Patents

Literature

305 results about "Cobaltous sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

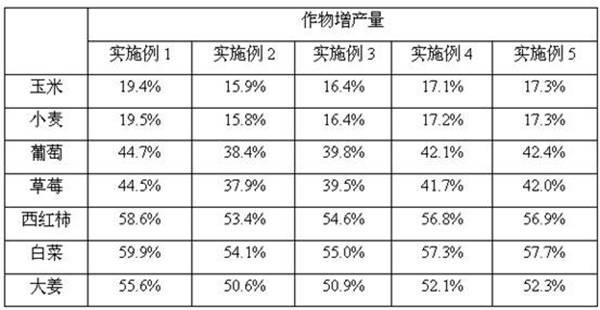

Polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer and preparation method thereof

The invention discloses a polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer and a preparation method of the liquid chelated fertilizer. The polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer comprises the components by weight percent: 5-25% of urea, 5-15% of ammonium polyphosphate, 5-25% of potassium nitrate, 0.2-3% of potassium silicate, 0.8-5% of potassium chloride, 0.008-0.1% of polyaspartic acid, 0.8-5% of ammonium sulfate, 0.8-5% of ethylene diamine tetraacetic acid (EDTA) calcium, 0.2-3% of EDTA magnesium, 0.02-1.5% of EDTA boron, 0.005-0.1% of EDTA zinc, 0.005-0.1% of EDTA iron, 0.005-0.05% of EDTA copper, 0.005-0.05% of EDTA manganese, 0.001-0.01% of nickel sulfate, 0.001-0.01% of ammonium molybdate, 0.0008-0.01% of cobaltous sulfate, 0.008-0.1% of polyacrylamide and the balance of water. The polypeptide-ammonium polyphosphate trace element liquid chelated fertilizer disclosed by the invention is simple in technology, scientific in proportion, balanced in fertilization, low in cost and good in effect.

Owner:张朝晖

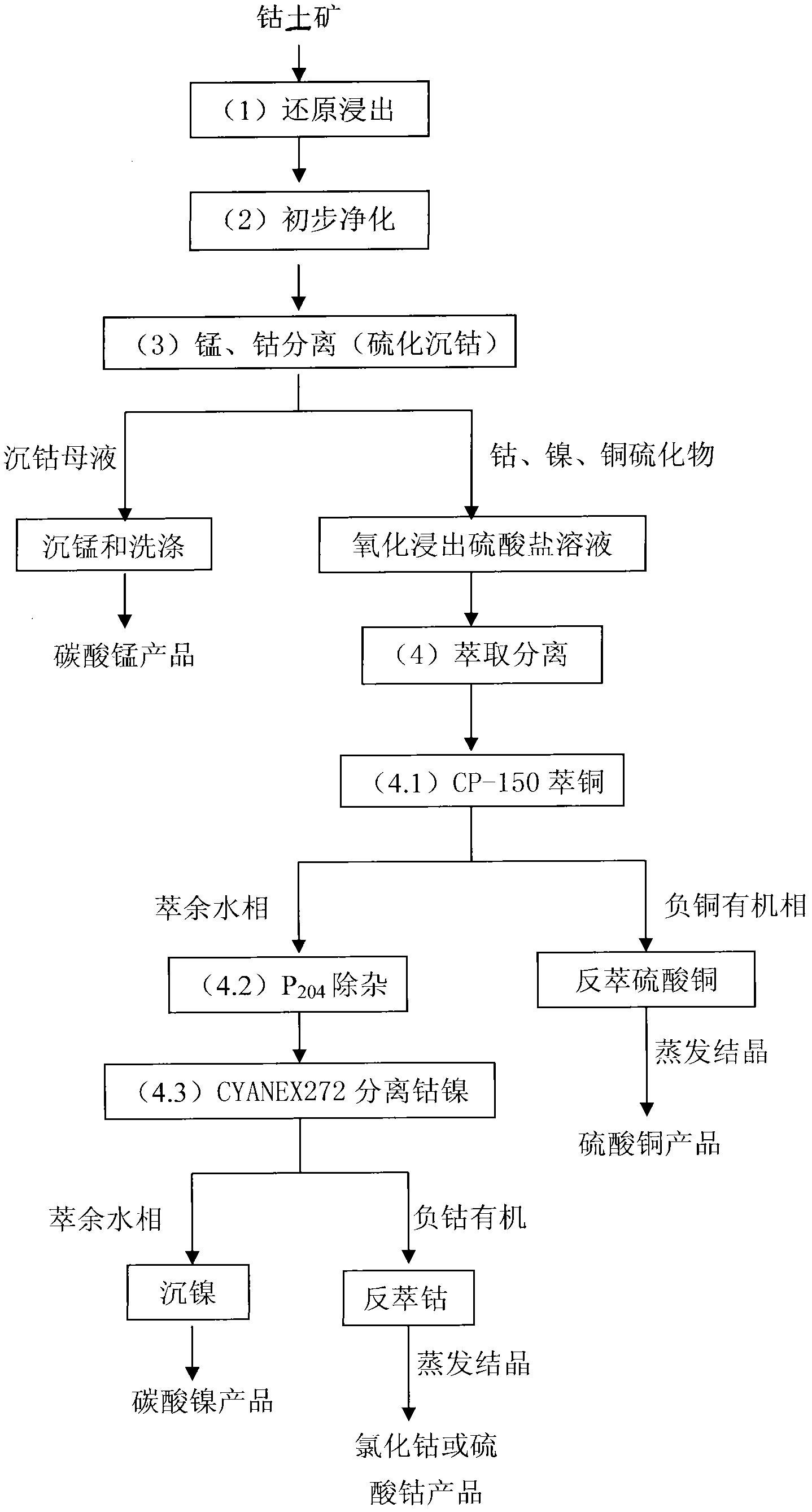

Processing method for comprehensively recovering high manganese asbolite

InactiveCN102021331AIncrease costLow recovery rateProcess efficiency improvementManganeseHydrometallurgy

The invention discloses a processing method for comprehensively recovering high manganese asbolite, belonging to the field of hydrometallurgy. In the processing method, the high manganese asbolite is processed through four processing steps comprising (1) reduction leaching, (2) primary cleaning, (3) manganese and cobalt separation and (4) extraction separation to obtain a product manganese carbonate, copper sulfate, nickel carbonate or cobaltous sulfate. The processing method has the advantages that the source of raw materials is wide, the process and equipment are simple, the operation is stable, the energy consumption is low, the production cost is low, the practicability is wide, and the economic effect and the society effect are obvious.

Owner:HAINAN ZHONGDAO ENERGY DEV

Method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste

ActiveCN102061390AMeet high purity requirementsImprove overall recoveryProcess efficiency improvementTotal recoveryGoethite

The invention provides a method for directly producing high-purity electronic level cobaltous sulfate by using cobalt-containing waste, in particular a process for producing cobaltous sulfate by using cobalt-containing waste. The method comprises the steps of: checking and classifying raw materials, wet-milling and size-mixing, acid-decomposing, filtering, washing, separating, and extracting copper sponge. The method is characterized by also comprising the steps of: removing iron with a goethite process, extracting P2O4 and removing impurities, separating nickel from cobalt, extracting N235, purifying, concentrating and crystallizing. The high purity electron level cobaltous sulfate is directly regenerated by using various kinds of cobalt wastes, the requirement of the modern high-technology industry on high purity of the cobaltous sulfate is met; the total recovery of the cobalt is higher than or equal to 98 percent; various usable elements can be comprehensively recycled, and coppersponge, tungsten carbide, iron hydroxide and nickel carbonate can be regenerated while the electronic level cobaltous sulfate as a main product is regenerated. The invention has the advantages of comprehensively utilizing waste cobalt resources, recycling the wastes, improving the enterprise benefit, and being beneficial to the development of energy conservation, emission reduction, environment protection and circular economy.

Owner:HUNAN JINYUAN NEW MATERIALS CO LTD

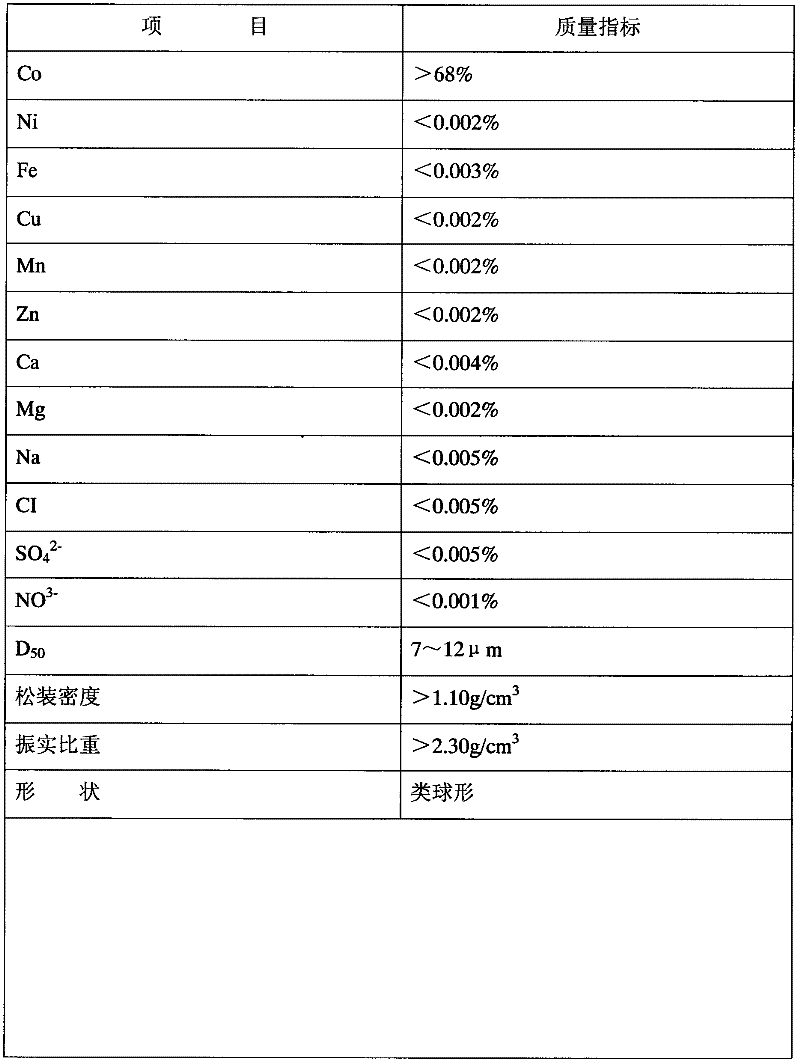

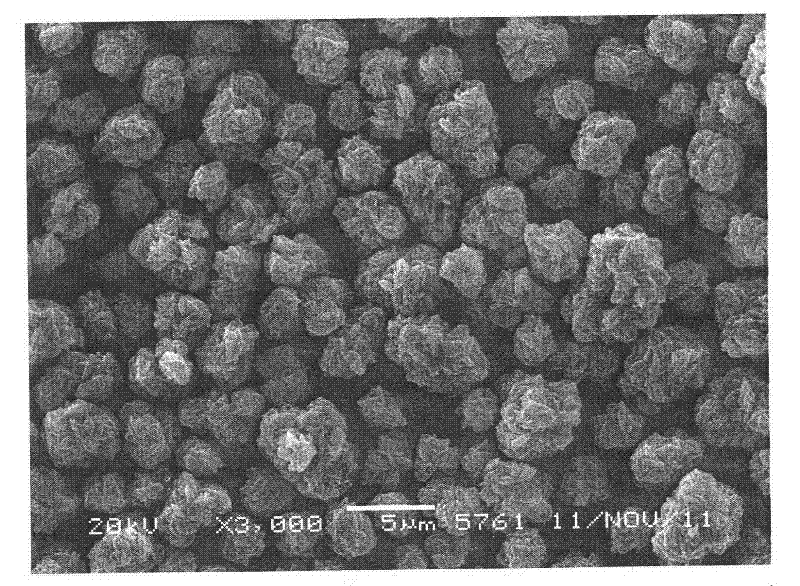

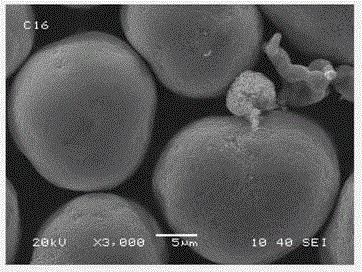

Method for producing hydroxy cobalt oxide

InactiveCN102689933AThe production process is easy to controlImprove product qualityCobalt oxides/hydroxidesEthylene diamineReaction temperature

The invention discloses a method for producing hydroxy cobalt oxide, comprising the following steps of: firstly, preparing a cobaltous sulfate solution with cobalt content of 75-85g / l; adjusting a pH value of the solution to be 3.0-4.5; adding EDTA (Ethylene Diamine Tetraacetic Acid) into the solution according to the proportion of cobalt to EDTA of 100:(1-3); preparing sodium hydroxide solution with alkali concentration of 7-9mol; performing cocurrent flow on two solutions and flowing into a reaction groove; introducing the air for performing synthetic reaction; controlling the reaction temperature to be between 50 and 70 and a pH value to be between 10.0 and 12.0 for reacting for 15-25 hours; flowing into an aging groove for aging for 50-60 minutes; and finally, filtering, washing and slurrying to prepare a hydroxy cobalt oxide solid product. According to the method, the production process is controllable, particles of the product are uniformly distributed with good consistency, the shape is spherical and the product has good dispersibility; and the production process is free of ammonia nitrogen pollution, so that continuous production is realized, and the equipment utilization rate and the production efficiency are improved.

Owner:湖南红太阳电源新材料股份有限公司

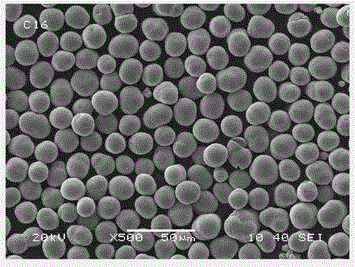

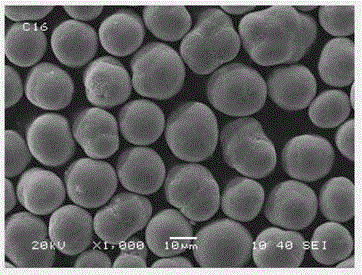

Method for preparing high-sphericity-degree and large-particle cobaltosic oxide

InactiveCN105800699AGuarantee quality stabilityPromote productionCell electrodesCobalt oxides/hydroxidesSodium bicarbonateReaction temperature

The invention relates to a method for preparing high-sphericity-degree and large-particle cobaltosic oxide. The method includes the steps that at least one of cobalt chloride, cobaltous sulfate and cobalt nitrate serves as a raw cobalt salt material, and is purified and prepared to obtain a cobalt salt solution; at least one of ammonium carbonate, ammonium bicarbonate, sodium carbonate and sodium bicarbonate serves as a precipitant; a precursor is prepared with the solution direct precipitation method, and added into a reaction vessel with the concurrent adding method, the parameters of the injecting speed, the reaction temperature, the stirring speed, the PH value and the like of the solution are controlled, the batch-type crystallization technology and the kettle dividing technology are adopted, the chemical impurities of the precursor and the crystallinity degree, the granularity, the density and the like of crystals are effectively controlled, a precipitate precursor is synthesized, washing and centrifuging are carried out, then sintering is carried out twice, and the high-sphericity-degree and large-particle cobaltosic oxide is finally obtained. The method is simple in technology and low in cost, and the prepared cobaltosic oxide is high in cut-off voltage, tap density and stability.

Owner:HUNAN HINA NEW MATERIALS

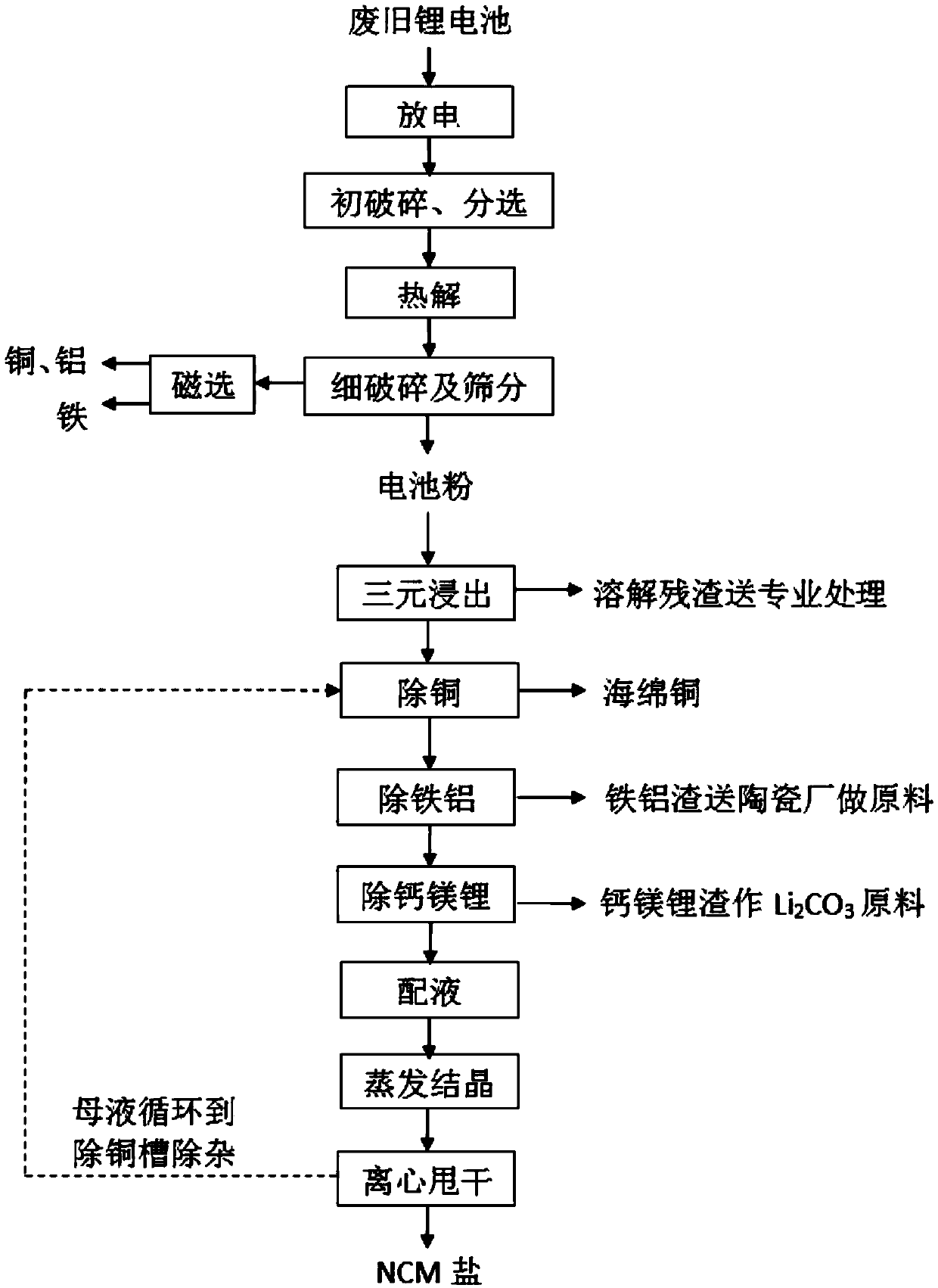

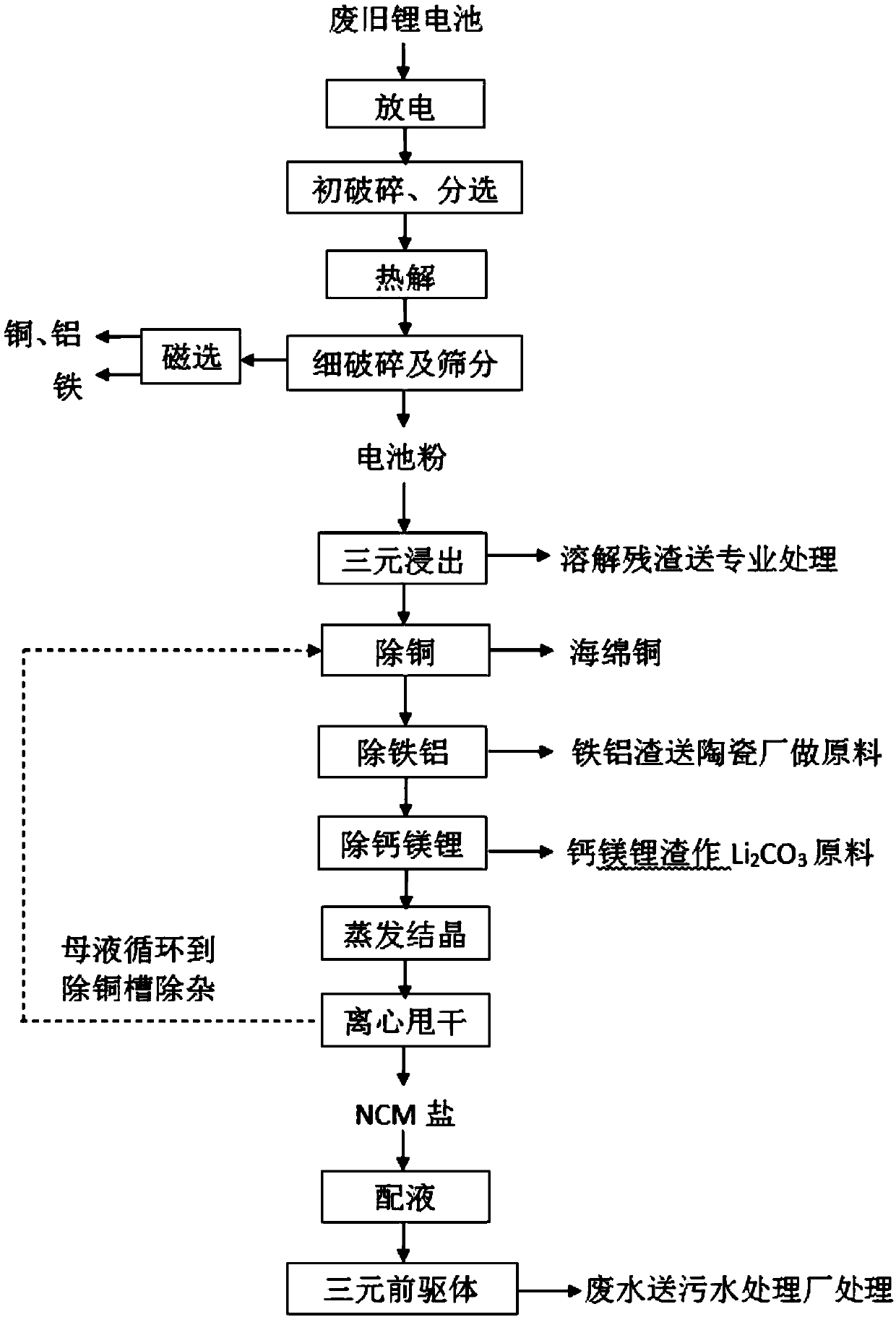

Method for recycling spent lithium-ion batteries to manufacture NCM salt

ActiveCN107768763AAchieve recyclingAchieving zero emissionsWaste accumulators reclaimingBattery recyclingPotassiumManganese

The invention provides a method for recycling spent lithium-ion batteries to manufacture NCM salt (a sulfate mixture containing nickel, cobalt and manganese). The process comprises the steps of crushing, pyrolyzing, sorting, leaching, purifying, dosing and crystalizing. The method provided by the invention has the beneficial effects that on one hand, no soluble alkali metal ions (such as potassiumand sodium) is carried in the whole production process, so that water recycling can be realized, wastewater zero discharging is realized, and a lot of water resources are saved; on the other end, after a purification liquid is dosed, a certain proportion of NCM salt is obtained by utilizing a crystalizing principle, so that an extraction process is avoided in the process, and the generation of alot of wastewater and waste gas is avoided. In addition, the NCM slat provided by the invention can be used as a raw material for producing a precursor, and according to a proportion requirement of the precursor material, bits of nickel sulfate, cobaltous sulfate and manganese sulfate are used for adjusting so as to accomplish the preparation before precursor synthesis, so that the process is simplified, and meanwhile, the production efficiency is improved.

Owner:湖北碧拓新材料科技有限公司

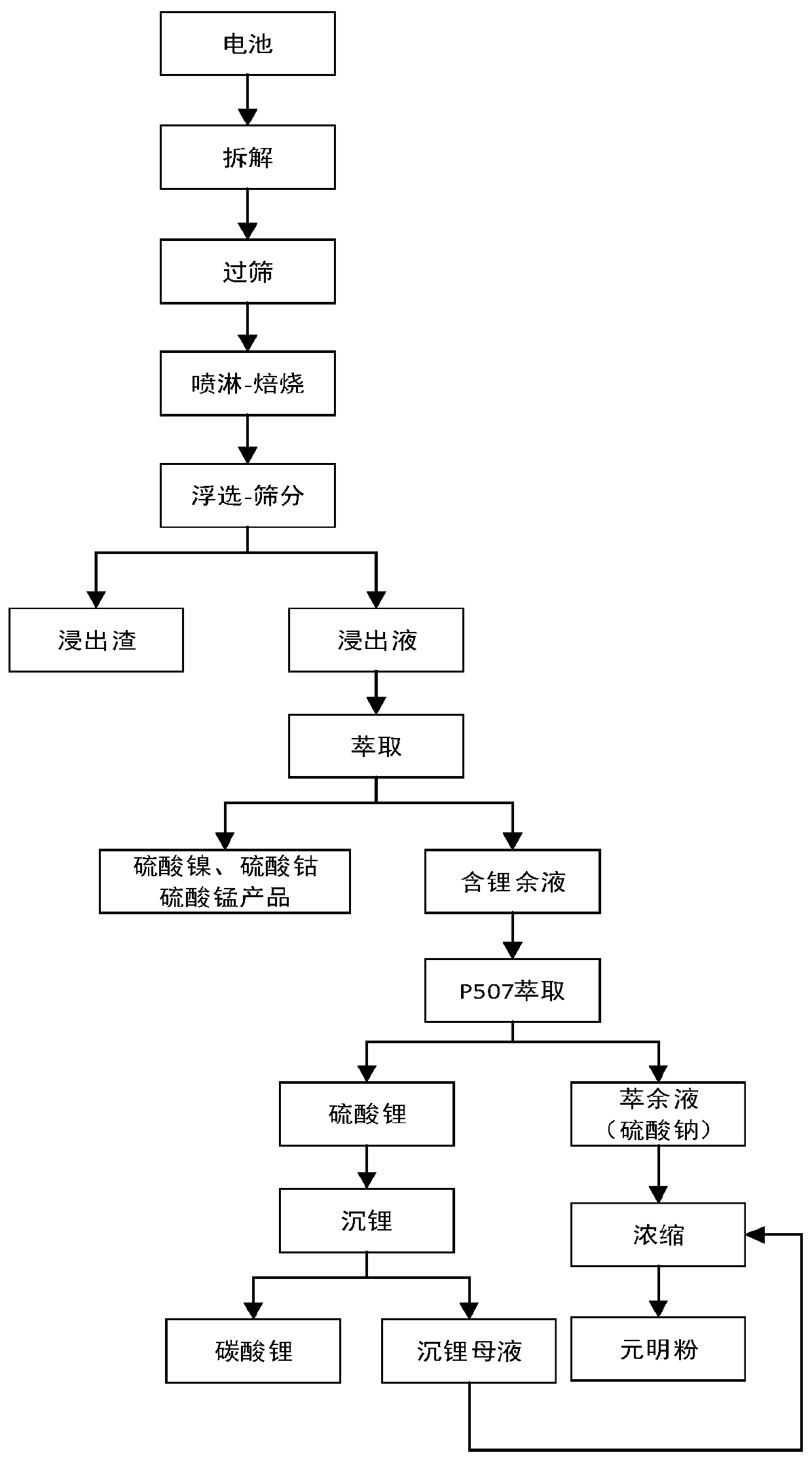

Power lithium ion battery all metal recycling and cyclic utilizing method

ActiveCN110616331AAchieve recyclingShort processCobalt sulfatesWaste accumulators reclaimingElectrical batteryLithium carbonate

The invention discloses a power lithium ion battery all metal recycling and cyclic utilizing method. Waste lithium ion batteries serve as raw materials, the disassembling-screening and roasting procedures are adopted for separating battery pole powder from other parts in the batteries, then, acid leaching is conducted, and leaching liquid containing cobalt, nickel, manganese and lithium is obtained; through extraction, separation and purification of cobalt, nickel, manganese and lithium are achieved, battery-level cobaltous sulfate, nickel sulfate and manganese sulfate are obtained, then, lithium-sodium separation is conducted, and lithium carbonate and sodium sulfate products are obtained through lithium deposition and concentration. The power lithium ion battery all metal recycling and cyclic utilizing method is green and efficient, danger waste generation is avoided, and large-scale production can be achieved. Various valuable metals are systematically recycled from the waste powerlithium batteries, according to the recycling rates, Co is larger than 95%, Ni is larger than 95%, Mn is larger than 98%, Li is larger than or equal to 94%, and the water cyclic utilization rate is larger than 95%. Nickel sulfate liquid, cobaltous sulfate liquid, manganese sulfate liquid and lithium carbonate obtained through the power lithium ion battery all metal recycling and cyclic utilizing method meet the battery level product standard.

Owner:衢州华友资源再生科技有限公司

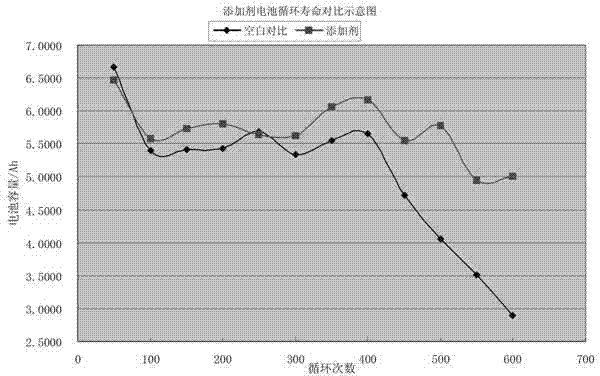

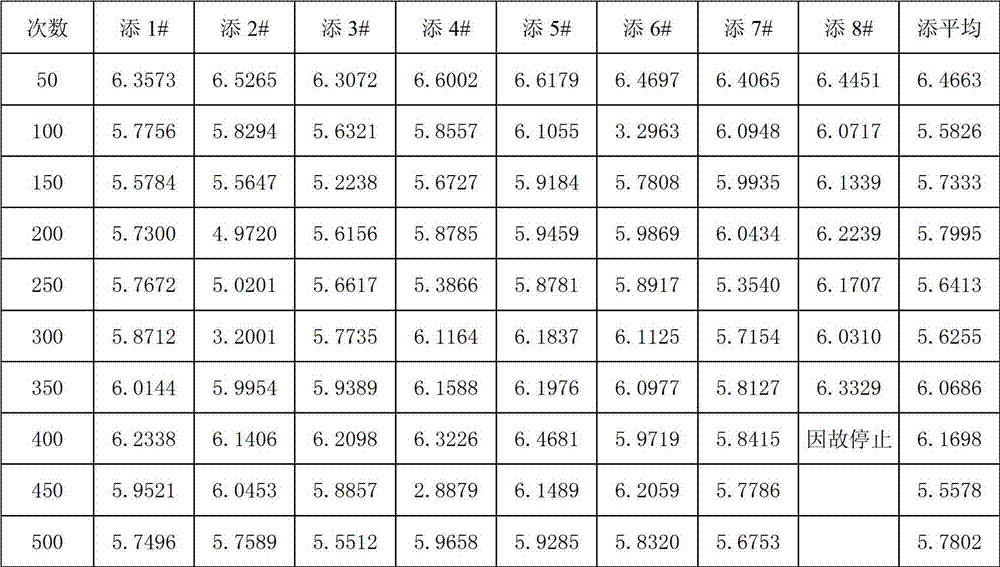

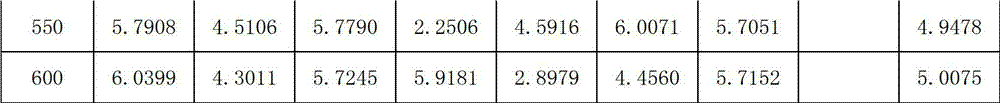

Lead acid storage battery electrolyte additive and preparation method thereof

ActiveCN103050738ALower internal resistanceReduce heatLead-acid accumulatorsEthylenediamineInternal resistance

The invention discloses a lead acid storage battery electrolyte additive and a preparation method thereof. Concentrated sulphuric acid is added into a certain quantity of purified water obtained through ion exchange to prepare dilute sulfuric acid, EDTA (Ethylene Diamine Tetraacetic Acid), aluminum sulfate, sodium sulfate, cadmium sulfate, stannous sulfate, magnesium sulfate, cobaltous sulfate, copper sulfate and potassium sulfate are added into 1L dilute sulfuric acid, which is taken out and heated, step by step according to the formula quantity, and the mixture is fully stirred and cooled to the room temperature to obtain the lead acid storage battery electrolyte additive. According to the invention, the cycle life of a traditional storage battery is remarkably improved, lead dendritic crystals in the battery are effectively prevented from short circuit, the internal resistance of the battery in the later period of cycle life is reduced, the charge acceptance capability is improved, water loss during charging is reduced, heat generated during battery charging is decreased and the battery is protected against thermorunaway. The lead acid storage battery electrolyte additive is suitable for various lead acid storage batteries, such as lead acid storage batteries for starting up automobiles and motorcycles, deep-cycle batteries and AGM (Absorptive Glass Mat) valve-regulated sealed lead acid storage batteries for power vehicles, flat-plate / tubular flooded storage batteries and flat-plate / tubular colloid storage batteries and the like.

Owner:易德维能源科技(深圳)有限公司

Method for preparing nanometer cobalt blue dye

InactiveCN1831047ASmall particle sizeSimple production processPigmenting treatmentTitanium tetrachlorideSodium hydroxide

This invention discloses a preparation method of nm cobalt blue, and it belongs to synthetic technique of nm spinel style colorant. This method includes following procedures cobaltous sulfate and aluminium sulphate, chromic chloride and titanium tetrachloride are mixed with water and agitated to solve, there mol ratio is that 1:(0.5-2): (0-3): (0-3), then they are heated and sodium hydrate solution is added to adjust pH value to 8-10. They are agitated, aging and water flushed, the precipitate stuff is hydrothermal cultivated at 160-260 degrees centigrade, then the hydrothermal cultivated stuff is filtrated, dried and crashed, finally it is solid phase high temperature crystallized at 900-1200 deg.C to get nm cobalt blue product. The advantage of this invention is that two step ways synthetic technique are used, so the particles can reach nm grade after high temperature crystallization, the particle diameter of cobalt blue particles made is small, the average particle diameter is 30-80nm, and its production technique is simple, energy consumption is relatively low.

Owner:TIANJIN UNIV

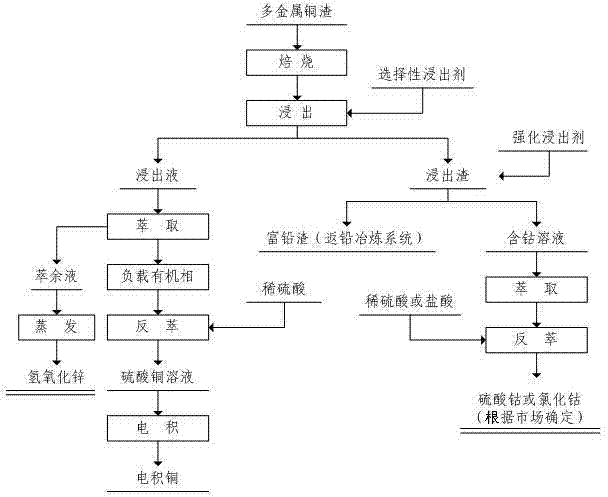

Method for producing electrodeposited copper from polymetallic copper slag

ActiveCN104846202AImprove leaching efficiencyHigh recovery ratePhotography auxillary processesProcess efficiency improvementZinc hydroxideLead smelting

The invention discloses a method for producing electrodeposited copper from polymetallic copper slag, which includes the following steps: the polymetallic copper slag is roasted to oxidize, so that the complex states of valuable metals in the polymetallic copper slag are transformed into oxides, changed into a state which can be selectively leached; leaching first adopts selective leaching agent to leach copper and zinc, the leachate is extracted, reextracted and electrodeposited, so that electrodeposited copper is obtained, and raffinate is vaporized and crystallized, so that zinc hydroxide is obtained; mechanical intensified leaching agent is then used for intensely leaching leaching residue, so that cobalt, nickel and the like in the leaching residue are leached, lead, iron and the like are enriched into the slag, the lead-rich slag is adopted as material for lead smelting, the leachate is extracted and reextracted, so that cobaltous sulfate or cobalt chloride is obtained, and if the nickel content in the leachate is overhigh, multi-stage extraction can be carried out to separate cobalt and nickel, so that nickel sulfate or nickel chloride is produced. The method can comprehensively recover a variety of metals, the leaching efficiency is high, the recovery rate is high, the method is environment-friendly, and is easy to implement, the method ensures that all the valuable metals in the polymetallic copper slag can be effectively separated and recycled, and the solid waste utilization rate can reach more than 99 percent.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

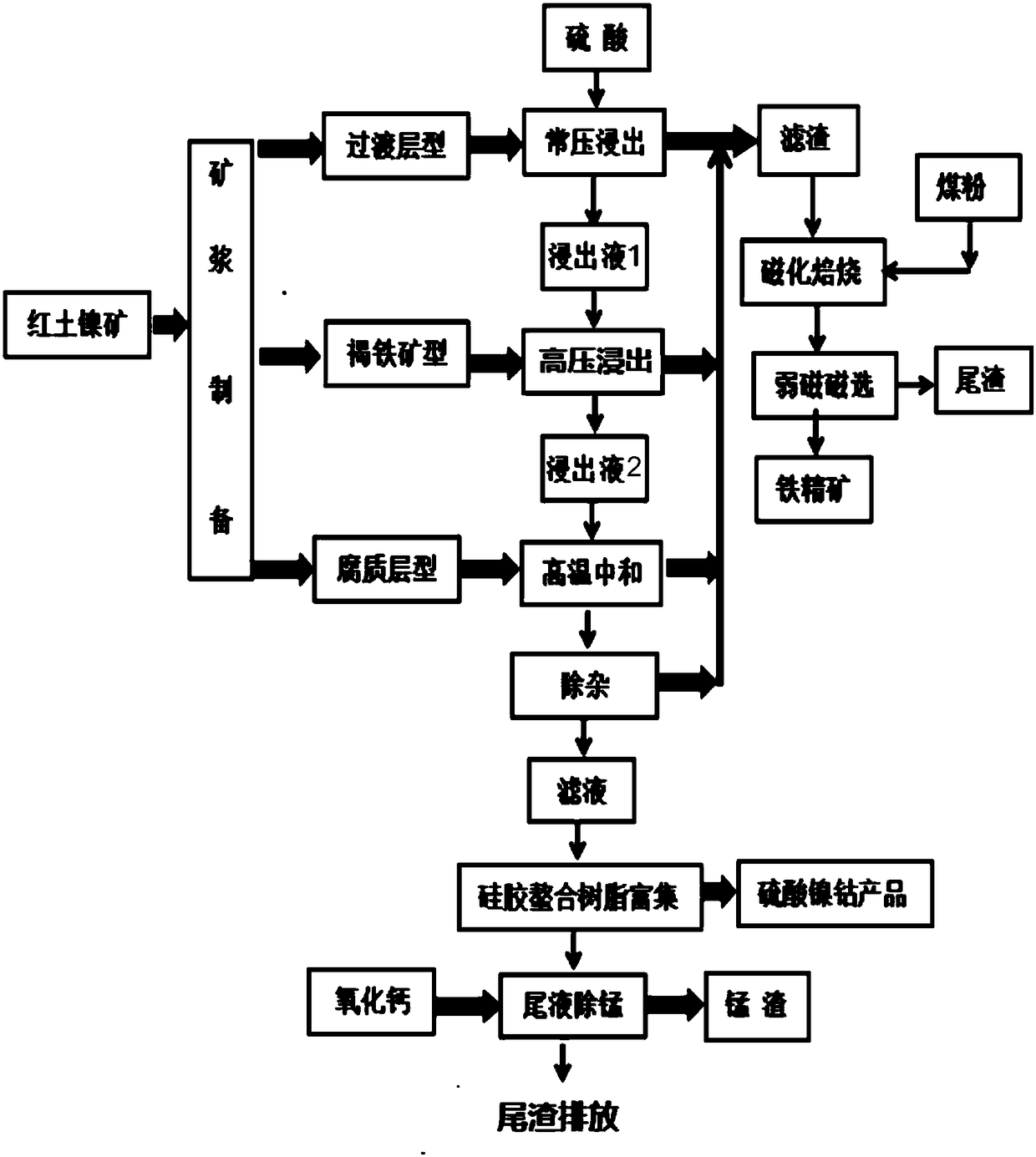

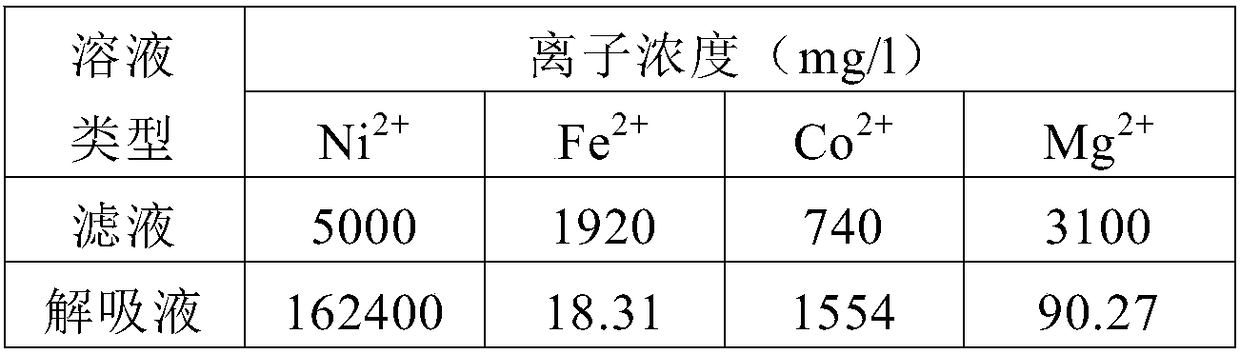

Method for producing nickel sulfate and cobaltous sulfate through purification of laterite nickel ore sulfuric acid leaching solution and silica gel chelate resin

InactiveCN108396157ASolve the solid-liquid separation processReduce production and operation costsProcess efficiency improvementMagnetic separationManganeseSilica gel

The invention provides a method for producing nickel sulfate and cobaltous sulfate through purification of a laterite nickel ore sulfuric acid leaching solution and silica gel chelate resin. The method comprise the steps that (1), laterite nickel ores (the limonite type, transition layer type and detritus layer type) are subjected to ore grinding to -0.15 mm of ore powder accounting for 95% or above; (2), sulfuric acid and water are added into the transition layer type of laterite nickel ore after ore grinding for atmospheric pressure leaching to separate a leaching solution 1 from filter residues 1; (3), the limonite type of laterite nickel ore is placed into an autoclave, and sulfuric acid and water are added for high pressure leaching to separate a leaching solution 2 from filter residues 2; (4), the leaching solutions are added into the detritus layer of laterite nickel ore for neutralization impurity-removing leaching to separate a neutralization solution from filter residues 3; (5), hydrogen peroxide is added for reaction precipitation, and solid-liquid separation is conducted to separate a filtrate from filter residues 4; (6), the filtrate is subjected to silica gel chelateresin separation to produce nickel sulfate and cobaltous sulfate; (7), pulverized coal is added into the filter residues, magnetizing roast is conducted, then weak magnetic separation is conducted, and iron ore concentrate and tailings are separated; (8), manganese removing of a tail liquid is conducted; and (9), the tailings is discharged.

Owner:李宾

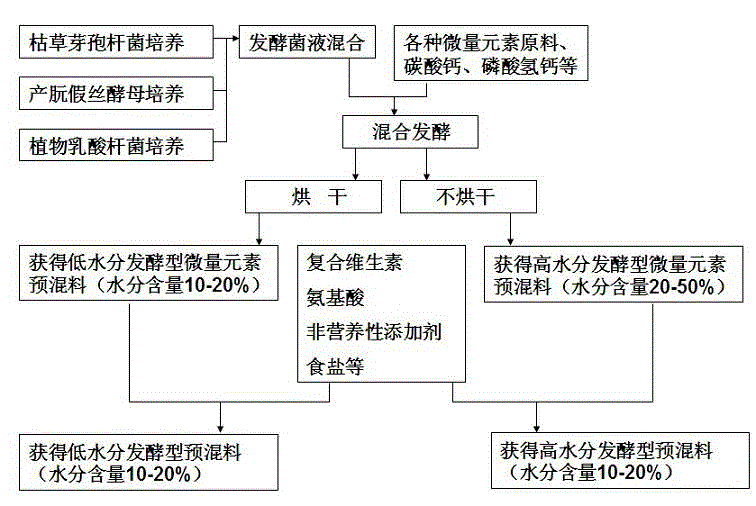

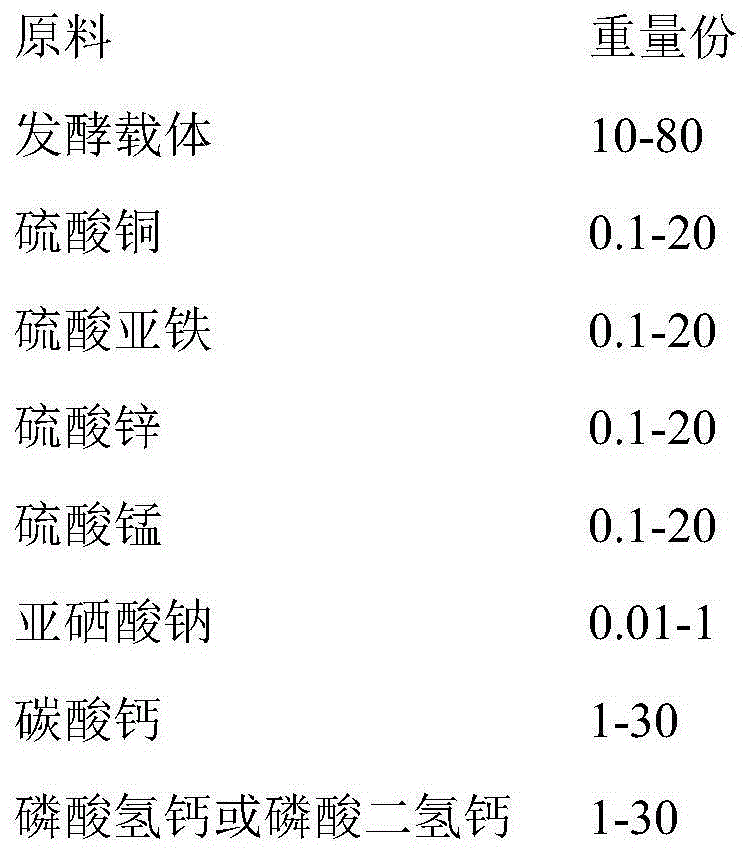

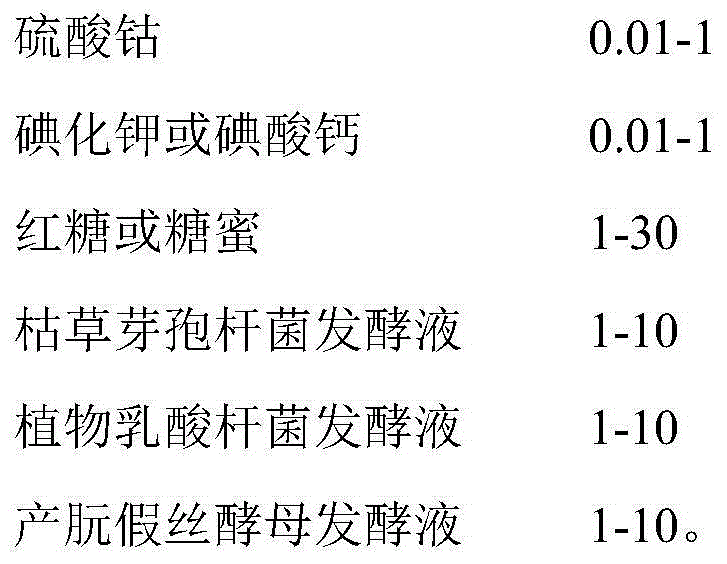

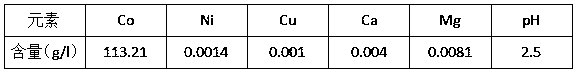

Fermentation trace element premix and preparation method thereof as well as fermentation composite premix and preparation method thereof

ActiveCN104798990AAdd lessImprove utilization efficiencyAnimal feeding stuffManganesePotassium iodine

The invention discloses a fermentation trace element premix and a preparation thereof as well as a fermentation composite premix and a preparation method thereof. The fermentation trace element premix comprises raw materials of bacillus subtilis, lactobacillus plantarum, candida utilis, a fermentation carrier, copper sulfate, ferrous sulfate, zinc sulfate, manganese sulfate, sodium selenite, calcium carbonate, calcium hydrophosphate, cobaltous sulfate and potassium iodide. The preparation method of the fermentation trace element premix comprises the following steps of uniformly mixing the raw materials according to a certain proportion; adjusting the water content; packaging the mixture with an airtight packaging bag; tightening a bag mouth and fermenting; drying or not drying a fermented product to obtain the fermentation trace element premix. The preparation method of the fermentation composite premix comprises the following steps of mixing the prepared fermentation trace element premix with vitamin, edible salts, an enzymic preparation, a non-nutritional additive, amino acid and the like according to the certain proportion, and packaging. According to the fermentation trace element premix and the fermentation composite premix, the formula is reasonable, the use is convenient, the animal feed intake is improved, the utilization rate of feed is improved, the animal diarrhea rate is reduced, the immunity and disease resistance of animals are improved, the environmental pollution is reduced, and the sustainable development of animal husbandry is promoted.

Owner:王升平

Production method of electronic-grade cobaltous sulfate solution

InactiveCN108441633AImprove qualityGuaranteed ExtractionProcess efficiency improvementDissolutionImpurity

The invention belongs to the technical field of chemical engineering, and relates to a production method of an electronic-grade cobaltous sulfate solution. The production method comprises the steps that cobalt raw materials are subjected to slurrying dissolution and purification and iron removal to obtain a crude cobaltous sulfate solution with the high impurity content, impurities such as Ca, Cuand Mn are removed through a P204 organic extracting agent, obtained raffinate is extracted with a P507 organic extracting agent to separate nickel and cobalt and remove Mg, sulfuric acid is adopted as reverse extraction liquid in the reverse extraction section of the P507 organic extracting agent, then a high-quality refined cobaltous sulfate solution is obtained, supplementary extraction is conducted on the refined cobaltous sulfate solution through the P204 organic extracting agent, Ca and Cu are removed through deep purification, and a high-quality cobaltous sulfate solution is obtained. The impurities are discharged out of the system in an acid pickling mode in all washing sections in the extraction process and then recycled after being organically regenerated.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

Method for measuring sulfur dioxide content in food

InactiveCN102590193AAccurate determination of residuesOvercome the disadvantage of being easily interfered by the color of the food itselfChemiluminescene/bioluminescenceLuminol chemiluminescenceSulfite

The invention relates to a sulfur dioxide detecting method, in particular to a method for detecting sulfur dioxide content in food by utilizing the luminol chemiluminescence principle. In the method, luminol is taken as a lighting agent, oxygen in air is taken as an oxidizing agent, a sulphurous acid root is taken as a sensitizing agent, cobaltous sulfate is taken as a catalyst of a luminol-air-sulphurous acid root ion chemiluminescence system, and the concentration of the sulfite can be determined in a way that the change of the total lighting intensity of the system before and after sulfitesolution is determined, and the change is compared with that of the standard series, and furthermore, the sulfur dioxide content in the food can be determined. According to the method, the stability is good, the measuring result is reliable, the using amount of reagents is less, the convenience and the rapidness are achieved, and the cost is low. The method in the invention is adopted to accurately determine the residual amount of sulfur dioxide in dried fruits, dried vegetables, silk noodles and other food.

Owner:SHANXI UNIV

Process for recycling spent lithium-ion batteries to manufacture ternary precursor

ActiveCN107768764AMeet quality requirementsAvoid it happening againCell electrodesWaste accumulators reclaimingPotassiumManganese

The invention provides a process for recycling spent lithium-ion batteries to manufacture a ternary precursor. The process mainly comprises the steps of crushing, pyrolyzing, sorting, leaching, purifying, dosing, crystalizing and precursor synthesizing. The method provided by the invention has the beneficial effects that (1) no soluble alkali metal ions (such as potassium and sodium) is carried inthe whole sulfate production process, so that water recycling can be realized in the whole sulfate production process, and a lot of water resources are saved; (2) a certain proportion of NCM sulfatemixture is obtained by utilizing a crystalizing principle, so that a quality requirement on producing the ternary precursor can be met, an extraction process is avoided, and the generation of a lot ofwastewater and waste gas is avoided; (3) according to an ingredient proportion requirement of the ternary precursor material, bits of nickel sulfate, cobaltous sulfate and manganese sulfate are usedfor adjusting so as to accomplish the preparation before synthesis, so that the process is simplified, and meanwhile, the production efficiency is improved.

Owner:湖北碧拓新材料科技有限公司

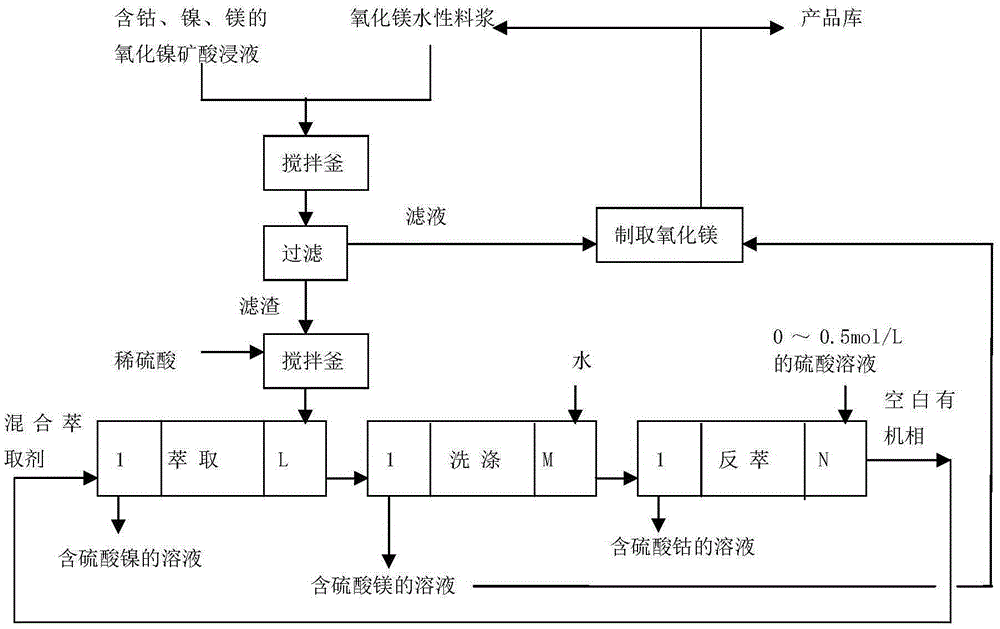

Method for separating cobalt, nickel and magnesium from nickel oxide ore pickle liquor

ActiveCN105296753AReduce concentrationAchieve separationProcess efficiency improvementProcess engineeringMagnesium

The invention discloses a method for separating cobalt, nickel and magnesium from nickel oxide ore pickle liquor. The method comprises the following steps that the pickle liquor on which iron removing operation is carried out is arranged in a stirring kettle, the pickle liquor contains cobalt, nickel and magnesium, magnesium oxide water-based slurry is added, the mass concentration of magnesium oxide in the magnesium oxide water-based slurry is controlled to be smaller than or equal to 80%, and the dosage of magnesium oxide is 0.001-0.01 time of the mass of nickel oxide ore pickle liquor; the stirring reaction is carried out till thorough deposition, filtering and separating are carried out to obtain filter residues and filter liquor, and the filter liquor is fed in the pickle liquor treatment procedure to prepare magnesium oxide for repeated utilization; after being dissolved through dilute acid, the filter residues are introduced into an extraction system, extraction separation is carried out through a mixing extraction agent, a solution containing nickel sulfate and cobaltous sulfate is obtained at an outlet of an extraction trough and an outlet of a reverse extraction trough, and after reverse extraction is carried out on the mixing extraction agent through dilute acid, the mixing extraction agent returns to the extraction trough to be circularly utilized. According to the method, complete separation of cobalt, nickel and magnesium is achieved, saponification of the extraction agent is not needed, the cobalt and nickel separation efficiency is high, the consumption of a reagent is low, and the separation cost is low.

Owner:GUANGXI NORMAL UNIV

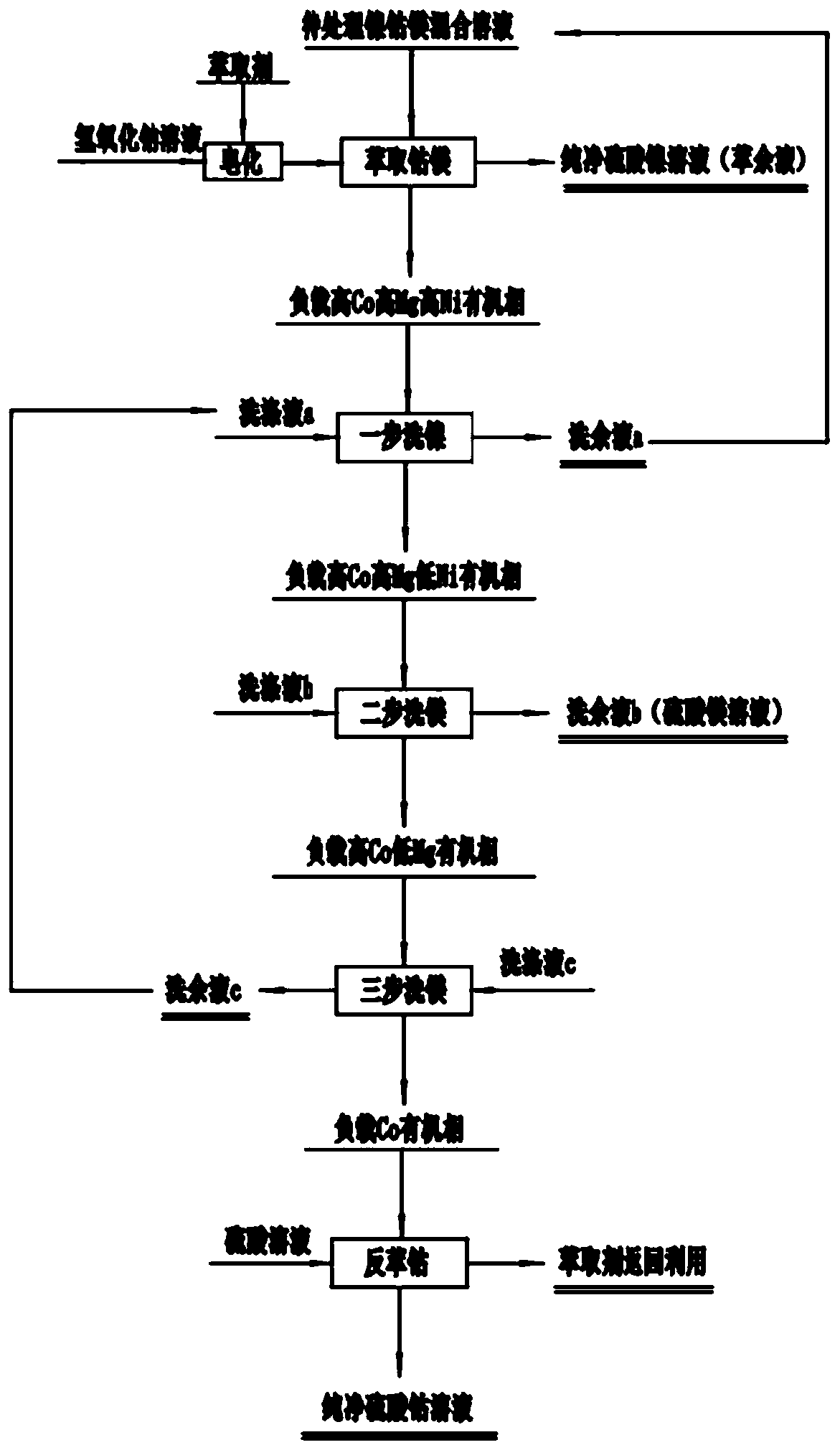

Method for extracting and separating nickel, cobalt and magnesium from nickel, cobalt and magnesium mixed solution

ActiveCN111411228AReduce lossesHigh yieldProcess efficiency improvementElectrical batteryPhysical chemistry

The invention relates to the technical field of batteries, and discloses a method for extracting and separating nickel, cobalt and magnesium from a nickel, cobalt and magnesium mixed solution. The method is applied to the nickel, cobalt and magnesium mixed solution with the nickel content of 50-100 g / L, the cobalt content of 5-20 g / L and the magnesium content of 3-15 g / L. The method includes the following steps of firstly, extracting cobalt and magnesium; secondly, washing nickel in the first step; thirdly, washing magnesium in the second step; fourthly, washing magnesium in the third step; and fifthly, performing reverse extraction on cobalt. By means of the method, it is ensured that the content of impurities in a nickel sulfate product and a cobaltous sulfate product meet the requirement of battery materials in the nickel washing and magnesium washing process, the loss of nickel and cobalt is reduced, the product quality is good, the nickel yield and cobalt yield are high, the technological process is simple, cost is low, and the nickel sulfate product and the cobaltous sulfate product for the battery materials can be obtained after deoiling and crystallizing steps are performedon a pure nickel sulfate solution and a pure cobaltous sulfate solution.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

Textile fabric coloring agent

The invention discloses a textile fabric coloring agent. The textile fabric coloring agent is prepared from the following raw materials in parts by weight: 8 to 12 parts of cobaltous sulfate, 7 to 10 parts of aluminum ammonium sulfate, 3 to 7 parts of butyl methacrylate, 2 to 5 parts of ethyl acetate, 3 to 6 parts of trimethylolpropane, 7 to 9 parts of camphor tree leaf extract liquor, 6 to 8 parts of ferrous sulfate, 5 to 10 parts of aluminum sulfate, 3 to 7 parts of glycerol, 2.5 to 3.2 parts of hydroxypropyl methyl cellulose, 1 to 4 parts of imidazoline, 1.2 to 2.4 parts of 2-naphthol and 12 to 26 parts of modified starch. The textile fabric coloring agent has the beneficial effects of high colorability, prevention of fading, bright color and harmlessness to human bodies.

Owner:QINGDAO DEXITUOCHUANG HIGH TECH CO LTD

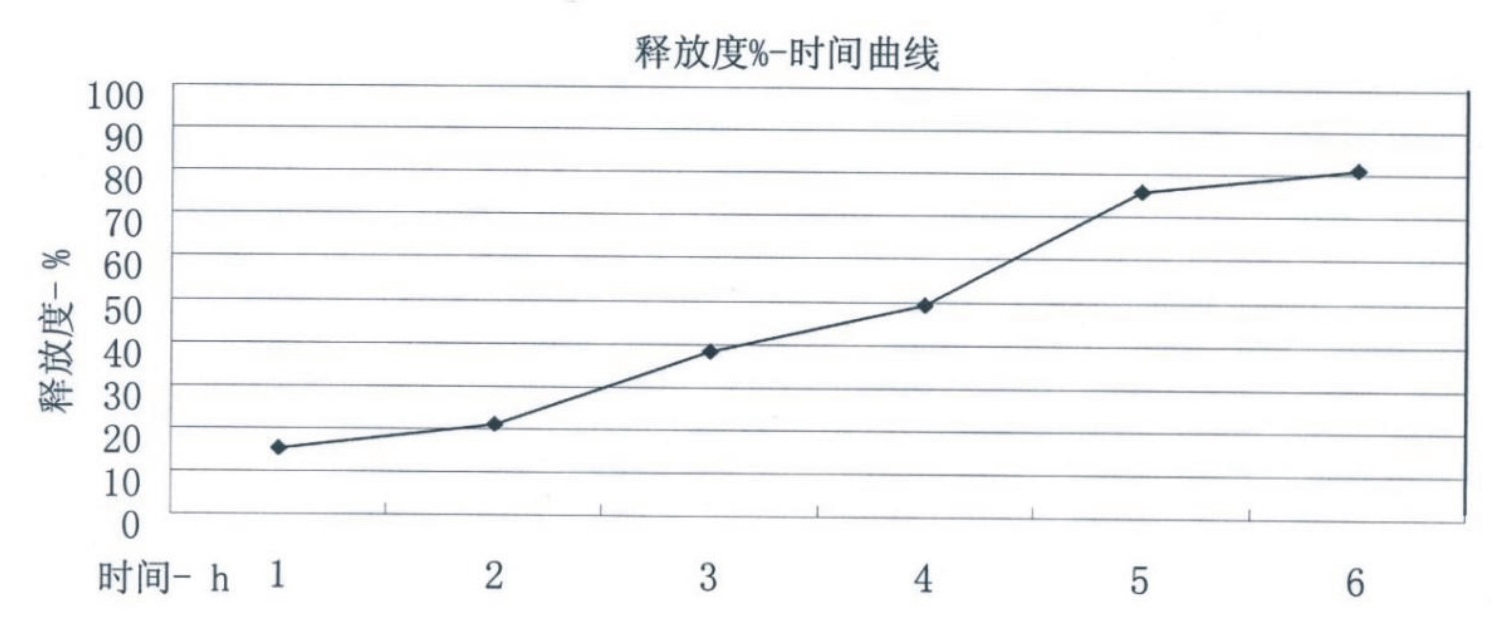

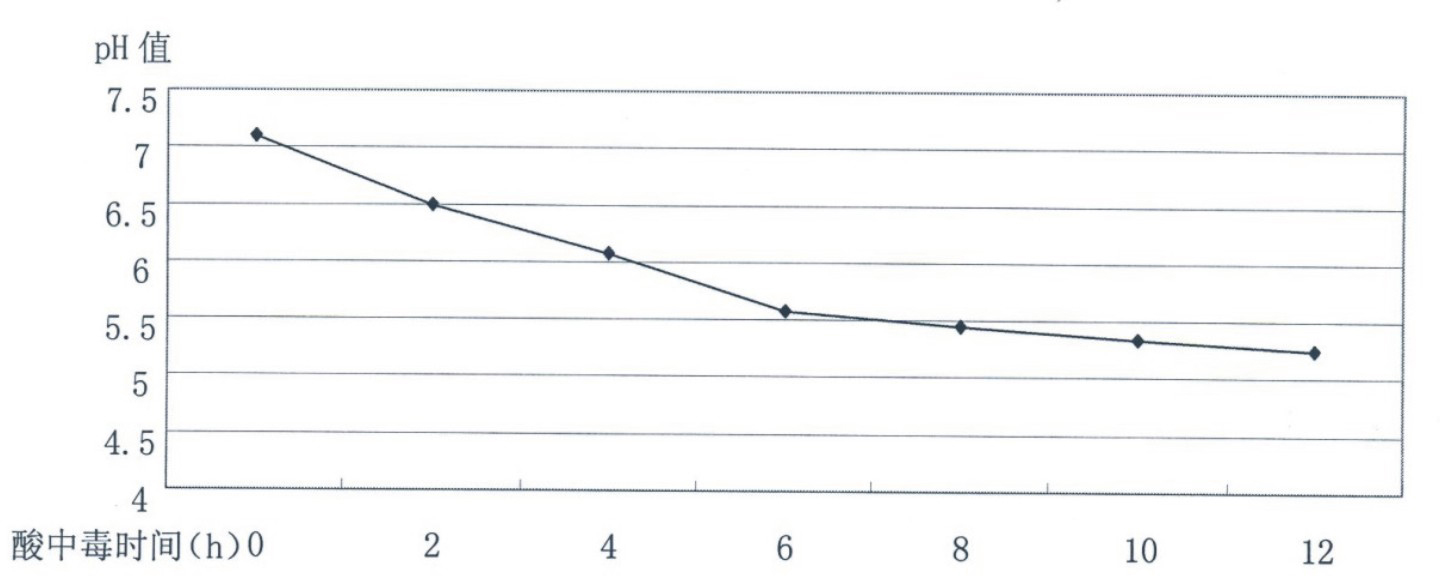

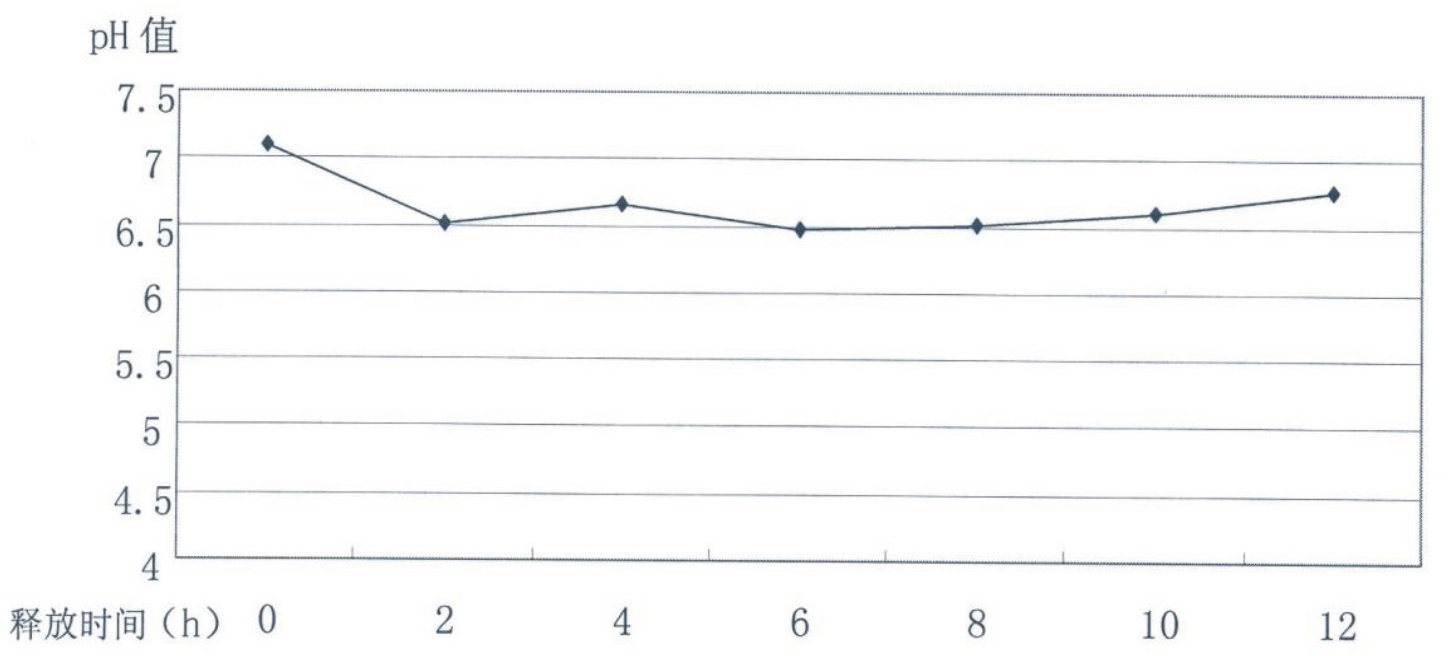

Slow-release regulating agent for preventing rumen acidosis and preparation method thereof

ActiveCN102068454AImprove fermentation functionPromote repairOrganic active ingredientsHeavy metal active ingredientsSodium bicarbonateVolatile fatty acids

The invention discloses a slow-release regulating agent for preventing rumen acidosis and a preparation method thereof, which relate to the field of scientific nutrition of animals. The slow-release regulating agent comprises the following raw material components by gram: 0.3 to 0.5 gram of sodium bicarbonate, 0.15 to 0.17 gram of magnesium oxide, 0.01 to 0.03 gram of nicotinic acid, 0.01 to 0.03 gram of cobaltous sulfate, 0.01 to 0.03 gram of zinc sulfate, 0.01 to 0.03 gram of hydroxypropyl methyl cellulose and 0.3 to 1.5 gram of starch. The preparation method comprises the following preparation steps of: 1. sieving the sodium bicarbonate, the magnesium oxide, the nicotinic acid, the cobaltous sulfate and the zinc sulfate; 2. uniformly mixing the sieved components and an appropriate amount of starch; 3. adding an appropriate amount of absolute ethyl alcohol and stirring for pelletizing; 4. drying and weighing; 5. adding the sodium bicarbonate and mixing uniformly; and 6. calculating tablet weight and tableting. With the invention, the conventional method in which excessive volatile fatty acid produced in a rumen is neutralized by directly filling sodium bicarbonate or adding magnesium oxide is changed. Rumen acidosis is prevented, the treatment effect on rumen acidosis is enhanced, and direct damages to the rumen membranes of ruminants and microbial floras in rumens are reduced.

Owner:SICHUAN AGRI UNIV +2

Method for extracting cobalt-manganese metal compound from active sludge

InactiveCN101037235AAvoid pollutionHigh recovery rateSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationActivated sludgeFiber

The present invention relates to a method of extracting metallic compound of cobalt and manganese from activated sludge, which belongs to the technique field of environmental protection comprehensive treatment and utilization. In the present invention, the activated sludge is subjected to drying, incinerating, acid-dissolution and relative adsorption, and extraction technology so as to obtain cobaltous sulfate and manganess sulfate. The rate of recovery of cobalt and manganese is more than 90%; the cost is low, the processing cost of metallic cobalt is only 50 thousand yuan per tone; the purity is high, the purity of cobaltous sulfate and manganese sulfate can meet the relative standard. The present invention has obvious economic benefits and social benefits, which can not only solve the sludge pollution caused by chemical fiber industry, but also obtain economic interest during the harnesing of sludge pollution.

Owner:YIZHENG MAORUI CHEM

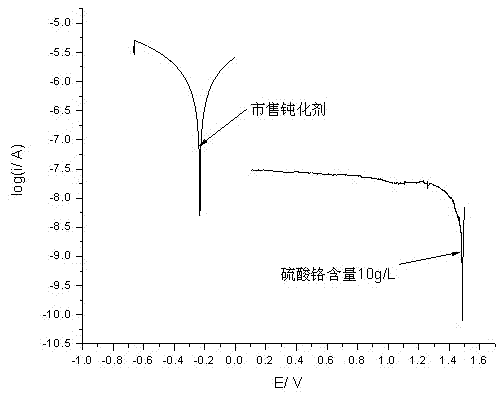

High corrosion resistance trivalent chromium blue and white passivating liquid as well as preparation method and application of blue and white passivating liquid

ActiveCN103046037AImprove performanceExtended service lifeMetallic material coating processesSodium Hypophosphite MonohydrateSodium phosphates

The invention discloses high corrosion resistance trivalent chromium blue and white passivating liquid and a preparation method of the blue and white passivating liquid. Calculated by each litre, the high corrosion resistance trivalent chromium blue and white passivating liquid consists of 5-25g of chromium sulfate, 2-8g of sodium fluoride, 1-6g of sodium hypophosphite, 0.3-1.5g of citric acid, 1-5g of sodium nitrate, 5-15g of cobaltous sulfate heptahydrate and the balance of deionized water. The preparation method comprises the following steps of: dissolving the chromium sulfate into the deionized water; adding citric acid to stir and dissolve; adding the sodium hypophosphite and the sodium nitrate to stir again until the solutions are completely dissolved; adding the cobaltous sulfate heptahydrate into the solutions to be dissolved; and finally adding the sodium fluoride to continuously stir to uniformly mix the raw materials to obtain the high corrosion resistance trivalent chromium blue and white passivating liquid which is stable in performance, long in service life, low in production cost and environment-friendly, and avoids toxicity. The preparation method for the trivalent chromium blue and white passivating liquid is simple, easy to operate, and suitable for industrial production.

Owner:SHANGHAI INST OF TECH

An improved novel fertilizer and a preparation method thereof

InactiveCN103641587ASimple structureEasy to get materialsFertilizer mixturesPlant growthCopper sulfate

The invention discloses an improved novel fertilizer and a preparation method thereof. The fertilizer is prepared from following raw materials in parts by weight: 40-50 of decomposed farmyard manure, 25-30 of straw scraps, 15-20 of urea, 10-15 of alginic acid, 11-14 of boric acid, 5-10 of acrylic acid, 5-8 of polyacrylamide, 15-20 of sodium sulfate, 10-15 of zinc sulfate, 2-5 of cobaltous sulfate, 4-9 of potassium chloride, 3-8 of glycol, 11-14 of copper sulfate, 10-13 of sodium molybdate, 5-10 of manganese sulfate, 1-2 of an EM microbial inoculum and 7-11 of a soil modifier. The decomposed farmyard manure, the straw scraps, and other raw materials are adopted by the fertilizer. The raw materials are convenient to take, low in cost and comprehensive in nutrition, and can improve the soil structure. The urea, the alginic acid, the boric acid, the acrylic acid, and other chemical raw materials are added for supplementation, thus fully utilizing resources, reducing the production investment, and reducing pollution caused by chemical fertilizers. The added alginic acid not only contains a large quantity of organic materials, more than forty mineral elements such as potassium, calcium, magnesium, iron, etc. and rich vitamins, but also contains algal polysaccharides, highly unsaturated fatty acids and a plurality of natural plant growth regulators, and has high biological activity.

Owner:MAANSHAN KEBANG ECO FERTILIZER

Cobalt nickel phosphorus-silicon carbide electroplating solution and electroplating method

The invention relates to a cobalt nickel phosphorus-silicon carbide electroplating solution and an electroplating method, and solves the technical problems of high brittleness, poor wear resistance, low electrodeposition speed, and existence of microcracks in the surface and holes after plating in the existing electroplated tungsten alloy. The electroplating solution contains the following components in parts by weight: 1000 parts of deionized water, 1-5 parts of cobaltous sulfate, 120-180 parts of nickel sulfate, 5-20 parts of phosphorous acid, 10-40 parts of silicon carbide, 45-75 parts of sodium citrate, 15-25 parts of lactic acid, 1-2 parts of saccharin and 0.2-0.6 part of dimethyl hexynol. The invention also relates to an electroplating method. The electroplating solution and electroplating method can be widely used for surface treatment of metal workpieces.

Owner:合鸿新材科技有限公司

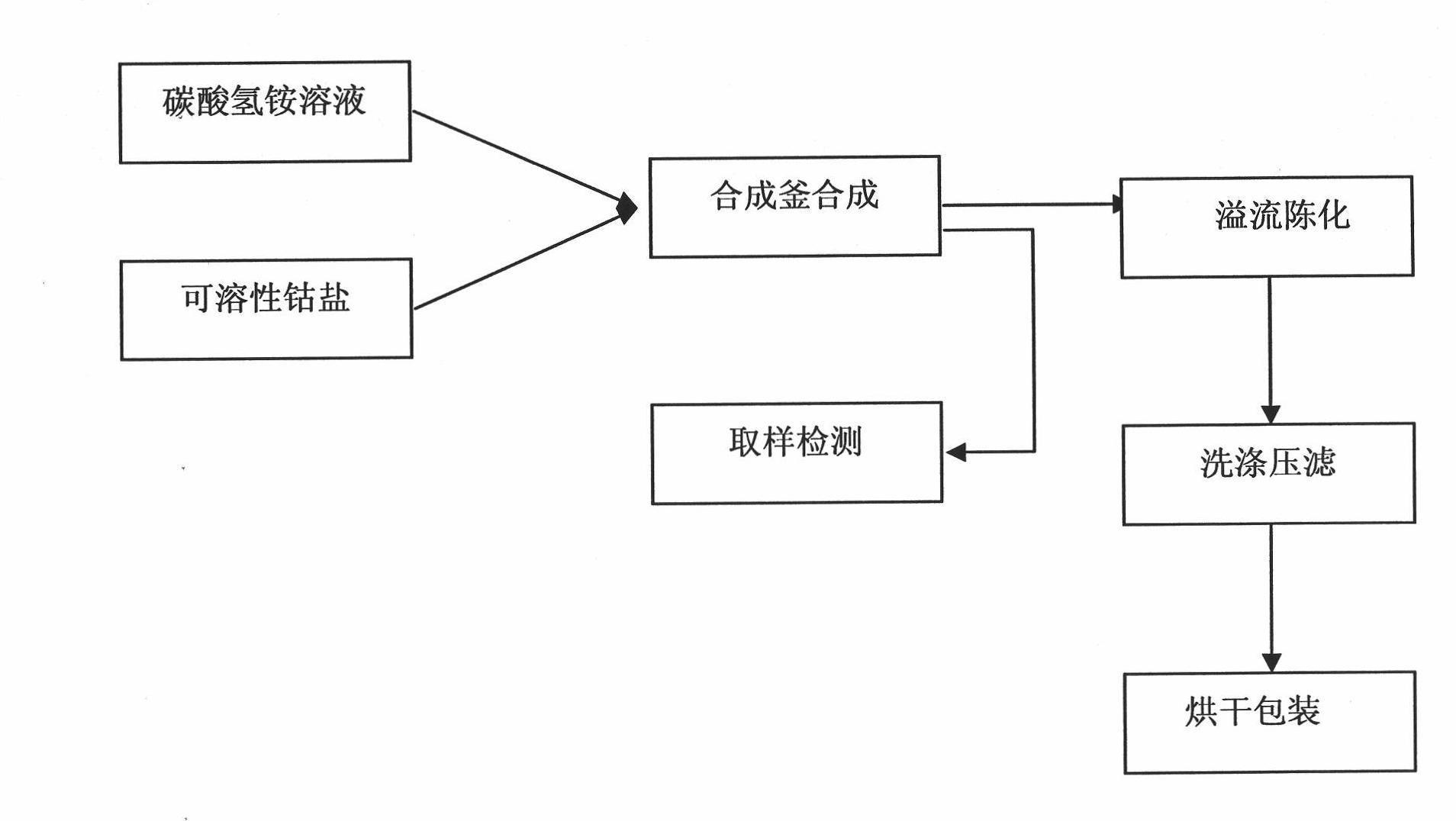

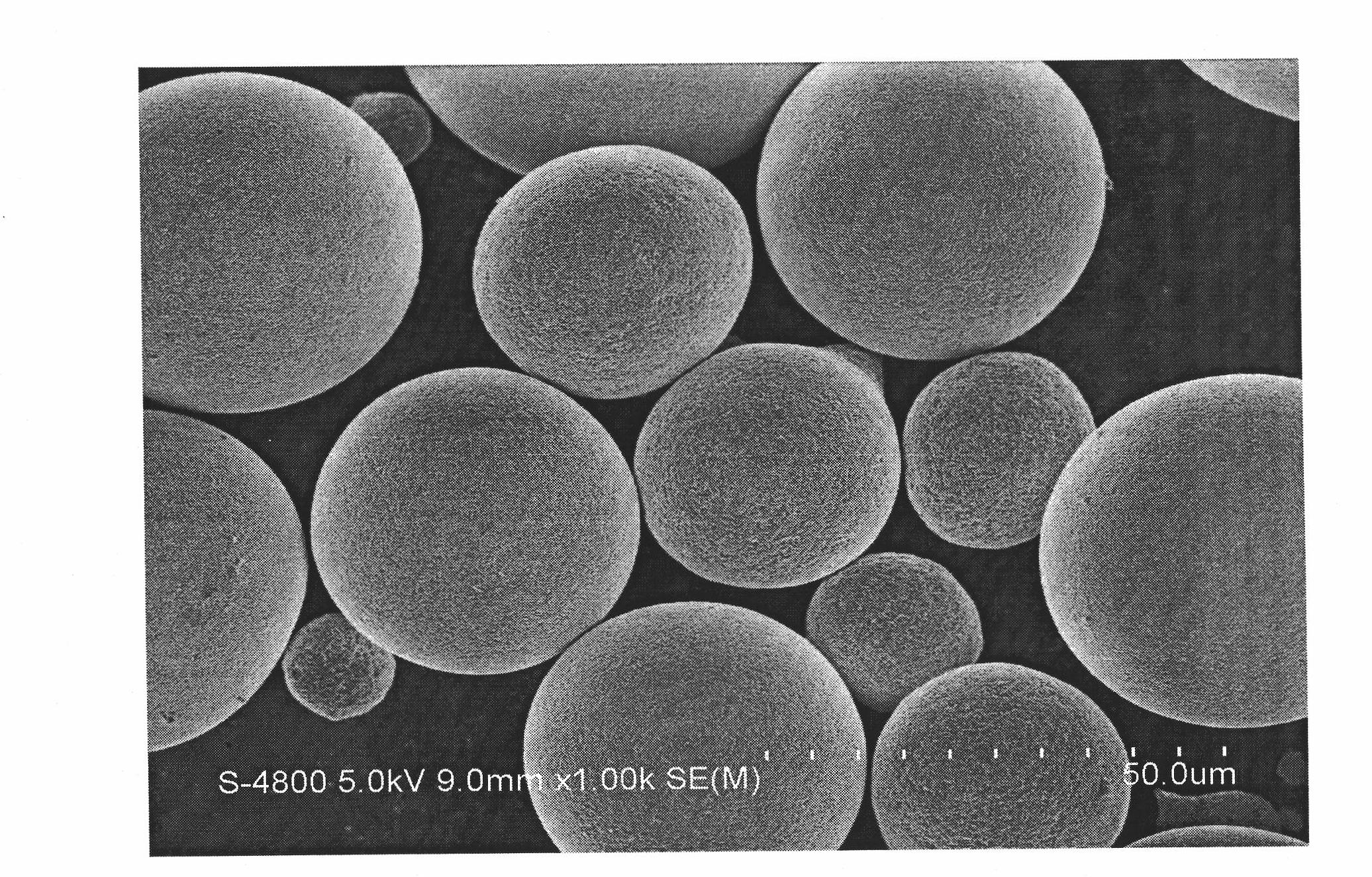

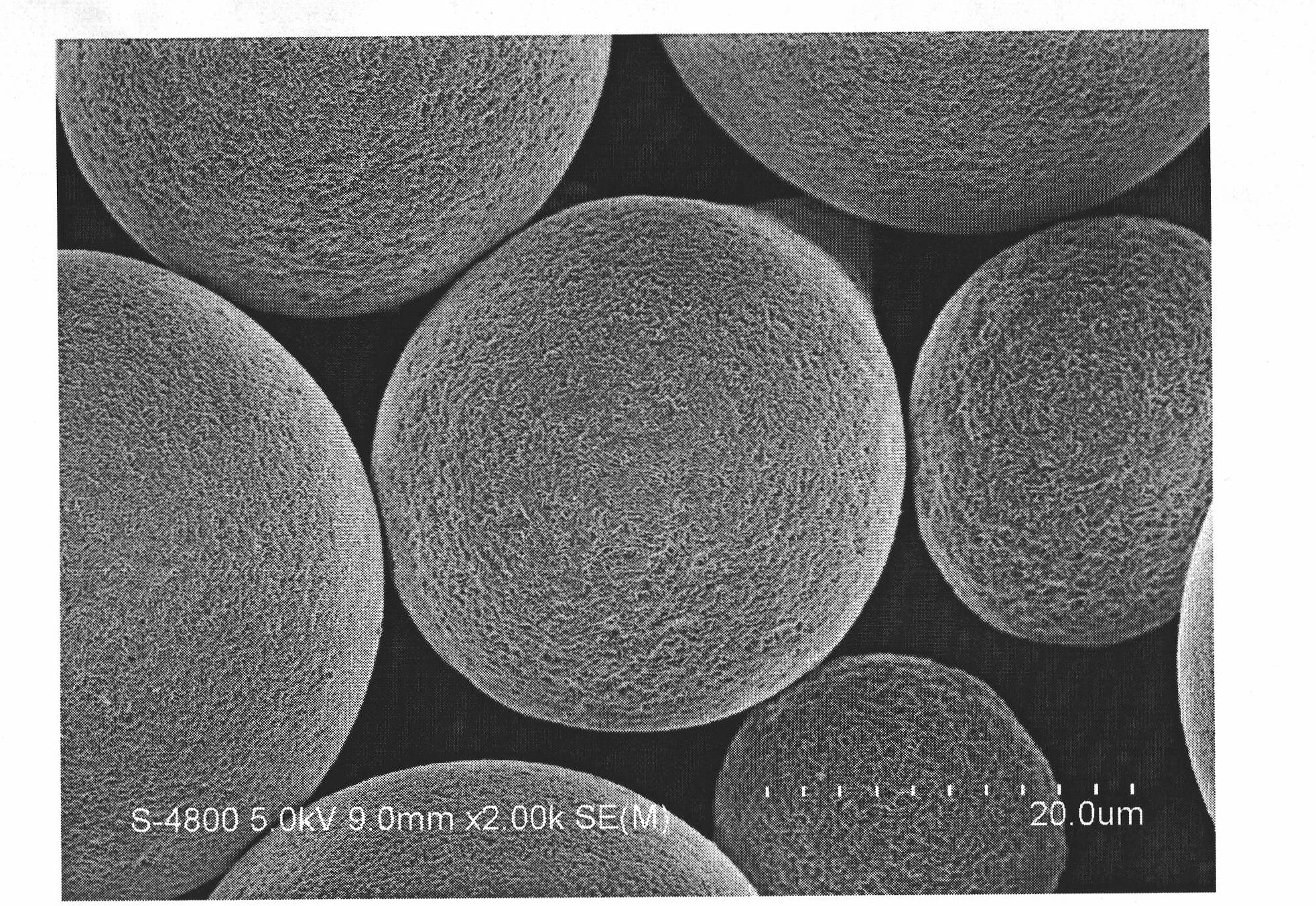

Method for producing spherical cobalt carbonate by continuous process

The invention discloses a method for producing spherical cobalt carbonate by a continuous process, which comprises the following steps of: a, preparing a cobaltous sulfate solution; b, preparing an ammonium hydrogen carbonate solution; c, carrying out a synthesis reaction; d, ageing and washing; e, drying; and f, packaging, wherein the synthesis reaction is carried out for realizing continuous production under the process condition that temperature is 50+ / -2DEG C, pH value is controlled to be 7.9-8.1, alkalinity is 20+ / -2g / L, solid content is controlled to be 120+ / -10g / L and stirring rotating speed is 80-100r / min. By adopting the continuous production process, the production efficiency is high; and the produced cobalt carbonate has good globulation and excellent consistence of a crystal nucleus structure.

Owner:ANHUI ALAND NEW ENERGY MATERIALS

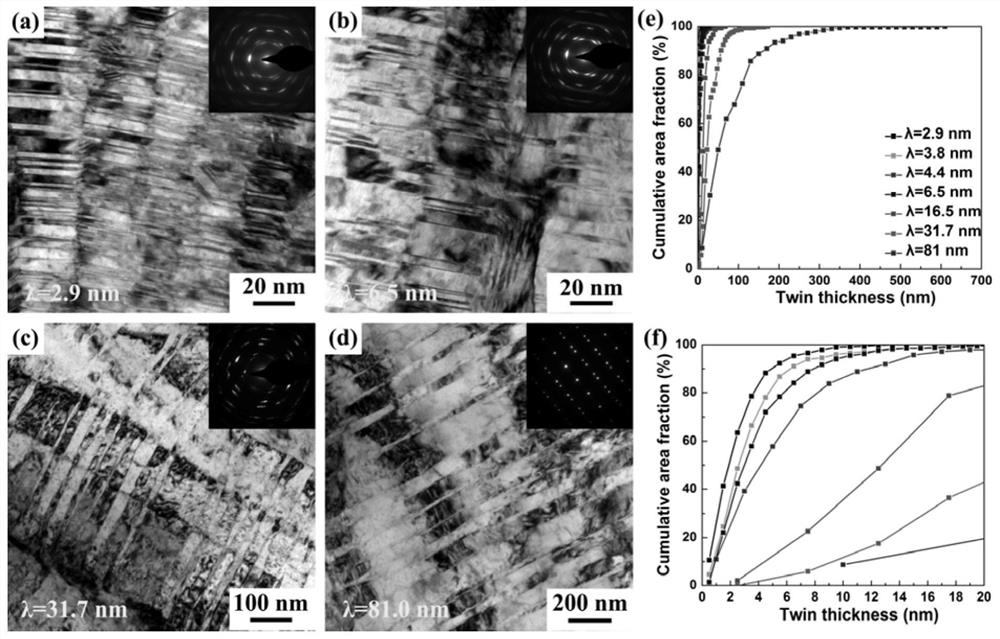

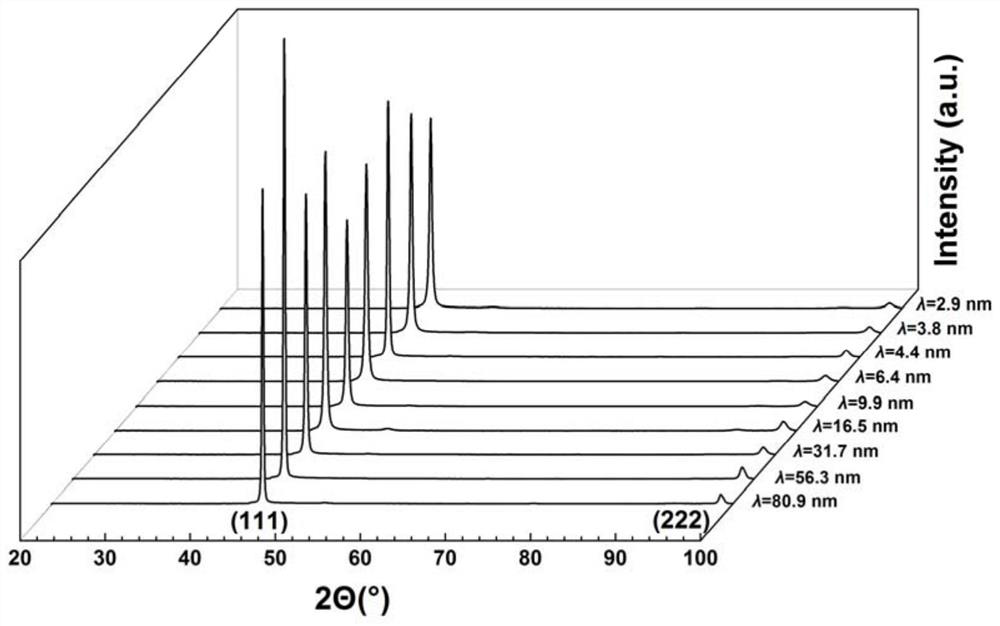

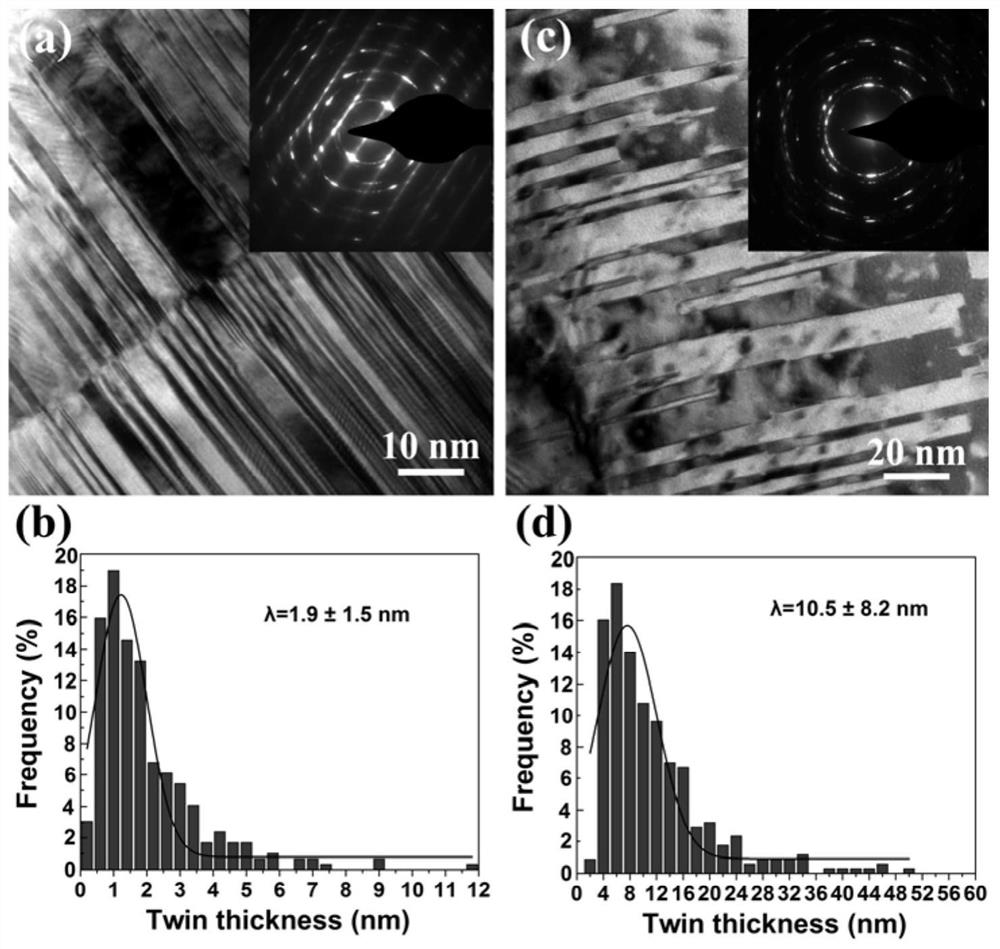

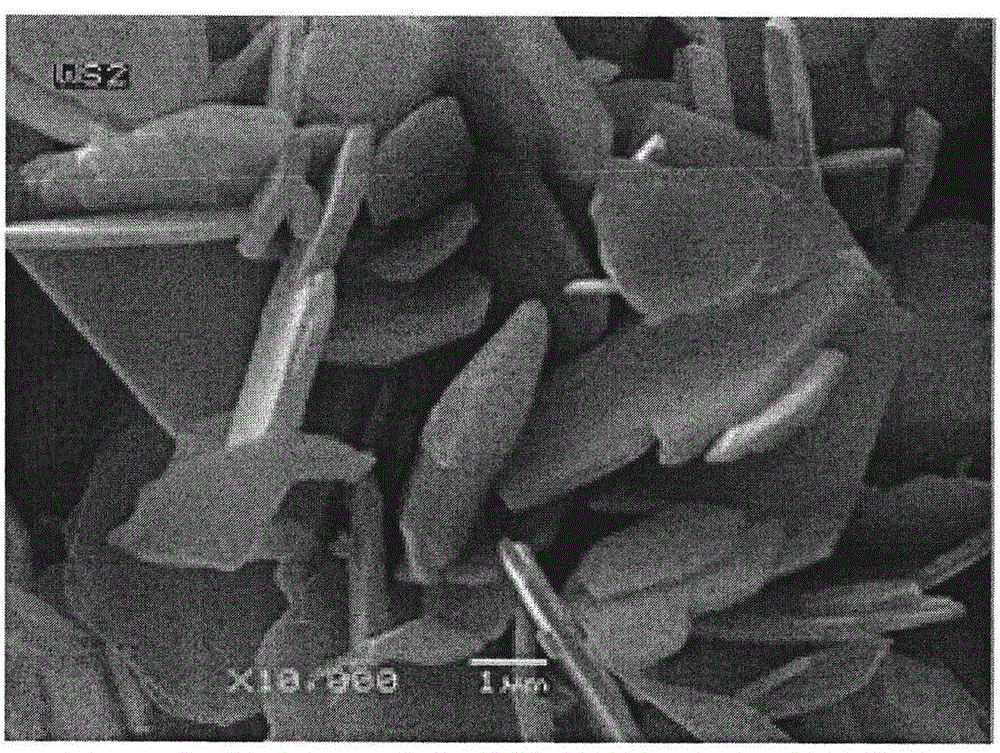

Pure nickel or nickel-based alloy plating layer with nano twin crystal structure and electro-deposition preparation method of pure nickel or nickel-based alloy plating layer

The invention discloses a pure nickel or nickel-based alloy plating layer with the nano twin crystal structure and an electro-deposition preparation method of the pure nickel or nickel-based alloy plating layer, and belongs to the technical field of preparation of nano crystal metal materials and plating protection. The plating solution adopts a citrate system and mainly comprises nickel source-nickel sulfate, an alloy source (sodium molybdate or cobalt sulfate or copper sulfate), a complexing agent-sodium citrate, an additive, and the balance water; and the pure nickel and nickel alloy plating prepared through direct-current electrodeposition are both composed of columnar crystal particles, the columnar crystal particles internally contain high-density twin crystal sheet layers arranged in parallel, the average thickness of the twin crystal sheet layers ranges from 1.0 nanometer to 100 nanometers, the nano twin crystal nickel / nickel-based alloy plating has high hardness and high thermal stability, under the condition of room temperature, the Vickers hardness value of the pure nickel plating layer is 2.0-8.5 GPa, and the maximum structure roughening temperature can exceed 600 DEG C, the Vickers hardness value of the nickel-based alloy plating is 4.0-8.5 GPa, and the structure roughening temperature is higher than 400 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electroplating liquid adopting nickel-cobalt tungsten sulfide nanocrystalline alloy electroplating for piston rings instead of hard chrome plating, and production process of electroplating liquid

ActiveCN104562105AImprove wear resistanceImprove glue resistanceElectrolytic coatingsNanotechnologyBiological activationChrome plating

The invention relates to an electroplating liquid adopting nickel-cobalt tungsten sulfide nanocrystalline alloy electroplating for piston rings instead of hard chrome plating. The electroplating liquid comprises the following components according to the ratio: 100-165 g / l of nickel sulfate, 80-136g / l of cobaltous sulfate, 40-50 g / l of boric acid, 3-9 g / l of potassium chloride, 5-38 g / l of nano tungsten disulfide plating pulp, 3-5 g / l of a brightening agent and saccharin, 0.3-0.7 g / l of a wetting agent (lauryl sodium sulfate), and 20 g / l of sodium citrate. A production process of the electroplating liquid adopting nickel-cobalt tungsten sulfide nanocrystalline alloy electroplating for piston rings instead of hard chrome plating comprises the following steps: (1) checking before plating, (2) product hanging, (3) high-temperature degreasing, (4) electrolytic degreasing, (5) washing with deionized water, (6) activation with weak acid, (7) nickel preplating, (8) electroplating, (9) washing and recycling, and (10) heat treatment for removing hydrogen. Through the adoption of the electroplating liquid adopting nickel-cobalt tungsten sulfide nanocrystalline alloy electroplating for piston rings instead of hard chrome plating, and the production process of the electroplating liquid, which are provided by the invention, the overall performance and the life cycle of an electroplated layer can completely exceed those of the existing hard chrome plated layer, the environment is protected, and the energy is saved.

Owner:长沙润佰特新材料科技有限公司

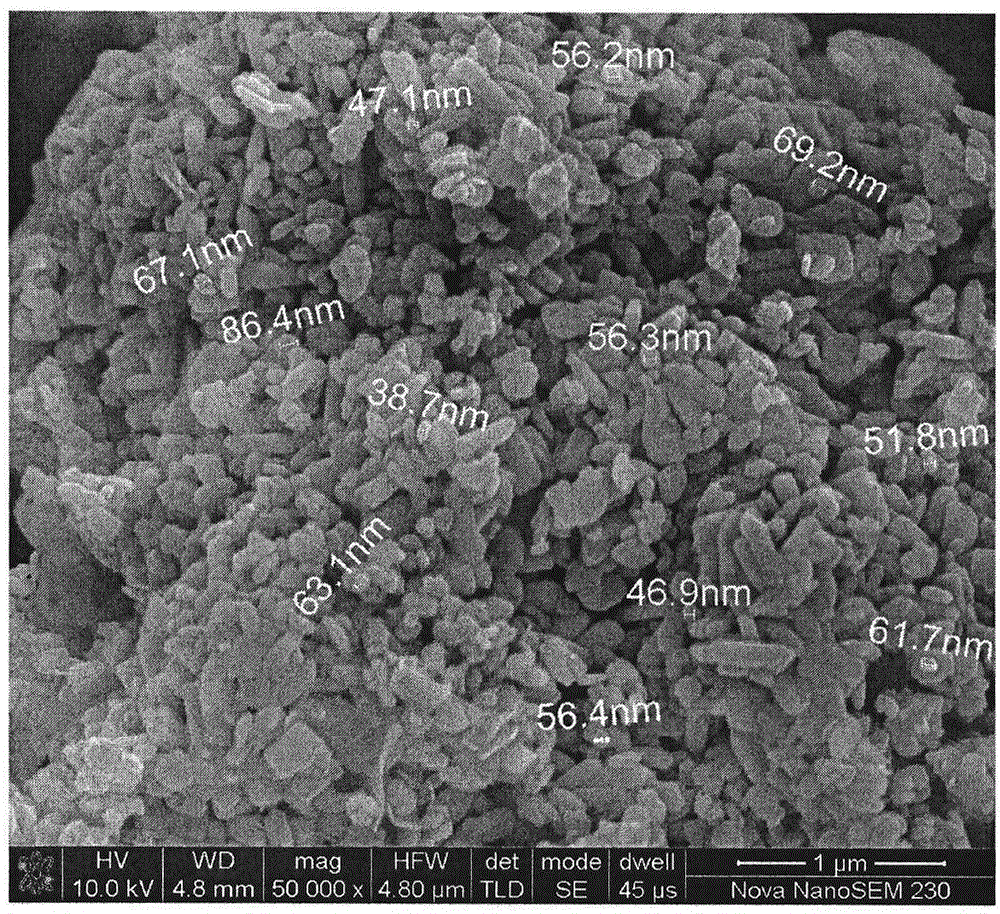

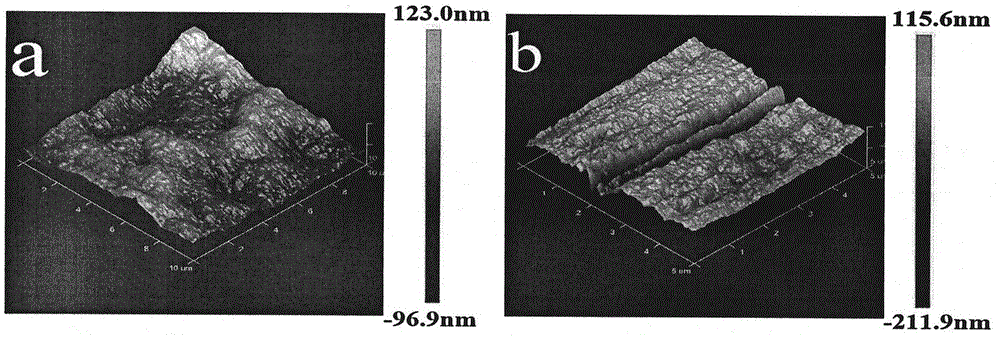

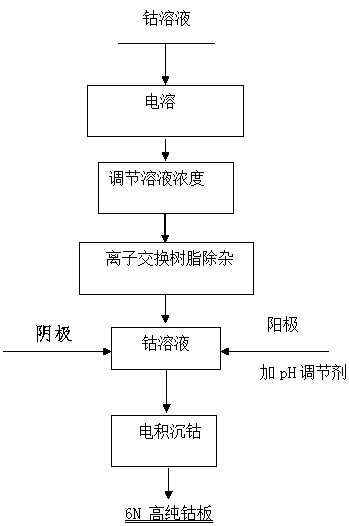

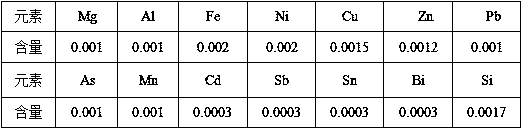

Method for preparing ultra-pure cobalt board

InactiveCN108560020AUniform dense depositionFlat surfacePhotography auxillary processesIon exchangeMass spectrometry

The invention provides a method for preparing ultra-pure cobalt, and relates to a method for producing a high-pure cobalt board by adopting a hydrometallurgy technology. The purity of the produced high-pure cobalt board can reach 99.9999% or above. The method for producing the high-pure cobalt board by adopting the hydrometallurgy technology is characterized in that cobalt of which the brand number is Co9998 is electrochemically dissolved to prepare cobaltous sulfate stoste, after deep purification of the cobalt solution is achieved through ion exchange, a cobalt metal in the high-pure cobaltsolution is refined by adopting an electrodeposition refining technology in an electrodeposition cell, so that the cobalt is evenly precipitated on a cathode starting sheet, and the technology processcomprises that the concentration of the cobaltous sulfate stoste is adjusted to 80-90 grams per liter, the ph value is controlled to 4.5-5, the flow velocity of the solution is controlled at 25-30 liter per hour, adsorption and decontamination are carried out on the cobaltous sulfate stoste through ion exchange resin 711 to obtain a high-pure cobaltous sulfate solution, then the purified solutionis put into the electrodeposition cell, the precipitation of the ultra-pure cobalt in the cathode is achieved through an electrodeposition refining purification technology, and the voltage of the cell is controlled to 1.1-1.3 volts. The prepared high-pure cobalt board has the advantages that the inner portion is compact, the surface is flat, the thickness is 1-2 millimeters, and the purity detected by a glow mass spectrum detector can reach 99.9999% or above.

Owner:JINCHUAN GROUP LIMITED +1

Preparation method of magnetic cobalt-loaded ordered mesoporous carbon material, and applications of magnetic cobalt-loaded ordered mesoporous carbon material in catalytic degradation of levofloxacin waste water with Oxone

InactiveCN107890869AIncrease the areaLarge pore volumeWater contaminantsCatalyst activation/preparationSodium hydroxideWater treatment

The invention discloses a magnetic cobalt-loaded ordered mesoporous carbon material, and applications of magnetic cobalt-loaded ordered mesoporous carbon material in catalytic degradation of levofloxacin waste water with Oxone, and belongs to the technical field of mesoporous carbon material synthesis and organic waste water treatment. According to the preparation method, cobaltous sulfate heptahydrate, sodium hydroxide, and ammoniacal liquor are taken as raw materials to prepare Co3O4 solid, and the obtained Co3O4 solid, melamine, and F127 are subjected to hydrothermal reaction so as to obtain the magnetic cobalt-loaded ordered mesoporous carbon material. The magnetic cobalt-loaded ordered mesoporous carbon material is relatively high in specific surface area and pore volume; an oxidationsystem composed of the magnetic cobalt-loaded ordered mesoporous carbon material and Oxone possesses high degradation efficiency on levofloxacin waste water, no toxic or harmful side product is generated in degradation process, and recycling is realized.

Owner:HENAN NORMAL UNIV

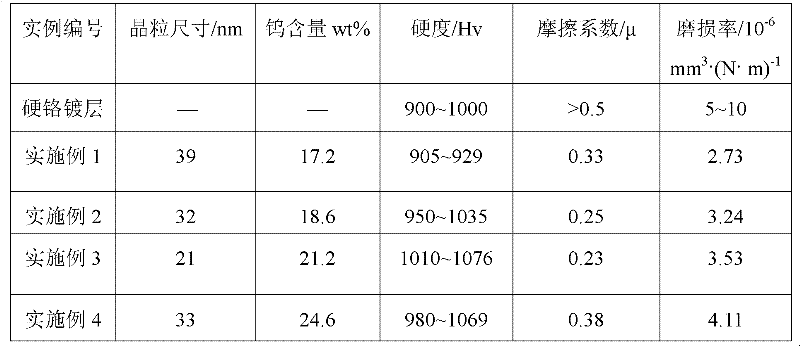

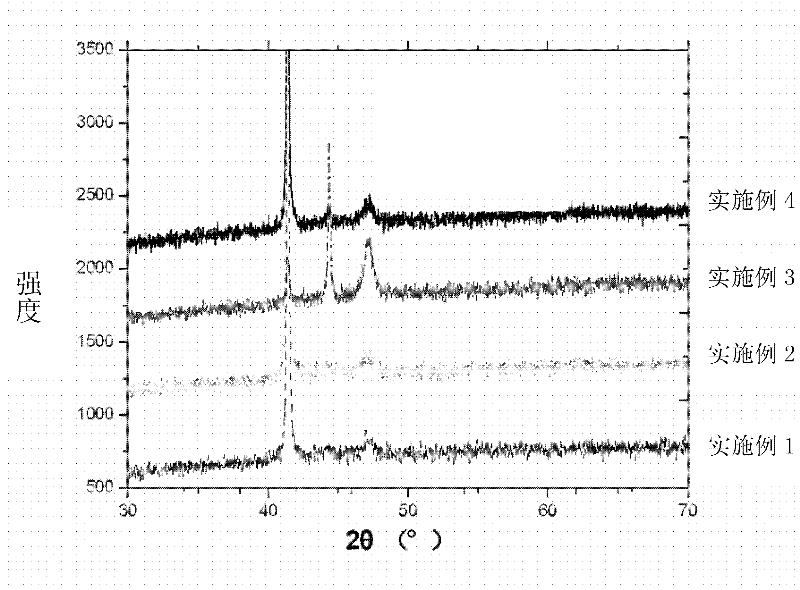

Cobalt-tungsten nanometer alloy plating layer and preparation method thereof

InactiveCN102337569AHigh hardnessImprove wear resistanceCellsMaterial nanotechnologyFriction reductionSodium sulfate

The invention discloses a preparation method of a cobalt-tungsten nanometer alloy plating layer, which comprises steps of electroplating by using a platinum titanium or cobalt-tungsten alloy as an anode and a workpiece to be plated as a cathode and using a mixed solution as electrolyte, wherein the mixed solution contains 100-200 g / L of cobaltous sulfate, 10-70 g / L of sodium tungstate, 50-150 g / L of g / L of sodium sulfate, 15-50 g / L of boracic acid, 1-4 g / L of saccharin sodium salt, 0.01-0.1 g / L of surfactant and 40-120 g / L of complexing agent; the alloy plating layer is of a nanometer crystal structure, and the dimension of a crystalline grain is 20-40 nm; and the tungsten content in the nanometer alloy plating layer is 13.2-25.1 wt%. The invention has the advantages that the preparation method of the plating layer is simple, and the plating layer not only has the hardness of a hard chromium plating layer, but also has better wearing resistance and friction reduction performance than the hard chromium plating layer. The plating layer is suitable for components with high hardness, high wearing resistance and low friction coefficients and has an extensive application range.

Owner:SOUTH CHINA UNIV OF TECH

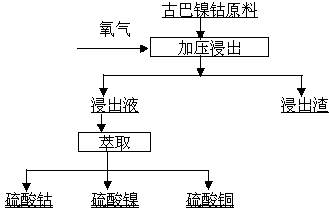

Method for leaching Cuba nickel-cobalt raw material

InactiveCN103725899AReduce pollutionReduce manufacturing costProcess efficiency improvementPregnant leach solutionHydrometallurgy

The invention discloses a method for leaching the Cuba nickel-cobalt raw material and relates to a hydrometallurgy method for extracting nickel, cobalt and copper through leaching the Cuba nickel-cobalt raw material. The method is characterized by comprising the following steps: pulpifying the Cuba nickel-cobalt raw material and the sulfuric acid solution, putting the pulpified Cuba nickel-cobalt raw material and the sulfuric acid solution in a kettle, performing heating, pressurizing and oxidizing leaching, filtering the lixivium, and performing extraction and separation on copper, nickel and cobalt. With adoption of the method, the leaching rates of nickel, copper and cobalt are greater than or equal to 99.1%, and the lixivium can be pressurized and oxidized by adopting P204 and P507 to perform extraction and separation on copper, nickel and cobalt to obtain copper sulfate, cobaltous sulfate and sulfuric acid, so that the pollution to the environment is effectively reduced, and the production cost is reduced.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com