Perfect compound feed for groupers

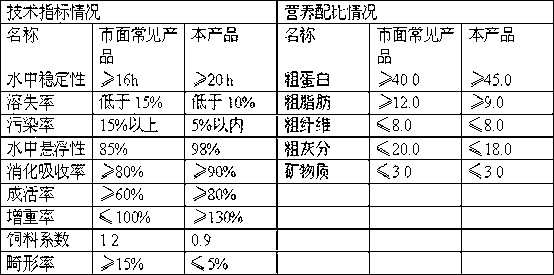

A technology of compound feed and grouper, which is applied in the field of fish feed, can solve problems such as unsatisfactory formula nutrition and processing technology, restricting the development of grouper aquaculture industry, and slow growth of cultured fish, so as to protect the liver of grouper , reduce the serious problem of fatty liver, and improve the effect of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The formula of the fish full-price compound feed components in this example is (unit: Kg): fish meal 43; Insect 4, fish oil 3, soybean lecithin 3, DHA 0.6, EPA 0.4, compound mineral salt 1.8, compound enzyme preparation 0.3, compound immune enhancer 0.3, liver strengthening agent 0.3, compound microecological preparation 0.3.

[0014] Its preparation process includes:

[0015] a) First mix fish meal, fermented bean curd, squid meal, krill meal and Artemia worm according to the ratio, and carry out primary crushing and superfine crushing to make the raw material fineness reach 300 mesh, and then add α-starch and yeast according to the ratio Paste, soybean lecithin, DHA, EPA and flour are fully mixed to obtain material A;

[0016] b) Add fish oil, compound mineral salt, compound enzyme preparation, compound immune enhancer, liver-enhancing agent, and compound microecological preparation to material A according to the proportion, and then carry out conditioning and emulsi...

Embodiment 2

[0023] The formula of the full-price fish compound feed components in this example is (unit: Kg): fish meal 40; Insect 4, fish oil 2, soybean lecithin 3, DHA 0.6, EPA 0.4, compound mineral salt 1.8, compound enzyme preparation 0.3, compound immune enhancer 0.3, liver strengthening agent 0.3, compound microecological preparation 0.3.

[0024] The obtained product is through the same test process as in Example 1, and the main technical indicators detected are close to those in Example 1, and will not be repeated here.

Embodiment 3

[0026] The formula of the fish full-price compound feed components in this example is (unit: Kg): fish meal 37; Insect 4, fish oil 2, soybean lecithin 3, DHA 0.6, EPA 0.4, compound mineral salt 1.8, compound enzyme preparation 0.3, compound immune enhancer 0.3, liver strengthening agent 0.3, compound microecological preparation 0.3. The obtained product is through the same test process as in Example 1, and the main technical indicators detected are close to those in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com