Patents

Literature

383 results about "Antarctic krill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antarctic krill (Euphausia superba) is a species of krill found in the Antarctic waters of the Southern Ocean. It is a small, swimming crustacean that lives in large schools, called swarms, sometimes reaching densities of 10,000–30,000 individual animals per cubic metre. It feeds directly on minute phytoplankton, thereby using the primary production energy that the phytoplankton originally derived from the sun in order to sustain their pelagic (open ocean) life cycle. It grows to a length of 6 centimetres (2.4 in), weighs up to 2 grams (0.071 oz), and can live for up to six years. It is a key species in the Antarctic ecosystem and in terms of biomass, is one of the most abundant animal species on the planet (approximately 500 million tons, corresponding to 300 to 400 trillion individuals).

Method for extracting krill oil with high phosphatide content from Antarctic krills

InactiveCN102041166AImprove enrichment effectImprove extraction efficiencyFatty-oils/fats productionOrganic solventPrawn

The invention discloses a method for extracting krill oil with high phosphatide content from Antarctic krills. The method comprises the following steps: (1) drying fresh Antarctic krills to obtain dry Antarctic krills; (2) performing extraction to dry Antarctic krills for 3 times with organic solvent; (3) mixing the extracting solutions, evaporating the mixed extracting solution to obtain Antarctic krill oil with the phosphatide content of 30-35%; then introducing nitrogen or carbon dioxide to remove the residual organic solvent; and adding polar organic solvent in the Antarctic krill oil, mixing evenly, standing to ensure that the mixed solution performs natural layering; and evaporating the lower solution to obtain the Antarctic krill oil with high phosphatide content, and then introducing nitrogen or carbon dioxide to remove the residual polar organic solvent so as to obtain a product. The extraction technology is performed at a low temperature, thus the red color of krill oil can be maintained and the beneficial ingredients in the product can not be damaged. The invention has high extraction efficiency and good phosphatide accumulation effect. Therefore, the Antarctic krill oil with high phosphatide content can be obtained and other byproducts can also be obtained.

Owner:SHANDONG NORMAL UNIV +1

Method for preparing antarctic krill low-fluorine hydrolysis polypeptide

The invention discloses a method for preparing antarctic krill low-fluorine hydrolysis polypeptide. The method comprises the following steps of: performing enzymolysis on antarctic krill powder used as raw materials, heating and inactivating enzyme, centrifuging, adding calcium oxide at different concentration, defluorinating, uniformly stirring, performing centrifugal separation, adjusting a solution until the solution has a certain pH value, and performing spray drying on supernatant obtained through separation to obtain the antarctic krill low-fluorine hydrolysis polypeptide of which the fluorine content is 10 to 30ppm. The process is easy to operate, the obtained product has low fluorine content, the nutrition constituents are damaged slightly, consumed time is short, and the process is simple and efficient, and is an ideal method for removing fluorine from enzymatic hydrolysate. The method lays the foundation for developing the multi-functional antarctic krill low-fluorine polypeptide.

Owner:辽渔集团有限公司

Method for extracting phospholipid-enriched krill oil from Antarctic krill

InactiveCN102071101ARich sourcesSafe storageFatty-oils/fats productionDocosahexaenoic acidPhospholipid

The invention discloses a method for extracting phospholipid-enriched krill oil from Antarctic krill. The method comprises the following steps: using Antarctic krill as the raw material and using the autologous protease to decompose the Antarctic krill and release lipids, quickly heating to inactivate the enzymes in the krill, drying at low temperature, and extracting krill oil with rich eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) phospholipids at low temperature by using low carbon alcohol as the solvent. The method disclosed by the invention is simple to operate, has the advantages of clear process and high input-output ratio; and compared with other organic solvents, ethanol or isopropanol is safer for storage, transportation and use, has abundant sources, and has obvious advantages of being used as the solvent for extracting oil of krill type crustacean.

Owner:SHANDONG KERUIER BIOLOGICAL PRODS

Method for extracting antarctic krill grease and separating biological active substance

InactiveCN102676291ARealize comprehensive utilizationHigh extraction rateFatty oils/acids recovery from wasteFatty-oils/fats productionSolubilityOrganic solvent

The invention discloses a method for extracting antarctic krill grease and separating other biological active substances, and belongs to the technical field of deep processing of marine food products. Aiming at the characteristics that the water content of antarctic krill is high and the antarctic krill is easy to autolyze, the grease can be directly extracted from the frozen antarctic krill at low temperature by using hydrophobic and hydrophilic mixed solvents; a salt solution and a common organic solvent are added into residues and an organic solvent / salt multi-phase salting-out extracting system is formed by using salting-out extracting effect; the distributions of biological active substances with different polarities in the antarctic krill in each phase are different according to a solubility difference; and furthermore, the residual grease is extracted to obtain astaxanthin; and shrimp meat proteins are separated and the solvents in the residues are recycled. The method disclosed by the invention is simple in operation and easy to realize, and has low cost, short period and moderate extracting conditions, and the organic solvents are cheap and easy to recycle, so that the method is easy to industrialize.

Owner:DALIAN UNIV OF TECH +1

Method for simultaneously extracting high-phospholipid krill oil and high-astaxanthin krill oil

The invention relates to a method for simultaneously extracting high-phospholipid-content krill oil and high-astaxanthin-content krill oil. The method comprises the following steps: carrying out countercurrent ultrasonic extraction on Antarctic krill meal by adopting a mixed solvent; finally, carrying out three-grade filtering and filtering krill residues to obtain filtrate, namely an extracting solution; decompressing and evaporating the extracting solution; removing an organic solvent in the extracting solution to obtain crude oil; adding an ethanol solution with the volume which is equal to that of the crude oil and has the mass concentration of 45 percent to 75 percent into the crude oil; standing and layering for 2h to 4h; collecting supernatant and subnatant respectively; decompressing and evaporating respectively to obtain the high-phospholipid-content krill oil and the high-astaxanthin-content krill oil respectively. According to the method provided by the invention, the krill oil is extracted by adopting a mixed solvent of n-hexane and ethanol, so that the dissolution rate and dissolution efficiency of the krill oil are greatly improved; the three-grade filtering and precipitation of the 45 percent to 75 percent ethanol solution are combined and the obtained krill oil has high purity; two products including the high-phospholipid-content krill oil and the high-astaxanthin-content krill oil can be obtained in one step; an extraction process is simple and the production cost is low.

Owner:徐霞 +1

Method for enriching lipid in Antarctic krill

InactiveCN102224855AIncrease profitImprove extraction efficiencyEdible oils/fatsEngineeringEnvironmental engineering

The invention provides a method for enriching lipid in Antarctic krill, which comprises the following steps: (1) preprocessing the Antarctic krill serving as a raw material; (2) leaching the Antarctic krill obtained in the step (1) with a solvent to obtain a leaching liquid; (3) concentrating the leaching liquid obtained in the step (2) to a certain volume; (4) refining the concentrated leaching liquid obtained in the step (3); and (5) performing vacuum concentrating on the refined leaching liquid obtained in the step (4) until the residual volume of the solvent is 0.1% lower than the volume of the solvent used in the step (2) so as to obtain the lipid of Antarctic krill. According to the invention, the Antarctic krill or head capsule of Antarctic krill is preferentially used as a raw material, the lipid extraction efficiency is increased through the preprocessing, solvent leaching and refining methods, the lipid quality is improved, the comprehensive utilization rate of Antarctic krill is remarkably increased, the product quality is improved, and the obtained lipid in Antarctic krill is applied to healthcare foods.

Owner:OCEAN UNIV OF CHINA

Method for extracting krill oil with high phospholipid content from krill

ActiveCN102405988AIncrease contentPrevent corruption and denaturationEdible oils/fatsOrganic solventEvaporation

The invention discloses a method for extracting krill oil with high phospholipid content from krill. In the method, Antarctic krill is taken as a raw material, the dried Antarctic krill raw material is ground into krill powder, the krill powder is extracted by using an organic solvent, shear extraction is adopted in the extraction process, extracting solutions are mixed and residual organic solvent is removed from the mixed extracting solution through evaporation, and the Antarctic krill oil with 40 to 45 percent of phospholipid is obtained. The process is easy to operate, a final product has high phospholipid content, and the method can serve as the most simple and feasible method for extracting oil, particularly oil with rich phospholipid.

Owner:辽渔南极磷虾科技发展有限公司

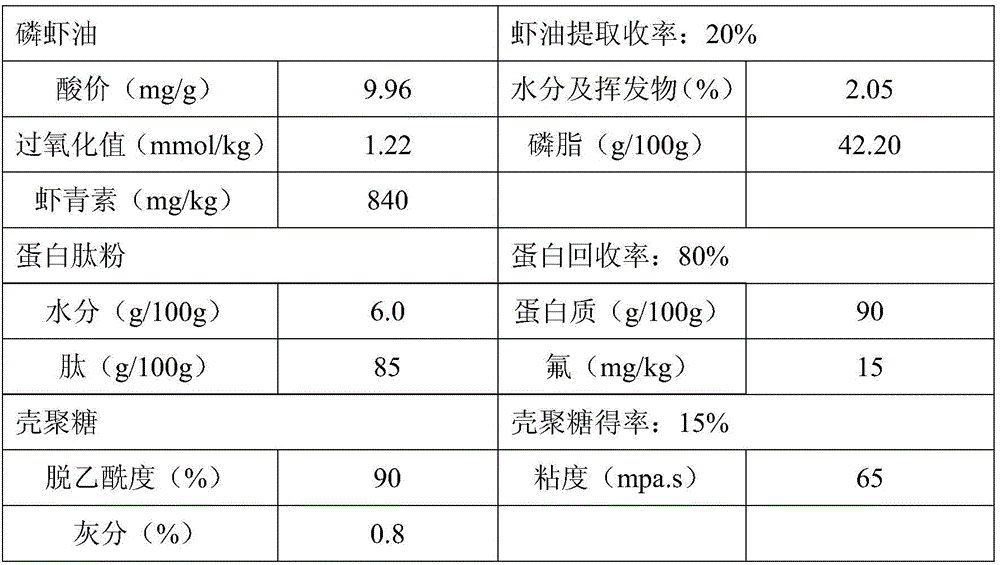

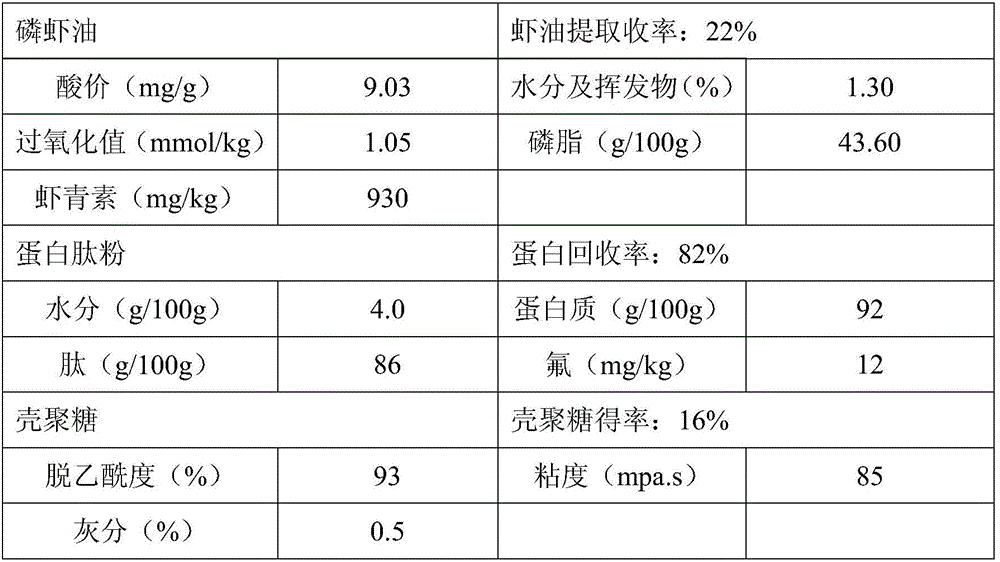

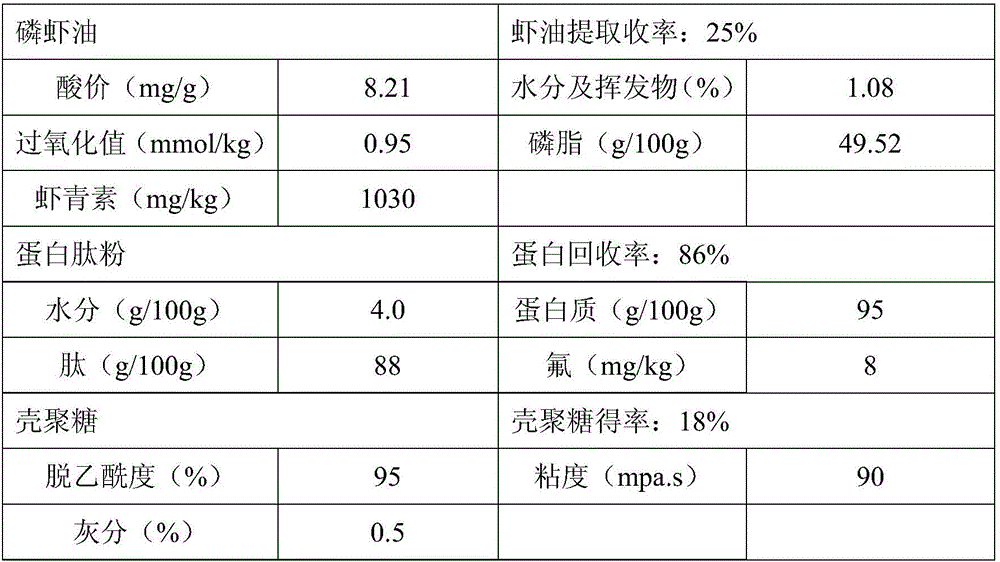

Method for producing krill oil, protein peptide powder and chitosan by full utilization of Antarctic krill powder

InactiveCN106010783ARealize high-value comprehensive utilizationRealize full utilization of high valueCultivating equipmentsFatty-oils/fats productionResource utilizationAdditive ingredient

The invention discloses a method for producing krill oil, protein peptide powder and chitosan by full utilization of Antarctic krill powder. The method comprises the following steps: 1. extraction of krill oil: extracting the Antarctic krill powder by adopting an organic solvent, and carrying out low-temperature decompression desolvation, extraction and concentration on the extracting solution, wherein the contents of obtained krill oil phospholipid and astaxanthin are high; 2. preparation of protein peptide powder: carrying out compound enzymolysis on degreased shrimp meal to obtain an enzymolysis solution, and refining and then spray-drying the enzymolysis solution to obtain the protein peptide powder, wherein the peptide content of the obtained protein peptide powder is greater than or equal to 85%; and 3. preparation of chitosan: decalcifying the shrimp shell meal which is degreased by the organic solvent and is subjected to deproteinization by enzymolysis by adopting microorganism fermentation, further carrying out deproteinization, carrying out oxidative decoloration, and carrying out deacetylation to obtain chitosan and byproduct organic calcium. The method really realizes high-valued full utilization of the Antarctic krill powder, can be used for extracting nutritional ingredients in the Antarctic krill powder to the maximum extent so as to improve the resource utilization ratio, can avoid generation of waste residues, and can ensure the benefit maximization of an enterprise.

Owner:青岛南极维康生物科技有限公司 +1

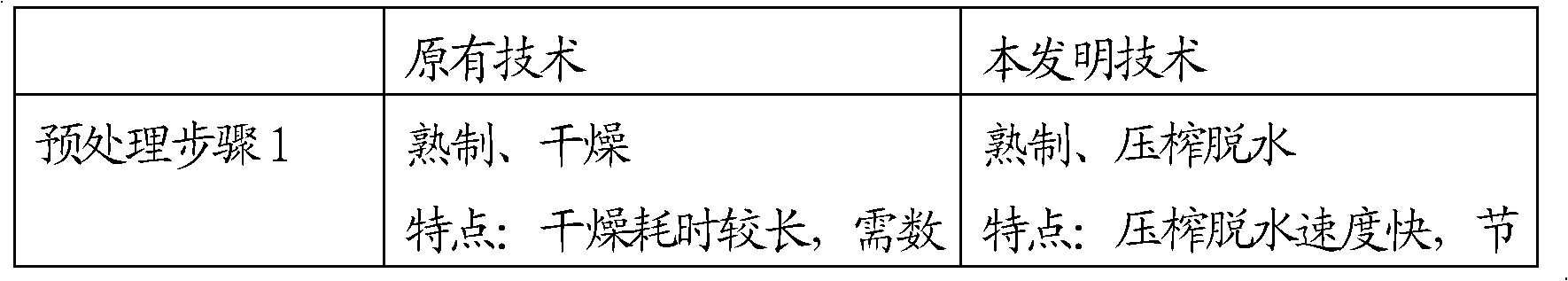

Methods for extracting high-quality shrimp oil from Antarctic krill and for preparing defatted krill protein powder

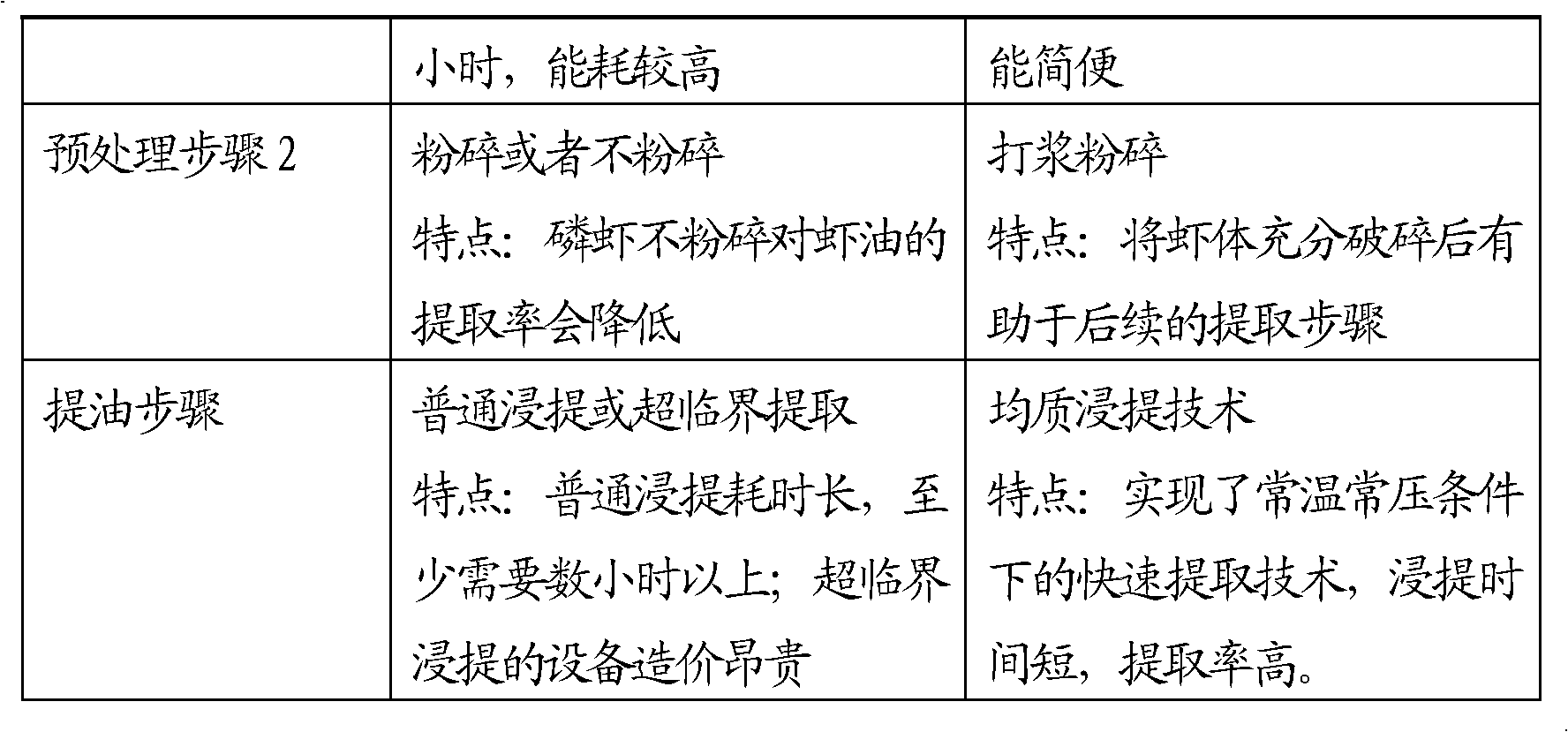

ActiveCN102492545AReduce moistureReduce dosageProtein composition from fishFatty-oils/fats refiningOrganic solventShrimp

The invention relates to methods for extracting high-quality shrimp oil from Antarctic krill and for preparing defatted krill protein powder. The methods comprise steps that: an Antarctic krill raw material is pretreated; the pretreated raw material is cooked; the cooked raw material is dehydrated by pressing; the dehydrated raw material is crushed and beaten, such that a cream is obtained; an organic solvent is added to the obtained cream, and shrimp oil lixiviation is carried out with a homogenization technology; shrimp oil is repeatedly lixiviated; obtained lixiviation liquids are combined; the mixed liquid is subject to a cold preservation treatment, and is filtered; an obtained filtrate is subject to vacuum evaporation, such that the filtrate is precipitated and dehydrated, and refined shrimp oil is obtained. According to the invention, water content in Antarctic krill is reduced by using a pressing technology which is used for replacing a heating drying technology, such that an energy-saving effect is substantial. With the beating crushing technology and the homogenization extraction technology, the lixiviation efficiency is substantially improved. Therefore, a low-temperature normal-pressure high-efficiency fresh krill wet lixiviation technology is realized, and the shrimp oil with high astaxanthin content can be obtained. The cream obtained by lixiviation by using the organic solvent is dried by heating, such that defatted krill protein powder with water content lower than 10% is obtained, and the solvent is recycled. The method provided by the invention has feasibility for industrialized implementations.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

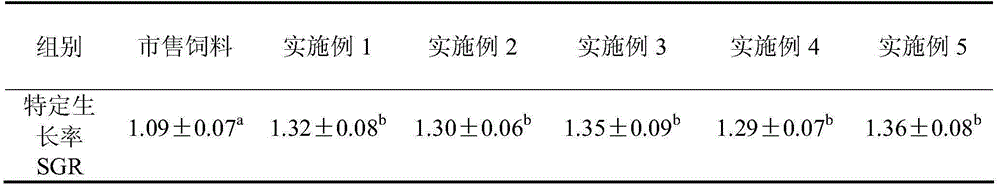

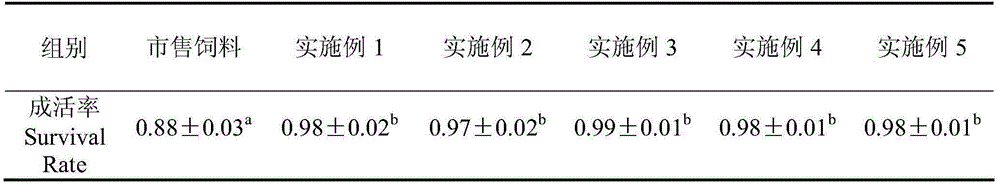

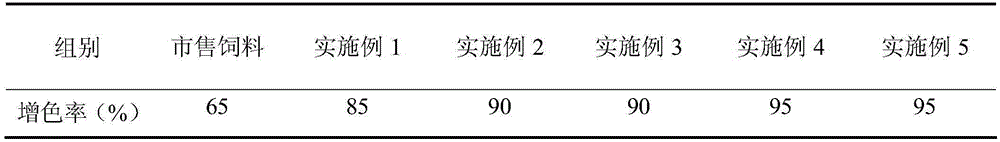

Compound feed capable of enabling color of cryprinus carpiod to be enhanced and preparation method of compound feed

InactiveCN105231088AEnsure safetyLike to eatFood processingClimate change adaptationGenus ChenopodiumHouttuynia

The invention relates to the technical field of feed processing of aquarium fishes, in particular to a compound feed capable of enabling the color of cryprinus carpiod to be enhanced. The invention further relates to a preparation method of the compound feed capable of enabling the color of the cryprinus carpiod to be enhanced. The compound feed capable of enabling the color of the cryprinus carpiod to be enhanced comprises the following components in parts by weight: 20-30 parts of fish meal, 10-20 parts of Antarctic krill powder, 8-12 parts of dried earthworm powder, 8-12 parts of dried red worn powder, 8-16 parts of rice bran, 8-16 parts of soybean meal, 8-12 parts of agars, 6-10 parts of dulse, 4-8 parts of corn flour, 4-8 parts of sweet potato flour, 4-6 parts of chenopodium serotinum, 4-6 parts of leaf mustard, 4-6 parts of dried carrot meal, 4-6 parts of distillers' grains, 3-5 parts of cordate houttuynia, 3-5 parts of watermelon peels, 3-5 parts of Chinese wolfberries, 3-5 parts of magnoliopsida, 3-5 parts of dried orange peels, and the like. According to the compound feed disclosed by the invention, the bright color of the cryprinus carpiod can be kept, and the survival rate of the cryprinus carpiod can be increased.

Owner:QINGDAO HAIZHIYUAN INTELLIGENT TECH

Preparation method of antarctic krill phospholipid

The invention discloses a preparation method of antarctic krill phospholipid. The preparation method comprises the steps: 1, draining and drying the antarctic krill and homogenizing; 2, irradiating homogenate liquid by using ultraviolet rays for 10-30 mins and autolyzing for 2-10 hours; 3, adding water into the homogenate liquid, ultrasonically processing, adjusting the pH value to be 7.5-8.0, adding alkali protease, and enzymatically hydrolyzing to obtain enzymolysis liquid; and drying the enzymolysis liquid to obtain dry powder; and 4, extracting the antarctic krill phospholipid by utilizing an ethanol extraction method. The preparation method is particularly suitable for use after fresh and alive antarctic krill are fished by fishing ships, and is simple in operation and high in efficiency. Particularly, the usage amount of exogenous enzymes is reduced by utilizing the strong autolysis capability of the fresh and alive antarctic krill, so that the production cost is lowered. Moderate conditions are provided for the extraction method, so that original physiological activators in the antarctic krill phospholipid can be stored to the maximum extent, and products are endowed with both nutritional and functional properties.

Owner:DALIAN POLYTECHNIC UNIVERSITY

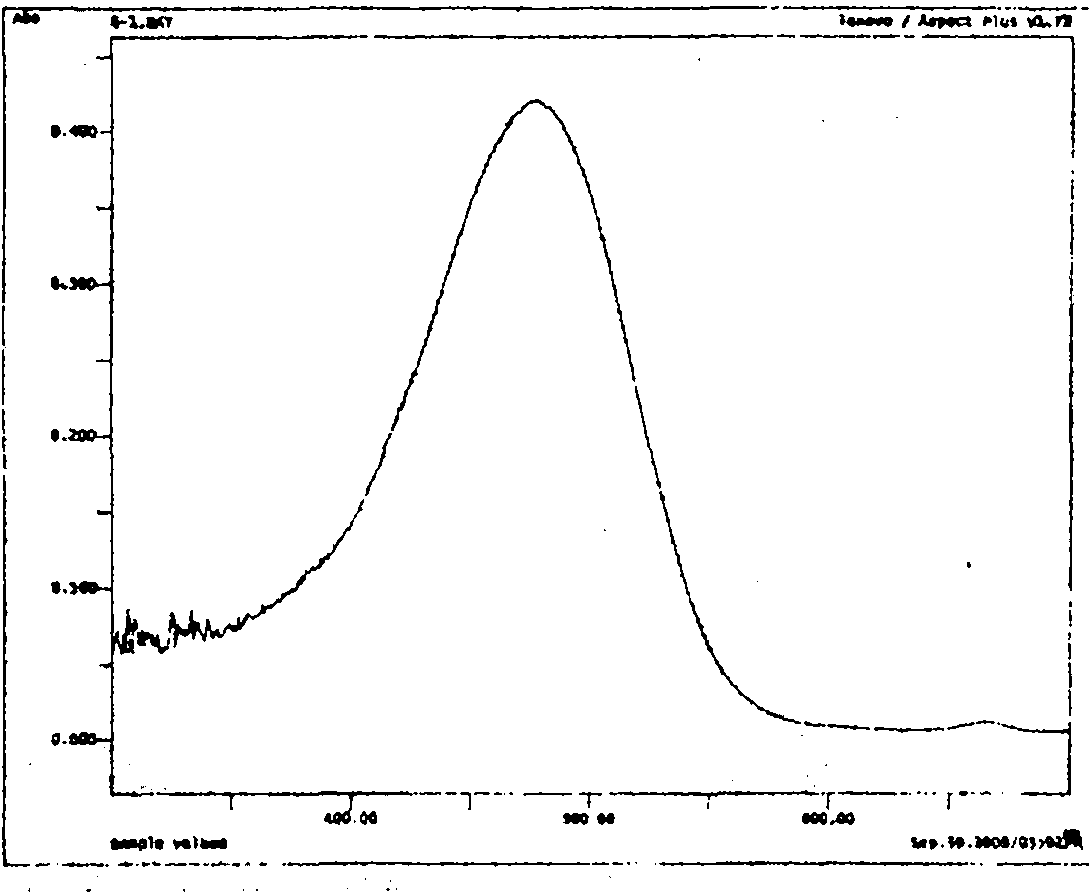

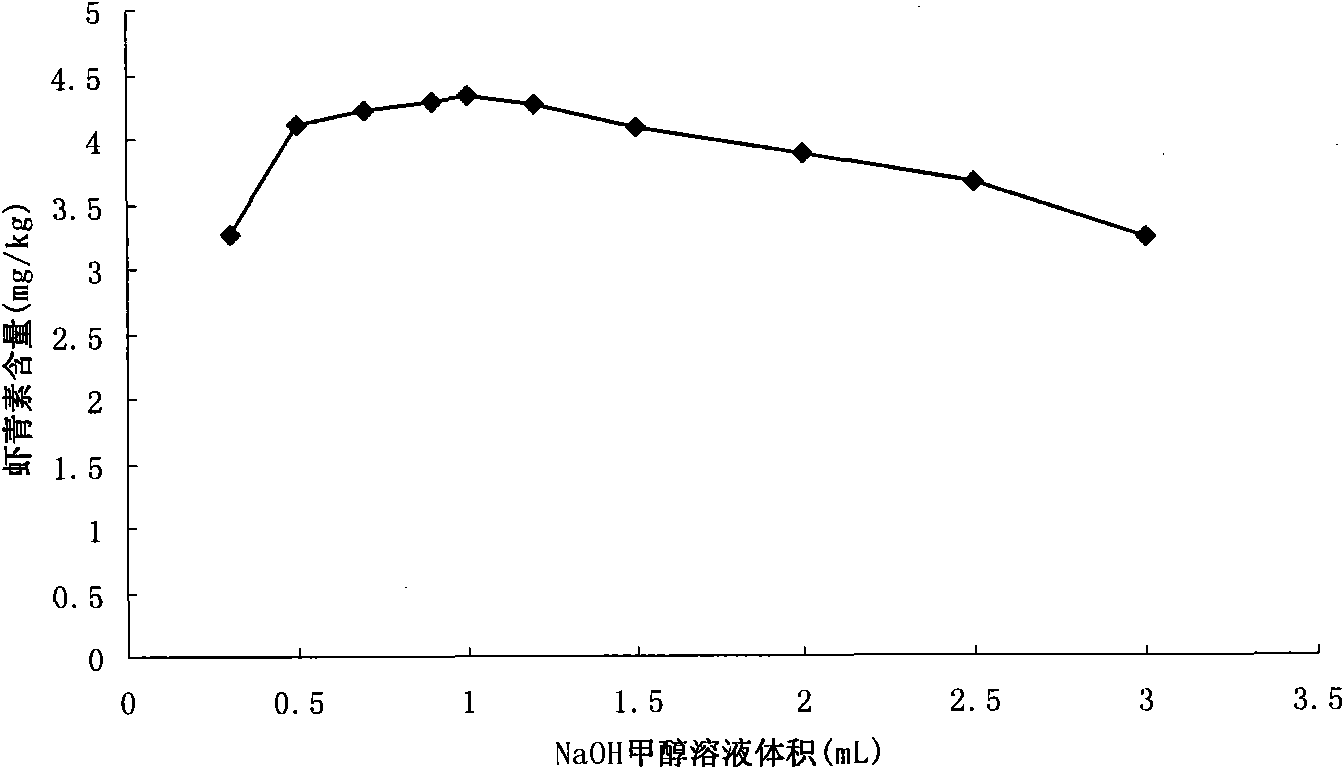

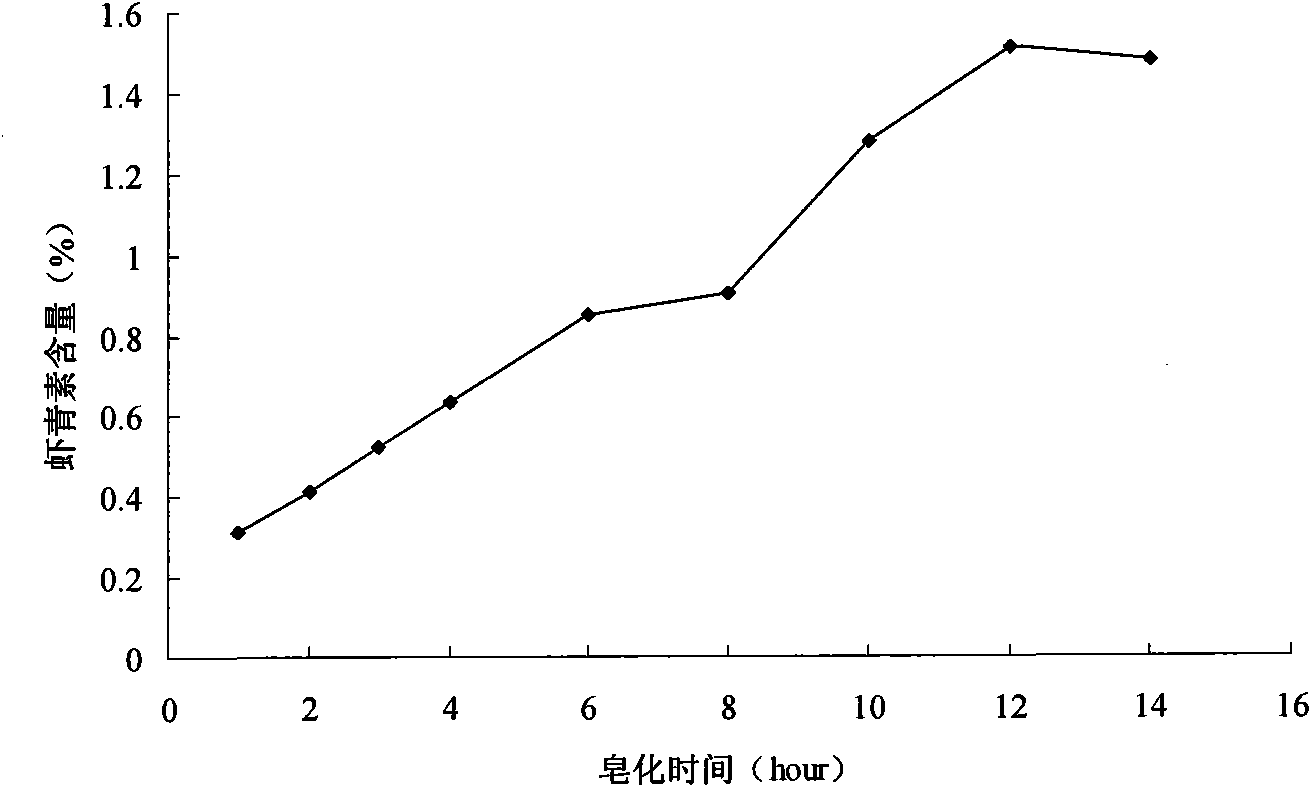

Method for determining content of astaxanthin in antarctic krill oil by chromatography

The invention relates to a method for determining the content of astaxanthin in antarctic krill oil by chromatography, which comprises the steps of adopting a gel purification column with a BIO-3X packing, taking ethyl acetate and cyclohexane as eluant according to the proportion of 1:1, and collecting a fractions at 7.48-12.60min; carrying out low-temperature saponification in a solvent formed by methylene dichloride and methanol after purification, and completely converting astaxanthin esters to free astaxanthin; adopting a YMC-Carotenoid C30 chromatographic column; carrying out gradient elution by taking water solution of the methanol, methyl tert-butyl ether and 1% of phosphoric acid as a mobile phase; leading the flow rate to be 1.0mL / min, using an ultraviolet detector as the detector, and leading the detecting wavelength to be 474nm; and determining three isomers of the astaxanthin and adopting the sum of three peak areas for quantifying. The gel chromatographic column can better separate fat from the astaxanthin in the antarctic krill oil, and the adoption of the C30-reversed phase high performance liquid chromatography can accurately determine the content of the astaxanthin, thereby objectively and truly evaluating the quality of the antarctic krill oil.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Extraction process of phosphatidylcholine with antarctic krill as source and preparation method of phosphatidylserine

InactiveCN103509047AReduce dosageEmission reductionPhosphatide foodstuff compositionsFermentationAlcoholFreeze-drying

The invention provides an extraction process of phosphatidylcholine with antarctic krill as a source. The extraction process comprises the following steps: collecting heads of the antarctic krill, adding water for decoction, stirring, sending the krill head decoction liquid to a cold pressing machine for solid-liquid separation, to obtain an oily liquid rich in phospholipid and krill heads and other solids; adding absolute ethyl alcohol into the krill heads and other solids, carrying out high shearing extraction, carrying out centrifugal separation, and concentrating to obtain an oily liquid; merging the oily liquids, drying under a reduced pressure, then filtering through a plate frame filter to remove insoluble substances, followed by carrying out membrane separation and concentration, carrying out column chromatography separation and purification, carrying out freeze drying, and thus obtaining the phosphatidylcholine product. The invention also provides a preparation method for phosphatidylserine with the antarctic krill as the source. The preparation method comprises the steps of hydrolyzing the extracted phosphatidylcholine by phospholipase D, and extracting to obtain phosphatidylserine rich in DHA and EPA. The extraction process and the preparation method are environmentally friendly, and are low in cost; and the obtained products have high content and good activity, and can be industrially produced.

Owner:ACERCHEM INT

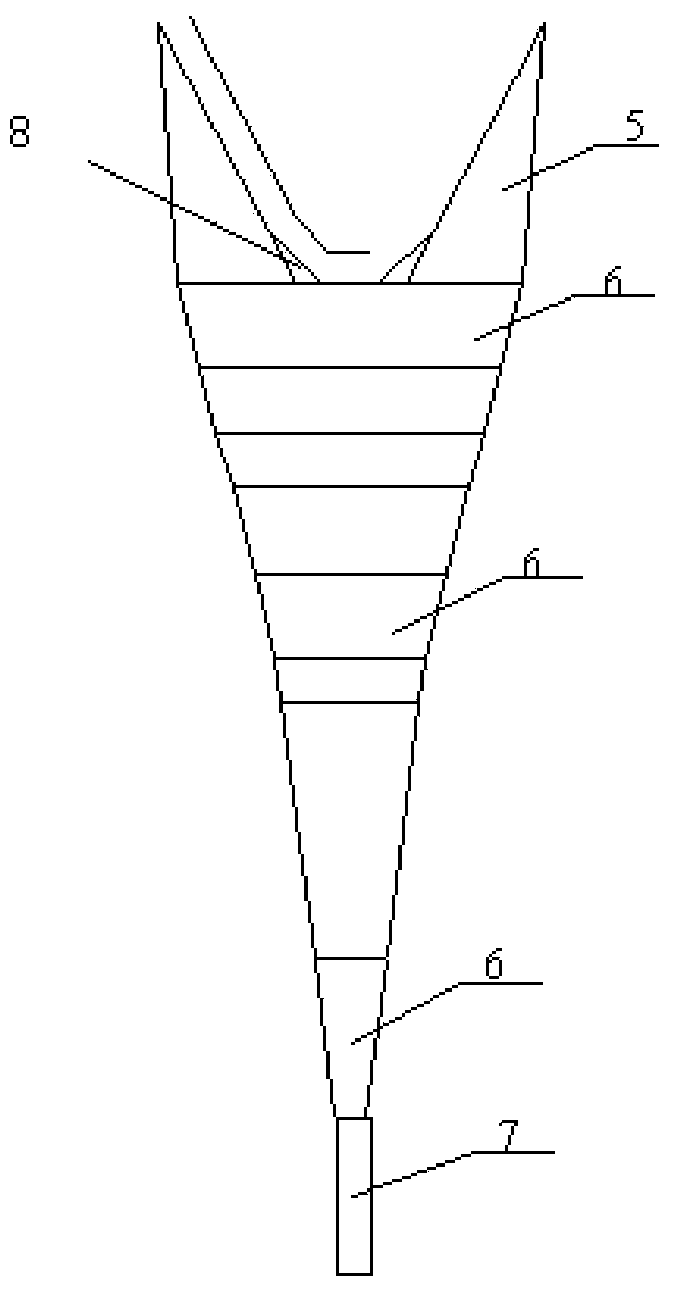

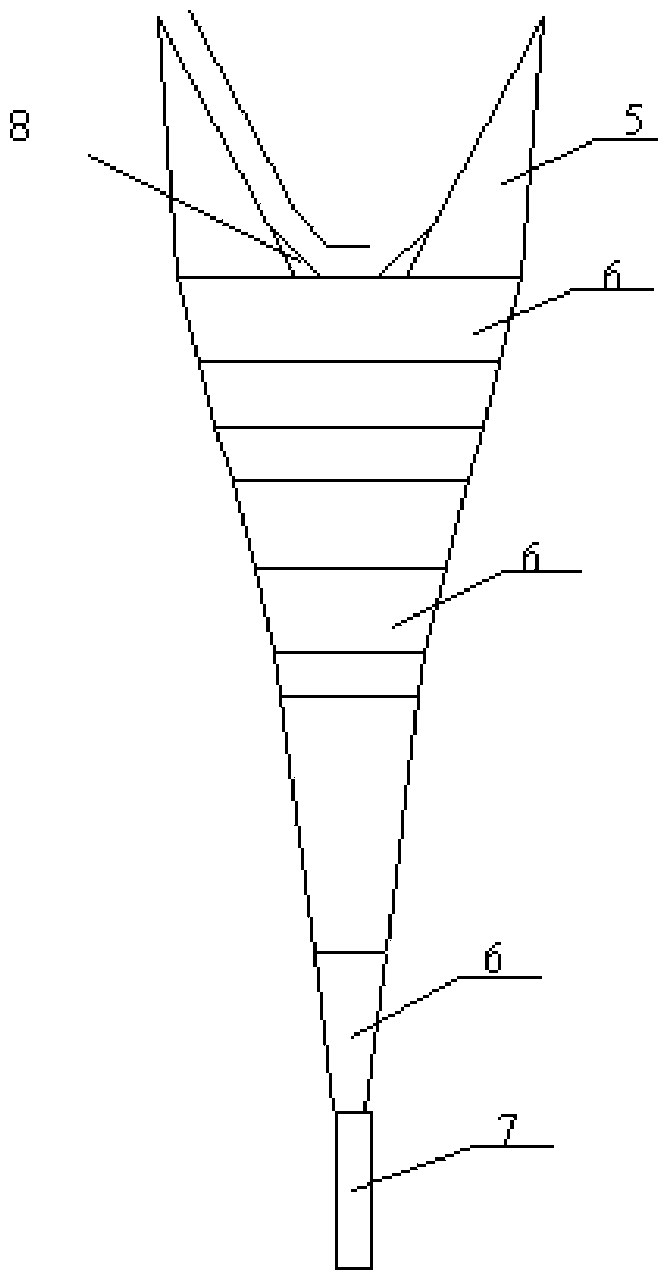

Antarctic krill trawl fishing net

An Antarctic krill trawl fishing net is composed of an upper rope, a lower rope, a side rope, a strength rope, a wing, a net body and a fish bag. The Antarctic krill trawl fishing net is characterized in that the wing and the net body are single-deck nettings of a four-piece type symmetrical structure, the mesh of the wing is 0.24 meter, and the tension height of the wing is 24 meters; the net body is composed of a back net, a belly net and four-piece symmetrical eight-section polyethylene nettings of two side nets, and the mesh sizes of all sections of nettings are 0.16 meter, 0.12 meter, 0.10 meter, 0.08 meter, 0.08 meter, 0.08 meter, 0.04 meter and 0.02 meter from the net opening downwards sequentially; the netting tension circumference of the net opening is 256 meters, and the tension height of the net body is 79 meters; the netting of the net body shrinks in a trapezoidal shape; the middle 70-mesh positions of the back net, the belly net and the two side nets of the front end of the net body are provided with middle ropes of the upper rope, the side rope and the lower rope respectively, the length of the middle ropes is 5.6 meters, and the total length of the upper rope, the side rope and the lower rope is 56.6 meters; 5-8-mesh nettings on all sides of the back net, the belly net and the two side net nettings are used for net piece sewing.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

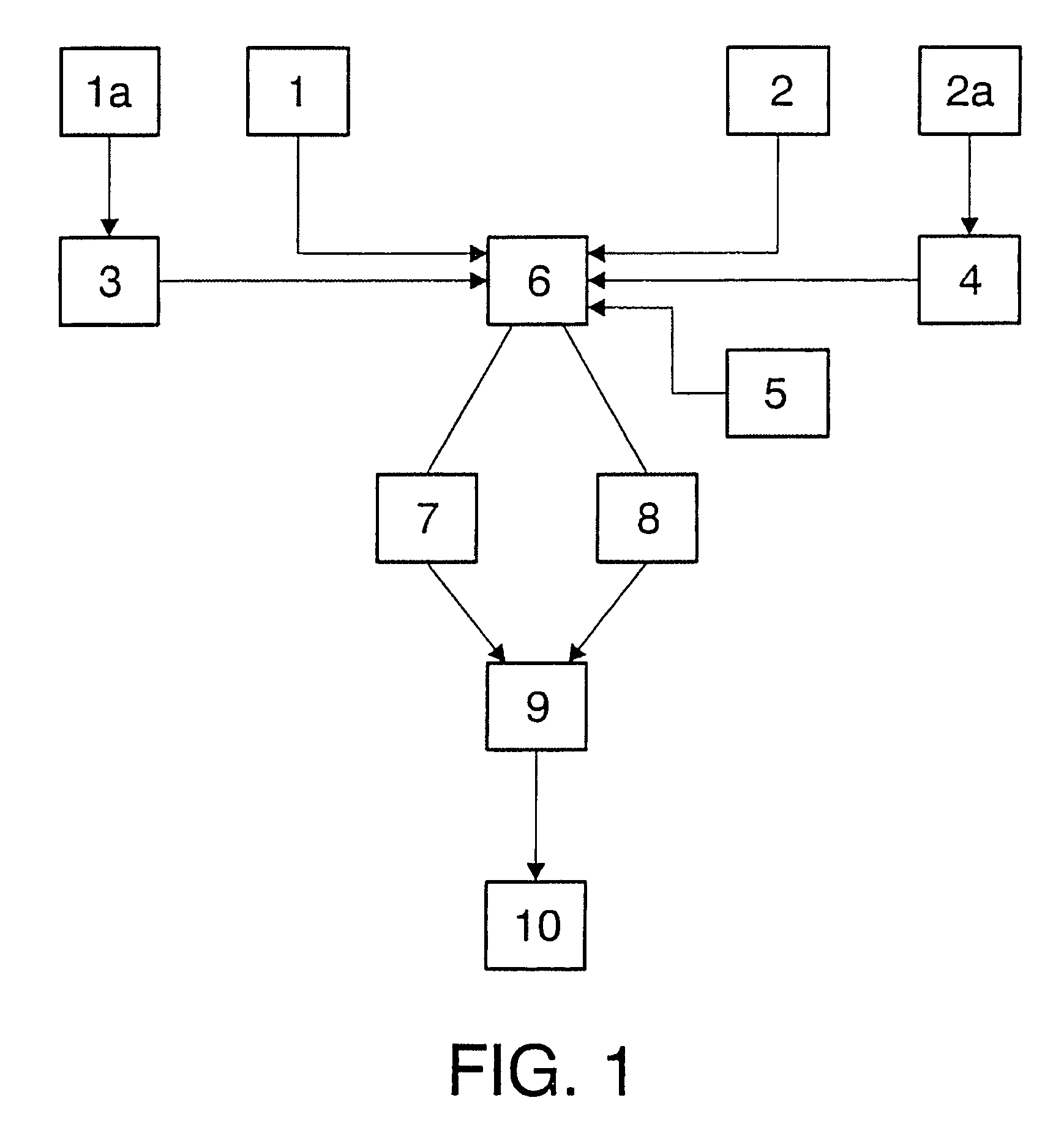

Method for obtaining hot-formed products from the liquid and dense fractions of antarctic krill

A method for obtaining hot-formed products from the liquid and dense fractions of Antarctic krill comprising the steps of separating the Antarctic krill into two fractions, a liquid fraction and a dense fraction, remixing and homogenizing these fractions and adding additives to the mixture such as salt, carbohydrates and fats, to then use an appropriate heat treatment to obtain its jellification in molds or in a heat extruder.

Owner:ANGULAS AGUINAGA

Method for extracting krill oil from antarctic krill

ActiveCN102492537AResidues in line with national standardsPrevent strong odorFatty-oils/fats productionOrganic solventLiquid ratio

The invention relates to a method for extracting krill oil from antarctic krill. The method comprises: heating the captured antarctic krill for 3-20 minutes at a temperature of 60-100 DEG C; drying the antarctic krill, wherein the drying temperature is 60-89 DEG C; crushing the dried antarctic krill into the krill powder with the particle size of 30-100 meshes; adopting an ethanol solution with the concentration more than 95% to soak the krill powder at the temperature of 4-30 DEG C, wherein a solid / liquid ratio is 1:2-1:10, and the time is 0.5-2 hours; carrying out shear extraction on the soaked suspension liquid by using a shearing emulsifying machine, and carrying out standing or stirring extraction on the resulting suspension liquid after the shear extraction; separating the extracting solution, and carrying out extracting separation on the extracting solution 2-4 times; and evaporating the resulting extracted solution at the temperature of 30-60 DEG C and under the vacuum degree of from -0.05 to -0.1 MPa to remove the organic solvent in the extracted solution to obtain the antarctic krill oil with the phospholipid content of 40-45%. According to the present invention, the operation of the method of the present invention is simple, the phospholipid content of the final product is high, and the method can be used as the most simple and feasible method for extracting the greases, and especially the phospholipid-rich greases.

Owner:辽渔南极磷虾科技发展有限公司

Method for extracting Antarctic krill oil with high phosphatide content from Antarctic krill

ActiveCN102492538AKeep it fresh and strongAvoid enzymatic digestionFatty-oils/fats productionOrganic solventPhospholipid

The invention relates to a method for extracting Antarctic krill oil with high phosphatide content from Antarctic krill, which takes fresh Antarctic krill as a raw material, the method comprises the following steps: heating, killing enzyme, disinfecting, removing moisture, drying and crushing, extracting Antarctic krill powder by an organic solvent, cutting and extracting in the extraction process, evaporating the separated extract, removing the residual organic solvent to obtain the Antarctic krill oil with the phosphatide content of 40%-45%. The invention has the advantages of simple operation and high phosphatide content of the final product, and can be the most available method for extracting grease, especially phosphatide-rich grease.

Owner:辽渔南极磷虾科技发展有限公司

Process for extracting fluoride-free shrimp oil from dried antarctic krill

The invention discloses a process for extracting fluoride-free shrimp oil from dried antarctic krill. The process is characterized in that the process comprises the following steps of: (1) adding acetone to dried antarctic krill, extracting for three times, combining extracting liquid, and evaporating the extracting liquid in a rotation mode to obtain the shrimp oil; (2) filtering the extracting liquid to obtain shrimp residues after the extracting liquid is extracted at last time in the step (1), adding ethanol into the shrimp residues for extracting for three times, combining the extracting liquid, and evaporating the extracting liquid in a rotation mode to obtain a concentrate; (3) adding acetone into the concentrate for stirring and extracting for 0.5-1h twice, filtering and combining the filtrates obtained in the steps (1) and (2), and evaporating in a rotation mode to obtain the shrimp oil; and (4), combining the shrimp oil obtained in the step (1) and the shrimp oil obtained in the step (2), adding ethanol, coldly placing the mixture, removing a precipitate to obtain a supernate, coldly placing the supernate, removing a precipitate to obtain the supernate, and evaporating the supernate in a rotation mode to obtain the fluoride-free shrimp oil. According to the invention, the process for extracting the shrimp oil from the dried antarctic krill is optimized, and the yield of the shrimp oil is high; and because the obtained shrimp oil does not contain fluoride, the quality of the shrimp oil is improved, and contribution to development of related shrimp oil products of the antarctic krill is achieved.

Owner:SHANDONG NORMAL UNIV

Krill oil microcapsule with antioxidation effect and preparation process thereof

InactiveCN106360437AImprove antioxidant capacityHigh content of bioactive substancesFood shapingCarrageenanFreeze-drying

The invention relates to the technical field of health care food, in particular to a krill oil microcapsule with an antioxidation effect and a preparation process thereof. Antarctic krill oil, DHA algal oil and haematococcus pluvialis are used as core materials; a proper amount carrageenan is added into an oil phase; chitosan oligosaccharide and gamma-cyclodextrin are used as wall materials, and are proportionally mixed with an oil phase antioxidant, a water phase antioxidant, an emulsifying agent, a dispersing agent and the like to be prepared into microemulsion; through freeze drying, powder grinding, sieving and the like, the krill oil microcapsule is prepared. The krill oil microcapsule obtained by the process has the advantages that the stability of the krill oil on the factors such as light, temperature and humidity is improved; the content of bioactive substances such as astaxanthin and DHA in the microcapsule is high; the antioxidation performance of the krill oil is greatly improved.

Owner:GUANGZHOU KOHEALA BIOTECHNOLOGY CO LTD

Antarctic krill paste and making method thereof

ActiveCN105614828AIncrease nutritionImprove economySugar food ingredientsFood ingredient as taste affecting agentBiologyFermentation

The invention belongs to the technical field of higher value application of Antarctic krill, relates to shrimp paste and a making method thereof, in particular to Antarctic krill paste and a making method thereof. Fresh Antarctic krill is adopted as the raw material, the treatment steps of impurity removing, shell removing, grinding, enzymolysis and salting fermenting are conducted, and the Antarctic krill paste which is low in salt and free of fishy smell is made. The invention provides the Antarctic krill paste which is low in salt, free of fishy smell and nutritional and the processing technological process of the Antarctic krill paste. A bio-enzyme method is adopted to be combined with a fermentation method to make the Antarctic krill paste, and higher value application of Antarctic krill protein is achieved.

Owner:OCEAN UNIV OF CHINA

Method for enriching phosphatidyl inositol from antarctic krill

InactiveCN102746941AHigh enrichment efficiencyFatty-oils/fats productionPhosphatidyl inositolAntarctic krill

The invention discloses a method for enriching phosphatidyl inositol from antarctic krill. The method includes the steps: (1) adding 1 kilogram of frozen antarctic krill to 1-1.3 liters of ethanol solution with the volume fraction of 90-100%, stirring to extract for 4-6 times under natural conditions, keeping extraction each time for 1-3h, and filtering and combining extracting solutions so as to obtain filtrate; (2) concentrating the obtained filtrate under the pressure of negative 0.07-negative 0.09Mpa at the temperature of 60-65 DEG C until 8-10% of the volume of the filtrate remains so as to obtain concentrated extracting solution; (3) adding isometric normal hexane into the obtained concentrated extracting solution, uniformly mixing and statically layering so as to obtain transparent reddish bottom solution; and (4) removing the normal hexane from the obtained bottom solution by vaporizing under the pressure of negative 0.07-negative 0.09Mpa at the temperature of 50-55 DEG C so as to obtain oily solution, namely, a phosphatidyl-inositol-enriched product, wherein the product comprises 2.70-2.76% of phospholipid, and the phosphatidyl inositol accounts for 50.5-51.92% of the phospholipid. Re-extraction, separation, purification and the like can be further performed on the basis so as to obtain the phosphatidyl inositol.

Owner:SHANDONG NORMAL UNIV

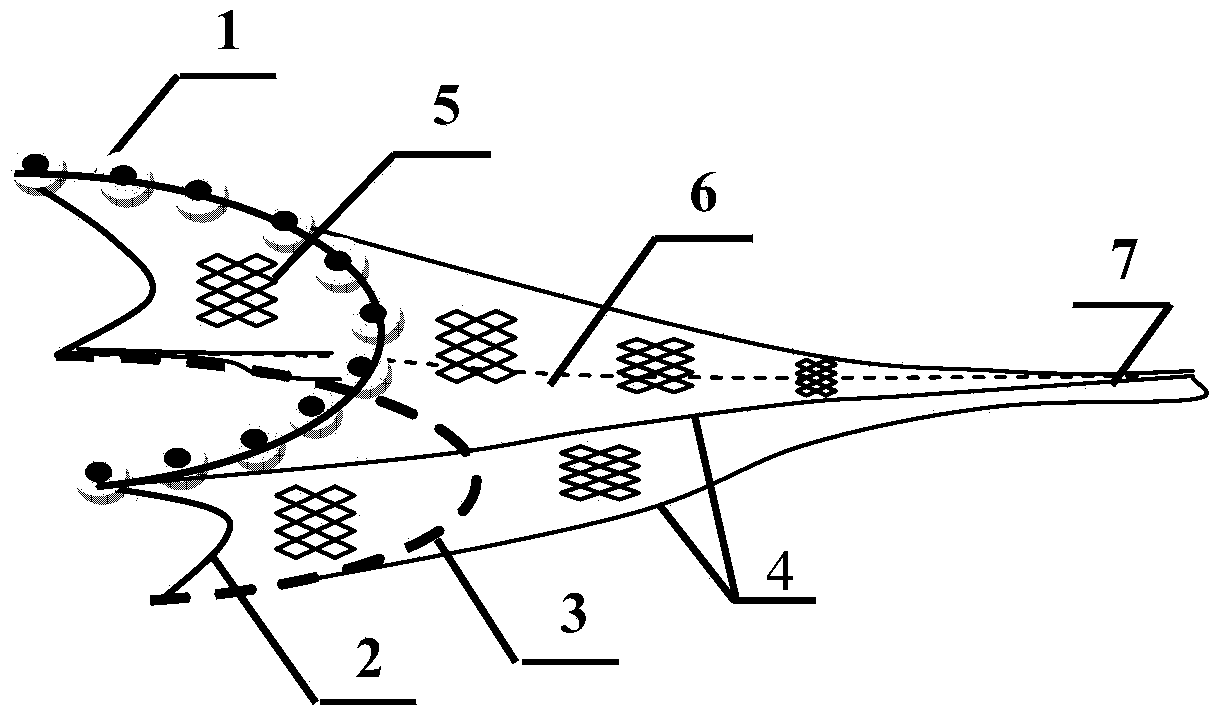

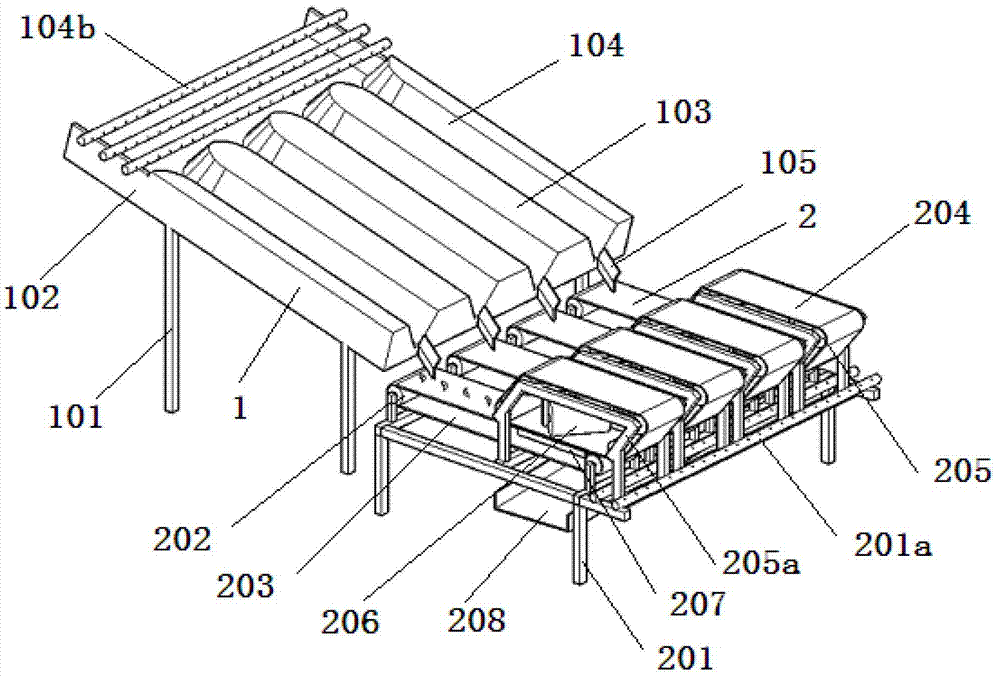

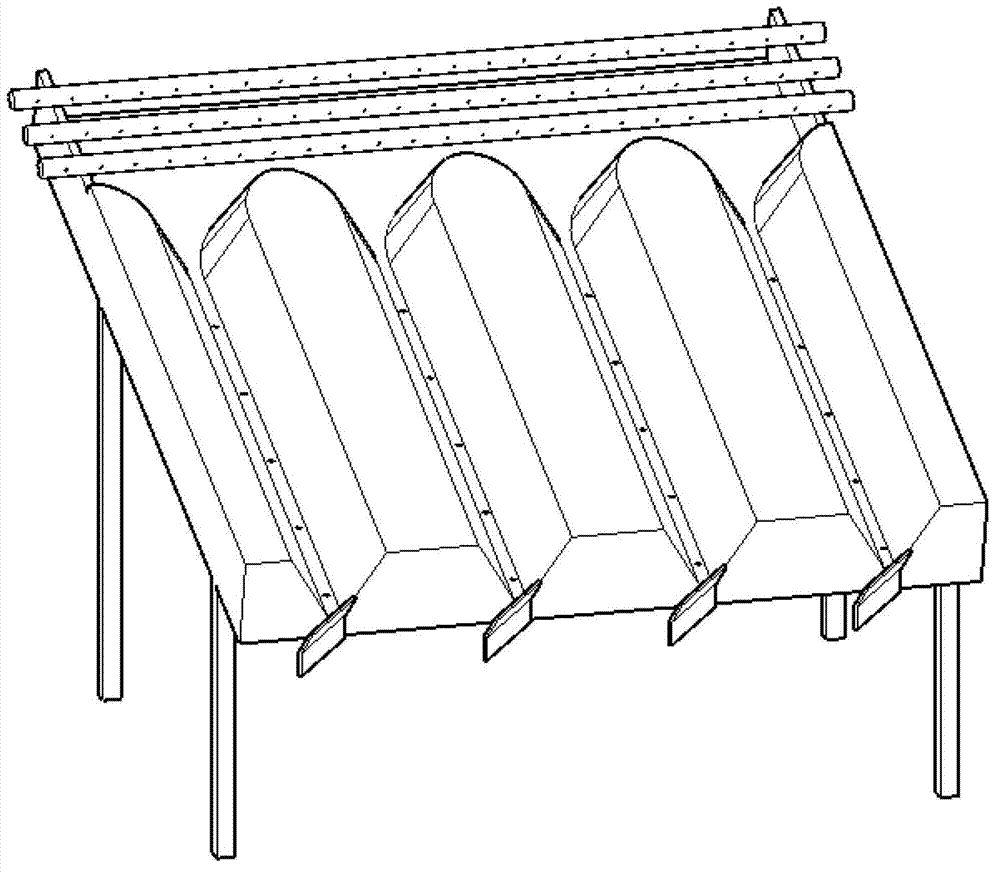

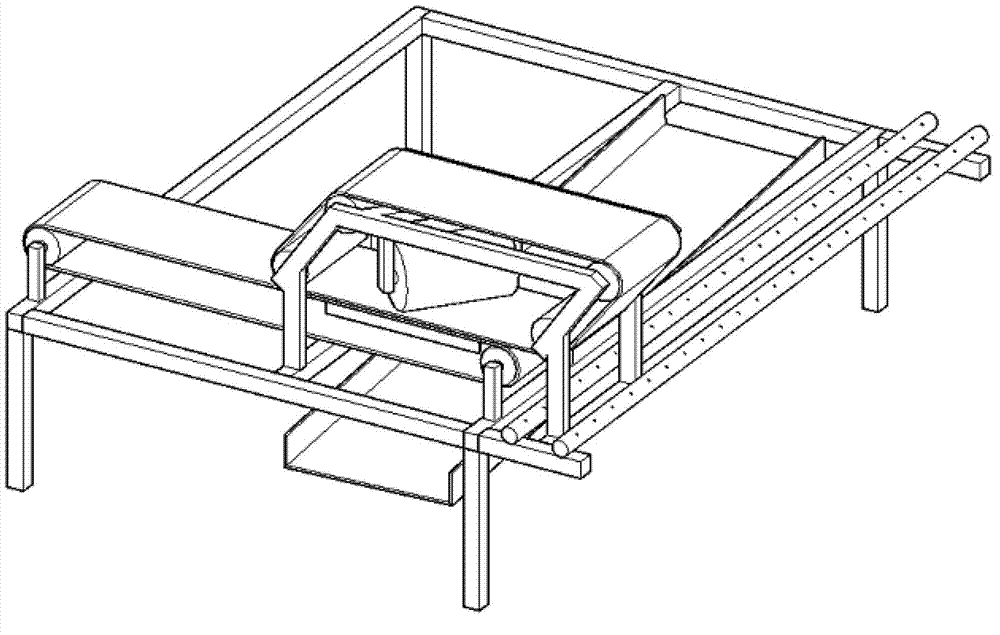

Shrimp unshelling device

The invention relates to a shrimp unshelling device which comprises a chute feeding mechanism (1) and a shell-meat separation mechanism (2). The chute feeding mechanism (1) and the shell-meat separation mechanism (2) are connected together. According to the invention, a shrimp shell can be rapidly stripped from a shrimp body; shrimp meat obtained after the shell-meat separation is carried out by the device is of a shelled shrimp shape and the appearance of the shrimp meat is kept complete; the shrimp unshelling device can be used for processing the complete-shaped shrimp meat of antarctic krill; and the integral shrimp unshelling device has simple structure and low price and is convenient to install on an ocean fishing ship.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Method for refining krill oil from Antarctic krill powder

InactiveCN103981021AImprove liquidityHigh transparencyFatty-oils/fats refiningFatty-oils/fats productionDistillationAstaxanthin

The invention relates to a method for refining krill oil from Antarctic krill powder, belonging to the technical field of deep processing of Antarctic krill. Acccording to the invention, the solvent ethanol and a small part of water in the extracting solution are removed not directly by one-step reduced pressure distillation, but are removed by the following steps: removing part of the solvent, adding deionized water, concentrating phospholipid, unsaturated fatty acids, krill astaxanthin and other effective substances by utilizing the characteristics of phospholipid, adding anhydrous ethanol to remove most of polysaccharides, proteins and salts, and finally, distilling under reduced pressure to remove the solvent and water. By using the refinement technique, the contents of the phospholipid DHA, EPA and other unsaturated fatty acids, astaxanthin and other effective components in the obtained krill oil are obviously enhanced, and the quality (flowability and transparency) of the obtained krill oil is obviously improved.

Owner:SHANDONG QIANQINGXIANGTAI BIOLOGICAL PROD CO LTD

Carp bait

The invention relates to the technical field of bait, in particular to carp bait. The carp bait is prepared from raw materials, by weight, 3-4% of antarctic krill meal, 2-3% of European whitefish meal, 12-15% of rye, 10-12% of rice bran, 25-30% of corn flour, 12-15% of soybean meal, 8-10% of wheat straw powder, 5-6% of corn immature stem leaves, 5-6% of fresh corn steep liquor, 4-5% of strong flour, 1-2% of lamb liver meal, 2-3% of mushroom residue, 2-3% of pumpkin seeds, 0.2-0.5% of ground sesame seed oil, 1-2% of cyperus rotundus, 2-3% of puffed field snail meal, proper salt and 0.2-0.5% of phagostimulant. The carp bait contains various raw materials that carps like to eat, the raw materials are subjected to fermentation treatment to enable the bait to have unique fragrance and flavors of the ground sesame seed oil, the cyperus rotundus, the field snail meal and the like, and accordingly the carps can be well baited; after entering water, the bait is not easy to dissolve, so that probability of hooking of the carps is increased.

Owner:ANHUI SANFENZHONG FISHING TACKLE

Fishing bait

InactiveCN1820626AIntense hungerAvoid nestAnimal feeding stuffOther angling devicesFlavorFood material

The fishing bait is prepared with 11 kinds of food materials and perfumes, including musk, Lingpaicao herb, asafetida, cyanide, clove, milk scent material, amino acid, Antarctic krill powder, fish phagostimulant, Shuizhongxiang and puffed adhering powder in certain weight proportion, and through milling into powder and mixing. It can attract fish effectively and possesses unique phagostimulant effect.

Owner:吴孝顺

Antarctic krill peptide preparation method

InactiveCN107974480ALow in peptide fluorideSmall molecular weightPeptide preparation methodsFermentationAdditive ingredientHydrolysate

The invention provides an Antarctic krill peptide preparation method. Antarctic krills as raw materials undergo homogenization, enzymolysis and centrifuging operation, so that layered enzymatic hydrolysate is obtained, wherein a free oil layer and an emulsion layer can be used for the extraction of Antarctic krill oil. A solution of a water layer is collected, compound protease is added for secondary enzymolysis, enzymatic hydrolysate is added with calcium oxide, and defluorination and centrifuging are carried out. After centrifuging, clear liquid passes through membrane separation equipment to intercept macromolecular substances, filtrate undergoes vacuum concentration, and spray-drying is carried out, so that Antarctic krill oligopeptide powder with low fluorin content and small molecular weight is obtained. The process is easy to operate, the fluorin content of the obtained Antarctic krill peptide is low, the destruction of nutritional ingredients is little, moreover, the molecularweight is low, the absorptivity of a human body is high, and a foundation is laid for the development of functional low-fluorin Antarctic krill oligopeptide.

Owner:DALIAN SHENLAN PEPTIDE TECH R & D CO LTD

Efficient environmentally-friendly compound feed for groupers

InactiveCN105211536AGood for healthImprove digestion and absorption rateAnimal feeding stuffFish oilAbsorption rate

The invention discloses an efficient environmentally-friendly compound feed for groupers. The compound feed comprises the following components in percentage by weight: 35-45% of white fish meal, 5-10% of squid powder, 6-14% of Antarctic krill powder, 10-20% of peeled soybean meal, 7-15% of vital wheat gluten, 6-12% of strong flour, 0.3-1% of calcium dihydrogen phosphate, 2-6% of fish oil, 1-3% of soybean oil, 1-3% of liquid phosphatide, 0.1-0.3% of bacillus, 0.2-0.5% of tributyrin, 1% of a vitamin premix, and 1% of a mineral substance premix. According to the compound feed disclosed by the invention, the health of intestinal tracts of the groupers can be improved, the damage of the intestinal tracts is avoided, the digestive absorption rate of the feed can be increased, the feed coefficient is reduced, and the discharge of nitrogen is reduced, so that the purpose that the compound feed is efficient and environmentally-friendly is achieved.

Owner:GUANGDONG EVERGREEN FEED INDAL

Preparation method of antarctic krill oil

ActiveCN102559369AEasy to operateReduce dosageFatty-oils/fats productionAlkaline proteaseMaximum level

The invention discloses a preparation method of antarctic krill oil, which comprises the following steps: directly homogenizing harvested fresh live antarctic krill, and allowing low-temperature autolysis of the homogenate after ultraviolet irradiation; adding water, sodium chloride and ethanol to the low-temperature autolyzed homogenate, heating the homogenate after ultraviolet irradiation treatment to 30-65 DEG C in a gradient manner, and allowing high-temperature autolysis; performing ultrasonic treatment of the high-temperature autolyzed homogenate, adjusting pH, adding alkali protease for extraneous enzyme enzymolysis; and adding n-hexane to the enzymatic hydrolysate to extract krill oil. The method of the invention is especially suitable for operation immediately in a fishing boat after the fresh live antarctic krill are harvested. The method is simple in operation and has high efficiency. Especially, the use amount of the extraneous enzyme is reduced by using the strong autolysis capacity of the fresh live antarctic krill, so as to reduce production cost. The extraction method has mild conditions, so that some original physiologically active substances in the krill oil can be stored at a maximum level, and the product is both nutritional and functional.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for extracting krill oil with high phosphatide content from Antarctic krills

InactiveCN102041166BImprove enrichment effectImprove extraction efficiencyFatty-oils/fats productionOrganic solventPrawn

The invention discloses a method for extracting krill oil with high phosphatide content from Antarctic krills. The method comprises the following steps: (1) drying fresh Antarctic krills to obtain dry Antarctic krills; (2) performing extraction to dry Antarctic krills for 3 times with organic solvent; (3) mixing the extracting solutions, evaporating the mixed extracting solution to obtain Antarctic krill oil with the phosphatide content of 30-35%; then introducing nitrogen or carbon dioxide to remove the residual organic solvent; and adding polar organic solvent in the Antarctic krill oil, mixing evenly, standing to ensure that the mixed solution performs natural layering; and evaporating the lower solution to obtain the Antarctic krill oil with high phosphatide content, and then introducing nitrogen or carbon dioxide to remove the residual polar organic solvent so as to obtain a product. The extraction technology is performed at a low temperature, thus the red color of krill oil can be maintained and the beneficial ingredients in the product can not be damaged. The invention has high extraction efficiency and good phosphatide accumulation effect. Therefore, the Antarctic krill oil with high phosphatide content can be obtained and other byproducts can also be obtained.

Owner:SHANDONG NORMAL UNIV +1

Method for extracting high-purity phospholipid from Antarctic krill oil

ActiveCN104498180AReduce manufacturing costImprove separation and purification efficiencyGroup 5/15 element organic compoundsFatty-oils/fats refiningOrganic solventVaporization

The invention discloses a method for extracting high-purity phospholipid from Antarctic krill oil. The method comprises the following steps: mixing a low polarity solvent, ethanol and water at the volume ratio of 10:10:1, fully oscillating, mixing, standing and layering, wherein the upper layer refers to a low polarity solvent phase, and the lower layer refers to an ethanol phase; separating the upper low polarity solvent phase; dissolving the Antarctic krill oil in the ethanol phase prepared in the step (1); adding the prepared low polarity solvent phase into the Antarctic krill oil dissolved liquid for extracting, and fully mixing; standing or centrifuging, so that the mixed solution is layered, thereby obtaining the upper dark red low polarity extracting solution and the lower orange-yellow ethanol phase extracting solution; extracting the ethanol phase extracting solution by using the low polarity solvent phase until the low polarity solvent phase is nearly colorless, and finally obtaining the orange-yellow ethanol phase extracting solution; and performing reduction vaporization on the finally obtained ethanol phase extracting solution, thereby obtaining the orange-yellow cream, namely the Antarctic krill phospholipid. According to the method disclosed by the invention, the high-purity phospholipid is prepared from the Antarctic krill oil by utilizing the organic solvent extraction method, and the phospholipid content is 85-92 percent.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com