Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

A technology of artificial false roof and cemented filling, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of low loss rate, small production capacity, and dilution, and achieve the effect of low loss and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

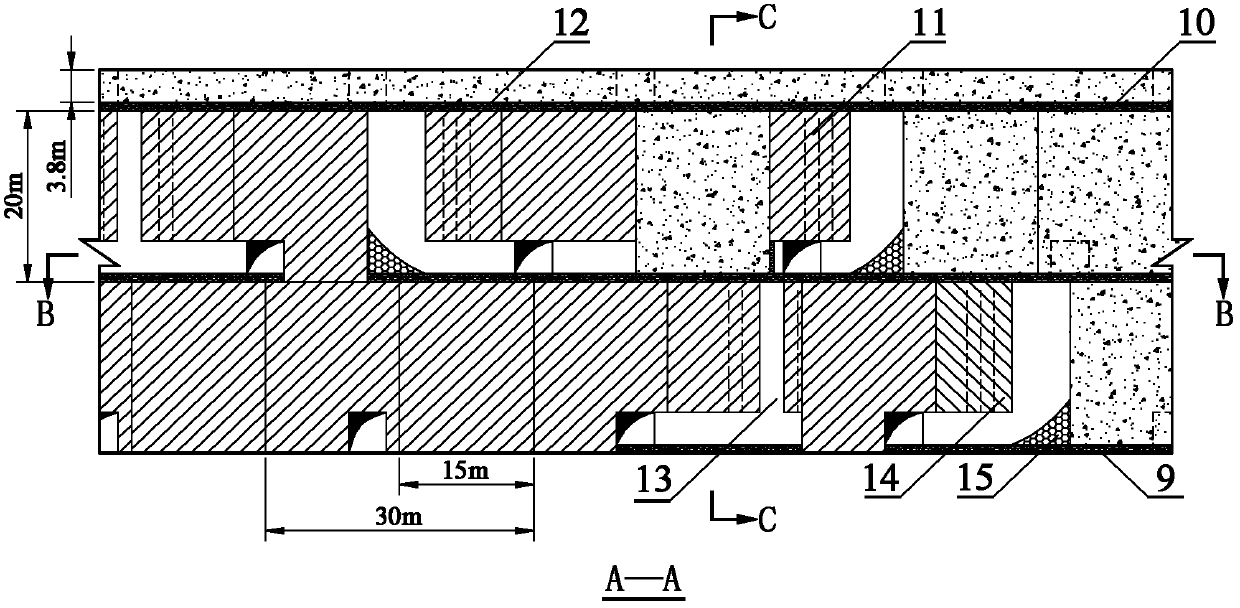

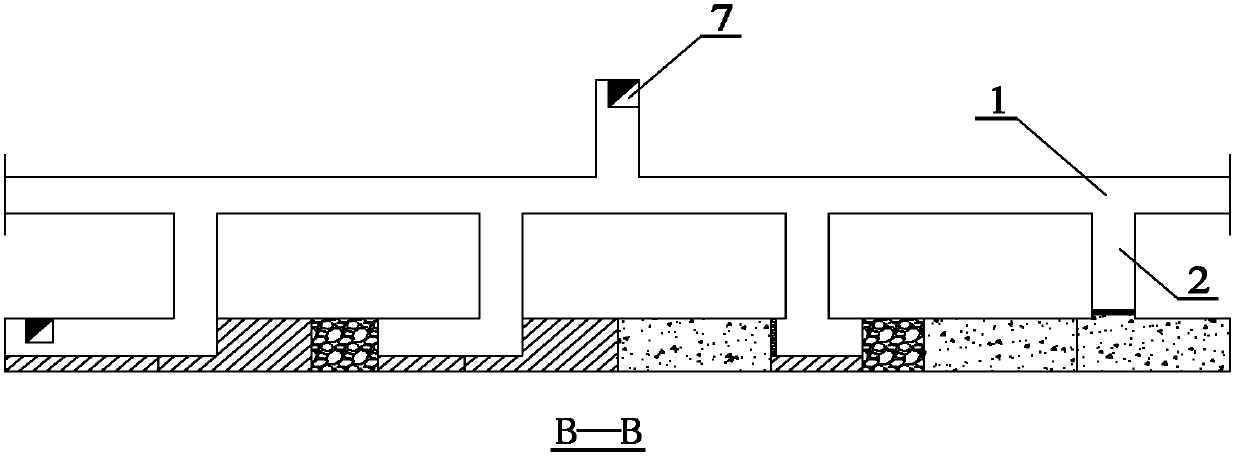

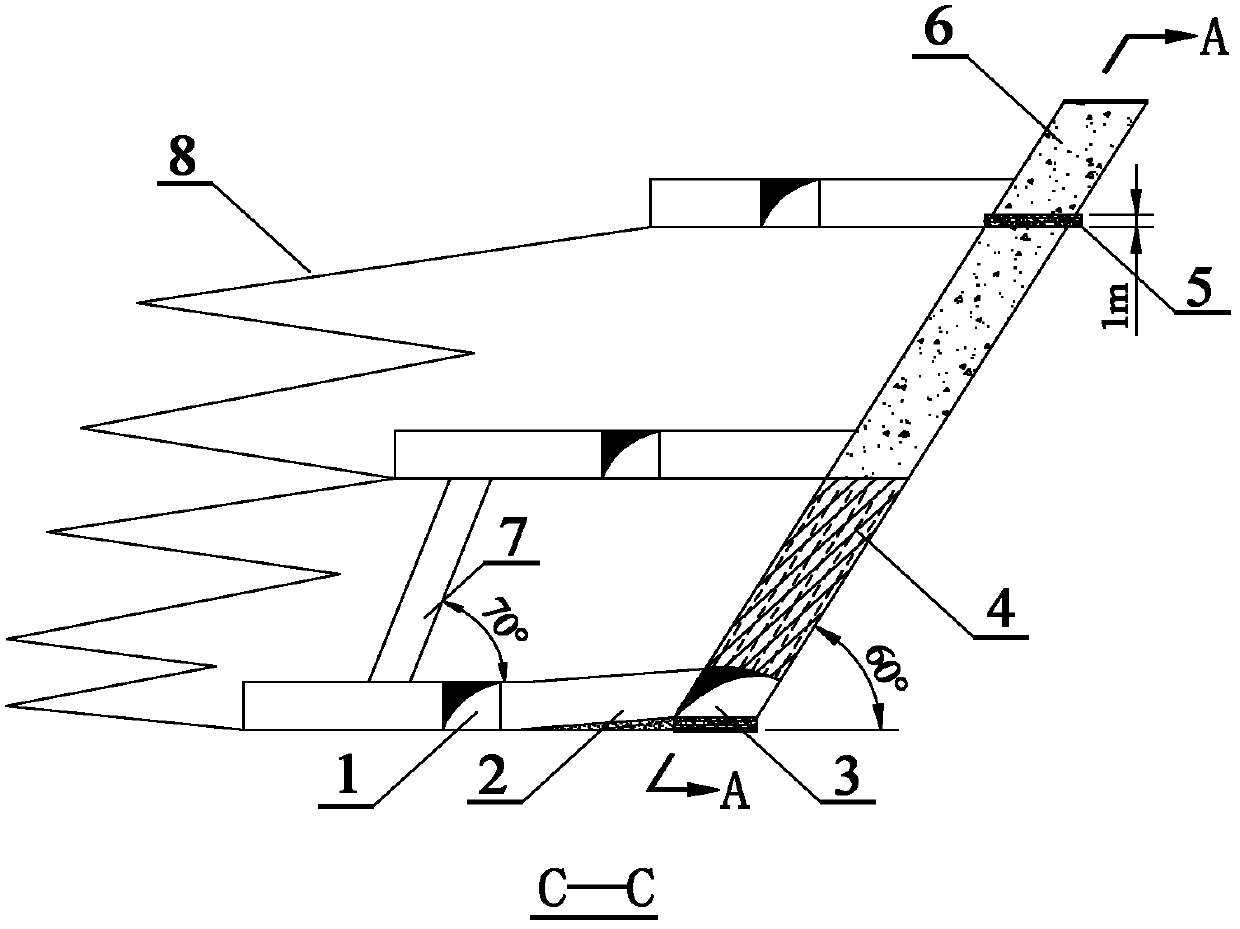

[0031] Example 1: The frame-type artificial false roof of the Shaba Mine used in Kailin, Guizhou is downwardly and segmentally cemented and filled.

[0032] Yongshaba Mine is the main mine of Guizhou Kailin Co., Ltd. The ore body is a slanted medium-thick and broken phosphate rock body, with a thickness of 3-8m, an average of 6m, an inclination of 20-90°, and a strike length of more than 3,300 m. On the two wings of the ore body, there are sharply inclined (50-90°) broken ore bodies with a strike length of nearly 400m. The stability of the ore is extremely poor. mining methods etc. By adopting the frame-type artificial false roof downward segmented cemented filling method, the safe, efficient and low-dilution loss rate recovery of the sharply inclined broken ore body in Shaba Mine has been realized.

[0033] specific implementation plan

[0034] ①. The height of the middle section of the ore block is 40m. According to the middle section of the ore body, it is divided into 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com