Patents

Literature

1281results about How to "Simplify operating procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

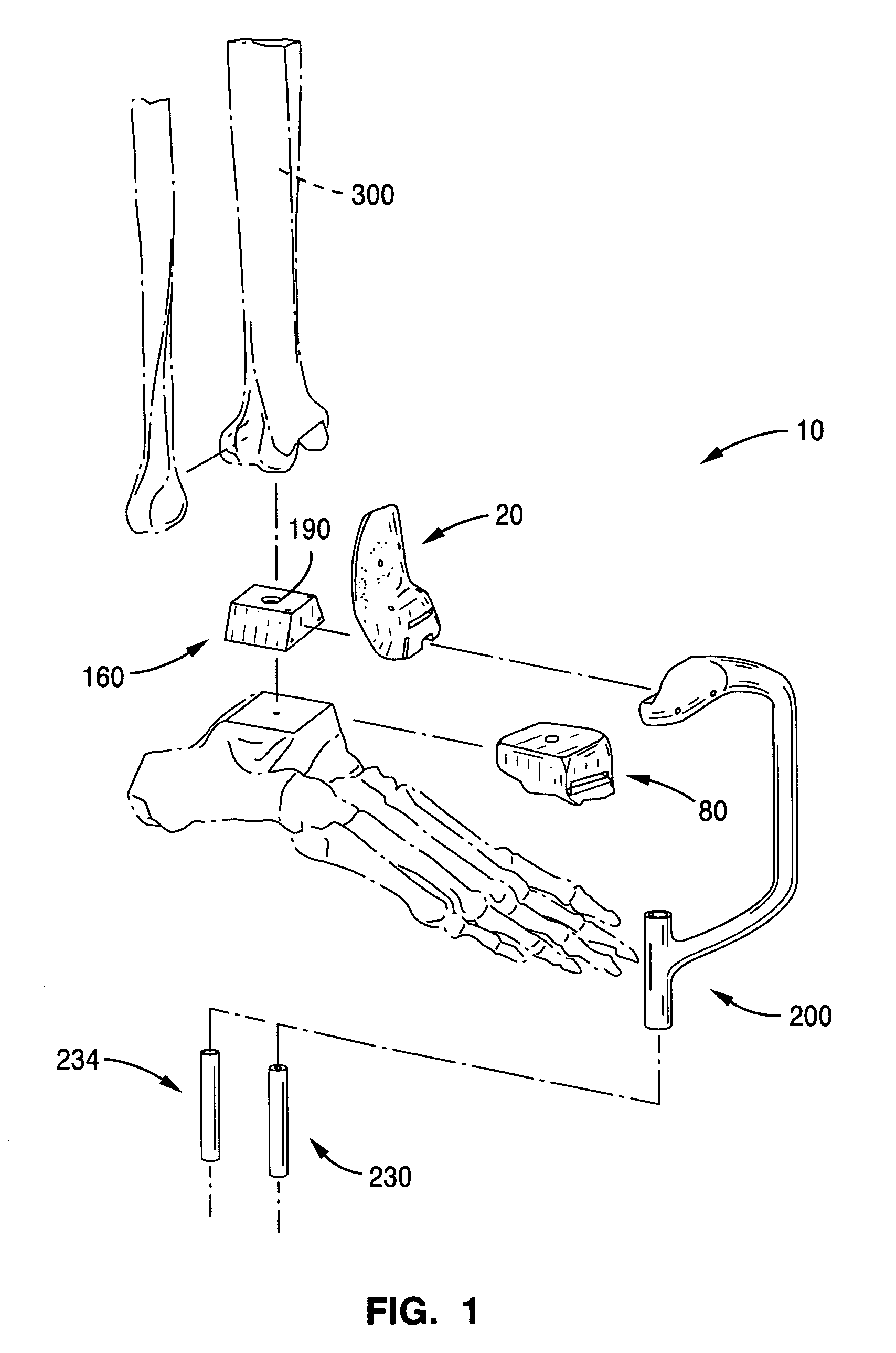

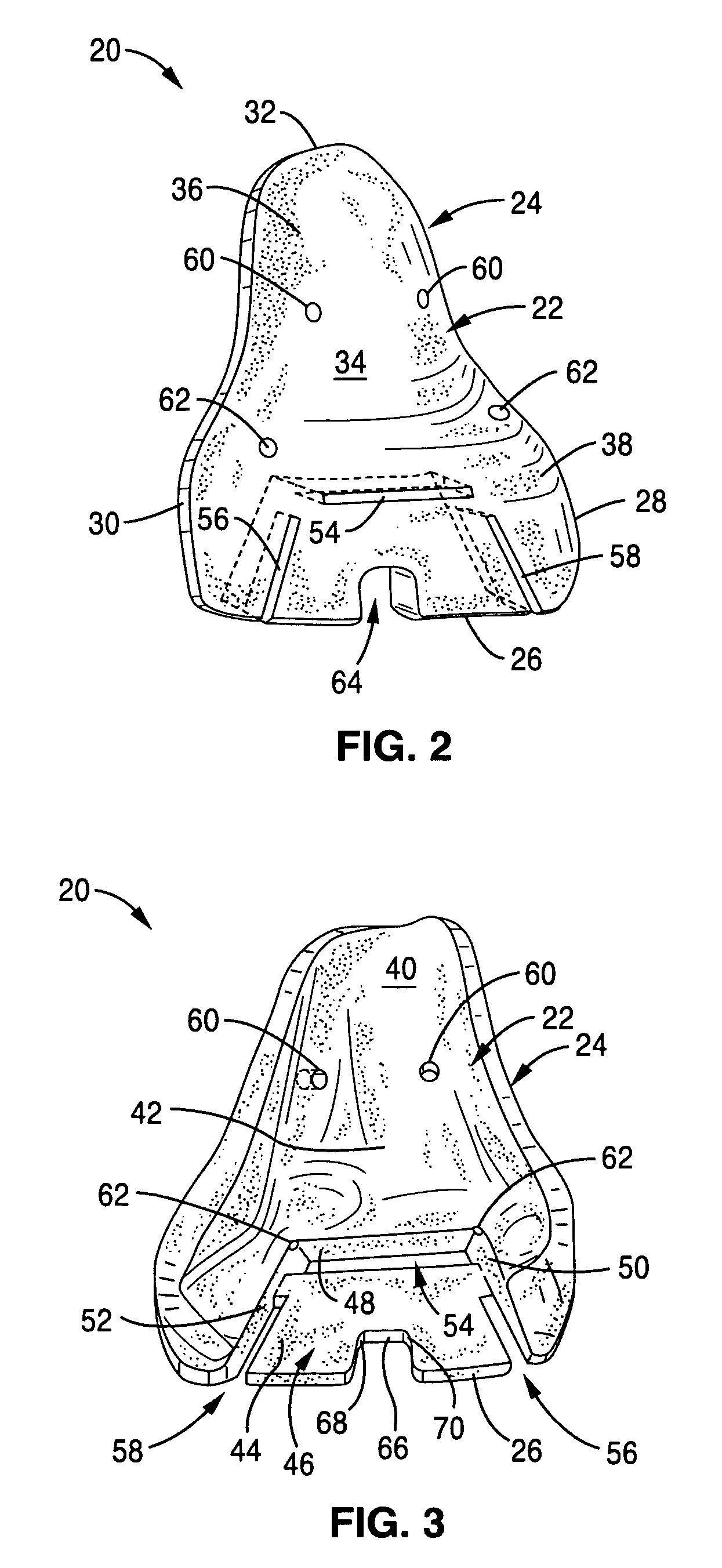

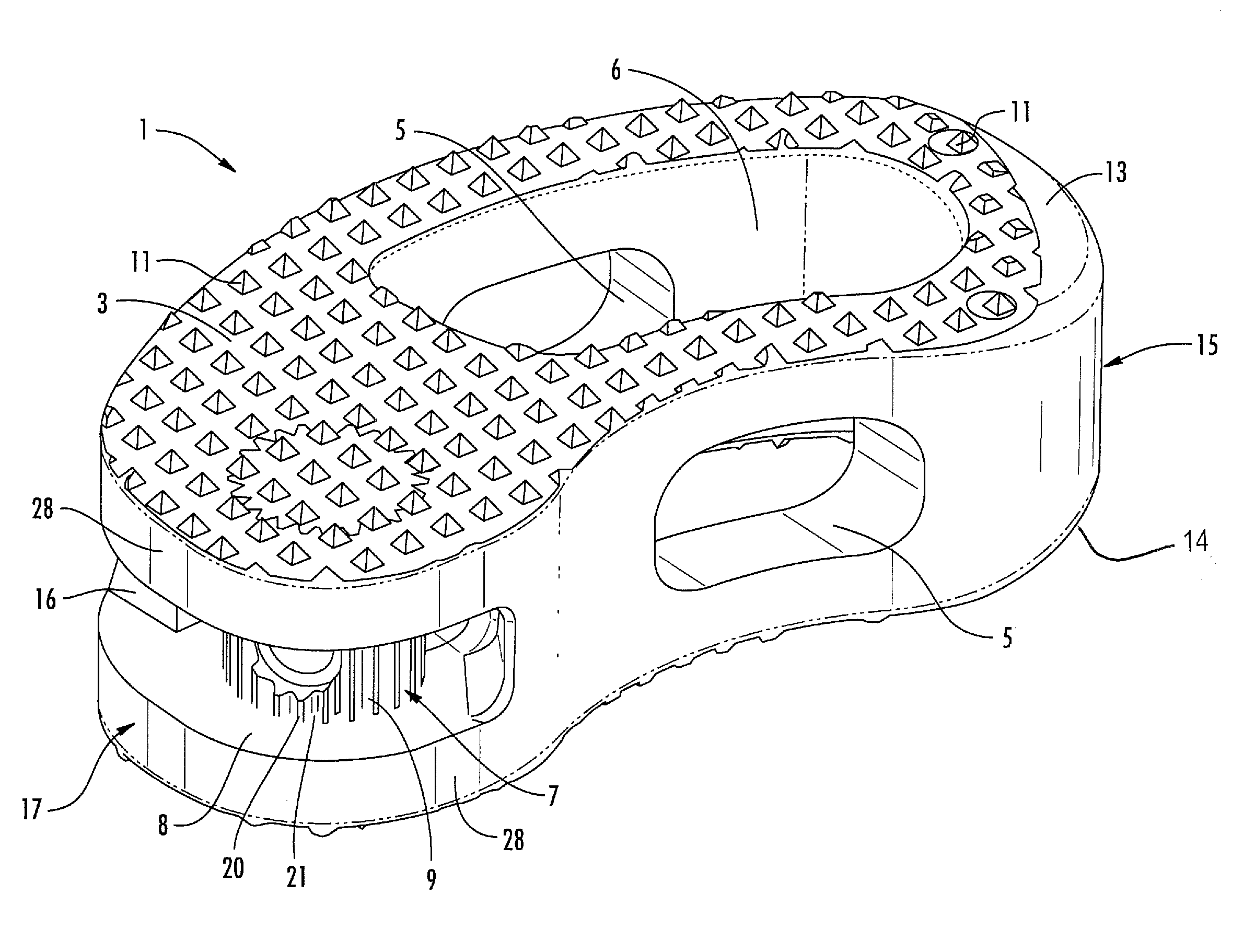

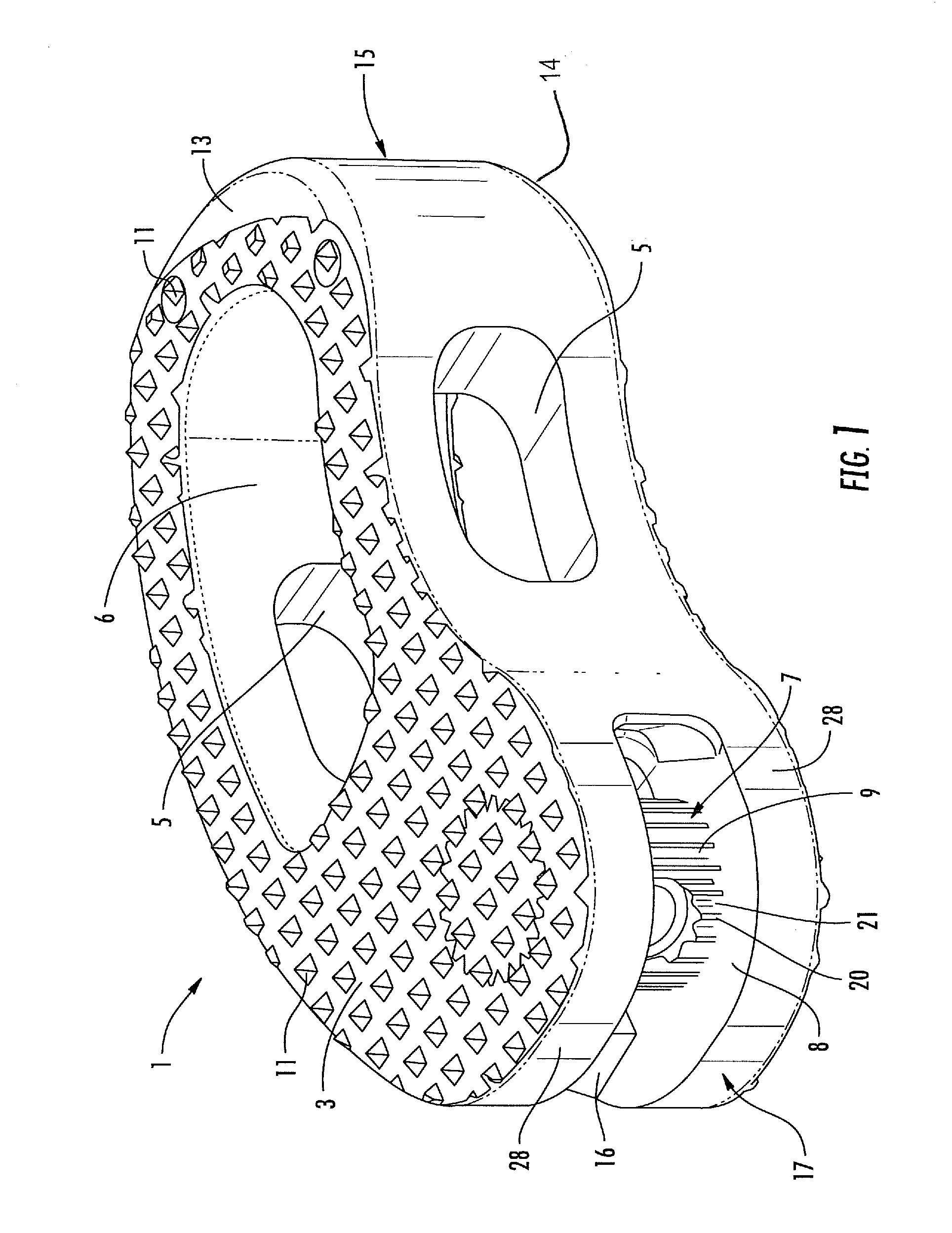

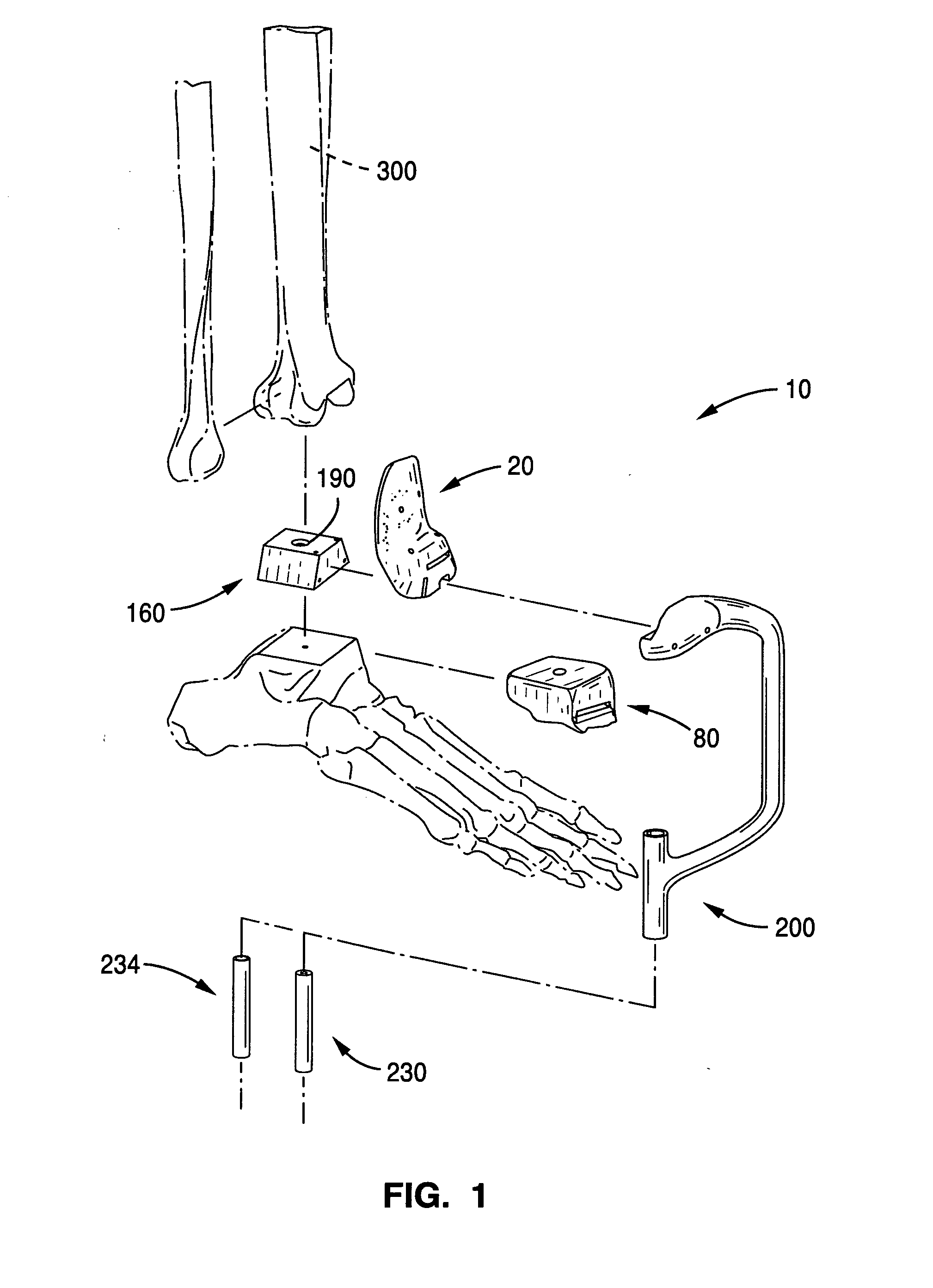

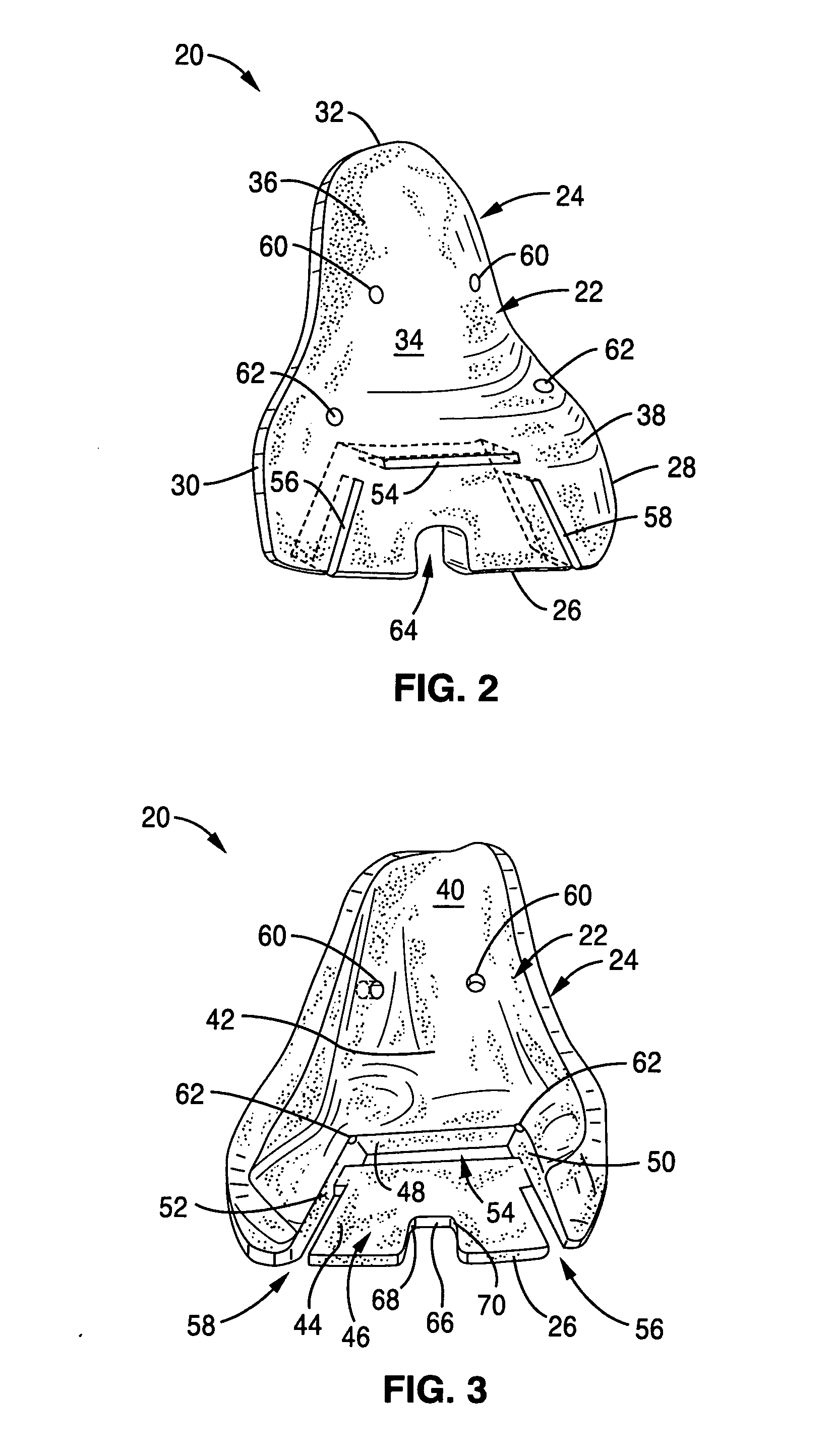

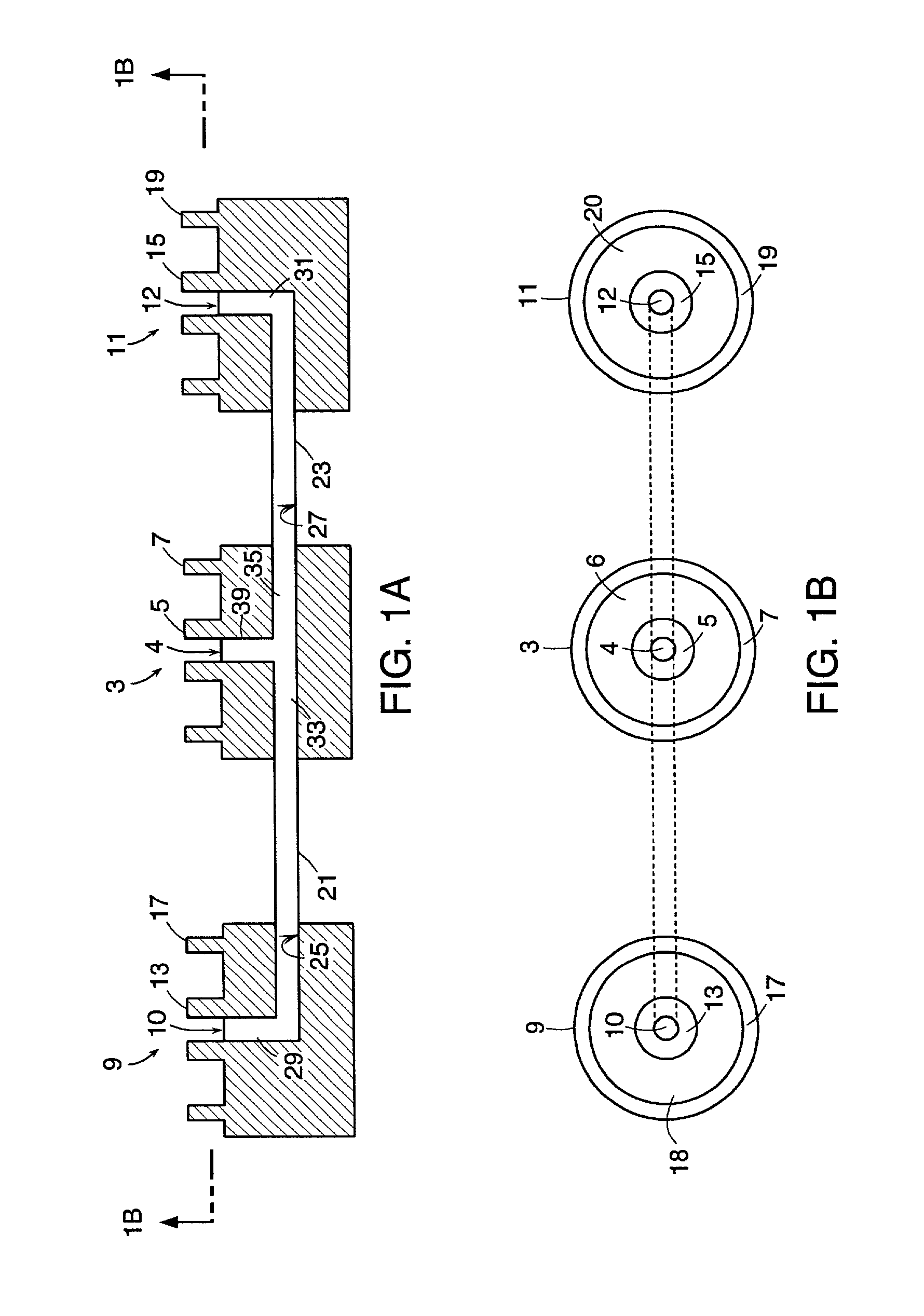

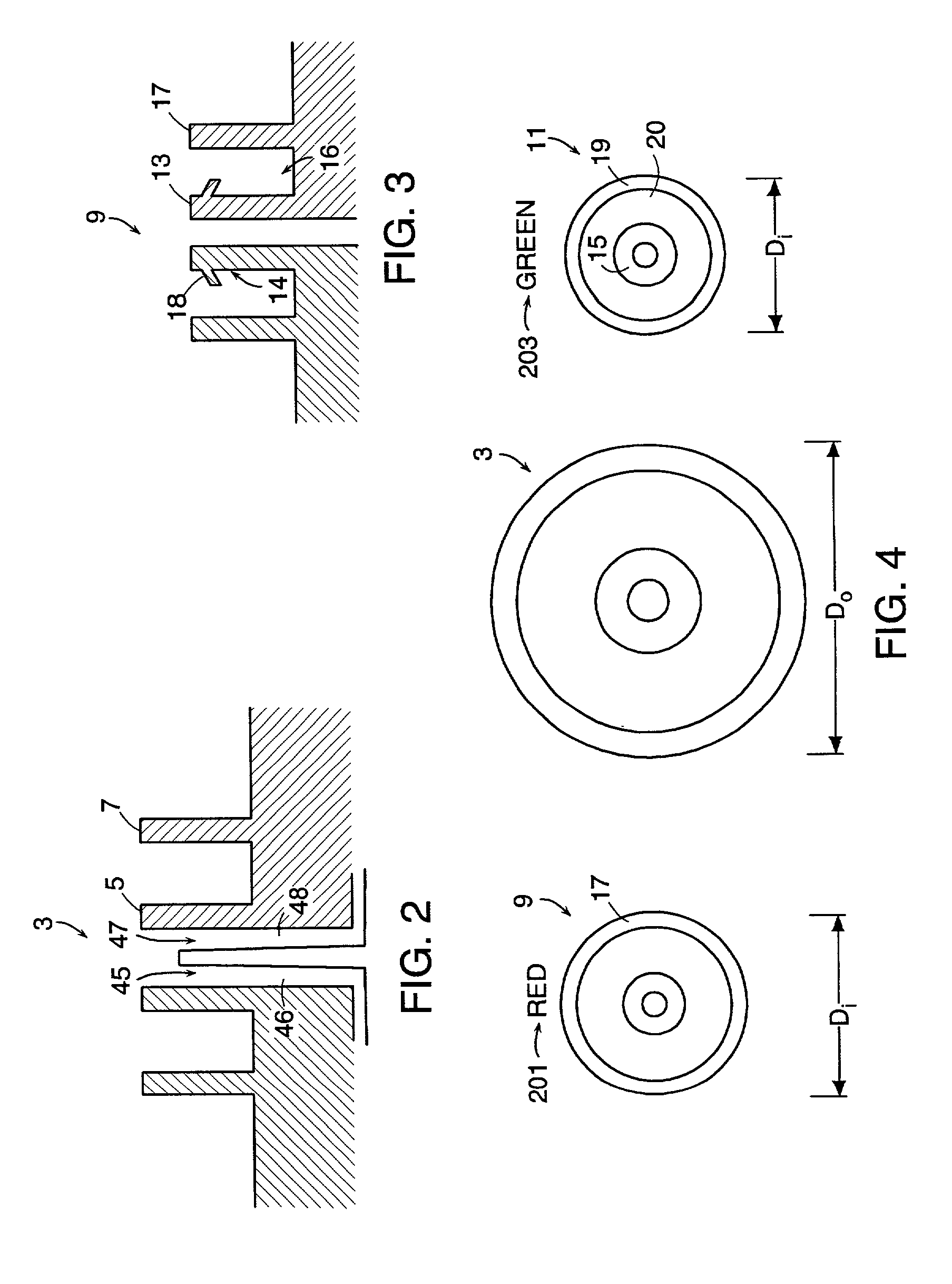

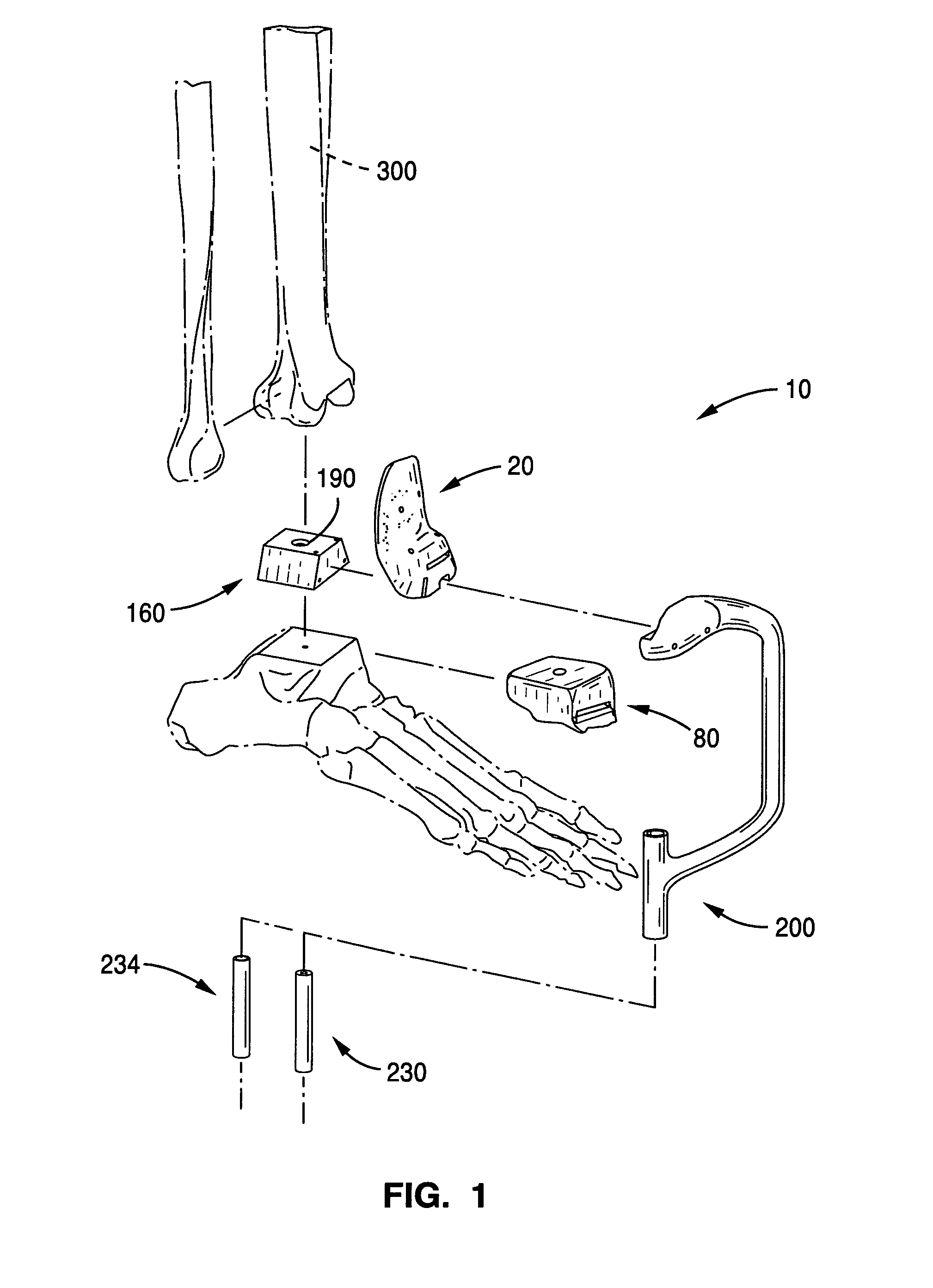

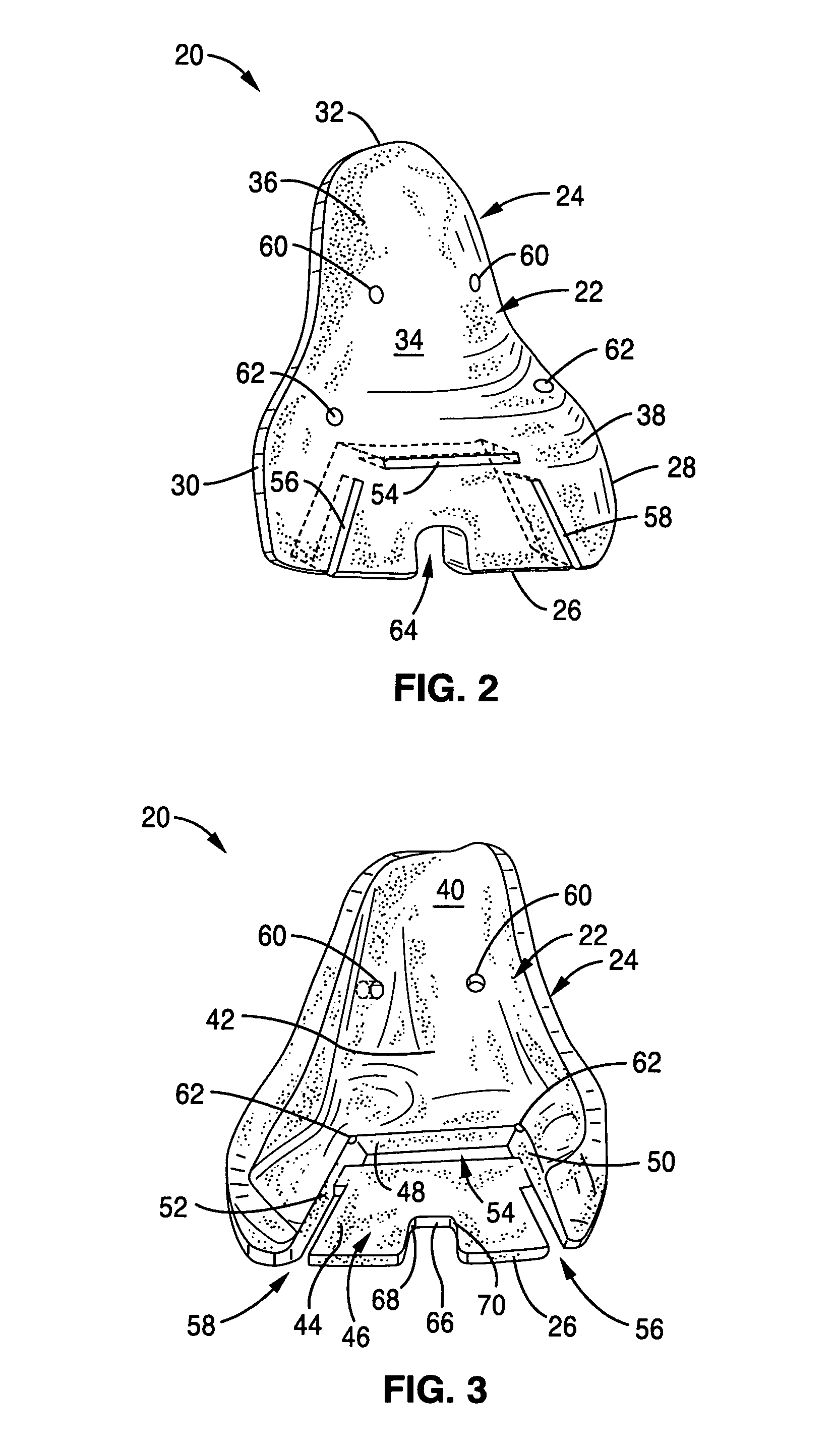

Custom radiographically designed cutting guides and instruments for use in total ankle replacement surgery

ActiveUS8337503B2High precisionSimplify operating proceduresWrist jointsAnkle jointsTibiaSacroiliac joint

A system comprised of custom radiographically designed tibial and talar cutting guides, a tibial reaming guide and bit, and instrumentalities for use in total ankle replacement surgery and a computer-based system and method for making the custom radiographically designed tibial and talar cutting guides.

Owner:LIAN GEORGE JOHN

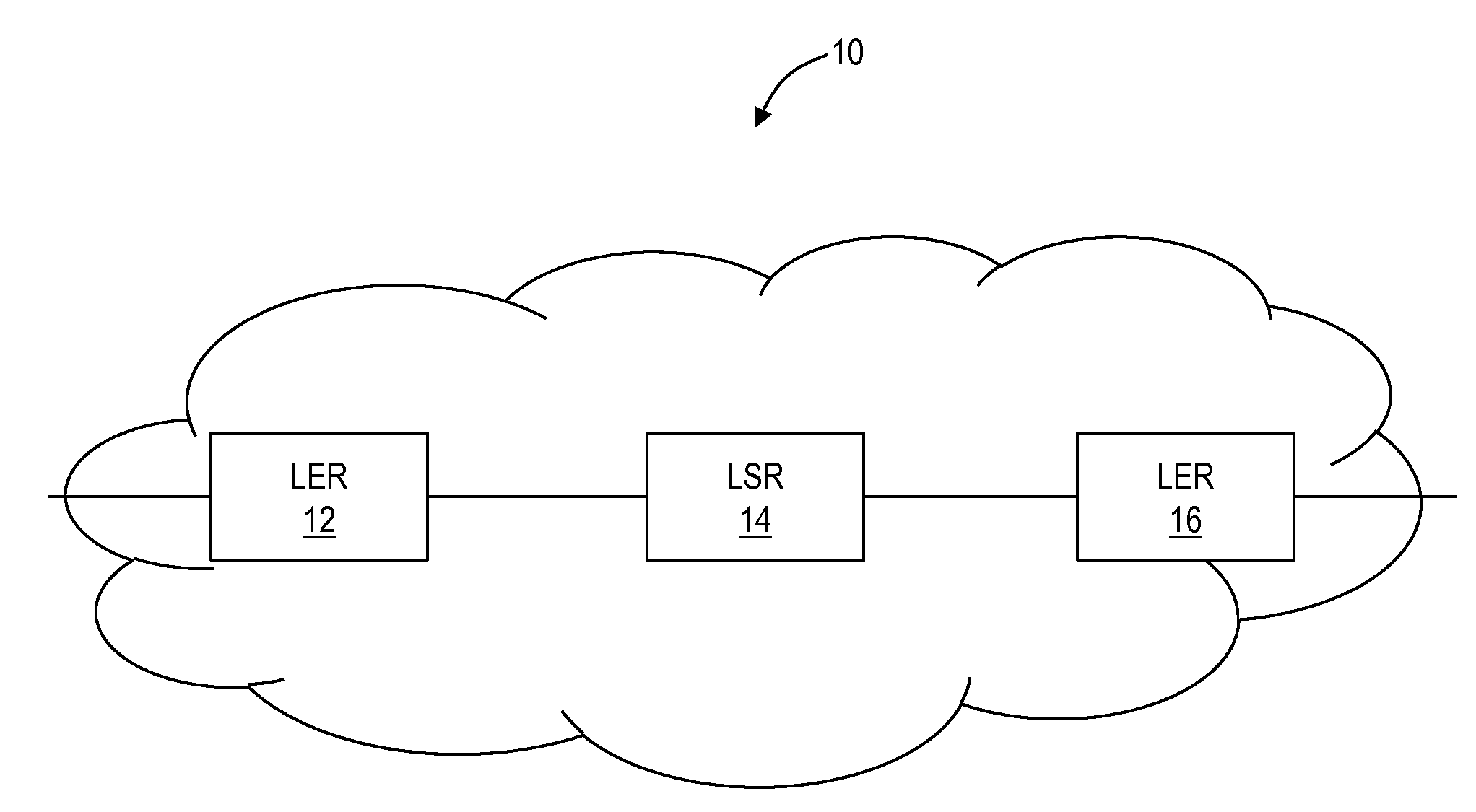

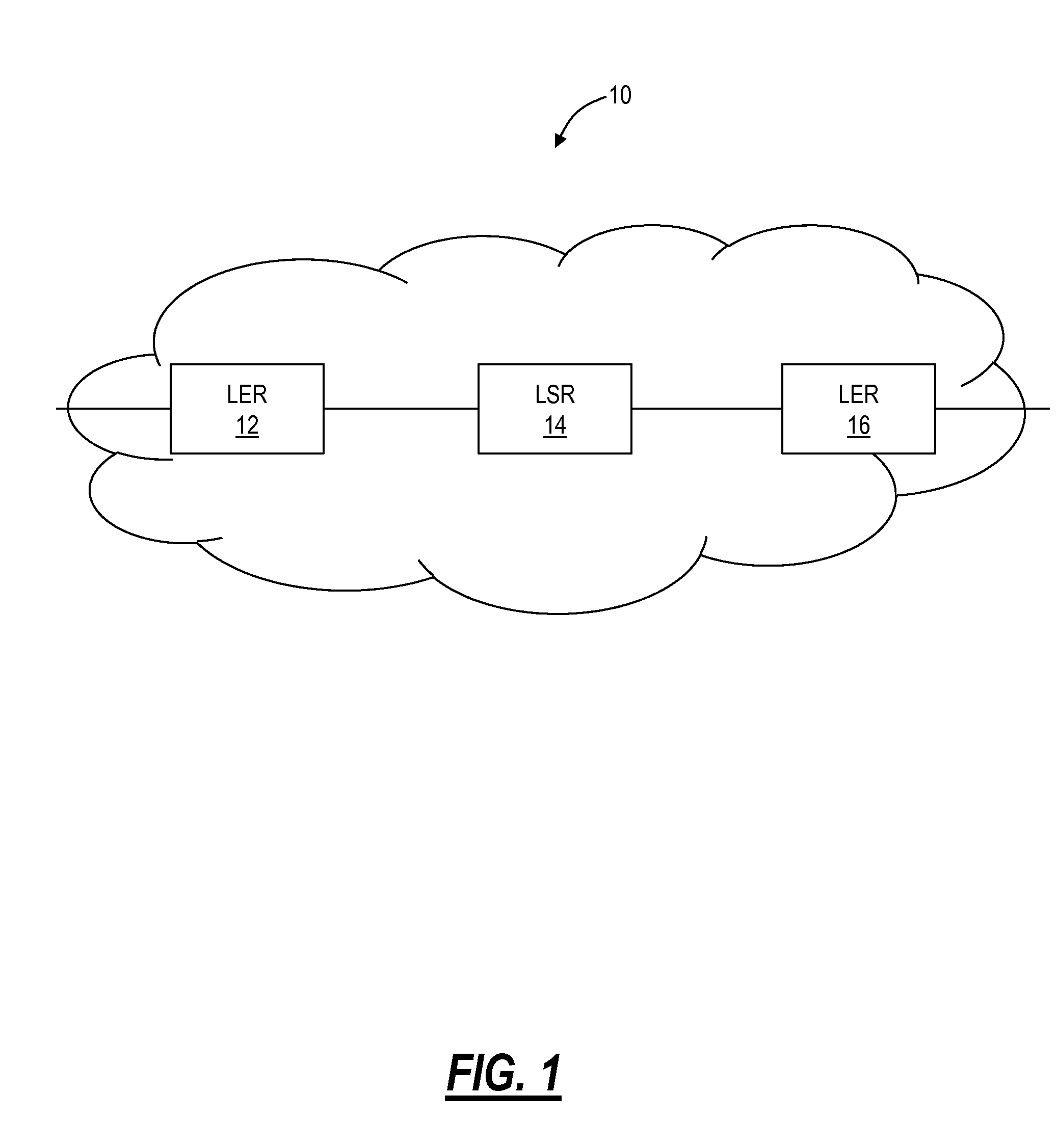

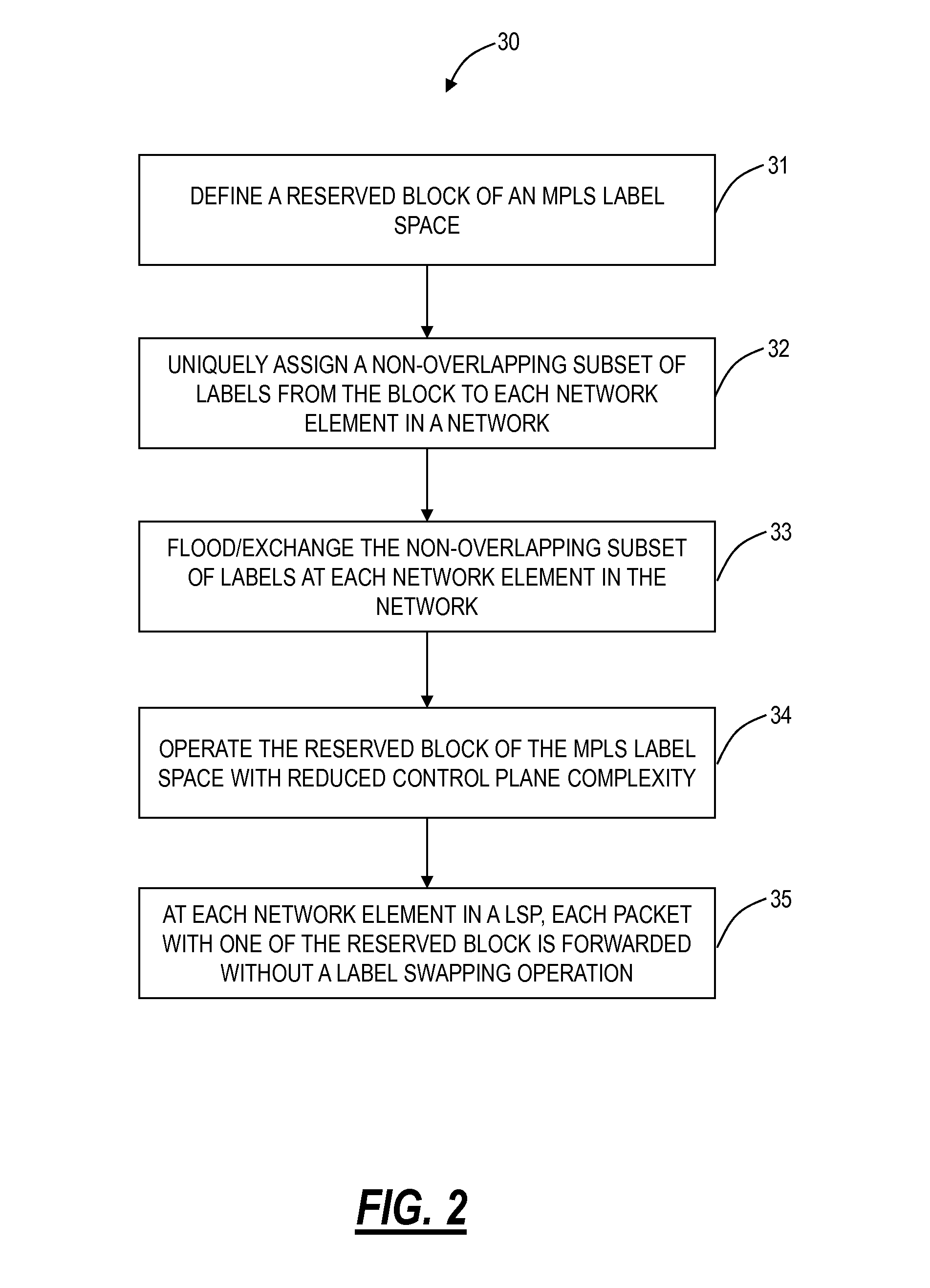

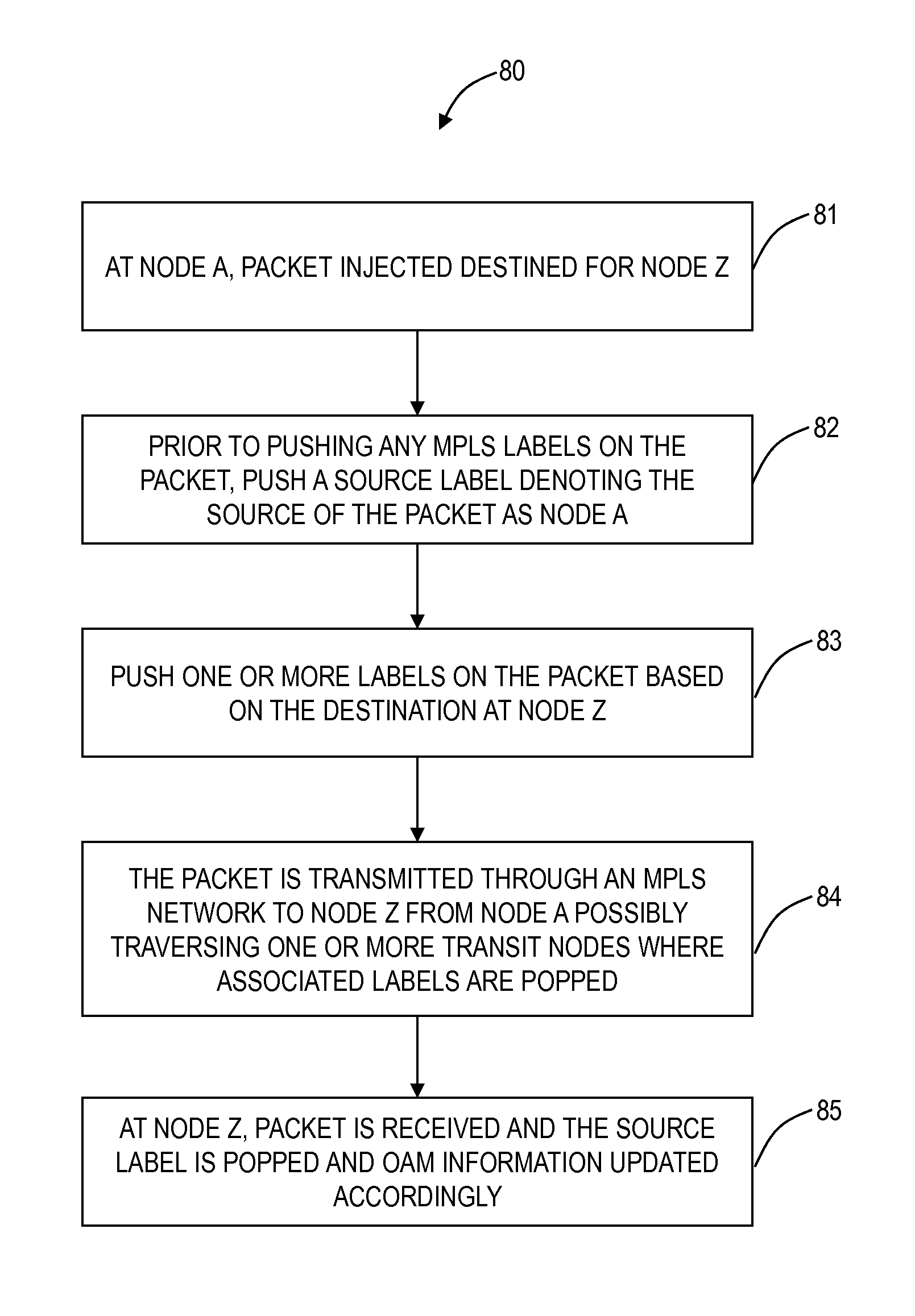

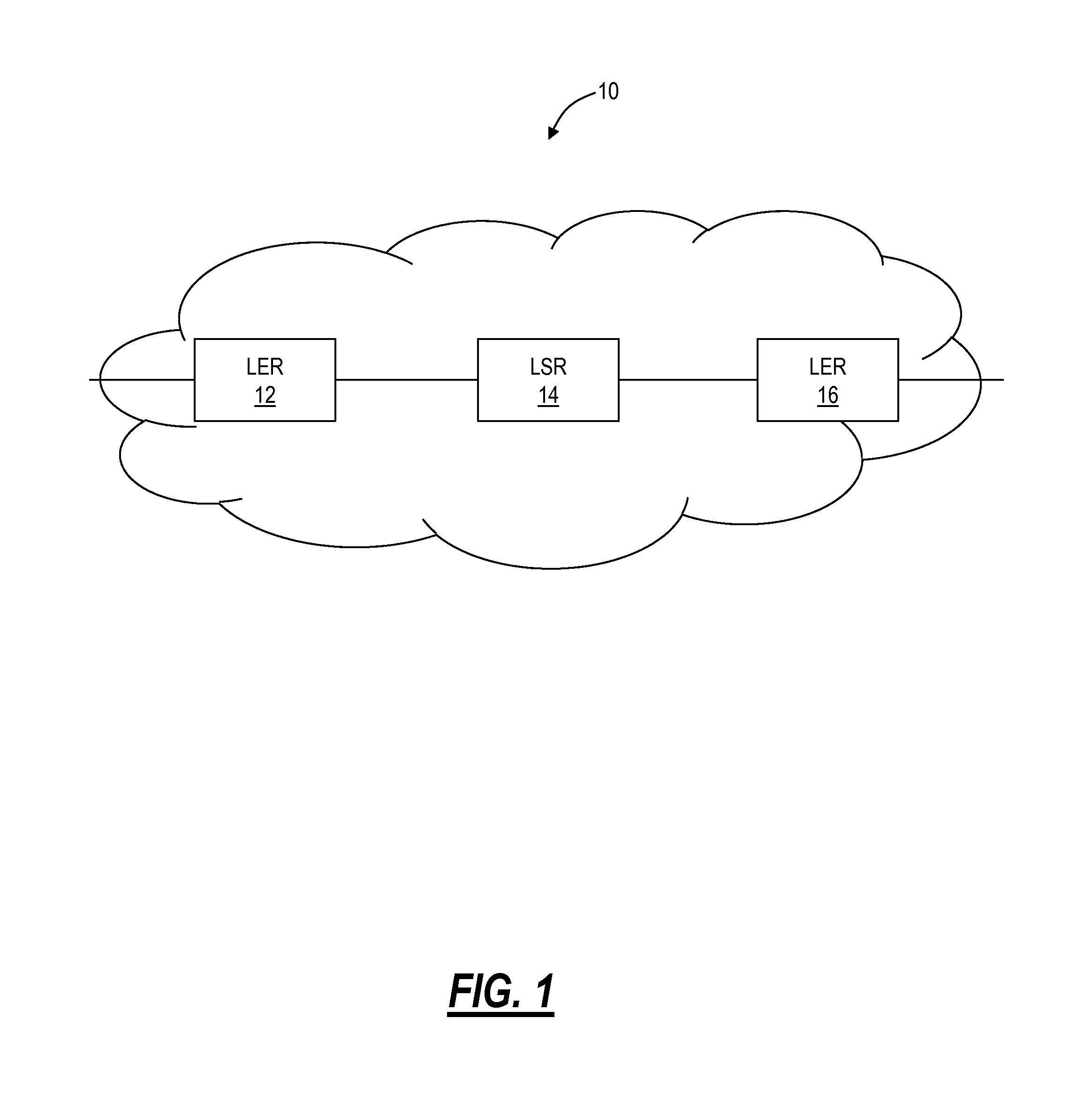

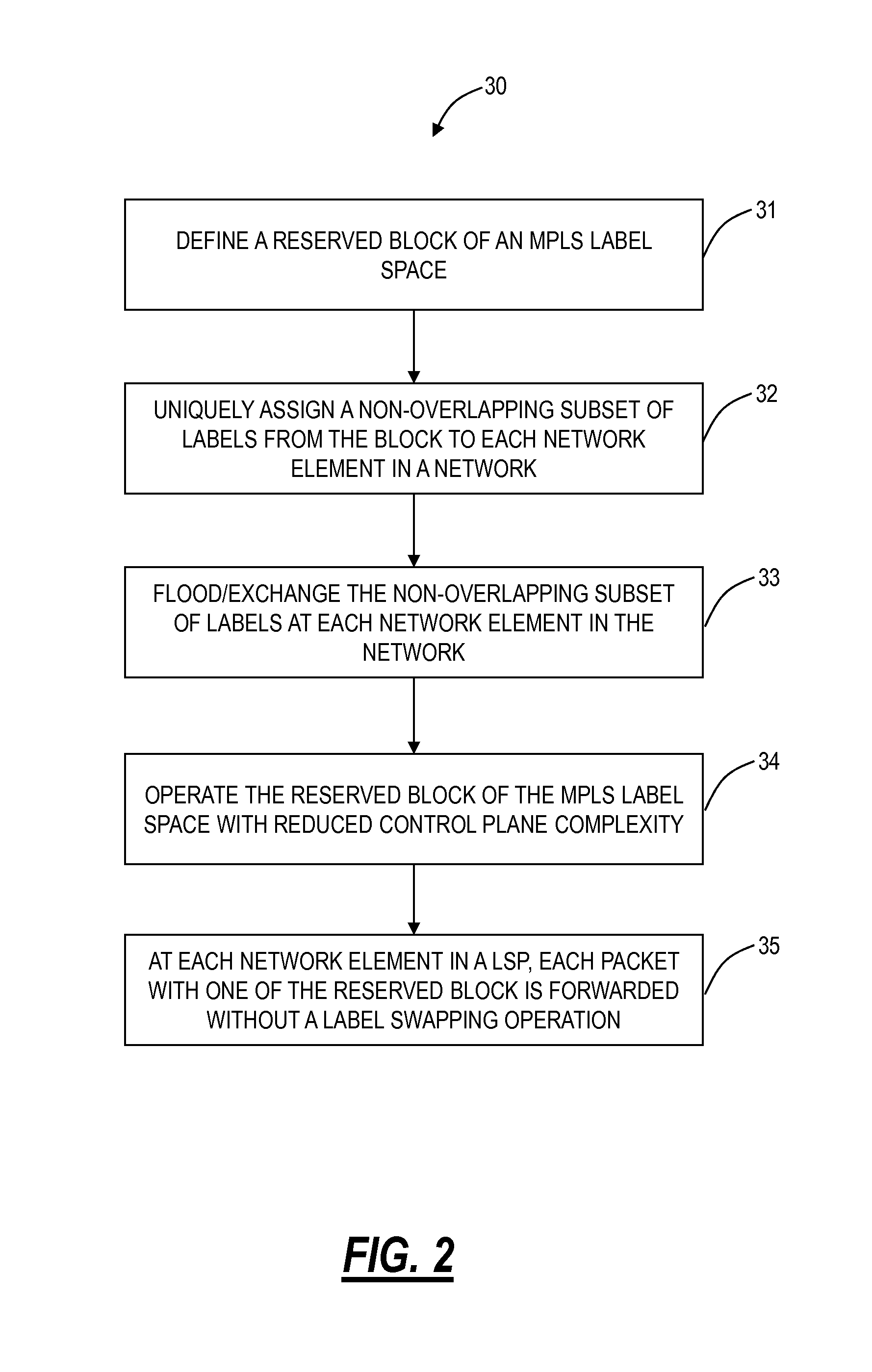

Source identification preservation in multiprotocol label switching networks

ActiveUS20140177638A1Simplify operating proceduresReduce complexityData switching by path configurationMultiprotocol Label SwitchingProtocol for Carrying Authentication for Network Access

A Multiprotocol Label Switching (MPLS) method, a MPLS network element, and a MPLS network include receiving a packet destined for a destination node at a source node in an MPLS network; pushing an identifier in an MPLS label on an MPLS label stack associated with the packet, wherein the identifier denotes the source node as the source of the packet and is pushed prior to any other MPLS labels on the MPLS stack; pushing one or more labels on the MPLS stack indicative of a route of the packet to the destination node; and transmitting the packet from the source node into the MPLS network. The identifier is located at the bottom of the MPLS stack thereby being a last item popped in the MPLS stack at the destination node, and the identifier can be used for updating OAM data efficiently without requiring deep packet inspection.

Owner:CIENA

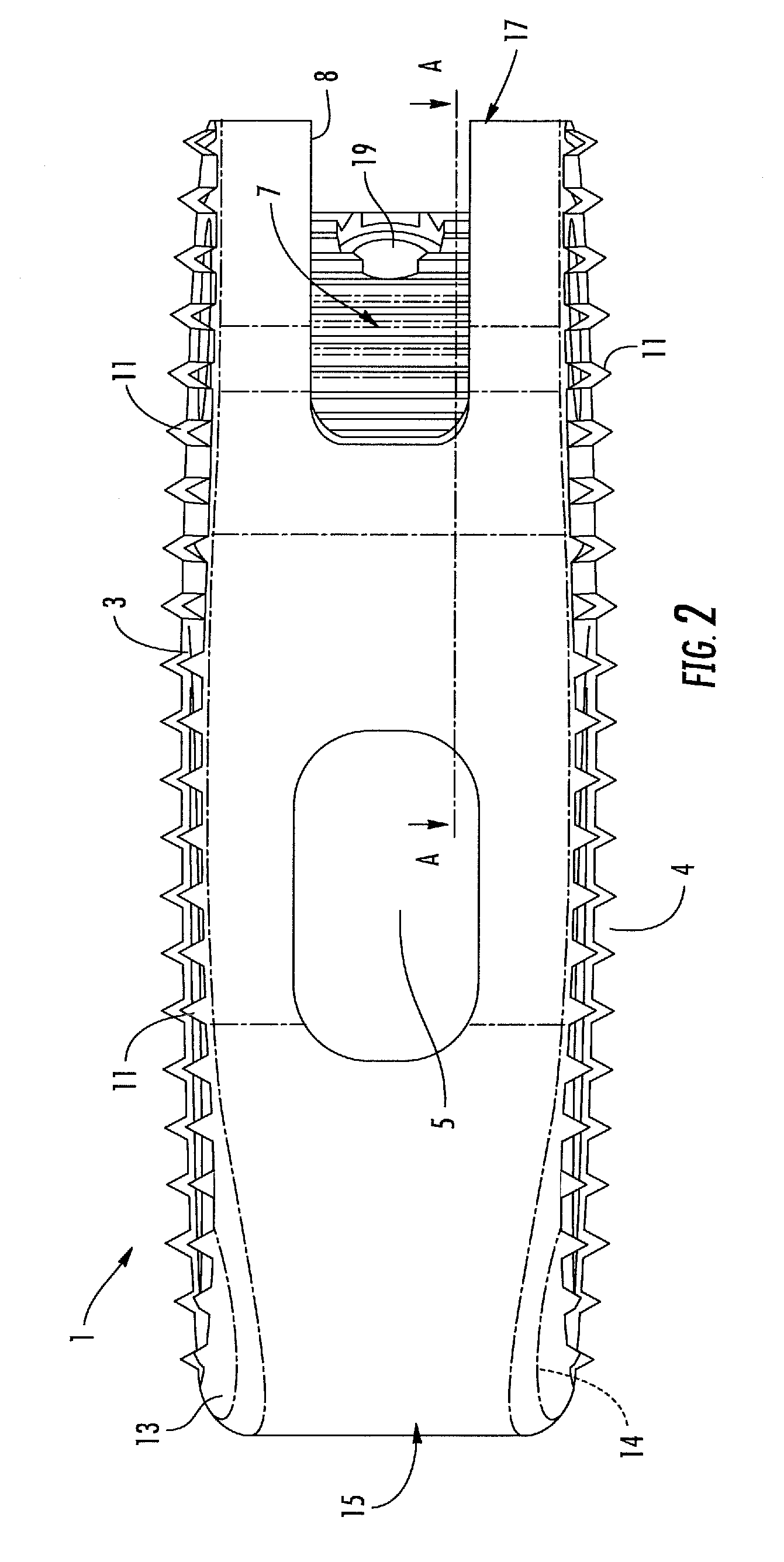

Intervertebral implant for the fusion between two vertebral bodies of a vertebral column and corresponding positioning instrument

ActiveUS20120277869A1High primary stabilitySimplify operating proceduresBone implantSpinal implantsBone growthLumbar vertebral column

An intervertebral implant for the fusion between two vertebral bodies of a vertebral column may include a body having two opposite surfaces and holes or cavities for filling purposes during bone growth, and an engagement portion for receiving a gripping end of a positioning instrument. The engagement portion may be shaped as a splined shaft accessible through an opening of the body.

Owner:MEDACTA INT SA

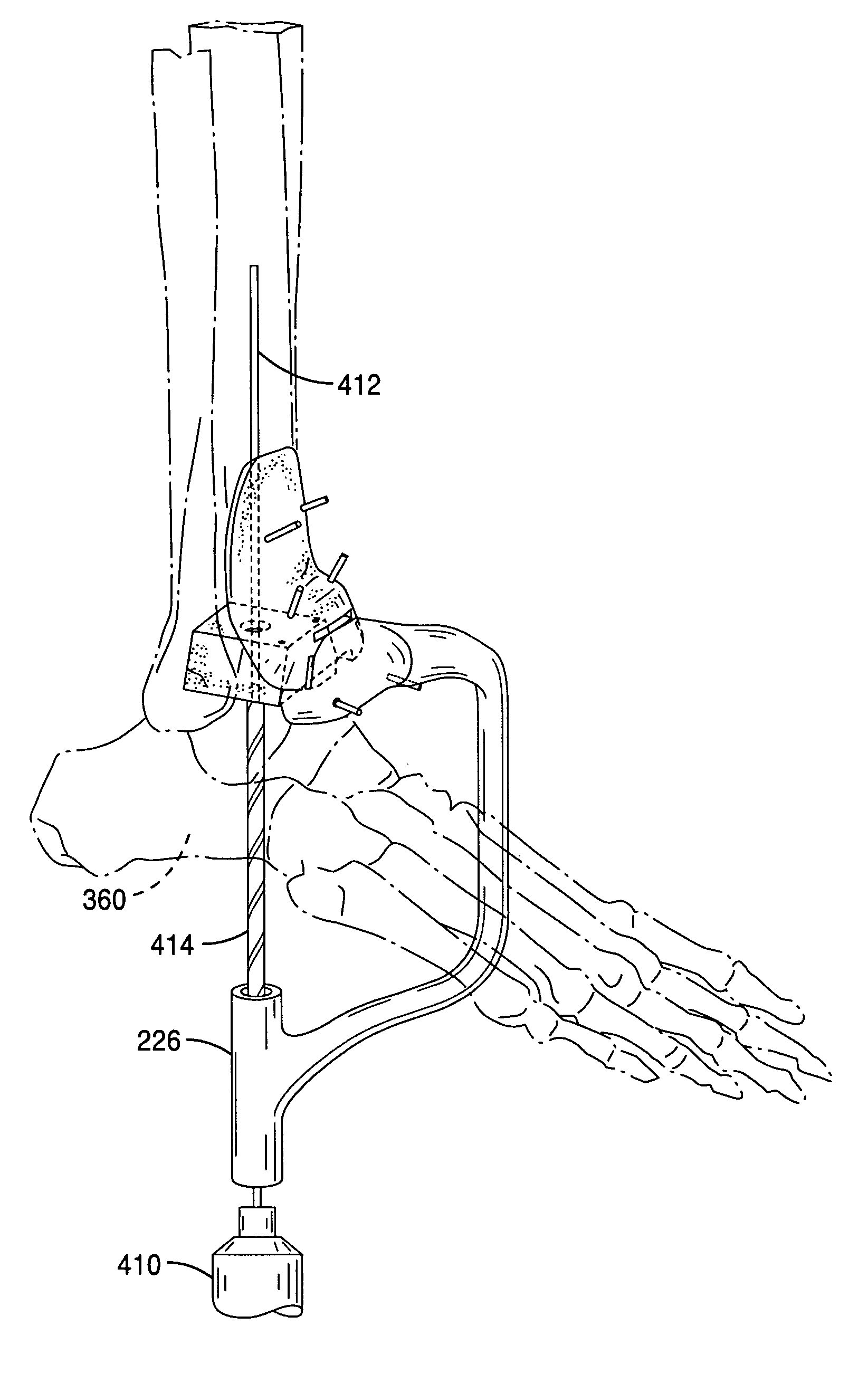

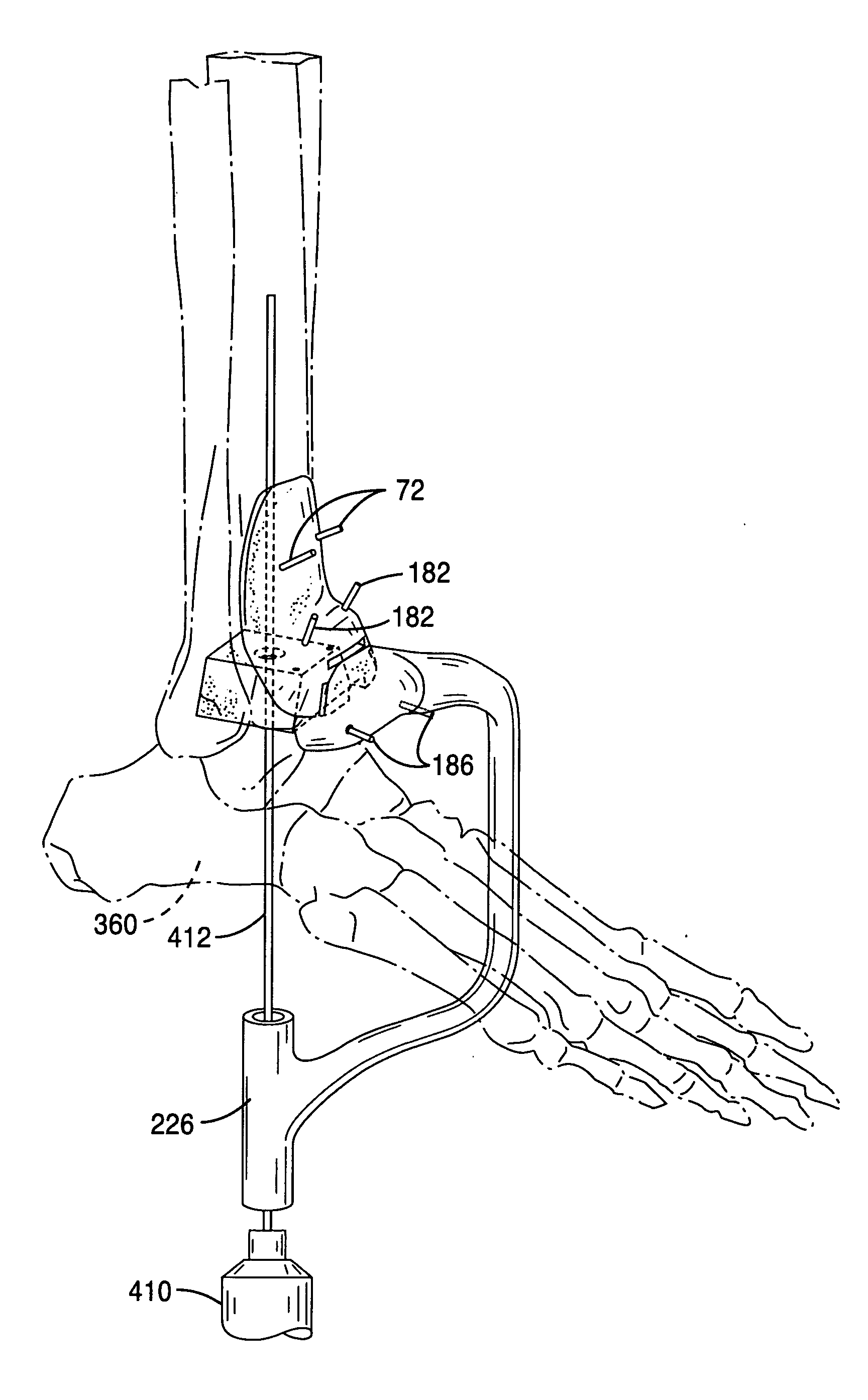

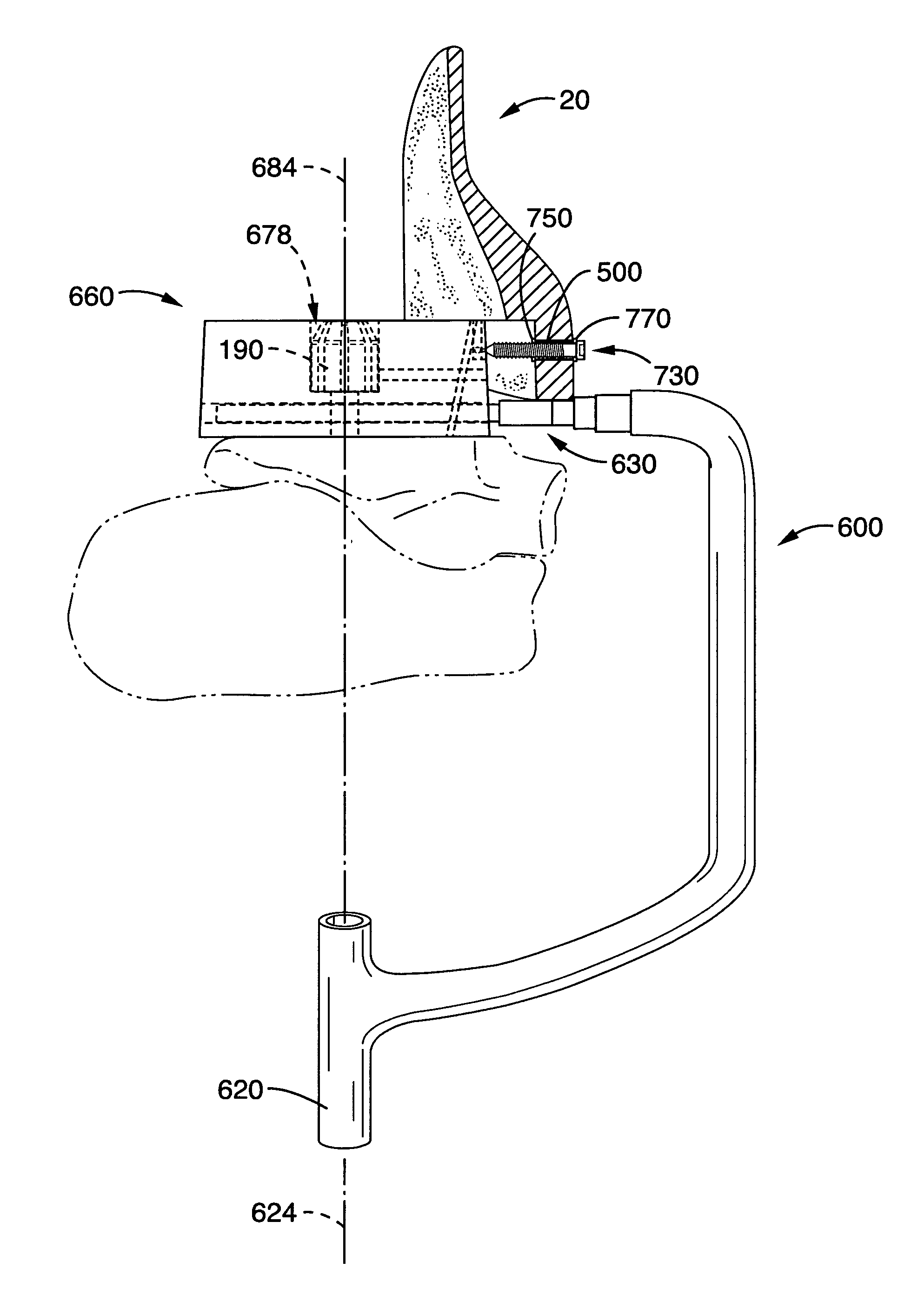

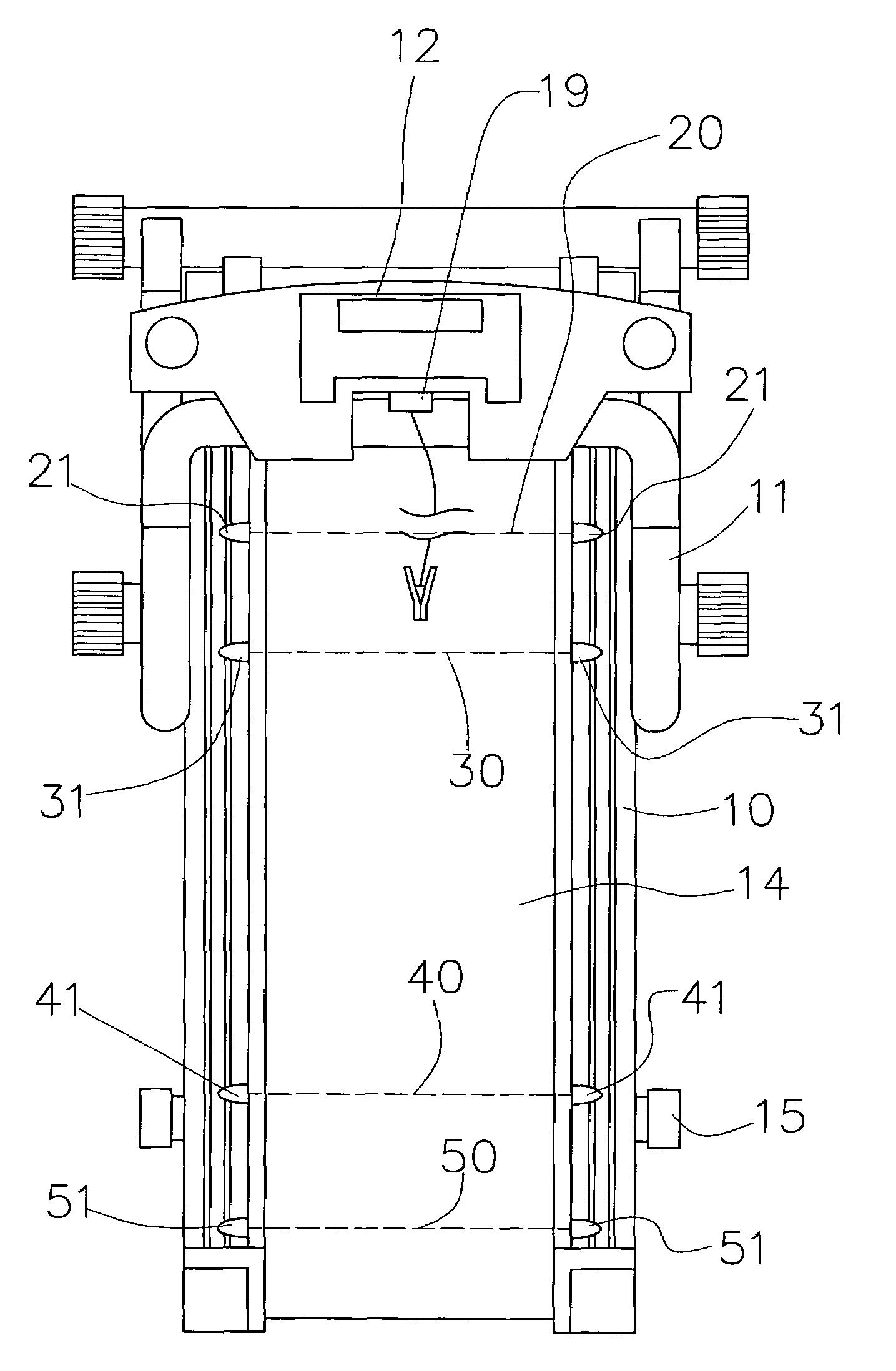

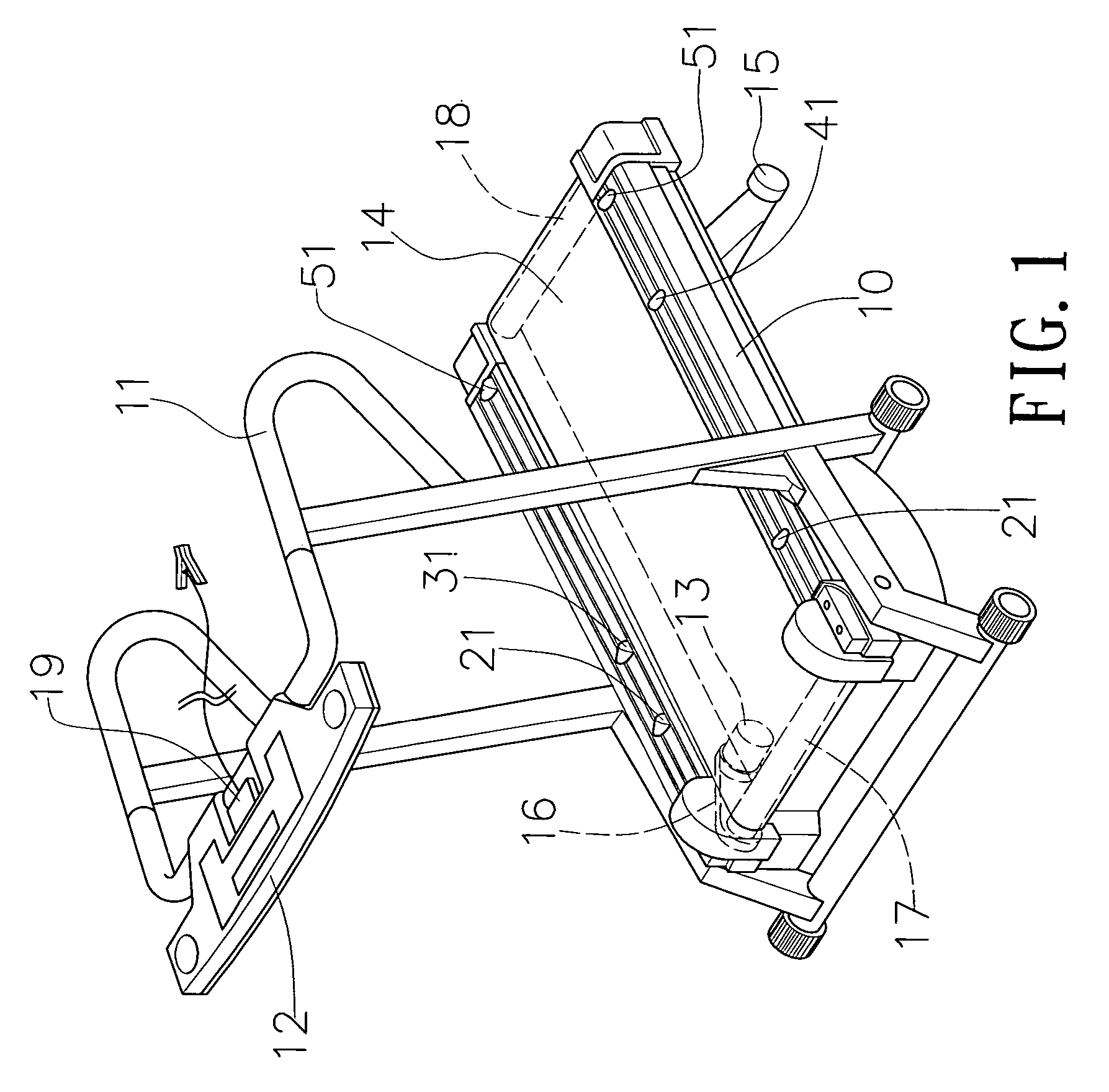

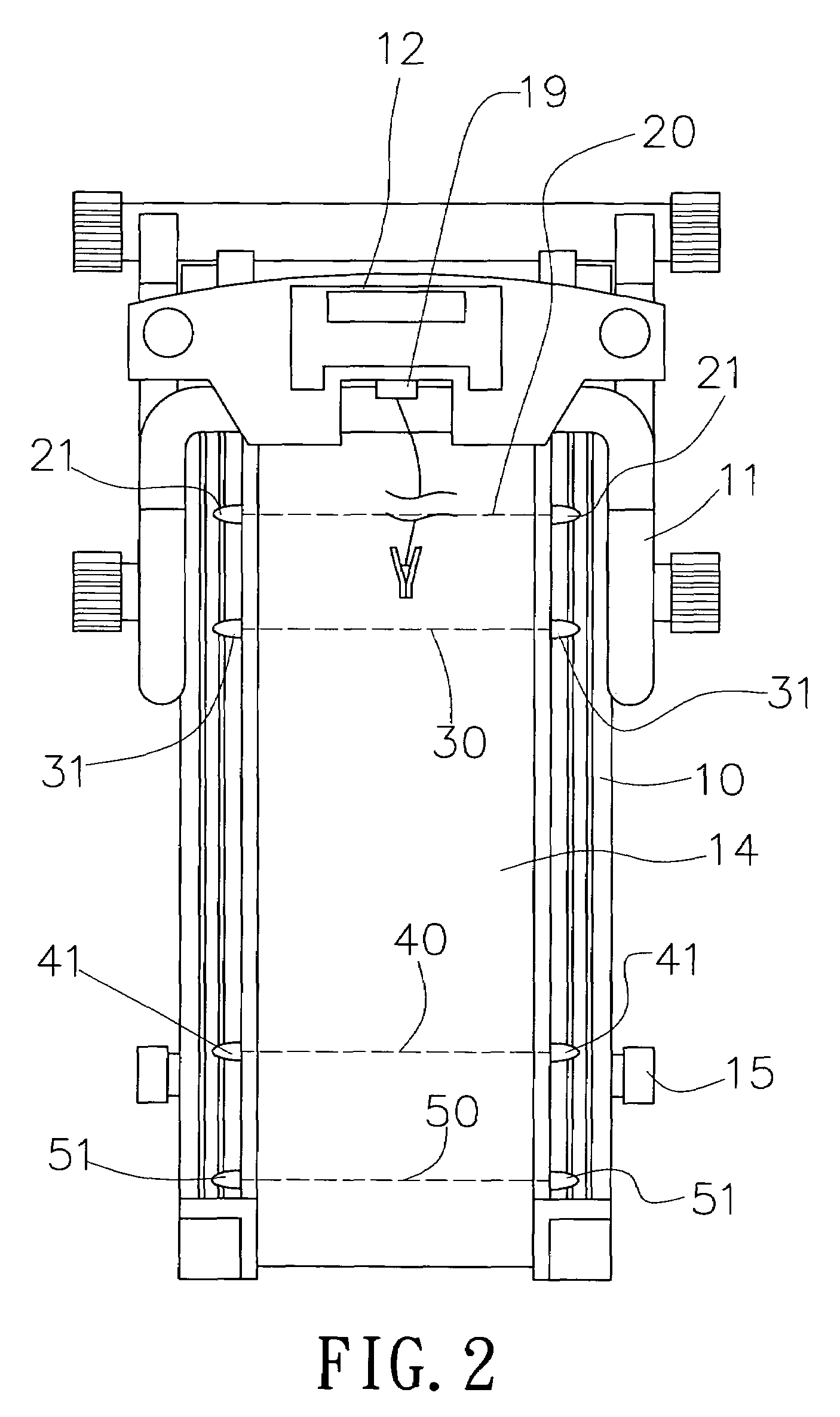

Systems and instrumentalities for use in total ankle replacement surgery

ActiveUS20110218542A1High precisionSimplify operating proceduresWrist jointsAnkle jointsTotal Ankle ReplacementsComputer based

Custom radiographically designed tibial and talar cutting guide system and instrumentalities including a tibial cutting guide position verification device is disclosed. A computer-based system and method for making the custom radiographically designed tibial and talar cutting guides is also disclosed. Further disclosed is an adjustable tibial reaming guide positioning system for allowing a position for reaming of a distal tibia to be adjusted during total ankle replacement surgery and, particularly, during total ankle arthroplasty for prostheses with an intramedullary stem.

Owner:LIAN GEORGE J

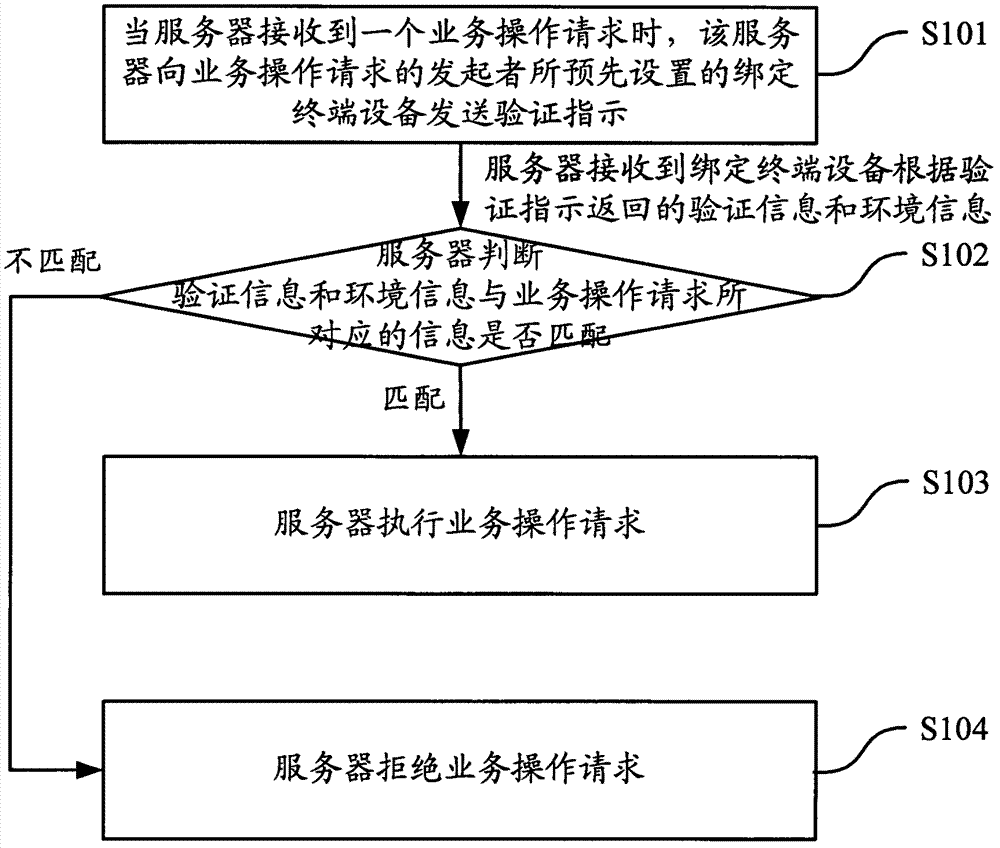

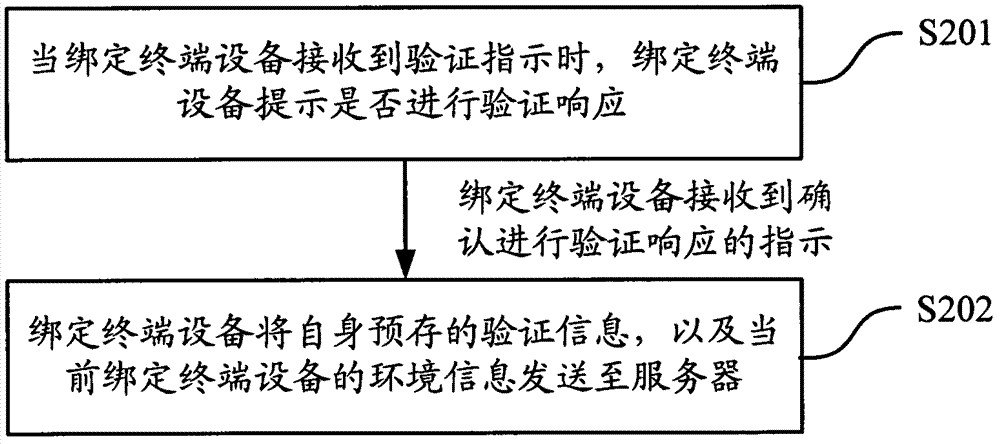

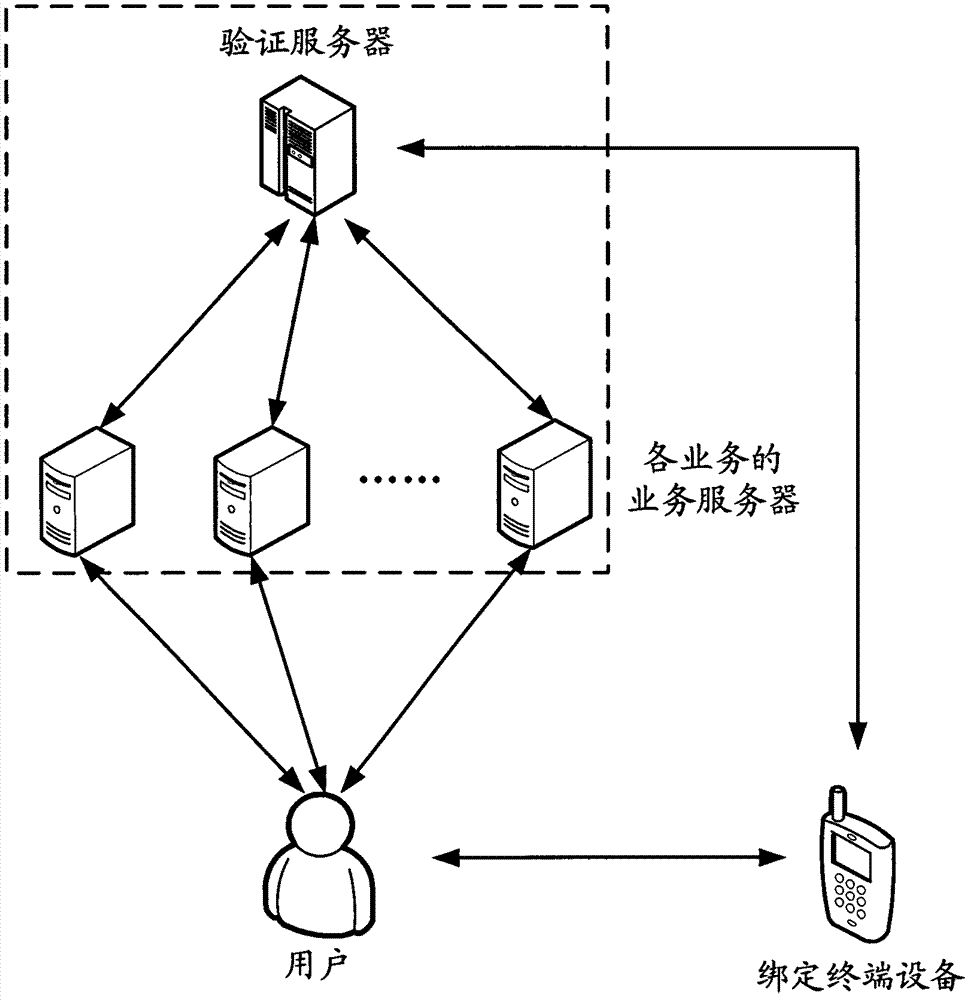

Authentication method, equipment and system

ActiveCN102790674AImprove securitySimplify operating proceduresUser identity/authority verificationTerminal equipmentComputer terminal

The embodiment of the invention discloses an authentication method, authentication equipment and an authentication system. By applying the technical scheme adopted by the embodiment of the invention, when a service operation request is received, preset binding terminal equipment can be triggered to carry out authentication, the matching judgment is carried out on information corresponding to the service operation request according to returned authentication information and environment information and the corresponding service operation request can be executed only under the condition of successful matching, so that the operation program of an operator is simplified and the fussy operation and the security hole which are caused by manual input of authentication information are avoided; and meanwhile, under the assist of authentication of the environment information, the matching of characteristic information such as an actual position of a user and the like and the information corresponding to the service operation request is ensured, so that the safety of the service processing is further improved.

Owner:ALIBABA GRP HLDG LTD

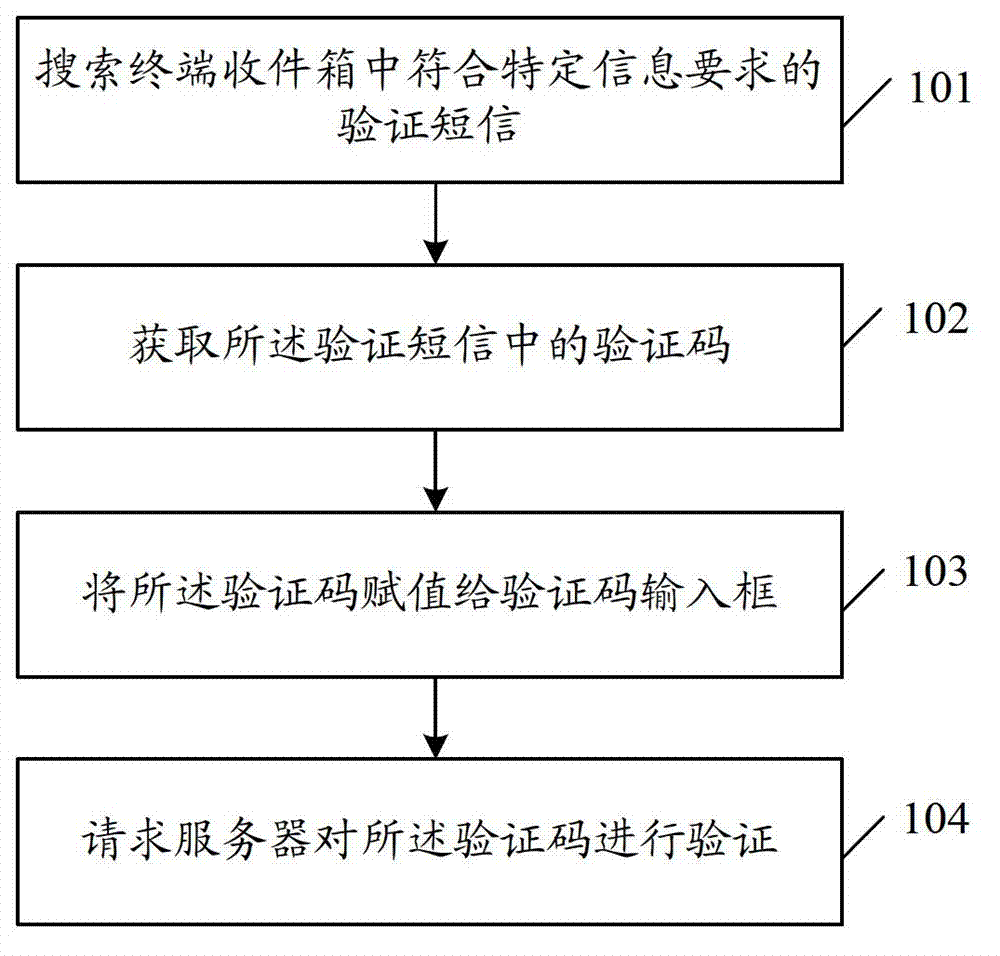

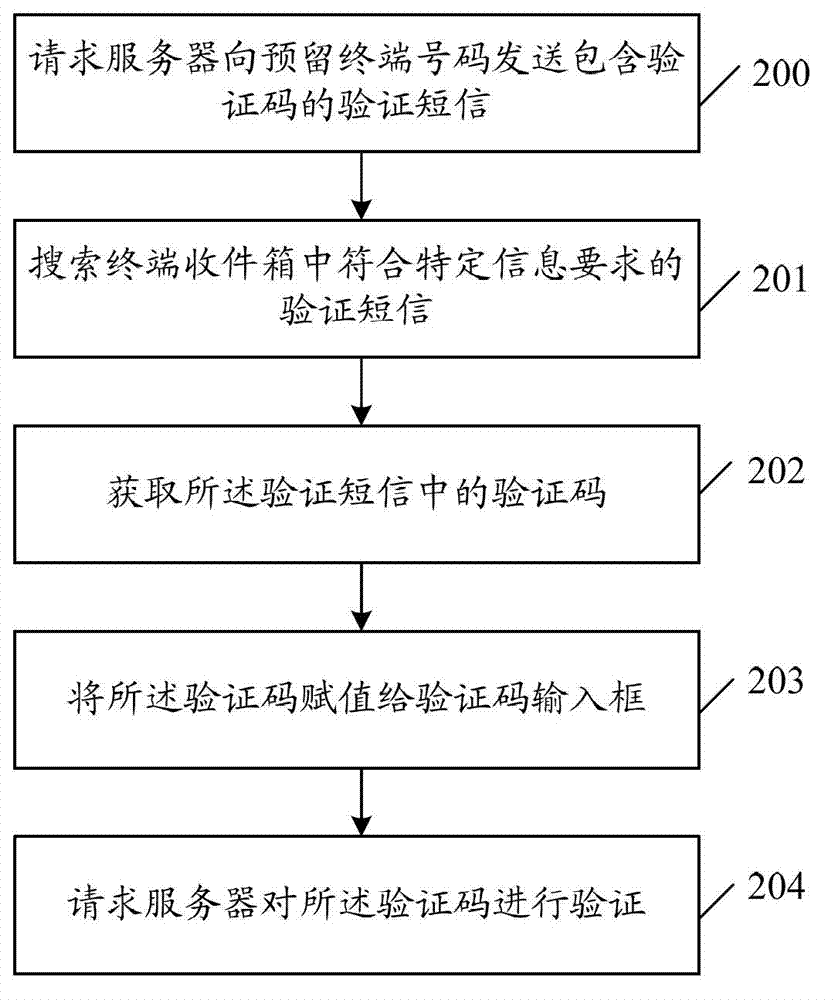

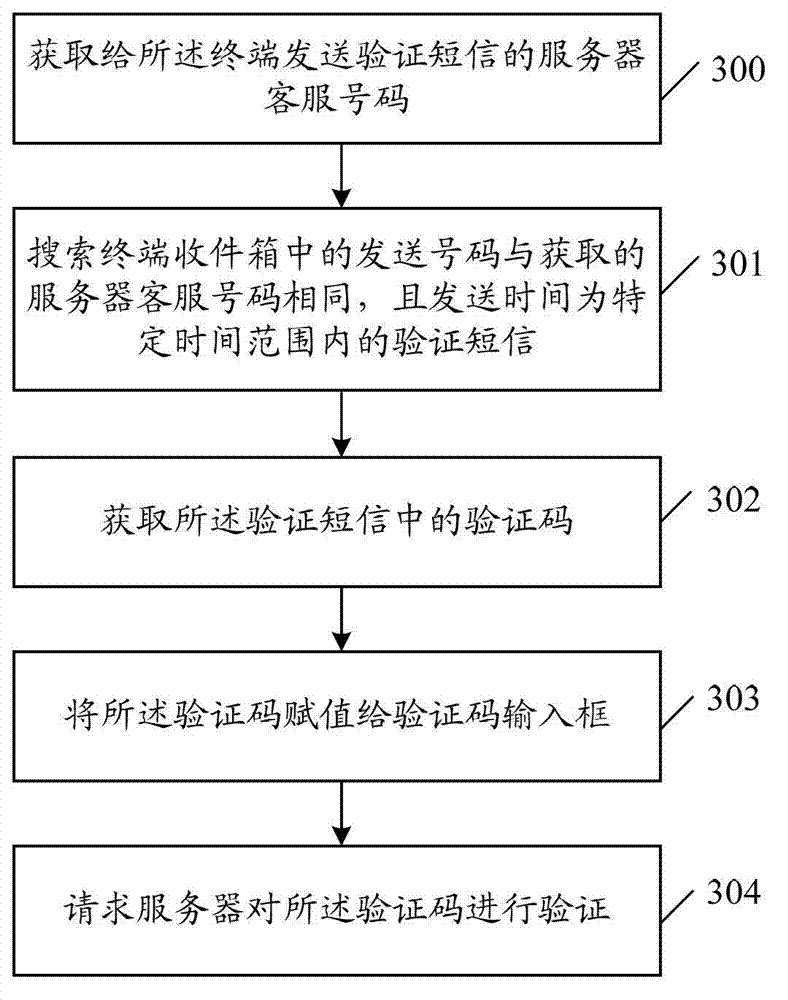

Short message verification method, device and system

InactiveCN102958022ASimplify operating proceduresFast and Efficient AuthenticationMessaging/mailboxes/announcementsSecurity arrangementText messageComputer hardware

The embodiment of the invention provides a short message verification method, device and system. The short message verification method comprises the following steps: searching for a verification short message meeting a specific information demand in a terminal receiving box; obtaining a verification code in the verification short message; supplying a verification code evaluation to a verification code input frame; and requesting a server to verify the verification code. According to the technical scheme provided by the embodiment of the invention, a user can quickly and effectively verify the identity.

Owner:NETAK TECH KO LTD

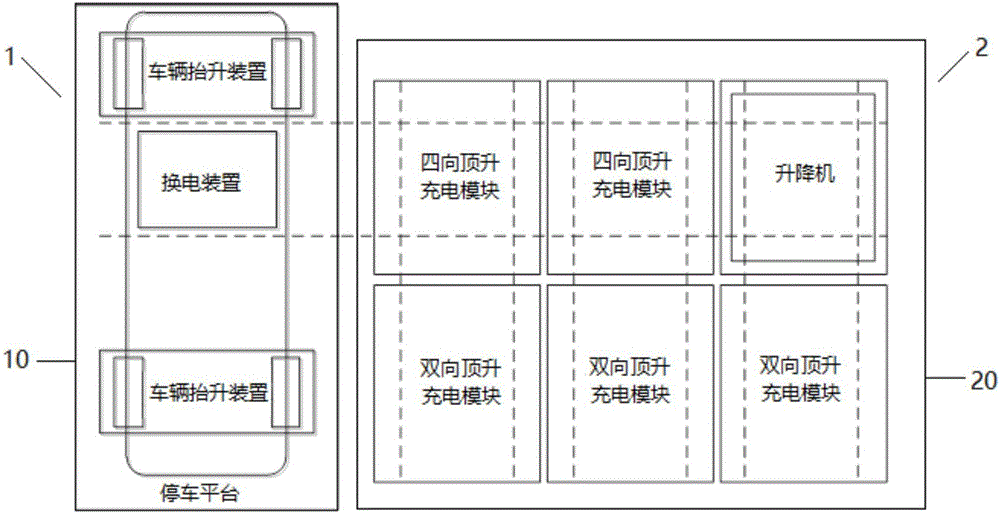

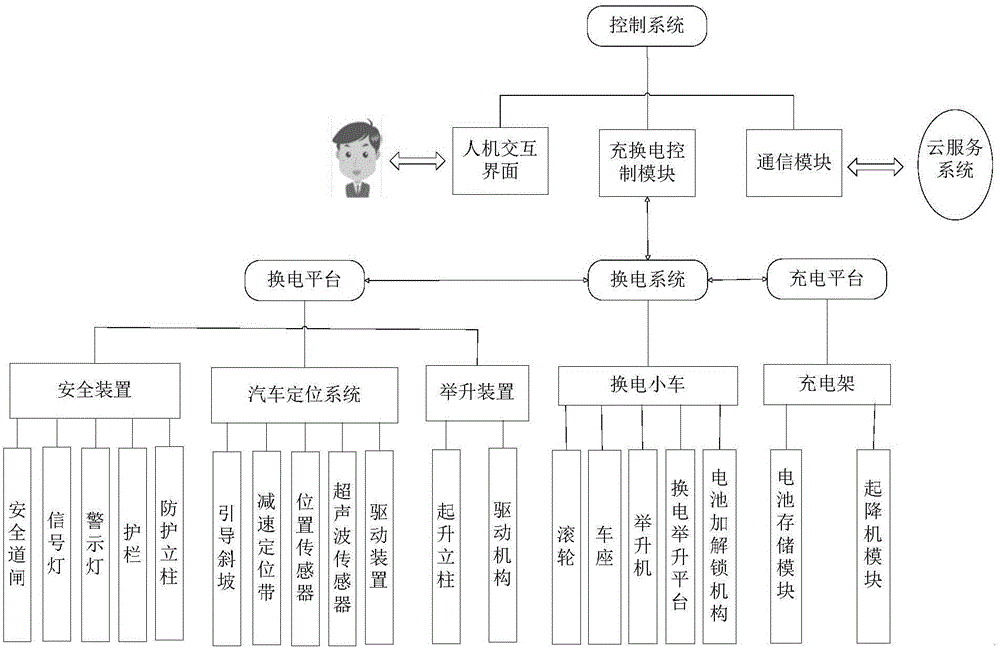

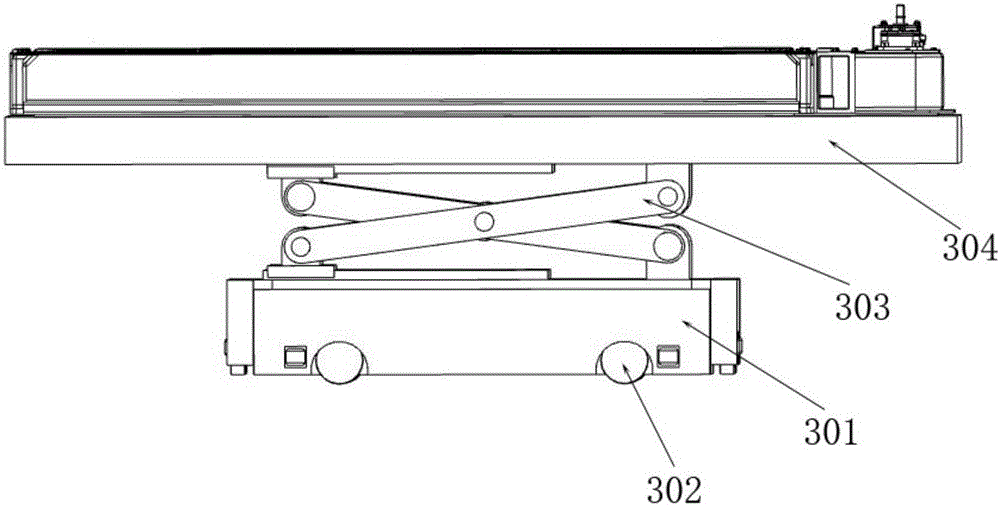

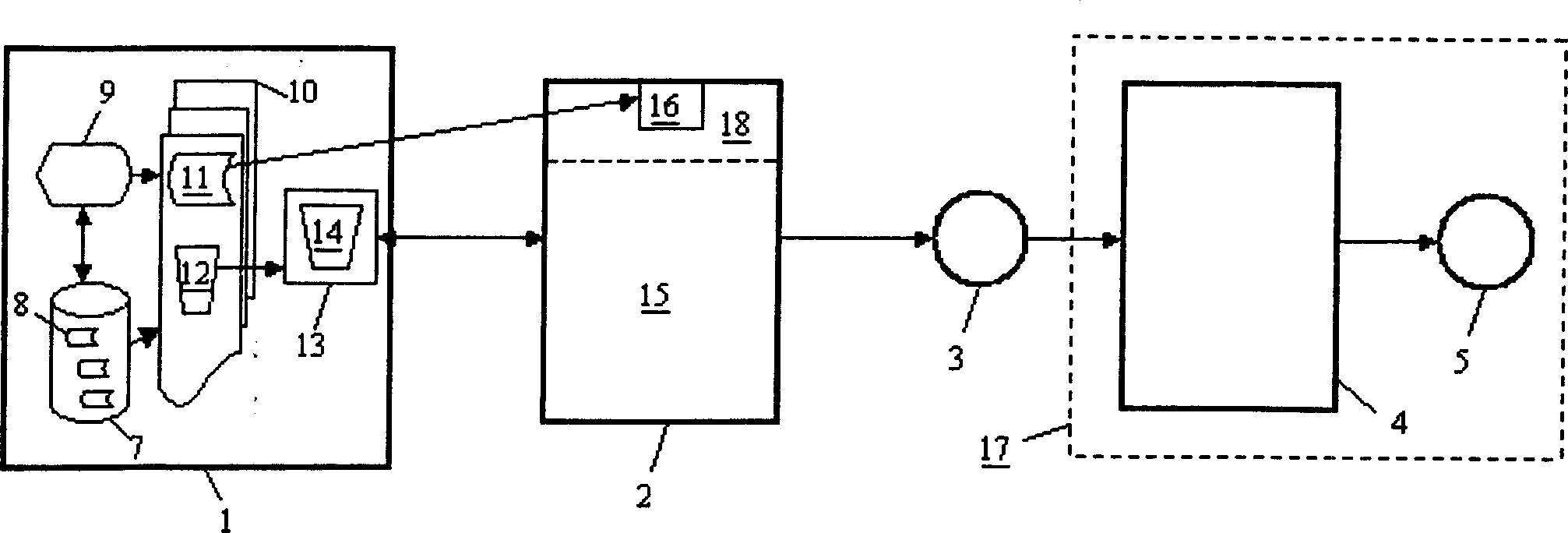

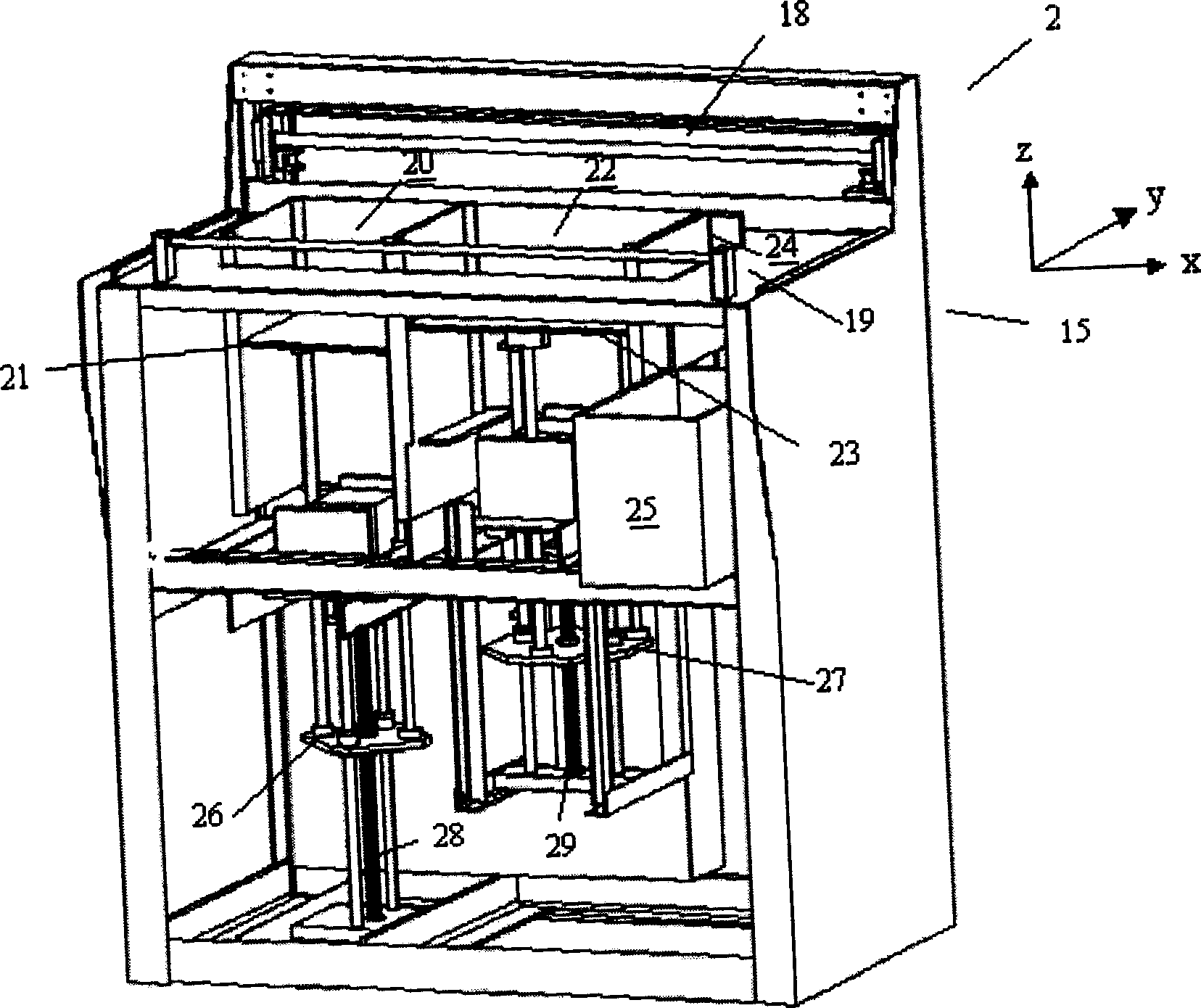

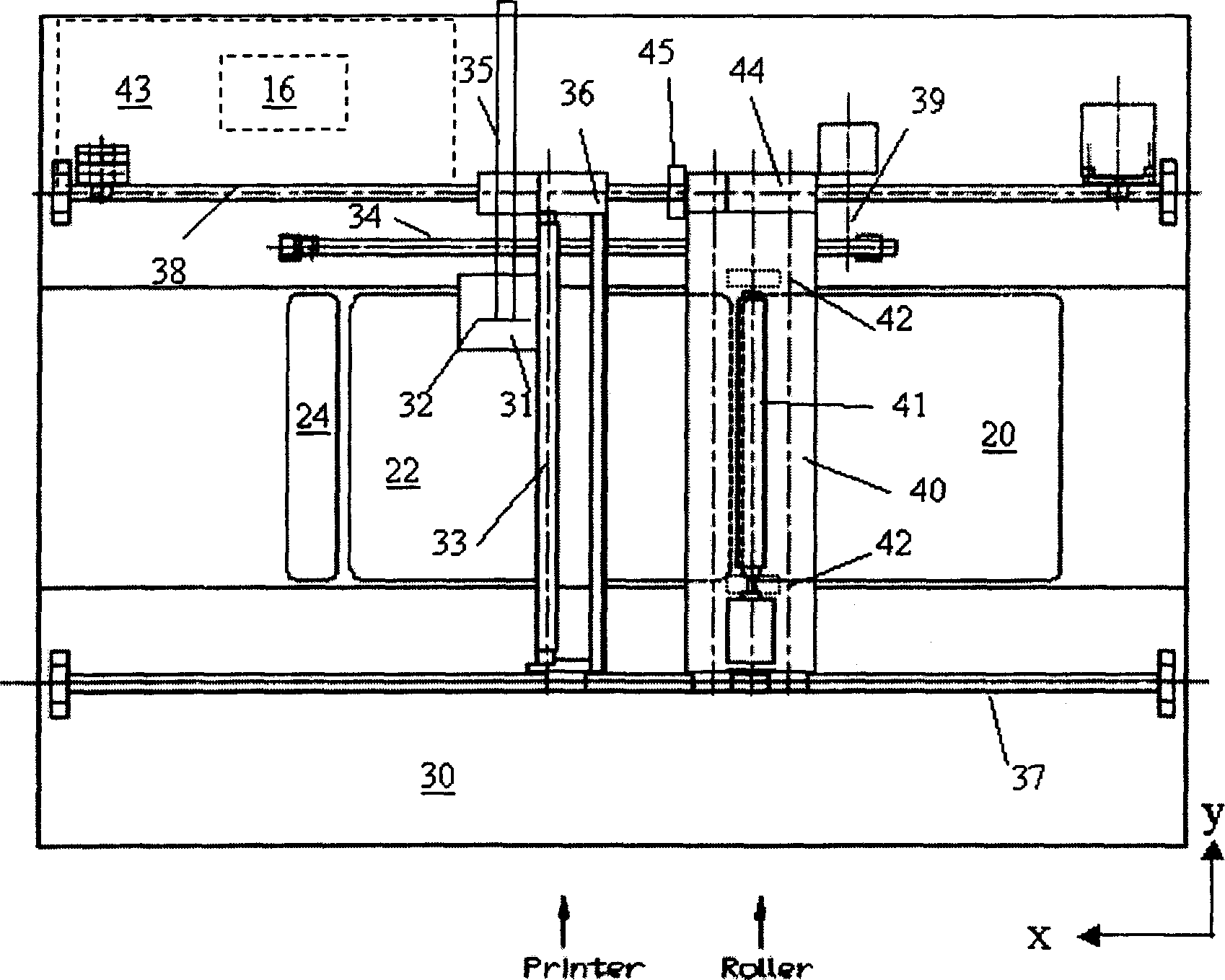

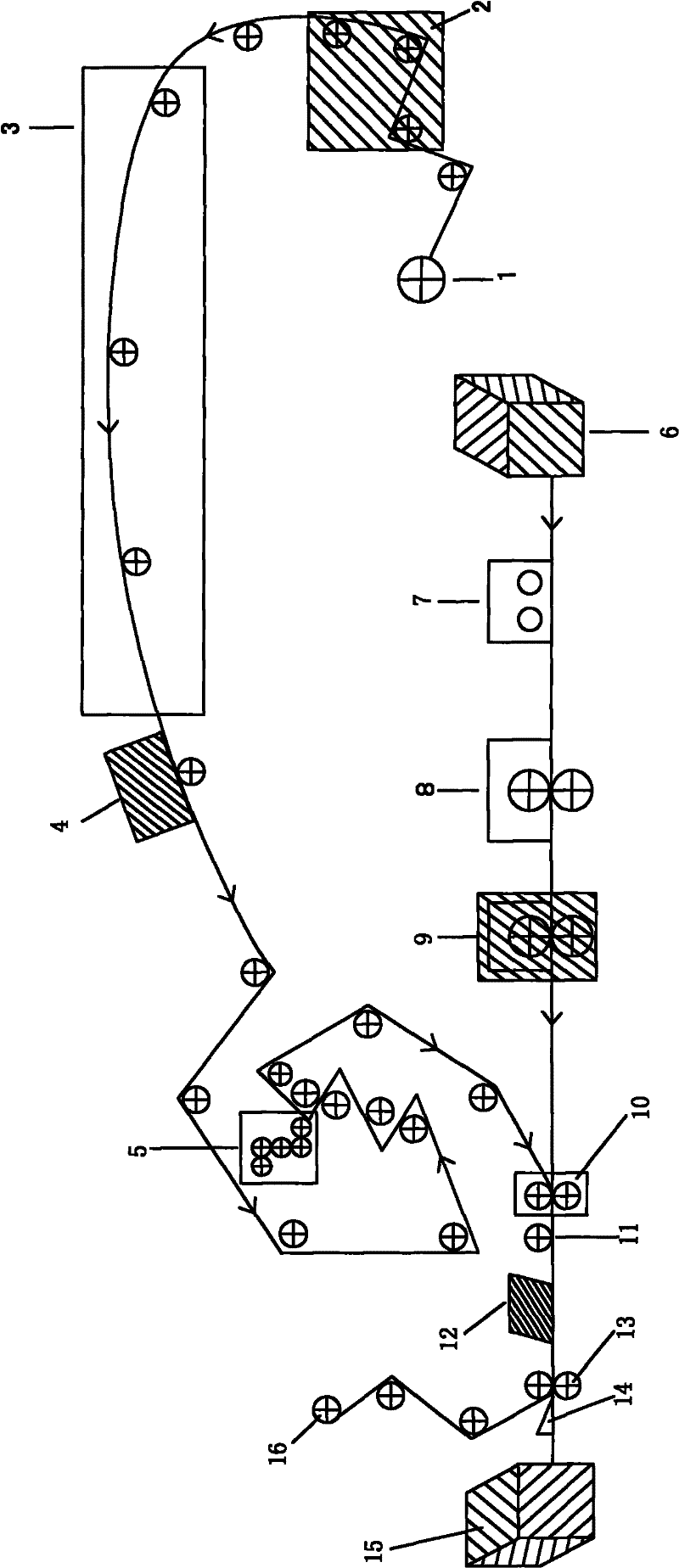

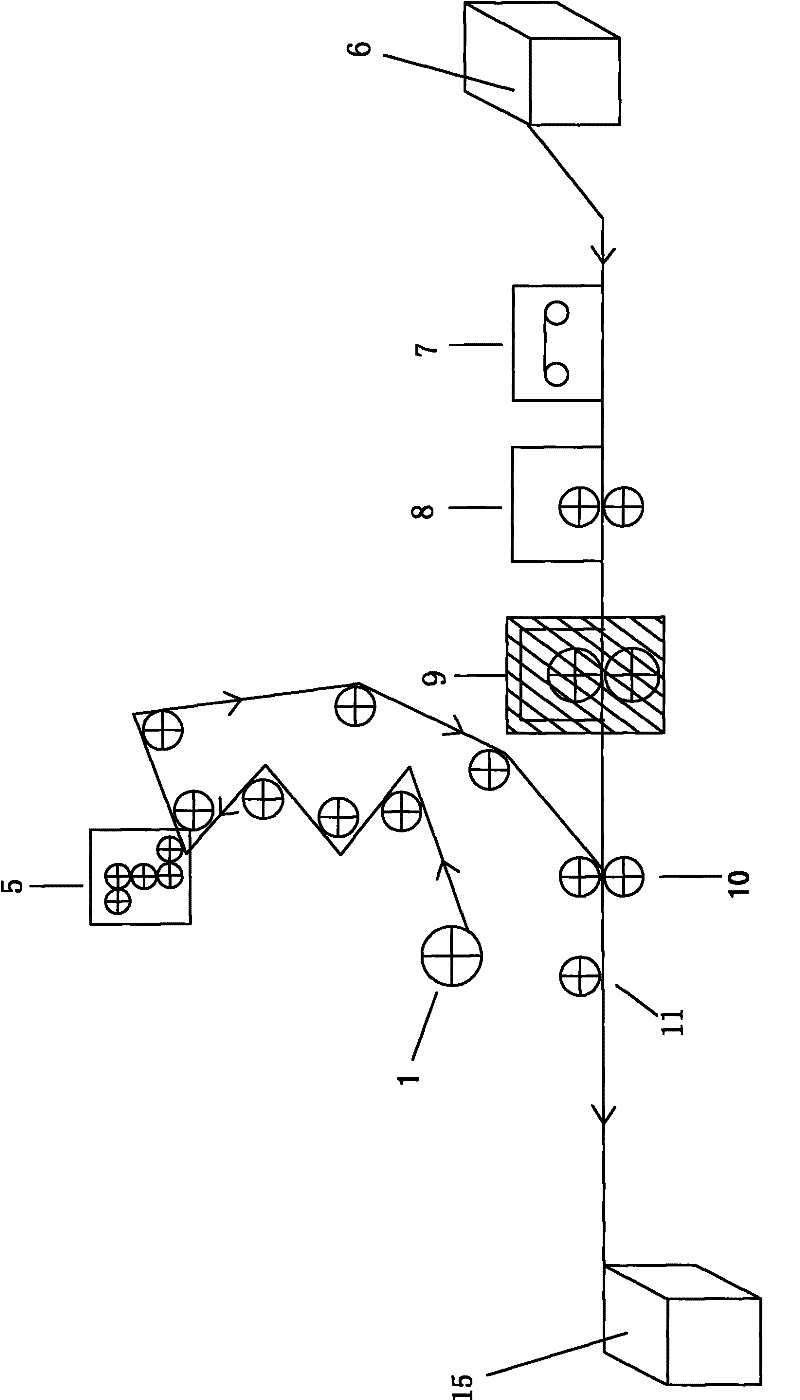

Small automatic charging and electrical changing station for electric vehicle

InactiveCN106143183ASave spaceSimplified pick and place structureCharging stationsElectric propulsion mountingElectricityControl system

The invention belongs to the technical field of charging and electrical changing of electric vehicles and in particular relates to a small automatic charging and electrical changing station for an electric vehicle. The invention aims at solving the problems that an existing electrical changing station occupies large area, and is low in modularization degree and inconvenient to maintain, and scale can not be changed once the existing electrical changing station is built. For the purpose, the small automatic charging and electrical changing station for the electric vehicle comprises an electrical changing platform, a charging platform, an electrical changing system and a control system, wherein the electrical changing platform, the charging platform and the electrical changing system are respectively connected with the control system. The small automatic charging and electrical changing station for the electric vehicle is characterized in that an electrical changing trolley of the electrical changing system can freely shuttle between the electrical changing platform and the charging platform, a battery can be directly taken out from a charging frame of the charging platform, and a replaced battery is directly put back onto the charging frame. By adopting the technical scheme, the small automatic charging and electrical changing station for the electric vehicle occupies small area and can be flexibly set on an existing cit surface parking lot, and underground and other various environments appropriate for parking.

Owner:NIO NEXTEV LTD

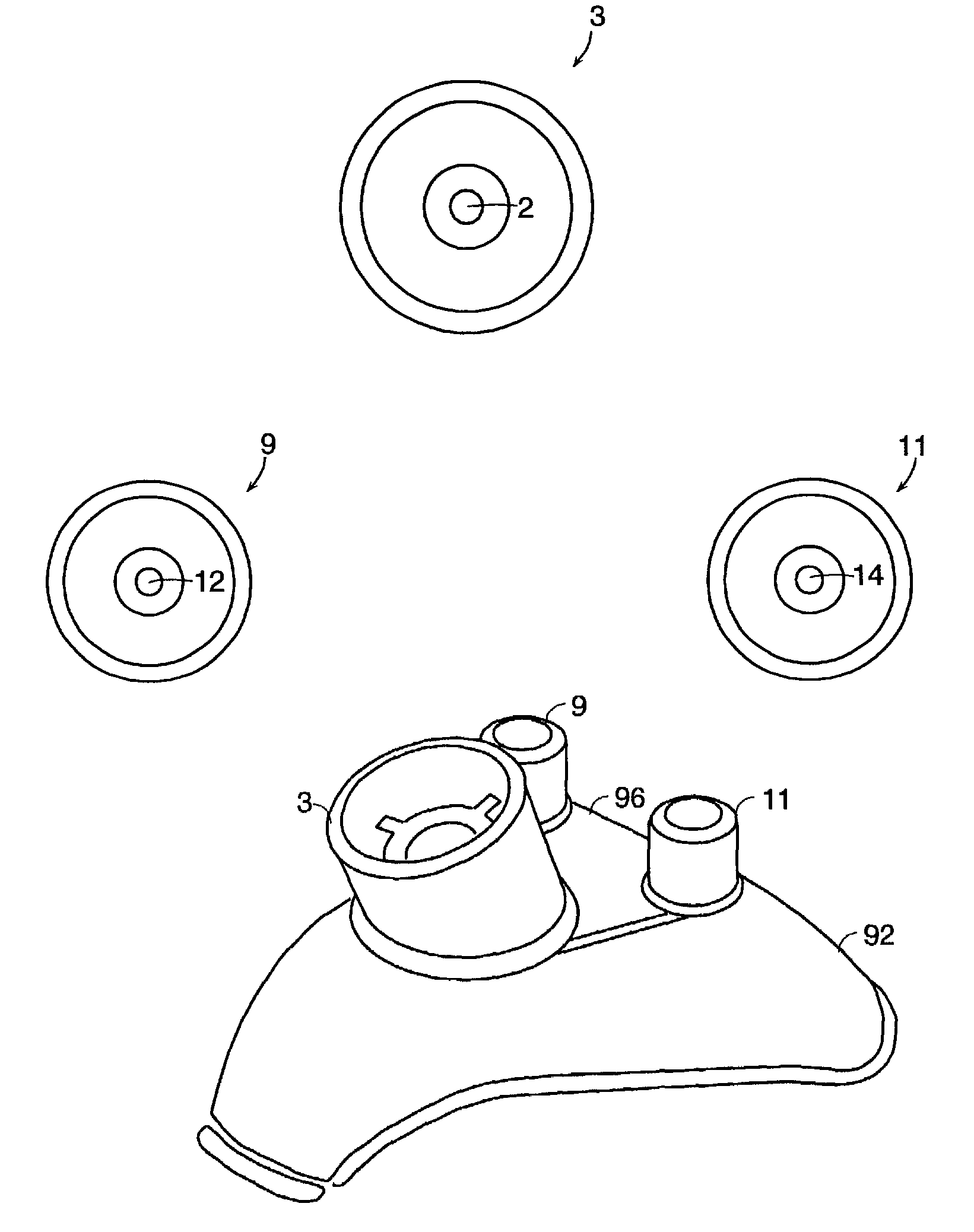

Graft delivery system

InactiveUS7175336B2Simplifies operative procedureReduce possibilityBone implantSurgeryBiomedical engineeringDelivery system

Owner:DEPUY ACROMED INC

Fast shaping device for making body from image of computer and with printing machine

InactiveCN1911635AImprove stabilityImprove printing accuracyCoatingsPrintingEngineeringRapid prototyping

The present invention is one fast forming apparatus, in which the virtual image stored in the memory of computer is tomographically treated and the tomographical treatment obtained contours are jet printed one layer by one layer with fluid onto the powder in the constituting platform for combining with powder so as to form stereo real object. The fast forming apparatus includes the jet printing mechanism and firmware interfaces of a printer or a plotter, one work platform with tomographically operating software and jet printing control firmware, and one computer with memory with stored virtual image.

Owner:赖维祥 +1

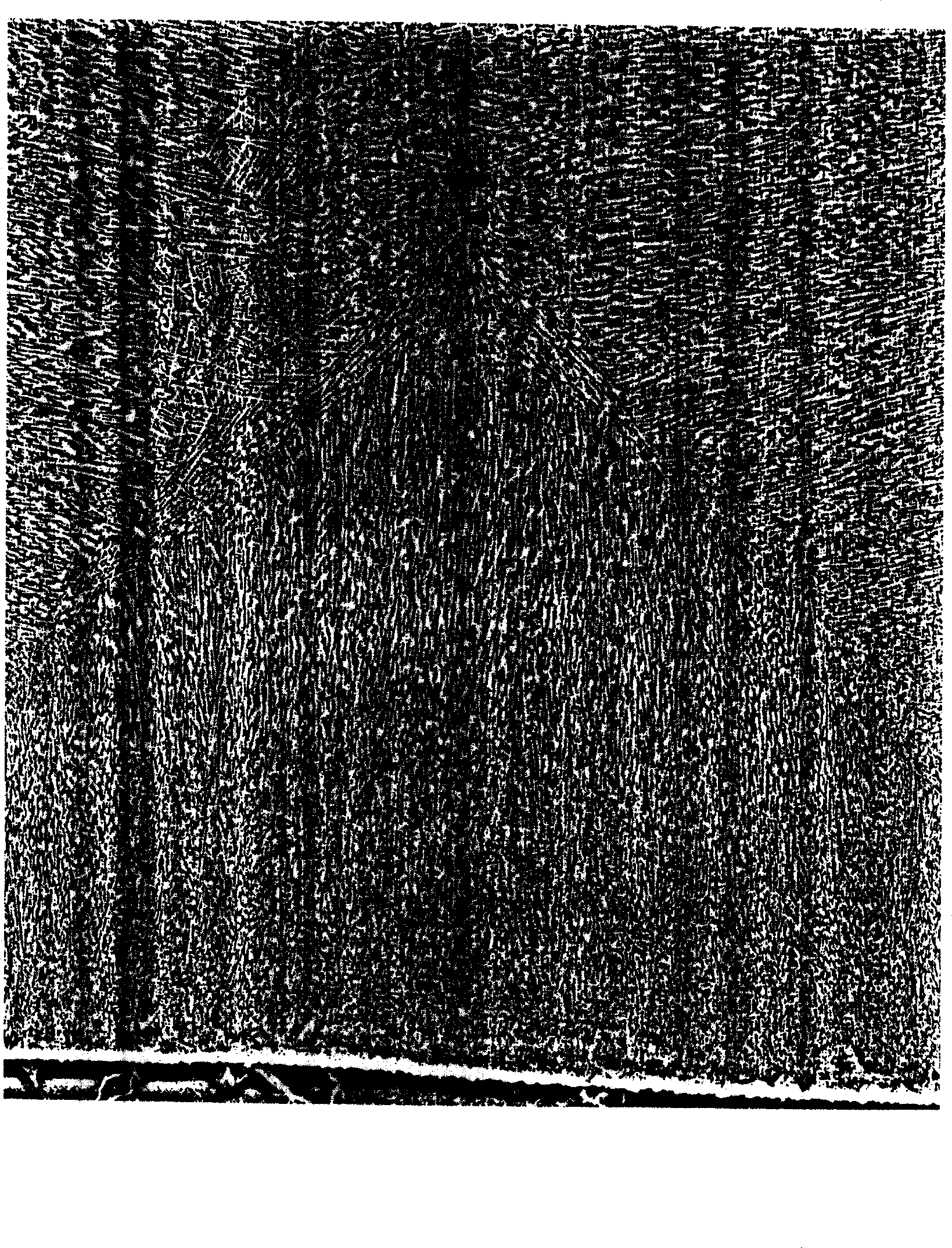

Corrosive agent for displaying silicon steel coagulation tissue and its preparation method

InactiveCN101144762AReactive and restrictiveAvoid irritation hazardsPreparing sample for investigationChemical agentPrecipitation

The invention provides a corrosive for the revealing of the silicon steel solidification structure. The invention has the component and blending ratio of the corrosive that 0.9 to 1.2 gram of a picronitric acid and / or 0.9 to 1.2 gram of a stannous acid, 10 to 20 gram of a ferric chloride, 20 to 50 milliliter of an absolute ethyl alcohol, 15 to 18 milliliter of a hydrochloric acid, 0.2 to 0.5 gram of a copper chloride, 0.2 to 0.5 gram of a magnesium chloride and 80 to 100 milliliter of a distilled water. The invention has the dosing method of the corrosive that the picronitric acid and / or the stannous acid and the ferric chloride are put into a container; the distilled water is divided into two shares, and one share is added into a medicine container; the absolute ethyl alcohol is divided into two shares, one share is added into an aqueous solution which is mixed with medicine, and the other share is added into the distilled water; the hydrochloric acid is added into the ethyl alcohol aqueous solution; the aqueous solution containing ethyl alcohol and hydrochloric acid is poured into the aqueous solution which is mixed with medicine, and the copper chloride and the magnesium chloride are added in. The chemical agent which is used in the corrosive reciprocally reacts mutually and has the strong conditionality, the efficiency of the core corrosive is exerted without forming a surface precipitation membrane, and a clear tree like crystal shape can be directly observed; the corroding time of the corrosive is short, and is suitable for a large size continuous casting semi finished metal; the dosing method of the corrosive is scientific, and the operating procedure is simple, convenient and easy to operate.

Owner:ANGANG STEEL CO LTD

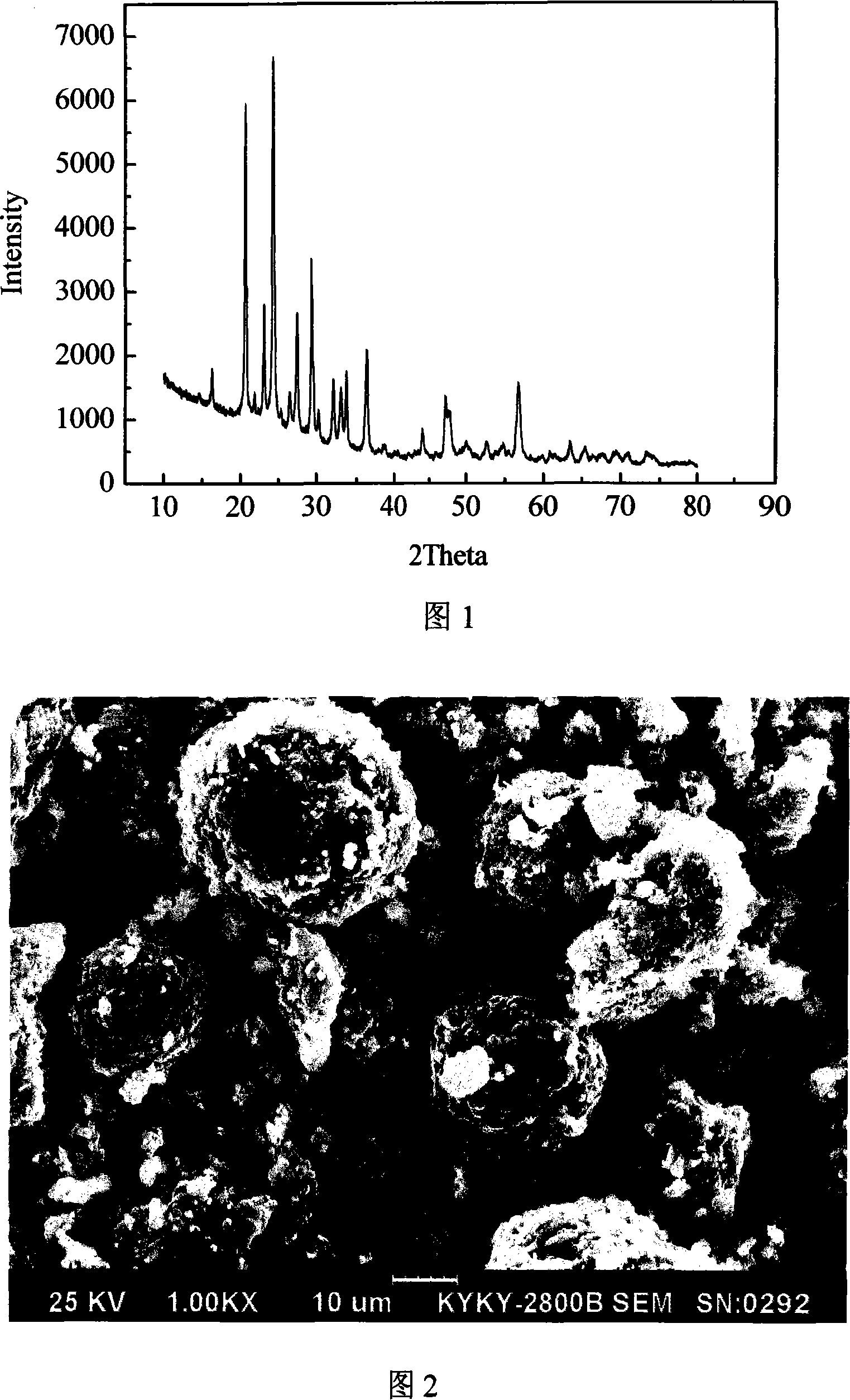

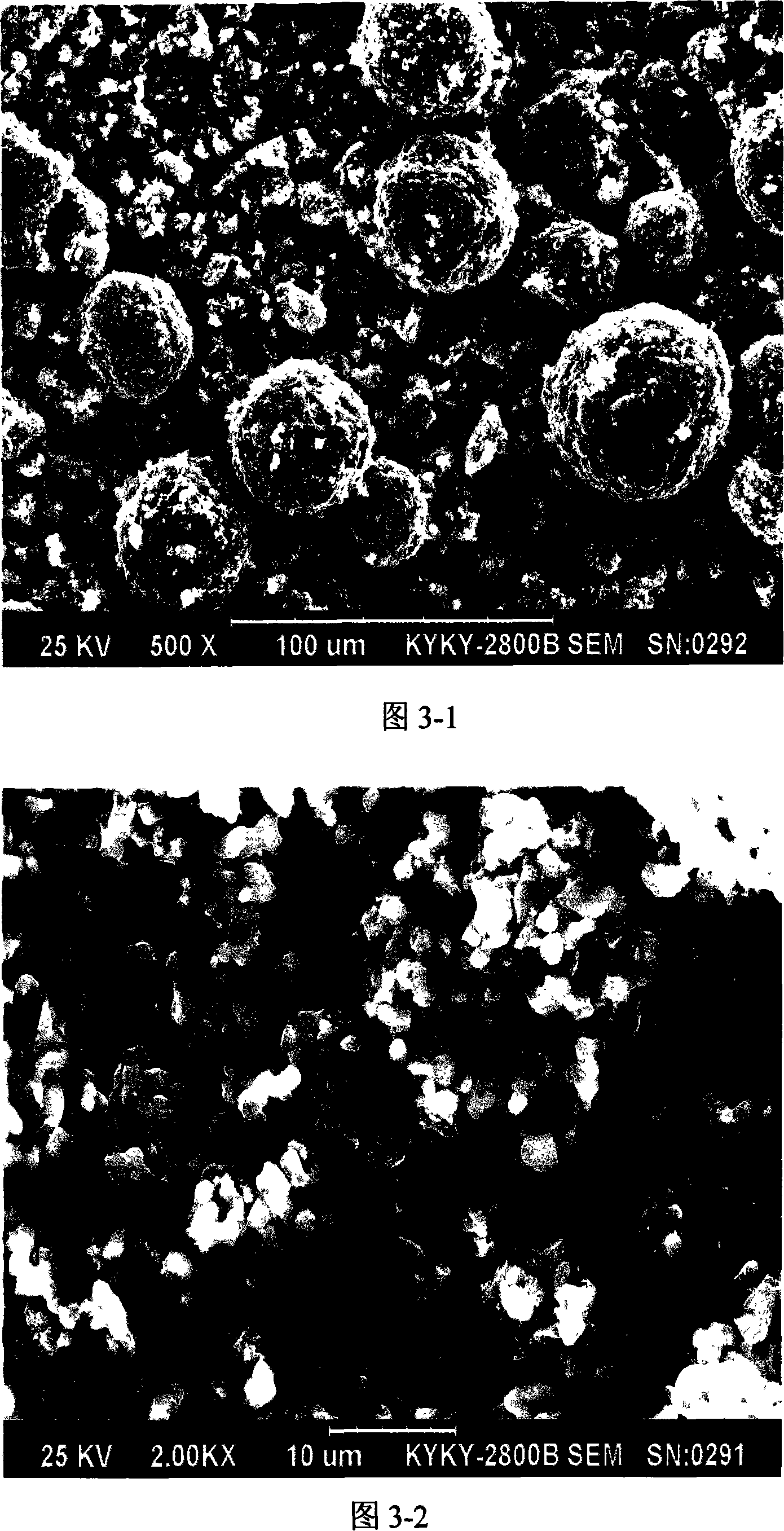

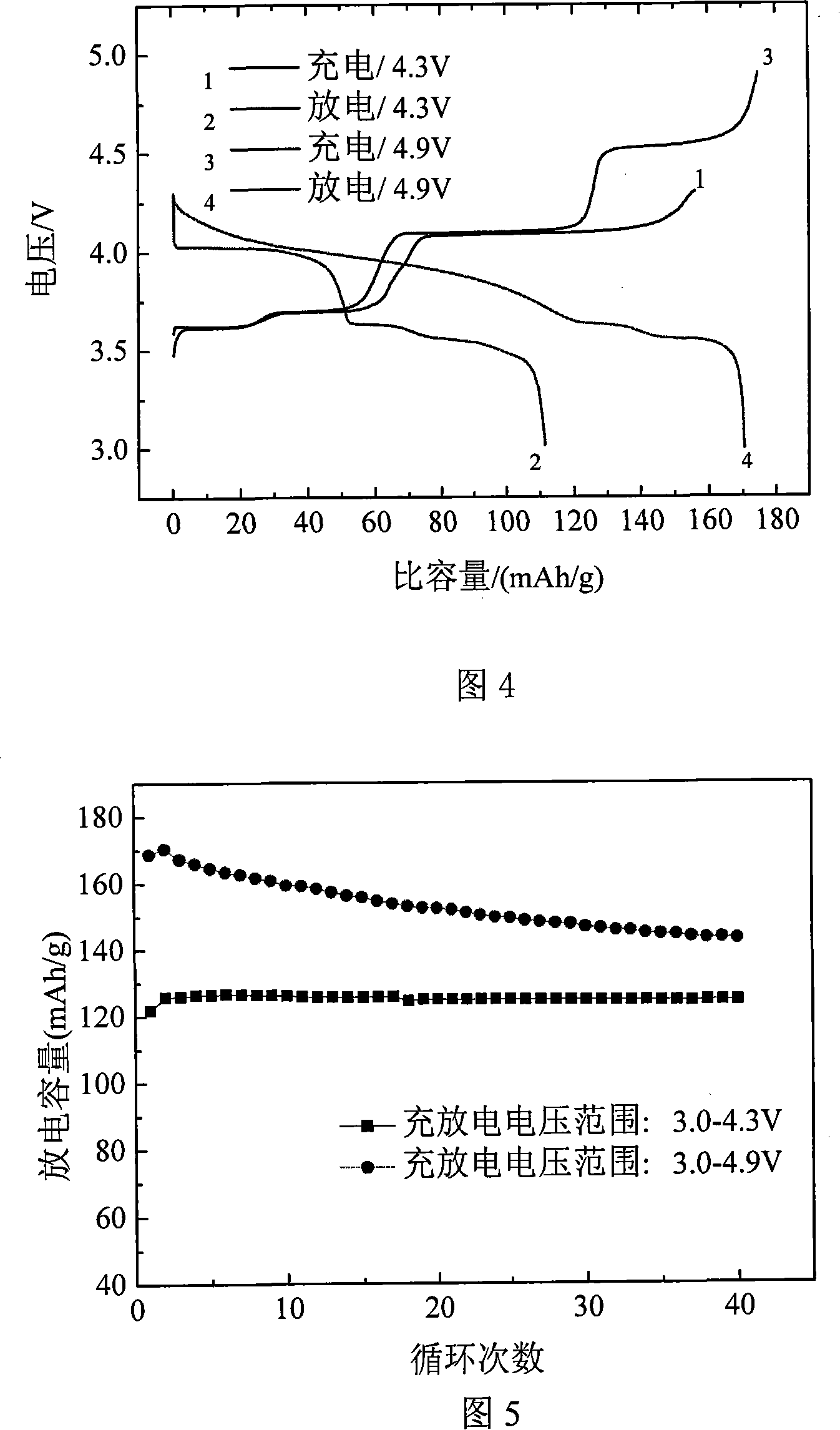

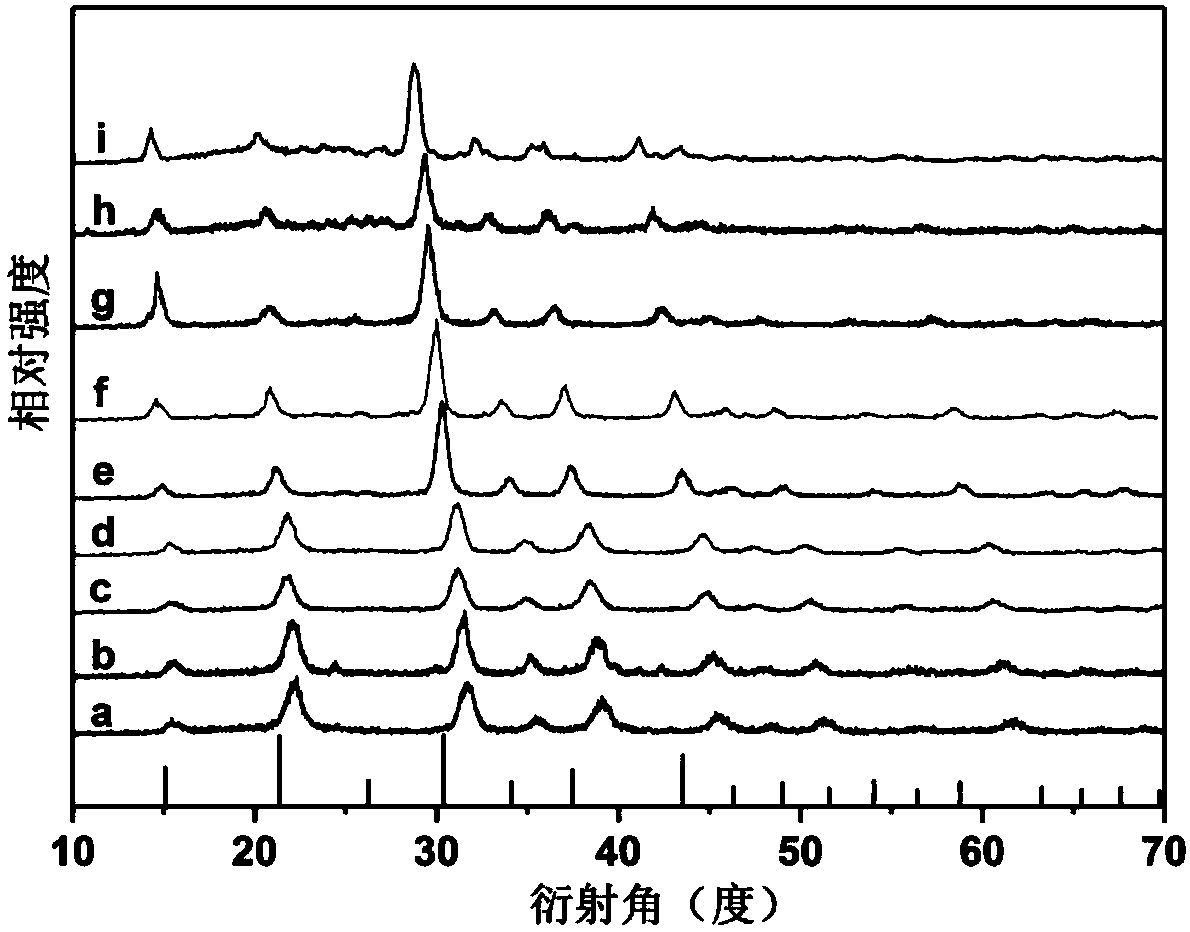

Cathode material Li3V2(PO4)3 of lithium ion battery and its making method

ActiveCN101106194ASmall and evenly dispersedAvoid reunionElectrode manufacturing processesChemical/physical/physico-chemical processesNanoparticlePhysical chemistry

The invention discloses a lithium-ion battery positive material-lithium vanadium phosphate, and the preparation method thereof, the main technical proposal is to enhance the purity of positive material and simplify the synthesizing method. The positive material in the invention is provided with a base body of lithium vanadium phosphate, carbon materials are coated outside the base body, the positive material is provided with some microscopic features like spheres, semi-spheres with the length of long axis and short axis of 5-30 micron, diamonds, cones, flakes, laminates and / or blocks, the size thereof is 5-30 micron, and the specific surface area is 5-15m2 / g. The preparation method includes preparing nano particles, liquid mixing reacting, preparing precursors, pretreament, activated roasting, coating the organic materials which can be carbonized, and then high-temperature processing. Compared with the prior art, by utilizing the nano particle secondary-molding liquid method for synthesizing the positive material-lithium vanadium phosphate, the invention simplifies operation processes and reduces production cost, with the positive material with higher charging-discharging capacity and excellent cyclical steady.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

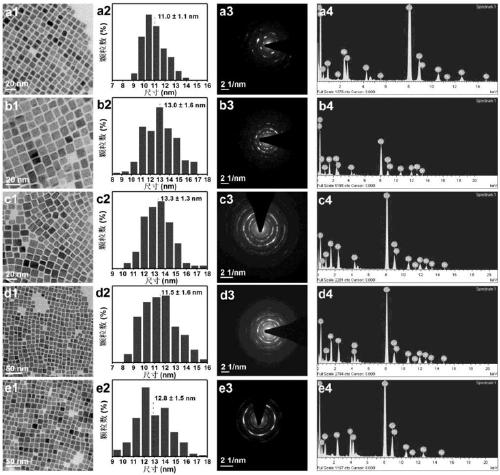

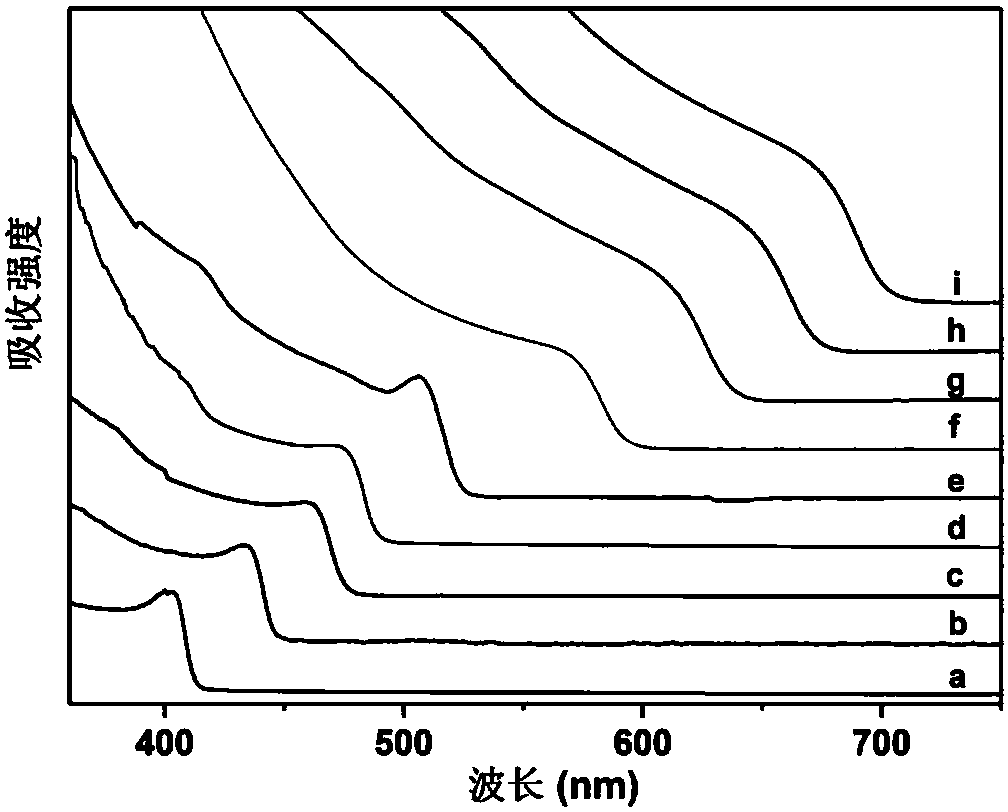

Preparation method of abx3 type all-inorganic perovskite nanocrystal

The invention discloses a preparation method of an ABX3 type all-inorganic perovskite nanocrystal. In the preparation process, a solvent is used in a small amount, and the raw material unit price is low (for example, an expensive PbX2 raw material is replaced by cheap lead acetate), environmental requirements are not high in the preparation process, a glove box is not required, the operation procedure is simple, and the cost of raw materials and instruments is greatly reduced. The nanocrystal can synthesize a target product in a wide temperature range of 0 to 300 DEG C in the preparation process, and the morphology, phase, size and luminous performance of the nanocrystal can be controlled by changing the raw material ratio, solvent ratio, reaction temperature and / or reaction time, for example, perovskite nanowires can be prepared at the reaction temperature of greater than or equal to 0 DEG C and less than 90 DEG C, and perovskite quantum dots can be prepared at the reaction temperature of 90 to 300 DEG C. The nanocrystal has good stability and high fluorescence quantum yield (26%-80%), and can realize full visible spectrum (400-700 nm) luminescence. The preparation method is simple in process, short in time consumption, low in cost, easy to amplify and synthesize, and suitable for industrial large-scale preparation.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

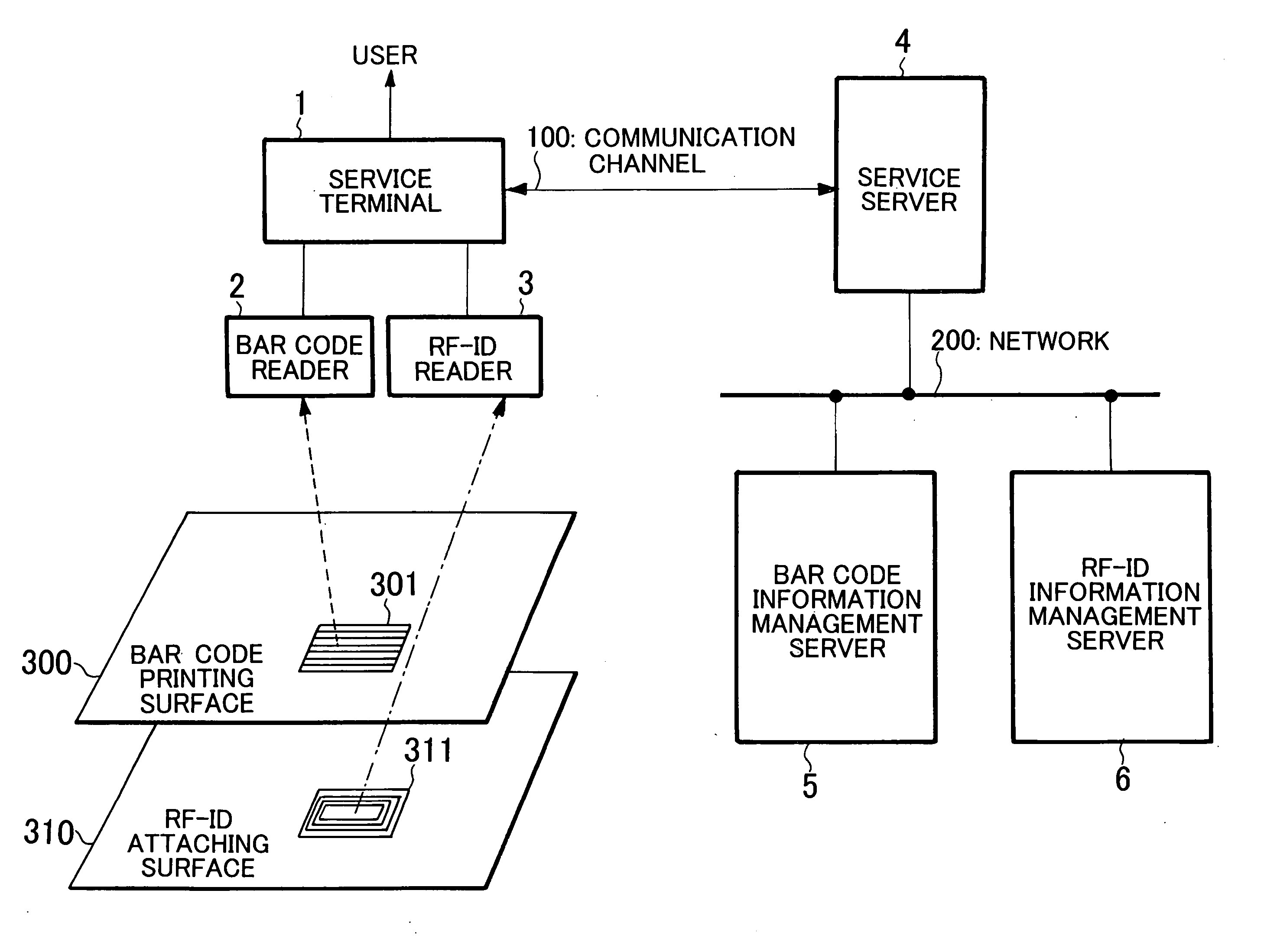

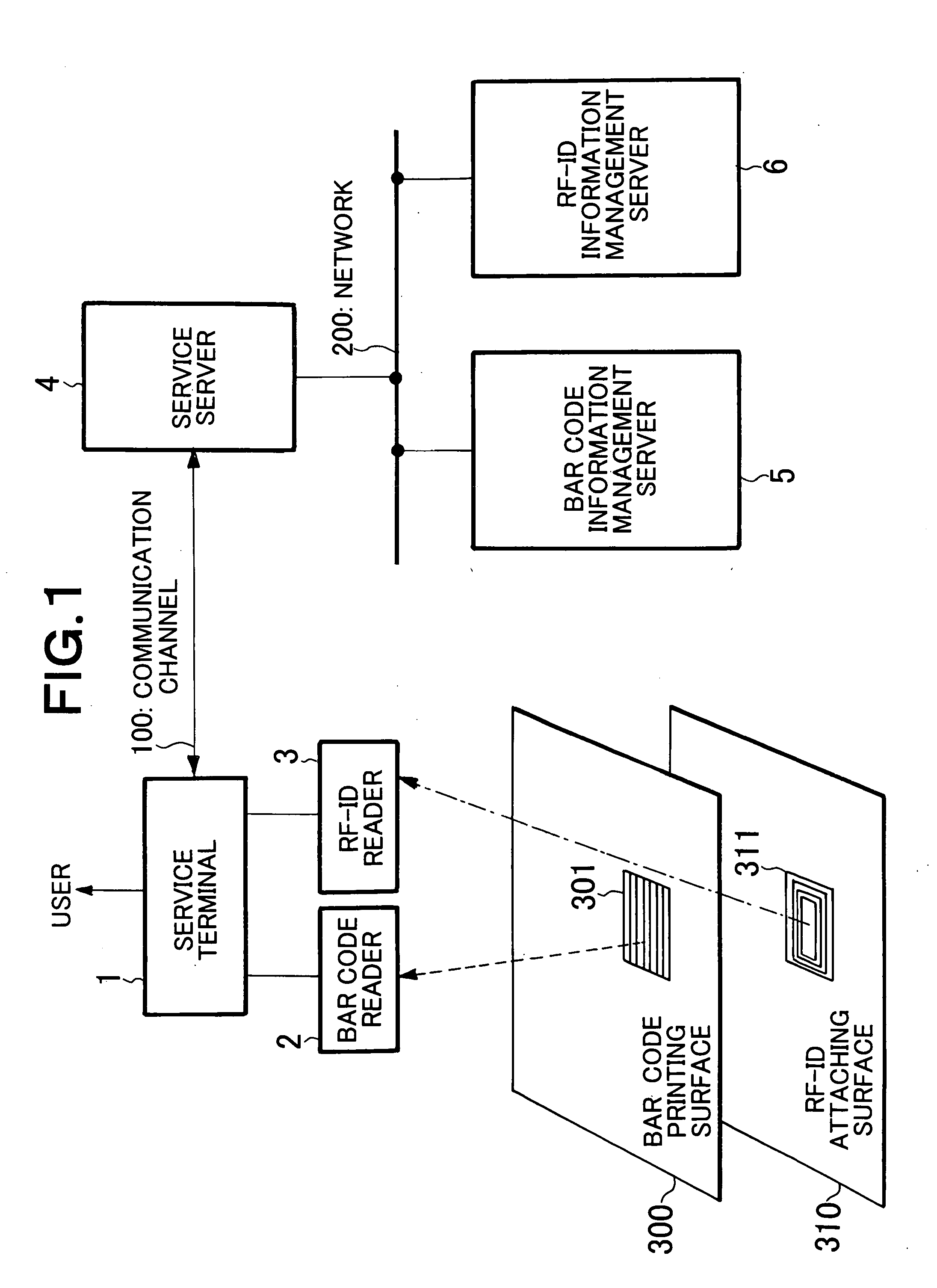

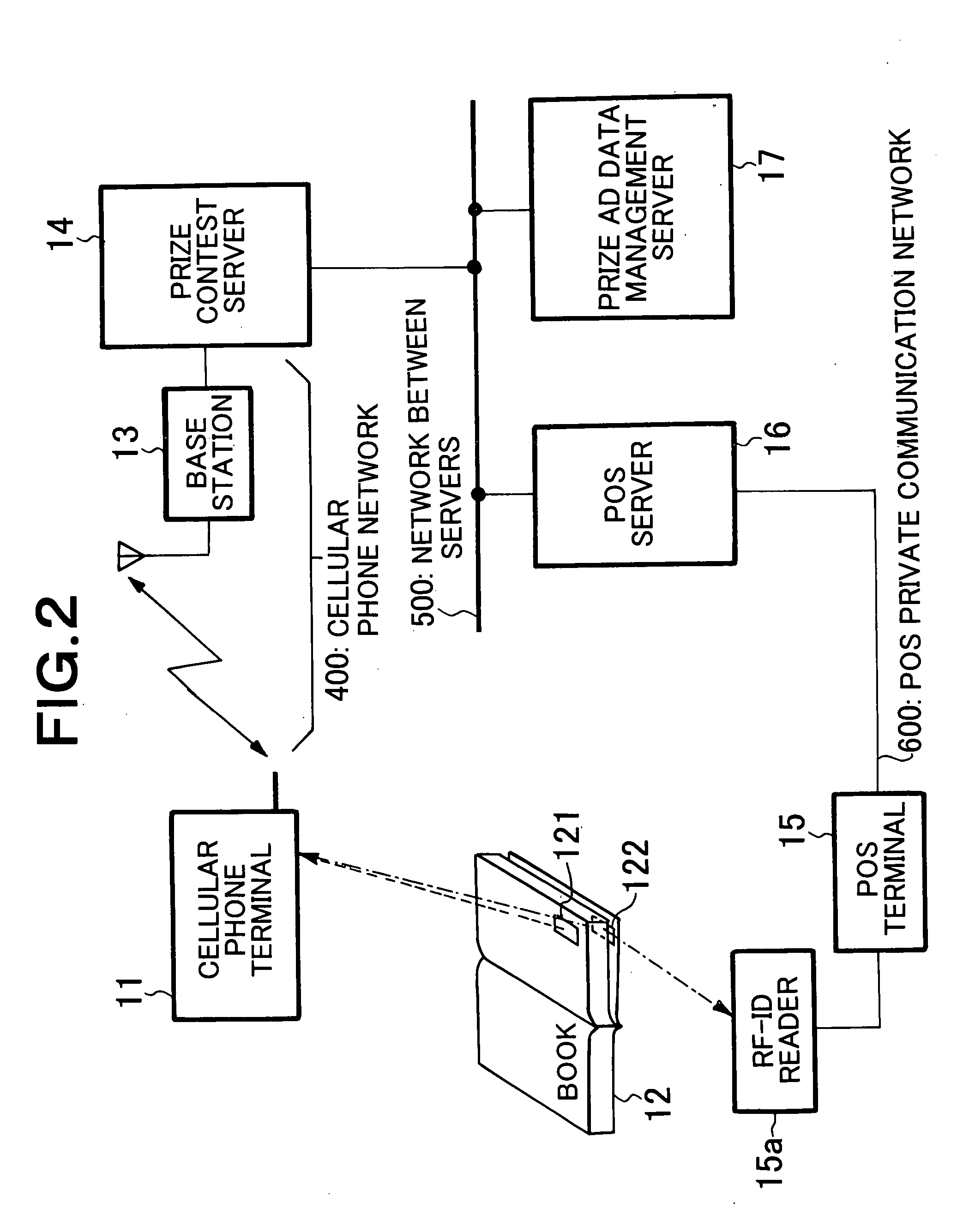

Information processing device for using bar code and radio frequency-identification tag

ActiveUS20050178832A1Simple operationAdd valueMemory record carrier reading problemsHybrid readersBarcodeComputer hardware

The service terminal 1 which contains bar code reader 2, RF-ID reader 3 and information processing block is moved to a medium containing the bar code and RF-ID tag. Both of the bar code reader 2 and RF-ID reader 3 are set to the positions that information can be read from the bar code and RF-ID tag. In this case, the information processing block controls the bar code reader 2 and RF-ID reader 3 to read information from the bar code and RF-ID tag.

Owner:NEC CORP

Method for preparing antarctic krill low-fluorine hydrolysis polypeptide

The invention discloses a method for preparing antarctic krill low-fluorine hydrolysis polypeptide. The method comprises the following steps of: performing enzymolysis on antarctic krill powder used as raw materials, heating and inactivating enzyme, centrifuging, adding calcium oxide at different concentration, defluorinating, uniformly stirring, performing centrifugal separation, adjusting a solution until the solution has a certain pH value, and performing spray drying on supernatant obtained through separation to obtain the antarctic krill low-fluorine hydrolysis polypeptide of which the fluorine content is 10 to 30ppm. The process is easy to operate, the obtained product has low fluorine content, the nutrition constituents are damaged slightly, consumed time is short, and the process is simple and efficient, and is an ideal method for removing fluorine from enzymatic hydrolysate. The method lays the foundation for developing the multi-functional antarctic krill low-fluorine polypeptide.

Owner:辽渔集团有限公司

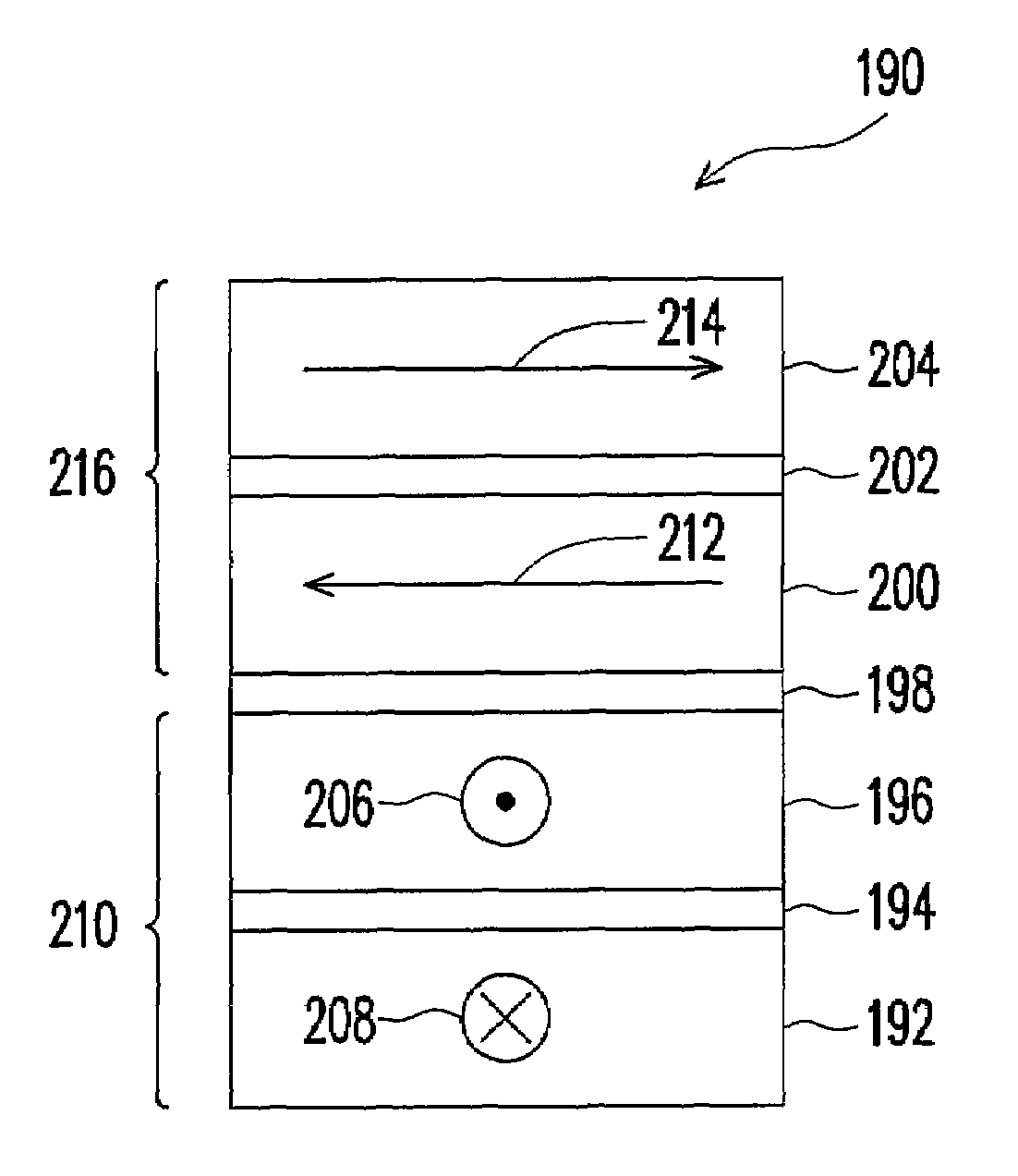

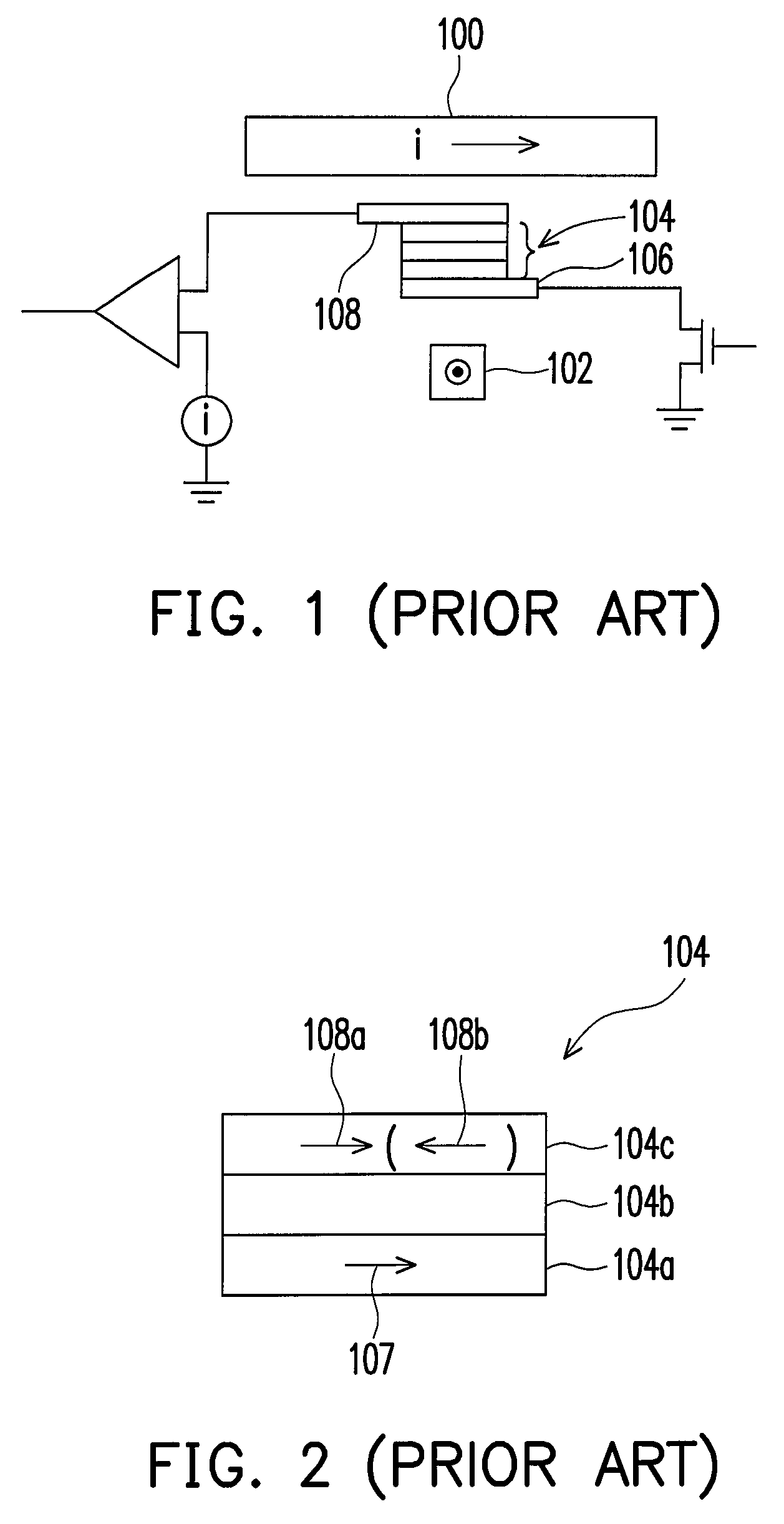

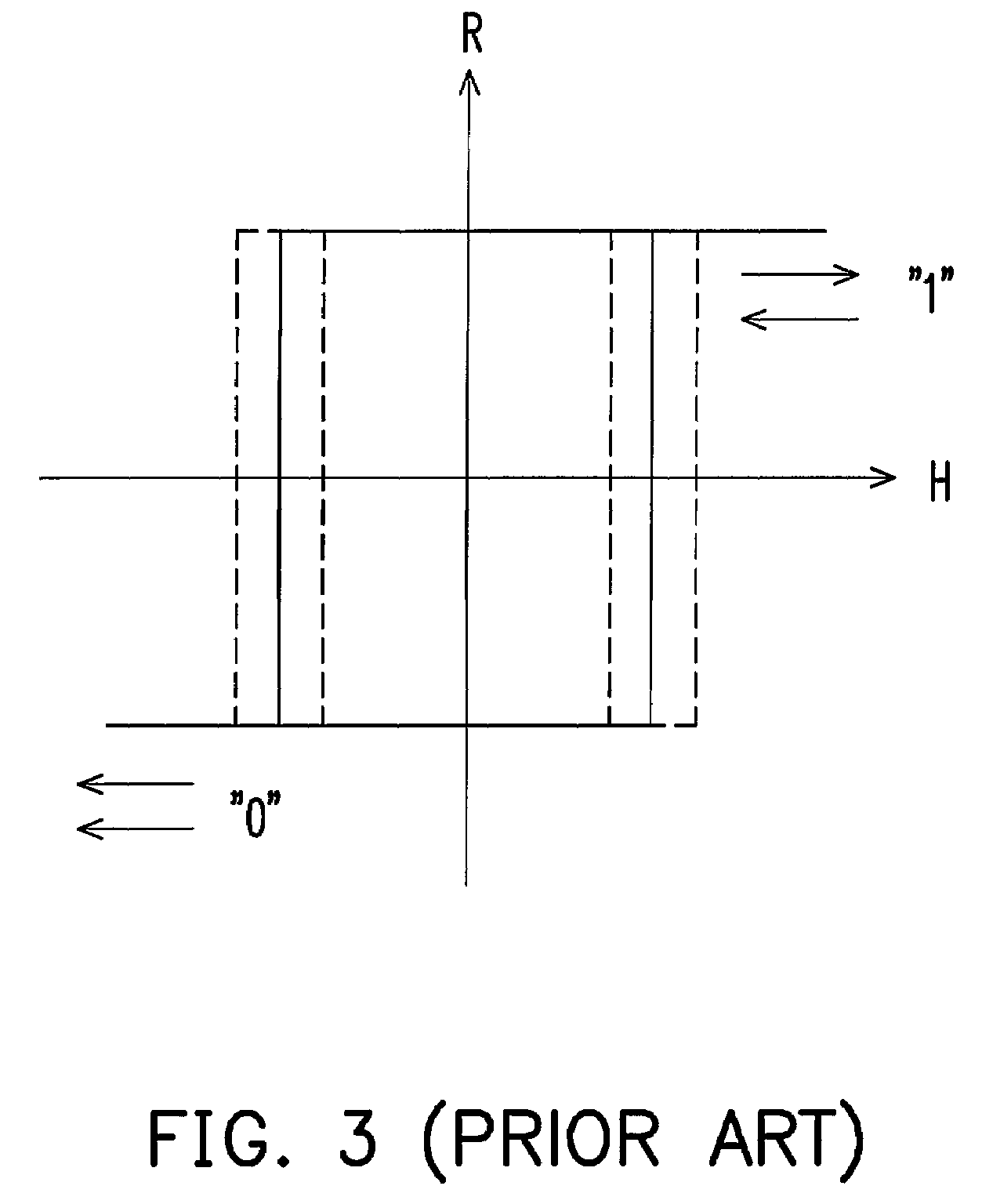

Structure and access method for magnetic memory cell and circuit of magnetic memory

InactiveUS7515458B2Lower average currentSimplify operating proceduresDigital storageAccess methodCoupling

A magnetic memory cell, used in a magnetic memory device, includes a stacked magnetic pinned layer, serving as a part of the base structure. The stacked magnetic pinned stacked layer has a top pinned layer and a bottom pinned layer, between which there is a sufficient large magnetic coupling force to maintain magnetization of the top pinned layer on a reference direction. A tunnel barrier layer is disposed on the stacked magnetic pinned layer. A magnetic free stacked layer is disposed on the tunnel barrier layer. The magnetic free stacked layer includes a bottom free layer having a bottom magnetization and a top free layer having a top magnetization. When no assisted magnetic field is applied, the bottom magnetization is anti-parallel to the top magnetization and is perpendicular to the reference direction on the top pinned layer. A magnetic bias layer can be also disposed on the top free layer.

Owner:IND TECH RES INST

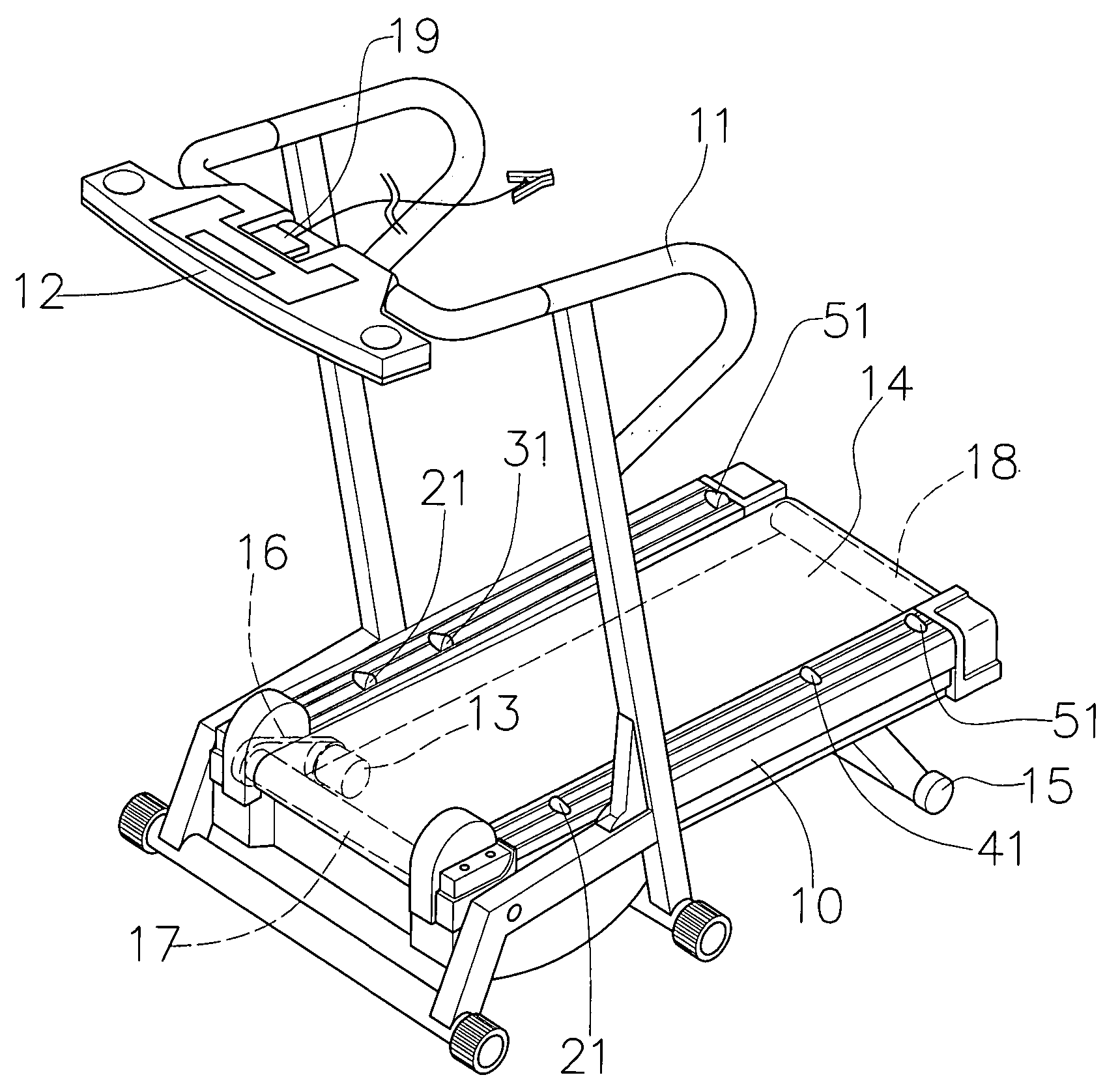

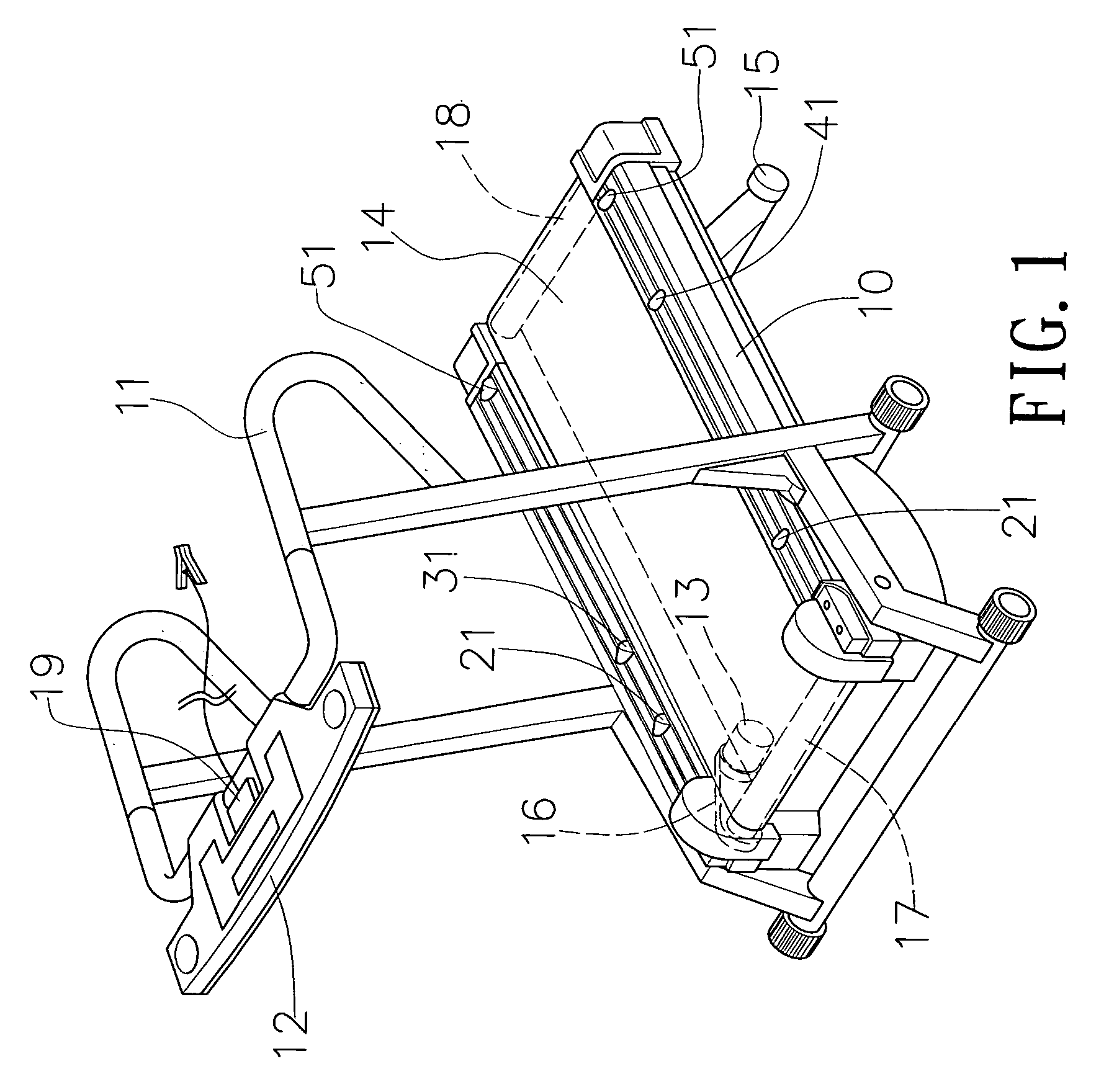

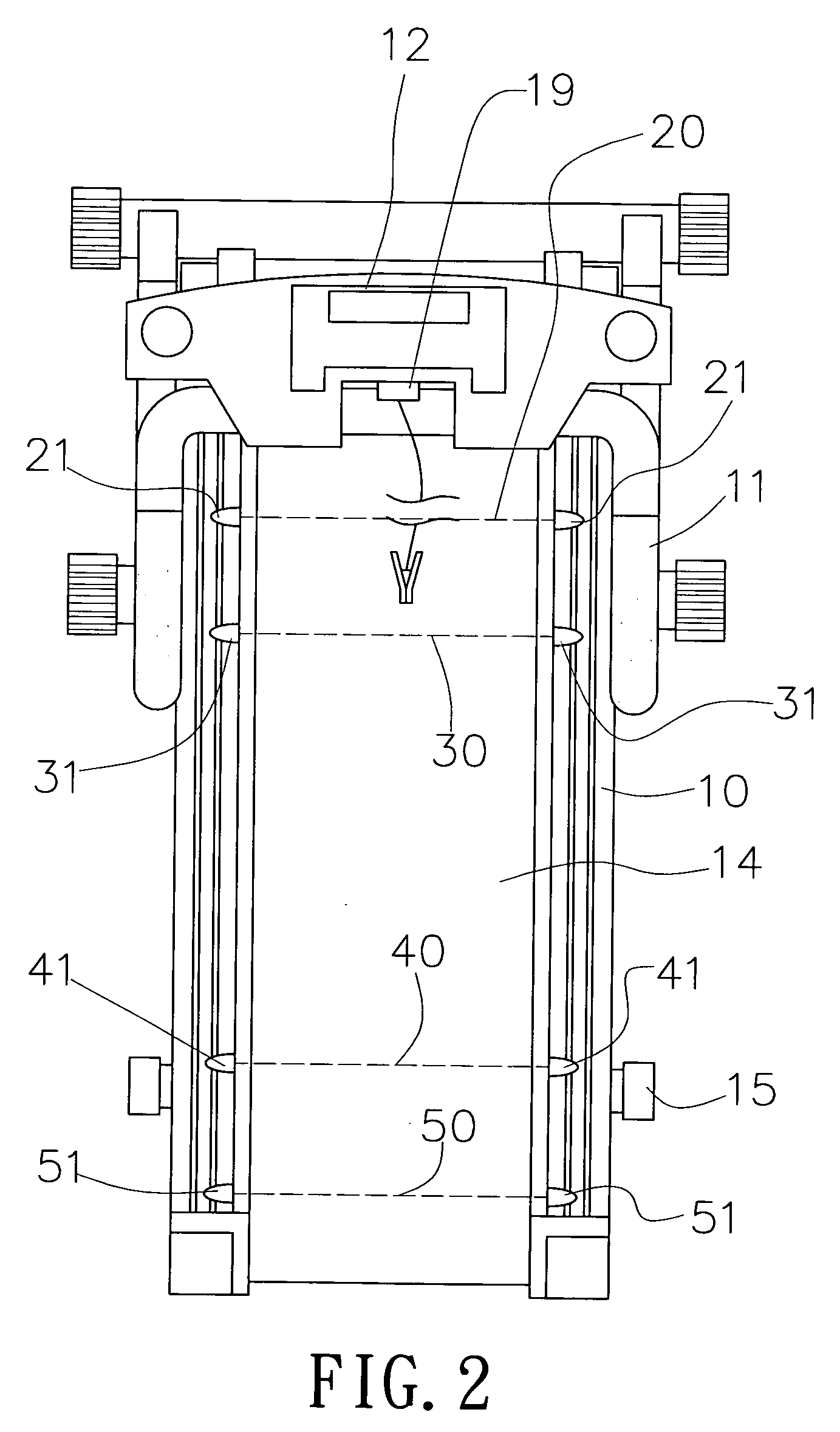

Electric treadmill

InactiveUS20060009333A1Improve abilitiesSimplify operating proceduresMovement coordination devicesCardiovascular exercising devicesElectric machineryLight wave

The present invention relates to an electric treadmill in which the tread base neighboring upon the running belt and based upon the central reference point is provided with sensing lines for acceleration, sensing lines for deceleration both of which are arranged one after the other. When the runner touches the fixed sensing position by light wave or acoustic wave, a CPU located within the electric console gives a command according to the sensing position to accelerate or decelerate the motor such that an immediate control of the rotational speed of the running belt is achieved. In addition, a sensing line for stop can be disposed behind the decelerating sensing line. When the operator continues to be shifted forwards, thereby contacting with the sensing line for stop, CPU gives a command to stop the motor immediately. Thus, the safety of the operator can be more ensured.

Owner:WANG LEAO

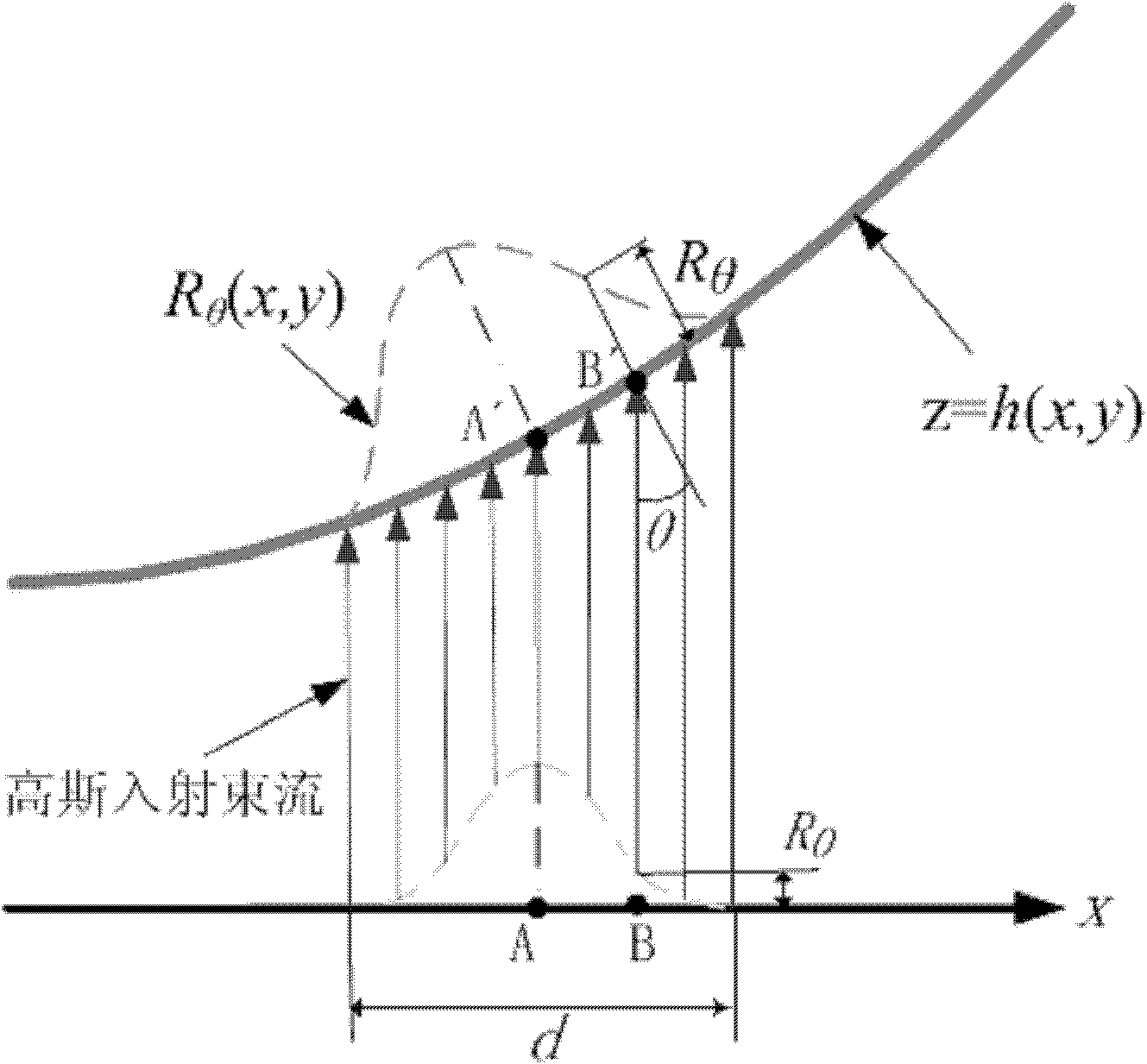

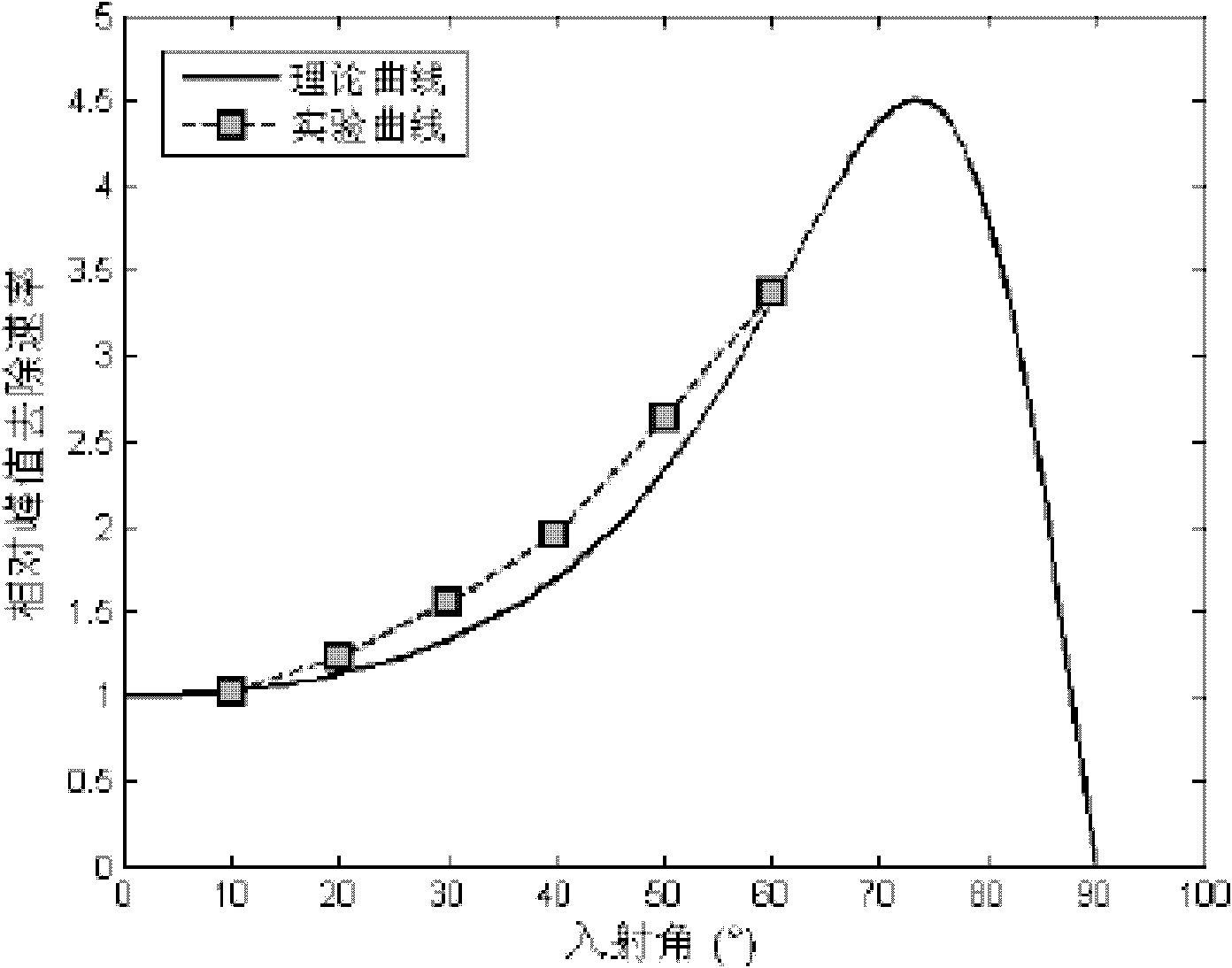

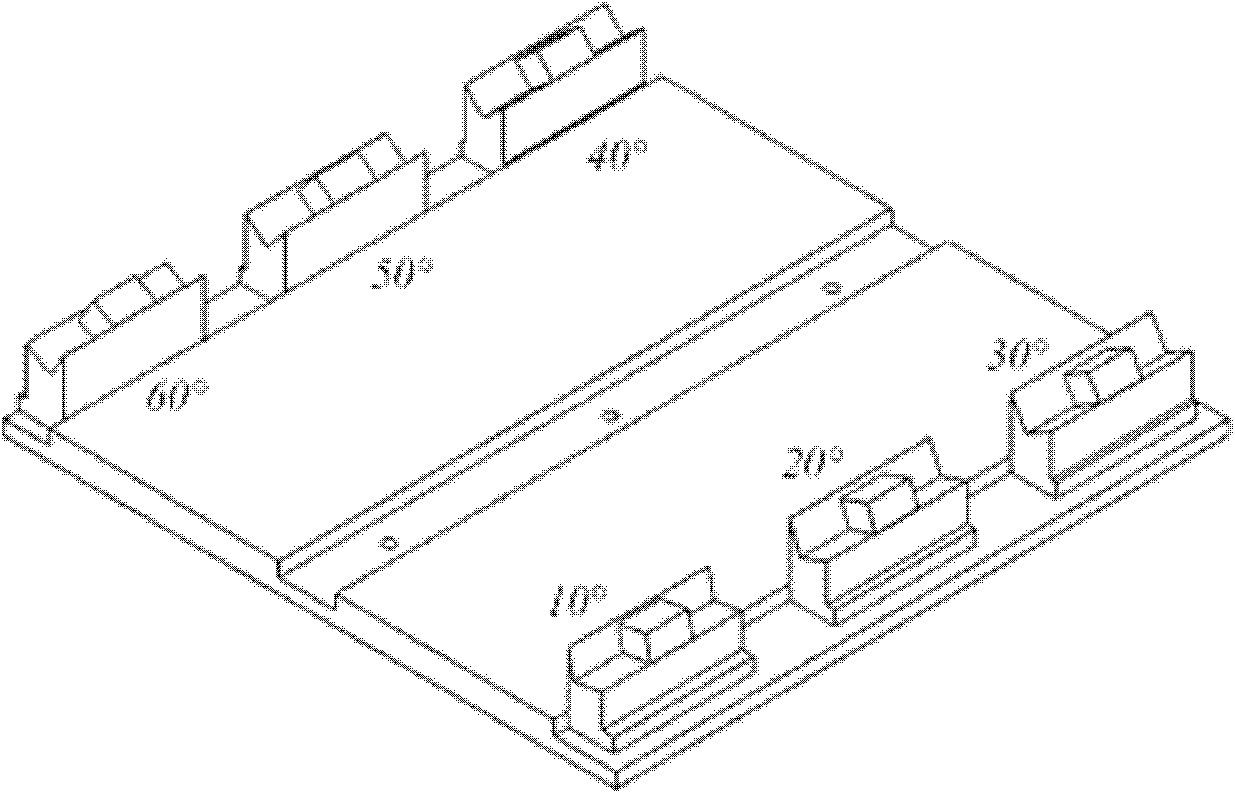

Method for polishing ion beam with high-gradient mirror surface

InactiveCN101898324ASolve the problems in polishingAchieving Deterministic PolishingOptical surface grinding machinesElectric discharge tubesNumerical controlOptical axis

The invention discloses a method for polishing an ion beam with a high-gradient mirror surface. The method comprises the following steps of: (1) measuring incidence angles theta of all points on the mirror surface; (2) confirming a compensation factor K of each point according to a model; (3) measuring an initial surface error E of a workpiece by utilizing interferometry; (4) compensating the E according to the K to acquire a compensation surface error E'; (5) acquiring a removal function R of an ion beam in the vertical incidence of the mirror surface through removal function experiment; (6) confirming residence time distribution T and generating a numerical control code according to E' and R; (7) processing by utilizing a generating device of the removal function and the generated numerical control code, enabling the ion beam to enter the mirror surface along a direction parallel to the optical axis direction of the workpiece in processing and trimming the mirror surface through a triaxiality linkage system; and (8) repeating the steps until the trimming result satisfies the requirement of surface convergence accuracy. The method of the invention has the advantages of simple operation, good stability, high processing accuracy, strong controllability, low requirement for equipment, and the like in processing the high-gradient mirror surface.

Owner:NAT UNIV OF DEFENSE TECH

Source identification preservation in multiprotocol label switching networks

ActiveUS9094337B2Simplify operating proceduresReduce complexityData switching networksMultiprotocol Label SwitchingReal-time computing

A Multiprotocol Label Switching (MPLS) method, a MPLS network element, and a MPLS network include receiving a packet destined for a destination node at a source node in an MPLS network; pushing an identifier in an MPLS label on an MPLS label stack associated with the packet, wherein the identifier denotes the source node as the source of the packet and is pushed prior to any other MPLS labels on the MPLS stack; pushing one or more labels on the MPLS stack indicative of a route of the packet to the destination node; and transmitting the packet from the source node into the MPLS network. The identifier is located at the bottom of the MPLS stack thereby being a last item popped in the MPLS stack at the destination node, and the identifier can be used for updating OAM data efficiently without requiring deep packet inspection.

Owner:CIENA

Systems and instrumentalities for use in total ankle replacement surgery

ActiveUS8475463B2High precisionSimplify operating proceduresWrist jointsAnkle jointsAnkle boneTotal ankle arthroplasty

Custom radiographically designed tibial and talar cutting guide system and instrumentalities including a tibial cutting guide position verification device is disclosed. A computer-based system and method for making the custom radiographically designed tibial and talar cutting guides is also disclosed. Further disclosed is an adjustable tibial reaming guide positioning system for allowing a position for reaming of a distal tibia to be adjusted during total ankle replacement surgery and, particularly, during total ankle arthroplasty for prostheses with an intramedullary stem.

Owner:LIAN GEORGE J

Electric treadmill

InactiveUS7153241B2Improve abilitiesSimplify operating proceduresMuscle exercising devicesMovement coordination devicesElectric machineryAcoustic wave

The present invention relates to an electric treadmill in which the tread base neighboring upon the running belt and based upon the central reference point is provided with sensing lines for acceleration, sensing lines for deceleration both of which are arranged one after the other. When the runner touches the fixed sensing position by light wave or acoustic wave, a CPU located within the electric console gives a command according to the sensing position to accelerate or decelerate the motor such that an immediate control of the rotational speed of the running belt is achieved. In addition, a sensing line for stop can be disposed behind the decelerating sensing line. When the operator continues to be shifted forwards, thereby contacting with the sensing line for stop, CPU gives a command to stop the motor immediately. Thus, the safety of the operator can be more ensured.

Owner:WANG LEAO

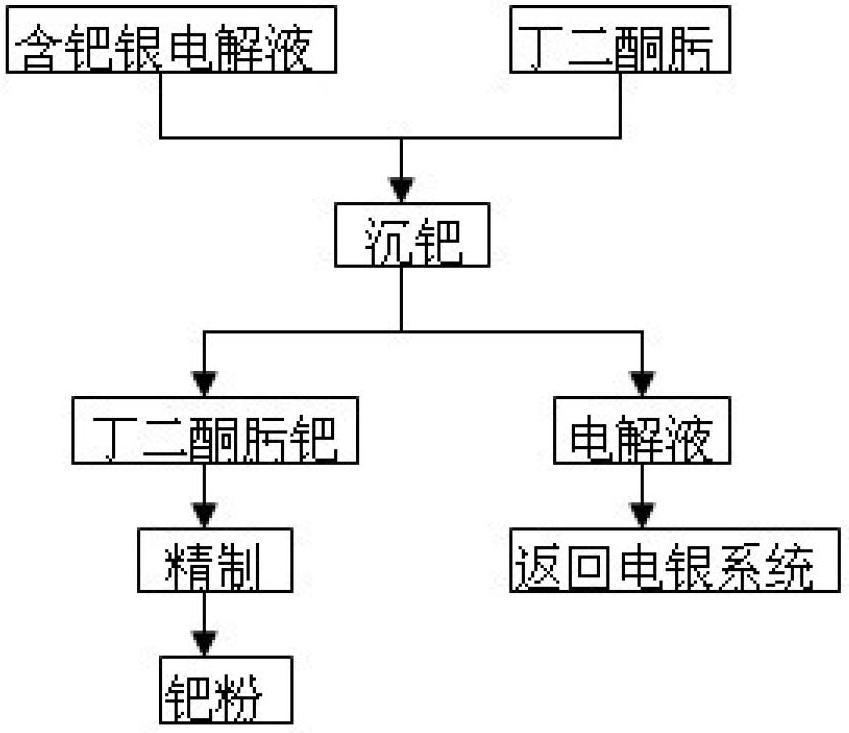

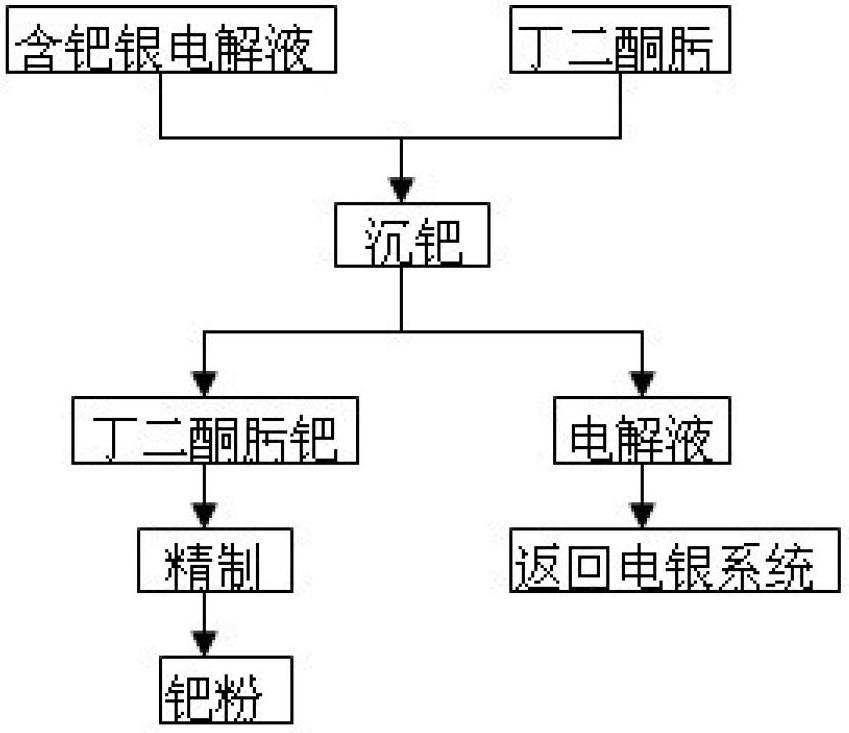

Method for recycling palladium from silver electrolyte by using dimethylglyoxime

InactiveCN102676837ANo heating requiredSimplify operating proceduresProcess efficiency improvementElectrolyteEthanol

The invention discloses a method for recycling palladium from a silver electrolyte by using dimethylglyoxime. The method comprises the following steps: adding dimethylglyoxime into a palladium-containing electrolyte for precipitating palladium; performing solid-liquid separation, returning filtrate as an electrolyte, and eluting filter residue with nitric acid acidification water to obtain a dimethylglyoxime palladium crude product; dissolving the dimethylglyoxime palladium crude product with aqua regia, and then precipitating palladium with ammonium chloride; eluting an obtained ammonium chloropalladate precipitate with an ammonium chloride solution until filtrate is colorless; and adding water, heating, and dissolving; filtering, and cooling filtrate; adding ammonia water, complexing and dissolving; cooling, filtering, and eluting the filter residue with ammonia water; adding hydrochloric acid for acidifying filtrate; filtering to obtain a diammonium dichloropalladite precipitate; and reducing the precipitate by hydrazine hydrate to obtain palladium sponge with the grade of 99.99%. Heating and pH regulation are not required, and only quantitative precipitation of palladium is required; the selectivity is good; and the precipitated dimethylglyoxime palladium can achieve a very high purity after simple eluting, so that the palladium purifying process is greatly shortened and the palladium recycling rate is improved; the using amount of dimethylglyoxime is low; and except a small amount of ethanol, other ions are not brought, so that the reuse of the electrolyte is not affected.

Owner:SIHUI CITY HONGMING PRECIOUS METALS

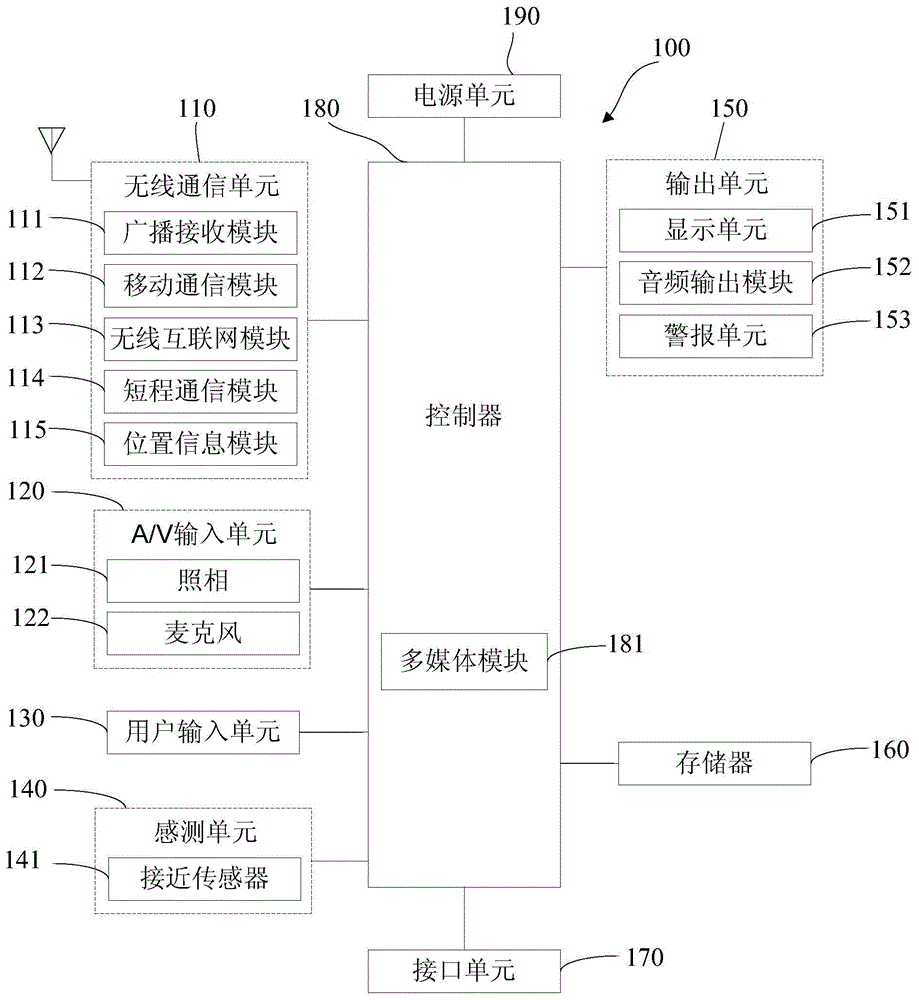

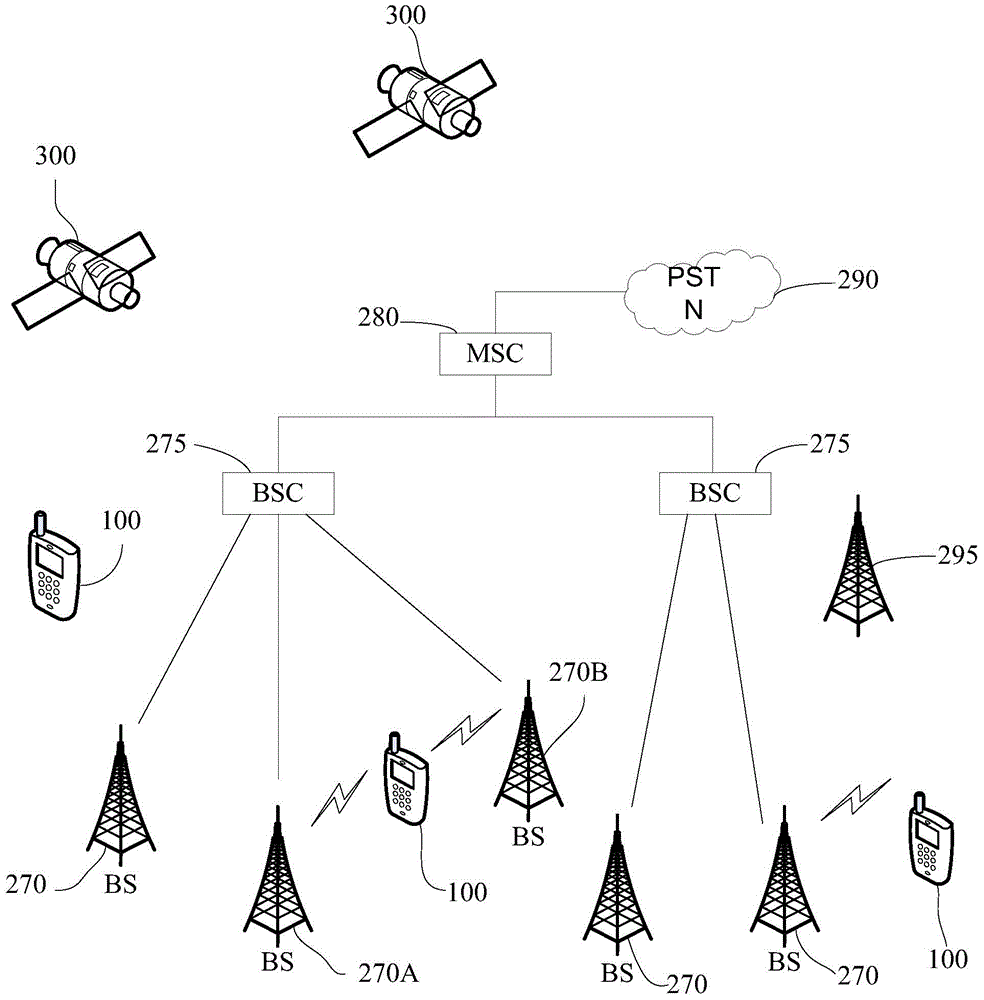

Mobile terminal and method for realizing function adjustment by utilizing virtual frame areas of mobile terminal

ActiveCN104935725AQuick searchImprove user experienceSubstation equipmentWireless communicationComputer terminalComputer engineering

Owner:NUBIA TECHNOLOGY CO LTD

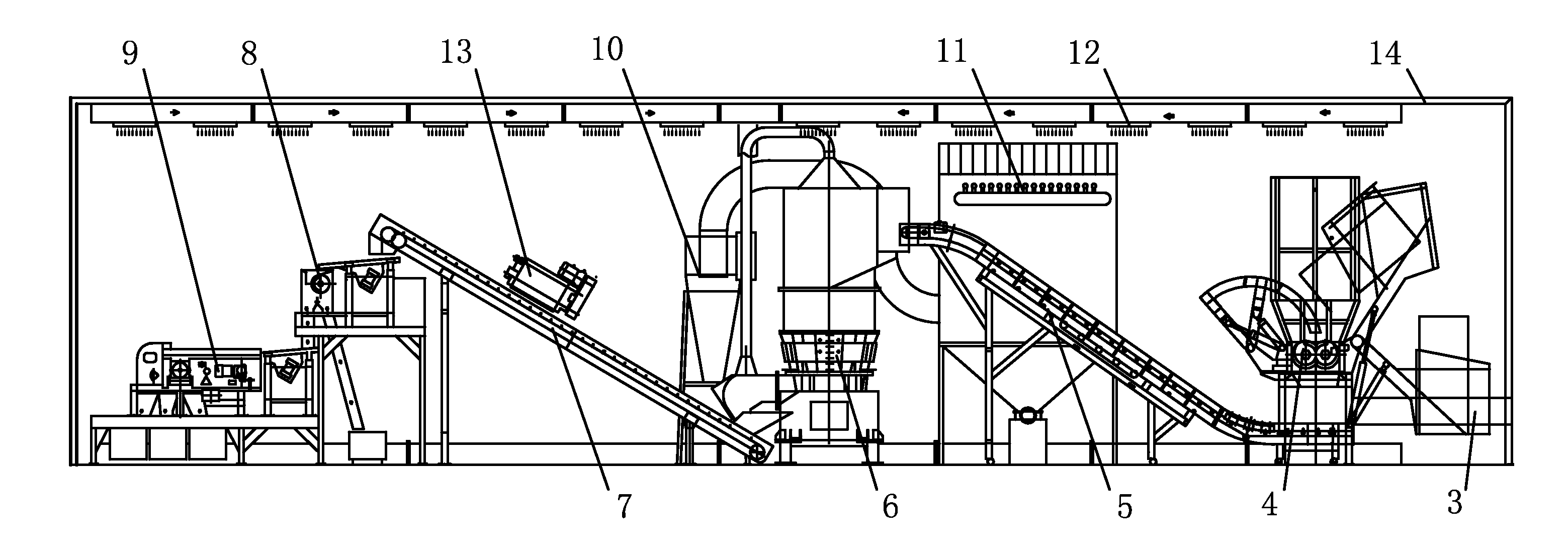

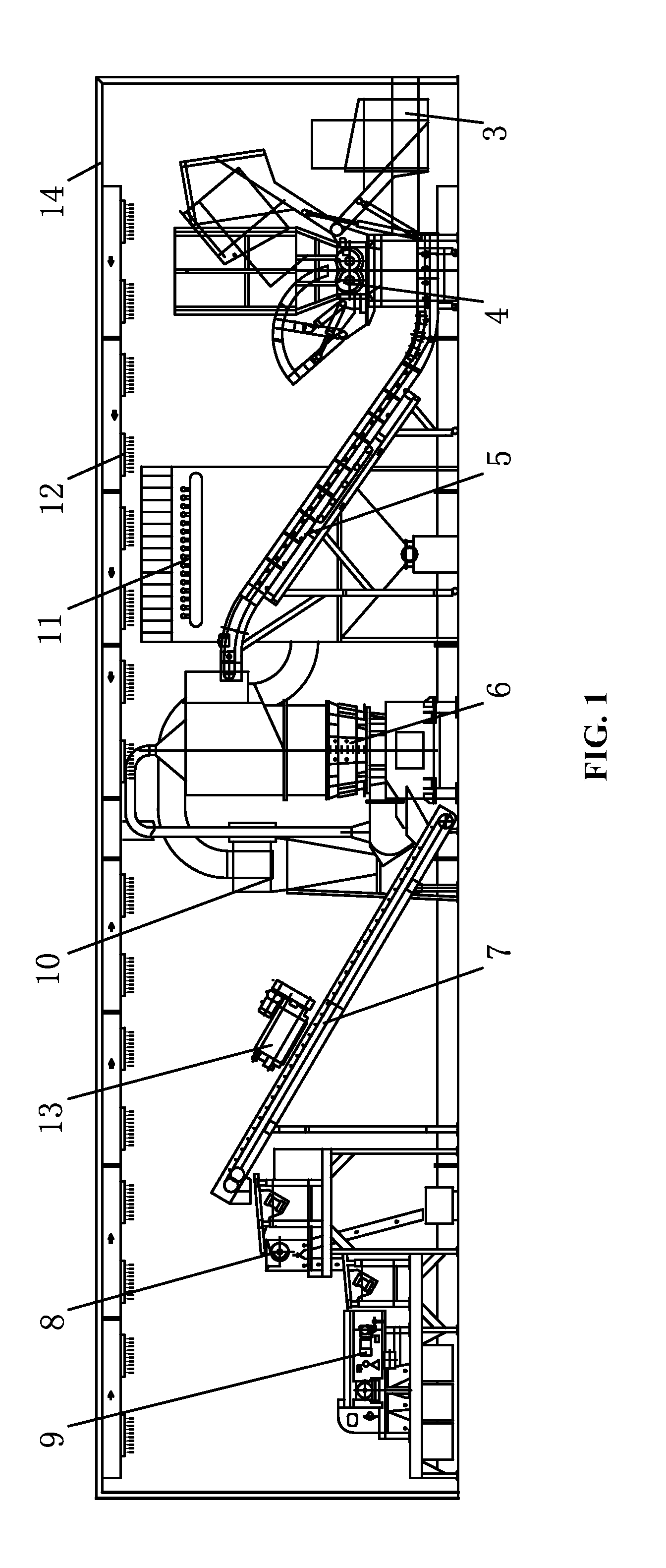

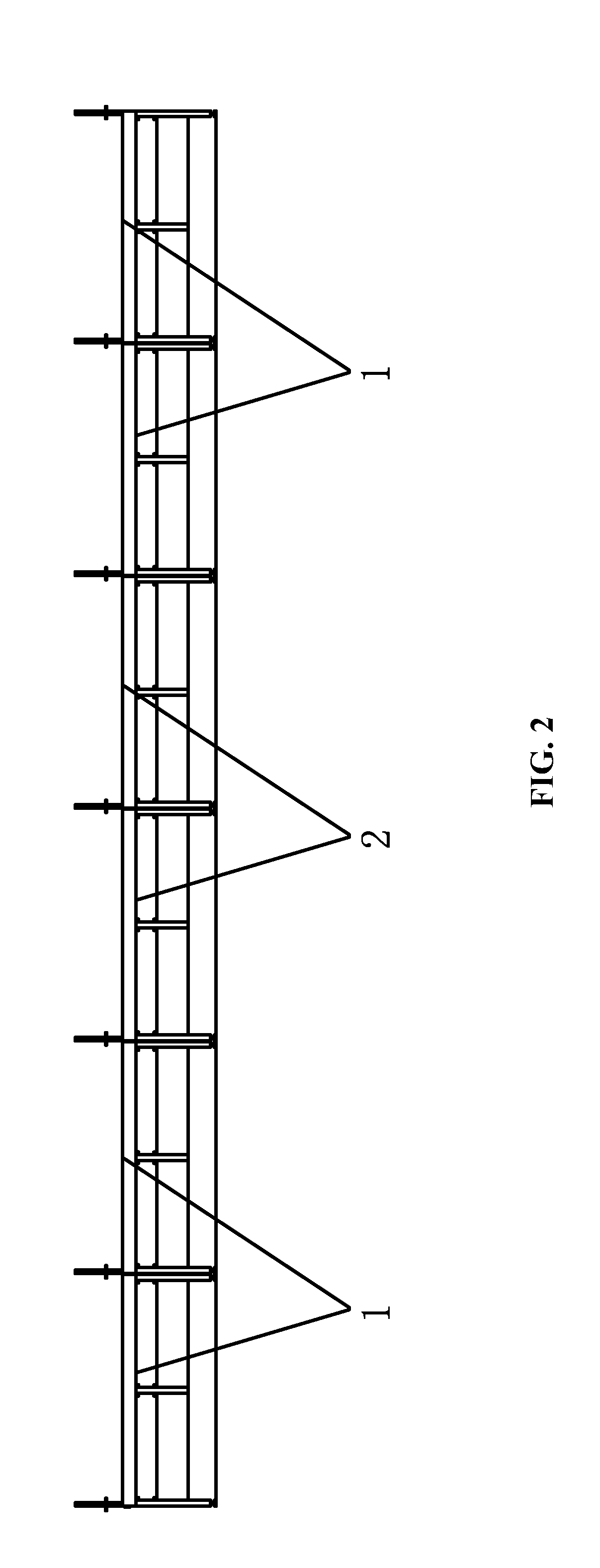

Method and device for treatment and recycling of waste refrigerators

ActiveUS20120174369A1Efficient recyclingReduce manufacturing costSolid waste disposalTransportation and packagingCrusherNitrogen gas

A method and device for harmless treatment and recycling of waste refrigerators. Plastic parts, electrical boxes, compressors, and condensers are disassembled at a disassembling station. Refrigerants from compressors are recycled at a fluoride-extracting station. Refrigerator bodies and doors are transferred to a double shaft shredder and a rolling crusher for crushing. Crushed materials are sorted out by wind force, by a self-discharge type iron remover made of permanent magnet and a cylindrical iron remover for magnetic separation. The device is placed in an enclosed workshop equipped with a multistage ventilation system, a protective device of nitrogen, a device for spraying, dedusting, and cooling, and an on-line detection and alarm control device for cyclopentane gas concentration, polyurethane dust concentration, and temperature. The method and device have low manufacturing and operating costs and are dustproof, explosion proof, environmentally friendly and has excellent recycling effects.

Owner:MING GUOYING +4

High strength and low density oil well cement

ActiveCN1721353AImprove early strengthImprove stabilitySolid waste managementLow densityUltimate tensile strength

The high strength and low density oil well reinforcing cement has cement mortar density of 1.60 g / cu cm, and consists of oil well cement, weight reducing material, cement mortar stabilizer and admixture. It has optimized material composition, high early stage strength, improved rheologic performance and controllable thickening time, and meets the requirement for reinforcing low stratum pressure oil well.

Owner:JIAHUA SPECIAL CEMENT

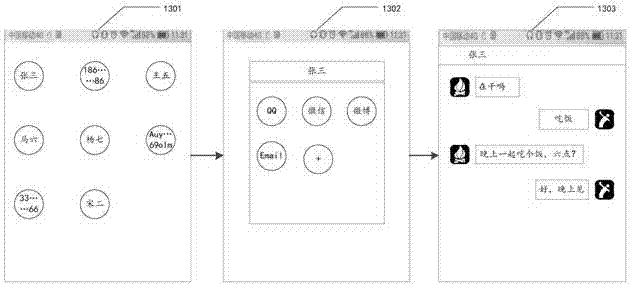

Terminal and interface interaction control method, contact object creation method and device

ActiveCN106873854ARestore Communication PropertiesEasy to optimizeInput/output processes for data processingInteraction controlOperational system

The invention discloses an operating system user interface interaction control method and a relevant device. The method specifically comprises the following steps: displaying a user interface, and displaying a system address book contact object list in the user interface; in response to a touch instruction for a random contact object in the list, displaying an associated application container menu interface, and displaying a communication application shortcut icon pre-associated with the contact object in the menu interface; and in response to the touch instruction for the random shortcut icon, opening a communication function interface corresponding to the touch contact object in the application corresponding to the shortcut icon. By creating the solution of integrally displaying a plurality of communication application shortcut icons by selecting the contact objects, the search time of a user is shortened, the user experience is improved, the operation flow is simplified, and the response speed of the system is improved.

Owner:西安欧思奇软件有限公司

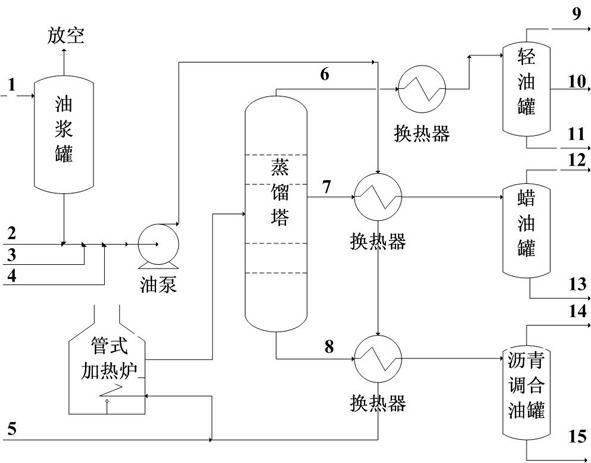

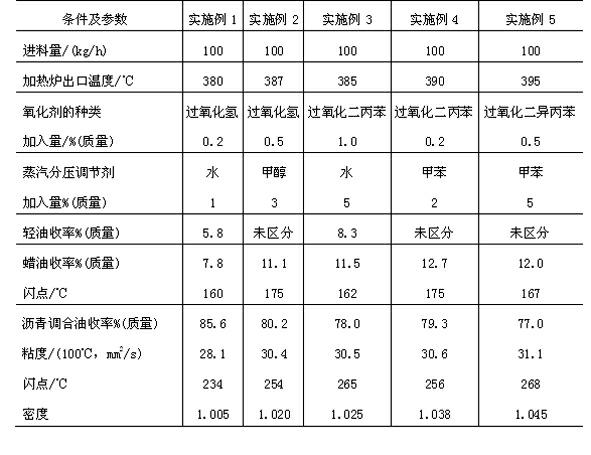

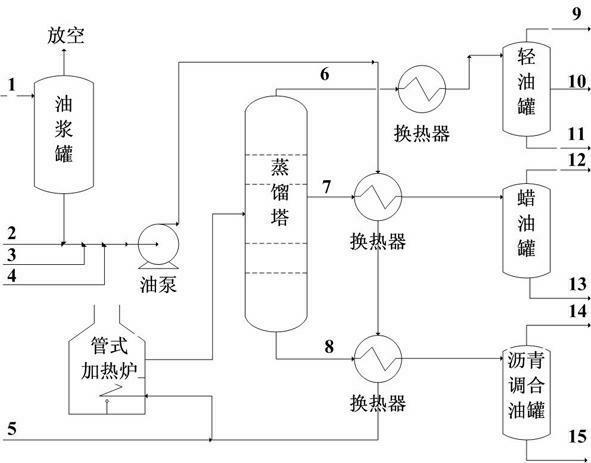

Method for producing asphalt blending oil by normal pressure distillation of catalytic slurry oil

InactiveCN102559250ALess investment in equipmentSimplify operating proceduresTreatment with plural serial refining stagesWaxBoiling point

Owner:甘黎明 +2

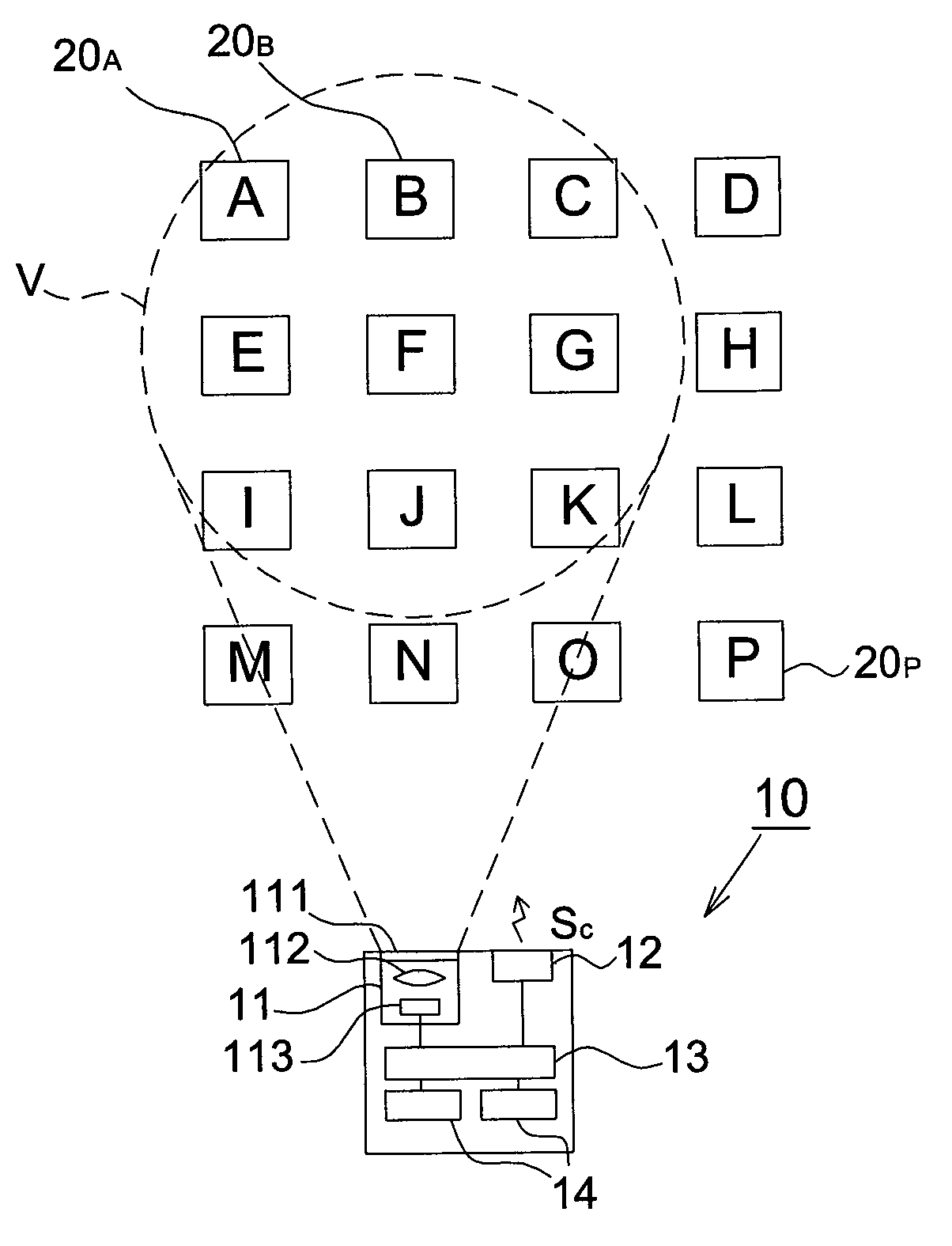

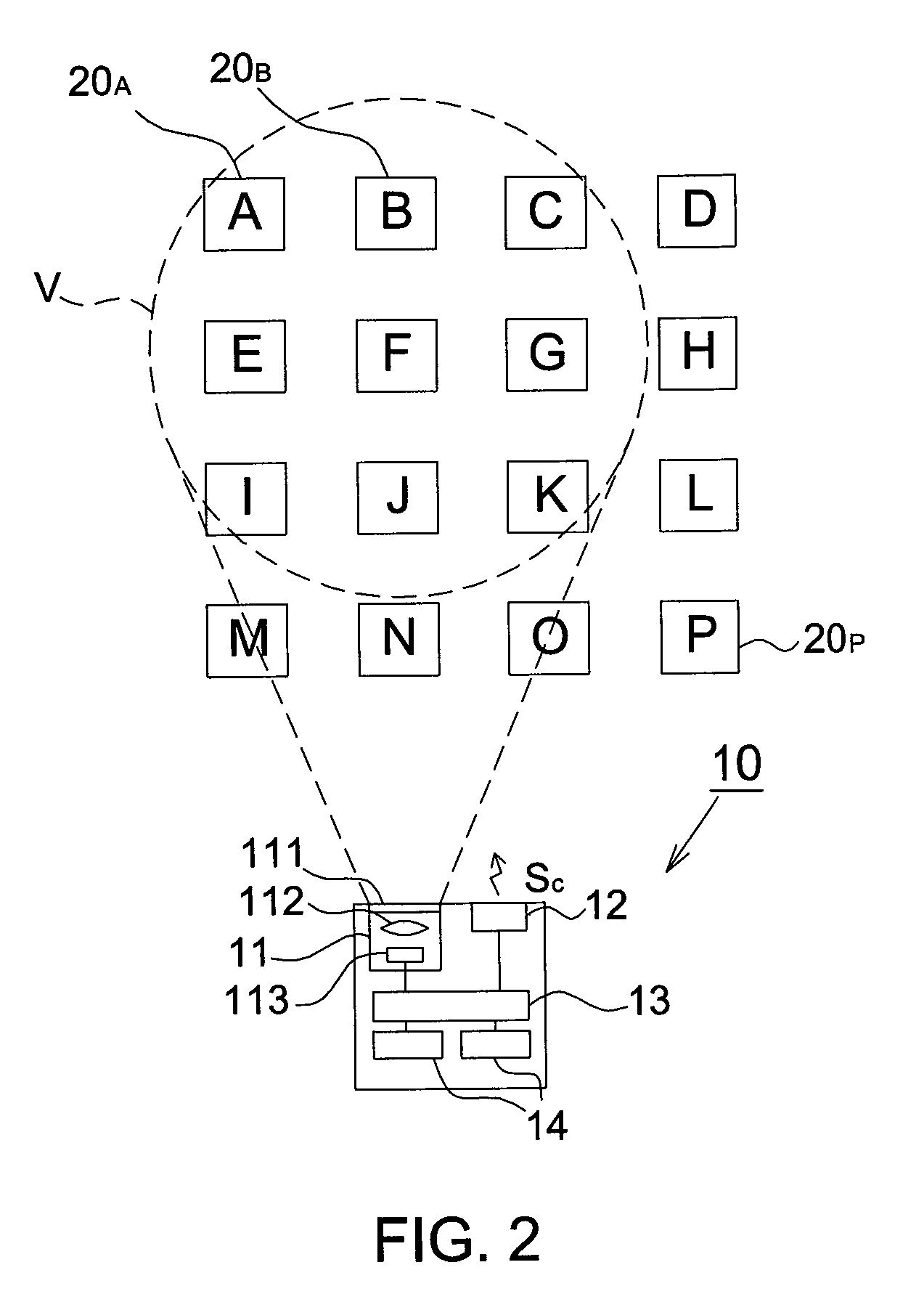

Light control system and control method thereof

InactiveUS20100295457A1Limiting practicabilitySimplified installation procedureElectrical apparatusElectric light circuit arrangementWireless controlSignal generator

A light control system includes at least one illumination module and a remote controller. Each illumination module includes an identification signal generator, at least one light source, a receiving unit and a control circuit. When the receiving unit receives a first wireless control signal, the control circuit controls the identification signal generator to emit an identification signal; when the receiving unit receives a second wireless control signal, the control circuit controls the ON / OFF of the light source. The remote controller sends the first and second wireless control signals to the illumination module, acquires the identification signal emitted from the identification signal generator to generate a plurality of images, and identifies the illumination module according to the images. The present invention further provides a control method of a light control system.

Owner:PIXART IMAGING INC

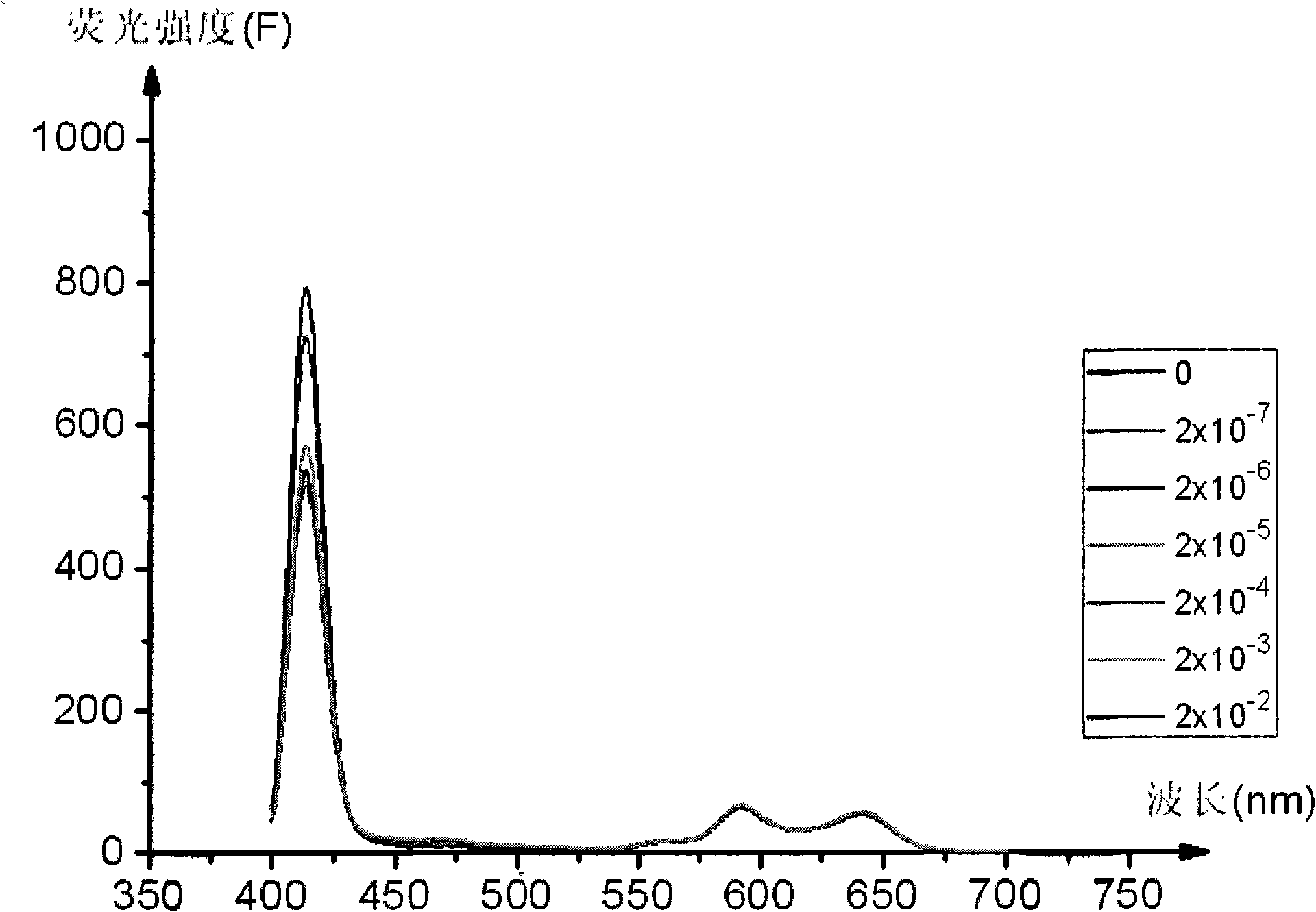

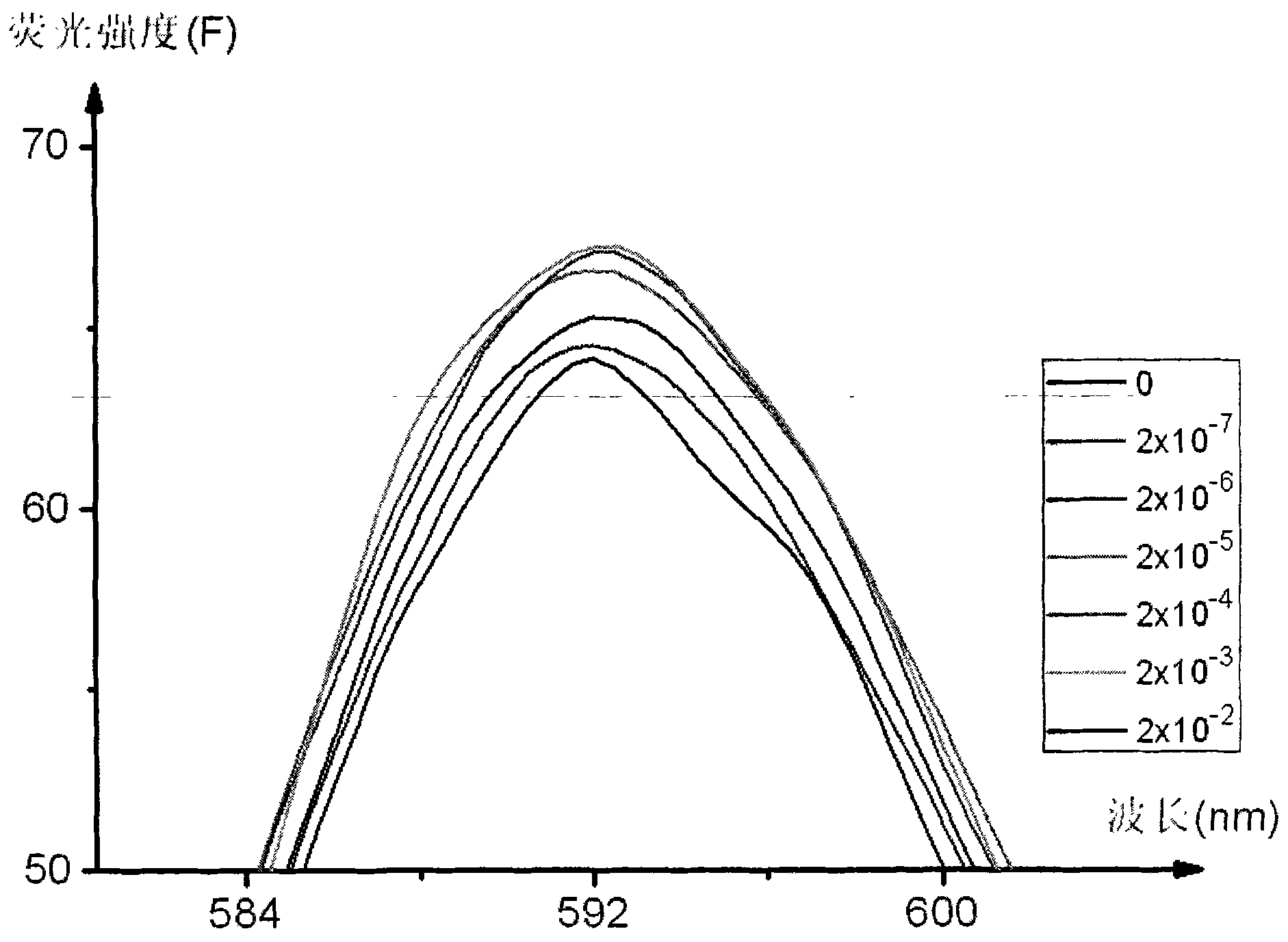

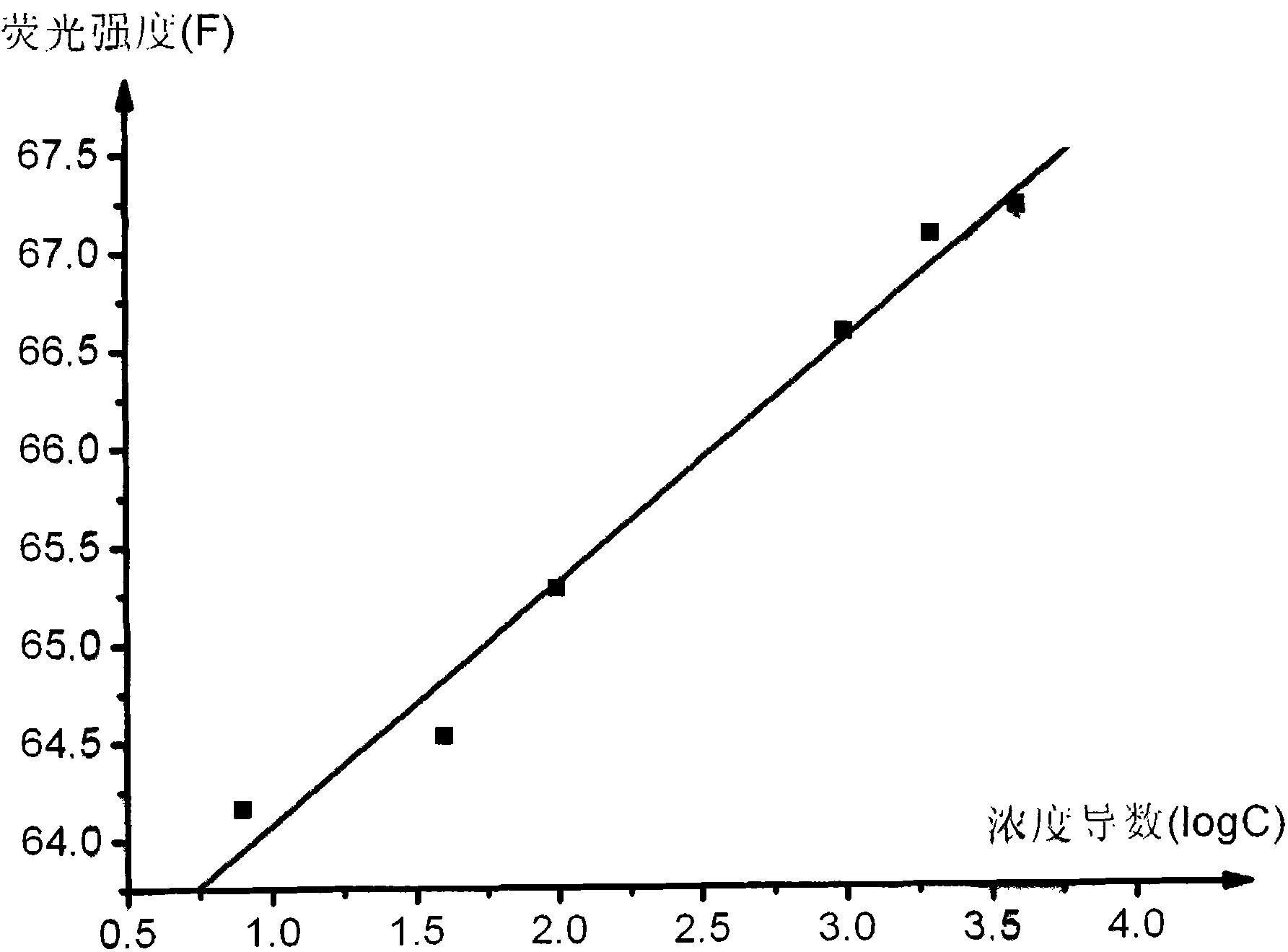

Method for fast detecting pesticide residue

ActiveCN101776601AEasy to operateEasy to detectPreparing sample for investigationFluorescence/phosphorescencePesticide residueLiquid state

The invention provides a method for fast detecting pesticide residue, which relates to a fluoroscopic detection method of organic phosphor pesticide. The invention utilizes a fluorescence spectrophotometer with program, uses porphyrin compounds as fluorescence indicating agents and developers, and detects the organic phosphor pesticide in the liquid state porphyrin detection solution through preparing a porphyrin solution, an organic phosphor pesticide solution and a liquid state detection solution. The invention has the characteristics of high detection sensitivity, low detection limitation, high accuracy, simple and convenient operation, convenient and fast in-site detection, high economical efficiency, convenient popularization and application and the like. The invention can be widely used for the trace amount detection of foodgrain, food and the like which easily contain the organic phosphor pesticide residue, and can also be used in the security assessment of food such as vegetables, fruit and the like and the environment detection.

Owner:LUZHOU LAOJIAO GRP CO LTD +1

Pipe jacking construction method

ActiveCN104455725AControl level deviationControl high-level deviationPipe laying and repairComing outArchitectural engineering

The invention discloses a pipe jacking construction method. The pipe jacking construction method is characterized by comprising the steps that firstly, surveying and setting out are carried out; secondly, working well construction is carried out; thirdly, assembling type back wall installation is carried out; fourthly, a guide rail is installed; fifthly, a main jacking jack is installed; sixthly, a pipe jacking auxiliary device is installed; seventhly, a pipeline is jacked; eighthly, deviation is rectified, and mould weights are stacked at the front end of a water draining pipe to increase the weight of a pipe section; ninthly, coming out of a hole is carried out. According to the pipe jacking construction method, the horizontal deviation and high-level deviation of a pipe jacking axis are effectively controlled, the stability of an excavation face can be effectively kept, the disturbance on the soil body around a pipe body is small, and the pipeline floating is avoided.

Owner:鸿昊建设集团有限公司

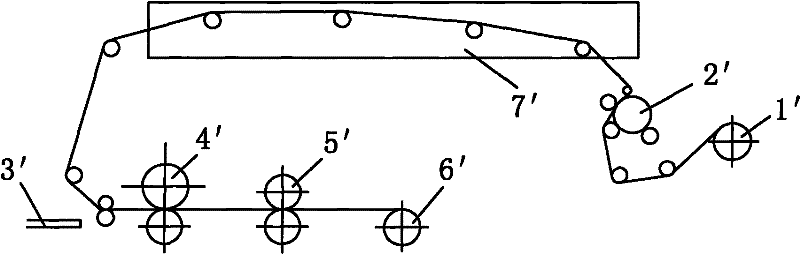

Control system and method for printing paper or coating film

InactiveCN102173193ASimplify operating proceduresImprove processing efficiencyRotary pressesPrinting press partsControl systemEngineering

The invention discloses a control system and a control method for printing paper or coating a film. The control system at least comprises a film unreeling device, a film gluing unit, a single-sheet unreeling device, a compounding unit, a film cutting device and a single-sheet delivery device. The control method at least comprises steps of feeding, gluing, compounding and reeling. The film coating, a film surface secondary pressing process, curing and cold foiling, and a laser transfer process are integrated, the operating procedures are simplified, the technological processing efficiency is improved, the additional value of a product is improved, a compound transfer process can be completed, the transferred film can be recycled, the cost is saved and the environment is protected.

Owner:东莞市博森印刷器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com