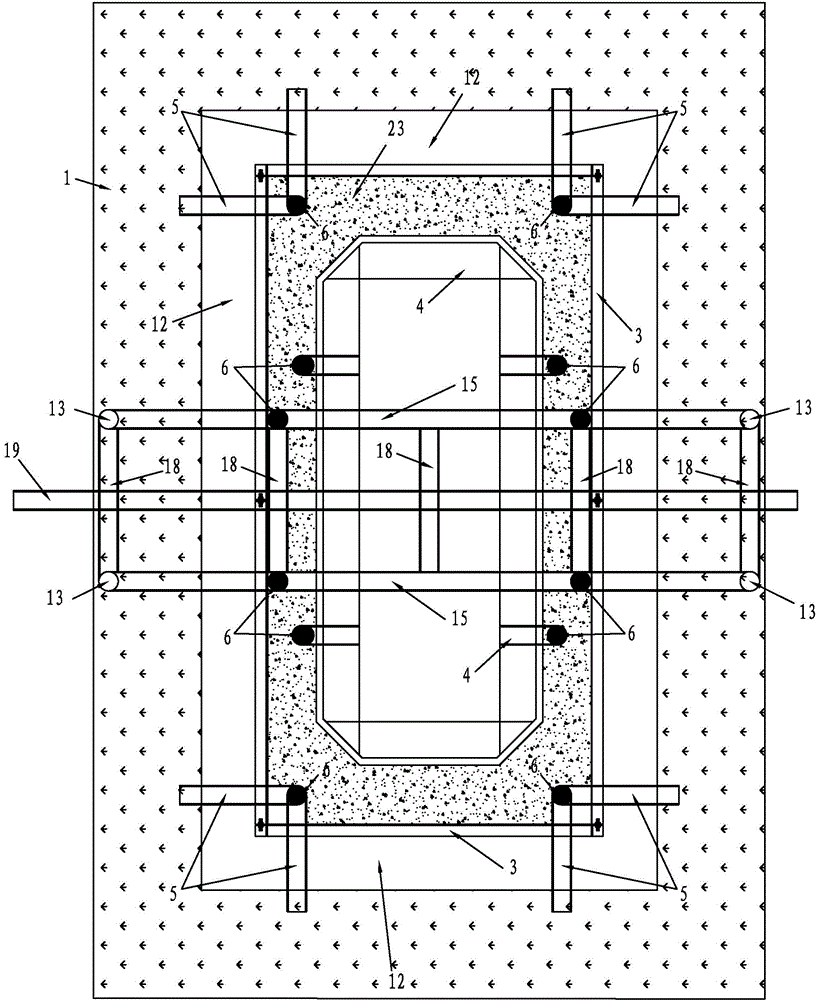

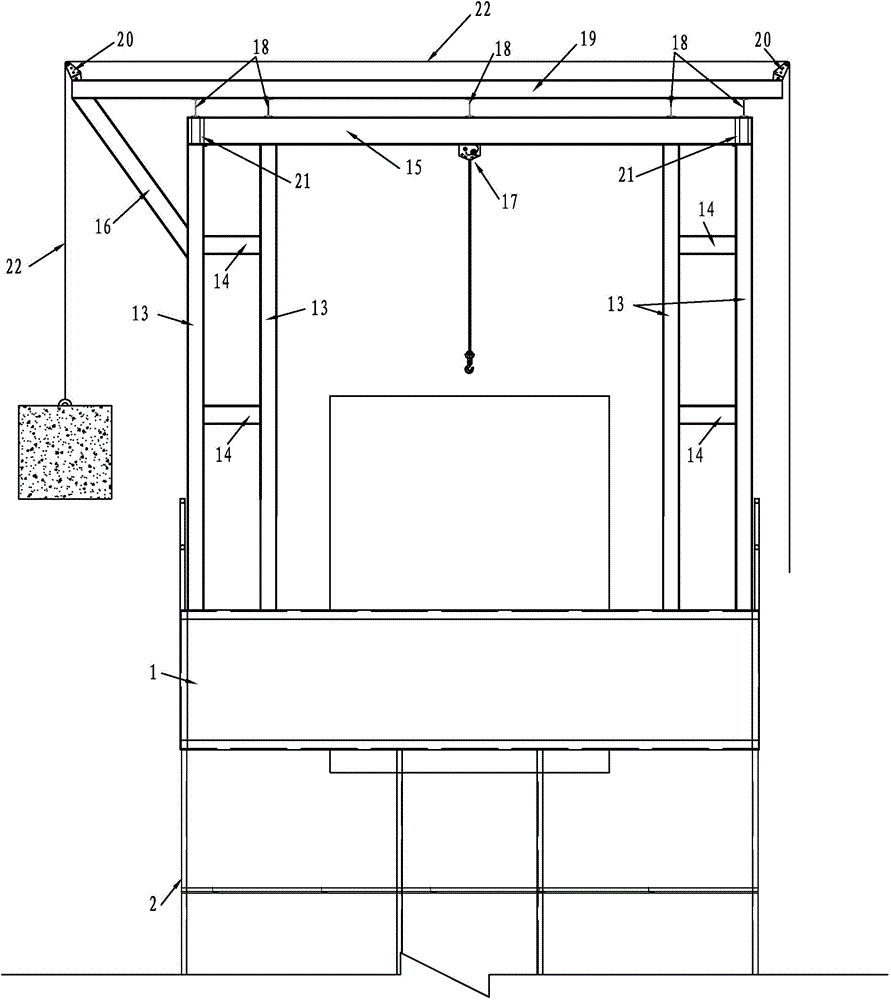

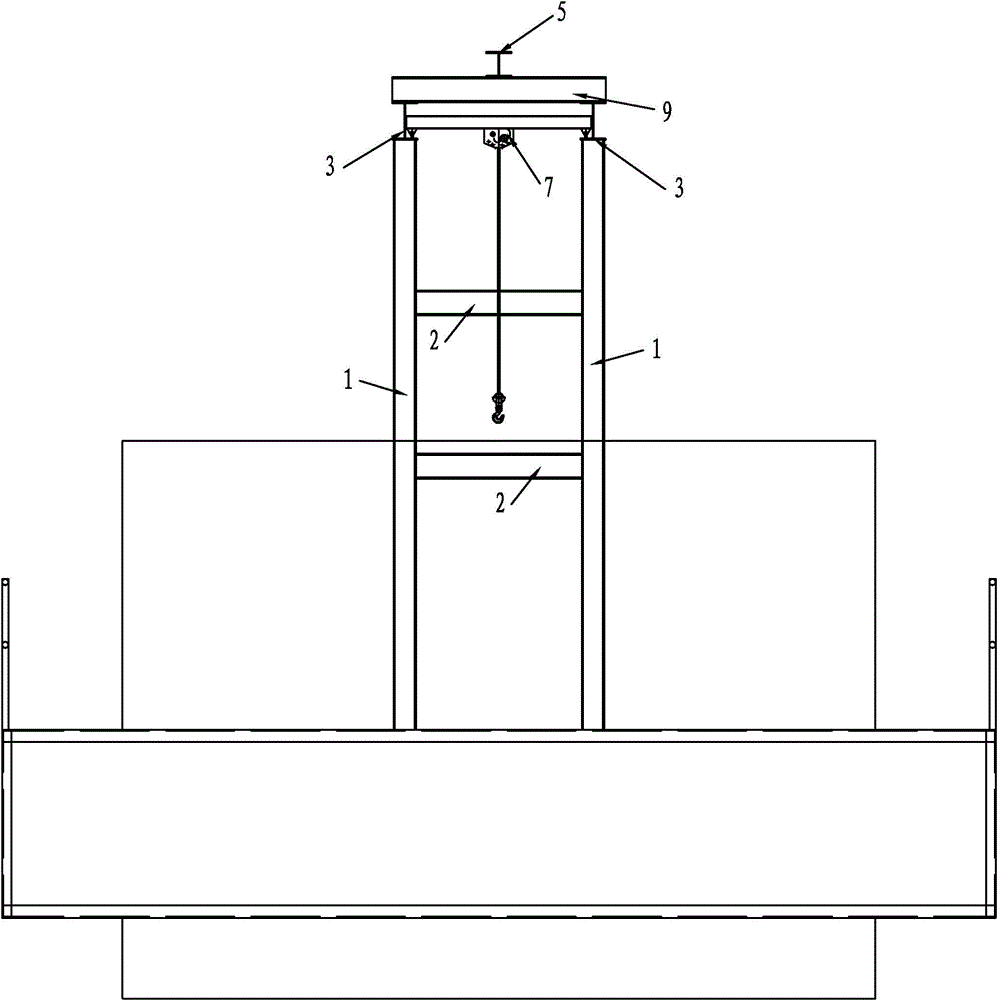

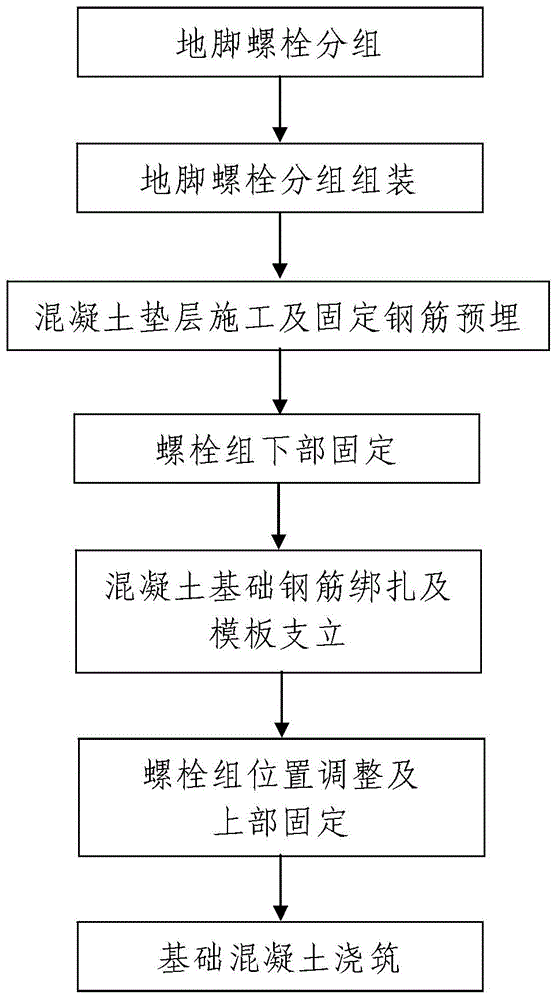

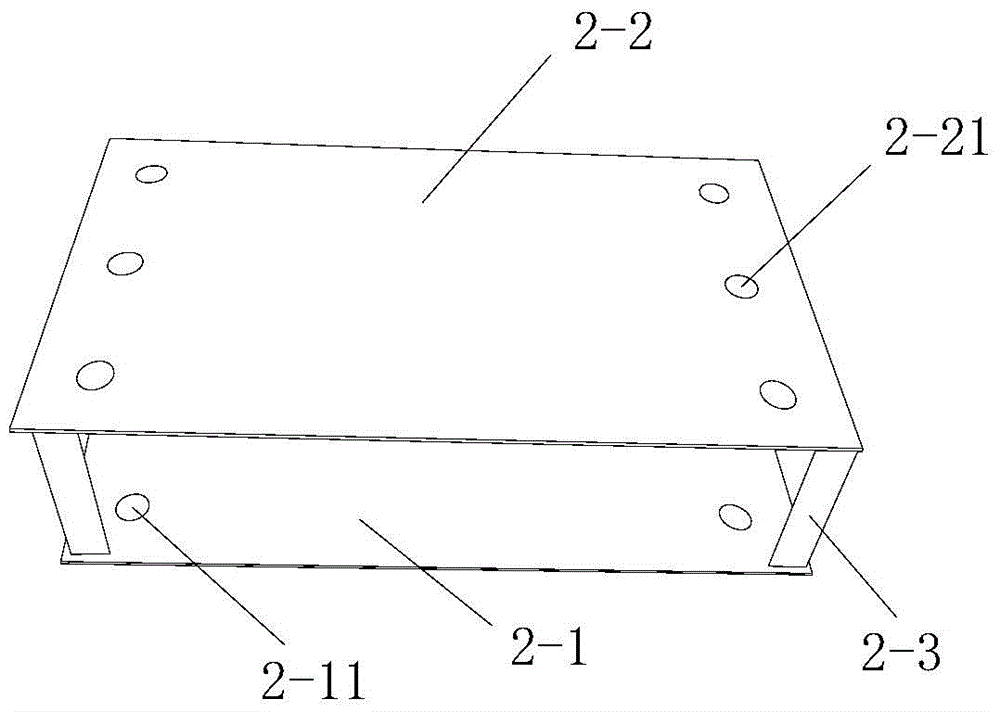

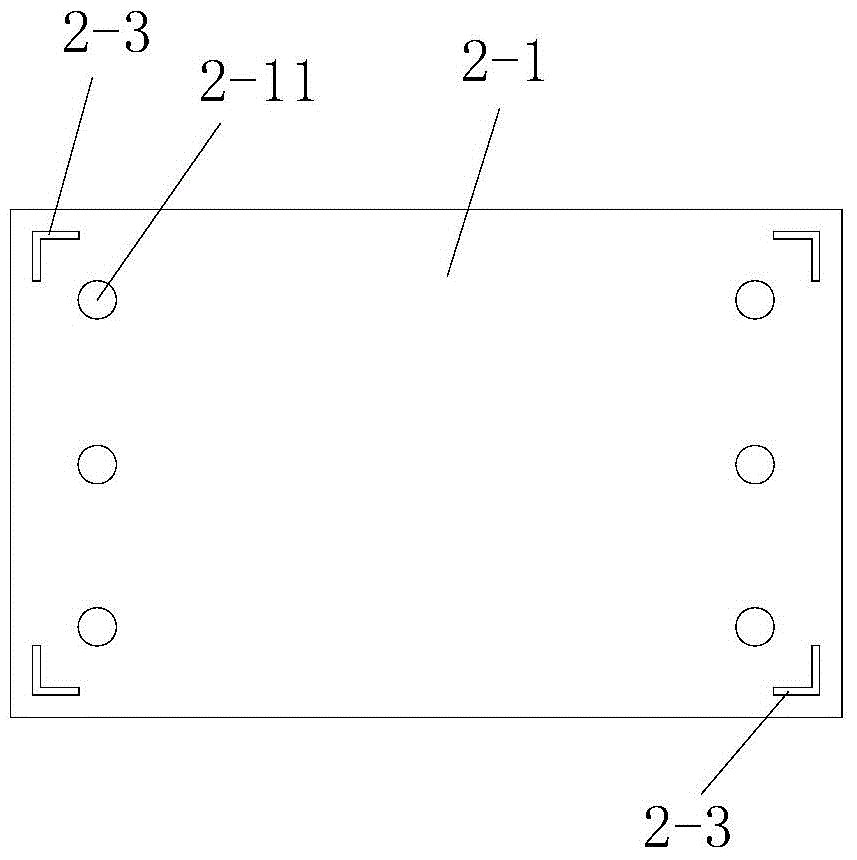

Steel structure building construction method for one-step pre-burying of foundation bolts

The invention discloses a steel structure building construction method for pre-burying of foundation bolts. The steel structure building construction method comprises the following steps: 1. grouping of the foundation bolts: all the foundation bolts to be pre-buried are divided into a plurality of groups, the groups of the foundation bolts are respectively distributed in a plurality of bolt pre-burying areas in a concrete foundation, and the foundation bolts in each group form a bolt group; 2. grouped assembly of the foundation bolts: the bolt groups are respectively assembled, and the assembly procedure comprises manufacturing of a positioning mold, inserting of the foundation bolts, fixing of the foundation bolts, and separating of the bolt groups from positioning mold; 3. concrete cushion construction and pre-burying of fixing steel bars; 4. lower part fixing of the bolt groups; 5. binding of the steel bars and support arrangement of a template erection in the concrete foundation; 6. a position adjustment and upper part fixing of the bolt groups; 7. concrete foundation pouring. The method provided by the invention is simple in procedure, reasonable in design, convenient in implementation, and good in use effects, and has the advantages that the construction process for the high-precision pre-burying of the foundation bolts in the concrete foundation can be simply, conveniently and rapidly completed with high quality.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

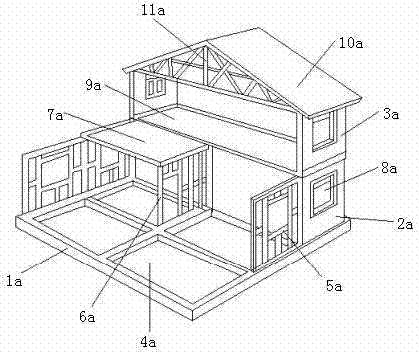

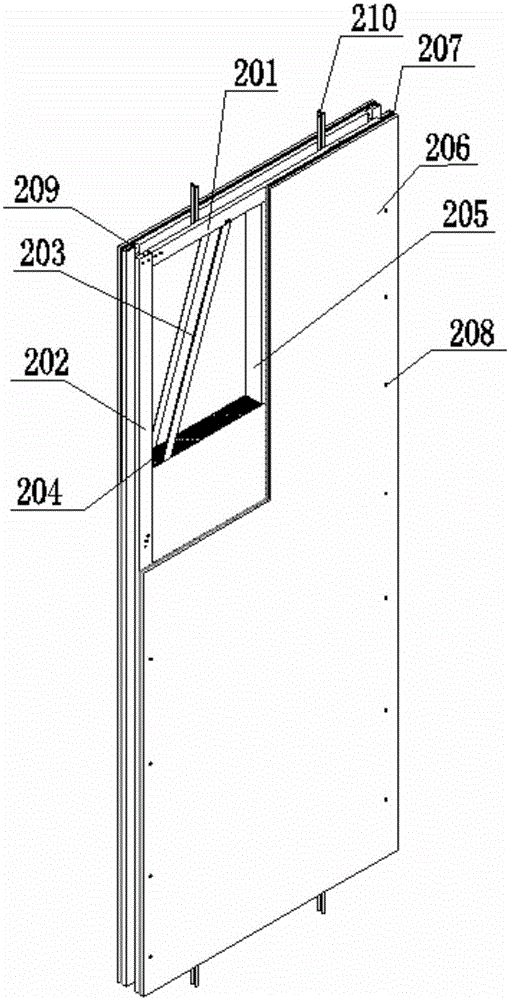

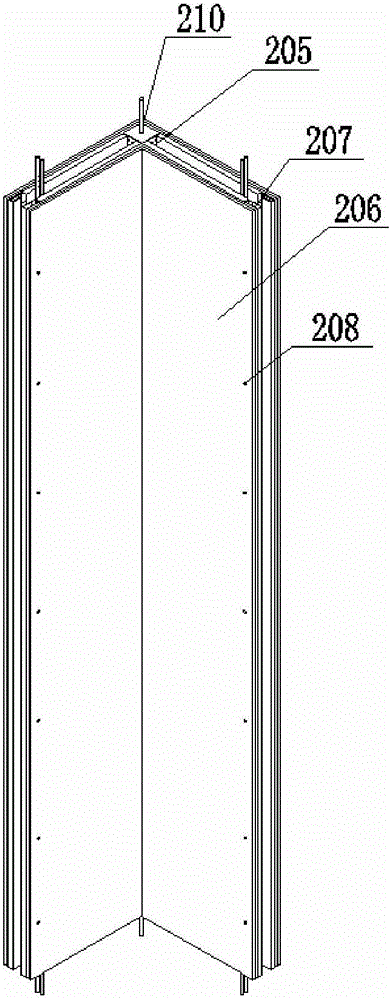

Light-weight steel structure house and construction method thereof

ActiveCN106948472AFast adjustmentEasy to adjustFloorsFoundation engineeringNoise reductionUltimate tensile strength

The invention relates to a light-weight steel structure house and a construction method thereof. The light-weight steel structure house comprises a house frame, double-layer outer wall plates, inner wall plates and lightweight floor plates. The house frame comprises a foundation, supporting upright columns, truss beams and cross sleeve connecting pieces; the supporting upright columns comprise four corner supporting upright columns, a plurality of outer supporting upright columns and a plurality of inner supporting upright columns; each supporting upright column is of an I-shaped steel structure; and the supporting upright columns are mounted on the foundation in mutually-parallel mode. The double-layer outer wall plates are arranged between every two adjacent outer supporting upright columns or between the adjacent corner supporting upright columns and the outer supporting upright columns. The inner wall plates are arranged between every two adjacent inner supporting upright columns or between the adjacent inner supporting upright columns and the outer supporting upright columns. The lightweight floor plates are parallelly arranged between every two adjacent truss beams. The light-weight steel structure house and the construction method thereof have the advantages that by means of the house frame, the double-layer outer wall plates, the inner wall plates and the lightweight floor plates and adjustment of connection of all the structures, the house is convenient for correction, effective heat dissipation and noise reduction are achieved, and meanwhile the overall strength of the house is guaranteed.

Owner:西藏藏建科技股份有限公司

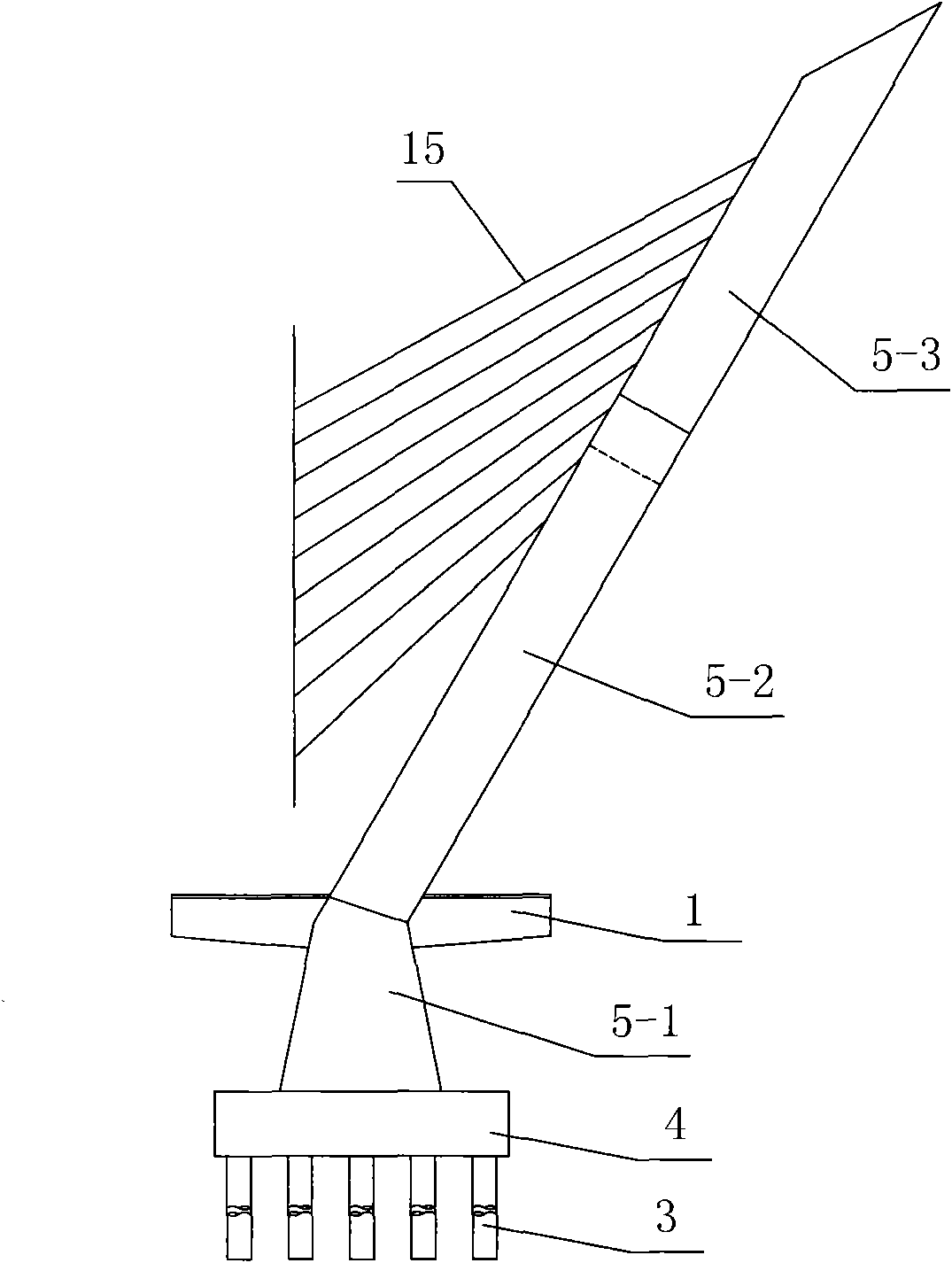

Integral lifting template of main pylon of single-pylon cable-stayed bridge without dorsal cables and lifting construction method thereof

ActiveCN101781878AReasonable structural designEasy to processCable-stayed bridgeBridge structural detailsCable stayedEngineering

The invention discloses an integral lifting template of a main pylon of a single-pylon cable-stayed bridge without dorsal cables and a lifting construction method thereof. The method comprises the following steps of: (1) preparation before construction; (2) lower bridge structure construction; (3) upper bridge structure construction comprising the following construction processes of: lower pylon concrete pouring construction, lower beam construction, middle pylon segmental pouring construction, alternate segmental pouring construction of an upper pylon and a middle suspension cable beam segment and stayed-cable mounting, wherein an integral lifting template is used for segmental construction on both the middle pylon and the upper pylon; and (4) bridge surface system construction. The integral lifting template has reasonable structural design, convenient processing, manufacture, mounting and arrangement, low investment cost, simple construction method and steps and high construction speed and can quickly and safely complete the construction task of the main pylon of the cable-stayed bridge by utilizing simple construction tools and investing less labor, and various technical indexes of the main pylon of the constructed and molded cable-stayed bridge meet the requirements of the design and a construction specification.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Single-layer latticed shell structure with drum type nodes, and assembly method

ActiveCN105089150AImprove securityReasonable structureArched structuresVaulted structuresStructure of the EarthHoneycomb

The invention relates to a latticed shell structure, in particular to a single-layer latticed shell structure with drum type nodes, and an assembly method, and belongs to the field of steel structures. The single-layer latticed shell structure comprises more than two groups of honeycomb assemblies, and is formed by assembling the two groups of the honeycomb assemblies; each honeycomb assembly comprises seven drum type nodes and web members, wherein a hexagon is defined by six drum type nodes, and the other drum type node is arranged at the middle position of the six drum type nodes; every two adjacent drum type nodes are connected and positioned through one web member. The assembly method comprises the following steps: determining a structural style; determining assembly principles; manufacturing nodes; and performing unit assembly. According to the single-layer latticed shell structure with drum type nodes and the assembly method, disclosed by the invention, the structure is reasonable, the construction accuracy is high, construction cost is low, the safety of steel structures is improved, and the construction efficiency is high.

Owner:成都东南钢结构有限公司 +1

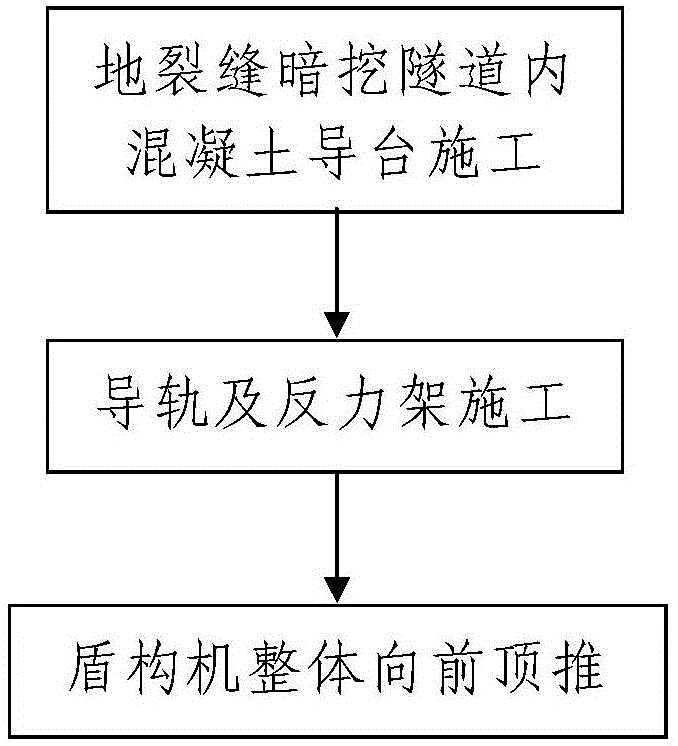

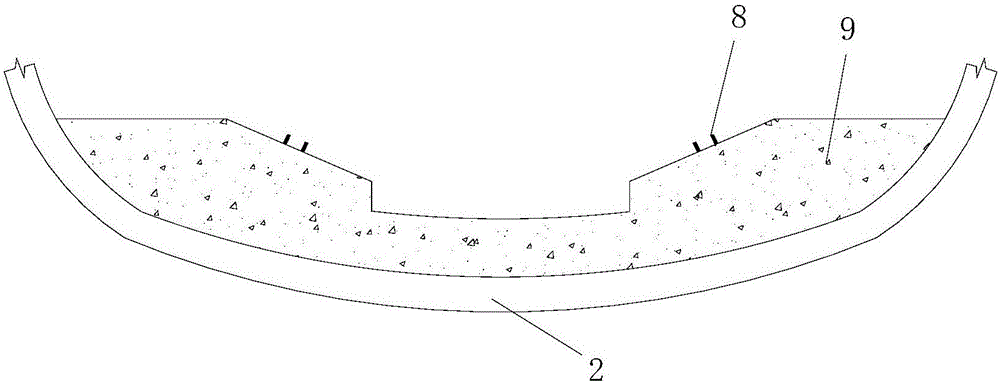

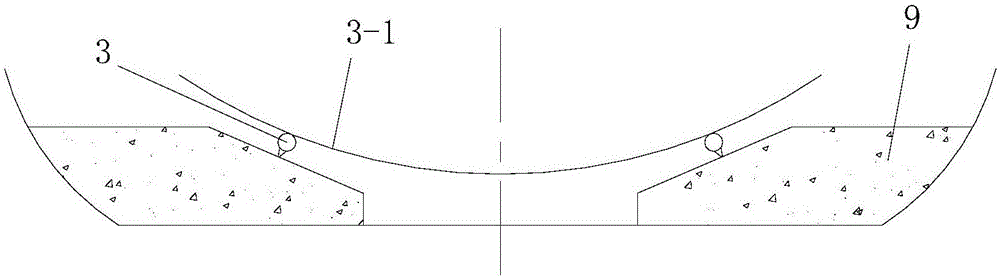

Construction method for shield driving type empty pushing ground fracture bored tunnel

The invention discloses a construction method for a shield driving type empty pushing ground fracture bored tunnel. The construction method comprises the following steps: 1) constructing a concrete guide platform in the ground fracture bored tunnel; 2) constructing a guide rail and a counterforce frame; 3) integrally forward pushing the shield tunneling machine: forward pushing the shield tunneling machine, supporting the shield tunneling machine on two guide rails, and utilizing a boosting cylinder of the shield tunneling machine and the counterforce frame to integrally forward push till being in place; in a pushing process, utilizing a shield segment assembling device for the shield tunneling machine to mount a plurality of shield segments on the concrete guide platform from back to front, wherein the shield segments are bottom segments and are located on the rear side of the boosting cylinder; supporting the boosting cylinder on the counterforce frame through the bottom segments, wherein the bottom segments form a trolley translation channel for forward moving the rear matched trolley of the shield tunneling machine. The method provided by the invention has the advantages that the steps are simple, the design is reasonable, the construction is simple and convenient, the use effect is good, the inverted arch backfill structure in the tunnel is utilized to simply and conveniently finish the construction process of the shield driving type empty pushing ground fracture bored tunnel and the construction process is safe.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Spiral-unearthing pipe-jacking pipe curtain construction method and device

ActiveCN103590833AReduce disturbanceImprove construction accuracyDrilling rodsTunnelsArchitectural engineeringSteel tube

Provided are a spiral-unearthing pipe-jacking pipe curtain construction method and device. The method comprises the steps that the step 1, foundation pits and a site are prepared; the step 2, the spiral-unearthing pipe-jacking pipe curtain construction device and an electric welding machine are installed and debugged; the step 3, a common drill, a guide head, a stub, deviation correction oil cylinders, an initial-section spiral drill pipe, an initial-section outer sleeve and an initial-section pipe curtain steel pipe are installed on the spiral-unearthing pipe-jacking pipe curtain construction device; the step 4, a hole-entering angle is regulated; the step 5, drilling and jacking are conducted; the step 6, lengthening is conducted; the step 7, drilling, jacking and lengthening are circulated; the step 8, the common drill, the guide head, the stub and the deviation correction oil cylinders are dismounted at the position of the receiving foundation pit; the step 9, disassembly is circulated; the step 10, the spiral-unearthing pipe-jacking pipe curtain construction device is moved to a second hole, and the steps 3-10 are repeated; the step 11, in this way, construction of pipe curtain steel pipes of all other holes is finished. The method for combining spiral unearthing and oil cylinder jacking is adopted, disturbance in stratums is small, and construction accuracy is high.

Owner:BEIJING SHOUER ENG TECH

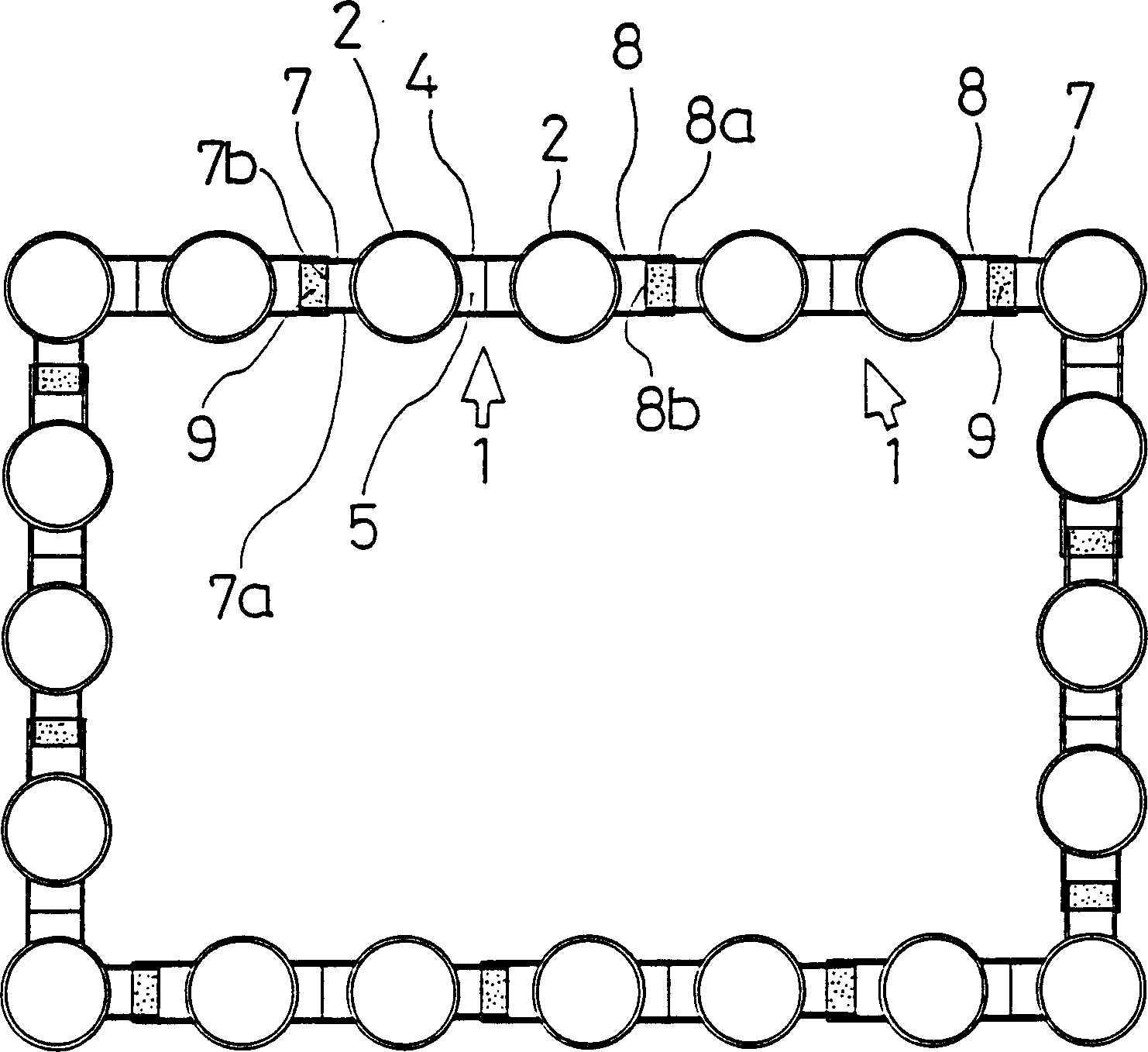

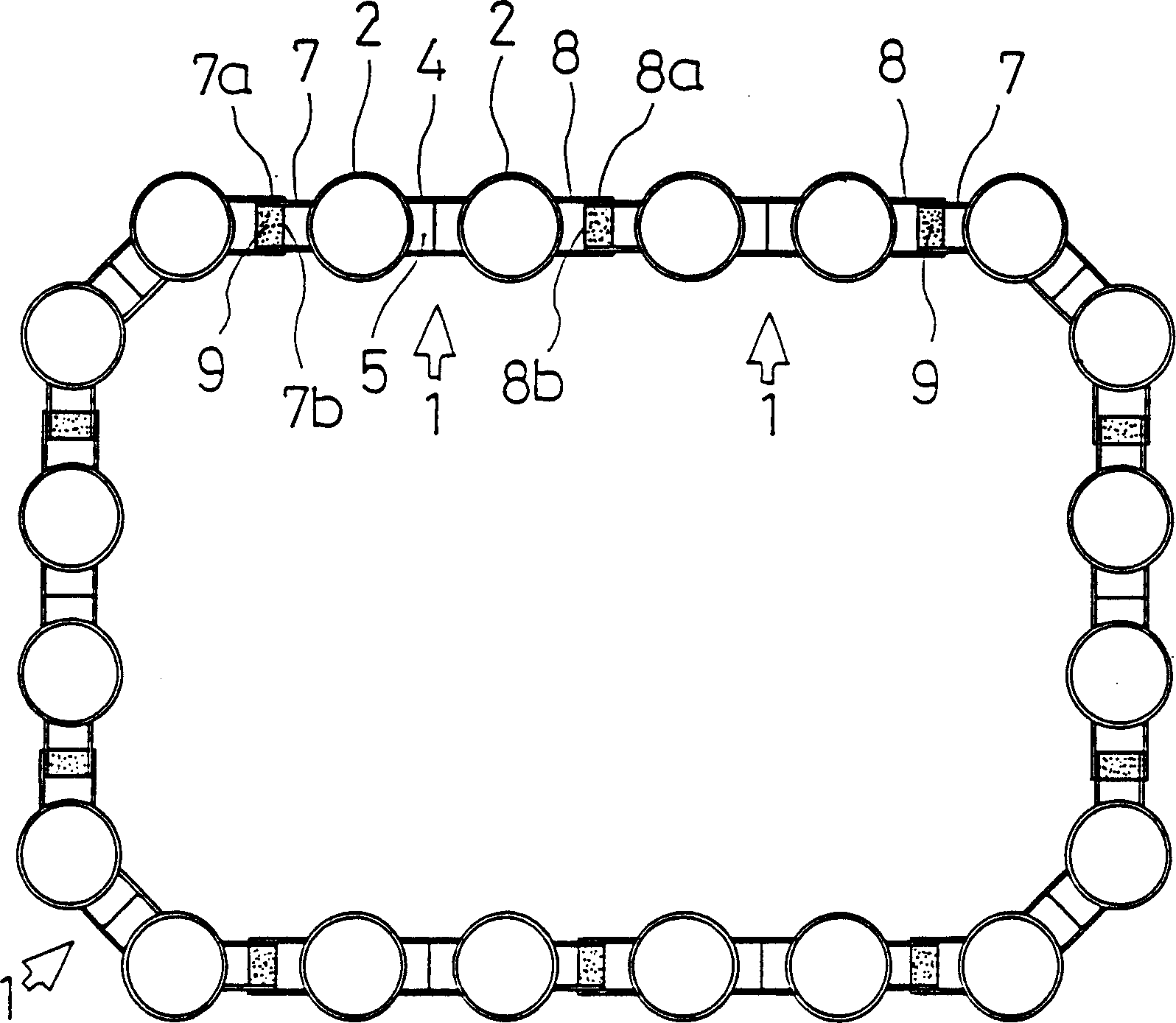

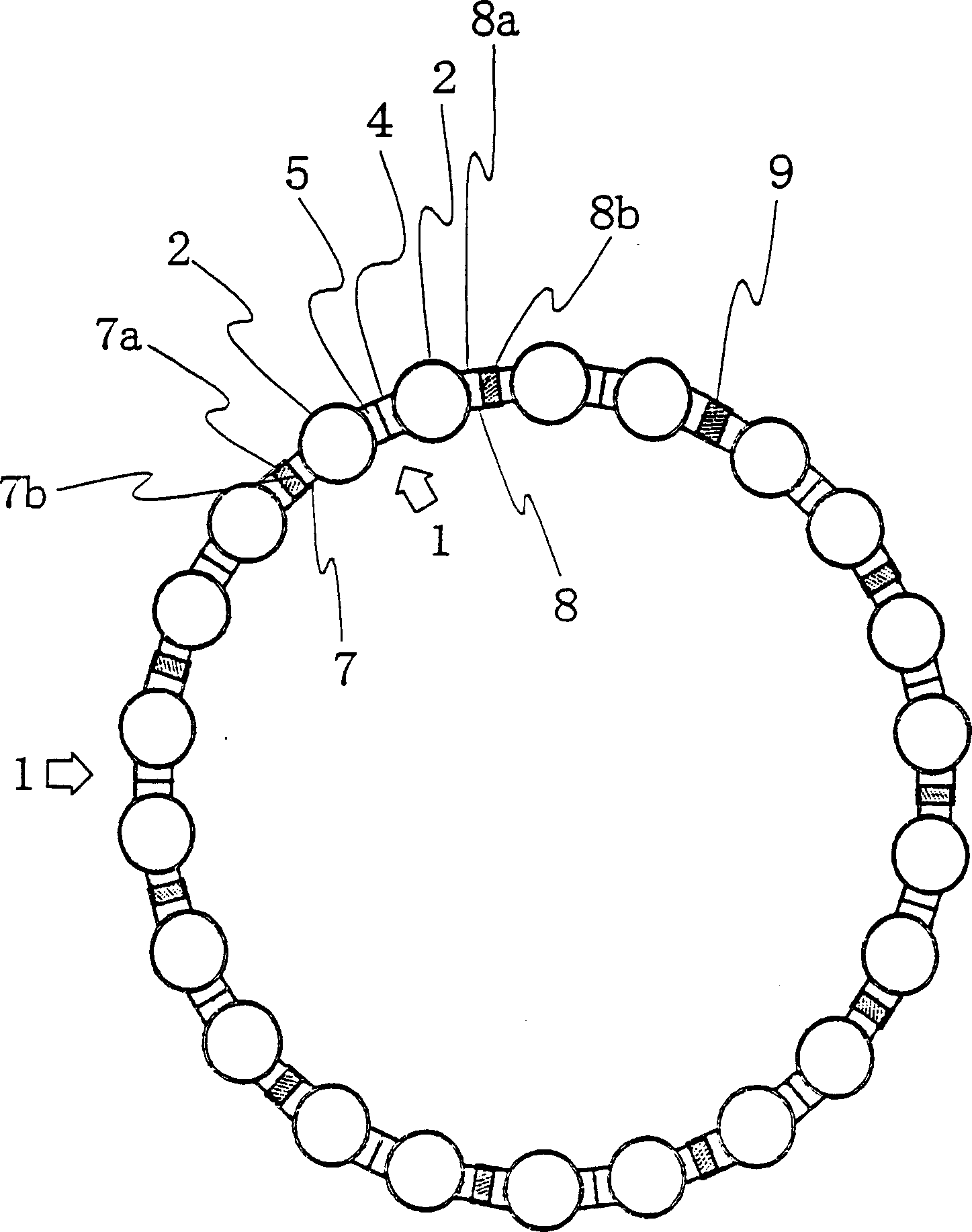

Steel-tube-sheet pile sunk-well foundation and steel-tube-sheet pile used thereof

A twin-type steel pipe sheet-pile well foundation and a twin-type steel pipe sheet-pile used therefor are provided to improve economical effects and to remarkably improve shear resistance of a connection part. A twin-type steel pipe sheet-pile well foundation is formed by joining several twin-type steel pipe sheet-piles(1) in a closed shape while combining connection members. In the twin-type steel pipe sheet-pile, an H-shaped steel male connection part(7) or female connection part(8) as a connection part is arranged to an H-shaped steel connection steel pipe wherein steel pipes(2) are integrally connected by the H-shaped steel connection member the flange edges of which are combined to the periphery of each steel pipe. The H-shaped steel male connection part shakes to be combined to a space surrounded by the flange inside of the H-shaped female connection part and the wave face. The H-shaped male connection part or H-shaped female connection part is inclined at a proper angle with respect to the H-shaped steel connection member in a projecting direction, to enable combination in a closed shape.

Owner:DATA TOO +2

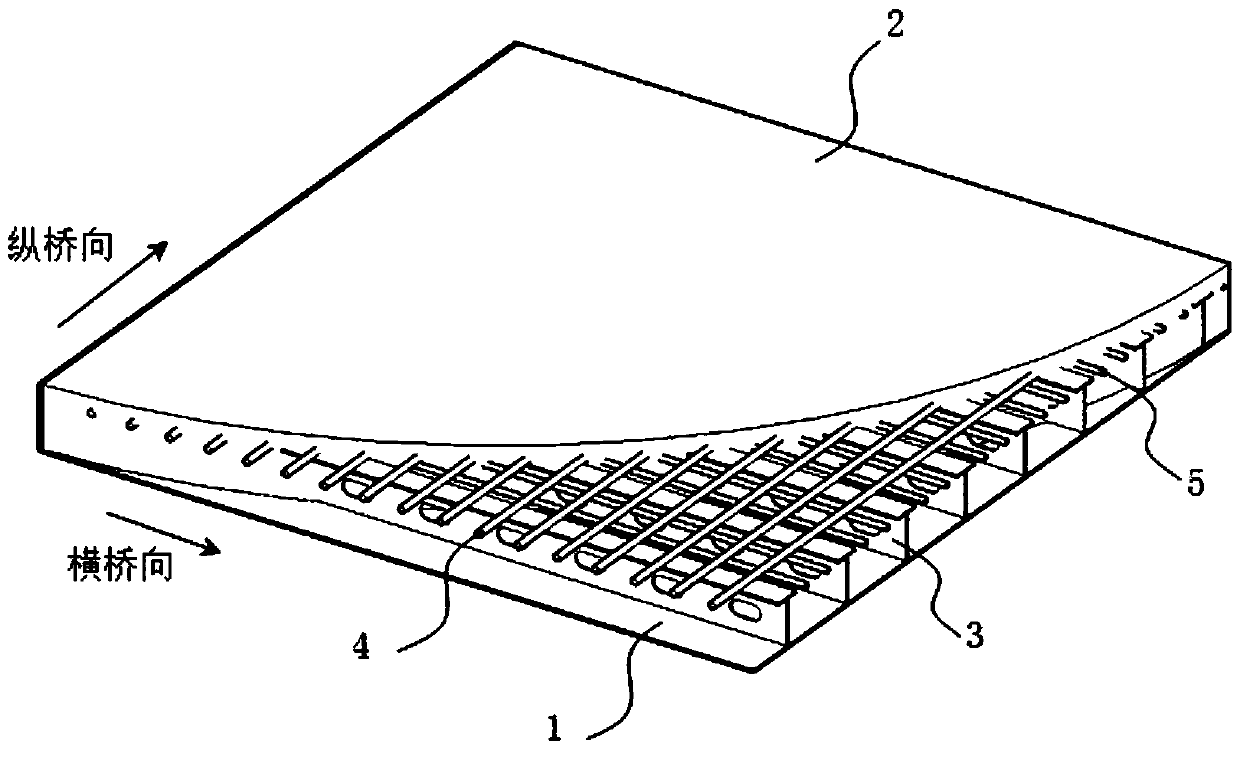

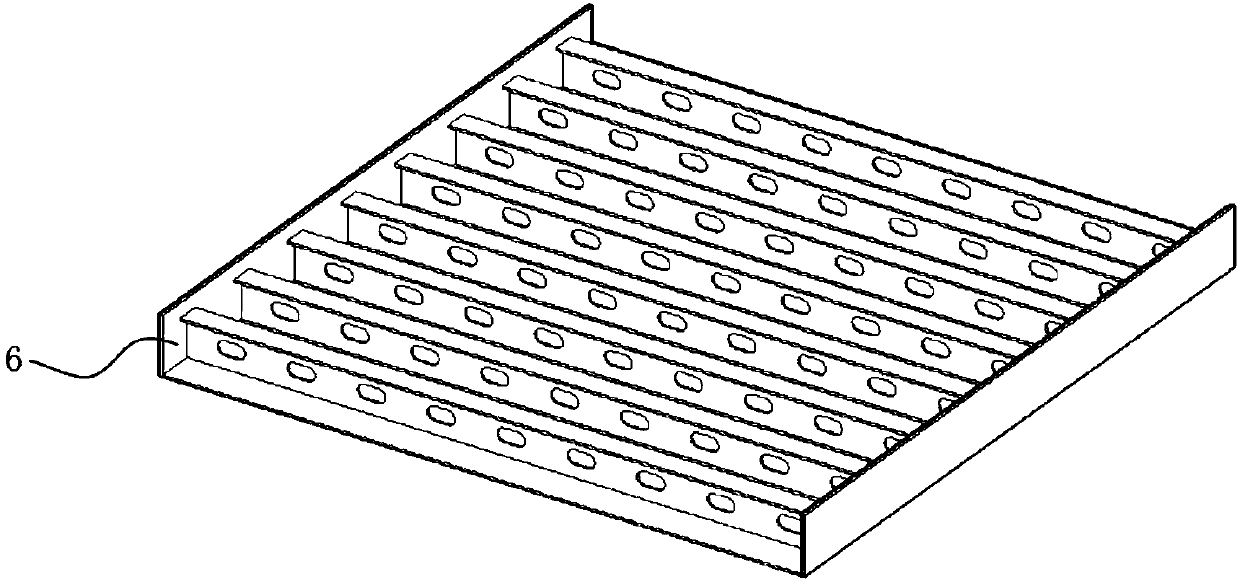

Orthotropic steel plate-concrete composite bridge deck and construction method thereof

InactiveCN107938511AReduce thicknessImprove the bending resistance of the transverse bridgeBridge structural detailsBridge erection/assemblyBridge deckRebar

The invention provides an orthotropic steel plate-concrete composite bridge deck and a construction method thereof. The composite bridge deck comprises orthotropic steel plates, a reinforcement mesh and a concrete structure layer, wherein the orthotropic steel plates include a steel bottom plate and a plurality of T-shaped steel sections; the plurality of T-shaped steel sections are arranged at intervals on the upper surface of the steel bottom plate along a longitudinal direction of a bridge; the reinforcement mesh is paved above flanges of the T-shaped steel sections; and a plurality of flange baffle plates are also welded on the upper surface of the steel bottom plate. During working, the concrete structure layer and the orthotropic steel plates are cooperatively stressed. The construction method of the composite bridge deck comprises the steps of processing the orthotropic steel plates, hoisting the orthotropic steel plates, paving the reinforcement mesh, pouring the concrete structure layer and the like. The composite bridge deck increases the bending resistance in a transverse direction of the bridge, reduces the thickness of the bridge deck, reduces the dead load, enhances the bending resistance of the bridge deck in the transverse direction of the bridge as well as the overall crossing capacity of a main body of the bridge, reduces the manufacturing cost, improves the durability of the structure, and has wide application prospects.

Owner:CHONGQING UNIV

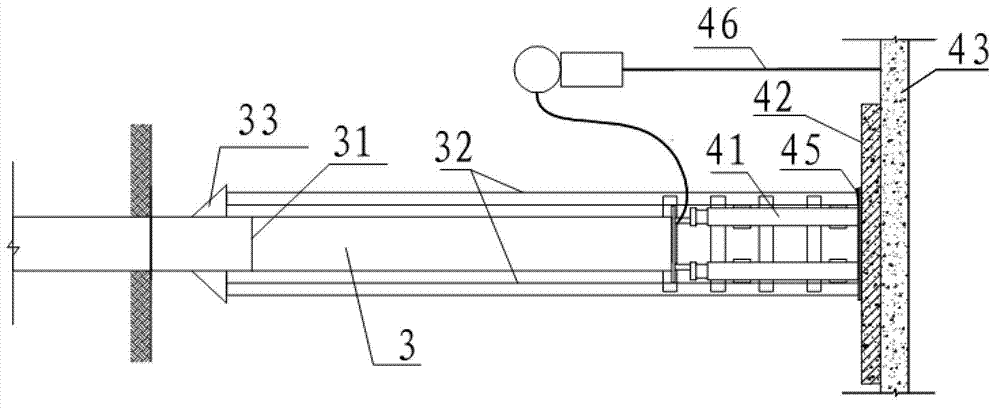

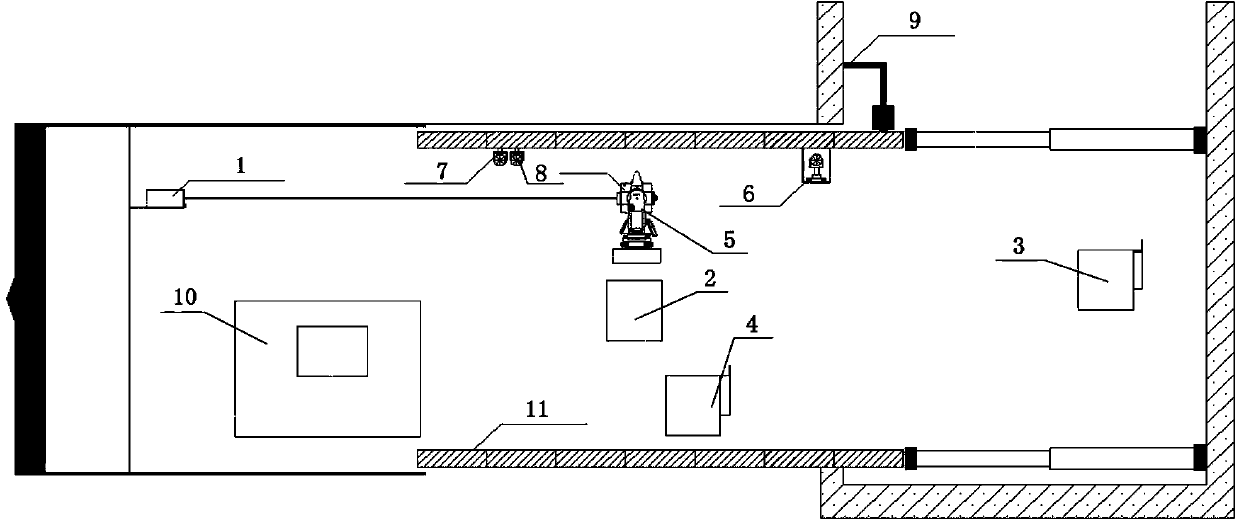

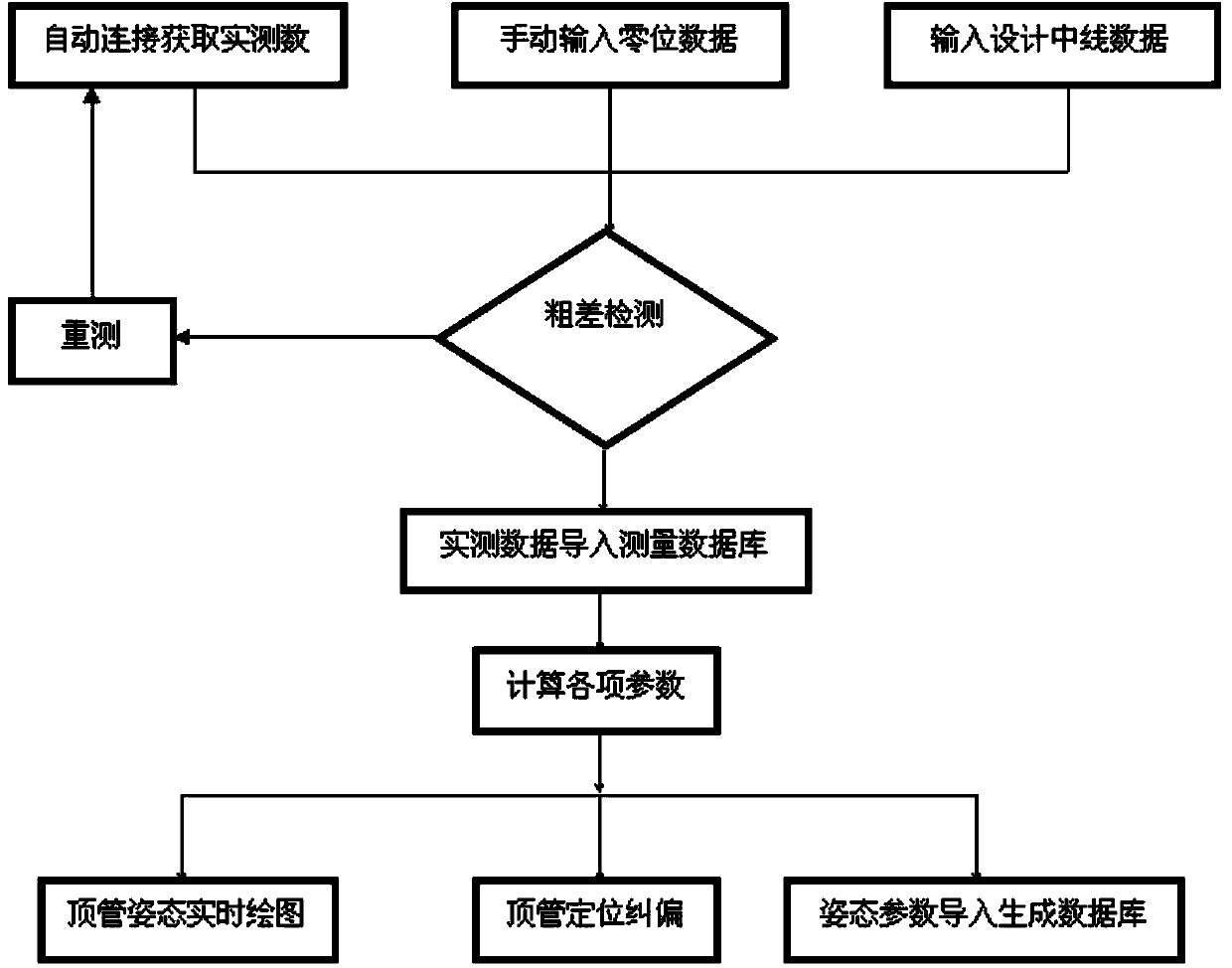

Automatic measurement and guidance system and automatic measurement and guidance method related to pipe pushing construction

ActiveCN103994752AReduce labor intensityImprove work efficiencyAngle measurementHeight/levelling measurementGuidance systemReal-time data

The invention relates to the field of construction and tunnel measurement technique, and particularly relates to an automatic measurement and guidance system and an automatic measurement and guidance method related to pipe pushing construction. The automatic measurement and guidance system comprises a full-automatic total station instrument, a wireless radio station, remote control equipment, a computer, an application tool, a pipe pusher, an MTG-T optical target, a prism, a sensor and a control cabinet, wherein the MTG-T optical target is arranged on the head of the pipe pusher; during the pipe pushing process, the whole pipe moves forwards, a travel sensor is arranged on the top of a tunnel portal, a forward vision prism and a reference prism are arranged on the upper wall of an inner cavity of a second tunnel pipe joint of the pipe, and can continuously move according to the pipe joint of the pipe, a back vision prism is arranged on the upper wall of an inner cavity of previous pipe joint of the tail end pipe joint of the pipe, and the total station instrument is arranged at the central position of an inner cavity of the front end pipe joint of the pipe. Compared with the prior art, the automatic measurement and guidance system has the advantages of alleviating the labor intensity of workers, improving the working efficiency and the construction precision of the pipe pushing construction, as well as analyzing and treating, timely controlling and timely making a decision through real-time data, so that the through accuracy between two wells is guaranteed.

Owner:中铁市政环境建设有限公司

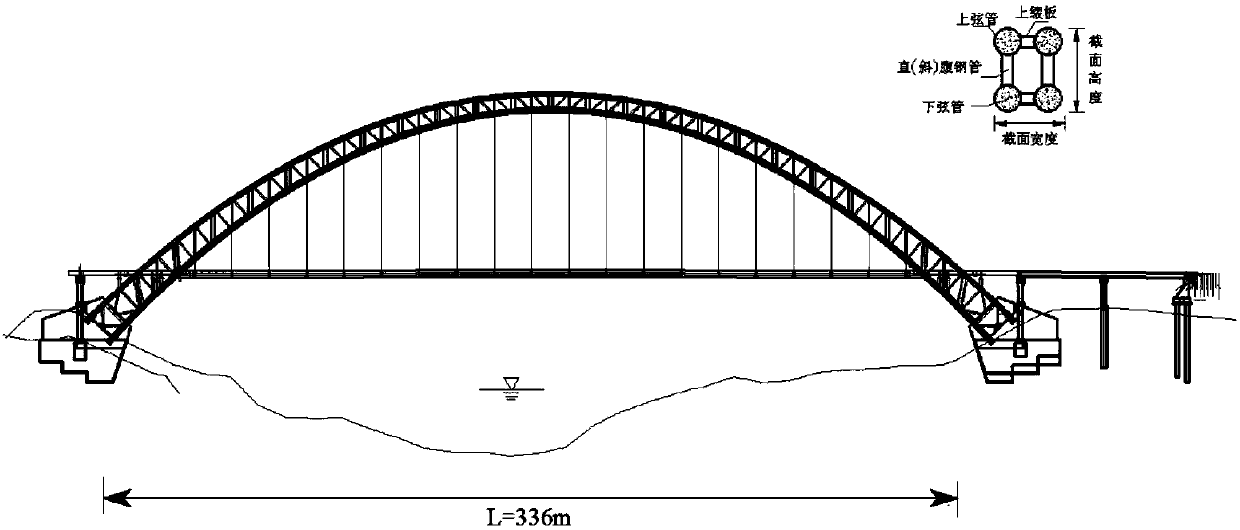

Construction method of steel pipe arch bridge

InactiveCN102367650ASafe and efficient constructionTake up less time on the channelBridge erection/assemblyArch-type bridgeEngineeringSteel tube

The invention discloses a construction method of a steel pipe arch bridge, which comprises the following steps: step 1) constructing a first bridge pier and a second bridge pier and pouring a cast-in-place beam on the first bridge pier; step 2) fixedly splicing multiple sections of steel beams into a steel beam middle section on one side corresponding to the second bridge pier; step 3) transporting the steel beam middle section to a designed position, and enabling the two ends of the steel beam middle section to be respectively supported on the first bridge pier and the second bridge pier; step 4) pouring the cast-in-place beam on the second bridge pier; and step 5) respectively butting and folding two folding sections at the two ends of the middle section so as to form a main beam. The construction of the main body part of the main beam is completed on the land, thereby having the advantages of safety, high efficiency, short time occupied by a fairway and high construction precision.

Owner:中铁一局集团厦门建设工程有限公司

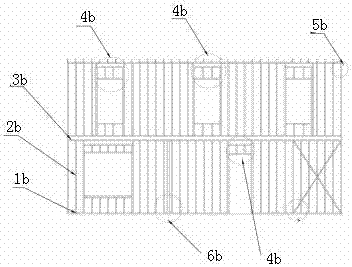

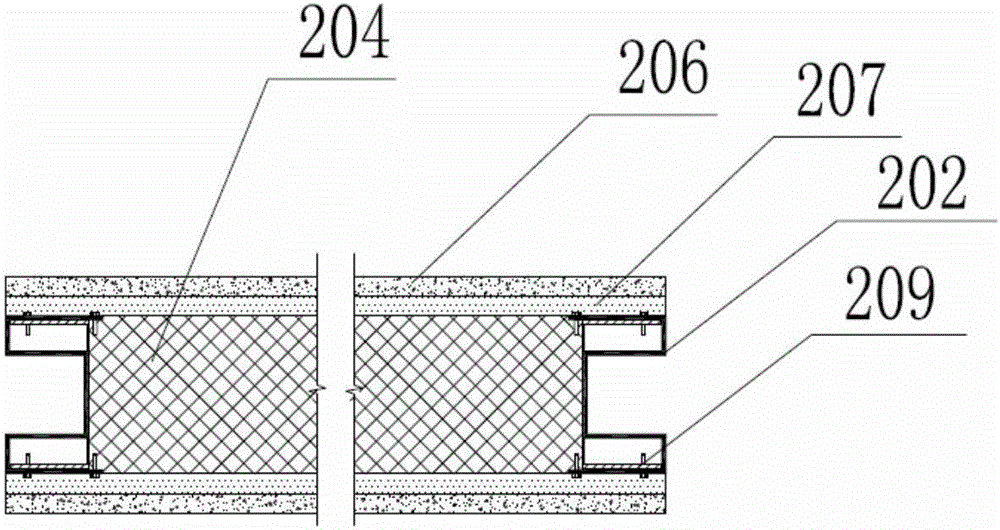

DGC board-type assembled house system and construction method and manufacturing method thereof

InactiveCN105804233AImprove prefabrication rateEnsure structural safetyWallsFloorsModular compositionInsulation layer

The invention discloses a DGC board-type assembled house system and a construction and a manufacturing method thereof. A basic unit of the system is formed by floor slabs and wallboards which are combined and assembled in a modularized manner; the wallboards are prefabricated composite boards, each wallboard mainly consists of a light-steel frame, a peripheral guard board, a sandwich insulation layer, a heat insulating layer and turnbuckles, and different wallboard standard modules such as in-line wallboards, L-shaped wallboards, T-shaped wallboards and cross-shaped wallboards are adopted and freely combined; the floor slabs are prefabricated composite boards, the floor slabs are used as foundation slabs, floor slabs or roof slabs of the DGC board-type assembled house system, and vertical connection between the floor slabs and the wallboards in the system consists of combined connection of lateral connection of horizontal M-shaped steel, M-shaped chord members and square steel pipes through tapping screws and vertical connection of the turnbuckles in trusses. According to the DGC board-type assembled house system and the construction method and the manufacturing method thereof, the structure is simple, the construction speed is fast, the construction period is reduced, the cost is low, and the defects of single structure, complex installation process and high labor cost of the existing assembled house structure can be overcome.

Owner:江苏保力自动化科技有限公司

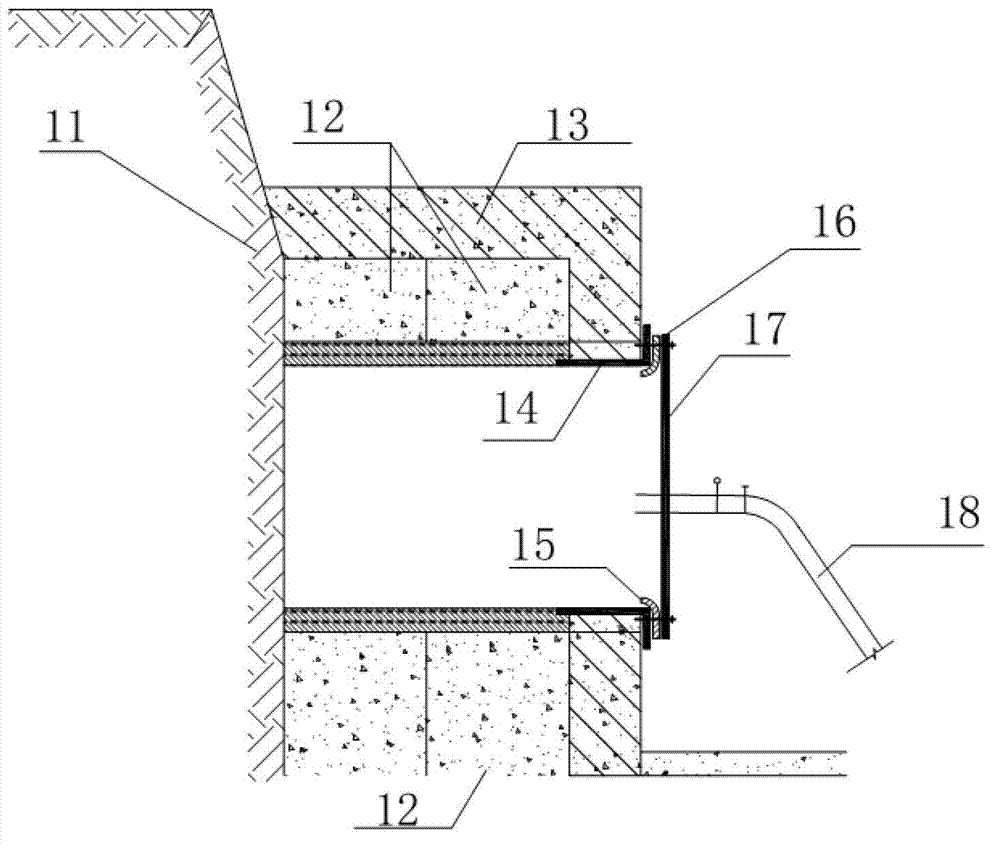

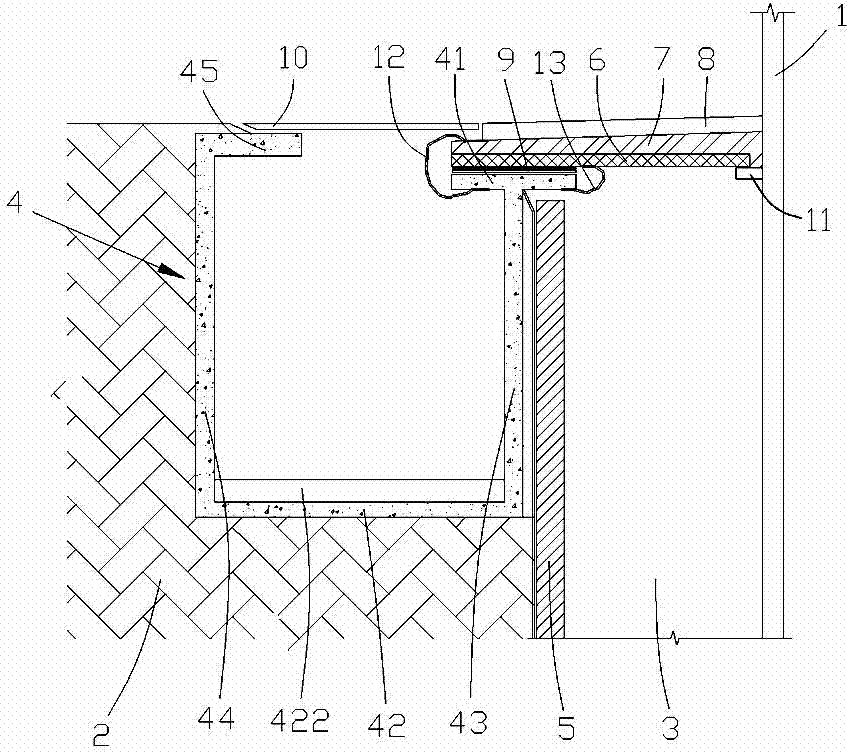

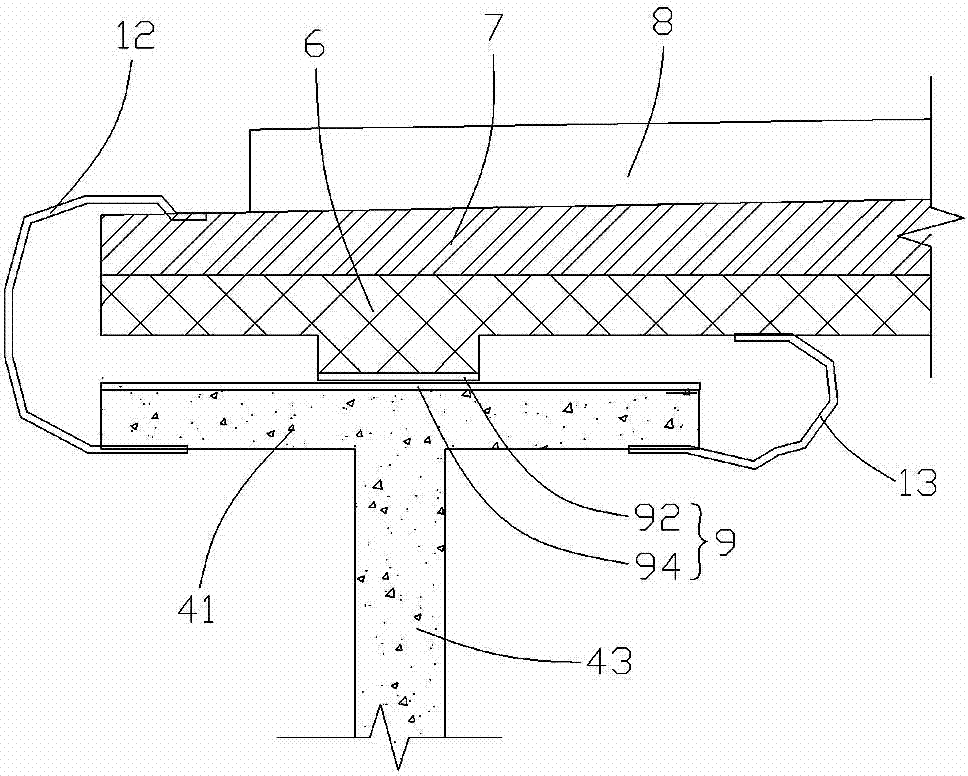

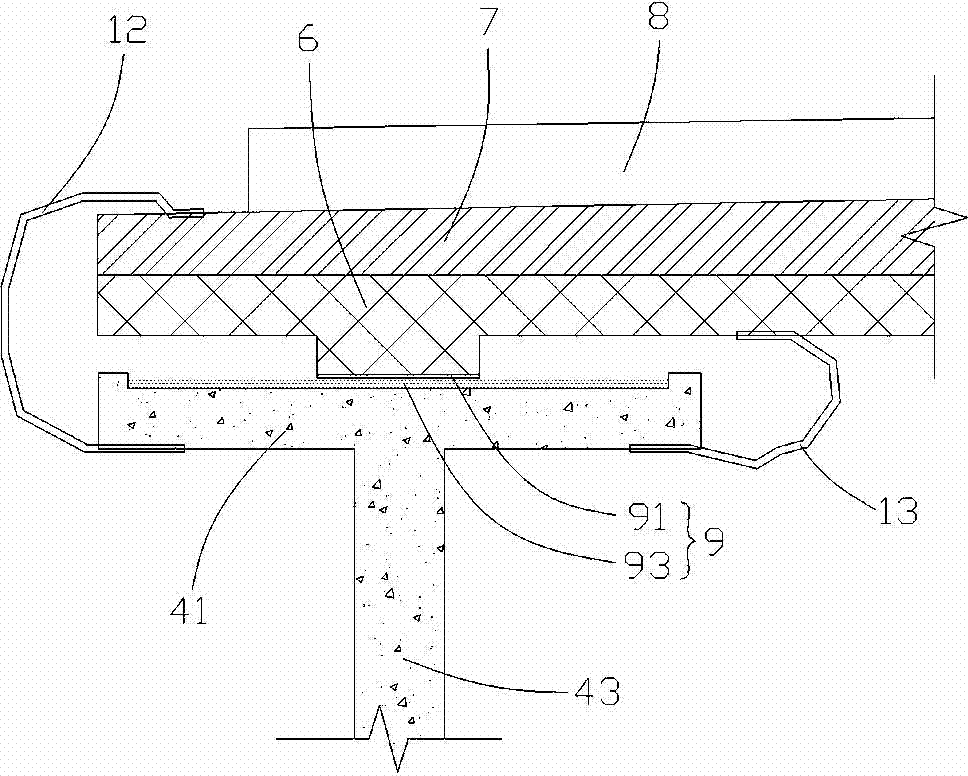

Building shock insulation ditch cover plate structure

ActiveCN103790186ASimple installation and constructionReduce misuseProtective foundationArchitectural engineeringRetaining wall

The invention provides a building shock insulation ditch cover plate structure. The building shock insulation ditch cover plate structure comprises a shock insulation ditch arranged between a shock insulation building body and a field soil body, a water draining component arranged in the field soil body and a shock insulation ditch retaining wall arranged in the shock insulation ditch. A supporting plate is arranged at the end, close to the shock insulation ditch, of the water draining component, a prefabricated cover plate and a cast-in-place laminated layer arranged on the prefabricated cover plate are connected between the supporting plate and the shock insulation building body, both the prefabricated cover plate and the cast-in-place laminated layer are fixedly connected to the shock insulation building body, and a sliding layer is arranged between the prefabricated cover plate and the supporting plate so that the prefabricated cover plate and the shock insulation ditch retaining wall can move more relatively freely under the effects of earthquakes. The building shock insulation ditch cover plate structure is simple in installation and construction, reduces false operations of construction personnel, improves the construction precision and guarantees the fact that the shock insulation building body and a space enclosing structure around can slide freely, and the shock insulation efficiency of the shock insulation structure is improved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

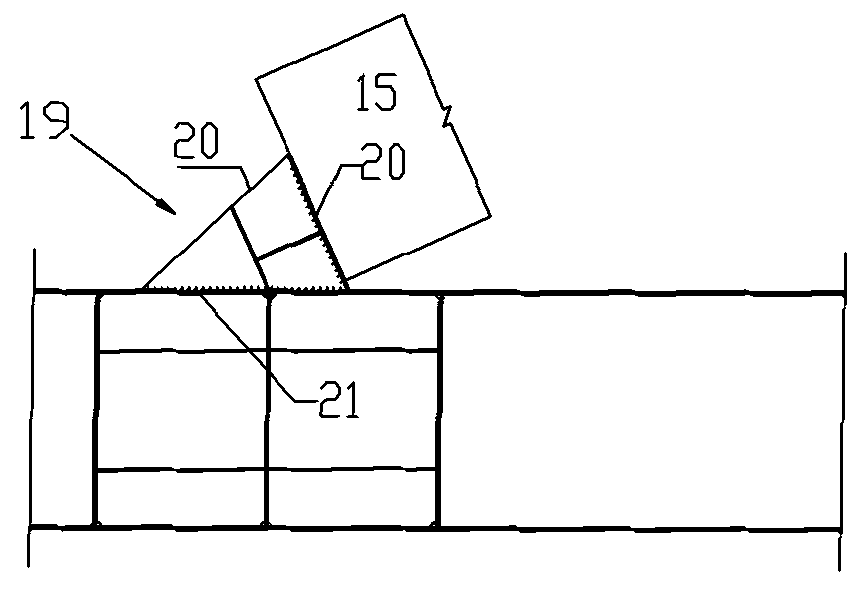

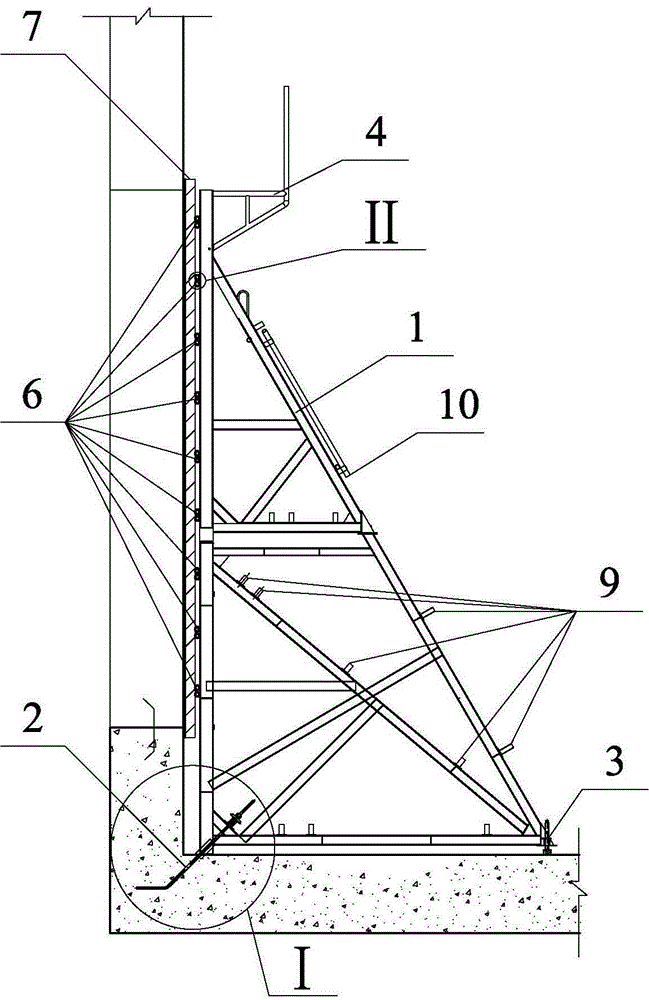

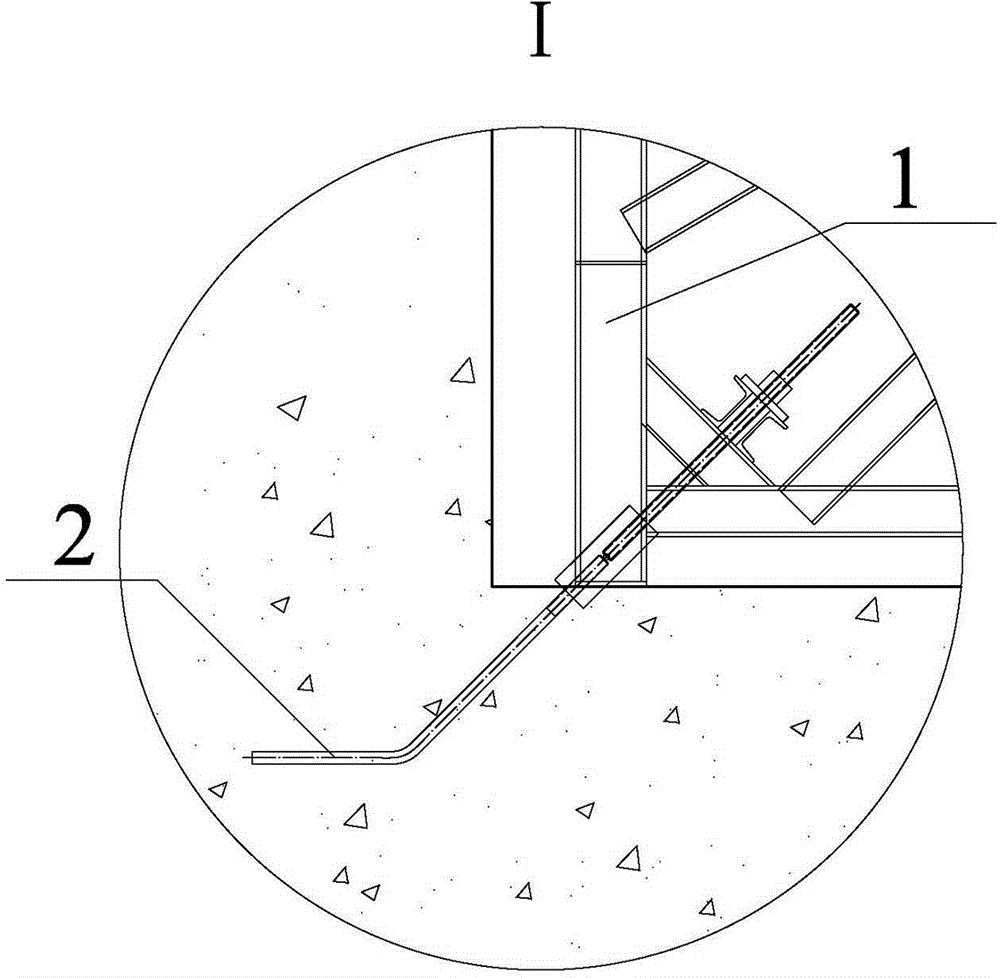

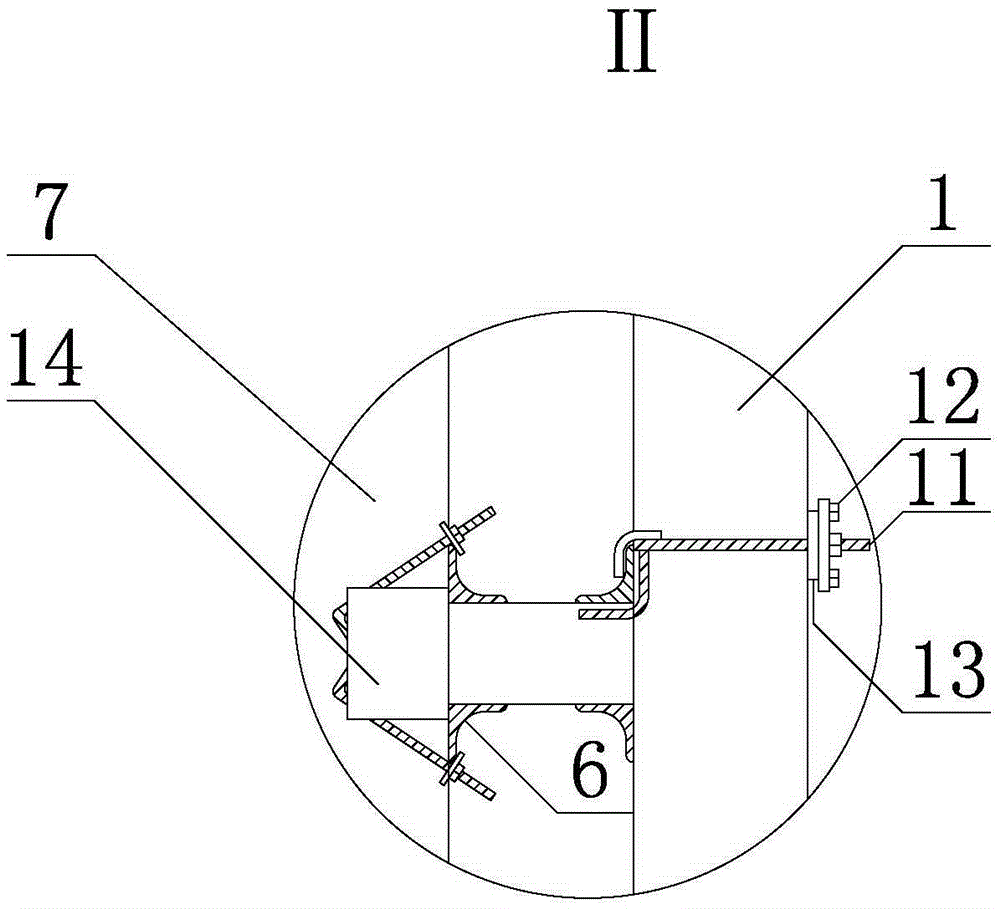

Open trench tunnel main structure tall side wall unilateral vertical mold and construction process thereof

InactiveCN105401599AImprove stabilityImprove waterproof performanceArtificial islandsUnderwater structuresSupporting systemRight triangle

The invention discloses an open trench tunnel main structure tall side wall unilateral vertical mold and a construction process thereof. The open trench tunnel main structure tall side wall unilateral vertical mold comprises a right triangle-shaped profile steel triangular truss; an embedded foundation bolt is inclined at one side of the bottom of the profile steel triangular truss; multiple pressing beam channel steels are arranged on the profile steel triangular truss; a template is mounted at the outer side of the long edge of the right-angled edge of the profile steel triangular truss; multiple connecting devices are arranged between the profile steel triangular truss and the template; one ends of the connecting devices are positioned in the template at one side of the profile steel triangular truss; a transverse connecting steel pipe is mounted on the inclined edge of the profile steel triangular truss in the length direction; and an operation platform is mounted at the upper part of the profile steel triangular truss. The profile steel triangular truss and an embedded part are used as support systems of the template; the unilateral mold standing can be performed; a bracket is high in stability and excellent in water resistance; the steel pipe use level is low; the disassembly is convenient; enough sidesway and buoyancy resistance can be provided to the tunnel tall side wall template; the template construction precision is improved; and the construction efficiency and the engineering progress are greatly improved.

Owner:CHINA RAILWAY SHISIJU GROUP CORP +1

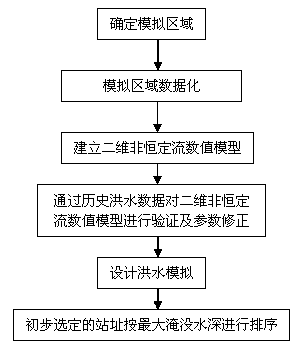

Two-dimensional unsteady-flow numerical model based power engineering location method

ActiveCN103886135AEnsure flood safetyReduce consumptionClimate change adaptationSpecial data processing applicationsDesign floodPower grid

The invention discloses a two-dimensional unsteady-flow numerical model based power engineering location method. On the basis of a plurality of site locations primarily selected according to design requirements of a power grid transmission line, the two-dimensional unsteady-flow numerical model is subjected to verification, parameter modification and design flood simulation by determining a simulation area, digitizing the simulation area and establishing the two-dimensional unsteady-flow numerical model and historical flood data, the site locations primarily selected are sorted according to largest submerged depth, and a primary selection sequence of the site locations is obtained. By the two-dimensional unsteady-flow numerical module flood routing technology, hydrologic characteristics in a certain area and flood hydraulic elements during simulation of flood routing can be truly and objectively reflected, flood control safety of electric power engineering can be guaranteed, construction accuracy can be improved, land source consumption can be reduced, and construction cost can be lowered.

Owner:STATE GRID CORP OF CHINA +3

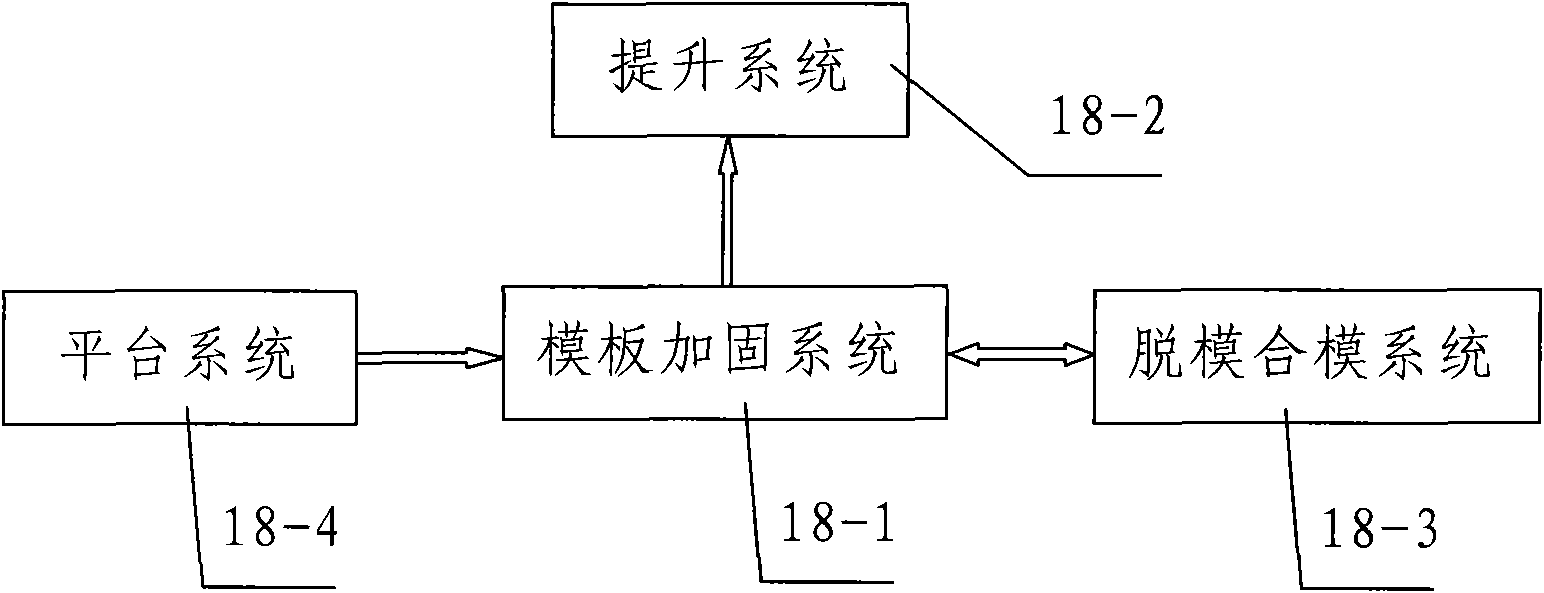

Method for achieving template unmanned construction

InactiveCN104460506AImprove construction accuracyEasy to operateNumerical controlControl systemData information

The invention discloses a method for achieving template unmanned construction. According to the method, data information and a control program are generated through digital processing of a template construction drawing by a control system; data information is written into cloud intelligent labels on a template and a template supporting piece; a robot / mechanical arm conducts separation on the template and the template supporting piece and loads the template and the template supporting piece to a carrying device; information identification authentication is conducted on the loaded template and template supporting piece, and then the loaded template and template supporting piece are transported to a construction site through the carrying device by means of the robot / mechanical arm; information identification authentication is conducted on the template and the template supporting piece after the template and the template supporting piece reach the construction site, and corresponding construction program commands are generated; the robot / mechanical arm finishes construction according to the construction program commands; the robot / mechanical arm conducts detaching and recycling works on the template and the template supporting piece according to the control commands. The method is free of restriction of environment elements, safer and more reliable, higher in construction accuracy and better in construction quality, and unmanned operation and remote intelligent management of template construction are achieved.

Owner:HUNAN PUYUN INTELLIGENT TECH

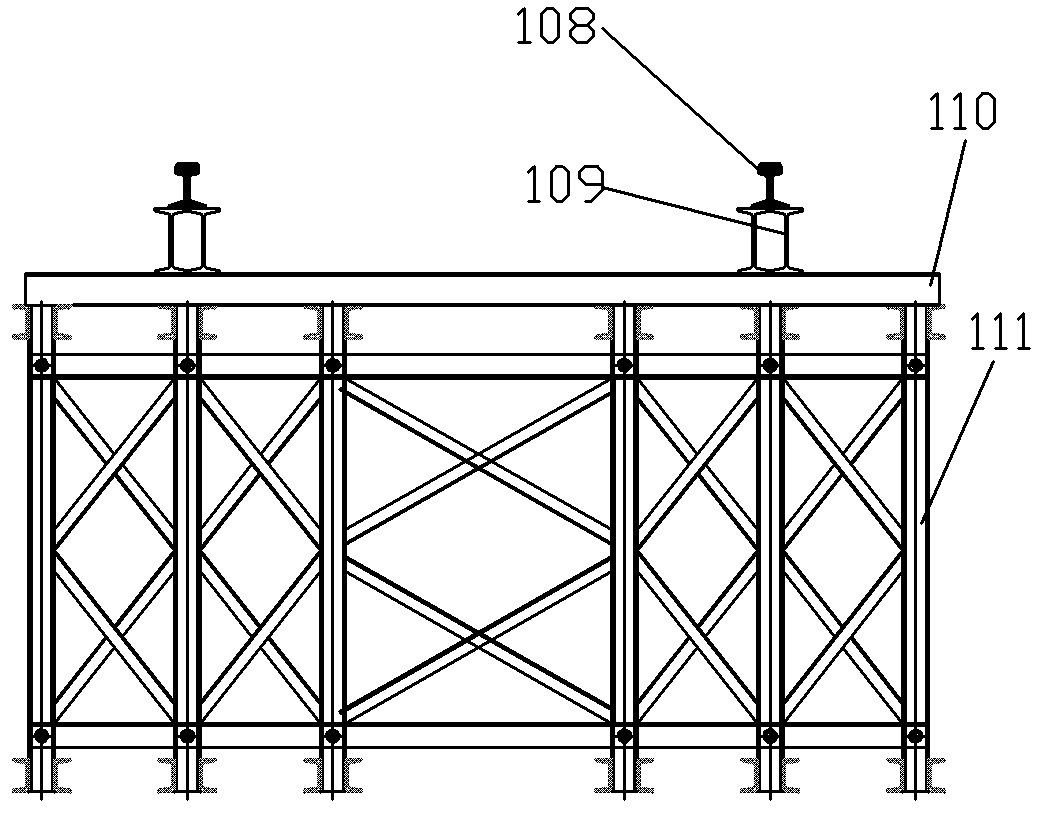

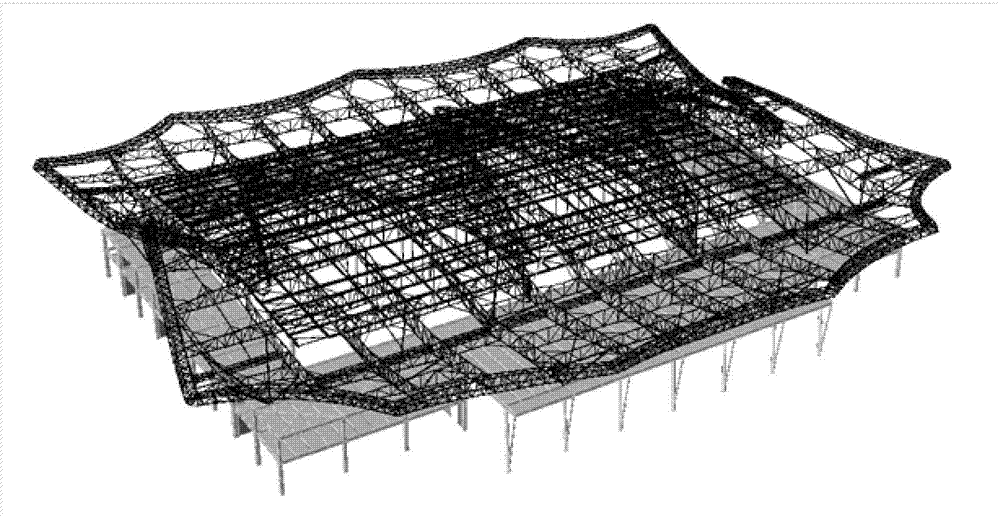

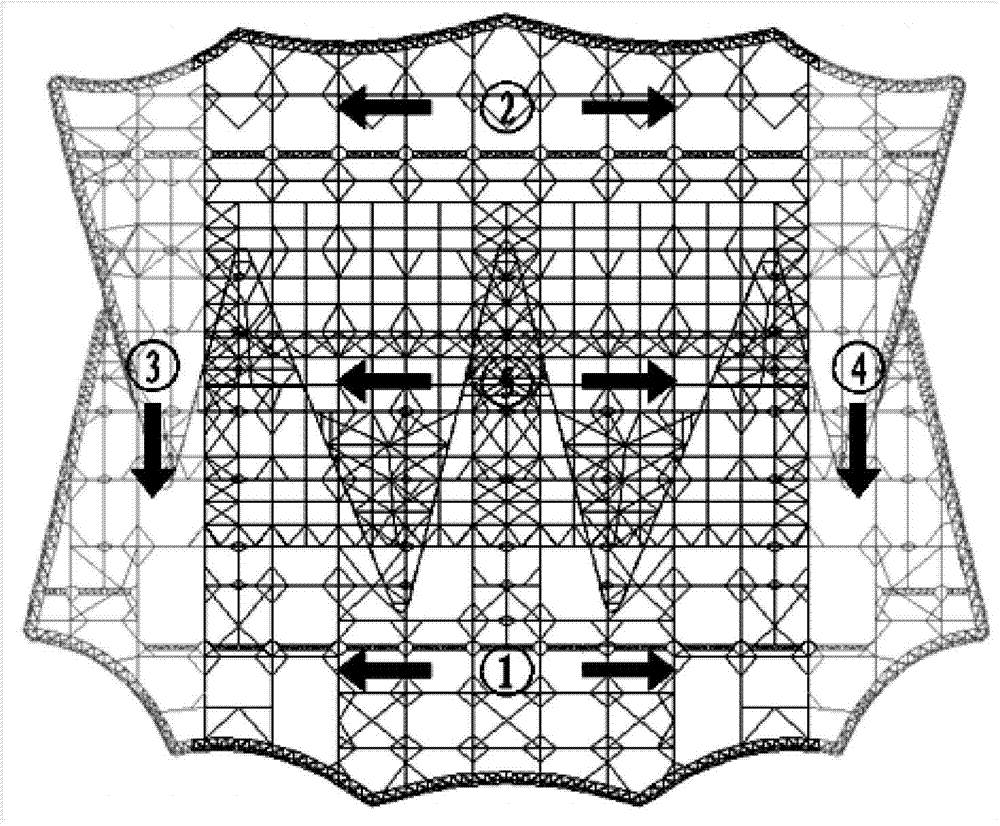

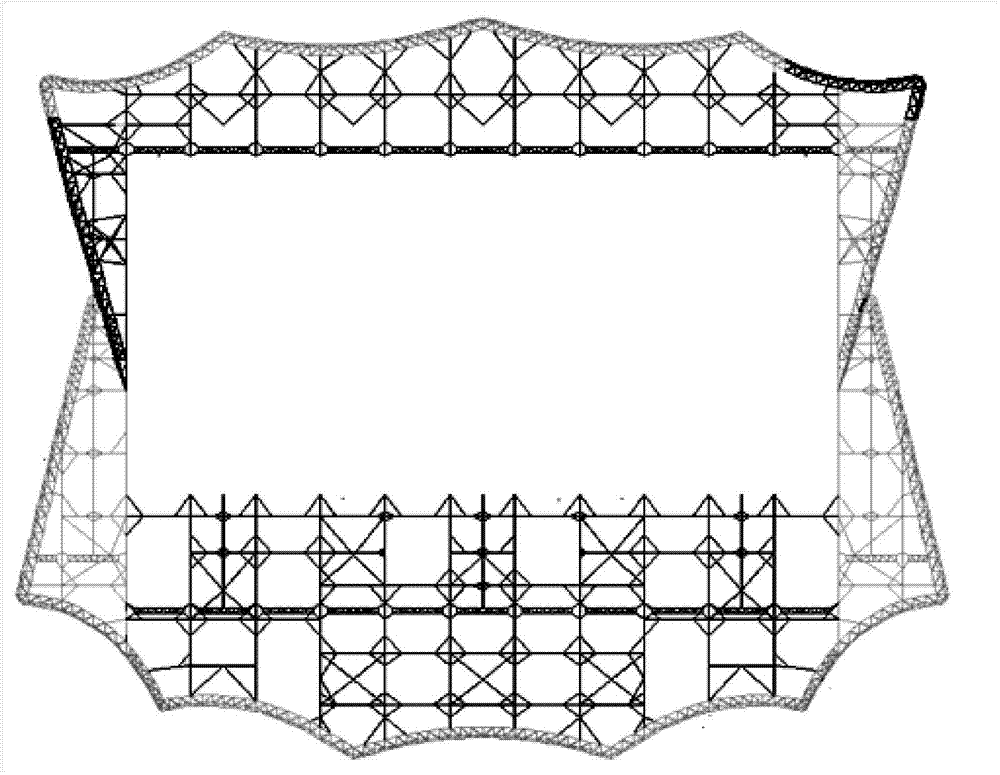

Computer control hydraulic synchronous hoisting construction method for complex space truss structure

ActiveCN103696494AImprove work efficiencyImprove construction accuracyBuilding constructionsControl engineeringHydraulic pressure

The invention relates to a computer control hydraulic synchronous hoisting construction method for a complex space truss structure. According to the method, computer control hydraulic pressure is adopted for synchronously hoisting the combination of an interior roof truss and a lower ceiling platform system. The computer control hydraulic synchronous hoisting construction method mainly comprises the following construction steps: assembling a perpheral roof truss and an interior hoisting truss in turn in an assembling sequence according to an onsite condition and a design demand; wholly hoisting after completely assembling an interior roof structure according to design elevation; welding and closing a perpheral roof, assembling other roofs, and meanwhile, detaching a hoisting device; in a root position for assembling, vertically unloading some temporary jig frame structures adopted in the process of detaching the assembly. The computer control hydraulic synchronous hoisting construction method for the complex space truss structure overcomes the defects of large high-altitude bulk welding quantity, low precision and high safety risk of a steel structure roof and shortens the construction period.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com