Patents

Literature

201 results about "Sodium polysulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium polysulfide is a general term for salts with the formula Na₂Sₓ, where x = 2 to 5. The species Sₓ²⁻, called polysulfide anions, include disulfide (S₂²⁻), trisulfide (S₃²⁻), tetrasulfide (S₄²⁻), and pentasulfide (S₅²⁻). In principle, but not in practice, the chain lengths could be longer. The salts are dark red solids that dissolve in water to give highly alkaline and corrosive solutions. In air, these salts oxidize, and they evolve hydrogen sulfide by hydrolysis.

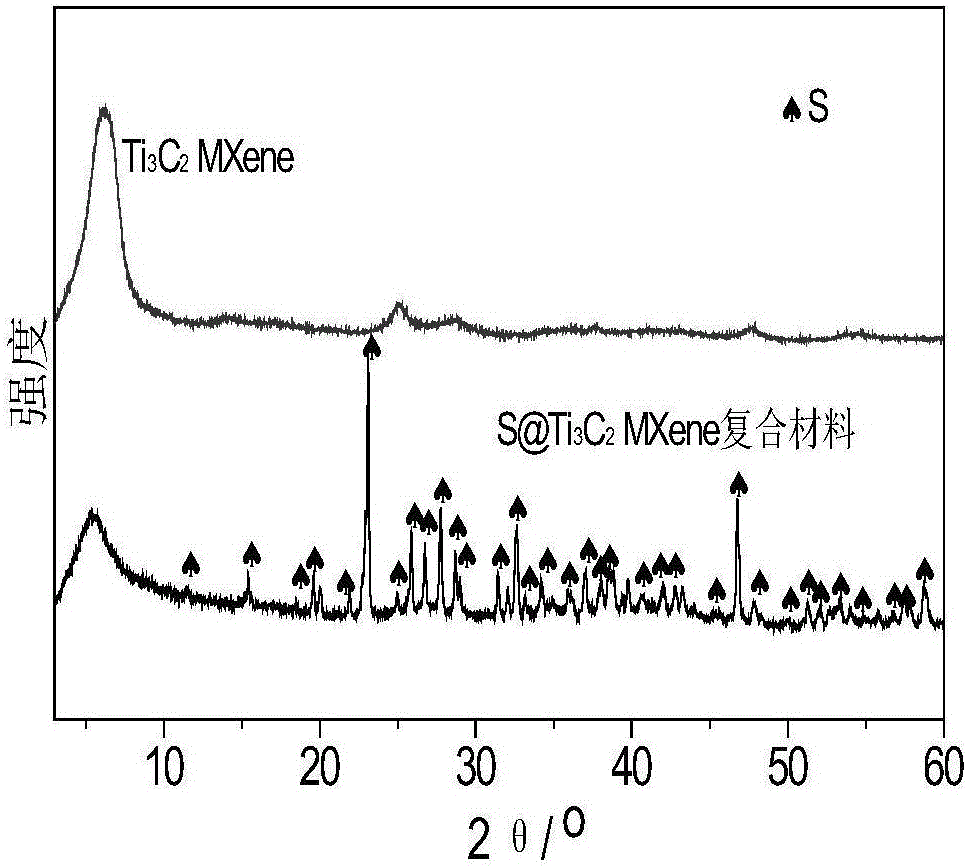

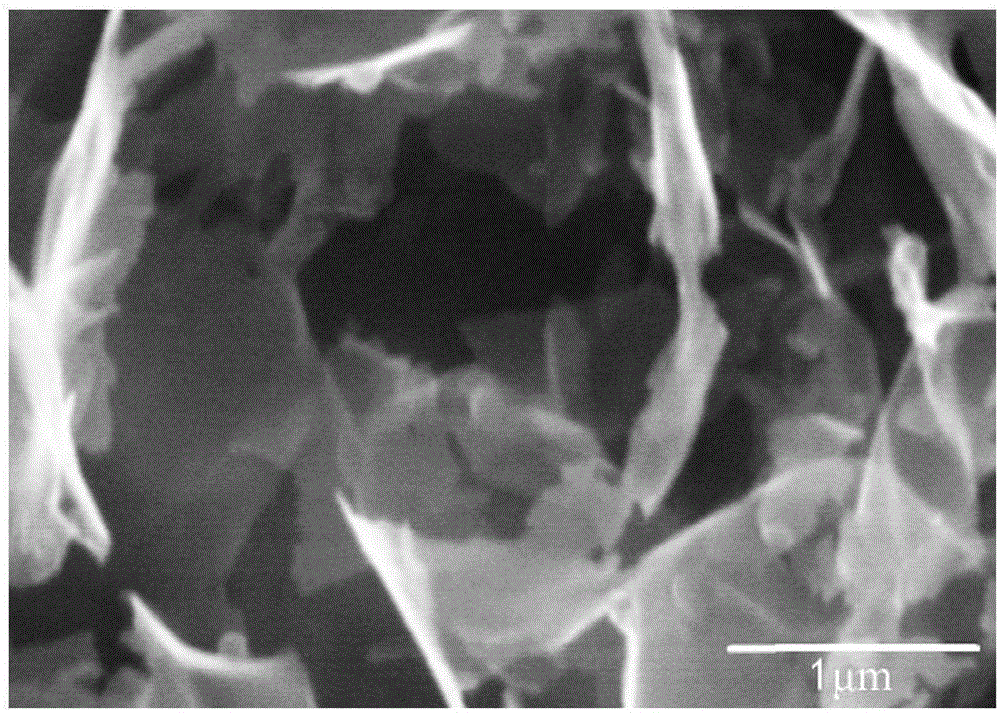

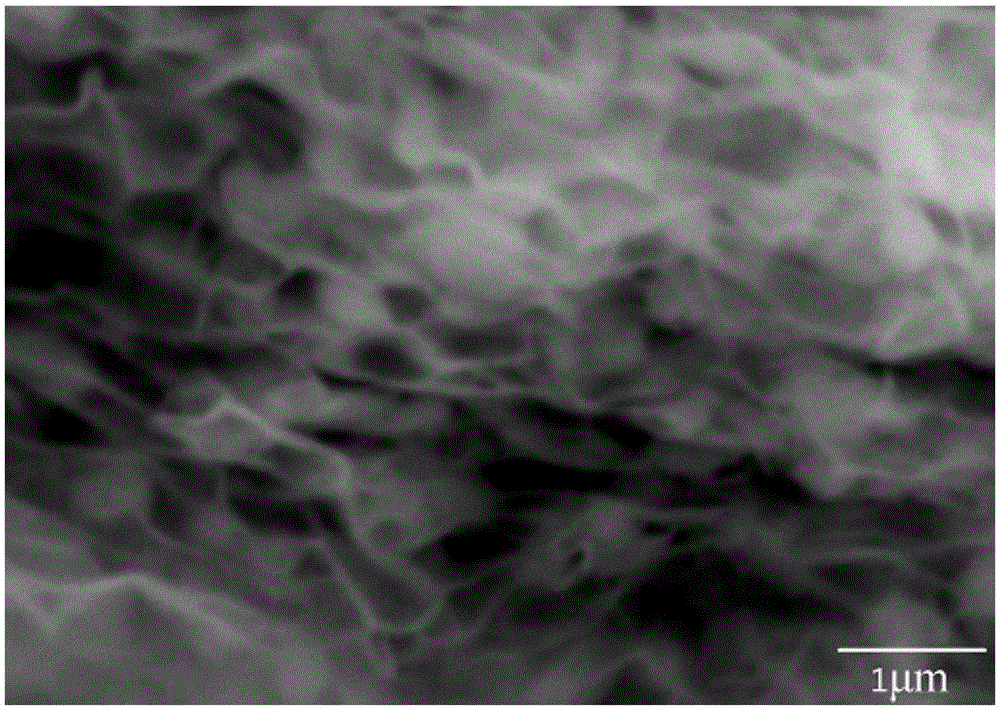

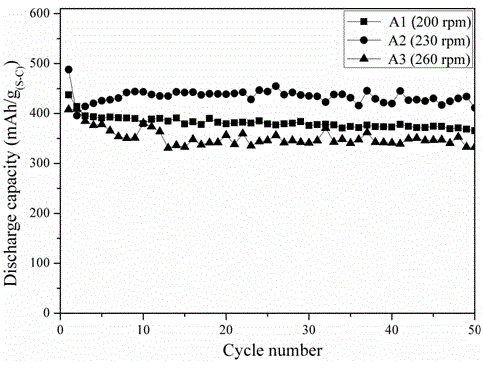

Two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite as well as preparation and application thereof

ActiveCN106450205AGive full play to the sulfur fixation effectEvenly dispersedMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesSodium polysulfideReducing agent

The invention relates to a two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite as well as preparation and application thereof. The composite is formed by two-dimensional transition metal carbide (nitride) MXene nanosheets and nano sulfur particles, wherein the nano sulfur particles grow on the surface of the two-dimensional transition metal carbide (nitride) MXene nanosheets in an in-situ manner, marked as S@MXene. The stable suspension of a single layer or a few layers of two-dimensional transition metal carbide (nitride) MXene nanosheets is mixed with a sodium thiosulfate or sodium polysulfide solution; with formic acid as a reducing agent, the nano sulfur generated by the reaction uniformly grows on the surface of the two-dimensional MXene nanosheet; and the two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite is obtained through neutralization, washing and centrifugation and serves as the anode of a lithium-sulfur battery. According to the invention, a high-conductivity two-dimensional transition metal carbide (nitride) MXene nanosheet carrier is uniformly compounded with nano sulfur particles, introduction of a binder and a conductive agent is not needed, and the composite has excellent electrochemical performance as the anode of a lithium-sulfur battery; and moreover, the technology is simple and can meet the requirements of large-scale production.

Owner:NANJING TECH UNIV

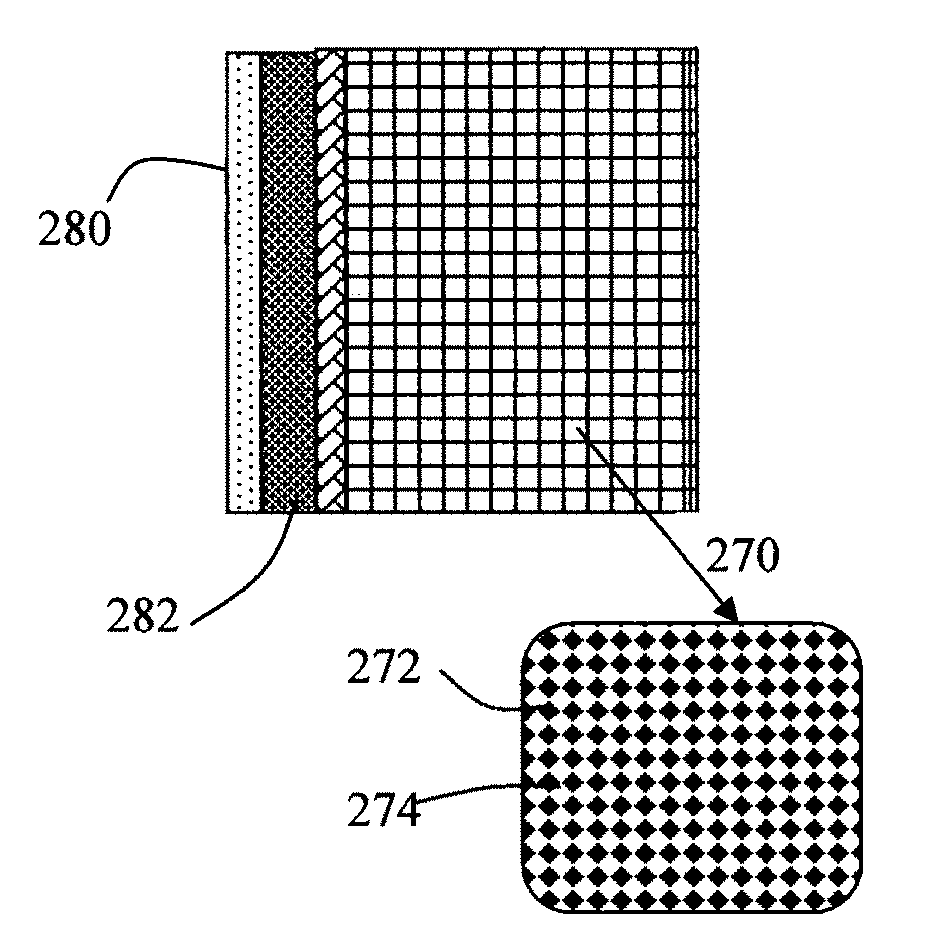

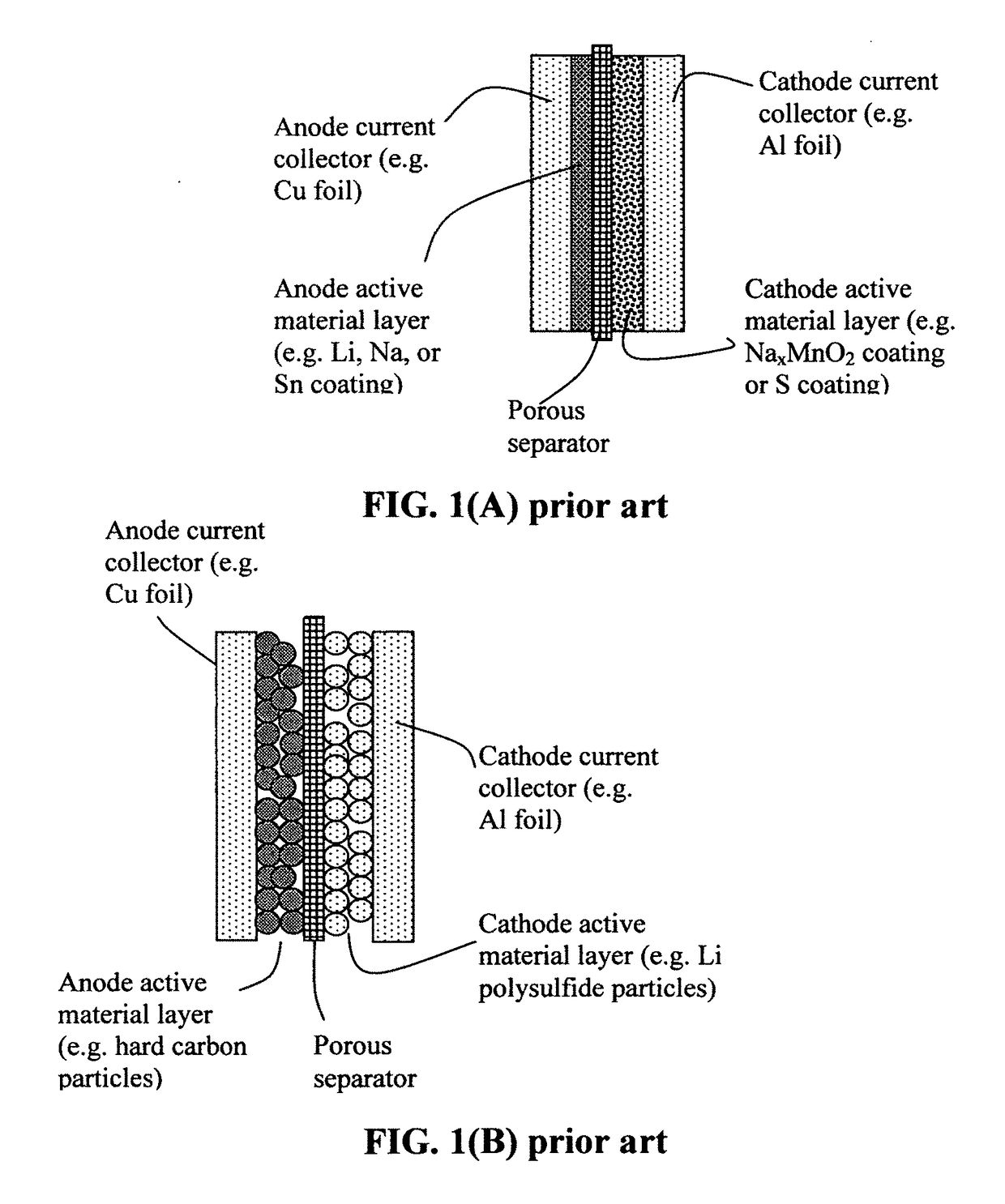

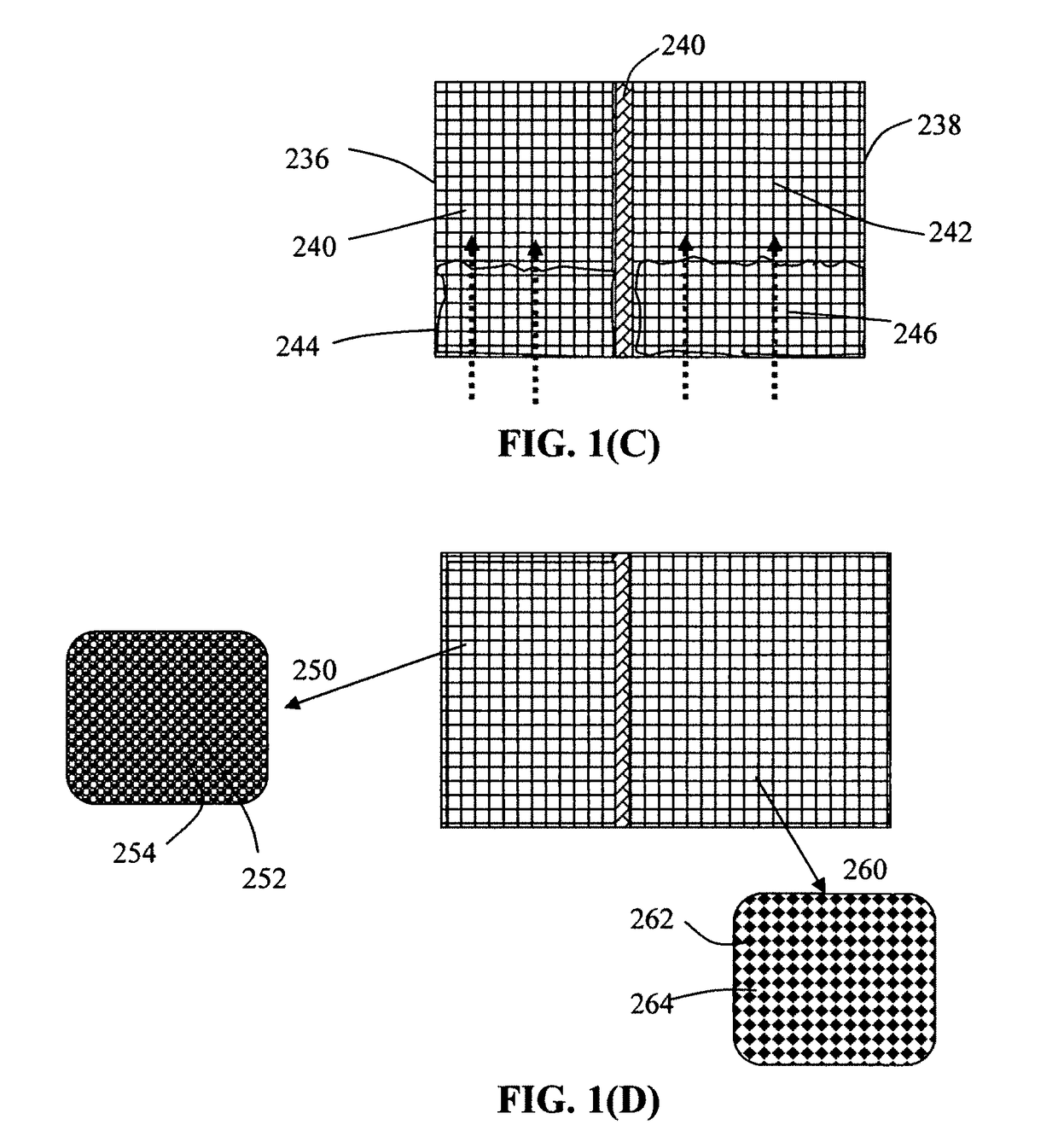

Alkali Metal-Sulfur Batteries Having High Volumetric and Gravimetric Energy Densities

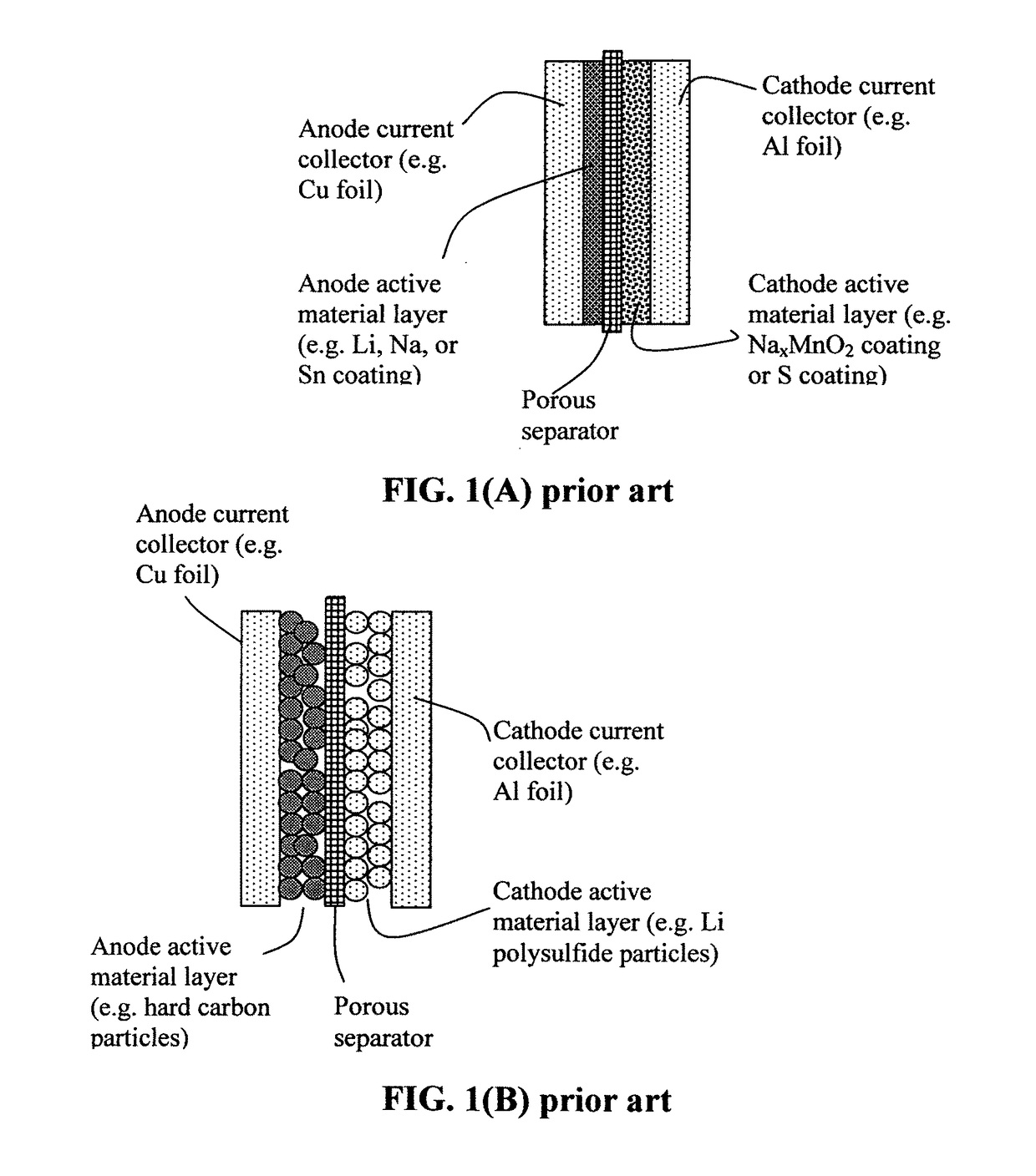

ActiveUS20170207484A1Large capacityImprove the immunityFinal product manufactureElectrode carriers/collectorsCarbon compositesSlurry

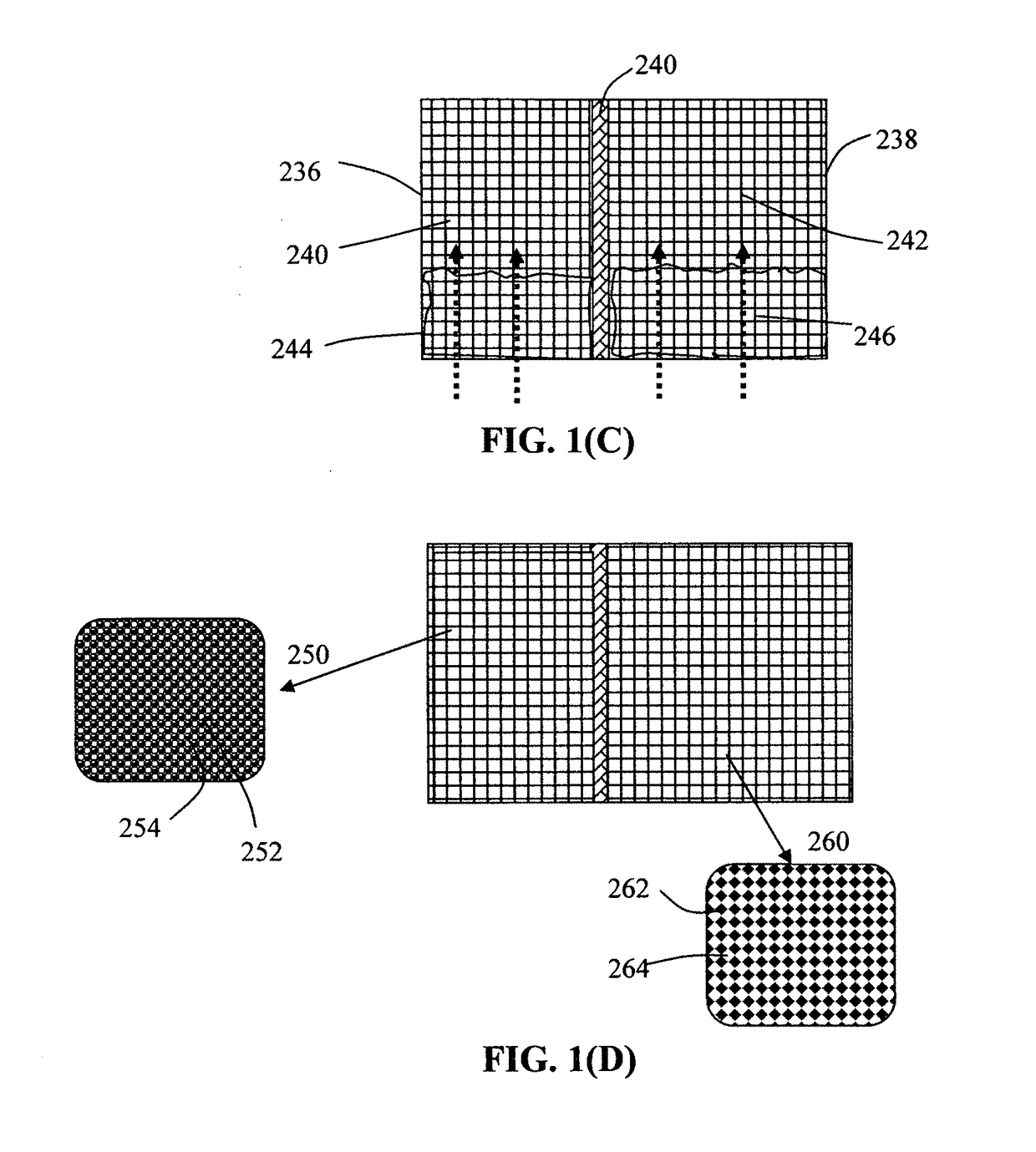

Provided is an alkali metal-sulfur battery, comprising: (a) an anode; (b) a cathode having (i) a cathode active material slurry comprising a cathode active material dispersed in an electrolyte and (ii) a conductive porous structure acting as a 3D cathode current collector having at least 70% by volume of pores and wherein cathode active material slurry is disposed in pores of the conductive porous structure, wherein the cathode active material is selected from sulfur, lithium polysulfide, sodium polysulfide, sulfur-polymer composite, sulfur-carbon composite, sulfur-graphene composite, or a combination thereof; and (c) a separator disposed between the anode and the cathode; wherein the cathode thickness-to-cathode current collector thickness ratio is from 0.8 / 1 to 1 / 0.8, and / or the cathode active material constitutes an electrode active material loading greater than 15 mg / cm2, and the 3D porous cathode current collector has a thickness no less than 200 μm (preferably thicker than 500 μm).

Owner:GLOBAL GRAPHENE GRP INC

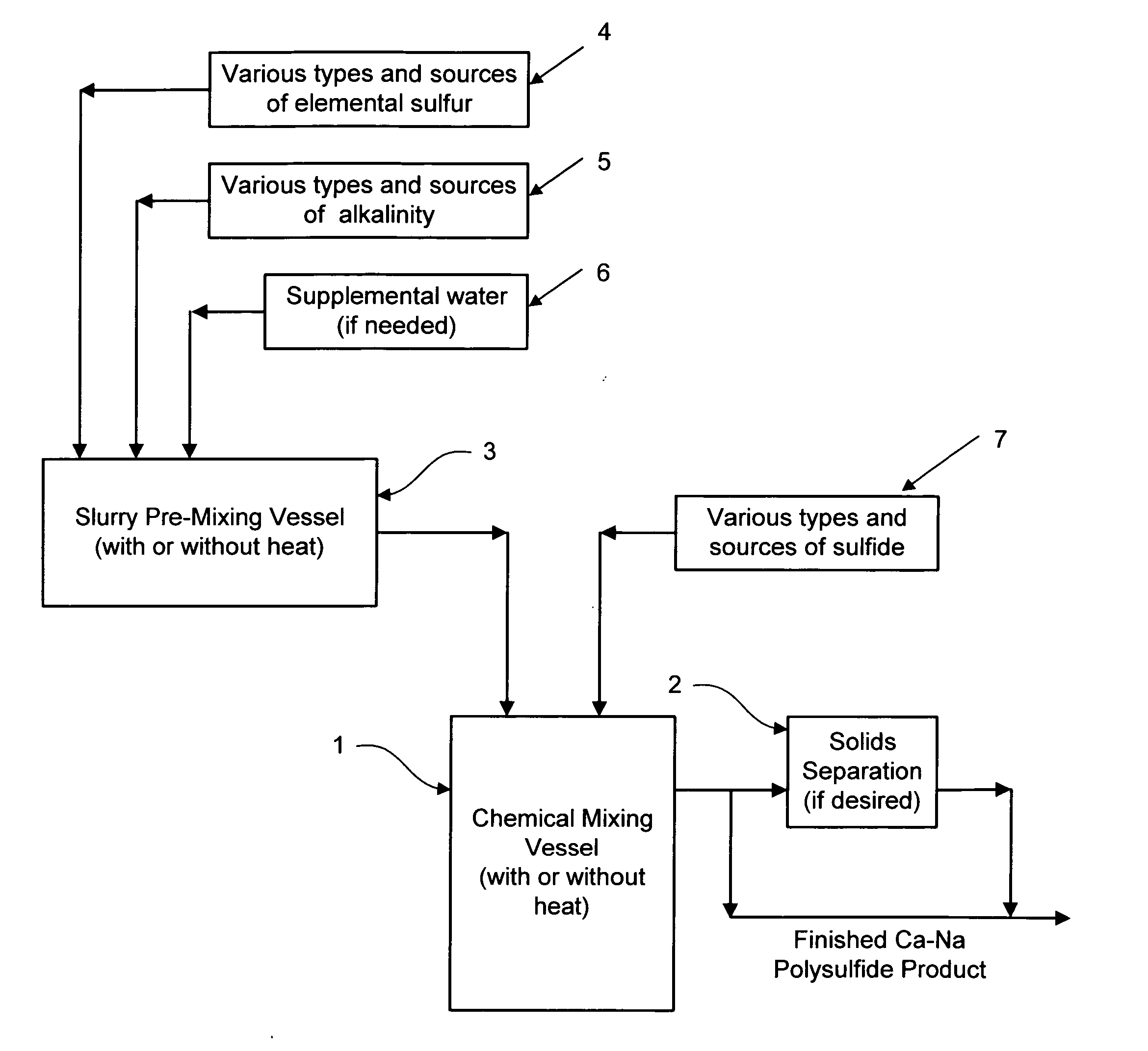

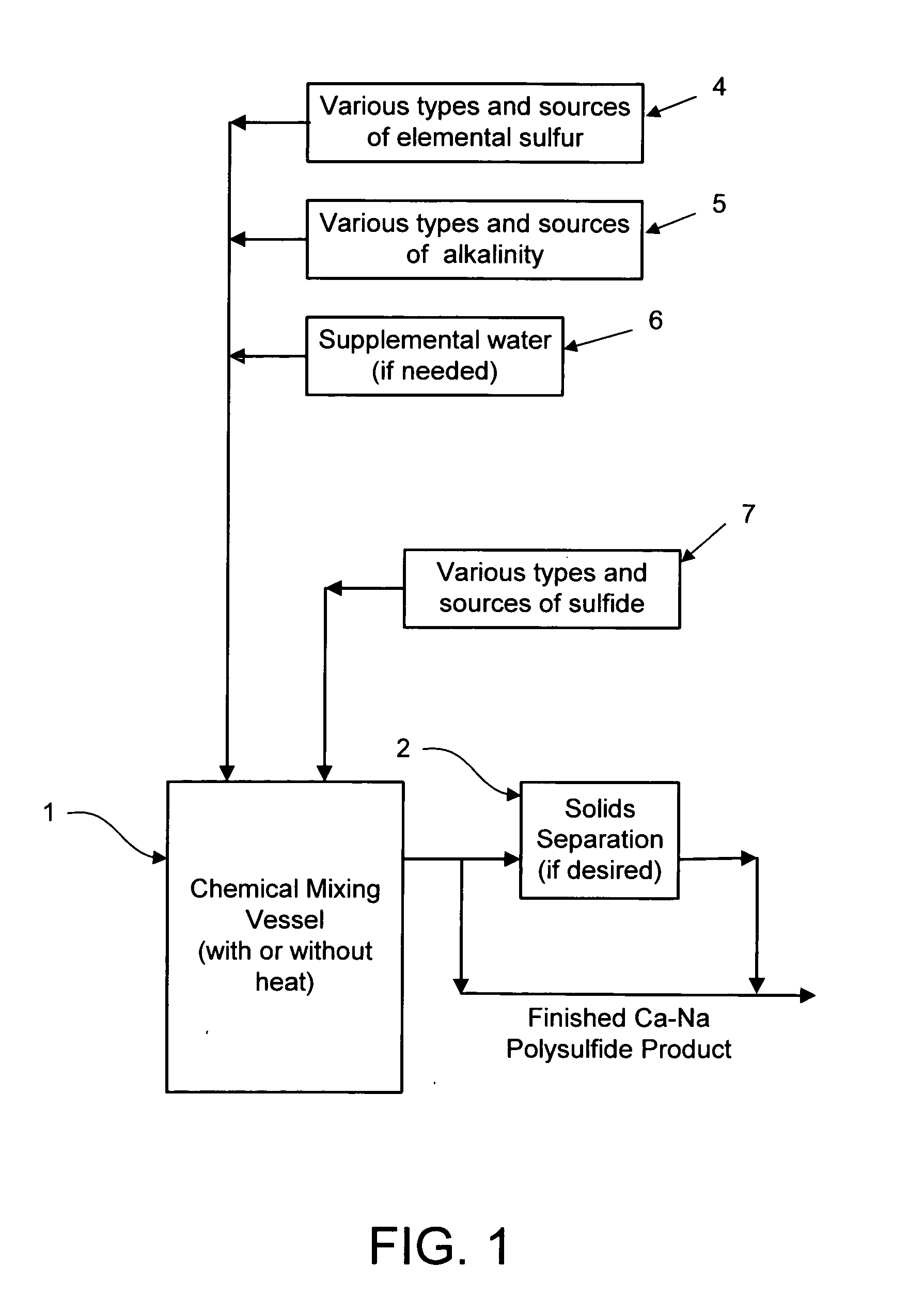

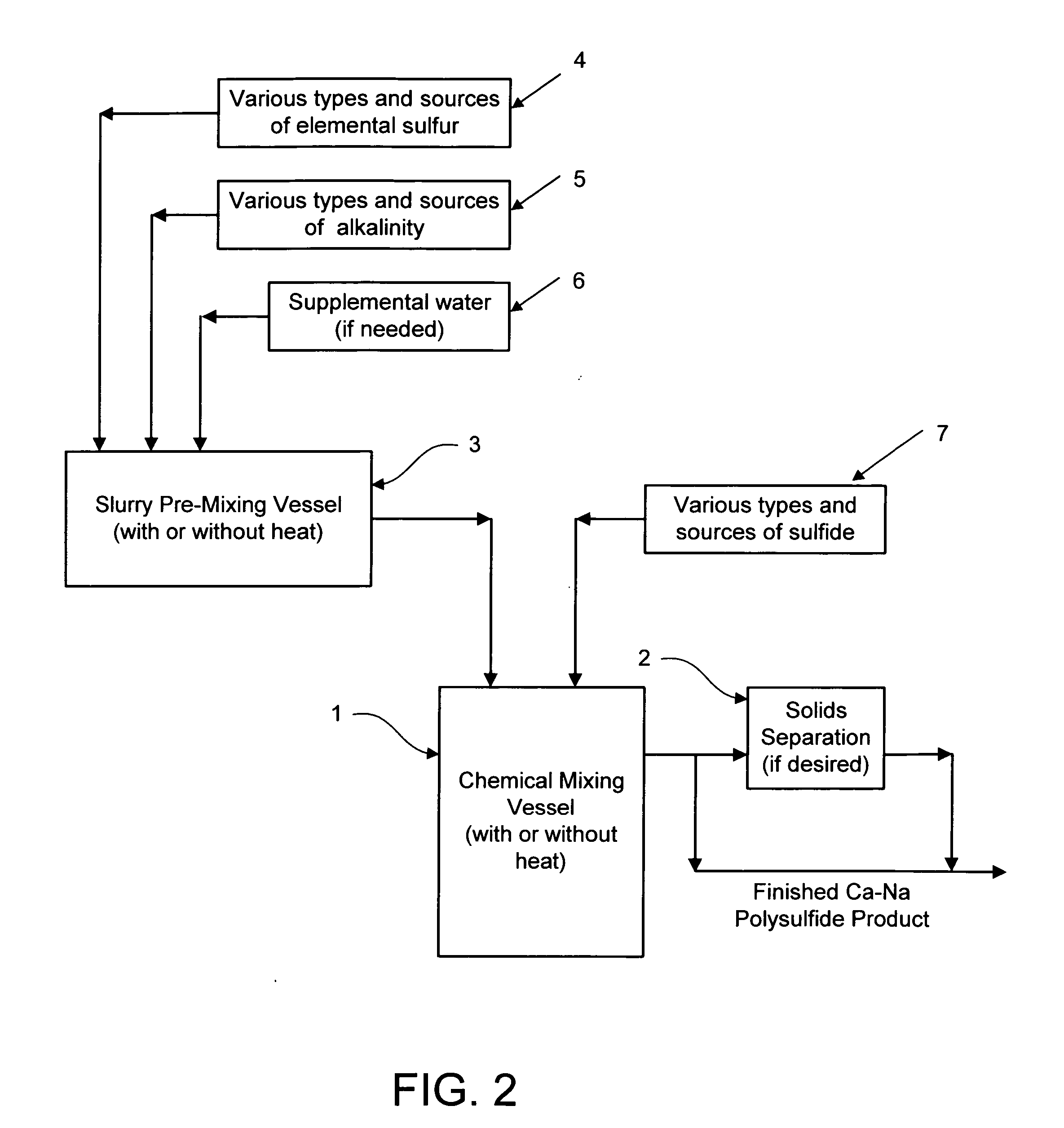

Calcium-sodium polysulfide chemical reagent and production methods

Owner:REDOX TECH GRP

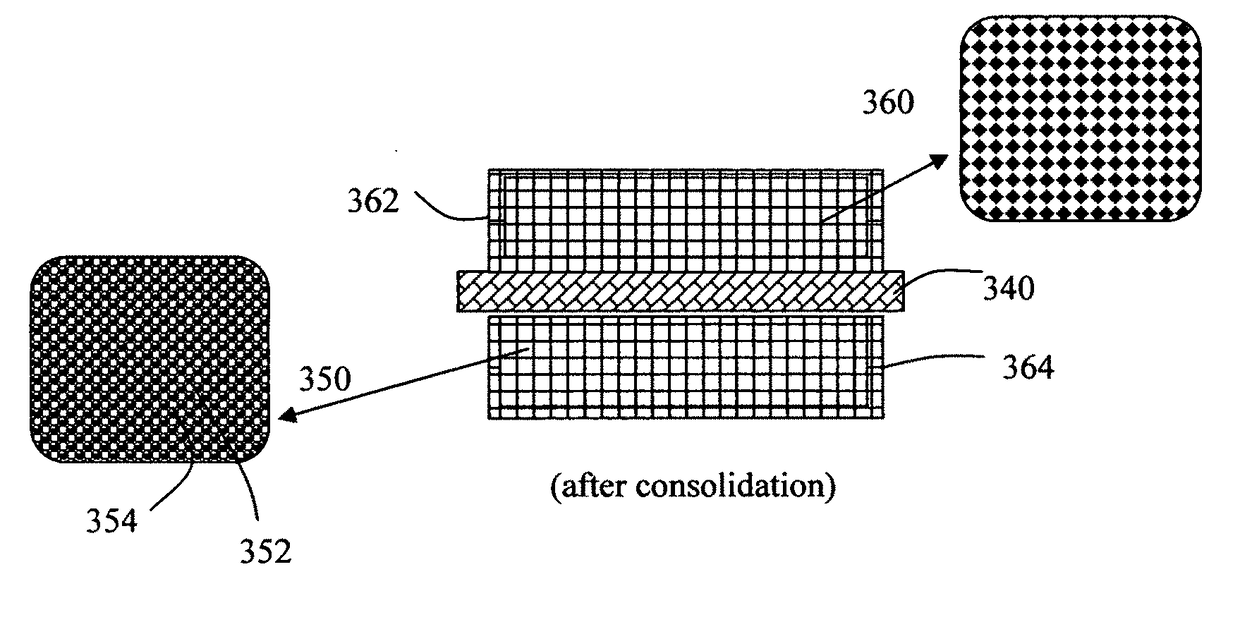

Production process for alkali metal-sulfur batteries having high volumetric and gravimetric energy densities

ActiveUS20170207488A1Large capacityImprove the immunityFinal product manufactureElectrode carriers/collectorsCarbon compositesSodium polysulfide

Process for producing an alkali metal-sulfur battery, comprising: (a) Preparing a first conductive porous structure; (b) Preparing a second conductive porous structure; (c) Injecting or impregnating a first suspension into pores of the first conductive porous structure to form an anode electrode, wherein the first suspension contains an anode active material, an optional conductive additive, and a first electrolyte; (d) Injecting or impregnating a second suspension into pores of the second conductive porous structure to form a cathode electrode, wherein the second suspension contains a cathode active material (selected from sulfur, lithium polysulfide, sodium polysulfide, sulfur-polymer composite, organo-sulfide, sulfur-carbon composite, sulfur-graphene composite, or a combination thereof), an optional conductive additive, and a second electrolyte; and (e) Assembling the anode electrode, a separator, and a cathode electrode into the battery.

Owner:GLOBAL GRAPHENE GRP INC

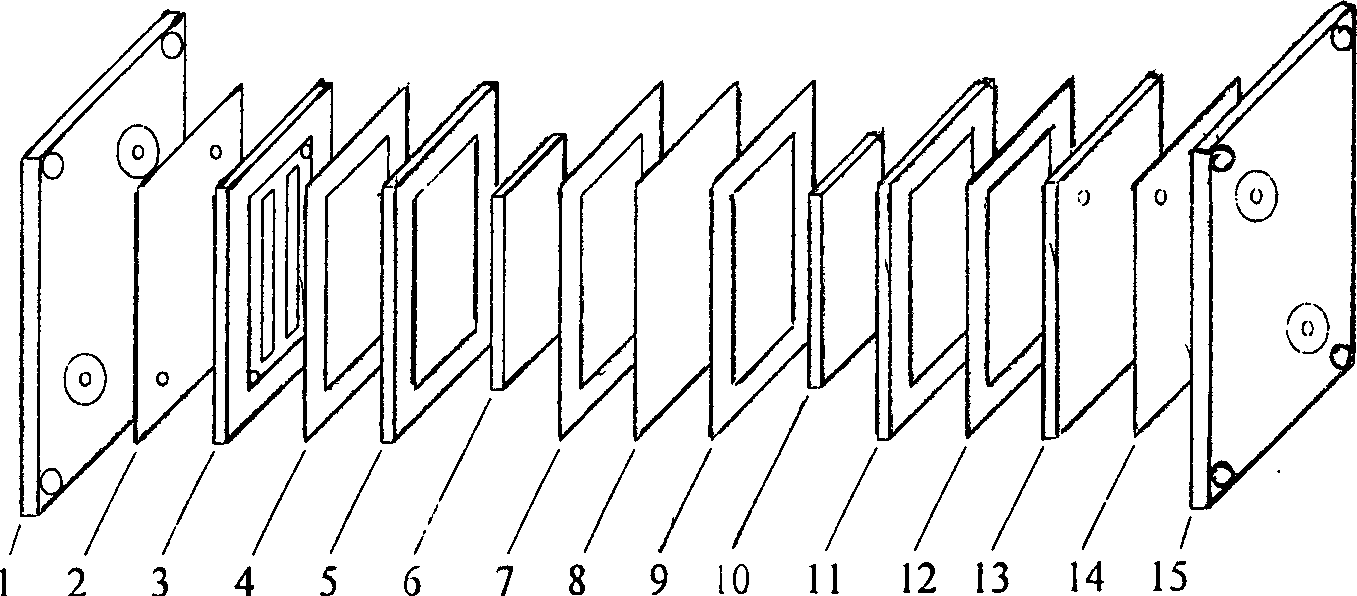

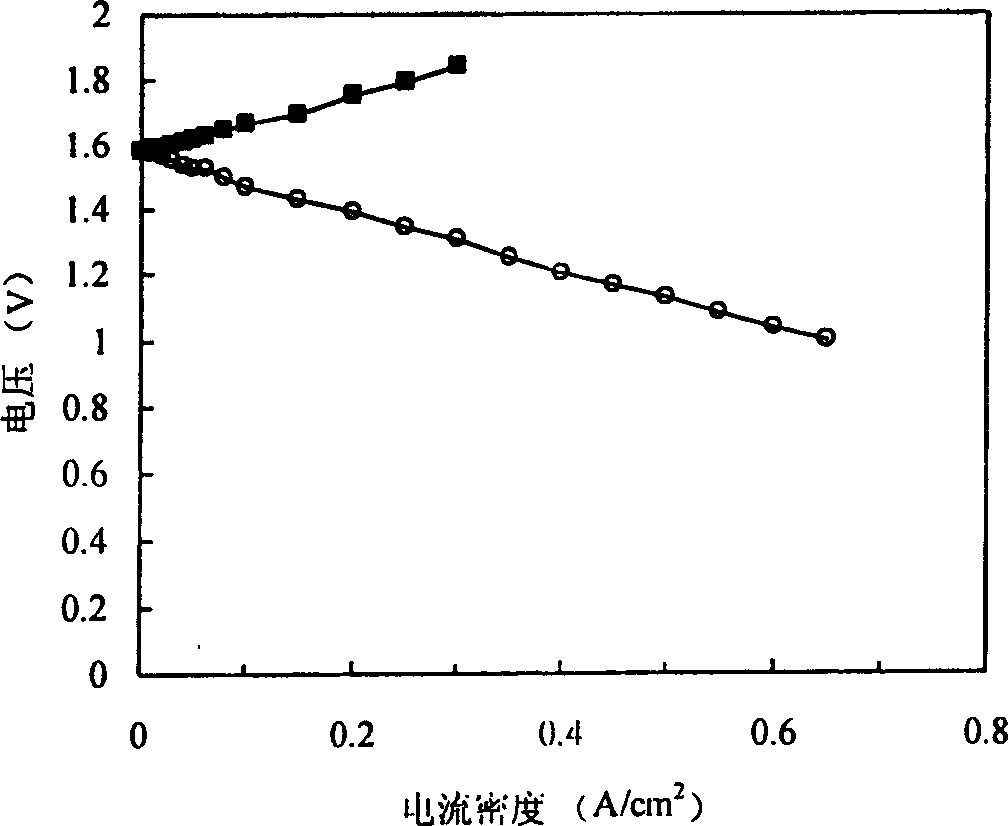

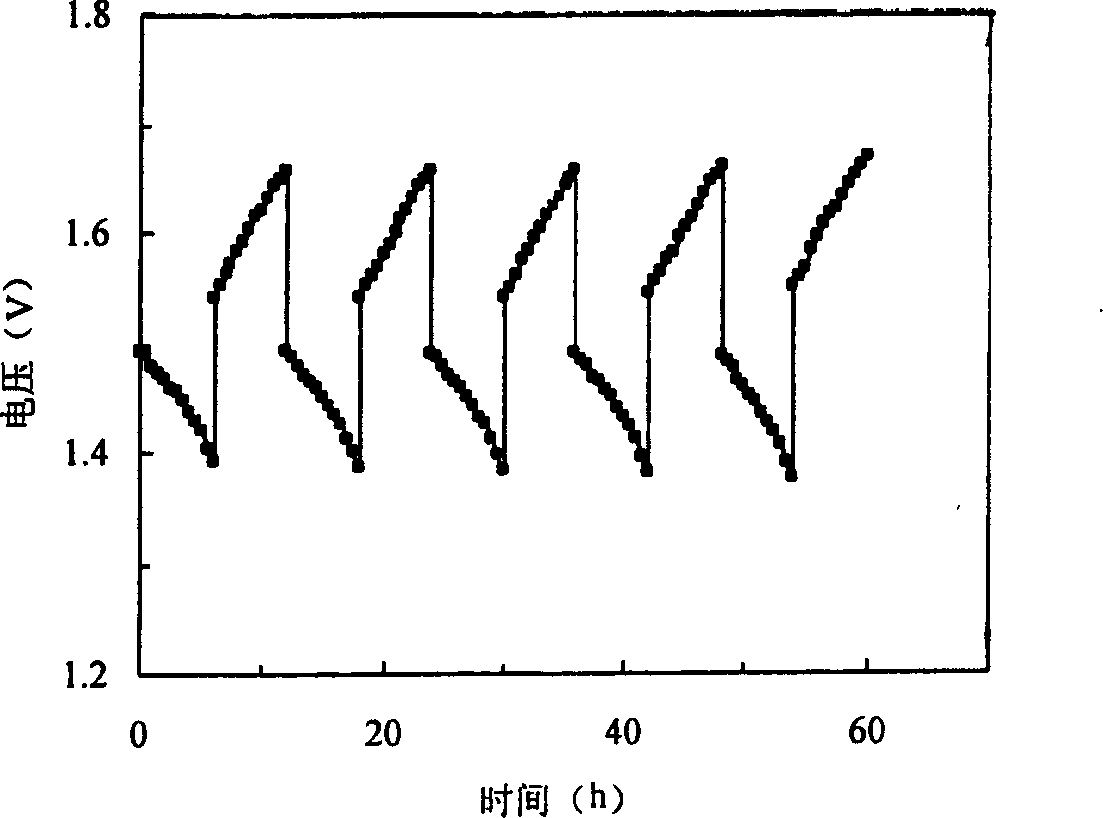

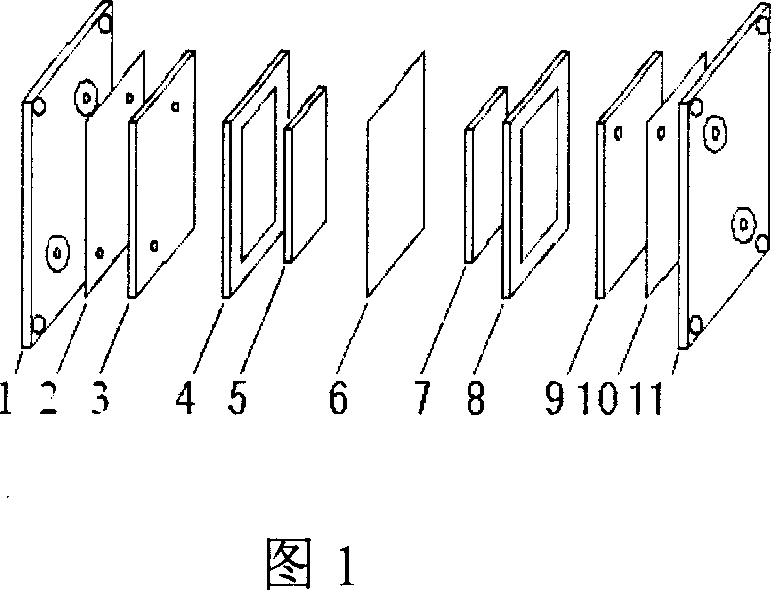

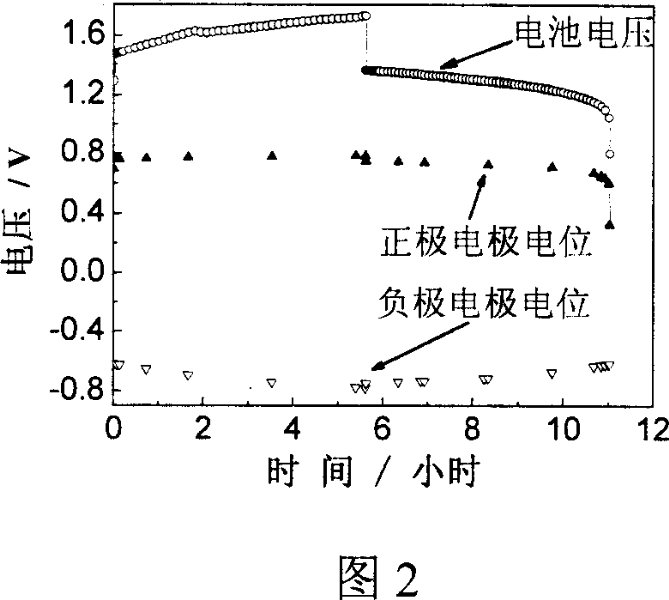

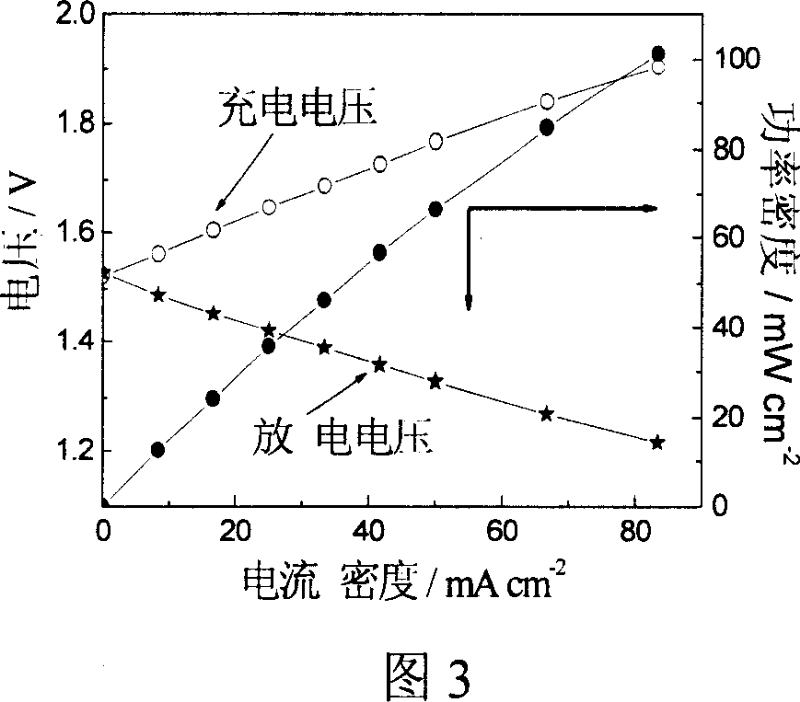

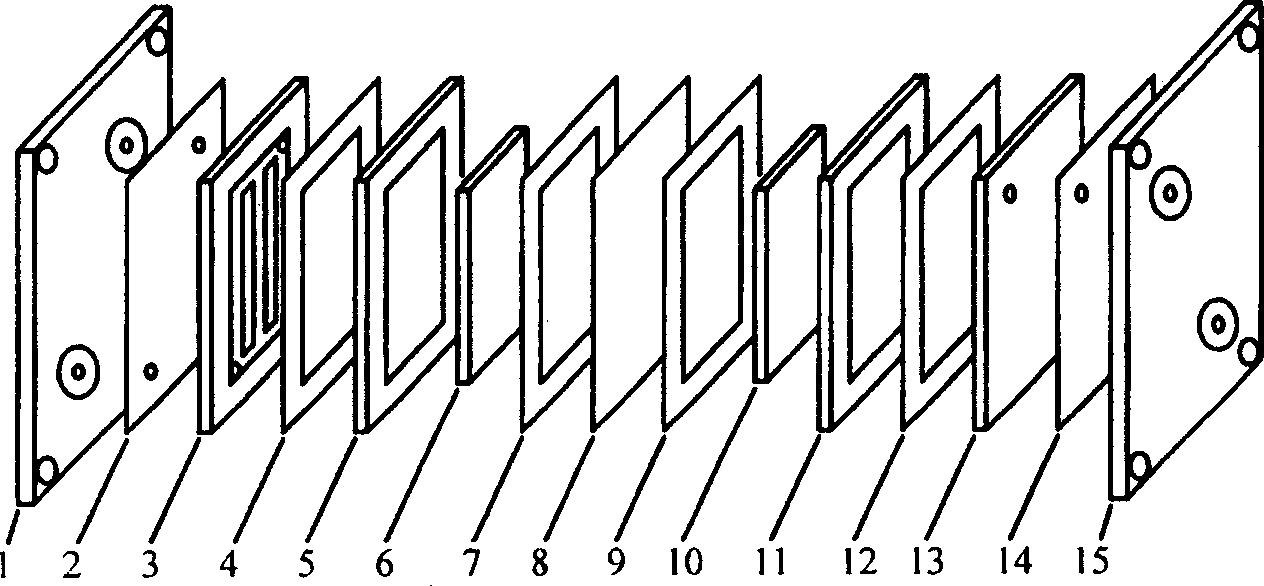

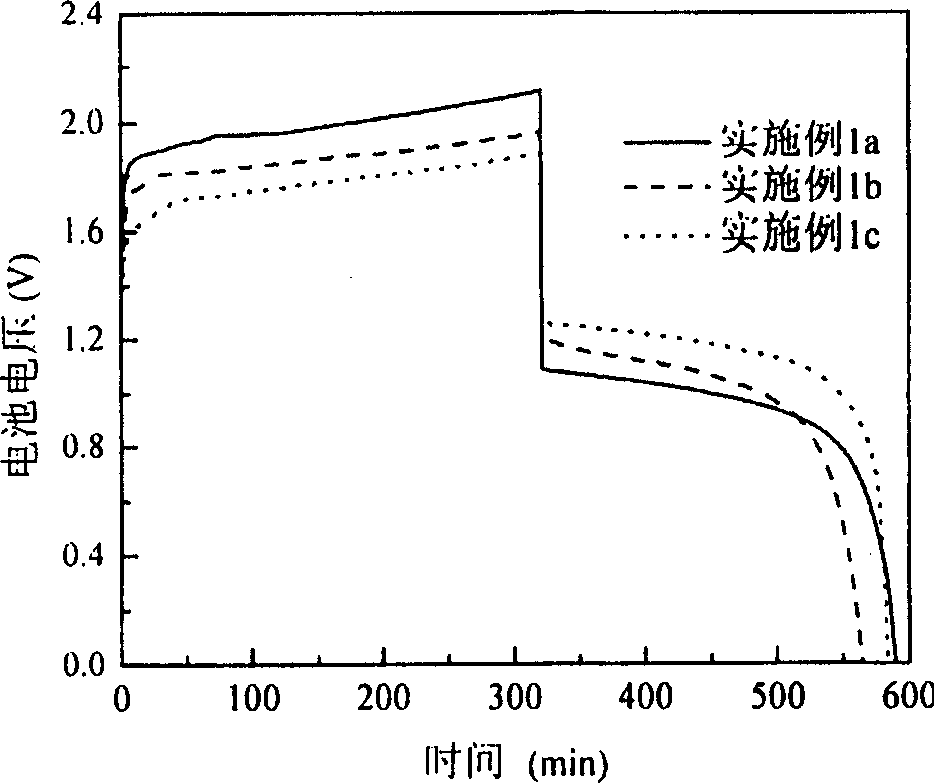

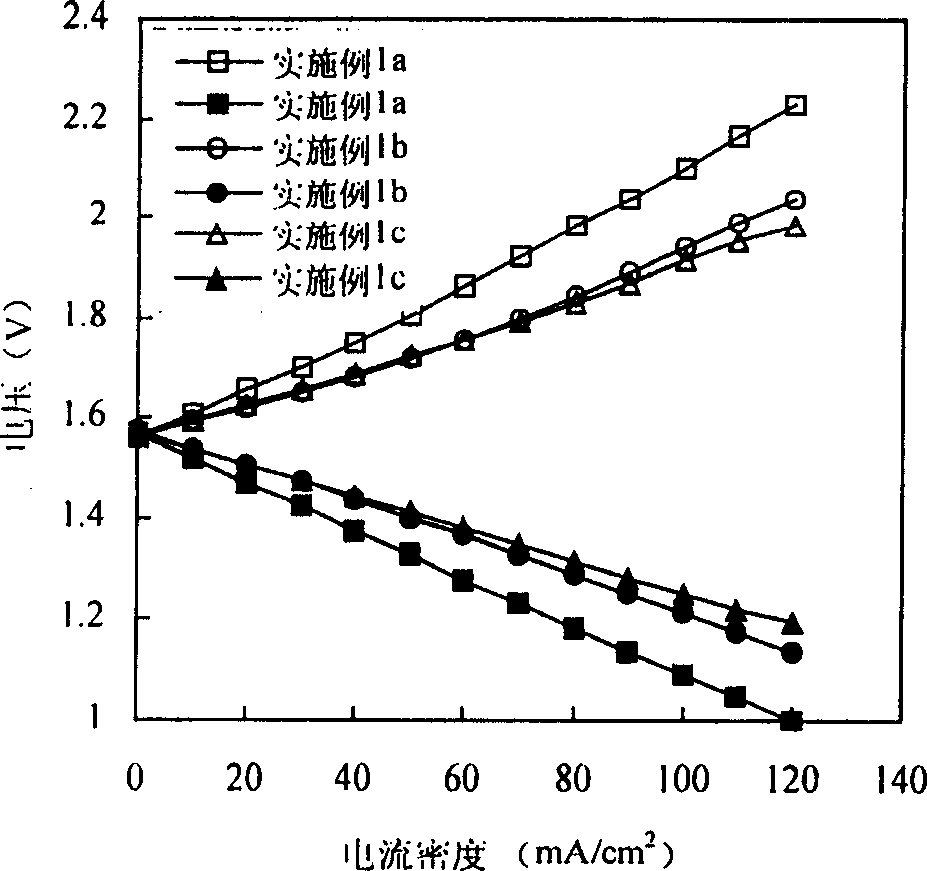

Method for producing electrode of sodium polysulfide/bromine novel energy storage cell

InactiveCN1474470AHigh mechanical strengthImprove conductivityCell electrodesSodium polysulfideChemistry

An electrode process method for multiple Na / Br sulfide type energy storage battery is to mix carbon loading transition metal catalyst and perfluorinated sulfonic acid resin uniformly to be coated on the supporting carbon paper or felts as the negative pole, and mix carbon loading Pt catalyst and perfluorinated sulfonic acid resin evenly to be coated on carbon paper or felts as the positive pole. The inverted electrodes have rather high mechanical strength, good conductance.

Owner:DALIAN RONGKE POWER

Novel environment-friendly reagent for reducing leaching concentration of various heavy metals

InactiveCN103555340AReduce usage ratioSimplify the restoration construction processWater contaminantsOrganic fertilisersPhosphatePotassium manganate

The invention discloses a novel environment-friendly reagent for reducing leaching concentration of various heavy metals. The formula of the environment-friendly reagent comprises 0-30wt% of sodium polysulfide, 1-25wt% of sodium silicate, 0-15wt% of organic sulfur TMT-15, 0-20wt% of hydrazine hydrate, 1-20wt% of phosphate, 1-10wt% of sodium sulphide, 0-15wt% of ferrous sulfate, 0-5% of potassium permanganate, 0-5wt% of citric acid and 0-5wt% of edetic acid (EDTA). The novel environment-friendly reagent can be applied to ex-situ remediation of the traditional hazardous waste containing the heavy metals, and can also be applied to in-situ remediation of pollution site soil and underground water containing the heavy metals.

Owner:SHAOXING ENVIRONREM ENVIRONMENTAL TECH CO LTD

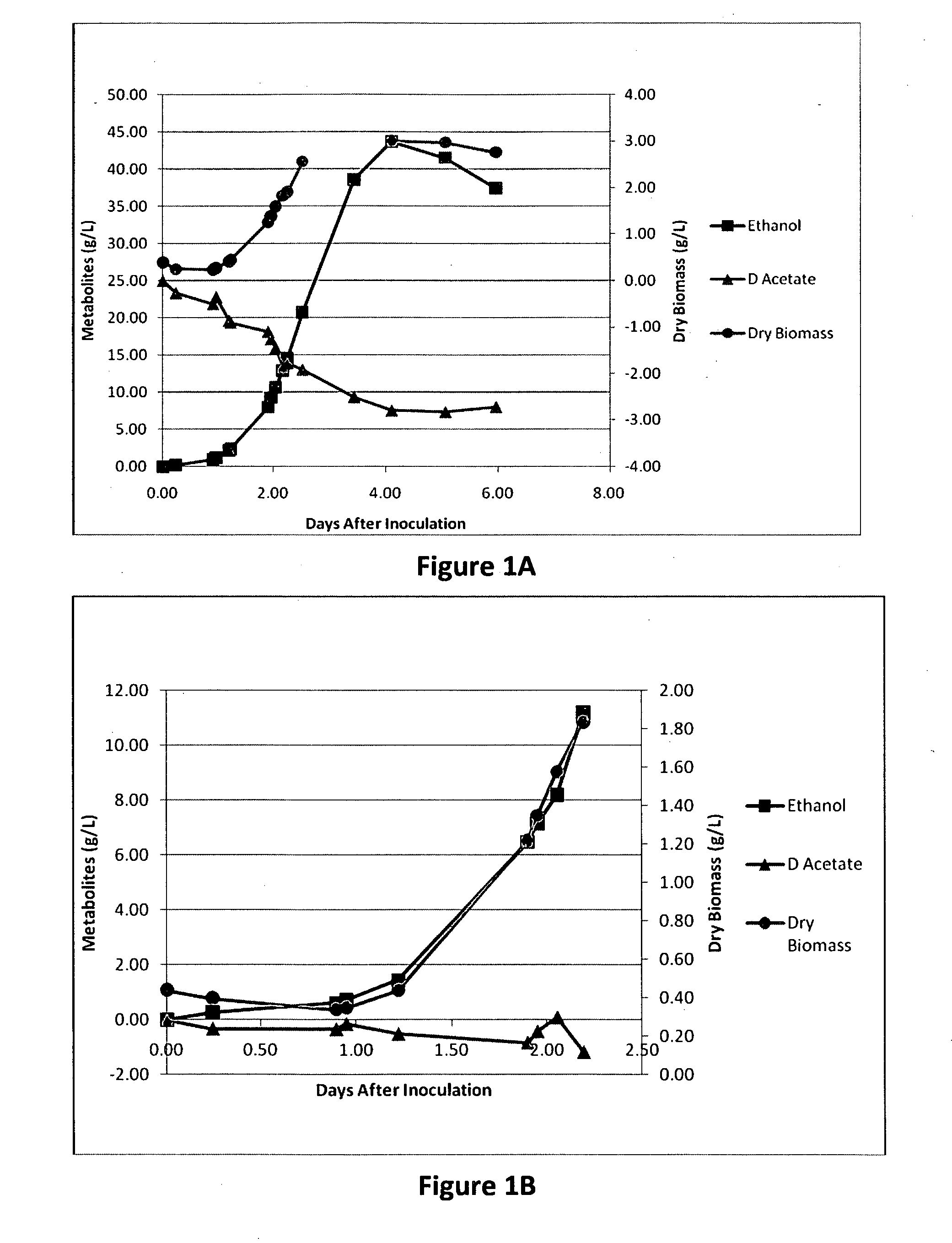

Optimised fermentation media

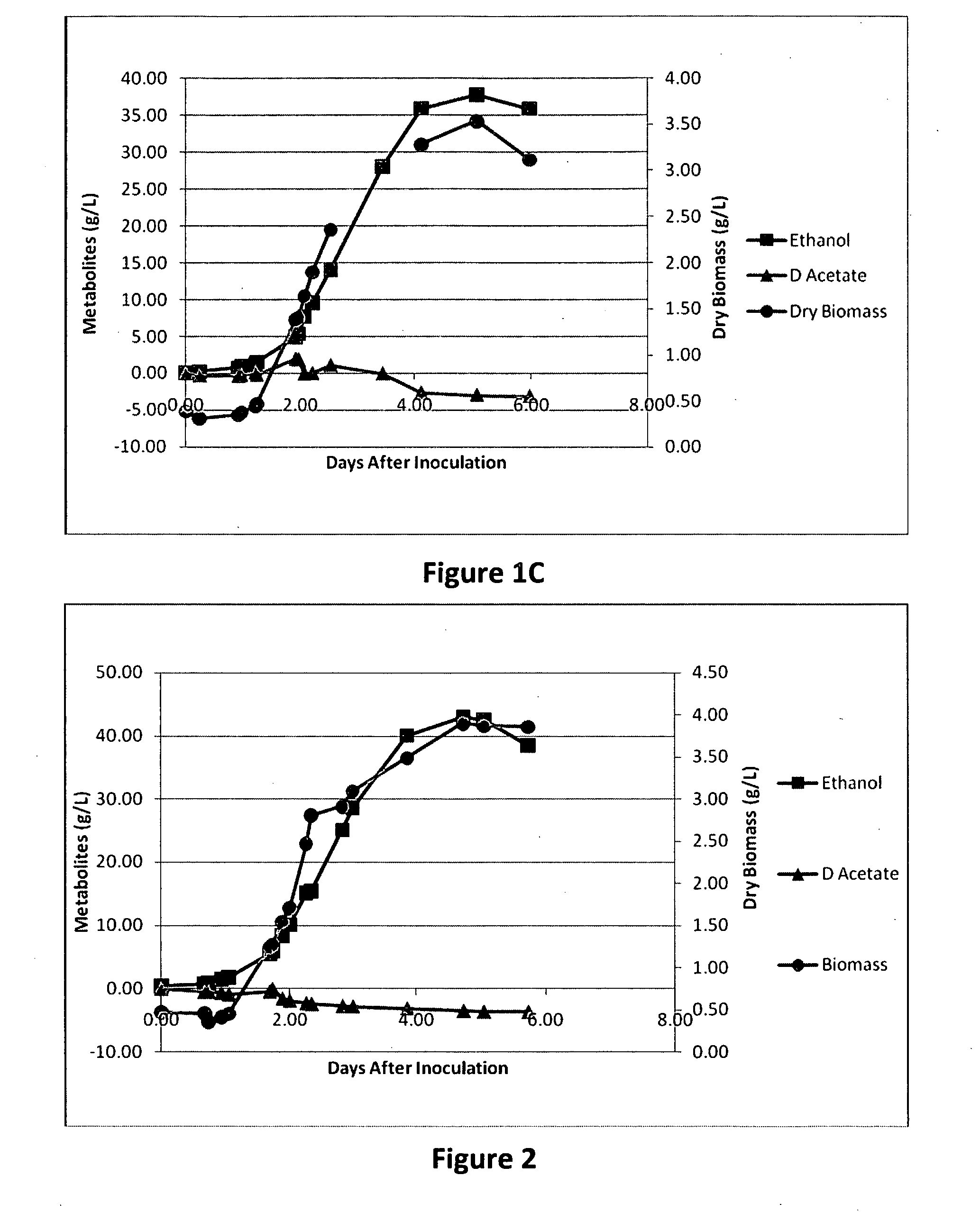

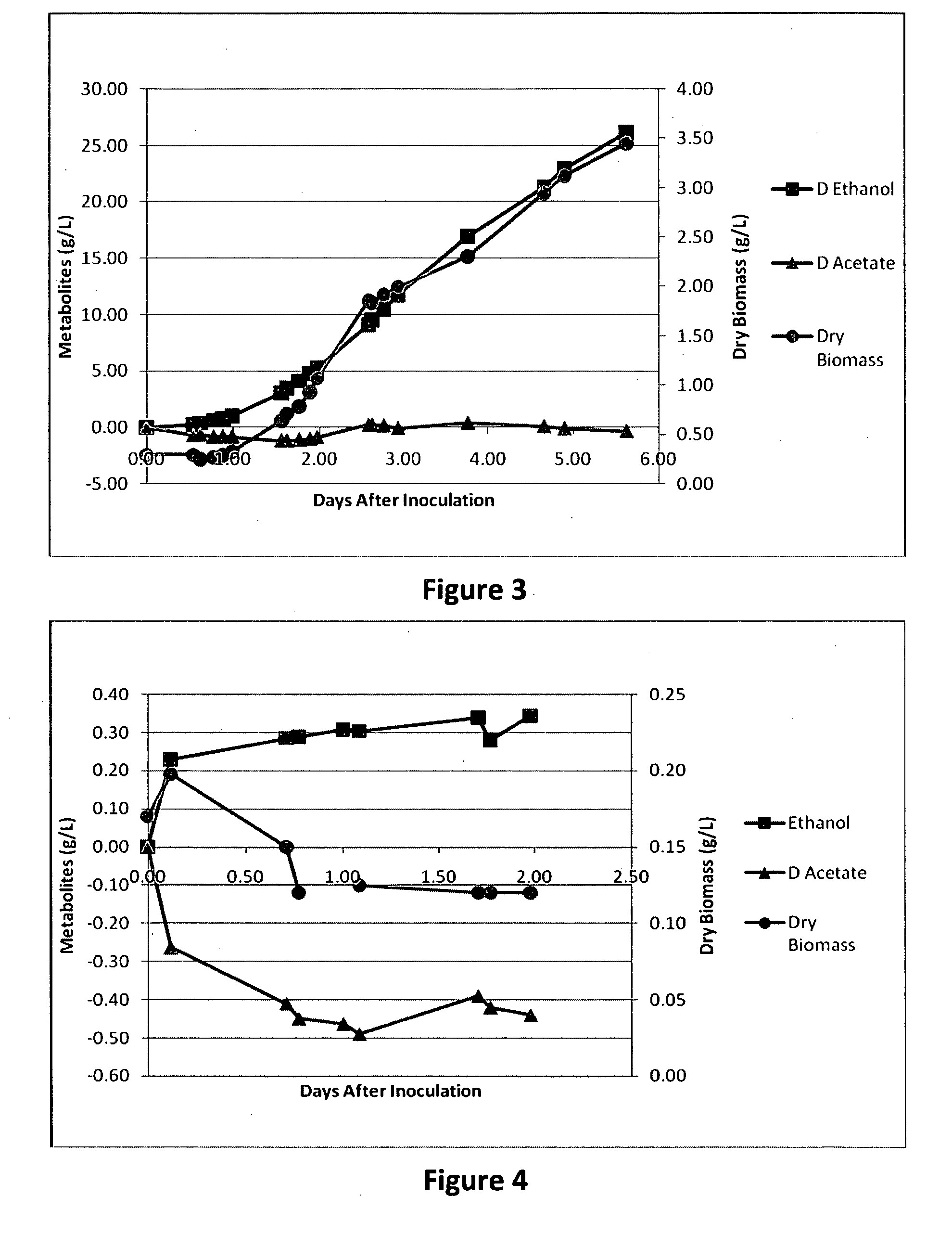

InactiveUS20110300593A1Improve growth efficiencyMaintaining and increasing production rateBacteriaSulfur compoundsAlcohol2,3-Butanediol

The invention relates to improvements in the production of alcohols by microbial fermentation, particularly to production of alcohols by microbial fermentation of a substrate comprising CO. It more particularly relates to the provision of an inorganic organic sulfur source to a fermentation system such that one or more micro-organisms convert a substrate comprising CO to alcohols. In a particular embodiment, a microbial culture is provided with sodium polysulfide, wherein a substrate comprising CO is converted to products including ethanol and 2,3-butanediol.

Owner:LANZATECH NZ INC

Application of polyporous material in sodium polysulfide/bromine accumulation energy power cell electric pole

InactiveCN101043077ASimple preparation processNo complex equipment requiredElectrode manufacturing processesFinal product manufactureHigh energySodium polysulfide

The invention relates to chemical power source energy storage cell, specially an application of porous material in sodium polysulfide / bromine energy storage cell electrode, said porous material is as the cathode of cell to applied in sodium polysulfide / bromine energy storage cell, said porous material is foam type, agglomeration type or fibre type transition metal, or carbonyl or graphite-base fabric felt of electrodeposition or chemical deposition transition metal. The anode adopts the carbonyl felt or graphite-base felt without activator. The electrode produced possesse higher conductivity, better mechanical intensity, and perfect active, chemical and electrochemical stability in sodium polysulfide / bromine energy storage cell. The cell assembled by the electrode possesses higher energy efficiency and longer circle life. The invention possesses higher practicality value, and easy to be produced in batch, the cost of energy storage cell can be decreased, and it fits for quickening the commercialization course of sodium polysulfide / bromine energy storage cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

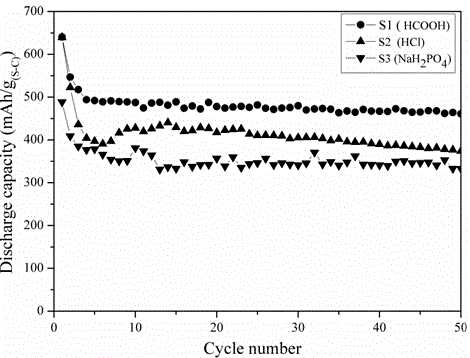

Sulfur-carbon composite positive electrode material for lithium-sulfur battery and preparation method of sulfur-carbon composite positive electrode material

ActiveCN104600247AIncrease contentImprove cycle stabilityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsHigh concentrationCarbon composites

The invention particularly relates to a preparation method of a sulfur-carbon composite positive electrode material for a lithium-sulfur battery. Sodium polysulfide is taken as the raw material, and the nano-scale sulfur particles generated by use of a chemical reaction are promoted to be melted by virtue of high-speed ball milling and go into carbon pores of conductive carbon black, and finally, the sulfur-carbon composite positive electrode material is prepared. The high-performance sulfur-carbon composite material is prepared by use of an in-situ wet ball milling method. According to the preparation method, the operation is simple and easy, the energy consumption is low, the cost is low, an environment-friendly effect is achieved, and the industrial production is easy. The thorough dispersion and fixation of sulfur on a conductive substrate are realized; besides, a high-concentration lithium salt electrolyte is adopted to inhibit the solution of polysulfide, and therefore, the cyclic stability and the active substance utilization rate of the material are improved. As a result, the sulfur-carbon composite material prepared by use of the in-situ wet ball milling method is a positive electrode material which is high in specific capacity, long in cycle life and high in rate performance and can be applied to the field of lithium secondary batteries.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

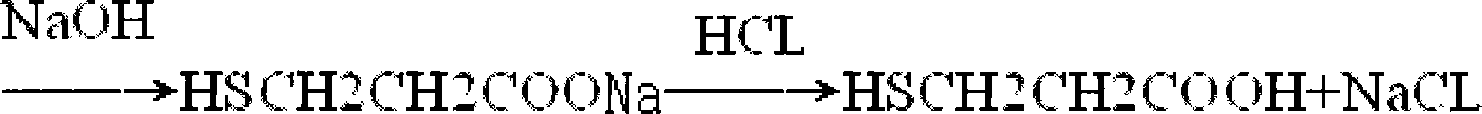

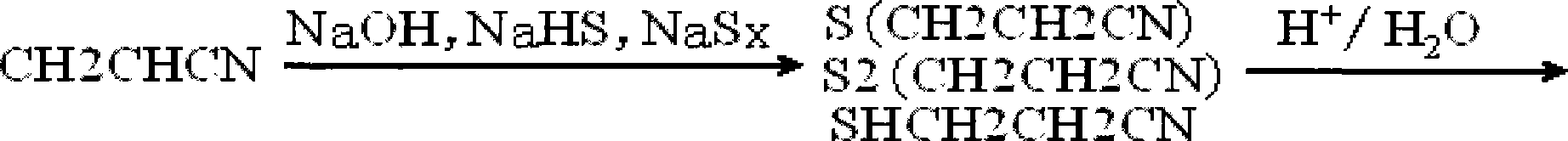

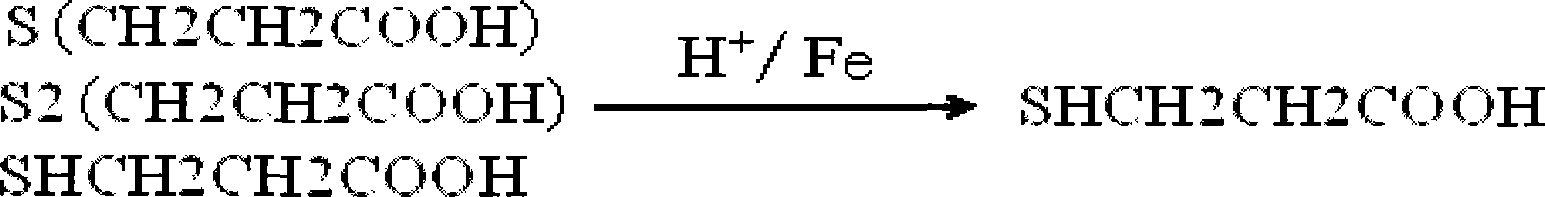

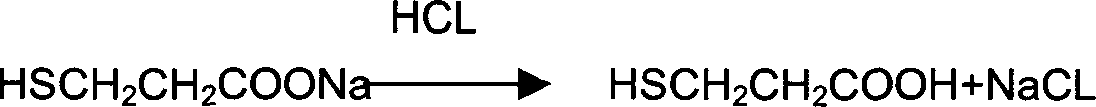

Method for preparing 3-mercaptopropionic acid

The invention relates to a preparation method of 3-mercaptopropionic acid. Sodium hydroxide solution, sodium hydrosulfide and sodium polysulfide (as catalyst) are mixed, then acrylonitrile is dripped into the mixture at the temperature of 20-70 DEG C to produce under insulated temperature the mixed solution of a plurality of intermediates, then hydrochloric acid is added for acidification and iron powder is added for deoxidization, thus acquiring the solution of 3-mercaptopropionic acid. The raw material sodium hydrosulfide selected in the reaction is cheap, reducing the production cost; hydrogen sulfide gas that is produced after the hydrochloric acid is added can be recycled to produce hydrogen sulfide nano, the production cost is further reduced; the final waste liquid mainly contains surplus hydrochloric acid and ammonia chloride, which is easy to be disposed; pollution is hardly caused during the whole reaction process.

Owner:顾建荣

Sulfide heavy metal chelating agent and preparation method thereof

ActiveCN101628750ASimple preparation processEasy to useWater contaminantsWater/sewage treatment by flocculation/precipitationAluminium chlorideWater insoluble

The invention discloses a sulfide heavy metal chelating agent and a preparation method thereof; the method adopts a reaction between sodium sulfide water solution and sulfur to generate sodium polysulfide and uses aluminum sulfate, aluminium chloride and other aluminum salts as stabilizers so as to strengthen the flocculation effect and increase the catching effect on heavy metal ions. The chelating agent is used to treat the industrial wastewater containing heavy metal ions, can effectively restrain the generation of hydrogen sulfide, and reacts with all kinds of heavy metal ions quickly at room temperature to generate water insoluble sulfides precipitate, wherein, the particles of the produced sulfides is large, the floccule is dense and the settling time is reduced so that the concentrations of the heavy metal ions in wastewater are easy to be reduced below the national discharge standard, the generated residue can be used for recycling heavy metals and secondary pollution is not easy to cause; the method of the invention has simple devices, convenient operation and low cost, thus being applicable to the wastewater treatment in industries such as circuit board industry, plating industry, metal finishing industry, manufacturing industry, coal power stations, municipal or industrial waste incineration industry, battery production and the like.

Owner:南京正隆环保工程有限公司

Secondary aluminum battery and preparation method of anode thereof

InactiveCN101764254AIncrease the effective reaction areaWide variety of sourcesCell electrodesSecondary cellsHalogenCarbonyl sulfide

The invention discloses a secondary aluminum battery and a preparation method of anode thereof; the secondary aluminum battery comprises a battery anode, a battery cathode, an electrolyte, a diaphragm and a current collector; the battery cathode is made of aluminum or aluminum alloy; the battery anode is made of polystyrene polysulfide or carbonyl sulfide composite material; and the electrolyte is halogen aluminic acid ionic liquid. The preparation method of secondary aluminum battery anode material (polystyrene polysulfide) comprises the following steps: (1) preparing chlorination polystyrene; (2) preparing polystyrene polysulfide; (3) slowly dropping sodium polysulfide solution into chlorination polystyrene solution according to the proportion of Na to C1 being 1: 1 at the temperature of 50 to 150 DEG C, stirring so as to react about 24 hours. Powder product is obtained after cleaning and extracting to obtain polystyrene polysulfide product dried about 24 hours in vacuum at the temperature of 80 DEG C.

Owner:无锡欧力达新能源电力科技有限公司

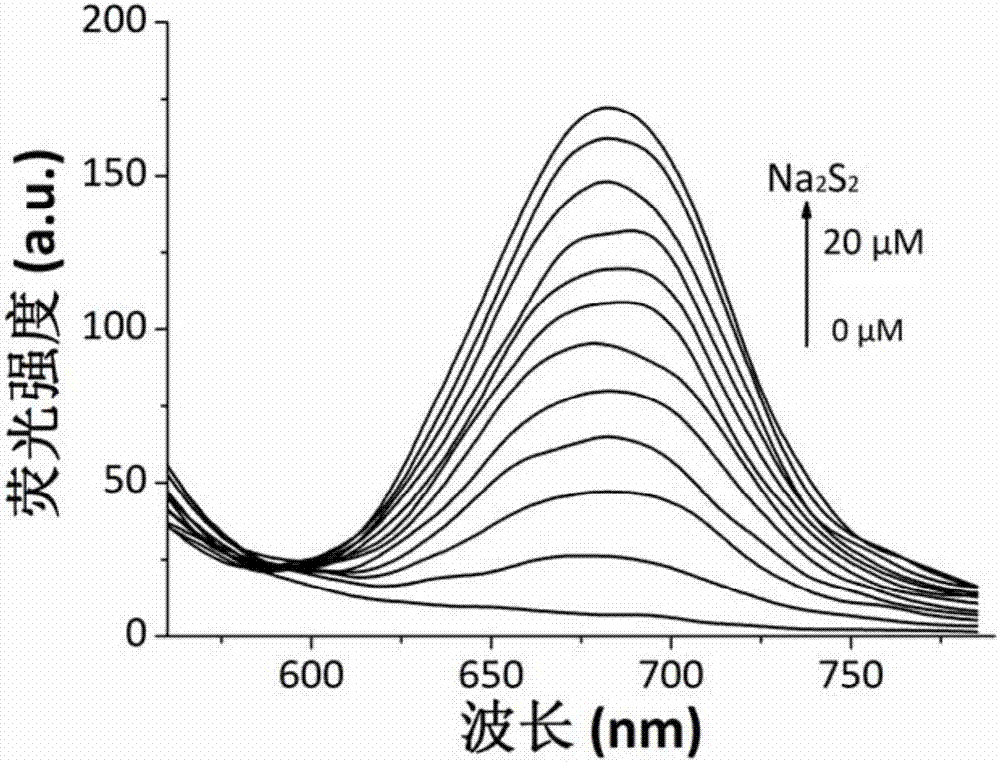

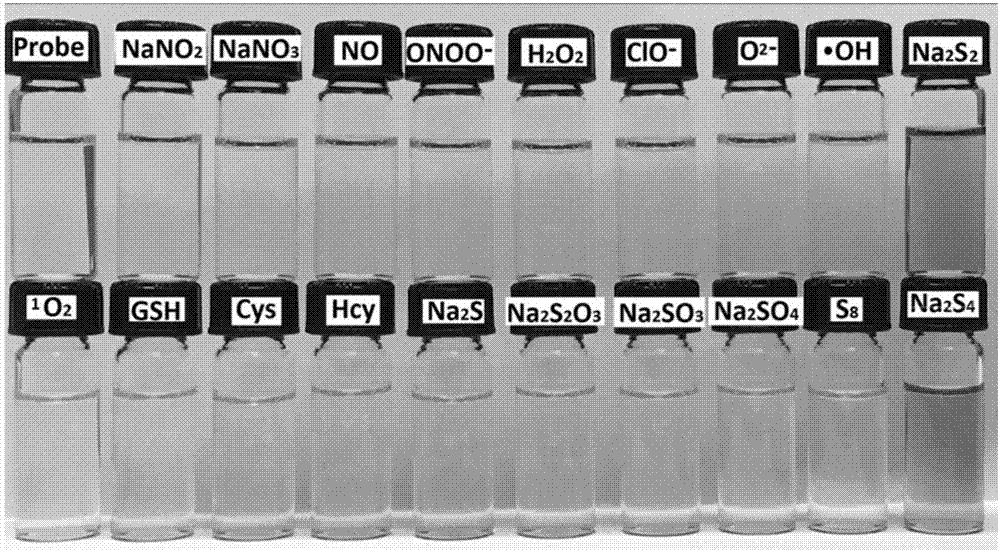

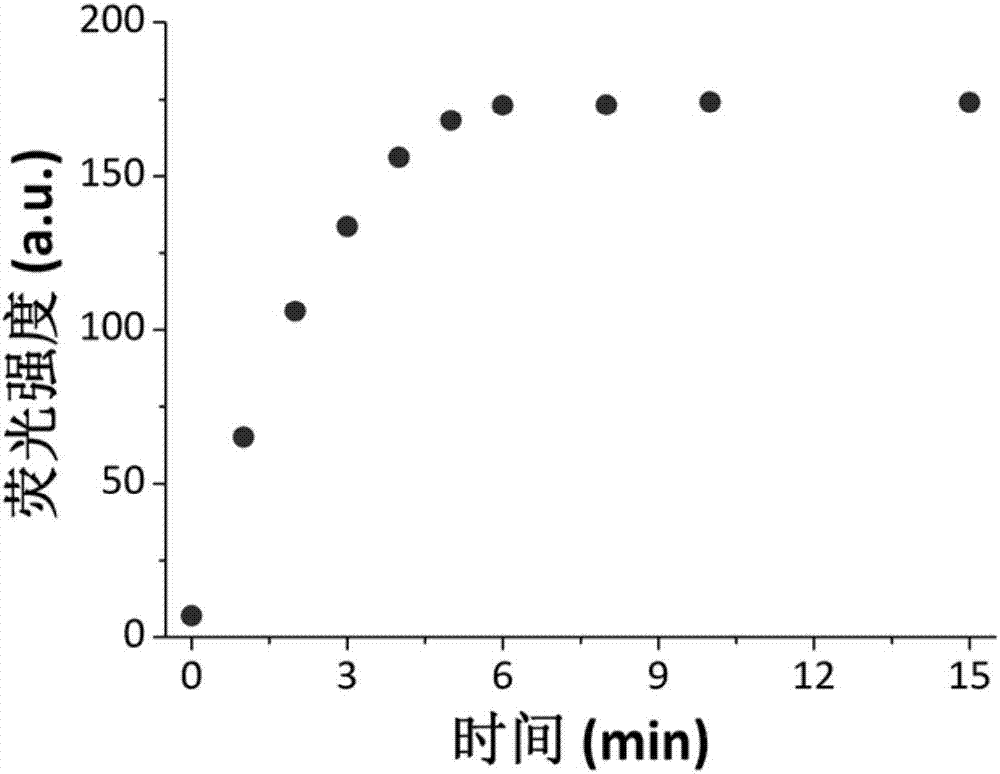

Synthesis and application of near infrared fluorescence probe for detecting hydrogen polysulfide

The invention relates to a synthesis method and application of a novel high-selectivity and high-sensitivity near infrared fluorescence probe for visually detecting hydrogen polysulfide. The method comprises the steps of making benzopyran carbonitrile and p-hydroxy benzaldehyde react to obtain a precursor, and then conducting an esterification reaction with 2-fluoro-5-nitrobenzoic acid to obtain the fluorescence probe. The probe reacts with sodium polysulfide to generate a strengthened fluorescence change, which is that the fluorescence at the 682 nm is strengthened remarkably. Besides, a dynamic experiment result shows that the reaction time of the compound and hydrogen polysulfide is shorter than 5 min, and the interference rejection is strong. Thus, the pyran carbonitrile compound can serve as the application of the near infrared fluorescence probe for detecting hydrogen polysulfide.

Owner:TAIZHOU UNIV

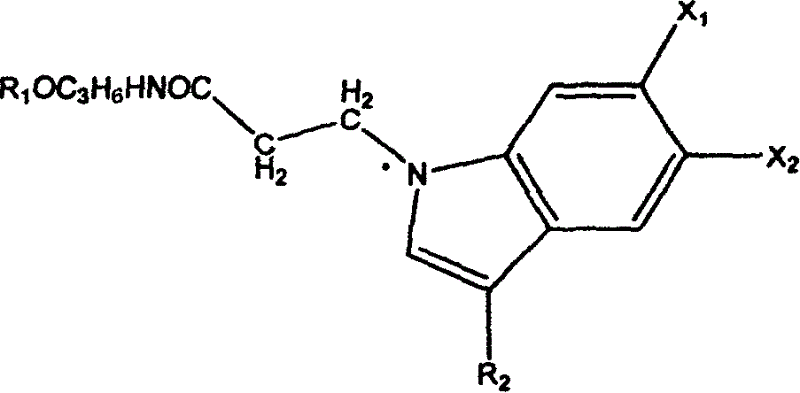

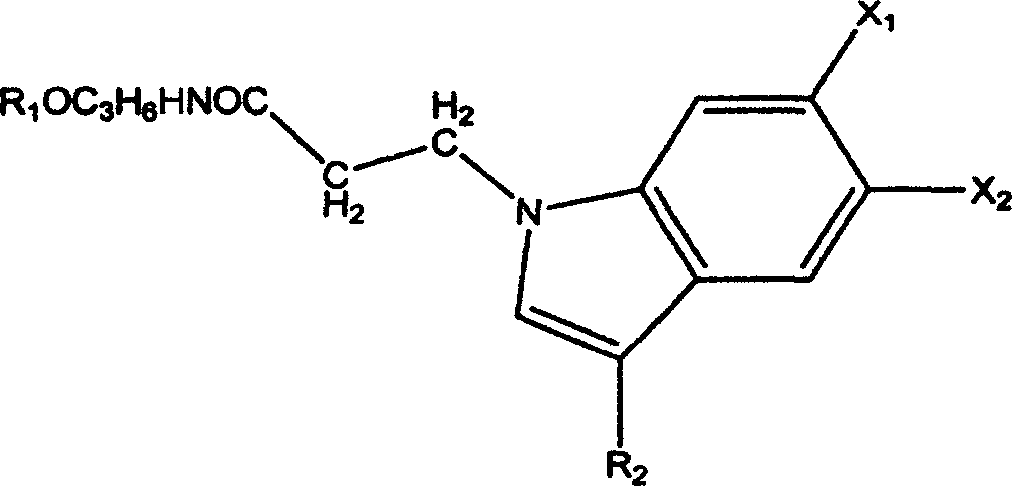

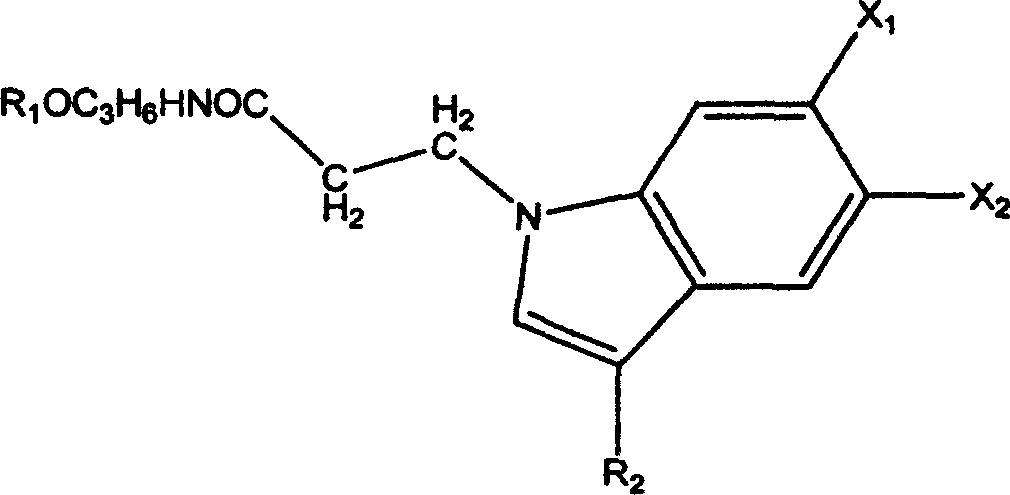

Amide derivative of indole, its preparation method and application

InactiveCN1651412AHighly effective antifouling activityHigh bactericidal activityOrganic chemistryAntifouling/underwater paintsNon target organismGramine

An indoleamide derivative C14H14X1X2N2O2R1R2 used as antifoulant for preparing marine anti-fouling point is prepared through reaction between sodium polysulfide and methyl acrylate to obtain dimethyl dithiobipropionate, reaction on alkoxypropylamine to obtain N,N'-dialkylpropyl dithiopropanamide, and reaction on indole, haloindole, gramine, or halogramine to obtain target product.

Owner:OCEAN UNIV OF CHINA

Process for preparing 3-mercaptopropyl acid

The invention relates to a manufacture method for 3-thiohydracrylic acid. The feature is that is mixing the NaOH water solution, sodium hydrosulphide, sodium polysulfide, dropping acrylonitrile at 20-70 degree centigrade, keeping temperature to form kinds of inter mixture liquid, adding HCl to acidify, adding zinc powder to deoxidize to gain 3-thiohydracrylic acid solution. The invention could decrease cost, and the waste liquid is easy to process.

Owner:顾建荣

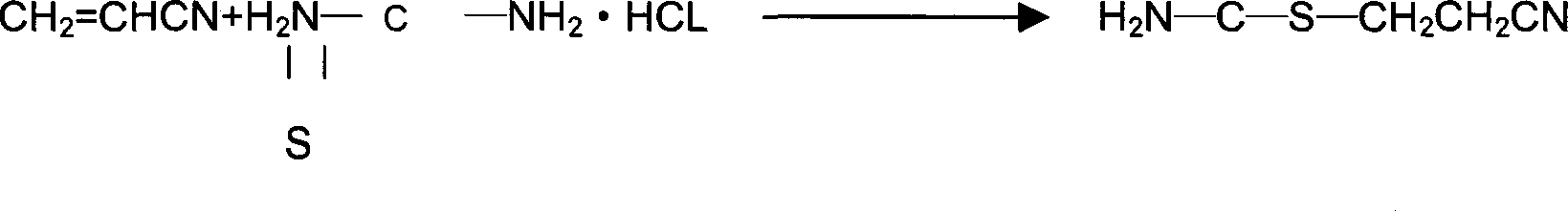

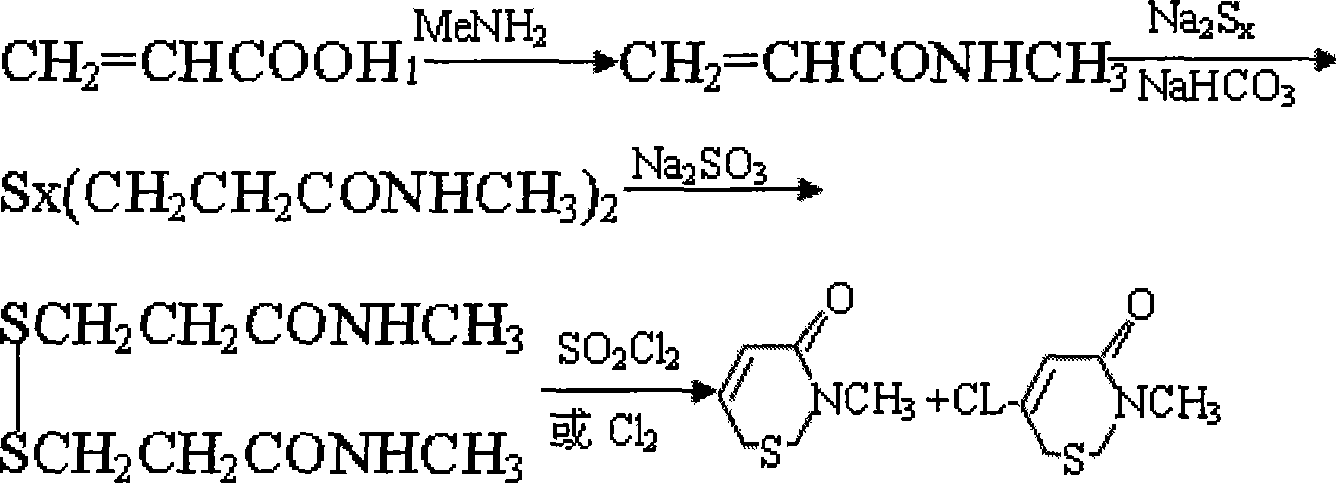

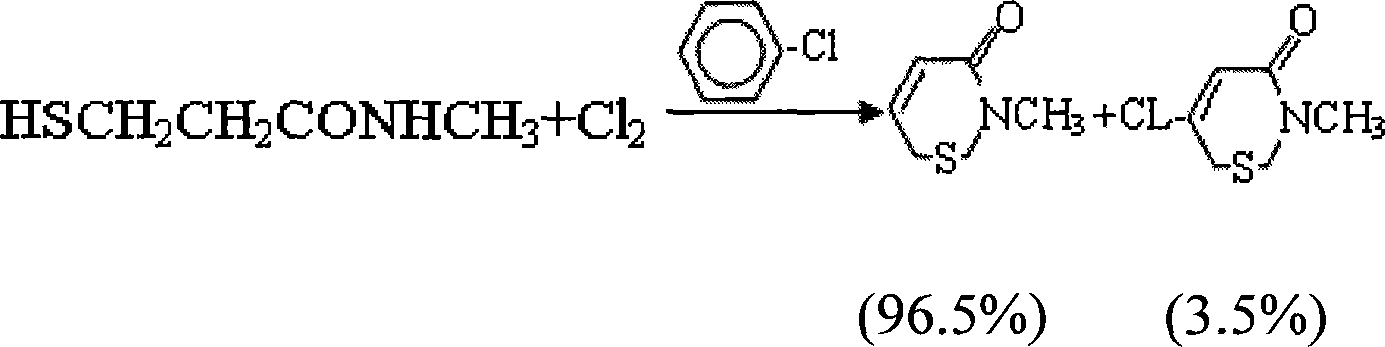

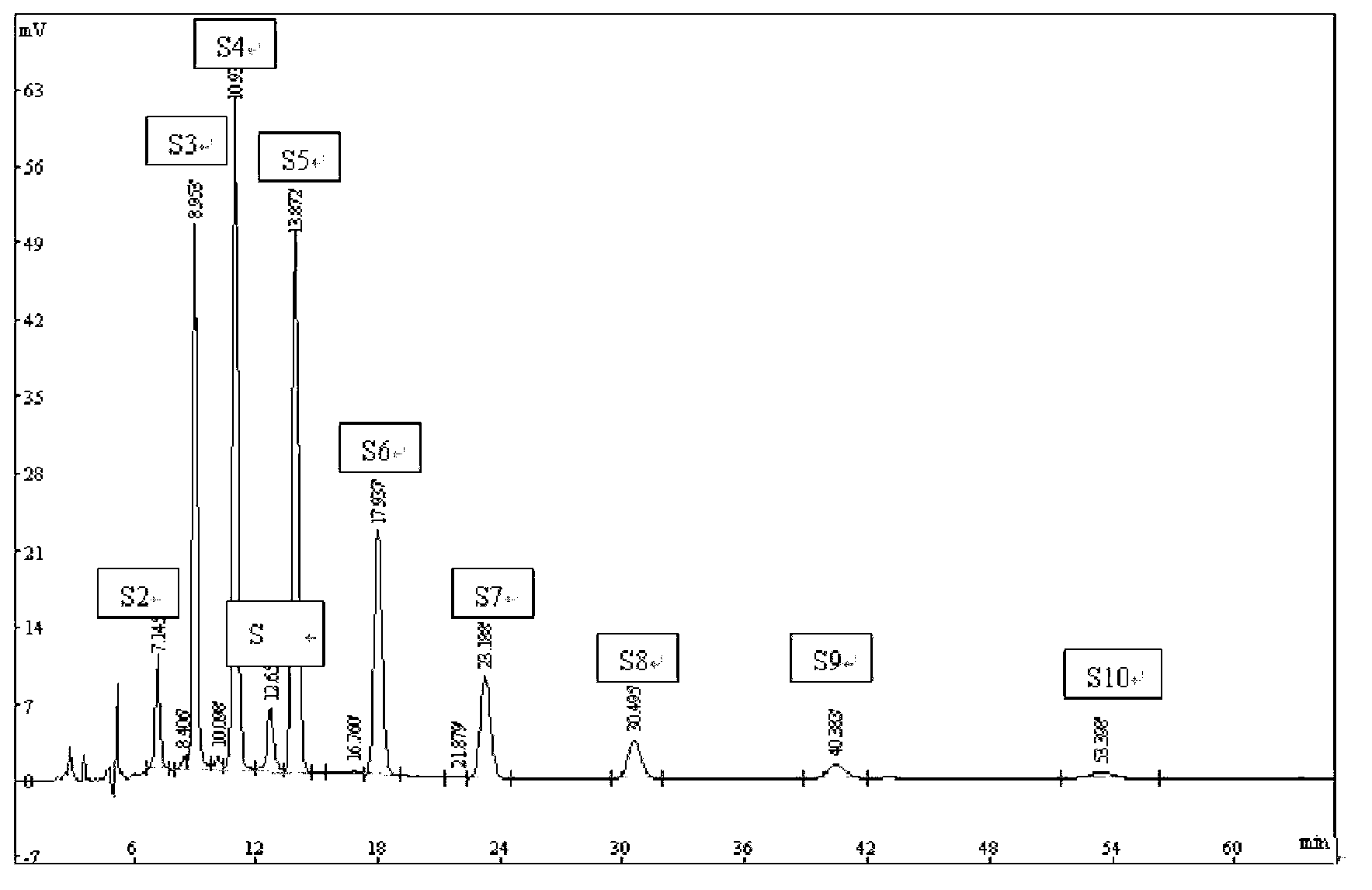

Method for preparing new type bactericide of iso-thiazolinone

InactiveCN101050203AHigh yieldOvercomes the drawback of containing trace amounts of waterOrganic chemistryIsothiazolinoneMethyl acrylate

This invention relates to a method for preparing a novel bactericide isothiazolinone. The method comprises: (1) adding sodium polysulfide into methyl acrylate for reaction, separating the products, and purifying to obtain dimethyl dipropionate disulfide; (2) adding DMF solution of methylamine, acylating, separating the products, and purifying to obtain N,N'-dimethyl dipropionamide disulfide; (3) dissolving in 1,2-dichloroethane, microwave-irradiating for ring-closing reaction, separating the products, and purifying to obtain isothiazolinone. The method has such advantages as high yield, and little pollution.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

Method for synthesizing sulfur-containing silane coupling agent from sodium polysulfide

ActiveCN102875587AStable ratioImprove qualityGroup 4/14 element organic compoundsSilanesReaction temperature

The invention relates to a method for synthesizing a sulfur-containing silane coupling agent from sodium polysulfide, belonging to the technical field of organic chemistry. The method comprises the following steps: reacting sodium hydroxide and sulfur to prepare sodium polysulfide, and synthesizing the sulfur-containing silane coupling agent from the sodium polysulfide. The invention solves the problems of great product quality fluctuation and heavy environmental pollution in the sulfur-containing silane in the production of sodium polysulfide from sodium sulfide and sulfur, and the problem of high cost in the sodium polysulfide prepared from sodium metal and sulfur at present in China. Since the temperature is low in the whole reaction process, no sulfur is volatilized, no sulfur dioxide (SO2) gas due to contact oxidation of air is generated, thus, the environmental pollution is slight, and the produced sulfur-containing silane product has stable sulfur distribution. The invention has the advantages of low cost, high control stability, stable product quality and light color.

Owner:JINGZHOU JIANGHAN FINE CHEM

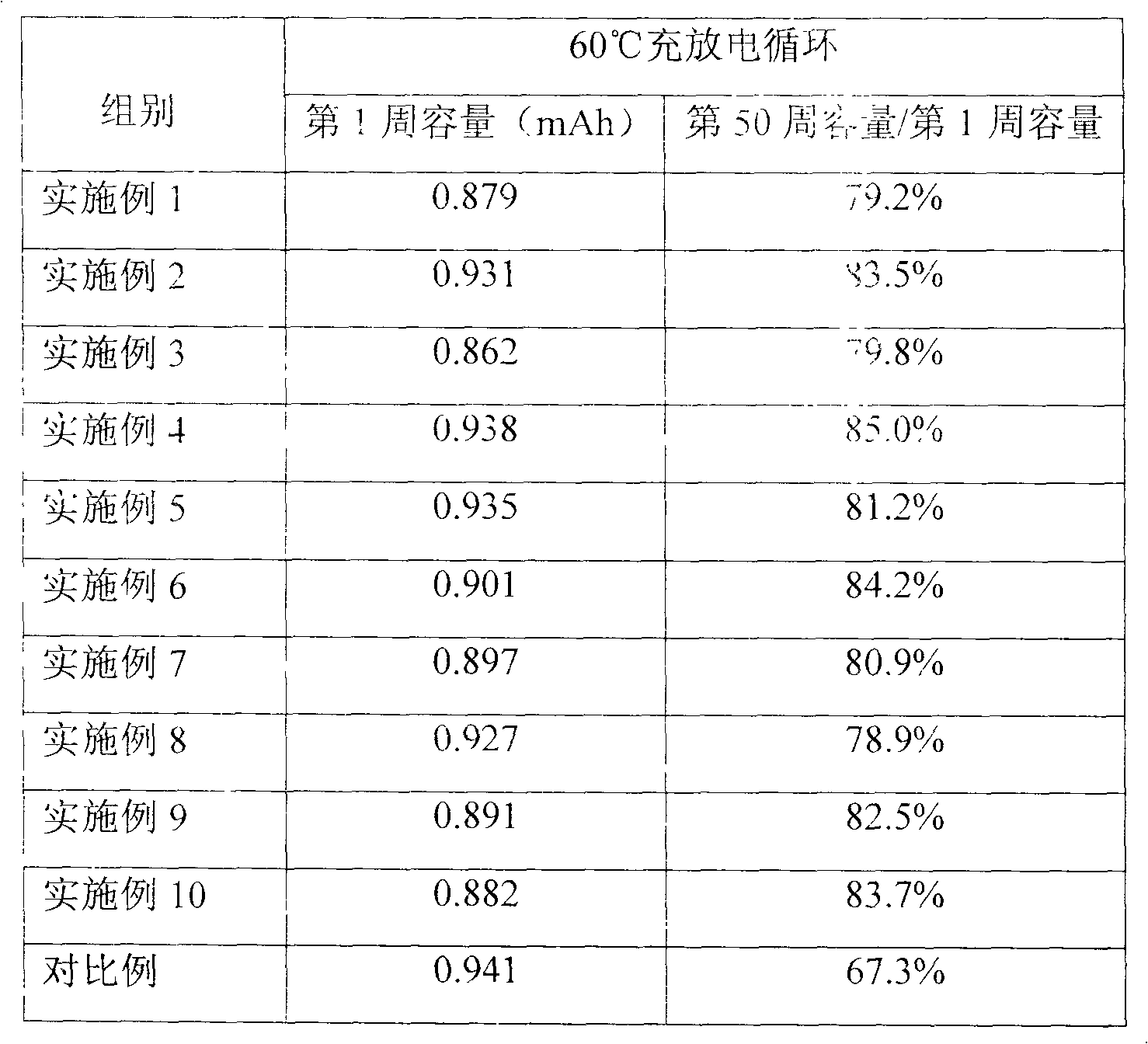

Lithium secondary battery and cathode plate thereof

ActiveCN102593416AAvoid destructionImprove high temperature performanceCell electrodesSecondary cellsManganeseSulfide

The invention belongs to the technical field of lithium secondary batteries and particularly relates to a cathode which can improve the high-temperature cycling property of a battery using a manganese-contained material as an anode. The cathode comprises a cathode current collector and a cathode active material layer coated on the cathode current collector, wherein the cathode active material layer contains an additive; the additive refers to at least one of elemental sulfur, alkali-metal sulfide and alkali-metal polysulfide; and the additive accounts for 0.1wt%-2wt% of the total mass of the cathode active material layer. Compared with the prior art, the elemental sulfur and the sodium polysulfide added in the cathode plate provided by the invention are easily reduced to S2-, sulfur in the elemental sulfur refers to S2-, and the interaction between S2- and manganese ions is strong, therefore the manganese ions dissolved out of electrolyte can be precipitated; and the cathode contains the sulfur, the sulfide or the polysulfide, so that the damage caused by precipitation, on the surface of the cathode, of the manganese dissolved out of the anode can be avoided and consequently the high temperature performance of the battery can be enhanced.

Owner:NINGDE AMPEREX TECH +1

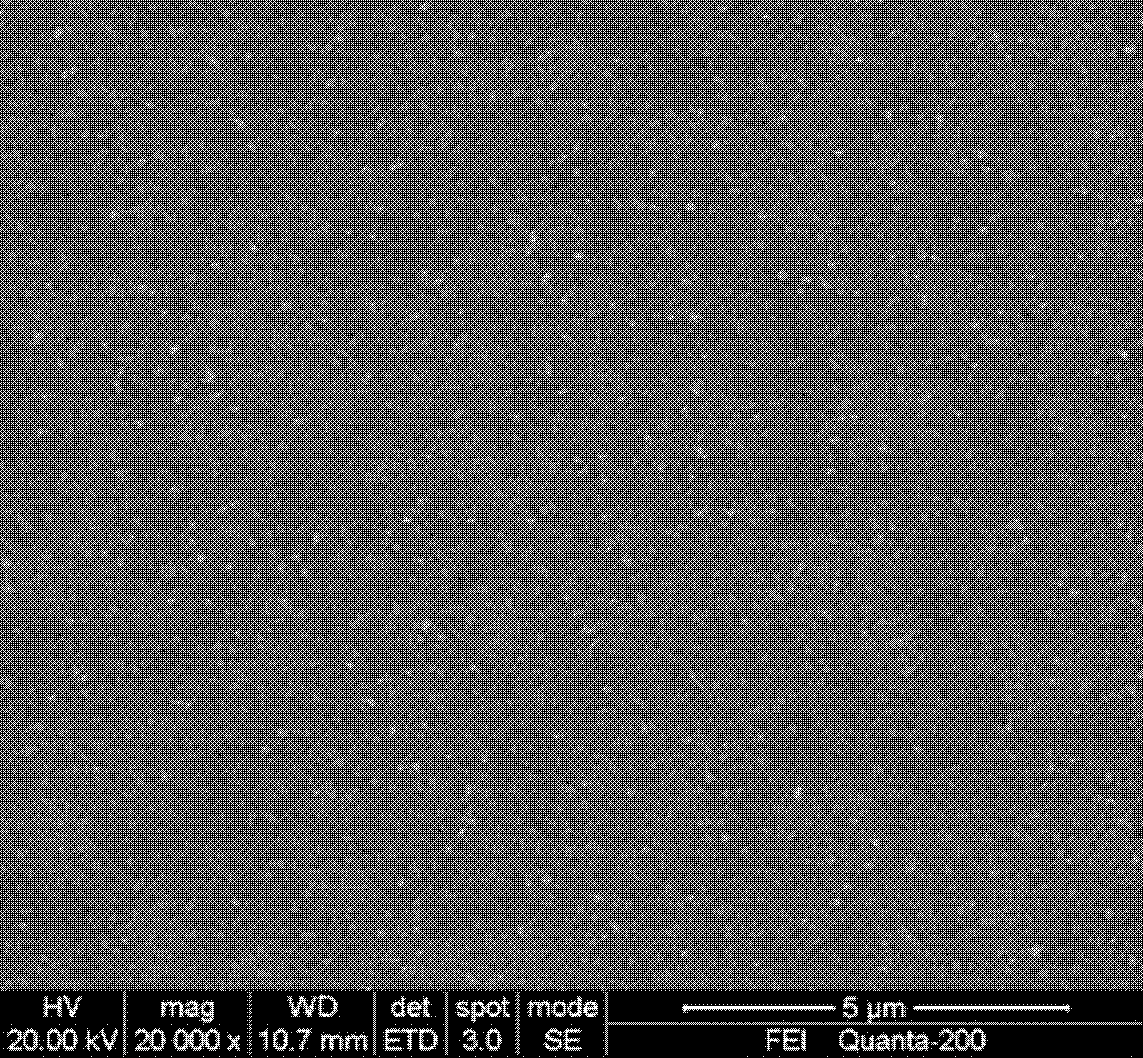

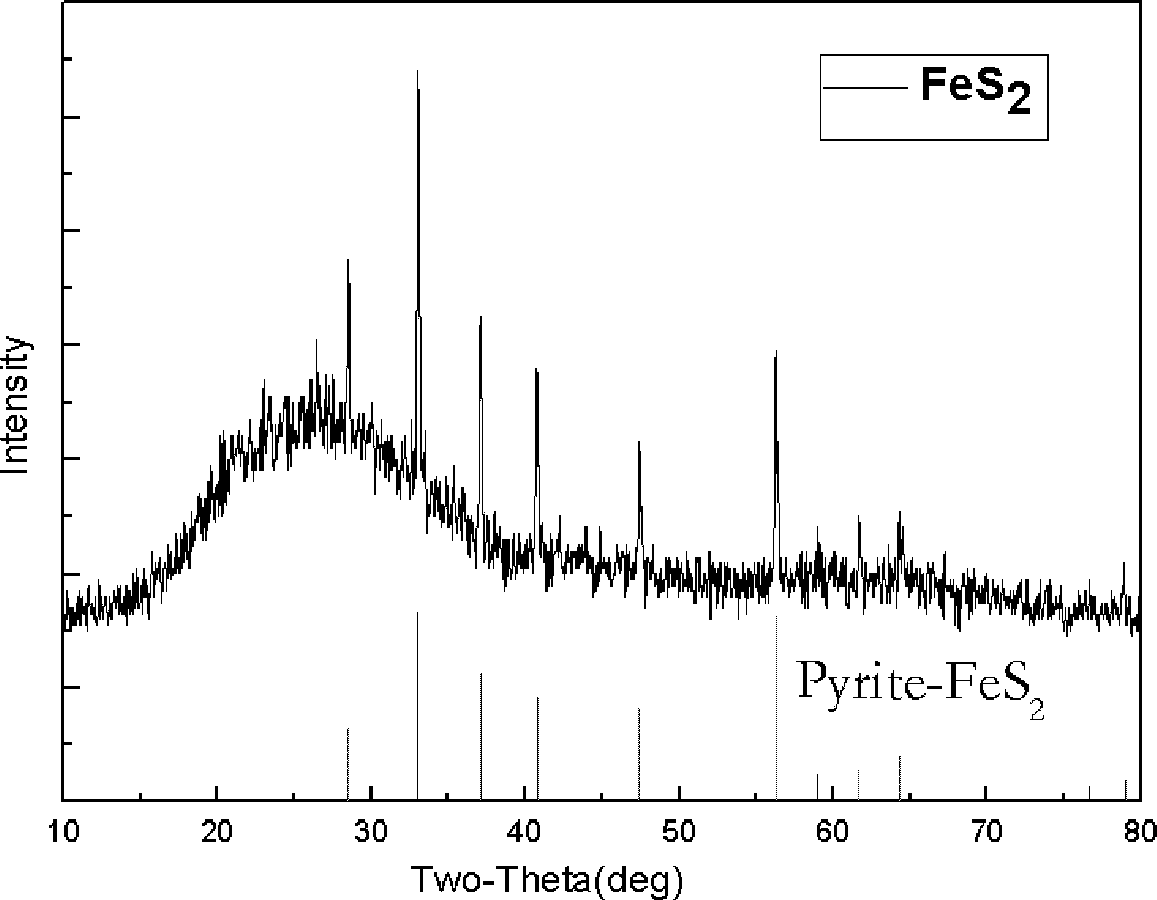

Ferrous disulfide semiconductor film preparation method

ActiveCN102642874AThickness is easy to controlEasy for large-scale continuous productionIron sulfidesVulcanizationIron(II) chloride

The invention discloses a ferrous disulfide semiconductor film preparation method, which relates to the field of preparation of compound semiconductor films for solar cells and the like. The method includes: by an aqueous solution deposition method, using ferrous sulfate or ferrous chloride aqueous solution as cation precursor solution, and using sodium polysulfide aqueous solution as anion precursor solution; controlling immersion time of a substrate in the precursor solution and circulation times to deposit a ferrous disulfide film premade layer; and subjecting the premade layer to vulcanization heat treatment at the high temperature to obtain a ferrous disulfide film. The ferrous disulfide semiconductor film preparation method is short in procedure, low in cost, high in reproducibilityand easy in massive continuous production, and the film is controllable in component and suitable for large-area growth. The deposition substrate can be normal soda lime glass, conductive glass, flexible stainless steel plates, titanium plates, molybdenum plates or plastic plates. The film prepared by the method is controllable in thickness and component, compact and uniform in appearance, high in crystallizing performance and photoelectric property and applicable to thin film solar cells.

Owner:CENT SOUTH UNIV

Method for preparing porous carbon radical electrode of sodium polysulfate / bromine energy storage cell

InactiveCN1595691AHigh mechanical strengthImprove conductivityCell electrodesPorous carbonSodium polysulfide

isclosed is a manufacturing method of multi-hole carbon electrode for sodium polysulfide / bromine storage battery, electrode is manufactured by the hot press method of conductor carbon material, active carbon particle, polymer agglomerant and pore forming material. The invention has simple manipulation, low cost, suitable for production in large quantity, its carbon electrode has easily controllable in symmetric structure, fairly high mechanical strength, good electrical conductivity, and excellent activity, chemical and electrochemical stability showed in sodium polysulfide / bromine storage battery. The invention has fairly high value of practical use, can reduce use cost of sodium polysulfide / bromine storage battery and advance its commercialized use .

Owner:DALIAN RONGKE POWER

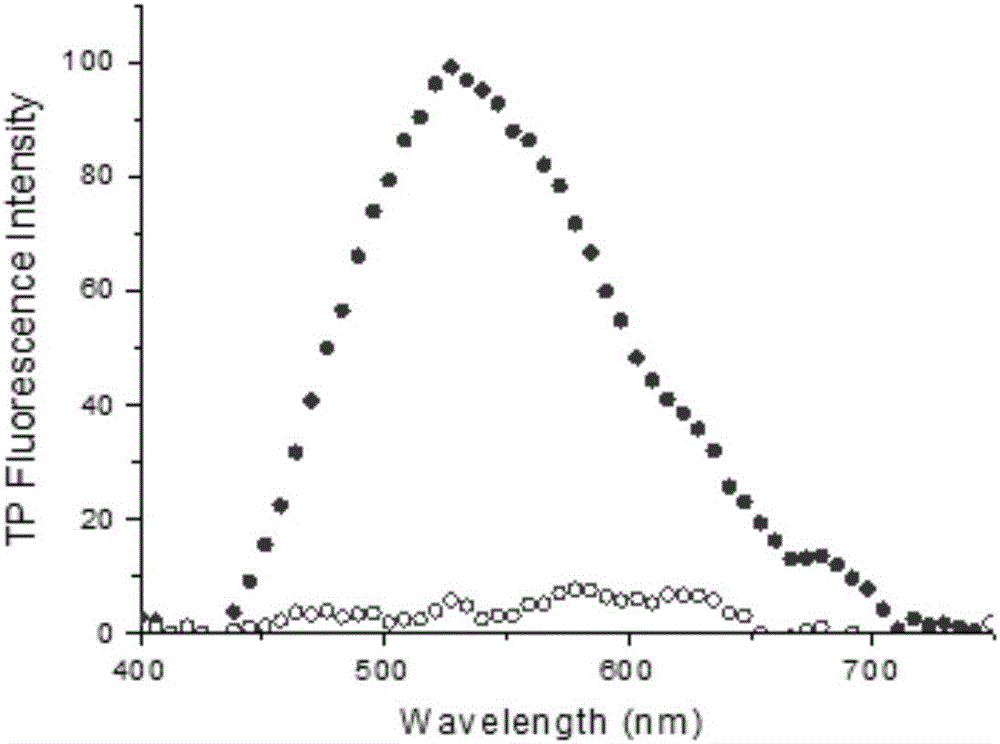

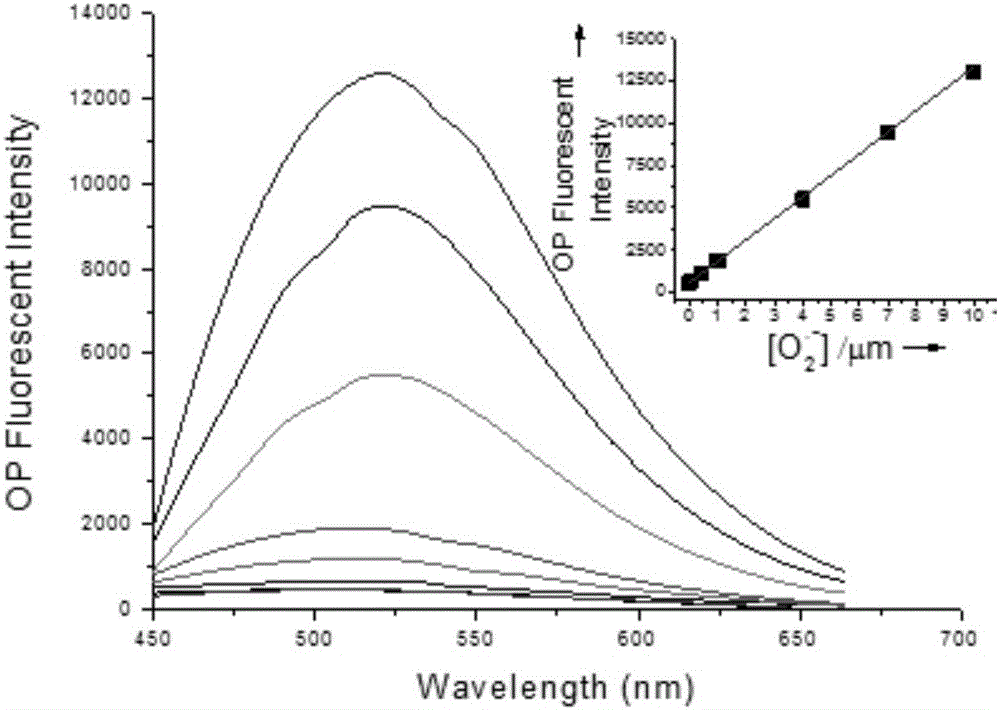

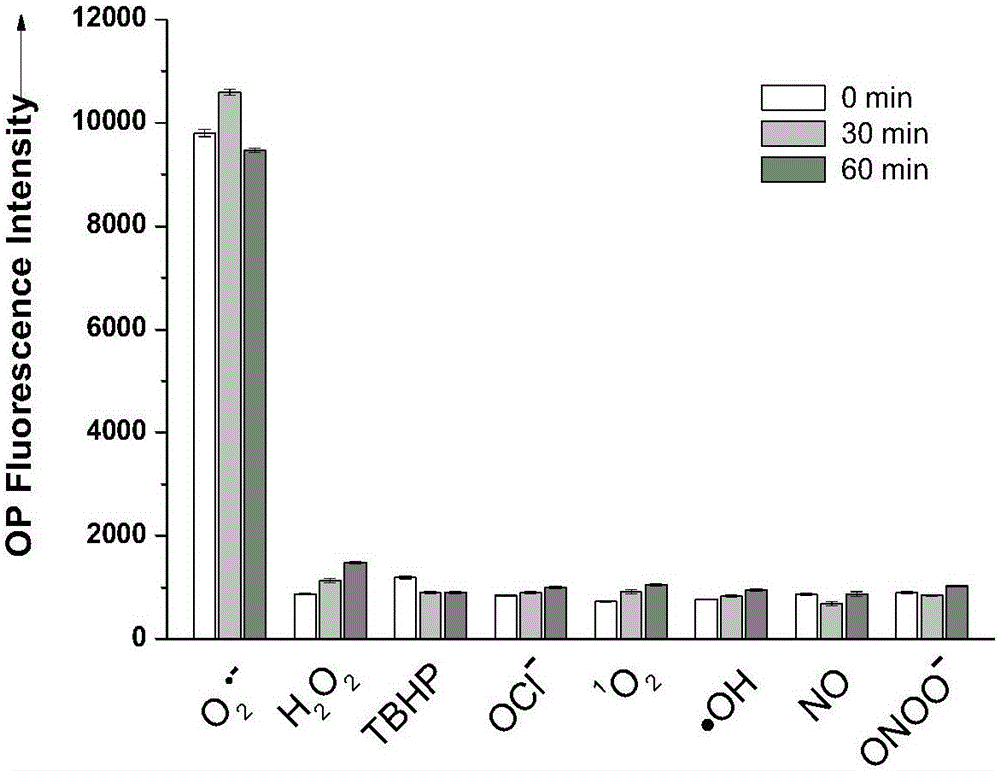

Fluorescent probe as well as preparation method and application thereof

InactiveCN105154071AGood chemical stabilityGood photophysical stabilityOrganic chemistryFluorescence/phosphorescenceFluorescenceCaffeic acid

The invention discloses a fluorescent probe as well as a preparation method and application thereof. A structural formula of the fluorescent probe is shown in a formula I in the specification. The preparation method of the fluorescent probe comprises the following steps: mixing p-nitrobenzaldehyde, 2,5-dimethylpyrazine and a catalyst to obtain mixed liquor and heating the mixed liquor to 150-180 DEG C to react, thus obtaining PY-NO2; adding sodium polysulfide to PY-NO2 to react to obtain PY-NH2; adding PY-NH2, caffeic acid, triethylamine, HOBT and EDC.HCL to a mixed solvent of dichloromethane and DMF to obtain mixed liquor; and stirring the mixed liquor under the protection of an inert gas to obtain a crude product of a two-photon fluorescent probe, and purifying the crude product to obtain a pure product of the two-photon fluorescent probe. The fluorescent probe has good chemical stability and photo-physical stability, can sensitively respond to O2<.-> in acidic, neutral and alkaline ranges, has higher measurement sensitivity and is very short in response time.

Owner:SHANDONG NORMAL UNIV

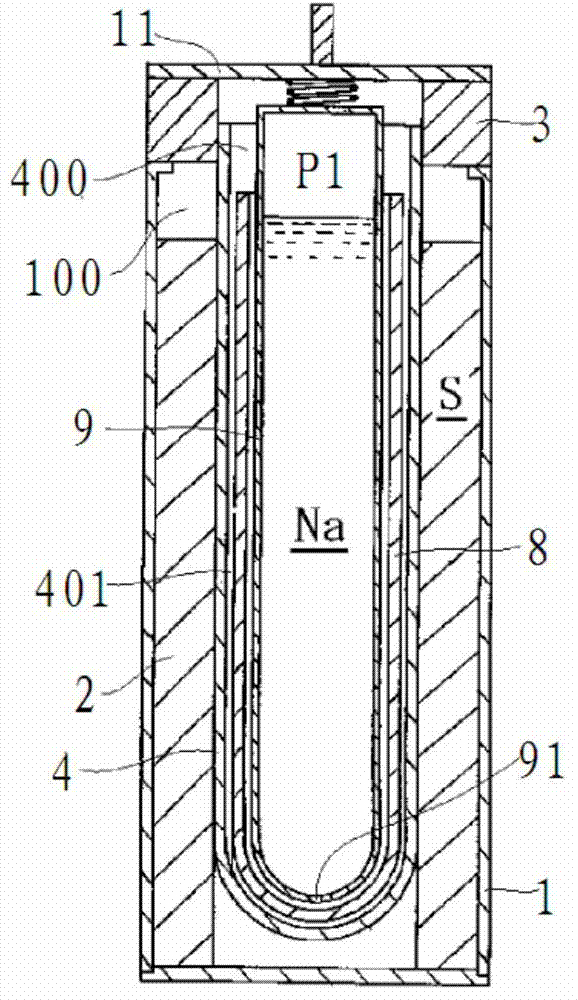

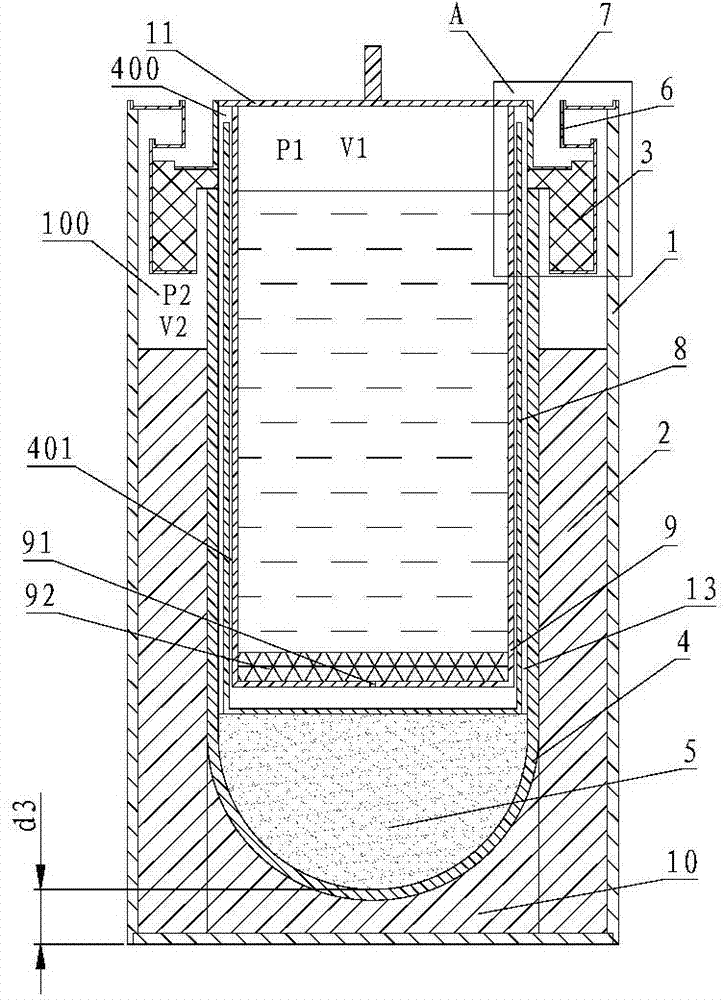

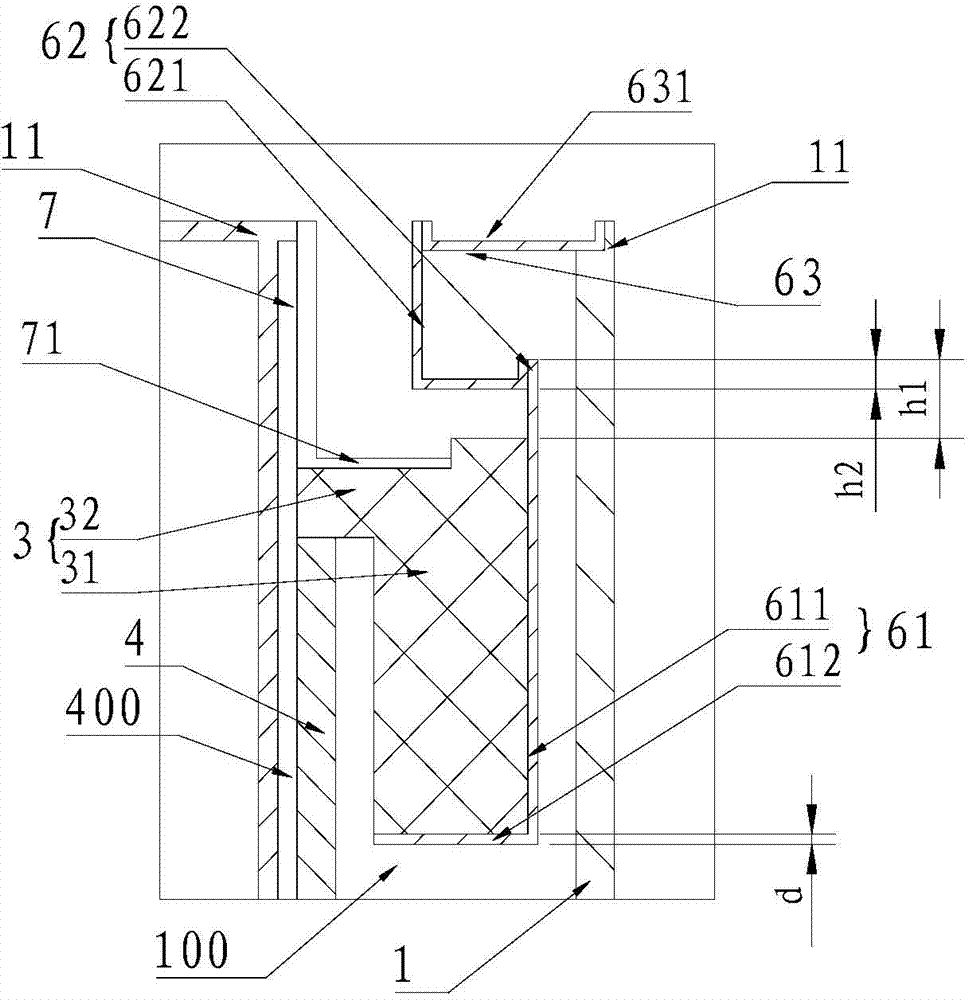

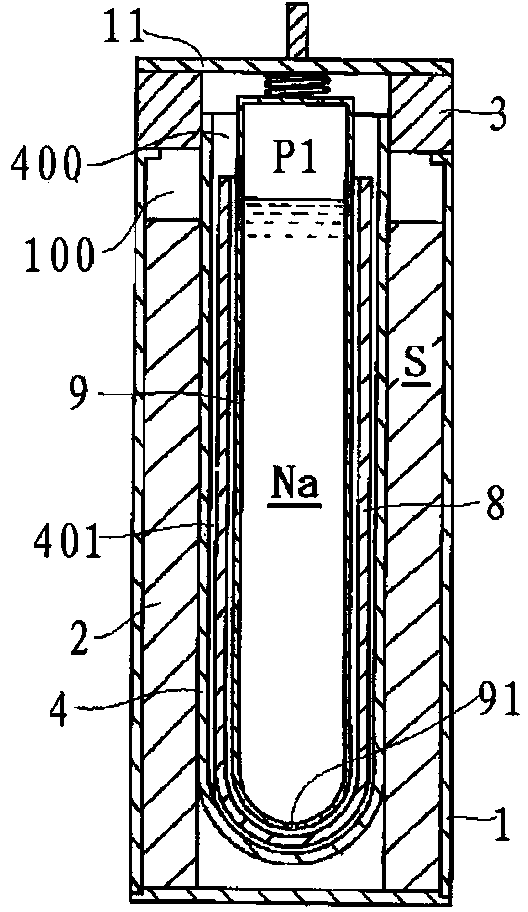

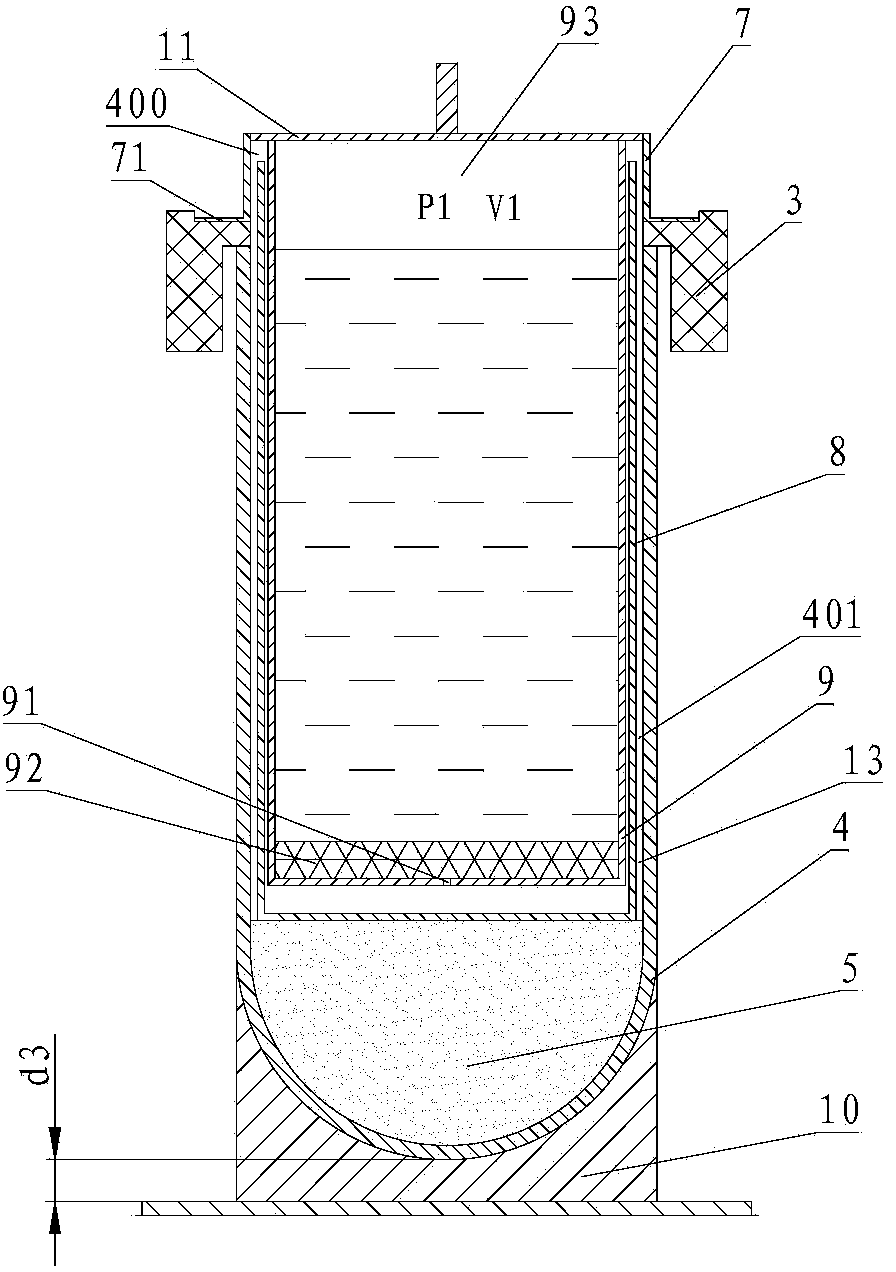

Sodium-sulfur cell

ActiveCN103500855AControl verticalityLower requirementSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsFiberProtection layer

The invention discloses a sodium-sulfur cell in the chemical energy storage field. The sodium-sulfur cell comprises a shell and an electrolyte ceramic tube nested inside the shell. An anode chamber radially forms between the shell and the electrolyte ceramic tube. A cathode chamber radially forms inside the electrolyte ceramic tube. The anode chamber is filled with a porous conducting fiber felt. The top of the electrolyte ceramic tube is provided with a ceramic insulating ring radially projecting out. An anode seal is disposed between the ceramic insulating ring and the shell and closes the anode chamber. A sodium storage tube and a safety tube connected to the outside of the sodium storage tube in a sleeving manner are disposed inside the cathode chamber. The top of the sodium storage tube is closed through a cathode seal cap. A cathode seal ring is disposed between the ceramic insulating ring and the cathode seal cap and closes the cathode chamber. An insulated buffer layer non-wettable to liquid sodium is disposed between the bottom of the outer wall of the safety tube and the bottom of the inner wall of the electrolyte ceramic tube. The bottom of the outer wall of the electrolyte ceramic tube is provided with an insulated bottom protection layer non-wettable to sulfur and sodium polysulfide.

Owner:上海电气企业发展有限公司

Alkaline cleaner for removing simple substance mercury in natural gas separator and cleaning technique thereof

InactiveCN101671606AReduce concentrationNo concentration surgeOrganic detergent compounding agentsNon-ionic surface-active compoundsSodium phosphatesPhosphoric acid

The invention discloses an alkaline cleaner for removing simple substance mercury in a natural gas separator and a cleaning technique thereof, which can thoroughly remove residual paraffin in the separator, converts the simple substance mercury into non-volatile compound, avoids corrosion for carbon steel and stainless steel, and has the advantages of low cost and no pollution. The alkaline cleaner contains the raw materials by weight percent: at least two of 1-40% of sodium sulfide, 0.1-15% of sodium polysulfide and 1-35% of sodium thiosulfate, at least one of 0.1-10% of sodium nitrate, sodium phosphate and sodium sulfate, at least one of 0.1-15% of sulfuric acid and phosphoric acid, 0.5-20% of non-ionic surface active agent, 0.5-10% of anion surface active agent, 0.5-15% of oxygen-containing solvent, 0.1-10% of inhibiter and less than or equal to 90% of water; and the pH value is more than 10.0.

Owner:DALIAN SANDAAOKE CHEM

Preparation method of bis [propyl triethoxysilane] disulfide

ActiveCN103772427AWide variety of sourcesLarge industrial production operation safetyGroup 4/14 element organic compoundsPtru catalystTriethoxysilane

The invention aims at providing a method for synthesizing bis [propyl triethoxysilane] disulfide under an aqueous phase condition free from a buffer. The method comprises the steps of A. carrying out reaction on a sodium polysulfide aqueous solution and chloropropyl triethoxysilane under an aqueous phase condition in presence of a phase transfer catalyst and a water-insoluble organic solvent to generate a reaction mixture; and B. separating bis [propyl triethoxysilane] disulfide from the reaction mixture, wherein the way of separating the product bis [propyl triethoxysilane] disulfide from the reaction mixture in the step B comprises the steps of a. separating an organic phase: separating an organic phase from the upper layer of the reaction mixture obtained from the step A, wherein the lower layer of the reaction mixture is an aqueous phase; and b. purifying the organic phase: distilling and purifying the organic phase to obtain the product bis [propyl triethoxysilane] disulfide. The method disclosed by the invention can improve yield, reduce generation of three wastes and relieve environmental protection pressure.

Owner:南京曙光精细化工有限公司

Method for producing light-color polysulfide silane coupling agent without buffer agent

ActiveCN103788121AReduce manufacturing costPromote safe productionGroup 4/14 element organic compoundsPtru catalystDistillation

The invention provides a method for producing a light-color polysulfide silane coupling agent by an aqueous phase process without a buffer agent. The method specifically comprises the following steps: (a) synthesis of a sodium polysulfide aqueous solution, namely adding sodium chloride, sodium hydroxide, sulfur and deionized water into a reactor, stirring and heating to 50-70 DEG C, reacting until the solid is completely dissolved, and preserving heat; (b) addition of a catalyst, namely adding a phase transfer catalyst aqueous solution into the sodium polysulfide aqueous solution, and mixing uniformly; (c) synthesis of a crude product, namely in a stirring state, adding (3-chloropropyl)triethoxy-silane into the solution, controlling the reaction temperature at 70-85 DEG C, and preserving heat; (d) phase separation, namely separating an organic phase on the upper layer from an aqueous phase on the lower layer in the solution, and removing solids in the organic phase; and (e) decoloration and purification, namely decoloring the treated organic phase solution and purifying by distillation to obtain the light-color polysulfide silane coupling agent. The polysulfide silane coupling agent prepared by the method has the advantages of safety and reliability in production, no polymerization, light color, few impurities, high content of active ingredients and high yield.

Owner:南京曙光精细化工有限公司

Method for preparing bis (triethoxypropylsilane) polysulfide

InactiveCN101768181AMeet the requirements of energy saving and emission reductionReduce manufacturing costGroup 4/14 element organic compoundsLiquid wasteTriethoxysilane

The invention relates to a method for preparing bis (triethoxypropylsilane) polysulfide, which can obviously improve the yield of the product. The method for preparing the bis (triethoxypropylsilane) polysulfide is that in aqueous solution of NaCl with a concentration by mass percent of not less than 10 percent, sodium polysulfide reacts with chloropropyl triethoxy silane under the action of a phase transfer catalyst to obtain the bis (triethoxypropylsilane) polysulfide. The bis (triethoxypropylsilane) polysulfide is shown as the formula (1). The invention has the advantages that: (1) the process is simple and easy to be implemented; (2) the generated liquid waste can be totally recycled so as to correspond to the requirement for energy saving and emission reduction; and (3) the product production cost is low, the process is stable, the product has high quality, the yield is over 95 percent and no polymerism occurs by cycling tests dozens of times.

Owner:南京市化学工业研究设计院有限公司

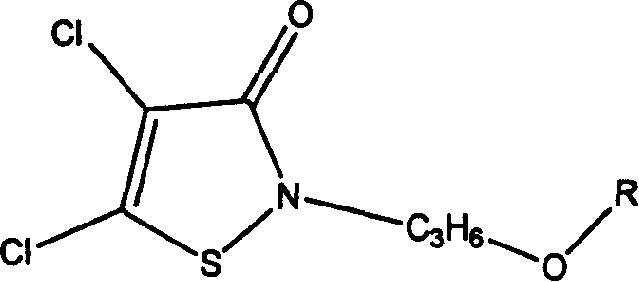

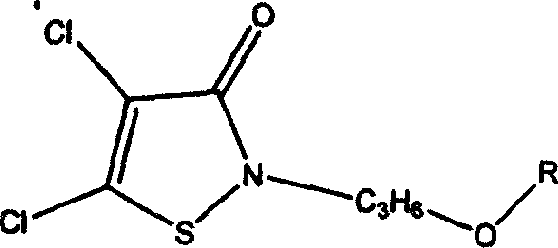

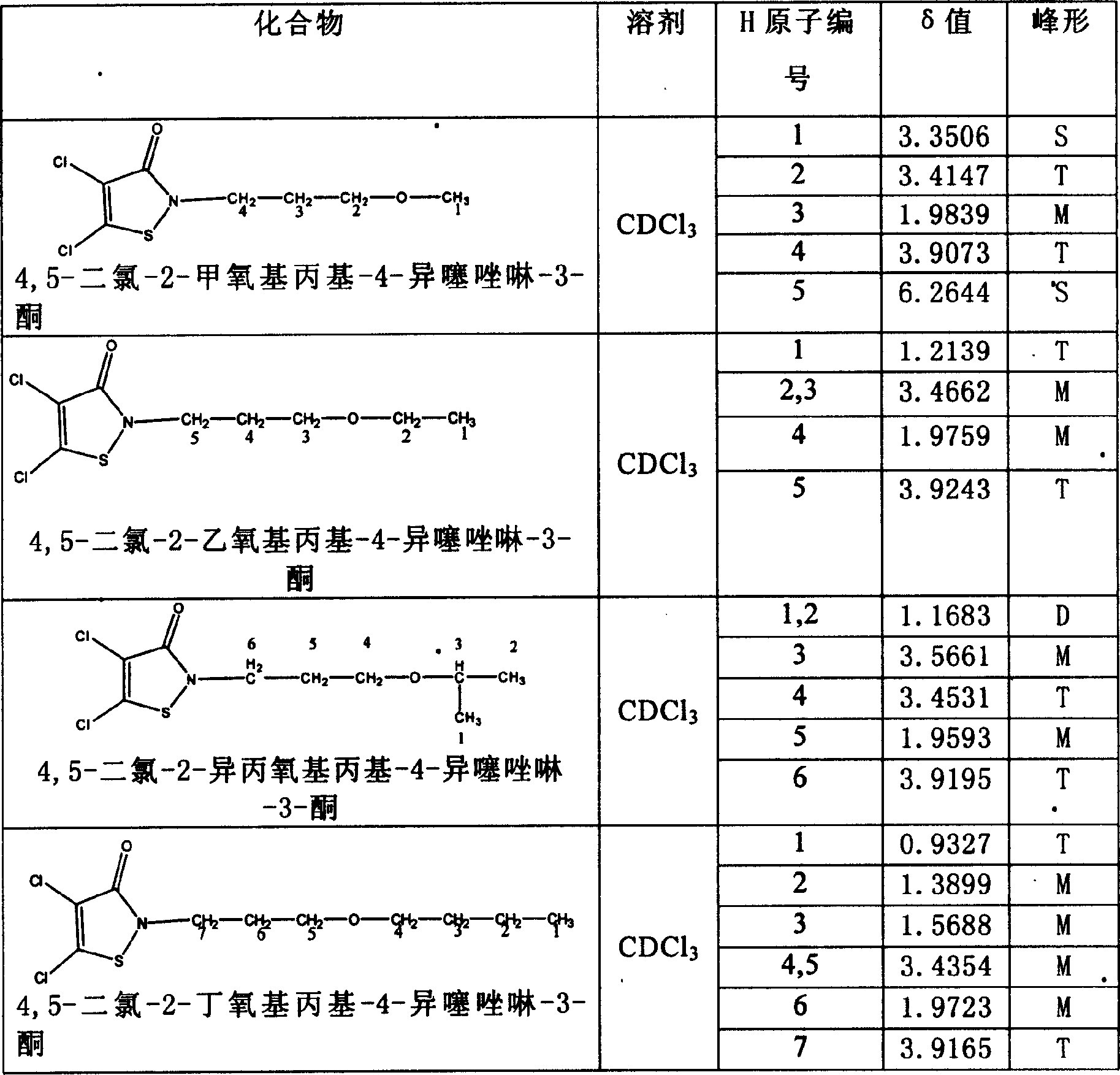

Alkoxy propyl isothiazolinone and its preparation process and use

Alkoxy propyl isothiazolinone is characterized in that its molecular formula is C6H6Cl2NO2SR, wherein R is CH3, CH2CH3, CH(CH3)2 or CH2CH2CH2CH3. The preparation process comprises sodium polysulfide reacts with methyl acrylate to yield dithio dimethyl dipropionate, aminolysis between dithio dimethyl dipropionate and alkoxy propylamine is carried out to produce Nú¼N'-dialkoxy propyl dithio dipropionamide, and the latter reacts with sulfuric chloride. Alkoxy propyl isothiazolinone in high yield and low cost can be used as anti-fouling agent for preparing marine anti-fouling coating.

Owner:OCEAN UNIV OF CHINA

Cathode of sodium-sulfur cell

ActiveCN103531856AGuaranteed safe operationControl verticalitySpecific condition cell workingSecondary cellsStorage tubeSodium polysulfide

The invention discloses a cathode of a sodium-sulfur cell in the field of chemical energy storage. The cathode of the sodium-sulfur cell comprises an electrolyte ceramic tube, wherein a cathode room is formed at the radial inner side of the electrolyte ceramic tube; a ceramic insulated ring which protrudes outwards in a radial manner is arranged at the top surface of the electrolyte ceramic tube; a sodium storage tube and a safety tube sleeved at the outer side of the sodium storage tube are arranged inside the cathode room; the top of the sodium storage tube is sealed through a cathode sealing cover; a cathode sealing ring is arranged between the ceramic insulated ring and the cathode sealing cover to seal the cathode room; a buffer layer which is insulated and does not infiltrate into liquid sodium is arranged between the bottom of the outer wall of the safety tube and the bottom of the inner wall of the electrolyte ceramic tube; a bottom protecting layer which is insulated and does not infiltrate into sulfur and sodium polysulfide is arranged at the bottom of the outer wall of the electrolyte ceramic tube. The cathode of the sodium-sulfur cell has the technical effects that the demands on the verticality and the bottom roundness of the electrolyte ceramic tube are reduced when the bottom of the electrolyte ceramic tube is prevented from participating into reaction.

Owner:上海电气企业发展有限公司

Production process of organosilane polysulfide

ActiveCN103073569AEfficient removalReduce dosageGroup 4/14 element organic compoundsSilanesReaction temperature

The invention discloses a production process of organosilane polysulfide. The production process comprises the following steps of: 1, adding elemental sulfur in sodium hydroxide at a temperature of 90-100 DEG C by batches according to the calculation proportion, controlling the reaction temperature and keeping for a period of time to form polysulfide Na2Sn, wherein n has the meaning described in the specification; 2, enabling the polysulfide obtained in the step 1 to condensate with an organosilane compound in the following formula (2) under the existence of a phase transfer catalyst and a hydrolysis buffer agent to obtain a sulfur-containing silane crude product (RO)3-mRmSi-Alk-X(2), wherein X is chlorine, bromine and iodine, and R, Alk and m have the meanings described in the specification; 3, separating a water phase from an organic phase; 4, enabling the organic phase to be in contact with ion change resin for carrying out decoloring and desalting; and 5, distilling, cooling and filtering to obtain an organosilane polysulfide finished product.

Owner:江西宏柏新材料股份有限公司

Composite type sodium polysulfide corrosion inhibitor and preparation thereof

InactiveCN101280429AAvoid accumulation of depositsGood corrosion inhibition effectMetallic material coating processesCracking reactionSodium polysulfide

The invention relates to compound type sodium polysulphide corrosion inhibitor, which is suitable for the hydrogenation cracking reaction effluent air cooler. The compound type sodium polysulphide corrosion inhibitor is formed by combining sodium polysulphide, benzotriazole and organic amine film forming agent, wherein, the organic amine film forming agent is the combination of one or more of sodium molybdate, sodium chromate and zinc sulfate. The product integrates complexing, dispersing, corrosion prevention and film forming into a whole, has good synergistic inhibition effect under the low temperature and the high temperature and has good corrosion inhibition on the corrosion of the sulfide and the prussiate, the corrosion rate is reduced obviously, the temperature at the air-cooled water outlet opening can be guaranteed effective not to rise, the temperature of the tube bundle is even, the current bias phenomenon can not be caused, and the protective film formed on the surface of the equipment is steadier.

Owner:宜兴市星光宝亿化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com