Patents

Literature

250 results about "Dealkalization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dealkalization is a process of surface modification applicable to glasses containing alkali ions, wherein a thin surface layer is created that has a lower concentration of alkali ions than is present in the underlying, bulk glass. This change in surface composition commonly alters the observed properties of the surface, most notably enhancing corrosion resistance.

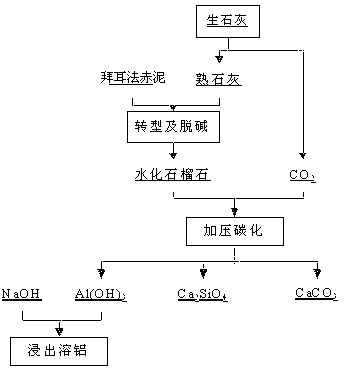

Method for dissolving Bayer process red mud

ActiveCN102757060AMeet industrial requirementsReduce sodiumCalcium/strontium/barium carbonatesSludge treatmentCalcium silicateAluminium hydroxide

The invention discloses a method for dissolving red mud. The method comprises the following specific steps of: mixing Bayer process red mud with white lime in the mass ratio of 1:(0.3-0.9); stirring at the temperature of 80-140 DEG C for reacting for 1-15 hours for calcifying, transforming and dealkalizing; mixing calcified, deformed and dealkalized Bayer process red mud with clear water or a low-concentration sodium aluminate solution in an enclosed container; introducing CO2 into the container to obtain calcified slag containing calcium silicate, calcium carbonate and aluminum hydroxide serving as main components; and extracting aluminum hydroxide from the calcified slag by using a sodium hydroxide solution or an aluminum hydroxide solution. In the method disclosed by the invention, the structure and composition of red mud are changed by adopting calcification transformation and pressurizing calcification transformation methods, so that dealkalization and extraction of aluminum can be realized; and iron is extracted properly, so that the structure and the composition of red mud can meet the requirements of cement production, and the aim of dissolving red mud on a large scale at low cost is fulfilled.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

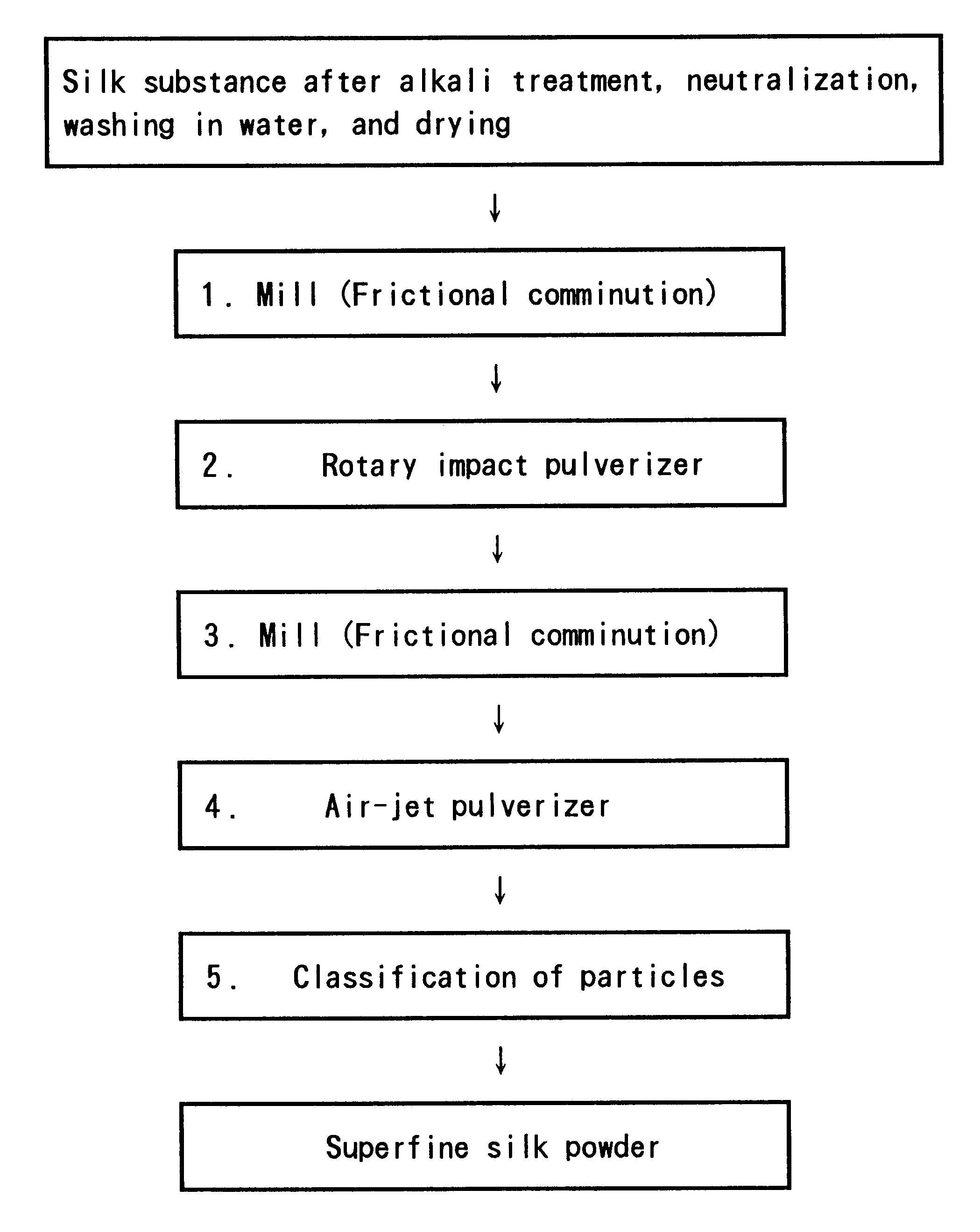

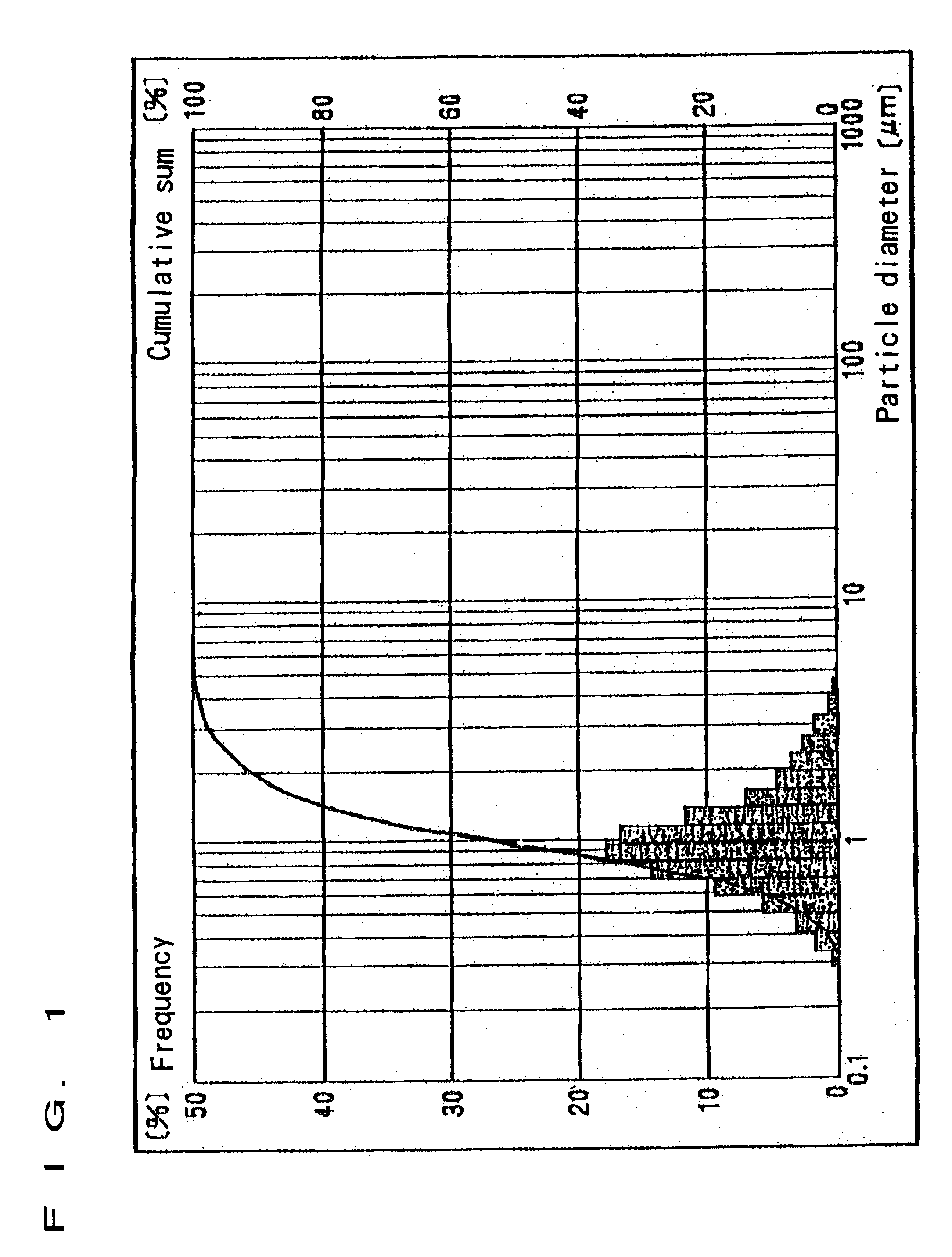

Method for manufacturing crystalline superfine silk powder

The main theme of the invention is to provide a method for manufacturing industrially, by mechanically comminuting silk yarn, crystalline silk fibroin powder below 3 mum in an average particle diameter, which can be used for various applications. A silk substance such as cocoon filament, silk yarn, or raw silk is brought into an alkali aqueous solution under a pressure of 1 through 5 atmospheric pressure at temperatures from 100° C. through 150° C. to reduce the tensile strength of the silk substance to around 0.02 g / d or less. Thereafter, the resultant silk substance is subjected to dealkalization and drying. Subsequently, the resultant dried silk substance is comminuted into powder below 3 mum in an average particle diameter. Thus, the crystalline silk fibroin powder below 3 mum in an average particle diameter is manufactured.

Owner:JAPAN AS REPRESENTED BY DIRECTOR GENERAL OF NAT INST OF SERICULTURAL & ENTOMOLIGICAL SCI MINIST OF AGRI FORESTRY & FISHERIES +1

Red mud dealkalization method

ActiveCN101423318ALow alkali contentRemarkable effect of sodium removalSludge treatmentSocial benefitsBrick

The invention discloses a dealkalization method for red mud. The method comprises a dilute sulphuric acid dealkalization step and a pressure calcium oxide dealkalization step. Red mud is prepared into slurry and introduced into a grinder to be ground; according to the content of alkaline in the red mud, the slurry is slowly added with required dilute sulphuric acid to be ground, filtered and washed to obtain a filter cake and the content of alkaline in the filter cake is analyzed; according to the analyzed content of alkaline in the filter cake, the filter cake is added with calcium oxide and uniformly mixed to be introduced to a high pressure reaction kettle and heated for reaction, and after reaction, the mixture is cooled, filtered and washed; and the obtained filter cake is dried and content of alkaline in the dried filter cake is analyzed. The invention can use only the pressure calcium oxide method to carry out dealkalization of the red mud. Red mud subjected to dealalization treatment of the method has low alkaline content and can be used more in fields such as concrete production, high quality brick and transformed brickproduction. The method solves the problem of the red mud of severe pollution and achieves remarkable economic and social benefits.

Owner:中国长城铝业有限公司

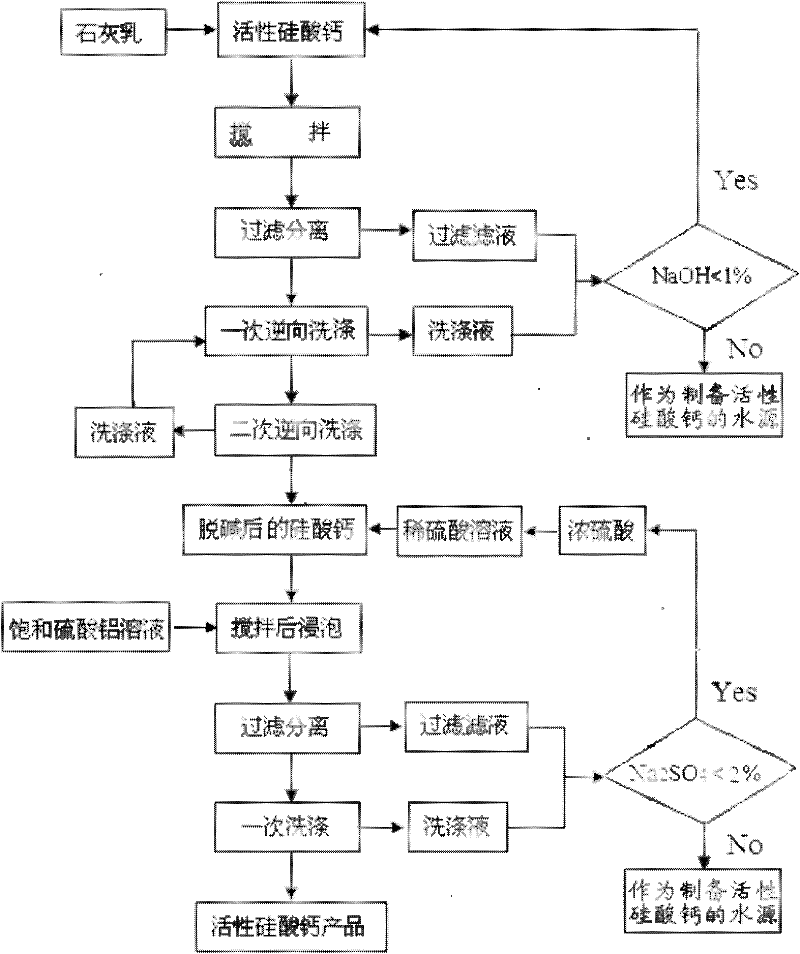

Method for lowering pH value of active calcium silicate

InactiveCN102190309AIncrease profitComply with environmental policyAlkaline-earth metal silicatesCalcium silicateDealkalization

The invention discloses a method for lowering the pH value of active calcium silicate. The method comprises the following steps of: adding lime milk to high-alkality active calcium silicate for dealkalization when the Na2O content (weight percent) in the high-alkality active calcium silicate is greater than or equal to 1%, and then carrying out acidification treatment; and directly carrying out acidification treatment on high-alkality active calcium silicate when the Na2O content (weight percent) in the high-alkality active calcium silicate is smaller than 1%. The invention overcomes the defects of the prior art, and realizes the advantages of wide raw material sources, low price, simple operation steps and low energy consumption. The pH value of high-alkality active calcium silicate treated by the method can be lowered to 8-10, thereby meeting the requirements on filler performance in the industries of plastic, rubber, paper making, paint and the like, and high-alkality active calcium silicate treated by the method can be used as a heat-insulation material.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

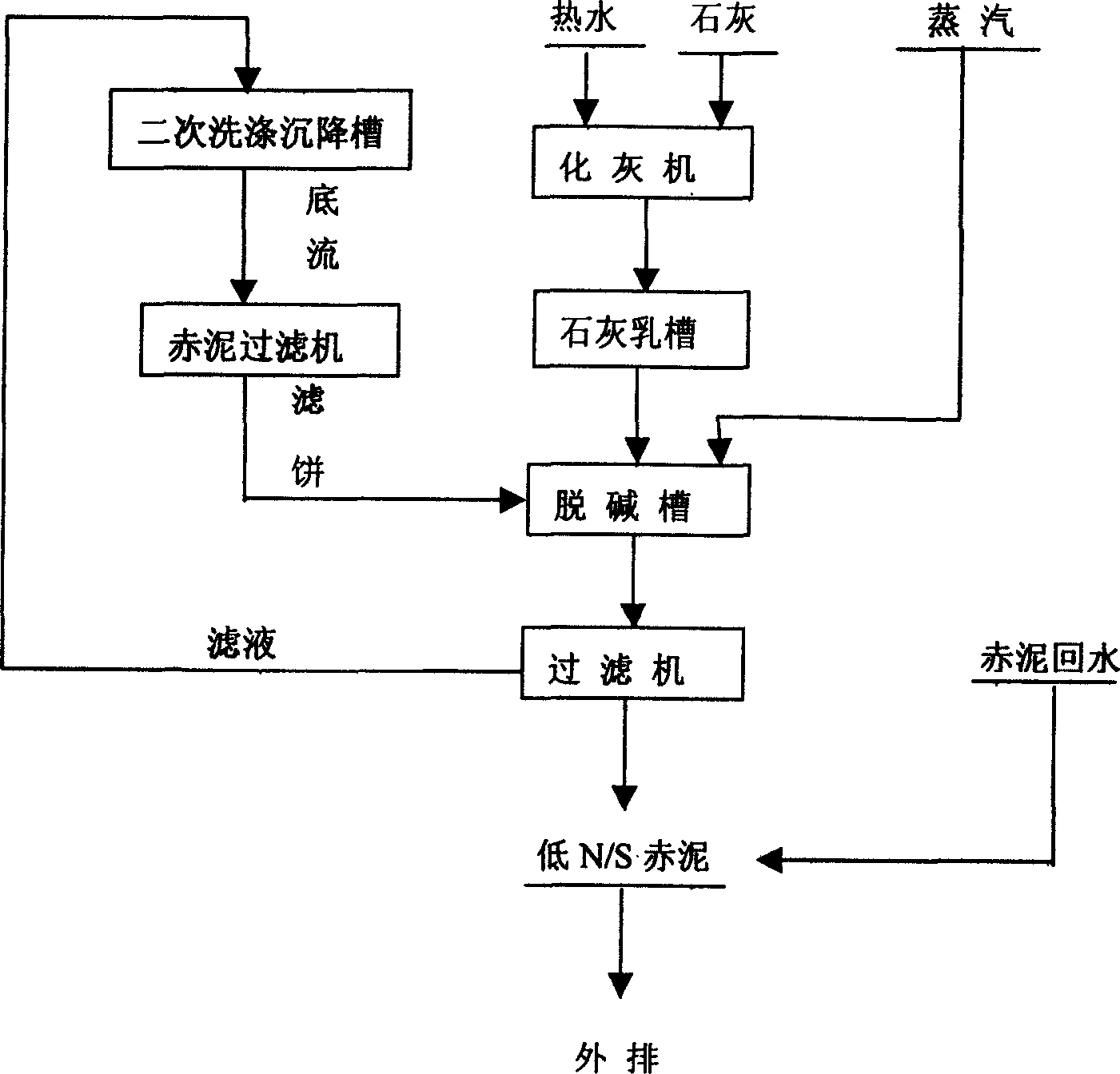

Red mud dealkalization method at normal pressure by Bayer process

InactiveCN1594093ASatisfy evacuation requirementsIncrease productivityAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxides/hydroxidesDealkalizationPetroleum engineering

The invention discloses a red mud dealkalization method at normal pressure by Bayer process, wherein the dealkalizing step consists of, washing and filtering the red mud, charging lime cream into the red mud filter cake, mixing for dealkalizing reaction, subjecting the reaction slip to washing, filtering, drying and discharging.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for producing alumina by using high sulphur bauxite

ActiveCN101456572AImprove energy efficiencyPromote dissolutionAluminium oxides/hydroxidesFluidized bedSulfur

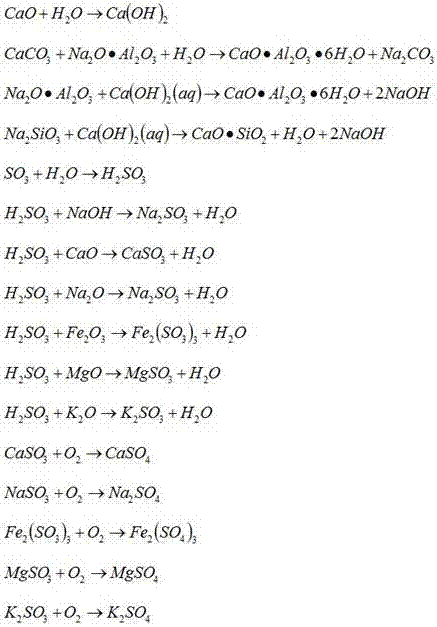

The invention relates to a method for producing alumina by utilization of high-aluminum alumyte, which belongs to the technical field of metallurgy. The method comprises: firstly, grinding alumyte ores, and adopting a fluidized bed to perform roasting and desulfurization pretreatment; secondly, treating obtained roasted ores by a Bayer process, and obtaining Al2O3 products after stripping, crystal seed decomposition and calcining treatment; and thirdly, introducing roasted tail gas generated by roasting into red mud under the stirring condition, and absorbing SO2 in the tail gas. The method has low stripping temperature, can effectively remove sulfur element in the ores, has great significance in developing and using the ores for alumina industrial production practice, uses the red mud during industrial production of alumina as an absorbent of the low concentration SO2 tail gas during roasting, and realizes dealkalization and modification treatment and comprehensive utilization of the red mud.

Owner:NORTHEASTERN UNIV

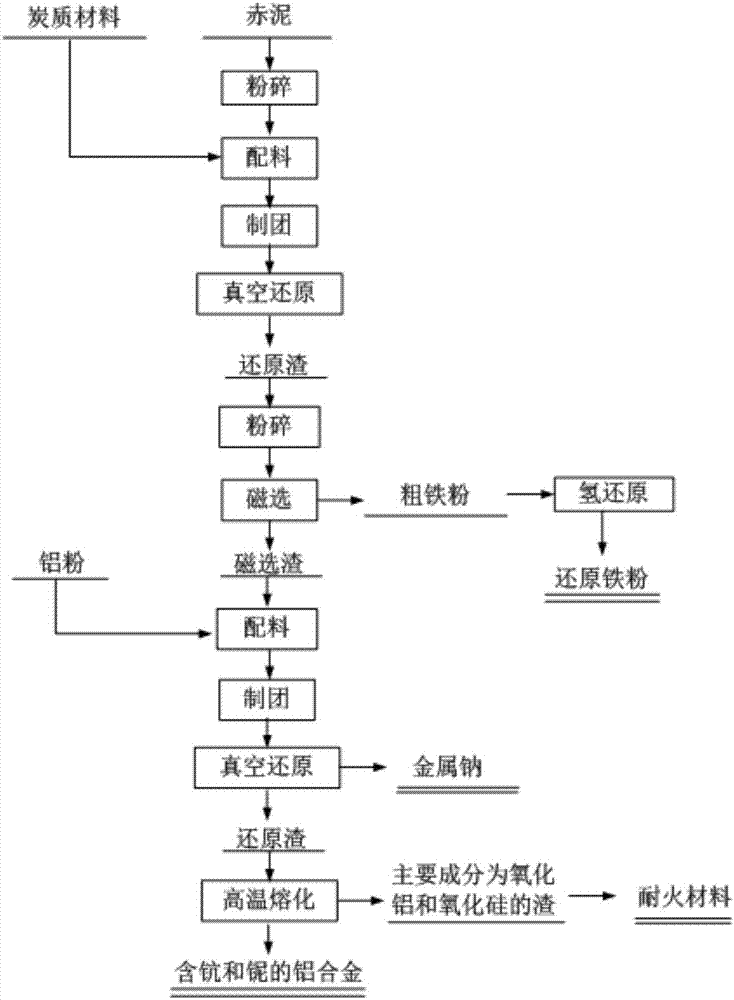

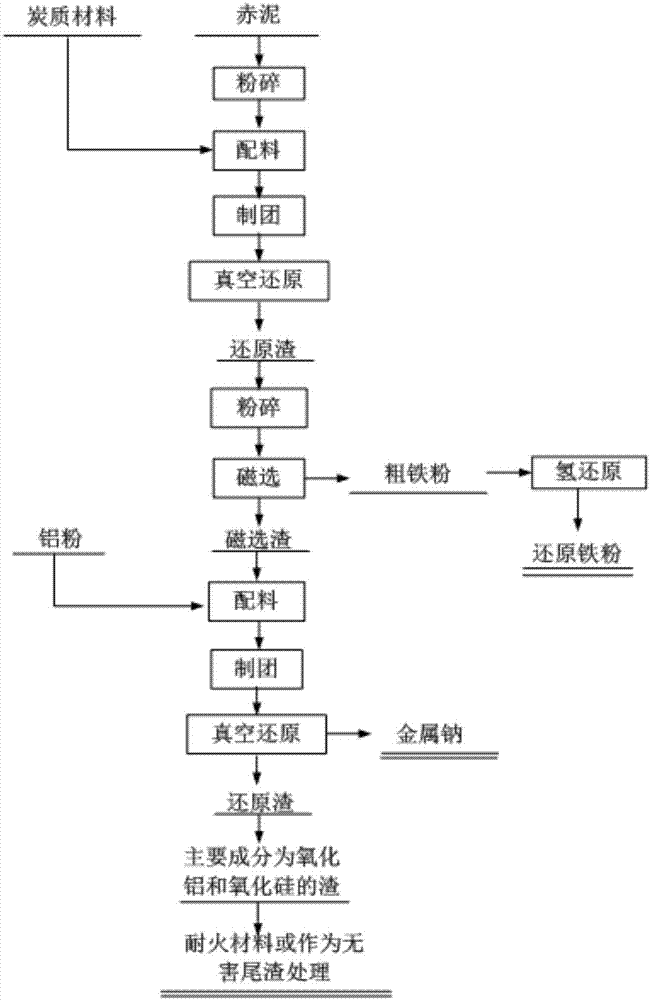

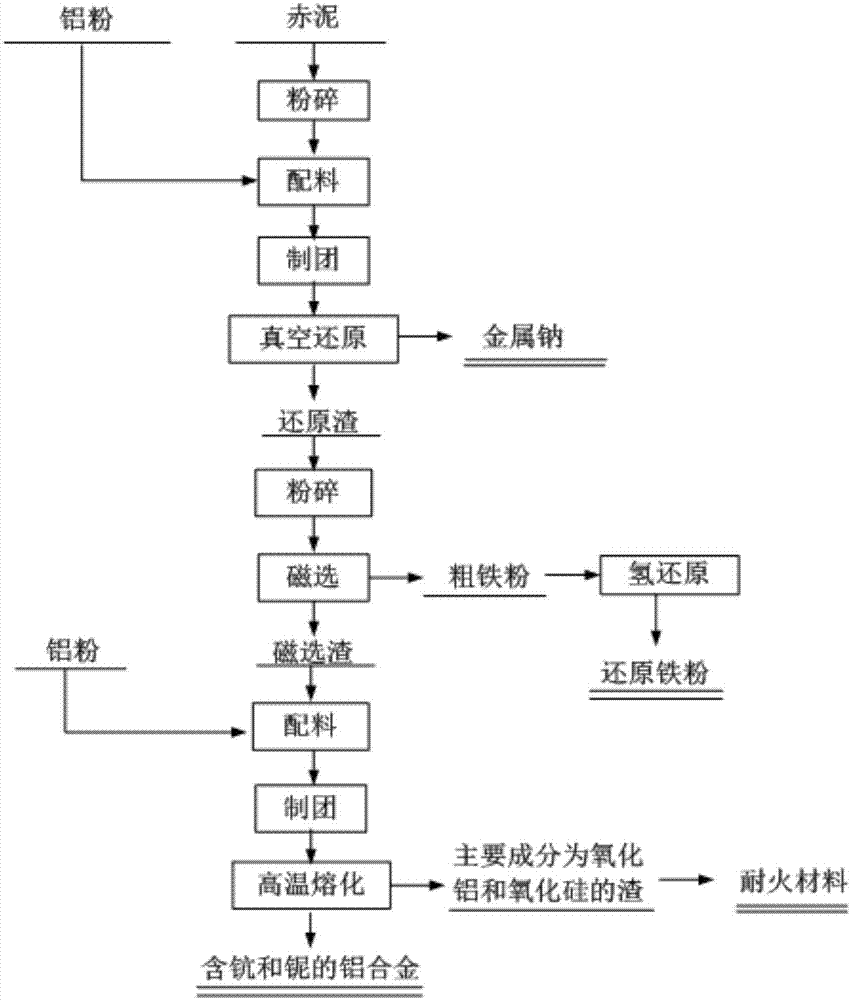

Comprehensive utilization method for aluminum oxide red mud

ActiveCN107083485AAchieve removalAchieve recyclingRetort furnacesProcess efficiency improvementNiobiumSlag

The invention belongs to the technical field of metallurgy and environmental protection, and particularly relates to a comprehensive utilization method for aluminum oxide red mud. The comprehensive utilization method for the aluminum oxide red mud aims at solving the problem that the aluminum oxide red mud is difficult to treat and recycle effectively, the red mud is treated by adopting a vacuum thermal reduction method, carbon or aluminum serves as a reducing agent, iron oxide in the red mud is reduced into metal iron under a vacuum condition, then iron in reducing slag is separated out through magnetic separation to be used for producing reduced iron powder, combined-state sodium oxide is reduced into metallic sodium and is distilled out, and therefore, the purposes of dealkalization and alkali recovery from the red mud can be achieved; and meanwhile, other valuable substances (such as scandium, niobium, cesium) in the red mud are reduced to metallic states and form an alloy with aluminum so as to be separated from the slag with the main components being silicon oxide and aluminum oxide, and therefore the effects of harmless treatment of the aluminum oxide red mud and comprehensive recovery and utilization of the valuable elements can be achieved, and no waste gas, waste water, waste slag or other secondary pollution is generated in the treatment process.

Owner:NORTHEASTERN UNIV

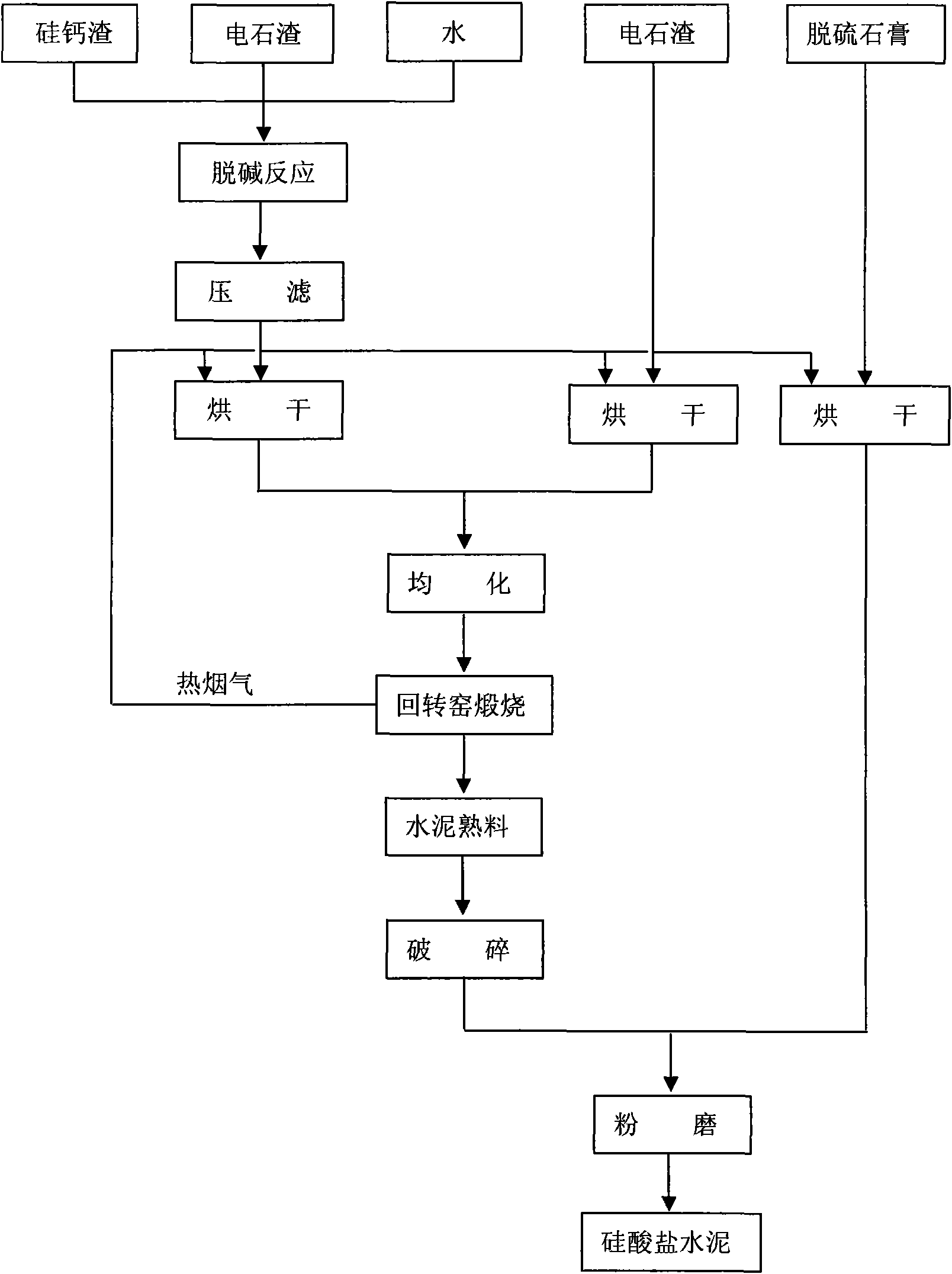

Method for producing silicate cement by using silico-calcium dregs and carbide dregs

InactiveCN101591150AReduce contentMeet the requirements of alkali contentCement productionCalcinationMaterials science

The invention provides a method for producing silicate cement by using silico-calcium dregs and carbide dregs, relating to the technical field of building materials. The method has the following steps: 1. adding carbide dregs and water into silico-calcium dregs followed by dealkalization and carrying out pressure filtering and drying on the dealkalized silico-calcium dregs if the alkali content in the silico-calcium dregs is high, or directly drying the silico-calcium dregs if the alkali content in the silico-calcium dregs is low; and drying the carbide dregs and desulfurated plaster respectively; 2. dosing and homogenizing the dealkalized silico-calcium dregs and carbide dregs after drying; 3. sending the homogenized crude materials into a rotary kiln for high temperature calcinations and obtaining the cement clinker after cooling; and 4. smashing the cement clinker and sending the smashed cement clinker and the dried desulfurated plaster into a cement grinding mill for grinding to prepare the silicate cement. Compared with the prior art, the method of the invention is simple in process, low in investment, low in production cost, low in energy consumption, and stable in the prepared silicate cement performance.

Owner:TONGFANG ENVIRONMENT

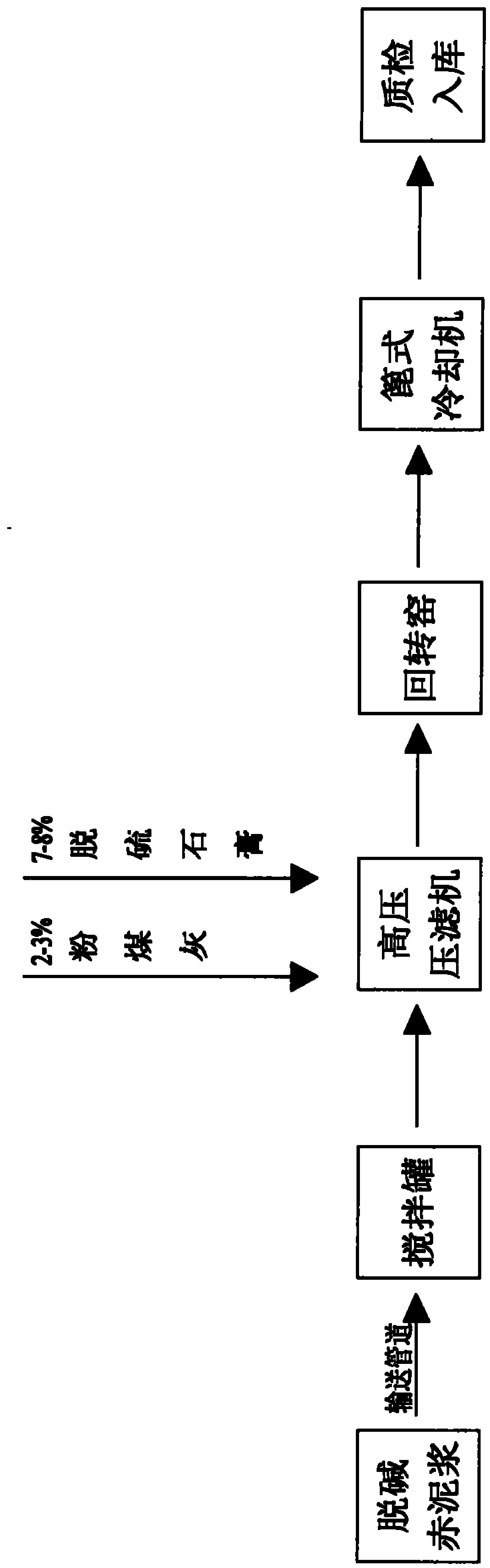

Method for producing cement clinker by utilizing red mud

InactiveCN102531423AThere is no problem of consolidation and hardeningAdvanced technologyCement productionFiltrationHigh pressure

The invention relates to a method for producing cement clinker by utilizing red mud. The method mainly comprises the following processes of: transporting dealkalization red mud into a stirring tank through a discharge transportation pipeline, wherein the concentration of the dealkalization red mud is about 30%, the temperature is about 85 DEG C, the content of Na2O is below 1%; adding 7-8% of dealkalization gypsum and 2-3% of coal ash in the dealkalization red mud, evenly mixing the three materials in the stirring tank, and simultaneously adding water so that the concentration of the mixture is regulated to 30%; carrying out press filtration with a plate and frame high-pressure filter press so that the content of water in the red mud produced after press filtration is less than 25%; feeding the mixture into a rotary kiln with a belt conveyer for calcination, wherein the process firing temperature of the clinker is 1200-1250 DEG C, and firing time is about 80 minutes; after the cement clinker is fired, carrying out forced cooling on the fired cement clinker by adopting a traditional grate cooler; and when the clinker is cooled below 300 DEG C, the cement clinker can be subjected to quality control and put in storage. The method has the advantages that the process is advanced, energy is saved, and the comprehensive utilization rate of the red mud is greatly improved.

Owner:赵广明

Method for carbon dioxide suspension dealkalization of red mud for alumina plant

InactiveCN101927255ANo emissionsRealize sustainable comprehensive reuseSolid waste disposalCement productionChemical industryClosed loop

The invention relates to a dealkalization reutilization method of red mud which is a waste material produced by an alumina plant, which belongs to the technical field of chemical industry and environmental protection. The process comprises the following steps: (1) firstly baking the red mud in a muffle furnace, removing crystallization water in the red mud, and further smashing and grinding the red mud into powder; (2) placing the red mud powder after pretreatment in a dealkalization reactor, adding water, fully stirring and mixing into slurry; (3) introducing CO2 into the slurry-like red mud, and carrying out gas-liquid-solid three-phase dealkalization reaction; and (4) carrying out centrifugal separation on clarifying solution and solid residue after the reaction is finished and obtaining the red mud after the dealkalization. The method can realize the sustainable comprehensive reutilization of the waste; compared with the traditional quicklime dealkalization process, the CO2 suspension process has the advantages of simple operation, high dealkalization rate, high alkali purity of the obtained product, no emission of the wastes and the like; and the whole process can realize the closed loop circulation, and the reaction process does not produce the pollution of three wastes, thereby belonging to a green, environment-friendly and clean production process.

Owner:KUNMING UNIV OF SCI & TECH

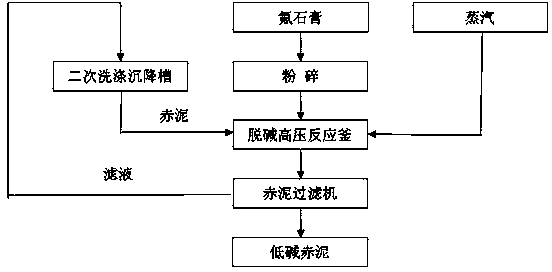

Method for performing dealkalization on Bayer process red mud by using fluorgypsum

InactiveCN103408204APromote resource utilizationEfficient resource utilizationSludge treatmentSocial benefitsReaction temperature

The invention discloses a method for performing dealkalization on bayer process red mud by using fluorgypsum. The method comprises the following steps: step 1, adding crushed fluorgypsum in red mud slurry produced in a bayer process technological process proportionally, wherein the mass fraction of the fluorgypsum is 35-50 percent, and the liquid-solid ratio of the red mud slurry is 5 to 10; step 2, stirring the mixture in a reaction vessel, and pressurizing and heating the mixture for 40-120 minutes, wherein the mixing speed is 100-200 rpm, the pressure is 1.0-1.6 MPa, and the reaction temperature is 40-100 DEG C; step 3, filtering out liquid reactant, namely completing the dealkalization process. The method has the characteristics that the process is simple, the cost is low, the dealkalization rate is high, and the dealkalized red mud can be recycled, so that not only is the environment pollution caused by red mud and the fluorgypsum avoided to create good social benefits, but also an excellent economic effect is provided.

Owner:HENAN POLYTECHNIC UNIV

Comprehensive utilization method of red mud

ActiveCN106882932AEfficient desulfurizationEfficient dealkalizationGas treatmentDispersed particle separationFlue gasSlurry

The invention discloses a comprehensive utilization method of red mud, comprising the following steps: mixing the red mud and calcareous dealkalize agent; adding water and mixing to prepare red mud-calcareous dealkalize agent mixed slurry, wherein the red mud-calcareous dealkalize agent mixed slurry is in countercurrent contact with sulfur-containing flue gas in a tower to absorb sulfur dioxide; discharging desulfurized flue gas from the top of the tower; discharging red mud mixed slurry from the bottom of the tower; and continuing to process the red mud mixed slurry to prepare ordinary silicate cement. The comprehensive utilization method of the red mud disclosed by the invention has a plurality of benefits such as utilization of industrial waste residue, high-efficiency flue gas desulfurization, high-efficiency red mud dealkalization, recycled utilization and the like.

Owner:河南恒信检测研究院有限公司

Sodium sulfide-free, lime-free depilation caustic dip method for lining leather of high-grade pig leather shoes

The invention relates to a depilation caustic dipping method of the lining leather of high quality pigskin shoes without using sodium sulfide and lime, which is characterized in that the method can greatly reduce the pollution of S and waste residue in waste water caused by sodium sulfide, sodium sulfhydrate and the lime in the process of traditional leather manufacturing process, and the discharge amount of the waste water is reduced by 40% and is easy to treat compared with the conventional depilation liming working procedure. Meanwhile, a non-ammonia dealkalization method is adopted to greatly reduce the content of NH3-N in the waste water. Compared with the traditional technique, the method can shorten the production period, save materials and reduce the comprehensive cost of production.

Owner:湖南省怀其皮革集团制革有限公司

Method for recycling alkali and aluminum in process of treating bayer red mud by calcification-carbonization method

ActiveCN103934258APromote incomeReduce energy consumptionSolid waste disposalContaminated soil reclamationHigh concentrationRecovery method

The invention relates to the field of environment protection, and in particular relates to a method for recycling alkali and aluminum in a process of treating bayer red mud by a calcification-carbonization method. The method comprises the steps of mixing the bayer red mud with calcium aluminate or lime and the calcium aluminate to obtain a mixture, performing calcification dealkalization transformation on the mixture in high-concentration alkali liquid with the caustic alkali concentration being 100-300g / L, totally converting silicon-containing phases in the red mud into calcified slag generated in a dealkalization process in the form of hydrate garnet, carbonizing the calcified slag to obtain carbonized slag, then o carrying out low-temperature aluminum smelting and aluminum precipitation to obtain a calcium aluminate product, and recycling the calcium aluminate product in the red mud calcification dealkalization transformation process. Part of alkali and aluminum-containing liquid phases subjected to calcification dealkalization transformation can be reused as supplement alkali in a bayer production process. The method disclosed by the invention can realize recycling of alkali and aluminum in the red mud and harmless treatment of the bayer red mud, and is an energy-saving and environment-friendly red mud utilization method.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

Dealkalized red mud-containing flame-retardant polyvinyl plastic and preparation method thereof

The invention relates to dealkalized red mud-containing flame-retardant polyvinyl plastic and a preparation method thereof, and belongs to the technical fields of dealkalization and comprehensive utilization of red mud and flame-retardant plastic. Polyethylene and an in-situ dealkalizing agent are used as resin bases, and the red mud is used as a flame retardant. The method comprises the following steps of: crushing the red mud; drying; grinding and sieving; adding the red mud into an internal mixer with the polyethylene and the in-situ dealkalizing agent for melting and internal mixing; and machine-shaping with a flat vulcanizing machine to obtain a flame-retardant polyvinyl plastic finished product, wherein the plastic has smooth appearance, the pH value is between 9 and 11, and the limiting oxygen index ranges from 23 to 31 percent. The polyvinyl plastic prepared by the method is suitable for fire disaster safety protection in important public places in the fields of electronic appliances, building materials and traffic; a dealkalization process used for the red mud serving as the flame retardant is simplified by in-situ dealkalization; the in-situ dealkalizing agent can effectively reduce the alkalinity of the red mud, improve the flame-retardant effect and improve the compatibility between the red mud and the polyethylene base; and the polyvinyl plastic is low in cost and causes small damage to environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Red mud on-line comprehensive treatment method

ActiveCN104071995AHigh in calciumWith online dealkalizationSolid waste managementCement productionMaterials preparationSludge

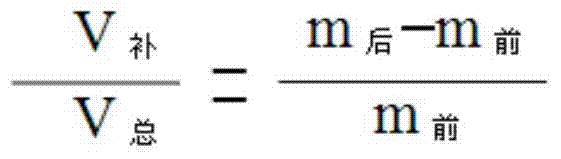

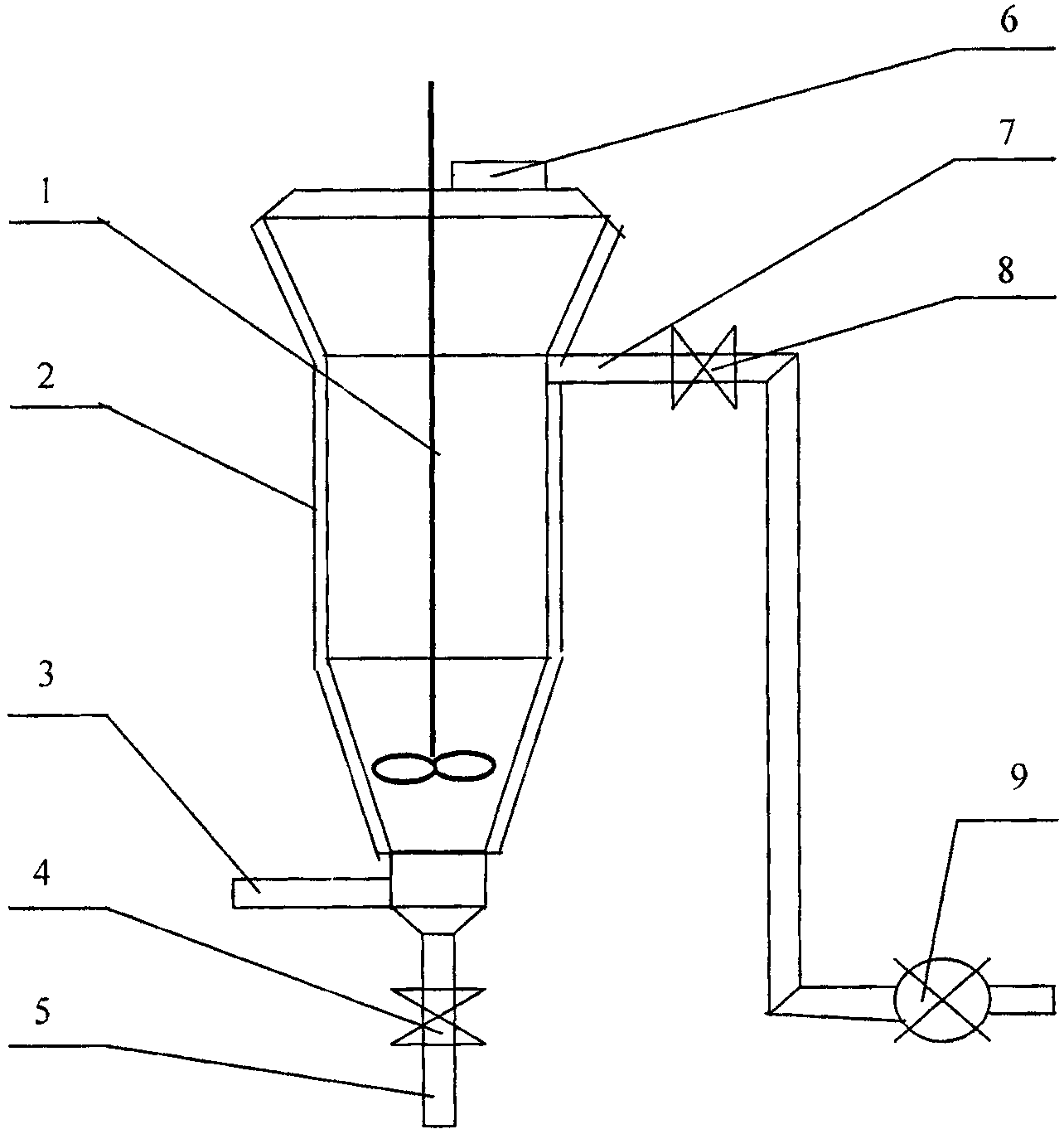

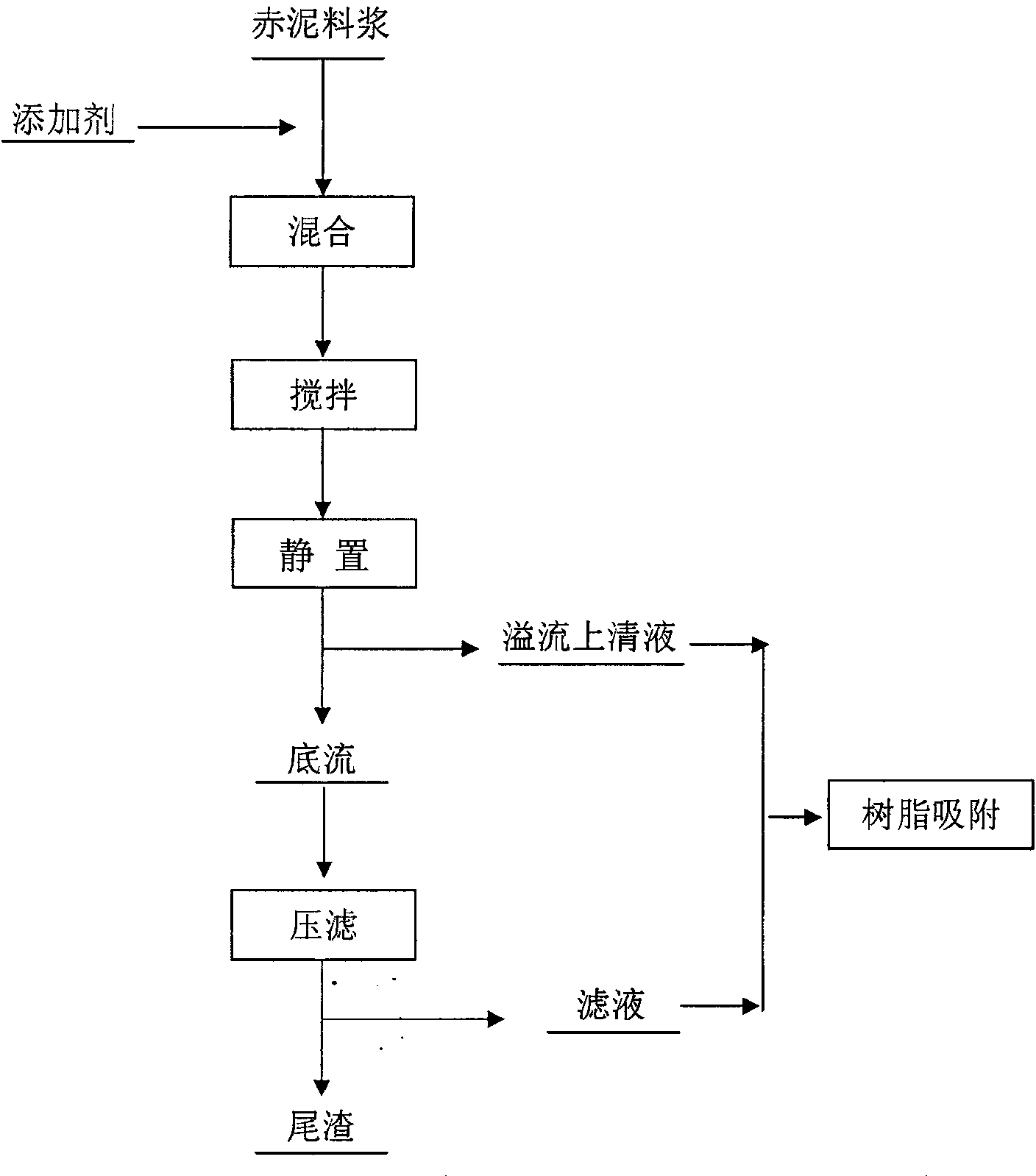

The invention relates to a red mud on-line comprehensive treatment method. The scheme of the method comprises the following steps: directly discharging red mud slurry produced in an aluminium oxide factory into a stirring device with a heat-insulating property through a slurry inlet, then adding acetylene sludge of which the mass fraction is 10-30% to be used as an additive through a feeding opening, stirring under the condition that the stirring strength is 100-500 r / min for 60-360 min, performing still standing for 5-10 min after finishing stirring, then discharging a supernatant from an overflow pipe of the stirring device, discharging bottomflow into a filter press through a slurry outlet to be subjected to filter pressing, mixing a filtrate and the supernatant, and conducting next alkali recycle operation through 001*7 resin adsorption. Tailings are used for preparing building materials, and the red mud on-line dealkalization and the improvement of the activity of the tailings after the dealkalization are realized. The method has the characteristics that the process is simple, the dealkalization rate is high, the energy consumption is low, and the dealkalized red mud can meet requirements on building material preparation.

Owner:HENAN POLYTECHNIC UNIV

Method for removing heavy metals in urban waste incineration flying ash through bioleaching technology

InactiveCN105907981AEfficient extractionGreen ExtractProcess efficiency improvementBrickResource utilization

Flying ash is hazardous waste which is produced during household garbage incineration power generation and contains various toxic metals, the stabilization / solidification landfill cost of the mainstream disposal process of the flying ash is 2000-3000 yuan / ton, and the environmental risk of the toxic metals still exists. Removal of the toxic metals from the flying ash is the premise of low-limit / non-limit resource utilization of the flying ash. Low-price inorganic energy substrates such as sulphur are used as working media, and efficient, environment-friendly and safe extraction of the toxic metals in the flying ash is achieved under the conditions of normal temperature and pressure through the direct / indirect action of autotrophy leaching inocula. Besides, through desalting and dealkalization with water scrubbing, bacterial strain compounding and breeding of high-salt-tolerance bacterial strains, the regeneration performance of leachate organisms is obviously improved, the circulation leaching frequency is greatly increased, and thus the consumption of inorganic salt culture solutions in the leaching process is greatly lowered, and the bioleaching cost is further reduced. The detoxified flying ash is used for resource utilization such as manufacturing of bricks, roadbeds and concrete, the high cost of the traditional landfill process is saved, and the potential environmental risk is eliminated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for comprehensively utilizing alumina red mud

InactiveCN102500592AReduce alkalinitySimple processSludge treatment by thermal conditioningSolid waste disposalSlagCarbide

The invention relates to a method for processing the content of alkali in alumina red mud. The method comprises the following steps of: 1, pulping the alumina red mud, and feeding slurry into a dealkalization reaction tank; 2, dealkalizing: adding a dealkalizing agent into the red mud slurry, uniformly stirring, rapidly reacting the dealkalizing agent in the reaction tank, and carrying out solid-liquid separation after reacting; 3, roasting and reducing: reducing the dealkalized red mud by adopting an iron oxide roasting and reducing process; and 4, magnetically separating: feeding the red mud into a magnetic separator by using a mortar pump so that the red mud is separated into magnetic red mud and non-magnetic red mud, feeding the magnetic red mud into a ball mill to be ball-milled, after filter-pressing and drying the non-magnetic red mud, taking the non-magnetic red mud separated through magnetic separation for two times as medium and fine sands for dry mortar, for later use, and exciting and activating components of SiO2 and AL2O3 in the red mud by adding alkaline materials, such as carbide slag or limestone powder and the like. The method disclosed by the invention has the characteristics of simple process and low investment, so that the alkali content in the red mud is greatly reduced.

Owner:CHIPING COUNTY XINFA SHENGJI RED MUD TREATMENT

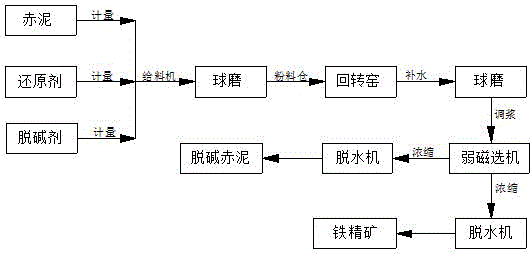

Integrated calcination method for dealkalization and magnetization of Bayer process red mud

The invention discloses a method for calcination dealkalization and magnetization of Bayer process red mud, and relates to a treatment and utilization technology for waste-red mud produced in the aluminum oxide industry. The method aims at conducting reduction on sponge iron and magnetite or dealkalization on the red mud; based on the principle that the temperature spot of red mud magnetization calcination and the temperature spot of red mud dealkalization calcination are similar, 5%-20% of a dealkalization agent and 5%-25% of a reducing agent are added into the Bayer process red mud and calcinated at a temperature ranging from 1,100 DEG C to 1,240 DEG C at the same time, and calcinated materials are ground to separate out the sponge iron and magnetite with the iron content larger than 55% and dealkalized red mud with the alkali content smaller than 2%. The extracted sponge iron or magnetite can be used as raw materials in the ferrous metallurgy industry, the dealkalized red mud can be widely applied to the field of building materials, and extremely high actual application value is achieved. Tailing-free utilization of the red mud is really achieved, and a new technical route is provided for comprehensive utilization of the red mud.

Owner:SHANDONG JIANZHU UNIV

A method for recovering alkali and aluminum in course of treatment of bayer red mud by using calcification-carbonation method

ActiveUS20170036920A1Comprehensive utilization of valuable elementLow costSolid waste disposalContaminated soil reclamationHigh concentrationRecovery method

A method for recovering alkali and aluminum during treatment of Bayer red mud using a calcification-carbonation method, including steps of mixing the Bayer red mud with calcium aluminate or with calcium aluminate and lime, performing calcification dealkalization conversion in a high-concentration alkaline liquor, and carbonizing the calcified residues produced during dealkalization to obtain carbonized residues; and then performing low-temperature aluminum dissolution, aluminum precipitation and the like to obtain calcium aluminate products, which is returned to the calcification dealkalization conversion of the red mud for recycling. Part of an alkali-containing and aluminum-containing liquid phase after calcification dealkalization conversion can be used as supplementary alkali in the Bayer production course for recycling. The method is energy-saving and environmentally-friendly, and allows recovering alkali and aluminum from the red mud and harmless treatment of the Bayer red mud.

Owner:NORTHEASTERN UNIV

Method of dealkalizing red mud and recovering aluminum and iron

InactiveCN103031443AHigh activityReduce processing costsProcess efficiency improvementSlagPolymeric adsorbent

The invention discloses a method of dealkalizing red mud and recovering aluminum and iron. The method comprises the steps of mixing the red mud and sulfuric acid, roasting, or stirring and leaching, conducting water-leaching, washing and filtering on roasted or leached products, reducing the content of Na2O in solid slag to below 1%, and recovering the aluminum and the iron in a solution by methods such as neutralization sedimentation and resin adsorption. The method has the characteristic that the method is simple in treatment process, low in cost, easy to automatize and large in scale.

Owner:GUIZHOU UNIV

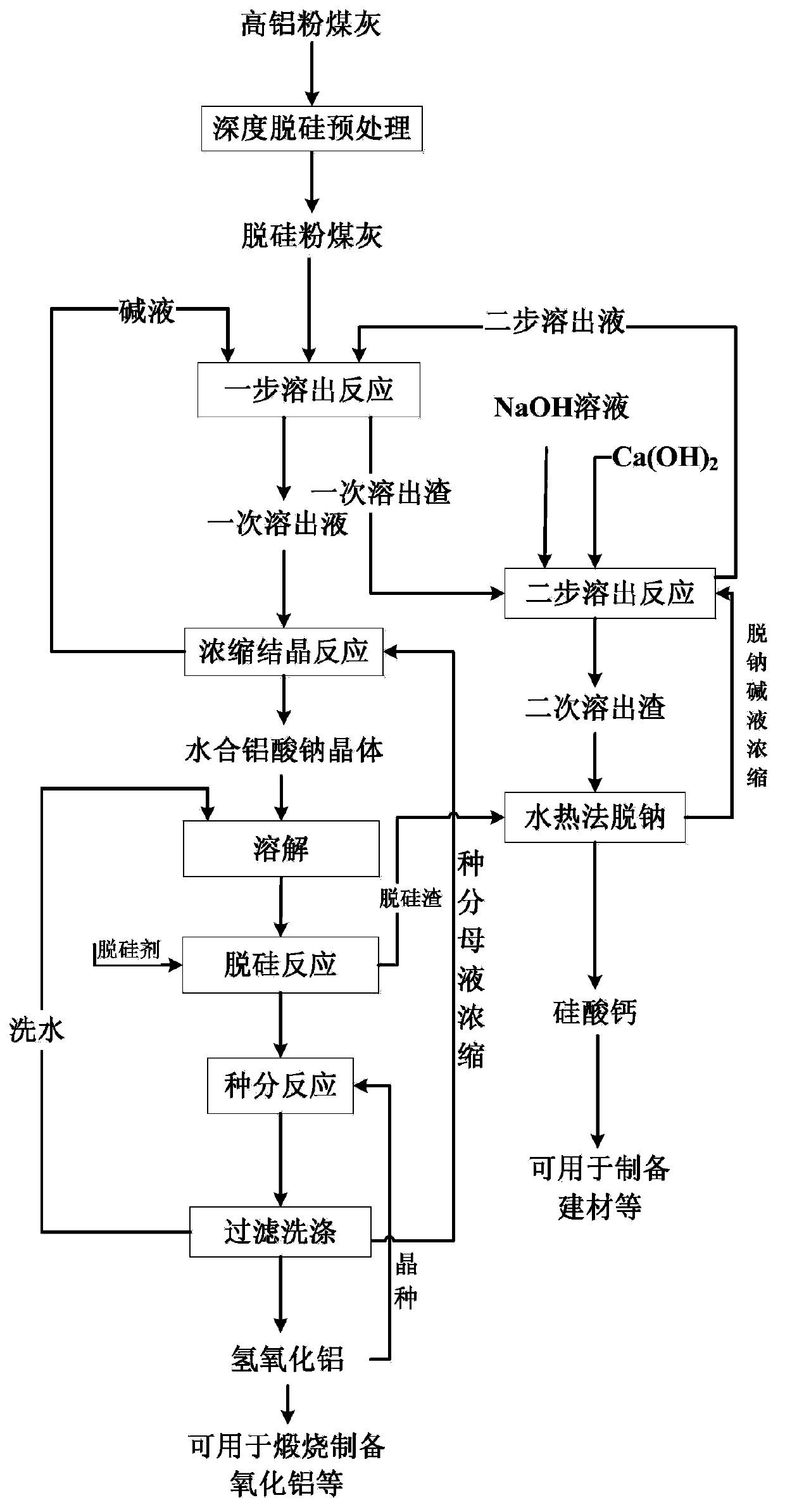

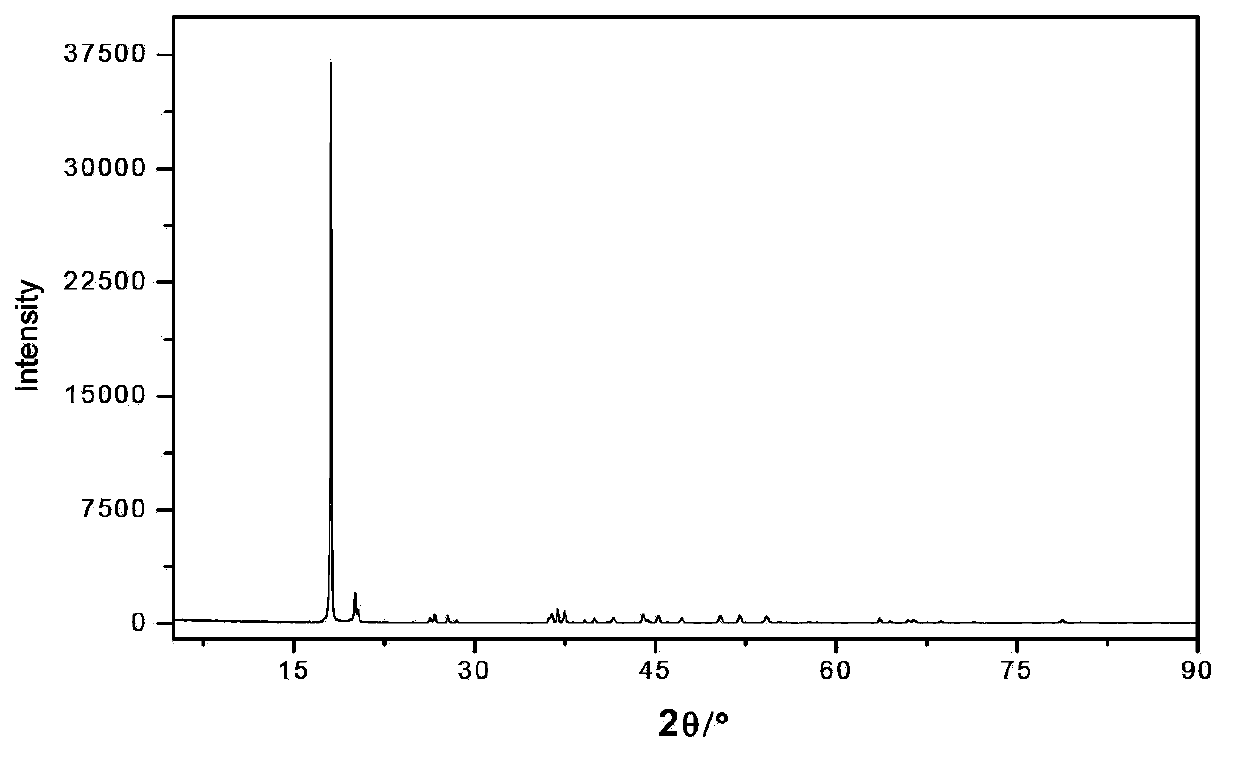

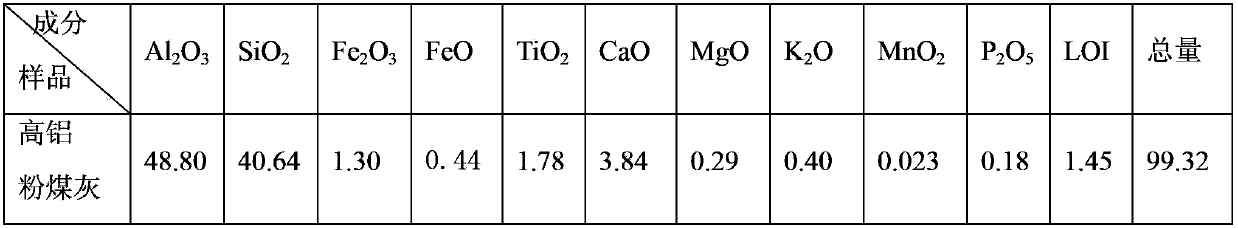

Method for preparing aluminum hydroxide by utilizing high-alumina coal ash

ActiveCN103663516AIncrease Al-Si RatioReduce productionAluminium oxides/hydroxidesAluminium hydroxideSodium aluminate

The invention relates to a method for preparing aluminum hydroxide by utilizing high-alumina coal ash. By adopting the deep desilicication process and the two-step sub-molten salt dissolution process, not only can the secondary enrichment of the silicon component be realized, but also the aluminum component can be adequately dissolved under the low temperature and low pressure, the operation condition is moderate, the silicon and aluminum can be adequately utilized, and the dissolution rate of the aluminum can reach more than 95 percent. The method comprises the following steps: pretreating the high-alumina coal ash in a deep desilicication way; primarily dissolving; secondarily dissolving; concentrating and crystallizing the dissolution liquid; dissolving hydrated sodium aluminate crystals; performing desilicication on the sodium aluminate coarse liquid; seed precipitating the aluminium hydroxide; and dealkalizing tailings. The obtained desilicication liquid can be used for preparing a liquid controlled process silicon-base product such as white carbon black, and the dealkalized tailings obtained in the process can be used for preparing a solid controlled silicon-base building material such as cement. The raw materials used in the method are wide in source, the price is low, the process is simple, the alkali circulation volume is small, the energy consumption and the water consumption are low, the utilization rate of raw materials is high, and the method is applicable to the industrialized popularization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for manufacturing pig leather

InactiveCN101519700ANon-toxic by-productsNo rain resistanceTanning treatmentPre-tanning chemical treatmentSide effectHazardous substance

The invention relates to a method for manufacturing pig leather, in particular to the method for manufacturing the pig leather without environmental pollution. The invention mainly solves the technical problems of more components with toxic and side effects, no rain proofness, poor gas permeability and the like of the prior art and provides the method for manufacturing the pig leather which has no components with toxic or side effects, rain resistance and good gas permeability. The technical proposal of the method is as follows: the step of enzyme coating is increased after the traditional step of enzyme dipping, the step of dealkalization is increased after the traditional step of caustic dipping, and the residual harmful substances during the manufacturing process are removed, while the quality and the performance of pig skin are further enhanced.

Owner:石章莲

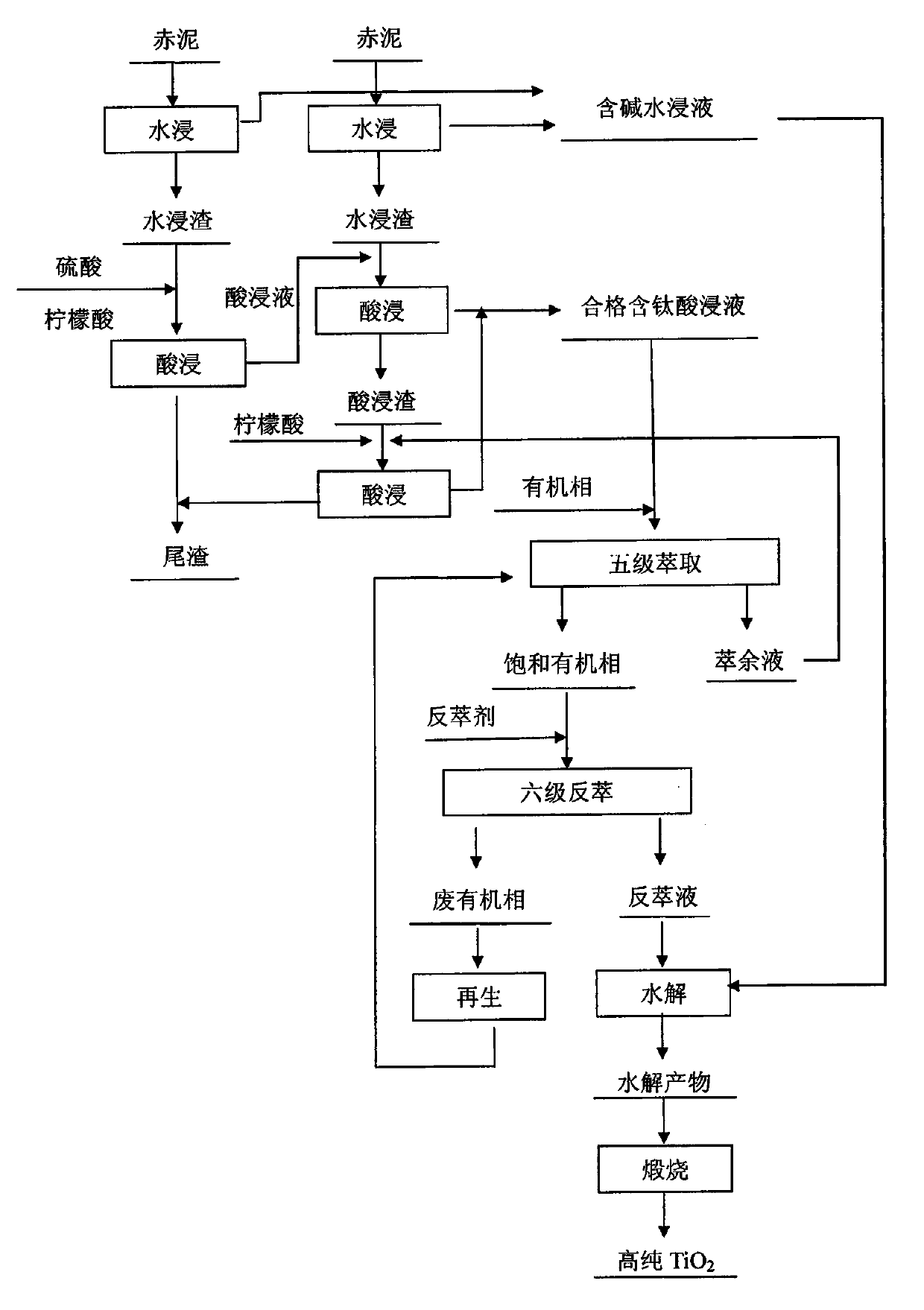

Method for extracting titanium from red mud

ActiveCN104195341AChange particle shapeFacilitated DiffusionProcess efficiency improvementOrganic solventEnvironmental engineering

The invention relates to a method for extracting titanium from red mud. According to the scheme, the method comprises the steps of carrying out water leaching and dealkalization operation on the red mud to obtain a water leachate and water leaching resides; collecting the water leachate as a pH value regulator for subsequent titanium dioxide hydrolysis operation, and carrying out two-stage secondary acid leaching operation on a mixed solution of the water leaching residues, sulfuric acid and citric acid in an acid leaching tank to obtain tailings and qualified acid leachate containing titanium; then, mixing the qualified acid leachate containing titanium and an organic solvent, and carrying out five-stage extraction to obtain a saturated organic phase and a raffinate; returning the raffinate as a leaching agent to acid leaching operation; mixing the saturated organic phase and a back extraction agent, and carrying out six-stage extraction to obtain an organic waste phase and a back extraction solution; after regenerating the organic waste phase, recycling the organic waste phase to extraction operation; after regulating the pH value of the back extraction solution by using the water leachate obtained by dealkalization operation, carrying out hydrolysis operation; and calcining a hydrolysis product to obtain a titanium dioxide product with the purity of larger than 99.5% and the titanium recovery rate of larger than 80%. The method has the advantages of simple process, low agent consumption, high product purity, high titanium recovery rate and wastewater recycling.

Owner:HENAN POLYTECHNIC UNIV

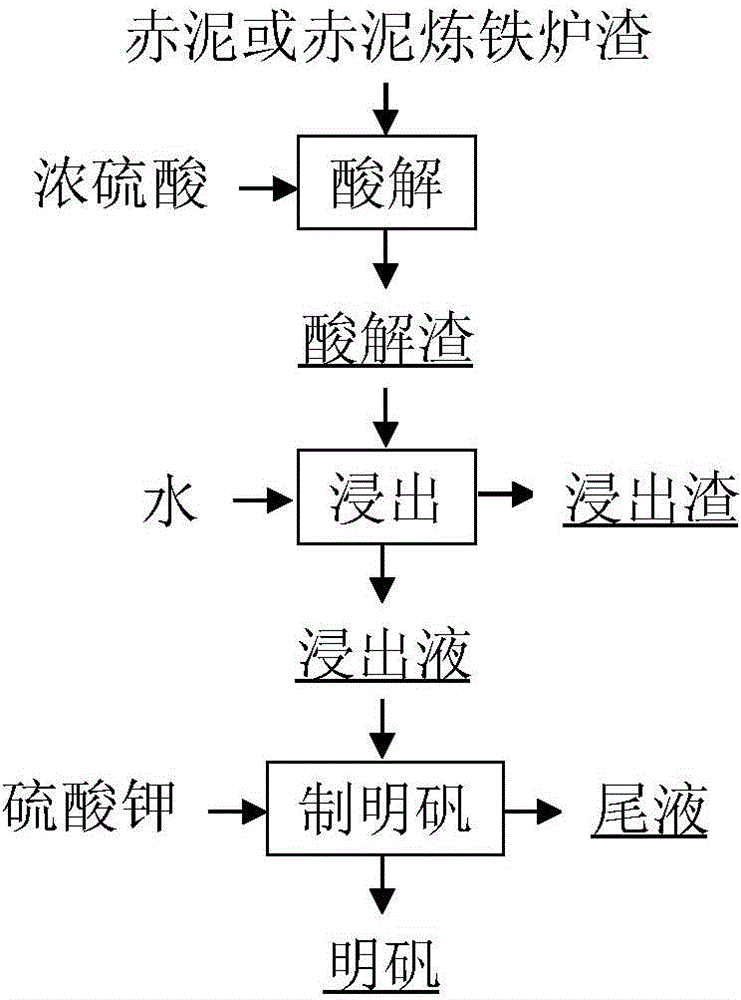

Method for recovering aluminum from alumina production waste red mud

InactiveCN103979592AEasy to separateDealkalization availableAluminium sulfatesThermal insulationSlag

The invention relates to a method for recovering aluminum from alumina production waste red mud. The method comprises: 1, blending a raw material and industrial concentrated sulfuric acid into a mineral slurry with a liquid-solid volume mass ratio of 0.6-2.0:1, and carrying out stirring acidolysis for 20-120 min under a condition of self-heating or thermal insulation at a temperature of 150-250 DEG C; 2, according to the raw material amount liquid-solid volume mass ratio of 2-7:1, adding water to the acidolysis residue to carry out slurry blending, and carrying out a stirring leaching reaction for 20-120 min at a temperature of 60-100 DEG C; and 3, according to the aluminum content in the leaching solution, adding 1-1.2 times the theoretical value of potassium sulfate, carrying out a reaction for 20-120 min, and filtering to obtain alum, wherein the end temperature is 5-25 DEG C. According to the present invention, the industrial waste material is adopted as the main raw material so as to reduce environmental pollution and recover the aluminum element, the process is simple, the production is easy to achieve, the dealkalization treatment of the leaching slag is achieved, and other valuable metals are transferred and enriched into the end solution so as to provide conditions for comprehensive recovery.

Owner:广西冶金研究院有限公司

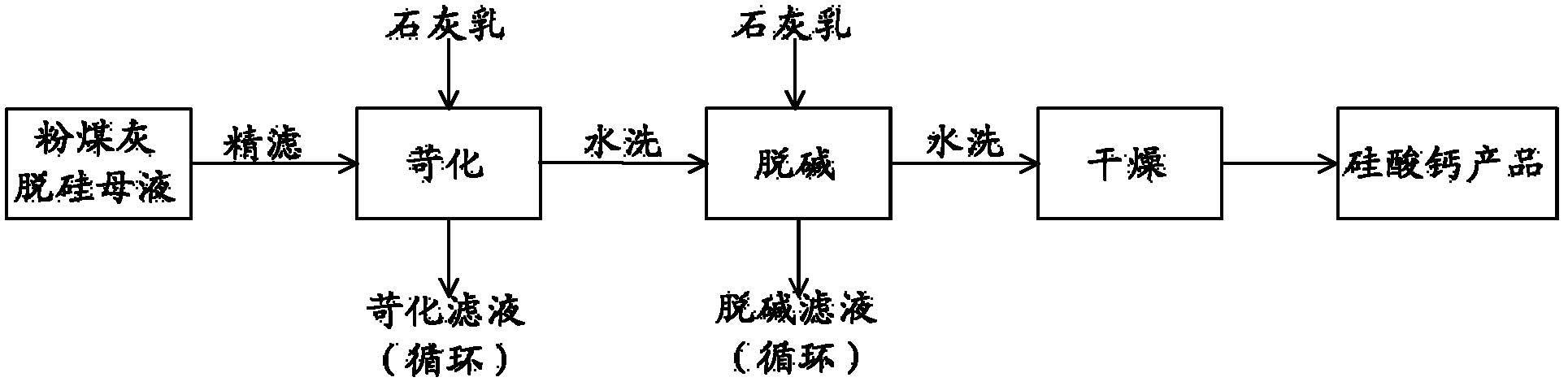

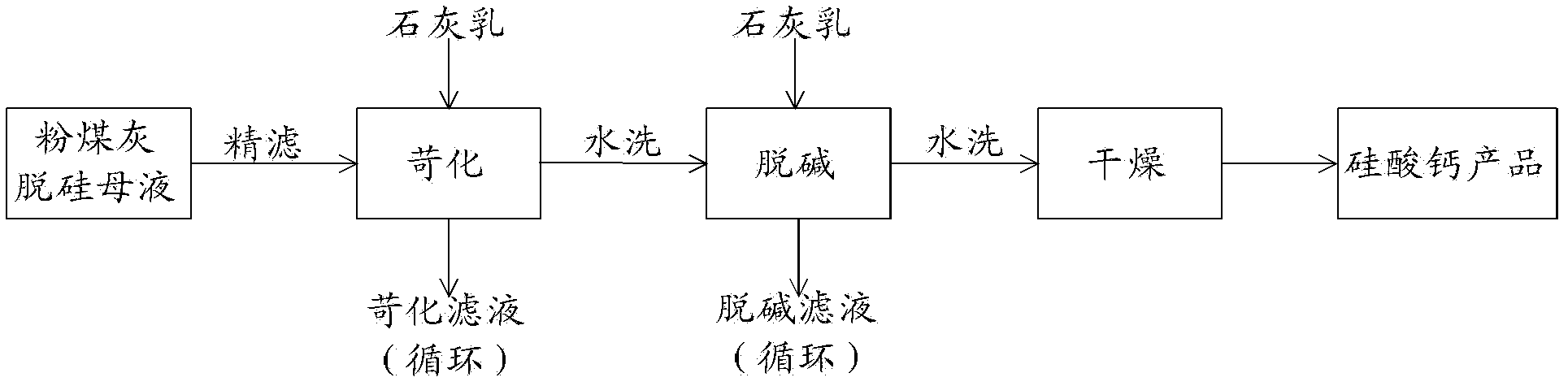

Method for producing active calcium silicate by using fly ash desilication mother solution

ActiveCN102583410AFully recycleReduce pollutionAlkaline-earth metal silicatesCalcium silicateFly ash

The invention relates to the technical field of production of active calcium carbonate, in particular to a method for producing calcium carbonate by using a fly ash desilication mother solution. According to the method, the fly ash desilication mother solution serving as a raw material is subjected to causticization, water washing, dealkalization, water washing and drying to obtain a calcium silicate product. Compared with the prior art, the method has the characteristics of wide source of raw materials, strong raw material adaptability, uniform performance of the calcium silicate product, high whiteness, low impurity content and the like, the production cost is low, the energy consumption is low, and the environmental and economical benefits are remarkable.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Alkaline aluminum extraction and dealkalized red mud obtaining method and dealkalized red mud obtained and application of dealkalized red mud

ActiveCN104649304ALess quantityIncrease added valueMagnesium silicatesAluminium oxides/hydroxidesRed mudAluminium hydroxide

The invention discloses an alkaline aluminum extraction and dealkalized red mud obtaining method, which comprises the following steps: (1) raw materials including an aluminiferous raw material, a sodium oxide precursor, a magnesium oxide precursor and an optional calcium oxide precursor are prepared according to a raw material formula; (2) the raw materials are roasted at 800-1300 DEG C to obtain a sintered clinker; (3) the sintered clinker undergoes dissolution and solid-liquid separation to obtain red mud and a digested liquor; (4) the digested liquor undergoes desilicication and carbonating disintergration so as to obtain aluminium hydroxide; and (5) the red mud is dealkalized to obtain the dealkalized red mud containing magnesium silicate, wherein the raw material formula satisfies that molar ratio of the components oxides ([MgO]+[CaO]) / ([SiO2]+[TiO2]) is 0.9-1.1. The invention also discloses dealkalized red mud obtained by the above method and an application of the dealkalized red mud. By the method provided by the invention, high standard dissolution rate of aluminium oxide can be maintained, and added value of aluminum extraction is high.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

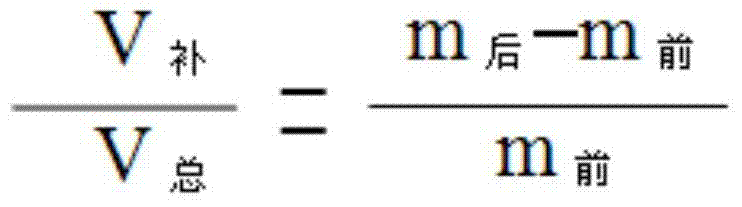

Red mud slurrying multistage circulating dealkalization method

InactiveCN102172598ASolve pollutionLow implementation costSolid waste disposalCement productionSlurryDealkalization

The invention discloses a red mud slurrying multistage circulating dealkalization method which comprises the following steps: dealkalizating by slurrying red mud, filtering the red mud slurry to separate alkali, recovering the alkali from the dealkalization solution, and the like. The invention effectively treats the solid waste red mud discharged in alumina industry, and implements comprehensiveutilization; and since no three wastes are discharged, the method does not generate secondary environmental pollution and has the advantages of simple technique and low cost.

Owner:TIANJIN URBAN CONSTR COLLEGE

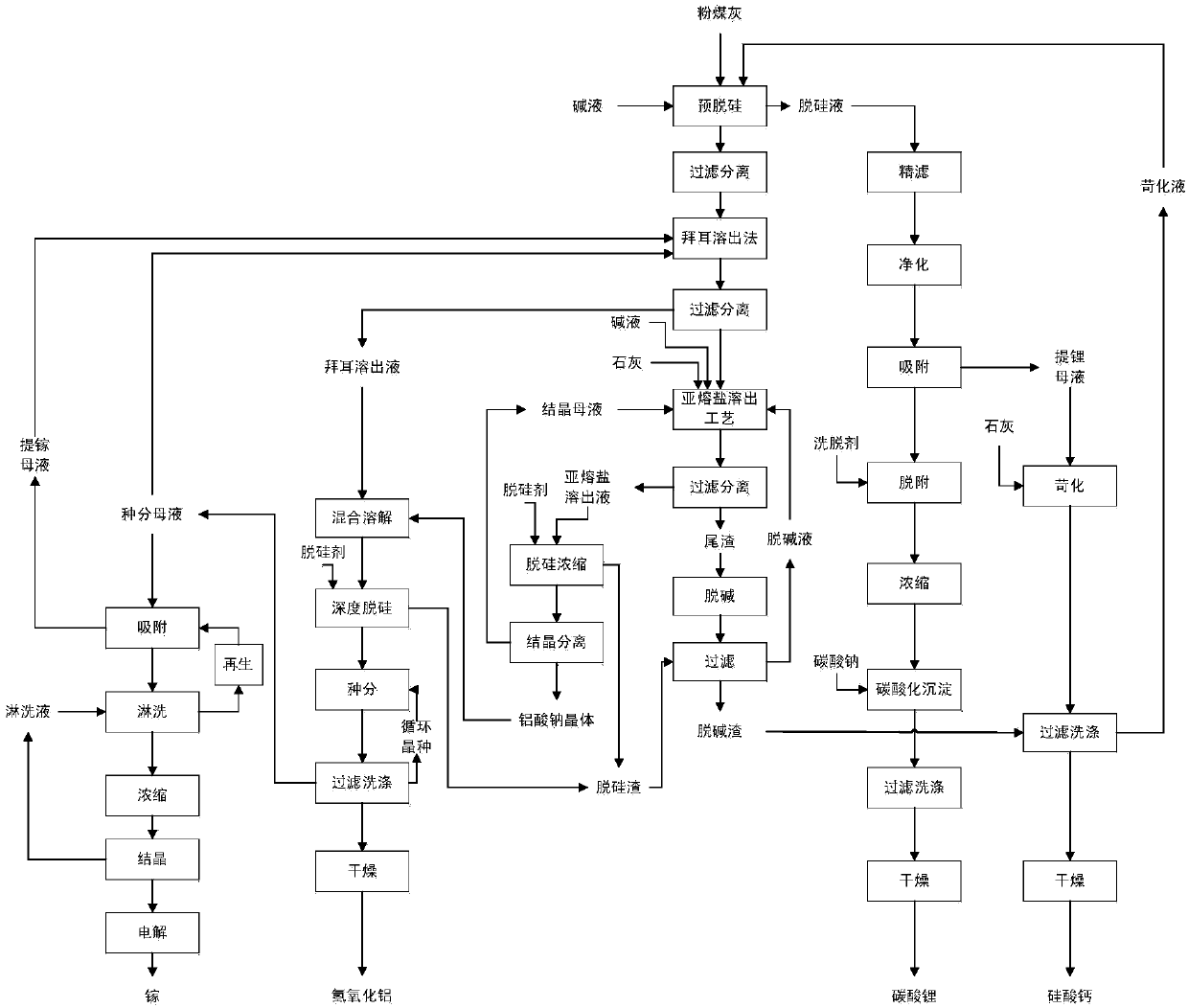

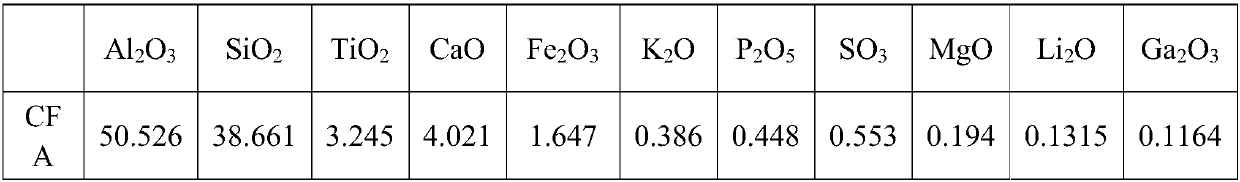

Extraction method for cooperating with aluminum-silicon-lithium-gallium combination method in coal ash

ActiveCN107758714ARealize wet productionHigh extraction rateAlkaline-earth metal silicatesProcess efficiency improvementCalcium silicateElectrolysis

The invention discloses an extraction method for cooperating with an aluminum-silicon-lithium-gallium combination method in coal ash. The method comprises the steps of aluminum oxide extraction, wherein pre-desiliconization, dissolving-out through a Bayer method, dissolving-out of sub-molten salt, crystallization and separation, desilicication and seed precipitation are conducted; gallium extraction, wherein adsorption, drip washing, concentration and electrolysis are conducted; lithium extraction, wherein purification, adsorption, desorption, concentration and carbonation sedimentation; preparation of calcium silicate products, wherein causticization of desilicication liquid and dealkalization of desilicication residue are conducted. According to the extraction method, aluminum, silicon,lithium and gallium elements in the coal ash are comprehensively extracted through a whole-wet method, substep and stairstep comprehensive utilization of aluminum, silicon, lithium and gallium is achieved, energy consumption is low, the technological process is simple, the extraction rate of aluminum, lithium and gallium is high, the additional value of solid waste is effectively improved, and themethod is a good comprehensive utilization technology for processing the coal ash through a whole-alkali method and is suitable for industrialization popularization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Ultra-high purity purifying technique for native graphite

The invention discloses a hyper-high purity extracting technology of natural graphite, which comprises the following steps: (1) putting natural graphite in the container to do oxidizing disposal with low-middle carbon content more than 98%; (2) fusing at high temperature; (3) inputting in the metal erosion-proof container; proceeding dealkalization; (4) deacidifying to wash to neutral; (5) proceeding electromagnetic black metal removing disposal in the floating pool; (6) heating in the autoclave from 118 deg, 206 deg and 220 deg separately; (7) using pure water to dispose; (8) dehydrating; (9) drying until the water content is less than 0.1%.

Owner:LUOYANG GUANQI INDAL & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com