Automatic measurement and guidance system and automatic measurement and guidance method related to pipe pushing construction

A guidance system and automatic measurement technology, applied in the direction of measurement device, measurement angle, surveying and navigation, etc., can solve the problems of penetration error exceeding the limit, time-consuming and laborious, nose deviation, etc., to ensure the penetration accuracy and reduce the labor intensity of personnel. , The effect of improving work efficiency and construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

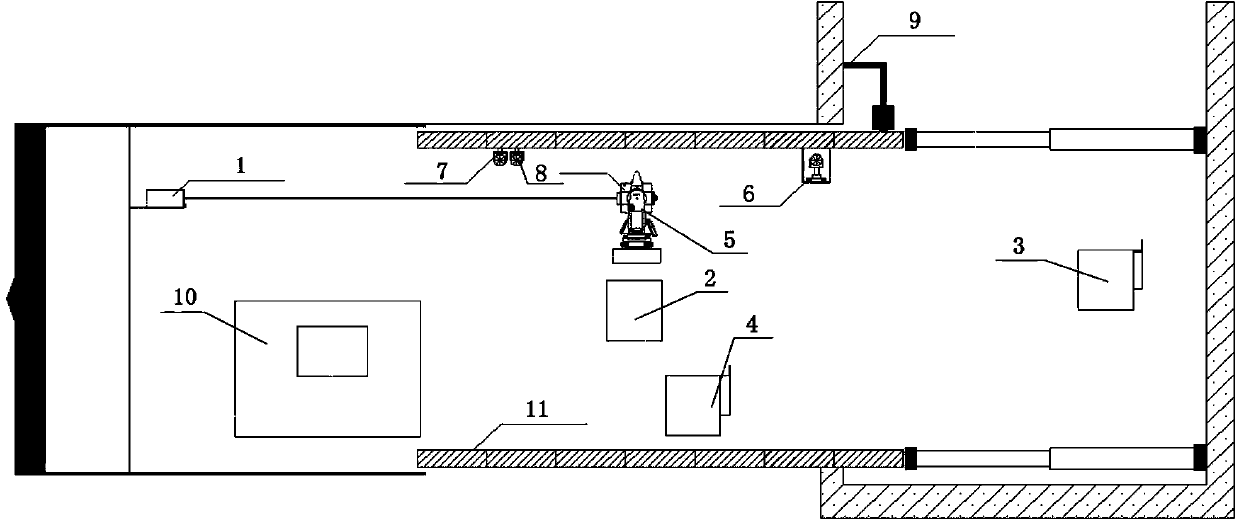

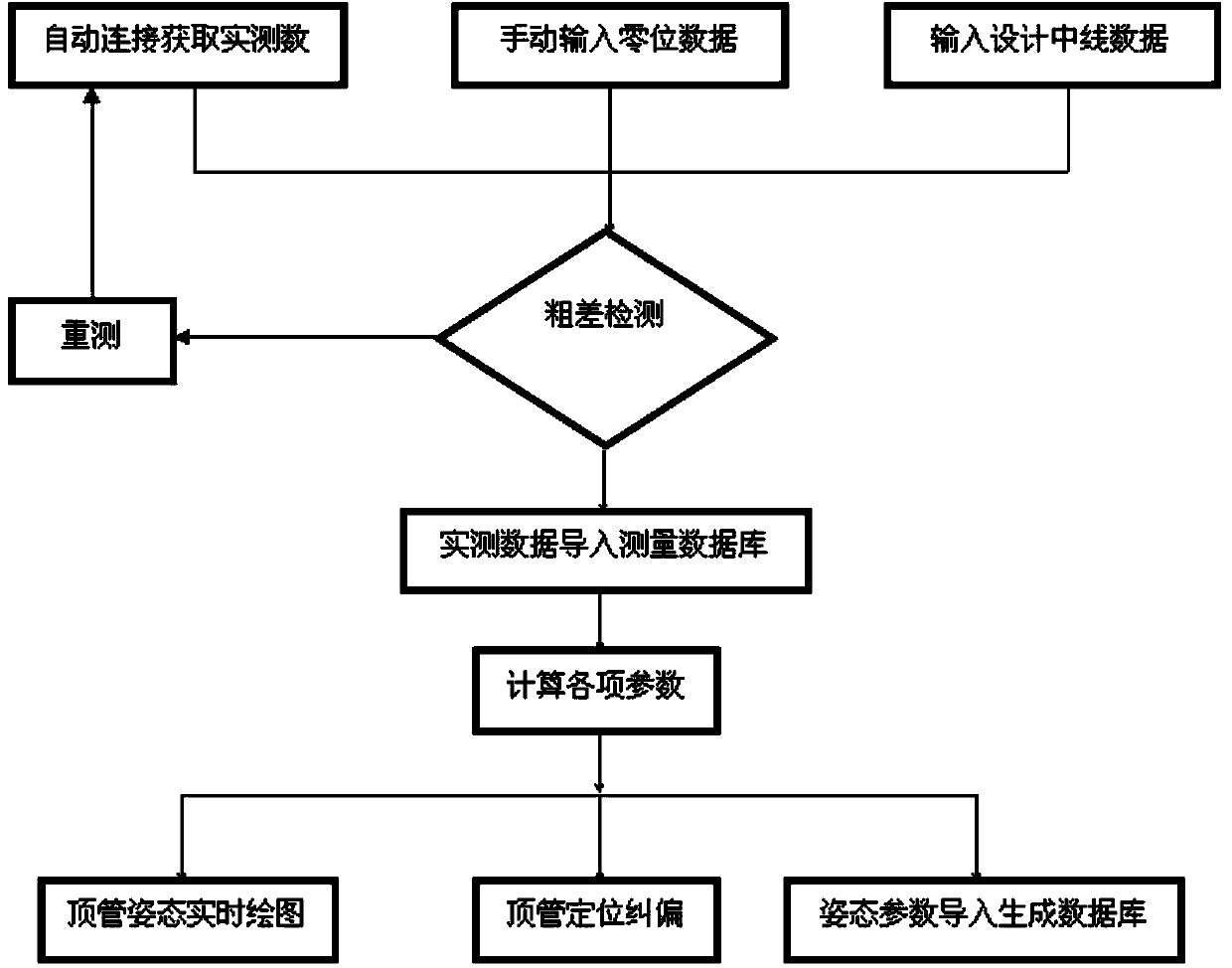

[0018] Such as figure 1 , figure 2 As shown, the automatic measurement method for pipe jacking is as follows: through manual input of zero position data, design midline data and on-site measured data, it is automatically imported into the measurement database, thereby calculating various parameters such as the real-time attitude of the pipe jacking machine, the design axis deviation, etc., so as to guide construction.

[0019] The specific method steps of the above-mentioned automatic pipe jacking measurement method are as follows:

[0020] a. System assembly and commissioning, installation of reference prisms, connecting cables, total stations, industrial computers and other corresponding equipment, commissioning of communication and other preparations are completed, see attached figure 1 ;

[0021] b. Input relevant parameters, and enter various index parameters such as design midline data, zero position data, and preset deviation values into the computer;

[0022] c....

Embodiment 2

[0025] Take the Kunming tail water discharge pipe jacking project as an example. Kunming Tail Water Outward Drainage Pipe Jacking Project is one of Kunming Dianchi Sewage Treatment Projects. There are 11 working wells divided into 10 sections of jacking lines on the whole line, and the longest top section 9# well-pump station# well top section has a total length of 1.2 kilometers , belongs to the ultra-long-distance pipe jacking construction. Since the pipe joints follow up with the extension of the top section during the pipe jacking construction, it belongs to dynamic measurement, and must be jacked in one direction to the exit shaft. The accuracy requirements for tunnel measurement higher. There is 2 hours of free time for real-time measurement of each pipe section from transfer, installation to top opening. After the pipe jacking tunnel has a long jacking distance, the traditional method cannot guarantee that the machine can be completed within a limited time without makin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com