Patents

Literature

342 results about "Eicosapentaenoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Eicosapentaenoic acid (EPA; also icosapentaenoic acid) is an omega-3 fatty acid. In physiological literature, it is given the name 20:5(n-3). It also has the trivial name timnodonic acid. In chemical structure, EPA is a carboxylic acid with a 20-carbon chain and five cis double bonds; the first double bond is located at the third carbon from the omega end.

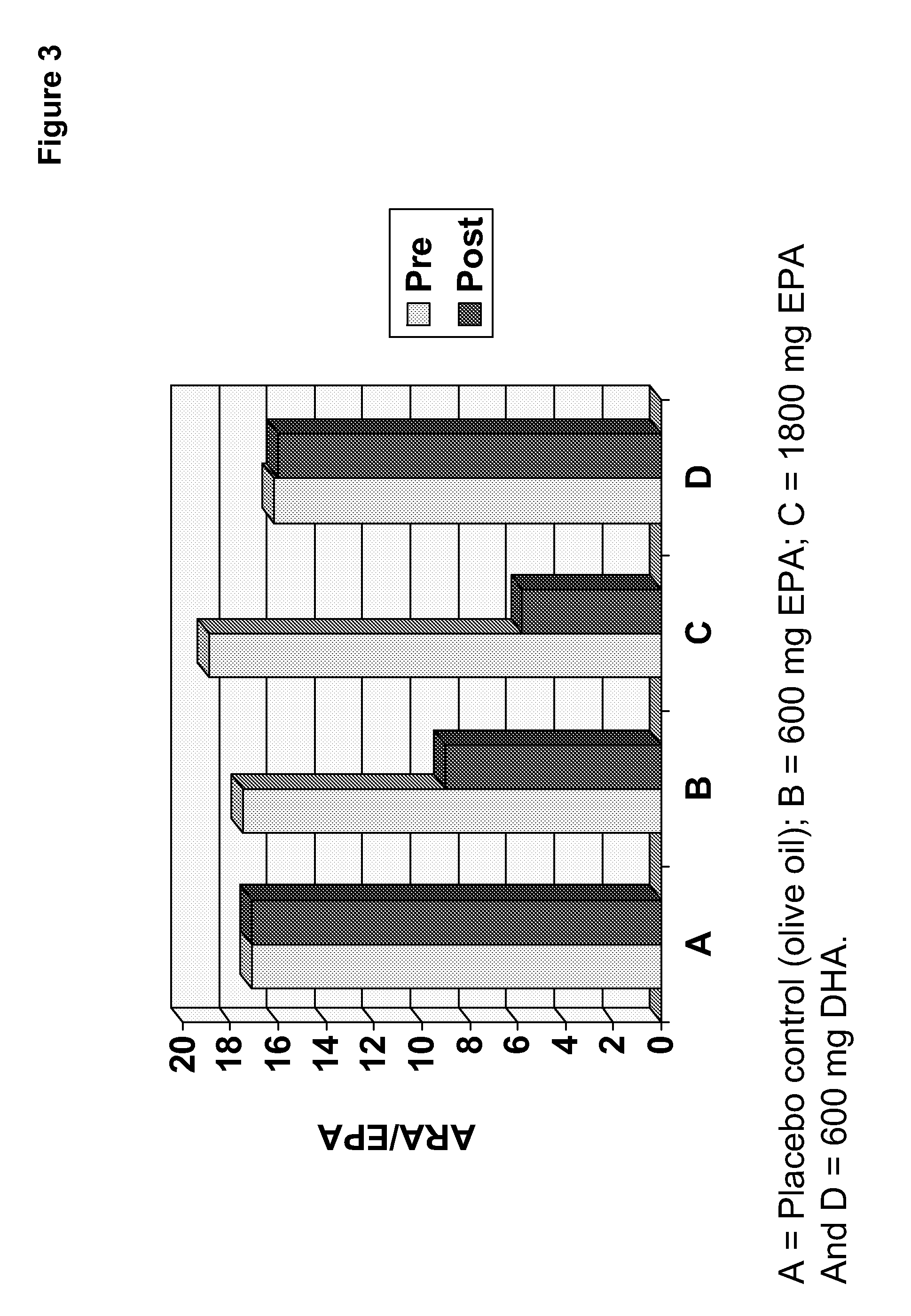

Pharmaceutical Composition and Method for Treating Hypertriglyceridemia and Hypercholesterolemia in Humans

InactiveUS20090182049A1Lower triglyceridesIncreasing HDL (good) cholesterolBiocideMetabolism disorderDocosahexaenoic acidSerum cholesterol

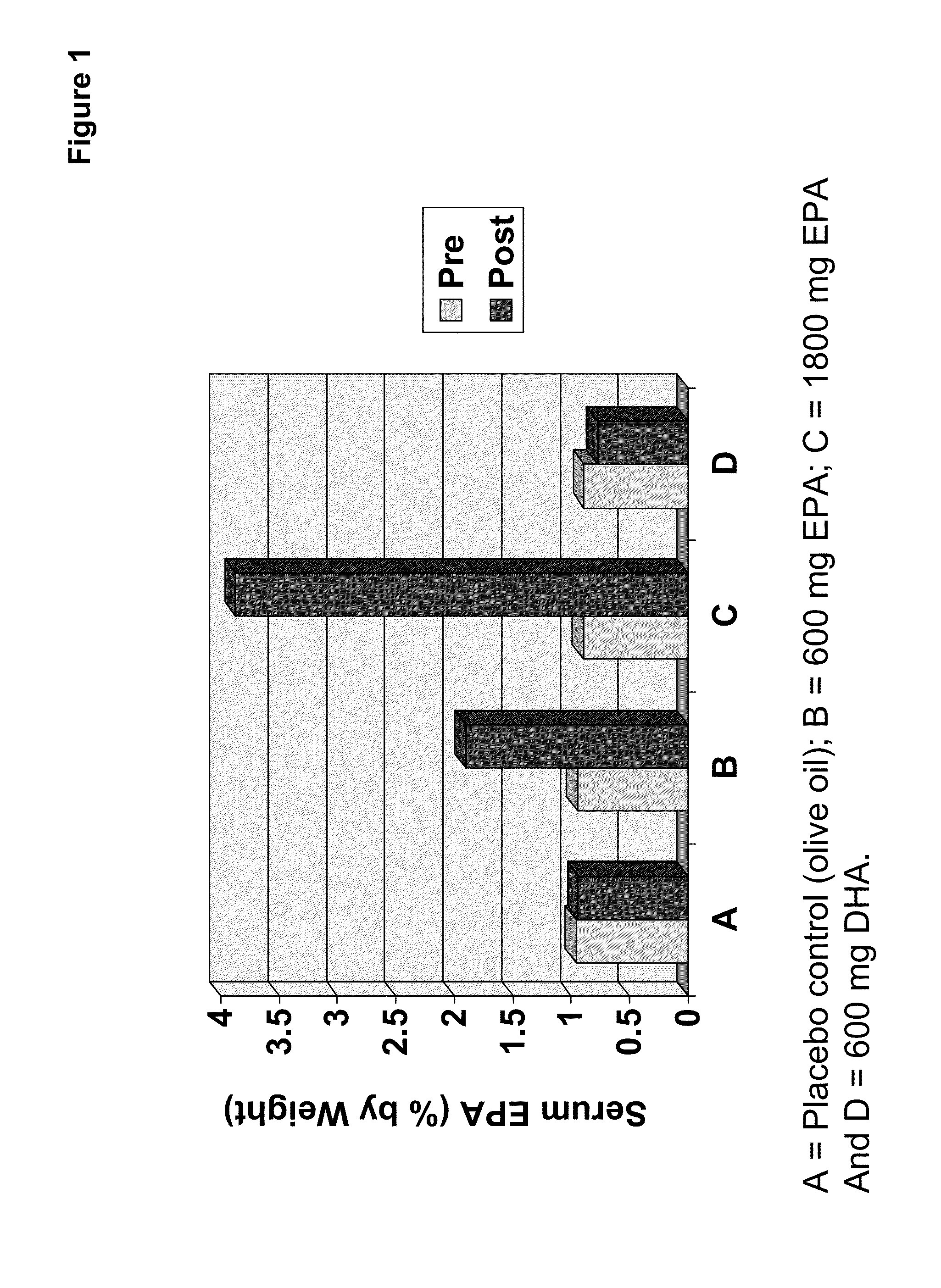

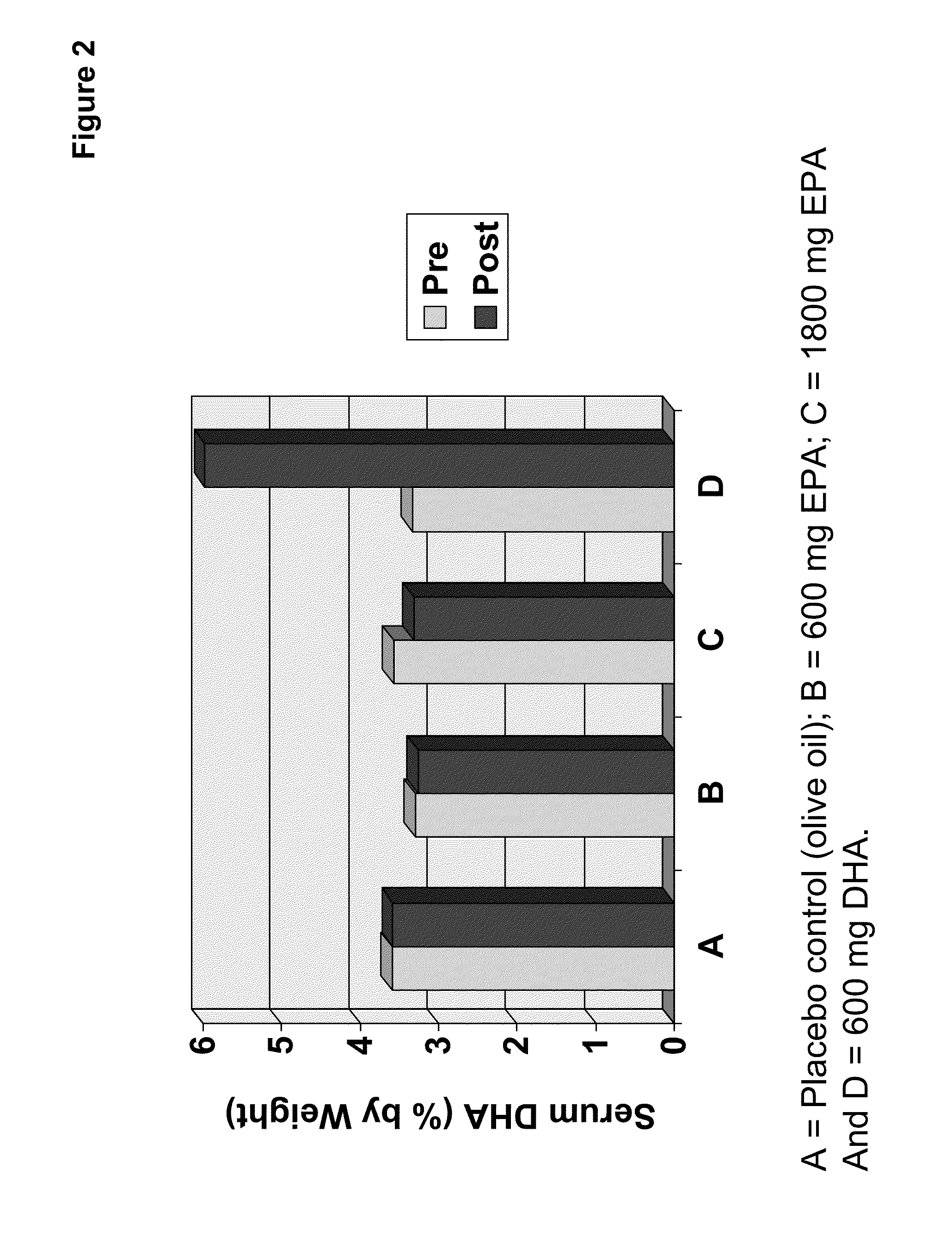

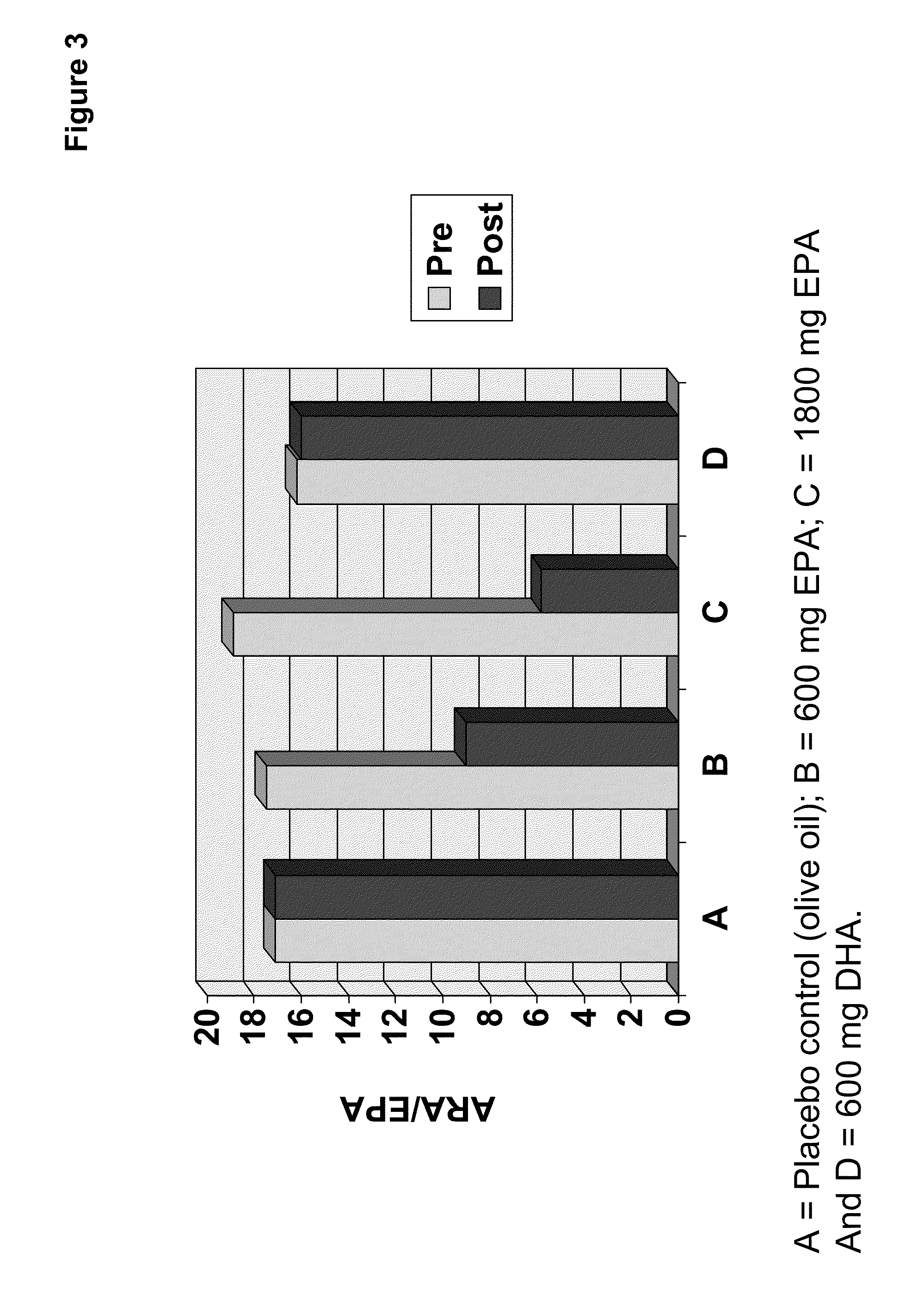

A method for the treatment or prophylaxis of hypertriglyceridemia and hypercholesterolemia without concomitantly increasing LDL-serum cholesterol, in a human subject requiring such treatment, which method comprises orally administering to the patient an effective amount of a pharmaceutical composition in which the active ingredients comprise a mixture of fatty acids, wherein said mixture comprises at least about 60% by weight a combination of eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) in a weight ratio of EPA:DHA of from about 1.4:1 to about 5:1, wherein said combination is at least about 60% in the triglyceride form of the fatty acids and the balance is at least about 80% of mono and di-glycerides.

Owner:OPHEIM JOAR ARILD

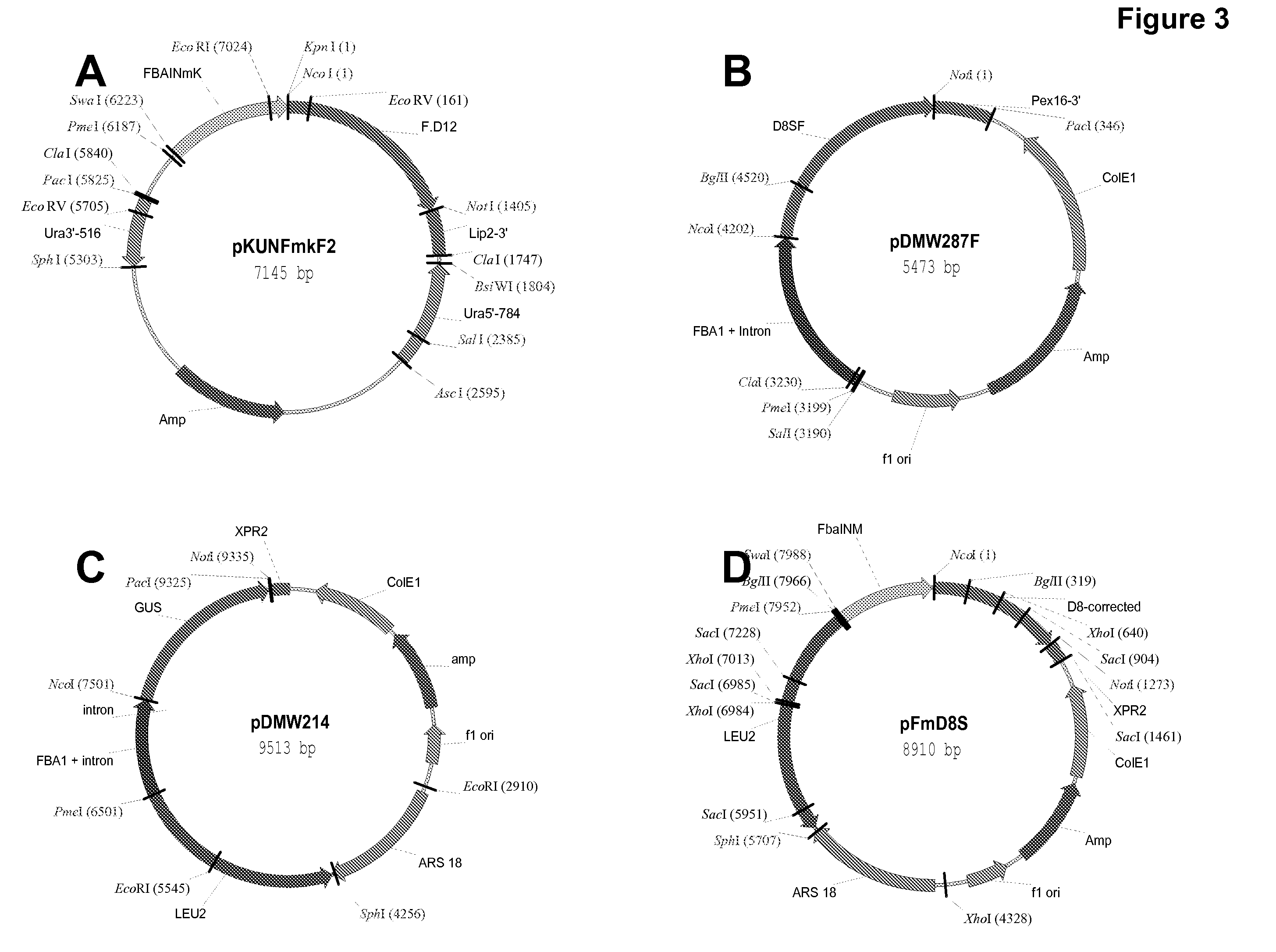

Optimized strains of yarrowia lipolytica for high eicosapentaenoic acid production

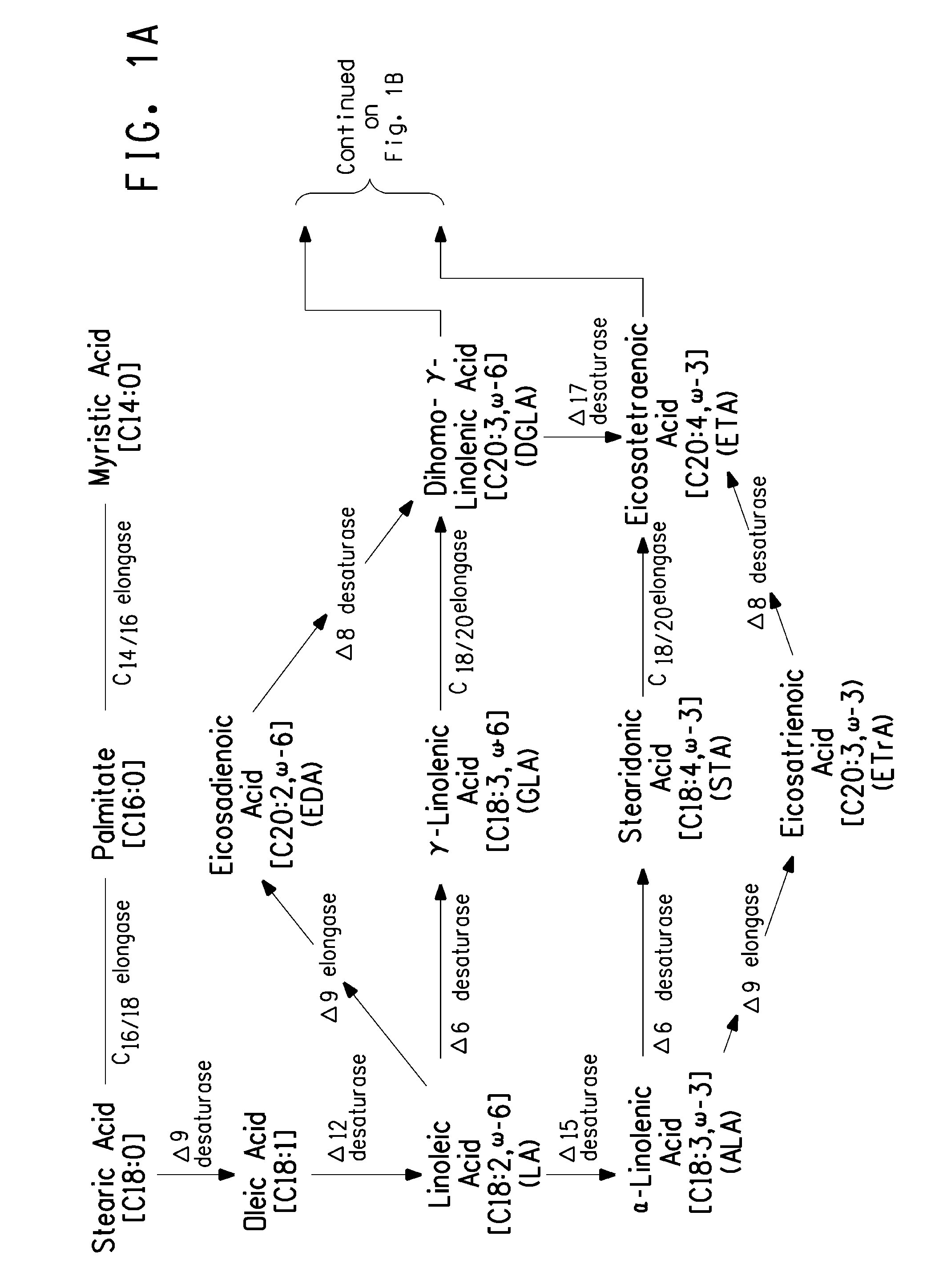

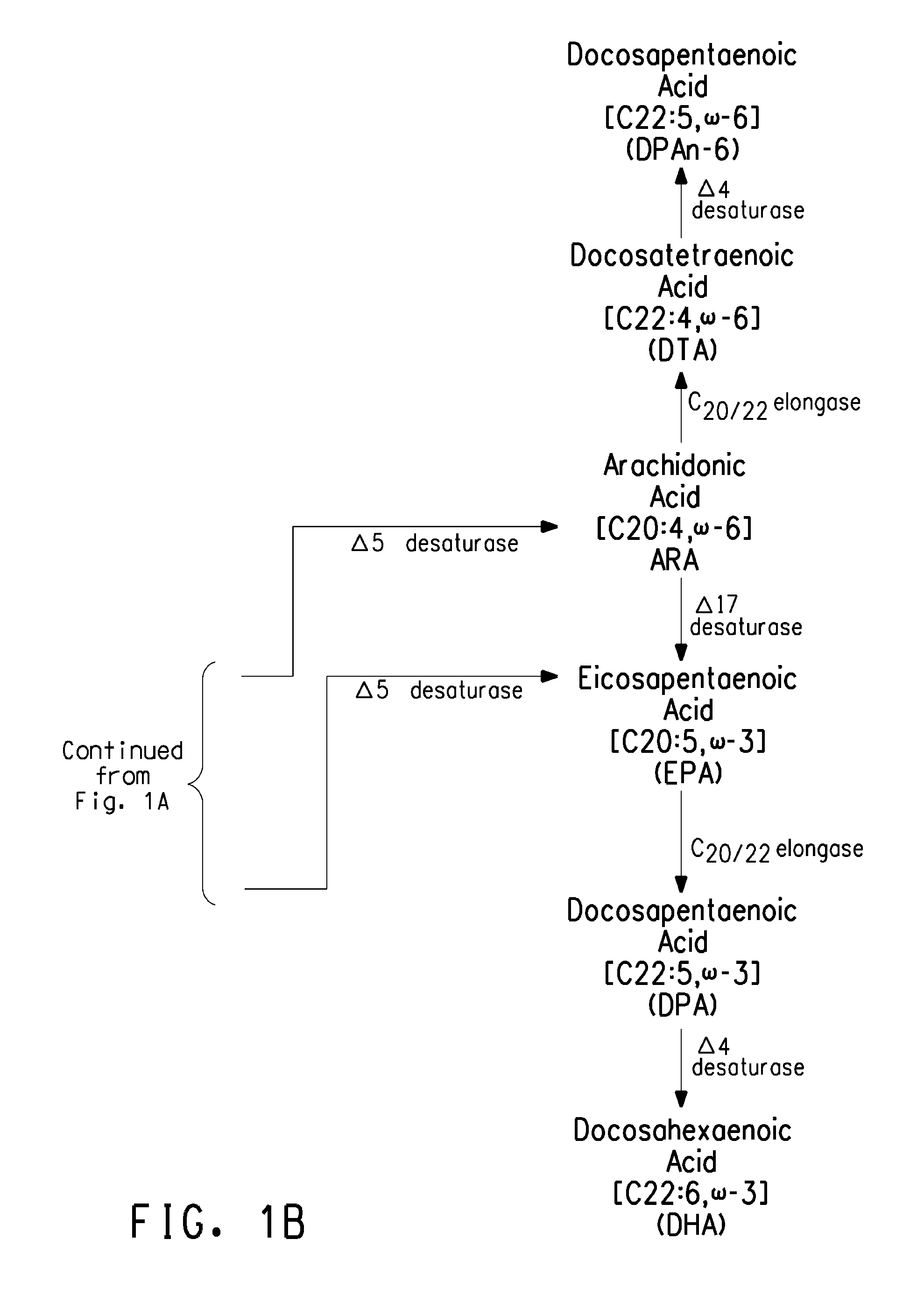

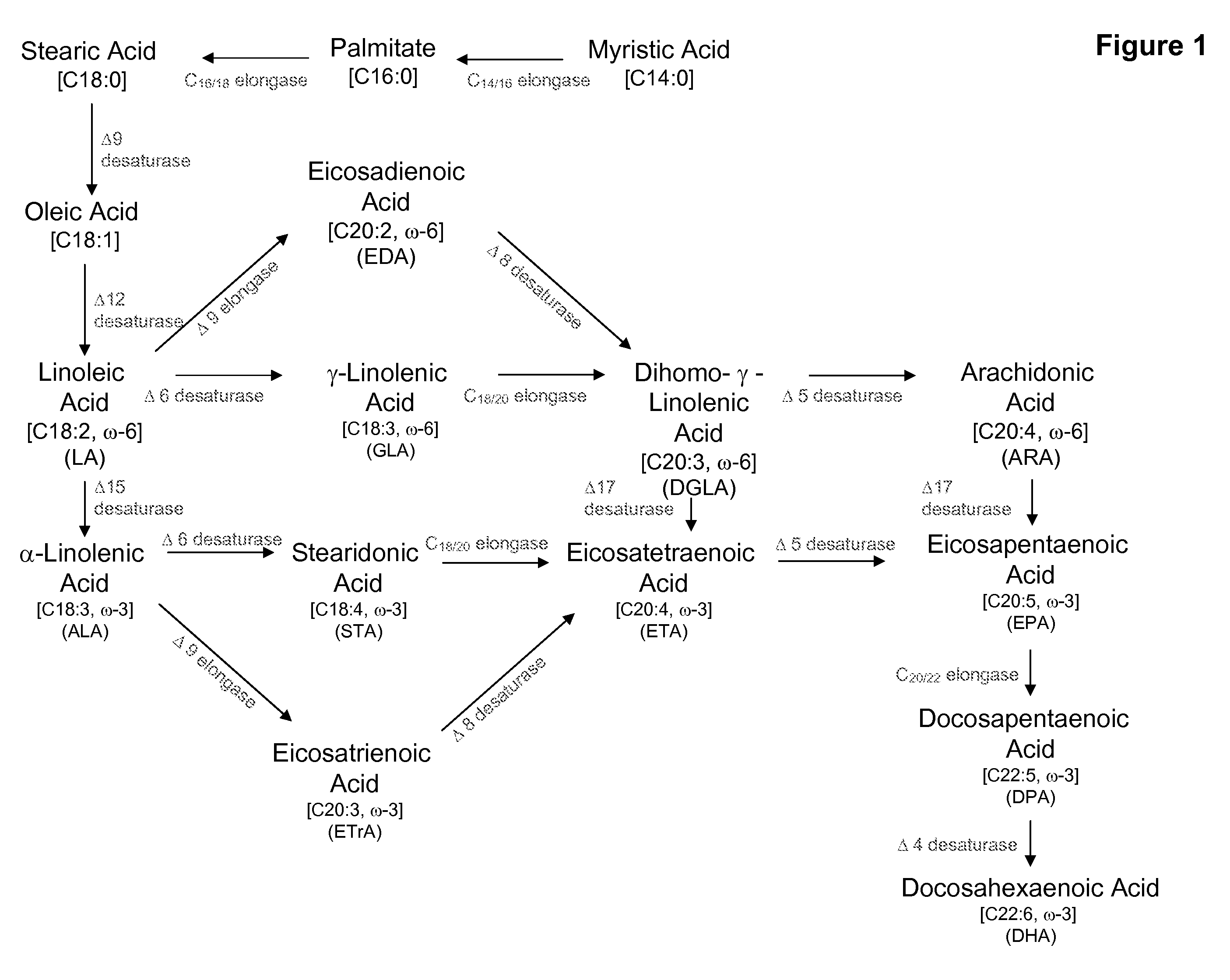

Engineered strains of the oleaginous yeast Yarrowia lipolytica capable of producing greater than 50 weight percent of eicosapentaenoic acid [“EPA”], an ω-3 polyunsaturated fatty acid, in the total oil fraction are described. These strains over-express heterologous Δ9 elongases, Δ8 desaturases, Δ5 desaturases, Δ17 desaturases, Δ12 desaturases and C16 / 18 elongases, and optionally over-express diacylglycerol cholinephosphotransferases. Preferred gene knockouts are also described. Production host cells, methods for producing EPA within said host cells, and products comprising EPA from the optimized Yarrowia lipolytica strains are claimed.

Owner:DUPONT US HLDG LLC

Treatment and prevention of major adverse cardiovascular events or major coronary evens by administering Omega-3 fatty acids

InactiveUS20080306154A1Effective treatmentReduce generationBiocideMetabolism disorderDyslipidemiaCoronary event

Omega-3 fatty acid compositions comprising eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) are provided, where the compositions are useful for treating, reducing the occurrence of, or preventing major adverse cardiovascular events or major coronary events in patients who have established cardiovascular disease without prior myocardial infarction, preventing their further progression, and treating underlying risk factors for CVD such as hypertension, dyslipidemia, obesity and / or diabetes.

Owner:PRONOVA BIOCARE AS

Compositions and methods for reducing triglyceride levels

InactiveUS20100130608A1Reducing plasma triglyceride levelReduce the amount requiredBiocideMetabolism disorderDocosahexaenoic acidEicosapentaenoic acid

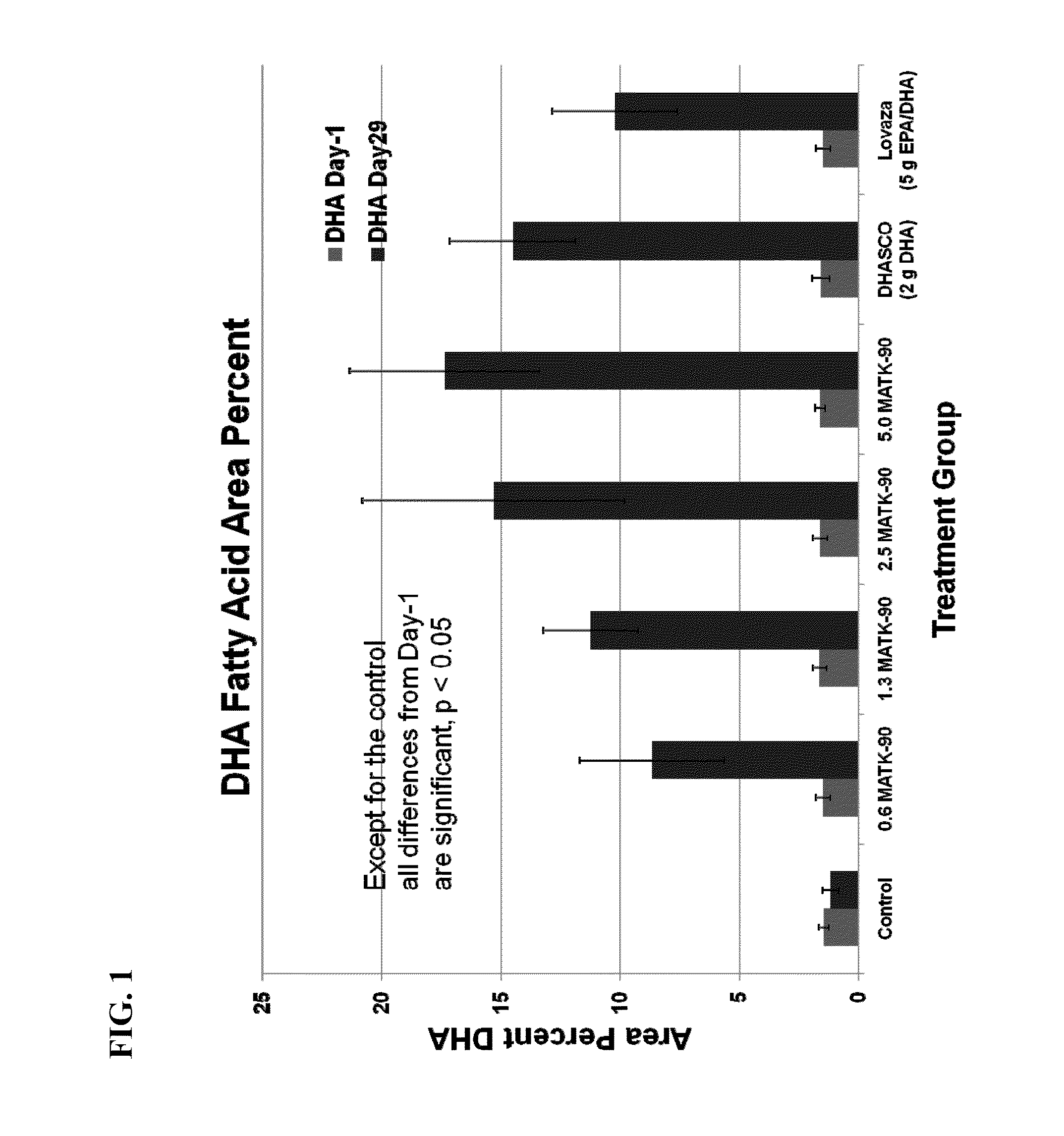

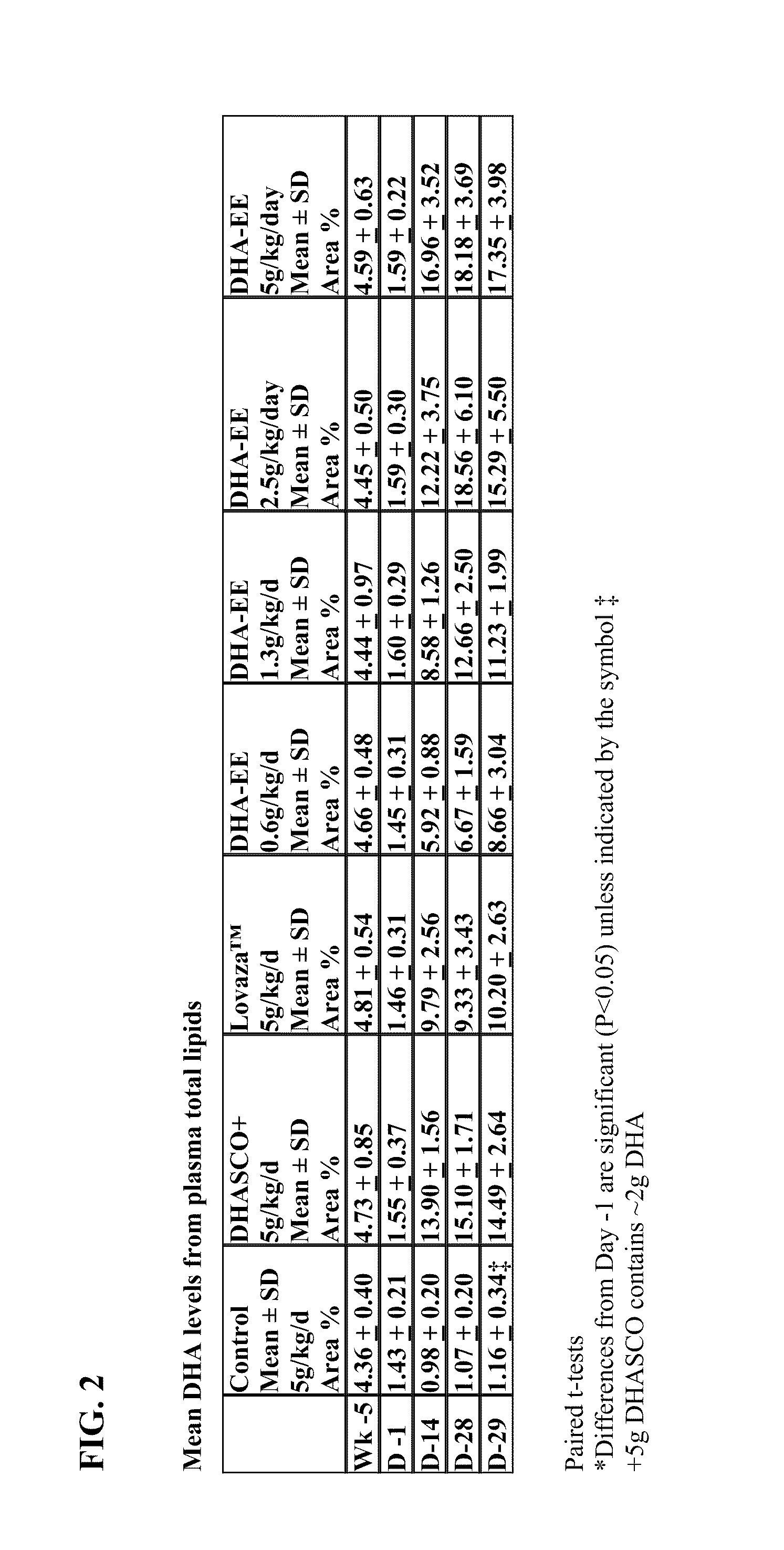

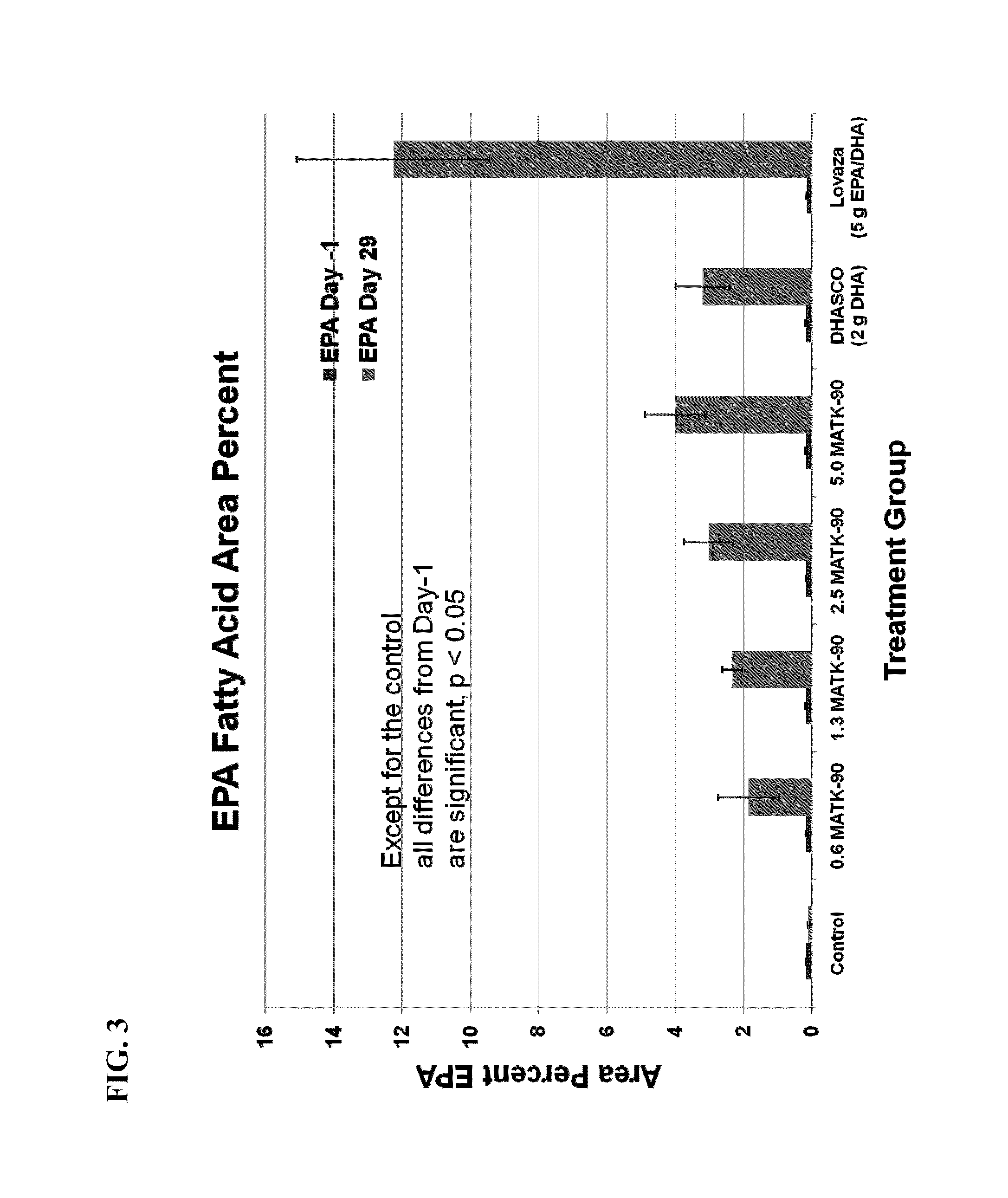

The present invention is directed to methods of reducing plasma triglyceride level in subjects by administering docosahexaenoic acid (DHA). The method can comprise administering daily to the subject a dosage form comprising docosahexaenoic acid ester substantially free of eicosapentaenoic acid (EPA), wherein the DHA is derived from an algal source. In some embodiments, the method comprises administering daily to the subject a dosage form comprising DHA ester substantially free of EPA, wherein the DHA ester is about 60% to about 99.5% (w / w) of the total fatty acid content of the dosage form. In some embodiments, the method comprises administering daily to the subject a dosage form comprising about 200 mg to about 4 g of DHA ester substantially free of EPA. In some embodiments, the foregoing methods also result in a lowering of the amount of total cholesterol in the subject.

Owner:DSM IP ASSETS BV

Clinical benefits of eicosapentaenoic acid in humans

InactiveUS20110178105A1Maintaining and lowering Lp-PLA levelWithout raising LDL cholesterol levelBiocideMetabolism disorderEicosapentaenoic acidOMEGA-3 POLYUNSATURATED FATTY ACIDS

Methods are provided for maintaining or lowering lipoprotein-associated phospholipase A2 [“Lp-PLA2”] levels, stabilizing rupture prone-atherosclerotic lesions, decreasing the Inflammatory Index and increasing Total Omega-3 Score™ in humans, by administering an effective amount of eicosapentaecnoic acid [“EPA”], an omega-3 polyunsaturated fatty acid [“PUFA”].

Owner:EI DU PONT DE NEMOURS & CO

Drug for improving prognosis for subarachnoid hemorrhage

InactiveUS20060135607A1Improved prognosisImprove recovery rateBiocideAnimal repellantsEicosapentaenoic acidBULK ACTIVE INGREDIENT

It is intended to provide a drug for improving prognosis for subarachnoid hemorrhage which contains, as the active ingredient, at least one member selected from the group consisting of eicosapentaenoic acid (EPA) and pharmaceutically acceptable salts and esters thereof, and a method of improving prognosis for subarachnoid hemorrhage which comprises orally or gastrically administering the above drug.

Owner:MOCHIDA PHARM CO LTD

Drug for reducing side effects in ribavirin interferon combination therapy

InactiveUS20060088502A1Eliminate side effectsReduces side effects found in ribavirin/IFNBiocideElcosanoid active ingredientsChronic viral hepatitis CSide effect

There is provided a drug for reducing side effects, anemia in particular, in combination therapy of chronic hepatitis C with ribavirin and interferon, which contains as the active ingredient at least one member selected from the group consisting of eicosapentaenoic acid (EPA) and pharmaceutically acceptable salts and esters thereof.

Owner:MOCHIDA PHARM CO LTD

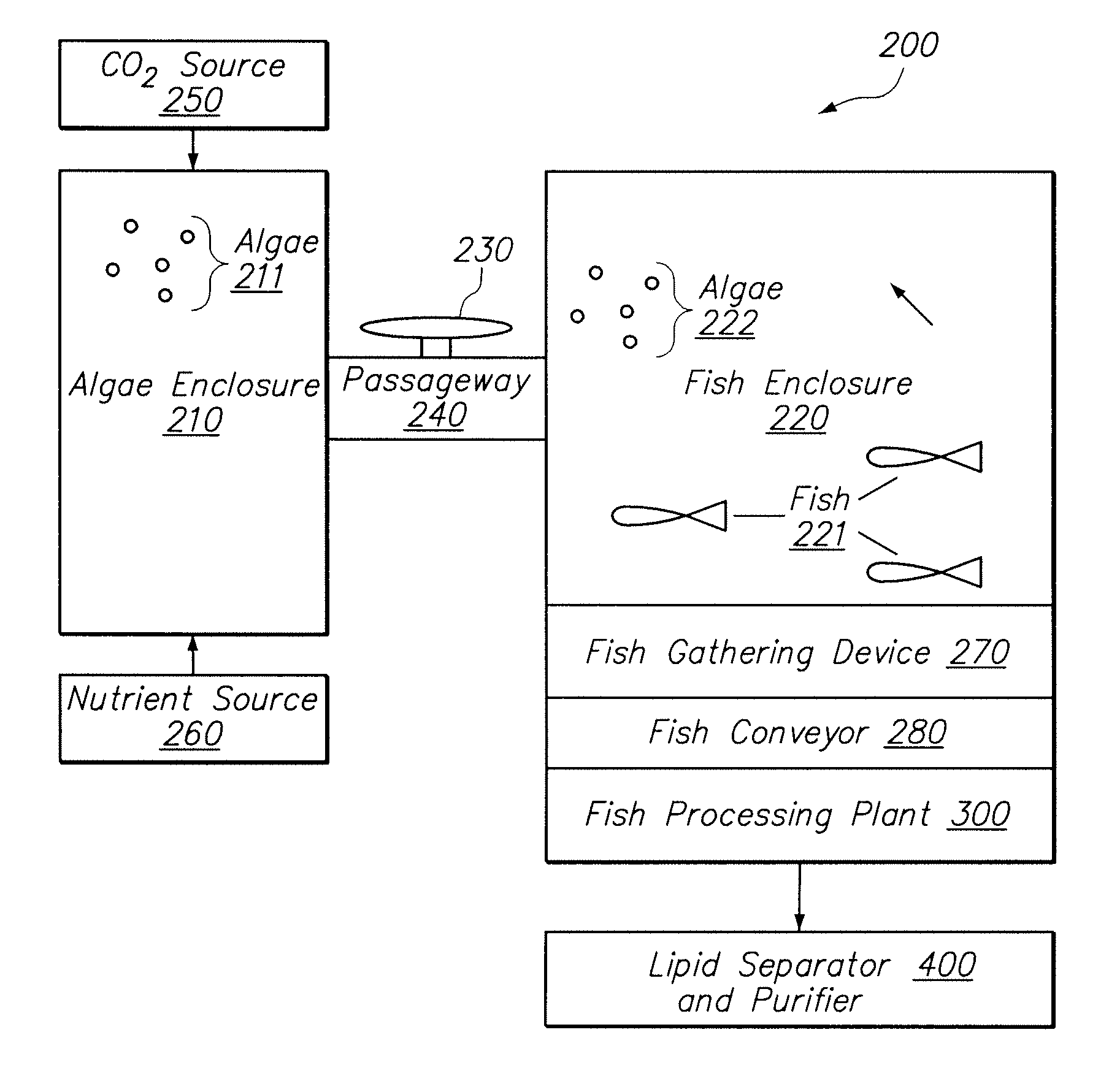

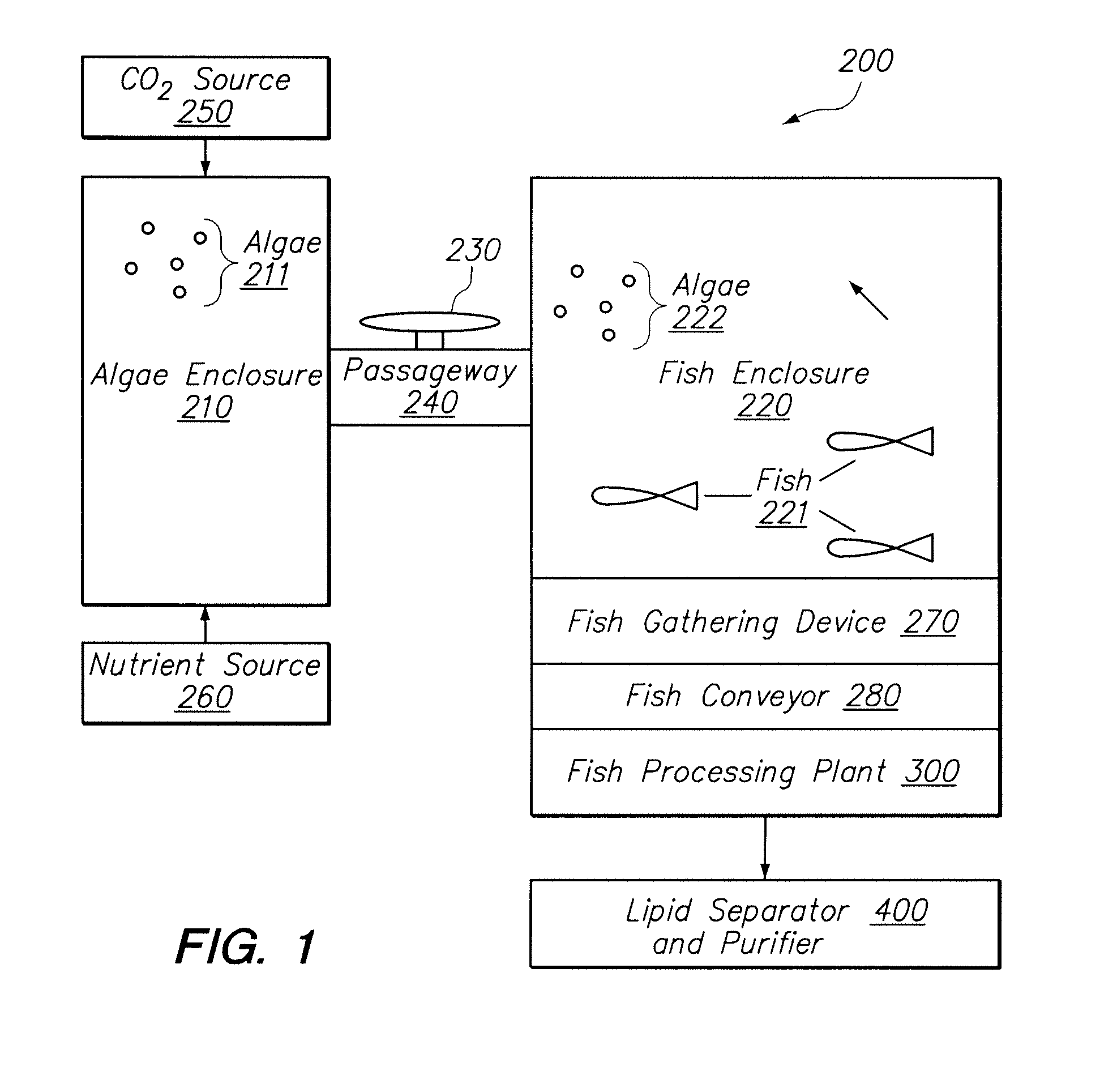

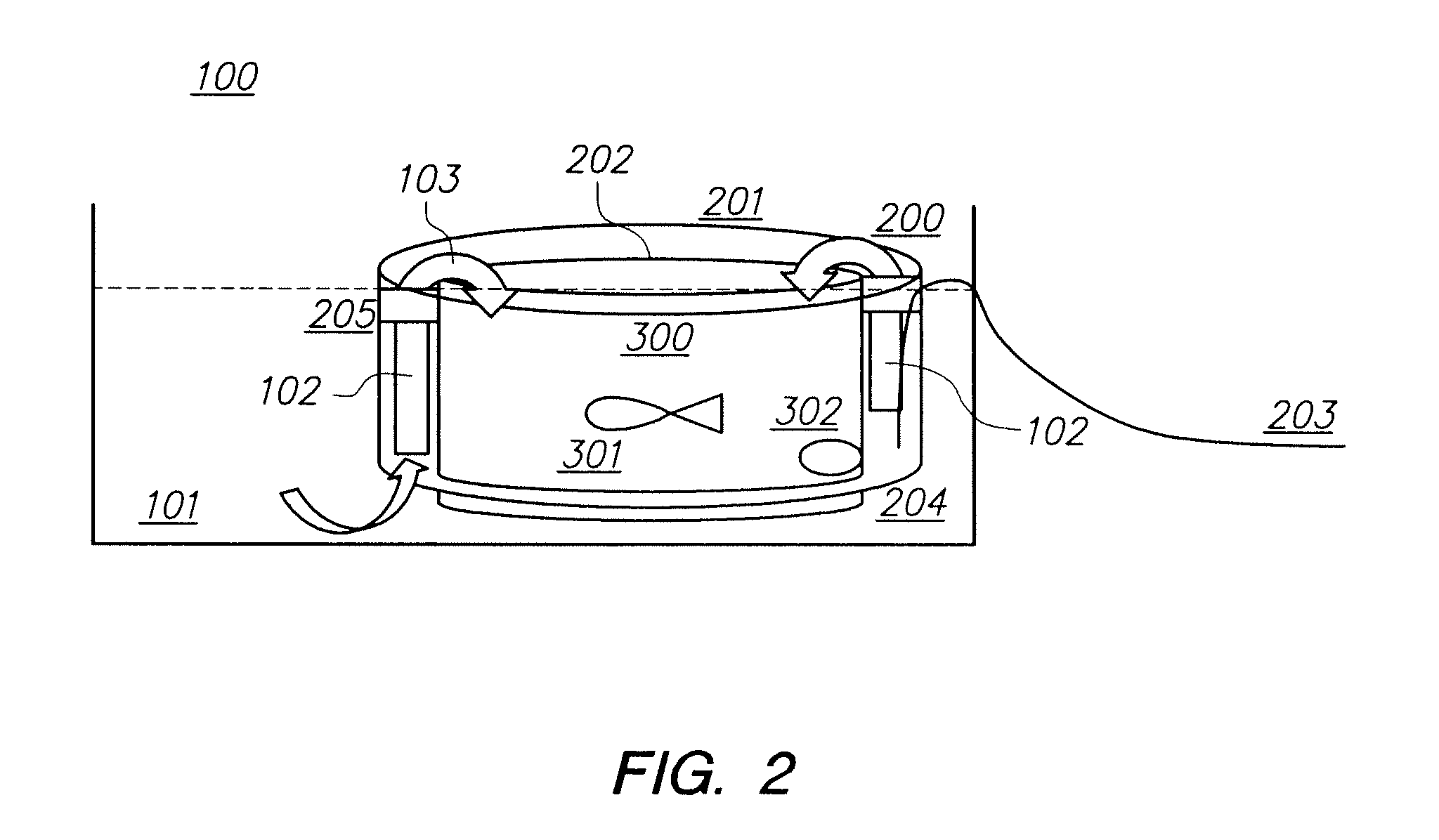

Systems and methods for producing eicosapentaenoic acid and docosahexaenoic acid from algae

InactiveUS20100236137A1Inexpensive and energy-efficient methodOrganic chemistryFatty acid esterificationDocosahexaenoic acidEicosapentaenoic acid

Provided herein are systems and methods for producing eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) and / or derivatives and / or mixtures thereof by growing algae that produce the oils containing EPA and / or DHA and / or derivatives and / or mixtures thereof, harvesting the algae with fish in one or more enclosed systems, and then processing fish to separate and purify the EPA and / or DHA. The multi-trophic systems provided herein comprise at least one enclosure that contains the algae and the fishes, and means for controllably feeding the algae to the fishes. Also provided herein are the lipid compositions extracted from the fishes.

Owner:LIVEFUELS

Feed formulation for terrestrial and aquatic animals

InactiveUS20070082008A1Function increaseSpeed up the conversion processBiocideAlgae medical ingredientsDocosahexaenoic acidPastoralism

The use of macroalgal, microalgal, and fungally-derived materials provide, in combination with higher-plant derived materials, complete feeds for animal husbandry. The products and methods of the invention provide nutritional feed formulations, that reduce or eliminate the need for animal-derived materials. The feeds are useful for terrestrial or aquatic animals, and comprise docosahexaenoic acid and eicosapentaenoic acid.

Owner:ADVANCED BIONUTRITION CORP

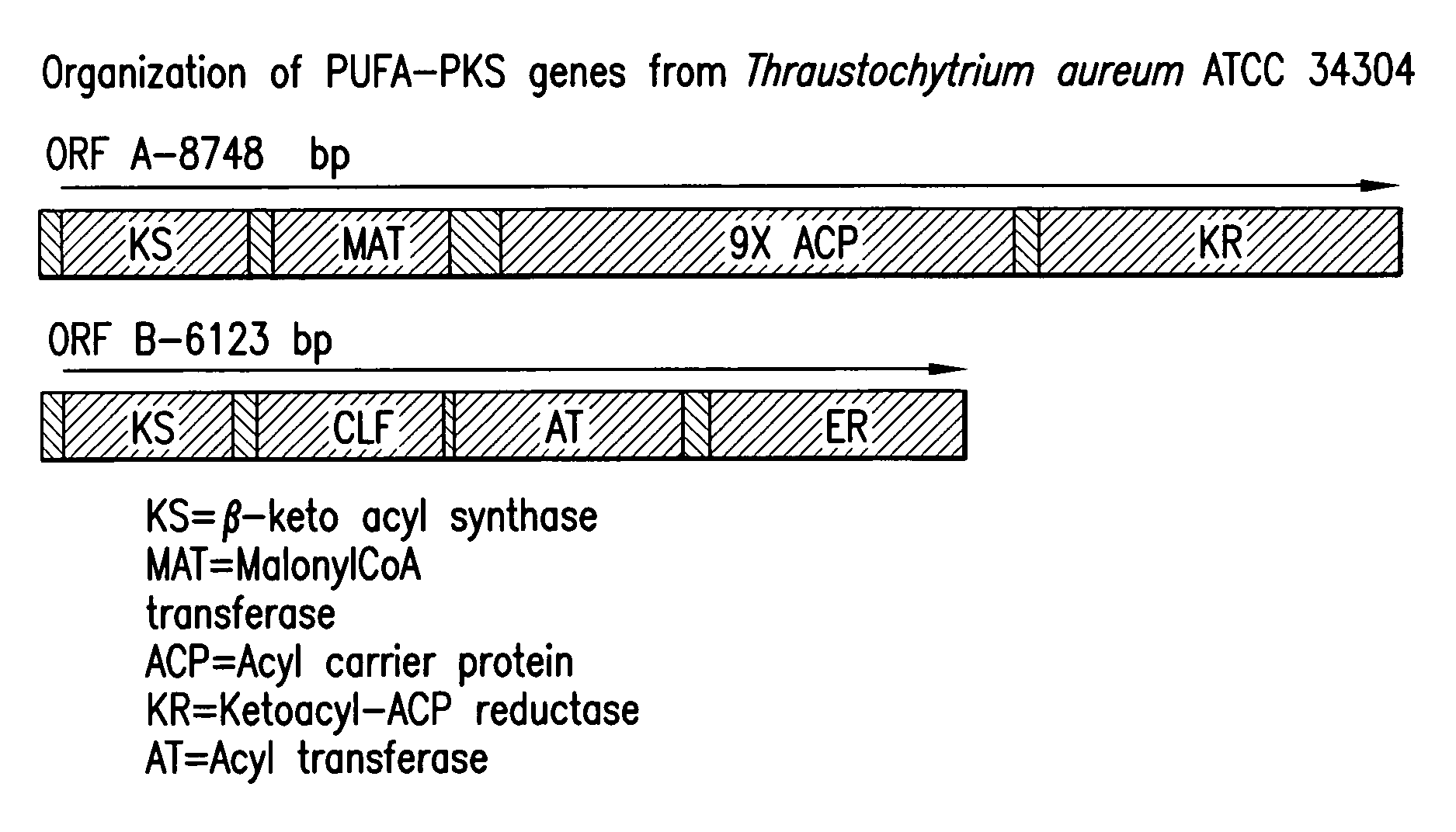

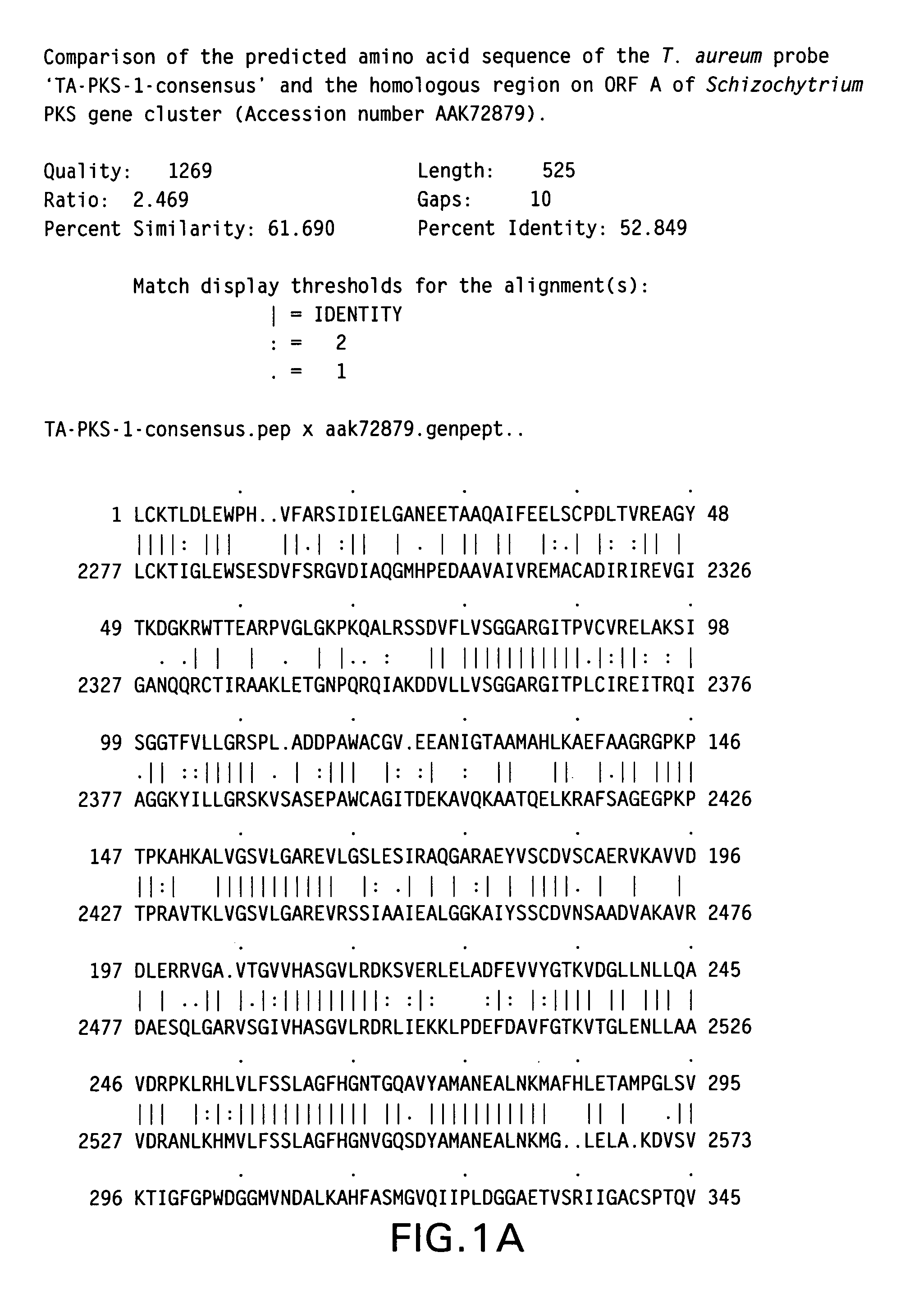

Genes involved in polyketide synthase pathways and uses thereof

The subject invention relates to isolated nucleic acid sequences or genes involved in polyketide synthase (PKS) biosynthetic pathways. In particular, such pathways are involved in the production of polyunsaturated fatty acids (PUFAs) such as, for example, Eicosapentaenoic acid (EPA) and Docosahexaenoic acid (DHA). Specifically, the invention relates to isolating nucleic acid sequences encoding proteins involved in eukaryotic PUFA-PKS systems and to uses of these genes and encoded proteins in PUFA-PKS systems, in heterologous hosts, for the production of PUFAs such as EPA and DHA.

Owner:ABBOTT LAB INC

Dietary regimen of nutritional supplements for relief of symptoms of arthritis

InactiveUS6136795AReduce inflammationPermits healingBiocideAcidic food ingredientsDocosahexaenoic acidRegimen

This invention is directed to a dietary regimen and a unique combination of nutritional supplements and a method. More specifically, this invention is directed to a unique combination of nutritional supplements which provides symptomatic relief from arthritis. The unique combination of nutritional supplements of this invention is believed to function by both increasing the available (effective blood level) of anti-inflammatory agents and promotion of the healing / regenerative process in the effected joints, thus, producing unexpected and lasting symptomatic relief from the debilitating effects of both osteoarthritis and rheumatoid arthritis. The essential nutritional supplements of the dietary regimen of this invention are as follows: (a) gamma linolenic acid (unrefined), hereinafter "GLA"(b) a mixture of eicosapentaenoic acid and docosahexaneoic acid, hereinafter collectively "EPA"(c) a mixture of chondroitin sulfate, N-acetyl glucosamine sulfate, glucosamine sulfate and manganese aspartate, hereinafter collectively "CHONDROX"The regimen is adjusted based upon the weight of the individual, and once symptomatic relief is achieved, the individual remains essentially free from the debilitating effects of arthritis so as long the daily regimen is faithfully followed.

Owner:IRWIN NATURALS 4HEALTH INC +1

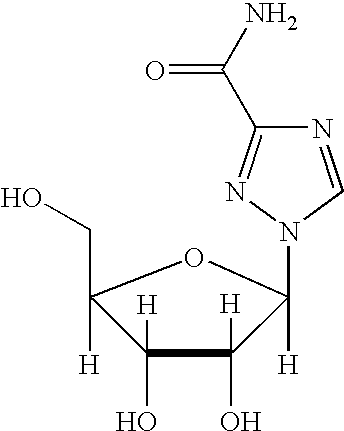

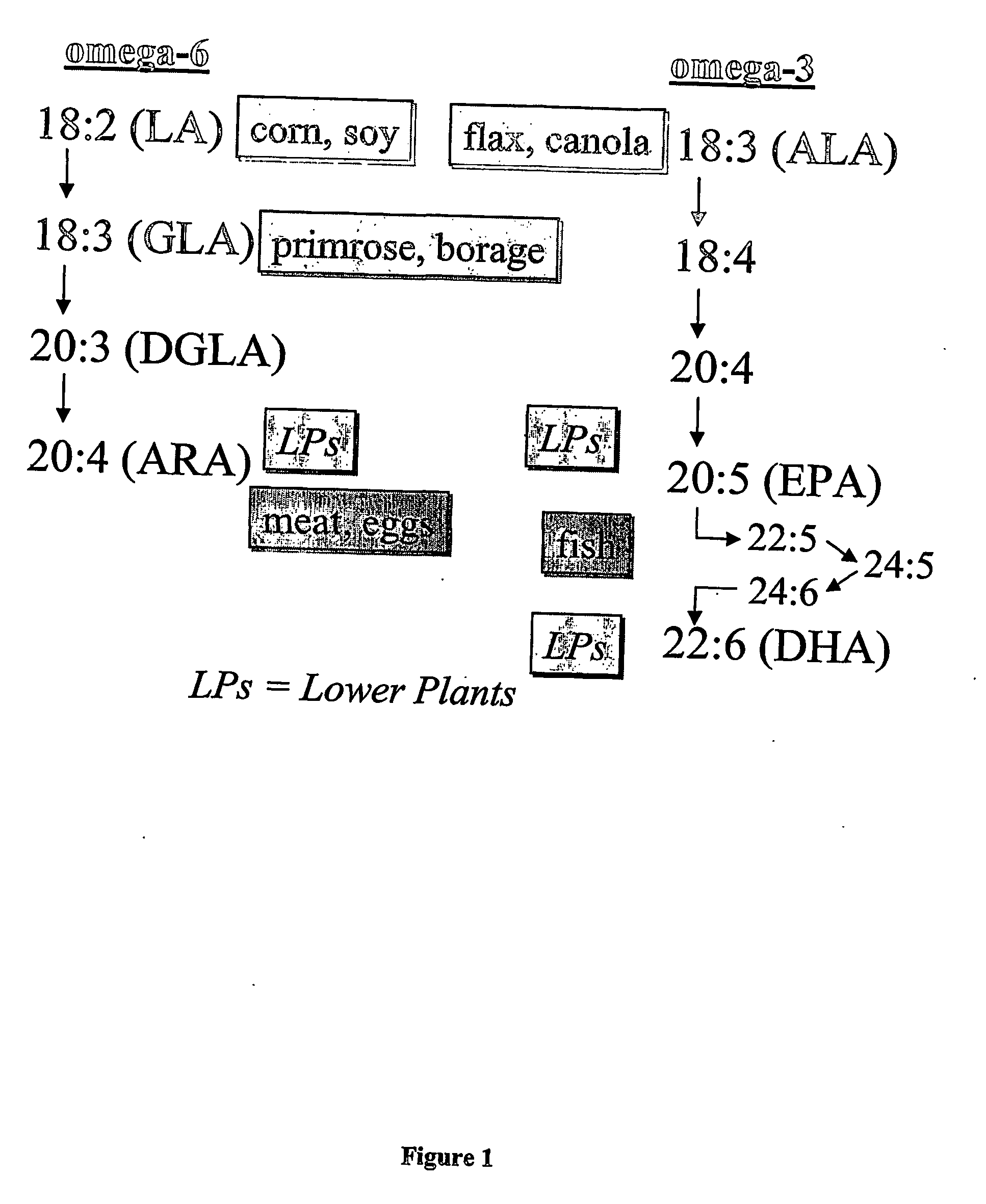

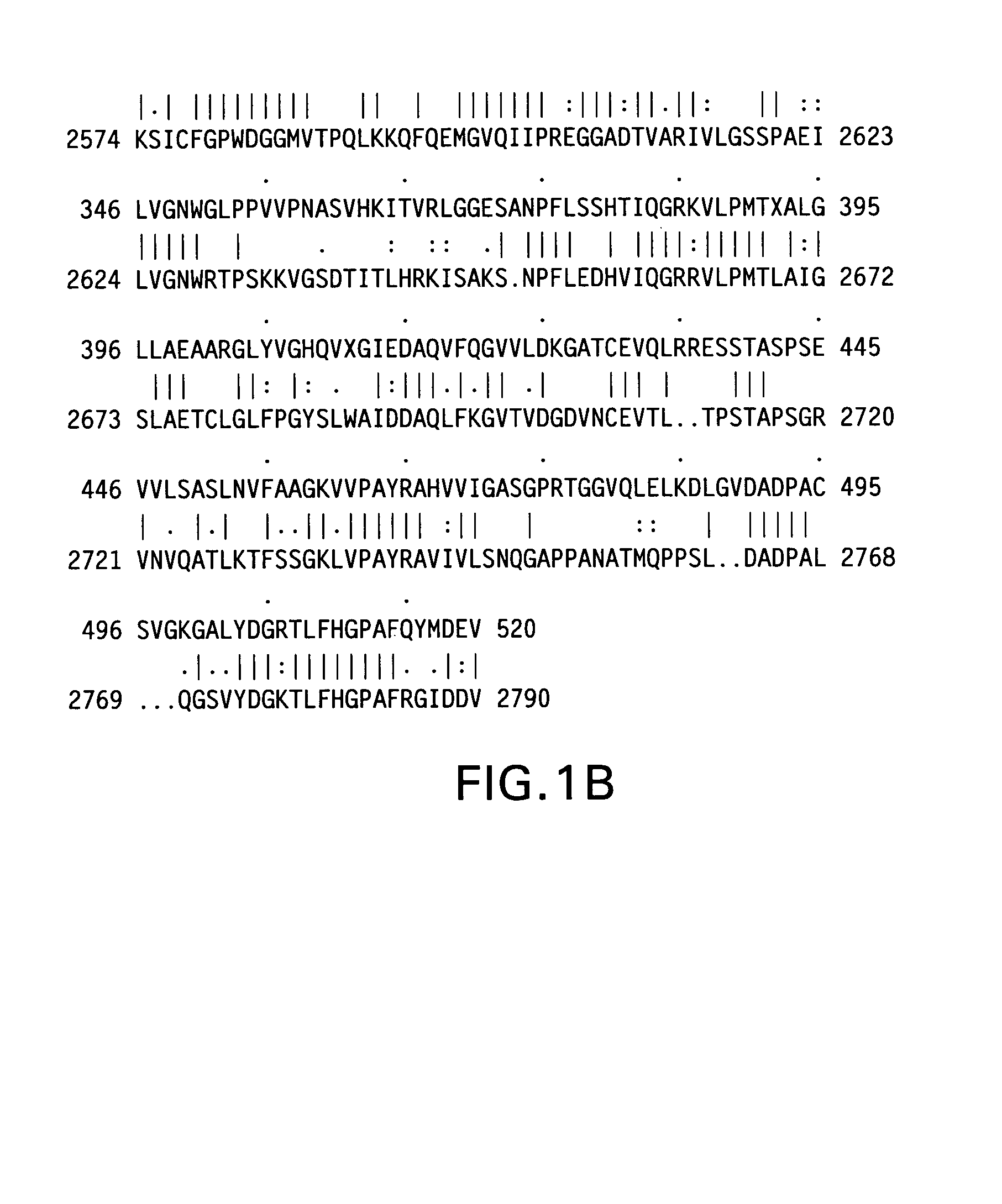

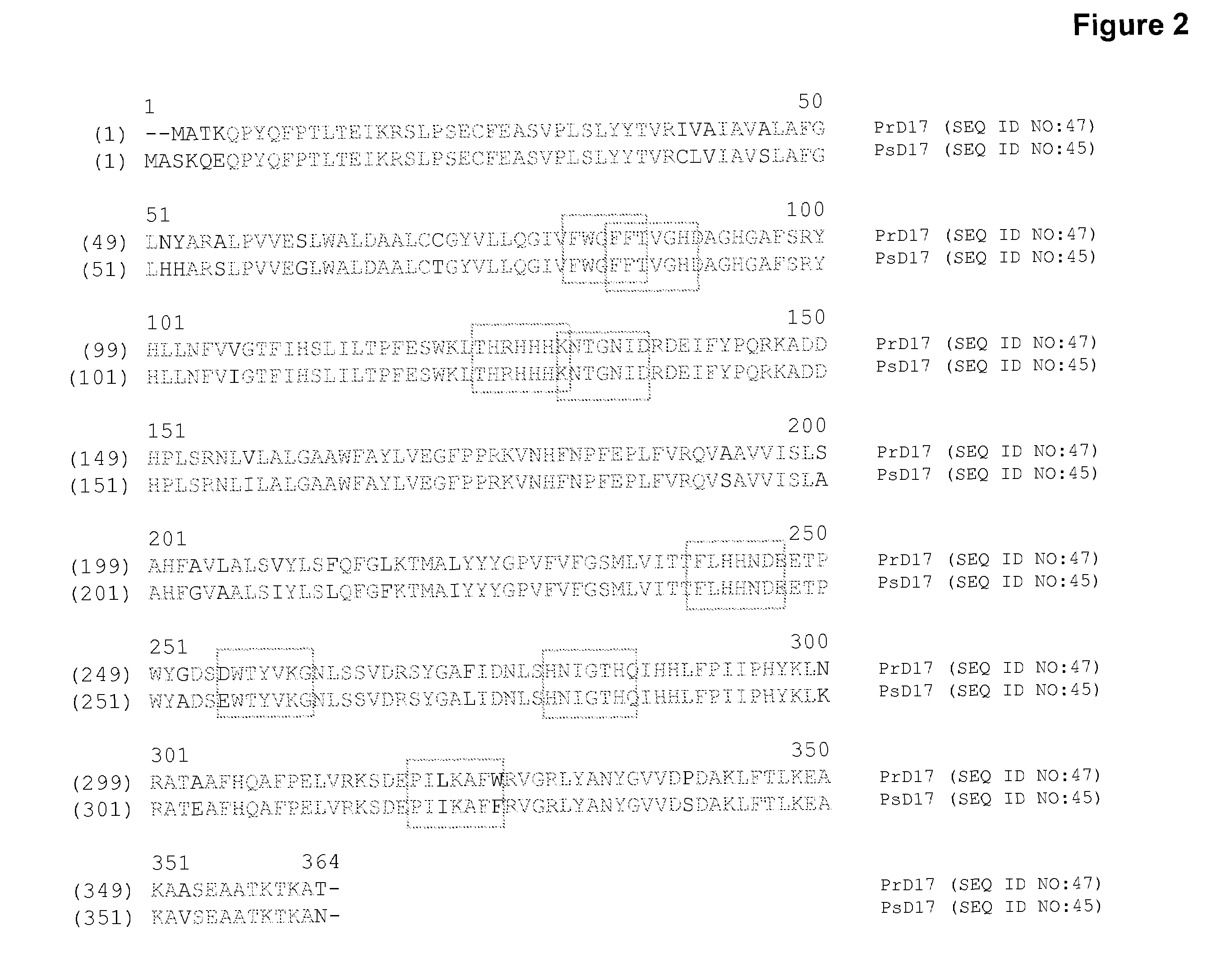

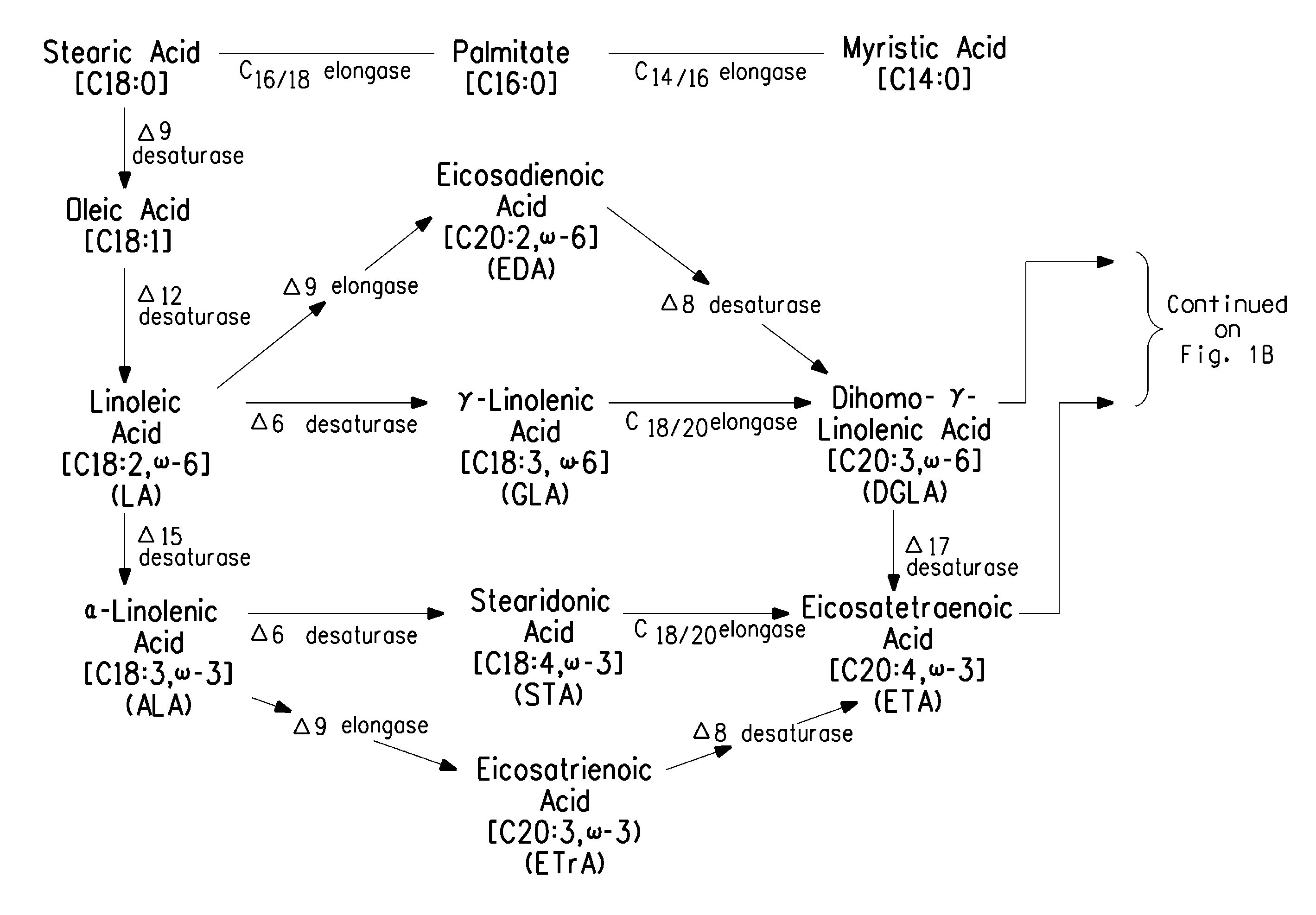

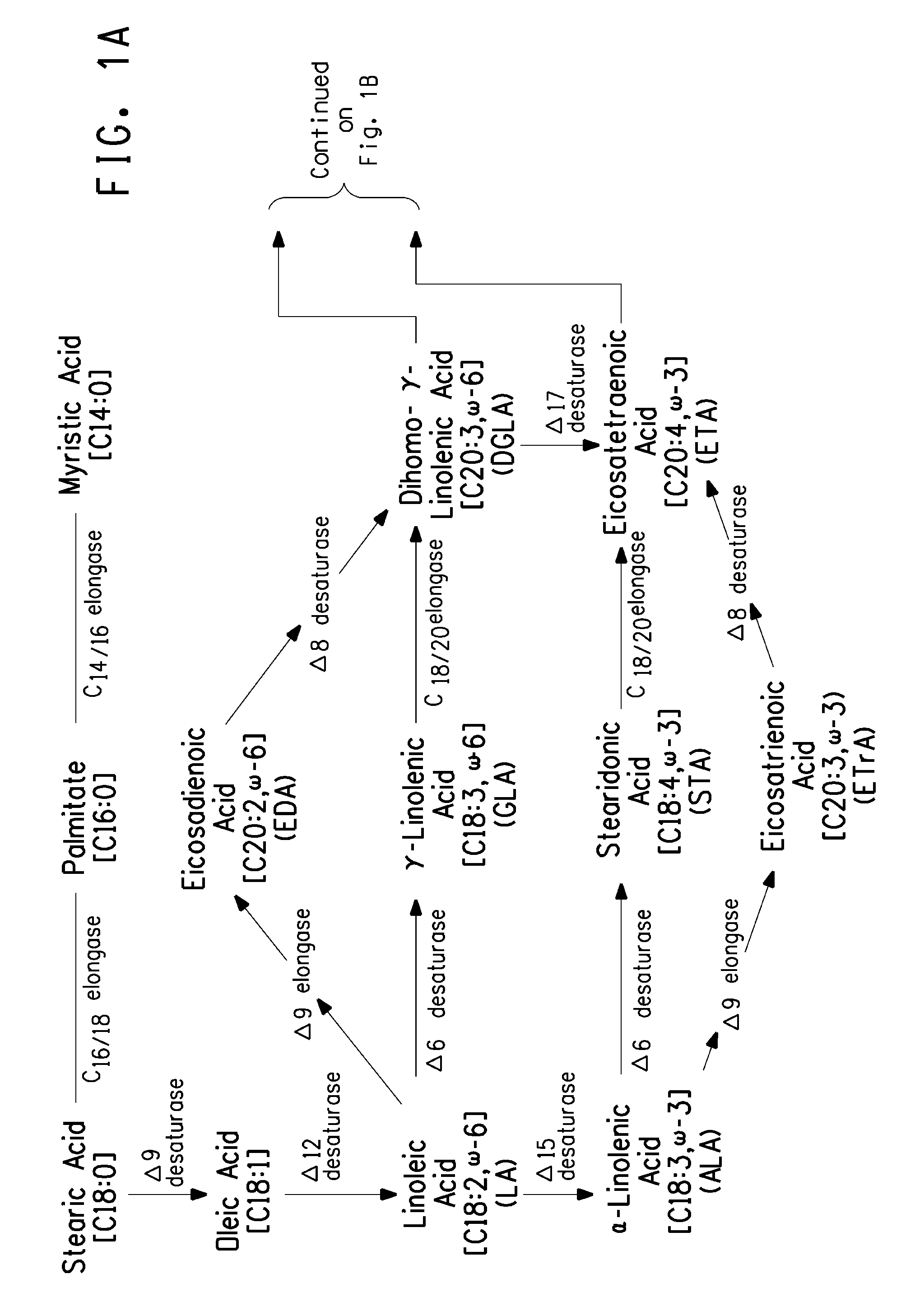

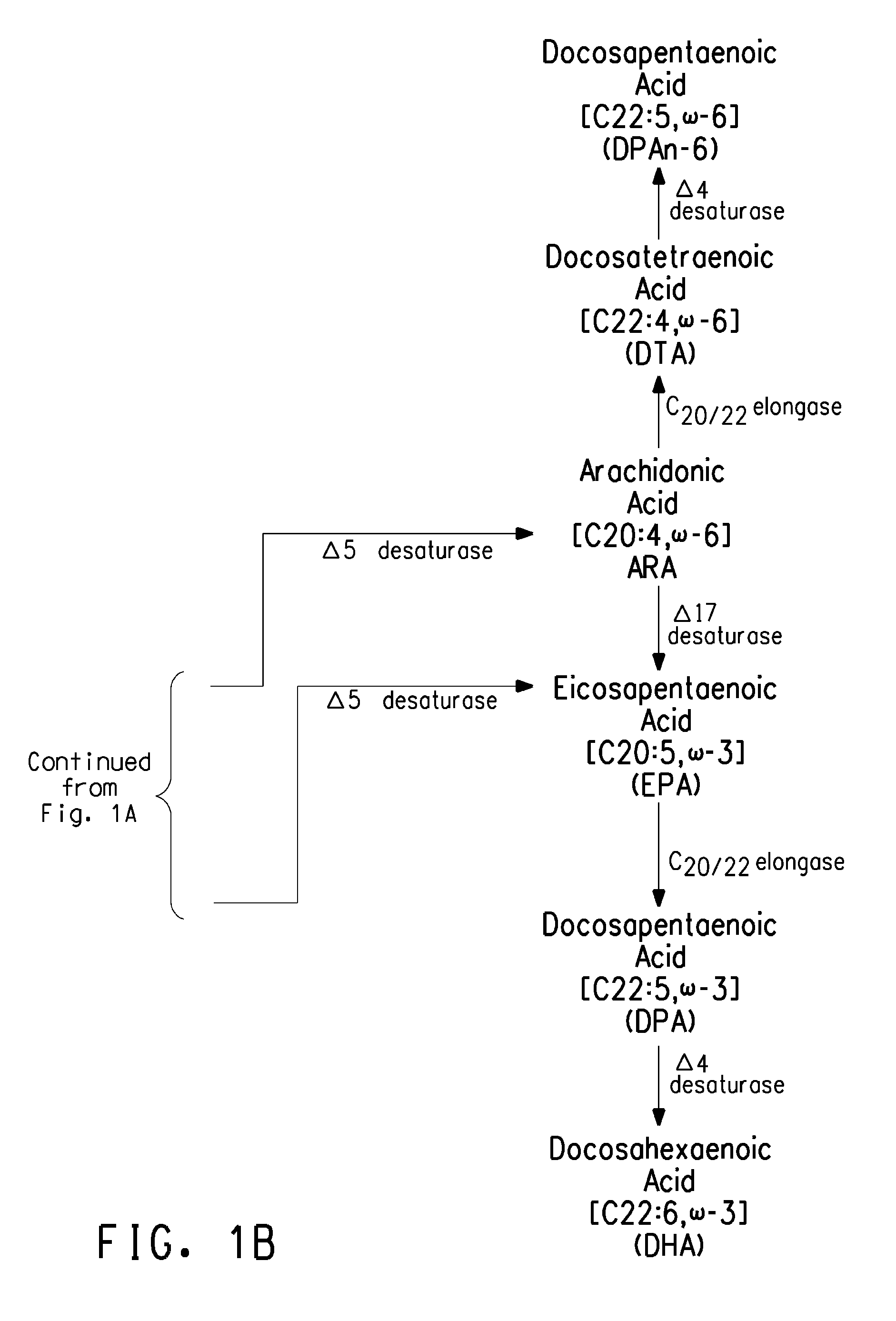

Delta17 desaturase and its use in making polyunsaturated fatty acids

The present invention relates to Δ17 desaturases, which have the ability to convert ω-6 fatty acids into their ω-3 counterparts (i.e., conversion of arachidonic acid [20:4, ARA] to eicosapentaenoic acid [20:5, EPA]). Isolated nucleic acid fragments and recombinant constructs comprising such fragments encoding Δ17 desaturases along with a method of making long-chain polyunsaturated fatty acids (PUFAs) using these Δ17 desaturases in oleaginous yeast are disclosed.

Owner:DUPONT US HLDG LLC

Clinical benefits of eicosapentaenoic acid in humans

Methods are provided for maintaining or lowering lipoprotein-associated phospholipase A2 [“Lp-PLA2”] levels, stabilizing rupture prone-atherosclerotic lesions, decreasing the Inflammatory Index and increasing Total Omega-3 Score™ in humans, by administering an effective amount of eicosapentaenoic acid [“EPA”], an omega-3 polyunsaturated fatty acid [“PUFA”].

Owner:EI DU PONT DE NEMOURS & CO

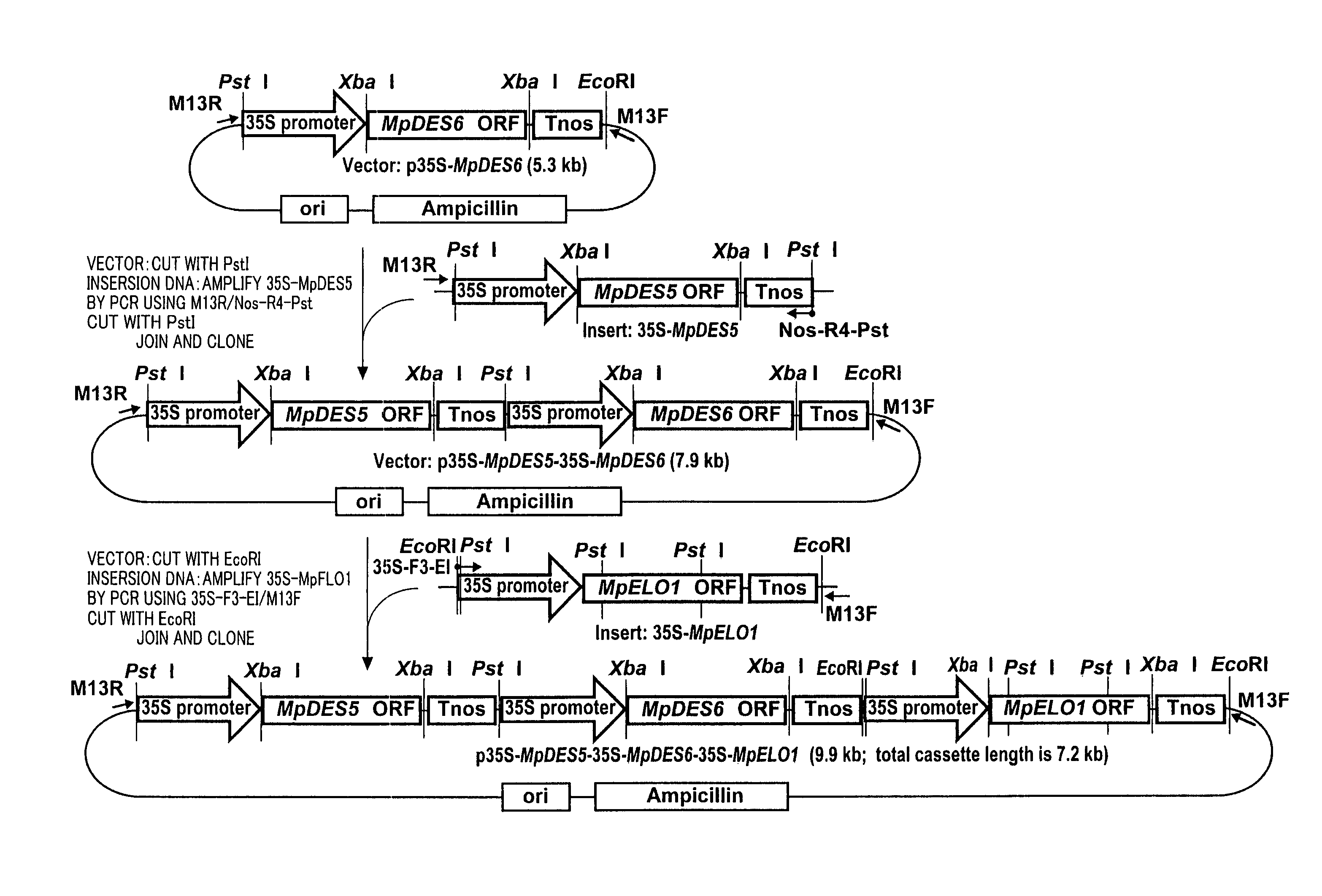

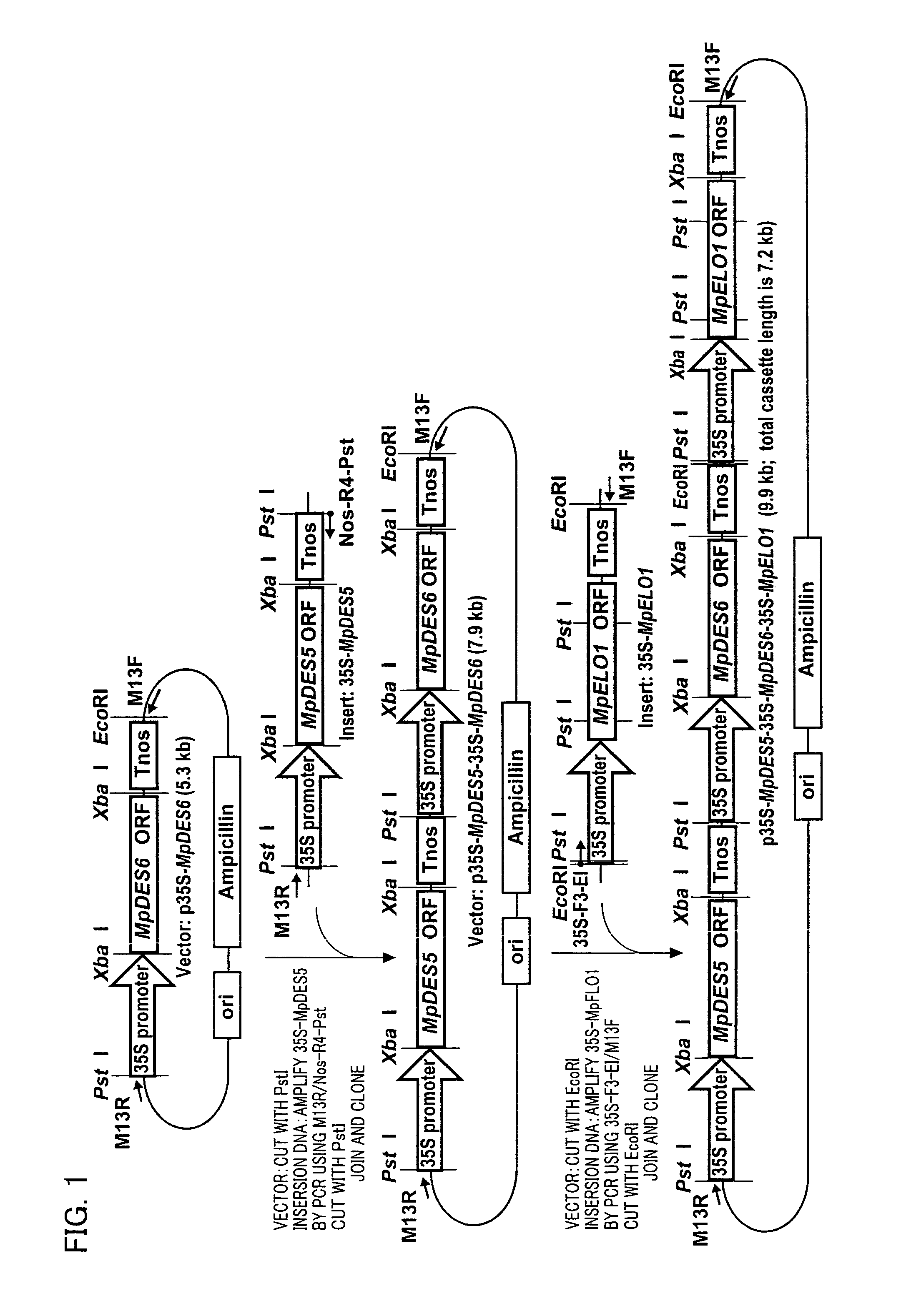

Marchantiales-Derived Unsaturated Fatty Acid Synthetase Genes And Use Of The Same

InactiveUS20080057495A1ImmunoglobulinsOxidoreductasesUnsaturated fatty acid synthesisEicosapentaenoic acid

A Δ5 fatty acid desaturase gene, a Δ6 fatty acid desaturase gene, and a Δ6 fatty-acid-chain elongase gene are isolated from a single species of Marchantiales. By introducing these genes into higher plants, transformed plants which can produce arachidonic acid and eicosapentaenoic acid (EPA) are obtained.

Owner:SUNTORY HLDG LTD

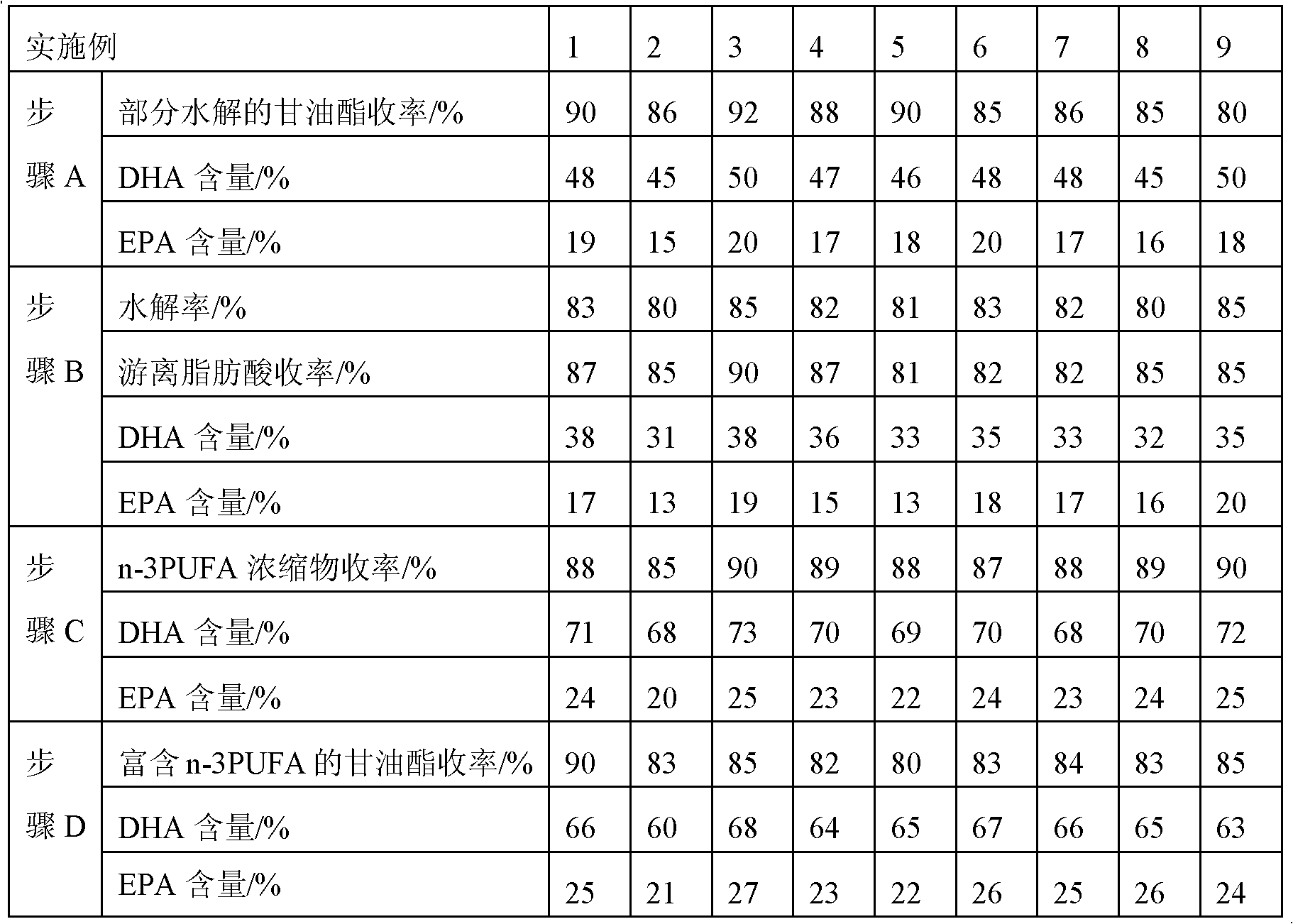

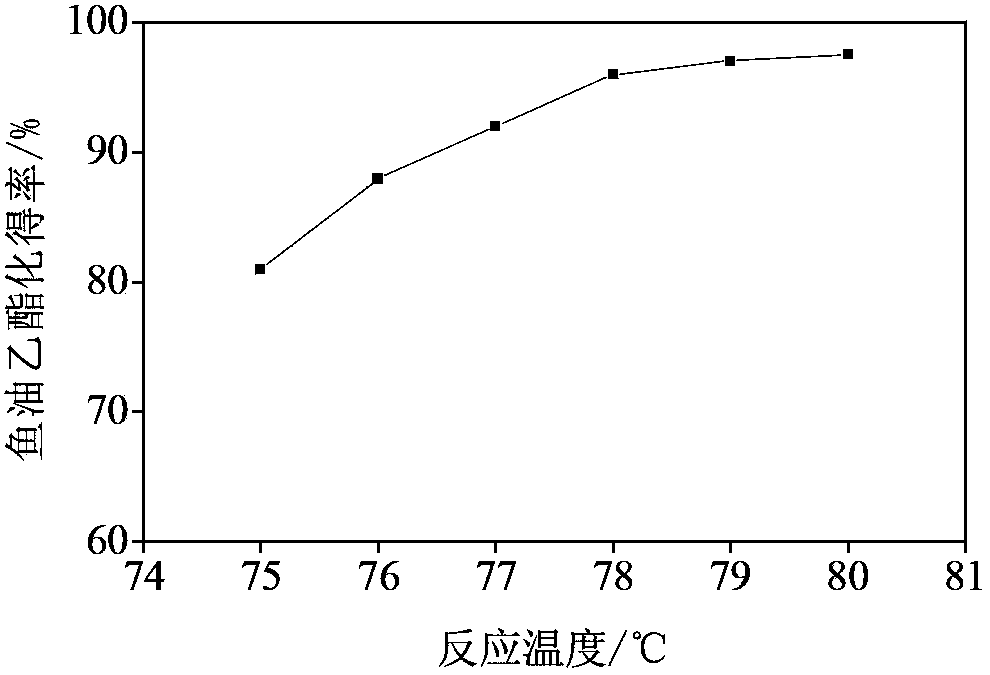

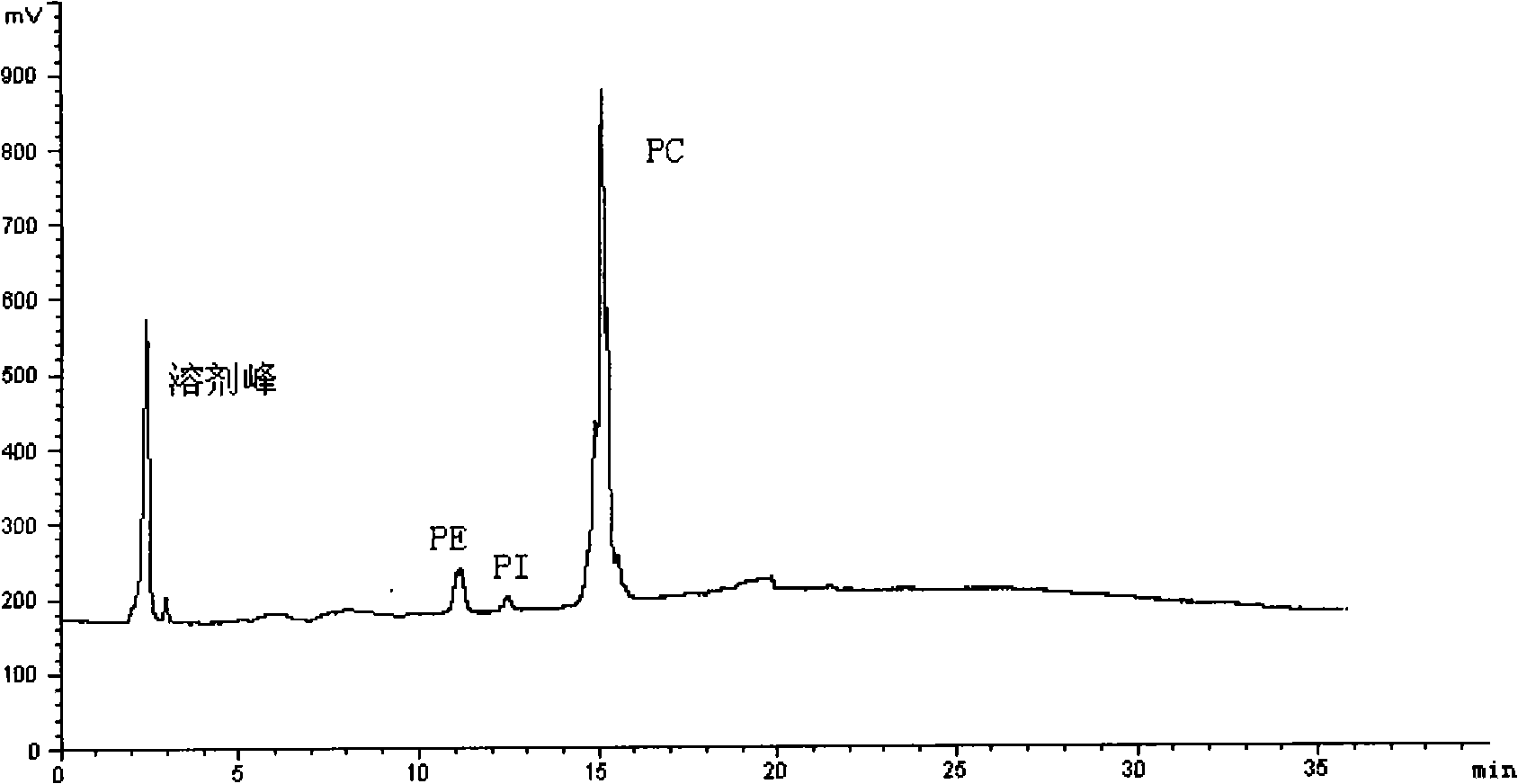

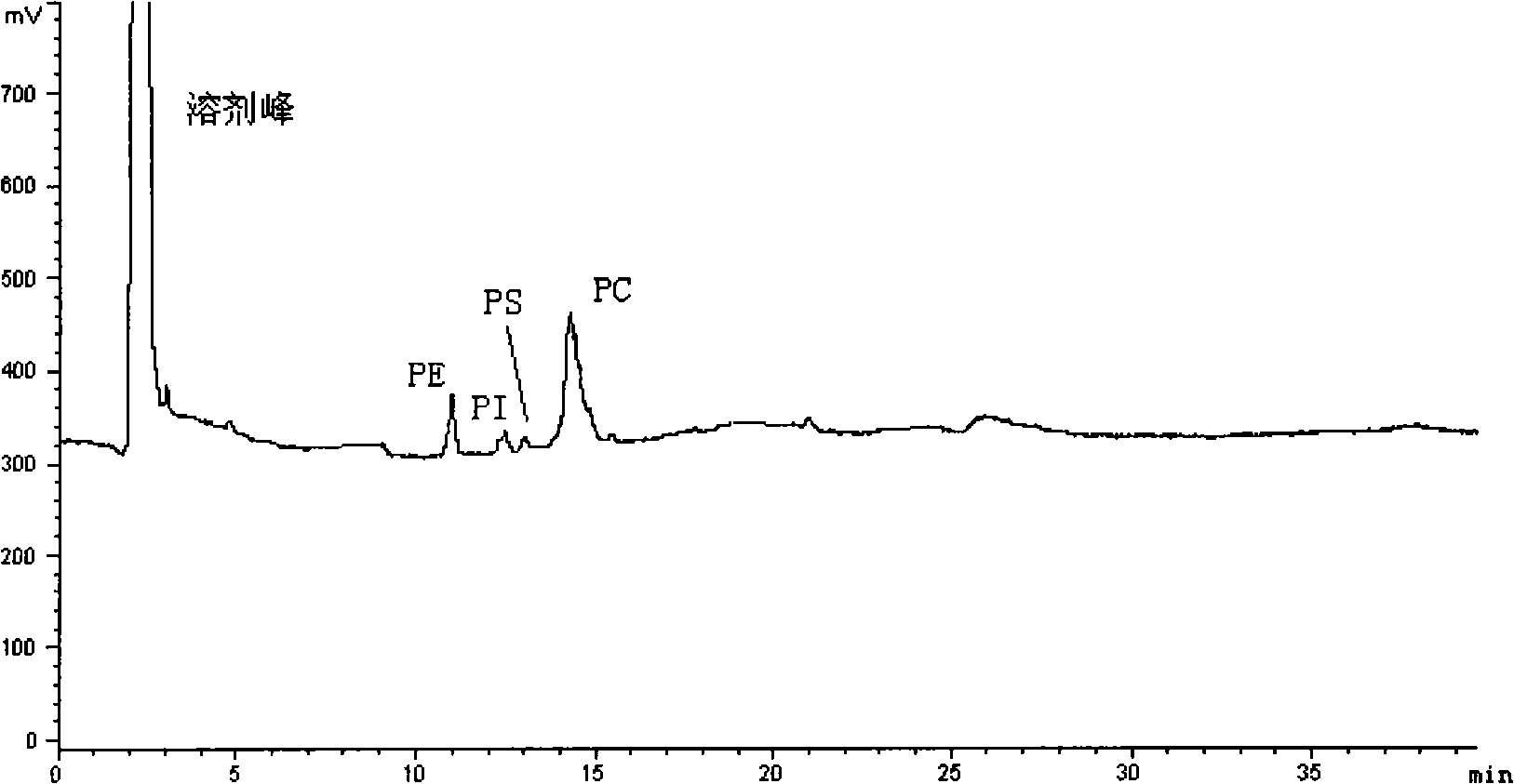

Method for enrichment of n-3 polyunsaturated fatty acid glyceride from fish oil

InactiveCN101348807AAchieve enrichmentImprove app targetingFermentationCarboxylic compound separation/purificationDocosahexaenoic acidEicosapentaenoic acid

The invention relates to a method for enriching n-3 polyunsaturated fatty acid (n-3PUFA) from fish oil, which belongs to the food organism and functional health product technical field. The method takes the fish oil as a raw material, uses the chemical hydrolysis method to hydrolyze the fish oil, respectively obtains high-purity eicosapentaenoic acid (EPA) and high-purity docosahexaenoic acid (DHA) from the hydrolyzed fish oil through separation and purification, uses glycerol and the purified EPA or DHA as raw materials and utilizes lipase to respectively catalyze and synthesize an EPA glyceride product or a DHA glyceride product in an organic phase. The products are mainly n-3PUFA triglyceride; the purity of the products is high; and the concentration of EPA triglyceride in the EPA glyceride is between 90 and 95 percent, and the concentration of DHA triglyceride in the DHA glyceride is between 92 and 94 percent. The high-purity EPA triglyceride product and the high-purity DHA triglyceride product prepared by the method well improve the application pertinence of different health care efficacies of natural fish oil products and improve the functional health care value of the fish oil products.

Owner:JIANGNAN UNIV

Oil or fat composition

ActiveUS20050129830A1Edible oils/fats with fatty acid estersAnimal feeding stuffMonoglycerideEicosapentaenoic acid

The present invention relates to an oil or fat composition containing the following components (A) and (B): (A) from 80 to 99.9 wt. % of a monoglyceride containing 20 to 75 wt. % of docosahexaenoic acid (DHA) and 0.1 to 25 wt. % of icosapentaenoic acid (IPA), as the constituent fatty acids thereof, wherein the weight ratio of DHA / IPA being 2 or more; and (B) from 0.1 to 20 wt. % of a diglyceride.

Owner:KAO CORP

Method for extracting phospholipid-enriched krill oil from Antarctic krill

InactiveCN102071101ARich sourcesSafe storageFatty-oils/fats productionDocosahexaenoic acidPhospholipid

The invention discloses a method for extracting phospholipid-enriched krill oil from Antarctic krill. The method comprises the following steps: using Antarctic krill as the raw material and using the autologous protease to decompose the Antarctic krill and release lipids, quickly heating to inactivate the enzymes in the krill, drying at low temperature, and extracting krill oil with rich eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) phospholipids at low temperature by using low carbon alcohol as the solvent. The method disclosed by the invention is simple to operate, has the advantages of clear process and high input-output ratio; and compared with other organic solvents, ethanol or isopropanol is safer for storage, transportation and use, has abundant sources, and has obvious advantages of being used as the solvent for extracting oil of krill type crustacean.

Owner:SHANDONG KERUIER BIOLOGICAL PRODS

Dietary supplement system for multifunctional anti-aging management and method of use

A dietary supplement system includes a dietary supplement composition for oral administration by an individual in the morning, the composition, including (a) a telomere maintenance complex including: Purslane extract (aerial parts); Turmeric rhizome extract (95% curcuminoids); Quercetin dehydrate, Cayenne pepper fruit; Vanadium (as vanadyl sulfate); Fenugreek seed; Astragalus root extract, Omega fatty acid complex including linoleic acid; alpha-linolenic acid; oleic acid borage seed oil gamma-linolenic acid), evening primrose oil fish body oil (eicosapentaenoic acid; docosahexaenoic acid); (b) a calorie restriction mimetics and gene expression complex including Trans-resveratrol (from Polygonum cuspidatum root extract); Pterostilbene Fisetin 50% (Buxus microphlla Sieb (stem and leaf; Alpha lipoic acid, Coenzyme Q-10, Betaine HCl, Sulfur (from methylsulfonylmethane); L-Carnitine tartrate; L-Carnitine HCl, and (c) a free radical scavenger complex, including Green tea leaf extract catechin and polyphenols); Anthocyanins (from bilberry fruit and grape skin extracts).

Owner:LIFE SCI INT

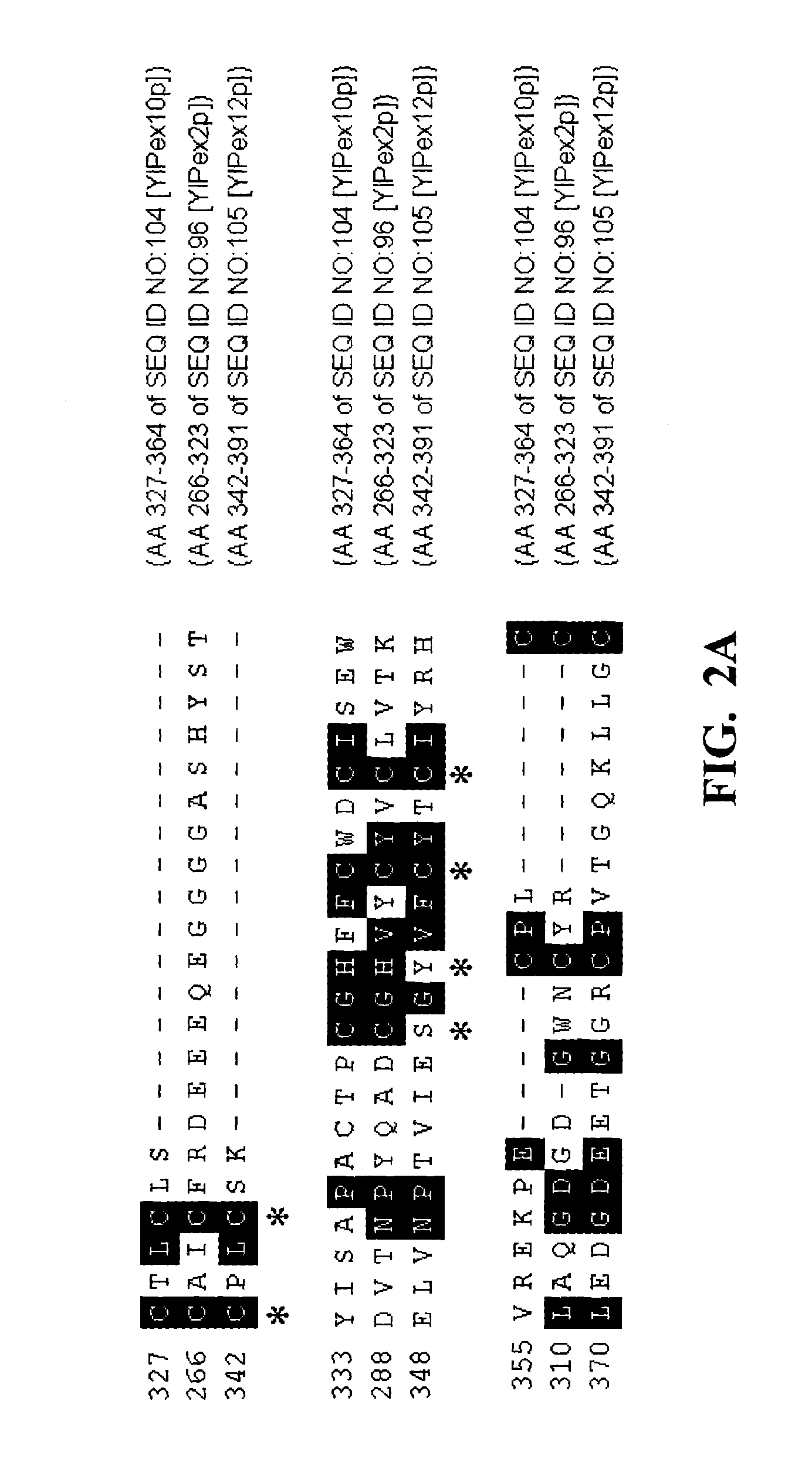

Mutant delta-5 desaturases and their use in making polyunsaturated fatty acids

The present invention relates to mutant Δ5 desaturases, which have the ability to convert dihomo-γ-linolenic acid [DGLA; 20:3 ω-6] to arachidonic acid [ARA; 20:4 ω-6] and / or eicosatetraenoic acid [ETA; 20:4 ω-3] to eicosapentaenoic acid [EPA; 20:5 ω-3] and which possess at least one mutation within the HPGG motif of the cytochrome b5-like domain. Isolated nucleic acid fragments and recombinant constructs comprising such fragments encoding Δ5 desaturases, along with a method of making long chain polyunsaturated fatty acids [“PUFAs”] using these mutant Δ5 desaturases in oleaginous yeast, are disclosed.

Owner:DUPONT US HLDG LLC

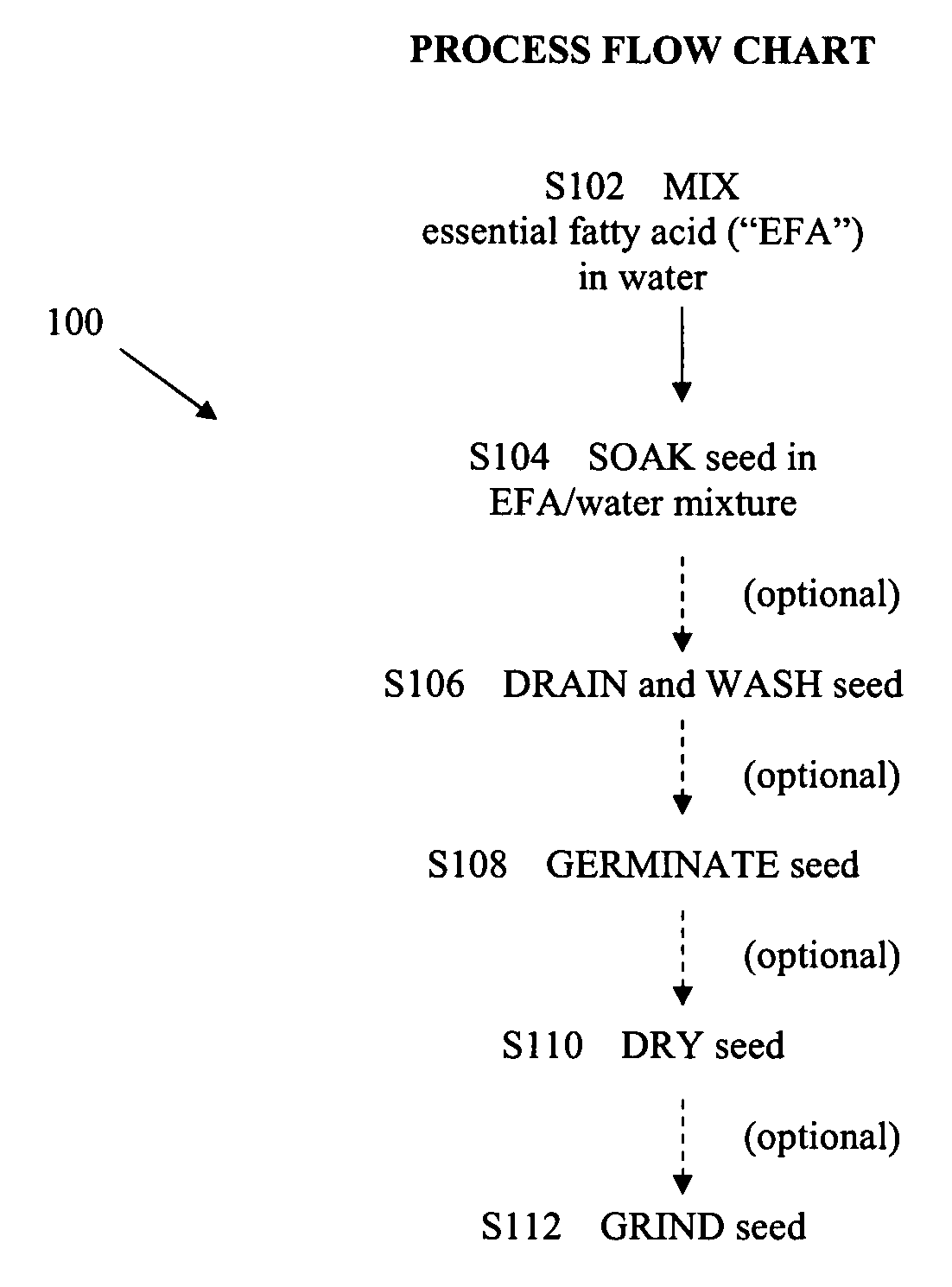

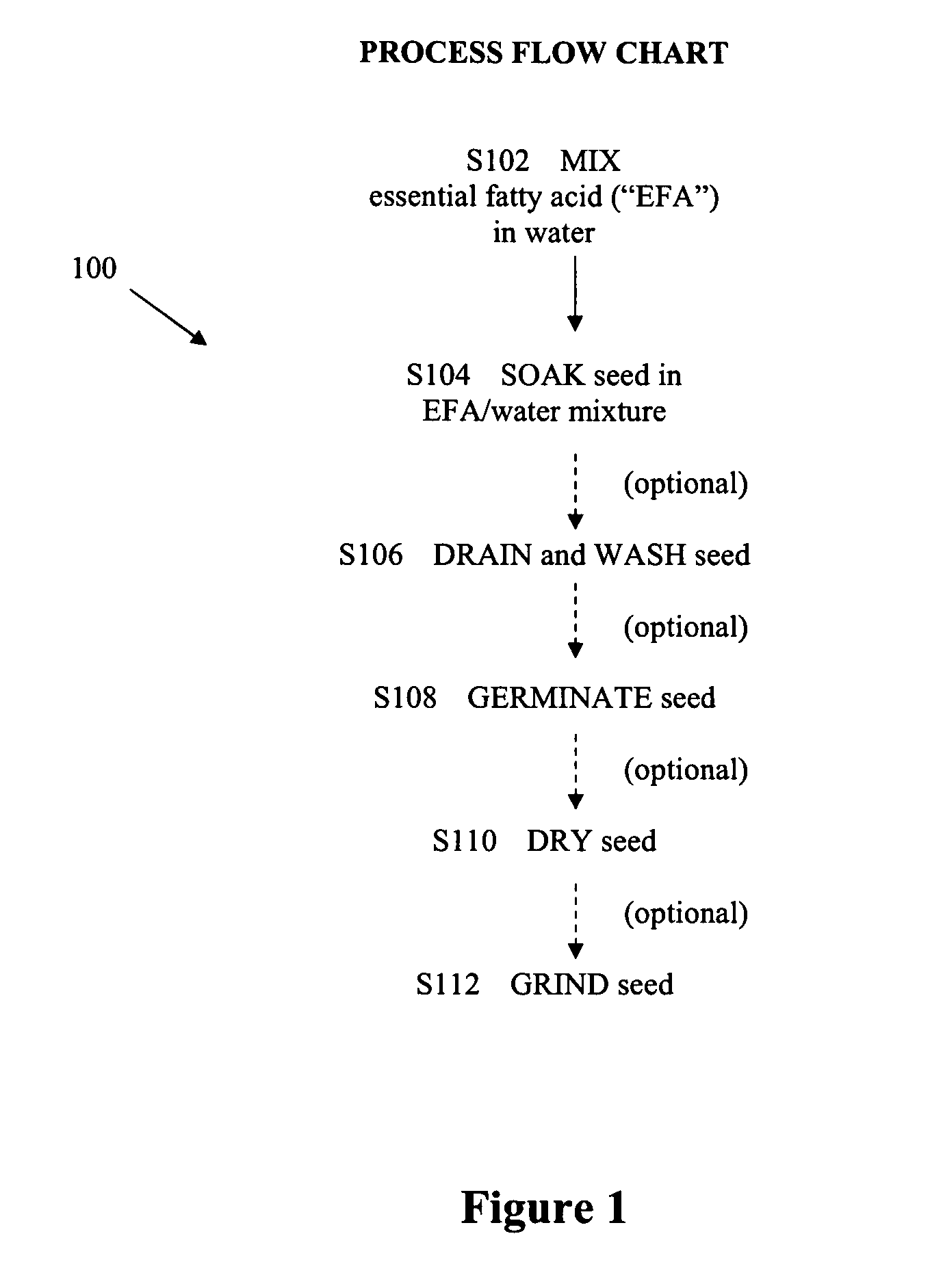

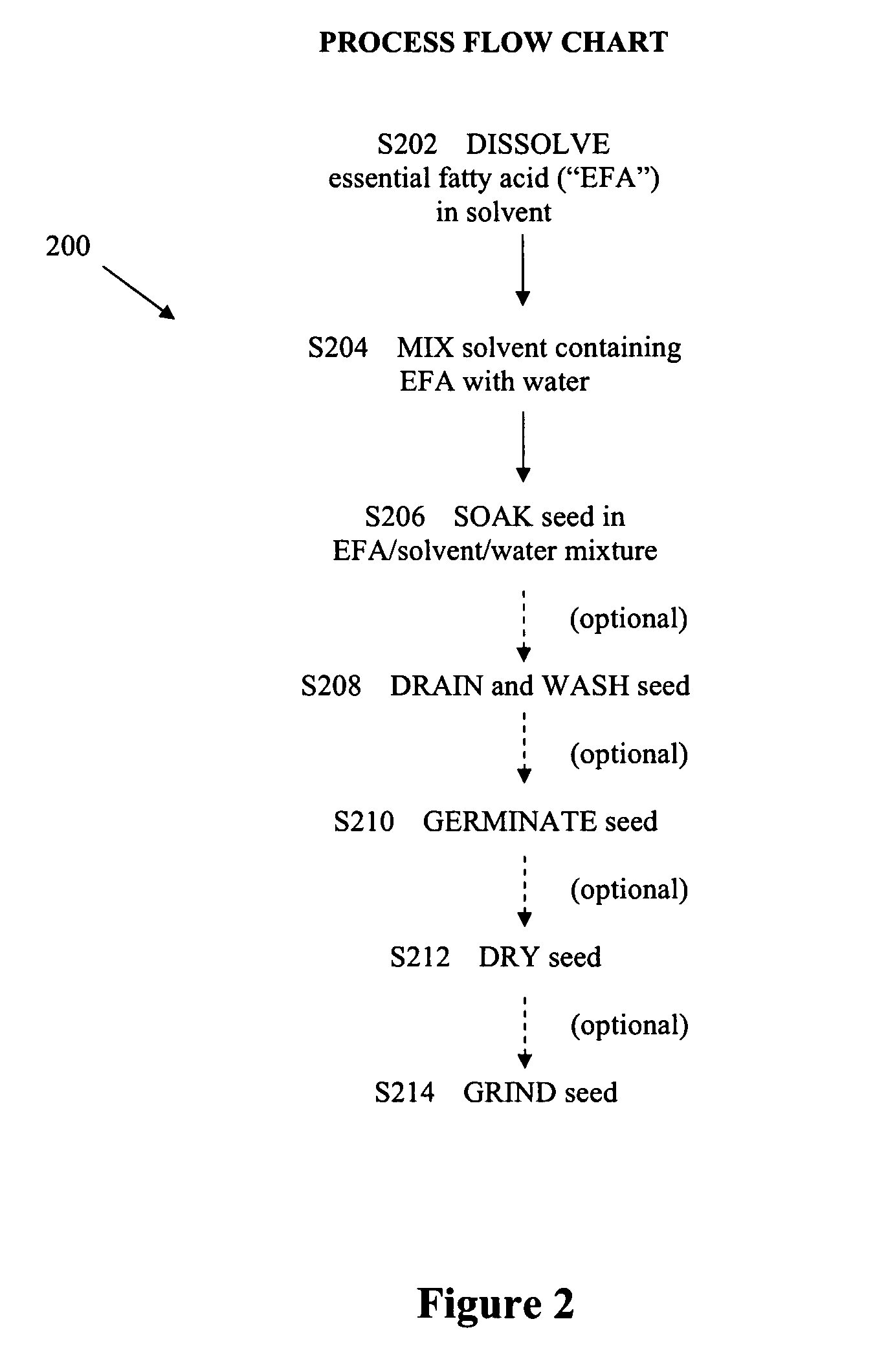

Method of fortifying seeds with an essential fatty acid, fortified seed and food product

Owner:SHARP INGRAINED FUNCTIONAL FOODS

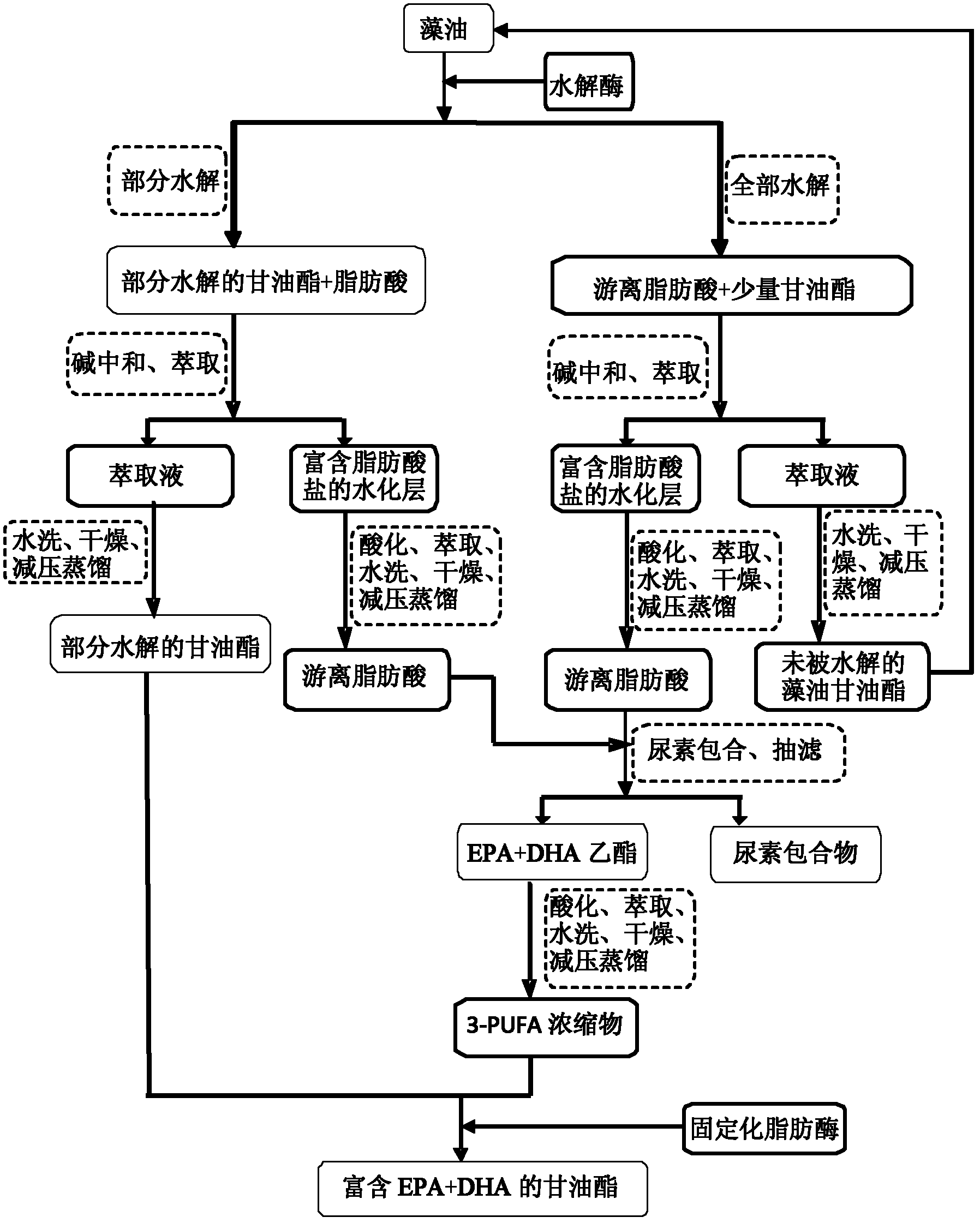

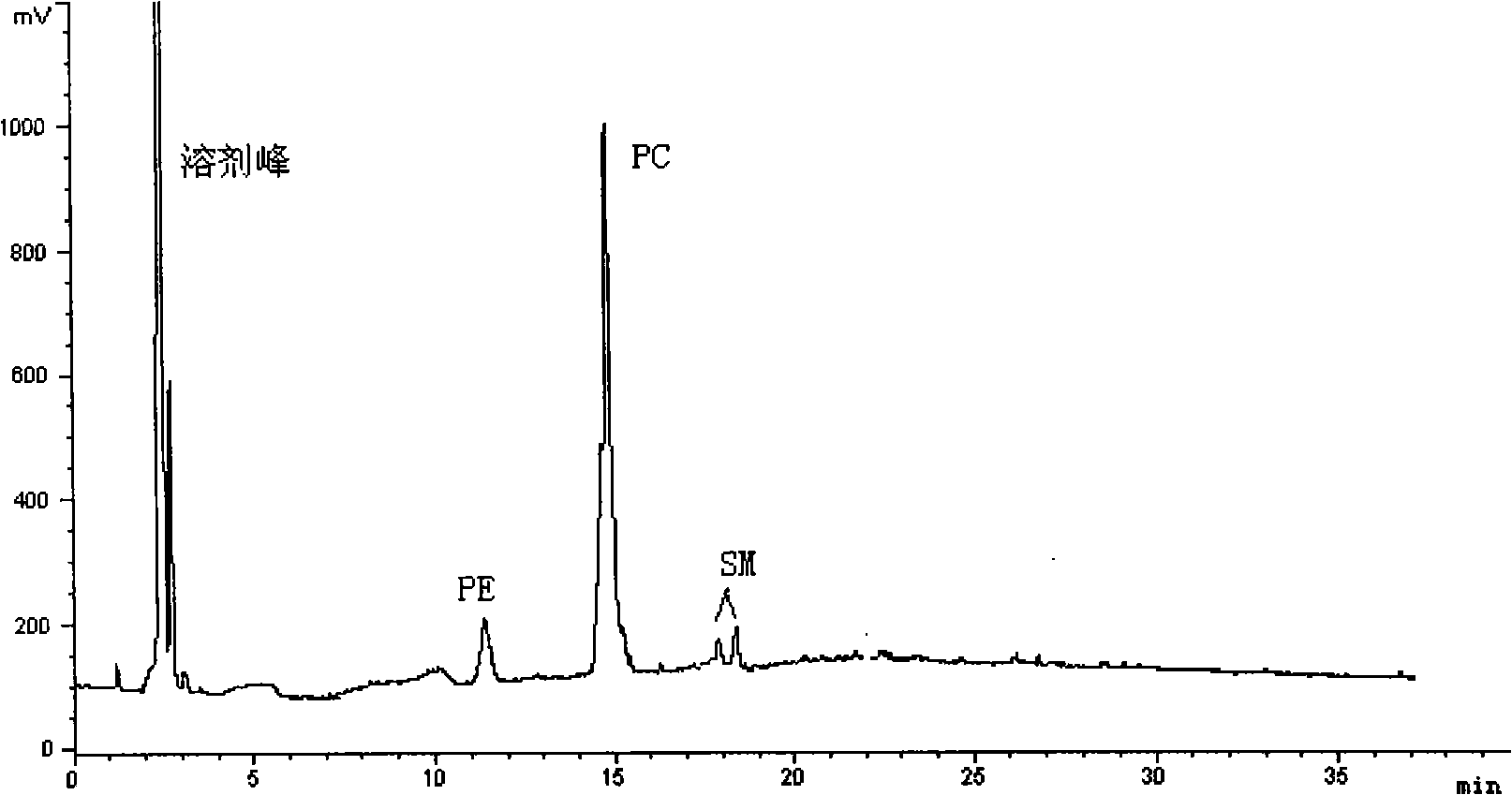

Method for preparing glyceride rich in algal oil n-3 polyunsaturated fatty acid through enzyme process

ActiveCN102660593APromote digestionPromote absorptionChemical recyclingFermentationDocosahexaenoic acidHydrolysis

The invention relates to a method for preparing glyceride rich in algal oil n-3 polyunsaturated fatty acid through the enzyme process. The method comprises the following steps: taking microbial algal oil as raw material, carrying out hydrolysis of part or all of algal oil respectively through controlling the hydrolysis rate under the catalysis of lipases to obtain glyceride partially hydrolyzed and free fatty acid; enabling the free fatty acid to enrich n-3 polyunsaturated fatty acid eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) through the urea adduct method to obtain an n-3 polyunsaturated fatty acid condensate; and taking the n-3 polyunsaturated fatty acid condensate and glyceride partially hydrolyzed as substrates, taking immobilized lipases as catalysts, and efficiently synthetizing glyceride rich in algal oil n-3 polyunsaturated fatty acid in an organic phase. The invention adopts a complete biological enzymatic enrichment process, the raw material is clean and safe, the process route is scientific and reasonable, the catalytic activity of enzyme is high, the catalyst can be recycled, the cost is low, the reaction condition is mild, the energy consumption is low, the environment is friendly, and the market prospect is wide.

Owner:BEIJING UNIV OF CHEM TECH

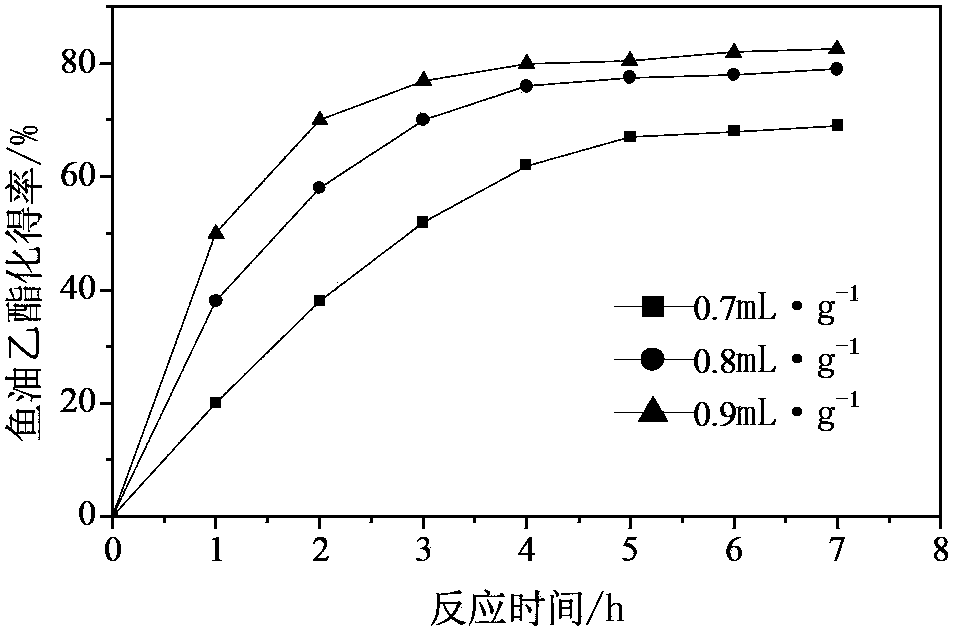

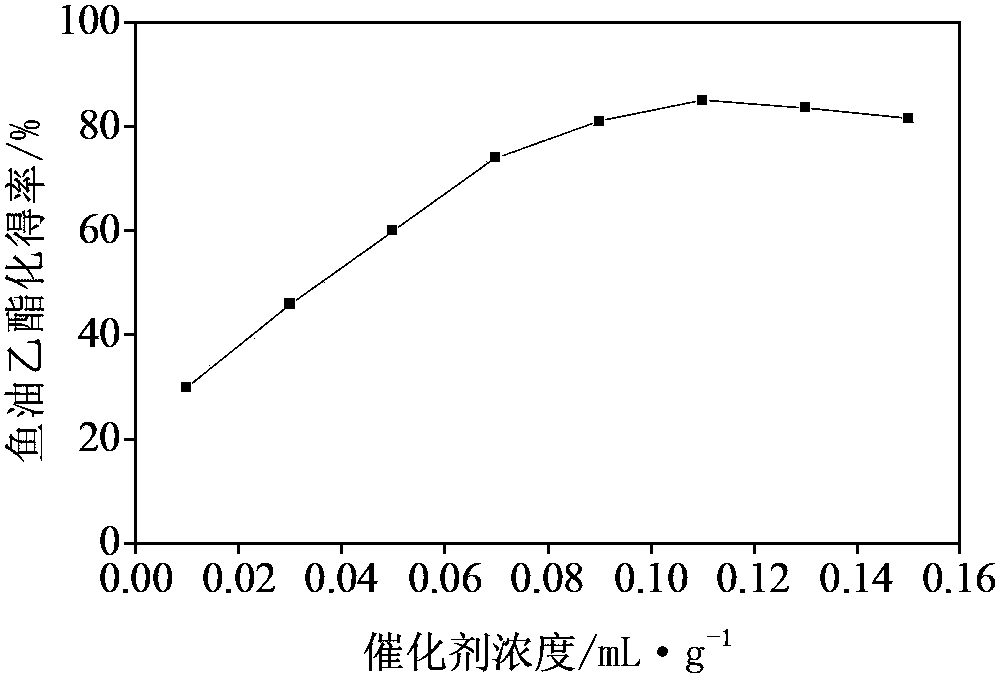

Method for extracting ethyl ester enriched fish oil from fish oil refining byproduct

ActiveCN103509651ASolving Recycling ProblemsIncrease contentFatty oils/acids recovery from wasteFatty acid chemical modificationDocosahexaenoic acidDistillation

The invention relates to a method for extracting ethyl ester enriched fish oil from a fish oil refining byproduct, which comprises the following steps: by taking soapstock and solid lipid of the fish oil refining byproduct as raw materials, recovering the soapstock through an acid-based ethyl ester catalysis process, recovering the solid lipid through an alkali-based ethyl ester catalysis process, performing a secondary three-stage molecular distillation and primary urea inclusion combined process, and enriching to obtain the ethyl ester fish oil having high EPA (eicosapentaenoic acid) and DHA (docosahexaenoic acid) content. According to the invention, the process is simple and low in cost, solves the byproduct recovery problem during fish oil refining, avoids environmental pollution, changes the wastes into valuable substances, and greatly increases the value of the product; and the physical and chemical indices of the extracted ethyl ester fish oil product conform to the standard, the fish oil has no rancid flavor, the total content of EPA and DHA is respectively increased to 78.42% and 76.15%, and the fish oil achieves better economic benefits.

Owner:舟山新诺佳生物工程有限责任公司

Methods and compositions to promote ocular health

Embodiments include a composition to promote ocular health and a method of treatment for a subject exposed to a source of oxidative or visual stress to the eye or having a degradation of the eye. The composition may include amounts of vitamin A, which includes beta-carotene; vitamin C; vitamin D; vitamin E; zinc; copper; selenium; non-vitamin A carotenoids, which include lutein and zeaxanthin; omega-3 fatty acids, which include eicosapentaenoic acid and docosahexaenoic acid; taurine; alpha lipoic acid; pine bark extract; astaxanthin; and Piper spp. extract. The method includes the step of administering to the subject a daily dose of a composition to promote ocular health.

Owner:WOOLDRIDGE CONSTR CO

Novel health care oil

InactiveCN102232429AIncrease intakeDoes not accelerate hardeningEdible oils/fatsBiotechnologyDocosahexaenoic acid

The invention provides novel health care oil and belongs to edible oil. The health care oil is formed by mixing fish oil with vegetable oil, the using quantity of the fish oil is 3-60% of the weight of the vegetable oil, and the vegetable oil is one or more of soybean oil, peanut oil, corn germ oil, sunflower seed oil, olive oil, sesame oil, cottonseed oil and the like. As for the health care oil, the fish oil and the vegetable oil are mixed together, the fish oil is added into food during the cooking process, the uptake of the fish oil can be conveniently realized, the health care oil can be easily accepted by old people and children, and the problem of forgetting to eat can be simultaneously avoided. For the children, docosahexaenoic acid (DHA) and eicosapentaenoic acid (EPA) contained in the fish oil are polyunsaturated fatty acids, thereby improving the brain capacity and enhancing the memory and understanding facility. For the old people, by adopting the novel health care oil, arteriosclerosis can be slowed down, hypercholesterolemia, plasma cholesterol and triglycerides can be reduced, and the concentration of plasma lipoprotein, the blood viscosity and the blood pressure can be reduced.

Owner:张瑞新

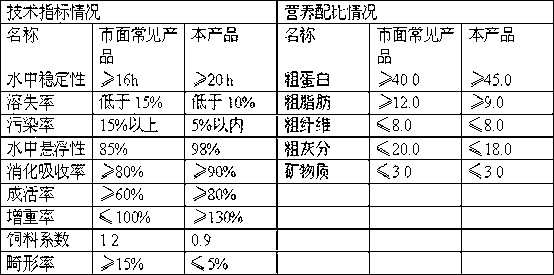

Perfect compound feed for groupers

ActiveCN103005183APromote digestion and absorptionImprove immunityAnimal feeding stuffDocosahexaenoic acidFish oil

The invention discloses a perfect compound feed for groupers, which is a compound feed suitable for the culture of grouper large-size fish seeds. The perfect compound feed is prepared by adopting imported fish meal, fermented soybean meal, alpha-starch, flour, squid meal, krill meal, yeast extracts, fairy shrimps, fish oil, soybean phospholipids, DHA (Docosahexaenoic Acid), EPA (Eicosapentaenoic Acid), composite mineral salt, compound vitamins, compound enzyme preparations, compound immunopotentiators, hepatinica and compound microecologic preparations as raw materials. The perfect compound feed disclosed by the invention can promote the digestion and absorption of the groupers, regulate the stability of the intestinal flora of the groupers, enhance the immunity of the groupers and play a lipotropic role by sufficiently considering the digestion and physiology characteristics of the culture period of the groupers and adding various additives to the feed, has the advantages of balanced and complete nutrition without drugs, namely added antibiotics and the like, and no pollution on water bodies and belongs to a high-efficiency environment-friendly nuisanceless feed.

Owner:广东越群海洋生物科技股份有限公司

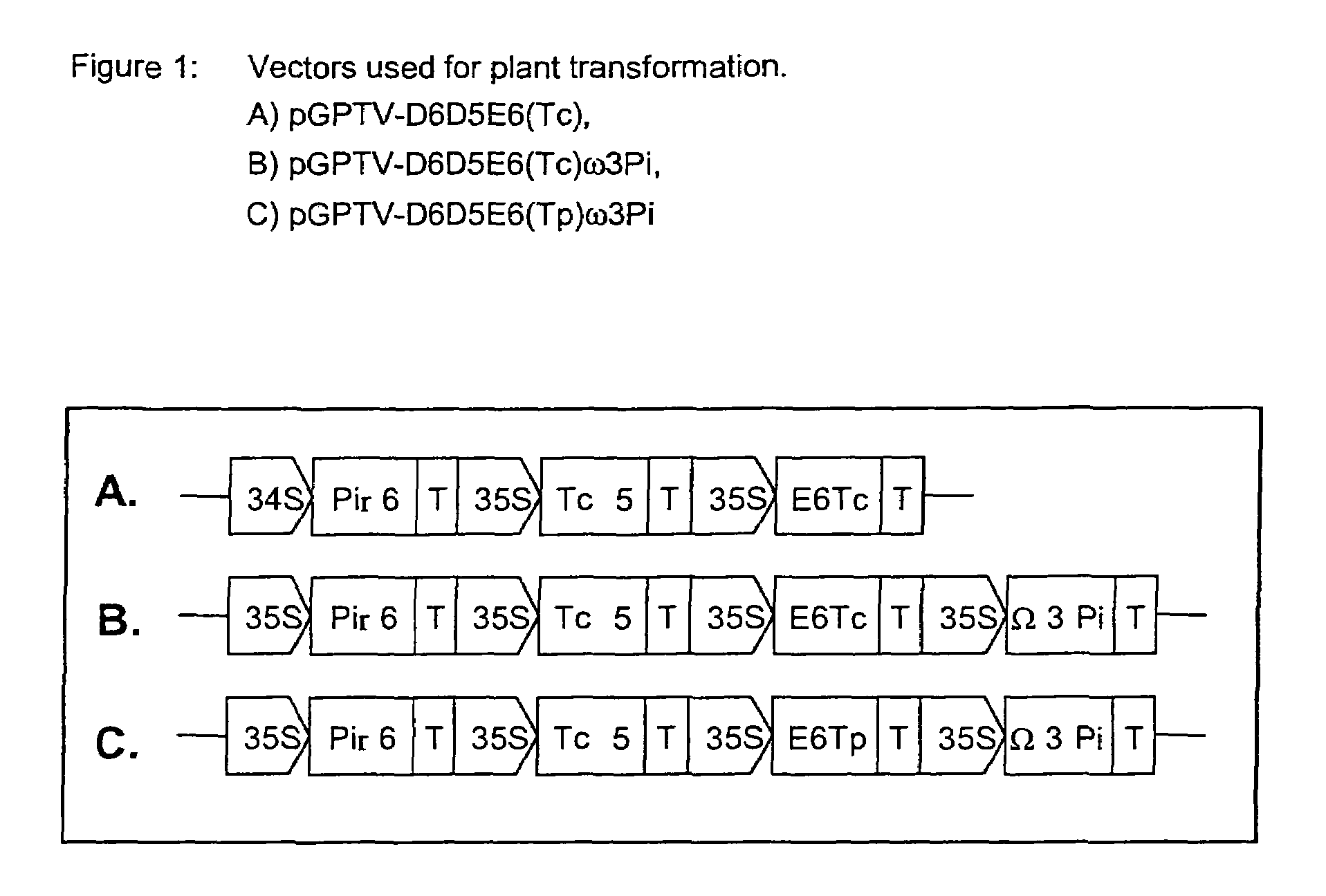

Method for producing arachidonic acid and/or eicosapentaenoic acid in useful transgenic plants

InactiveUS8134046B2Simple and inexpensive and economicalHigh nutritional valueCosmetic preparationsBiocideBiotechnologyTransgene

The present invention relates to a process for producing arachidonic acid and / or eicosapentaenoic acid in transgenic useful plants by introducing into the plant nucleic acids coding for polypeptides having Δ6-desaturase, Δ6-elongase or Δ5-desaturase activity. Furthermore, a gene coding for an ω3-desaturase is advantageously expressed in said useful plants. In another advantageous embodiment of the process, further nucleic acid sequences coding for polypeptides of fatty acid or lipid metabolism biosynthesis may be expressed in the plants. Particularly advantageous nucleic acid sequences here are those coding for a Δ8-desaturase, Δ12-desaturase, Δ15-desaturase, Δ4-desaturase, Δ9-elongase and / or Δ5-elongase activity.The invention further relates to the use of the oils, lipids and / or fatty acids produced in the process according to the invention in feedstuffs or foodstuffs, cosmetics or pharmaceuticals.

Owner:BASF PLANT SCI GMBH

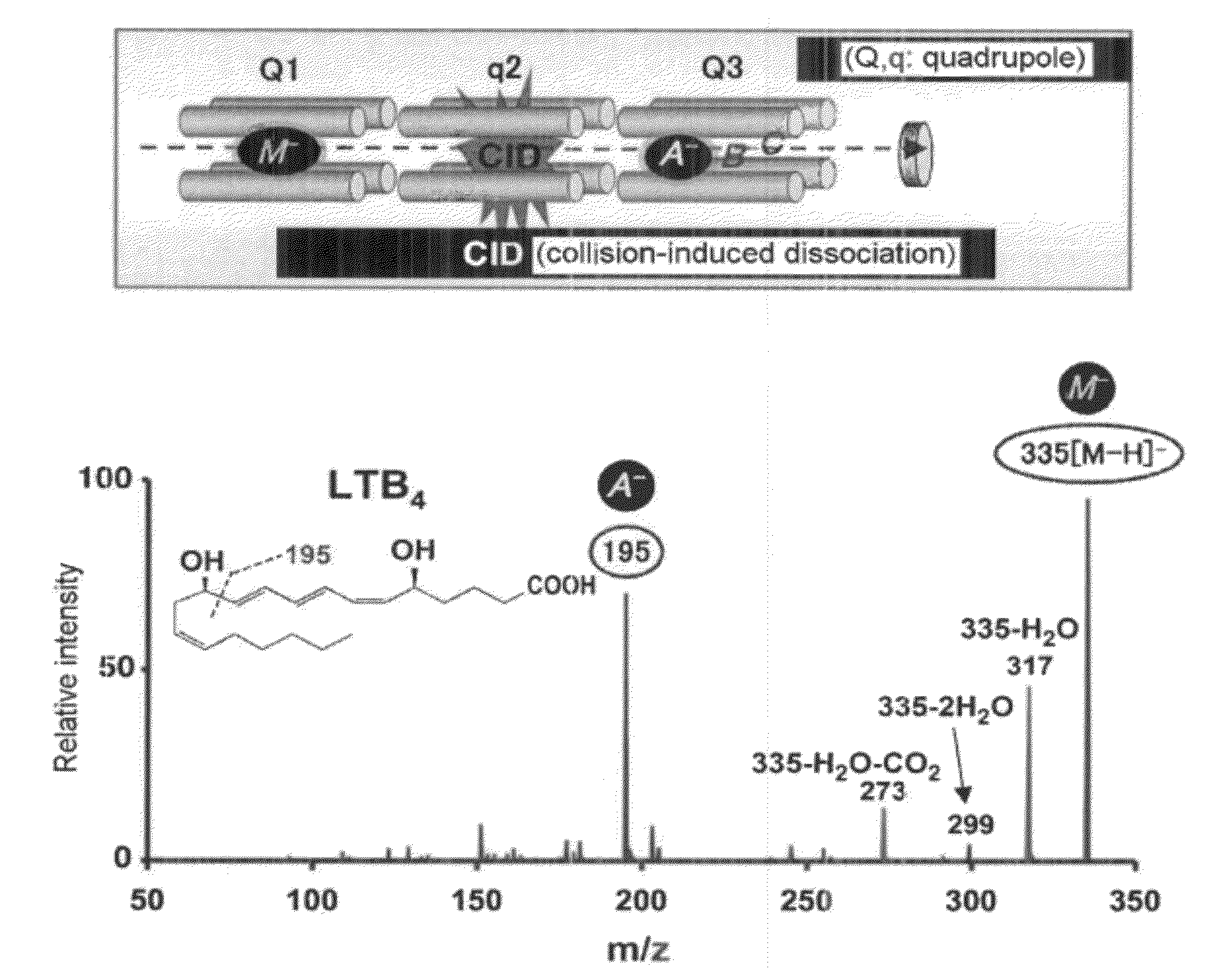

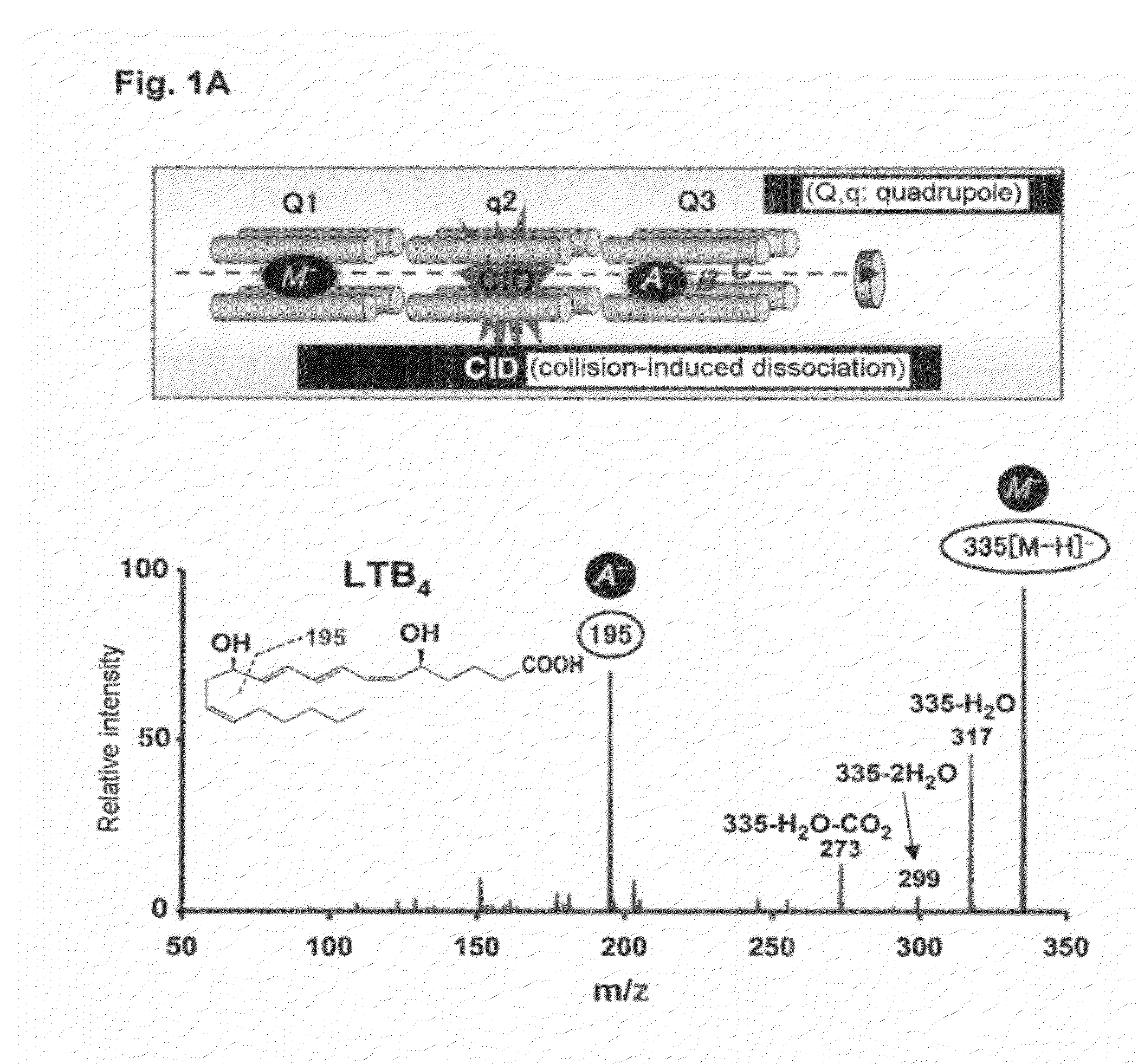

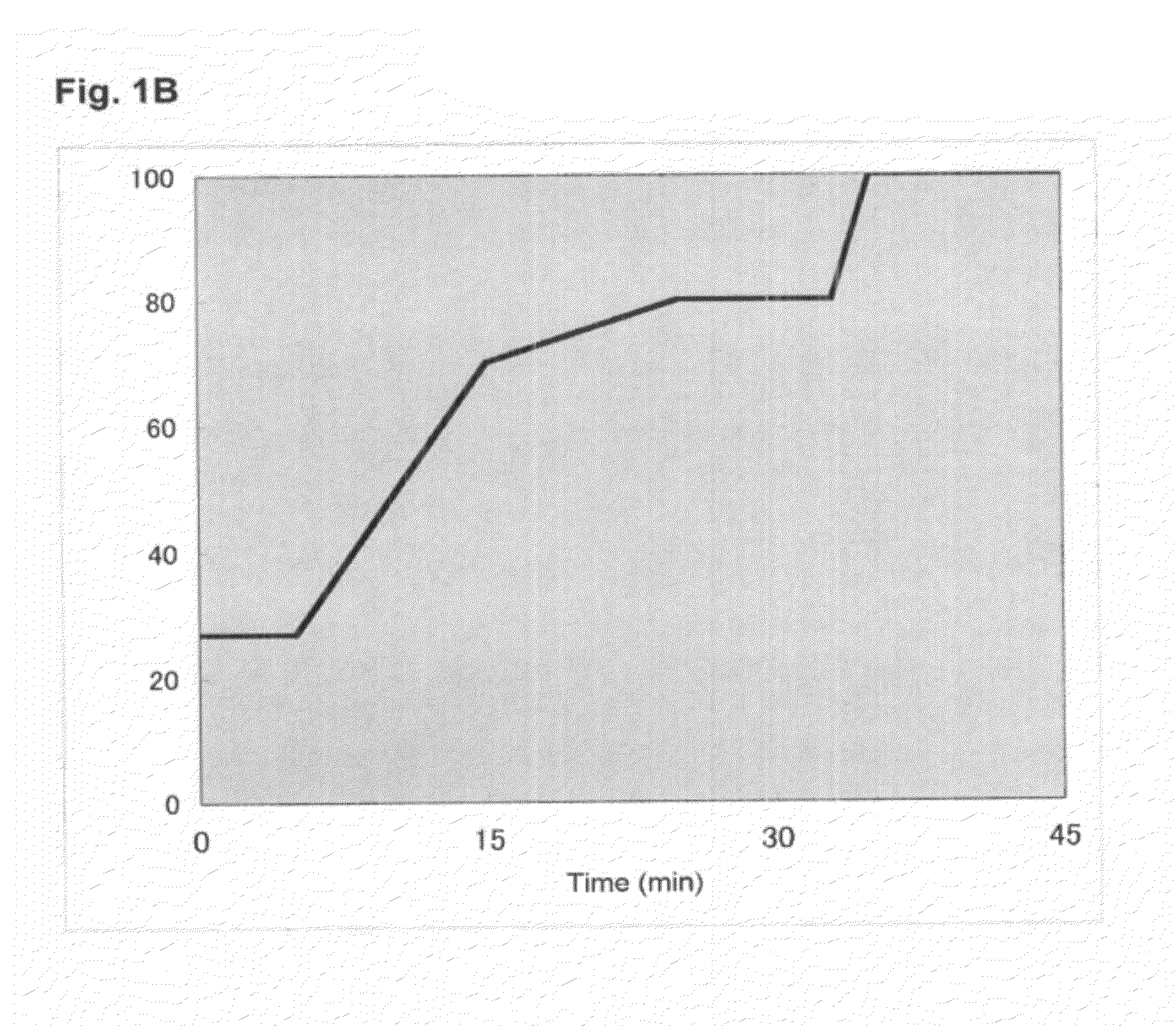

Novel Anti-inflammatory compounds

An object of the present invention is to provide a compound having a novel structure for overcoming the defects of conventional steroid agents and NSAIDs. It is found that the particular dihydroxy bodies of eicosapentaenoic acid and docosahexaenoic acid, which have not conventionally been known (11,18-dihydroxy eicosapentaenoic acid (11,18-diHEPE), 17,18-dihydroxy eicosapentaenoic acid (17,18-diHEPE) etc.), have activity of inhibiting neutrophil, thereby solving the object. The present invention unexpectedly remarkably inhibits infiltration into a tissue of, and activation of neutrophil found out at acute inflammation. The compound of the present invention is a compound which has not conventionally been known. Therefore, utility as a new therapeutic is provided.

Owner:THE UNIV OF TOKYO

Process for extracting phospholipid rich-containing eicosapentaenoic acid and docosahexenoic acid

InactiveCN101333229ANo pollution in the processPromote growth and developmentPhosphatide foodstuff compositionsFish material medical ingredientsDocosahexaenoic acidPhospholipid

A method for extracting a phospholipid rich in eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) is characterized in that firstly marine animal materials are grinded into homogenate solution with colloid; the homogenate solution is frozen and dried and then crushed through a crushing mill; neutral fat and cholesterol in the material powder are removed through supercritical carbon dioxide; and then the phospholipid is extracted with ethanol aqueous solution. The product extracted through the method has high yield and purity; the extraction process has no pollution to the environment and the production staff; the extracted product can promote growth and development of infant brain, enhance memory, promote infant optic nerve and retina development and prevent and cure heart vascular diseases, and has anti-inflammatory, anti-cancer, immunity-enhancing and other physical activities, thereby having higher development and utilization value as health care products or raw materials of medicine.

Owner:OCEAN UNIV OF CHINA

DHA microcapsule food additives, DHA soft capsule health product and uses thereof

ActiveCN1927050AReduce fishy smellImprove food safetyOrganic active ingredientsMetabolism disorderFood additiveFatty acid

The invention relates to a kind of DHA microcapsule food additive and DHA microcapsule functional food, both of which are made up of core material and capsule wall material. What's unique about the products is that the core material contains the docosahexaenoic acid and / or the compound which docosahexaenoic acid is its component fatty acid. Besides, the ratio of docosahexaenoic acid and icosapentaenoic acid is 7 or higher. The products are low in EPA, pollutants, and offensive smell of fish. So they are quite safe to serve as the additive or functional food for infants and children.

Owner:GUANGDONG RUNKE BIOLOGICAL ENG

All-soybean peptide nourishment and preparation method thereof

ActiveCN101731443AOvercoming Nutritional MonotonySolve the degradabilityProtein composition from vegetable seedsVegetable proteins working-upNeutral proteinaseBifidus factor

The invention relates to an all-soybean peptide nourishment comprising oligopeptide, small peptide, polypeptide, a linoleic acid, a linolenic acid, an oleic acid, an eicosapentaenoic acid, a bifidus factor, phosphorus, saponin, vitamins and trace elements and a preparation method thereof, solving the problem of thorough beany flavor elimination and low percent conversion from protein into peptides. The preparation method of the all-soybean peptide nourishment comprises the following steps of: freezing soybeans, and then grinding into soybean milk; sequentially grinding the soybean milk 2 to 3 times through a colloid grinder and a high-pressure homogenizing grinder with the pressure of 600-700 Kg and the fineness of 500-600 meshes, and then stirring at the pressure of 0.7-0.8 MPa and the temperature of 130-132 DEG C; after the temperature is reduced, adding a lipase for biochemical degradation; after an enzyme is inactivated, knocking into a nano-grade high-pressure homogenizing grinder with the pressure not lower than 1000 Kg and the fineness not higher than 0.3-0.5 mu for grinding; then adding a neutral proteinase for biochemical reaction; filtering through vacuum micropores of 10-20 micrometers so as to obtain an all-soybean peptide stock solution; and finally preparing the all-soybean peptide nourishments of various types.

Owner:黑龙江万物生生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com