Lead acid storage battery electrolyte additive and preparation method thereof

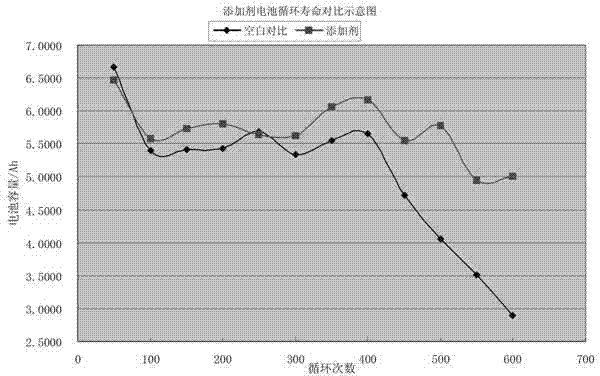

An electrolyte additive and lead-acid battery technology, applied in the direction of lead-acid batteries, etc., can solve the problems such as cycle life needs to be improved, and achieve the effect of improving charge acceptance, improving cycle life, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

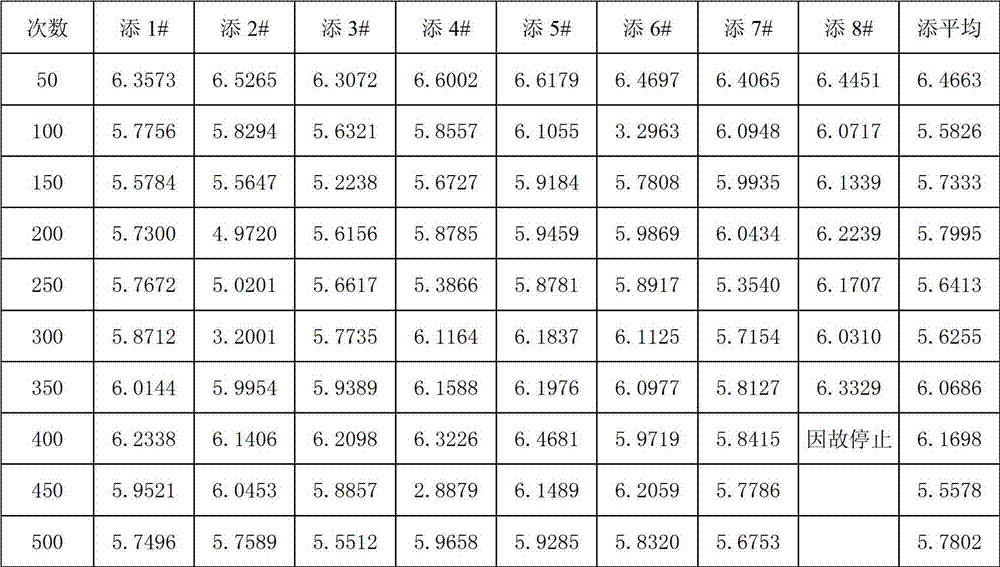

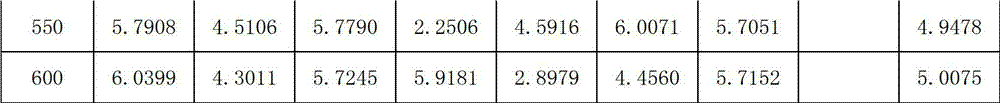

Examples

Embodiment 1

[0026] Preparation of electrolyte additive for 1# lead-acid battery

[0027] It is to use a certain amount of pure water obtained by ion exchange, add concentrated sulfuric acid and adjust the density to 1.28g / ml to prepare dilute sulfuric acid, take out 1L of dilute sulfuric acid and heat it to 40-45 degrees Celsius, and then gradually add ethylenediaminetetraacetic acid dilute Sodium 1500mg, aluminum sulfate 150mg, sodium sulfate 1000mg, cadmium sulfate 1200mg, stannous sulfate 1500mg, magnesium sulfate 4500mg, cobalt sulfate 350mg, copper sulfate 300mg, potassium sulfate 1000mg, and fully stirred, cooled to room temperature to obtain.

Embodiment 2

[0029] Preparation of electrolyte additive for 2# lead-acid battery

[0030] It is to use a certain amount of pure water obtained by ion exchange, add concentrated sulfuric acid and adjust the density to 1.30g / ml to prepare dilute sulfuric acid, take out 1L of dilute sulfuric acid and heat it to 40-45 degrees Celsius, and then gradually add ethylenediaminetetraacetic acid di Sodium 1600mg, aluminum sulfate 160mg, sodium sulfate 1100mg, cadmium sulfate 1300mg, stannous sulfate 1600mg, magnesium sulfate 5000mg, cobalt sulfate 380mg, copper sulfate 320mg, potassium sulfate 1100mg, and fully stirred, cooled to room temperature to obtain.

Embodiment 3

[0032] Preparation of electrolyte additive for 3# lead-acid battery

[0033] It is to use a certain amount of pure water obtained by ion exchange, add concentrated sulfuric acid and adjust the density to 1.32g / ml to prepare dilute sulfuric acid, take out 1L of dilute sulfuric acid and heat it to 40-45 degrees Celsius, and then gradually add ethylenediaminetetraacetic acid dilute Sodium 1600mg, aluminum sulfate 160mg, sodium sulfate 1100mg, cadmium sulfate 1300mg, stannous sulfate 1600mg, magnesium sulfate 5000mg, cobalt sulfate 380mg, copper sulfate 320mg, potassium sulfate 1100mg, and fully stirred, cooled to room temperature to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com