Patents

Literature

487 results about "Sodium hydrosulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium hydrosulfide is the chemical compound with the formula NaHS. This compound is the product of the half-neutralization of hydrogen sulfide (H₂S) with sodium hydroxide. NaHS is a useful reagent for the synthesis of organic and inorganic sulfur compounds, sometimes as a solid reagent, more often as an aqueous solution. Solid NaHS is colorless, and typically smells like H₂S owing to hydrolysis by atmospheric moisture. In contrast with sodium sulfide (Na₂S), which is insoluble in organic solvents, NaHS, being a 1:1 electrolyte, is more soluble. Alternatively, in place of NaHS, H₂S can be treated with an organic amine to generate an ammonium salt. Solutions of HS⁻ are sensitive to oxygen, converting mainly to polysulfides, indicated by the appearance of yellow.

Method for preparing sodium hydrosulfide

InactiveCN101337661AQuality improvementIncrease profitSulfur compoundsHydrogenCALCIUM HYDROXIDE SOLUTION

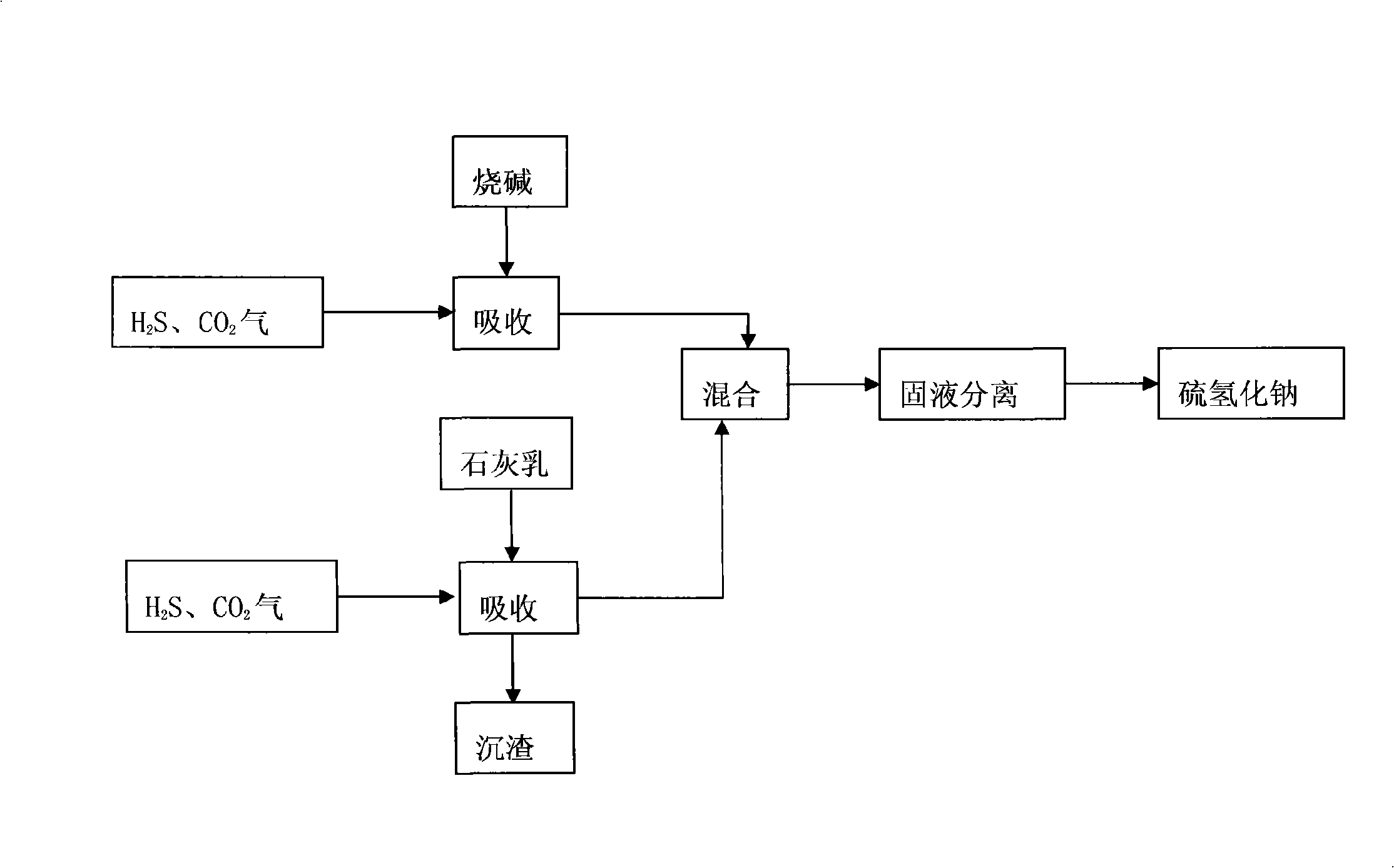

The invention discloses a method for preparing sodium hydrosulfide. The production process is as follows: introducing a mixed gas containing sulfureted hydrogen H2S with the content larger than 10 percent and carbon dioxide CO2 with the content not larger than 90 percent into lime cream of about 12 percent of concentration, under the condition of a certain temperature and pressure and under agitation; stopping reaction when CaS is less than or equal to 0.5 percent; separating sediments out to obtain a sulfur calcium hydroxide solution; introducing a mixed gas of sulfureted hydrogen and carbon dioxide into a caustic soda solution with concentration larger than 30 percent under the condition of a certain temperature and pressure and under agitation; stopping reaction when Na2S is less than or equal to 0.5 percent to obtain a sodium hydrosulfide solution containing carbonate ions; and adding slightly not enough sodium hydrosulfide solution under agitation according to the amount of the carbonate ions in the sodium hydrosulfide solution, and separating sediments out to obtain sodium hydrosulfide with low carbonate ions.

Owner:褚亚华

Chromium residue detoxifying process

InactiveCN101816829AReduce dosageImprove mixing uniformityChemical protectionSodium hydrosulfideSlurry

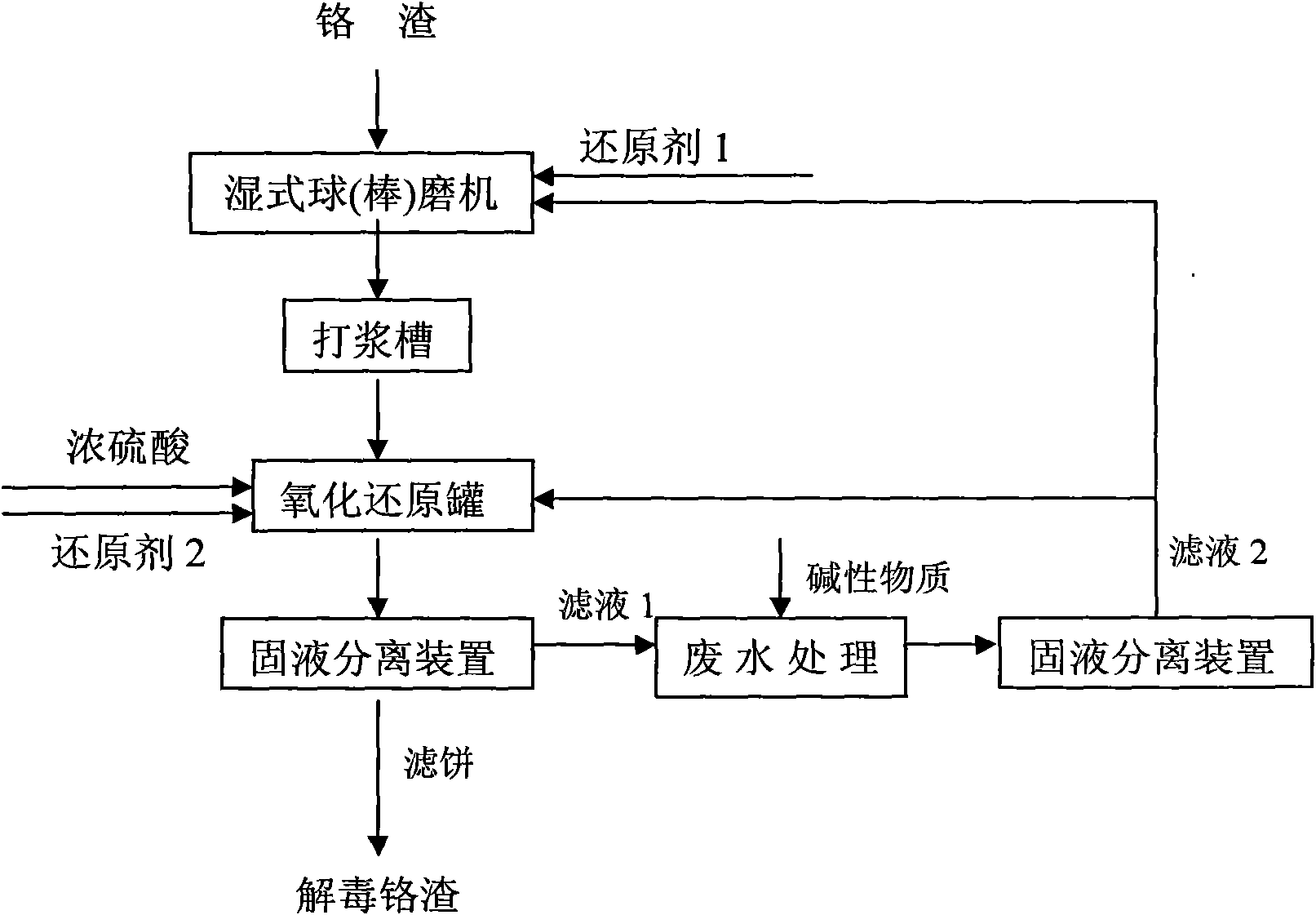

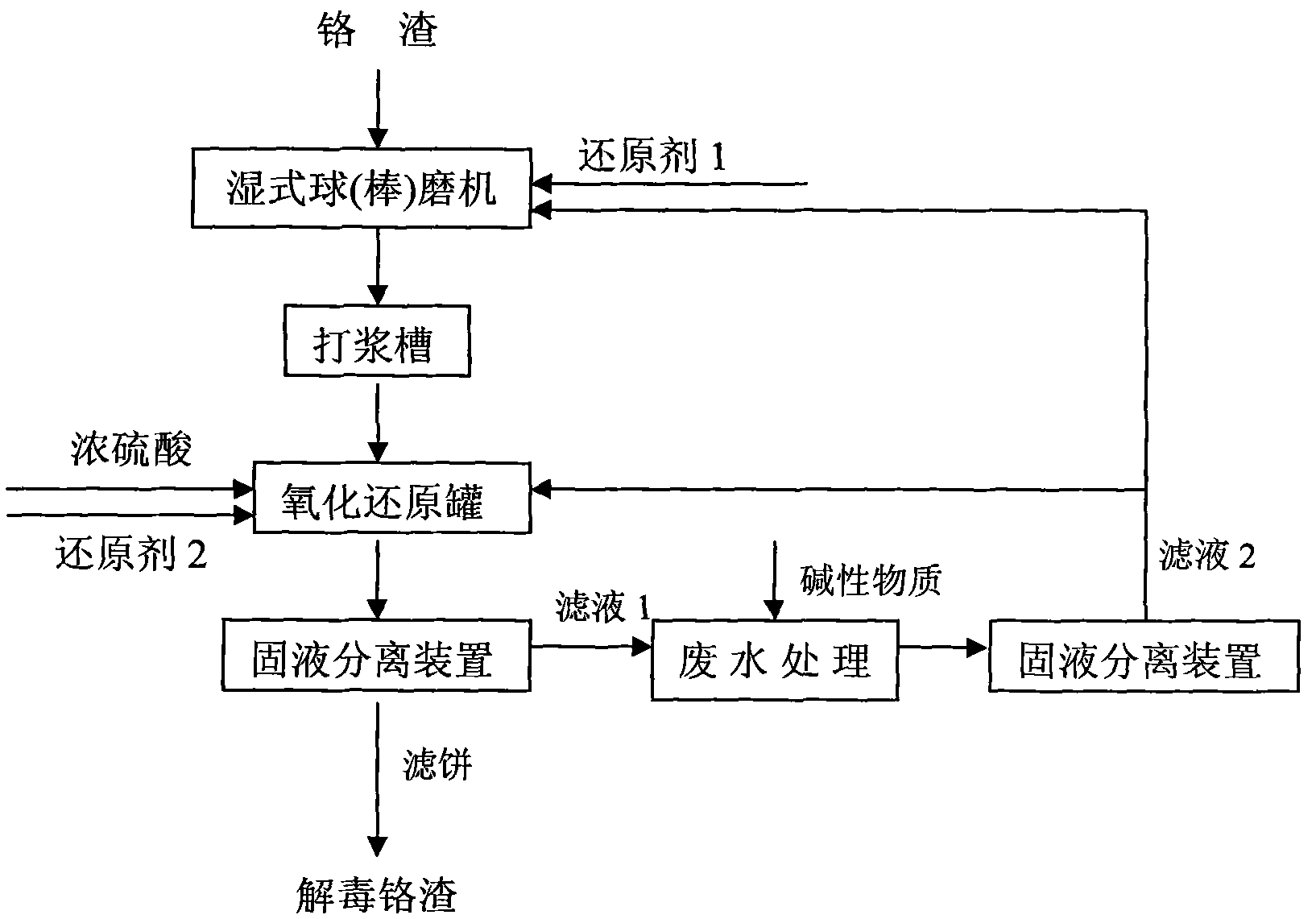

The invention belongs to the technical field of chromium residue detoxifying, and discloses a chromium residue detoxifying process. The process comprises the following steps of: performing wet grinding on chromium residue, adding water into the chromium residue to prepare chromium residue slurry; and after being subjected to acid-leaching reduction reaction, performing solid-liquid separation on the chromium residue slurry to obtain a filter cake, namely the detoxified chromium residue. The process is characterized in that: under the condition of not changing the original alkaline environment of the chromium residue, a reducing agent 1 is added into the chromium residue directly, and then the reducing agent and the chromium residue are subjected to wet grinding to form particles with 100 to 300 meshes; and the water is added to prepare the chromium residue slurry with 30 to 45 baume degrees, wherein the reducing agent 1 is sodium sulphide, sodium bisulfide, sodium thiosulfate or sodium pyrosulfite. The process has simpleness, thorough detoxification, no chromium return phenomenon and easy implementation of mass production; and the process prolongs effective reduction reaction time, improves reaction efficiency, saves the using amount of acid during the acid-leaching reduction, and has low processing cost because Cr6+ in the chromium residue is subjected to two times of dissolution and reduction.

Owner:河南金谷环保工程设备有限公司

Method for preparing sodium sulfhydrate from hydrogen sulfide tail gas

InactiveCN101186280AImprove protectionReduce pollutionSulfur compoundsSodium hydrosulfideAbsorption rate

A purpose of the invention is to provide a sodium hydrosulfide preparation method utilizing hydrogen sulfide exhaust. The invention not only can resolve the treatment problems of the three wastes of barium carbonate and strontium carbonate enterprises, but also can reuse calcium sulfate, the byproduct from the preparation of sodium hydrosulfide, as raw materials for other chemical production, which realizes the recycling of raw materials and products. The production ability of the traditional alkali solution absorbing method, the absorbing adaptability of mixed hydrogen sulfide exhaust and the sodium hydrosulfide preparation rate are enhanced; while the production cost is reduced and the exhaust can be discharged according to standards after being absorbed by alkali solution. The invention resolves the problems of low absorption rate of hydrogen sulfide gas, low production efficiency of preparation of sodium hydrosulfide, large investment of technical devices and difficulty of solid phase recycling existing in a method of 'one step for preparation of sodium hydrosulfide' using hydrogen sulfide gas, calcium hydroxide and sodium sulfide as raw materials.

Owner:QINGDAO AOHAIKE TRADE

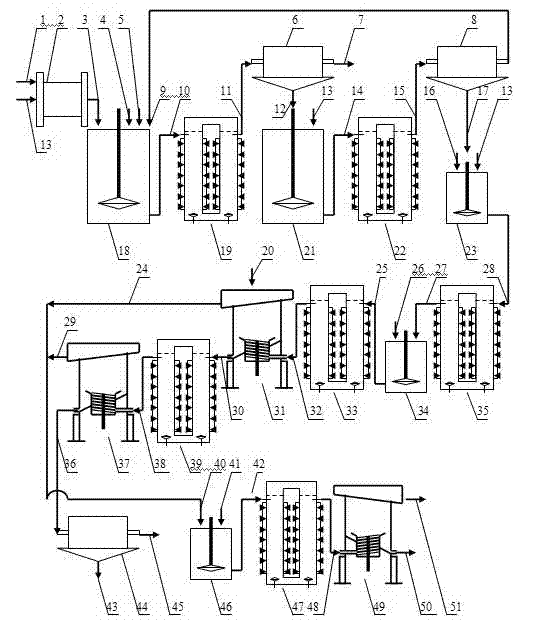

Technique method for producing sodium bisulfide

InactiveCN102765700AReduce power consumptionProduction costSulfur compoundsSodium bisulfideSodium hydrosulfide

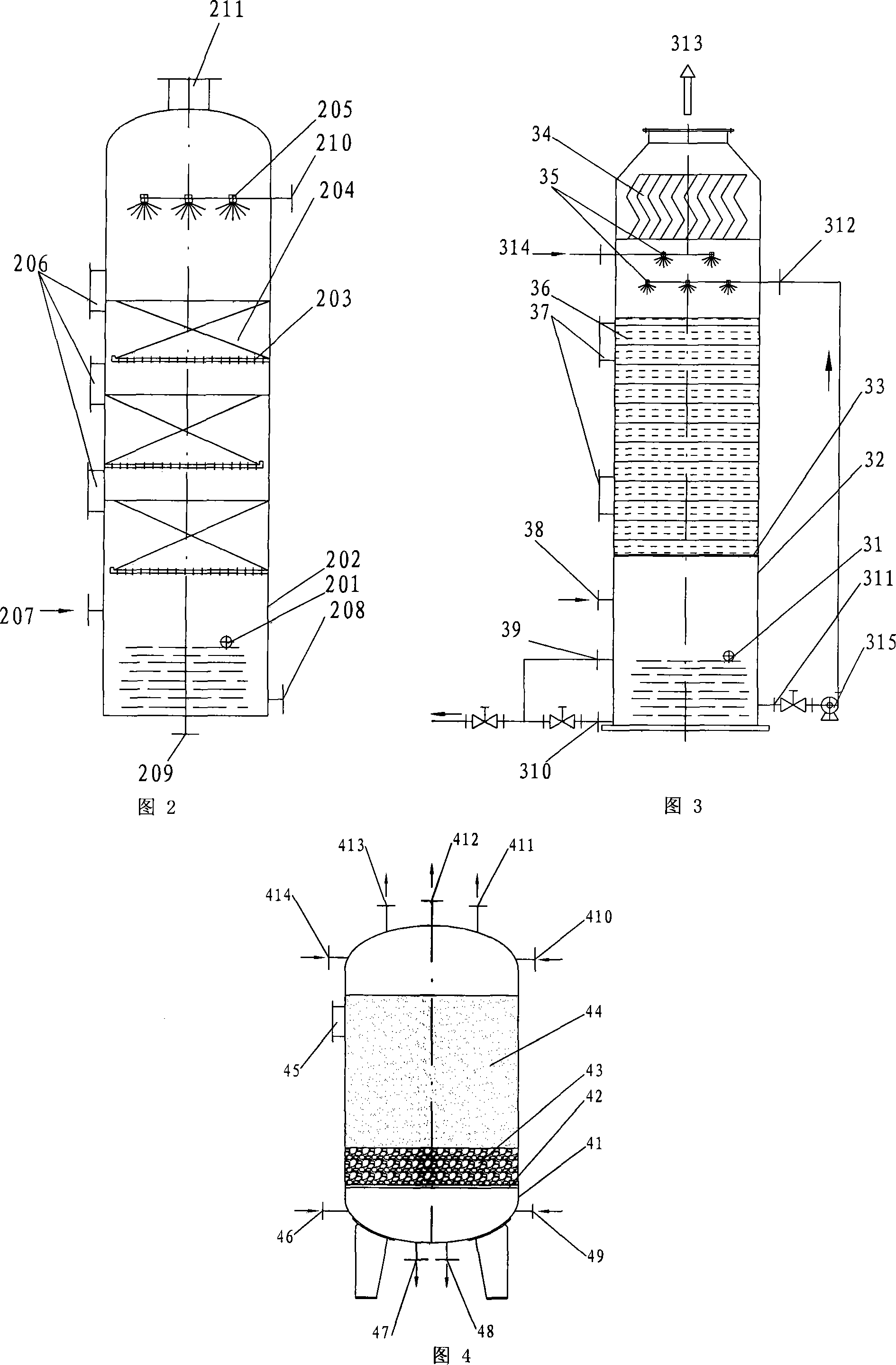

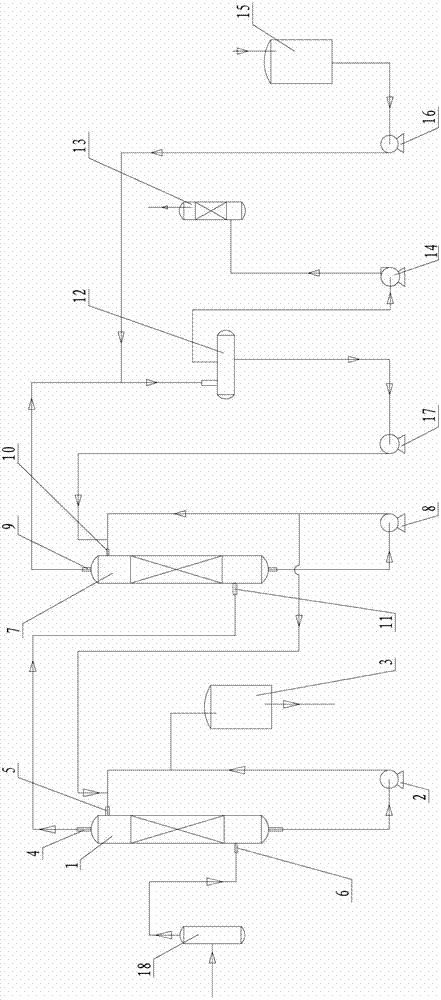

The invention discloses a technique method for producing sodium bisulfide and belongs to the technical field of the chemical engineering production technology. The technique method for producing sodium bisulfide is low in production cost and can control product quality easily during production. The technique method includes: feeding buffered hydrogen sulfide and process absorption liquid with sodium sulphide as the main ingredient into an absorption tower respectively from the lower portion and the upper portion of the absorption tower, absorbing the hydrogen sulfide and the process absorption liquid on the surface of packing in the absorption tower to generate solution with the sodium bisulfide as the main ingredient, enabling the solution to flow to the bottom of the absorption tower, and discharging the unabsorbed hydrogen sulfide tail gas from the top of the absorption tower; pumping the solution at the bottom of the absorption tower out, returning most of the solution back to the absorption tower for recycling, feeding the small amount of solution to a sodium bisulfide production solution storing tank, and simultaneously adding the process absorption liquid in the absorption tower from the upper portion of the absorption tower during the absorption circulating process; and finally performing evaporation, concentration and dehydration on the solution, cooling the solution for molding, packaging and finishing the production of the sodium bisulfide.

Owner:CHENGDU DEMEI ENG TECH

Separation technology of hydrogen sulfide and carbon dioxide in acid gas of oil refinery

InactiveCN103446849AHigh selectivityImprove stabilityHydrogen sulfidesDispersed particle separationSeparation technologyGas phase

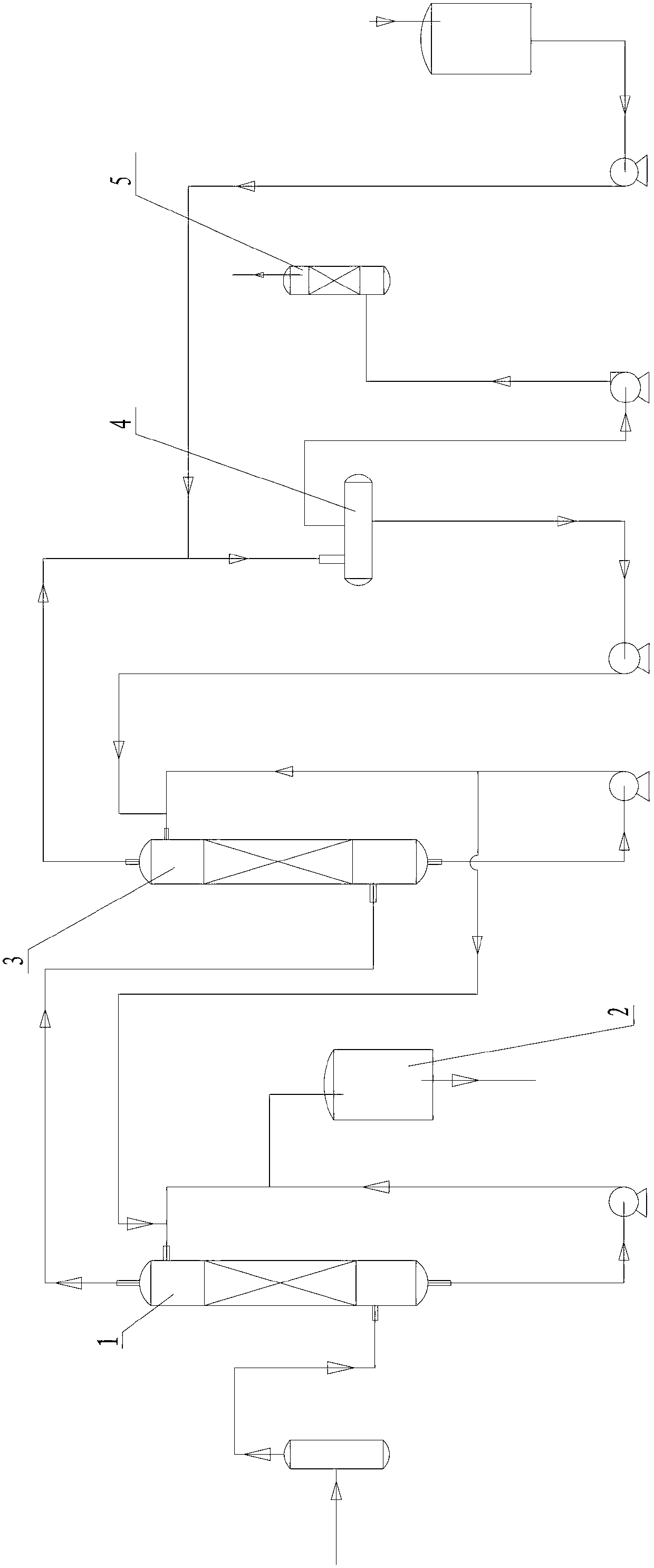

The invention relates to a separation technology of hydrogen sulfide and carbon dioxide in acid gas of an oil refinery. According to the technical scheme, the separation technology comprises the following processing steps that the acid gas of the oil refinery flows through an acid gas separating tank and an acid water separating tank and then enters a first absorbing column; the acid gas at the bottom part of the first absorbing column is in contact with barren liquor from the upper part of the column, thus hydrogen sulfide in the acid gas can be fully absorbed to generate rich liquor; the rich liquor and barren liquor enter a first-grade rich-barren heat exchanger to exchange the heat and then enter a first regenerating column to regenerate; H2S gas generated at the top of a second regenerating column is condensed through a second condenser and then flows into a separating tank; a separated liquid phase is used for backflow in the top of the regenerating column; and a gas phase, namely, H2S gas, is used as sodium hydrosulfide to prepare some of raw materials. The separation technology has the beneficial effects that a methyldiethanolamine extracting agent at a concentration of 50% is selected; and compared with other extracting agents, the methyldiethanolamine extracting agent has relatively high selectivity and stability, causes a very little loss, and is low in energy consumption of devices.

Owner:SHANDONG KENLI PETROCHEM GRP

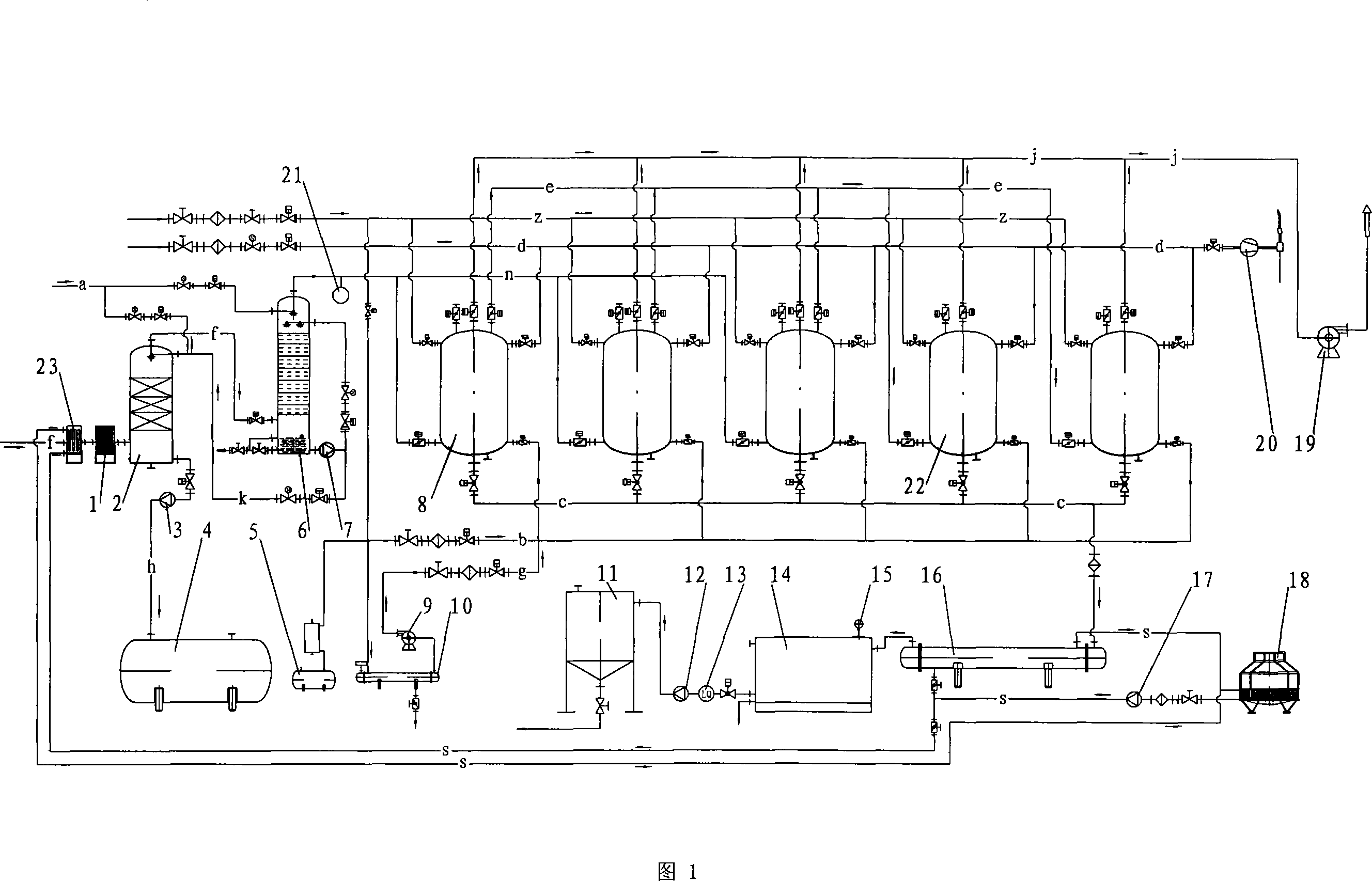

Device for recovering viscose fiber production exhaust-gas with soda washing-adsorption condensing method

The invention relates to a device for recycling waste gas generated by viscose through an alkali cleaning-absorbing condensation method, which relates to the equipment for recycling waste gas generated by industries. The device for recycling waste gas generated by viscose through an alkali cleaning-absorbing condensation method has relatively good processing effects and can recycle useful resources in the waste gas with high efficiency. The device is equipped with a waste gas filter, an alkaline tower, a solution transfer pump, a storing tank of sodium hydrosulfide, an air compressor, a washer, a recycle pump, an adsorption tank, an air heater, a heater, a storing tank of carbon bisulfide, a gear transfer pump, a flowmeter, a solution separator, a magnetic levitation ball liquid level switch, a condenser, a water pump, a cooling tower, a draft fan, a vacuum pump, a concentration analyzer of H2S and CS2, an adsorption tank, a cooler and a pneumatic ball valve. Sulfureted hydrogen gas in the waste gas is transformed into sodium hydrosulfide liquid and carbon bisulfide gas in the waste gas is transformed into carbon bisulfide liquid through washing, absorbing, condensing and separating. The carbon bisulfide liquid is employed as raw materials and is directly sent back to the production of the viscose.

Owner:QUANZHOU TIANLONG ENVIRONMENTAL ENG

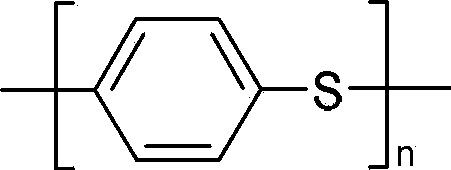

Synthesis method of fiber-grade polyphenylene sulfide (PPS) resin

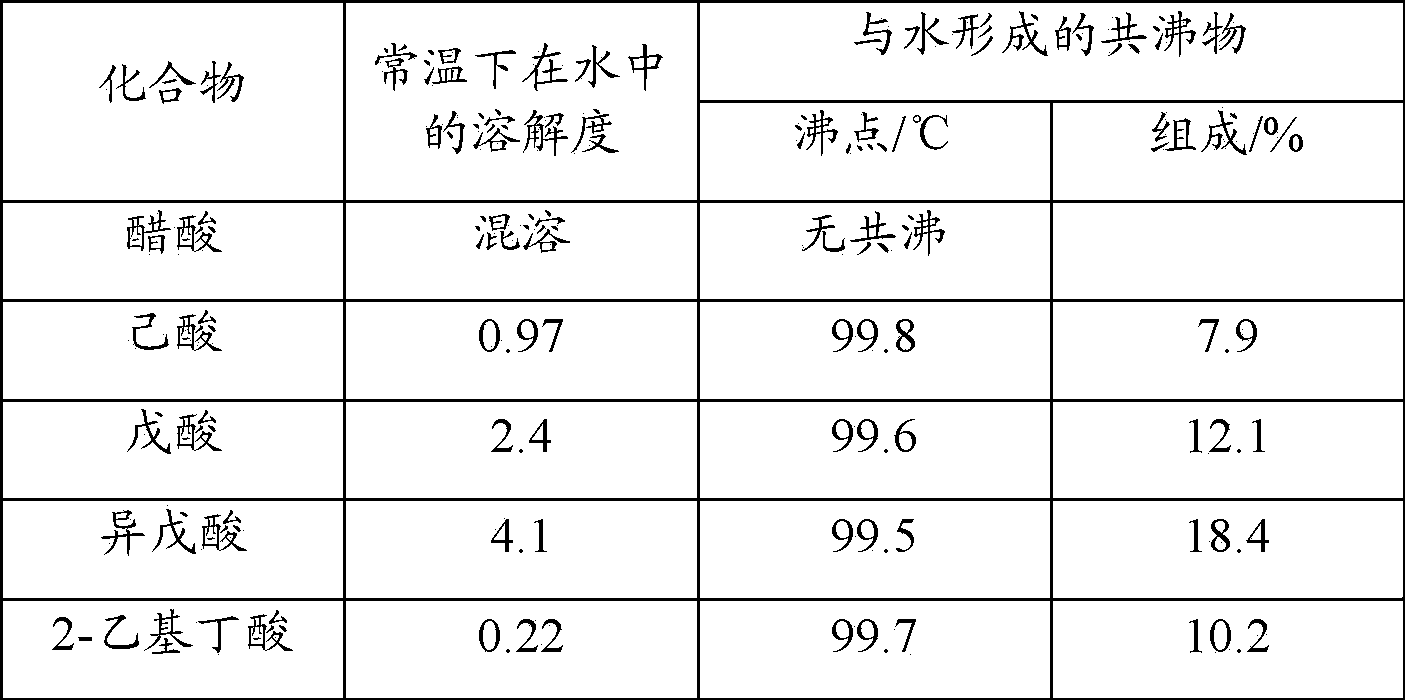

Disclosed is a method for synthesizing a fibre-grade polyphenylene sulphide resin, comprising synthesizing via a polycondensation reaction by using a sodium hydrosulphide solution and p-dichlorobenzene as raw materials, N-methyl-2-pyrrolidone as a solvent, and a C5-C6 fatty acid salt formed by dehydration of a C5-C6 fatty acid and sodium hydroxide as an auxiliary for the polycondensation reaction. The reaction liquid is subjected to acidification and washing to obtain a white polyphenylene sulphide resin, the melt flow rate of the product is less than 125 g / 10 min, the weight-average molecular weight measured by GPC is greater than 4.2 × 104, and the whiteness is higher than 90, meeting the requirements of the fibre-grade polyphenylene sulphide resin. In the method of the present invention, the C5-C6 fatty acid salt used has good solubility in NMP and can better promote the polycondensation reaction, all of it enters a filtrate after reaction and filtration, and it is again converted into a free fatty acid through acidification with hydrochloric acid; and the C5-C6 fatty acid can co-boil with water, has low solubility in water, and can be recovered from the filtrate by the method of co-boiling with water, thereby avoiding the problem that both the auxiliary and sodium chloride are dissolved in water and cannot be separated and recovered.

Owner:ZHEJIANG NHU SPECIAL MATERIALS +3

Method for carrying out unhairing and liming treatment without dust and akali sulphide during buffalo hide tanning

ActiveCN101445843AEasy to handleSo as not to damagePre-tanning chemical treatmentSodium hydrosulfidePollution

Owner:国家皮革质量监督检验中心(浙江) +1

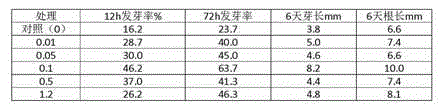

New use of sodium hydrosulfide for promoting wheat seeds sprouting under heavy metal stress

InactiveCN101385466APromote germinationGerminate fastBiocidePlant growth regulatorsAmylaseNormal growth

The invention discloses a new application of sodium hydrosulfide for promoting germination of wheat seeds under the stress of heavy metals, namely, the application is that the sodium hydrosulfide is taken as a sprout-promoting agent of germination in the soil polluted by heavy metals of Al<3+>, Cd<2+>, Cr<3+>, Cr<6+>, Pb<2+>, Hg<2> and the like. The invention can effectively improve the germinability of the wheat seeds under the stress of heavy metals, and induces the seeds to germinate fast and regularly. Research proves that the sodium hydrosulfide of the hydrogen sulfide donor is adopted to preprocess the wheat seeds, which can remarkably induce the activity expression of hydrolytic enzyme of amylase, protease, lipase and the like, in the seeds, enhances the oxygenolysis of storage matter, relieves the oxidative damage caused by the stress of the heavy metals in the seeds and maintains the lower membrane lipid overoxidation level in the seeds and the seedlings, thus being beneficial to the normal growth of embryo and radicle. The invention solves the key problem of restoring the production of the wheat in the areas polluted by heavy metals, has simple operation; the needed reagent is single and is easy to be obtained.

Owner:HEFEI UNIV OF TECH

Production device for sodium bisulfide continuous absorption reaction

InactiveCN102807193AReduce power consumptionProduction costDispersed particle separationSulfur compoundsSodium bisulfideAbsorption column

The invention discloses a production device, particularly a production device for sodium bisulfide continuous absorption reaction, and belongs to the technical field of chemical engineering production equipment. The invention provides the production device for the sodium bisulfide continuous absorption reaction, which is low in power consumption and production cost and easy in control of product quality. The production device comprises an absorption tower, an absorption column bottoms pump and a sodium bisulfide production solution storage tank, a process tail gas output interface is arranged at the top of the absorption tower, a process absorption liquid input interface is arranged at the upper part of the absorption tower, a hydrogen sulfide gas input interface is arranged at the lower part of the absorption tower, an input end of the absorption column bottoms pump is connected with the bottom of the absorption tower, and an output end of the absorption column bottoms pup is connected with the process absorption liquid input interface and the sodium hydrosulfide production solution storage tank respectively.

Owner:CHENGDU DEMEI ENG TECH

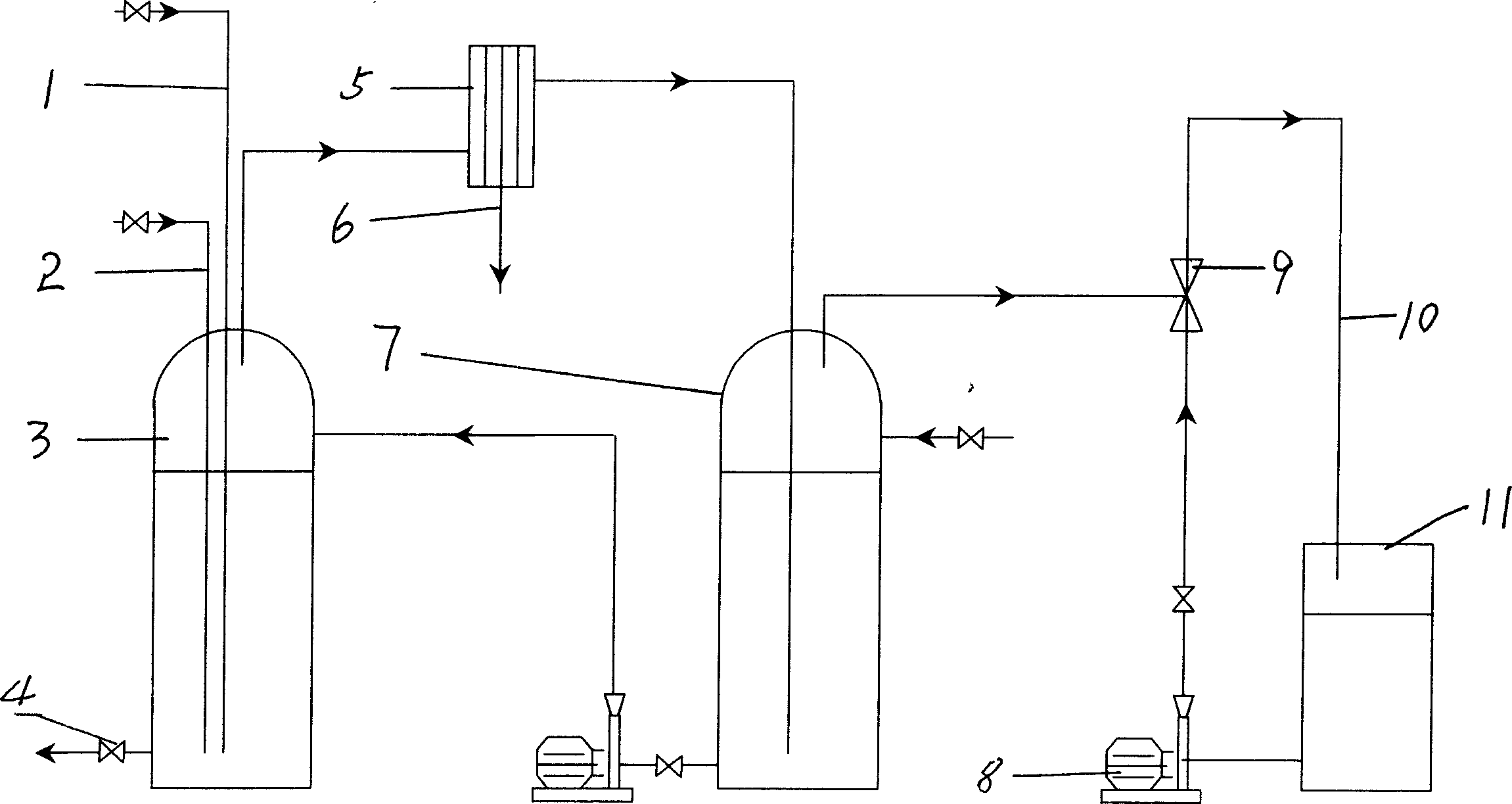

Method and apparatus for managing hydrogen sulfide tail gas

InactiveCN1745877AAvoid pollutionEasy to operateDispersed particle separationSodium hydrosulfideProduct gas

A process for treating the tail gas containing hydrogen sulfide includes such steps as introducing said tail gas to the solution of sodium hydroxide, reacting at 50-80 Deg C. until the sodium hydroxide and hydrogen sulfide become saturated solution of sodium thiohydride for recovering it, and condensing CS2 gas into liquid in condenser for recovering it. Its apparatus is composed of a stage-one reactor with tail gas inlet and outlet tubes, liquid draining valve and steam heating tube, a stage-two reactor with tail gas inlet and outlet tubes, liquid draining valve and water jetter, and a condenser between said two reactors.

Owner:XINXIANG CHEM FIBER

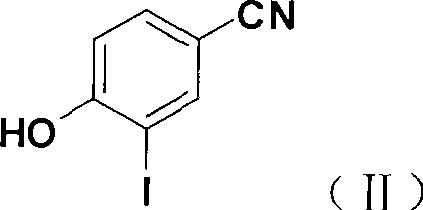

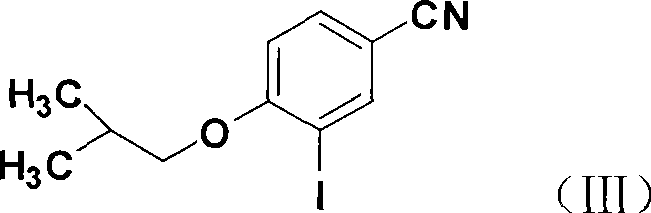

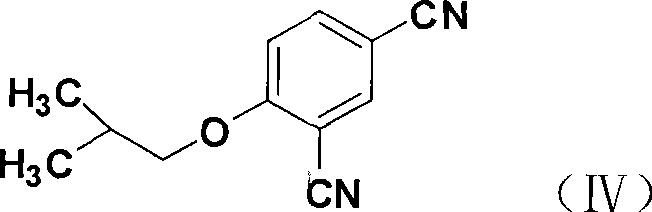

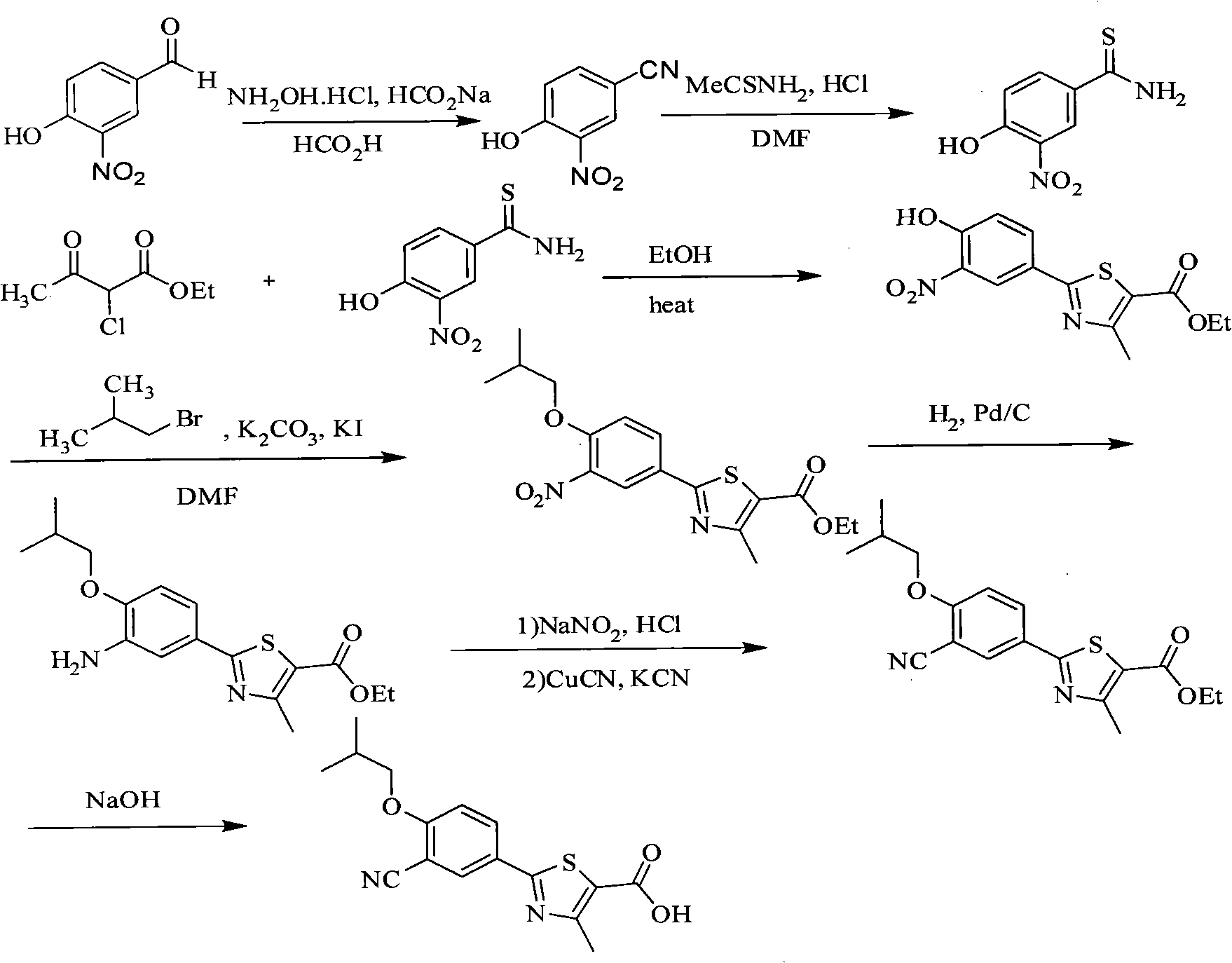

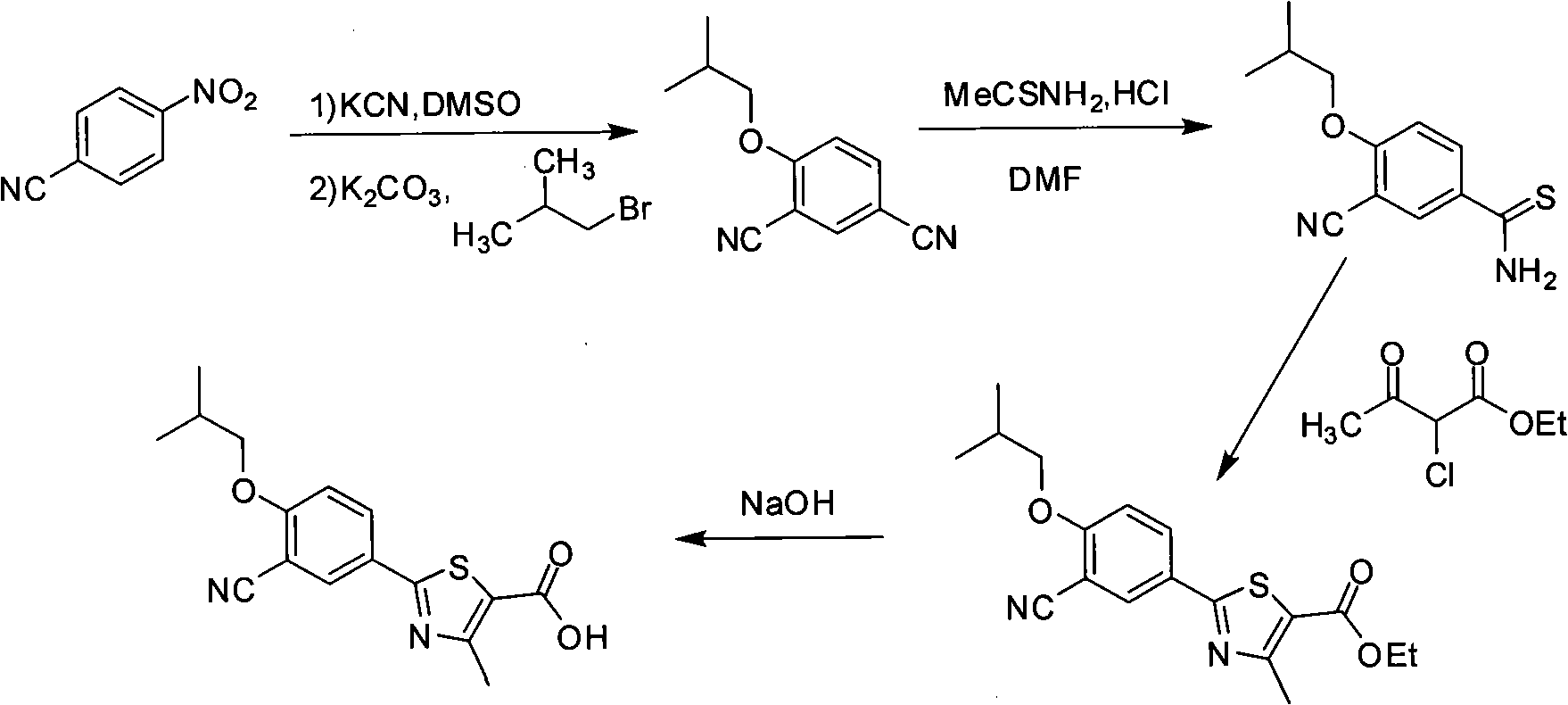

Method for synthesizing 2-(3-cyano-4- isobutoxy phenyl)-4-methyl-carboxylate

ActiveCN101497589ARaw materials are easy to getSimple and fast operationOrganic chemistrySkeletal disorderBenzeneSodium bisulfide

The invention belongs to the technical field of medicine, and relates to a method for synthesizing 2-(3-cyano-4-isobutoxy phenyl)-4-methyl-5-thiazole formic acid. The method comprises that: 4-hydroxyl cyanobenzene is used as a raw material, and subjected to iodination, hydrocarbylation and cyanation to obtain an intermediate of 4-isobutoxy-1,3-benzene dinitrile, the intermediate reacts with sodium bisulfide and anhydrous magnesium chloride to obtain a key intermediate of 3-cyano-4-isobutoxy phenyl thioformamide, and the 3-cyano group-4-isobutoxy phenyl thioformamide is subjected to cyclization and hydrolysis reaction to obtain the 2-(3-cyano-4-isobutoxy phenyl)-4-methyl-5-thiazole formic acid. The method has the advantages of easily obtained materials, simple and convenient operation, high yield, low cost and suitability for industrialized production.

Owner:SHENYANG PHARMA UNIVERSITY +1

Auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process

The invention discloses auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process. The formula of raw materials required in the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is as follows: the mole ratio of sodium sulfide to sodium hydroxide to santochlor to N-methyl-2-pyrrolidinone is 0.93-1.15 to 1.00-1.28 to 1.98-2.98 to 1.18 to 1.48. The industrial synthetic process mainly comprises the following steps: firstly, in a sodium hydrosulfide dehydration treatment stage, a pipeline filter is adopted to filtrate a sodium hydrosulfide solution to treat mechanical impurities in the solution, then a sodium hydroxide solution with the concentration 84 mol percent is added in the formula for chemical treatment on the sodium hydrosulfide; secondly, in the condensation polymerization stage, anaerobic deionized water is added to further appropriately adjust the molecular weight and molecular weight distribution coefficient of synthesized polyphenylene sulfide resin; thirdly, deionized water is adopted for repeatedly scrubbing for 3 to 6 times, and finally, the target product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process provided by the invention is obtained. The resin in the obtained product of the auxiliary-addition-free polyphenylene sulfide resin industrial synthetic process is low in polydispersity index and high in oxygen index, and has an excellent electrical insulation property.

Owner:周洪

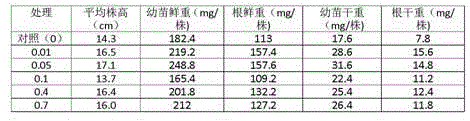

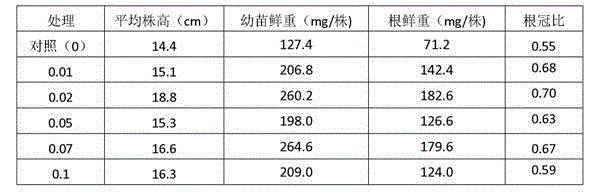

Method for improving wheat drought resistance and salt stress resistance by taking sodium hydrosulfide as hydrogen sulfide donor

The invention discloses a method for improving wheat drought resistance and salt stress resistance by taking sodium hydrosulfide as a hydrogen sulfide donor. The method concretely comprises the steps of before sowing, soaking wheat seeds into a sodium hydrosulfide water solution with the concentration of 0.03-1.2mmol / L for 12-24 hours under the condition of room temperature, or carrying out root soaking, root-irrigation or foliage spray treatment on wheat seedlings at the seedling stage by using a sodium hydrosulfide mixed water solution with the concentration of 0.01-0.6mmol / L under the condition of room temperature; and at the later period of wheat growth, spraying a sodium hydrosulfide mixed solution with the concentration of 0.05-0.8mmol / L onto the leaf surfaces of the wheat plants. According to the method, different sodium hydrosulfide application ways and concentrations are adopted according to the different growth stages of the wheat plants, so that the substances related with stress resistance in the plants can be increased, and the stress resistance of the plants can be improved.

Owner:HENAN AGRICULTURAL UNIVERSITY

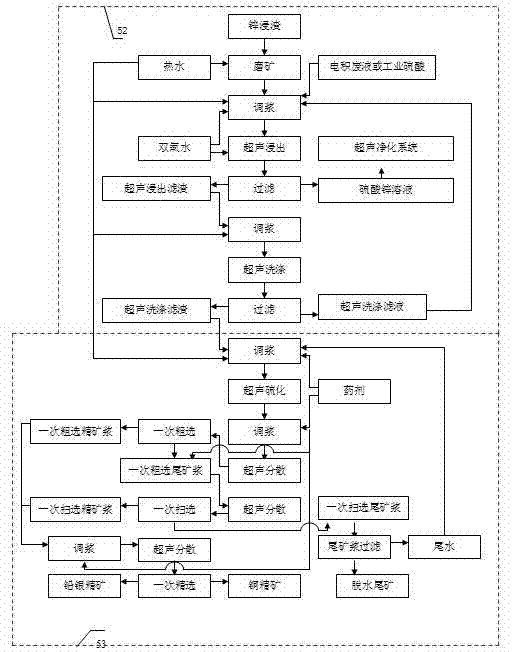

Reagent formula used for zinc leaching residue floatation process and application method of reagent formula

The invention relates to a reagent formula used for a zinc leaching residue floatation process and an application method of the reagent formula. The reagent is a floatation reagent which is added into floatation processes such as sulfurizing, rough floatation, scavenging and concentration. The reagent formula is characterized in that 1) one or two of sodium sulphide and sodium hydrosulfide are added into a sulfurizing process as a sulfurizing reagent; 2) in the rough floatation process, N,N-sodium diethyldithiocarbamate, butyl ammonium black powder and 25# black powder are added as lead mineral collecting agents, Y89 and (or) pentyl xanthate are added as silver mineral collecting agent(s); 3) in a scavenging process, one or two of sodium sulphide and sodium hydrosulfide are added as the sulfutizing agent(s), N,N-sodium diethyldithiocarbamate, butyl ammonium black powder and 25# black powder are added as the lead mineral collecting agents, and the Y89 and (or) pentyl xanthate are added as the silver mineral collecting agent(s); and 4) carboxymethylcellulose is added as a gangue inhibiting agent in a concentration process. After applying the reagent formula disclosed by the invention, by adopting one-time rougher floatation, one-time scavenging and one-time concentration, lead yield can reach up to more than 95% and lead tail run can reach 0.1-0.2%.

Owner:XINGMIN TECH ZHUZHOU

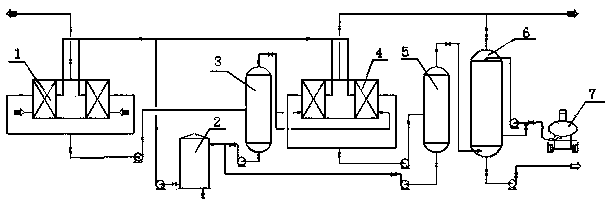

Device and method for producing sodium bisulfide by utilizing refinery dry gas

ActiveCN103754833ARaise the possibilityRealize resource utilizationSulfur compoundsResource utilizationGas composition

The invention relates to a device and method for producing sodium bisulfide by utilizing refinery dry gas. Aiming at the gas composition characteristics of the refinery dry gas, the dry gas refining desulphurization process is processed by utilizing an ultra-high gravity technology, and H2S in acid tail gas after dry gas refining desulphurization is selectively removed, so that the content of the purified H2S is over 99 percent, the purified and refined H2S is absorbed for preparing high-purity NaHS by adopting a continuous alkali liquor cycle, the concentration purity is over 42 percent, the process technology is greatly innovated, the investment is saved, secondary pollution is avoided, a process of a traditional out-dated NaHS product can be replaced, the device has a certain economic benefits and high-efficiency resource utilization rate, the H2S in the acid gas is almost recycled completely, the requirements of environment friendliness and emission are met, high social benefits are achieved, and recycling comprehensive utilization of refinery acid tail gas is realized.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

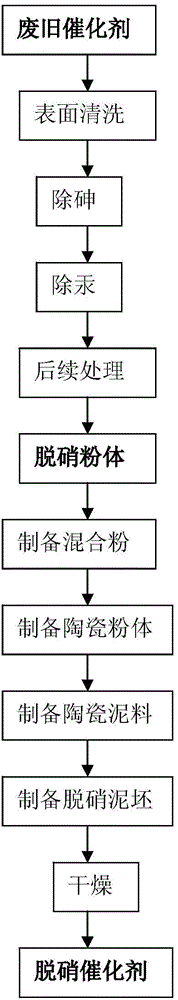

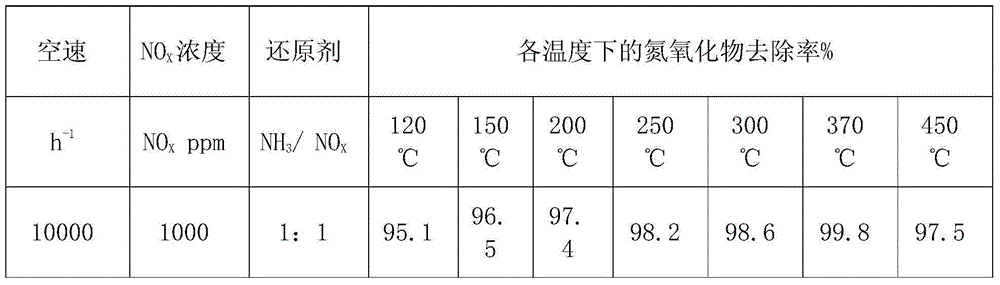

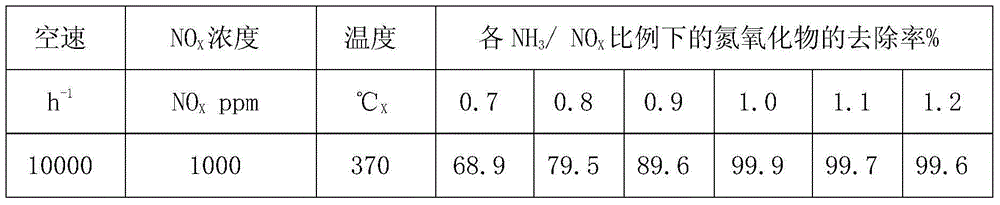

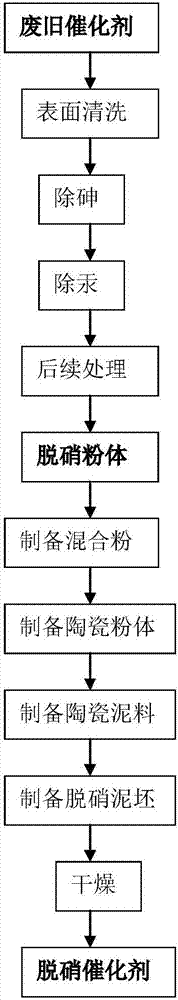

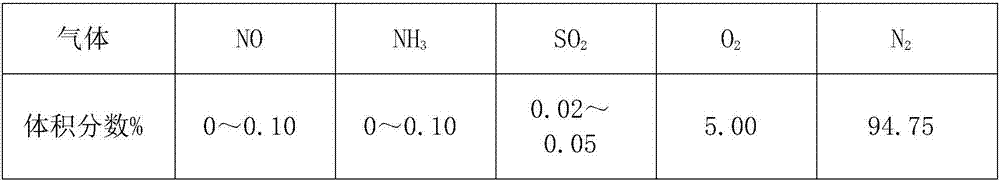

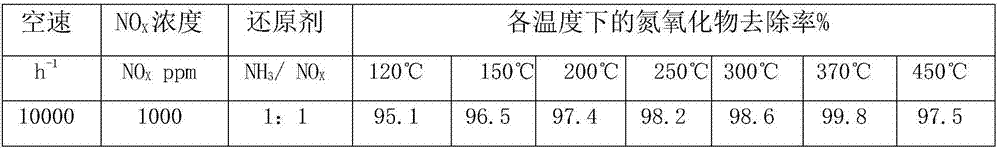

Method for recovering denitration powder from waste catalyst

InactiveCN104415768AAchieve recyclingAchieve recyclabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureSodium hydrosulfide

The invention relates to a method for recovering denitration powder from a waste catalyst, and belongs to the technical field of denitration catalysts. In the prior art, the recovered denitration powder has the poor activity. With the method of the present invention, the problem in the prior art can be solved. The method comprises: washing the surface of a waste denitration catalyst with a nitric acid solution with a mass percentage concentration of 5-30%, removing arsenic with a sodium hydroxide solution with a mass percentage concentration of 5-40%, removing mercury with sodium hydrosulfide with a mass percentage concentration of 2-20%, washing with deionized water, and then sequentially carrying out drying, calcination, crushing and jet milling to obtain the denitration powder. According to the present invention, the denitration catalyst obtained through the secondary preparation by adopting the denitration powder of the present invention as the raw material has the following characteristic that: the nitrogen oxide maintains 95% conversion efficiency when the gas reaction temperature is 150-420 DEG C.

Owner:SHANGHAI LANGT ELECTRIC POWER ENVIRONMENTAL PROTECTION TECH

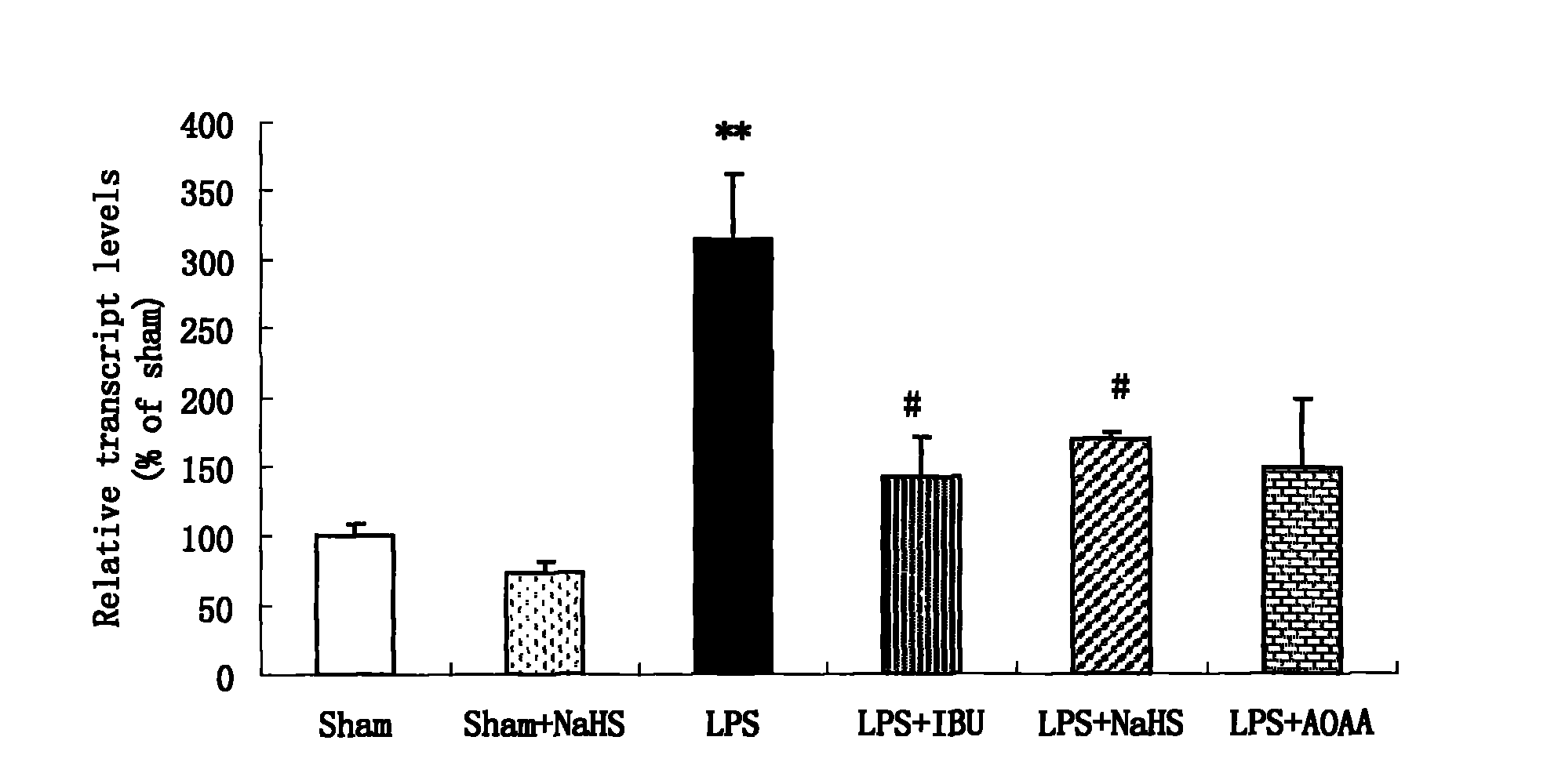

Application of hydrogen sulfide donor to preparation of medicine for treating central nervous system disease

ActiveCN102078327AAlleviate learning and memory lossPromote learning and memoryOrganic active ingredientsNervous disorderTumor necrosis factor alphaSodium hydrosulfide

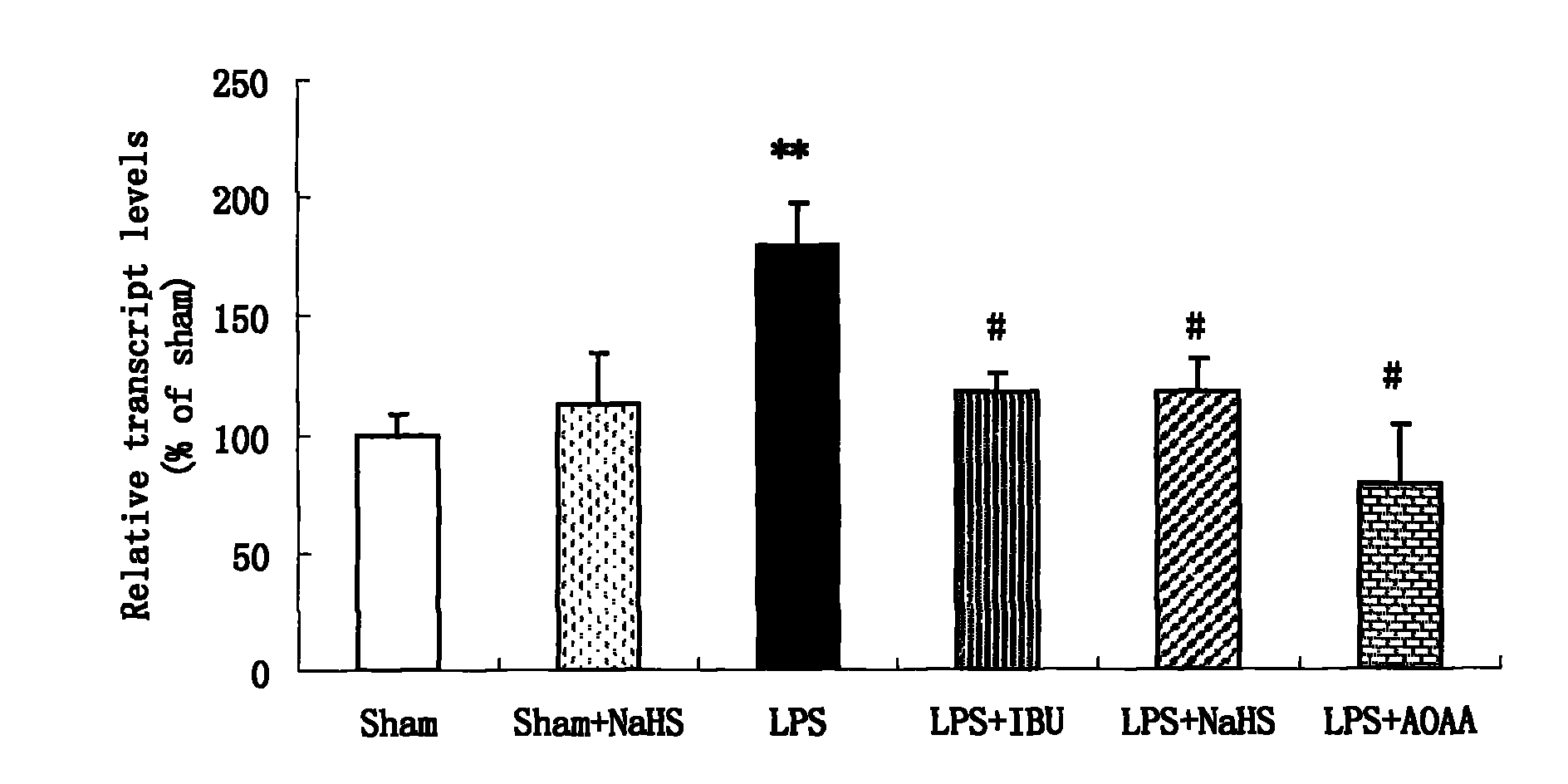

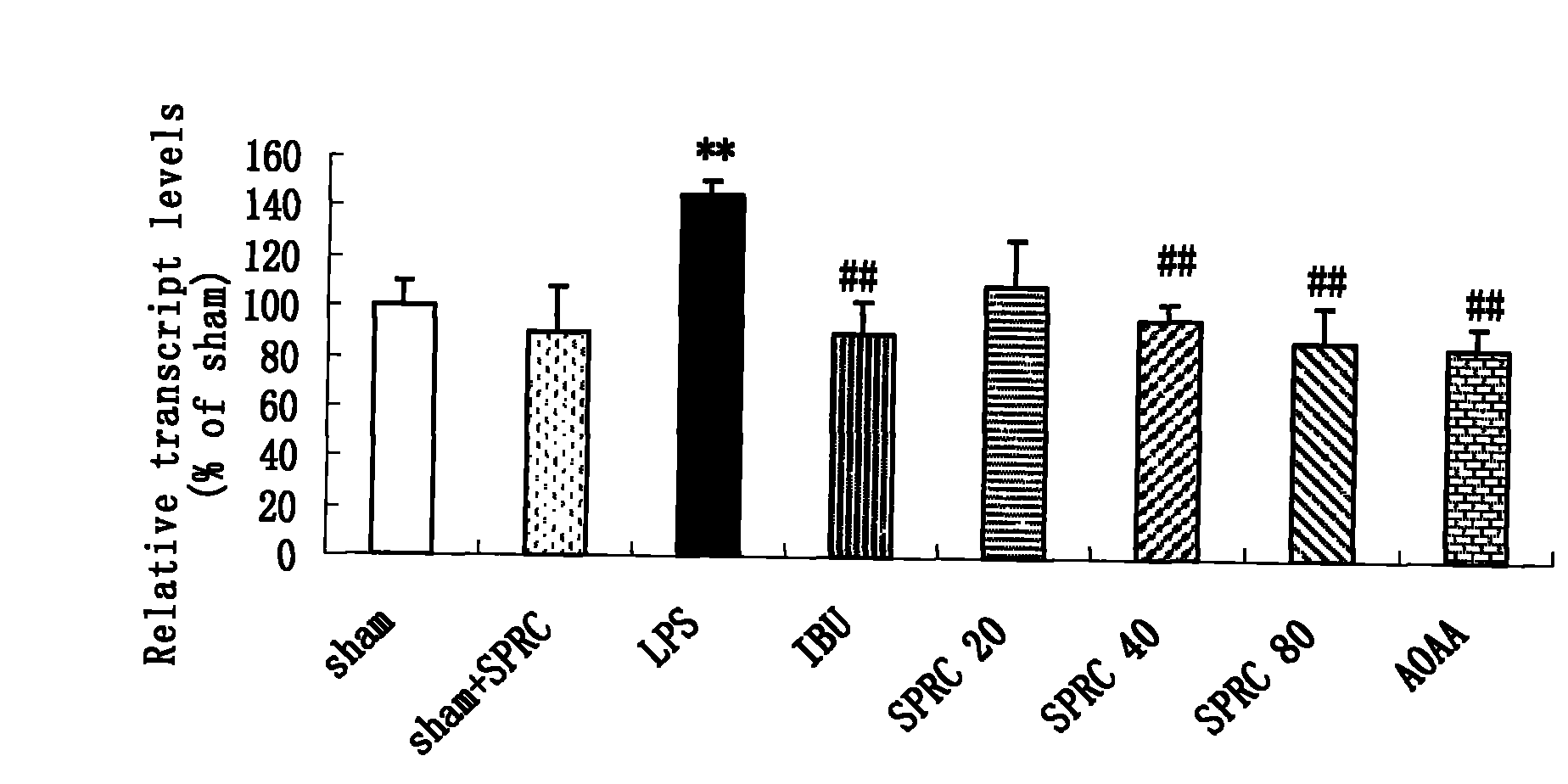

The invention belongs to the field of pharmacy, and relates to application of a hydrogen sulfide donor to the preparation of a medicine for treating central nervous system disease, in particular to application of the hydrogen sulfide donor, namely sodium hydrosulfide, or allyl cysteine and analogues thereof to the preparation of the medicine for treating the central nervous system disease. Integral animal model experiments prove that the sodium hydrosulfide and propargyl cysteine can reduce the learning and memory impairment of rats, increase the content of hydrogen sulfide in hippocampus tissues of the rats, inhibit the messenger ribonucleic acid (mRNA) expression of a tumor necrosis factor alpha and a receptor I thereof, inhibit an inflammatory mediator in the hippocampus tissues of rats with dementia and inhibit inflammation-related enzymes in the hippocampus tissues of the rats, and can be used as a medicine for treating Alzheimer disease and other inflammation-related central nervous system degenerative diseases such as Parkinson disease.

Owner:FUDAN UNIV

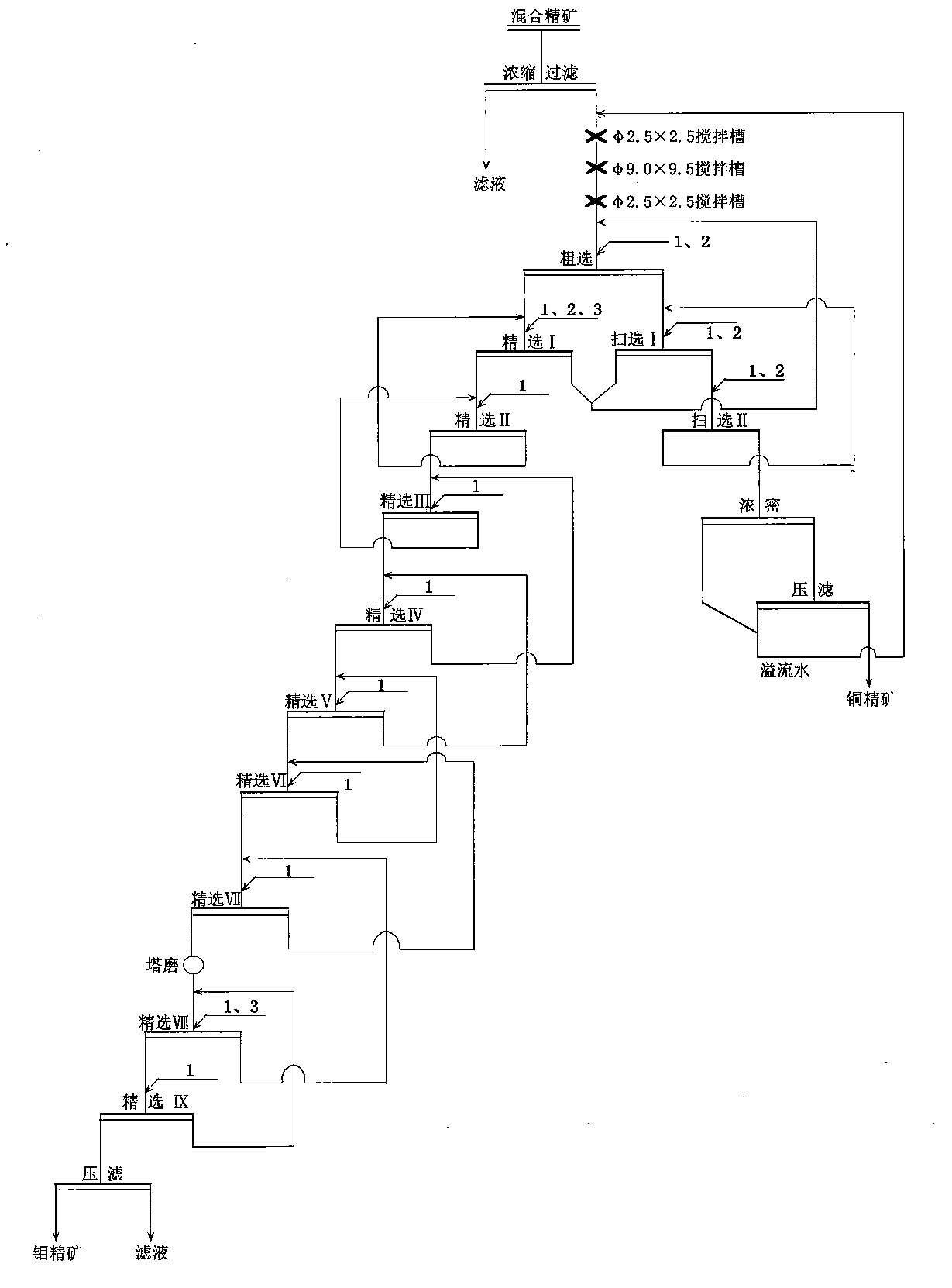

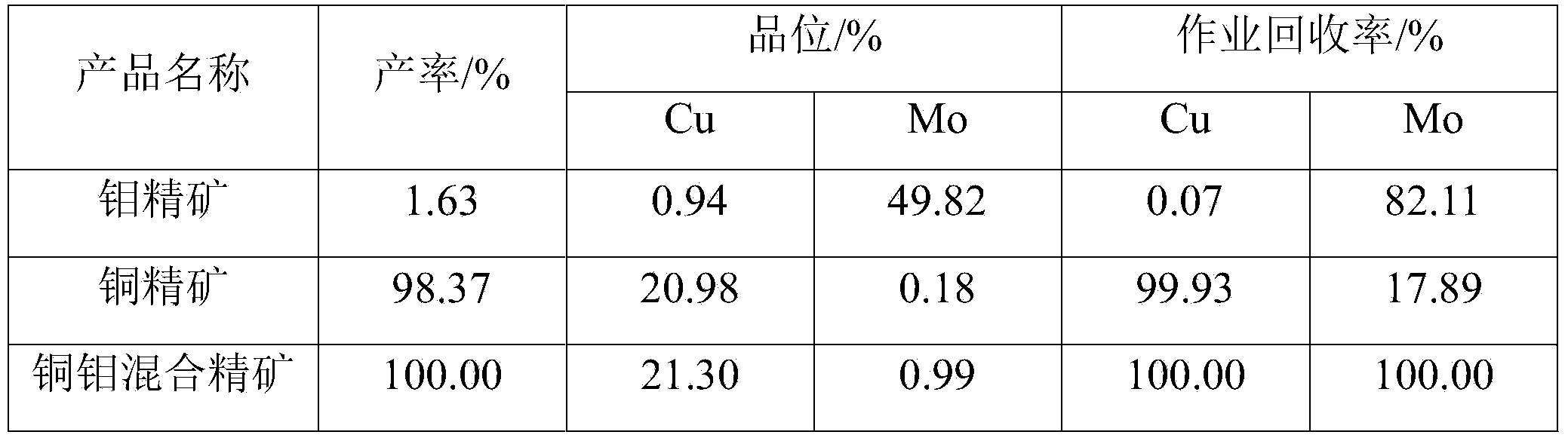

Method for separating copper-molybdenum mixed concentrate high in secondary copper content

InactiveCN103521347AEfficient separationSave waterSolid separationWater resourcesSodium hydrosulfide

The invention discloses a method for separating copper-molybdenum mixed concentrate high in secondary copper content. The method includes the steps of concentrating and filtering, water returning and size mixing, floatation separation, concentrate filtering and the like. The method abides by floatability property difference between copper molybdenum minerals, adopts sodium hydrosulfide to effectively inhibit primary copper and secondary copper and realizes high-efficiency separation of the copper-molybdenum mixed concentrate according to an idea of 'light pressing and slow selecting'. Copper concentrate going through dense overflow water can be used for size mixing of the copper-molybdenum mixed concentrate after concentrating and filtering, so that water resources are saved, and pollution caused by discharging of medicament is reduced. The method has the advantages of simplicity in medicament system and flowage structure, easiness in management operation, stability in technical process and production index and the like.

Owner:CHANGCHUN GOLD RES INST +1

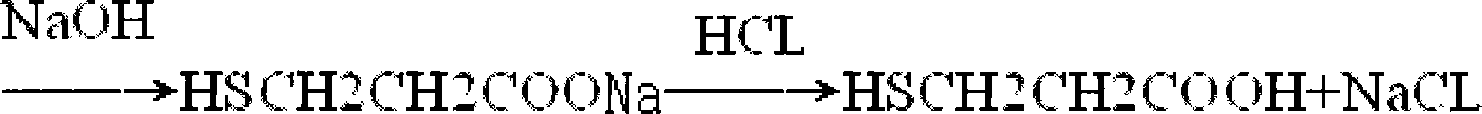

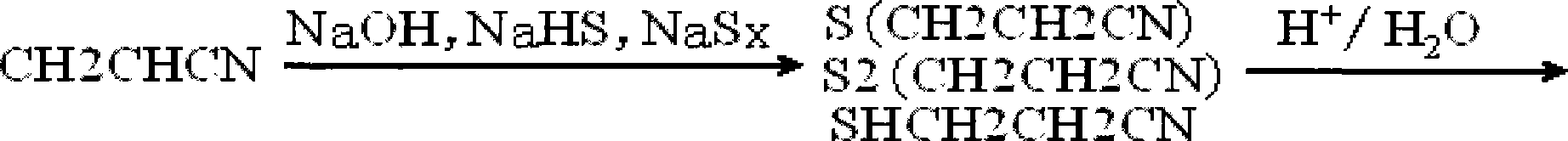

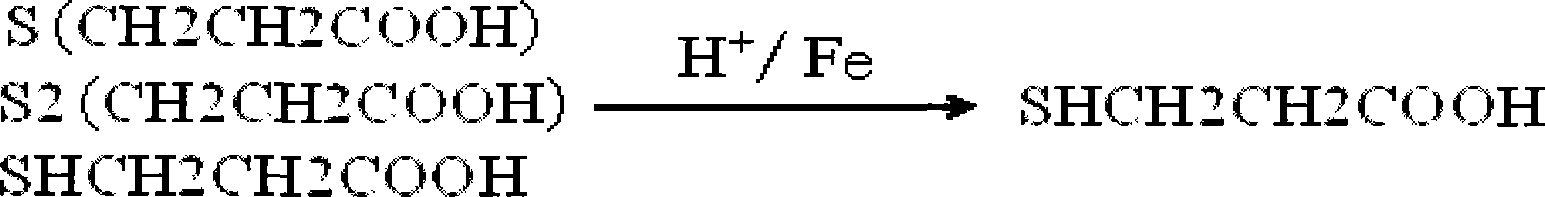

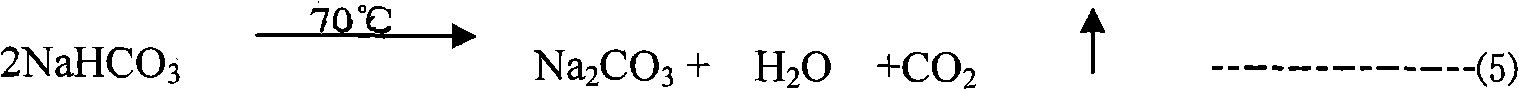

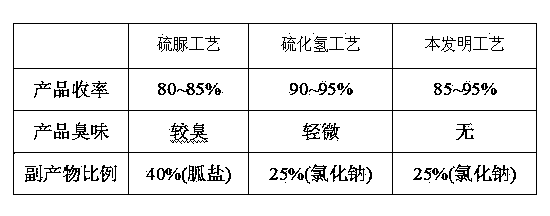

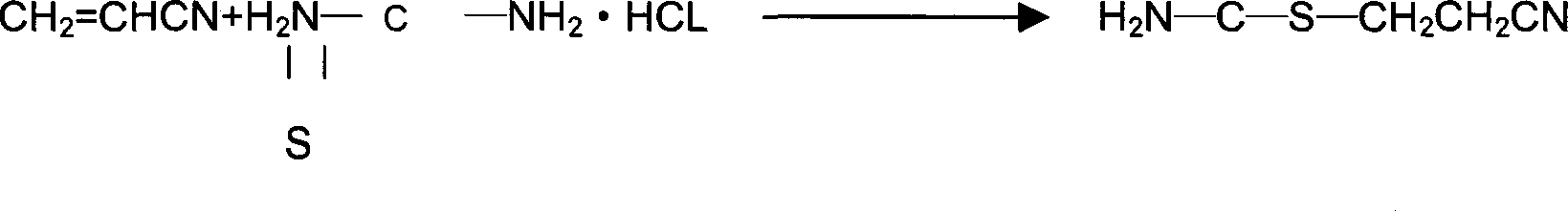

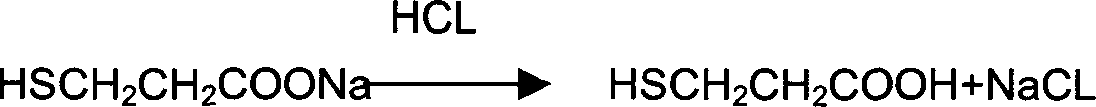

Method for preparing 3-mercaptopropionic acid

The invention relates to a preparation method of 3-mercaptopropionic acid. Sodium hydroxide solution, sodium hydrosulfide and sodium polysulfide (as catalyst) are mixed, then acrylonitrile is dripped into the mixture at the temperature of 20-70 DEG C to produce under insulated temperature the mixed solution of a plurality of intermediates, then hydrochloric acid is added for acidification and iron powder is added for deoxidization, thus acquiring the solution of 3-mercaptopropionic acid. The raw material sodium hydrosulfide selected in the reaction is cheap, reducing the production cost; hydrogen sulfide gas that is produced after the hydrochloric acid is added can be recycled to produce hydrogen sulfide nano, the production cost is further reduced; the final waste liquid mainly contains surplus hydrochloric acid and ammonia chloride, which is easy to be disposed; pollution is hardly caused during the whole reaction process.

Owner:顾建荣

New use of sodium hydrosulfide for promoting plant root morphogenesis

InactiveCN101385465APromote seedlingsPromote growth and reproductionPlant growth regulatorsBiocideForest industryHypocotyl

The invention relates to a new application of sodium hydrosulfide for promoting the morphogenesis of plant roots, namely, the application is that the sodium hydrosulfide is taken as root stimulate to promote the morphogenesis of side roots and adventitious roots of the seedling of the plant and the morphogenesis of the adventitious roots of cutting branches of the plant. The sodium hydrosulfide has obvious root-promoting effect to the seedlings of the plant such as rapes, mung beans, soybeans, cucumbers and the like, the hypocotyledonary axis of the cut segment thereof and the cutting branches of the plant such as willow branches, peach branches, grapes, batatas and the like, promotes the formation and growth of the side roots and the adventitious roots of the plant, enhances the water absorbing capacity of the plant, maintains the water balance in the body of the plant, reduces membrane lipid overoxidation damage of the hypocotyledonary axis of the cut segment and the cutting branches, maintains the relative stability of membrane structure of the explant and promotes the growth and propagation of the plant. The root-promoting agent can be used for growing roots of various plant seedlings, the hypocotyledonary axis of the cut segment and the cutting branches and is applicable to the root-promoting effect of promoting and culturing the seedlings of transplanting and cutting and the like, in the agriculture, forestry and gardening.

Owner:HEFEI UNIV OF TECH

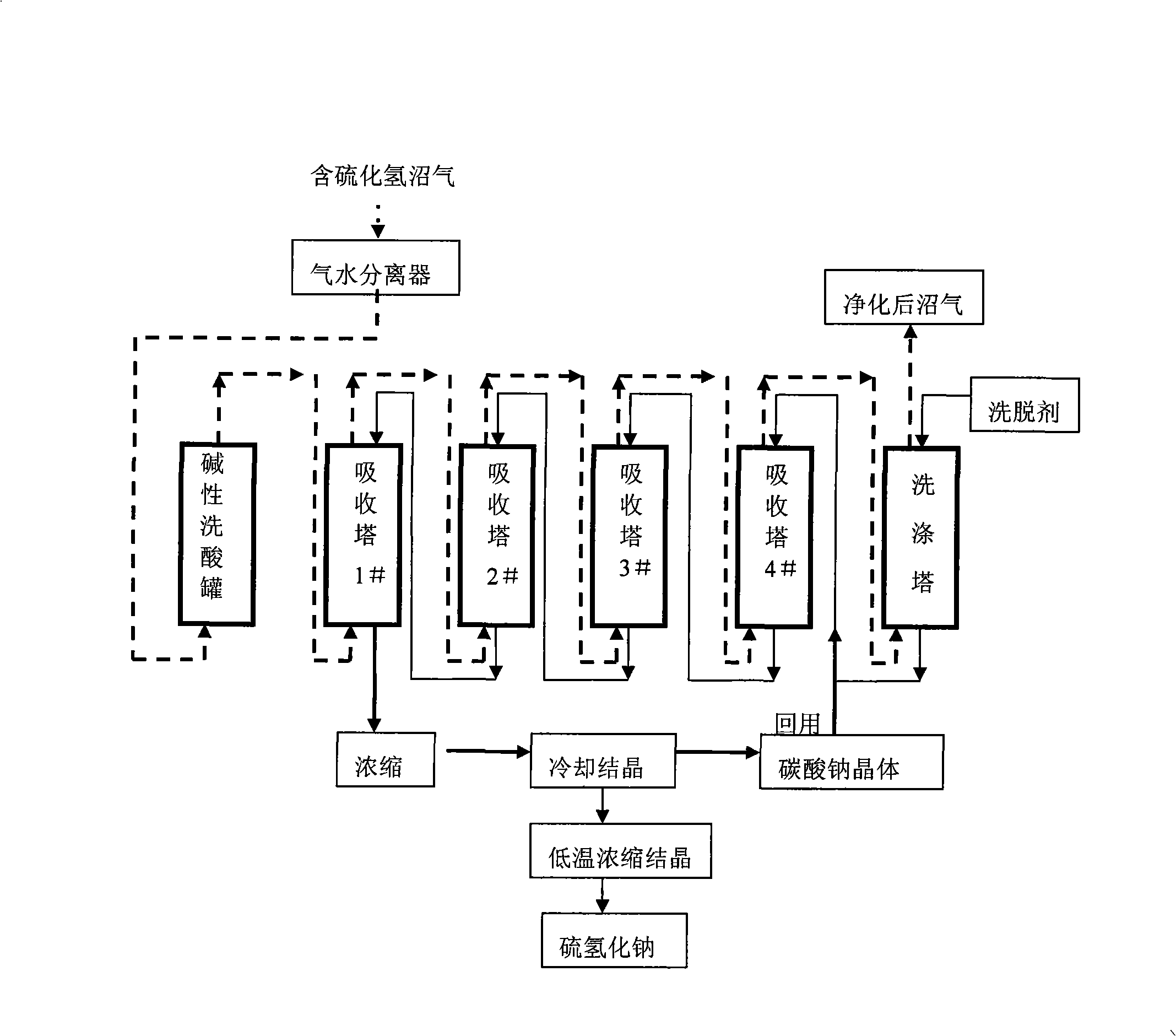

Process for recovering hydrogen sulfide form anaerobic fermentation methane

InactiveCN101306801AEffective protectionReduce manufacturing costGaseous fuelsHydrogen sulfidesSodium hydrosulfideFermentation

The invention relates to a hydrogen sulfide recovery process, particularly to a novel method for recovering hydrogen sulfide from anaerobic fermented biogas. The method comprises the step of countercurrent absorption of hydrogen sulfide-containing biogas with a sodium-containing alkaline solution as an eluent. The inventive method can effectively elute hydrogen sulfide gas from biogas to clean the biogas, and can produce sodium hydrosulfide with high added value.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

Essentially insoluble heavy metal sulfide slurry for wastewater treatment

A product and method for the removal of pollutant heavy metals from aqueous solutions which precludes the end user from storing, handling, feeding and controlling hazardous soluble sulfide materials. The product is a slurry which includes a mixture of a liquid medium and an essentially insoluble salt wherein the salt is the reaction product of heavy metal ions, preferably selected from Mn++ ions, Fe++ ions, and Fe+++ ions, and sulfide ions derived from soluble sulfide sources such as sodium sulfide, hydrogen sulfide, and sodium hydrosulfide. Addition of the subject slurry to a wastewater stream will effect the precipitation of heavy metals with lesser equilibrium sulfide ion concentrations than that of the essentially insoluble salt. Solids collected by this method may be returned to subsequent wastewater streams for additional removal of heavy metals by any excess heavy metal sulfide salt.

Owner:SOUTHERN WATER TREATMENT

Sodium sulfide-free, lime-free depilation caustic dip method for lining leather of high-grade pig leather shoes

The invention relates to a depilation caustic dipping method of the lining leather of high quality pigskin shoes without using sodium sulfide and lime, which is characterized in that the method can greatly reduce the pollution of S and waste residue in waste water caused by sodium sulfide, sodium sulfhydrate and the lime in the process of traditional leather manufacturing process, and the discharge amount of the waste water is reduced by 40% and is easy to treat compared with the conventional depilation liming working procedure. Meanwhile, a non-ammonia dealkalization method is adopted to greatly reduce the content of NH3-N in the waste water. Compared with the traditional technique, the method can shorten the production period, save materials and reduce the comprehensive cost of production.

Owner:湖南省怀其皮革集团制革有限公司

Preparation method of 3-mercaptopropyltriethoxysilane coupling agent

ActiveCN103408582AShort reaction stepsSimple production processGroup 4/14 element organic compoundsTriethoxysilaneCoupling

The invention relates to a preparation method of a 3-mercaptopropyltriethoxysilane coupling agent, belonging to the technical field of organic chemistry. The preparation method comprises the following steps of: with sodium hydrosulfide and 3-chloropropyltriethoxysilane as raw materials and water as a solvent, heating, stirring and reacting under the action of a phase transfer catalyst to obtain a crude product of silane; and drying the crude product, filtering and distilling to obtain the 3-mercaptopropyltriethoxysilane coupling agent product. The preparation method is simple in process, lower in production cost, high in product yield, little in odor, safe, environment-friendly and easy to realize large-scale industrial production.

Owner:JINGZHOU JIANGHAN FINE CHEM

Process for preparing 3-mercaptopropyl acid

The invention relates to a manufacture method for 3-thiohydracrylic acid. The feature is that is mixing the NaOH water solution, sodium hydrosulphide, sodium polysulfide, dropping acrylonitrile at 20-70 degree centigrade, keeping temperature to form kinds of inter mixture liquid, adding HCl to acidify, adding zinc powder to deoxidize to gain 3-thiohydracrylic acid solution. The invention could decrease cost, and the waste liquid is easy to process.

Owner:顾建荣

New application of sodium bisulfide as hydrogen sulfide donor in promoting storage and preservation of fruits and vegetables

InactiveCN102550652ALow application concentrationReduce water loss rateBiocideSeed preservation using chemicalsPEARSodium bisulfide

The invention discloses a new application of sodium bisulfide (hydrogen sulfide donor) in promoting the storage and preservation of fruits and vegetables, i.e. an application of the sodium bisulfide (hydrogen sulfide donor) as fresh cut fruit-vegetable fresh-keeping agent. The sodium bisulfide (hydrogen sulfide donor) has a fresh-keeping effect on fresh cut vegetables such as broccoli, asparagus lettuce, lotus root, yam, pumpkin, sweet potato and potato and the like, and fresh cut fruits such as apple, pear, Chinese goosebeery, tomato, Hami melon and peach and the like. The sodium bisulfide can notably delay the wilting, dehydration, ripening, aging and mildewing of fresh cut fruits and vegetables, keep the quality characteristics of picked fruits and vegetables and prolong the storage periods and shelf lives of picked fresh cut fruits and vegetables by 0.5 to 12 days. The fresh-keeping agent can be used for keeping freshing on a variety of the picked fresh cut fruits and vegetables.

Owner:HEFEI UNIV OF TECH +2

Method for preparing denitration catalyst by recycling raw material from waste catalyst

InactiveCN107456962AKeep the good stuffReduce investmentGas treatmentHeterogenous catalyst chemical elementsSodium hydrosulfideCerium

The invention provides a method for preparing a denitration catalyst by recycling a raw material from a waste catalyst, belongs to the technical field of denitration catalysts, and solves the problems that the conventional denitration catalyst prepared from an active component recycled from the waste denitration catalyst is poor in activity and low in catalytic efficiency. The method comprises the following steps: mixing denitration powder, glass fiber and cerium dioxide, then mixing with ordinary Portland cement, preparing ceramic powder, then kneading the ceramic powder, glycerol, ethylene glycol, carboxymethyl cellulose and water into a ceramic clay material, performing vacuum extrusion, and drying to obtain the final denitration catalyst, wherein the denitration powder is prepared according to the following steps: cleaning the surface of the waste denitration catalyst by using nitric acid, removing arsenic by using a sodium hydroxide solution, removing mercury by using sodium hydrosulfide, cleaning by using deionized water, drying, calcinating, crushing, and performing jet milling to obtain the denitration powder. The denitration catalyst prepared by the method provided by the invention still keeps the nitrogen oxide converting efficiency of 95% at 150-420 DEG C.

Owner:江苏浩日朗环保科技有限公司

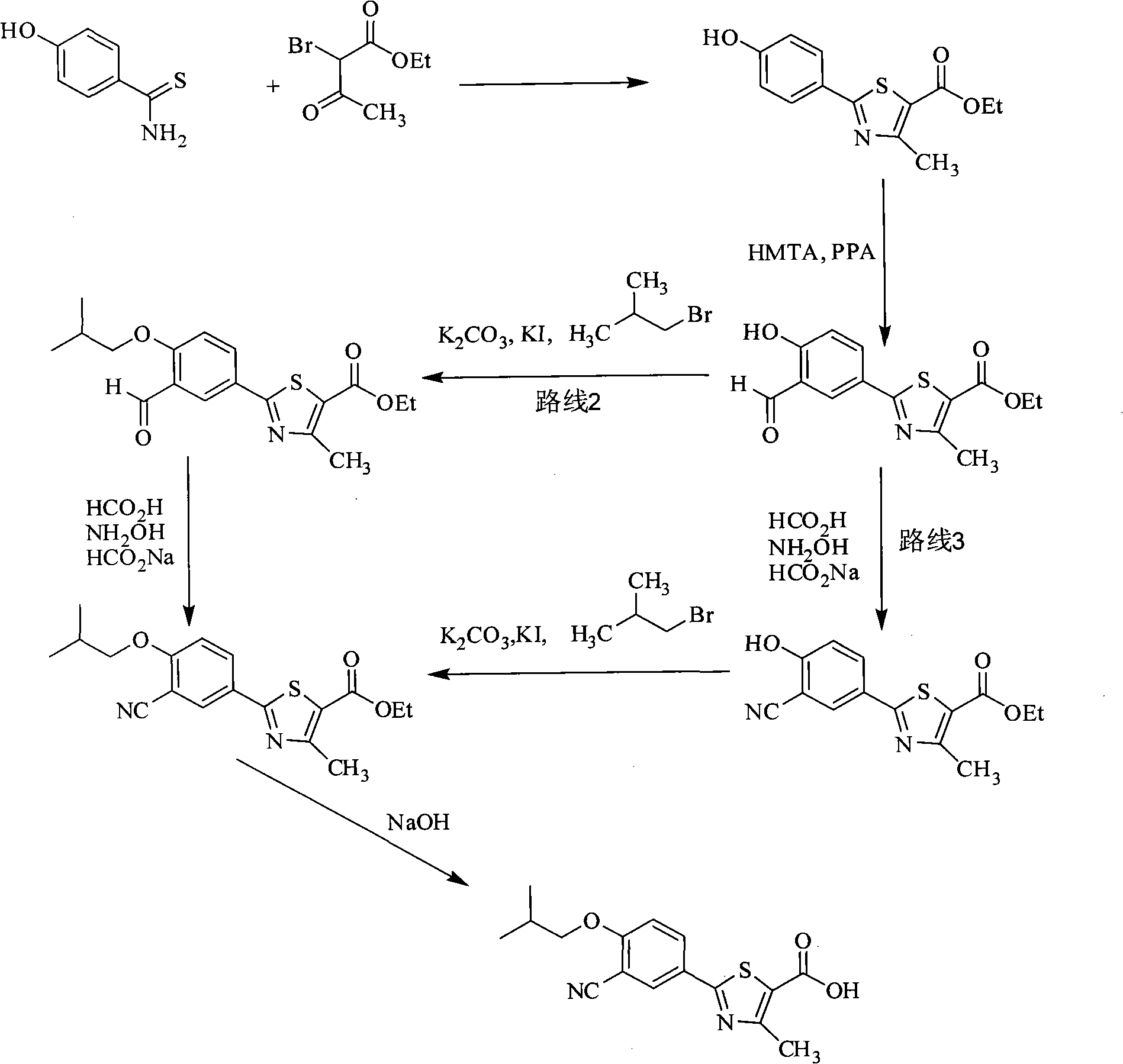

Synthesis method of 2-(3-cyan-4-isobutoxy) phenyl-4-methyl-5-thiazole formic acid

InactiveCN101863854ARaw materials are easy to getSimple and fast operationOrganic chemistryFormylation reactionSynthesis methods

The invention belongs to the technical field of medicine, relating to a synthesis method of 2-(3-cyan-4-isobutoxy) phenyl-4-methyl-5-thiazole formic acid. The synthesis method is characterized by comprising the following steps of: brominating to obtain 3-bromine-4-hydroxyl cyanobenzene by using 4-hydroxyl cyanobenzene as a raw material, alkylating by using bromo-isobutane to obtain 3-bromine-4-isobutoxy cyanobenzene, and cyaniding with cuprous cyanide to obtain 4-isobutoxy-1,3-benzene dinitrile; carrying out a formylation reaction with sodium bisulfide to prepare 3-cyan-4-isobutoxyphenylthioformamide in the presence of anhydrous magnesium chloride, and cyclizing with 2-chloroacetoacetic acid ethyl ester to prepare 2-(3-cyan-4-isobutoxy) phenyl-4-methyl-5-thiazole ethyl formate; and finally, hydrolyzing to prepare the 2-(3-cyan-4-isobutoxy) phenyl-4-methyl-5-thiazole formic acid. The method has the characteristics of easy raw material obtaining, simple and convenient operation, higher yield, lower cost and higher final product purity (the HPLC, High Performance Liquid Chromatography purity is not lower than 99.9 percent) and is suitable for industrial production.

Owner:SHENYANG PHARMA UNIVERSITY

Method for treating 2-mercaptobenzothiazole production waste

ActiveCN102603668AChemically stableSolve the pollution problemAmino compound purification/separationSulfur compoundsEnvironmental resistanceDistillation

The invention discloses a method for treating 2-mercaptobenzothiazole production waste. The method comprises the steps of: heating the 2-mercaptobenzothiazole production waste to 90-95 DEG C, carrying out solid-liquid separation to obtain solid matter and liquid A, returning the solid matter to an accelerator M workshop, refining and purifying the solid matter to obtain a product accelerator M, distilling and separating the liquid A to obtain a fraction B and a fraction C, cooling residues in a distillation kettle to obtain asphalt-shaped matter D, absorbing hydrogen sulfide gas generated in the distillation separation process by using a sodium hydroxide solution to obtain a sodium hydrosulfide solution, concentrating the sodium hydrosulfide solution to obtain sodium hydrosulfide solids, rectifying and separating the fraction C to obtain aniline and benzothiazole. The method disclosed by the invention is capable of realizing the resourceful treatment of the 2-mercaptobenzothiazole production waste and has the advantages of various by-products, good product quality, simpleness in process flow, easiness in operation, mildness in reaction condition, low production cost and is environment-friendly.

Owner:HEBI HENGLI RUBBER PLASTIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com