Patents

Literature

287results about How to "Efficient desulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desulfurizer comprising activated carbon and method of desulfurization

InactiveUS7029639B2Promote desulfurizationPromote formationCombination devicesExhaust apparatusWater contentChemistry

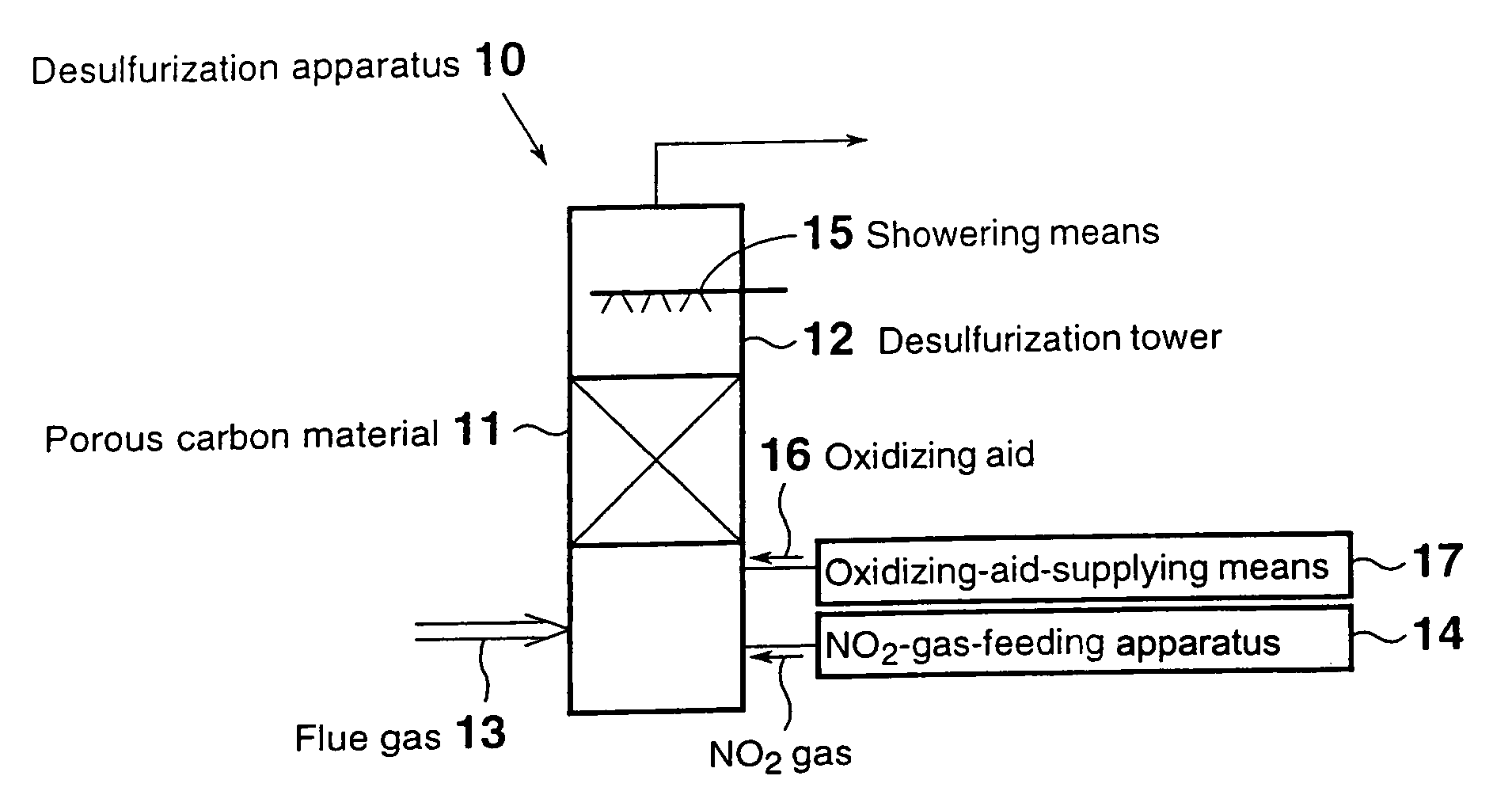

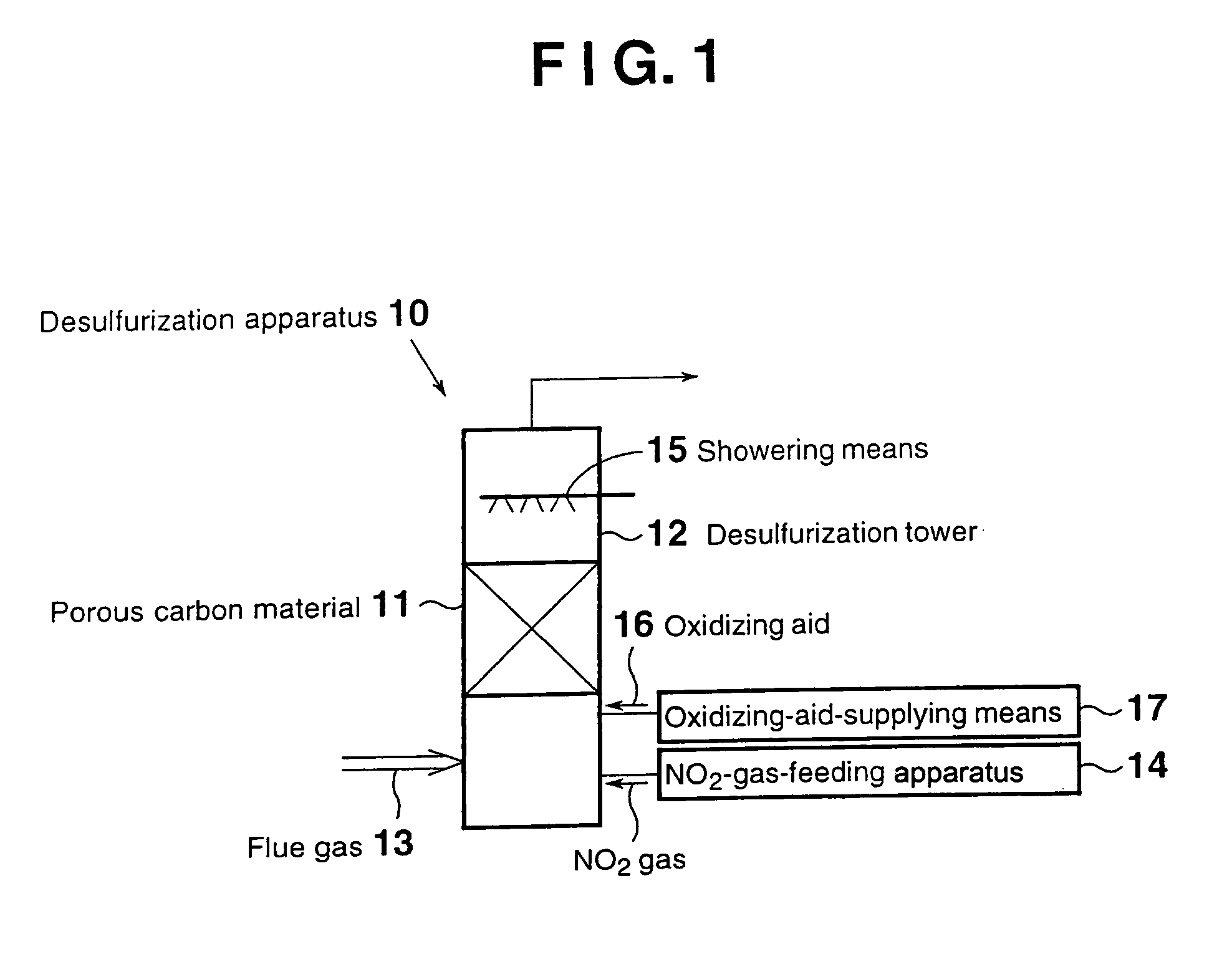

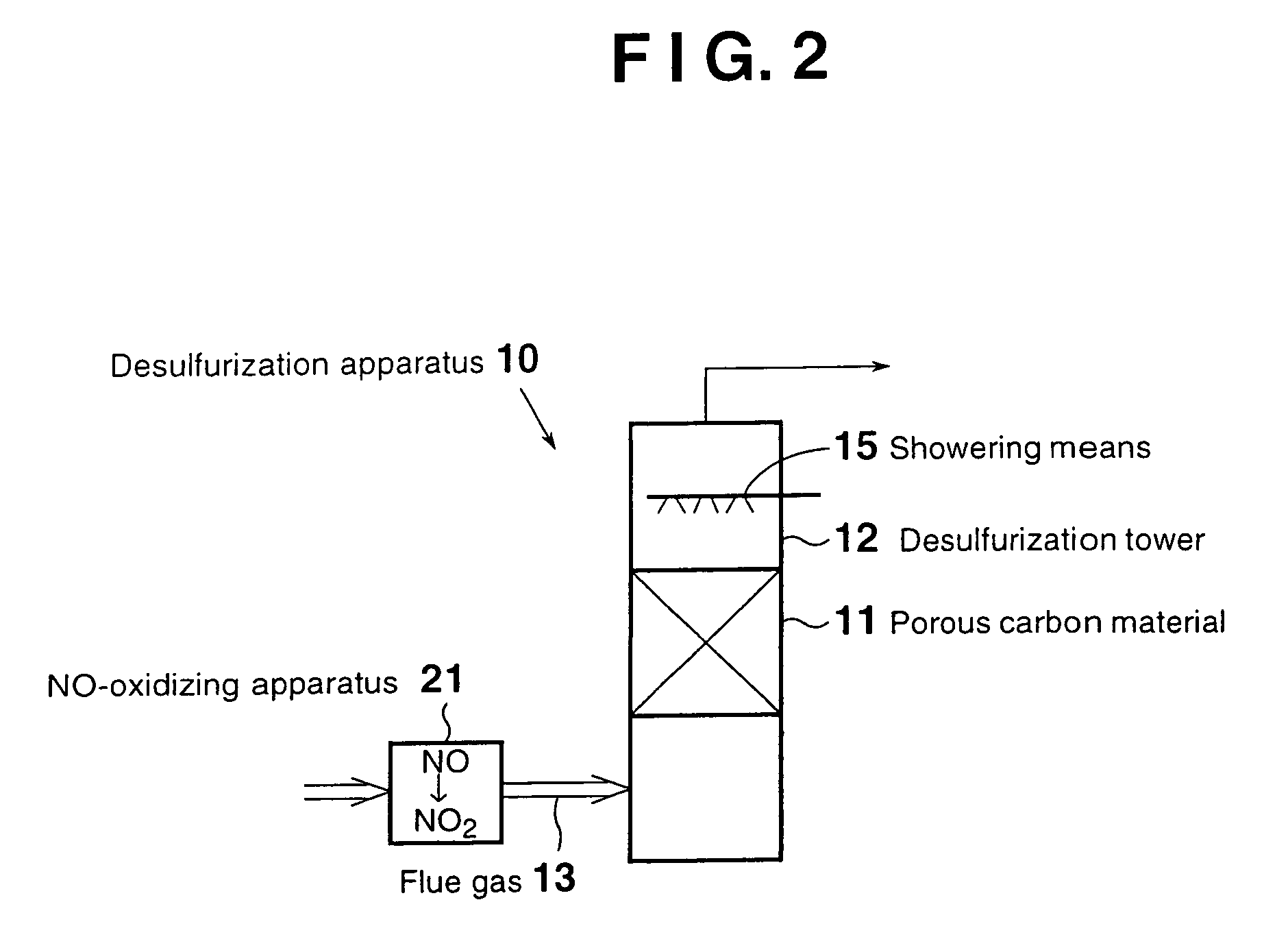

A desulfurization apparatus for desulfurizing a flue gas containing sulfur oxides through contact with a porous carbon material. The carbon material, which is provided in a desulfurization tower, is at least one species selected from activated carbon and activated carbon fiber. The apparatus contains an NO2-gas-feeding apparatus for feeding NO2 gas into the desulfurization tower. Within the desulfurization tower, a showering mechanism is provided at the top, the showering mechanism adjusting water content of the flue gas in the desulfurization tower to that corresponding to saturation with water vapor or higher at the treatment temperature.

Owner:OSAKA GAS CO LTD +1

High-strength toughness cold working die steel and method of producing the same

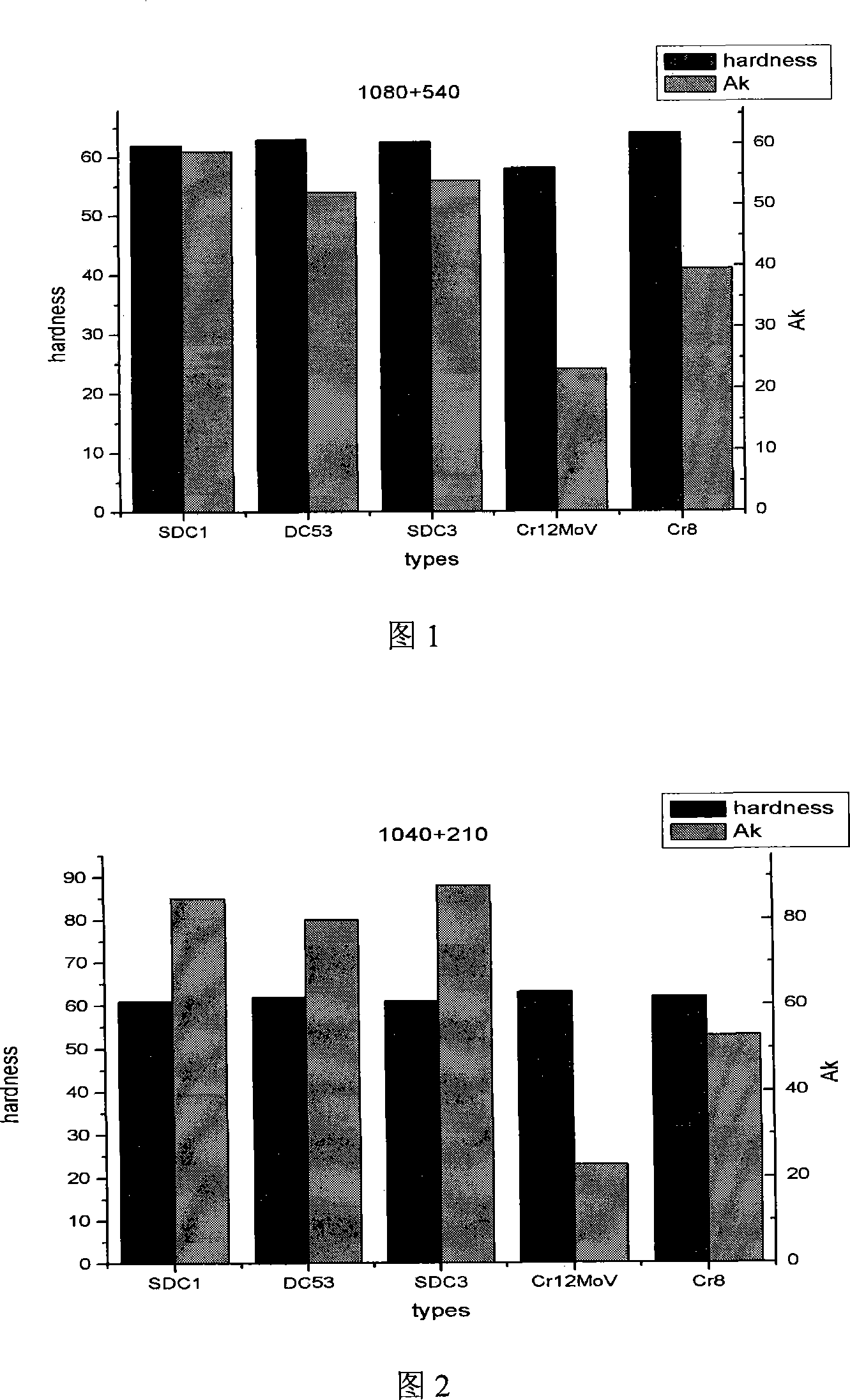

The invention relates to a high-strength toughness cold-working die steel and a manufacturing method thereof, belonging to the technical field of alloy steel manufacturing technology. The chemical composition and weight percentage of the alloy steel of the present invention: C 0.9~1.0%, Cr 9~10%, Mo 2.0%, V 0.8~1.0%, Si 1.0%, P<0.02%, S<0.02%, Fe surplus quantity. The preparation process and steps of the cold work die steel of the present invention are as follows: (1) smelting, (2) electroslag remelting, (3) annealing, (4) rough forging, (5) re-annealing, (6) spheroidizing annealing , (7) Quenching and tempering. The hardness of the alloy steel prepared by the method of the invention can reach 61-63HRC, and the impact energy AK can reach 61-85J, which is more than three times higher than that of the original Cr12MoV steel.

Owner:上大鑫仑材料科技(上海)有限公司

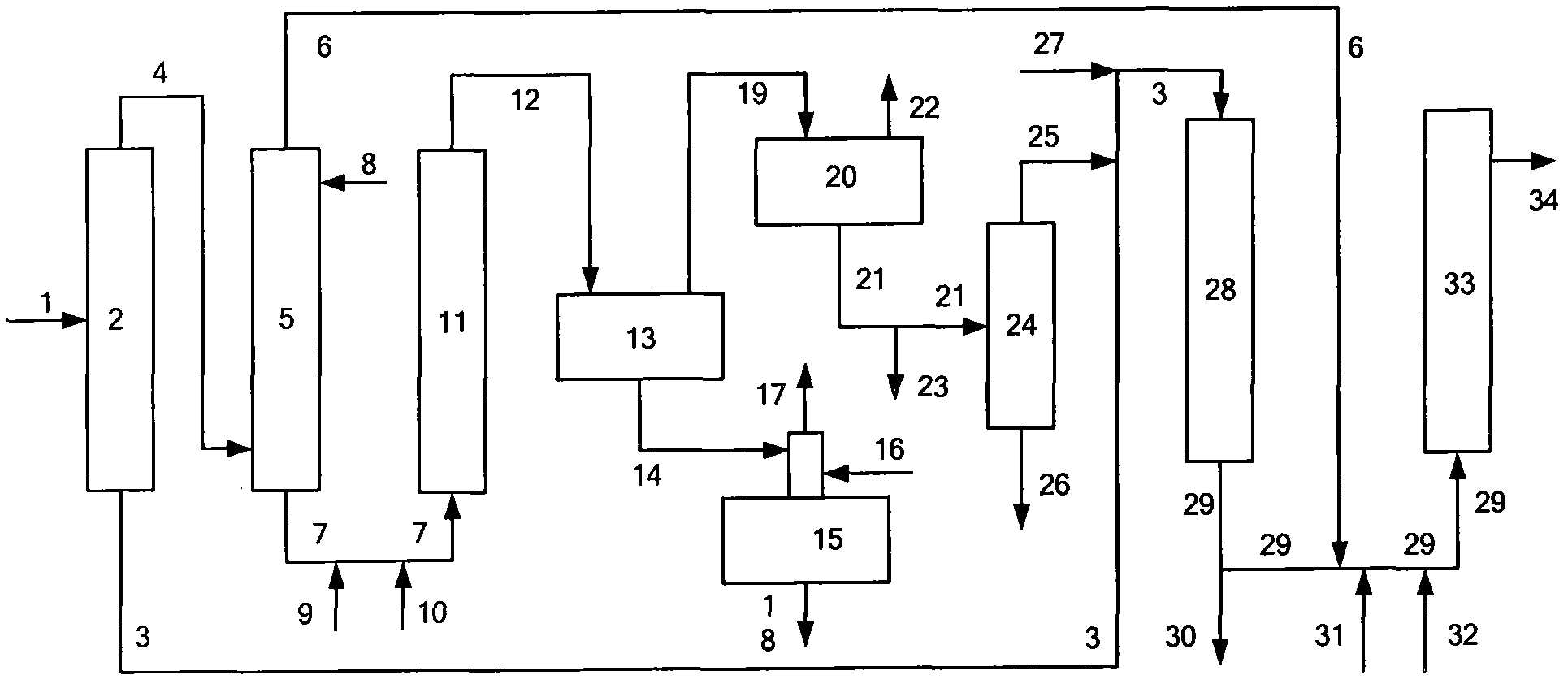

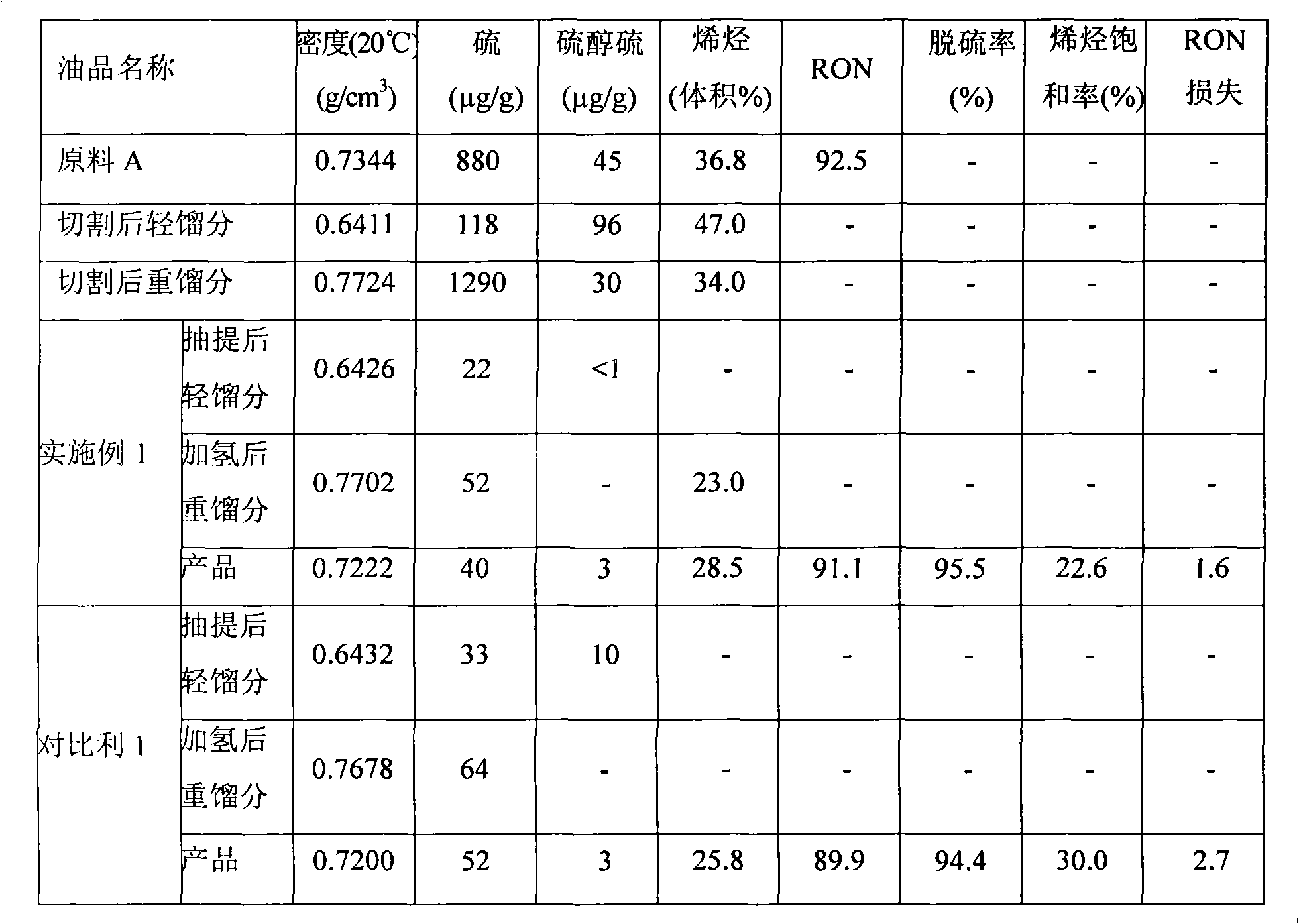

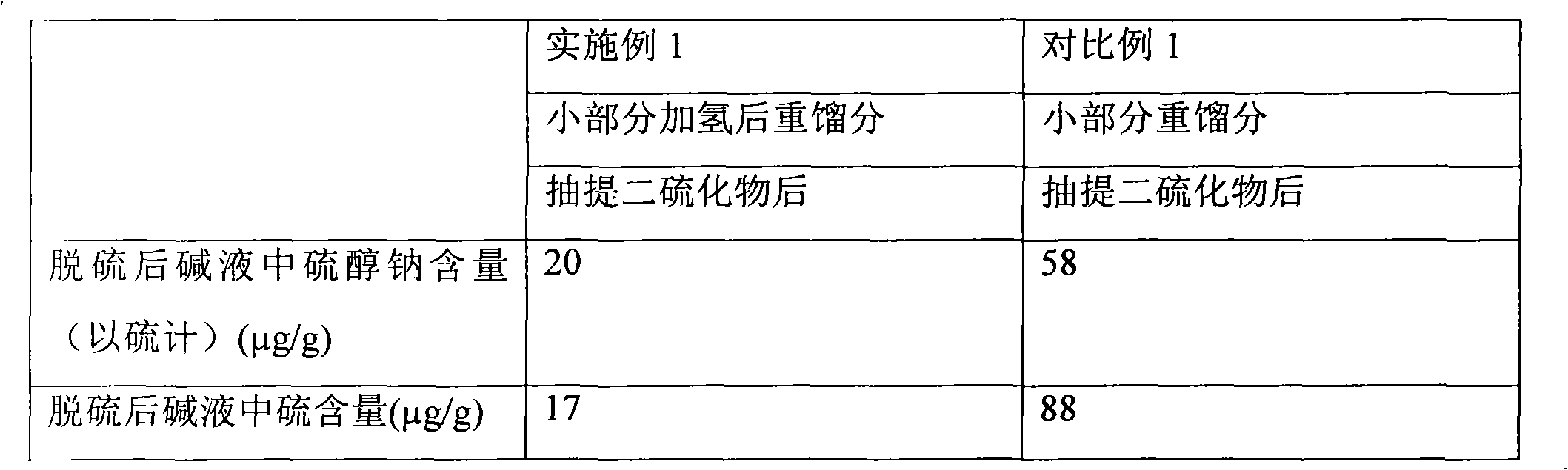

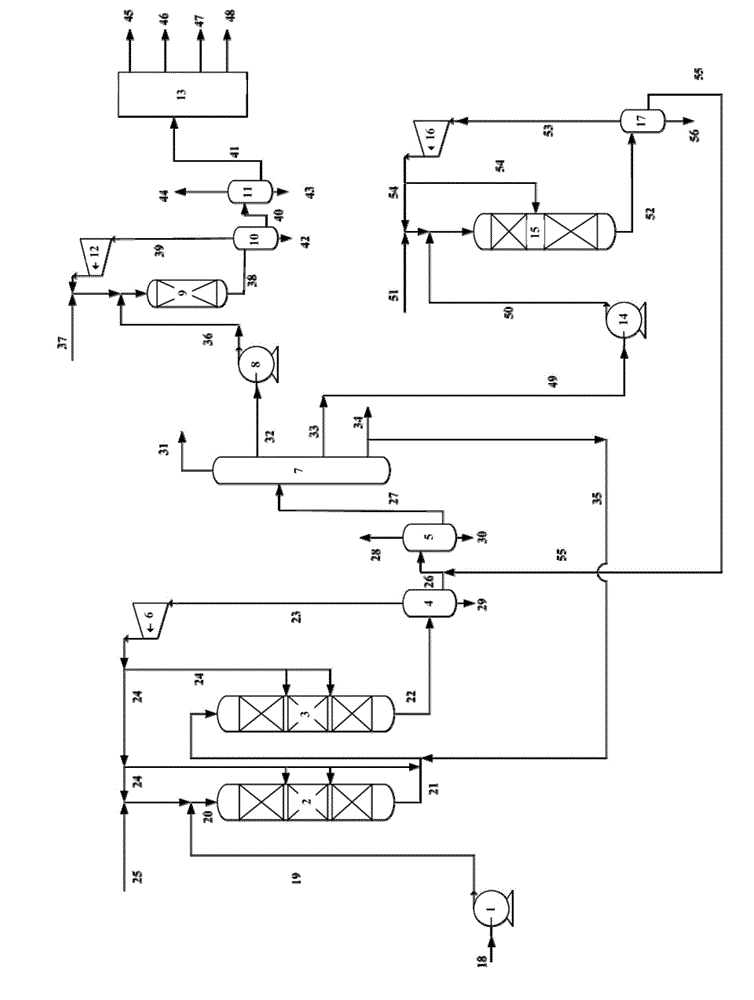

Gasoline desulfurization method

ActiveCN102851069AImprove the extraction effectAvoid inactivationTreatment with hydrotreatment processesHydrogenDistillation

The inventive gasoline desulfurization method includes performing cutting distillation on gasoline to obtain heavy fraction with high boiling range and light fraction having low boiling range; under selective hydrogenation desulfurization condition, contacting the heavy fraction and hydrogen gas with hydrogenation desulfurization catalyst to perform selective hydrogenation desulfurization, to obtain desulfurized heavy fraction; contacting the light fraction with alkali solution, to obtain sulfide-absorbed alkali solution and desulfurized light fraction; contacting the sulfide-absorbed alkali solution with oxidant, oxidation catalyst and a part of the desulfurized heavy fraction, to simultaneously perform alkali solution regeneration and desulfurization, so that sulfide salt in the alkali solution is oxidized into disulfide, which is extracted into the desulfurized heavy fraction; performing phase separation, and exhausting tail gas; returning at least part of the disulfide-absorbed heavy fraction to the heavy fraction after cutting distillation, to perform selective hydrogenation desulfurization; and mixing the desulfurized heavy and light fractions. The inventive method can obtain higher desulfurization rate and lower octane number loss.

Owner:CHINA PETROLEUM & CHEM CORP +1

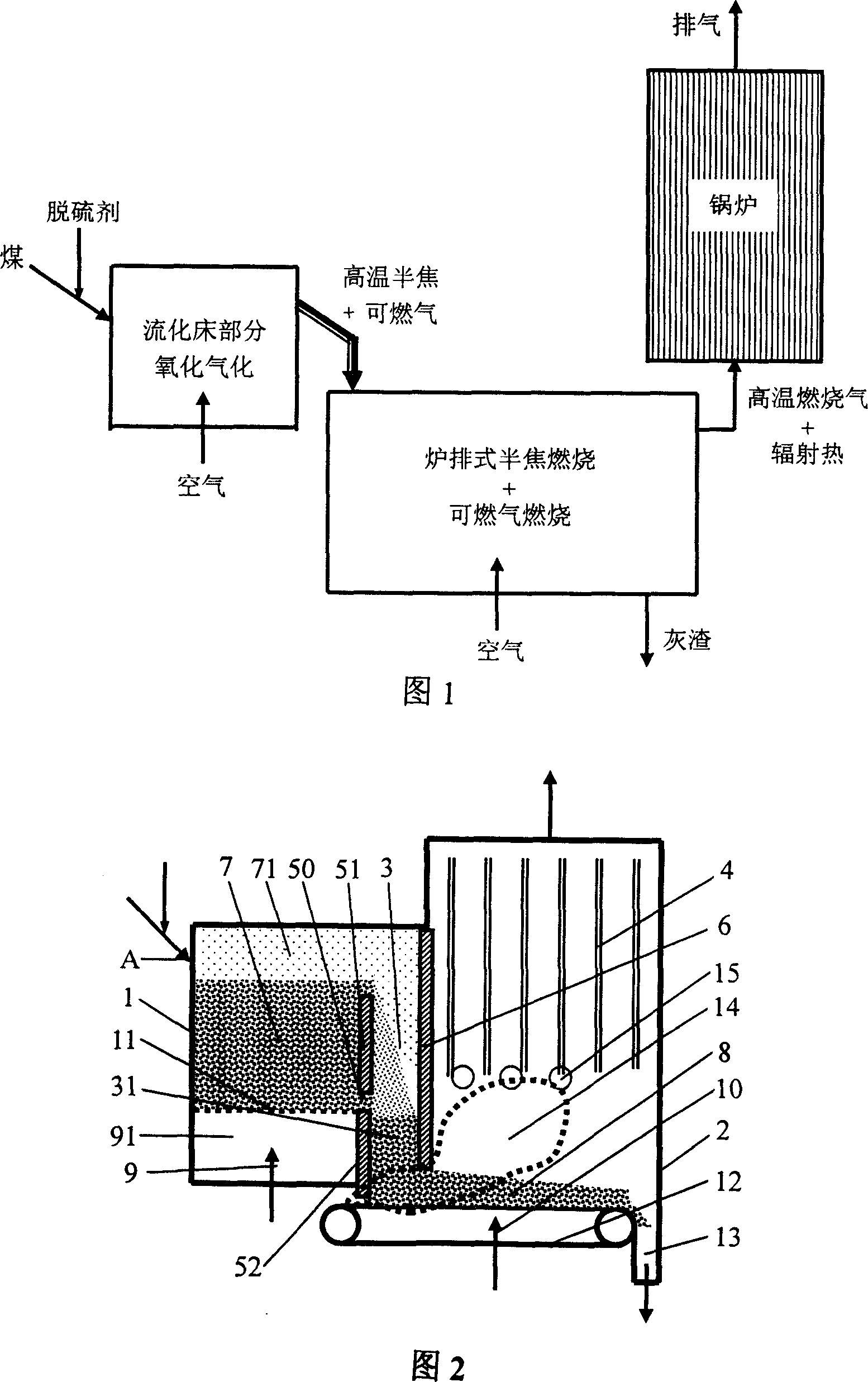

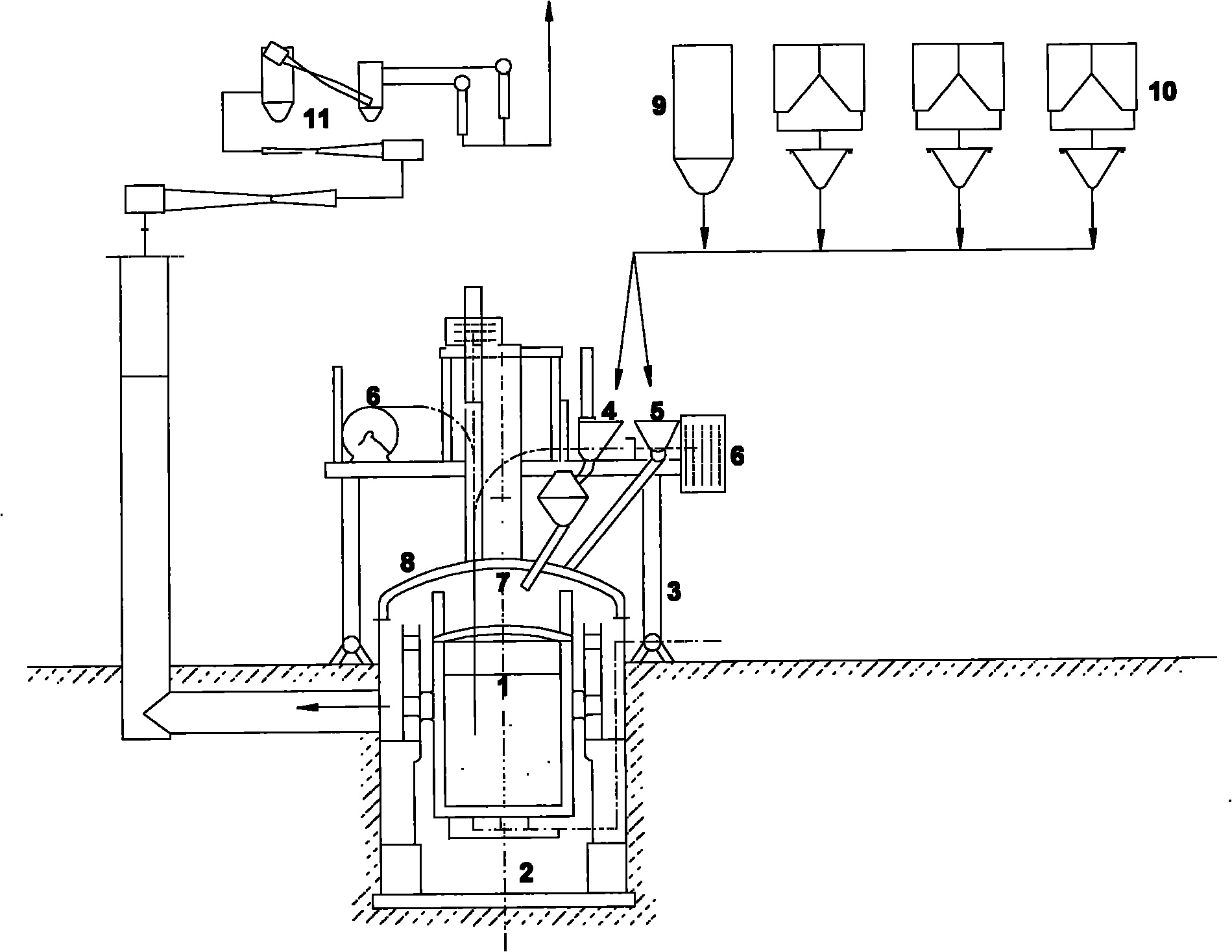

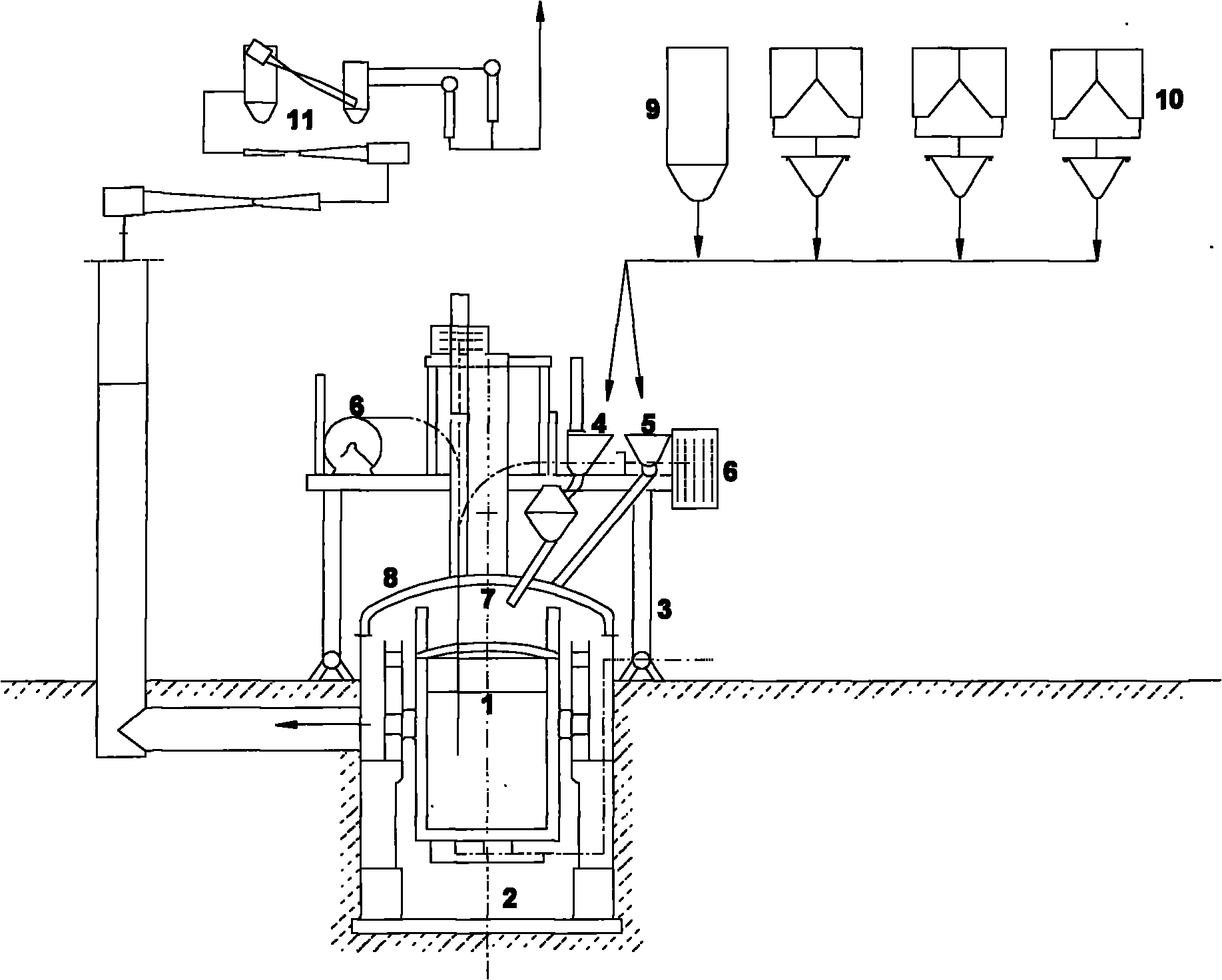

Low-pollution efficient combustion method for coal-burning boiler and combustion apparatus

InactiveCN101025266ASuppress generationEliminate burning black smokeFluidized bed combustionSolid fuel combustionFluidized bedProcess engineering

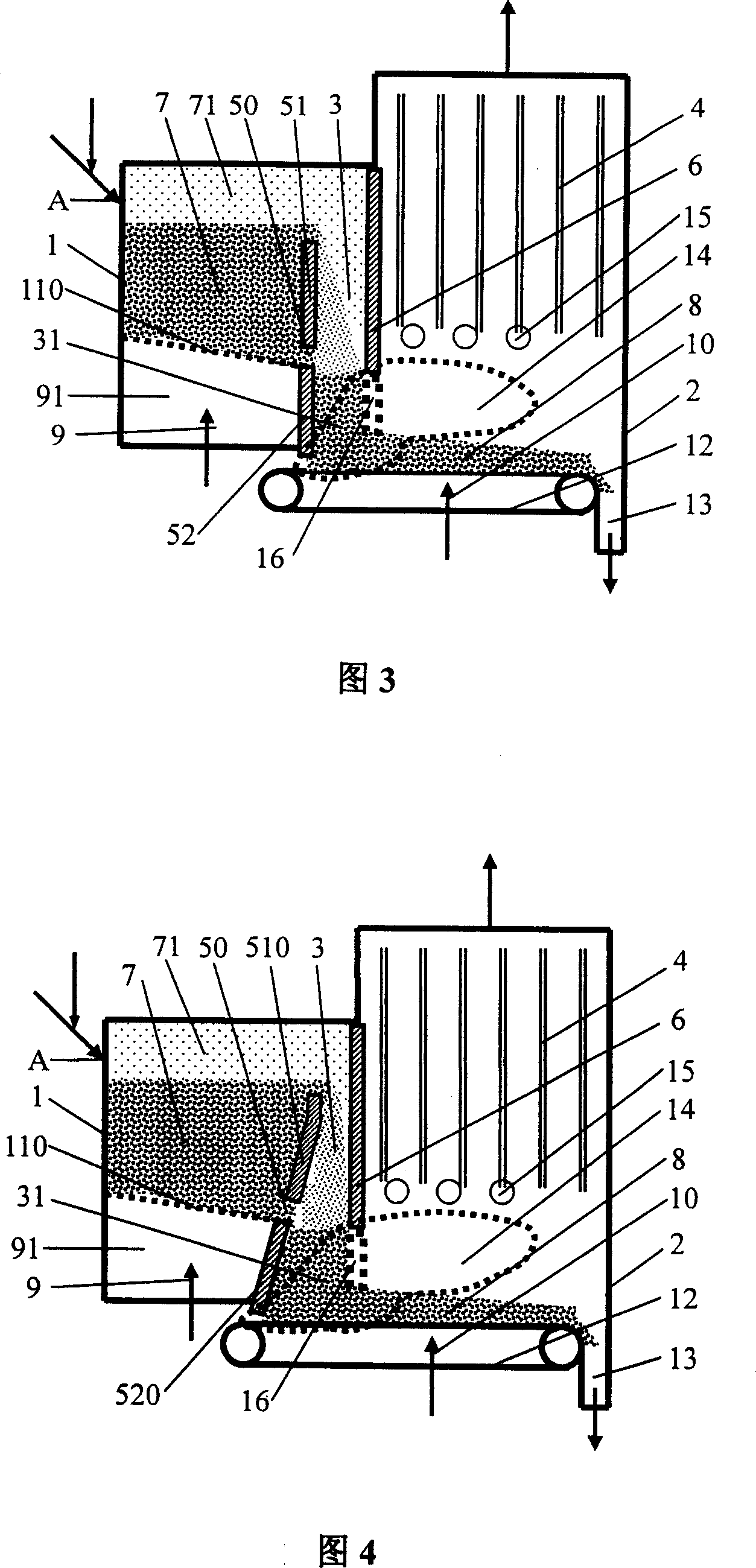

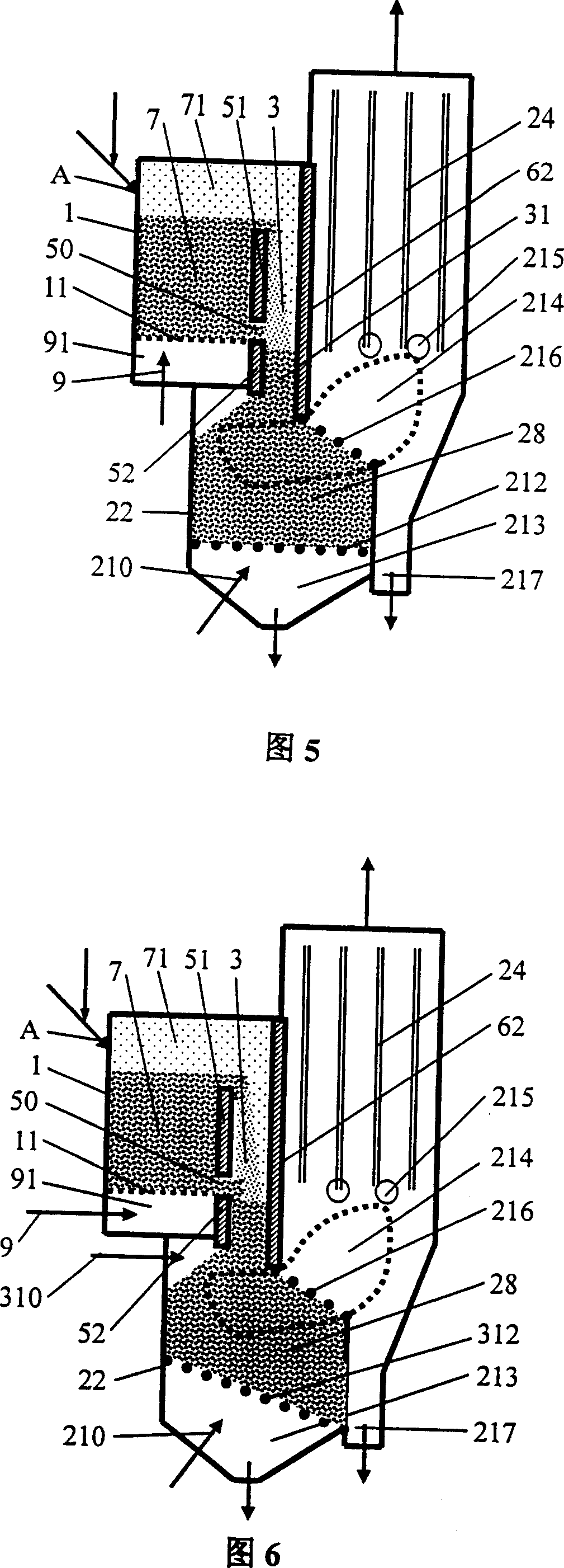

The invention relates to burning method and the device of low pollution and high efficiency for the coal-burning boiler which divides the burn into two processes. The two processes are the fluidized-bed oxidizing gasification and the burning of the carbocoal and fuel gas in grate burning furnace. The carbocoal and the fuel gas are transferred into the grate burning furnace through the moveable bed channel together; the fuel gas burn at the high temperature carbocoal layer and the carbocoal surface, so it can eliminate the black smoke and NOx; so the carbocoal and the fuel gas can be burned absolutely; the desulfurater added with the coal can remove the sulfide in the fluidized-bed part oxidizing gasification furnace which are dispersed between the carbocoal particle surface and the micropore to remove the oxysulfide sulfoxide of the burning furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

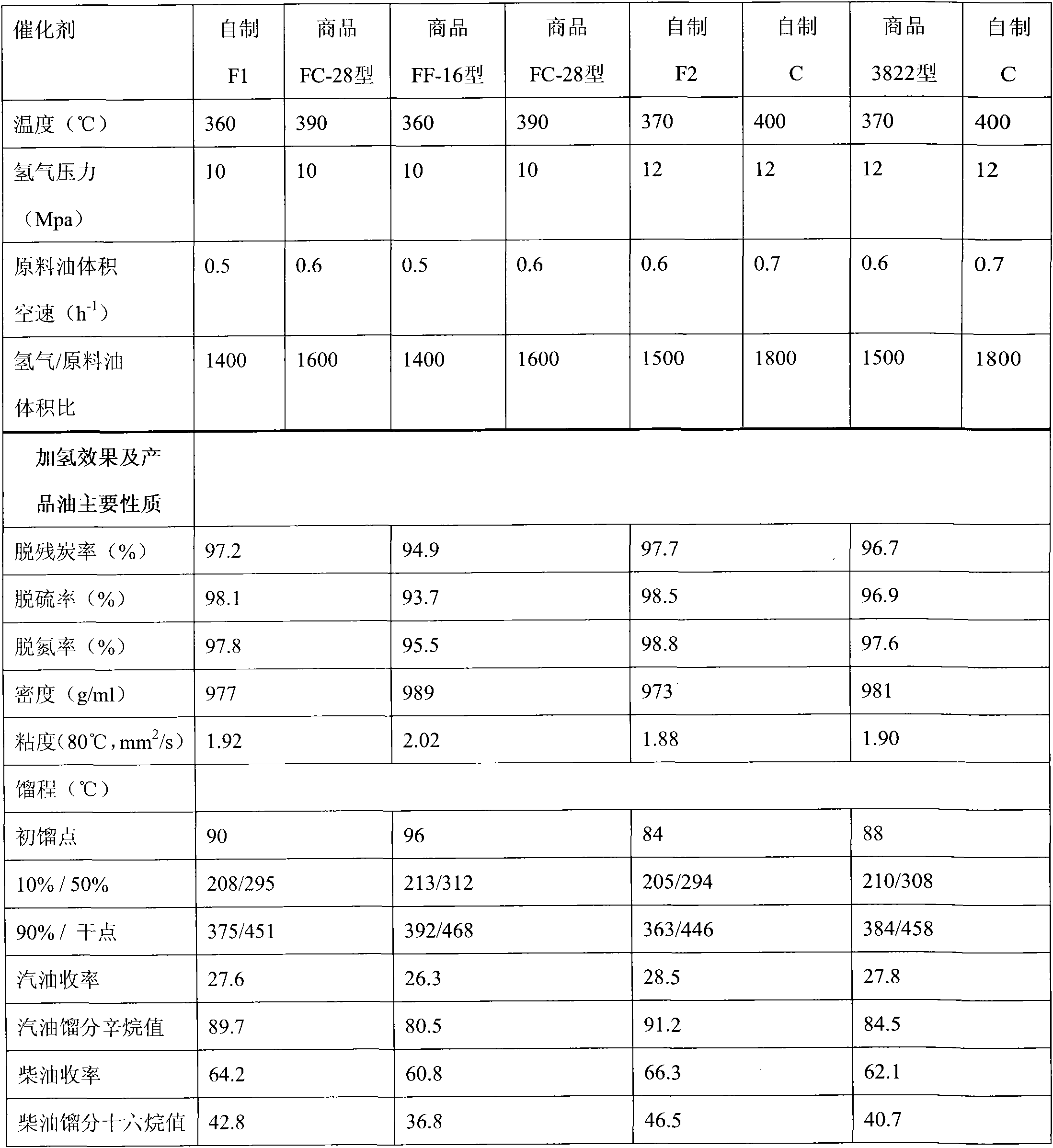

Hydrorefining catalyst for preparing fuel oil from coal tar, preparation method and application method thereof

ActiveCN102068992AImprove operational stabilityImprove handling strengthCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystProcess engineering

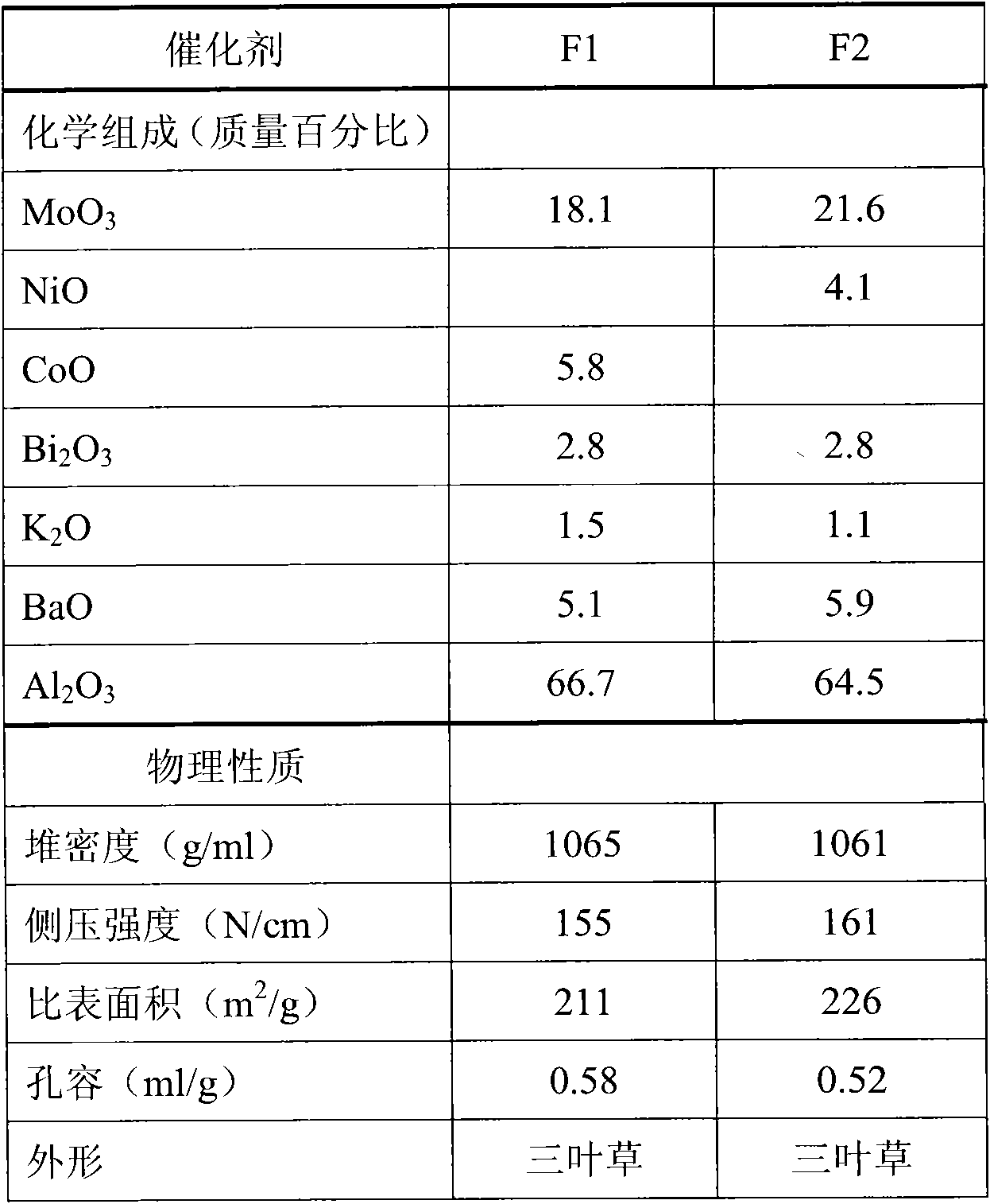

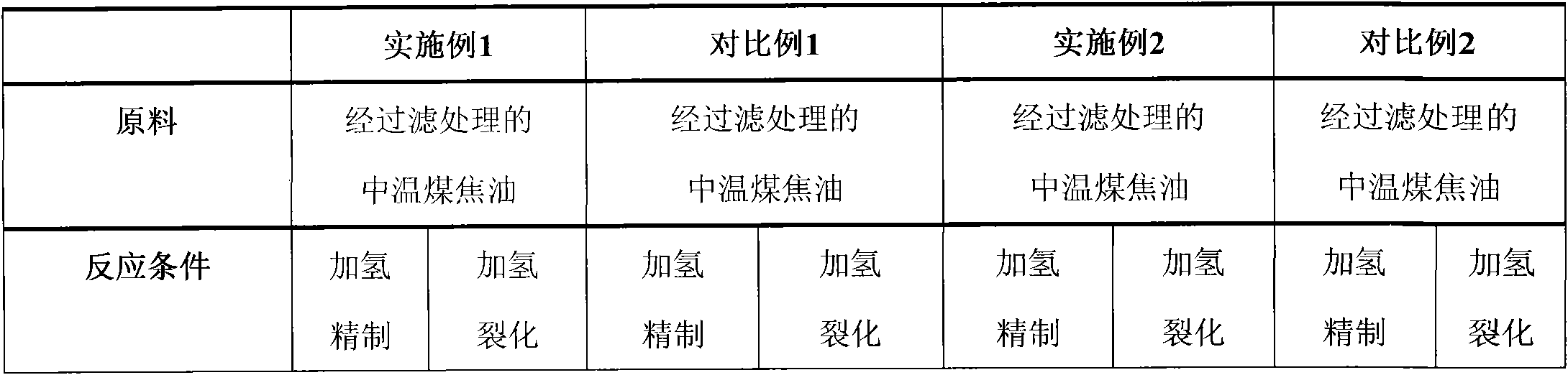

The invention provides a hydrorefining catalyst special for new coal tar, a preparation method and an application method thereof, which are used for solving problems existing in the conventional hydrogenation catalyst for coal tar. The hydrorefining catalyst consists of active components, aids and carriers, wherein the active components refer to MoO3 and NiO or MoO3 and CoO; the aids refer to Bi2O3 and K2O; and the carriers refer to alumina and barium oxide. According to calculation by the form of an oxide, the active components, the aids and the carriers account for 15 to 35 percent, 2 to 5 percent and 60 to 83 percent of the total mass of the catalyst respectively. The catalyst is prepared by the following steps of: kneading, grinding, extruding into strips, molding, soaking, performing catalyst post-treatment and the like. New ultrasonic soaking technology is introduced, and the preparation condition of the catalyst is controlled strictly. Compared with the prior art, the catalyst has high surface physical and chemical properties, high purified atom degumming activity, high hydrogenation saturation capability, high stability and high mechanical intensity, and the quality and yield of hydrogenation product oil can be enhanced effectively.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

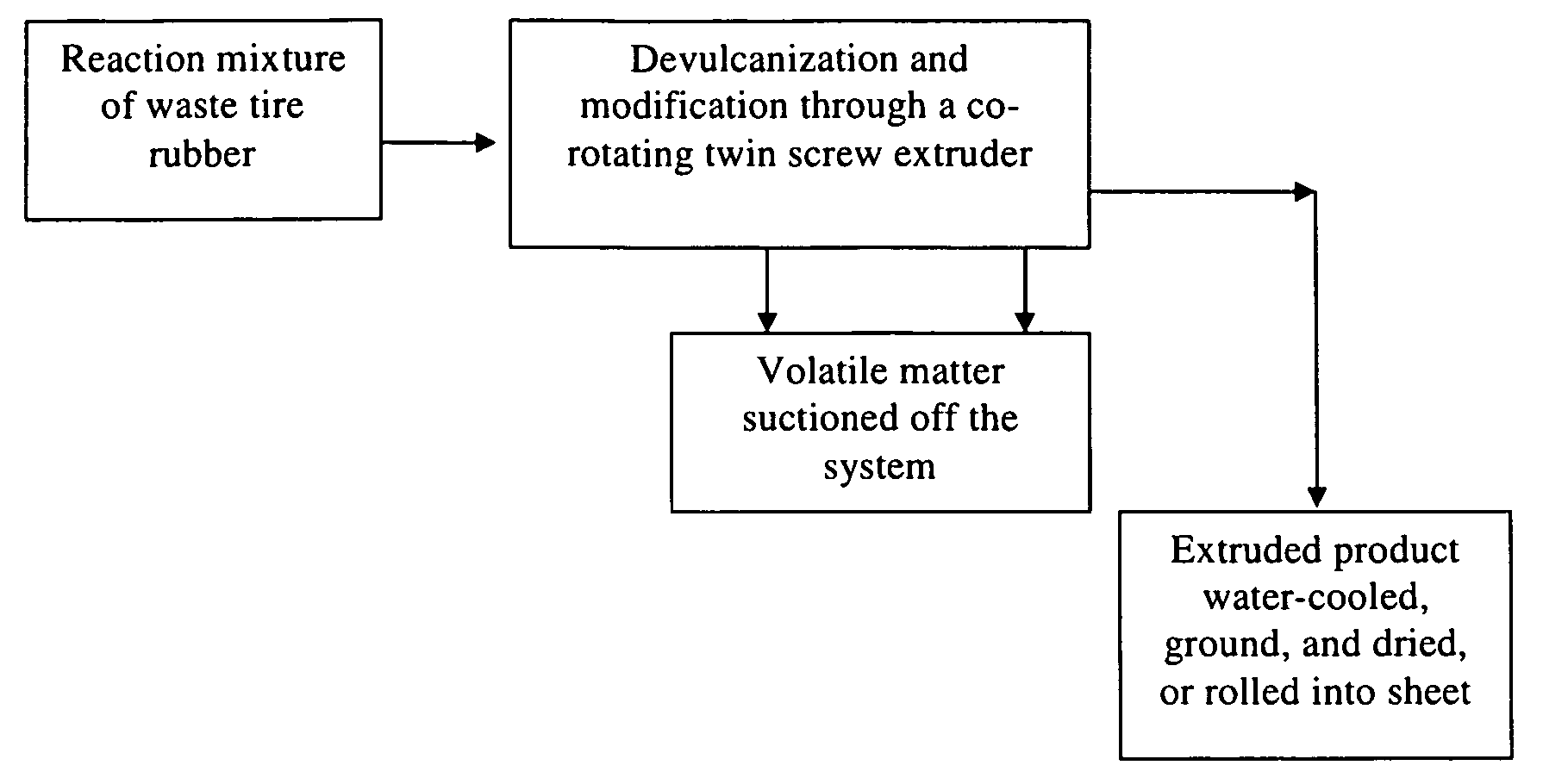

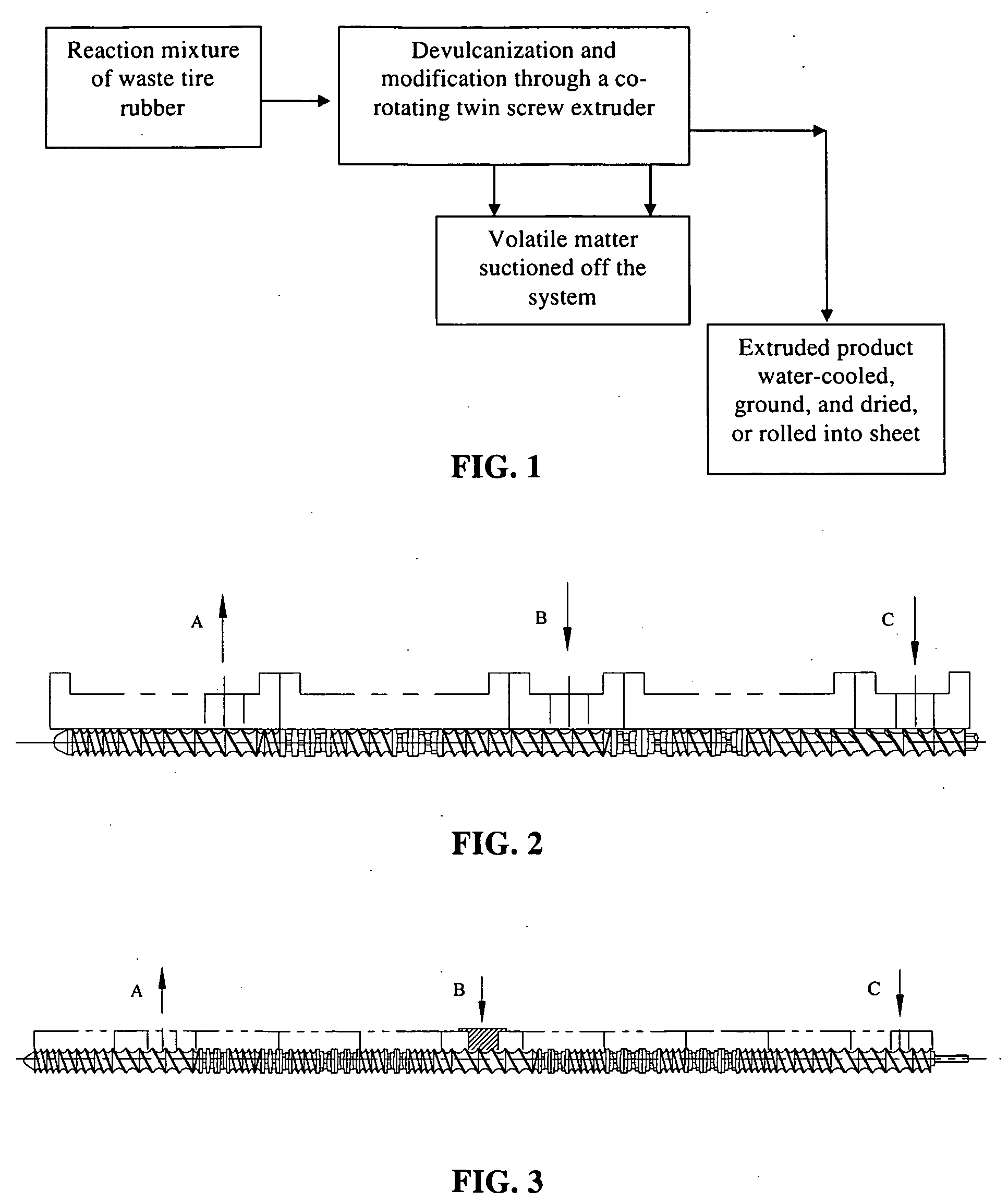

Process for devulcanization of rubber

InactiveUS20090082475A1Efficient desulfurizationIncrease shear stressPlastic recyclingPolymer scienceEnergy consumption

A process for devulcanization of vulcanized rubber, comprising the steps of: (a) preparing a mixture comprising: between about 5% w / w and about 50% w / w of thermoplastic polymer, between about 49% w / w and about 94% w / w of waste vulcanized rubber, and between about 0.01% w / w and about 1.8% w / w of stabilizing agent; and (b) kneading and desulfurizing the mixture by means of a co-rotating twin screw extruder at an extrusion temperature of between 150° C. and 320° C. to obtain devulcanized rubber. The devulcanized rubber is water-cooled, ground and dried or is rolled into sheet. This process combines the devulcanization, milling process and filtrating rubber as one process, possesses a higher devulcanization efficiency, treatment capability and lower energy consumption. Through the present invention, a controllable devulcanization process and a higher performance of the reformed materials with reclaimed rubber are achieved.

Owner:ZHANG YUNCAN +5

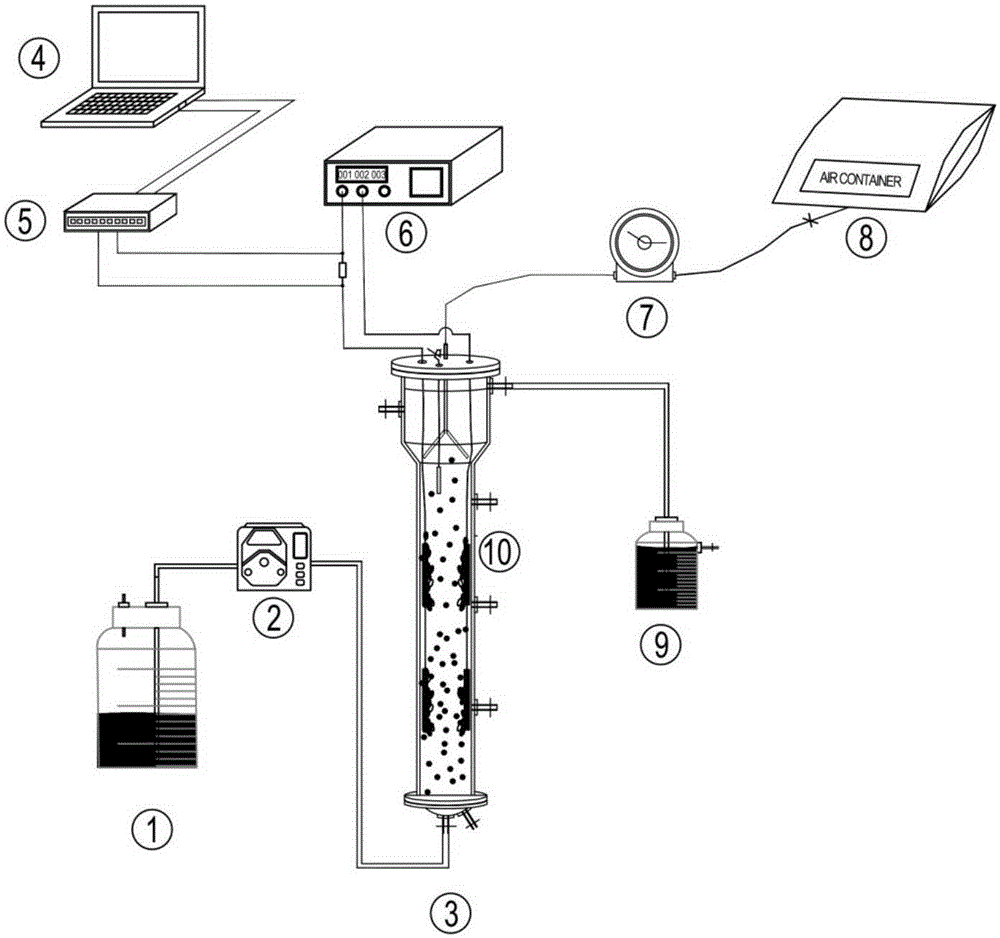

Microbial electrochemical in-situ biogas desulfurization method

ActiveCN105176614AEnhanced couplingEasy to operateGaseous fuelsDispersed particle separationCatalytic oxidationSulfide

The invention relates to a microbial electrochemical in-situ biogas desulfurization method. According to the method, sulfate is generated through microbial catalytic oxidation hydrogen sulphide with an anode electrochemical function, the sulfuretted hydrogen is prevented from being released into biogas, biogas in-situ desulfurization is completed, and the purity of methane in the biogas is improved; meanwhile, the electrons and H<+> released through sulphide oxidization are used for fixing carbon dioxide synthesis methane through cathodes, the concentration of carbon dioxide in the biogas is lowered, and synchronous in-situ desulfurization and biogas purification are achieved.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

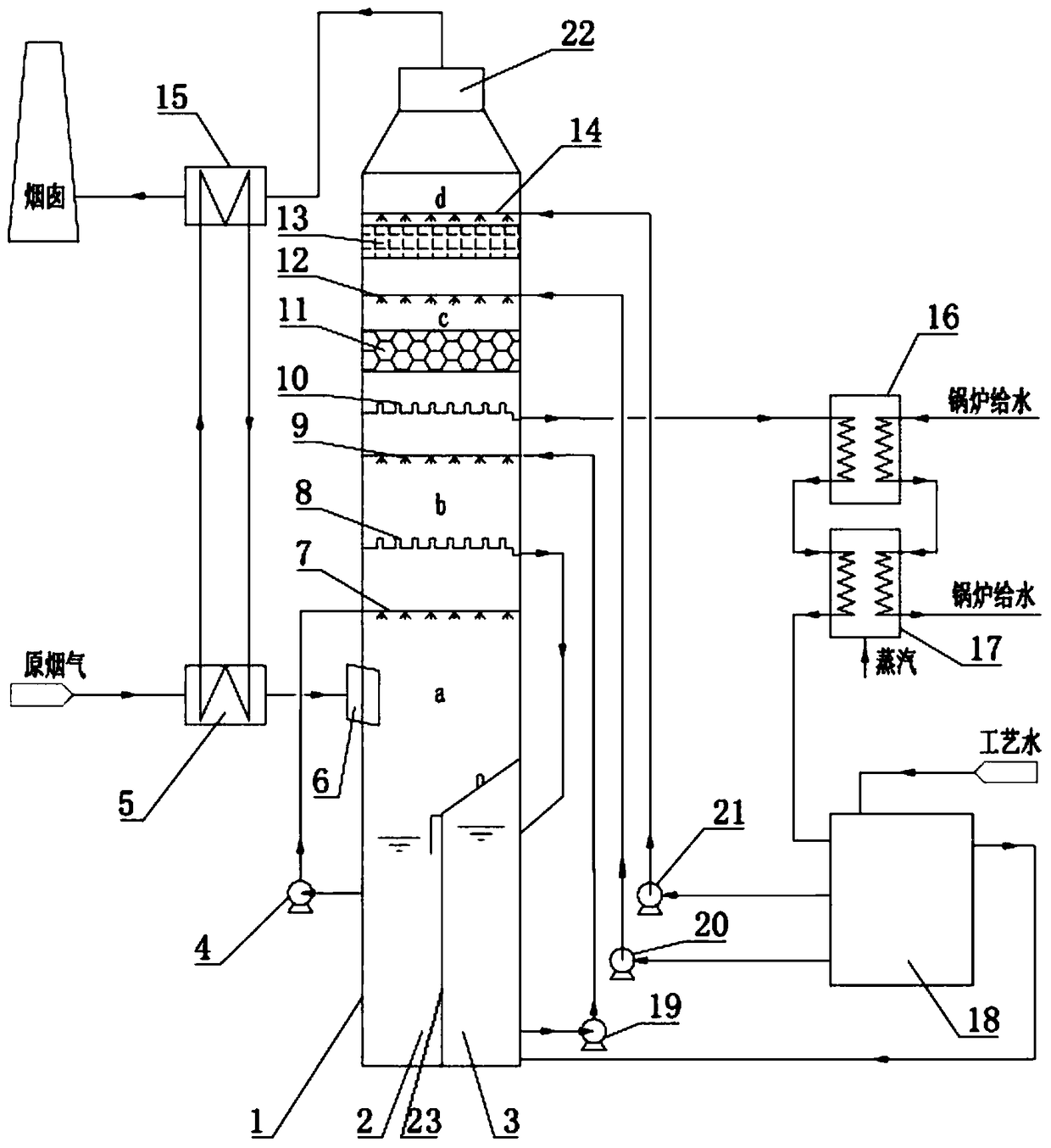

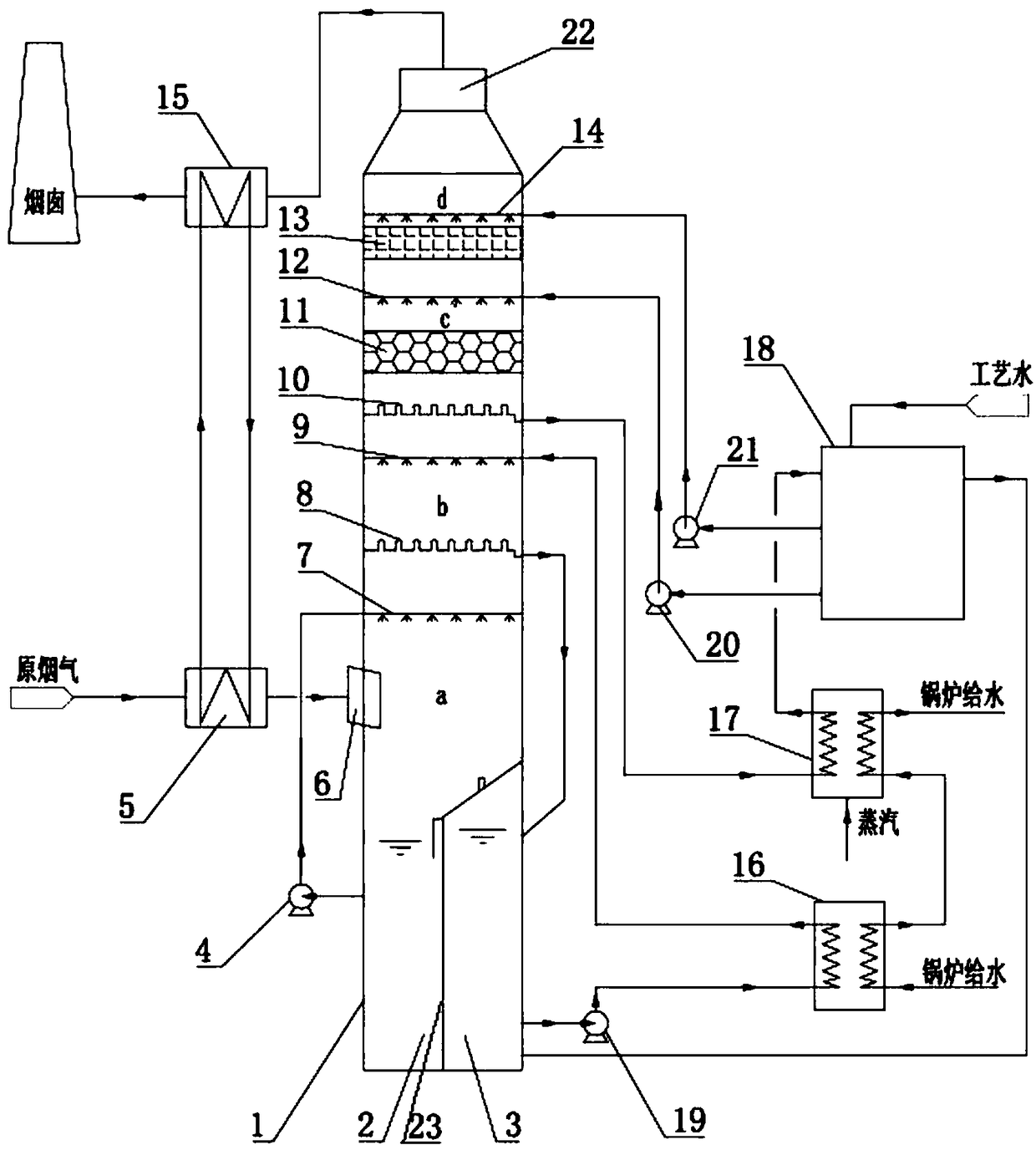

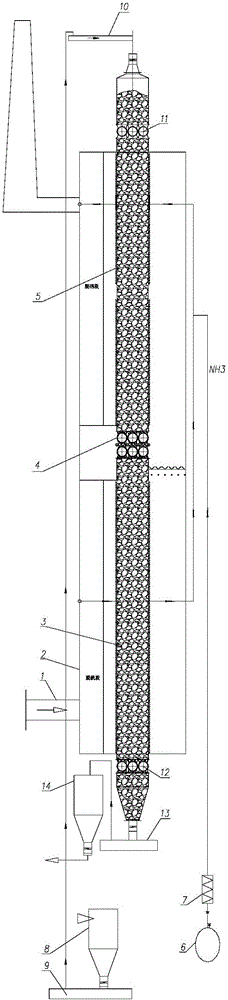

System for desulfurization, white smoke elimination and deep waste heat recovery based on ammonia process, and application

PendingCN109045976AImprove desulfurization efficiencyImprove cleanlinessGas treatmentDispersed particle separationRecuperatorAbsorption heat pump

The invention relates to a system for desulfurization, white smoke elimination and deep waste heat recovery based on an ammonia process. The system comprises a desulfurization tower, a circulating water tank, a heat exchanger, an absorption heat pump unit, a flue gas cooling section, a flue gas heating section, an inlet flue and an outlet flue; the desulfurization tower above a concentration tankis coaxially provided with a concentration section, a desulfurization section, a water washing section and a defogging section from the top to bottom in sequence; the inlet flue is arranged on the desulfurization tower between the concentration tank and the concentration section in a communicated mode; the outlet flue is arranged at the top of the desulfurization tower above the defogging sectionin a communicated mode; the heat exchanger and the absorption heat pump unit can perform two-stage cooling on circulating water, and can perform two-stage heating on supplemented boiler water; the supplemented boiler water can flow through the heat exchanger and the absorption heat pump unit to achieve two-stage heating. The system has the advantages of high desulfurization efficiency and high heat recycling rate, and flue gas desulfurization, white smoke elimination and deep waste heat recovery can be simultaneously realized.

Owner:AEROSPACE ENVIRONMENTAL ENG

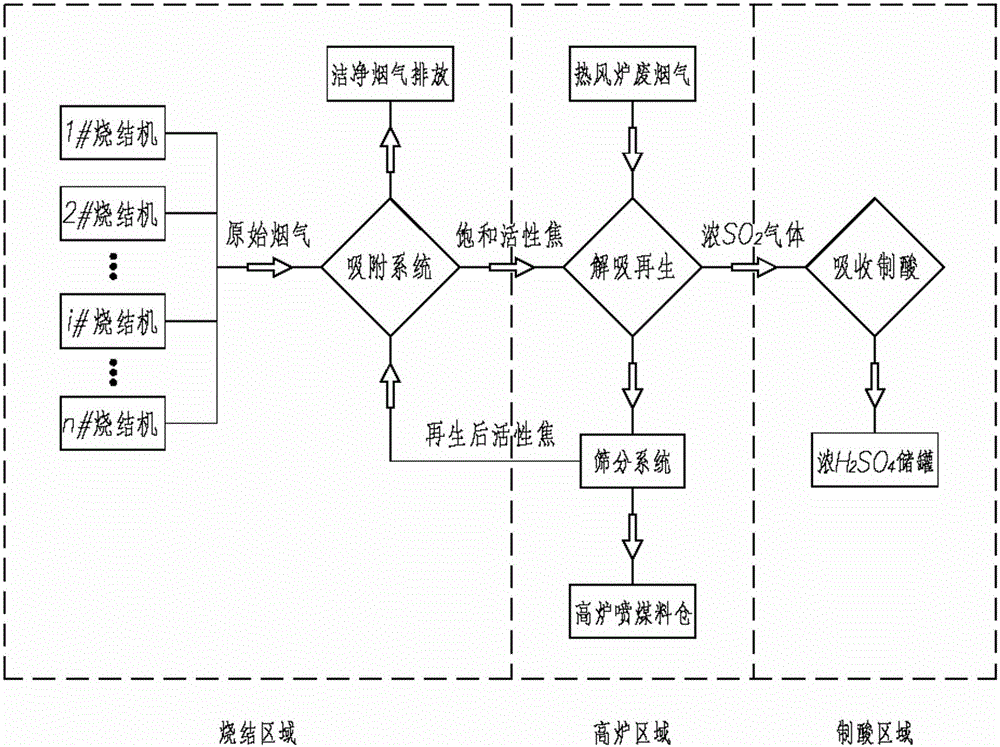

Resource utilization system for pellet sintering waste gas and method

ActiveCN105080332ALess investmentLow running costDispersed particle separationCombustionResource utilization

The invention discloses a resource utilization system for pellet sintering waste gas and a method. The system at least comprises a sintering waste gas adsorption system, an active-coke desorption regeneration system and an active-coke transportation device; the sintering waste gas adsorption system comprises a first-segment adsorption tower and a second-segment adsorption tower, the sintering waste gas successively passes through the first-segment adsorption tower and the second-segment adsorption tower for waste-gas purification, the gas is discharged through a sintering chimney, and saturated active coke in the adsorption tower is discharged by a saturated-active-coke discharge valve at the bottom of the second-segment adsorption tower; and the active-coke desorption regeneration system comprises a desorption tower, the desorption tower obtains waste gas output by a blast-furnace hot-wind combustion-supporting waste gas discharging port through leading of a hot wind pipeline and takes the waste gas as a deposition hot gas, a vibrating screen disposed at the outlet of the deposition tower is used to screen active coke particles with the diameter of 0.5 cm or less, and an active coke particle bin pump is arranged below sieve pores of the vibrating screen and is communicated with a blast-furnace coal bin via an active coke particle conveying pipe.

Owner:HUATIAN ENG & TECH CORP MCC

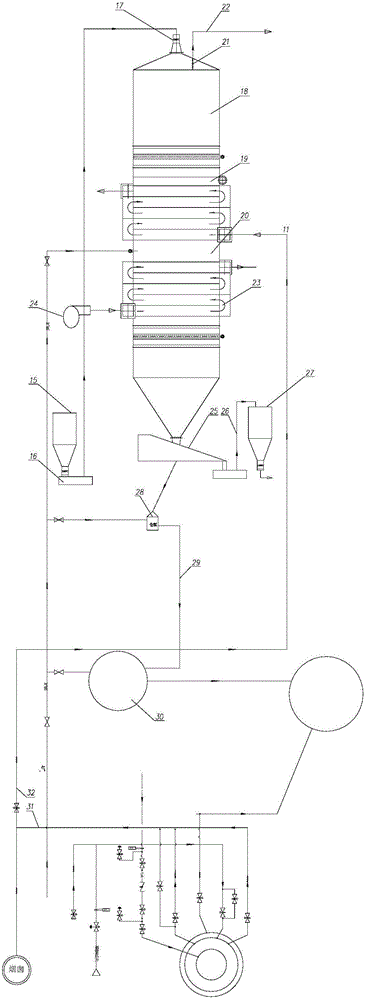

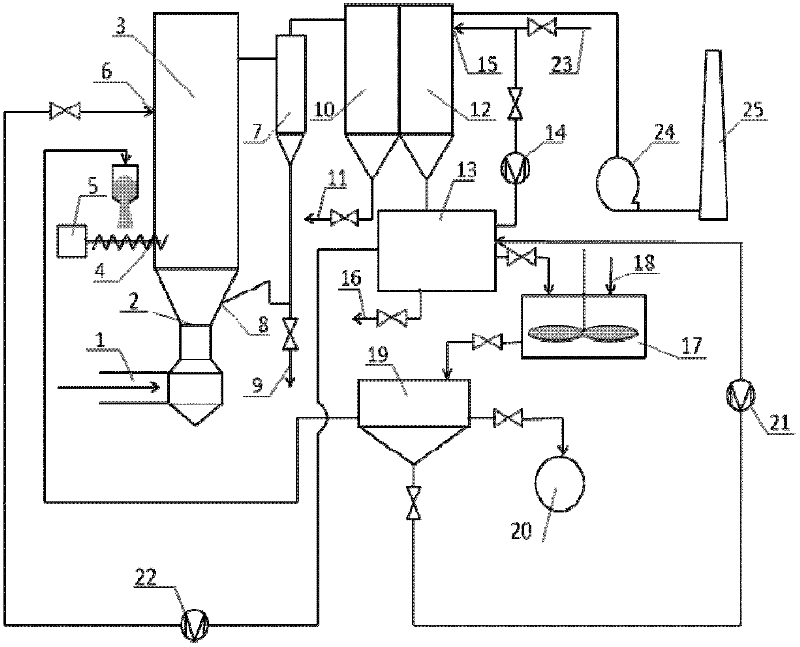

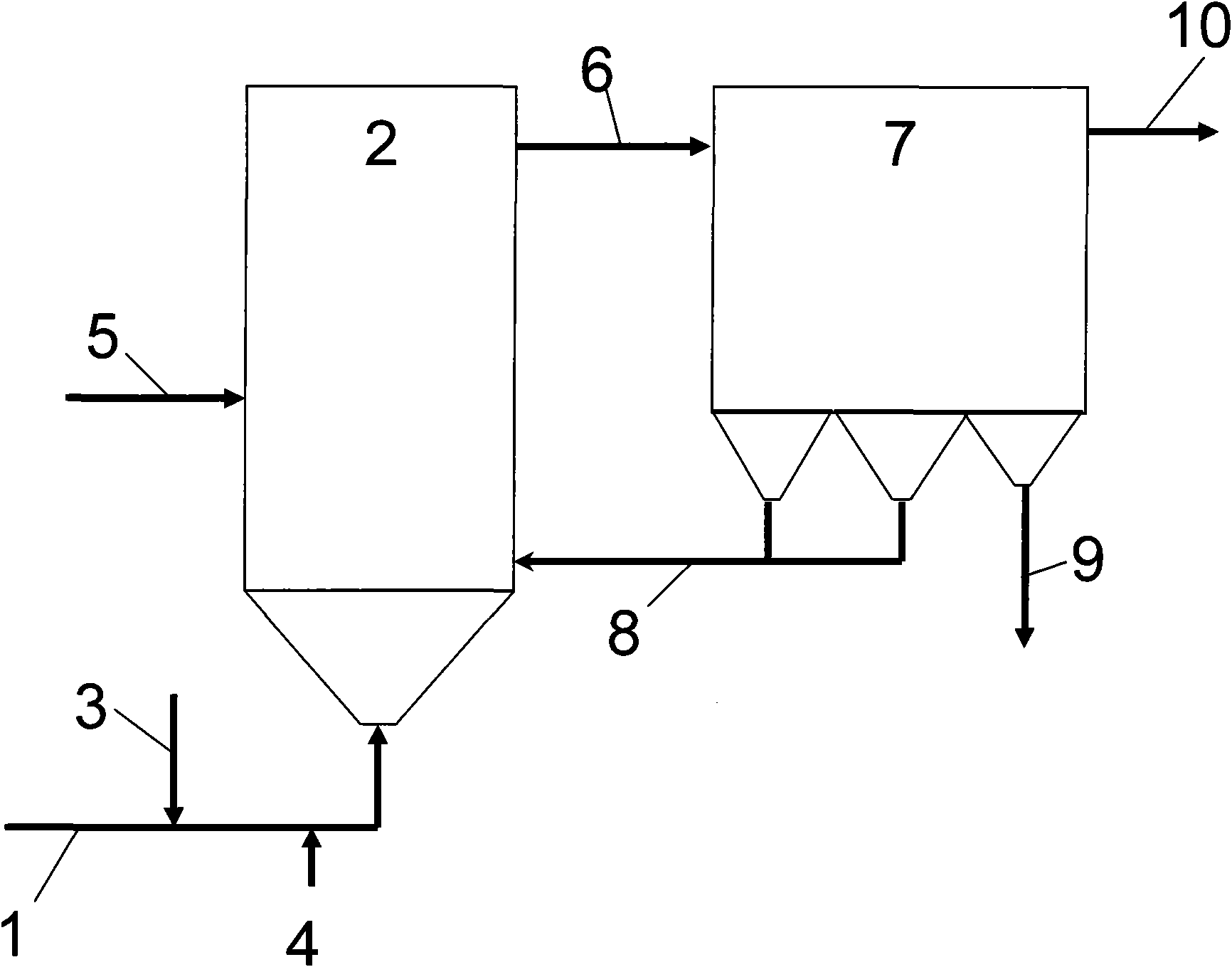

Constant-temperature half-dry smoke purification method and system

ActiveCN102350205AEfficient desulfurizationLow flow resistanceDispersed particle separationParticulatesPurification methods

The invention discloses a constant-temperature half-dry smoke purification method and system, relating to a removal method and system for sulfur oxide and dust in smoke discharged from combustion equipment. In the system, a circulating fluidized bed serves as a desulfuration reactor, quick hydration removal agent serves as desulfurizing agent, and a dry and wet combined electrostatic precipitator serves as dust removal equipment. The constant-temperature half-dry smoke purification system is characterized in that a cyclone separator is adopted to realize the material circulation of the quick hydration removal agent in a constant-temperature circulating fluidized bed reactor; the dry and wet combined electrostatic precipitator efficiently removes particles; and the wet electrostatic precipitator and the water for preparing the desulfurizing agent are reused to lower water consumption amount. The constant-temperature half-dry smoke purification system has the advantages of high desulfurization and dust removal efficiency and small system pressure loss. Compared with the wet-method desulfurization, the constant-temperature half-dry smoke purification system has the advantages of small water consumption amount and low investment and operation maintenance cost, and can be used for the smoke purification process of industrial boilers and power station boilers.

Owner:TSINGHUA UNIV

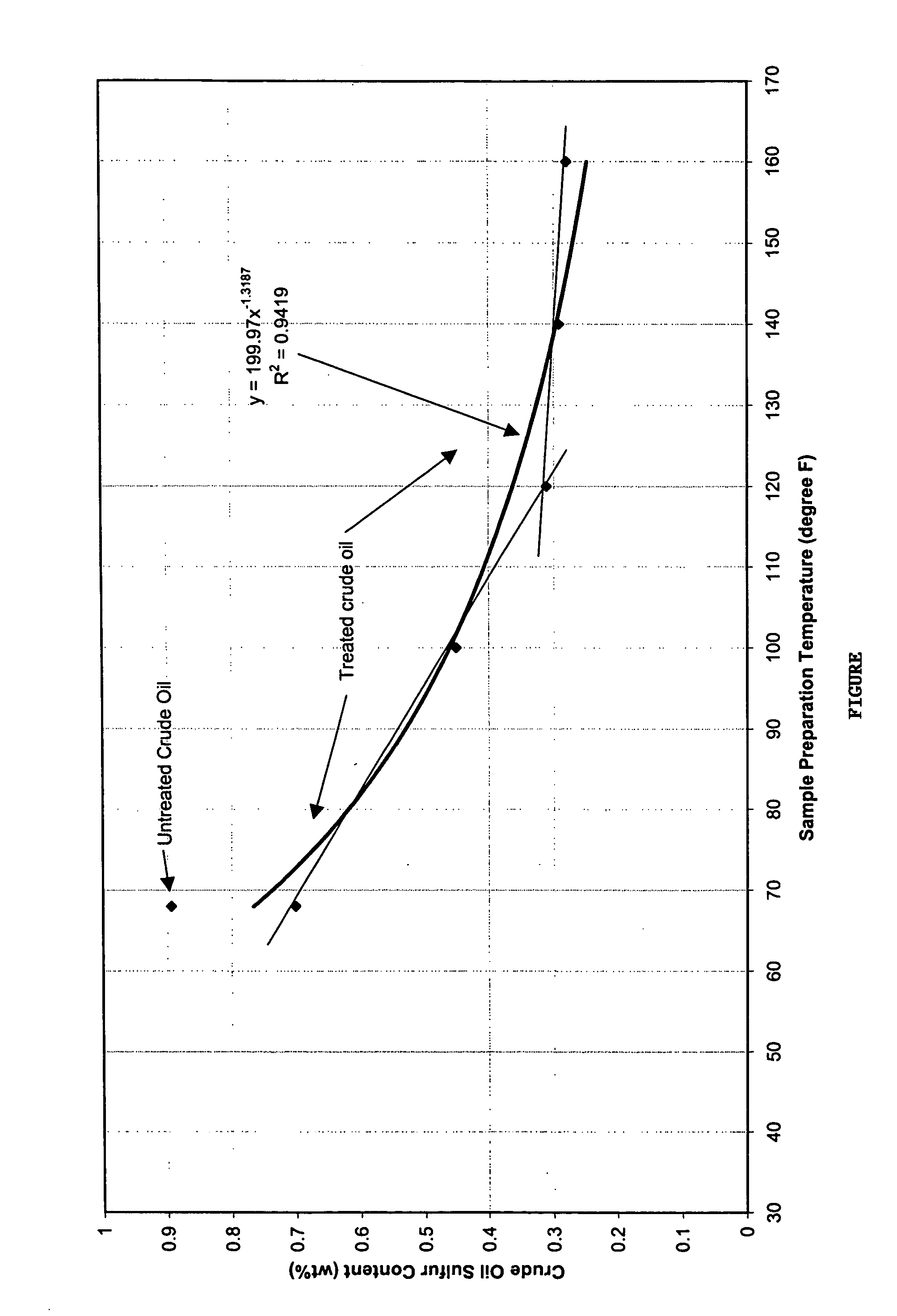

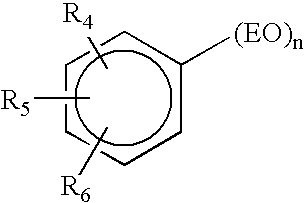

Methods and compositions for removing sulfur from liquid hydrocarbons

InactiveUS20060281638A1Efficient desulfurizationOrganic chemistryDistillation corrosion inhibitionLiquid hydrocarbonsAlkylphenol

Improved desulfurization compositions are provided for removing substantial fractions of sulfur, sulfur complexes, and sulfur compounds from liquid hydrocarbons such as crude oil and fuels. The preferred compositions comprise respective quantities of an alkylphenol ethoxylate, an amine, and an alkali metal nitrite. The compositions may be contacted with liquid hydrocarbons to achieve high levels of desulfurization.

Owner:JACAM CHEM COMPANY 2013

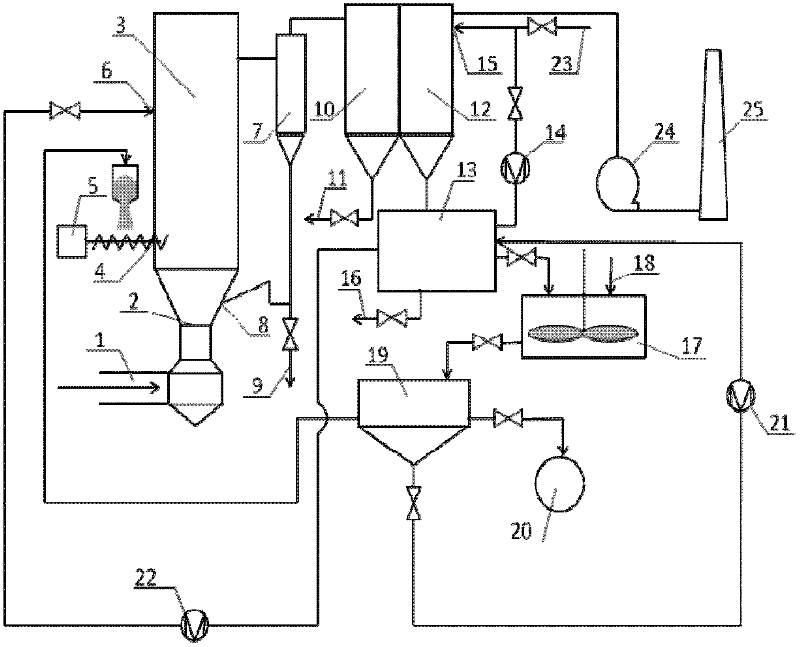

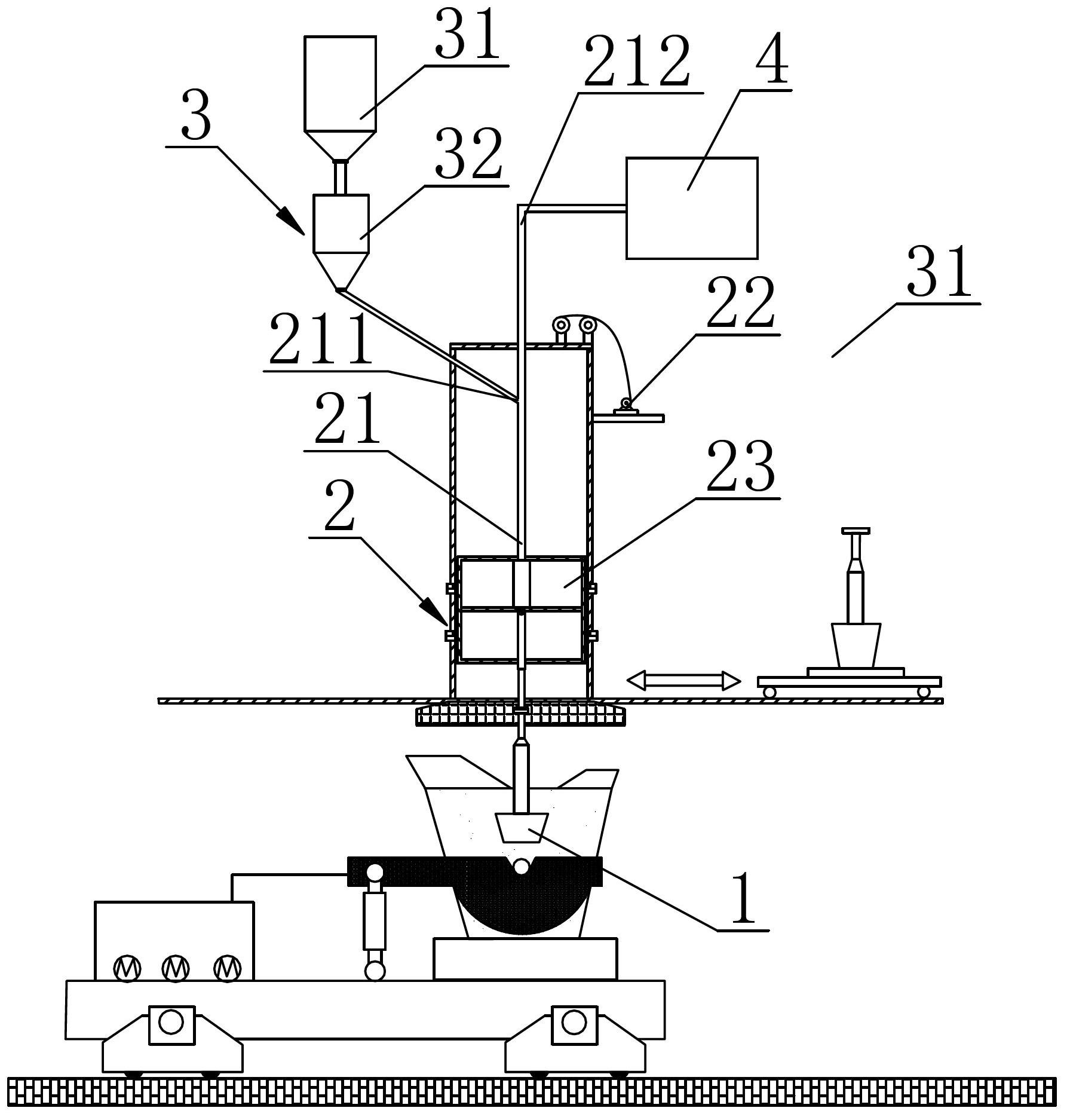

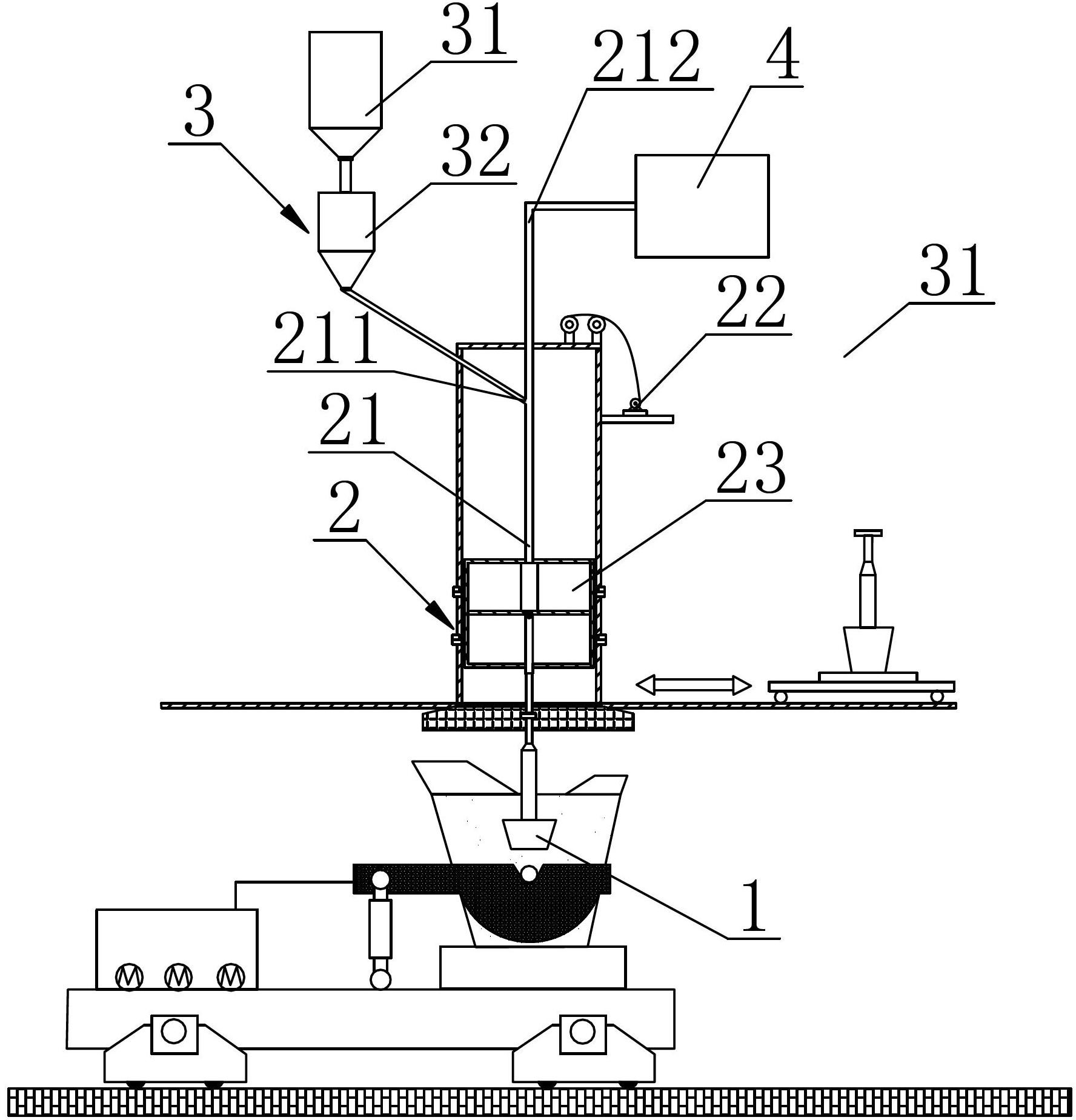

KR (knotted reactor) powder spraying, stirring and desulfurizing device and method

InactiveCN102676741AThe desulfurization cycle is shortenedReduced desulfurization working timeGranularityEngineering

The invention relates to a KR (knotted reactor) powder spraying, stirring and desulfurizing device. The KR powder spraying, stirring and desulfurizing device comprises a stirring head and a driving device for controlling the stirring head to act, wherein the driving device comprises a connecting rod linked with the stirring head, a lifting device for driving the connecting rod to move up and down and a stirring motor for driving the connecting rod to rotate. The KR powder spraying, stirring and desulfurizing device is characterized by further comprising a feeding system and a high-pressure gas source, wherein a through hole for introducing high-pressure inert gas and desulfurizing agents is formed on the stirring head, and an inlet of the through hole is communicated with a desulfurizing agent outlet and a high-pressure gas source outlet of the feeding system. The invention further relates to a method for desulfurizing molten iron by using the KR powder spraying, stirring and desulfurizing device. By using the device, efficient, fast and precise desulfurization can be realized, and the effects of reducing the requirements for granularity of desulfurizing agents, reducing the temperature drop and reducing the loss of the stirring head can be achieved.

Owner:ZENITH STEEL GROUP CORP

Iron oxyhydroxide modified active carbon desulfurizer as well as preparation method thereof

InactiveCN103521195AEasy to handleEfficient desulfurizationOther chemical processesActivated carbonLignin sulfate

The invention relates to an iron oxyhydroxide modified active carbon desulfurizer which is prepared from the following raw materials in parts by weight: 120-130 parts of active carbon, 12-14 parts of iron oxyhydroxide, 4-5 parts of lignin sulfate, 4-5 parts of polyvinyl alcohol, 8-10 parts of modified attapulgite and an appropriate amount of water. According to the iron oxyhydroxide modified active carbon desulfurizer disclosed by the invention, the iron oxyhydroxide is used to efficiently desulfurate and dechlorinate, and the desulfuration effect is long in lasting time. The lignin sulfate is further used, so that raw materials such as active carbon can be uniformly dispersed in water. Therefore, the desulfurizer has a better water treatment effect, free from toxic substances and low in production cost, and can be repeatedly and recycled, thereby not only saving the industrial cost, but also laying a foundation for industrial application.

Owner:BENGBU PIONEER FILTER

Process for preparing diesel oil hydrog-refining catalyst using TiO2-SiO2 compound oxide as carrier

InactiveCN1782032AAccelerated vulcanizationGood hydrofining activityCatalyst carriersRefining to eliminate hetero atomsHydrodesulfurizationCobalt

The diesel oil hydrorefining catalyst has composite oxide TiO2-SiO2 as carrier and active metal Co, Mo or Ni, and W components. The catalyst carrier is prepared through sol-gel process, granular hydrolyzing and coating process, or mixed sol process. The active metal components are supported onto the carrier through co-dipping or stepped dipping process. The composite TiO2-SiO2 hydrorefining catalyst has average pore diameter of 7-15 nm and pore volume of 0.2-0.7 ml / g, specific surface area of 100-300 sq m / g. The catalyst of the present invention has relatively high hydrodesulfurizing activity and dydrodenitrifying activity on different kinds of material.

Owner:PETROCHINA CO LTD +1

Method for producing small-molecule aromatics from diesel oil raw material

ActiveCN105295998AGood choiceWeakened hydrogenationHydrocarbonsTreatment with hydrotreatment processesFractionationContact reaction

The invention provides a method for producing small-molecule aromatics from a diesel oil raw material. According to the method, the inferior diesel oil raw material is subjected to reactions in a hydrofining reaction zone and a hydrocracking reaction zone I, and then a light gasoline fraction, a heavy naphtha gasoline fraction, an intermediate fraction and a tail oil fraction are obtained through separation and fractionation; the intermediate fraction enters a hydrocracking reaction zone II for a contact reaction with a second hydrocracking catalyst; the heavy gasoline fraction enters to a desulfurization reaction zone for further deep desulfurization, namely removal of thiofuran and mercaptan; after the removal is finished, the heavy gasoline fraction without thiofuran and mercaptan enters an aromatics extraction unit, and such small-molecule aromatics as benzene, toluene and dimethyl benzene are obtained through separation. Through adoption of the method, the inferior diesel oil raw materials can be effectively converted into benzene, toluene, dimethyl benzene and other high-value products; meanwhile, the blending components of part of light gasoline and low-sulfur diesel oil can be produced according to the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Highly effective coal combustion improver and preparation thereof

The invention relates to the fuel additive technical field, in particular to fuel coal additives and a method for preparing the same. The invention discloses the high-efficiency fuel coal additives, which mainly comprises raising agent, combustion improver and sulfur retention smoke agent and also comprises nano silicon dioxide with a weight ratio between 0.5 and 10 percent. The high-efficiency fuel coal additives makes fuel coal in the high temperature state; the boiler steam rate is gradually increased; the furnace temperature is improved by 100 DEG; the boiler thermal efficiency is improved by over 15 percent; the coal-saving rate reaches 5 to 20 percent; the desulfurization is obvious and the desulfurization degree is as high as 40 to 70 percent; the decoking process is quick; the total discharge of clinker is reduced by about 26 percent, thereby the carbon content of furnace cinder is reduced; by addition of the fuel coal additives, metals on the boiler heating surface can not be eroded, thereby the function of protecting equipment is brought into play and the service life of the equipment is prolonged. Moreover, the high-efficiency fuel coal additives can greatly reduce the environmental pollution and the atmospheric greenhouse effect, and greatly reduce the energy consumption so as to obtain obvious economic benefit.

Owner:陈睿红

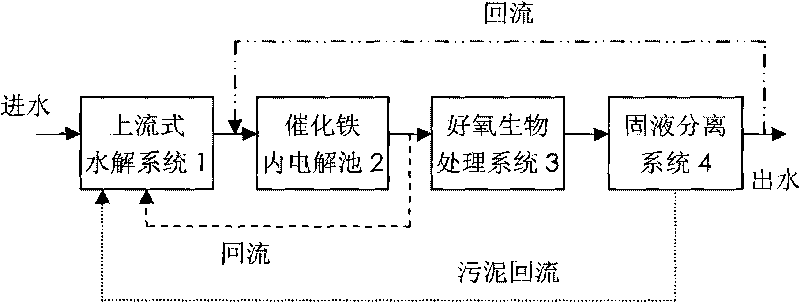

Method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water

InactiveCN101693581AGuaranteed reaction efficiencyEfficient removalWater/sewage treatmentMultistage water/sewage treatmentWater qualityTherapeutic effect

The invention pertains to the technical field of treatment of waste water, and particularly relates to a method of hydrolysis-catalytic iron-aerobic coupling for treating poisonous and harmful hard-degradation waste water, which comprises the following steps: waste water after primary treatment directly enters an up flow type hydrolysis system 1 and stays for 4.0-10.0 hours; the effluent enters an electrolytic cell in the catalytic iron; the mass ratio of iron scraps and copper scraps in the electrolytic cell of the catalytic iron is 1:1 to 20:1, the bulk specific weight thereof is 0.1 to 0.3, the contact time thereof in a filling area is 0.5 to 2.0 hours, and the reflux ratio of the effluent refluxing to the up flow type hydrolysis system is 20 to 100 percent; the effluent enters an aerobic biological treatment system and stays for 6.0 to 12.0 hours; then the effluent enters a solid-liquid separation system with a reflux ratio of sludge being 10 to 50 percent; and the effluent of the solid-liquid separation system refluxes to the electrolytic cell of the catalytic iron with the reflux ratio being 20 to 200 percent. Under the premise of fully playing the function of different treatment units and maintaining the treatment effect and respective advantages, the treatment method of waste water realizes the coupling synergetic action of the three units, strengthens the impact of the system to water quality and water quantity load, reduces a plurality of steps of pretreatment, effectively improves the removal rate of ammonia nitrogen, and can be flexibly adjusted.

Owner:TONGJI UNIV +1

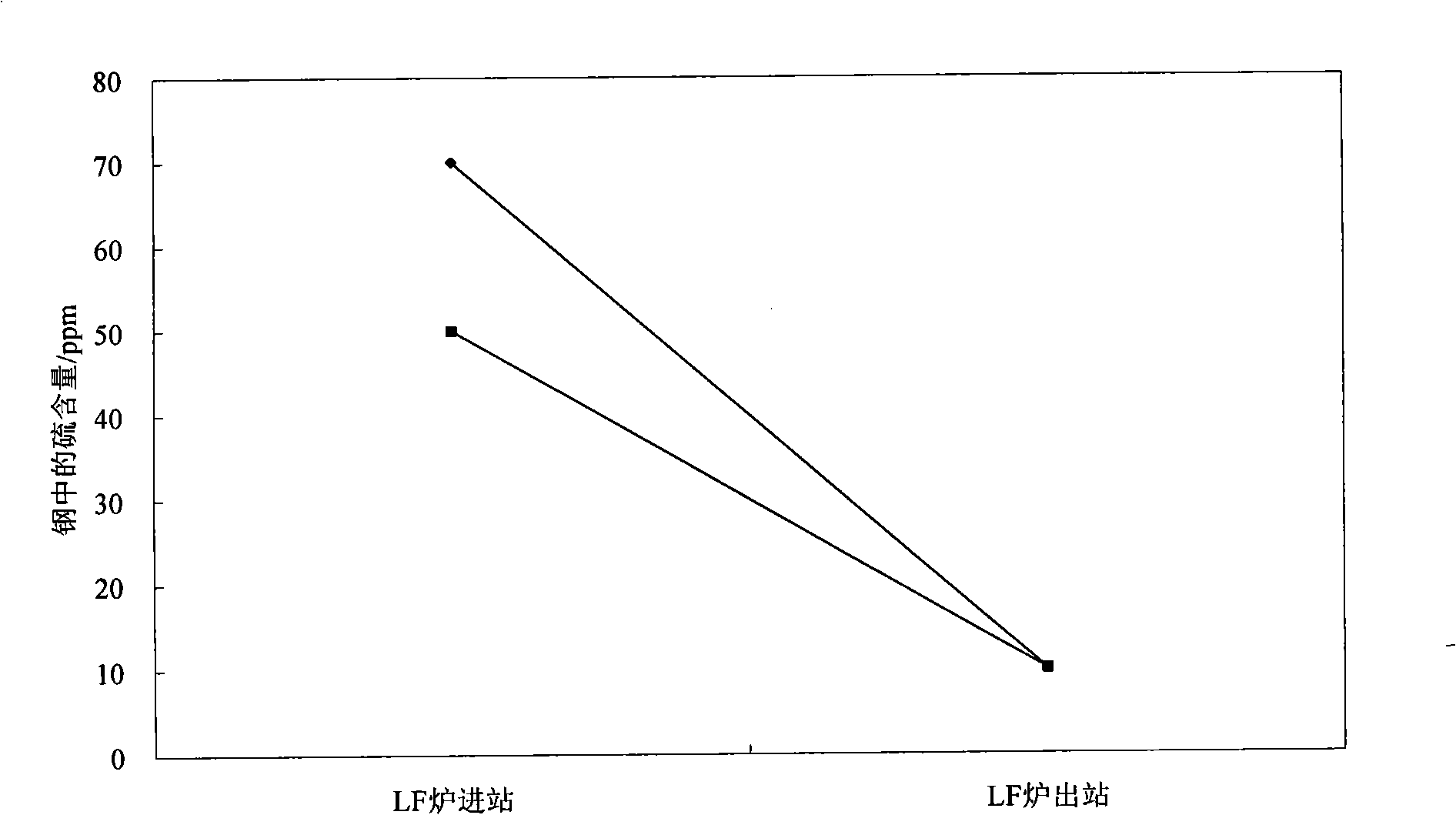

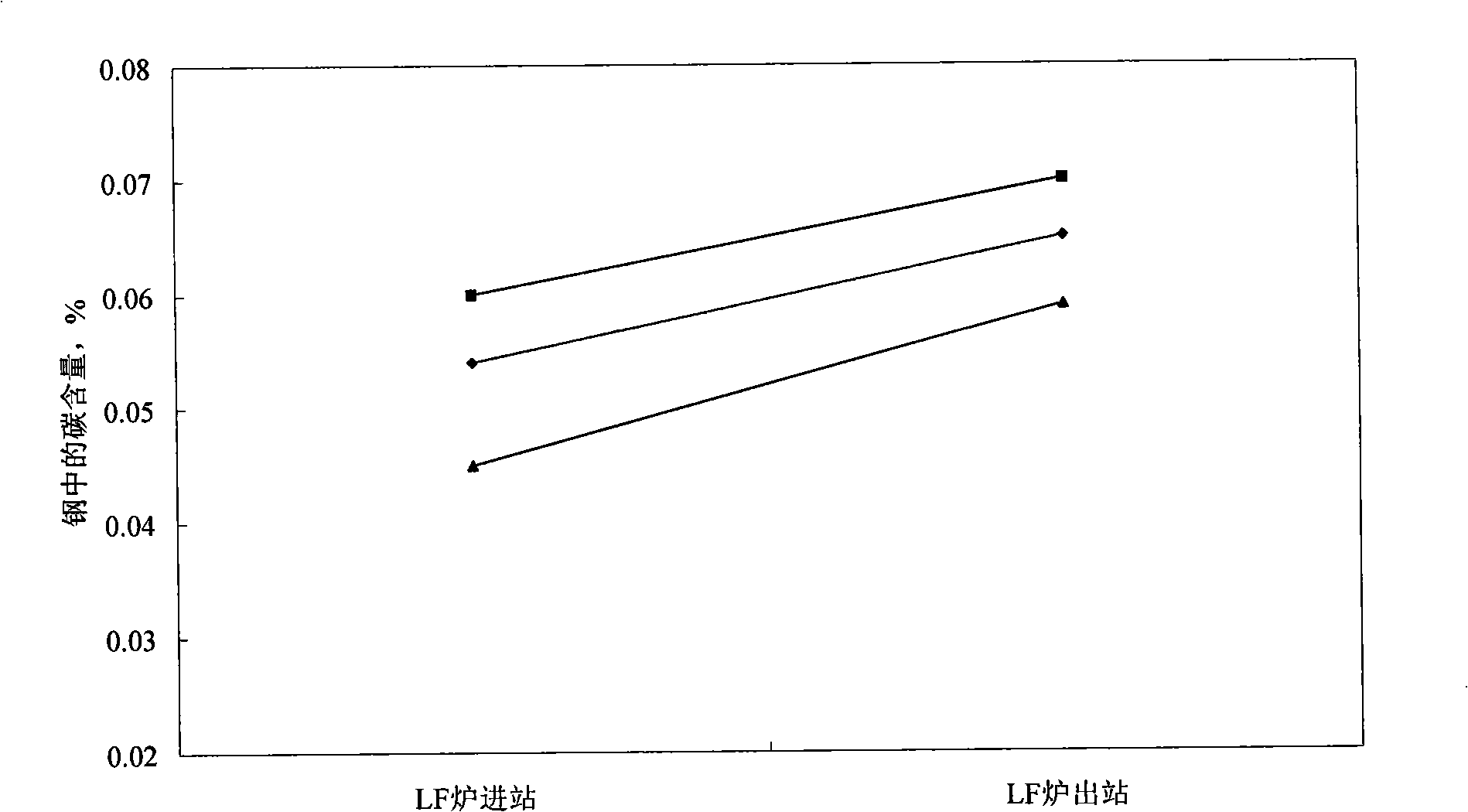

Refined-smelting ladle furnace carbon control deep desulphurization method for ultra-low-carbon steel production

ActiveCN101323896ASolve the problem of adding CShorten desulfurization treatment timeProcess efficiency improvementAlkalinitySulfur

The invention discloses a method for controlling carbon and deep desulphurization by a refined-smelting ladle furnace in the production of extreme low carbon steel, pertaining to the technical field of ladle refining. The technology of the invention is that the amount of roughing slag of a converter is controlled and the thickness of the slag is 30 mm to 60mm; the temperature of molten steel in an LF furnace ranges from 1590 DEG C to 1640 DEG C and the content of Al in the steel is equal to 0.05 percent to 0.09 percent; 6 to 12 kg / ton of refining slag with high basicity and 0.4 to 1.0 kg / ton of Al granules are added; the flow of bottom-blowing argon gas is controlled during the rapid deep desulphurization refining process. On the condition that no electrode is available, argon gas with mass flow of 6 to 8NL / (min question mark t) is adopted for melting slag. After slag melting, the electrode is arranged to control the flow of argon gas to 4.8-6NL / (min question mark t) and carbon pickup of the molten steel occurs; when the refining is completed, the oxidizability of steel slag (FeO+MnO) is required to be less than or equal to 1.0 percent and the weight percentage of alkalinity of (CaO) / (SiO2) is equal to 5.5 to 8.0. The method of the invention has the advantages of solving the problem of carbon pickup during the refining in the LF furnace and controlling the weight percentage of carbon increment within 0.015 percent, thereby realizing rapid deep desulphurization with the content of sulfur[S] which is less than or equal to 0.0010 percent after desulphurization, and shortening the smelting time of the LF furnace.

Owner:SHOUGANG CORPORATION

Fluid catalytic cracking catalyst having desulfurizing functions, process for production of the same, and process for production of low-sulfur catalytically cracked gasoline with the catalyst

InactiveUS20090230023A1Efficient productionMaximum functionCatalytic crackingMolecular sieve catalystsClay mineralsReverse osmosis

The present invention 1, 2 or 3 provides a desulfurization function-added FCC catalyst which can efficiently reduce the sulfur content of FCC gasoline while maintaining the yield of FCC gasoline in a process of producing FCC gasoline by cracking of heavy oil. The catalyst has vanadium supported on a carrier comprising (a) an alumina-coated zeolite and (b) a porous inorganic oxide except zeolite and / or a clay mineral, wherein the supported vanadium amount is from 500 to 20000 ppm by mass in terms of vanadium metal and the acid amount is from 20 to 450 μmol / g and the macropore surface area is from 30 to 150 m2 / g; or the catalyst has vanadium supported on a carrier containing from 5 to 40% by mass of (a) an alumina-coated zeolite and from 30 to 70% by mass of (b) an alumina, wherein the vanadium concentration ratio before and after grinding the catalyst is at least 2; or the catalyst has at least vanadium and manganese and / or phosphorus supported on a porous inorganic oxide-containing carrier, wherein the supported vanadium amount is from 500 to 20000 ppm by mass in terms of vanadium metal, vanadium and manganese and / or phosphorus form a complex ion in the supporting solution for use in supporting vanadium and manganese and / or phosphorus, and the permeability of the complex ion through a reverse osmosis membrane is at most 25% relative to the permeability of vanadium through the reverse osmosis membrane.

Owner:IDEMITSU KOSAN CO LTD +1

Wear-resistant flux-cored wire for stainless steel

InactiveCN106514047AHigh strengthHigh hardnessWelding/cutting media/materialsSoldering mediaWear resistantRare earth

The invention discloses a wear-resistant flux-cored wire for stainless steel. The wear-resistant flux-cored wire consists of a flux core and a stainless steel sheath coating the outer side of the flux core, wherein the flux core comprises the following raw materials in parts by weight: 15-22 parts of chromium powder, 1-4 parts of titanium powder, 0.5-2 parts of nickel powder, 1-4 parts of silicon calcium alloy, 1-4 parts of magnalium, 4.5-7 parts of ferromanganese, 2-5 parts of ferromolybdenum, 2-4 parts of ferrocolumbium, 4-8 parts of rare earth ferroalloy, 4-8 parts of vanadium-nitrogen alloy, 6-9 parts of carbonate, 3-6 parts of graphite and 100-150 parts of iron powder. The wear-resistant flux-cored wire for stainless steel has favorable wear resistance, corrosion resistance, heat resistance and mechanical property; a deposited metal structure is compact, pore-free and crack-free; and the wear-resistant flux-cored wire for stainless steel can be favorably combined with a base material and is stable in performance.

Owner:天长市通联焊业有限公司

Environmental-friendly solid fuel manufactured by municipal solid waste without manual classification and manufacturing method thereof

ActiveCN101831339AQuality improvementEfficient desulfurizationBiofuelsSolid fuelsBiotechnologySolid fuel

The invention discloses solid fuel manufactured by municipal solid wastes without manual classification. The solid fuel is manufactured by the following components in percentage by weight: 75%-85% of treated municipal solid wastes, 2%-7% of coal dust containing fixed carbon and 10%-20% of mixed additives. The invention aims at overcoming the defects in the prior art and increasing a novel treatment technology taking a biotechnology as a main technology to carry out advanced treatment on the municipal solid wastes, thereby providing the solid fuel which turns wastes into useful things by taking the municipal solid wastes as raw materials, has low production cost and little pollution, is beneficial to the environmental protection and has high combustion efficiency; and in addition, the invention has an other purpose of additionally providing a method which has simple process and environmental protection and is used for producing the solid fuel for changing a biochemical treatment methodof percolate generated in the wastes treatment process, wherein the biochemical treatment method has high production cost.

Owner:茹兆祥 +2

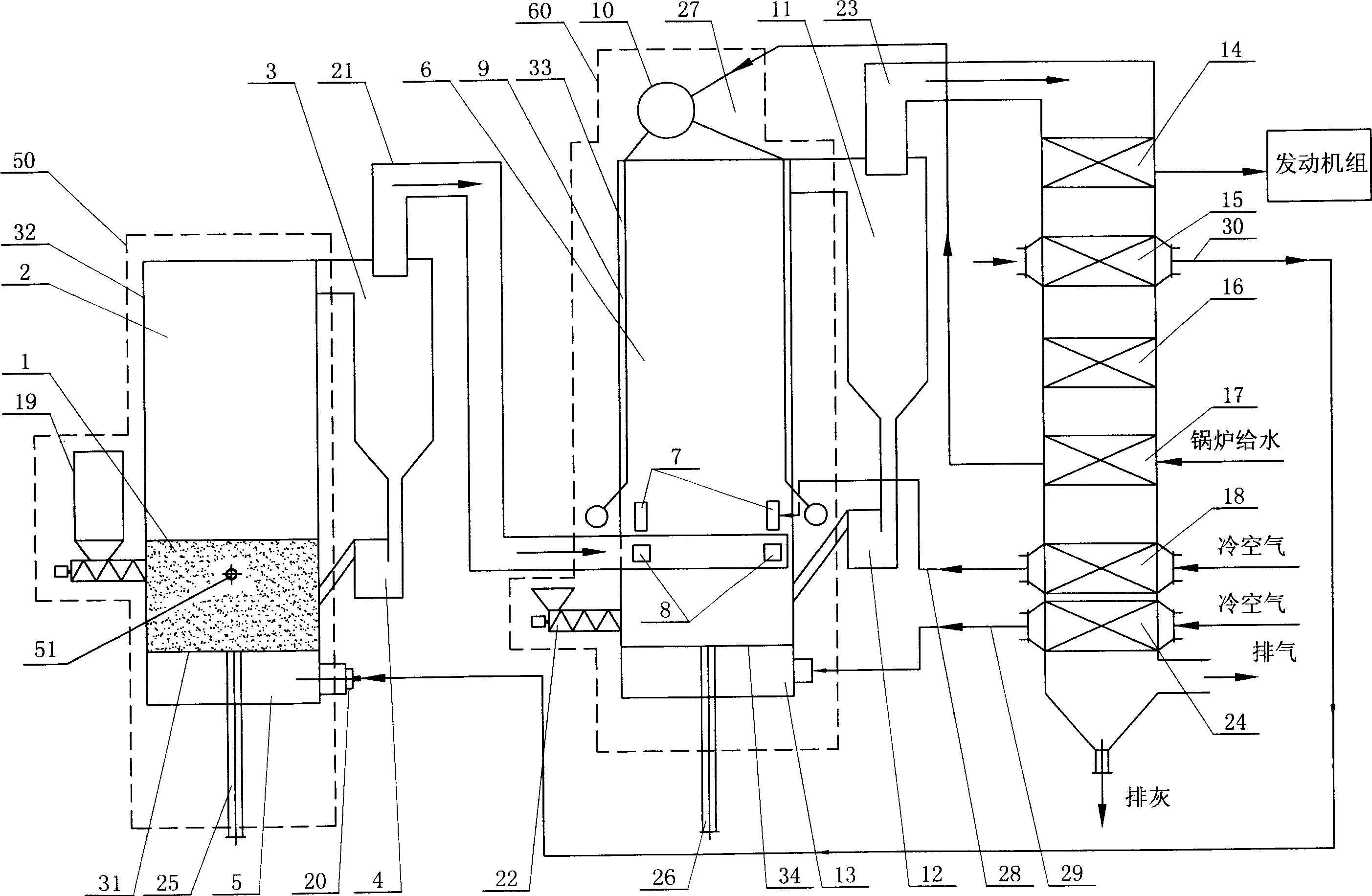

Double temperature double bed gasification, oxidization and fluidized bed incinerator for disposing high concentration organic effluent liquor

InactiveCN1632379ASolve cokingEmission reductionIncinerator apparatusHigh concentrationAir preheater

The utility model relates to a double-temperature double-bed gasification and oxidation fluidized bed incinerator for treating high-concentration organic waste liquid, which relates to a fluidized-bed incinerator for treating high-concentration organic waste liquid. The other end of the low-temperature flue 21 of the present invention is connected to the high-temperature oxidation circulating fluidized bed 60, and the two ends of the high-temperature air pipeline 30 are respectively connected to the high-temperature air preheater (15) and the low-temperature gasification fluidized bed 50. The combination of low-temperature gasification of low-temperature gasification fluidized bed and high-temperature combustion of high-temperature oxidation circulating fluidized bed in the present invention solves the problem of agglomeration and coking of fluidized bed materials, and effectively removes HCl and SO2 produced after incineration of high-concentration organic waste liquid Harmful gases such as NOx and NOx fully suppress the generation of dioxin in the furnace, and can completely incinerate the toxic organic substances in the waste liquid, and the incineration removal rate reaches more than 99.99%. The device almost solves all the problems encountered in incinerating high-concentration organic waste liquid in a fluidized bed.

Owner:HARBIN INST OF TECH

Method for producing molten iron with high-phosphorus and low-iron refractory iron ore

InactiveCN101643806AEfficient desulfurizationImprove reducibilityFluidised-bed furnacesIronstoneHigh energy

The invention provides a method for producing molten iron with high-phosphorus and low-iron refractory iron ore, comprising the following steps: taking high-phosphorus and low-iron refractory iron oreas raw material; taking wood coal as reducing agent; oxidizing roasting; directly reducing; magnetically separating and separating; melting and separating; dephosphorizing molten iron; and obtainingthe low-phosphorus molten iron. The method can process the extremely refractory iron ore with high P content, high S content, high SiO2 content and low iron level, has high ore iron recovery rate, completely solves the difficulties of the high-phosphorus and low-iron refractory iron ore such as ore selecting and smelting, removing coke, and eliminating high-energy consumption and high-pollution technical process such as ore selecting, sintering, palletizing, coking, etc. Phosphorus-containing slag can realize resource comprehensive utilization. A great number of experiments and semi-industrialproduction demonstrate that the technical economic effect of the method is remarkable and effectively solves the current problem of ore resources supply-demand contradiction in China.

Owner:KUNMING IRON & STEEL HLDG CO LTD

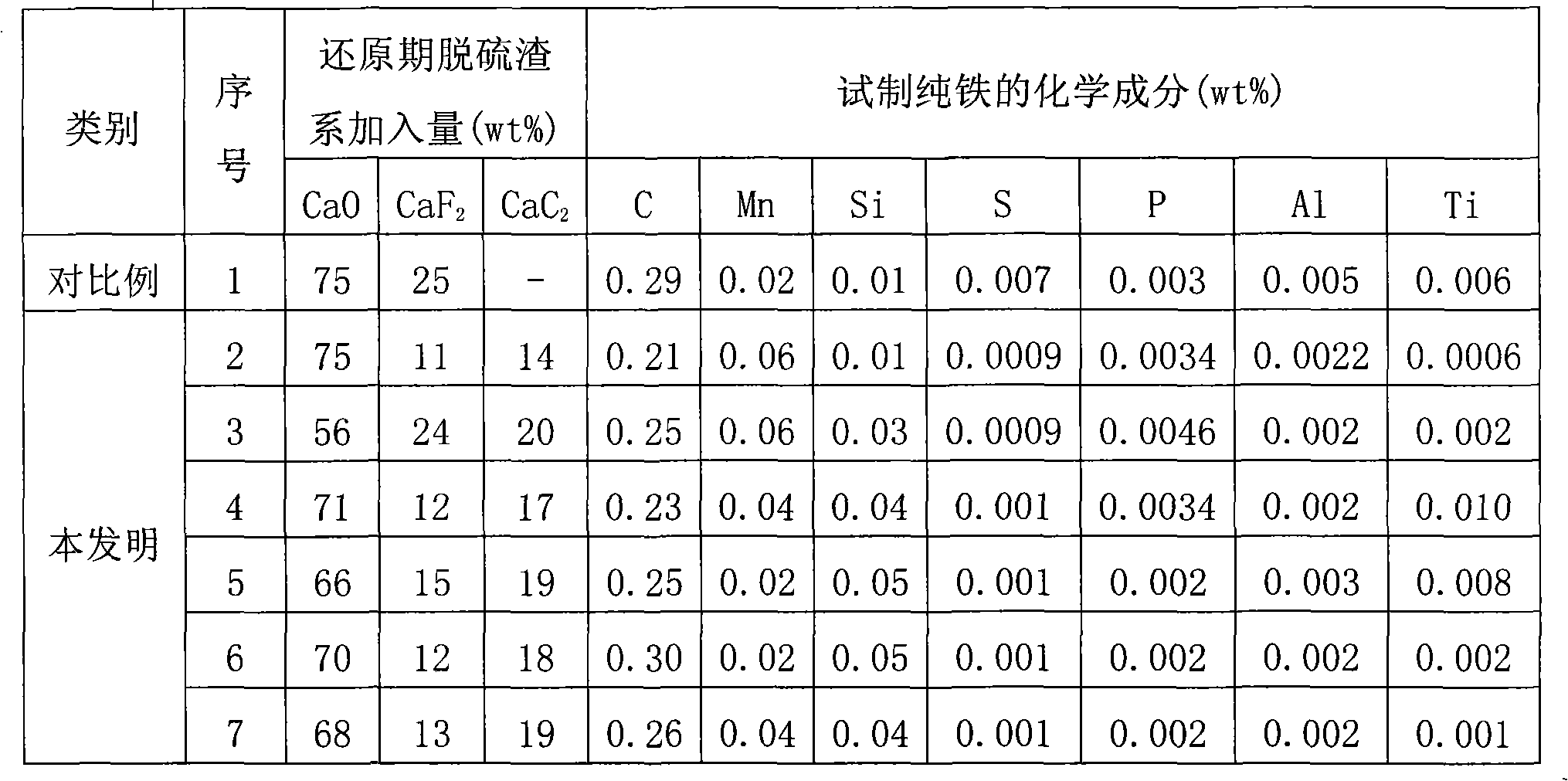

Desulfurization slag system of ultralow-sulfur raw steel and preparation and application methods thereof

ActiveCN101831524AContent meetsThe content also meets the control requirementsProcess efficiency improvementElectric furnaceSlagSulfur

The invention discloses a desulfurization slag system of ultralow-sulfur raw steel and preparation and application methods thereof. The desulfurization slag system is prepared from the following components in percentage by weight: 55-75 percent of CaO, 10-25 percent of CaF2 and 10-20 percent of CaC2. The desulfurization slag system is prepared by mixing fluorite, dry active lime and calcium carbide according to the percentage. The CaO-CaF2-CaC2 slag system is used for desulfurization and deoxidation processing, can simultaneously meet silicon and aluminum requirements, reach higher product indexes and fully satisfy the requirement for secondarily hardening steel. By adopting the invention, ultrahigh-purity pure iron can be prepared by fully utilizing traditional equipment, raw materials are provided for developing AerMet100 steel according with the ultrahigh-purity requirement, and the technical gap between China and developed countries in the world in the field of pure iron metallurgy can be shortened.

Owner:宝武特种冶金有限公司

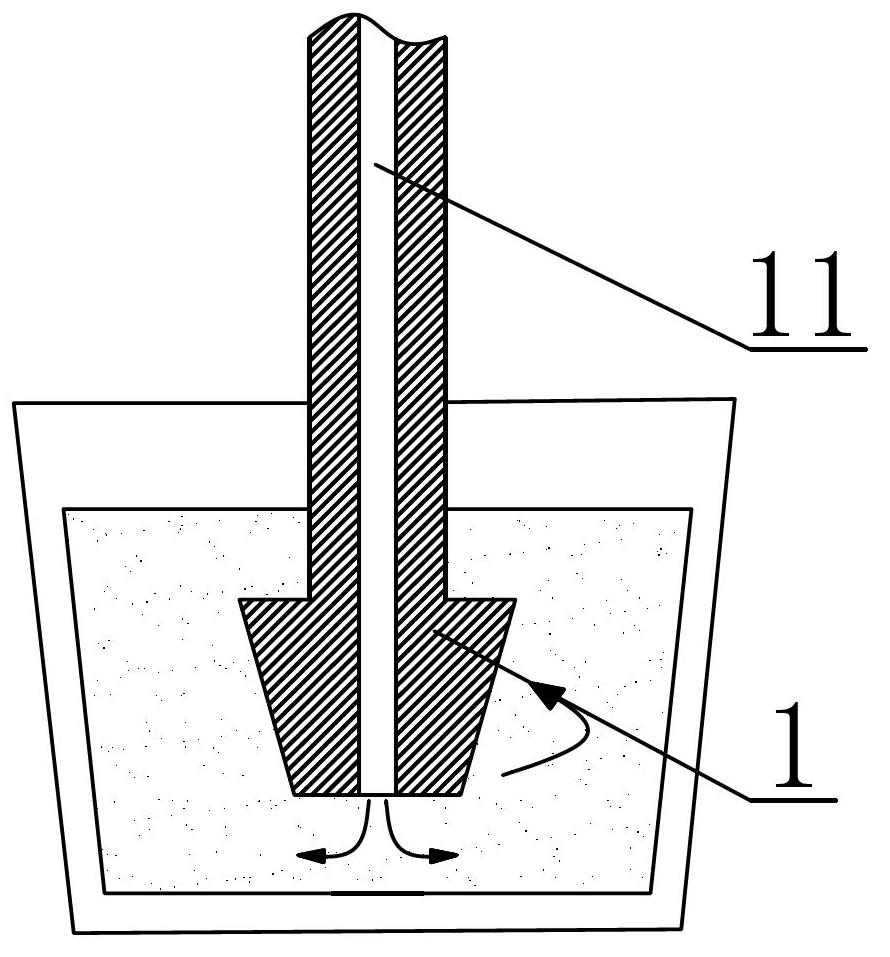

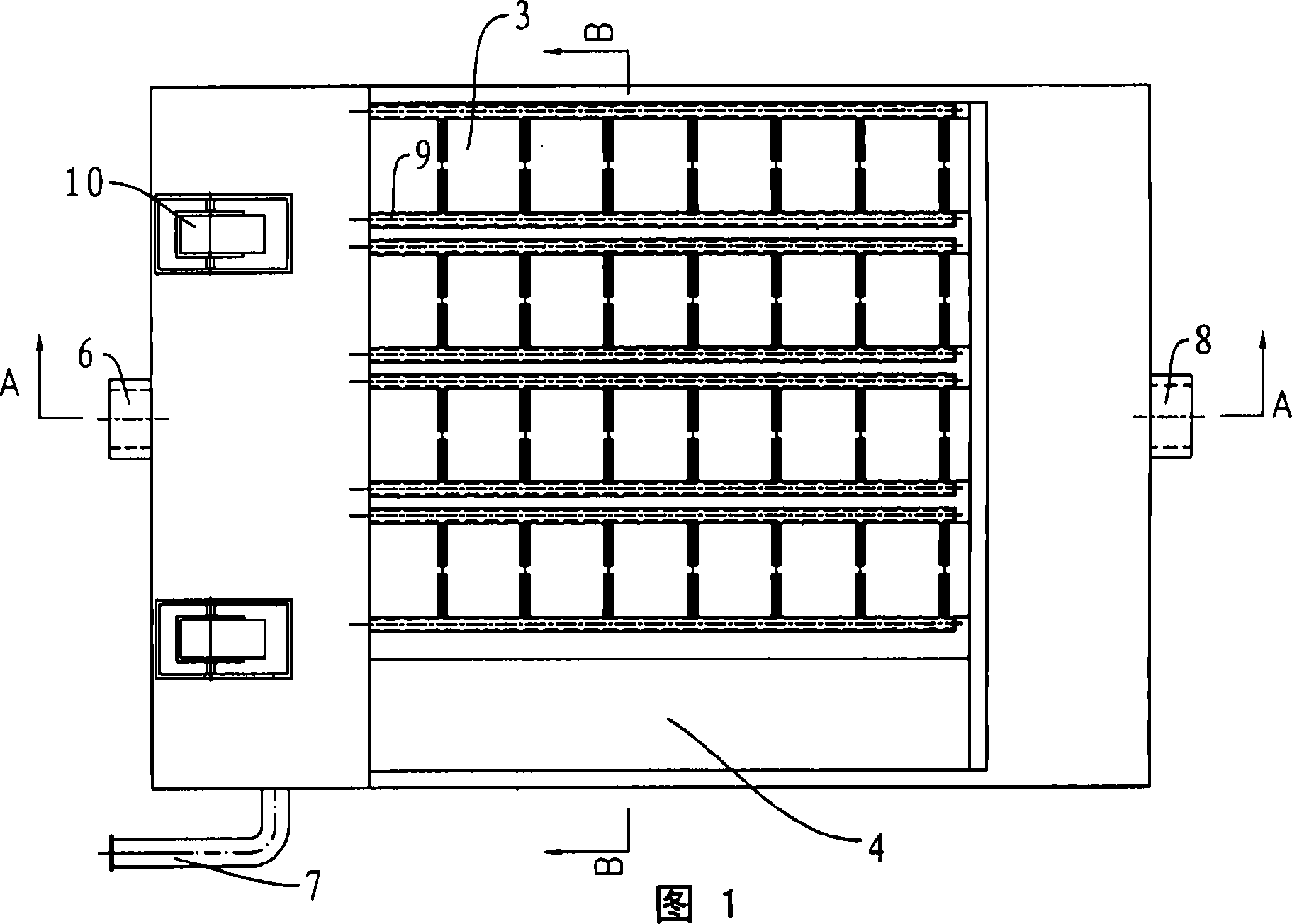

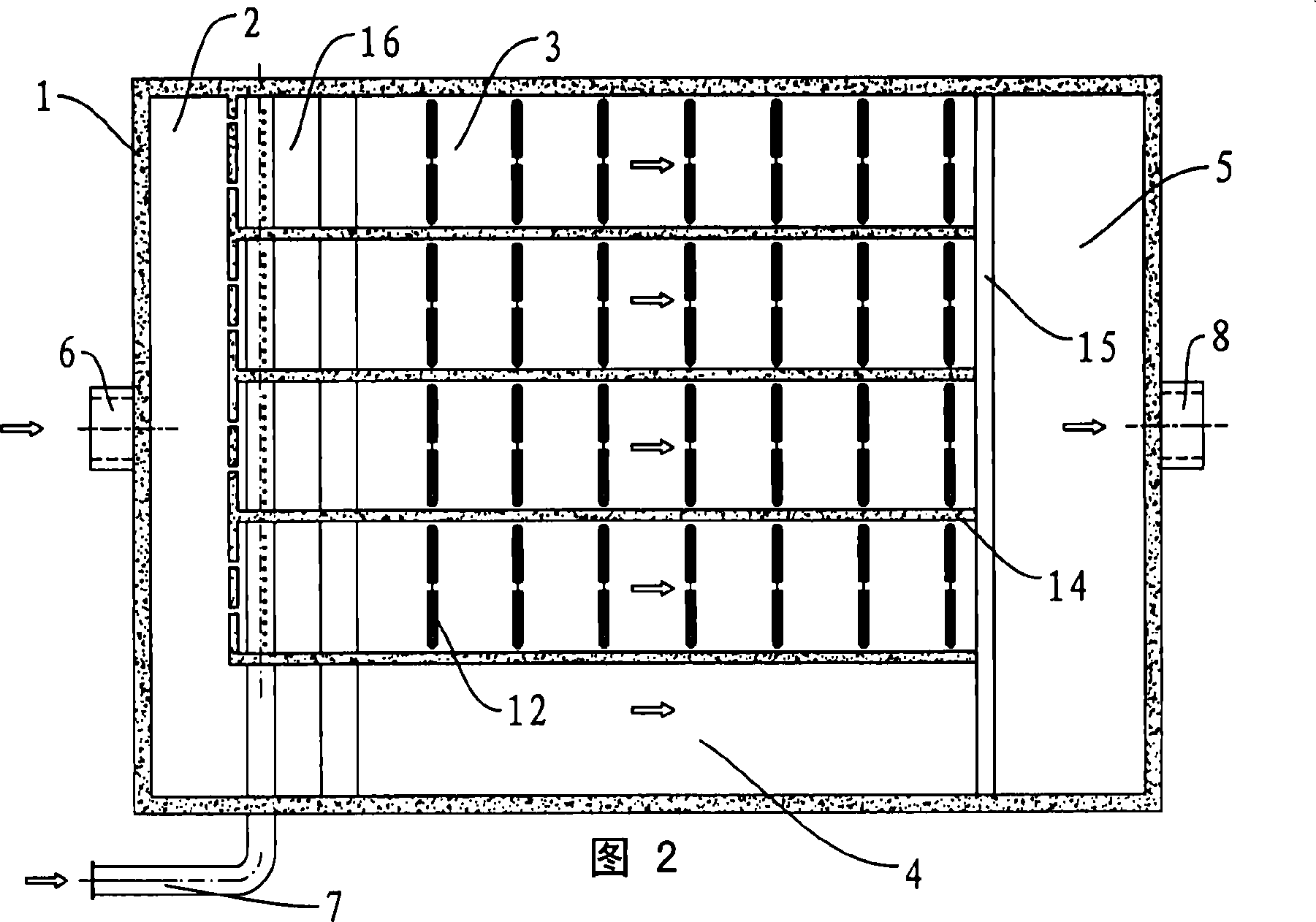

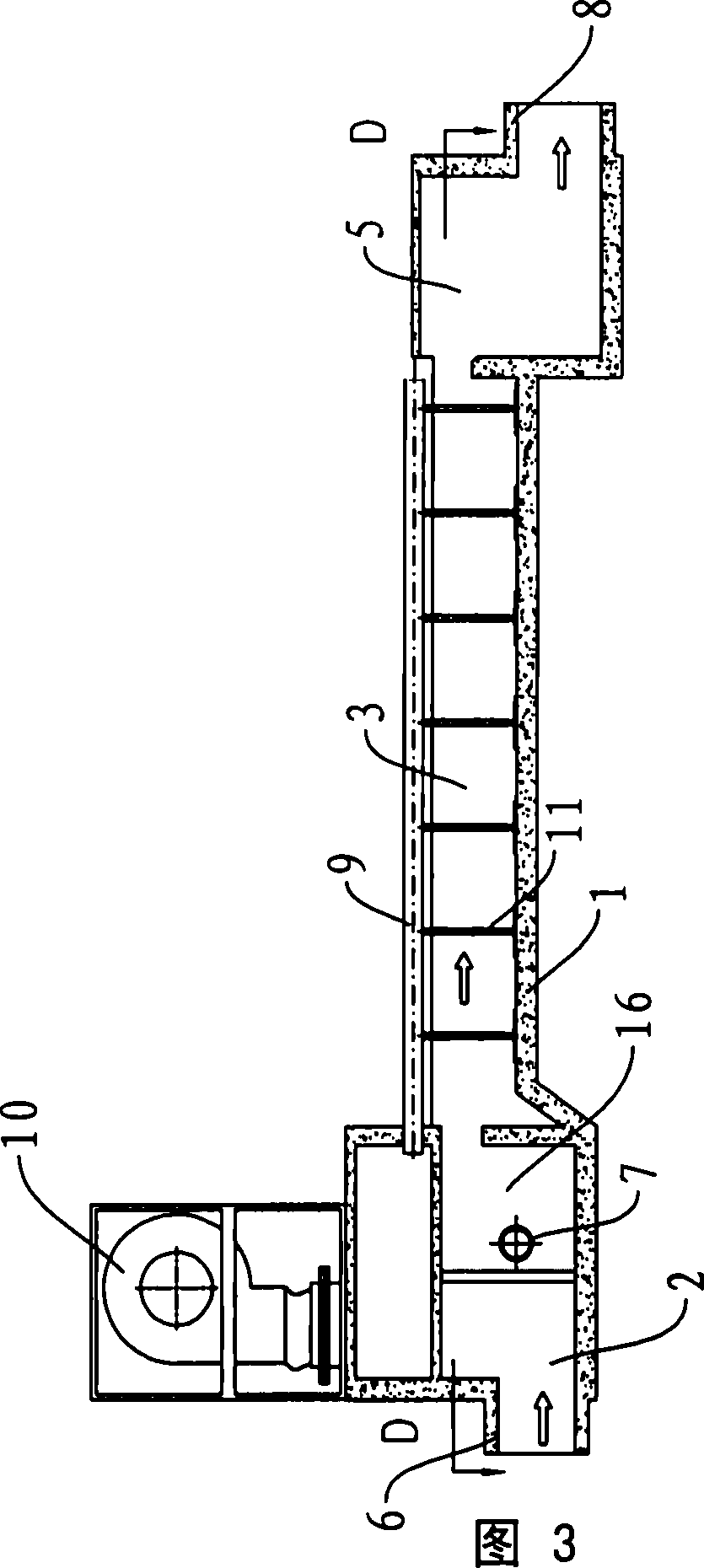

Device for desulfurization and recovery of seawater by industrial flue gas

InactiveCN1884124AEfficient desulfurizationLow costDispersed particle separationWater/sewage treatment by oxidationIndustrial gasFlue gas

The invention discloses a desulfurizing seawater restoring device of industrial flue gas seawater, which comprises the following parts: pool (1), distribution region (2) interconnected by several separated transverse baffles, blending region (16), aeration region (3) and discharge region (5), wherein the fresh seawater inlet (6) is set in the distribution region (2); the desulfurizing seawater input pipe (7) is set in the blending region (16); the seawater drainage (8) is set in the discharge region (5); the aeration pipe (9) is set on the aeration region (3), which connects aeration fan (10) and several branch-pipes (11) with each end of branch-pipe (11) lying at aeration head (12) with vent hole (13) on the bottom of pool.

Owner:陈玉乐 +2

Refining device and vacuum refining process for use in non-oriented silicon steel production

InactiveCN101871035AReduce manufacturing costIncrease productivityProcess efficiency improvementSlagDecarburization

The invention provides a refining device and a vacuum refining process for use in non-oriented silicon steel production, which belong to the technical field of steel refining. The refining device comprises a ladle, a VD vacuum chamber, a vacuum cover trolley, an alloy inlet, a coolant inlet, a coolant bin, an alloy bin and a vacuum pump, wherein the ladle is provided with a ladle cover on the top and a plurality of breathable bricks at the bottom; the two ends of the vacuum chamber cover trolley are provided with wire feeding devices; an oxygen blowing device is arranged on the vacuum chamber cover trolley; and the oxygen blowing opening is led to the inside of the ladle from the ladle cover directly. The refining device can meet the requirements for synchronous external decarburization, desulfuration and denitrification in non-oriented silicon steel production, reduce production cost and obviously improve production efficiency. When the novel external refining device is used in non-oriented silicon steel production, molten water blown in a converter is subjected to vacuum-oxygen decarbonization first at a VD station in a vacuum chamber to reduce carbon content to below 25ppm and then aluminum and slag are added into the molten steel in the ladle to perform high-efficiency desulfuration with forced stirring.

Owner:UNIV OF SCI & TECH BEIJING

Quake-proof construction steel with yield strength of 160MPa and production method thereof

InactiveCN101775541AImprove purityHigh strengthTemperature control deviceFurnace typesProof constructionChemical composition

The invention discloses quake-proof construction steel with the yield strength of 160MPa and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.002 to 0.005 percent of C, less than or equal to 0.03 percent of Si, 0.10 to 0.50 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.002 to 0.007 percent of Mg, 0.020 to 0.070 percent of Ti, 0.010 to 0.030 percent of Nb, 0.001 to 0.003 percent of N, less than or equal to 0.050 percent of Al, and the balance of Fe and inevitable impurities. The production method thereof comprises the steps of desulfuration of molten iron, converter blowing, vacuum treatment, continuous casting, hot rolling, cooling and the like. When the yield strength of steel products exceeds 180Mpa, an annealing treatment step is added after the cooling step. Experiments prove that the quake-proof construction steel with the yield strength of 160MPa has the characteristics of low yield strength, high elongation and excellent impact toughness; and the production method of the steel has the advantages of simple process flow and low production cost.

Owner:武钢集团有限公司

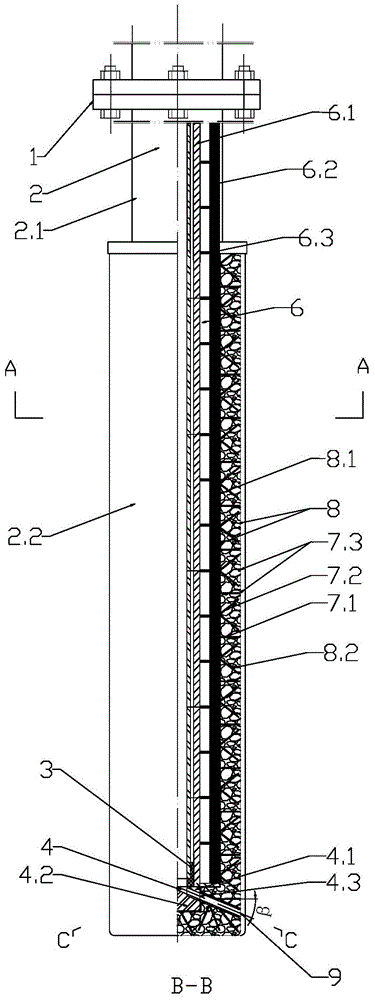

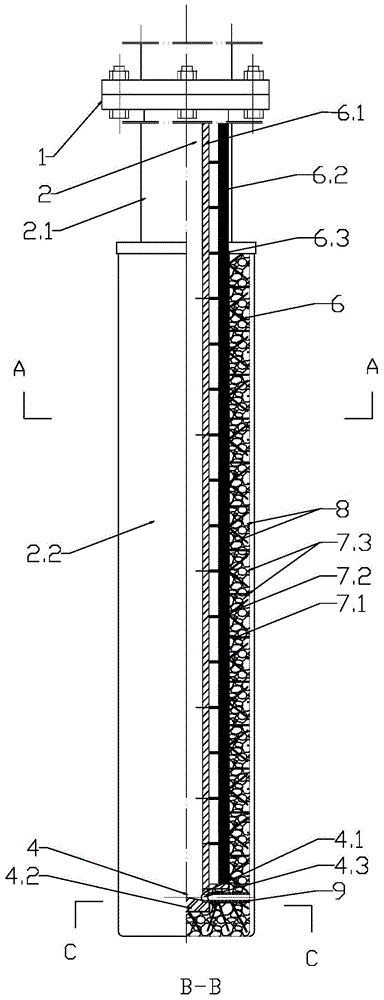

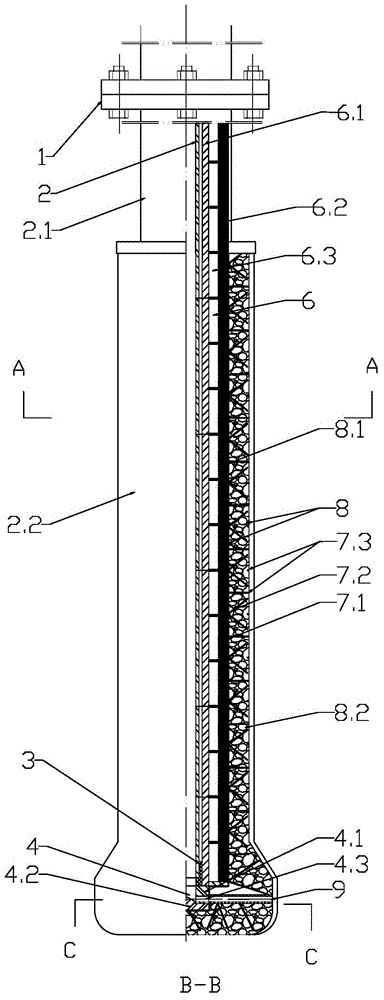

Direct injection molten iron desulphurization spray gun

The invention discloses a direct injection molten iron desulphurization spray gun for a metal particle magnesium or magnesium-based or calcium-based desulphurization agent. The direct injection molten iron desulphurization spray gun comprises a connecting flange and a gun barrel which are sequentially connected and communicated, wherein the gun barrel comprises a connecting section gun barrel and a gun body section gun barrel; the connecting section gun barrel comprises a gun core; a distributor is connected with the lower end of the gun core of the gun body section gun barrel; the distributor comprises an upper end short connecting pipe, a lower end plug platform and a plurality of through holes formed in the wall of the short connecting pipe; and each through hole is communicated with a jetting pipe, and the jetting pipes are distributed in a fire-proof pouring material liner positioned outside the side wall of the distributor. The direct injection molten iron desulphurization spray gun disclosed by the invention can be used for enhancing the jetting strength, extending the desulphurization reaction area and intensifying the gasification and dissolution of metal particle magnesium through structural design, and can be used for enhancing the adaptability on low-quality metal particle magnesium and jetting desulphurization of molten iron tanks with different sizes, extending the adaptive capacity of a process and reducing the consumption cost of the molten iron desulphurization metal particle magnesium through the improvement of desulphurization process steps.

Owner:武汉钢铁有限公司

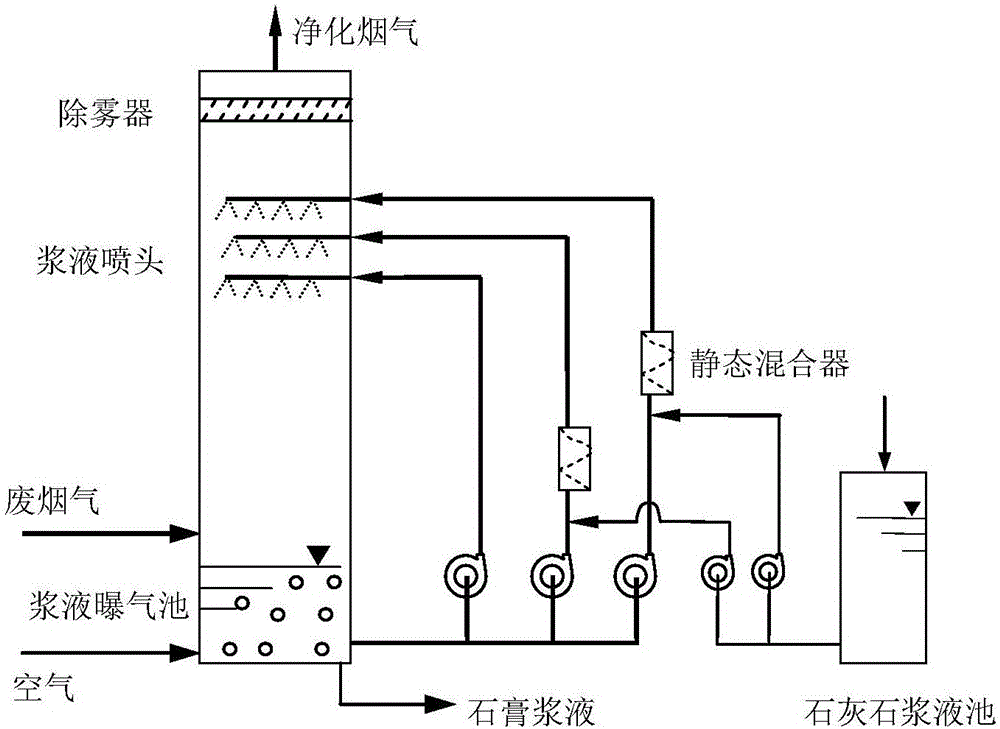

Gradient adjustment method of limestone content in wet desulphurization circulating liquid

ActiveCN106362559AEfficient desulfurizationEasy to operateDispersed particle separationFlue gasSulfur

The invention relates to a gradient adjustment method of limestone content in a wet desulphurization circulating liquid. The method comprises the following steps: detecting the flow rate of waste flue gas entering a desulfurizing tower and the sulfur dioxide content in the waste flue gas, and detecting the sulfur dioxide concentration in flue gas at the outlet of the desulfurizing tower; determining the opening number of spray layers according to the total amount and concentration of sulfur dioxide in the waste flue gas, and optimizing the limestone content in the mixed slurries entering the spray layers. The total new added calcium / sulfur ratio in the mixed slurry of all the opened spray layer is 1:(1.03-1.05); in the mixed slurries of all the spray layers from top to bottom, the limestone content sequentially lowers, thereby forming the limestone content gradient distribution along the spray layers in different heights; and when the desulfurization load of the desulfurizing tower changes along with the changes of the sulfur dioxide concentration and total amount in the waste flue gas, the limestone slurry amount is adjusted according to the total calcium / sulfur ratio to adapt to the corresponding sulfur dioxide increased load. The method implements high desulfurization efficiency under the single-tower single-circulation conditions. The desulfurization process is simple to operate and convenient to run, and lowers the cost.

Owner:SHANDONG UNIV

Method for simultaneously removing sulfur oxides and nitric oxides in flue gas

ActiveCN101632897AGood desulfurization and denitrificationLess investment in equipmentDispersed particle separationAir quality improvementFlueNitric oxide

The invention relates to a method for simultaneously removing sulfur oxides and nitric oxides in flue gas, which belongs to the technical field of flue gas purification. The method comprises the following steps: spraying water or steam into a flue before flue gas from burning equipment enters a fluidized bed reactor through the flue and controlling the temperature of the flue gas within a range of 90-200 DEG C, wherein the flue gas in the flue contains gas components of O2, H2O, SO2 and NOx; directly jetting CaO and / or Ca(OH)2 into the flue to oxidize NO; and controlling the temperature of the fluidized bed reactor to be between 50 DEG C and 90 DEG C for the flue gas to desulfurize and denitrate in the fluidized bed reactor. In the method, desulfurization and denitration can be simultaneously realized in the same system by adjusting processing steps and controlling a reaction condition. When a molar ratio Ca / (S+0.5N) of calcium to sulfur to nitrogen is 1.3, the removal rate of the SO2 can reach over 85 percent, and the removal rate of the NO can reach over 60 percent.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com