Hydrorefining catalyst for preparing fuel oil from coal tar, preparation method and application method thereof

A hydrofining and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of easy deactivation, general activity, hydrothermal stability and Insufficient high temperature resistance and other problems, to achieve the effect of improving quality, long service life and good operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

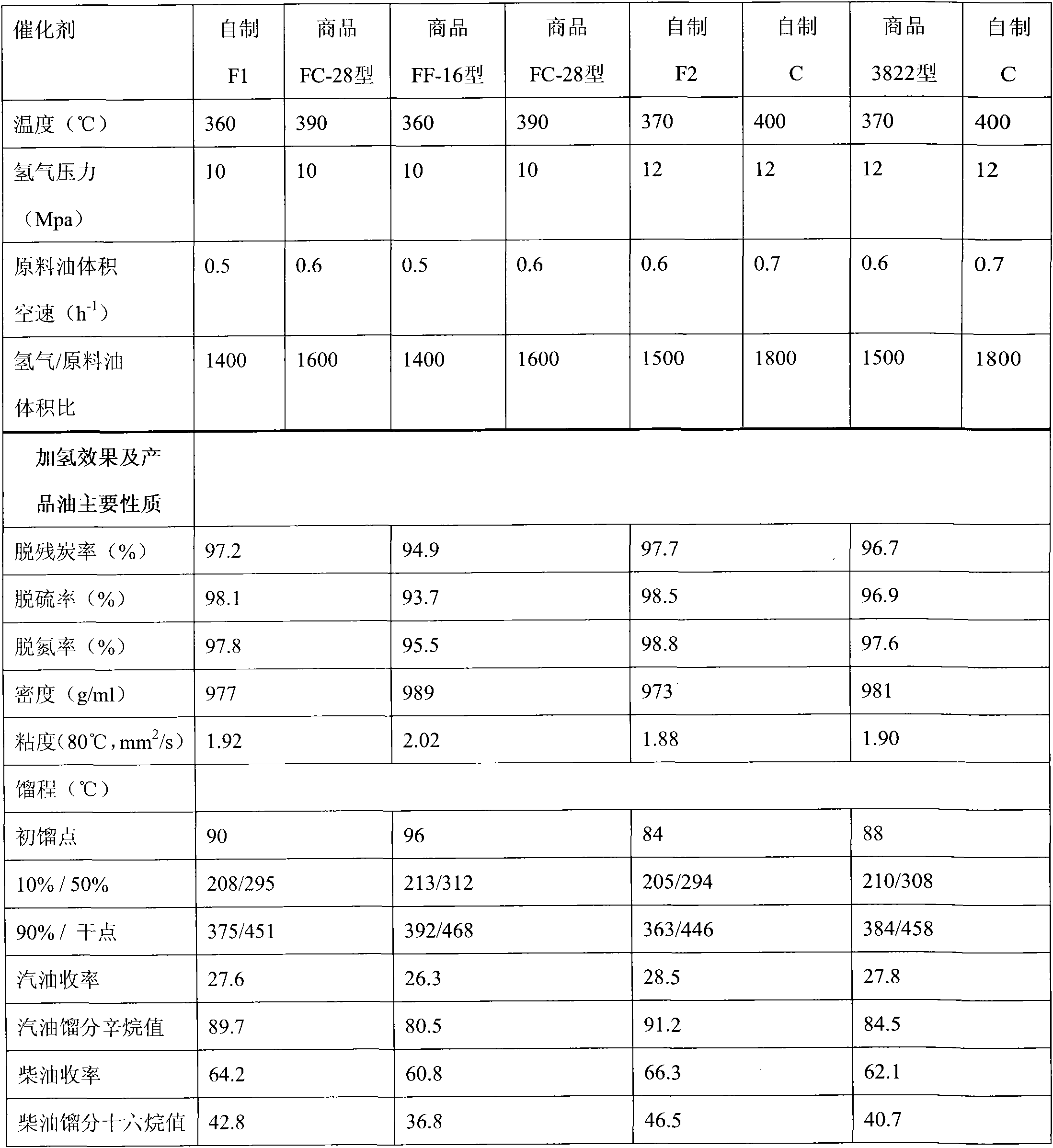

Embodiment 1

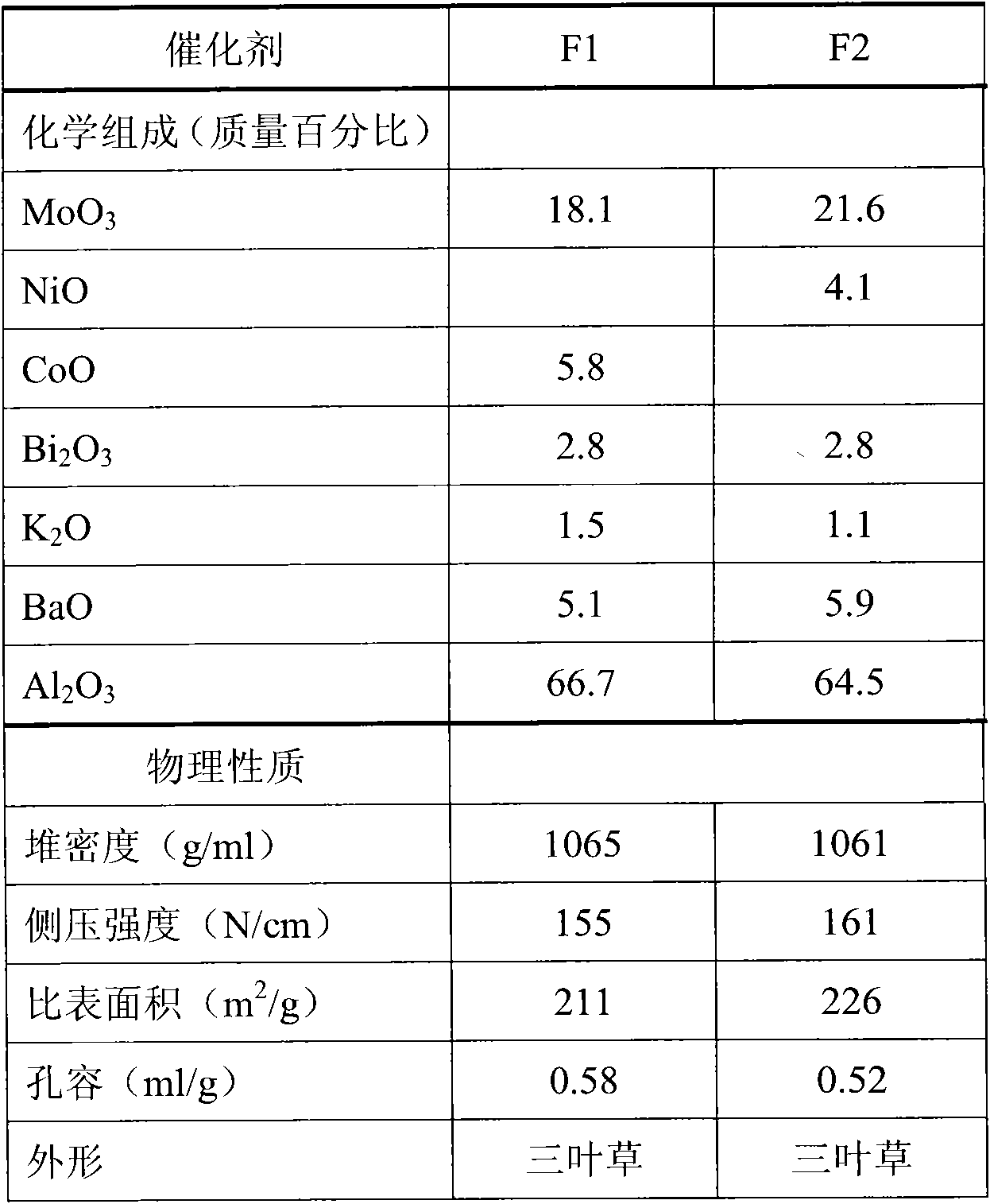

[0031] The preparation of hydrorefining catalyst F1 is as follows:

[0032] Commercially available SB aluminum hydroxide dry rubber powder 100g, add 8.4g barium nitrate fine powder, 1.1g nitric acid, 1.8g citric acid, reconcile into a wet rubber cake. The wet rubber cake is placed on a kneader, continuously sprinkled with 21.7g ammonium molybdate tetrahydrate fine powder, 22.9g cobalt nitrate hexahydrate fine powder, 1.2g cellulose, and knead evenly. Dry at 120°C for 14 hours and grind into fine powder.

[0033] Add 4g of safflower powder and a small amount of deionized water to the fine powder, and use a clover-shaped orifice plate to extrude on a screw extruder. The diameter of the extruded rod is 1.2mm, and the length is 3mm. The shaped strips were rinsed with acetic acid for 6 minutes. Dry at 110°C for 2 hours, and then bake at 490°C for 12 hours at a constant temperature of 490°C for 12 hours in an air atmosphere containing 35% molar concentration of water vapor with a...

Embodiment 2

[0040] The preparation of hydrorefining catalyst F2 is as follows:

[0041] Commercially available SB aluminum hydroxide dry rubber powder 100g, add 10g barium nitrate fine powder, 1g nitric acid, 1.2g acetic acid, 2g citric acid, reconcile into a wet rubber cake. The wet rubber cake is placed on a kneader, continuously sprinkled with 27.5g ammonium molybdate tetrahydrate fine powder, 15.9g nickel nitrate hexahydrate fine powder, 1g cellulose, and knead evenly. Dry at 120°C for 15 hours and grind into fine powder.

[0042] Add 3.2g safflower powder and a small amount of deionized water into the fine powder, and adopt clover-shaped orifice plate extrusion molding on the screw extruder. The extruded rod has a diameter of 1.5mm and a length of 3mm. The shaped strips were rinsed with acetic acid for 8 minutes. Dry at 110°C for 15 hours, and then bake at a constant temperature of 480°C for 12 hours in an air atmosphere containing 40% molar concentration of water vapor with an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com