Patents

Literature

606results about How to "Low recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively recycling valuable metals from spent lithium ion battery

ActiveCN107017443AThe pre-processing process is simpleHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementVulcanizationSlag

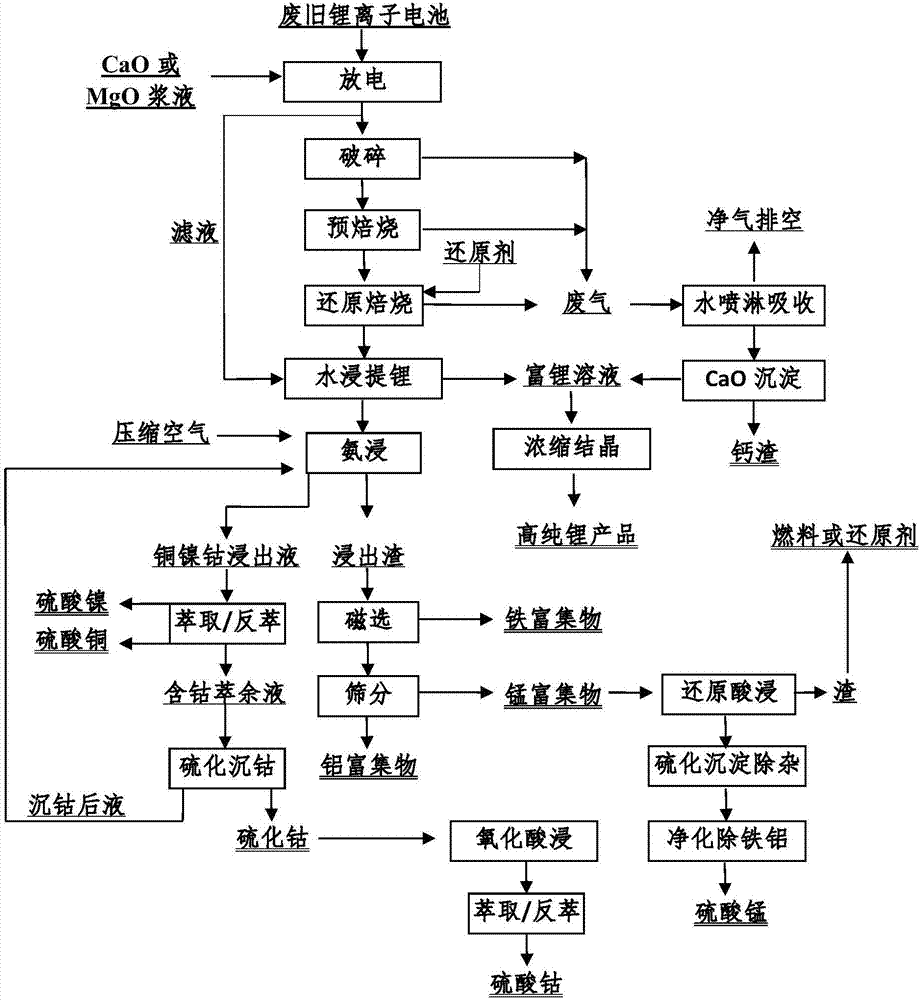

The invention discloses a method for comprehensively recycling valuable metals from a spent lithium ion battery. The method comprises the following steps: carrying out electric discharge treatment on a spent battery, crushing, pre-roasting at 300-400 DEG C, adding a reducing agent, and carrying out reduction roasting at 450-700 DEG C; carrying out water extraction and evaporative crystallization on fine aggregates obtained through the reduction roasting, so as to obtain a high-purity lithium product, leaching copper, nickel and cobalt from leached slag and roasted lump materials by virtue of ammonia oxide, carrying out magnetic separation and sieving on ammonia leaching slag so as to obtain iron and aluminum enriched products, and carrying out reduction acid leaching, purification and edulcoration on sieved products, so as to obtain a high-purity manganese sulfate solution; and carrying out extraction and selective reverse extraction on ammonia leaching liquid, so as to obtain a high-purity nickel sulfate solution and a high-purity copper sulfate solution, and carrying out vulcanization cobalt precipitation, oxidation acid leaching and extraction purification on raffinate, so as to obtain a high-purity cobalt sulfate solution. The method is high in extraction rate of valuable metals and applicable to the treatment of multiple waste lithium ion battery raw materials and efficient utilization of multiple elements, and sorting is not required.

Owner:GUANGDONG GUANGHUA SCI TECH

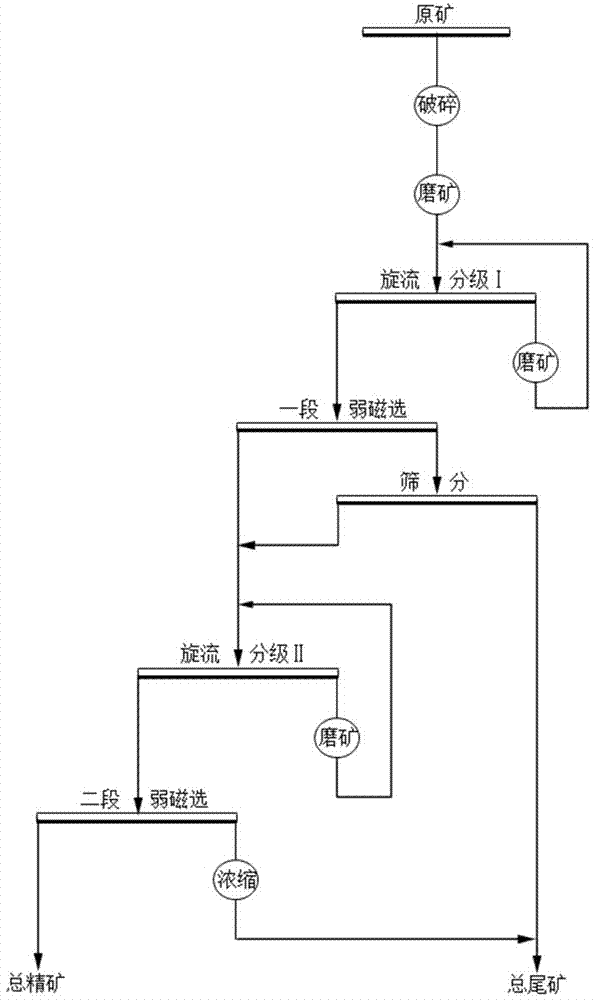

Vanadium titano-magnetite screen method

ActiveCN101564707AQuality improvementHigh recovery rateFlotationMagnetic separationMagnetiteMaterials science

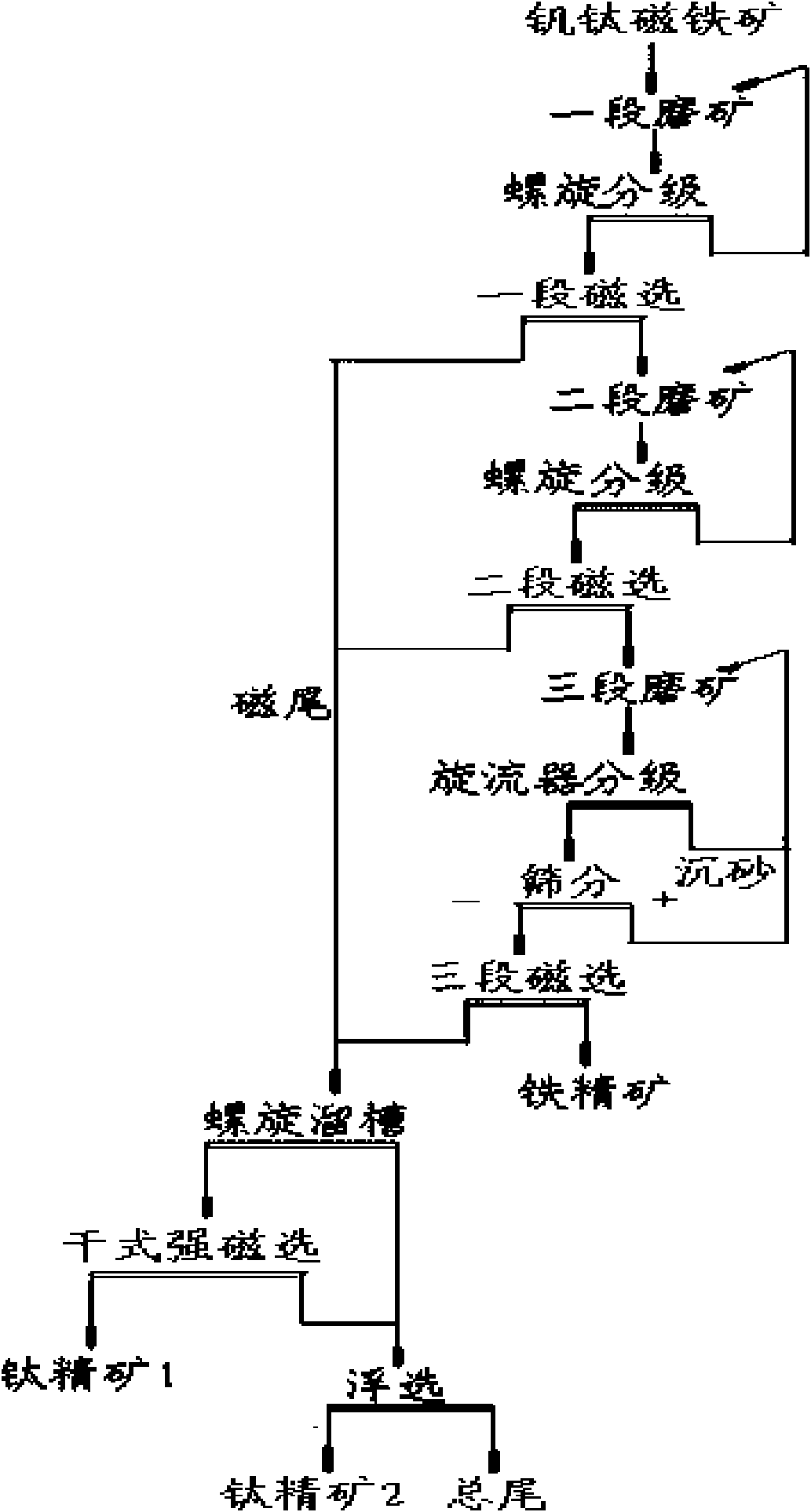

The invention relates to a screen method for vanadium titano-magnetite with high quality, belonging to the ore screen field. The method adopts three stage-grinding and stage-concentration process for magnetic separation, wherein the field intensity of one-stage magnetic separation is 3000-4000 Gs; the field intensity of two-stage magnetic separation is 1800-2200 Gs; and the field intensity of three-stage magnetic separation is 1300-1700 Gs. The recovery rate of the screened iron ore concentrate and the titanium ore concentrate is high and the screened cost of the screened iron ore concentrate and the titanium ore concentrate is low, thus providing a new selection for the low grade vanadium titano-magnetite resource and having a broad application prospect.

Owner:四川安宁铁钛股份有限公司

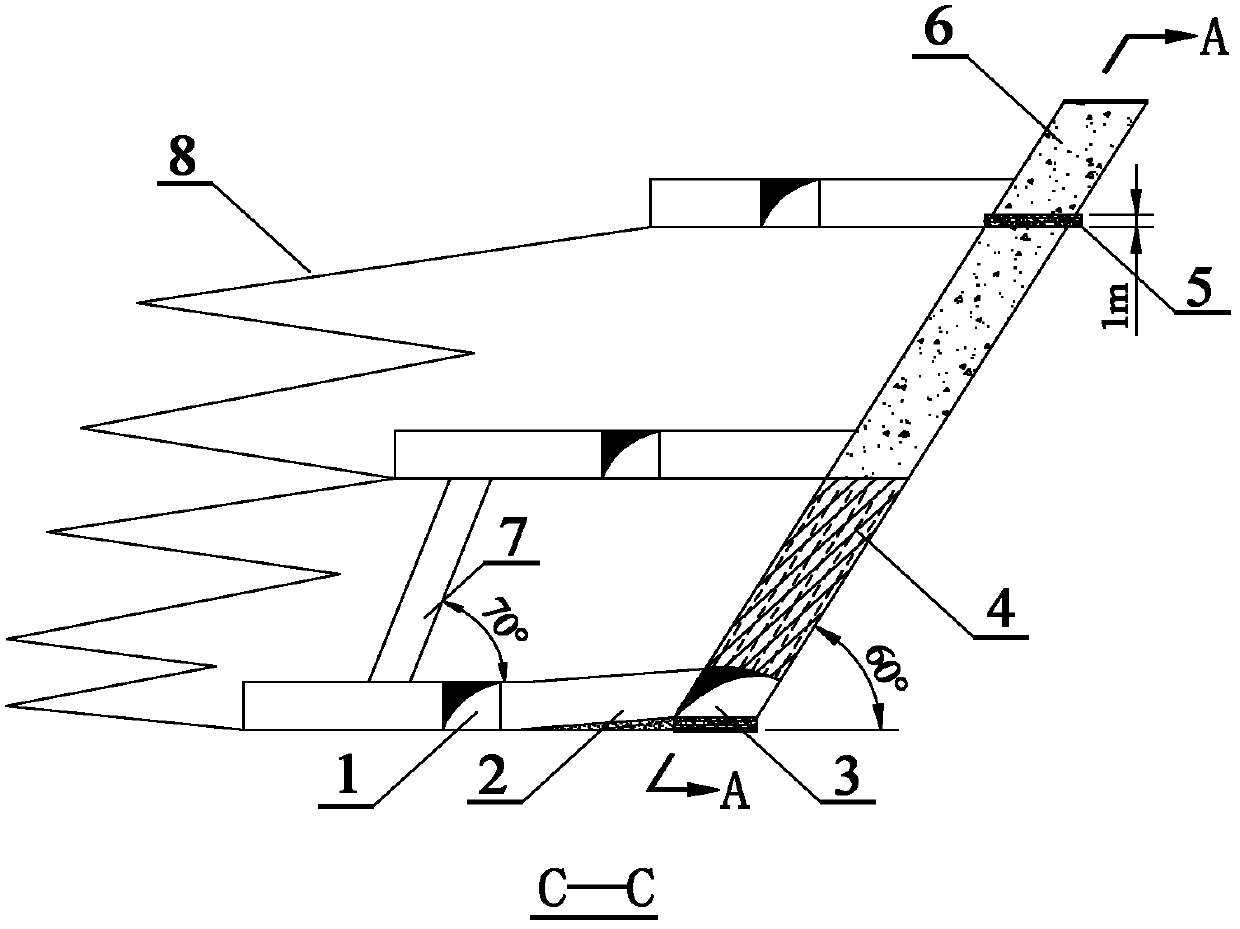

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

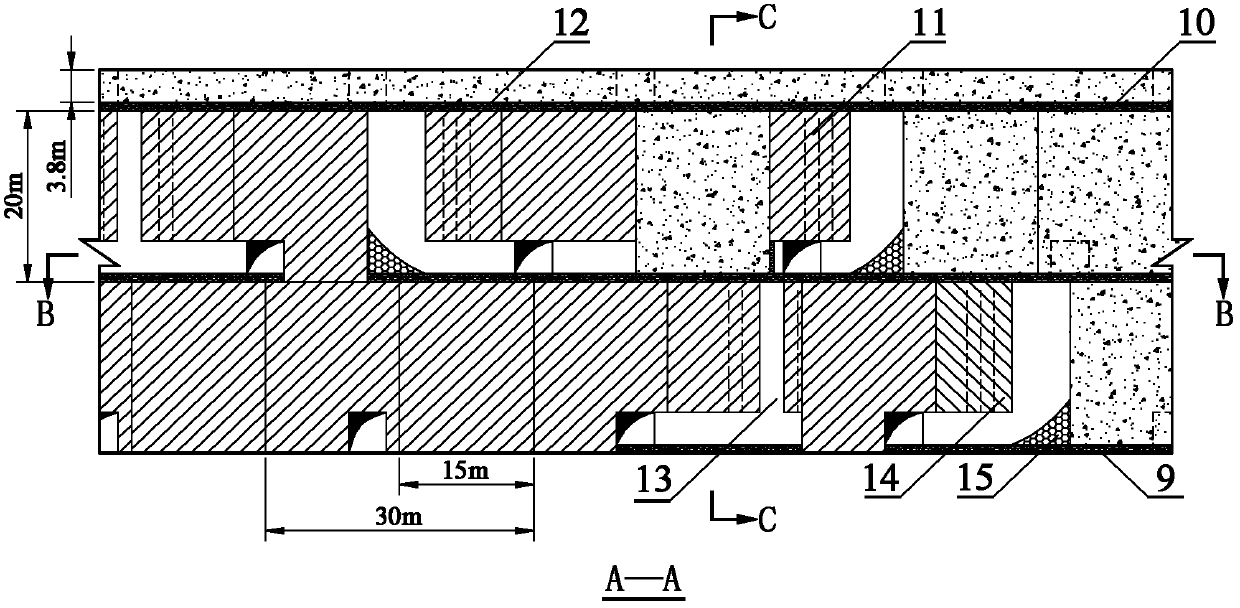

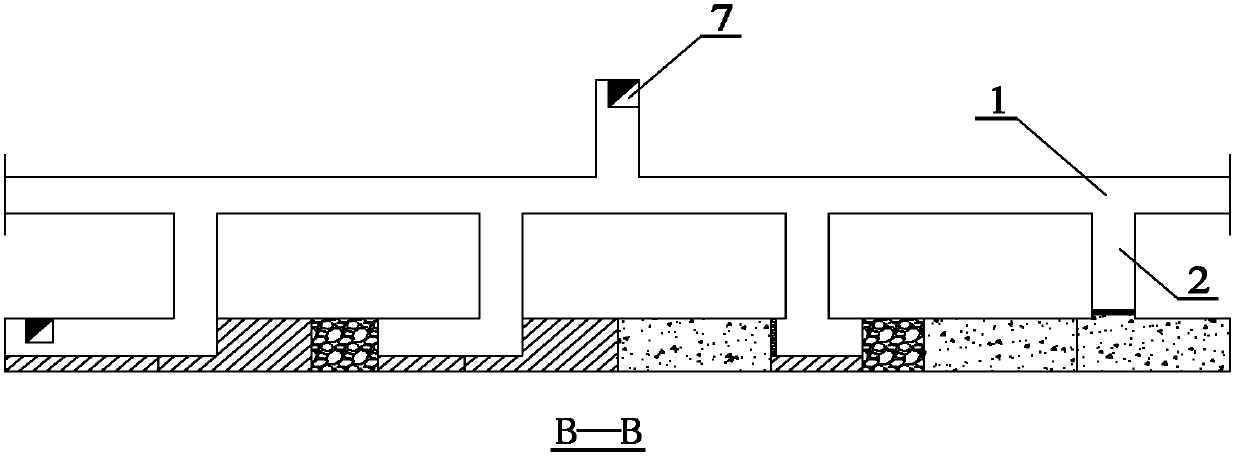

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

Method for recovering vanadium, tungsten and titanium from waste vanadium-tungsten-titanium-based denitration catalyst

ActiveCN103484678ASimultaneous recoveryLow recovery rateTitanium compoundsVanadium compoundsTungstateAmmonium metavanadate

The invention relates to a method for recovering non-ferrous metals from waste denitration catalysts, particularly relates to a method for recovering vanadium, tungsten and titanium from a waste vanadium-tungsten-titanium-based denitration catalyst, belonging to the field of non-ferrous metal recovery technologies. The method mainly comprises the steps of preparing the catalyst into powder with the grain size being smaller than 100 meshes, and adding concentrated alkali liquor; heating to react vanadium, tungsten and titanium with alkali, so as to produce slightly-soluble titanate, water-soluble vanadate and tungstate; filtrating to obtain a titanate filter cake, wherein titanate or titanic acid can be prepared from the filter cake; adding ammonium salt into a filtrate so as to precipitate ammonium metavanadate, and filtrating to obtain ammonium metavanadate and a new filtrate; adding concentrated acid into the new filtrate, thereby preparing solid tungstic acid. The method has the advantages of simple process, low energy consumption, good solid-liquid reaction contact, high vanadium, tungsten and titanium recovery rate, and the like.

Owner:BEIJING UNIV OF CHEM TECH

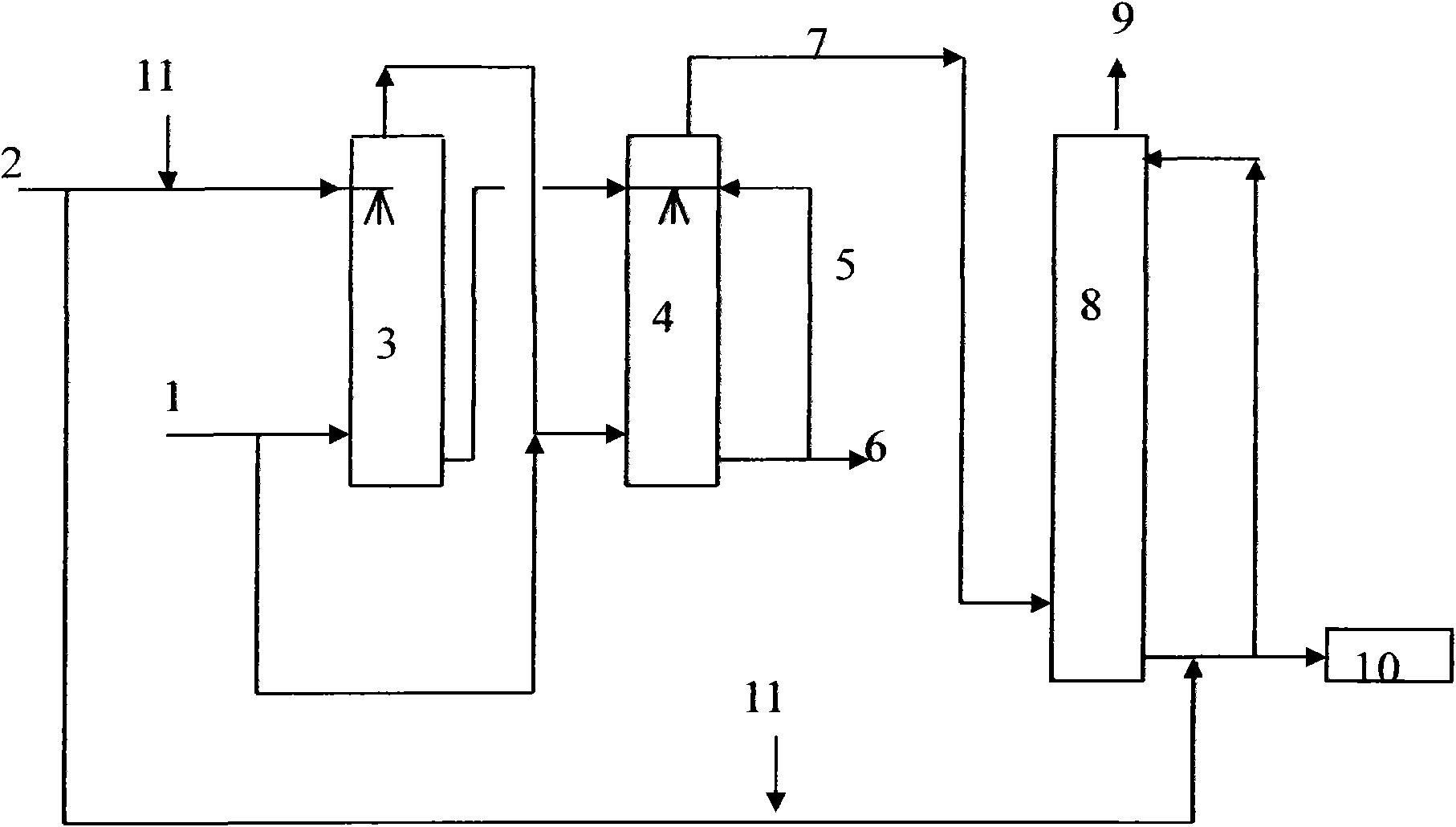

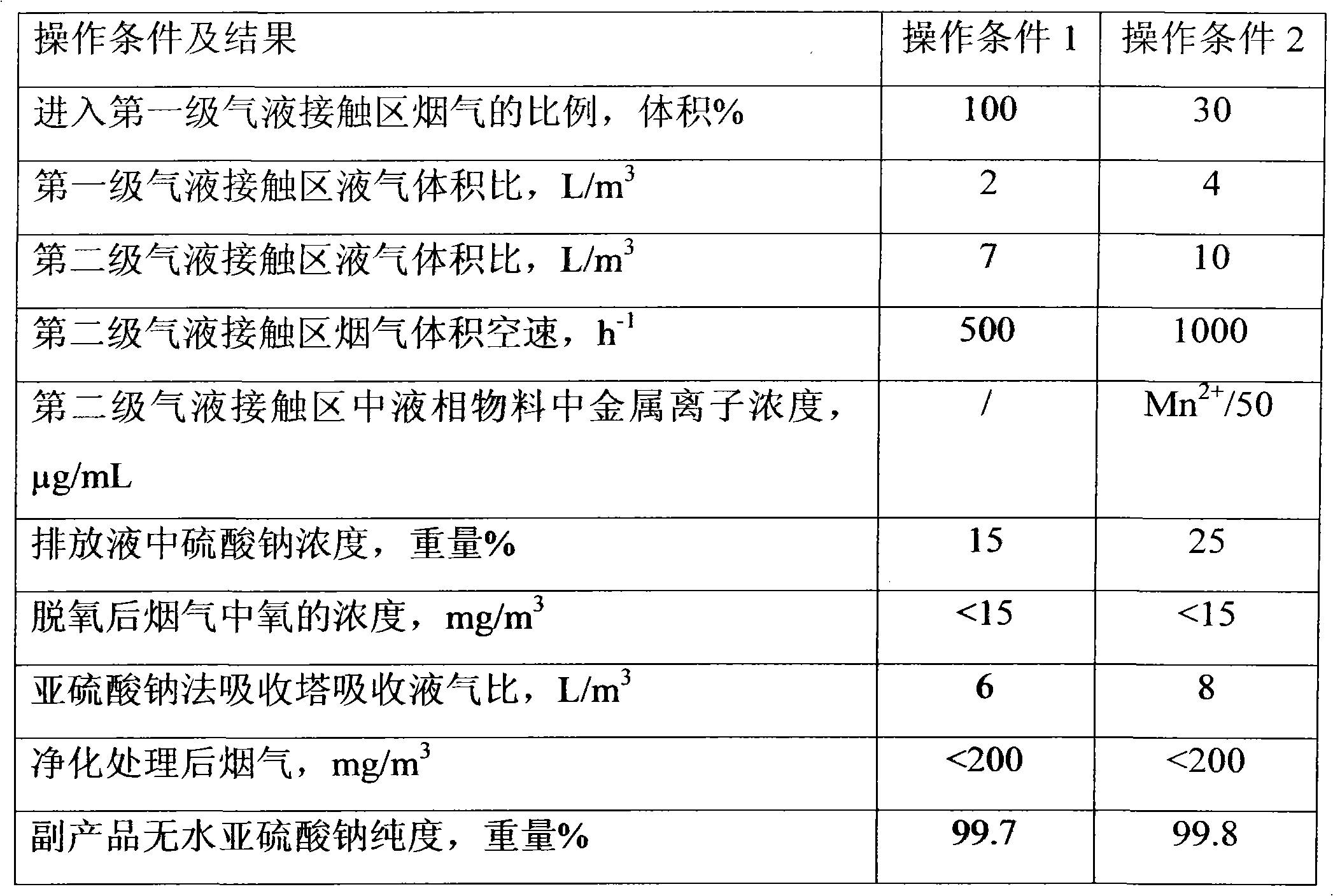

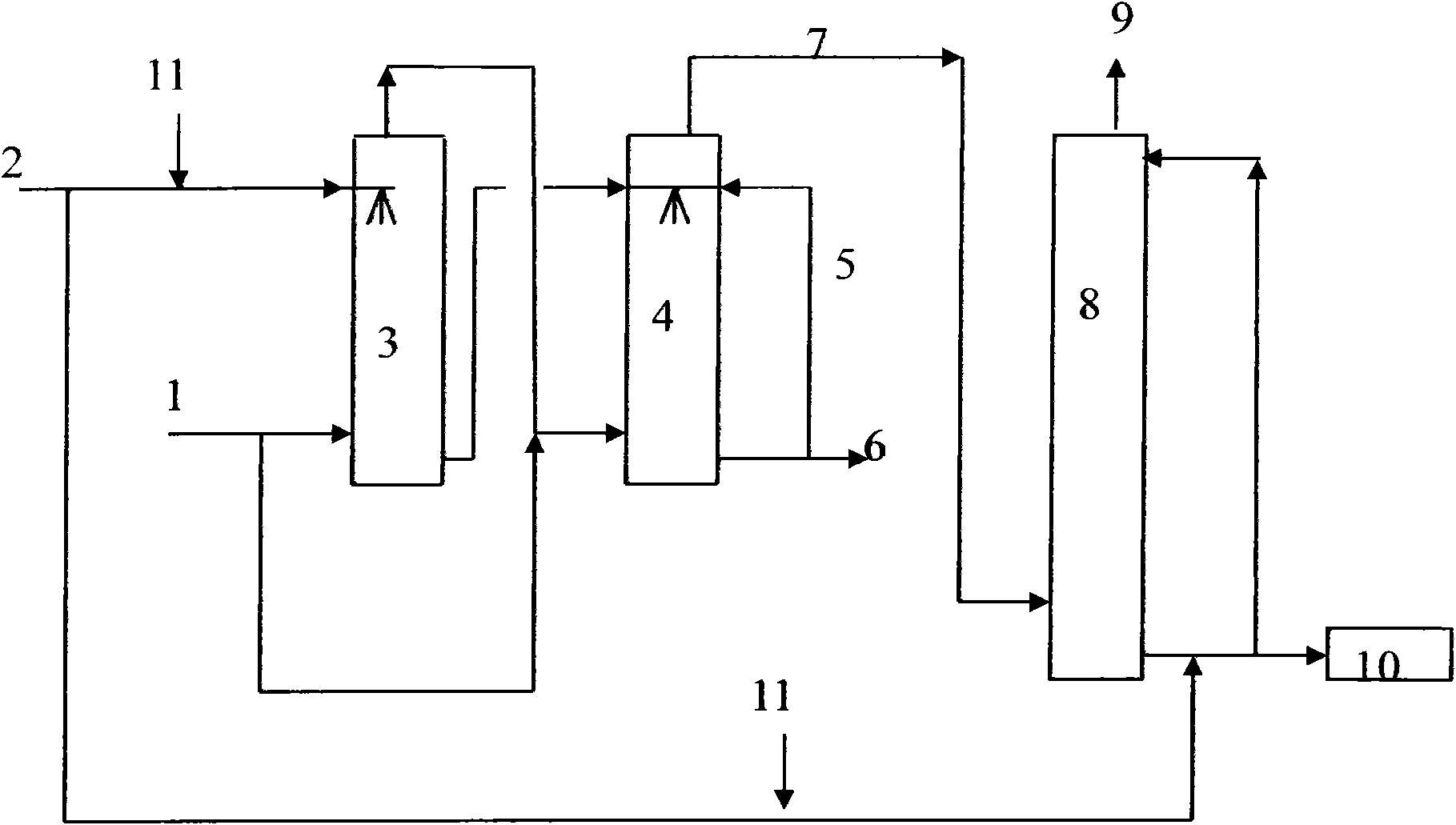

Method for desulfurizing high-concentration flue gas

ActiveCN102049186AIncrease valueLow recovery rateDispersed particle separationHigh concentrationSulfite salt

The invention discloses a method for desulfurizing high-concentration flue gas. The high-concentration flue gas is desulfurized through a sodium sulfite method, and meanwhile, the sodium sulfite is recovered as a by-product, wherein the flue gas needs to be deoxidized before being desulfurized through the sodium sulfite method. In the method for desulfurizing high-concentration flue gas disclosedby the invention, by deoxidizing the flue gas through an appropriate pretreatment process, the purity of the by-product sodium sulfite produced by the subsequent flue gas desulfurization process of the sodium sulfite method can be obviously improved, and the value of the by-product is improved, thereby obviously improving the comprehensive economic benefits. The pretreatment process of the flue gas is performed by using the sulfite and / or the hydrosulfite produced by the reaction of SO2 contained in the flue gas and alkali to react with oxygen without using any other deoxidizer. The method disclosed by the invention has simple production process and is easy to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

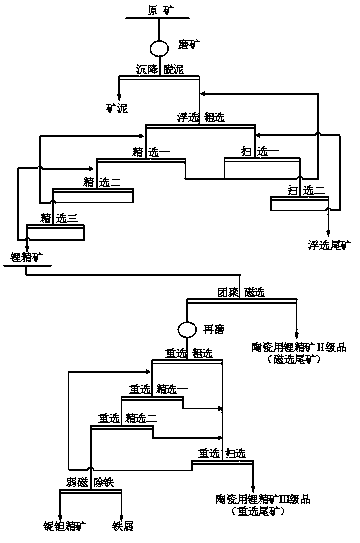

Comprehensive recovery process for lithium-containing polymetallic ore with associated fine-grained niobium-tantalum

InactiveCN103418488ASolve the problems of low recovery rate, single beneficiation products, and poor economic benefitsRaise the gradeFlotationMagnetic separationLithiumNiobium

The invention relates to a comprehensive recovery process for lithium-containing polymetallic ores with associated fine-grained niobium-tantalum. The process comprises the steps of raw ore crude grinding, settlement for desliming, flotation, agglomeration and magnetic separation, gravity separation and the like. The process provided by the invention is particularly applicable to the comprehensive recovery of lithium-containing polymetallic ores which contain a great amount of slime, are located in mining areas at low temperature all through the year, are low in grade of associated niobium-tantalum minerals and are fine in disseminated grain size, the process is advanced, reliable, simple, reasonable and highly targeted, the requirement on raw ore grinding fineness is not high, the regrinding amount is small, the operation cost is low, the comprehensive recovery rate is higher and the industrialization prospect is good.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

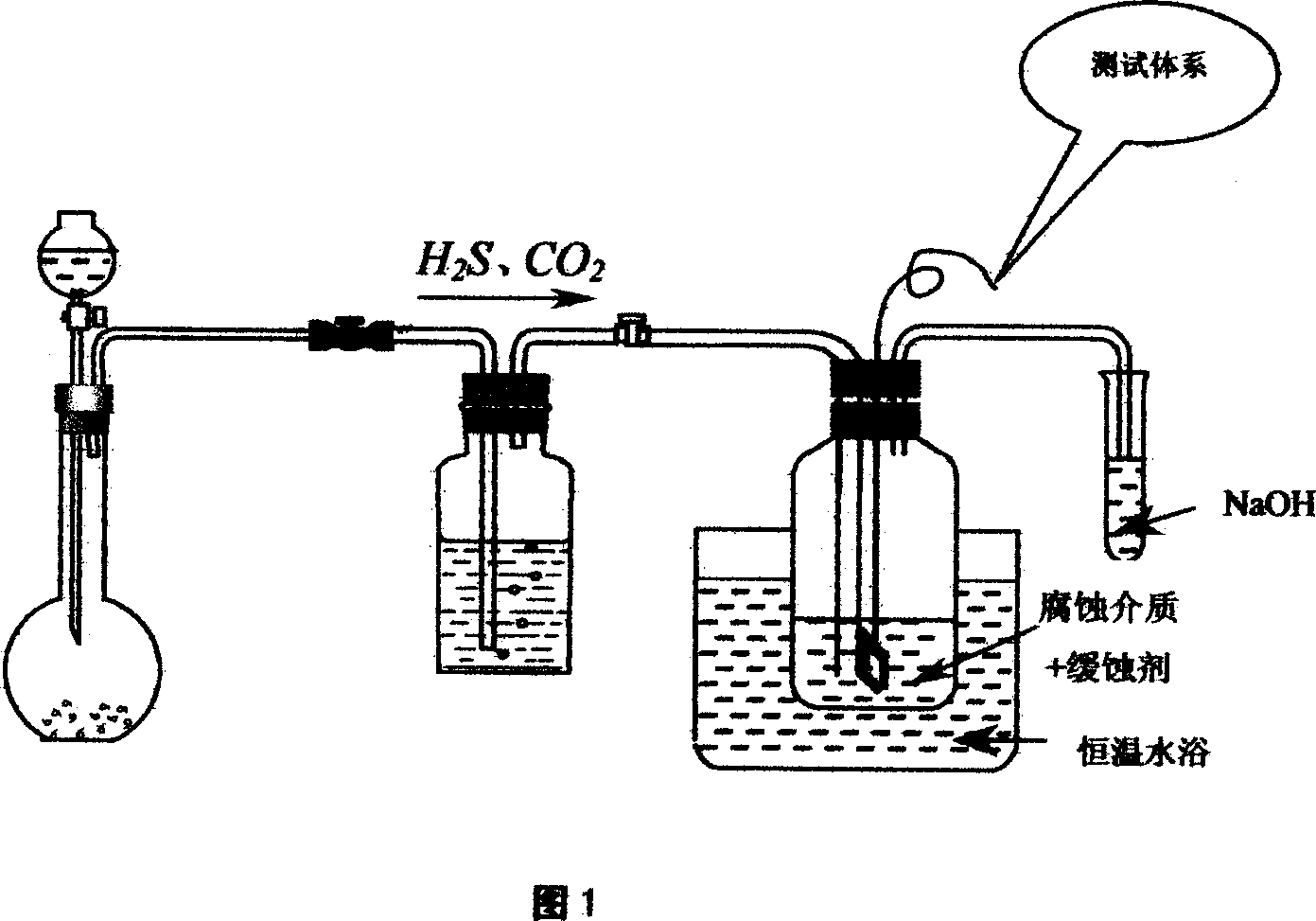

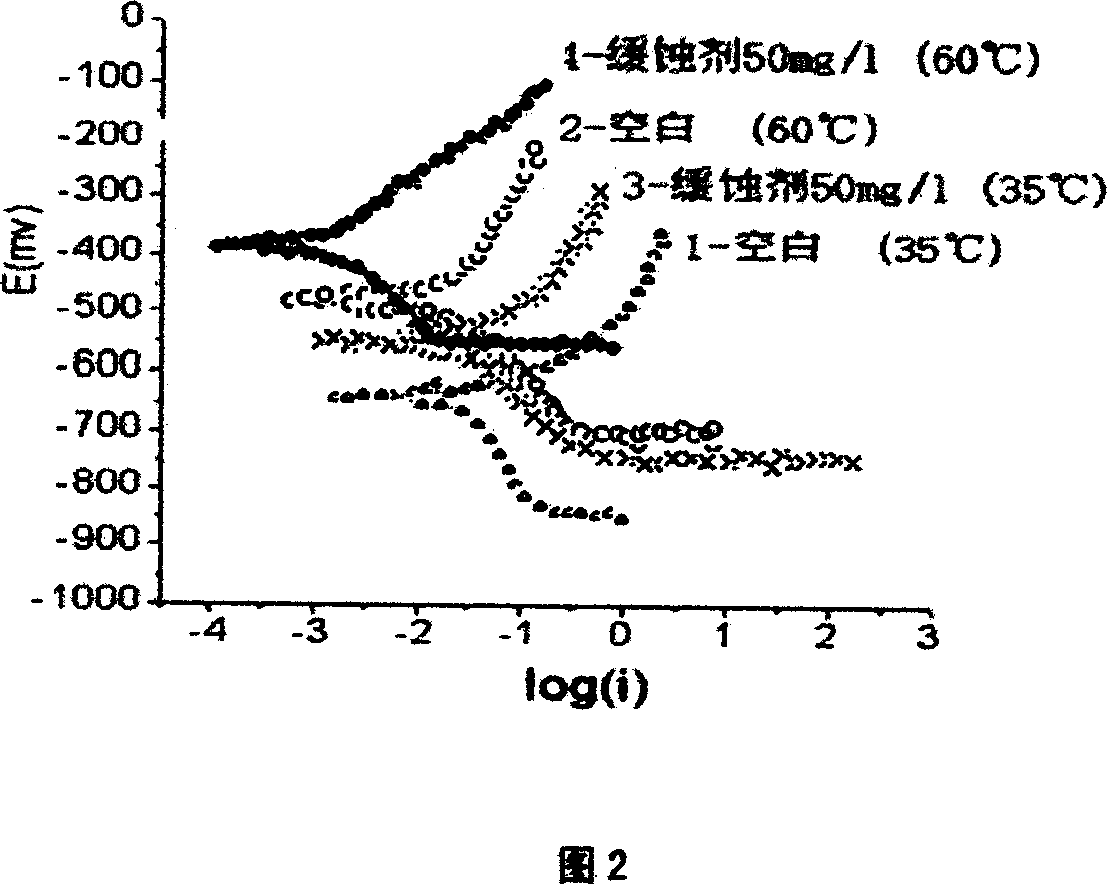

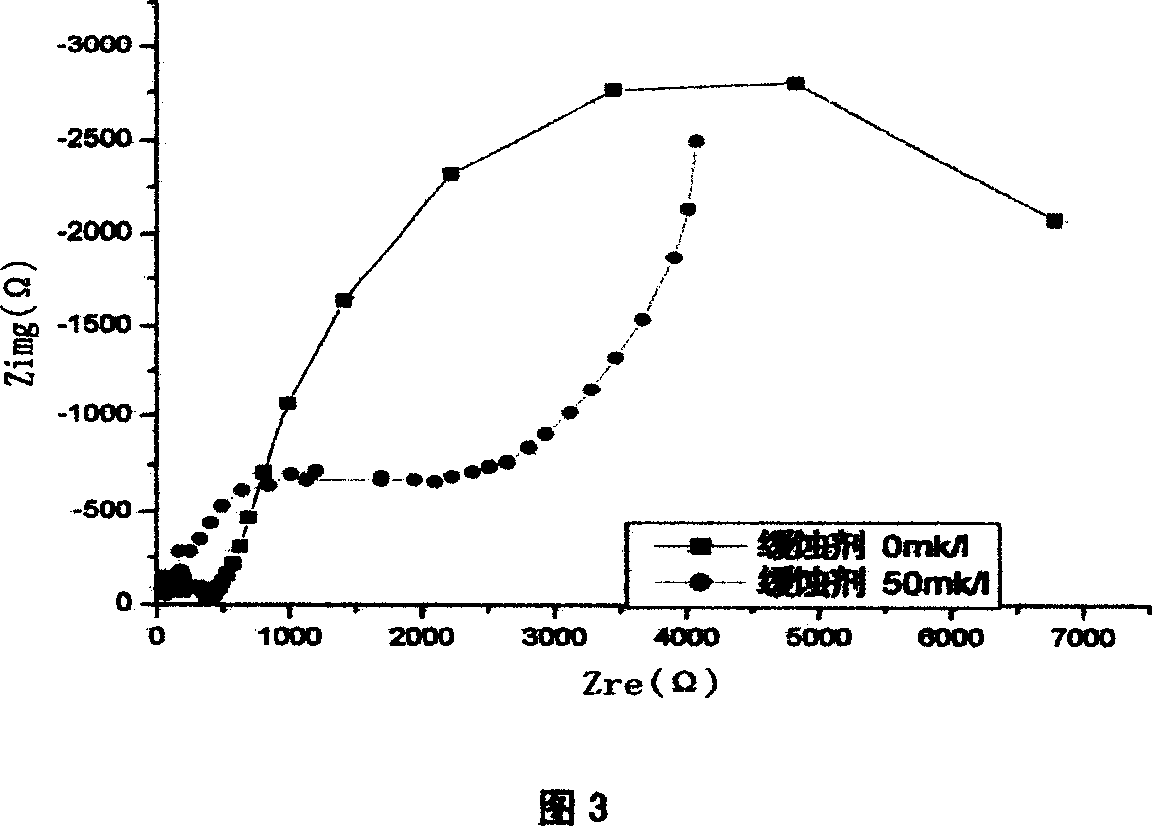

Corrosion inhibitor resistant to H2S and CO2

InactiveCN1966774ADoes not affect separation efficiencyGood corrosion inhibition effectBorehole/well accessoriesIsopropyl alcoholFatty alcohol

The invention relates the chemical engineering field, especially a H2 and CO2 inhibiter. H2 and CO2 are produced accompany to oil-gas field exploitation and transfusion process, and can corrode exploitation equipment. The inhibiter contains at least (by wt. %): isopropyl alcohol 10-30, fatty alcohol polyoxyethylene ether .1-0.5, and litol polyoxyethylene ether 0.1- 1.0. The inhibiter can be used in oil / water well with high temperature and pressure, and has the advantages of good corrosion resistance, low consumption, low cost and high efficiency.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

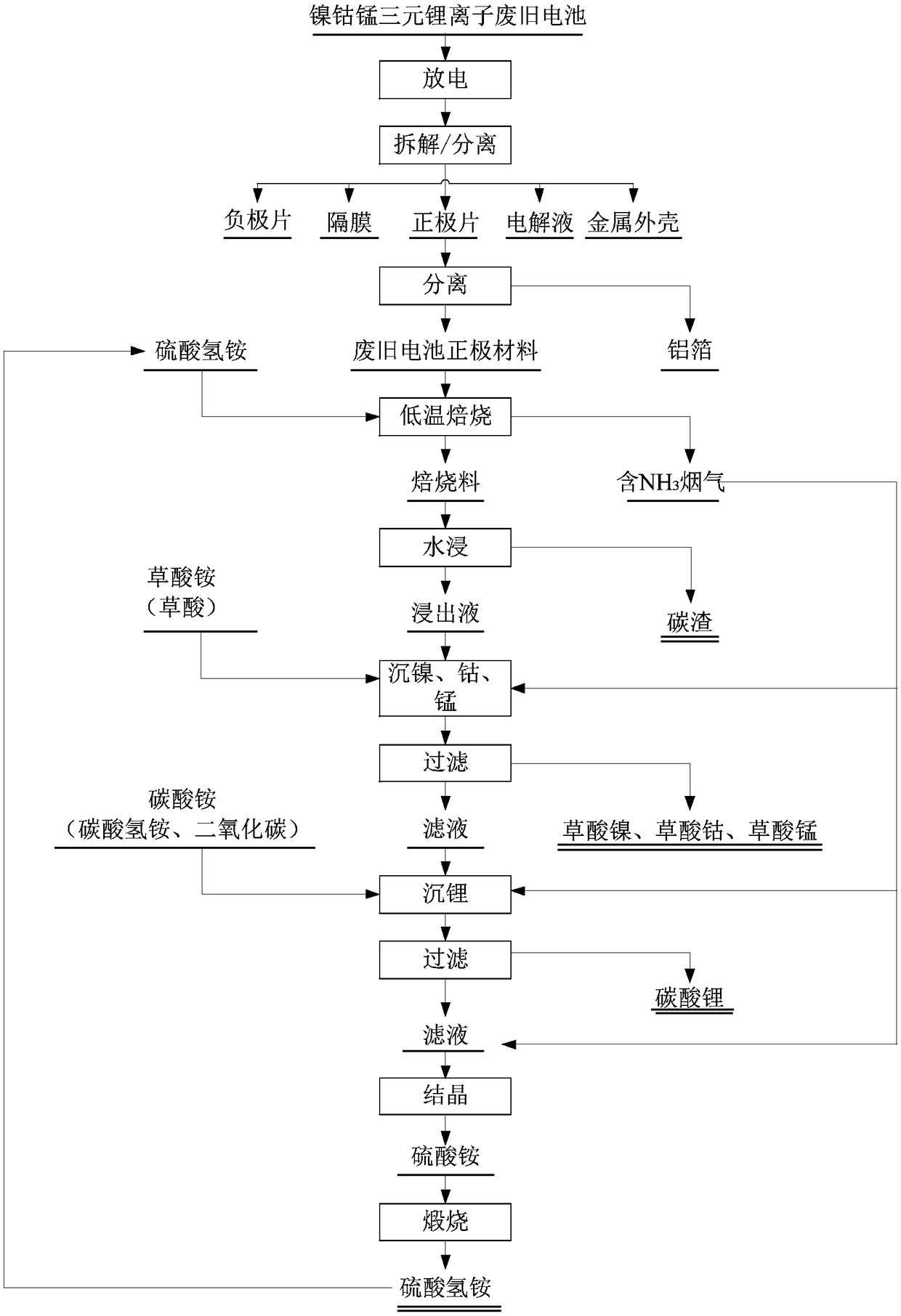

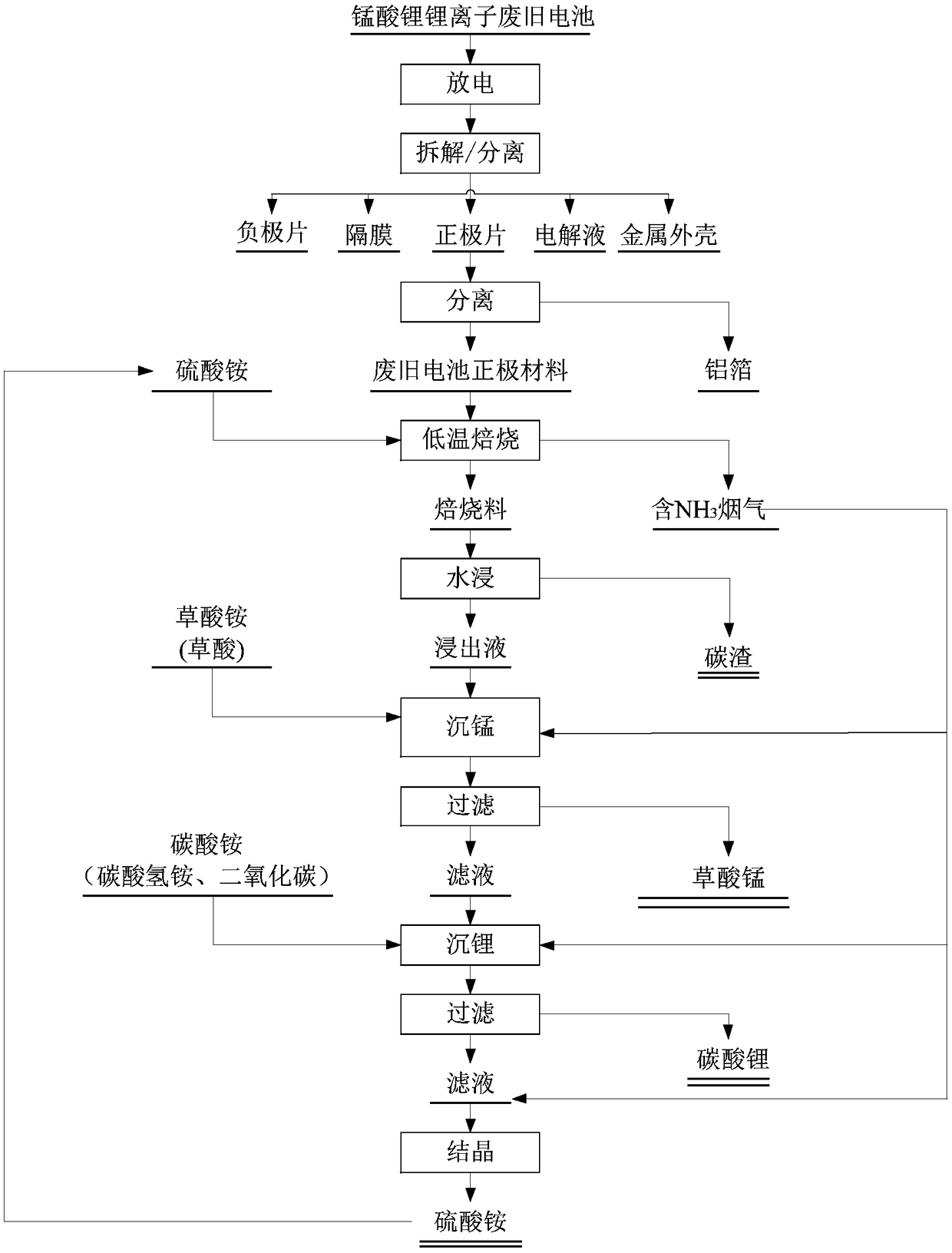

Method for recovering valuable metals from positive electrode material of waste lithium ion battery

ActiveCN108767354AHigh recovery rateAvoid it happening againWaste accumulators reclaimingProcess efficiency improvementLithium-ion batteryMaterials science

The invention provides a simple, efficient and environment-friendly method for recovering valuable metals from a positive electrode material of a waste lithium ion battery; the method comprises the following steps of performing discharging of a salt solution; performing disassembling to separate a positive plate; performing smashing on the positive plate to separate a positive electrode material and an aluminum foil; performing mixed low-temperature roasting on the positive electrode material and a roasting agent ammonium sulfate and / or ammonium bisulfate; performing leaching on the roasted material and separating to obtain carbon and a lixivium; adding a precipitant into the lixivium, and regulating the pH value by using NH<3>-containing flue gas, performing deposition on other metals except Li, and carrying out solid-liquid separation; regulating the pH value of a filtrate by using the NH3-containing flue gas, adding ammonium carbonate or ammonium bicarbonate or pumping CO<2> gas, and carrying out lithium precipitation to obtain a lithium carbonate product. The preparation process is simple, the process conditions are mild, the time required by the process is short, a large amount of acid and alkali do not need to be consumed, and the cost is low; and in addition, recovery of the valuable metals and carbon from the positive electrode material can be effectively realized, themethod is green and environment-friendly, and a large amount of solid waste and wastewater cannot be generated.

Owner:CENT SOUTH UNIV

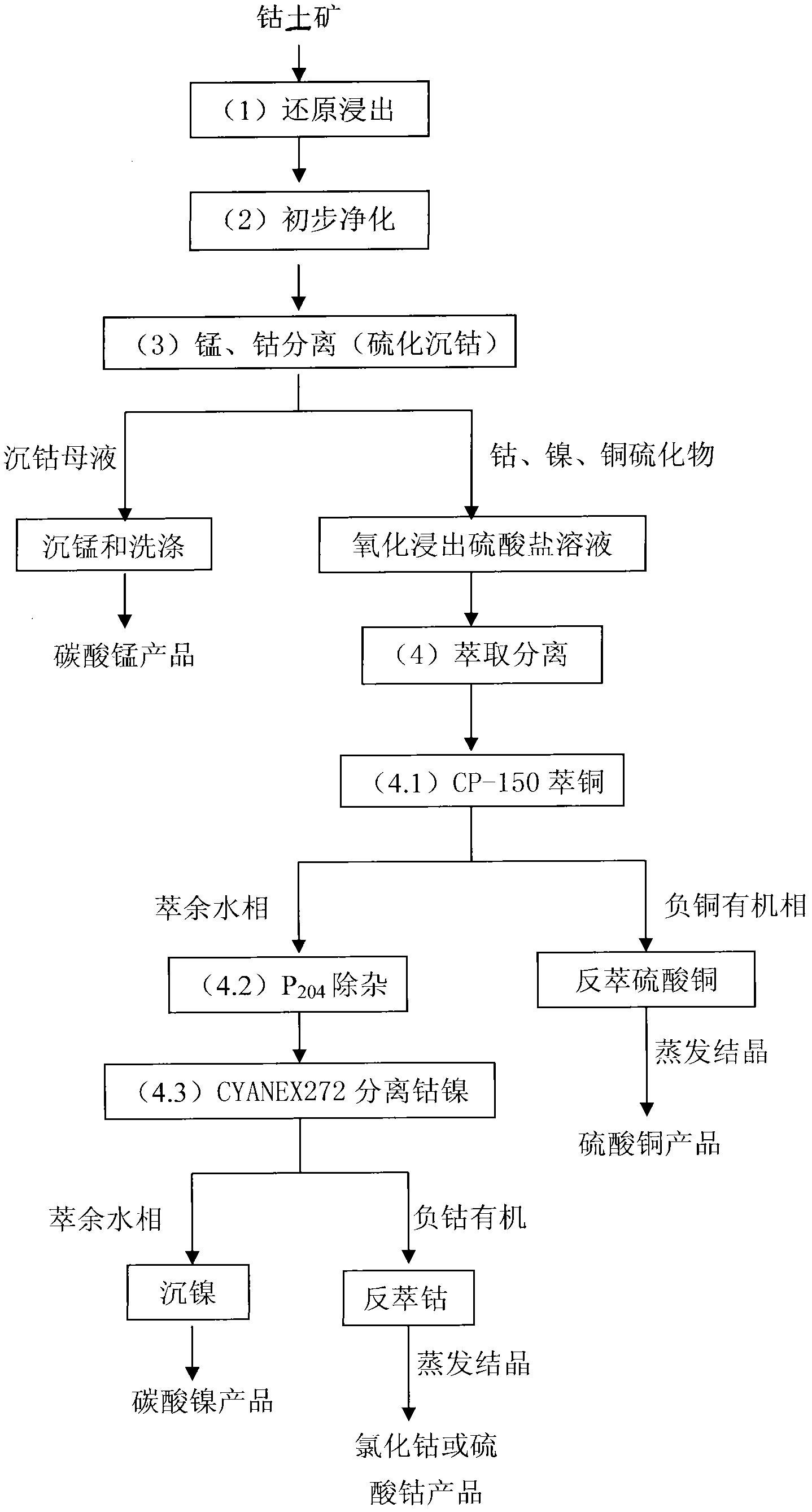

Processing method for comprehensively recovering high manganese asbolite

InactiveCN102021331AIncrease costLow recovery rateProcess efficiency improvementManganeseHydrometallurgy

The invention discloses a processing method for comprehensively recovering high manganese asbolite, belonging to the field of hydrometallurgy. In the processing method, the high manganese asbolite is processed through four processing steps comprising (1) reduction leaching, (2) primary cleaning, (3) manganese and cobalt separation and (4) extraction separation to obtain a product manganese carbonate, copper sulfate, nickel carbonate or cobaltous sulfate. The processing method has the advantages that the source of raw materials is wide, the process and equipment are simple, the operation is stable, the energy consumption is low, the production cost is low, the practicability is wide, and the economic effect and the society effect are obvious.

Owner:HAINAN ZHONGDAO ENERGY DEV

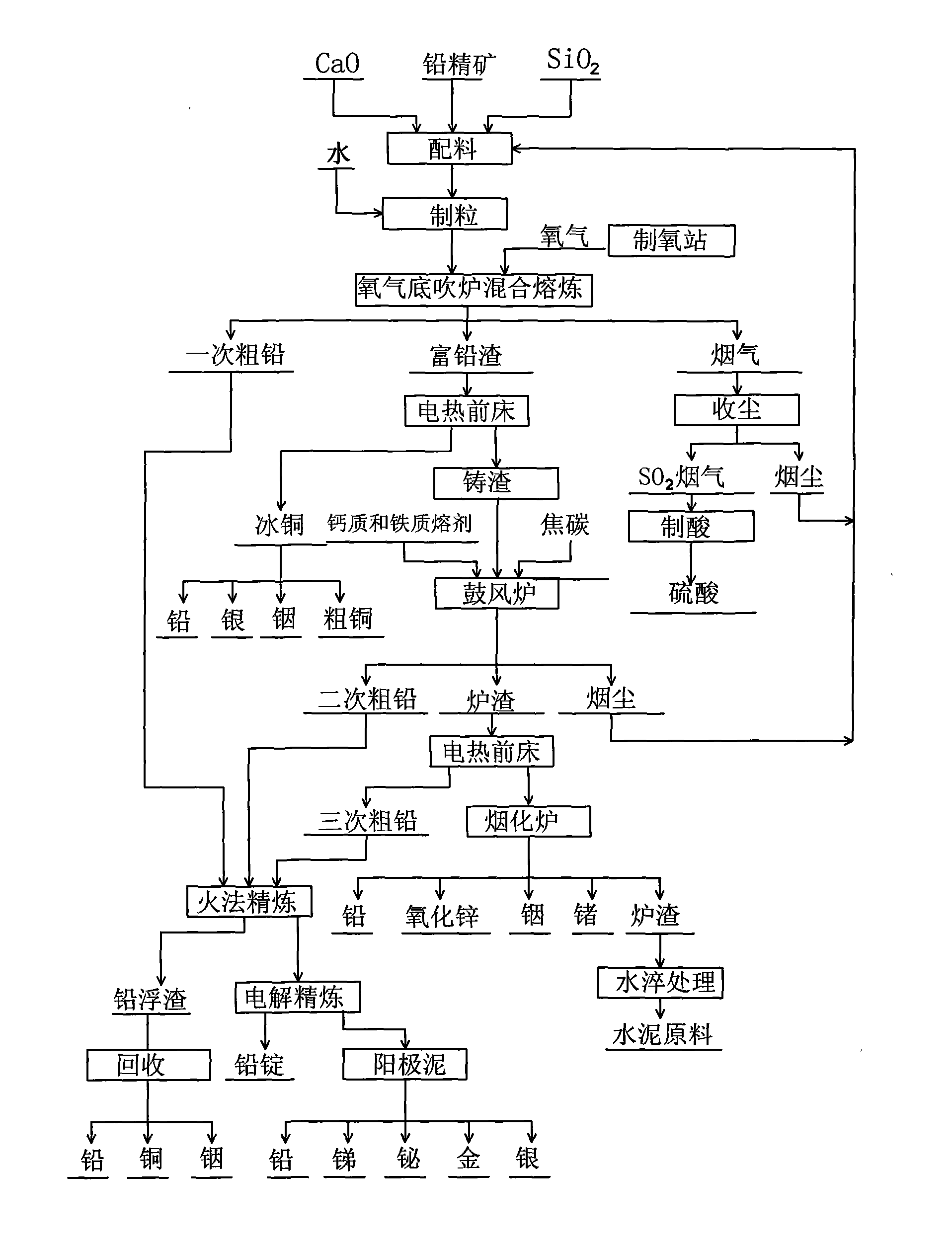

Balancing lead smelting process for comprehensive resource utilization and device thereof

InactiveCN101514399AHigh melting temperaturePromote oxidation reactionPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention relates to a balancing lead smelting process for comprehensive resource utilization and a device thereof. The process comprises the following steps: granulating a raw material containing lead and a fluxing agent after proportioning, sending to an oxygen bottom-blown smelting furnace for smelting to produce primary crude lead, lead ash and flue gas of SO2; sending the flue gas of SO2 to a sulfuric acid system for acid making after recovering waste heat by a waste heat boiler and duct collection by a dust arrester installation; adjusting form of the lead ash and adding the lead ash to a blast furnace together with coking coal for reducing smelting to produce secondary and third crude lead; electrorefining the crude lead to obtain refined lead and anode slime, treating and recovering the anode slime to obtain lead, stibium, bismuth, gold and silver metals; and separating slag of the blast furnace from the crude lead and sending to a fuming furnace to recover zinc oxide, the lead, indium and germanium. A system for realizing the process comprises the oxygen bottom-blown smelting furnace, an oxygen lance, an electrically-heated settler, a slag casting device, the waste heat boiler with a vertical ascending segment of membrane wall structure, the blast furnace, the fuming furnace and a ventilating device. The process design and system improvement help realize balancing optimized recovery of Pb, Zn, Au, Ag, Bi, Cu, In, Sb and S elements.

Owner:CHENZHOU YUTENG CHEM IND

Method for recovering vanadium and tungsten from tungsten containing vanadium-titanium based waste denitration catalyst

ActiveCN103436704ALow recovery rateReduce energy consumptionProcess efficiency improvementNonferrous metalAmmonium metavanadate

The invention relates to a method for recovering nonferrous metals from a waste denitration catalyst, and specifically relates to a method for recovering vanadium and tungsten from a tungsten containing vanadium-titanium based waste denitration catalyst. The method mainly comprises the following steps: crushing and grinding the catalyst, adding hydrogen peroxide to enable part of vanadium oxide to form pervanadic acid, and filtering to obtain a filter cake and a filtrate containing pervanadic acid; after heating the filtrate, filtering again to obtain V2O5, and mixing and circulating to use a novel filtrate and hydrogen peroxide; adding alkali liquor to the filter cake, stirring and heating, leaching the residual vanadium in form of metavanadate and leaching tungsten in form of metatungstate; filtering to obtain mixed liquor of metavanadate and metatungstate; adding ammonium salt into the mixed liquor to separate out ammonium metavanadate precipitate, further filtering to obtain an ammonium metavanadate filter cake and a third filtrate, and adding a concentrated acid into the third filtrate to separate out tungstic acid precipitate. The method and process provided by the invention are simple, and when metavanadate and tungstic acid are leached, calcination is avoided, so that the energy consumption is low, the solid-liquid reaction is good in contact, and the recovery rates of vanadium and tungsten are high.

Owner:BEIJING UNIV OF CHEM TECH

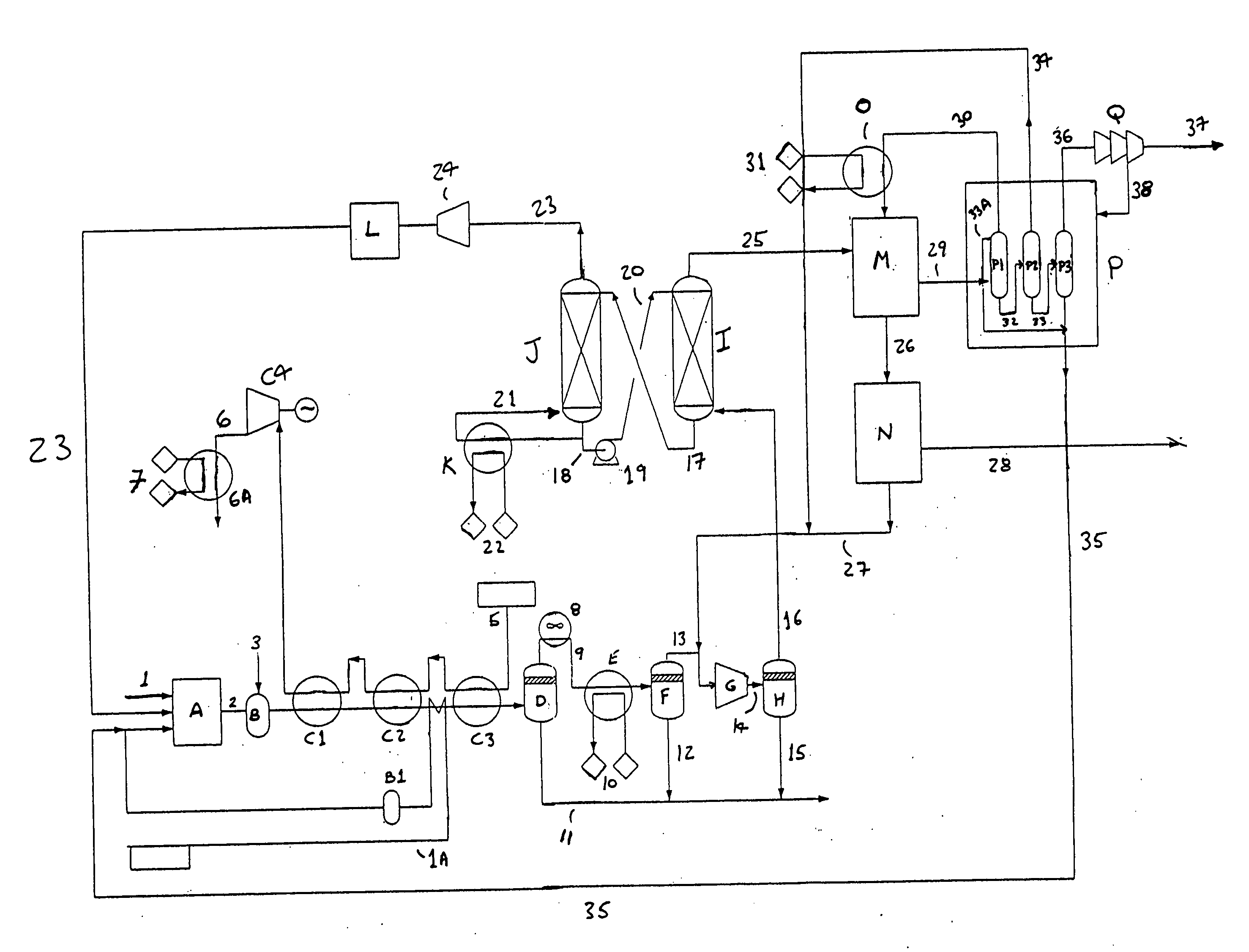

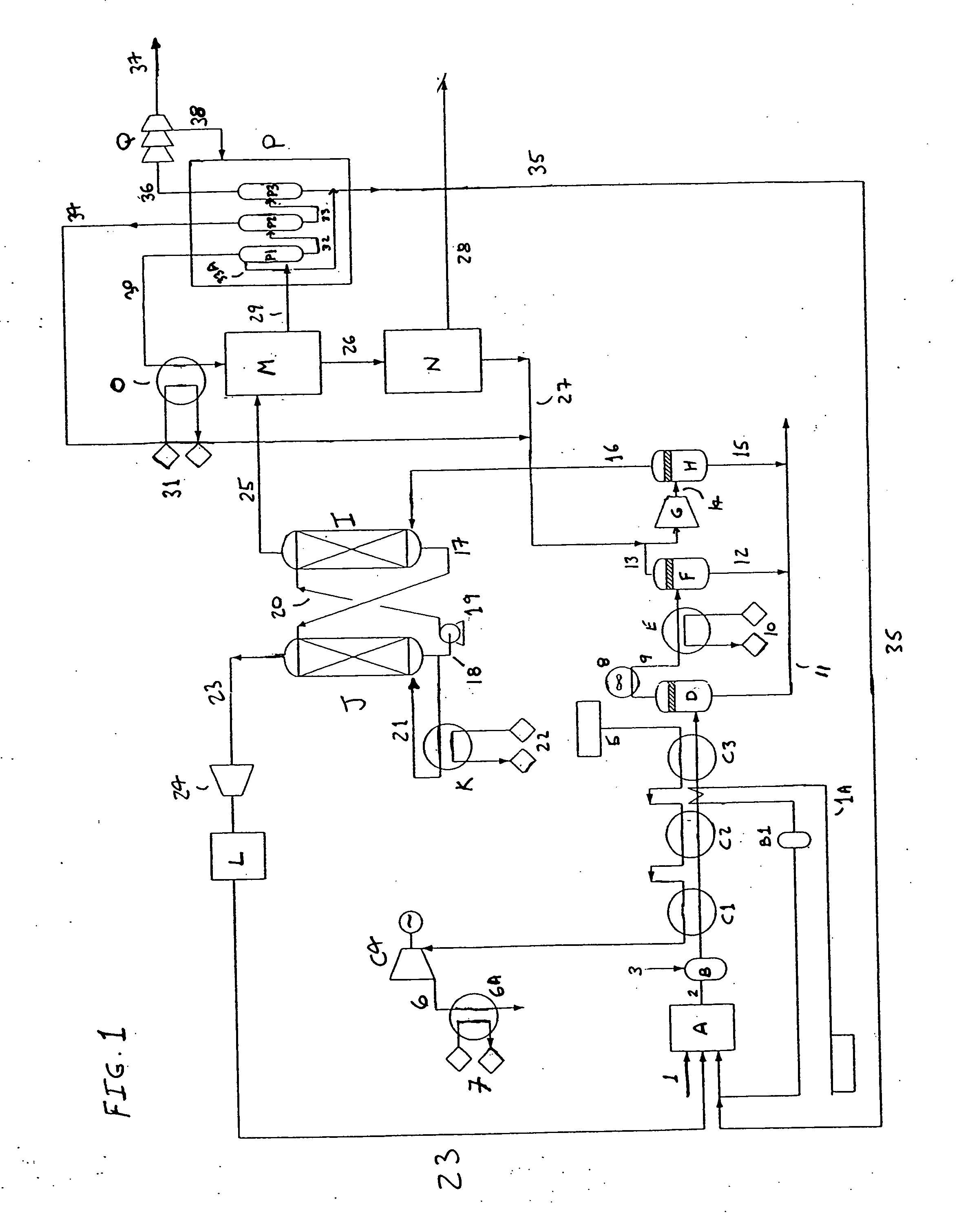

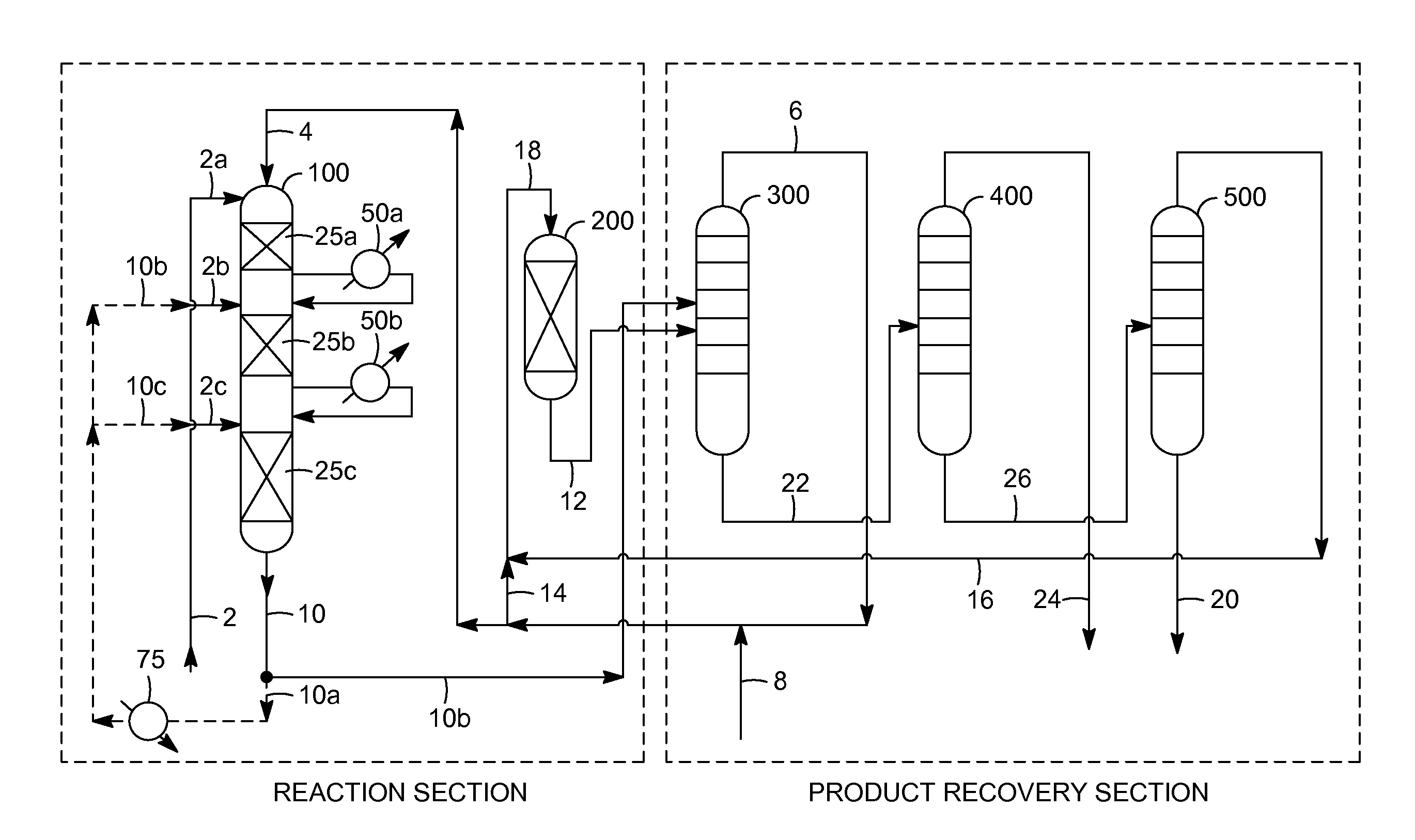

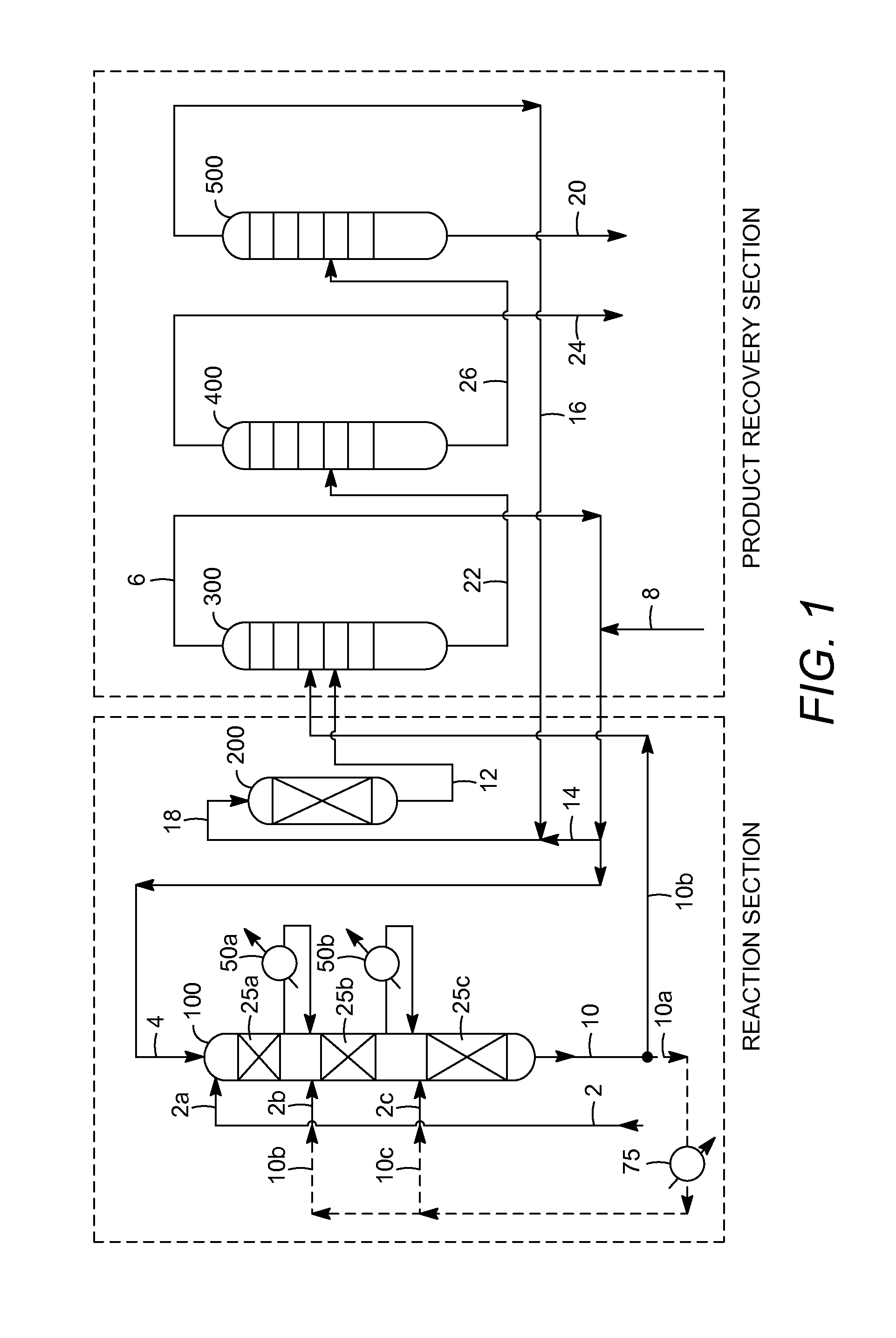

High recovery carbon monoxide production process

The present invention provides for a monolith reactor process for the production of syngas from hydrocarbon and oxygen feeds. The syngas is cooled and separated to produce carbon monoxide and hydrogen, and the purification equipment utilized in this separation process recycles tail gas and fuel gas to the syngas feed gas line and recycles methane from the carbon monoxide separation system for feed back to the monolith reactor. This process results in almost complete carbon to carbon monoxide conversion and very high carbon monoxide and hydrogen recoveries.

Owner:THE BOC GRP INC

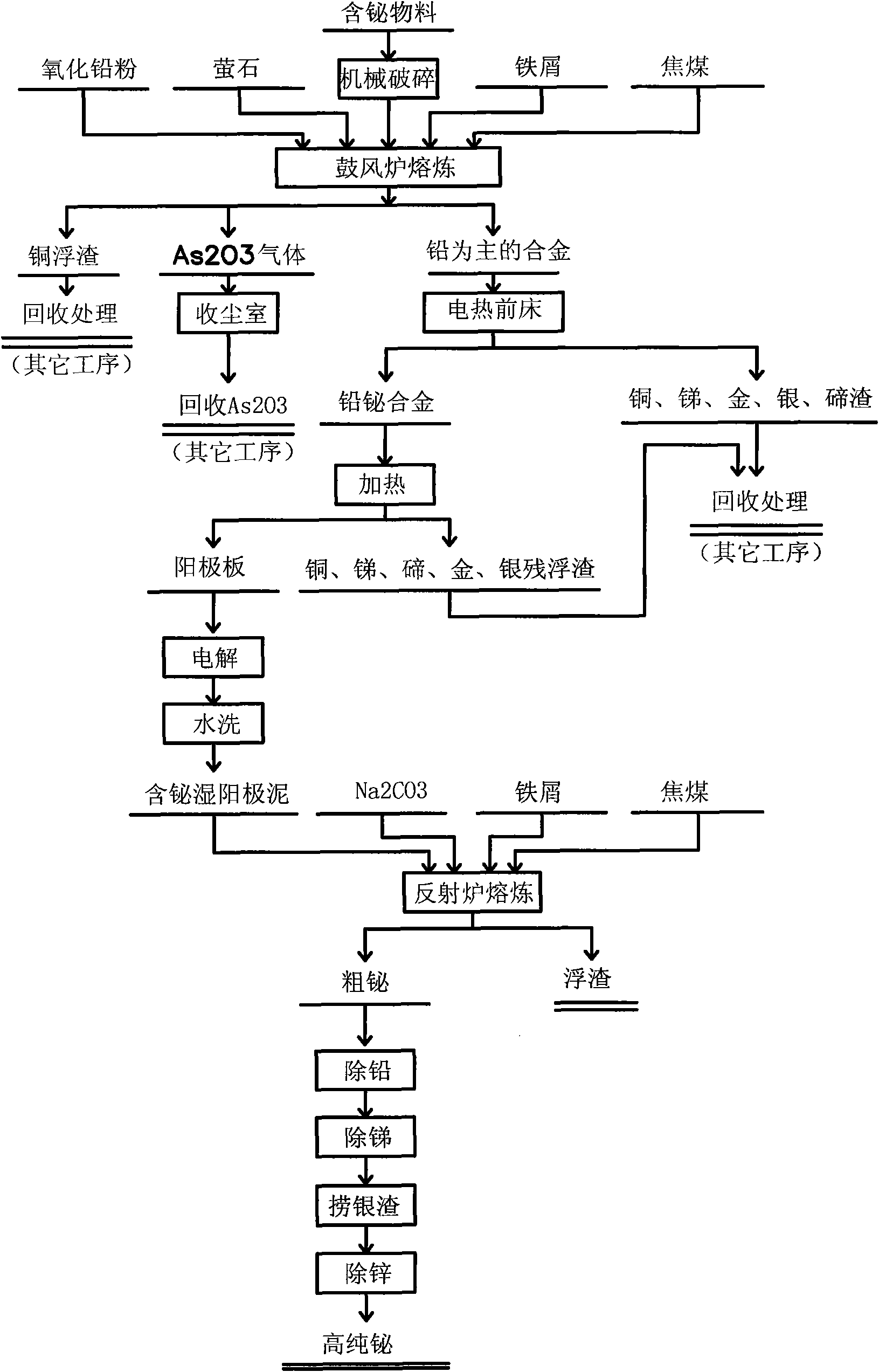

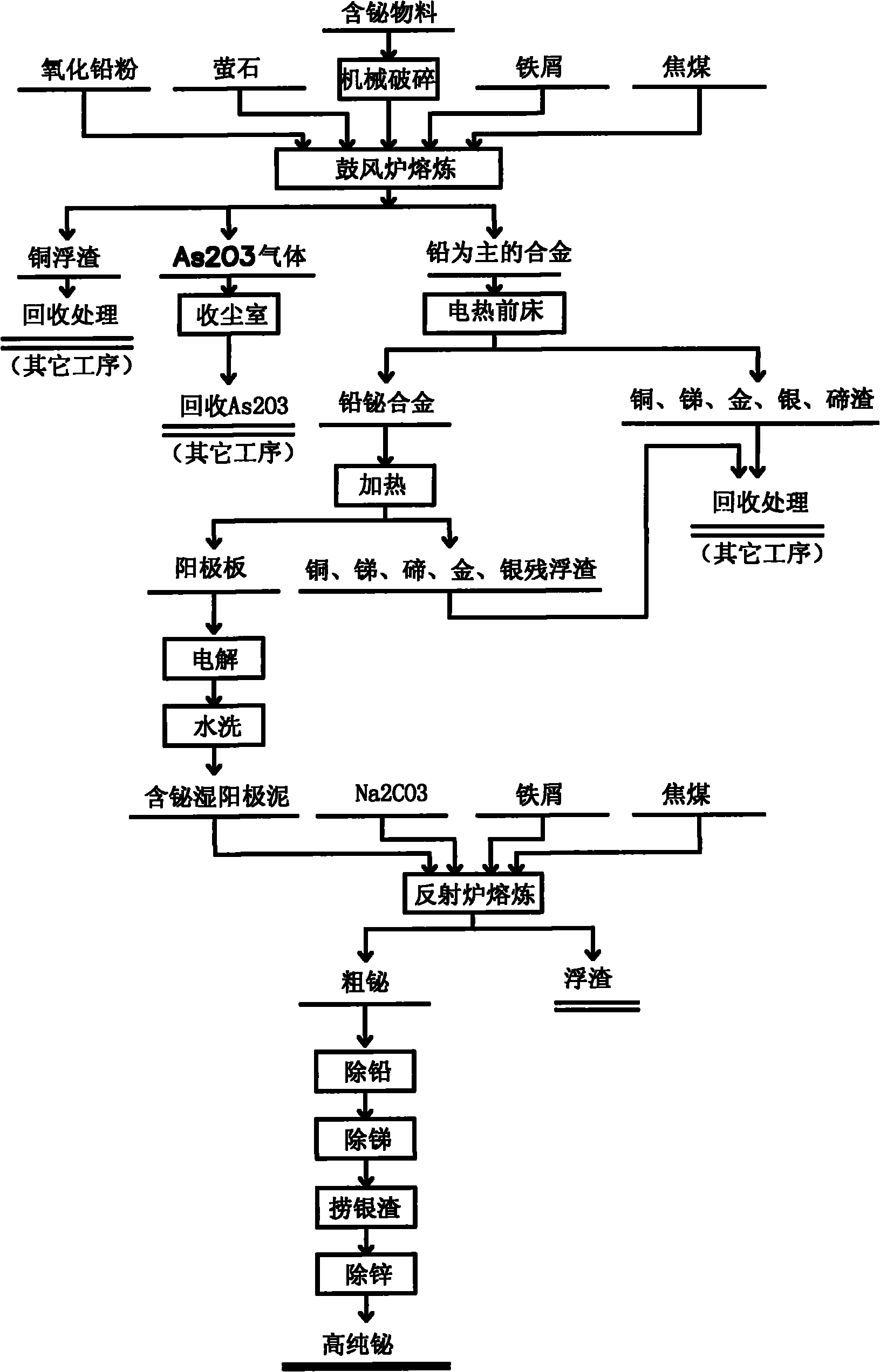

Process for refining high-purity bismuth from bismuth-containing material generated from anode mud recovery

ActiveCN101886174AReduction of Bismuth Content RequirementsExpand sourcePhotography auxillary processesProcess efficiency improvementTemperature controlBismuth

The invention relates to a process for refining high-purity bismuth from bismuth-containing materials generated from anode mud recovery, belonging to the technical field of processes of recovering smelting bismuth by combining a wet process and a pyrogenic process of non-ferrous metal. The process comprises the following steps of: firstly increasing the content of bismuth contained in the bismuth-containing materials to obtain crude bismuth by adopting an enrichment process; and then further refining and purifying the crude bismuth into the high-purity bismuth by adopting a selective accurate temperature-control smelting method according to different melting points of compounds between bismuth metal and impurity-containing metal. Compared with the prior art, the invention reduces the requirements for the content of the bismuth contained in raw materials and can realize the economic and high-efficiency recovery of the bismuth metal, refine the high-purity bismuth and reduce the environmental pollution.

Owner:郴州雄风环保科技有限公司

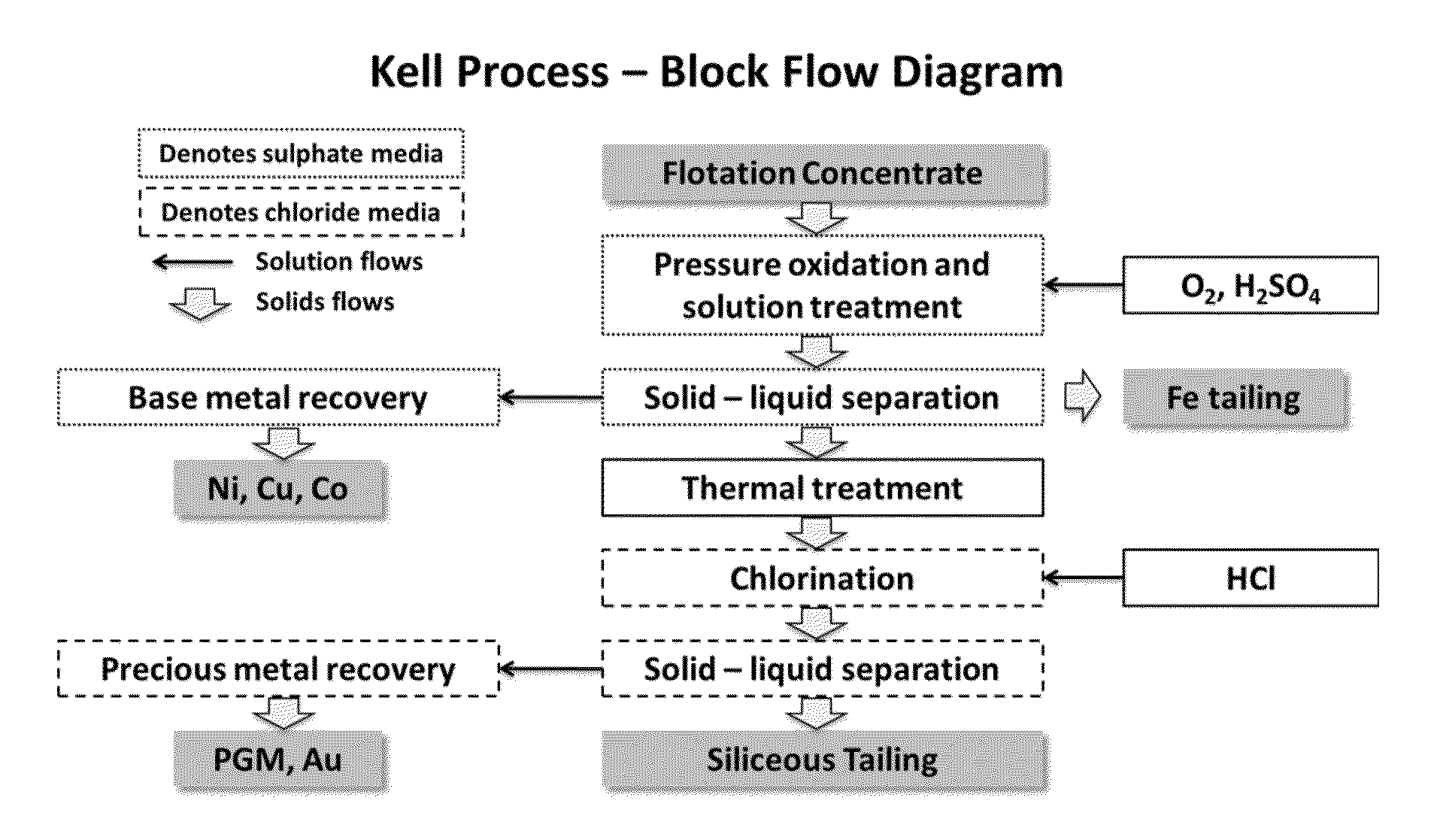

Treatment process for extraction of precious, base and rare elements

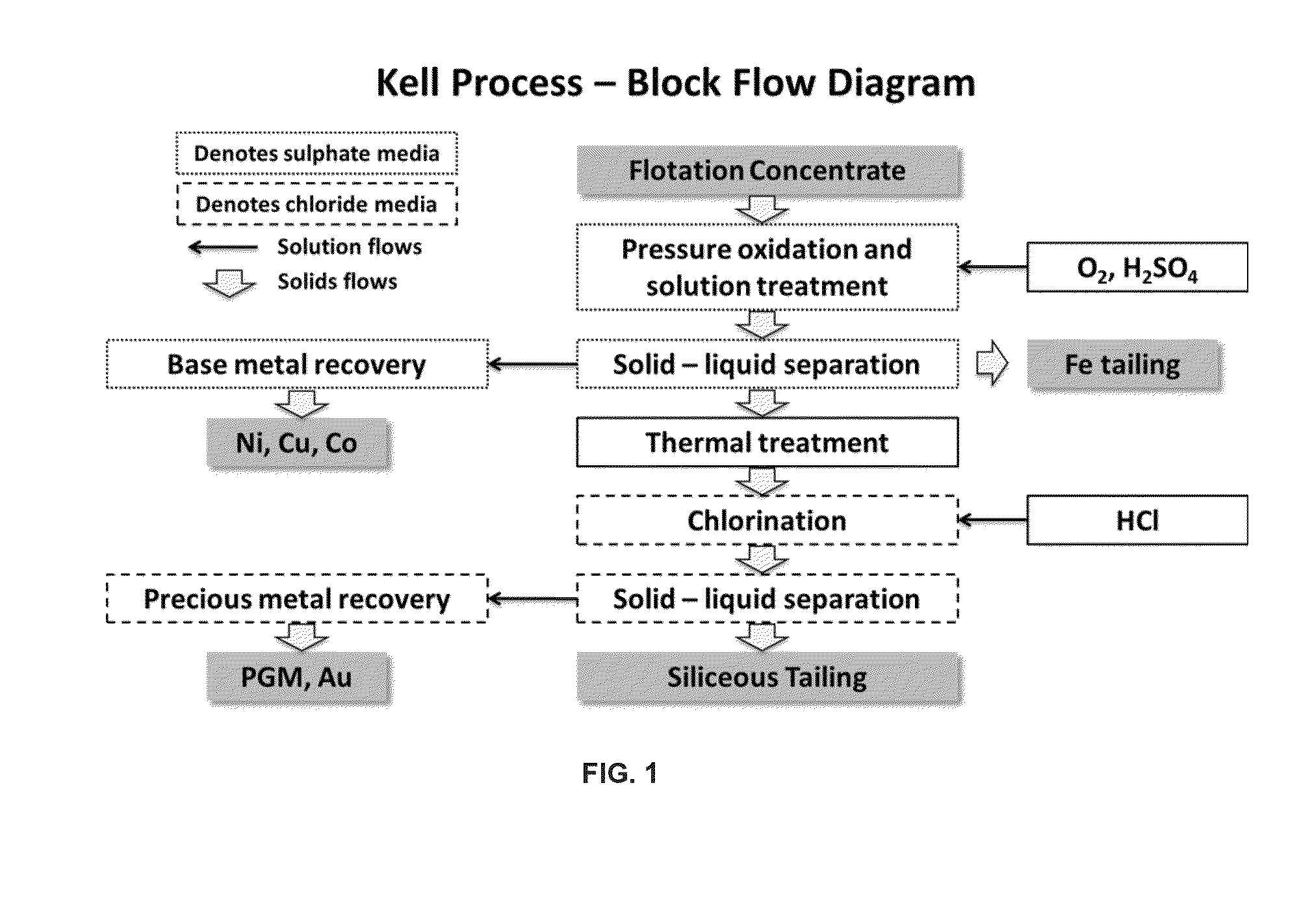

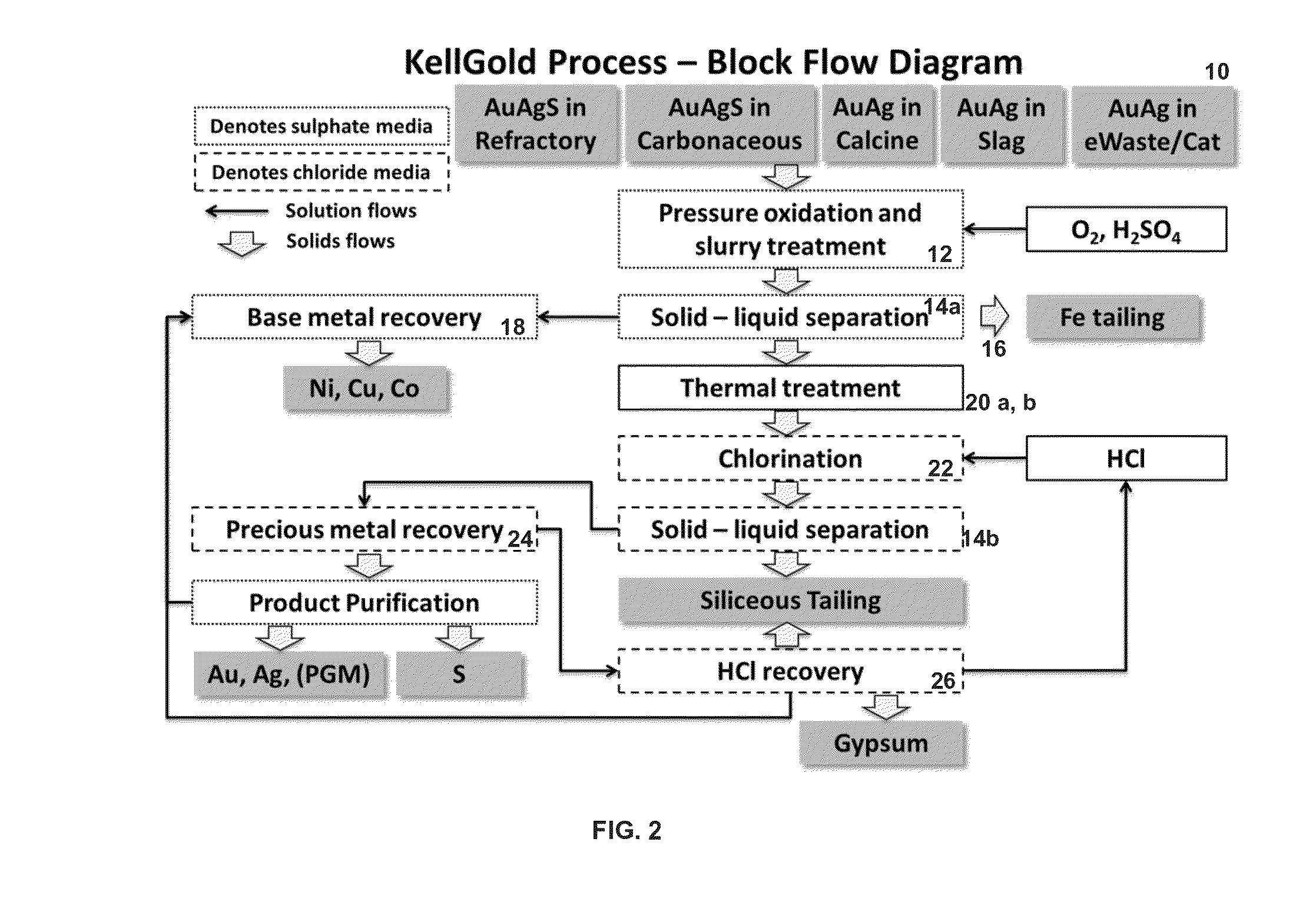

ActiveUS20160145714A1Low recovery ratePolycrystalline material growthChlorine/hydrogen-chloride purificationTrace elementRefractory

This invention describes a hydrometallurgical process for the recovery and separation of valuable elements, in particular gold and silver, from a feed material comprising a refractory, intractable or otherwise poorly responding to conventional treatment routes ores, concentrates and other materials. In particular, the process is a process integrated into one or more existing value element extraction processes.

Owner:LIFEZONE

Emulsifying liquid wastewater membrane treatment process

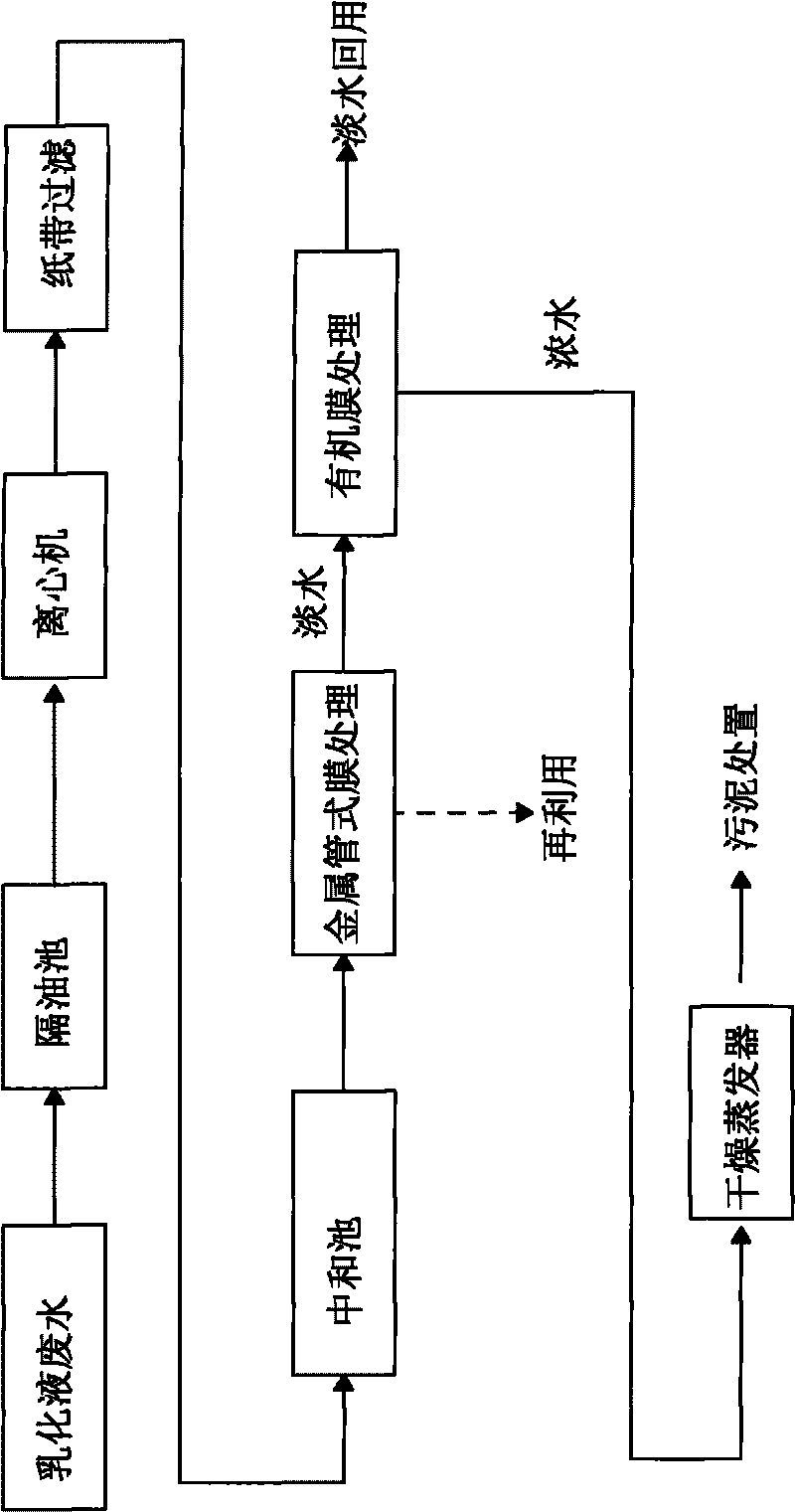

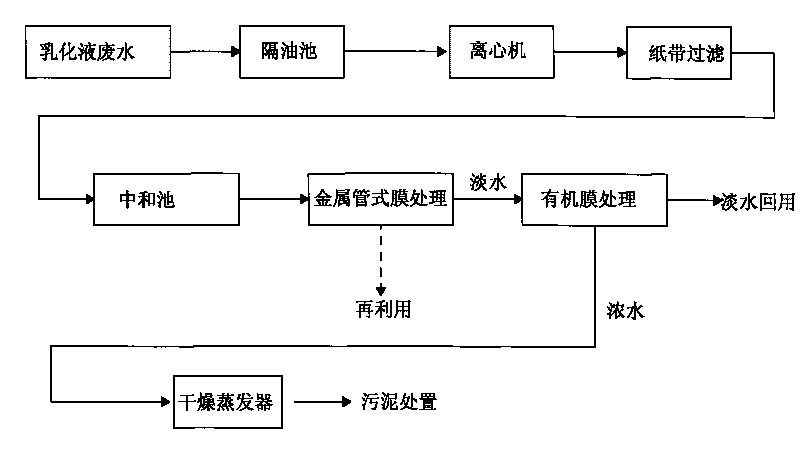

InactiveCN101708912AEfficient treatment processEasy to operateWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesUltrafiltrationChemistry

The invention discloses an emulsifying liquid wastewater membrane treatment process. The process comprises the steps of pretreatment, metal tube type membrane ultrafiltration and organic membrane pretreatment. The process has the advantages that the problem that the current emulsifying liquid wastewater treatment has high cost, complex operation, low treatment efficiency and poor comprehensive recycling effect can be effectively solved so that the oil content of the treated emulsifying liquid wastewater is 10mg / l or less, the suspended substance (SS) content is 30mg / l or less and the chemical oxygen demand (CODcr) is 100mg / l or less, the problem that the emulsifying liquid wastewater is treated and discharged according to the related standard or is reused is fully solved; and the comprehensive utilization of the emulsifying oil is realized, the treatment process is efficiency and energy-saving, is easy to operate and use, the environmental pollution is reduced, the cost is low, and the process has great economic and social benefits.

Owner:苏州凯新分离科技有限公司

Drilling, completing and stimulating a hydrocarbon production well

ActiveUS20080236809A1Easy to moveLow recovery rateInsulationFluid removalWell drillingFilling materials

An apparatus and method for drilling a well in a heavy oil or bitumen reservoir for in situ recovery of heavy oil and bitumen is provided. More particularly, an apparatus and method for drilling, completing and / or stimulating a heavy oil or bitumen well in a heavy oil or bitumen reservoir is provided, comprising: providing a concentric drill string having an inner tube and an outer tube defining an annulus therebetween, the outer tube further having a plurality of slots sealed with a temporary filler material; drilling a borehole into the reservoir using a drilling member connected at the lower end of the concentric drill string and delivering drilling medium through one of the annulus or inner tube and extracting the exhaust drilling medium through the other of the annulus or inner tube; leaving the concentric drill string in the well after drilling of the borehole is completed; and removing the temporary filler material to expose the plurality of slots in the outer tube and form a slotted liner.

Owner:J I LIVINGSTONE ENTERPRISES

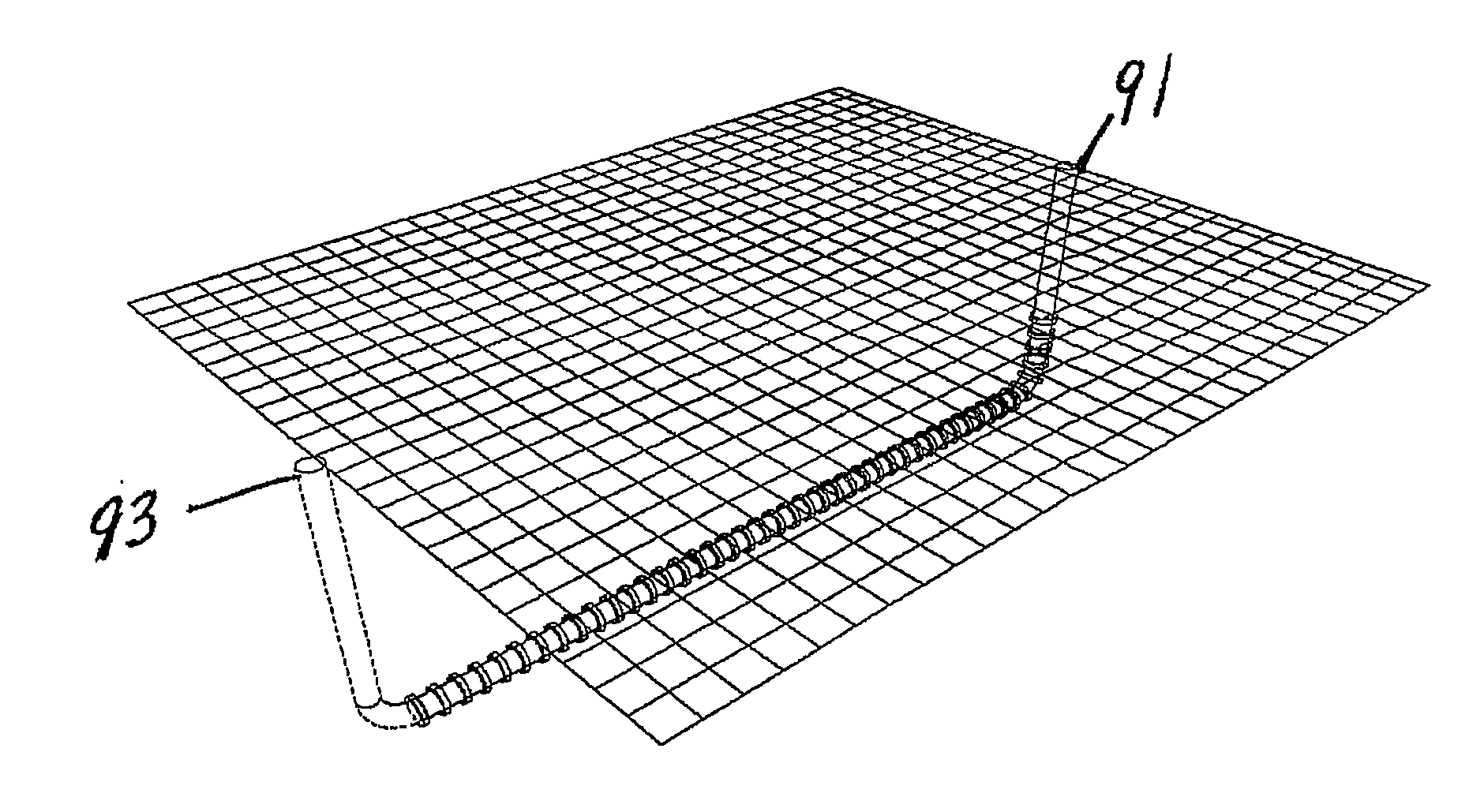

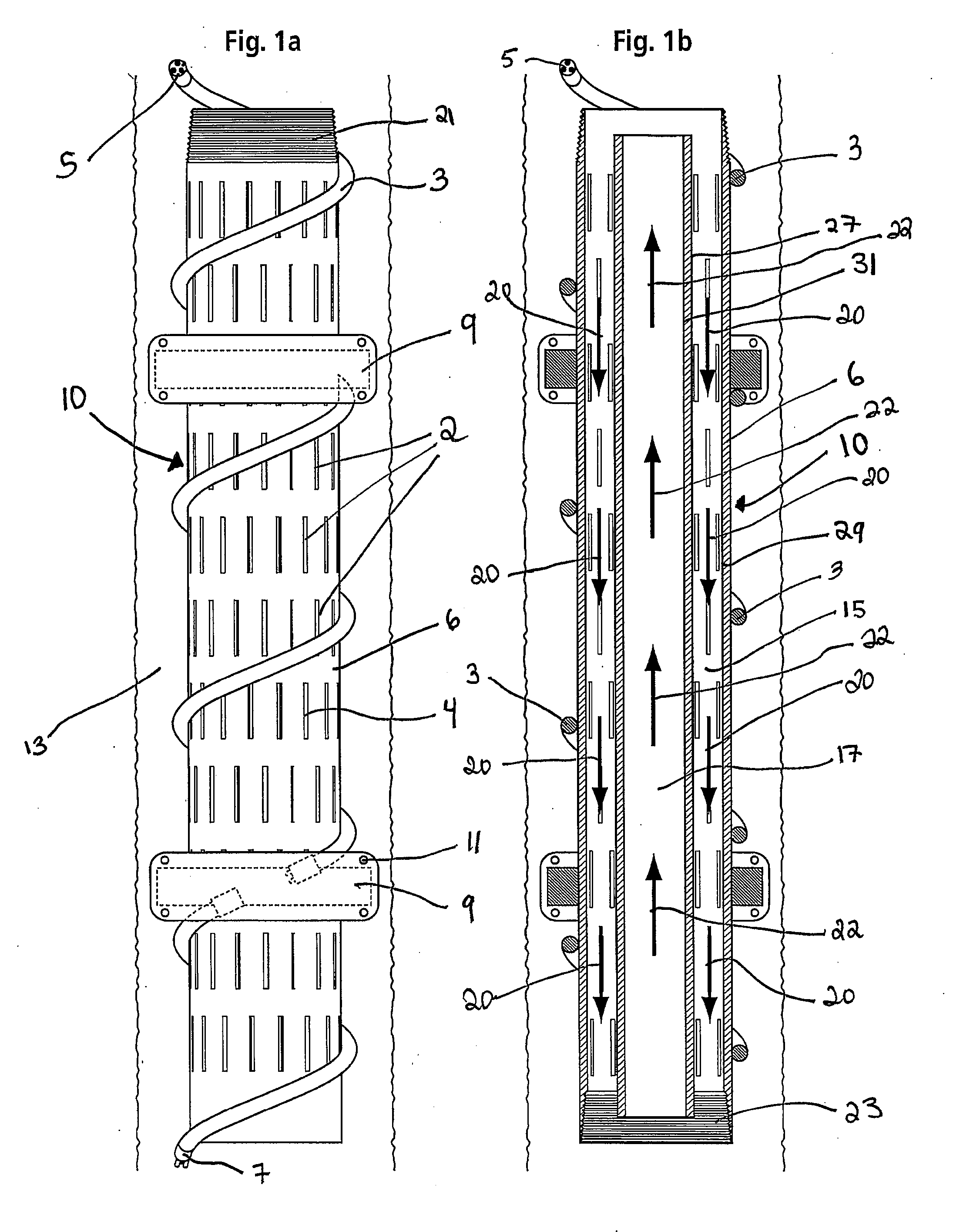

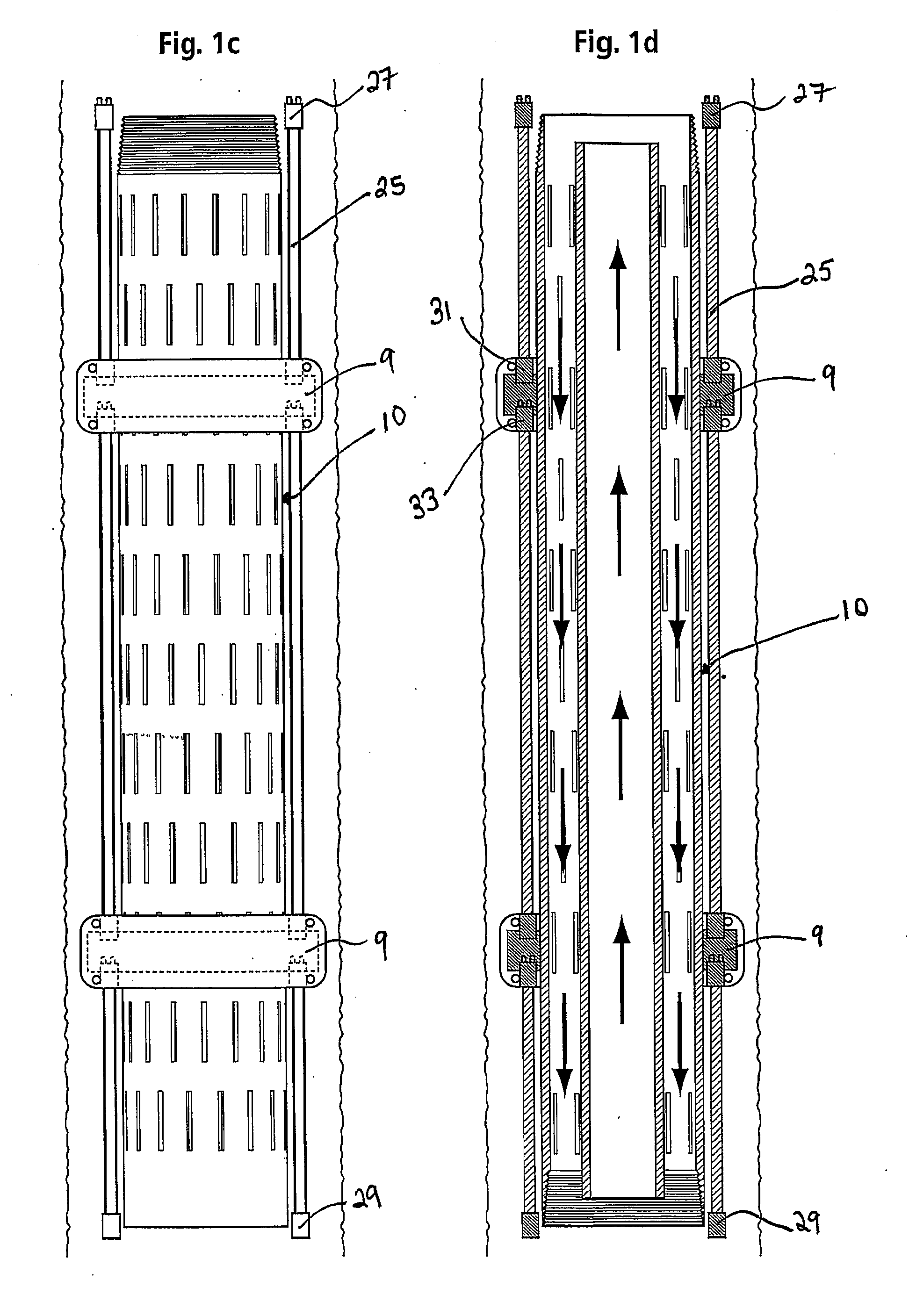

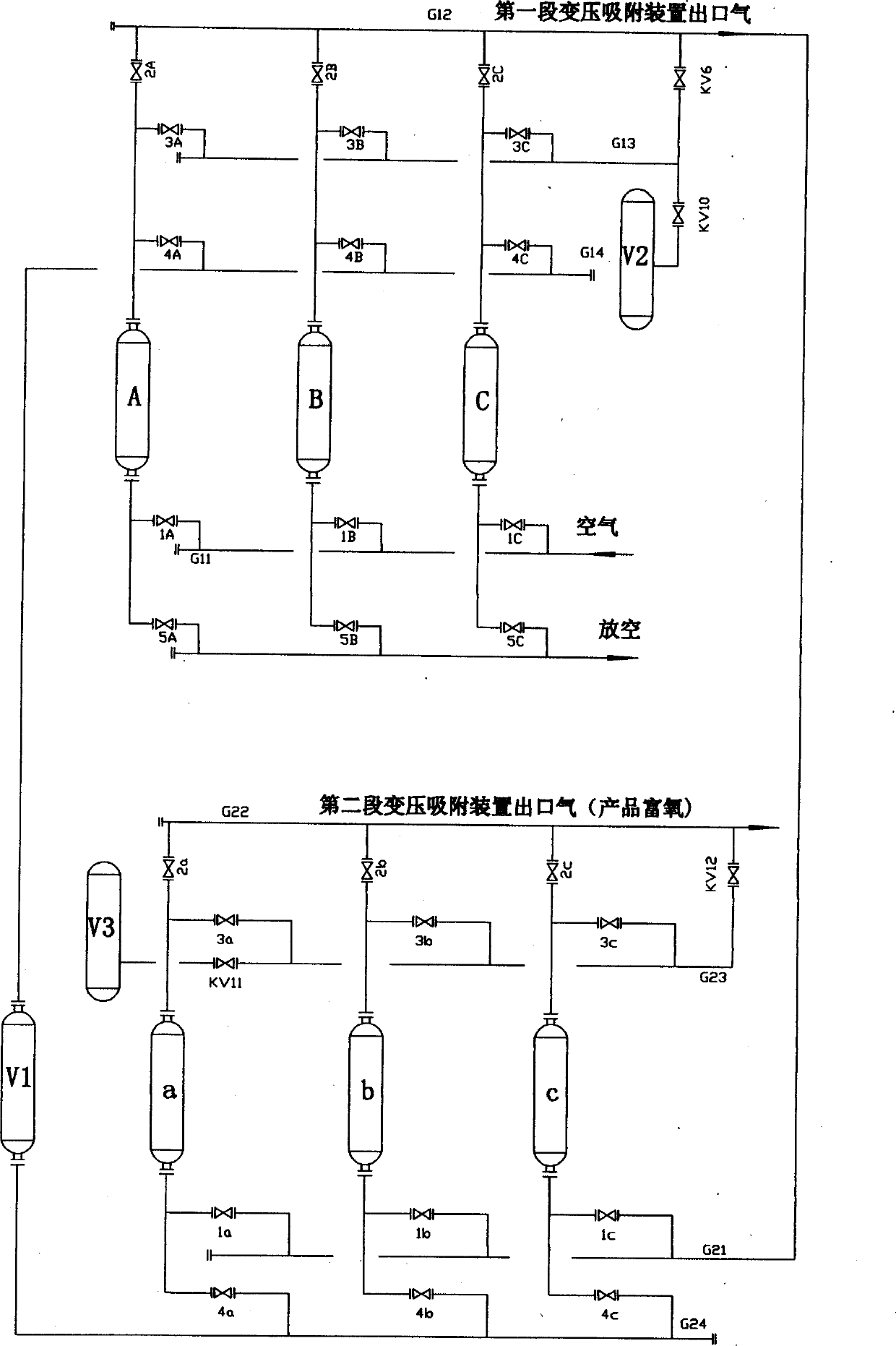

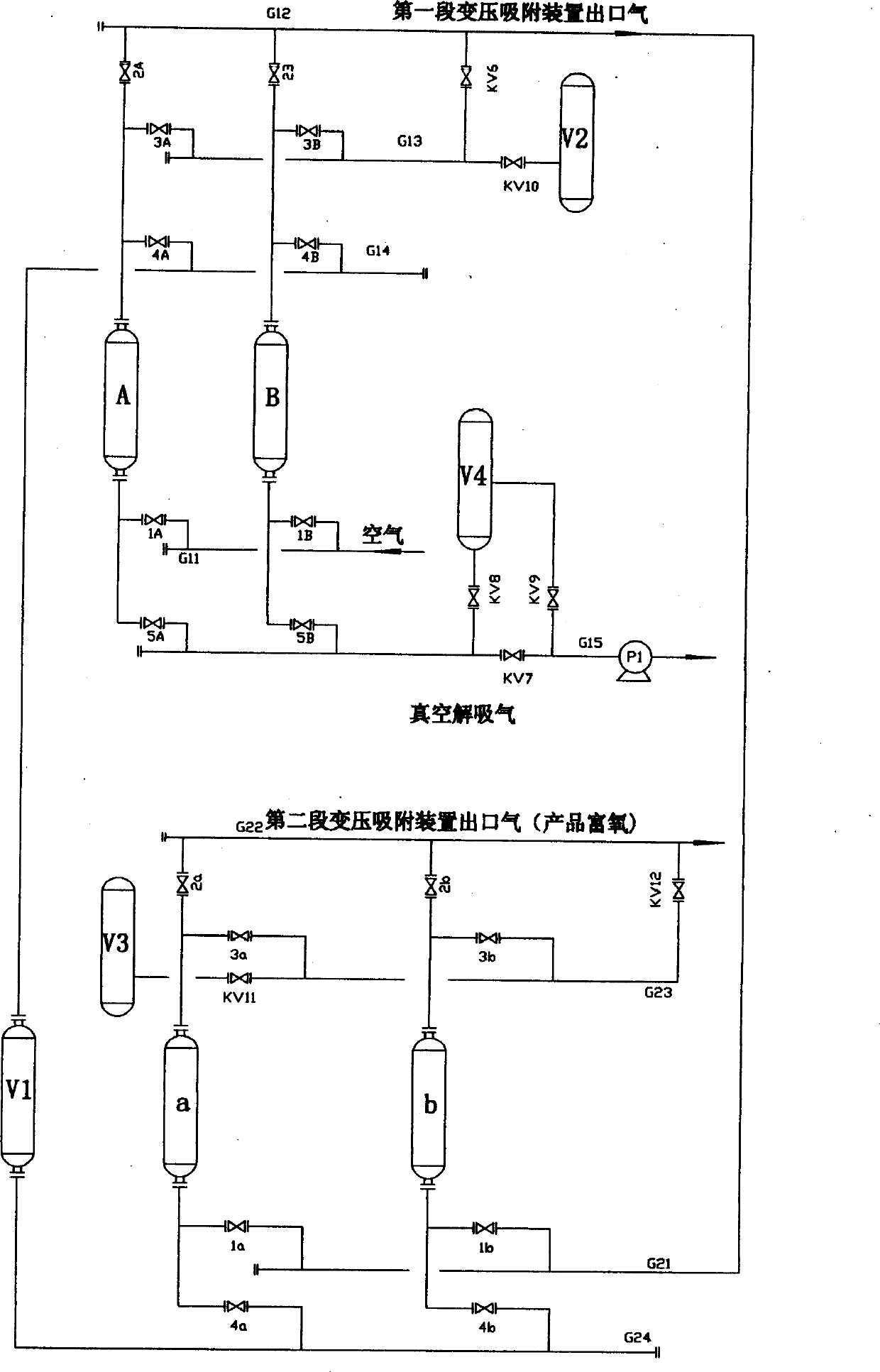

Process for enriching oxygen in air by two-stage pressure swing adsorption

A process for preparing oxygen-enriched air from ordinary air uses two pressure swing adsorption zones which are serially connected. Each of two adsorption zones is parallelly connected with two or more adsorption towers. The first adsorption zone is used for removing water, CO2 and part of nitrogen to increase the concentration of oxygen to 21-80 V%. The second one is used for removing the rest of nitrogen to increase the concentration of oxygen to 30-95 V%. It is characterized by that the process steps of each adsorption tower are staggered.

Owner:CHENGDU TIANLI CHEM ENG TECH

Method for preparing urea phosphoric acid with wet-process phosphoric acid

ActiveCN101318914AImprove conversion rateSimple processUrea derivatives preparationOrganic compound preparationPhosphoric acidReaction temperature

The invention discloses a method for producing urea phosphate by using wet-process phosphoric acid, belonging to the chemical engineering field. The method comprises the following steps of: taking the wet-process phosphoric acid with a concentration of between 25 and 50 percent of P2O5 as measured weight, and adding the wet-process phosphoric acid in a reaction kettle which is provided with a stirring device and a heating device; starting the stirring device to heat the wet-process phosphoric acid to a temperature of between 60 and 95 DEG C; adjusting a rotational speed of a stirrer to between 60 and 300 revolutions / min, and adding a reaction activating agent and a suspending agent in the reaction kettle, with a dosage of the activating agent being 0.1 to 1.2 per thousand of phosphoric acid in a reaction system, and a dosage of the suspending agent being 0.2 to 1.0 per thousand of the phosphoric acid in the reaction system; keeping stirring for 5 to 10 minutes, and adding urea, in which a mol ratio of the urea to the phosphoric acid is between 1.0 and 1.4, in the reaction kettle, and maintaining the reaction temperature for 0.5 to 1.5 hours; closing the heating device, cooling and crystallizing to room temperature, and separating a dried product; and using a separated mother solution to produce wood fire retardant or fertilizer. The method has the characteristics of simple process, high coefficient of recovery, high product purity, low manufacturing cost, cleanness without pollution and so on.

Owner:WENGFU (GRP) CO LTD

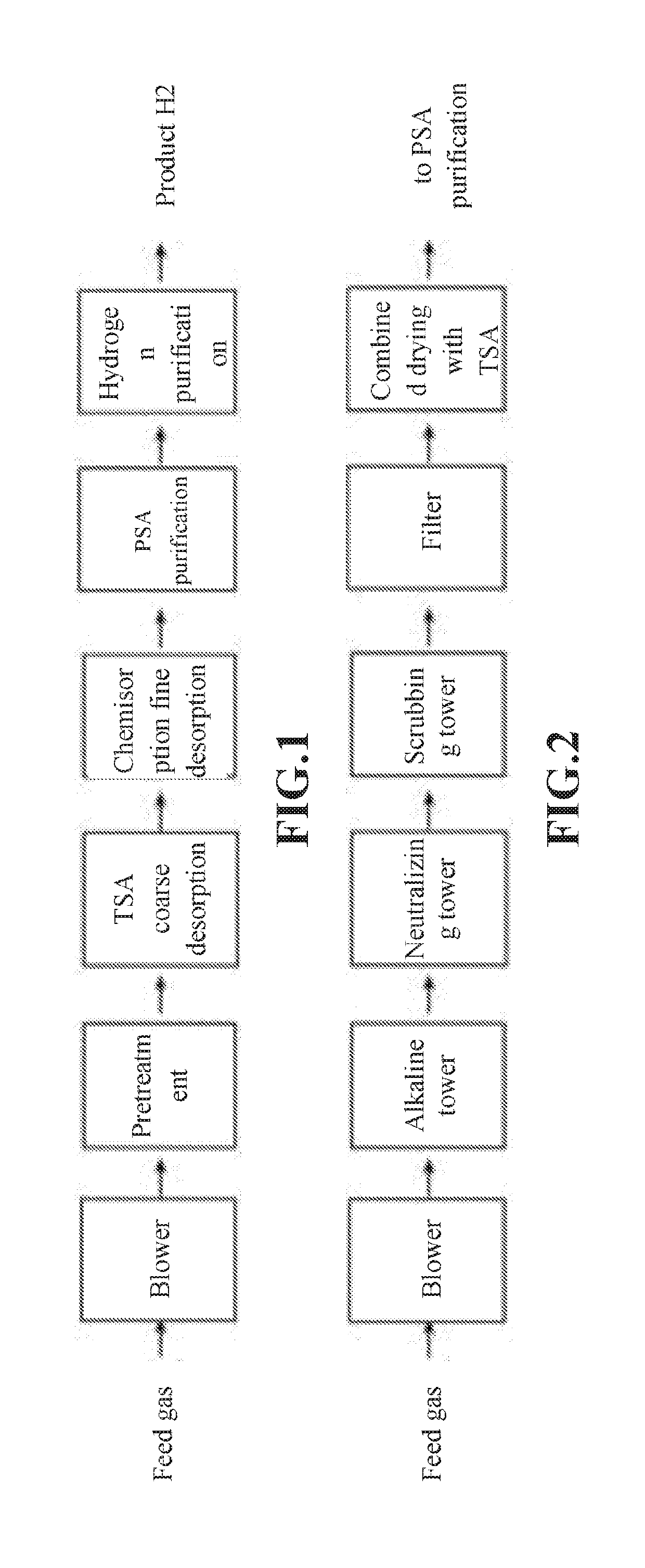

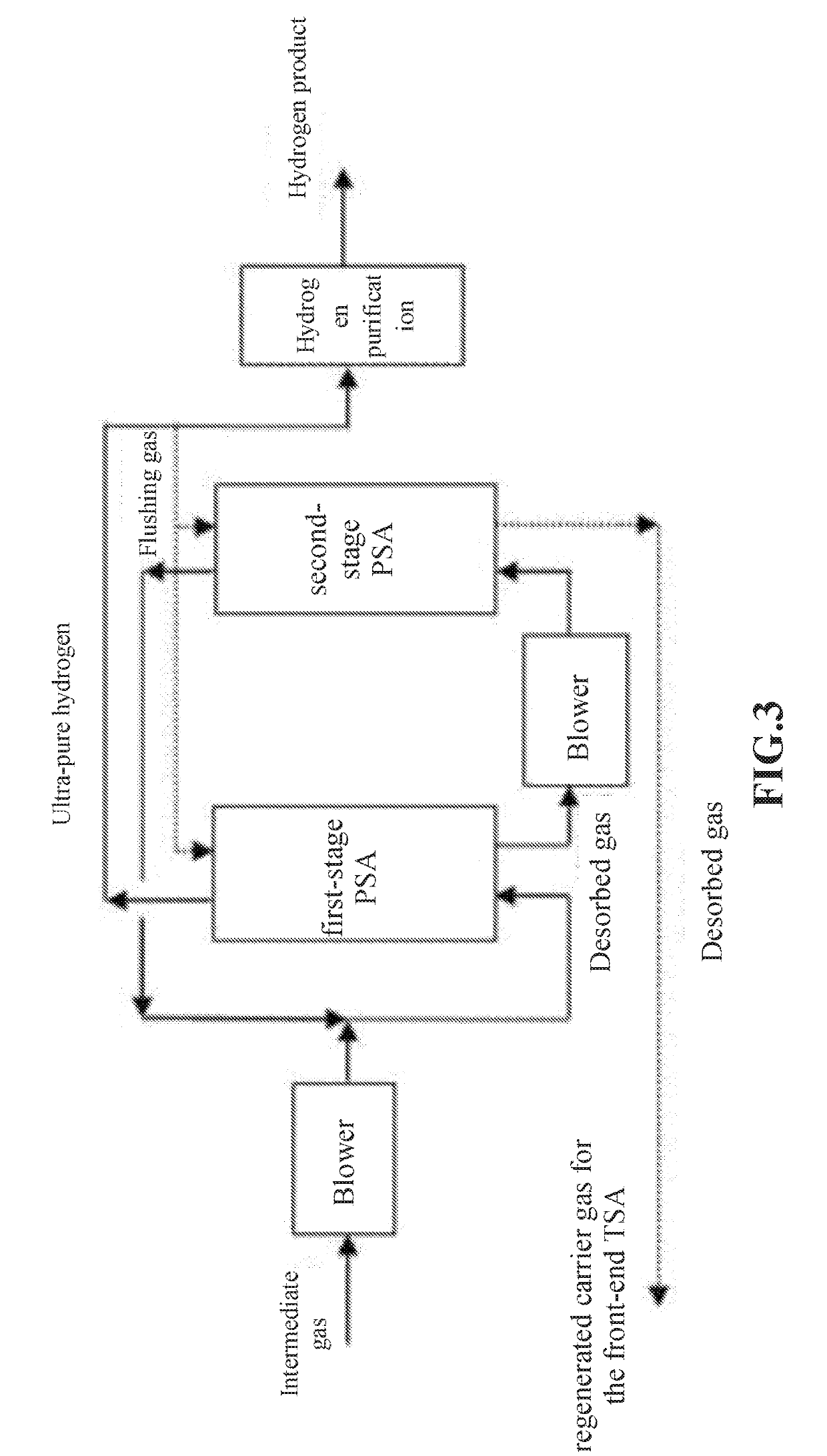

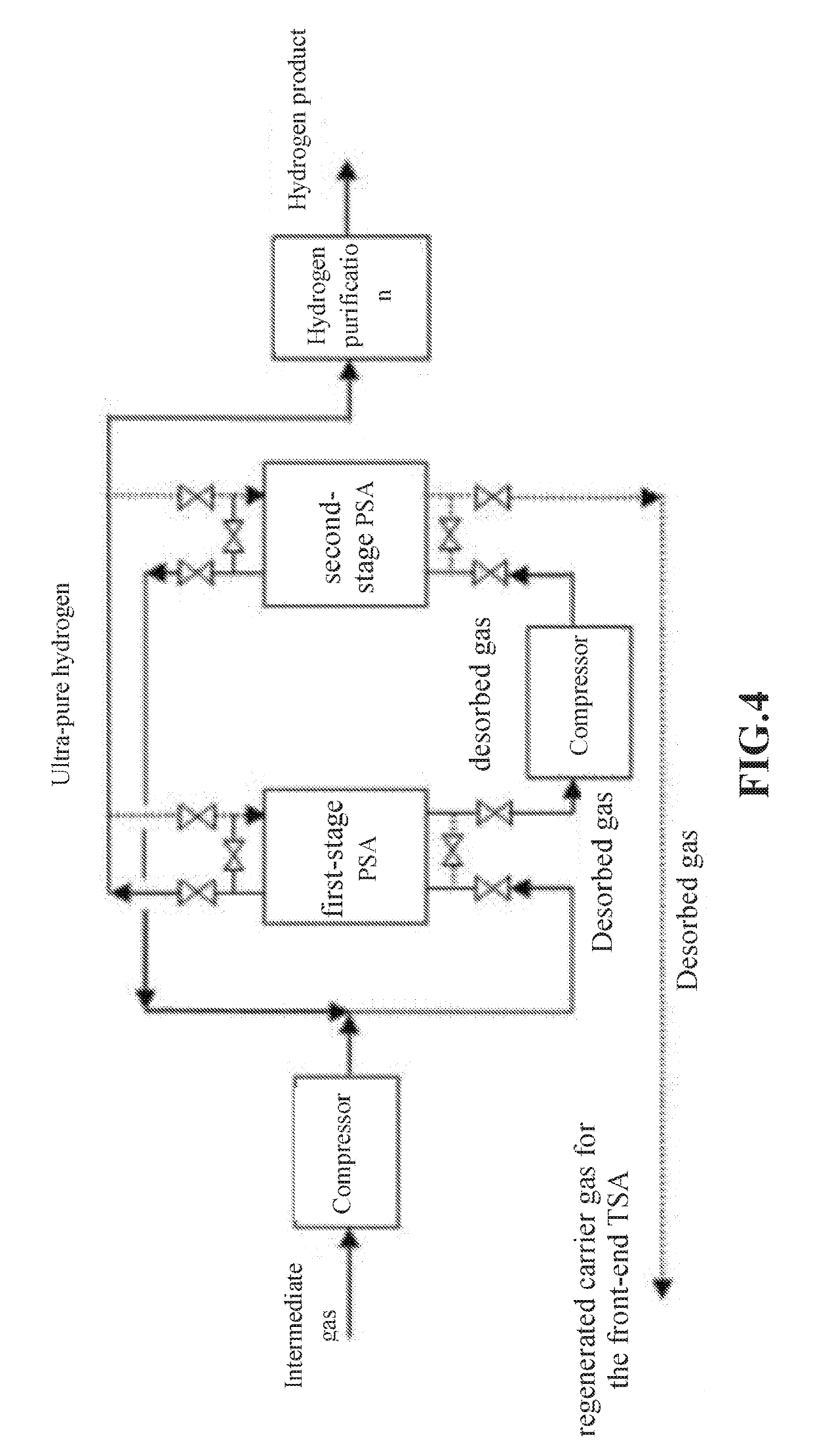

Method of Purifying and Recycling Normal-pressure Waste Hydrogen by Full Temperature Range Pressure Swing Adsorption (FTrPSA) in Manufacturing Process of Semiconductor

ActiveUS20190275460A1Low recovery rateIncrease consumptionGas treatmentHydrogen separation using solid contactSites treatmentDesorption

Through the procedures of pretreatment, temperature swing adsorption (TSA) coarse desorption, pressure swing adsorption (PSA) purification and hydrogen purification, the hydrogenous waste gas from various procedures in the manufacturing process of semiconductor (especially silicon wafer), including the off-gas from chemical vapor deposition (CVD), doping (diffusion and ion implantation), photolithography and cleaning, the combusted and washed discharged gas of the off-gas in other procedures after field treatment and centralized treatment, or the hydrogenous waste gas entering the hydrogen discharge system are purified to meet the standard for the electronic grade hydrogen required for the manufacturing process of semiconductor, the recycling of hydrogen resources is realized, and the yield of hydrogen is greater than or equal to 70-85%. The present invention solves the technical difficulty the normal-pressure waste hydrogen recovered in the manufacturing process of semiconductor can't be returned to the manufacturing process of semiconductor for reuse.

Owner:SICHUAN TECHAIRS

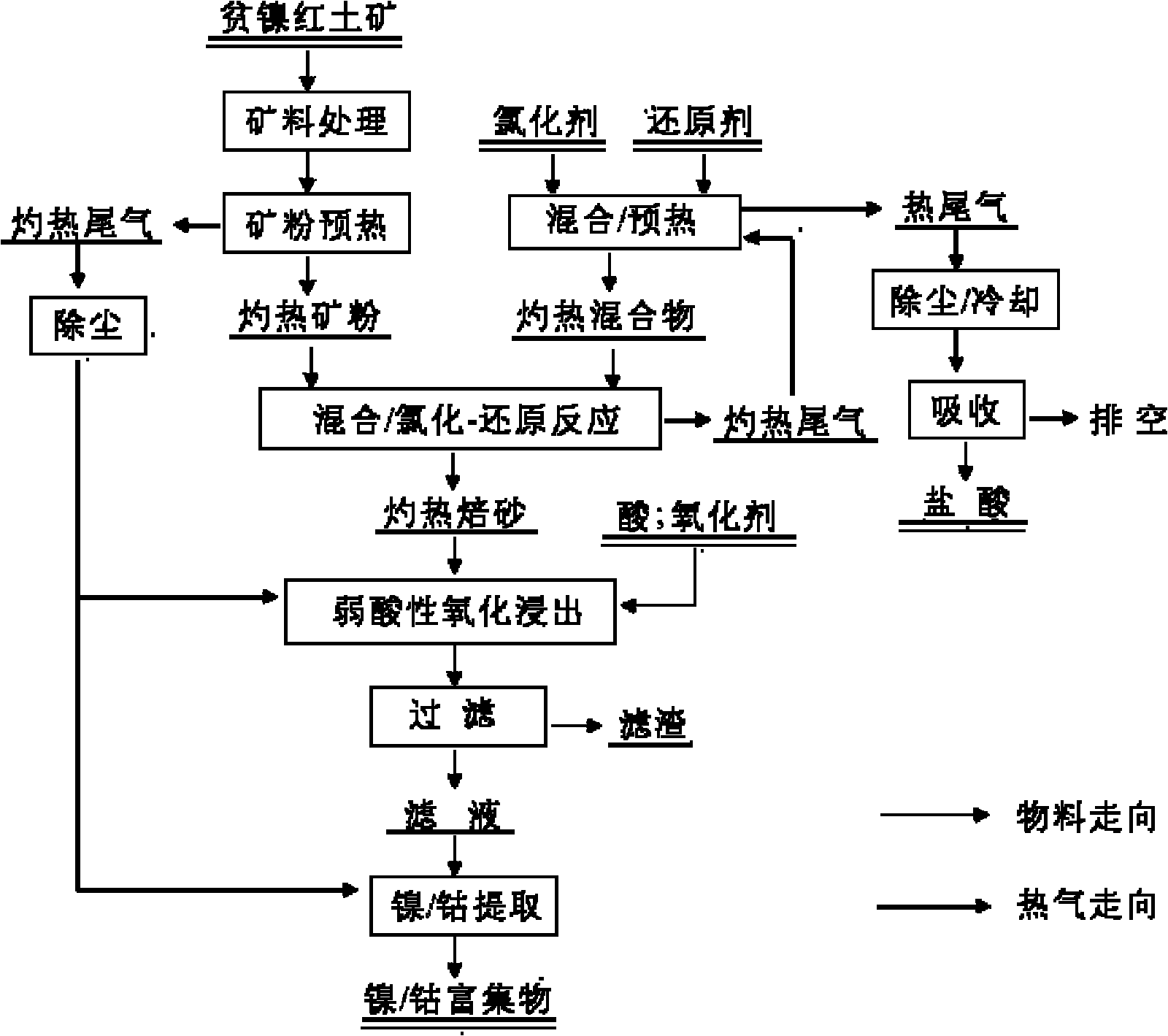

Method for extracting nickel and cobalt by processing poor nickel laterite

ActiveCN101914691AImprove adaptabilityLow melting pointProcess efficiency improvementLateriteMaceral

The invention discloses a method for extracting nickel and cobalt by processing poor nickel laterite, which is to process poor nickel laterite by using a pre-reduction roasting-oxidizing leaching process and extracting valuable metals such as nickel and cobalt from the poor nickel laterite. By using poor nickel laterite as a starting material, the economic and high-efficiency extraction of the valuable metals such as nickel and cobalt, and the closed-loop circulation and comprehensive utilization of a metallurgical system are realized by the process steps of mineral treatment, high-temperature reduction roasting, weak acid oxidizing leaching, nickel and cobalt extraction from leachate, recovery of leaching agent and the like.

Owner:CENT SOUTH UNIV

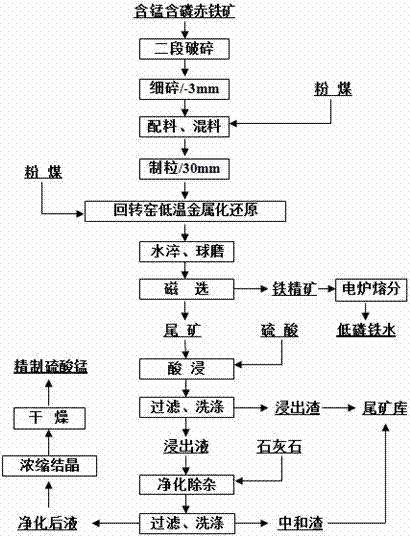

Method of processing manganese-containing and phosphorus-containing hematite

InactiveCN103088208AReduce pollutionHigh recovery rateMagnetic separationGrain treatmentsFiltrationManganese

The invention discloses a method of processing manganese-containing and phosphorus-containing hematite, relating to a method of comprehensively recovering iron and manganese in the manganese-containing and phosphorus-containing hematite. The method is characterized by comprising the steps in sequence: breaking crude manganese-containing and phosphorus-containing hematite, and then mixing evenly together with pulverized coal to prepare aggregate; conducting reduction roasting to the aggregate; conducting high-temperature water quenching and ball milling; conducting magnetic separating to obtain concentrate ferrous powder and tailings; conducting sulfuric acid leaching and filtration to the tailings, and purifying to remove impurities from the filtrate; and concentrating and crystallizing the purified filtrate to prepare manganese sulfate. The method is wide in applicability, the crude ore is not required for fine milling, coke and coking coal are not needed in the metallization roasting process, and the separation effect of Fe, Mn and P is good after roasting, ball-milling and magnetic separation; the manganese enrichment effect of the magnetically-separated tailings is good, and the concentrate manganese sulfate product is obtained by conducting sulfuric acid leaching through the conventional leaching agent, and conducting impurity removal and concentration and crystallization; and the equipment used in technological process is mature, the automation level is high, the control is easy, the environment pollution is small, and the product value is high.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

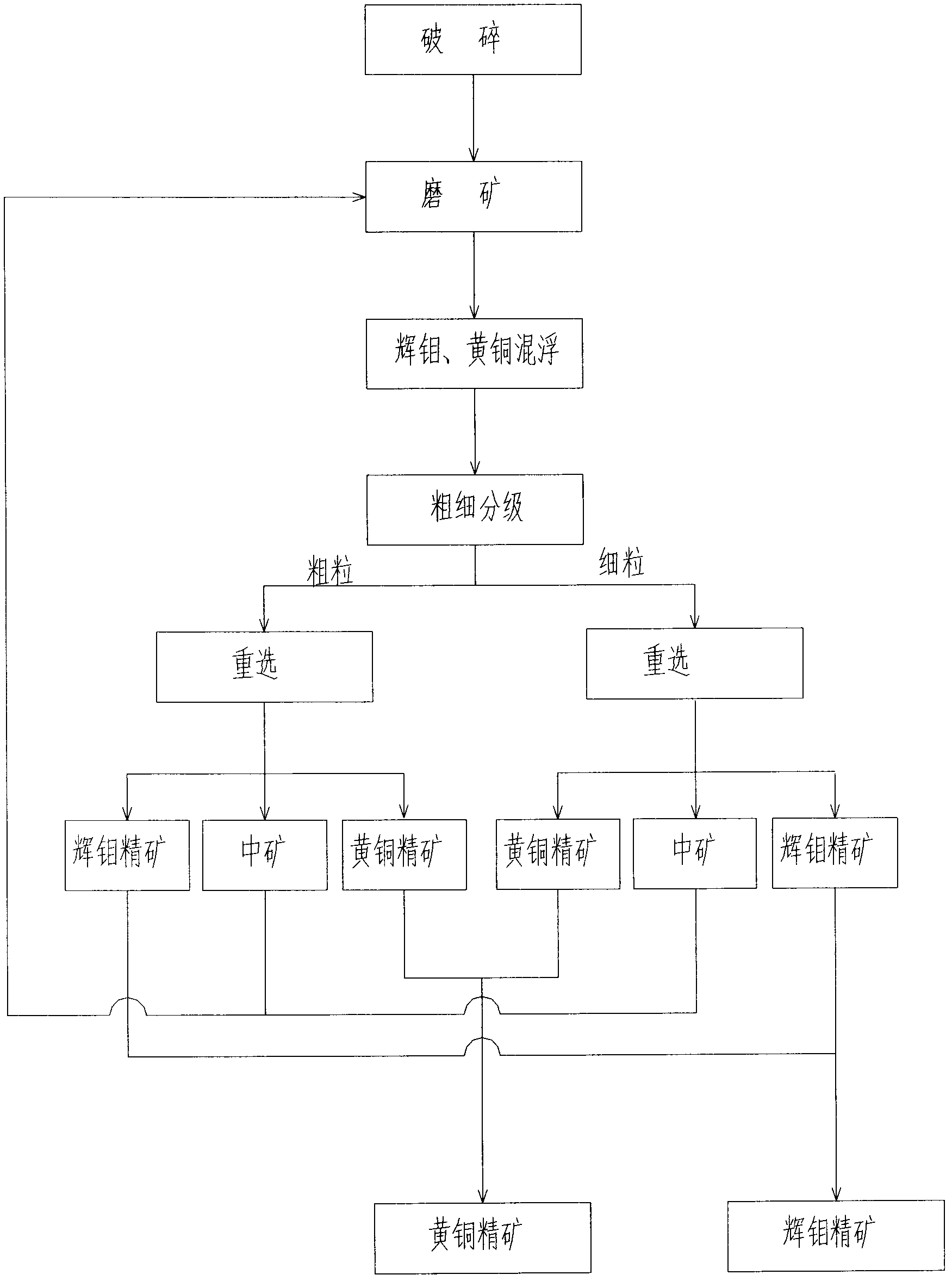

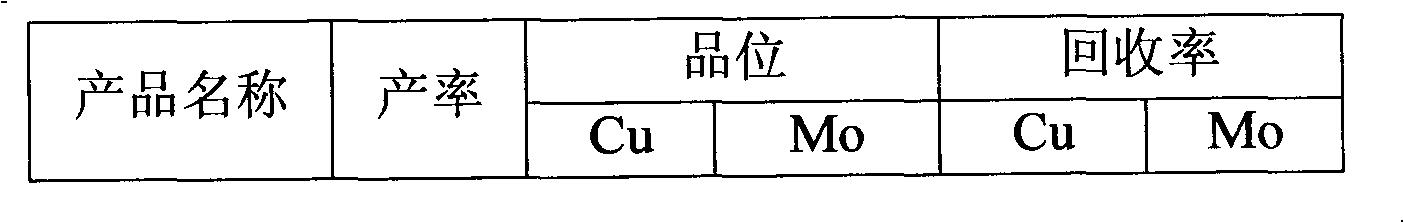

Method for separating bright molybdenum and brass in refractory molybdenum copper sulphide ore

InactiveCN102824954ALow recovery rateHigh recovery rateFlotationWet separationChalcopyriteRefractory

The invention discloses a method for separating bright molybdenum and brass in refractory molybdenum copper sulphide ore. According to the method, primordial bright molybdenum and brass ore are used as raw materials and are subject to general floatation after being crushed and ground, thereby enriching bright molybdenum and brass; the bright molybdenum and brass are subject to thickness grading in order to separate out coarse and fine products, the coarse particle portion and the fine particle portion are respectively subject to table re-separation in order to separate bright molybdenum and brass, thereby obtaining the qualified bright molybdenum and brass ore concentrate, mixed intermediate ore of bright molybdenum ore and brass ore, and qualified brass ore; the mixed intermediate ore is returned back to the re-grinding technique and introduced into the circulating system, thereby realizing the separation of the refractory bright molybdenum and brass. The technique has the following advantages that the disadvantages of greatly increased cost caused by the addition of a large amount of inhibitors in the common separation of bright molybdenum and brass for inhibiting the brass ore and the removing of the regents when brass is recovered from the tailings, in particular the disadvantages of the reduction of recovering ratio of the bright molybdenum particularly the brass when a large amount of brass ore inhibitors are existent in the water system, and the environmental impact due to the need of reagents in the common floating separation, are avoided.

Owner:北京华夏建龙矿业科技有限公司

Method for flotation after acid etching pretreatment of high-calcium fluorite

The invention discloses a method for flotation after acid etching pretreatment of high-calcium fluorite. Acid is added into high-calcium fluorite pulp before flotation, inhibitors are added while the acid is added, and acid etching pretreatment is carried out; pH regulators and collecting agents are sequentially added after pretreatment is completed, and then air agitation pulp mixing is carried out; foam flotation is carried out after pulp mixing is completed, and rough concentrate is obtained; and the rough concentrate is further subjected to concentration to obtain high-quality fluorite concentrate. The method is clean, environmentally friendly, efficient and low in cost, and the obtained fluorite concentrate is high in grade and recovery rate.

Owner:CENT SOUTH UNIV

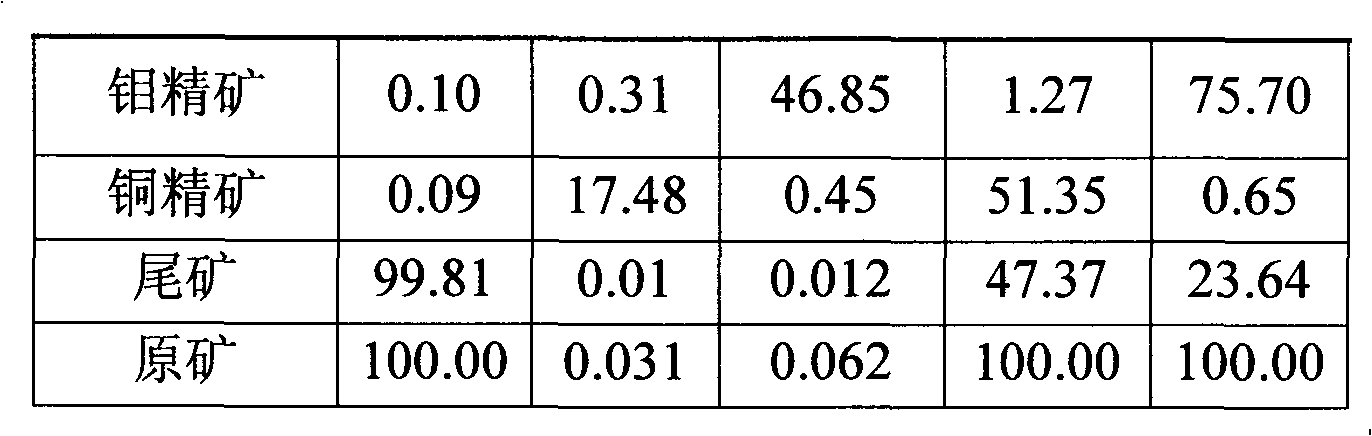

Process for recovering heavy minerals from oil sand tailings

ActiveUS7695612B2Quality improvementExpansion quantityWater/sewage treatment by centrifugal separationCentrifugal force sediment separationSilicon dioxideMaceral

A process is provided for recovering heavy minerals from aqueous oil sand tailings, the oil sand tailings having heavy minerals, other coarse solids such as silica, fines, residual bitumen and water, including desliming the oil sand tailings in a desliming means by removing a portion of free fines and residual bitumen from the oil sand tailings; attritioning the oil sand tailings in an attritioner to remove adhered fines and residual bitumen from the heavy minerals and other coarse solids; and subjecting the deslimed and attritioned tailings to separation in a separation means to separate the heavy minerals from the other coarse solids present in the deslimed and attritioned tailings and produce a concentrated heavy minerals fraction.

Owner:TITANIUM CORP

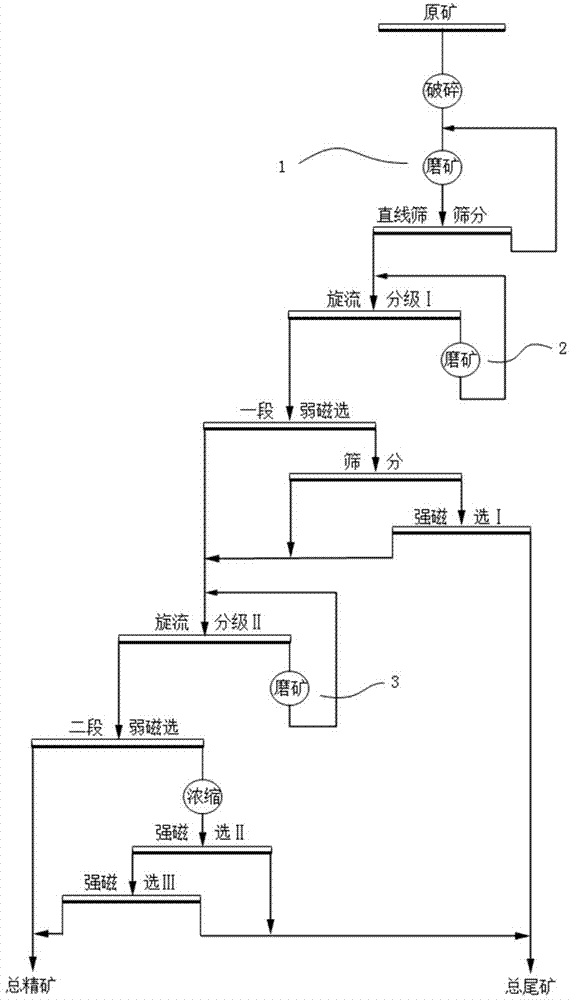

Efficient beneficiation method for low-grade titanic magnetite hard to select and smelt

ActiveCN107335535AHigh recovery rateWeakening of magnetic agglomerationWet separationMagnetiteRotational flow

The invention discloses an efficient beneficiation method for low-grade titanic magnetite hard to select and smelt. The method comprises the steps that in the crushing step, the low-grade titanic magnetite hard to select and smelt is crushed; in the first section ore grinding classification step, the titanic magnetite obtained after crushing is ground, first rotational flow classification is conducted, first fine particle overflow and first coarse grain pulp are obtained, and the first coarse grain pulp is subjected to first grinding again to return,; in the one-section low intensity magnetic separation step, the first fine particle overflow is subjected to first low intensity magnetic separation, and first iron concentrate pulp and first tailings pulp are obtained; in the screening classification step, the first iron concentrate pulp I is screened, and plus sieve coarse ore and minus sieve fine pulp are obtained; and in the second-section ore grinding classification step, the first iron concentrate pulp and the plus sieve coarse ore are combined and subjected to second rotational flow classification, second fine particle overflow and second coarse grain pulp II are obtained, and the second coarse particle pulp is subjected to second grinding to return to second rotational flow classification. For the low-grade titanic magnetite hard to select and smelt, the iron and titanium recycling rate is increased in combination of rotational flow classification and low intensity magnetic separation, and the method has the beneficial effects of being simple in technology, easy to operate and high in beneficiation efficiency.

Owner:YUXI DAHONGSHAN MINING

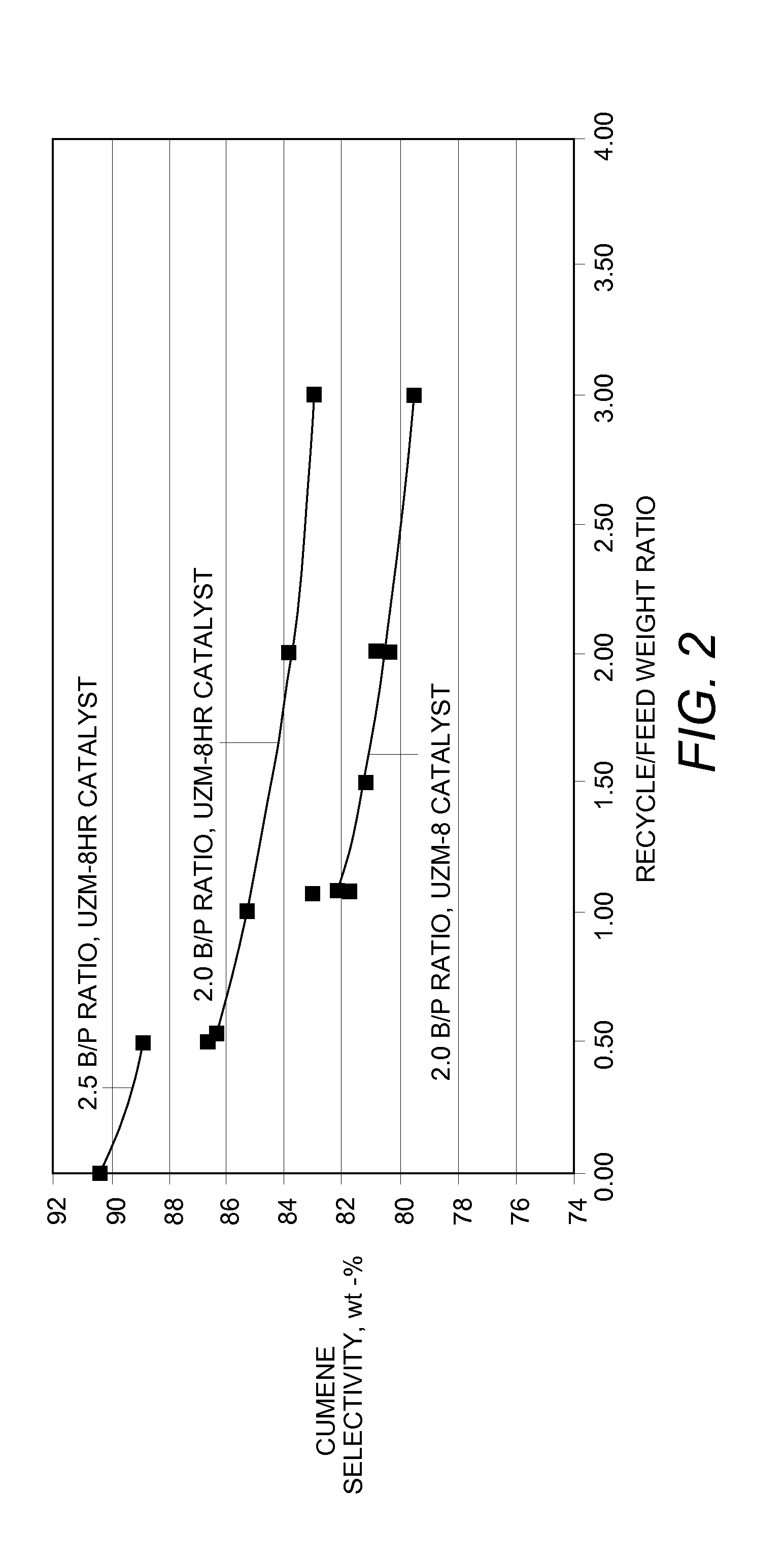

Cumene Production with High Selectivity

ActiveUS20110245558A1High selectivityReduction in equipment costMolecular sieve catalystsMolecular sieve catalystQuenchingChemistry

Cumene production methods are disclosed, based on the alkylation of benzene with propylene, in which byproducts of the alkylation reaction are advantageously reduced to achieve a high cumene selectivity. This may be attained by (i) reducing the portion of the total alkylation effluent that is recycled, after cooling, to the alkylation reaction zone for quenching or direct heat exchange and / or (ii) reducing the benzene:propylene molar ratio of the alkylation feedstock. To manage the temperature differential across catalyst bed(s) in the alkylation reaction zone, indirect heat exchange may be used to remove heat.

Owner:UOP LLC

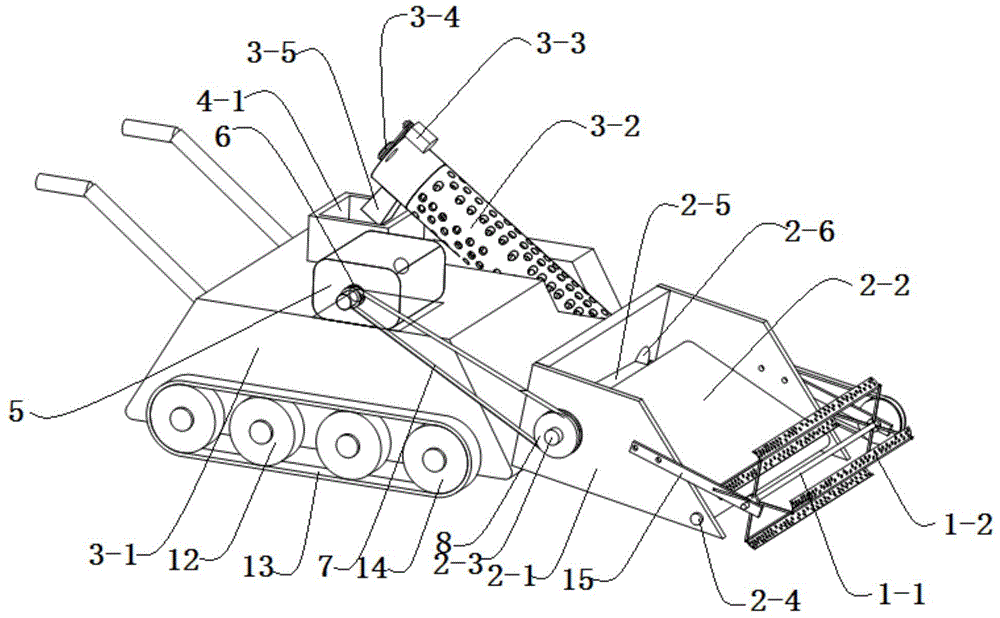

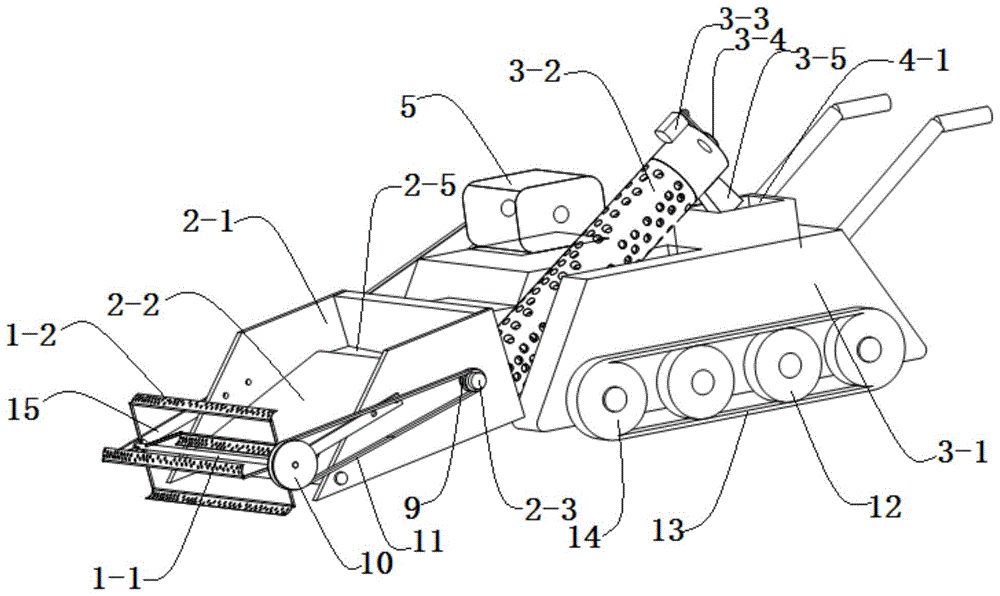

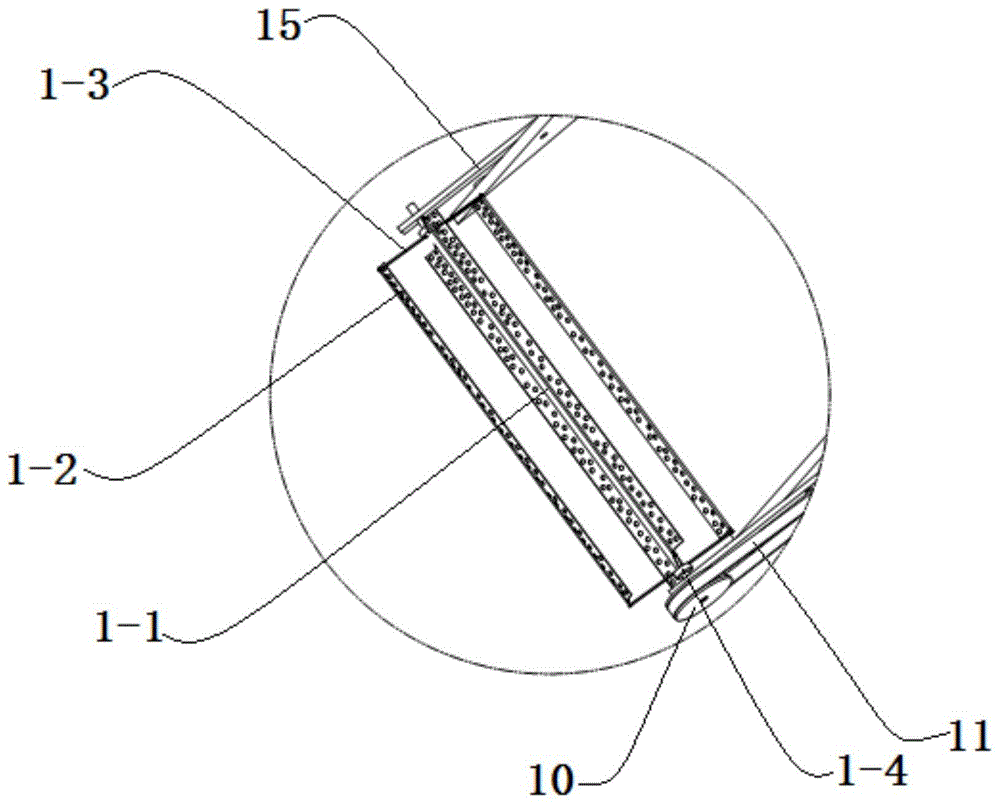

Mud snail collecting device

ActiveCN104886014ASimple structureReduce collection costsPisciculture and aquariaElectric machineryStructural engineering

The invention discloses a mud snail collecting device. The mud snail collecting device comprises a rolling collecting device, a conveying device, spiral cleaning device and a storage box which are sequentially disposed from front to rear, wherein the rolling collecting device comprises a rolling rod and a plurality of mesh collecting plates, the mesh collecting plates are parallel with the rolling rod and distributed on the periphery of the rolling rod, and the mesh collecting plates perform circling motion by using the rolling rod as the center; the conveying device comprises a box with a front opening and a top opening, an upper oblique conveying belt disposed in the box, and a drive and a driven rod which are respectively disposed at the upper and lower ends of the conveying belt, and a discharging oblique plate is disposed on the box and located on the rear side of the conveying belt; the spiral cleaning device comprises a vehicle body fixedly connected with the rear side of the box, a hollow mesh rod obliquely and upwardly disposed on the vehicle body, a small drive motor disposed at the top of the hollow mesh rod, and a spiral feeding rod which is disposed inside the hollow mesh rod and connected with the output end of the small drive motor. The mud snail collecting device has the advantages that the device is simple in structure, low in collecting cost, high in efficiency and low in collecting missing rate.

Owner:GUIPING PRODIVITY PROMOTION CENT

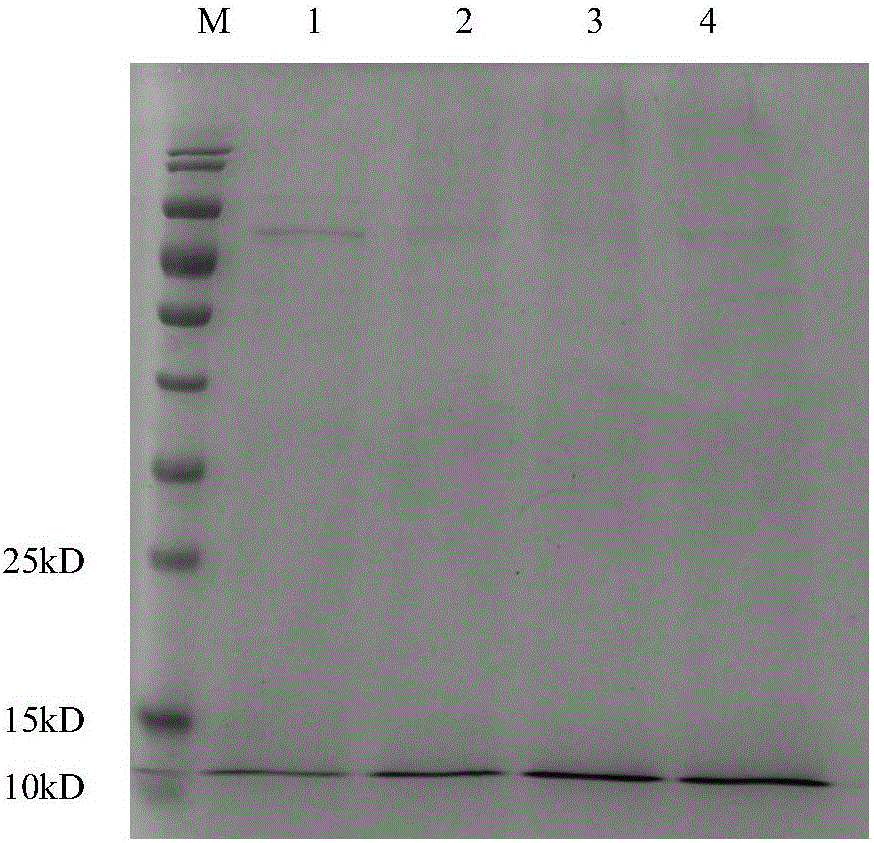

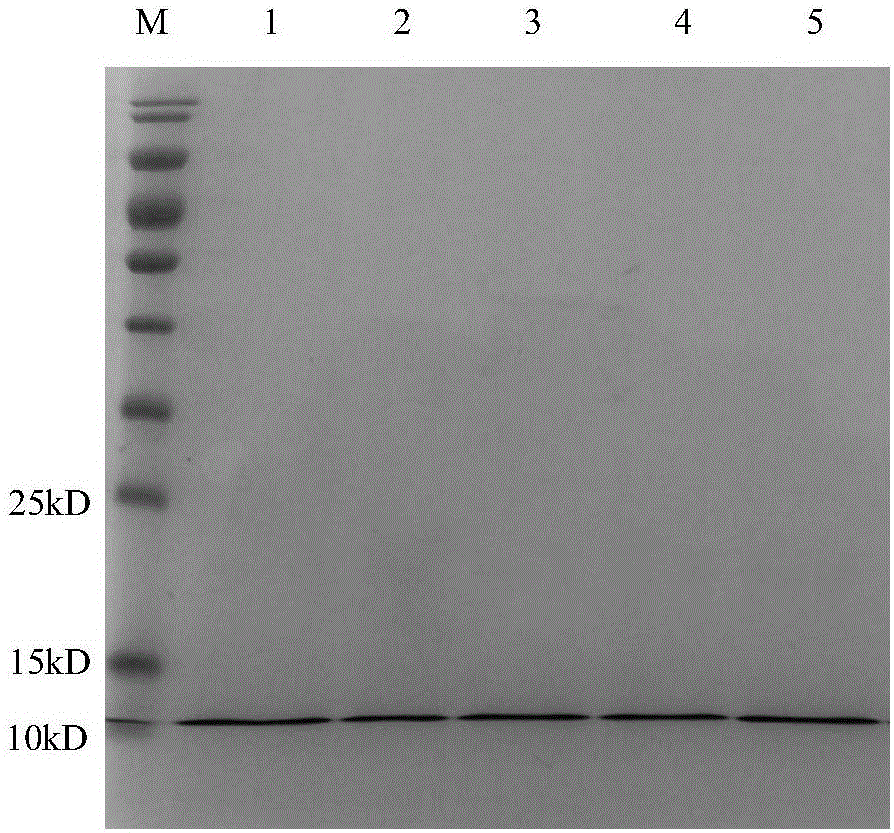

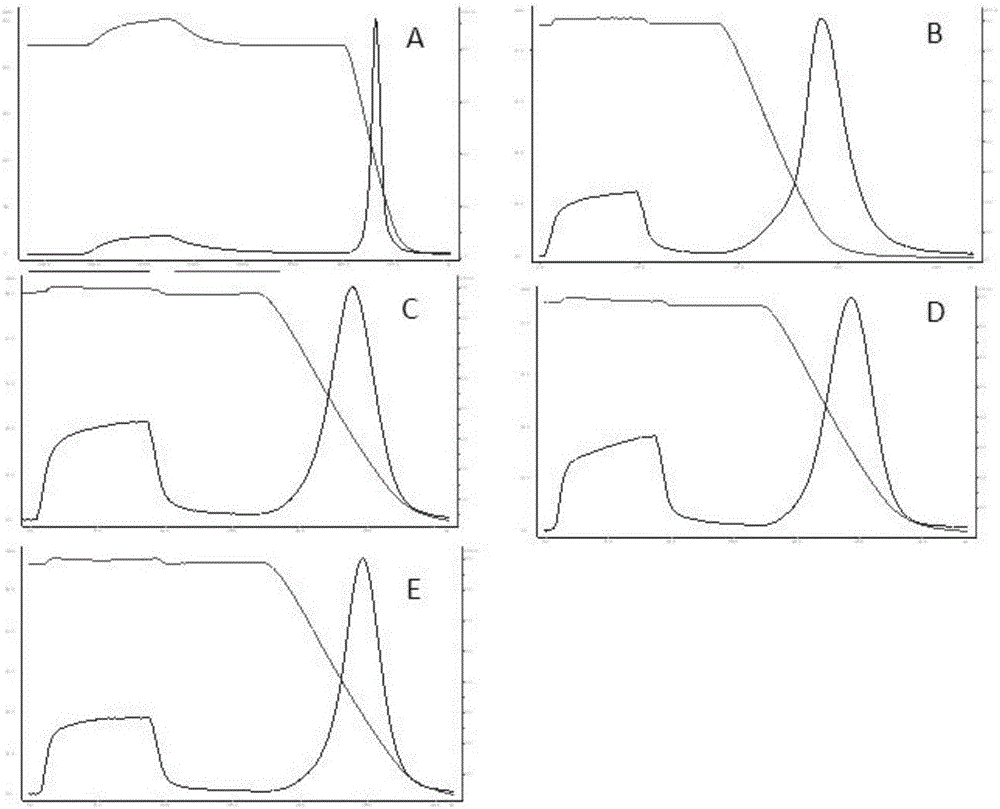

Method for isolating recombinant human nerve growth factor from mammalian cell culture

InactiveCN106478801AReduce stepsShorten the production cyclePeptide preparation methodsAnimals/human peptidesElutionOrganism

The invention discloses a method for isolating recombinant human nerve growth factor from mammalian cell culture, comprising the steps of carrying out strong cation exchange chromatography, to be specific, sampling supernate of clarified mammalian cell culture to strong cation exchange chromatography resin, eluting with elution buffer to obtain first recombinant nerve growth factor; carrying out hydrophobic chromatography, to be specific, treating the first recombinant nerve growth factor, sampling to hydrophobic chromatography resin, and eluting with elution buffer to obtain second recombinant nerve growth factor. The method has few operation steps, the production cycle is shortened, recovery rate is increased, the purity is high, the uniformity is good, and in-vitro bioactivity is very high, generally higher than 1.5*105 U / mg, which is far higher than that (0.5*105 U / mg) of mouse nerve growth factors for injection in the market.

Owner:SINOBIOWAY BIOMEDICINE

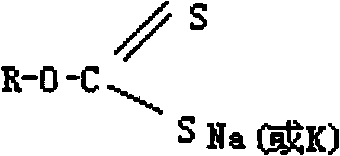

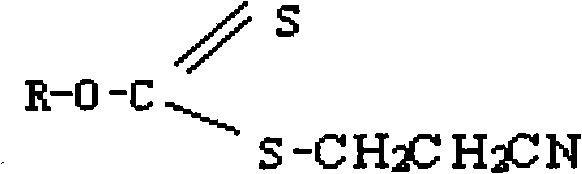

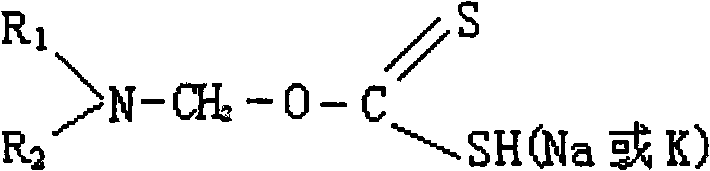

Amino methyl xanthogenic acid cyanogen ethyl ester compound and preparation method as well as collector thereof

InactiveCN102464599ALight weightReduce solubilityOrganic chemistryFlotationSolubilityMineral flotation

The invention relates to an amino methyl xanthogenic acid cyanogen ethyl ester compound and a preparation method thereof; and the compound can serve as a metallic mineral flotation collector to be used for recycling sulphide ore or oxidized ore containing metals in foam flotation. The aim of the invention is to provide the amino methyl xanthogenic acid cyanogen ethyl ester compound and the preparation method thereof. The other aim of the invention is to provide the amino methyl xanthogenic acid cyanogen ethyl ester to serve as a new sulfide mineral or oxidized mineral flotation collector and an application method of the flotation collector so as to enrich the variety of the xanthogenic acid cyanogen methyl ester collector and enlarge the range of selection of a flotation agent. The amino mthyl xanthogenic acid cyanogen ethyl ester compound synthesized by the method is generally of oily liquid, has special smell and little solubility and is slightly lower than water in specific gravity; the product is not needed to be purified and separated; and the mixed product containing impurities has better ore dressing and collecting performance for the metallic minerals. The preparation process is simple, efficient and economic; and the crude product can be used as the flotation collector; and the conversion yield of the crude product is in the range of 65%-100%.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com